Patents

Literature

184 results about "Optimal maintenance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

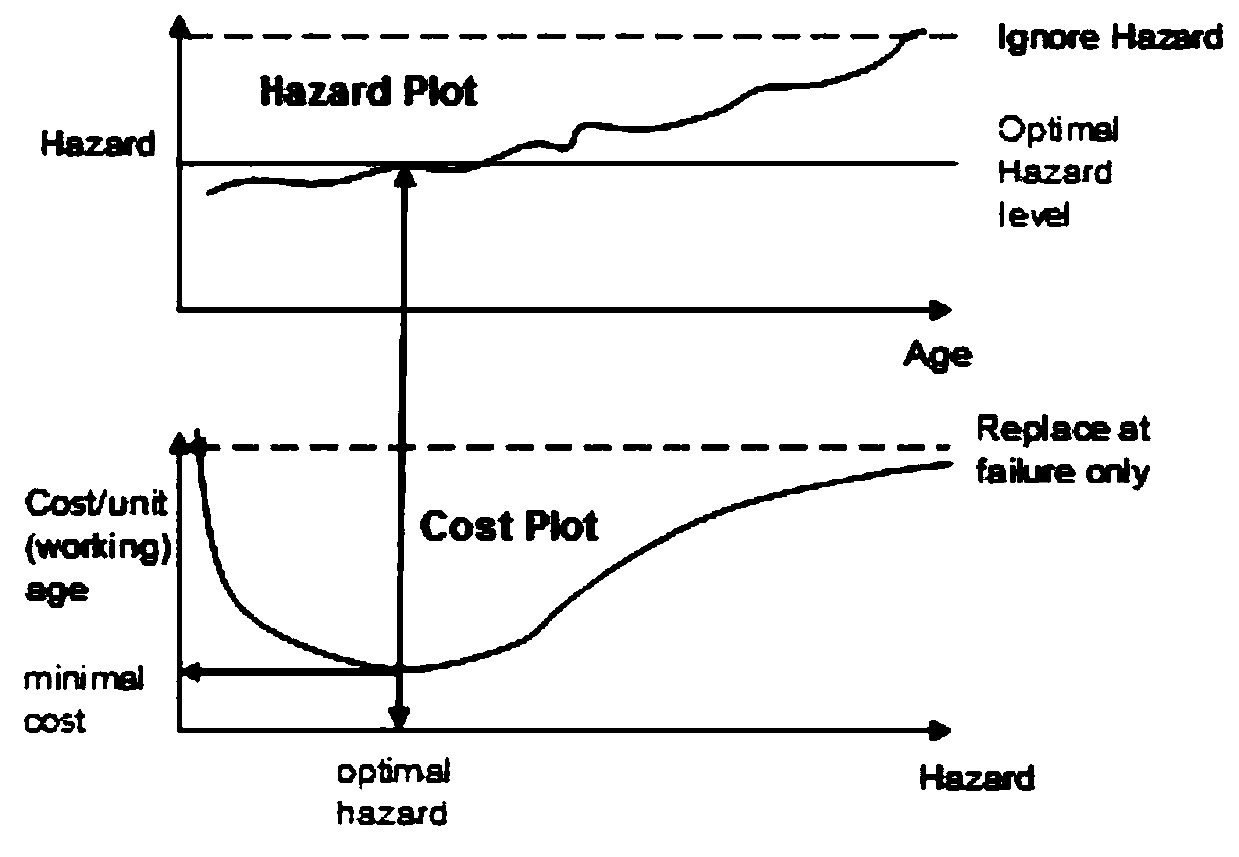

Optimal maintenance is the discipline within operations research concerned with maintaining a system in a manner that maximizes profit or minimizes cost. Cost functions depending on the reliability, availability and maintainability characteristics of the system of interest determine the parameters to minimize. Parameters often considered are the cost of failure, the cost per time unit of "downtime" (for example: revenue losses), the cost (per time unit) of corrective maintenance, the cost per time unit of preventive maintenance and the cost of repairable system replacement [Cassady and Pohl]. The foundation of any maintenance model relies on the correct description of the underlying deterioration process and failure behavior of the component, and on the relationships between maintained components in the product breakdown (system / sub-system / assembly / sub-assembly...).

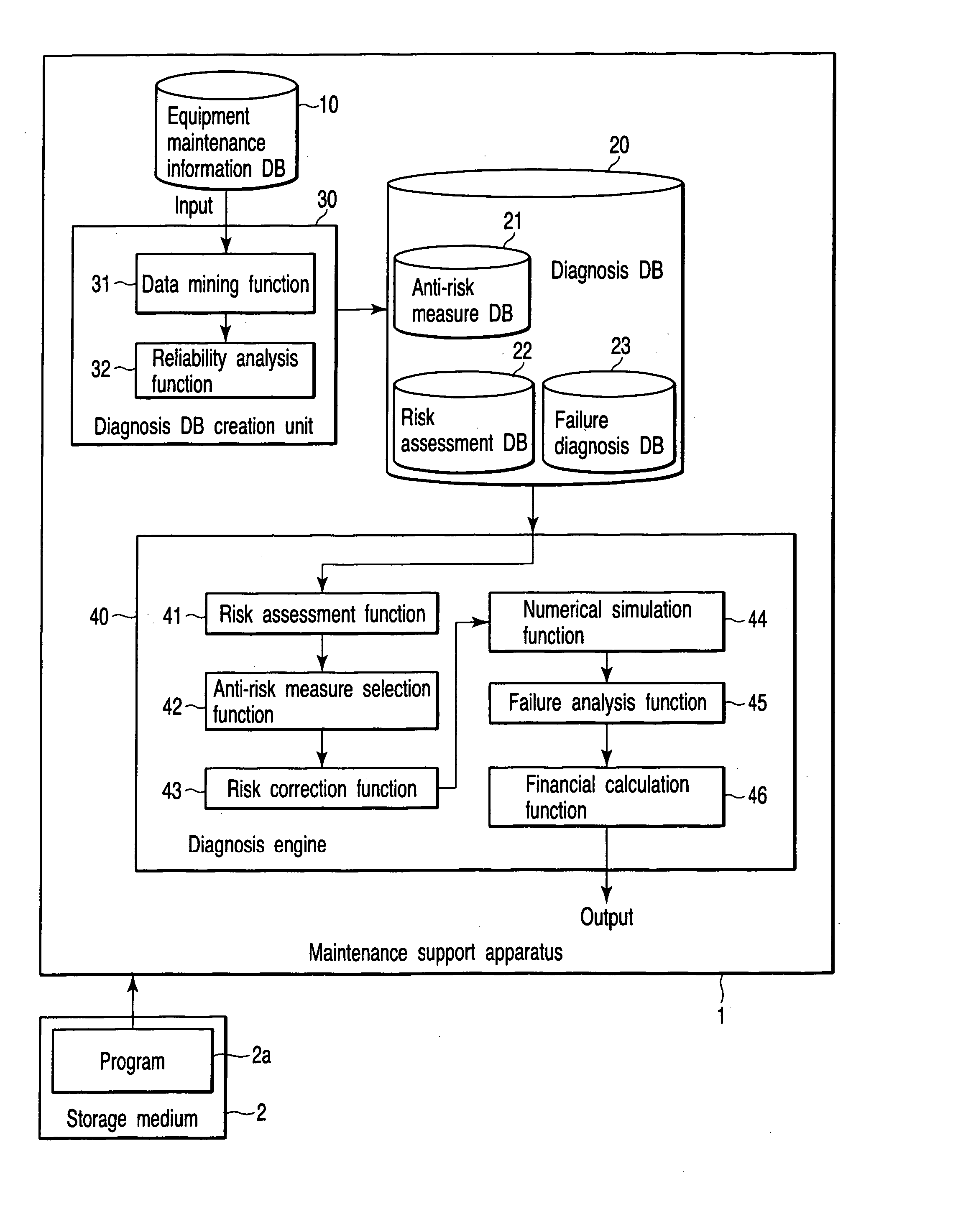

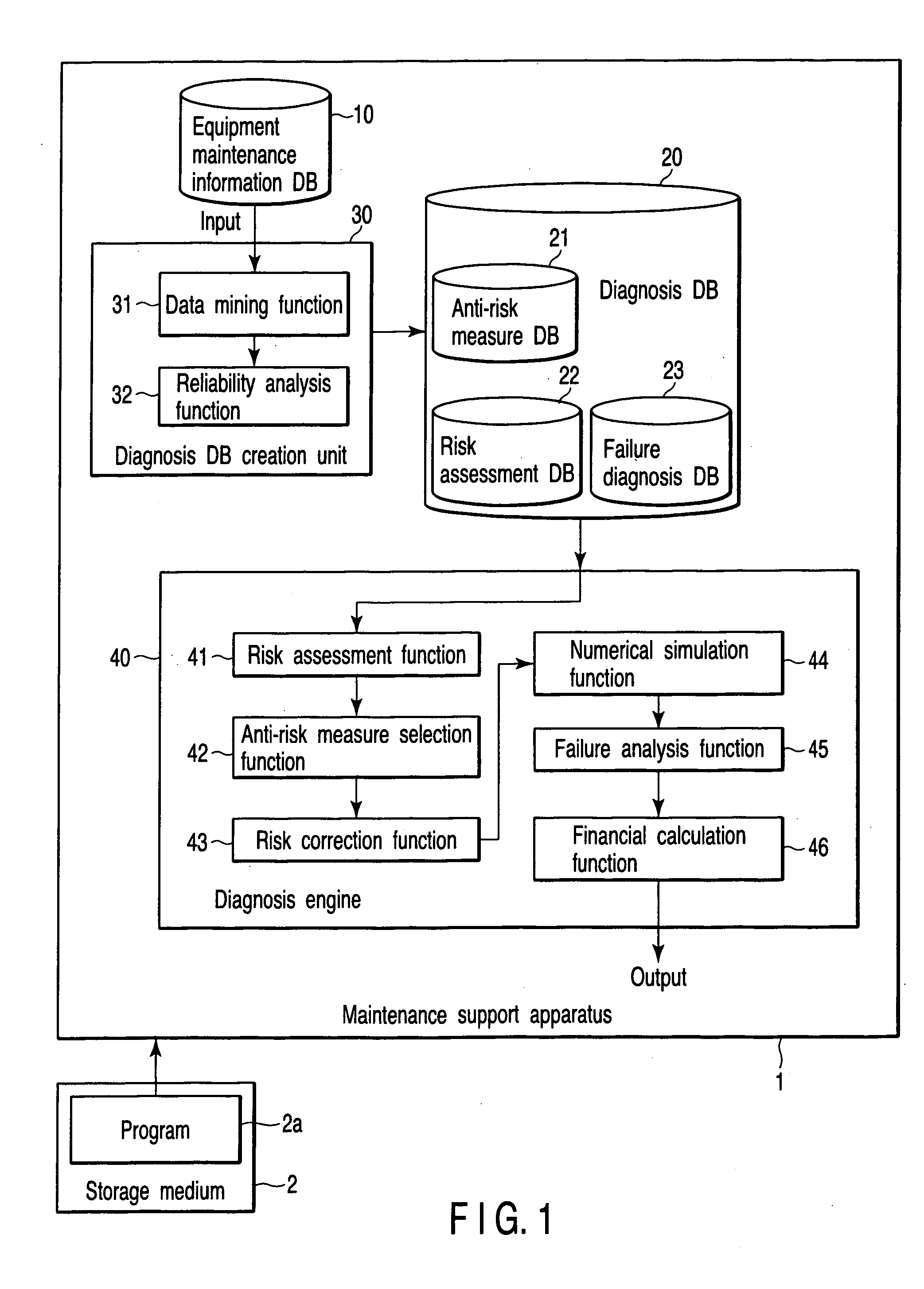

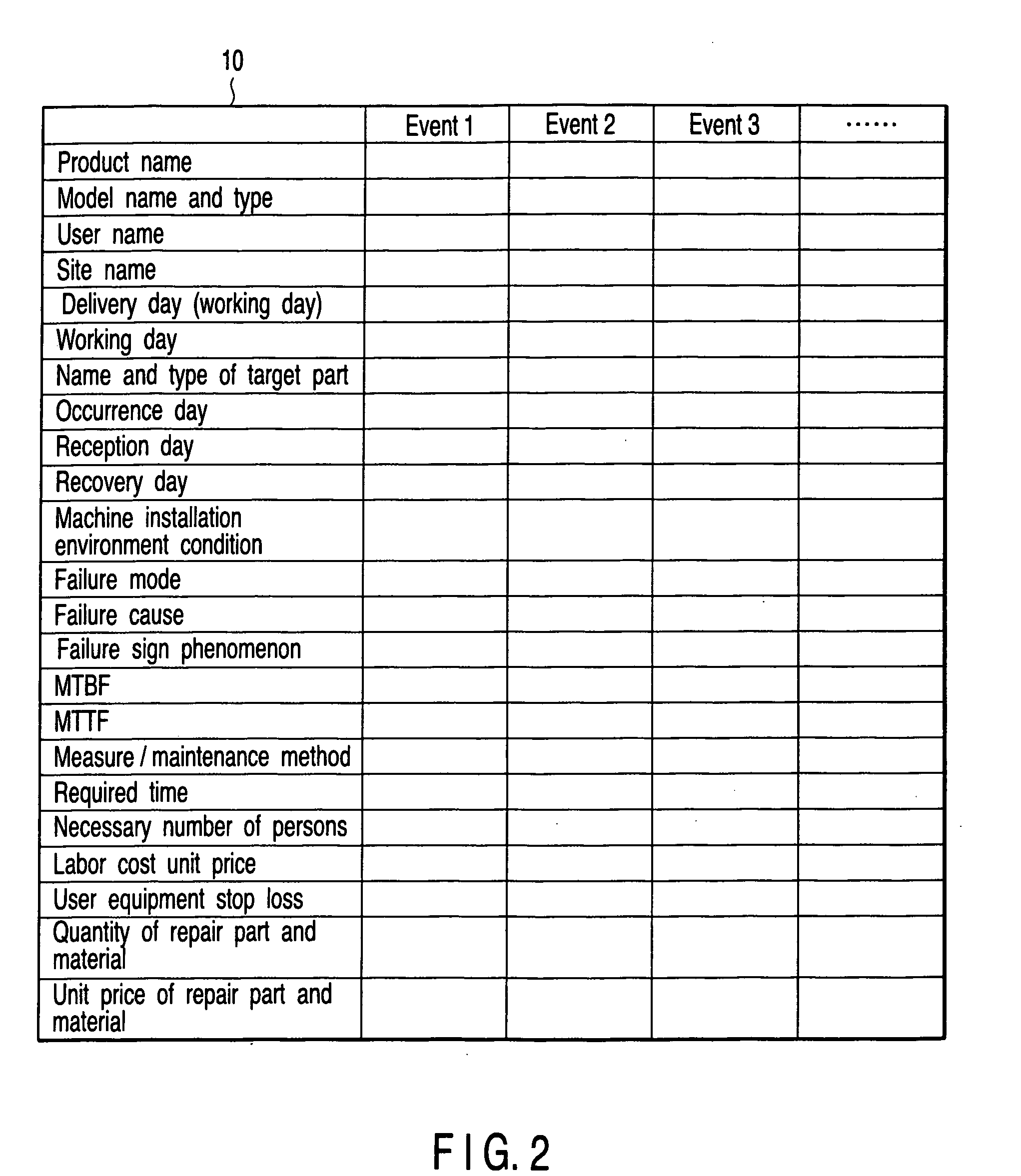

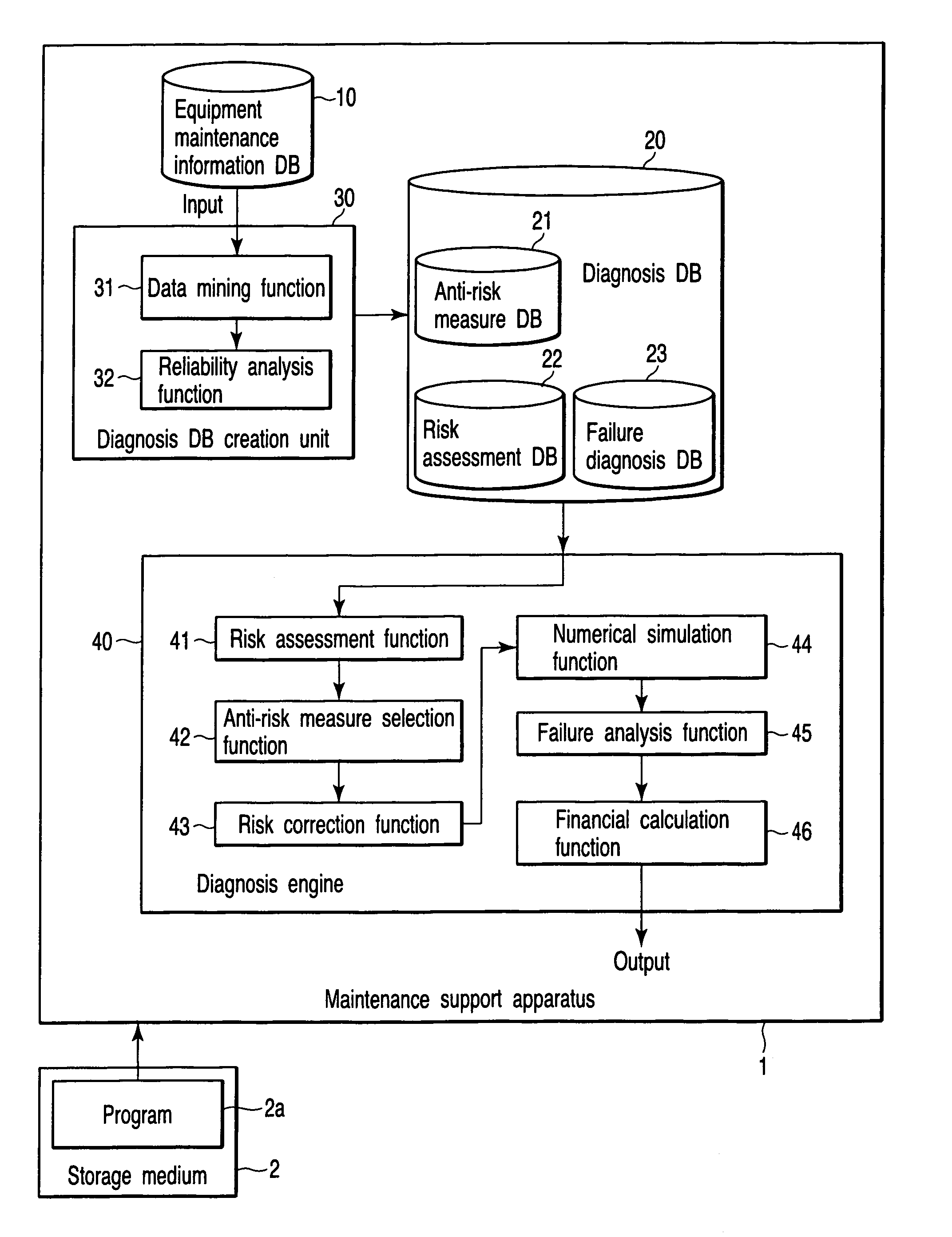

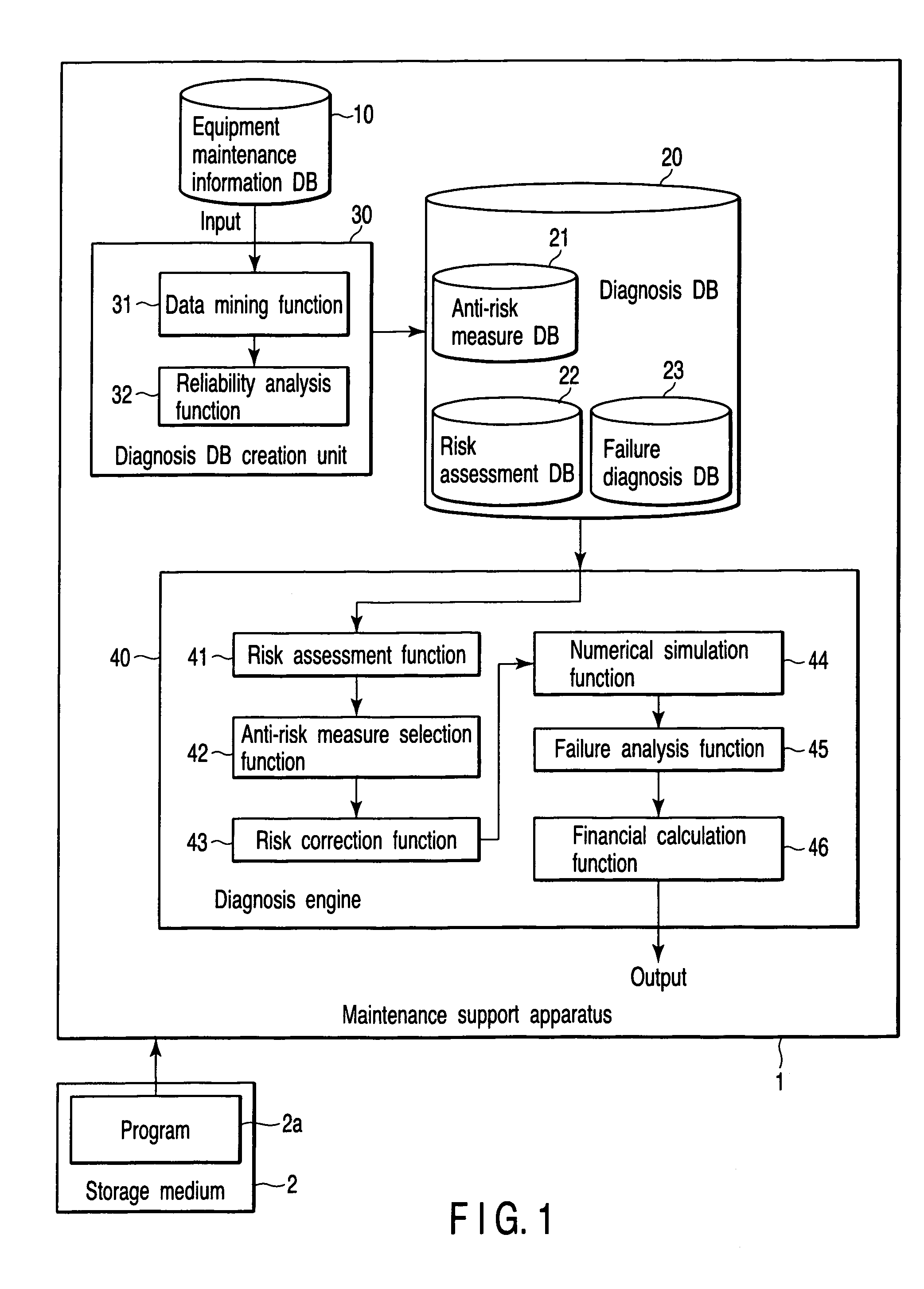

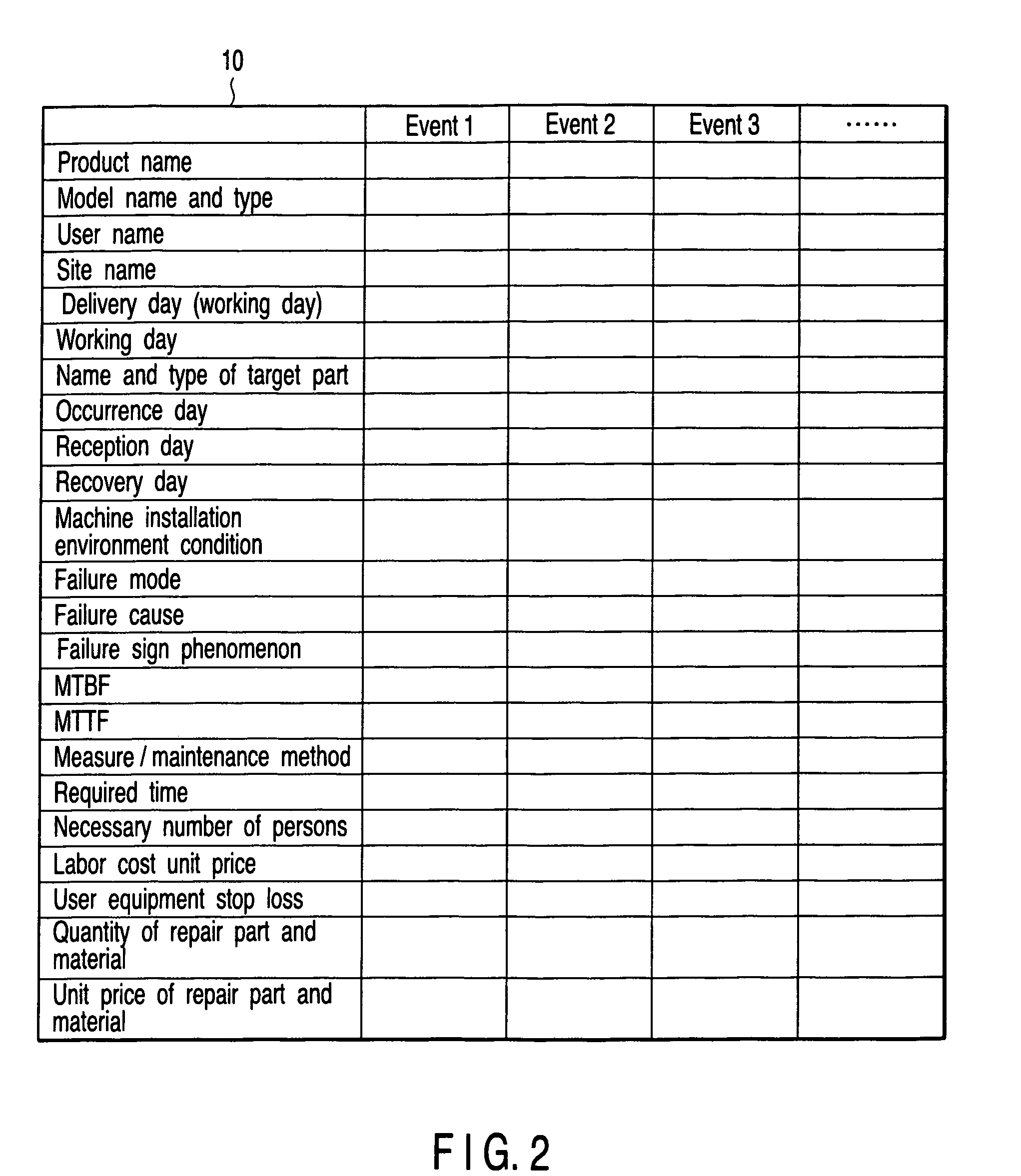

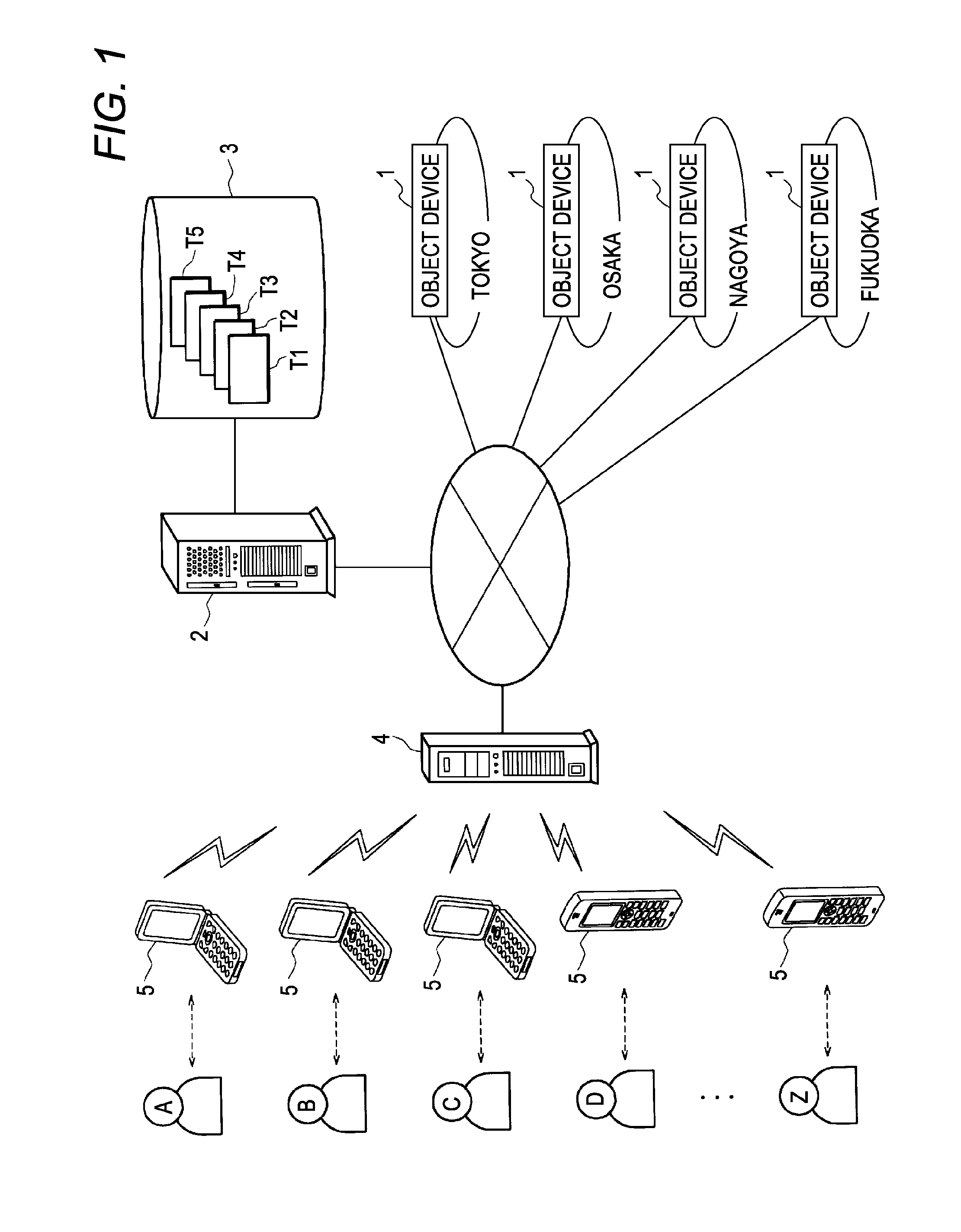

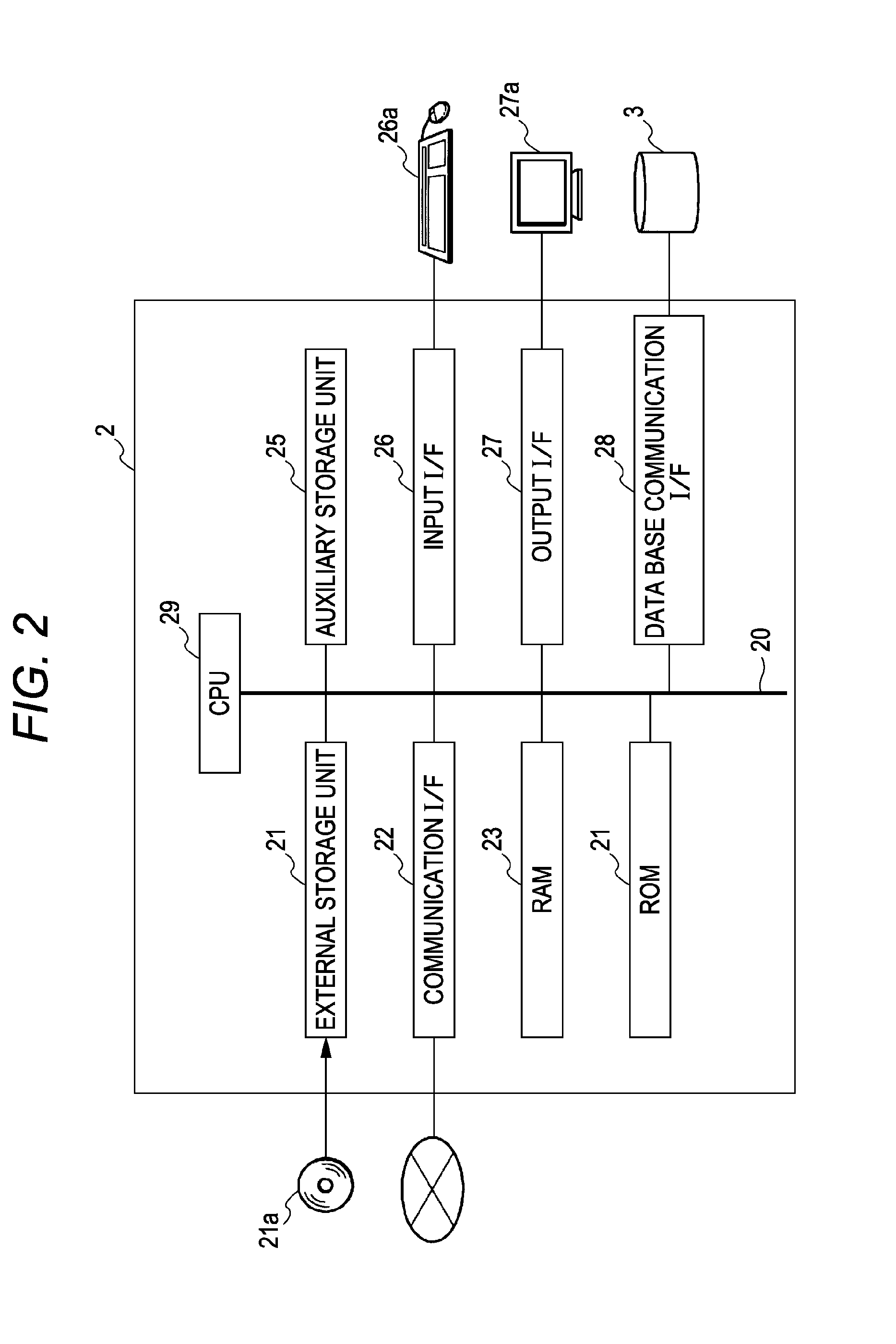

Maintenance support method, storage medium, and maintenance support apparatus

ActiveUS20050149570A1Maintenance cost along the time sequence is minimizedDigital computer detailsNuclear monitoringEngineeringOptimal maintenance

In an embodiment of this invention, a diagnosis engine refers to a risk assessment DB and anti-risk measure DB, calculates along the time sequence a risk estimate amount in case of failure for each device and a maintenance cost in executing a measure method in advance, and adds the risk estimate amount and maintenance cost along the time sequence to calculate an optimum maintenance period of the device. When a failure has occurred in the device, the diagnosis engine refers to a failure diagnosis DB on the basis of the identification information of the device and the failure mode and analyzes, on the basis of an operation record, a failure which is different from a secular change.

Owner:KK TOSHIBA

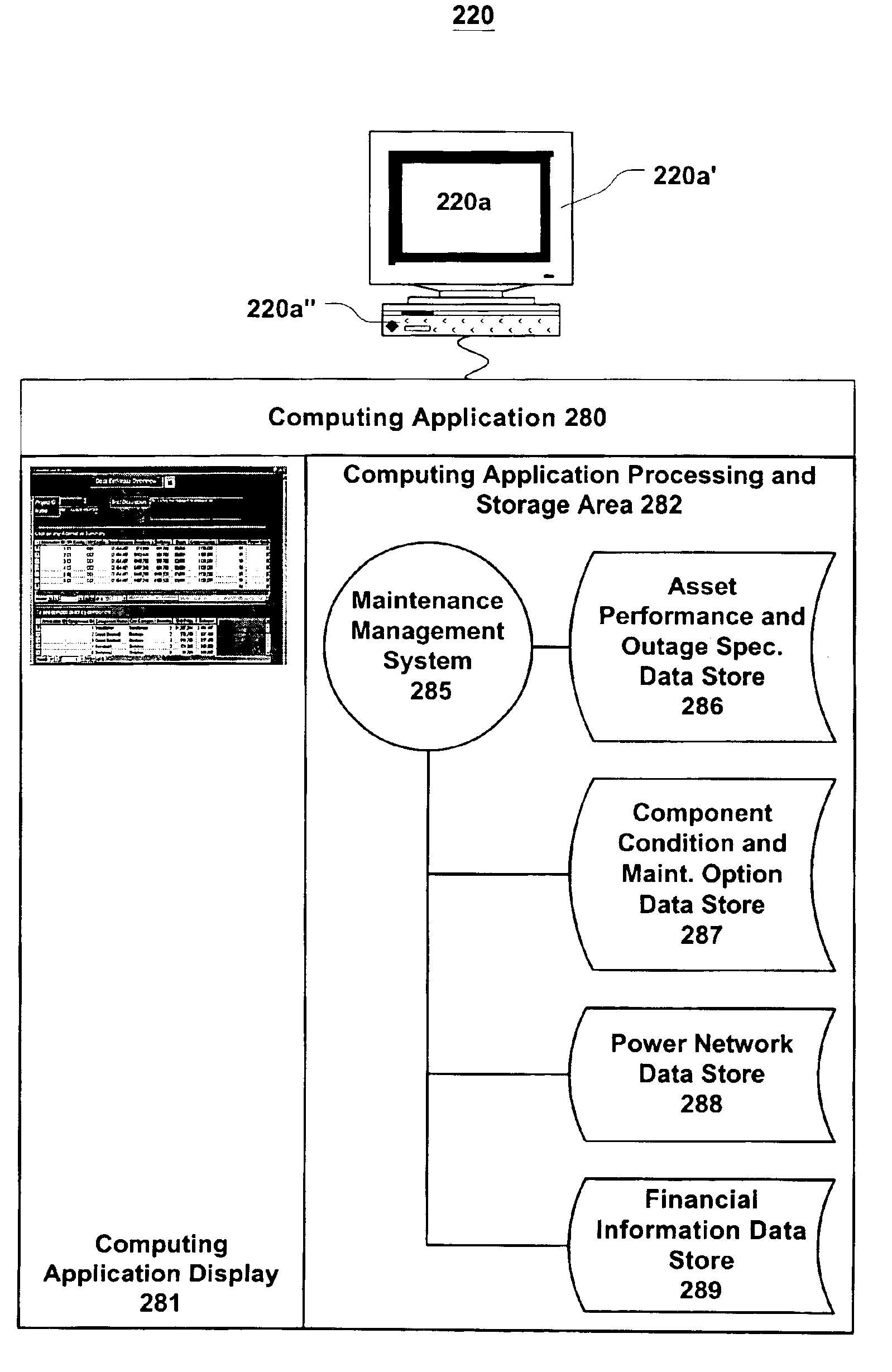

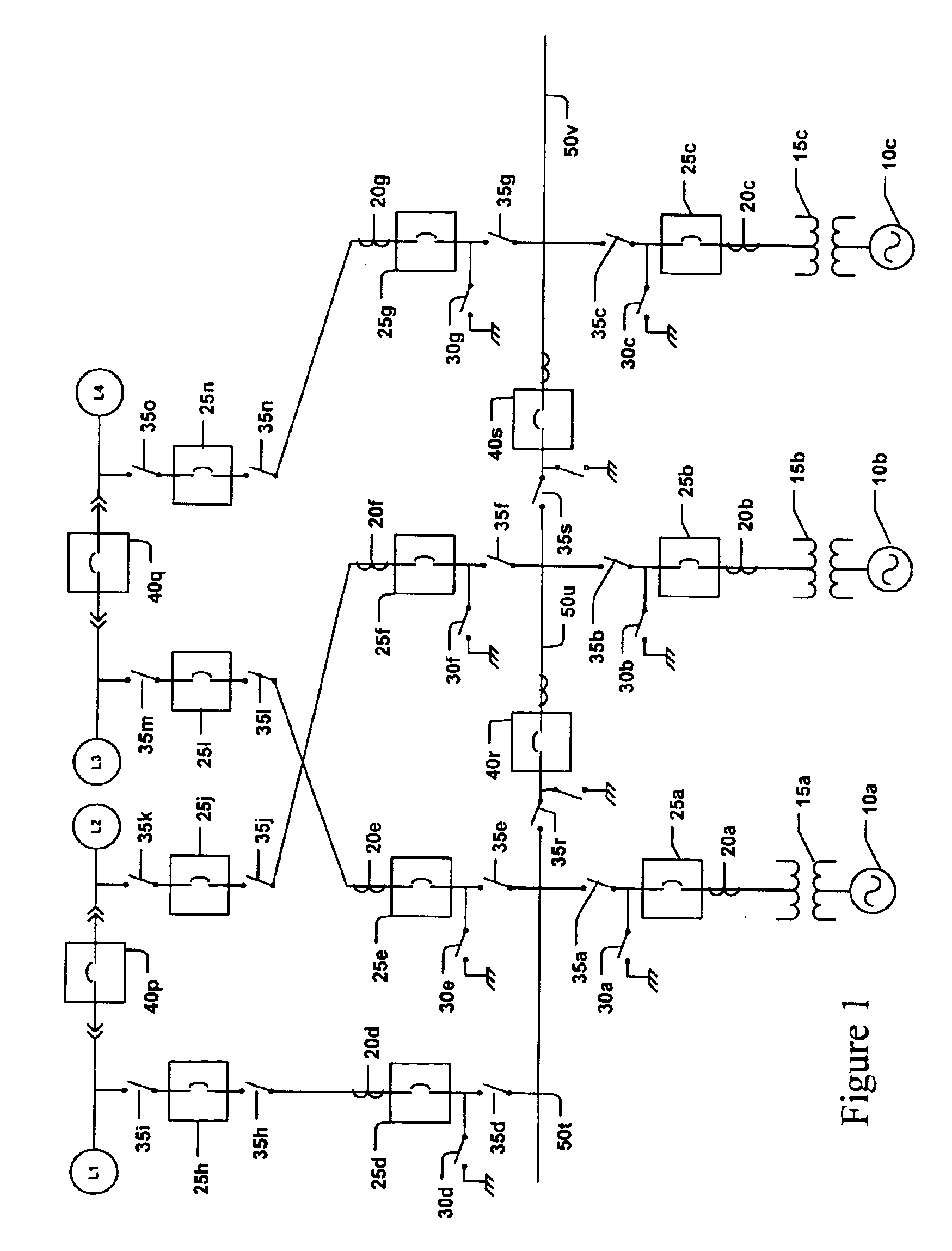

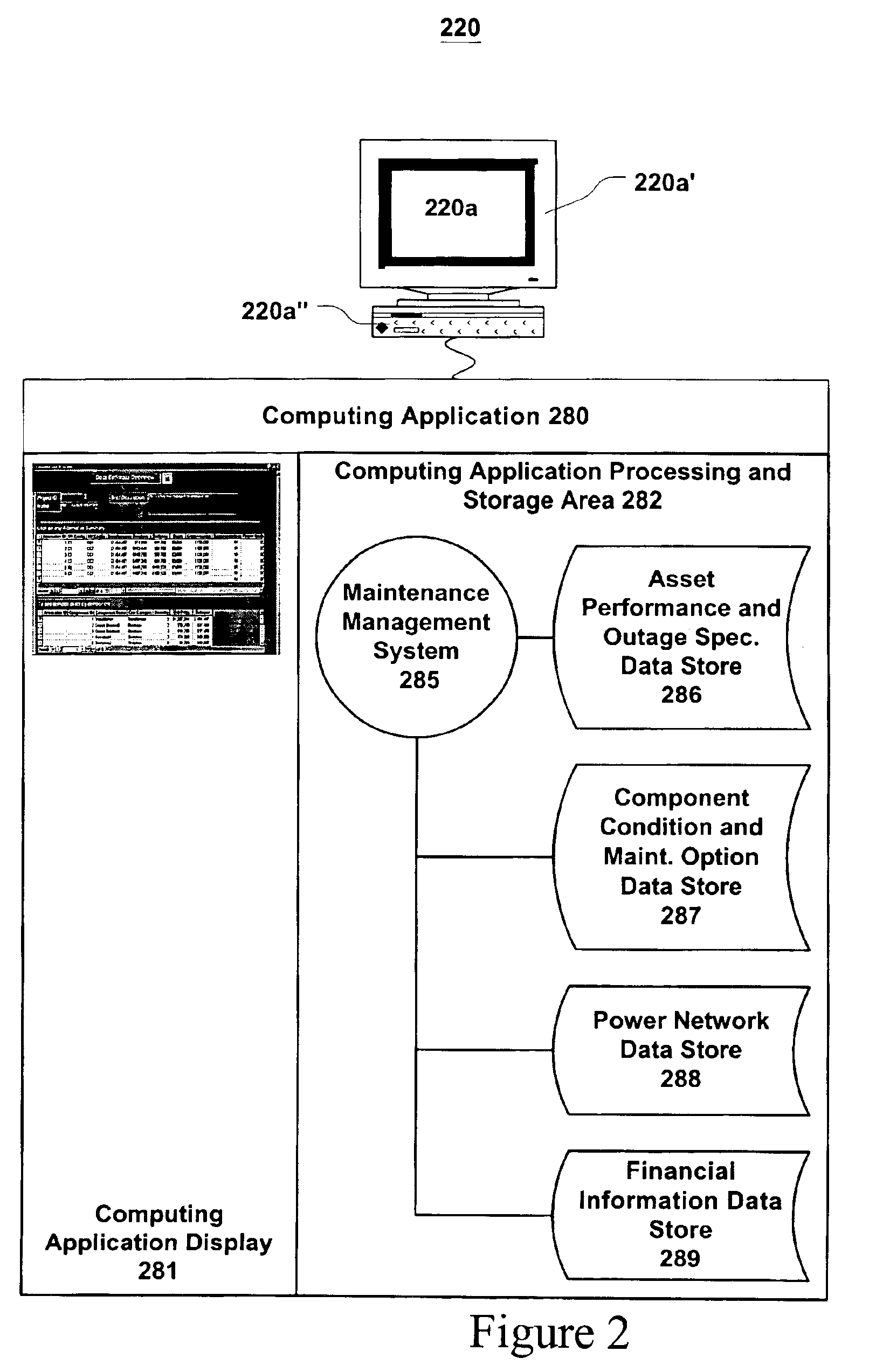

Value-based transmission asset maintenance management of electric power networks

A systematic approach is presented for the development and implementation of cost-effective transmission asset maintenance strategies. The overall concept and methodology are based on transmission reliability and risk management and address the value of preventive maintenance activities. This may help electric network utilities conduct maintenance policy assessment, region-wide criticality analysis, and optimal maintenance resource allocation and task scheduling.

Owner:ABB (SCHWEIZ) AG

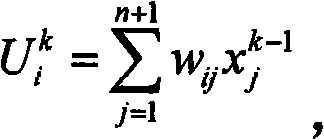

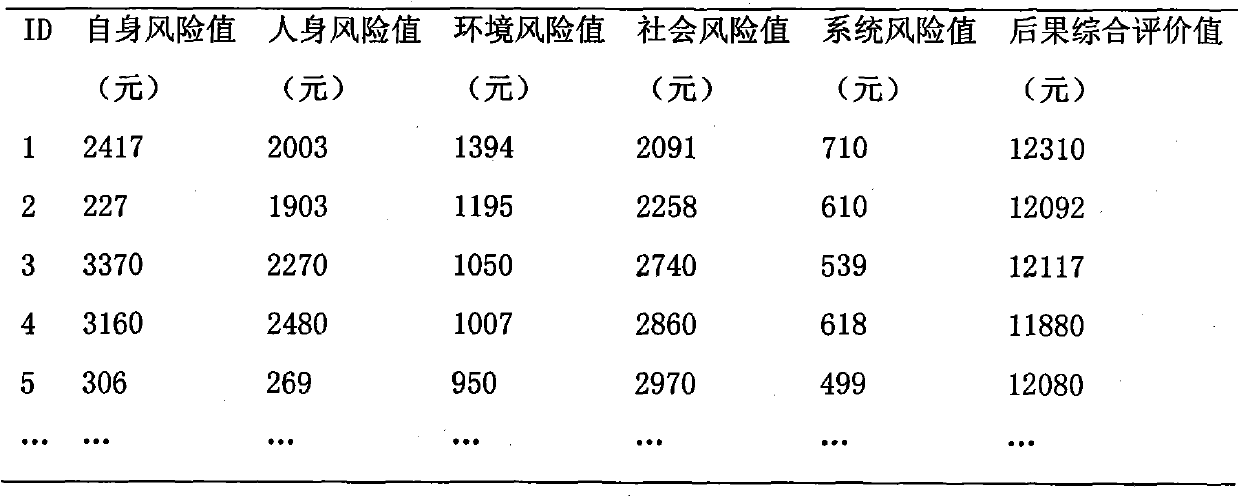

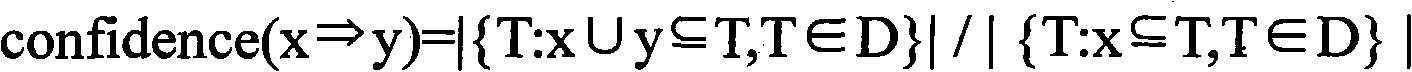

Method for optimal maintenance decision-making of hydraulic equipment with risk control

ActiveCN101950382ASolve the problem of processing impreciseIn line with the actual situationBiological neural network modelsSpecial data processing applicationsRisk ControlHydraulic equipment

The invention belongs to the field of maintenance decision-making of hydraulic equipment, and relates to a method for the optimal maintenance decision-making of hydraulic equipment with risk control. The method mainly comprises three steps: 1) judging whether a system is in a status of defect by using a variable-weight association rule algorithm, if so, calculating the probability values of occurrences of latent faults of the system; 2) calculating the comprehensive evaluation value for the consequence of each latent fault by using a BP neural network; and 3) multiplying the probability values obtained in step 1 by the comprehensive evaluation values obtained in step 2 so as to obtain the VaRs (values-at-risk) of the latent faults, judging whether the VaRs are more than a specified threshold, if so, ranking the VaRs in descending order so as to determine the maintenance sequence; otherwise, returning to the step of monitoring. The method can judge whether a device is in a status of defect, judge the type of the latent fault and calculate the probability values of occurrences of latent faults only through a calculation; and compared with traditional risk maintenance methods, the method of the invention improves the accuracy of fault diagnosis, speeds up the diagnosis speed, and provides a better reference for online decision-making.

Owner:天津开发区精诺瀚海数据科技有限公司

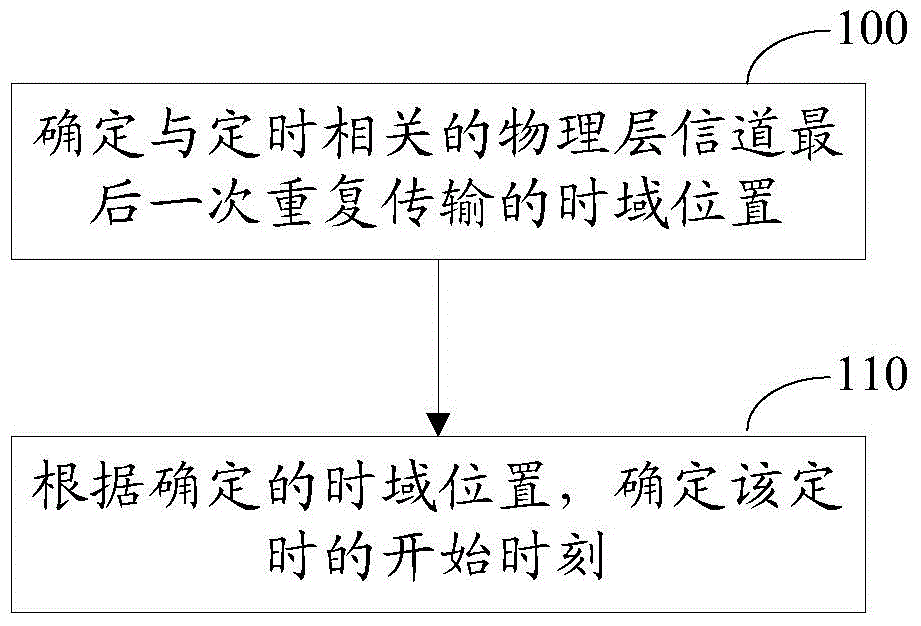

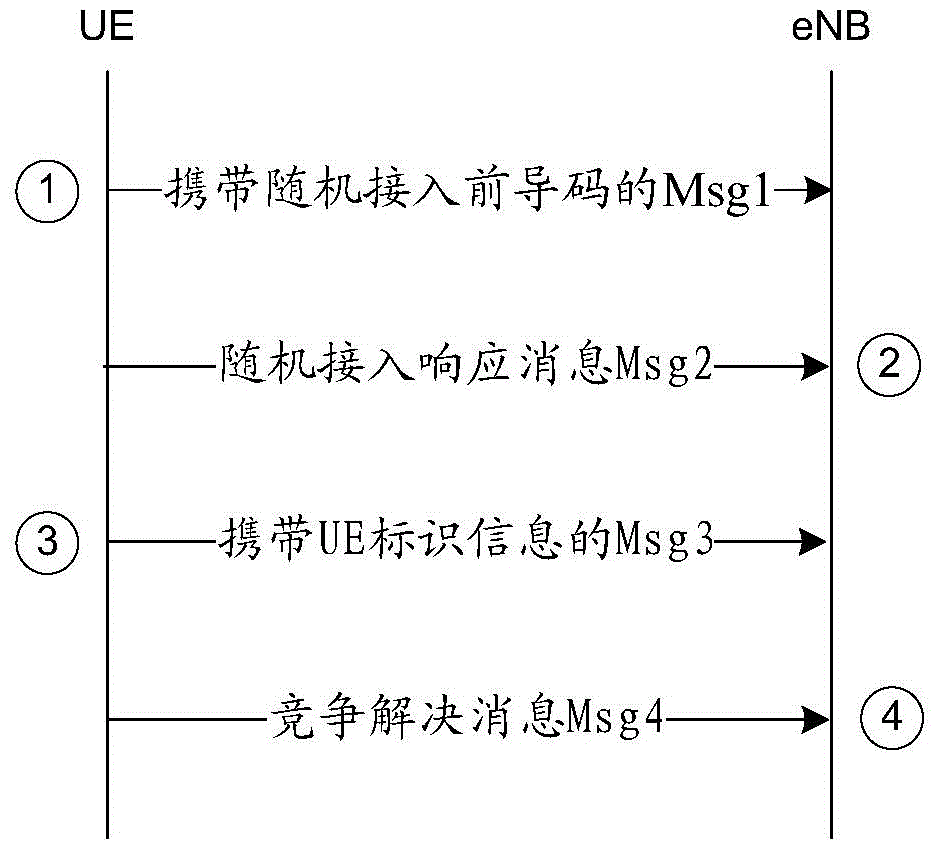

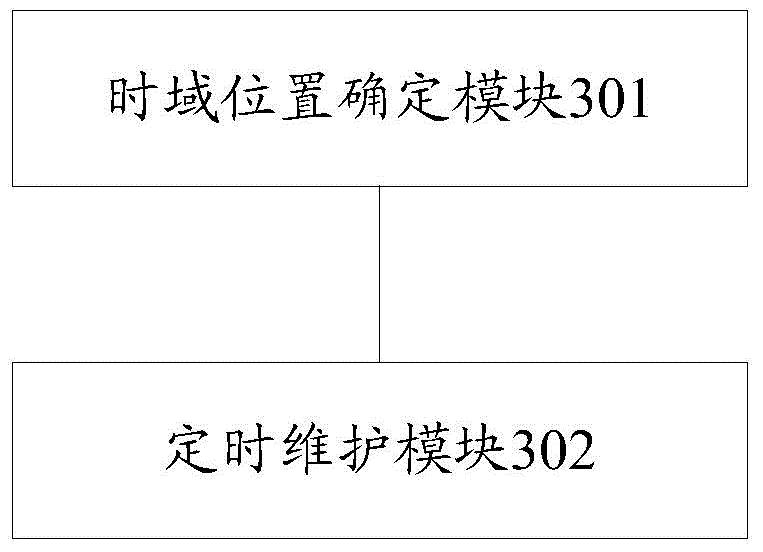

Method and device for timed maintenance under coverage enhancement mechanism

ActiveCN104581925ATroubleshoot scheduled maintenance issuesGuaranteed to workSynchronisation arrangementTime domainStart time

Disclosed in the present application are a method and apparatus for timing maintenance under a coverage enhancement mechanism. The method comprises: determining a time domain position for the last repeated transmission of a timing-related physical layer channel; and determining the start time of the timing according to the determined time domain position. According to the embodiment provided in the present application, the start time of the timing is determined according to the time domain position for the last repeated transmission of the timing-related physical layer channel. The invention avoids performing maintenance of said timing in a way as prescribed by the existing standards, and thereby solves the problem of how to perform physical layer channel-related timing maintenance under a coverage enhancement mechanism.

Owner:DATANG MOBILE COMM EQUIP CO LTD

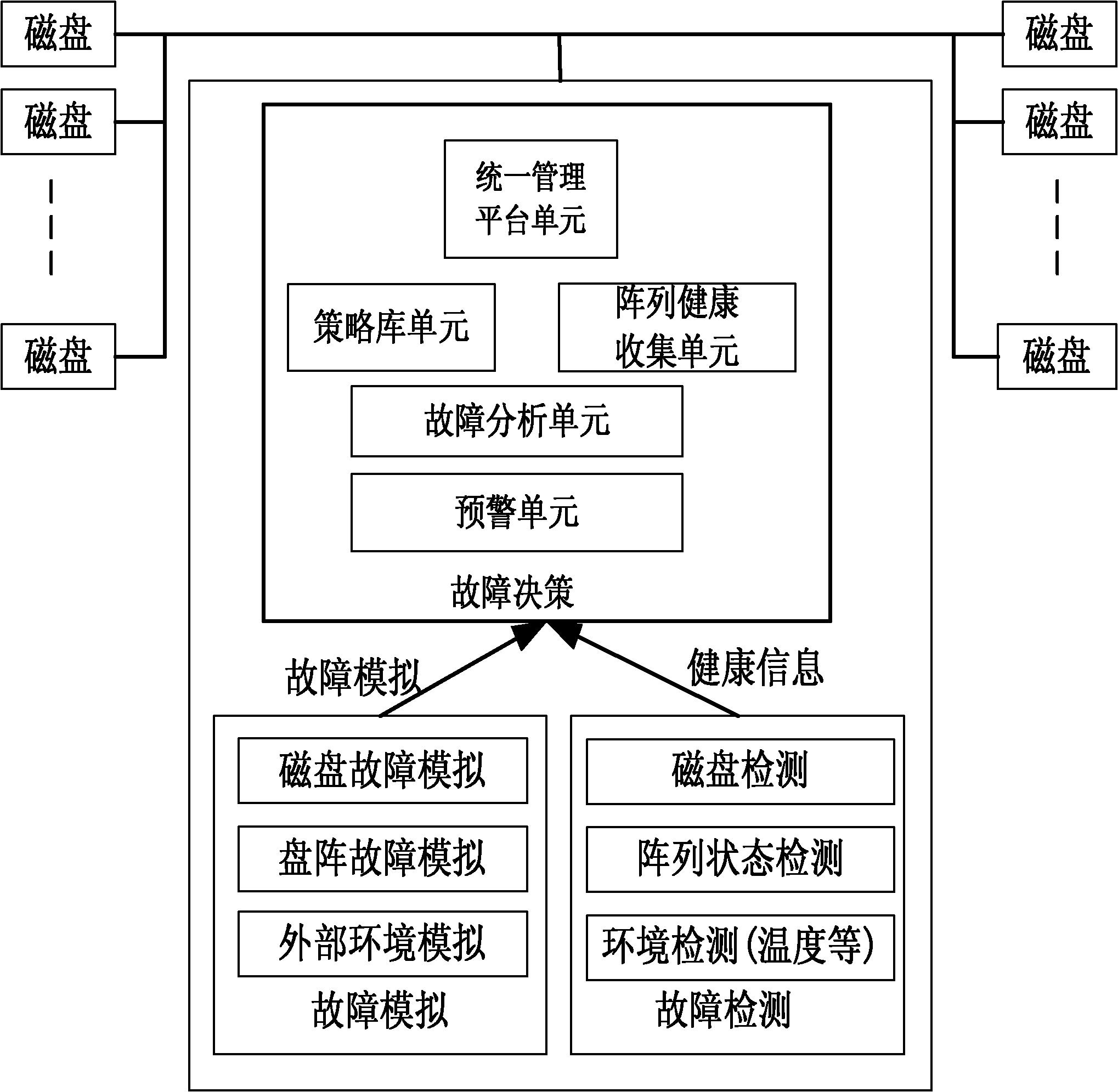

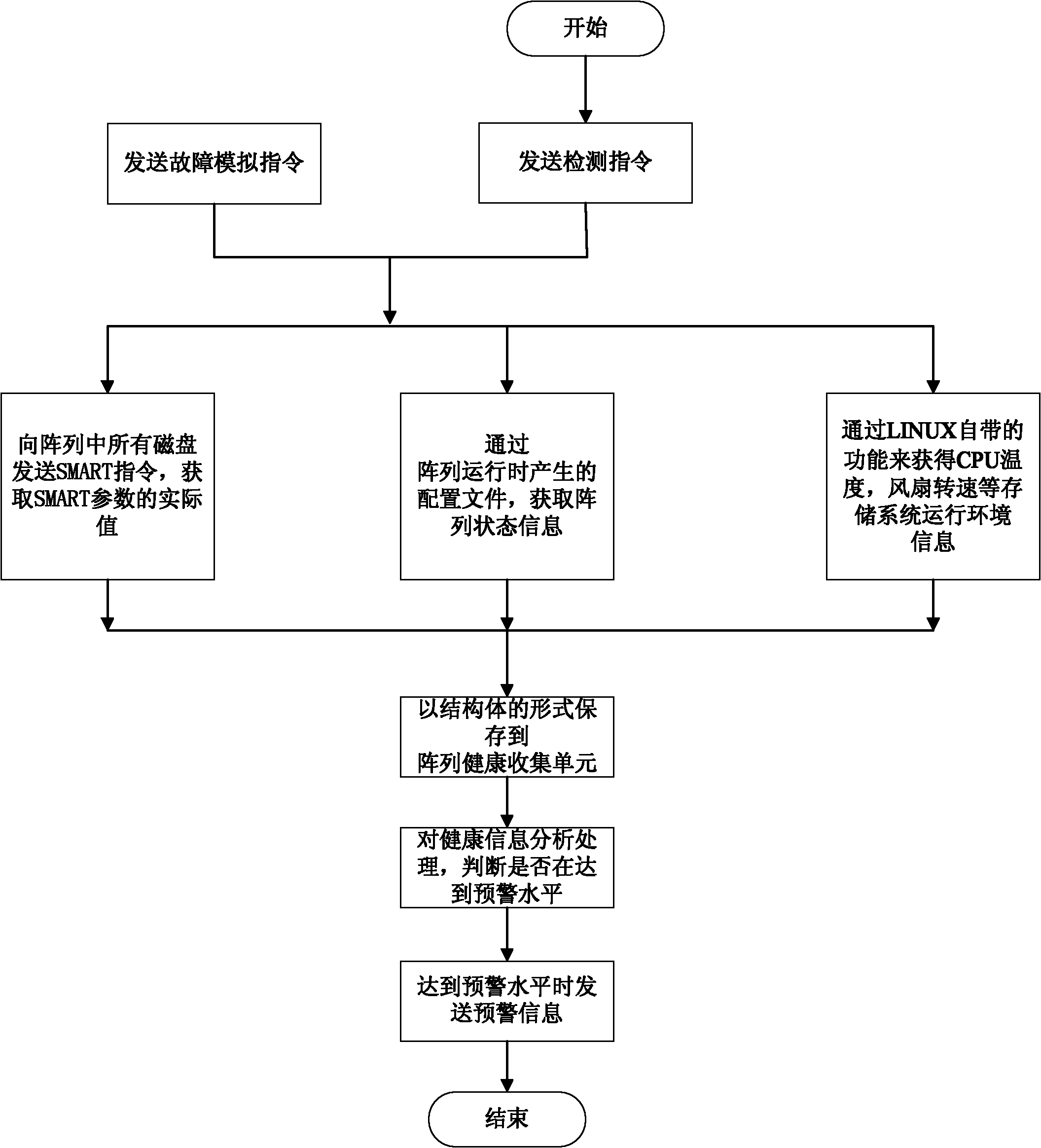

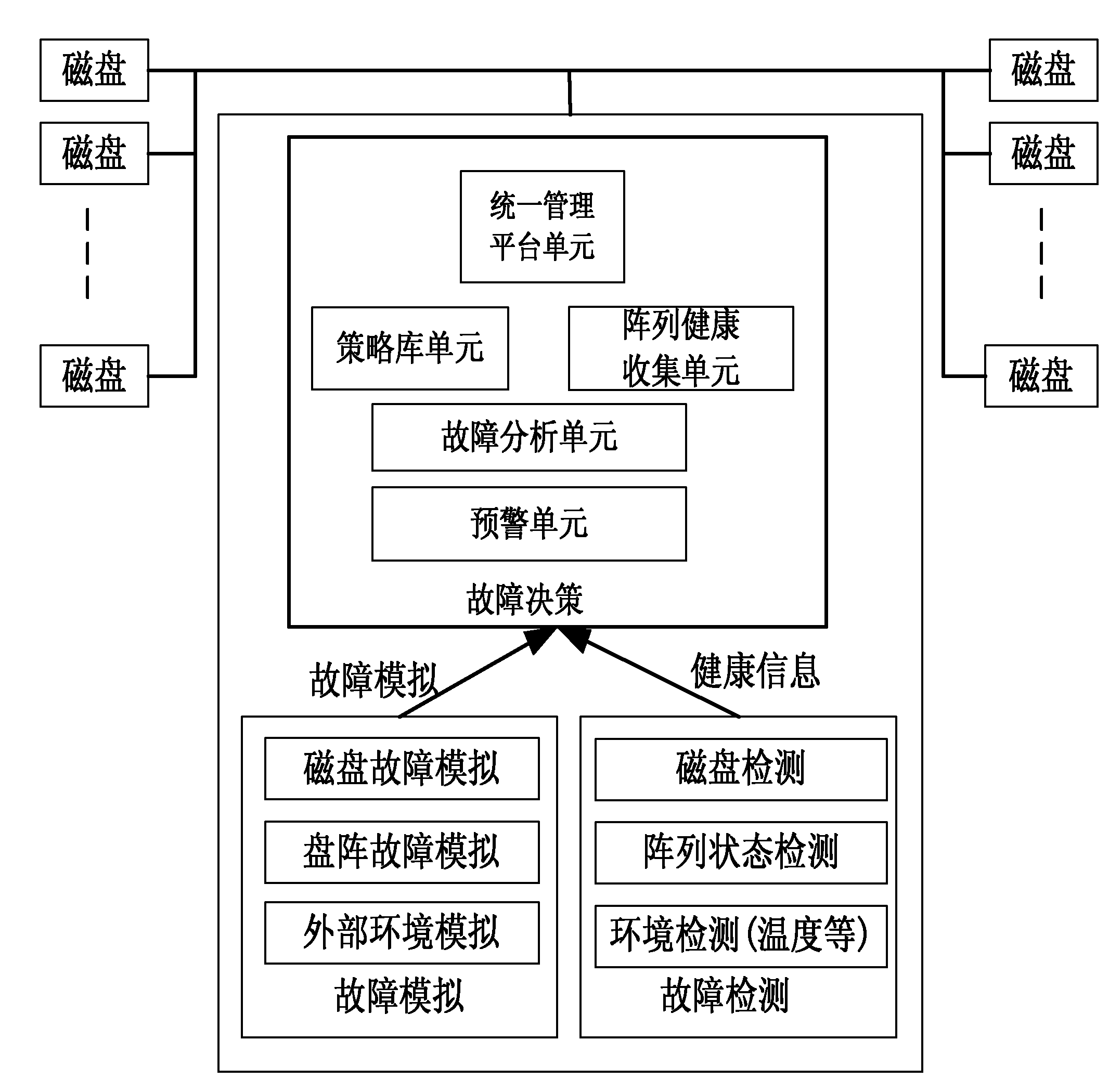

Security early warning system and method based on RAID

InactiveCN101866271AImprove robustnessProtection securityInput/output to record carriersError detection/correctionRAIDEarly warning system

The invention discloses a security early warning system and a method based on RAID, which belong to the field of computer system structure storage. The system comprises a fault decision unit, a fault detection unit and a fault simulation unit, wherein the fault decision unit is responsible for collecting the health information of a storage system in real time, and can send early warning information according to the preset health threshold value or other early warning strategies, the fault detection unit detects the operation state of a disc, detects the operation state of the disc array, and detects the sate of the operation environment, and the fault simulation unit is used for disc fault simulation, disc array fault simulation and external environment simulation, and can trigger the fault decision unit for implementing the early warning. The invention also provides a security early warning method based on RAID, and the security early warning is carried out on the storage system by using the system. The system and the method can be used for giving early warning on the fault of the RAID in advance, and users can adopt optimal maintenance management to ensure the data security and the system health.

Owner:HUAZHONG UNIV OF SCI & TECH

Maintenance support method, storage medium, and maintenance support apparatus

ActiveUS7082384B2Maintenance cost along the time sequence is minimizedElectric testing/monitoringDigital computer detailsEngineeringOptimal maintenance

In an embodiment of this invention, a diagnosis engine refers to a risk assessment DB and anti-risk measure DB, calculates along the time sequence a risk estimate amount in case of failure for each device and a maintenance cost in executing a measure method in advance, and adds the risk estimate amount and maintenance cost along the time sequence to calculate an optimum maintenance period of the device. When a failure has occurred in the device, the diagnosis engine refers to a failure diagnosis DB on the basis of the identification information of the device and the failure mode and analyzes, on the basis of an operation record, a failure which is different from a secular change.

Owner:KK TOSHIBA

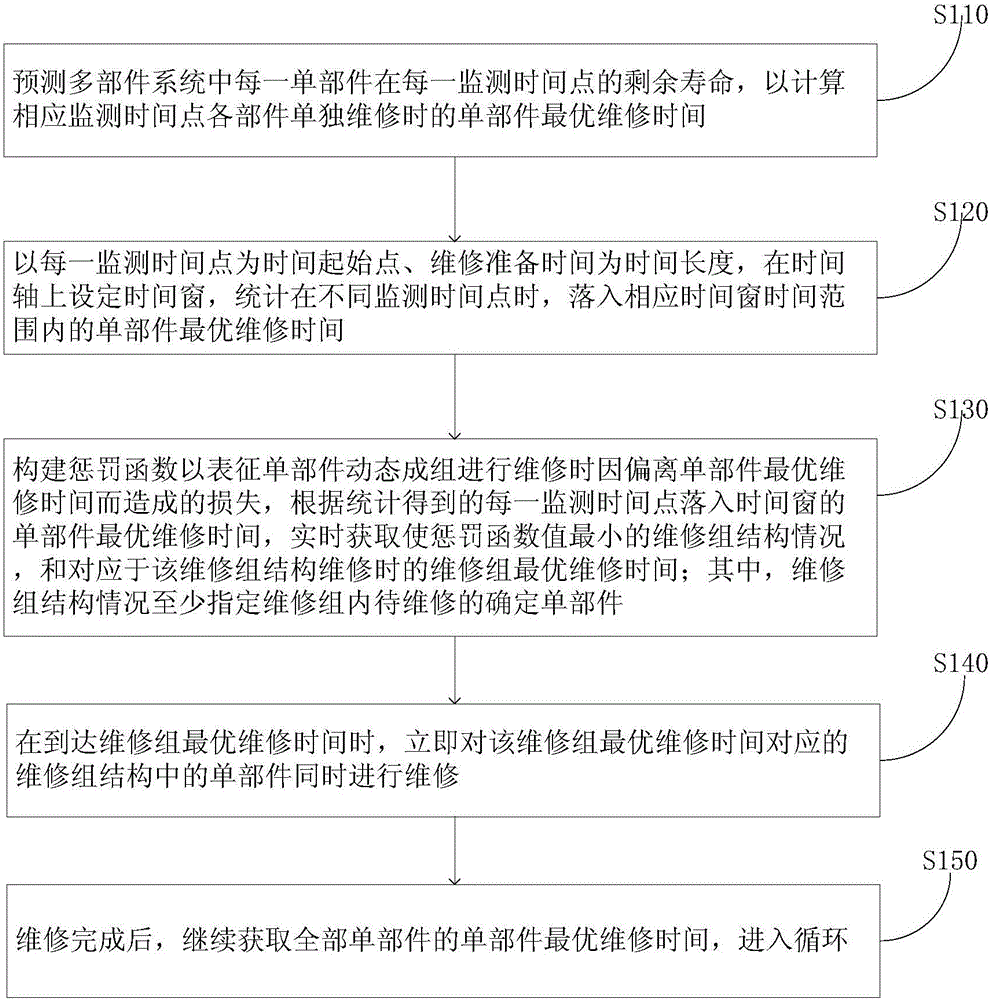

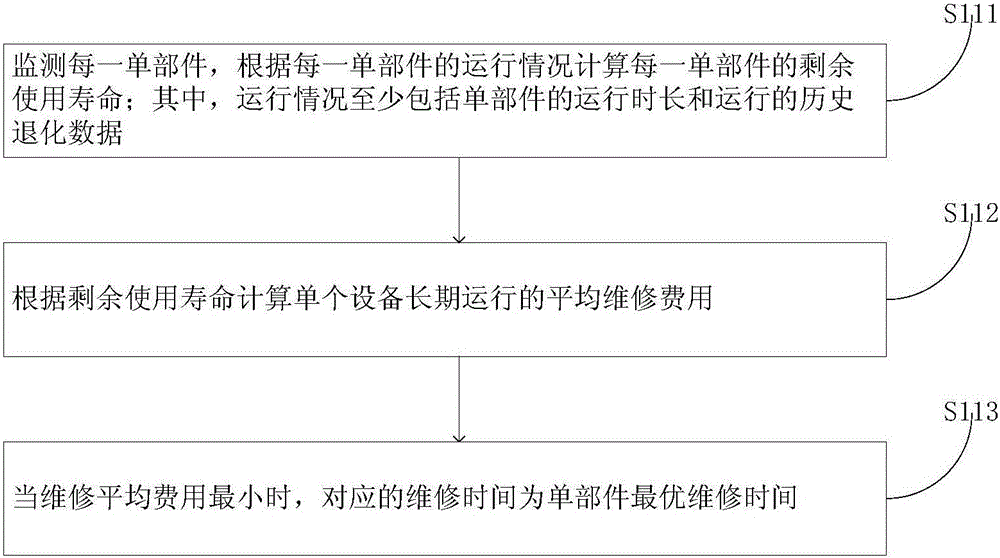

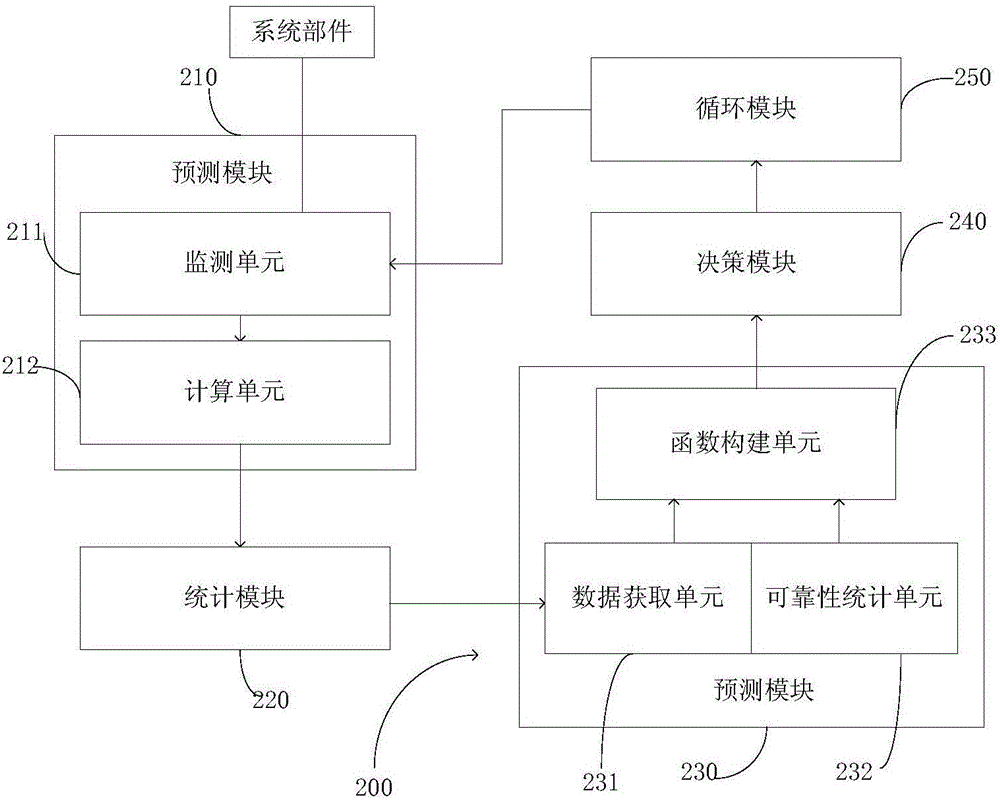

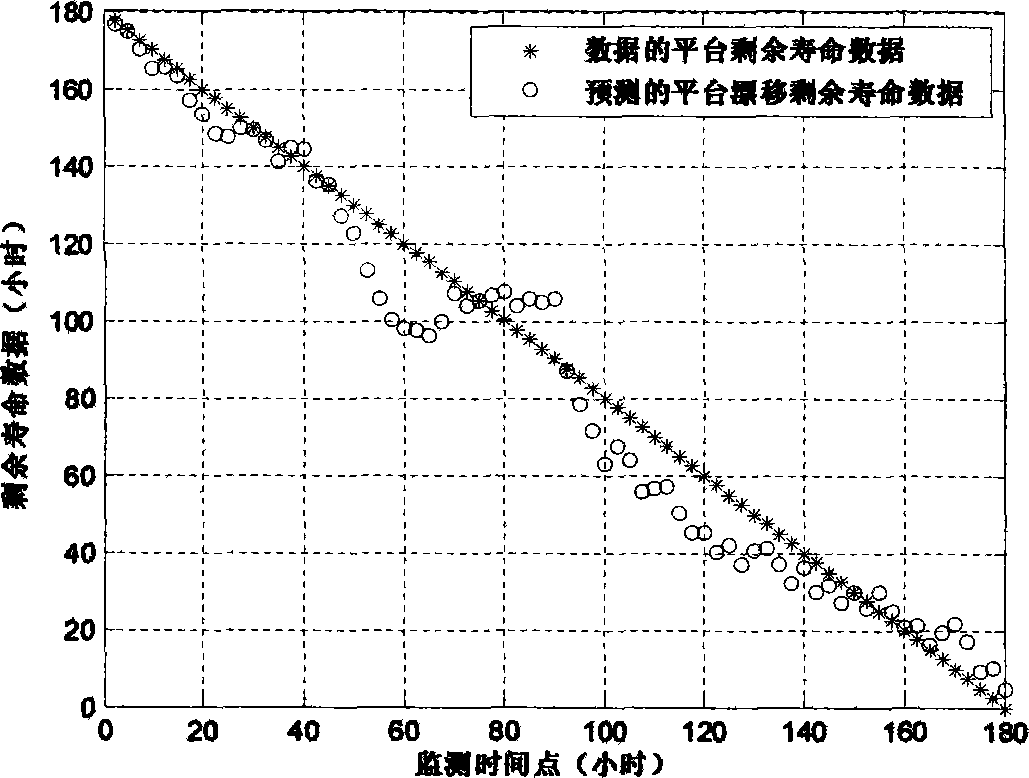

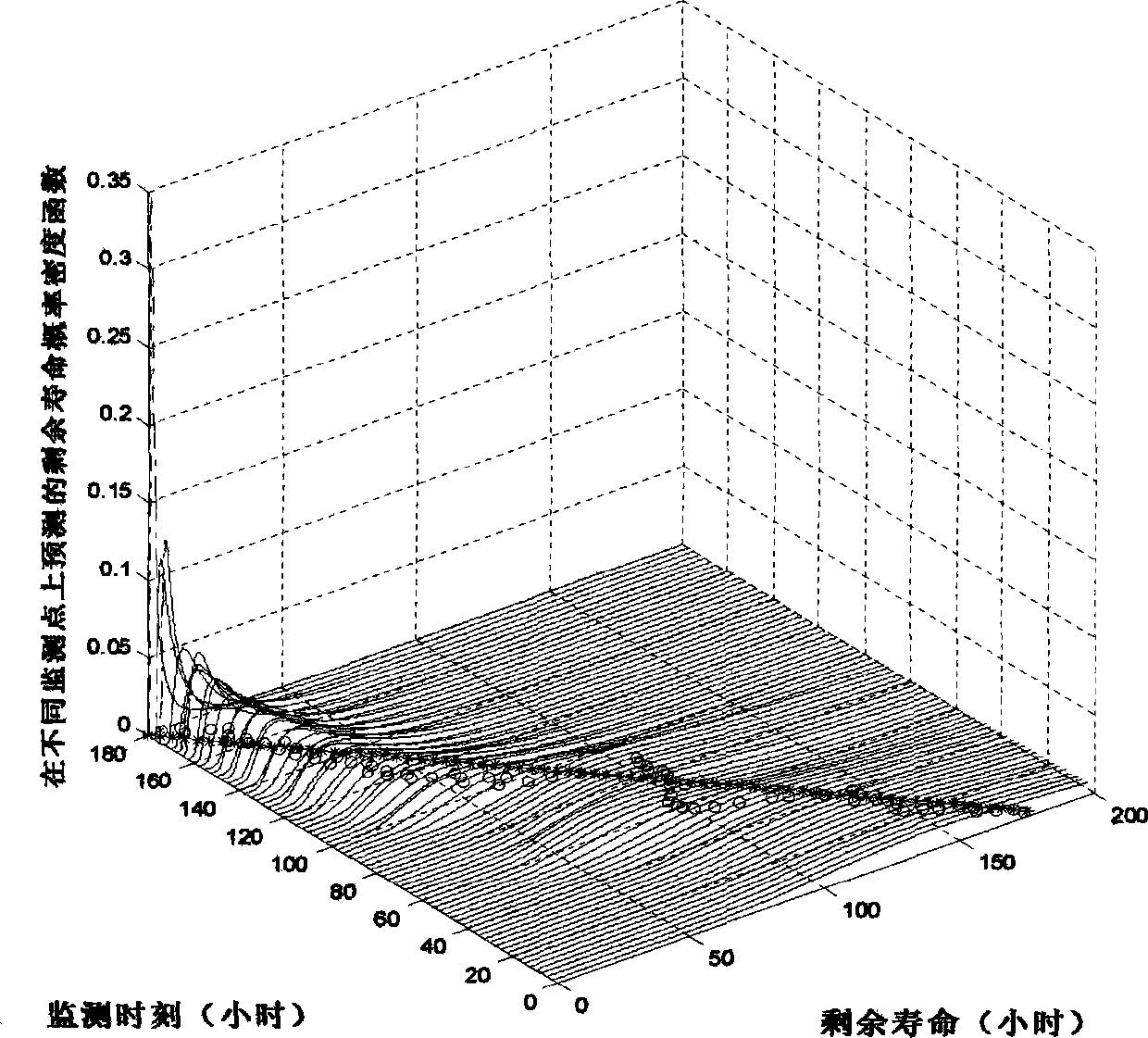

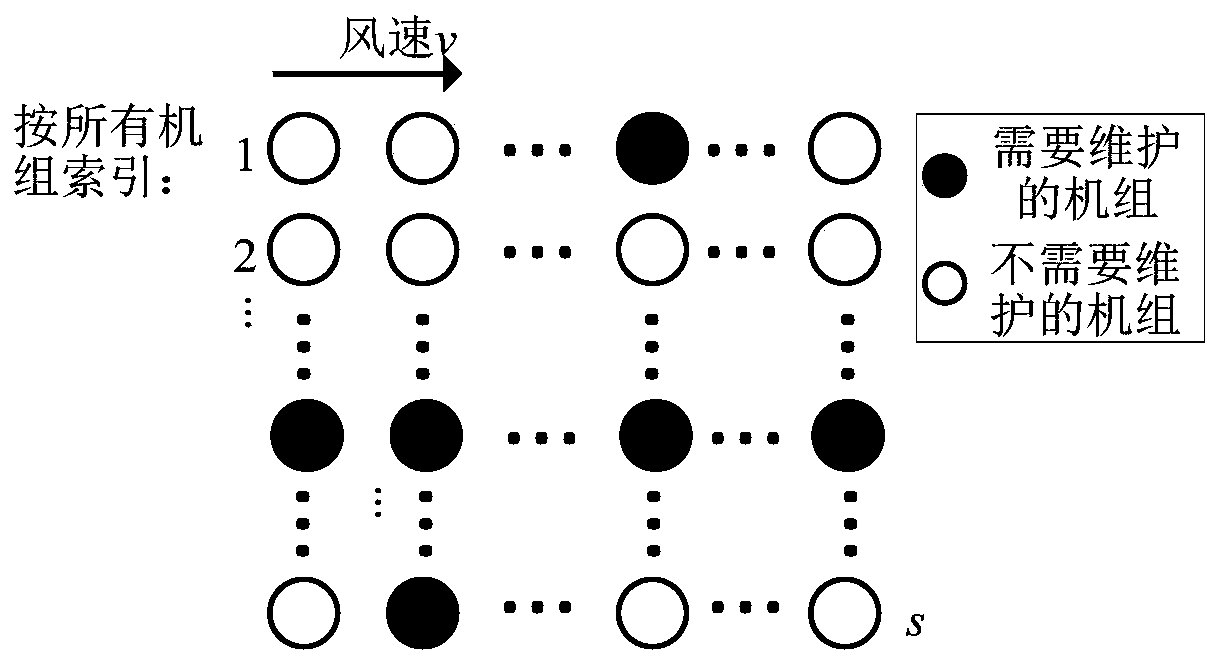

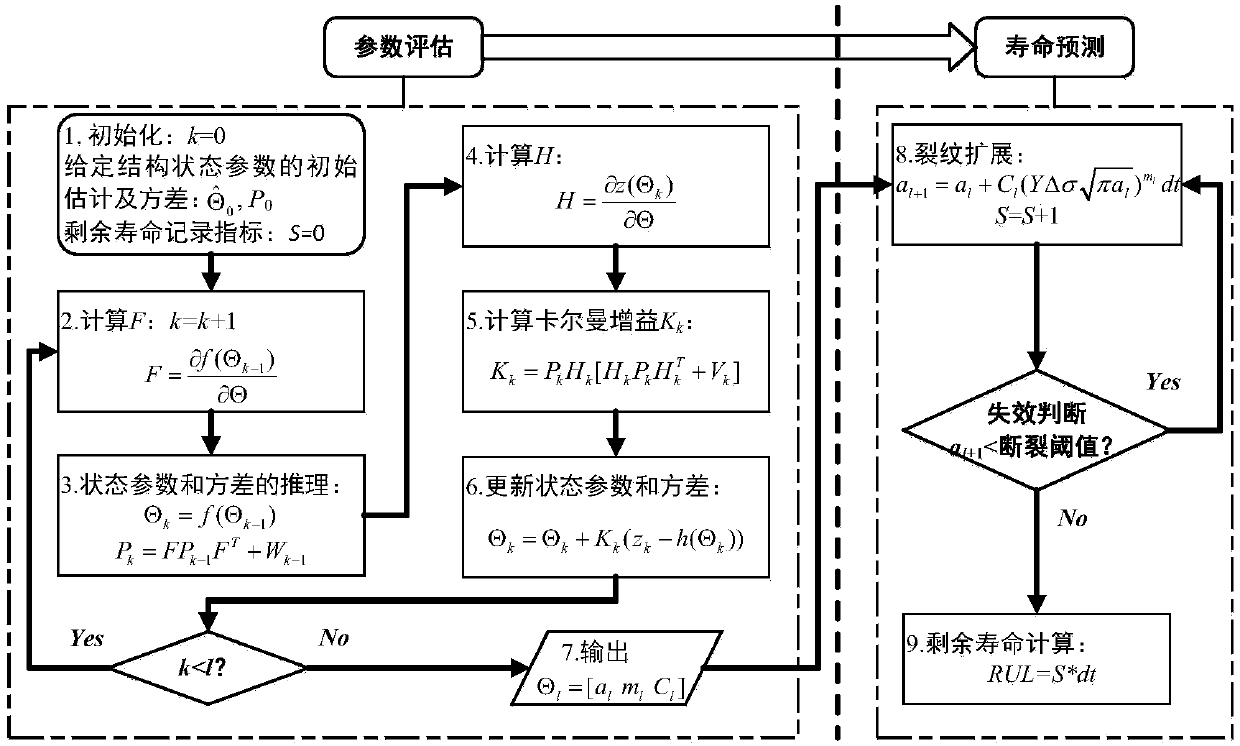

Multi-component system group maintenance decision method and multi-component system group maintenance decision device based on prediction

The invention discloses a multi-component system group maintenance decision method and a multi-component system group maintenance decision device based on prediction. The method comprises the following steps: predicting the residue life of single components at a monitoring time point, and calculating the single-component optimal maintenance time; setting a time window with each monitoring time point as the starting time point and the maintenance preparation duration as the time length, and calculating the single-component optimal maintenance time falling into the time range of the time window; building a penalty function, and acquiring a maintenance group structure with minimum penalty function value and the maintenance group optimal maintenance time according to the calculated single-component optimal maintenance time falling into the time window for each monitoring time point; grouping-maintaining the single components in the maintenance group structure; and after maintenance, continuing acquiring the single-component optimal maintenance time, and so on. According to the invention, the most saving group maintenance mode for maintenance of a multi-component system can be decided according to the predicted single-component residue life, so that the maintenance cost is saved, the downtime is reduced, and the loss is reduced.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

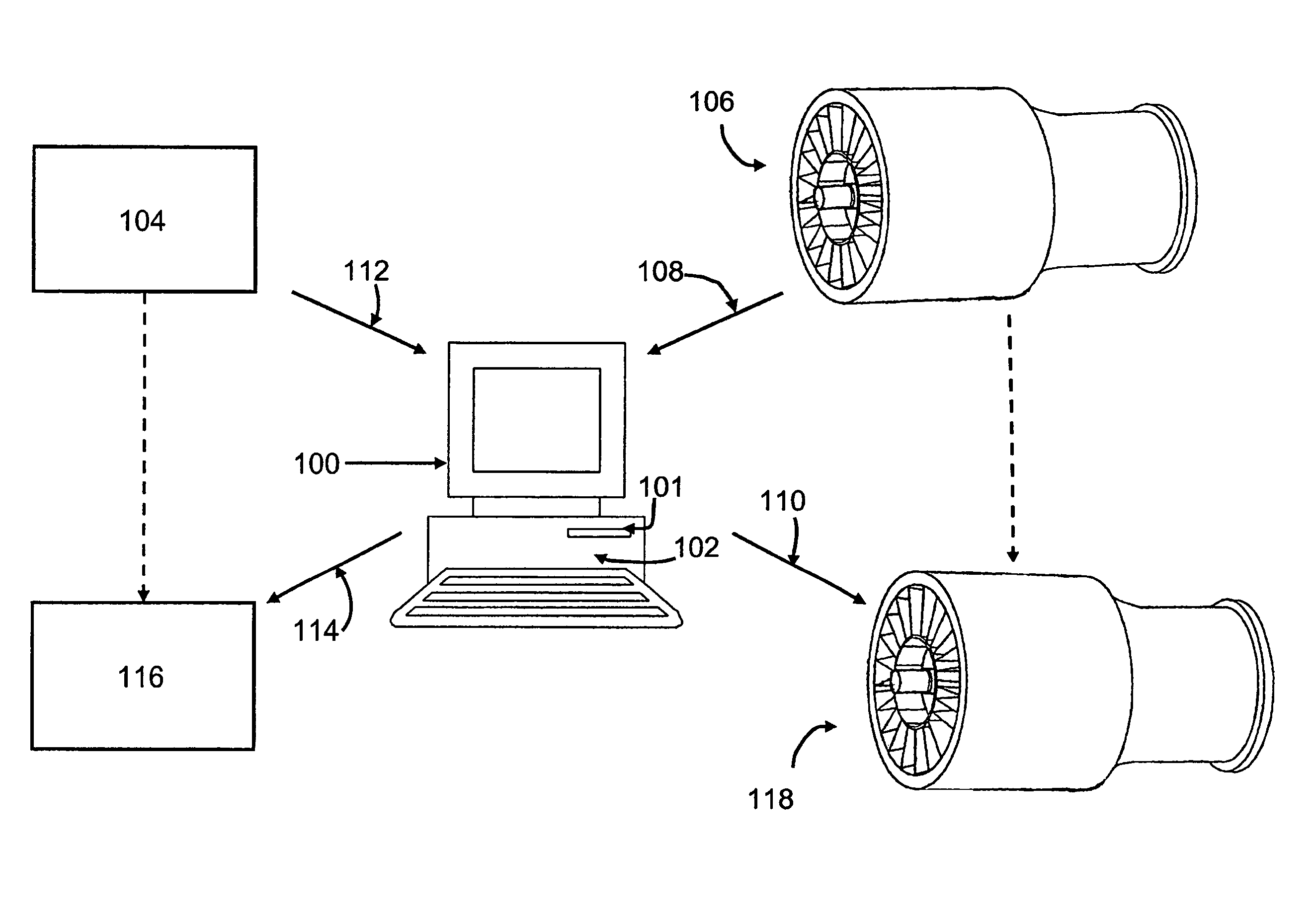

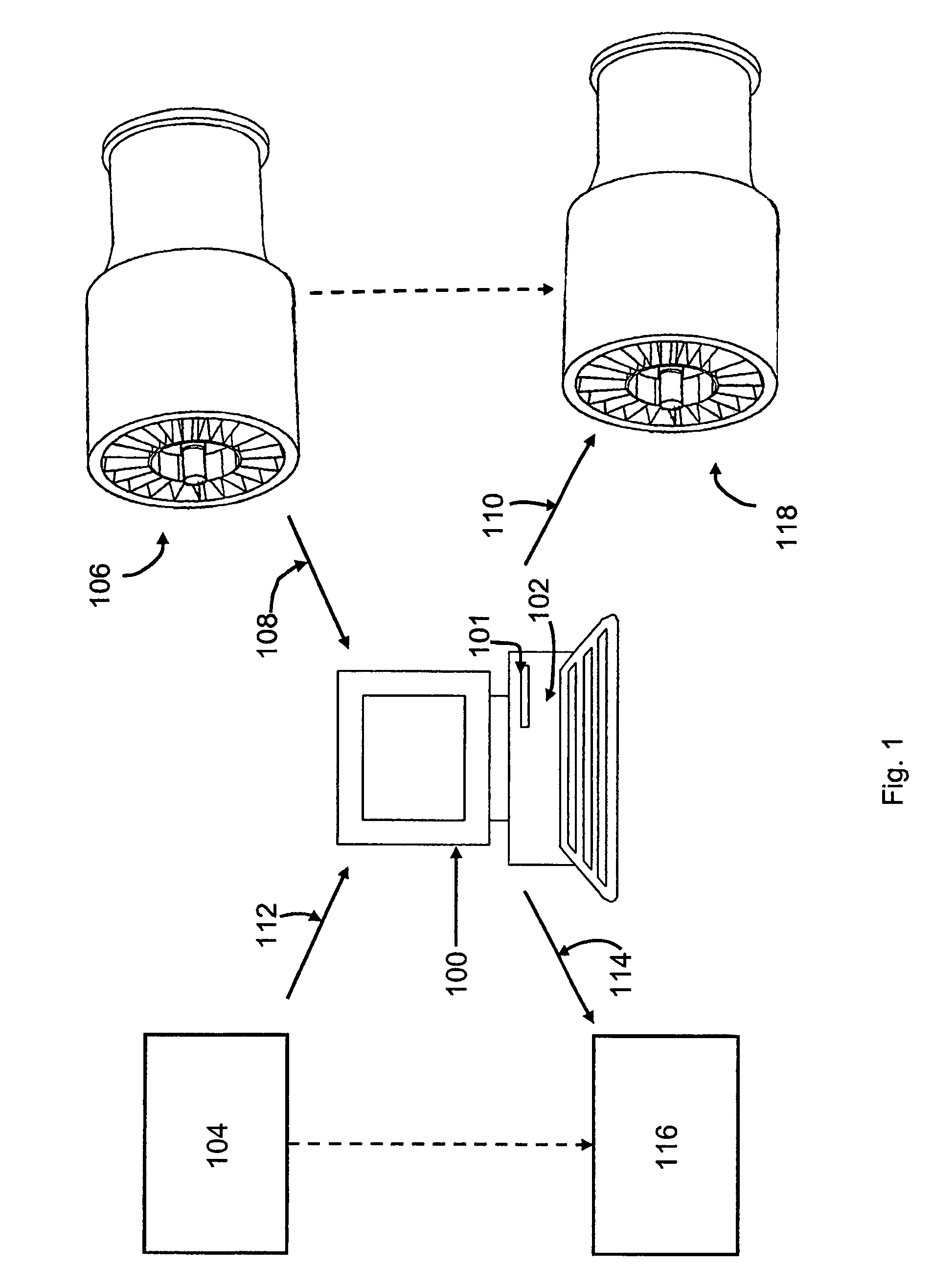

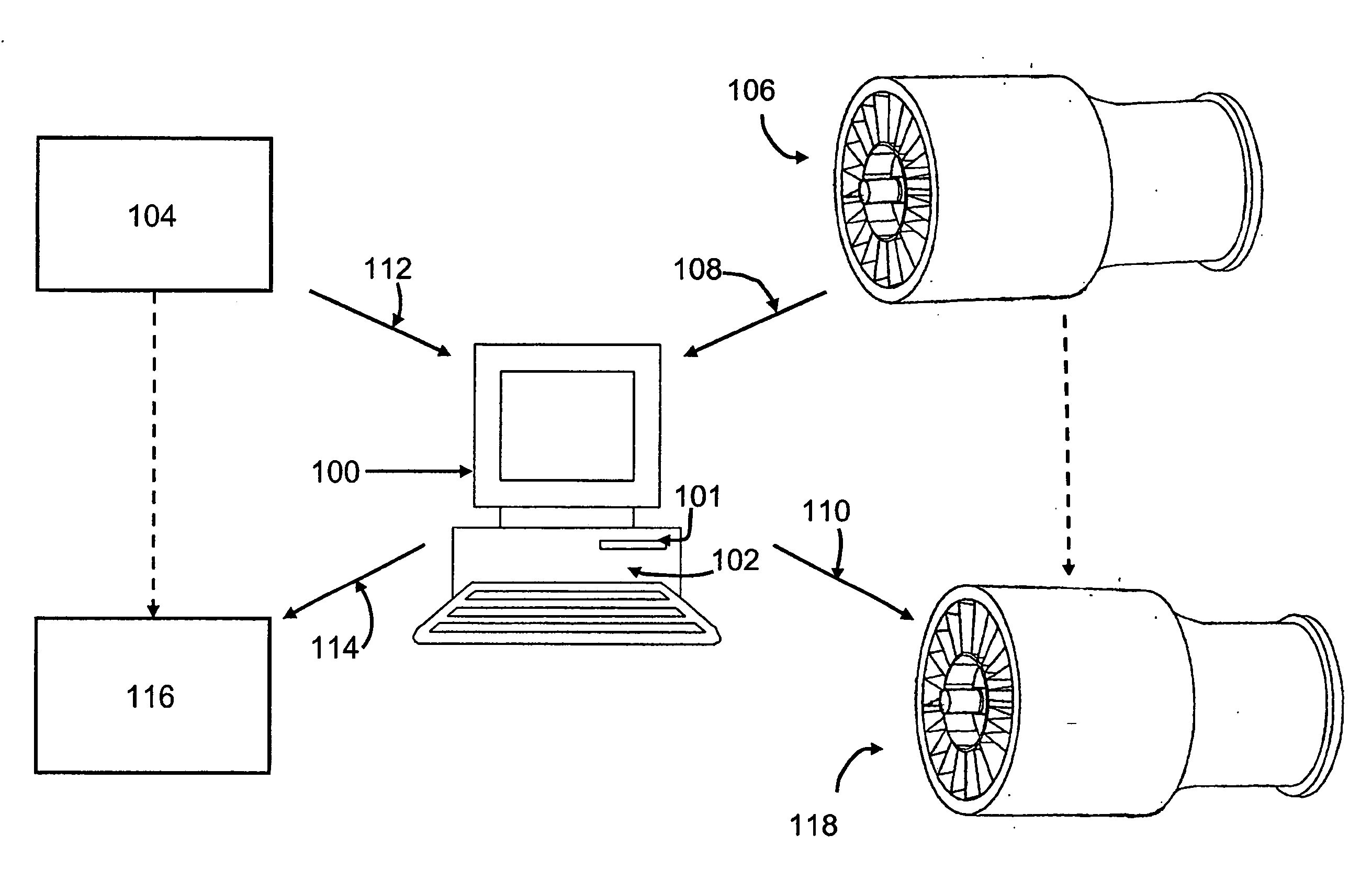

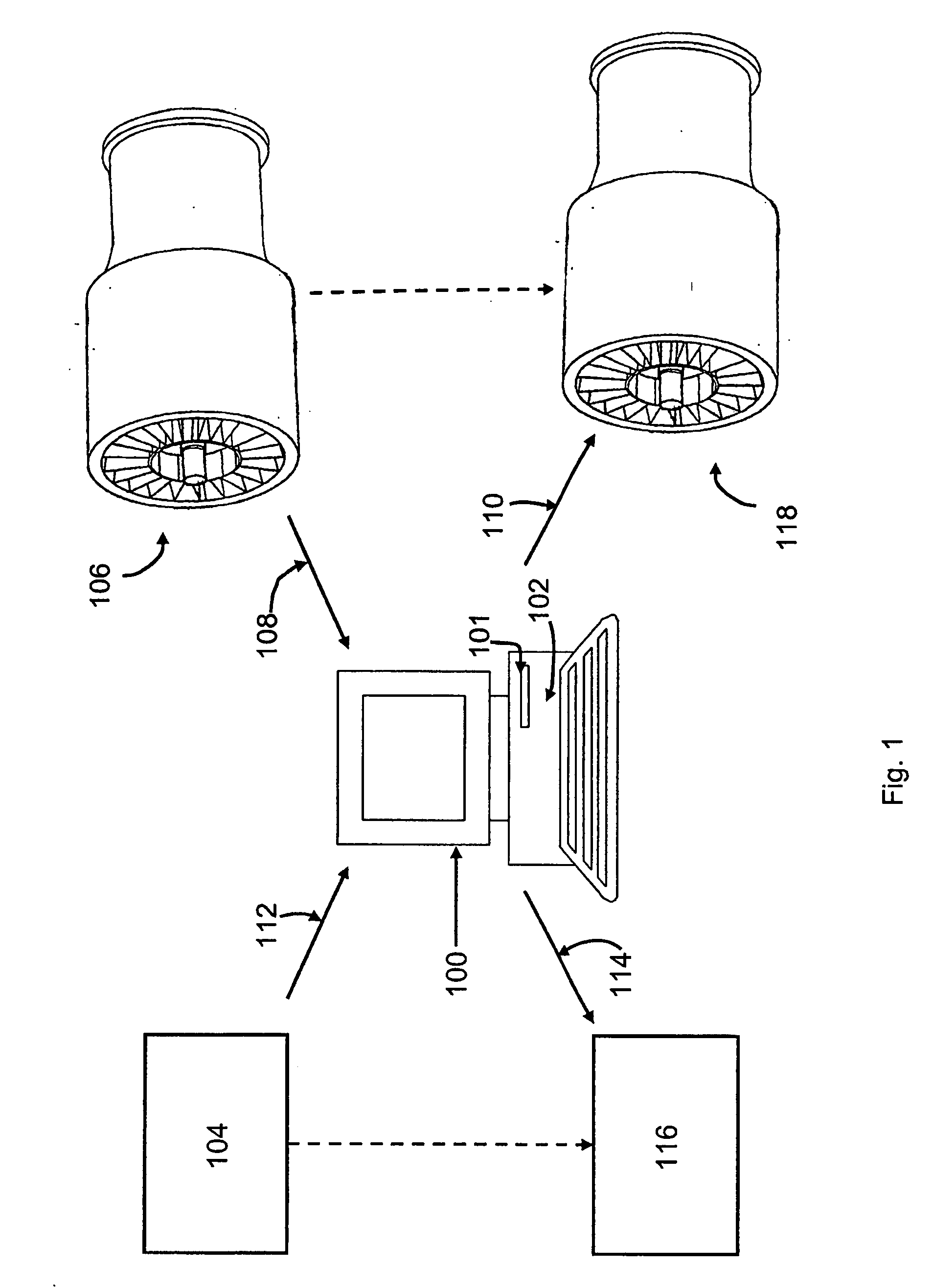

Process and system for multi-objective global optimization of maintenance schedules

A process for optimizing maintenance work schedules for at least one engine includes the steps of retrieving at least one set of data for an engine from a computer readable storage medium; selecting at least one scheduling parameter for the engine; selecting a set of maintenance rules for the engine; selecting at least one maintenance work decision; selecting at least one objective for the engine; optimizing the at least one objective to generate at least one optimal maintenance work decision; and generating at least one optimal maintenance work schedule for the engine.

Owner:RAYTHEON TECH CORP

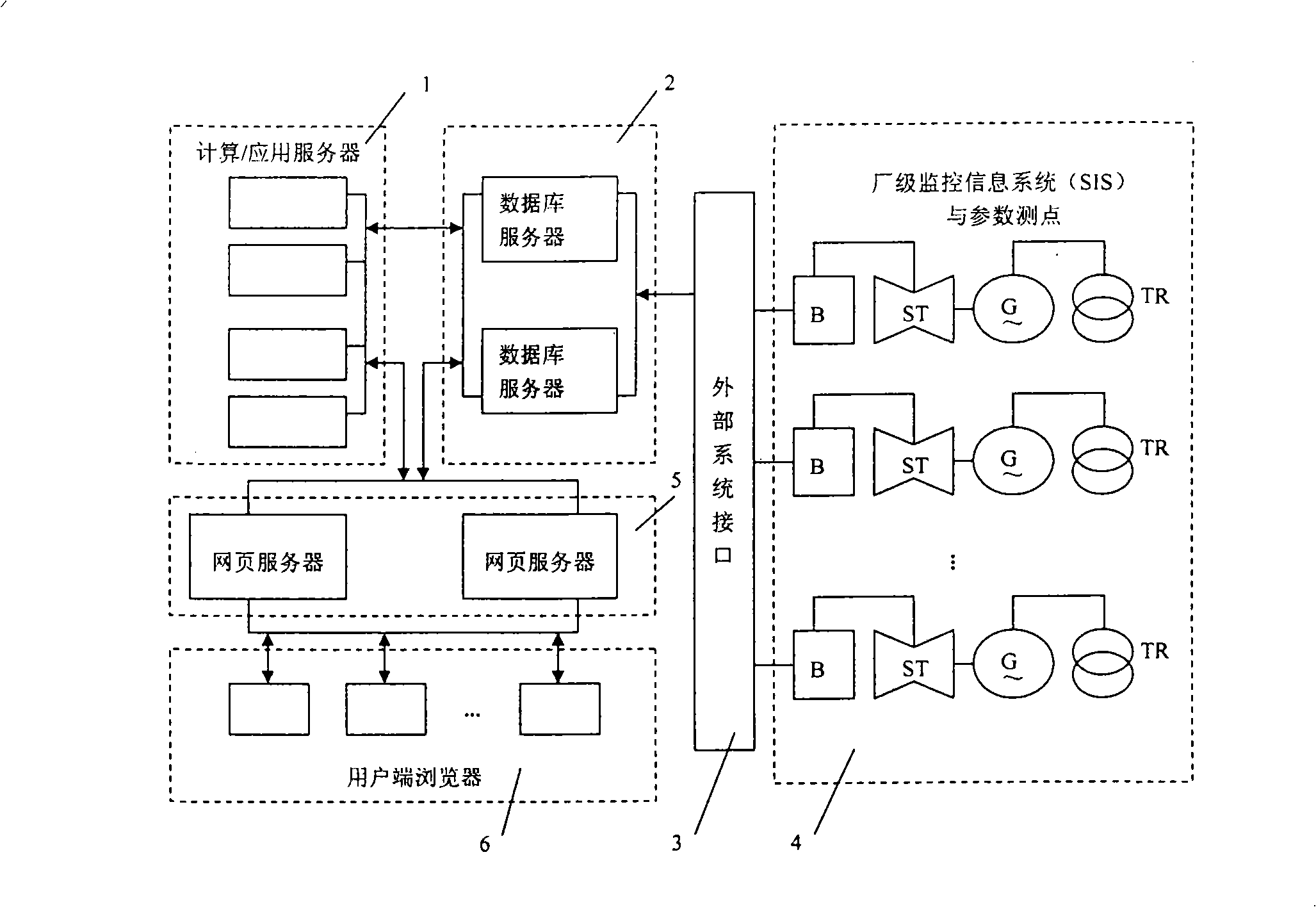

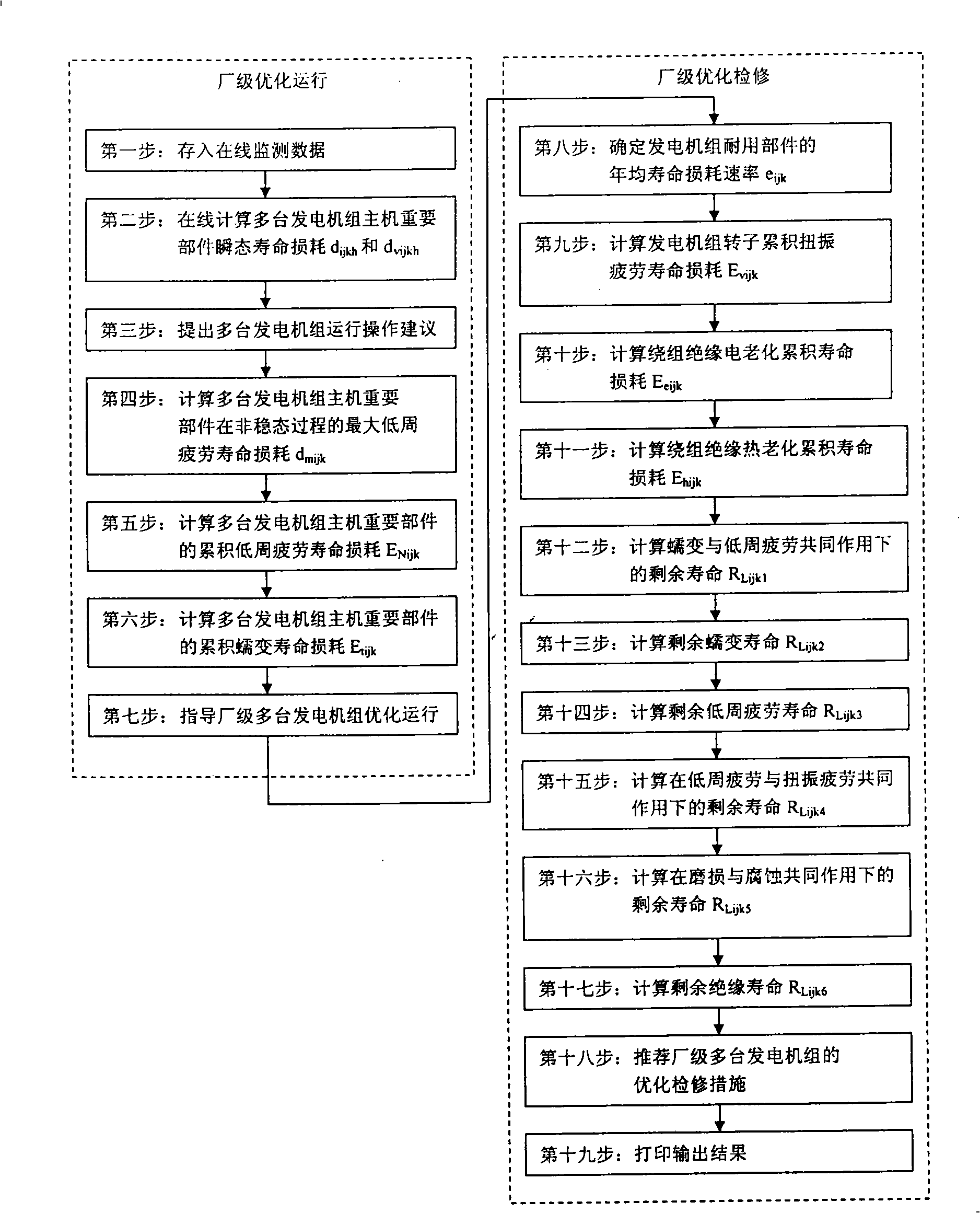

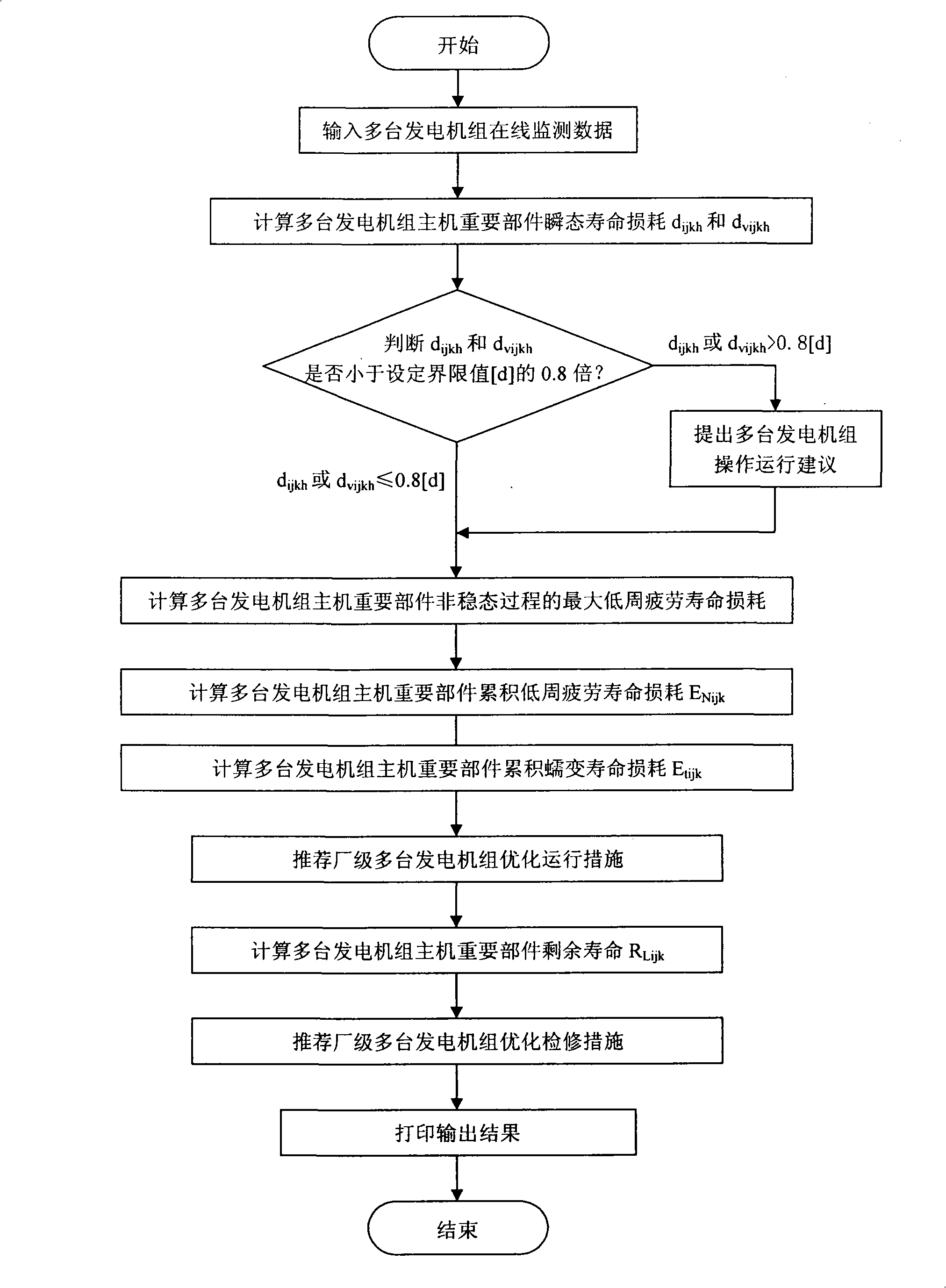

On-line management method and system for important component service life of plant-level multiple generator sets main unit

The invention realtes to an online service-life management system for the important parts of the host machine of plant-level multi-electric motor machine sets. The invention is characterized in that the system comprises a service-life calculation / application server and software, a database server, an external system interface, a plant-level supervisory information system SIS, a parameter measuring point, a web page server and a user-end browser. The online service-life management method is that the calculation analysis software for the host machine of the plant-level multi-electric motor machine sets, which is compiled by the C Language, is applied to the calculation / application server, carries through the online calculation of the transient life loss and the accumulative life loss of the importants parts of the host machine, directs the operational manipulation and the optimal operation of the electric motor machine sets, and recommends the optimal maintenance measures of the plant-level multi-electric motor machine sets. The management system has the advantages of realizing the online management for the important parts of the host machine of the plant-level multi-electric motor machine sets and achieving the technical effect that the service life of the important parts of the host machine of the multi-electric motor machine sets in a power plant are managed by a set of the service-life management system.

Owner:SHANGHAI POWER EQUIP RES INST

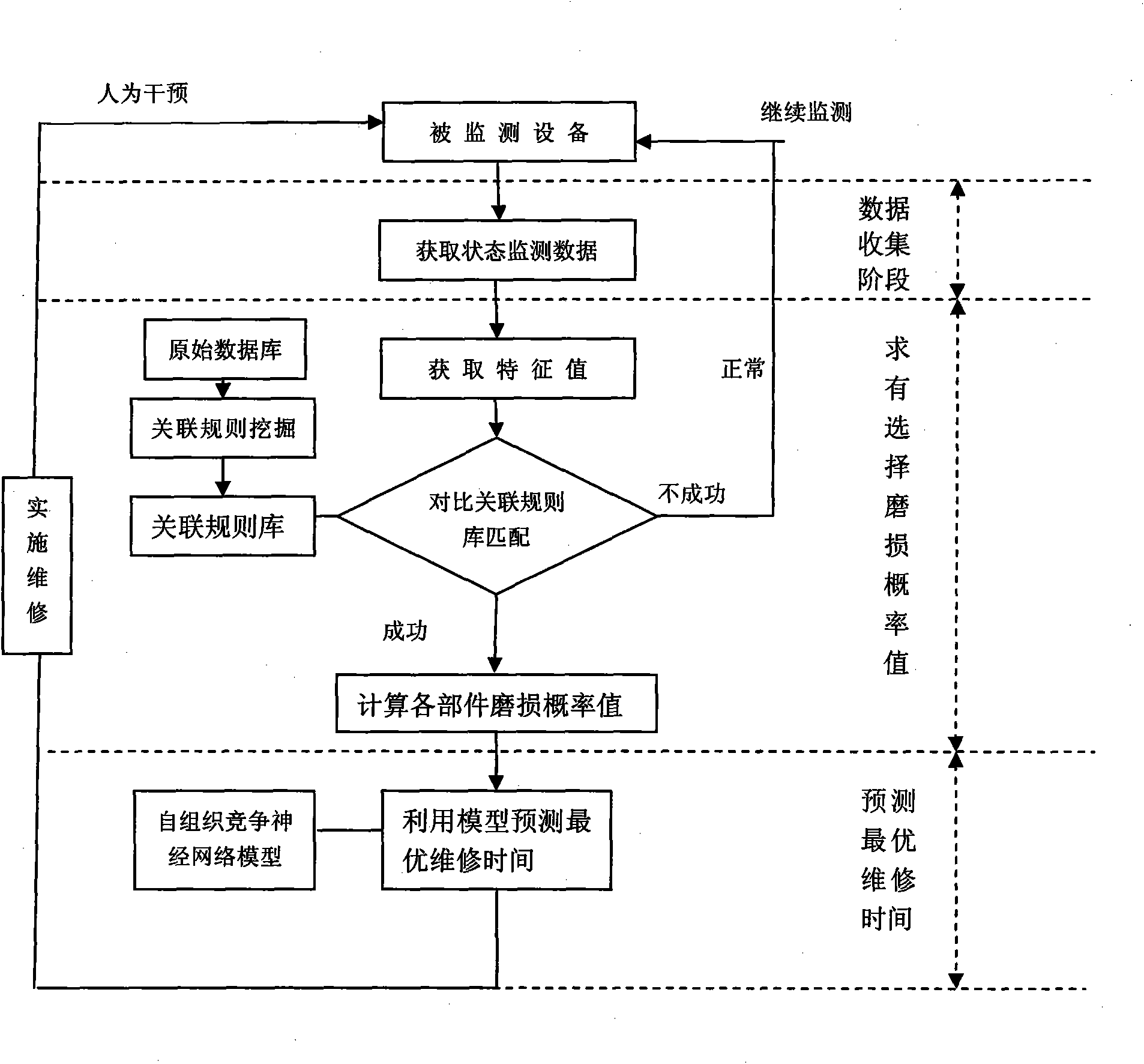

Selective wear-based equipment optimal maintenance time prediction method

ActiveCN101957889ASolve the problem of processing impreciseAvoid difficultiesNeural learning methodsSpecial data processing applicationsData setRepair time

The invention belongs to the field of equipment maintenance time prediction, and relates to a selective wear-based equipment optimal maintenance time prediction method. The method mainly comprises two steps of: solving a selective wear possibility value of each part of equipment in the current state by utilizing an association rule algorithm; and taking the solved possibility value as input, and solving the optimal maintenance time by neural network modeling. The method comprises the following steps of: constructing an association rule library; acquiring state monitoring data, extracting characteristic values from the data, and establishing an equipment monitoring data set; matching the equipment monitoring data set with the association rule library, and calculating the wear possibility value of each part under the condition of successful matching; and training a self-organizing competitive neural network model, and predicting the optical maintenance time by utilizing the model.

Owner:天津开发区精诺瀚海数据科技有限公司

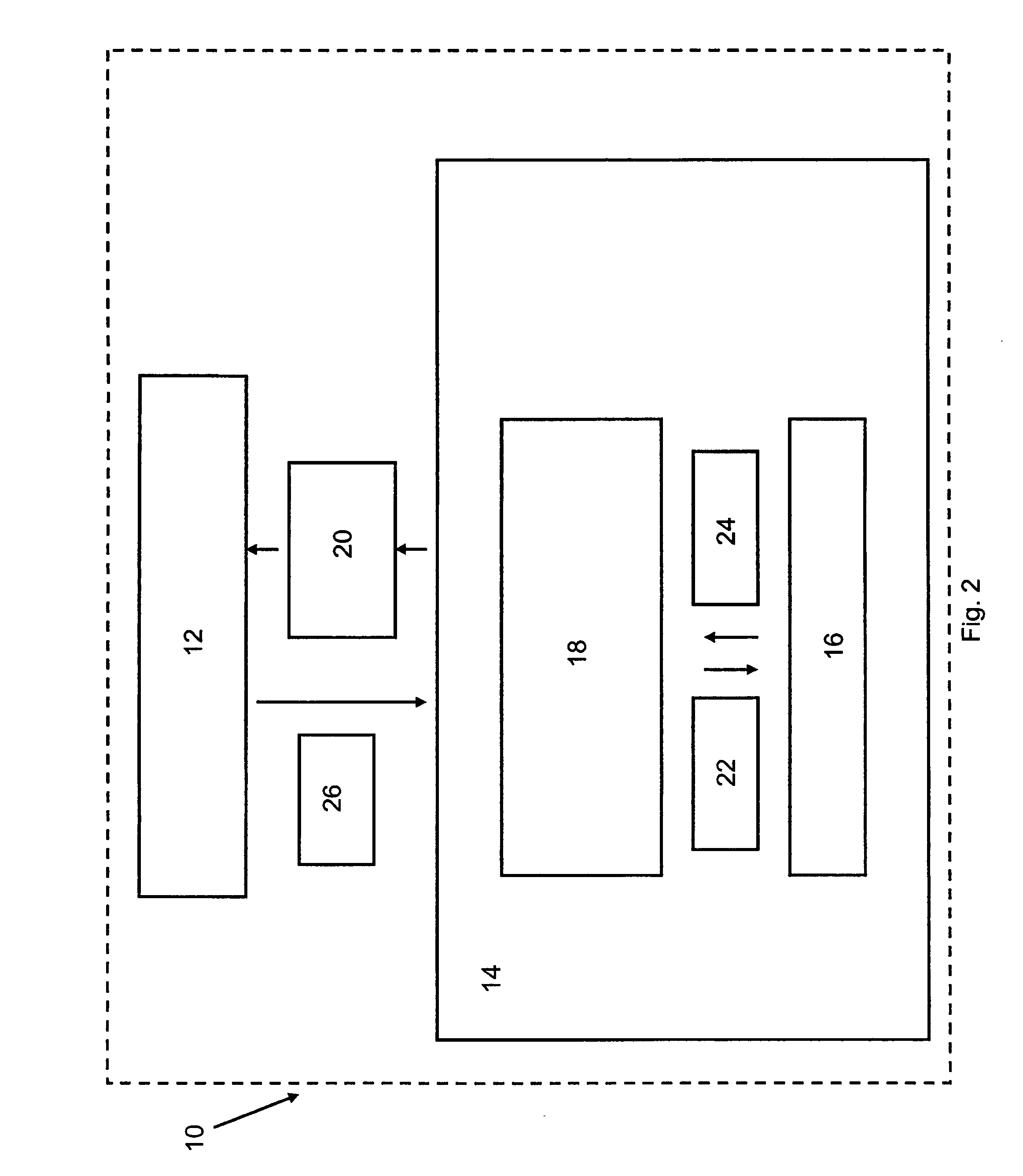

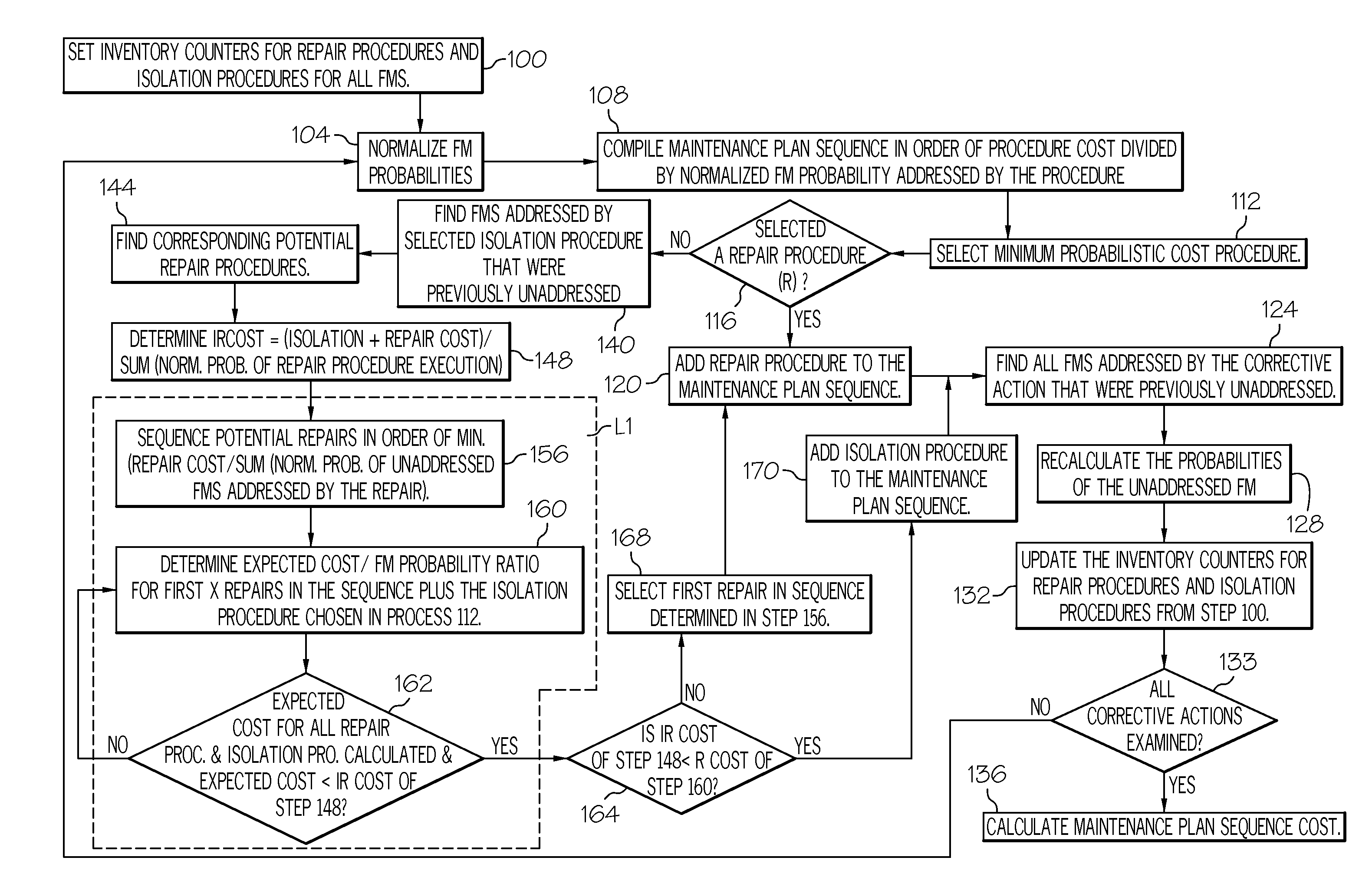

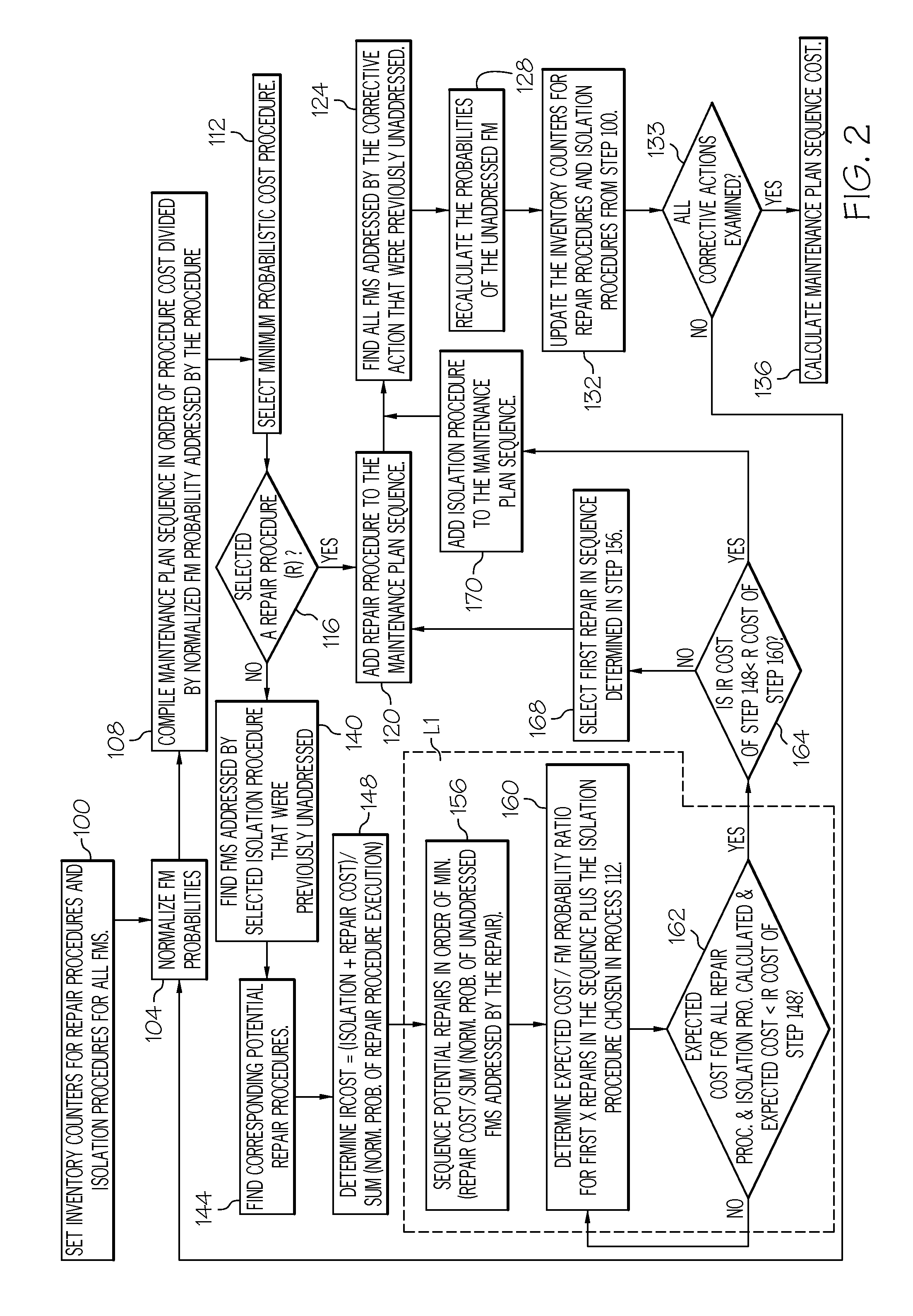

Systems and methods for creating a near optimal maintenance plan

Methods and apparatus are provided for determining a lowest total cost maintenance plan. The method comprises receiving a sequence of maintenance actions in an order of a waiting time for each maintenance action, wherein one of the maintenance actions is likely to repair the failure mode. Each maintenance action has an associated cost equal to a waiting time cost, an execution time cost and a material cost, wherein the waiting time of each maintenance action is the time required to requisition and receive material required to perform the maintenance action. The method also constructs a maintenance plan comprising a primary requisition and a secondary requisition by assigning each of the sequence of maintenance actions to one of the primary and secondary requisition.

Owner:HONEYWELL INT INC

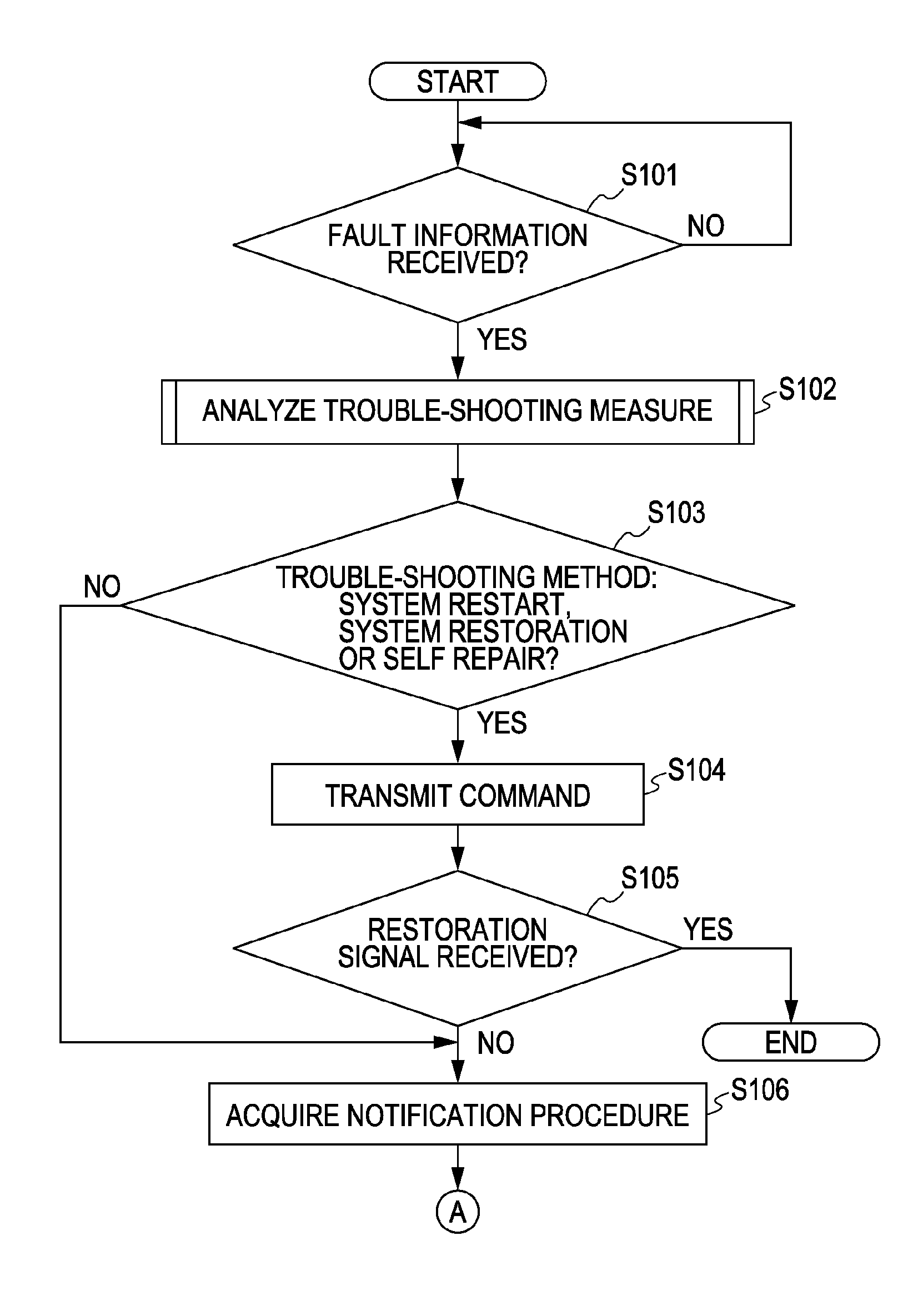

Support management method, support management system and information processing device

A trouble-shooting measure against a fault in an external device installed at a remote place is supported by receiving fault information on the fault that has occurred in the external device, acquiring an installation place of the external device in which the fault has occurred, a repair procedure acquisition unit for acquiring a repair procedure representing a list of candidates of qualified maintenance persons and an outline of the fault that can be dealt with by the maintenance persons included in the list, acquiring a job situation of the maintenance person, and transmitting a trouble-shooting instruction against the fault to a communication terminal unit of a qualified maintenance person in accordance with the acquired repair procedure. Further, trouble-shooting instruction is transmitted in priority to an optimum maintenance person selected based on a relation between the acquired repair procedure and the job situation.

Owner:FUJITSU LTD

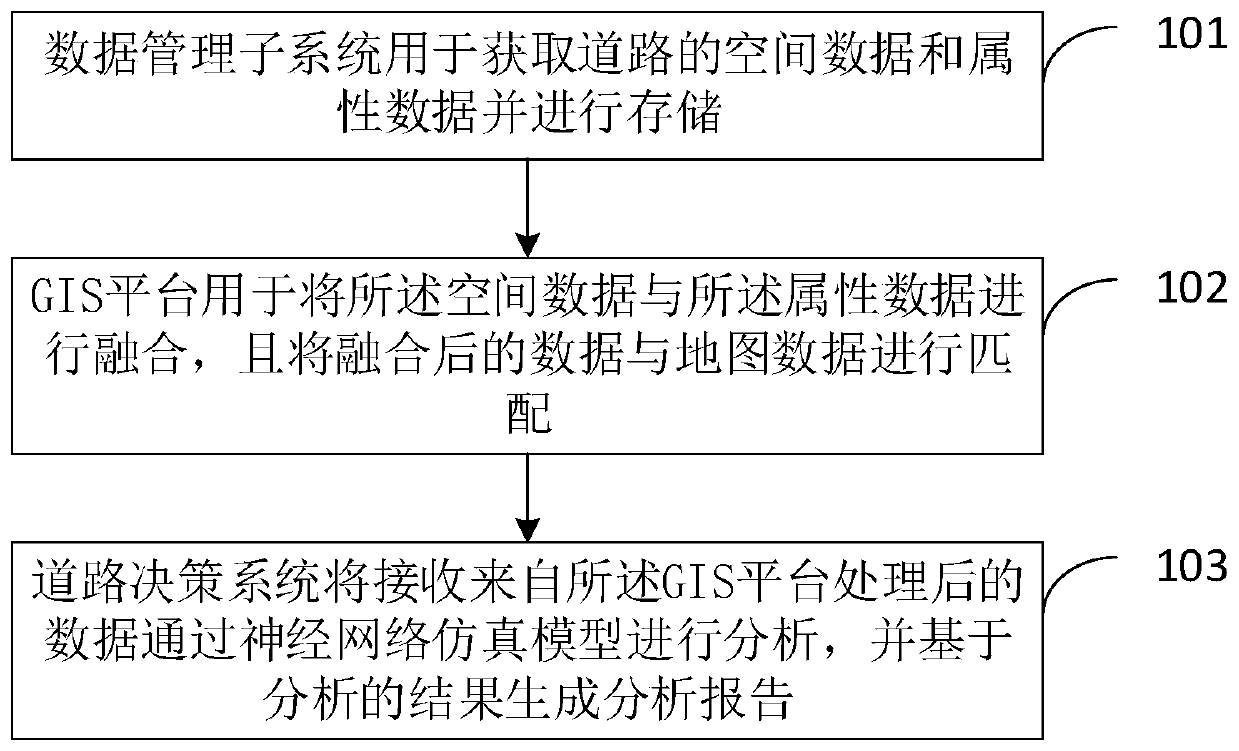

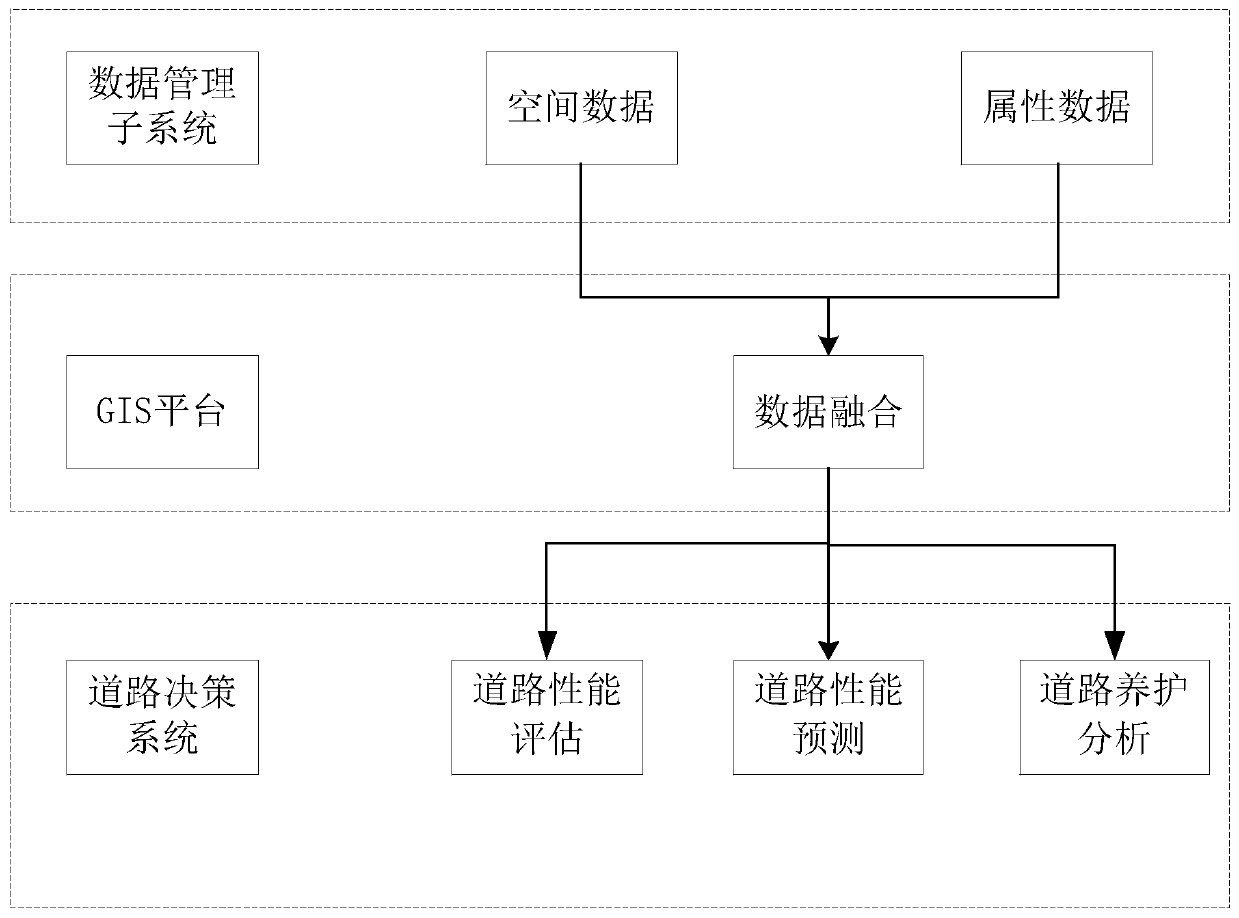

A network-level road maintenance management decision-making system

PendingCN109711722AFacilitate maintenance decisionsBenefit target maximizationResourcesStatistical analysisStatistical Report

Owner:江苏北极星交通产业集团有限公司

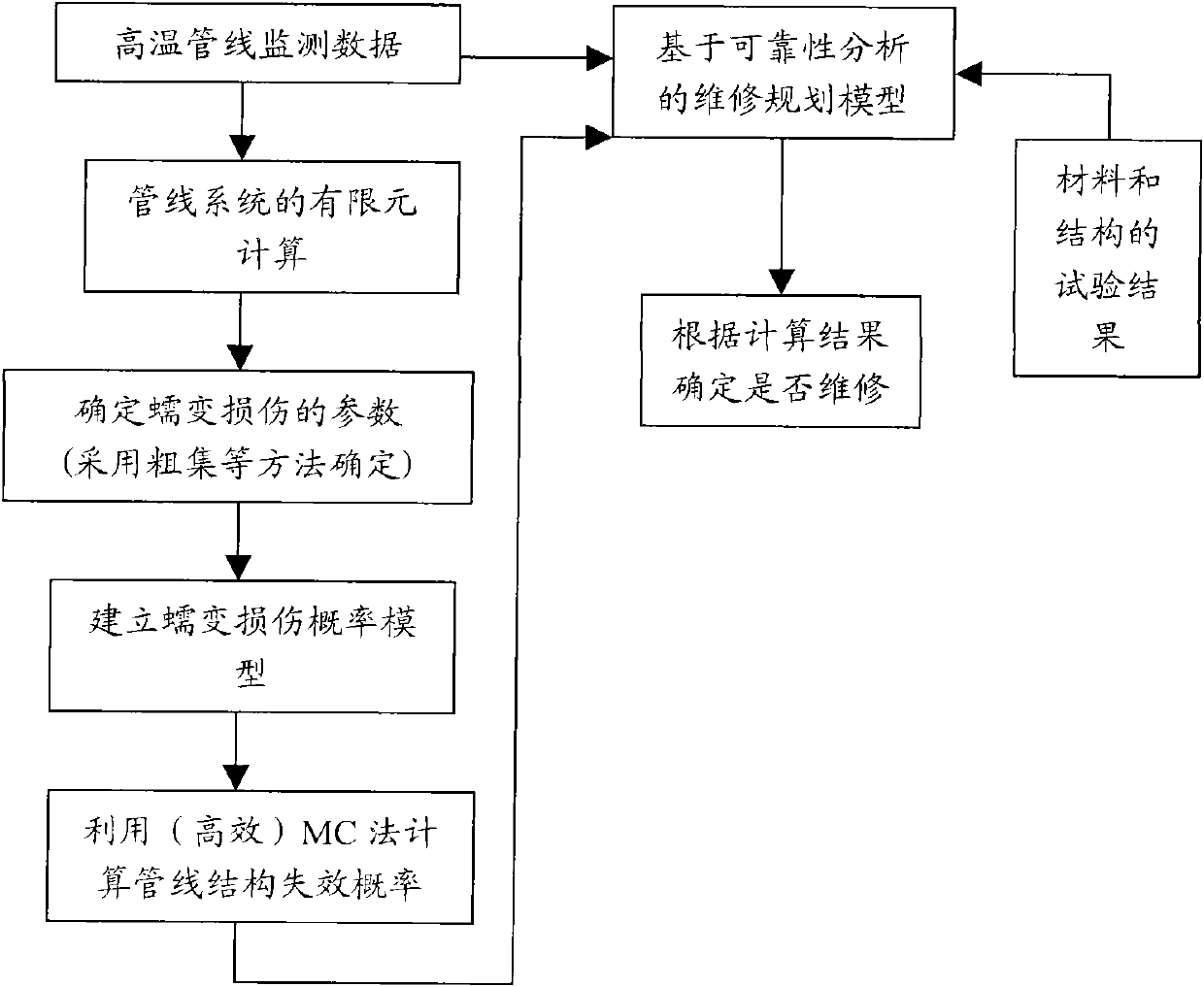

Method for realizing reliability maintenance planning of high temperature pipeline system

InactiveCN101994908AAccurately determineEfficient and accurate determinationStructural/machines measurementPipeline systemsStructural reliabilityMaintenance planning

The invention relates to a method for realizing reliability maintenance planning of a high temperature pipeline system, which comprises the following steps of: collecting and acquiring detection data of a high temperature pipeline system; calculating a finite element of the high temperature pipeline system; determining creep damage parameters according to the influence degree of all factors on the life of the high temperature pipeline; creating a creep damage probability model through determining the probability distribution of the creep damage parameters; calculating a structural failure probability according to the creep damage probability model; creating a maintenance planning model based on reliability analysis according to the detection data, test results of materials and structures of the high temperature pipeline system and the structural failure probability; and carrying out calculation processing according to the maintenance planning model to obtain the optimal maintenance time of the high temperature pipeline system. By adopting the method for realizing the reliability maintenance planning of the high temperature pipeline system, the structural reliability is determined efficiently and accurately, a maintenance scheme can be accurately determined, the similar problem of the maintenance planning of the high temperature pipelines in other fields can be solved, and the method has wider application range.

Owner:EAST CHINA UNIV OF SCI & TECH

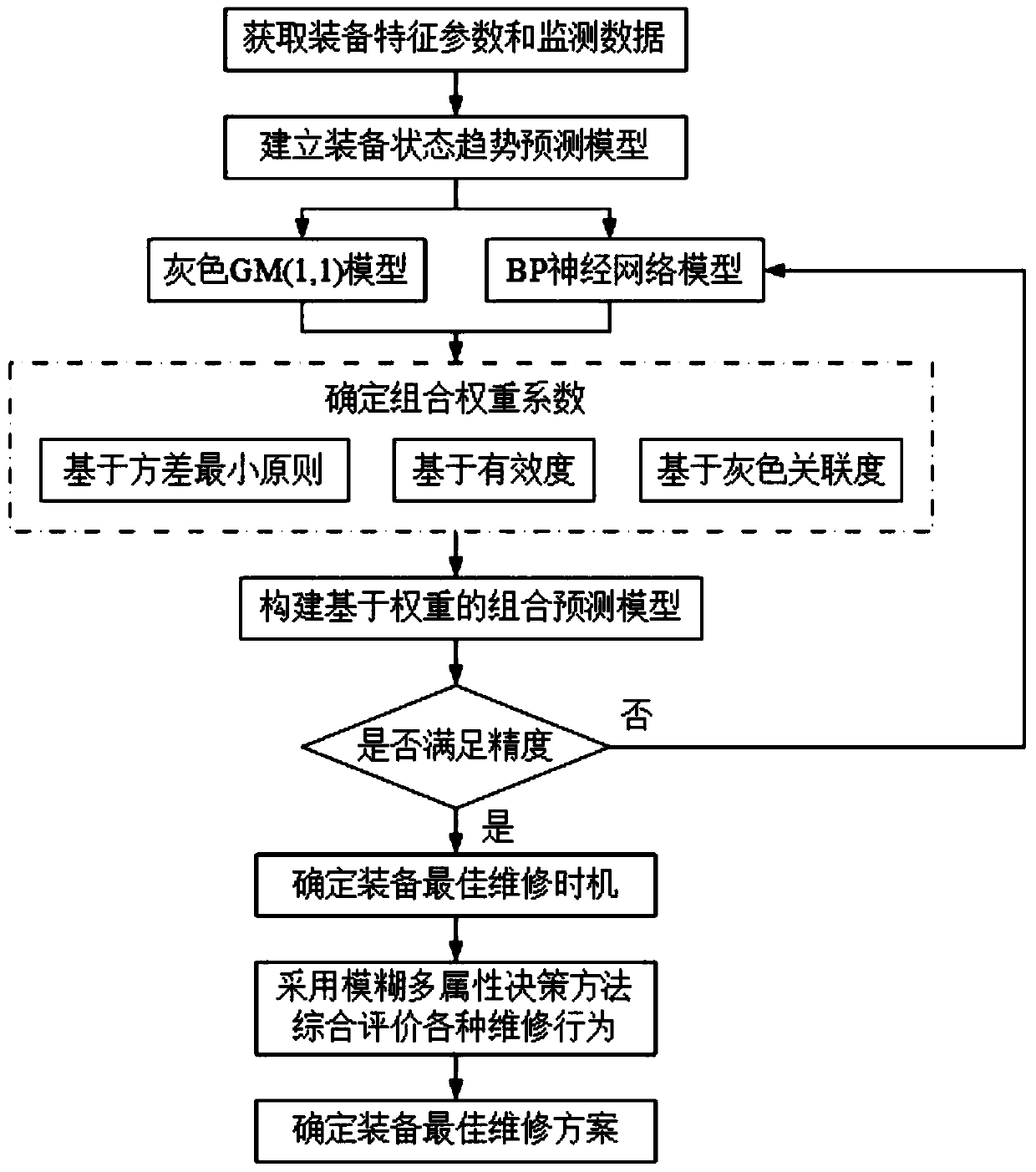

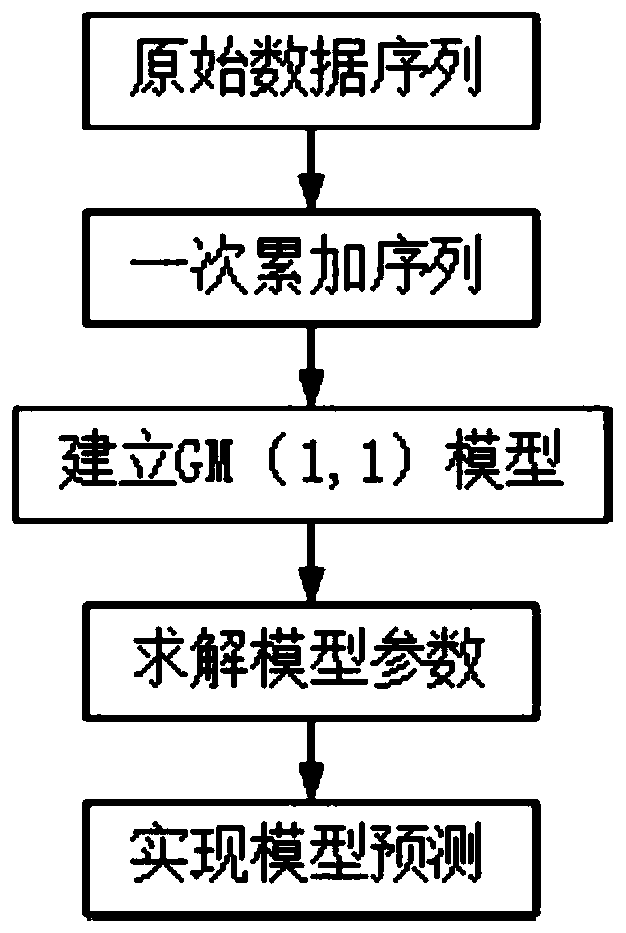

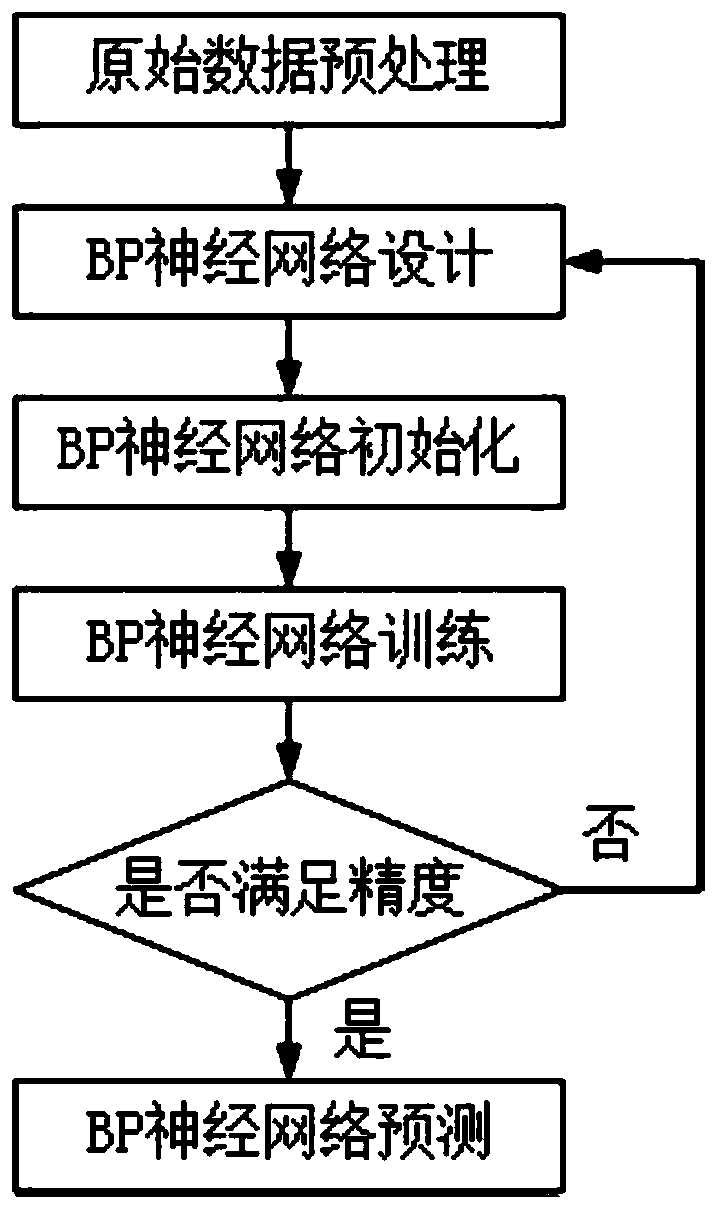

Complex equipment maintenance decision-making method based on fault prediction

ActiveCN111539515AStrong self-learning abilityThe result is accurateNeural architecturesNeural learning methodsEngineeringNetwork model

The invention provides a complex equipment maintenance decision-making method based on fault prediction. The method comprises the following steps: A, determining a feature factor related to an equipment fault, setting a fault threshold of the feature factor, and collecting the historical data of the feature factor; B, predicting the numerical value of the feature factor through a gray model and aBP neural network model respectively; C, determining weights of the gray model and the BP neural network model; and D, carrying out numerical prediction on the equipment feature factor based on the combination model determined by the weight, taking the moment when a fault threshold value is reached as a prediction fault moment, and determining the optimal maintenance opportunity. The method has the following advantages: the advantages that the gray model has low requirements for sample data volume and the BP neural network has strong autonomous learning capability are combined, high-precisionprediction of the feature factor is effectively realized, the maintenance time is determined in time according to comparison with a fault threshold, preventive maintenance can be carried out in time,and normal operation of equipment is ensured.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 38 RES INST

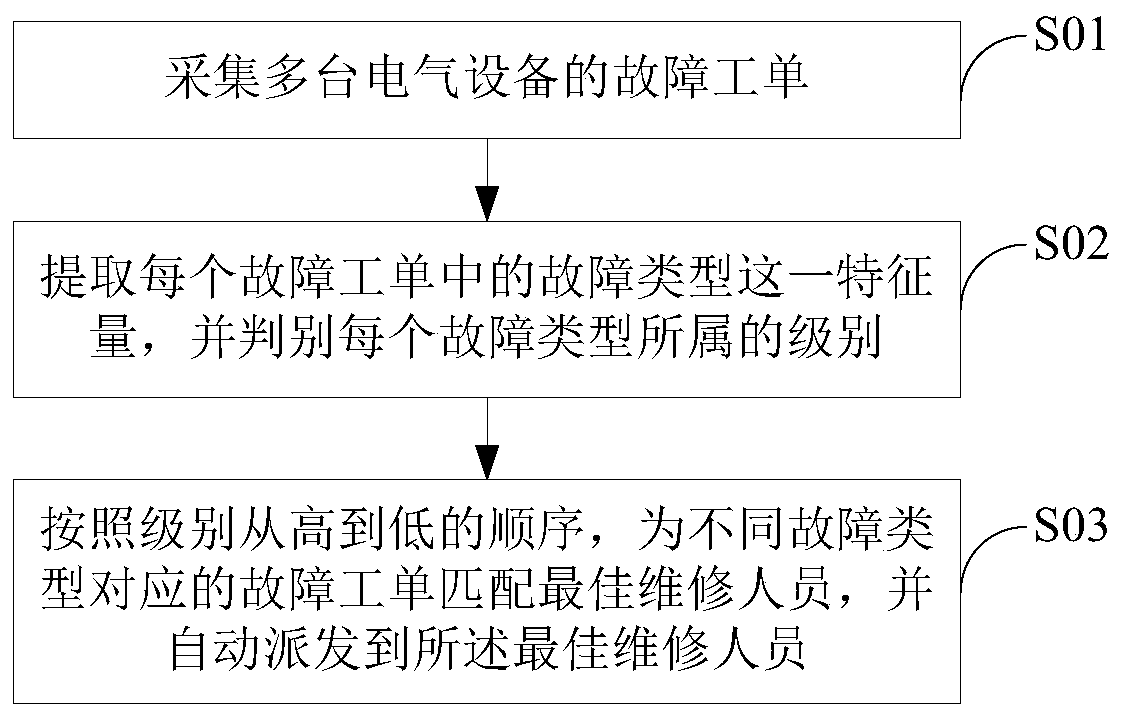

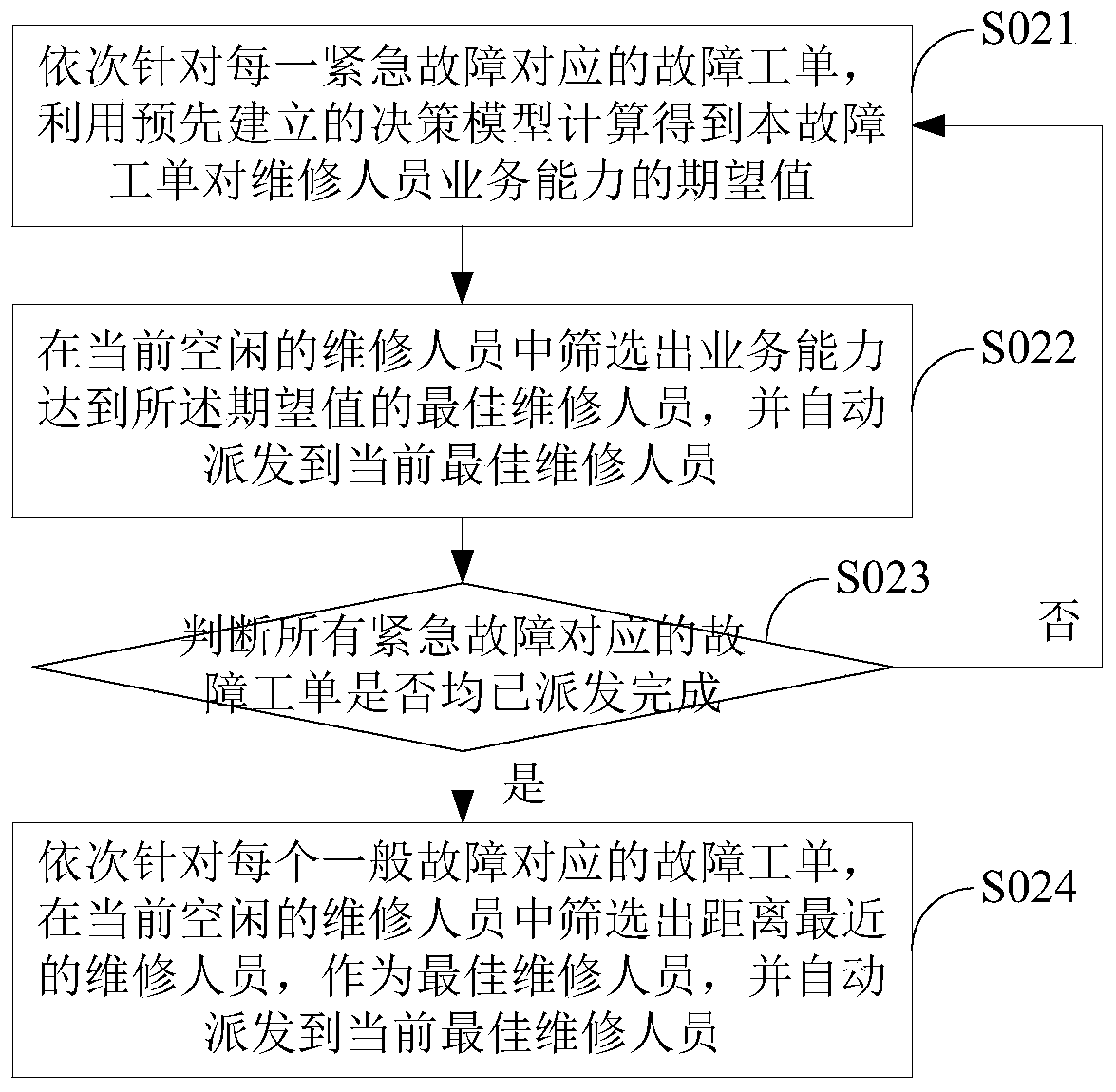

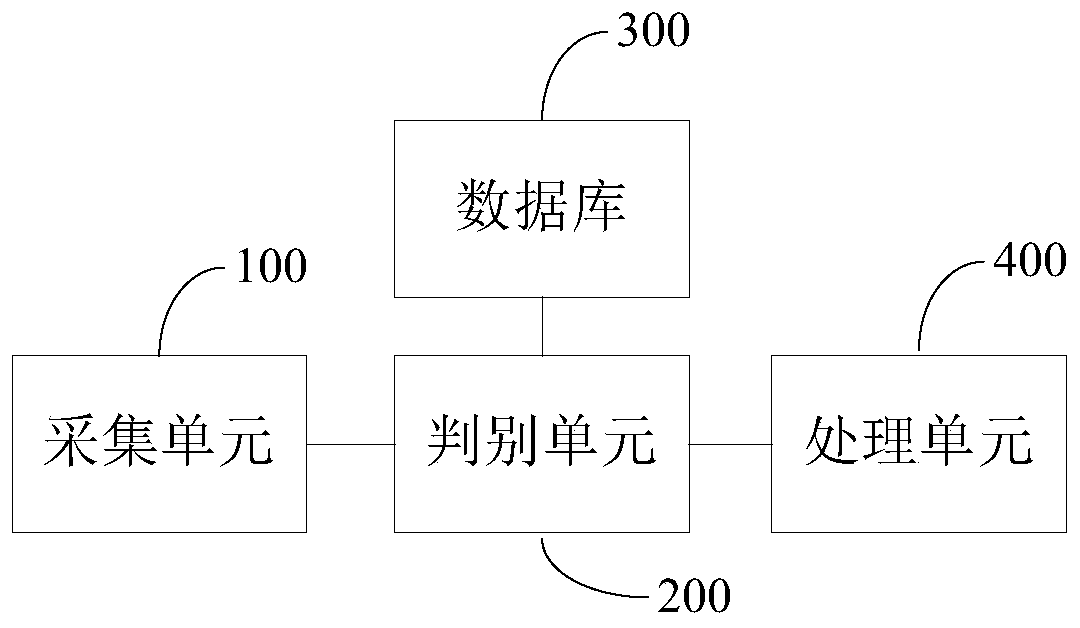

Fault work order distribution method and fault work order management system

InactiveCN109858746AImprove efficiencyNot easy to missForecastingResourcesOrder management systemDistribution method

The invention discloses a fault work order distribution method and a fault work order management system. The method comprises the steps of collecting fault work orders of a plurality of electrical devices; extracting a characteristic quantity of a fault type in each fault work order, judging the level of each fault type, and dividing the fault type of the electrical equipment into a plurality of levels in advance according to the influence degree of the fault type; and matching the optimal maintenance personnel for the fault work orders corresponding to different fault types according to the descending order of the levels, and automatically distributing the optimal maintenance personnel. According to the invention, high efficiency and high quality of mass fault work order distribution workare ensured.

Owner:SUNGROW POWER SUPPLY CO LTD

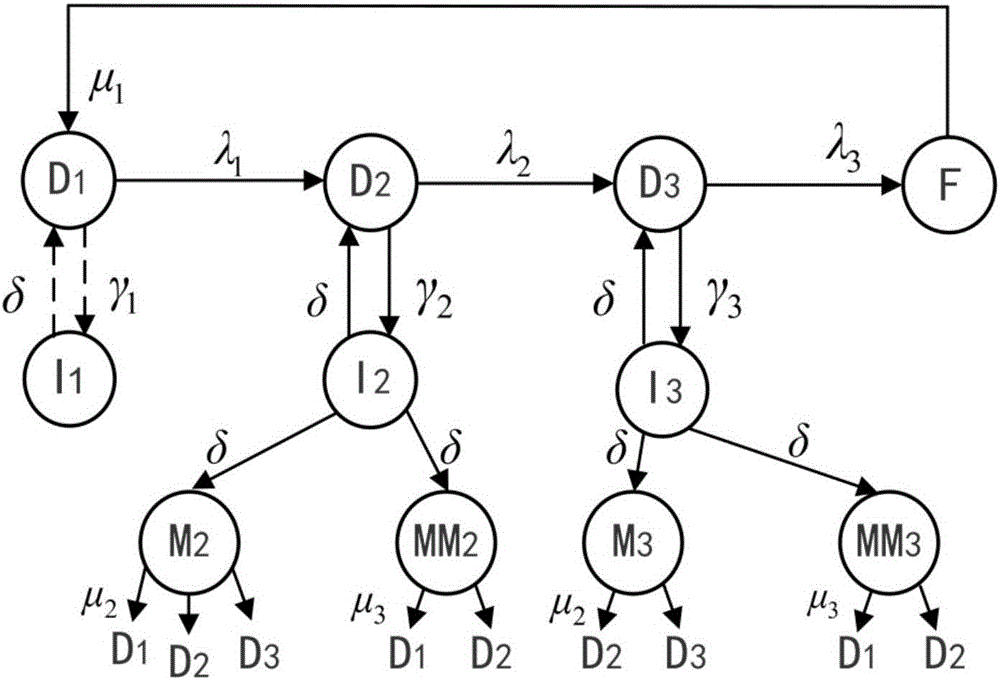

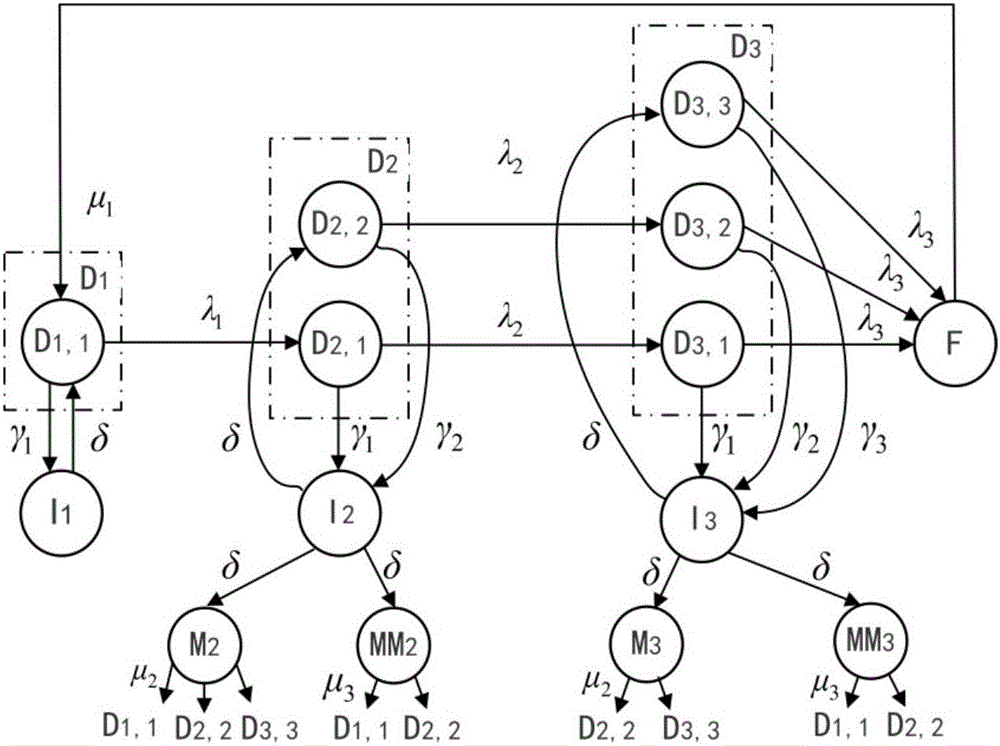

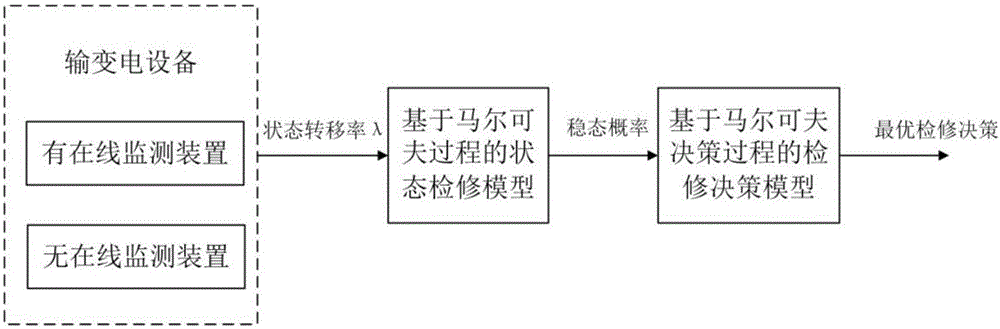

Optimal maintenance decision method of power transmission and transformation equipment based on Markov decision process

ActiveCN106447201AVerify suitabilityOptimal maintenance strategyDesign optimisation/simulationResourcesElectric power transmissionStable state

The invention discloses an optimal maintenance decision method of power transmission and transformation equipment based on a Markov decision process. The method comprises that a state transfer relation diagram, of transfer relation among different states, of the power transmission and transformation equipment is established; a state maintenance model of the power transmission and transformation equipment is established according to the state transfer relation diagram of the power transmission and transformation equipment; the Markov decision process is used to solve the stable-state probabilities of different states of the power transmission and transformation equipment; a function relation between a maintenance strategy and pay corresponding to the maintenance strategy is established; a Markov based maintenance decision model of the power transmission and transformation equipment is established by taking maximization of certain function value of a pay sequence in the maintenance strategy as a sequence decision problem; and according to the stable-state probabilities of the different states of the power transmission and transformation equipment, a strategy iteration method is used to obtain an optimal maintenance strategy by solving. The method has the advantages that the Markov decision is used to make compromise between the maintenance cost and fault loss, the optimal maintenance decision is obtained, and reference is provided for maintenance deciding staff.

Owner:ELECTRIC POWER RESEARCH INSTITUTE OF STATE GRID SHANDONG ELECTRIC POWER COMPANY +3

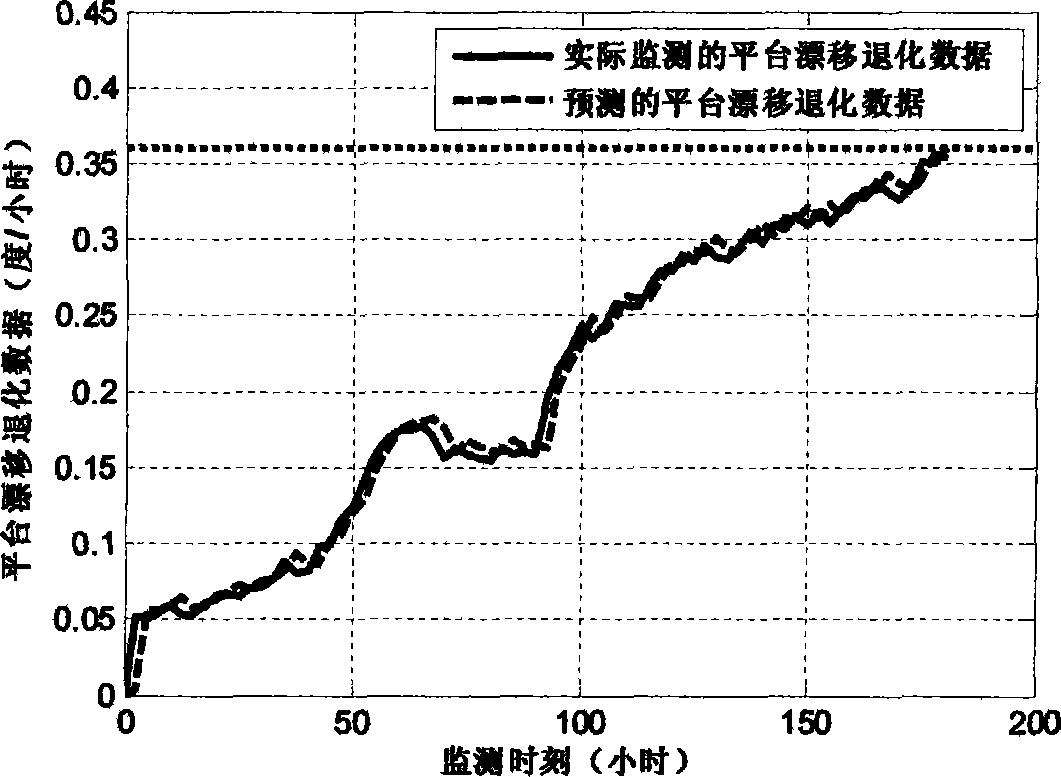

Optimal maintaining method for equipment with performance slow degradation

The invention belongs to the technical field of reliability engineering and relates to a method for carrying out optimal maintaining on high reliability equipment with a performance slow degradation characteristic. According to the operation of the equipment, performance degradation monitoring data is reasonably selected, and the performance degradation database of the equipment is established. The method concretely comprises the steps of constructing a dynamic performance degradation database, establishing an equipment performance degradation model, predicating the remaining life, and determining the optimal maintenance time. The invention provides a complex equipment optimal maintenance method in the condition that a product has slow performance degradation, the characteristic amount degradation of the equipment can be predicated and analyzed, the method can be used as an effective tool for predicating equipment individual life, a powerful theoretical basis and technical support are provided for the repair and maintenance of the equipment, thus the spending is saved, the unnecessary economic loss is avoided, and the method has a good engineering application value.

Owner:PLA SECOND ARTILLERY ENGINEERING UNIVERSITY

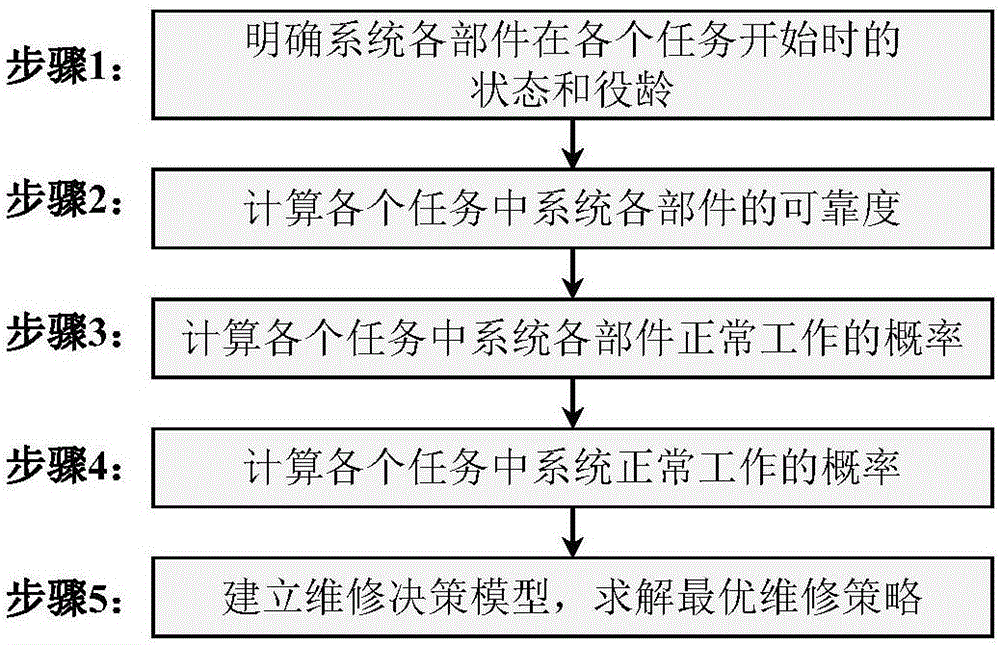

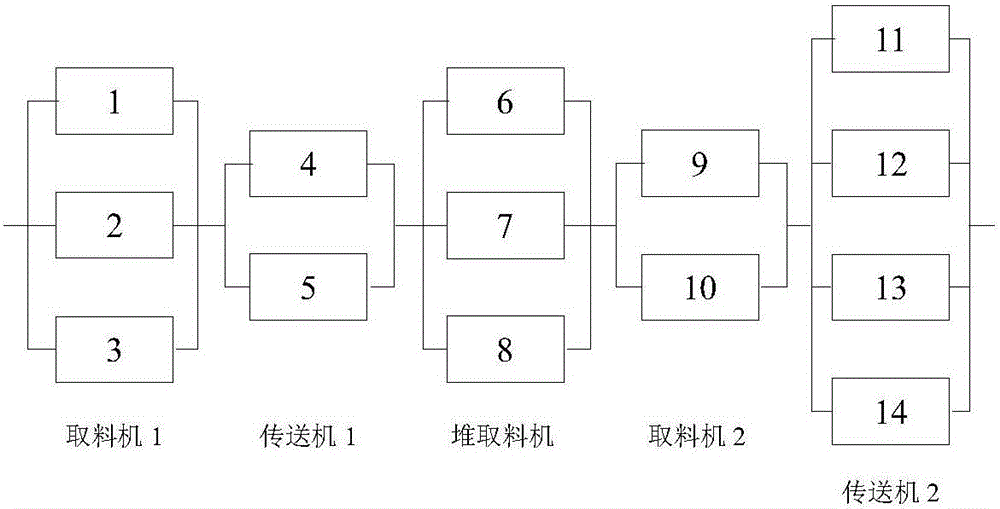

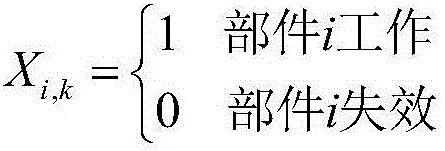

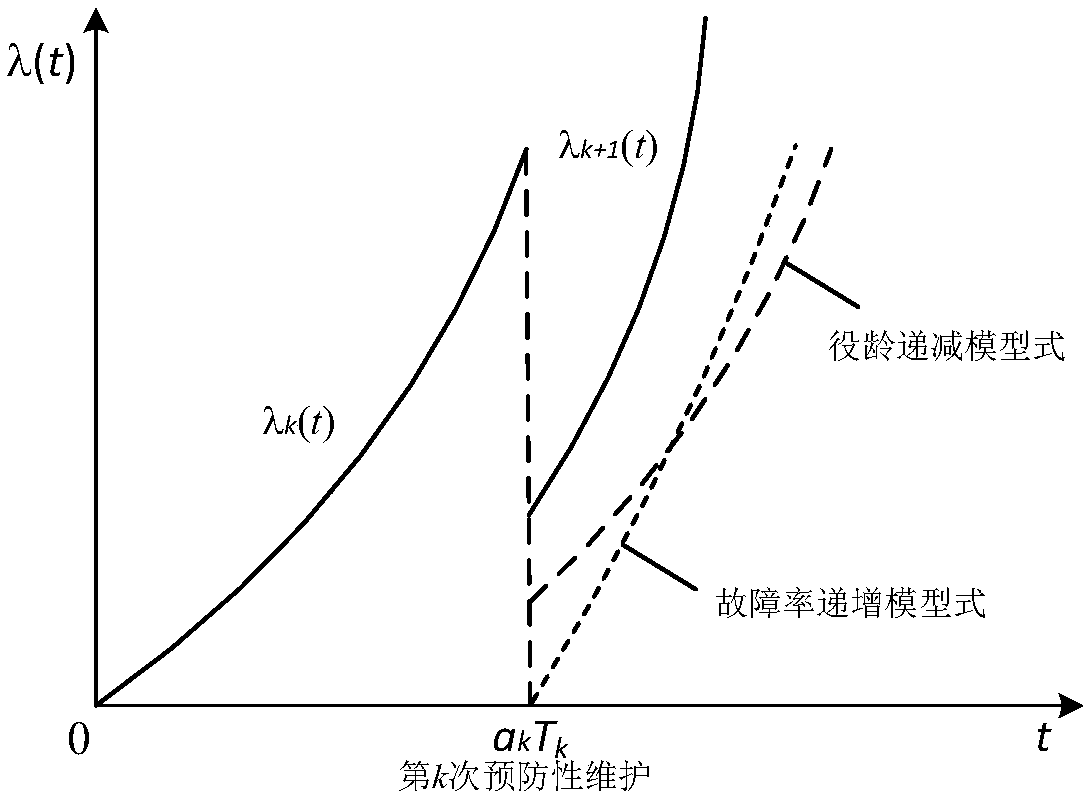

System selective maintenance decision-making method for multitask stage

The invention discloses a system selective maintenance decision-making method for a multitask stage, and the method comprises the steps: determining the state and service age of each part of a system at the beginning of each task; calculating the reliability of each part of the system in each task; calculating the normal operation probability of each part of the system in each task; calculating the normal operation probability of the system in each task; taking the task completing probability of each task of the system as a target function, taking a limited maintenance resource feasible set as a constraint condition, taking the maintenance behavior of each part of the system in each task as a decision-making variable, building a maintenance decision-making optimization model, and solving an optimal maintenance strategy. Through the comprehensive consideration of the task time uncertainty and failure time uncertainty of the multitask stage, a system decision maker can configure the limited maintenance resources to each maintenance interval more reasonably and effectively, so as to maximize the normal operation probability of the system in each task.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

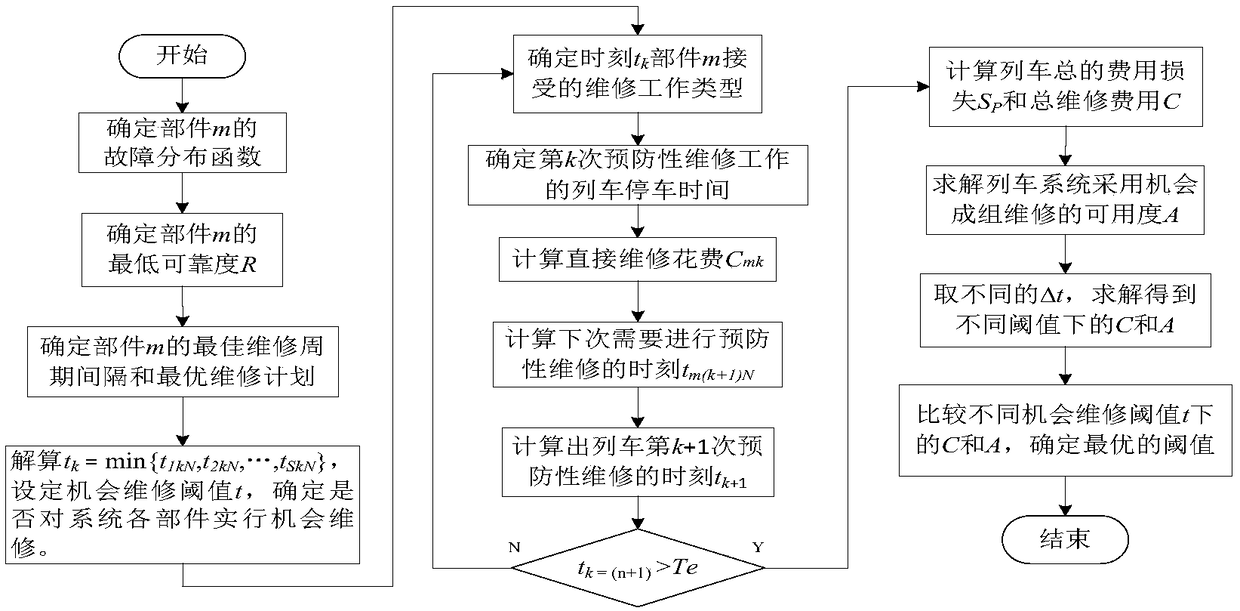

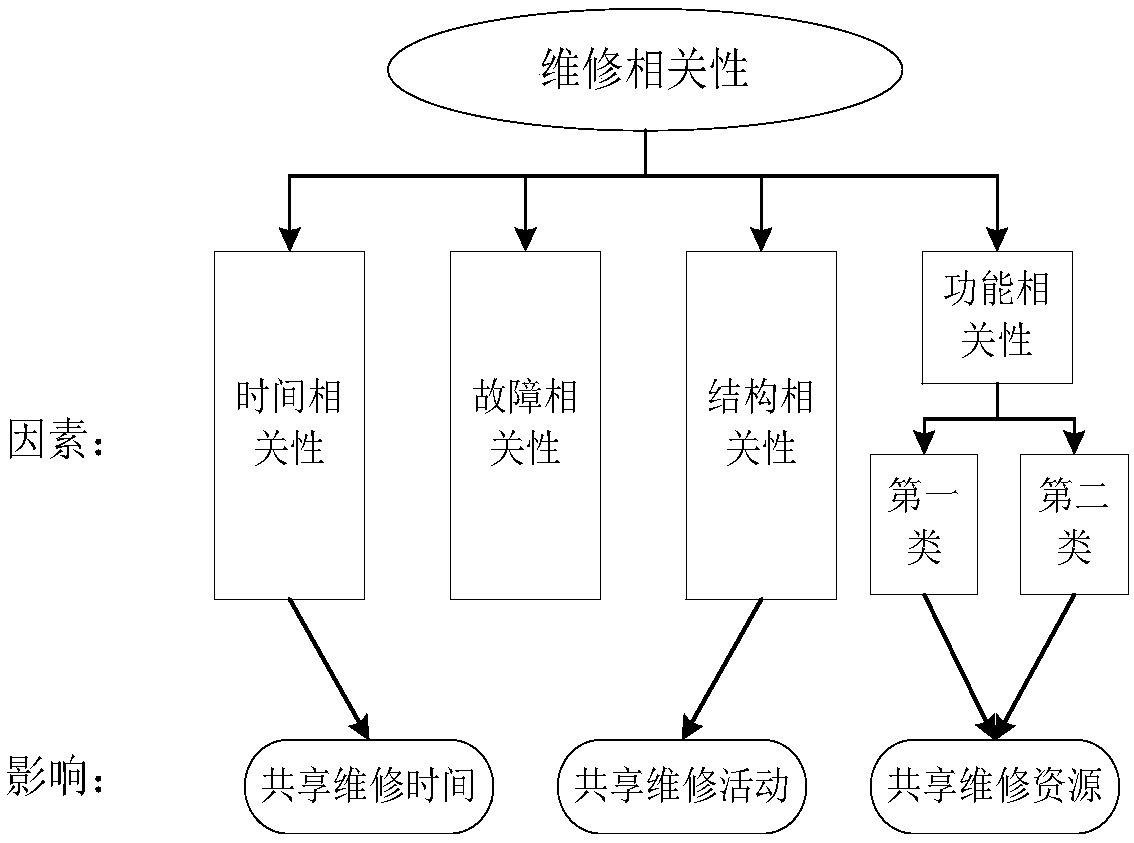

A reliability-based preventive maintenance optimization method for metro vehicle multi-components

ActiveCN109299517AReduce maintenance costsReduce parking timeInternal combustion piston enginesForecastingTime correlationMaintenance strategy

The invention discloses a reliability-based preventive maintenance optimization method for multi-components of metro vehicles, A method for determine that optimal maintenance interval of a single component of a metro vehicle is proposed, that is to say, imperfect maintenance mode is applied to each single component, based on component maintenance economy and train availability, By comparing the effects of component faults on equipment safety, the optimal maintenance interval is determined. Secondly, the opportunistic maintenance threshold delta t is introduced, and the opportunistic maintenance strategy of metro train multi-component system considering the time correlation between components is adopted. According to the operation and maintenance characteristics of metro train, the opportunistic maintenance model of metro train multi-component system is established. Finally, the steps to solve the model are given. On the premise that the invention can meet the reliability requirement, the maintenance cost and the train availability are optimized simultaneously, and the optimal maintenance plan can be obtained by solving the problem, thereby providing theoretical support for the maintenance optimization of the metro train.

Owner:GUANGXI UNIV

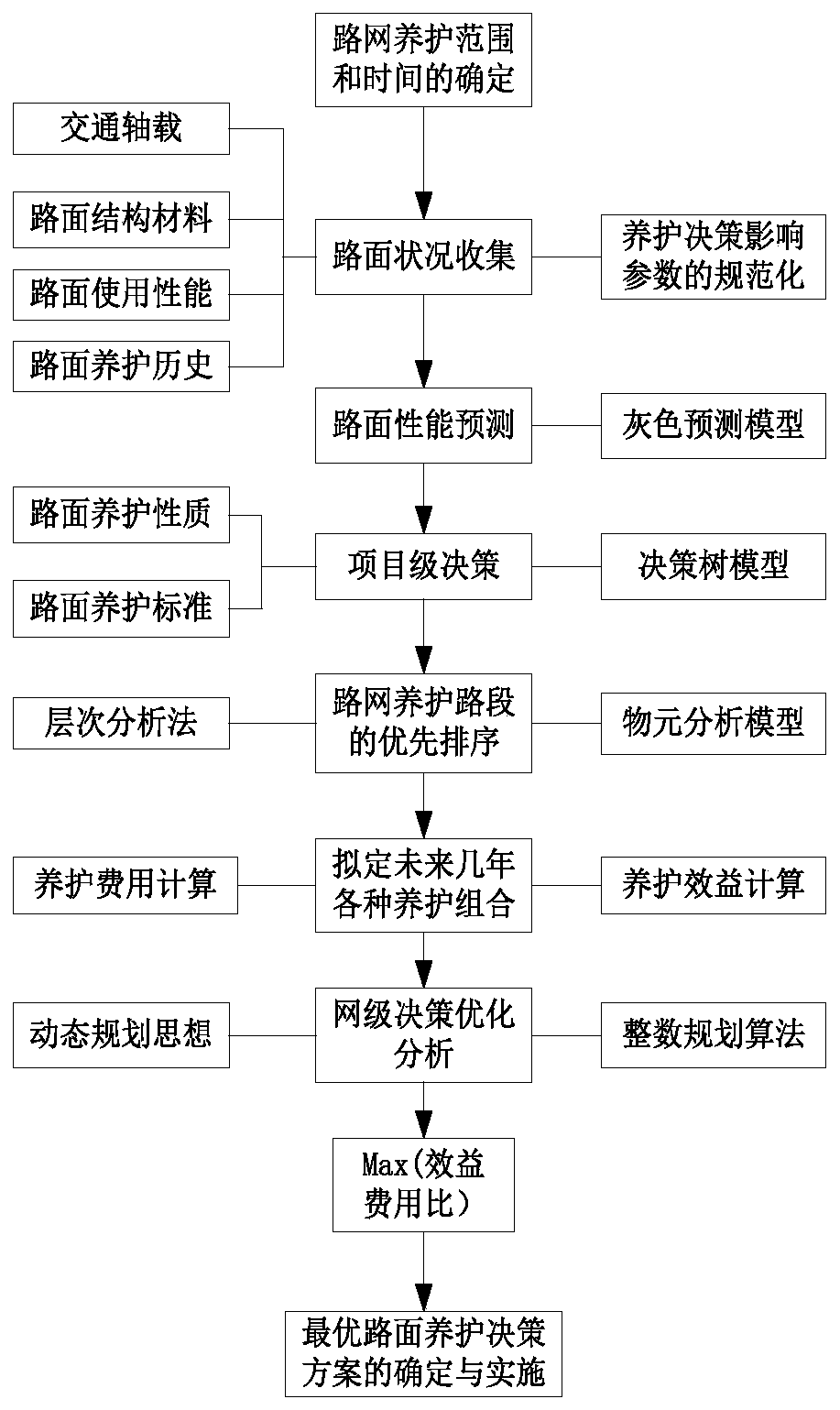

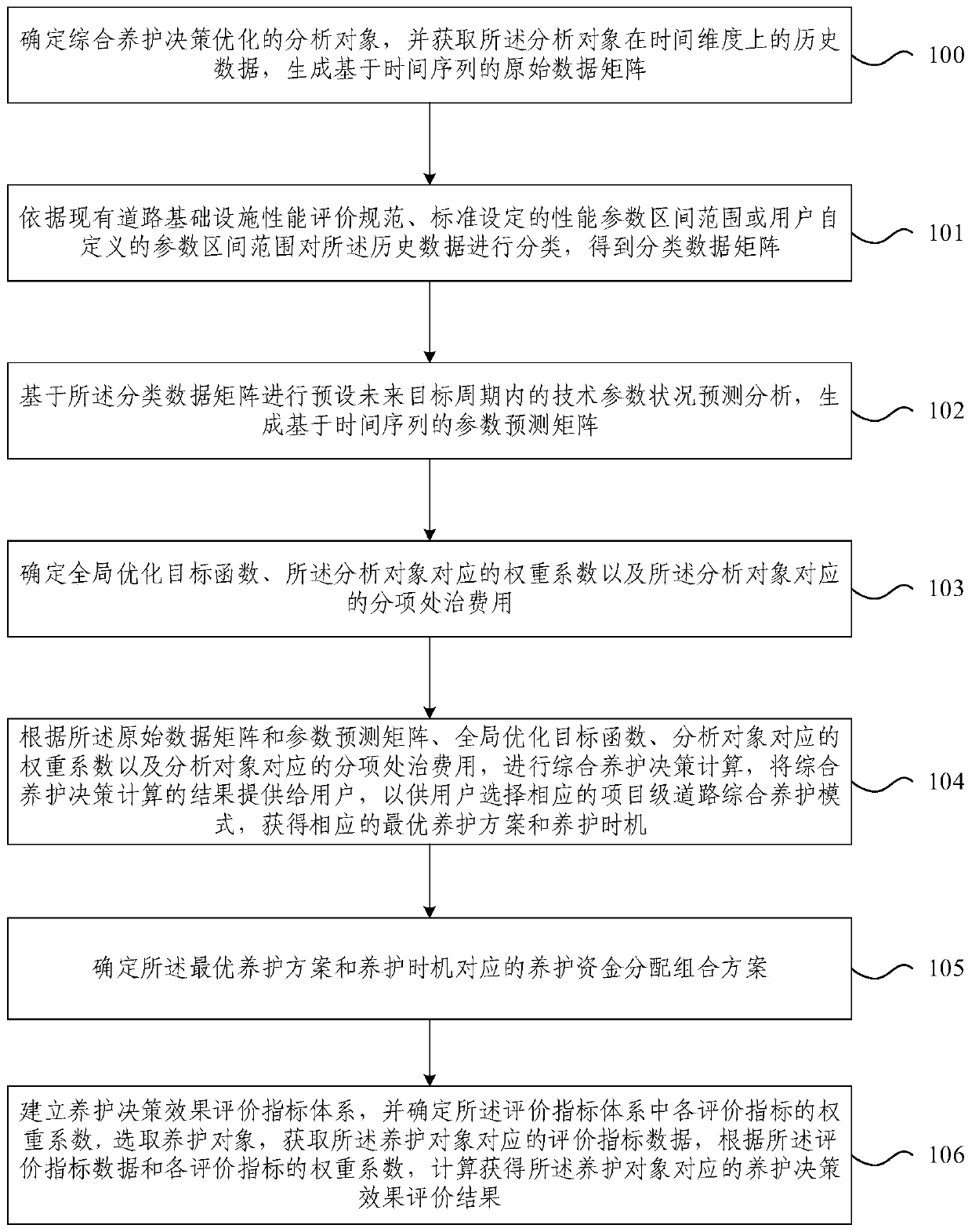

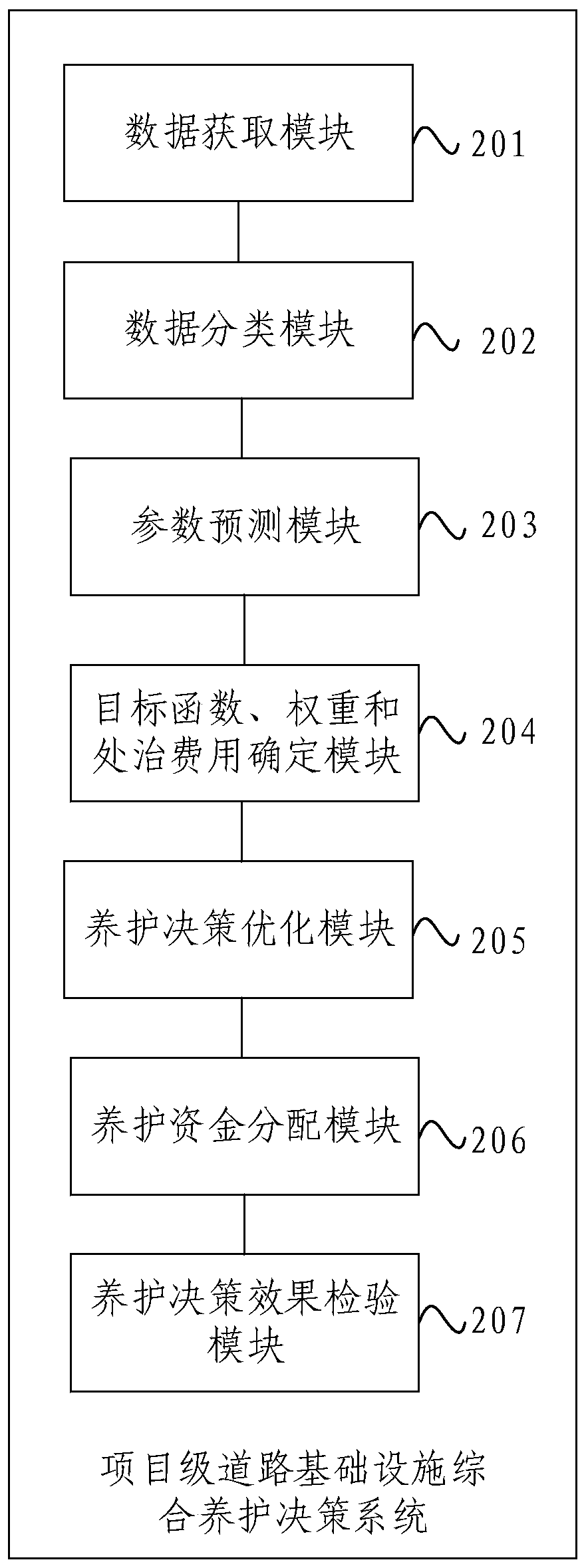

Project-level road infrastructure comprehensive maintenance decision-making method and system

ActiveCN110288210AImprove scienceImprove rationalityOffice automationResourcesWeight coefficientGlobal optimization

The invention provides a project-level road infrastructure comprehensive maintenance decision-making method and system, and the method comprises the steps of determining an analysis object, and obtaining the historical data of the analysis object; classifying the historical data of the analysis object to obtain a classification data matrix; performing prediction analysis based on the classification data matrix to generate a parameter prediction matrix; determining a global optimization objective function, a weight coefficient corresponding to the analysis object and the sub-item treatment cost; and according to the historical data, the parameter prediction matrix, the global optimization objective function, the weight coefficient corresponding to the analysis object and the sub-item treatment cost, carrying out comprehensive maintenance decision calculation to obtain an optimal maintenance scheme and an optimal maintenance opportunity; carrying out fund distribution based on the optimal maintenance scheme, and checking the maintenance effect. The method and the system are suitable for the comprehensive maintenance decision of the technical parameters between different project-level road infrastructure structures and the comprehensive maintenance decision of different technical parameters of the same project-level road infrastructure structure.

Owner:CHINA HIGHWAY ENG CONSULTING GRP CO LTD +1

Power equipment maintenance decision-making method utilizing equal degradation theory and equipment risks

ActiveCN106647263AImprove economyLower life cycle costsAdaptive controlElectric power systemPower equipment

The invention relates to a power equipment maintenance decision-making method, and particularly relates to a power equipment maintenance decision-making method utilizing an equal degradation theory and equipment risks. According to the invention, the equal degradation theory is introduced into the power industry, analysis and comparison are performed on changes in equipment risk before and after maintenance by sufficiently considering changes in equipment failure probability before and after maintenance, and the equipment maintenance cost is considered so as to acquire an optimal maintenance scheme. The power equipment maintenance decision-making method starts from the view of asset management, the cost required by equipment in the whole life cycle is enabled to reduce to minimum, and a balance point is found between self values of the equipment and economic benefits brought by the equipment to a system, between LCCM (Life Cycle Costing Management) and equipment maintenance and between technologies and management of the power system.

Owner:ELECTRIC POWER SCI RES INST OF GUIZHOU POWER GRID CO LTD

Equipment maintenance management method and system and computer readable storage medium

ActiveCN109933934AReduce workloadEnsure objectivitySpecial data processing applicationsMaintenance strategyMaintainability

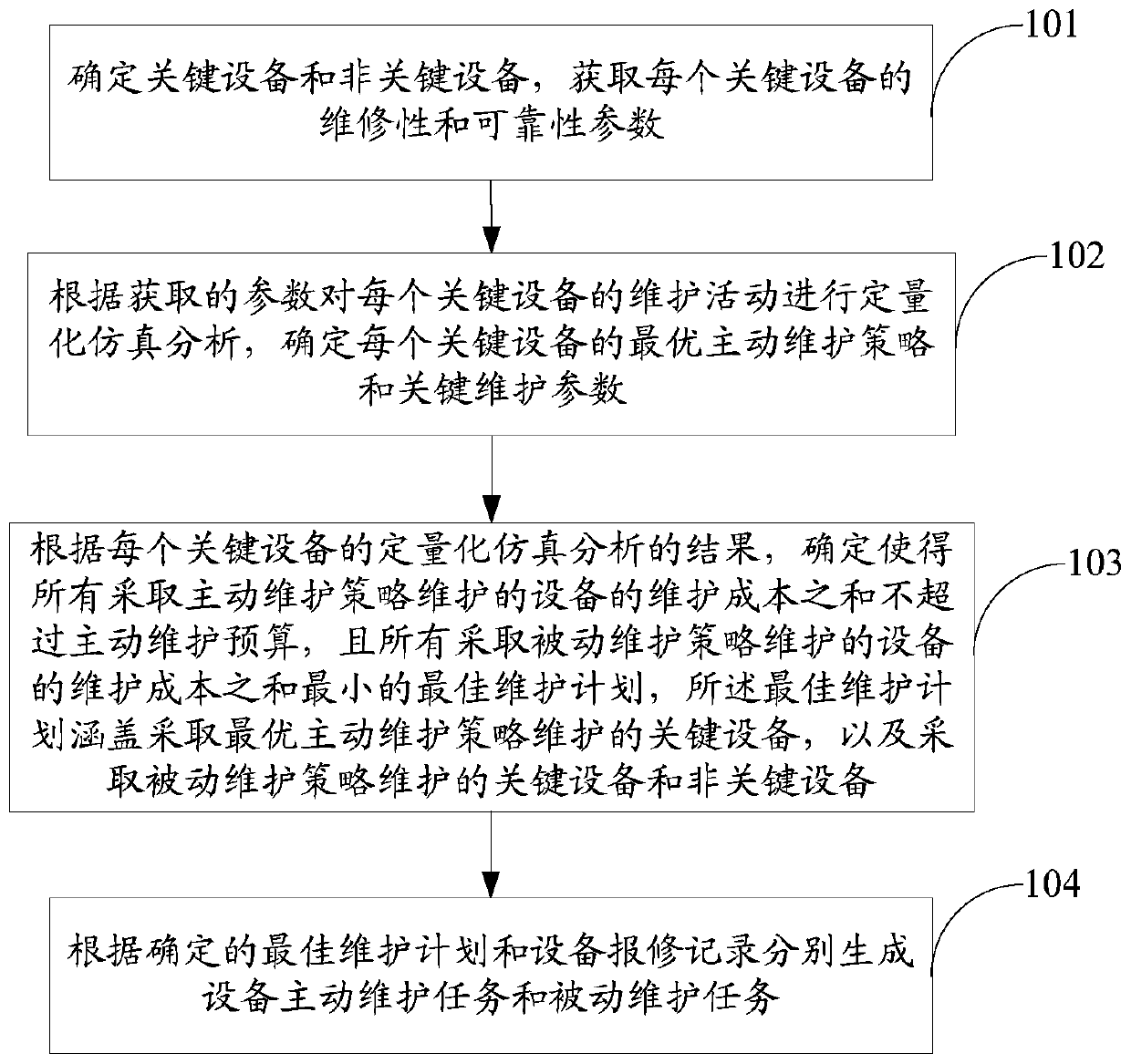

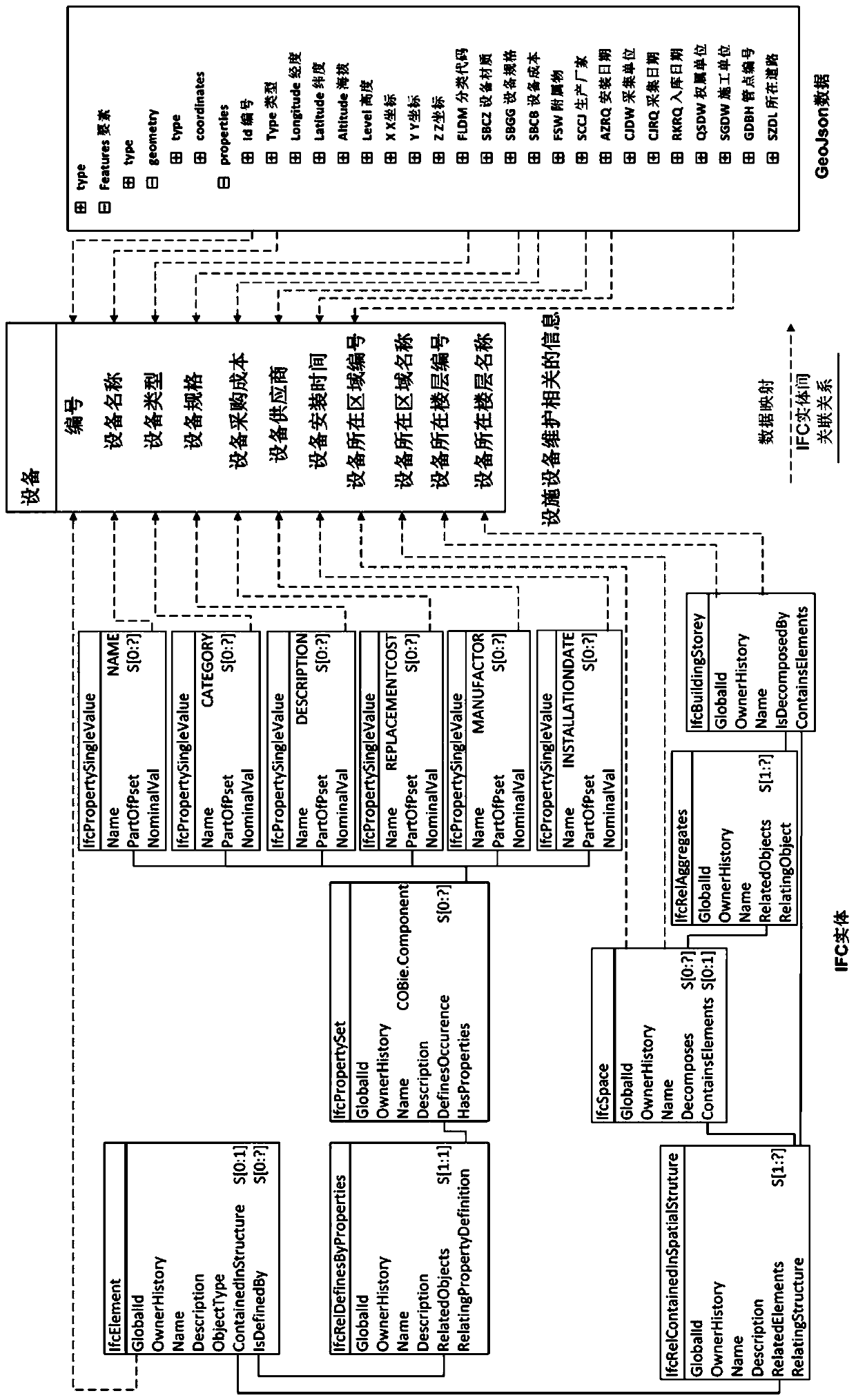

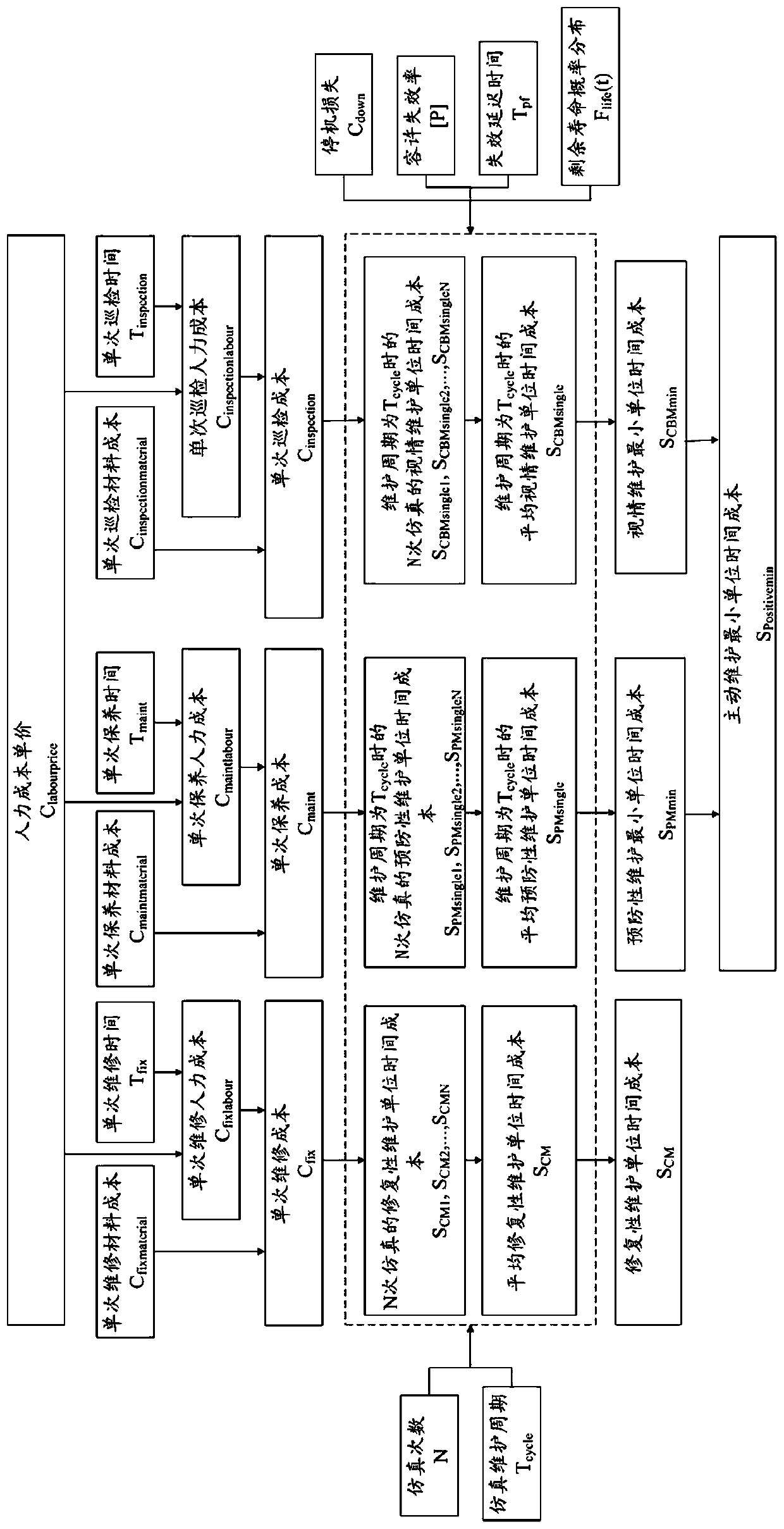

The invention discloses an equipment maintenance management method and system and a computer readable storage medium, and the method comprises the steps: determining key equipment and non-key equipment, and obtaining the maintainability and reliability parameters of each key equipment; quantitative simulation analysis is carried out on the maintenance activity of each key device, and an optimal active maintenance strategy and key maintenance parameters are determined; according to the result of the quantitative simulation analysis, determining an optimal maintenance plan which enables the sumof the maintenance costs of all the devices maintained by adopting the active maintenance strategy not to exceed the active maintenance budget and the sum of the maintenance costs of all the devices maintained by adopting the passive maintenance strategy to be minimum, and obtaining a maintenance strategy which should be adopted by each device; and generating an equipment maintenance task according to the optimal maintenance plan and the equipment repair request record. Expert experience analysis is replaced by computer-aided scientific analysis and calculation, the result objectivity is ensured, and the workload of maintenance plans is reduced.

Owner:TSINGHUA UNIV +1

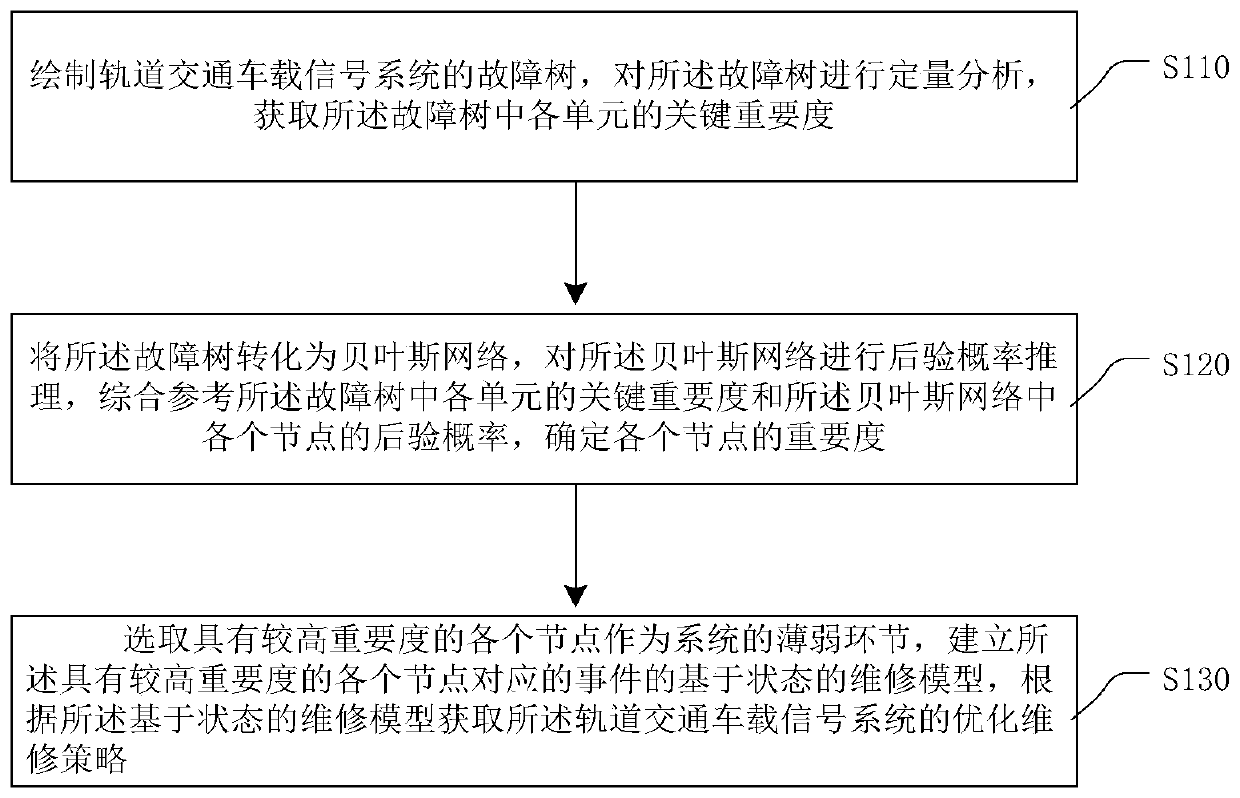

Method for obtaining optimized maintenance strategy of rail transit vehicle-mounted signal system

PendingCN111310948ABest maintenance timeImprove securityMarket predictionsForecastingIn vehicleMaintenance strategy

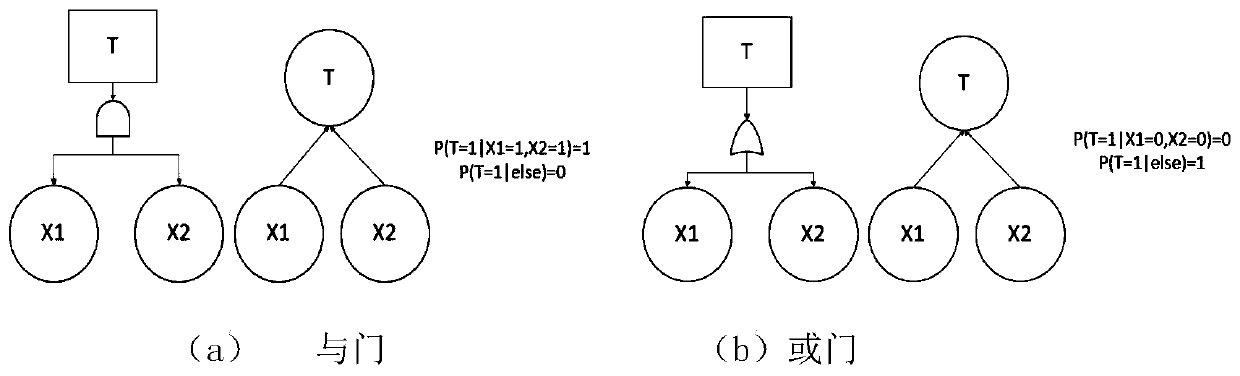

The invention provides a method for obtaining an optimized maintenance strategy of a rail transit vehicle-mounted signal system. The method comprises the following steps: drawing a fault tree of the rail transit vehicle-mounted signal system, and carrying out quantitative analysis on the fault tree to obtain key importance of each unit in the fault tree; converting the fault tree into a Bayesian network, performing posterior probability reasoning on the Bayesian network, and determining the importance of each node by comprehensively referring to the key importance of each unit in the fault tree and the posterior probability of each node in the Bayesian network; and selecting each node with relatively high importance as a weak link of the system, establishing a state-based maintenance modelof an event corresponding to each node with relatively high importance, and obtaining an optimized maintenance strategy of the rail transit vehicle-mounted signal system according to the state-basedmaintenance model. According to the method, a reference basis for quickly positioning the fault equipment can be provided when the system has a fault, and the optimal maintenance time of the vehicle-mounted signal equipment can be speculated.

Owner:BEIJING JIAOTONG UNIV +1

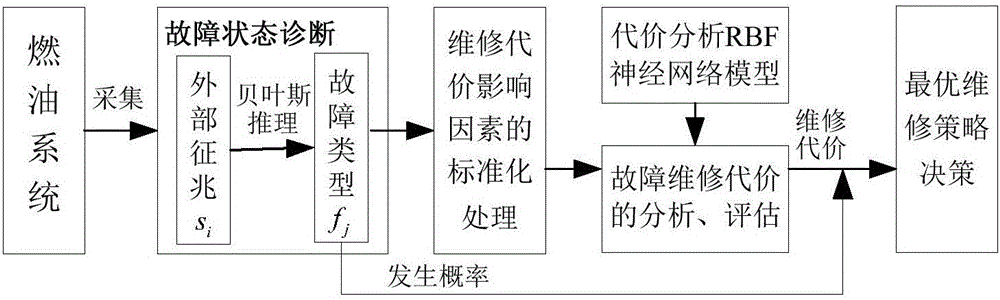

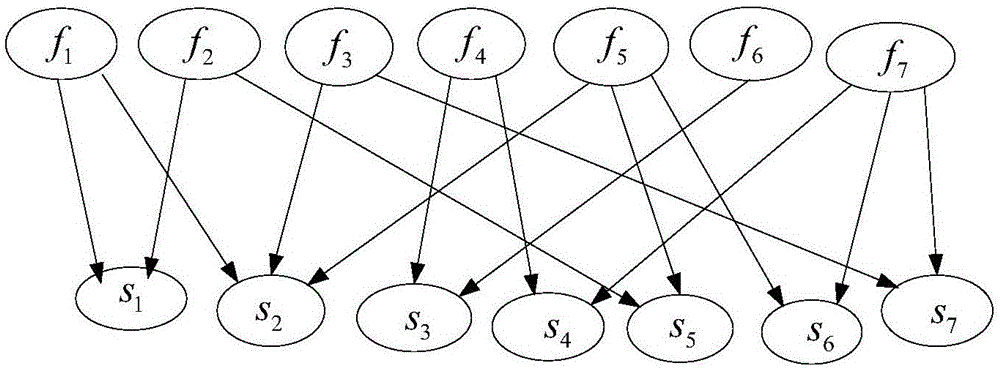

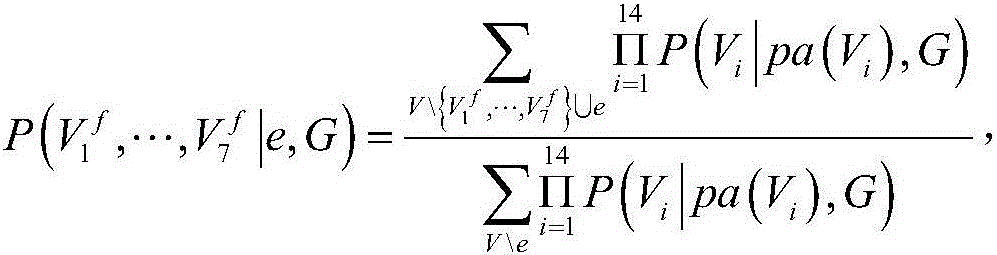

Maintenance decision-making method for diesel engine fuel oil system through cost analysis in combination with Bayesian network model

ActiveCN106547967AGuaranteed operational safetyReflect costDesign optimisation/simulationNeural learning methodsGaussian network modelFuel oil

The purpose of the invention is to provide a maintenance decision-making method for a diesel engine fuel oil system through cost analysis in combination with a Bayesian network model. The method comprises the steps of: firstly, establishing the Bayesian network model of the diesel engine fuel oil system, and carrying out fault diagnosis on the fuel oil system based on the model to obtain an occurrence probability of each fault; secondly, carrying out non-dimensional processing on factors which influence a maintenance operation cost of the fuel oil system by use of a standardization formula; thirdly, fusing a plurality of influence factors in maintenance operations by use of an RBF (Radial Basis Function) neural network, and evaluating a corresponding maintenance cost; and finally, comprehensively evaluating a fault occurrence probability and a maintenance cost through a multiplication formula, and ordering the maintenance operations according to a product decreasing rule to obtain an optimal maintenance strategy of the fuel oil system. According to the method, through the cost analysis in combination with the Bayesian network model, the fault probability and the maintenance cost are comprehensively evaluated, and a decision making is carried out on a maintenance strategy of the fuel oil system so that a decision-making result has reference value.

Owner:HARBIN ENG UNIV

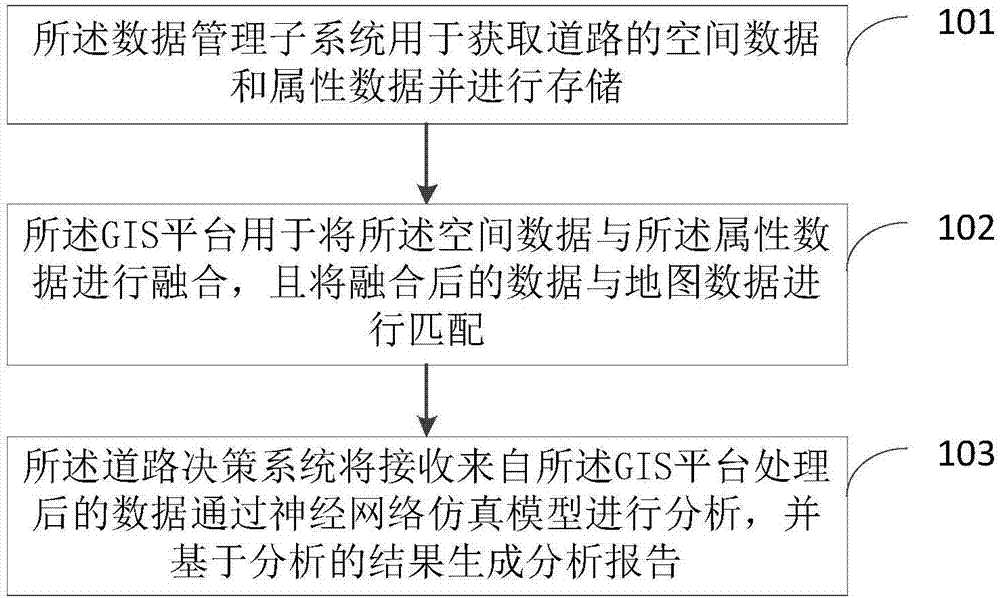

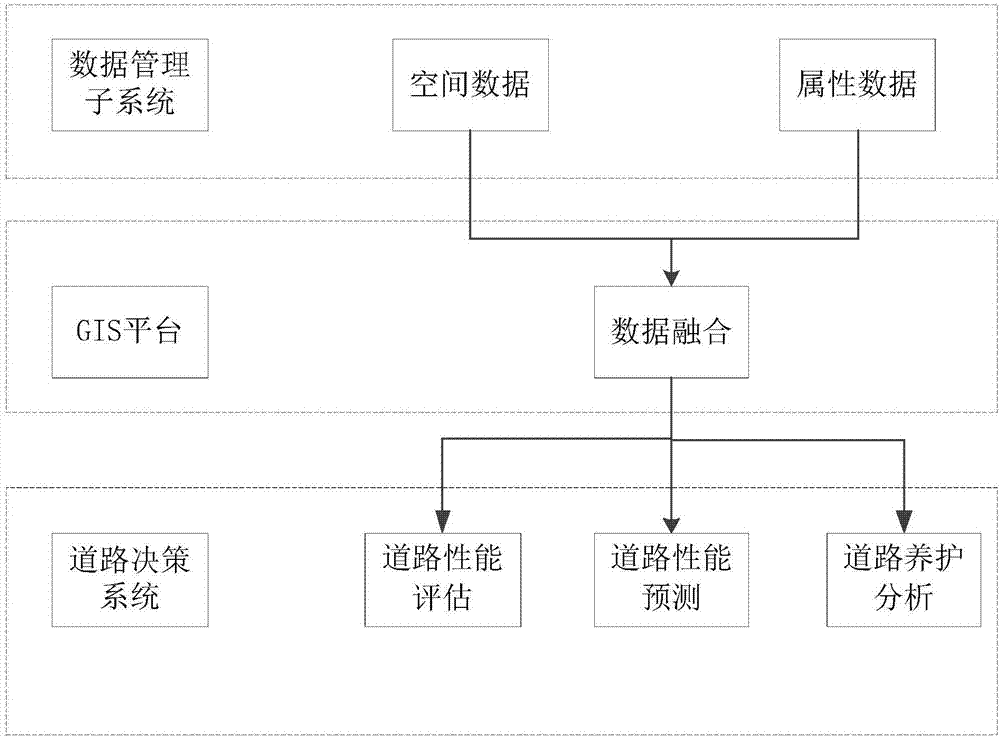

Road management decision system

The invention provides a road management decision system which comprises a data management subsystem, a GIS platform and a road decision system. The data management subsystem is used for acquiring spatial data and attribute data of the road and performs storage. The GIS platform is used for fusing the spatial data with the attribute data and matching the fused data with map data. The road decision system analyzes the received data processed by the GIS platform through a neural network simulating model and generates an analysis report based on an analysis result. Based on road true information, a road management decision system supported by a plurality of kinds of data is constructed. Furthermore a road database performs analysis in a data organizing manner, thereby facilitating road maintenance decision. Furthermore through restriction of preset budget fund and other resources, an optimal maintenance strategy is searched so that benefit is maximized.

Owner:江苏北极星交通产业集团有限公司

Electric power field operation risk management and control method and system

PendingCN112712230AImprove security control capabilitiesReduce lossesResourcesOperation schedulingRisk level

The invention discloses an electric power field operation risk management and control method and system. The system comprises an equipment operation management module, a fault management module, a risk assessment module, an employee safety management and control module, an operation scheduling module, a safety scheduling module and a remote terminal module. A fault type of equipment is collected on an operation site, a fault risk level is obtained through the fault management module, an operation risk value is calculated through the risk assessment module, an anti-risk value of maintenance personnel is calculated through the employee safety management and control module, maintenance reliability of each maintenance personnel is calculated through the operation scheduling module, According to a reliability threshold value, a fault risk assessment result is obtained. And deleting maintenance personnel conforming to safety attendance, obtaining the maintenance personnel with safety and reliability conforming to attendance through a safety scheduling module according to a set priority rule, sorting the maintenance personnel, scheduling the optimal maintenance personnel to go to repair, and listing a protection tool list required by repair by a maintenance equipment scheduling module according to a fault type.

Owner:国网浙江省电力有限公司龙游县供电公司

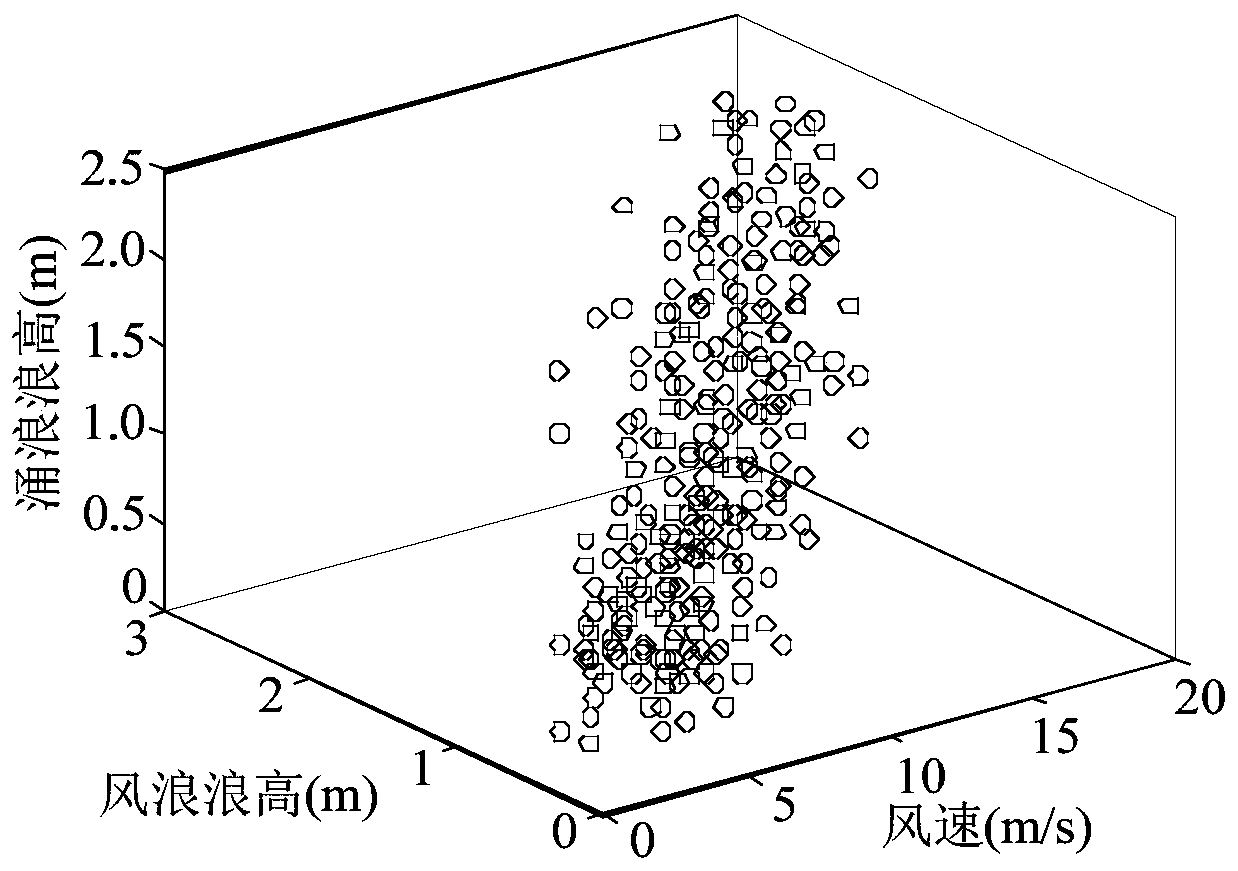

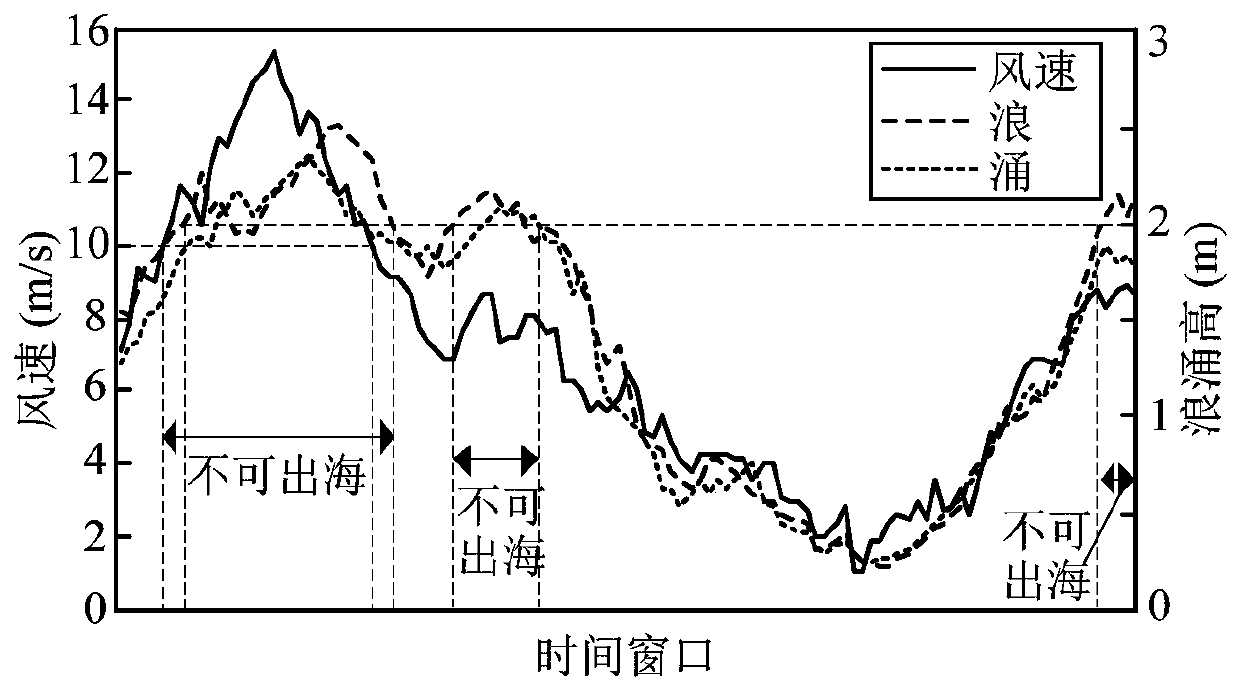

Offshore wind turbine generator maintenance path stochastic planning method considering wake effect

ActiveCN111310972ARefined Downtime LossAdaptableForecastingSingle network parallel feeding arrangementsMarine engineeringWind wave

The invention relates to an offshore wind turbine generator maintenance path stochastic planning method considering a wake effect. The method comprises the following steps: 1) describing correlation and uncertainty of wind, waves and surges in ocean weather; 2) considering the cost composition of personnel, ships, punishment and shutdown loss, taking the minimum maintenance cost as an objective function, and constructing corresponding constraint conditions based on the influence of wind, waves and surges on the navigation time of the ships and the accessible windows of the ships; 3) because the maintenance state changes the wake flow distribution among the units, describing the change of the input wind speed of each unit in combination with the wake flow model and the maintenance state, and refining the unit shutdown loss in the objective function; and 4) solving the target function to obtain an optimal maintenance path. Compared with the prior art, the method has the advantages of high adaptability, high economy, high solving speed and the like.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

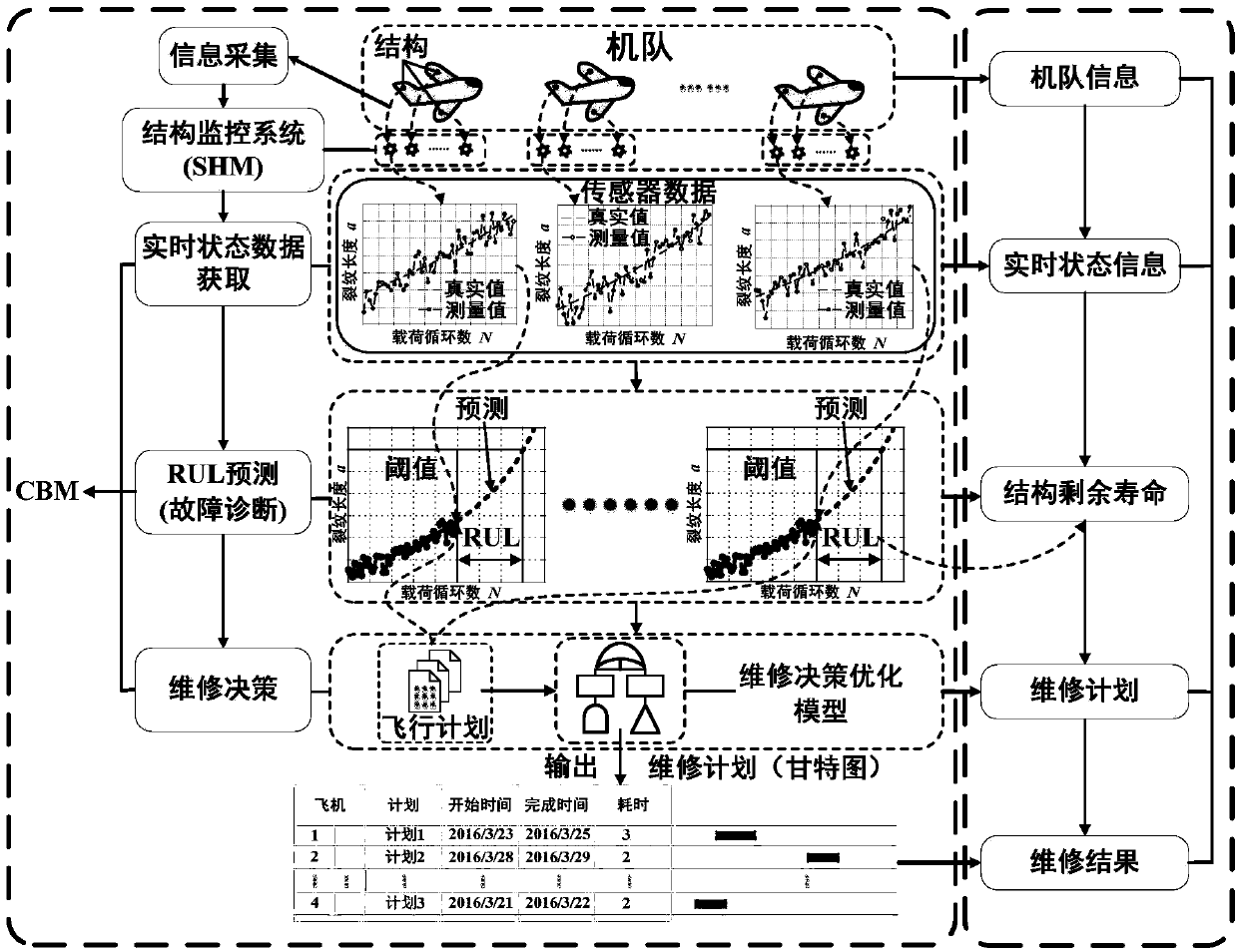

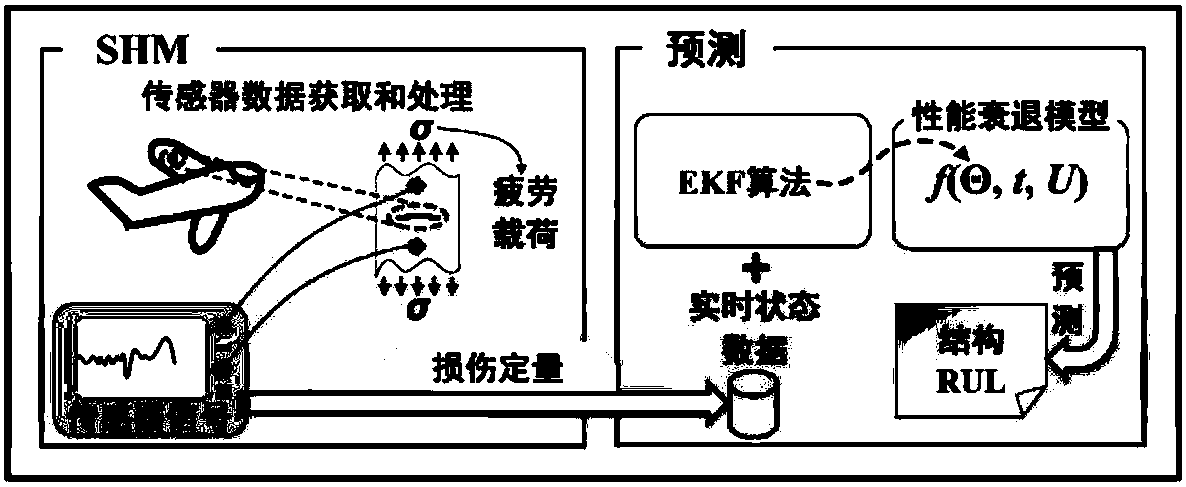

Fleet maintenance decision method based on CBM (condition-based maintenance)

ActiveCN107730014AImproving Life Prediction AccuracyGood life prediction accuracyForecastingAviationMulti objective optimization algorithm

The invention discloses a fleet maintenance decision method based on CBM (condition-based maintenance), so as to solve the problem that the existing method aims at a civil aero engine and an unstructured part, the single plane retention rate can not reach training requirements, and the fleet maintenance cost is not considered. The method comprises steps: 1, the residual life predication on the plane fatigue structure is carried out, and the remaining life of the fatigue structure is obtained; 2, according to the obtained remaining life of the fatigue structure, a single plane maintenance costdecision optimization model is built; 3, according to the single plane maintenance cost decision optimization model built in the second step, a fleet maintenance cost decision optimization model is built; 4, a fleet retention rate optimization model is built; and 5, a multi-objective optimization decision model for the fleet is built according to the third step and the fourth step, and according to the multi-objective optimization decision model, a nondominated sorting multi-objective optimization algorithm method is adopted to determine the optimal maintenance scheme for the fatigue structureof each plane in the fleet. The method is used in the fleet maintenance field.

Owner:HARBIN INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com