Patents

Literature

356 results about "Positioning aids" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

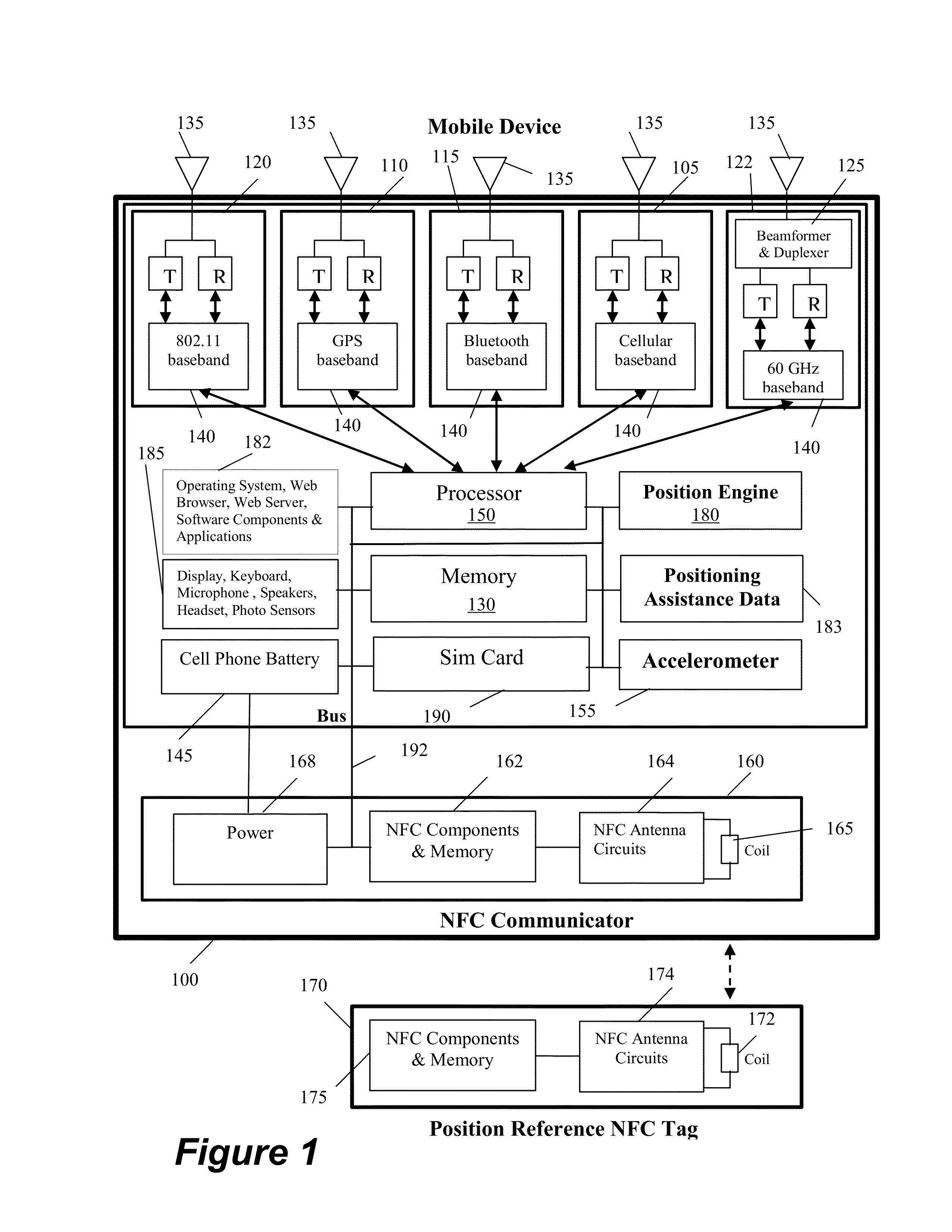

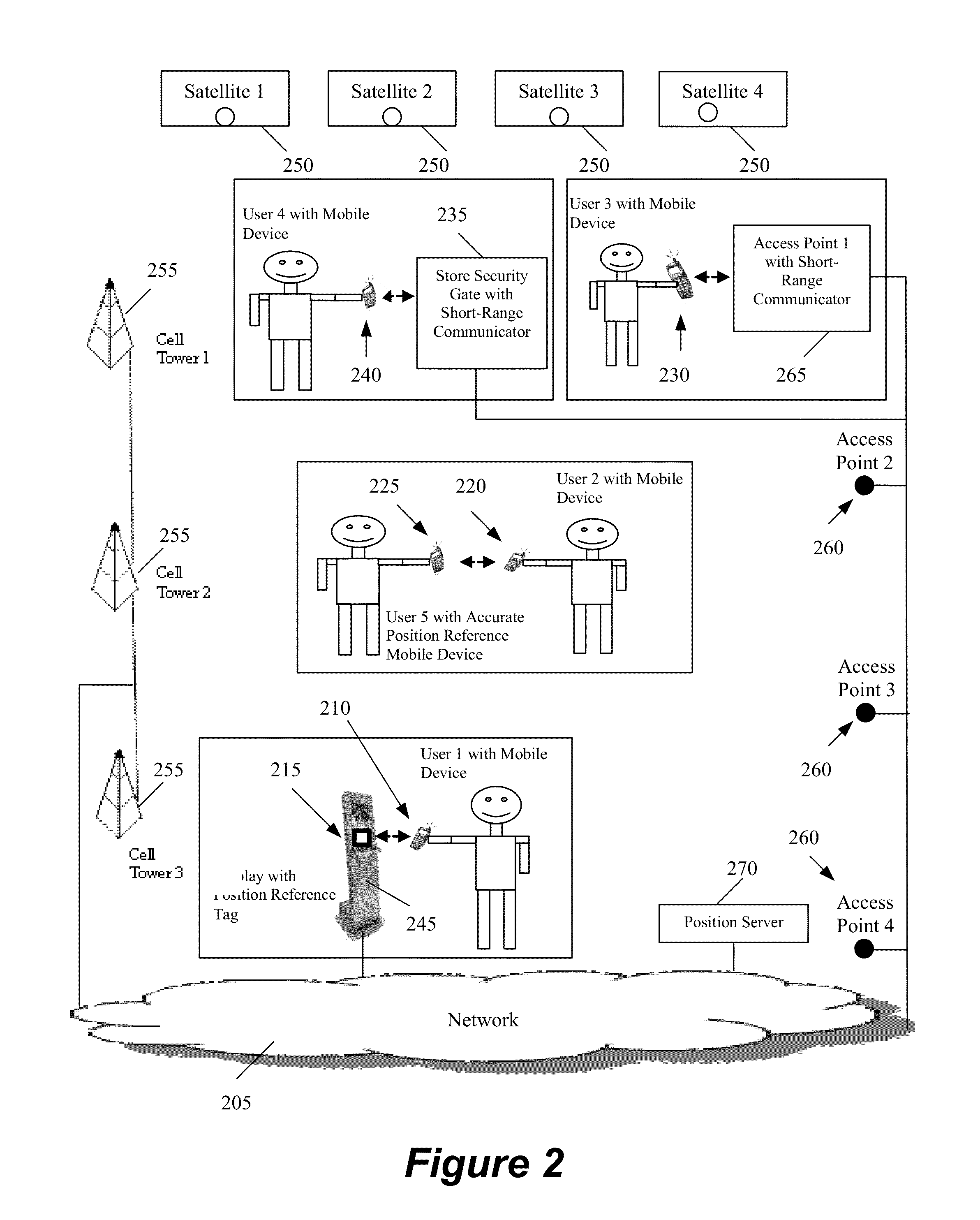

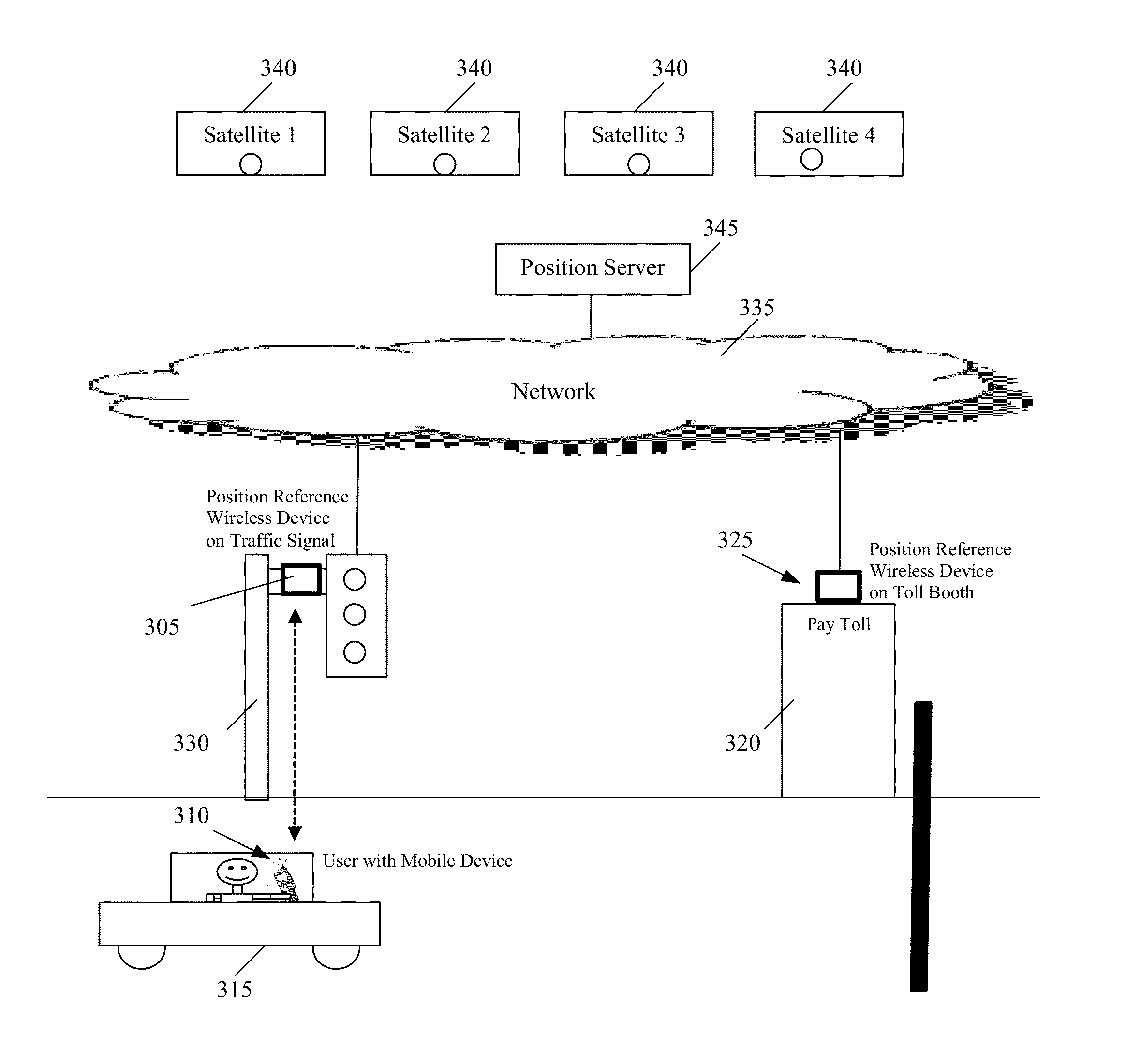

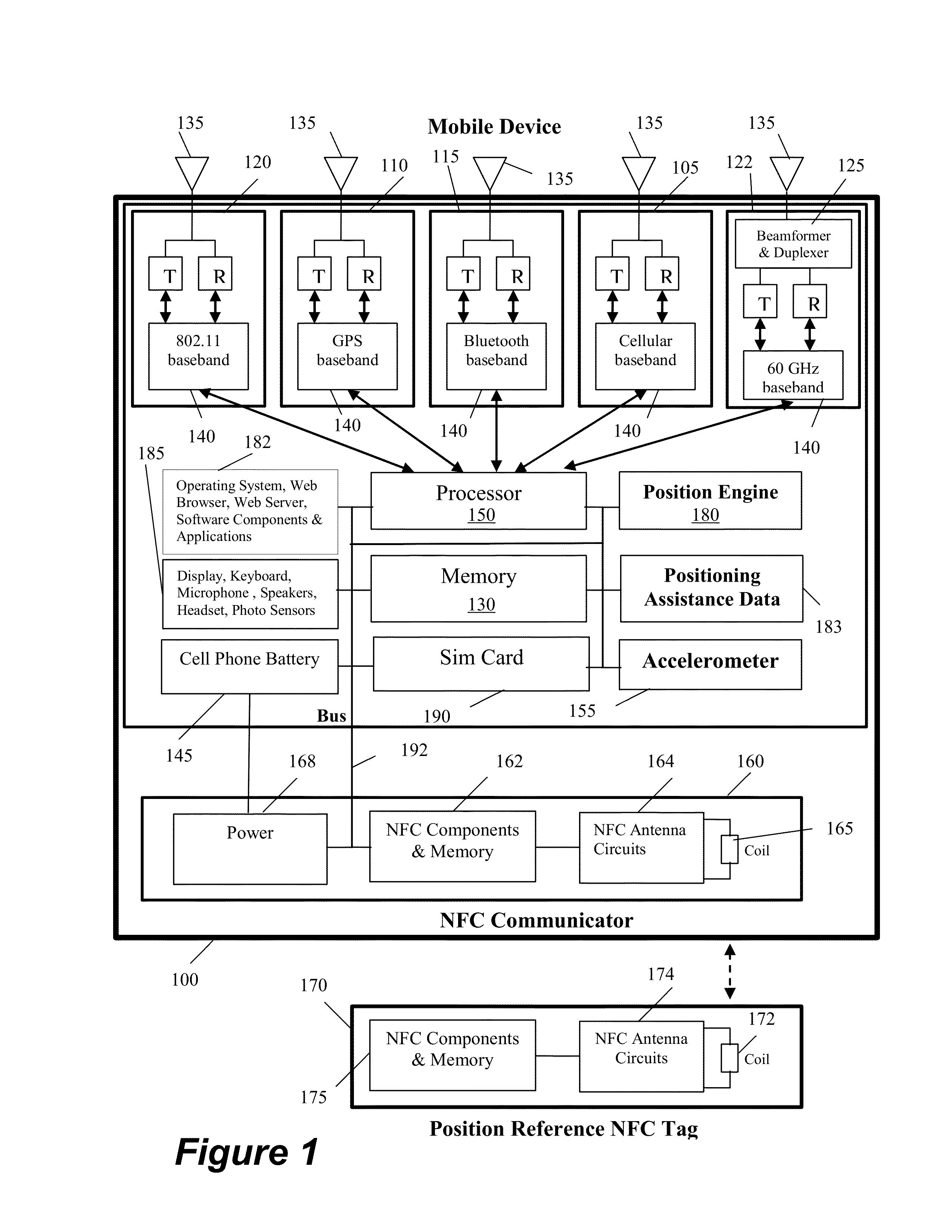

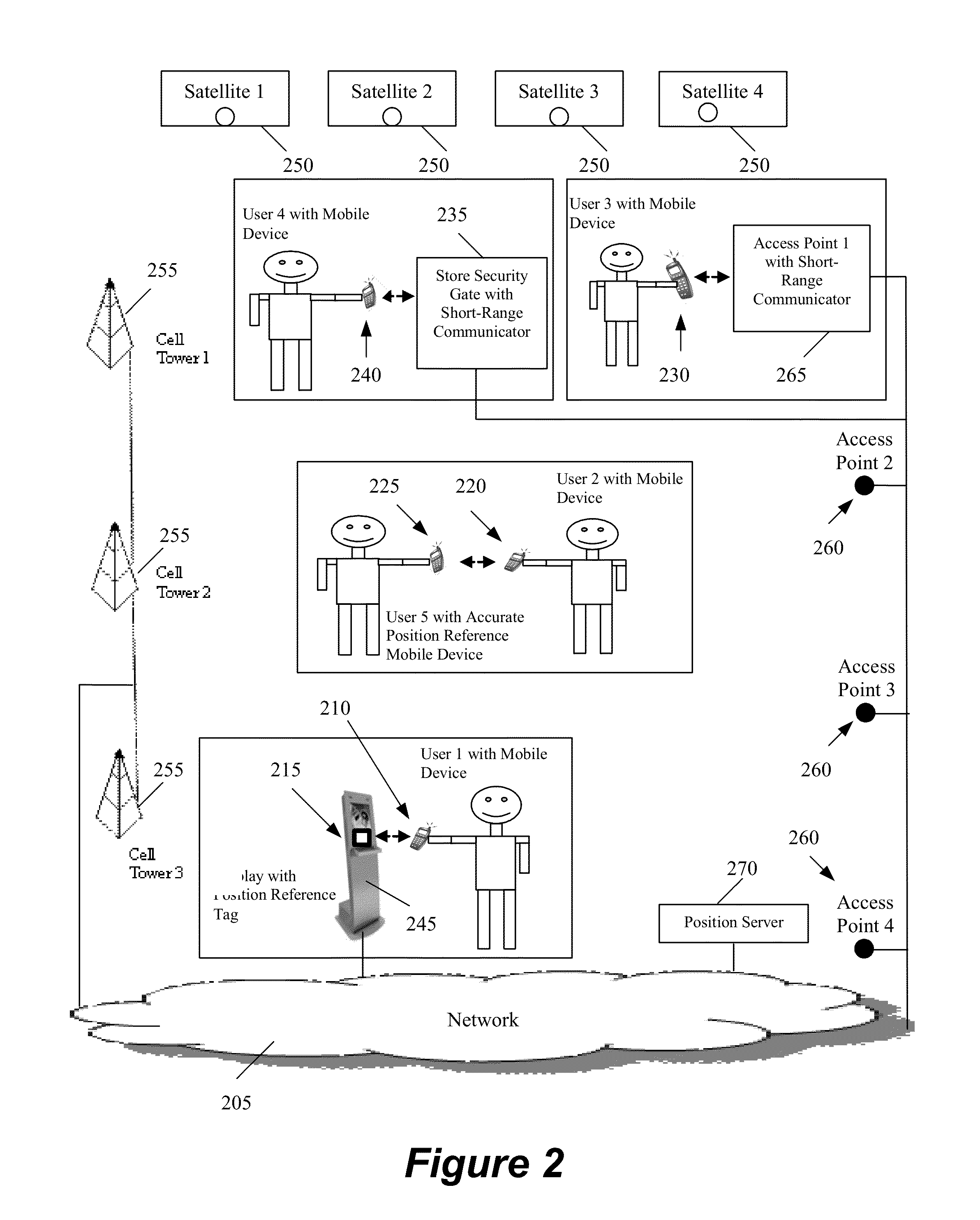

Distributed method and system for determining the position of a mobile device using long-range signals and calibrating the position using short-range signals

InactiveUS20130029685A1Energy efficient ICTNear-field transmissionWireless communication protocolTraffic signal

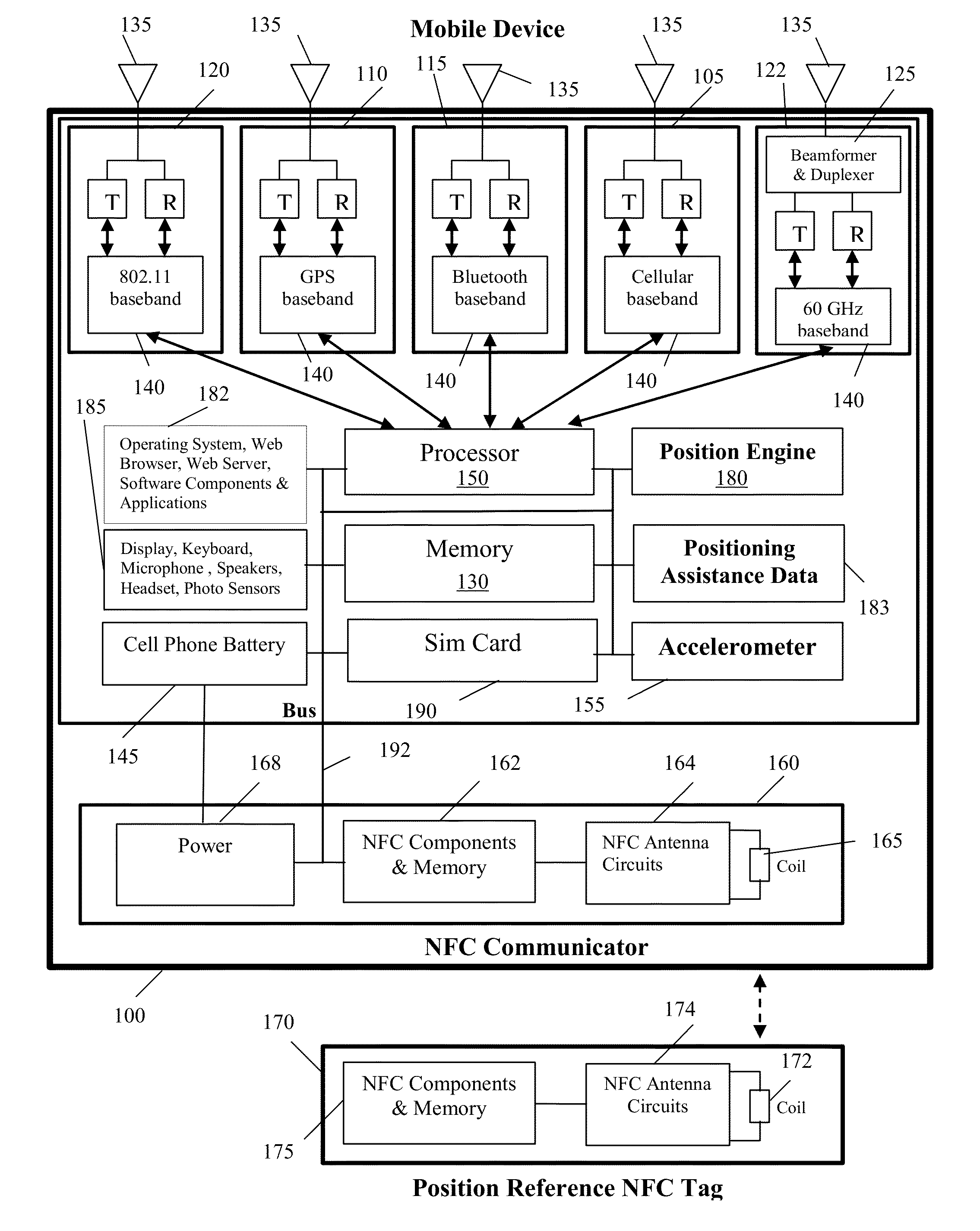

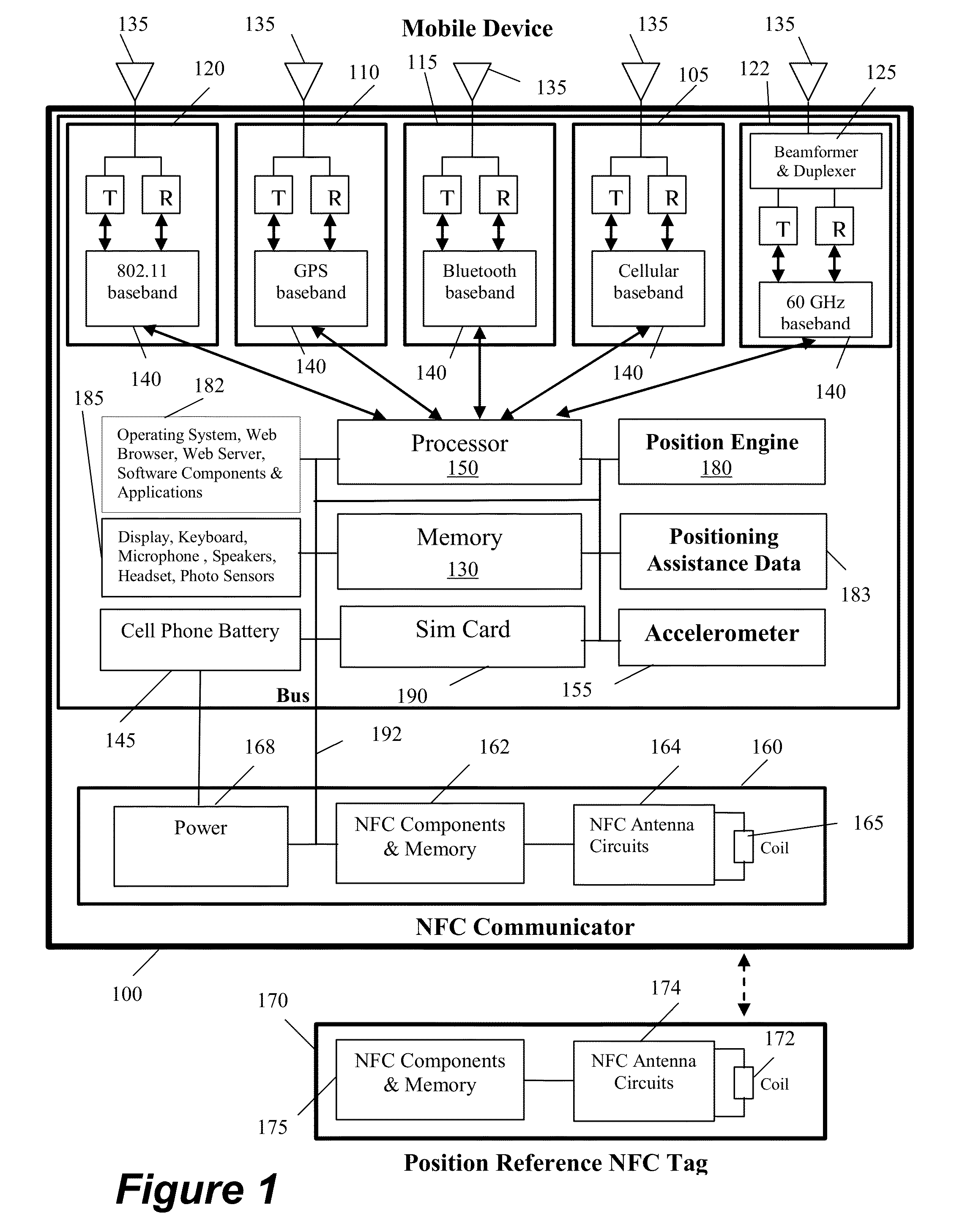

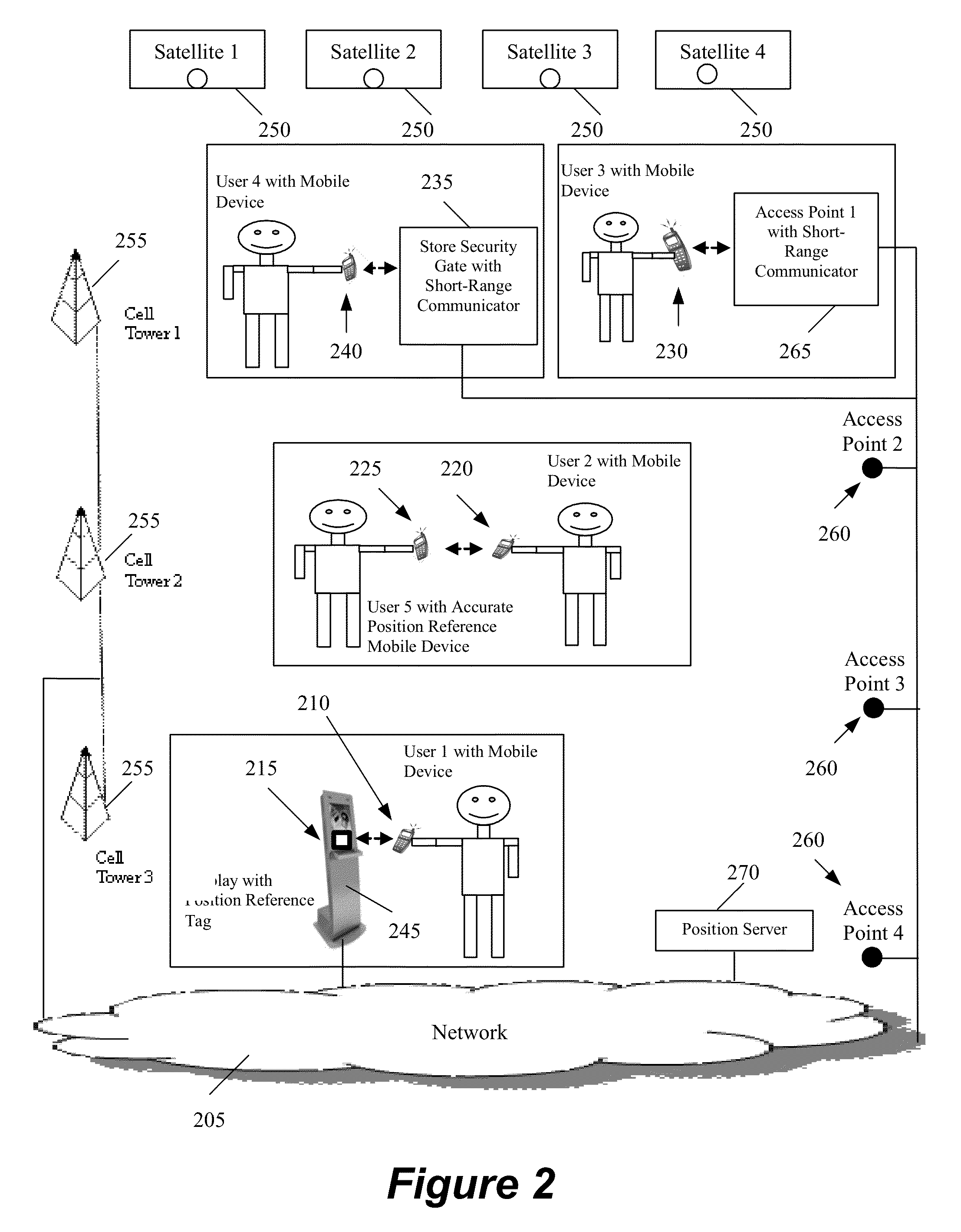

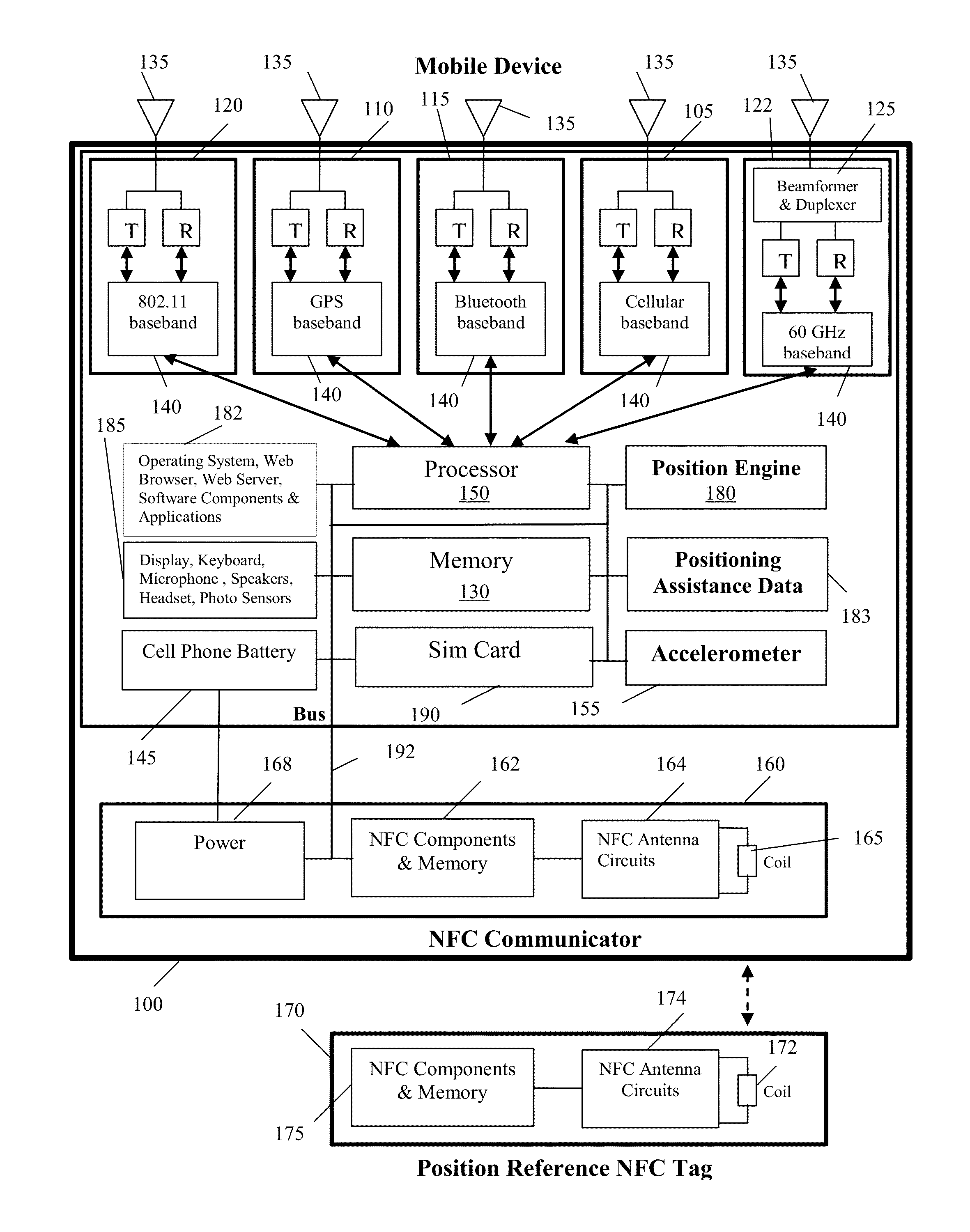

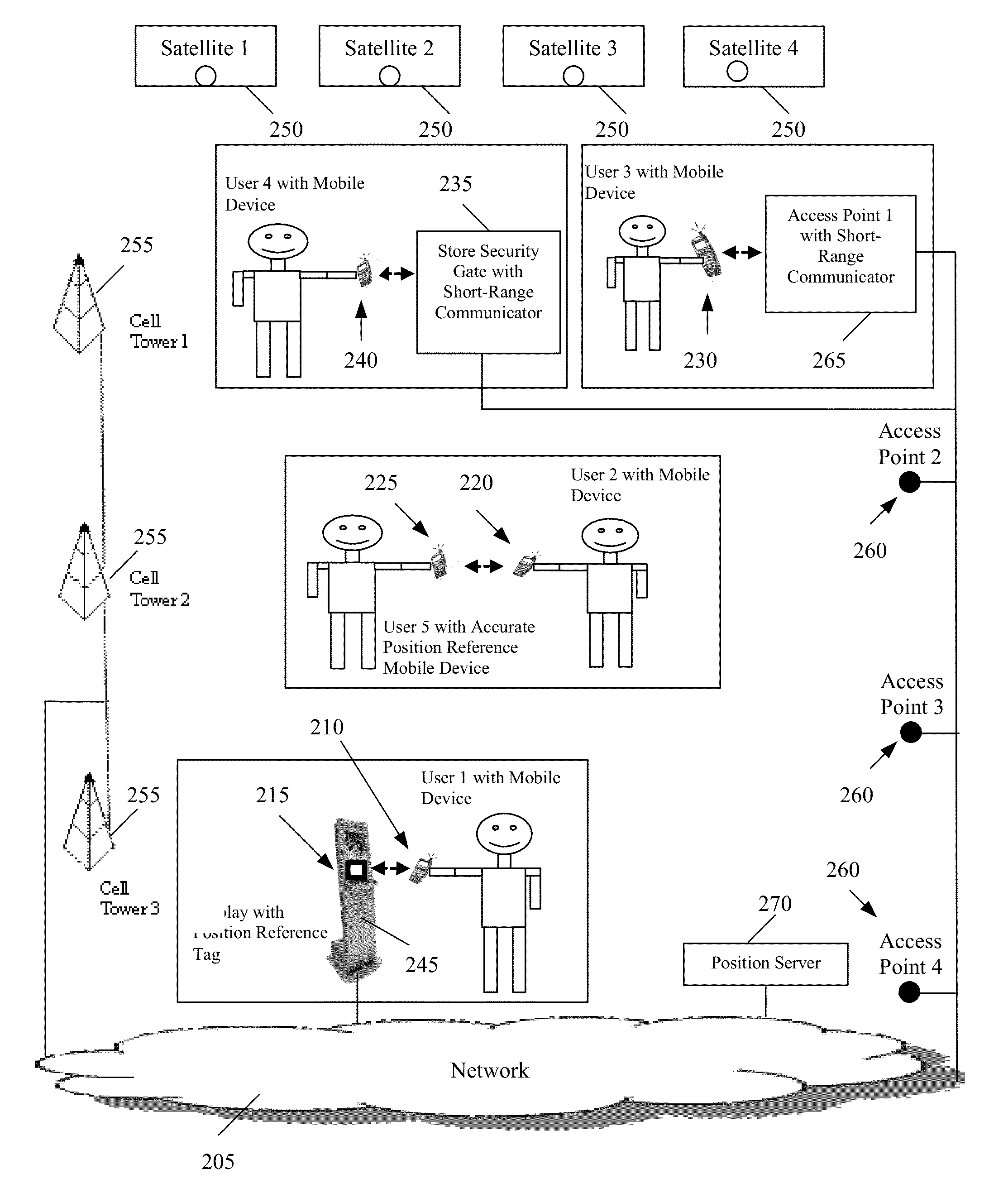

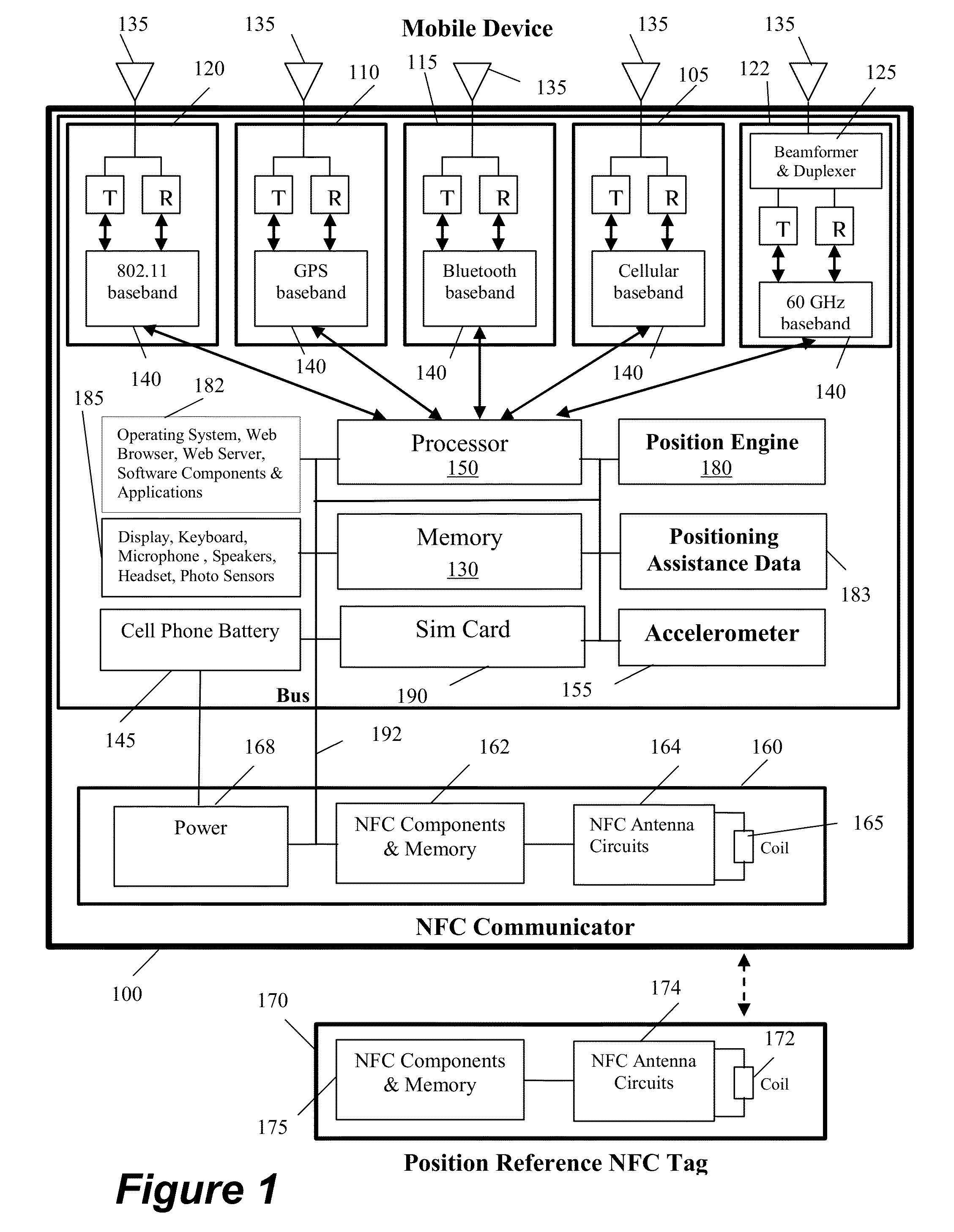

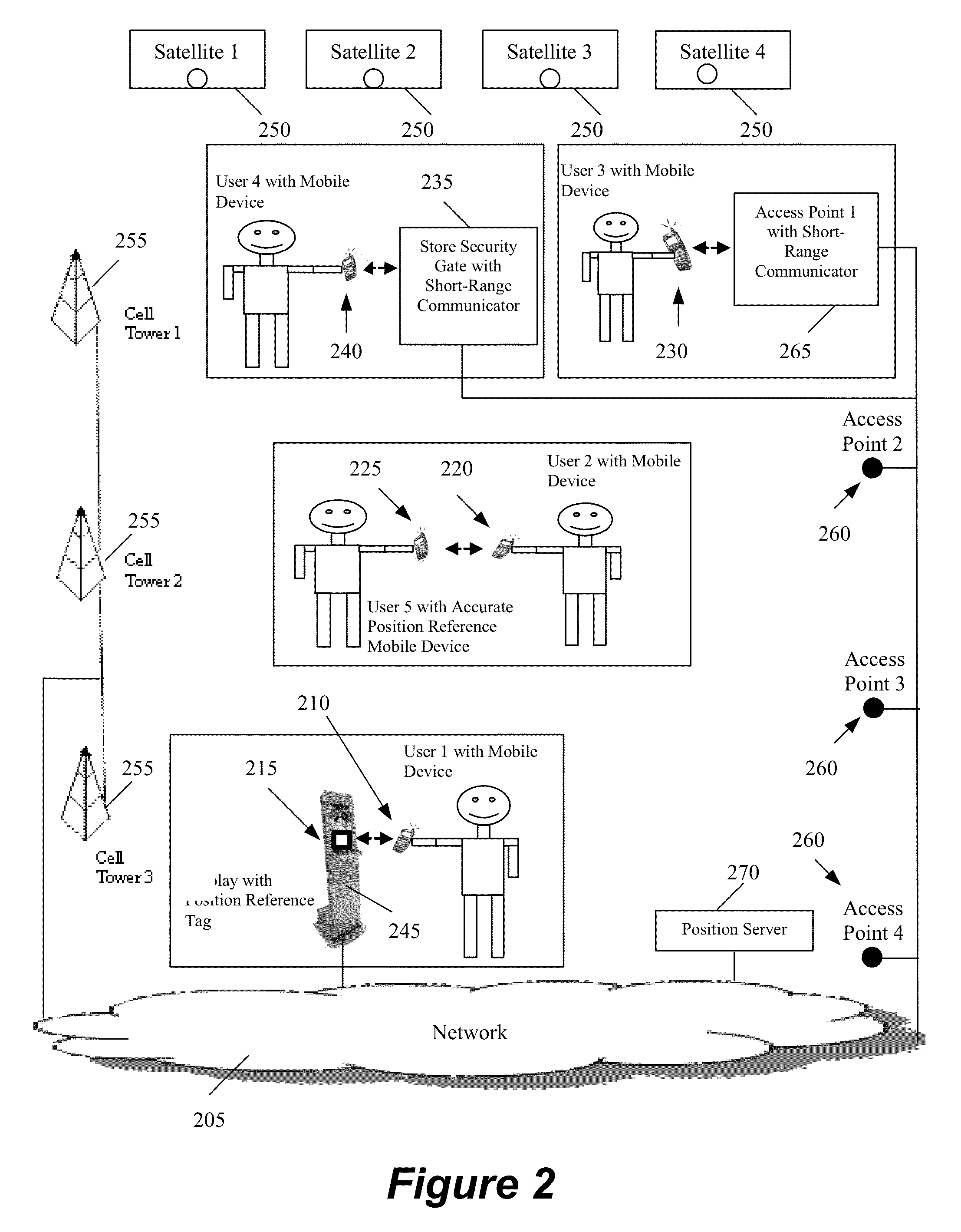

A method and system is described where a plurality of position reference devices use short-range wireless communication protocols to transmit positioning assistance data to nearby mobile devices, and the mobile devices use the assistance data to model errors and re-calibrate their positioning systems. The short-range communication methods include NFC, RFID, Bluetooth®, short-range 802.11, Wi-Fi Direct, and high frequency focused beams such as 60 GHz. The position reference devices are passive or active NFC tags, passive or active RFID tags, other devices that include such tags as their components, Bluetooth®-enabled devices, 60 GHz-enabled devices, and 802.11 access points that can lower their transmit power. The reference devices are located at various indoor and outdoor locations such as smart posters, kiosks, ATM machines, malls, store checkout counters, store security gates, wireless access points, cellular base-stations, tollbooths, traffic lights, and street lamp posts.

Owner:GOLBA LLC

Distributed method and system for calibrating the position of a mobile device

A method and system is described where a plurality of position reference devices use short-range wireless communication protocols to transmit positioning assistance data to nearby mobile devices, and the mobile devices use the assistance data to re-calibrate their positioning systems. In some embodiments, mobile device includes an accelerometer and the accelerometer measurements are used to calculate an updated velocity of the mobile device and an updated position of the mobile device based on the accelerometer measurements and previous velocity and position of the mobile device. The short-range communication methods include NFC, RFID, Bluetooth®, short-range 802.11, Wi-Fi Direct, and high frequency focused beams such as 60 GHz. The position reference devices are passive or active NFC tags, passive or active RFID tags, other devices that include such tags as their components, Bluetooth®-enabled devices, 60 GHz-enabled devices, and 802.11 access points that can lower their transmit power.

Owner:GOLBA LLC

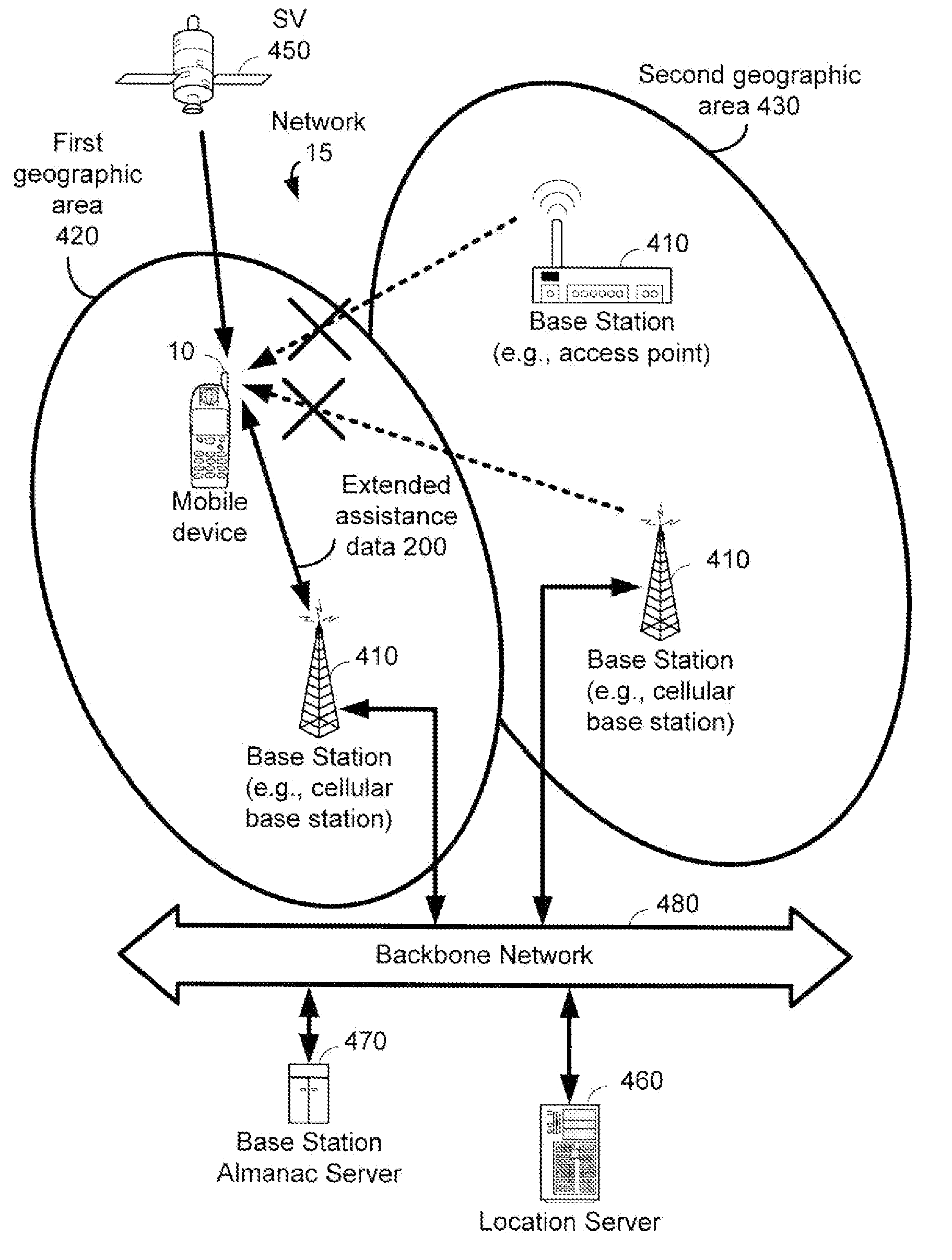

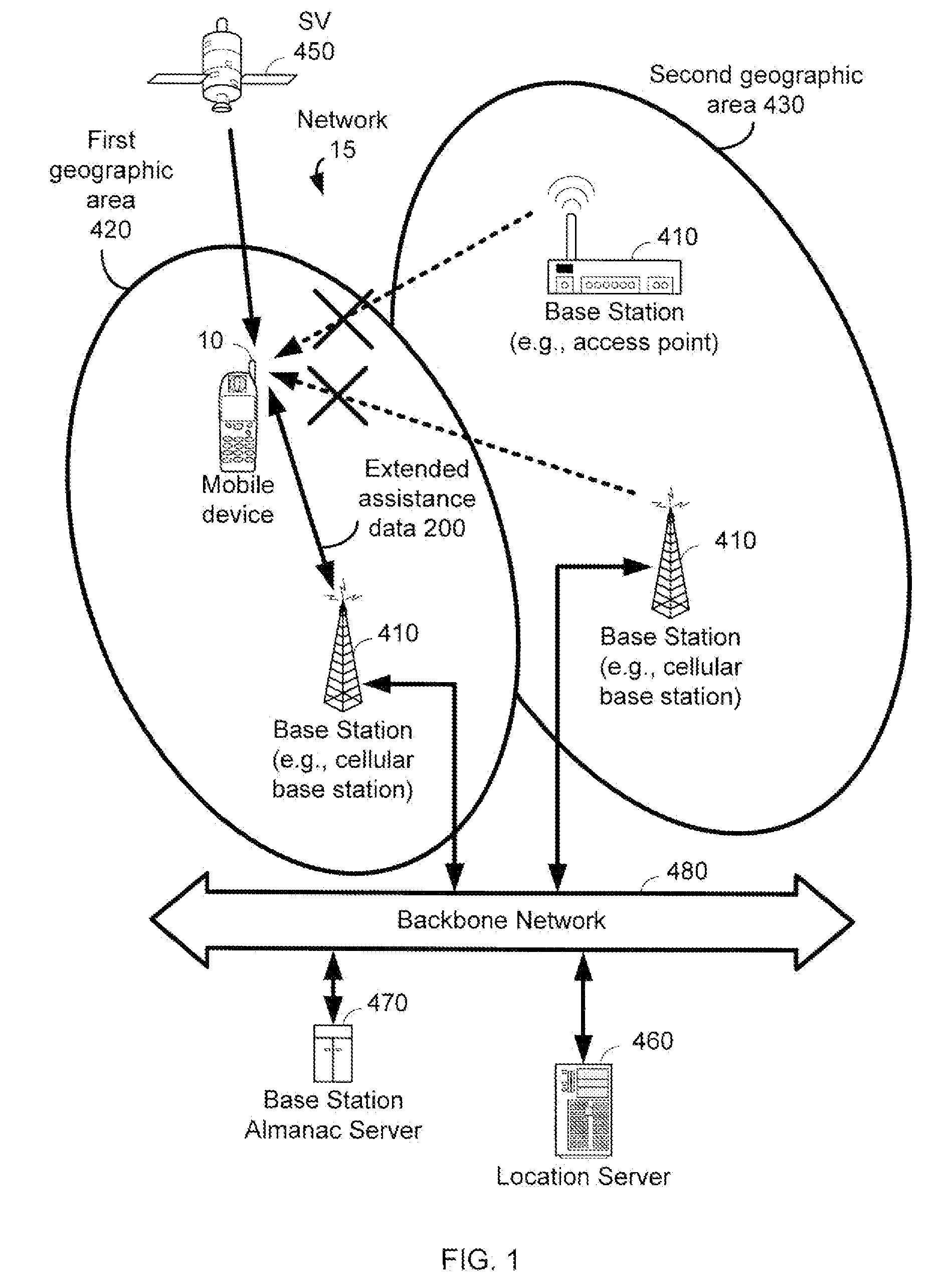

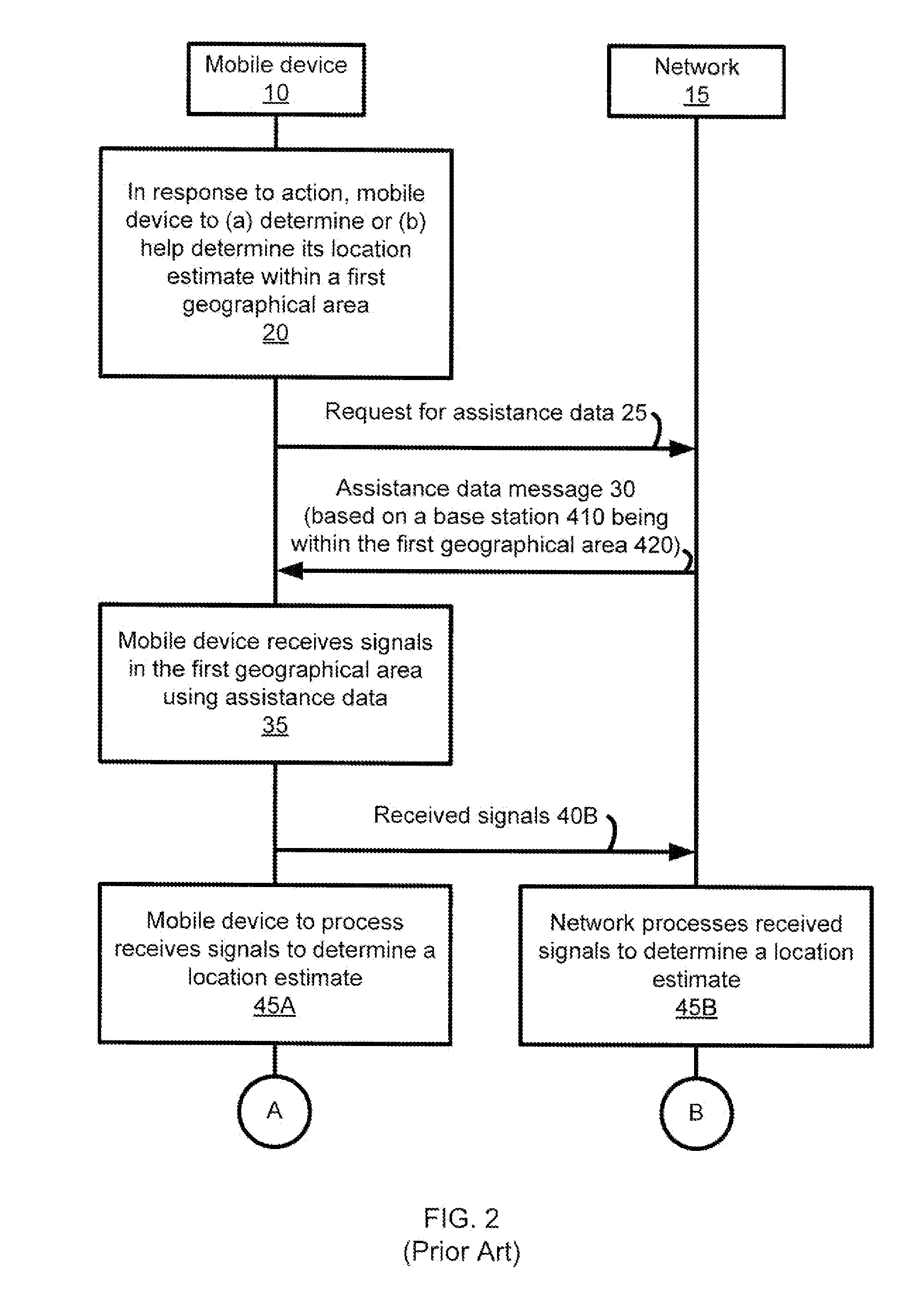

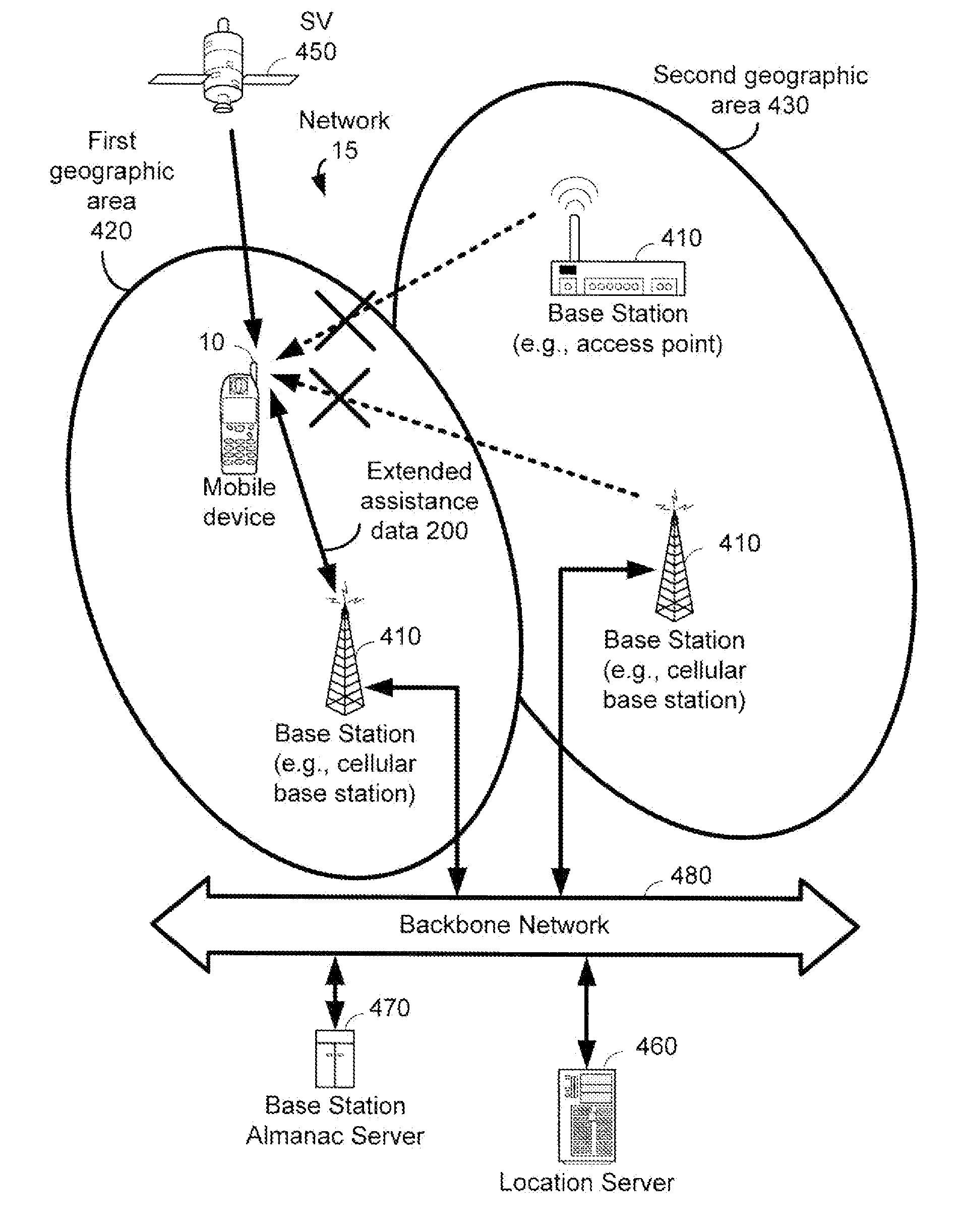

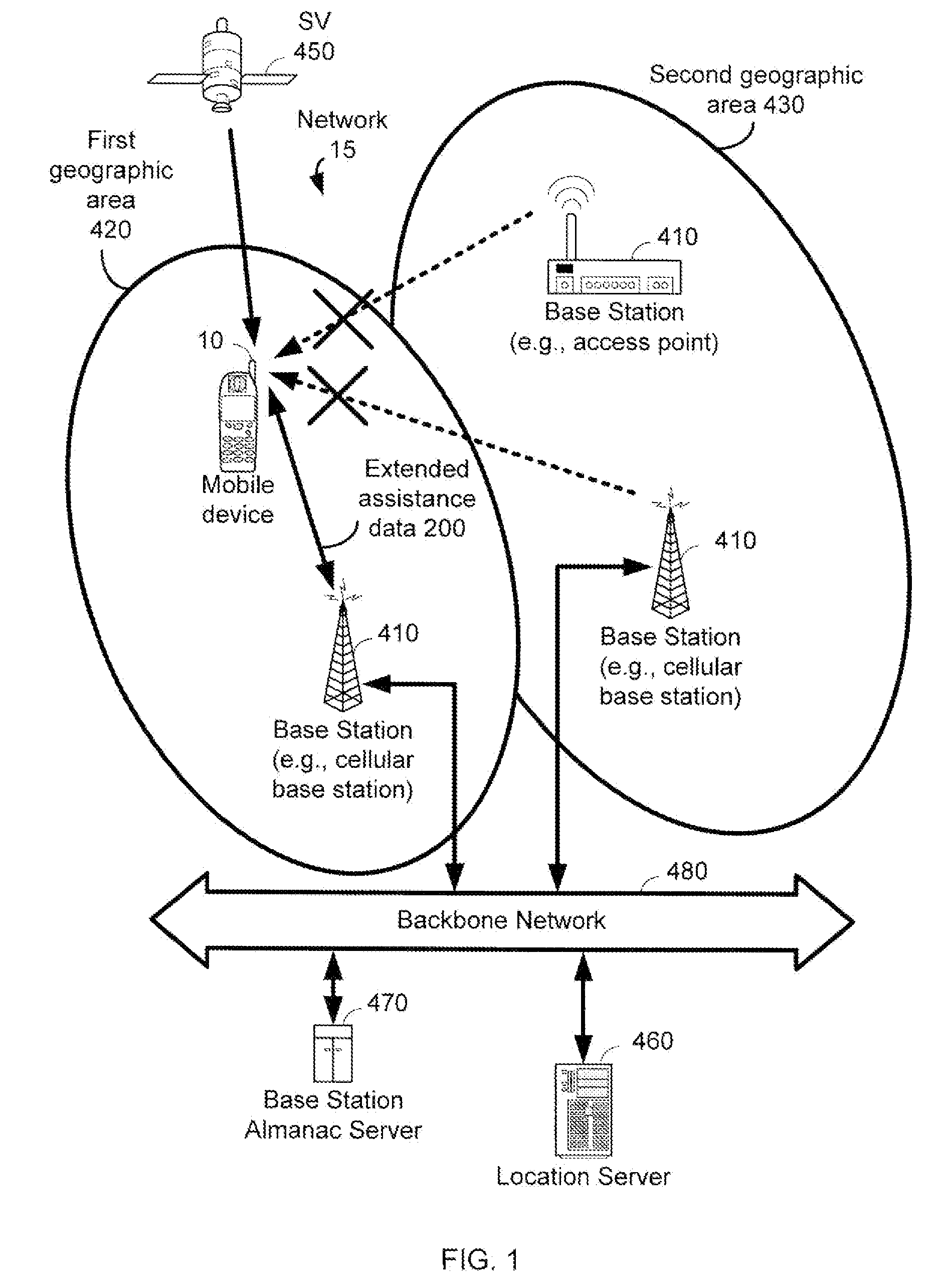

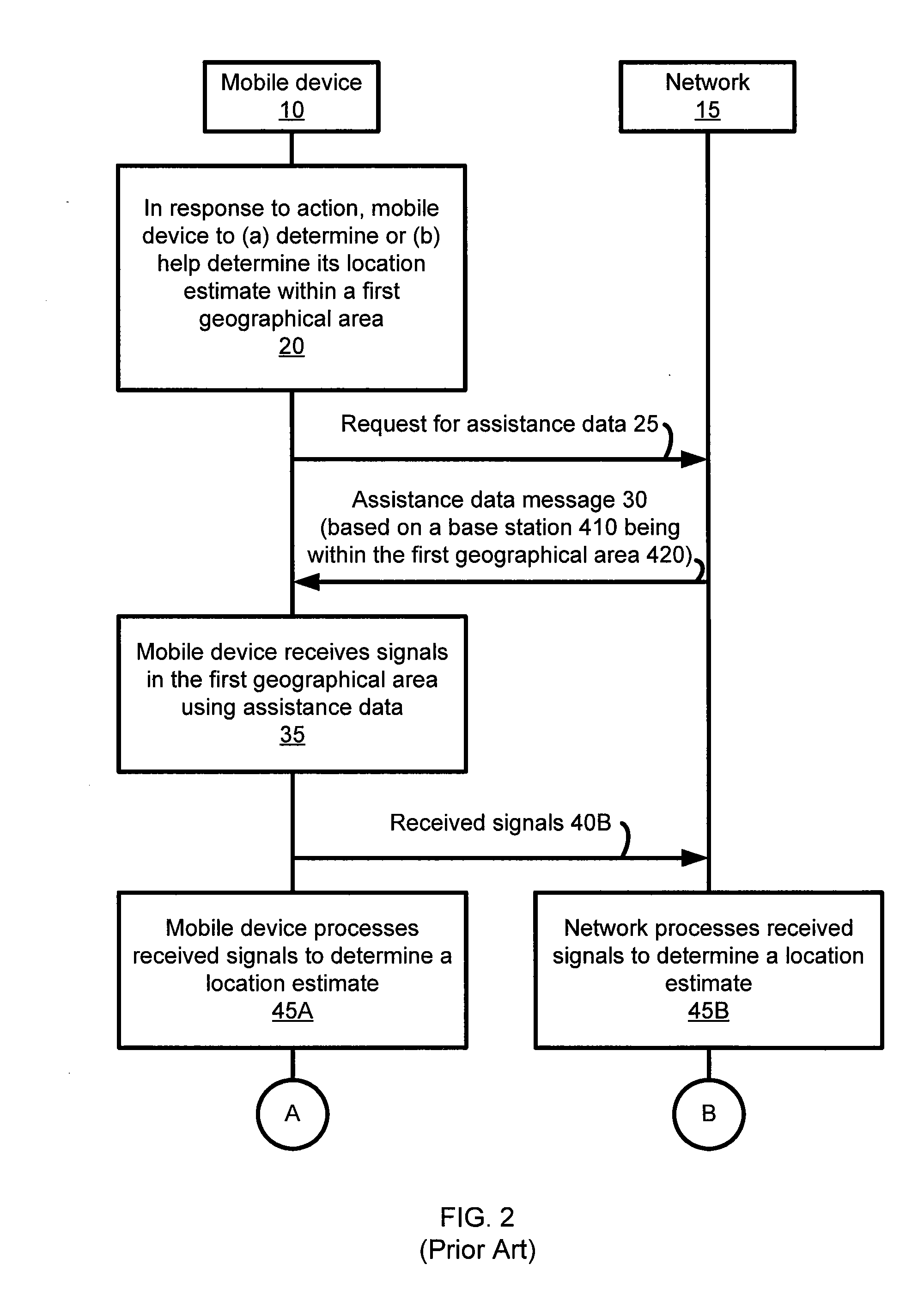

Enhanced Positioning Assistance Data For Reduced Signaling

Apparatus and methods for determining a location estimate of a mobile device based on an extended set of assistance data are presented. The extended assistance data includes assistance data for base stations, such as cellular base stations and access points, not expected to be viewable by the mobile device in a (current) first geographical area but expected to be viewable by the mobile device in a (future) second geographical area. By seeding the mobile device with assistance data expected to be useful in the future, the network reduces messaging between the network and mobile device and battery consumption by the mobile device.

Owner:QUALCOMM INC

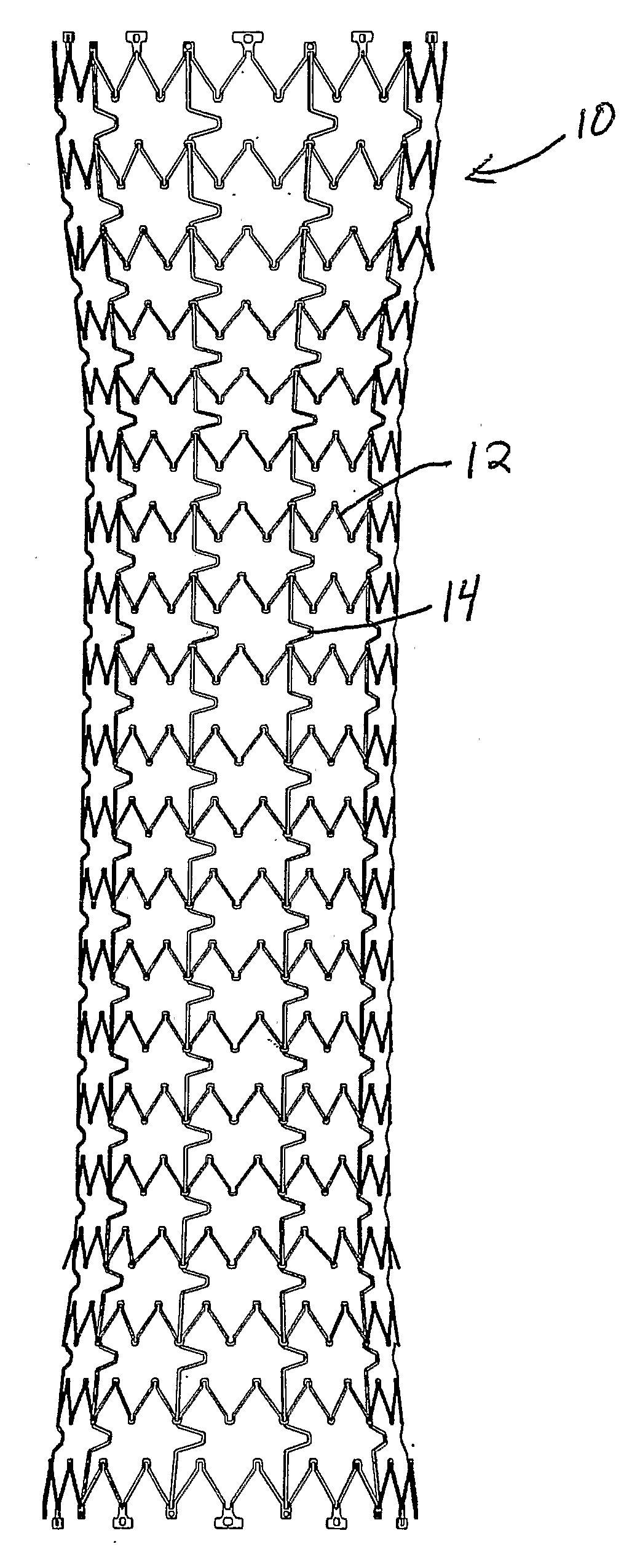

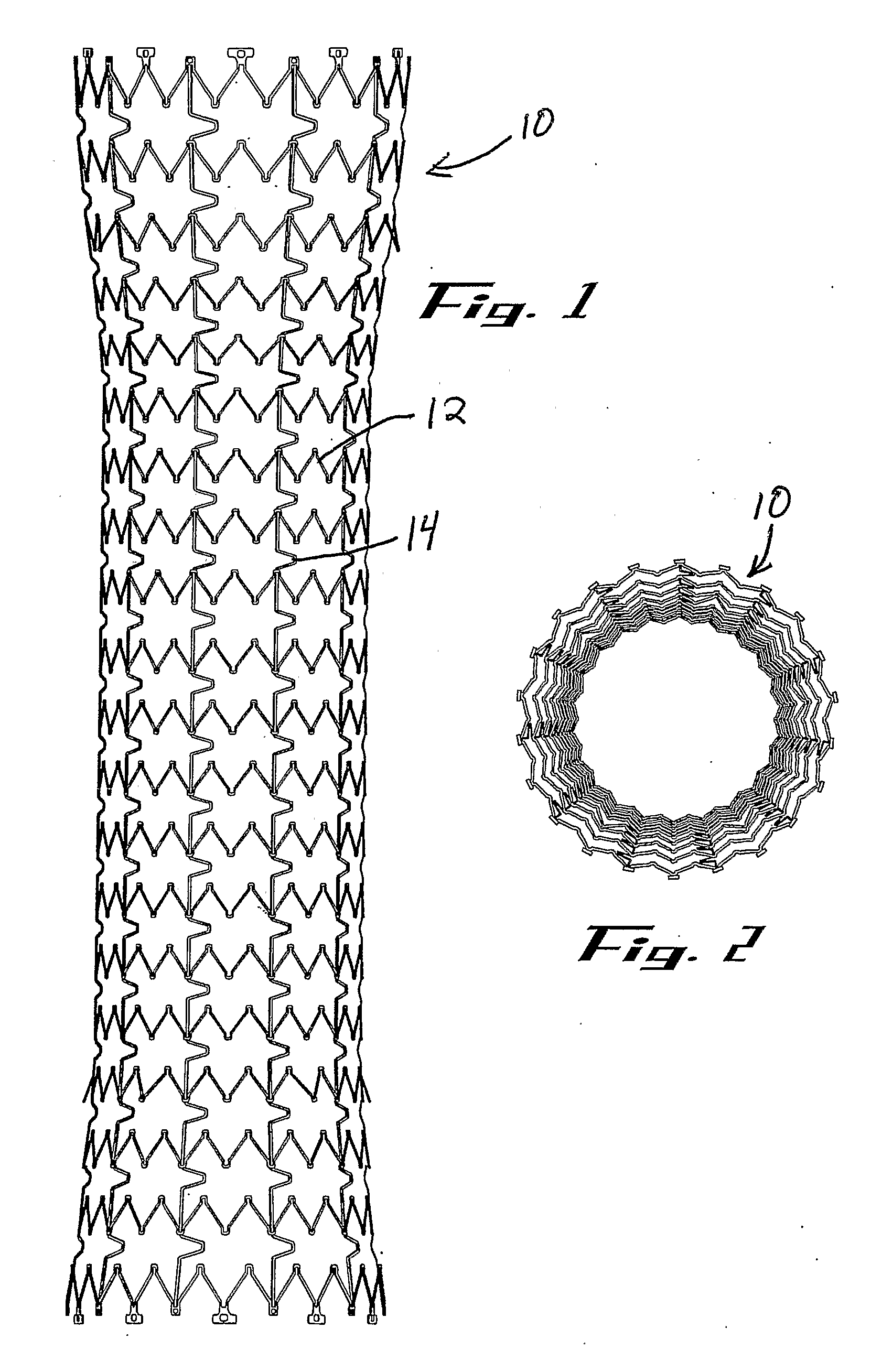

Stent Removal and Repositioning Aid and Associated Method

A removable stent for placement within a lumen is provided. The stent includes a scaffolding of struts configured to define a substantially cylindrical member having a proximal end and a distal end. The stent also includes at least one flexible element spirally wound along at least a portion of a respective strut, wherein the element comprises at least one engageable member such that a force applied to the engageable member does not result in purse-stringing.

Owner:MERIT MEDICAL SYST INC

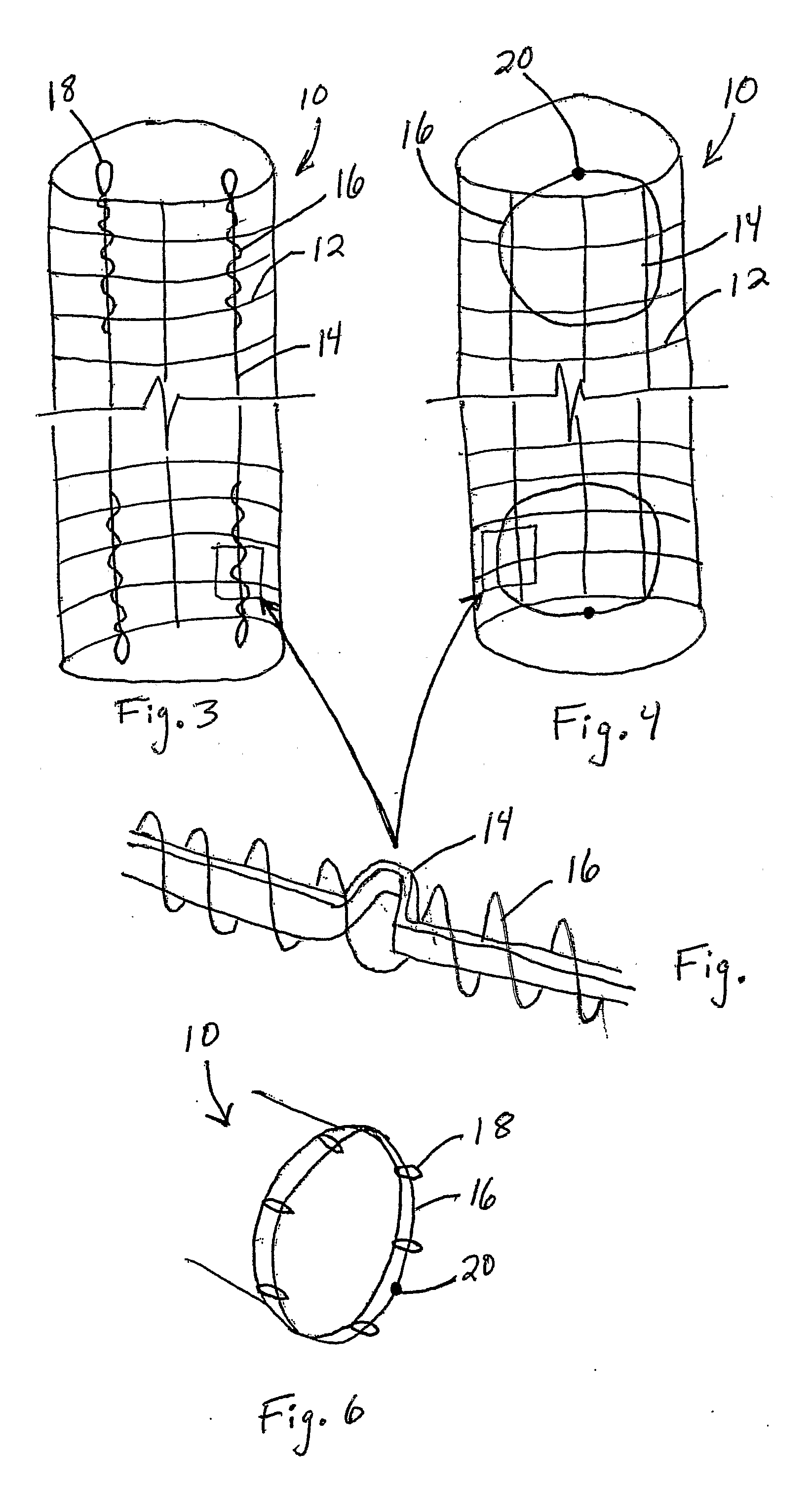

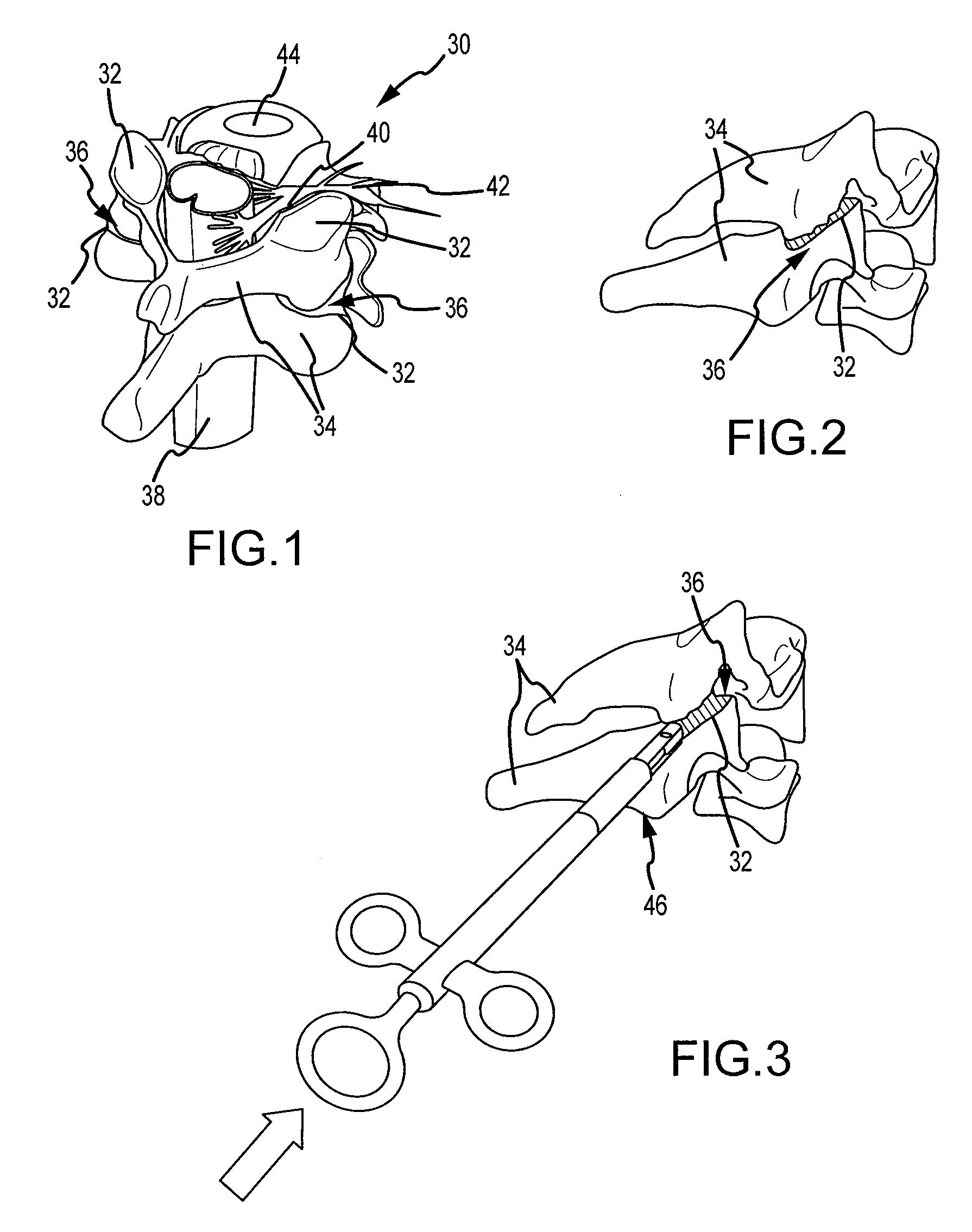

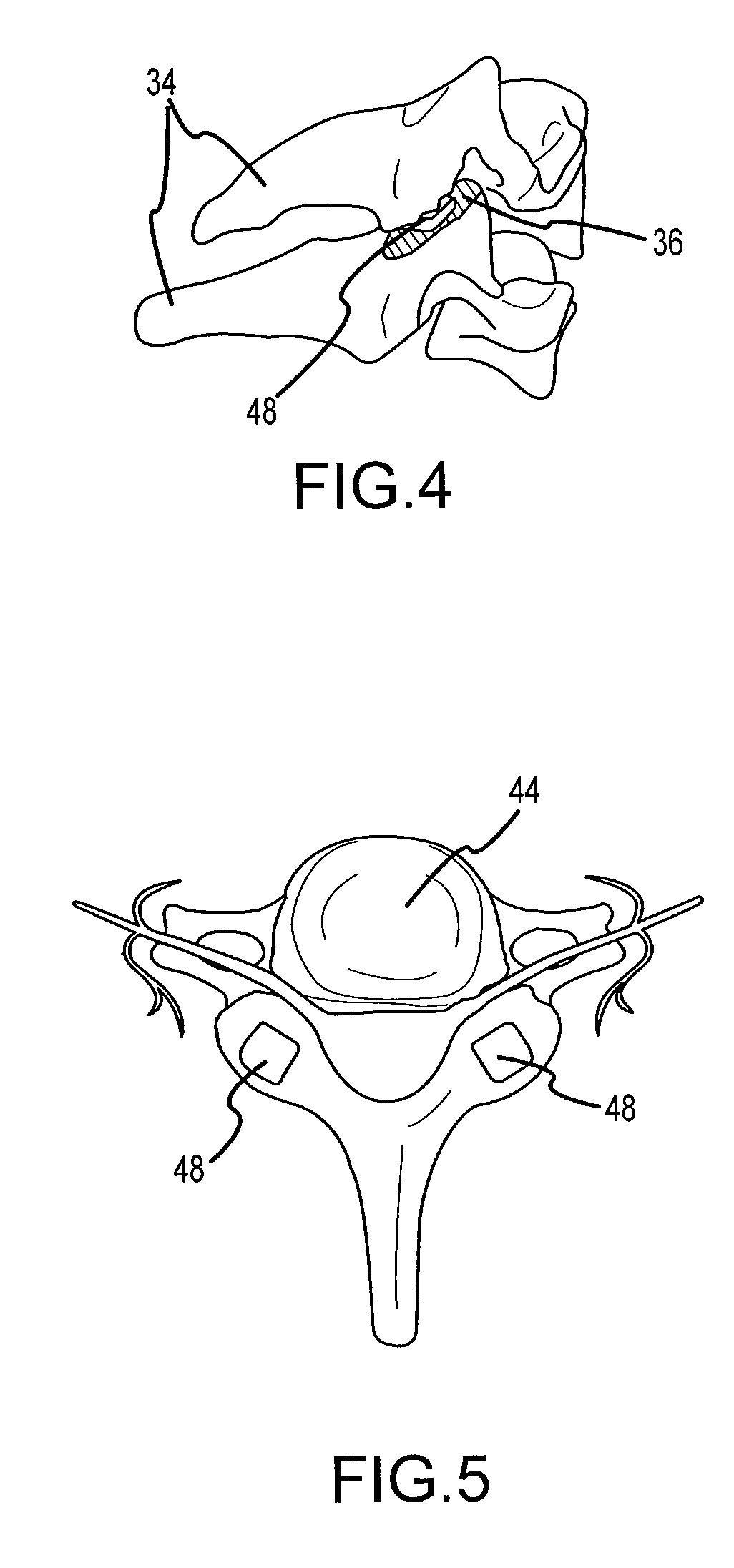

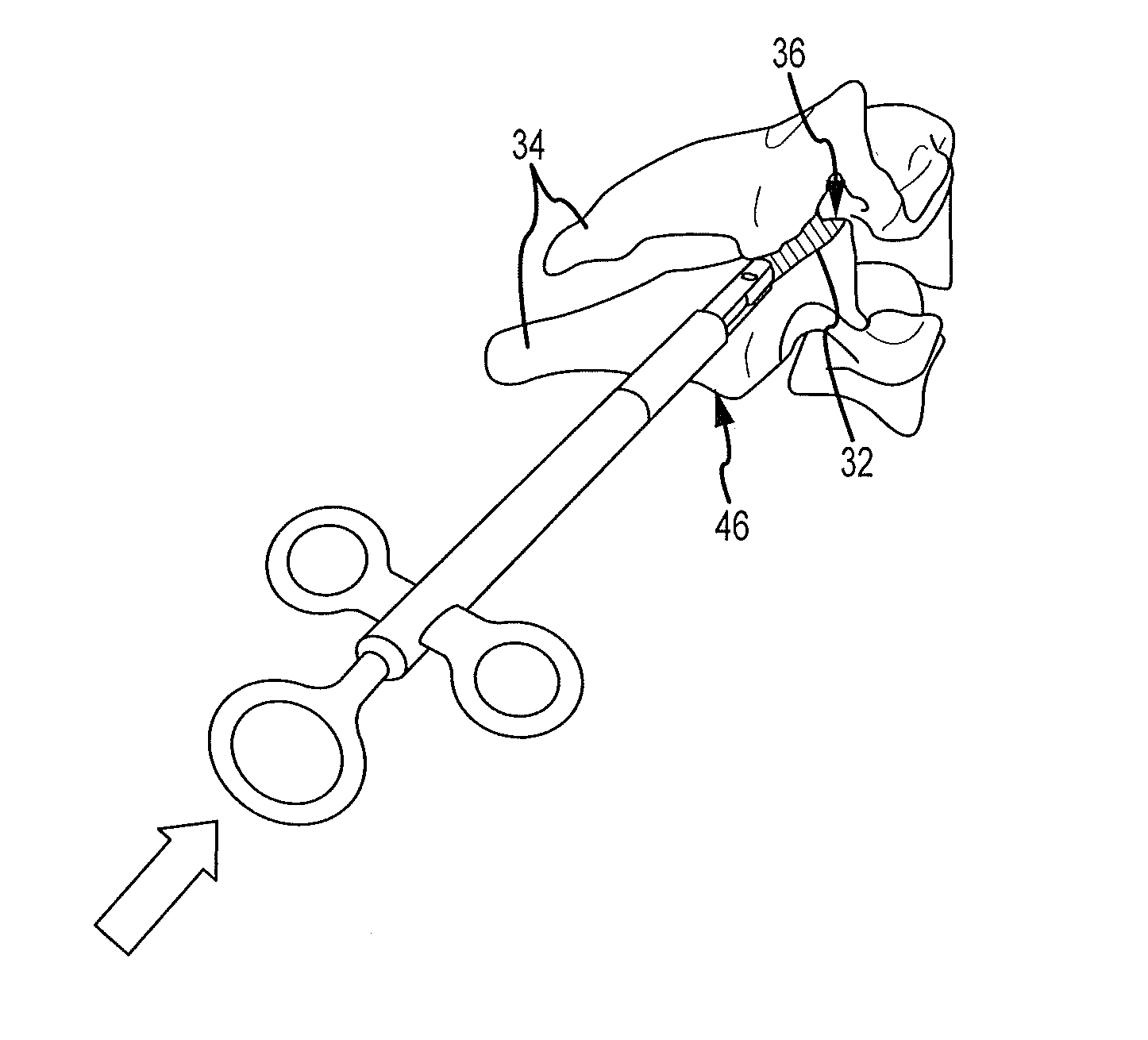

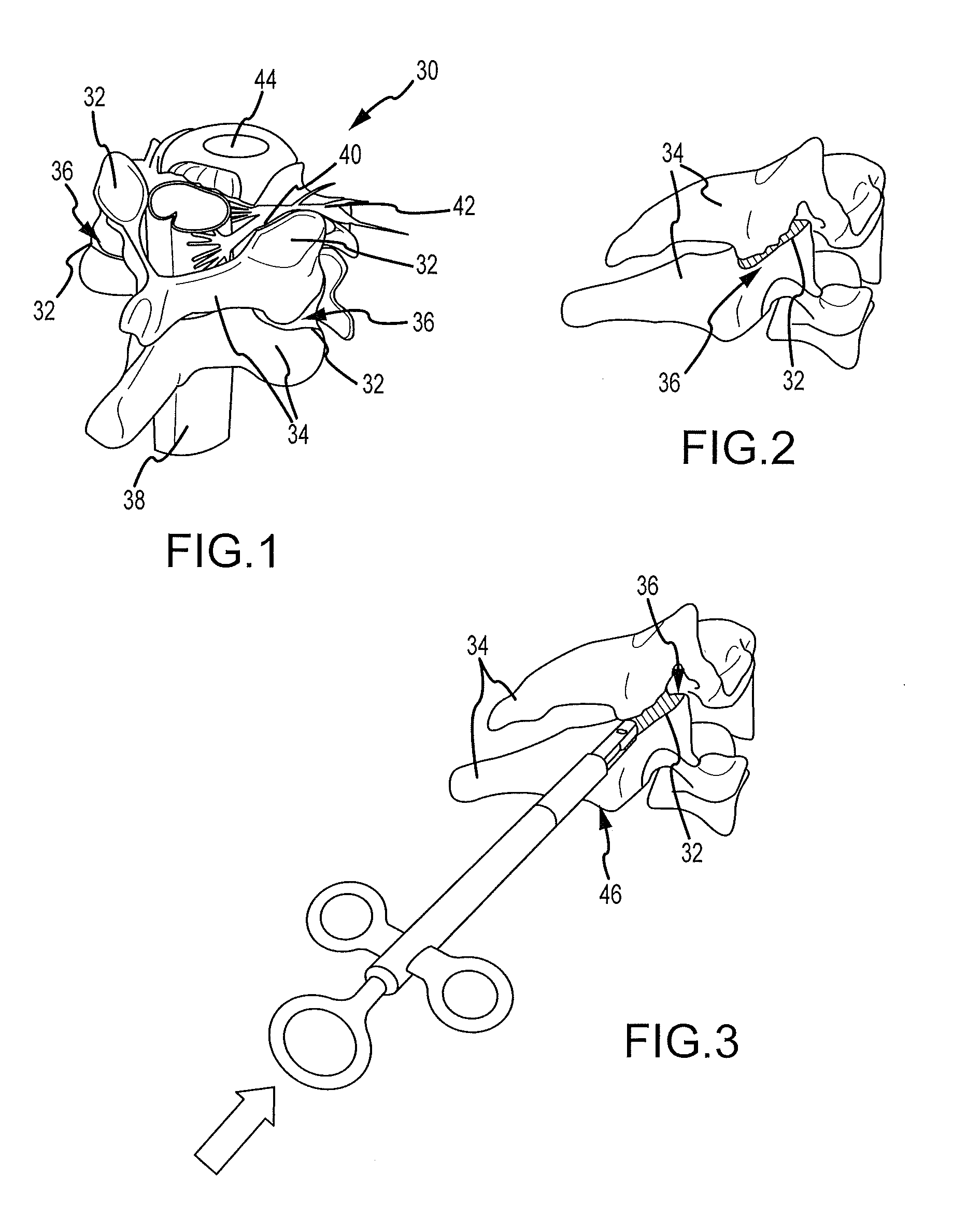

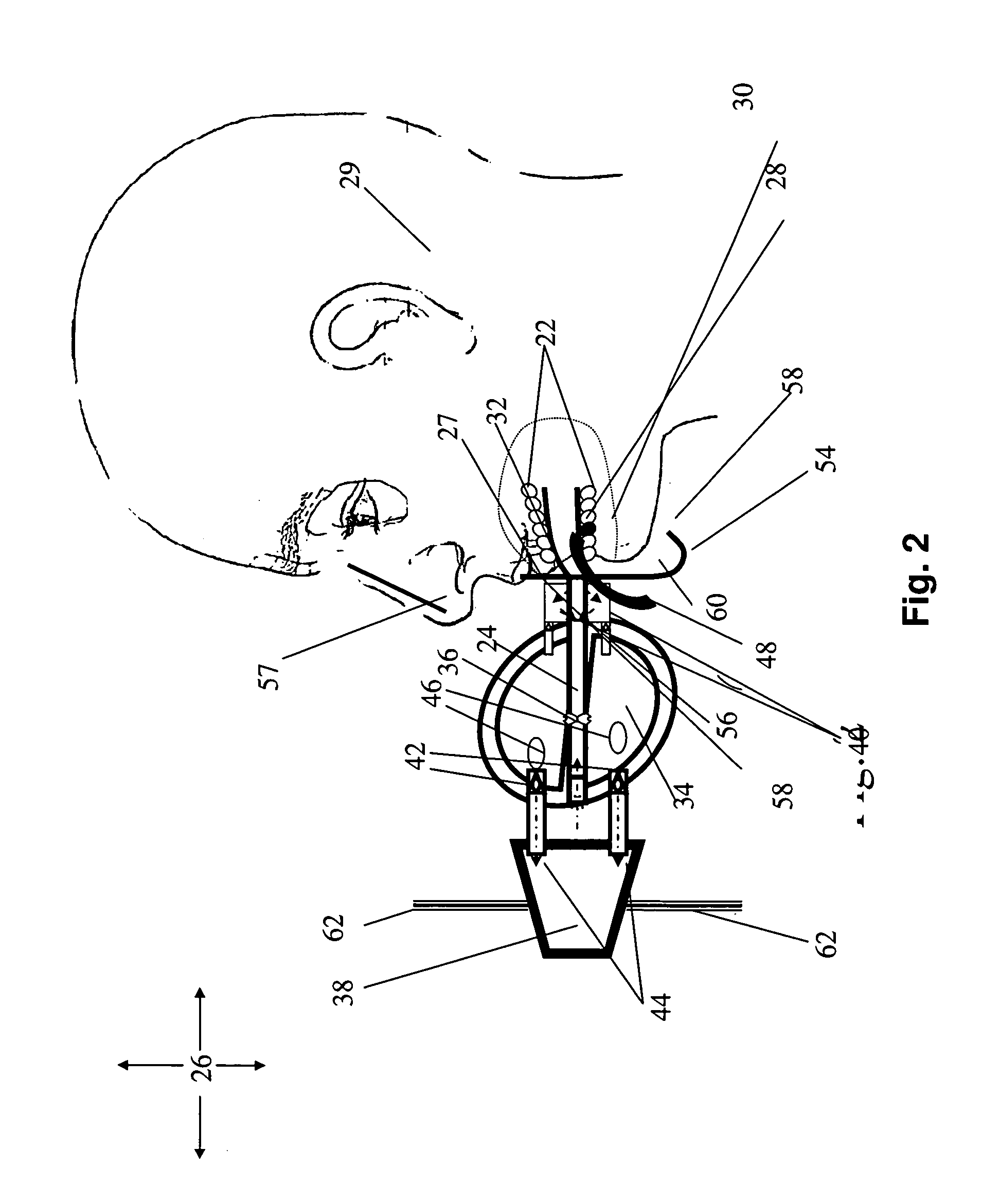

Cervical distraction/implant delivery device

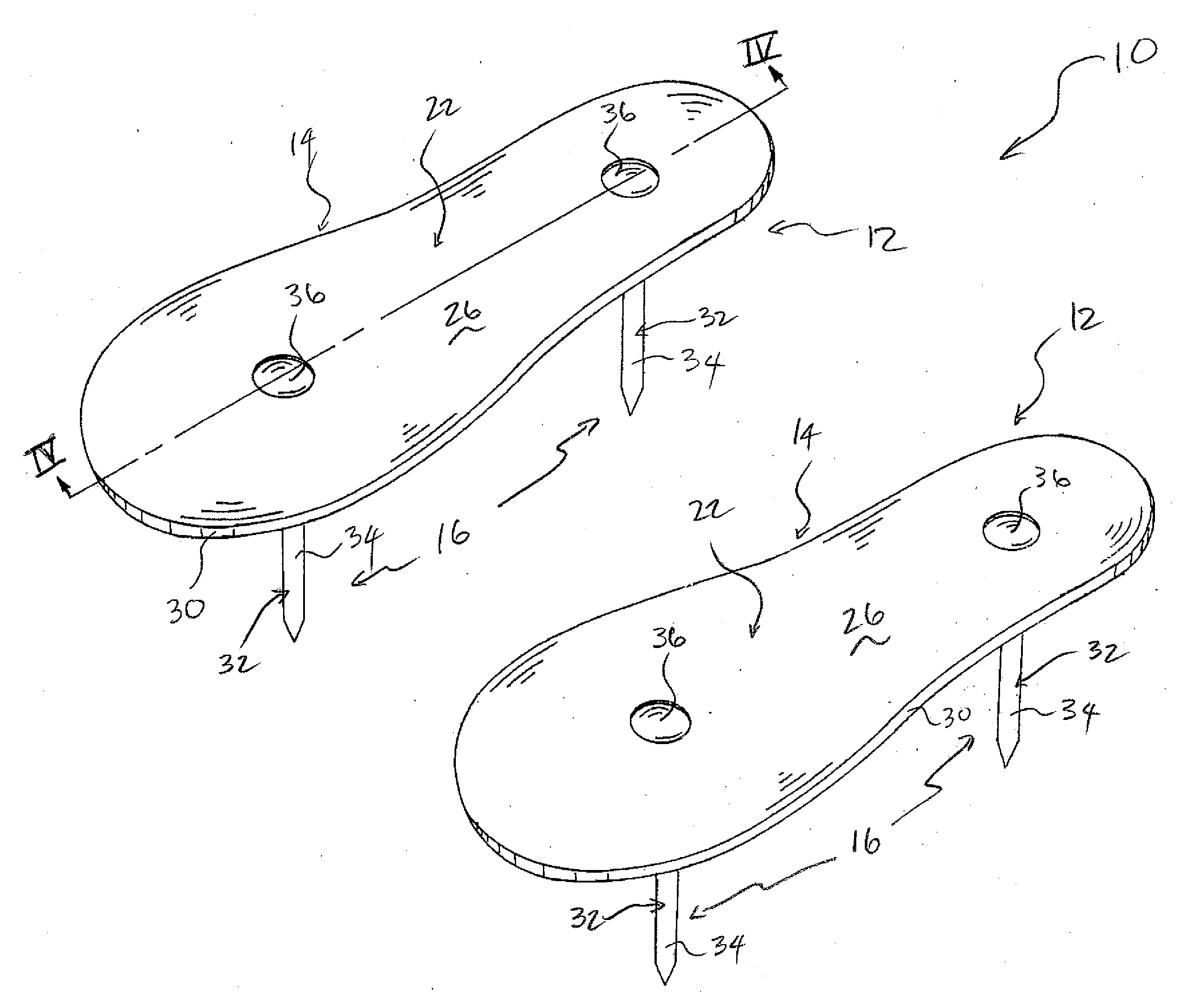

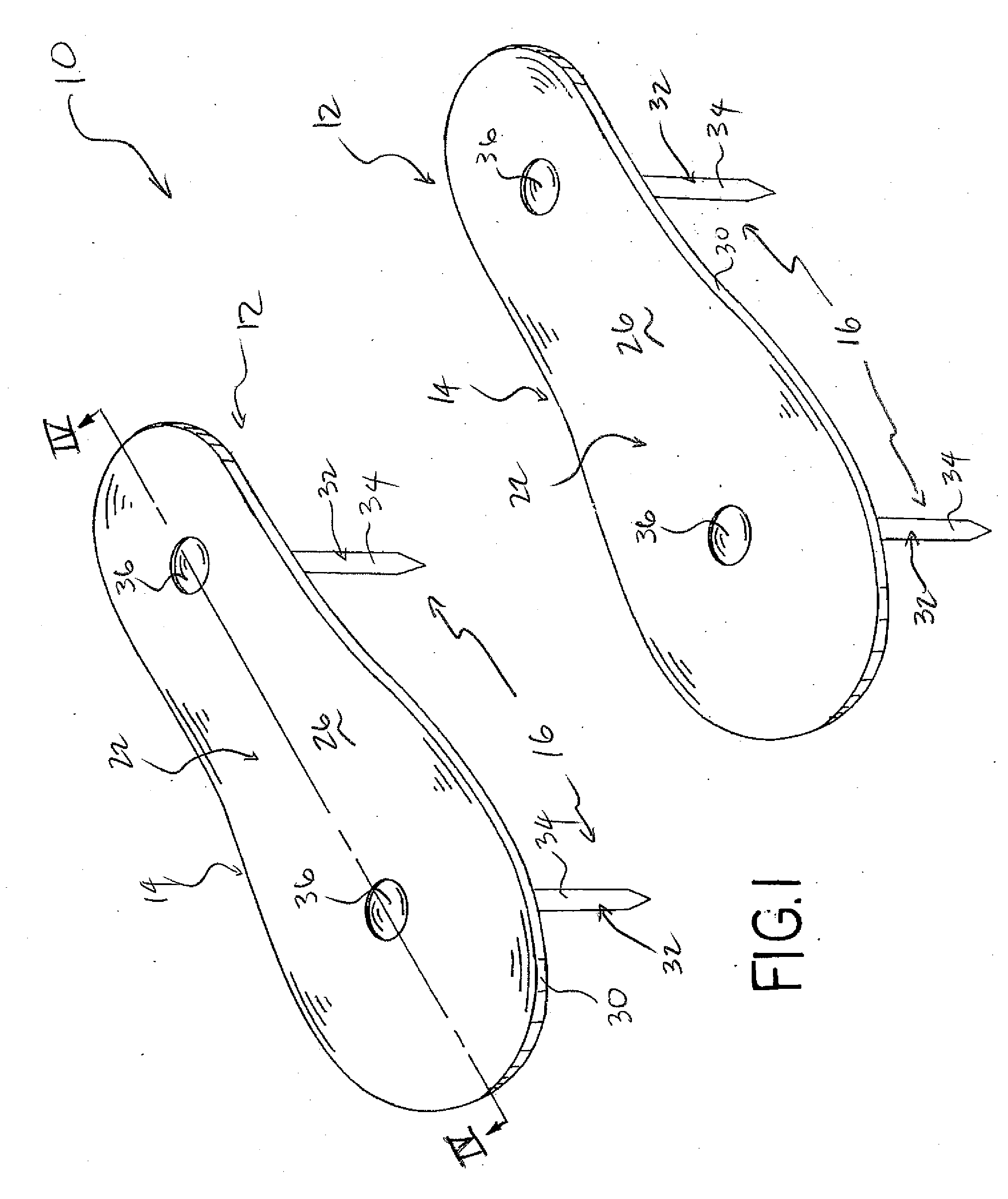

ActiveUS20100069912A1Minimum distanceIncrease foraminal dimensionInternal osteosythesisDiagnosticsDistractionPermanent implant

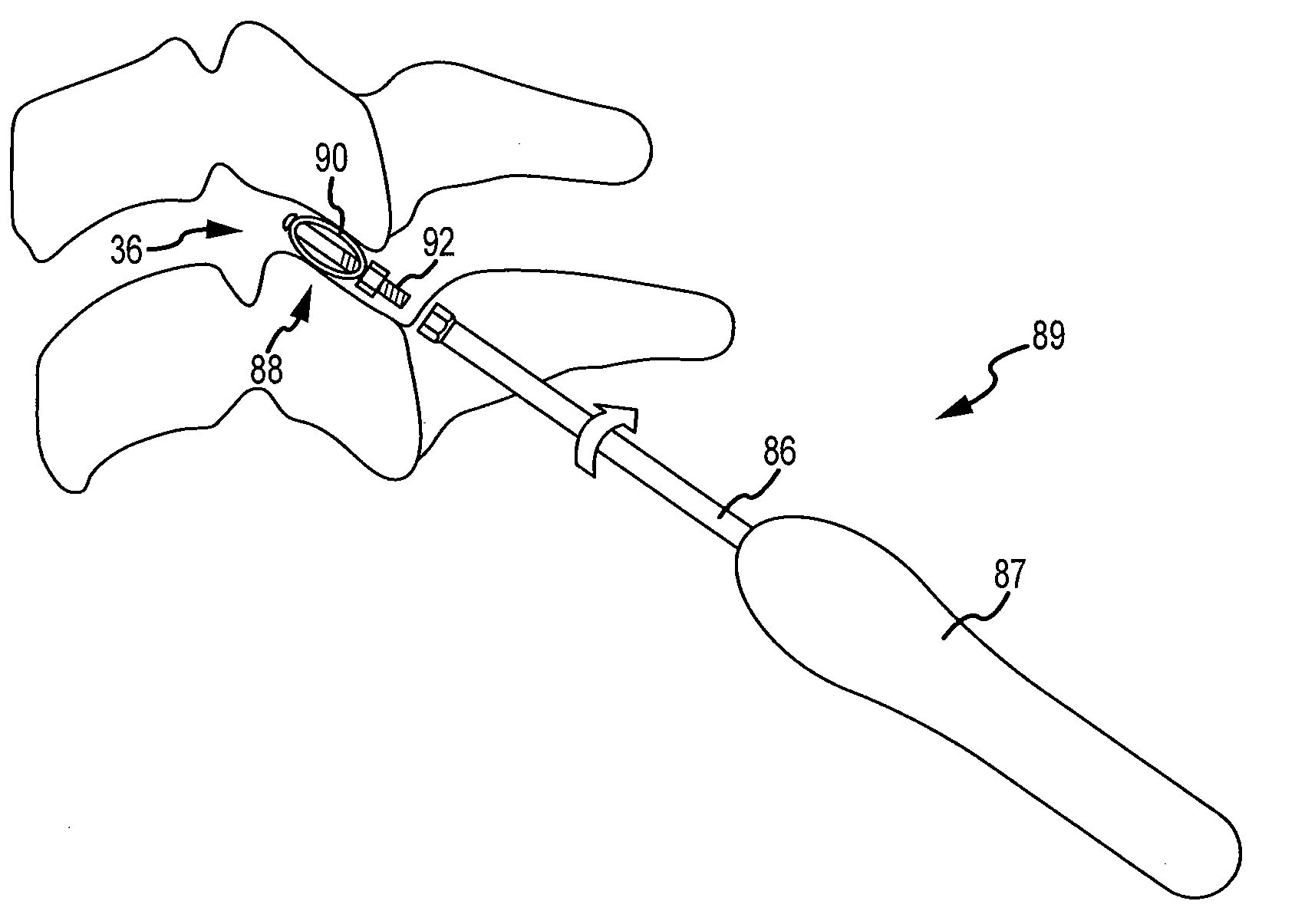

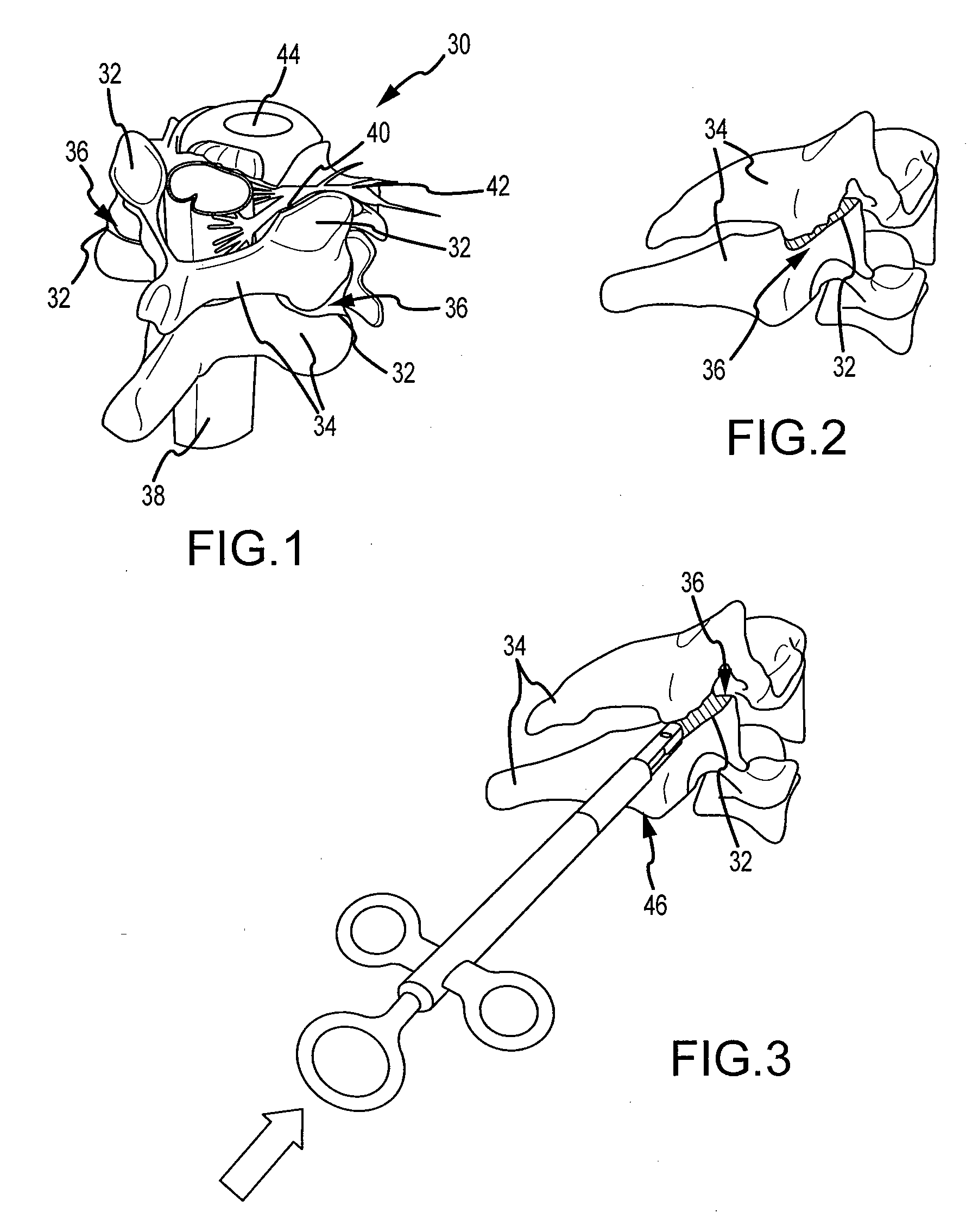

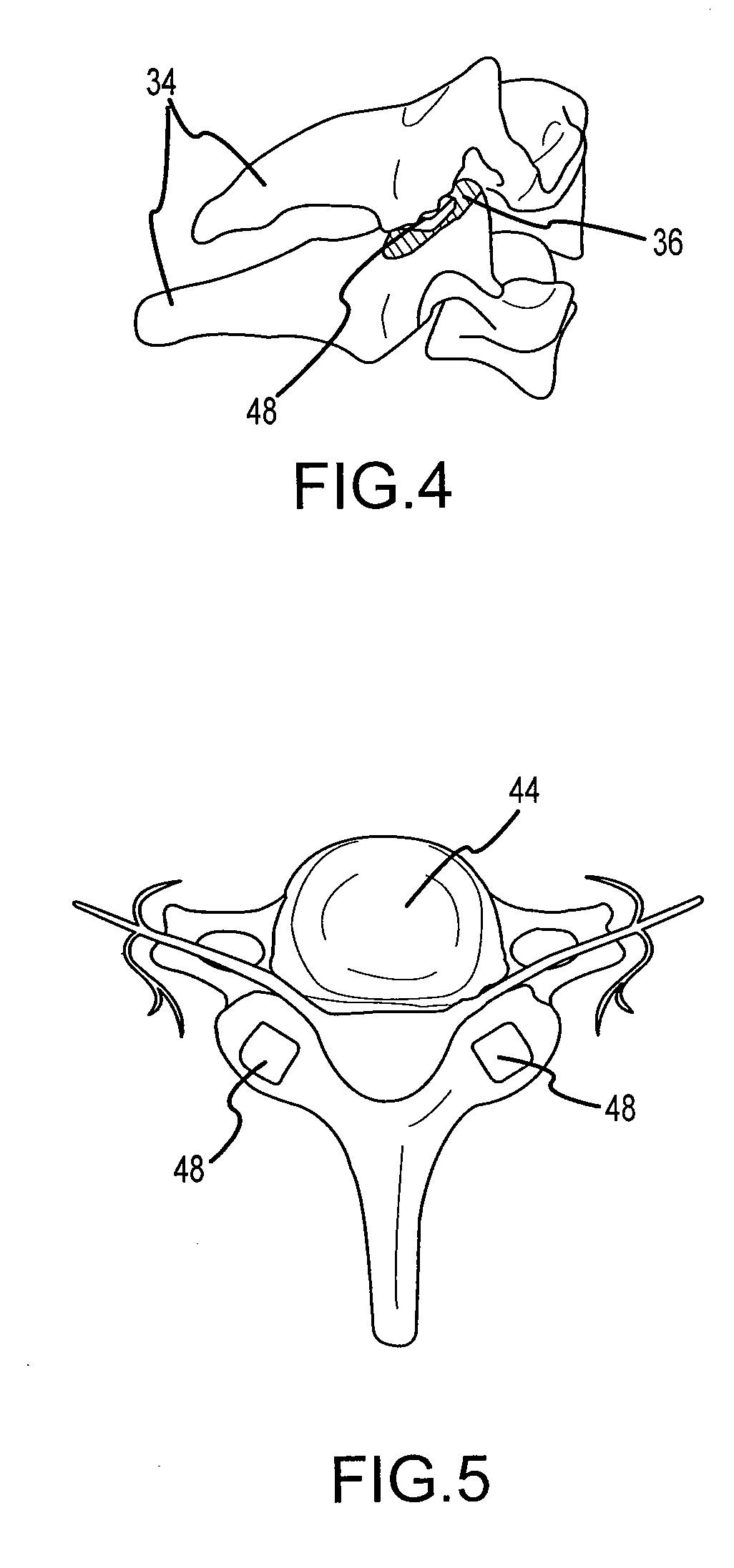

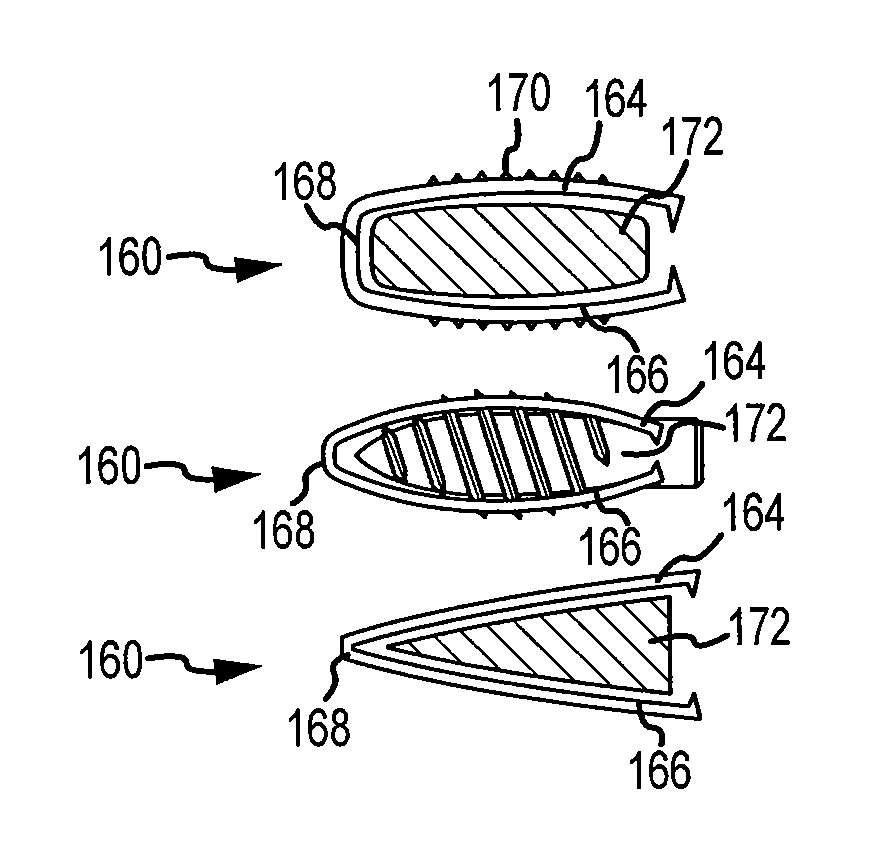

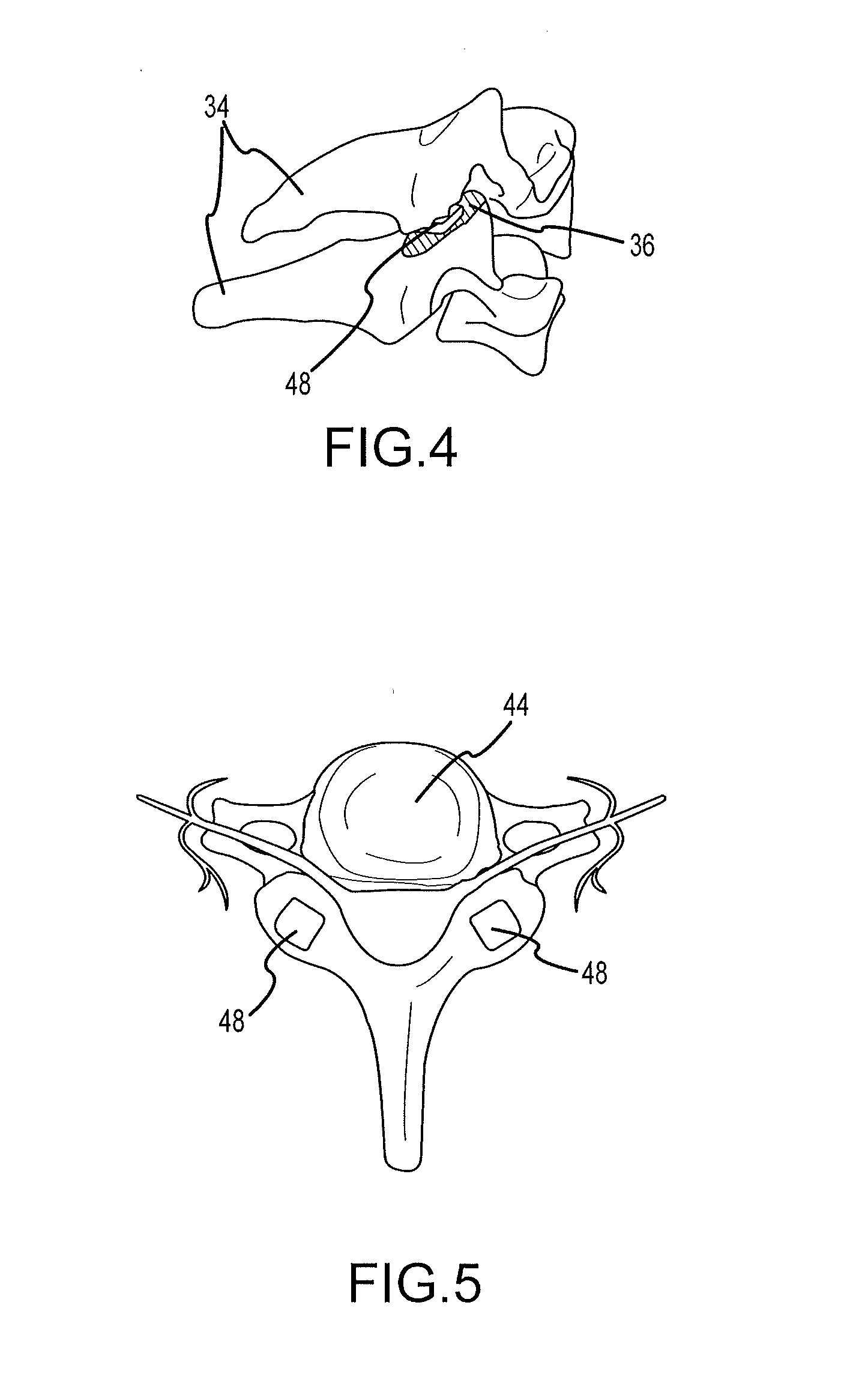

Systems for distracting a facet joint and positioning a permanent implant in the joint are disclosed. The implants serve to retain a distracted position of the facet joint which is achieved with positioning of the leading end of a distraction tool in the facet joint and then distracting or enlarging the joint a desired amount. The permanent implant could be part of the distraction mechanism which can be separated from the delivery tool once the joint has been distracted or an auxiliary implant may be positioned before the distraction mechanism is removed from the distracted joint. The permanent implants can be solid, mechanical devices that may have fixation means thereon to hold them in place or injected fluids such as hydrogels or fluids confined within balloons.

Owner:PROVIDENCE MEDICAL TECH

Cervical distraction/implant delivery device

ActiveUS8512347B2Increase spacingImprove the situationInternal osteosythesisDiagnosticsDistractionPermanent implant

Systems for distracting a facet joint and positioning a permanent implant in the joint are disclosed. The implants serve to retain a distracted position of the facet joint which is achieved with positioning of the leading end of a distraction tool in the facet joint and then distracting or enlarging the joint a desired amount. The permanent implant could be part of the distraction mechanism which can be separated from the delivery tool once the joint has been distracted or an auxiliary implant may be positioned before the distraction mechanism is removed from the distracted joint. The permanent implants can be solid, mechanical devices that may have fixation means thereon to hold them in place or injected fluids such as hydrogels or fluids confined within balloons.

Owner:PROVIDENCE MEDICAL TECH

Cervical distraction/implant delivery device

InactiveUS20130310839A1Increase spacingIncrease distanceInternal osteosythesisDiagnosticsDistractionPermanent implant

Systems for distracting a facet joint and positioning a permanent implant in the joint are disclosed. The implants serve to retain a distracted position of the facet joint which is achieved with positioning of the leading end of a distraction tool in the facet joint and then distracting or enlarging the joint a desired amount. The permanent implant could be part of the distraction mechanism which can be separated from the delivery tool once the joint has been distracted or an auxiliary implant may be positioned before the distraction mechanism is removed from the distracted joint. The permanent implants can be solid, mechanical devices that may have fixation means thereon to hold them in place or injected fluids such as hydrogels or fluids confined within balloons.

Owner:PROVIDENCE MEDICAL TECH

Distributed method and system for determining the position of a mobile device using long-range signals and calibrating the position using short-range signals

InactiveUS8838135B2Energy efficient ICTNear-field transmissionWireless communication protocolTraffic signal

A method and system is described where a plurality of position reference devices use short-range wireless communication protocols to transmit positioning assistance data to nearby mobile devices, and the mobile devices use the assistance data to model errors and re-calibrate their positioning systems. The short-range communication methods include NFC, RFID, Bluetooth®, short-range 802.11, Wi-Fi Direct, and high frequency focused beams such as 60 GHz. The position reference devices are passive or active NFC tags, passive or active RFID tags, other devices that include such tags as their components, Bluetooth®-enabled devices, 60 GHz-enabled devices, and 802.11 access points that can lower their transmit power. The reference devices are located at various indoor and outdoor locations such as smart posters, kiosks, ATM machines, malls, store checkout counters, store security gates, wireless access points, cellular base-stations, tollbooths, traffic lights, and street lamp posts.

Owner:GOLBA LLC

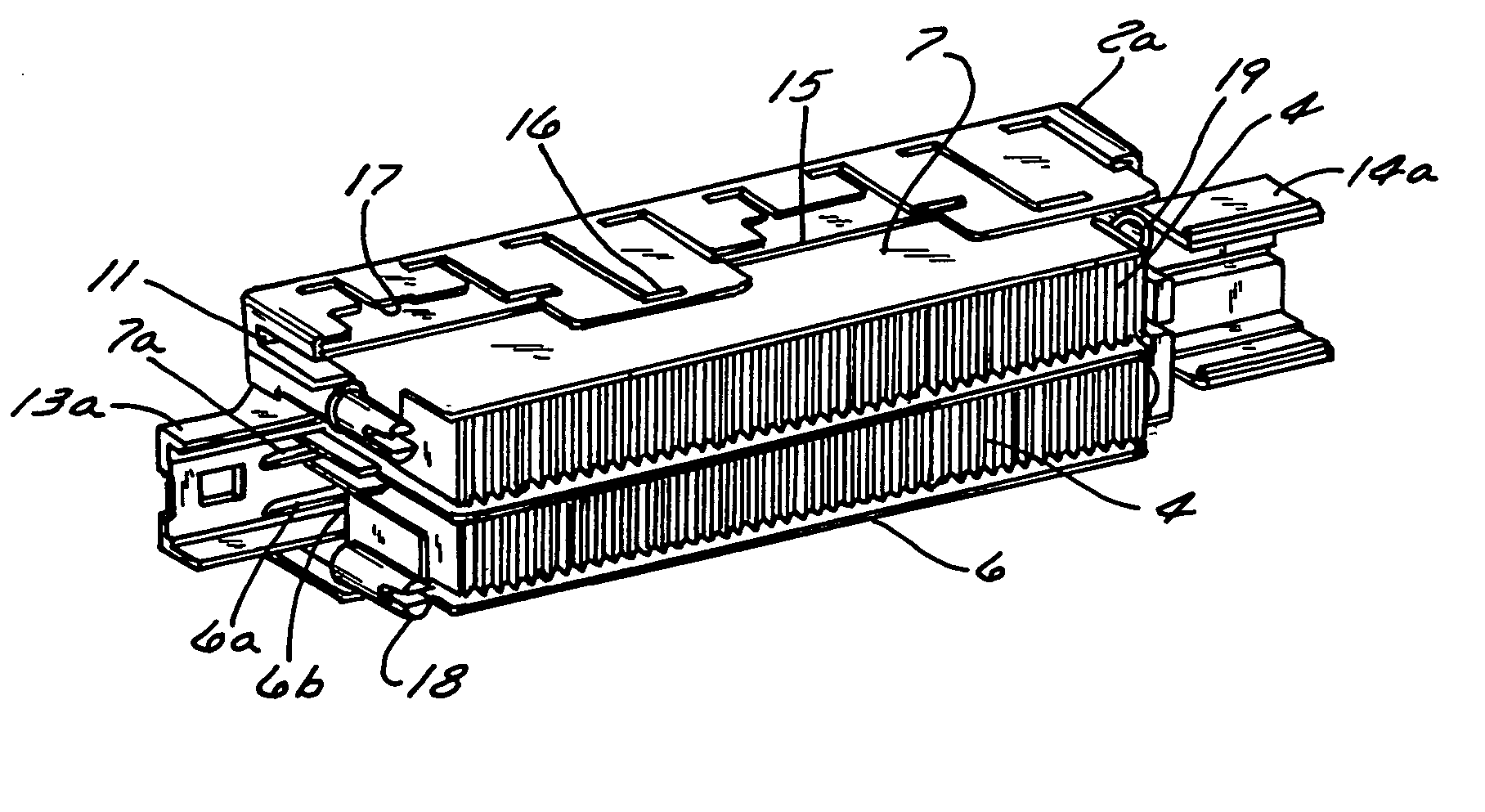

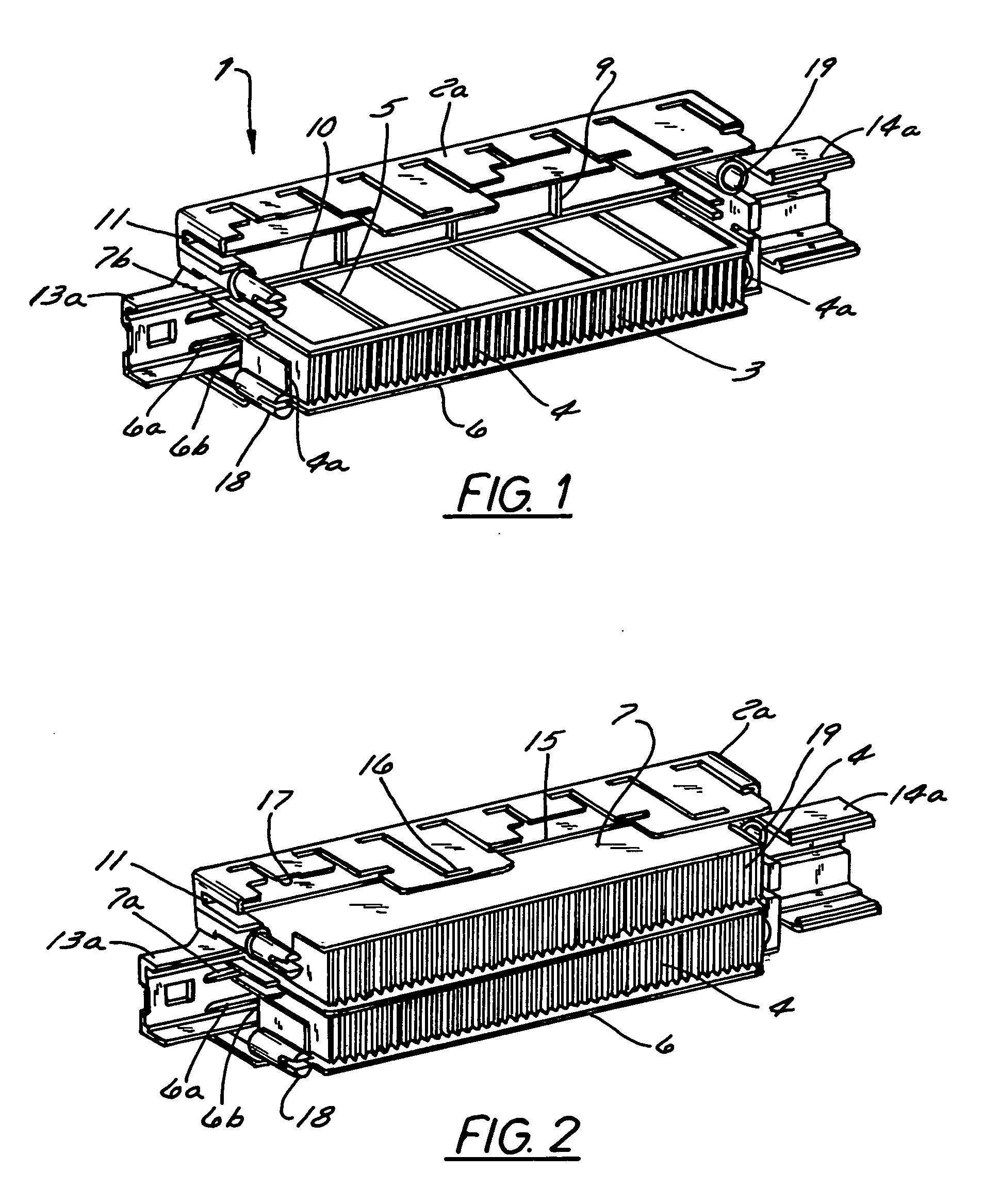

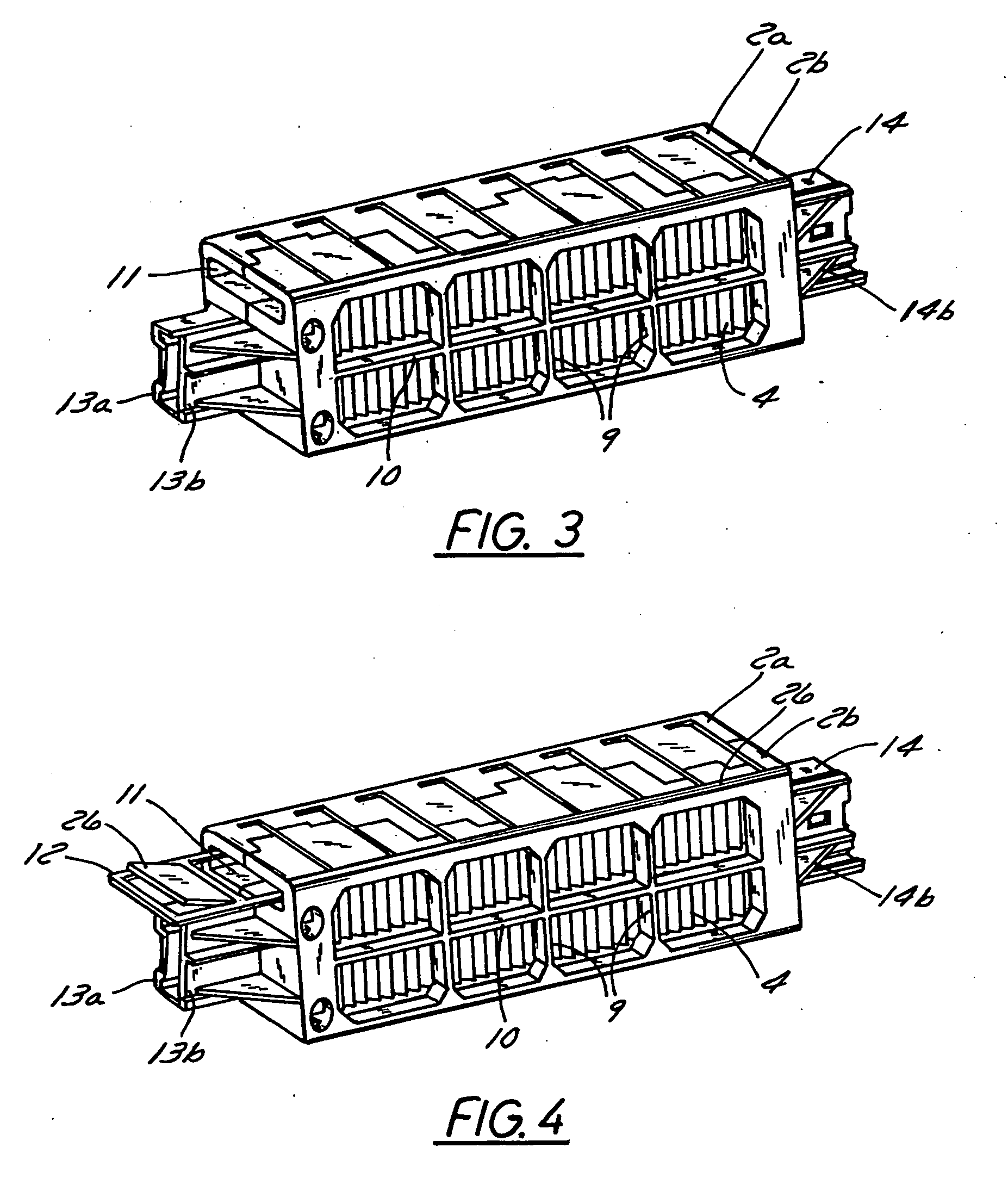

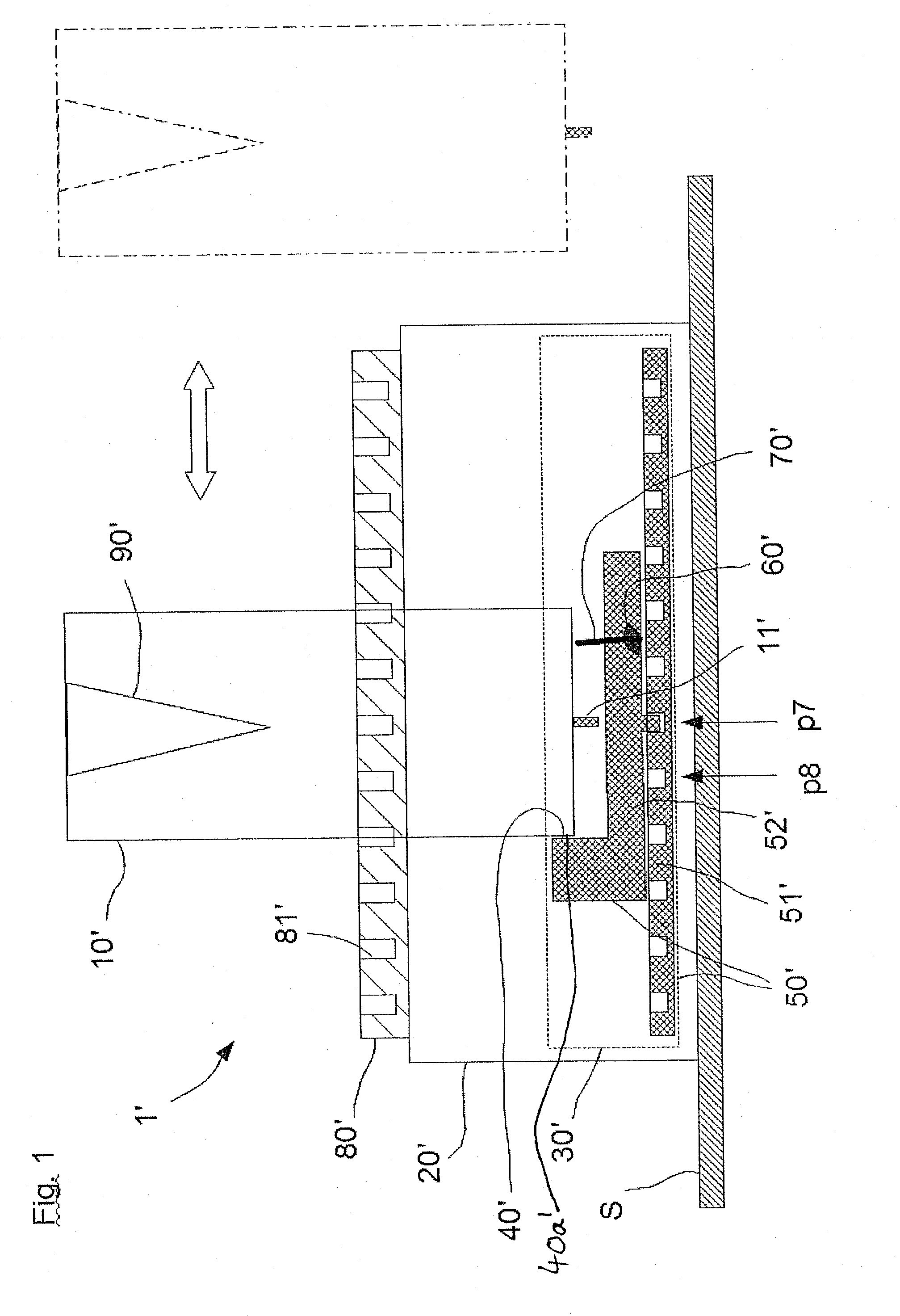

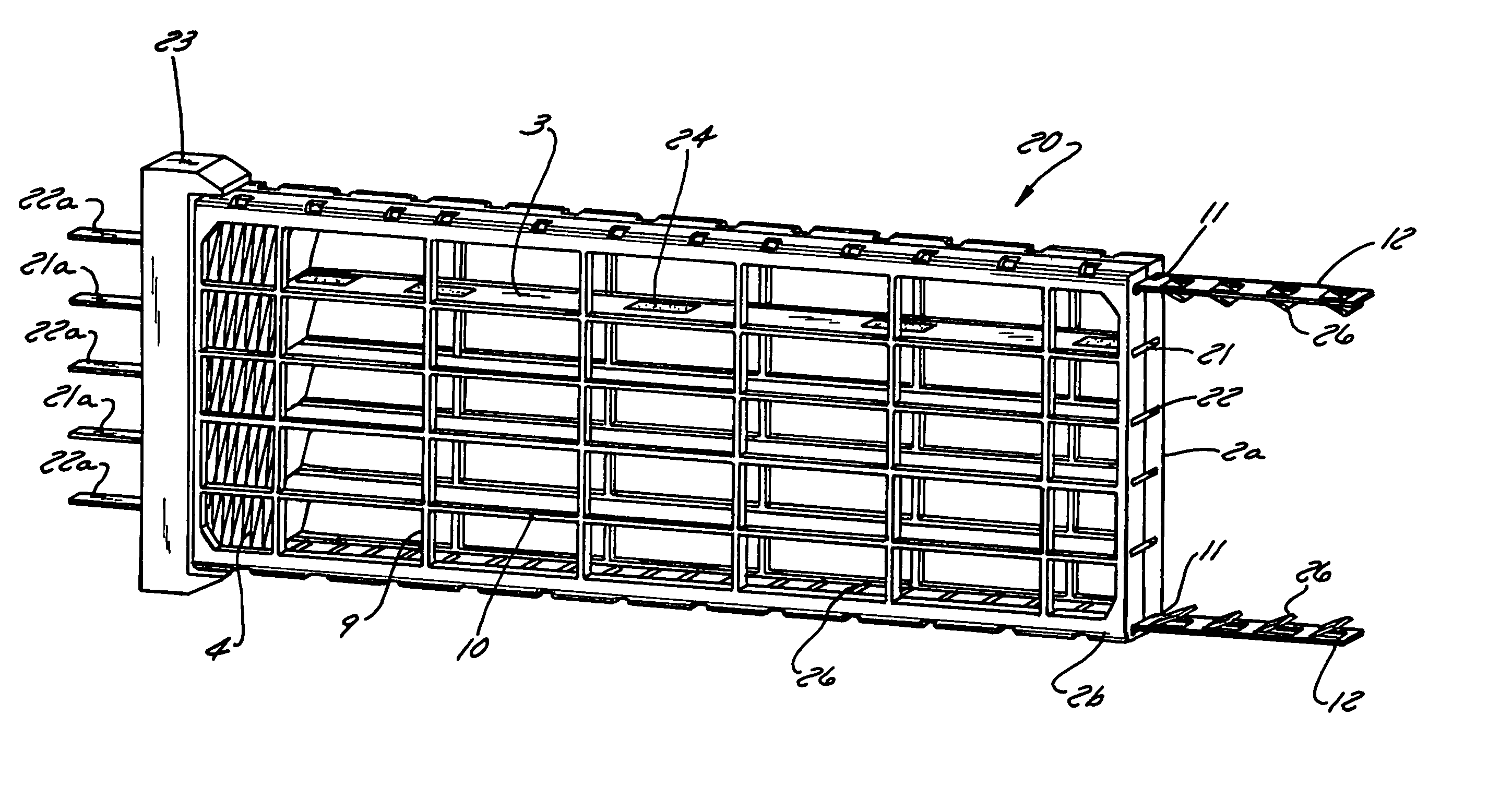

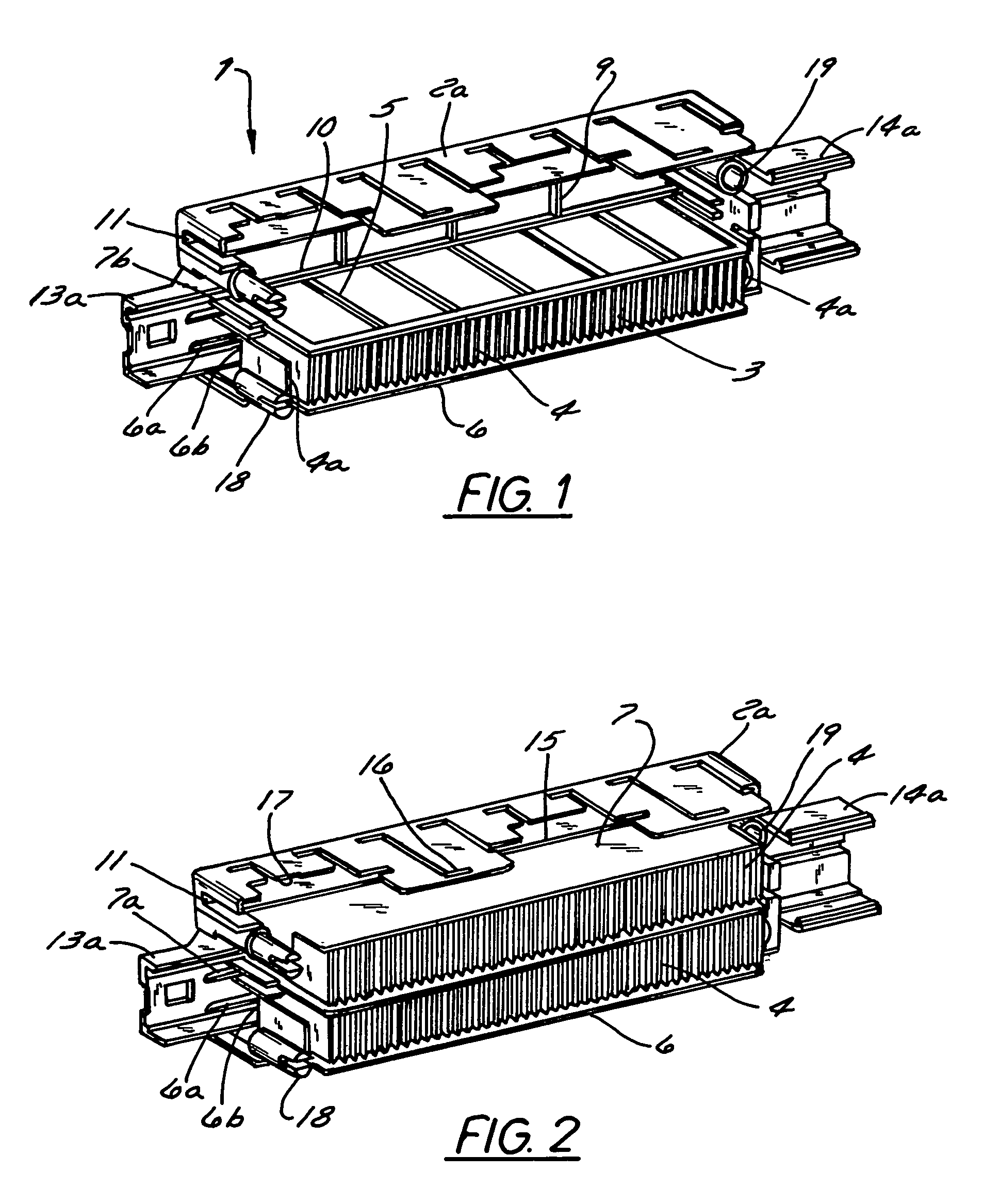

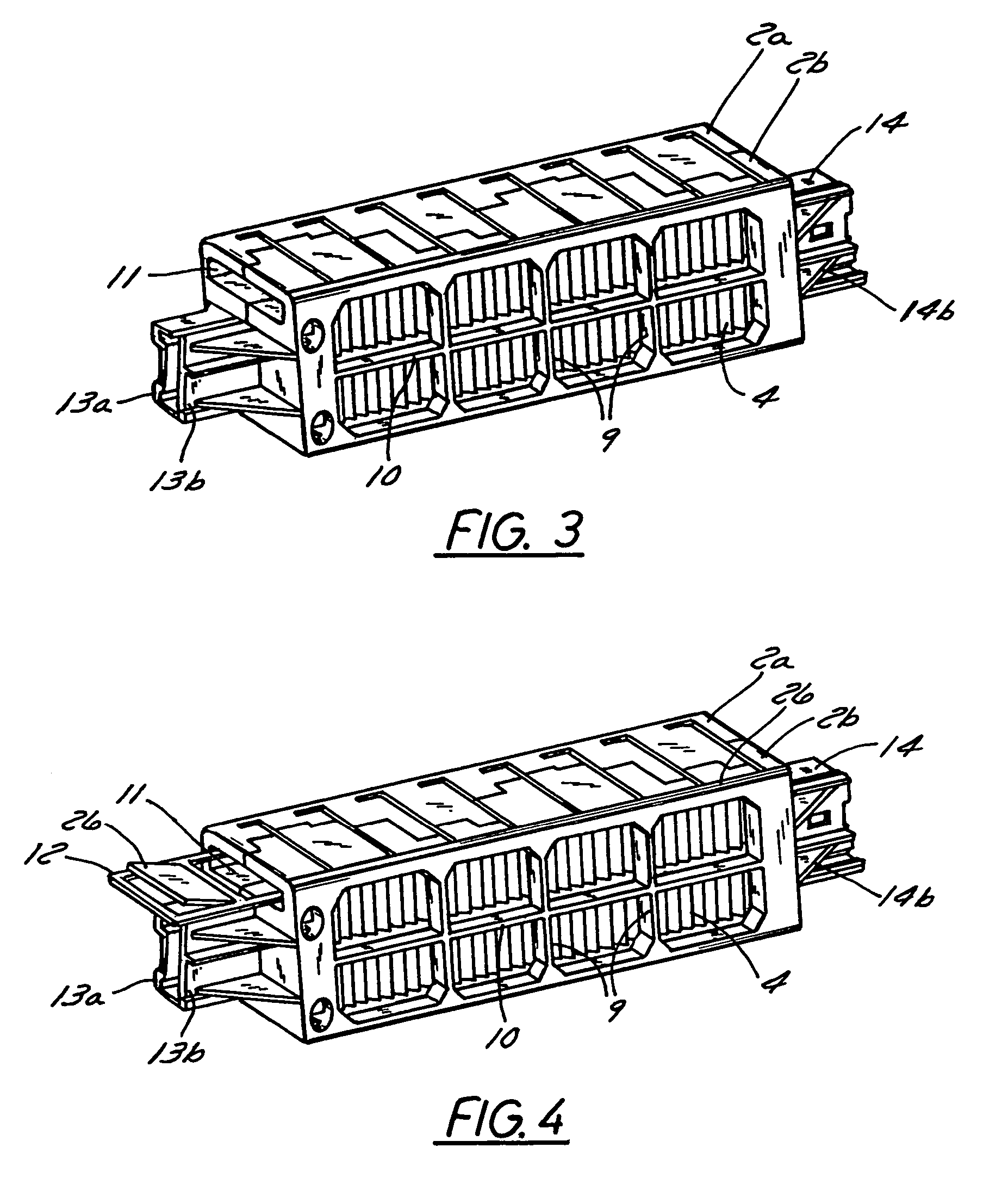

Electric heater with housing

ActiveUS20050072774A1Avoid throughputAvoid skewAir-treating devicesDomestic stoves or rangesPositioning aidsEngineering

The present invention relates to a novel constructional principle for electric heaters, wherein the functions of frame and resilient means are separated from one another. As a frame for an electric heater, a housing is used that consists of two half-shells. Positioning aids for the PTC heating elements are arranged in the housing. The longitudinal sides of the housing are essentially made open to allow for air throughput through the heating register. A resilient device is additionally inserted into the housing, the resilient device compressing the layered structure of radiator elements, PTC heating elements and contact sheets. After the heater has been assembled, the resilient device can be inserted through a lateral opening into the heater.

Owner:CATEM

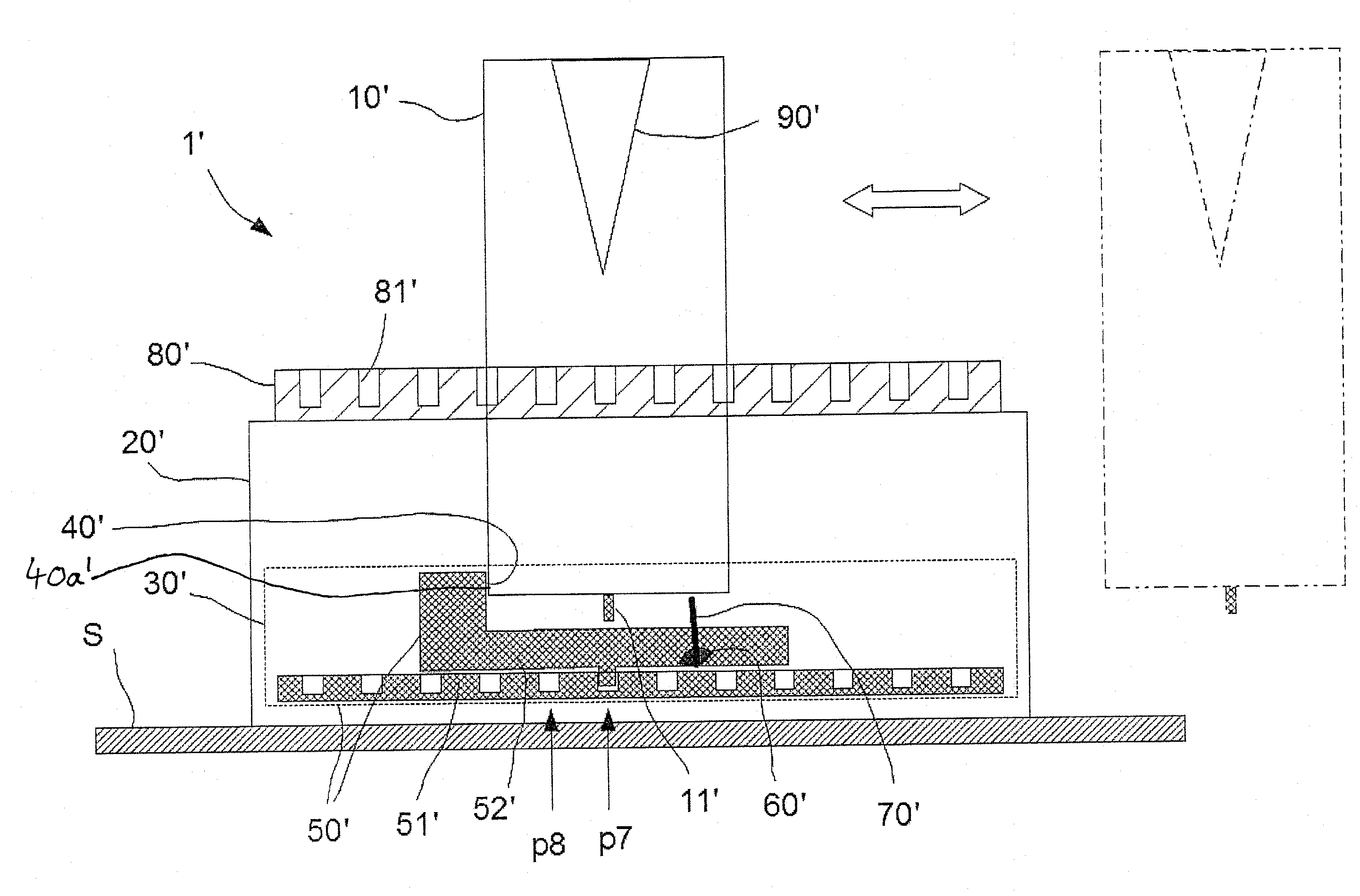

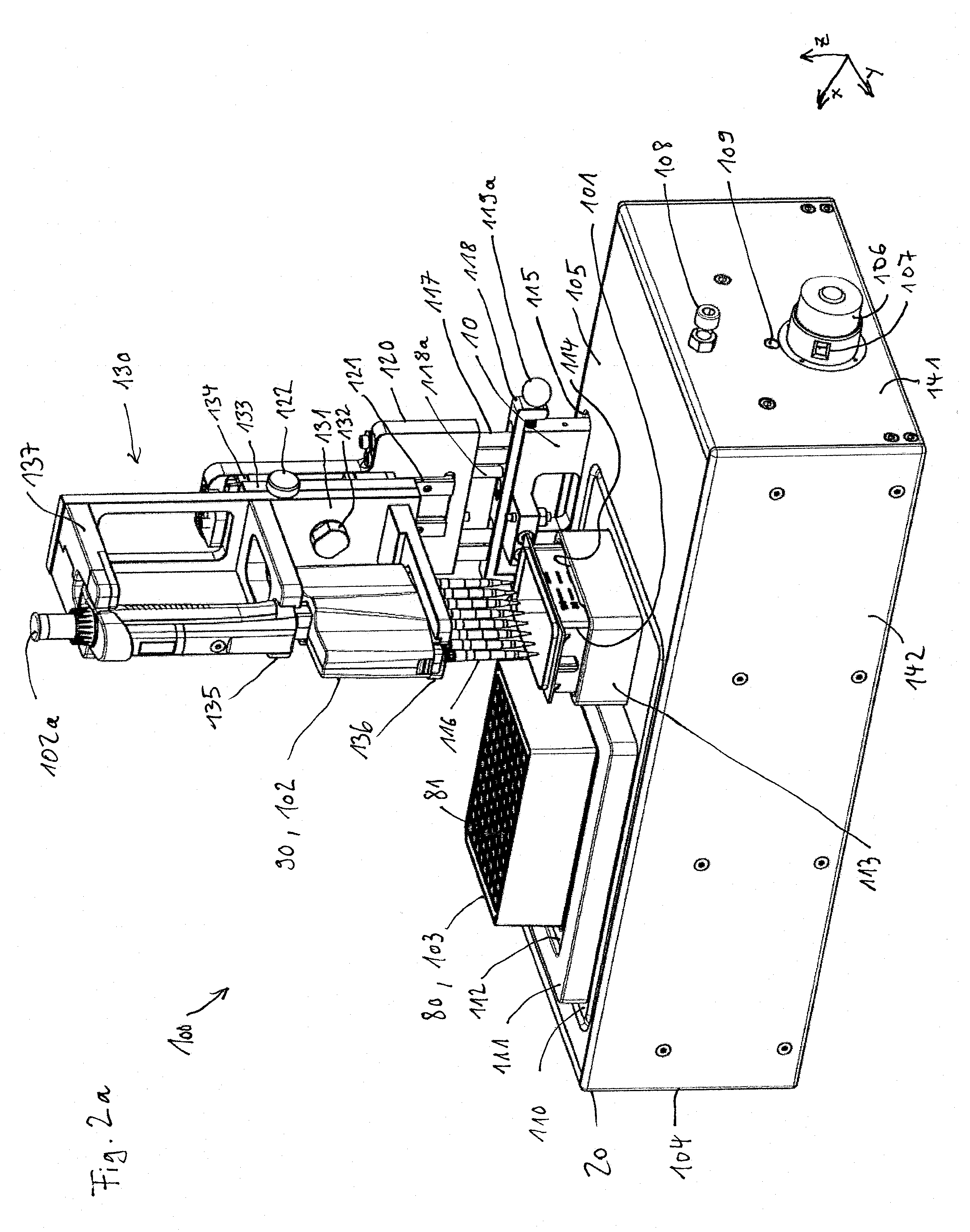

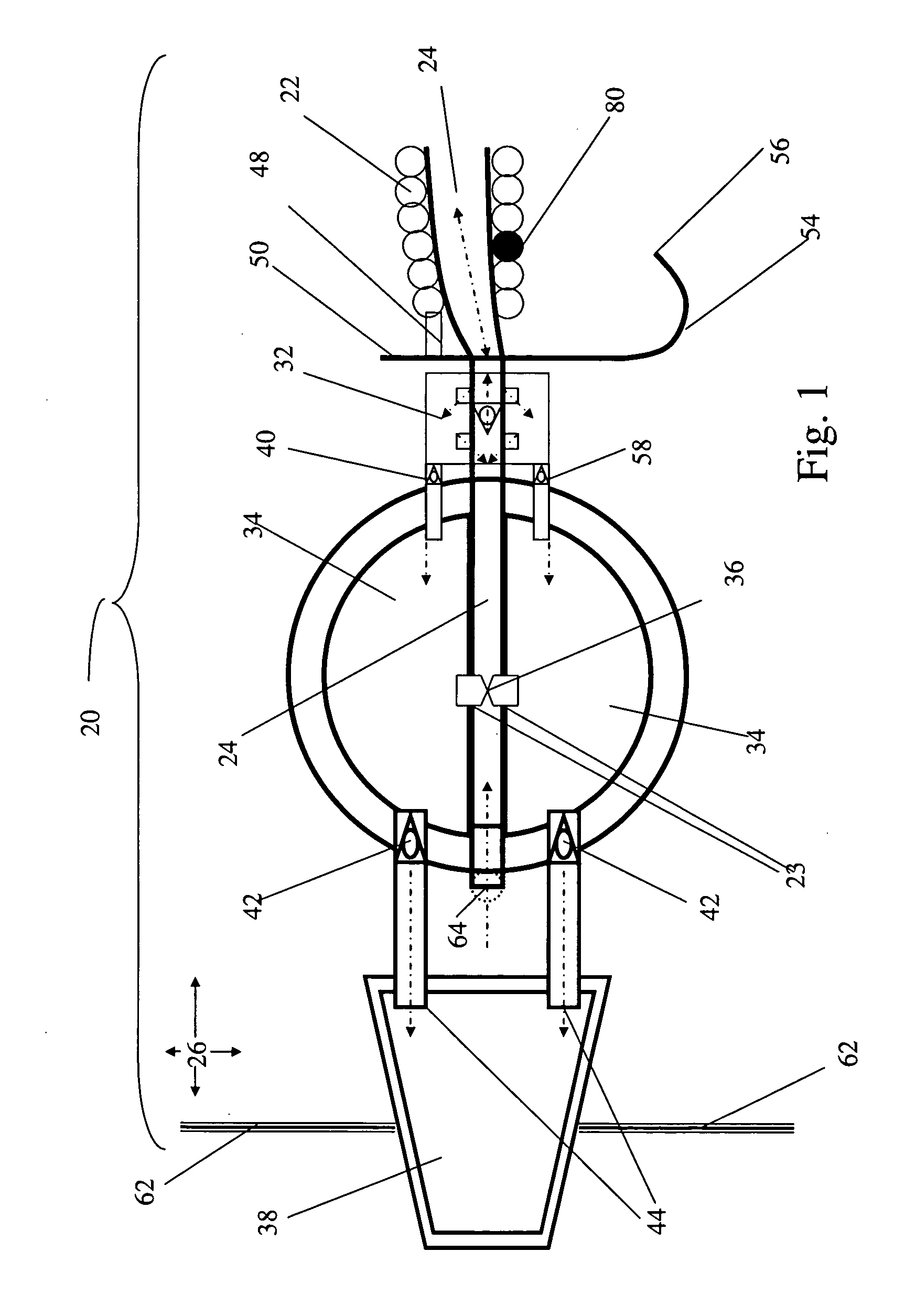

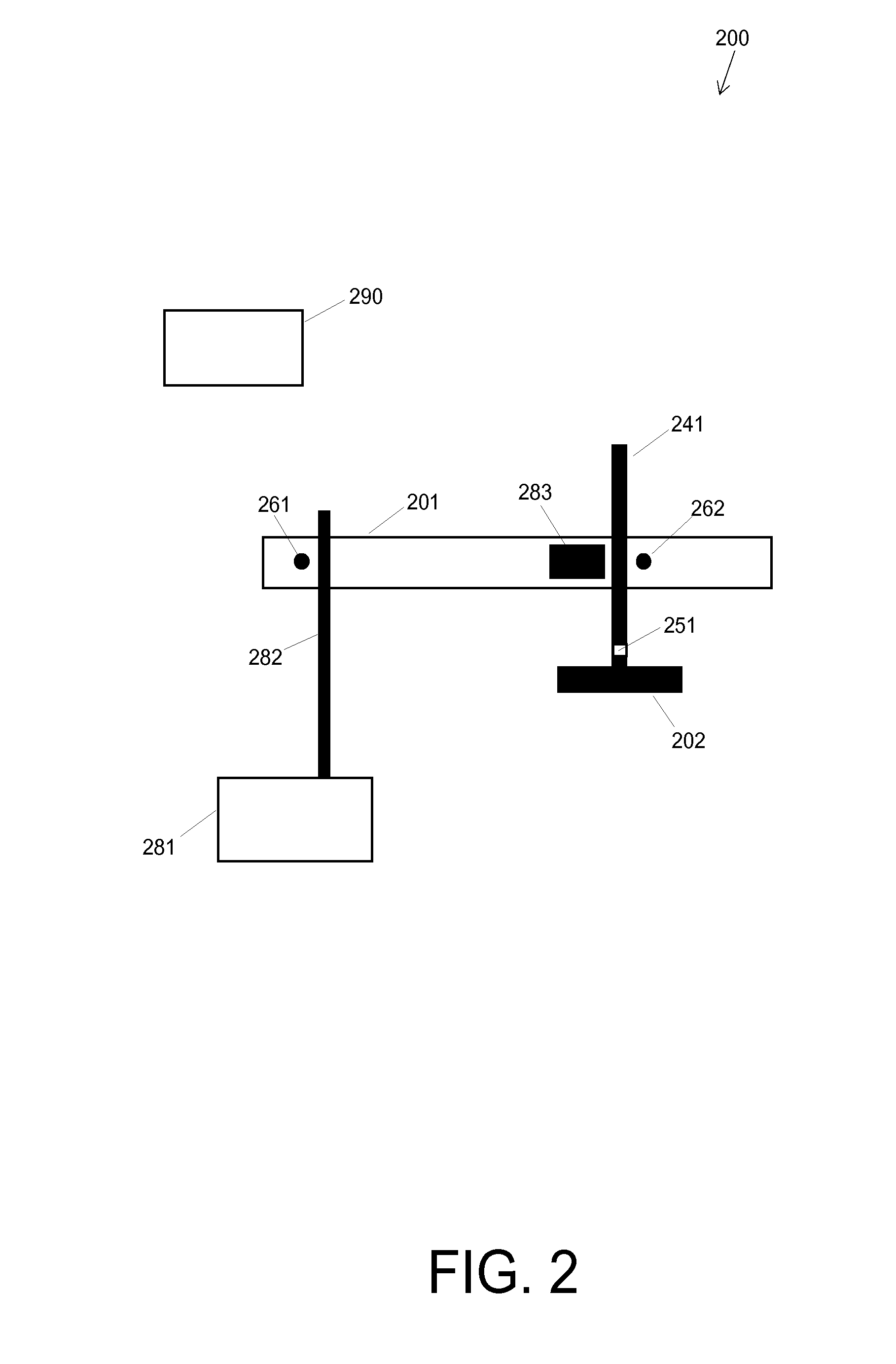

Positioning Device for a Sample Distribution Apparatus, Sample Distribution Apparatus with Positioning Device and Method for Positioning

ActiveUS20110209564A1Sufficient throughput of sampleSufficient error rateBurette/pipette supportsBurettes/pipettesCouplingEngineering

The invention relates to a positioning device for a sample distribution apparatus, in particular a pipetting apparatus, providing a first part, at which a sample transport device can be arranged, a second part, at which a sample holder can be arranged, wherein the first part and the second part are arranged moveable in relation to each other between a first position and an adjusted target position of the first and second part for performing a positioning motion, such that a sample can be conveyed towards the sample holder by the positioning motion between the first position and the adjusted target position and is conveyable at the target position by release from the sample transport device to the sample holder, or can be conveyed in the sample transport apparatus towards the sample holder by the positioning motion between the first position and the adjusted target position and is conveyable by a motion of the sample transport device relative to the first part into a release position and is conveyable at the release position by release from the sample transport device to the sample holder, wherein an actuation motion is provided, which serves the conveyance of the sample, a positioning auxiliary device, which provides at least one means for limiting and the relative mobility of the first and the second part in the adjusted target position, which provides, preferably, at least one means for adjusting the n-th target position from a plurality of N predetermined target position as the adjusted target position, which, preferably, provides at least one means for changing of the adjusted target position from the n-th target position to an (n+1)-th target position, and which further provides at least one first means for coupling of said actuation motion and said positioning auxiliary device, or to the at least one means for changing of the same such that the actuation motion can effect the change from said n-th target position to said (n+1)-th target position via said at least one first means for coupling. The invention relates to a corresponding working method for the automatical change of a position of a first part relative to a second part and relates further to a sample distribution apparatus with such a positioning device.

Owner:EPPENDORF AG

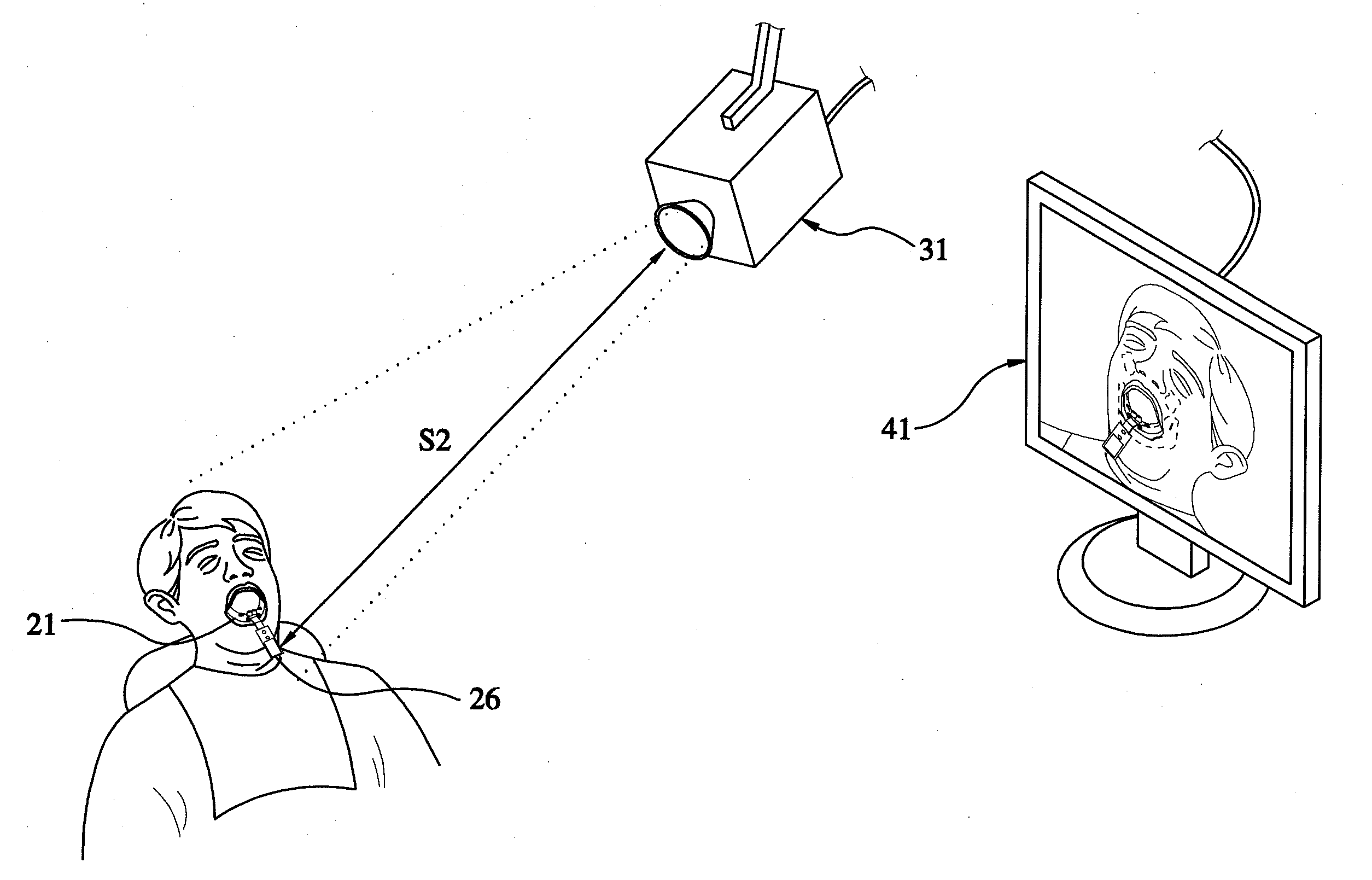

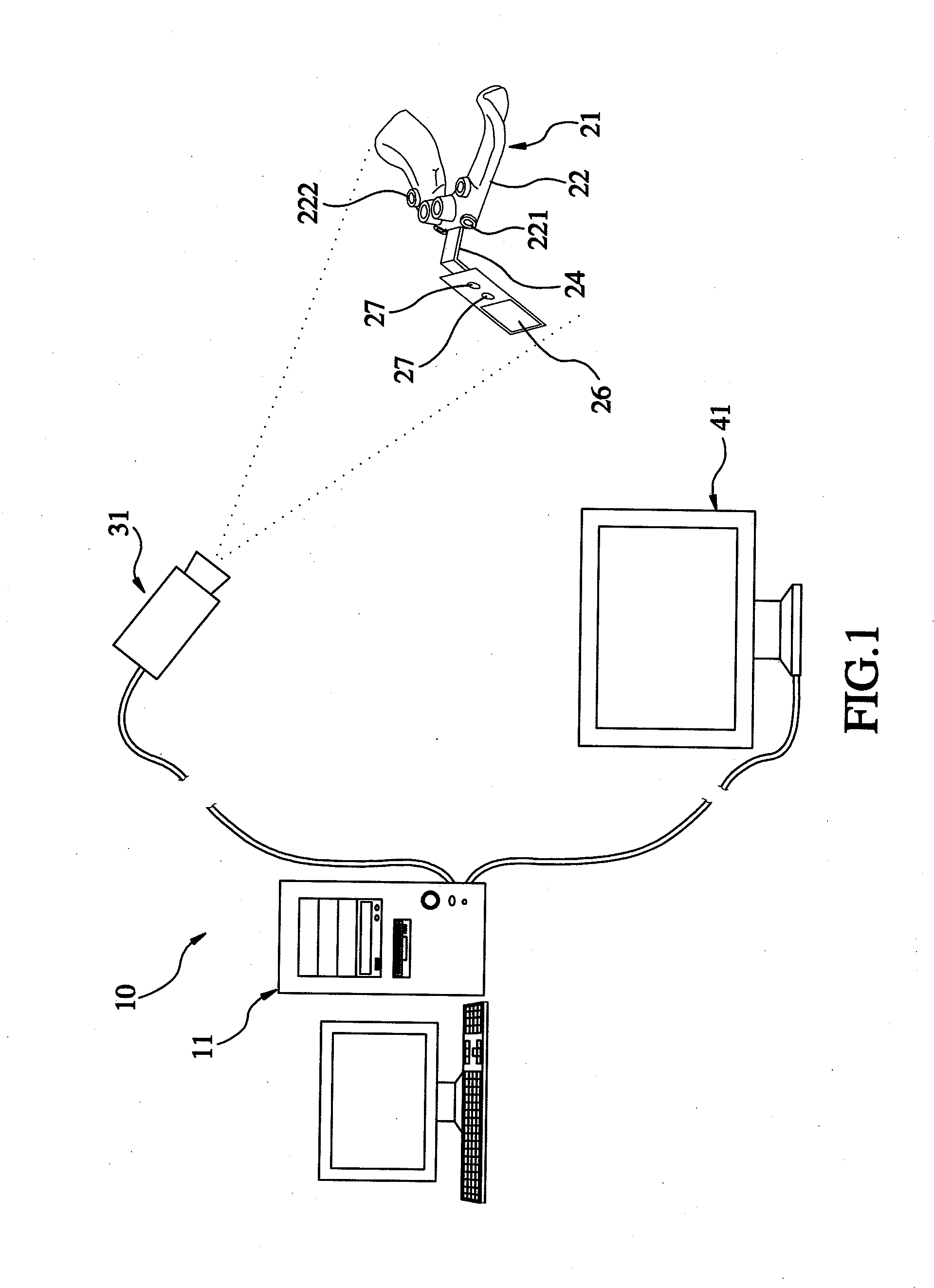

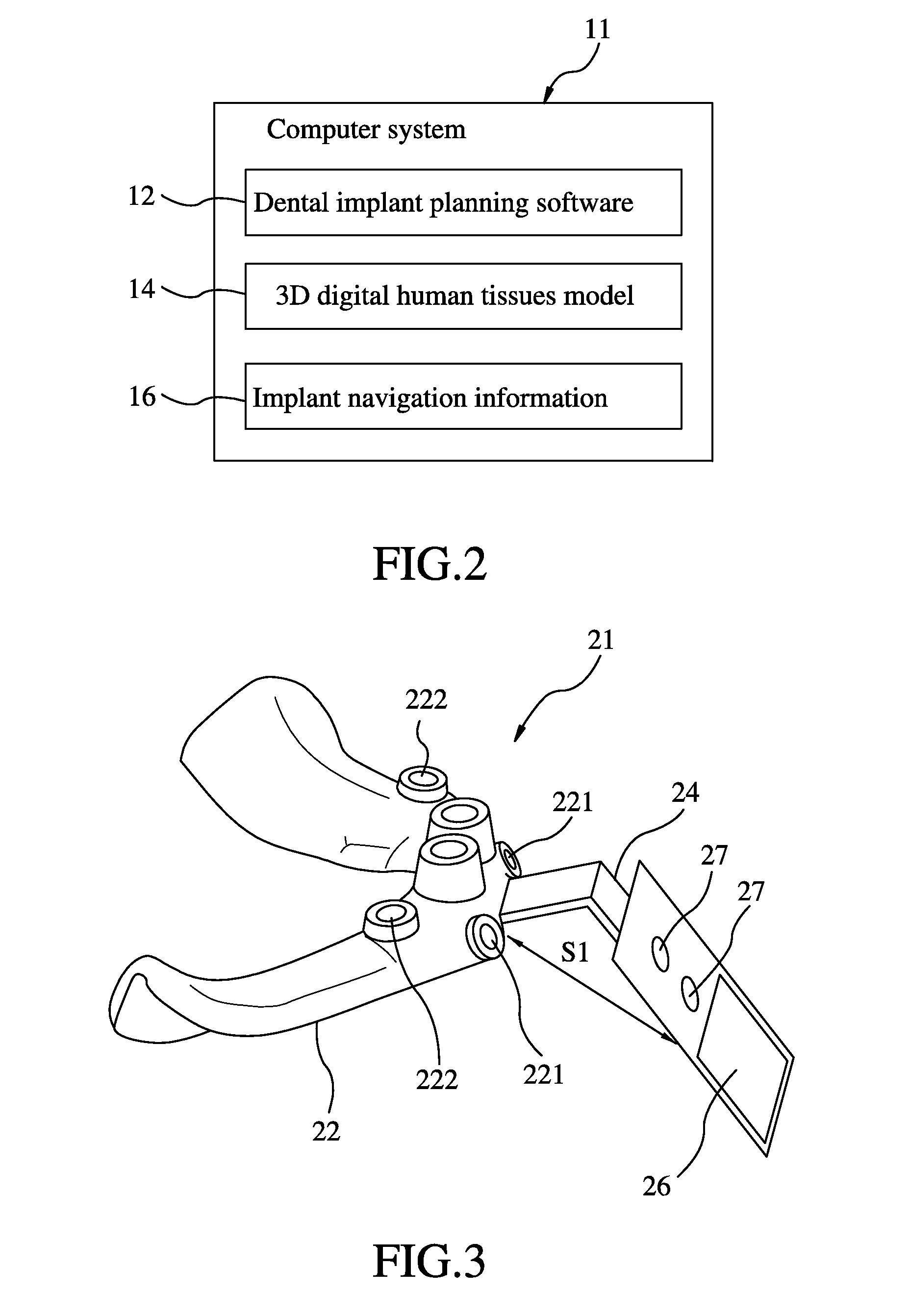

Computer-aided positioning and navigation system for dental implant

InactiveUS20140147807A1Improve accuracyImprove securityDental implantsSomatoscopeDisplay deviceComputer-aided

A computer-aided positioning and navigation system for dental implant includes a computer system having built therein a dental implant planning software and providing a 3D digital human tissues model to create an implant navigation information, a positioning assistive device including a body providing a positioning portion and a guide portion and a connection member carrying an optical positioning device, one or multiple optical capture devices, and a display device electrically connected to the computer system. The computer system controls the optical capture device to capture images and drives the display device to display a part of the content of the 3D digital human tissues model and the implant navigation information.

Owner:NATIONAL CHUNG CHENG UNIV

Electric heater with housing

ActiveUS7026584B2Avoid throughputAvoid skewAir-treating devicesDomestic stoves or rangesPositioning aidsEngineering

The present invention relates to a novel constructional principle for electric heaters, wherein the functions of frame and resilient means are separated from one another. As a frame for an electric heater, a housing is used that consists of two half-shells. Positioning aids for the PTC heating elements are arranged in the housing. The longitudinal sides of the housing are essentially made open to allow for air throughput through the heating register. A resilient device is additionally inserted into the housing, the resilient device compressing the layered structure of radiator elements, PTC heating elements and contact sheets. After the heater has been assembled, the resilient device can be inserted through a lateral opening into the heater.

Owner:CATEM

Distributed method and system for calibrating the position of a mobile device

InactiveUS8831633B2Energy efficient ICTNear-field transmissionWireless communication protocolAccelerometer

A method and system is described where a plurality of position reference devices use short-range wireless communication protocols to transmit positioning assistance data to nearby mobile devices, and the mobile devices use the assistance data to re-calibrate their positioning systems. In some embodiments, mobile device includes an accelerometer and the accelerometer measurements are used to calculate an updated velocity of the mobile device and an updated position of the mobile device based on the accelerometer measurements and previous velocity and position of the mobile device. The short-range communication methods include NFC, RFID, Bluetooth®, short-range 802.11, Wi-Fi Direct, and high frequency focused beams such as 60 GHz. The position reference devices are passive or active NFC tags, passive or active RFID tags, other devices that include such tags as their components, Bluetooth®-enabled devices, 60 GHz-enabled devices, and 802.11 access points that can lower their transmit power.

Owner:GOLBA LLC

Devices, for preventing collapse of the upper airway, methods for use thereof and systems and articles of manufacture including same

InactiveUS7823590B2Sufficient pressureCollapse thereof is preventedTracheal tubesRespiratory masksGas exchangeBiomedical engineering

Devices and methods to prevent airway collapse are disclosed. The device includes a mouthpiece featuring a positioning aid adjustable by inflation accomplished via a gas exchange port attachable to a source of pressure and a breathing tube. Inflation causes an asymmetric protrusion on the mouthpiece, preferably above the breathing tube so that the positioning aid fits into the roof of the mouth. Preferably, tongue movement is at least partially restricted. An additional device featuring a wearable battery operated compressor is further disclosed. A device in the form of a pacifier is disclosed as a preferred embodiment for use in young patients. Preferably, devices are supplied as articles of manufacture. Use of disclosed devices constitute methods of preventing collapse of the upper airway.

Owner:SLEEPUP

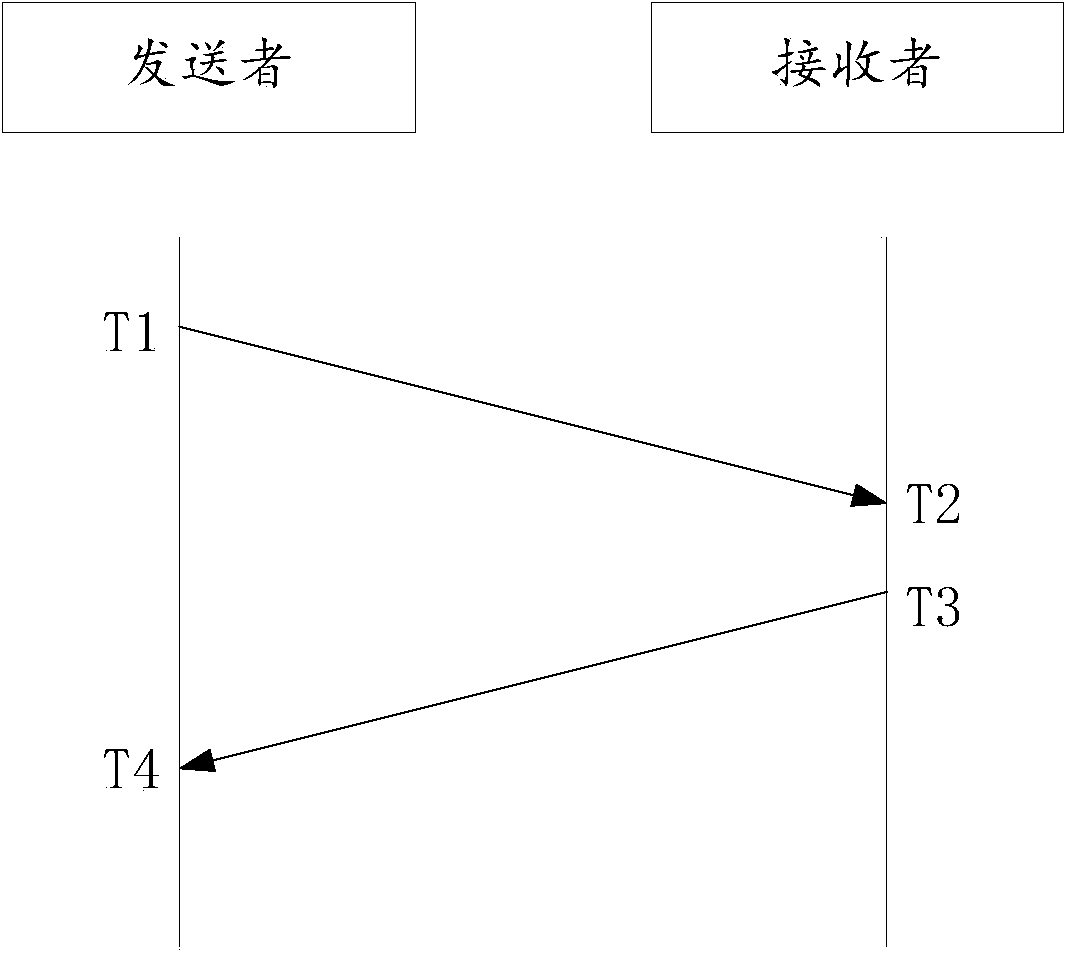

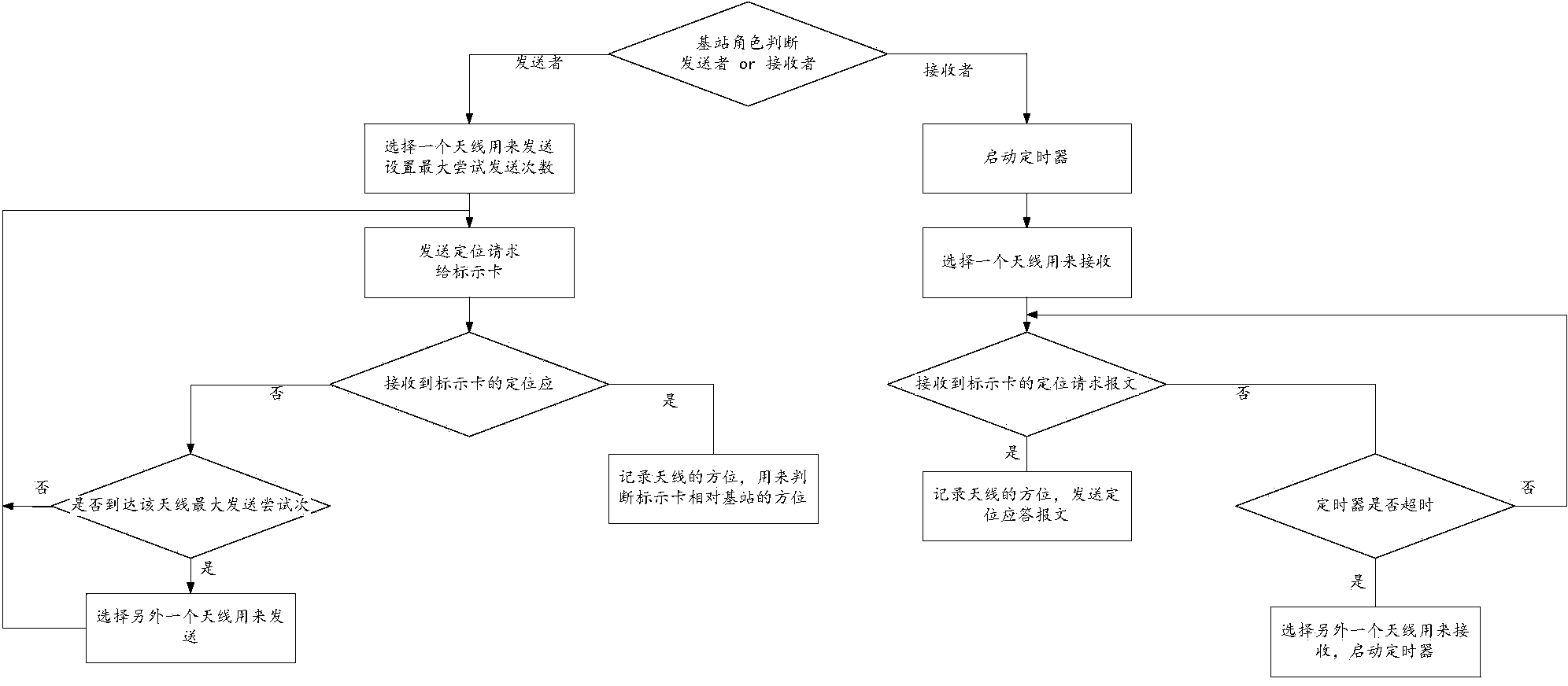

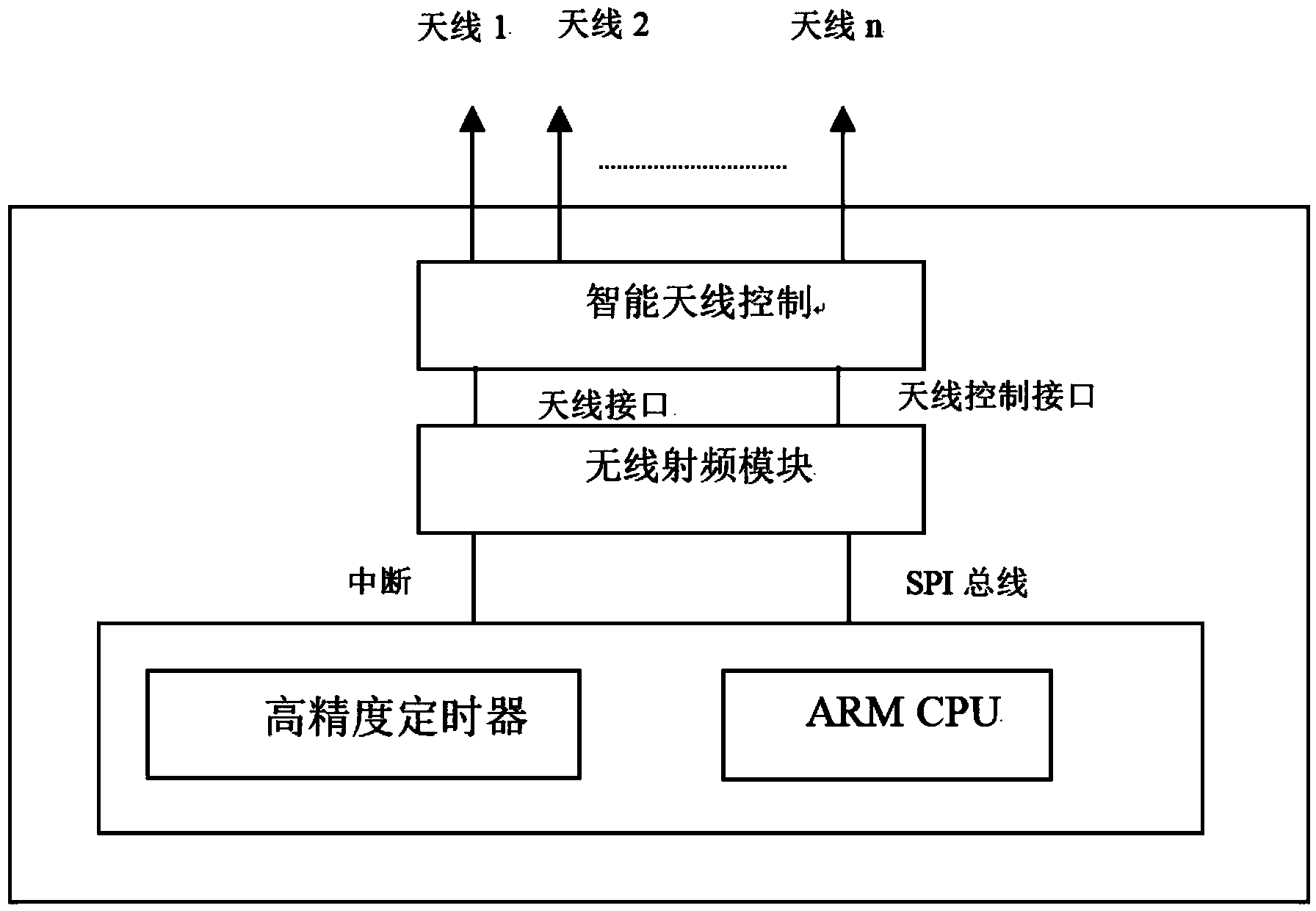

Method and system for precisely positioning mine

The invention discloses a method and system for precisely positioning a mine. The method for precisely positioning the mine comprises the steps that a plurality of positioning base stations and a plurality of marking cards which are used for positioning and are communicated with the positioning base stations through the wireless technology are arranged; distance data are calculated by measuring time spent by signals sent by the positioning base stations flying to the marking cards or the distance data are measured by measuring the time spent by signals sent by the marking cards flying to the positioning base stations; directed wireless antennas are arranged in roadway directions according to the roadway position of the positioning base stations under a coal mine well, the direction information of the positioning cards relative to the positioning base stations is calculated by obtaining antenna information used for communication between the positioning base stations and the positioning cards, and therefore the precise positions of the marking cards are obtained, and precise positioning is achieved. The method for precisely positioning the mine can be implemented under the condition that positioning auxiliary base stations are not required to be deployed, cost is reduced, engineering installation and deployment difficulty are greatly simplified, and time synchronization of the positioning base stations and the marking cards is not needed.

Owner:引通通讯科技(上海)有限公司

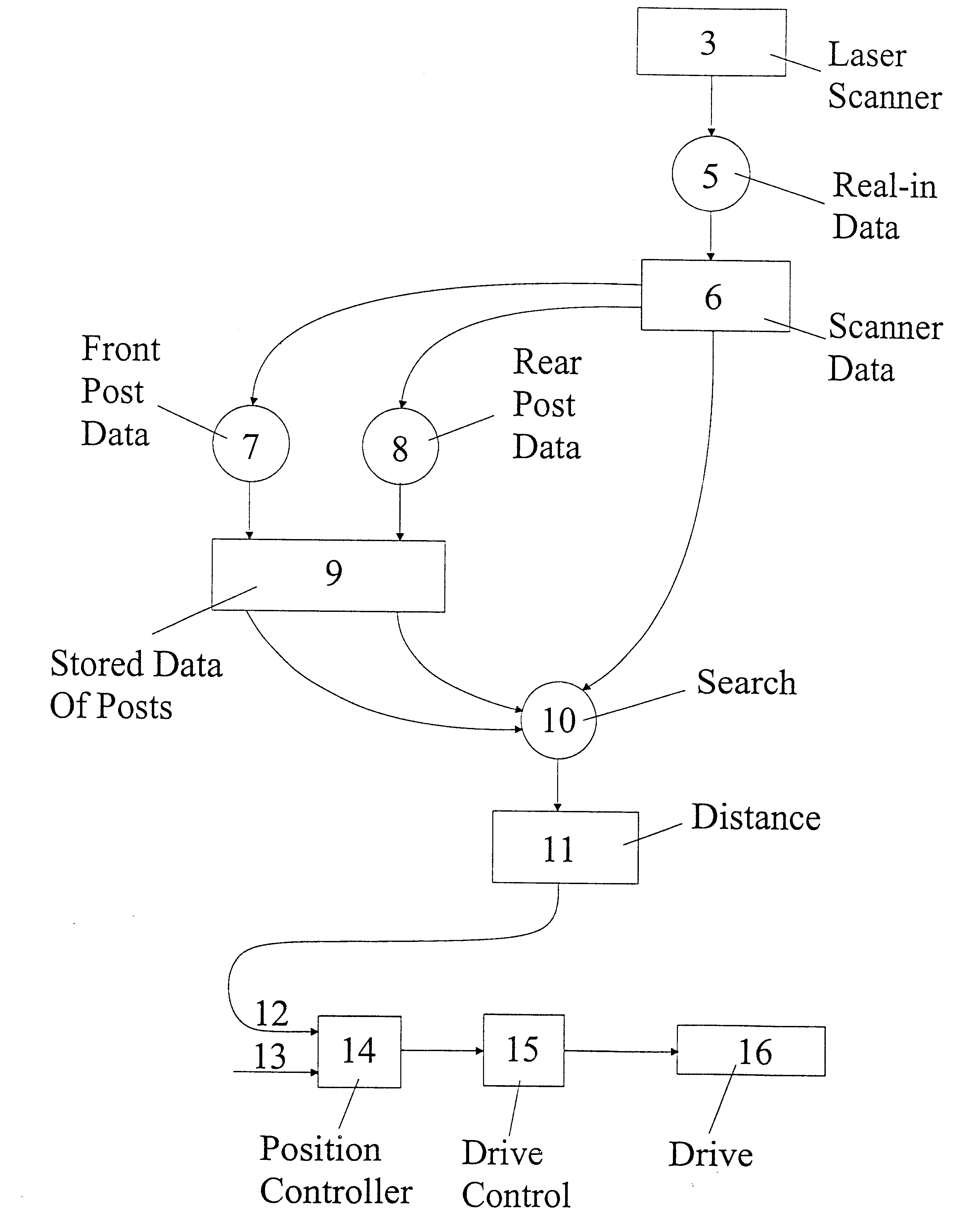

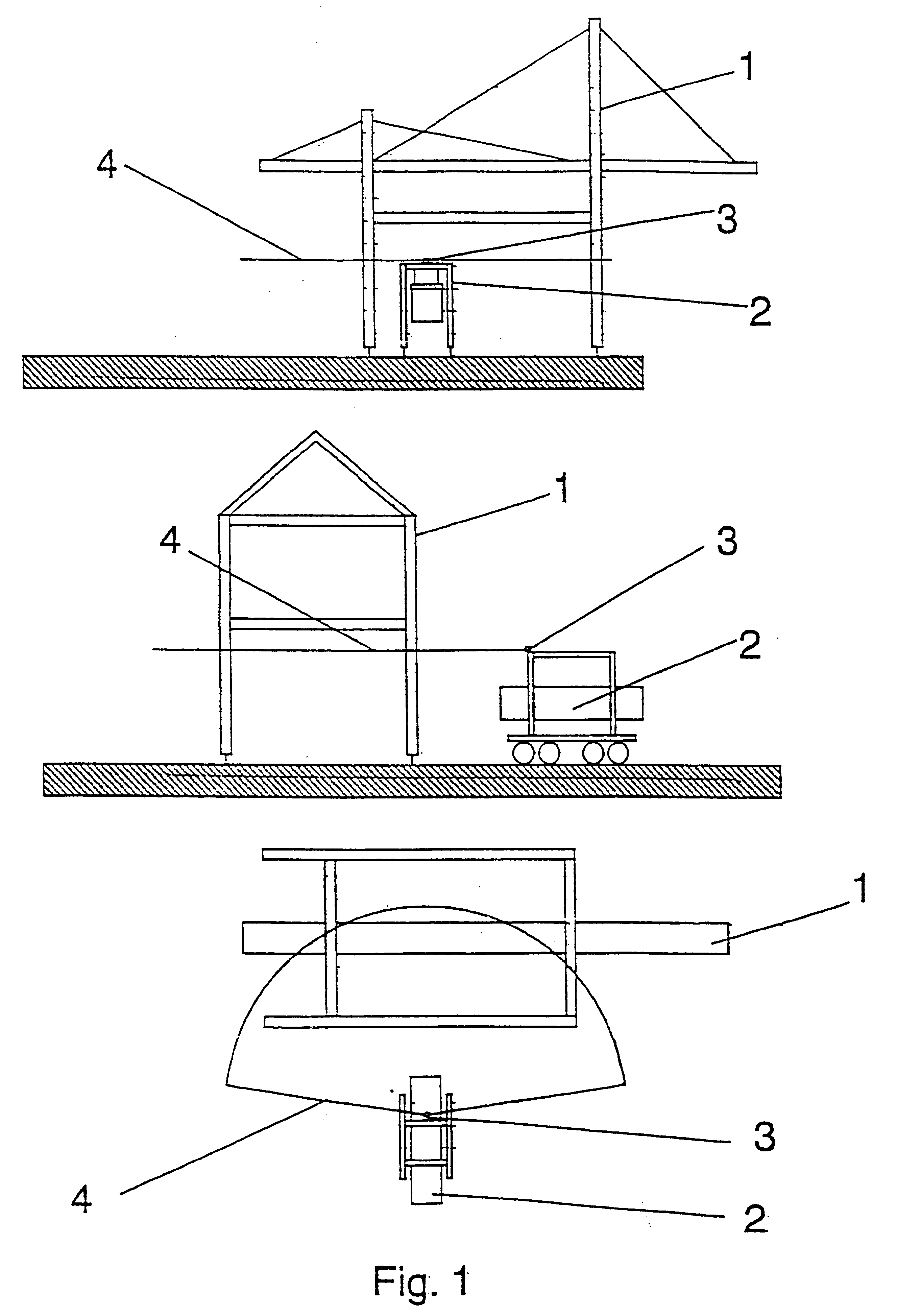

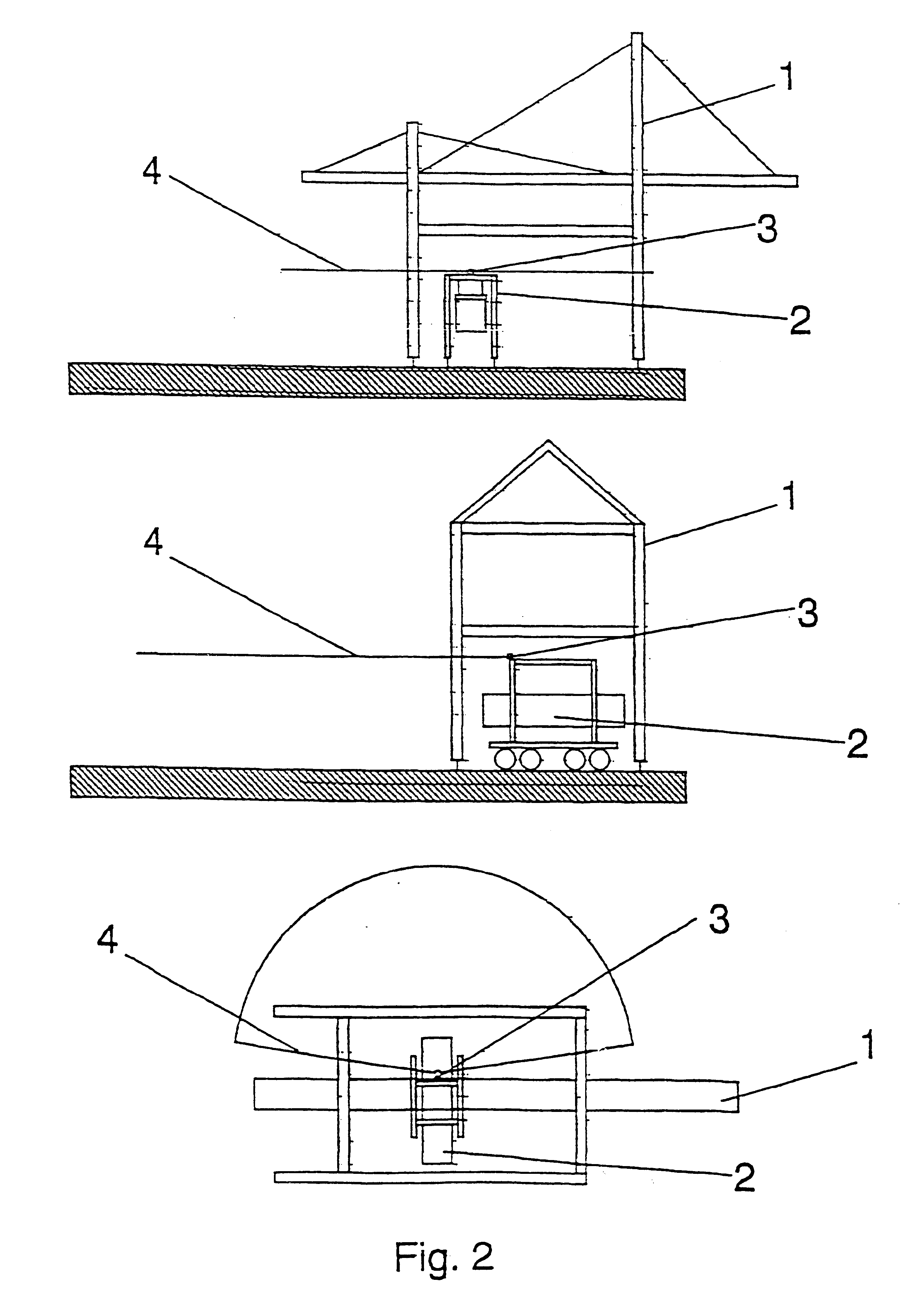

Method for determining the position of a vehicle in relation to a container crane

A method for determining the position of a vehicle, preferably of a portal stacking truck in relation to a container crane, in which a sensor serves for determining the position of the stacking truck, and evaluating devices are coupled to a detection device, and in which the posts of a container crane are detected as positioning aids in terms of angle and distance by means of a scanner mounted on the stacking truck and transmitted to an evaluating computer, which compares the signals with signals provided in its program and determines the exact position of the stacking truck in relation to the posts of the container, and drives the stacking truck from this position into an exactly predetermined position in relation to the posts of the container.

Owner:NOELL CRANE SYST

Sport Stance Trainer

Owner:BREND MICHAEL T

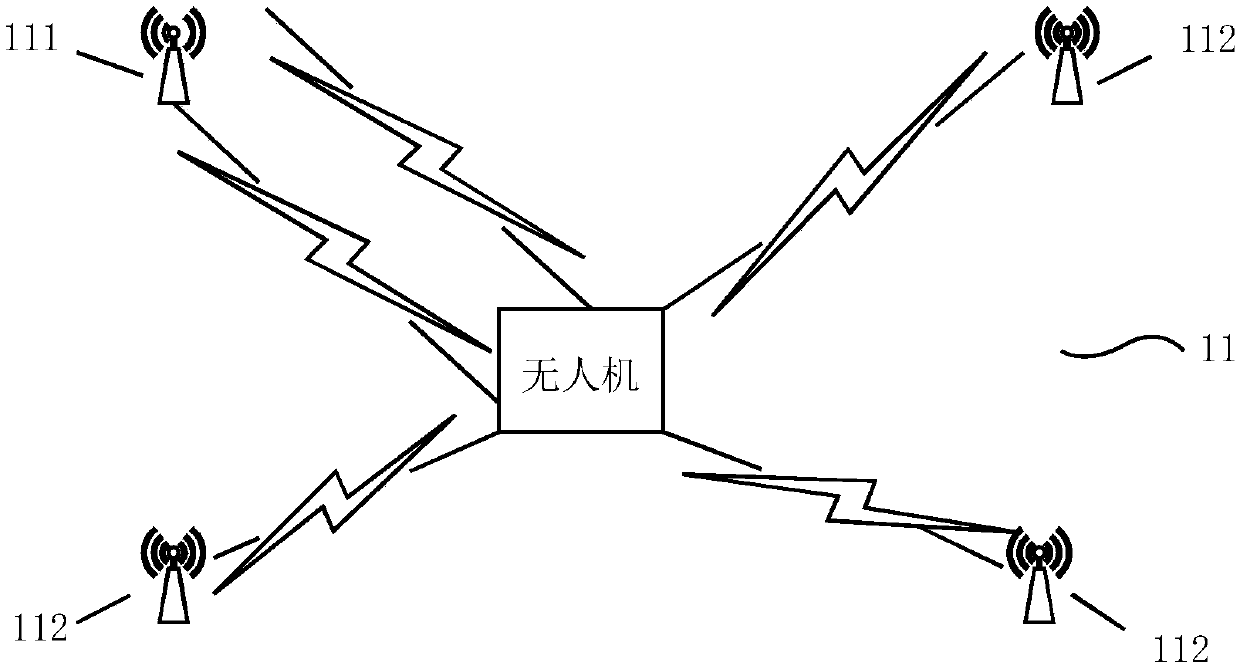

Unmanned aerial vehicle near field guiding system and method

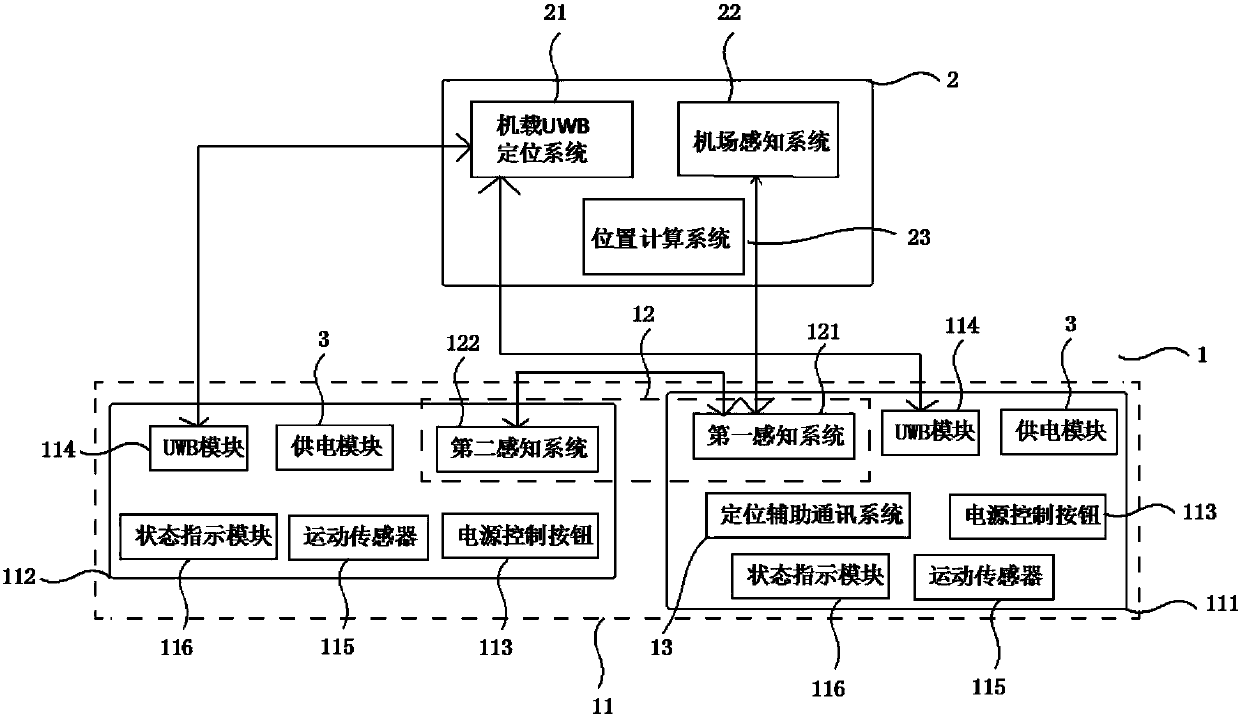

PendingCN107820215AAssisted landingEnsure positioning accuracy requirementsParticular environment based servicesVehicle wireless communication serviceCommunications systemPositioning aids

The invention belongs to the technical field of application such as wireless communication and unmanned aerial vehicle wireless precise positioning and provides an unmanned aerial vehicle near field guiding system. The system comprises a ground system and an onboard positioning system. The ground system comprises an unmanned aerial vehicle near field sensing system and a positioning base station which are connected in sequence. The onboard positioning system comprises an airport sensing system, an onboard UWB positioning system and a position computing system which are connected in sequence. The positioning base station is connected with power supply modules. The positioning base station and the onboard UWB positioning system are in wireless connection. The unmanned aerial vehicle near field sensing system and the airport sensing system are in wireless connection. The positioning base station and a positioning auxiliary communication system are connected. The invention also provides anunmanned aerial vehicle near field guiding method. The system and the method are clever in concept and simple and convenient for operation, and the technical problem that in the prior art, the precise positioning is greatly influenced by an environment and the technical cost is high is solved.

Owner:NANJING WOXU COMM TECH

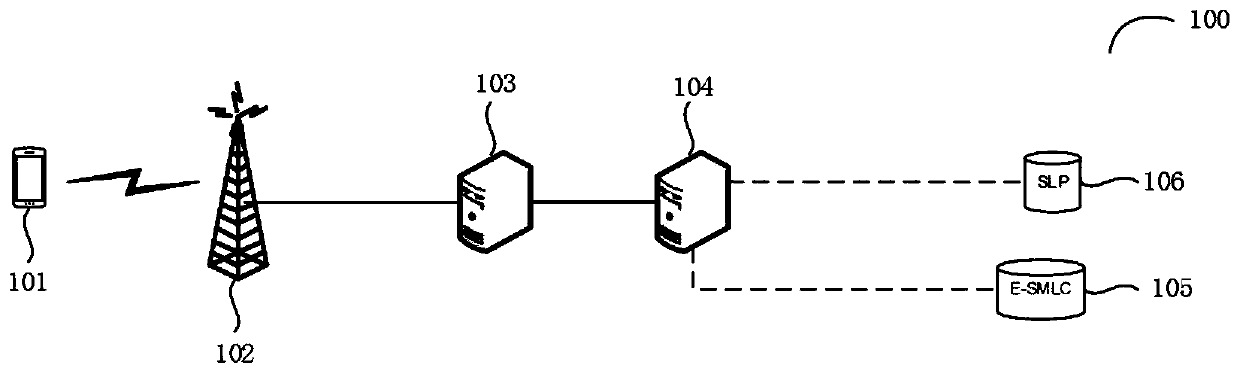

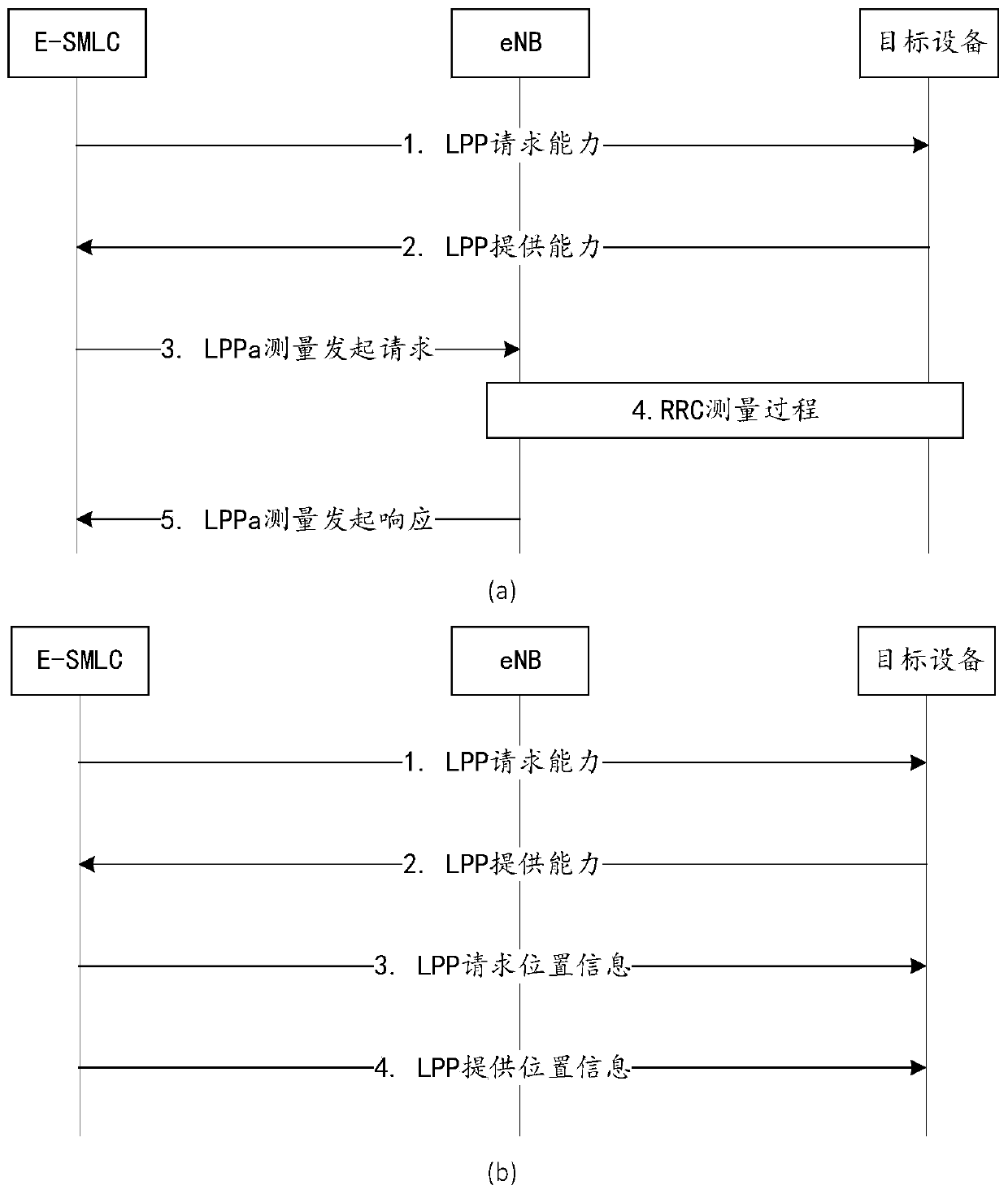

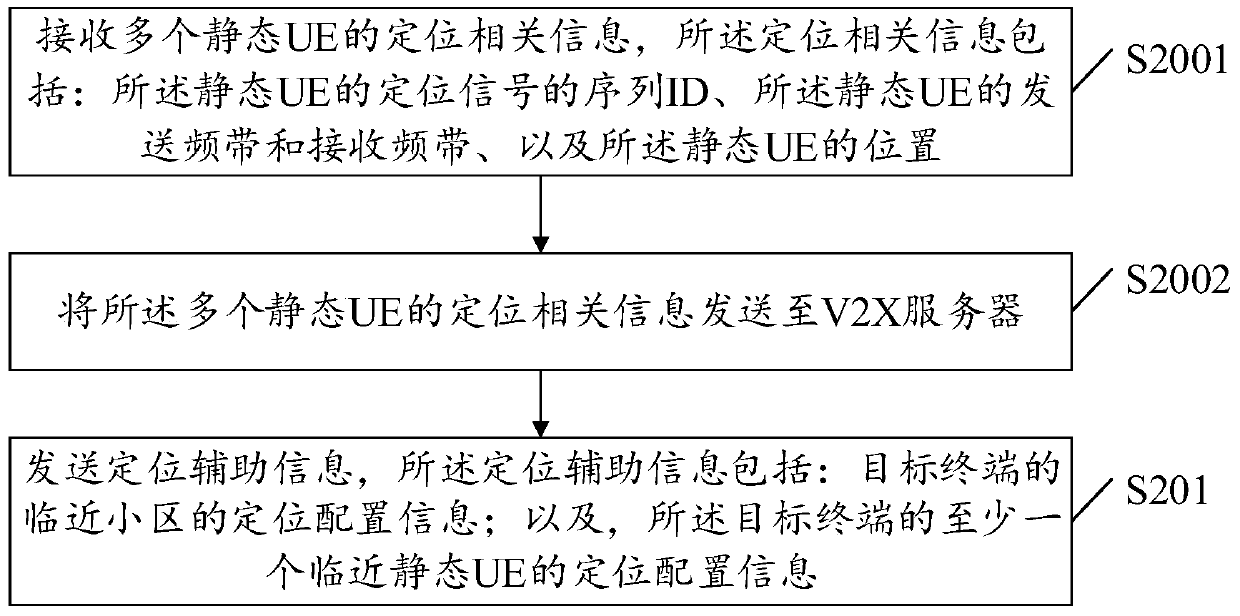

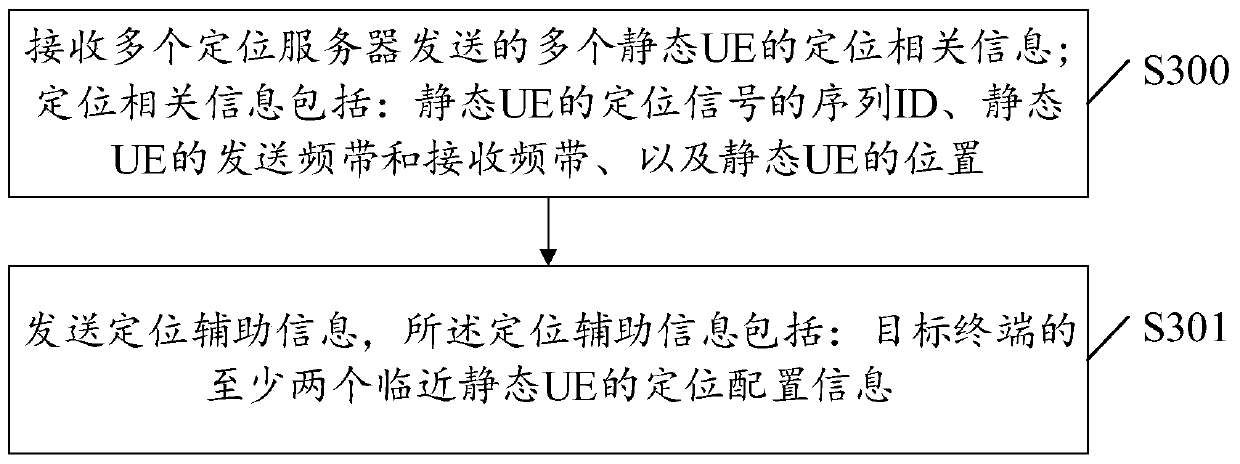

Multi-site positioning method and device

InactiveCN111356075APilot signal allocationLocation information based serviceTelecommunicationsPositioning aids

The invention provides a multi-site positioning method and device, relates to the technical field of communication, and is used for solving the problem of insufficient positioning precision caused byRTT measurement in a positioning architecture taking a positioning management function as a center. According to the method, the above problem is solved, RTT positioning is carried out through cooperation of multiple base stations, and the positioning precision is improved. The method comprises the following steps: target equipment receives positioning auxiliary information sent by a positioning center, wherein the positioning auxiliary information comprises cell identifiers and reference signal configurations of a service base station and at least one neighbor base station; the target equipment performs positioning measurement on the downlink reference signal according to the positioning auxiliary information; the target equipment sends an uplink reference to the serving base station andthe at least one neighbor base station according to the positioning auxiliary information; and the target equipment sends a downlink positioning measurement report to the positioning center, wherein the downlink positioning measurement report comprises the receiving and sending time difference of the reference signals corresponding to the service base station and the at least one neighbor base station measured by the target equipment.

Owner:HUAWEI TECH CO LTD

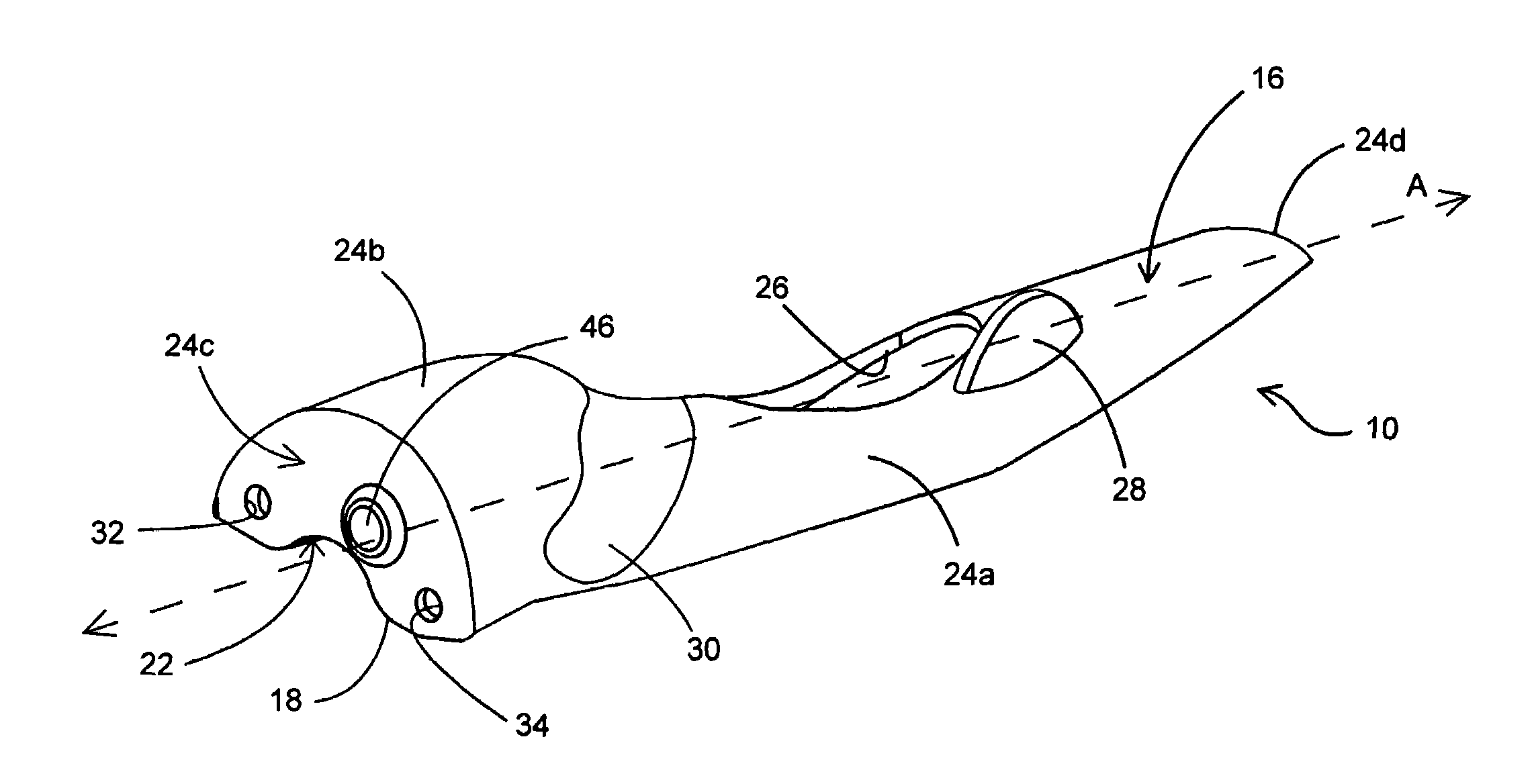

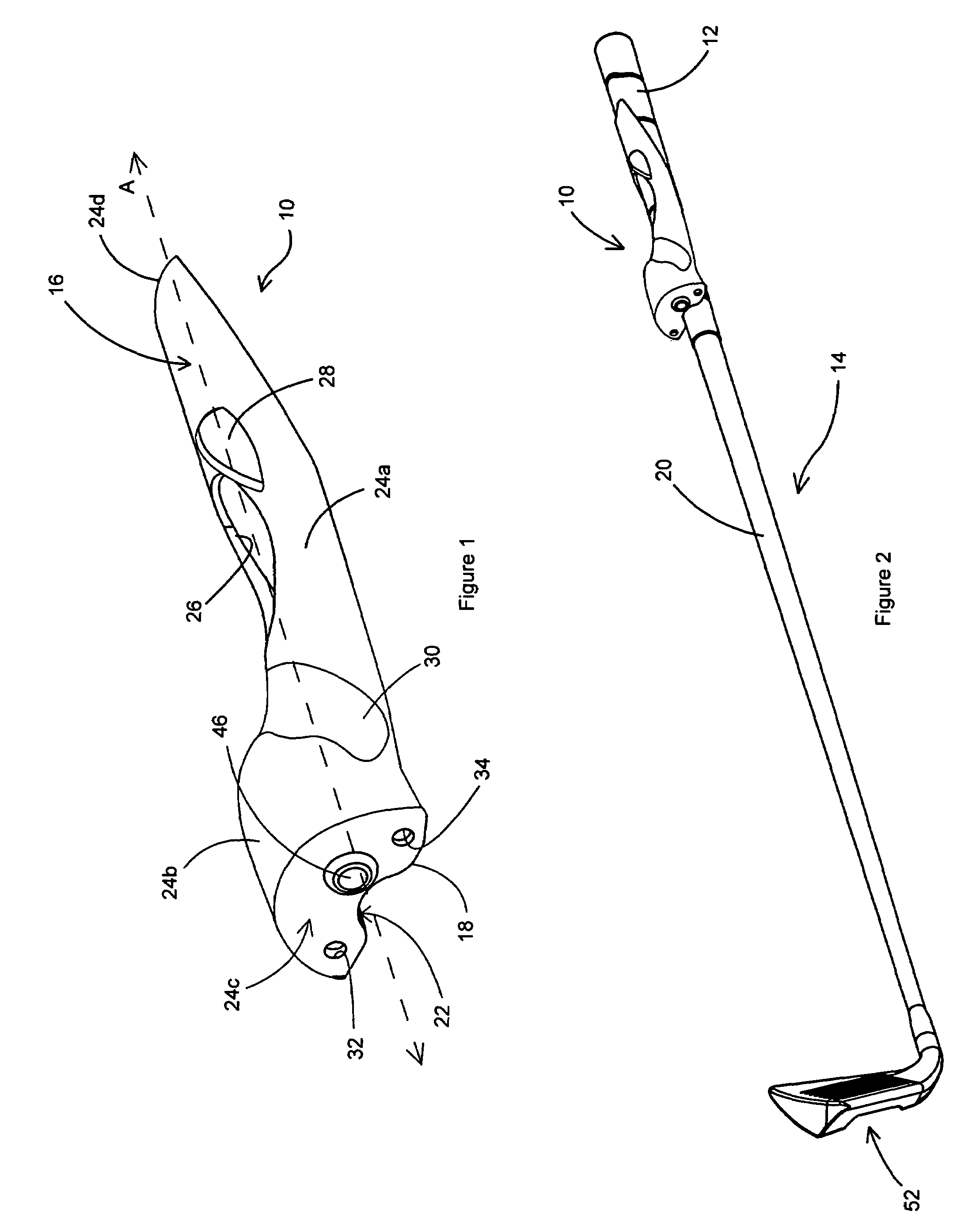

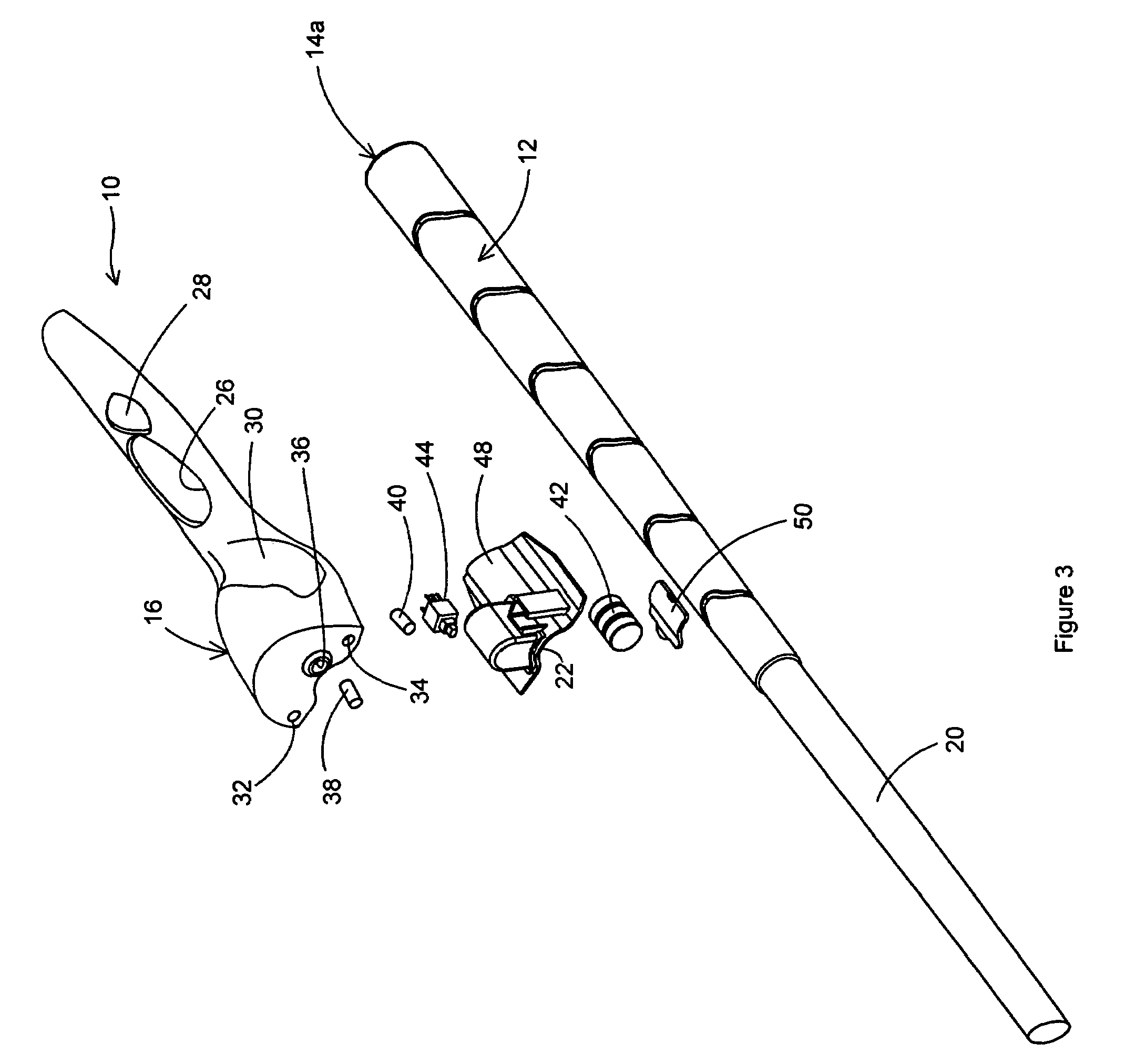

Golf training device

A golf training device for aiding a golfer in perfecting their grip on a golf club and their swing. The golf training device includes an elongated member made from a flexible plastic material and that is designed to frictionally engage the handle portion of the golf club. The device includes a gripping region with first and second positioning aids thereon for correct placement of the golfer's thumbs. The device further includes a pair of lasers that are mounted in a rest area that integrally formed with the gripping region. The lasers are mounted so as to emit a pair of divergent laser beams outwardly away from the lowermost end of the device and on either side of the golf club head. The lasers are used to correctly align the device on the golf club shaft and as an aid for the golfer to check his grip on the club and the position he assumes for addressing a golf ball. The device may further be provided with a third laser mounted on the uppermost end of the gripping region such that the third laser emits a beam of light outwardly from the uppermost end and aligned with the longitudinal axis of the device. The third laser beam is useful for the golfer to train himself to correctly swing the golf club.

Owner:BRUNTON INNOVATIONS

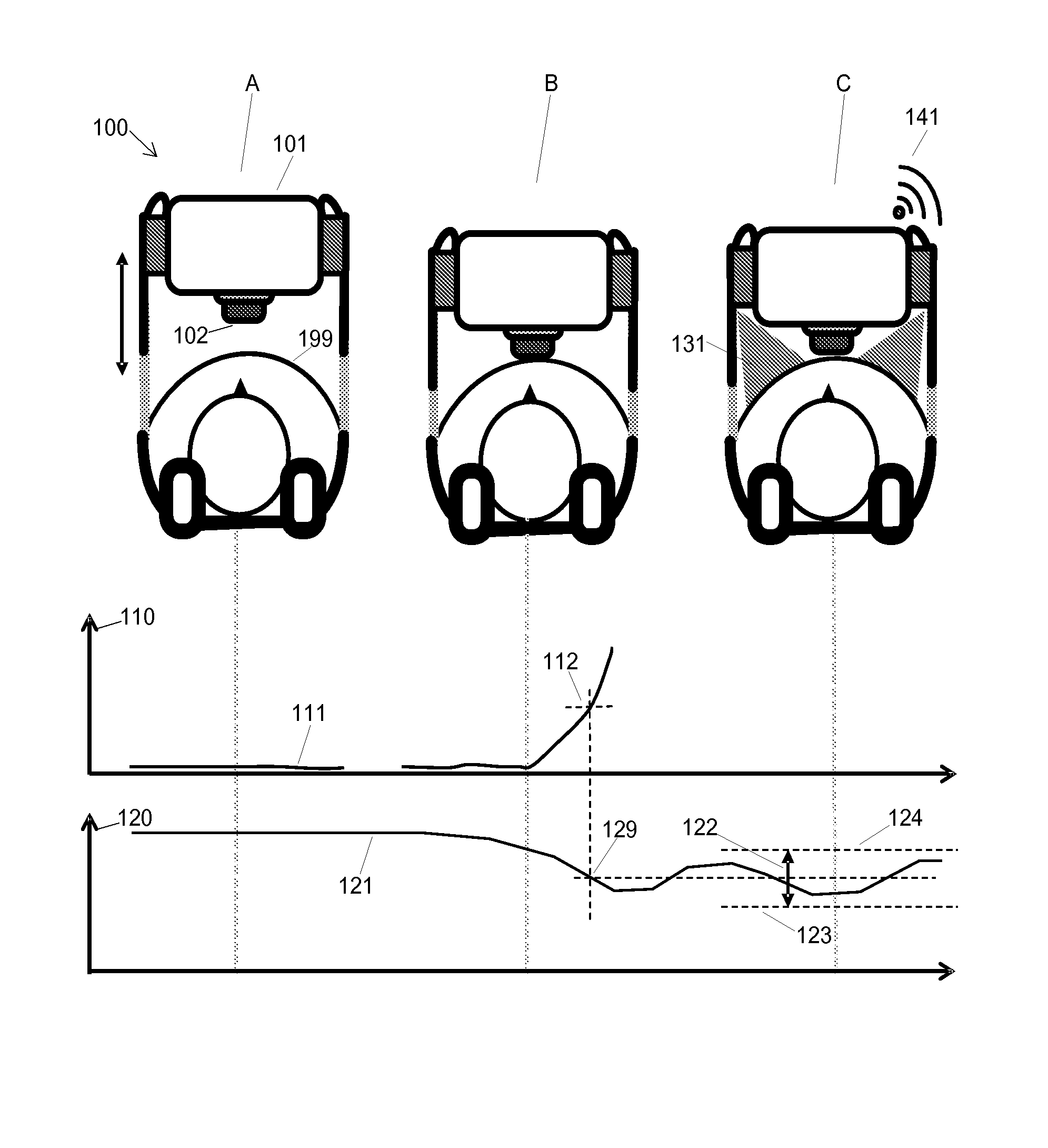

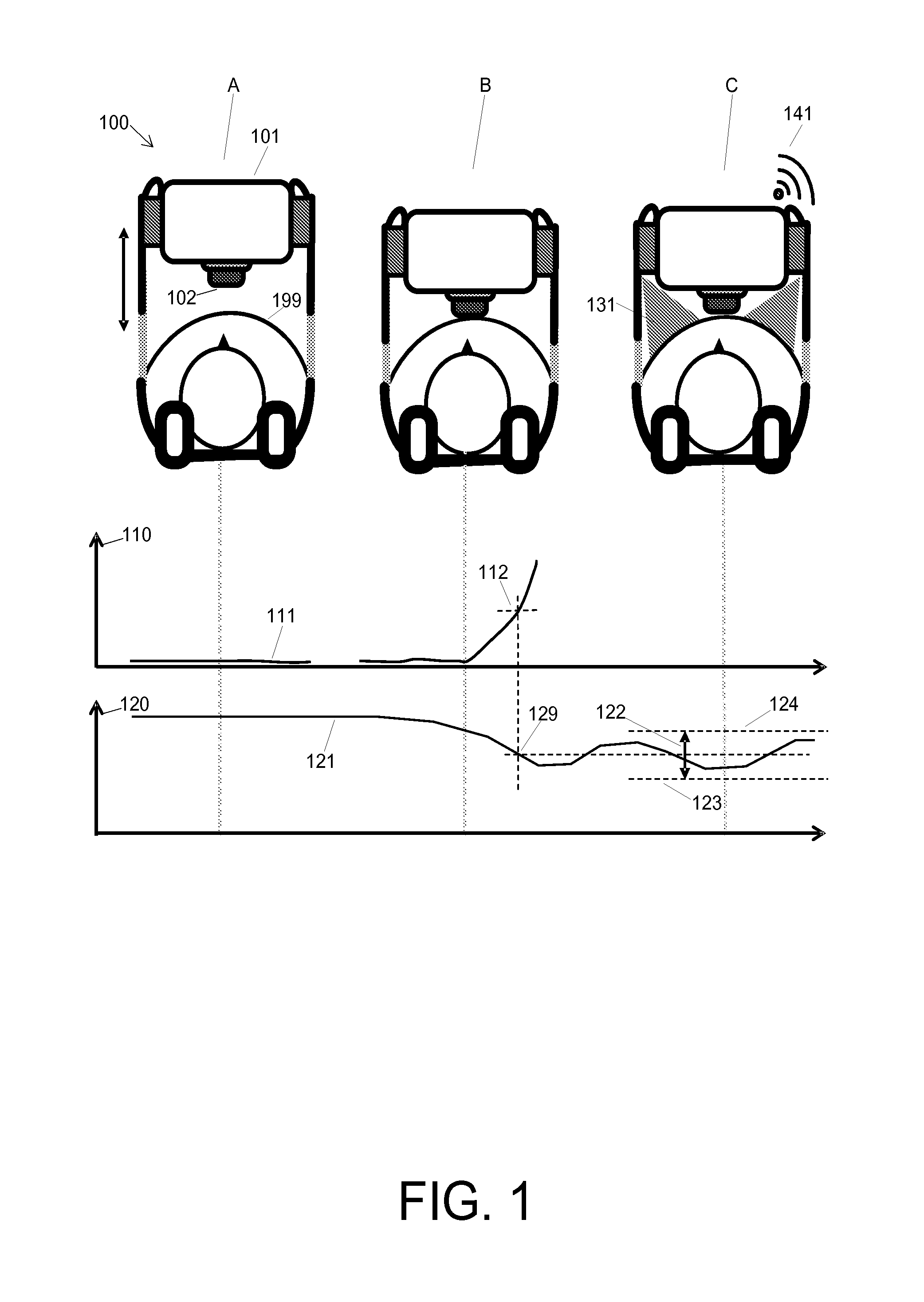

Cardio pulmonary resuscitation device with means for initial setup

InactiveUS20140171840A1Easy to set upMitigate, alleviate or eliminate oneElectrotherapyIron-lungsPositioning aidsEngineering

Initial setup of a Cardio Pulmonary Resuscitation device (100) is to be accomplished so that a contact pad (102) of the device makes the correct contact with the chest before the device starts giving chest compressions to the patient. Thereby situations where the contact pad is not in initial contact with the chest or situations where the contact pad initially compresses the chest too much are avoided. The position of the contact pad is measured during initial setup, and when contact between the chest and the contact pad is established, the actual position of the contact pad is measured and set as an initial position. Then a positioning range is set relative to the initial position. Therefore, the CPR device is provided with a positioning aid (131) which informs the rescuer when the contact pad is within the positioning range or when the contact pad is outside the initial positioning range.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

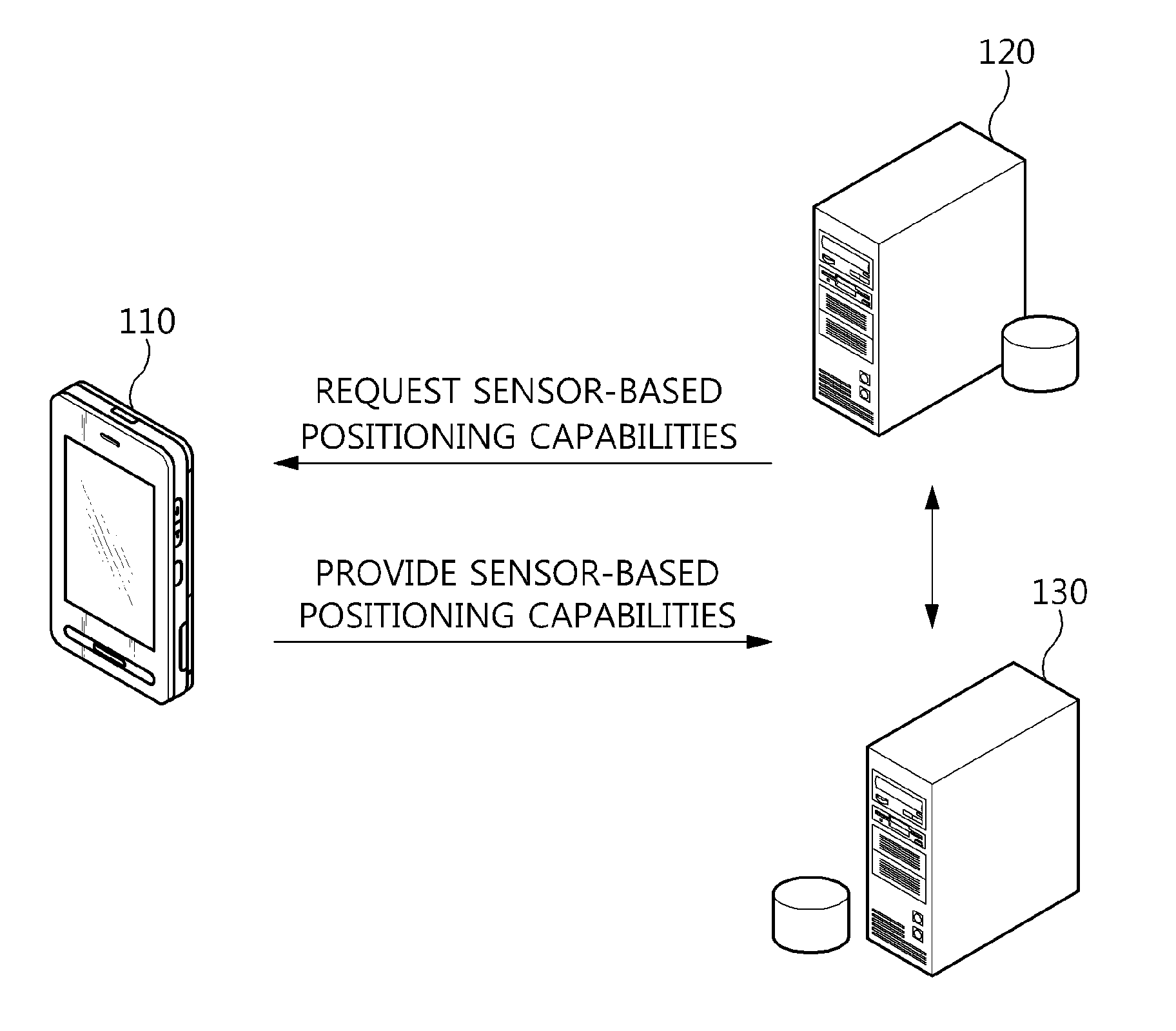

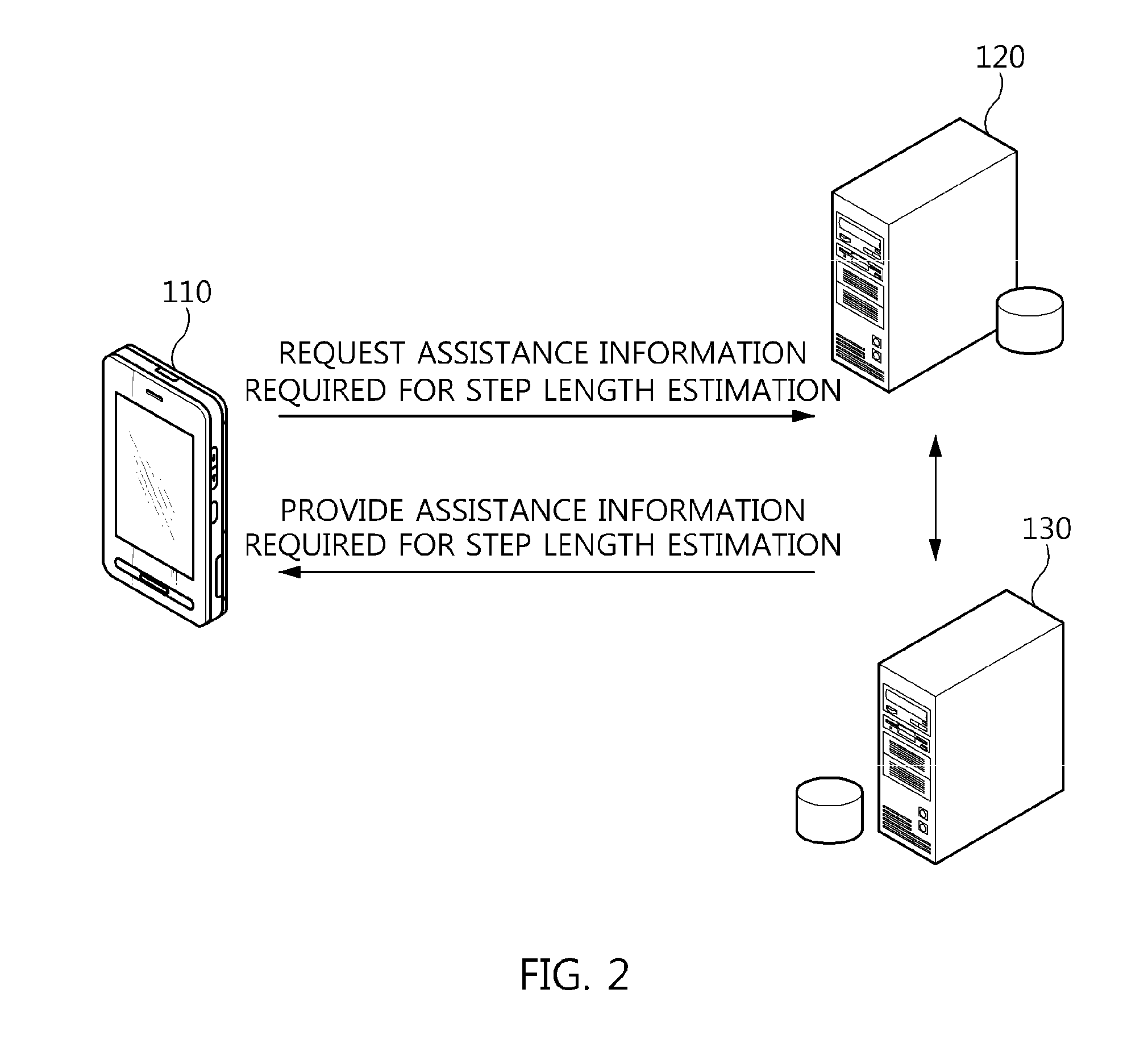

Method and apparatus for estimating location of pedestrian using step length estimation model parameters

ActiveUS20130273939A1Reduce complexityPrecise positioningNavigation instrumentsWireless communicationPositioning aidsSimulation

Disclosed herein is a method and apparatus for estimating the location of a pedestrian using step length estimation model parameters. In the method of estimating a location of a pedestrian according to the present invention, mobile User Equipment (UE) having sensors generates positioning measurement information. The mobile UE requests positioning assistance information from a positioning server. The positioning server generates the positioning assistance information. The positioning server provides the positioning assistance information to the mobile UE. The mobile UE performs location estimation of the pedestrian using the positioning measurement information and the positioning assistance information.

Owner:ELECTRONICS & TELECOMM RES INST

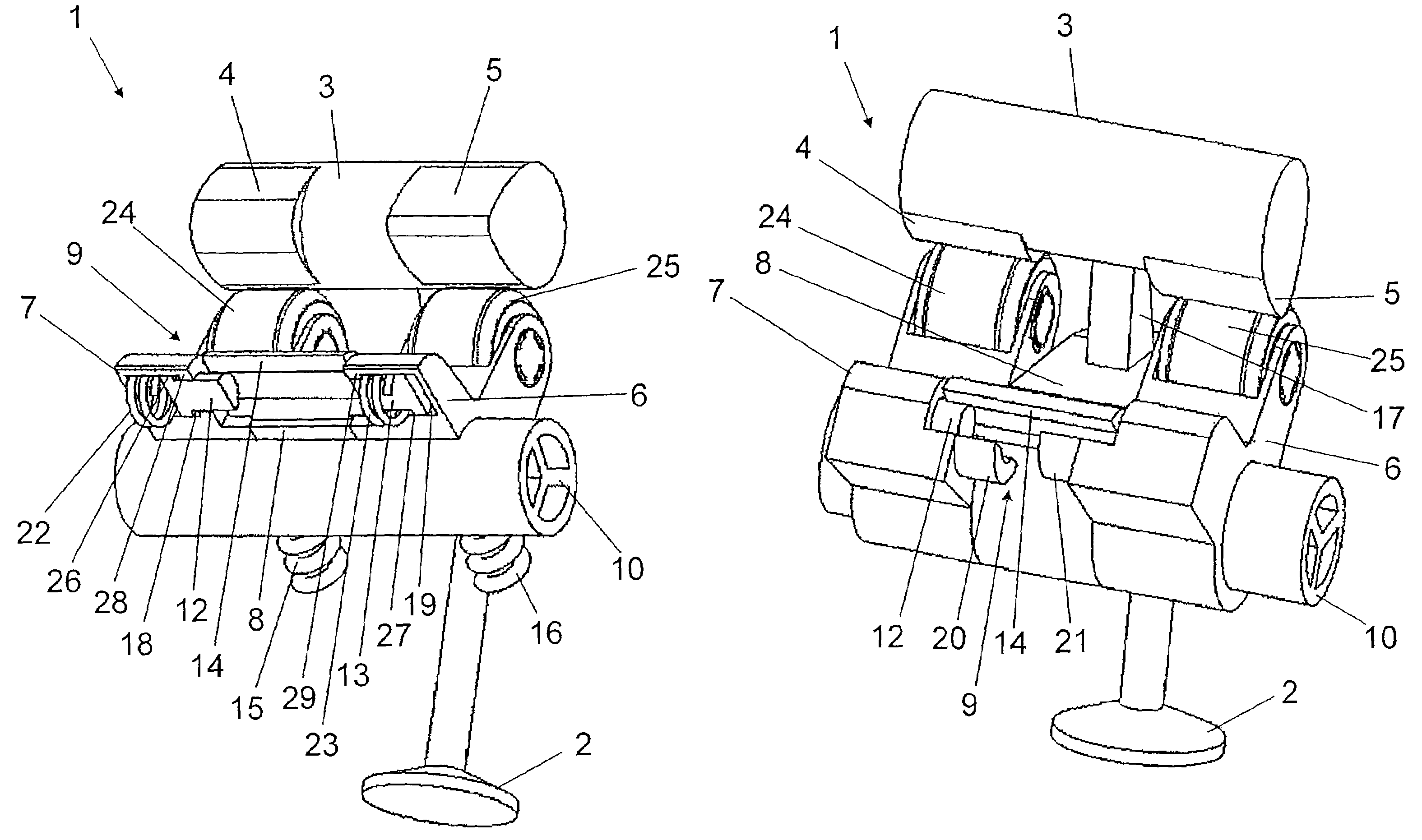

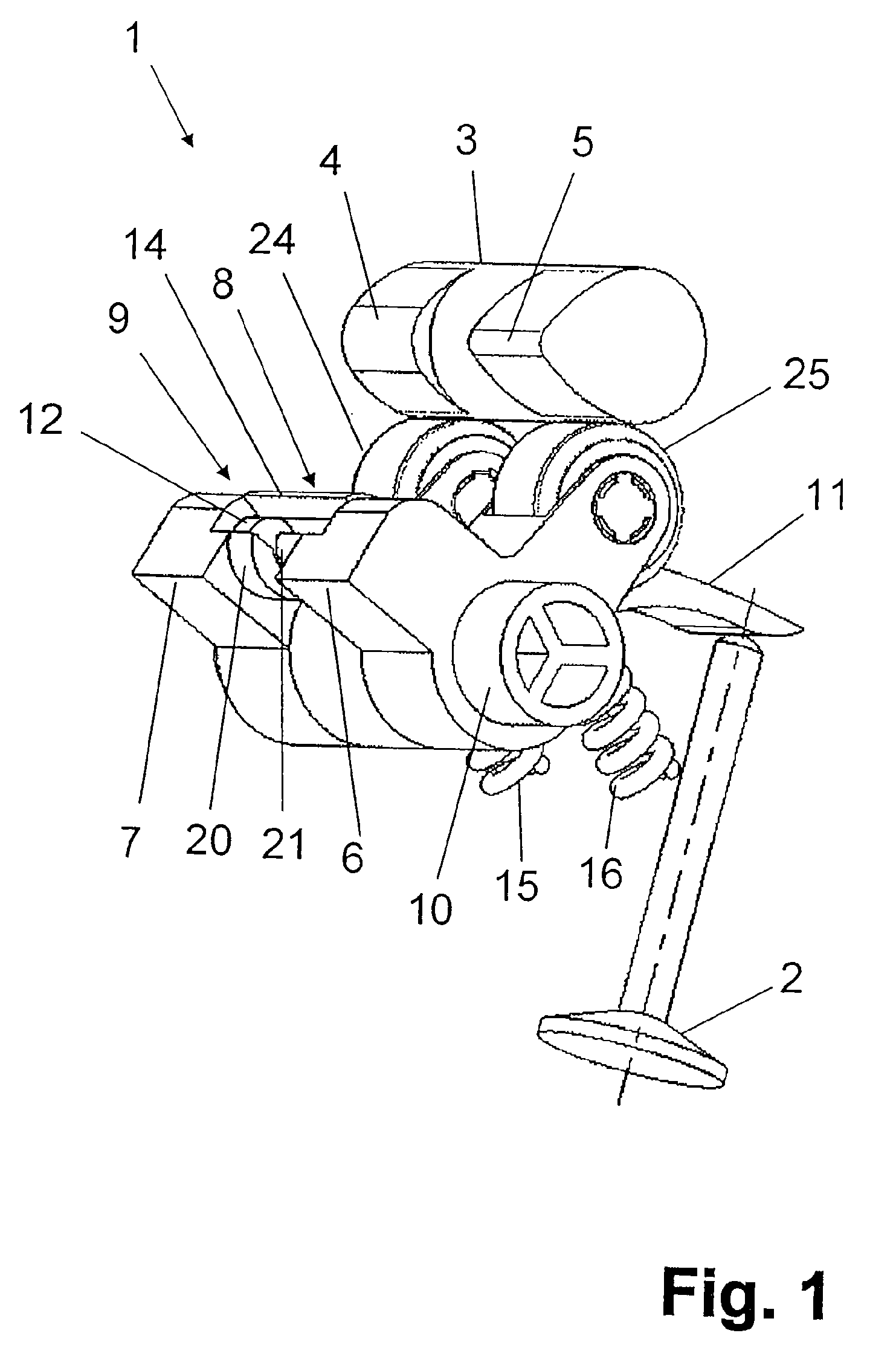

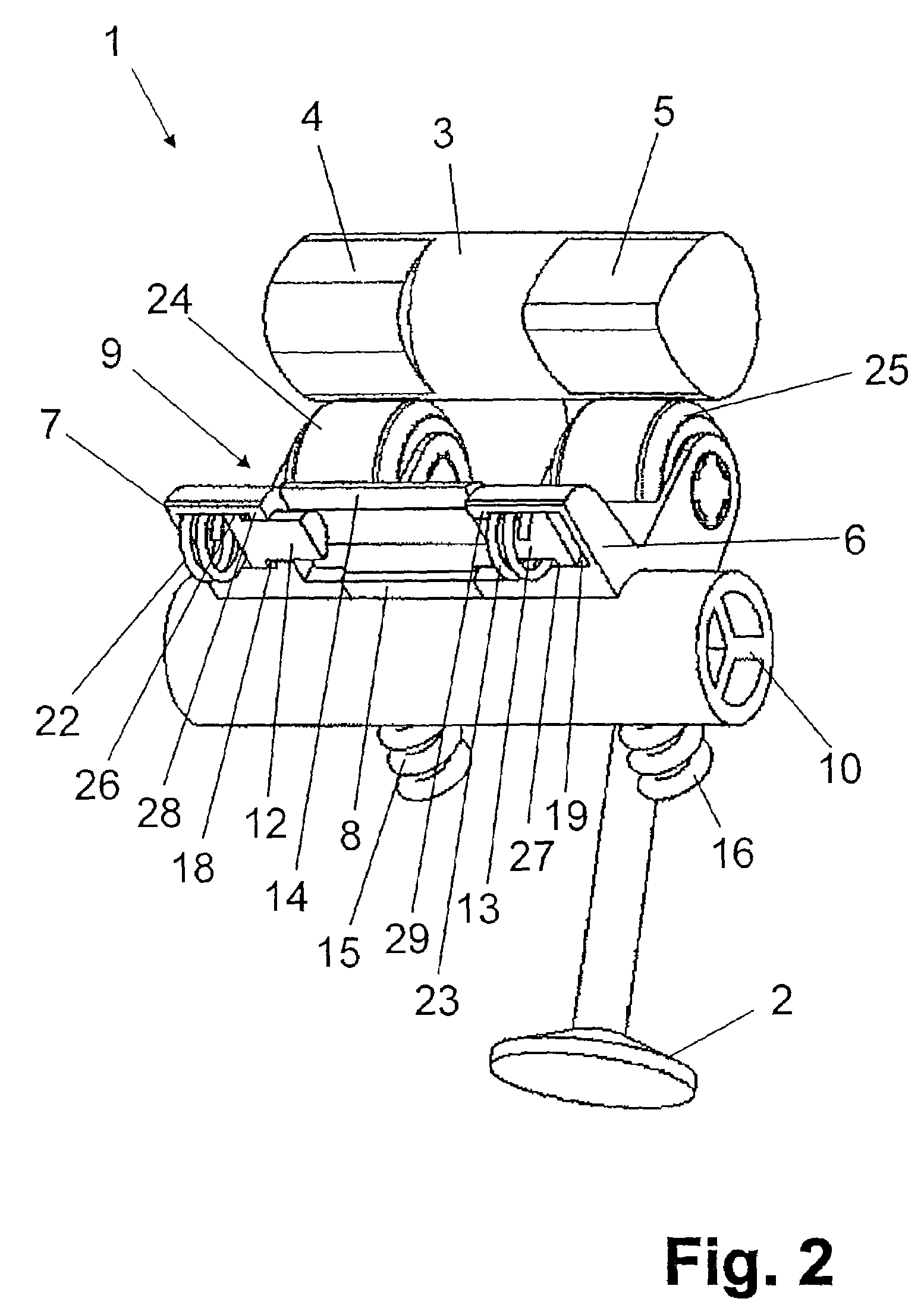

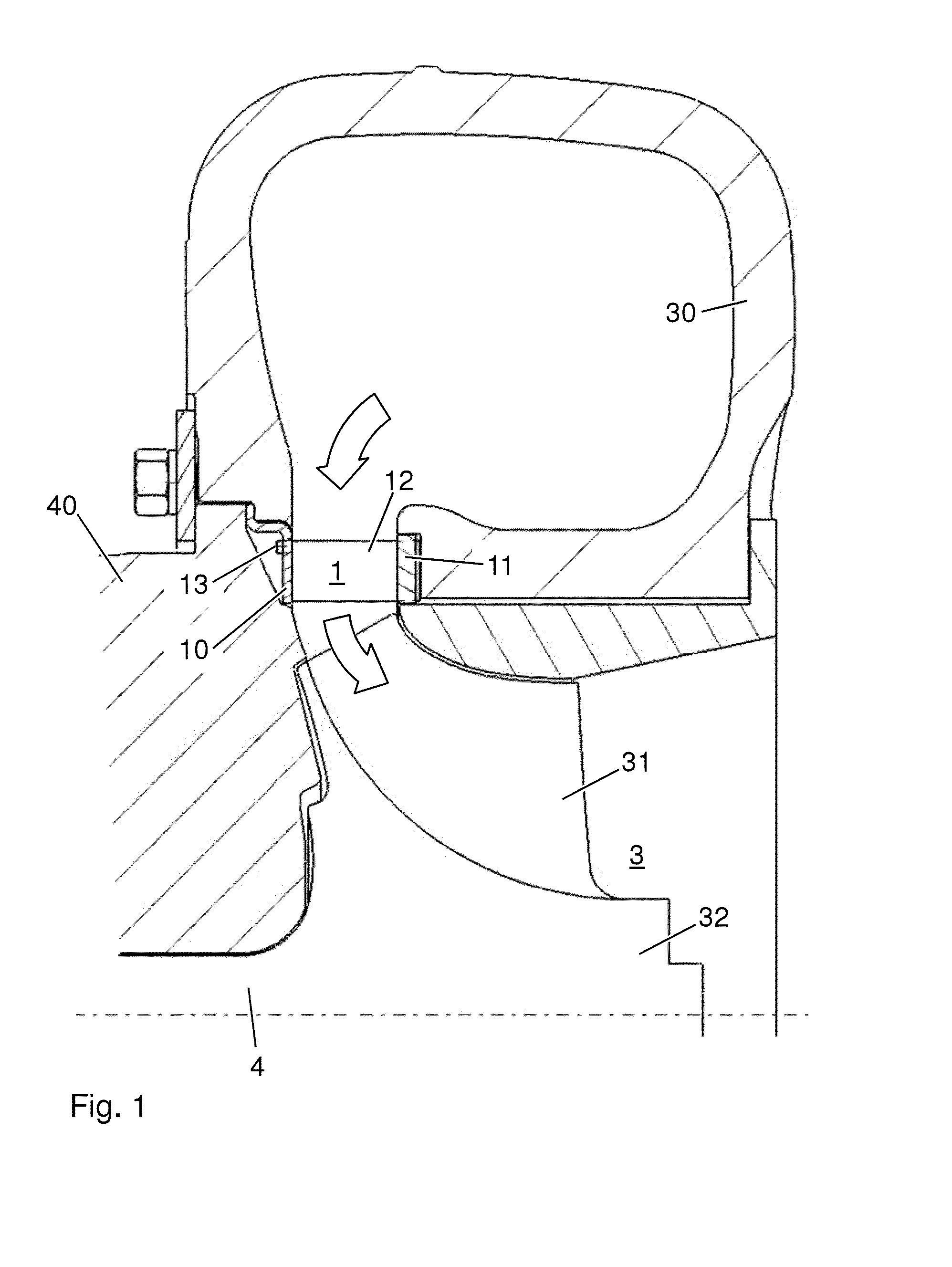

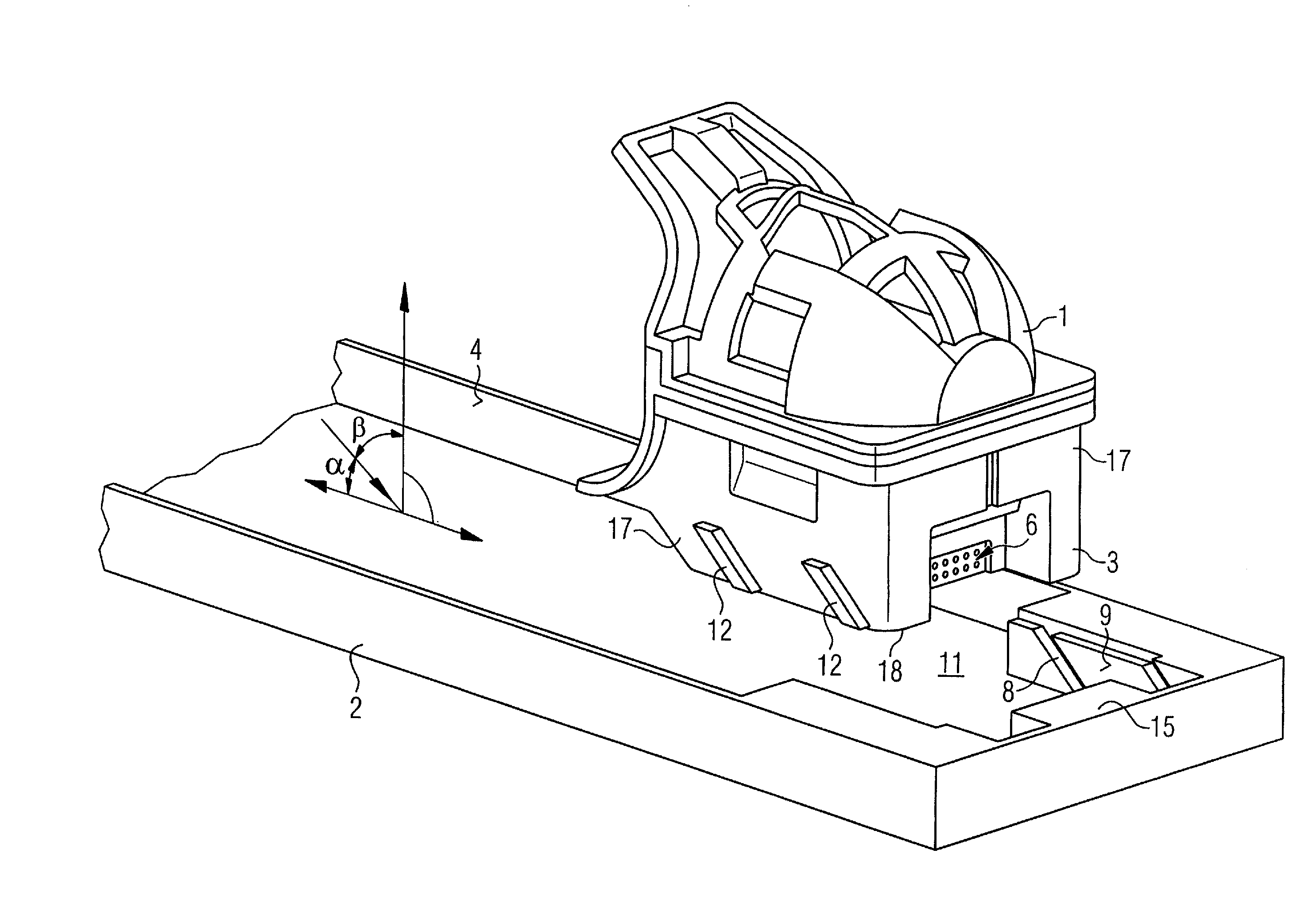

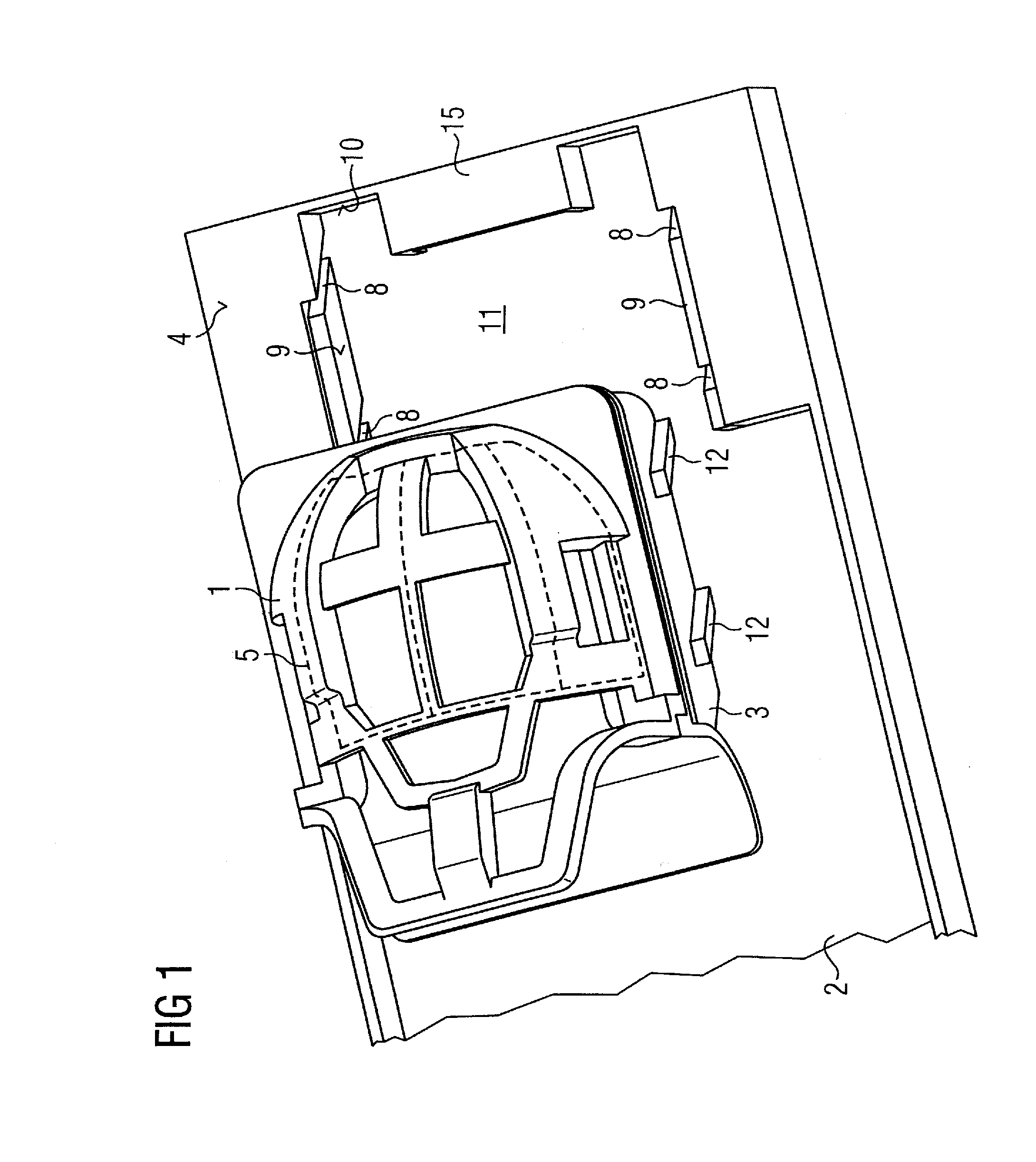

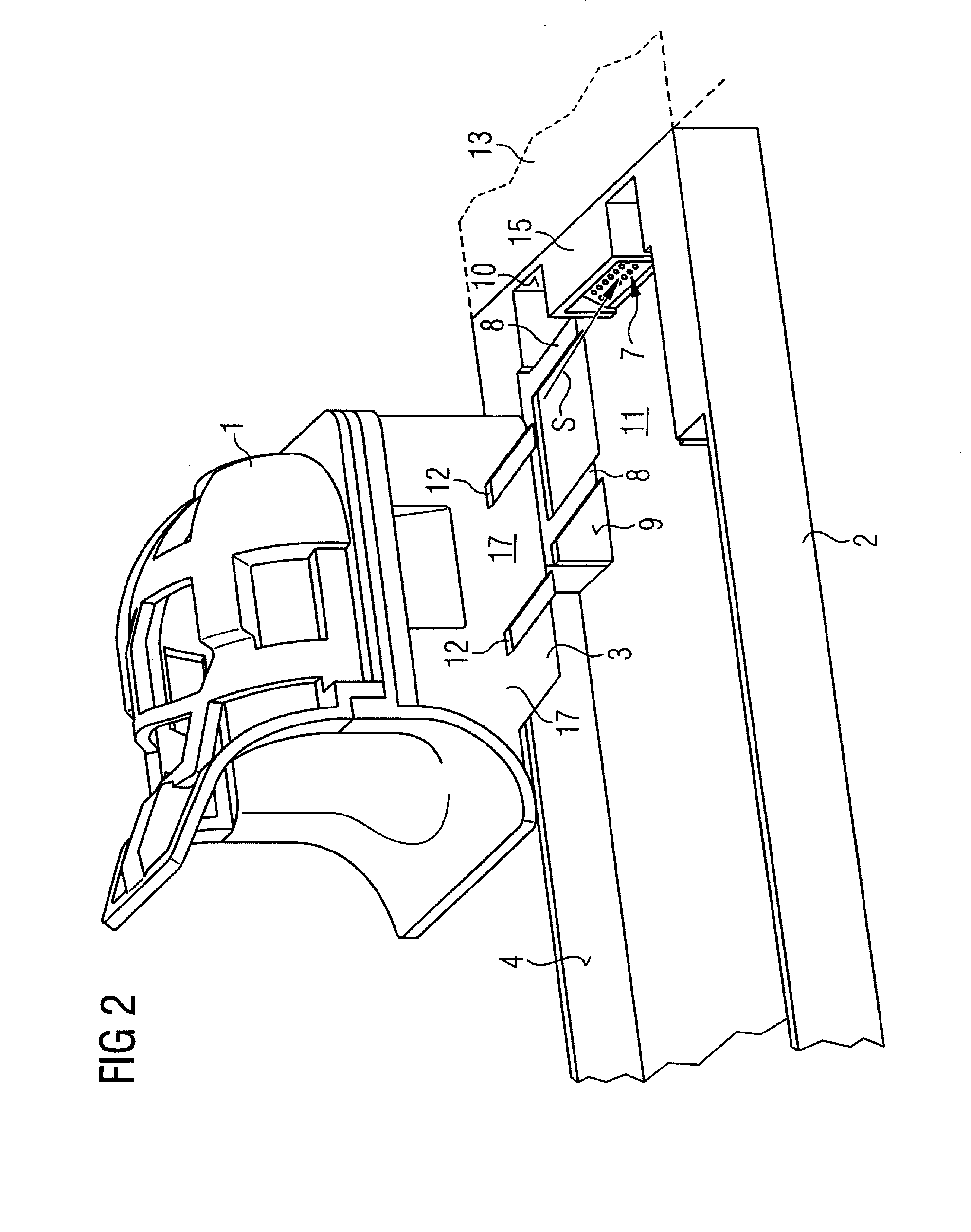

Valve train for an internal combustion engine

A valve train for an internal combustion engine is provided, with the valve train having a switchable rocker arm assembly (1) with a plurality of rocker arms (6, 7, 8) for activating at least one gas exchange valve (2), and also having at least one camshaft (3) with differently contoured cams (4, 5) through which different adjusting displacements can be imparted to individual rocker arms of the rocker arm assembly (1). The assembly further includes a switching device (9) for selectively activating the rocker arms for driving the gas exchange valve (2) with a varying valve lift. To create a valve train in which individual gas exchange valves can be operated in different modes of operation with only a small amount of construction work and expense, the rocker arm assembly (1) has a stationary rocker arm shaft (10) on which at least two outer rocker arms (6, 7), that are in continuous contact with associated, differently contoured cams (4, 5), and a center rocker arm (8) with a lever arm extension (11) through which the gas exchange valve (2), in operative connection to one of the two outer rocker arms (6, 7), can be selectively actuated, are mounted for tilting movement. Actuatable locking pins (12, 13) are arranged on the outer rocker arms (6, 7) for sliding axially parallel to the rocker arm shaft (10), a locking pin receiver (14) is arranged on the center rocker arm (8) and positioning aids (15, 16, 17) are arranged on the outer and the center rocker arms (6, 7, 8), so that the center rocker arm (8) can be selectively force-locked to one of the two outer rocker arms (6, 7) or be deactivated.

Owner:SCHAEFFLER TECH AG & CO KG

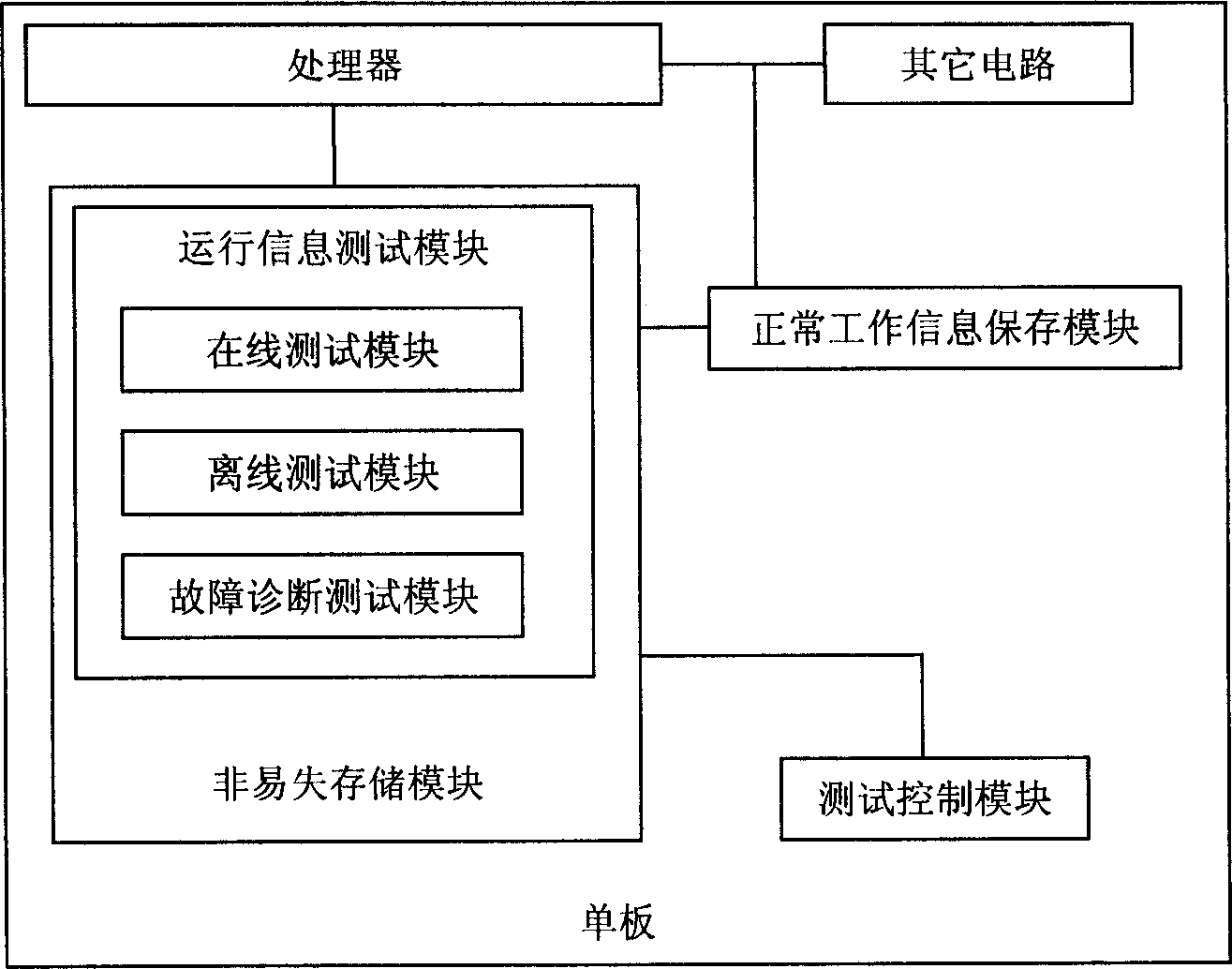

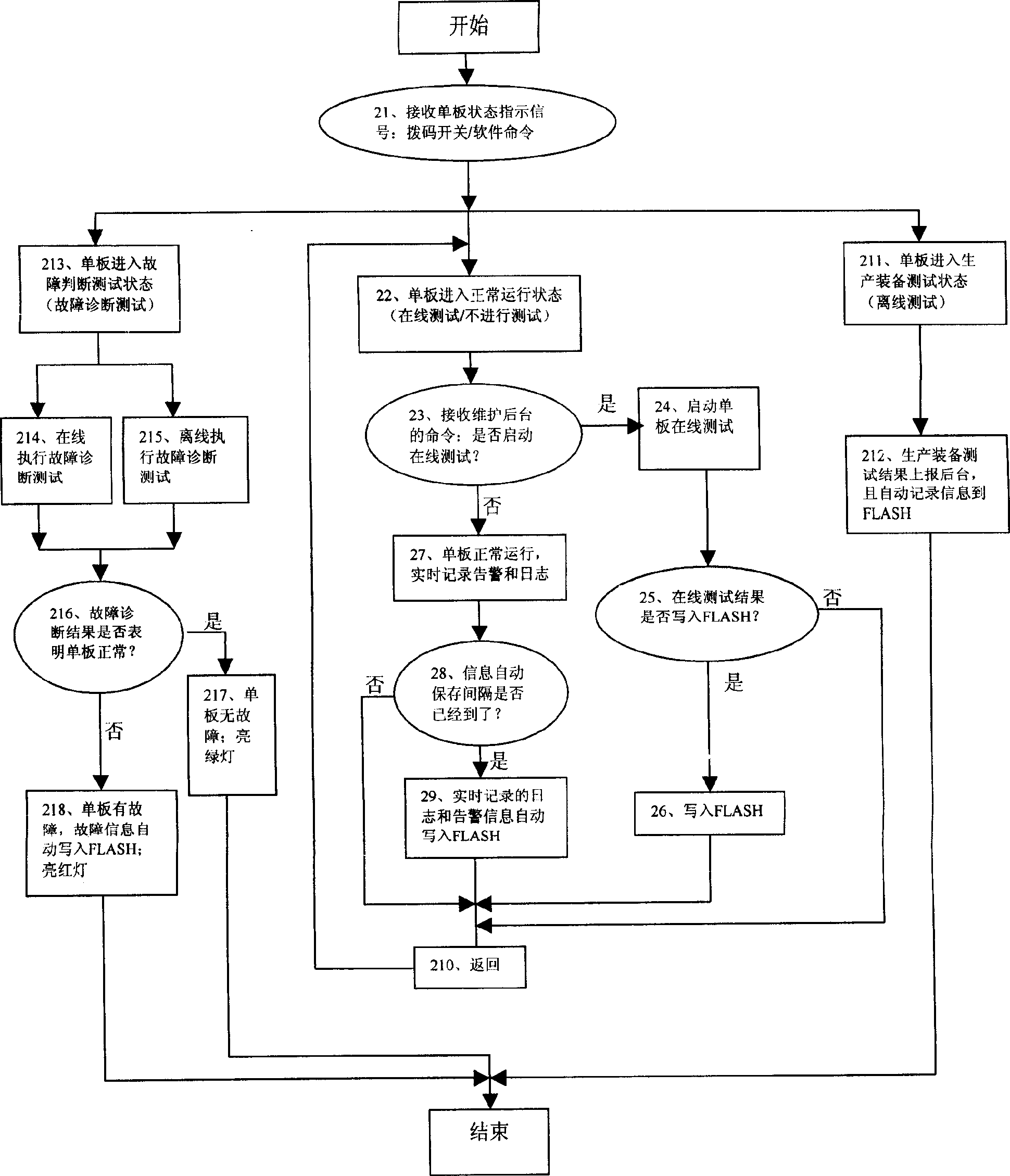

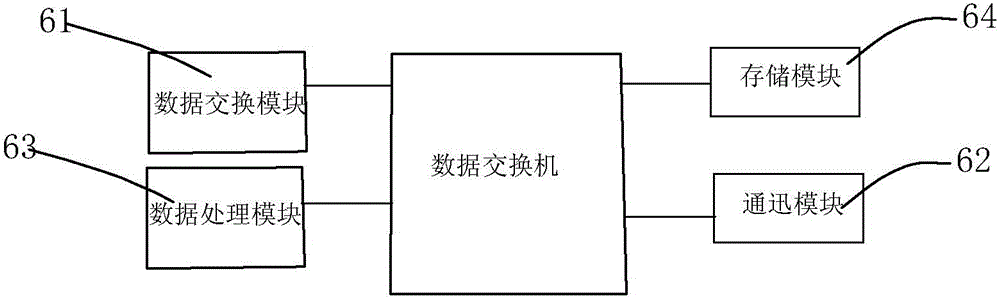

Single board fault positioning aid and positioning method

InactiveCN1862507AImprove pass rateReduce market repair rateHardware monitoringData switching networksElectricityPositioning aids

The present invention relates to a single board fault location auxiliary device and its location method. Said invention is mainly characterized by that on the single board a removable special-purpose nonvolatile storage chip is added, said chip can be matched with test function on said single board, the running state information (including fault information) of said single board can be stored in the nonvolatile storage chip so as to prevent the information from losing due to causes of powerfail, etc. Said invention is applicable to on-line, off-line and remote fault location.

Owner:HUAWEI TECH CO LTD

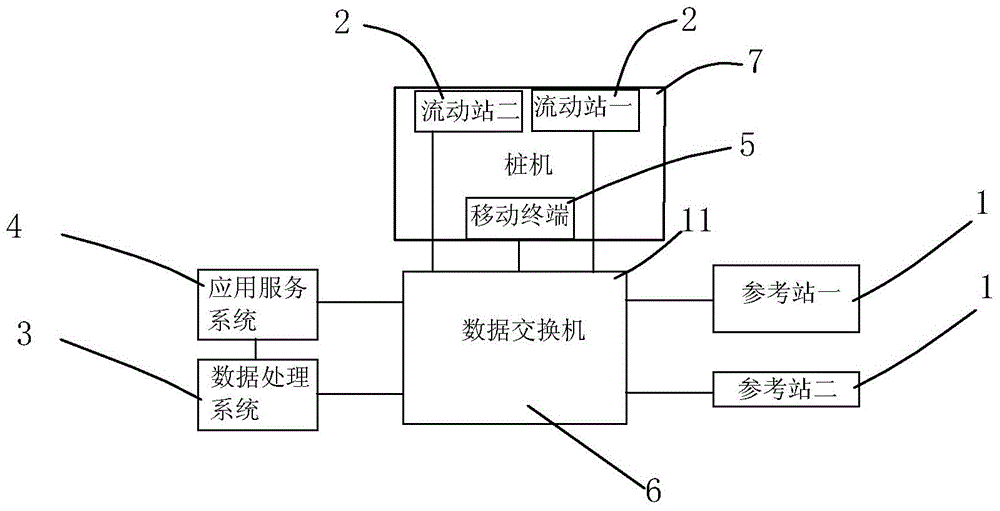

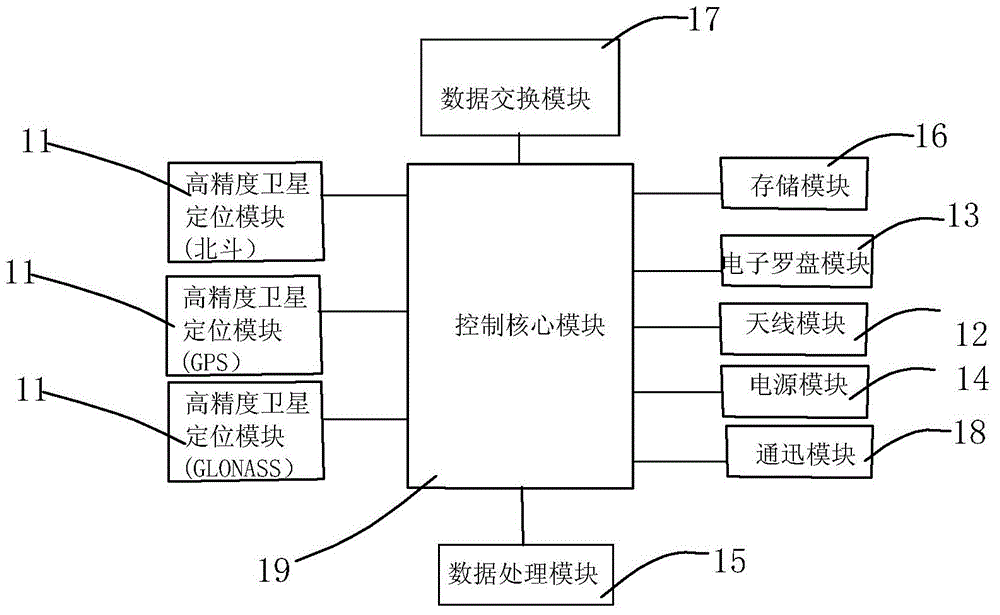

RTK (real time kinematic)-based piling positioning auxiliary system and utilization method thereof

ActiveCN104793226AInnovativePrecise piling positioningSatellite radio beaconingData processing systemPositioning aids

The invention provides a RTK (real time kinematic)-based piling positioning auxiliary system and a utilization method thereof. The system comprises a RTK-based reference station, a mobile station, a data processing system, an application service system, a mobile terminal, a data switcher and a pile driver. The reference station, the mobile station and the mobile terminal are connected with the data processing system and the application service system through the data switcher. The reference station is arranged at a relatively fixed known coordinate point of a target project, the mobile terminal is provided with the application service system, the mobile station and the mobile terminal are arranged on the pile driver, and the mobile station can be also arranged at an independent point outside the pile driver. An operator of the pile driver can complete pile driver positioning (piling position determination) according to display or prompt of the application service system installed on the mobile terminal, and accordingly intermediate links in a positioning process can be reduced, and directness, convenience and accuracy in operation of piling position determination are improved. Furthermore, construction efficiency of the pile driver is improved, the problems of pay-off difficulty in night construction and the like are solved, and the RTK-based piling positioning auxiliary system has the advantages of simplicity in operation, accuracy in positioning, monitorability in construction and sharability of construction data and achievements.

Owner:SHENZHEN BEIDOUYUN INFORMATION TECH CO LTD +1

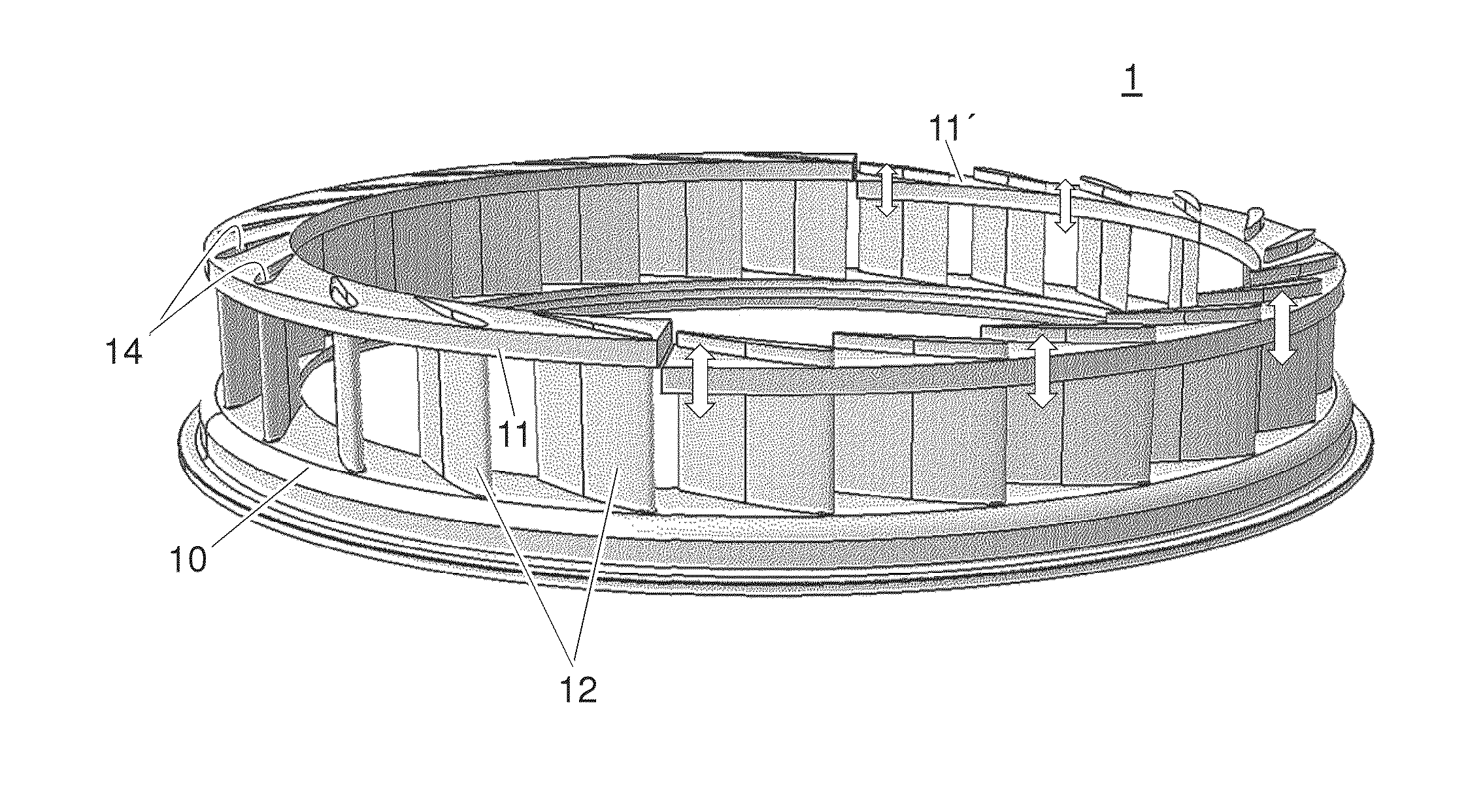

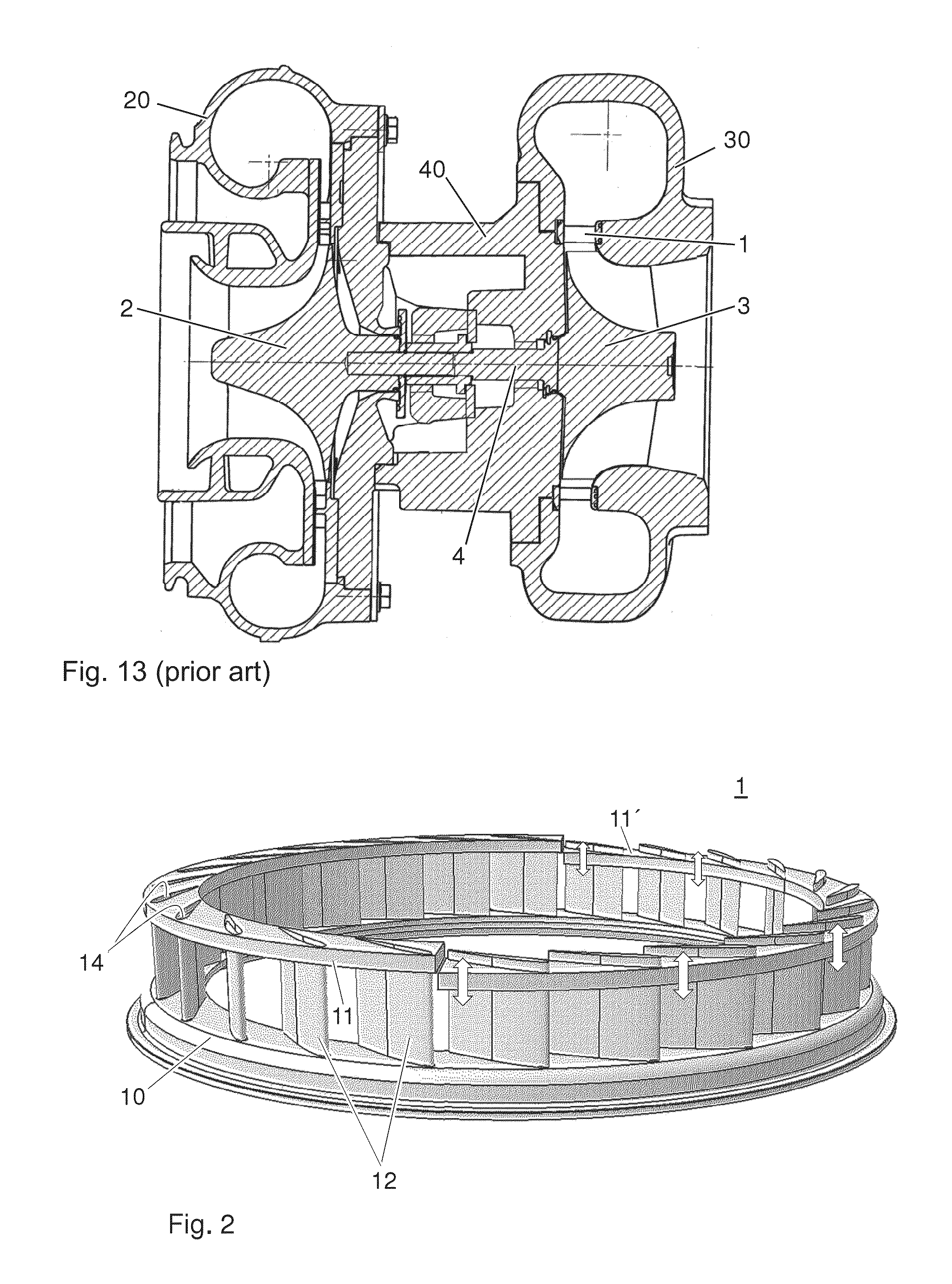

Nozzle ring

ActiveUS20140140834A1Increase flexibilityCost effectivePump componentsMetal-working apparatusPositioning aidsNozzle

An exemplary nozzle ring has two fastening rings and a plurality of guide vanes, wherein holes are provided in one of the fastening rings for accommodating pins of the guide vanes, and openings are provided in the other fastening ring for accommodating positioning aids on the guide vanes.

Owner:TURBO SYST SWITZERLAND LTD

Enhanced positioning assistance data for reduced signaling

Apparatus and methods for determining a location estimate of a mobile device based on an extended set of assistance data are presented. The extended assistance data includes assistance data for base stations, such as cellular base stations and access points, not expected to be viewable by the mobile device in a (current) first geographical area but expected to be viewable by the mobile device in a (future) second geographical area. By seeding the mobile device with assistance data expected to be useful in the future, the network reduces messaging between the network and mobile device and battery consumption by the mobile device.

Owner:QUALCOMM INC

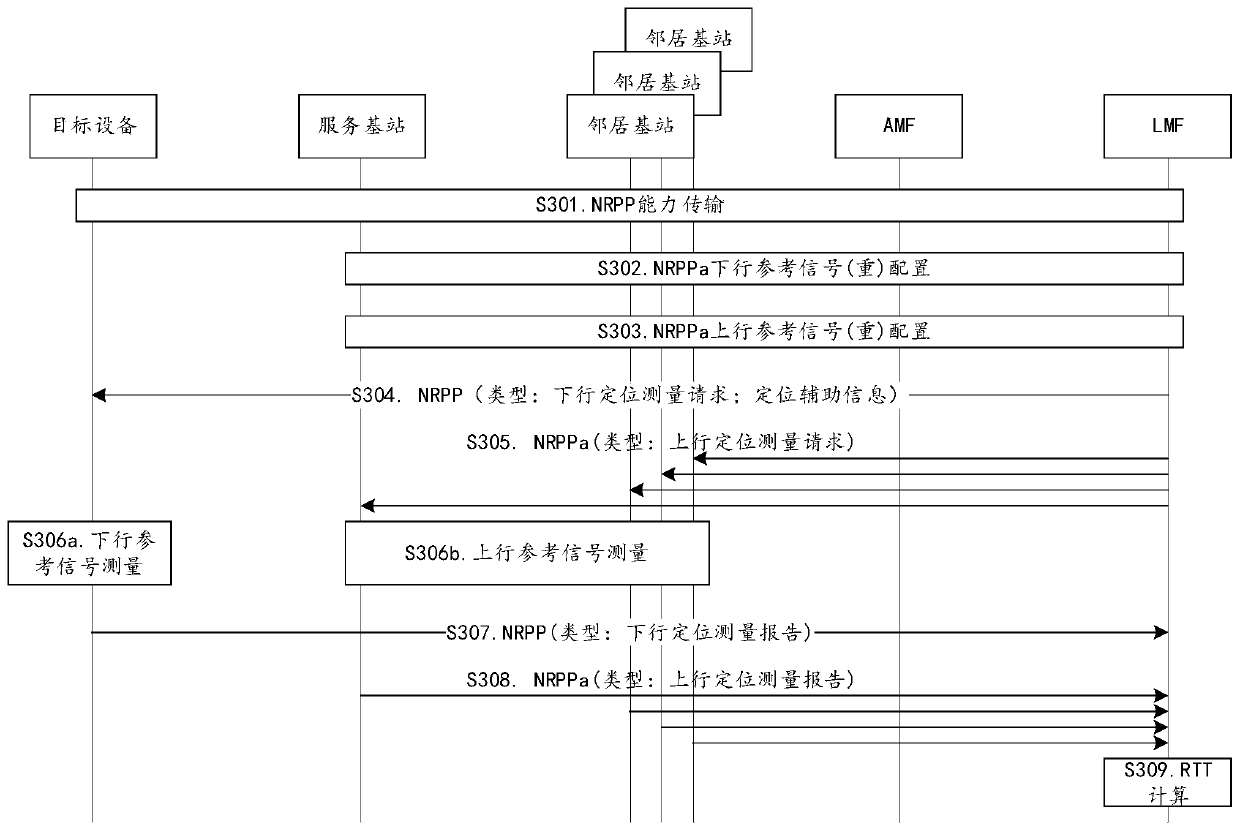

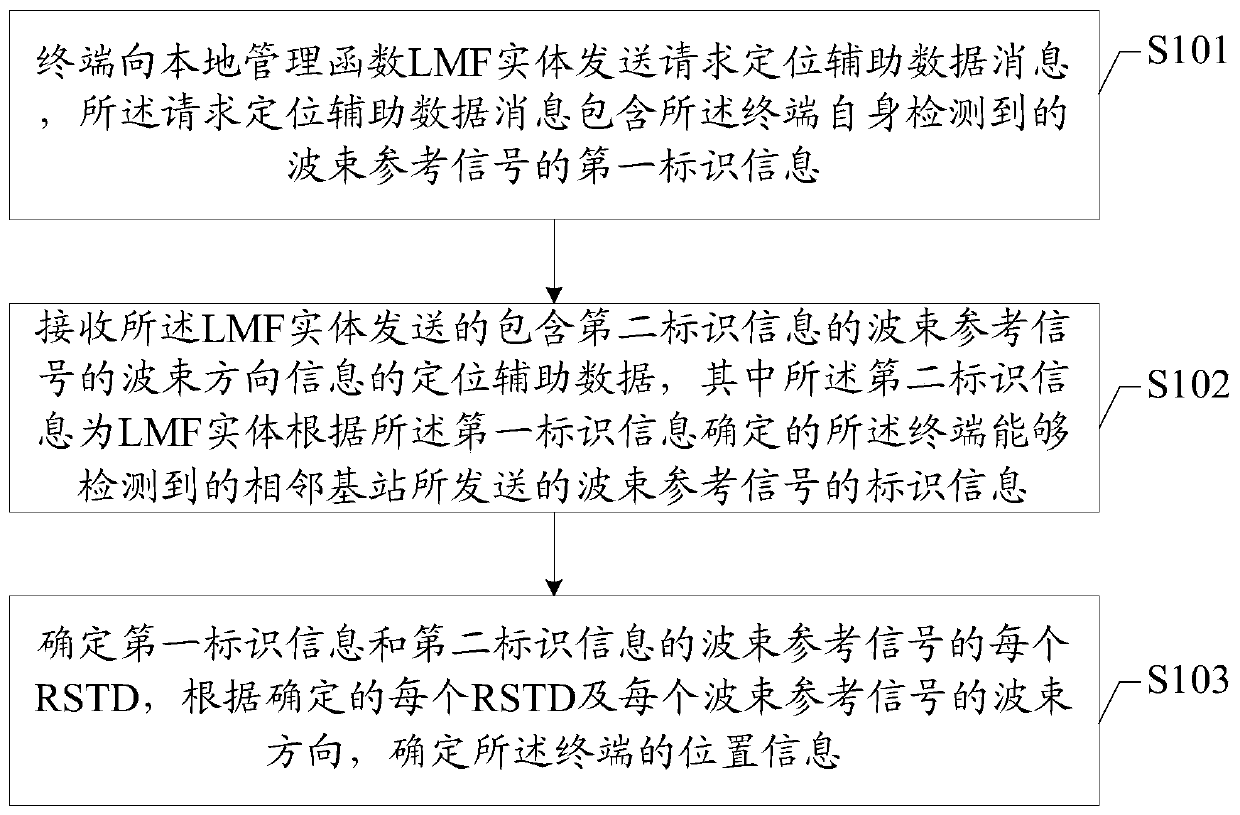

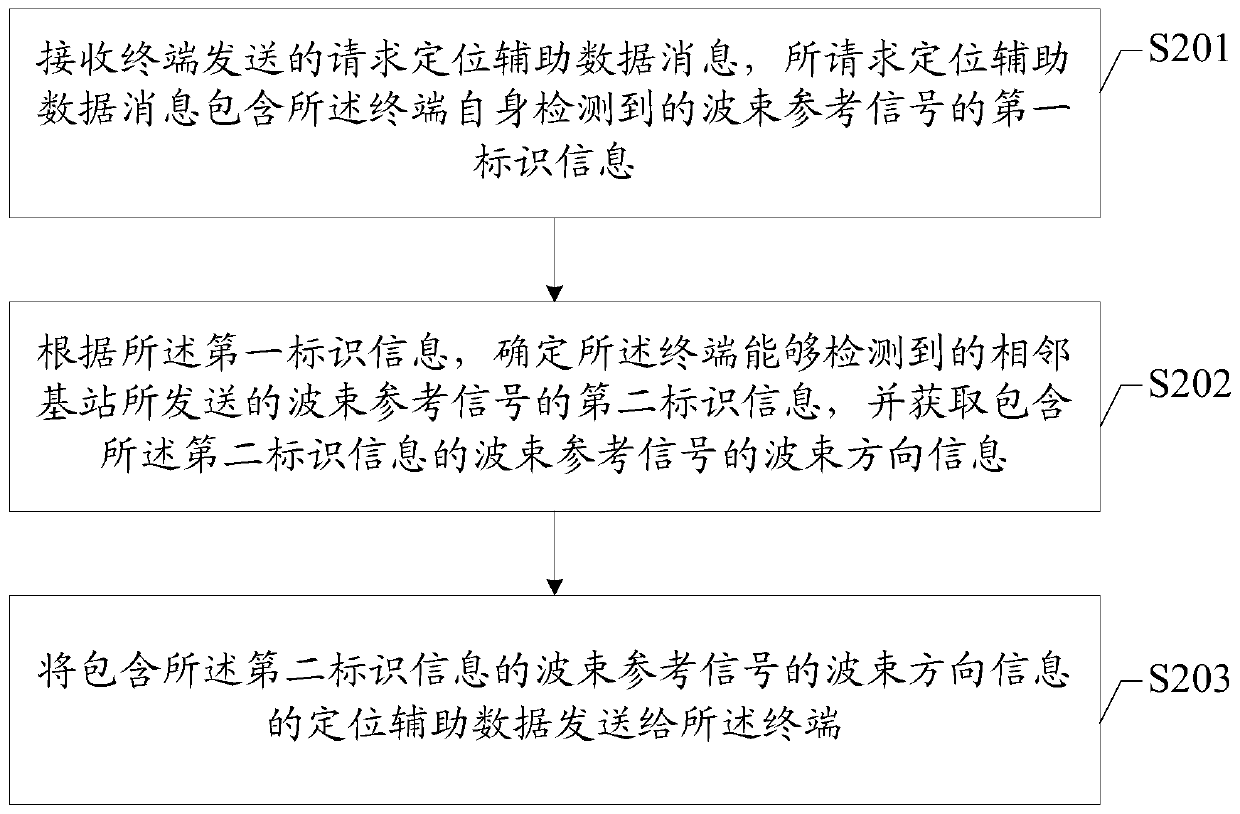

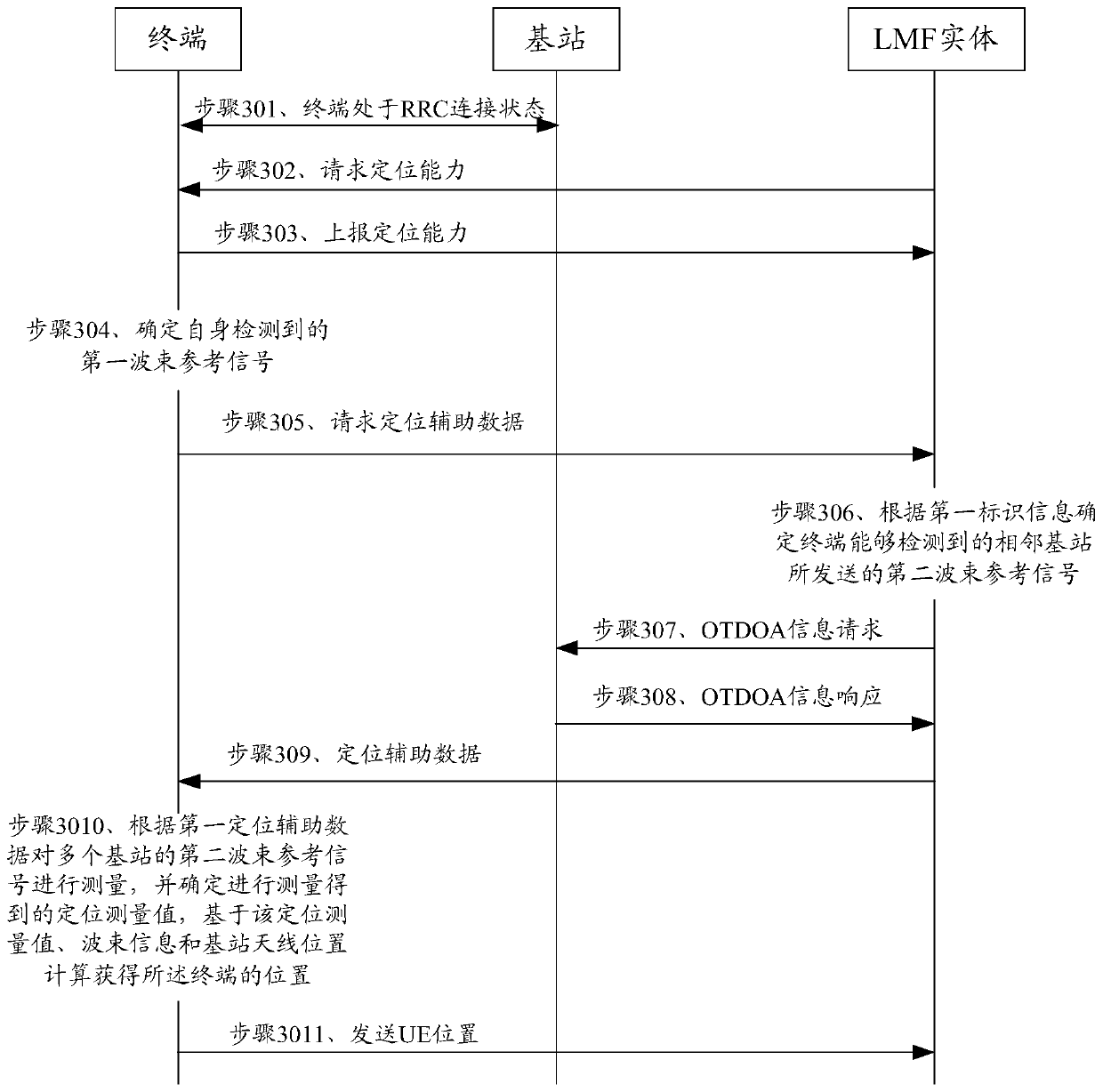

Positioning method, device and system, terminal, LMF entity and medium

ActiveCN111562546AHigh positioning accuracySpatial transmit diversityPosition fixationPositioning aidsBeam direction

The invention discloses a positioning method, device and system, a terminal, an LMF entity and a medium, which are used for solving the problem of low UE-based OTDOA positioning precision in the priorart. The method comprises the steps that a terminal sends a positioning assistance data requesting message to a local management function (LMF) entity, wherein the positioning assistance data requesting message comprises first identification information of a beam reference signal detected by the terminal; receiving positioning assistance data which is sent by the LMF entity and contains beam direction information of a beam reference signal of second identification information, wherein the second identification information is identification information of a beam reference signal sent by a neighboring base station that can be detected by the terminal determined by the LMF entity according to the first identification information; and determining each RSTD of the beam reference signals of thefirst identification information and the second identification information, and determining position information of the terminal according to each determined RSTD and the beam direction of each beamreference signal.

Owner:DATANG MOBILE COMM EQUIP CO LTD

Local coil arrangement for magnetic resonance applications and patient bed for a magnetic resonance system, with integrated electrical interfaces

A local coil arrangement for magnetic resonance applications has a mechanically dimensionally stable support element that rests on a patient bed so as to transfer the weight of the local coil arrangement to the patient bed. The local coil arrangement has at least one local coil to excite and / or to receive magnetic resonance signals and a multipole, prefabricated electrical interface via which the local coil can be electrically contacted. The electrical interface is arranged so as to be dimensionally stable at the support element. Positioning aids for positioning of local coil arrangement are arranged on the support surface that also transfer the weight of the local coil arrangement is transferred to the patient bed as well as plugging the electrical interface into an electrical counter-interface.

Owner:SIEMENS HEALTHCARE GMBH

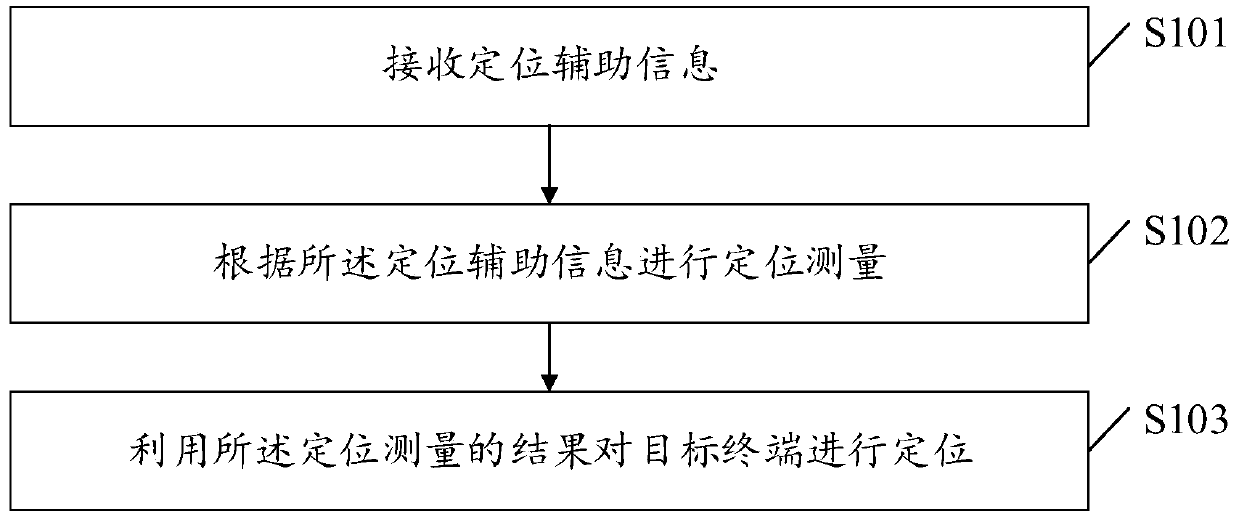

Positioning method and device, terminal equipment and storage medium

PendingCN111093154AAchieve positioningParticular environment based servicesPosition fixationComputer hardwarePositioning aids

The invention provides a positioning method and device, terminal equipment and a storage medium. The method comprises the steps: receiving positioning auxiliary information; performing positioning measurement according to the positioning auxiliary information; and positioning the target terminal by using the positioning measurement result. According to the invention, terminal equipment positioningin a vehicle wireless communication technology (V2X) scene can be realized.

Owner:ZTE CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com