Patents

Literature

121results about How to "Crawl fast" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

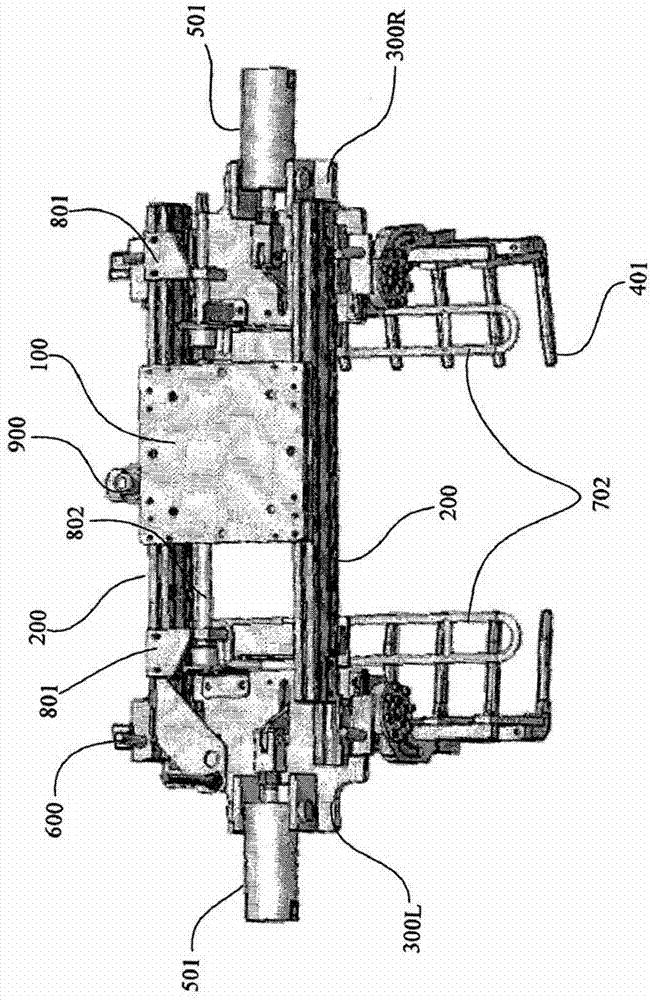

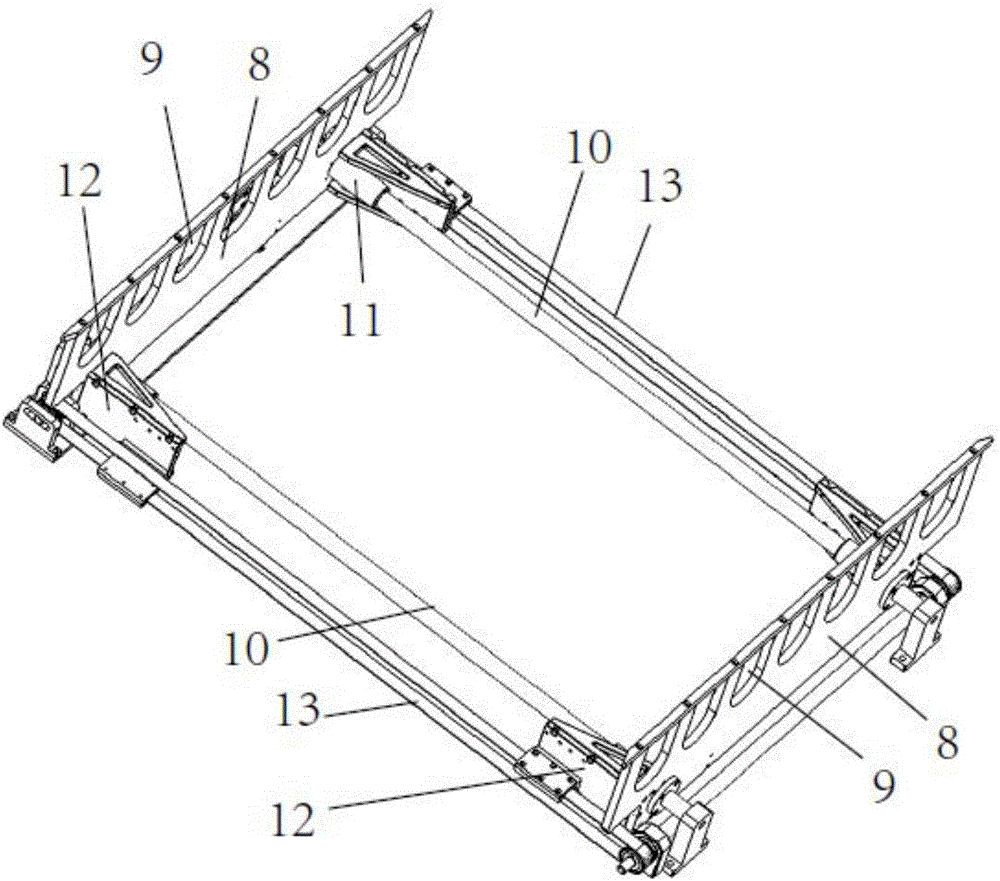

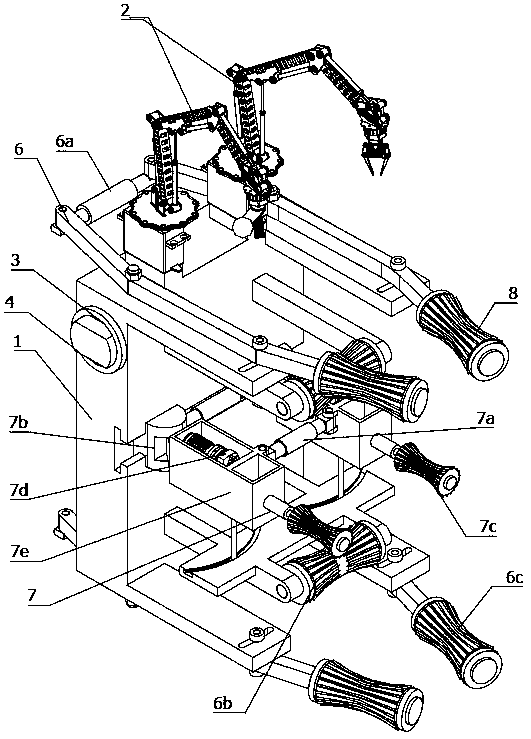

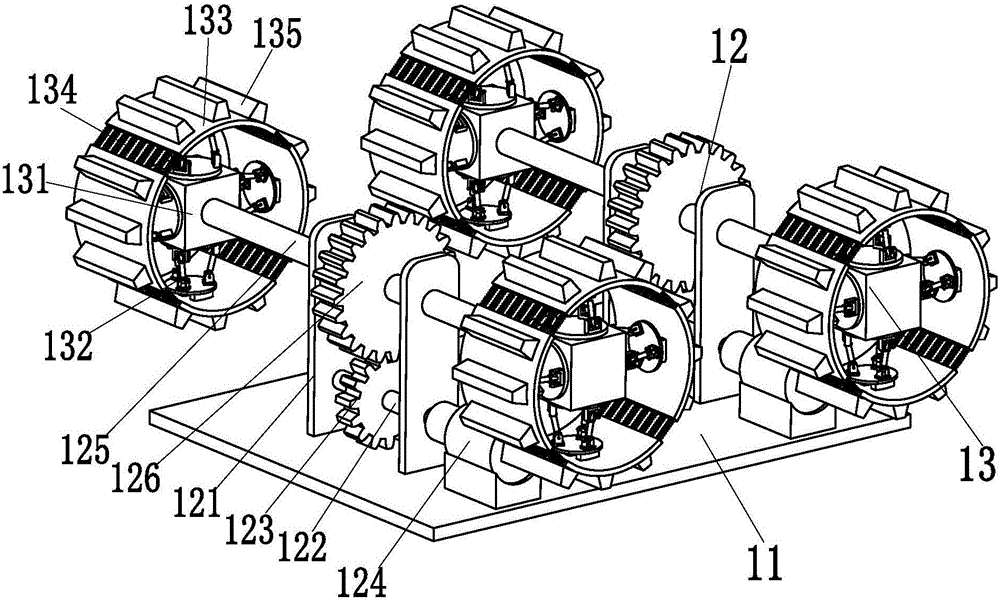

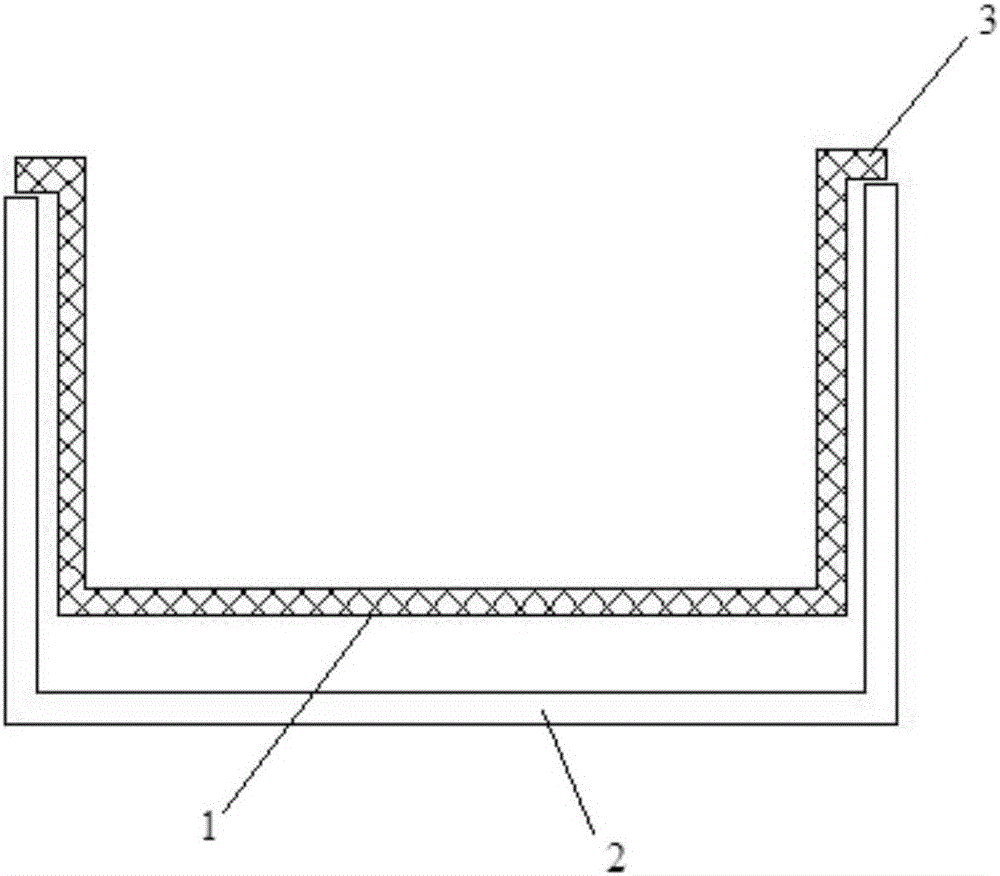

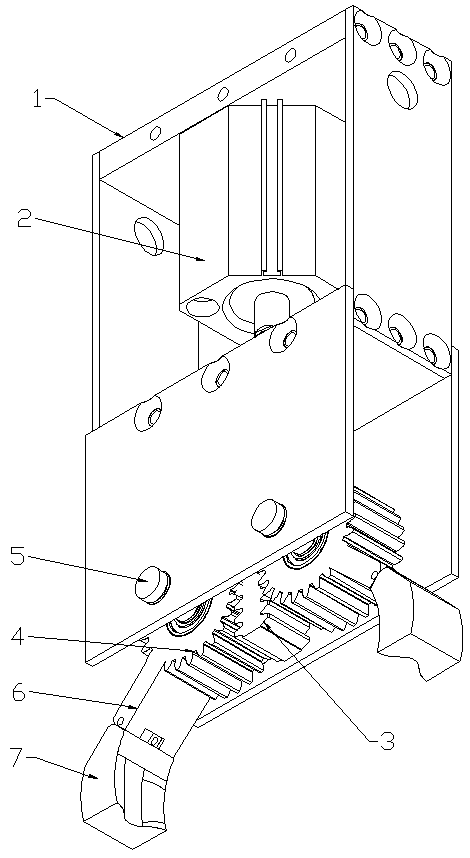

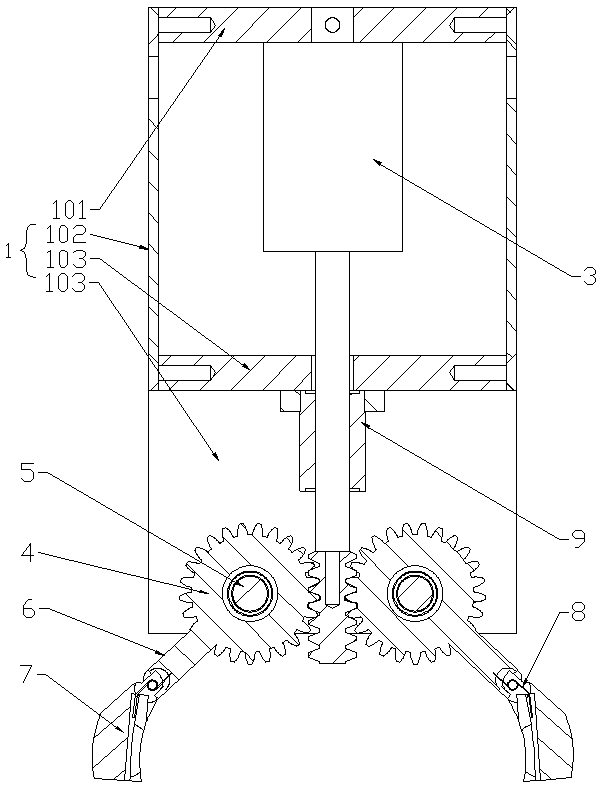

Stacking robot gripper

ActiveCN102729242ACrawl fastEasy to holdProgramme-controlled manipulatorGripping headsRear quarterRotational axis

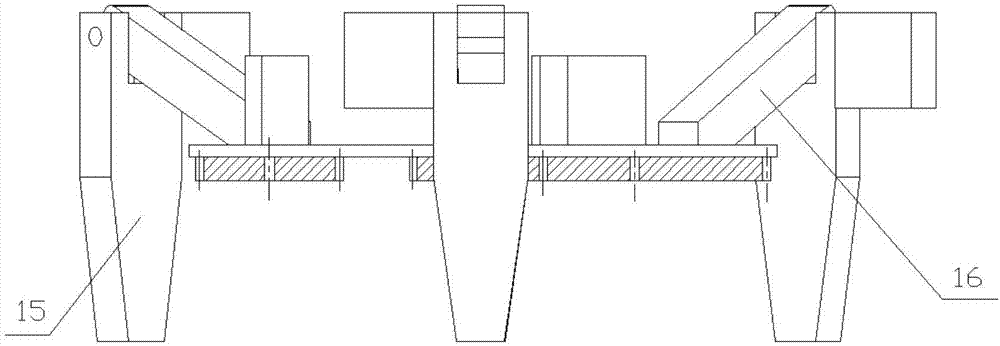

The invention relates to a stacking robot gripper in the field of robots for stacking during package and transportation. The stacking robot gripper comprises a main frame mechanism, a connecting plate and two groups of symmetrical tooth gripping mechanisms and also comprises light-type cylinders, wherein the main frame mechanism mainly comprises a front side plate, a rear side plate, a left side plate, a right side plate and a top plate; the connecting plate is fixed on the top plate; the tooth gripping mechanisms are rotatably supported at the front side plate and the lower side plate of the main frame mechanism; the light-type cylinders are symmetrically and obliquely arranged at the left side and the right side of the main frame mechanism and are used for driving the tooth gripping mechanisms to rotate; each group of tooth gripping mechanisms comprise a plurality of L-shaped gripping teeth which are fixedly connected by a plurality of connecting rods, are uniformly distributed and point to the same side; the gripping teeth are fixedly connected with two rows of parallel rotating arms by the connecting rods; rotating shafts are connected at the end parts of the two rotating arms; the front side plate and the rear side plate are correspondingly provided with mounted bearings for supporting and installing the rotating shafts; and the corresponding inner sides of the two groups of tooth gripping mechanisms are also provided with pressing plates with adjustable distance, and the pressing plates are used for clamping the two sides of a gripped object. The stacking robot gripper has the advantages of simple and compact structure, flexible operation, fast gripping speed, stable gripping and wide application range.

Owner:扬州牧羊唯美自动化控制有限公司

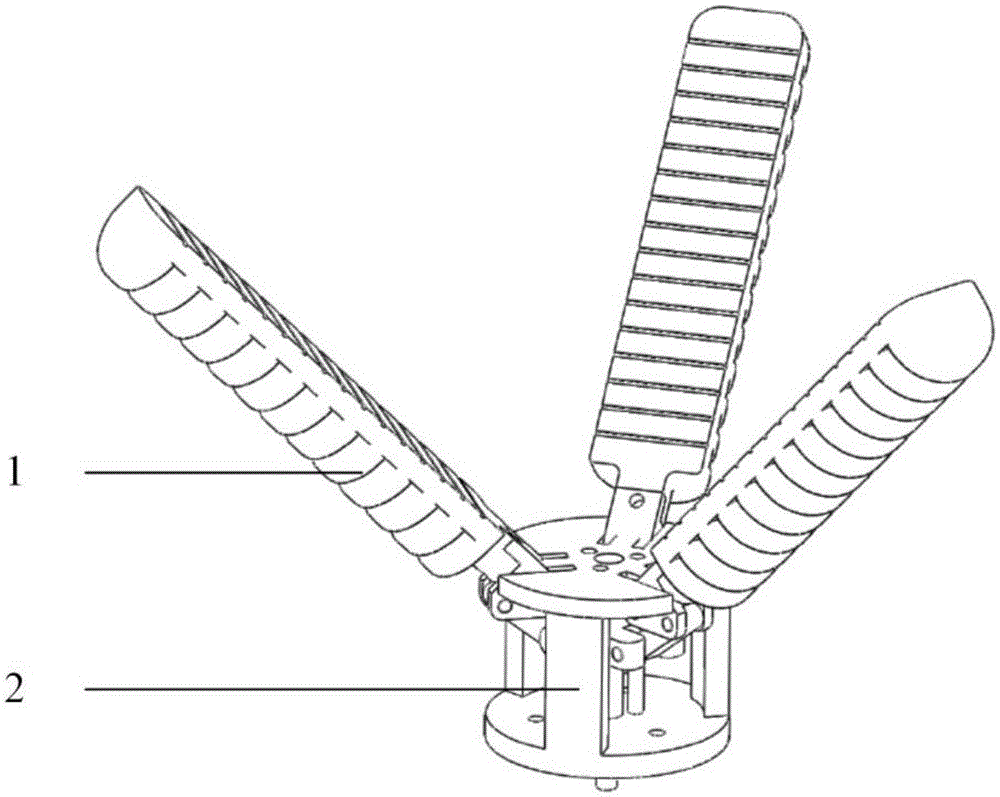

Under actuated fruit picking mechanical gripper with rigid and flexible mixed structure

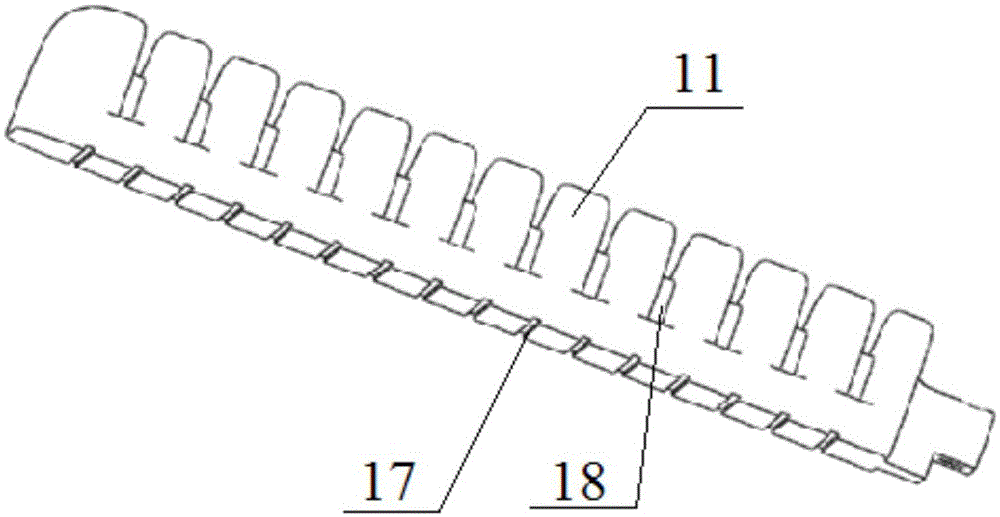

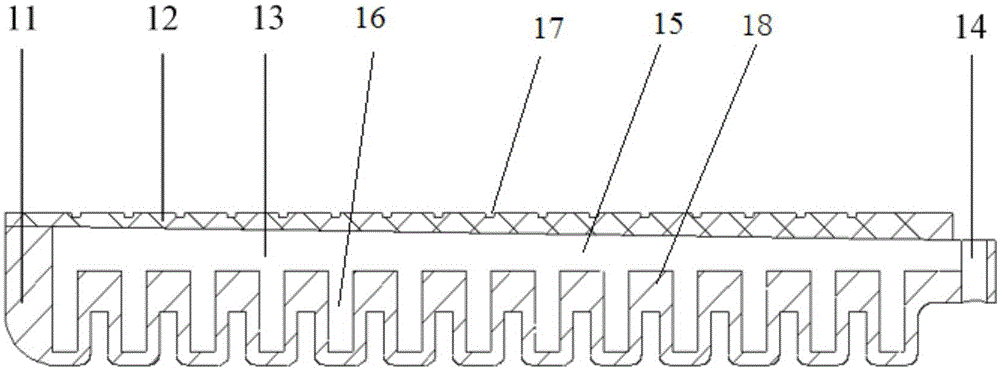

The invention discloses an under actuated fruit picking mechanical gripper with a rigid and flexible mixed structure. The under actuated fruit picking mechanical gripper with the rigid and flexible mixed structure comprises flexible fingers, each flexible finger comprises a bottom plate and a breather pipe part arranged on the bottom plate, an air passage is formed between each breather pipe part and the corresponding bottom plate, multiple comb-shaped protrusions are formed on the breather pipe parts from one end to the other end, each comb-shaped protrusion is provided with a sub ventilation room, and the air passages are communicated with the sub ventilation rooms. According to the under actuated fruit picking mechanical gripper with the rigid and flexible mixed structure, the flexible fingers which are driven in a pneumatic mode are adopted, complex structure is avoided, drive is simple, and control is easy; by means of a rapid closing mechanism which is rigidly combined, fruit gripping speed is improved; structural design is simplified, the structure is simple, the cost is reduced, and the reliability of a system is improved; the flexible fingers are adopted, the contact with fruits is flexible, and damage to the fruits caused by picking is avoided.

Owner:HUAZHONG AGRI UNIV

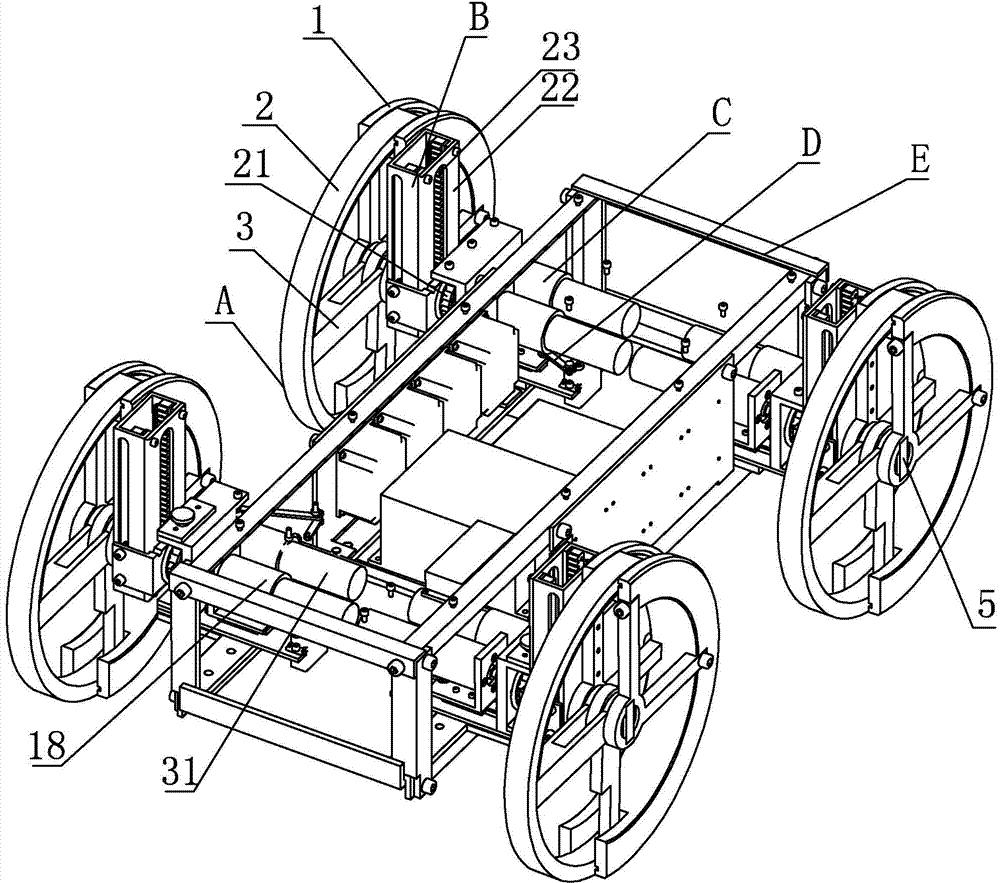

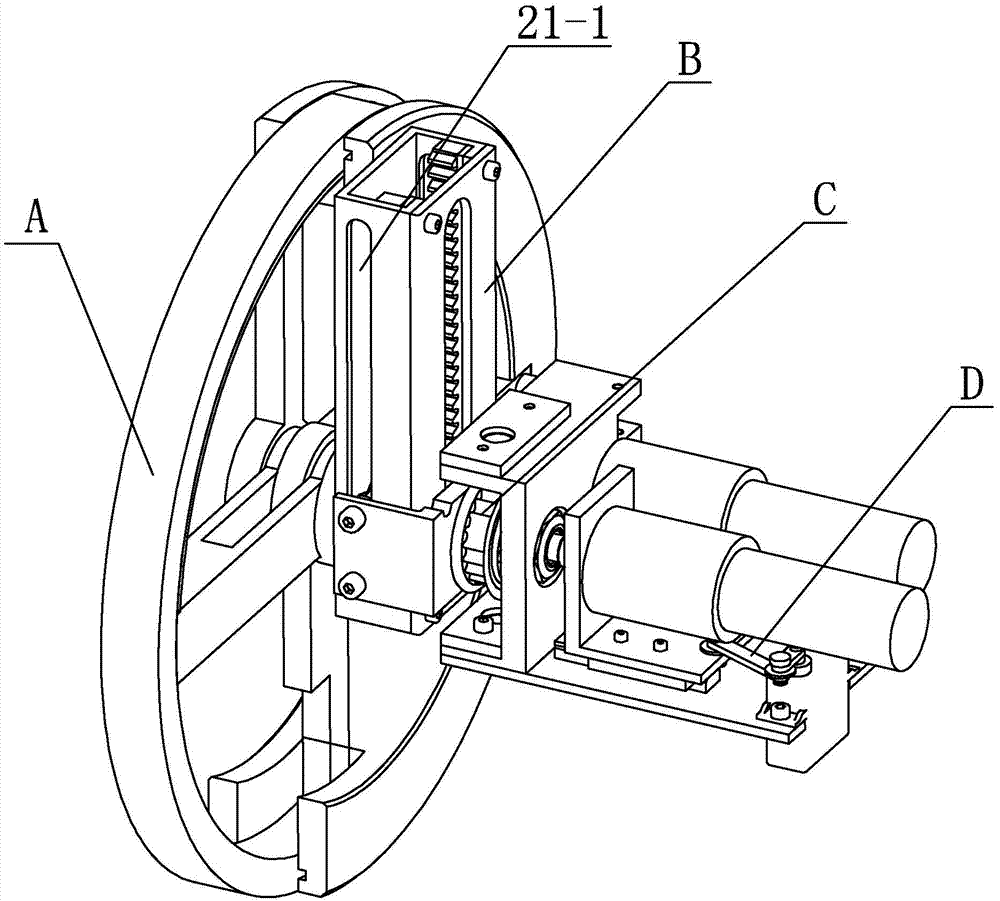

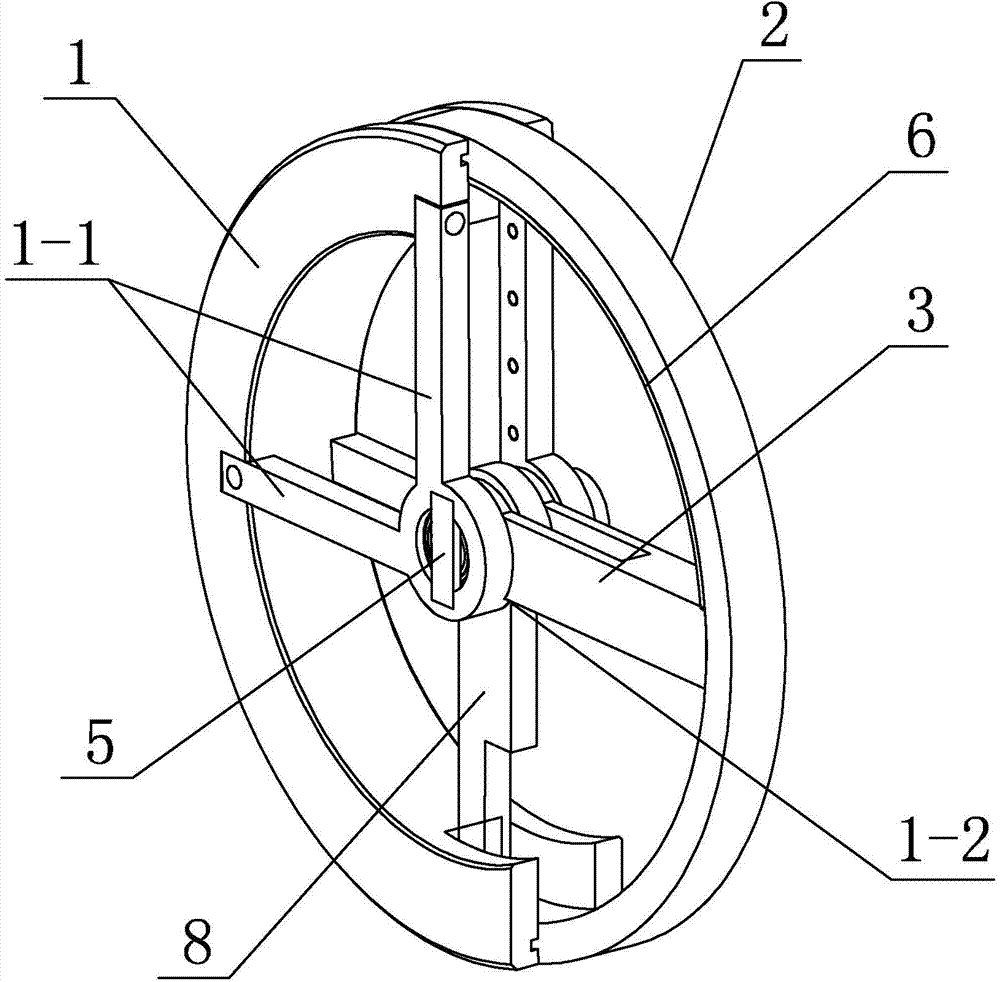

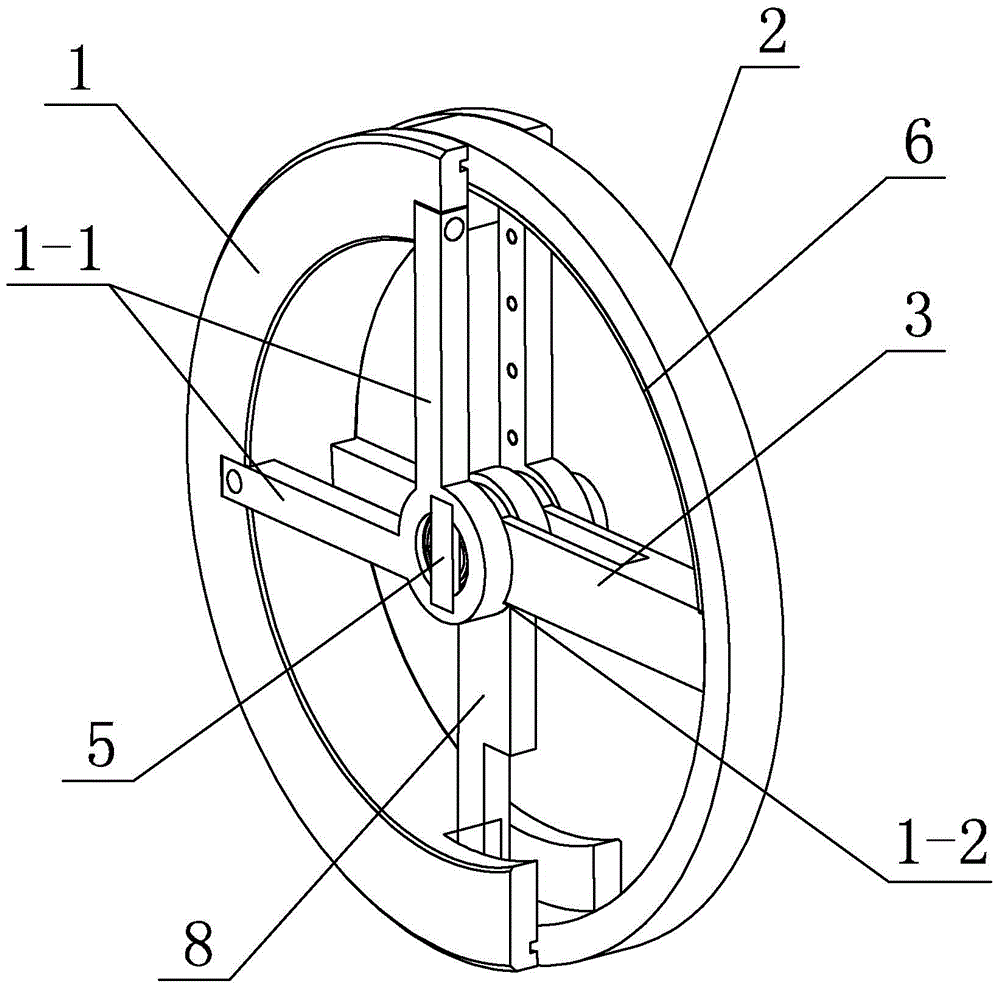

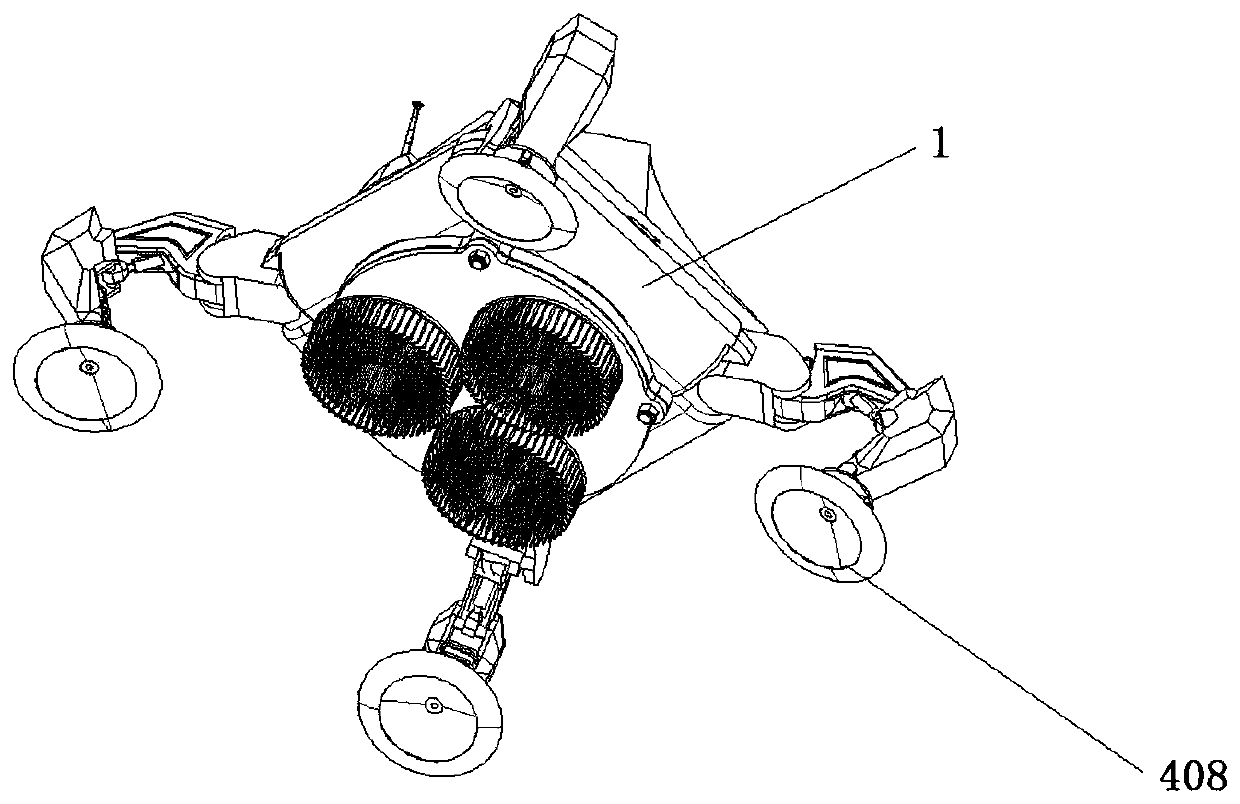

Wheel-foot conversion type mobile robot system

ActiveCN104773226ARealize the combinationImprove terrain adaptabilityVehiclesObstacle avoidanceControl theory

The invention provides a wheel-foot conversion type mobile robot system, relating to mobile robots. The wheel-foot conversion type mobile robot system is used for solving the problems that the obstacle avoidance ability of the existing wheeled robots is poor and the walking speed of the existing footed robots is low. According to the wheel-foot conversion type mobile robot system, one end of each central axle is fixedly connected and is axially locked through a corresponding first limiting block, a shoulder is arranged at the other end of each central axle, a spring sleeves each central axle and is located between a corresponding bearing and the corresponding shoulder, a central blind hole is formed in the other end of each central axle, and a first key groove is formed in each central blind hole; semi-annular grooves are formed in fixed half wheels along the circumferential direction, movable half wheels and the fixed half wheels are in turning connection relatively to the central axles, complete wheels are formed by the fixed half wheels and the movable half wheels during the conversion to a wheeled state, the movable half wheels are turned into the semi-annular grooves of the fixed half wheels during the conversion to a footed state, and single scrolls are mounted on the central axles. The wheel-foot conversion type mobile robot system belongs to the field of the mobile robots.

Owner:HARBIN INST OF TECH

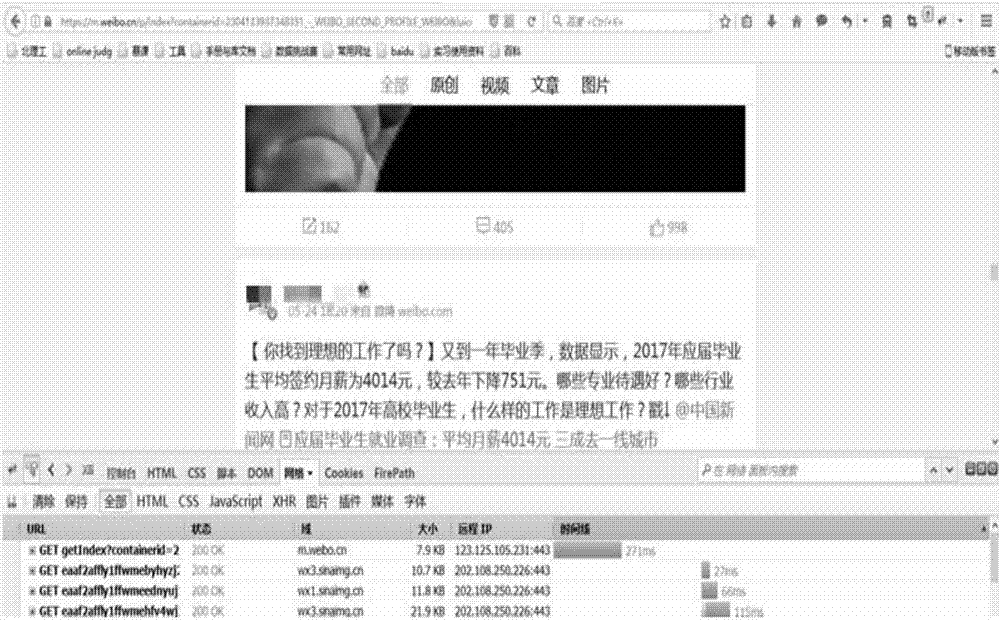

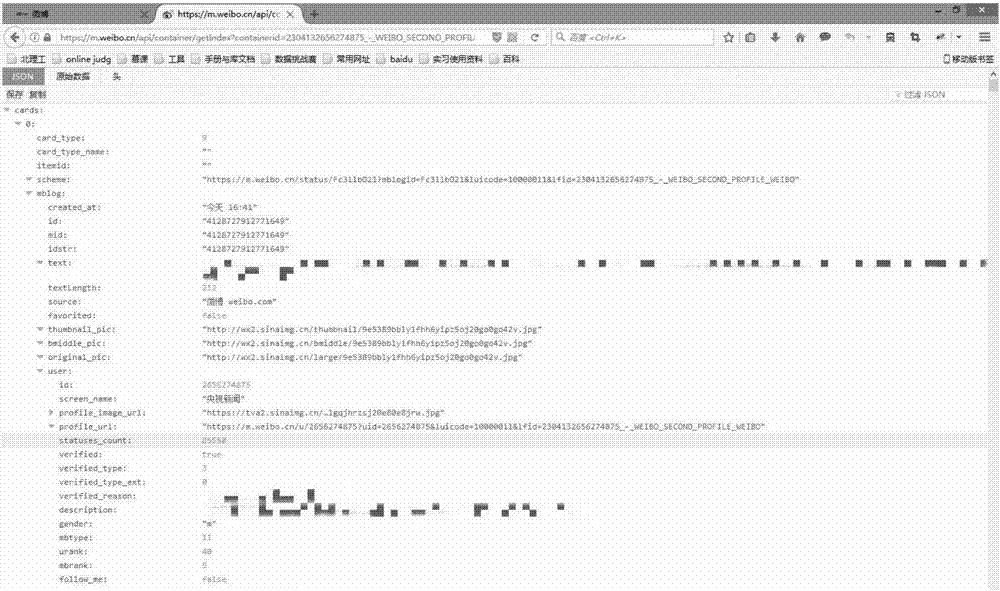

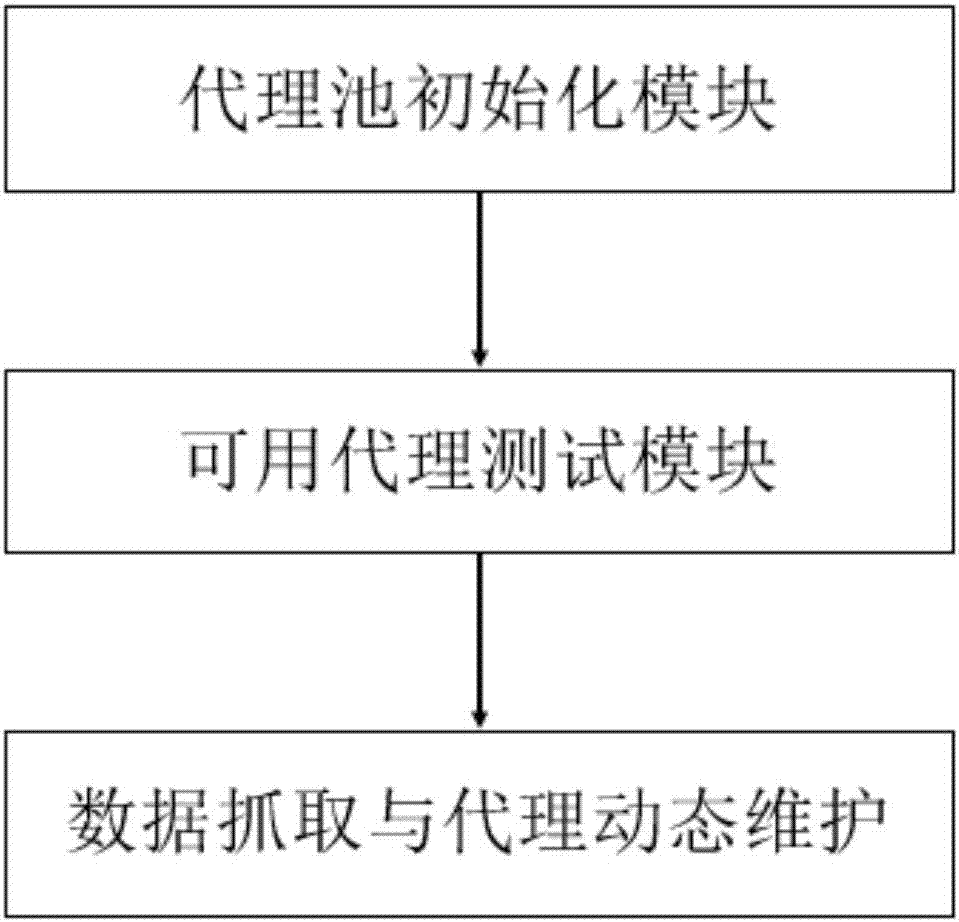

IP restricted controlled source information capture method based on agent pools

InactiveCN107395782AOvercoming high frequency of requestsCrawl fastWeb data indexingData switching networksSelect agentData acquisition

The invention relates to an IP restricted controlled source information capture method based on agent pools, and belongs to the field of data acquisition and processing in the computer science. The method comprises the following steps: maintaining two agent pools A and B, and storing all agents in the agent pool A; testing available agents and initializing the agent pool B; randomly selecting agents in the agent pool B for use in a capture process; triggering an updating operation of the agent pool B by a dynamic maintenance operation of the agent pool B in the capture process; and realizing efficient capture of an IP restricted controlled information source by using the agent pool algorithm. According to the IP restricted controlled source information capture method, the two agent pools are maintained, the available agents are dynamically regulated and controlled in the information capture process to solve the problems of instable agent and low capture efficiency and expand resources for all kinds of data drive experiments.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

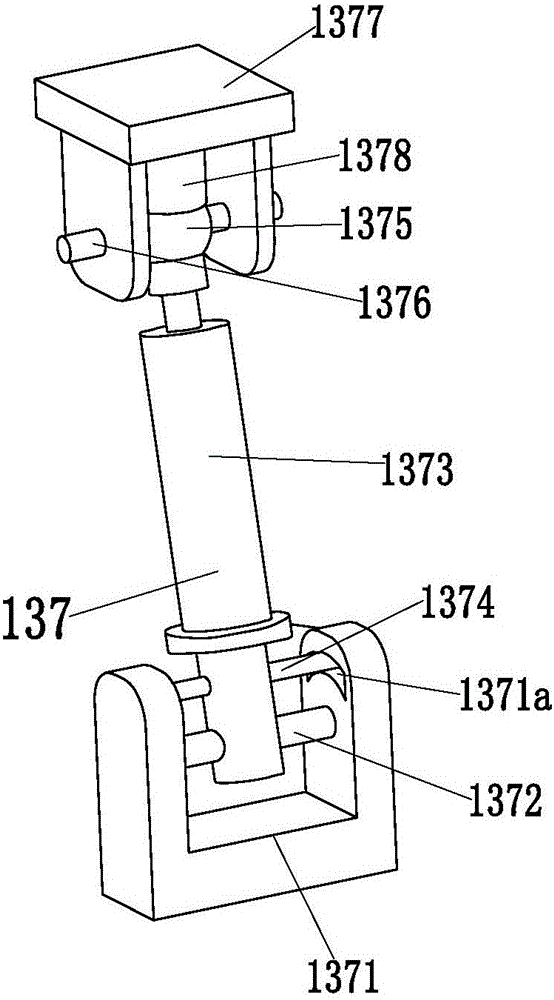

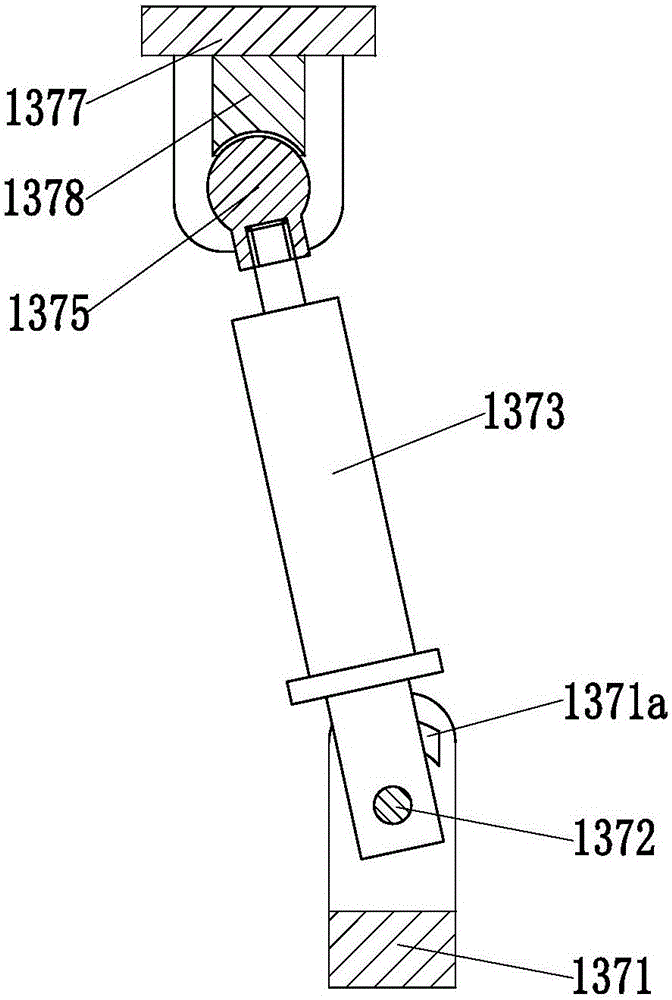

Hydraulic grabbing mechanical arm for anti-collapsing rock-soil retaining wall

InactiveCN106002952AGood dynamic responseIncrease stiffnessProgramme-controlled manipulatorGripping headsHydraulic cylinderLower limit

The invention relates to a hydraulic grabbing mechanical arm for an anti-collapsing rock-soil retaining wall. The hydraulic grabbing mechanical arm comprises a damping supporting mechanism, wherein the damping supporting mechanism comprises a fixed platform; three parallel-connection branch chains are evenly mounted on the upper end face of the fixed platform in the direction of the axis, and the top ends of the three parallel-connection branch chains are mounted on the lower end face of a movable platform; each parallel-connection branch chain comprises a concave support welded to the upper end face of the fixed platform, a lower limiting shaft is mounted between middles of two sides of each concave support, and two arc limiting grooves are symmetrically formed in the inner wall of the upper end of each concave support; each lower limiting shaft is sleeved with a first hydraulic cylinder, two limiting rods are arranged on the two sides of the bottom end of each first hydraulic cylinder, and the tail ends of two limiting rods are connected with corresponding two arc limiting grooves in a sliding fit manner; and a hydraulic grabbing device is mounted at the upper end face of the movable platform. According to the mechanical arm, the stable automatic hydraulic grabbing function of masonry can be achieved, the phenomenon of vertical shaking or left-and-right shaking in the carrying process can be avoided, and stability performance is good.

Owner:JILIN UNIV

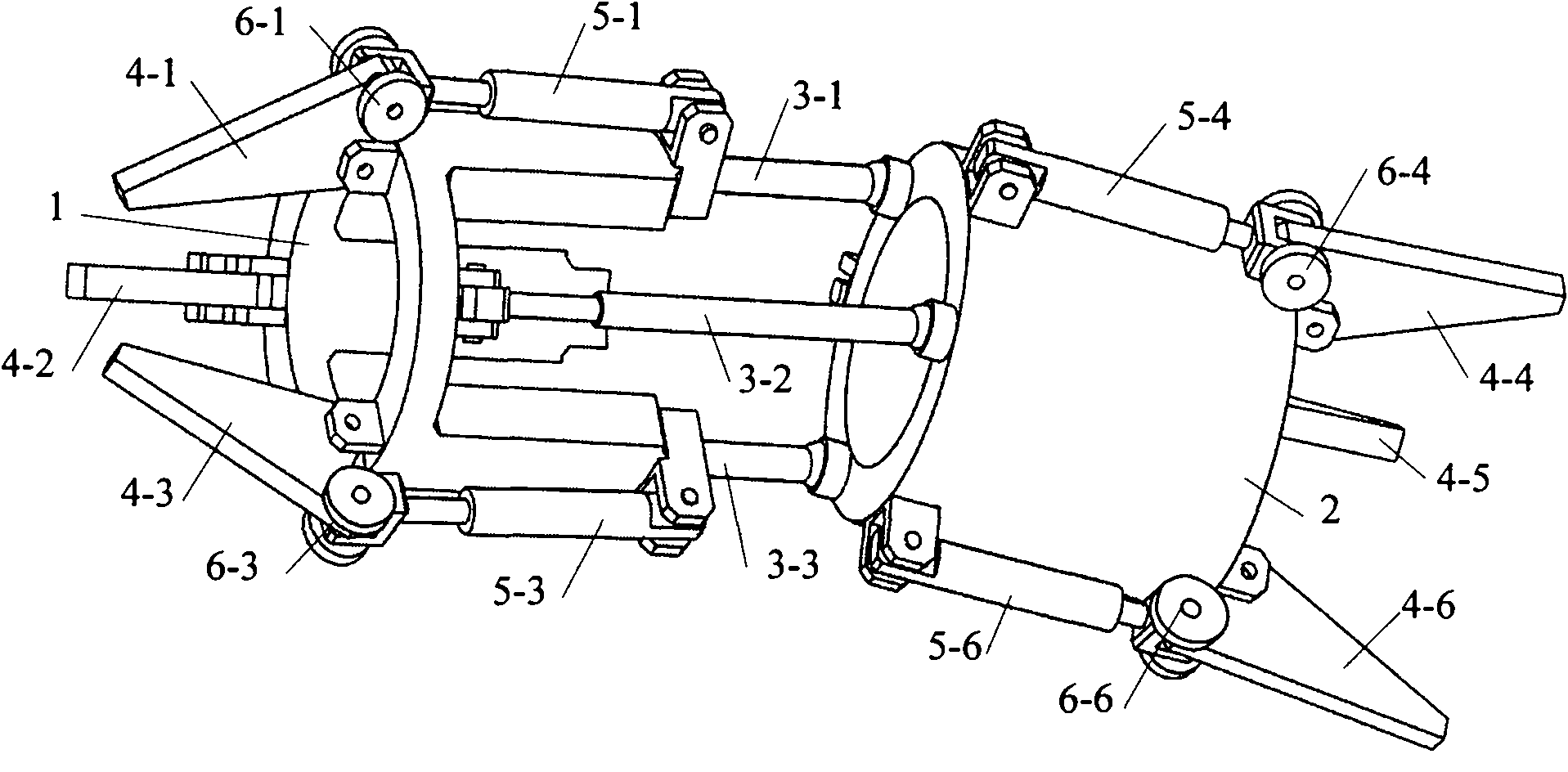

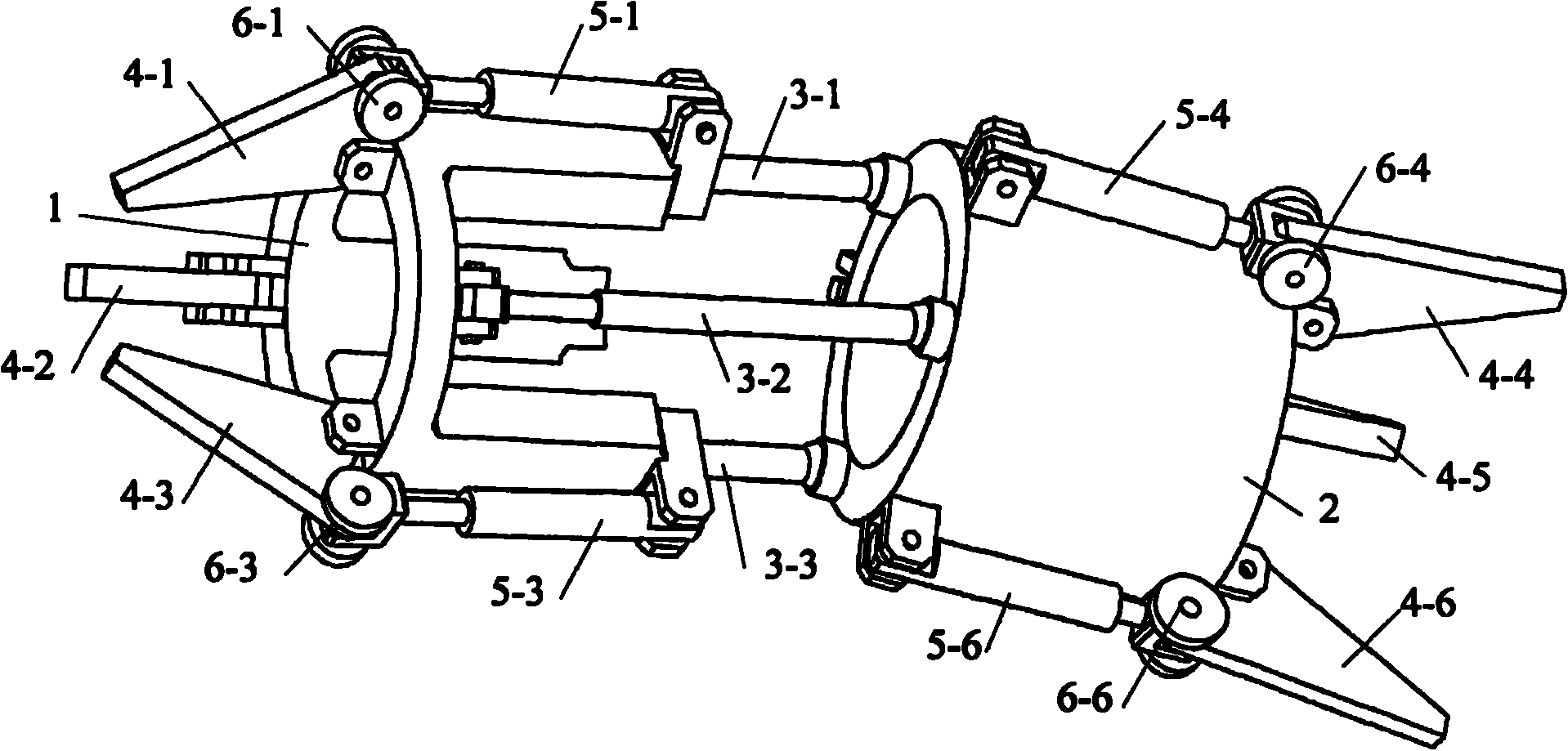

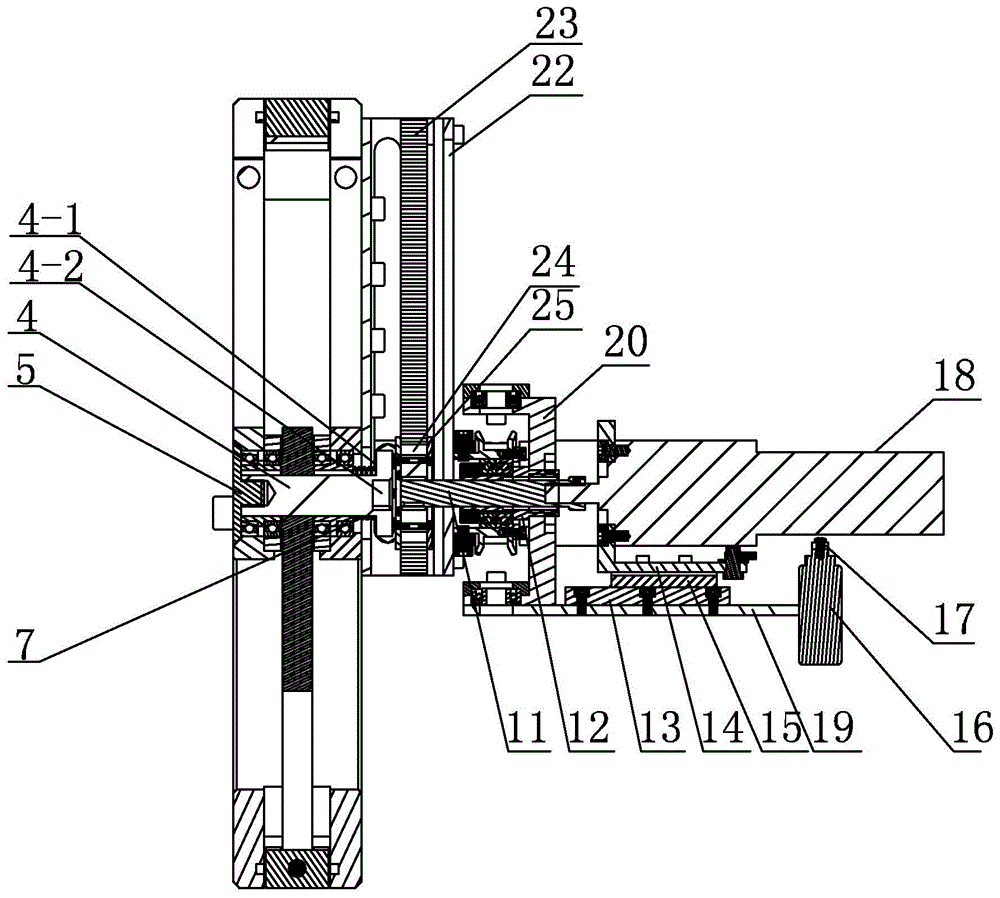

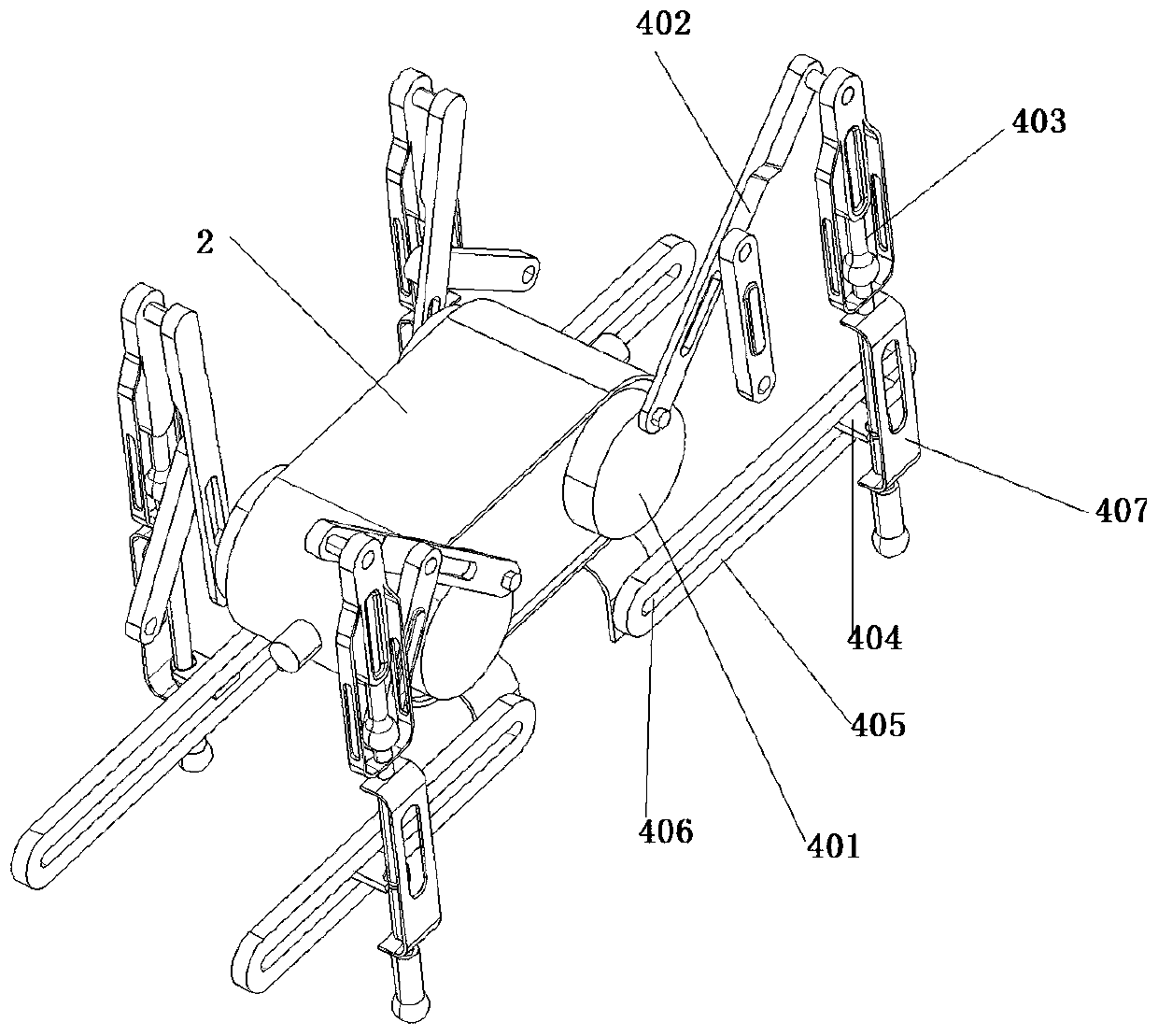

Danger rescue and pipe parallel robot

InactiveCN101961870AFast crawling driveCrawl fastBreathing protectionManipulatorSimulationDegrees of freedom

The invention relates to a danger rescue and pipe parallel robot, comprising a 3 degree of freedom (DOF) parallel waist mechanism, a hand operating device and a foot operating device. The robot can realize integral 3-free swinging and peristaltic expansion along the forward direction. The hand operating device can realize forward moving, forward grabbing, excavating, dredging, obstacle-eliminating and the like of the robot via a group of rocker mechanisms. The foot operating device can realize forward moving, anchoring, hacking or non-returning of the robot via a group of rocker mechanisms. Comprehensive utilization of the parallel waist mechanism, the hand and foot operating devices, supporting wheels and a control device can realize automatic walking, turning, climbing, turning over and the like of the robot. The robot is suitable for star probing, military reconnaissance, probing and eliminating of dangerous goods, earthquake field rescue and cable traction, dredging, obstacle-eliminating and the like in the straight / bend pipes for oil transport and pollution discharge and the variable diameter and vertical pipes.

Owner:YANSHAN UNIV

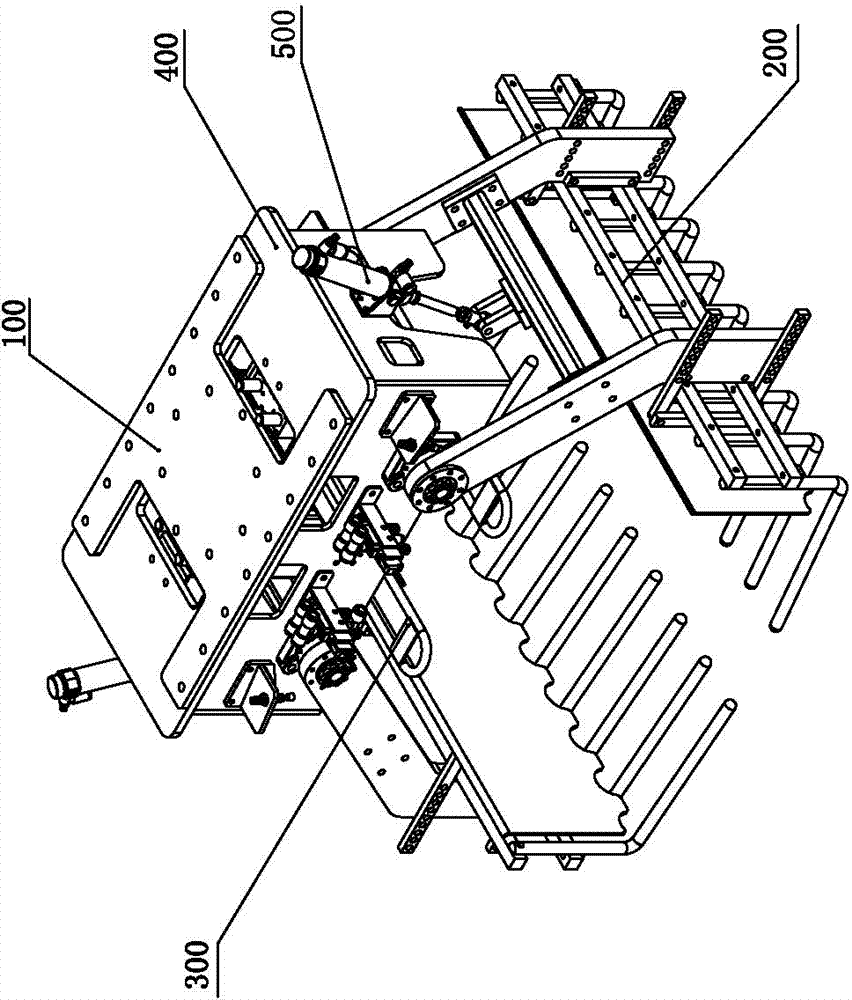

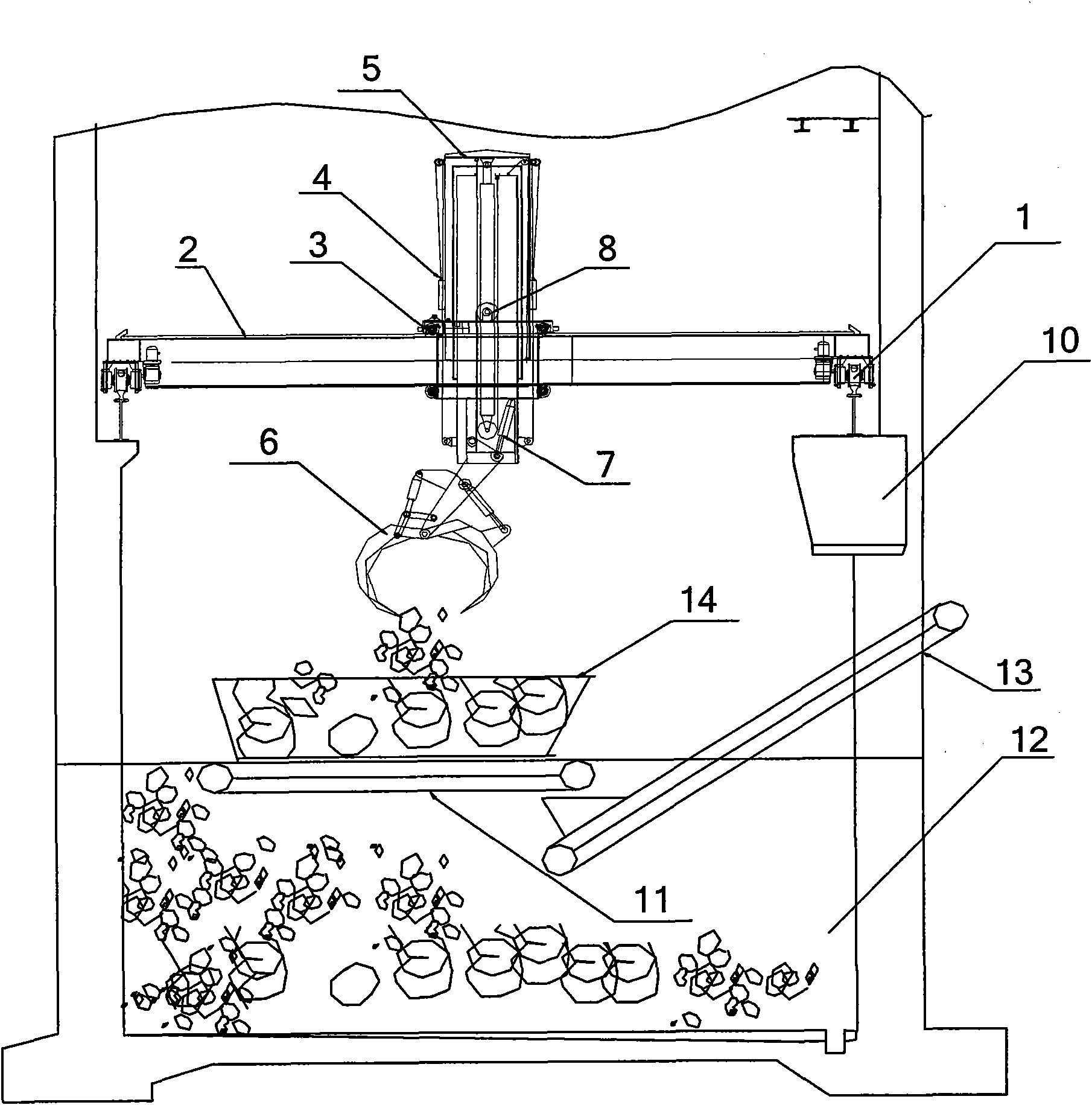

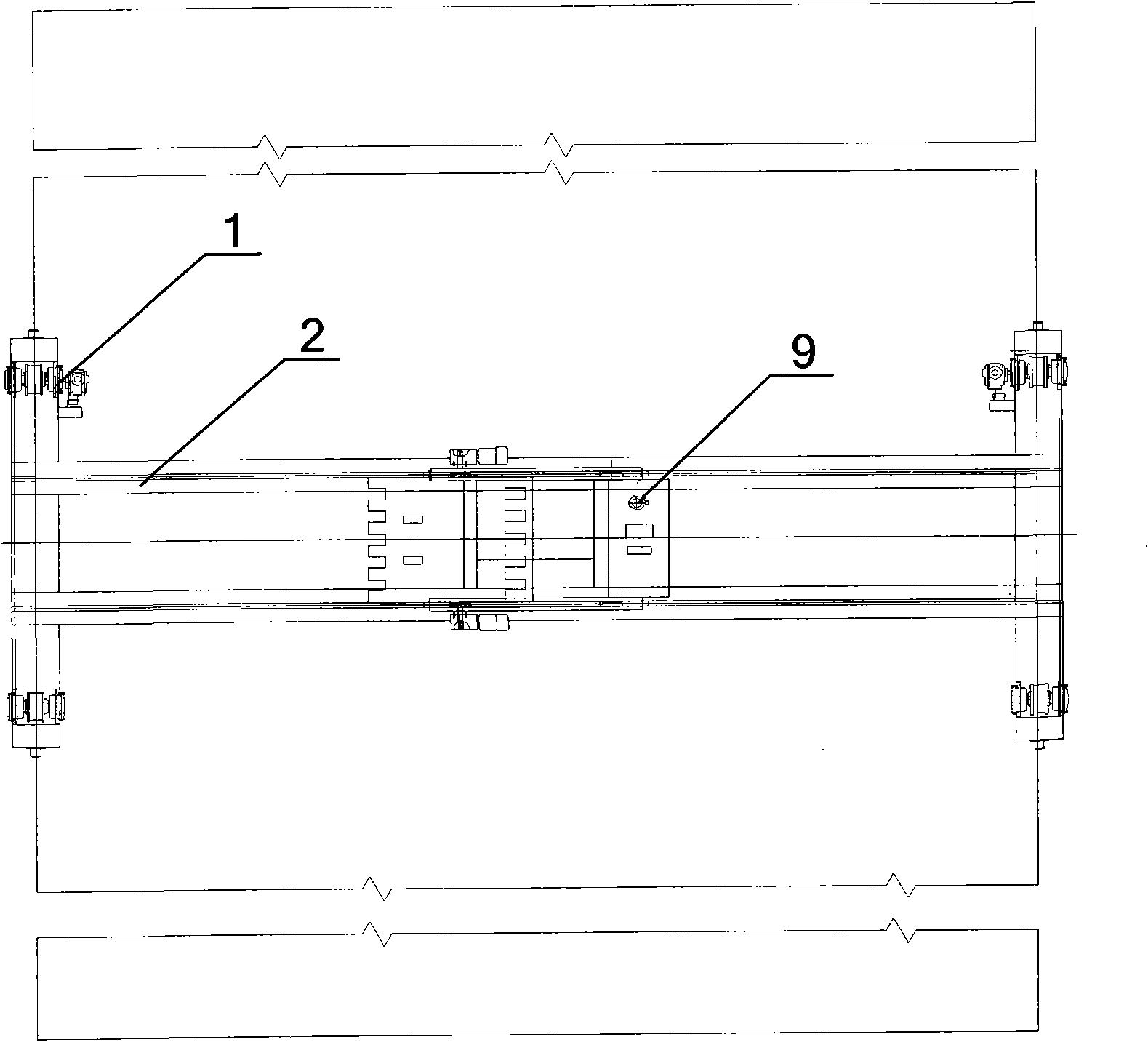

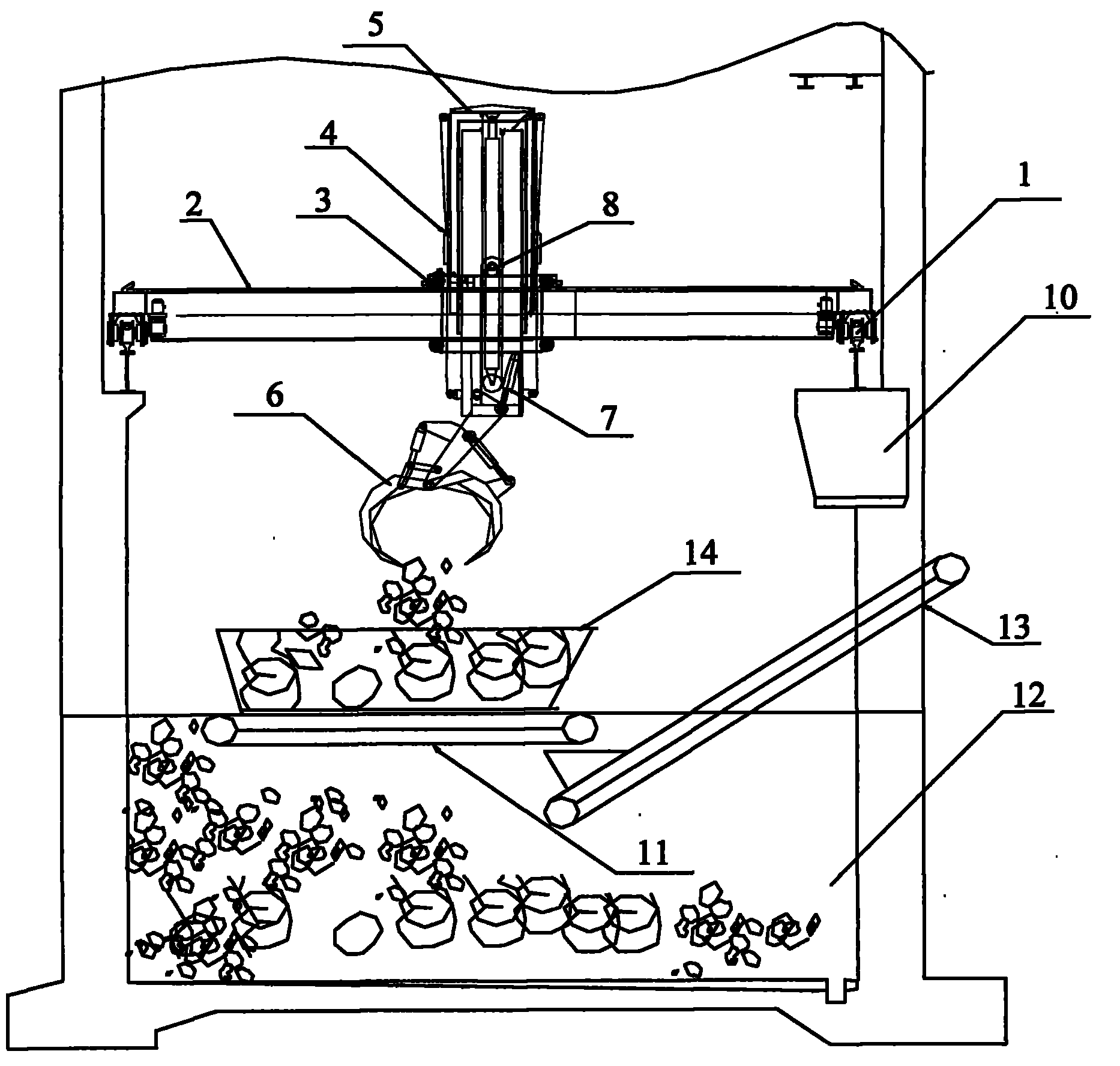

Manipulator device for feeding garbage

The invention discloses a manipulator device for feeding garbage and belongs to garbage processing equipment. The manipulator device comprises a beam, a cart traveling mechanism, a trolley running gear, an up and down moving mechanism, a manipulator swing device, a catching manipulator and a hydraulic device; the beam is arranged on the cart traveling mechanism; the trolley running gear is arranged on the beam and can freely move along the beam; the up and down moving mechanism is arranged on the trolley running gear; the lower end of the up and down moving mechanism is connected with the catching manipulator through the manipulator swing device; and the hydraulic device is arranged on the trolley running gear, and is respectively connected with the up and down moving mechanism, the manipulator swing device and the catching manipulator through hydraulic pipelines so as to drive the up and down moving mechanism to move the catching manipulator up and down, and the manipulator swing device to swing the catching manipulator. The manipulator device has simple structure and high catching speed, and can controllably swing the catching manipulator to quickly catch materials on a slope, thereby improving the catching efficiency.

Owner:EGUARD NEW ENERGY AUTOMOBILE CO LTD

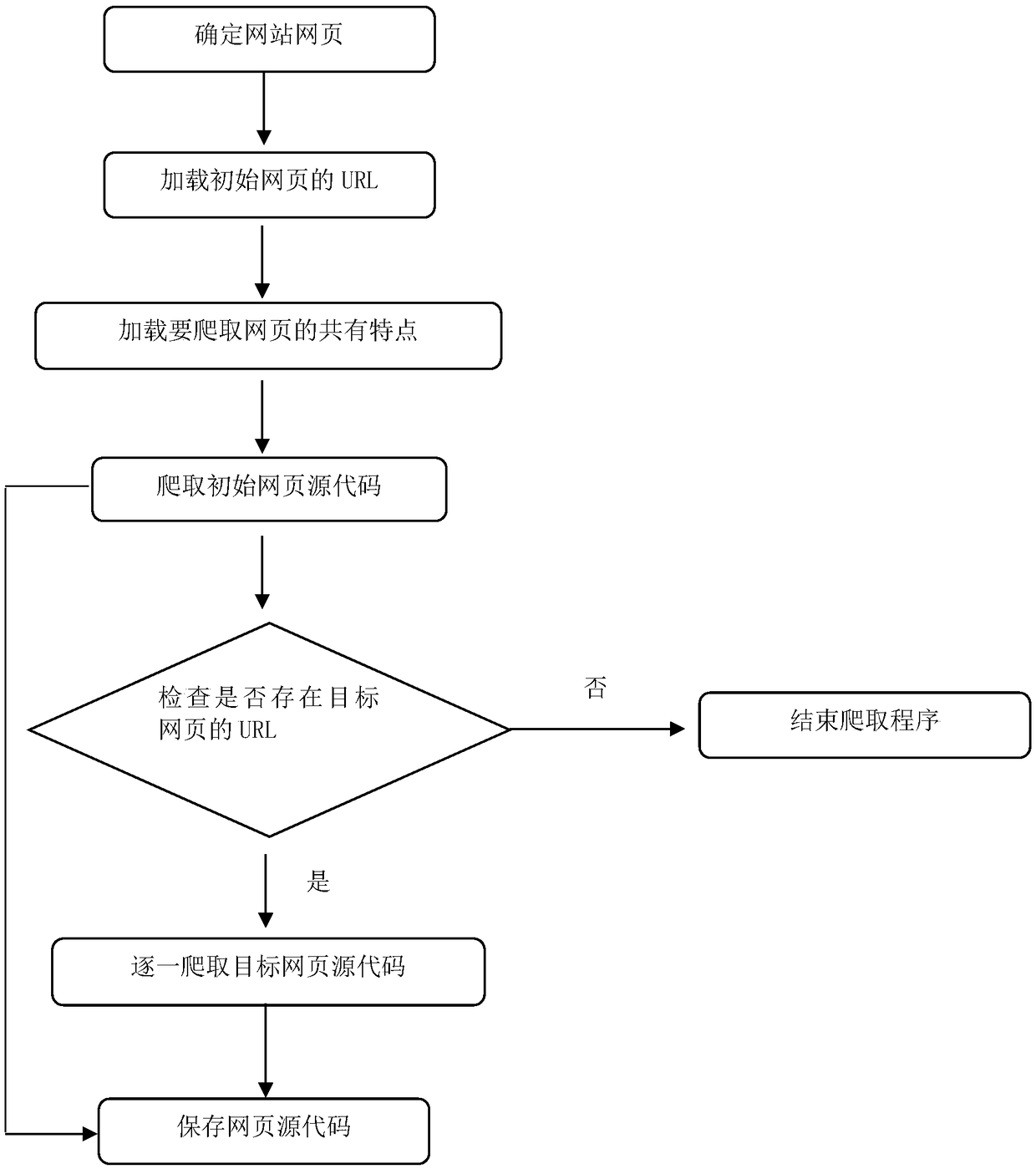

Website page source code automatic crawling method

PendingCN108664559AEasy extractionObvious commonalitySpecial data processing applicationsIp addressSource code

The present invention relates to a website page source code automatic crawling method. The website page source code automatic crawling method comprises the following steps of: crawling a webpage in adetermined website to enable the crawled webpage be more centralized and with obvious common features, so as to the webpage can be conveniently crawled in a compiling crawler program; crawling a webpage in a specific website to enable the target information to be crawled be more centralized, so as to the needed information can be completely and quickly crawled. When crawling a website page sourcecode, the crawl can be effectively counterfeited as a webpage request issued by a browser to prevent being recognized by the website as the website data is crawled by a machine code; Setting a certainwaiting time to enable the code to report an error and stops running when the website or the network occurs an abnormal situation and does not respond to the crawler program, so as to the code can beautomatically run to crawl the webpage source code for a long time; Adding a proxy IP address database to effectively prevent access being denied by the website when the IP of crawler code is blocked, the program can also automatically change the IP to continue crawling the webpage source code.

Owner:SUN YAT SEN UNIV

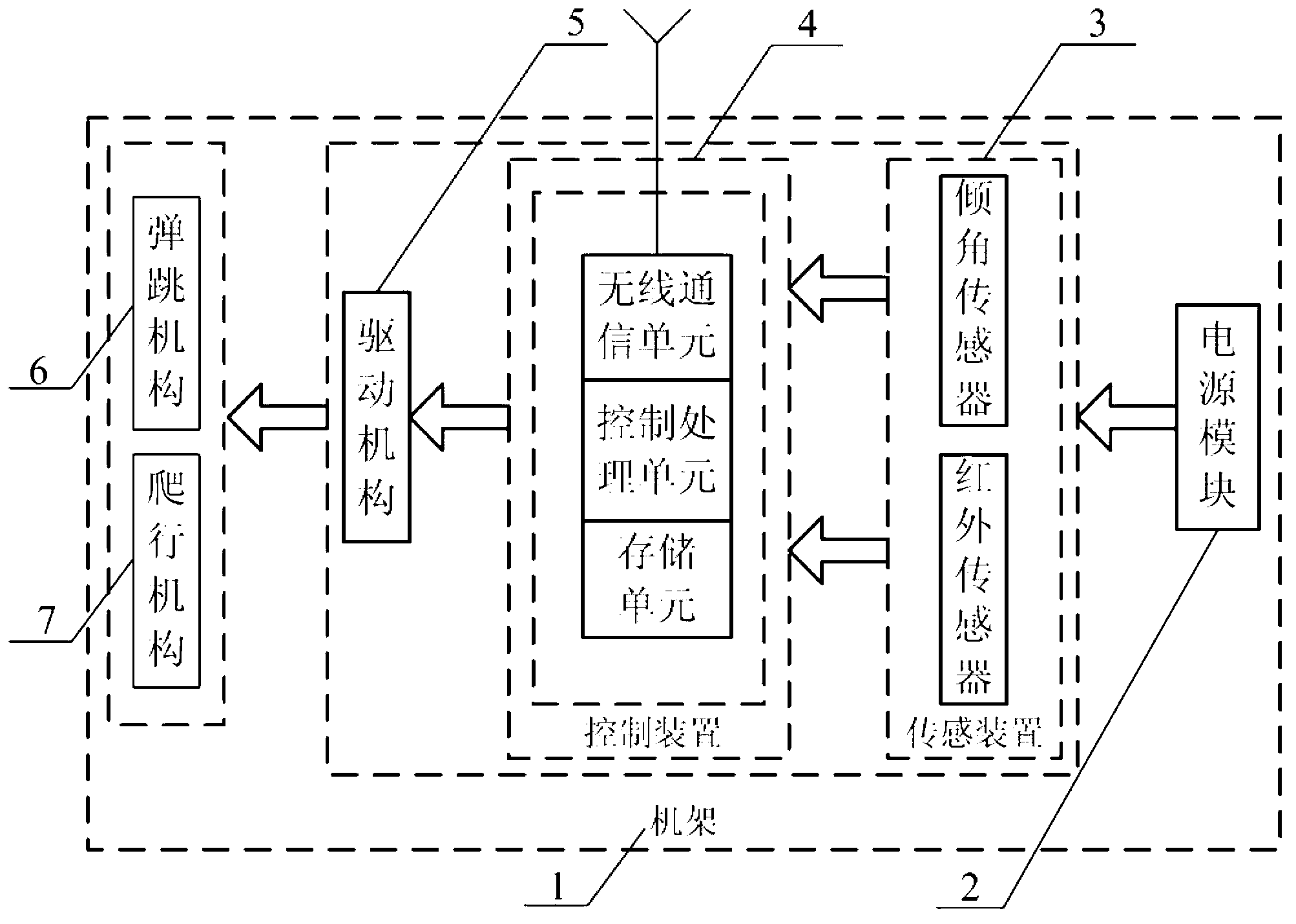

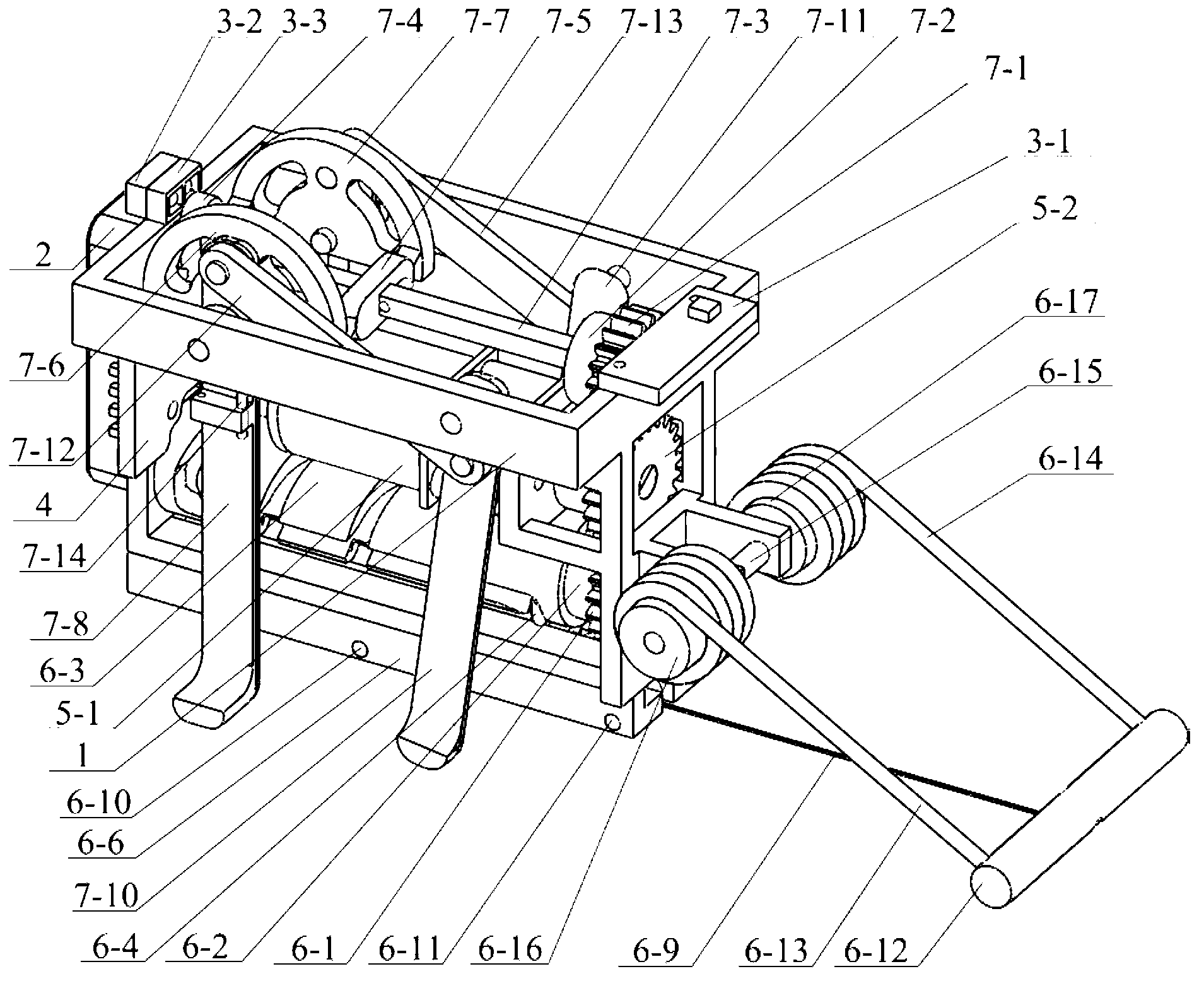

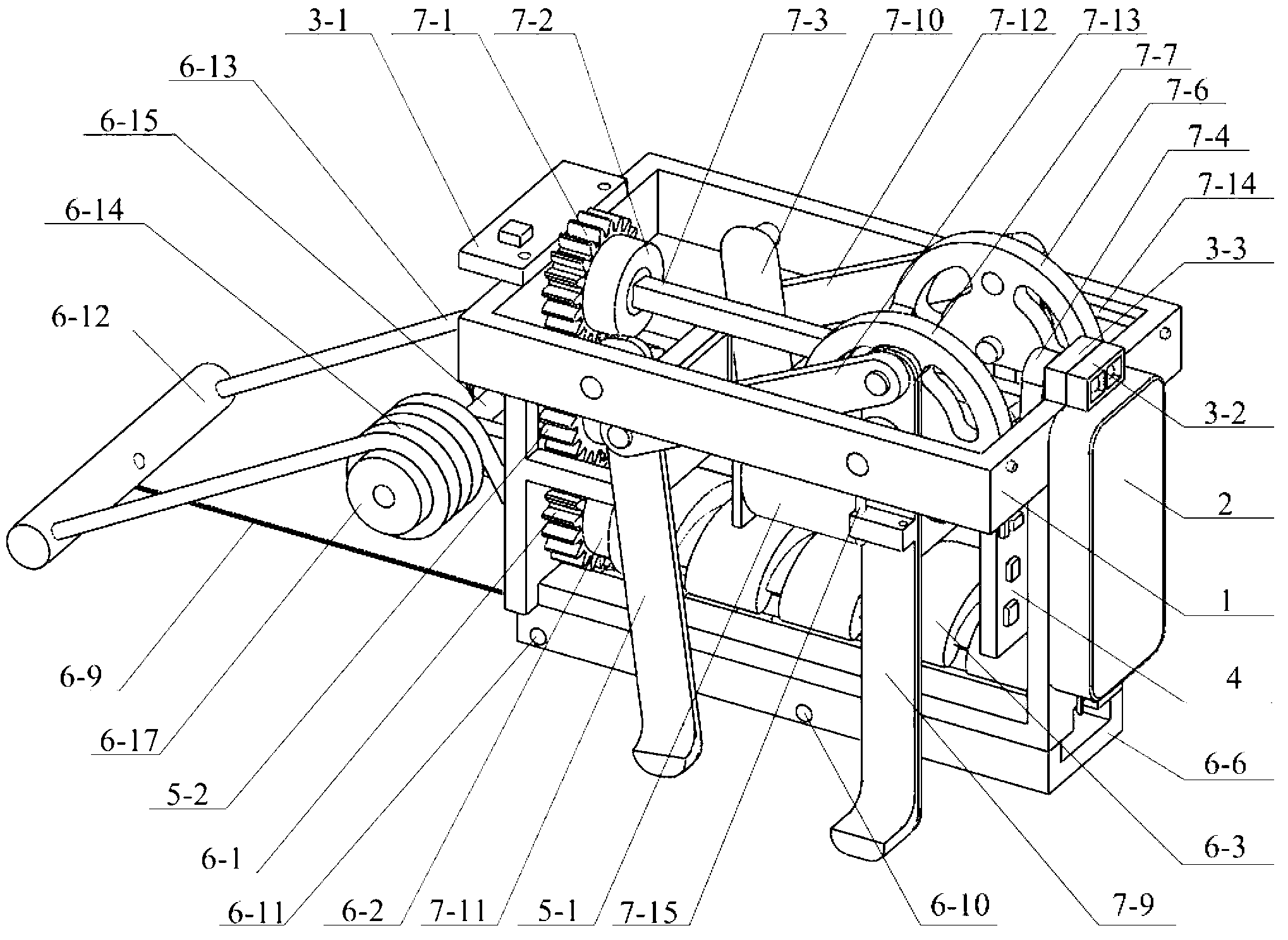

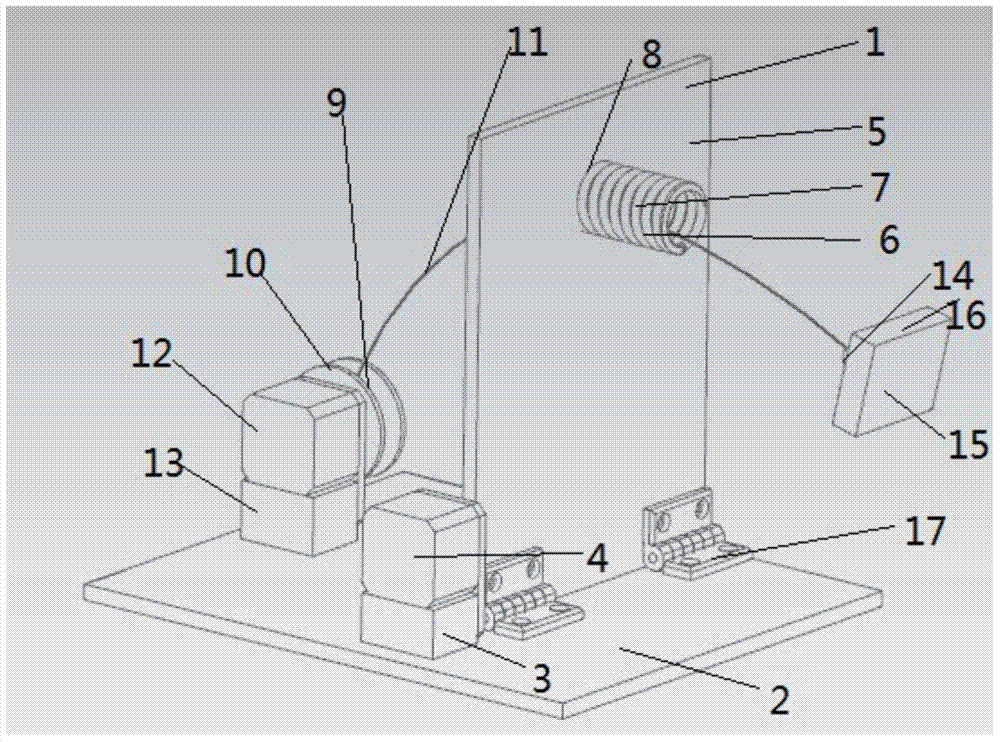

Single-motor driven climbing jumping robot

The invention relates to a single-motor driven climbing jumping robot which comprises a frame, a power module, a sensing device, a control device, a driving mechanism, a jumping mechanism and a climbing mechanism; the frame is used for installing other mechanisms and devices; a power unit provides energy for the driving mechanism and the control device; the sensing device is used for sensing the posture of the robot, whether an obstacle exists ahead or not and the positions of the rotating angles of driving rods; the control device completes the control over the robot, the remote transmission of data, and the collection and the storage of the data of a sensor; the driving mechanism drives the robot to complete the climbing and jumping motion through the forward and reverse rotation of a motor; the jumping mechanism is provided with a cylindrical cam which has a quick-return characteristic and can realize the slow energy storage and the quick energy release of jumping motion so as to realize jumping motion; and the climbing mechanism is provided with disc cams which are matched with the two crossed driving rods, and can drive the swinging of four legs by one motor, thus realizing the climbing motion.

Owner:SOUTHEAST UNIV

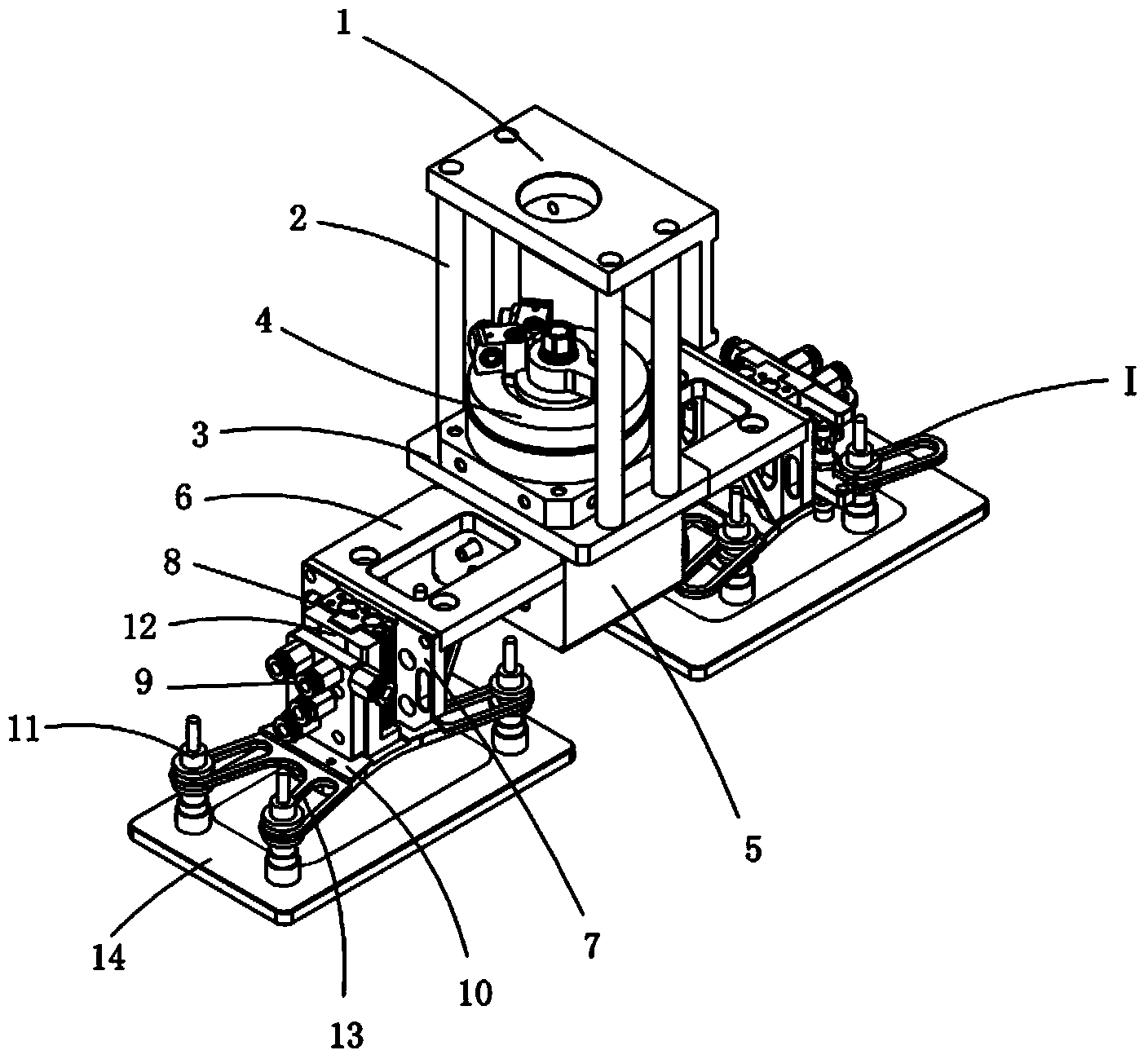

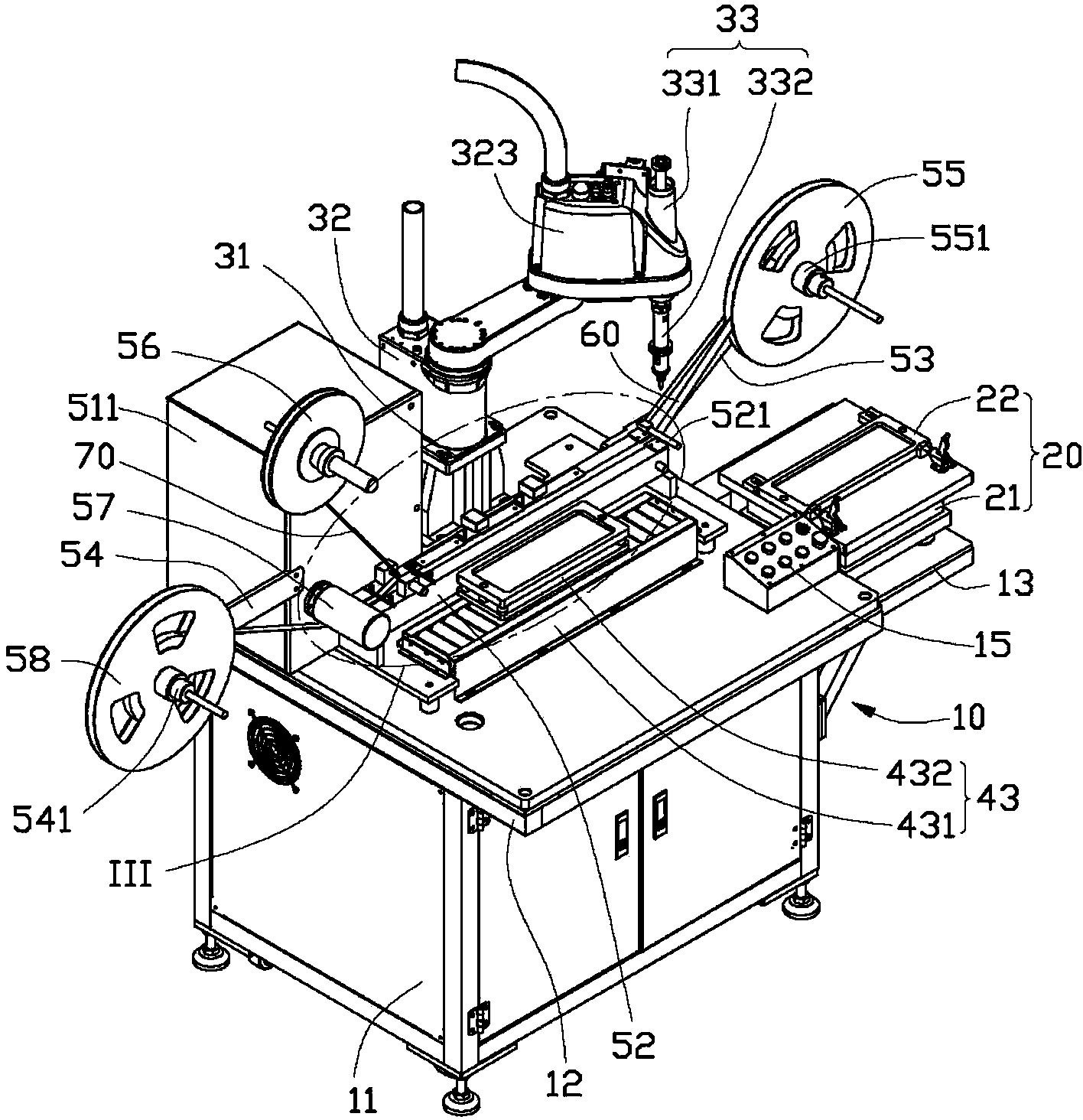

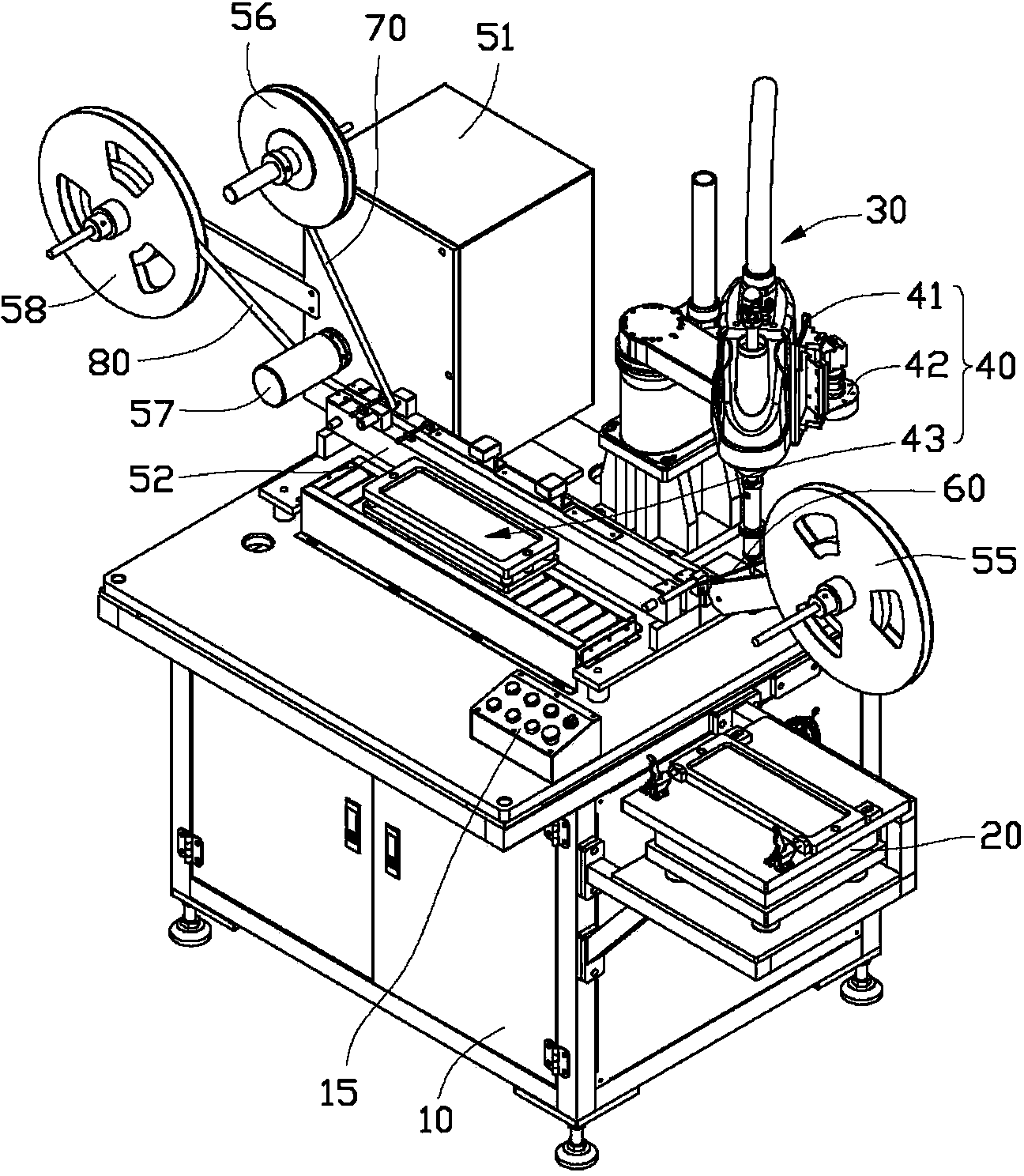

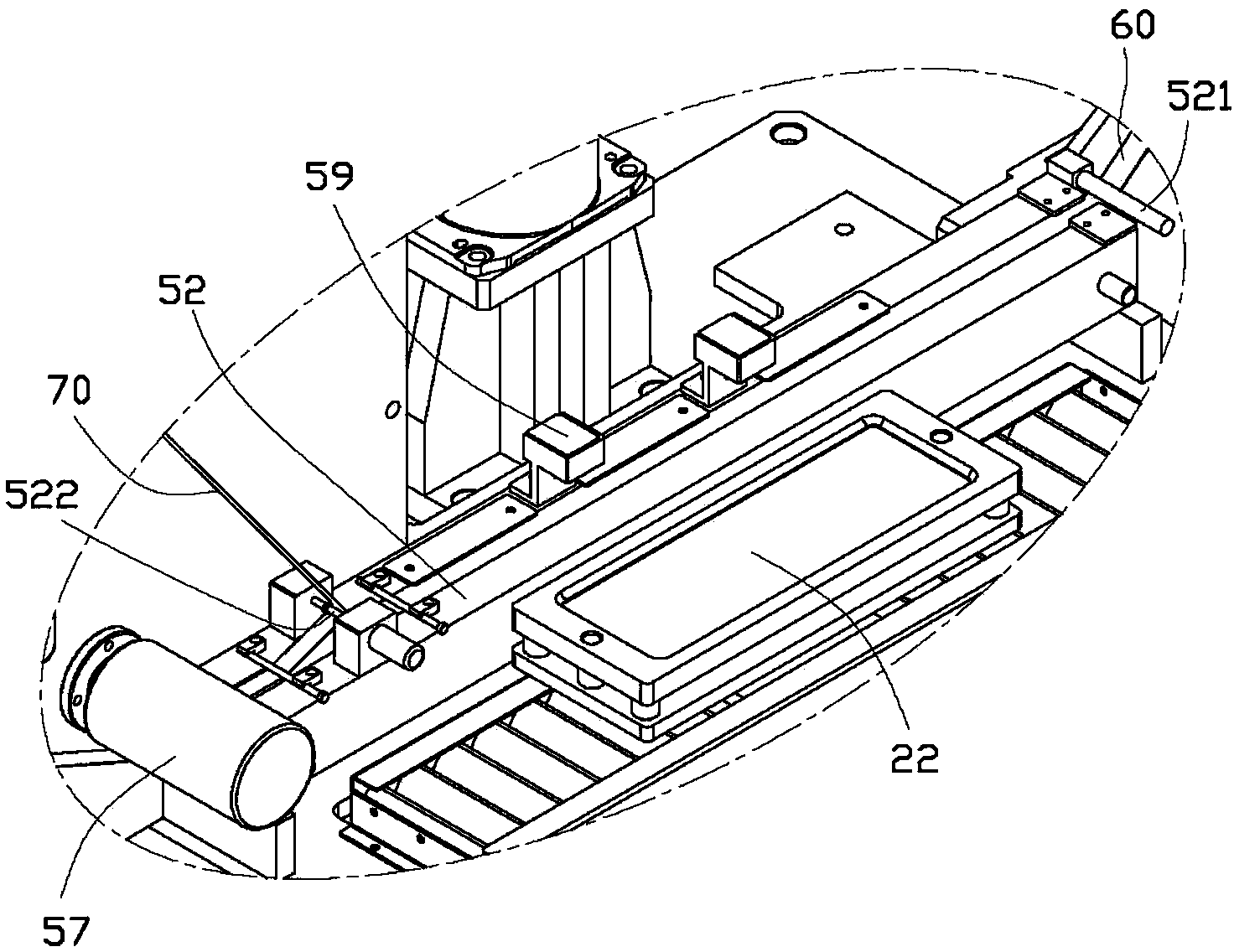

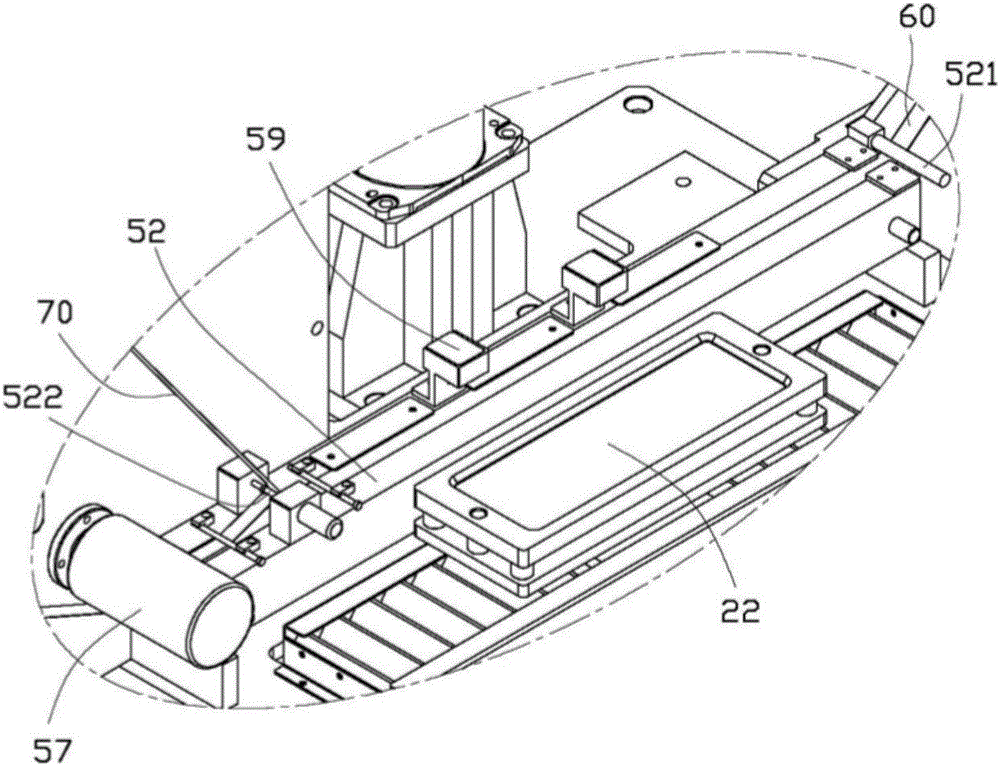

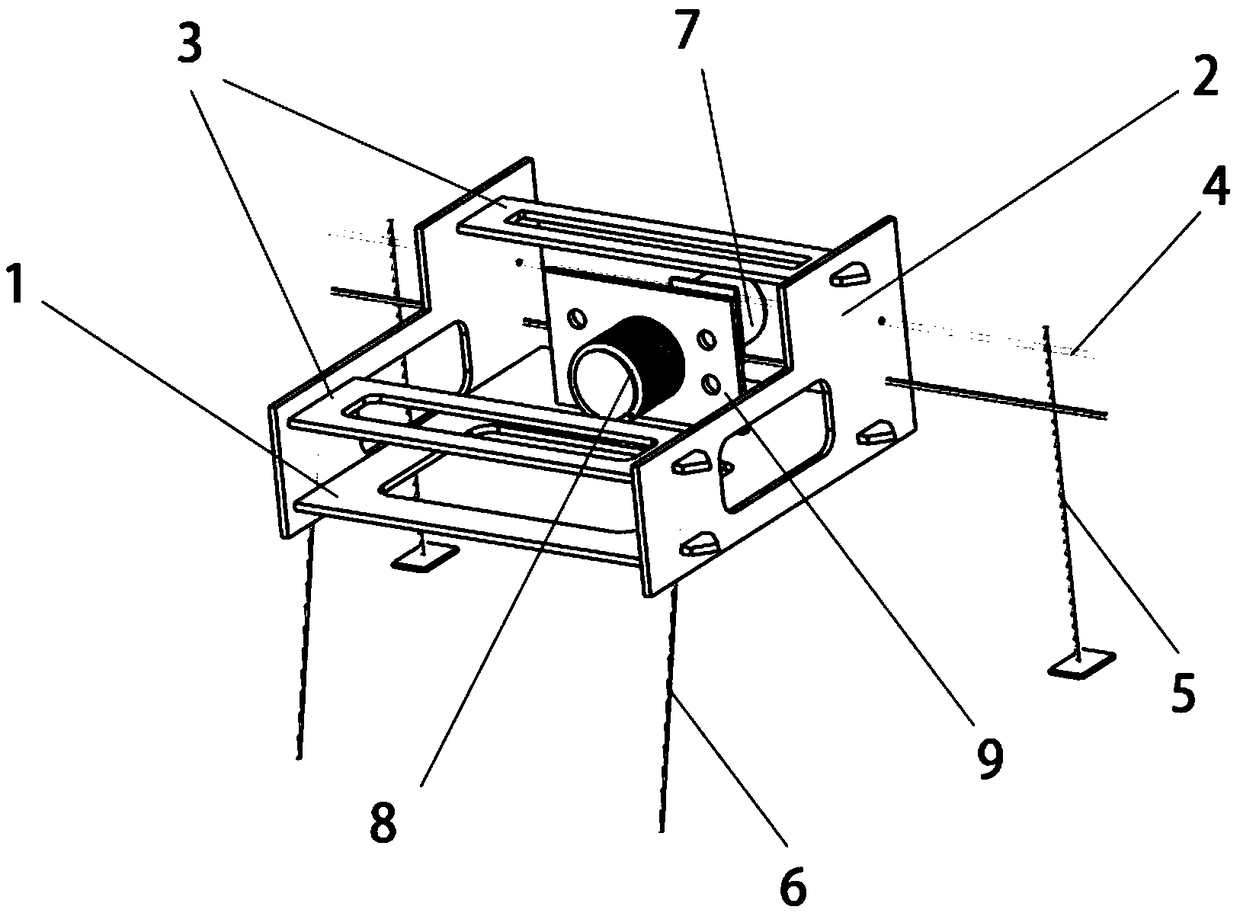

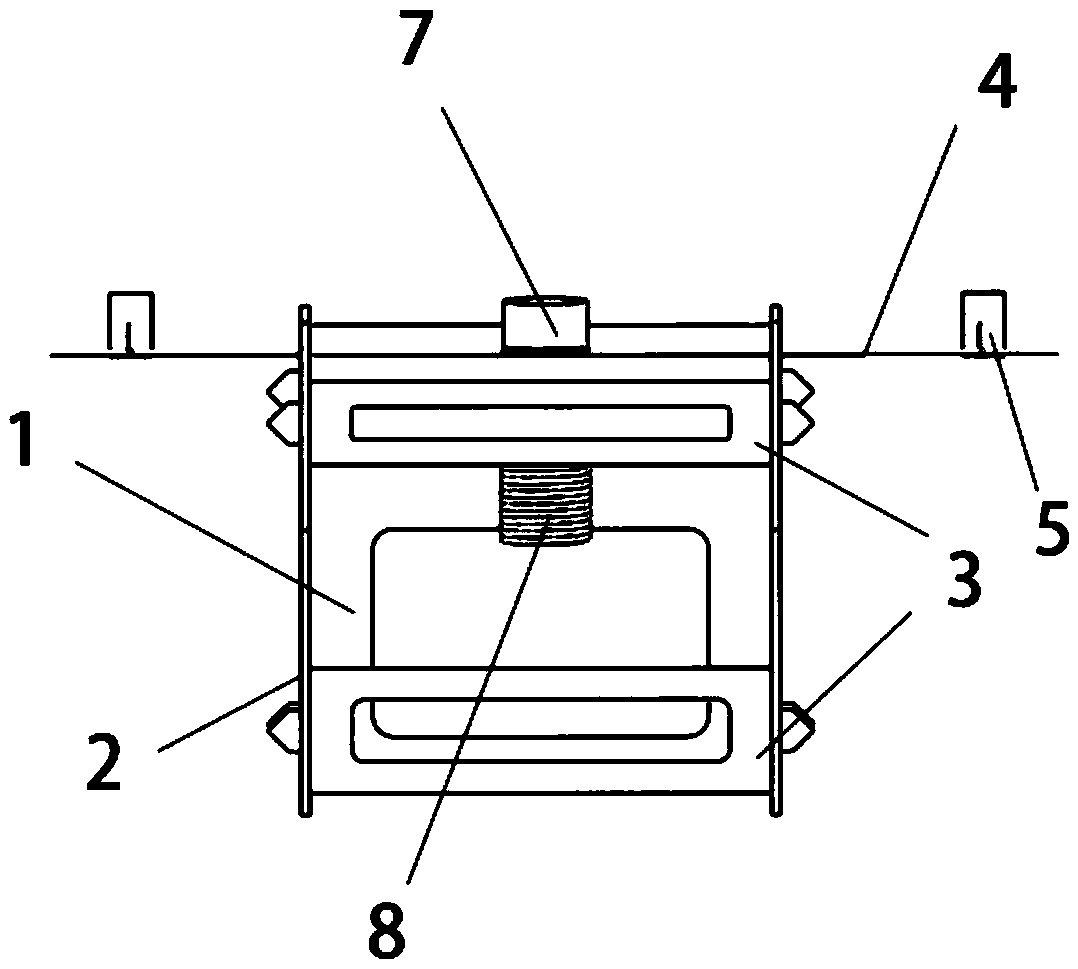

Automatic grabbing mechanism

Owner:BOZHON PRECISION IND TECH CO LTD

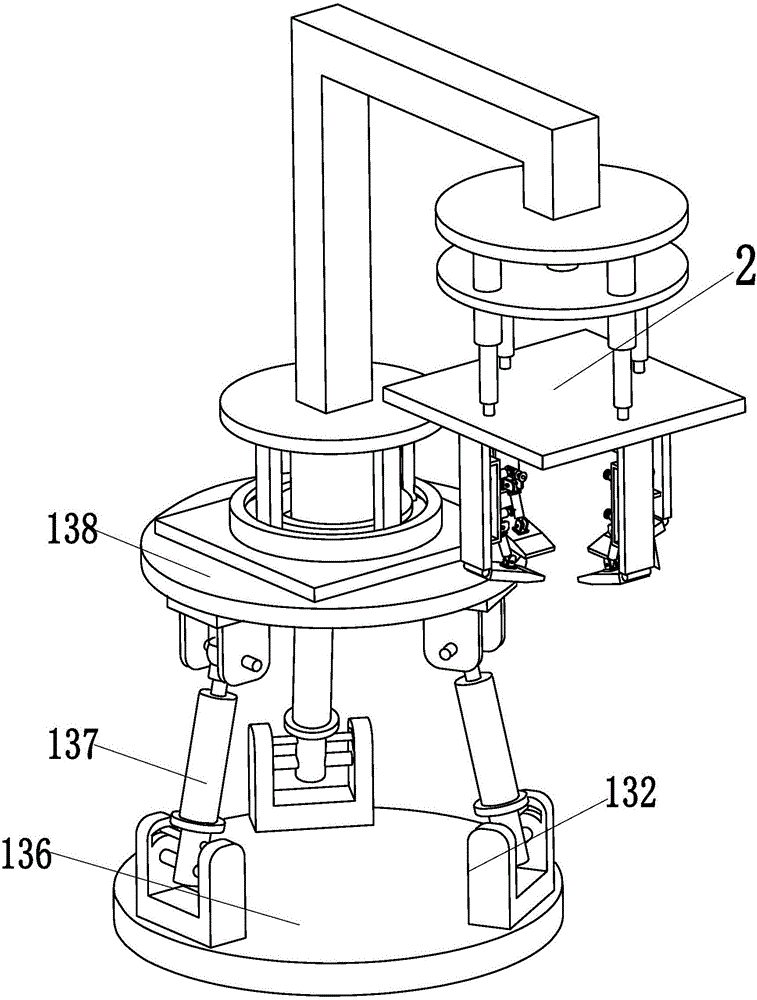

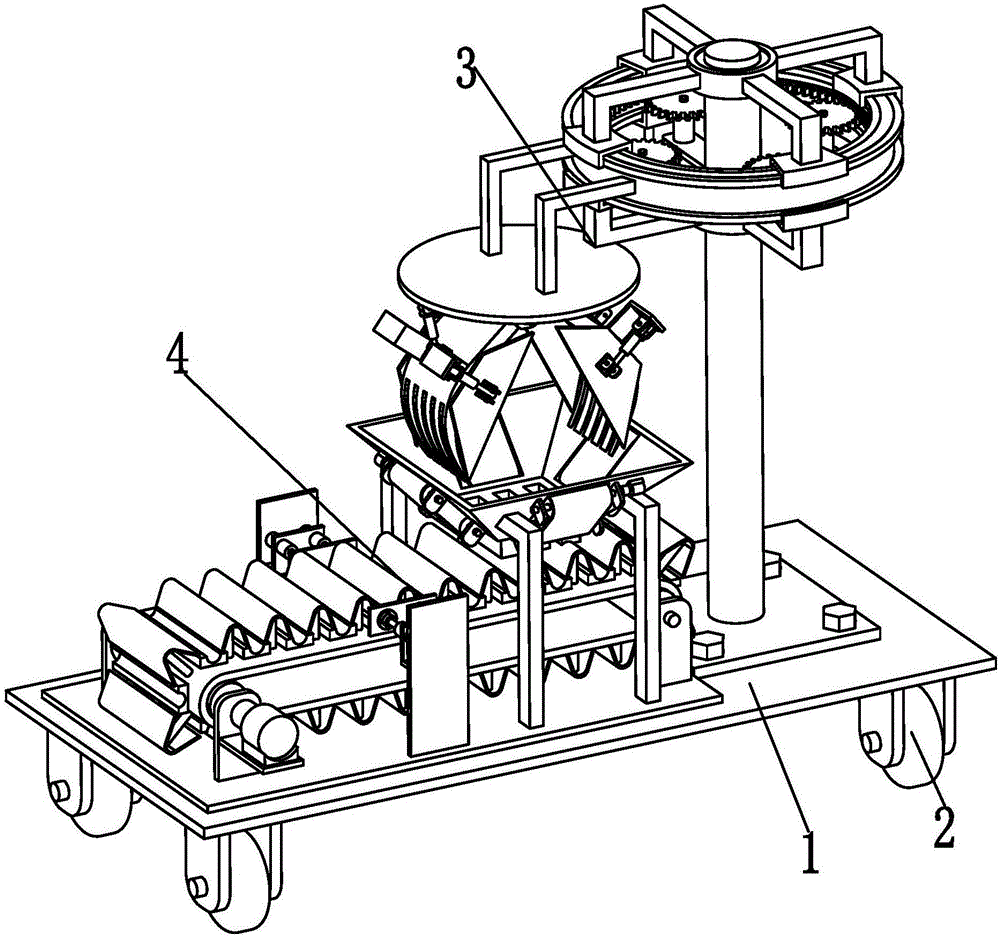

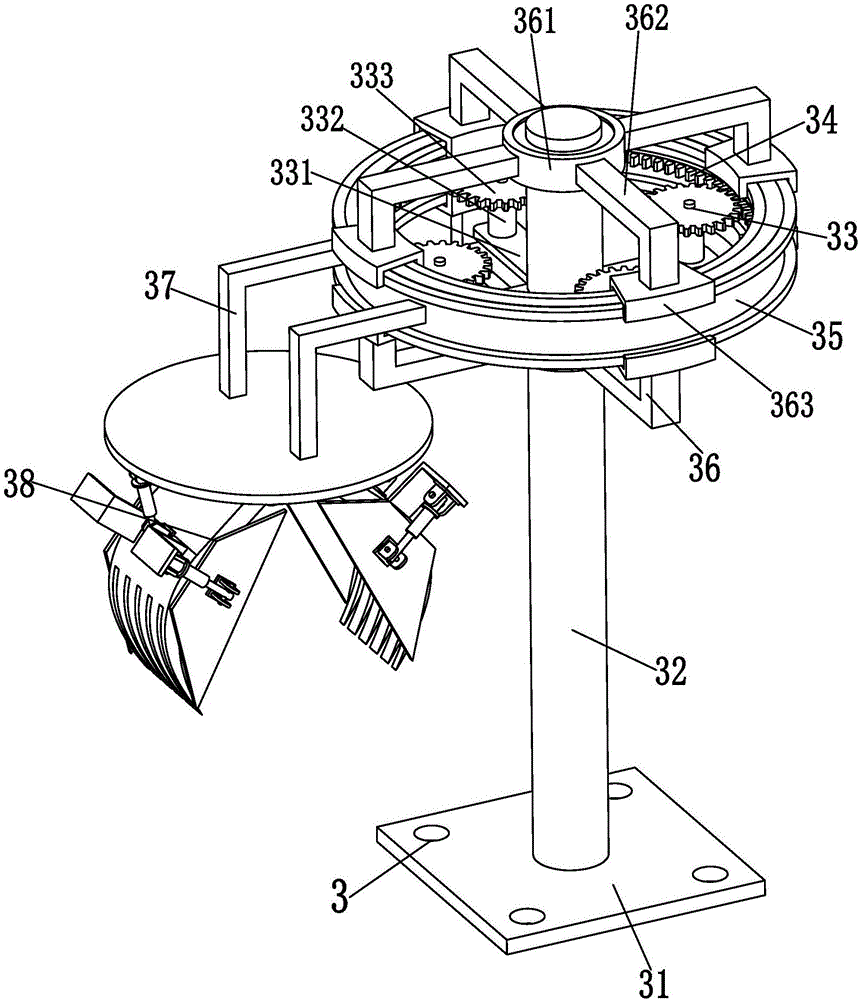

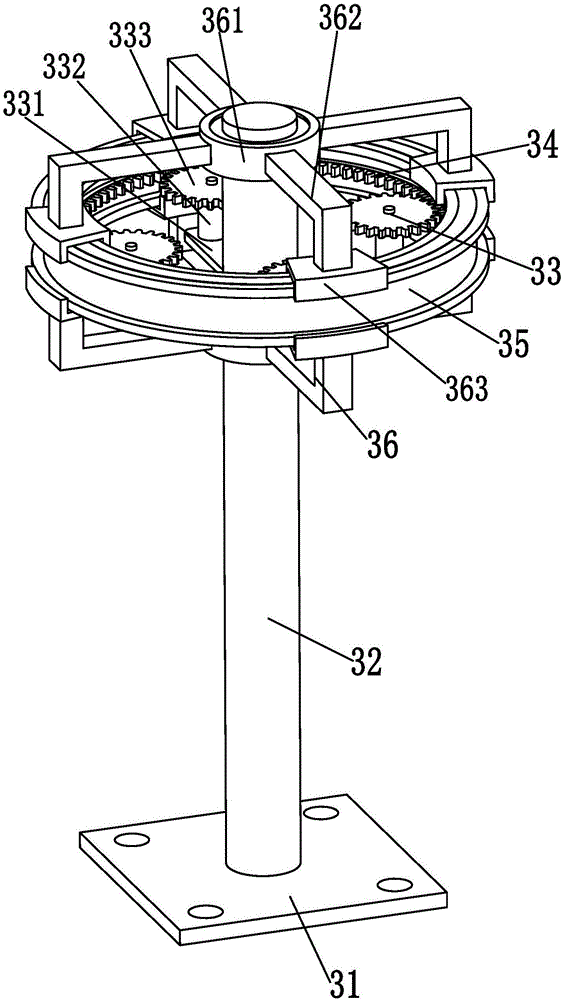

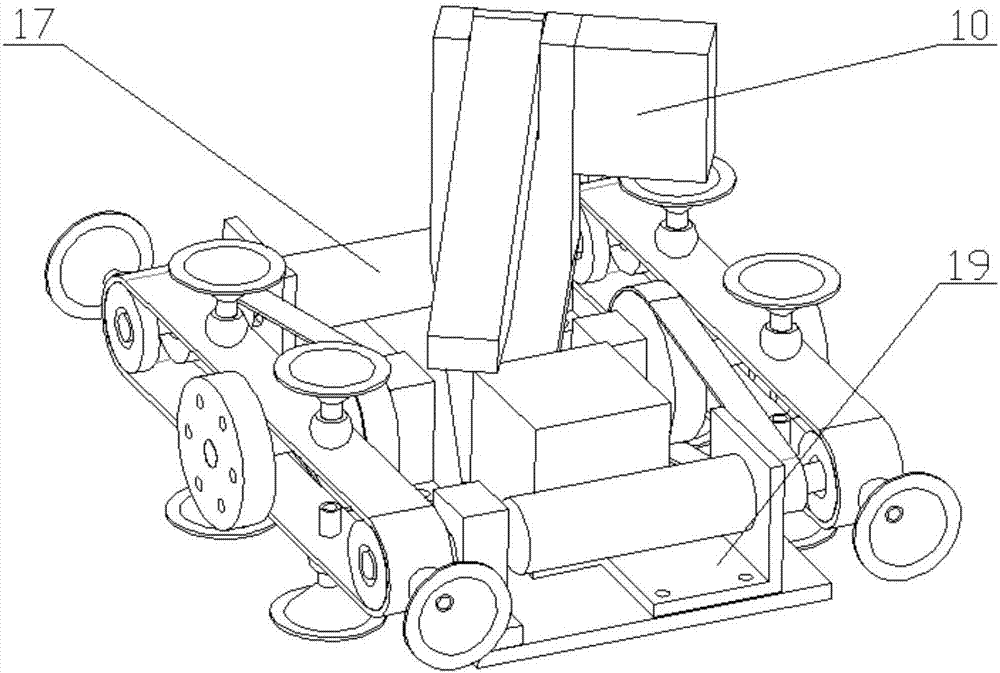

Electric automobile lithium battery cell capturing and conveying robot

The invention relates to an electric automobile lithium battery cell capturing and conveying robot which comprises a base plate. Four universal wheels are symmetrically installed on the lower side of the lower end face of the base plate, the robot is moved to a required cell processing position through the four universal wheels, and the electric automobile lithium battery cell capturing and conveying robot is simple and convenient to operate. A cell capturing device is installed on the right side of the upper end face of the base plate and can achieve a function of annular efficient quick capturing of lithium battery cells, and a cell conveying device is installed on the left side of the upper end face of the base plate and can achieve a function of continuous batch correction and quick conveyance of the lithium battery cells. The electric automobile lithium battery cell capturing and conveying robot can achieve the functions of annular efficient quick capturing, continuous batch correction and quick conveyance of the lithium battery cells, and the electric automobile lithium battery cell capturing and conveying robot is simple and convenient to operate and high in working efficiency. The electric automobile lithium battery cell capturing and conveying robot has the advantages that the capturing speed is quick, the capturing time is short, a plurality of cells can be quickly captured, the capturing efficiency is high, the transmission speed is quick, the transmission time is short, the cell deviation position can be automatically corrected, and the transmission efficiency is high.

Owner:烟台锂能环保科技有限公司

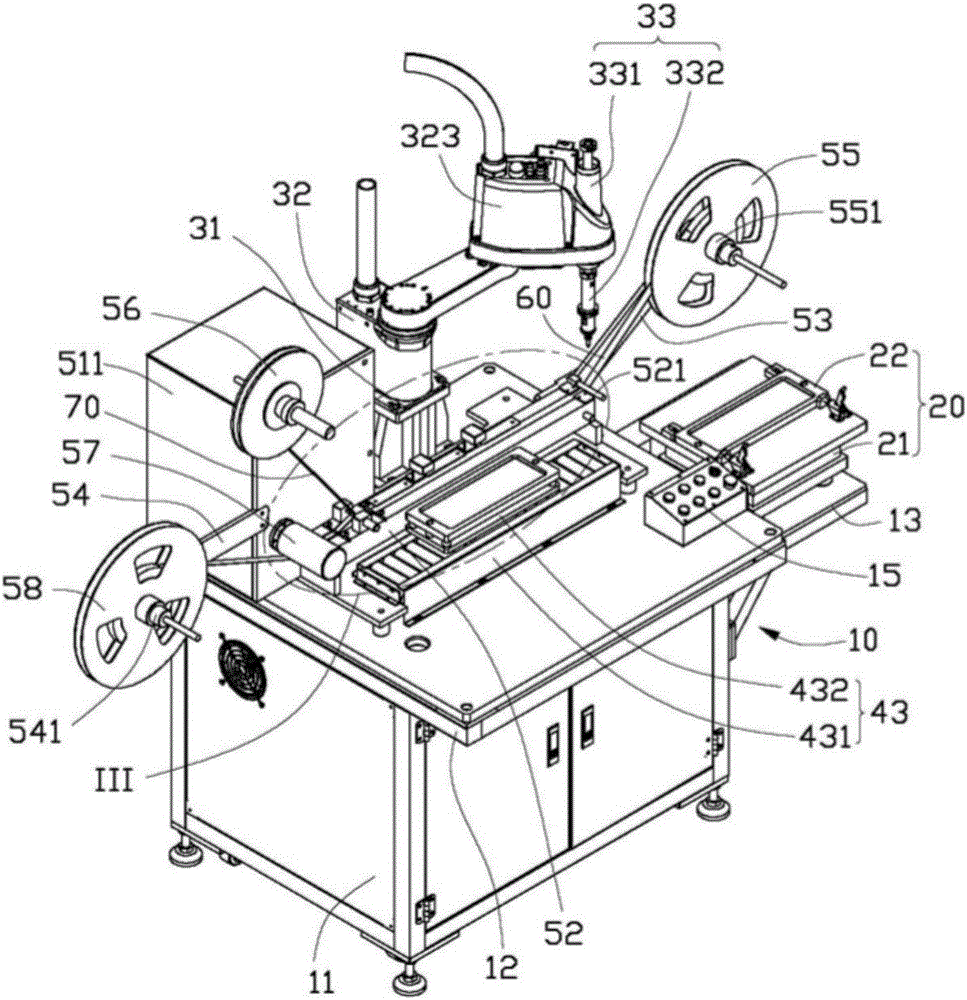

Packaging machine

InactiveCN103662210APrecise alignmentCrawl fastWrappingWrapper twisting/gatheringCcd cameraManipulator

The invention relates to a packaging machine used for packaging small workpieces. The packaging machine comprises a machine table, a control device, a jig plate bearing the workpieces, a vibration plate, a mechanical arm, a vacuum suction head installed on the mechanical arm, a packaging assembly and a positioning assembly. The vibration plate bears the jig plate to adjust the positions of the workpieces. The positioning assembly comprises a CCD camera and a transmission portion which are installed on the mechanical arm. The transmission portion bears the jig plate which is vibrated. The CCD camera is used for transmitting workpiece position signals in the jig plate to the control device which starts the mechanical arm to drive the vacuum suction head to accurately clamp the workpieces and put the workpieces into the packaging assembly to be packaged.

Owner:FIH PRECISION ELECTRONICS LANG FANG CO LTD

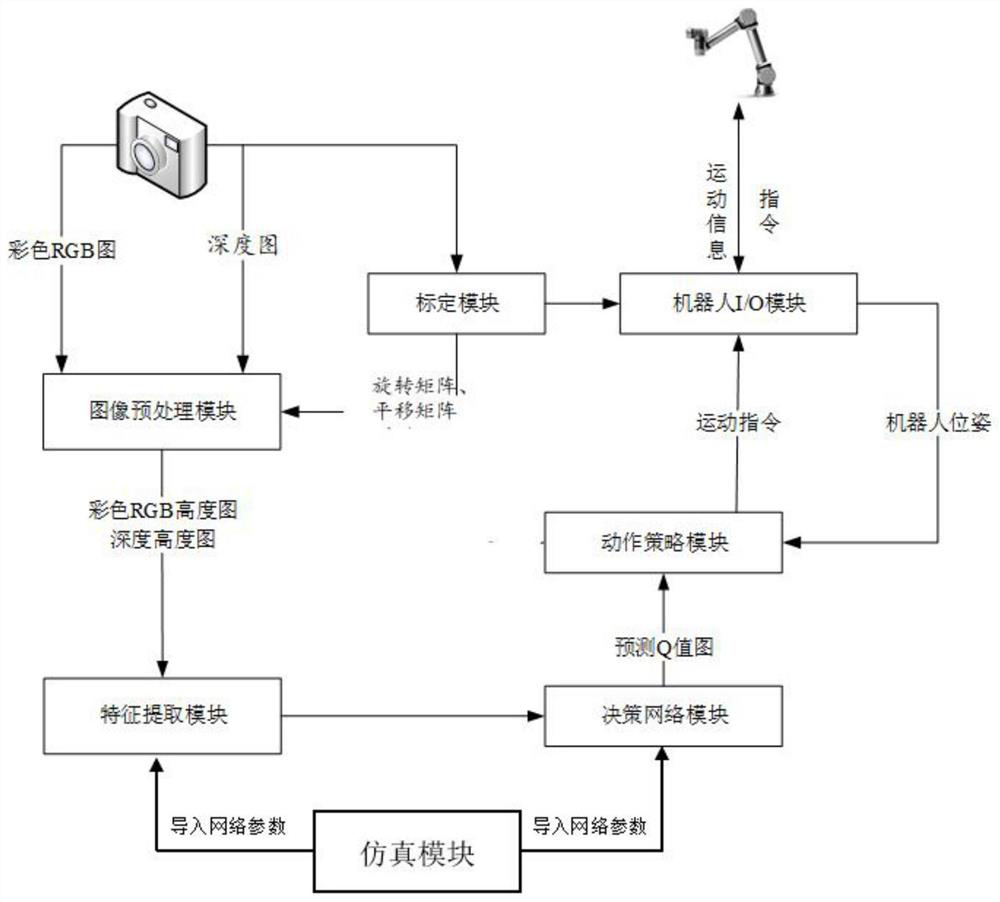

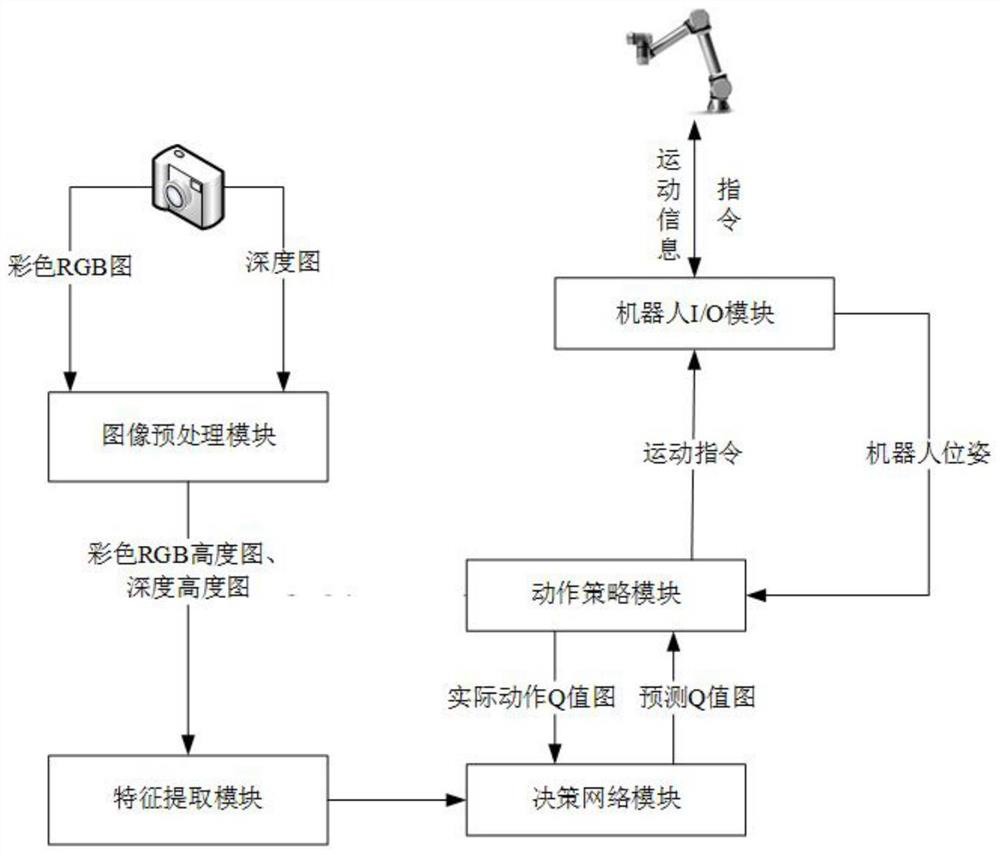

Mechanical arm pushing and grabbing system suitable for dense environment

ActiveCN112605983AAvoid damageCrawl fastProgramme-controlled manipulatorGripping headsLocal area networkColor depth

The invention discloses a mechanical arm pushing and grabbing system suitable for a dense environment. The system comprises a PC, a color depth camera, a mechanical arm and an intelligent clamping device; the software end comprises a CoppeliaSim simulation platform; the color depth camera is connected with the computer through a USB, and the mechanical arm is connected with the PC through a local area network; the color depth camera acquires a color RGB image and a depth image; the computer executes a mechanical arm control program; the mechanical arm executes actions; the intelligent clamper is used for grabbing or pushing the object block; and the CoppeliaSim simulation platform comprises a simulation module, a calibration module, an image preprocessing module, a feature extraction module, a decision network module, an action strategy module, a robot I / O module and a robot module. According to the method, simulation and reality are combined, robot damage caused by training is reduced, and the grabbing speed is increased; and the DQN of deep reinforcement learning is utilized, action semantics are dynamically planned in real time according to the current object environment, pushing and grabbing are combined, meanwhile, the most suitable grabbing direction is planned, and the success rate of grabbing the complex environment by the mechanical arm is greatly increased.

Owner:ZHEJIANG UNIV OF TECH

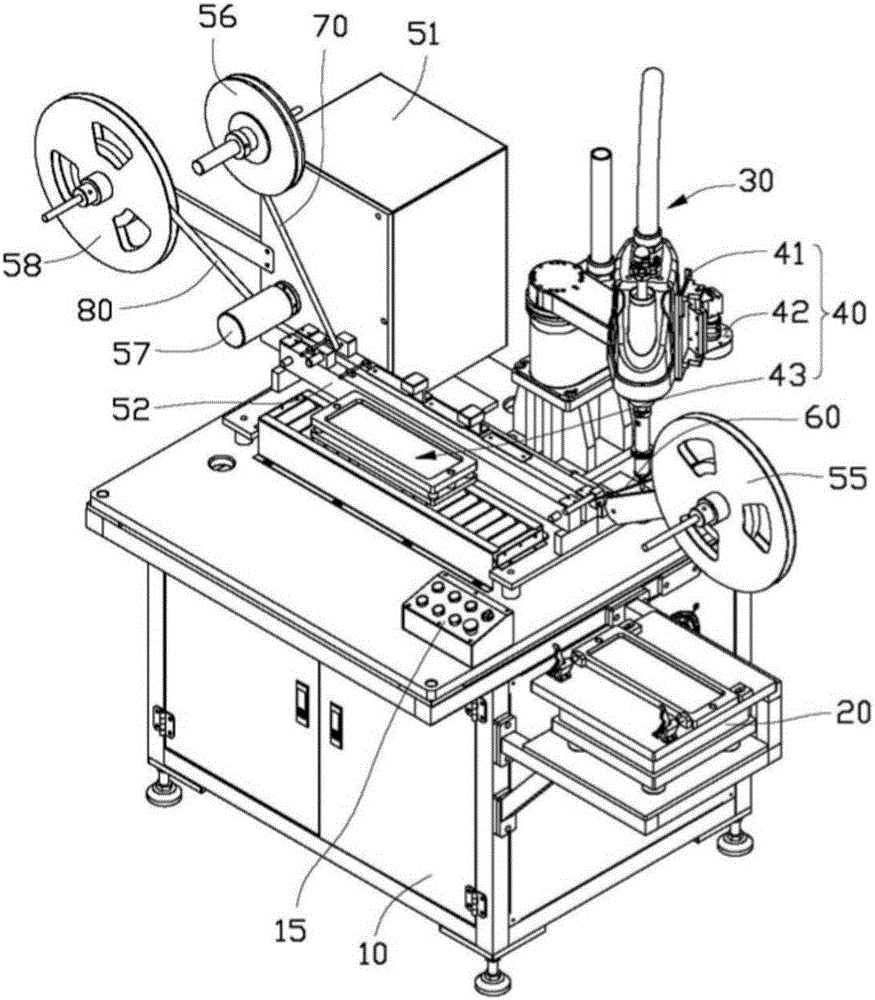

Packing machine

InactiveCN106428762APrecise alignmentCrawl fastWrapping material feeding apparatusEngineeringCcd camera

The invention discloses a packing machine which is used for packing small workpieces. The packing machine comprises a machine table and a control device, a jig disc for bearing a workpiece, a vibration disc, a manipulator, a vacuum sucking head arranged on the manipulator, a packing component and a positioning component, wherein the vibration disc bears the jig disc to adjust the position of the workpiece; the positioning component comprises a CCD camera which is arranged on the manipulator and a transmission part; the transmission part bears the vibrated jig disc; the CCD camera is used for transmitting the position signal of the workpiece in the jig disc to the control device; and the control device starts the manipulator to drive the vacuum sucking head to grab the workpiece accurately and put the workpiece in the packing component for packing.

Owner:霍进铭

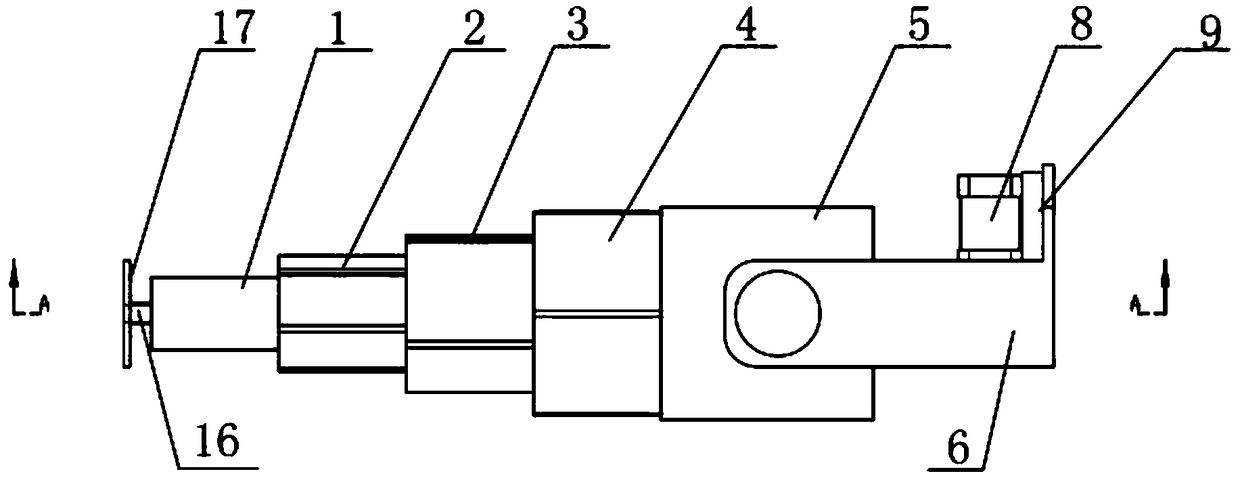

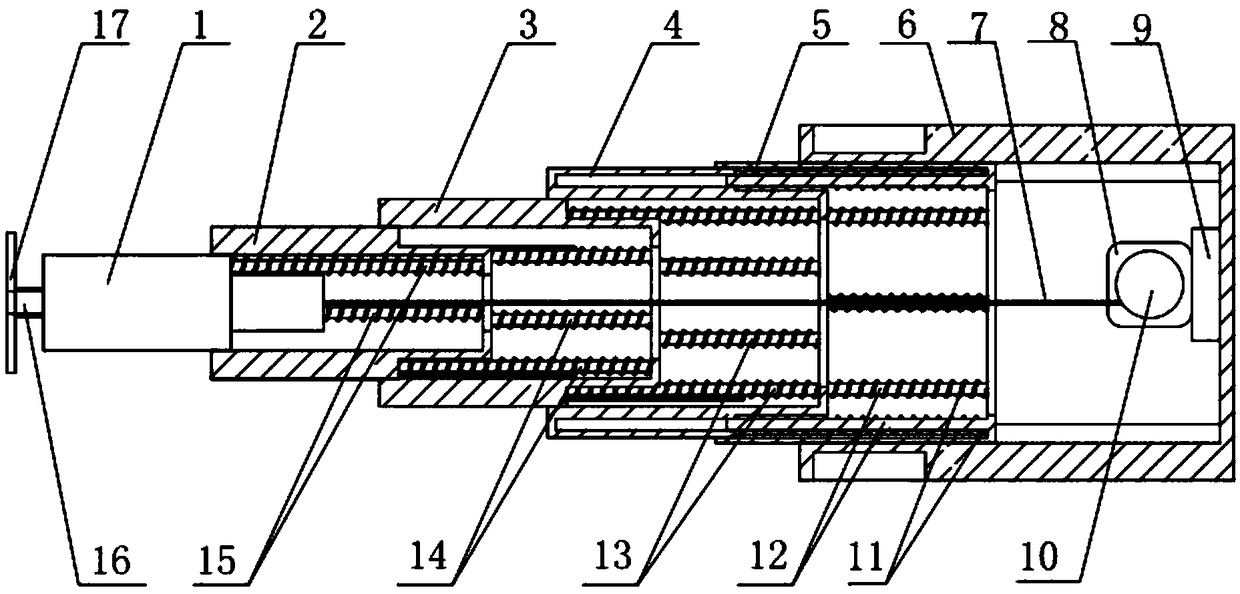

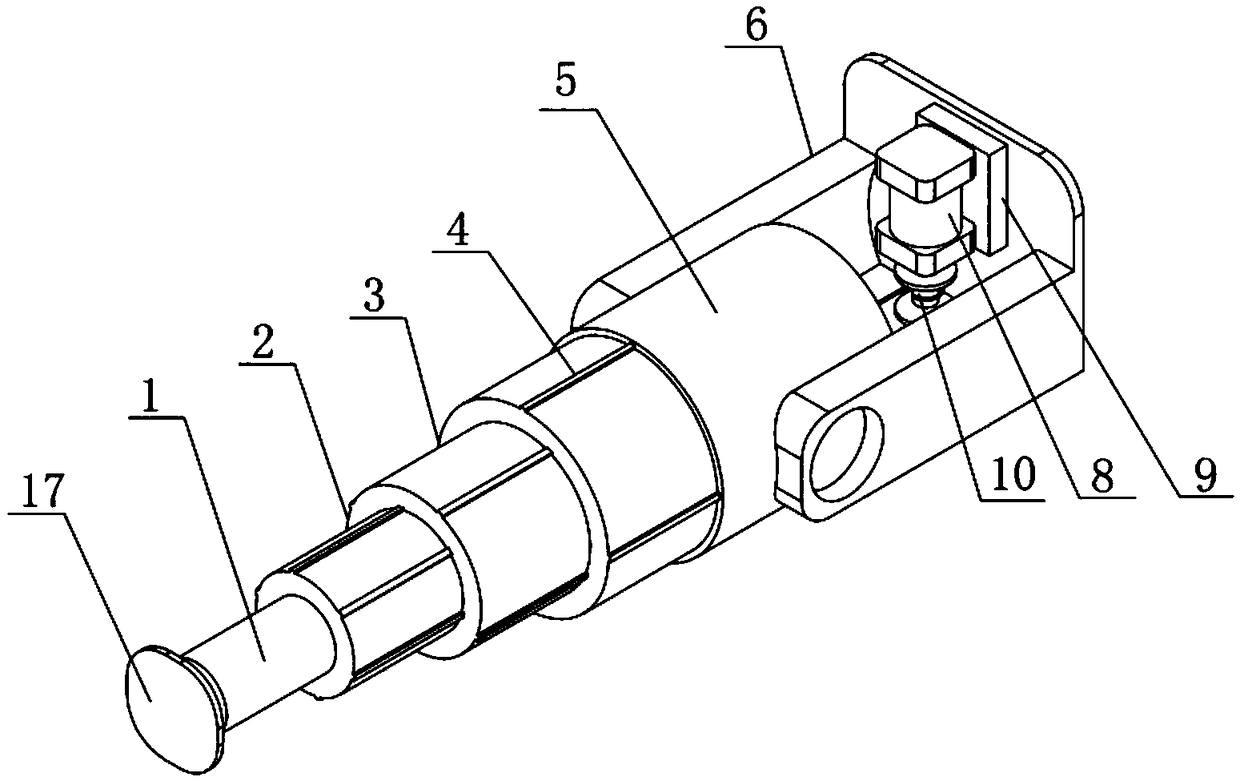

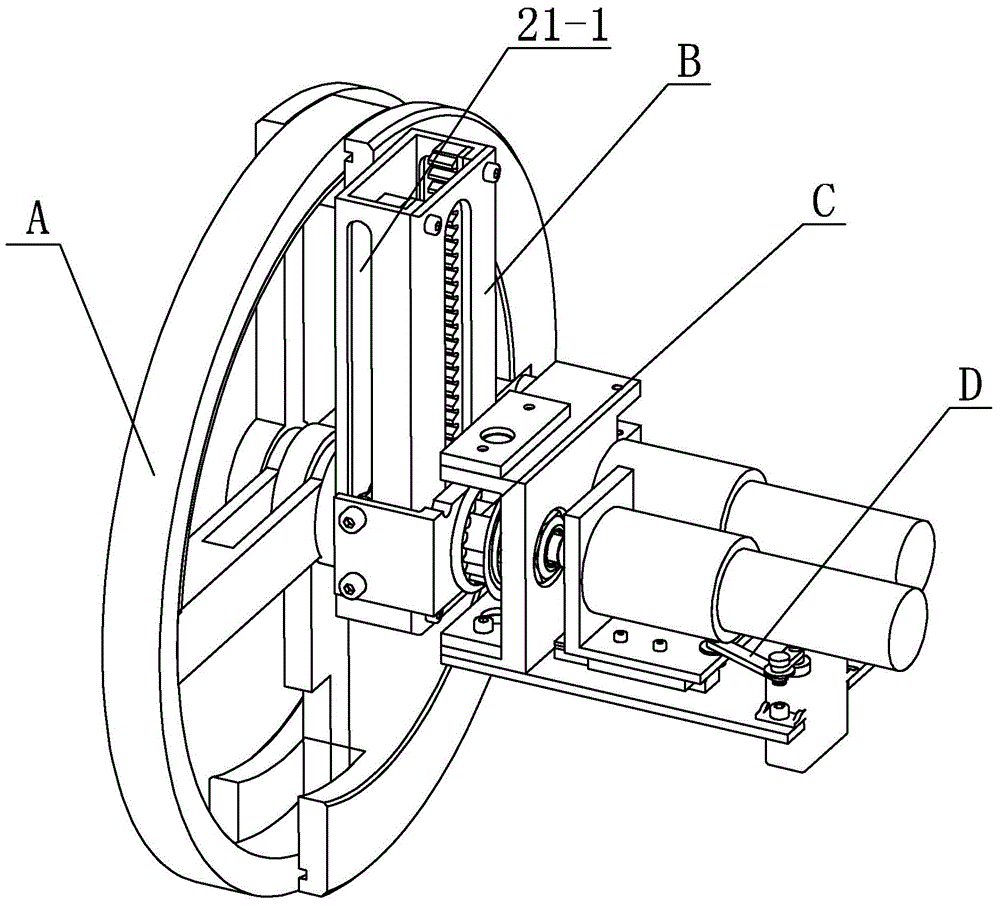

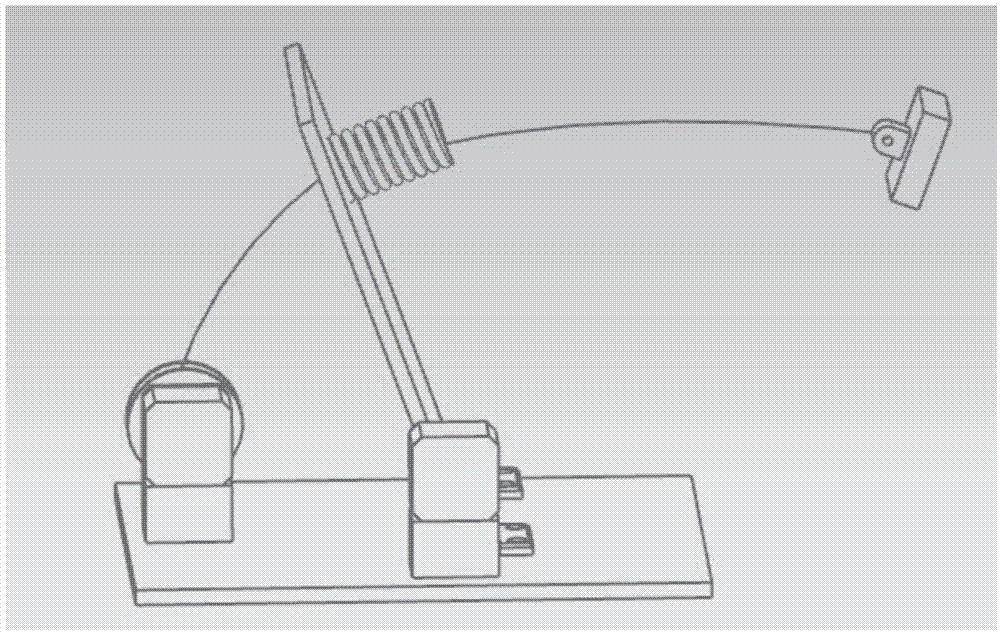

Catapulting type fast grabbing robot

InactiveCN108818615ASolve the problem of limited crawl spaceCompact structureProgramme-controlled manipulatorGripping headsEngineeringMechanical engineering

The invention relates to a catapulting type fast grabbing robot. The catapulting type fast grabbing robot comprises a trigger mechanism, a base, a shrinking mechanism and an adhering grabbing mechanism; the trigger mechanism comprises a first sleeve, a second sleeve, a third sleeve and a fourth sleeve which are sequentially connected in a nested manner from big to small; a trigger mechanism tail end is connected in the fourth sleeve in a nested manner; the sleeve walls of the second sleeve, the third sleeve and the fourth sleeve are each provided with a plurality of channels; the adjacent sleeves are connected through a plurality of cylinder pins and the fourth sleeve and the trigger mechanism tail end are connected through a plurality of cylinder pins; each cylinder pin is externally sleeved with a spring; the shrinking mechanism comprises a servo motor installed on the base and a rotating shaft; an output shaft of the servo motor is connected with the rotating shaft; the starting endof a non-elastic rope is fixed to the rotating shaft, and the tail end of an elastic rope is connected with the trigger mechanism tail end; and the adhering grabbing mechanism comprises an adhering plate which is connected with the trigger mechanism tail end through a connection device. Compared with a traditional grabbing robot, the characteristics that speed is high, the grabbing range is wide,maneuverability is high, and environment adaptability is high are achieved.

Owner:JIANGNAN UNIV

Wheel switching mechanism for mobile robot

ActiveCN104787145ARealize the combinationImprove terrain adaptabilityVehiclesFoot typeObstacle avoidance

The invention discloses a wheel foot switching mechanism for a mobile robot, and relates to the wheel foot switching mechanism. The problems that the obstacle avoidance ability of an existing wheeled robot is poor and an existing foot type robot walks slowly are solved. one end of a central shaft is fixedly connected and is locked axially through a first limiting block, the other end of the central shaft is provided with a shoulder, a spring sleeves the central shaft and is arranged between a first bearing and the shoulder, a center blind hole is formed in the other end of the central shaft, and a first key groove is formed in the interior of the center blind hole; a half-ring groove is formed in a fixed half wheel in the peripheral direction of the fixed half wheel, a moving half wheel is connected with the fixed half wheel in a rotating mode relative to the central shaft, when a wheeled type state is switched, a complete wheel is formed by the fixed half wheel and the moving half wheel, when a foot type state is switched, the moving half wheel rotates and is arranged in the half-ring groove of the fixed half wheel, and a single scroll is installed on the central shaft. The invention belongs to the field of the mobile robot.

Owner:HARBIN INST OF TECH

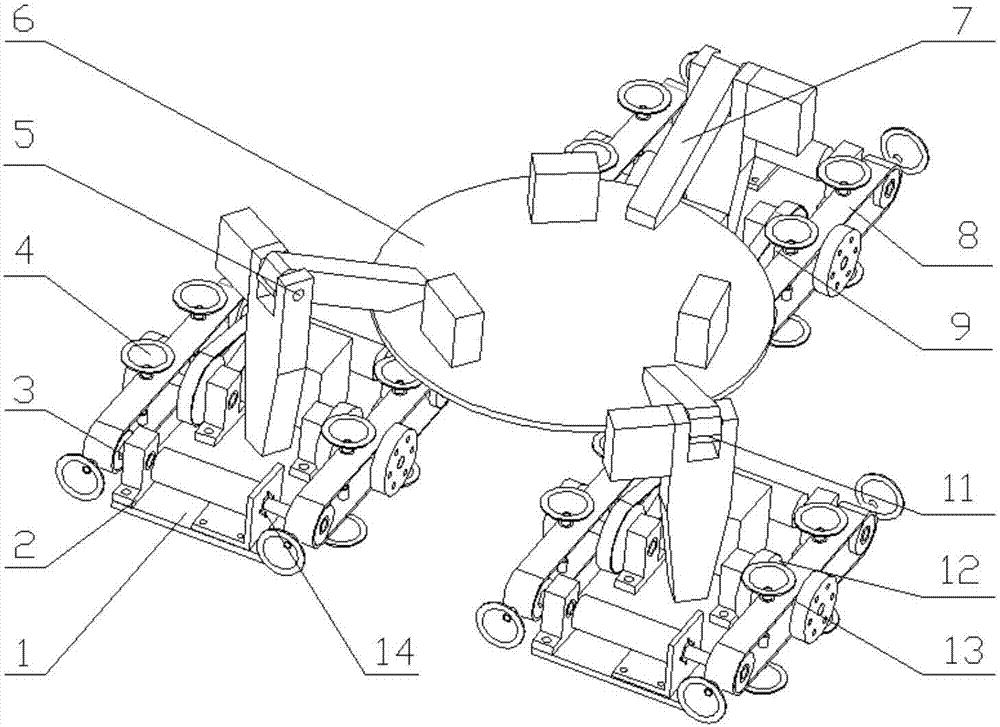

Wall-climbing robot

ActiveCN107985432AImprove obstacle performanceImprove adsorption capacityEndless track vehiclesDistribution systemEngineering

The invention discloses a wall-climbing robot. Currently, wall-climbing robots are urgently needed for replacing manual operation. The wall-climbing robot comprises an equipment carrier platform, foottype obstacle crossing mechanisms, tracked crawling mechanisms and air distribution systems. Each air distribution system comprises hinge type flat-bottom skirted suckers, an air distribution plate and sucker connectors, wherein the air distribution plate synchronously rotates along with the corresponding tracked crawling mechanism; the n sucker connectors are fixed to tracks; the sucker connectors are spherically hinged to tail ends of the hinge type flat-bottom skirted suckers; the sucker connectors are hollow internally, one end of each sucker connector is internally communicated with thecorresponding hinge type flat-bottom skirted sucker, and the other end of each sucker connector is communicated with an air distribution hole of the air distribution plate through an air guide pipe. Alternate air suction of every two hinge type flat-bottom skirted suckers in the same group is changed through a two-position four-way reversing valve, and an air suction port of each two-position four-way reversing valve is communicate with a vacuum generator through an air delivery pipe. By adoption of the foot type obstacle crossing mechanisms, great obstacle crossing performance is achieved; owing to a difference between pressure intensity in each sucker cavity and pressure intensity of the external barometric pressure, the wall-climbing robot is attached on a concrete wall surface.

Owner:HANGZHOU DIANZI UNIV

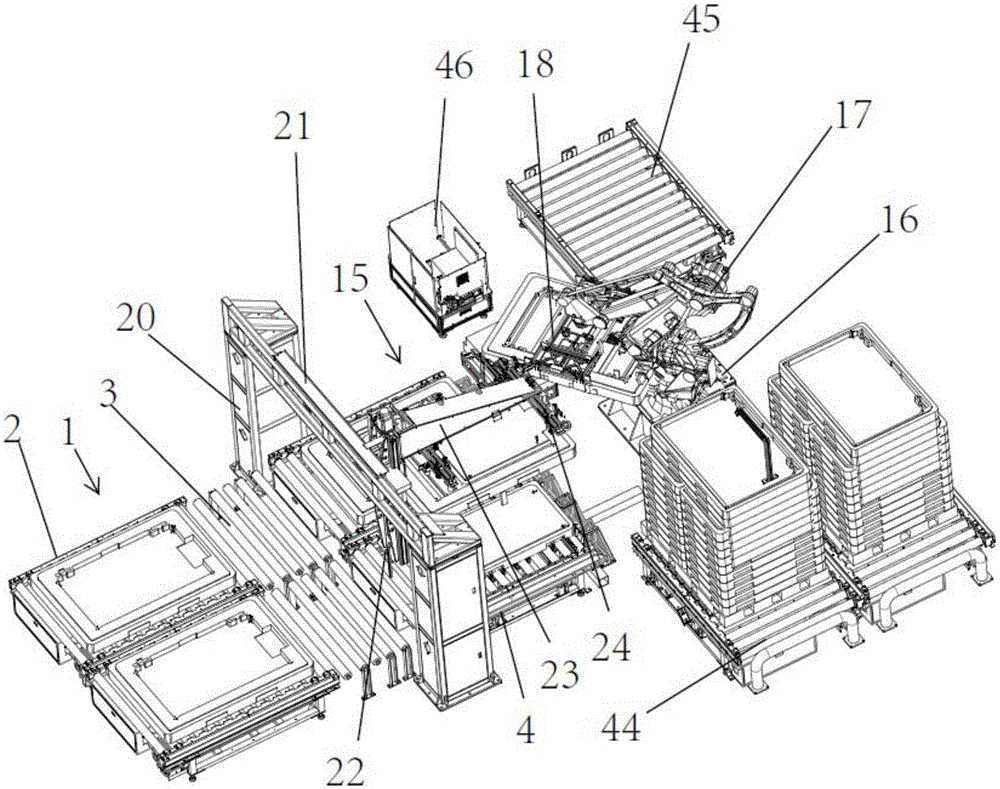

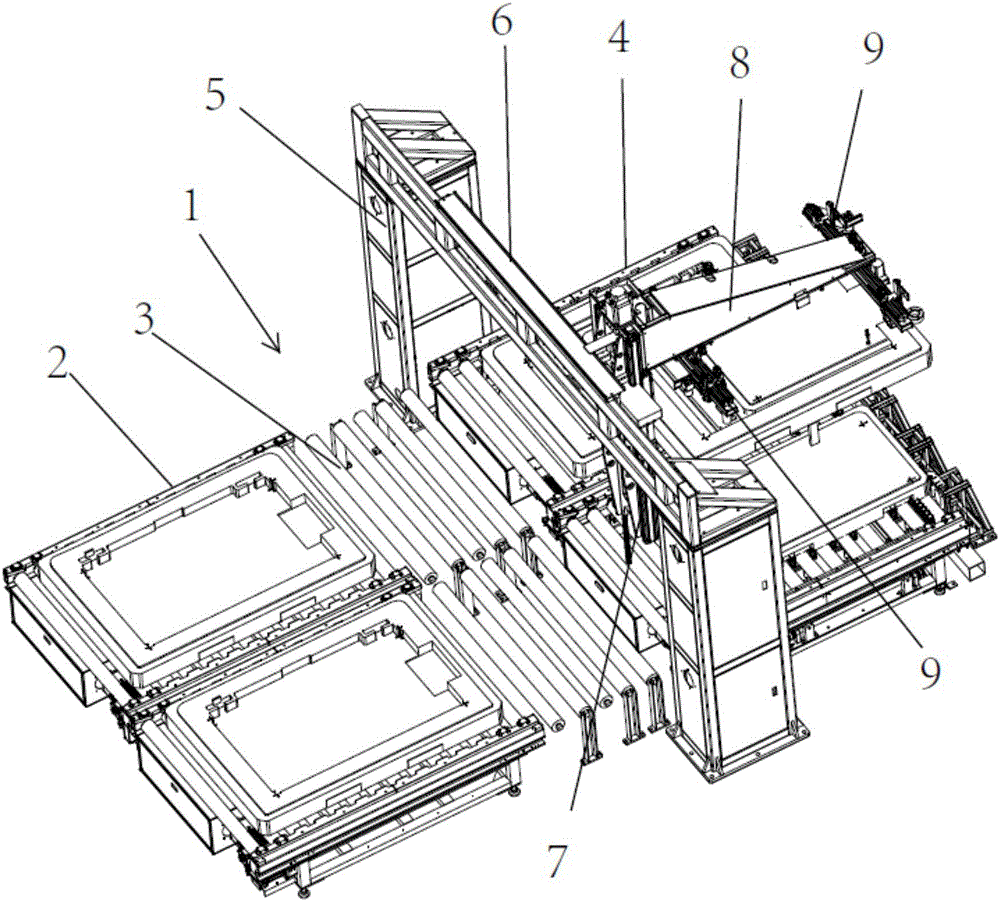

Classification stacking equipment based on manipulator

ActiveCN106144625AReduce the need for efficient positioningReduce impactStacking articlesDe-stacking articlesPosition effectEngineering

The invention discloses classification stacking equipment based on a manipulator. The classification stacking equipment comprises a carrier conveying line; the carrier conveying line includes a feeding roller way conveying belt, a driven roller way and a positioning roller way conveying belt arranged in sequence; a film tearing identification mechanism is arranged above the carrier conveying line; a base is arranged on one side of the positioning roller way conveying belt; a six-shaft manipulator is arranged on the base; a grabbing mechanism is arranged on the six-shaft manipulator; and a good product placing area, a defective product placing area and a labeling mechanism are arranged at the peripheral edge of the six-shaft manipulator. The classification stacking equipment is excellent in positioning effect and high in precision, reduces manual intervention, and is low in product harm.

Owner:SUZHOU LANGKUN AUTOMATION EQUIP CO LTD

Bionic crawling robot based on electromagnetic driving principle

The invention discloses a bionic crawling robot based on an electromagnetic driving principle. The bionic crawling robot based on the electromagnetic driving principle comprises a bottom plate structure, side plate structures, top plate structures, an external extending beam structure, supporting legs, a permanent magnet, a coil with an iron core and a supporting plate structure; the bottom platestructure, the side plate structures and the top plate structures are connected and fixed in an inserted manner to provide positioning and supporting for the whole structure; the external extending beam structure consists of two parallel SMA wires and is positioned by means of small holes in the side plate structures; the supporting legs comprise one pair of front legs and one pair of rear legs; the front legs and the rear legs are correspondingly bonded on the two sides of the external extending beam structure and the side plate structures; the permanent magnet is fixed at the middle part ofan external extending beam and is opposite to the coil with the iron core, which is bound on the supporting plate structure. After alternating current is applied to the coil, the permanent magnet drives the external extending beam structure to vibrate under an effect of an alternating electromagnetic force so that the front legs can swing to drive the whole mechanism to advance. The bionic crawling robot based on the electromagnetic driving principle has the advantages of simple structure, light weight, easy micromation and high moving speed.

Owner:BEIHANG UNIV

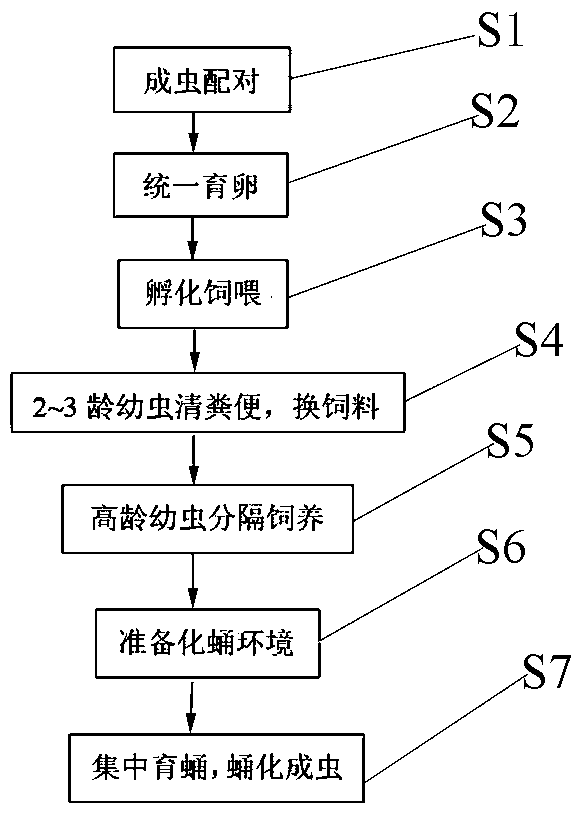

Method for in-lab breeding of Spodoptera frugiperda in winter

A method for in-lab breeding of Spodoptera frugiperda in winter comprises the steps of (S1) adult pairing, (S2) uniform egg cultivation, (S3) incubation and feeding, (S4) excrement cleaning and feed changing for first to third larvae, (S5) dividing and breeding of advanced-age larvae, (S6) preparation of a pupation environment, and (S7) centralized pupa breeding and worm formation by pupation. Different devices are used in different stages, disposable plastic cups are used during adult pairing and larva breeding, narrow space of the disposable plastic cups is beneficial for adult pairing, andescape of young-age larvae which are small in size and quick in creeping can be prevented through cup breeding; and a latticed breeding device is used for the advanced-age larva, so that mutual bitingcaused by competition can be avoided, space is saved, and the larvae of different ages can be bred at the same time. The method for in-lab breeding of Spodoptera frugiperda in winter effectively increases a survival rate, is high in breeding density and small in floor area, increases the yield, is convenient to operate and saves time and effort.

Owner:GUIYANG UNIV

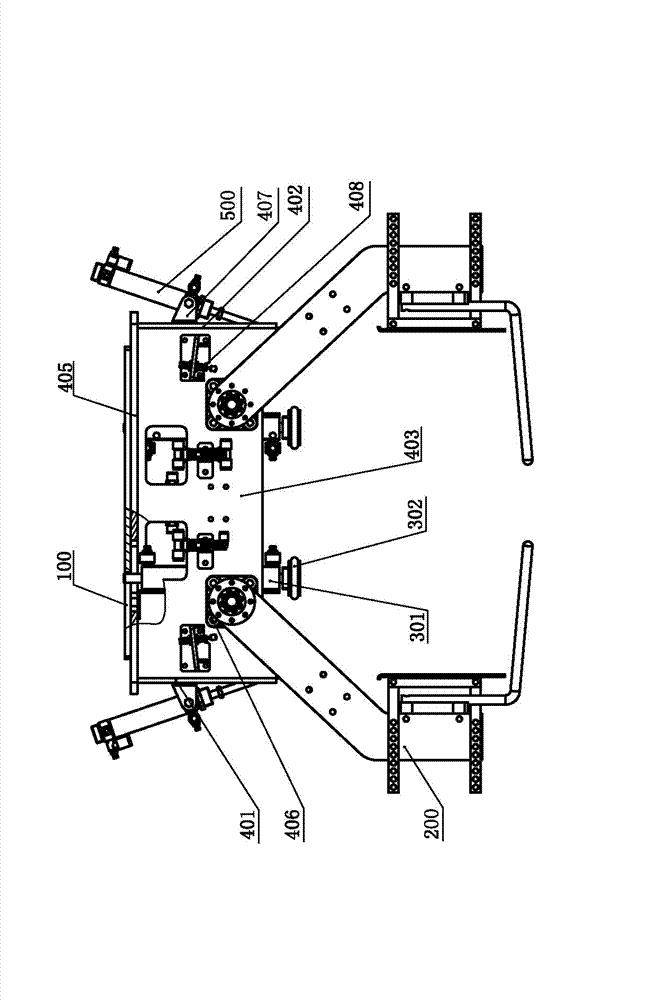

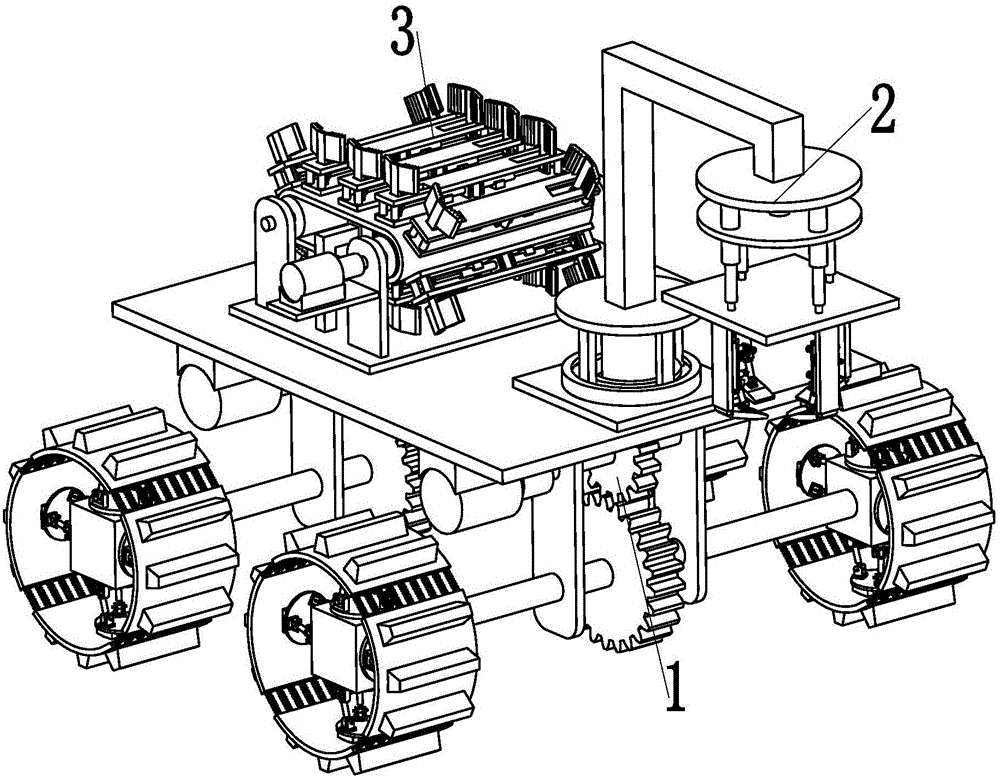

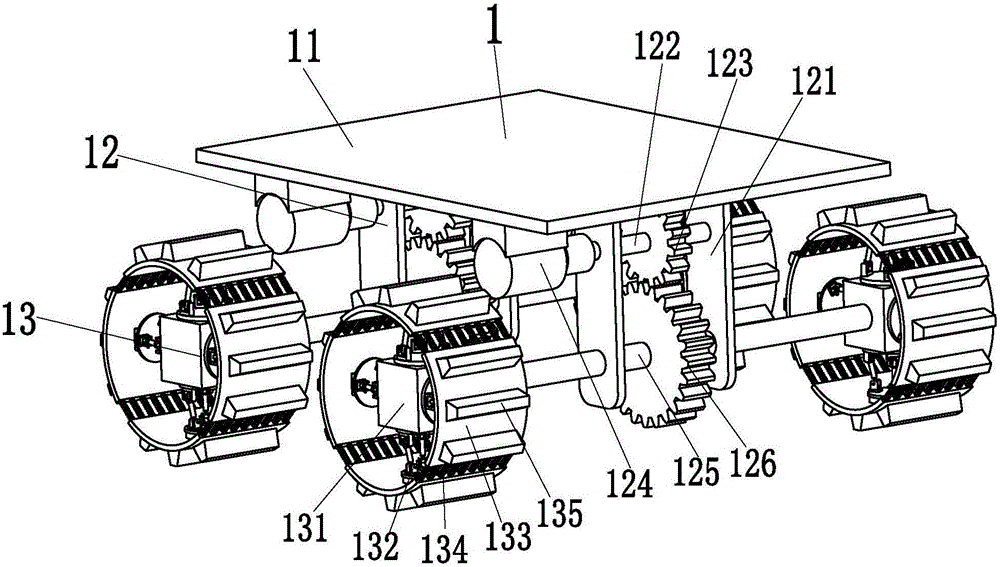

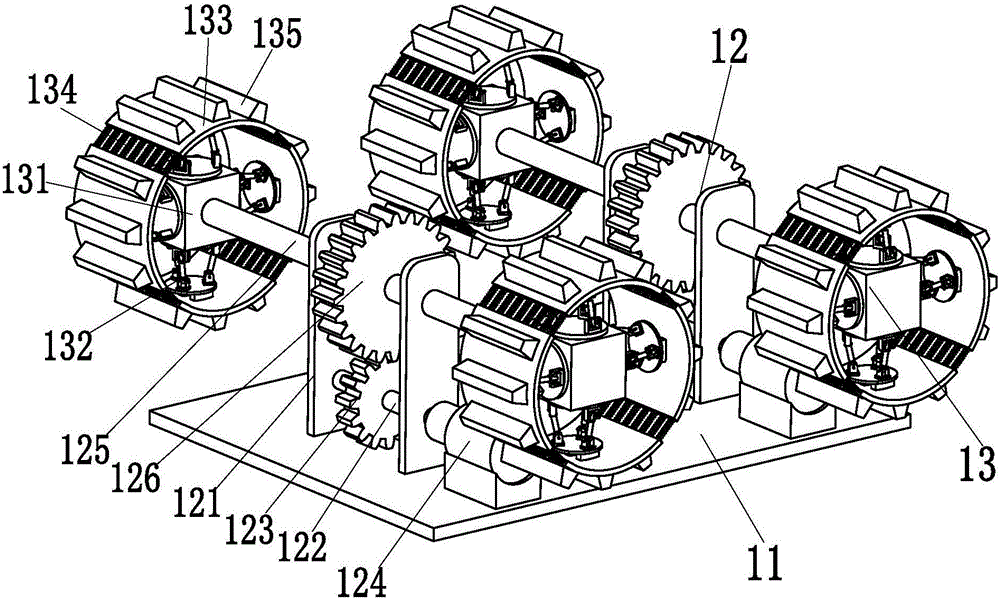

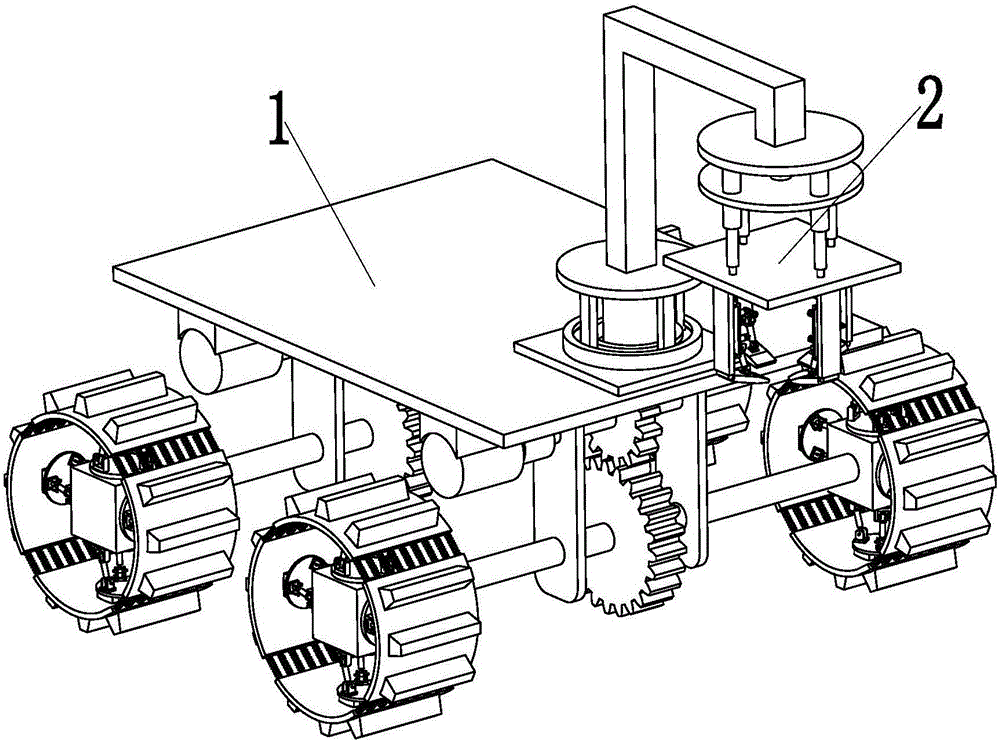

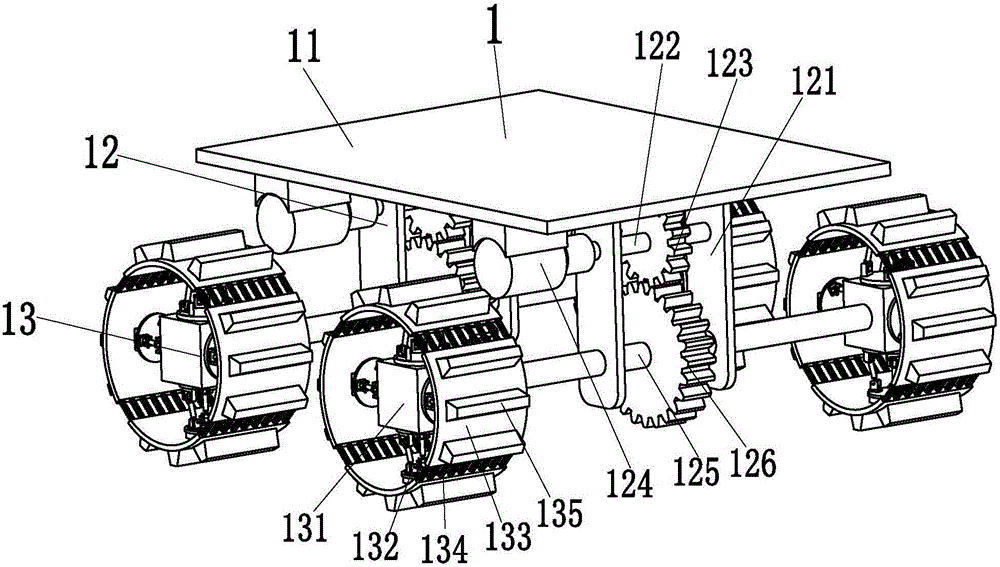

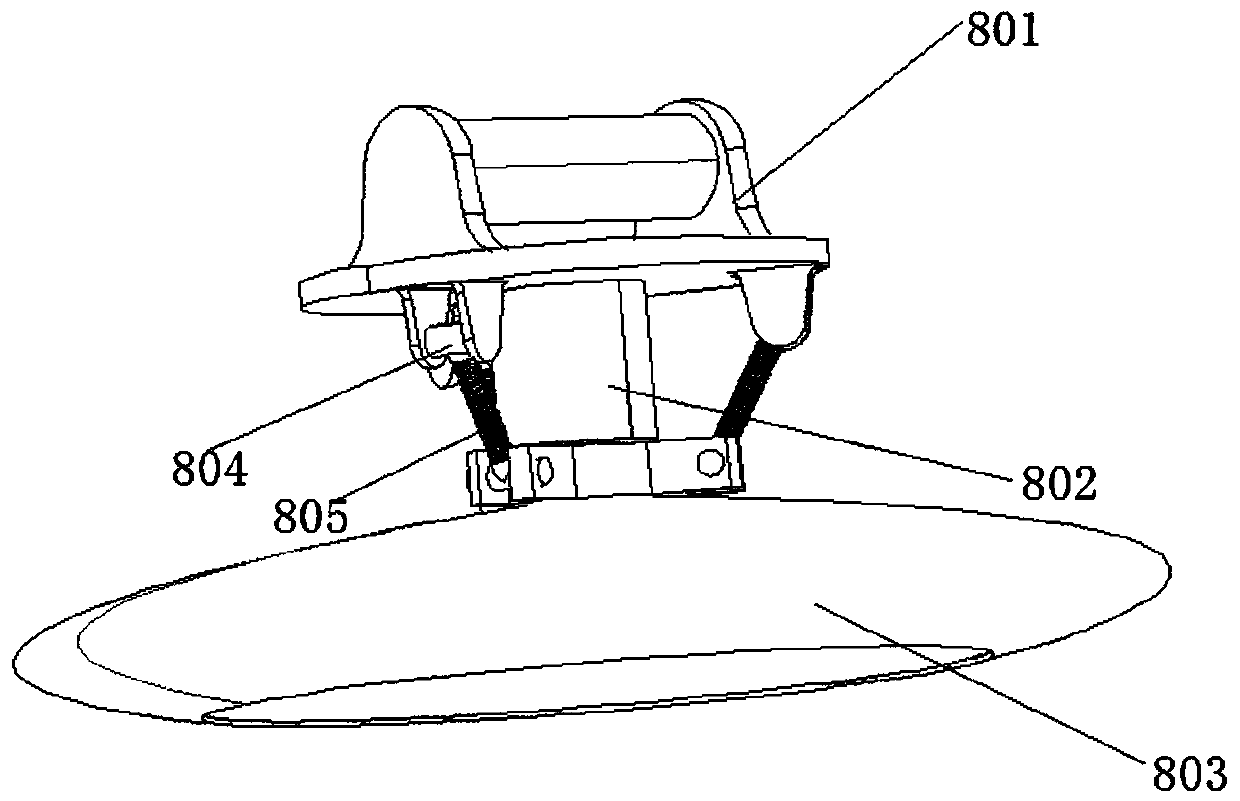

Grabbing and conveying robot for road retaining wall

ActiveCN106112954ANo manual operationImprove work efficiencyProgramme-controlled manipulatorGripping headsEngineeringRetaining wall

The invention relates to a grabbing and conveying robot for a road retaining wall. The robot comprises a self-stabilization walking platform, the self-stabilization walking platform has the good damping performance and the good stabilization performance, vertical shaking or left-and-right shaking phenomena appearing in the masonry carrying process are avoided, and therefore the robot is suitable for being work in uneven or muddy construction sites. A hydraulic grabbing device is arranged on the right side of the upper end face of the self-stabilization walking platform and can achieve the automatic hydraulic grabbing function of the masonry, manual grabbing and putting are not needed, a limiting conveying device is mounted in the middle of the upper rend of the self-stabilization walking platform, the limiting conveying device can achieve stable limiting conveying functions of the masonry, left-and-right limiting of the whole masonry conveying process is achieved, and the rolling hidden danger existing in the masonry conveying process can be removed. The automatic grabbing and conveying function of the masonry can be achieved, the vertical shaking or left-and-right shaking phenomena appearing in the masonry carrying process are avoided, and stable performance is good.

Owner:山东严格产业发展有限公司

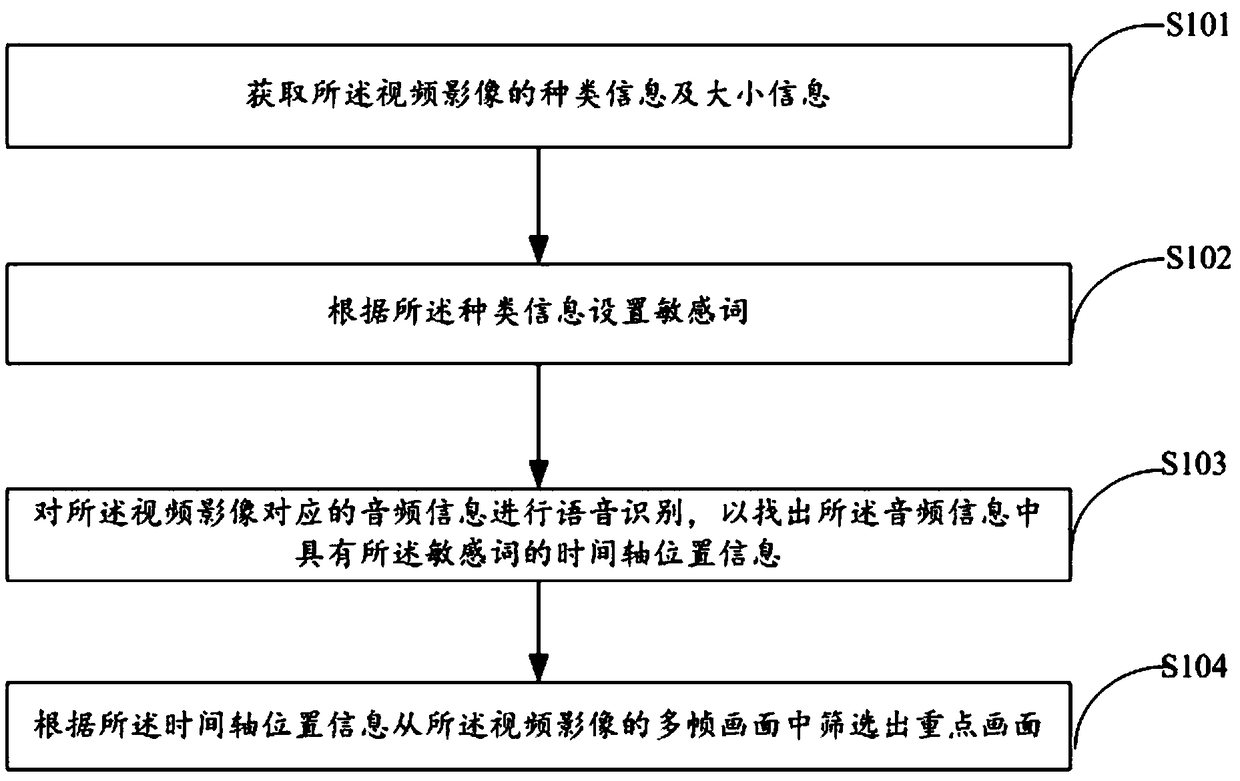

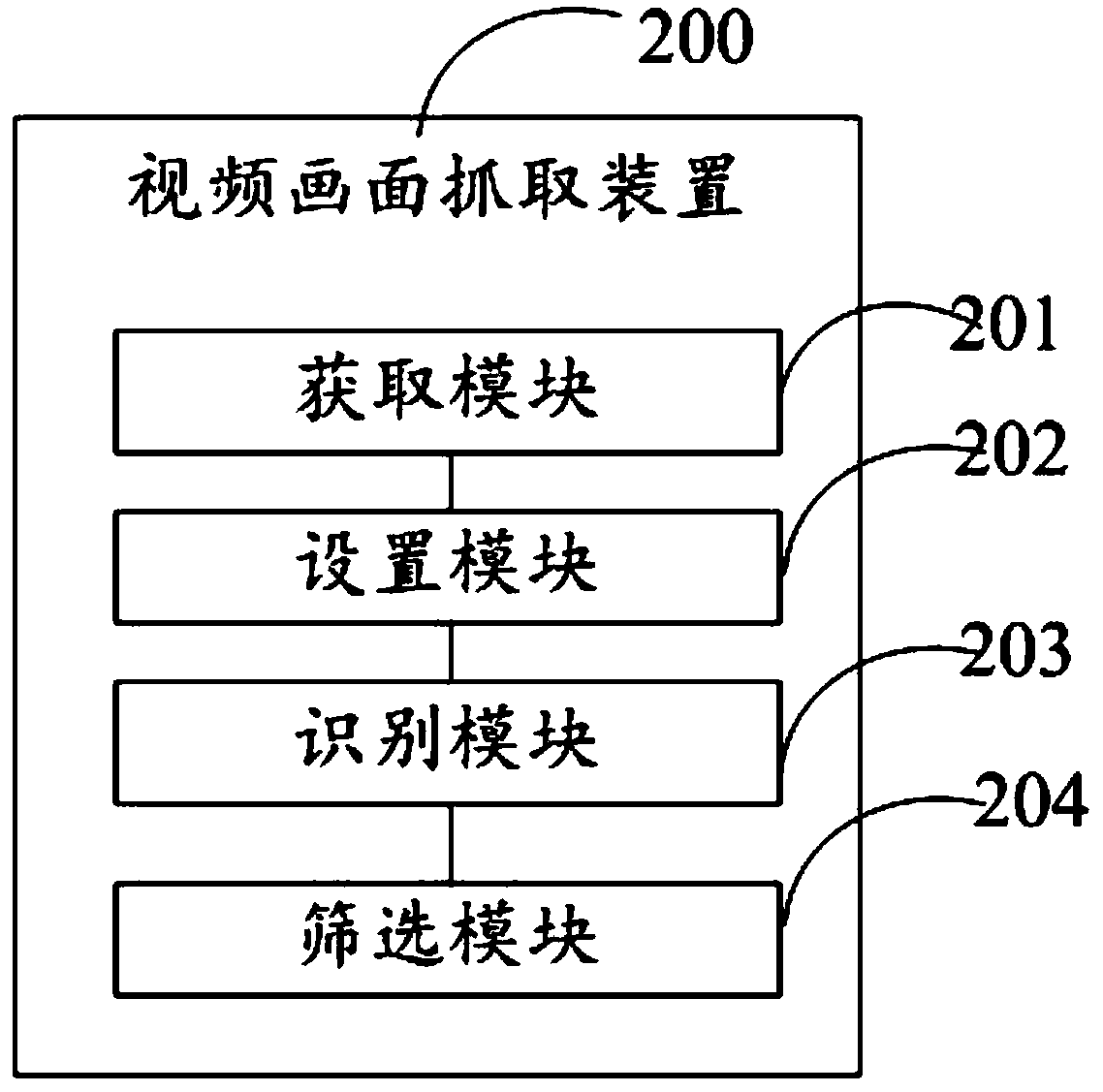

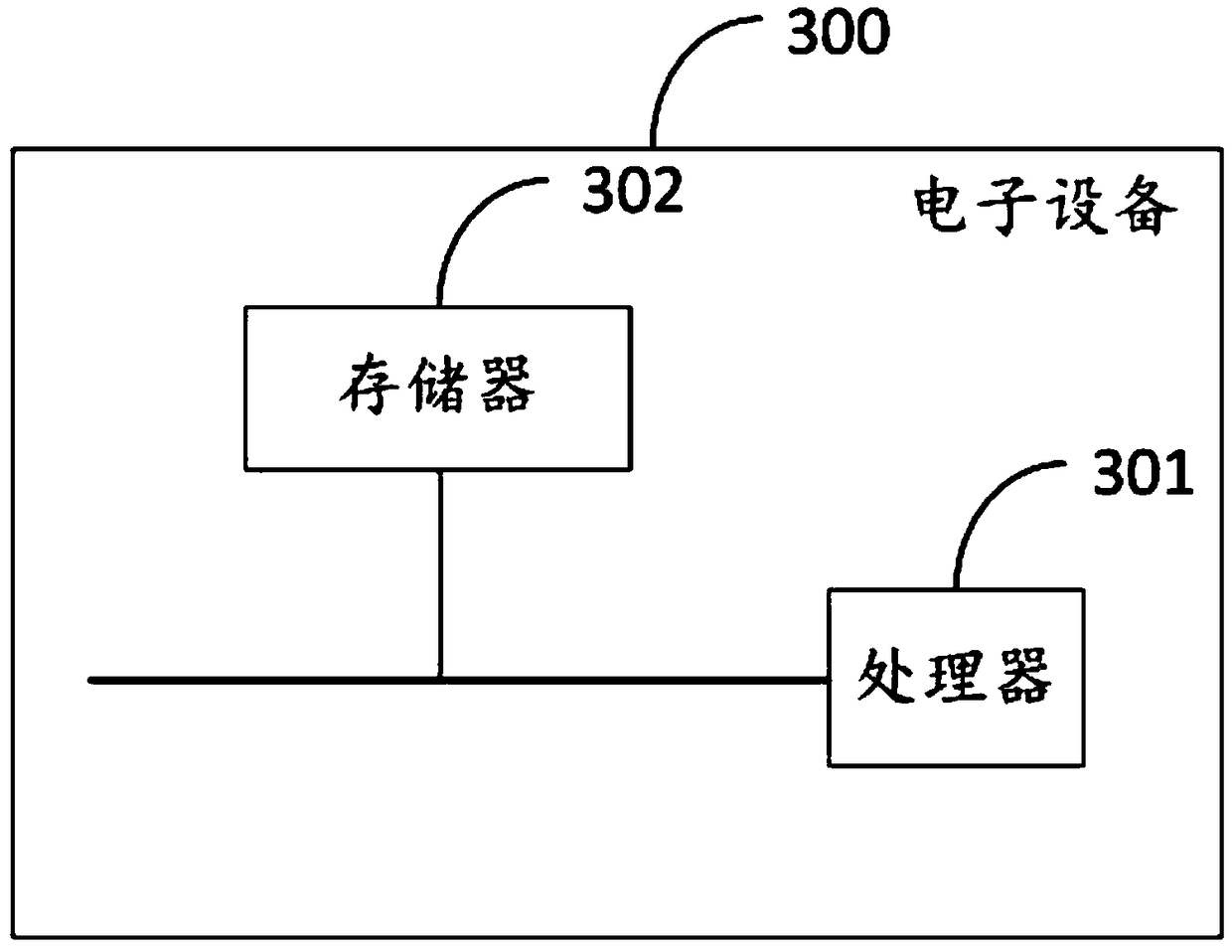

Video screen capture method and device, storage medium and electronic device

The invention provides a video screen capture method and device, a storage medium and an electronic device. Video images have audio information played therewith synchronously. The method comprises thefollowing steps: obtaining type information and byte information of the video images; setting sensitive words according to the type information and byte information; carrying out speech recognition on the audio information corresponding to the video images to find time axis position information having the sensitive words in the audio information; and screening out key screens from the multi-framescreens of the video images according to the time axis position information. The method has the beneficial effect of improving capture speed.

Owner:浙江威步机器人股份有限公司

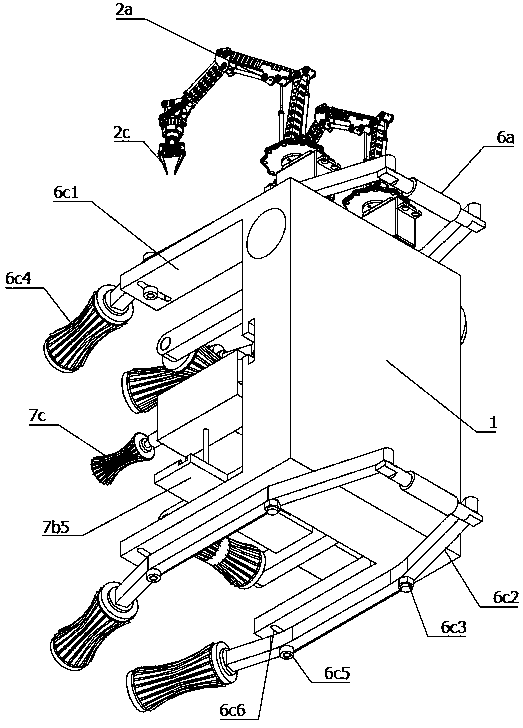

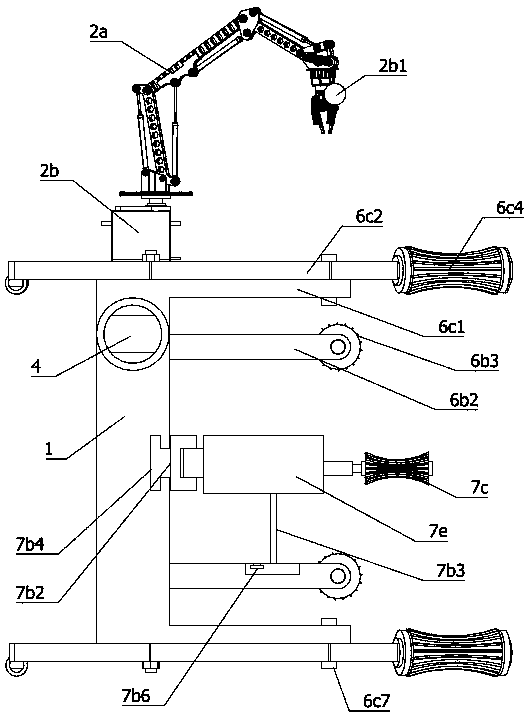

Smart coconut picking robot

InactiveCN109819774APrevent slippingHigh degree of mechanizationPicking devicesElectricityCoconut tree

The invention relates to the field of agricultural robots, in particular to a smart coconut picking robot. The smart coconut picking robot includes a creeping main body and a picking mechanism; the creeping main body is of a cuboid structure; the picking mechanism is arranged at the top of the creeping main body, a mounting cavity is formed inside the creeping main body, a controller and a storagebattery are arranged inside the mounting cavity, and two clamp devices capable of fixing the creeping main body to the trunk of a coconut tree are arranged at the two ends, in the height direction, of the creeping main body respectively; a drive mechanism is arranged at the side, in the width direction, of the creeping main body and is located between the clamp devices at the upper and lower endsof the creeping main body; the storage battery, the picking mechanism, the clamp devices and the drive mechanism are all electrically connected with the controller and are controlled by the controller, and the picking mechanism, the clamp devices and the drive mechanism are all electrically connected with the storage battery. The smart coconut picking robot creeps on the coconut tree through drive roll wheels and the clamp devices, a worker controls the whole robot to work through the controller, no manual creeping and picking are required, the labor intensity is reduced, the work efficiencyis improved, and thus the smart coconut picking robot is safe and efficient.

Owner:佘娟

Automatic hydraulic grabbing machine for building rock-soil mortar stones

ActiveCN106193145AImprove stabilityGood dynamic responseMechanical machines/dredgersWheel attachmentsArchitectural engineeringBuilding construction

The invention relates to an automatic hydraulic grabbing machine for building rock-soil mortar stones. The automatic hydraulic grabbing machine comprises a self-stabilizing travelling platform which has good vibration reducing performance and stability performance, and eliminates an up-down shaking phenomenon or a left-right waggling phenomenon in a mortar stone transportation process, so that the automatic hydraulic grabbing machine is suitable for working in an uneven or muddy construction site; a hydraulic grabbing device is mounted at the right side of the upper end surface of the self-stabilizing travelling platform; and the hydraulic grabbing device can realize a hydraulic automatic grabbing function on mortar stones without manual grabbing and placing, so that grabbing speed is high and grabbing efficiency is high. The self-stabilizing travelling platform comprises a mounting platform; two transmission branch chains are symmetrically mounted at the left side and the right side of the lower end surface of the mounting platform; and two travelling branch chains are symmetrically welded on the front side and the rear side of each transmission branch chain. The automatic hydraulic grabbing machine can realize the automatic grabbing function of mortar stones, eliminates the up-down shaking phenomenon or the left-right waggling phenomenon in the mortar stone transportation process, and is good in stability performance.

Owner:广州启赋知识产权有限公司哈尔滨分公司

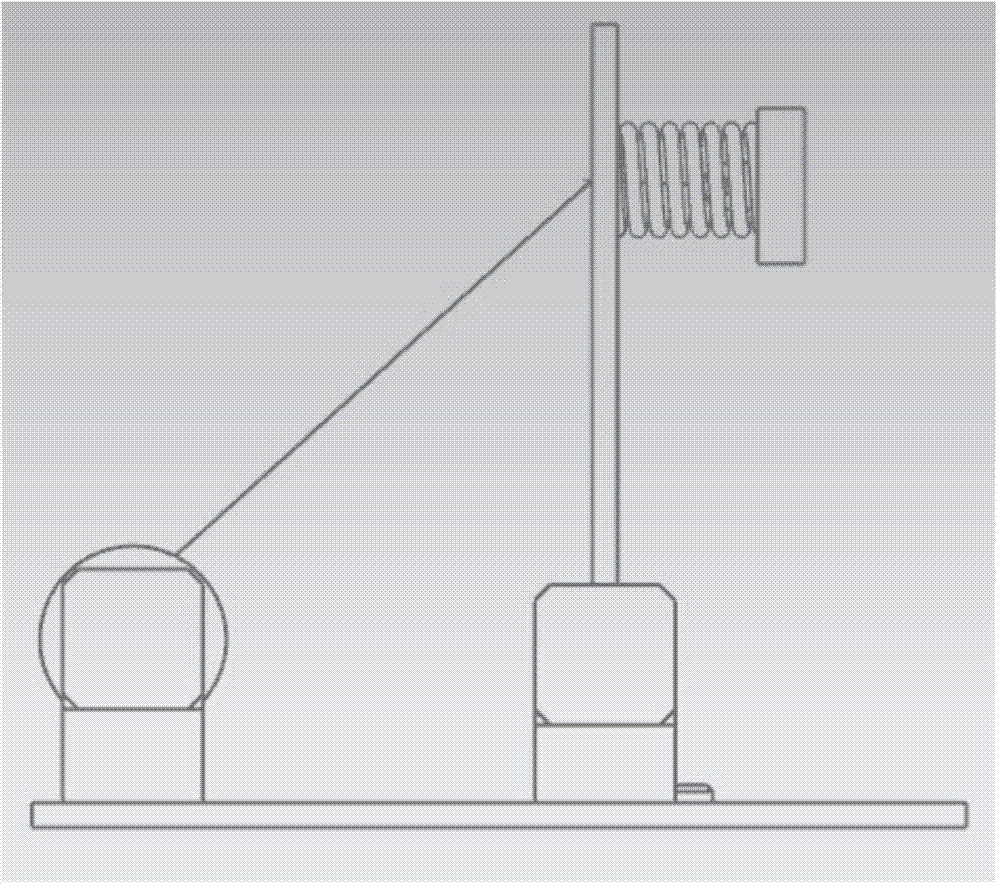

Catapulting type fast grabbing robot

The invention belongs to the field of robotics and machinery manufacturing and relates to a catapulting type fast grabbing robot comprising a base, a direction adjustment mechanism, a launching mechanism, a contracting mechanism, an adhering and grabbing mechanism and a controls system. The catapulting type fast grabbing robot can realize catapulting of the robot grabbing mechanism by generating elastic force through deformation of a compression spring and realizes withdrawing of the robot grabbing mechanism through the contracting mechanism, and multi-directional grabbing or obstacle-surmounting grabbing can be realized by adjusting the catapulting direction of the launching mechanism. The catapulting type fast grabbing robot has the advantages of simple structure, high grabbing speed, long grabbing distance and the like, the problem that the conventional industrial robot body is incapable of moving and limited to grabbing space can be solved, working efficiency of product sorting, conveying and the like is improved, and meanwhile the robot can be applied to the related fields such as agriculture.

Owner:JIANGNAN UNIV

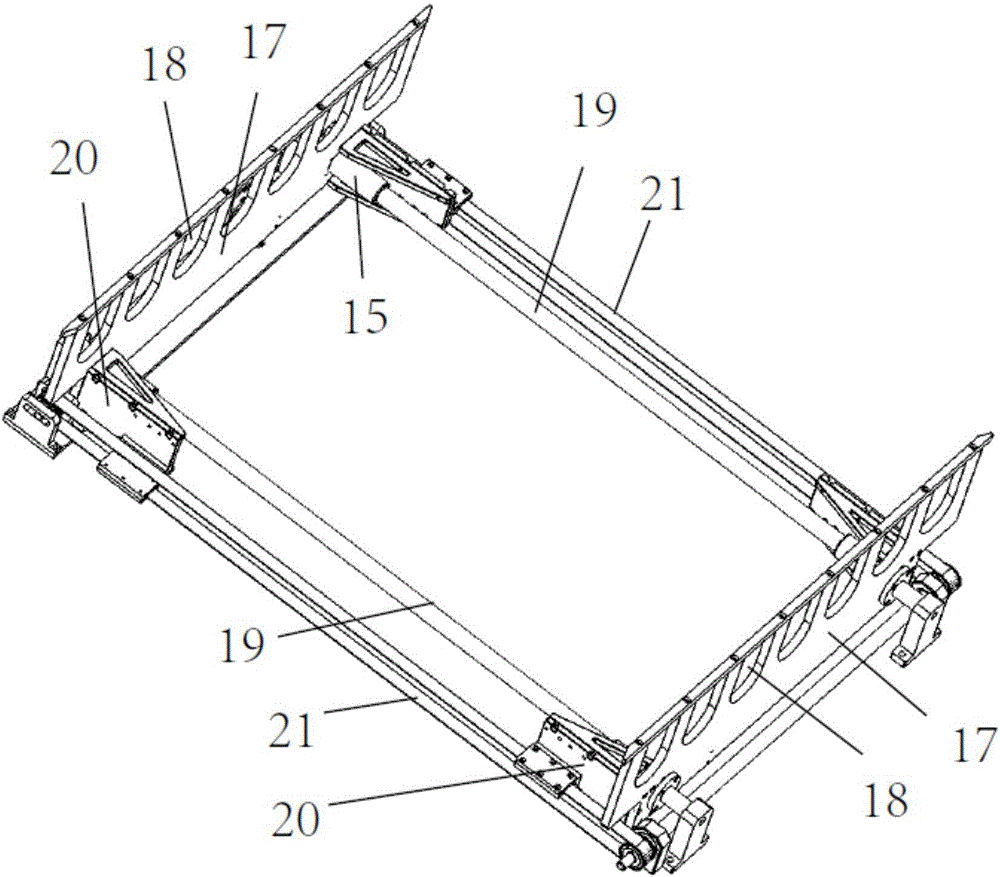

Self-positioning auxiliary code scanning mechanism

InactiveCN106144500AReduce the need for efficient positioningWon't hurtConveyorsControl devices for conveyorsPositioning aidsPortal frame

The invention discloses a self-positioning auxiliary code scanning mechanism. The mechanism comprises a carrier conveying line, and the carrier conveying line comprises a feeding roller way conveying belt, a driven roller way conveying belt and a positioning roller way conveying belt which are sequentially arranged; a portal frame is arranged above the carrier conveying line, a sliding main beam moving in the X-axis direction is arranged on the portal frame, and a sliding auxiliary beam which moves in the Z-axis direction is arranged on the sliding main beam; a supporting mounting plate is arranged on the sliding auxiliary beam, two detection beams moving in the Y-axis direction are arranged at the bottom of the supporting mounting plate, two mounting supports moving in the X-axis direction are arranged on the detection beams, and each mounting support is provided with a suction cup and a code scanning camera. Automatic film tearing and identifying can be achieved, the speed is high, and no damage exists.

Owner:SUZHOU LANGKUN AUTOMATION EQUIP CO LTD

Nematode culture apparatus and simple breeding method for test entomopathogenic nematodes

InactiveCN106035238AImprove reproductive efficiencyGuaranteed dosageAnimal husbandryWaxWater storage

A nematode culture device and a simple breeding method for entomopathogenic nematodes, relating to a nematode culture device and a nematode breeding method. The purpose of the method is to solve the problems of long time consumption, low yield and low reproduction efficiency in the live culture method of entomopathogenic nematodes for testing in existing laboratories. The device comprises an inner screen and an outer water storage basin, the edge of the inner screen extends outward to form an outer edge, and the outer edge of the inner screen is placed on the edge of the outer water storage basin. Method: 1. Cut two pieces of circular medium-speed qualitative filter paper with the same diameter, place them in the lid of the petri dish, put the last instar wax moth larvae on the filter paper in the petri dish, and infiltrate the filter paper with the water suspension of nematodes in the infection stage , buckle the bottom of the dish, put it in the incubator, and then put it in the incubator until all the wax moths die; 2. Transfer the dead wax moths to the inner screen of the nematode culture device, and the outer water storage basin Sterile water is housed inside, placed in the incubator, and the nematode suspension in the outer water storage basin is collected. The invention is used for cultivating nematodes.

Owner:NORTHEAST INST OF GEOGRAPHY & AGRIECOLOGY C A S

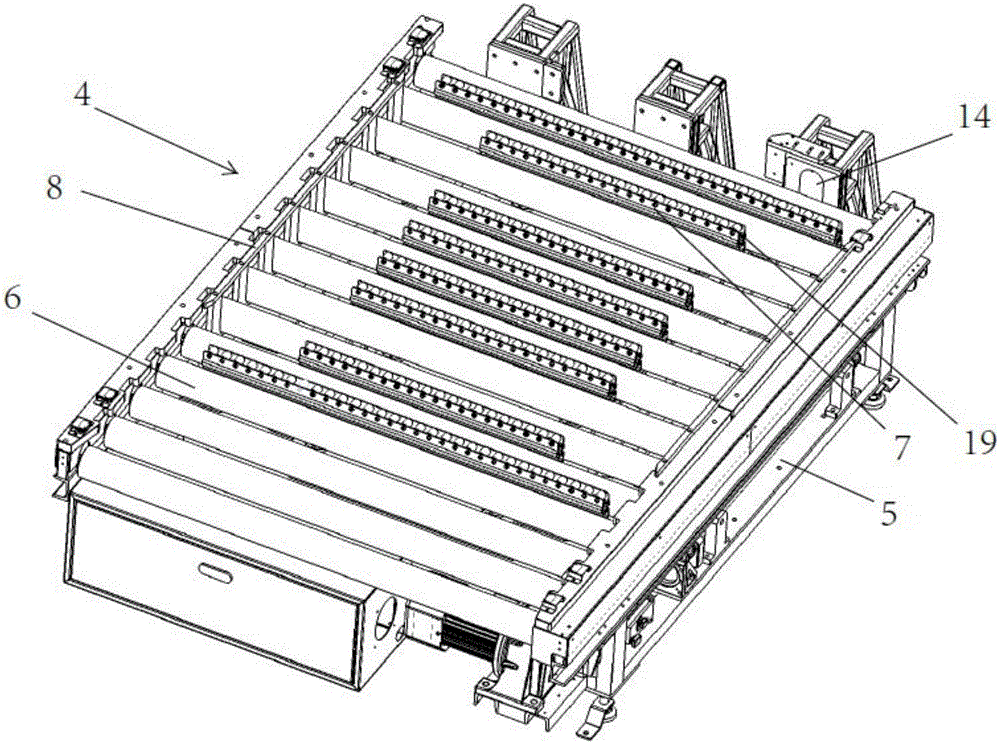

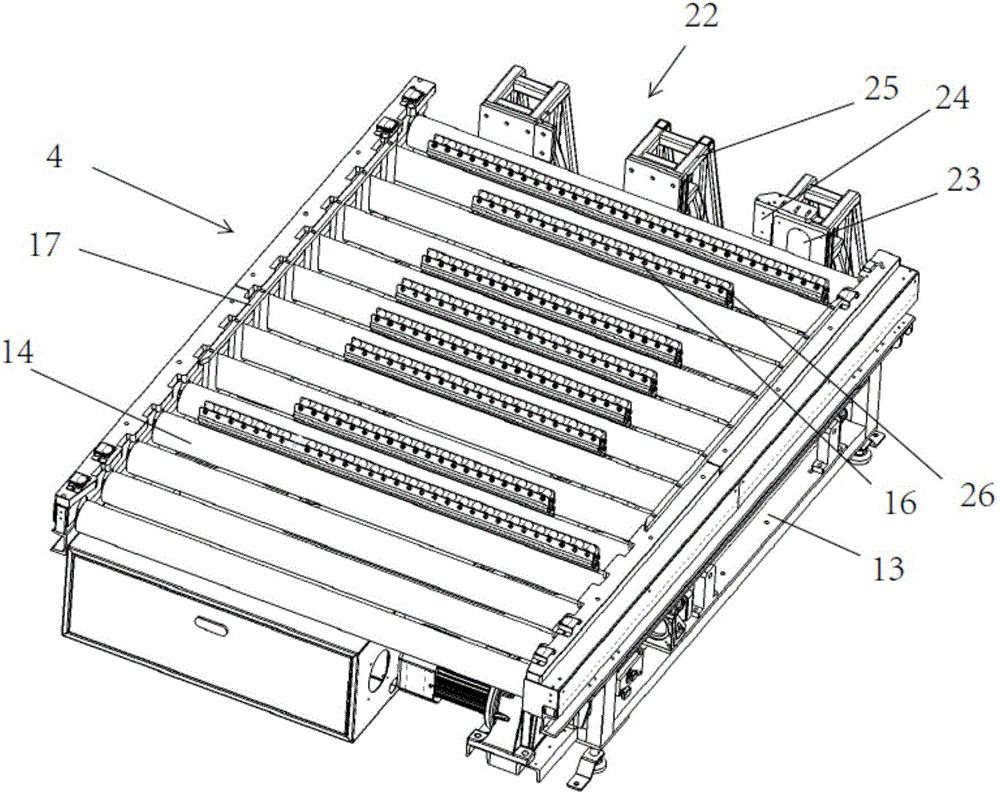

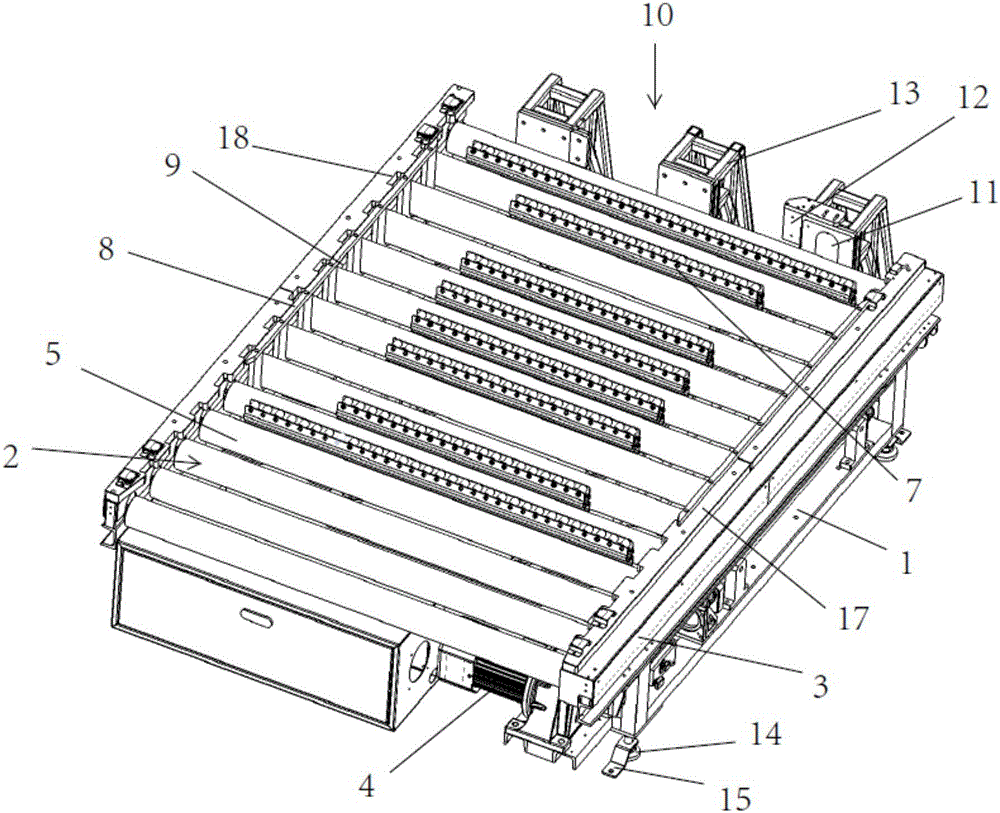

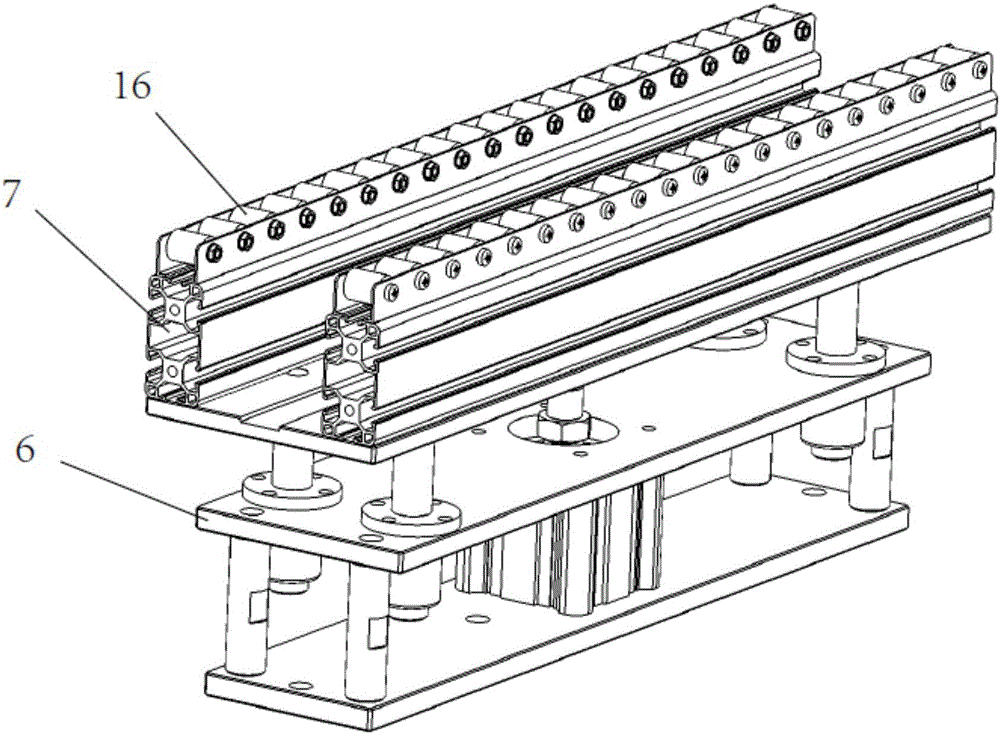

Carrier conveying line for mechanical arm

InactiveCN106167154AReduce the need for efficient positioningThe vehicle position is consistentRoller-waysEngineeringManipulator

The invention discloses a carrier conveying line for a mechanical arm. The carrier conveying line comprises a support platform. A conveyor belt is arranged on the surface of the support platform and connected with a motor through a belt transmission device. The conveyor belt comprises a plurality of roller beds, a plurality of jacking mechanisms are arranged below the conveyor belt, and a plurality of top plates are arranged on the tops of the jacking mechanisms and arranged between the two adjacent roller beds in the axial direction of the roller beds. Clamping plates are arranged at the two ends of the conveyor belt. A plurality of roller bed receding holes are formed in the surfaces of the clamping plates, and the clamping plates are connected with a thrust air cylinder. The carrier conveying line for the mechanical arm is reasonable in design and compact in structure, achieves a positioning and shaping effect and carries out grasping conveniently.

Owner:SUZHOU LANGKUN AUTOMATION EQUIP CO LTD

Flexible gripping device

The invention relates to the technical field of mechanical equipment, in particular to a flexible gripping device. The flexible gripping device comprises a frame and an air cylinder; a bottom seat ofthe air cylinder is connected with the upper end of the frame; a rack with left and right sides is arranged at the downward-extended end of an extension bar of the air cylinder; both ends of the rackare separately engaged with gears; the gears are connected with the frame by rotating shafts; connecting rods extend out of the gears in the radial direction; and two flexible gripping fixtures are arranged on the outer end of the connecting rods. According to the flexible gripping device, the gripping is fast and the efficiency is high by adopting the air cylinder to drive the two flexible gripping fixtures to grip bowls, cups and other fragile and irregular items; and through the arrangement of torsional springs on rotating shafts of the two flexible gripping fixtures, part of the gripping fixtures can be deformed outwards, thus stress in gripping is greatly reduced and the chance of broken items is reduced.

Owner:郑州莱发科技有限公司

Fully-automatic glass wall cleaning device and cleaning method

The invention discloses a fully-automatic glass wall cleaning device and cleaning method. The fully-automatic glass wall cleaning device comprises a support frame, a transmission case, brush sets, four groups of stealth components, a transmission component and two groups of drive components; each of the four groups of stealth components comprises a rotating wheel, a rotating rod, a vertical rod, aslide block, a limiting plate, a limiting groove, an adjusting rod and an absorption mechanism, wherein the rotating wheel is rotationally mounted on the support frame; the rotating rod hinged to thenon-circular center position of the rotating wheel; the top end of the vertical rod is hinged to the rotating rod; the slide rod is arranged on the inner side wall of the vertical rod in a sliding manner; the limiting plate is transversely fixed on the support frame and is positioned under the rotating wheel; the limiting groove is transversely formed in the limiting plate; the adjusting rod is fixed at the bottom of the vertical rod; the absorption mechanism is mounted at the bottom end of the adjusting rod; the sliding block is positioned in the limiting groove. The vertical rod moves upwards, downwards, forwards and backwards under the drive of the rotating rod and the limit of the limiting groove, so that the creeping speed is high; the front and rear two groups of stealth componentsare respectively controlled to be convenient for creeping.

Owner:NANJING HANMINGZHI INTELLIGENT TECHNOLOGY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com