Patents

Literature

654 results about "Preventive maintenance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preventive maintenance has the following meanings: The care and servicing by personnel for the purpose of maintaining equipment and facilities in satisfactory operating condition by providing for systematic inspection, detection, and correction of incipient failures either before they occur or before they develop into major defects. Maintenance, including tests, measurements, adjustments, and parts replacement, performed specifically to prevent faults from occurring. The primary goal of maintenance is to avoid or mitigate the consequences of failure of equipment. This may be by preventing the failure before it actually occurs which Planned Maintenance and Condition Based Maintenance help to achieve. It is designed to preserve and restore equipment reliability by replacing worn components before they actually fail. Preventive maintenance activities include partial or complete overhauls at specified periods, oil changes, lubrication and so on. In addition, workers can record equipment deterioration so they know to replace or repair worn parts before they cause system failure. The ideal preventive maintenance program would prevent all equipment failure before it occurs.

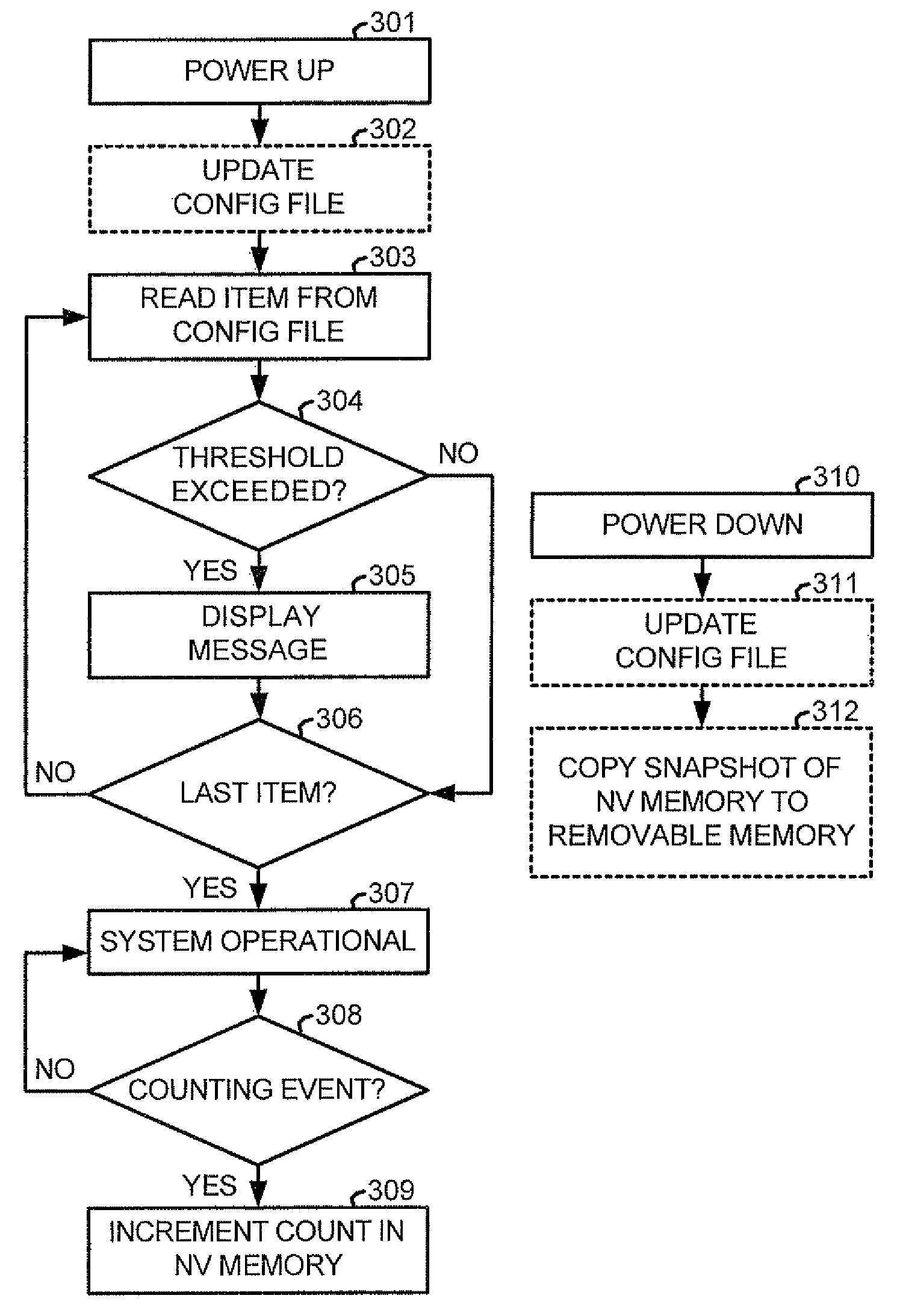

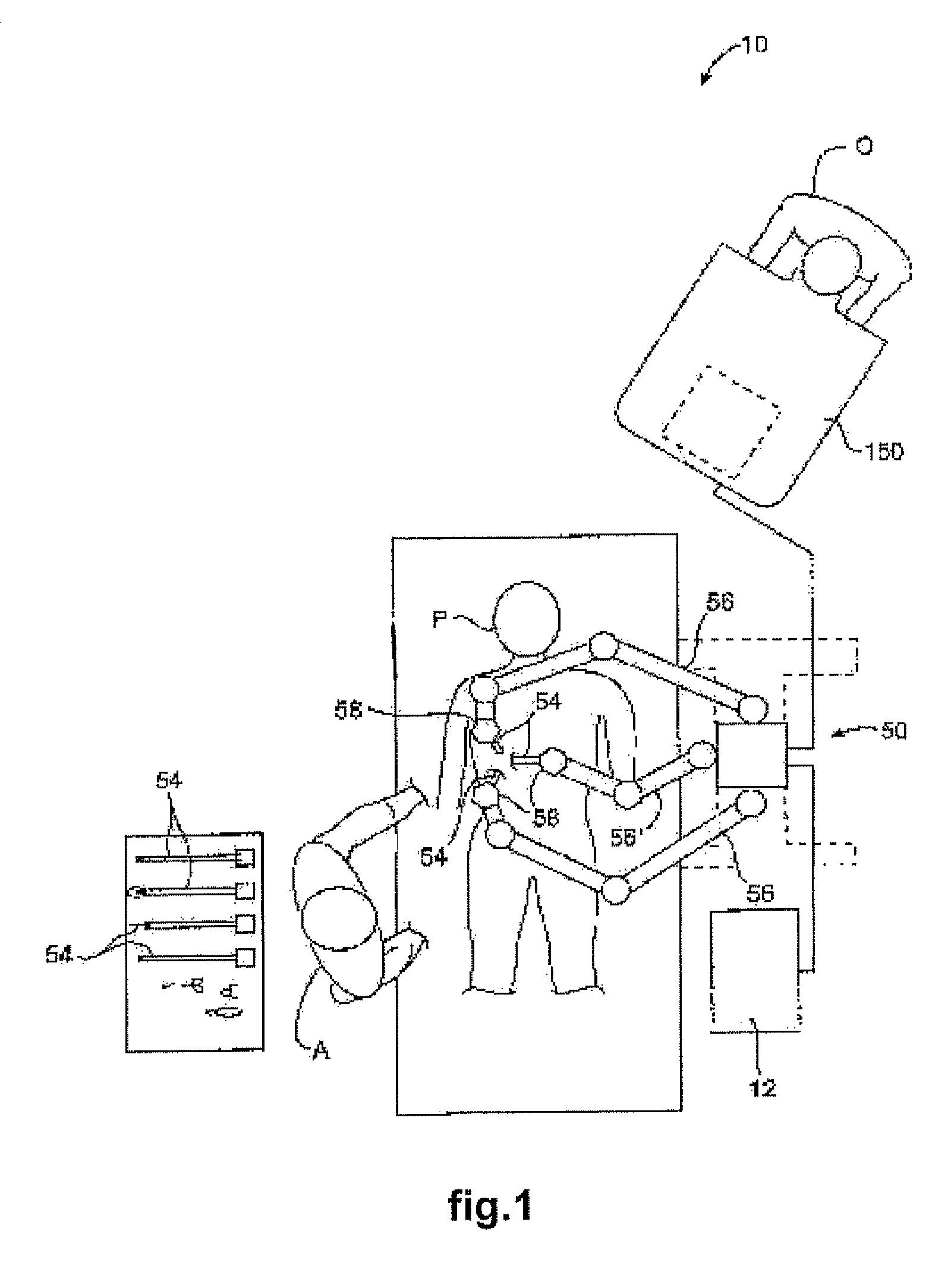

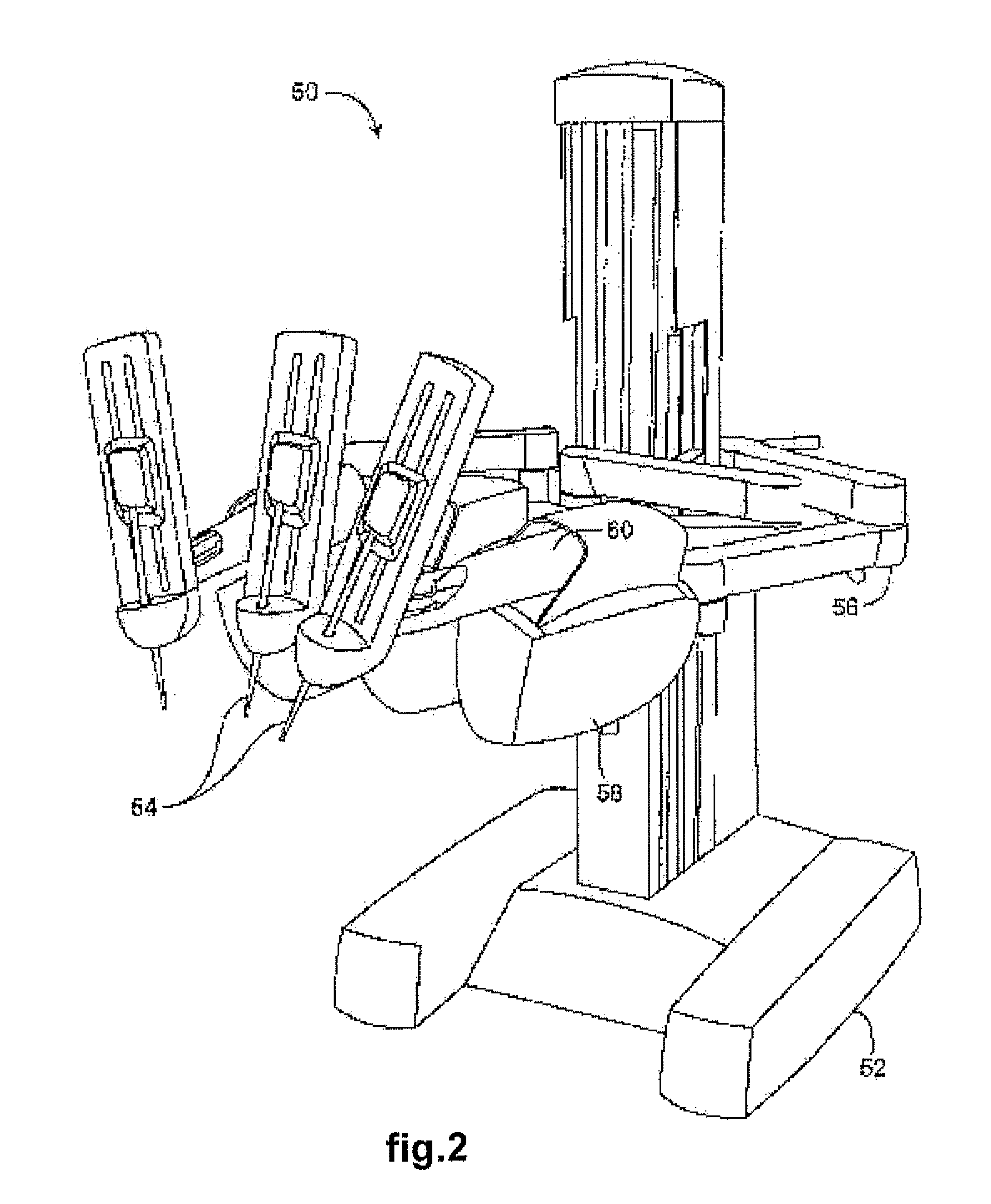

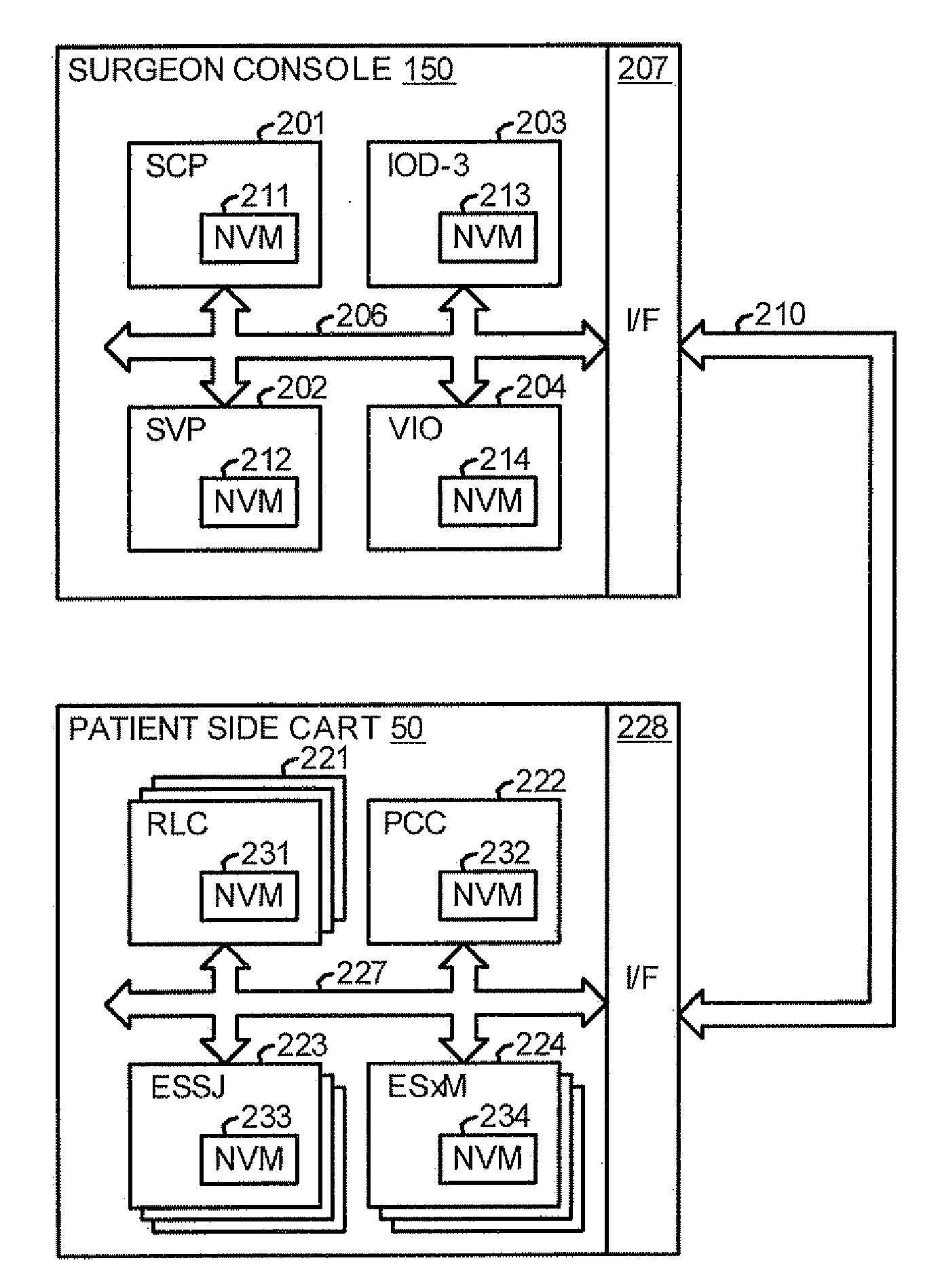

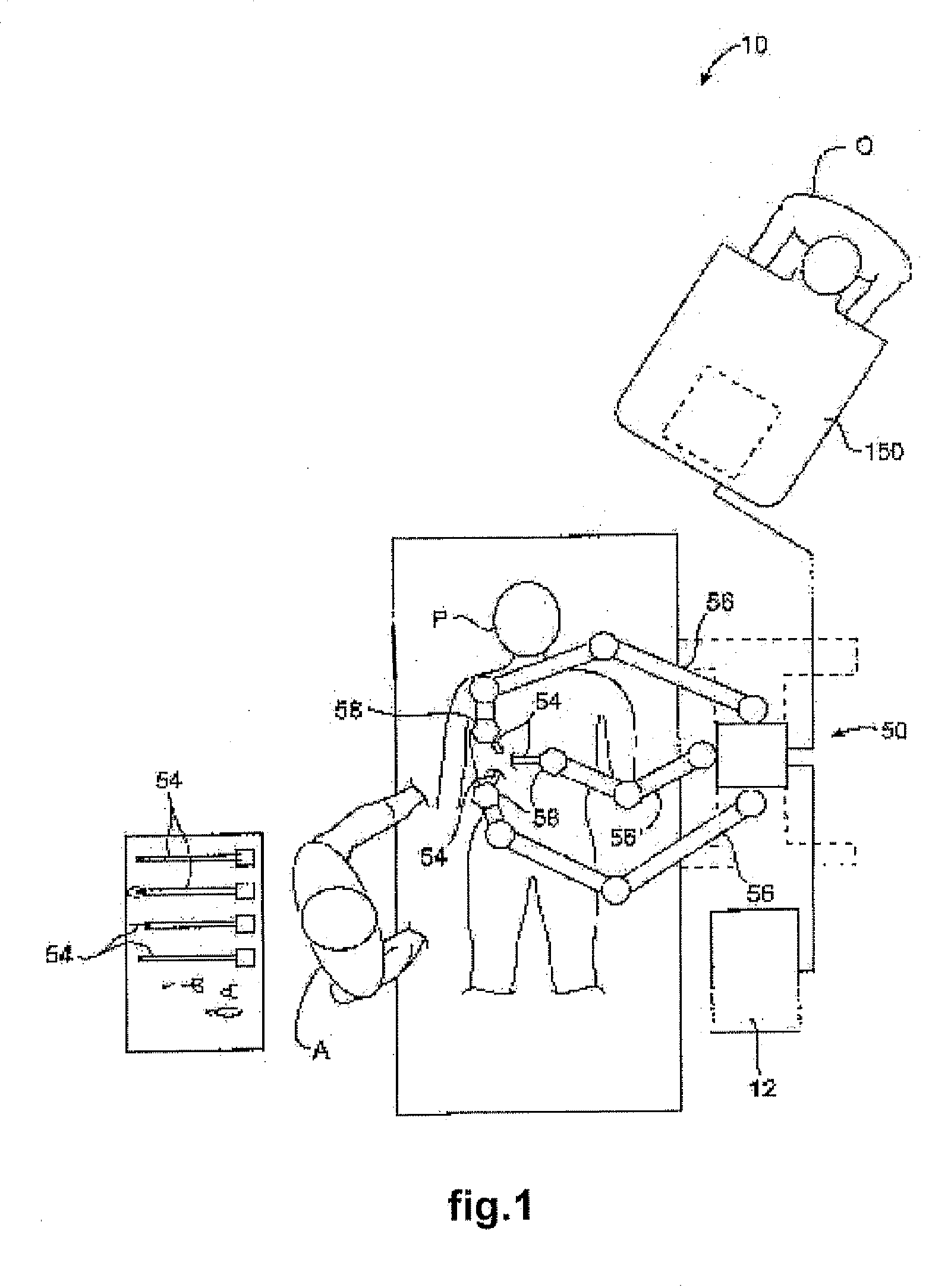

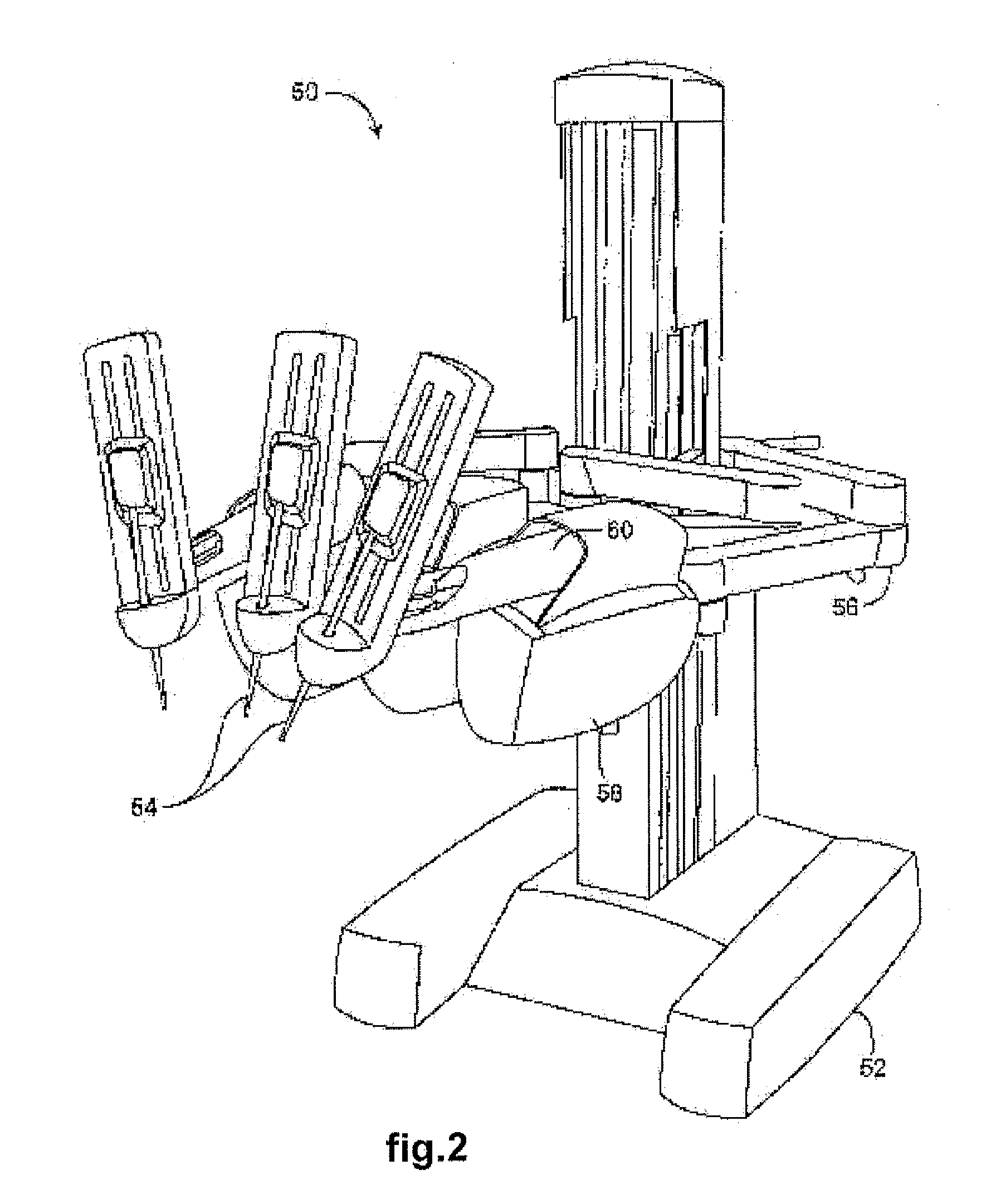

Method for tracking and reporting usage events to determine when preventive maintenance is due for a medical robotic system

A medical robotic system comprises a number of components that may be monitored to determine their preventive maintenance needs by recording usage-related information for the monitored components into associated non-volatile memories. When usage of the component exceeds a specified usage threshold, the system displays a warning message on its display screen to have preventive maintenance performed for the component. If the usage continues without such maintenance and exceeds a higher usage threshold, the system displays an error message on its display screen and the system transitions into an error state during which medical procedures are not allowed to be performed. The usage-related information may also be communicated to a remote computer which gathers and processes usage-related information from a number of medical robotic systems to estimate resource requirements for timely performing preventive maintenance on the medical robotic systems, and anticipated service revenues from such maintenance.

Owner:INTUITIVE SURGICAL OPERATIONS INC

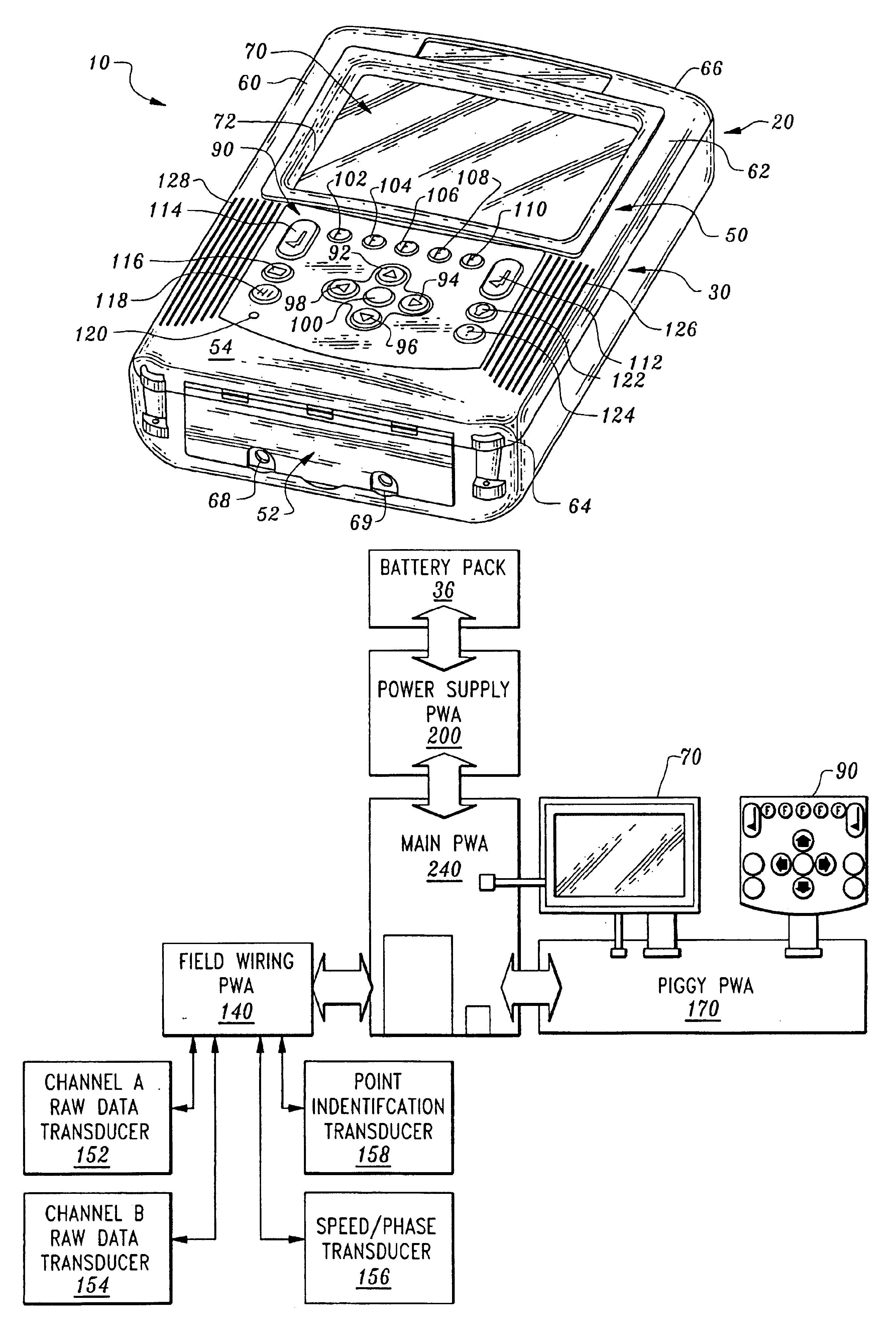

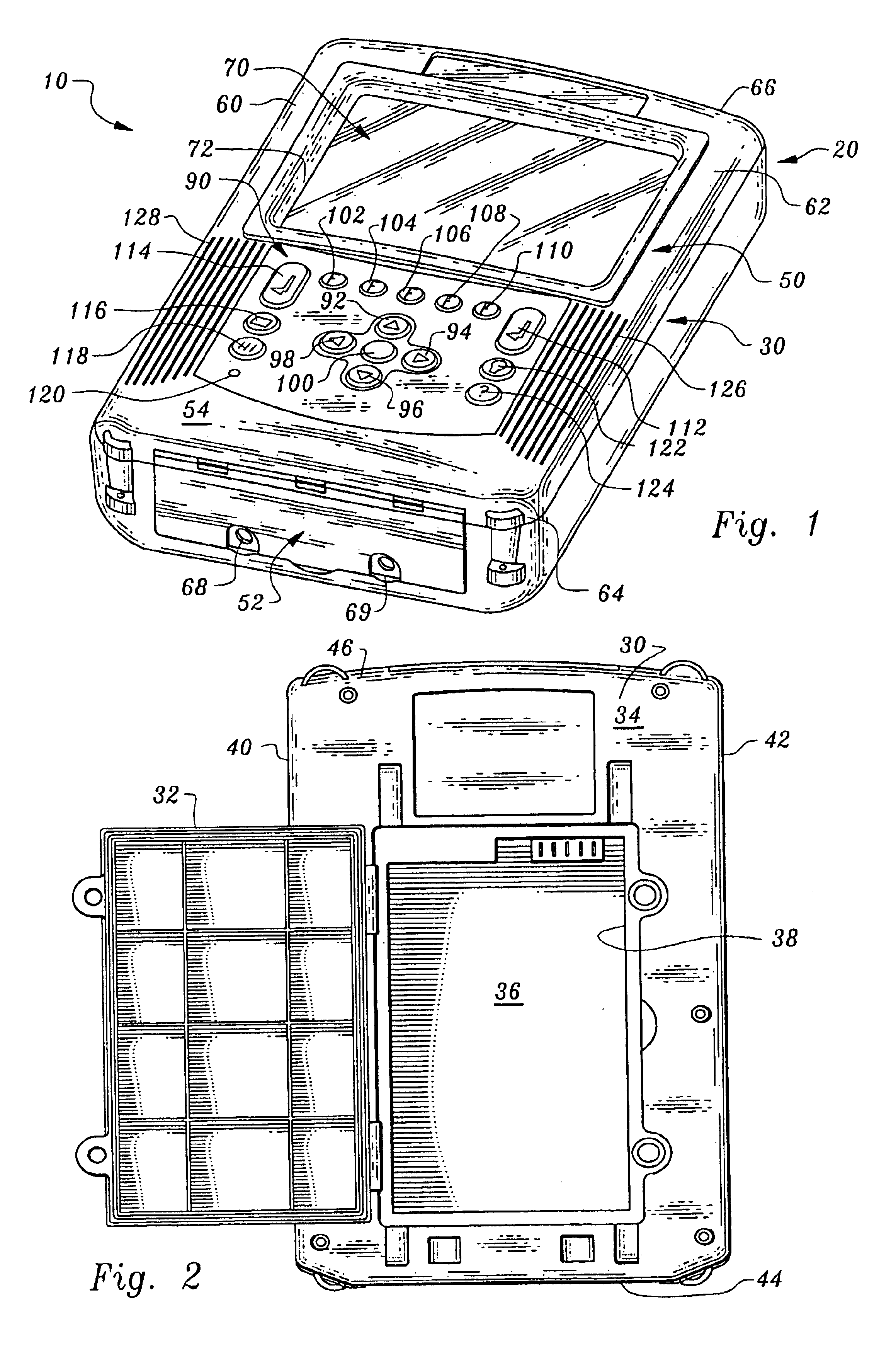

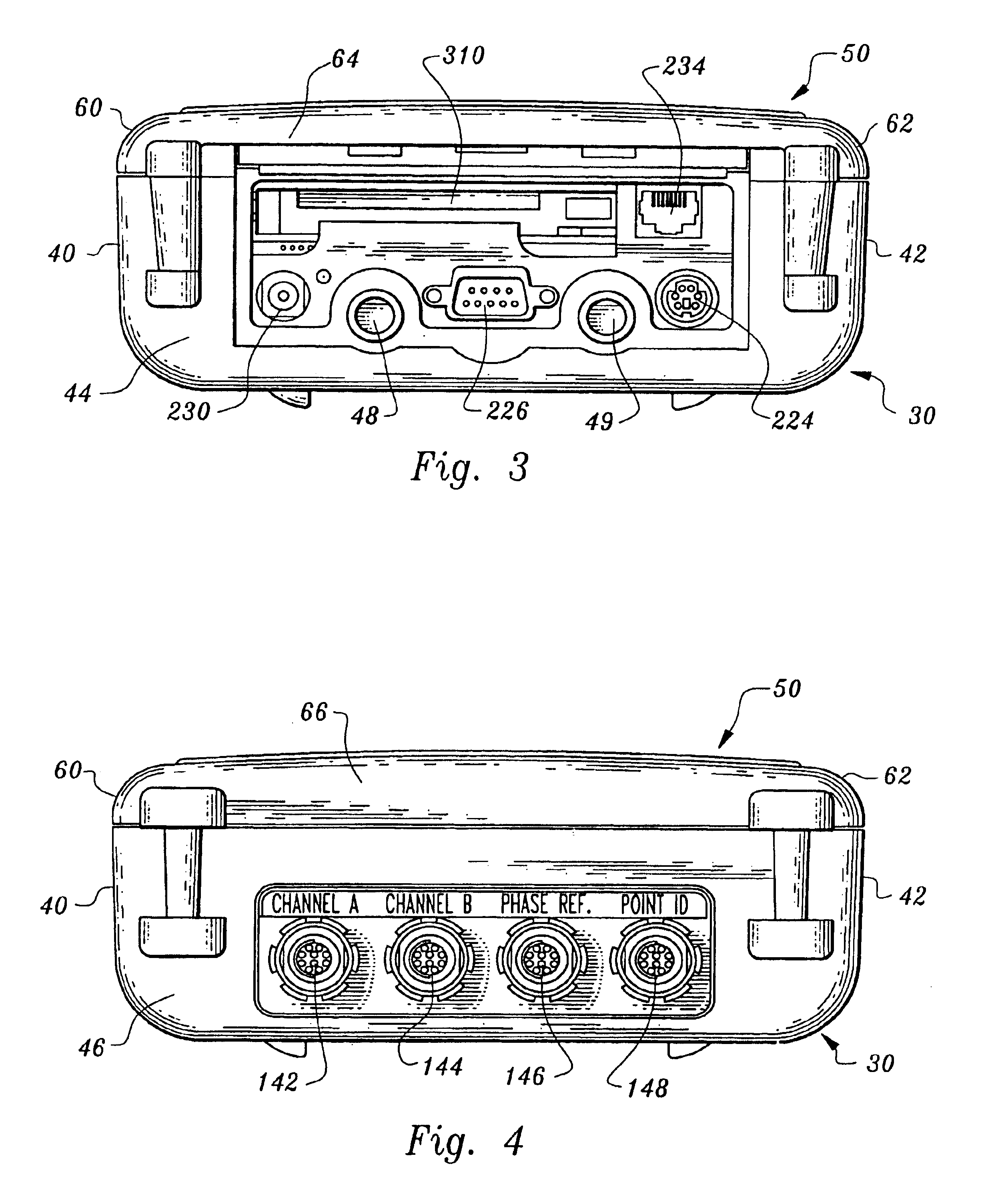

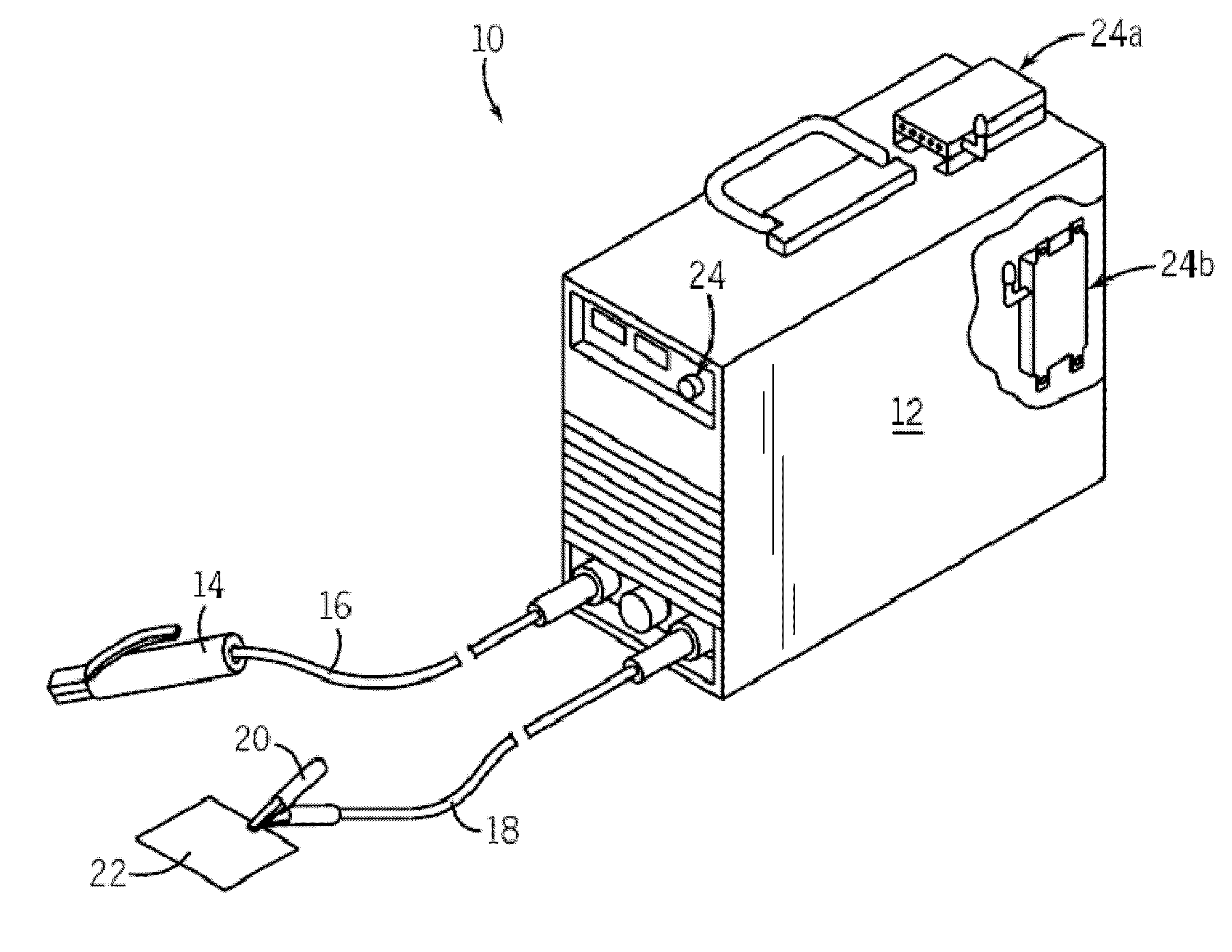

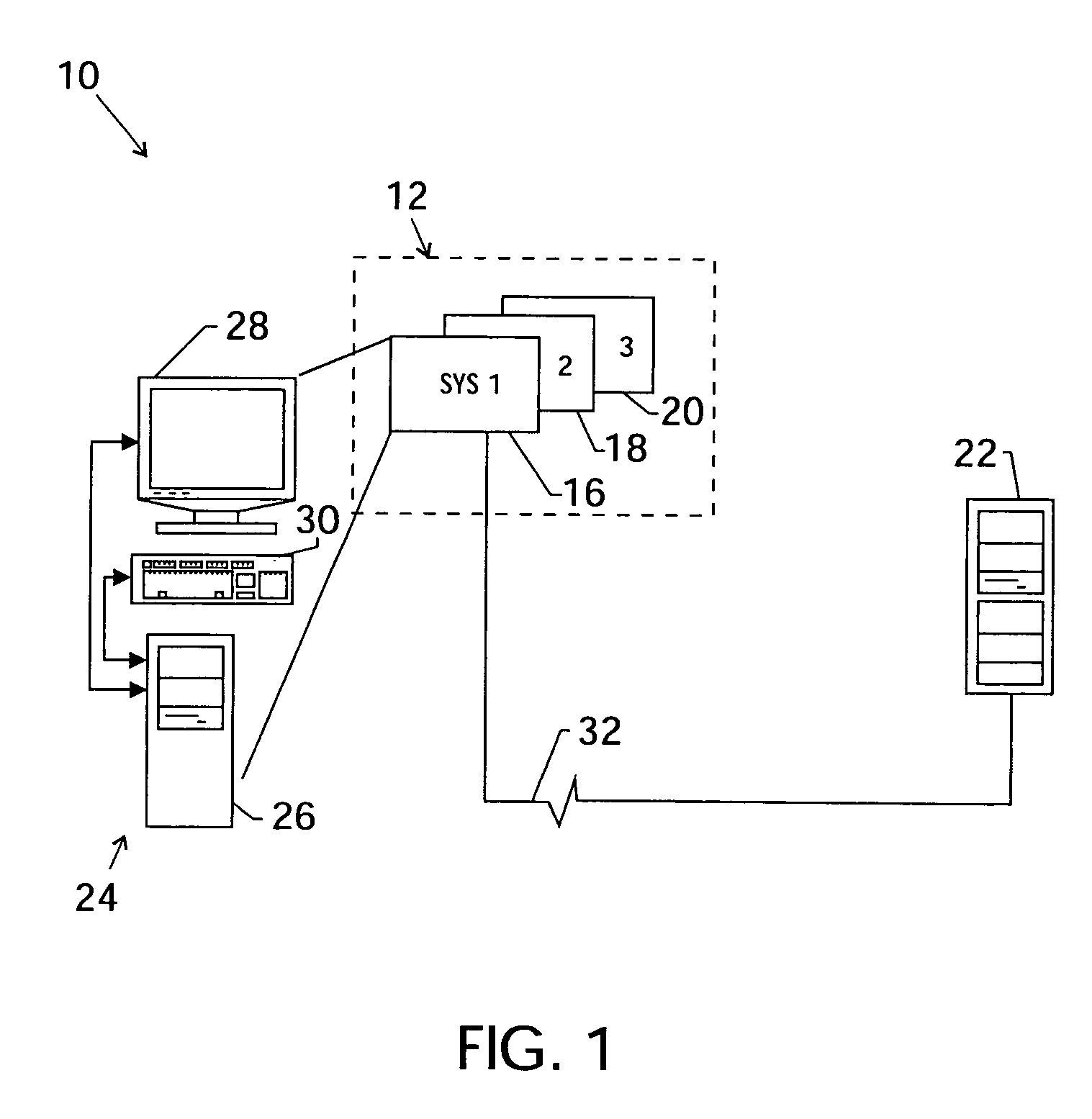

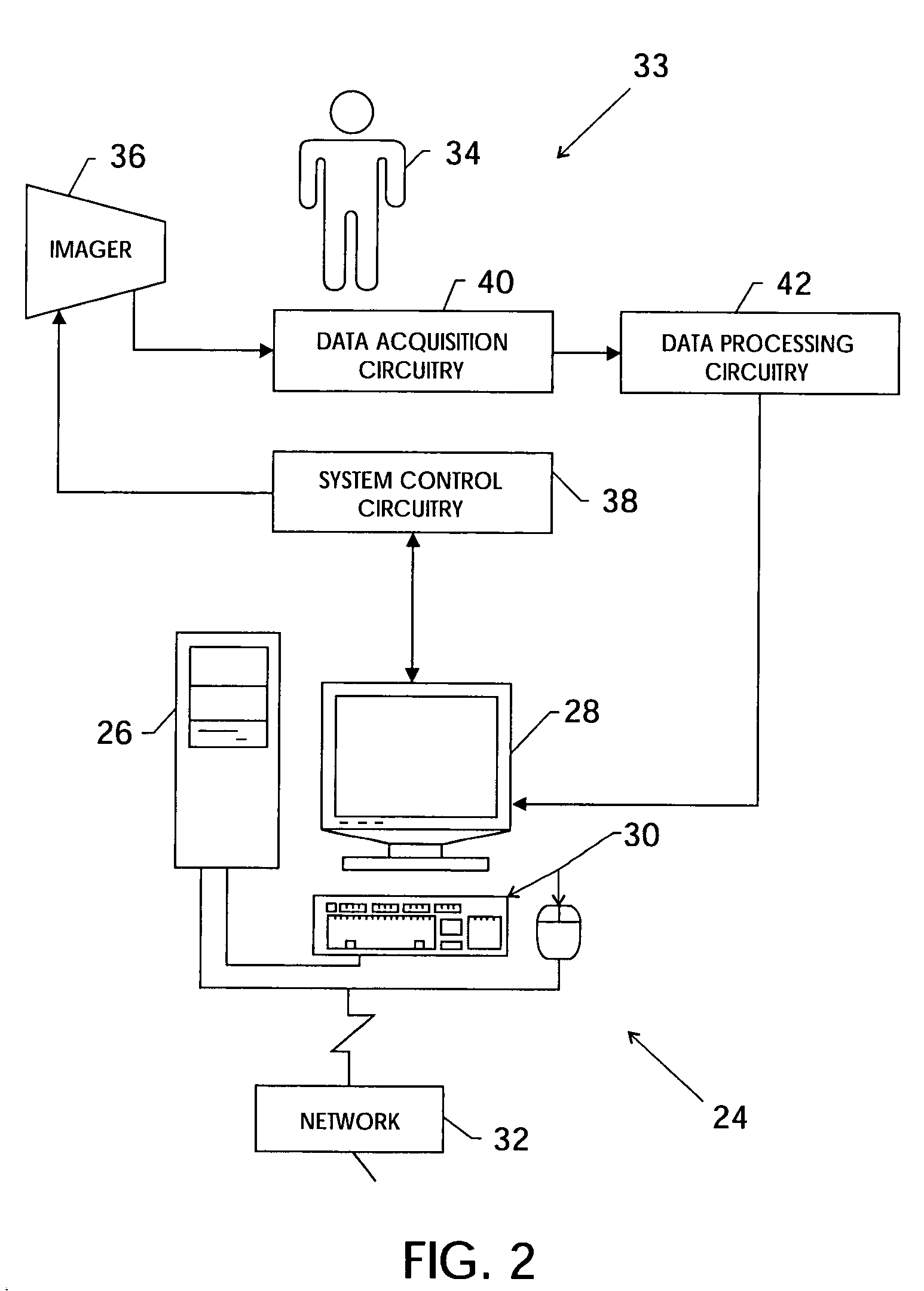

Portable data collector and analyzer: apparatus and method

InactiveUS6789030B1Efficient solutionIncreasing signal processing speedSpectral/fourier analysisNuclear monitoringFrequency spectrumTransducer

A portable data collector and analyzer apparatus and method provides predictive and preventative maintenance of a multiplicity of assets through the use of a unique architecture that allows a variety of different application programs to be downloaded to the apparatus for providing a single multi-purpose portable data collector and analyzer apparatus that can employ the variety of different application programs for configuring, inter alia, different measurements types, different transducers types and different signal processing types for collecting and analyzing sensed physical data from a variety of different assets found in industrial plants. A unique frequency shifting and decimation method is employed for spectrum calculation that, inter alia, retains DSP addressing efficiency and increases signal processing speed. Additionally, a unique synchronous sampling method is employed that generates synchronous sample waveforms from asynchronous sample waveforms. Furthermore, a unique clear touch screen overlying a quarter VGA display, an ergonomically designed keypad, and an intuitive user interface allow quick and easy setup and operation for in-field data acquisition, analysis and display.

Owner:BENTLY NEVADA INC

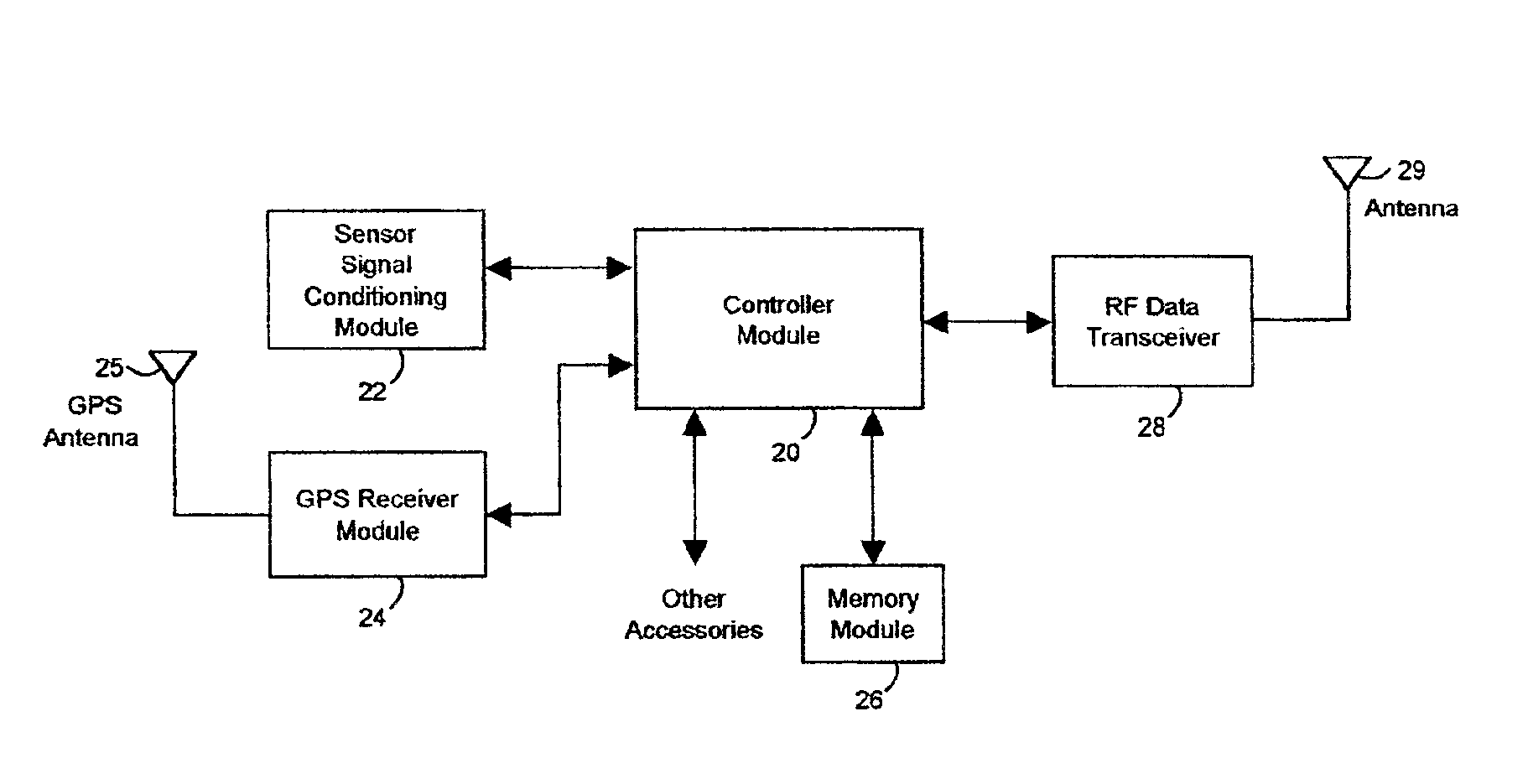

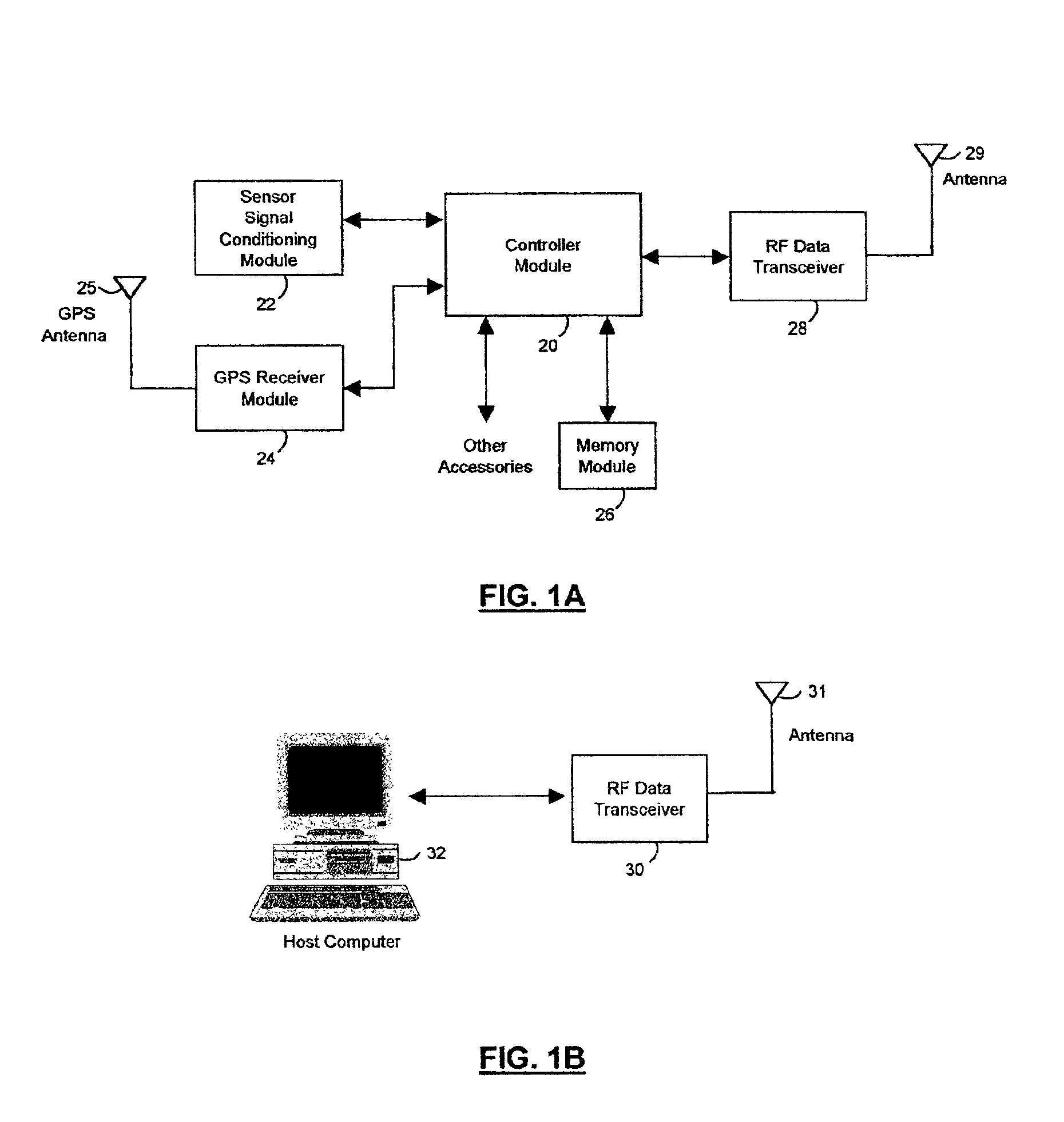

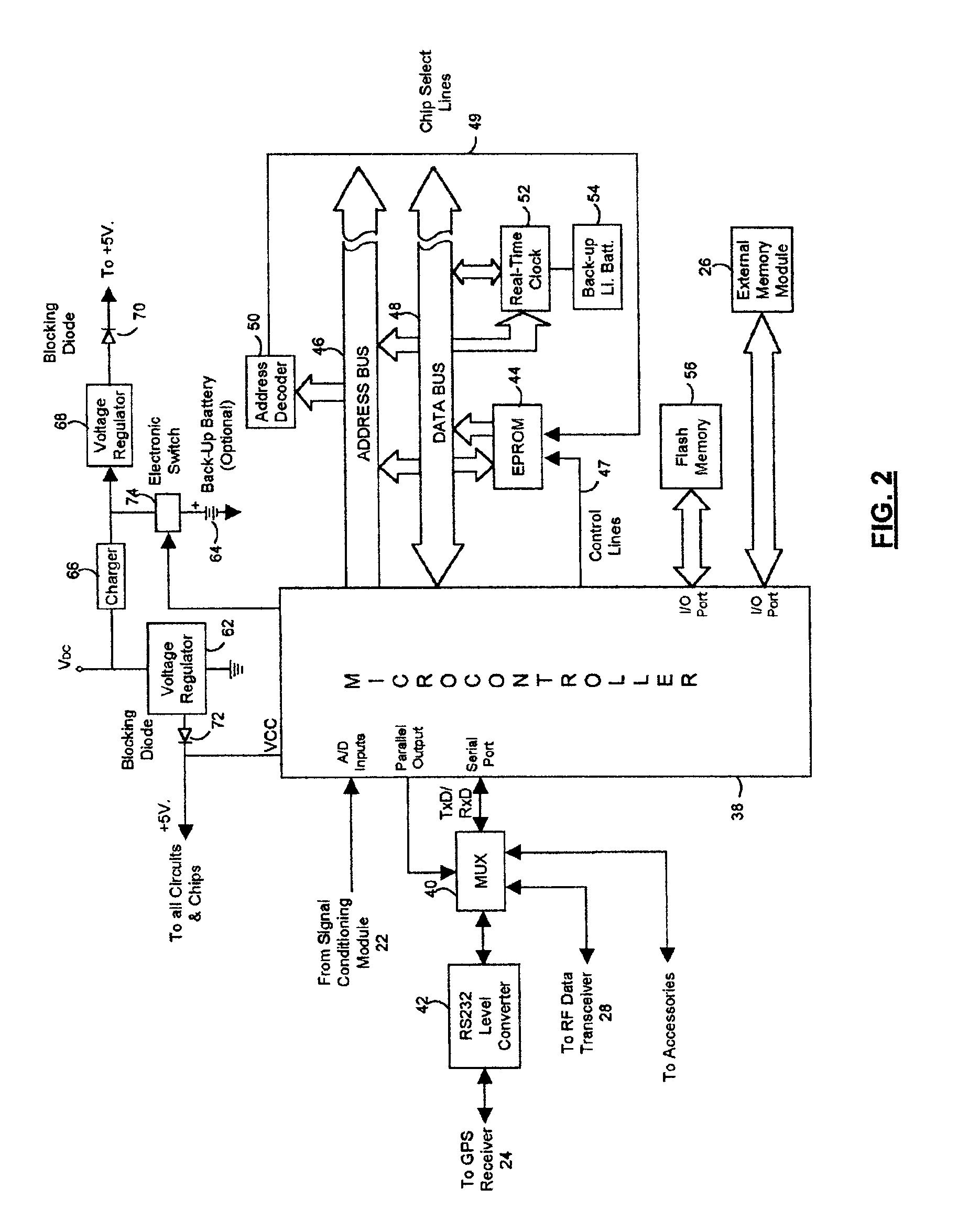

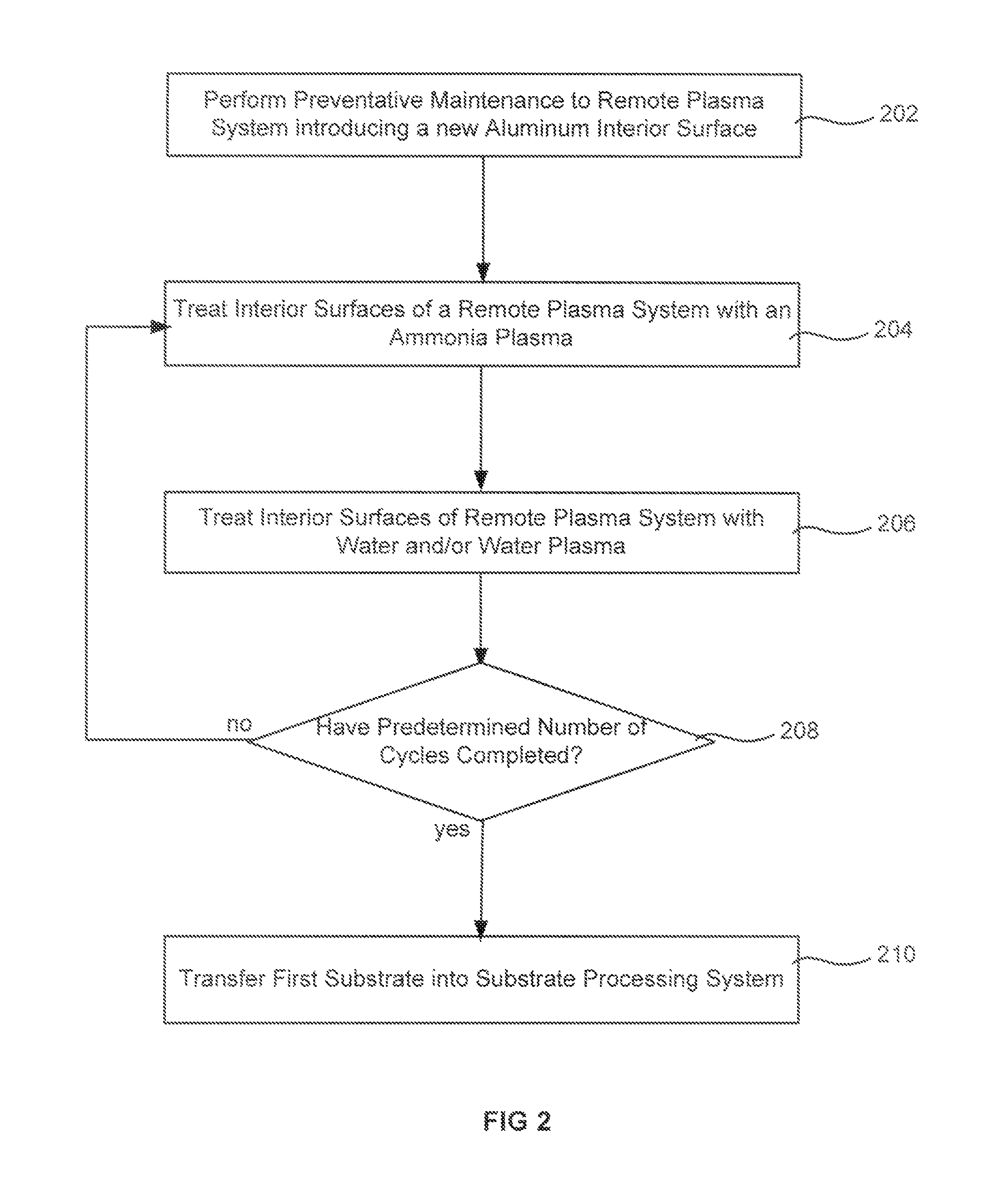

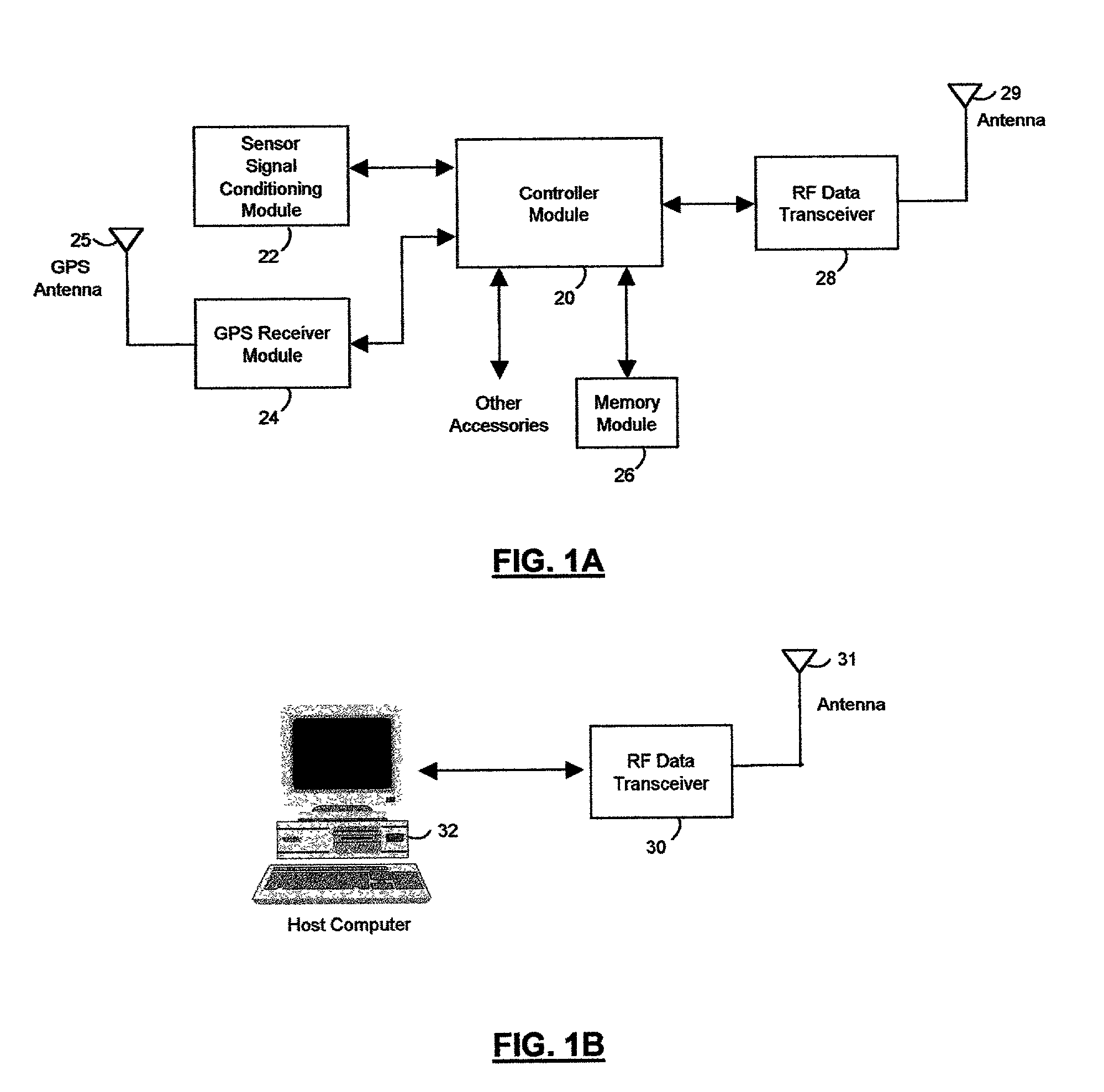

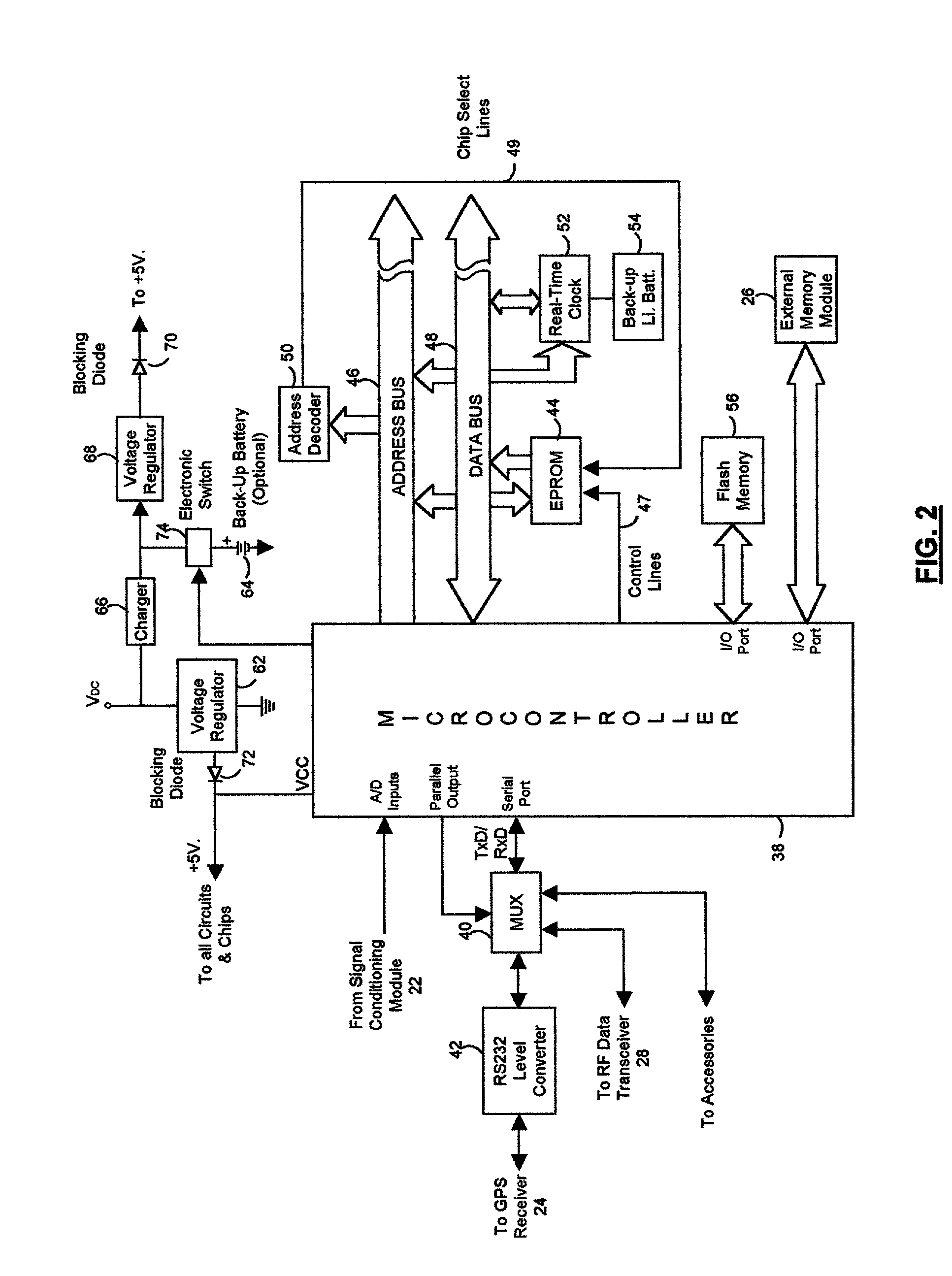

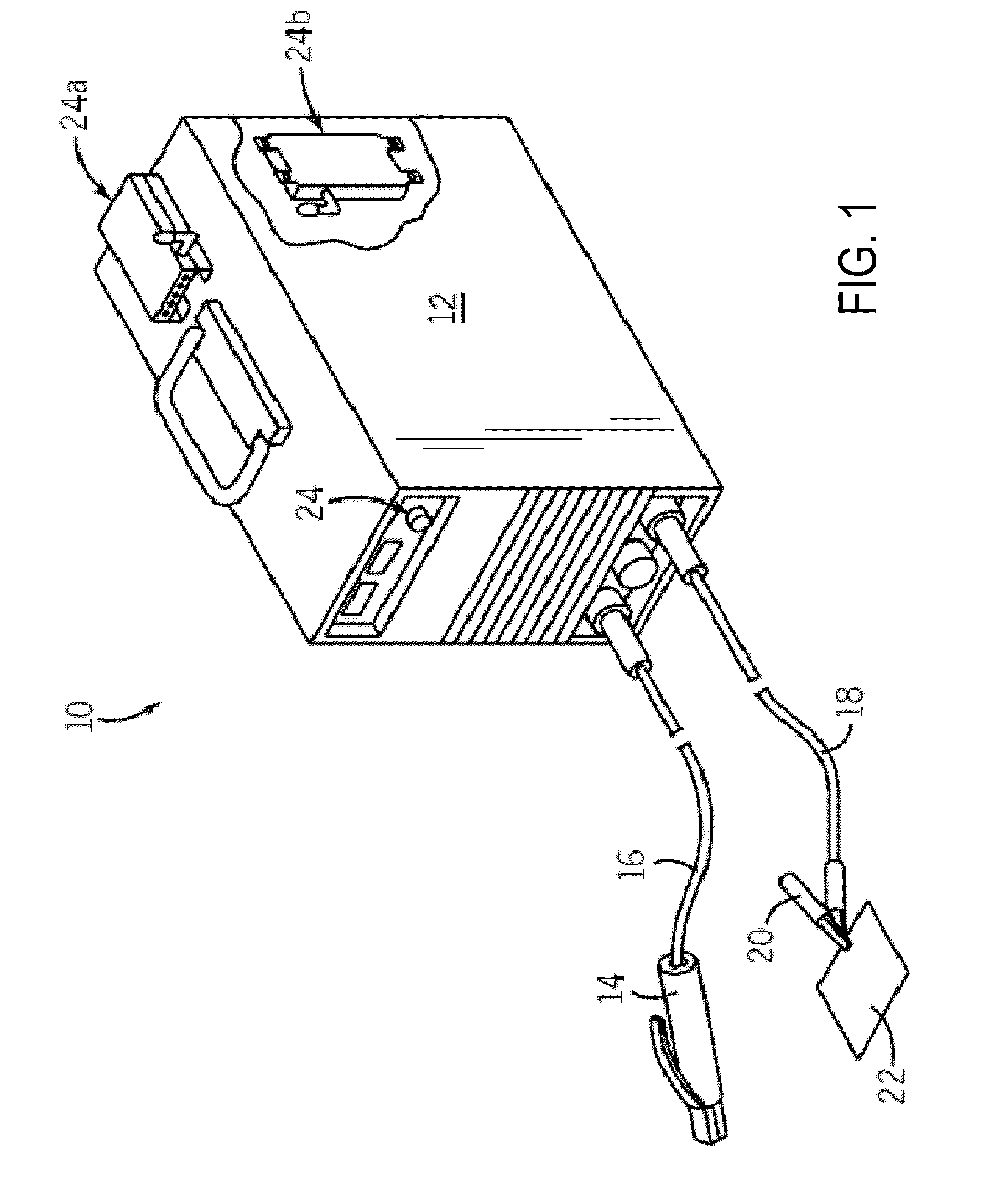

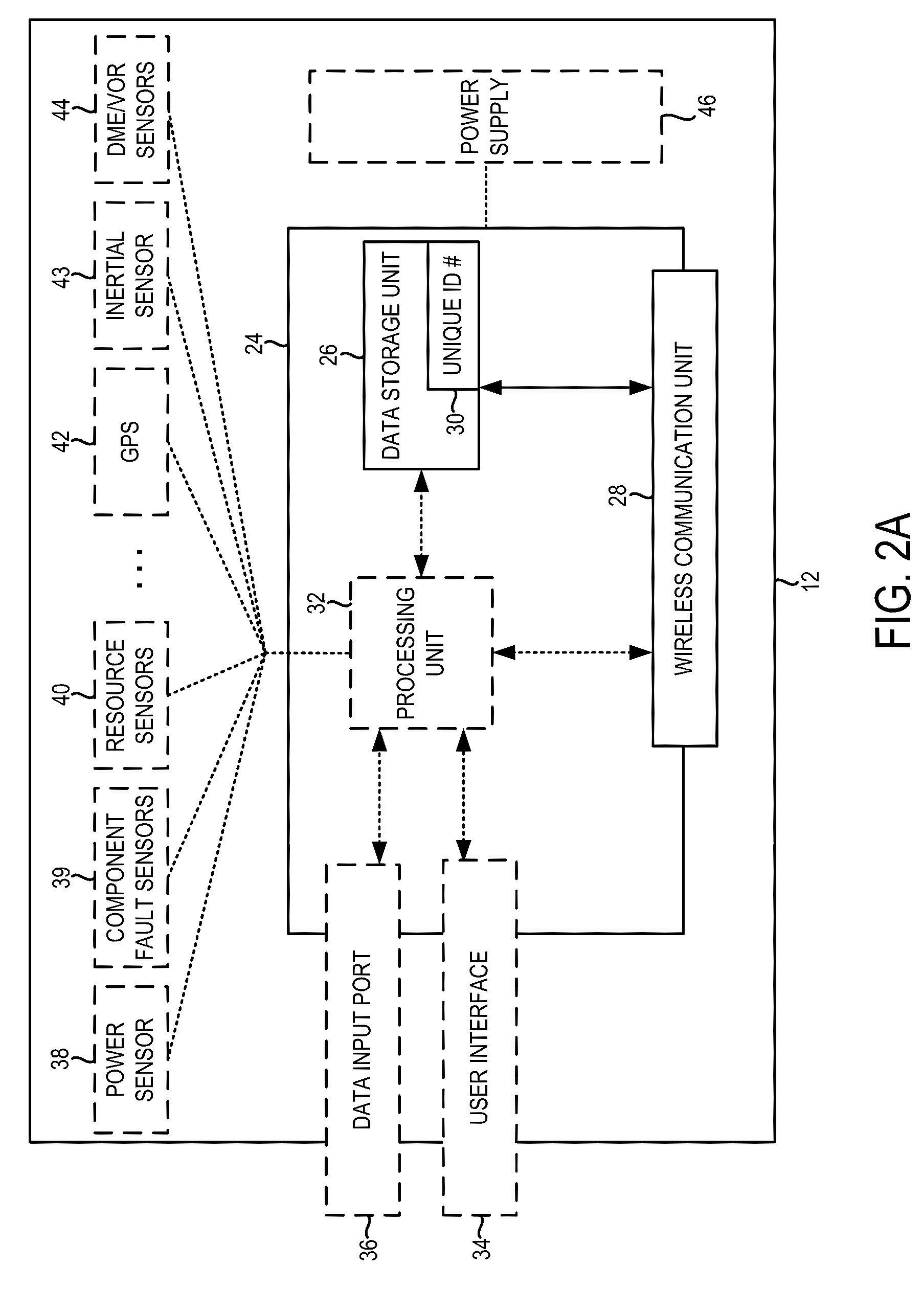

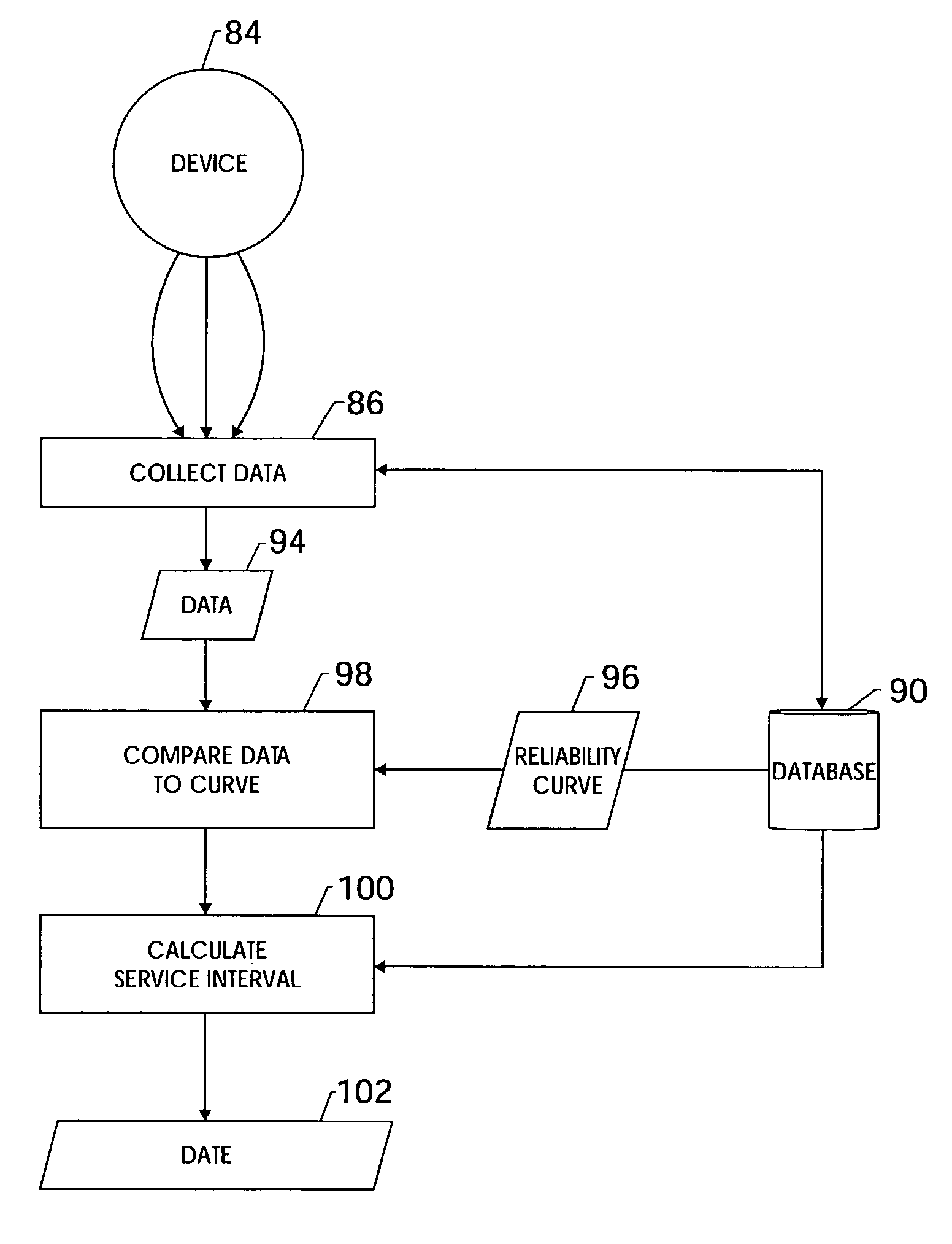

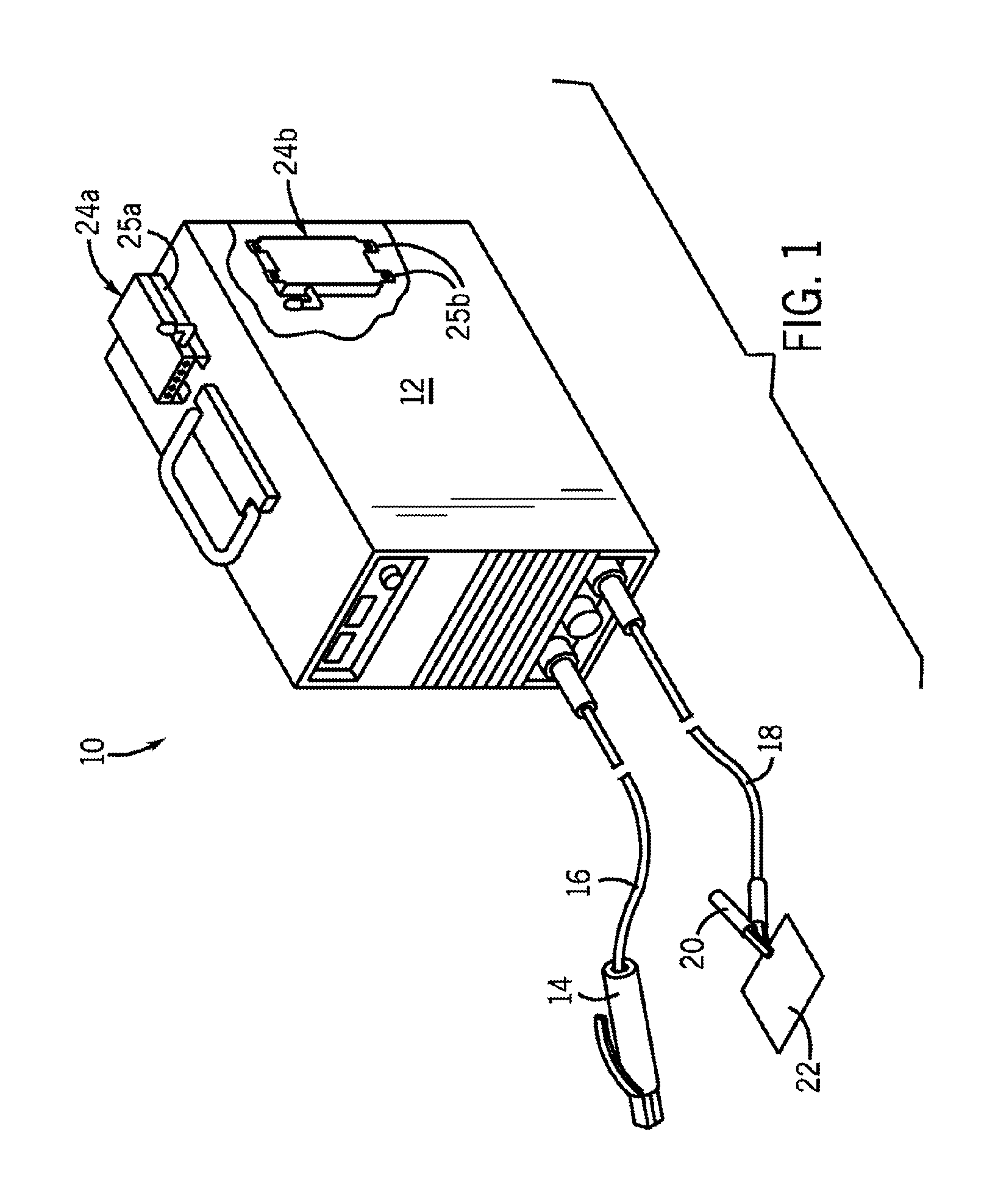

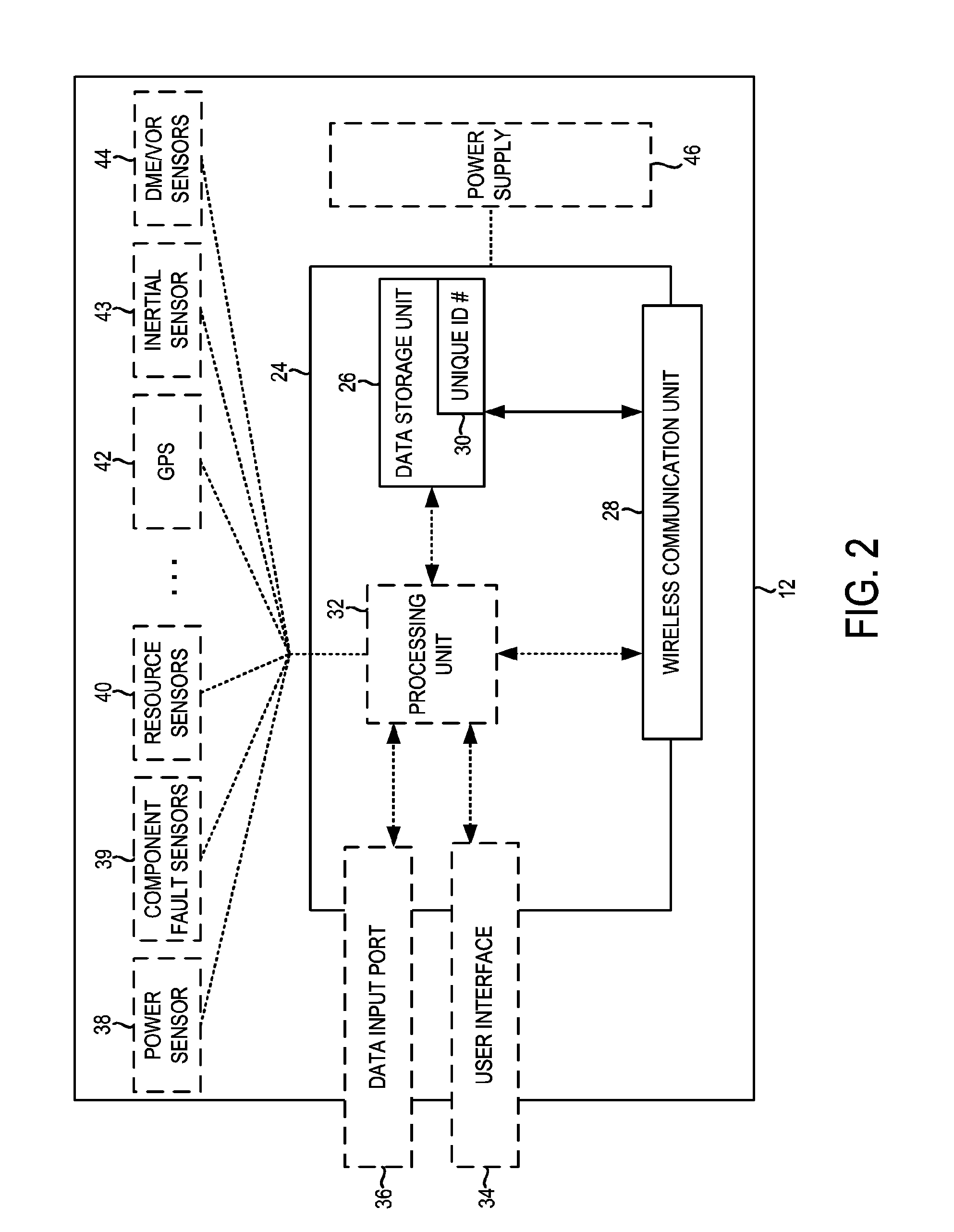

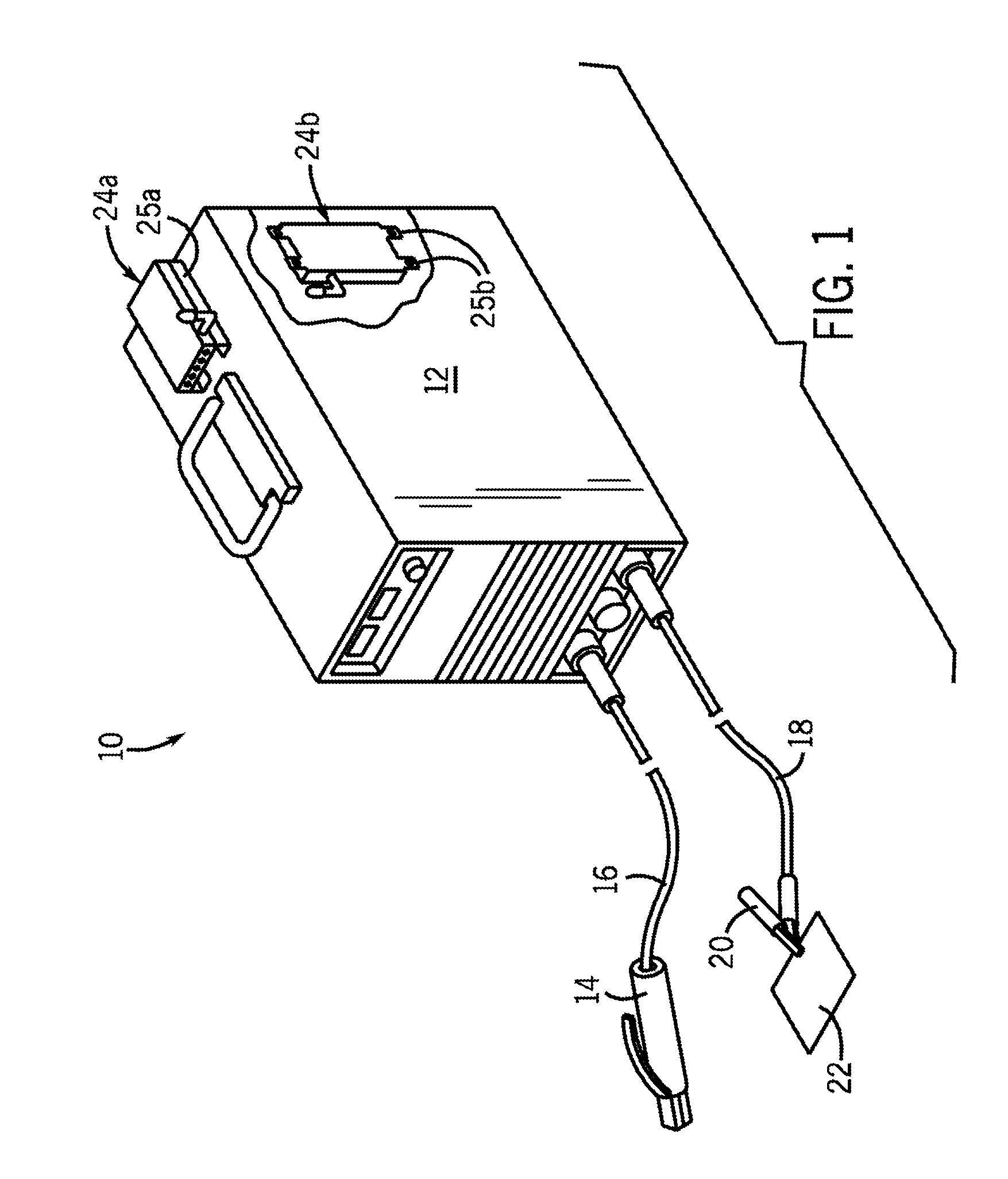

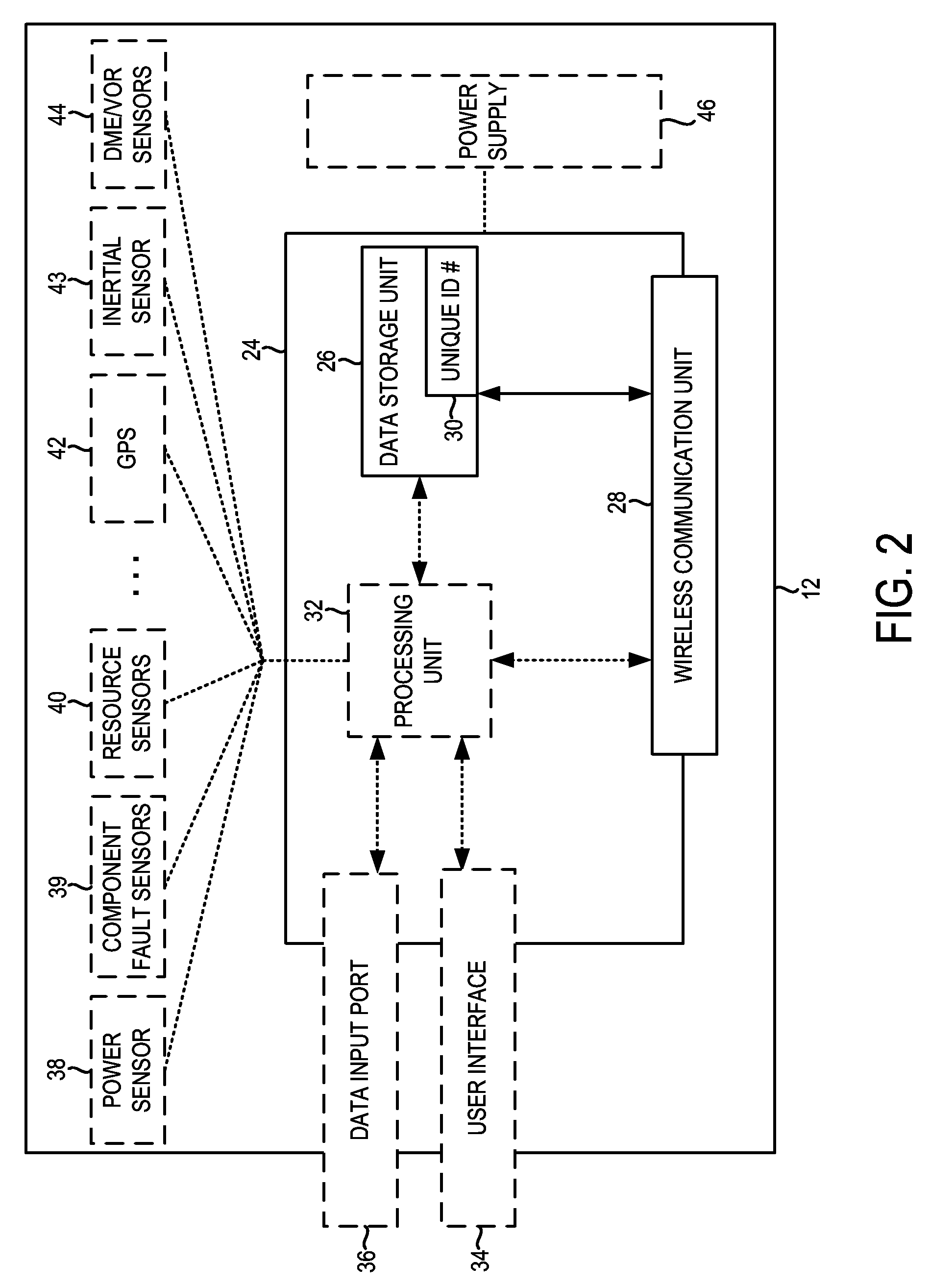

Self-contained flight data recorder with wireless data retrieval

A flight recorder designed for small aircraft captures various onboard flight data in real-time and stores it in non-volatile memory. Recorded data includes aircraft's instantaneous position, altitude, attitude, engine RPM, G forces, flap position, cockpit voice and others. These data are obtained from various sensors which are integrated into the recorder. At the end of a flight the recorded data is downloaded into a computer using a wireless communications data transceiver also integrated into the recorder. It does not require removal or attaching any equipment to be able to download data. In addition to accident investigation, applications include training, preventive maintenance and asset monitoring.

Owner:MICROLOGIC SYST

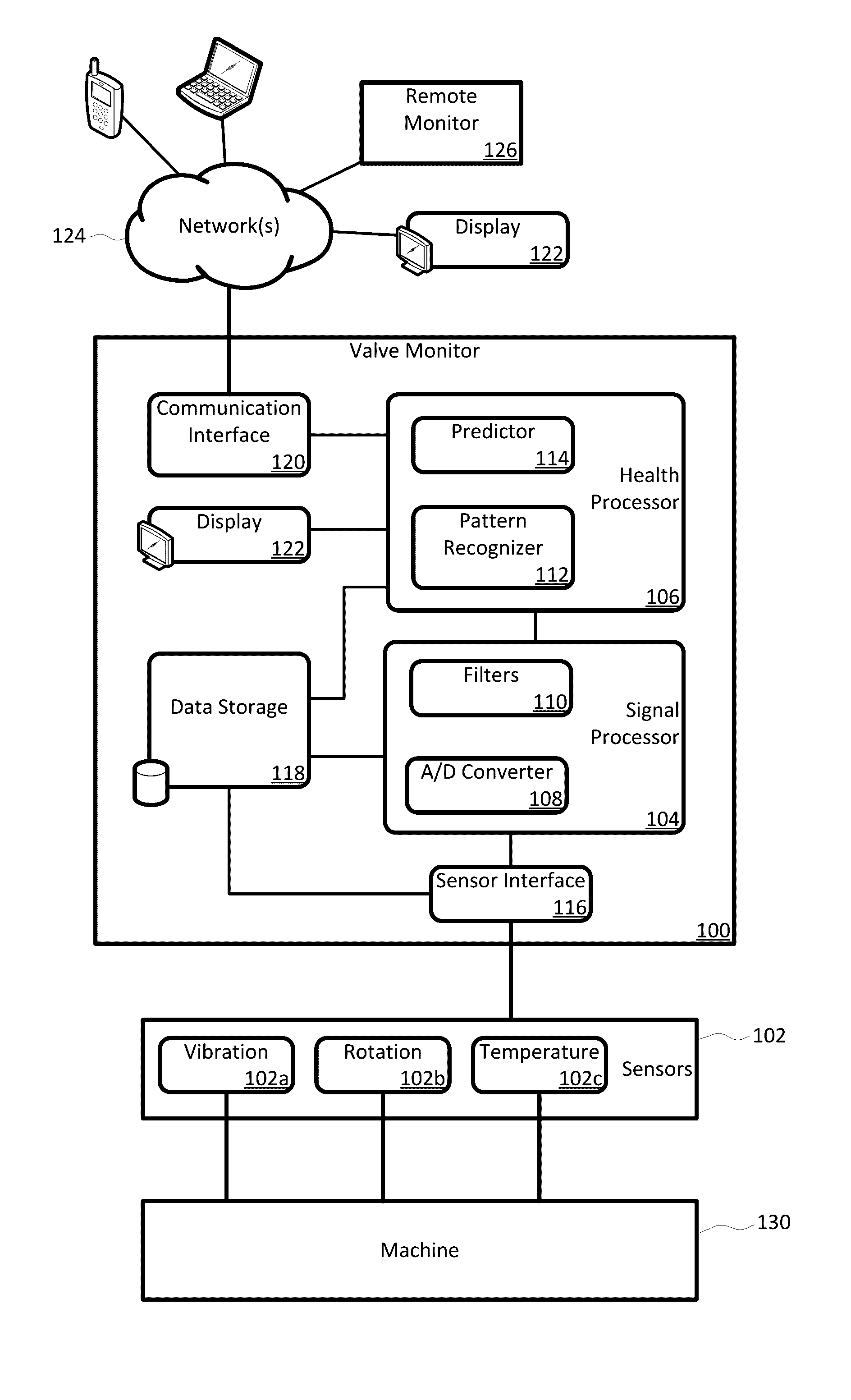

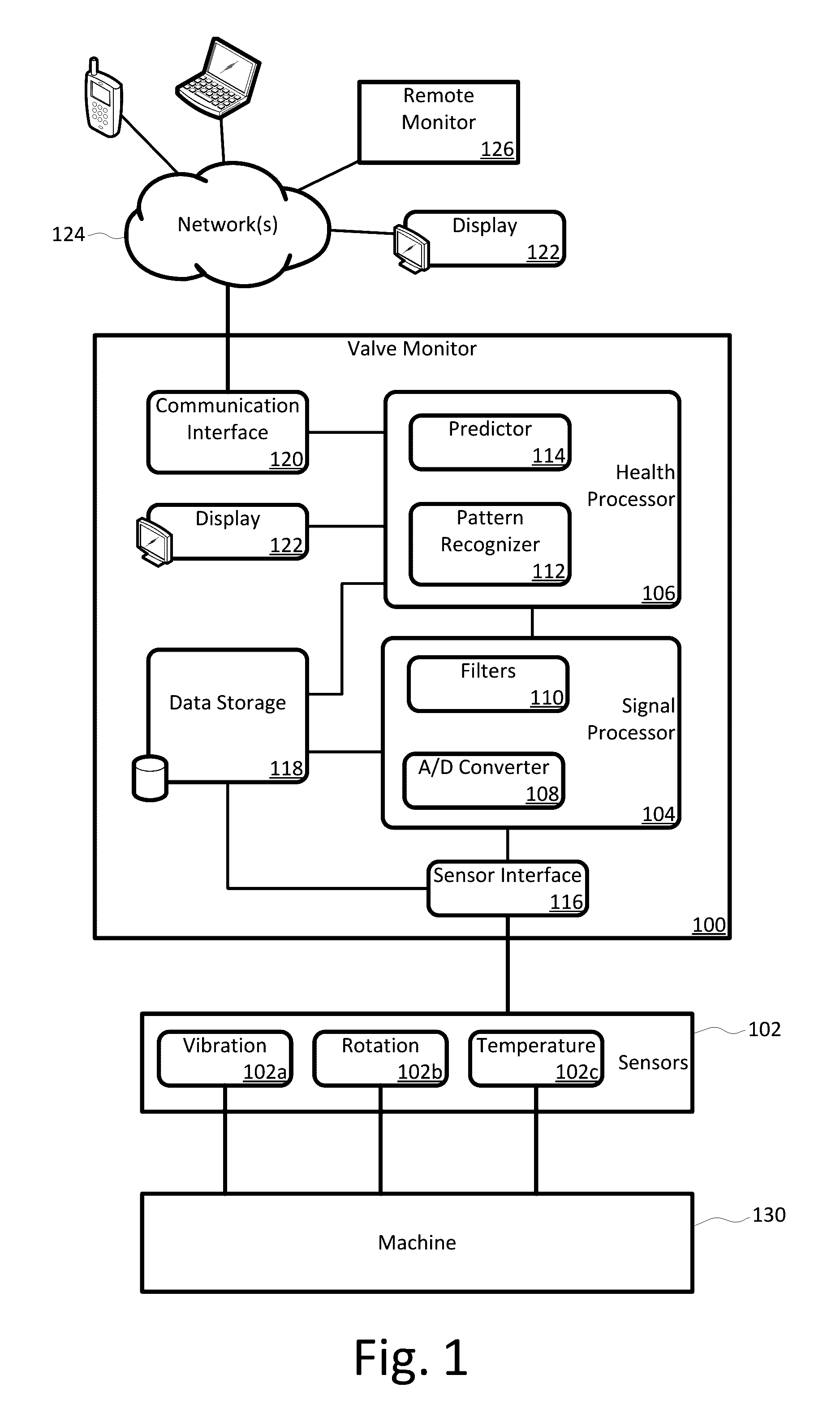

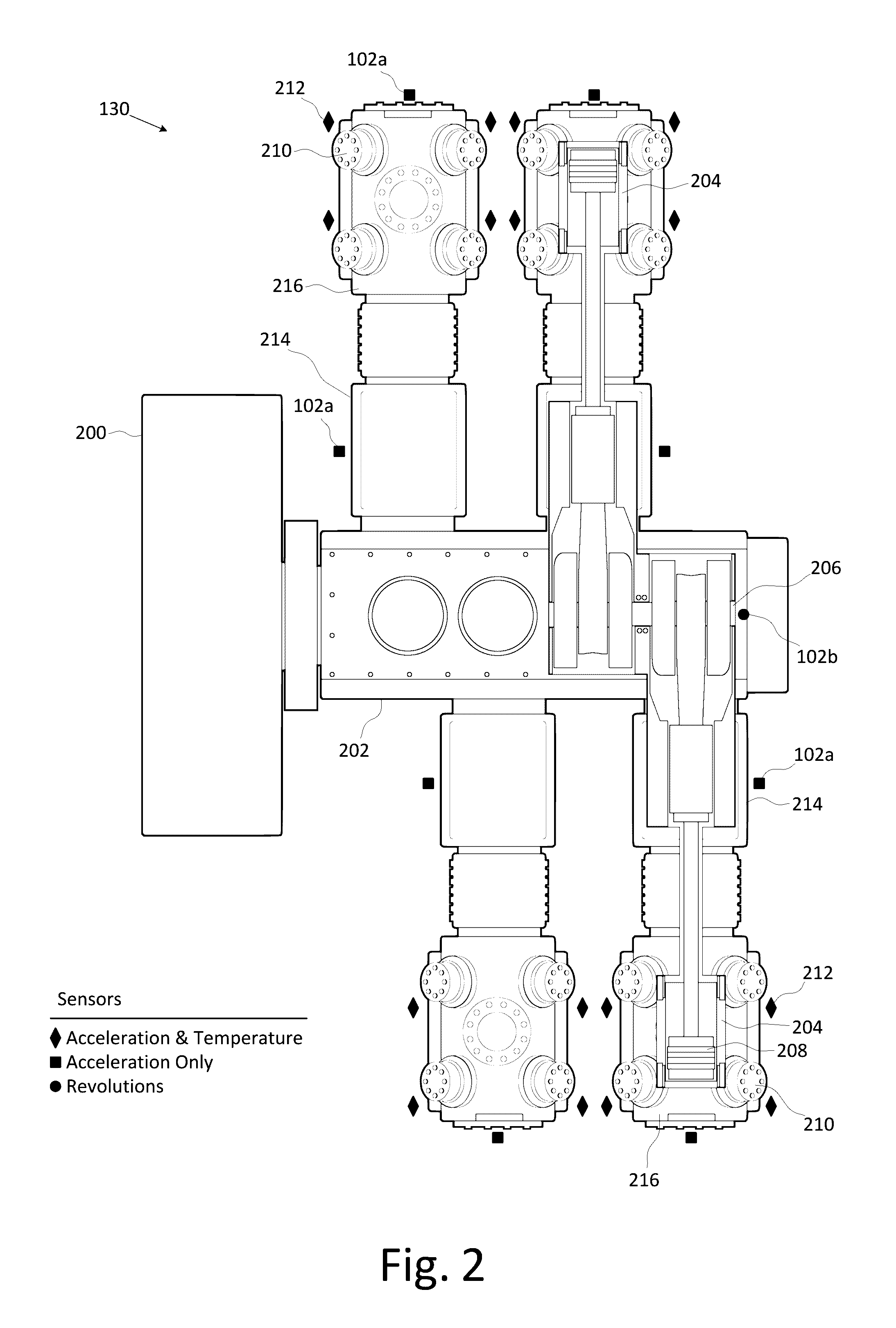

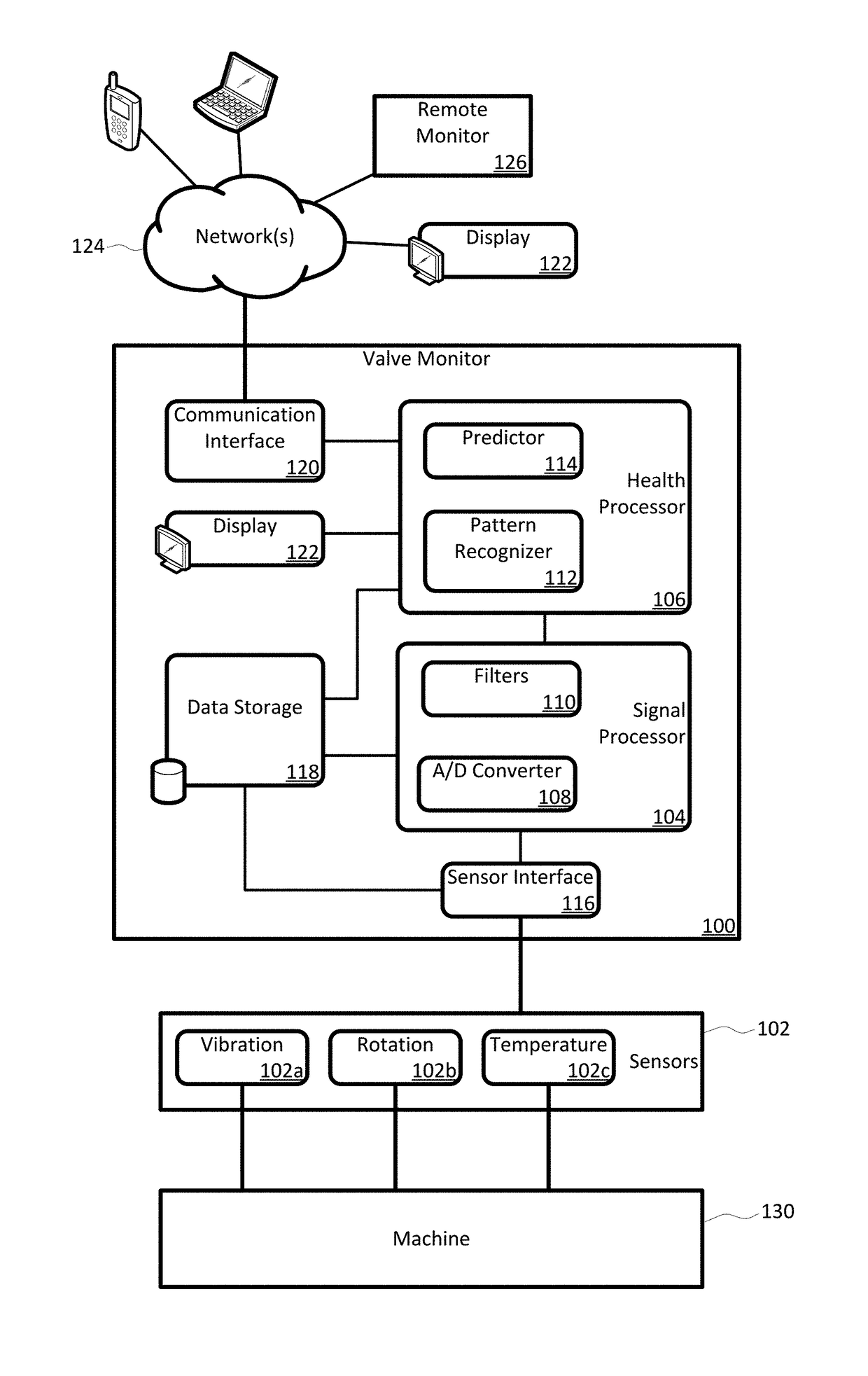

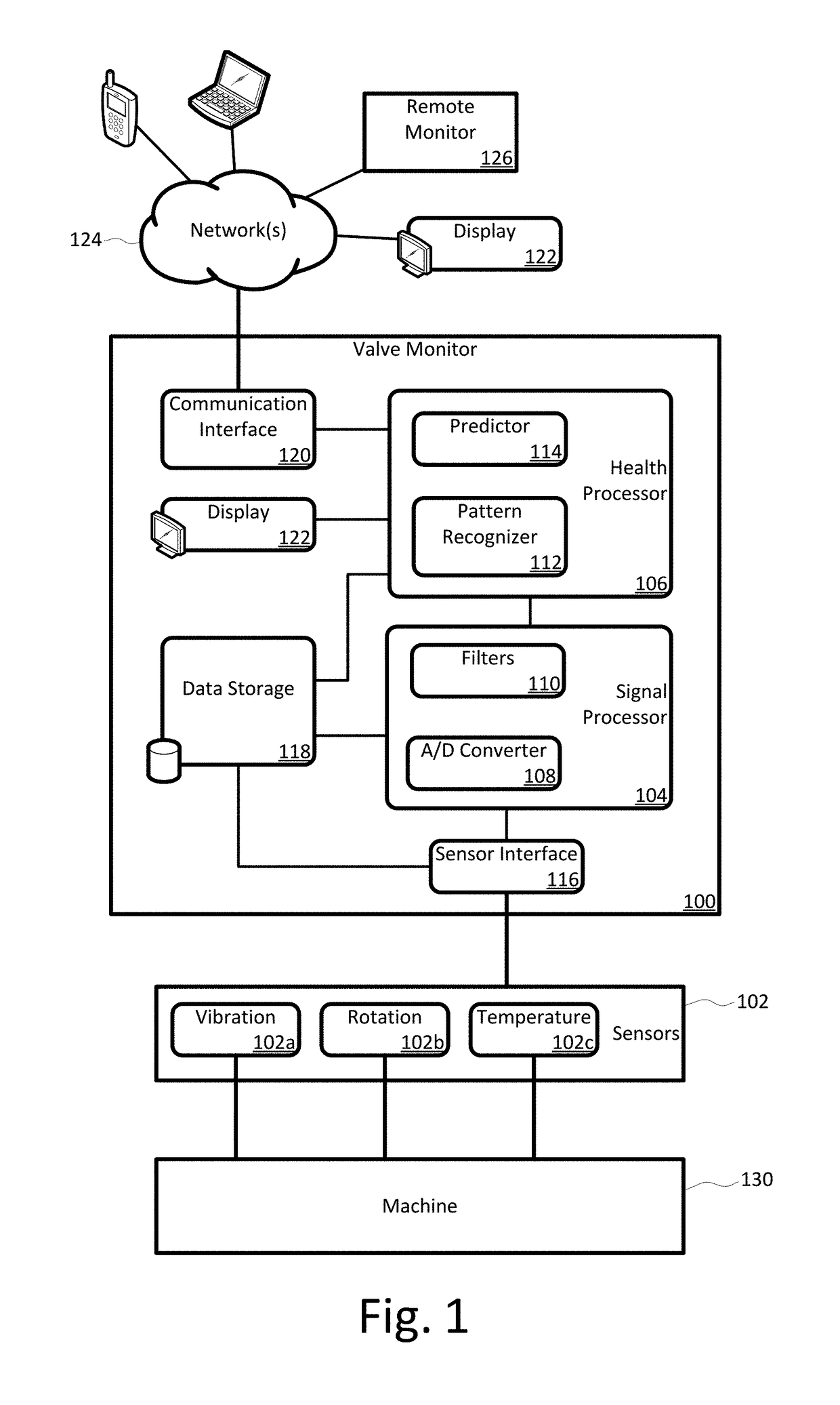

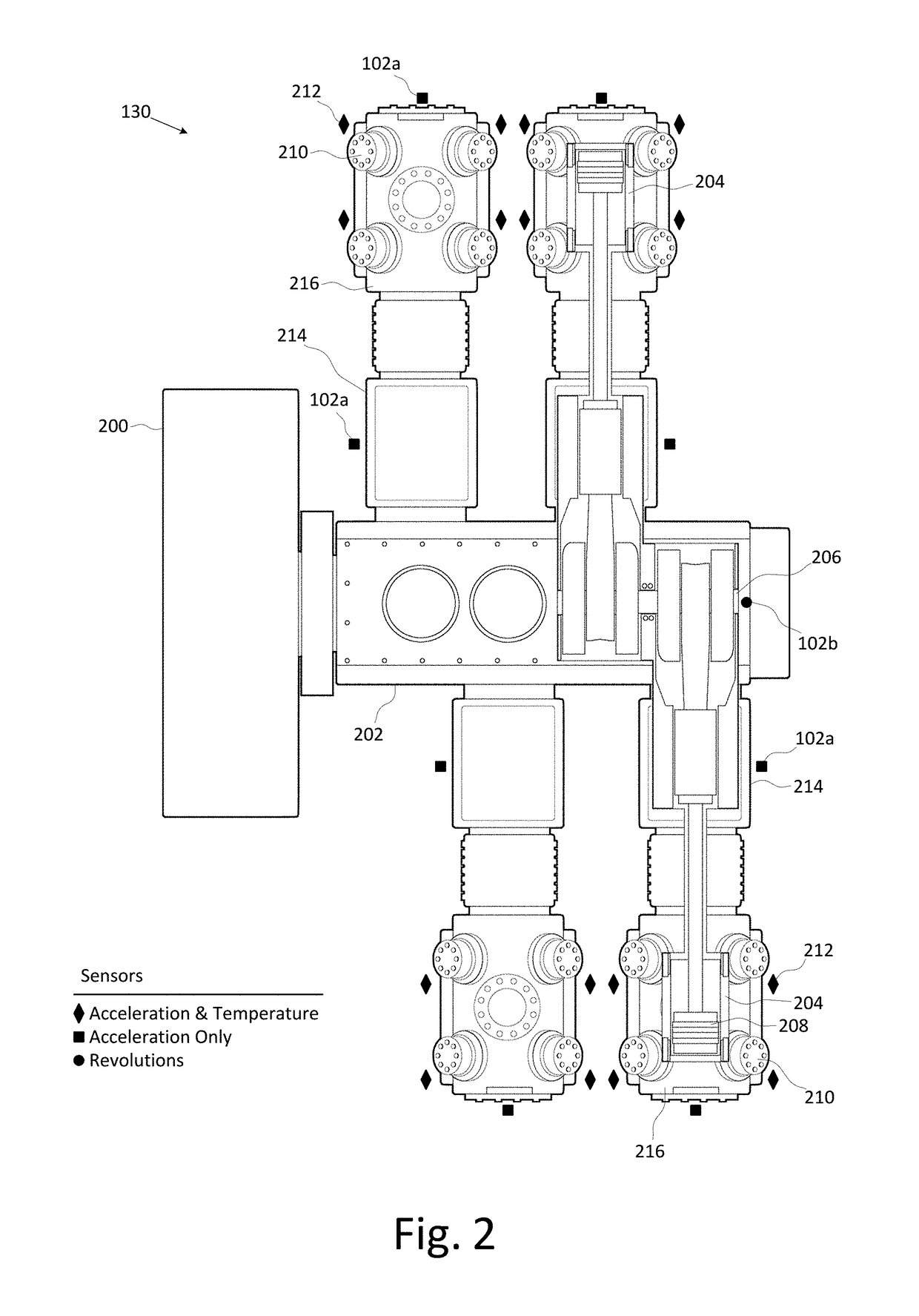

Compressor Valve Health Monitor

ActiveUS20170030349A1Improve analysisImprove notificationsExternal parameterPositive displacement pump componentsSignal-to-noise ratio (imaging)Engineering

A rotating machine valve health monitor. Aspects of the valve monitor include instrumenting each valve of a reciprocating compressor, or other rotating machine, with a sensor capable of detecting at least vibration and instrumenting the crank shaft with a sensor capable of detecting at least rotation. A controller directly monitors the operation and condition of each valve to precisely identify any individual valve exhibiting leakage issues rather than only identifying the region of the leakage. The valve monitor uses a relatively high frequency stress wave analysis technique to provide a good signal-to-noise ratio to identify impact events indicative of leakage. The valve monitor uses circular waveforms of vibration data for individual valves to identify leakage by pattern recognition or visual identification. The valve monitor provides ongoing data collection to give warning of predicted valve failure and scheduling of preventative maintenance for failing valves.

Owner:COMPUTATIONAL SYST

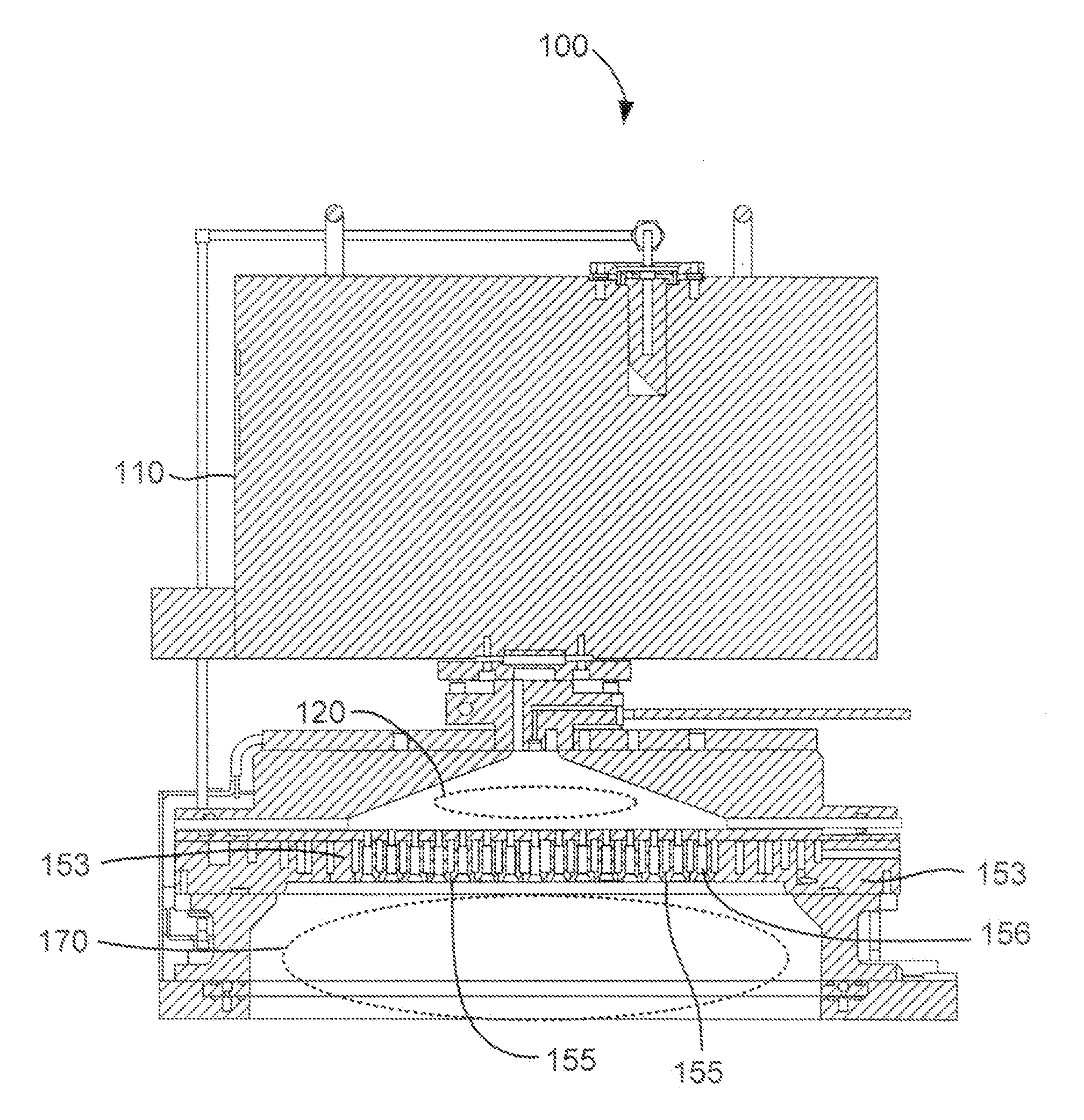

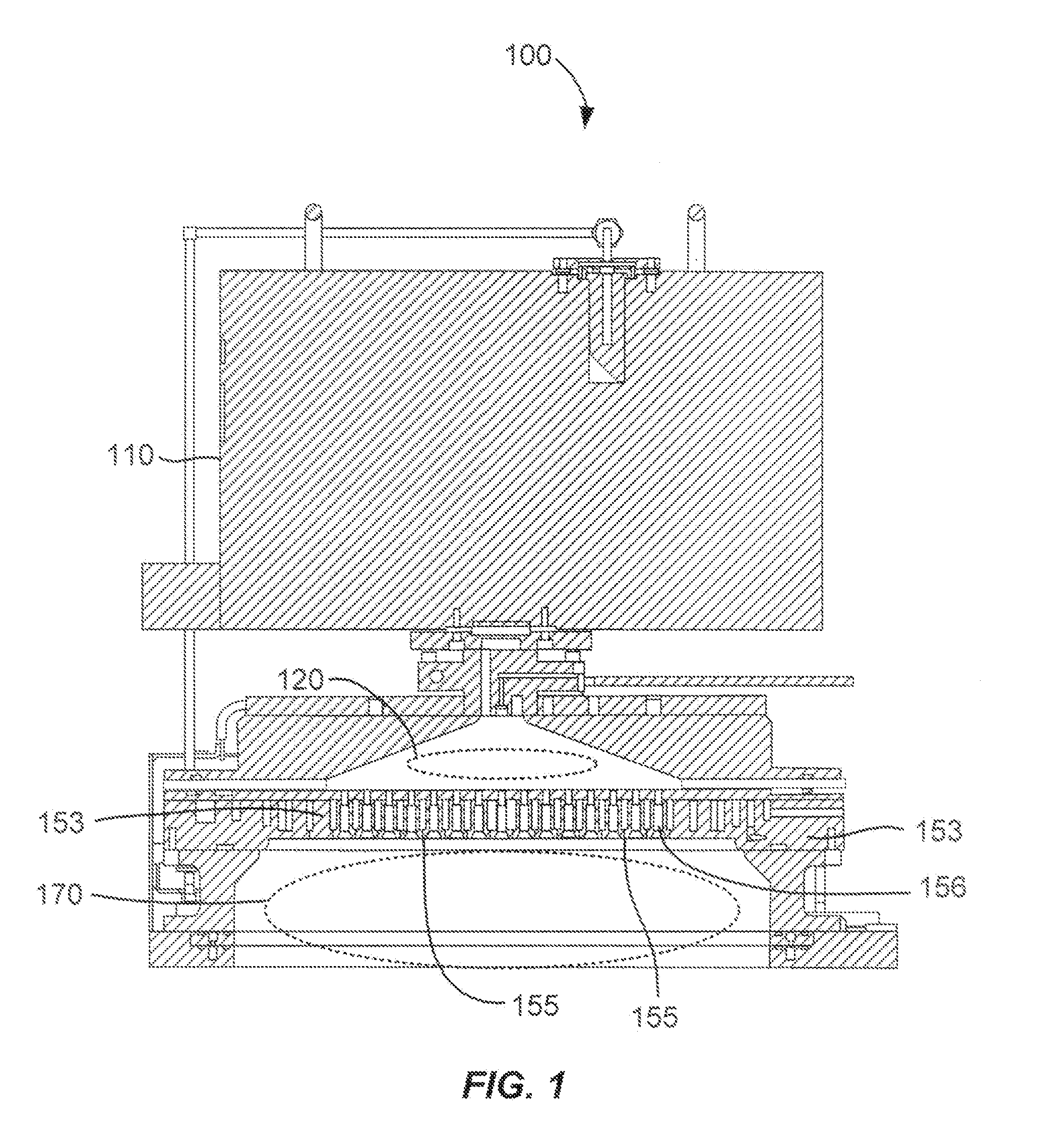

Remote plasma burn-in

InactiveUS8551891B2Electric discharge tubesSemiconductor/solid-state device manufacturingRemote plasmaHydrogen

Methods of treating the interior of a plasma region are described. The methods include a preventative maintenance procedure or the start-up of a new substrate processing chamber having a remote plasma system. A new interior surface is exposed within the remote plasma system. The (new) interior surfaces are then treated by sequential steps of (1) forming a remote plasma from hydrogen-containing precursor within the remote plasma system and then (2) exposing the interior surfaces to water vapor. Steps (1)-(2) are repeated at least ten times to complete the burn-in process. Following the treatment of the interior surfaces, a substrate may be transferred into a substrate processing chamber. A dielectric film may then be formed on the substrate by flowing one precursor through the remote plasma source and combining the plasma effluents with a second precursor flowing directly to the substrate processing region.

Owner:APPLIED MATERIALS INC

Self-contained flight data recorder with wireless data retrieval

A flight data recorder designed for small aircraft captures various onboard flight data in real-time and stores it in non-volatile memory. Recorded data includes aircraft's instantaneous position, altitude, attitude, engine RPM, G forces, flap position, cockpit voice and others. These data are obtained from various sensors which are integrated into the recorder. At the end of a flight the recorded data is downloaded into a computer using a wireless communications data transceiver also integrated into the recorder. It is an inexpensive system that does not require interfacing to any of the aircraft's instruments. It does not require removal or attaching any equipment to be able to download data. In addition to accident investigation, applications include training, preventive maintenance and asset monitoring.

Owner:MICROLOGIC SYST

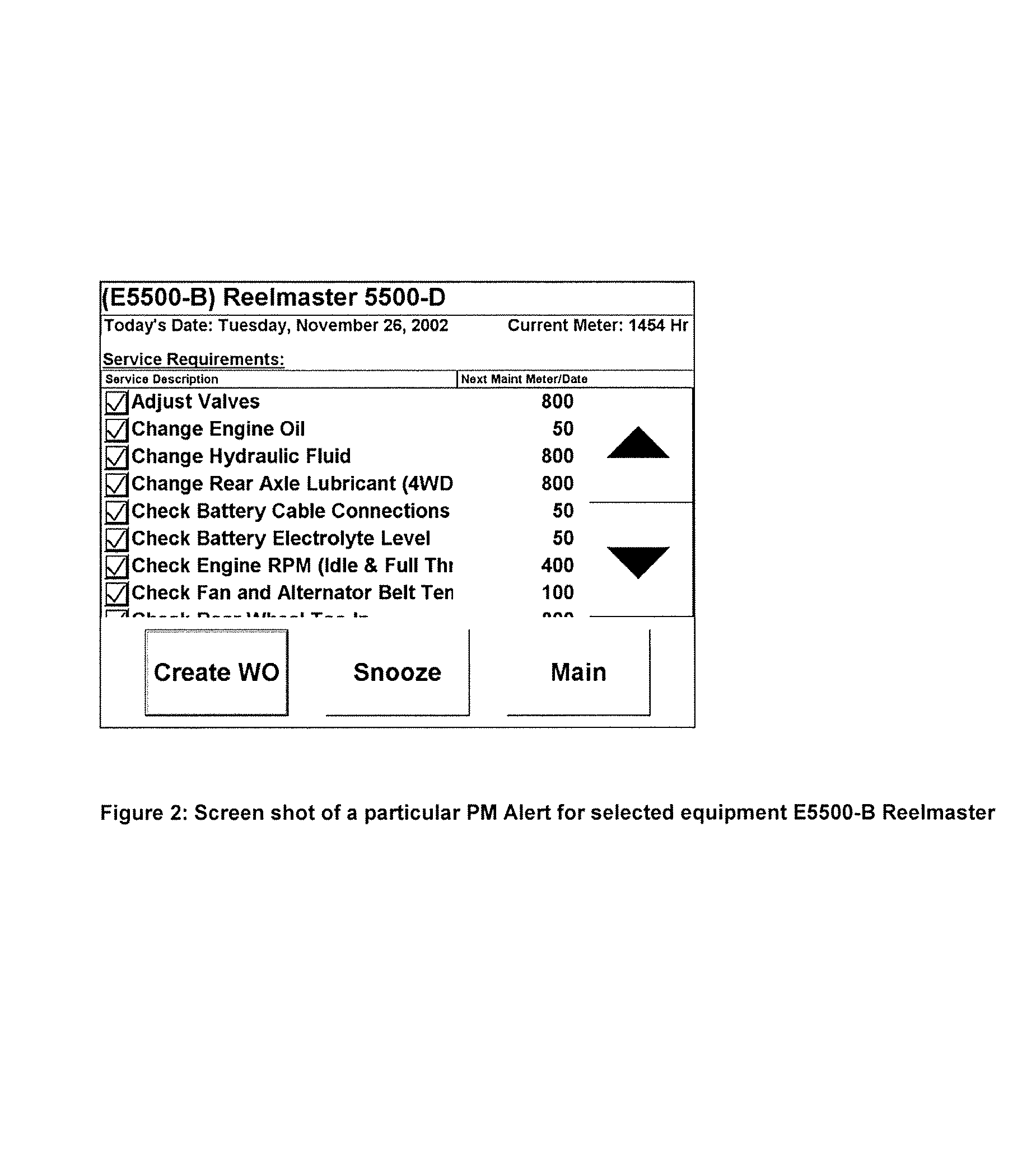

Integrated system for routine maintenance of mechanized equipment

ActiveUS7356393B1Easy accessEffective maintenanceVehicle testingRegistering/indicating working of vehiclesComputerized systemMaster processor

An apparatus and method for managing the preventative maintenance requirements and unscheduled repairs on a fleet of vehicles. The apparatus includes a computer system having a host processor and a database accessible by the host processor, and at least one maintenance response station communicating with the host processor. The database contains vehicle specific maintenance schedules indicating recommended maintenance intervals for scheduled maintenance, where each scheduled maintenance has associated maintenance tasks. The method involves periodically receiving signals at the host processor containing maintenance trigger data associated with a specific vehicle in the fleet of vehicles, comparing the received maintenance trigger data to maintenance schedule data contained in the database, and for each comparison, determining whether maintenance is indicated, and if so, identifying the vehicle at a vehicle response station.

Owner:TURFCENTRIC

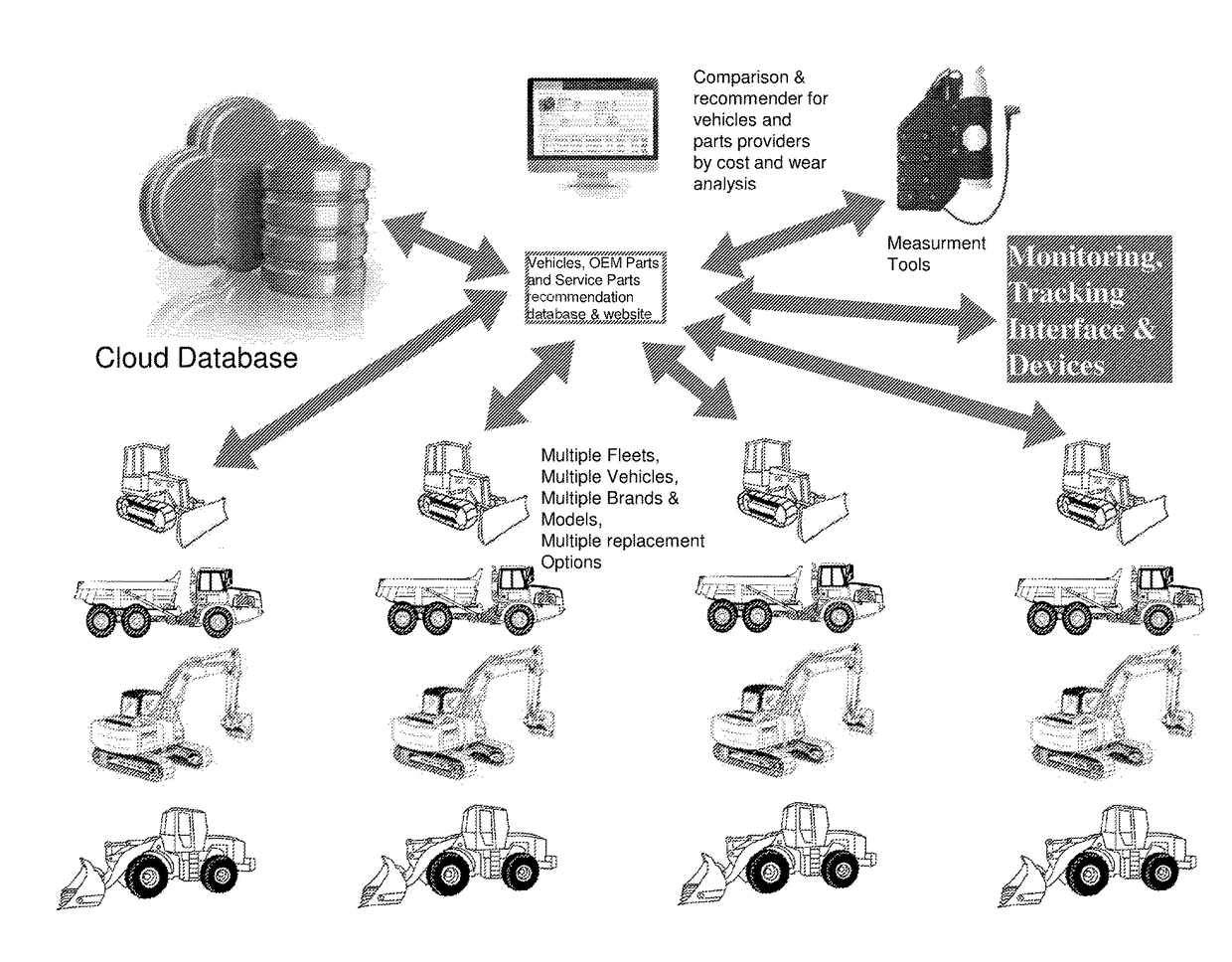

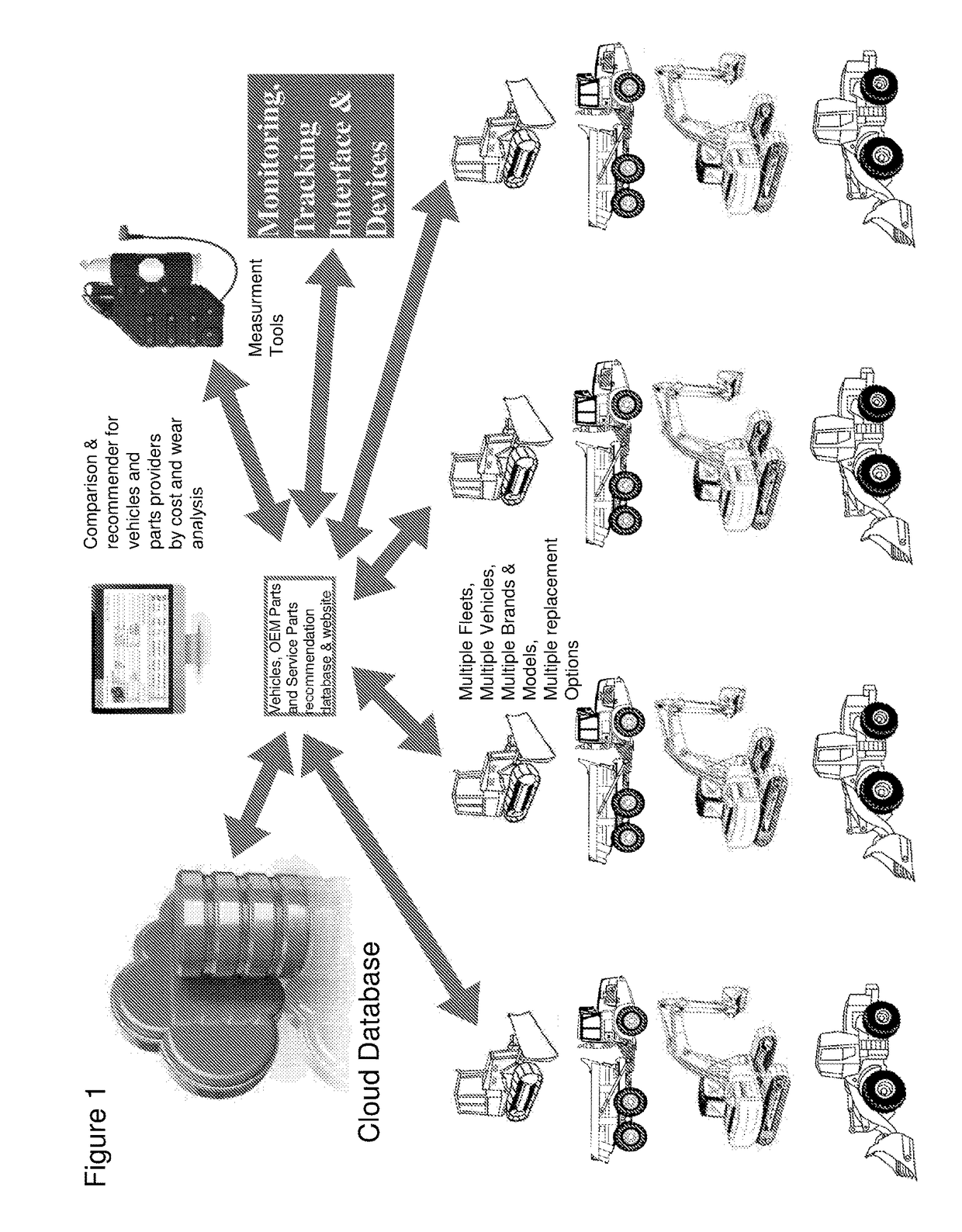

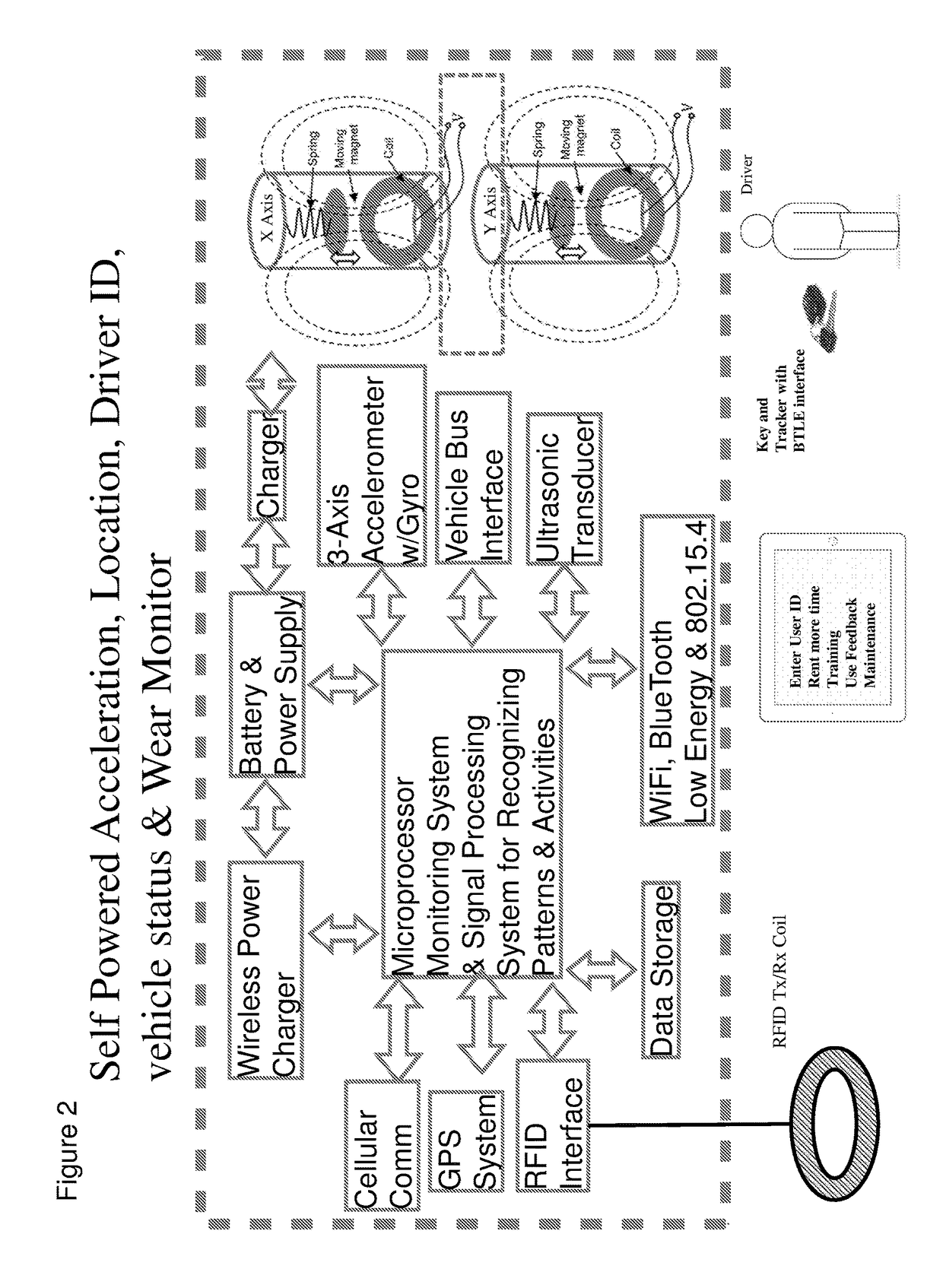

Configurable monitor and parts management system

InactiveUS20170372534A1Facilitate communicationRegistering/indicating working of vehiclesMechanical machines/dredgersFleet managementHeavy duty

A monitoring and maintenance system that utilizes imperial and theoretical data to compare parts, vehicles, users, regions, wear intensity indexes over time and tracking information to provide a sophisticated data collection system for heavy-duty equipment or rental equipment. This tracking is designed to better the specifications, designs, training, preventative maintenance, and replacement wear understanding of fleet management.

Owner:CATERPILLAR INC

Method for tracking and reporting usage events to determine when preventive maintenance is due for a medical robotic system

A medical robotic system comprises a number of components that may be monitored to determine their preventive maintenance needs by recording usage-related information for the monitored components into associated non-volatile memories. When usage of the component exceeds a specified usage threshold, the system displays a warning message on its display screen to have preventive maintenance performed for the component. If the usage continues without such maintenance and exceeds a higher usage threshold, the system displays an error message on its display screen and the system transitions into an error state during which medical procedures are not allowed to be performed. The usage-related information may also be communicated to a remote computer which gathers and processes usage-related information from a number of medical robotic systems to estimate resource requirements for timely performing preventive maintenance on the medical robotic systems, and anticipated service revenues from such maintenance.

Owner:INTUITIVE SURGICAL OPERATIONS INC

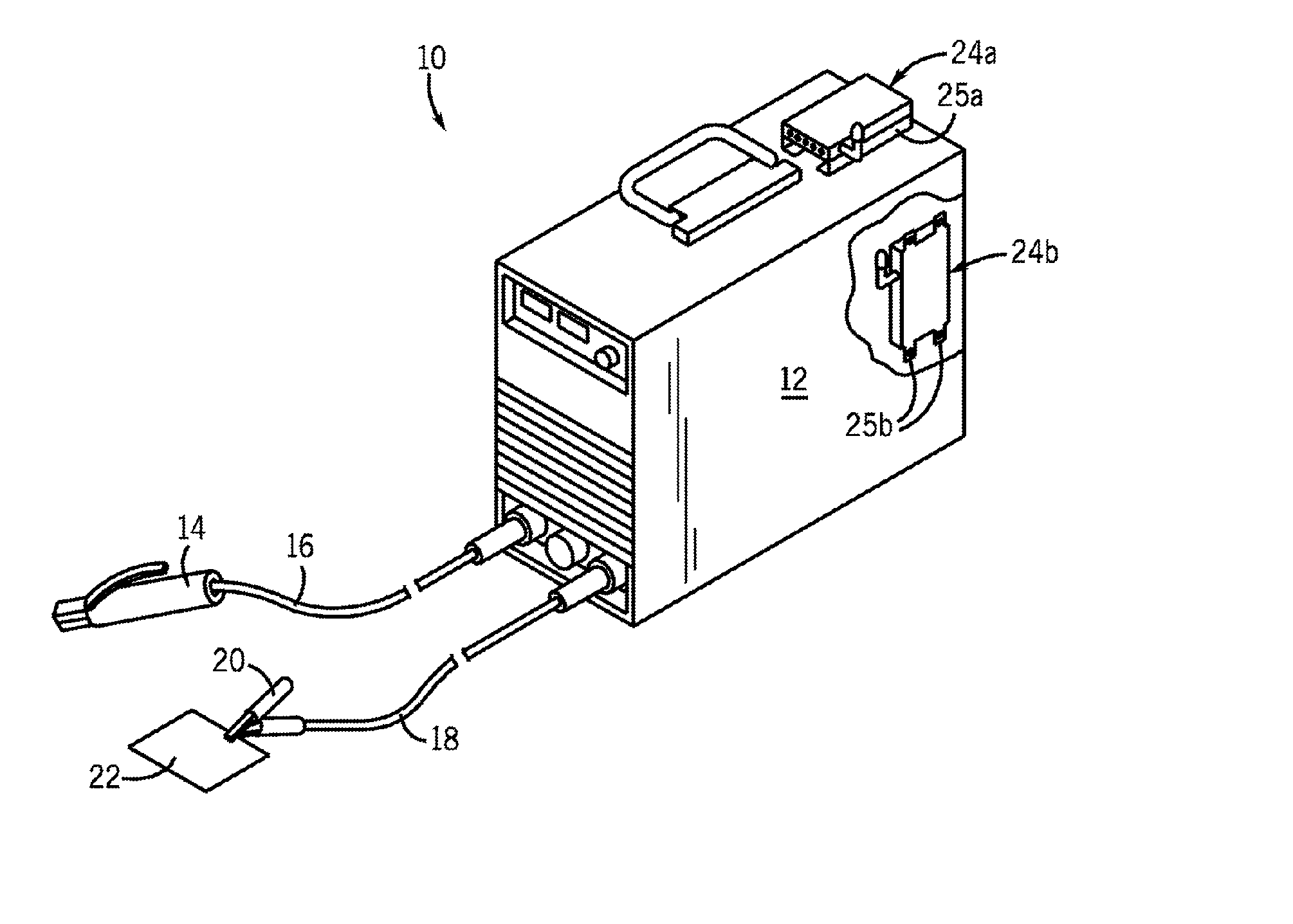

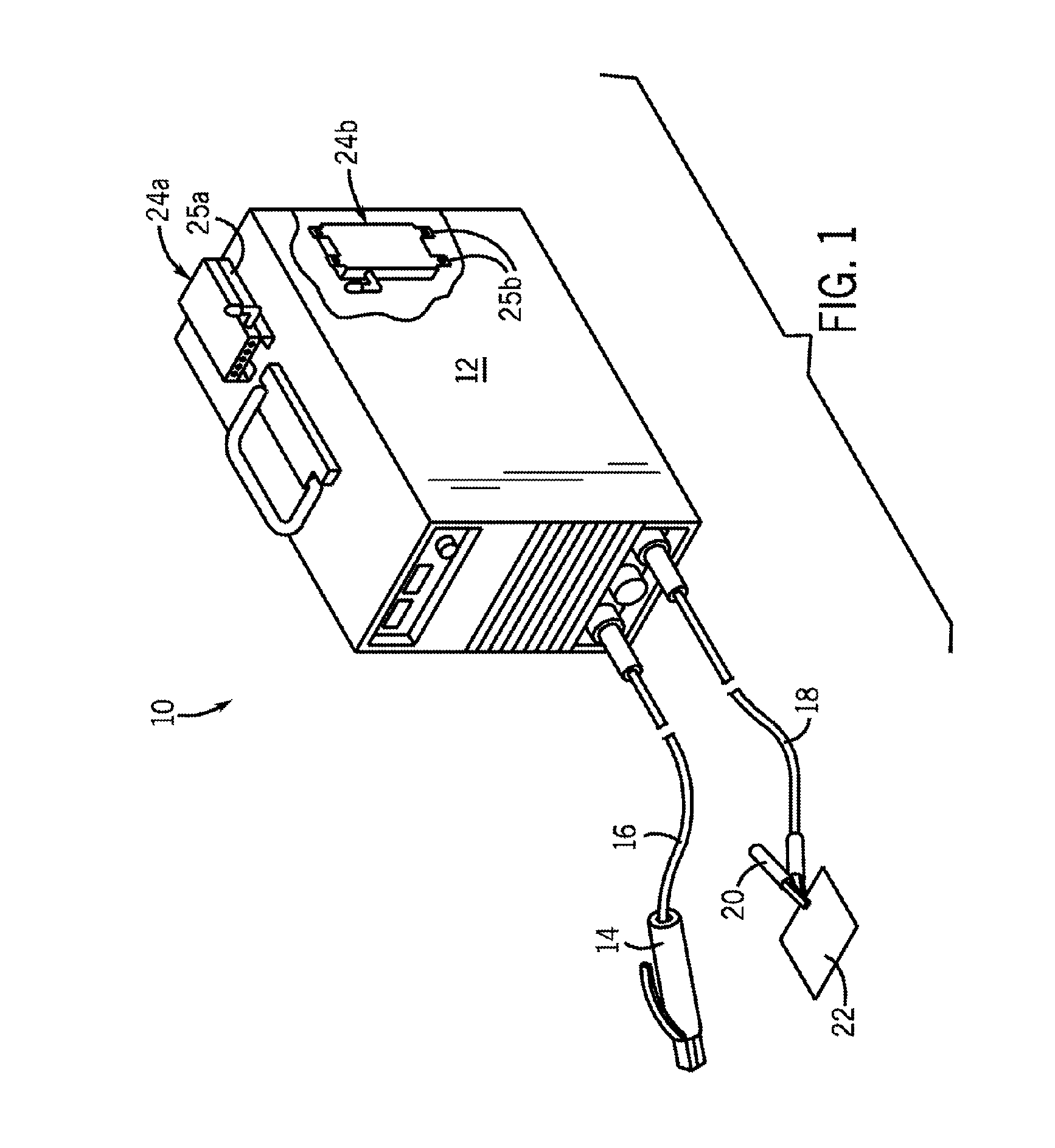

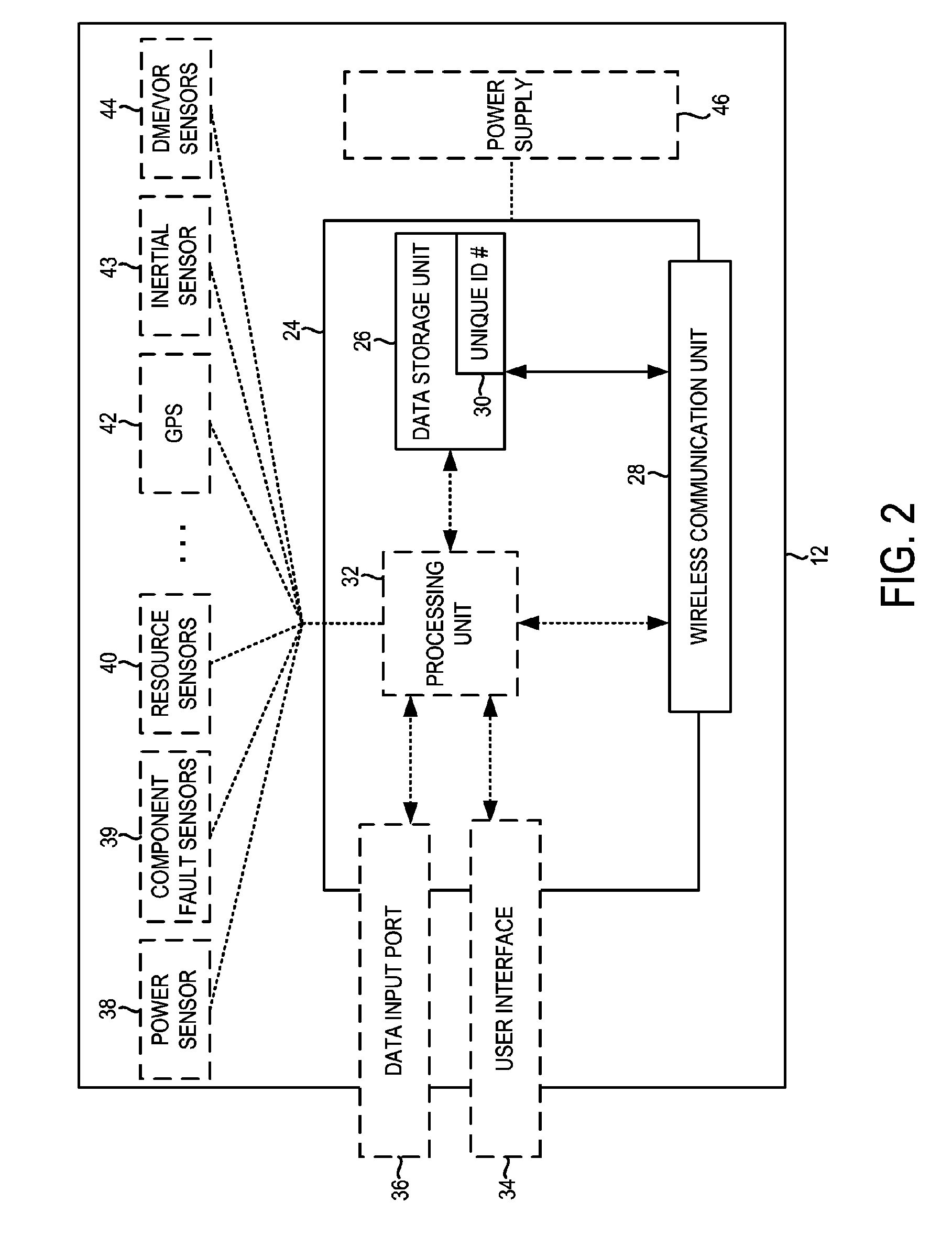

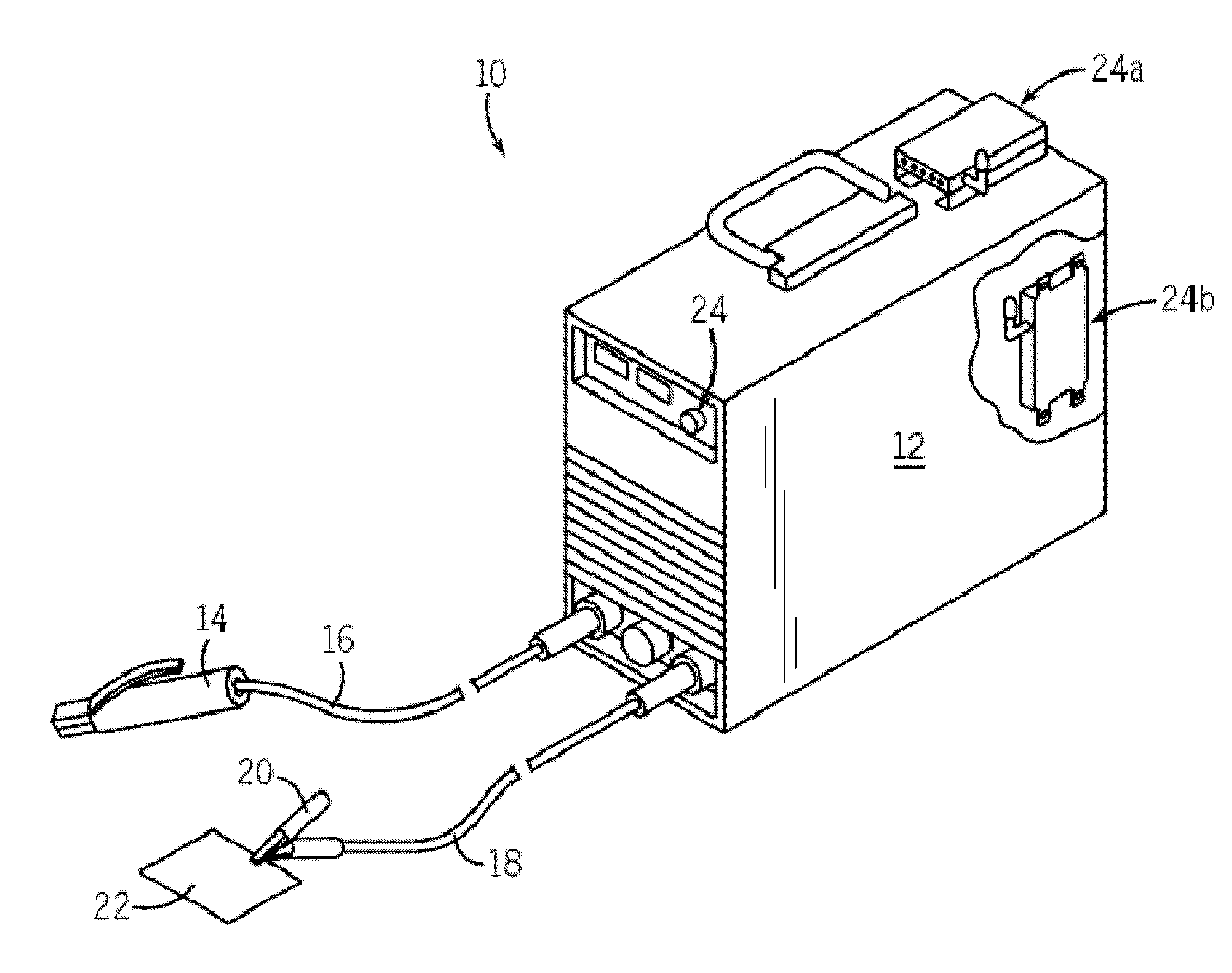

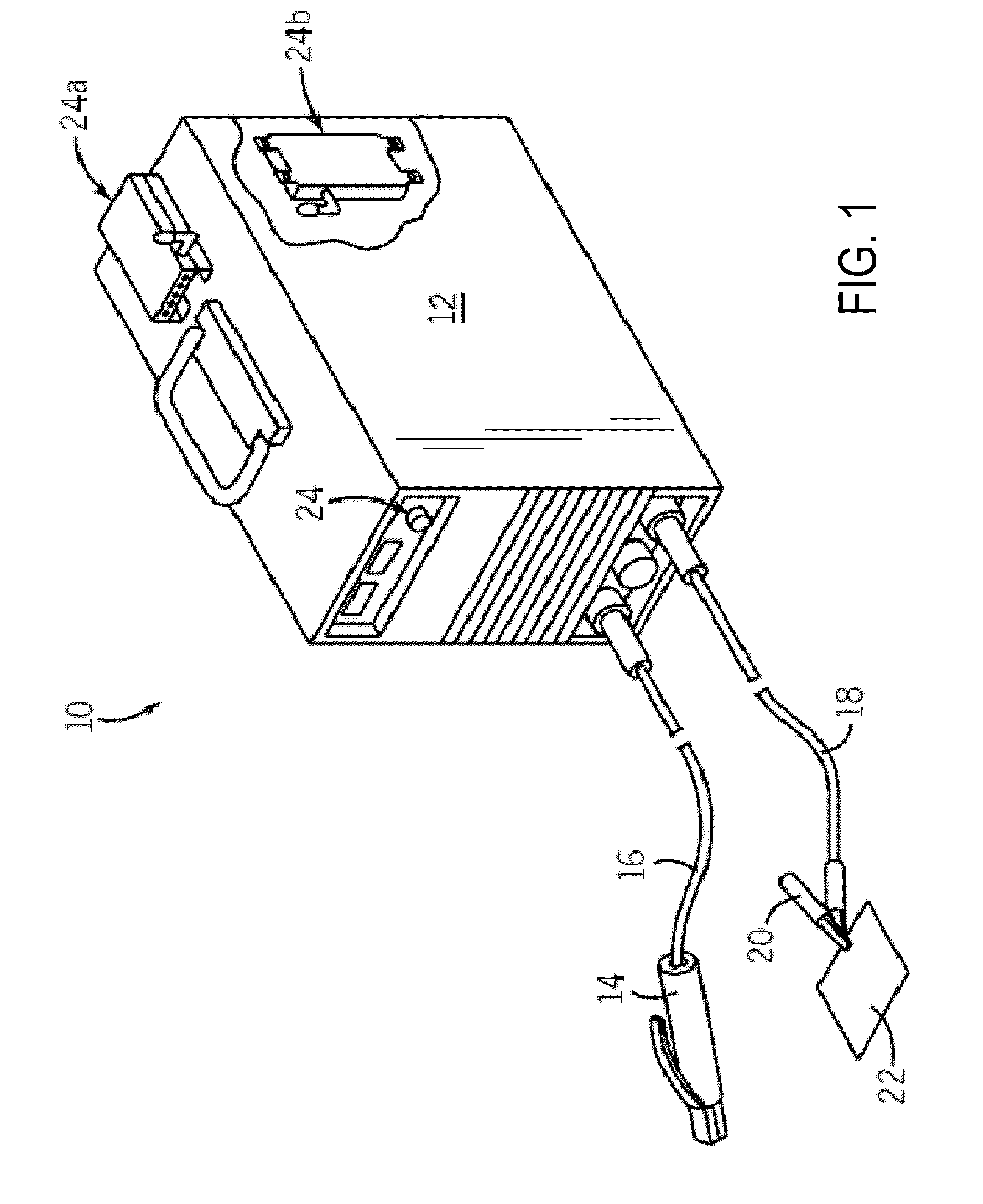

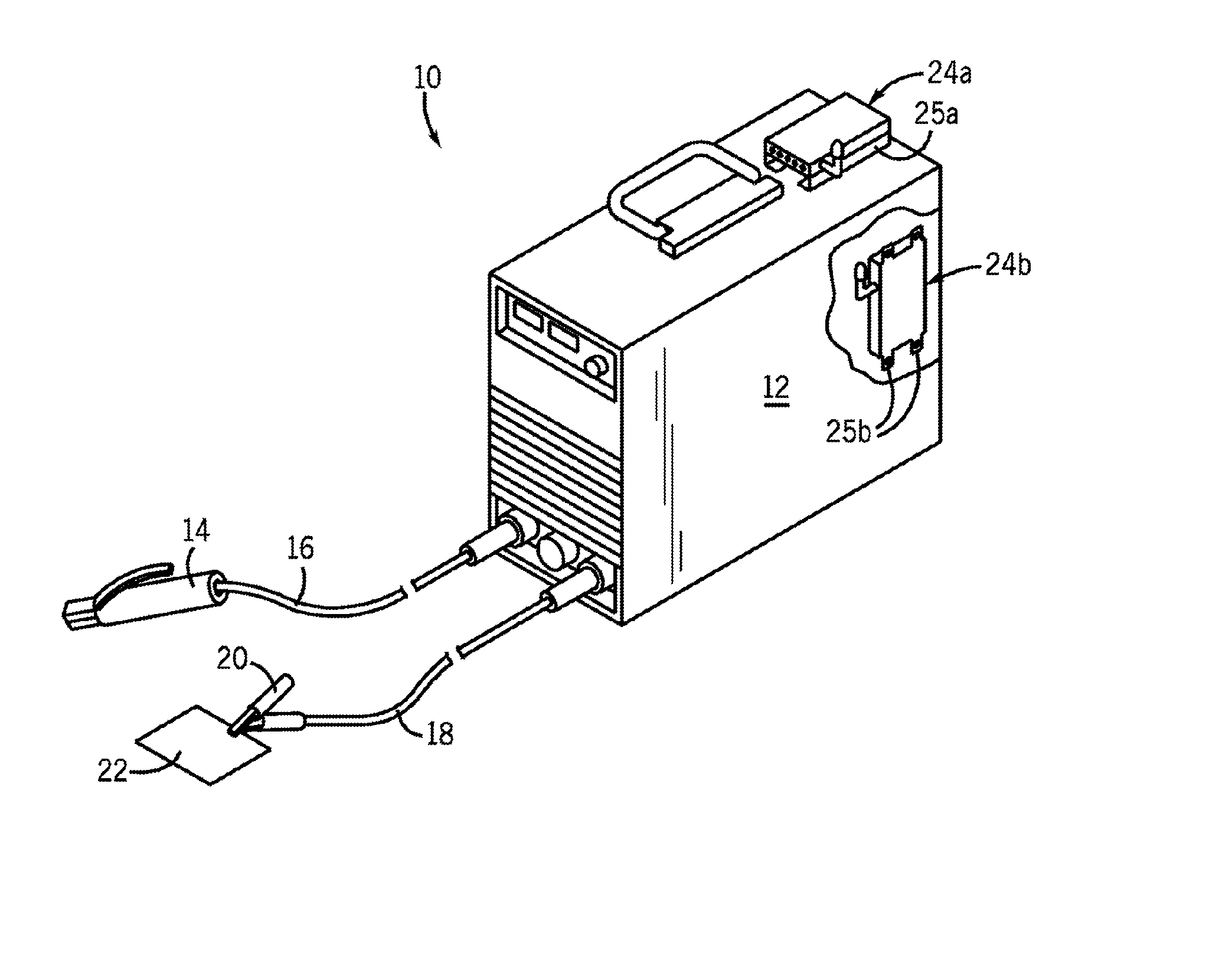

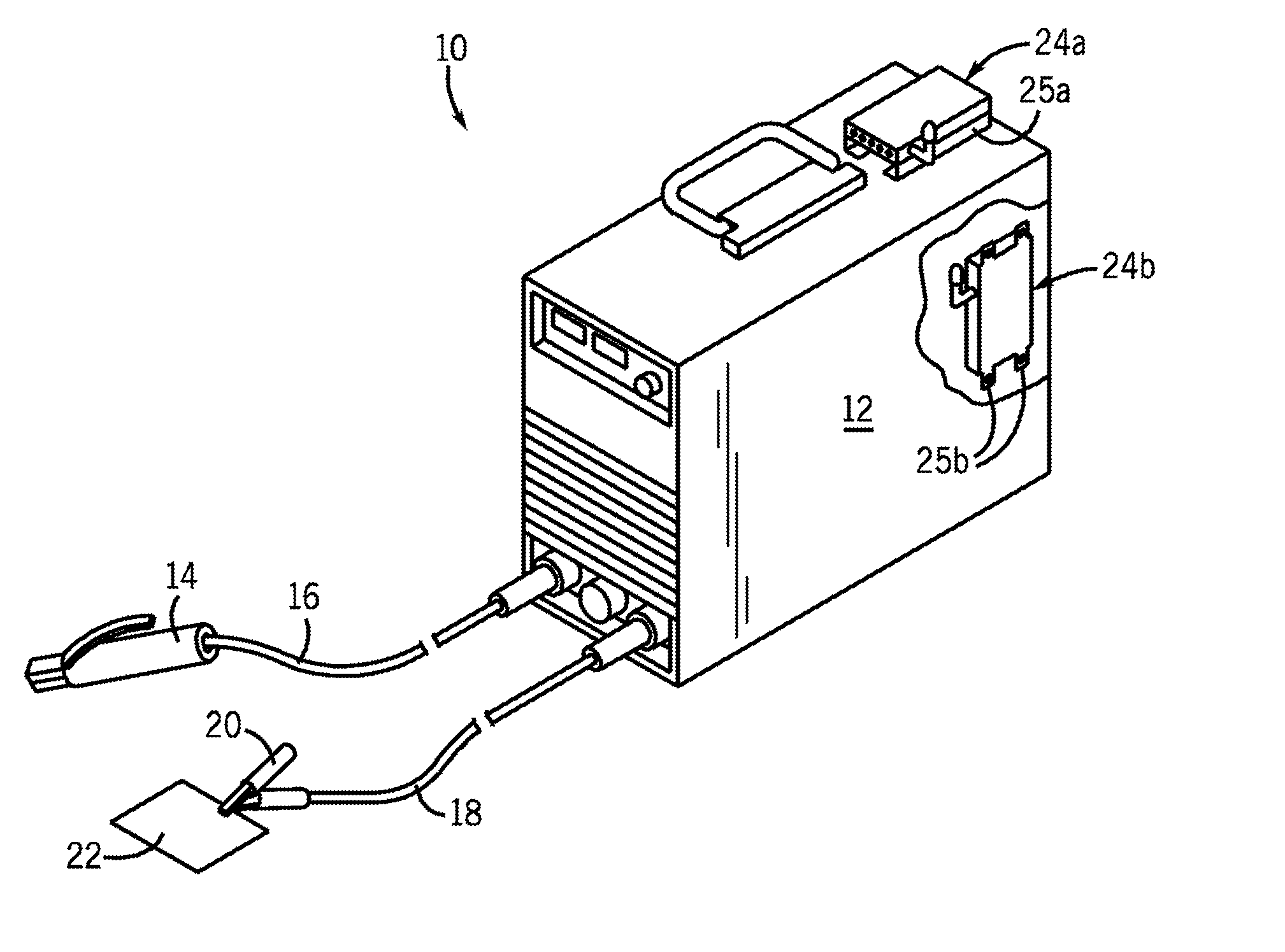

Wireless tracking and inventory monitoring for welding-type devices

ActiveUS20070080153A1Increase transmission strengthPosition fixationArc welding apparatusCommunications systemCommunication unit

A welding-type device has a wireless communication unit to transmit wireless signals comprising at least identification information or location information. The information may be transmitted either automatically or in response to request signals. Such a welding-type device may be configured to communicate with other welding-type devices, a monitoring device, or both. A wireless communication system has at least one welding-type device, at least one wireless communication assembly, and at least one monitoring device and is capable of assisting a user in locating particular welding-type devices, monitoring inventory, preventing theft of welding-type devices, and scheduling preventive maintenance.

Owner:ILLINOIS TOOL WORKS INC

Tire temperature and pressure monitoring sensors and systems

InactiveUS7075421B1Avoid degradationInhibit wearOptical signallingTyre measurementsMonitoring systemRadio frequency

A tire monitoring system providing tire status and notifying or warning the vehicle operator of early detection of imminent tire failure and performance degradation; thus improving safety by preventing blowouts from occurring, lengthening tire life by encouraging preventive maintenance, and improving fuel mileage by encouraging the operator to fill the tire to its proper pressure or repair it. The system monitors temperature of the rim of the wheel to which the tire is attached, such temperature being transmitted to the vehicle operator or other interested parties via means such as radio frequency.

Owner:TUTTLE JOHN R

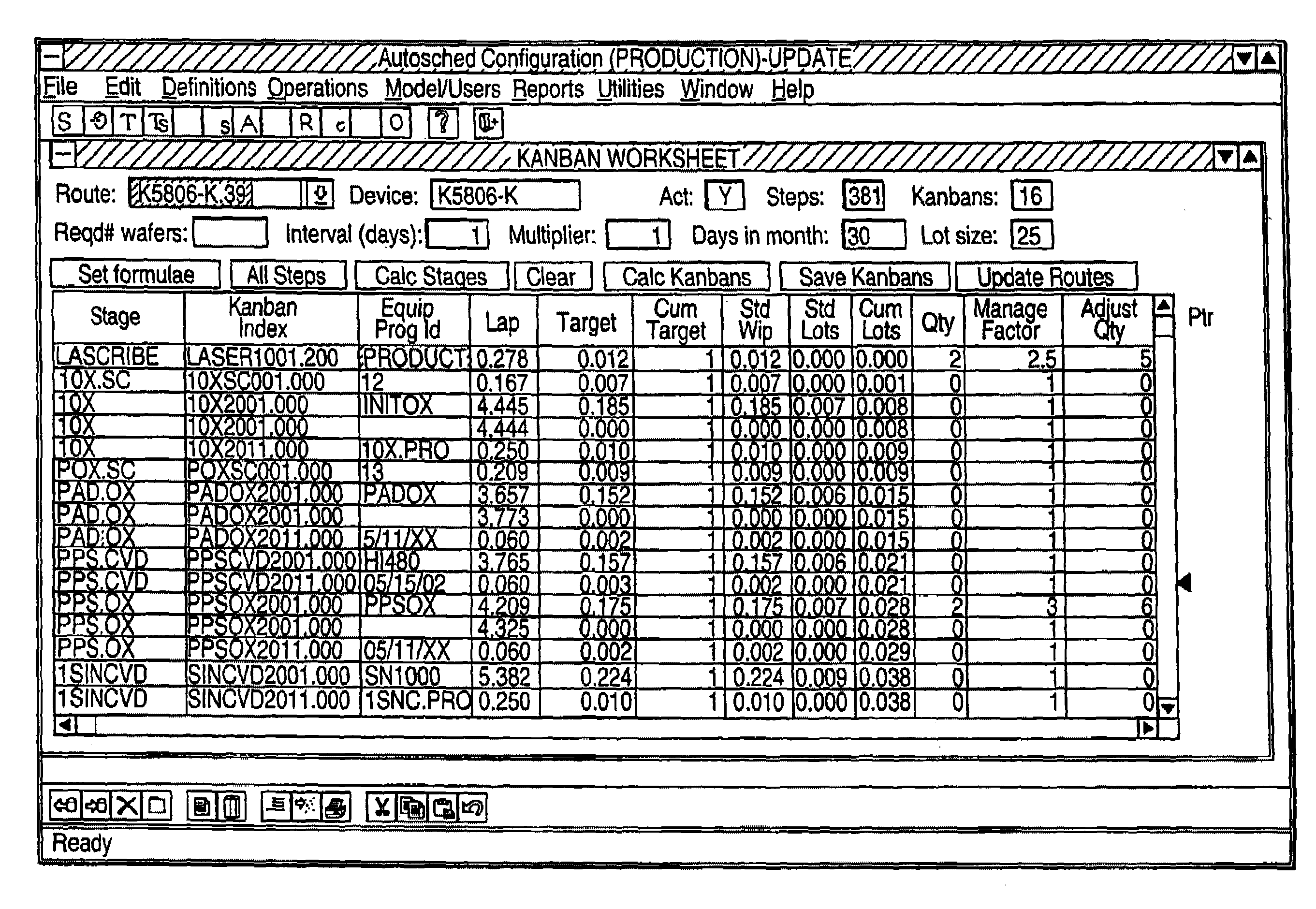

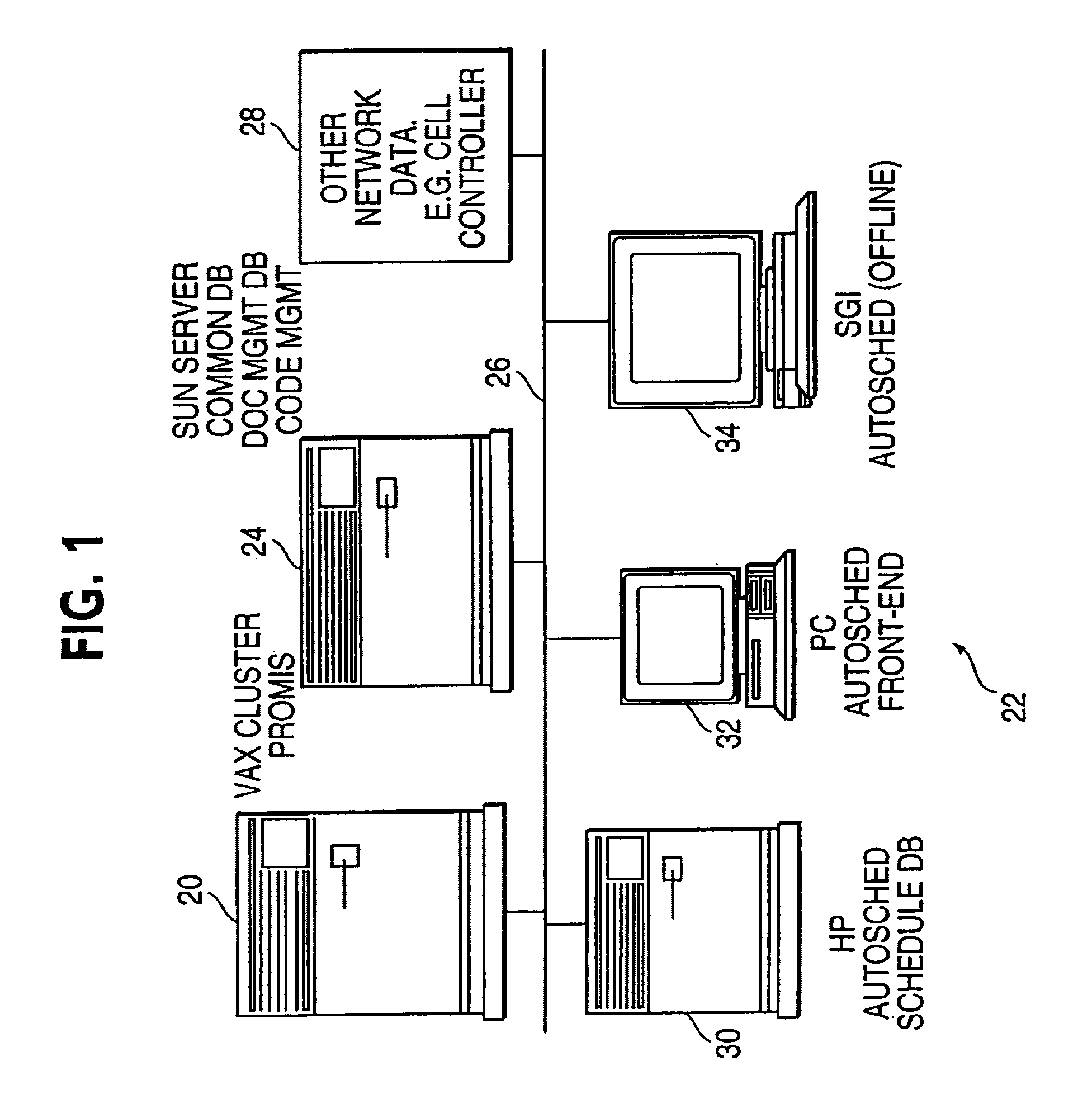

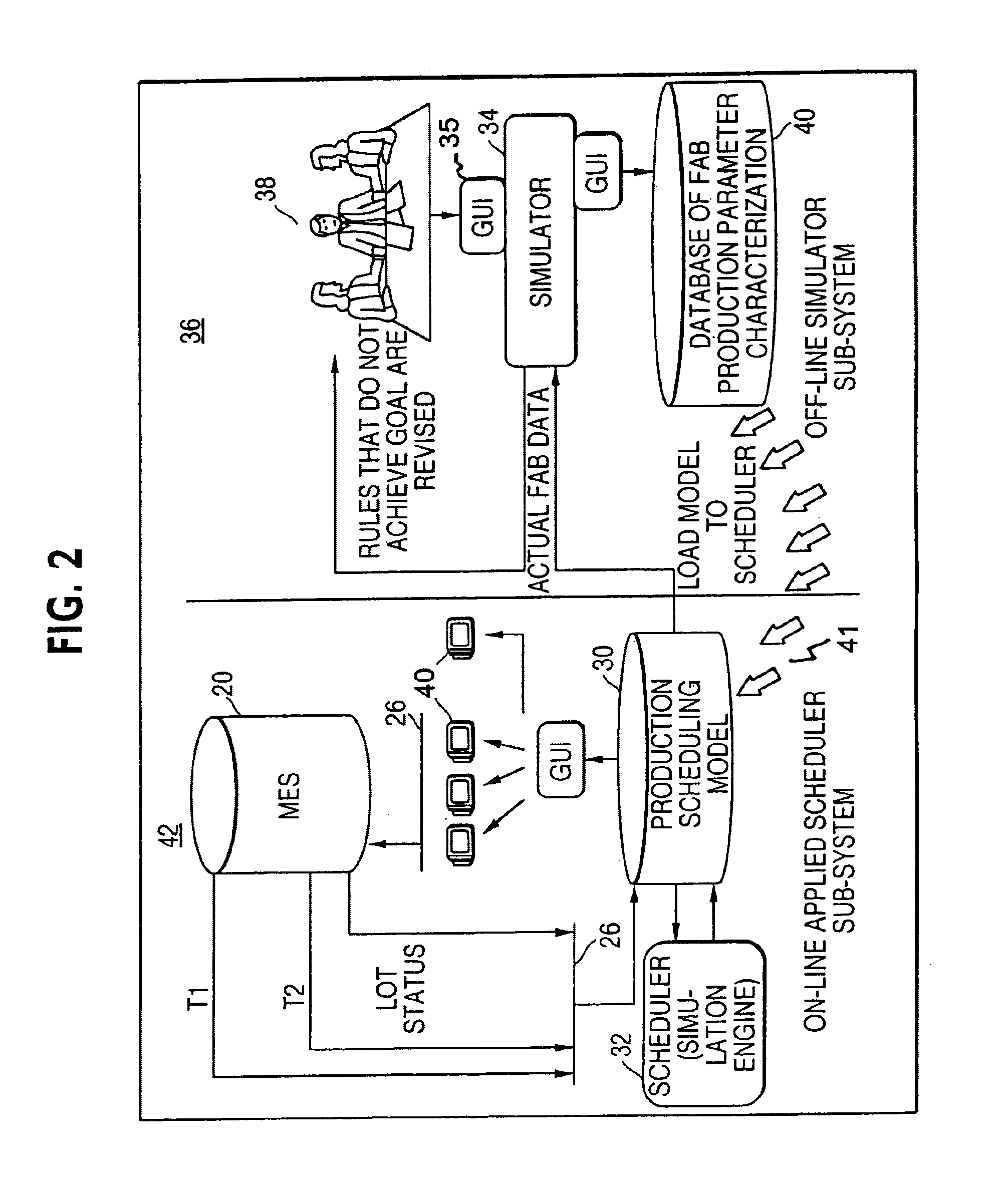

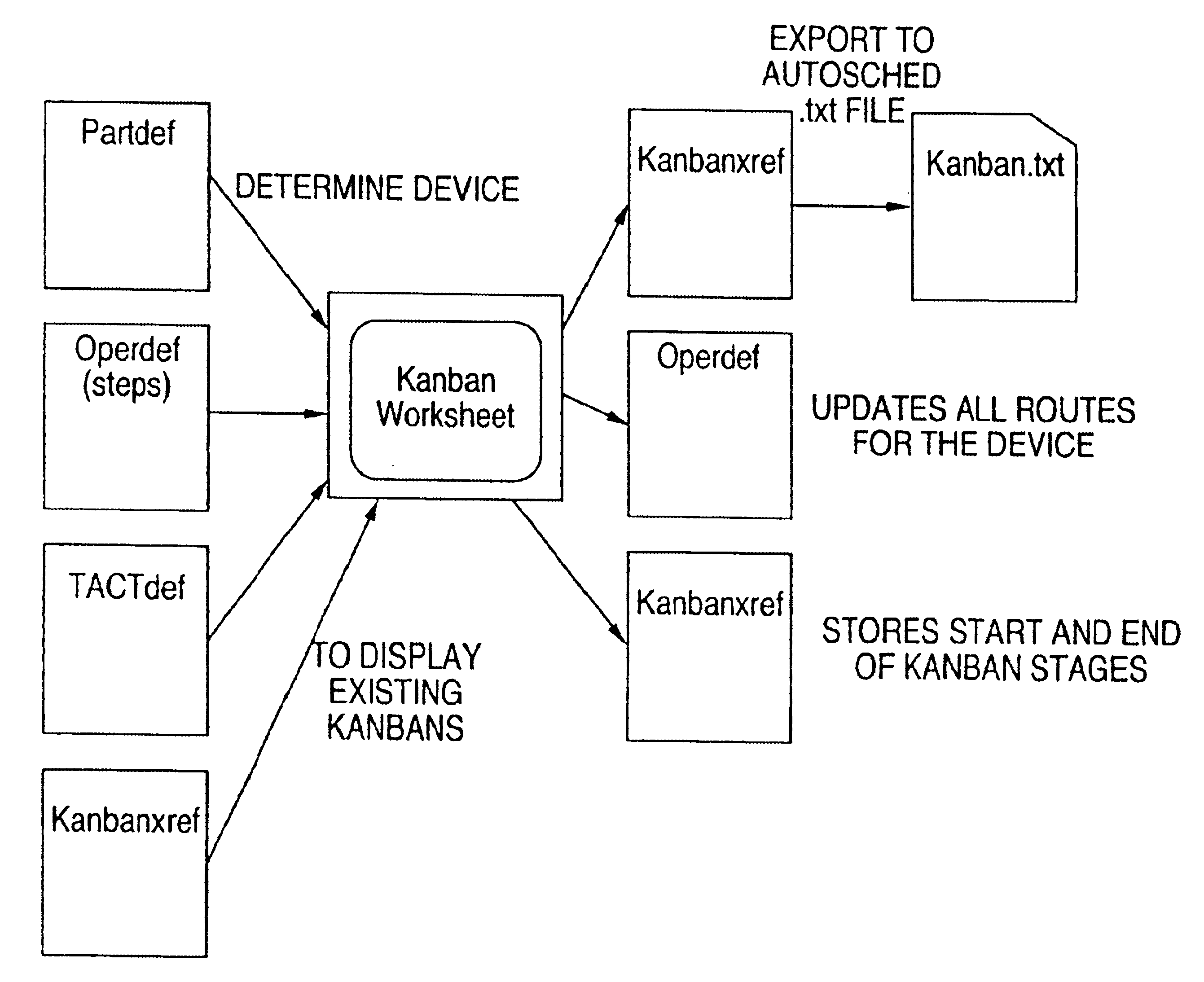

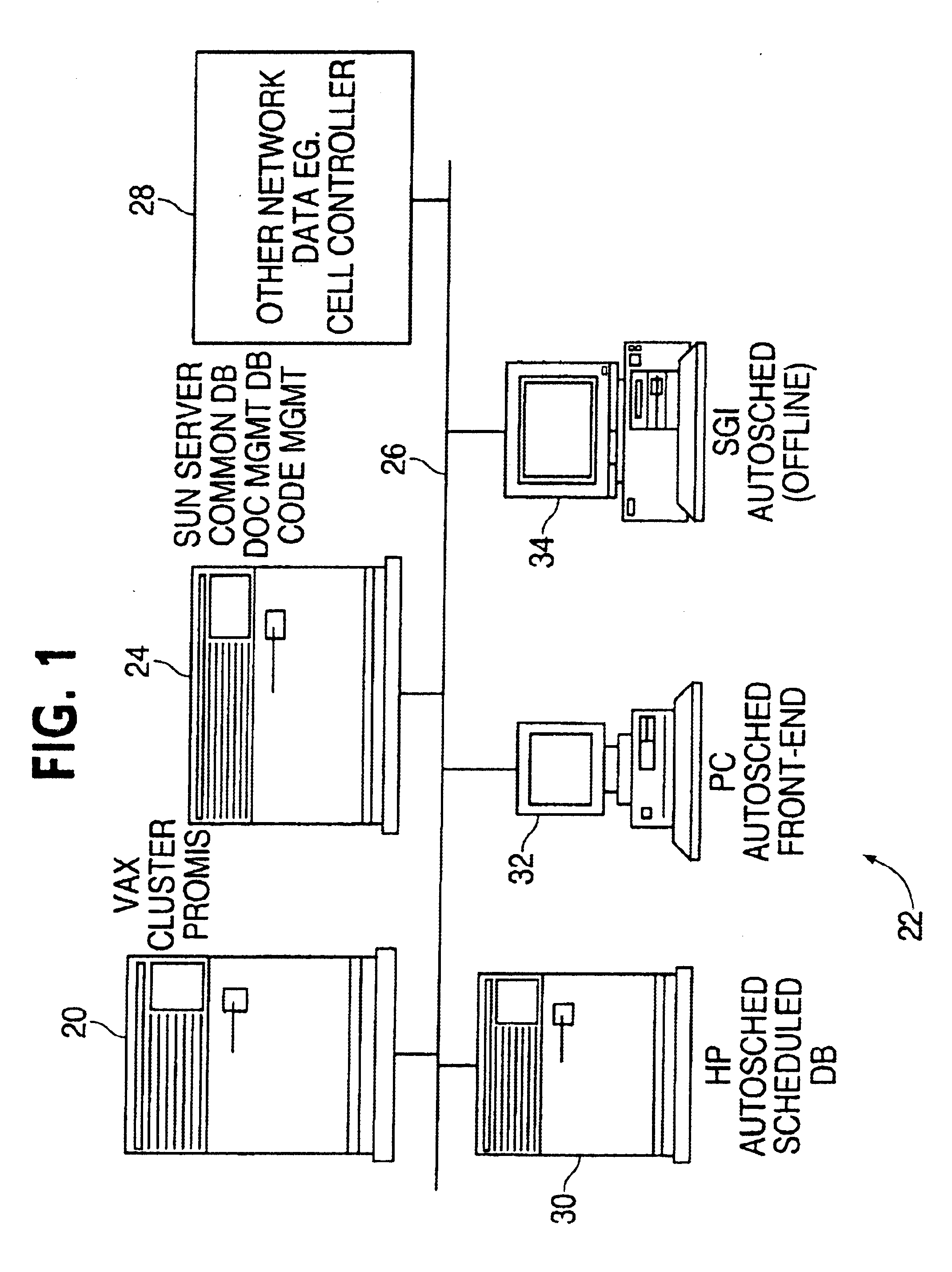

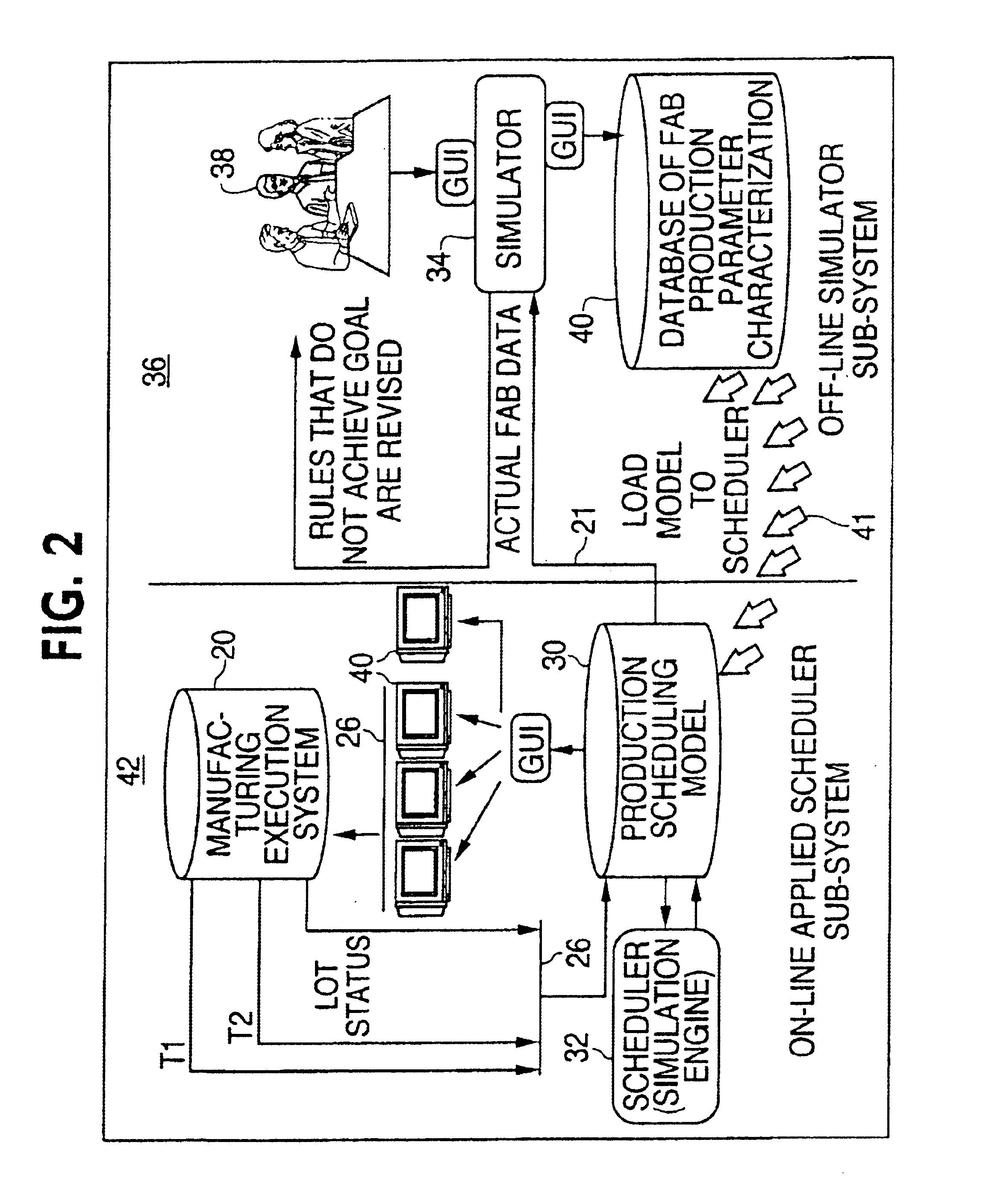

Electronic Kanban worksheet for the design and implementation of virtual or electronic Kanban systems

InactiveUS7020594B1ForecastingSpecial data processing applicationsManufacture execution systemSystems design

An integrated wafer fab production characterization and scheduling system incorporates a manufacturing execution system with a scheduling system based on simulation. The integrated characterization / scheduling system provides manufacturing with a simulation tool integrated with the manufacturing execution system to evaluate proposed production control logic as a practical alternative to expensive experimentation on actual production system. Furthermore, simulation models are used to create short term dispatch schedules to steer daily manufacturing operations towards planned performance goals. Innovative features include integration of preventive maintenance scheduling, Kanban based WIP control, an integrated time standard database, a, and real time lot move updates.

Owner:SONY CORP +1

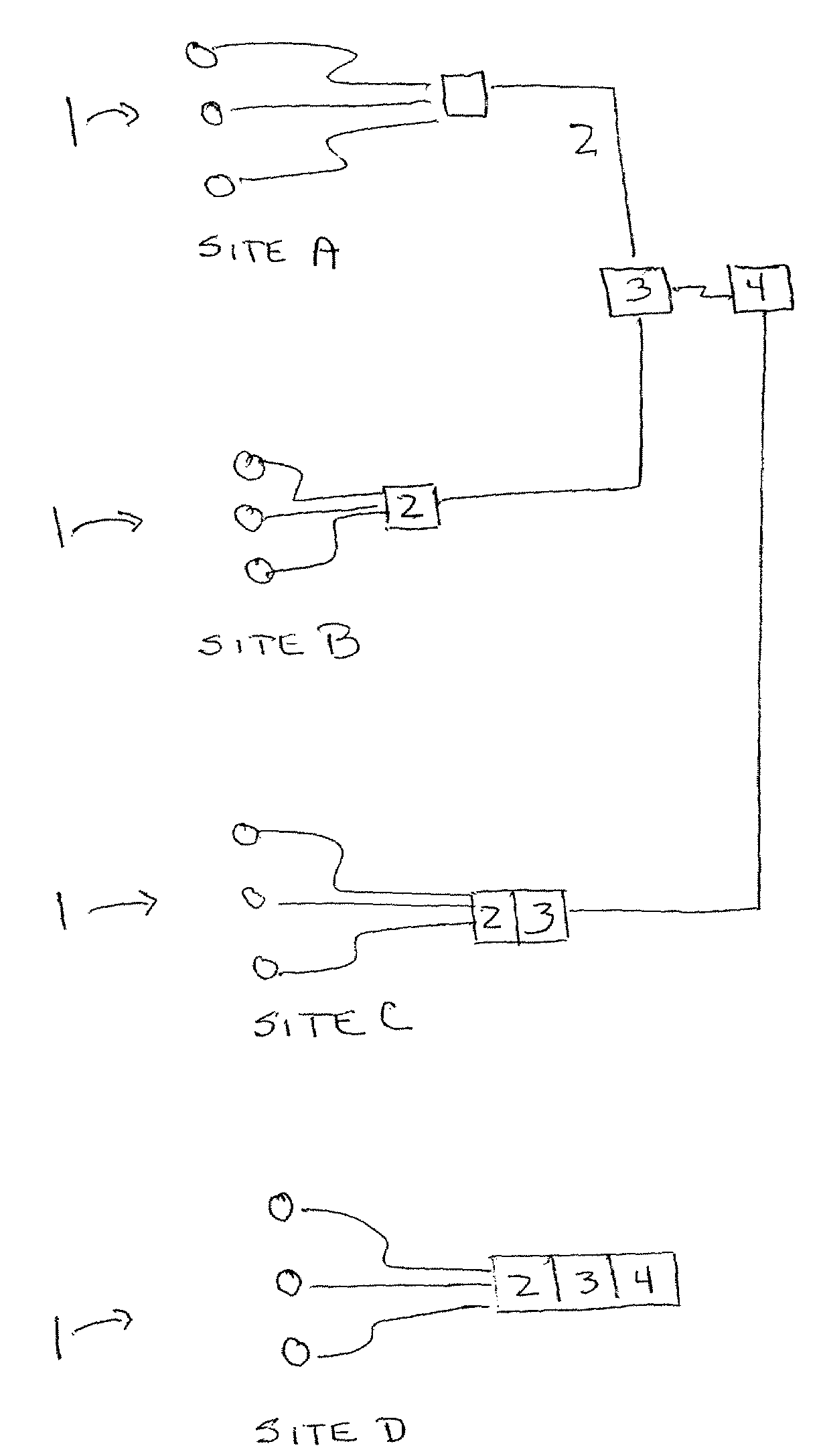

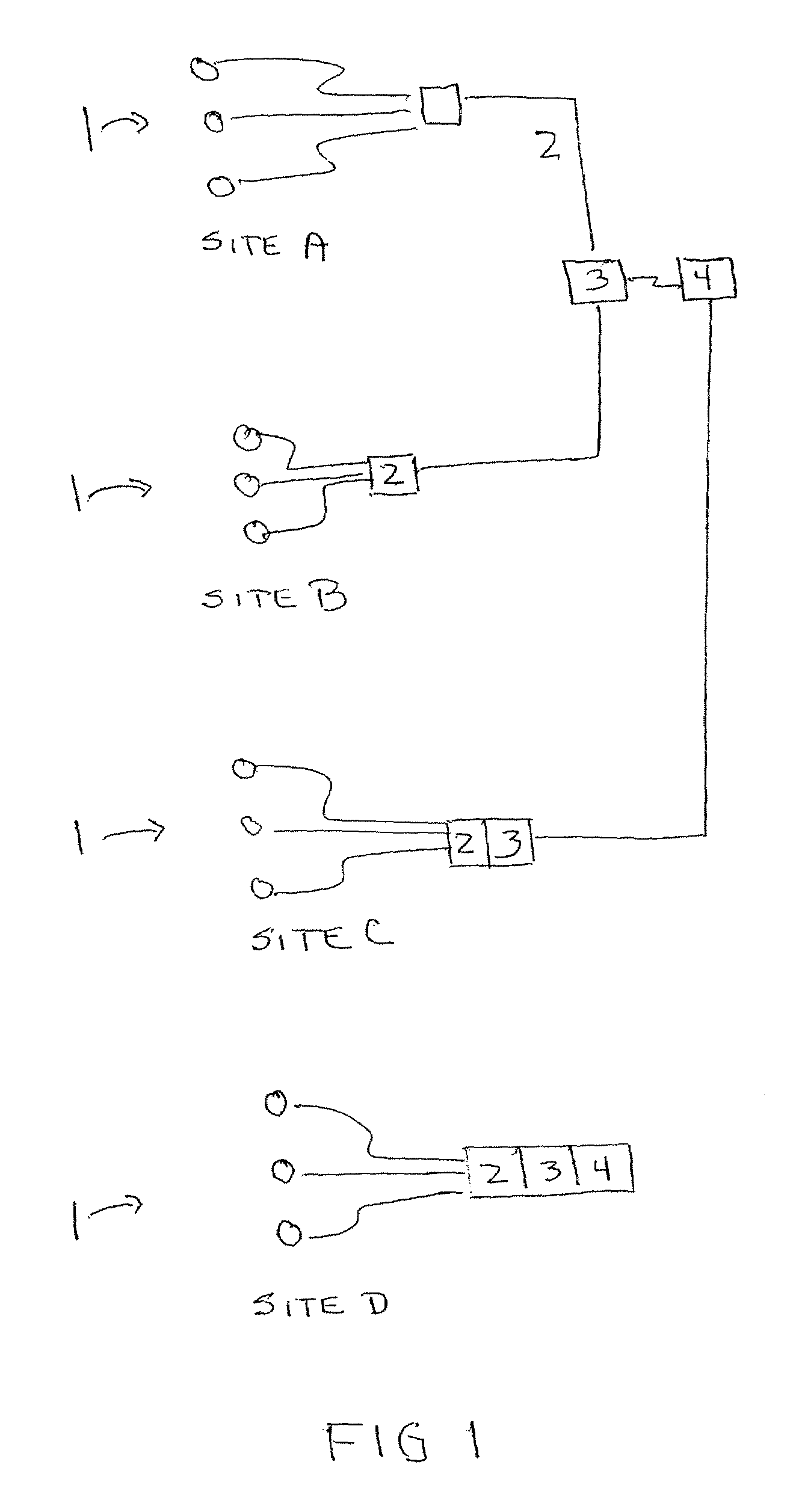

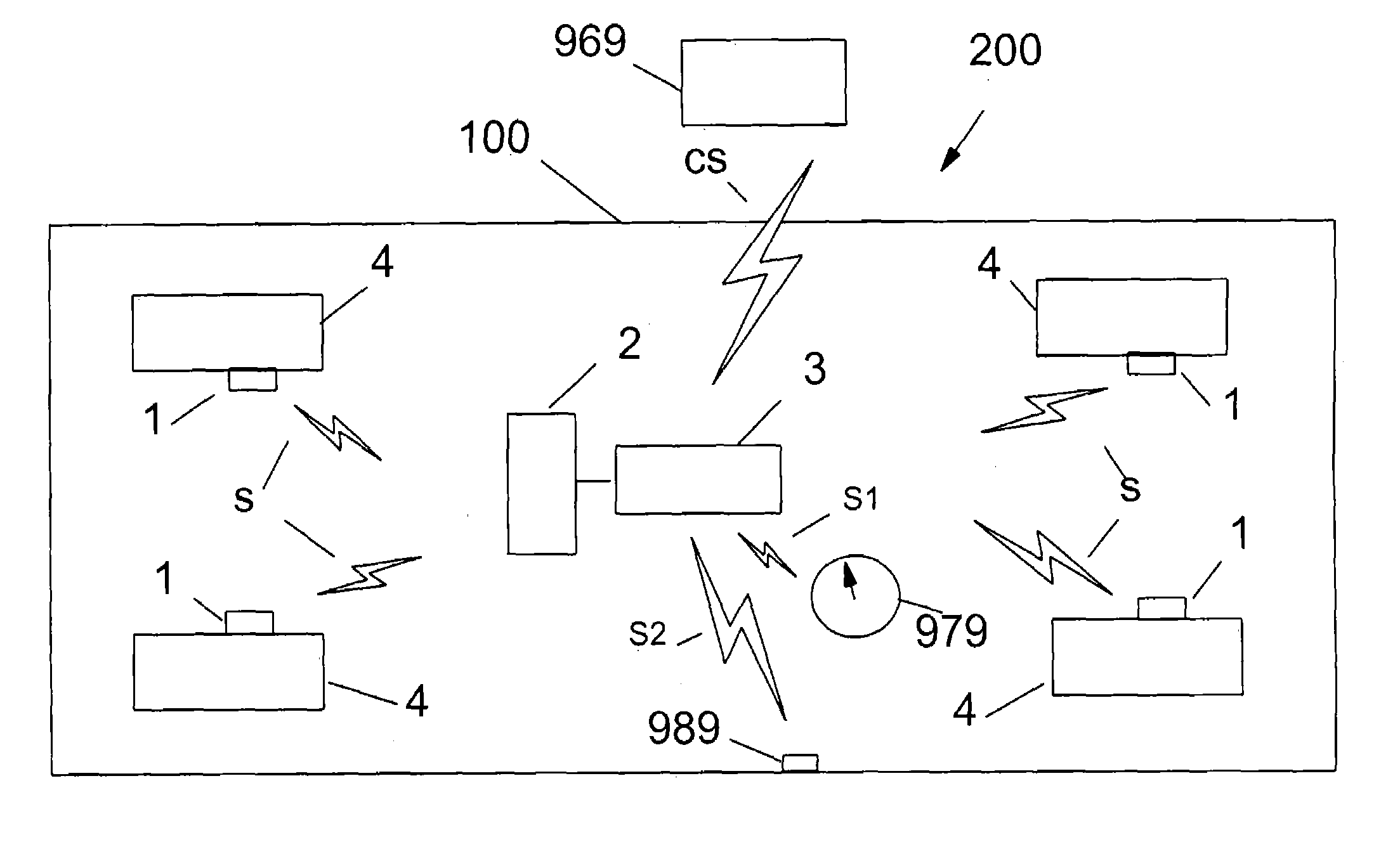

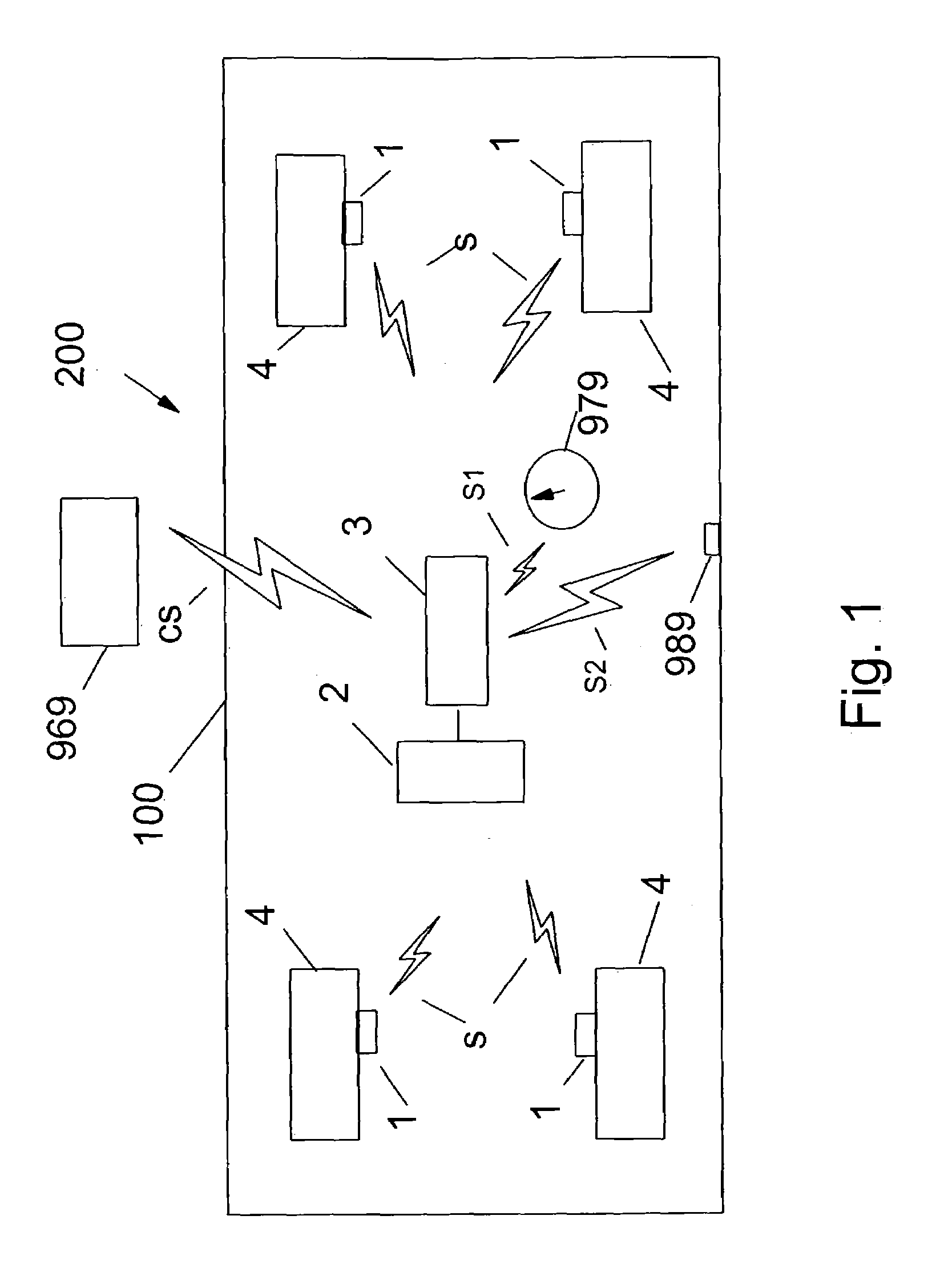

Wireless communication system for welding-type devices

A welding-type device has wireless communications to transmit wireless signals comprising at least identification information or location information. The information may be transmitted either automatically or in response to request signals. Such a welding-type device may be configured to communicate with other welding-type devices, a monitoring device, or both. A wireless communication system has at least one welding-type device, at least one wireless communication assembly, and at least one monitoring device and is capable of assisting a user in locating particular welding-type devices, preventing theft of welding-type devices, and scheduling preventive maintenance.

Owner:ILLINOIS TOOL WORKS INC

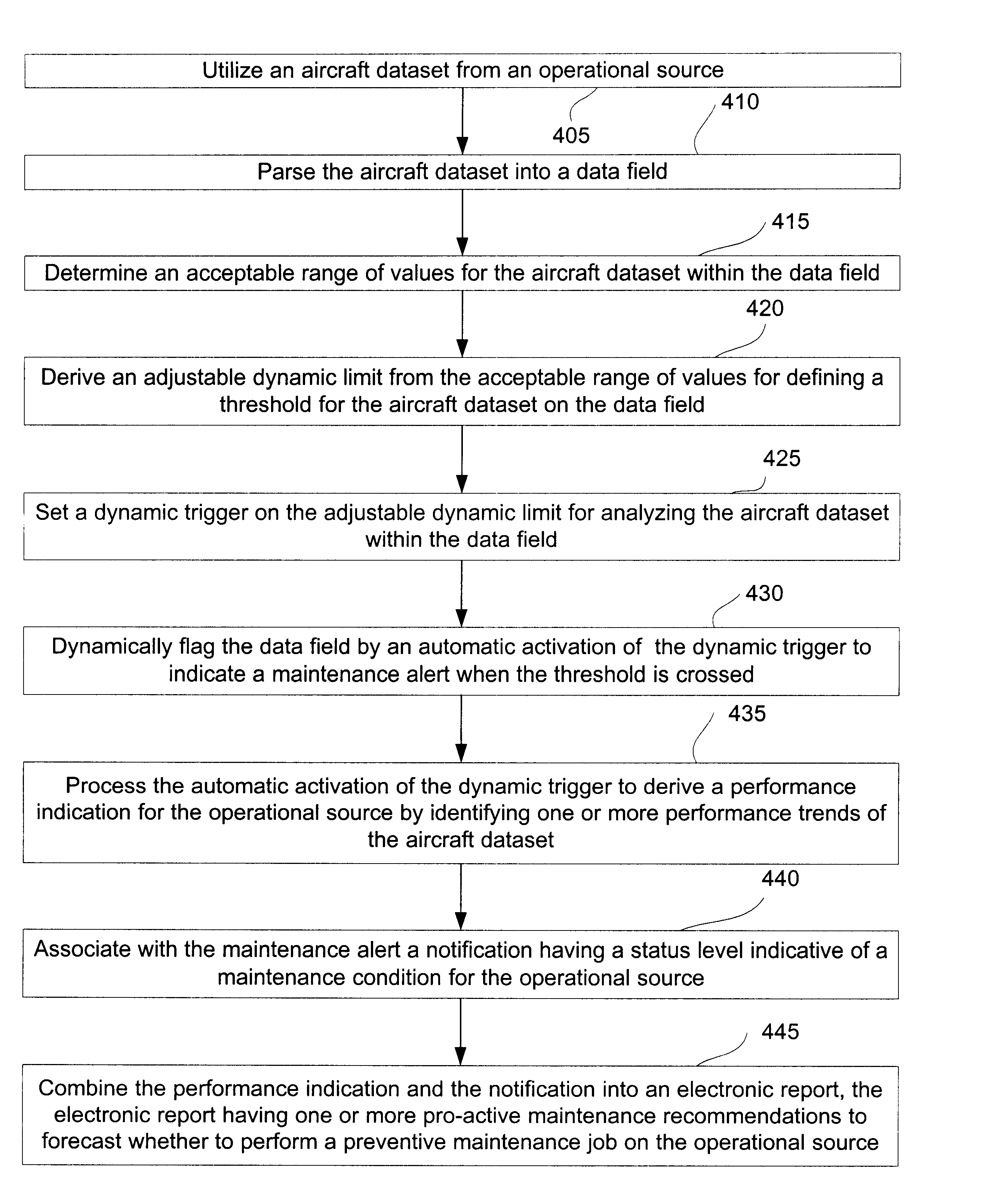

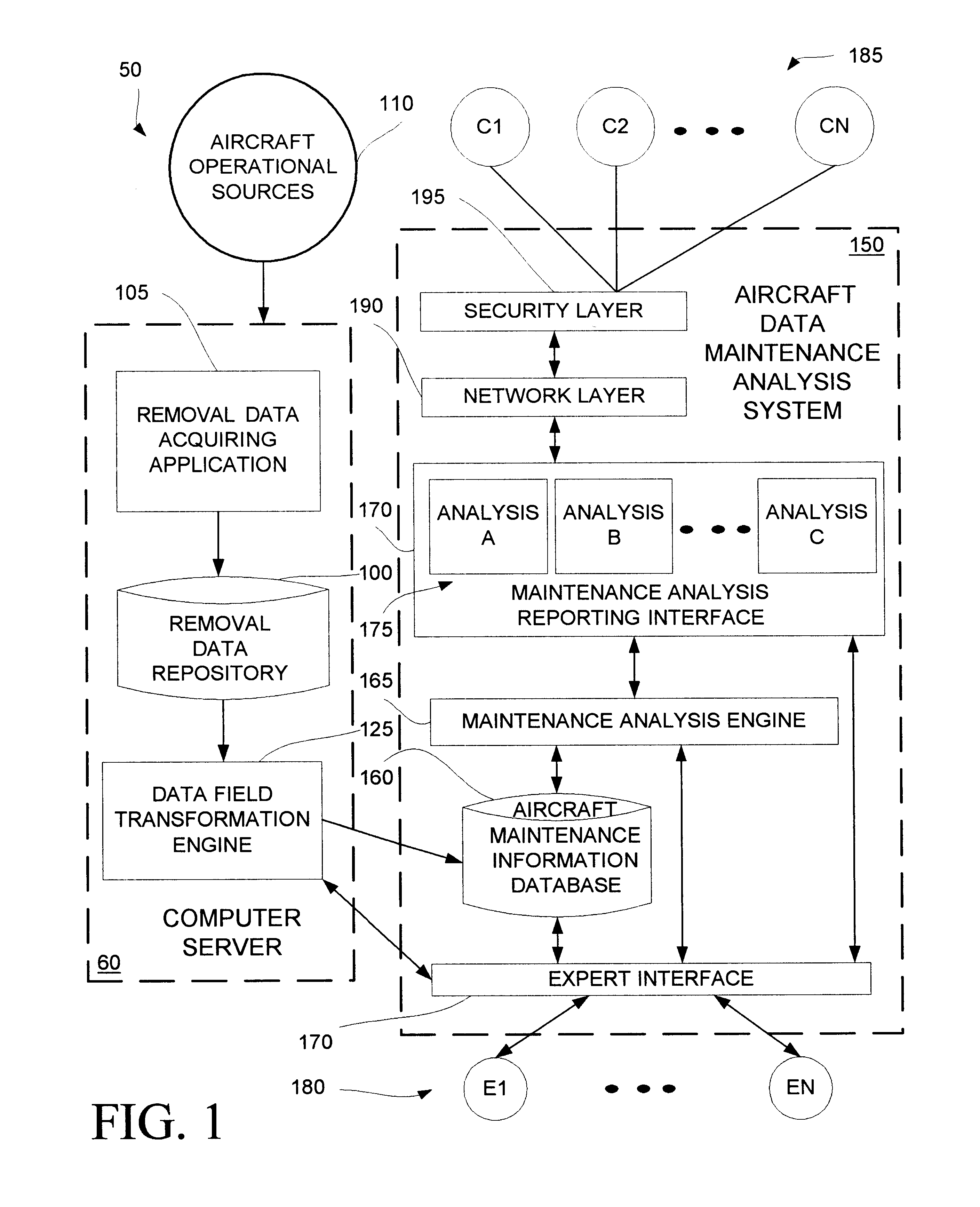

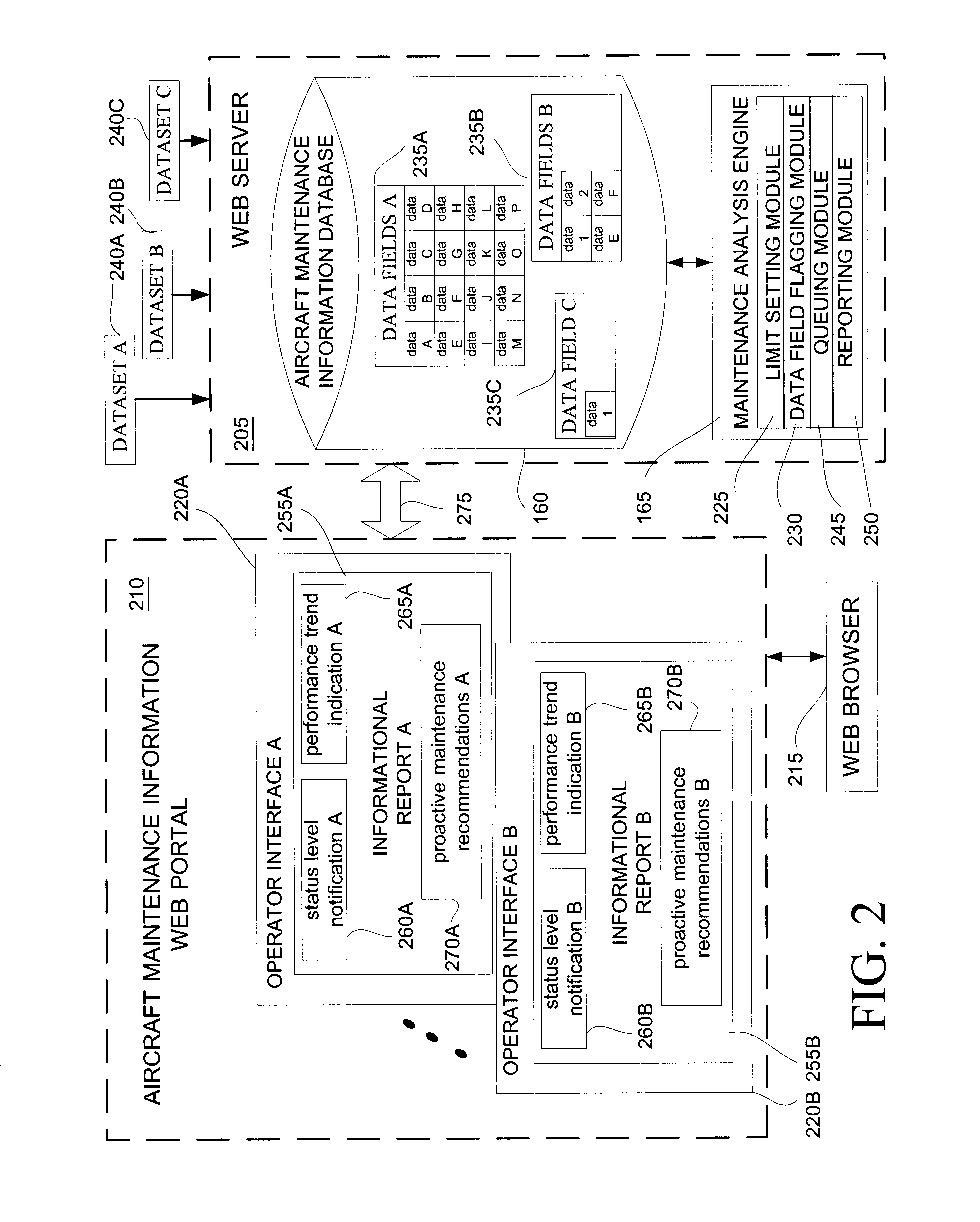

System and method of analyzing aircraft removal data for preventative maintenance

Techniques for analyzing aircraft data. An aircraft dataset is utilized from an operational source. The aircraft dataset is parsed into a data field. An acceptable range of values for the aircraft dataset within the data field is determined to define a threshold for the aircraft dataset. A dynamic trigger is automatically activated to indicate a maintenance alert when the threshold is crossed. A performance indication is derived for the operational source by determining one or more performance trends of the aircraft dataset. A notification having a status level indicative of a maintenance condition for the operational source is associated with the maintenance alert. The performance indication and the notification are combined into an electronic report that forecasts need for preventative aircraft maintenance, and the electronic report is automatically delivered to a predetermined location for retrieval by a consumer.

Owner:PT DIAGNOSTICS

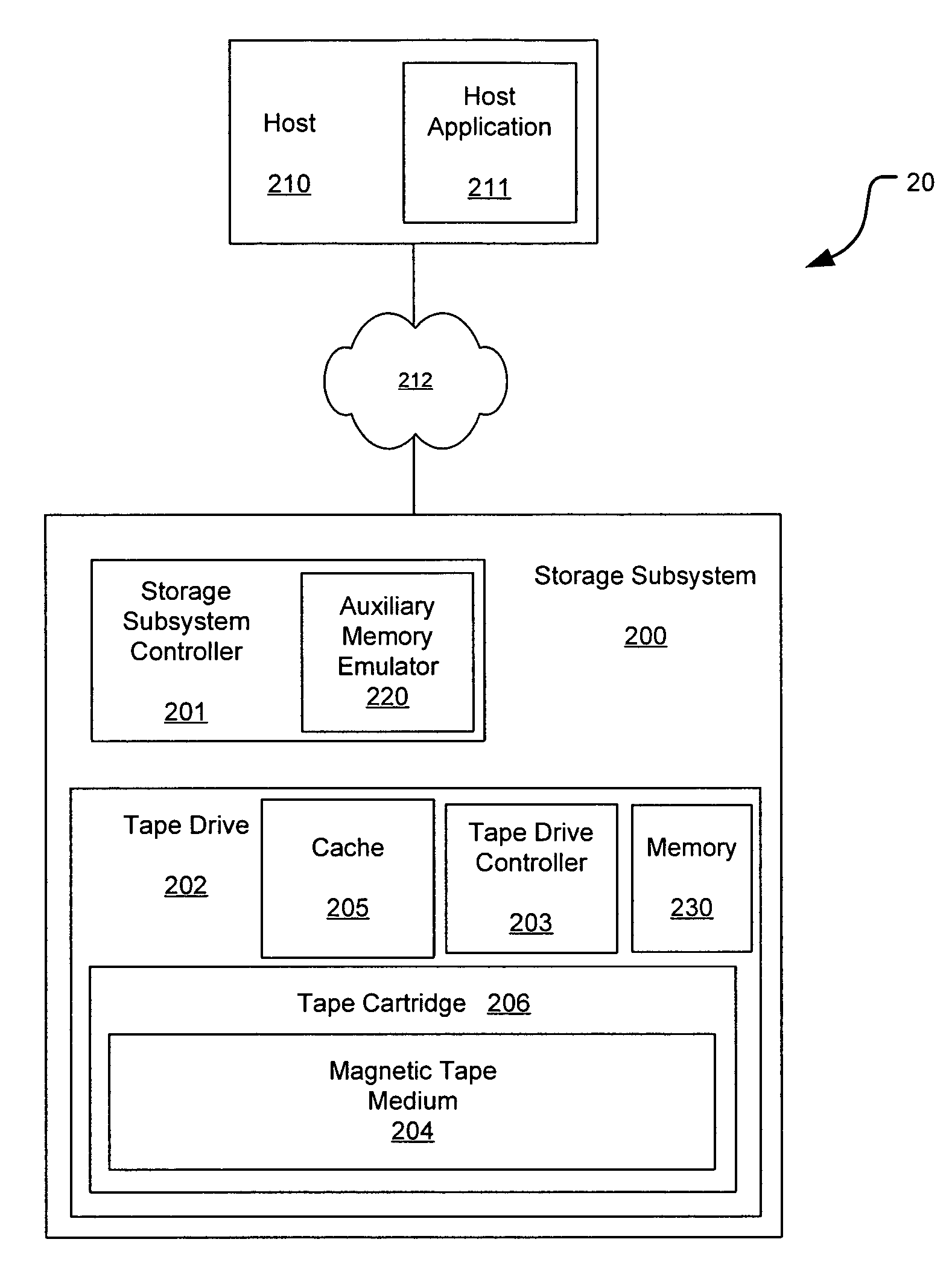

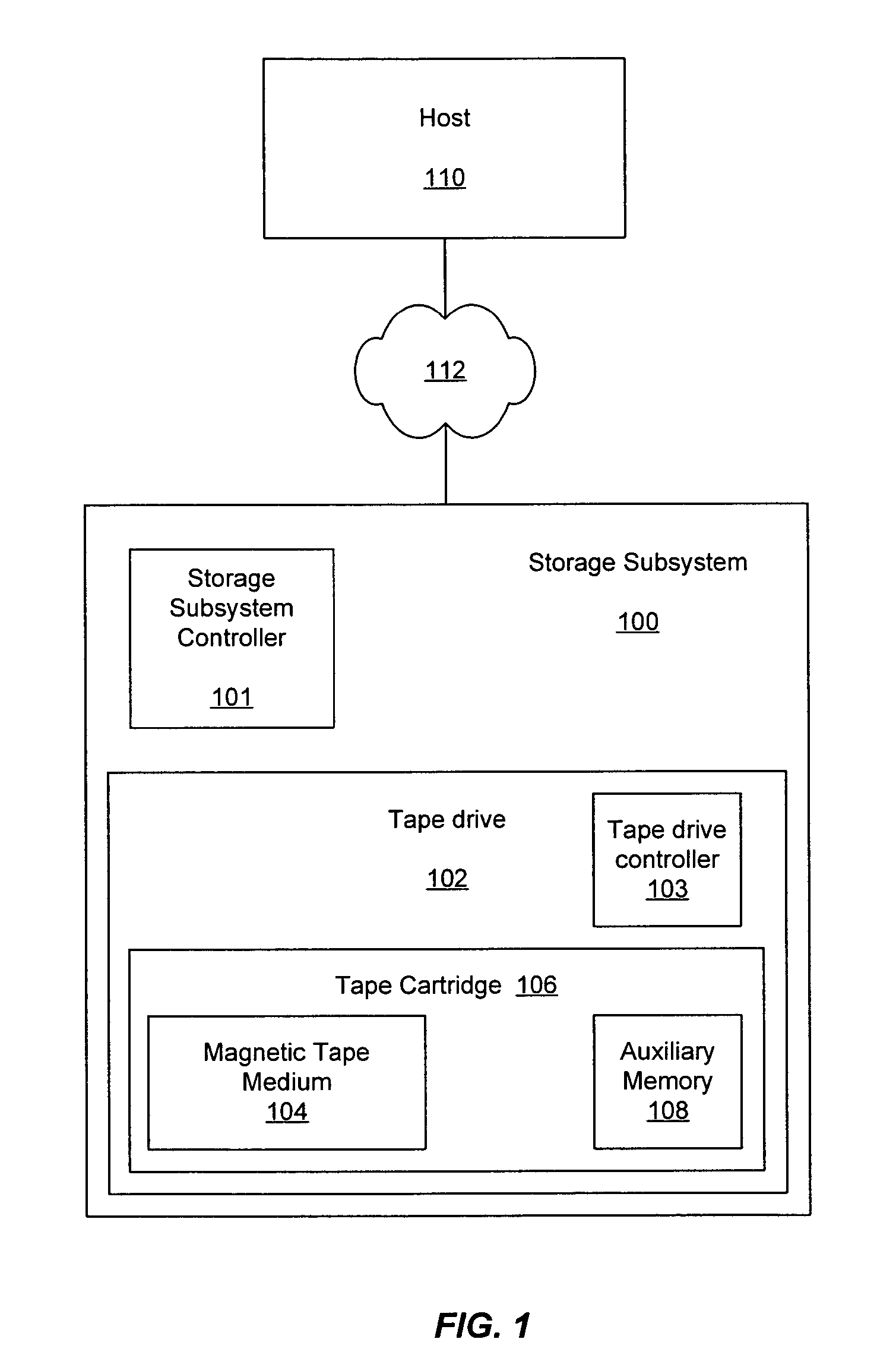

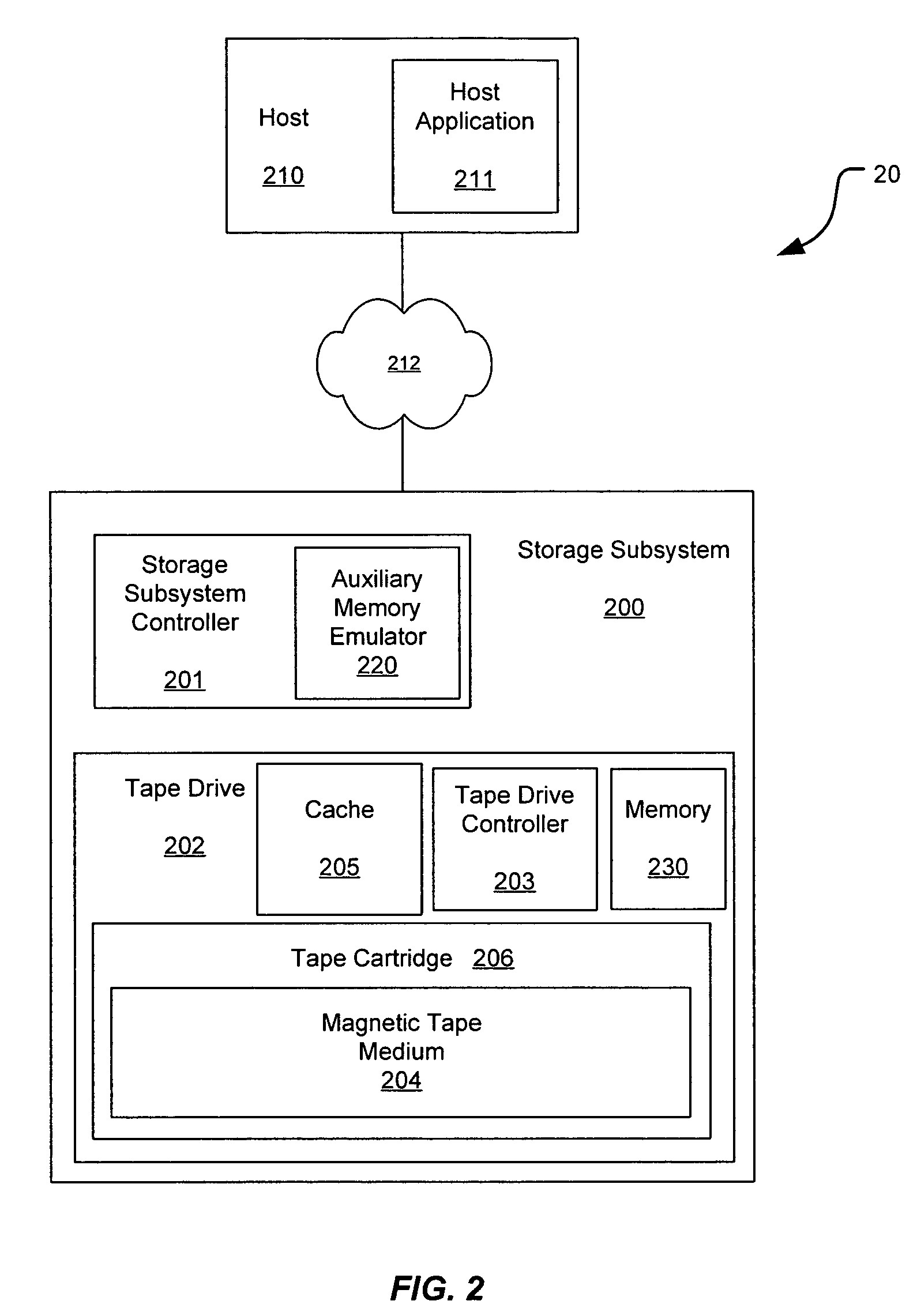

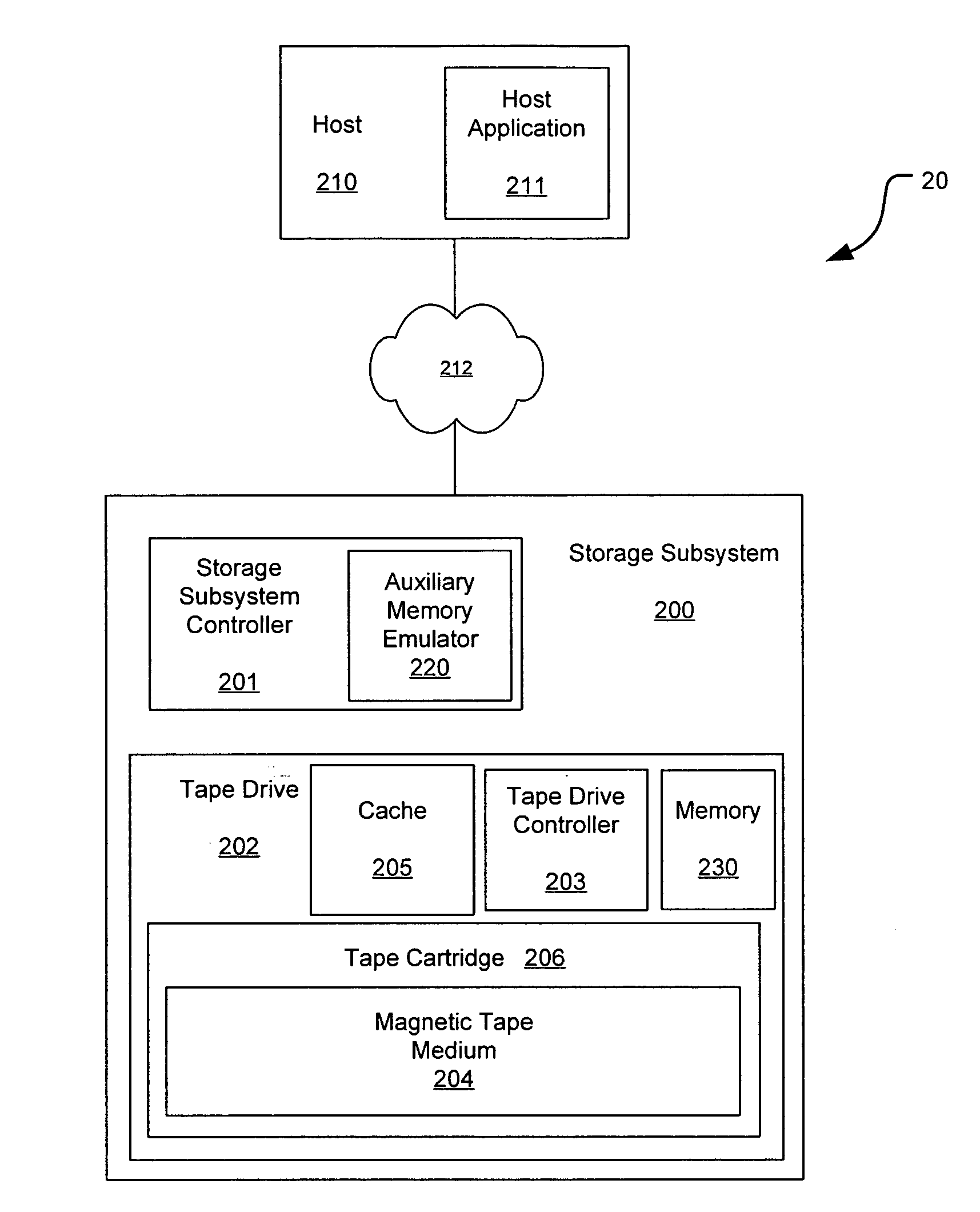

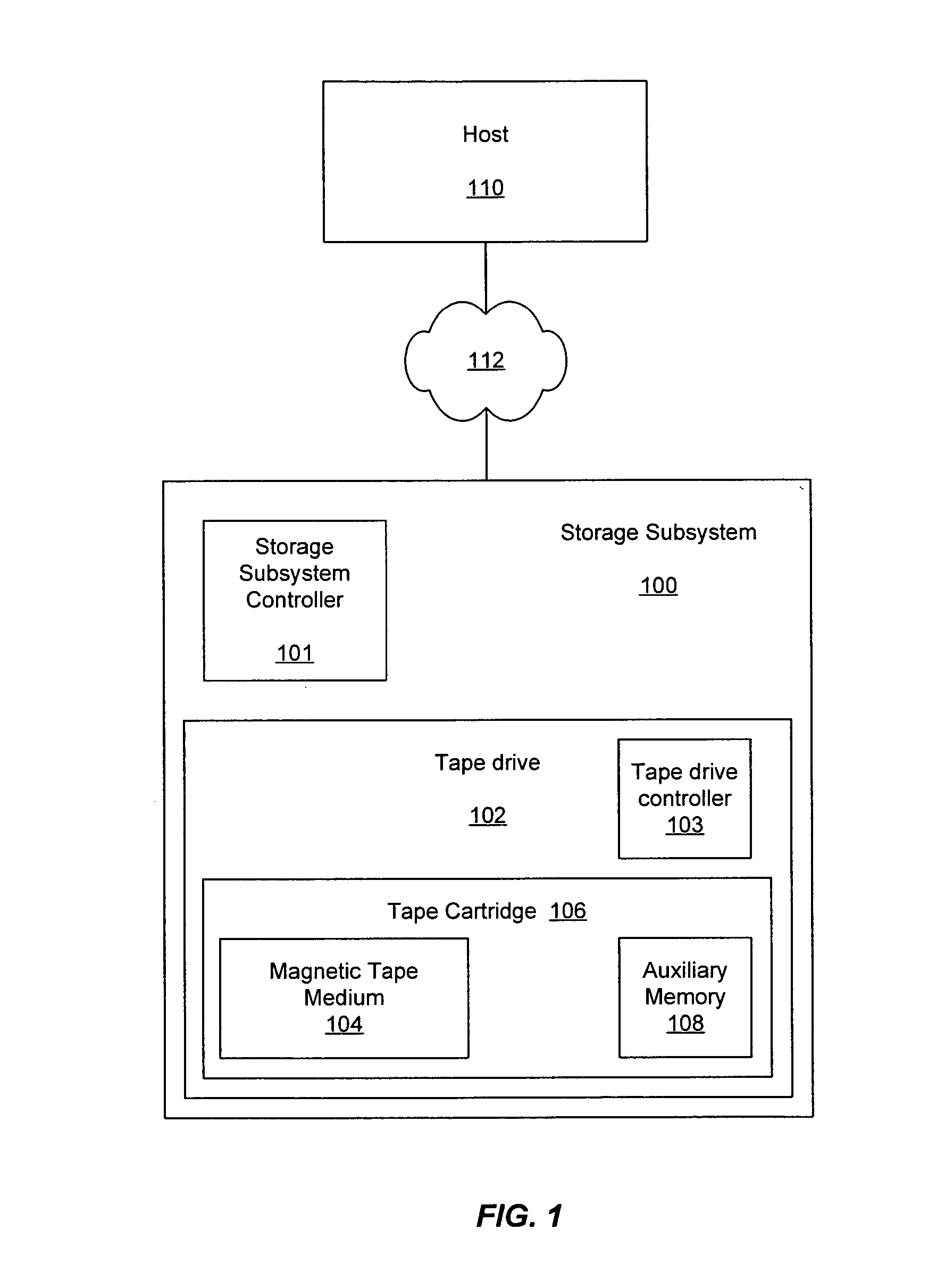

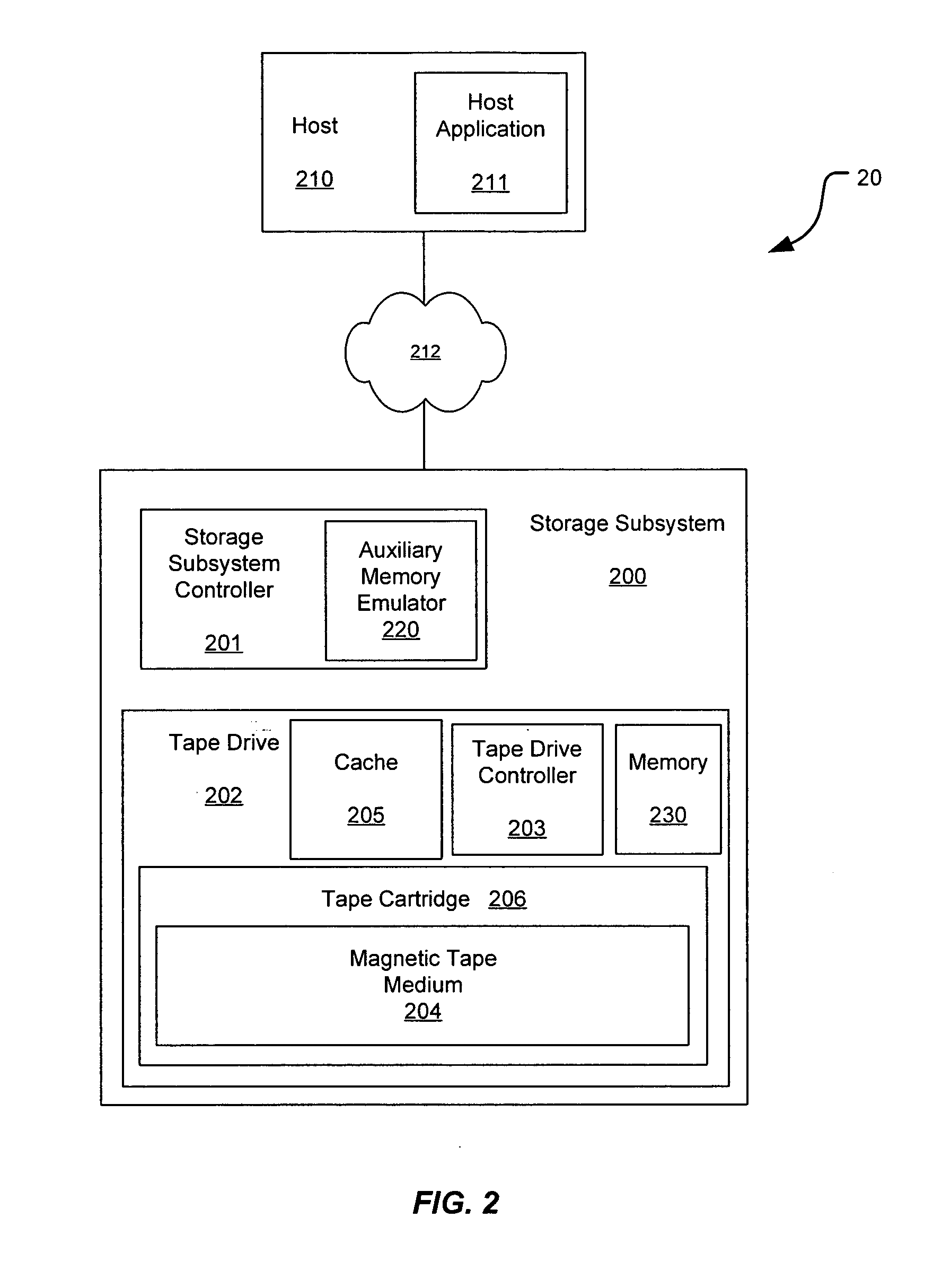

Methods and systems for providing predictive maintenance, preventative maintenance, and/or failure isolation in a tape storage subsystem

ActiveUS7277246B2Input/output to record carriersFilamentary/web record carriersMagnetic tapeAuxiliary memory

A system and method of operating a storage system is provided. The storage system includes a tape cartridge having a magnetic tape medium and a tape drive for reading and writing data to the magnetic tape medium of the tape cartridge. Performance data associated with specific operating loci (e.g., bands, directions, tracks, segments, etc.) of the tape drive and tape medium are collected, analyzed, and stored, allowing for analysis and detection of trends over time. In one example, tape usage events are monitored and when they cross a threshold the system may remove particular tapes in a preventative maintenance approach to reduce system outage. Performance data is collected and analyzed with a portion of the performance data being saved to emulated medium auxiliary memory (EMAM) on the magnetic tape, and a portion of the of the performance data saved in non-volatile storage in the drive.

Owner:QUANTUM CORP

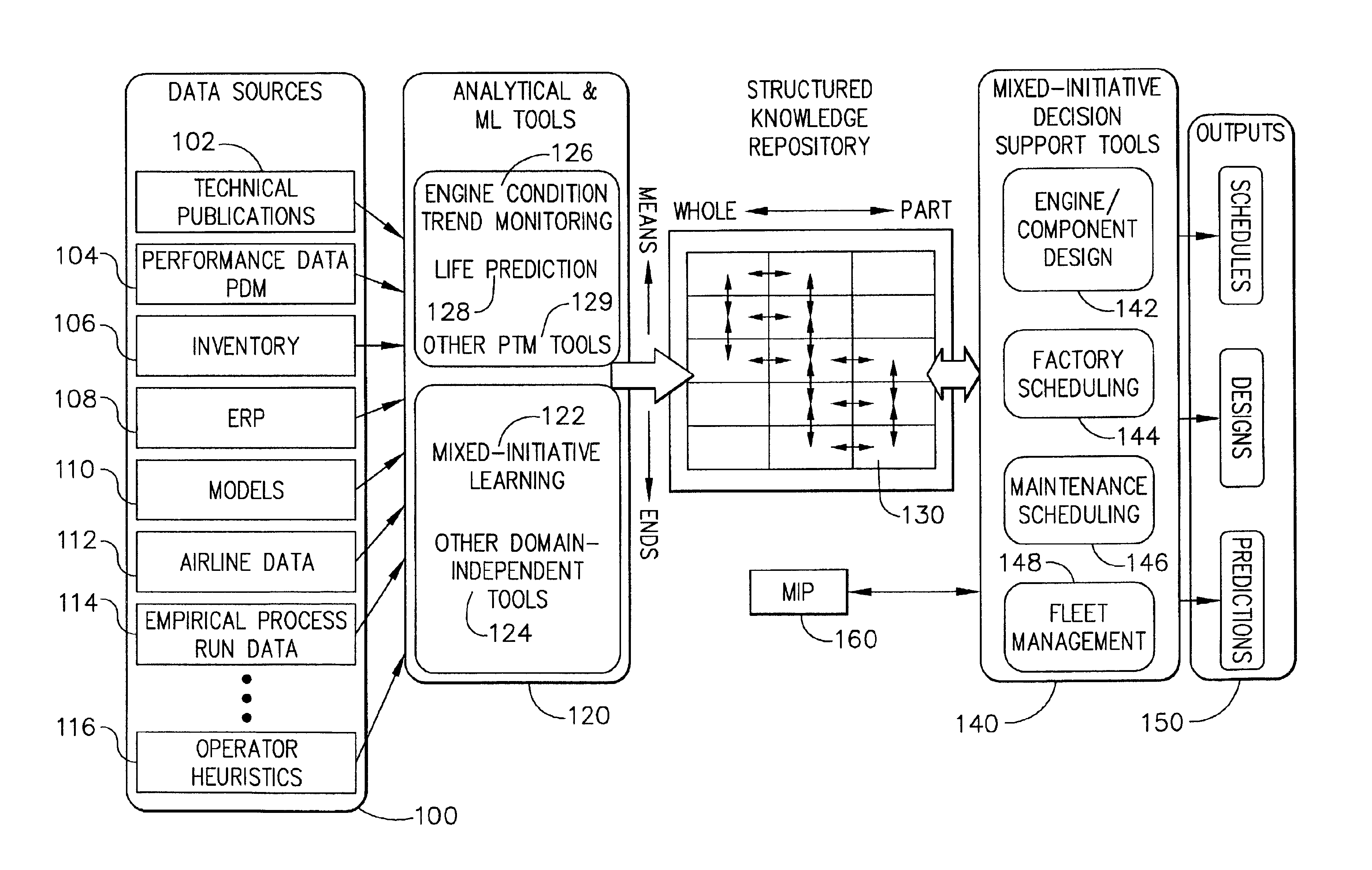

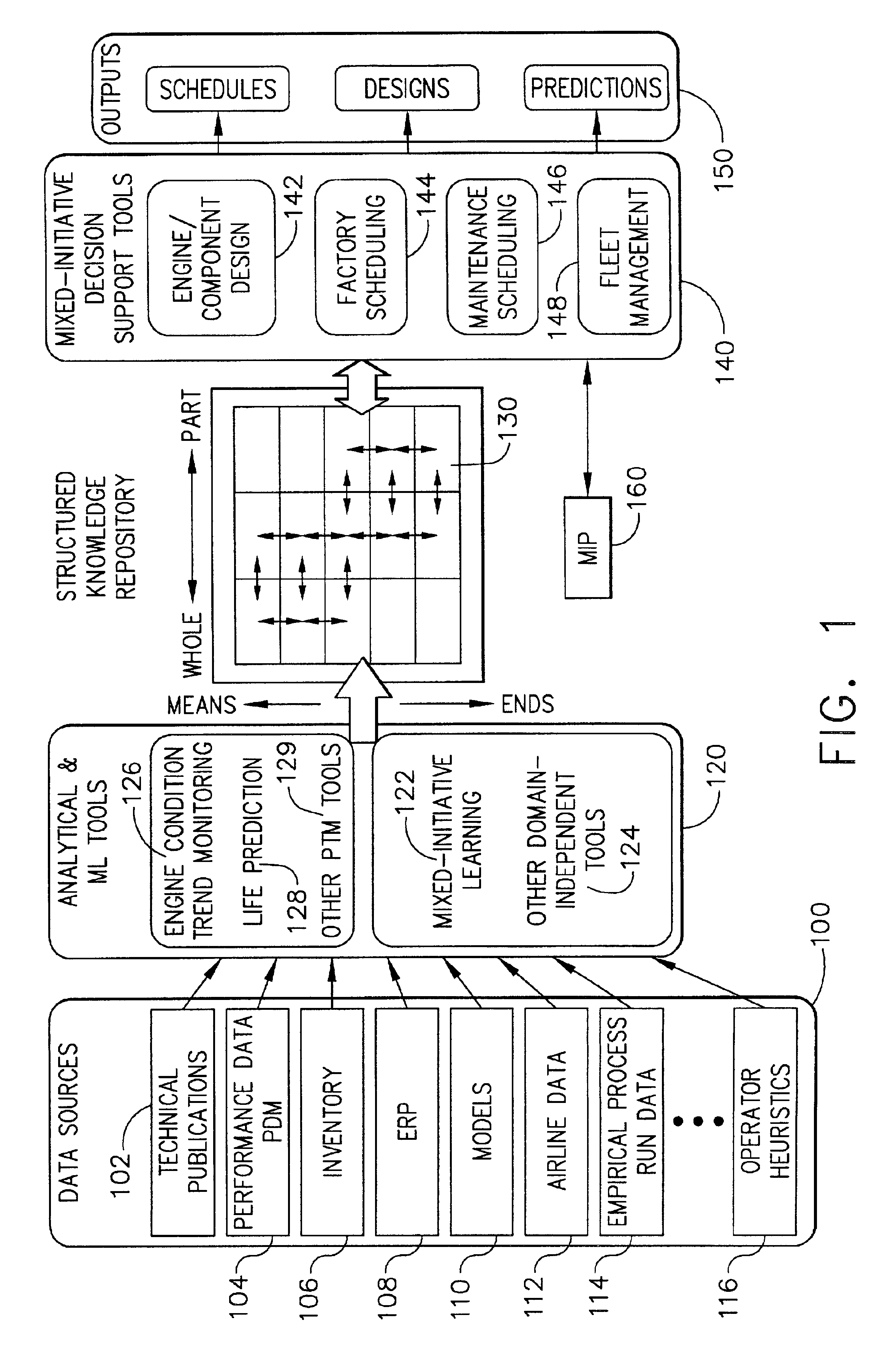

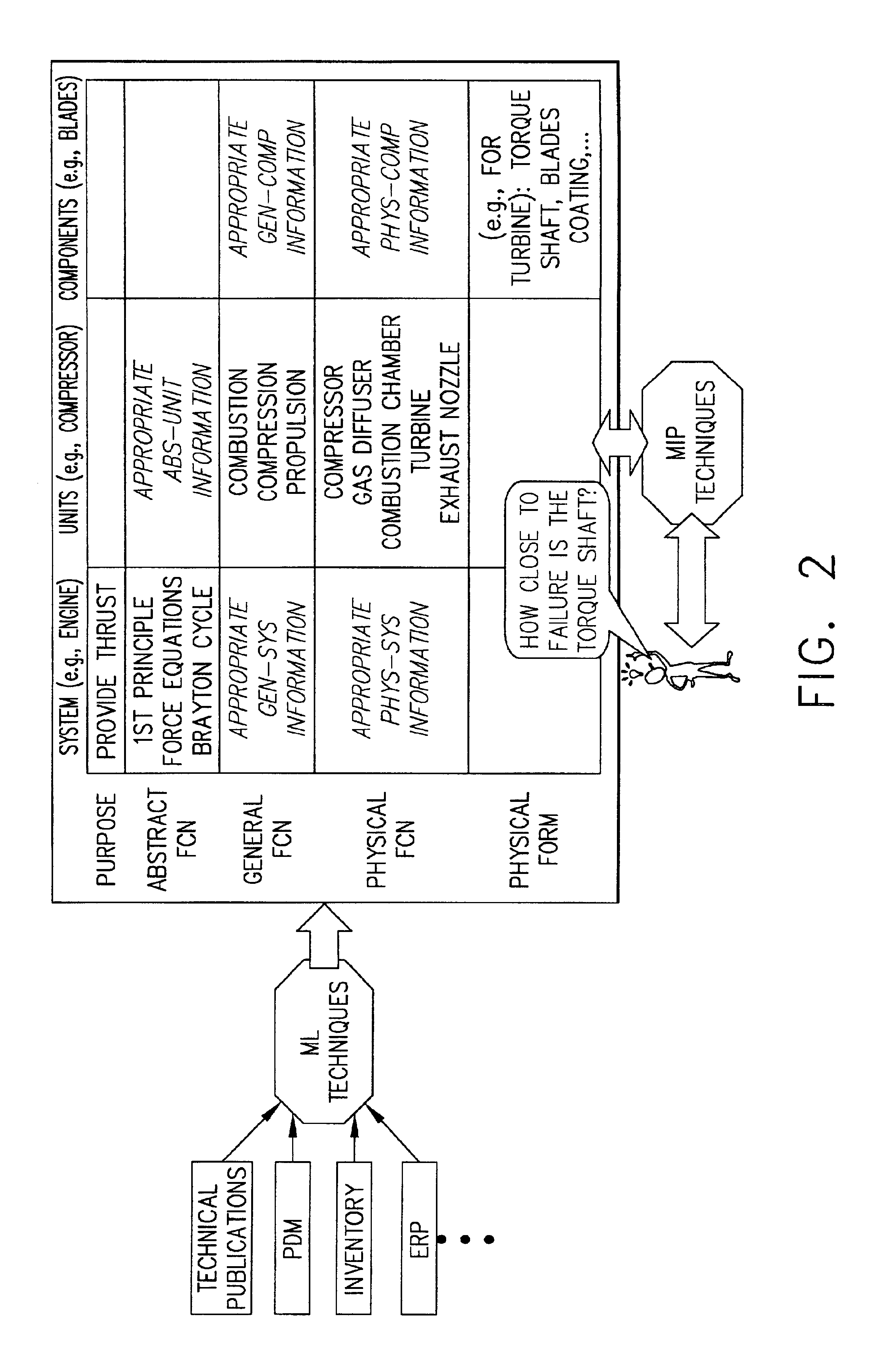

Adaptive knowledge management system for vehicle trend monitoring, health management and preventive maintenance

A method and an Adaptive Knowledge Management is provided. The Adaptive Knowledge Management System is used for assisting a user with decision making by providing real-time, on-line automated recommendations for actions in a monitored vehicle troubleshooting, performance trend monitoring, health management and preemptive maintenance domain diagnostics and prognostics. The system creates a Structured Knowledge Repository, constructed from models, historical data, and heuristics for organizing a model domain knowledge. It uses a plurality of Analytical and Machine Learning tools for capturing knowledge from data sources and populating cells of the Structured Knowledge Repository. A Mixed-Initiative Planning module is used for interpreting operation goals for the monitored vehicle and utilizing the Structure Knowledge Repository for developing recommendations for user decision making. A plurality of Mixed-initiative Decision Support tools use the feedback from the Mixed-initiative Planning module and query the Structured Knowledge Repository for incorporating the extracted knowledge and information into outputs dealing with current issues and contingencies.

Owner:HONEYWELL INT INC

Wireless tracking and inventory monitoring for welding-type devices

A welding-type device has a wireless communication unit to transmit wireless signals comprising at least identification information or location information. The information may be transmitted either automatically or in response to request signals. Such a welding-type device may be configured to communicate with other welding-type devices, a monitoring device, or both. A wireless communication system has at least one welding-type device, at least one wireless communication assembly, and at least one monitoring device and is capable of assisting a user in locating particular welding-type devices, monitoring inventory, preventing theft of welding-type devices, and scheduling preventive maintenance.

Owner:ILLINOIS TOOL WORKS INC

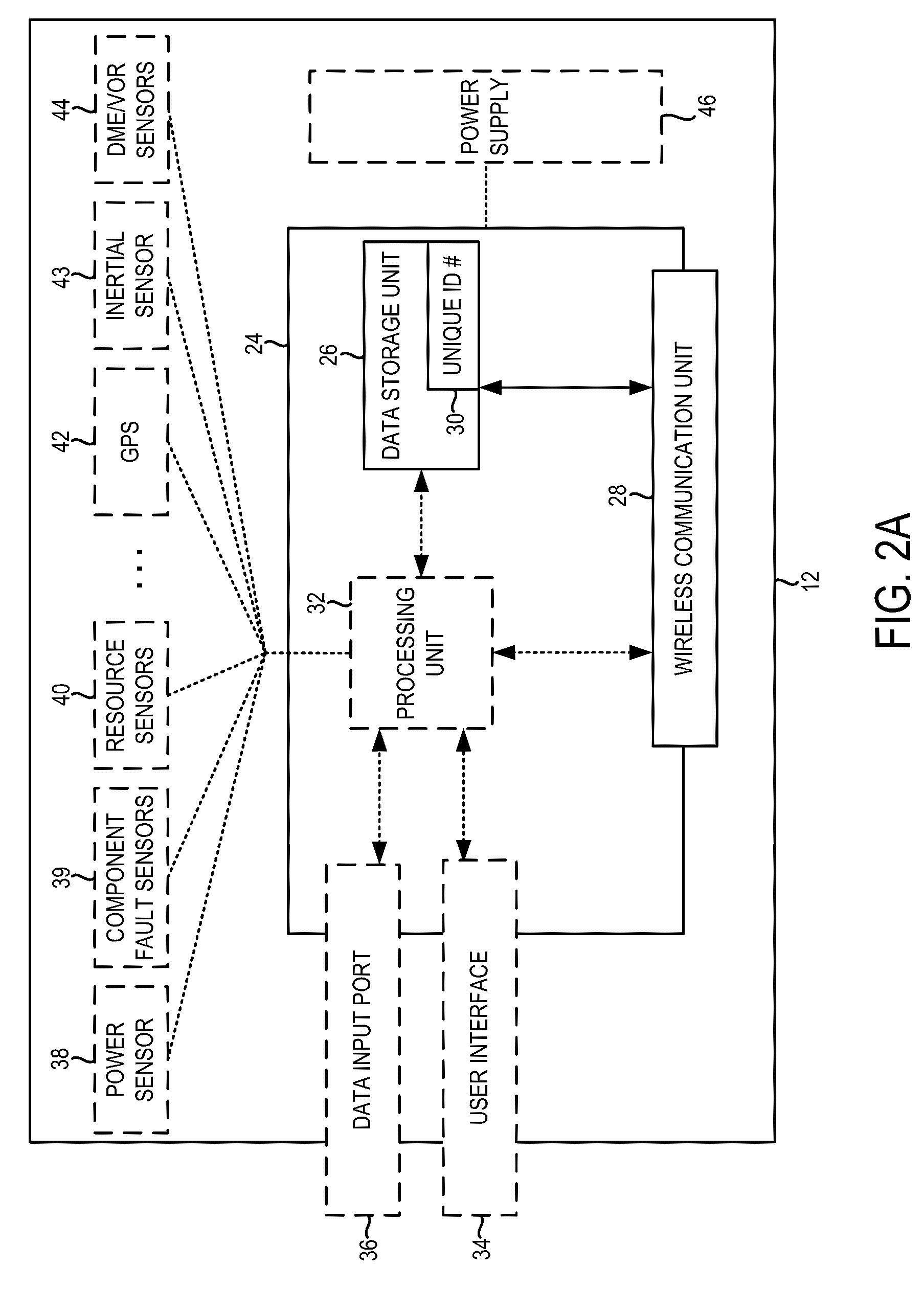

Customized medical equipment preventative maintenance method and system

A technique is provided for determining service intervals for devices, such as medical equipment. Data related to a device is collected and compared to data from a population of like devices. A service interval may be calculated based on the comparison. The data regarding the population of like devices may be raw quantitative or qualitative data or may be processed data, such as may be used to graph the reliability of the device as a function of some variable such as usage or age, i.e. a reliability curve. The data may representative of the device as a whole or one or more components of the device. Multiple service intervals may be generated for a single device by calculating a service interval for each data source, such as a component or subset of components, of the device. An optimal service interval may then be selected. In addition, the technique may be applied for selection of a service interval for more than one device.

Owner:GE MEDICAL SYST INFORMATION TECH

Methods and systems for providing predictive maintenance, preventative maintenance, and/or failure isolation in a tape storage subsystem

ActiveUS20050052772A1Input/output to record carriersFilamentary/web record carriersMagnetic tapeAuxiliary memory

A system and method of operating a storage system is provided. The storage system includes a tape cartridge having a magnetic tape medium and a tape drive for reading and writing data to the magnetic tape medium of the tape cartridge. Performance data associated with specific operating loci (e.g., bands, directions, tracks, segments, etc.) of the tape drive and tape medium are collected, analyzed, and stored, allowing for analysis and detection of trends over time. In one example, tape usage events are monitored and when they cross a threshold the system may remove particular tapes in a preventative maintenance approach to reduce system outage. Performance data is collected and analyzed with a portion of the performance data being saved to emulated medium auxiliary memory (EMAM) on the magnetic tape, and a portion of the of the performance data saved in non-volatile storage in the drive.

Owner:QUANTUM CORP

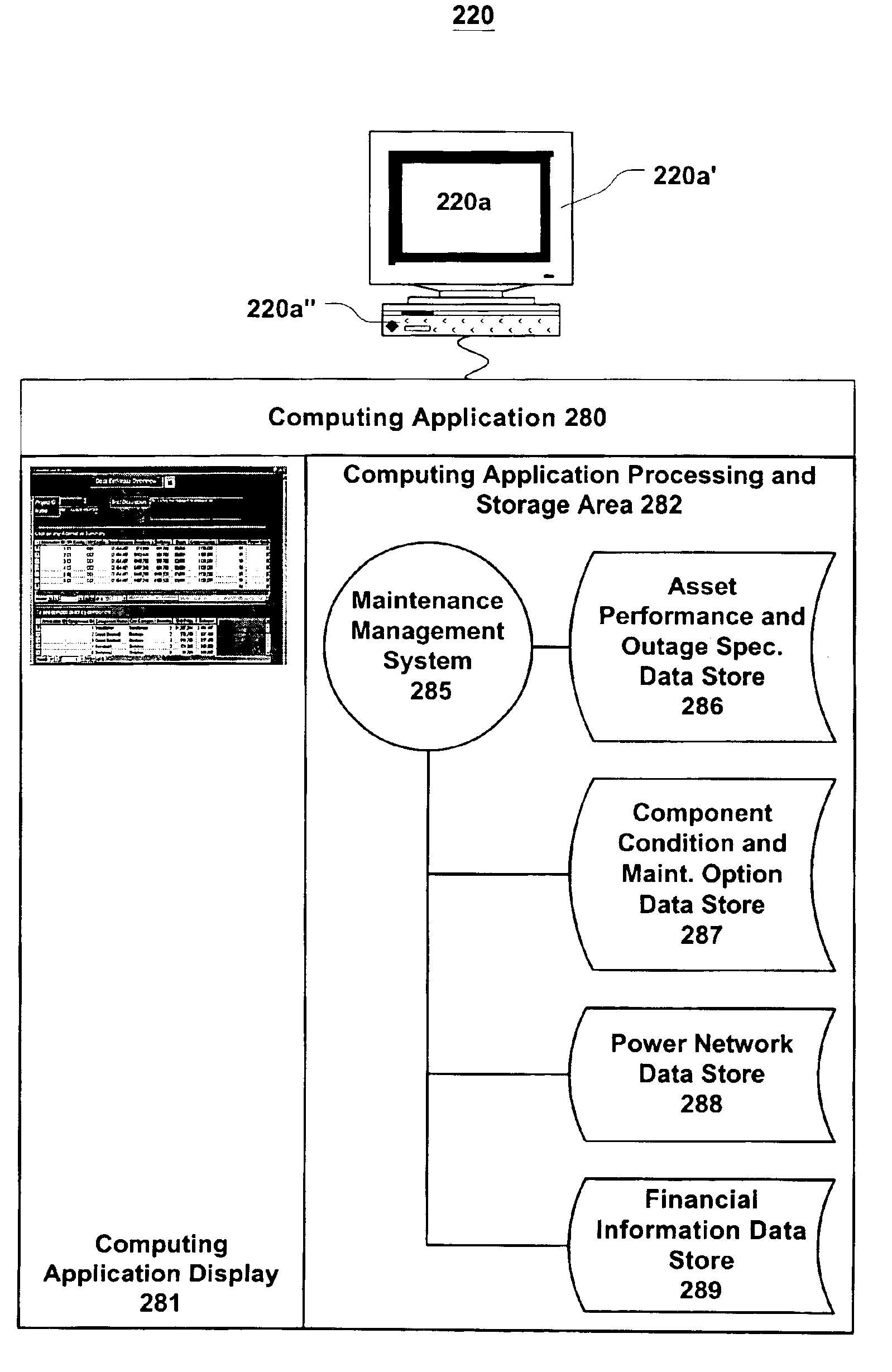

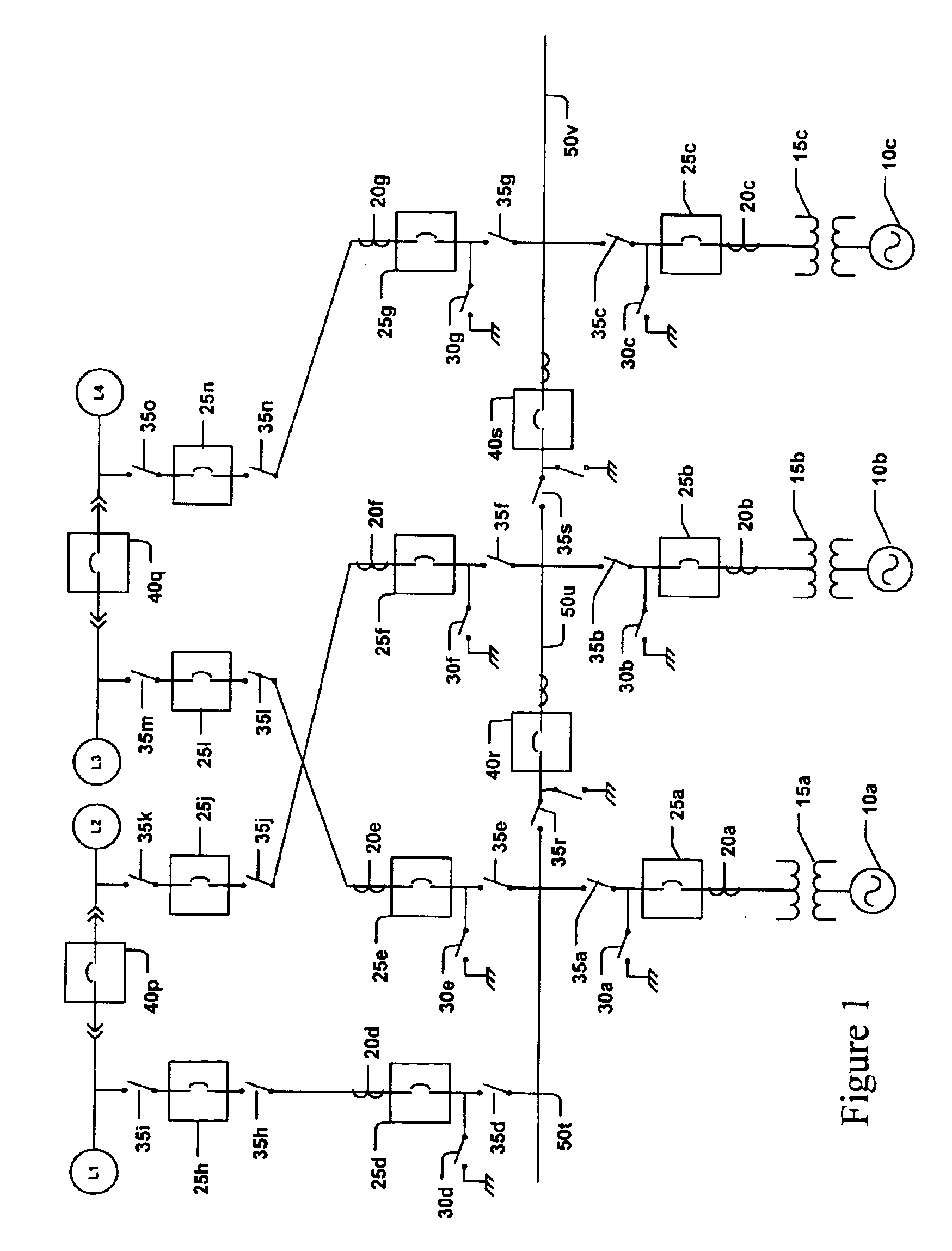

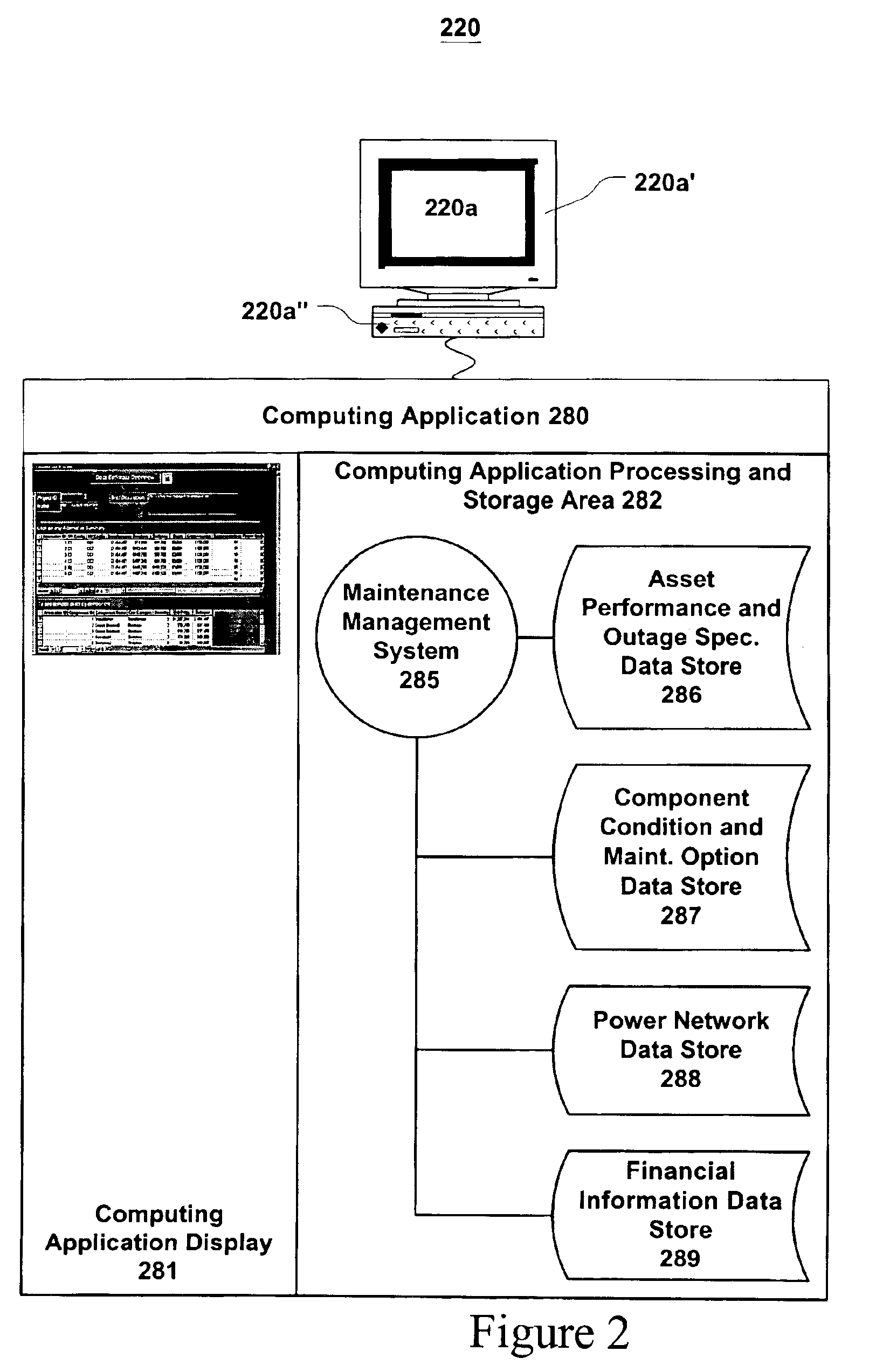

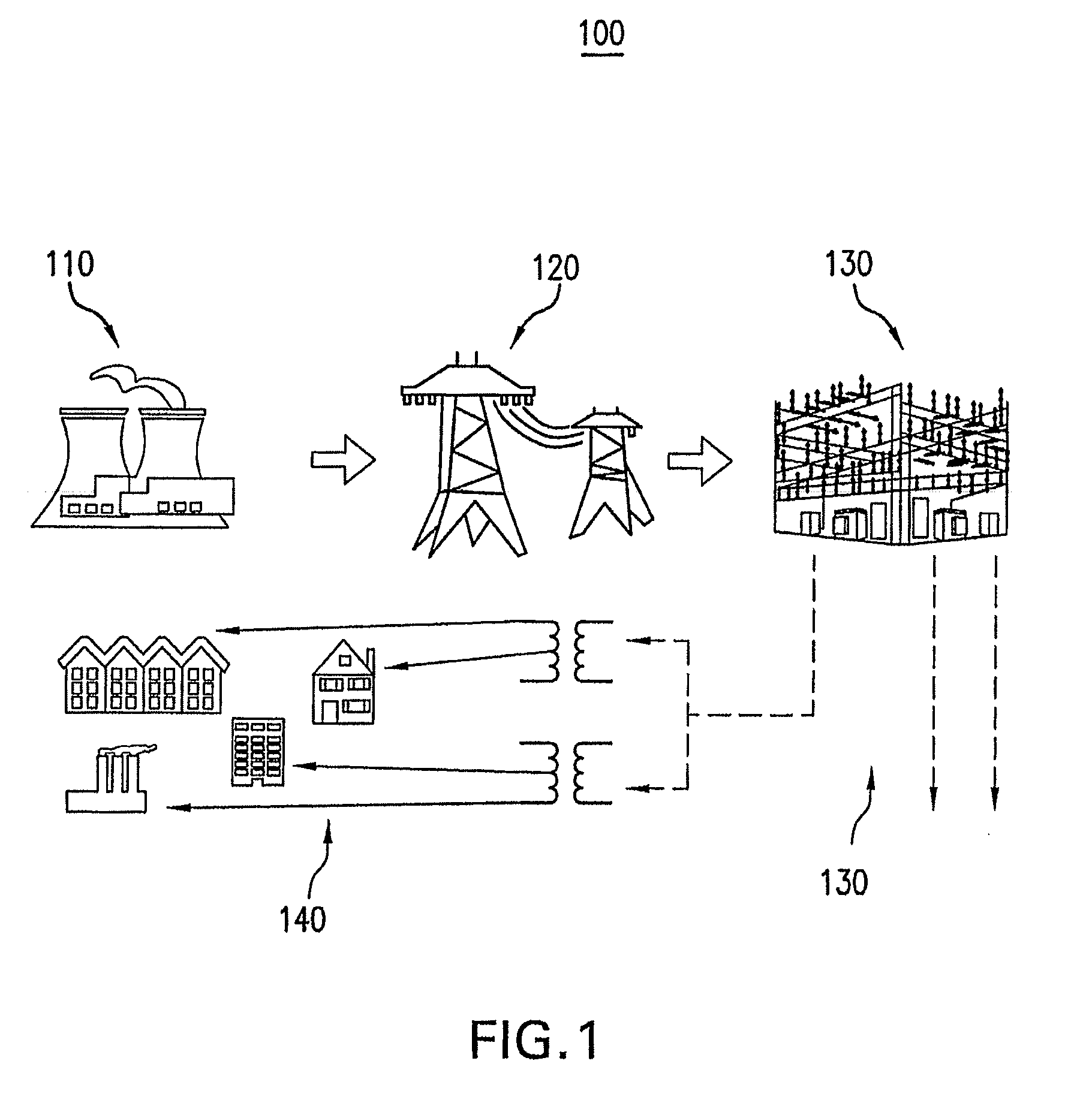

Value-based transmission asset maintenance management of electric power networks

A systematic approach is presented for the development and implementation of cost-effective transmission asset maintenance strategies. The overall concept and methodology are based on transmission reliability and risk management and address the value of preventive maintenance activities. This may help electric network utilities conduct maintenance policy assessment, region-wide criticality analysis, and optimal maintenance resource allocation and task scheduling.

Owner:ABB (SCHWEIZ) AG

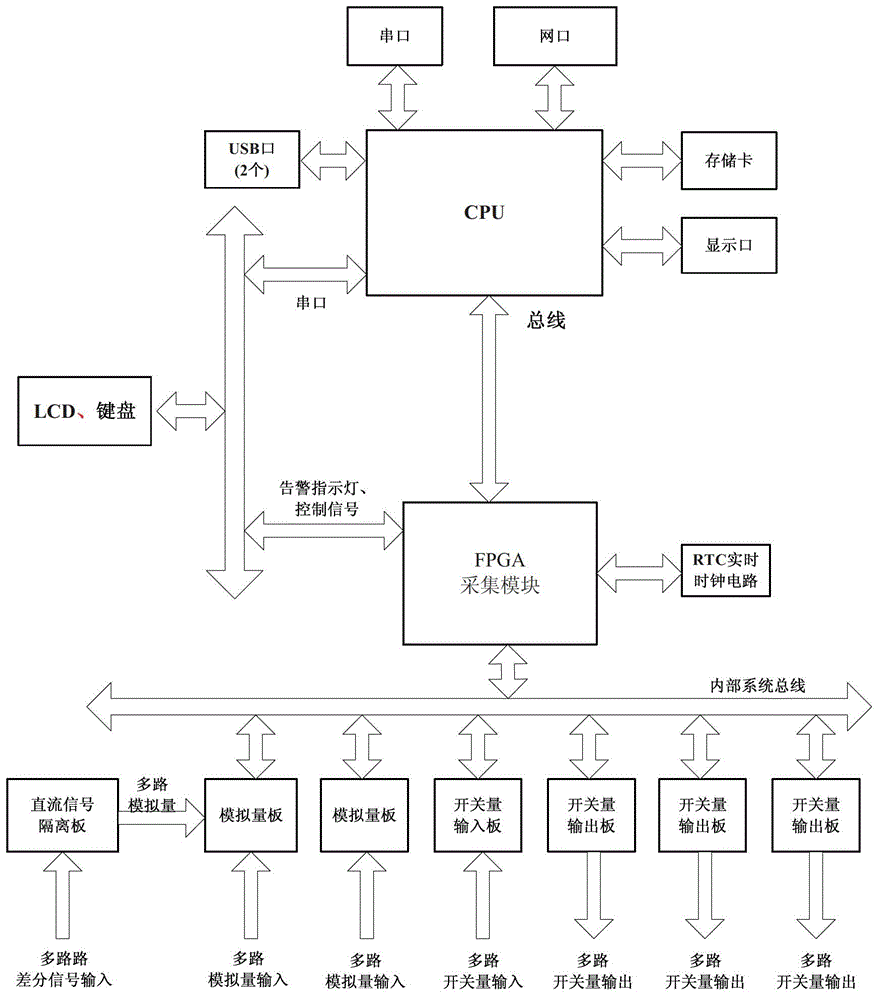

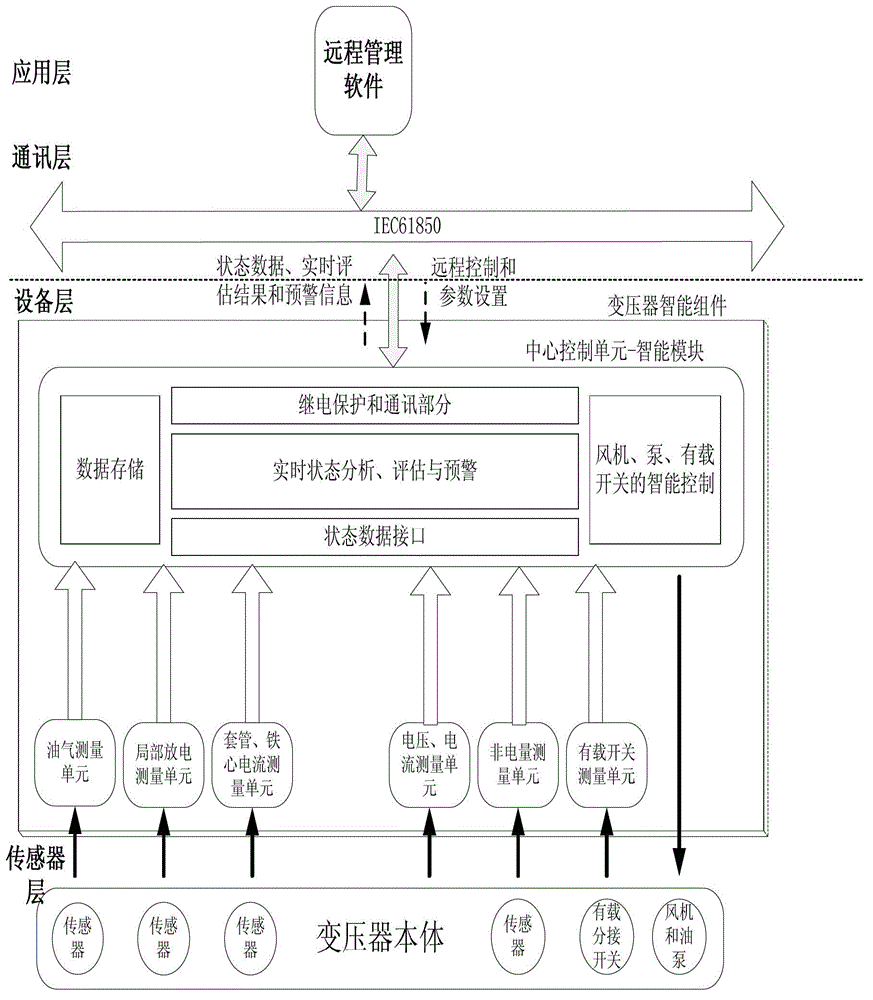

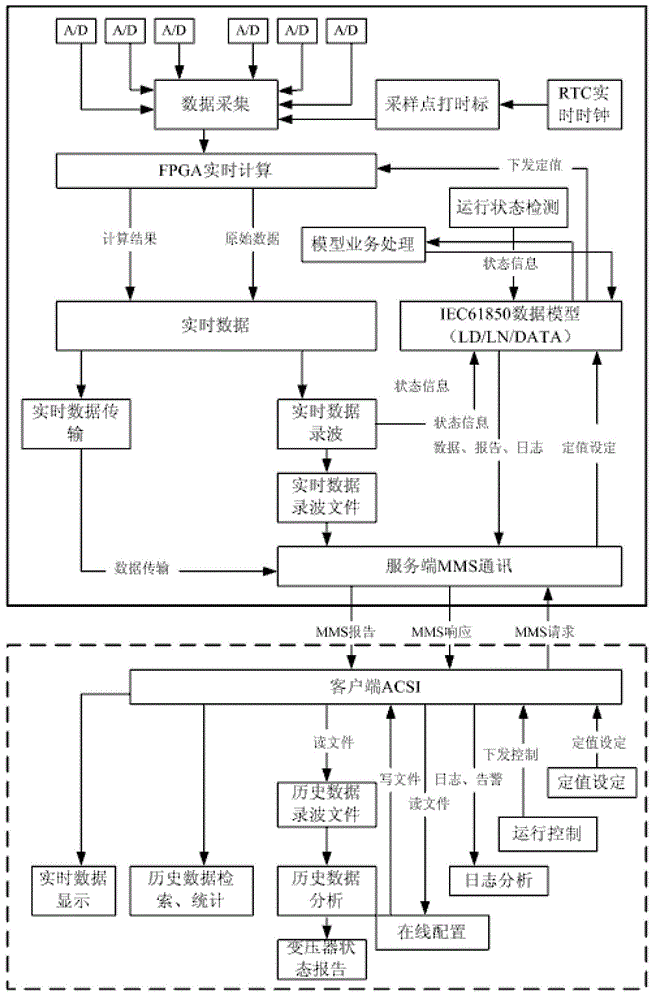

Comprehensive monitoring system for electric power system transformers

ActiveCN102981084AExtended service lifeImprove accuracyTesting dielectric strengthGas analysisMathematical model

A comprehensive monitoring system for electric power system transformers comprises an IEC61850-based unified modularized CPU (central processing unit) hardware platform, a sensor, a system terminal, at least one of nine monitoring logical devices, and further comprises an expert analysis system, including a thermal management mathematical model and an oil and gas analysis mathematical model, wherein by configuring and starting software, a function for monitoring corresponding LDs (logical device) which are independent of one another is achieved; and by performing independent effective data acquisition on the transformers respectively, and integrating and processing the data by the CPU, the electric power system transformers are comprehensively monitored in a configurable way. The comprehensive monitoring system for the electric power system transformers is convenient and flexible in application; current situations of repeated data acquisition, and shortage of data integration, data processing, information exchange and information sharing are changed; conversion from the conventional mechanism-based timed maintenance to the state-based preventative maintenance is facilitated; the maintenance cost is obviously saved; service lives of the transformers are prolonged; and a customer can obviously reduce the purchase cost and the management cost.

Owner:SHENZHEN SHUANGHE ELECTRIC CO LTD

Wireless communication system for welding-type devices

A welding-type device has wireless communications to transmit wireless signals comprising at least identification information or location information. The information may be transmitted either automatically or in response to request signals. Such a welding-type device may be configured to communicate with other welding-type devices, a monitoring device, or both. A wireless communication system has at least one welding-type device, at least one wireless communication assembly, and at least one monitoring device and is capable of assisting a user in locating particular welding-type devices, preventing theft of welding-type devices, and scheduling preventive maintenance.

Owner:ILLINOIS TOOL WORKS INC

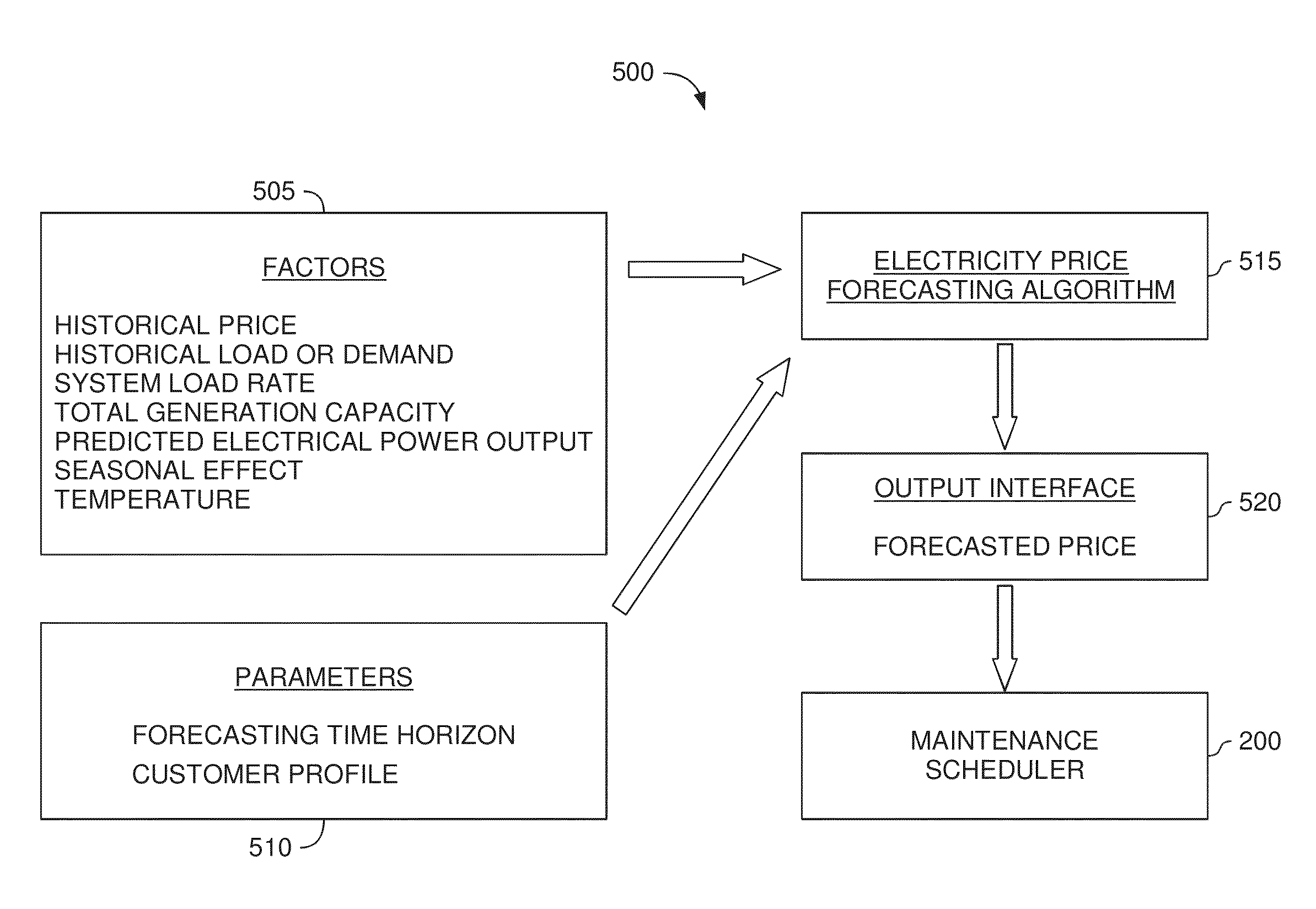

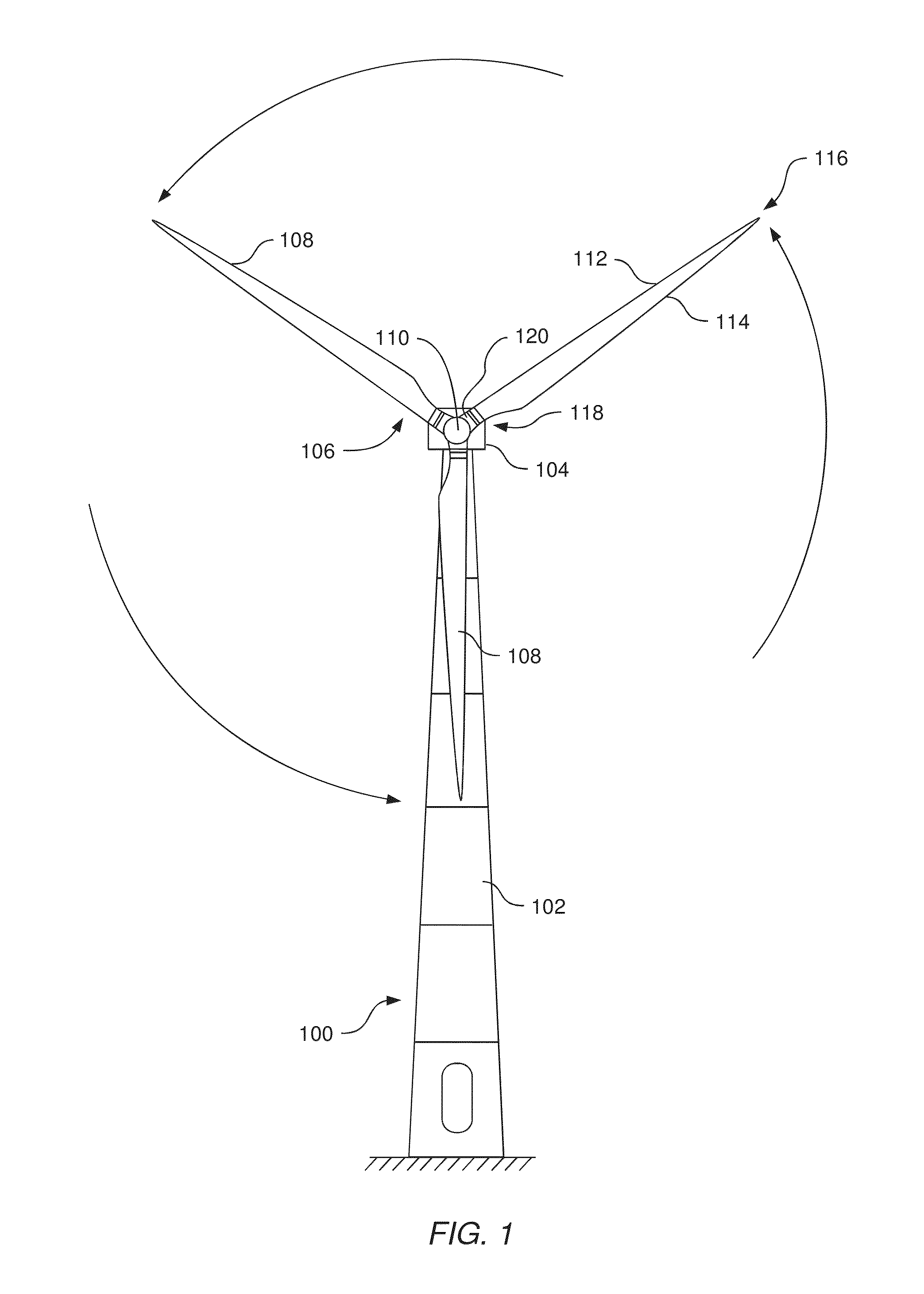

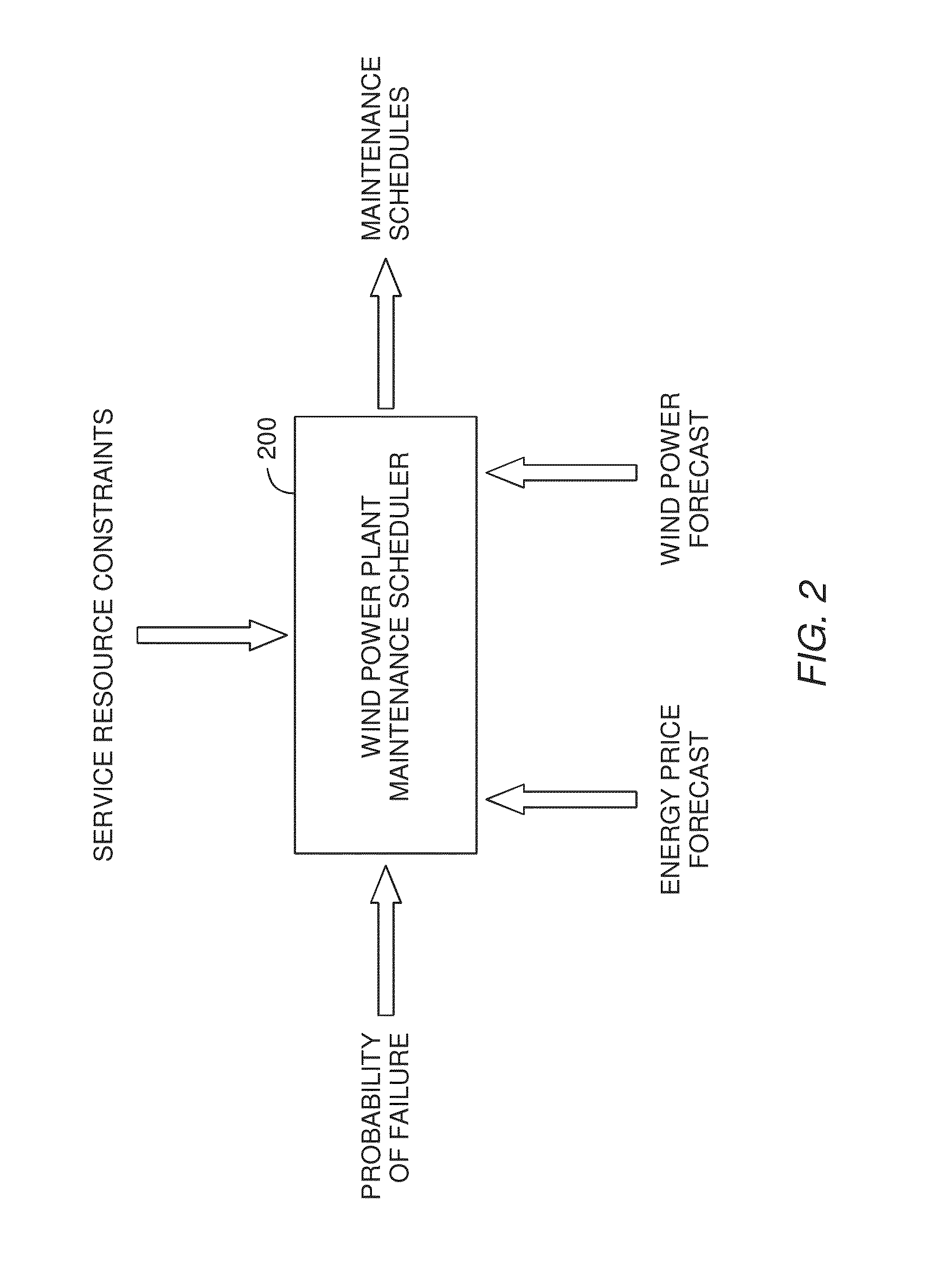

Wind turbine maintenance optimizer

Determining when to perform preventative maintenance is an important consideration for maximizing the revenue of a wind turbine. For example, performing preventative maintenance may be cheaper than replacing turbine components when they fail. When determining to perform preventative maintenance, a maintenance scheduler may consider multiple factors. These factors may include the probability of failure, the predicted price of energy, predicted wind power production, resource constraints, and the like. Specifically, the maintenance scheduler may predict the future values of these factors which are then integrated into a net present value (NPV) for each of the components. Based on the respective NPVs, the maintenance scheduler may determine which maintenance actions to perform and in what order.

Owner:VESTAS WIND SYST AS

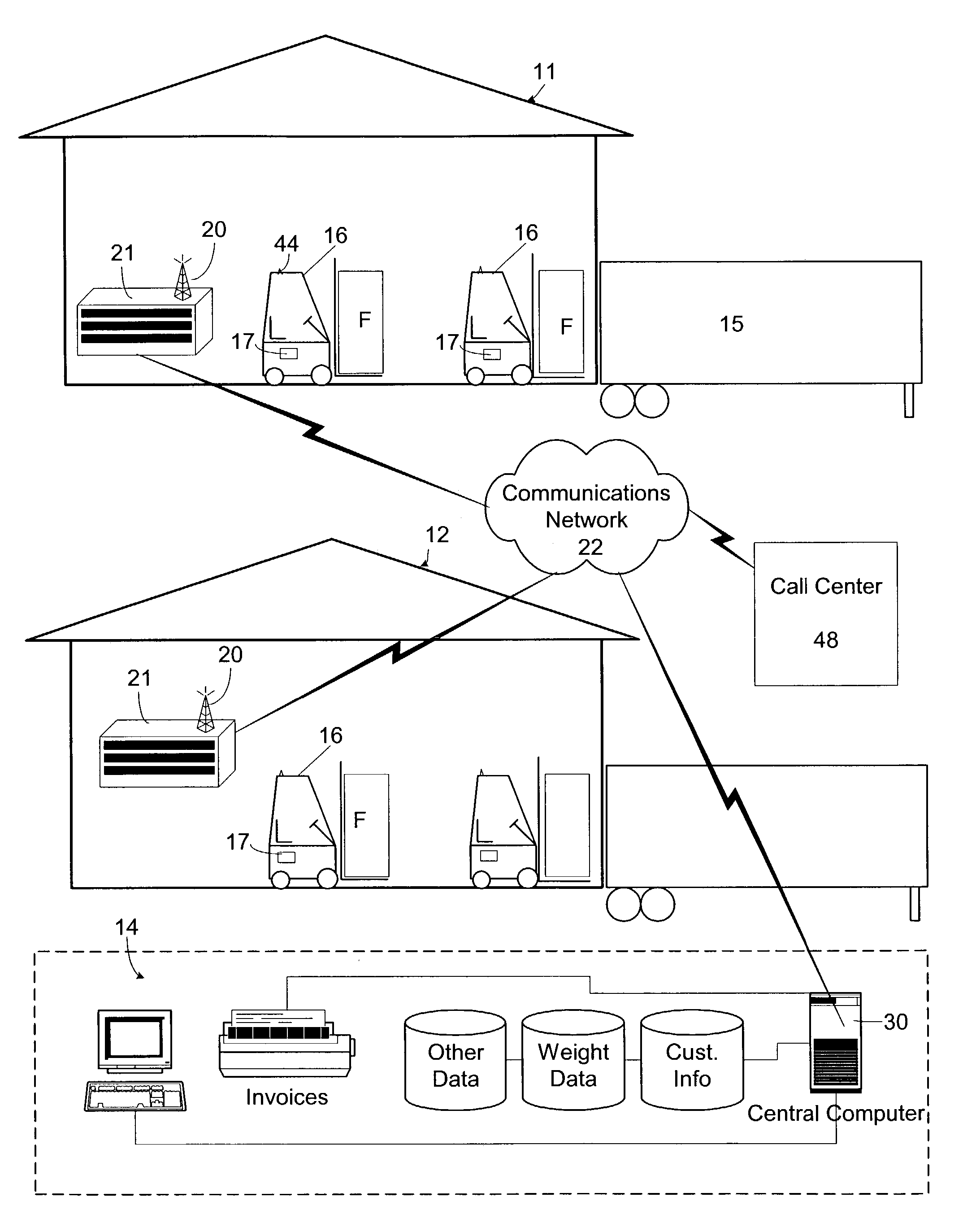

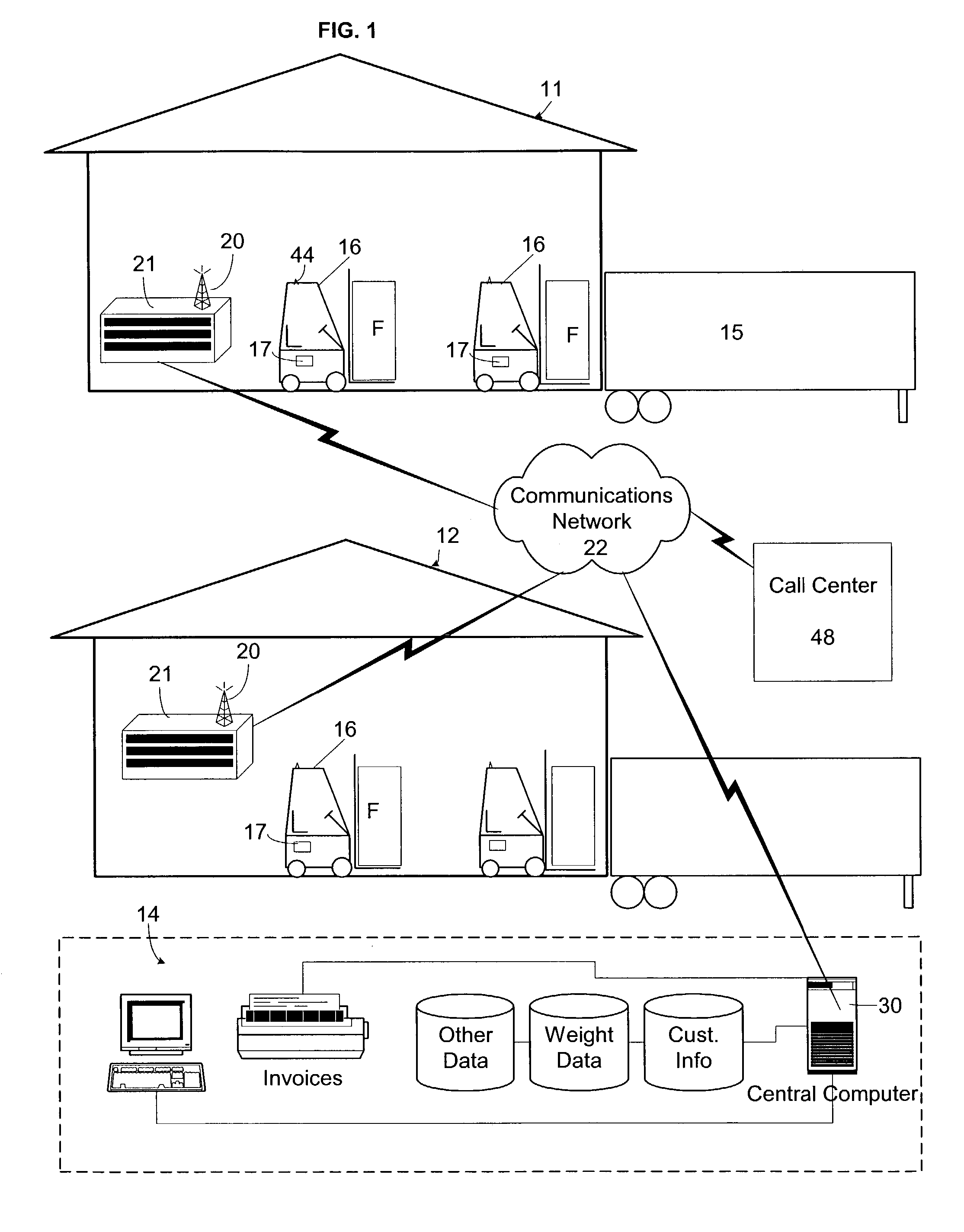

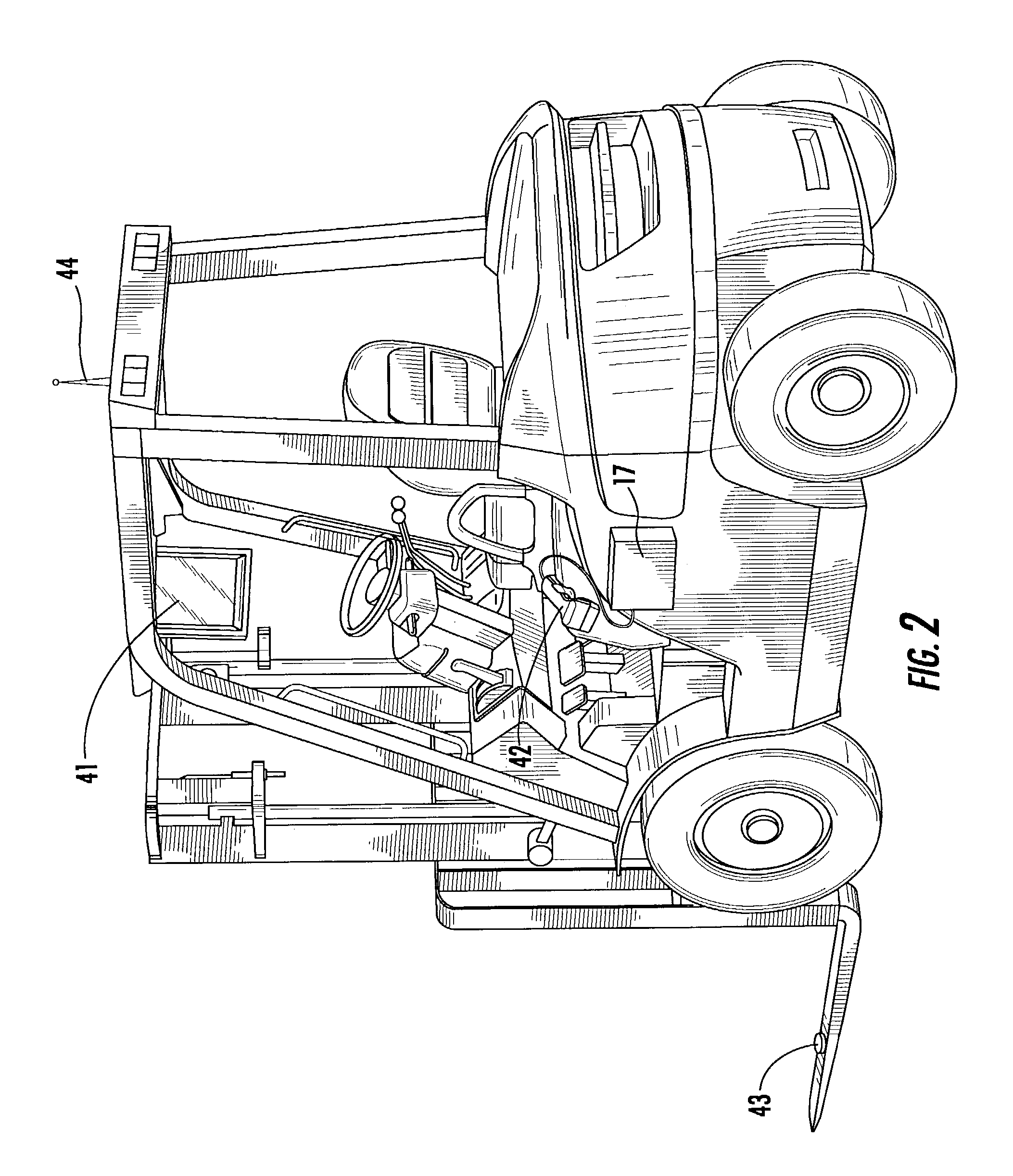

System and method for weighing and tracking freight

InactiveUS6983883B2Improve timelinessEnhanced labor savingAnalogue computers for trafficDigital computer detailsResource informationComputerized system

In a freight shipment system and method, the lift trucks used by the freight carrier for handling and loading freight shipments are equipped with a weighing device capable of weighing each piece of freight handled by the lift truck. The lift truck is also equipped with a scanner for scanning coded identifying information associated with each piece of freight. As each piece of freight is handled by the lift truck, the coded identifying information for that piece of freight is captured along with the weight of the load. This information is transmitted to a computer system where it can be used for real-time invoicing. The system can also use the captured information to perform additional automated functions, such as tracking of shipments, freight loss control, and assisting in avoiding overloaded trucks. The same system can monitor maintenance information for the lift trucks so as to provide timely preventive maintenance, and can also provide the human resources information, such as the lift truck driver identification and amount of time worked.

Owner:SPEED TRAC TECH

Integrated wafer fabrication production characterization and scheduling system

InactiveUS6889178B1Technology managementTotal factory controlManufacture execution systemWafer fabrication

An integrated wafer fab production scheduling and simulation system incorporates a manufacturing execution system with a scheduling system based on simulation. The integrated system provides manufacturers with a simulation tool integrated with the manufacturing execution system to evaluate proposed production control logic as a practical alternative to expensive experimentation on an actual production system. Furthermore, simulation models are used to create short-term dispatch schedules to steer daily manufacturing operations towards planned performance goals. Innovative features include integration of preventive maintenance scheduling, Kanban based WIP control, an integrated time standard database, and real time lot move updates.

Owner:SONY CORP +1

Compressor valve health monitor

ActiveUS9759213B2Improve analysisImprove notificationsExternal parameterPositive displacement pump componentsSignal-to-noise ratio (imaging)Engineering

A rotating machine valve health monitor. Aspects of the valve monitor include instrumenting each valve of a reciprocating compressor, or other rotating machine, with a sensor capable of detecting at least vibration and instrumenting the crank shaft with a sensor capable of detecting at least rotation. A controller directly monitors the operation and condition of each valve to precisely identify any individual valve exhibiting leakage issues rather than only identifying the region of the leakage. The valve monitor uses a relatively high frequency stress wave analysis technique to provide a good signal-to-noise ratio to identify impact events indicative of leakage. The valve monitor uses circular waveforms of vibration data for individual valves to identify leakage by pattern recognition or visual identification. The valve monitor provides ongoing data collection to give warning of predicted valve failure and scheduling of preventative maintenance for failing valves.

Owner:COMPUTATIONAL SYST

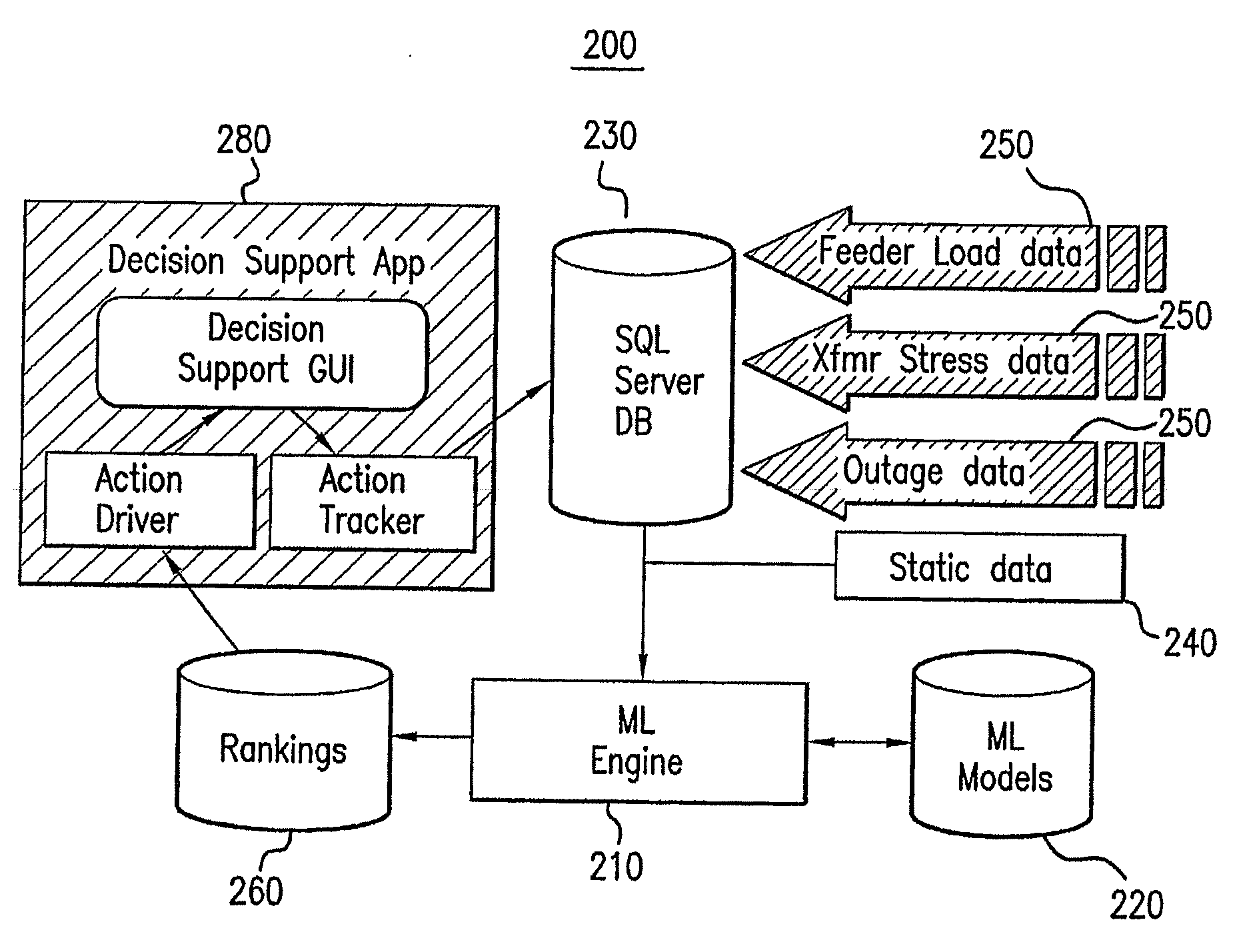

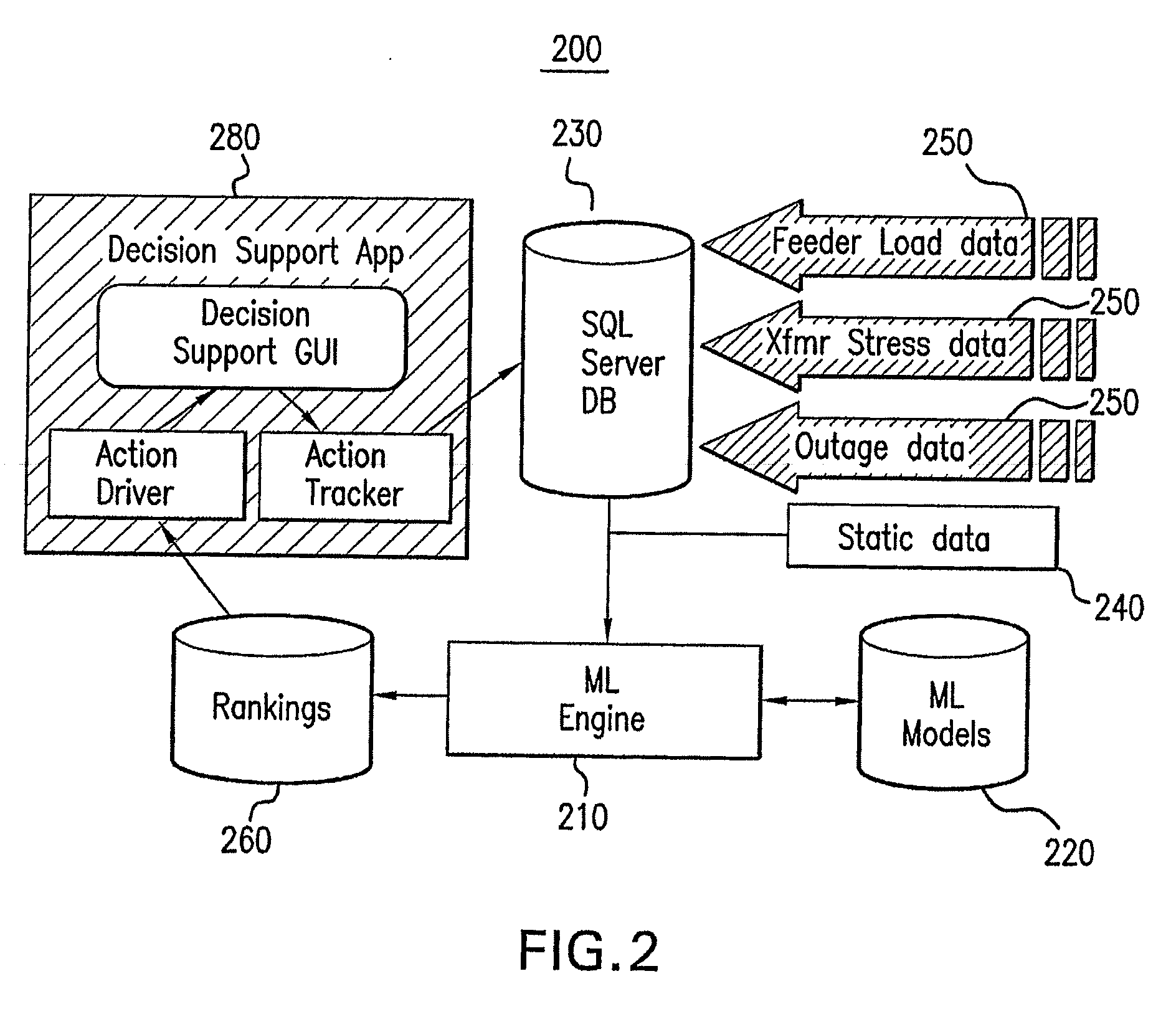

System And Method For Grading Electricity Distribution Network Feeders Susceptible To Impending Failure

InactiveUS20090157573A1Strategy is hamperedReduce operating costsDigital computer detailsMachine learningElectricitySupport vector machine

A machine learning system creates failure-susceptibility rankings for feeder cables in a utility's electrical distribution system. The machine learning system employs martingale boosting algorithms and Support Vector Machine (SVM) algorithms to generate a feeder failure prediction model, which is trained on static and dynamic feeder attribute data. Feeders are dynamically ranked by failure susceptibility and the rankings displayed to utility operators and engineers so that they can proactively service the distribution system to prevent local power outages. The feeder rankings may be used to redirect power flows and to prioritize repairs. A feedback loop is established to evaluate the responses of the electrical distribution system to field actions taken to optimize preventive maintenance programs.

Owner:CONSOL EDISON OF NEW YORK +1

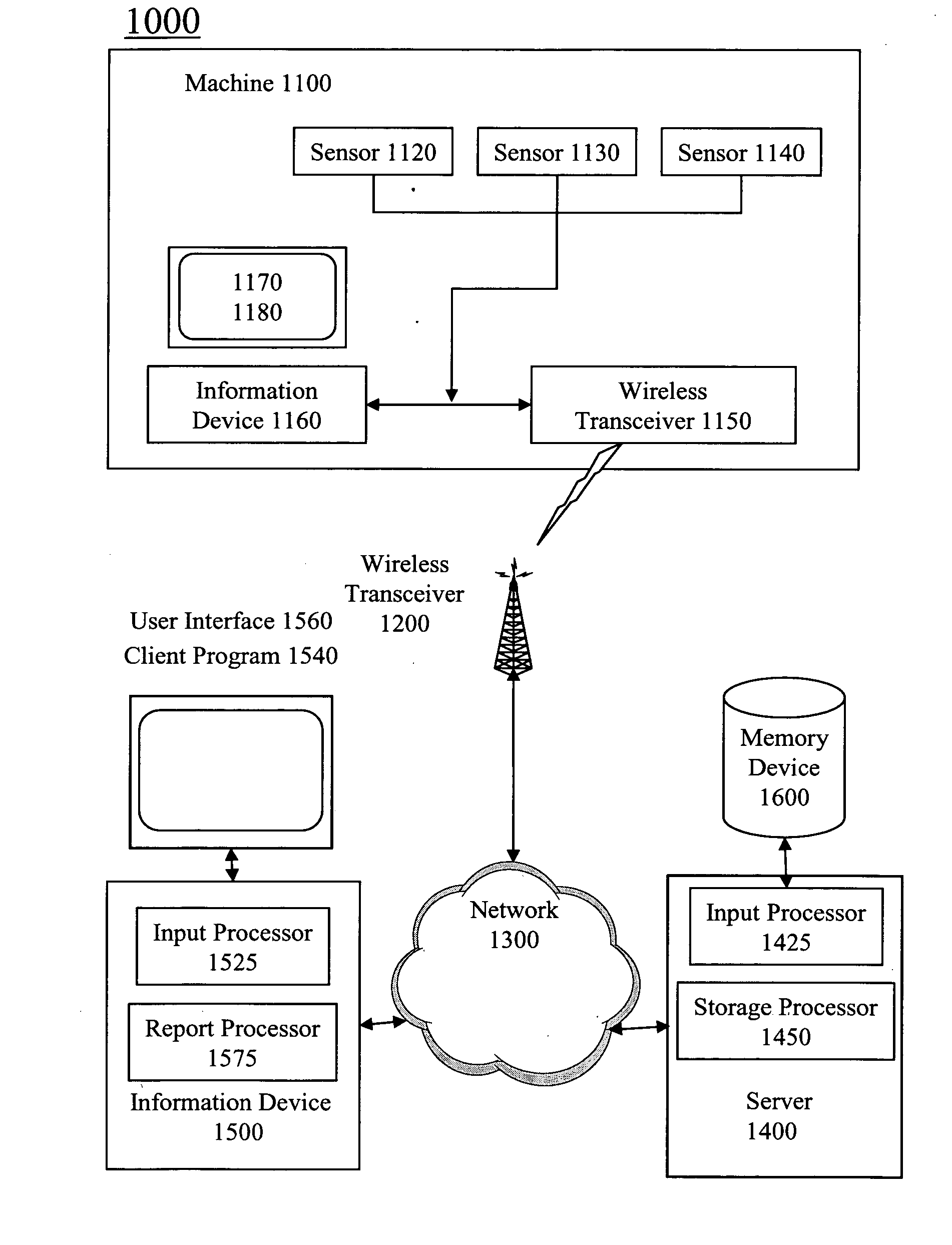

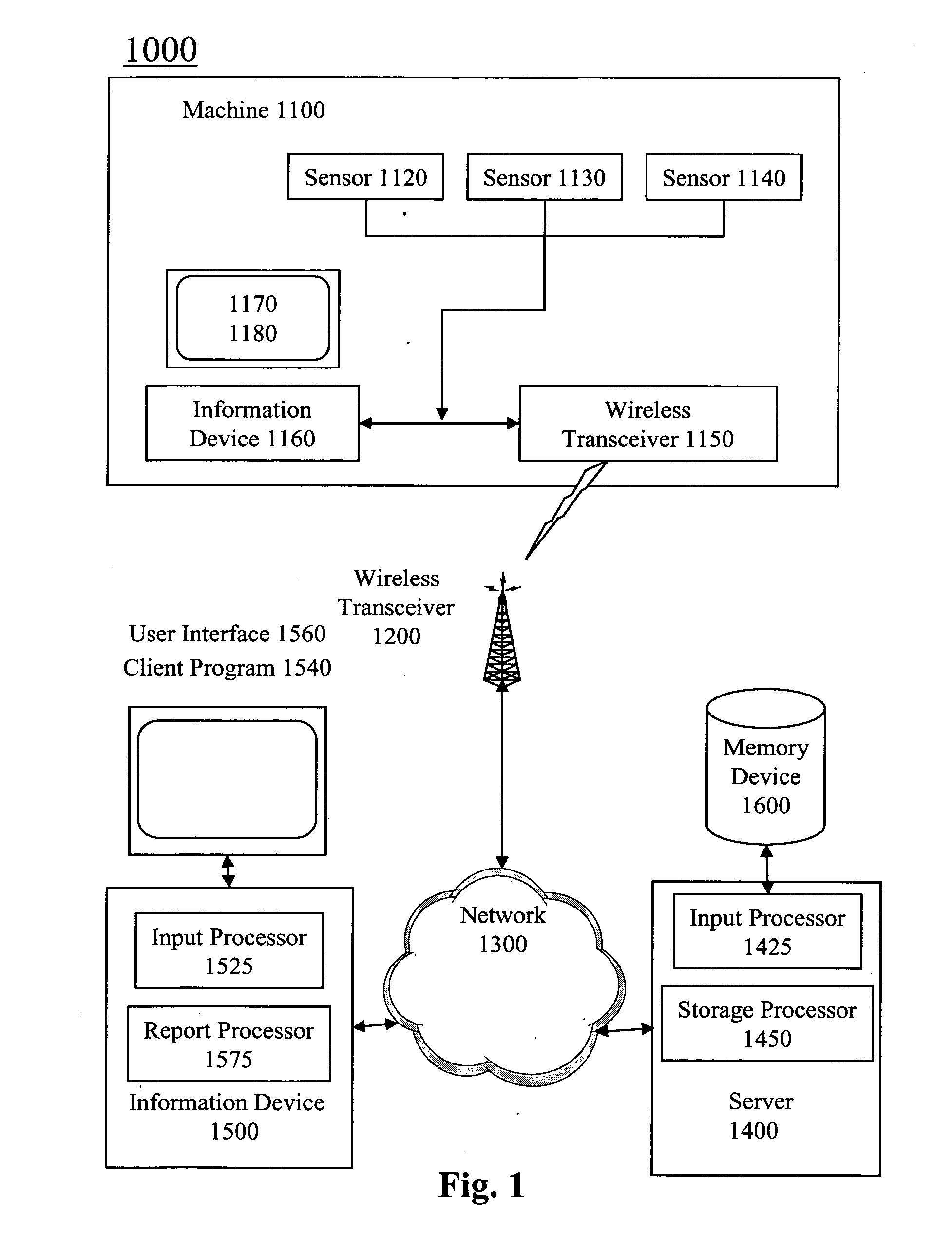

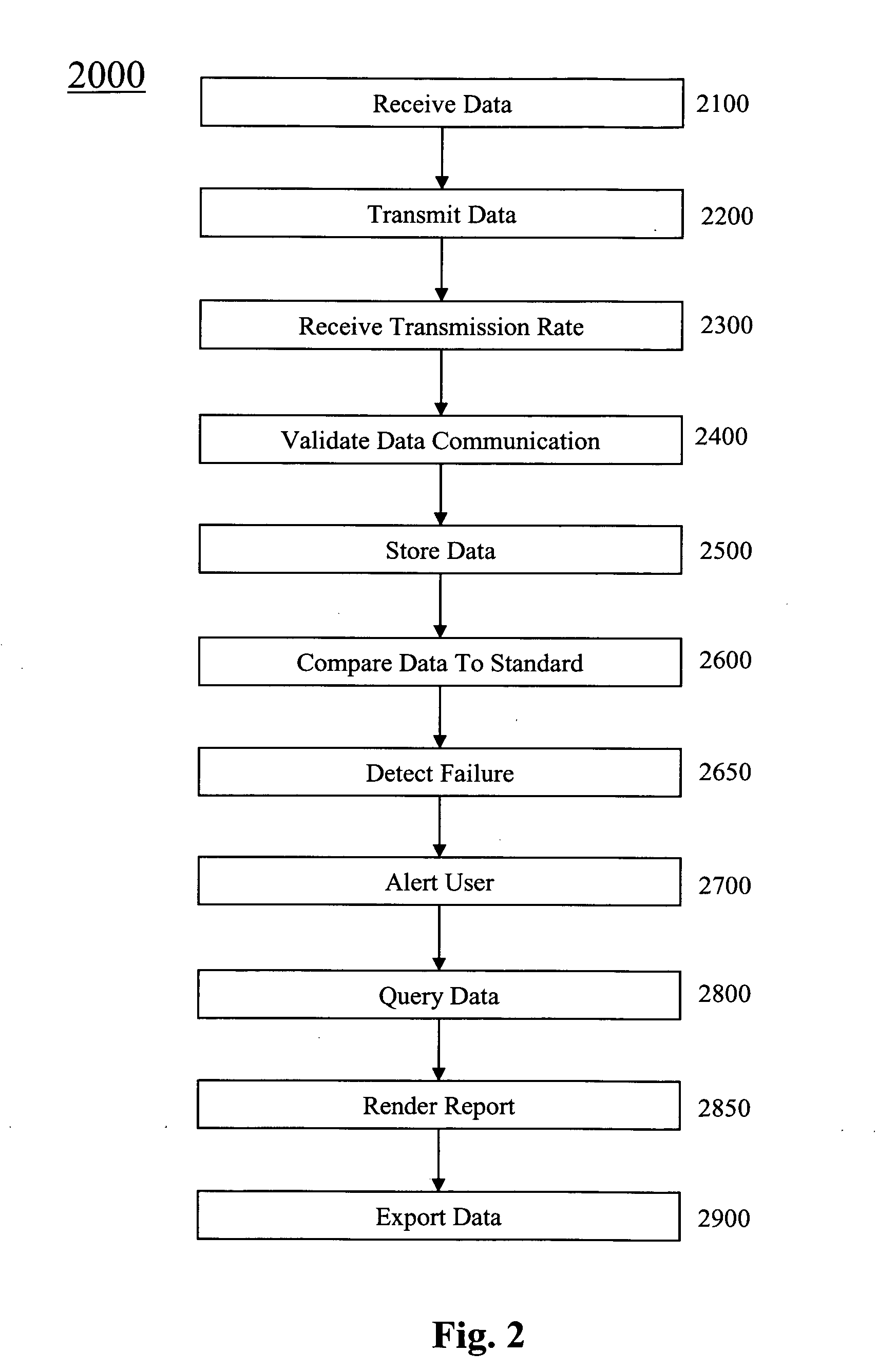

System and method for remotely obtaining and managing machine data

ActiveUS20050083196A1Electric signal transmission systemsAnalogue computers for trafficAnalysis dataComputer science

Certain exemplary embodiments can comprise obtaining and analyzing data from at least one discrete machine, automatically determining relationships related to the data, taking corrective action to improve machine operation and / or maintenance, automatically and heuristically predicting a failure associated with the machine and / or recommending preventative maintenance in advance of the failure, and / or automating and analyzing mining shovels, etc.

Owner:SIEMENS ENERGY & AUTOMATION INC

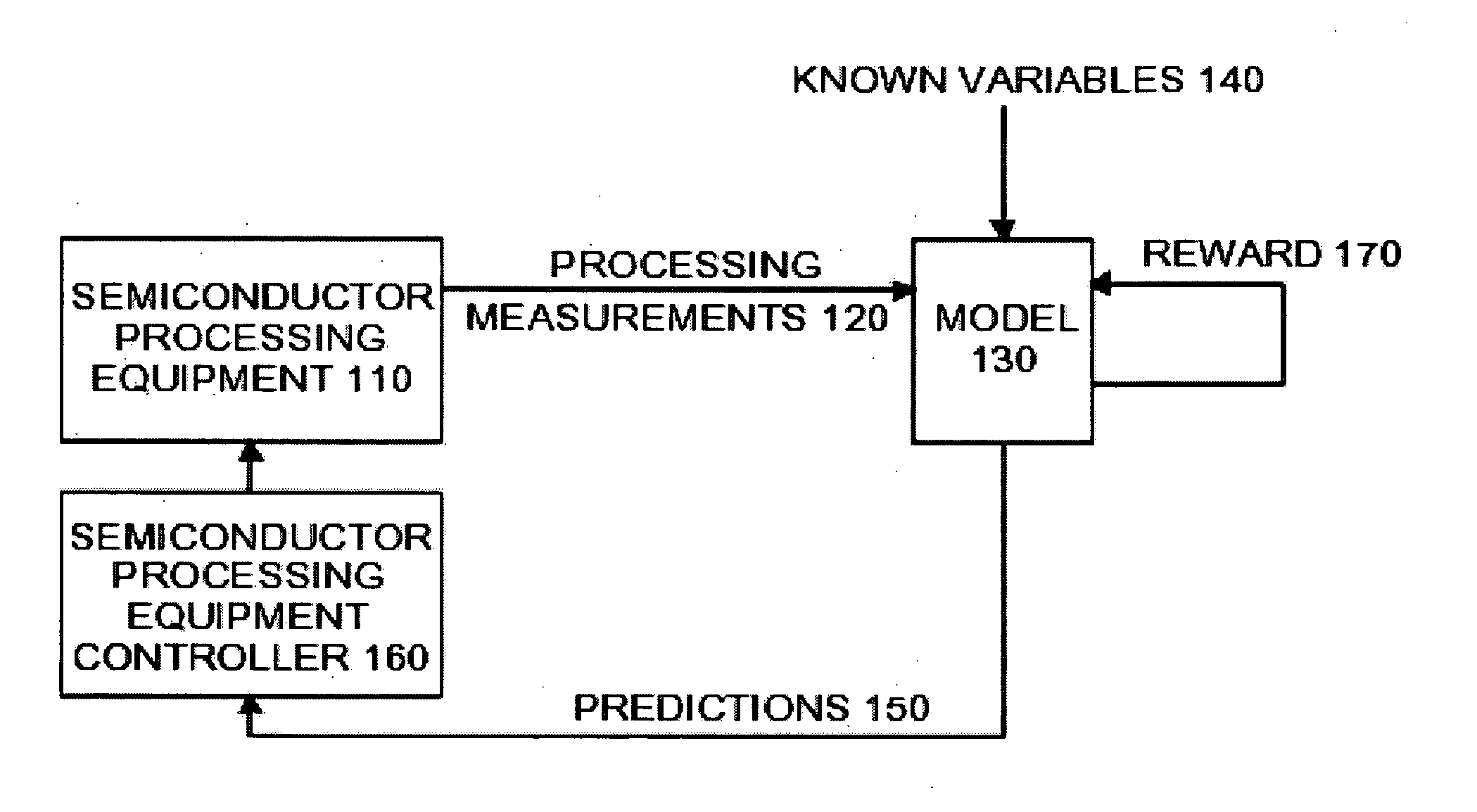

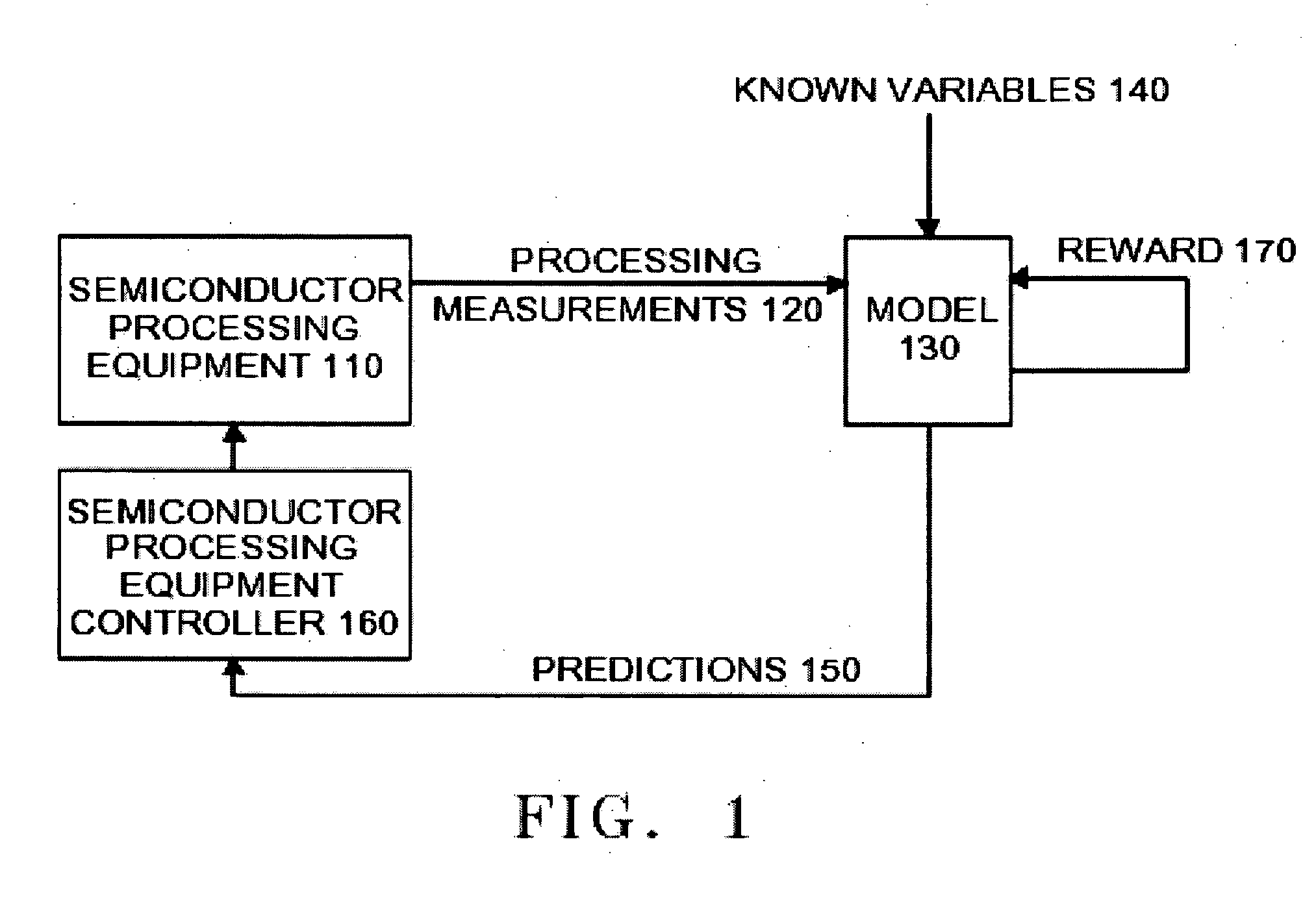

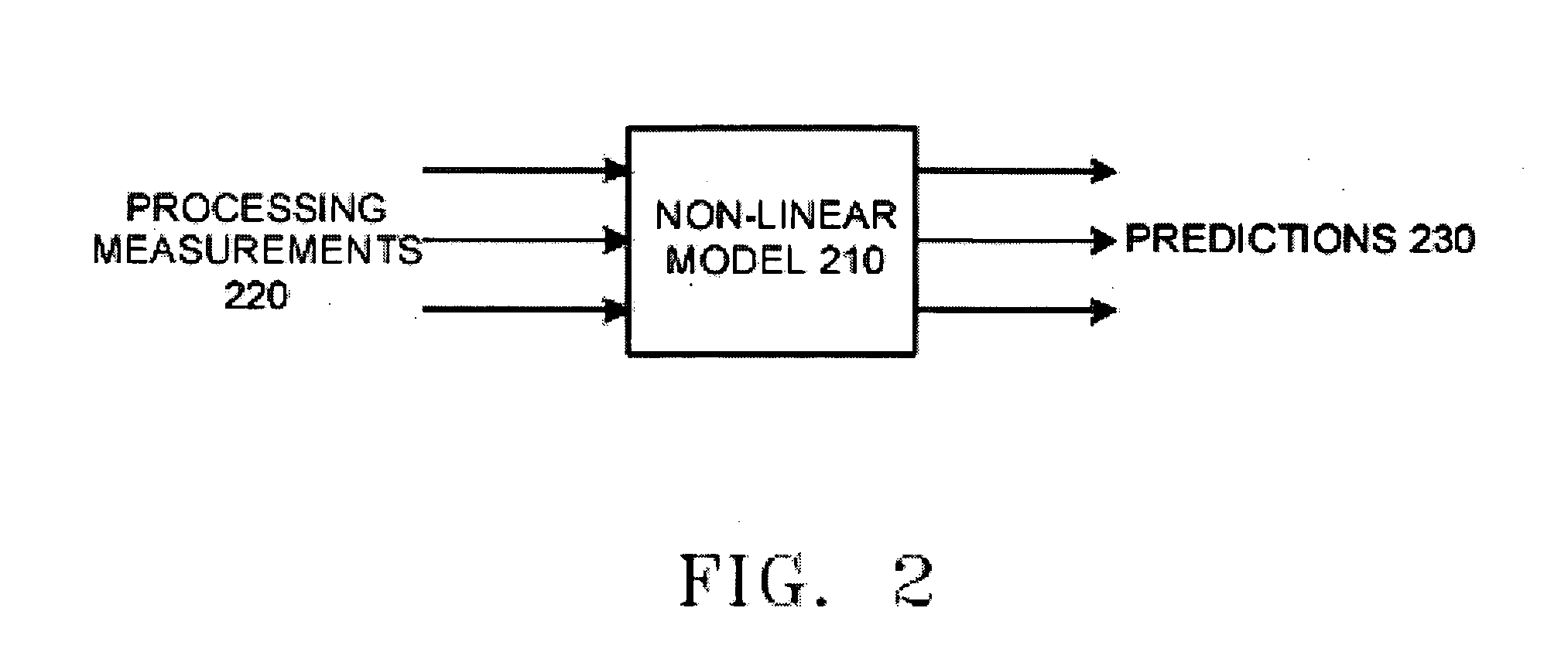

Intelligent system for detection of process status, process fault and preventive maintenance

Embodiments of an intelligent modeling method and system monitor and perform analysis of semiconductor processing equipment as well as predict future states of that equipment based on the analysis, predict failures of the semiconductor processing equipment and / or determine equipment maintenance schedules.

Owner:TOKYO ELECTRON LTD

Wireless system for prevantative maintenance of welding-type devices

A welding-type device has wireless communications to transmit wireless signals comprising at least maintenance information. The information may be transmitted either automatically or in response to request signals. Such a welding-type device may be configured to communicate with other welding-type devices, a monitoring device, or both. A wireless communication system has at least one welding-type device, at least one wireless communication assembly, and at least one monitoring device and is capable of assisting a user in scheduling preventive maintenance.

Owner:ILLINOIS TOOL WORKS INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com