Patents

Literature

365 results about "Container crane" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

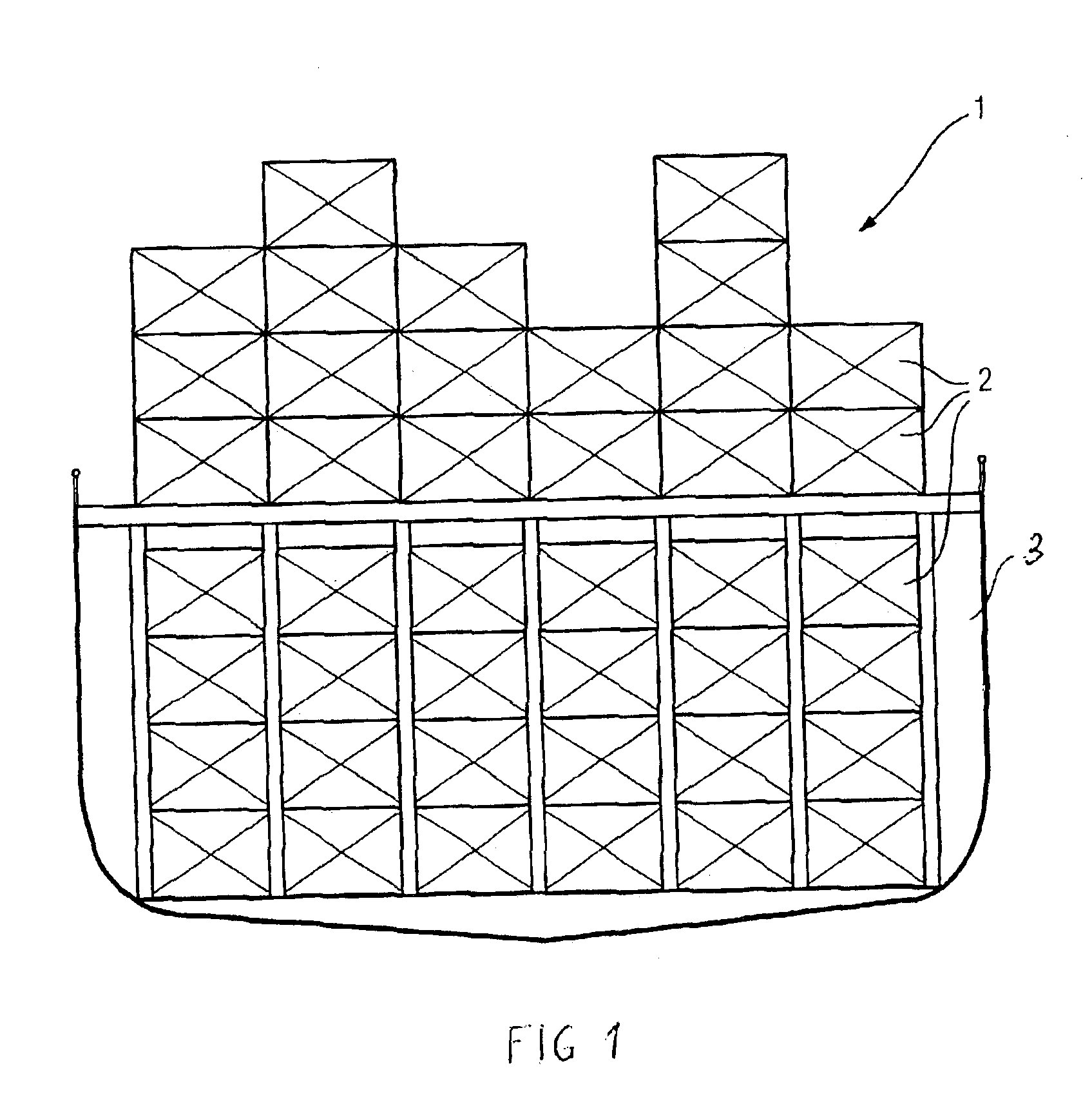

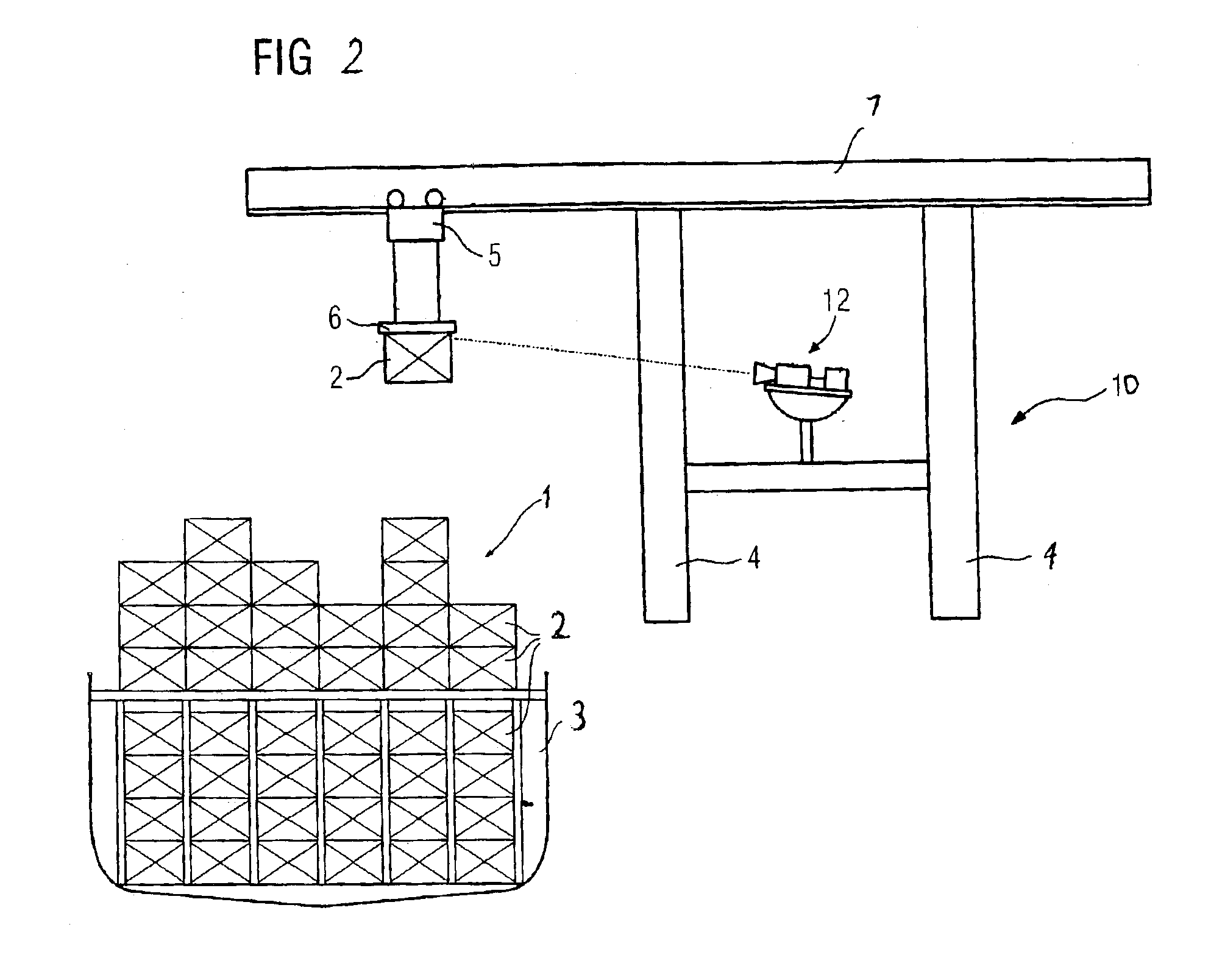

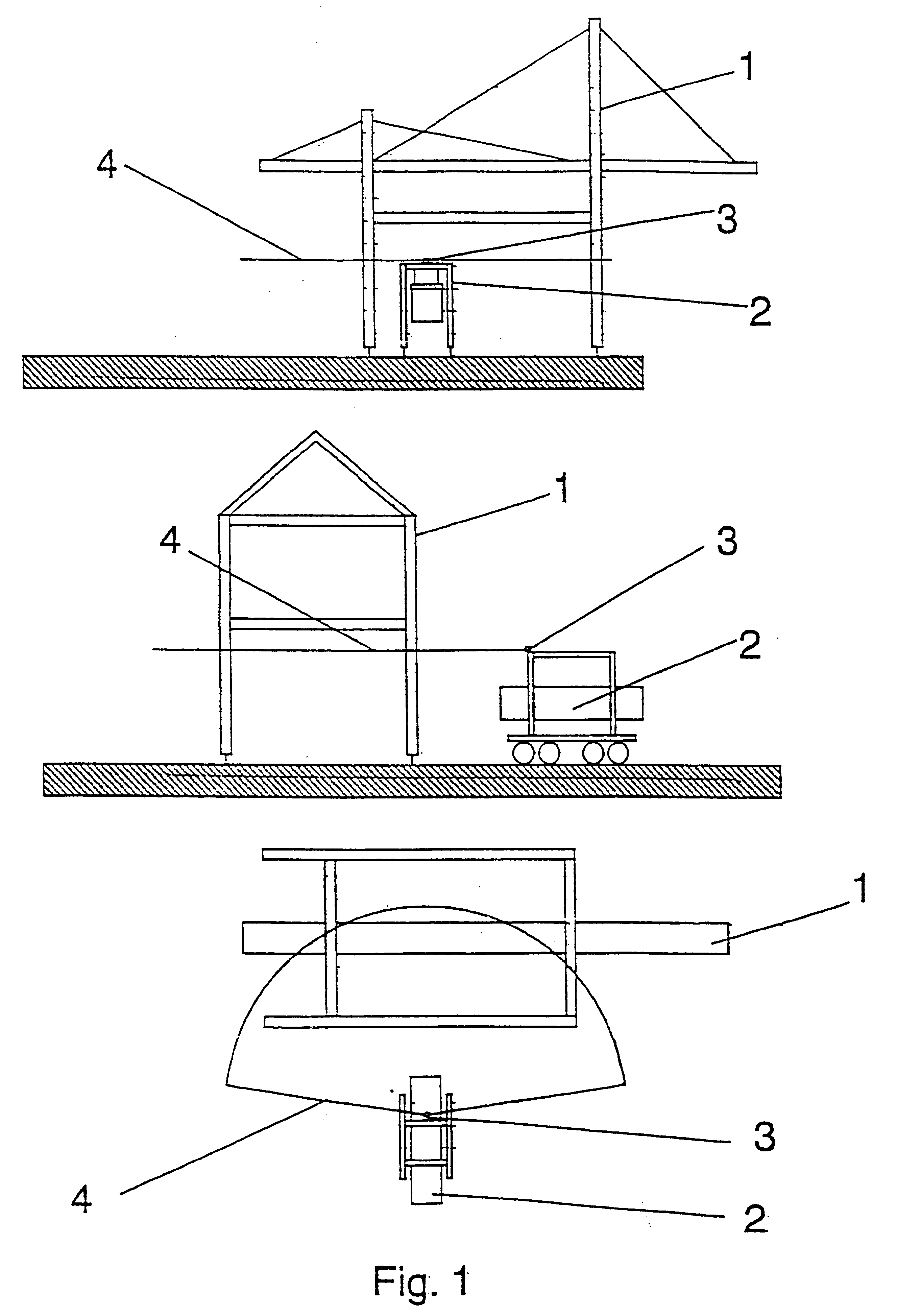

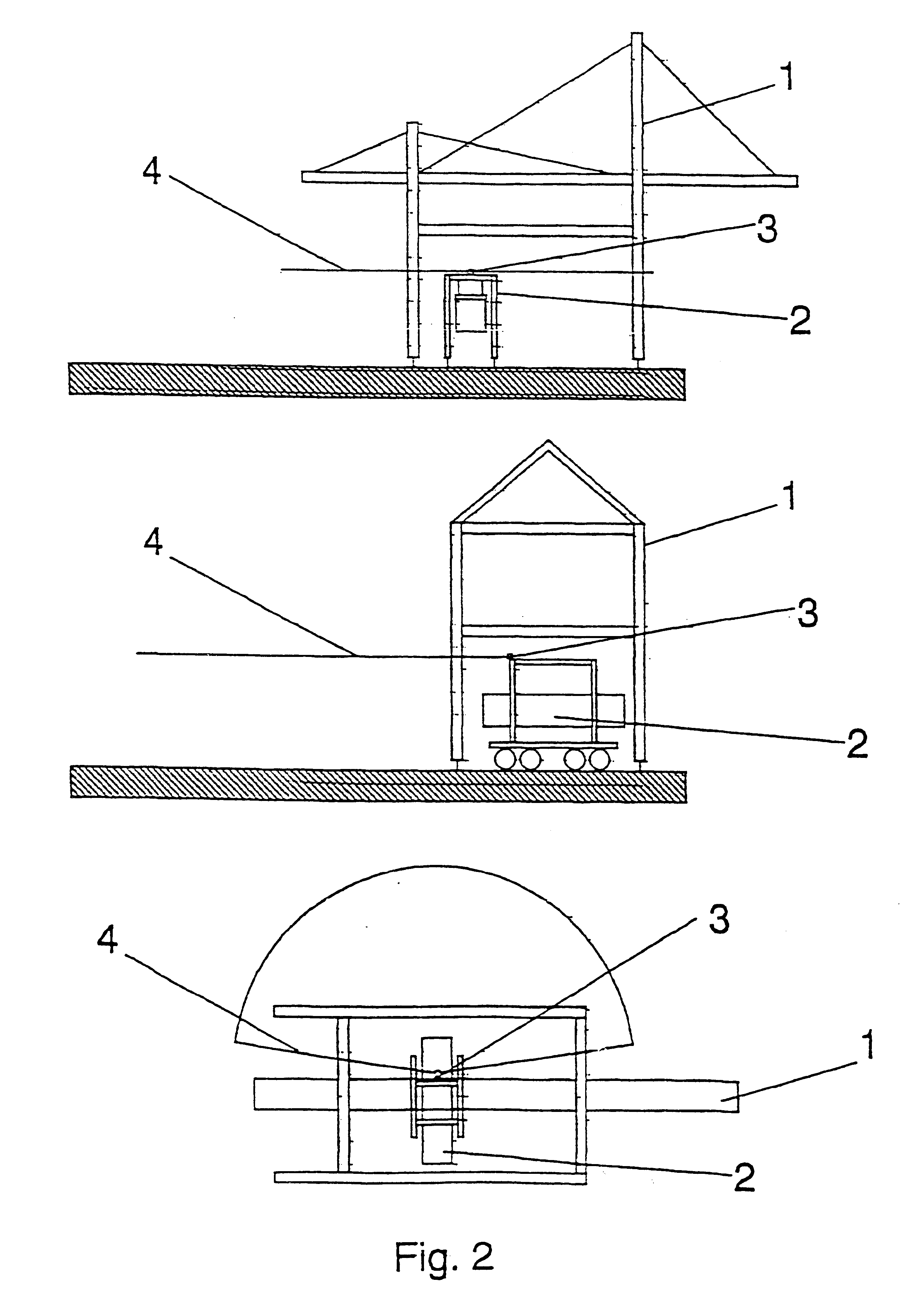

A container crane (also container handling gantry crane or ship-to-shore crane) is a type of large dockside gantry crane found at container terminals for loading and unloading intermodal containers from container ships.

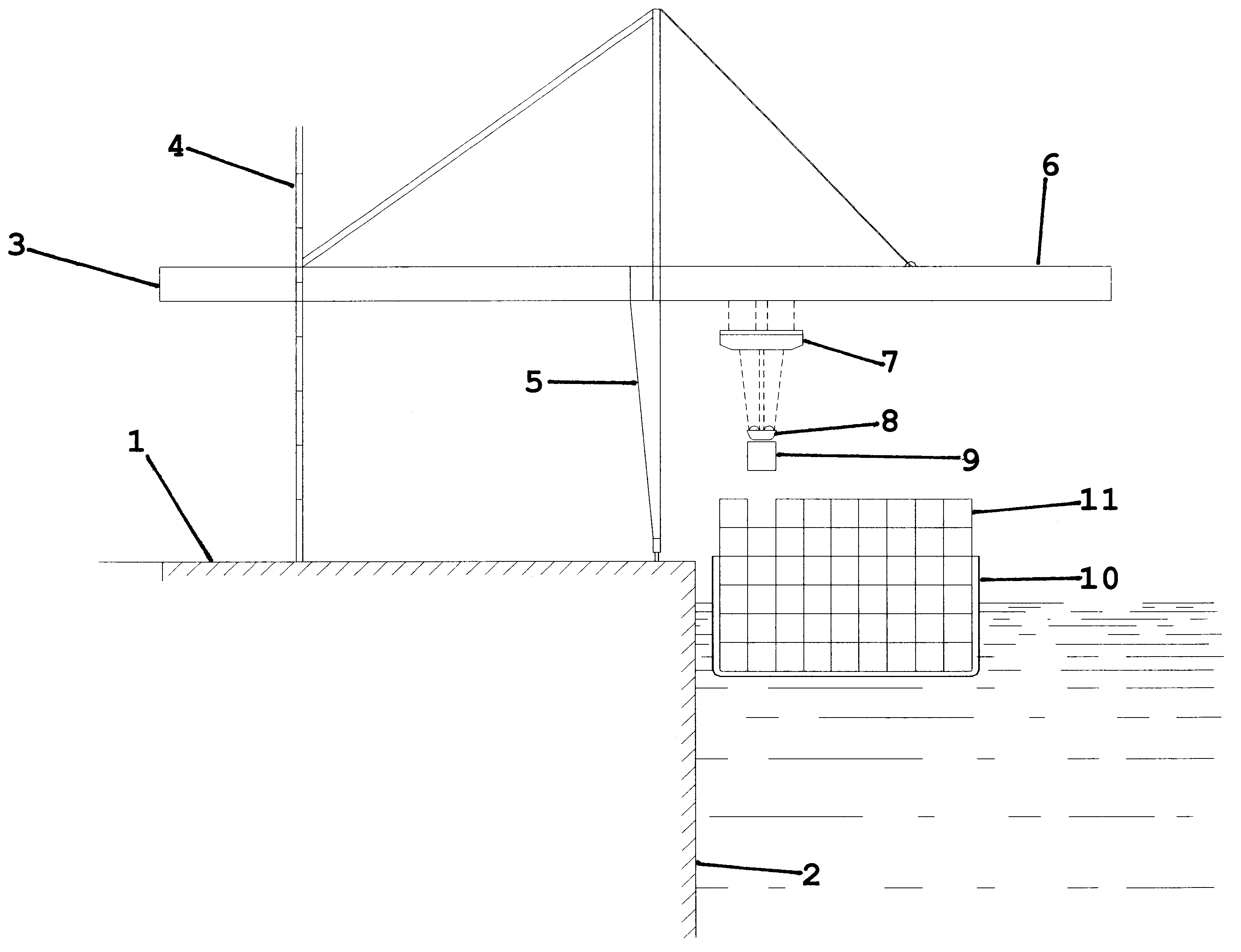

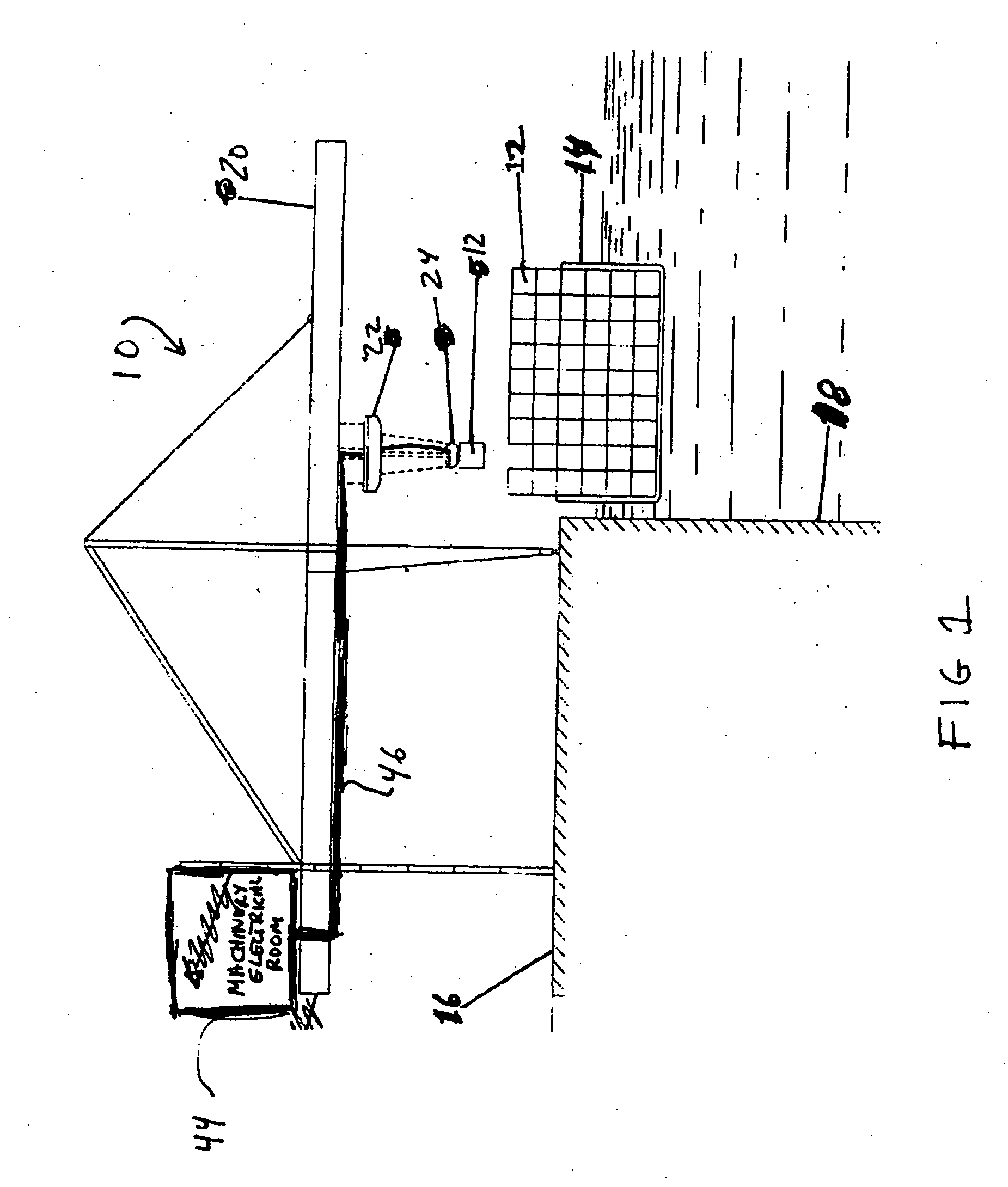

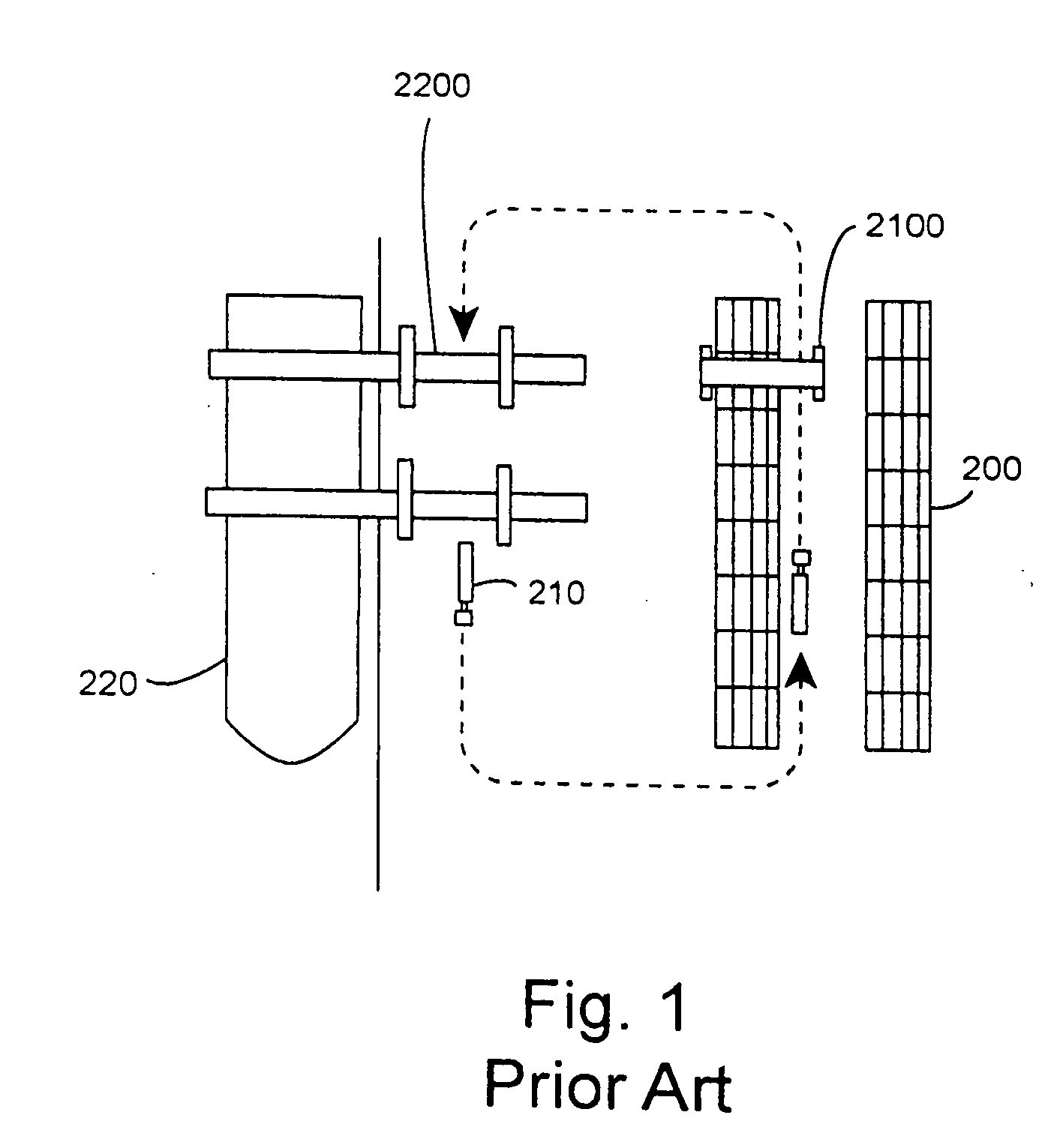

Container crane radiation detection systems and methods

InactiveUS6768421B1Trolley cranesMaterial analysis by transmitting radiationContainer craneEngineering

A container crane assembly is operable to lift shipping containers for transfer between a dock and a ship transporting the containers. Typically, the container crane includes a hoist attachment which engages the shipping container. A fissile or radioactive material detection device may be mounted to the hoist attachment such that as the shipping container is being engaged, the detection device is brought into proximity to the container so that the presence of fissile or radioactive material, or shielding materials to conceal the presence of such fissile or radioactive materials, may be detected prior to the shipping container being loaded onto or unloaded from a shipping vessel. A comparison may then be made of the output of the detector to a threshold to determine subsequent action regarding the shipping container.

Owner:VERITAINER ASSET HLDG LLC

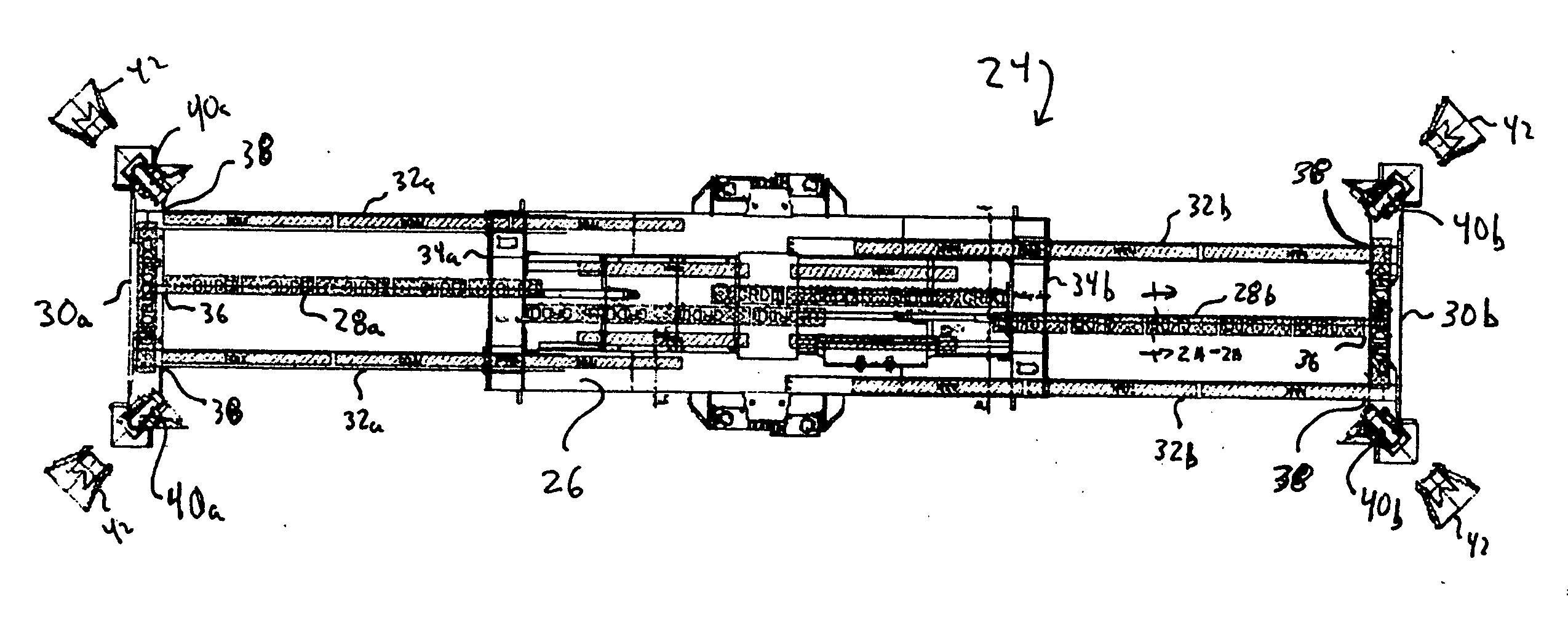

Load control device for a crane

ActiveUS20070289931A1Promote recoveryRapid responseAngle measurementTrolley cranesContainer craneEngineering

A control device and system for controlling a suspended load of a container crane with a trolley, a spreader and load lines arranged in a four point suspension for lifting a load and an optical sensor for sensing a deflection position of an orthogonal axis of a container suspended under the spreader. Two or more actuators are arranged attached to at least one load for moving at least one said suspension point closer to or farther away from an imaginary center line by shortening and / or lengthening the at least one load line.

Owner:ABB (SCHWEIZ) AG

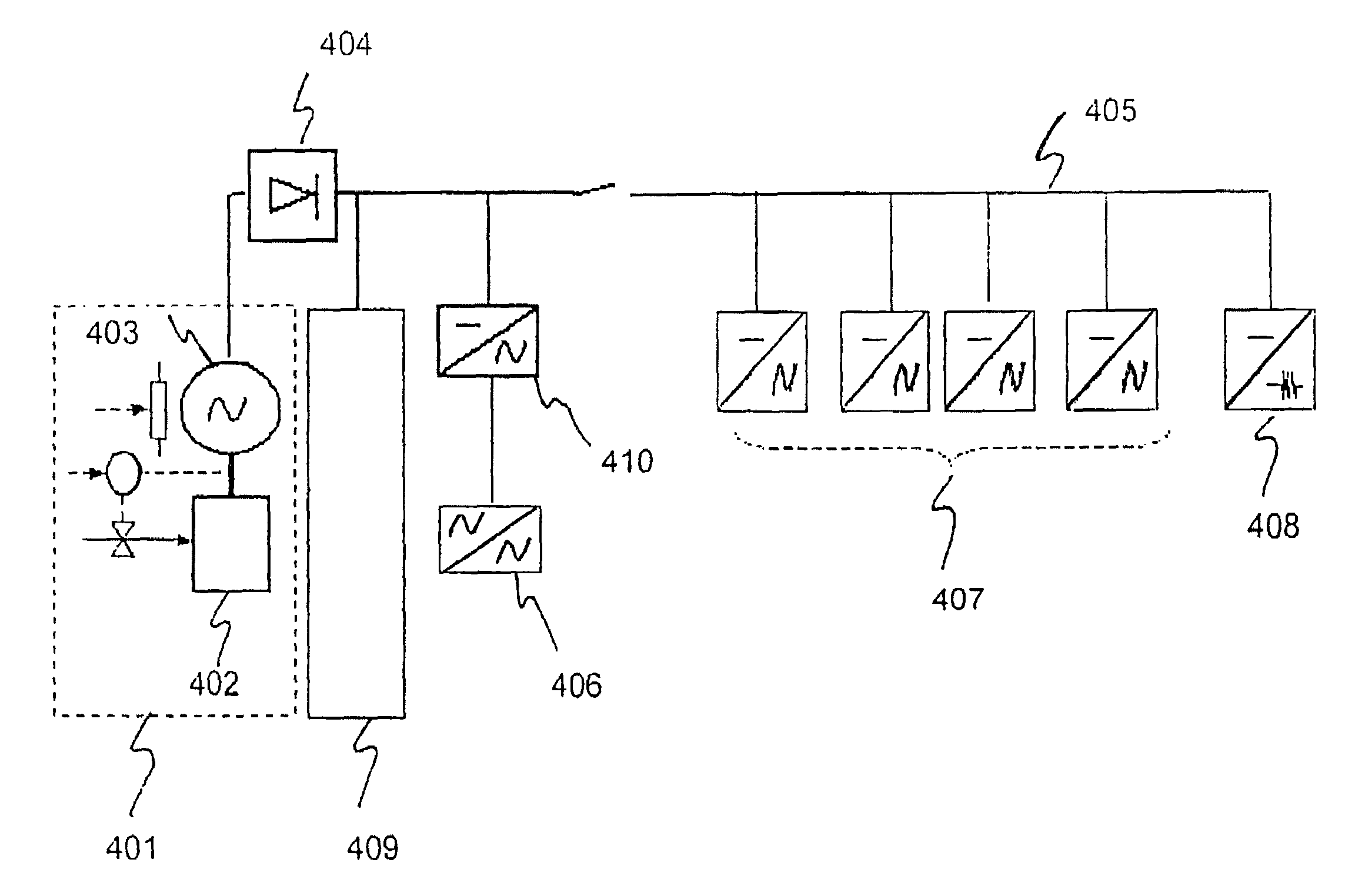

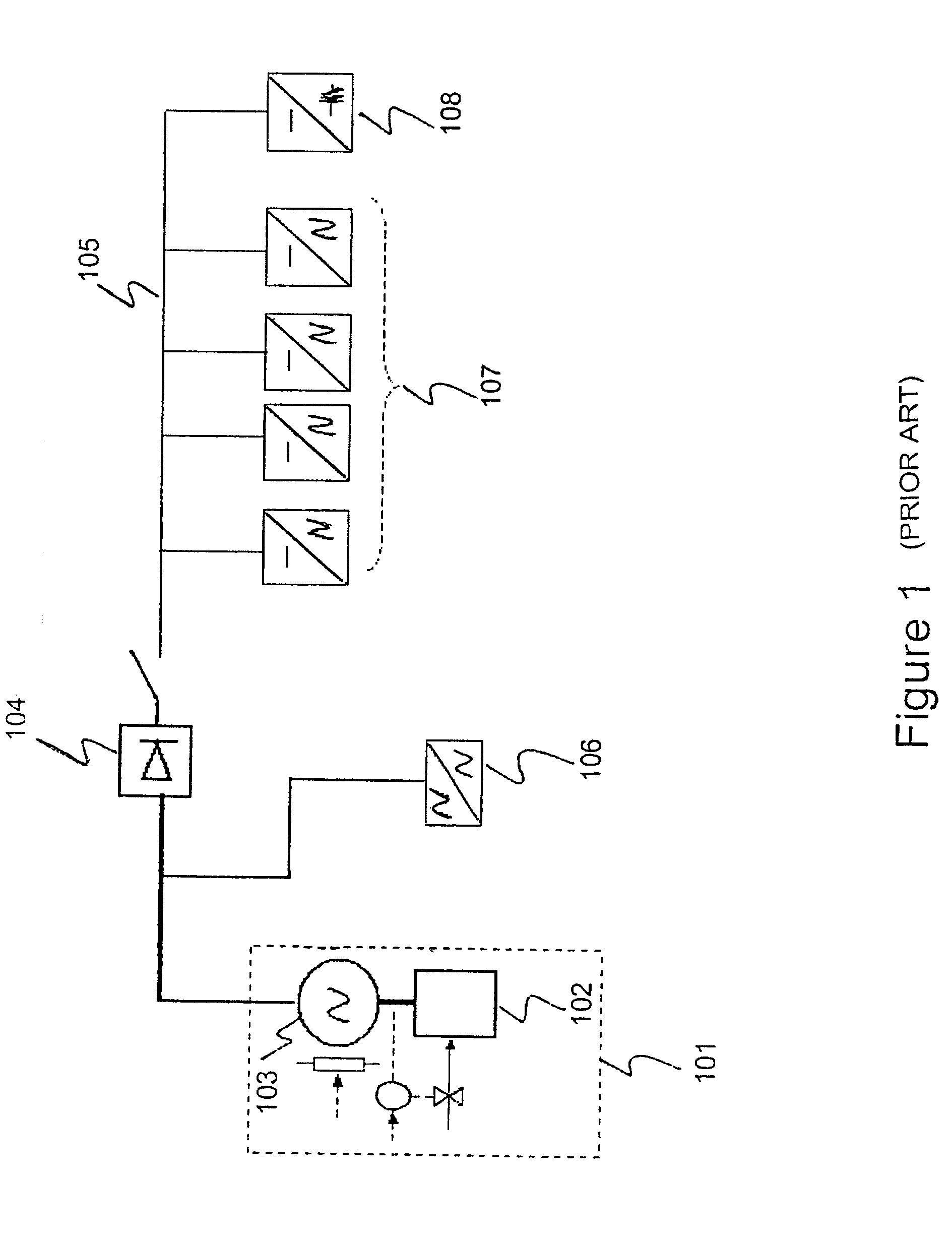

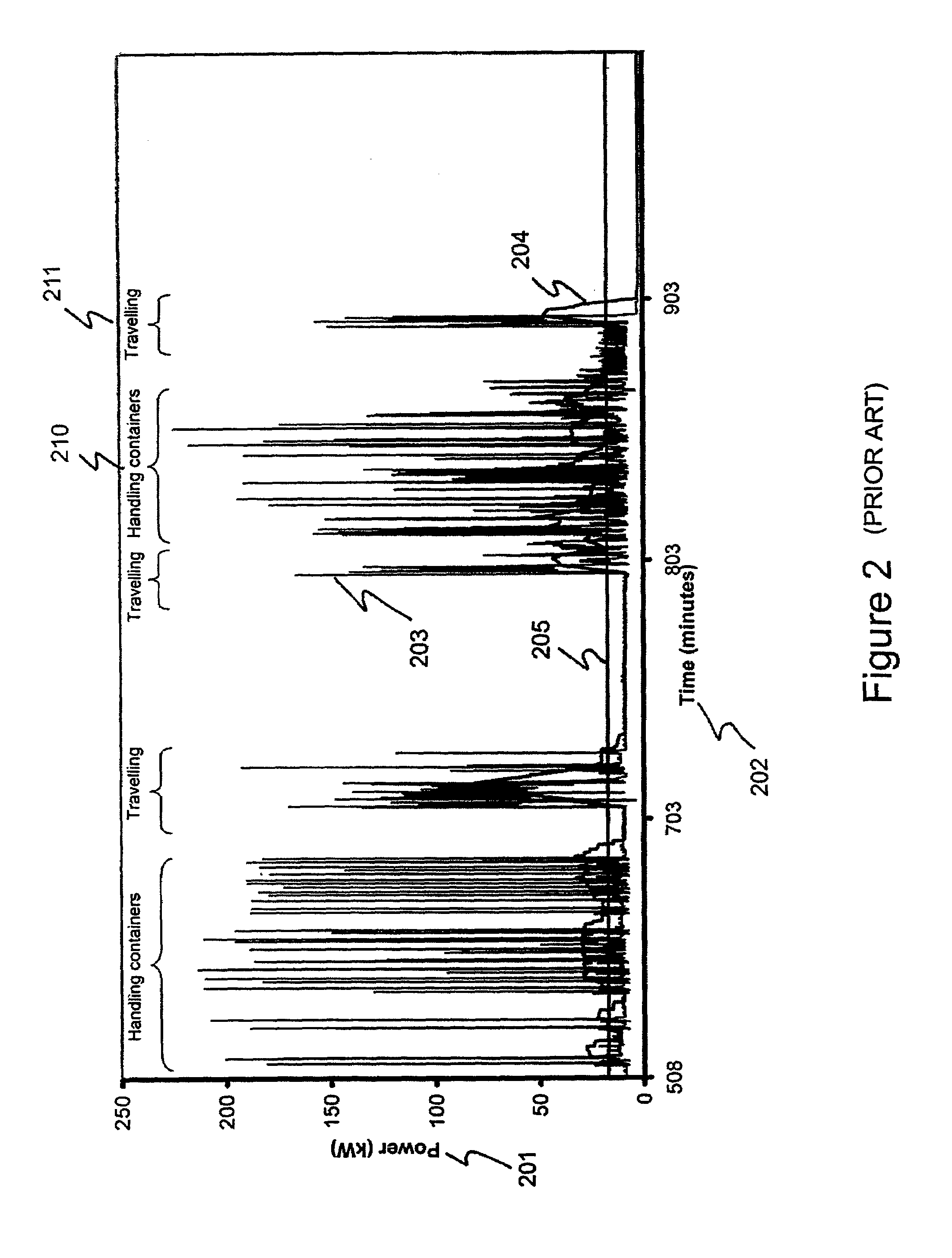

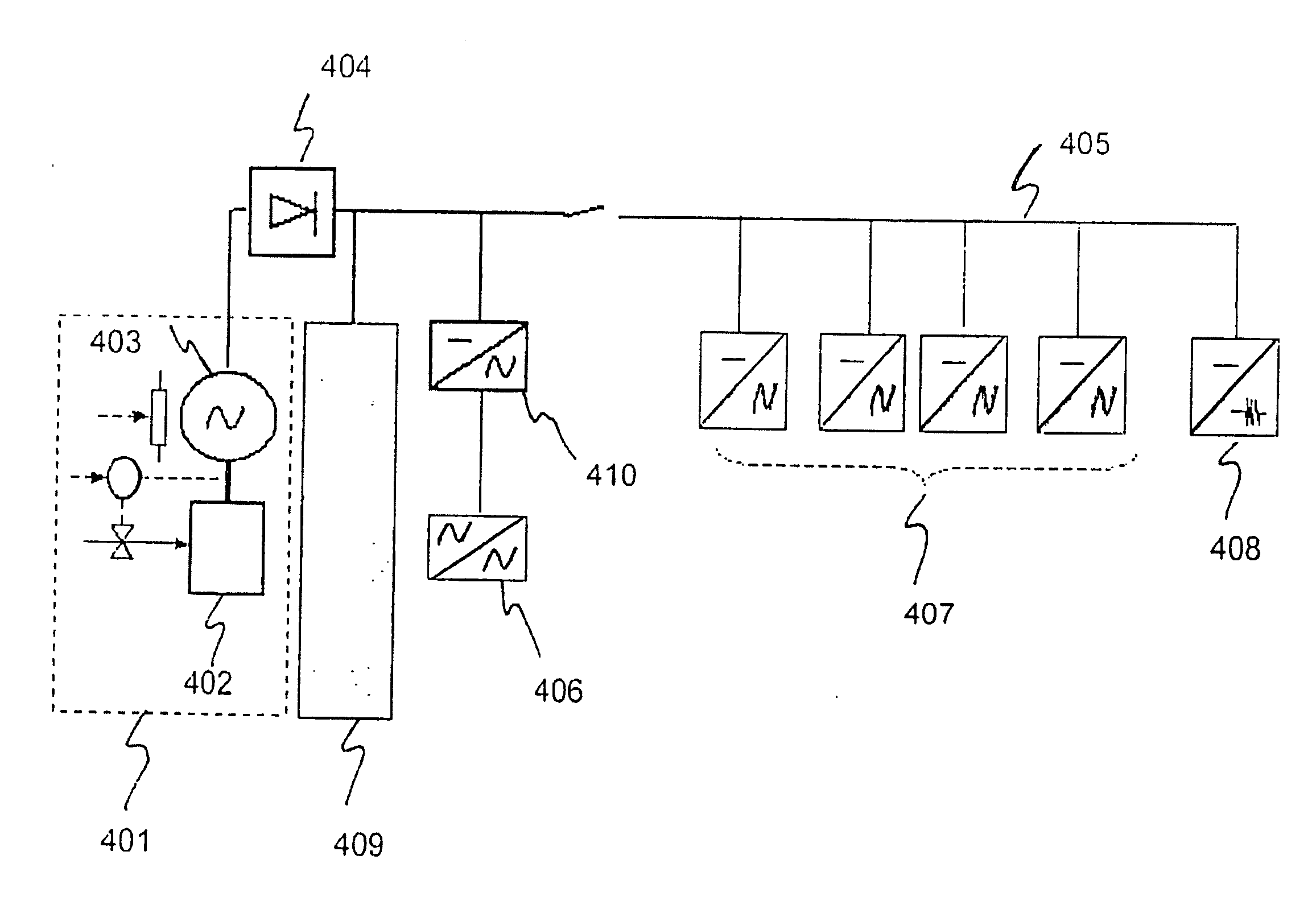

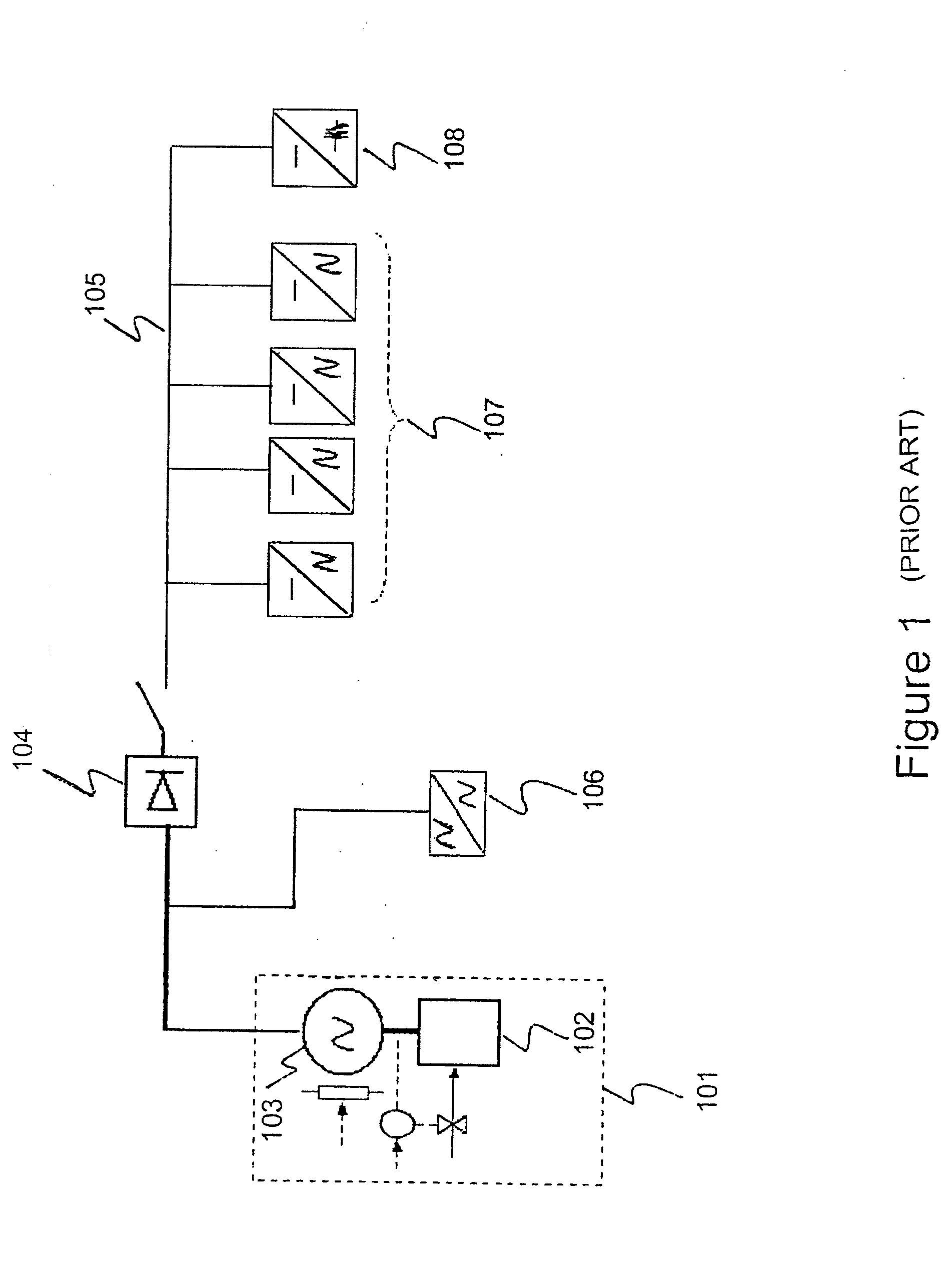

Load-lifting apparatus and method of storing energy for the same

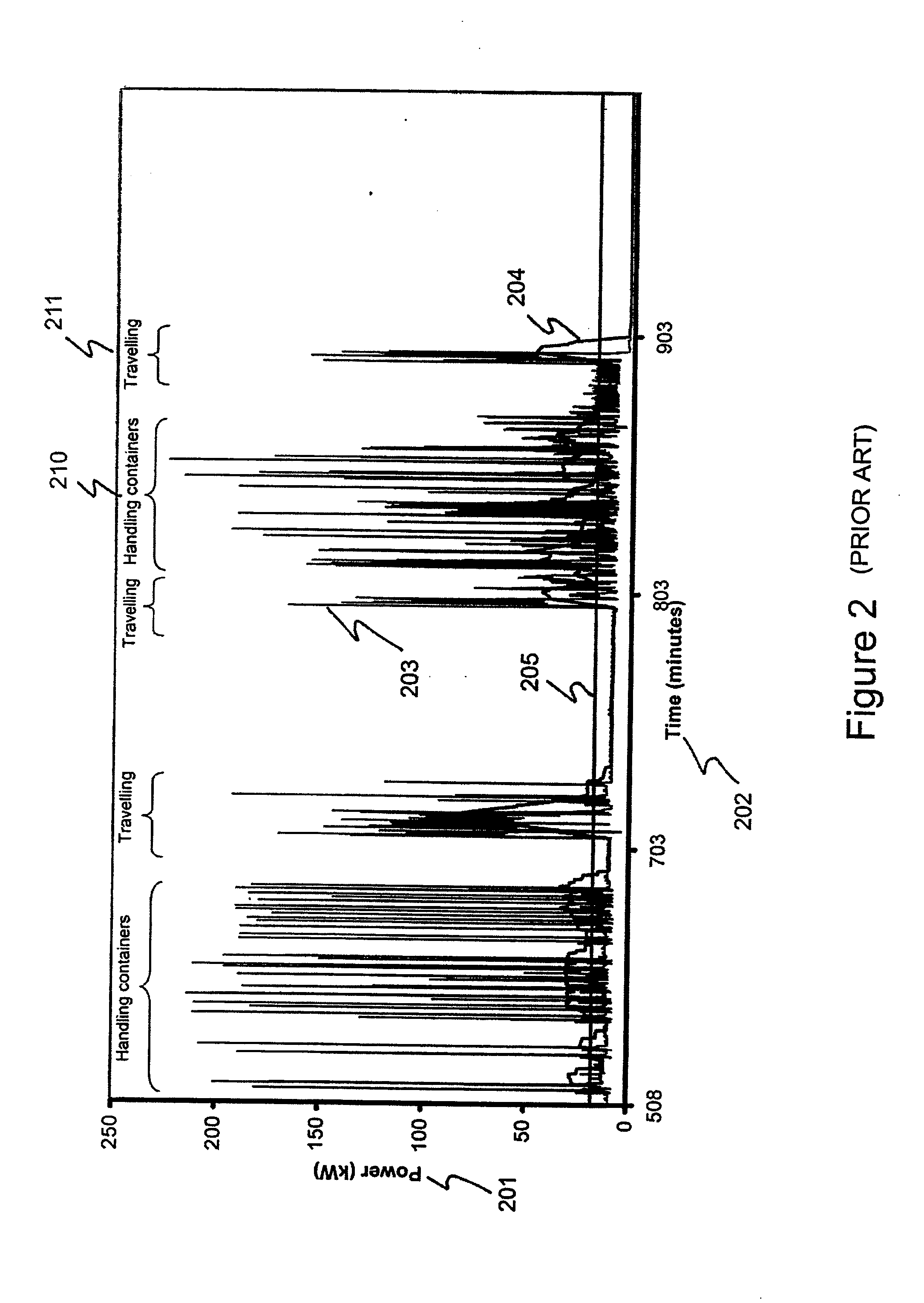

ActiveUS7554278B2Small sizeAlleviate power rating requirementDc motor stoppersDynamo-electric converter controlRegenerative brakeContainer crane

A load-lifting apparatus has one or more prime power sources, one or more energy storage systems and regenerative braking. Regenerative energy is recovered when the load-lifting apparatus lowers its load. The elements of the prime power sources, energy storage devices and electrical components may be distributed to provide stability for the load-lifting apparatus. The general power architecture and energy recovery method can be applied to cranes, rubber-tired gantry cranes, overhead cranes, mobile cranes, ship-to-shore cranes, container cranes, rail-mounted gantry cranes, straddle carrier cranes and elevators. In such an architecture, the energy storage system helps alleviate the power rating requirement of the prime power source with respect to the peak power requirement for lifting a load.

Owner:MI JACK CANADA

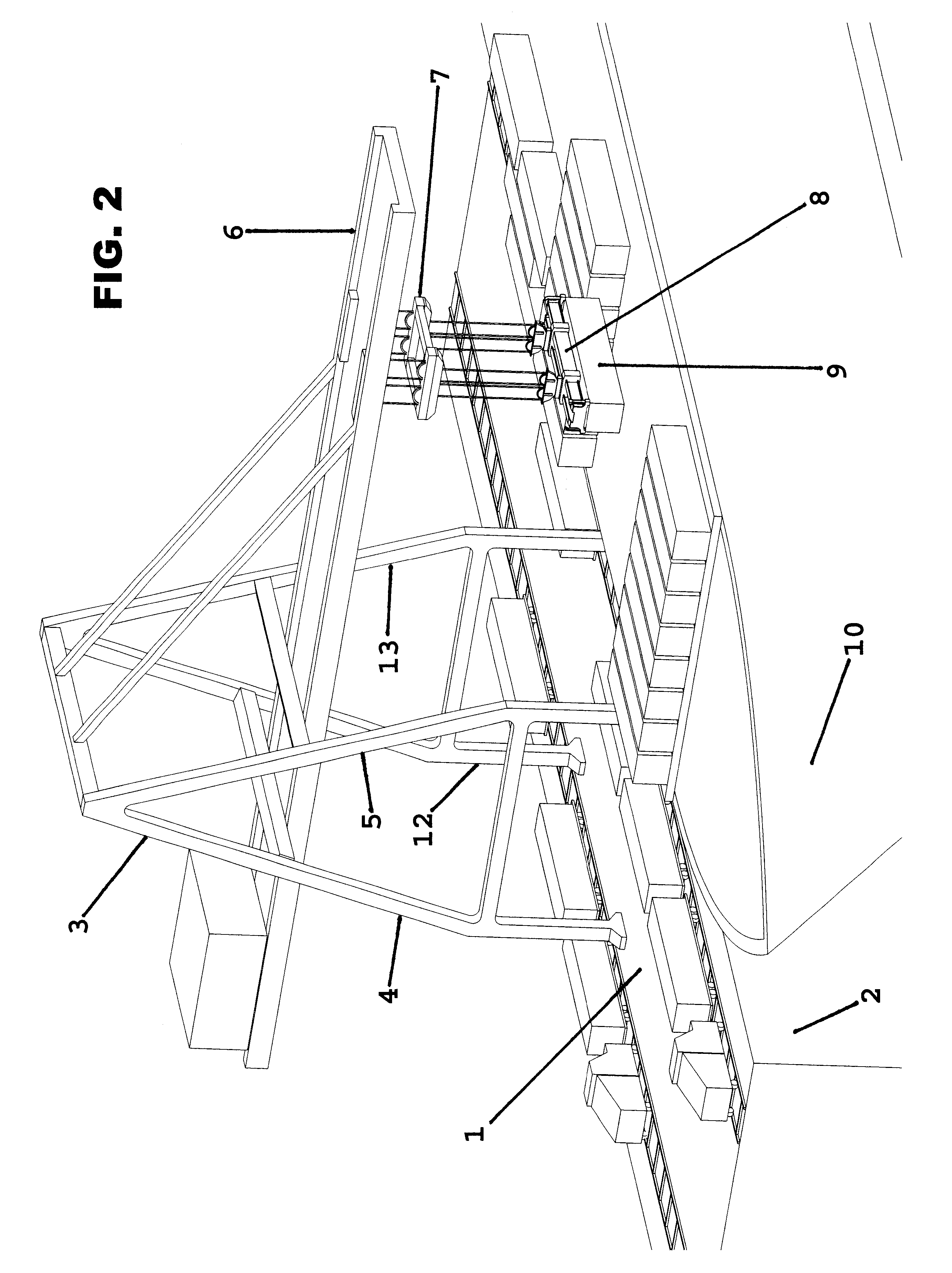

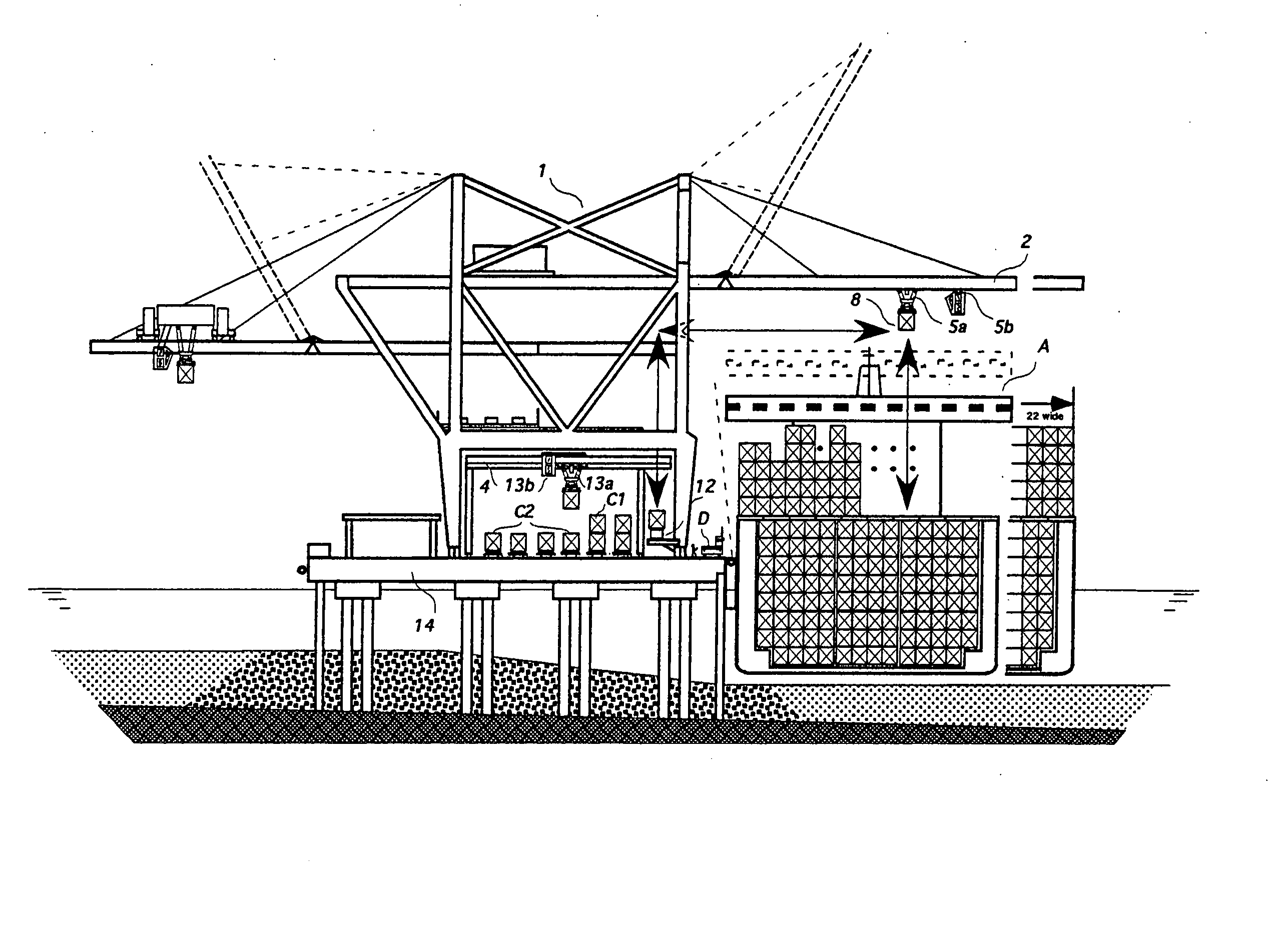

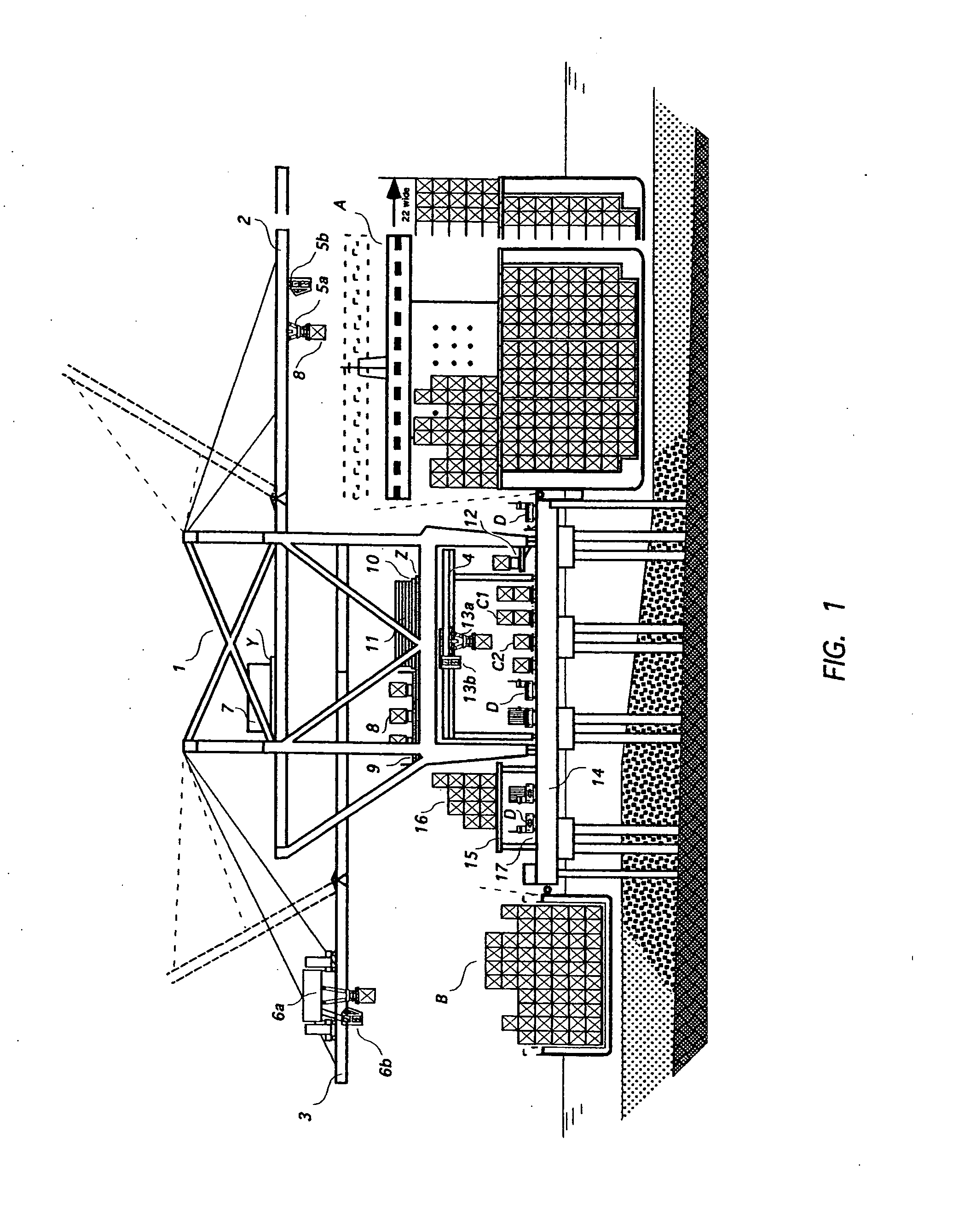

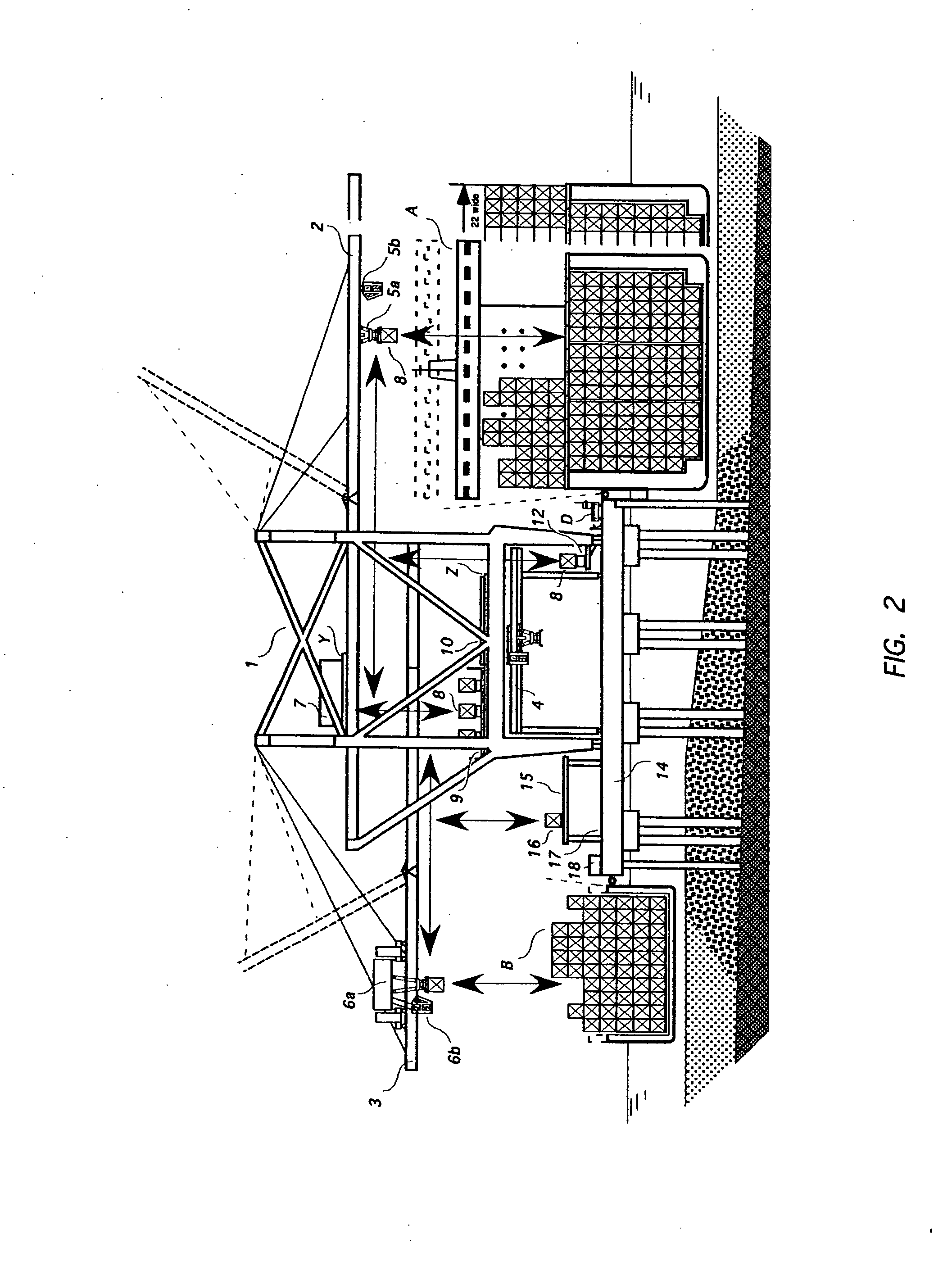

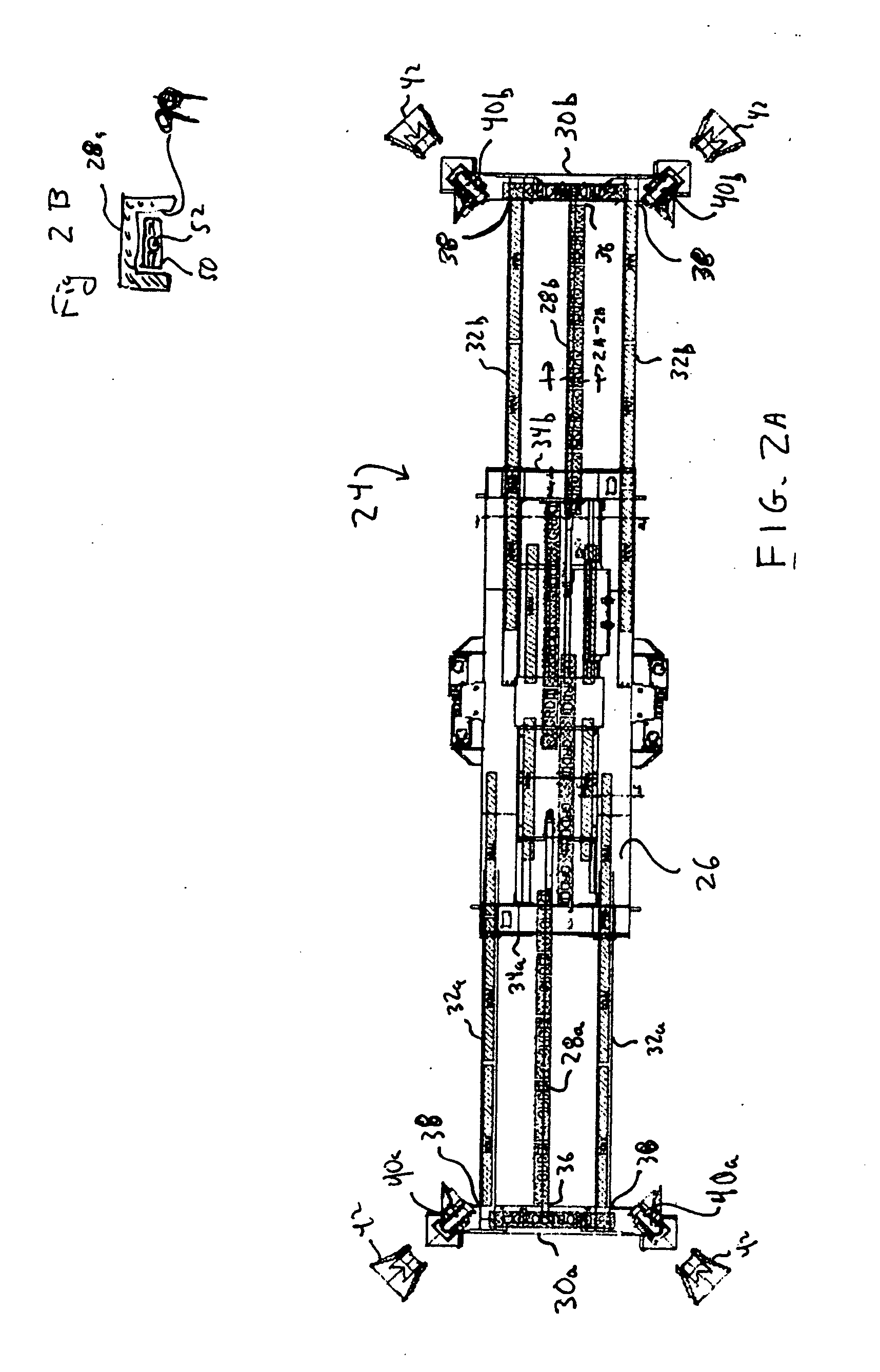

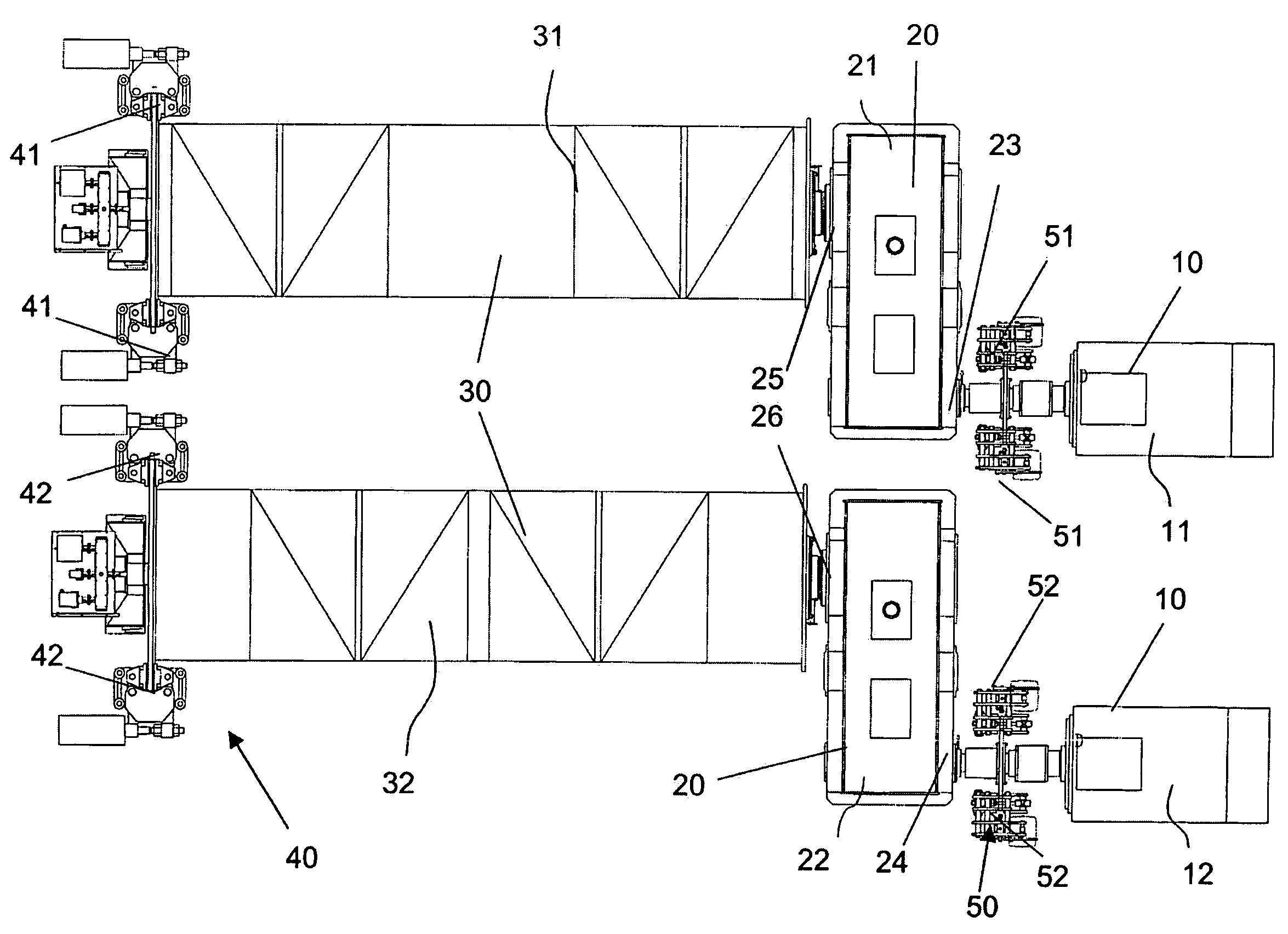

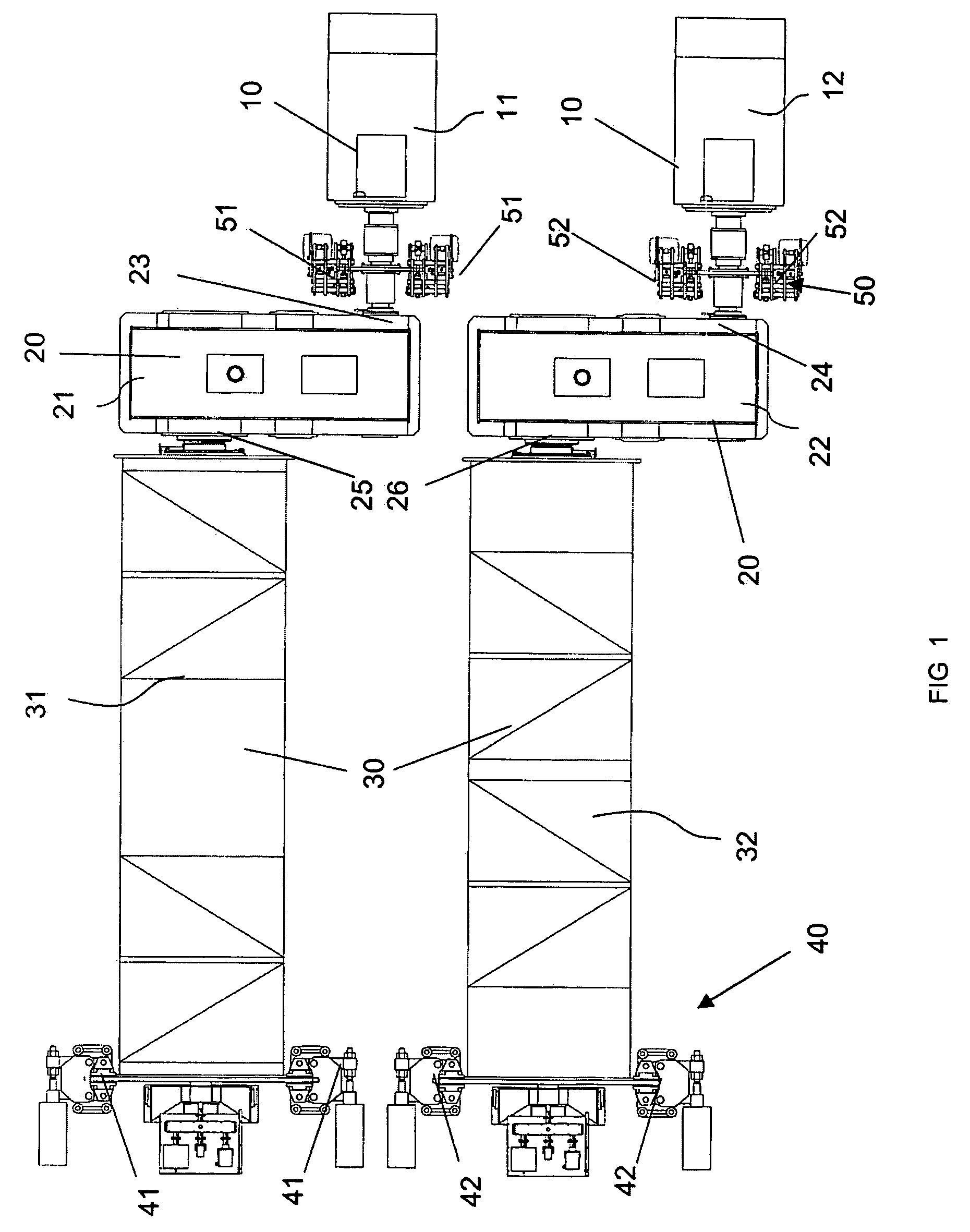

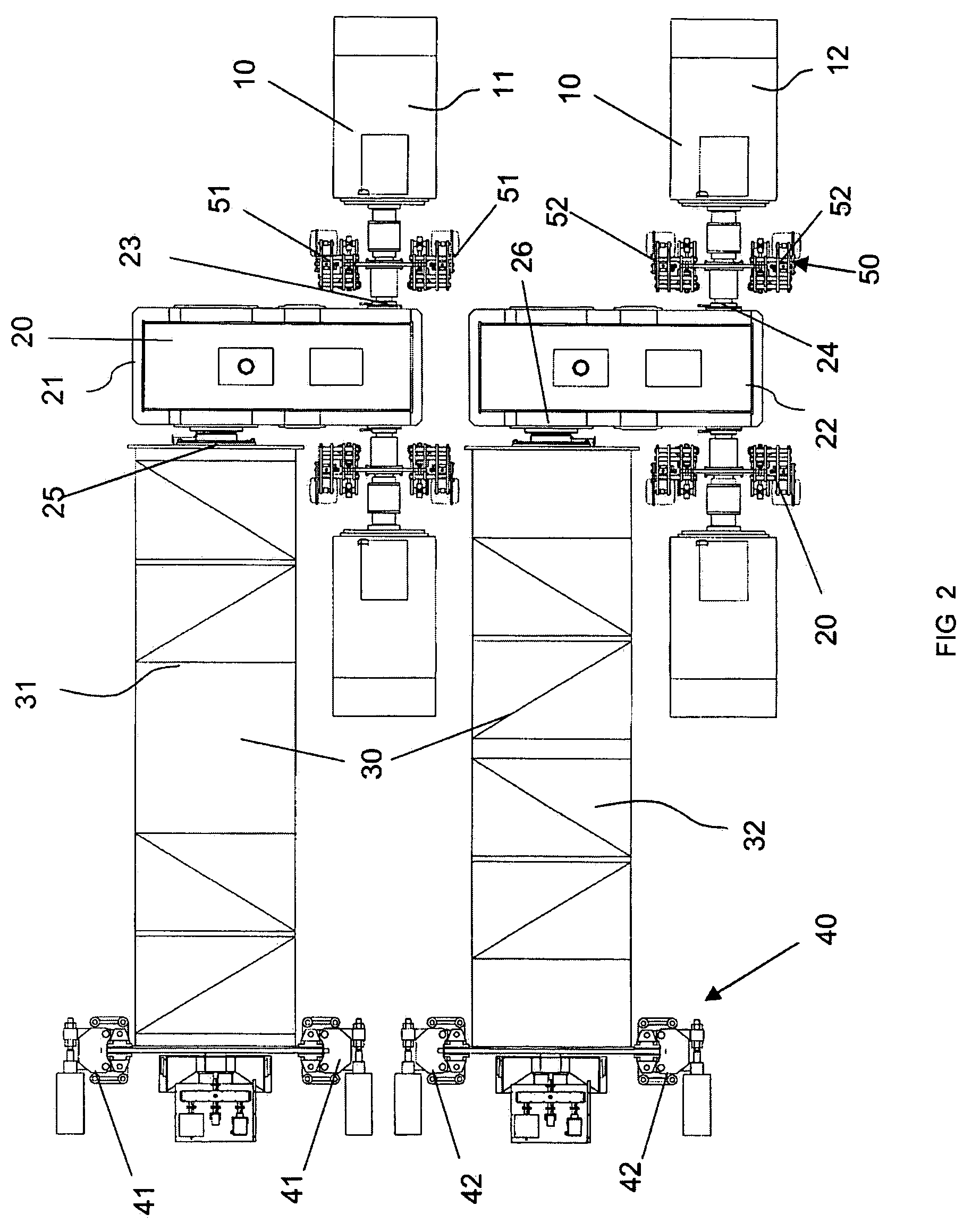

Container crane apparatus and method for container security screening during direct transshipment between transportation modes

InactiveUS20080219804A1Save a lot of costCargo handling apparatusBase supporting structuresContainer craneGround vehicles

A crane apparatus installed on a pier, wharf, bulkhead wharf or other foundation directly transships containers from a vessel moored alongside the foundation to another transportation mode without ground placement of the containers. The crane apparatus includes a parent crane displaceable along the foundation for unloading containers from the vessel and placing them on a first platform of the parent crane, and a sibling crane displaceable along the foundation independently of displacement of the parent crane for loading containers from the first platform directly onto over-the-ground vehicles or onto another vessel moored alongside the foundation. The parent crane has a first trolley-hoist-spreader movable along an outreach boom for unloading containers from the vessel and placing them on either the first platform or a second platform of the parent crane, and a second trolley-hoist-spreader movable along a backreach boom for loading containers from the second platform onto another vessel or onto over-the-ground vehicles. A container security scanning system may be provided on the second platform for scanning the containers while on the second platform to determine whether one or more preselected chemical, biological, explosive or nuclear materials are present in the containers.

Owner:CHATTEY NIGEL

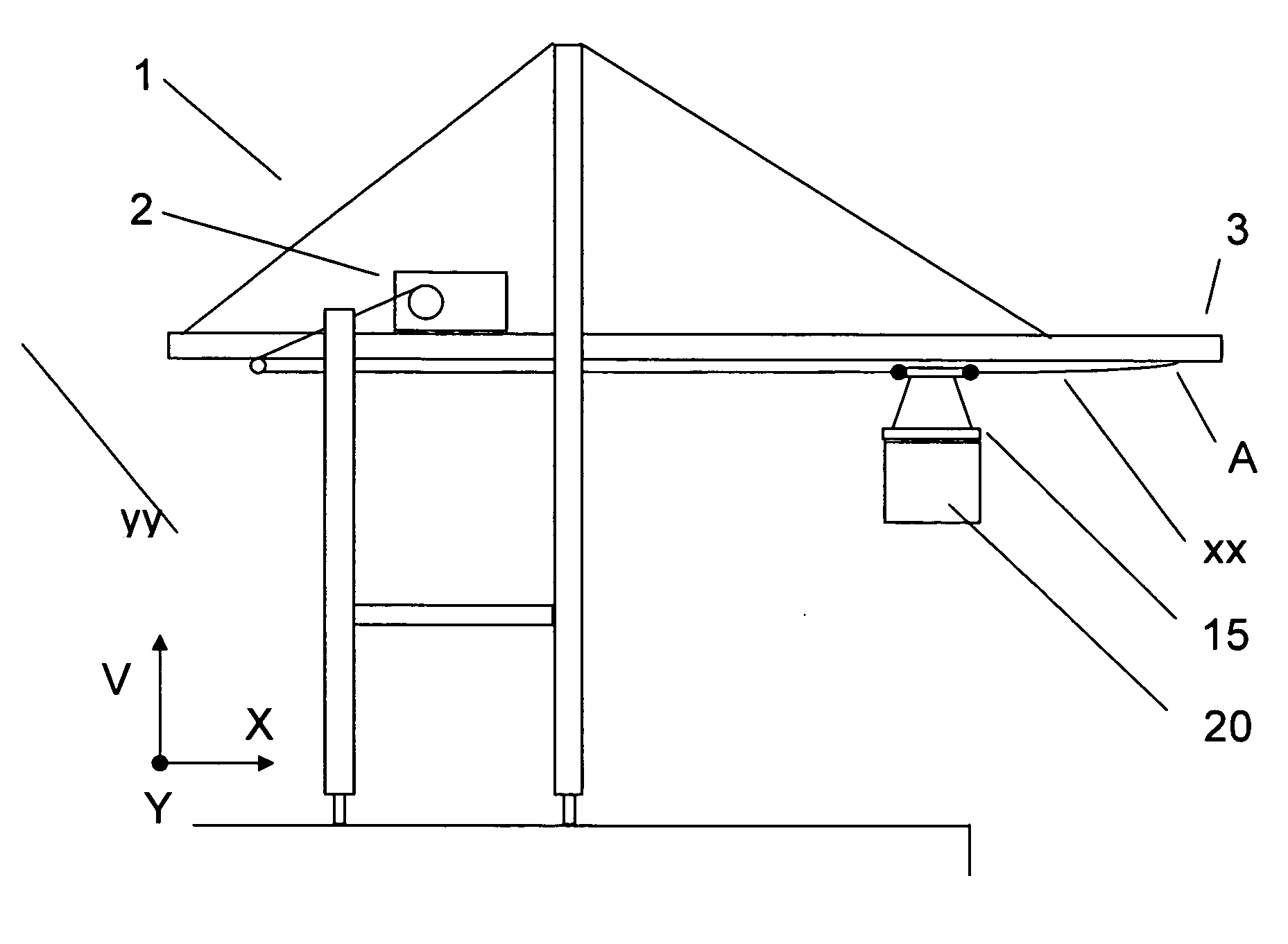

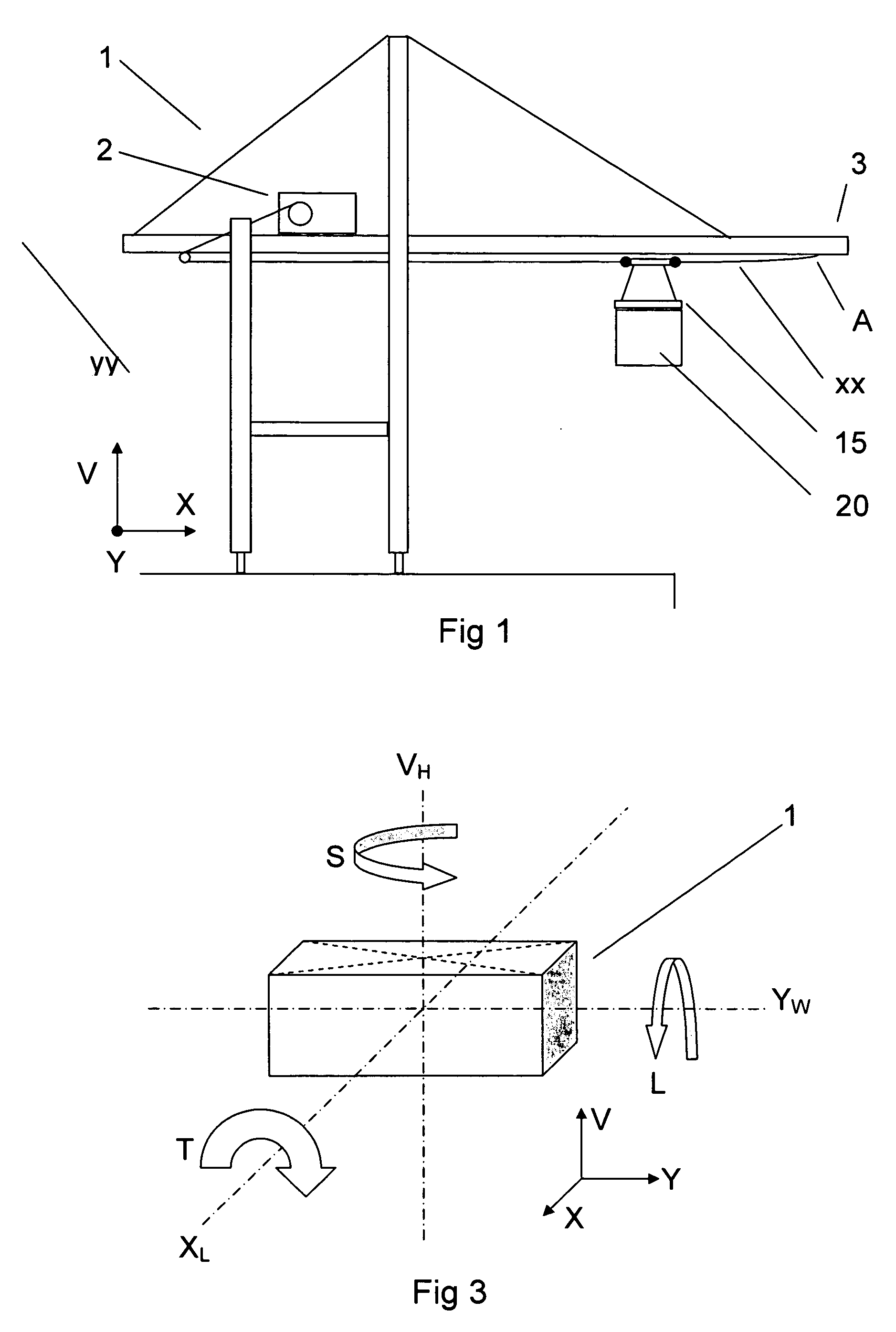

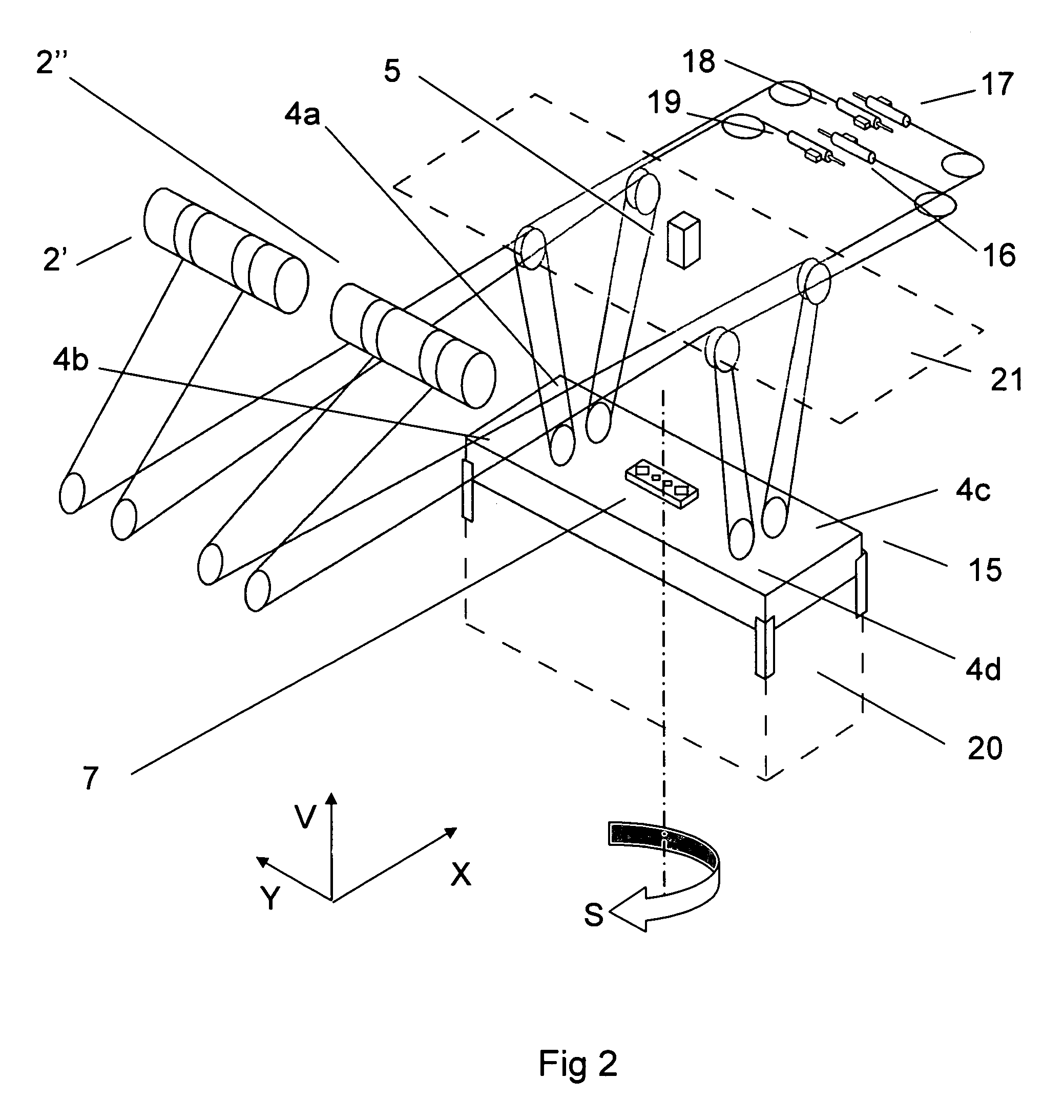

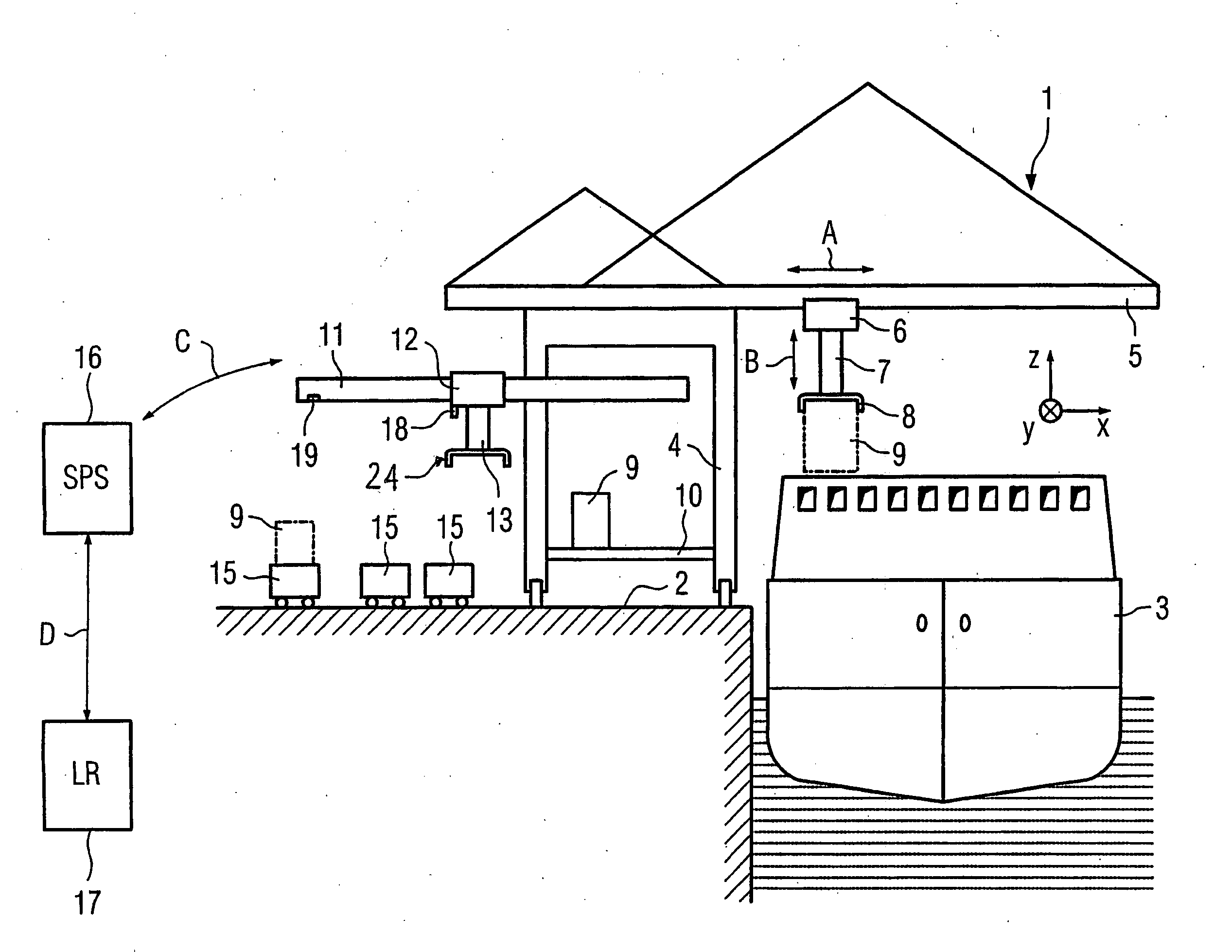

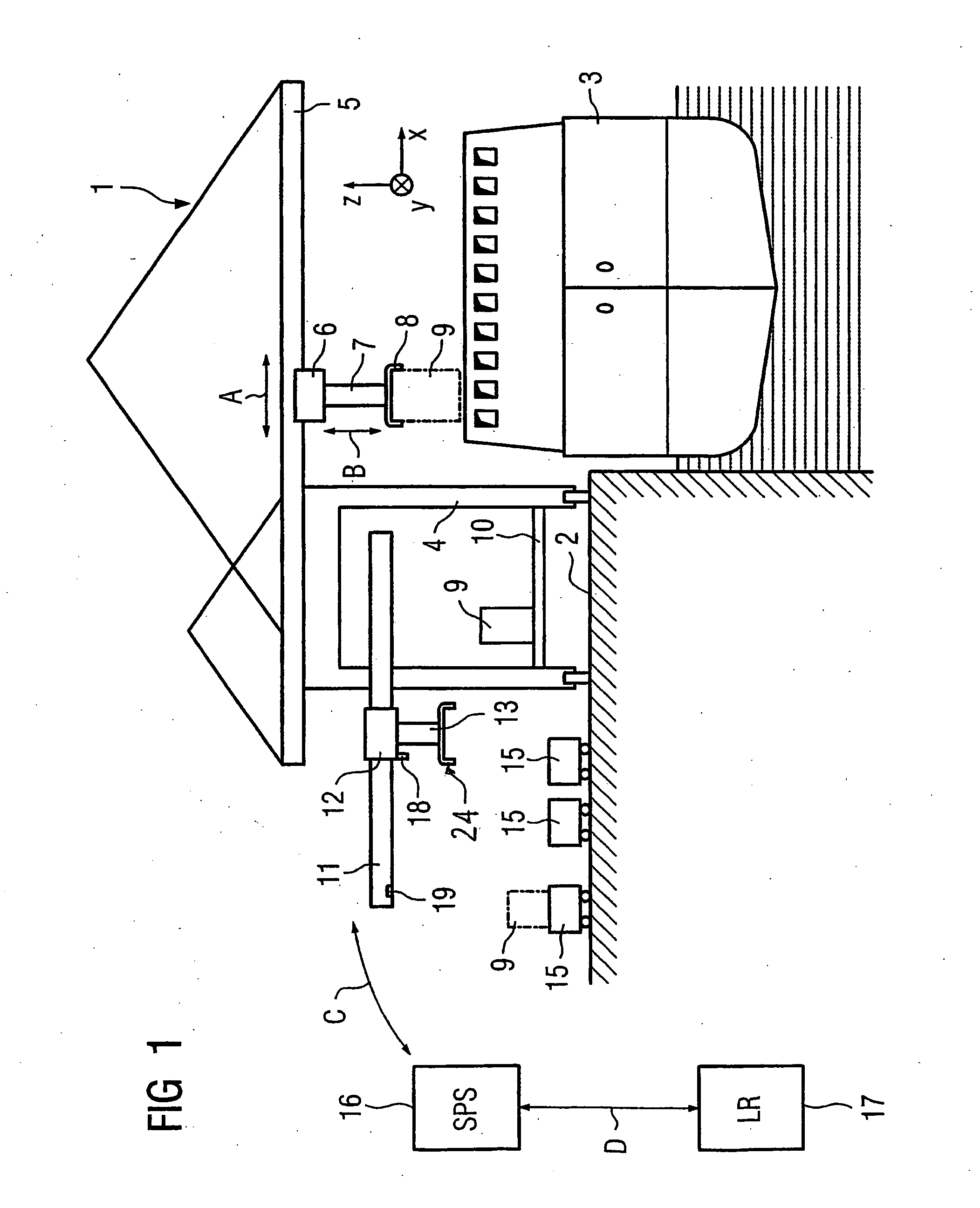

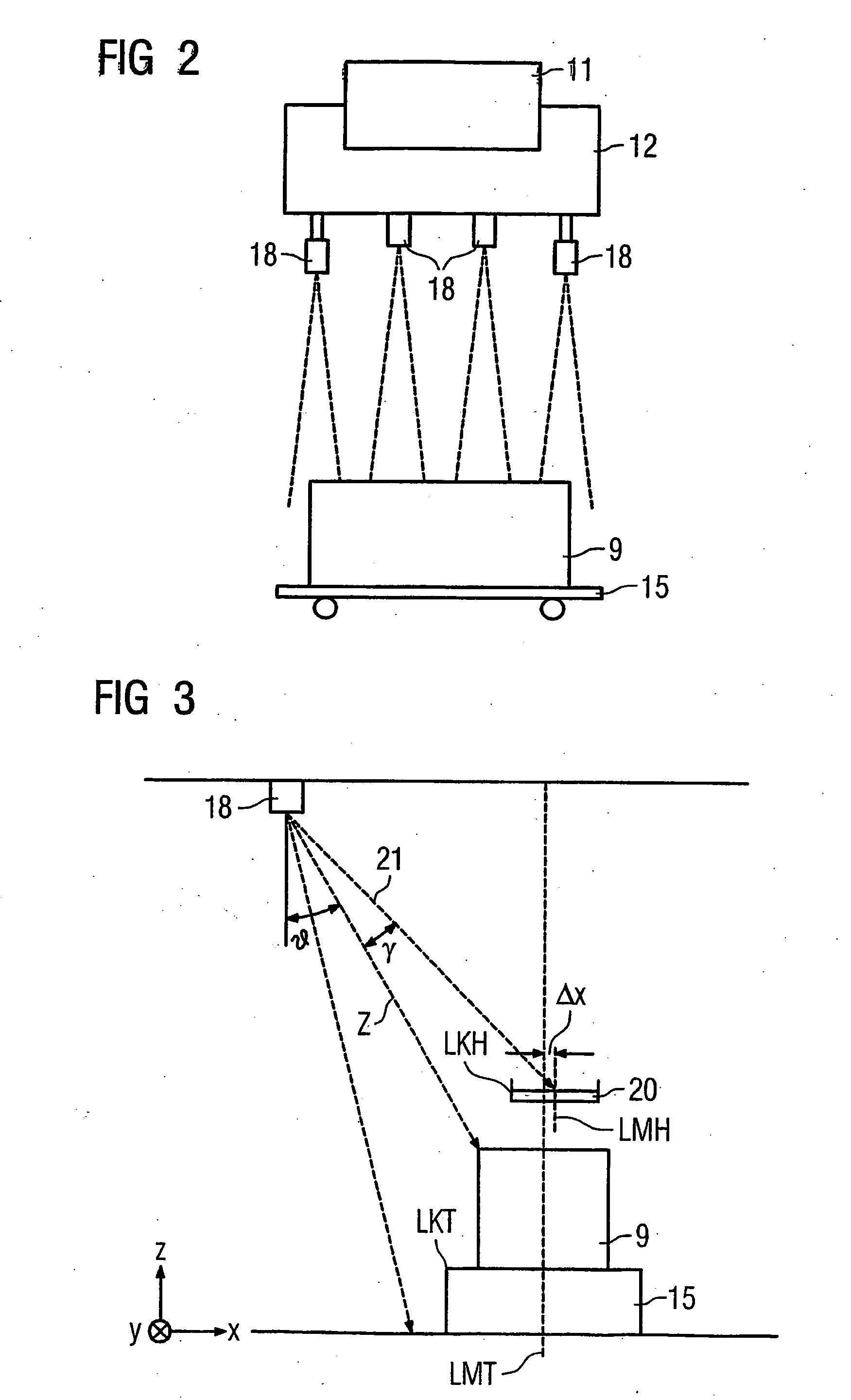

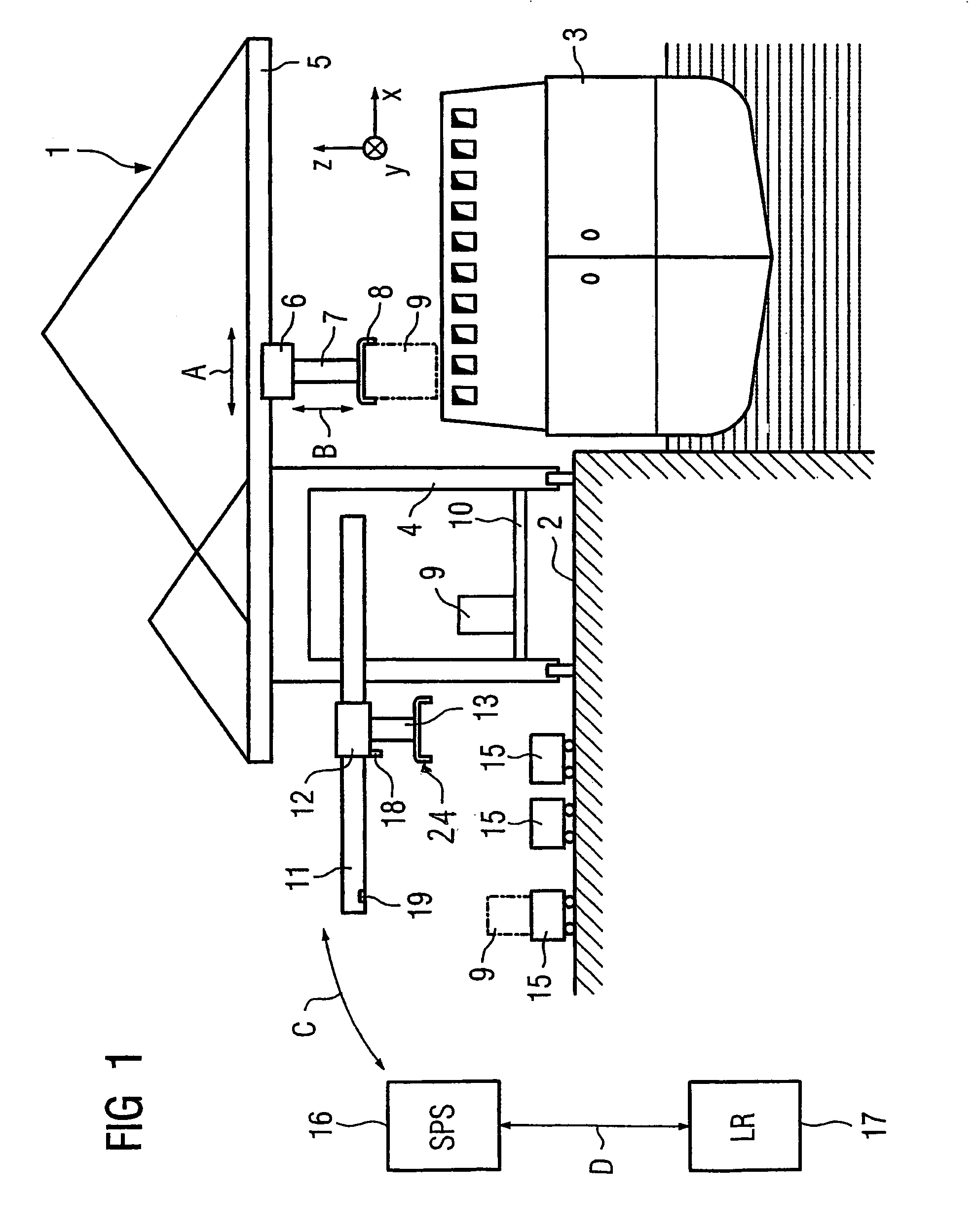

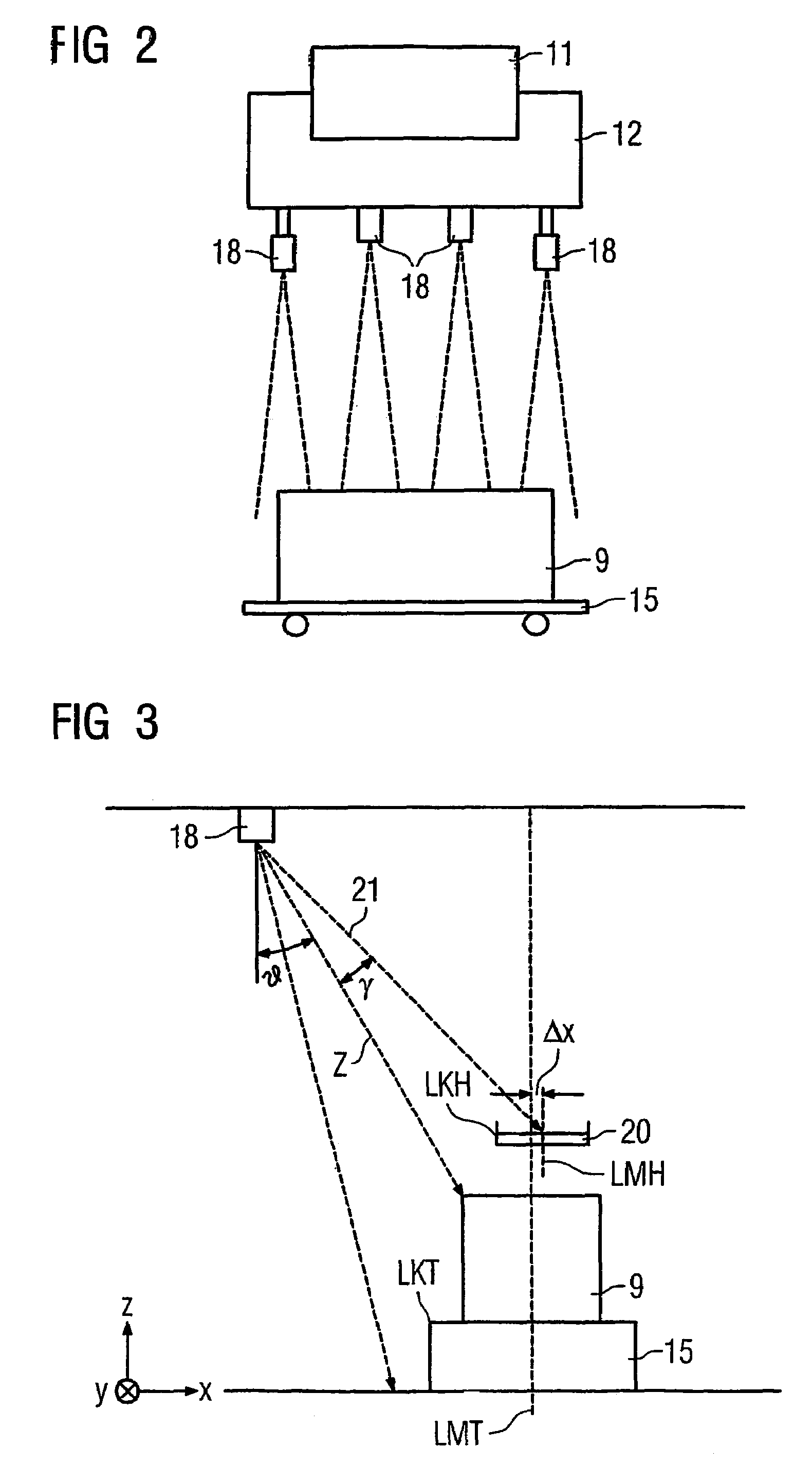

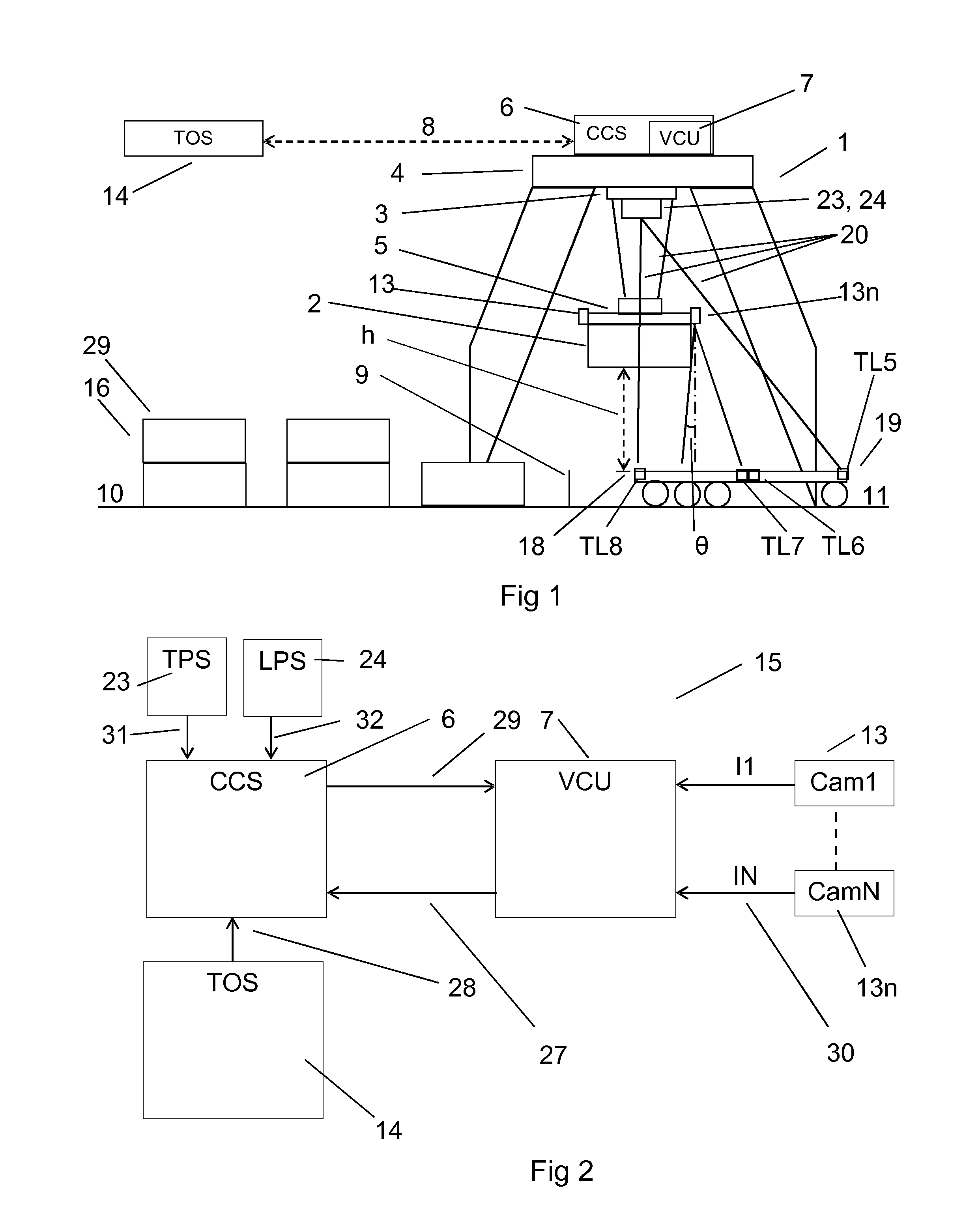

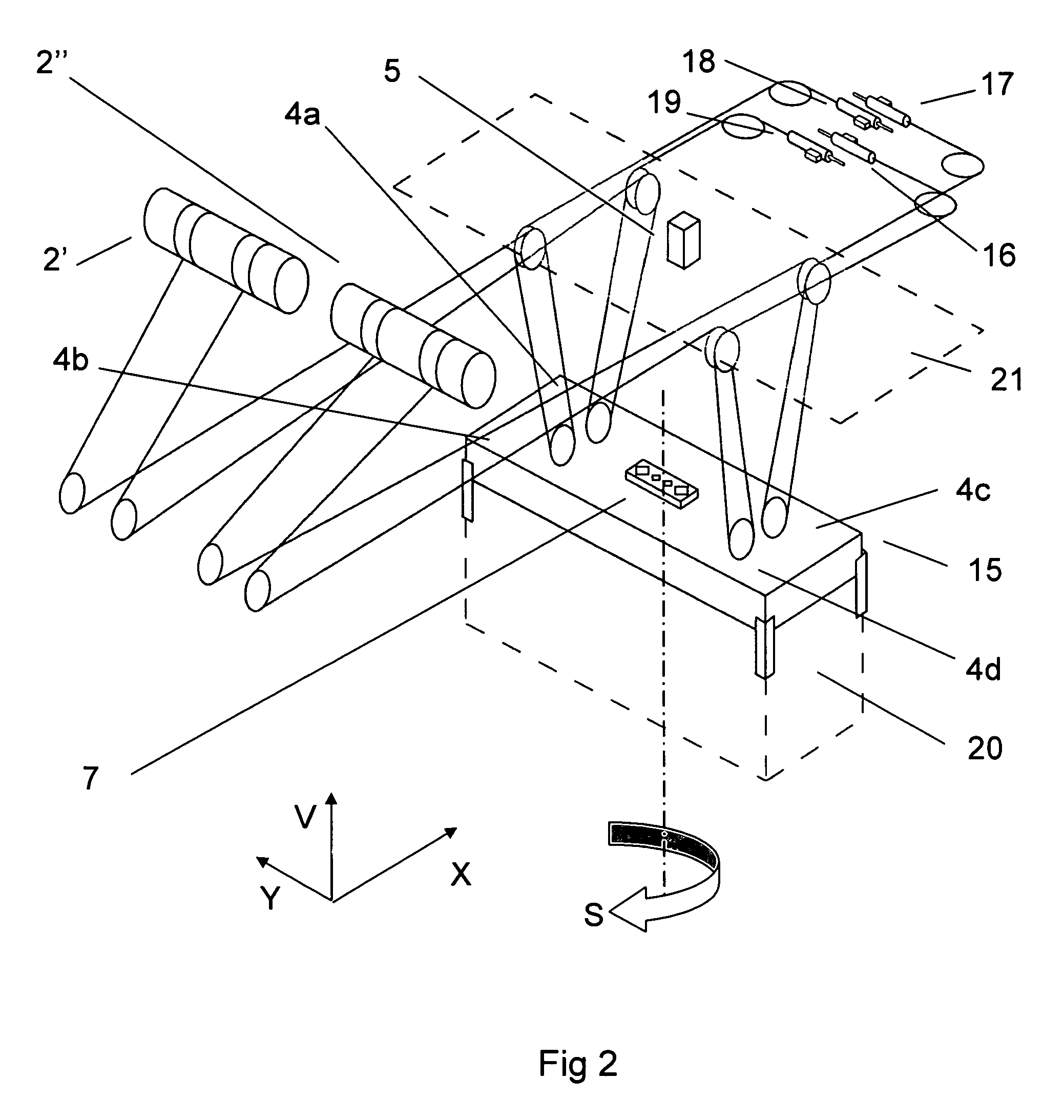

Container crane, and method of determining and correcting a misalignment between a load-carrying frame and a transport vehicle

ActiveUS20050281644A1Large enough scanning areaEnough recording areaDigital data processing detailsArticle unpackingContainer craneEngineering

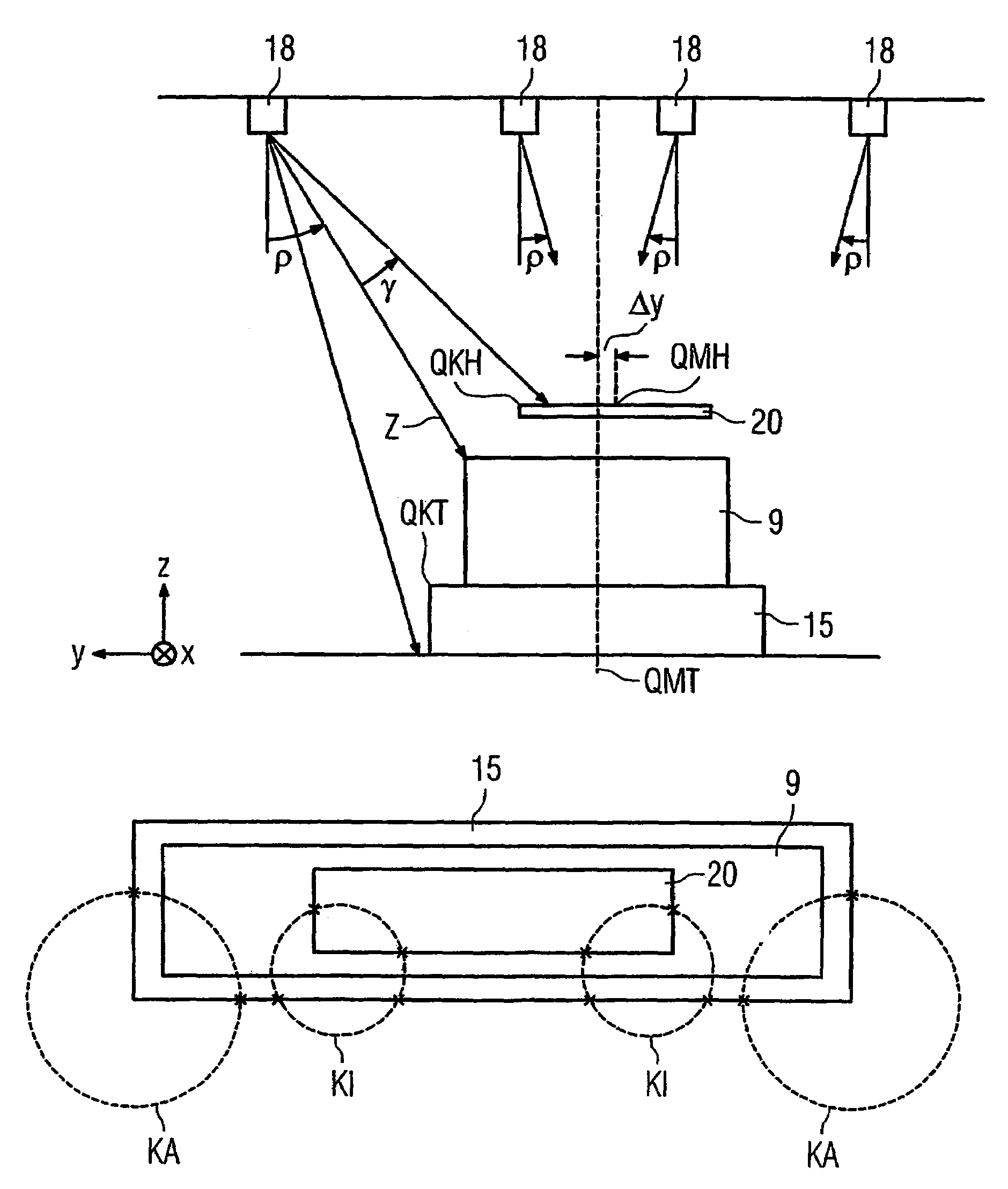

A container crane includes a movable trolley and a load-carrying frame pendantly connected to the trolley and comprised of a spreader and a head block, for transfer of a container from or to a transport vehicle. Plural optical detectors are mounted on the trolley for identifying longitudinal and transversal edges of the head block or spreader and the transport vehicle. Operatively connected to the detectors is a processing device for determining a spatial position of the edges and calculating a position of longitudinal and transversal center lines of the head block or spreader and the transport vehicle and their spatial positions in relation to one another. In this way a possible offset of the center lines of the head block or spreader with regard to those of the transport vehicle in longitudinal and transversal directions as well as a rotation angle of the center lines can be determined, whereby a detected offset or rotation angle is compensated by displacing the spreader relative to the head block.

Owner:SIEMENS AG

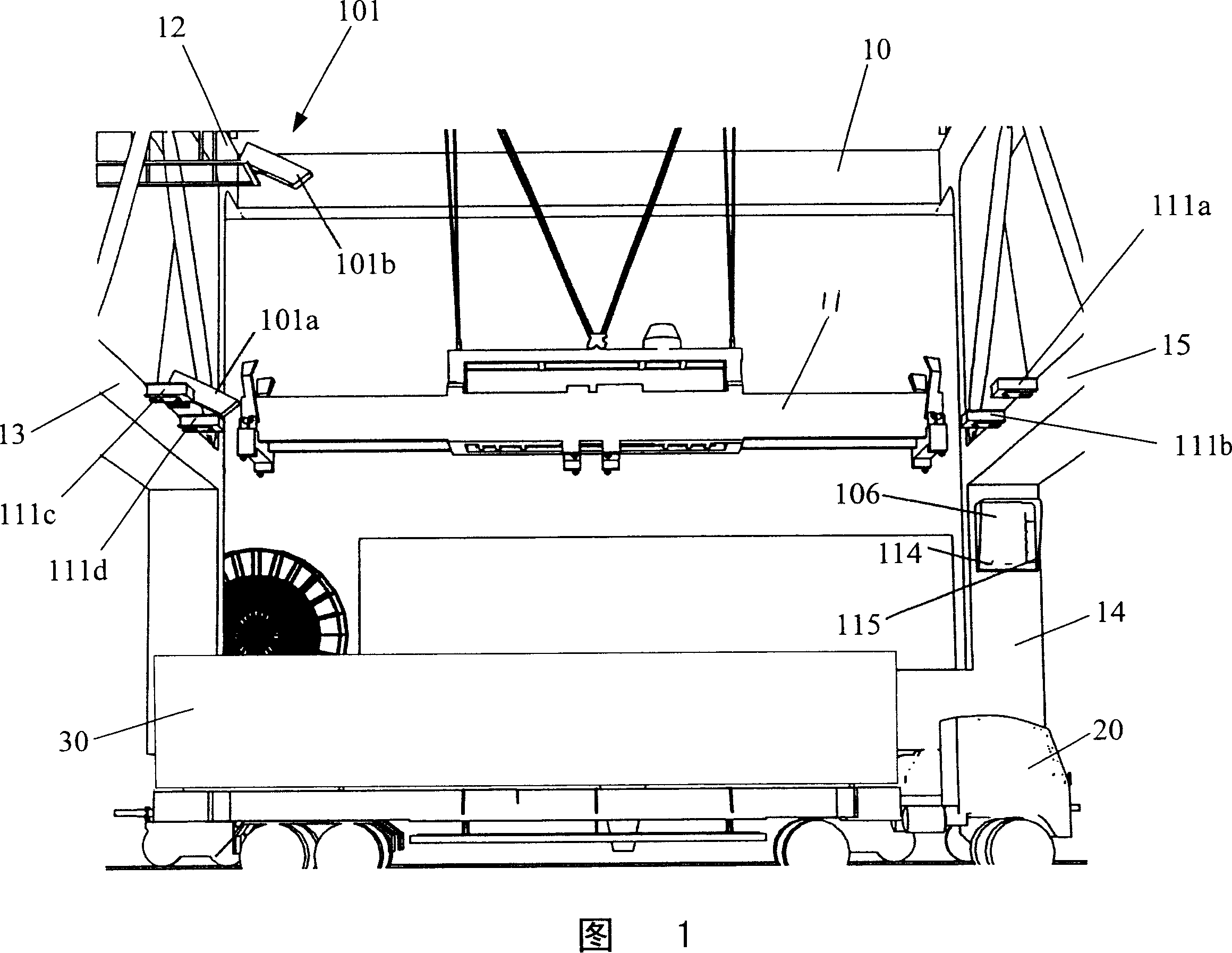

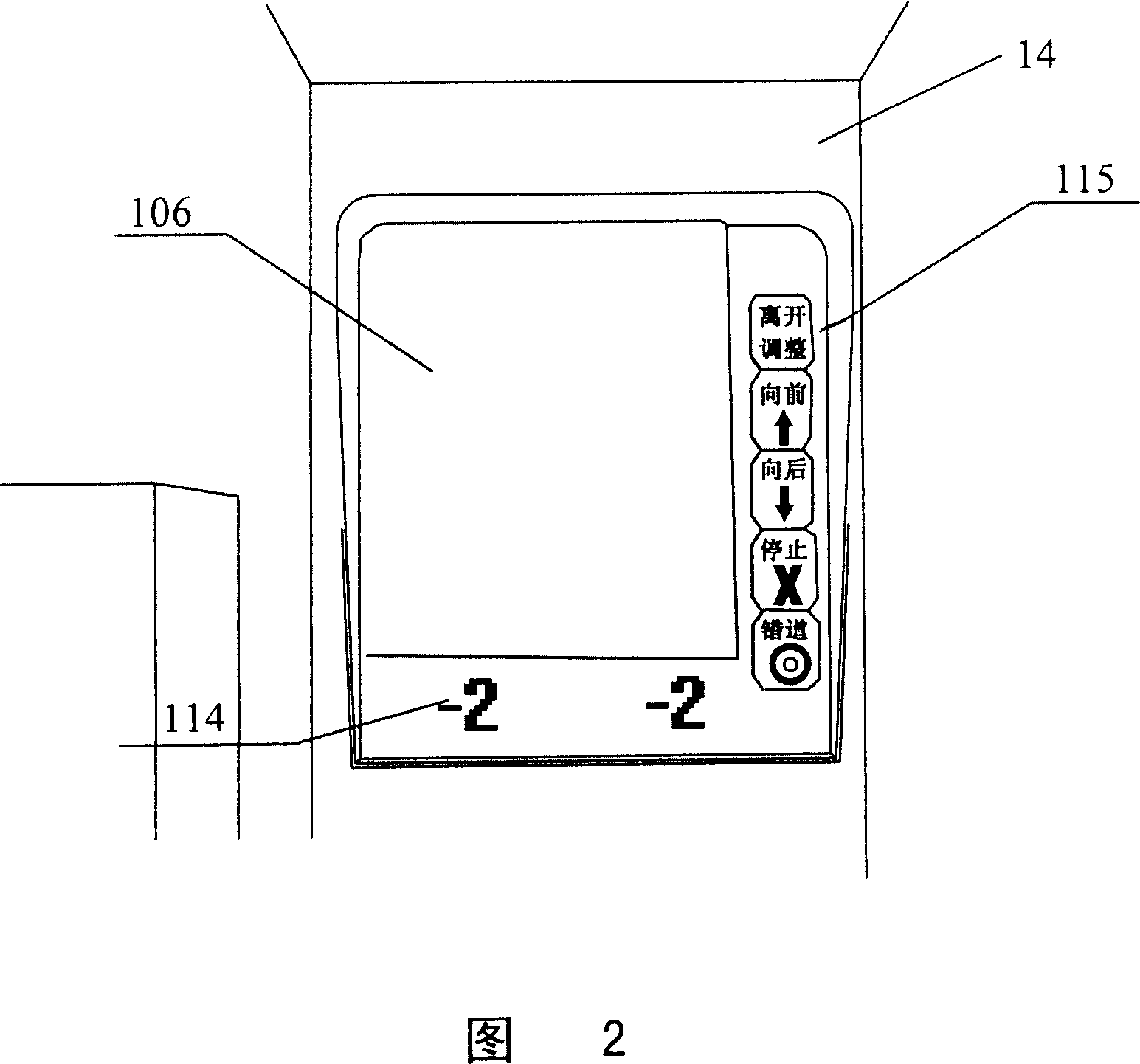

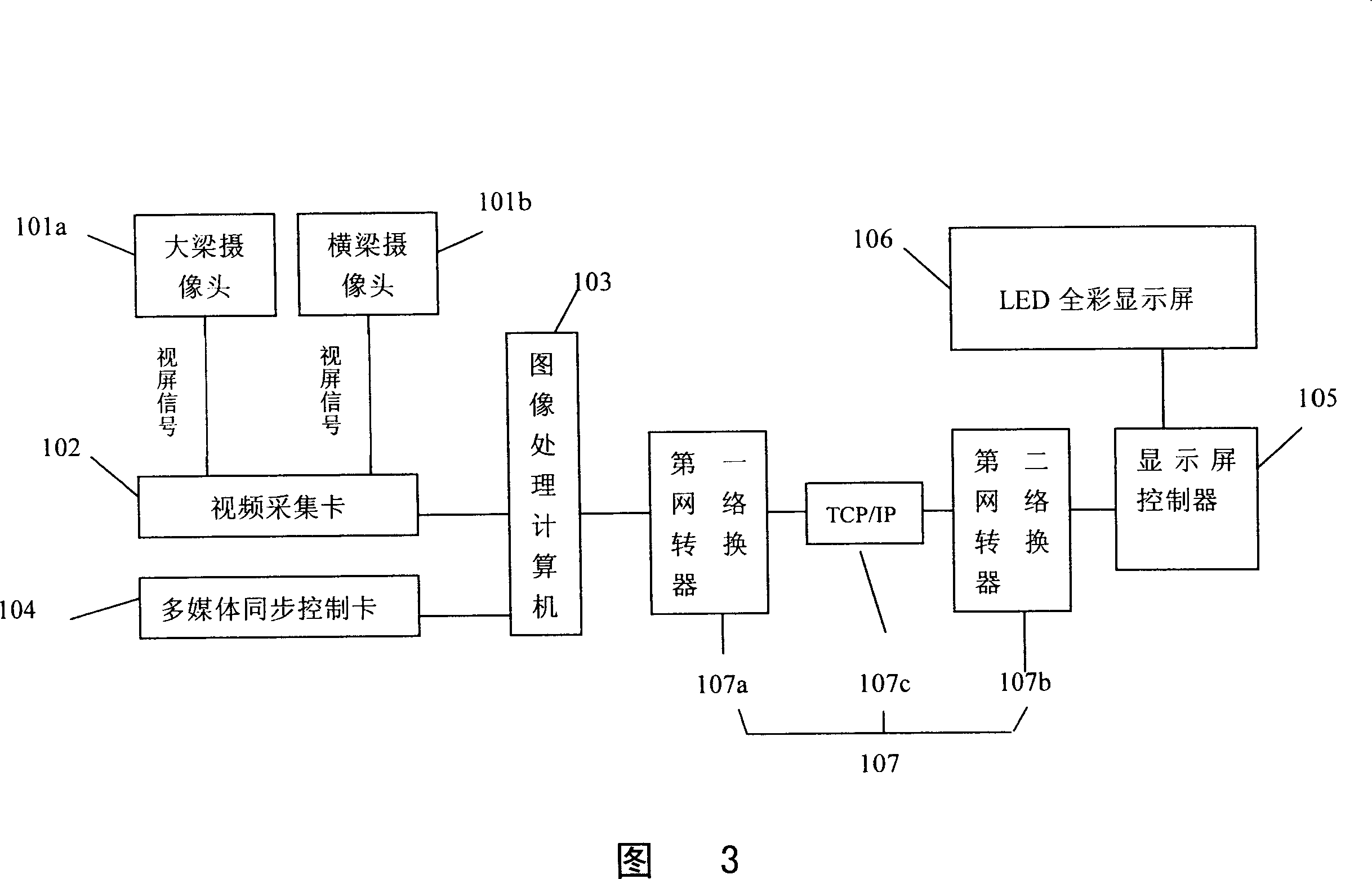

Container-truck positioning system and method for container crane

InactiveCN101096262AQuickly and accurately stop atQuick loading and unloadingLoad-engaging elementsImaging processingLaser scanning

The invention discloses a container-lorry alignment system of container crane and the method. Image pickup equipment set above the loading and unloading position of crane is used to shoot lorry image in real time and transfers the image to the image processing computer. The image processing computer combines pre-storing simulating lifting-tool profile into data image and transfers combined image to display controller by net in real time so as to control the display to display combined image set at the front of loading and unloading position of crane in visual field of lorry driver to help driver accomplish predetermining lorry. At least one suit of laser scanning equipment set on the front beam and back beam of crane is used to collect profile information of lorry or container on the lorry and transfer the information to computer system. The computer system carries out data filter to profile information and characteristic fitting. The information is contrasted with theoretical setting value and position error of lorry or container to the crane is analyzed and is transferred to the error display at the front of loading and unloading position of crane for displaying so as to help driver accomplish accurate position for lorry.

Owner:SHANGHAI ZHENHUA HEAVY IND

Load-lifting apparatus and method of storing energy for the same

ActiveUS20080048497A1Improve fuel efficiencyLower noxious prime power emissionBatteries circuit arrangementsDc motor stoppersPower ArchitectureContainer crane

A load-lifting apparatus has one or more prime power sources, one or more energy storage systems and regenerative braking. Regenerative energy is recovered when the load-lifting apparatus lowers its load. The elements of the prime power sources, energy storage devices and electrical components may be distributed to provide stability for the load-lifting apparatus. The general power architecture and energy recovery method can be applied to cranes, rubber-tired gantry cranes, overhead cranes, mobile cranes, ship-to-shore cranes, container cranes, rail-mounted gantry cranes, straddle carrier cranes and elevators. In such an architecture, the energy storage system helps alleviate the power rating requirement of the prime power source with respect to the peak power requirement for lifting a load.

Owner:MI JACK CANADA

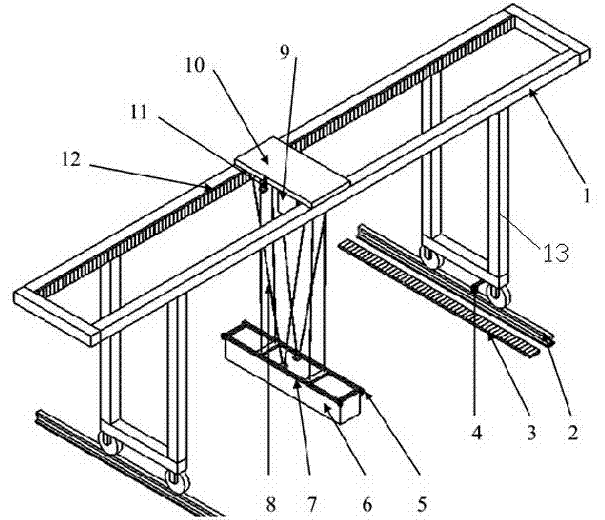

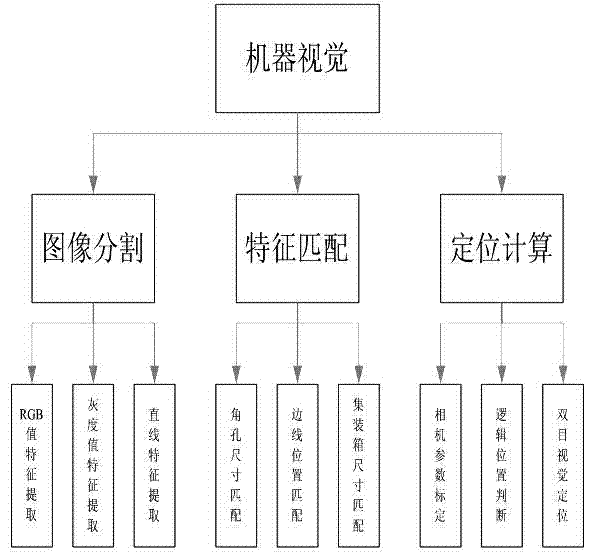

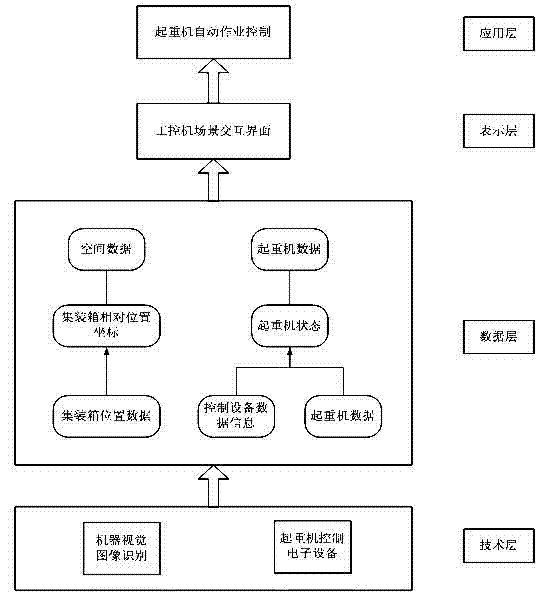

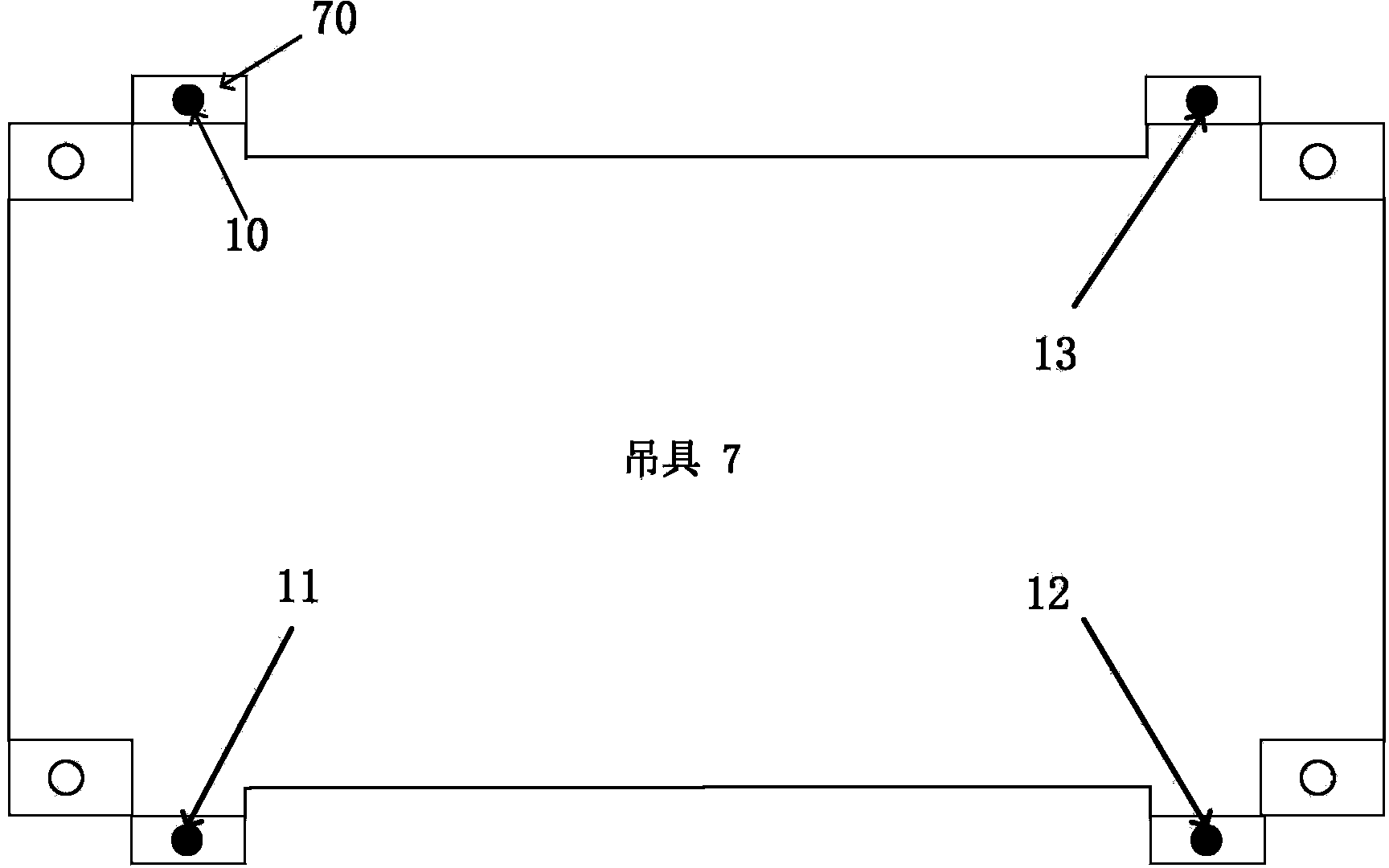

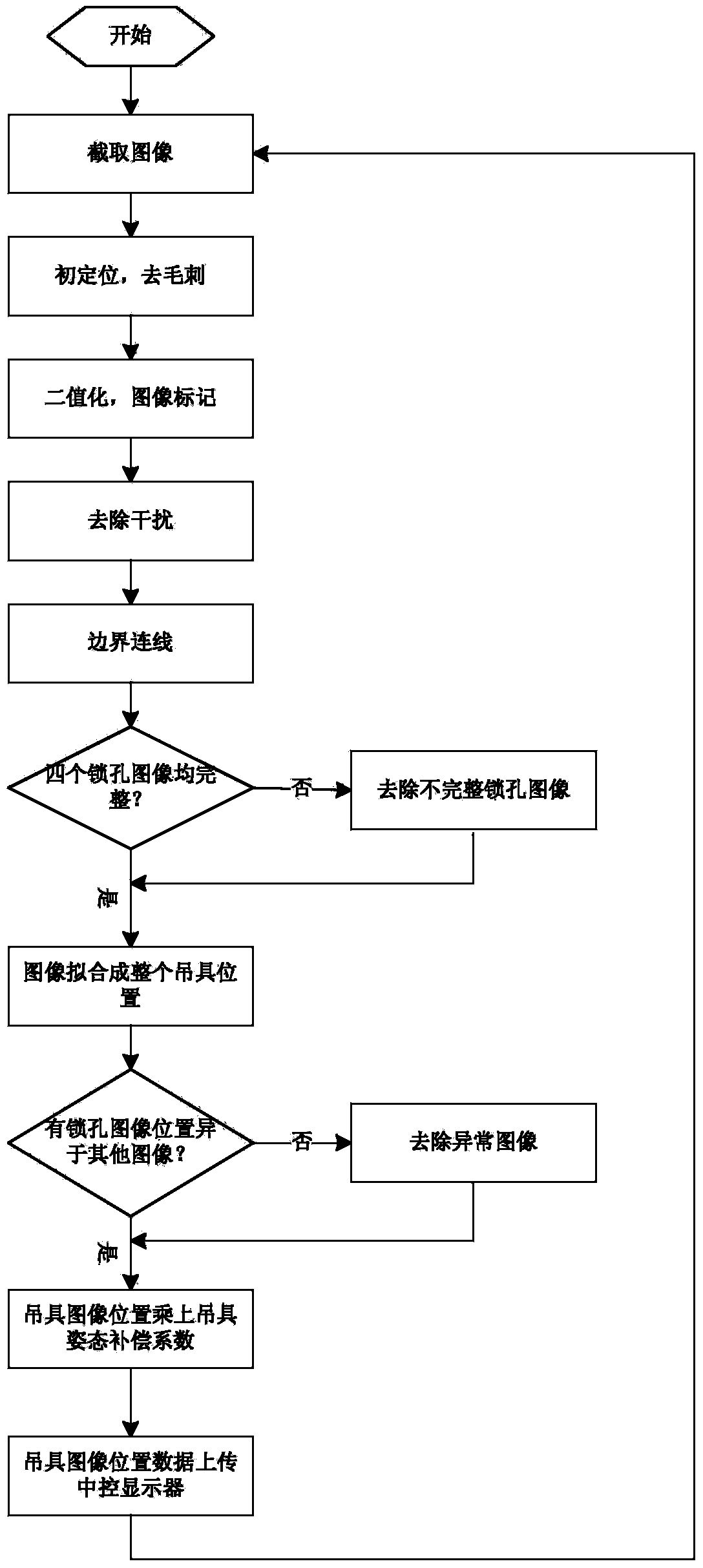

Automatic control system of efficient handing operation of container crane

InactiveCN102923578APrecise positioningMovement precisionLoad-engaging elementsLoop controlAutomatic control

The invention provides an automatic control system of an efficient handing operation of a container crane, and relates to the technical field of operation and production of container cranes. The machine vision and image recognition location technology is used to locate the relative position of a container and a lifting appliance, an image processing result is transmitted to a crane control system, a bar code location system is mounted near a crane cart track and a crane trolley track to accurately locate the position of the lifting appliance of the crane, then a position closed loop feedback control system is formed, and therefore an image recognition location method and an image recognition location device of the container crane are achieved, a lifting appliance movement closed loop control method of the container crane is achieved, and an automatic container grabbing method and an container grabbing device of the lifting appliance of the crane are achieved.

Owner:YANGZHOU CITY HUATAI ENVIRONMENT PROTECTION EQUIP MFG

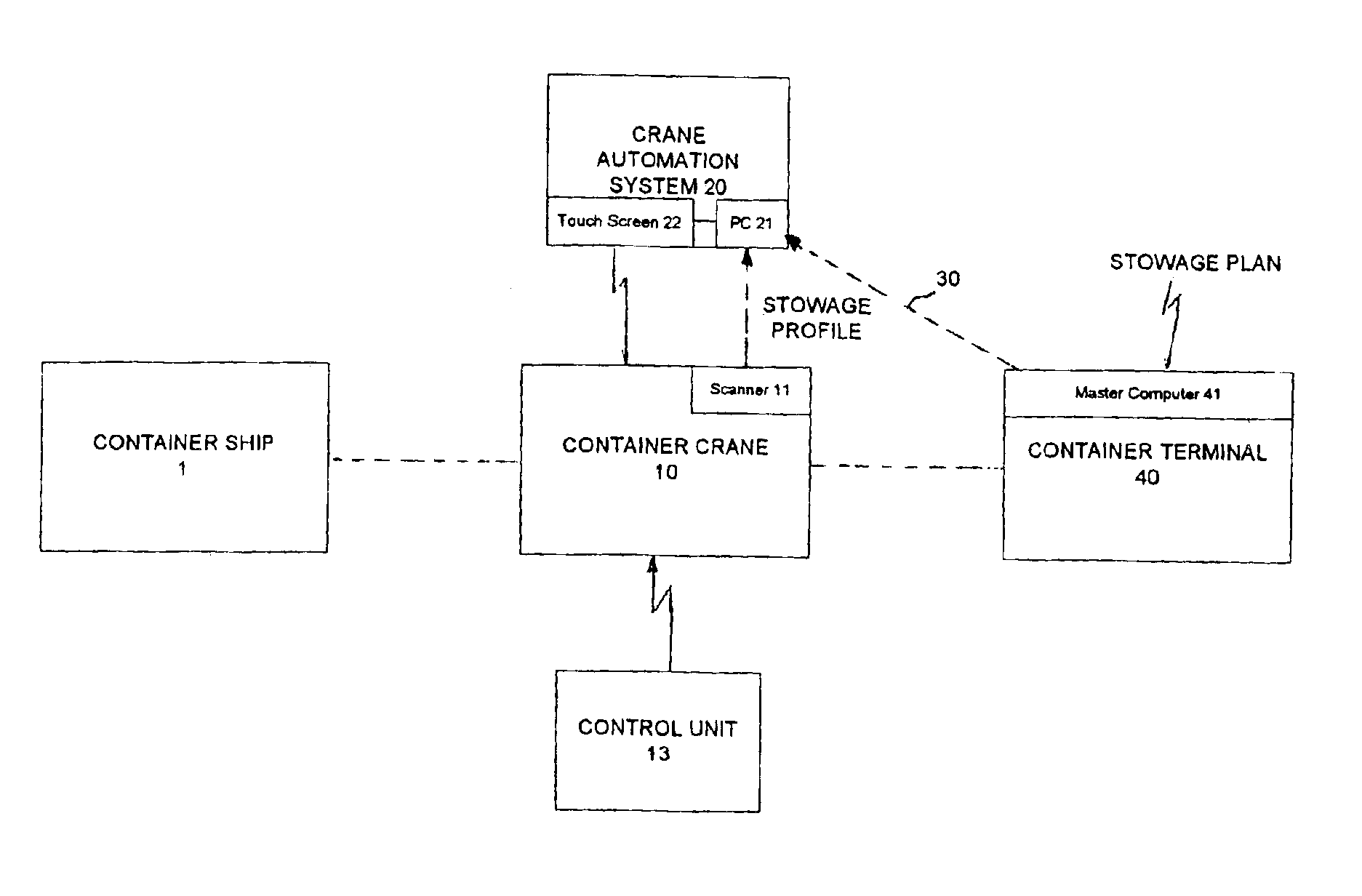

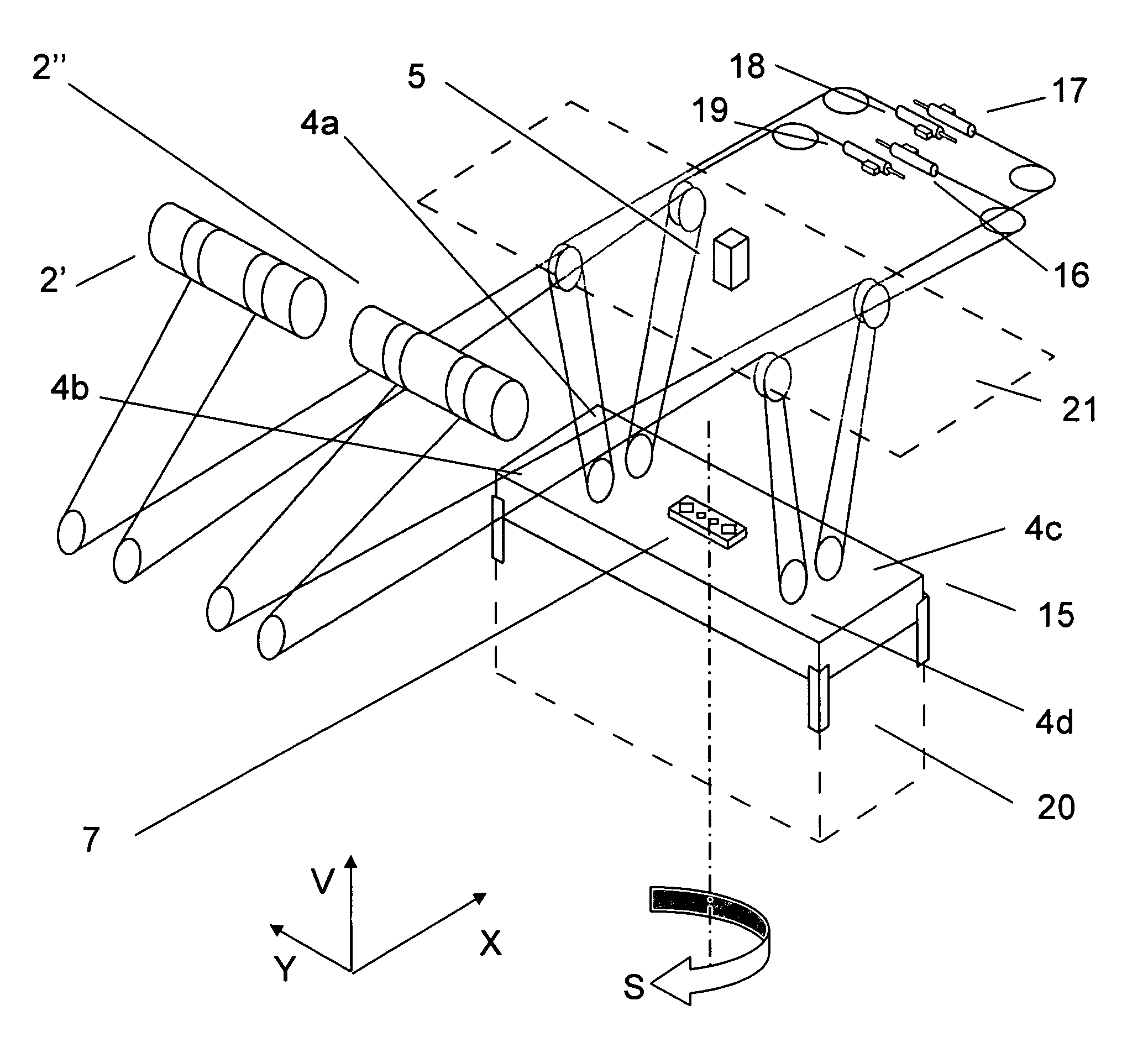

Method of automating a loading and unloading of container ships in container terminals, and crane automation system

In a method of automating the loading and unloading of container ships in container terminals, a stowage plan of a ship cargo compartment to be handled by a container crane is transmitted from a harbor-side master computer via a data link to a PC of a crane automation system which renders the container crane operative in response to the stowage plan for transporting containers between a container ship and a repository location in a container storage area of the container terminal. The stowage plan is displayed on a touch screen of the crane automation system, whereby a next following repository location to be handled in the stowage plan is indicated on the touch screen, e.g. through a change in color.

Owner:SIEMENS AG

Container crane, and method of determining and correcting a misalignment between a load-carrying frame and a transport vehicle

ActiveUS7289876B2Quick correctionQuick identificationDigital data processing detailsArticle unpackingContainer craneEngineering

A container crane includes a movable trolley and a load-carrying frame pendantly connected to the trolley and comprised of a spreader and a head block, for transfer of a container from or to a transport vehicle. Plural optical detectors are mounted on the trolley for identifying longitudinal and transversal edges of the head block or spreader and the transport vehicle. Operatively connected to the detectors is a processing device for determining a spatial position of the edges and calculating a position of longitudinal and transversal center lines of the head block or spreader and the transport vehicle and their spatial positions in relation to one another. In this way a possible offset of the center lines of the head block or spreader with regard to those of the transport vehicle in longitudinal and transversal directions as well as a rotation angle of the center lines can be determined, whereby a detected offset or rotation angle is compensated by displacing the spreader relative to the head block.

Owner:SIEMENS AG

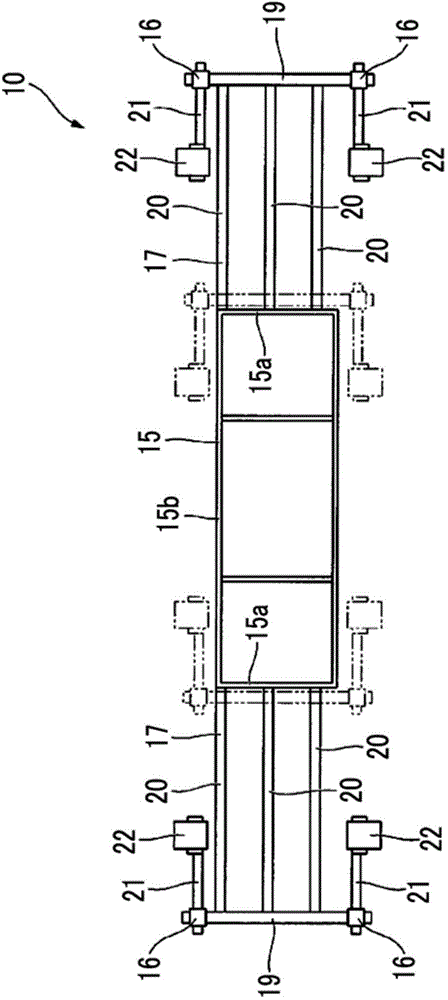

Radiation detection unit for mounting a radiation sensor to a container crane

A radiation detection unit includes a housing and isolators unitarily constructed from mechanical energy absorbent material. The housing is attached rigidly to a structure and its major dimensions are selected to exceed corresponding major dimensions of a radiation sensor. The isolators have a body portion and projections extending outwardly therefrom. The body portion engages the radiation detection sensor proximal a respective one of its radiation collection end and its interface end. The projections are disposed intermediate the body portion and an interior surface of the housing and have a distal end contacting the interior surface to carry the radiation sensor in a three dimensional spaced apart relationship to the interior surface. The length of the projections is selected to attenuate substantially mechanical energy that is induced at the distal end and propagates along the length of each projection prior to the propagated energy being incident upon the body portion.

Owner:VERITAINER ASSET HLDG LLC

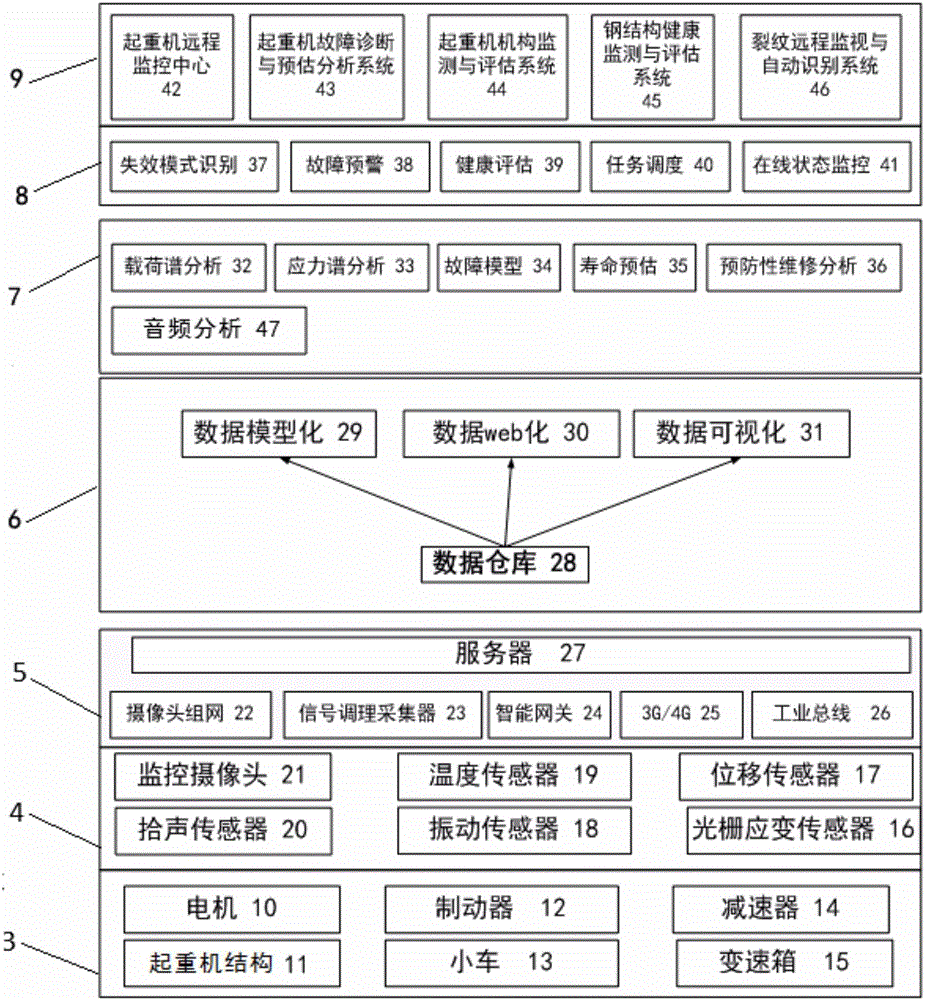

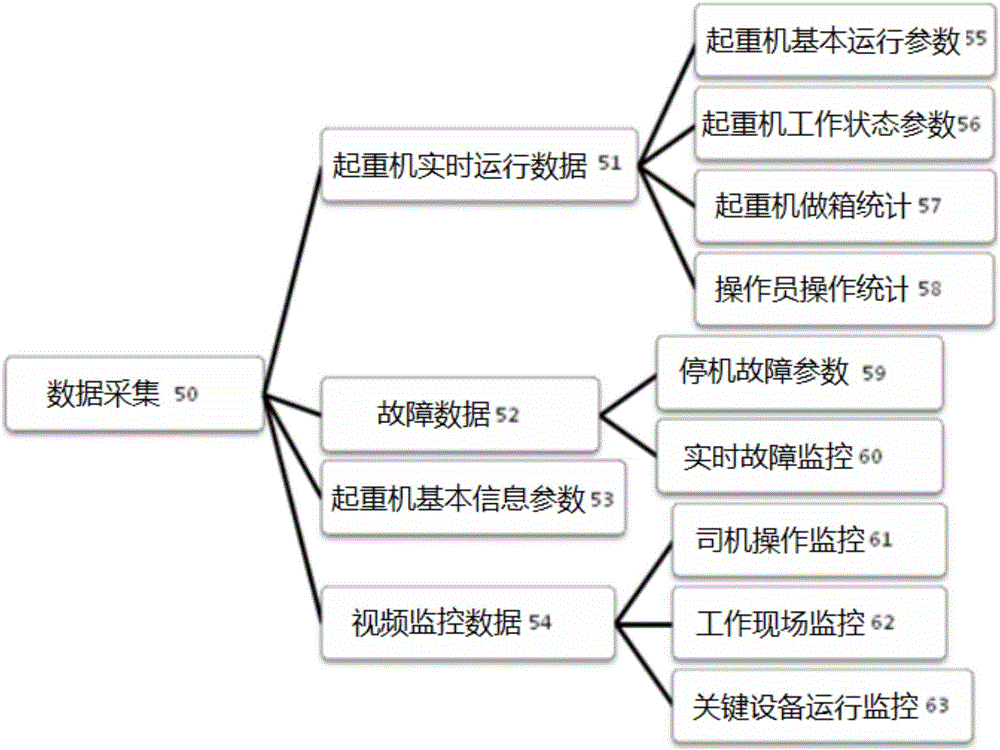

System for online diagnosis and preventive maintenance of container crane based on big data

ActiveCN106698197ARealize scientific testingAvoid wastingDesign optimisation/simulationSpecial data processing applicationsContainer craneFault model

The invention discloses a system for online diagnosis and preventive maintenance of a container crane based on big data. The system comprises a crane equipment layer, a sensor layer, a network layer and a data service layer, wherein the data service layer is further divided into a data analysis and model layer, a data application layer and a business system layer; the crane equipment layer receives operating parameters of the crane; the sensor layer receives sensor signals of key parts of the crane; the network layer transmits the operating parameters and the sensor signals to the data service layer; the data analysis and model layer presets a normal operating model and a fault model of the crane, and compares the operating parameters and the sensor signals with the model, so as to judge the operating state of the crane; the data application layer predicts the operating stable of the crane within a certain period of time in the future according to the operating parameters and the sensor signals, so as to generate a fault early warning; and the business system layer is provided with an external data interface, and outputs data of the data analysis and model layer as well as the data application layer to the outside world.

Owner:SHANGHAI ZPMC ELECTRIC +1

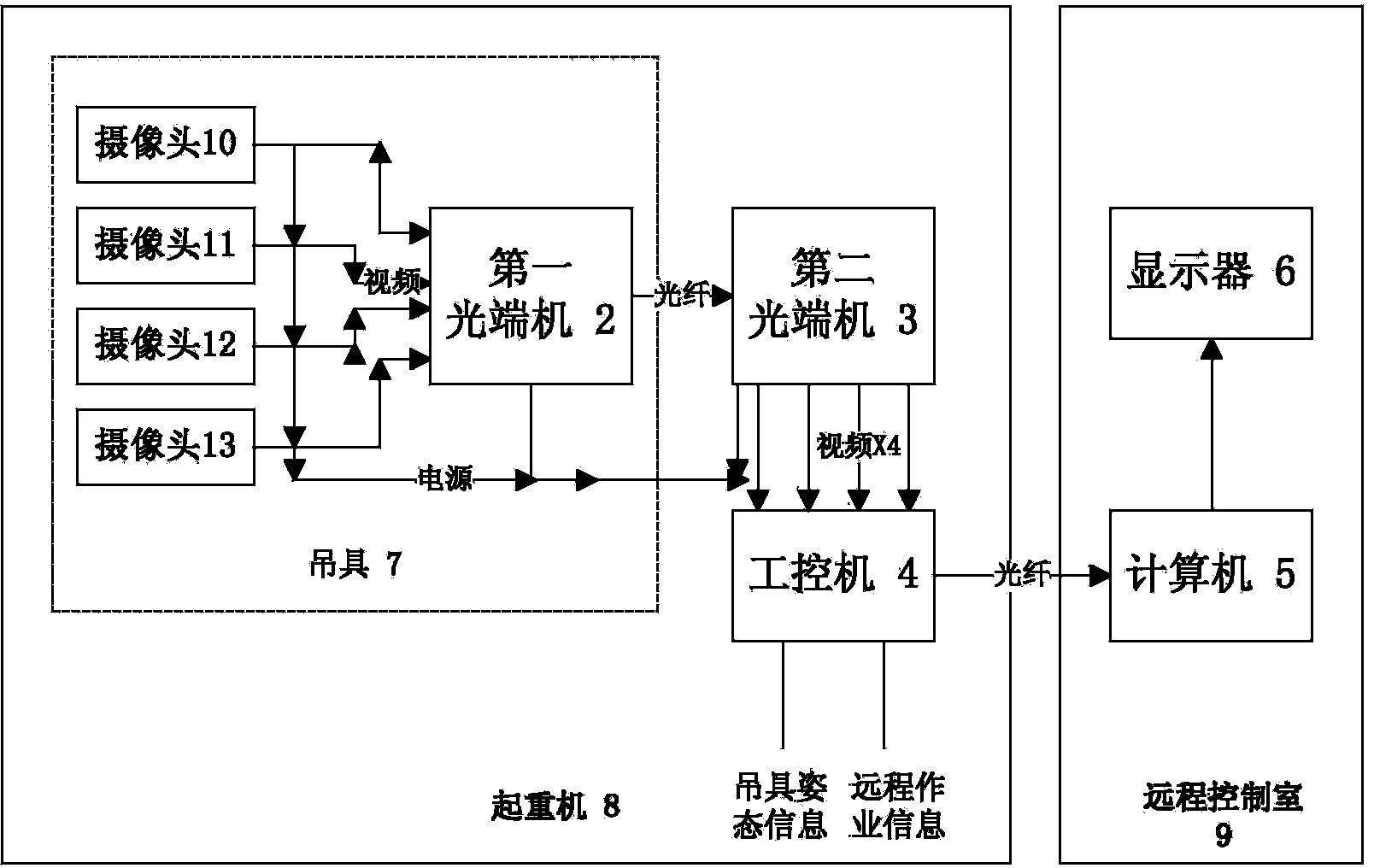

Container crane sling aligning guide system

ActiveCN103818828ASimplified work screenImprove digitizationLoad-engaging elementsInformatizationImaging processing

The invention discloses a container crane sling aligning guide system which greatly facilitates a driver's remote container aligning work, improves the degrees of the numeralization, informatization and intelligentialization of a crane, and has great application expansibility. The container crane sling aligning guide system adopts a technical scheme as follows: through an image processing technique and a position data fitting technique as well as a 'frame aligning' method, the original sling image viewed by a remote driver performing the remote container aligning work is processed and converted into a target frame and a present sling frame comparison display manner, and work data instruction is accompanied, and the sling falls into the target frame, and accordingly, the successful container aligning is shown.

Owner:SHANGHAI ZPMC ELECTRIC +1

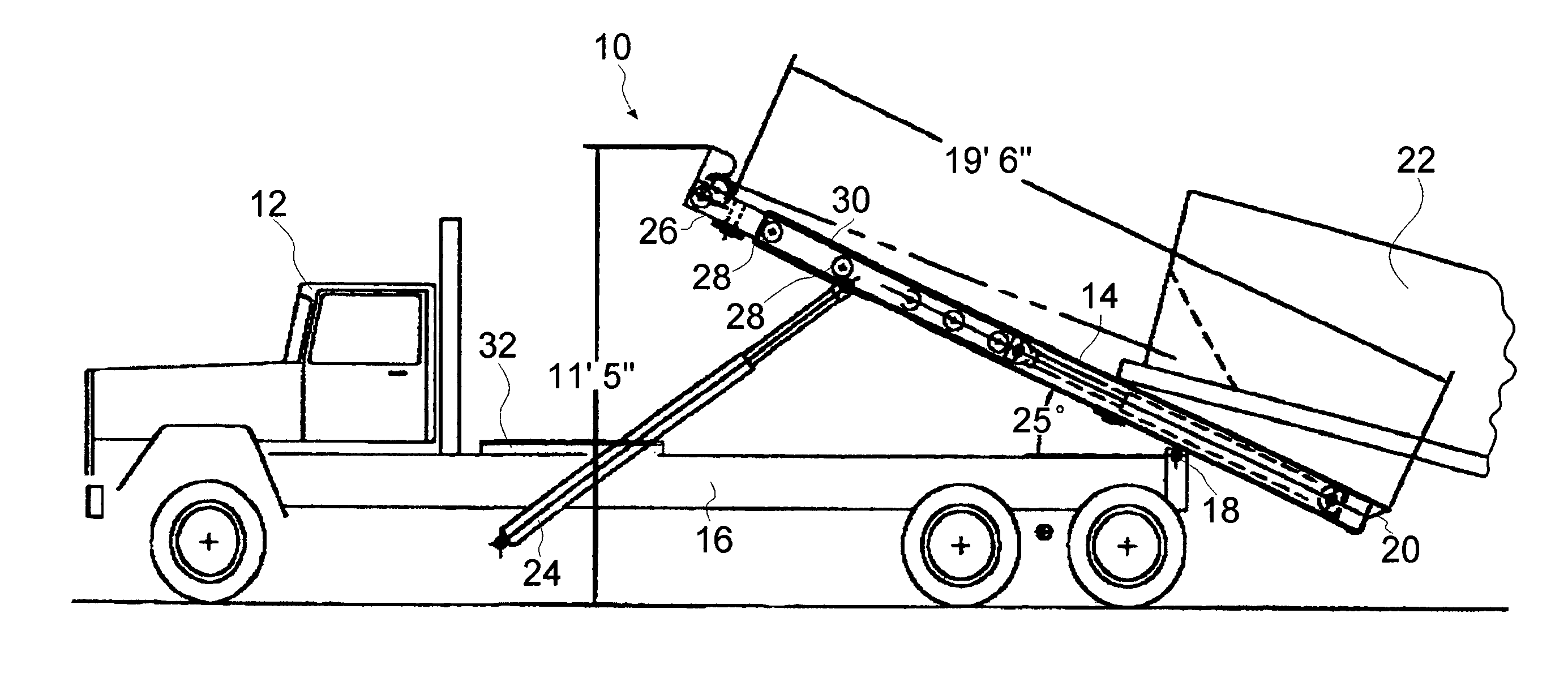

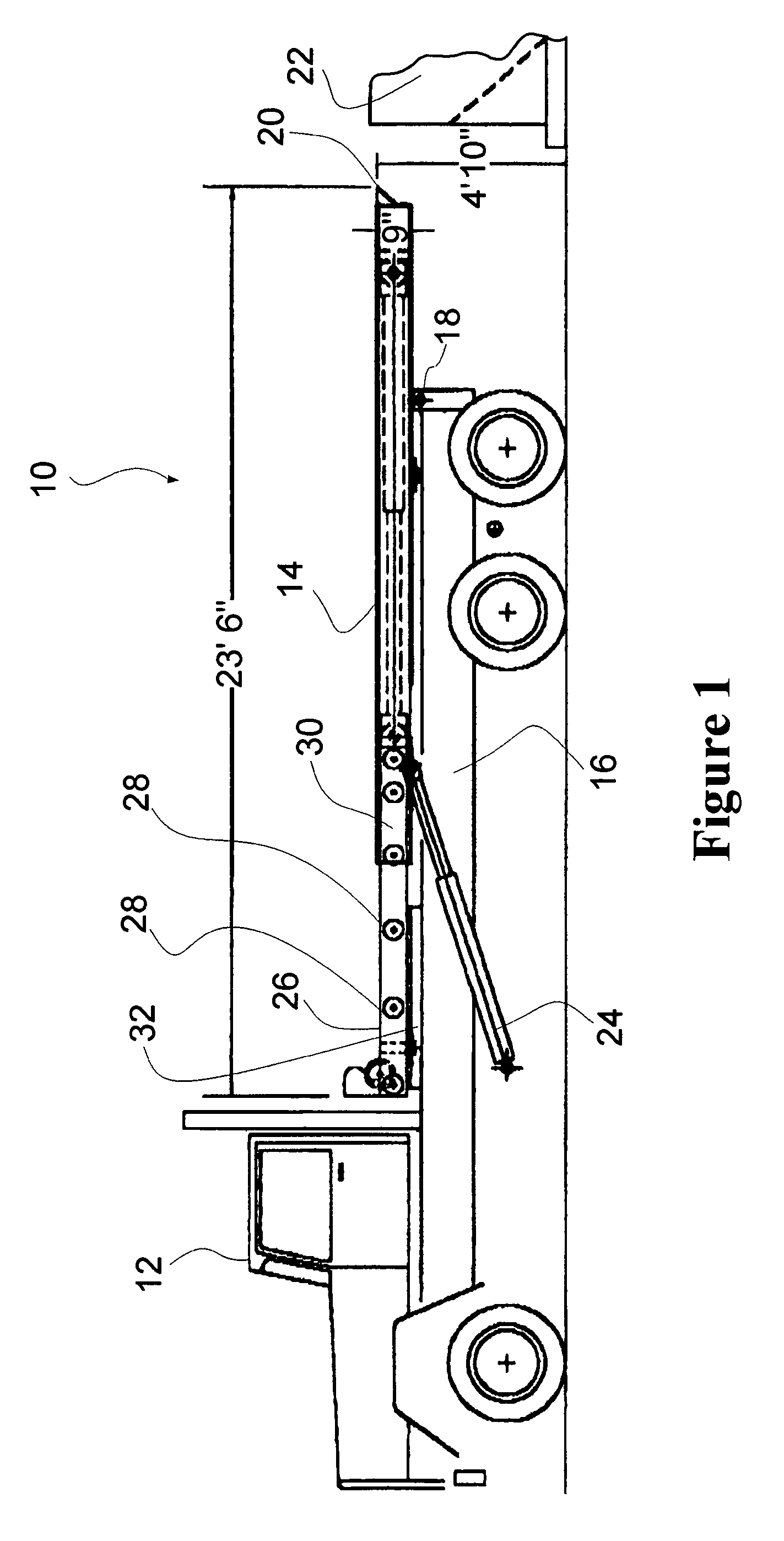

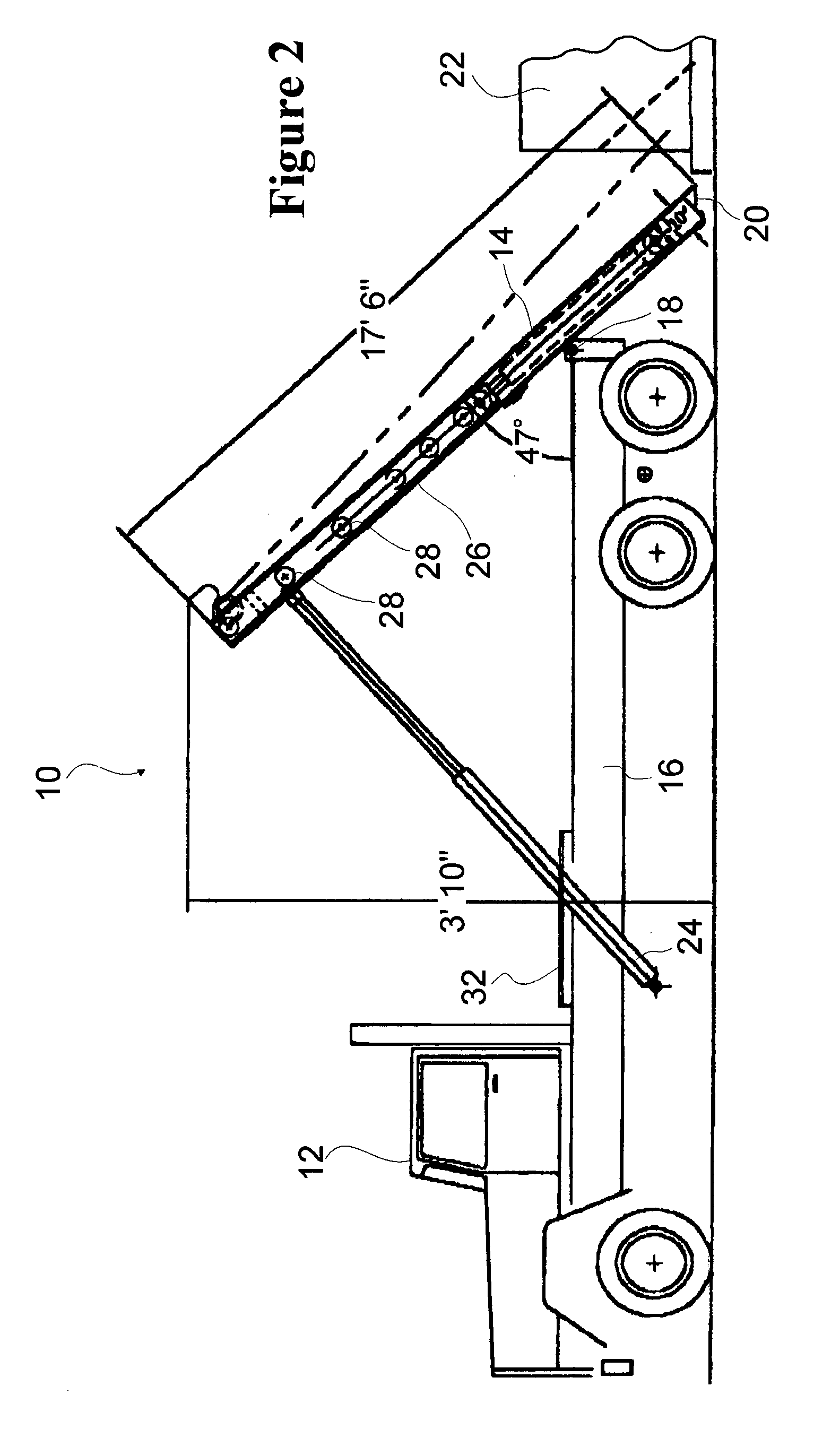

Roll off hoist with front retractable loading frame

InactiveUS7112030B2Vehicle with removable loadingHand carts with one axisVehicle frameContainer crane

A roll off container hoist with a front retractable loading frame includes a hoist with a break or discontinuity of the loadable frame structure at a forward end of the hoist. The roll off container hoist is mounted on a vehicle having hydraulic circuits for operating the hoist. The hoist includes a main hoist frame pivoted to a vehicle frame at a rear pivot point. The hoist includes a main lift cylinder attached to the vehicle frame and the main hoist frame for pivoting the main hoist frame to the loading / unloading position. The hoist includes an extension frame slidably coupled to the main hoist frame and extendable there-from that is loadable at any dump angle.

Owner:RENZIEHAUSEN DAN C

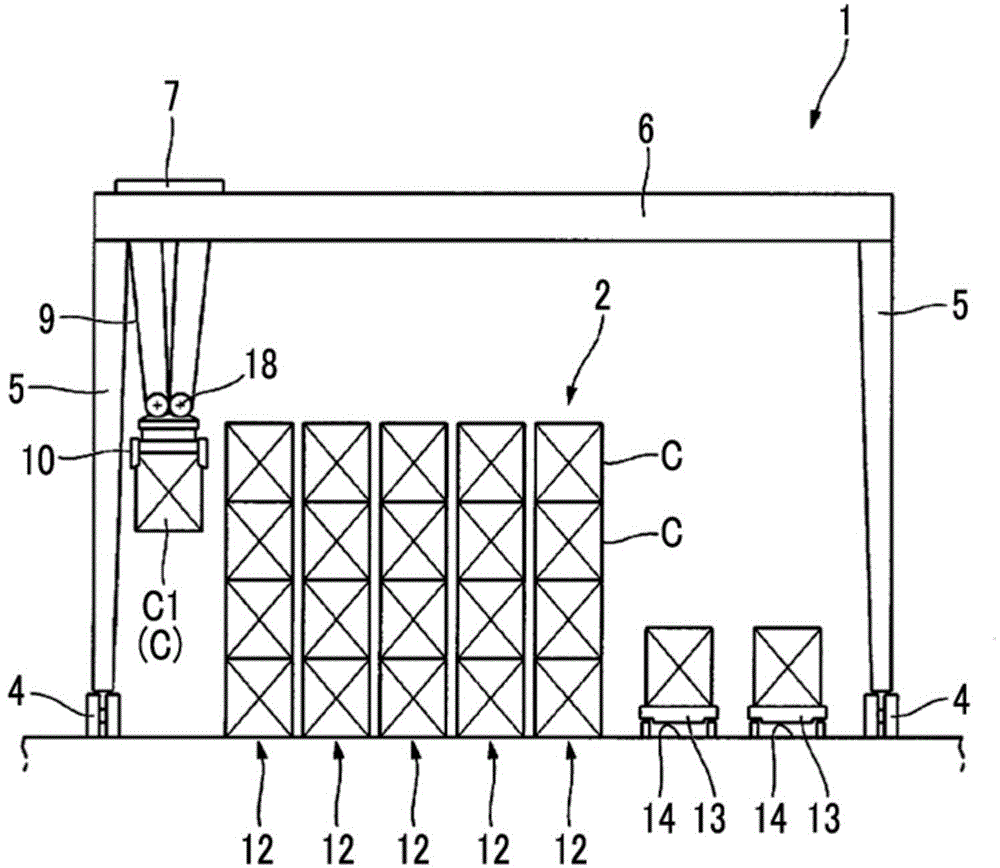

Container handling apparatus, container management system, and method of container handling

InactiveUS20060113384A1Improve container handling efficiencyTrolley cranesLogisticsContainer craneEngineering

A container handling apparatus, a container management system, and a method of container handling are provided in which information of a container to be handled is accurately recognized automatically, in order to improve the efficiency of a container handling operation. An RF-ID reader / writer (wireless communication device) is provided in a container crane, on a beam of a spreader holding the container, facing a lengthwise end face of the container. An RF-ID tag (wireless tag) that stores container information is installed on a lengthwise end part of the container. The construction is such that the RF-ID tag reader / writer performs wireless communication with the RF-ID tag when the spreader is located on the transporting route of the container. The container information includes output of sensors provided on the container that detect security information of the container.

Owner:MITSUBISHI HEAVY IND LTD

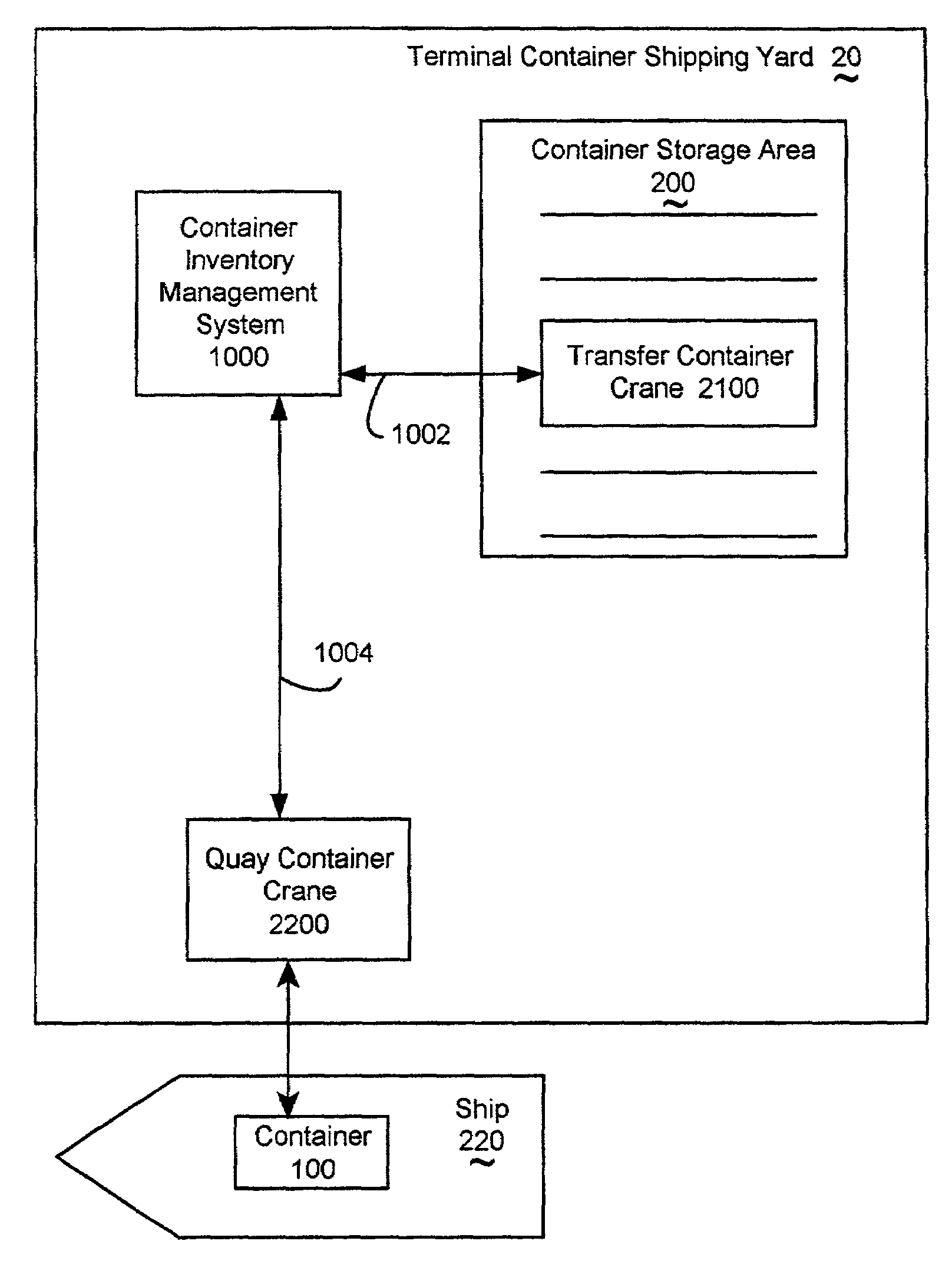

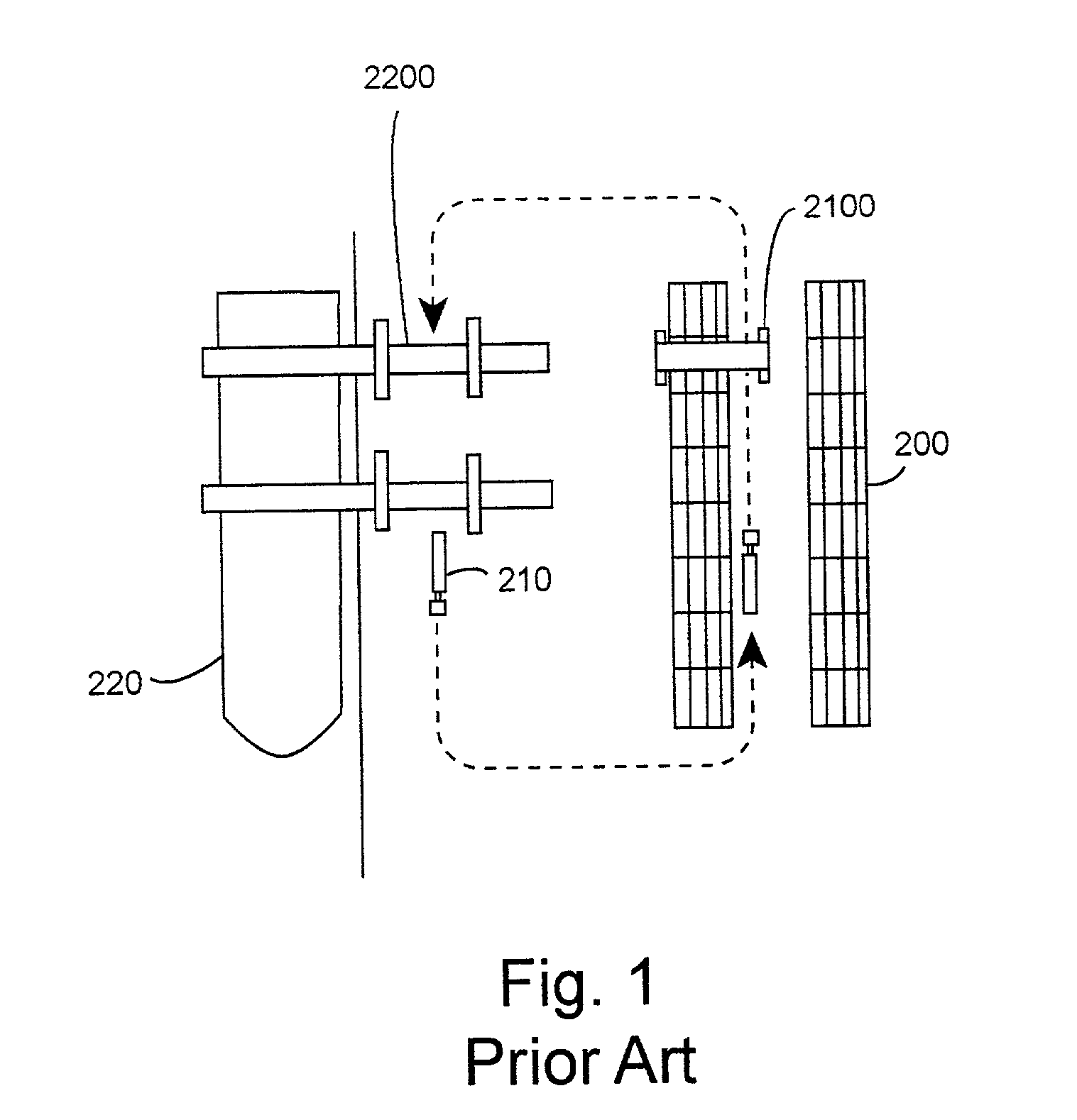

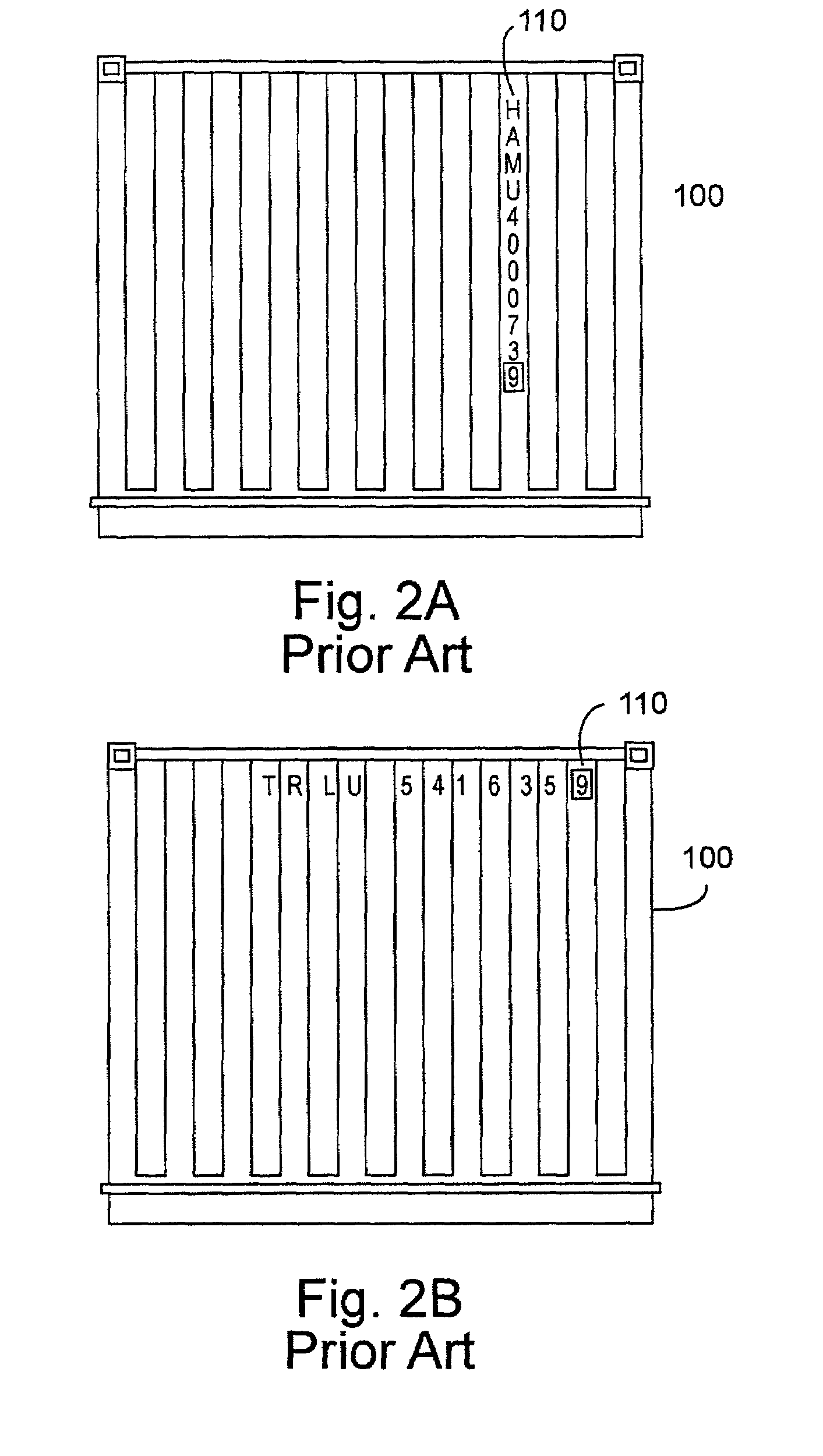

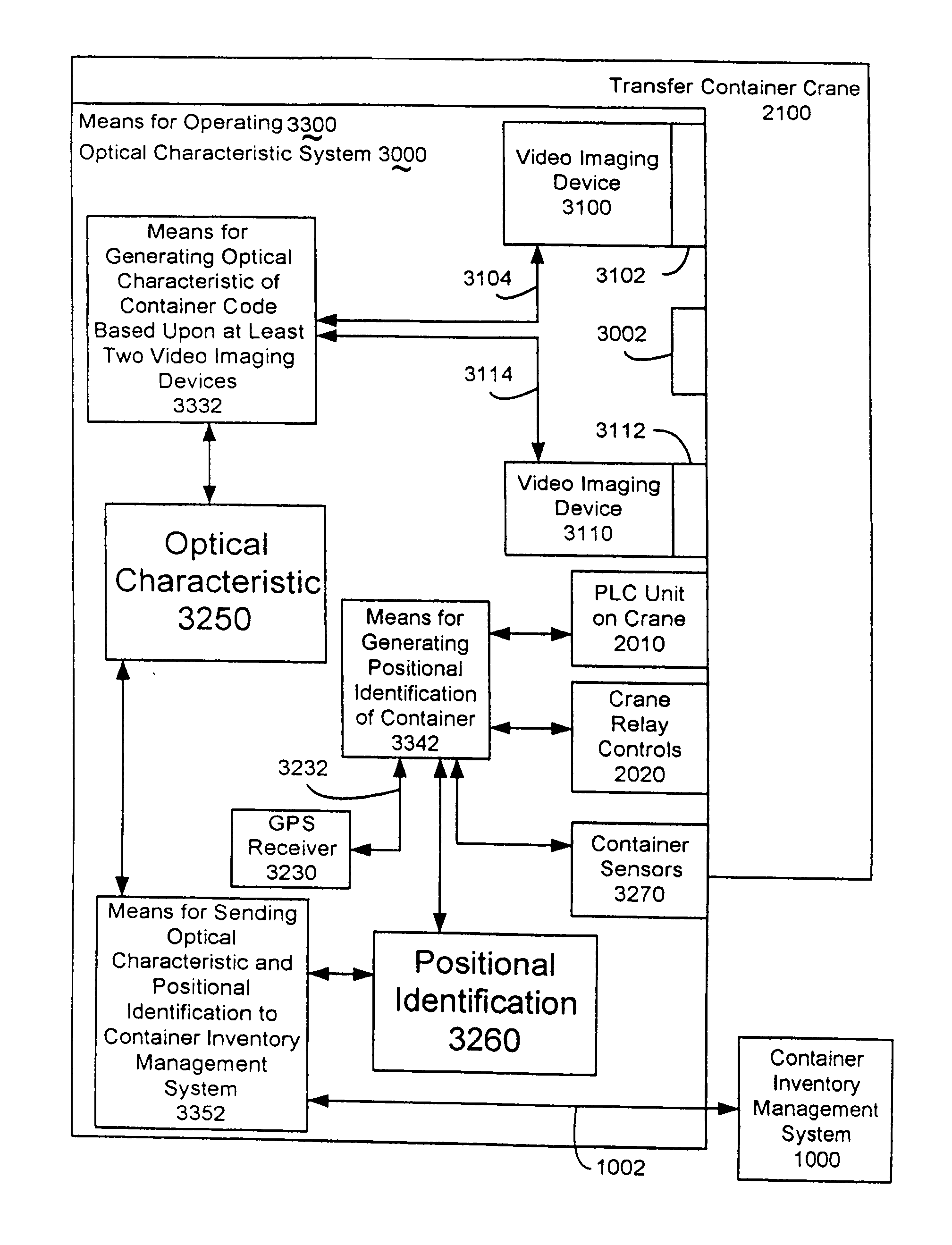

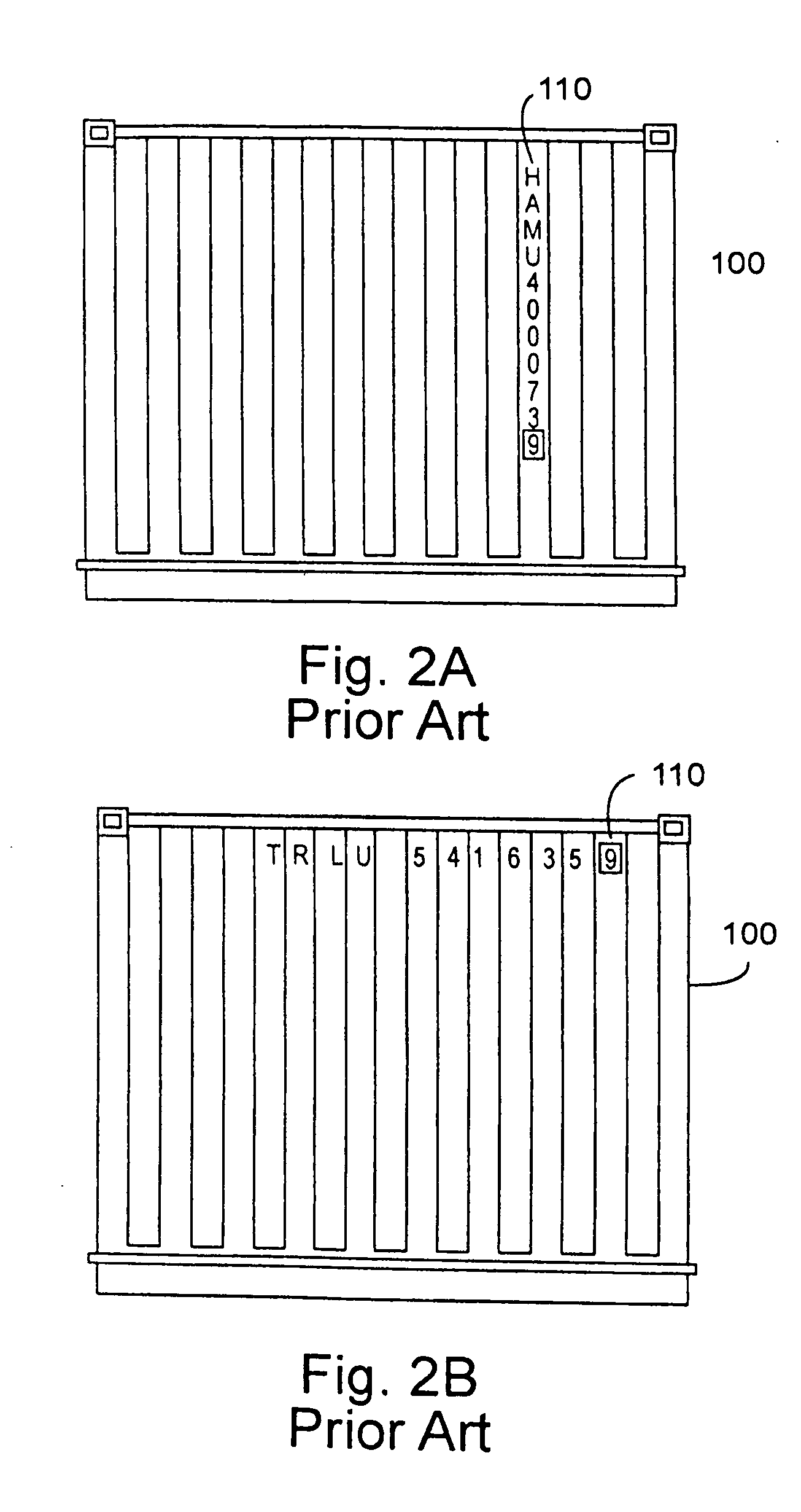

Method and apparatus of automated optical container code recognition with positional identification for a transfer container crane

InactiveUS7013026B2Reduces container inventory errorIncreases overall terminal efficiencyOptical rangefindersTrolley cranesContainer craneEngineering

A method and system providing a transfer container crane with container code recognition of a container identified by a container code to a container inventory management system is disclosed. The system and method are capable of performing these tasks without the use of non-standard container tagging.

Owner:HKI SYST & SERVICE

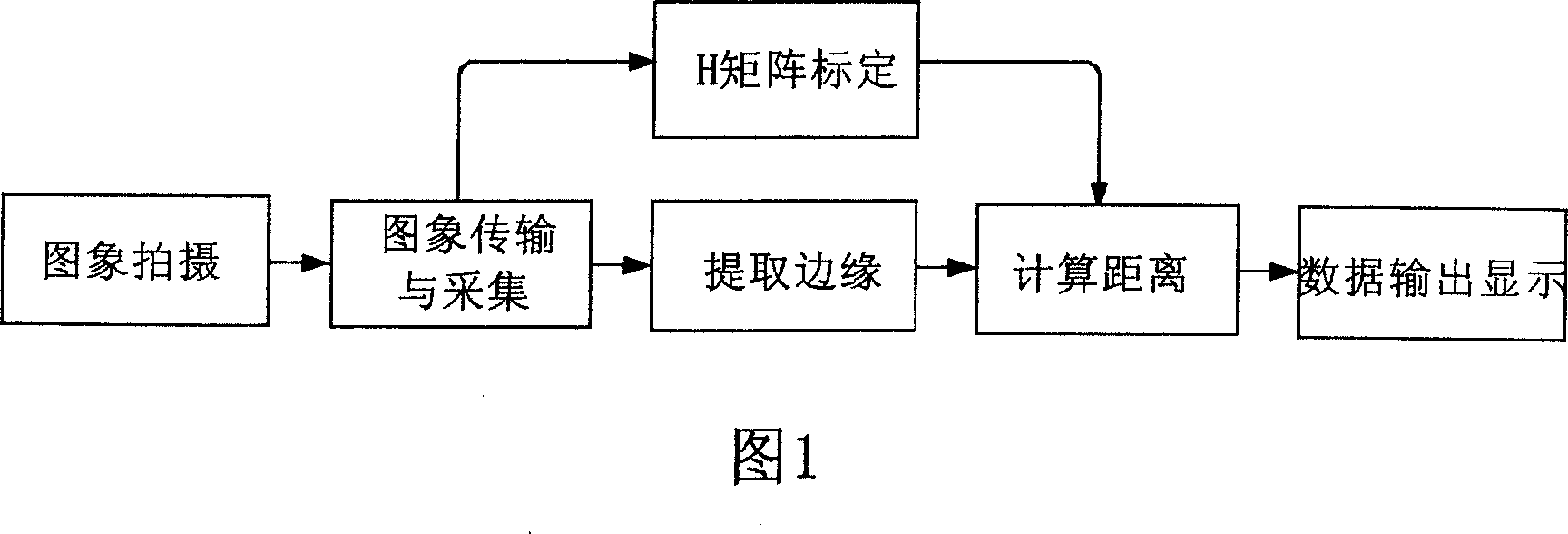

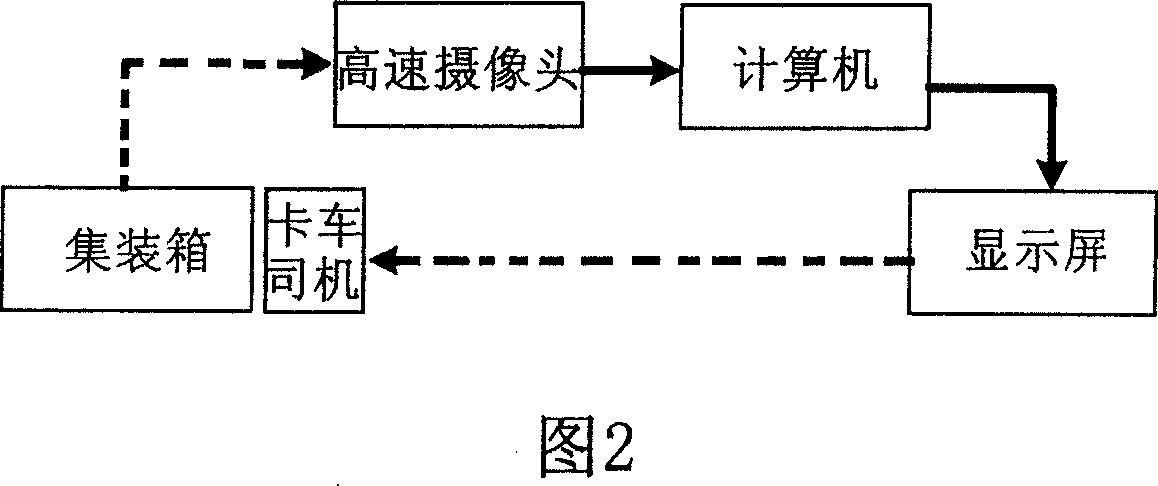

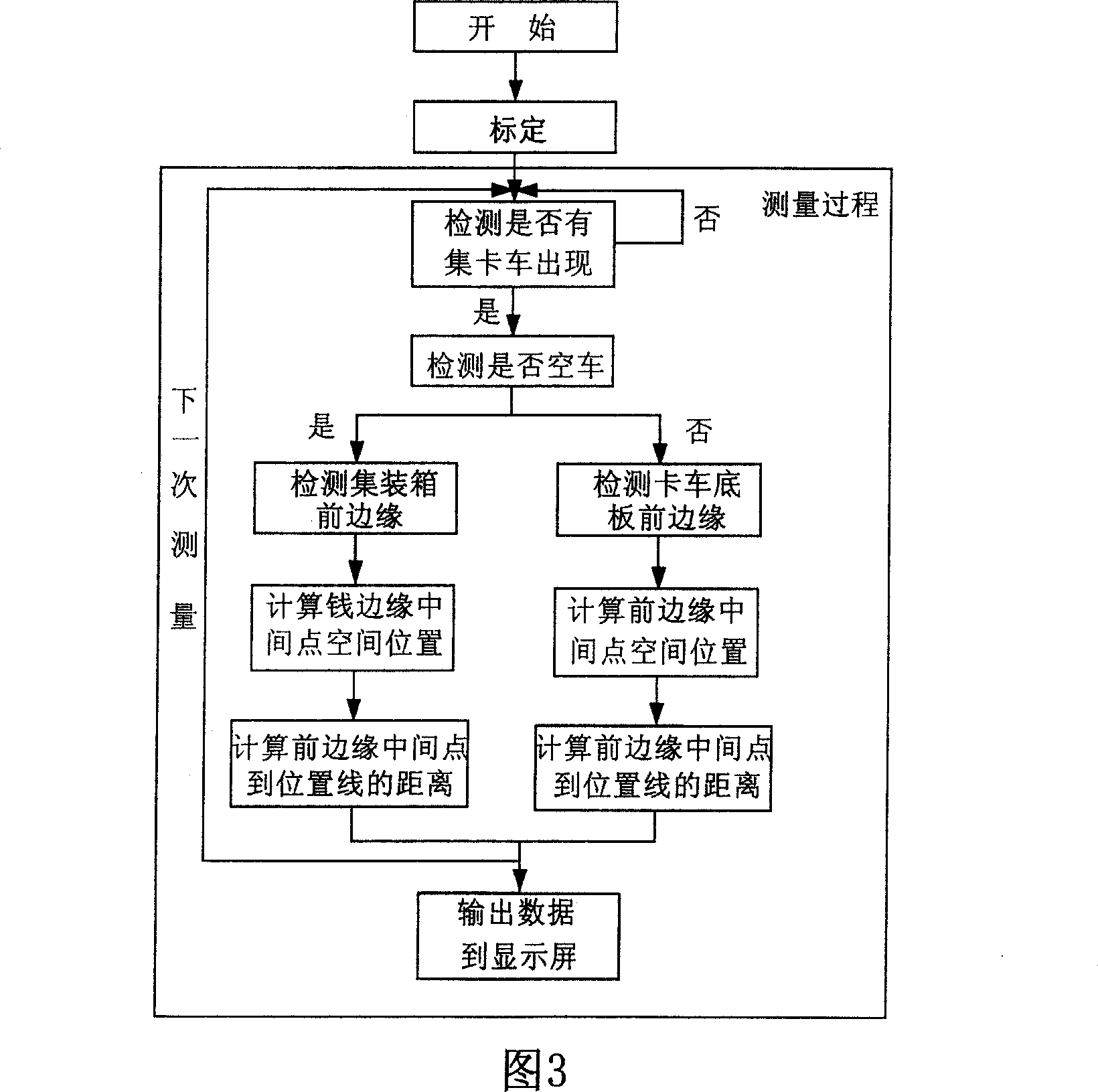

Method and device for positioning container lorry mobile in port

InactiveCN1958428AProcessing small amount of dataSimple structureLoad-engaging elementsComputer hardwareContainer crane

A locating method for the container trucks in port region includes such steps as taking image, transmitting and acquiring image, scaling in H array, extracting front edge, calculating distance, and outputting and displaying data. Its locating system is composed of high-speed camera head, computer, and electric display screen in the driver cab of container truck.

Owner:SHANGHAI MARITIME UNIVERSITY

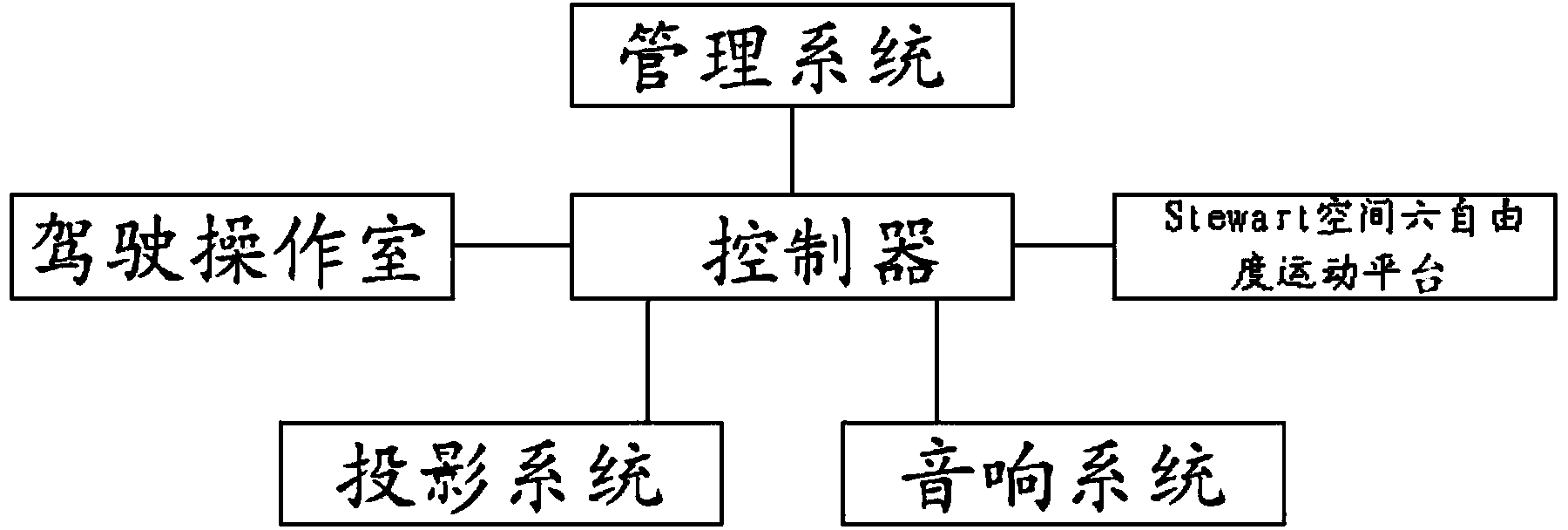

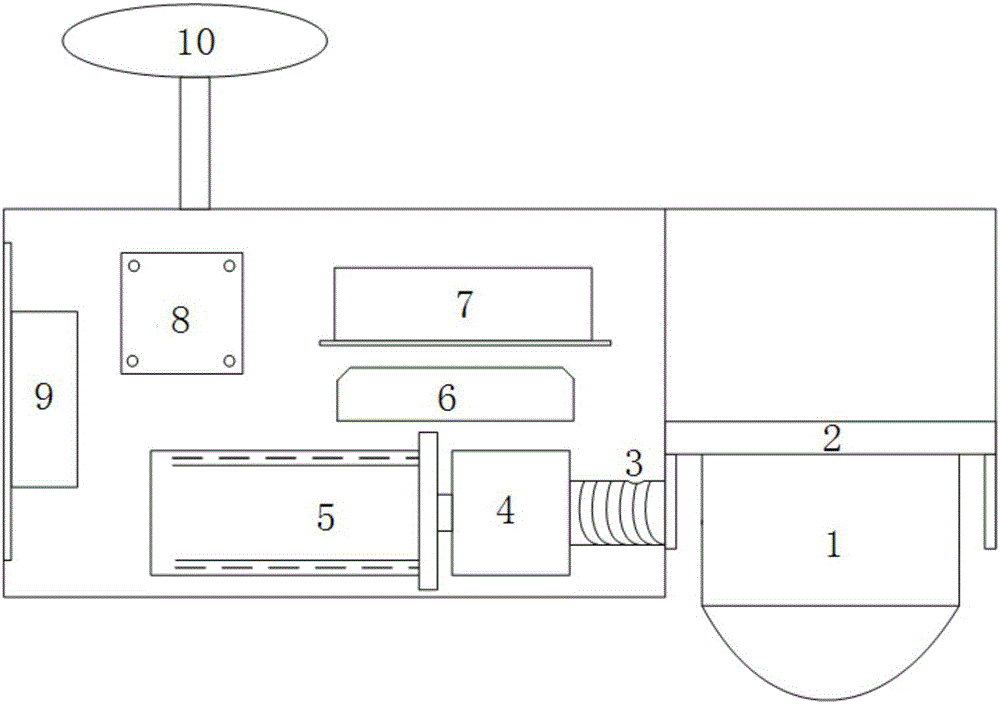

Method and simulator for virtual reality training of crane operation

InactiveCN103531051AStrong sense of spaceHigh degree of functional integrationCosmonautic condition simulationsSimulatorsKinematicsDynamic models

The invention relates to a method and a simulator for virtual reality training of crane operation. The method comprises the following steps that a controller calculates the operation state parameters of a crane according to the indoor operation status of simulated driving operation in accordance with the kinematics and the dynamic model of the crane; the simulation precision of a six-freedom degree movement platform of a Stewart space is set, the controller converts the calculated operation state parameters of the crane into a driving instruction of the six-freedom degree movement platform of the Stewart space and sends the instruction to the six-freedom degree movement platform of the Stewart space, and the six-freedom degree movement platform of the Stewart space correspondingly operates so that the corresponding real-time movement state is provided. The method and the simulator can be used for operation training on cranes, such as a port bank container crane and a bridge type bucket-grabbing crane, the integration degree of functions is high, the layering feeling of a virtual menu space is strong, the dynamic simulation effect is real, and parameters of a training environment can be customized.

Owner:WUHAN ONEW TECH CO LTD

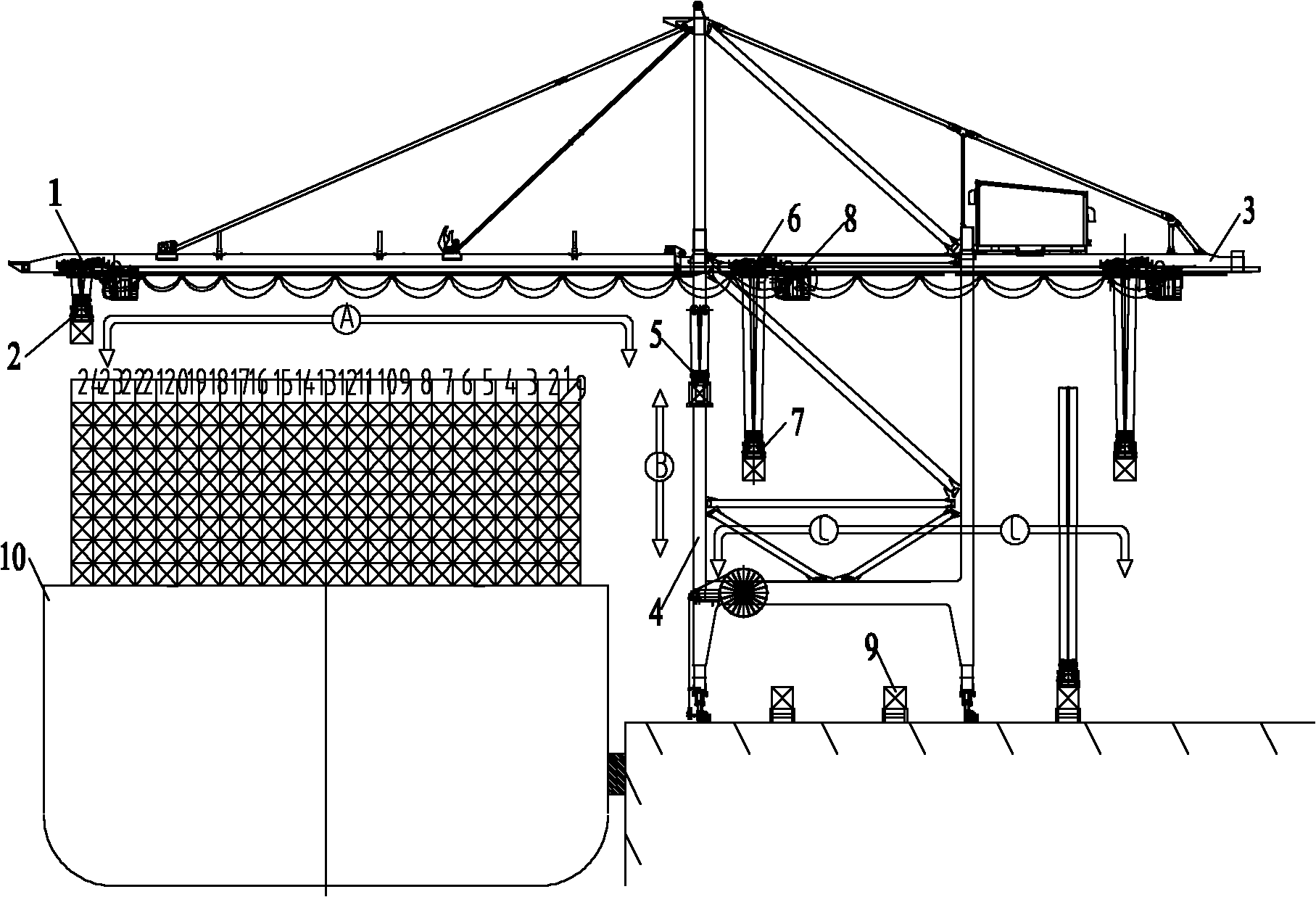

Twin lifting machinery for two 40 feet container shore crane

InactiveUS7461832B2Improve efficiencyFilament handlingWinding mechanismsReduction driveElectrical control

A twin lifting machinery for two 40 feet container shore crane is disclosed, comprising motors, high speed shaft brakes, two reductors, a plurality of multiple-project rope reels, and a plurality of reel brakes; wherein at least two motors and two reductors are provided; the input shafts of said two reductors connect to one of the output shafts of the motors respectively, and the output shafts of each reductor connect to the reels, the reel brakes are provided on each reel respectively. The synchronous operation or individual operation of two sets of lifting machineries under electrical control can be carried out, achieving the lifting and lowering operation of two hanger tools of sea side and land side The twin lifting machinery thus can carry out both the synchronous operation of two hanger tools and the individual operation of a single hanger tool, increasing the loading and unloading efficiency of the container crane by more than 60%.

Owner:SHANGHAI ZHENHUA HEAVY IND

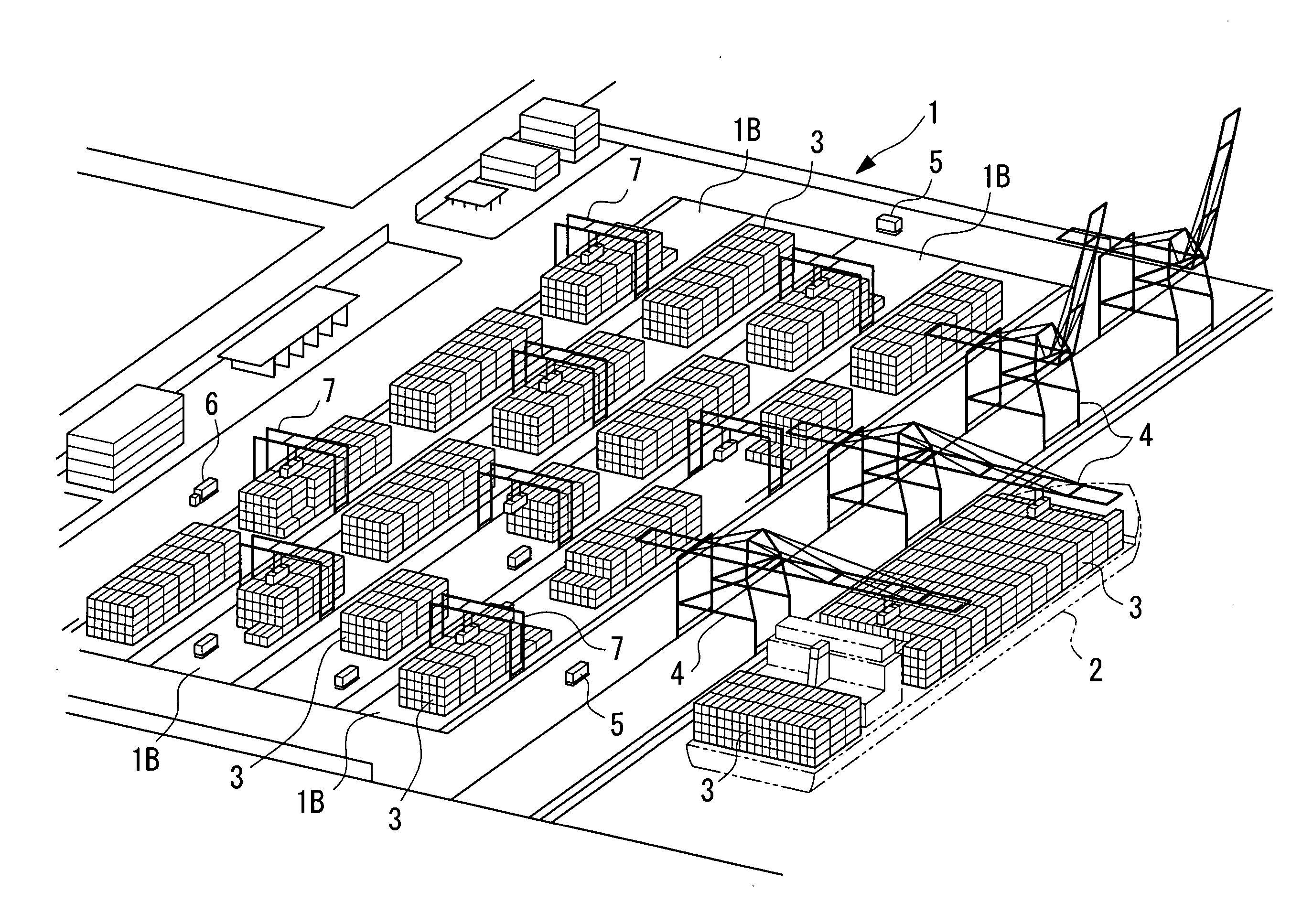

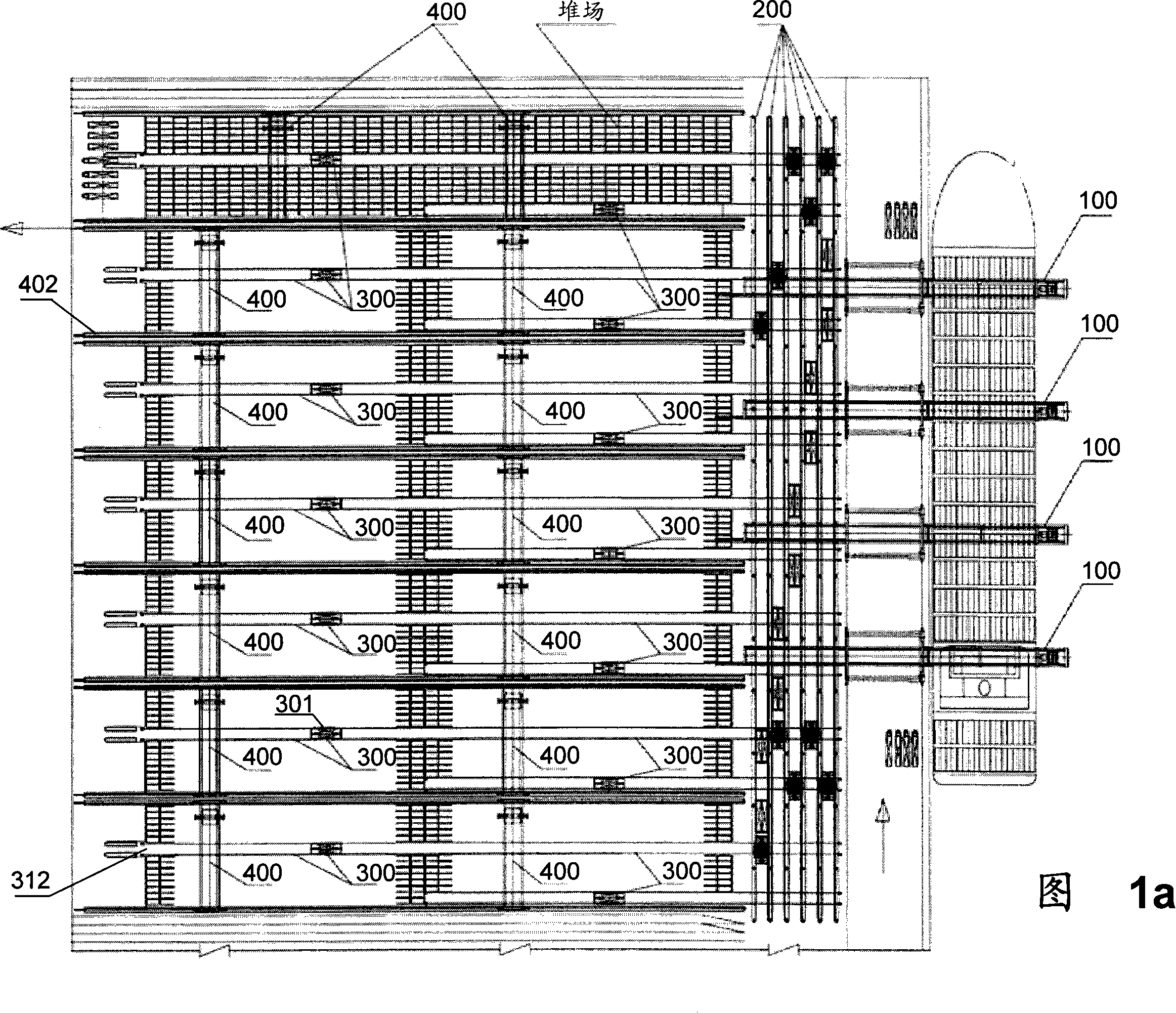

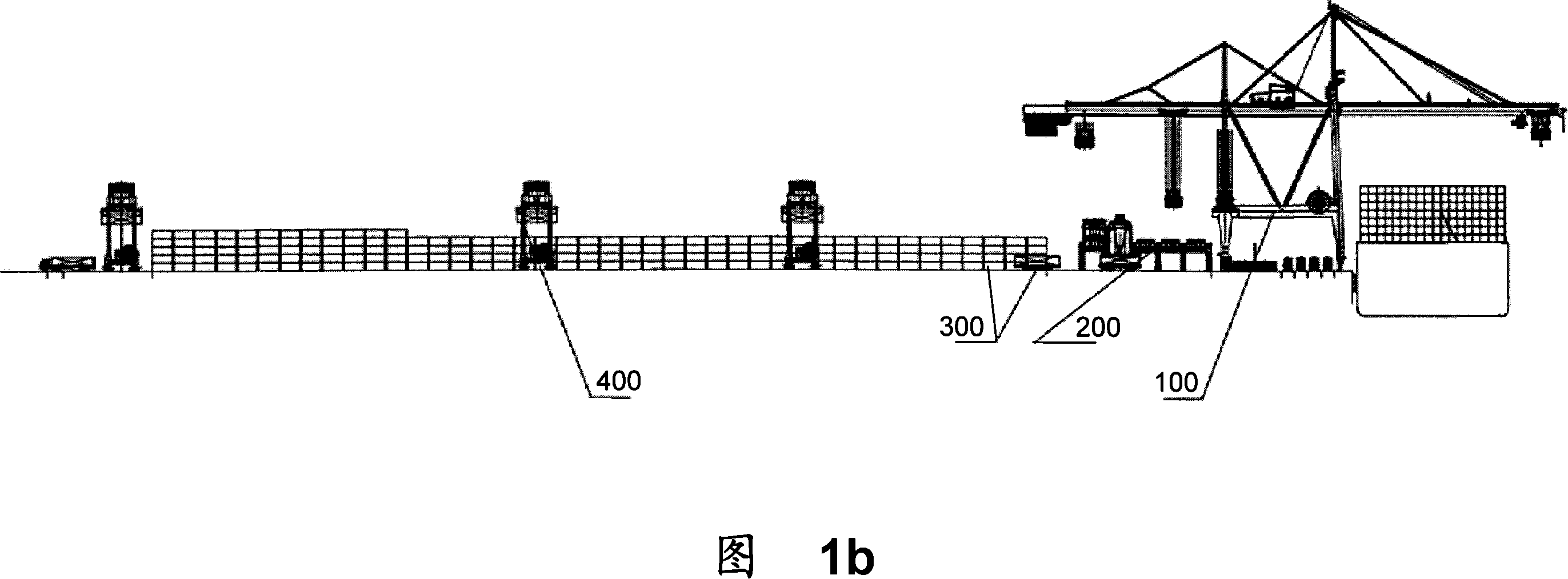

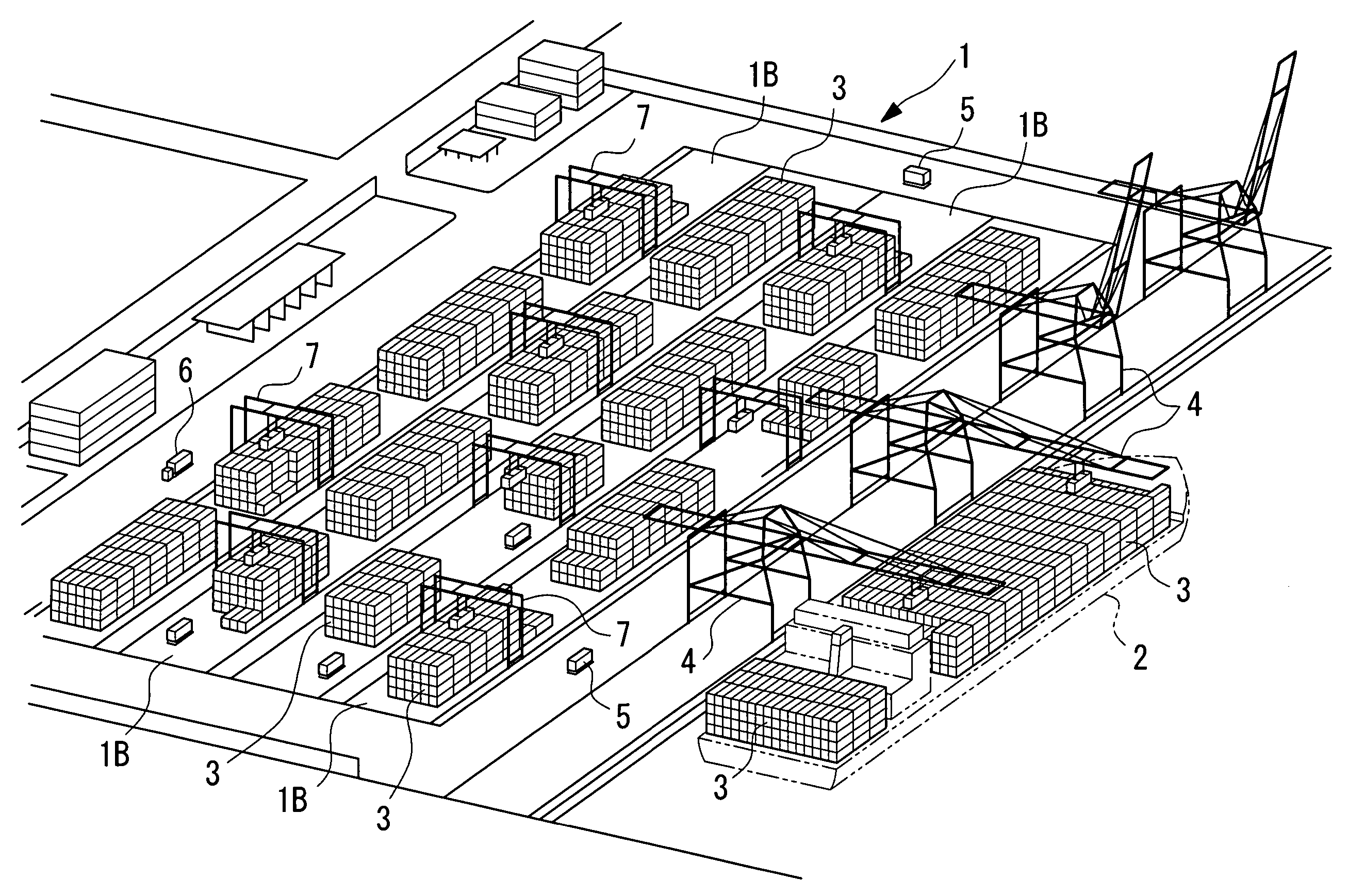

Container terminal loading and unloading system

InactiveCN101229883AHigh speedImprove safety and reliability performanceTrolley cranesLogisticsLand resourcesTransfer system

The invention relates to a container terminal handling system which consists of a quayside container crane and a yard crane and uses a stereometric low-bridge transfer system and a ground transportation car system to carry out connection. The low-bridge transfer system consists of a low-bridge transfer subsystem, wherein, the low-bridge subsystem is provided with a low-bridge rail which consists of a low-bridge crane rail and a low-bridge platform lorry rail; a low-bridge crane is arranged on the low-bridge crane rail; a low-bridge platform lorry rail is arranged on the low-bridge platform lorry rail. The ground transportation car system consists of a ground transportation car rail which consists of a car running along the transportation car rail. The invention carries out transportation in a form with the rail, uses commercial power as energy during the whole process and provides the stereometric low-bridge transfer system and the ground transportation system to realize the stereo transportation, which also realizes high-efficiency energy saving, environmental protection and automation, effectively utilizes land resources and is the extension and development of the applicant to the patent of the invention (200510111464.0).

Owner:SHANGHAI ZHENHUA HEAVY IND

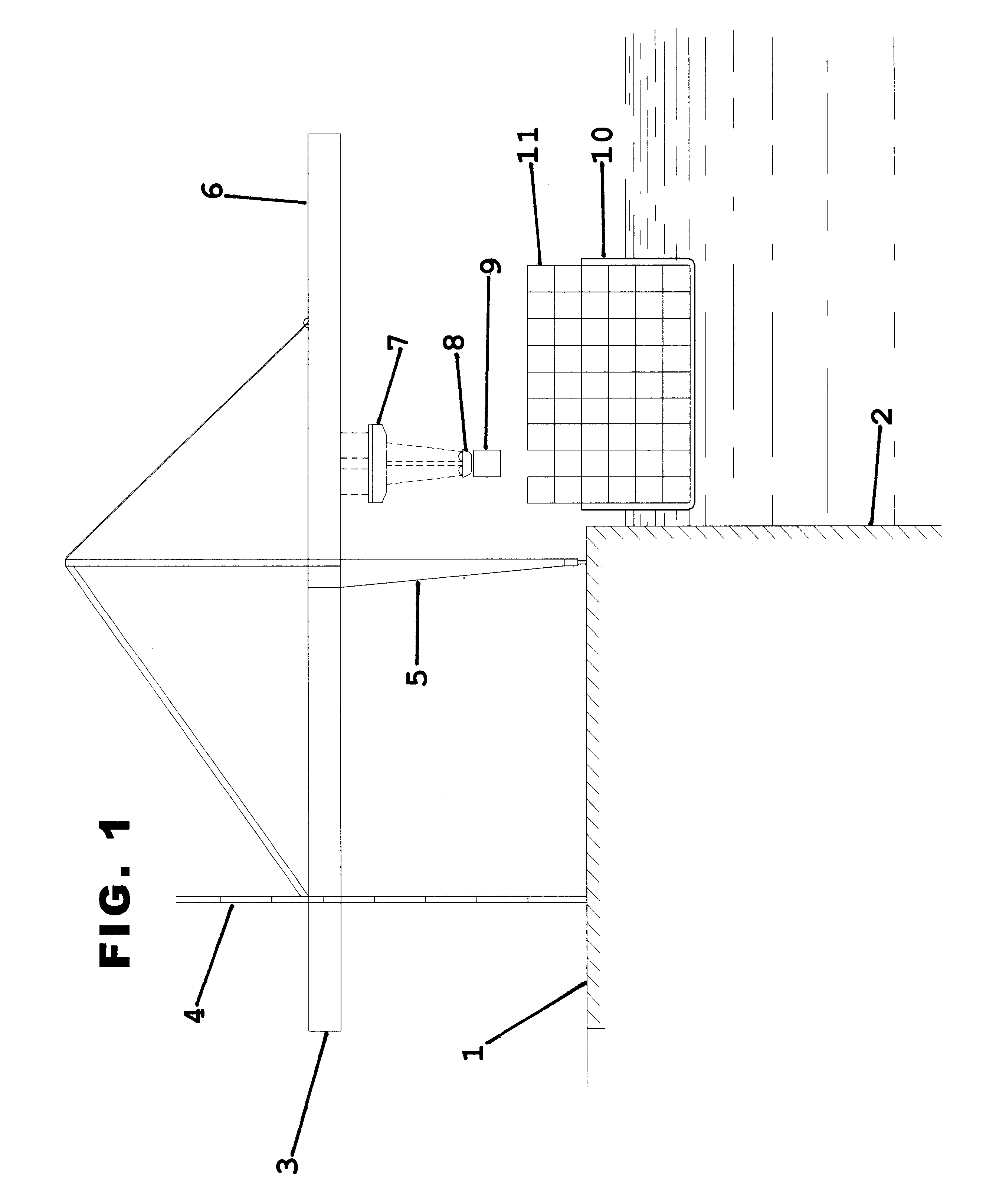

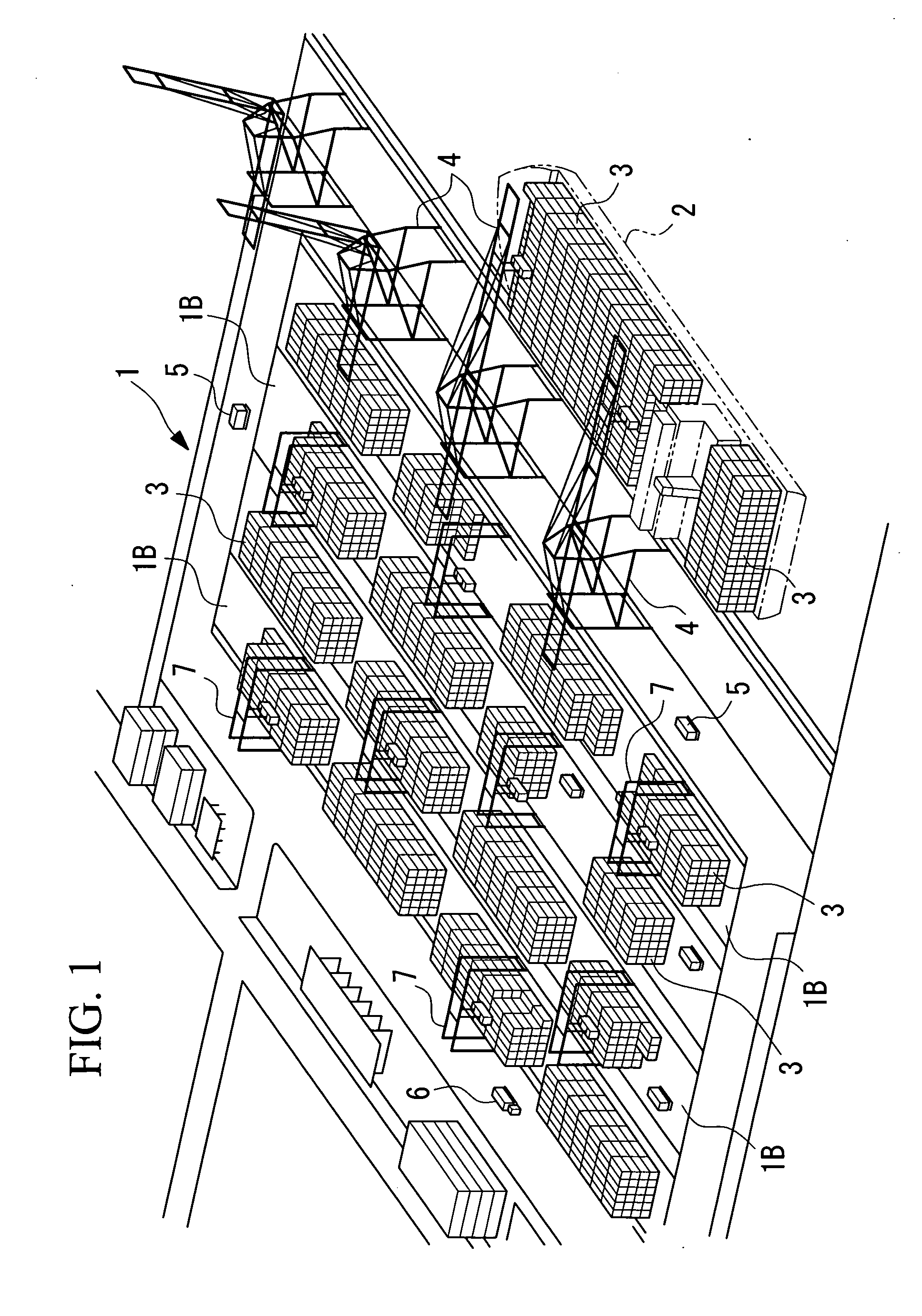

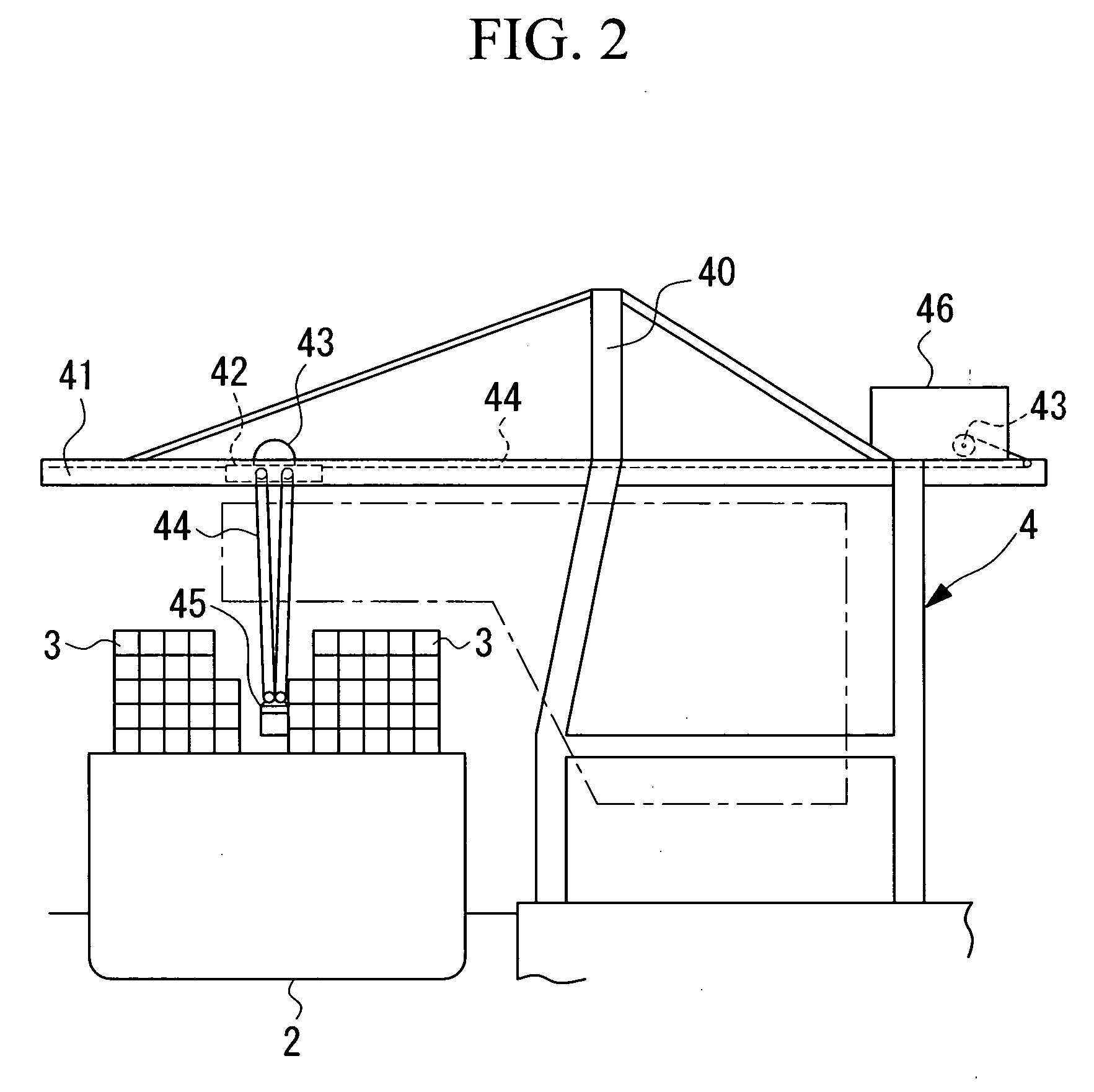

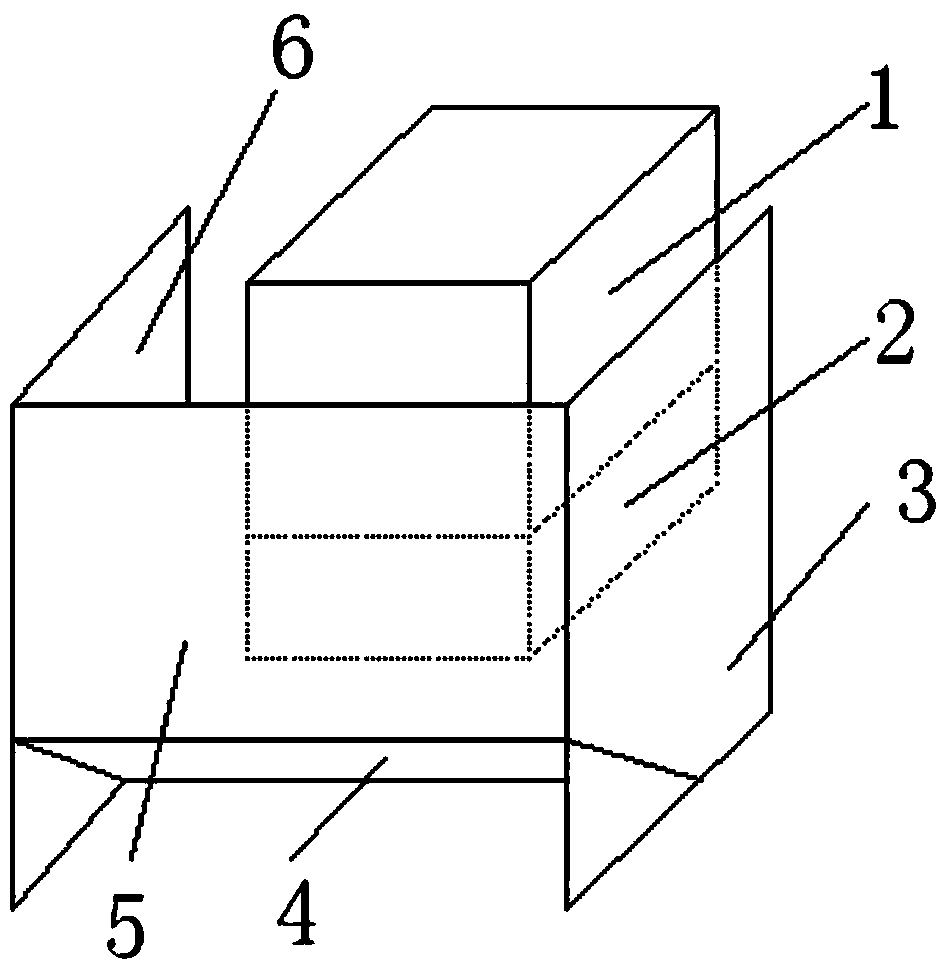

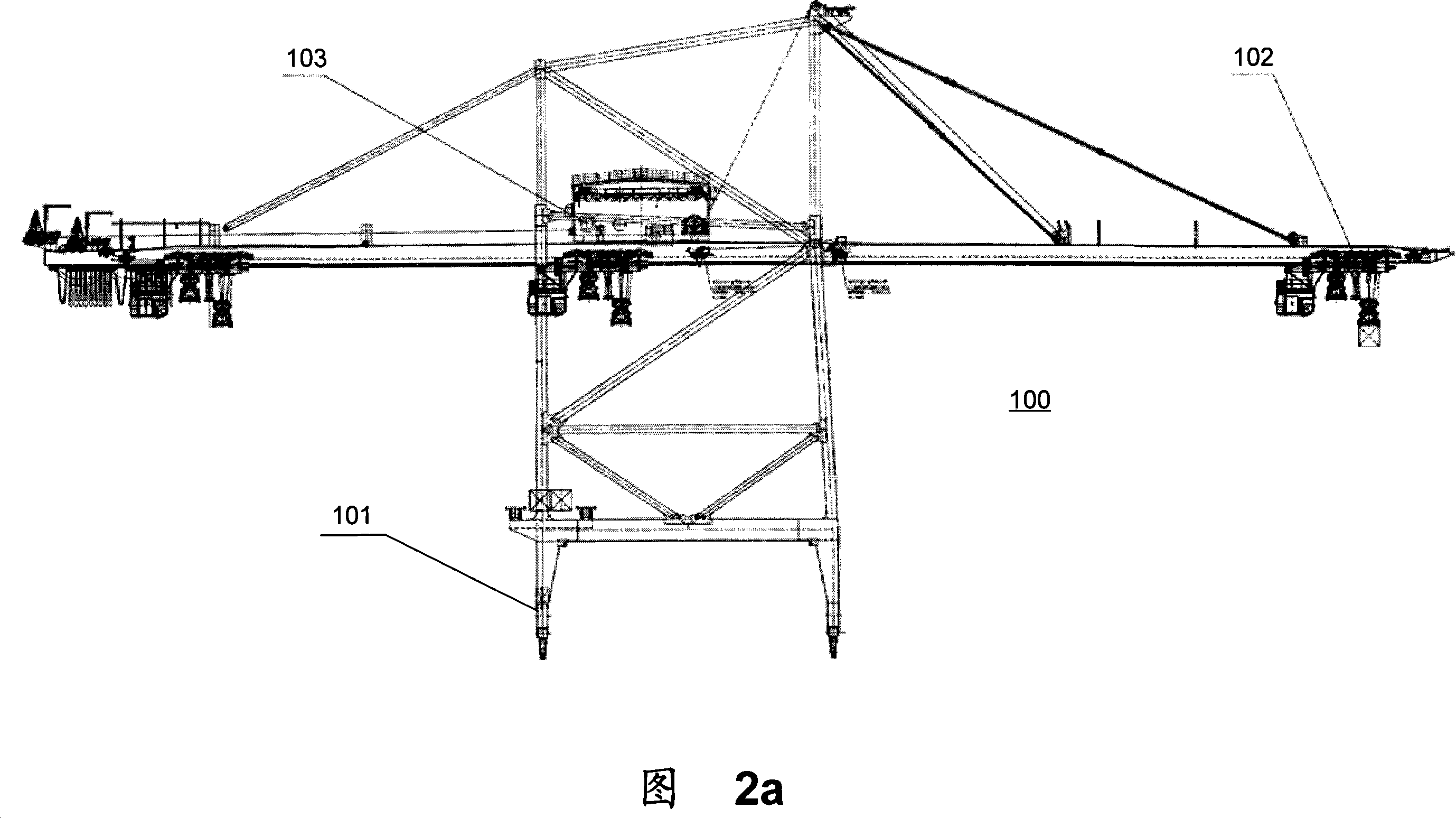

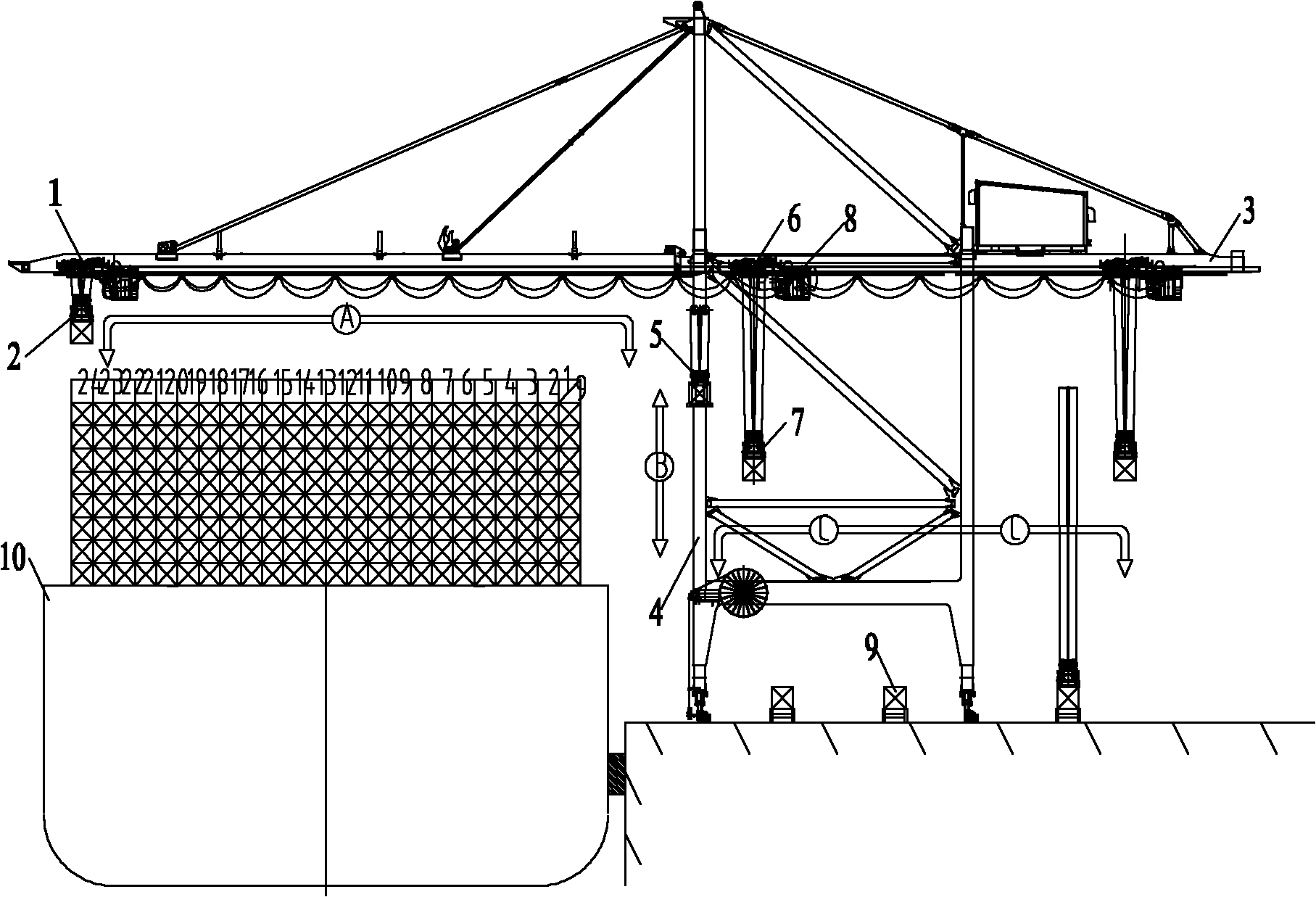

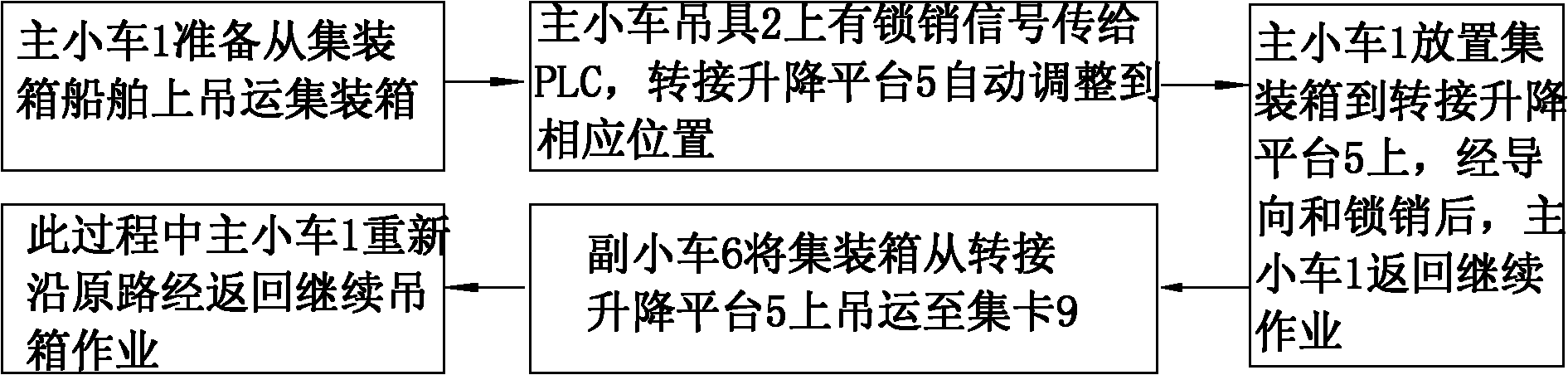

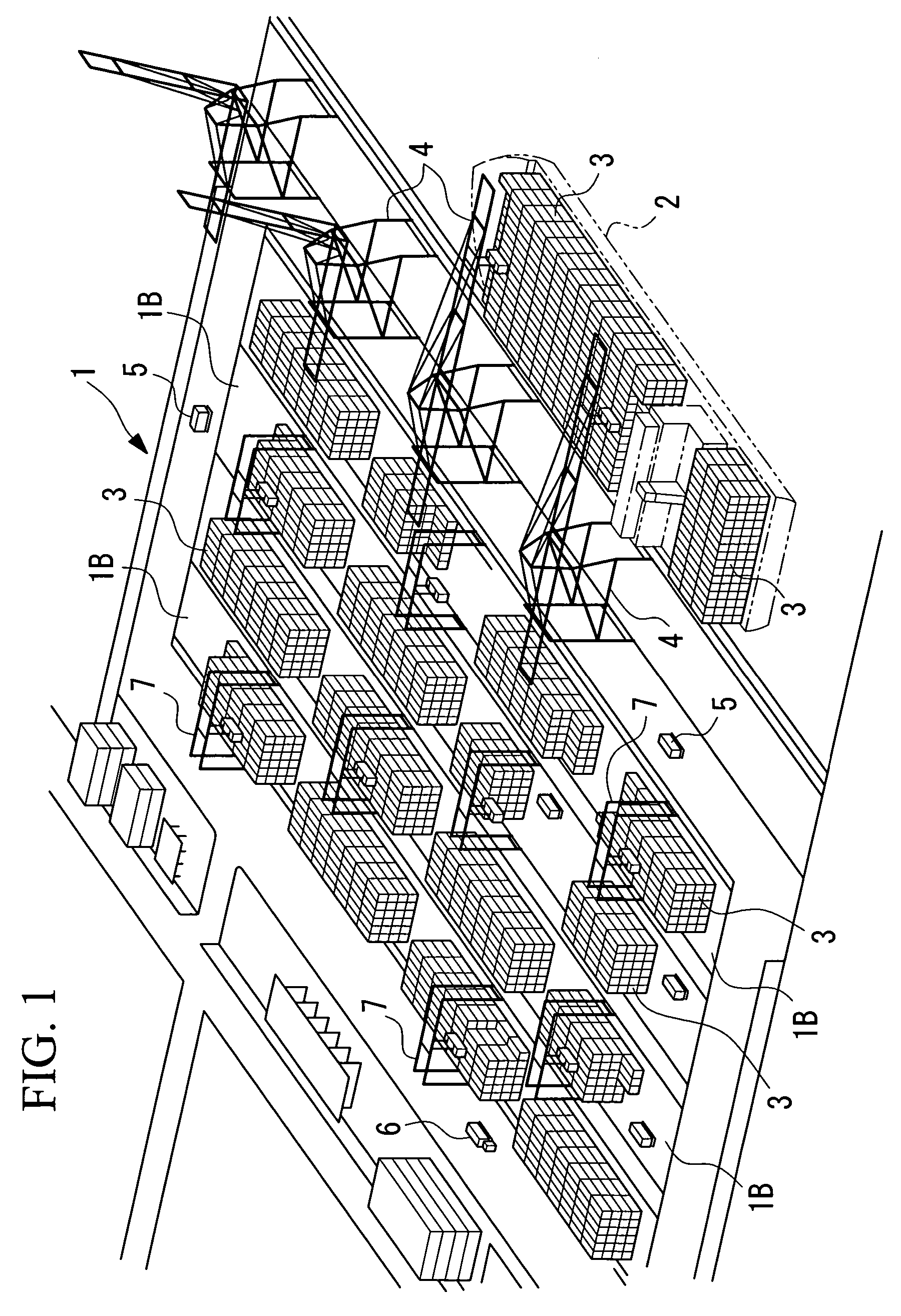

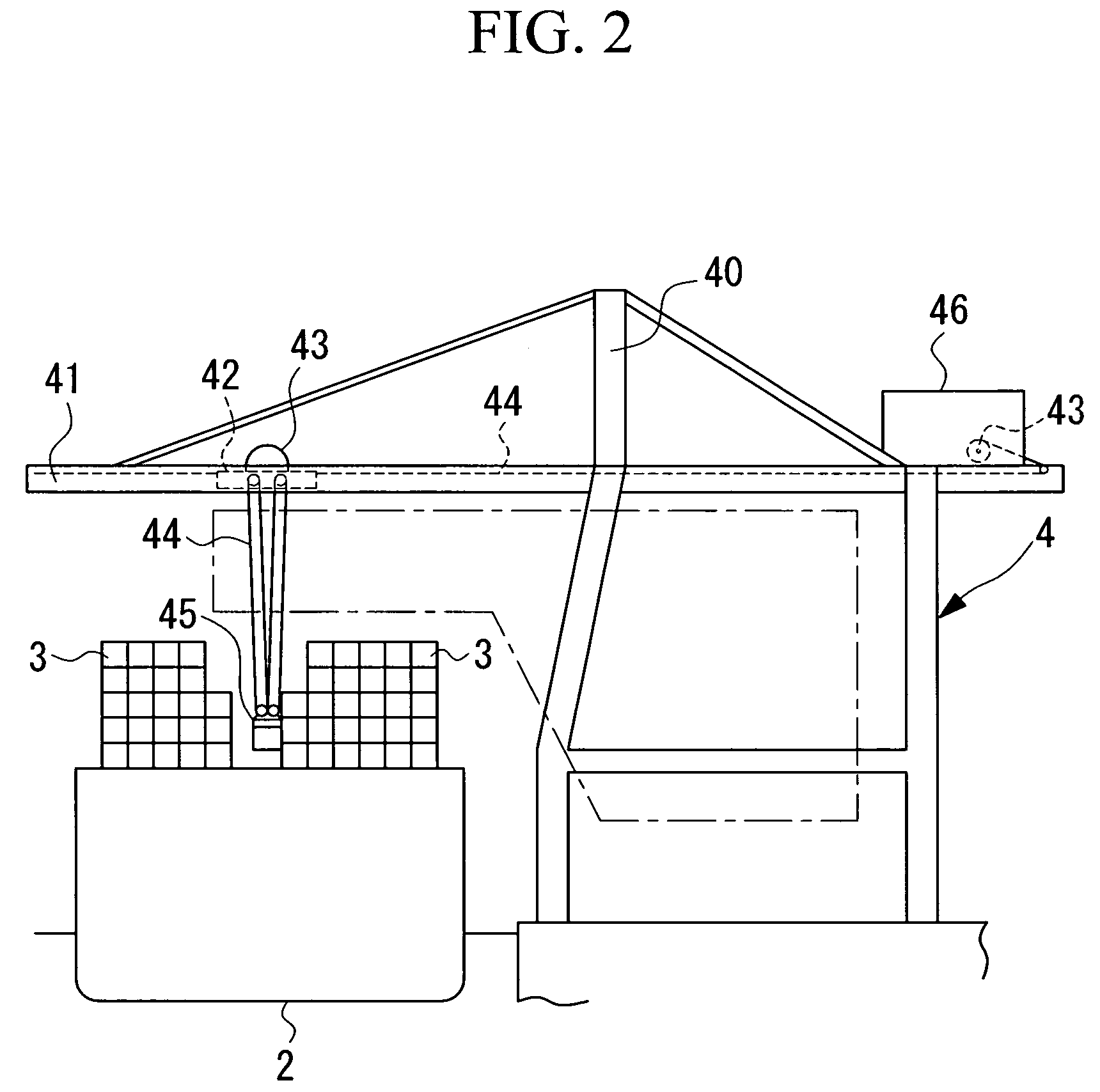

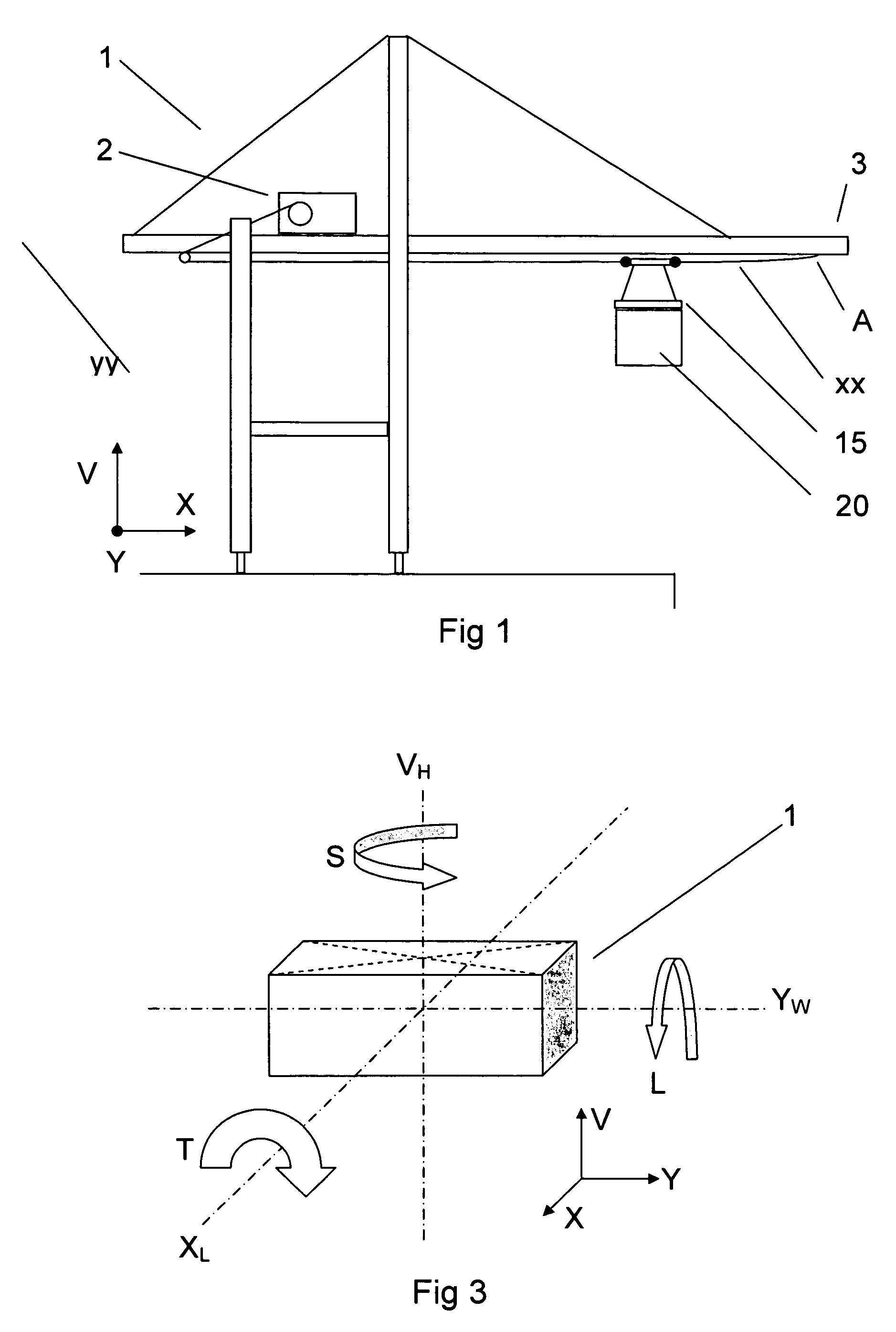

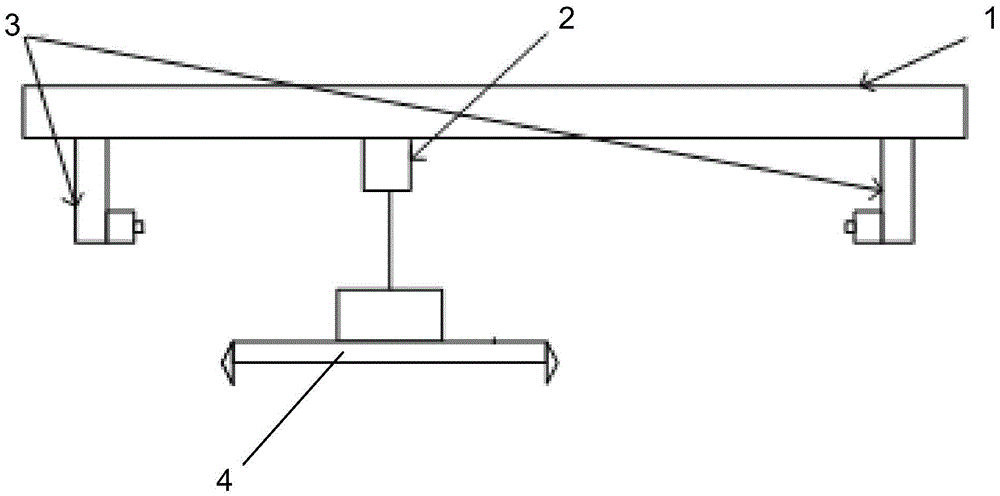

Container crane and method for loading and unloading containers using crane

InactiveCN102139831AReasonable optimization of combined job node settingsReduce waiting time for card collectionTrolley cranesContainer craneEngineering

The invention provides a container crane and a method for loading and unloading containers using the crane. The container crane comprises a crane girder (3), a main trolley (1) which can move along the crane girder (3), a main trolley lifting appliance (2) which moves along with the main trolley (1), a support pillar (4), a transferring and lifting platform (5) for lifting up and down the containers to be loaded and unloaded, and an auxiliary trolley mechanism, wherein, the auxiliary trolley mechanism comprises an auxiliary trolley (6) which is movably arranged along the crane girder (3), and an auxiliary trolley lifting appliance (7) which is arranged on the auxiliary trolley (6) and is used for loading and unloading the containers on the transferring and lifting platform (5). The container crane provided by the invention has the advantages of reasonably optimizing setup of combined operation nodes, maximally reducing the possibility of waiting for a container truck during the loading and unloading process, enhancing cost performance of equipment, and improving operating efficiency. The container crane is used for loading and unloading the containers by utilizing the method.

Owner:SANY MARINE HEAVY IND

Container handling apparatus, container management system, and method of container handling

InactiveUS7216806B2Improve container handling efficiencyTrolley cranesLogisticsContainer craneEngineering

A container handling apparatus, a container management system, and a method of container handling are provided in which information of a container to be handled is accurately recognized automatically, in order to improve the efficiency of a container handling operation. An RF-ID reader / writer (wireless communication device) is provided in a container crane, on a beam of a spreader holding the container, facing a lengthwise end face of the container. An RF-ID tag (wireless tag) that stores container information is installed on a lengthwise end part of the container. The construction is such that the RF-ID tag reader / writer performs wireless communication with the RF-ID tag when the spreader is located on the transporting route of the container. The container information includes output of sensors provided on the container that detect security information of the container.

Owner:MITSUBISHI HEAVY IND LTD

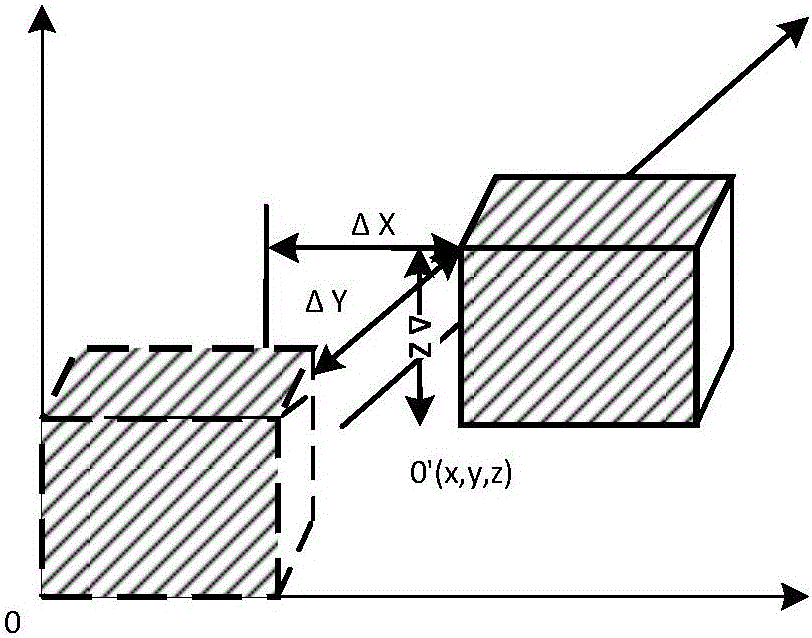

3D data acquisition system and method for identifying and positioning container

ActiveCN106017351ASimple structureEasy to implementUsing optical meansElectromagnetic wave reradiationPoint cloudContainer crane

The invention discloses a 3D data acquisition system and method for identifying and positioning a container. The system comprises a data processor and a 2D laser scanner, a motor driver, an inertia device and a switch respectively connected with the data processor. The system and method are relatively simple and easy to realize, combine multi-sensor data fusion technology to realize high-precision and rapid scanning of a detected target. A high-precision rotation holder is developed based on a mature 2D laser scanner and a high-precision servo motor. An axis rotating amount is added based on the 2D laser scanner, and three-dimensional point cloud data are obtained by calculating the sensor data. Through the system and method, a tyre type container crane can automatically identify the position of a target container. The requirements of identifying container area contour and position during operation of the tyre type container crane are met. The system and method are of great importance to crane work efficiency and safety.

Owner:CATHAY NEBULA SCI & TECH CO LTD

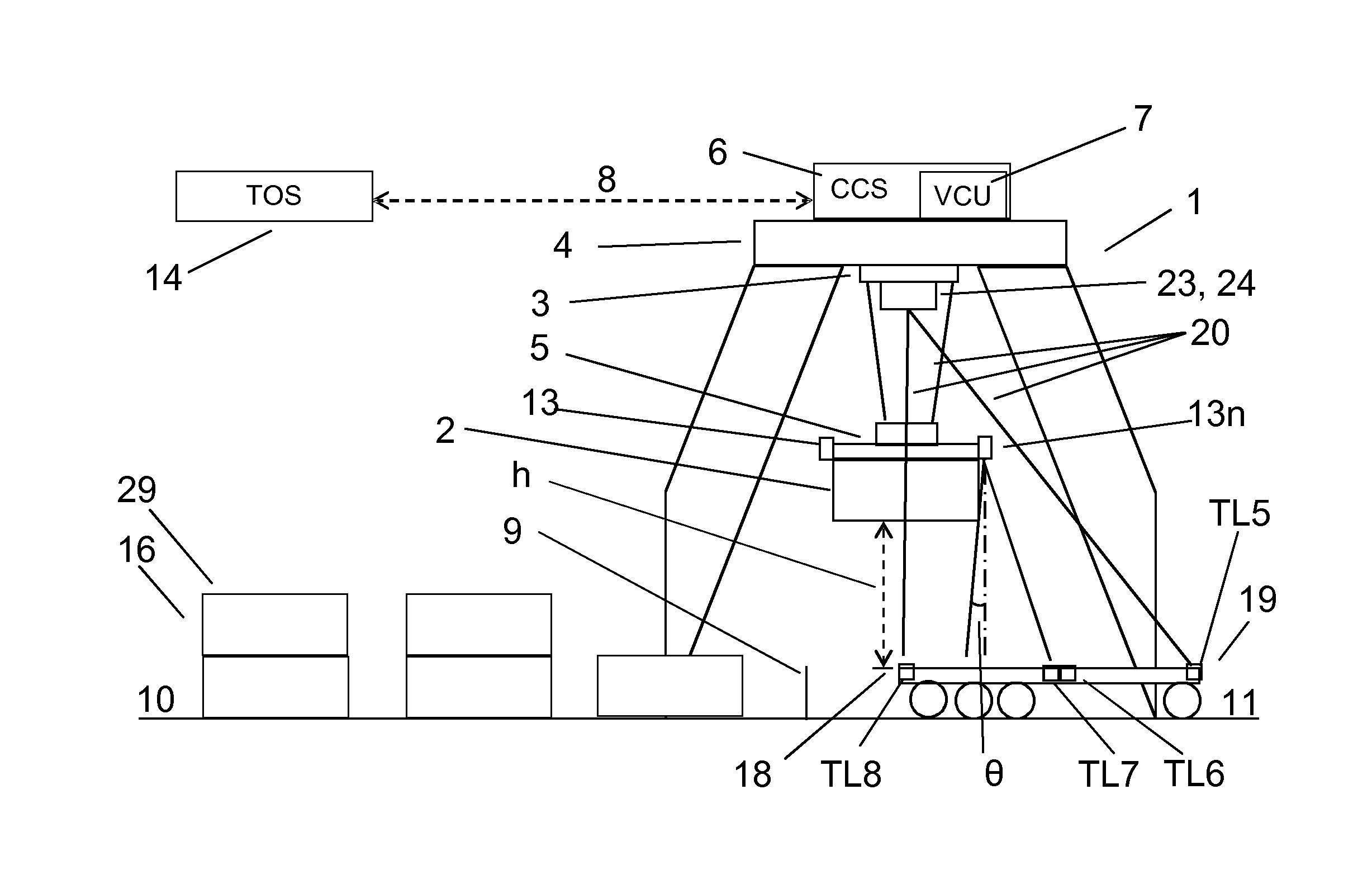

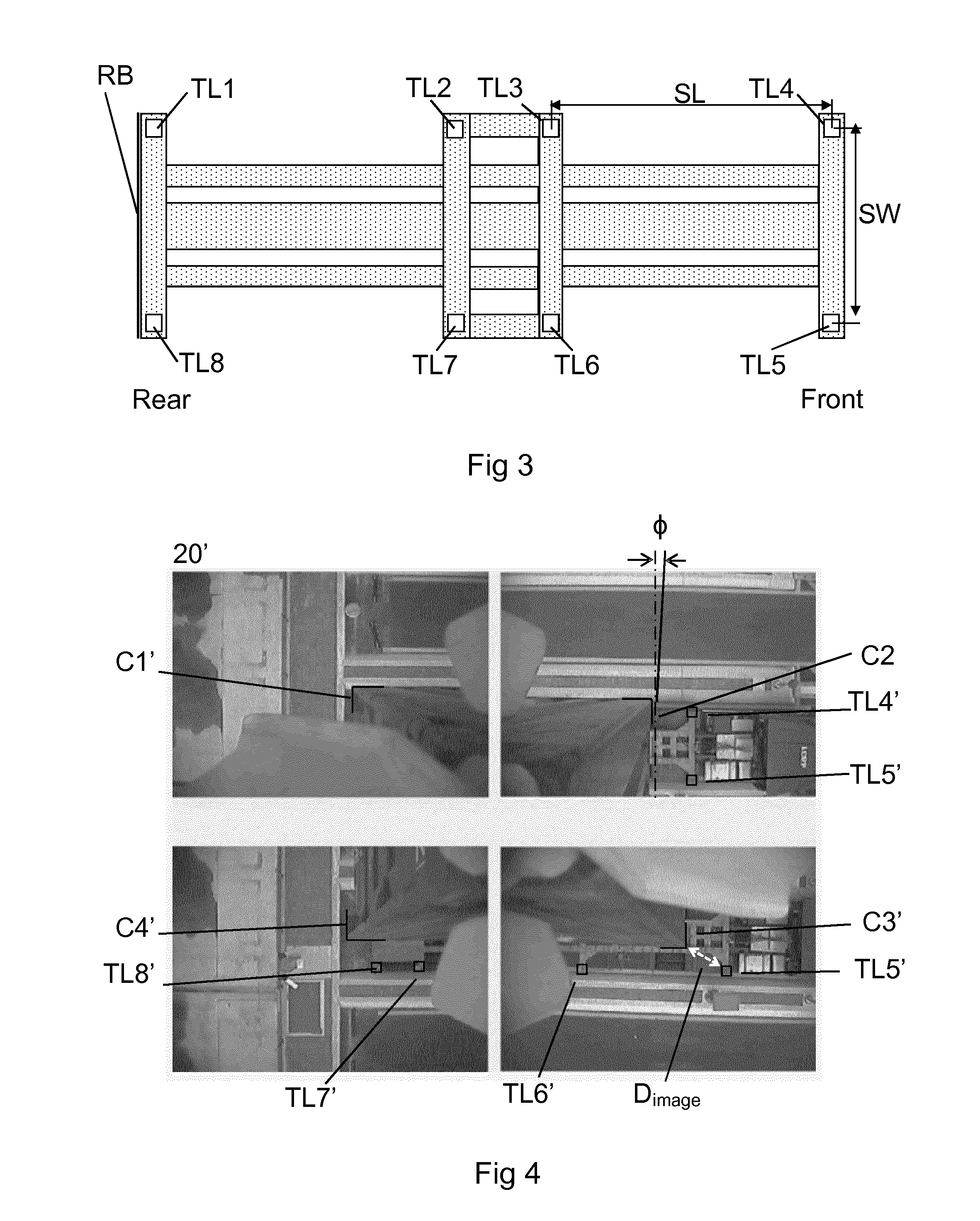

Method and system for automatically landing containers on a landing target using a container crane

ActiveUS20160167932A1Increase speedHigh resolutionDigital data processing detailsCharacter and pattern recognitionControl systemContainer crane

A method for automatically landing a container on a landing target using a container crane is disclosed. The container crane includes a trolley and spreader for holding and lifting the container and a crane control system for controlling movements of the container crane. A distance from the container to the landing target is measured and the container is moved towards the landing target dependent on the measured distance. A plurality of images of the landing target is made using at least one camera mounted on the spreader. The images are processed to identify one or more landing features in the images of the landing target. Distances from the container to the landing target are calculated based on a measurement of distance between the container and the landing features in the images. A video control unit, a system for controlling automatic landings of a container, a computer readable data carrier comprising a computer program and a computer program product arranged for carrying out the methods are also described.

Owner:ABB (SCHWEIZ) AG

Load control device for a crane

ActiveUS7950539B2Promote recoveryMinimize delayAngle measurementTrolley cranesContainer craneEngineering

A control device and system for controlling a suspended load of a container crane with a trolley, a spreader and load lines arranged in a four point suspension for lifting a load and an optical sensor for sensing a deflection position of an orthogonal axis of a container suspended under the spreader. Two or more actuators are arranged attached to at least one load for moving at least one said suspension point closer to or farther away from an imaginary center line by shortening and / or lengthening the at least one load line.

Owner:ABB (SCHWEIZ) AG

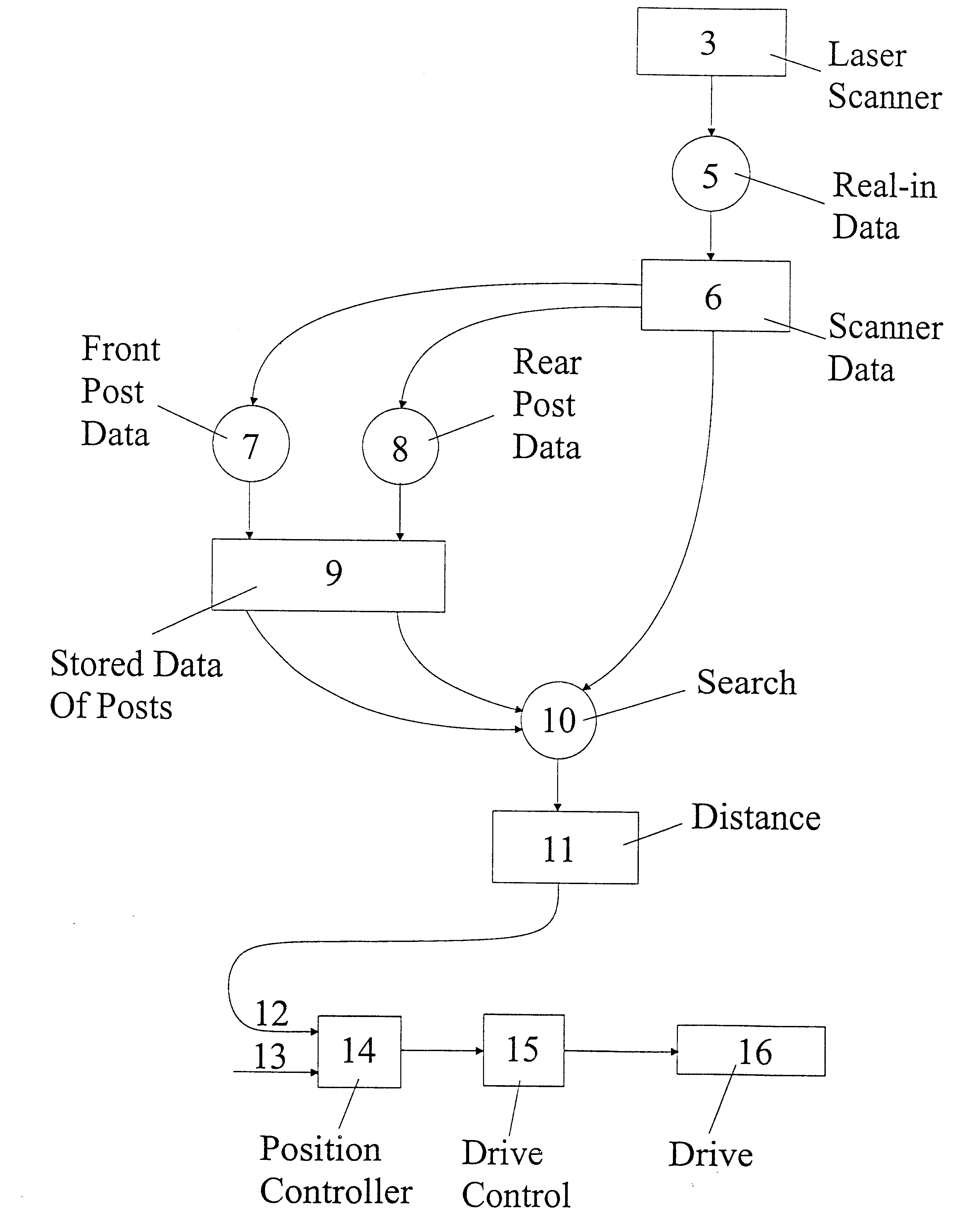

Method for determining the position of a vehicle in relation to a container crane

A method for determining the position of a vehicle, preferably of a portal stacking truck in relation to a container crane, in which a sensor serves for determining the position of the stacking truck, and evaluating devices are coupled to a detection device, and in which the posts of a container crane are detected as positioning aids in terms of angle and distance by means of a scanner mounted on the stacking truck and transmitted to an evaluating computer, which compares the signals with signals provided in its program and determines the exact position of the stacking truck in relation to the posts of the container, and drives the stacking truck from this position into an exactly predetermined position in relation to the posts of the container.

Owner:NOELL CRANE SYST

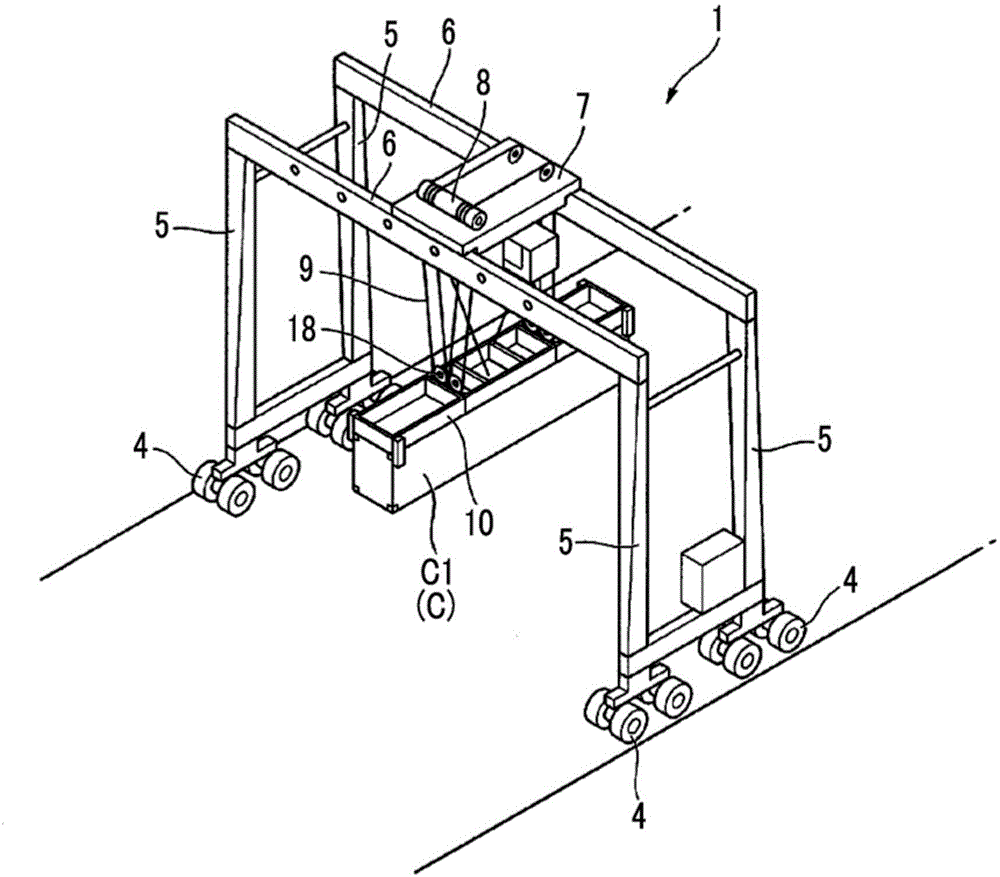

Container crane

ActiveCN104379489AAccurate detectionSuppresses an increase in the number of componentsTrolley cranesLoad-engaging elementsContainer craneLaser scanning

In the present invention, a container crane comprises a travelling apparatus, a girder, a trolley, a splitter (10), an elevating mechanism, a laser scanner (22), and a crane control apparatus. The girder is supported by the travelling apparatus and extends in the horizontal direction. The trolley is capable of travelling along the girder. The splitter (10) is hung from the trolley and is capable of engaging and disengaging the container. The elevating mechanism moves the splitter (10) up and down. The laser scanner (22) is provided in the splitter (10) and emits laser light and obtains the coordinates of the point of incidence on an article of interest. The crane control apparatus controls the driving of the trolley and the splitter (10) based on the coordinates of the point of incidence obtained using the laser scanner (22).

Owner:SUMITOMO HEAVY IND MATERIAL HANDLING SYST

Method and apparatus of automated optical container code recognition with positional identification for a transfer container crane

InactiveUS20060153455A1Minimizes bandwidth requirementDecrease stockProgramme controlElectric signal transmission systemsContainer craneEngineering

A method and system providing a transfer container crane with container code recognition of a container identified by a container code to a container inventory management system is disclosed. The system and method are capable of performing these tasks without the use of non-standard container tagging.

Owner:HKI SYST & SERVICE

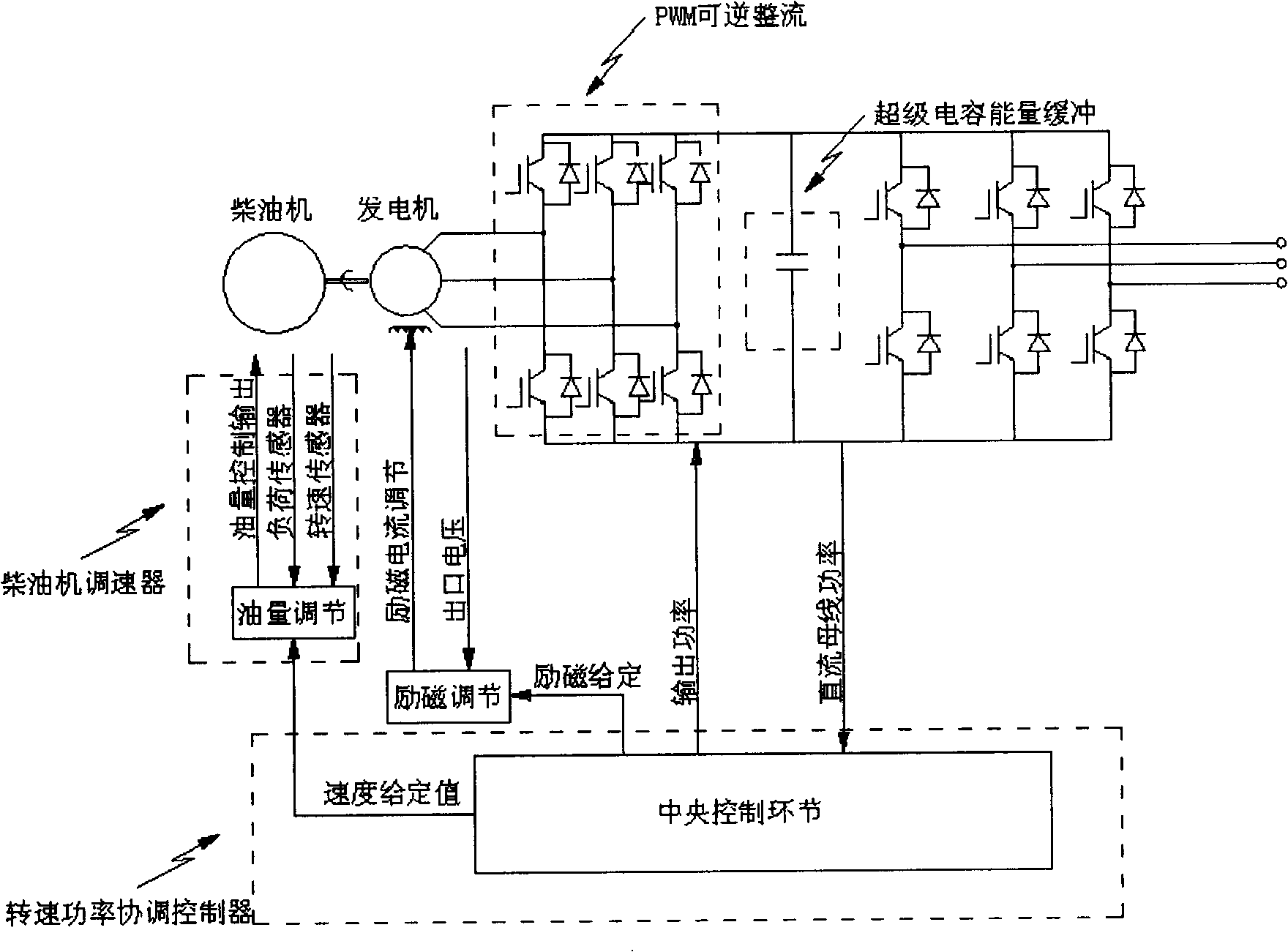

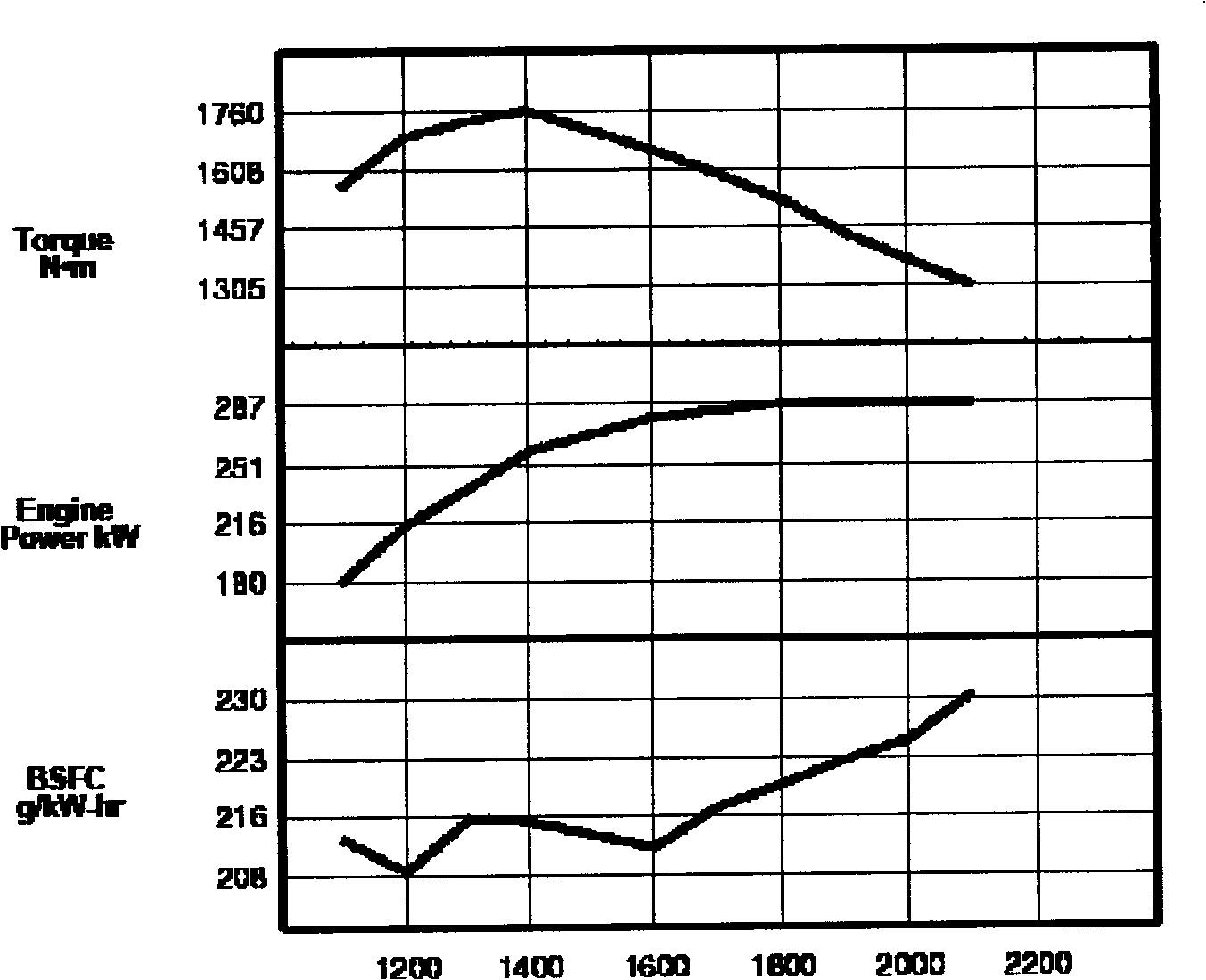

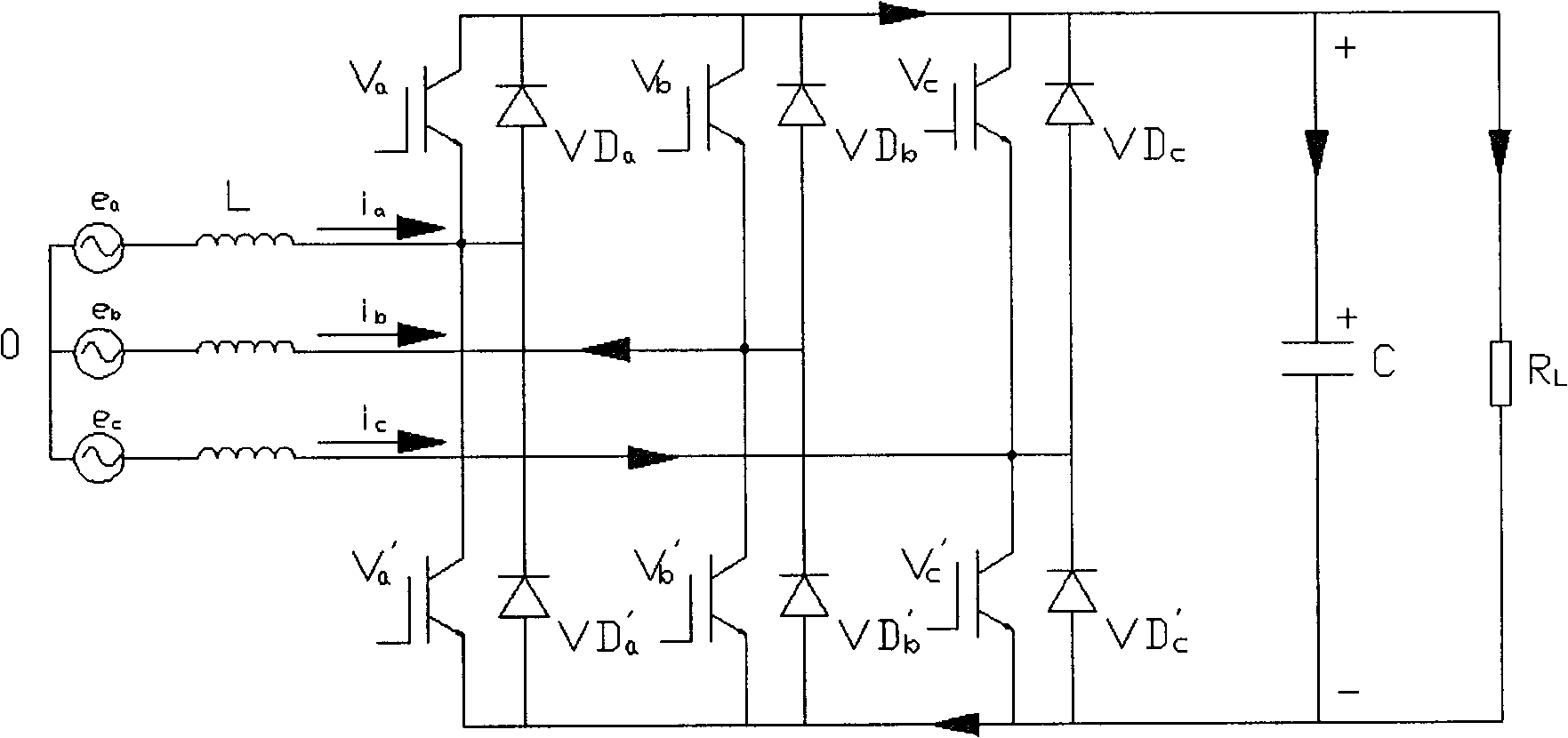

Velocity modulation fuel saving diesel-electric set electric supply tyre type gantry container crane

InactiveCN101348215ALow costMeet normal operation requirementsBase supporting structuresBraking devices for hoisting equipmentsFrequency changerCapacitance

The invention relates to a tire-type gantry container crane with power supplied by a speed-control fuel-saving diesel generating set, which is characterized in that the crane comprises an electrical system; a three-phase AC power source generated by the diesel generating set capable of operating at variable speed, together with a speed control device thereof, is converted into a DC power source via a power electronic reversible rectifying device used for controlling the generated electricity quantity of the diesel generating set, and then direct current is directly supplied to frequency converters driving mechanisms to operate; the DC power source is converted into an AC power source with adjustable frequency so as to be used for driving a hoisting mechanism, a cart mechanism and a trolley mechanism; a super capacitor set is connected with a DC side bus in parallel; the total capacitance of the super capacitor set is below 10 farad; and a central control link is formed by an intelligent industrial control system and is used for detecting the current and voltage states on the DC bus so as to calculate the power situation of the DC bus, and then the power situation is used as the speed control basis of the diesel generating set so as to control the rotating speed and torque of a generator. The container crane has the advantages of low cost, energy conservation and environmental protection.

Owner:北京运达伟业科贸有限责任公司

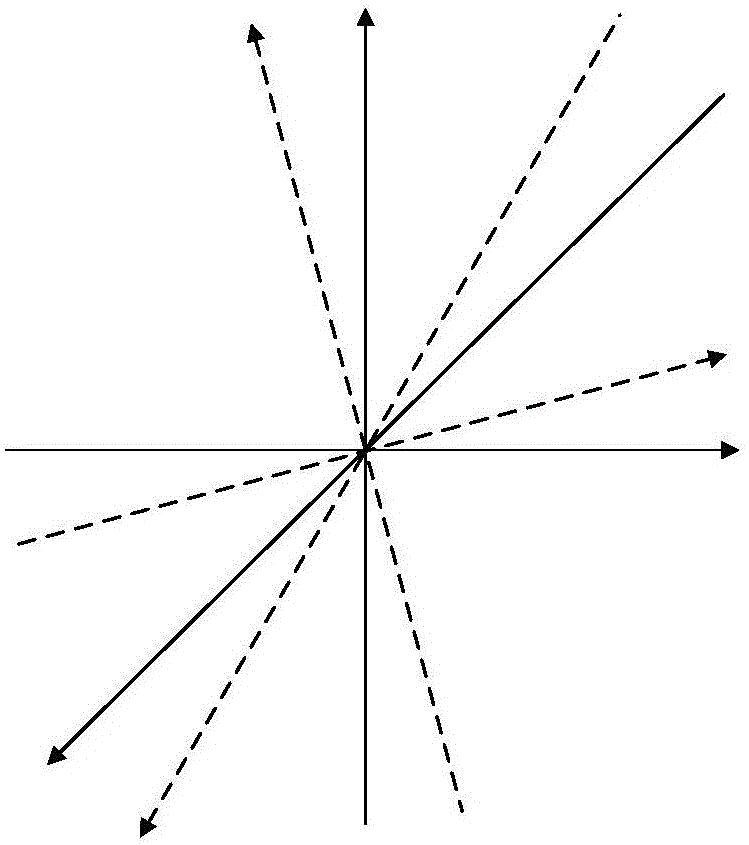

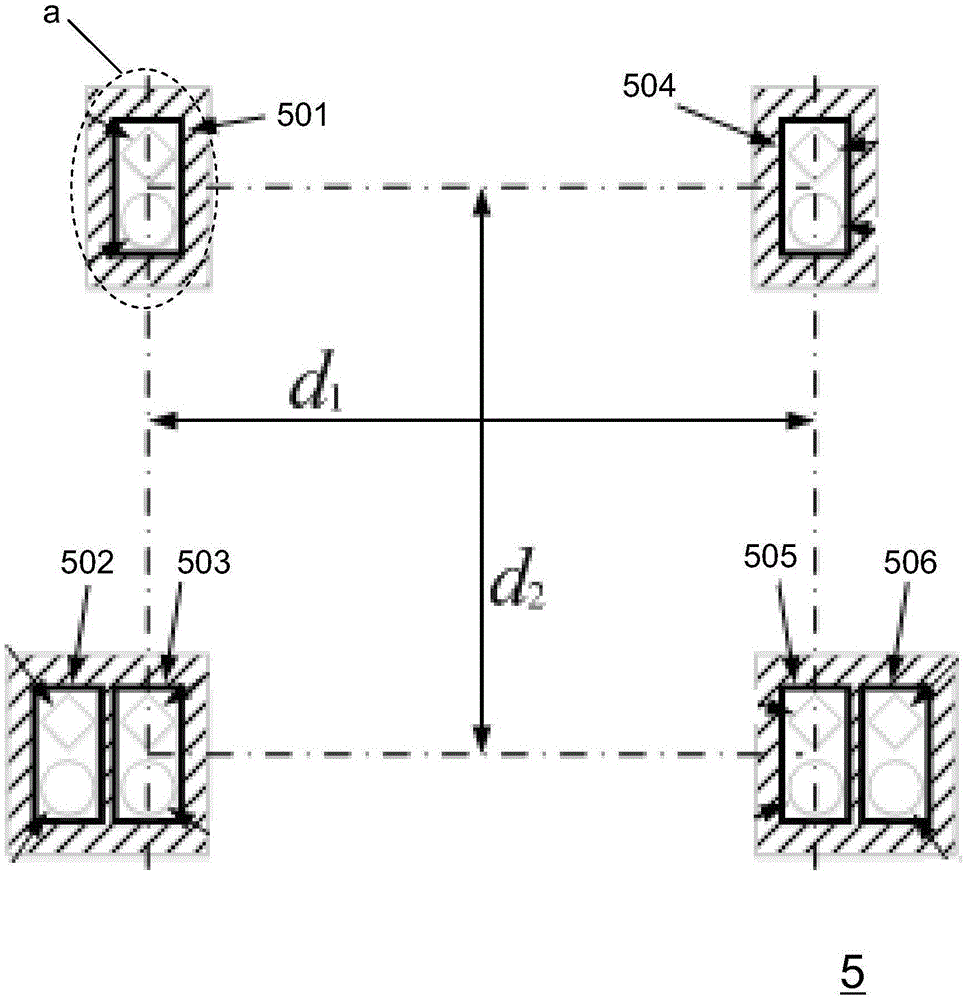

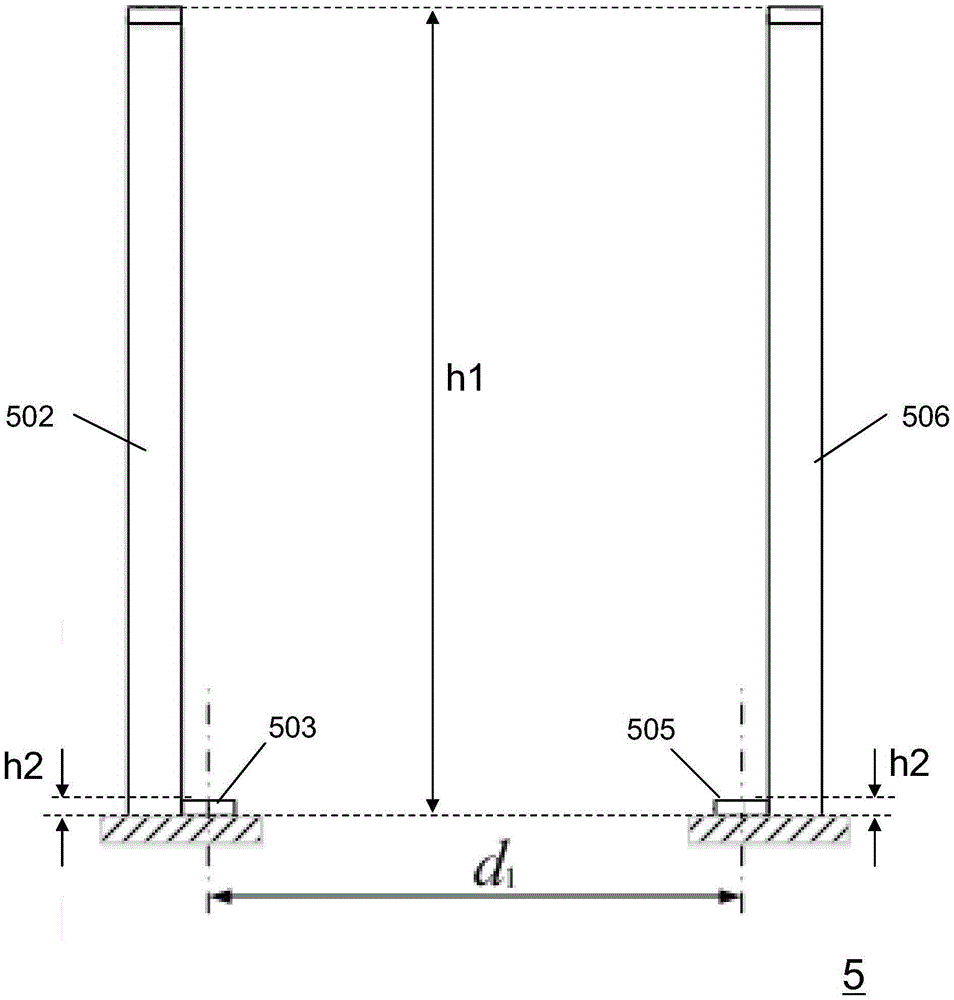

Automatic detecting and calibrating system and method for container crane

ActiveCN105480864AImprove calibration efficiencyTrolley cranesLoad-engaging elementsContainer craneEngineering

The invention discloses an automatic detecting and calibrating system and method for a container crane. The system comprises a rail hoisting trolley and a sling connected to the portion below the rail hoisting trolley and further comprises a calibrating device, target detecting devices and a sling detecting device. The sling detecting device is arranged at the connecting position of the rail hoisting trolley and the sling. The two target detecting devices are connected to the portion below the rail hoisting trolley and correspondingly arranged on the two sides of the rail hoisting trolley. The calibrating device is composed of six identification blocks, wherein the four identification blocks form a rectangle and are consistent in height, and the other two identification blocks are arranged on the outer side and are consistent in height but higher than the four identification blocks. Each identification block is composed of an active identification block and a passive identification block, wherein the active identification block is used for calibration of the sling detecting device, and the passive identification block is used for calibration of the corresponding target detecting devices. By means of the calibrating device, space coordinate systems of the sling detecting device and the target detecting devices can be conveniently and rapidly converted into the same reference coordinate system.

Owner:SHANGHAI ZPMC ELECTRIC +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com