Patents

Literature

4176 results about "Contact pad" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Contact pads or bond pads are designated surface areas of a printed circuit board or die of an integrated circuit. Possibilities to contact to pads include soldering, wirebonding, flip chip mounting, or probe needles.

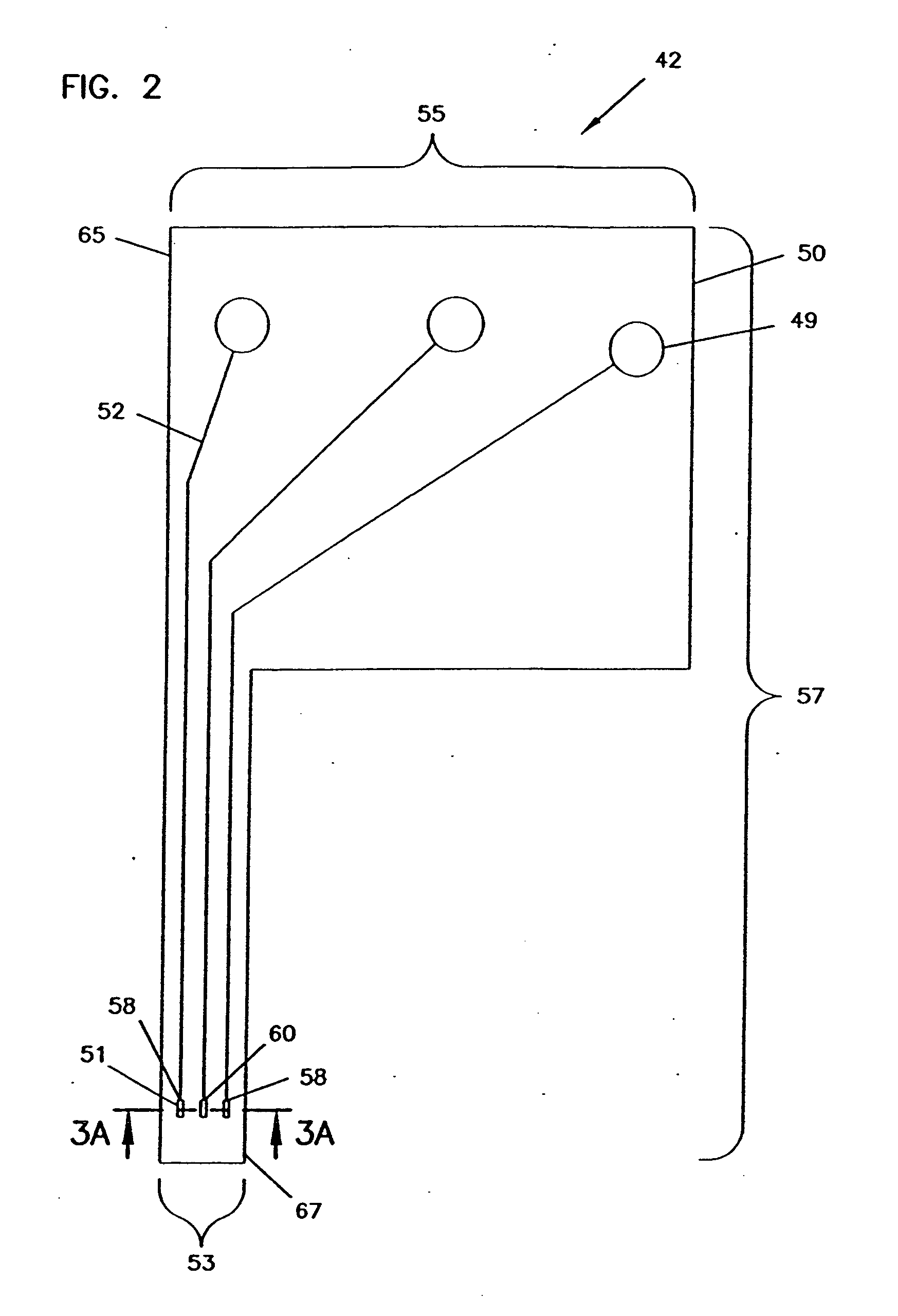

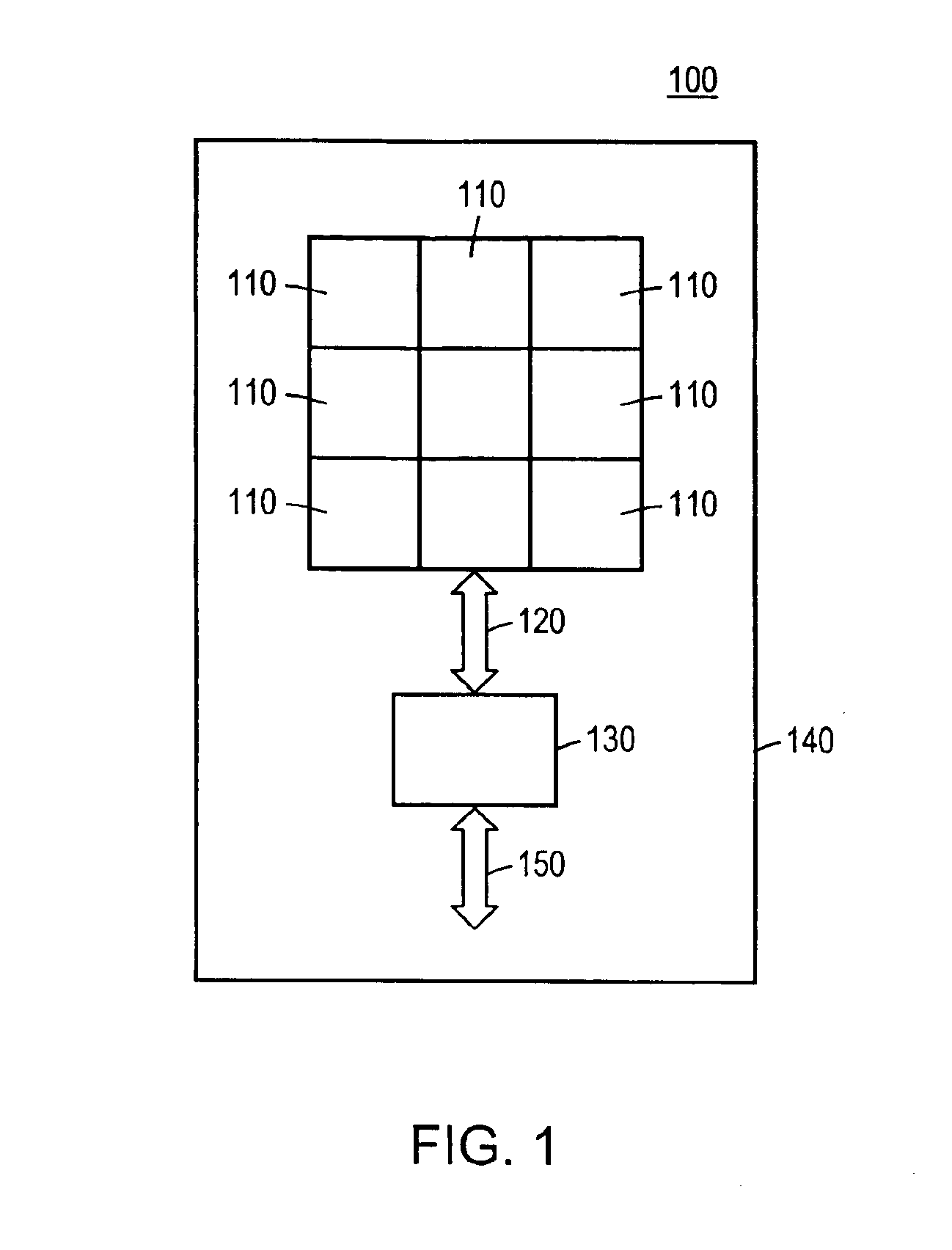

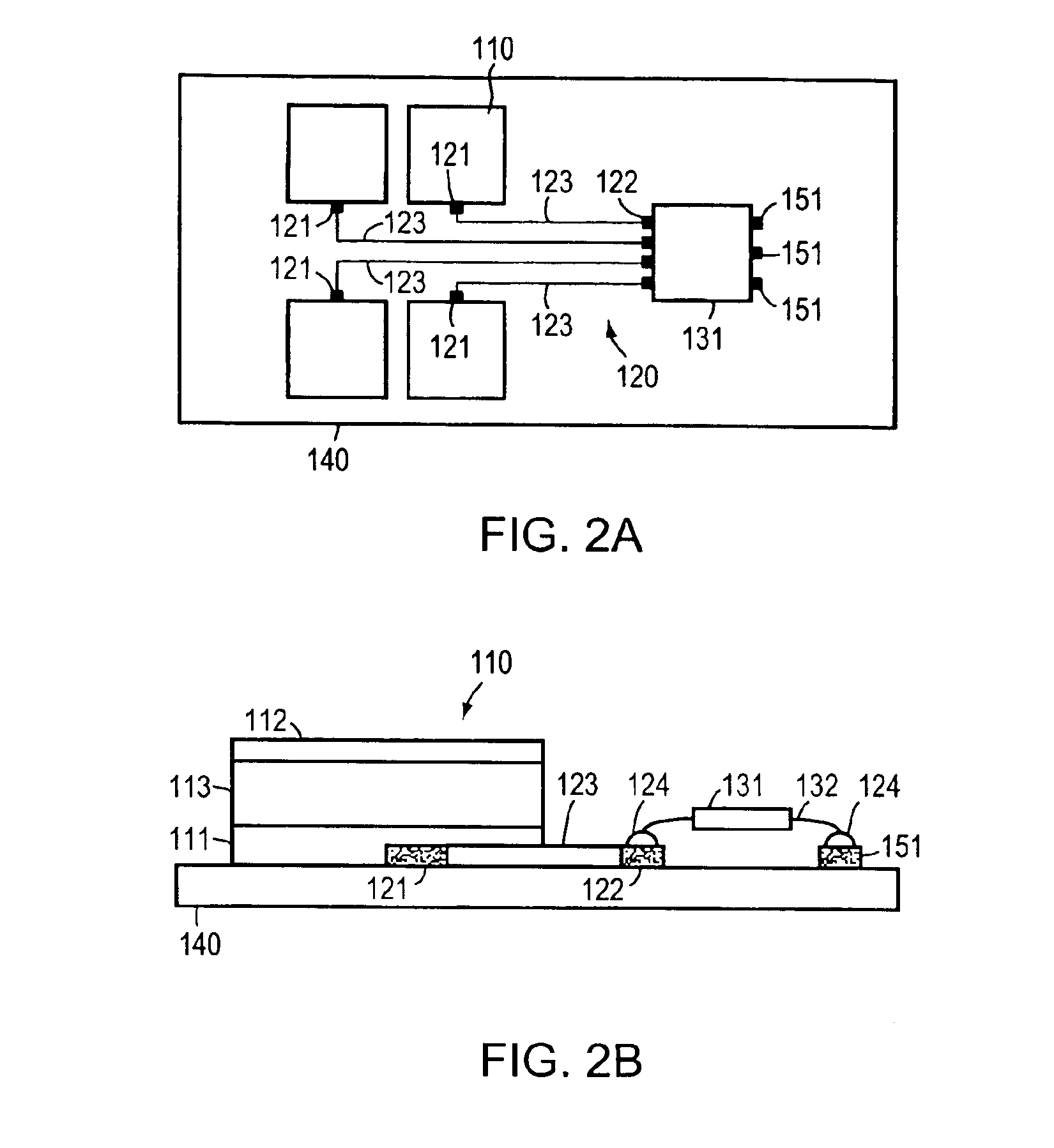

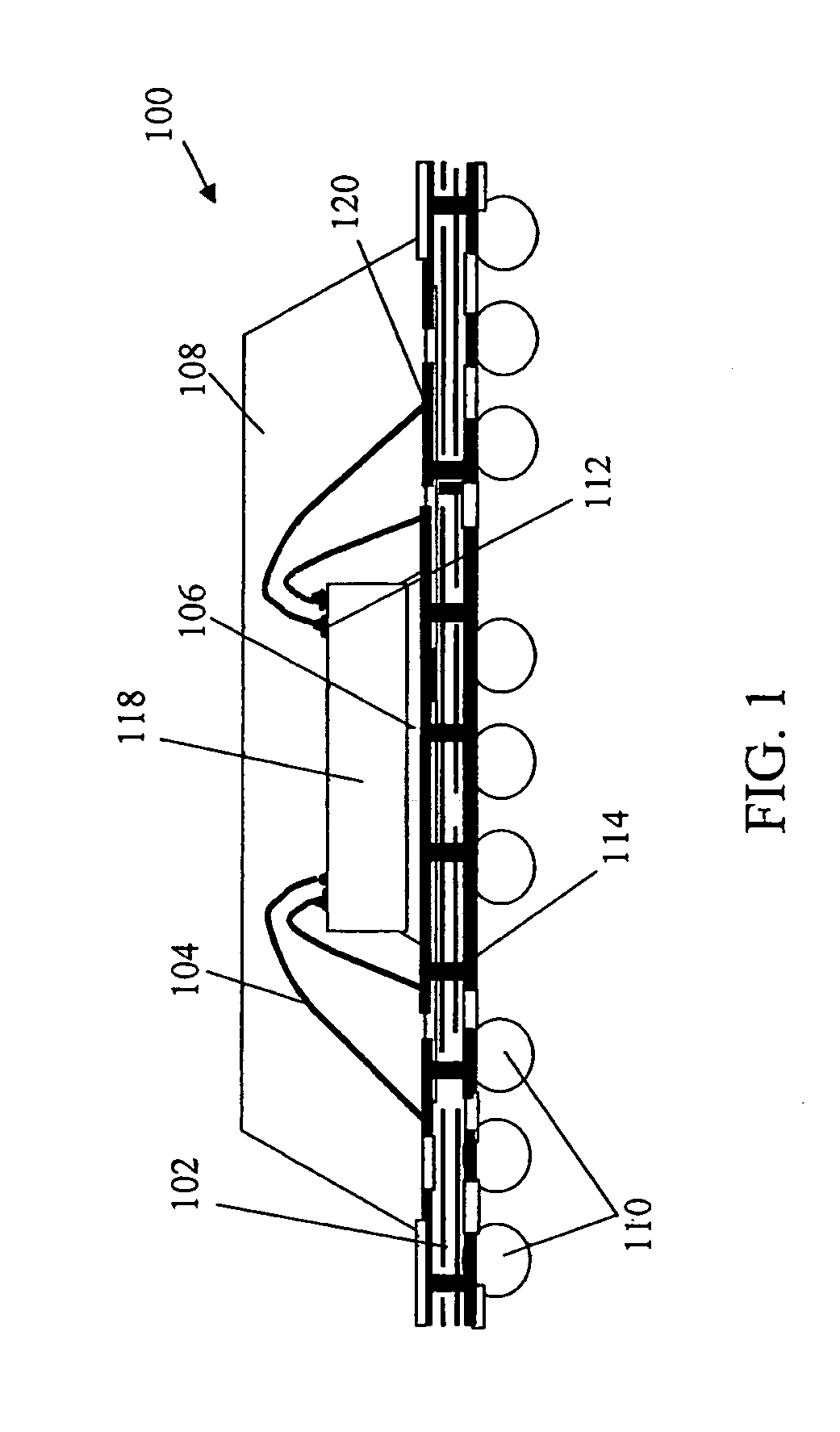

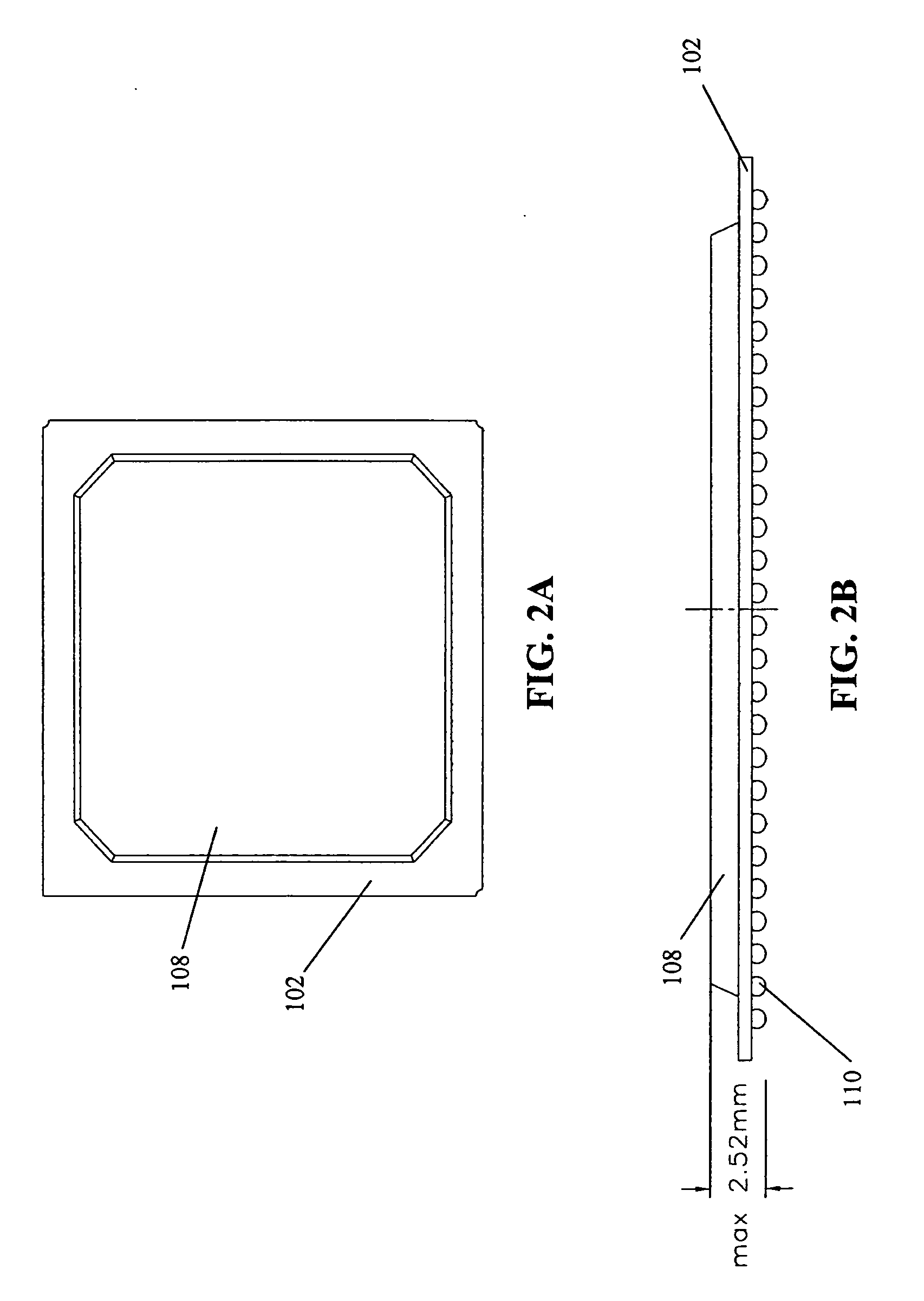

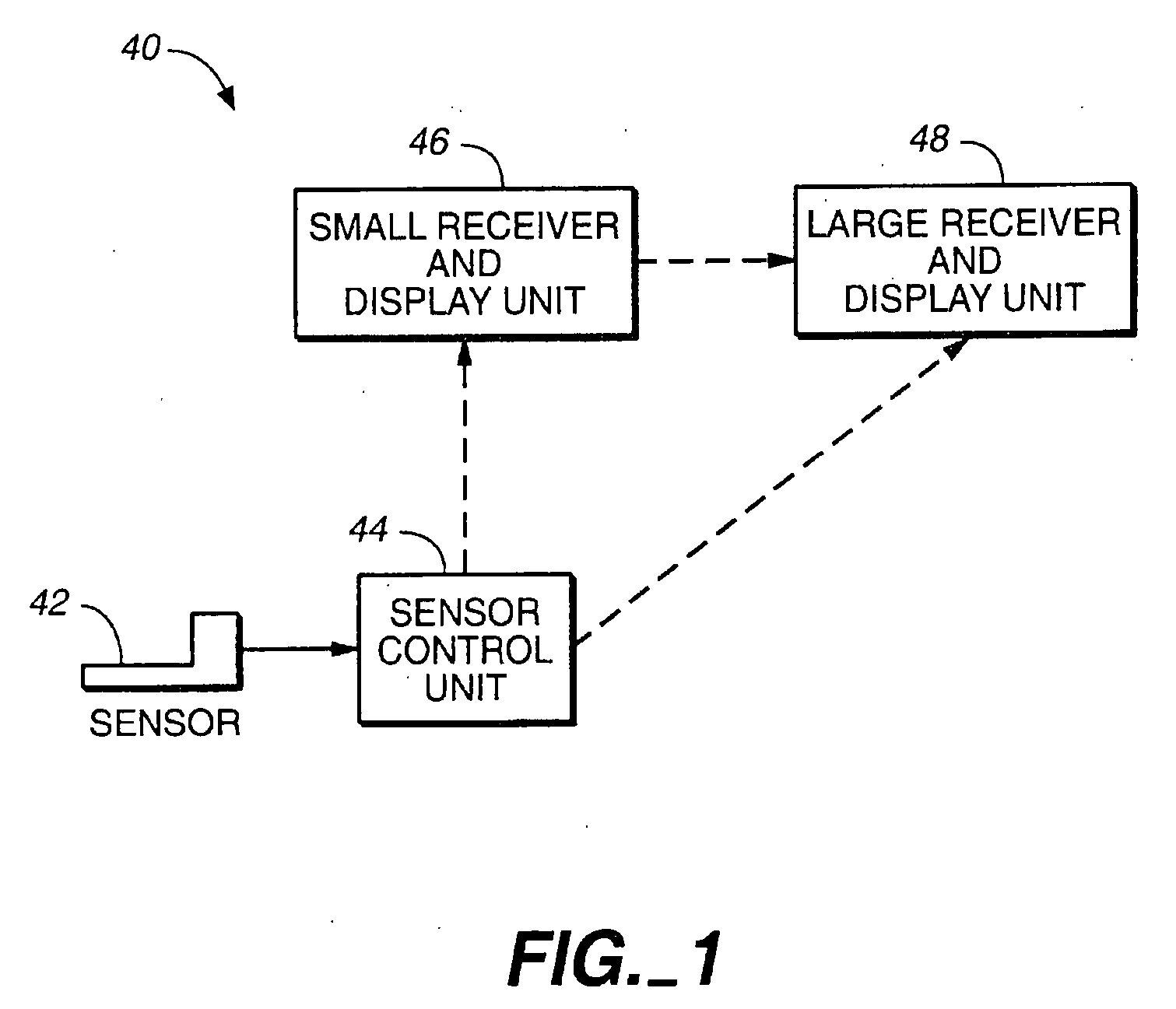

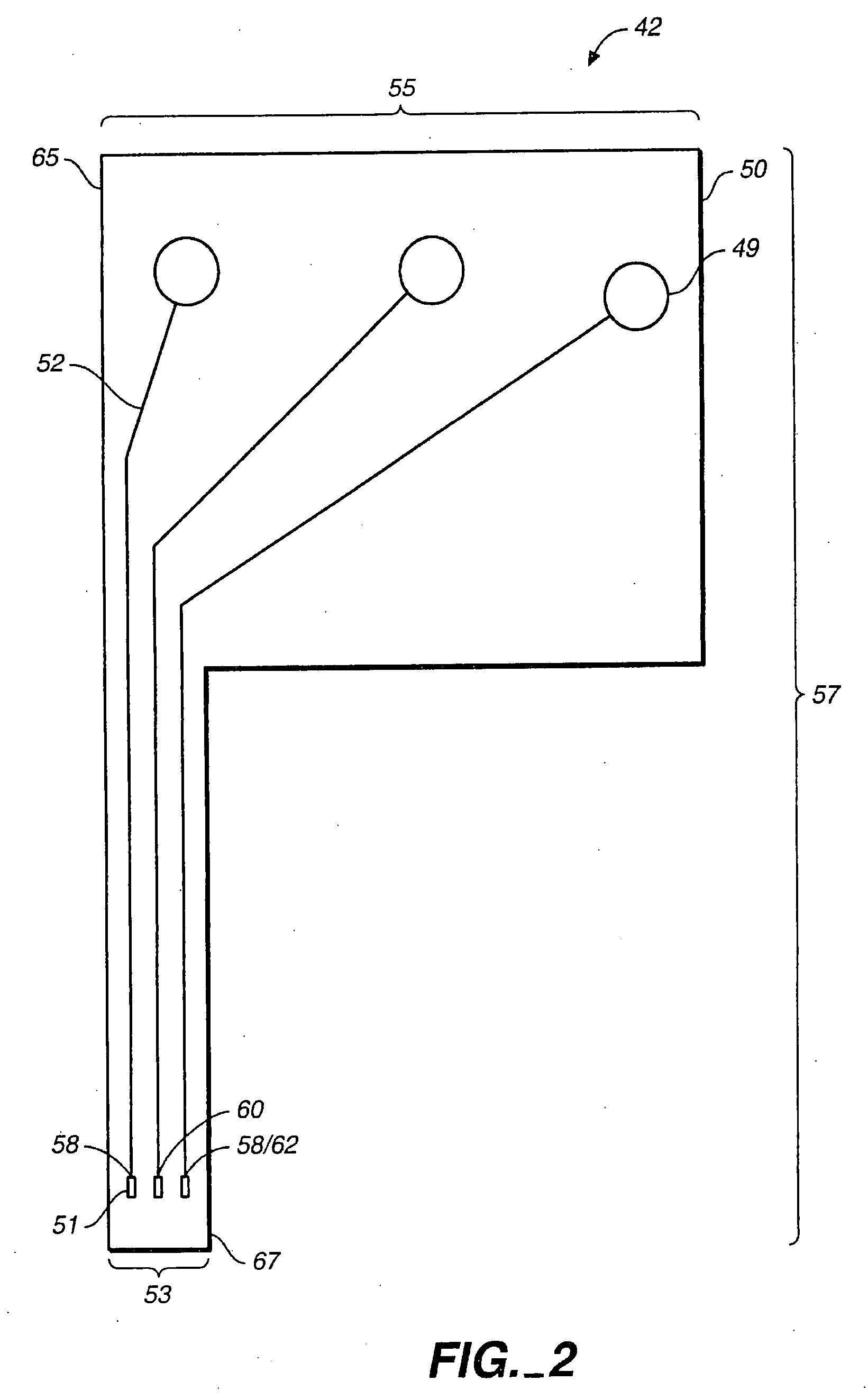

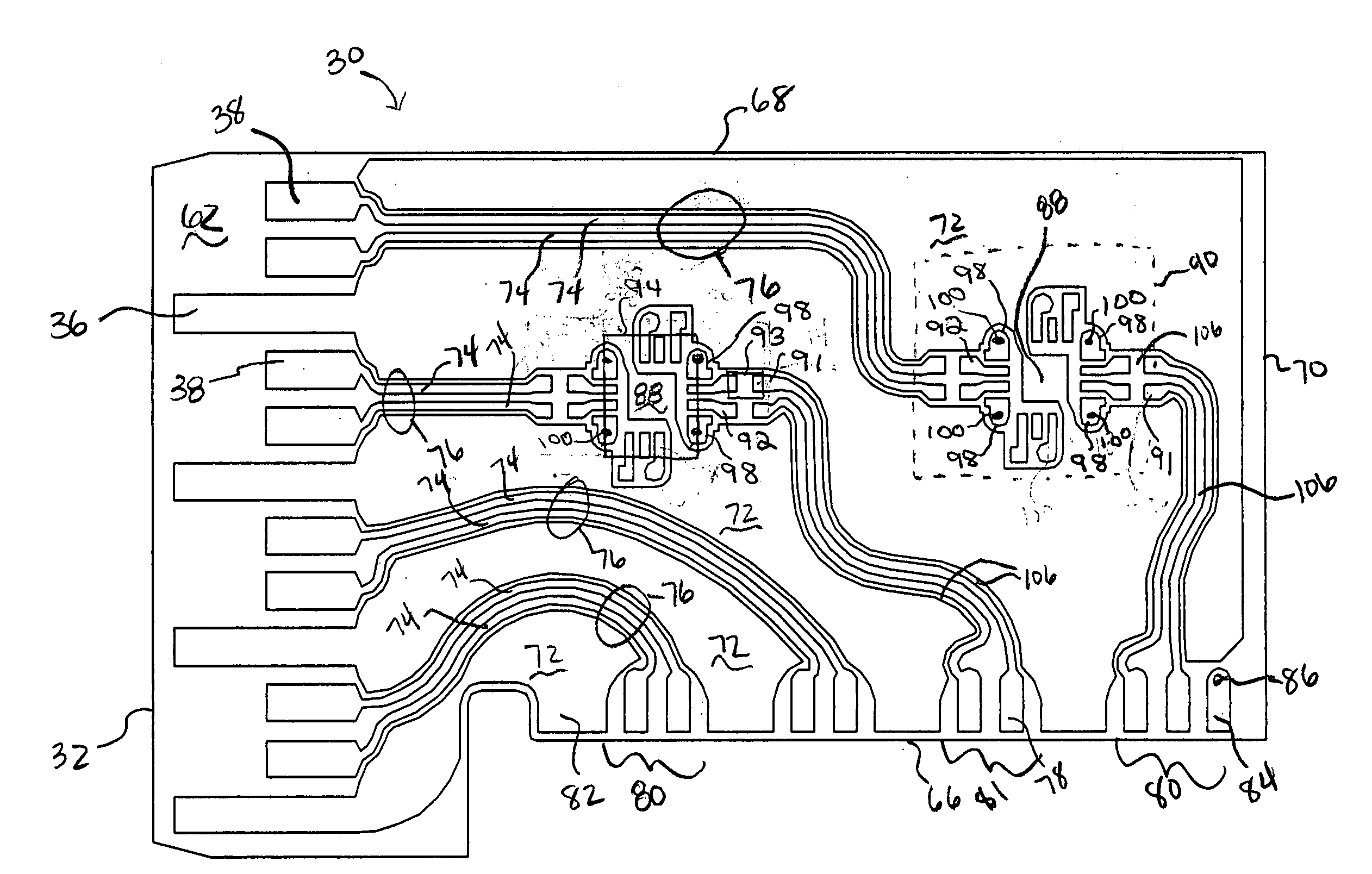

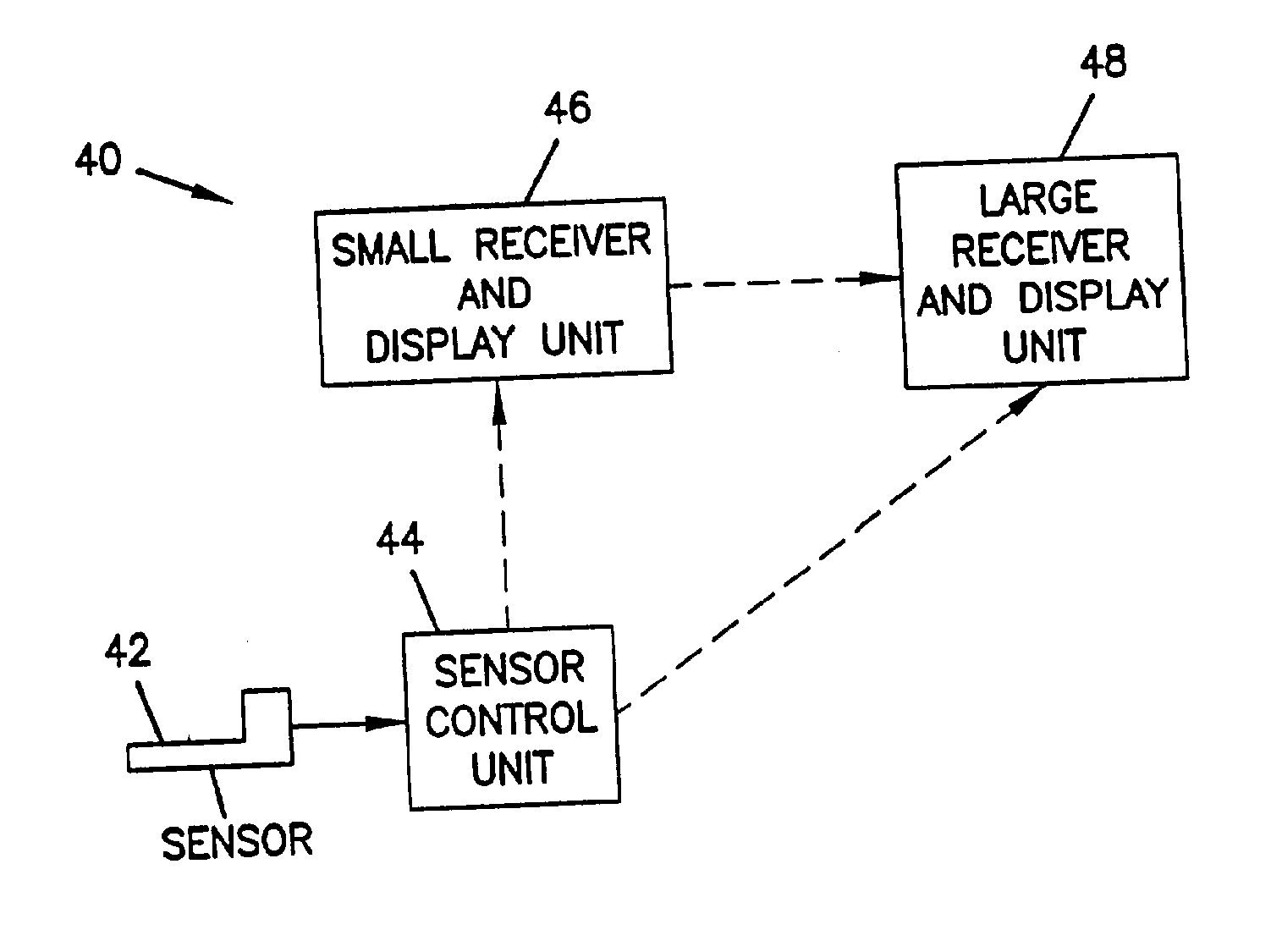

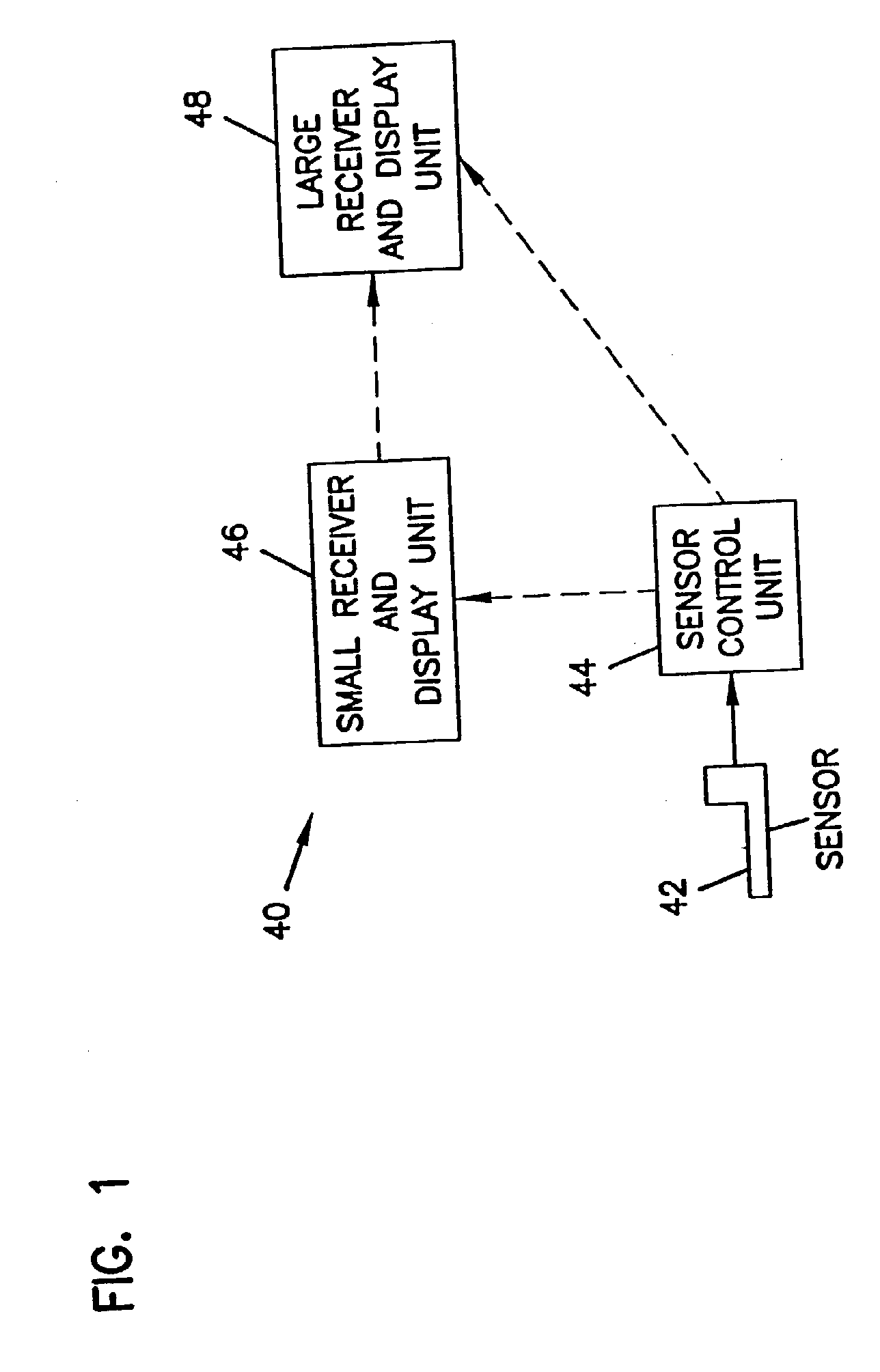

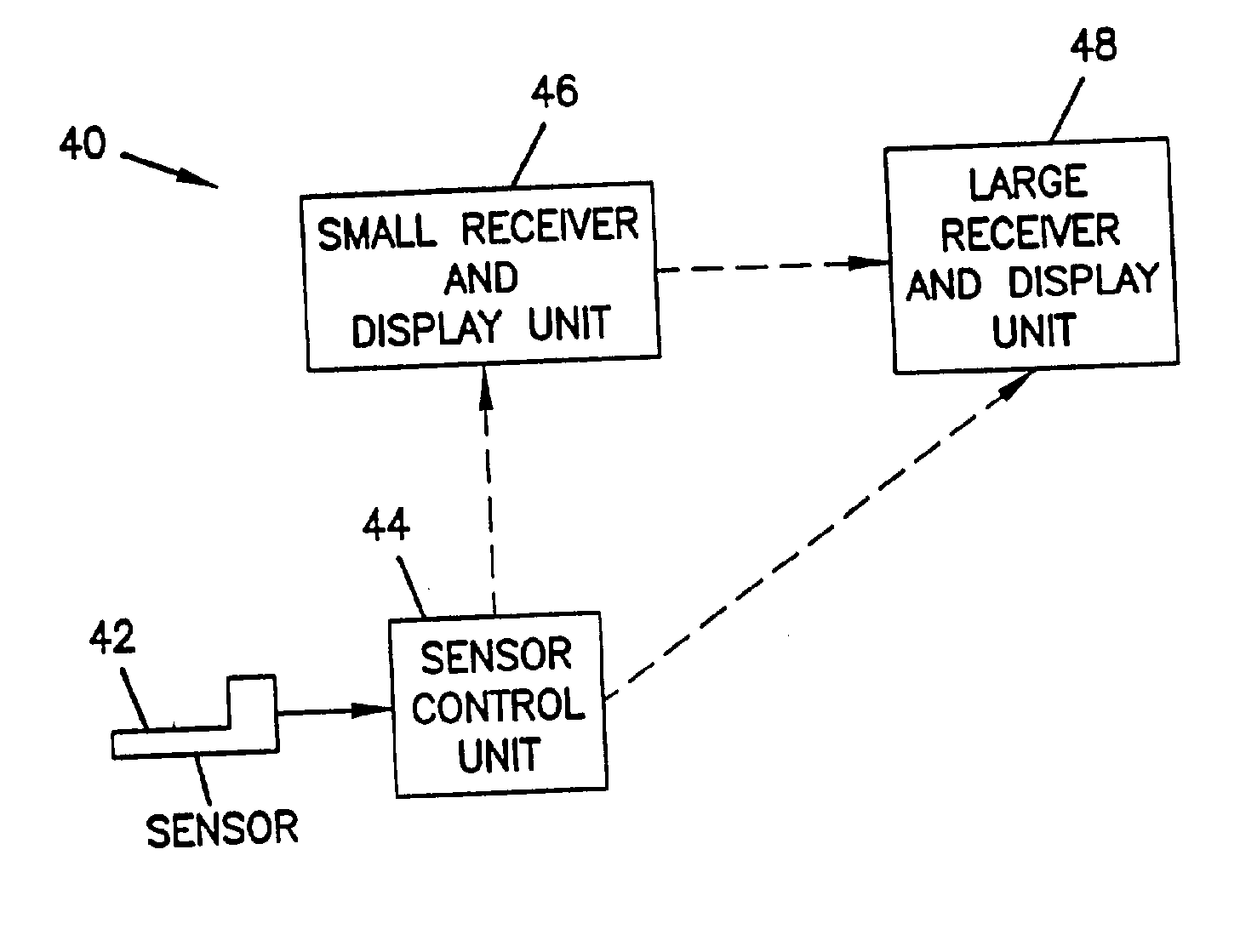

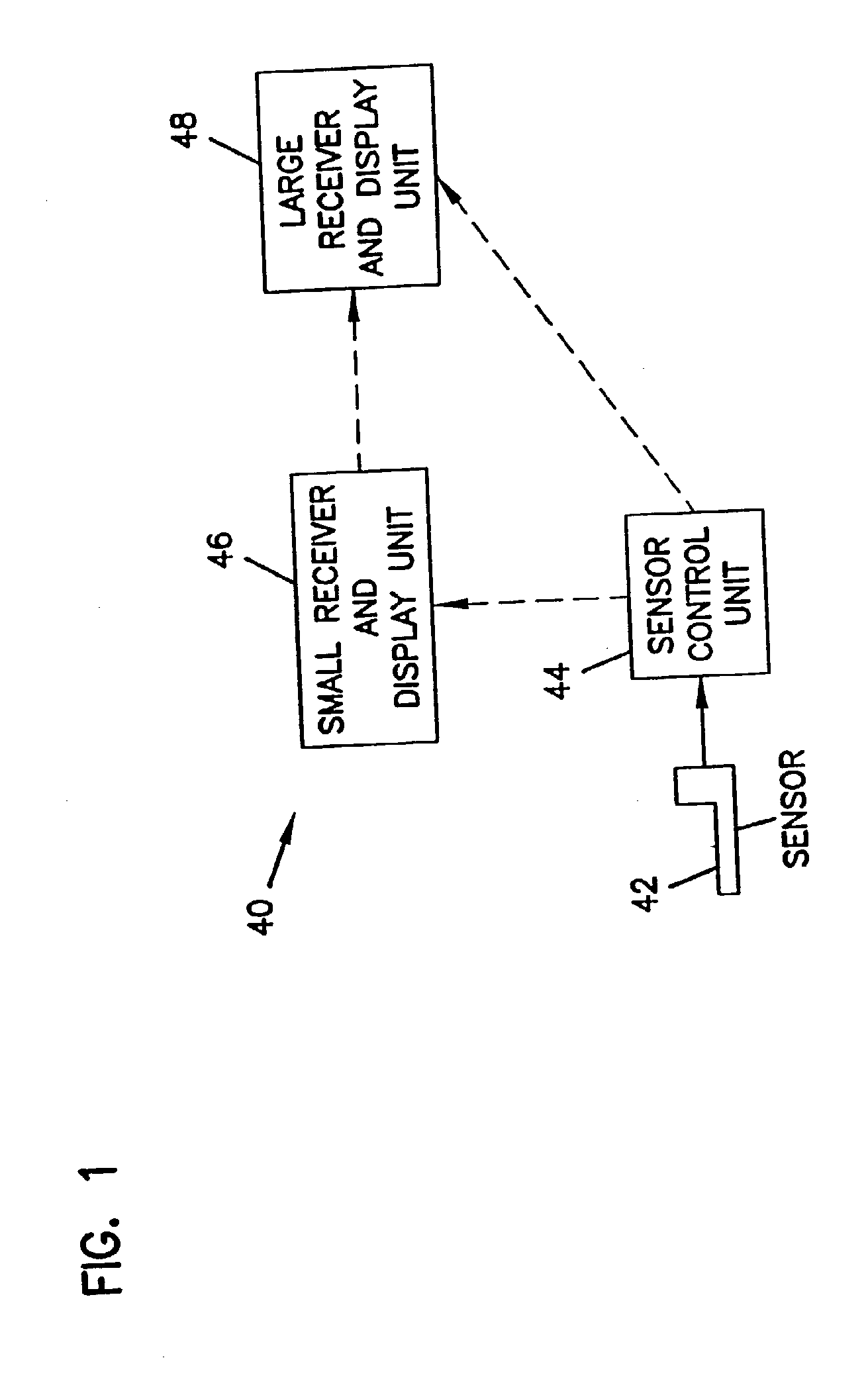

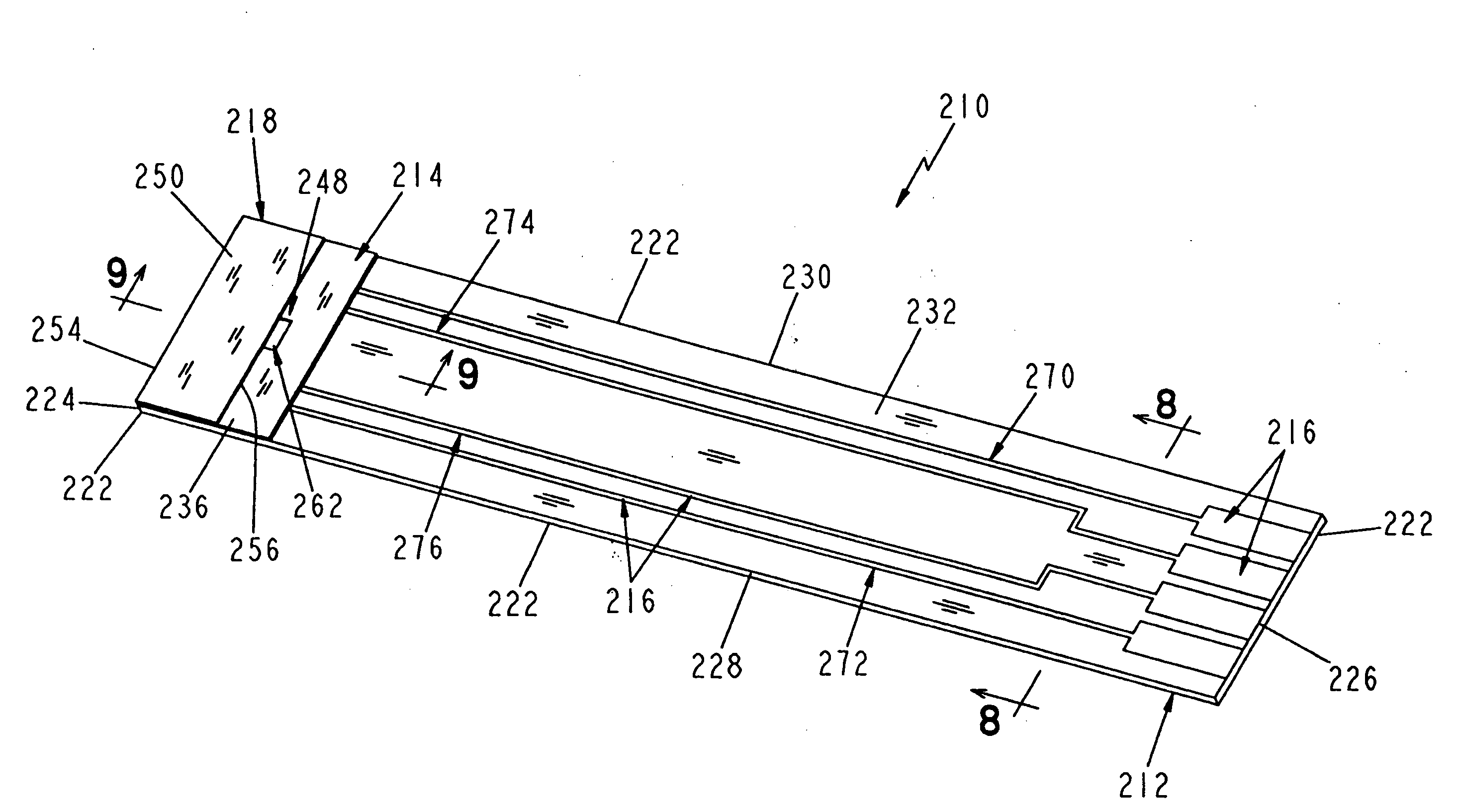

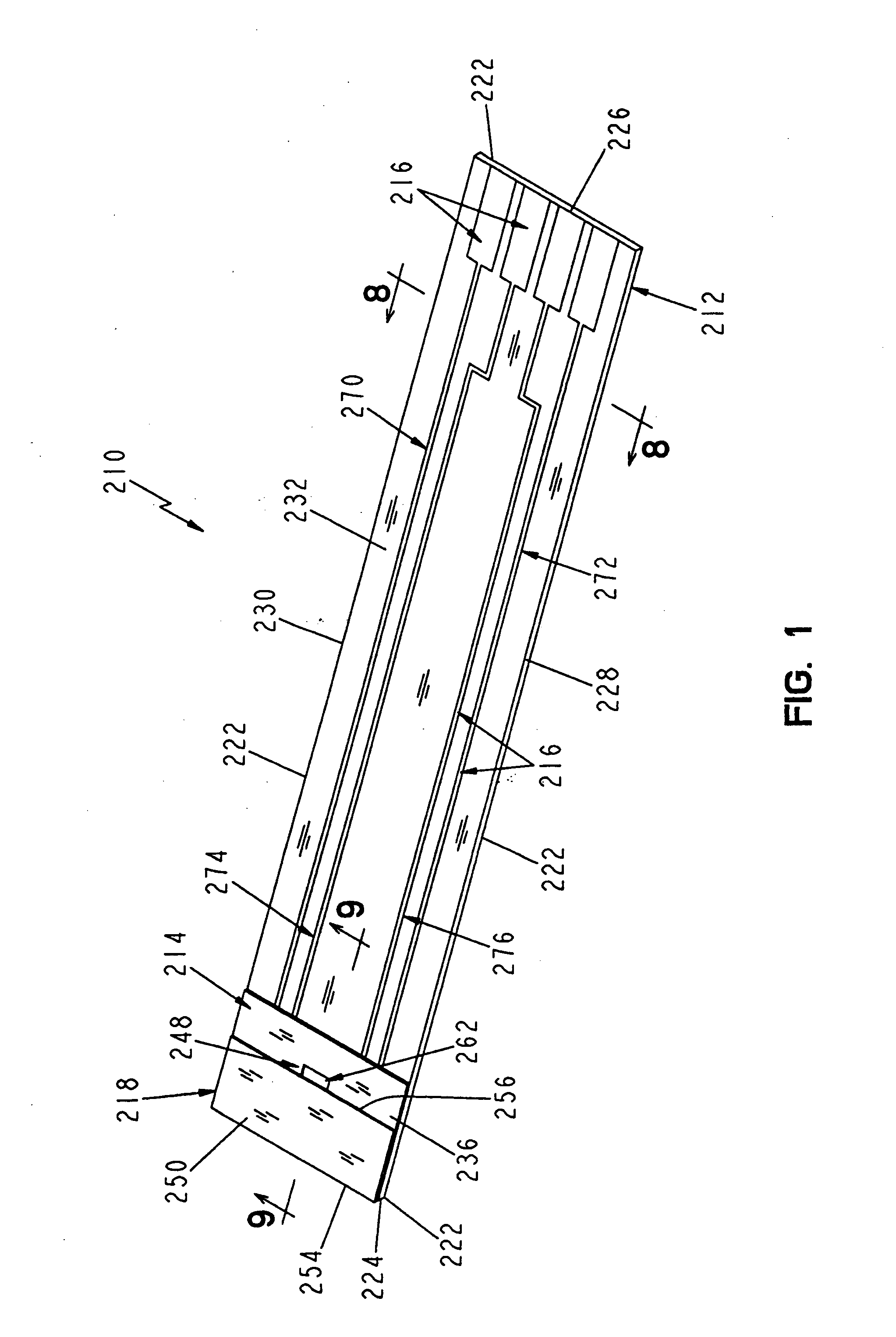

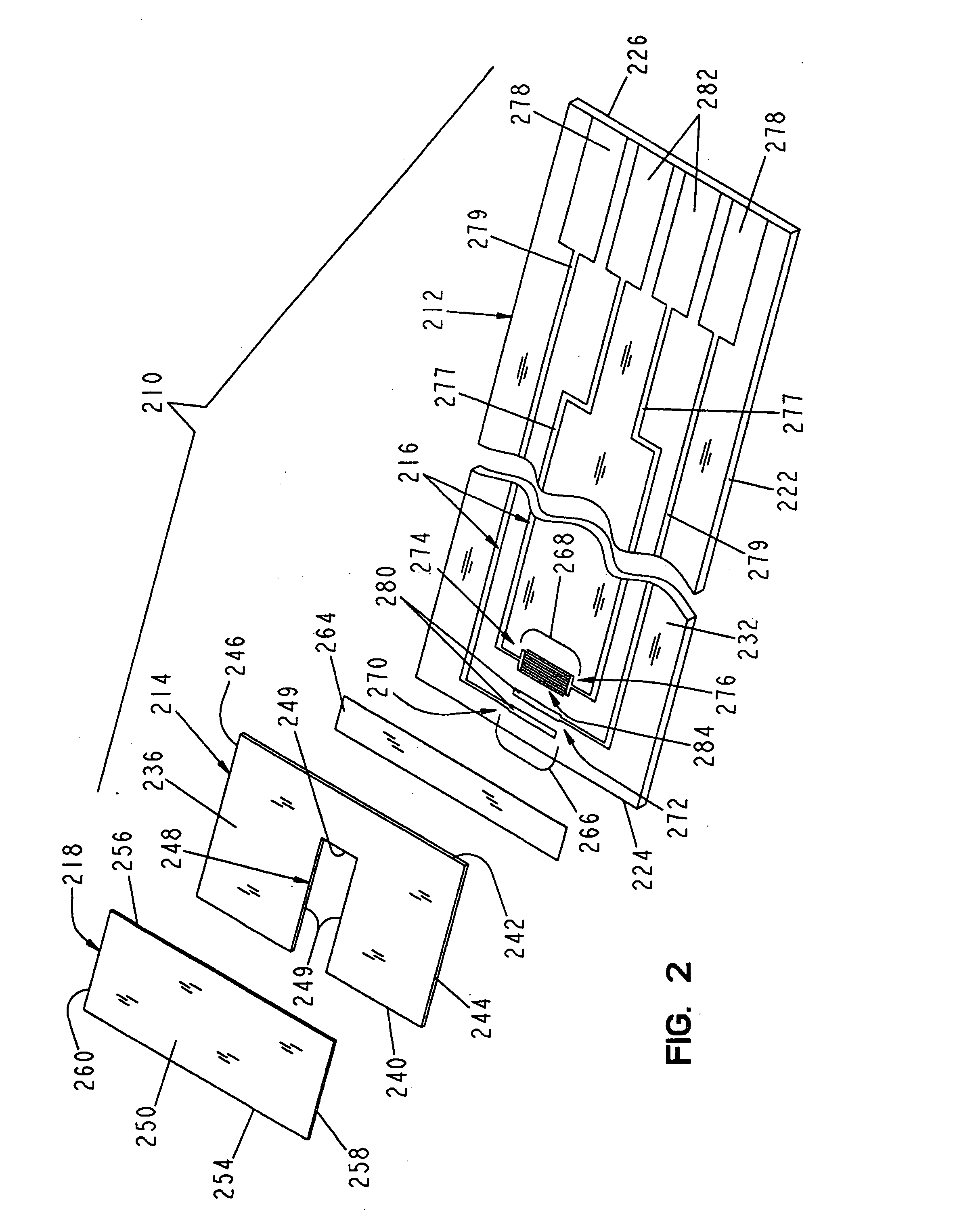

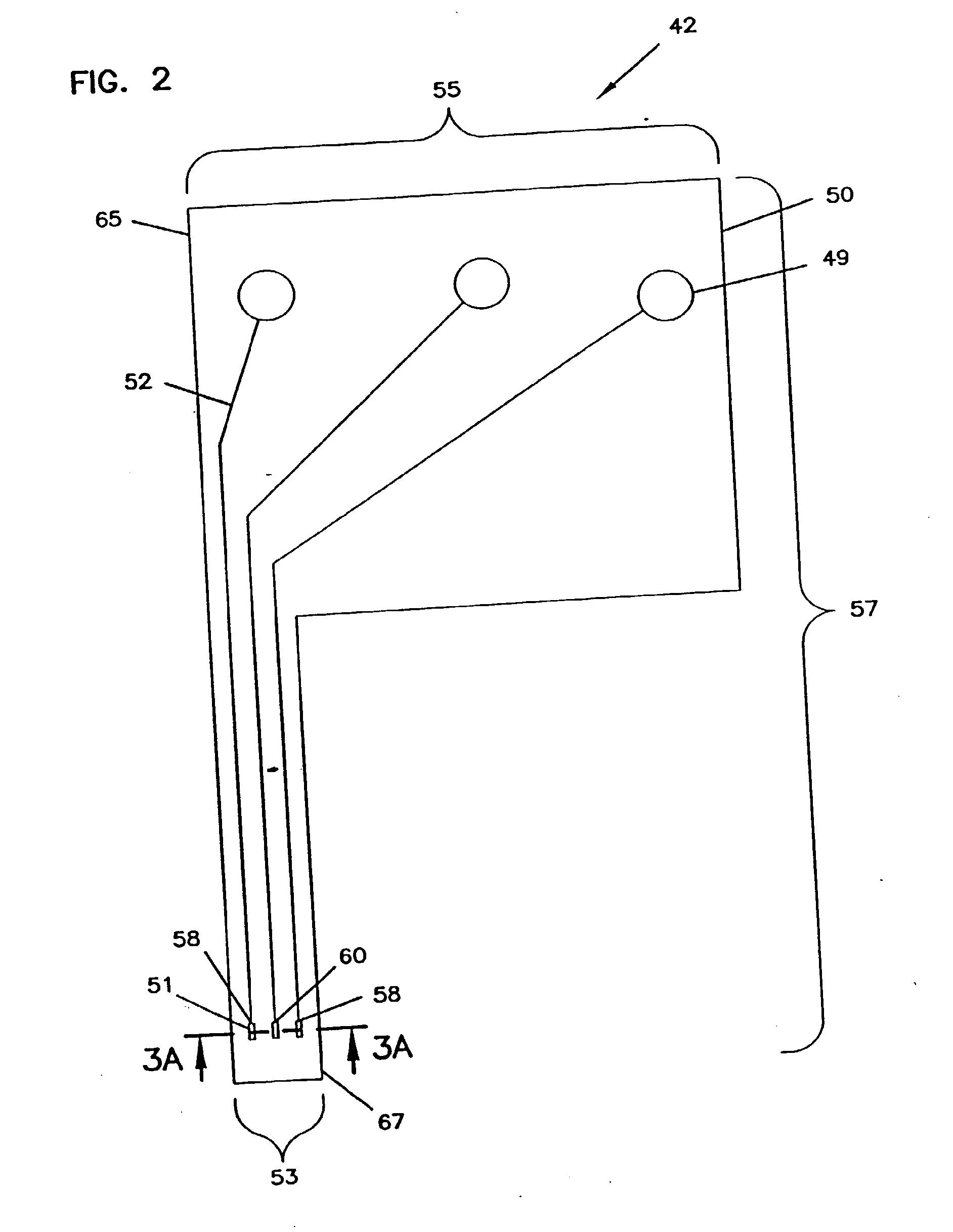

Analyte monitoring device and methods of use

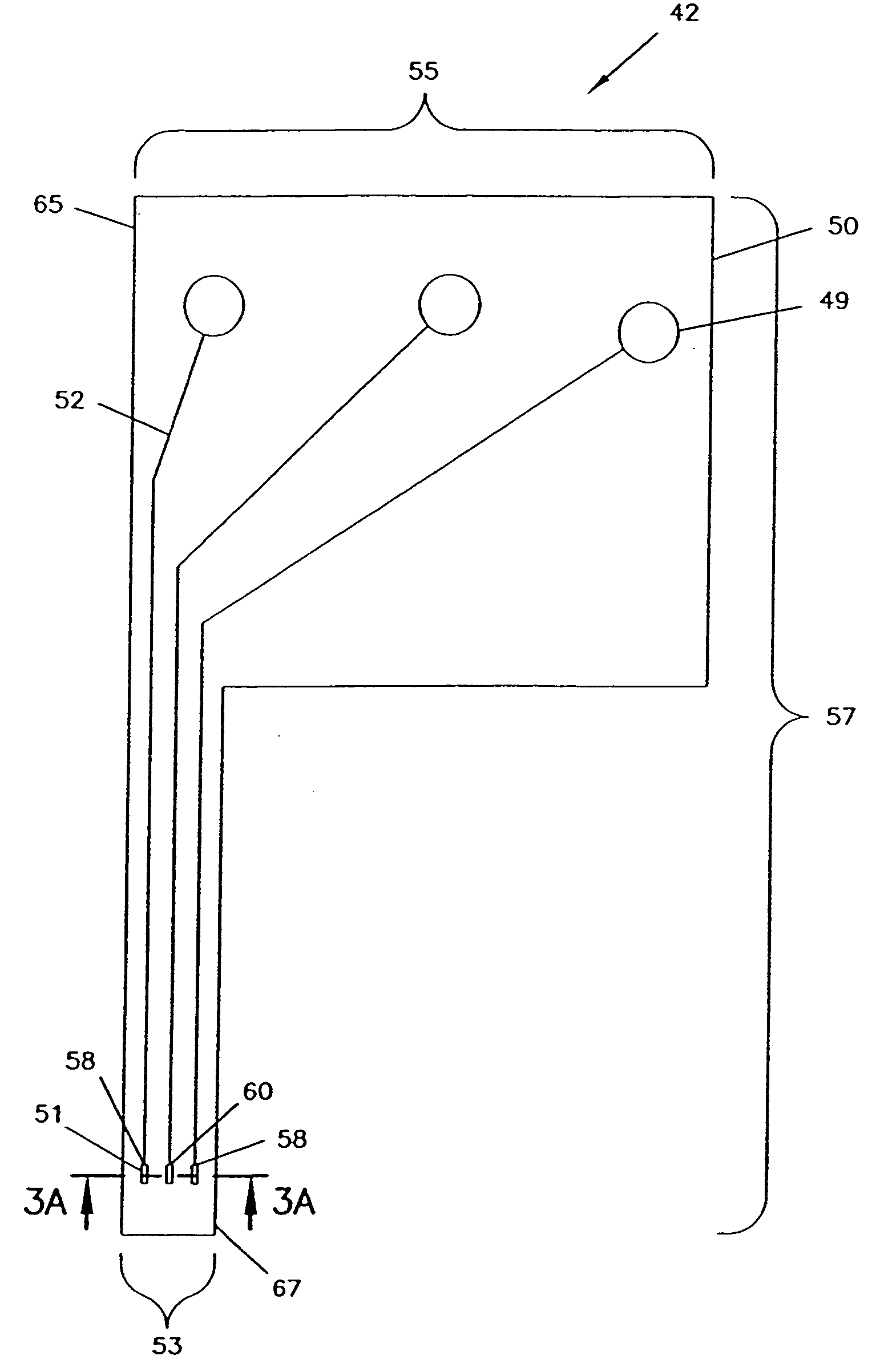

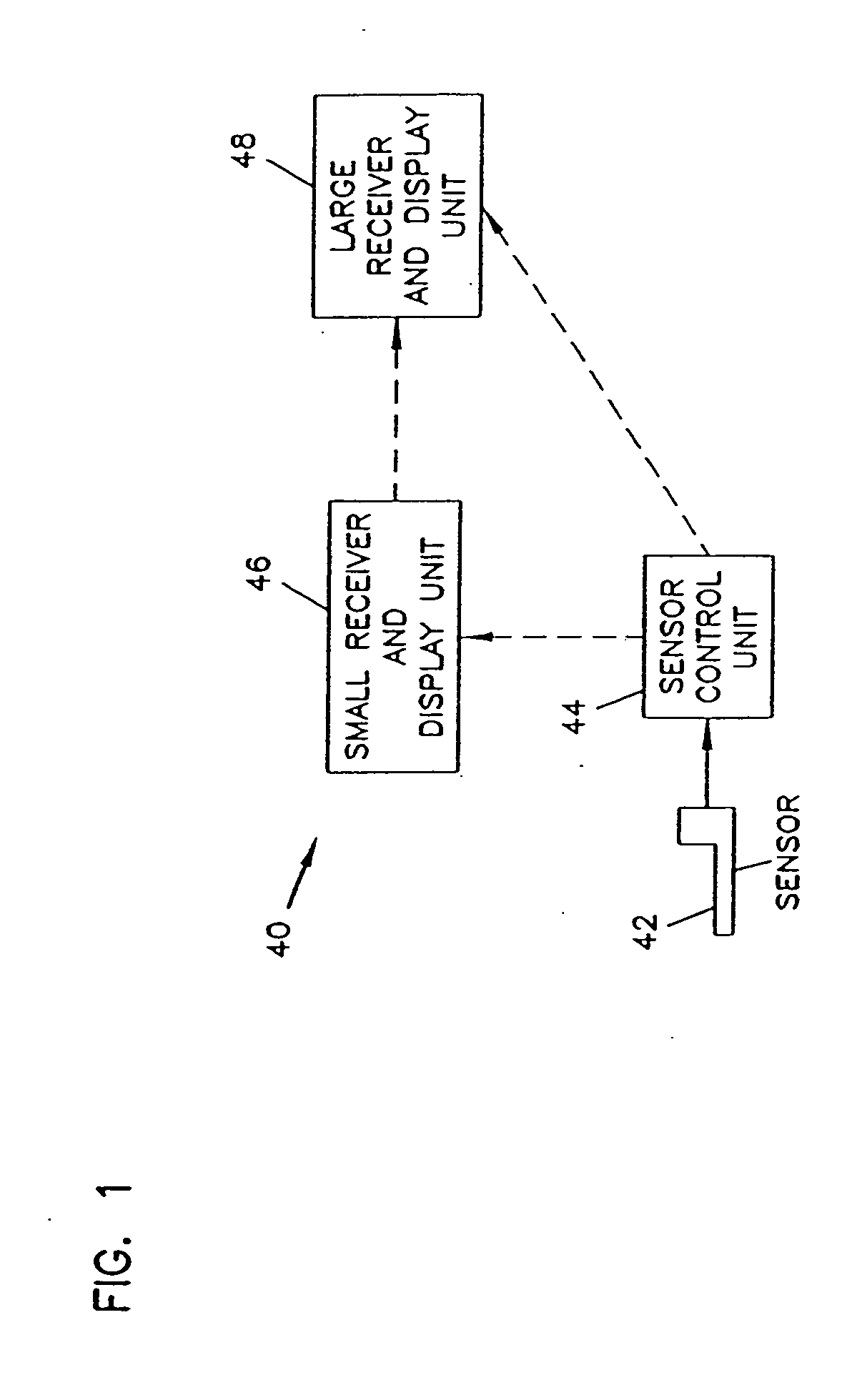

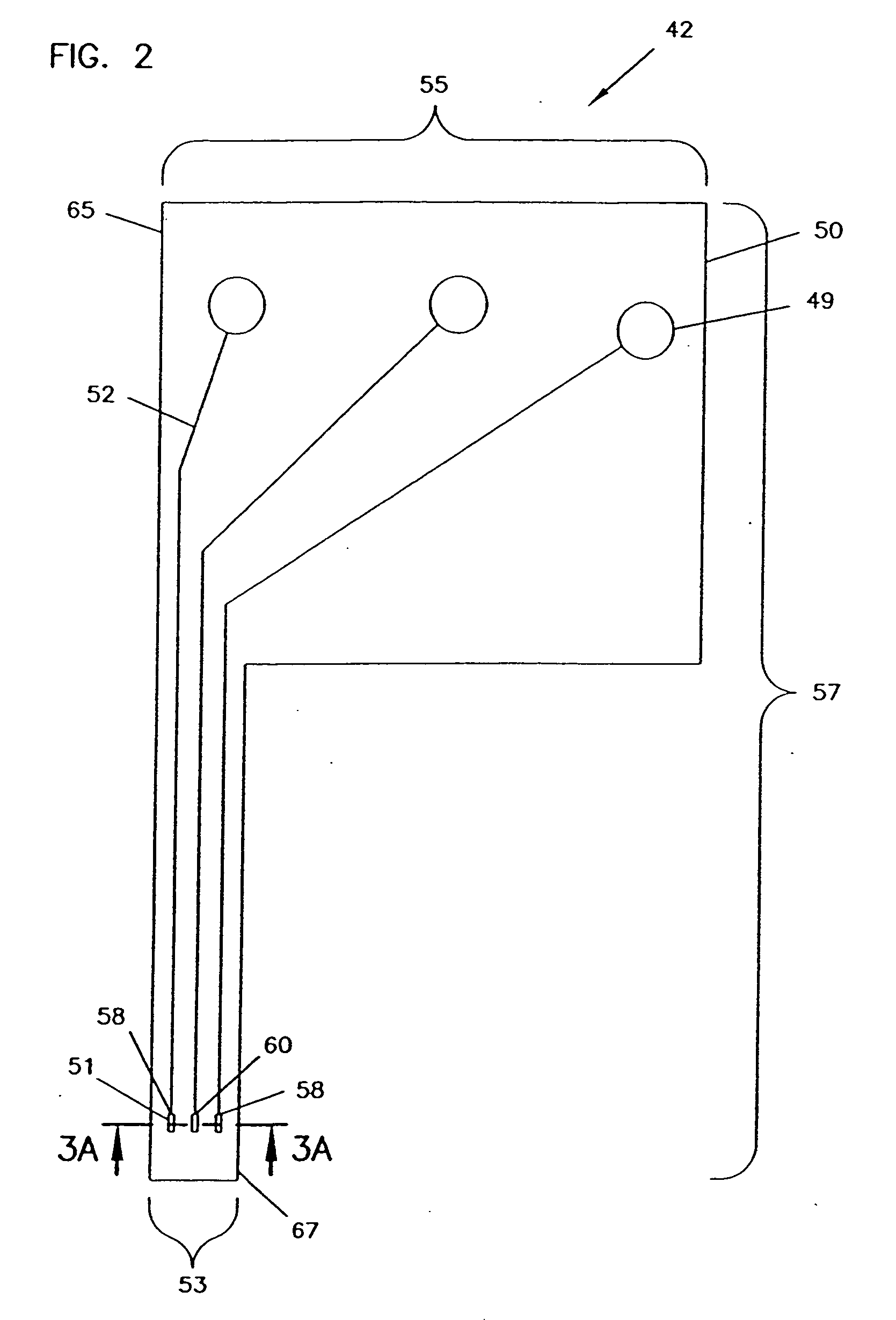

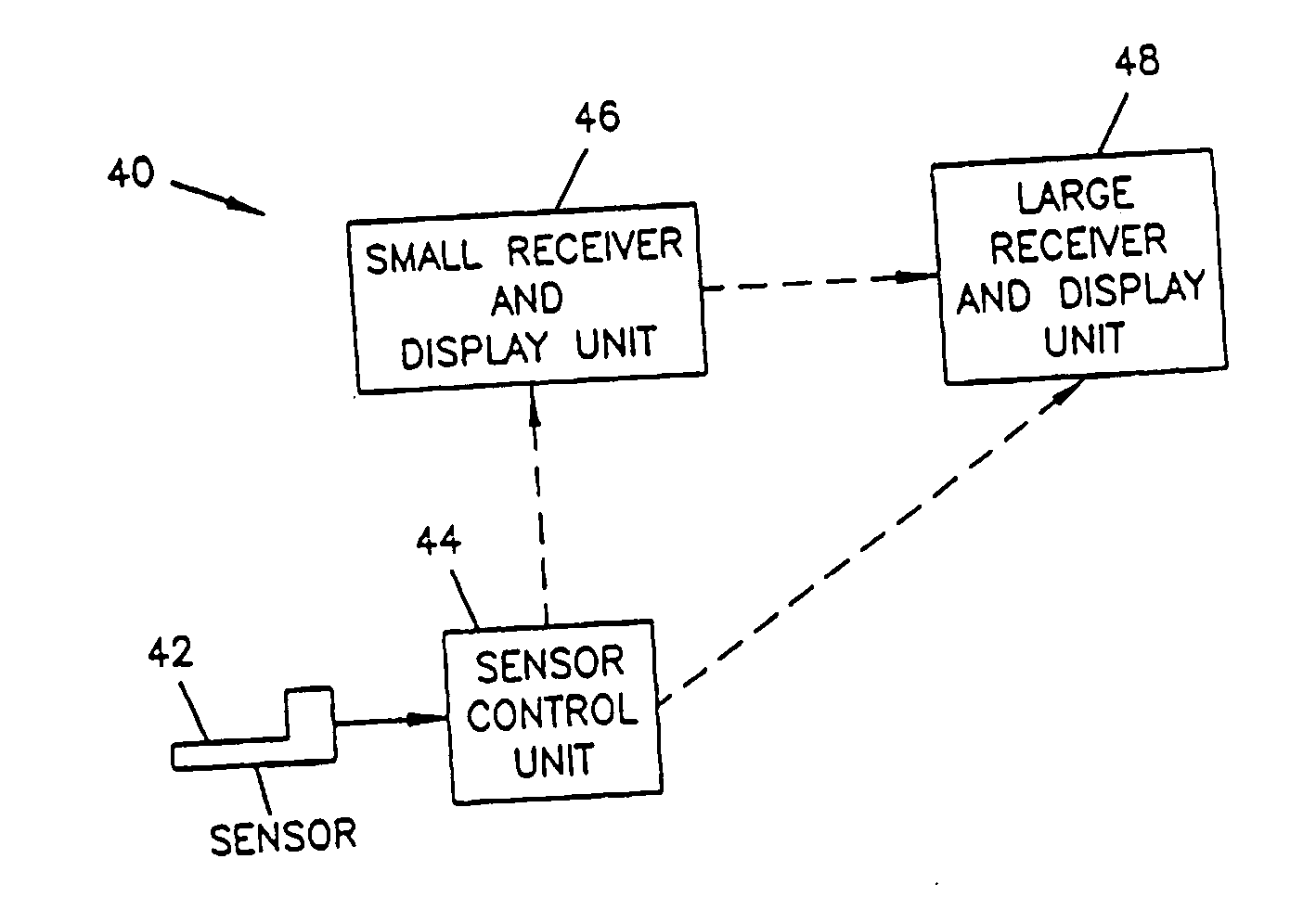

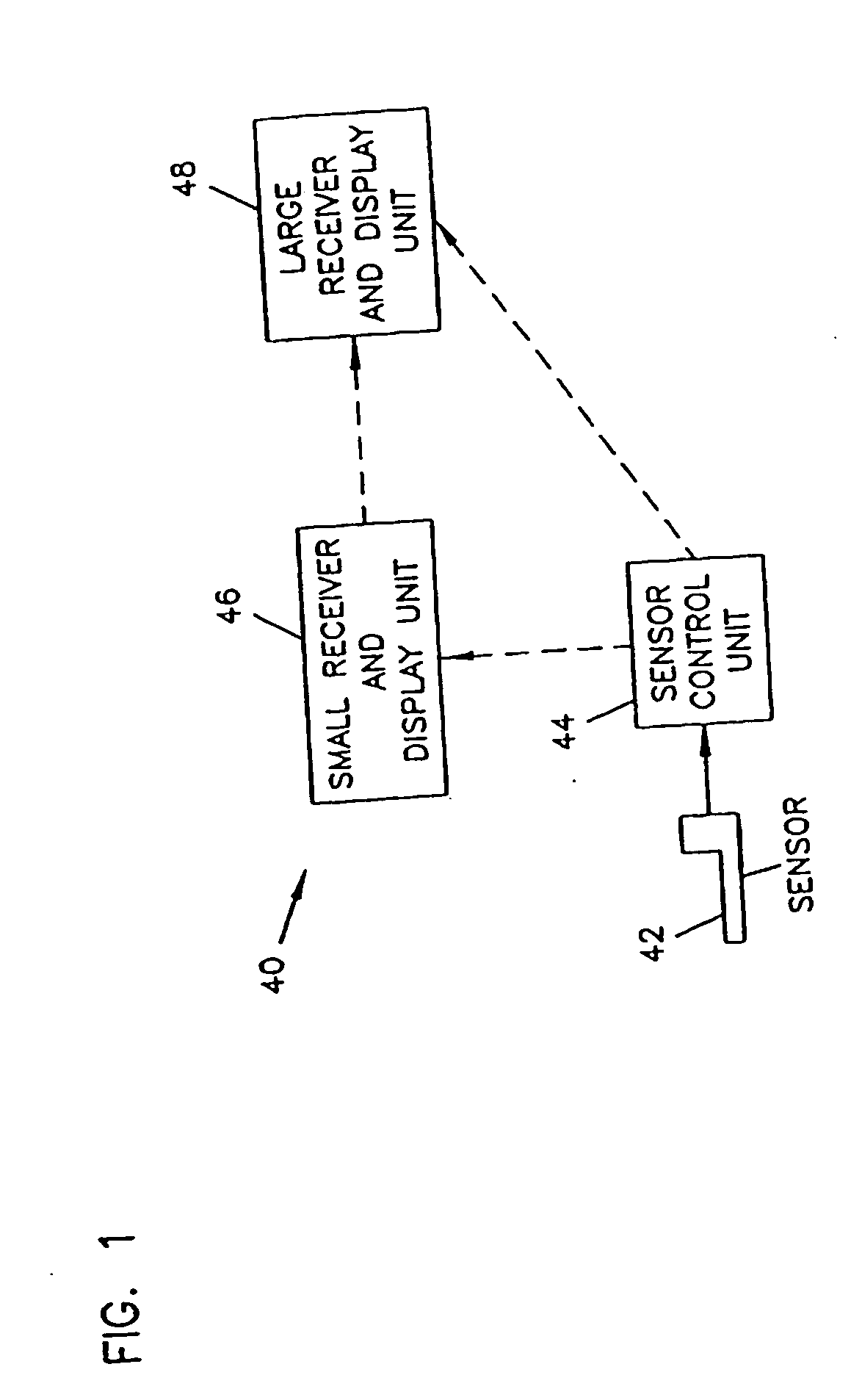

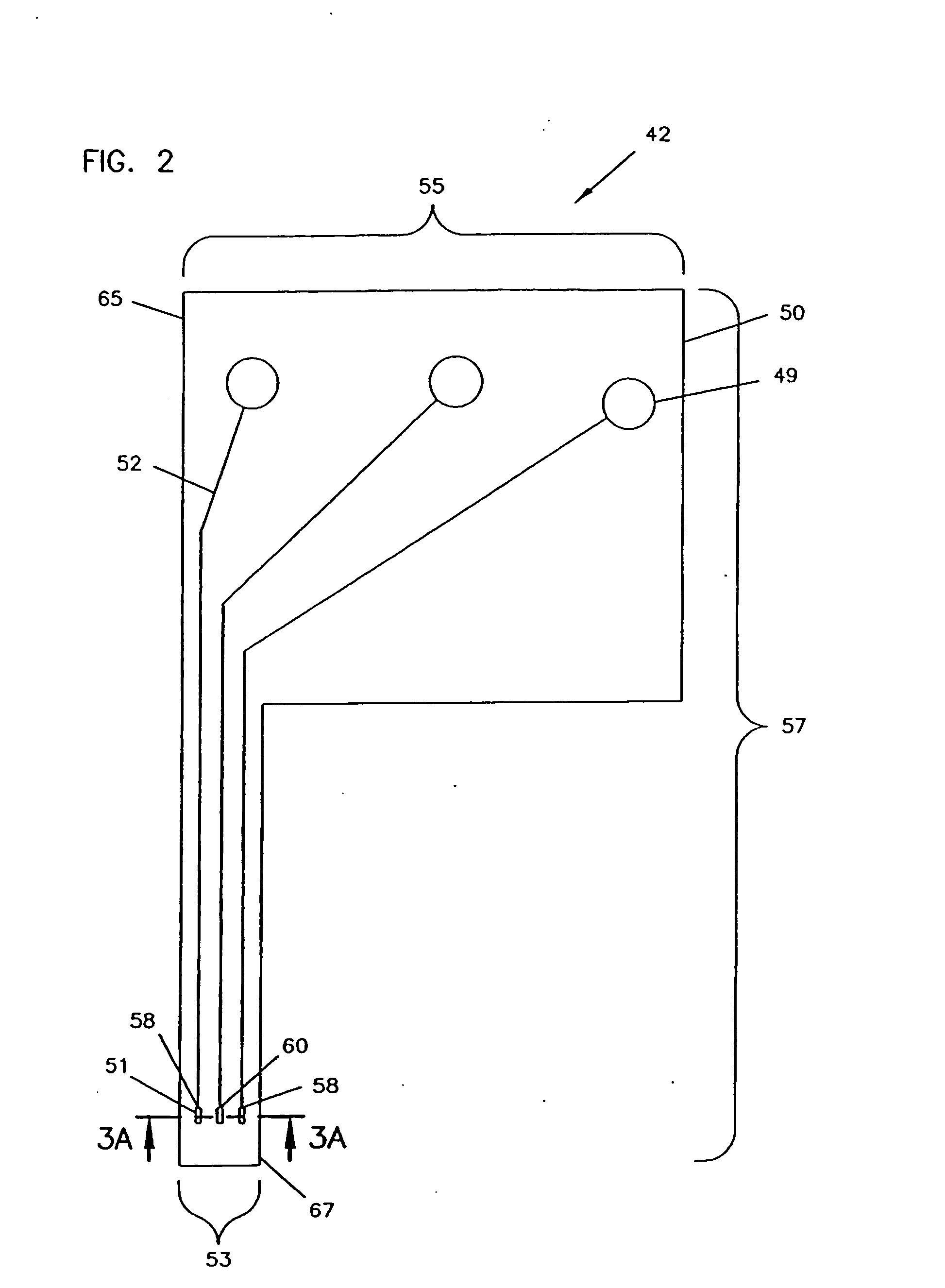

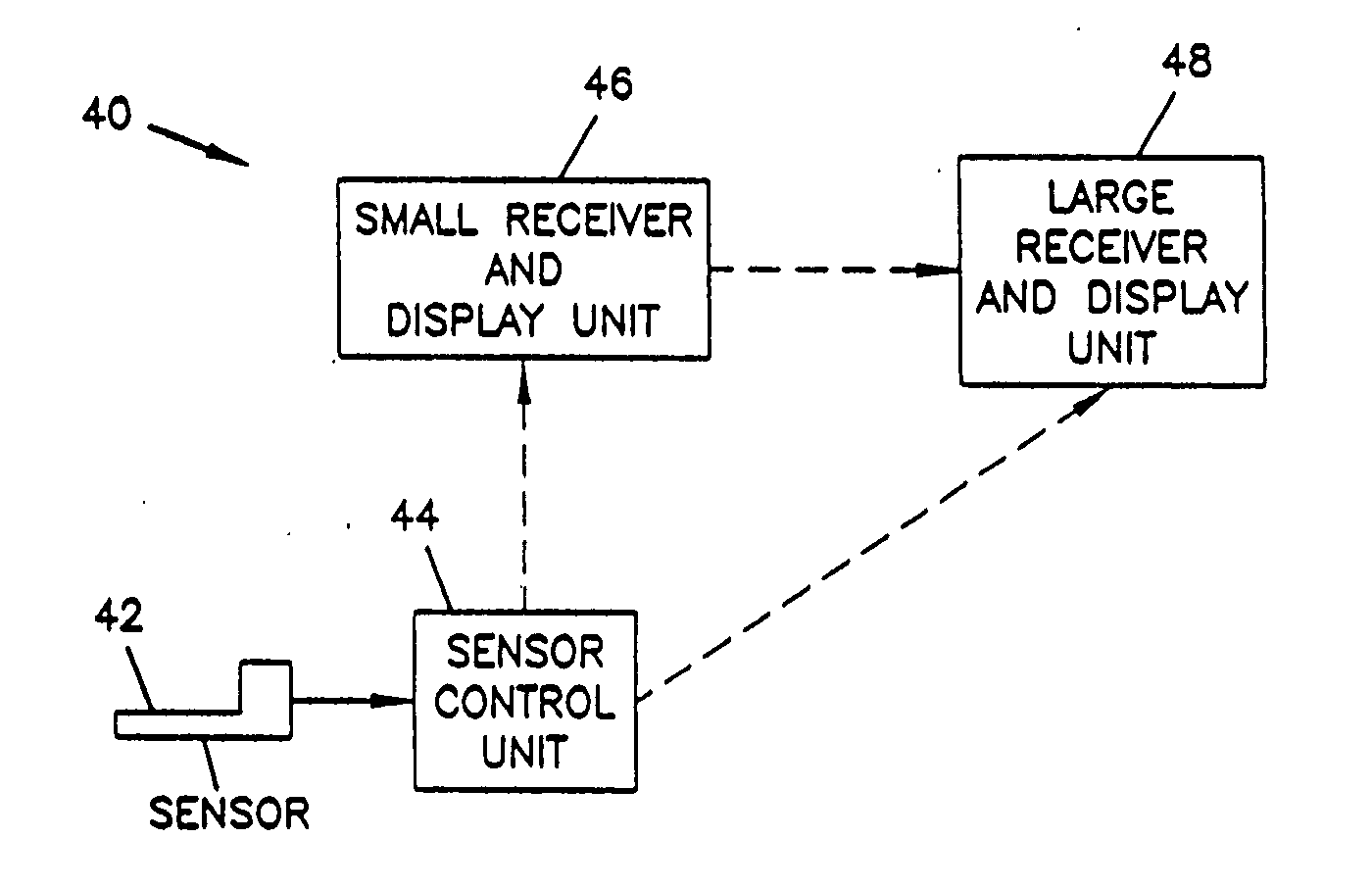

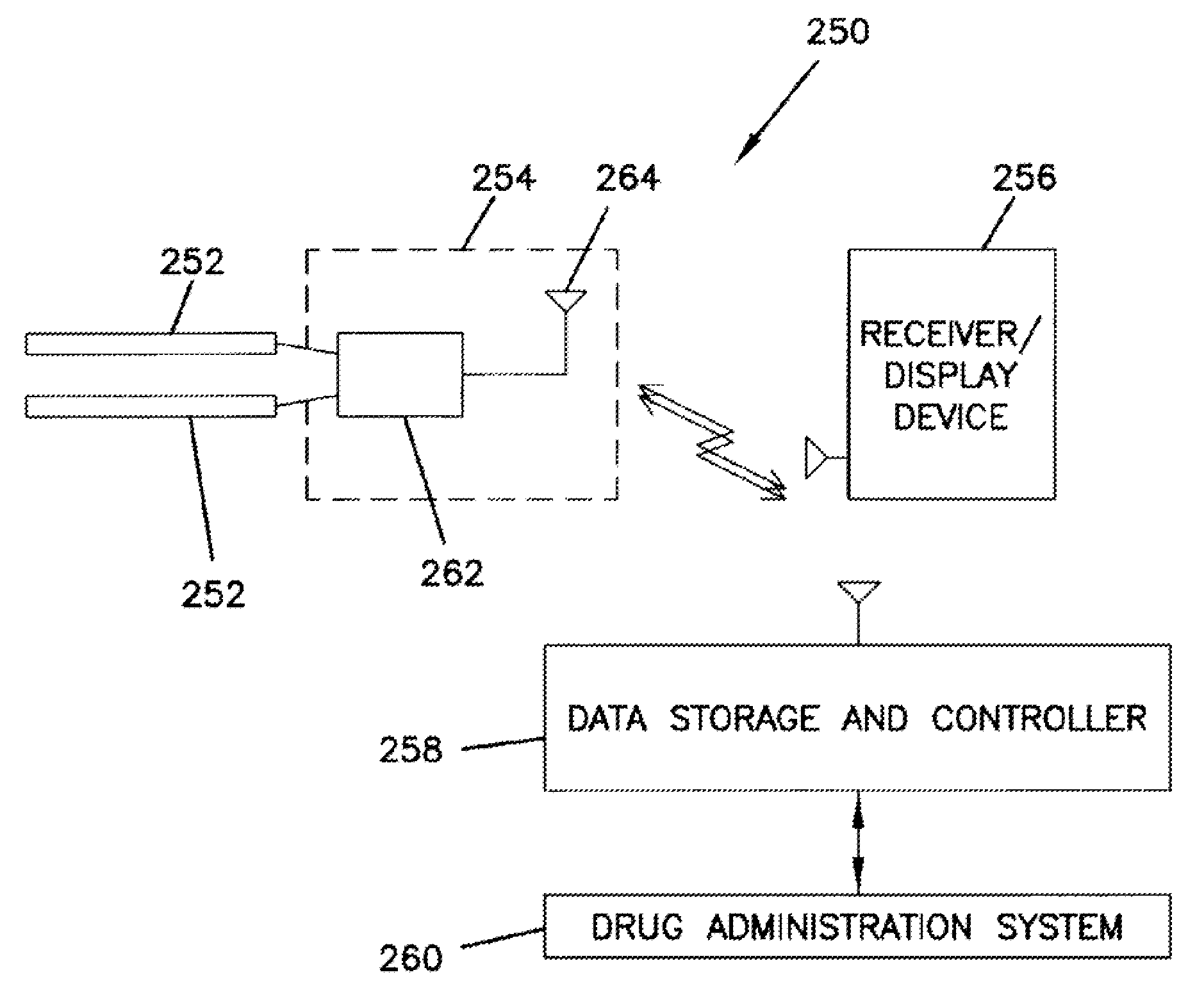

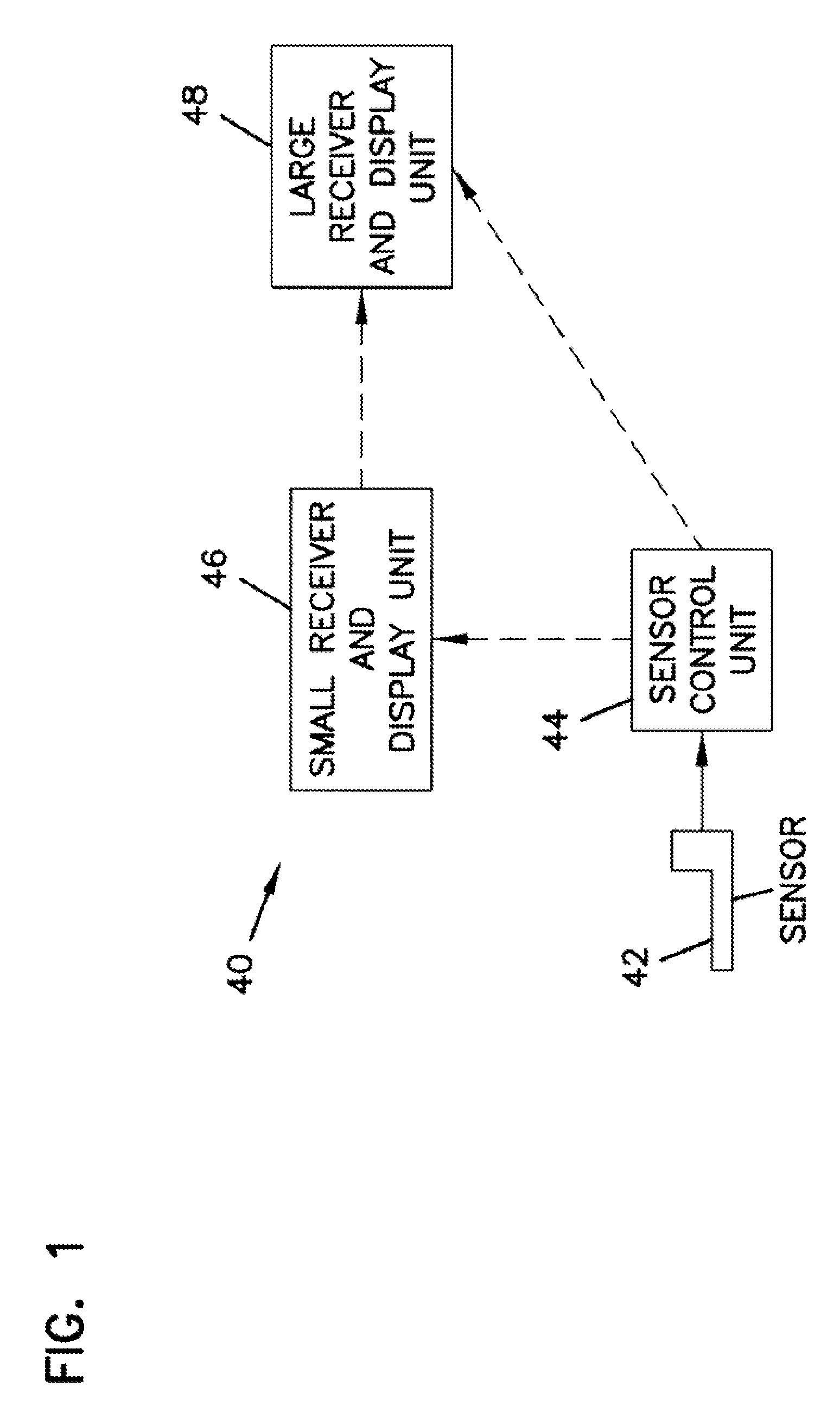

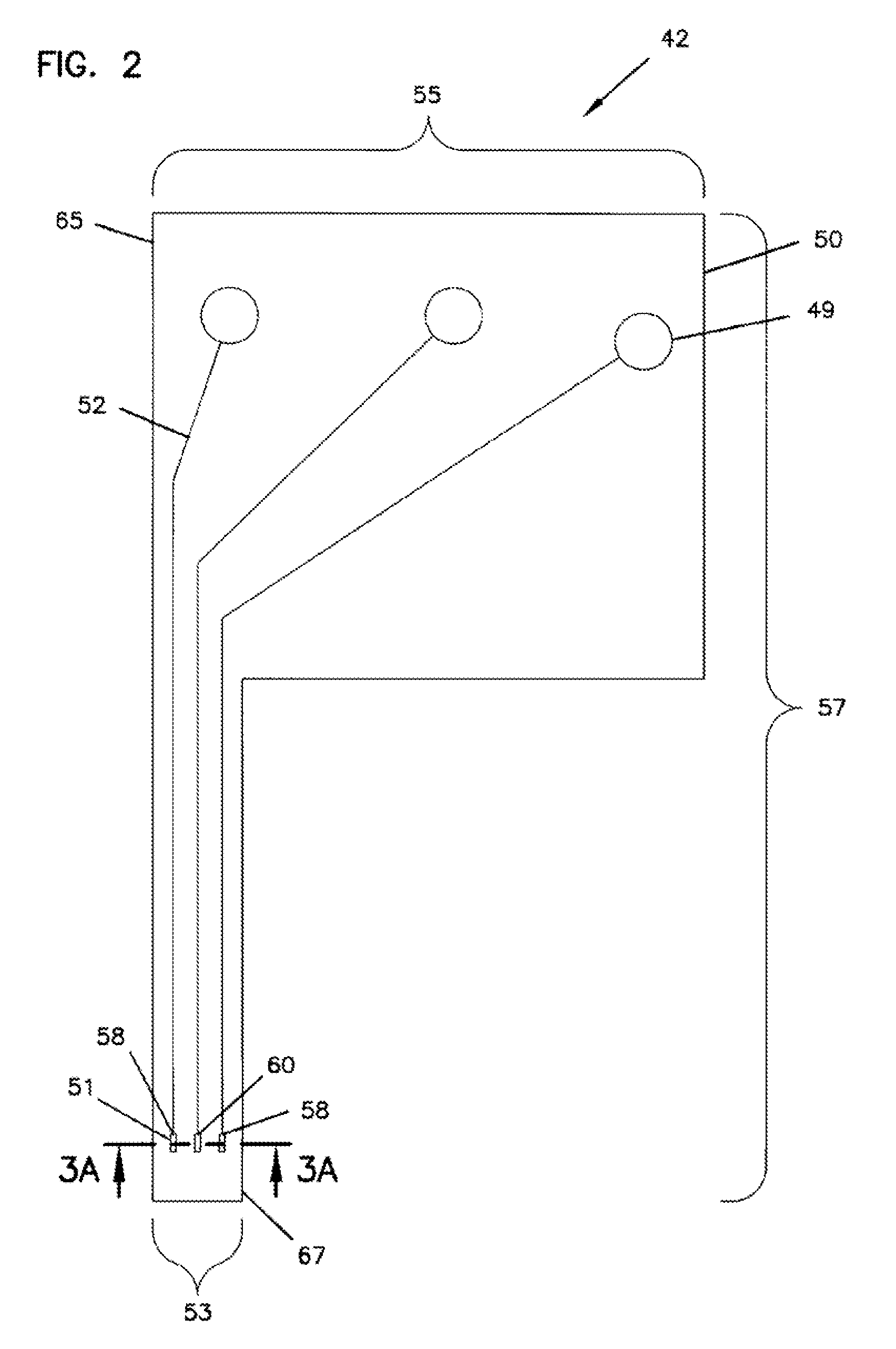

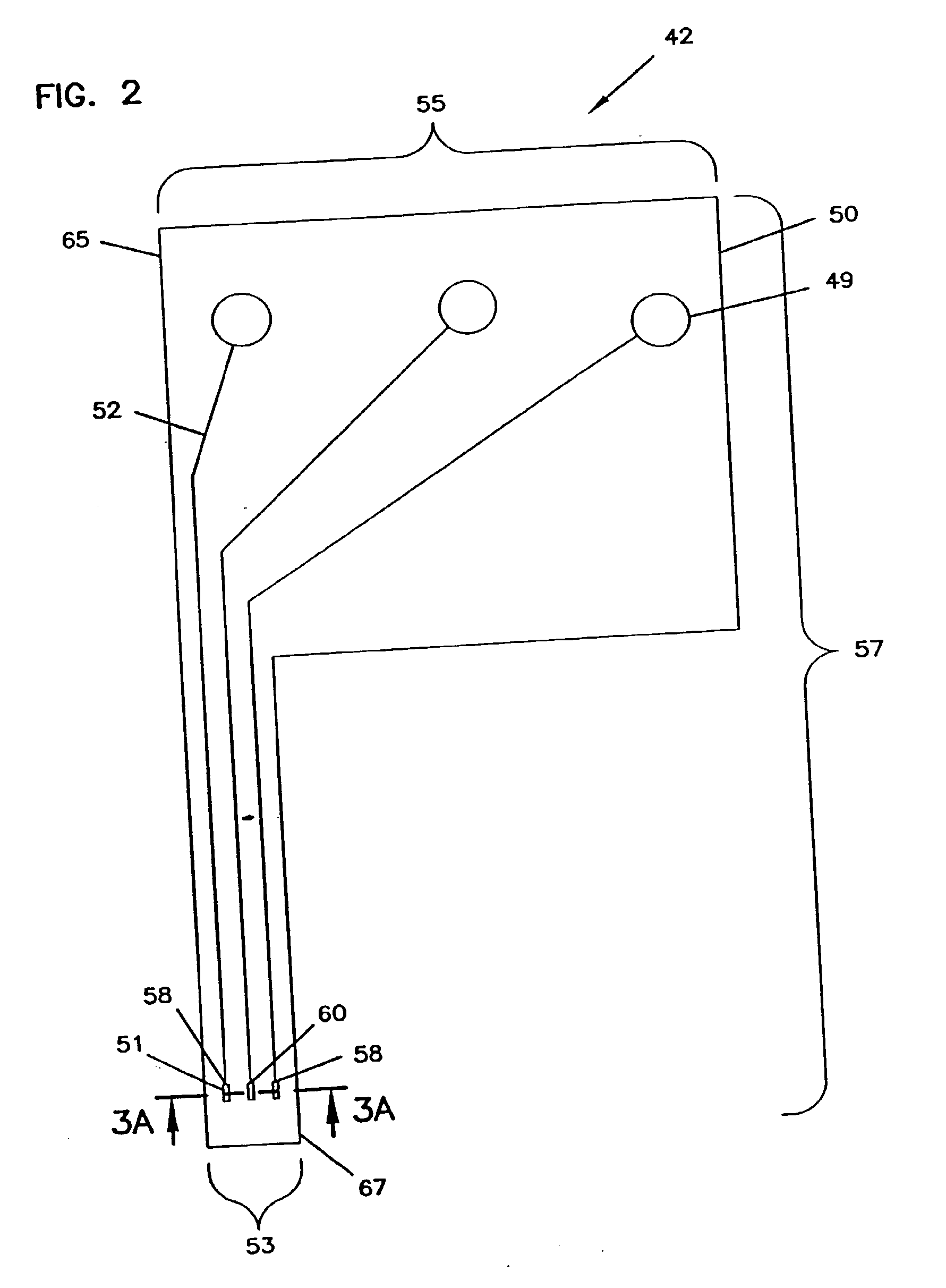

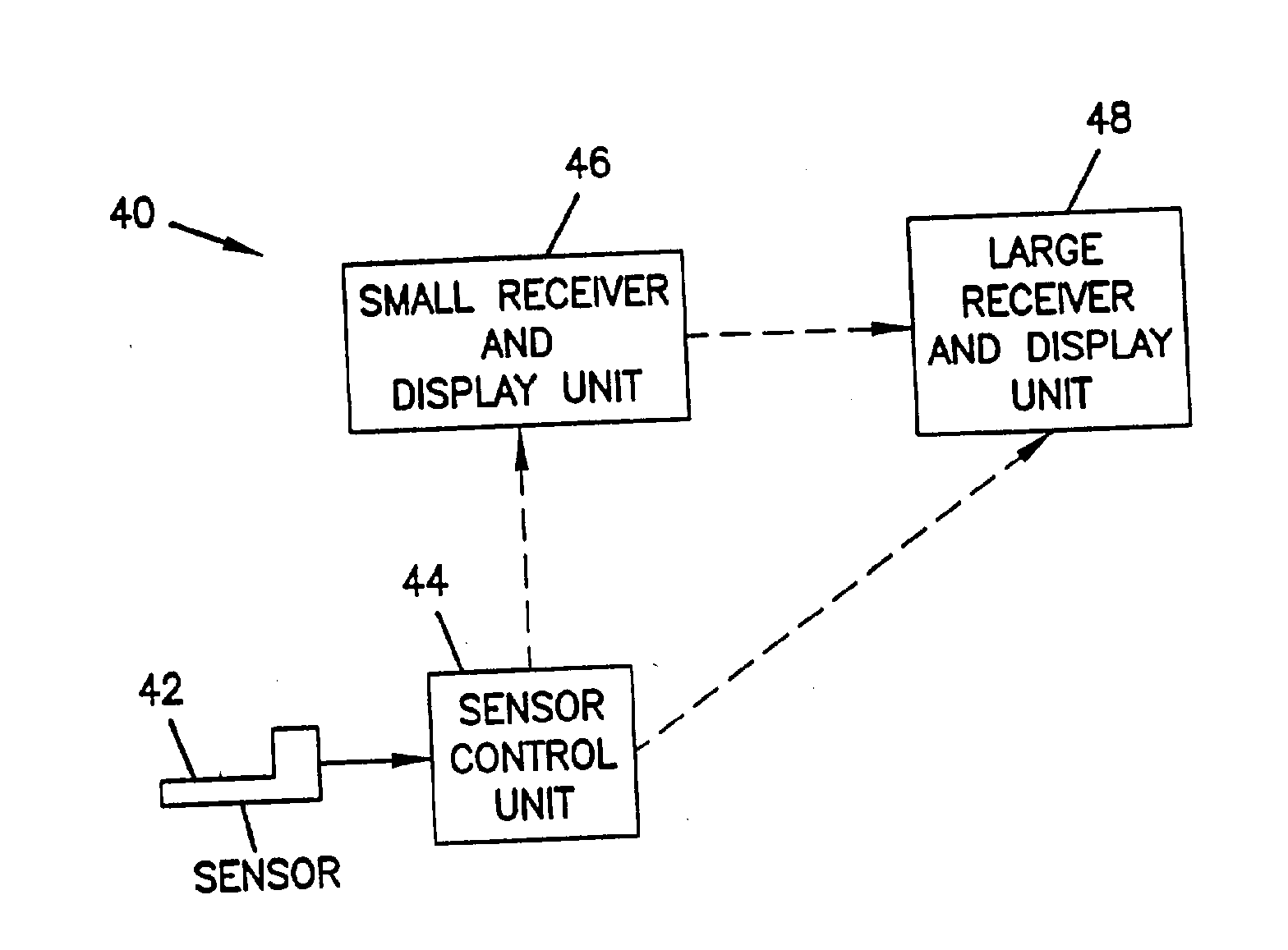

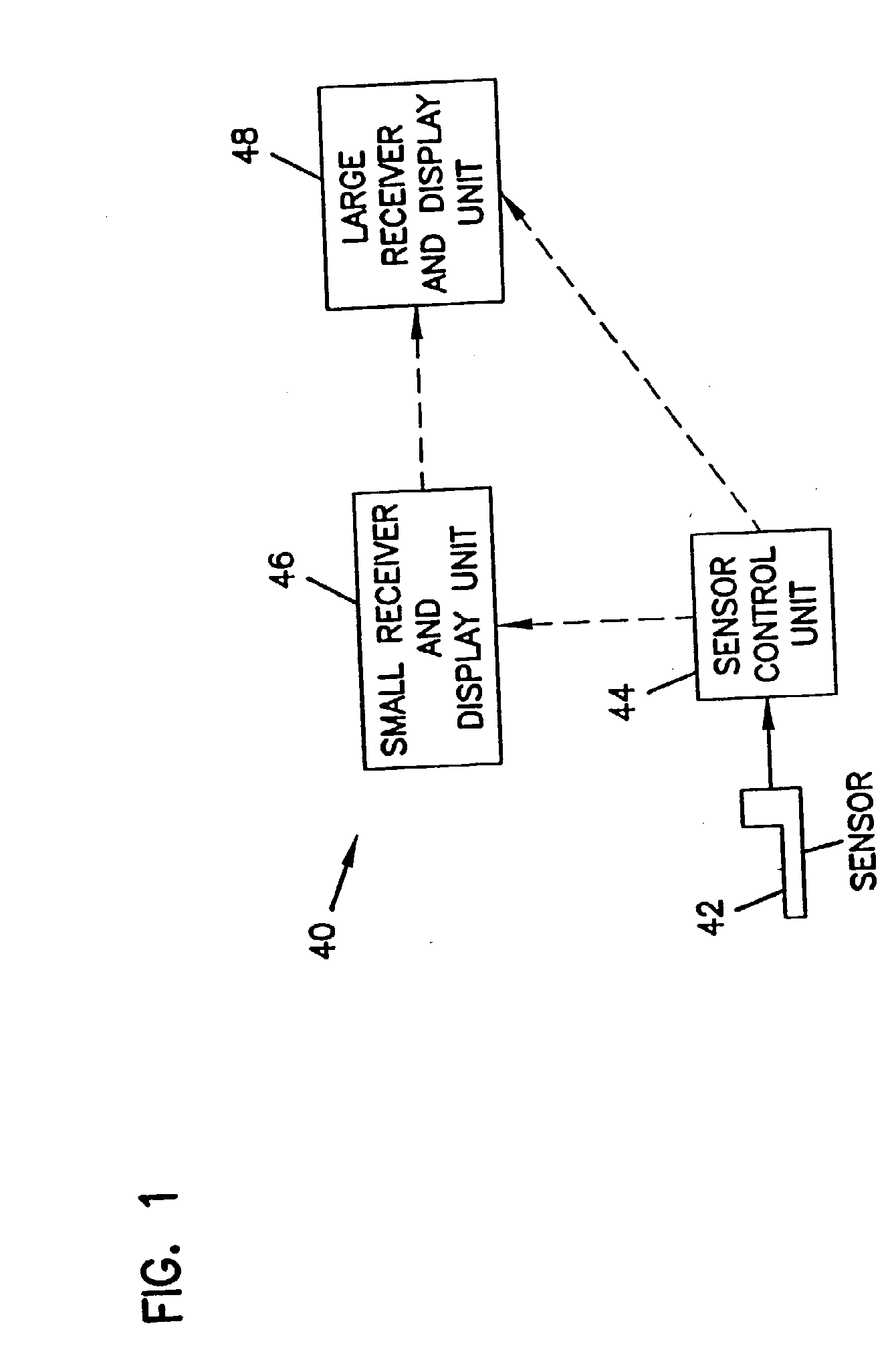

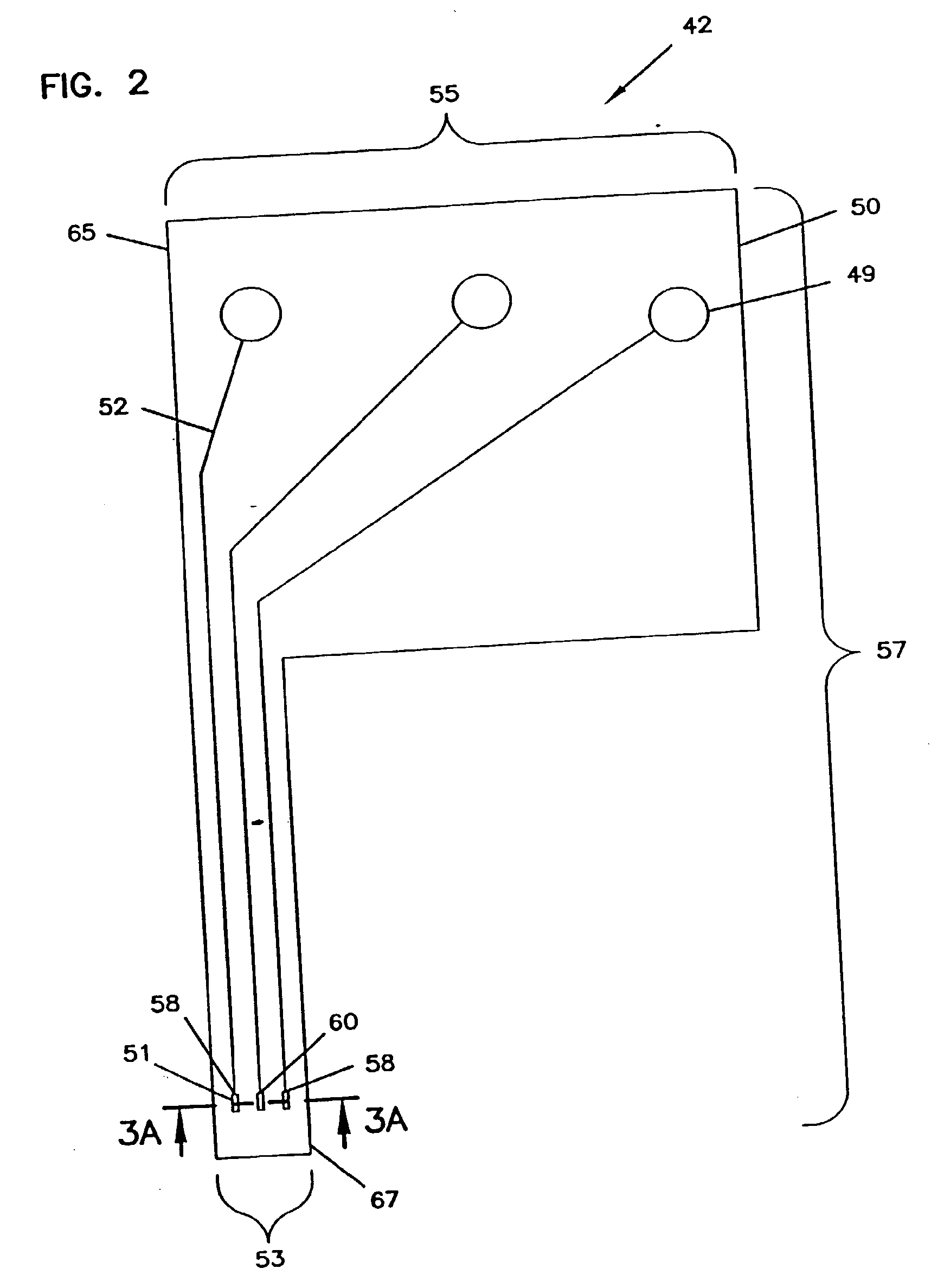

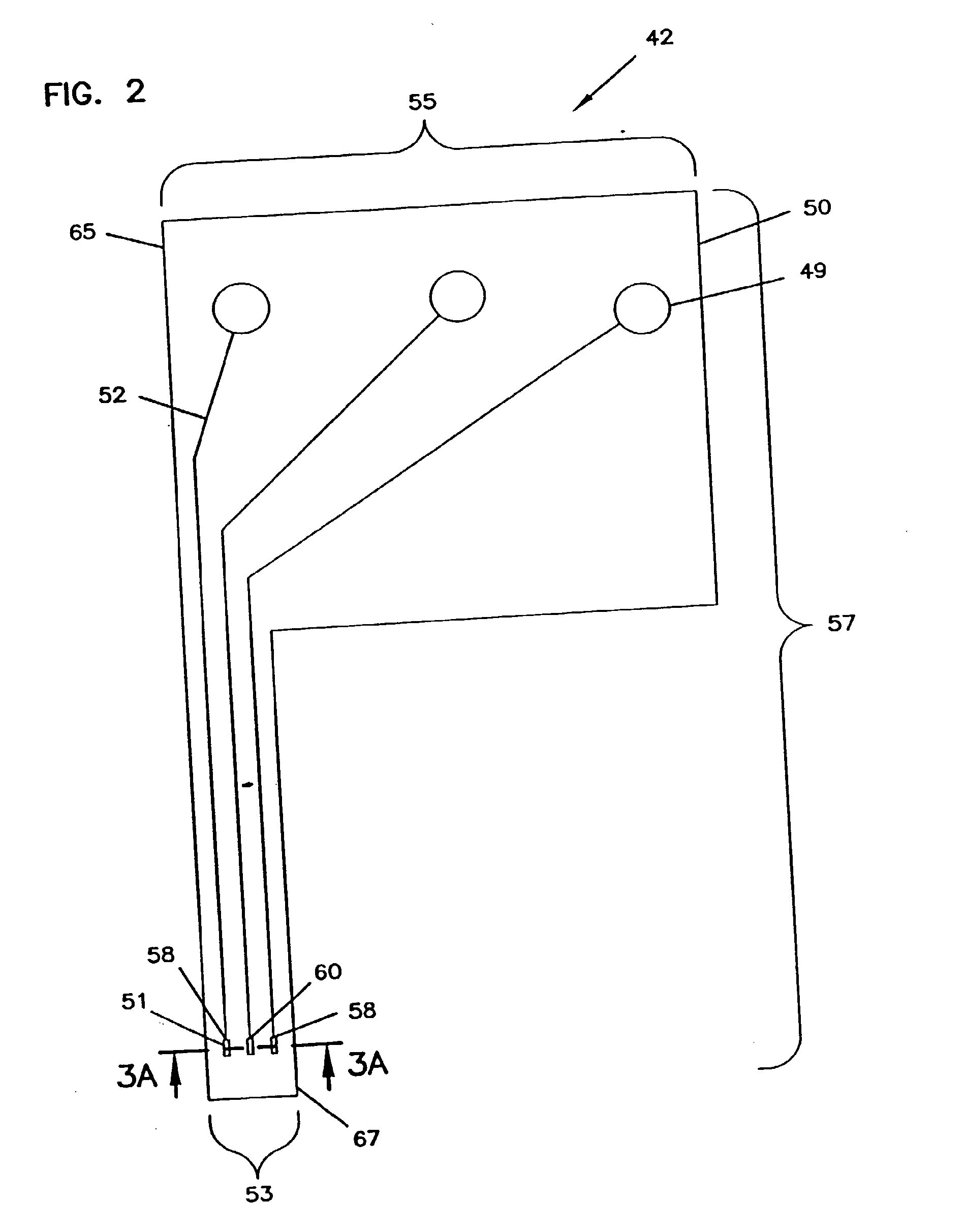

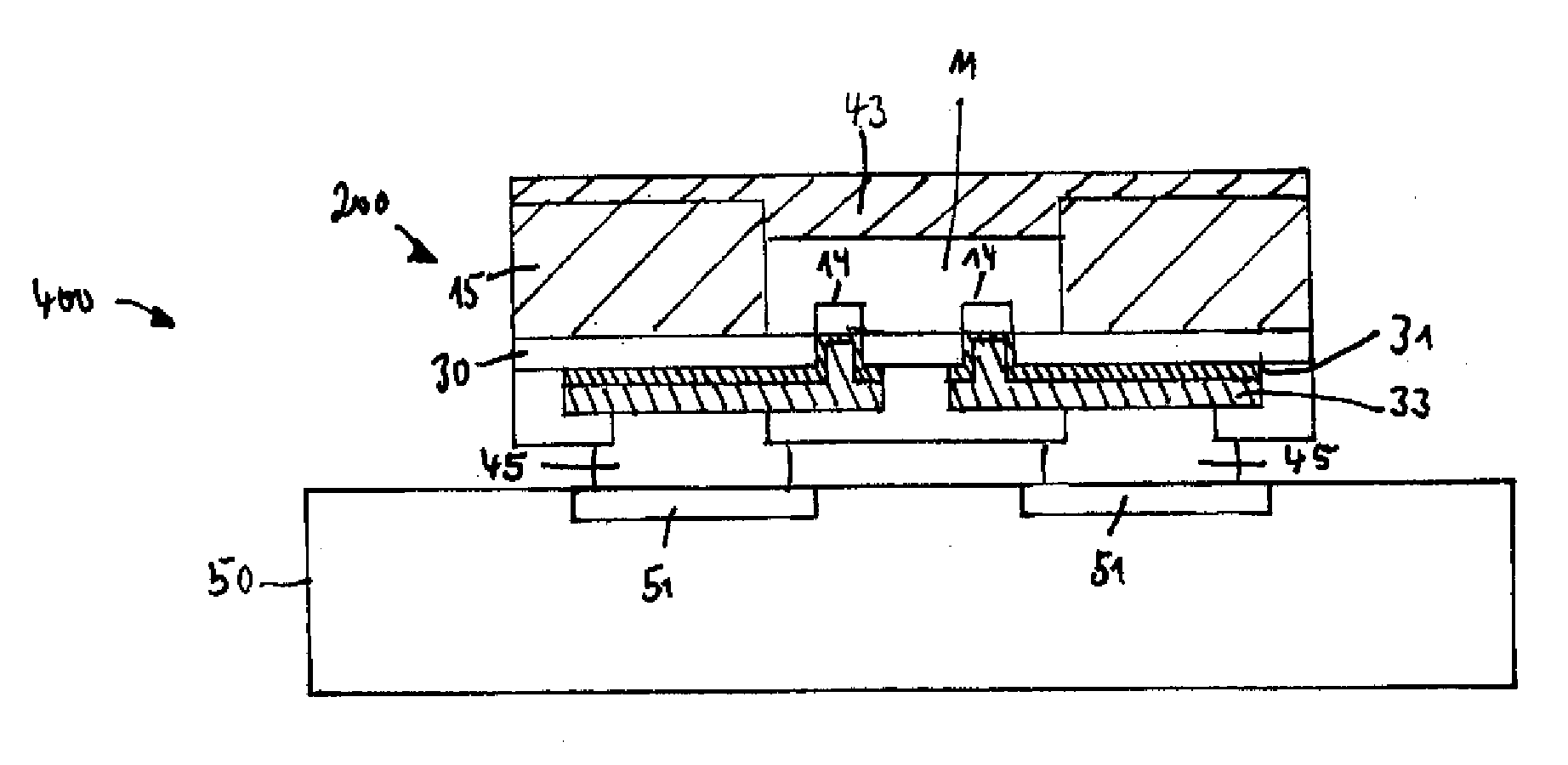

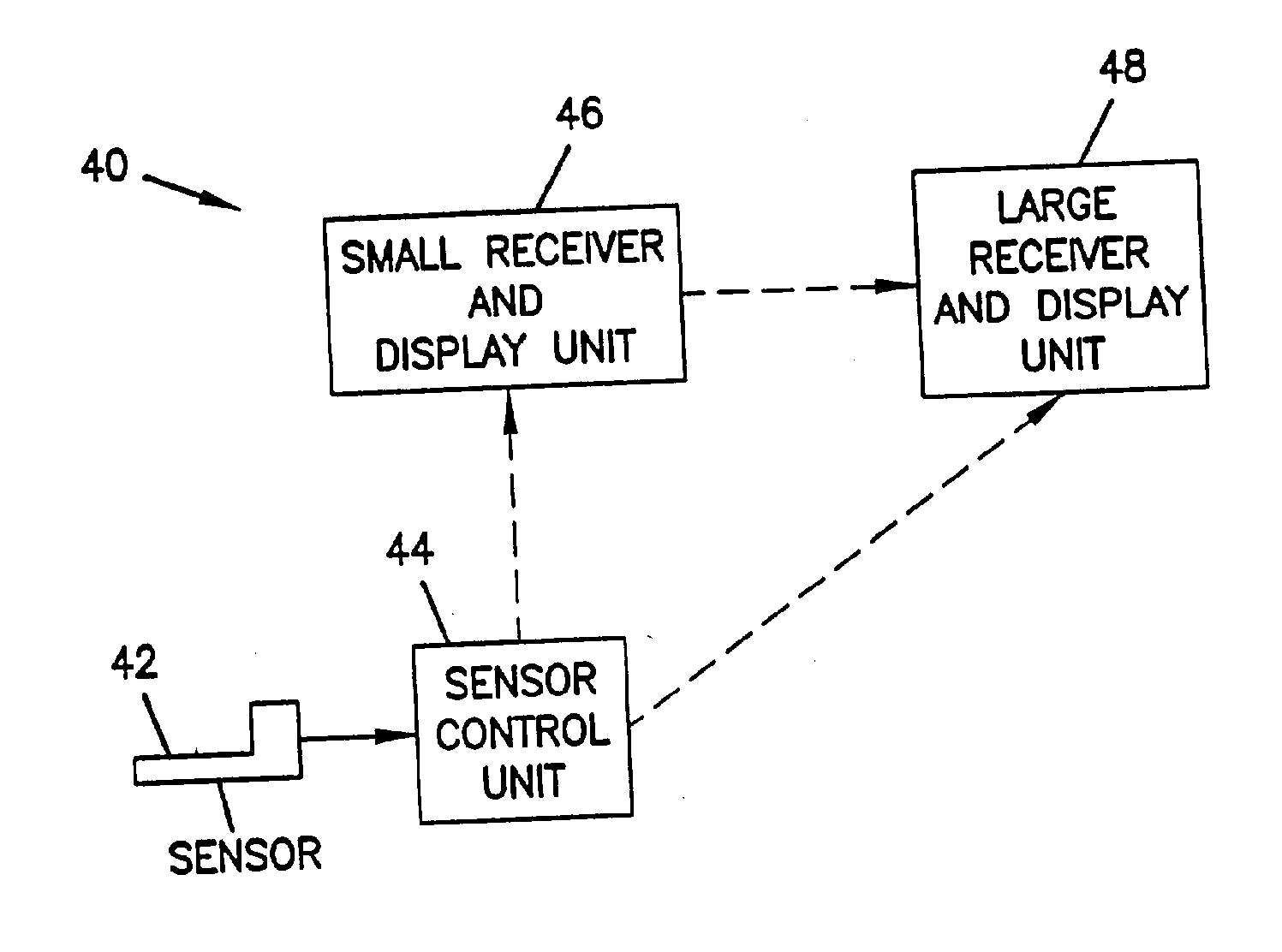

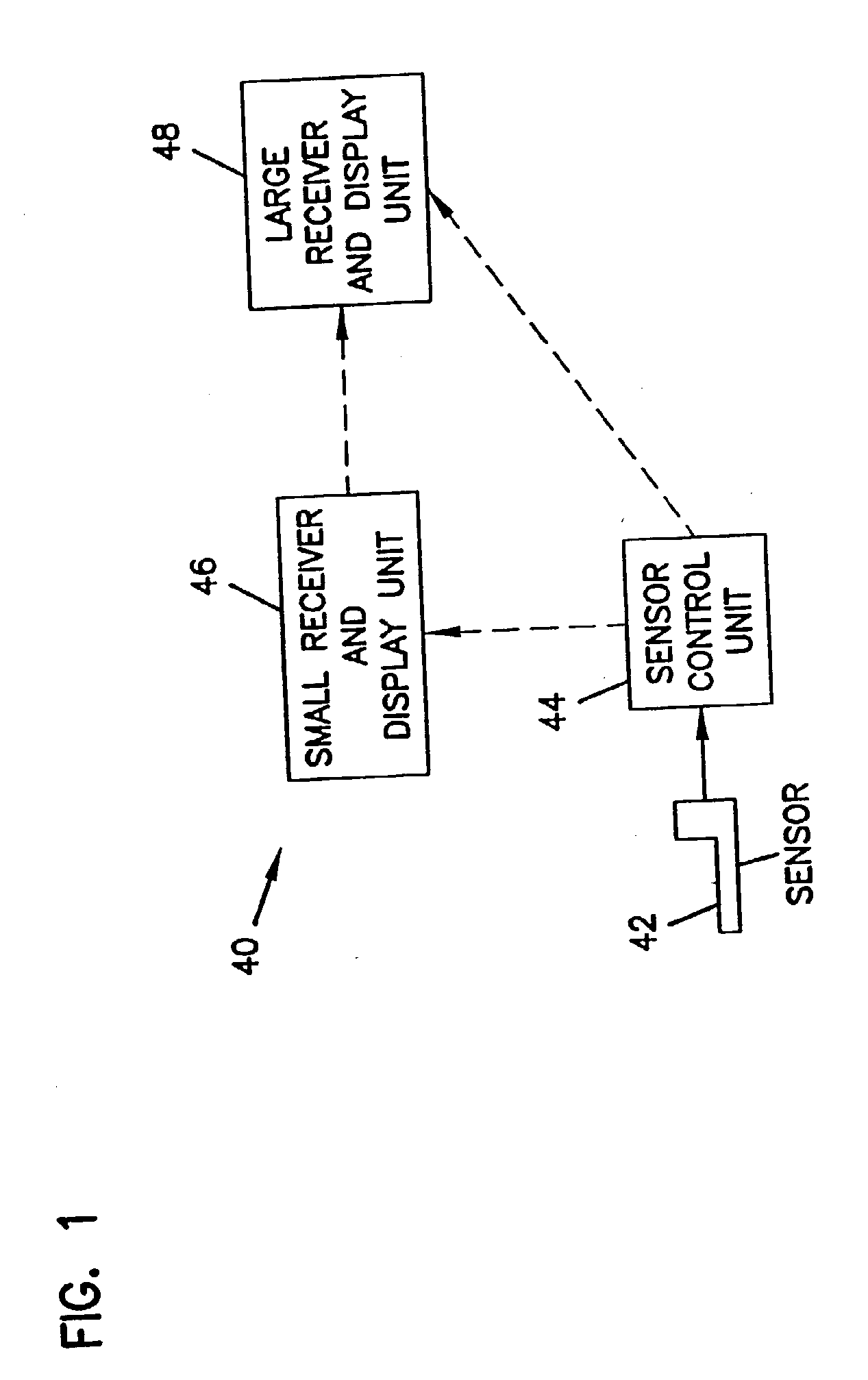

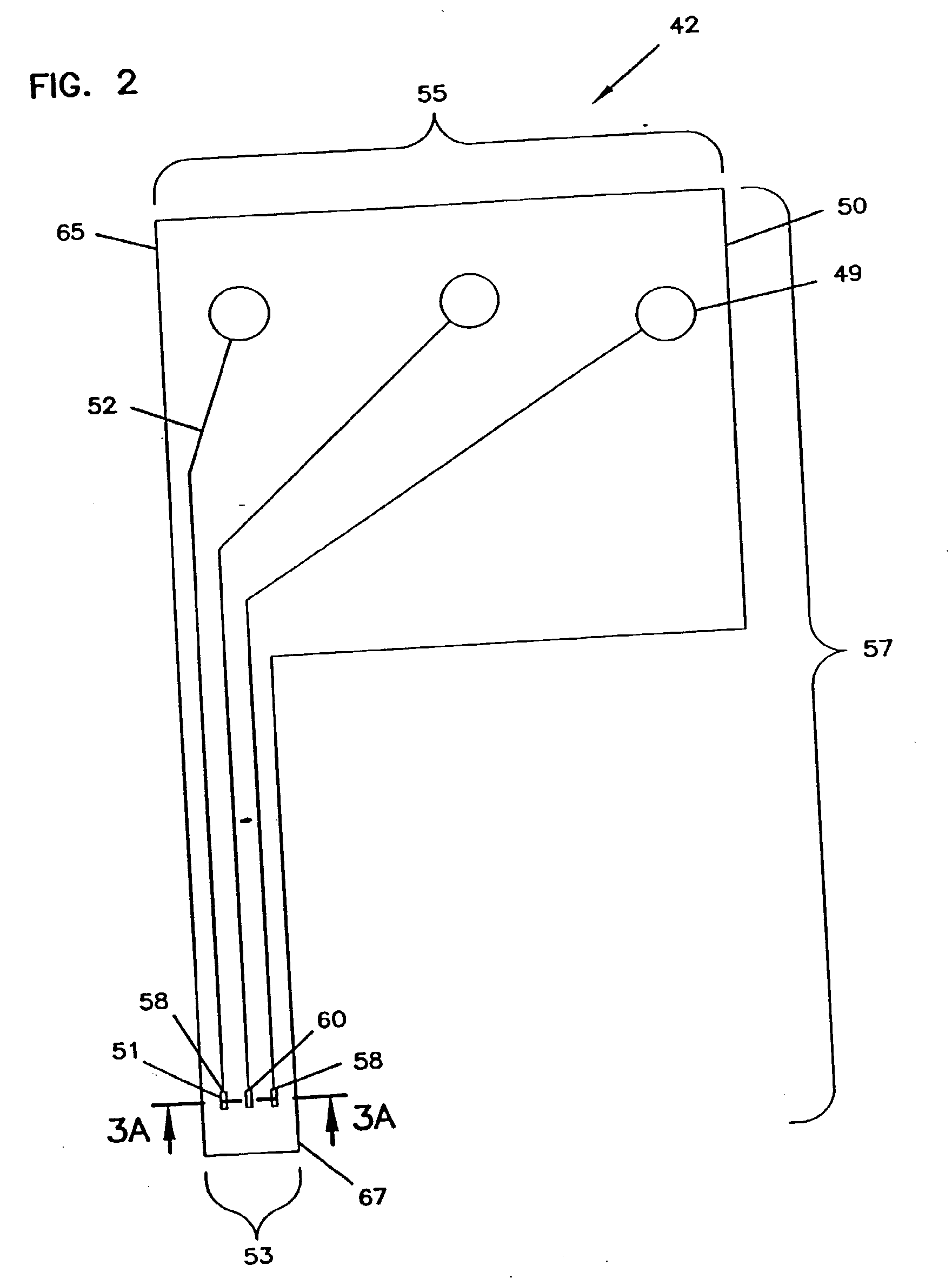

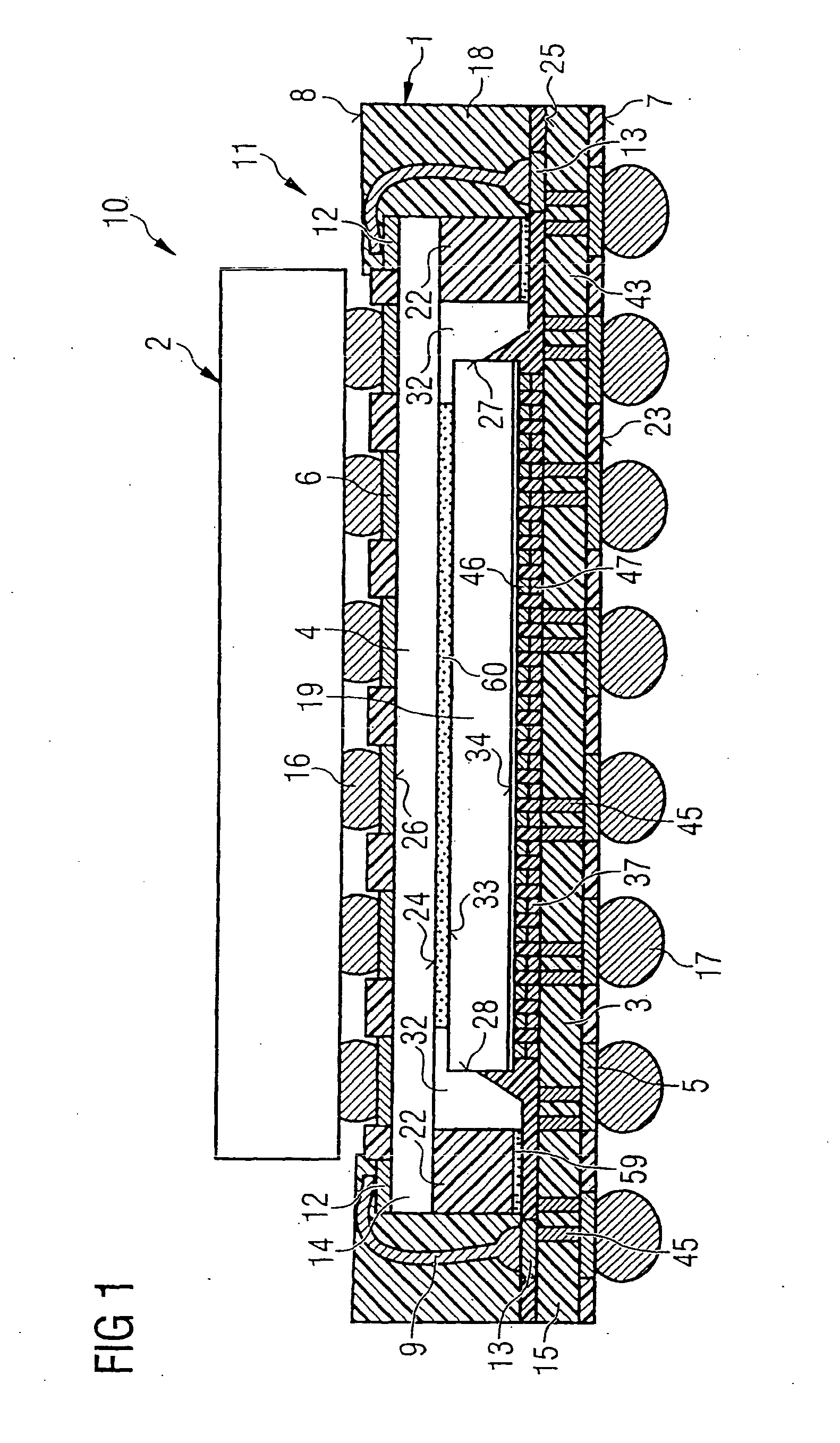

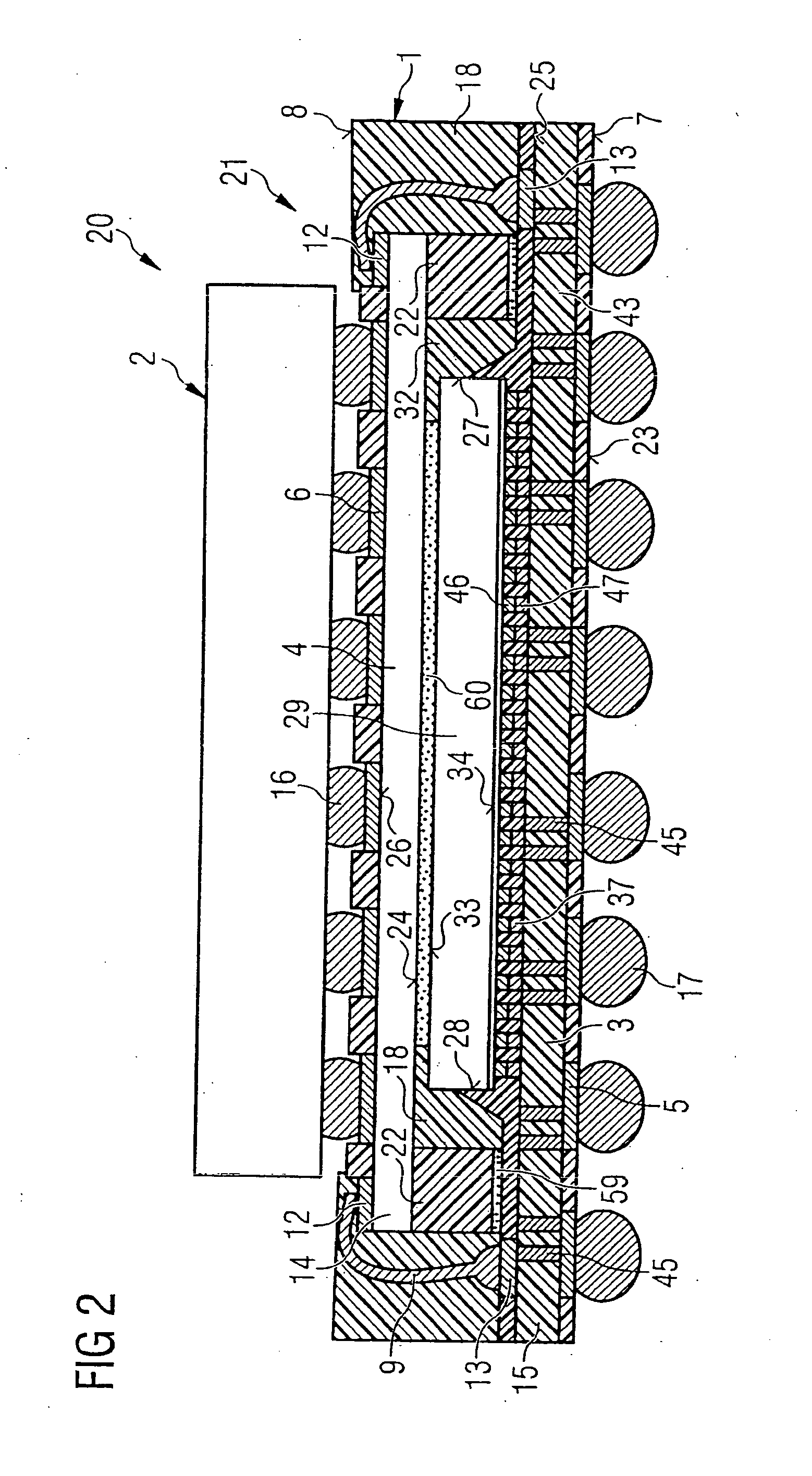

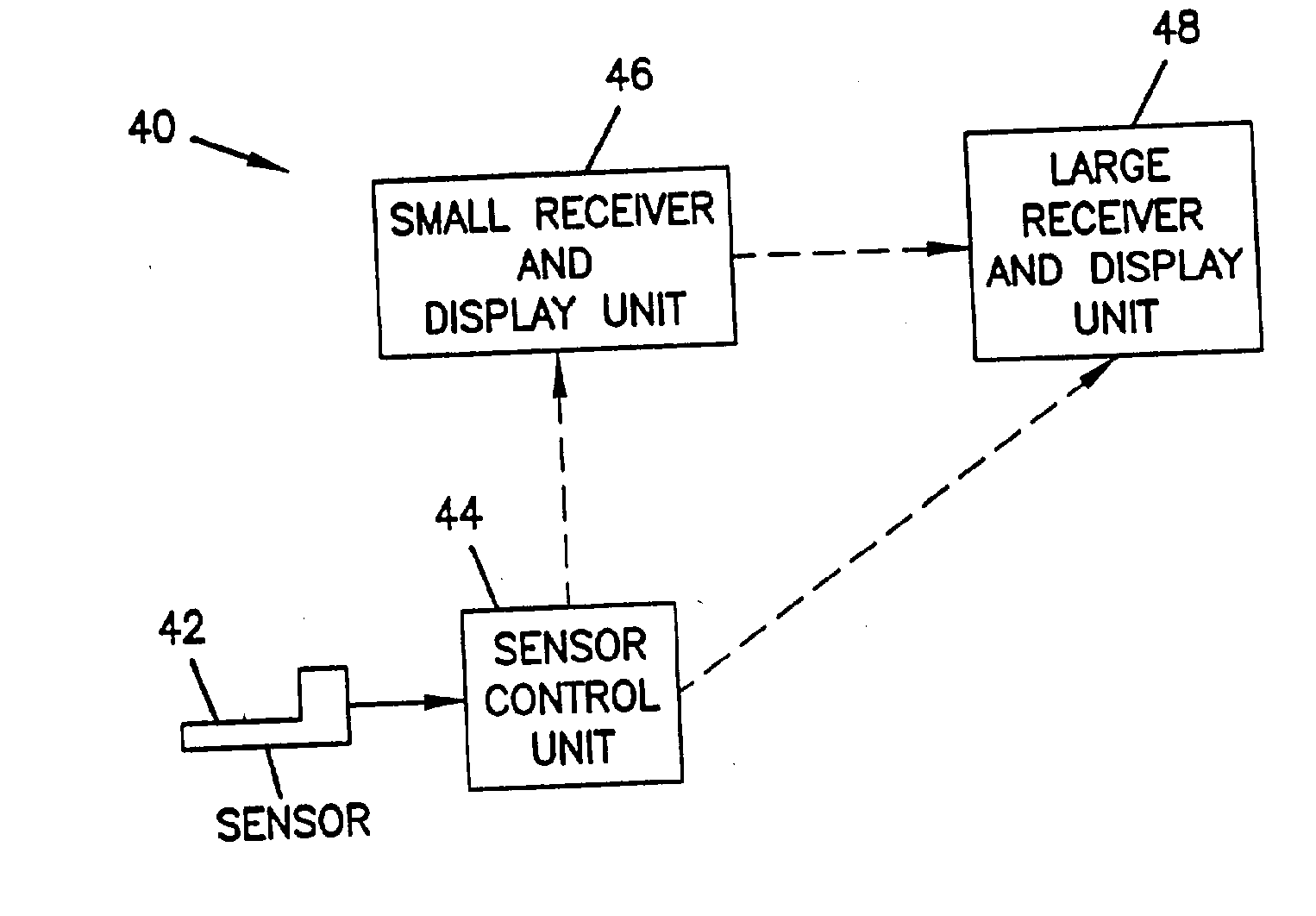

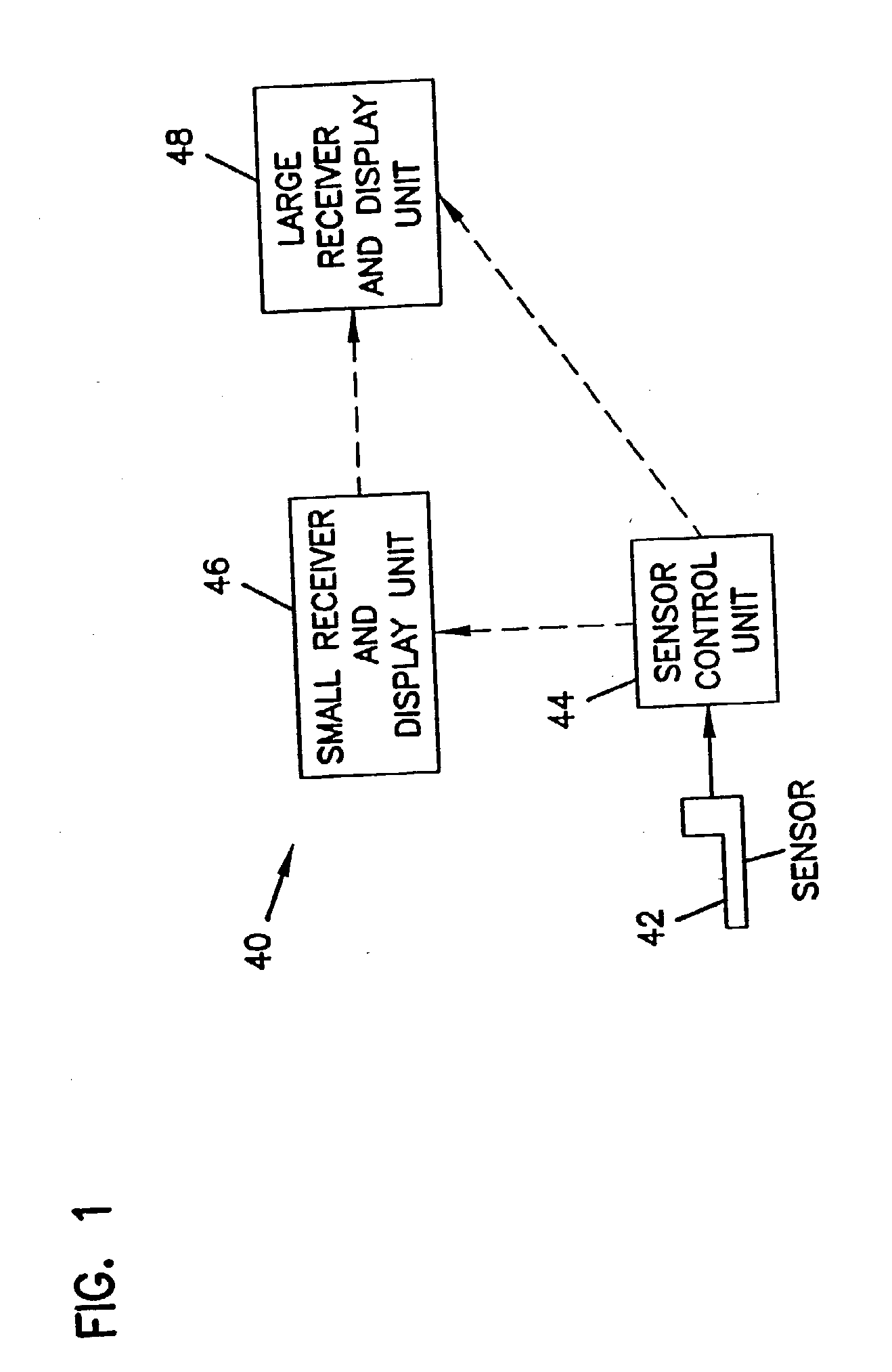

An analyte monitor includes a sensor, a sensor control unit, and a display unit. The sensor has, for example, a substrate, a recessed channel formed in the substrate, and conductive material disposed in the recessed channel to form a working electrode. The sensor control unit typically has a housing adapted for placement on skin and is adapted to receive a portion of an electrochemical sensor. The sensor control unit also includes two or more conductive contacts disposed on the housing and configured for coupling to two or more contact pads on the sensor. A transmitter is disposed in the housing and coupled to the plurality of conductive contacts for transmitting data obtained using the sensor. The display unit has a receiver for receiving data transmitted by the transmitter of the sensor control unit and a display coupled to the receiver for displaying an indication of a level of an analyte. The analyte monitor may also be part of a drug delivery system to alter the level of the analyte based on the data obtained using the sensor.

Owner:THERASENSE

Analyte monitoring device and methods of use

An analyte monitor includes a sensor, a sensor control unit, and a display unit. The sensor has, for example, a substrate, a recessed channel formed in the substrate, and conductive material disposed in the recessed channel to form a working electrode. The sensor control unit typically has a housing adapted for placement on skin and is adapted to receive a portion of an electrochemical sensor. The sensor control unit also includes two or more conductive contacts disposed on the housing and configured for coupling to two or more contact pads on the sensor. A transmitter is disposed in the housing and coupled to the plurality of conductive contacts for transmitting data obtained using the sensor. The display unit has a receiver for receiving data transmitted by the transmitter of the sensor control unit and a display coupled to the receiver for displaying an indication of a level of an analyte. The analyte monitor may also be part of a drug delivery system to alter the level of the analyte based on the data obtained using the sensor.

Owner:ABBOTT DIABETES CARE INC

Analyte monitoring device and methods of use

An analyte monitor includes a sensor, a sensor control unit, and a display unit. The sensor has, for example, a substrate, a recessed channel formed in the substrate, and conductive material disposed in the recessed channel to form a working electrode. The sensor control unit typically has a housing adapted for placement on skin and is adapted to receive a portion of an electrochemical sensor. The sensor control unit also includes two or more conductive contacts disposed on the housing and configured for coupling to two or more contact pads on the sensor. A transmitter is disposed in the housing and coupled to the plurality of conductive contacts for transmitting data obtained using the sensor. The display unit has a receiver for receiving data transmitted by the transmitter of the sensor control unit and a display coupled to the receiver for displaying an indication of a level of an analyte. The analyte monitor may also be part of a drug delivery system to alter the level of the analyte based on the data obtained using the sensor.

Owner:ABBOTT DIABETES CARE INC

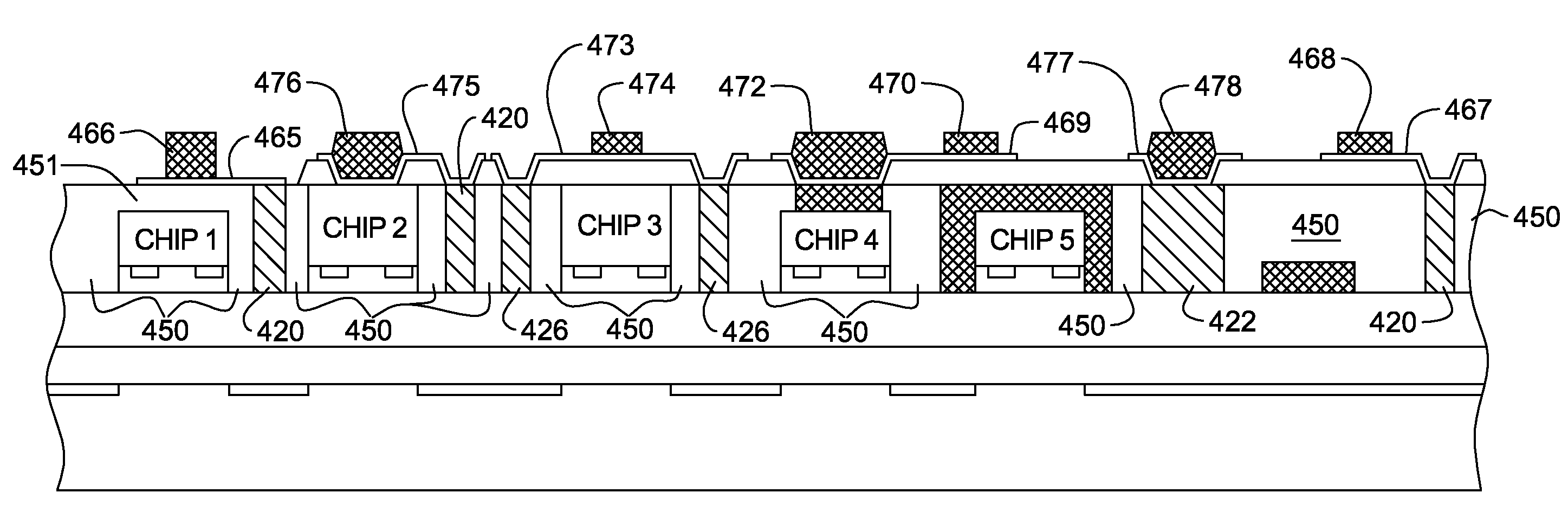

Integrated structures and fabrication methods thereof implementing a cell phone or other electronic system

ActiveUS7619901B2Semiconductor/solid-state device detailsSolid-state devicesElectronic systemsContact pad

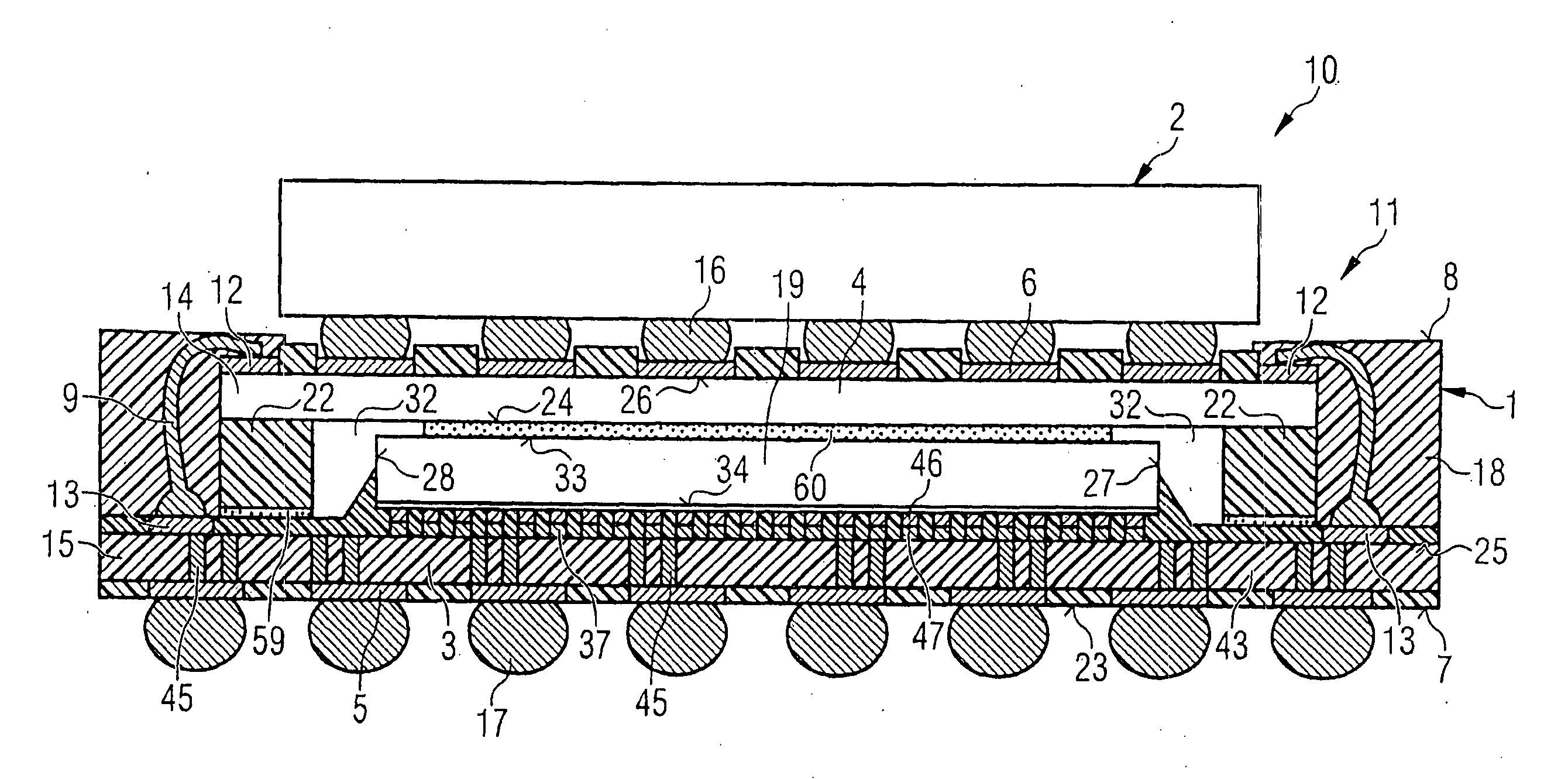

Circuit structures and methods of fabrication are provided for facilitating implementing a complete electronic system in a compact package. The circuit structure includes, in one embodiment, a chips-first multichip base layer with conductive structures extending therethrough. An interconnect layer is disposed over the front surface of the multichip layer and includes interconnect metallization electrically connected to contact pads of the chips and to conductive structures extending through the structural material. A redistribution layer, disposed over the back surface of the multichip layer, includes a redistribution metallization also electrically connected to conductive structures extending through the structural material. Input / output contacts are arrayed over the redistribution layer, including over the lower surfaces of at least some integrated circuit chips within the multichip layer, and are electrically connected through the redistribution metallization, conductive structures, and interconnect metallization to contact pads of the integrated circuit chips of the multichip layer.

Owner:EPIC TECH INC

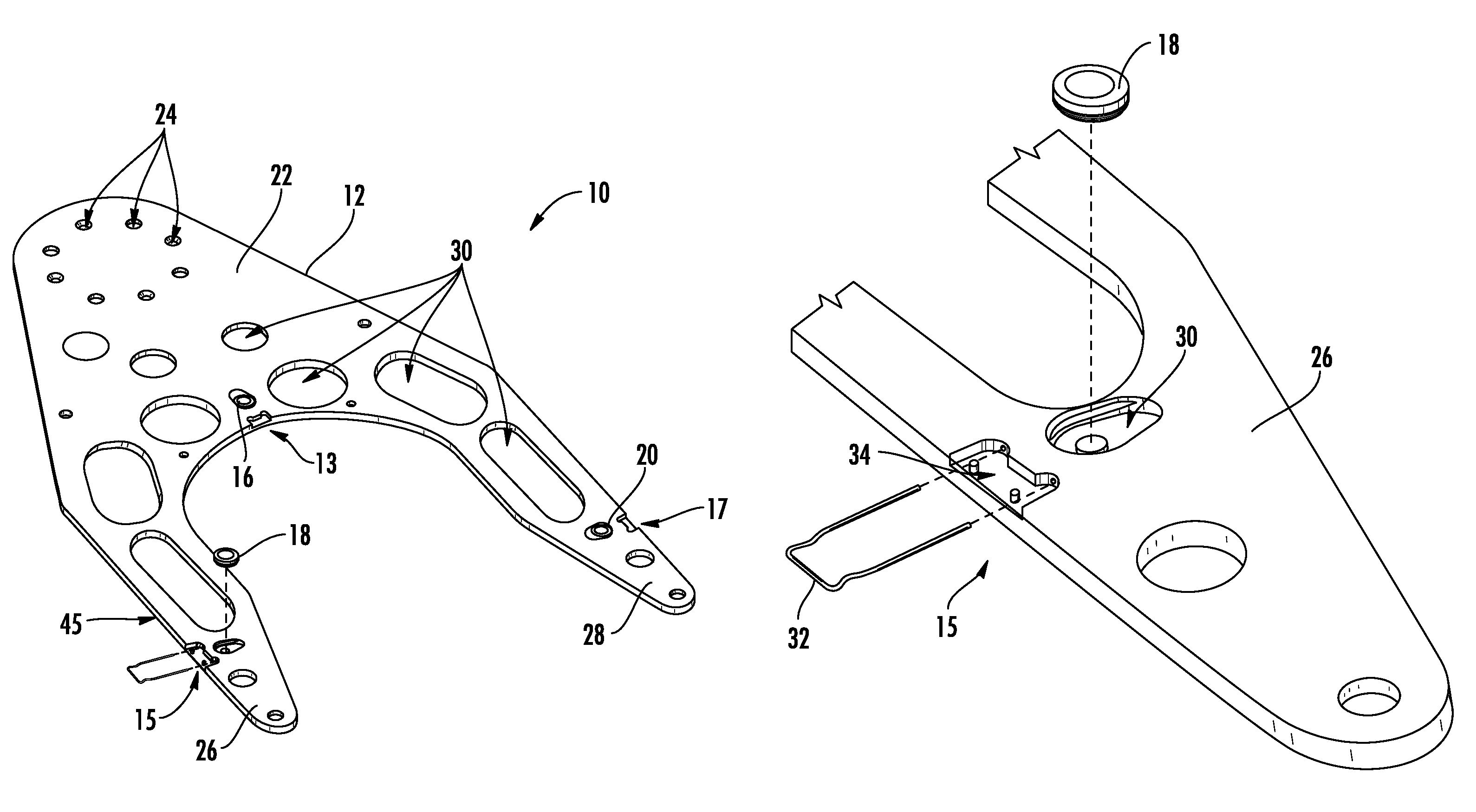

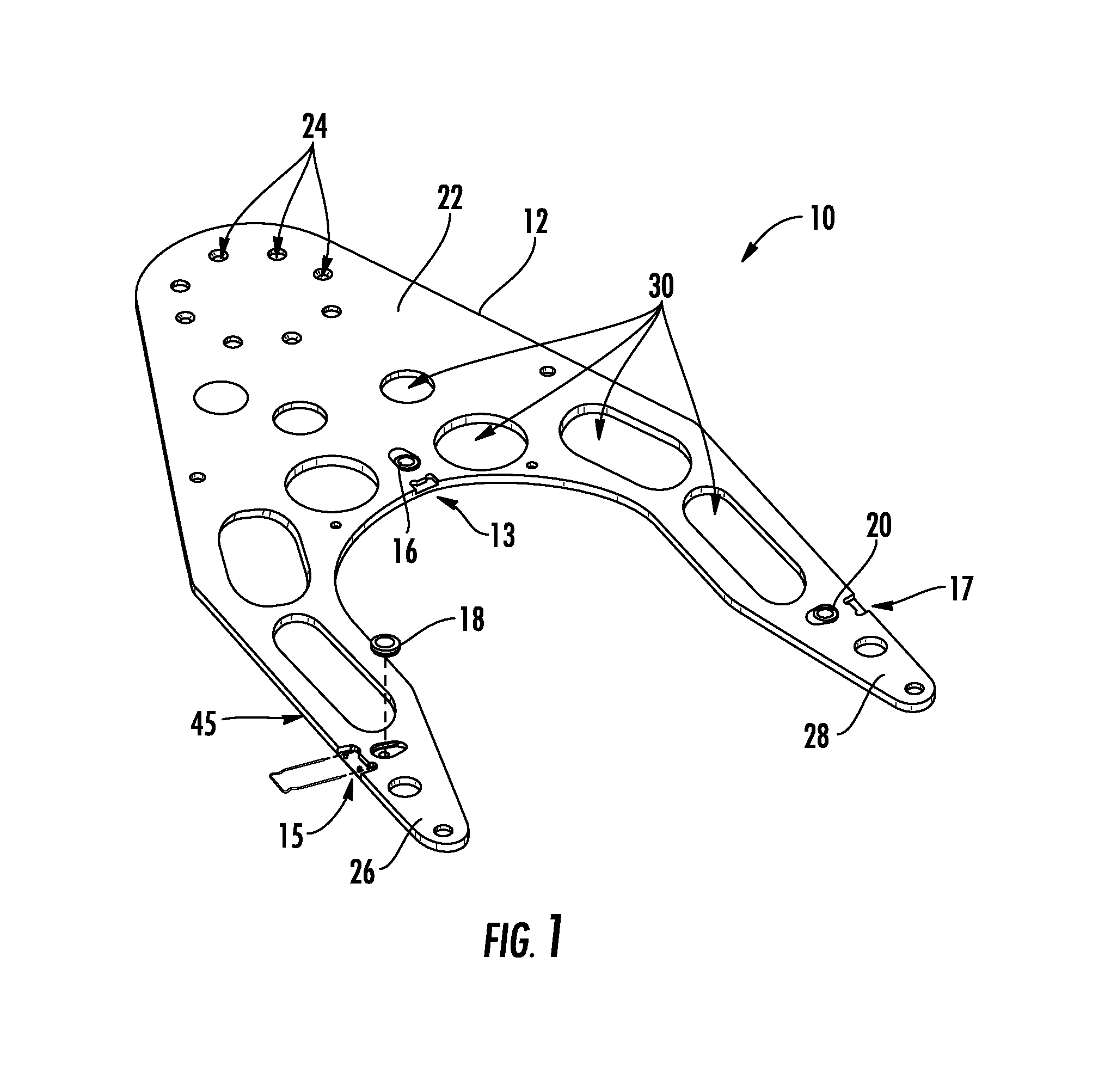

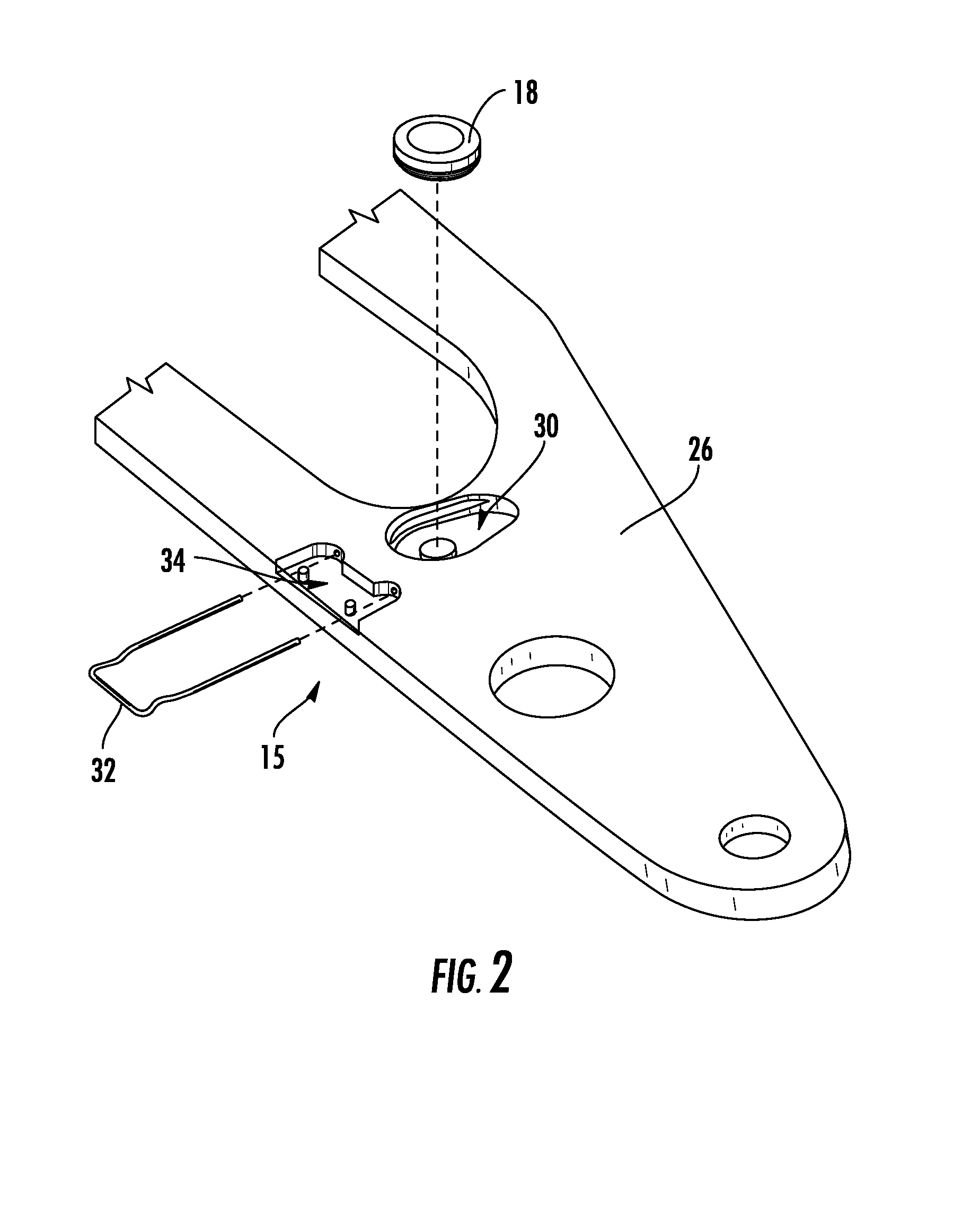

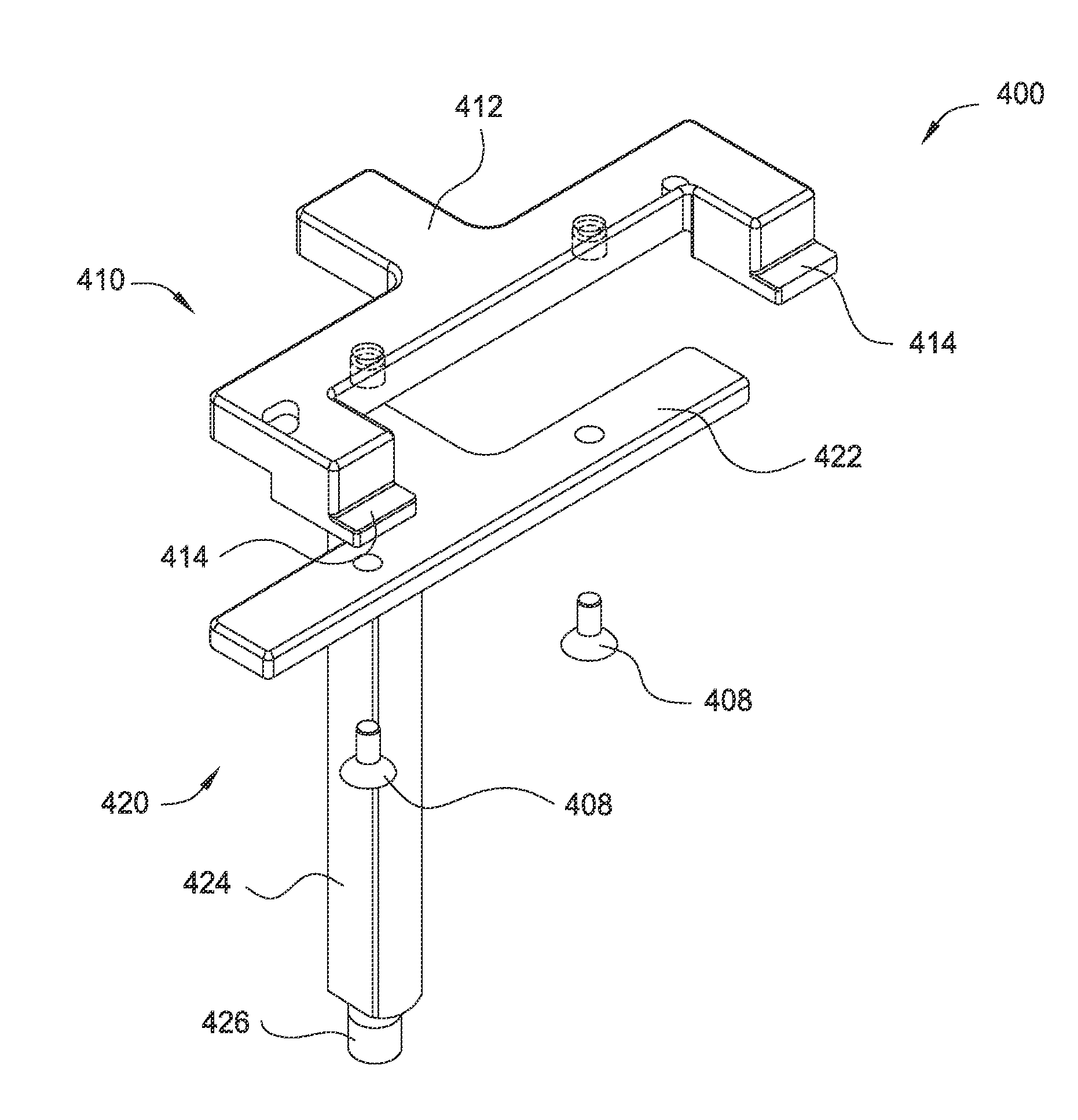

Spring retained end effector contact pad

ActiveUS8864202B1Reduce dispersionSecure attachmentGripping headsSemiconductor/solid-state device manufacturingContact padActuator

An end effector is disclosed for use in substrate processing. The end effector includes a effector body portion, a contact pad pocket formed in the end effector body, a spring retaining pocket formed in the end effector body adjacent the contact pad pocket and extending to an edge of the end effector body, and a pair of through-holes extending from the spring retaining pocket to the contact pad pocket. The end effector can include a contact pad seated within the contact pad pocket, the contact pad having at least one retaining channel formed therein, and a retaining spring having a pair of retaining arms extending from the retaining spring pocket through the through-holes and into the contact pad pocket. The retaining arms may extend at least partially into the at least one retaining channel of the contact pad and may thereby restrict movement of the contact pad.

Owner:VARIAN SEMICON EQUIP ASSOC INC

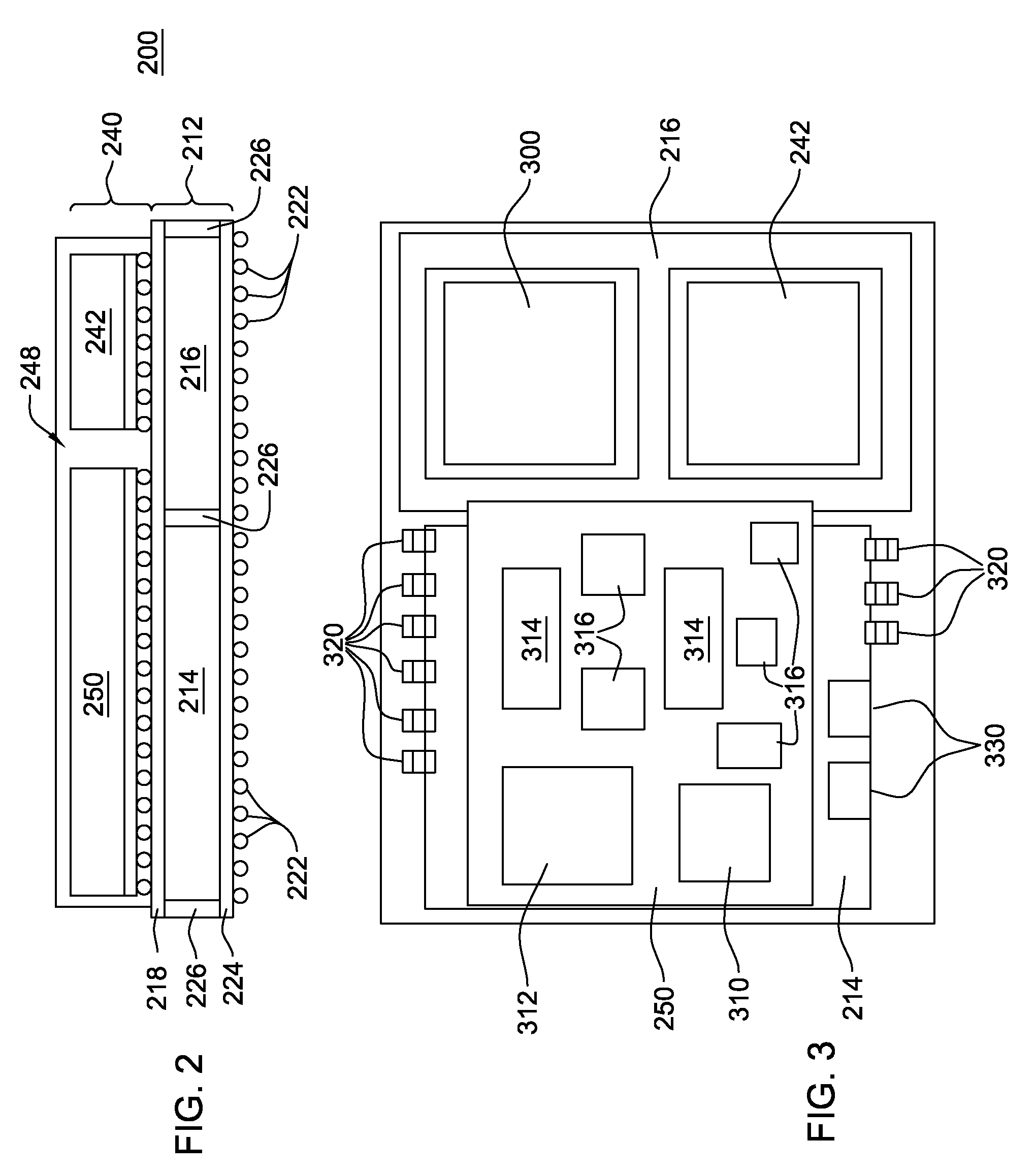

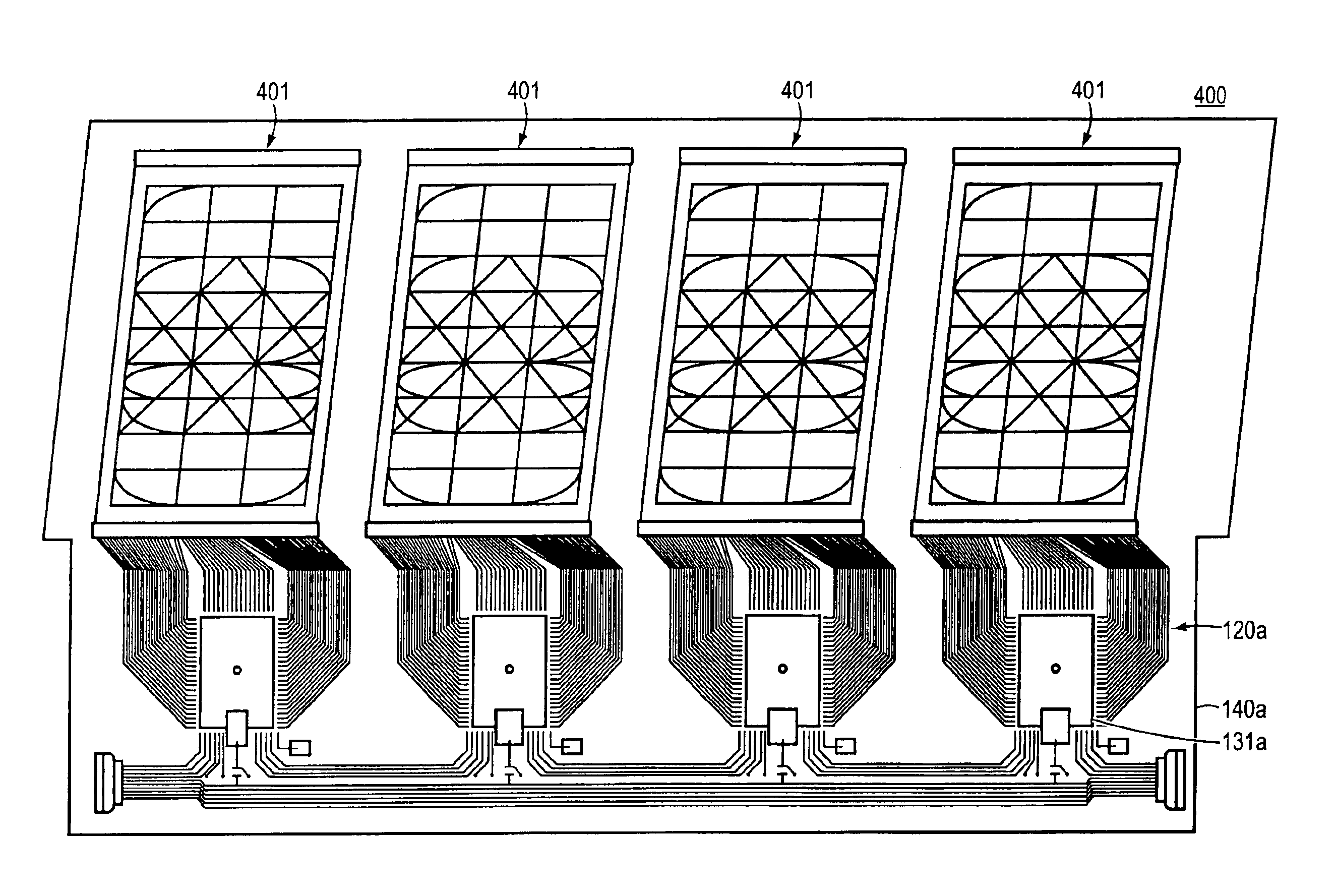

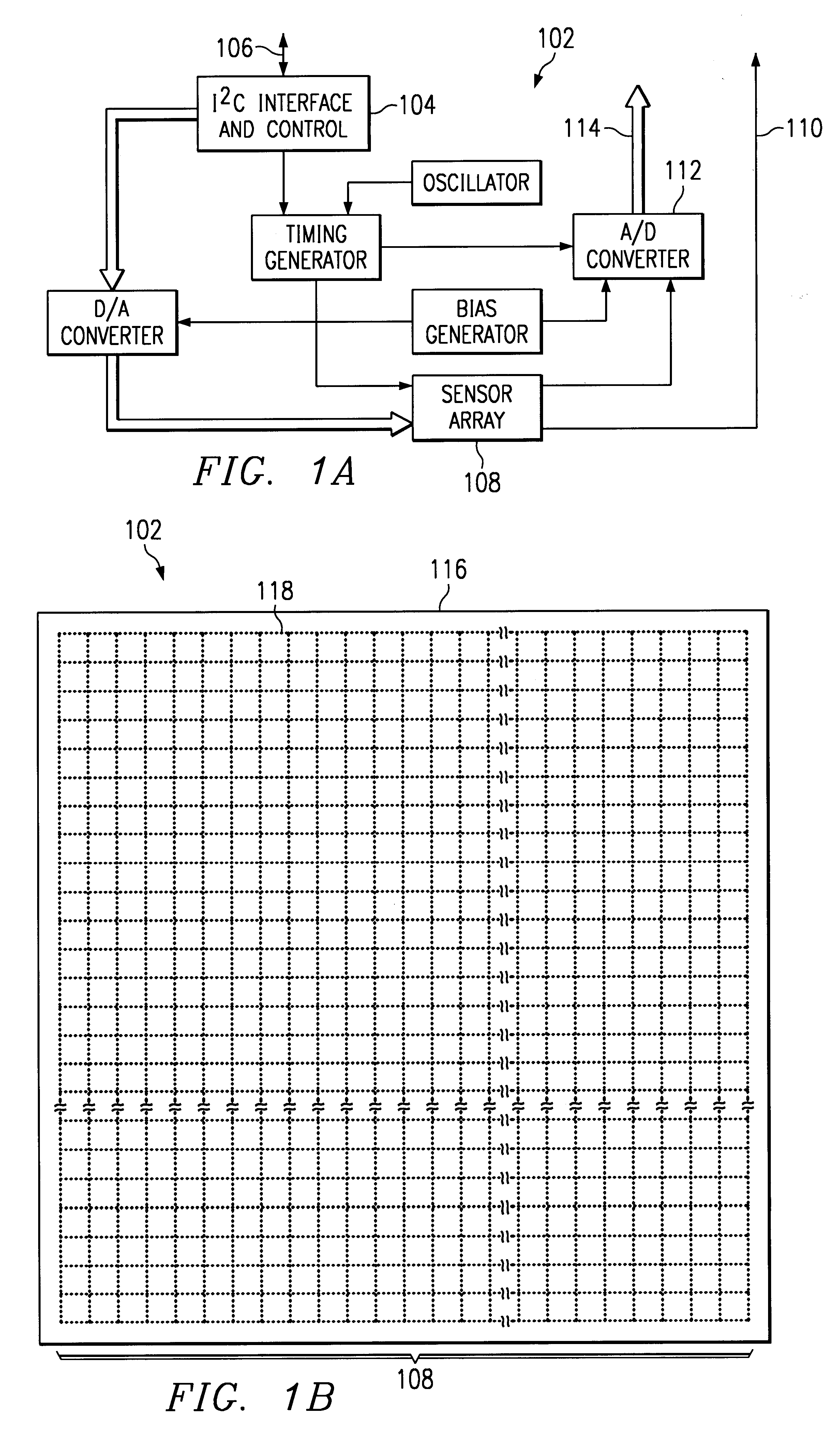

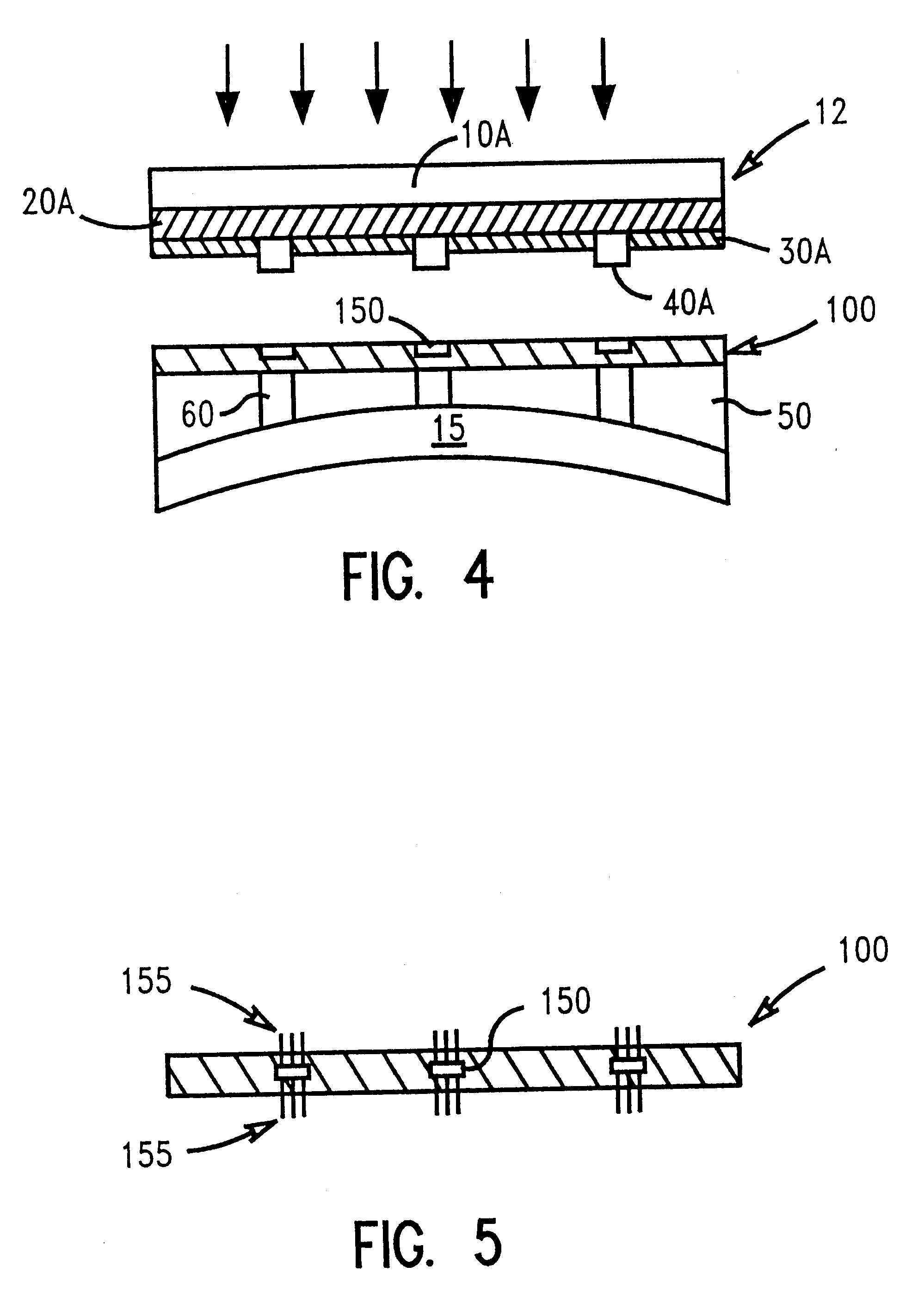

Microencapsulated electrophoretic display with integrated driver

InactiveUS6967640B2Method of manufacture is costEasy to useStatic indicating devicesPrinted electric component incorporationElectricityContact pad

A mounted display assembly comprises a flexible substrate that supports both display elements and control circuits. The display assembly generally comprises: an electrical connection formed on the flexible substrate, the electrical connection having first and second contact pads; a display element in electrical communication with the first contact pad; and a control circuit mounted on the flexible substrate and in electrical communication with the second contact pad. In a preferred embodiment, the display element comprises a microencapsulated electrophoretic display medium. In another preferred embodiment, printing processes are employed in manufacturing methods for the display assembly.

Owner:E INK CORPORATION

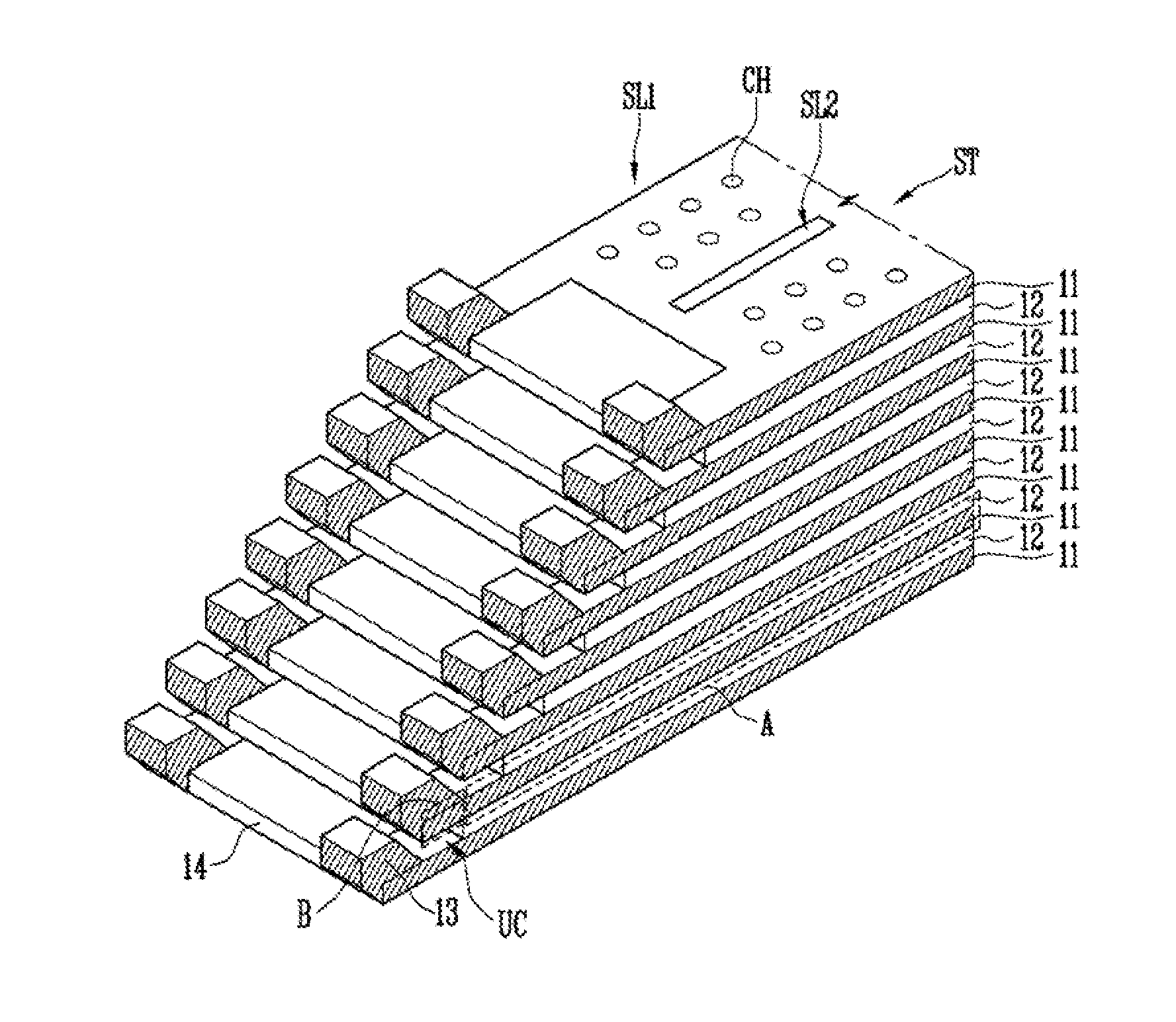

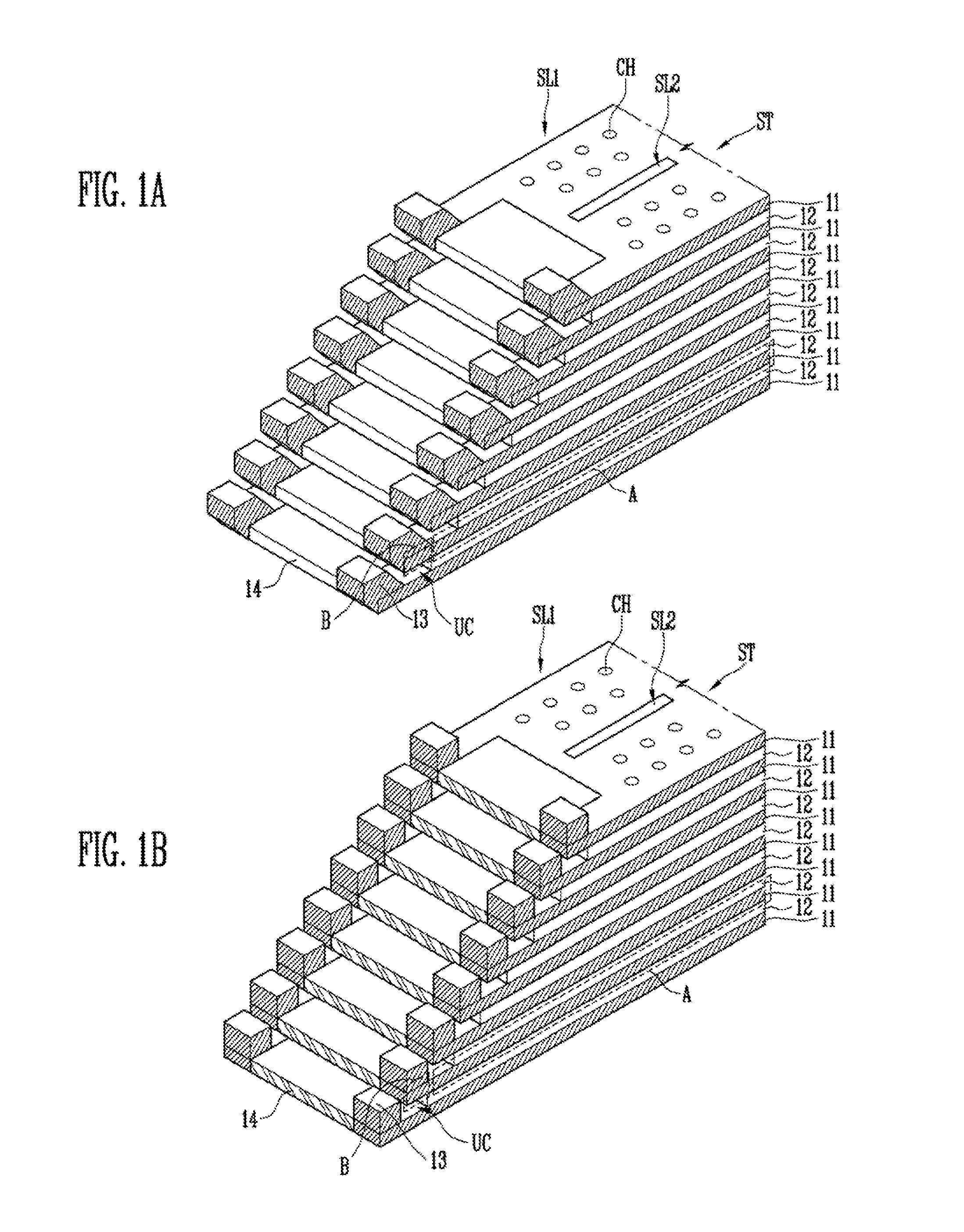

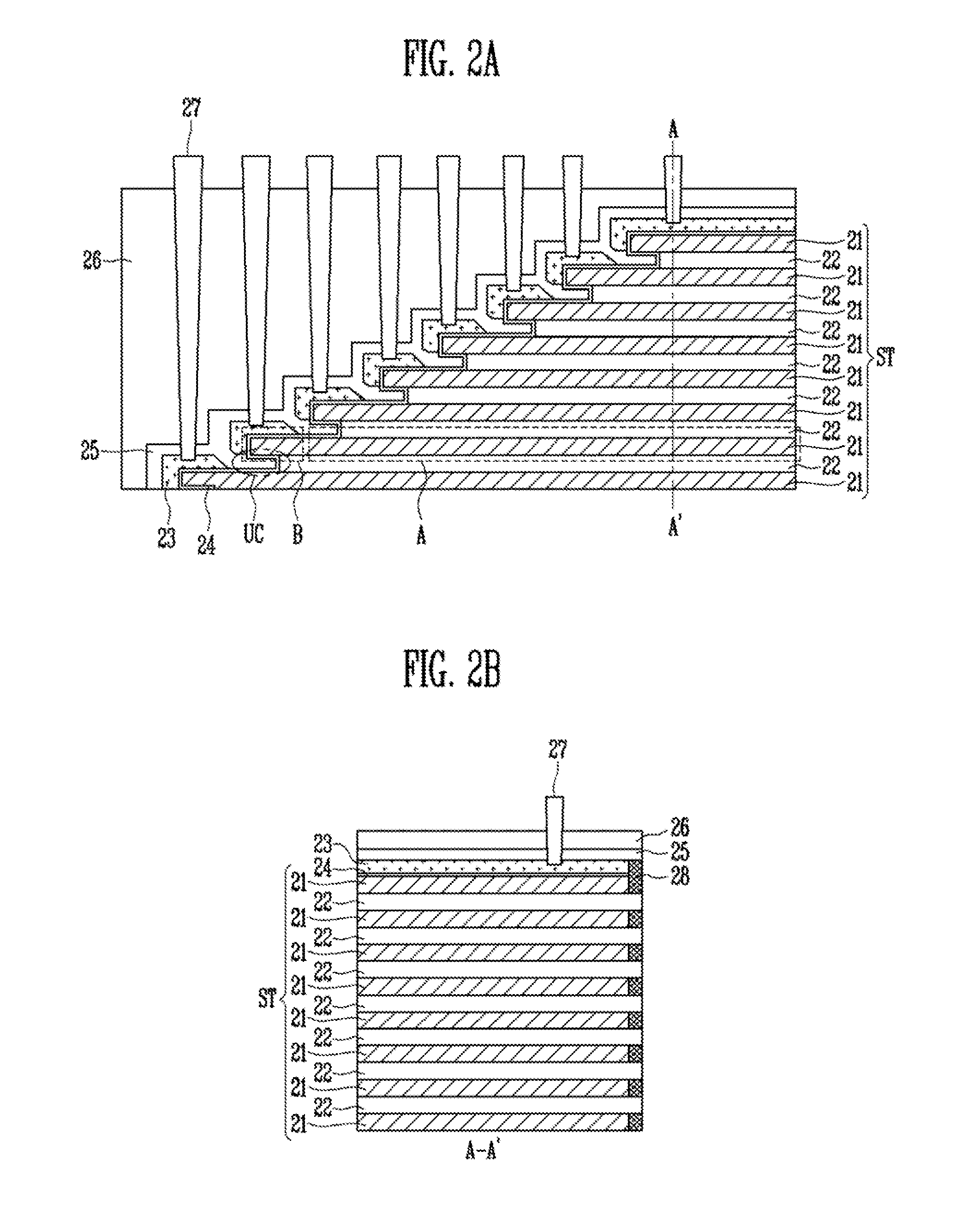

Semiconductor device and method of manufacturing the same

ActiveUS20150179564A1Simple manufacturing processStable structureSemiconductor/solid-state device detailsSolid-state devicesContact padSemiconductor

A semiconductor device includes a stacked structure having first conductive layers stacked stepwise and first insulating layers interposed between the first conductive layers, wherein undercuts are formed under the first conductive layers and each of the first conductive layers includes a first region covered by the first conductive layer and a second region extending from the first region, contact pads coupled to the second regions of the respective first conductive layers, and a liner layer formed on the contact pads and filling the undercuts.

Owner:SK HYNIX INC

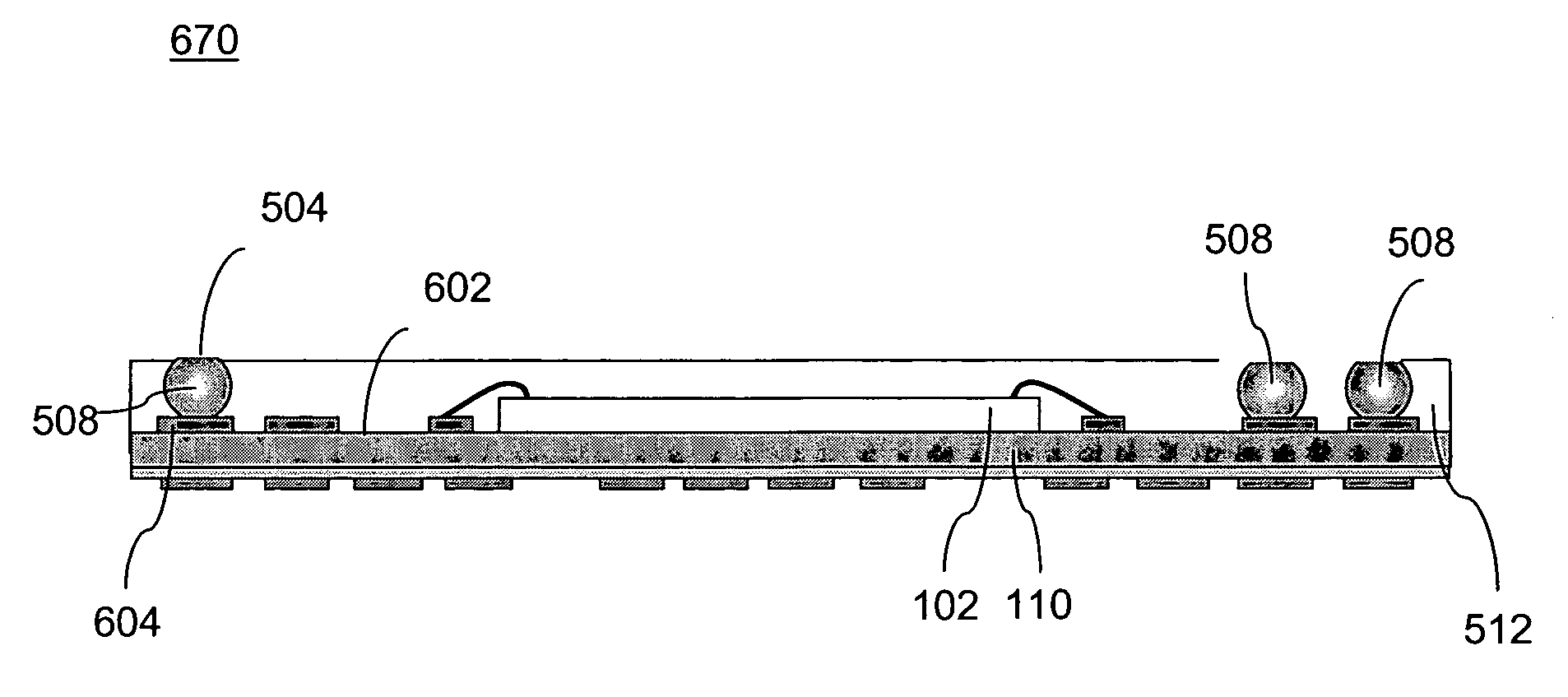

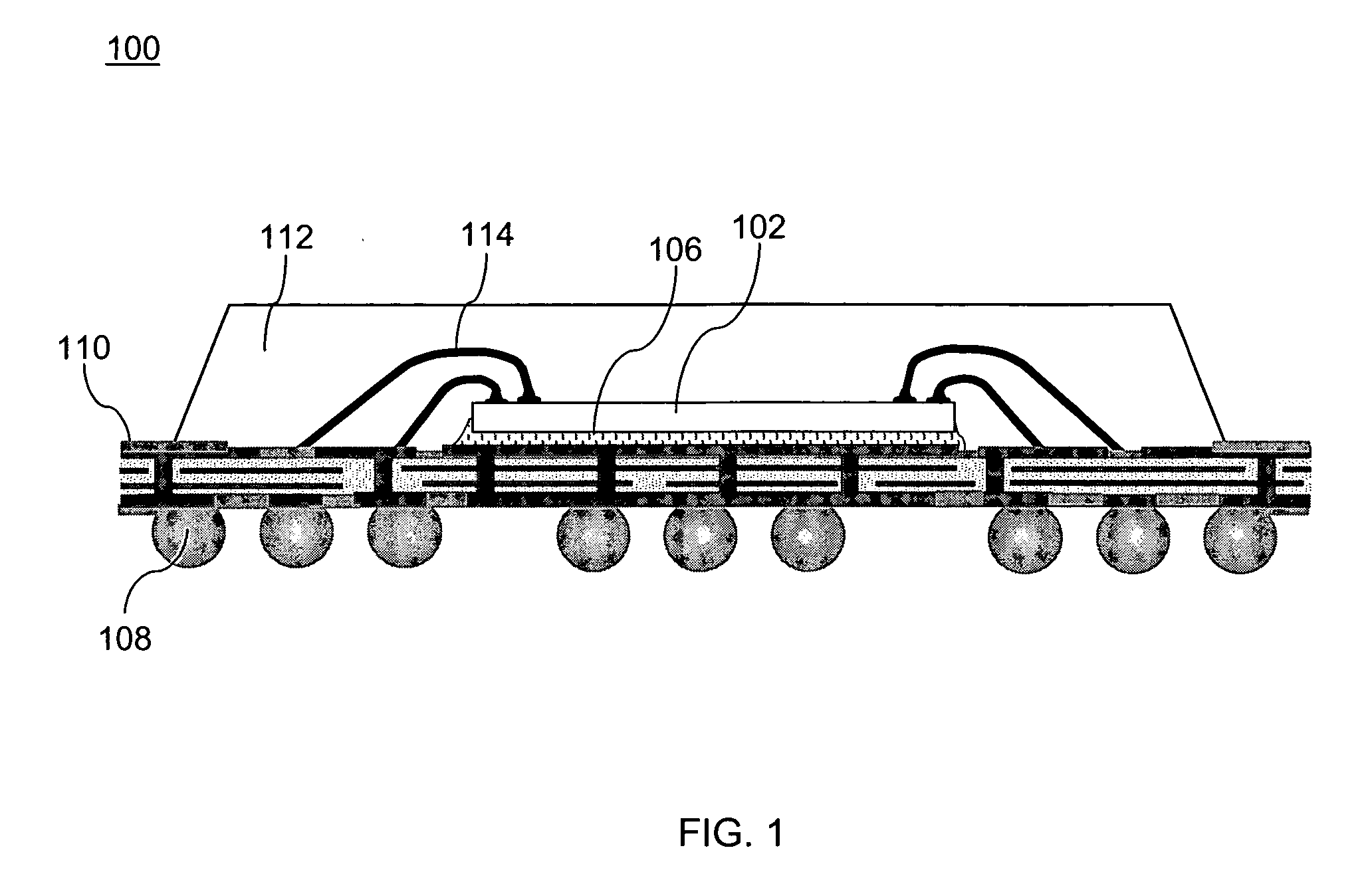

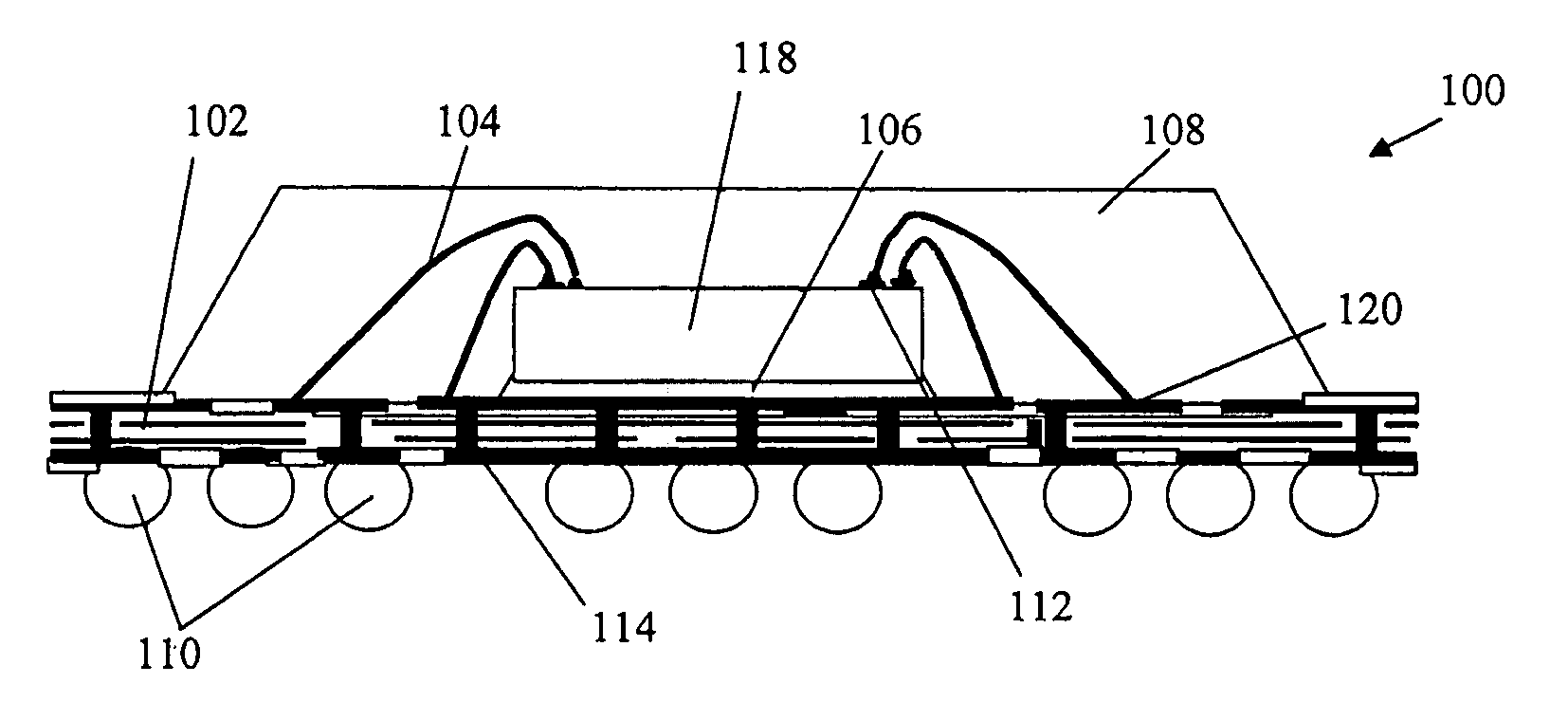

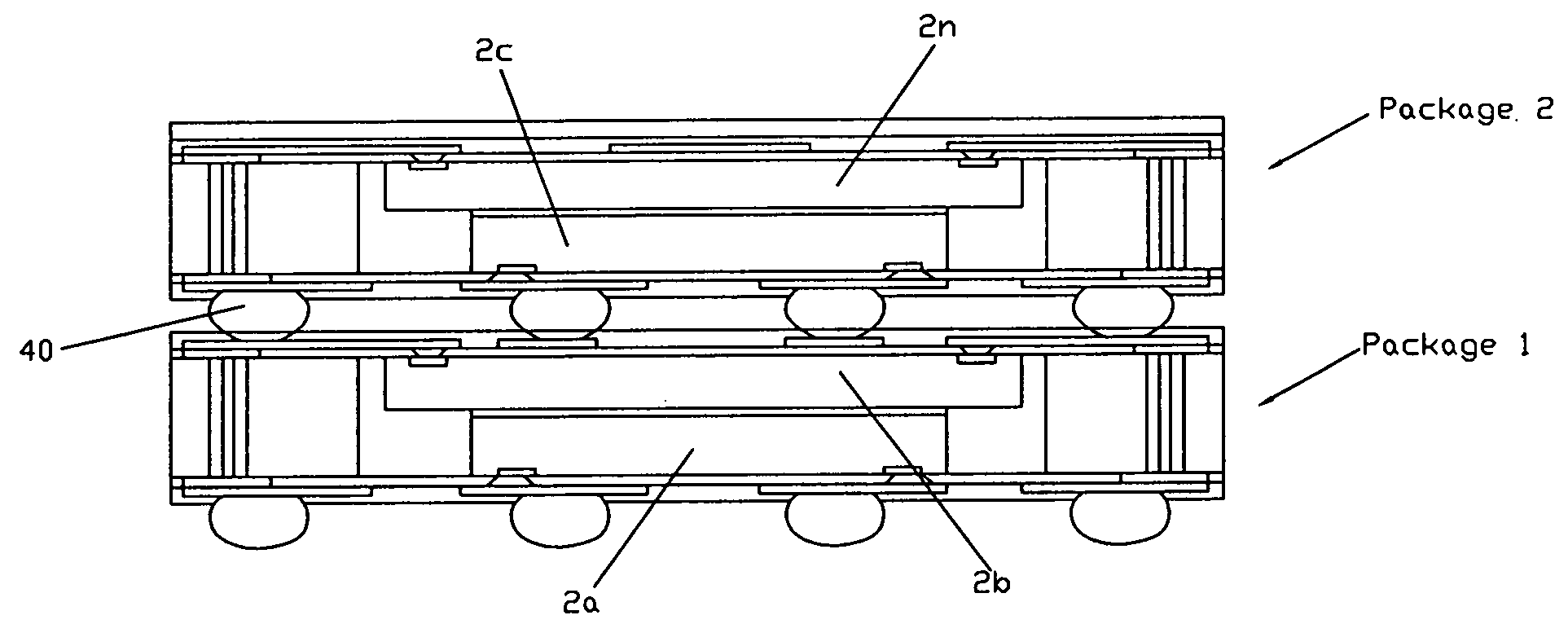

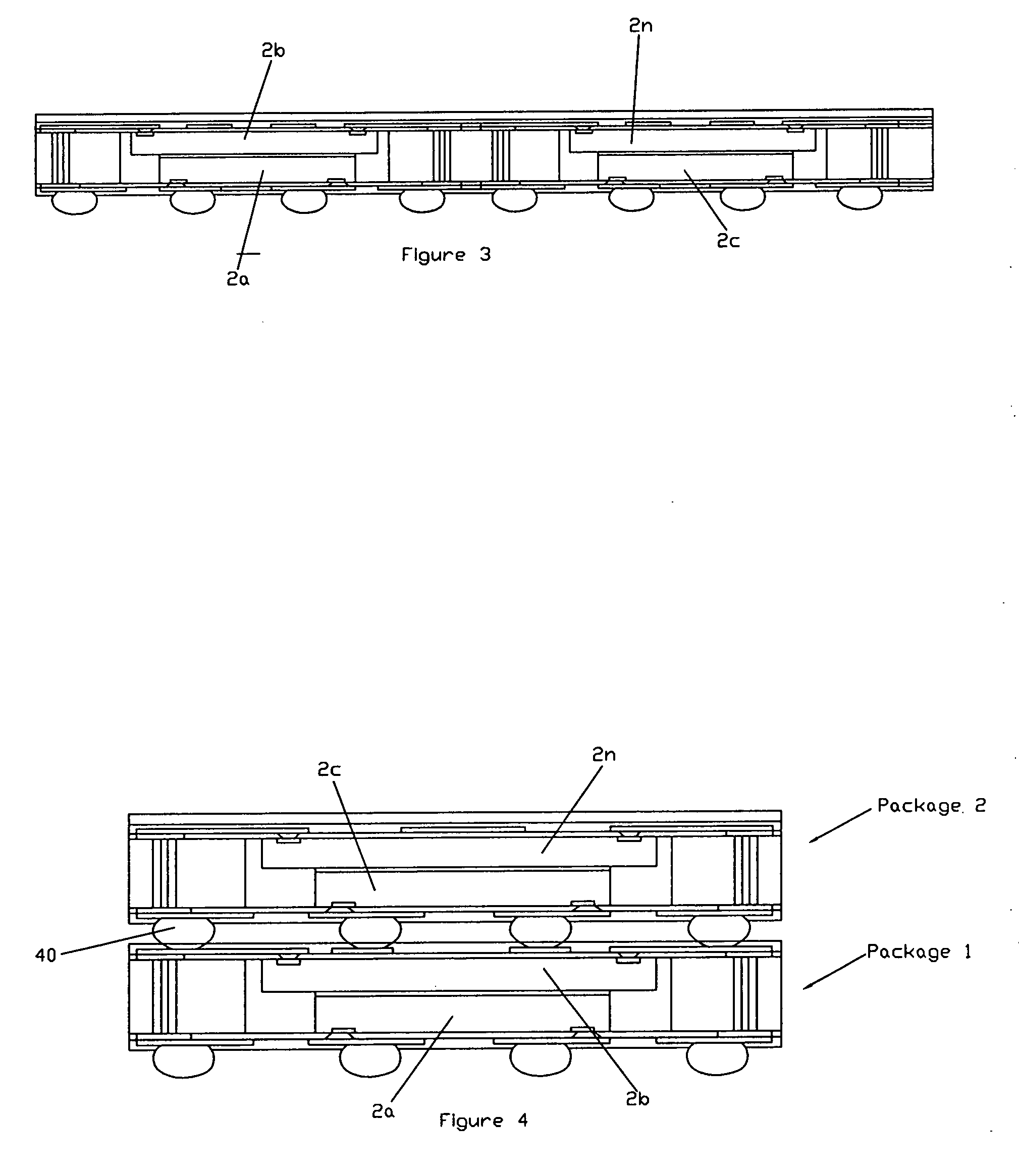

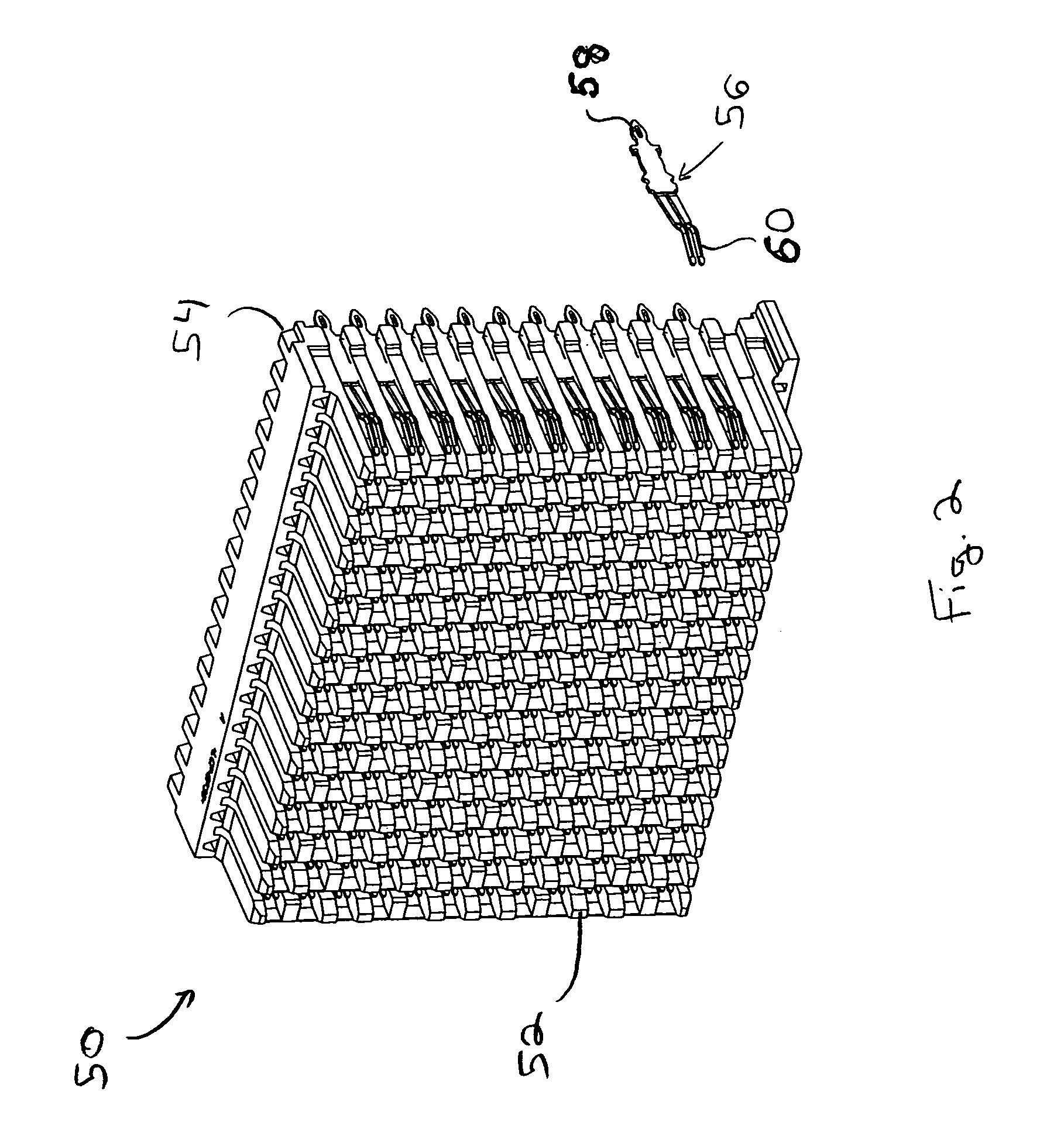

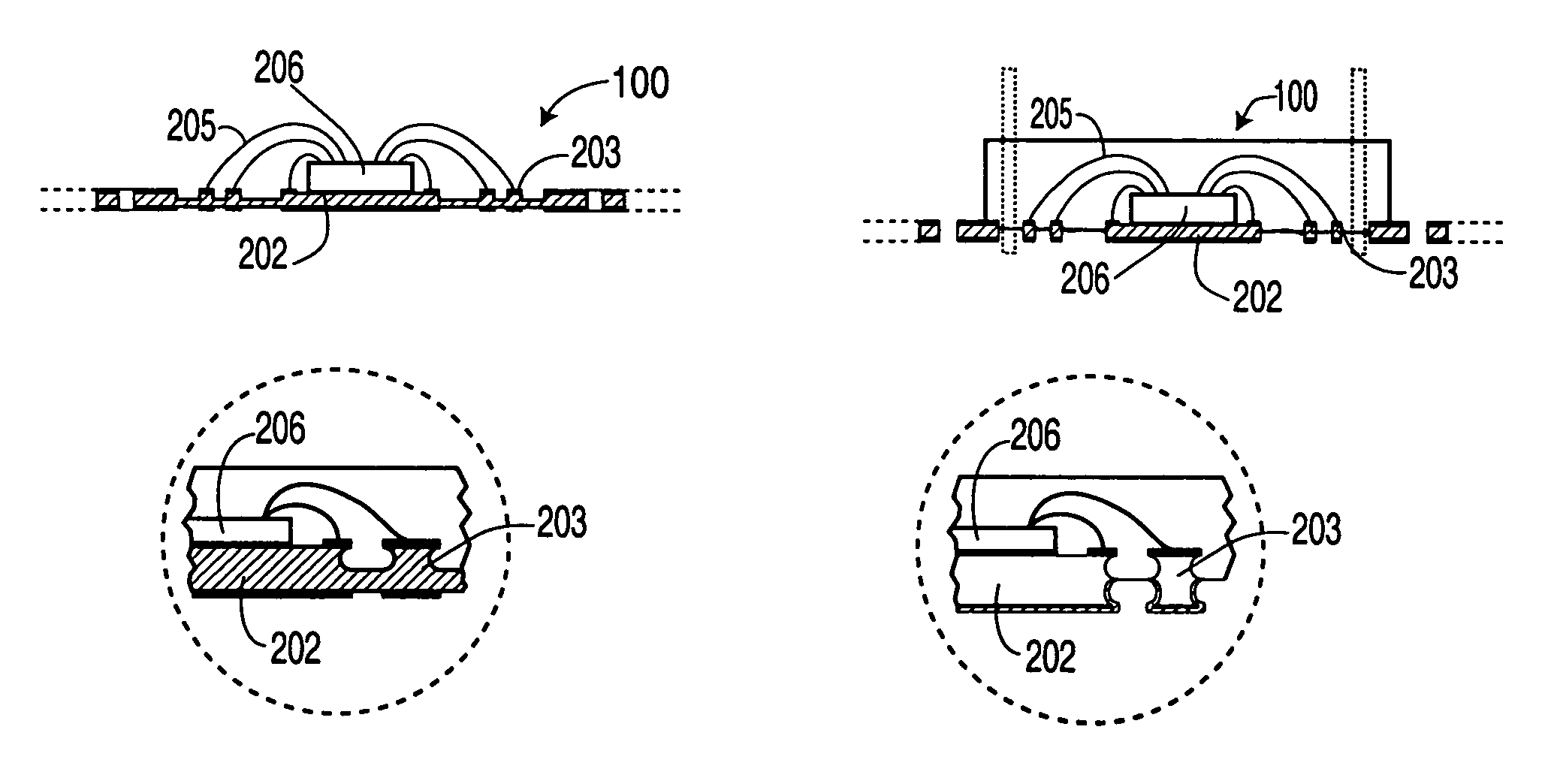

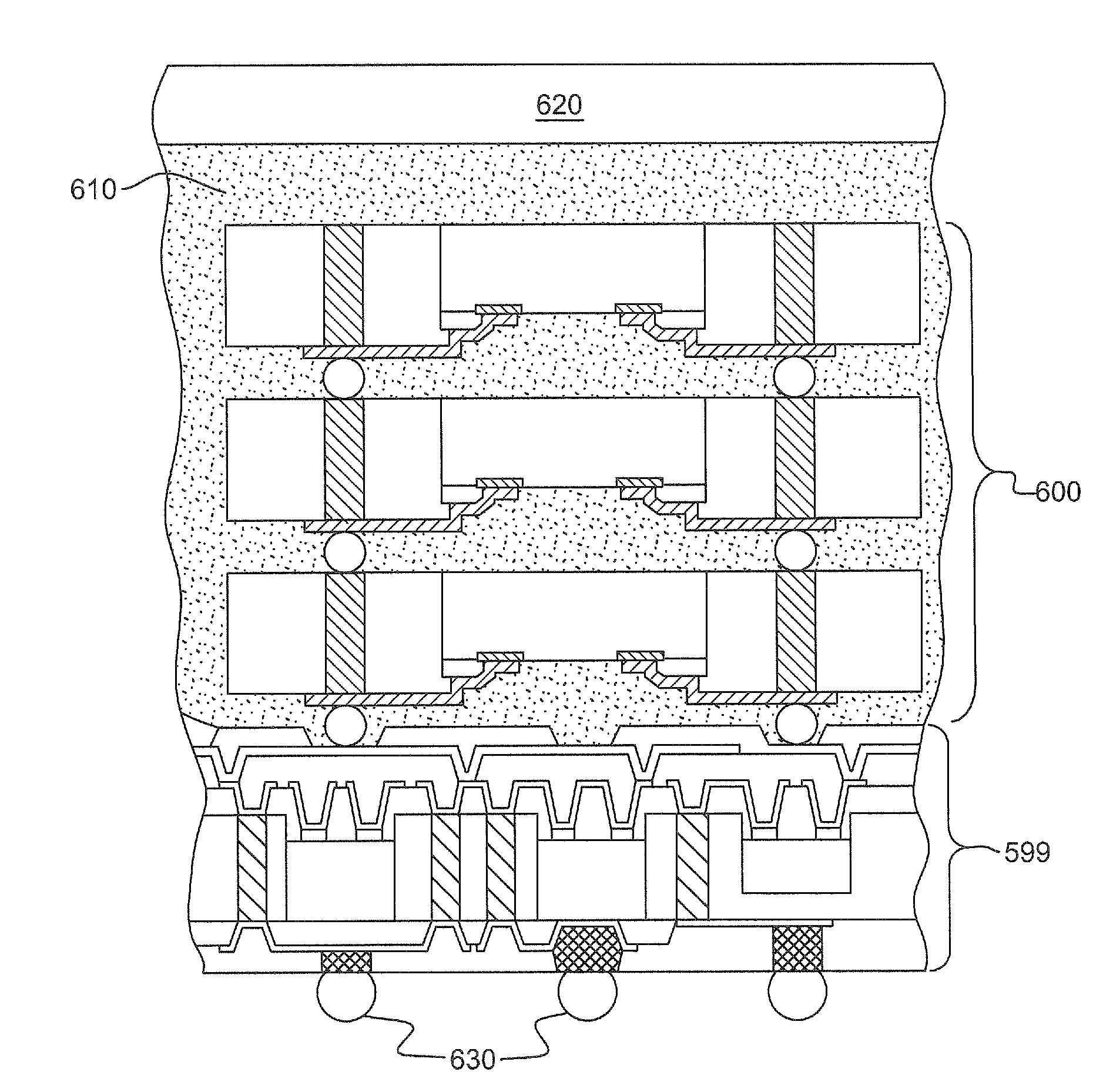

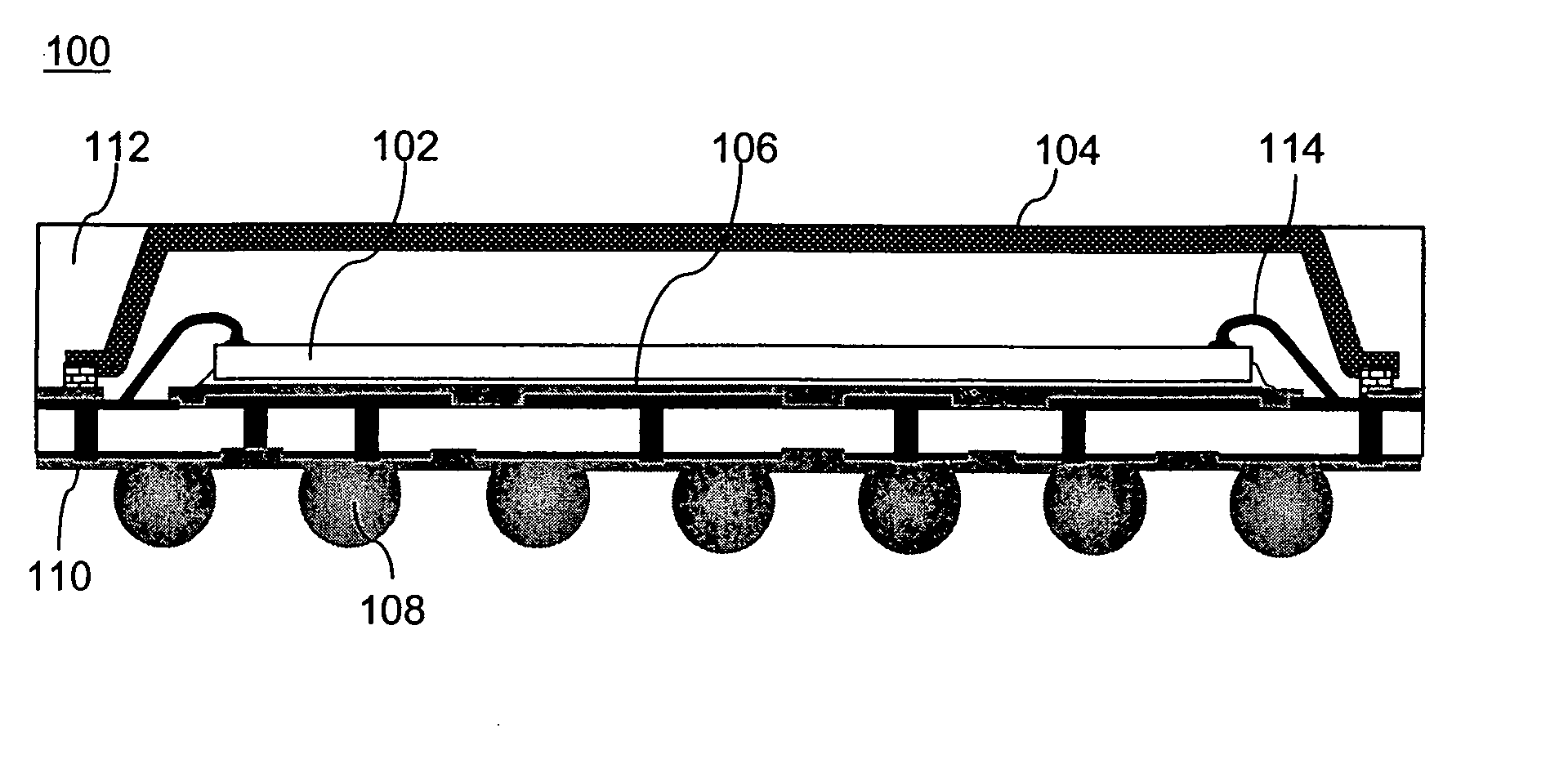

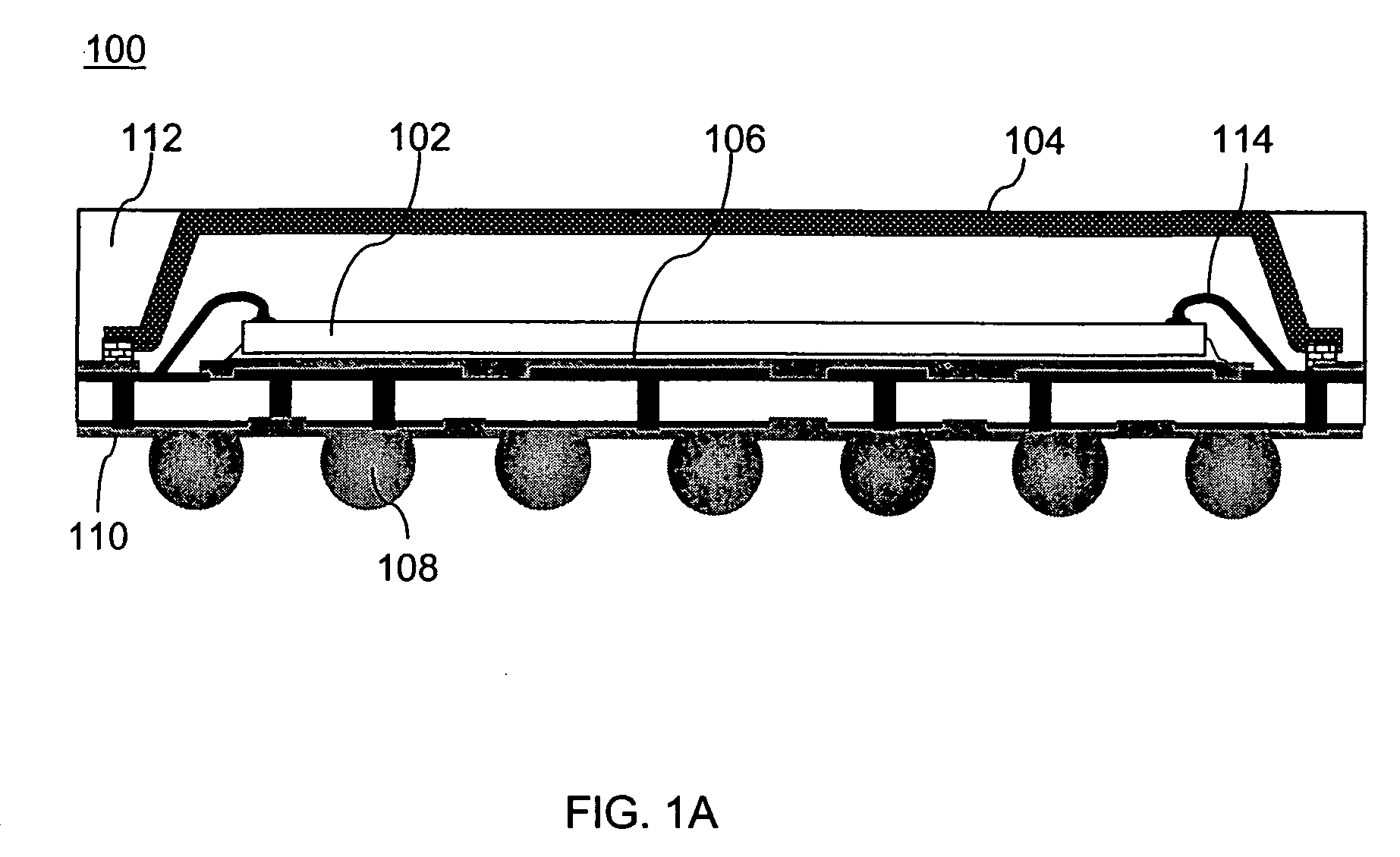

Integrated circuit (IC) package stacking and IC packages formed by same

ActiveUS20070290376A1Semiconductor/solid-state device detailsSolid-state devicesContact padSolder ball

Methods, systems, and apparatuses for integrated circuit (IC) package vertical interconnection are described herein. In an aspect of the invention, an IC package includes an IC die with contact pads. The IC package also includes interconnect members which are coupled to the die at the contact pads. An encapsulating material encapsulates the IC die and the interconnect members such that a contact surface of each interconnect member is accessible at a surface of the encapsulating material. A second IC package is coupled to the first IC package through the plurality of interconnect members of the first IC package. In an example, solder balls attached to a bottom of the second IC package are coupled to the contact surfaces of the interconnect members to couple the first IC package and the second IC package.

Owner:AVAGO TECH INT SALES PTE LTD

Analyte Monitoring Device and Methods of Use

InactiveUS20080021436A1Semiconductor/solid-state device detailsSolid-state devicesAnalyteContact pad

An analyte monitor includes a sensor, a sensor control unit, and a display unit. The sensor has, for example, a substrate, a recessed channel formed in the substrate, and conductive material disposed in the recessed channel to form a working electrode. The sensor control unit typically has a housing adapted for placement on skin and is adapted to receive a portion of an electrochemical sensor. The sensor control unit also includes two or more conductive contacts disposed on the housing and configured for coupling to two or more contact pads on the sensor. A transmitter is disposed in the housing and coupled to the plurality of conductive contacts for transmitting data obtained using the sensor. The display unit has a receiver for receiving data transmitted by the transmitter of the sensor control unit and a display coupled to the receiver for displaying an indication of a level of an analyte. The analyte monitor may also be part of a drug delivery system to alter the level of the analyte based on the data obtained using the sensor.

Owner:ABBOTT DIABETES CARE INC

Interconnect structure and formation for package stacking of molded plastic area array package

ActiveUS20070273049A1Semiconductor/solid-state device detailsSolid-state devicesContact padShell molding

Apparatuses, methods, and systems for improved integrated circuit packages are described. An integrated circuit (IC) package includes a substrate having opposing first and second surfaces, an IC die, a plurality of conductive elements, and an encapsulating material. The substrate has a plurality of contact pads on the first surface that are electrically coupled to a plurality of electrically conductive features on the second surface. The plurality of conductive elements is formed on the first surface of the substrate. The IC die is located on the first surface of the substrate. The encapsulating material encapsulates the IC die and a portion of each element of the plurality of conductive elements.

Owner:AVAGO TECH WIRELESS IP SINGAPORE PTE

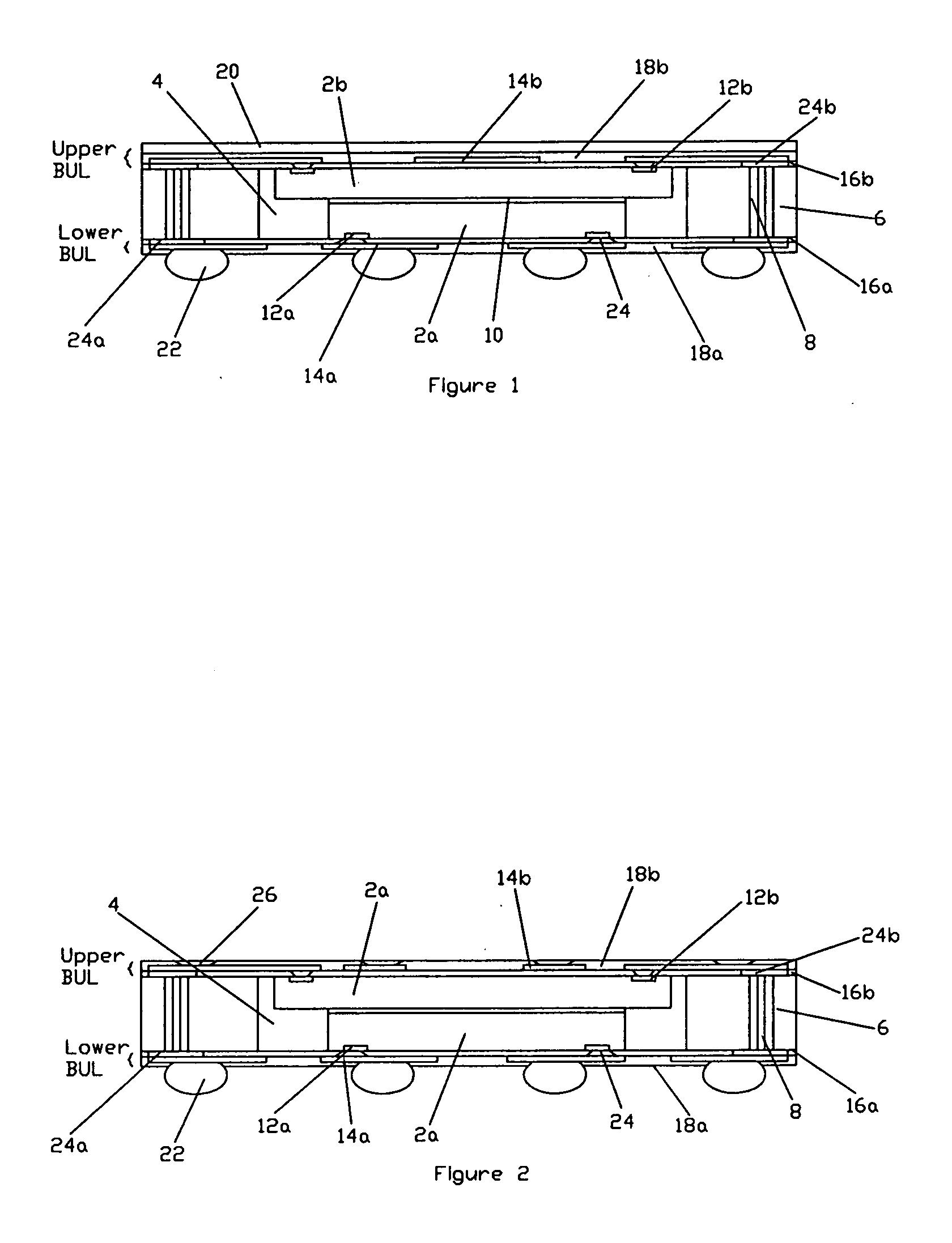

Stacking die package structure for semiconductor devices and method of the same

InactiveUS20090127686A1Low costImprove performanceSemiconductor/solid-state device detailsSolid-state devicesContact padEngineering

The present invention disclosed a first multi-die package structure for semiconductor devices, the structure comprises a substrate having die receiving window and inter-connecting through holes formed therein; a first level semiconductor die formed under a second level semiconductor die by back-to-back scheme and within the die receiving window, wherein the first multi-die package includes first level contact pads formed under the first level semiconductor die having a first level build up layer formed there-under to couple to a first bonding pads of the first level semiconductor die; a second level contact pads formed on the second level semiconductor die having a second level build up layer formed thereon to couple to second bonding pads of the second level semiconductor die; and conductive bumps formed under the first level build up layer.

Owner:ADVANCED CHIP ENG TECH

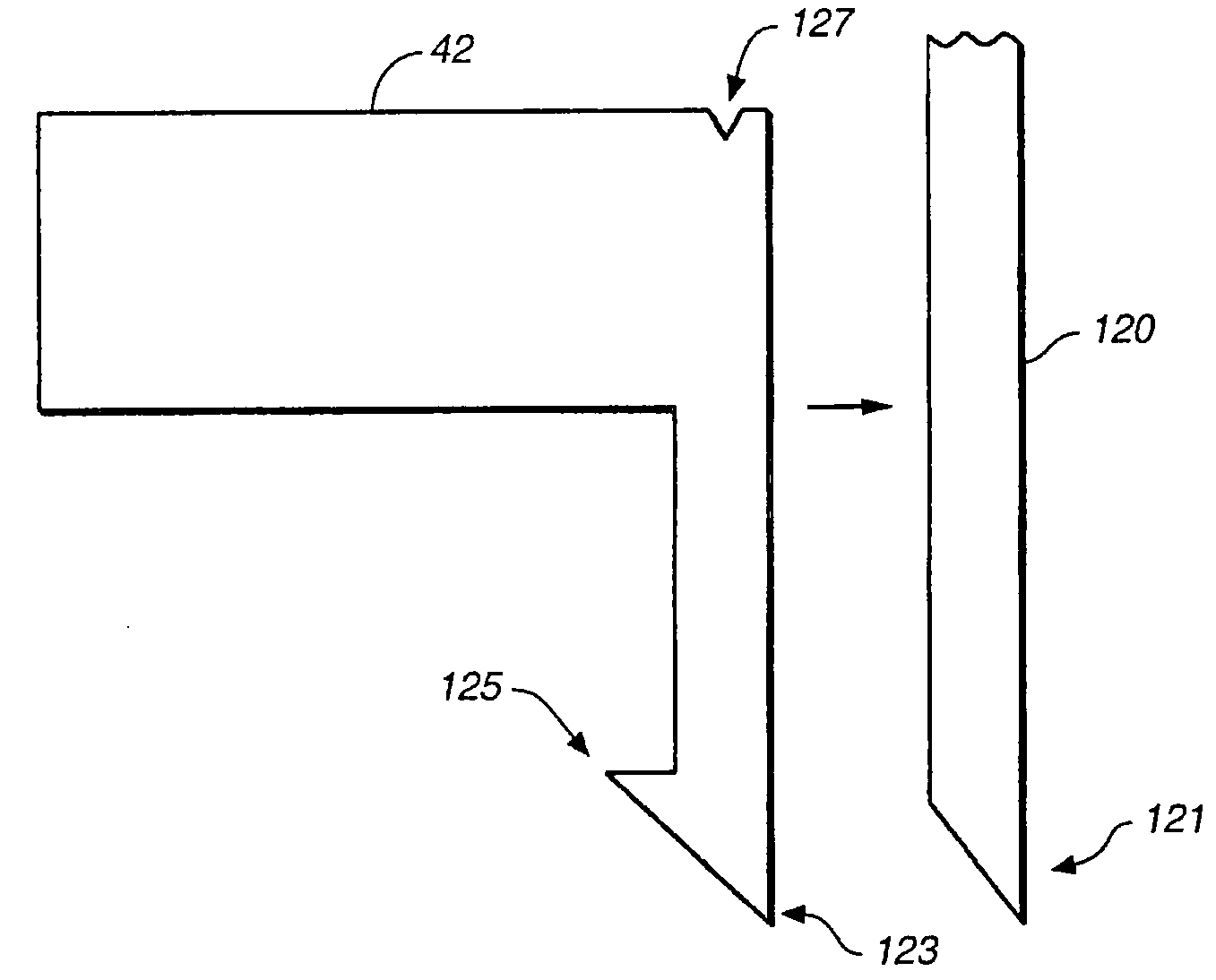

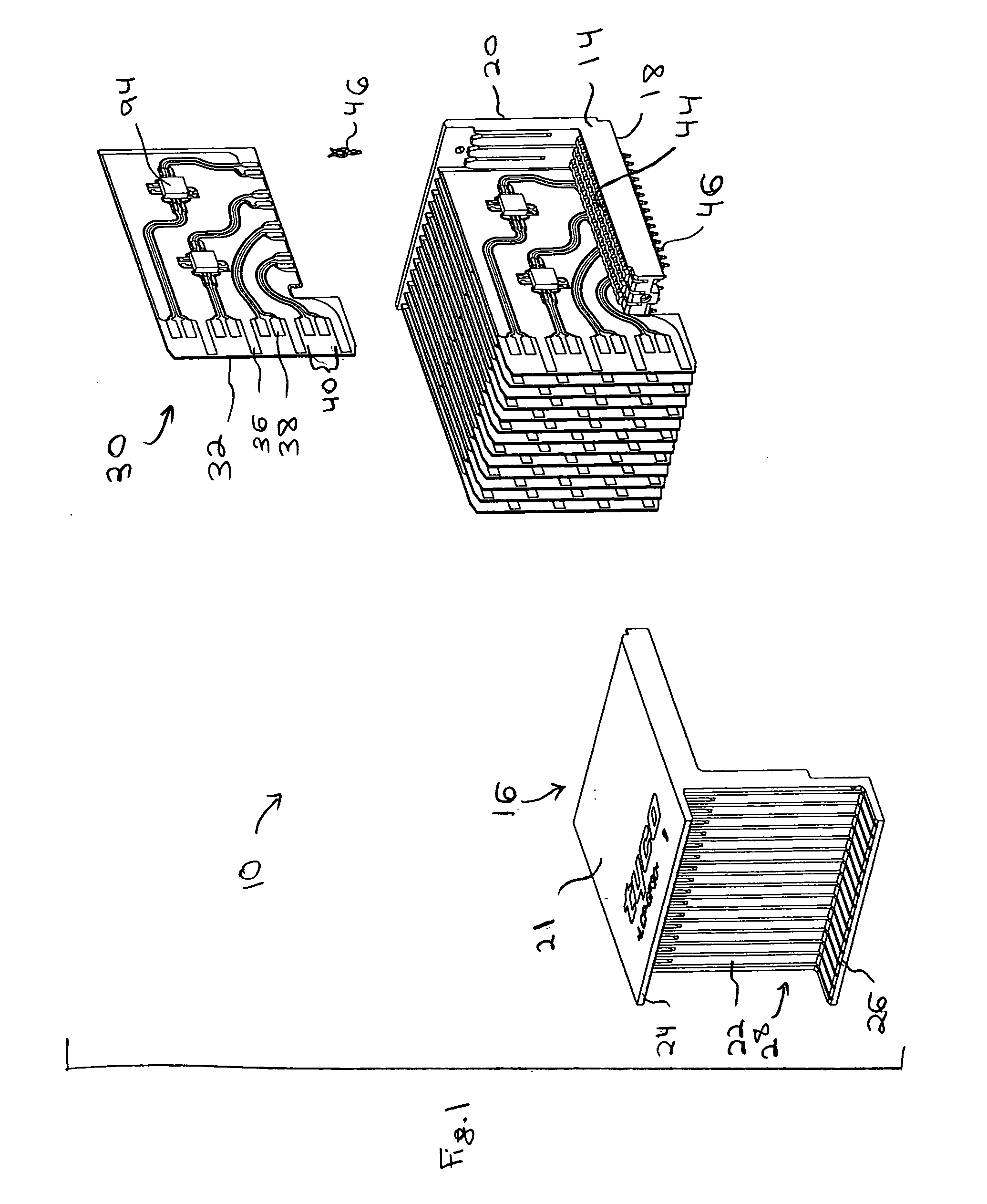

Sensor inserter methods of use

An analyte monitor includes a sensor, a sensor control unit, and a display unit. The sensor control unit typically has a housing adapted for placement on skin and is adapted to receive a portion of an electrochemical sensor. The sensor control unit also includes two or more conductive contacts disposed on the housing and configured for coupling to two or more contact pads on the sensor. A transmitter is disposed in the housing and coupled to the plurality of conductive contacts for transmitting data obtained using the sensor. The display unit has a receiver for receiving data transmitted by the transmitter of the sensor control unit and a display coupled to the receiver for displaying an indication of a level of an analyte, such as blood glucose. An inserter having a retractable introducer is provided for subcutaneously implanting the sensor in a predictable and reliable fashion.

Owner:ABBOTT DIABETES CARE INC

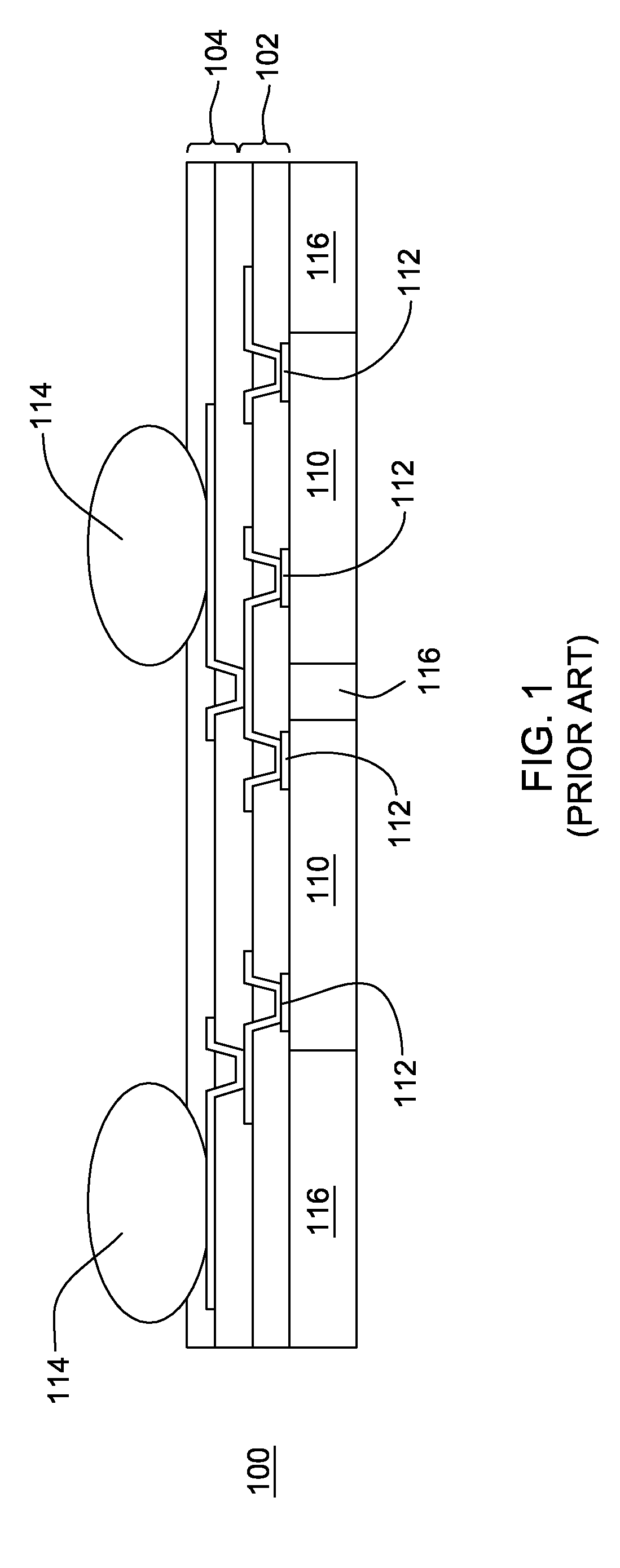

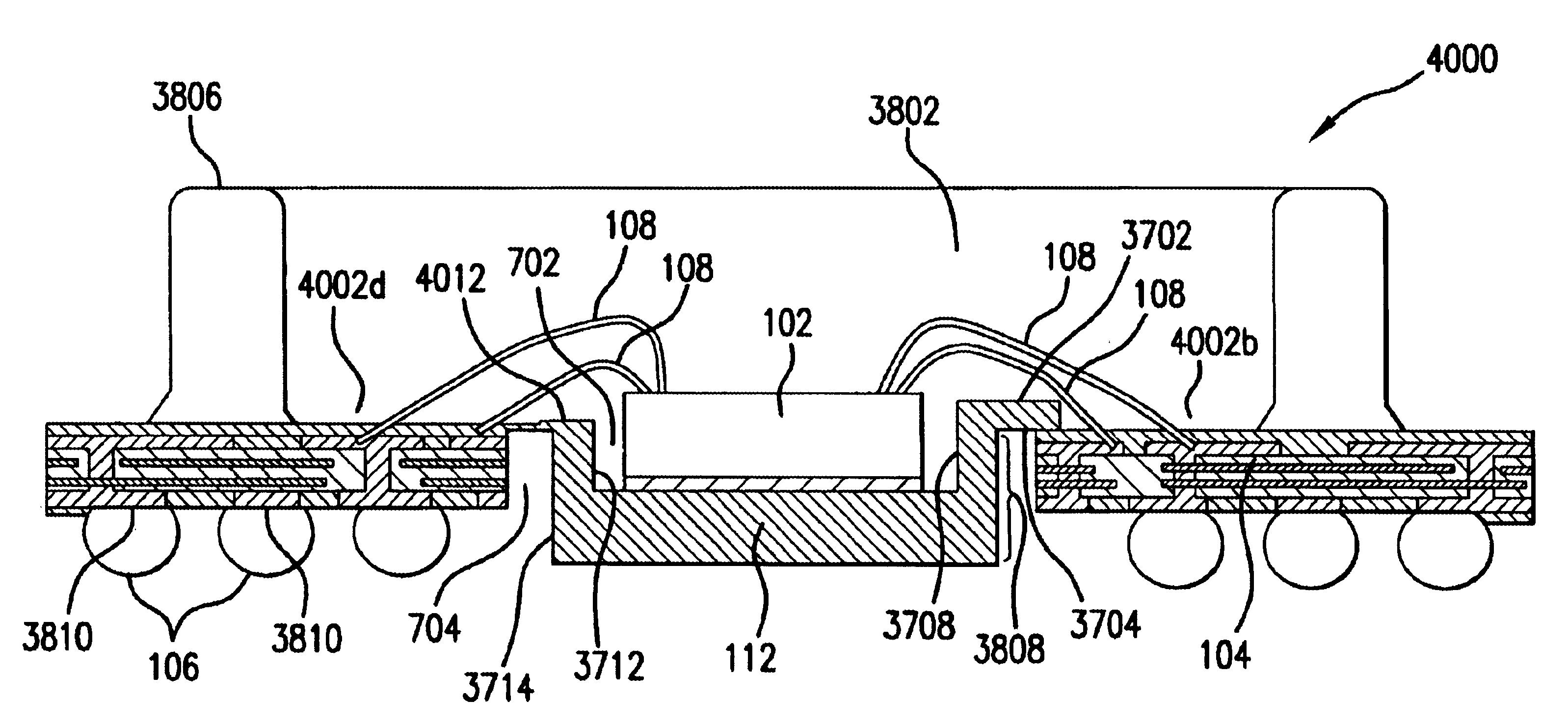

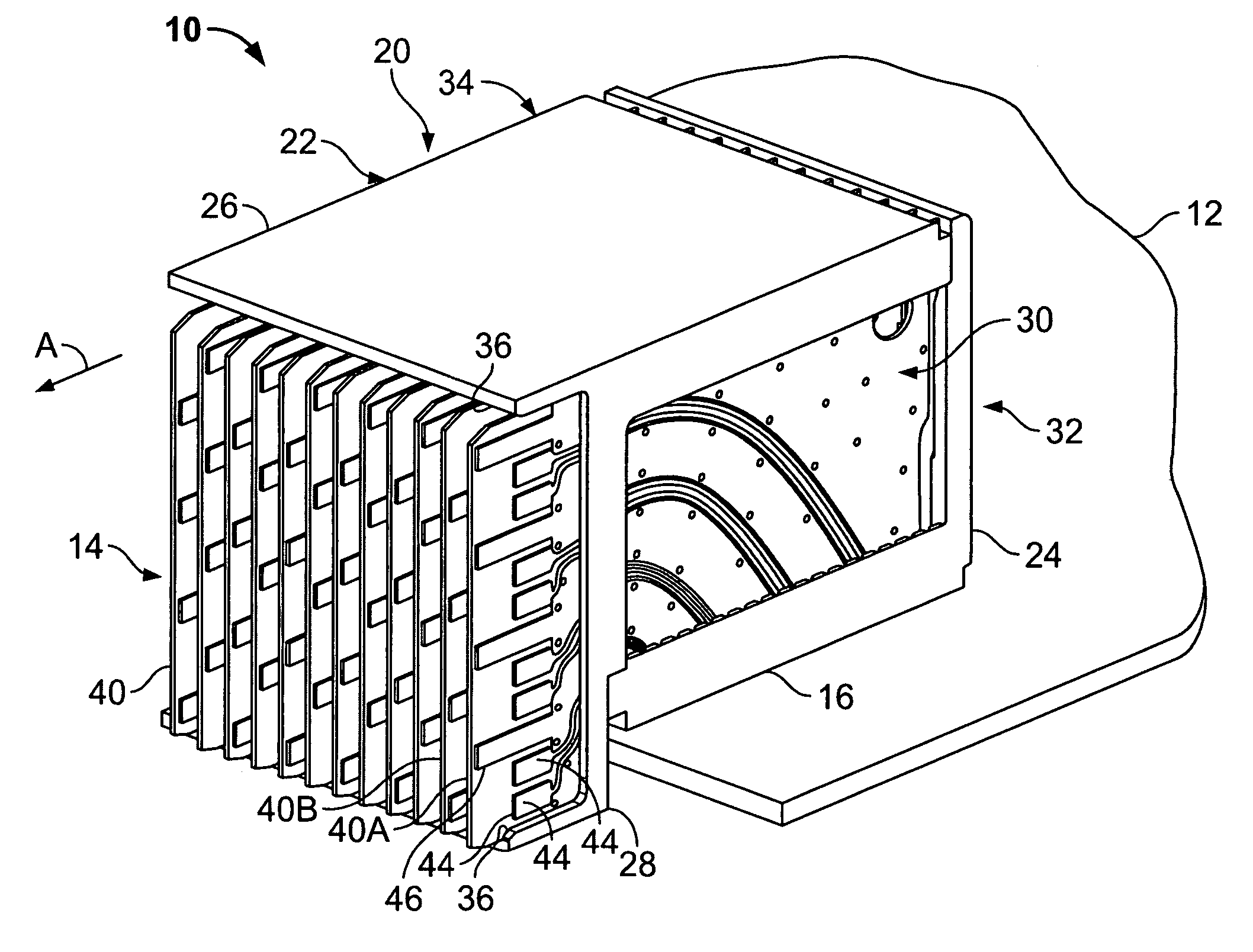

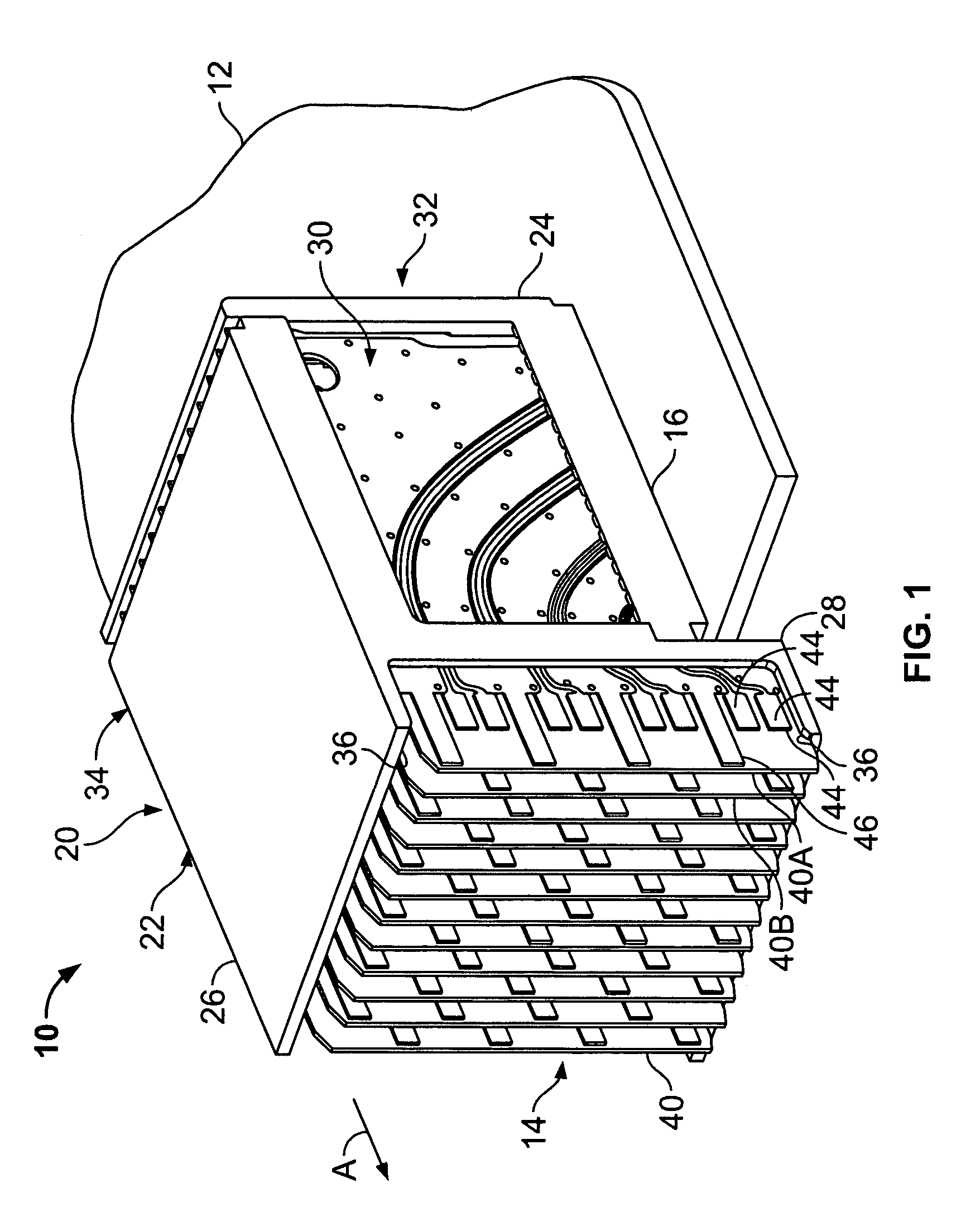

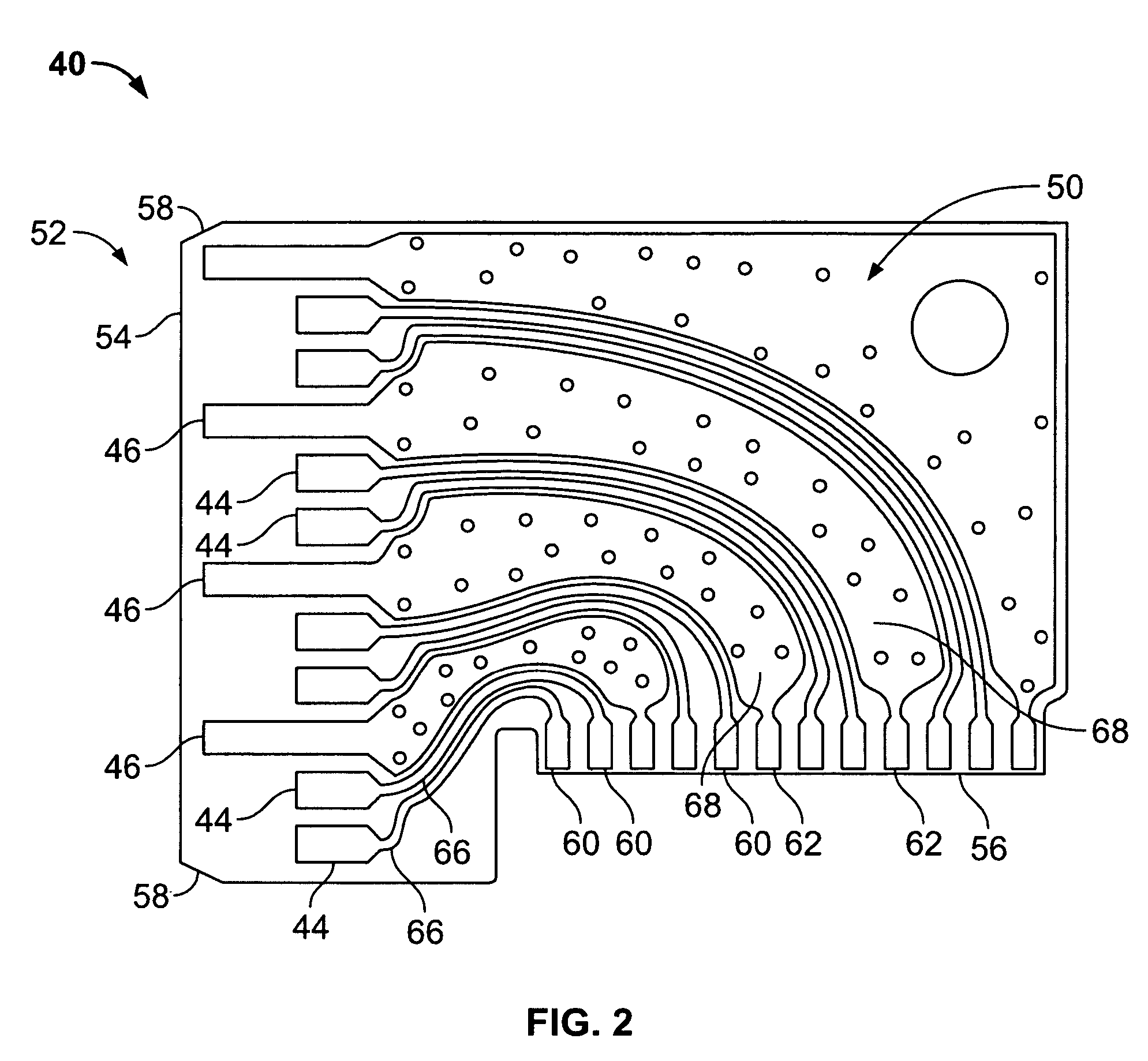

Active wafer for improved gigabit signal recovery, in a serial point-to-point architecture

ActiveUS6932649B1Increase magnitudeCoupling device detailsPrinted circuitsContact padDifferential signaling

An electrical connector is provided for operation in a point-to-point application. The connector includes an insulated housing having first and second card interfaces configured to mate with associated first and second circuit cards. An electrical wafer is held in the housing and configured to operate in a point-to-point architecture. The signal traces end at signal contact pads located proximate to first and second edges, respectively. The signal contact pads receive a unidirectional signal. Each of the signal traces include a break section at an intermediate point along a length thereof to form a disconnect in the signal traces. The connector further includes an active compensation component bridging the break section in the signal traces. The active compensation component compensates the differential signal incoming from the input contact pads for signal degradation and transmits a compensated signal outward to the output contact pads. The active compensation component transmits the signal only in a single direction within the point-to-point architecture.

Owner:TYCO ELECTRONICS LOGISTICS AG (CH)

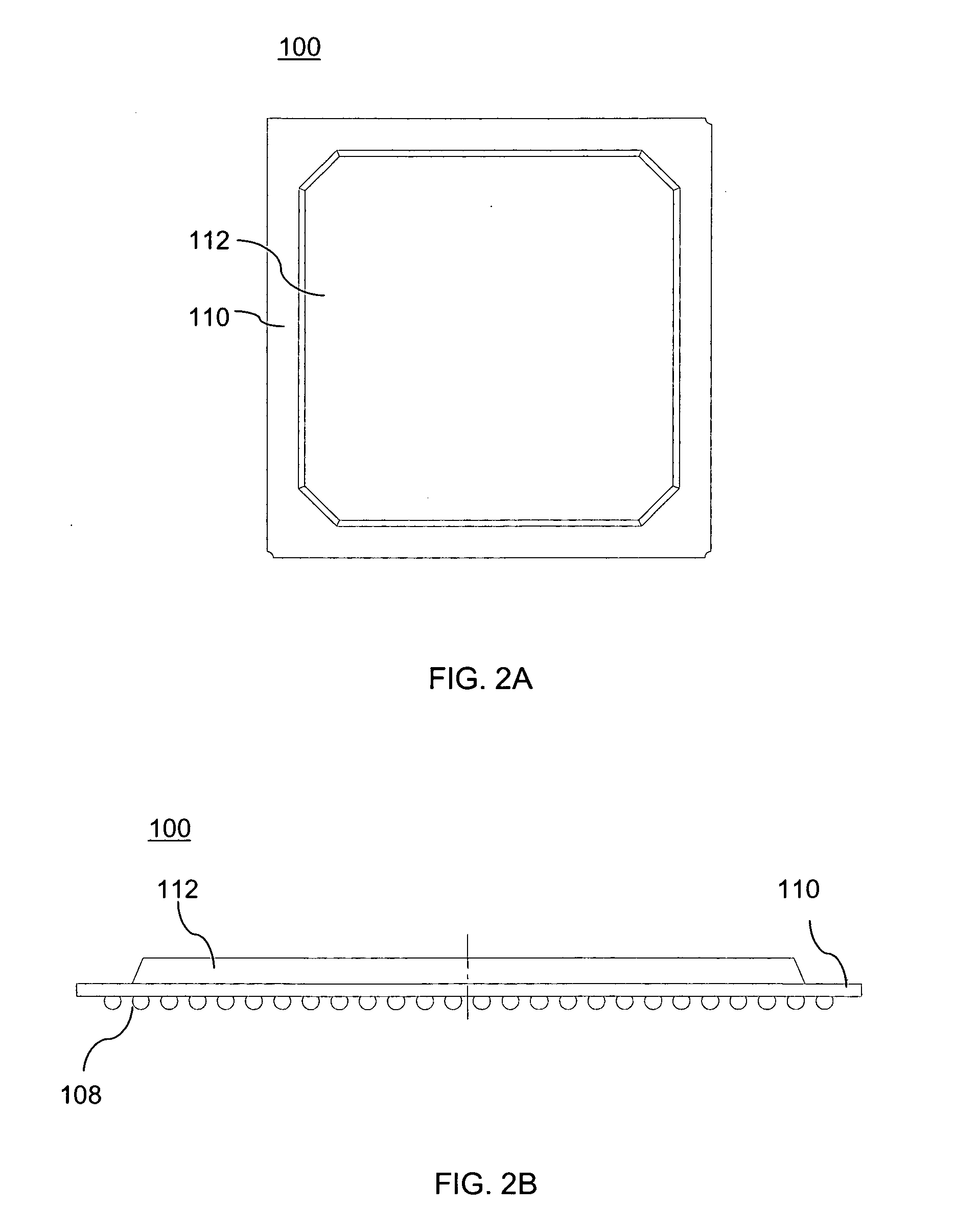

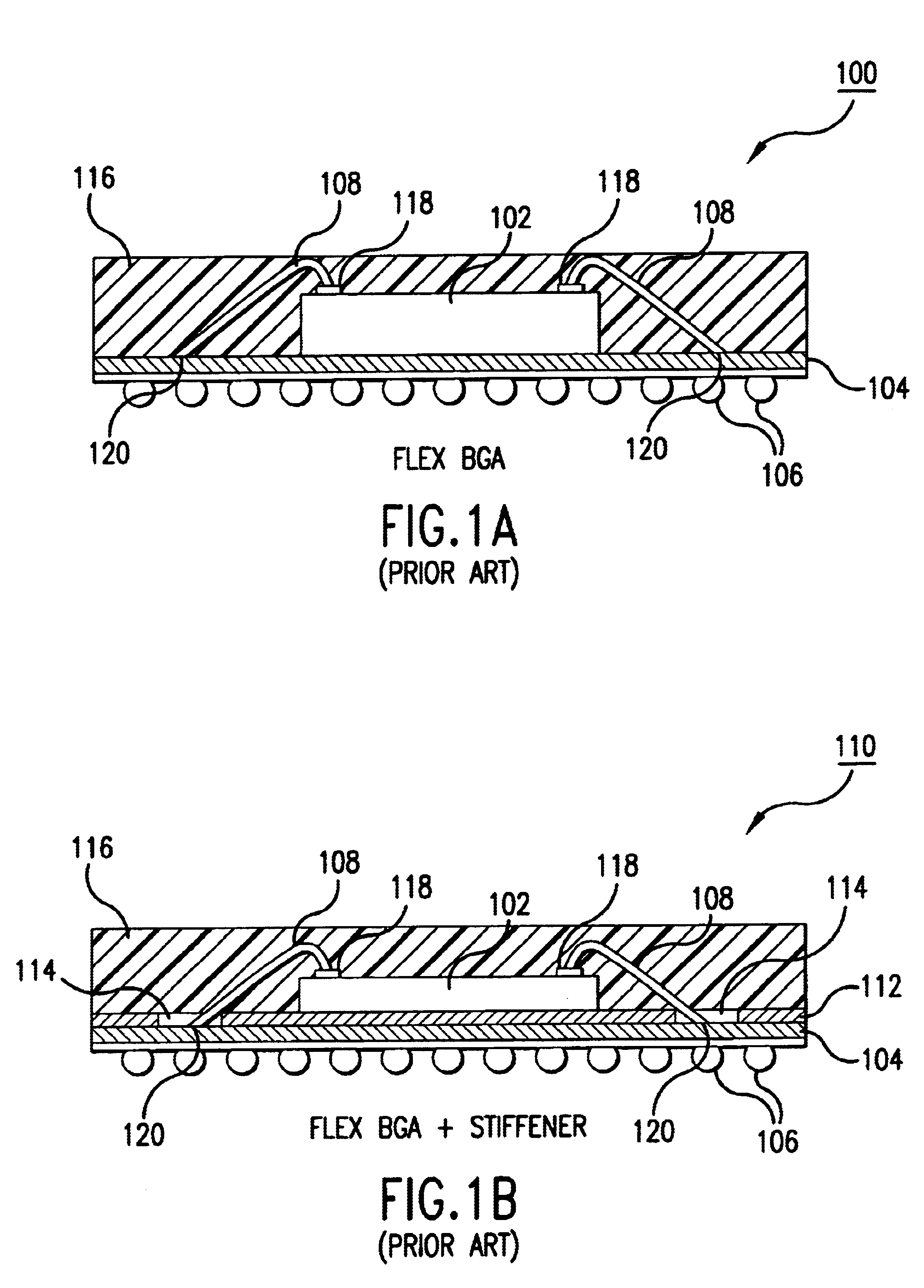

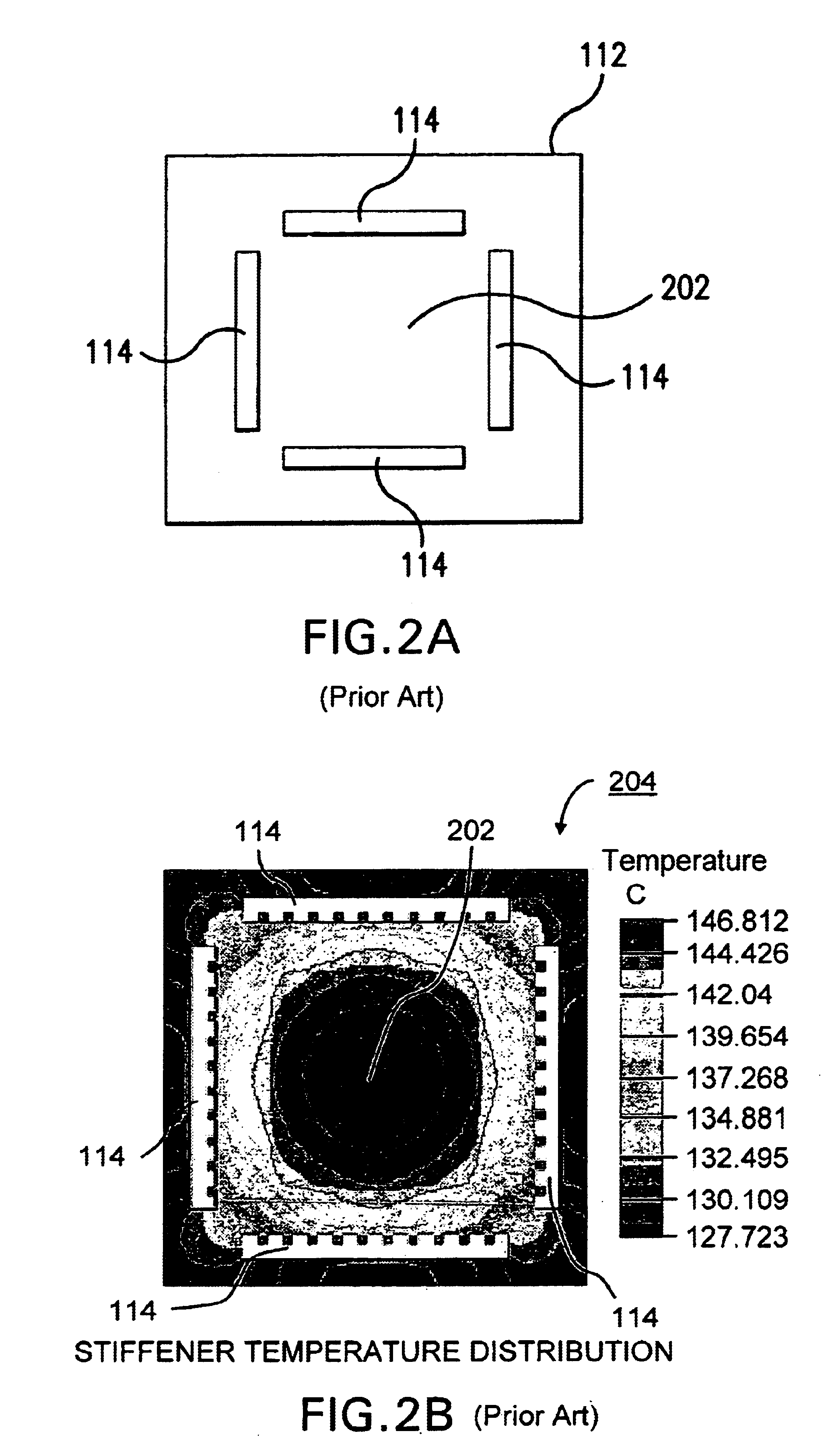

Ball grid array package with patterned stiffener layer

InactiveUS6906414B2Semiconductor/solid-state device detailsSolid-state devicesContact padEngineering

Electrically, mechanically, and thermally enhanced ball grid array (BGA) packages are described. An IC die is mounted in a centrally located cavity of a substantially planar first surface of a stiffener. The first surface of a substrate is attached to a substantially planar second surface of the stiffener. The second surface of the stiffener is opposed to the first surface of the stiffener. A centrally located protruding portion on the second surface of the stiffener is opposed to the centrally located cavity. The protruding portion extends through an opening in the substrate. A wire bond is coupled from a bond pad of the IC die to a contact pad on the first surface of the substrate through a through-pattern in the stiffener. The through-pattern in the stiffener is one of an opening through the stiffener, a recessed portion in an edge of the stiffener, a notch in an edge of the recessed portion, and a notch in an edge of the opening.

Owner:AVAGO TECH INT SALES PTE LTD

Analyte Monitoring Device And Methods Of Use

An analyte monitor includes a sensor, a sensor control unit, and a display unit. The sensor has, for example, a substrate, a recessed channel formed in the substrate, and conductive material disposed in the recessed channel to form a working electrode. The sensor control unit typically has a housing adapted for placement on skin and is adapted to receive a portion of an electrochemical sensor. The sensor control unit also includes two or more conductive contacts disposed on the housing and configured for coupling to two or more contact pads on the sensor. A transmitter is disposed in the housing and coupled to the plurality of conductive contacts for transmitting data obtained using the sensor. The display unit has a receiver for receiving data transmitted by the transmitter of the sensor control unit and a display coupled to the receiver for displaying an indication of a level of an analyte. The analyte monitor may also be part of a drug delivery system to alter the level of the analyte based on the data obtained using the sensor.

Owner:ABBOTT DIABETES CARE INC

Analyte Monitoring Device And Methods Of Use

An analyte monitor includes a sensor, a sensor control unit, and a display unit. The sensor has, for example, a substrate, a recessed channel formed in the substrate, and conductive material disposed in the recessed channel to form a working electrode. The sensor control unit typically has a housing adapted for placement on skin and is adapted to receive a portion of an electrochemical sensor. The sensor control unit also includes two or more conductive contacts disposed on the housing and configured for coupling to two or more contact pads on the sensor. A transmitter is disposed in the housing and coupled to the plurality of conductive contacts for transmitting data obtained using the sensor. The display unit has a receiver for receiving data transmitted by the transmitter of the sensor control unit and a display coupled to the receiver for displaying an indication of a level of an analyte. The analyte monitor may also be part of a drug delivery system to alter the level of the analyte based on the data obtained using the sensor.

Owner:ABBOTT DIABETES CARE INC

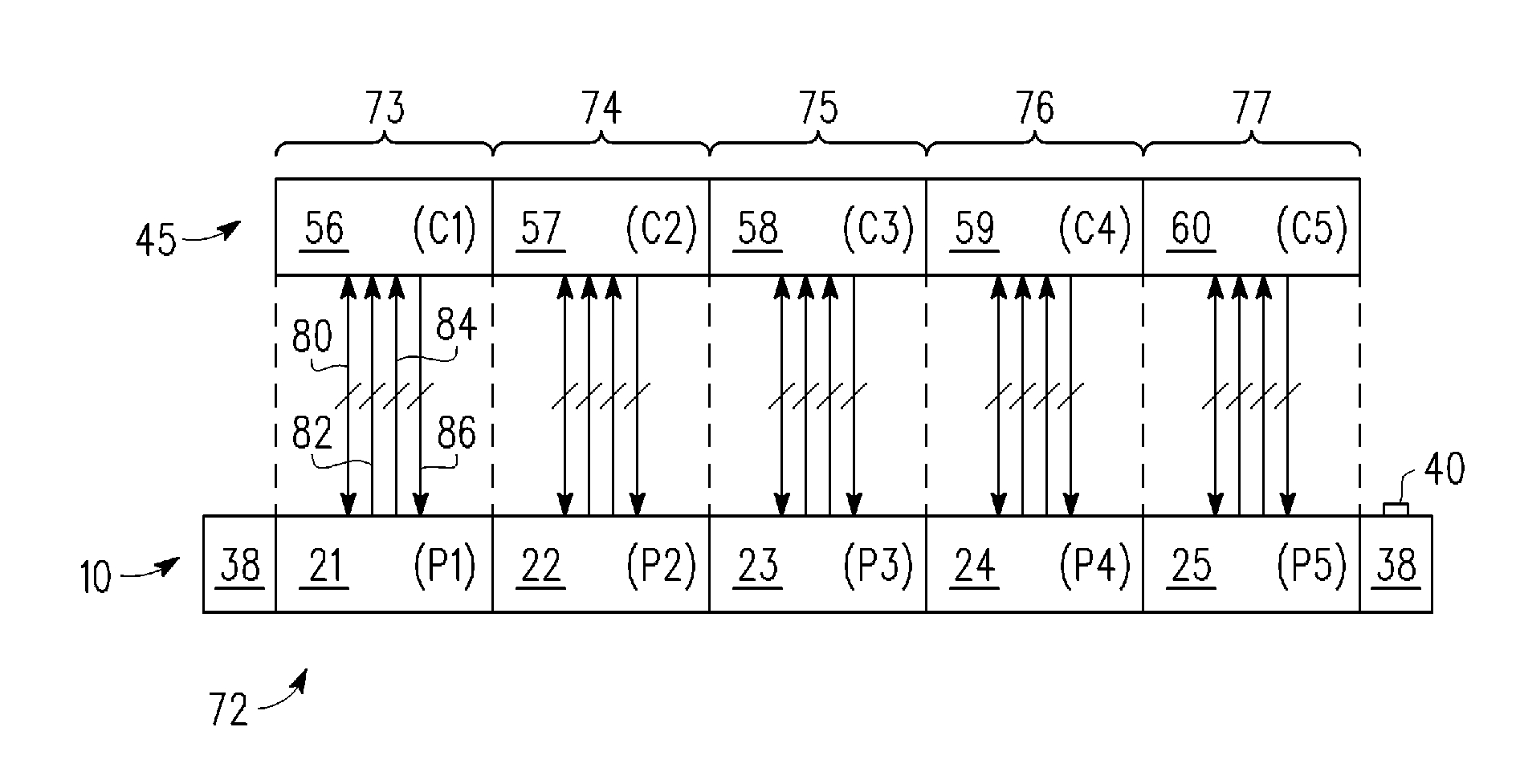

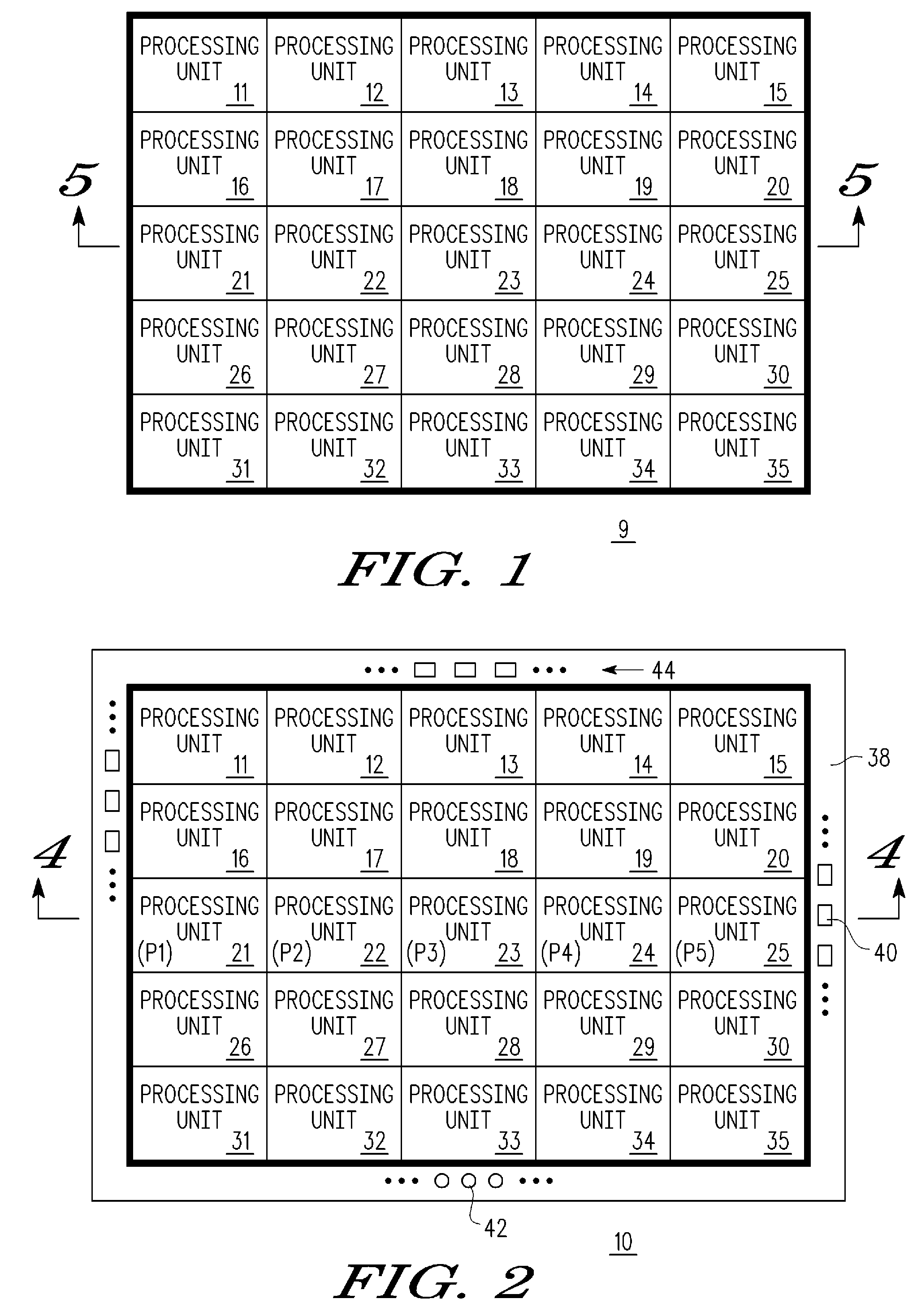

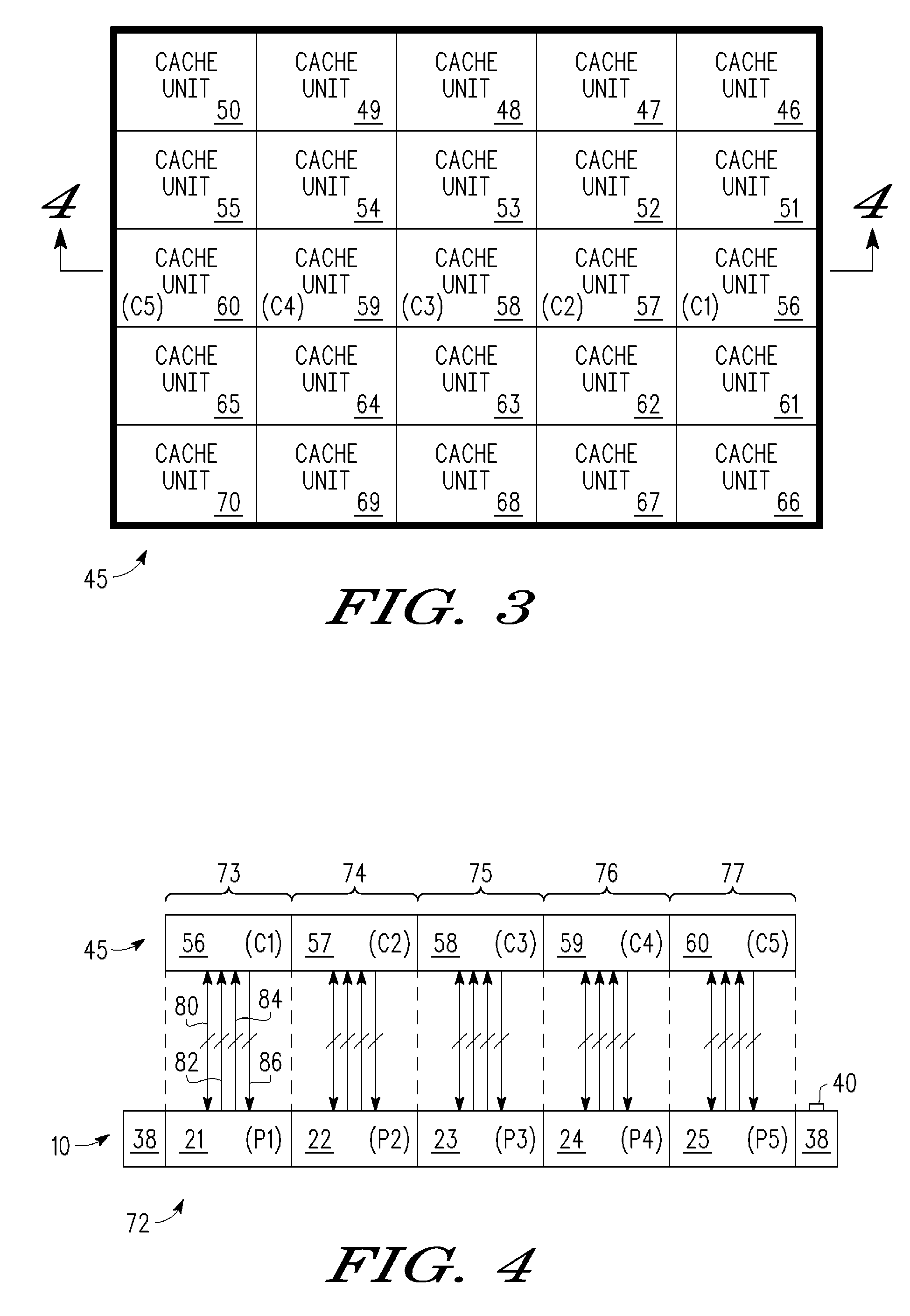

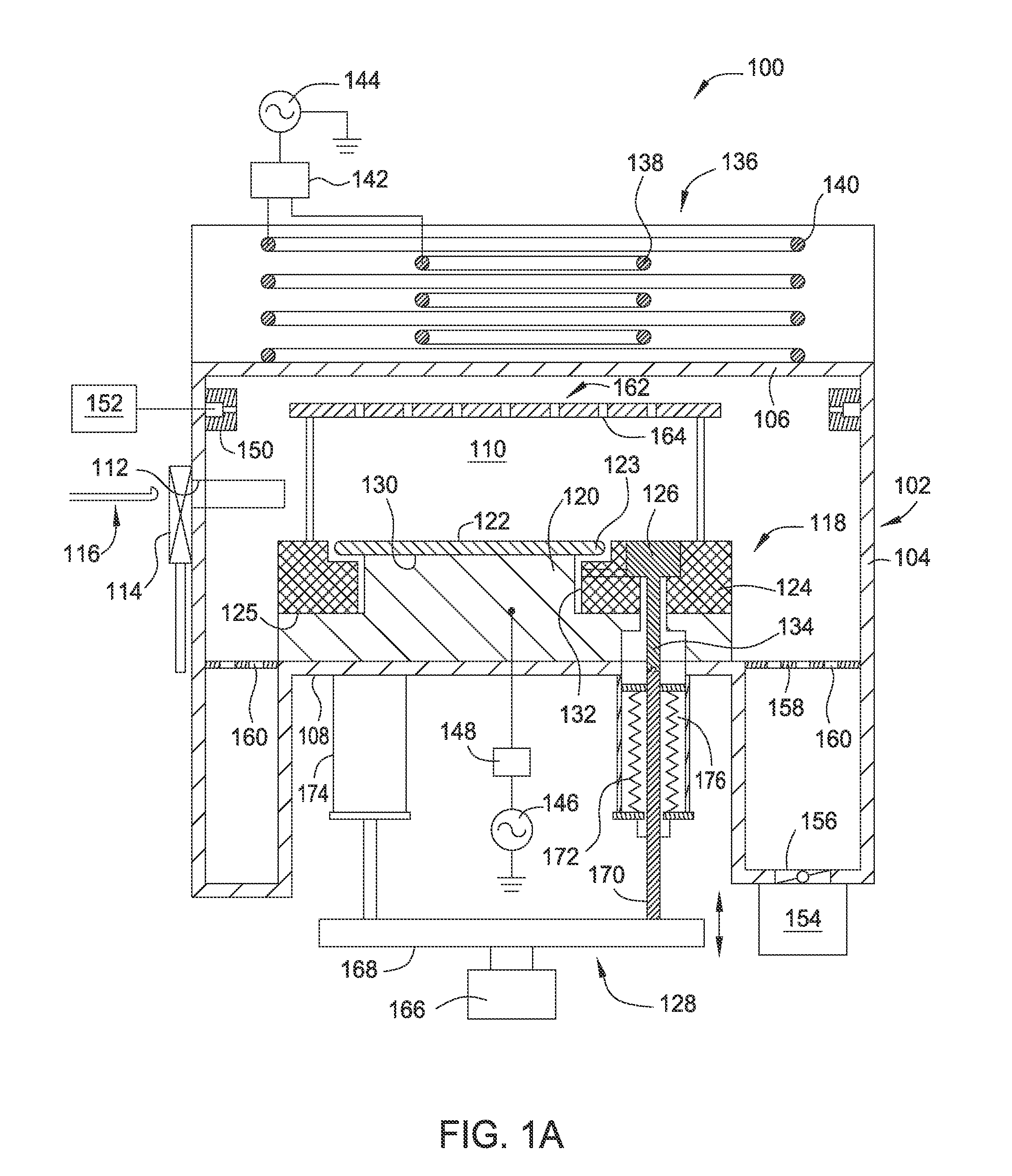

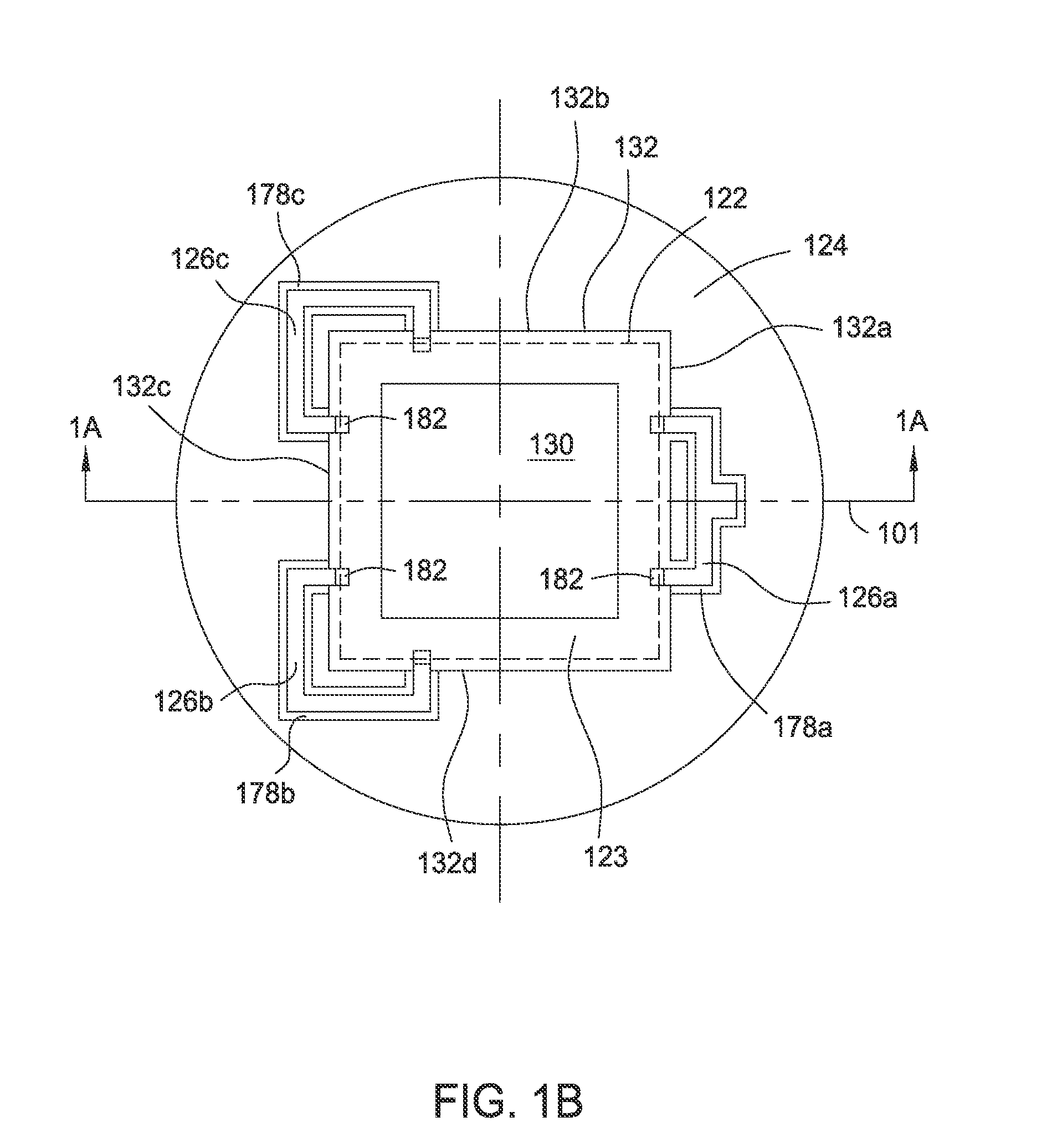

High bandwidth cache-to-processing unit communication in a multiple processor/cache system

InactiveUS7777330B2Semiconductor/solid-state device detailsSolid-state devicesContact padHigh bandwidth

A processor / cache assembly has a processor die coupled to a cache die. The processor die has a plurality of processor units arranged in an array. There is a plurality of processor sets of contact pads on the processor units, one processor set for each processor unit. Similarly, the cache die has a plurality of cache units arranged in an array. There is a plurality of cache sets of contact pads on the cache die, one cache set for each cache unit. Each cache set is in contact with one corresponding processor set.

Owner:NORTH STAR INNOVATIONS

Leadless plastic chip carrier with standoff contacts and die attach pad

ActiveUS7049177B1Improve motherboard assemblyRelieve pressureSemiconductor/solid-state device detailsSolid-state devicesEtchingContact pad

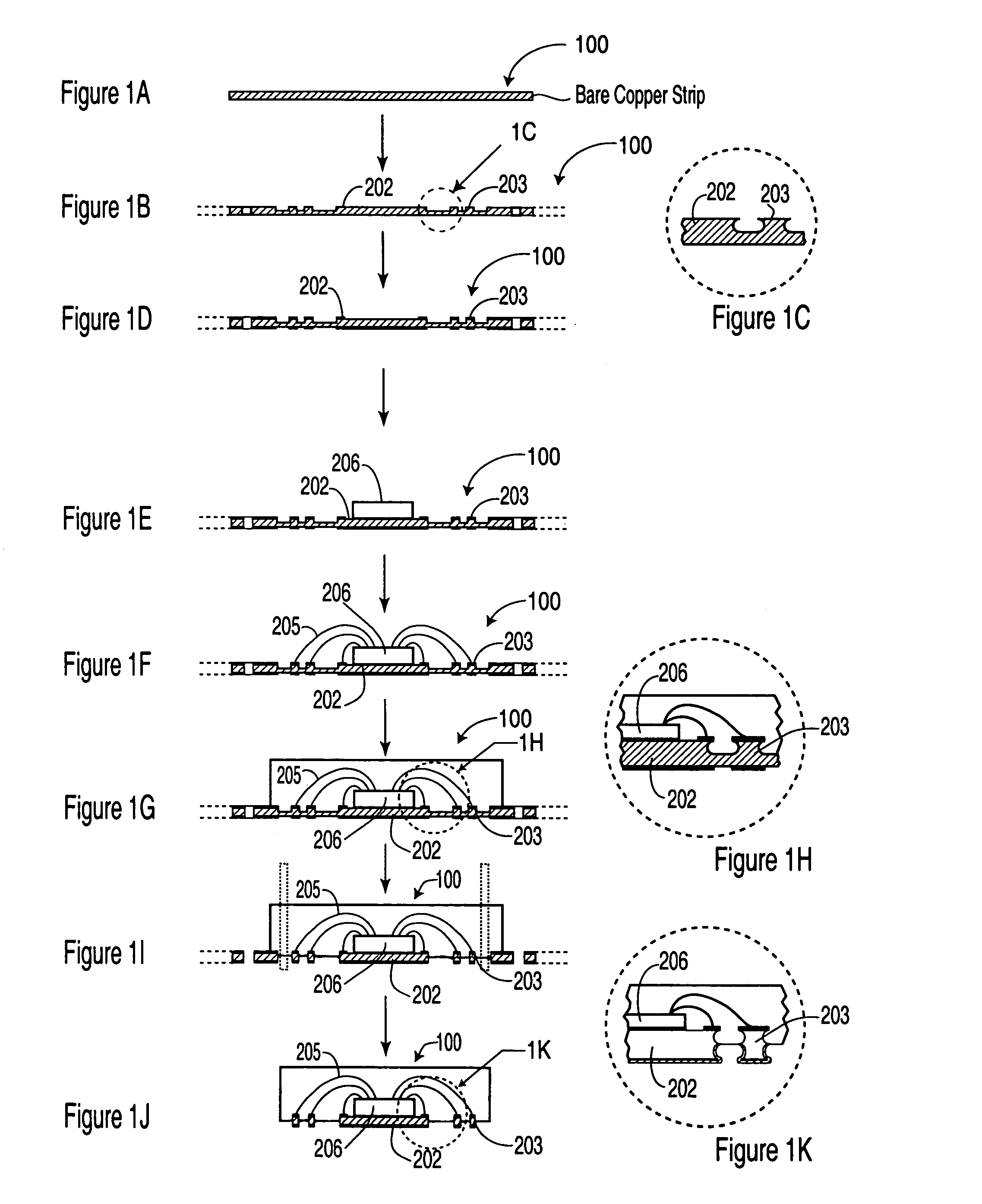

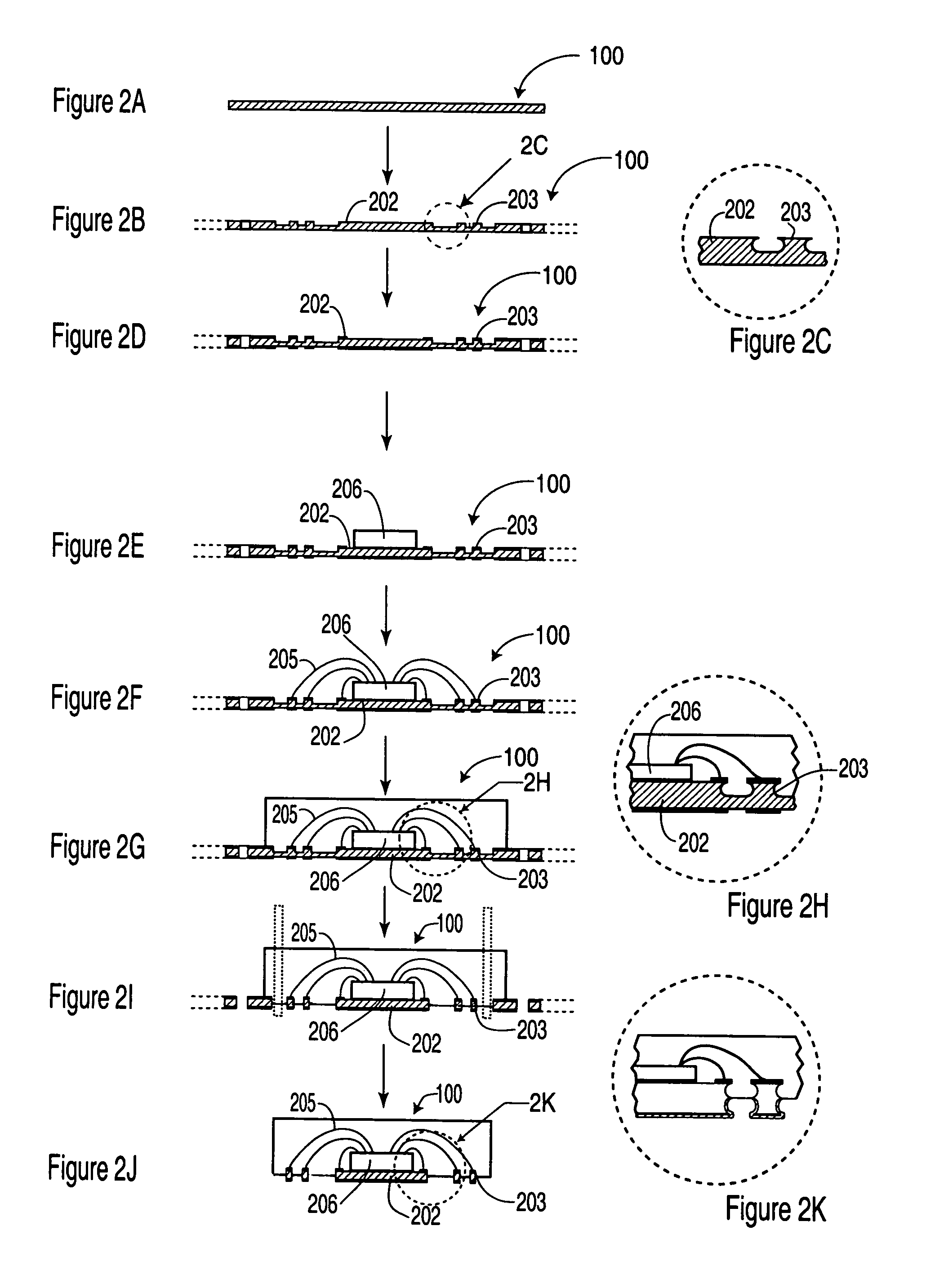

A process for fabricating a leadless plastic chip carrier includes selectively etching at least a first surface of a leadframe strip to partially define at least a plurality of contact pads and a die attach pad; selectively plating at least one layer of metal on a second surface of the leadframe strip, on an undersurface of at least the plurality of contact pads and the die attach pad; mounting a semiconductor die on the first surface, on the partially defined die attach pad; wire bonding the semiconductor die to ones of the contact pads; encapsulating the wire bonds and the semiconductor die in a molding material such that the molding material covers a first portion of the die attach pad and first portions of the contact pads; selectively etching a second surface of the leadframe strip to define a second portion of the contact pads and a second portion of the die attach pad by etching the second surface with the at least one layer of metal resisting etching; and singulating the leadless plastic chip carrier from the leadframe strip.

Owner:UTAC HEADQUARTERS PTE LTD

Analyte Monitoring Device And Methods Of Use

ActiveUS20080086043A1ElectrotherapyMaterial analysis by electric/magnetic meansData displayContact pad

An analyte monitor includes a sensor, a sensor control unit, and a display unit. The sensor has, for example, a substrate, a recessed channel formed in the substrate, and conductive material disposed in the recessed channel to form a working electrode. The sensor control unit typically has a housing adapted for placement on skin and is adapted to receive a portion of an electrochemical sensor. The sensor control unit also includes two or more conductive contacts disposed on the housing and configured for coupling to two or more contact pads on the sensor. A transmitter is disposed in the housing and coupled to the plurality of conductive contacts for transmitting data obtained using the sensor. The display unit has a receiver for receiving data transmitted by the transmitter of the sensor control unit and a display coupled to the receiver for displaying an indication of a level of an analyte. The analyte monitor may also be part of a drug delivery system to alter the level of the analyte based on the data obtained using the sensor.

Owner:ABBOTT DIABETES CARE INC

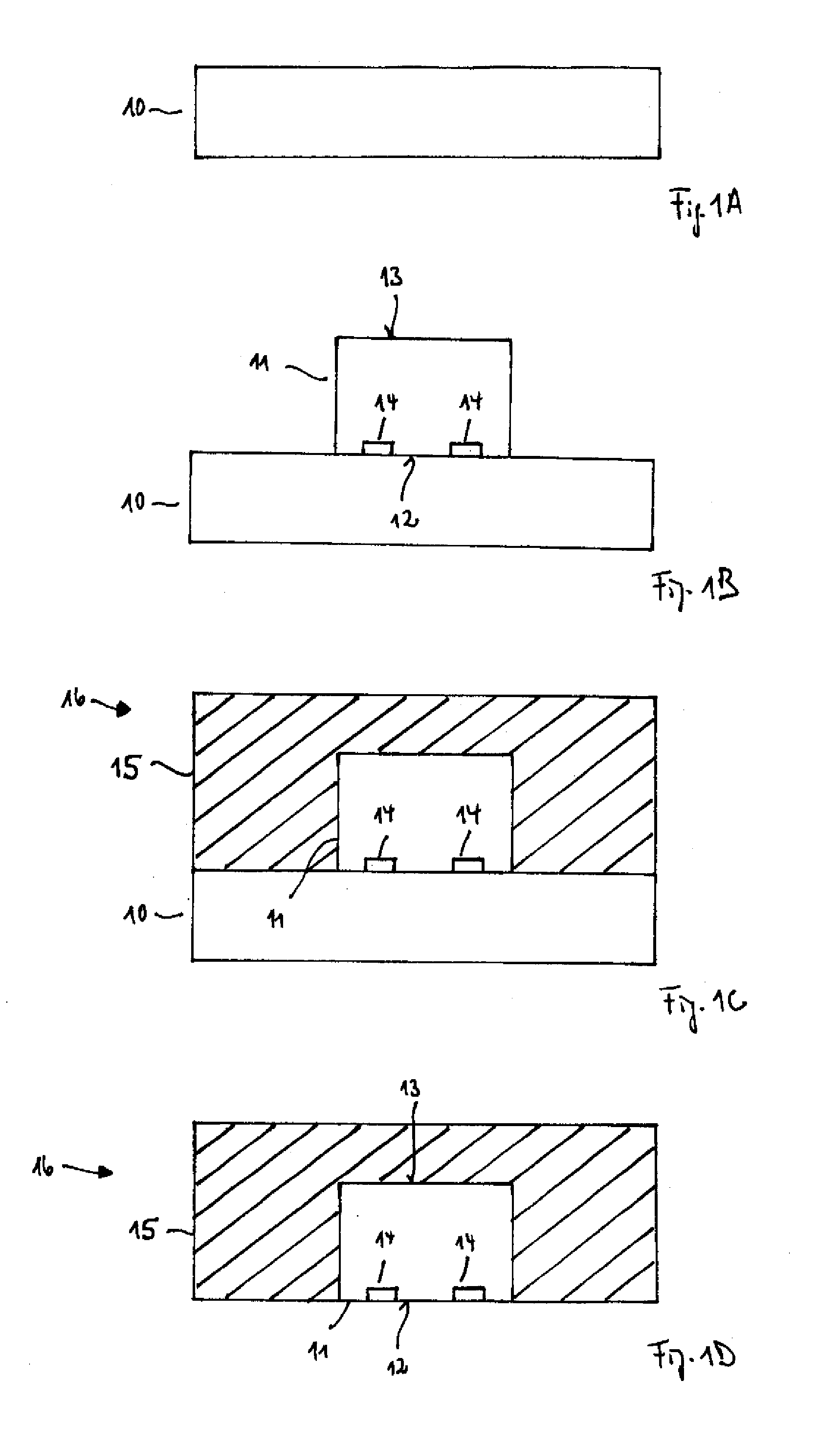

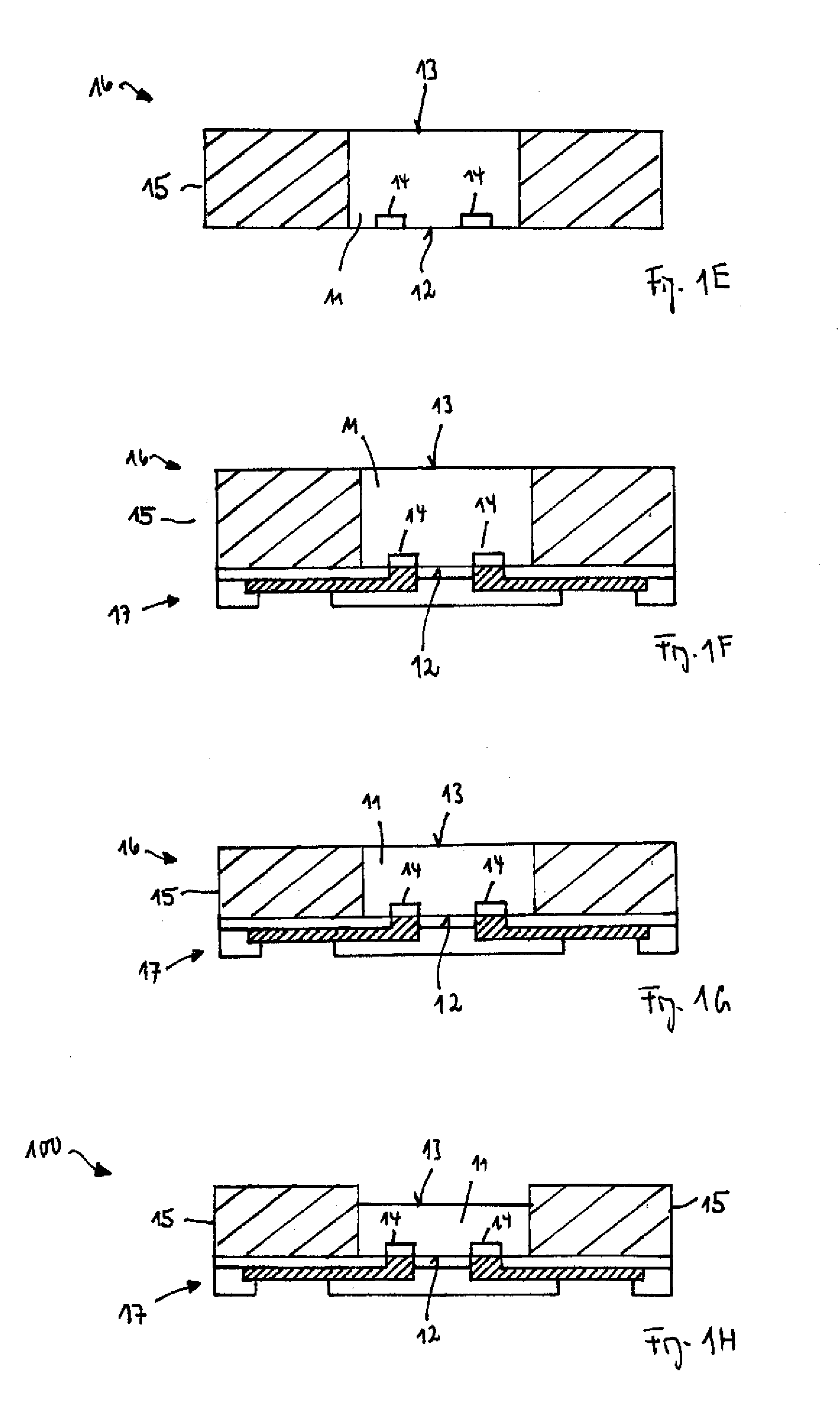

Semiconductor Device and Method of Manufacturing a Semiconductor Device Including Grinding Steps

ActiveUS20130049205A1Semiconductor/solid-state device detailsSolid-state devicesSemiconductor materialsContact pad

A method of manufacturing a device includes providing a semiconductor chip having a first face and a second face opposite to the first face with a contact pad arranged on the first face. The semiconductor chip is placed on a carrier with the first face facing the carrier. The semiconductor chip is encapsulated with an encapsulation material. The carrier is removed and the semiconductor material is removed from the second face of the first semiconductor chip without removing encapsulation material at the same time.

Owner:INTEL CORP

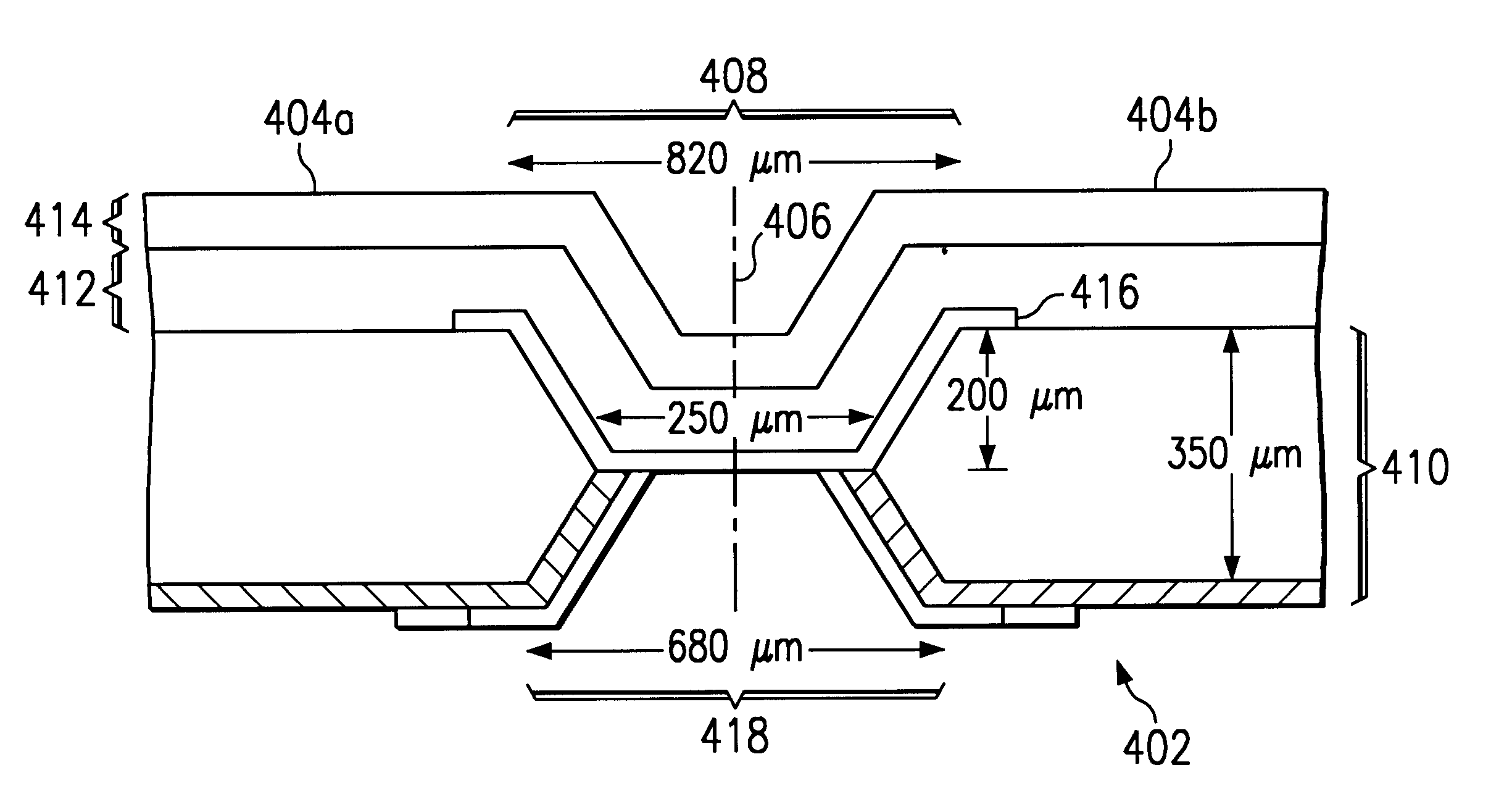

Biosensor and method of making

InactiveUS20050103624A1Immobilised enzymesBioreactor/fermenter combinationsElectrochemical biosensorNanosecond

An electrochemical biosensor with electrode elements that possess smooth, high-quality edges. These smooth edges define gaps between electrodes, electrode traces and contact pads. Due to the remarkable edge smoothness achieved with the present invention, the gaps can be quite small, which provides marked advantages in terms of test accuracy, speed and the number of different functionalities that can be packed into a single biosensor. Further, the present invention provides a novel biosensor production method in which entire electrode patterns for the inventive biosensors can be formed all at one, in nanoseconds—without regard to the complexity of the electrode patterns or the amount of conductive material that must be ablated to form them.

Owner:ROCHE DIABETES CARE INC +1

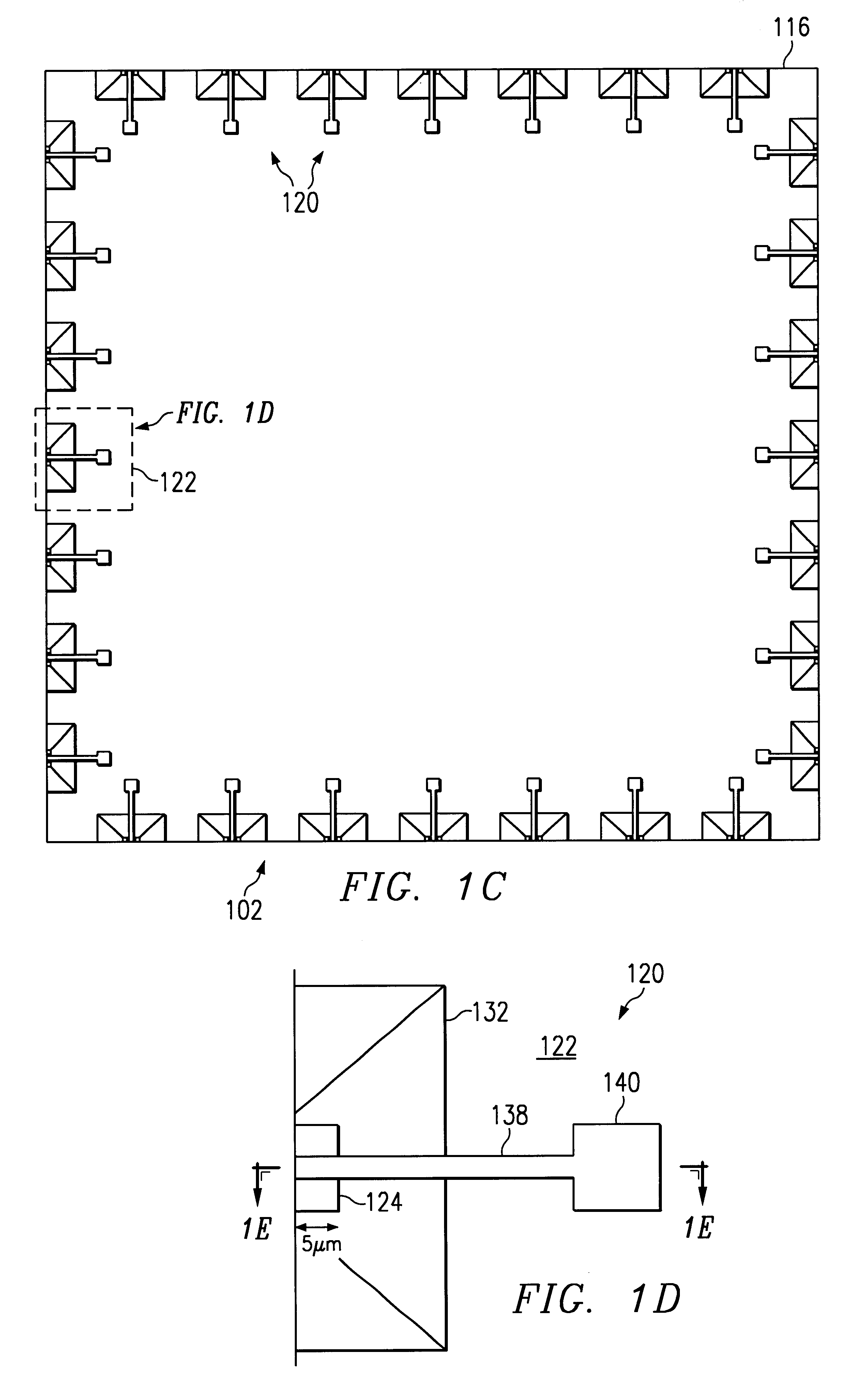

Backside contact for touchchip

InactiveUS6326689B1Semiconductor/solid-state device detailsSolid-state devicesContact formationContact pad

A contact is formed within an active region of a substrate at the edge of a die, preferably within the first metallization level in the active region of the substrate. An opening having sloped sidewalls is then etched into the back side of the substrate, exposing a portion of the active region contact. An interconnect is formed on the opening sidewall to connect the active region contact with a die contact pad on the backside surface of the substrate. The active region contact preferably spans a boundary between two die, with the opening preferably etched across the boundary to permit inter-connects on opposing sidewalls of the opening to each contact the active region contact within different die, connecting the active region contact to die contact pads on different dice. The dice are then separated along the boundary, through the active region contact which becomes two separate active region contacts. By forming a shared contact opening spanning two dice, the backside contact is formed around the die edge and the backside surface area necessary for the contact opening is minimized. The backside contact allows direct placement of the integrated circuit die on contacts within the packaging, such as a ball grid array, eliminating the need for wire bonds. The need for a pad etch through passivation material overlying active devices on the front side of the die is also eliminated, and no mask levels are added for the devices formed on the front side.

Owner:STMICROELECTRONICS SRL

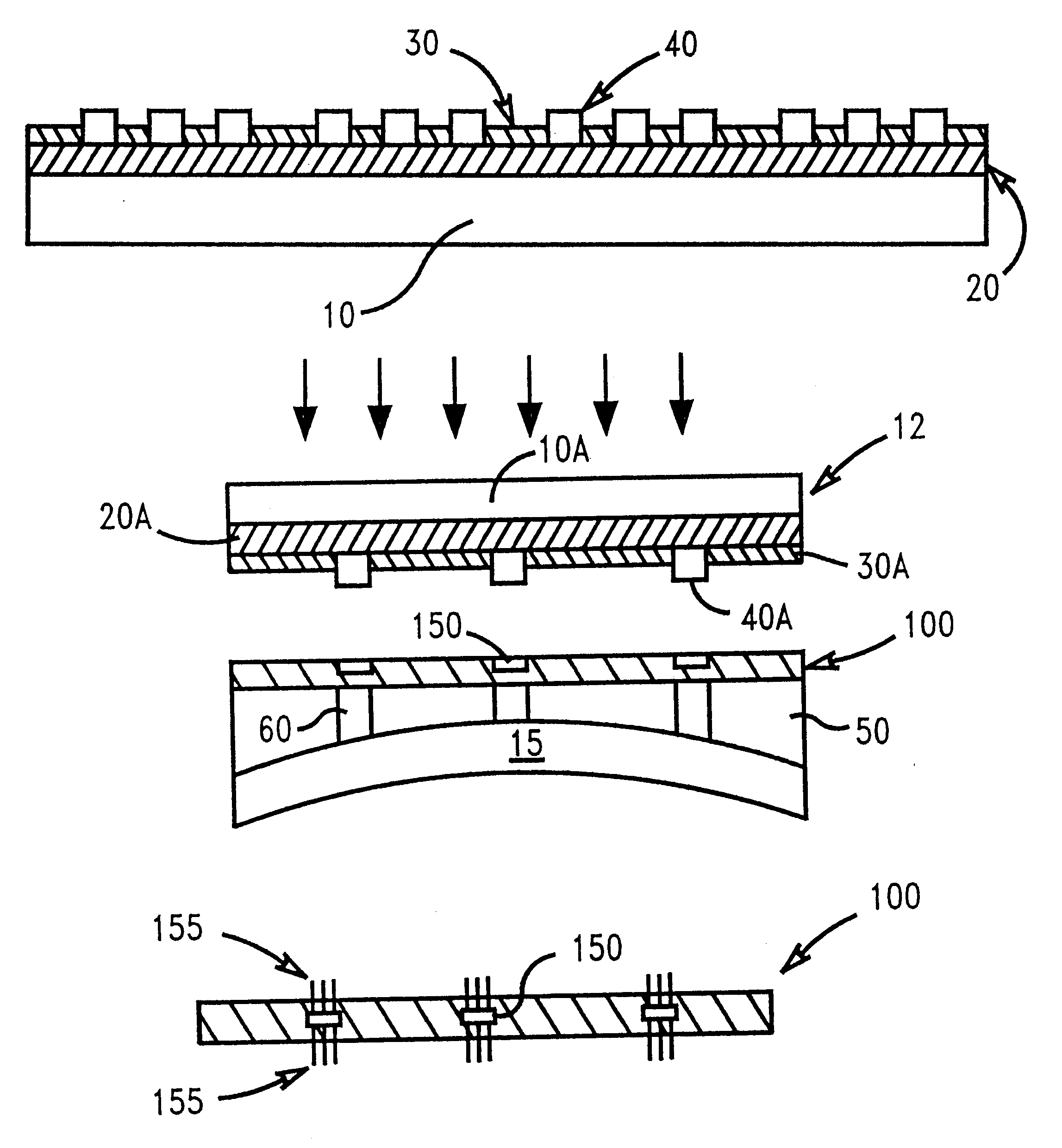

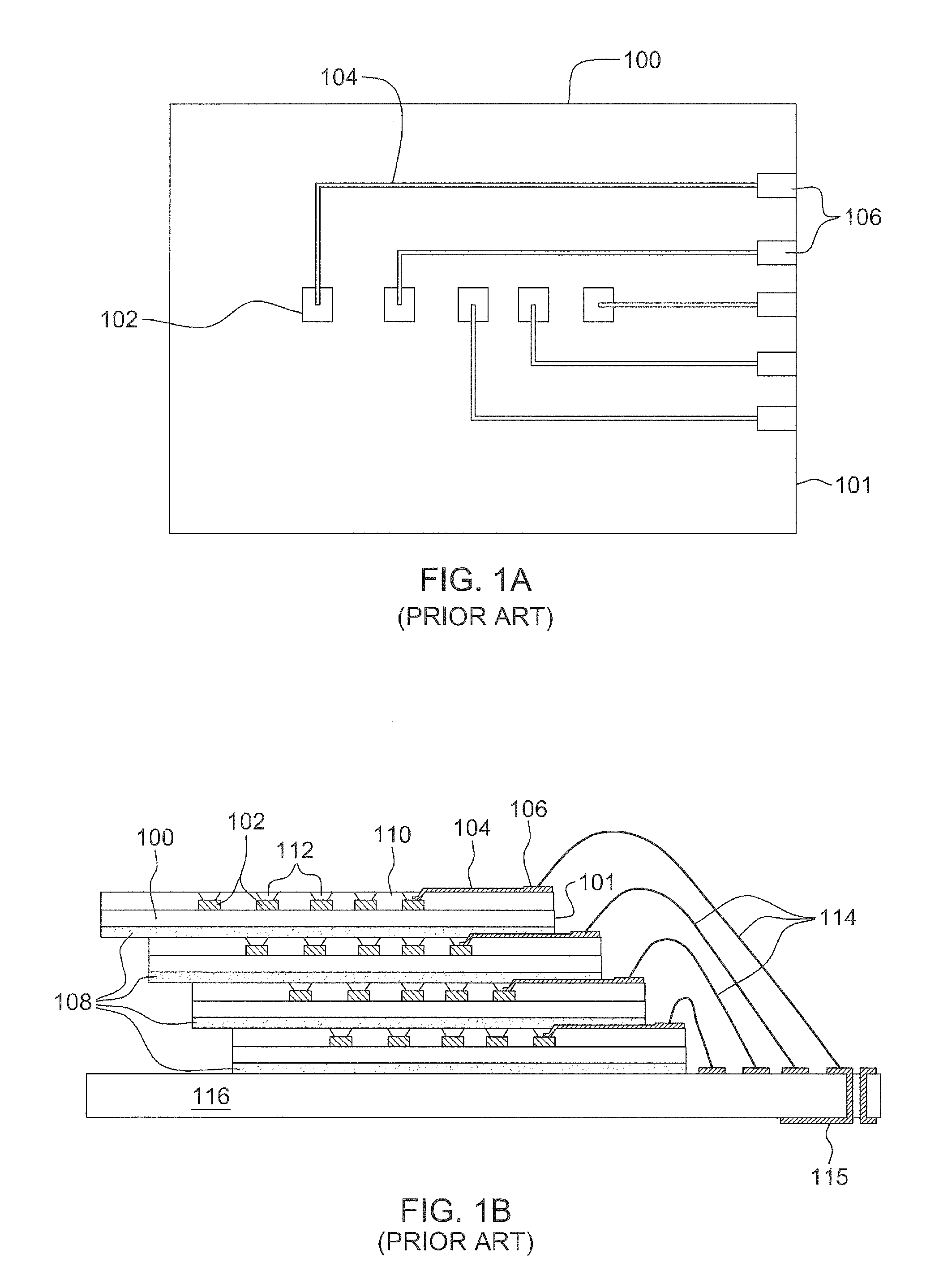

Method of interconnecting electronic components using a plurality of conductive studs

InactiveUS6258625B1Printed circuit assemblingSemiconductor/solid-state device detailsDielectricContact pad

A method of interconnecting electronic components by using a plurality of conductive studs on a surface of a first electronic component and a plurality of corresponding conductive vias on the surface of a second electronic component. Camber on the surface of electronic components may be overcome by coating the surface with a dielectric, planarizing the dielectric, and forming conductive vias corresponding to the contact pads thereon. The conductive studs are substantially lead-free and preferably comprise of copper.

Owner:IBM CORP

Direct lift process apparatus

ActiveUS20150364347A1Electric discharge tubesSemiconductor/solid-state device manufacturingContact padMechanical engineering

The present disclosure provides a substrate support assembly includes a substrate pedestal having an upper surface for receiving and supporting a substrate, a cover plate disposed on the substrate support pedestal, and two or more lift pins movably disposed through the substrate support pedestal and the cover plate. The cover plate includes a disk body having a central opening. The two or more lift pins are self supportive. Each of the two or more lift pins comprises one or more contact pads, and the contact pads of the lift pins extend into to the central opening of the cover plate to receive and support a substrate at an edge region of the substrate.

Owner:APPLIED MATERIALS INC

Analyte Monitoring Device And Methods Of Use

An analyte monitor includes a sensor, a sensor control unit, and a display unit. The sensor has, for example, a substrate, a recessed channel formed in the substrate, and conductive material disposed in the recessed channel to form a working electrode. The sensor control unit typically has a housing adapted for placement on skin and is adapted to receive a portion of an electrochemical sensor. The sensor control unit also includes two or more conductive contacts disposed on the housing and configured for coupling to two or more contact pads on the sensor. A transmitter is disposed in the housing and coupled to the plurality of conductive contacts for transmitting data obtained using the sensor. The display unit has a receiver for receiving data transmitted by the transmitter of the sensor control unit and a display coupled to the receiver for displaying an indication of a level of an analyte. The analyte monitor may also be part of a drug delivery system to alter the level of the analyte based on the data obtained using the sensor.

Owner:ABBOTT DIABETES CARE INC

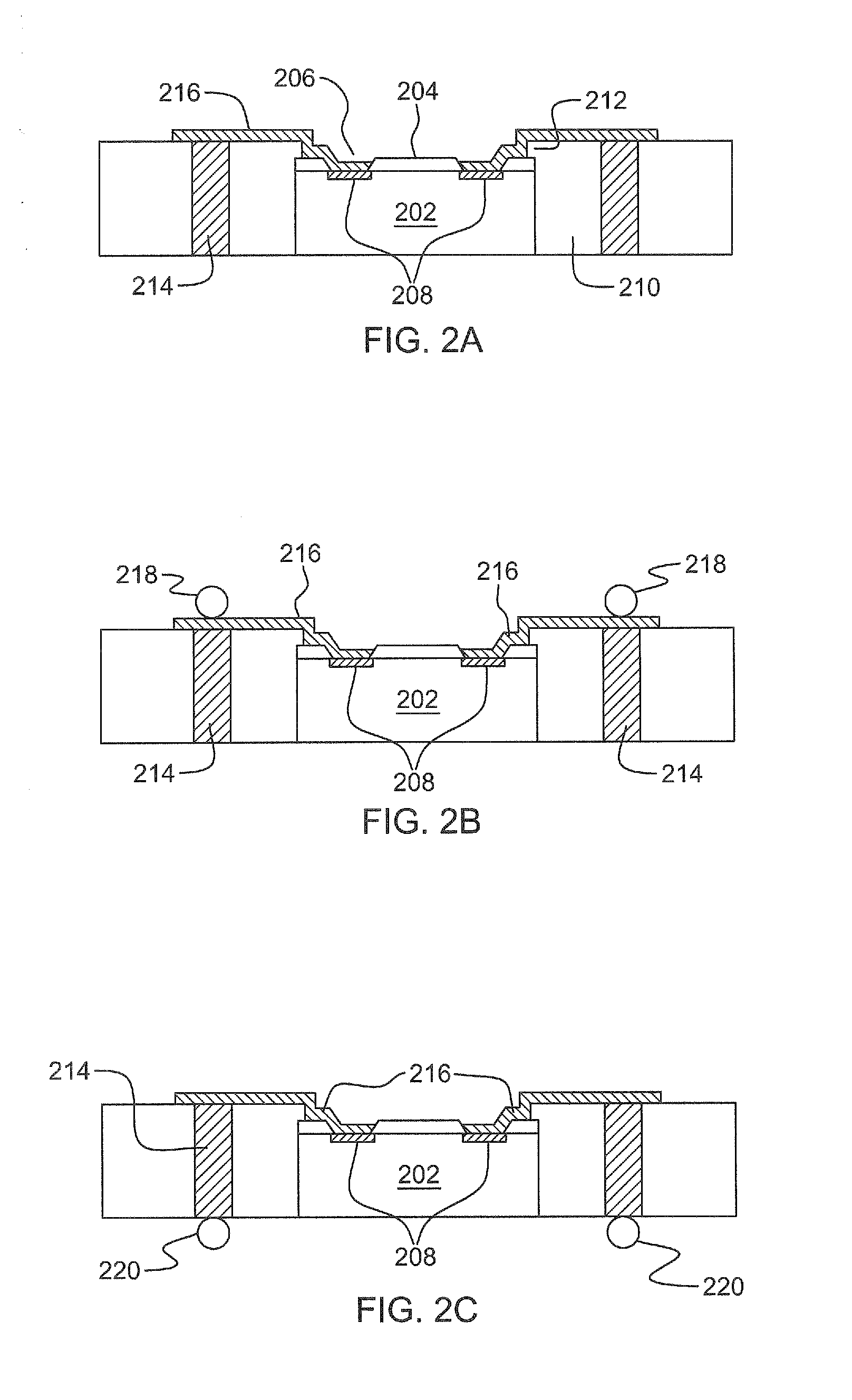

Semiconductor module with a semiconductor stack, and methods for its production

InactiveUS20050133932A1Reduce complexityImprove reliabilitySemiconductor/solid-state device detailsSolid-state devicesContact padEngineering

An electronic semiconductor module component with a semiconductor stack includes semiconductor components arranged in a vertically stacked relationship. A basic semiconductor component includes a lower interposing unit, on which lower external contact pads are arranged. The basic semiconductor component further includes an upper interposing unit, on which upper external contact pads are arranged. The two interposing units are electrically connected to one another via bonding connections disposed at their edge areas. The basic semiconductor component is a compact component on which different, customer-specific semiconductor components can be stacked.

Owner:INFINEON TECH AG

Analyte Monitoring Device And Methods Of Use

An analyte monitor includes a sensor, a sensor control unit, and a display unit. The sensor has, for example, a substrate, a recessed channel formed in the substrate, and conductive material disposed in the recessed channel to form a working electrode. The sensor control unit typically has a housing adapted for placement on skin and is adapted to receive a portion of an electrochemical sensor. The sensor control unit also includes two or more conductive contacts disposed on the housing and configured for coupling to two or more contact pads on the sensor. A transmitter is disposed in the housing and coupled to the plurality of conductive contacts for transmitting data obtained using the sensor. The display unit has a receiver for receiving data transmitted by the transmitter of the sensor control unit and a display coupled to the receiver for displaying an indication of a level of an analyte. The analyte monitor may also be part of a drug delivery system to alter the level of the analyte based on the data obtained using the sensor.

Owner:ABBOTT DIABETES CARE INC

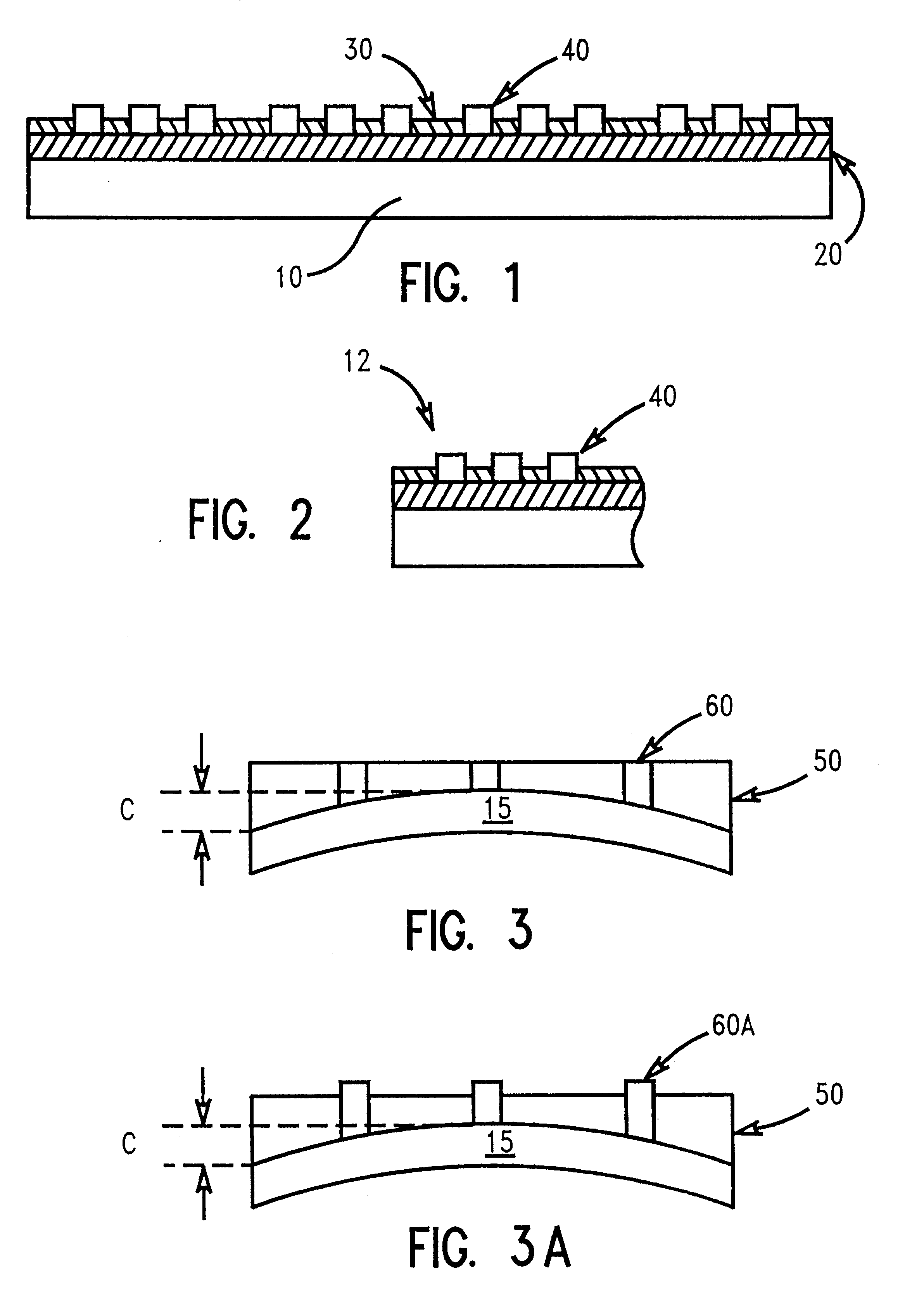

Stackable circuit structures and methods of fabrication thereof

ActiveUS20110147911A1Semiconductor/solid-state device detailsSolid-state devicesContact padHemt circuits

Stackable circuit structures and methods of fabrication are provided employing first level metallization directly on a chips-first layer(s), which includes: a chip(s), each with a pad mask over its upper surface and openings exposing its contact pads; electrically conductive structures; and structural dielectric material surrounding the side surfaces of the chips and the conductive structures. Each chips-first layer further includes a metallization layer on the front surface of the layer, residing at least partially on the pad mask and extending over an edge of the chip. Together, the pad mask and the structural material electrically isolate the metallization layer from the chip. Input / output interconnect structures physically and electrically contact the metallization layer over the front surface and / or the lower surfaces of the electrically conductive structures at the back surface of the chips-first layer, to facilitate input / output connection to chips of the layers in a stack.

Owner:EPIC TECH INC

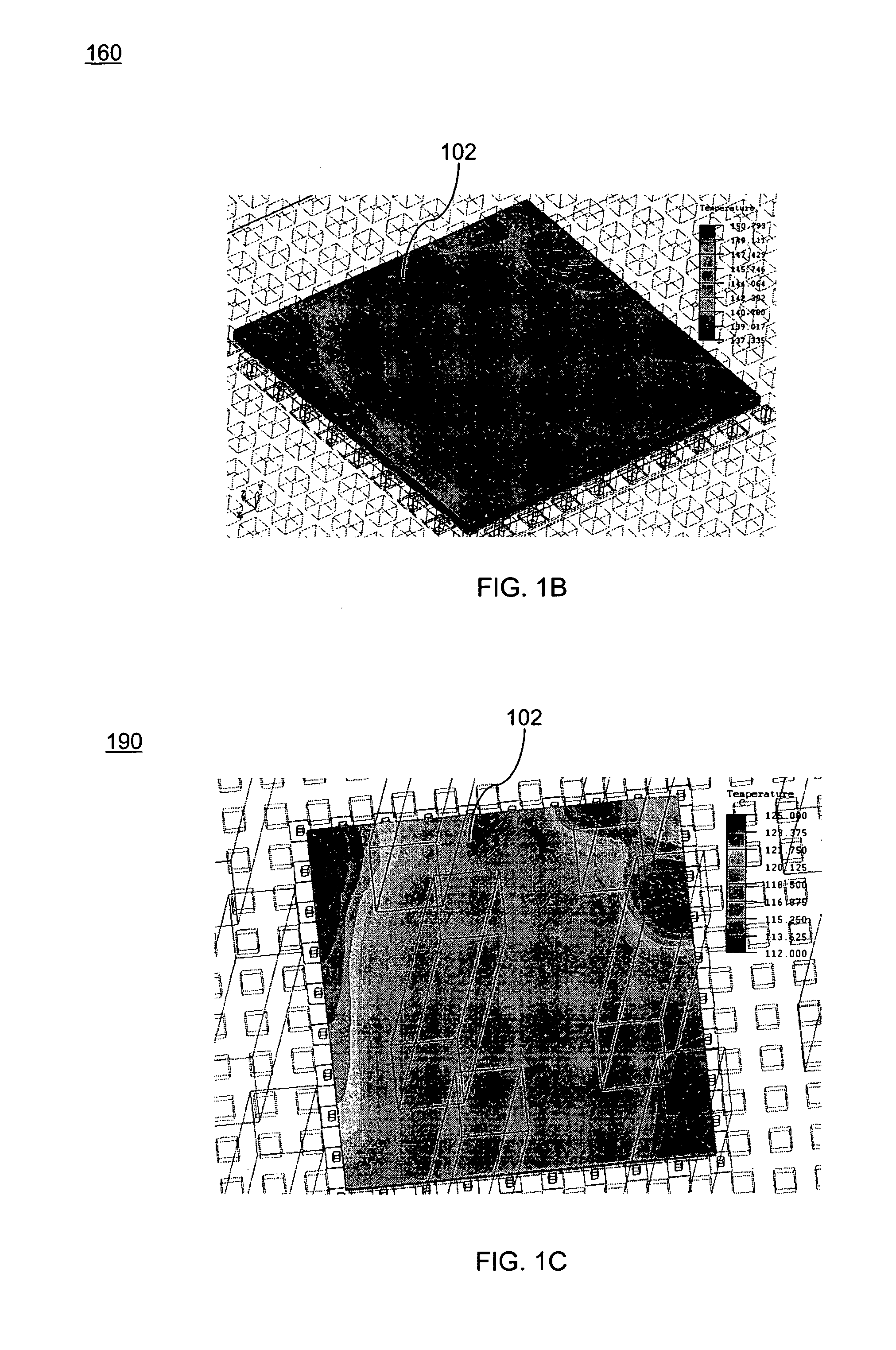

Thermal improvement for hotspots on dies in integrated circuit packages

ActiveUS20070290322A1Semiconductor/solid-state device testing/measurementSemiconductor/solid-state device detailsContact padEngineering

Methods and apparatuses for improved integrated circuit (IC) packages are described herein. In an aspect, an IC device package includes an IC die having a contact pad, where the contact pad is located on a hotspot of the IC die. The hotspot is thermally coupled to a thermal interconnect member. In an aspect, the package is encapsulated in a mold compound. In a further aspect, a heat spreader is attached to the mold compound, and is thermally coupled to the thermal interconnect member. In another aspect, a thermal interconnect member thermally is coupled between the heat spreader and the substrate.

Owner:AVAGO TECH INT SALES PTE LTD

Electrical connector with ESD protection

ActiveUS7044794B2Two-part coupling devicesCoupling protective earth/shielding arrangementsContact padEngineering

An electrical connector includes a dielectric housing that holds a plurality of electrical wafers. Each of the wafers includes a first side, a second side opposite the first side, and a forward mating edge. A plurality of contact pads on the first side are recessed from the forward mating edge, and a perimeter conductive trace is closer than the contact pads to the forward mating edge.

Owner:TYCO ELECTRONICS LOGISTICS AG (CH)

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com