Under actuated fruit picking mechanical gripper with rigid and flexible mixed structure

A technology with a hybrid structure and mechanical gripper, which is applied in the directions of picking machines, agricultural machinery and implements, harvesters, etc., can solve the problems of increased cost and difficulty of the control system, limited bending speed, and low grasping efficiency, so as to avoid fruit damage. , The effect of simple driving and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

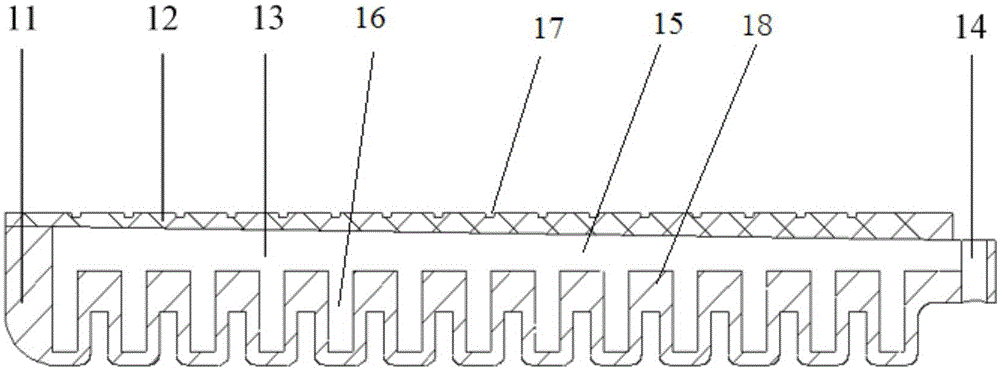

[0031] An underactuated fruit-picking robotic gripper with a rigid-flexible hybrid structure, including a soft finger 1, the soft finger 1 includes a bottom plate 12 and an air pipe portion 18 arranged on the bottom plate 12, the air pipe portion 18 and the bottom surface An air passage 15 is formed between the flat plates 12, and several comb-shaped protrusions 11 are provided from one end to the other end of the air pipe portion 18, and sub-ventilation chambers 16 are arranged inside the comb-shaped protrusions 11, and the air passage 15 communicates with each sub-ventilation chamber 16 .

[0032] Preferably, the soft finger 1 is provided with an air inlet 14 communicating with the air channel 15 at the root, and the cross-sectional area of the air channel 15 increases sequentially from the root of the soft finger 1 to the end; the thickness of the bottom plate 12 is The direction from the base of the soft finger 1 to the end decreases successively.

[0033] Preferably, t...

Embodiment 2

[0040] According to the structure and method described in the present invention, it can be used for fruit and vegetable picking, and can be applied to other grasping tasks. For the convenience of description, the example of the present invention uses a 3-finger layout as an illustration.

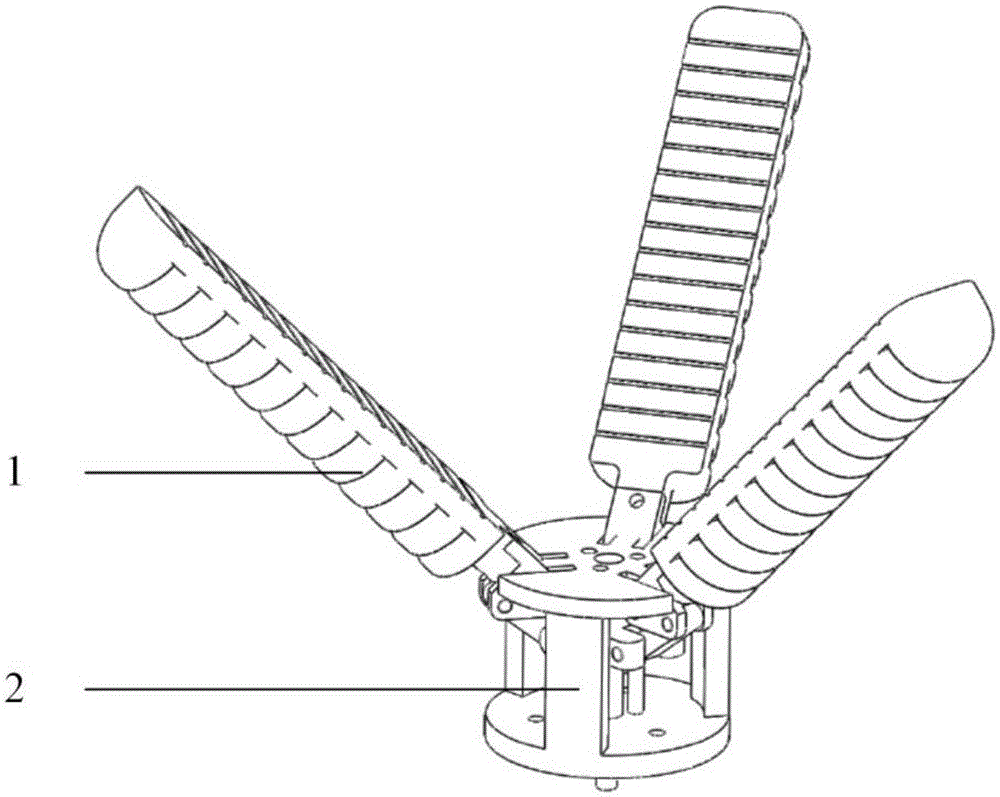

[0041] Such as figure 1 As shown, the figure is a schematic diagram of the overall structure of the robotic gripper system of the present invention, which mainly includes a soft finger 1 and a holding mechanism 2 .

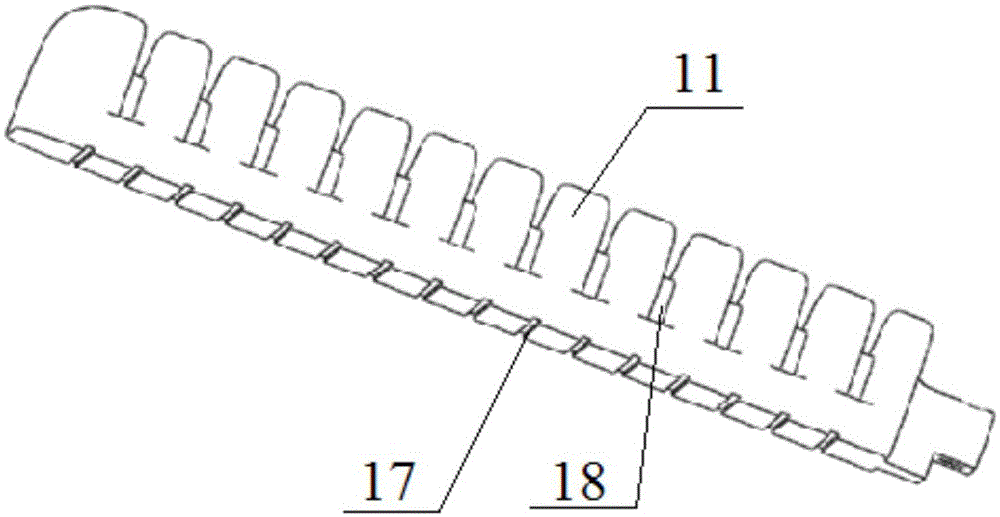

[0042] Such as figure 2 As shown, the figure is the state when the soft finger of the present invention is not working. The soft finger 1 is a semi-cylindrical body, and the bottom plane 12 is the contact surface with the grasped object. Friction, there are evenly distributed anti-skid grooves 17 on the plane; the structure of comb-shaped protrusions 11 is on the cylindrical arc surface, and there are sub-cavities in the comb-shaped protrusions 11, that is, sub-ventilation cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com