Screen printing device for solar batteries

A screen printing device and solar cell technology, applied in screen printing machines, printing machines, printing machines, etc., can solve the problems of slurry flow, avoid drying and waste, uniform fluidity, improve electrode printing efficiency and The effect of print quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

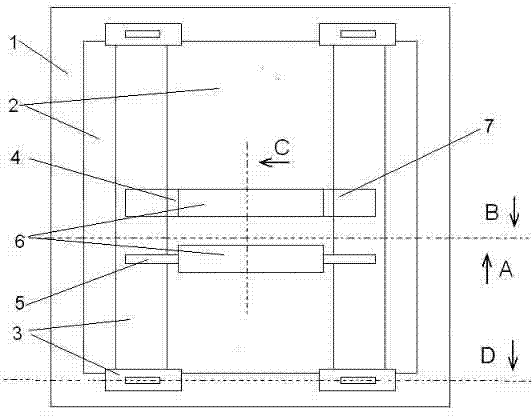

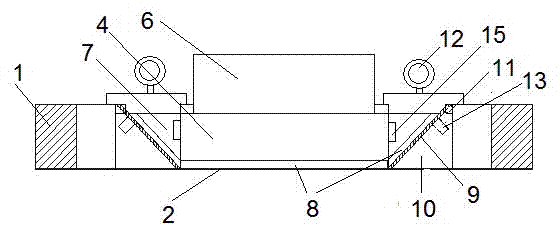

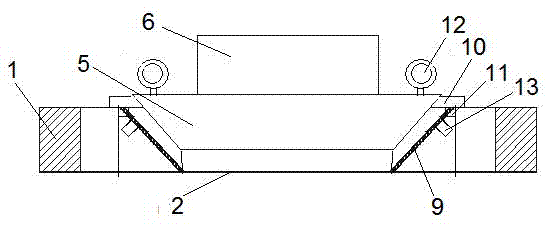

[0025] figure 1 It is a top view of the structure of the printing device in the embodiment. The printing device is mainly composed of screen frame (1), screen (2), baffle (3), scraper (4), return knife (5), knife holder (6), auxiliary scraper (7), scraper (squeegee) (8) and baffle surface (9), baffle mounting frame (10), baffle frame (11), baffle lifting ring (12), baffle angle fine-tuning structure (13), baffle positioning Bolt (14), auxiliary scraper elastic control (15), baffle mounting groove and other structural components.

[0026] The baffle (3) is installed in the baffle installation groove (16) on the screen frame (1) through the baffle mounting bracket (10), and the baffle can be adjusted on the screen frame by the baffle positioning bolts (14) location (eg Figure 5 shown), to fine-tune the contact pressure between the baffle surface (9) and the scraper (8) inlaid with the auxiliary scraper and the edge of the return knife (5).

[0027] After the baffle (3) is i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com