Patents

Literature

146 results about "Plant level" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

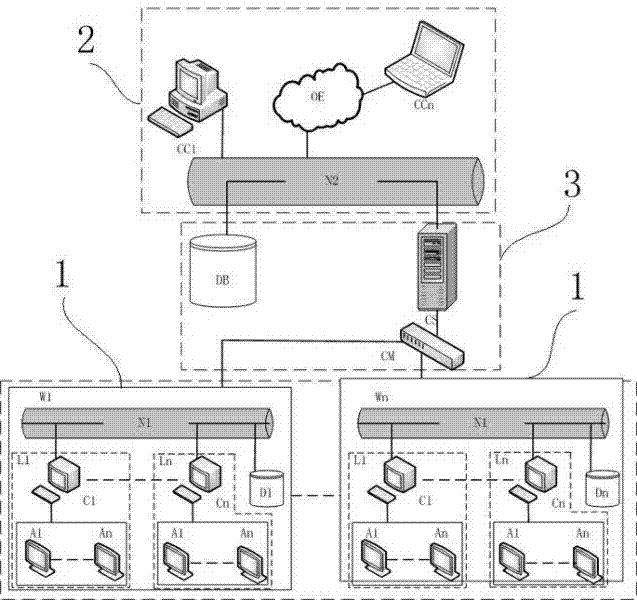

Plant-level comprehensive supervision platform

InactiveCN105187771ARealize centralized managementQuality improvementClosed circuit television systemsTransmissionVideo monitoringIntelligent lighting

The invention relates to a monitoring system and specifically relates to a plant-level comprehensive supervision platform. The plant-level comprehensive supervision platform comprises a front-end system, a transmission network and a master station system, wherein the front-end system is integrated with subsystems of video monitoring, environmental monitoring, security guard, fire alarm, one-card-through, entrance and exit control, maloperation prevention, gps positioning, intelligent lighting, intelligent control and the like in a thermal power plant; the transmission network functions as a bridge for connecting the front end and the platform; the master station system comprises a local monitoring center, a cloud computing system, an application platform and a whole network operation and maintenance platform. The comprehensive supervision platform is a large online monitoring system integrated with hardware, software and network; the platform software is taken as the core to realize centralized management on all zones; besides, centralized monitoring and uniformed management on the front-end system can be realized at a regulation and control center; in short, the plant-level comprehensive supervision platform escorts the smart grid.

Owner:SHANDONG CHUANGDE SOFTWARE TECH

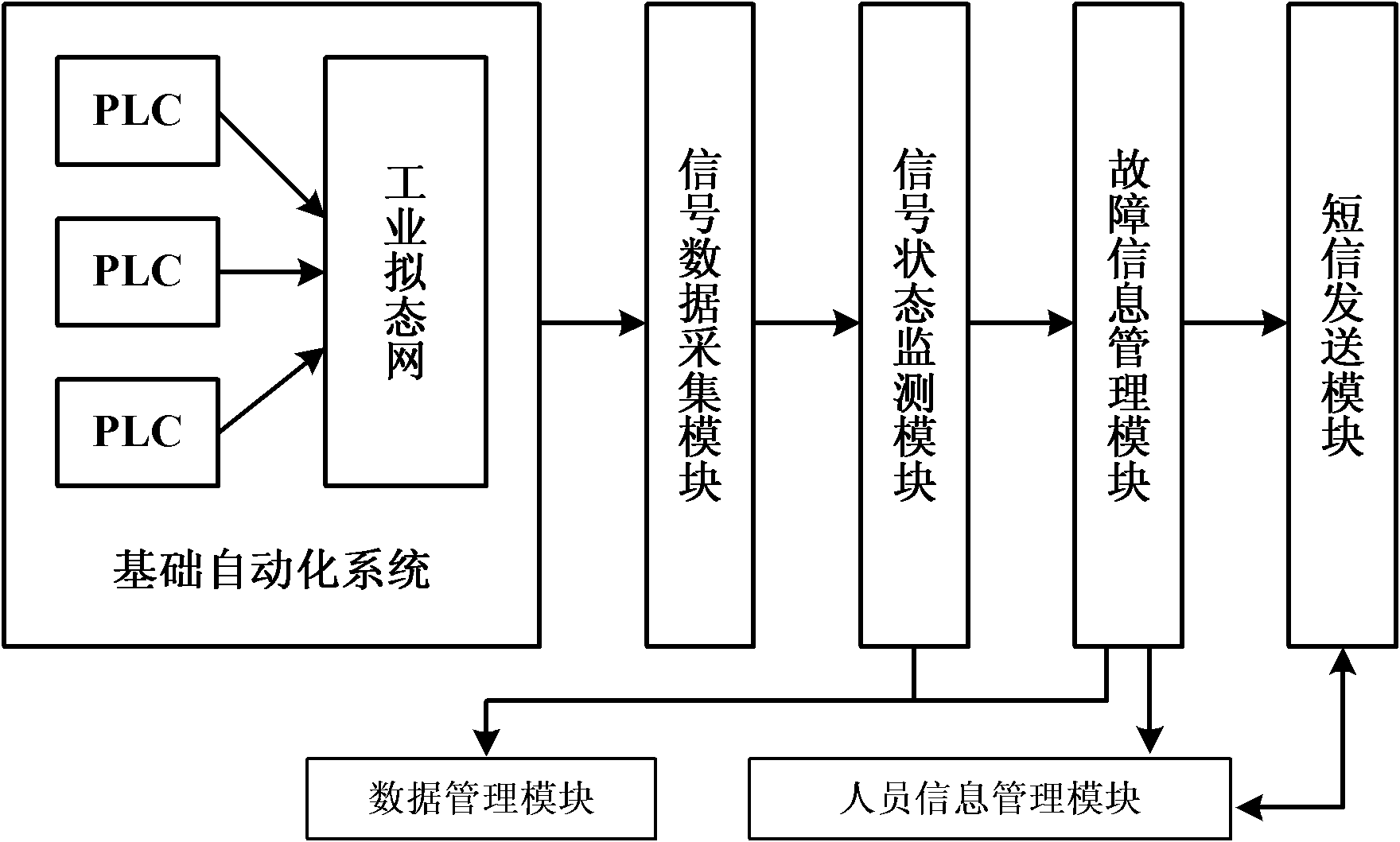

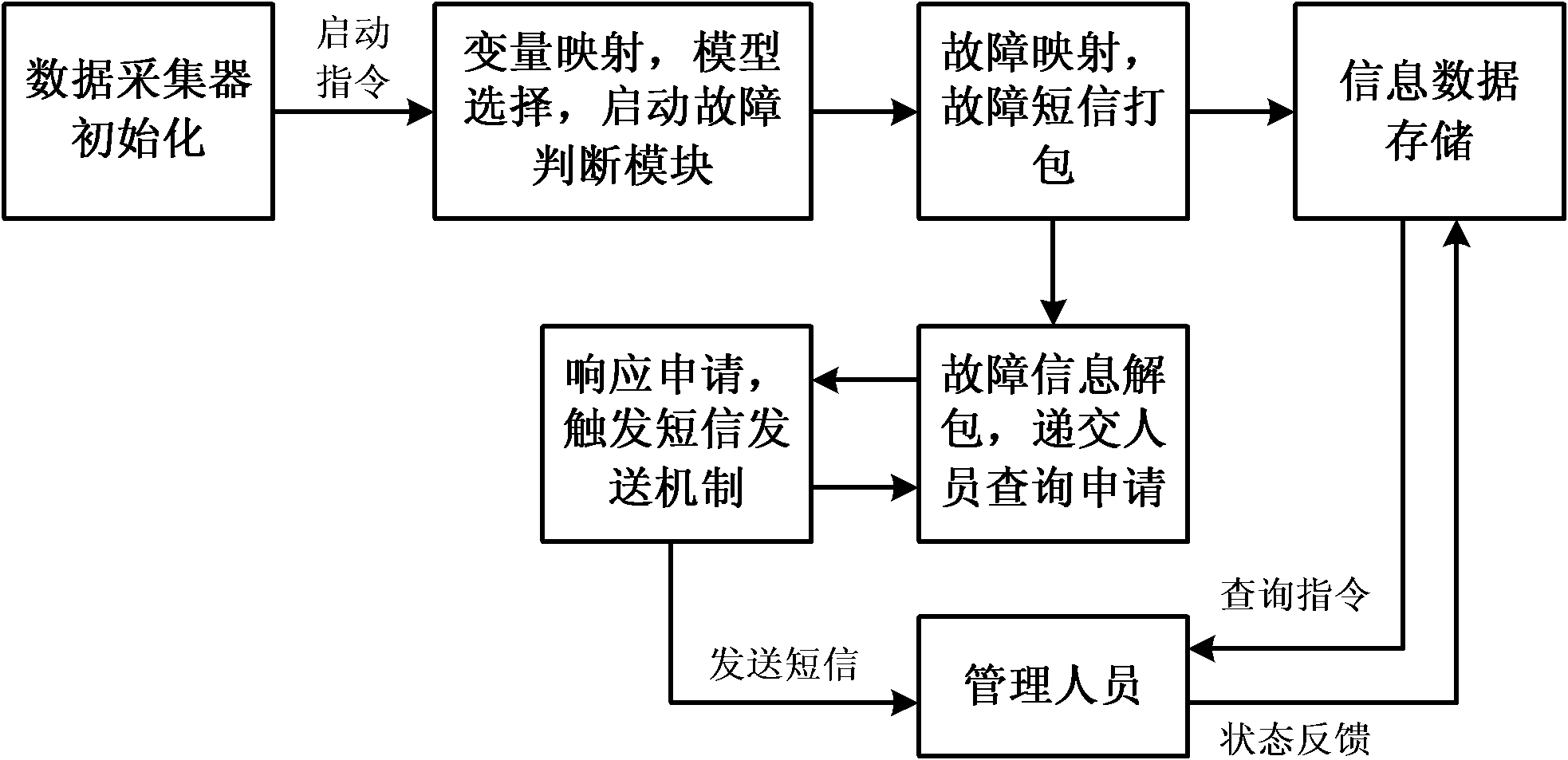

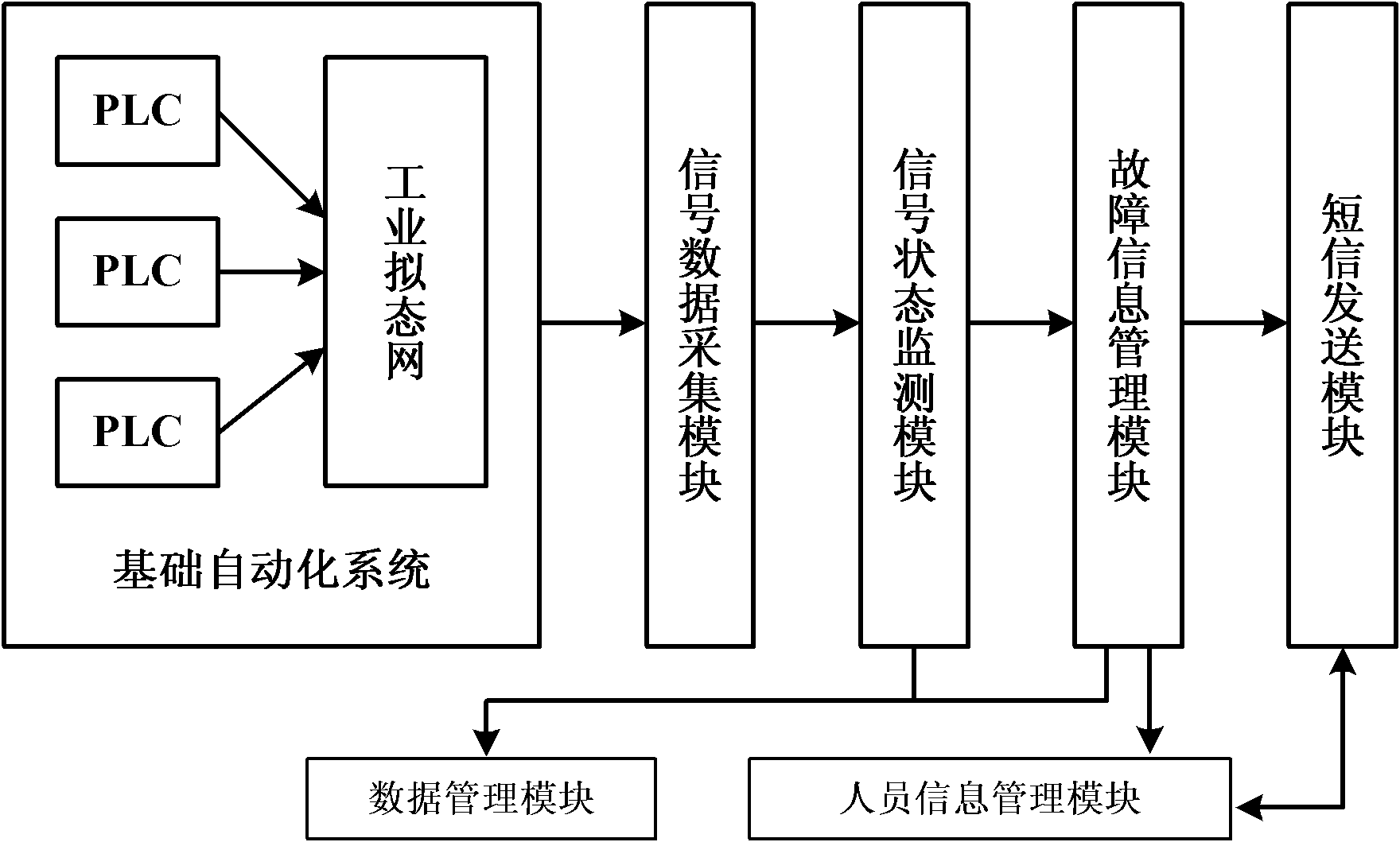

Basic automation-based plant-level equipment management and alarming system and method

ActiveCN102156447AReduce distractionsIt is convenient to inquire and understand in timeTotal factory controlProgramme total factory controlControl systemData acquisition

The invention relates to the technical field of equipment maintenance and management, in particular to a basic automation-based plant-level device management and alarming system and method. The system comprises a signal data acquisition module, a signal status monitoring module, a data management module, a failure information management module, a staff information management module and a short message sending module. Independent of an operation station and an engineering station, the plant-level device management and device and system failure short-message pre-warning and alarming system usedfor monitoring and analyzing maintenance data of a basic automation control system and various devices on line, providing short-message early warning and alarming for failures of devices and systems in time, and providing analysis and recommendation reports for repairing and maintenance schemes of the devices. By the system, maintainers are convenient to search and understand the state of the systems and the equipment in time, and can grasp pre-warning and alarming information of device and system failures in real time, thereby reducing interference to the maintainers and improving productionand maintenance efficiency simultaneously.

Owner:QIDONG YONGAN VALVE CO LTD

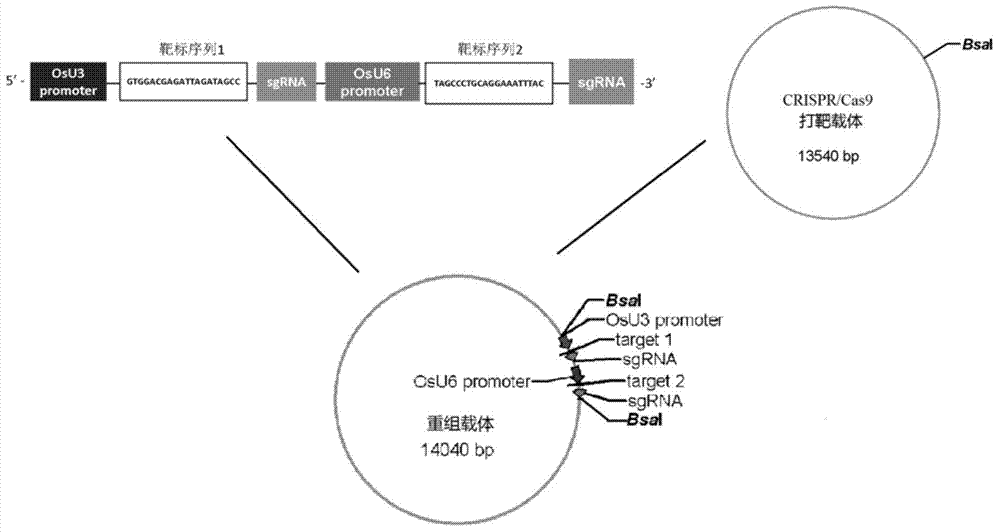

Method for deleting selection marker gene of transgenic rice

ActiveCN104846010AHigh distribution frequencyEasy to operateVector-based foreign material introductionAngiosperms/flowering plantsGenetically modified ricePlant genetic engineering

The invention provides a method for deleting a selection marker gene of transgenic rice and belongs to the field of plant gene engineering. The method for efficiently deleting the marker gene of the transgenic rice in a plant level is established by utilizing a genome fixed-point editing technology mediated by a CRISPR / Cas9 system. The whole segment of the marker gene can be effectively deleted by utilizing the method, and only an expression frame of the marker gene is deleted pointedly without change of the expression of other components in the transgenic rice. Thus, the transgenic rice without the selection marker gene can be efficiently bred by utilizing the method, so that the safety doubt of people about the selection marker gene can be completely removed.

Owner:RICE RES ISTITUTE ANHUI ACAD OF AGRI SCI

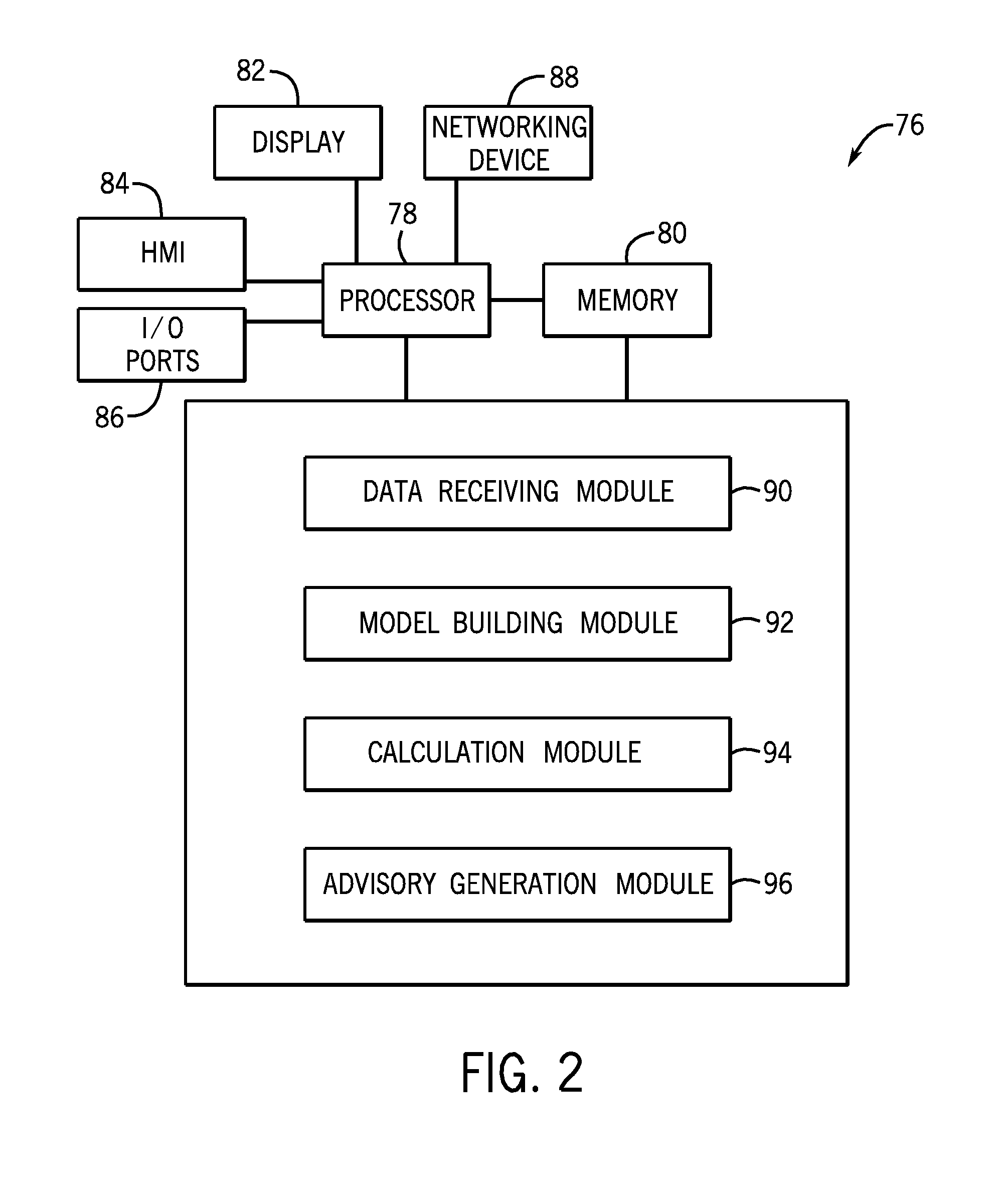

Plant control optimization system

Systems and methods provided herein output an operational advisory based upon a plurality of models derived from a plurality of data, in which the plurality of models comprise at least one of a plant transfer function, a degradation contributor model, or a plant level cost model, and in which the plurality of data is derived from at least one of current plant data, historical plant data, business data, environmental data, component data, degradation contribution data, an optimization goal, or a combination thereof.

Owner:GENERAL ELECTRIC CO

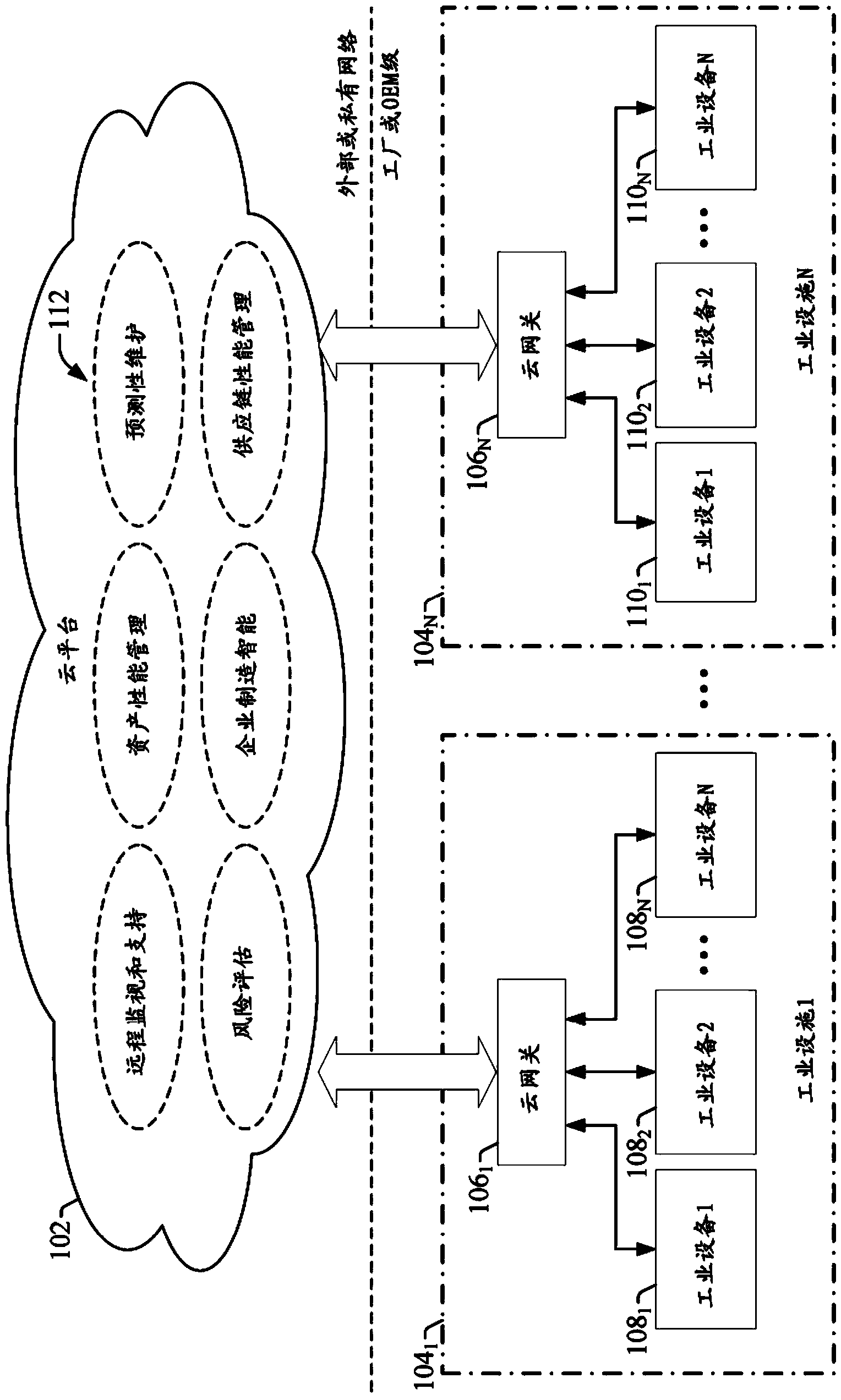

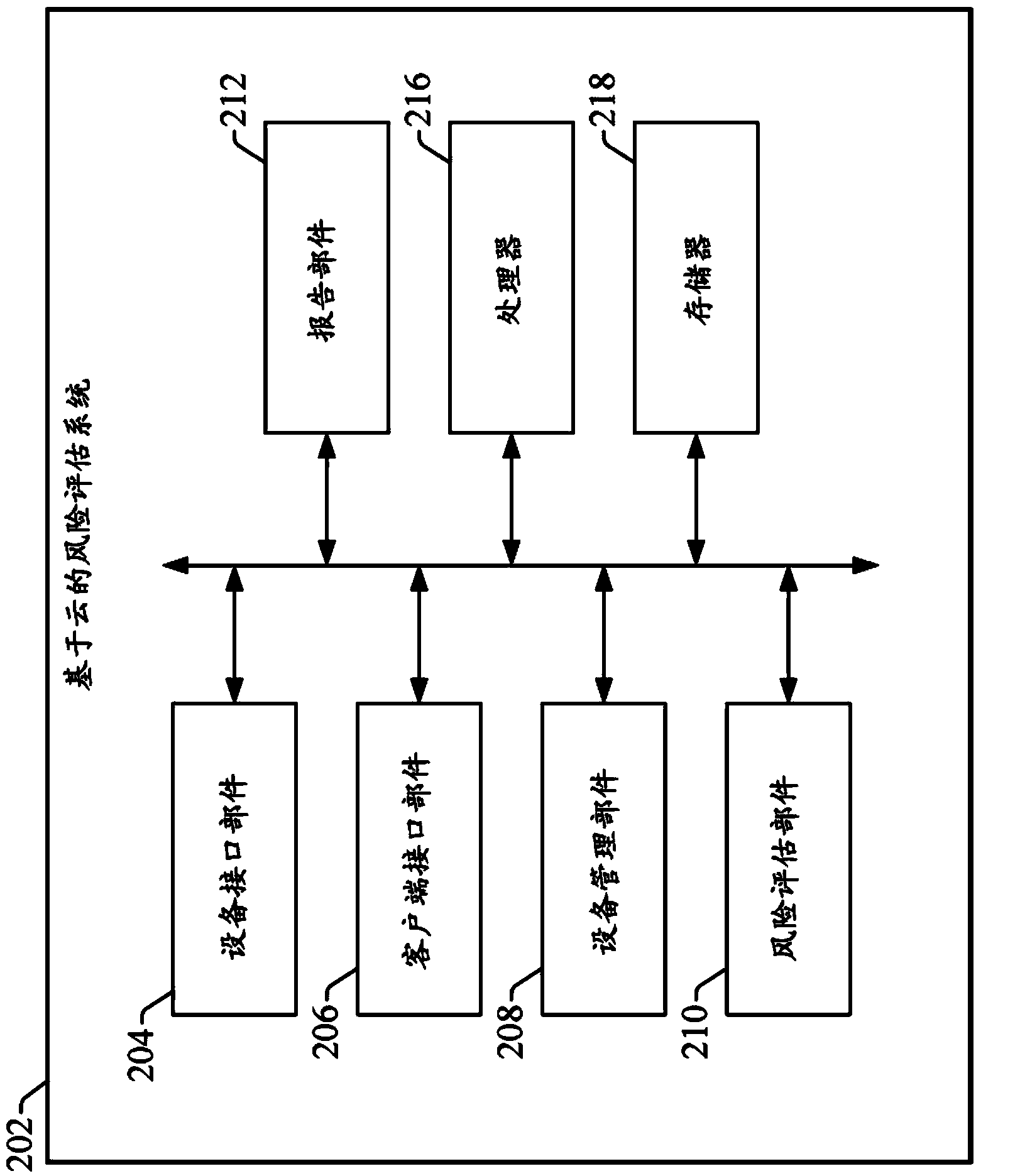

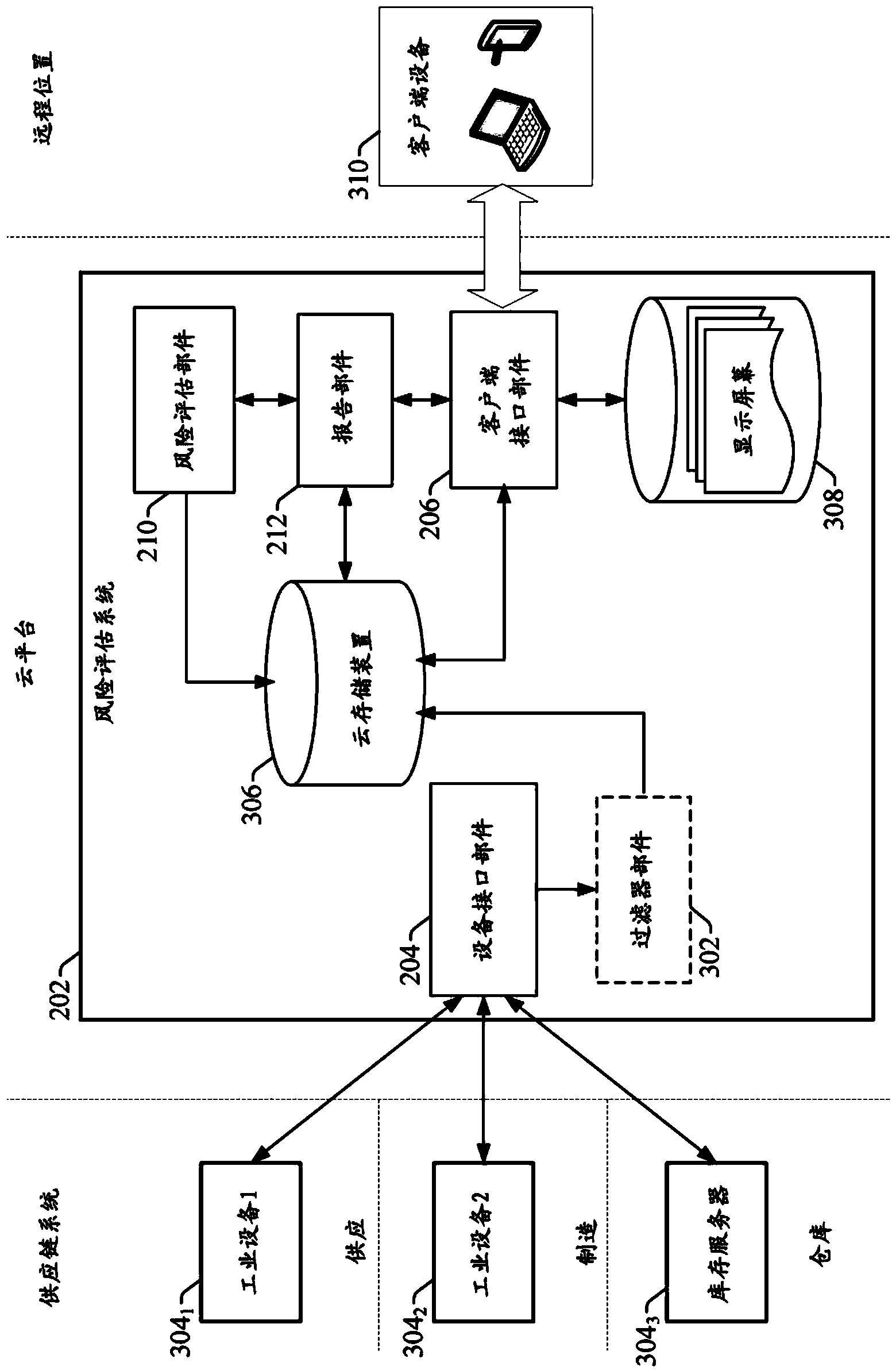

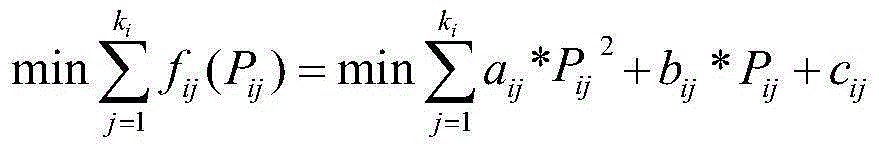

Risk assessment for industrial systems using big data

A cloud-based risk assessment service collects industrial data from multiple relevant and connected sources for storage and analysis on a cloud platform. The service analyzes gathered data from internal and external sources and customers across different industries to identify operational trends as a function of industry type, application type, equipment in use, device configurations, and other such variables. Based on the analysis, the risk assessment service identifies risk factors inherent in a customer's particular industrial enterprise. The cloud-based system generates a risk profile for the customer that identifies the determined risks and recommends risk aversion strategies based on the customer's specific profile, compared to industry standards, product information, internal business expectations, external regulatory bodies, and / or past performance. Risk profiles are tailored for both plant-level users and business-level users to provide intelligent strategies to improve performance and prevent avoidable losses.

Owner:ROCKWELL AUTOMATION TECH

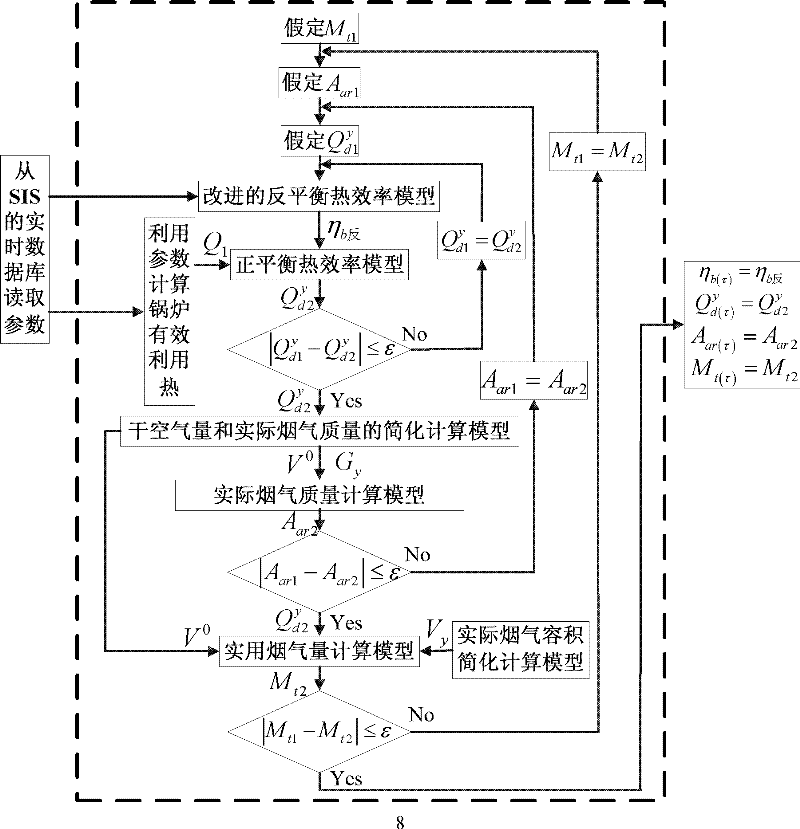

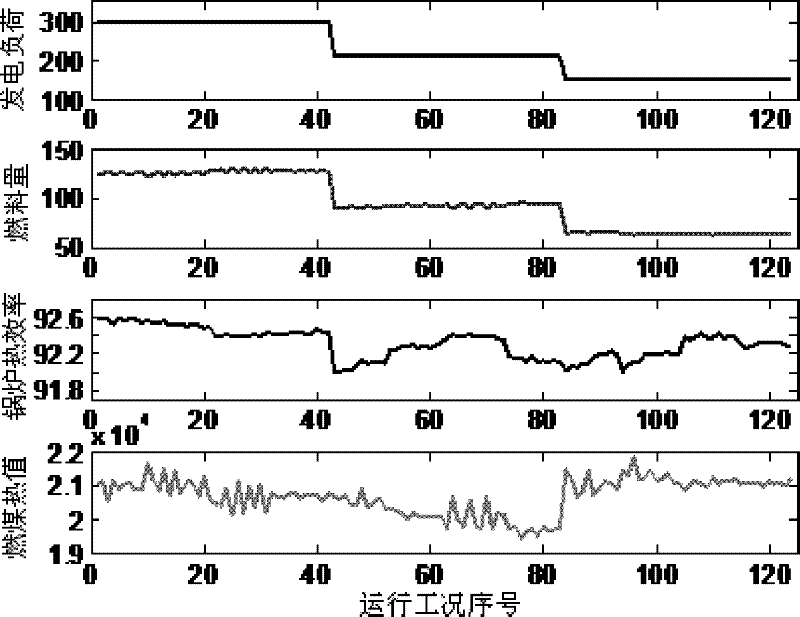

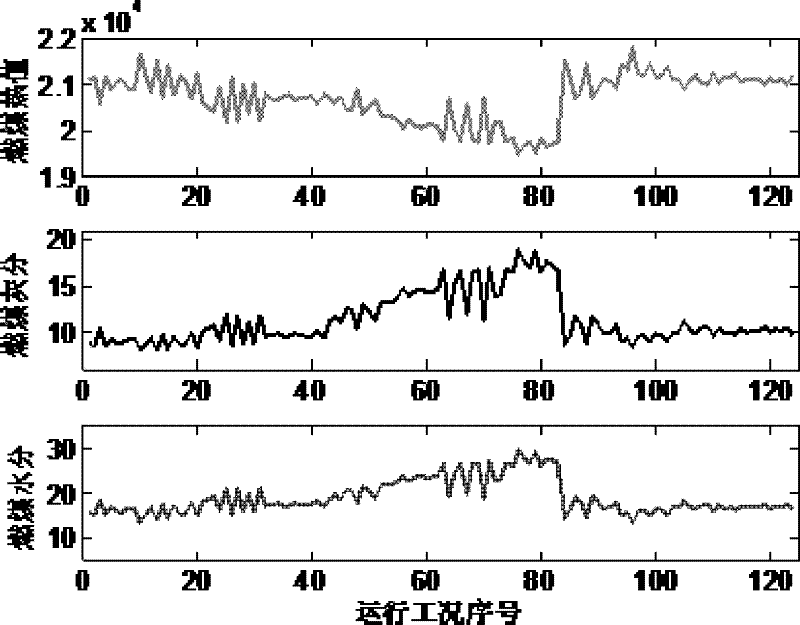

Synchronous reckoning method of utility boiler efficiency and coal heat value as well as ash content and moisture content

InactiveCN102494714AVerify correctnessImprove calculation accuracyStructural/machines measurementSteam pressureEvaporation

The invention relates to a synchronous reckoning method of utility boiler efficiency and coal heat value as well as ash content and moisture content, wherein air supply temperature, smoke exhaust temperature, smoke exhaust oxygen content, carbon content in fly ash, boiler-fed fuel content, boiler evaporation amount, assembly electric generating load, main steam pressure temperature, reheated steam inlet / outlet pressure temperature, water supply pressure temperature and flow rate, steam drum pressure, reheater temperature lowering water jet amount and steam extraction pressure temperature of each heater of high pressure cylinder are read through a plant-level supervisory information system (SIS) of a thermal power plant; and the parameters as the water temperature and drainage temperature of the inlet / outlets of different-level heaters of the high pressure cylinder are synchronously reckoned by hypothesizing the initial values of the coal heat value, the coal ash content and the coal moisture content, utilizing a boiler anti-balance heat efficiency model, a dry air amount required for theoretical combustion and actual smoke quality simplified calculating model, an actual smoke quality calculating model, an actual smoke volume calculating model, an actual smoke amount calculating model, a boiler positive-balance heat efficiency model and a boiler effective utilized heat model, and establishing prediction and rectification methods.

Owner:SOUTHEAST UNIV

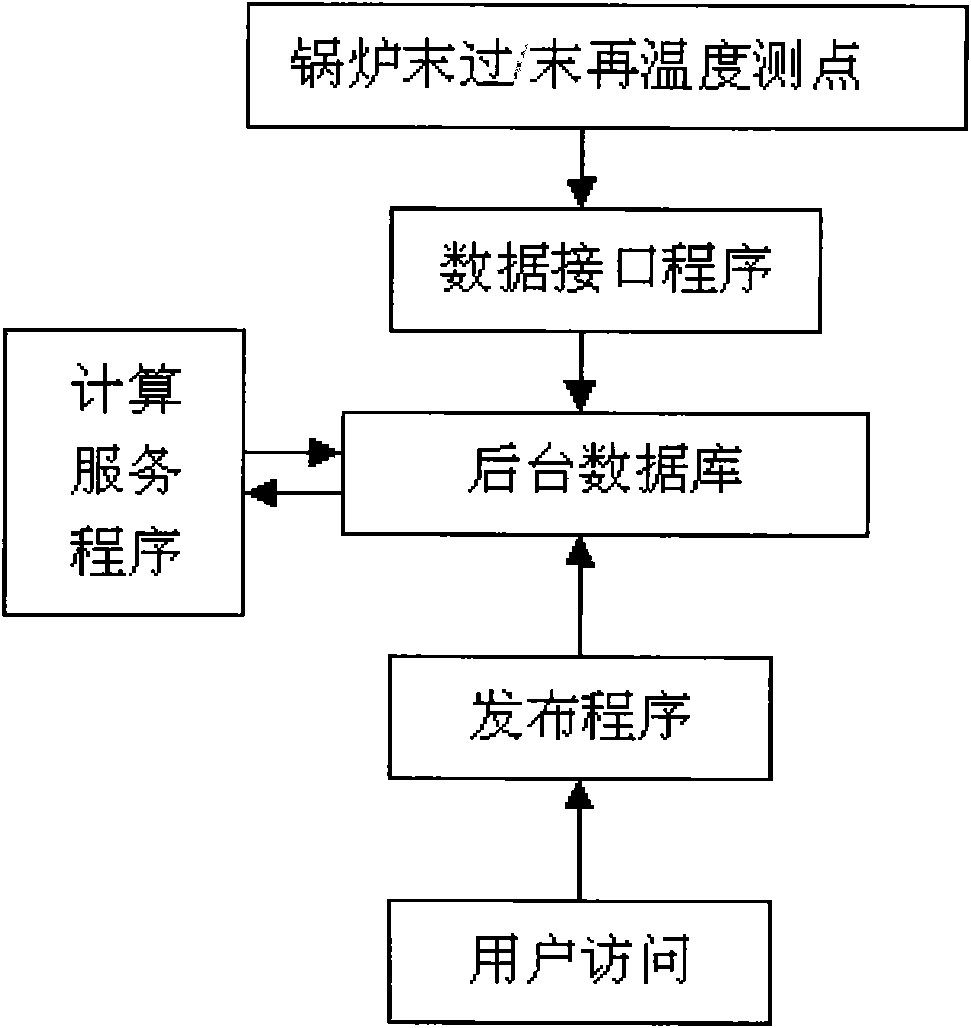

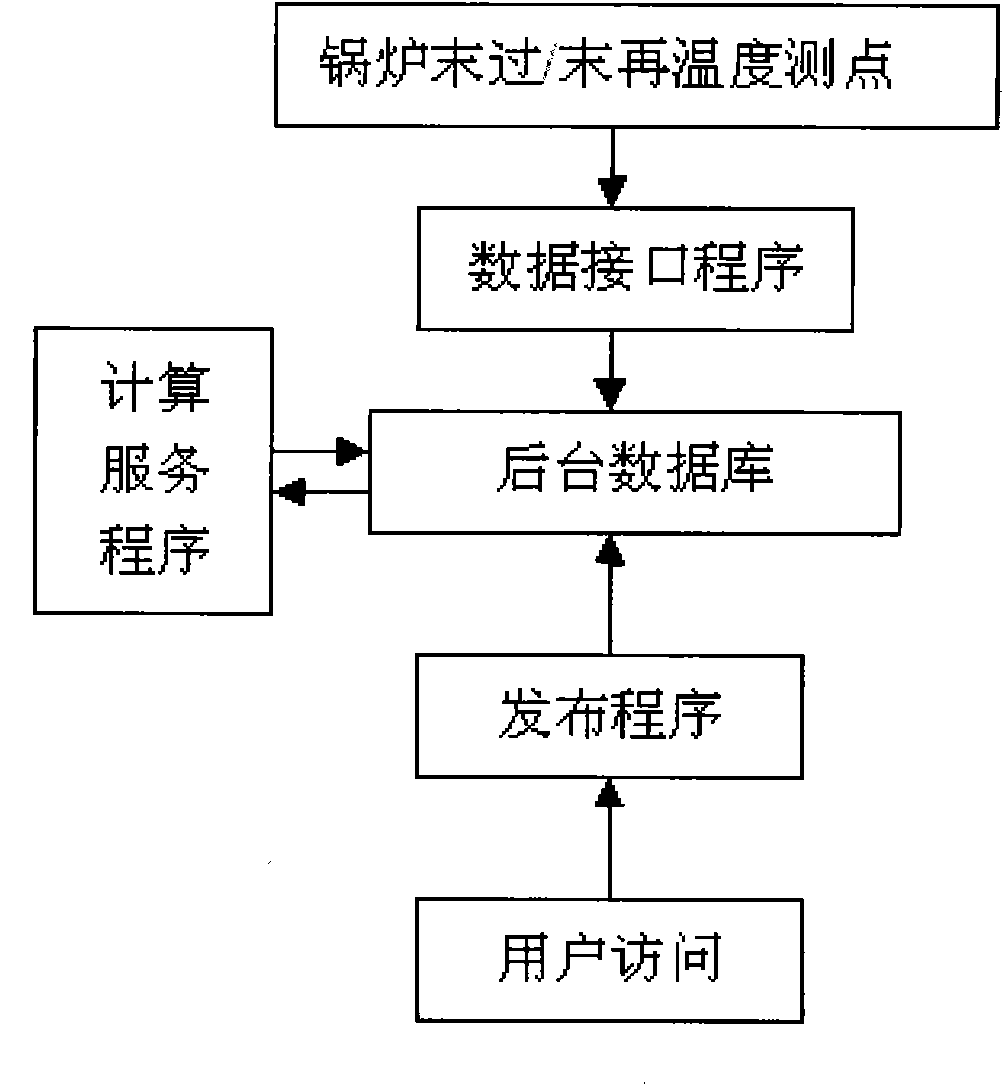

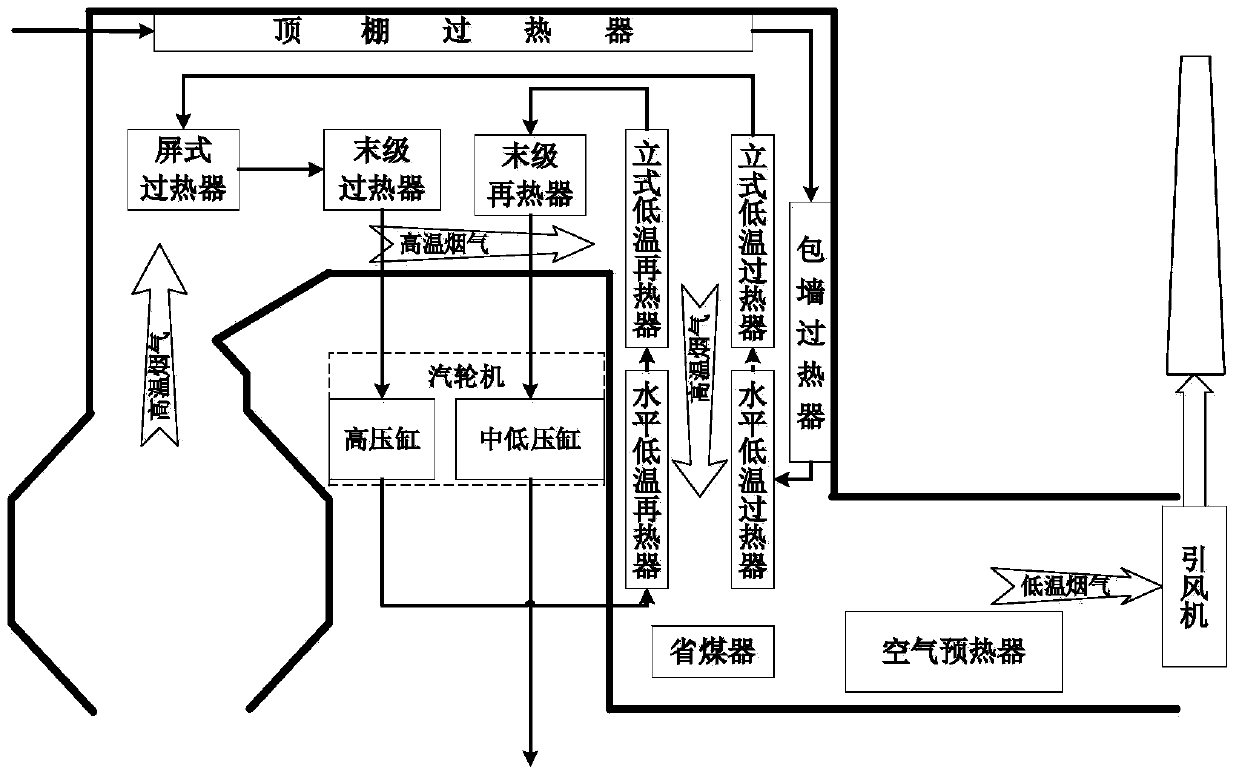

Method for intelligently managing wall temperature of final superheater and final reheater of boiler of power station

The invention provides a method for intelligently managing wall temperatures of a final superheater and a final reheater of a boiler of a power station. The method comprises the following steps of: firstly, building an online monitoring device, then reading online detection data of the final superheater and the final reheater of the boiler in a plant-level supervisory information system database and storing the data into a local relation type database; calculating the steam temperature and the tube wall temperature of each calculation point in the boiler according to the read online detection data; counting the data distribution range of historical temperatures of each screen, each tube and each calculation point of the final superheater and the final reheater and the over-temperature running time of each calculation point; and finally displaying the calculated result in real time. The invention has the advantages of realizing the fast online real-time calculation and the online monitoring and controlling of the wall temperatures of the final superheater and the final reheater of the boiler, realizing the safety operation of the final superheater and the final reheater of the boiler within the service period, and prolonging the service life of the final superheater and the final reheater of the boiler.

Owner:SHANGHAI POWER EQUIP RES INST +1

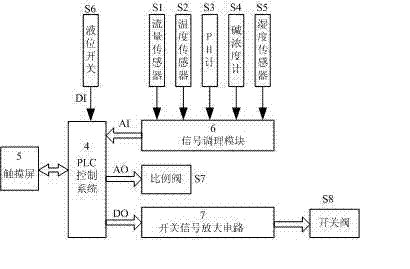

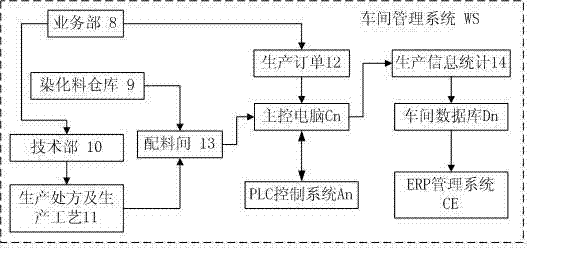

ERP-based intelligent intensive control system of continuous dyeing production line

InactiveCN102385363AImprove efficiencyReduce energy consumptionTotal factory controlProgramme total factory controlEnterprise resource planningPlant level

The invention mainly discloses an ERP-based (Enterprise Resource Planning-based) intelligent intensive control system of a continuous dyeing production line, comprising a plant-level monitoring system, an enterprise-level management system, and an intermediate information management system for connecting the two former systems. The ERP-based intelligent intensive control system establishes a process model based on orders so that the process parameters of the production process can be automatically regulated and controlled when a machine tool works; therefore, the influence of human factors onthe production process and the quality of products is effectively reduced; the quality stability of the products is improved; the unit energy consumption of the products is reduced; and the enterprise revenue is increased.

Owner:ZHEJIANG SCI-TECH UNIV +1

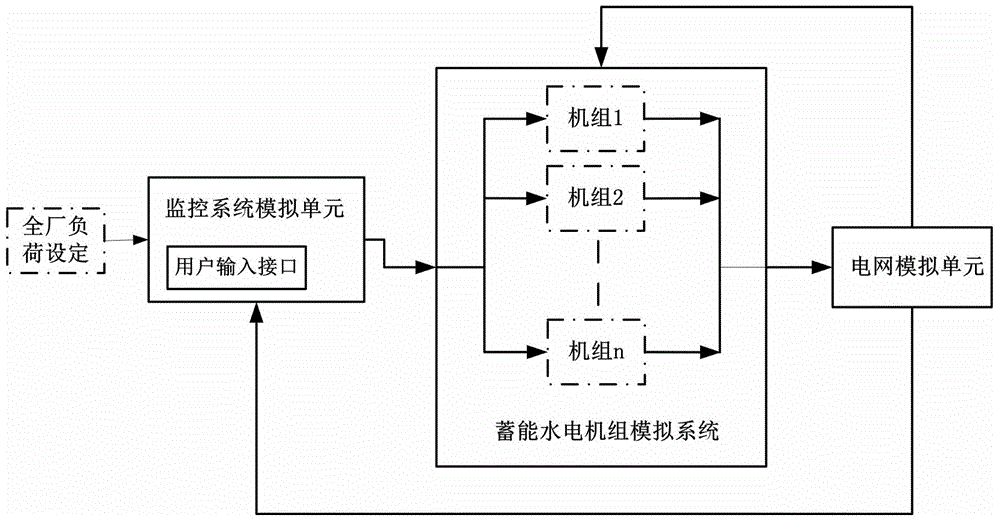

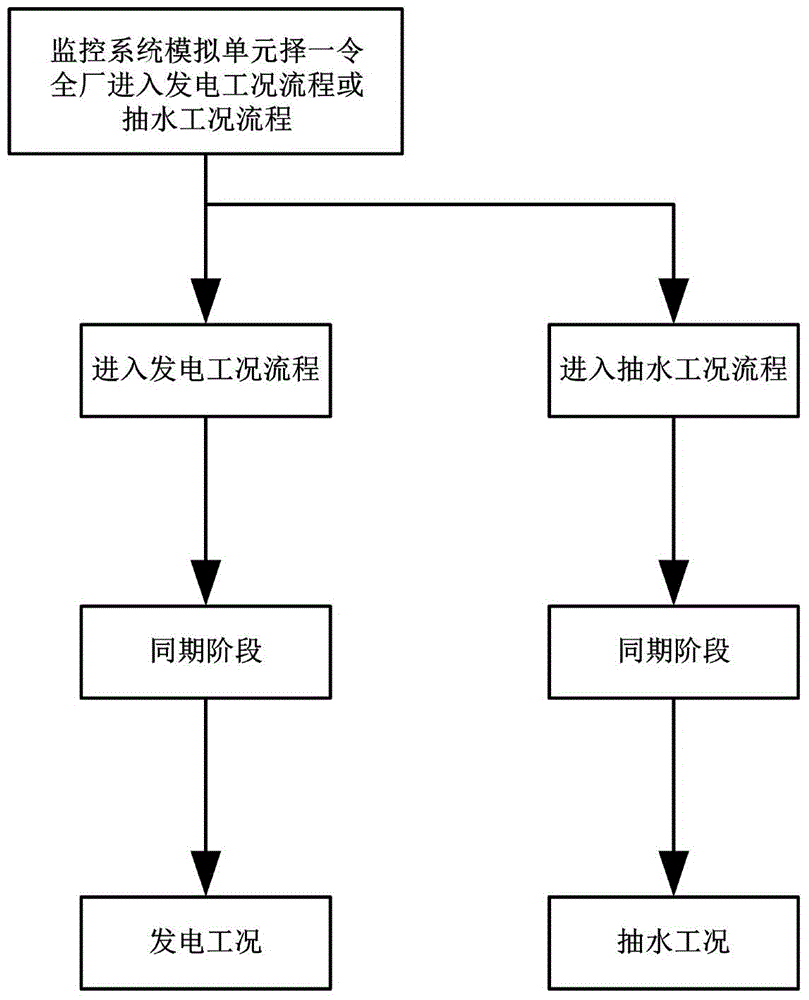

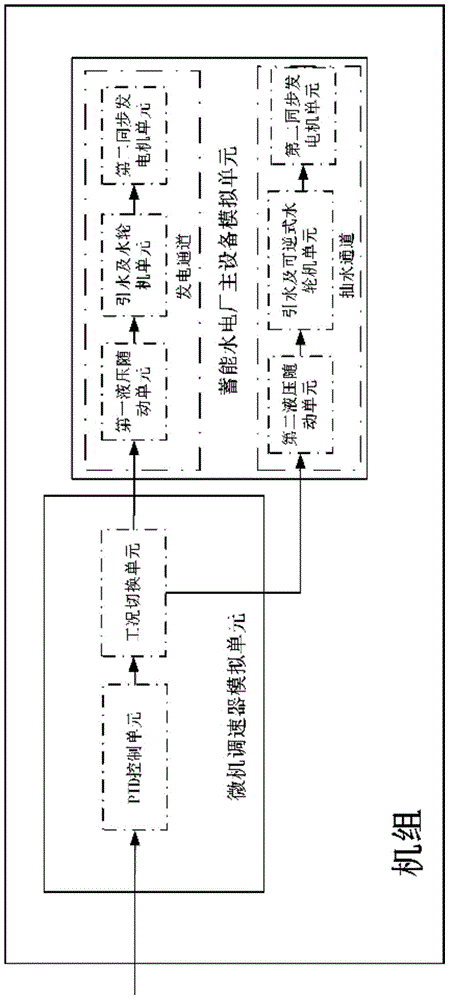

Speed regulating simulation system and method applicable to pumped storage unit

ActiveCN103606108AImplement co-simulationImplement characterization analysisData processing applicationsSoftware simulation/interpretation/emulationUnit speedLoad following power plant

The invention provides a speed regulating simulation system applicable to a pumped storage unit and a speed regulating simulation method applicable to the pumped storage unit. The speed regulating simulation system applicable to the pumped storage unit is composed of a monitoring system simulation unit, a storage hydroelectric generating unit simulation system and a power grid simulation unit; and the speed regulating simulation system applicable to the pumped storage unit can realize a plurality of simulation modes such as real-time simulation, super real-time simulation and under real-time simulation of a pumped storage unit speed adjustment system through diversified simulation. With the speed regulating simulation system and method applicable to the pumped storage unit of the invention adopted, a whole power regulation loop of load setting, load regulation and load output of a pumped storage power station can be simulated authentically, and machine-network joint simulation based on a pumped storage unit speed regulating system model can be realized, and pumped storage unit characteristic analysis and power grid stability research under the background of a large power grid can be facilitated. Compared with other platforms which can only realize a single-unit plant-level speed adjustment system function, the speed regulating simulation system and method applicable to the pumped storage unit of the invention are advantageous in excellent functional performance and greater benefit for satisfying requirements of experiments, analysis researches and the like, and positive significance for the promotion of development and the improvement of production efficiency.

Owner:广东蓄能发电有限公司

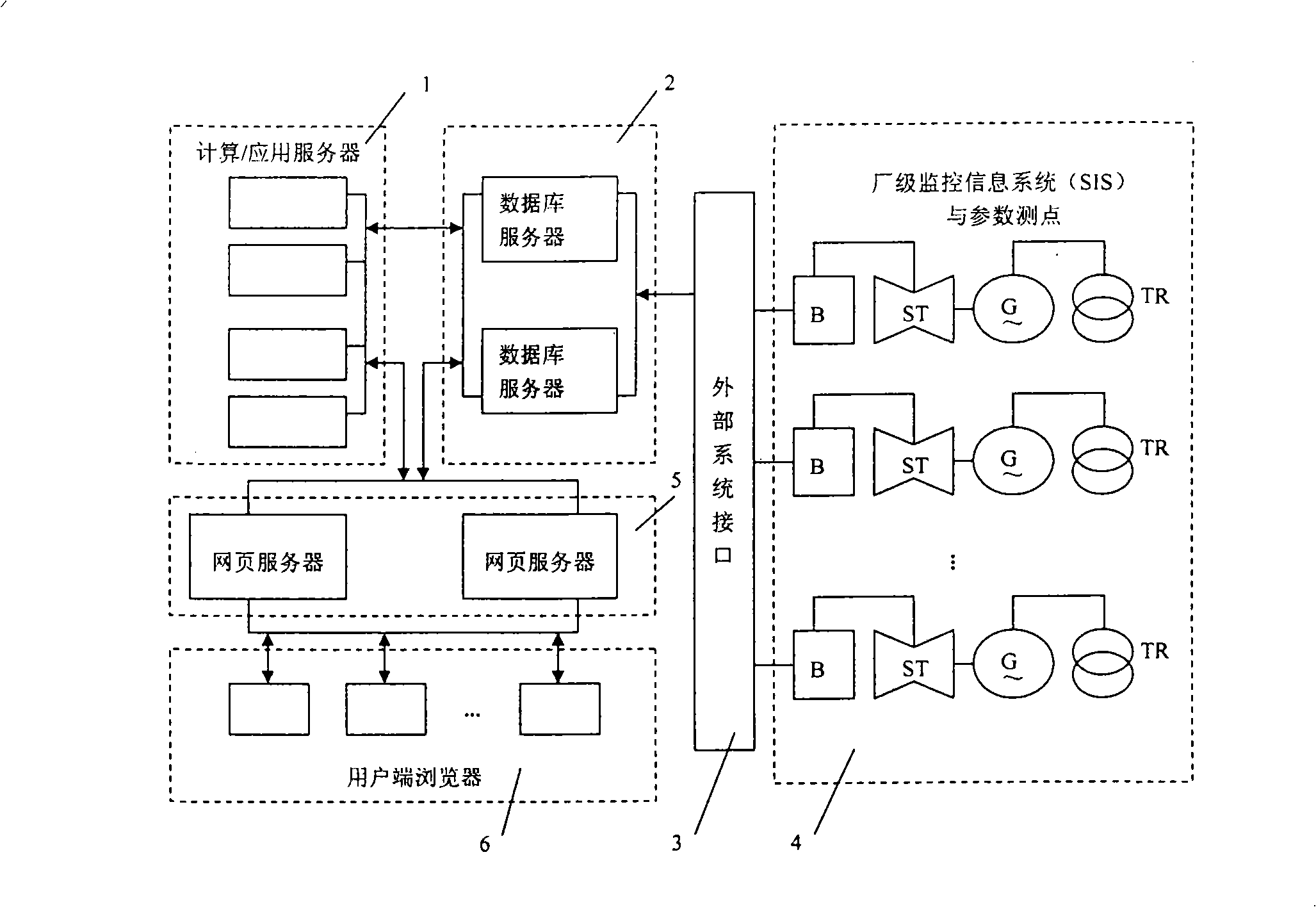

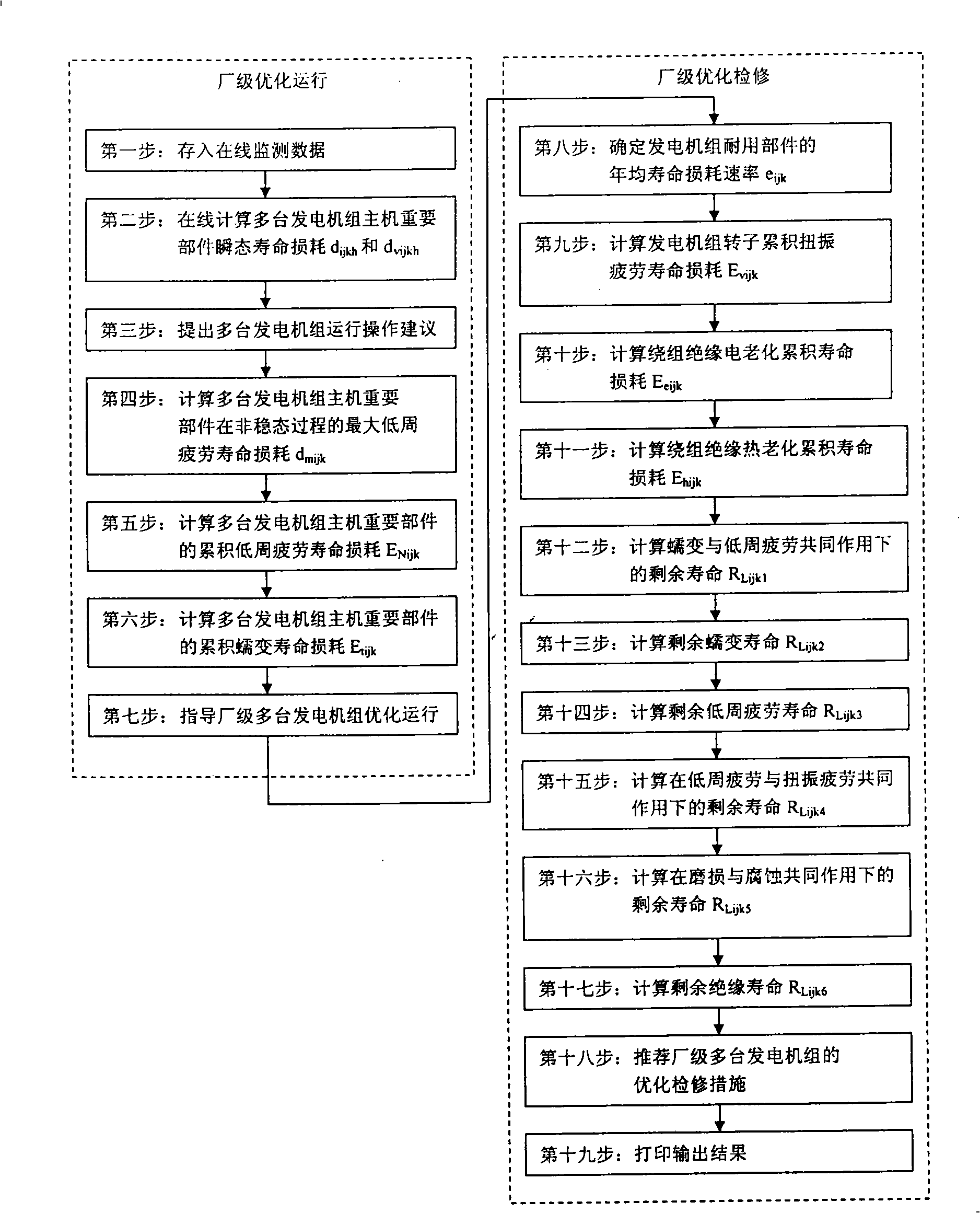

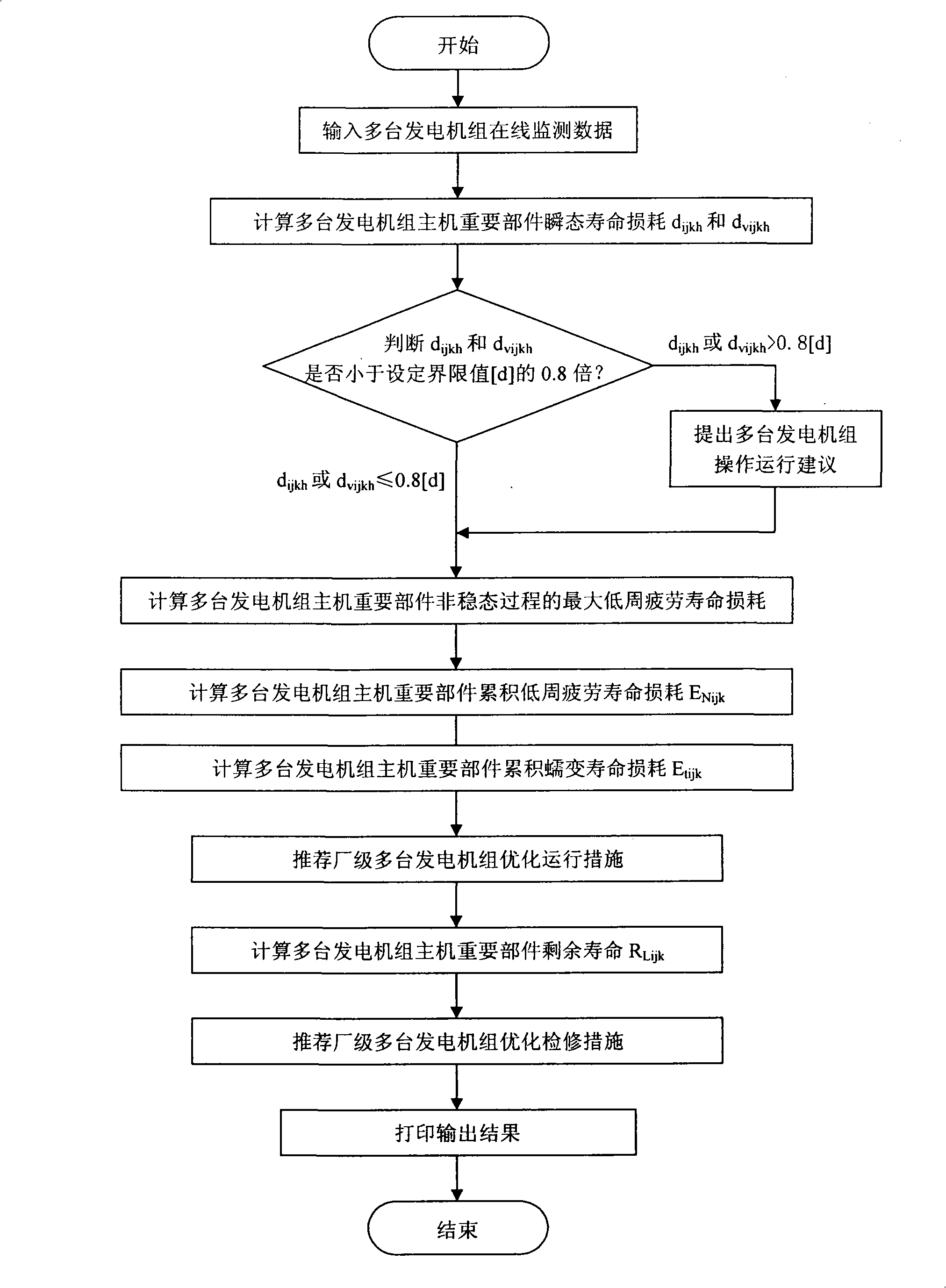

On-line management method and system for important component service life of plant-level multiple generator sets main unit

The invention realtes to an online service-life management system for the important parts of the host machine of plant-level multi-electric motor machine sets. The invention is characterized in that the system comprises a service-life calculation / application server and software, a database server, an external system interface, a plant-level supervisory information system SIS, a parameter measuring point, a web page server and a user-end browser. The online service-life management method is that the calculation analysis software for the host machine of the plant-level multi-electric motor machine sets, which is compiled by the C Language, is applied to the calculation / application server, carries through the online calculation of the transient life loss and the accumulative life loss of the importants parts of the host machine, directs the operational manipulation and the optimal operation of the electric motor machine sets, and recommends the optimal maintenance measures of the plant-level multi-electric motor machine sets. The management system has the advantages of realizing the online management for the important parts of the host machine of the plant-level multi-electric motor machine sets and achieving the technical effect that the service life of the important parts of the host machine of the multi-electric motor machine sets in a power plant are managed by a set of the service-life management system.

Owner:SHANGHAI POWER EQUIP RES INST

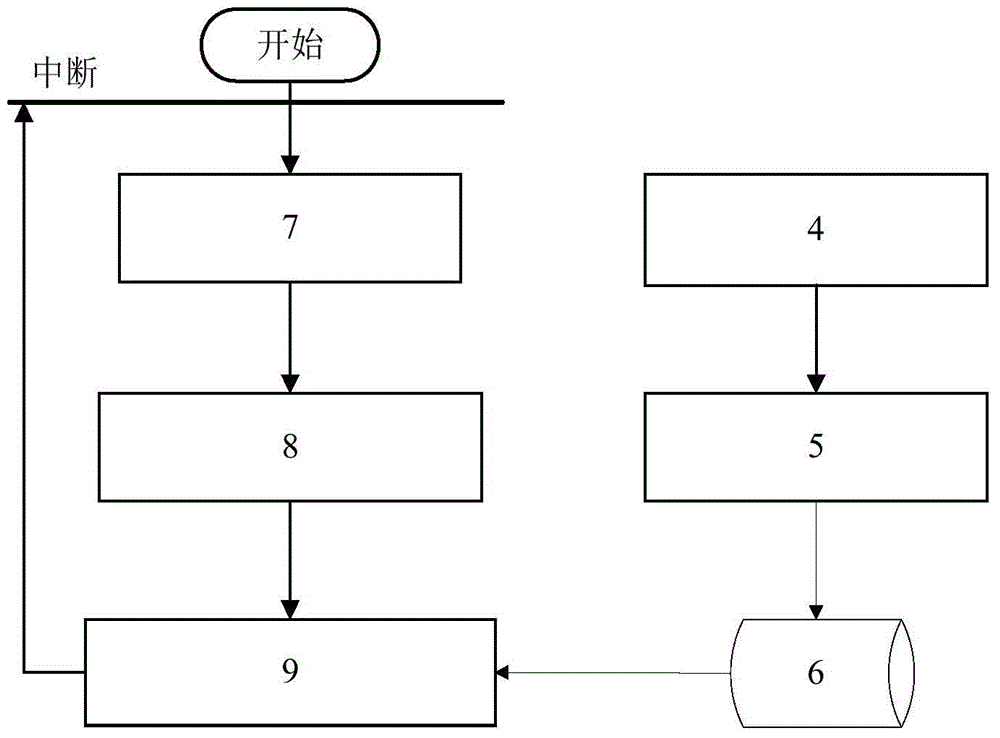

Power plant level automatic power generation control system applied load optimizing and distributing method and system

ActiveCN105098843AReduce the number of variablesMeet the requirements of FMSingle network parallel feeding arrangementsForecastingAutomatic controlSafety control

The invention discloses a power plant level automatic power generation control system applied load optimizing and distributing method. The method is carried out through the following steps: pre-classifying a plurality of sub-clusters of generator sets according the properties of the generator sets of the power plant; optimizing and distributing load to the plurality of sub-clusters of generator sets according to the principle of using the least amount of coals; attaining the best load state space of each generator set in each sub-cluster of the generator sets within an allowed load and storing best load state space in a database of a system; performing load distribution according to a speed regulation priority method or a coal consumption optimizing method so as to check the best load state space of the sub-clusters of generator sets and attaining the best load of all generator sets in the power plant with the attained best load of all machines transmitted to an automatic control system through a monitoring apparatus of a plant level AGC system. The invention further provides a system corresponding the method. According to the invention, the method is capable of effectively shortening the calculation and distribution time for load when a power plant comprises a great number of generator sets with vast type difference so as to fulfill the requirement of safety control to a power grid and to improve the authenticity and the accuracy of an optimization result.

Owner:NR ELECTRIC CO LTD +1

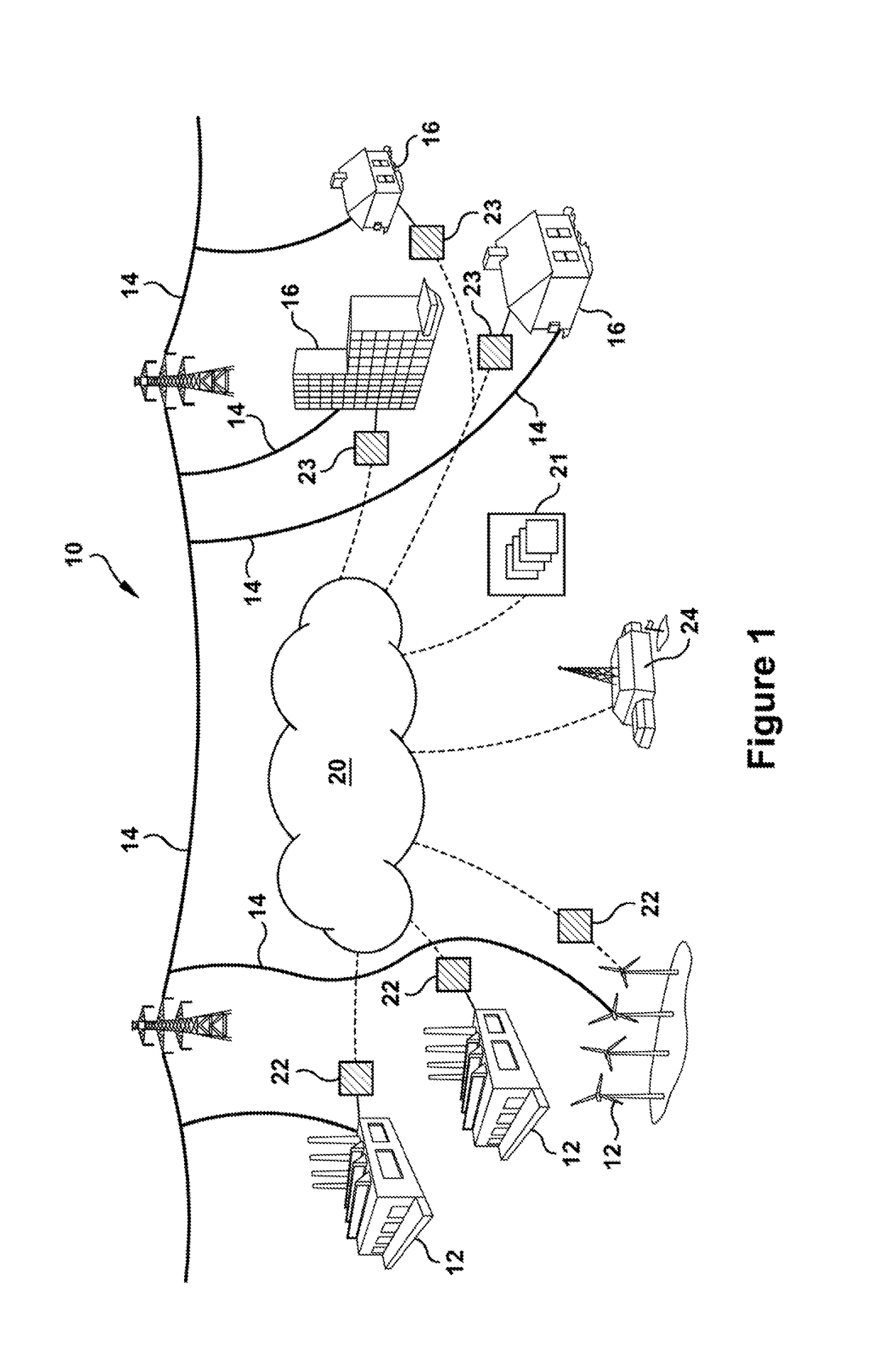

Methods and systems for controlling generating units and power plants for improved performance

A method for controlling a power plant that includes: presenting on a first user device a proposed version of the generating plan for a future generating period; receiving at the first user device a user input making a first modification to the proposed version to create a bid version of the generating plan; presenting on a second user device the bid version of the generating plan so that an indicator indicates the aspect that was modified by the first modification; receiving a user input on the second user device for creating a bid based on the bid version of the generating plan; transmitting from the second user device the bid; receiving at the second user device a response comprising an awarded fleet capacity; and transmitting from the second user device to the first user device an awarded plant-level capacity based on the awarded fleet capacity.

Owner:GENERAL ELECTRIC CO

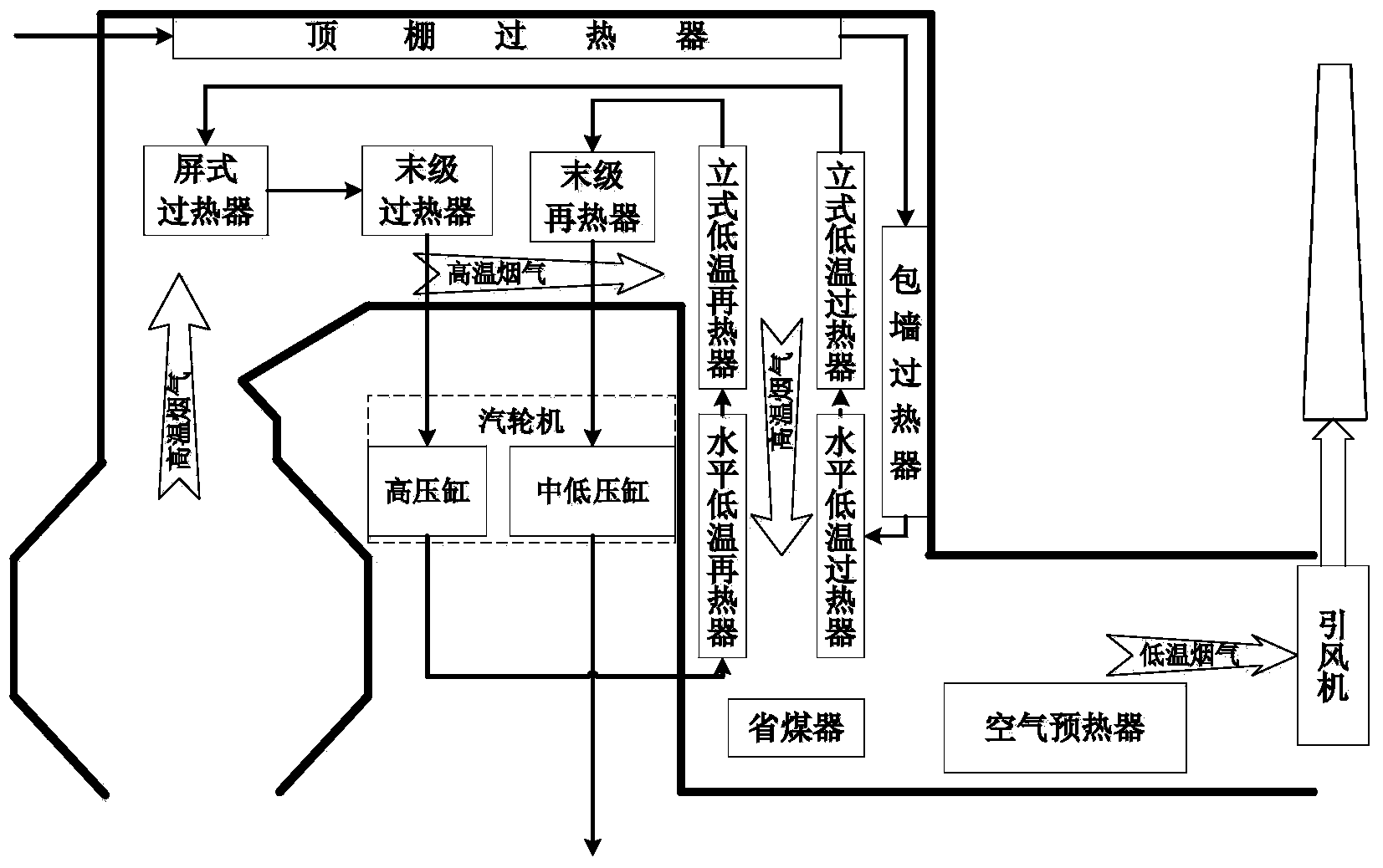

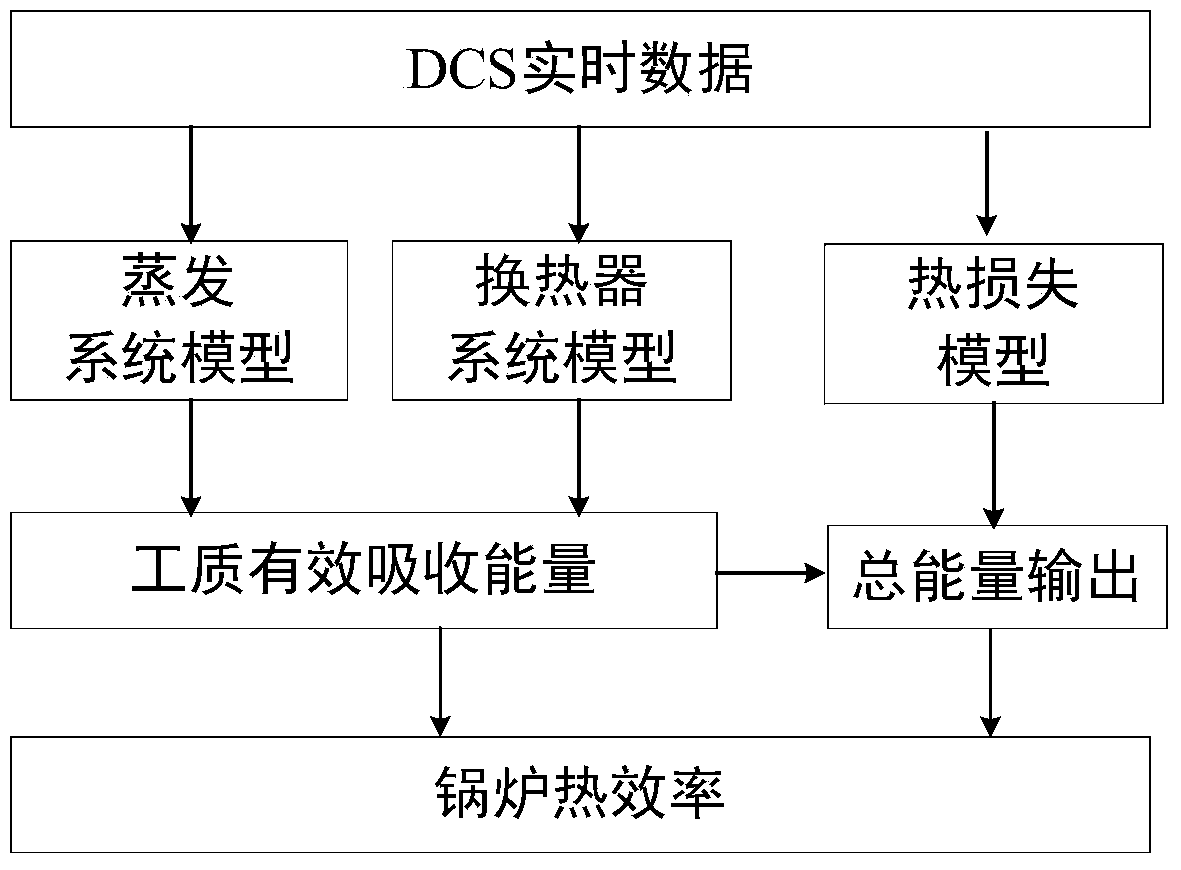

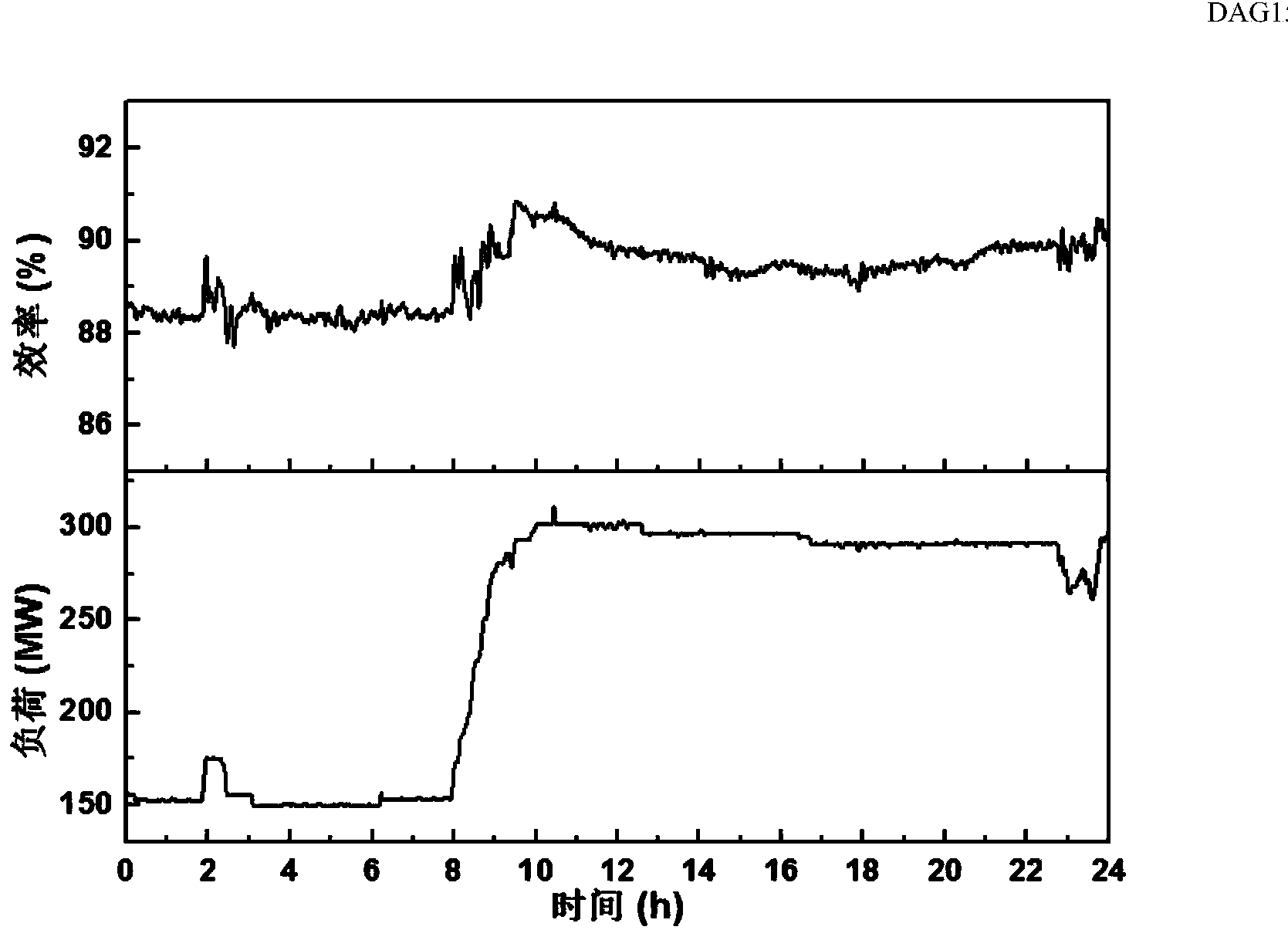

Method for measuring boiler thermal efficiency of coal fired power plant in real time

InactiveCN103778334AStable productionRealize online measurementBoiler indication operationsSpecial data processing applicationsVolumetric Mass DensityEngineering

The invention provides a method for measuring boiler thermal efficiency of a coal fired power plant in real time. The method comprises the following steps: step 1, obtaining boiler structure parameters according to the boiler operation design discipline, and reading a real-time value of an operation working condition measuring point at a set moment from the real-time database of a DCS (Distributed Control System); step 2, calculating the specific enthalpy and density of a working medium and the specific heat and density of fume according to a working medium physical property parameter library and a fume physical property parameter library; step 3, respectively determining the energy output of each part on the boiler side and the total energy output at the set moment according to an vaporization system model, a heat exchanger system (including a superheater system and a reheater system) model and a heat loss model on the boiler side; Step 4, determining the boiler thermal efficiency. The method can be used for measuring the boiler thermal efficiency in an online manner and further providing a technical support for plant-level load scheduling.

Owner:SHANGHAI JIAO TONG UNIV +1

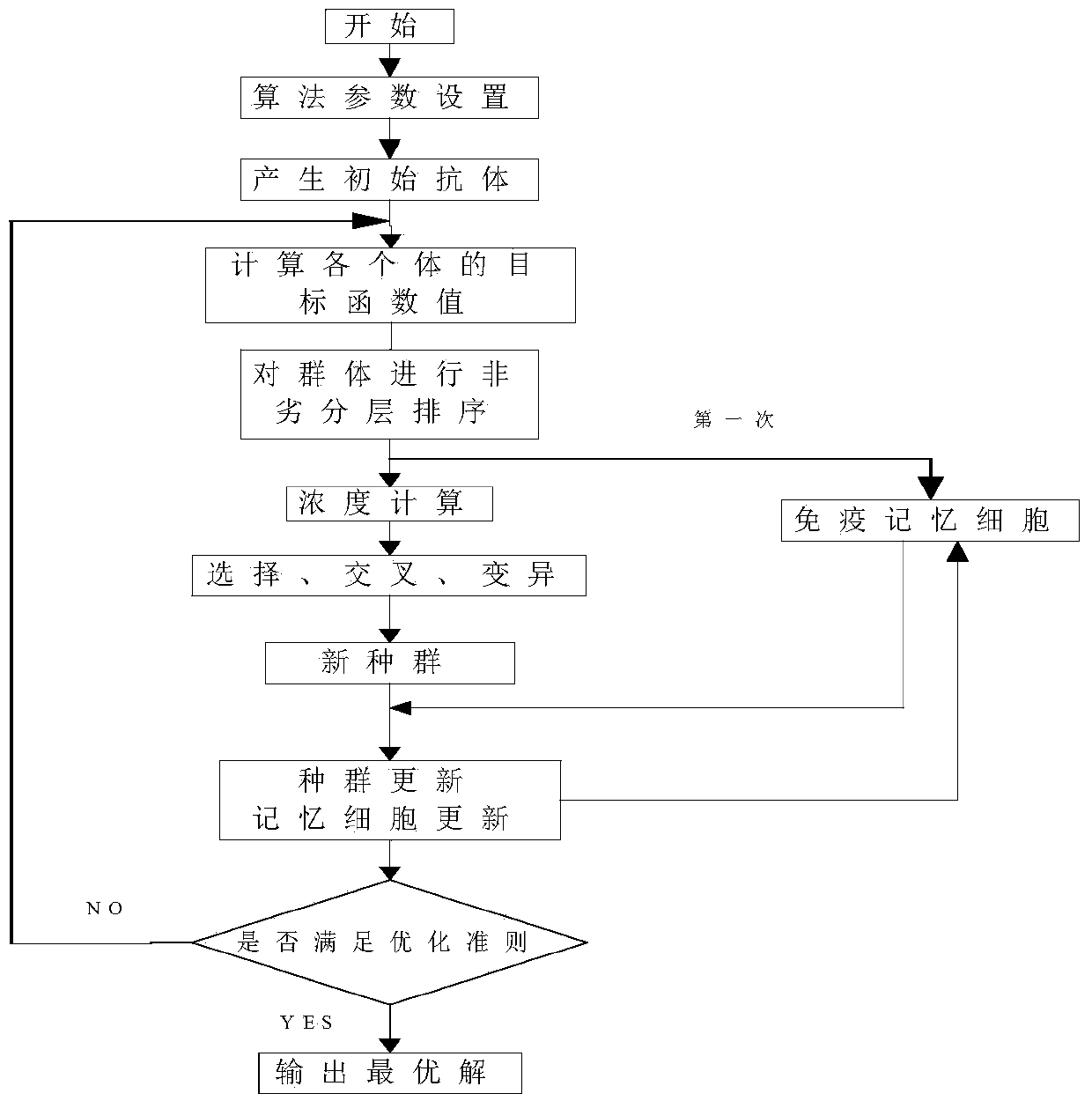

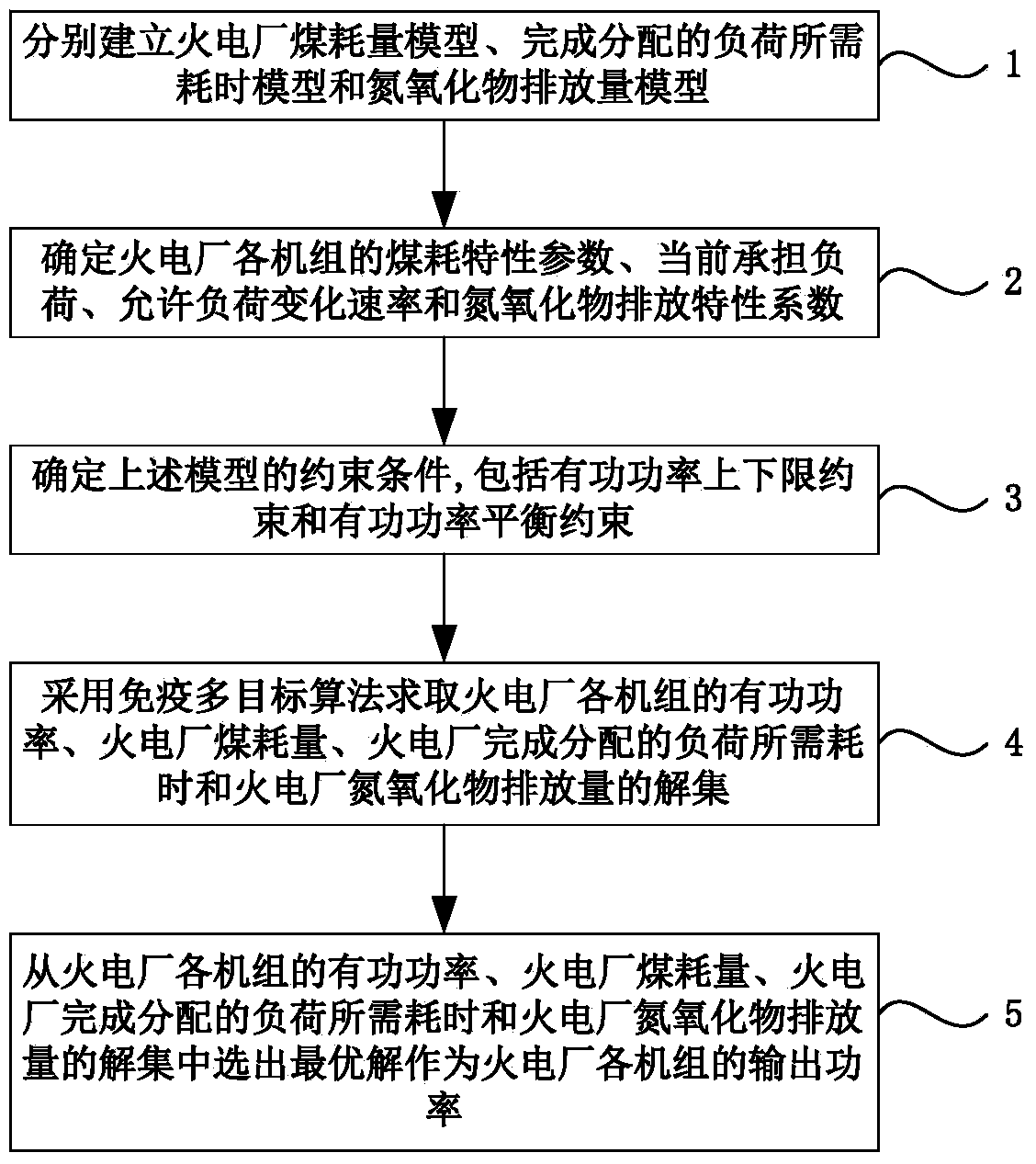

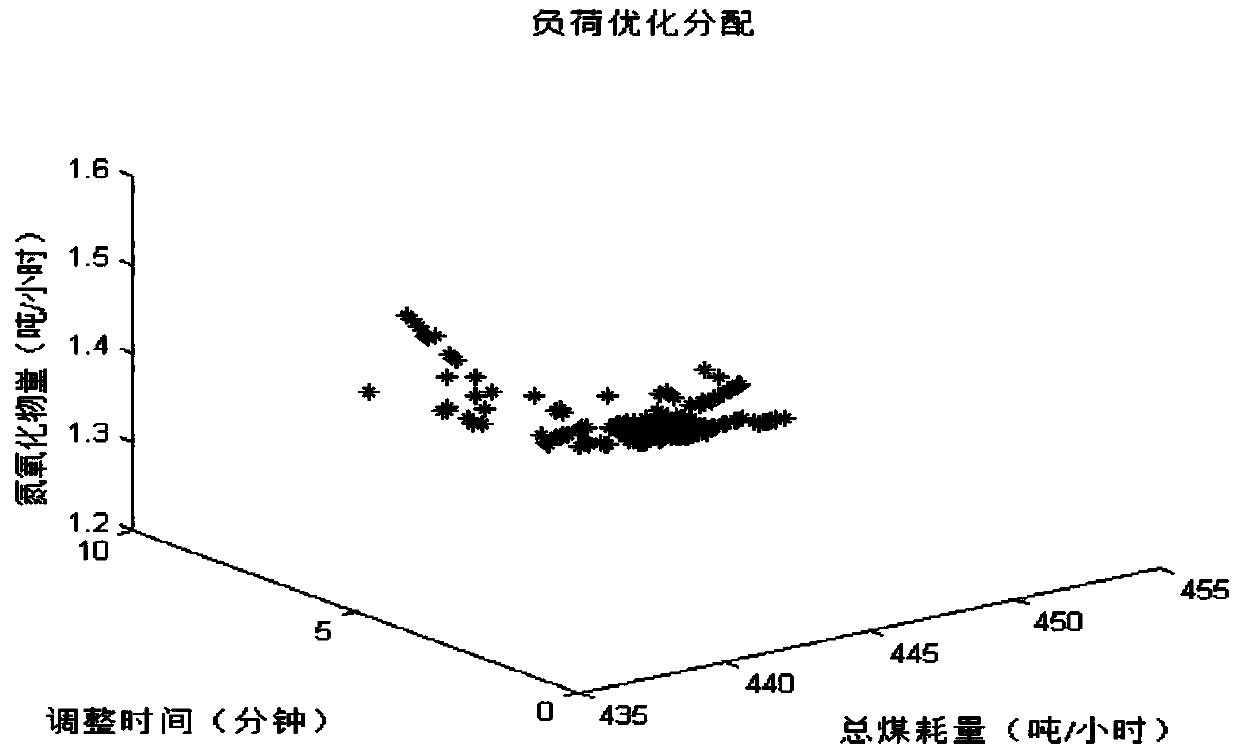

Multi-target plant level load optimization method based on immune optimization and fuzzy decision

InactiveCN103440535AThe calculation process is fast and accurateForecastingLower limitFuzzy decision

The invention discloses a multi-target plant level load optimization method based on immune optimization and fuzzy decision in the technical field of energy-saving power generation. The multi-target plant level load optimization method comprises the steps that a thermal power plant coal consumption model, a model of time needed for completing distributed loads, and a nitric oxide emission model are established respectively; coal consumption characteristic parameters, current bearing loads, permitted load change rates and nitric oxide emission characteristic coefficients of all units in a thermal power plant are determined; constraint conditions of the models are determined, including upper limit and lower limit constraint conditions and balance constraint conditions of active power; a solution set including the active power of all the units in the thermal power plant, thermal power plant coal consumption, time needed for completing the distributed loads of the thermal power plant, and the nitric oxide emission of the thermal power plant is obtained through an immune multi-target algorithm; an optimal solution is selected from the solution set to serve as output power of all the units in the thermal power plant. According to the multi-target plant level load optimization method based on immune optimization and fuzzy decision, the immune multi-target algorithm is used for realizing multi-target plant level load distribution, an optimal power distribution scheme for the power plant units is decided according to a fuzzy decision theory, and therefore the computational process is faster and more accurate.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

Method for measuring drainage pump output of low pressure heater system of thermal generator set based on energy balance

InactiveCN101737311AEnsure safetyGuaranteed economyPump testingPositive-displacement liquid enginesEnergy balancedEngineering

The invention relates to a method for measuring the drainage pump flow of a regenerative system of a thermal generator set based on energy balance. A thermodynamic system in the method consists of low pressure heaters connected in series. The method comprises the following steps of: mixing drained water of a first-stage low pressure heater with outlet condensed water of the first-stage low pressure heater by using a drainage pump, wherein the drained water of the other low pressure heaters of all stages flows automatically stage by stage; acquiring the extraction temperature and pressure, the outlet water temperature and pressure and the drained water temperature of each low pressure heater from a database of a plant-level supervisory information system (SIS) or a decentralized control system (DCS) of a thermal power plant; calculating the stream extraction enthalpy value of each low pressure heater, the outlet water enthalpy value of the low pressure heater and the drain water enthalpy value of the low pressure heater; establishing a heat balance equation for each low pressure heater, and establishing a flow balance equation and a mixing point heat balance equation for a mixing point of outlet water of the drainage pump of the first-stage low pressure heater; deducing an iteration-free soft measurement model according to the balance equations, and calculating flow shares of the drainage pump; and finally, calculating the drainage pump flow according to a flow detection value of the condensed water.

Owner:SOUTHEAST UNIV

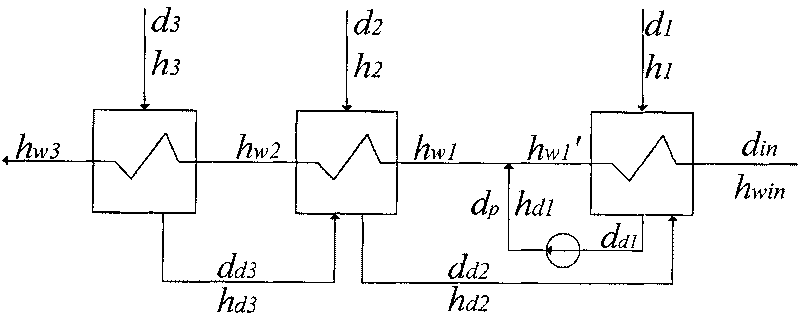

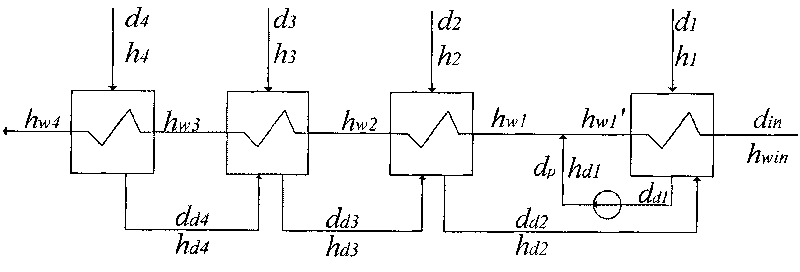

Plant-level process fault detection and diagnosis method based on distributed data model

InactiveCN103389701ARealize accurate fault diagnosisAvoid dependenceTotal factory controlProgramme total factory controlComputer sciencePlant level

The invention discloses a plant-level process fault detection and diagnosis method based on a distributed data model. Aiming at the complex large plant-level production process, the existing commonly used fault detection and diagnosis methods are mostly built on the basis of a data driving model, wherein the most typical method includes first dividing the whole plant-level process into a plurality of sub modules according to operation units and functions and then building corresponding fault detection and diagnosis models aiming at the different sub modules respectively. The methods often rely on process knowledge to a large extent, and the requirement is harsh for the complex plant-level process. A novel method for dividing the sub modules completely based on data analysis is provided, and the corresponding fault detection and diagnosis method is constructed on the basis to achieve the whole situation monitoring of the plant-level process. The method has important application value for improving fault detection and diagnosis performance and product quality in the plant-level production process.

Owner:ZHEJIANG UNIV

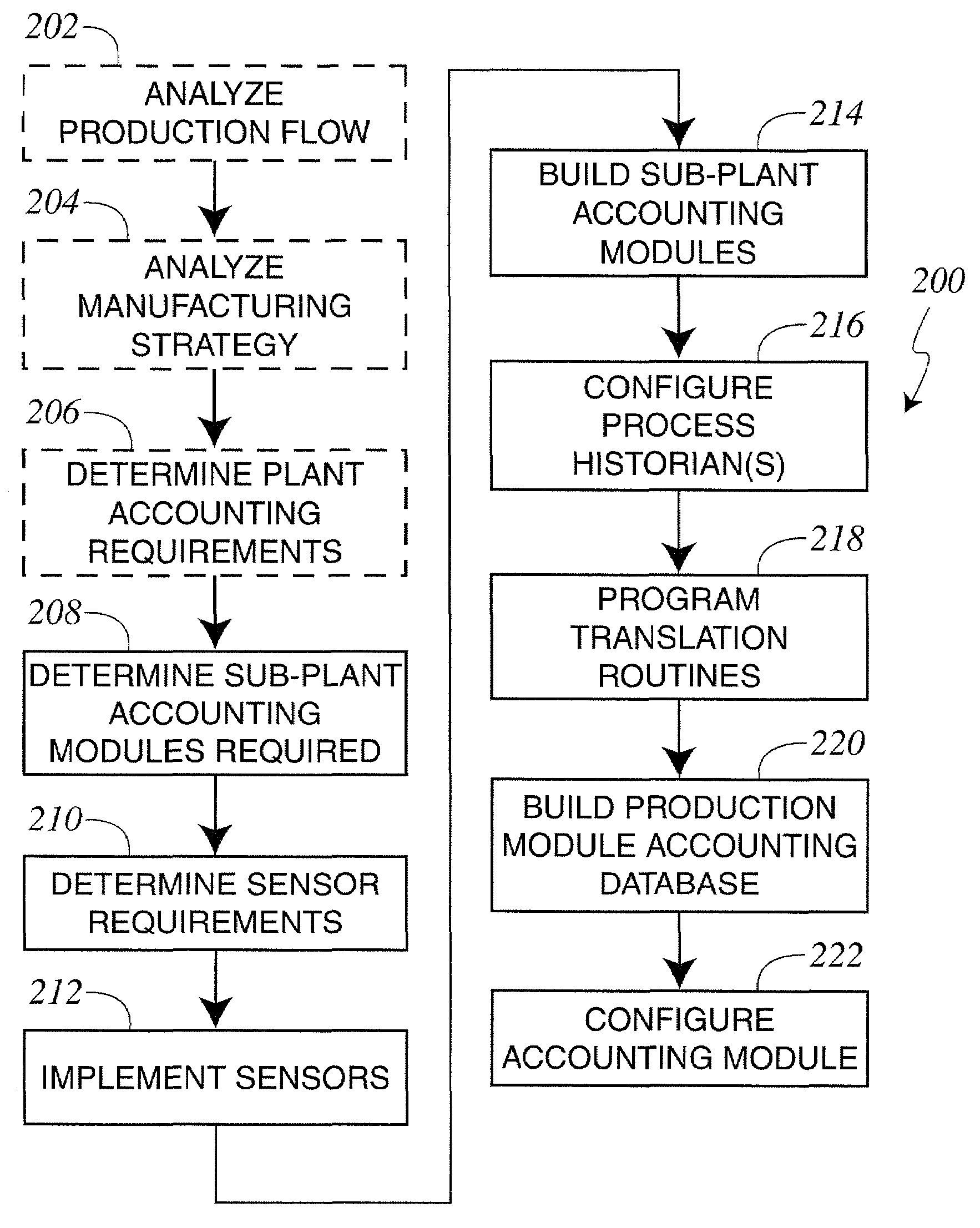

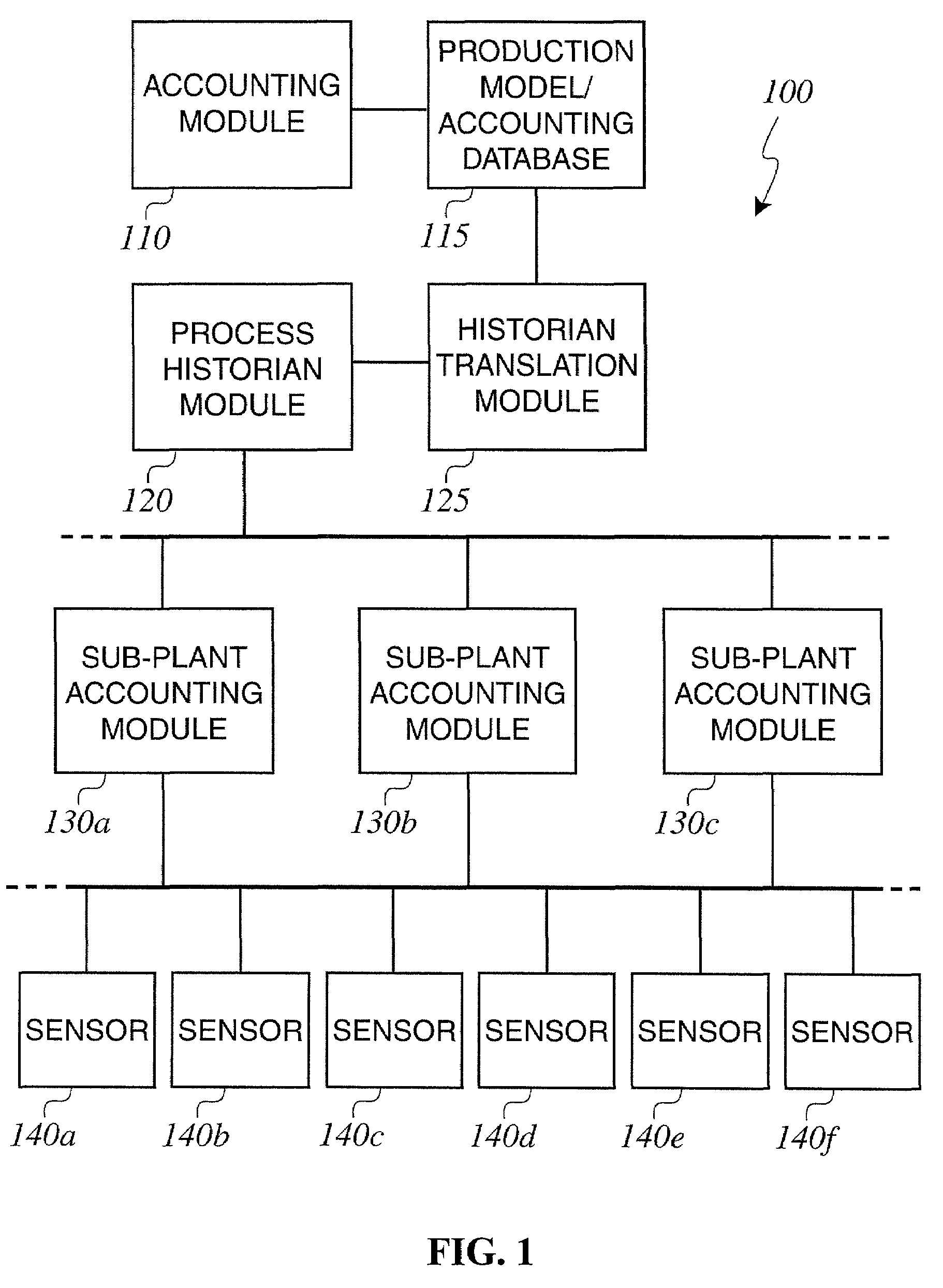

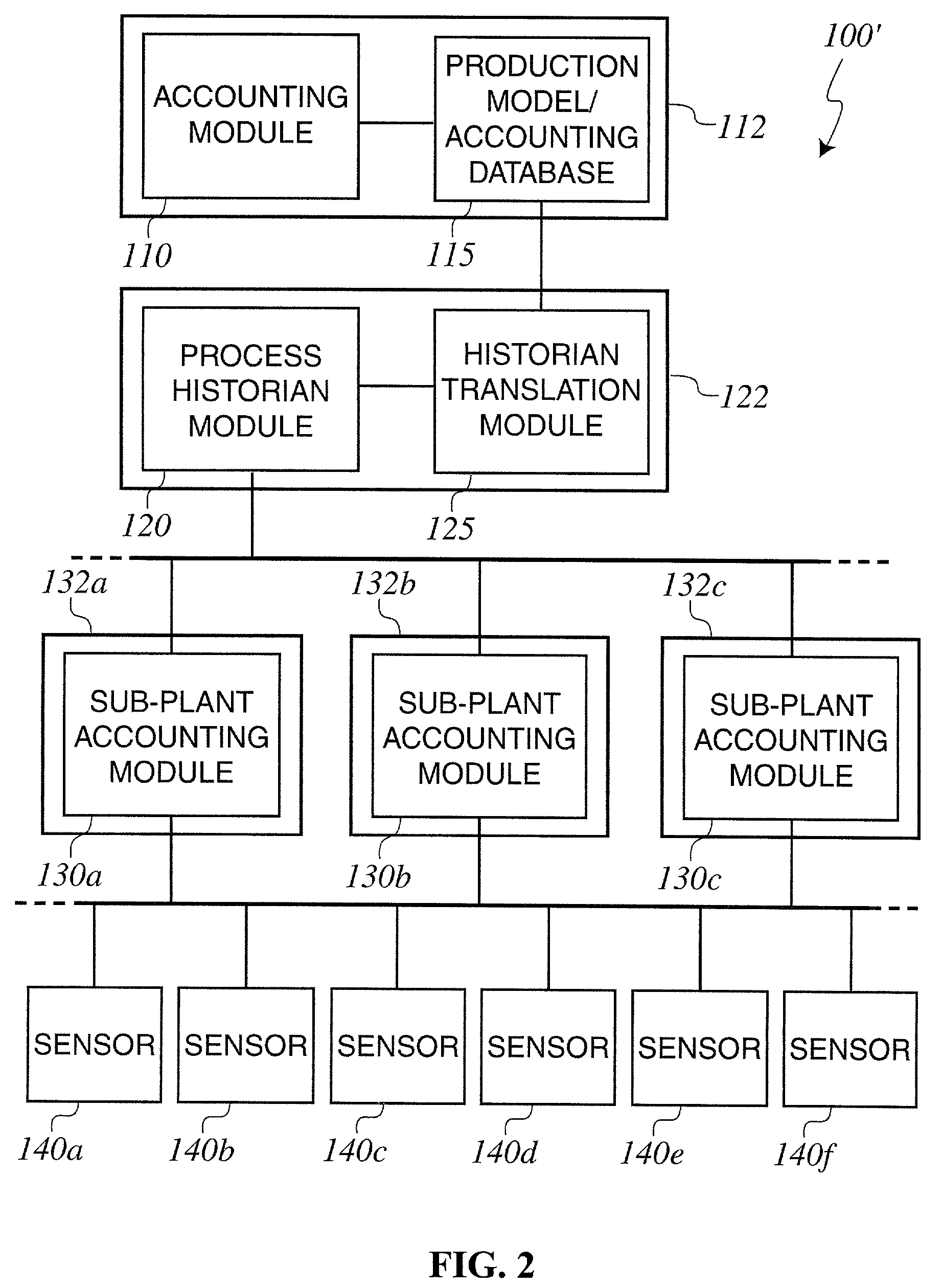

System and method for real-time activity-based accounting

ActiveUS7685029B2Complete banking machinesRegistering/indicating time of eventsProduction modelProcess equipment

An accounting method and system is disclosed that provides for real time financial accounting of plant performance at a sub-plant level. A multiplicity of process variable transmitters is utilized to sense, in real time, the current state of the processes and process equipment used in a manufacturing plant. Sub-plant accounting modules utilize the sensed process data to calculate a plurality of sub-plant accounting measures, which are stored in one or more real time plant historian. The accounting measures are typically converted to a suitable format and subsequently stored in a production model accounting database where they are accessible to an accounting module.

Owner:SCHNEIDER ELECTRIC SYST USA INC

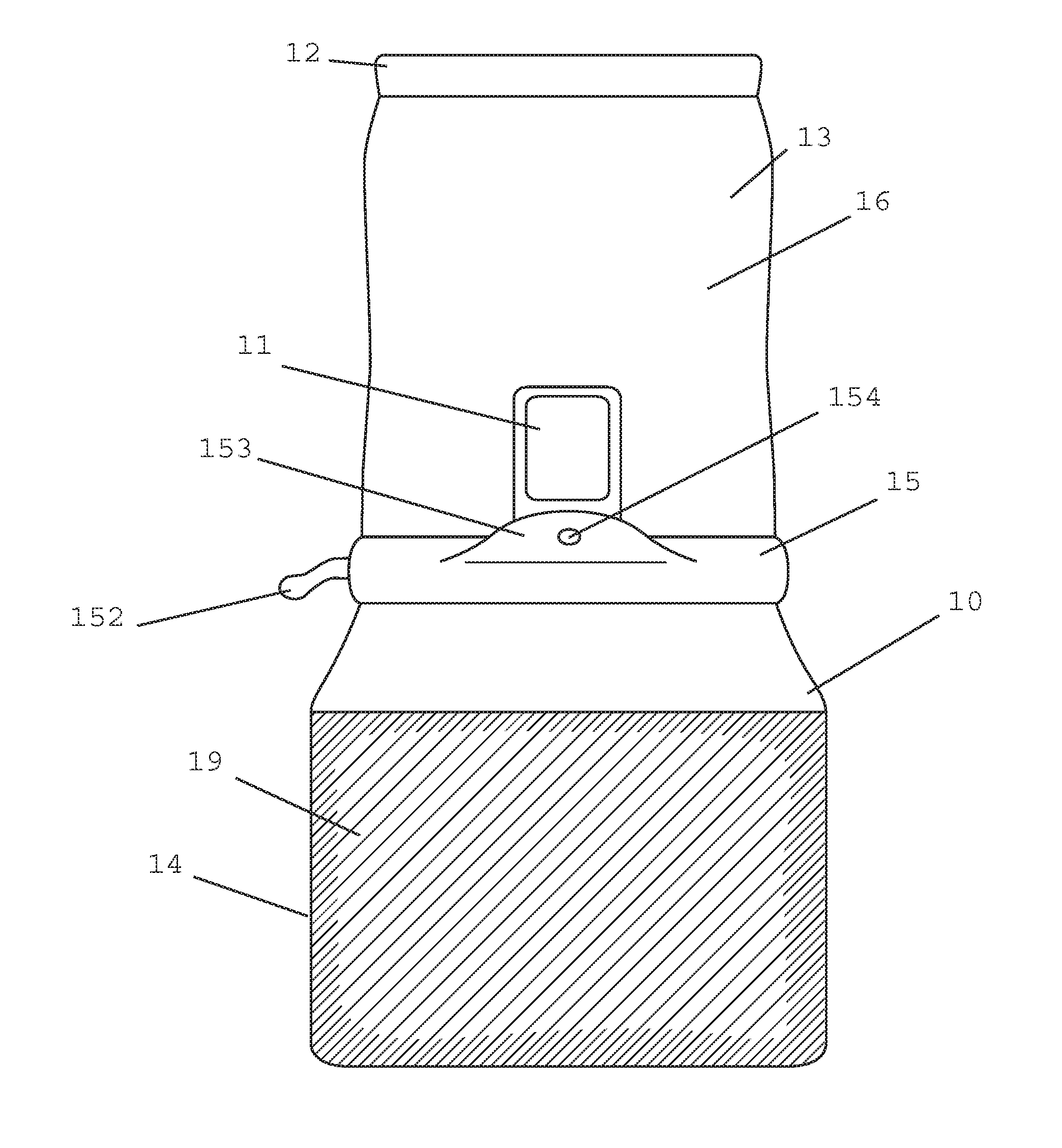

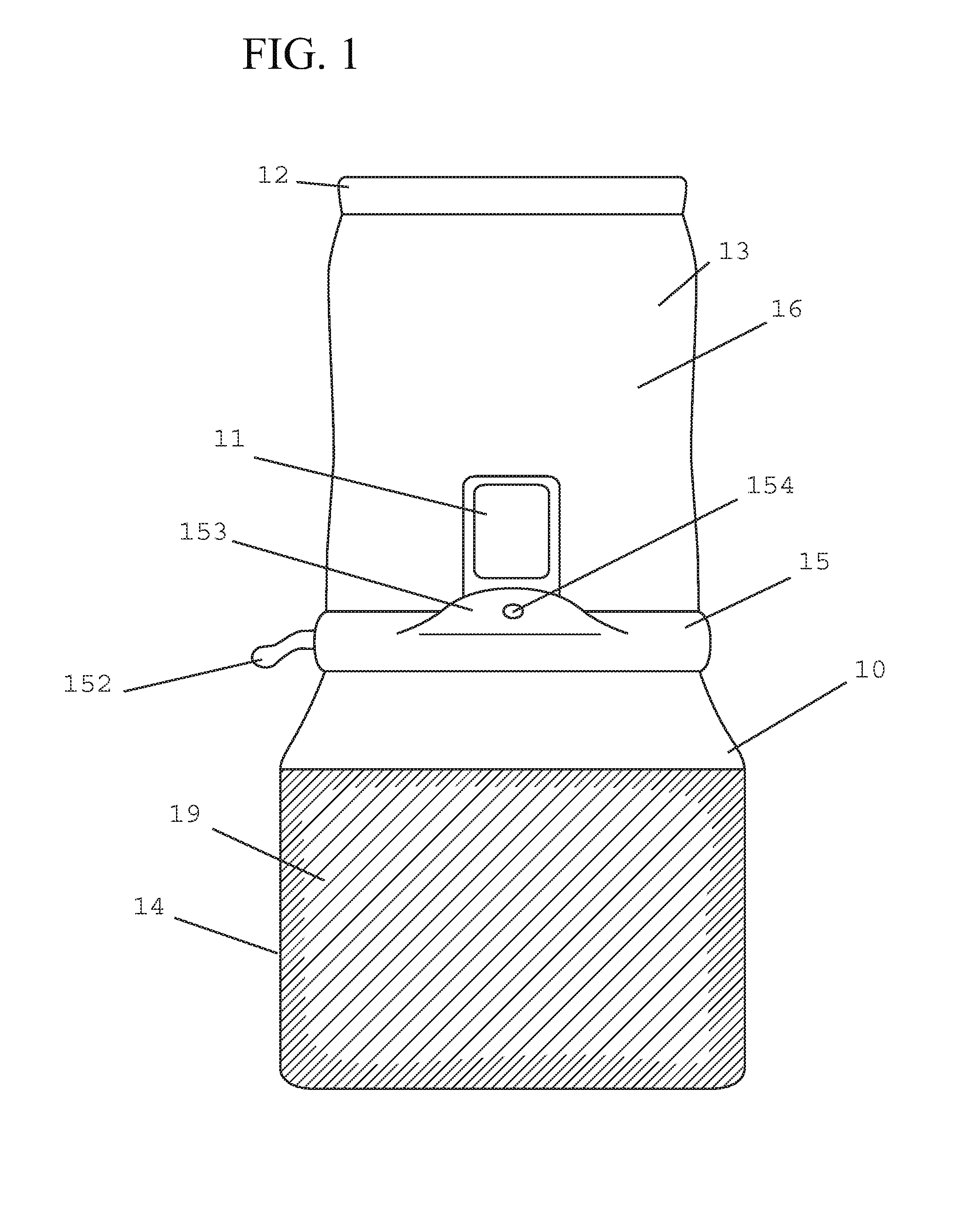

Carbon Dioxide Supplementation Product with Delayed Activation Control

ActiveUS20150373920A1Extended shelf lifePrevents unsightly and foul infestationCultivating equipmentsHorticulture methodsAir exchangeEngineering

A consumer product for supplementing carbon dioxide is provided with delayed activation control in the form of a clamp. A bag, having a top and a bottom seal and a filter, contains a mycelial mass prepared under sterile laboratory conditions using aseptic techniques. The bag may be selectively clamped at various locations on its exterior. During manufacturing, the mycelial mass is sealed away from the air exchange portal by the clamp. The manipulation delays the optimized carbon dioxide generation and extends the product shelf-life significantly. The fungi are utilized on-demand by removal of the clamp and carbon dioxide flows from the product. Consumers will place the product near indoor plants. The precise clamping method delays the expiration of the product for storage and shipping optimization. The clamp is relocated to the top of the bag in order to provide a hanger for the carbon dioxide generator above plant level.

Owner:BABCOCK GLEN +1

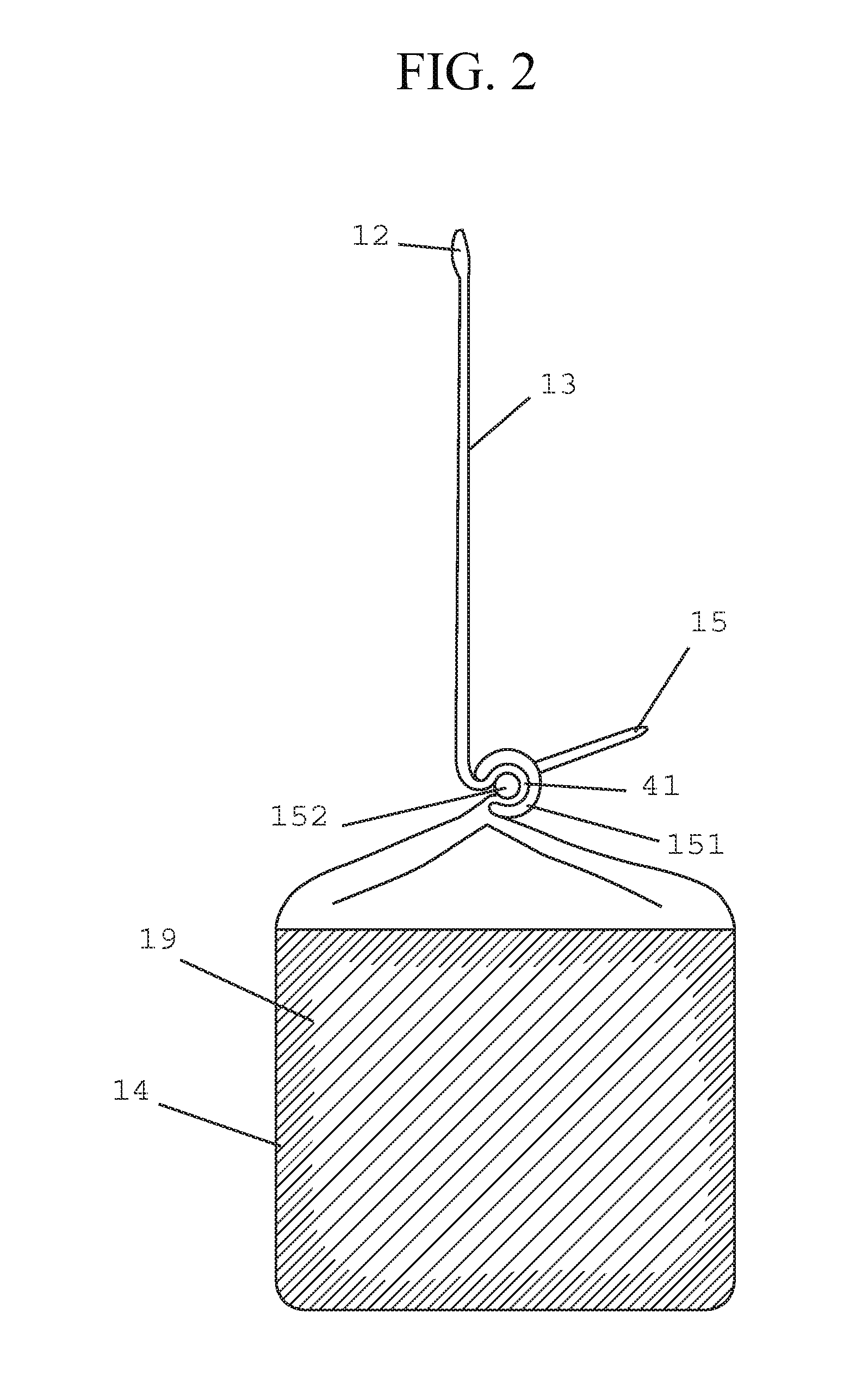

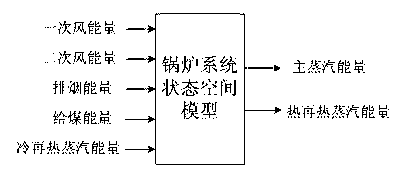

Subspace identification based forecasting method for superheated steam output of boiler of firepower power station

ActiveCN102840571AClear physical meaningHigh precisionBoiler controlCombustion regulationSpatial modelHankel matrix

The invention discloses a subspace identification based forecasting method for superheated steam output of a boiler of a firepower power station, which comprises the following steps: firstly, acquiring production data from plant-level DCS (Distributed Control System) configuration software at regular time; secondly, correcting bad points, filtering and denoising; thirdly, calculating input and output variables required by model identification; fourthly, constructing an Hankel matrix by utilizing continuous acquired and processed data and rolling to update; fifthly, approximating the boiler process to a linear state space model; sixthly, using a subspace theory to identify a matrix of the state space model [A, B, C and D]; seventhly, utilizing the latest input energy information as the obtained input variables of the state space model after the identification and calculating output energy of future moments; eighthly, calculating the mean value at the same time by utilizing a historical forecast value and a current forecast result and correcting by utilizing the past forecast deviation; and ninthly, rolling to update the data of identification of the model. The forecasting method is applicable to online forecast of superheated steam output energy in the boiler production process and provides guidance and reference for the optimization control of boiler combustion.

Owner:ELECTRIC POWER SCI RES INST OF GUIZHOU POWER GRID CO LTD +1

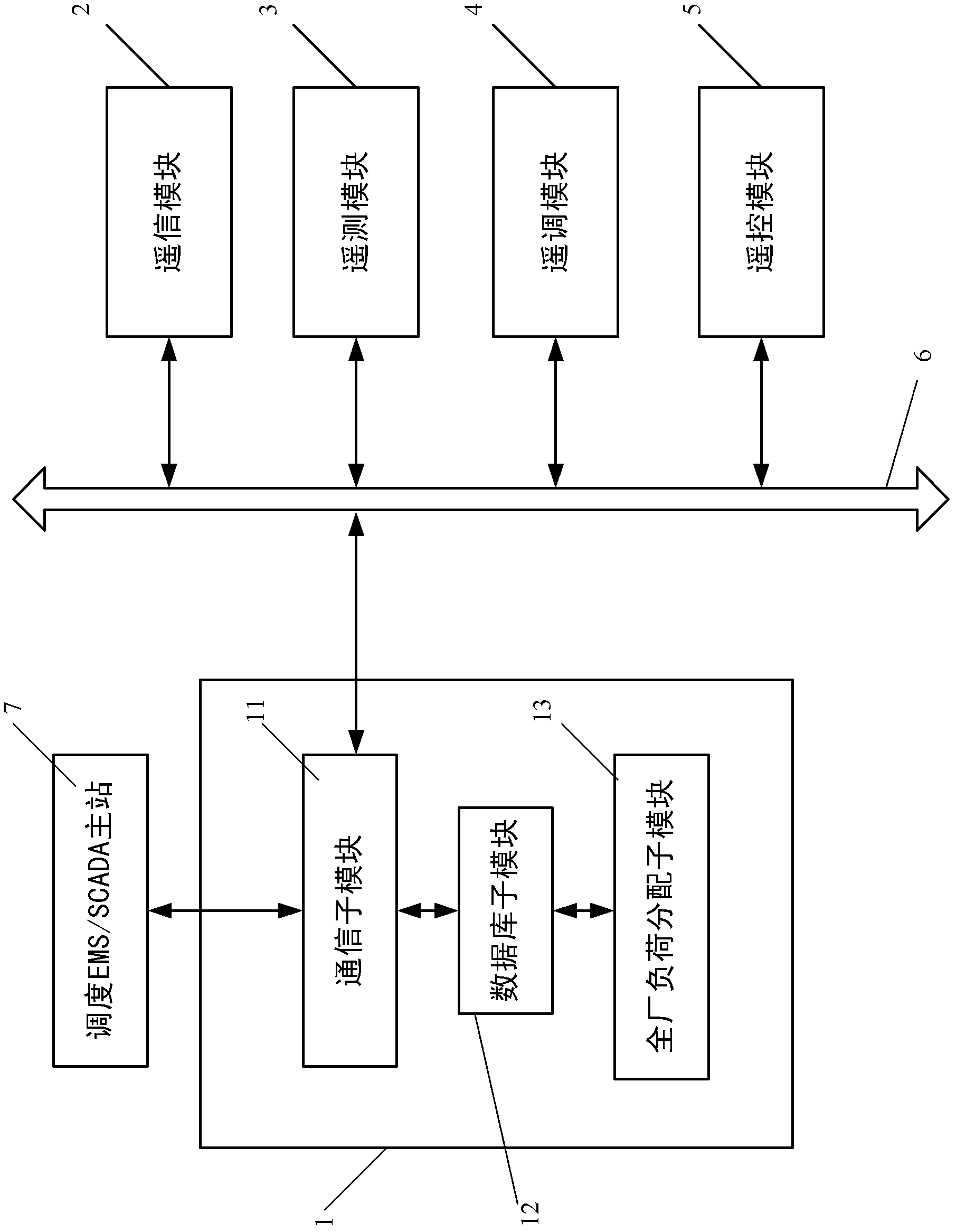

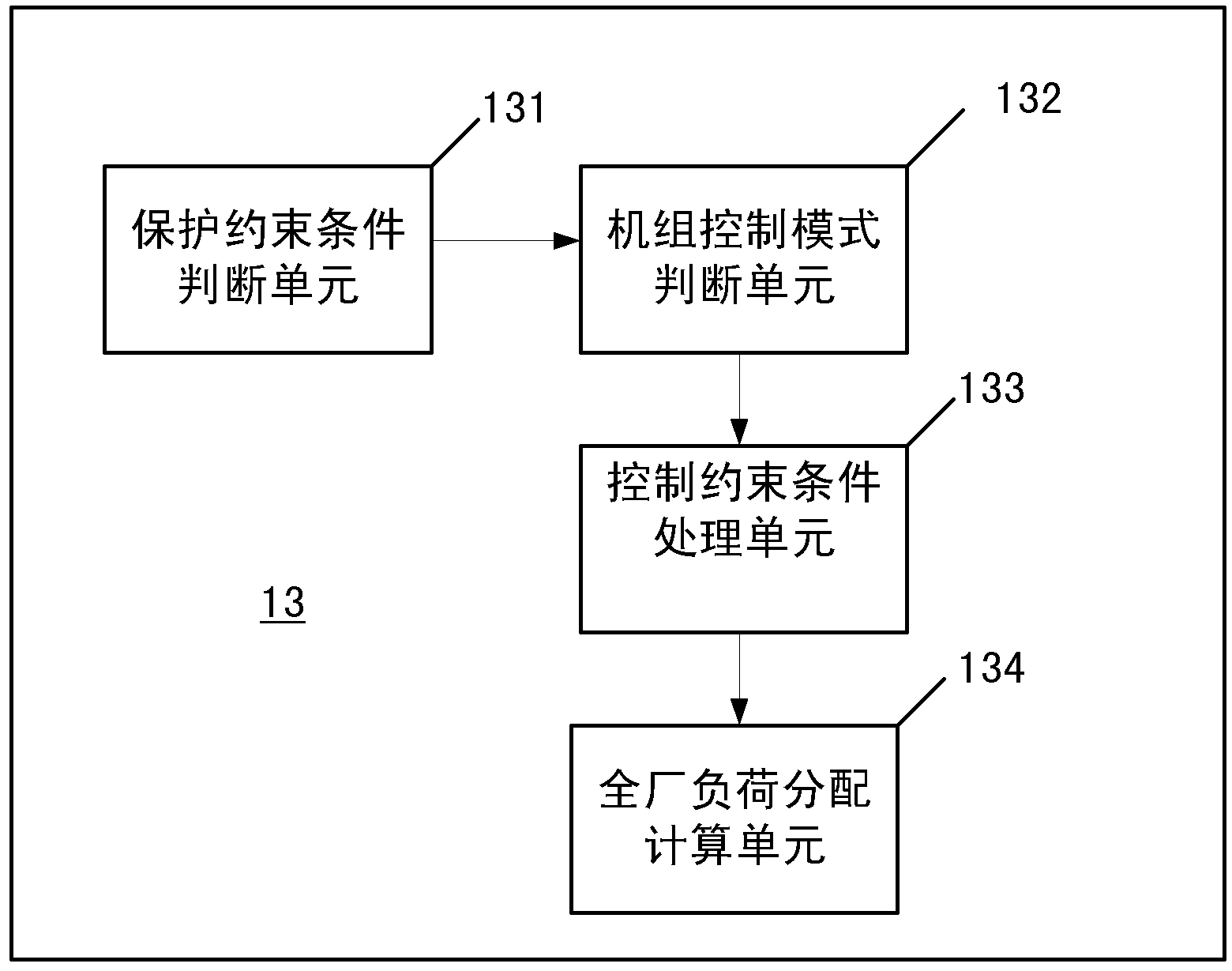

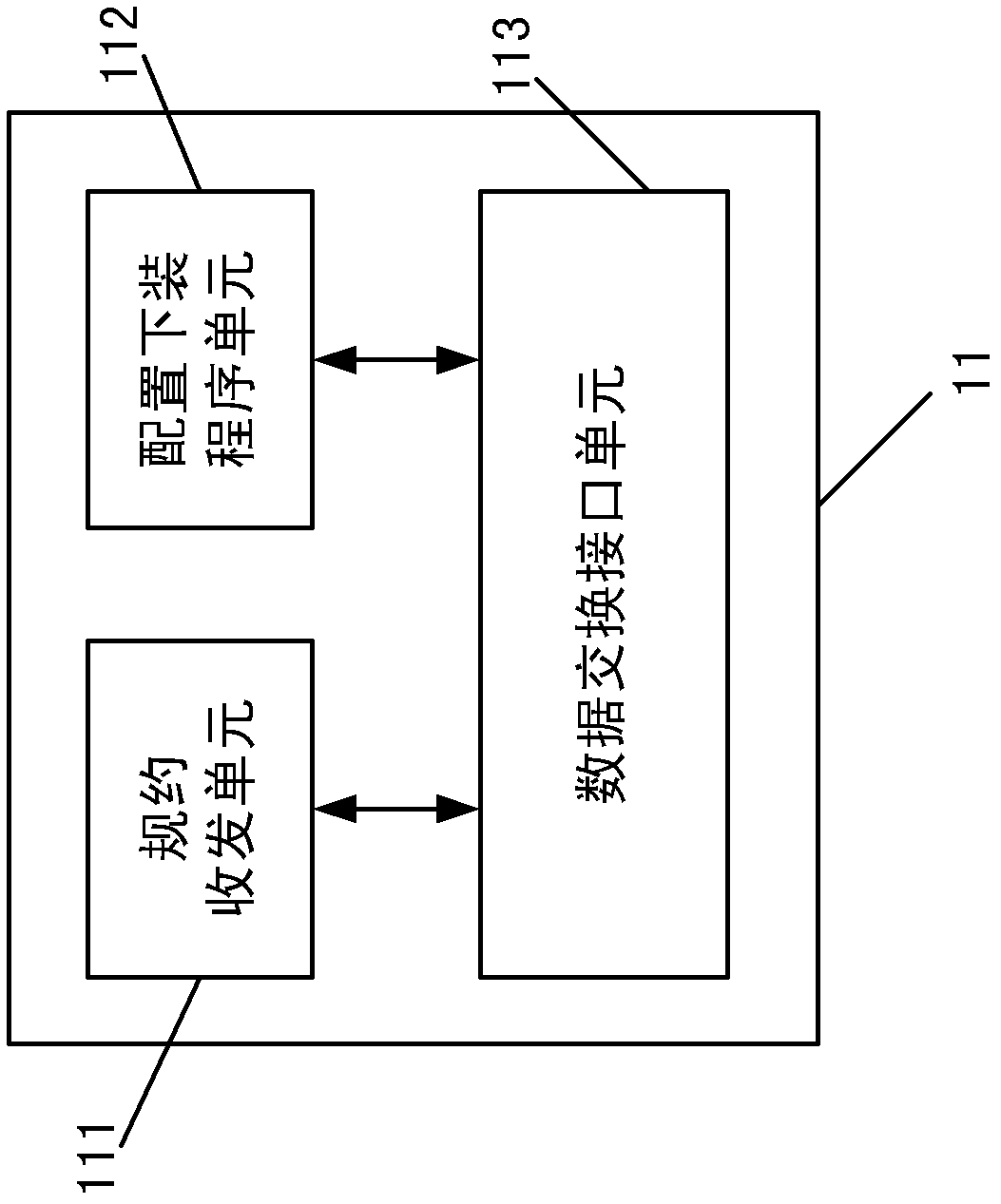

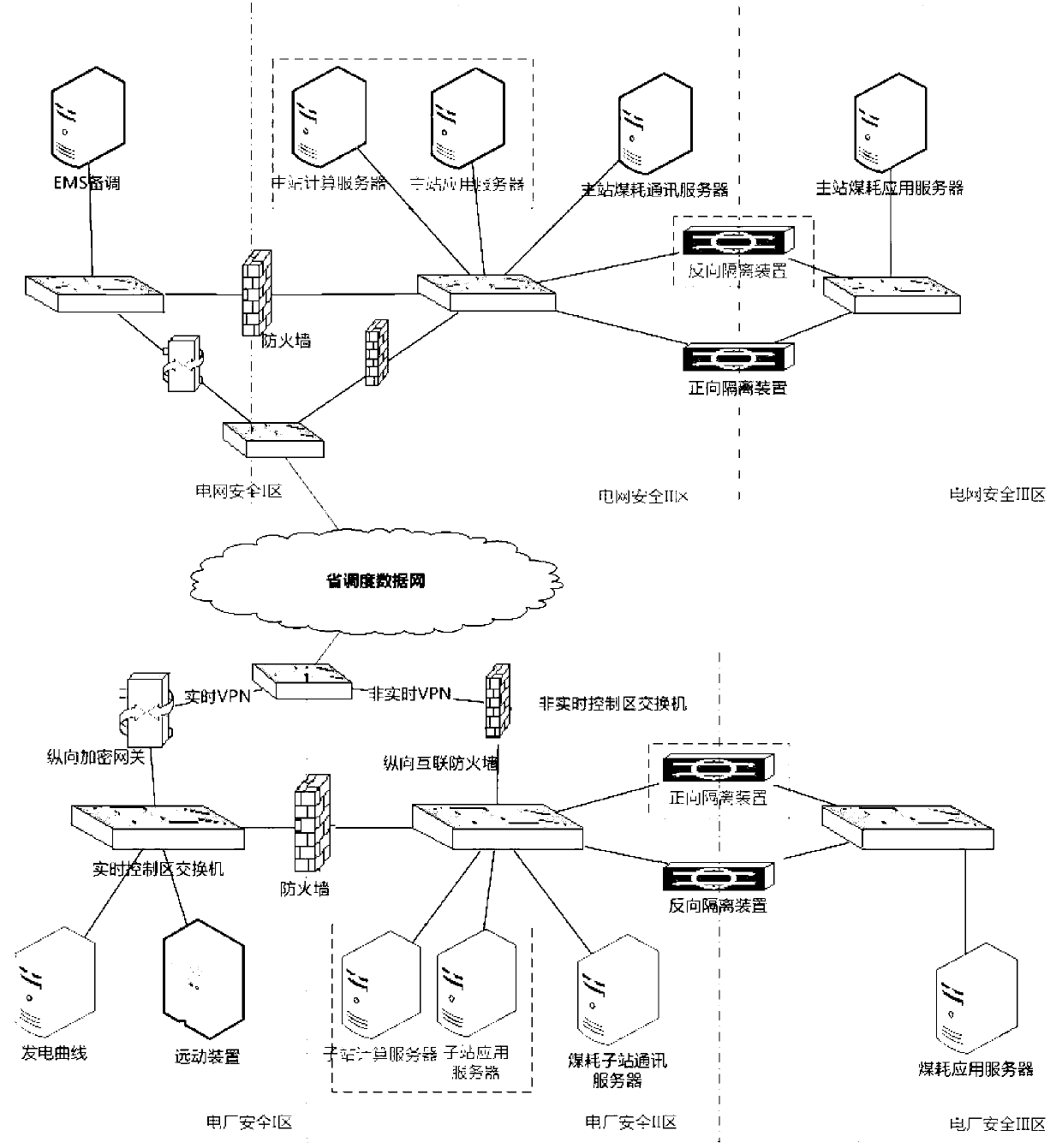

Electrical telemechanical host with plant-level automatic power generation function

InactiveCN102222914AEnsure consistencyGuaranteed operating accuracyAc networks with different sources same frequencyInformation technology support systemControl signalEngineering

The invention provides an electrical telemechanical host with a plant-level automatic power generation function. The electrical telemechanical host is connected with a remote signaling module, a remote measuring module, a remote invoking module, a remote control module and an invoking EMS / SCADA main station. The electrical telemechanical host specifically comprises a communication sub-module, a database sub-module, and a full-plant load distribution sub-module, wherein the communication sub-module is used for realizing data communication between the invoking EMS / SCADA main station and the database sub-module and the data communication among the remote signaling module, the remote measuring module, the remote invoking module, the remote control module and the database sub-module; the database sub-model is used for memorizing data required for plant-level AGC (automatic gain control) and carrying out data interaction respectively with the communication sub-module and the full-plant load distribution sub-module; and the full-plant load distribution sub-module generates a control signal of a generator unit active power output based on the data memorized in the database sub-module and sends the control signal to the remote invoking module in sequence through the database sub-module and the communication sub-module. In the electrical telemechanical host, on the basis of sufficiently playing the function of the existing electrical telemechanical host, the quantity of field hardware equipment is reduced, and the operation precision of the data is improved during the unit active adjustment process.

Owner:上海惠安系统控制有限公司

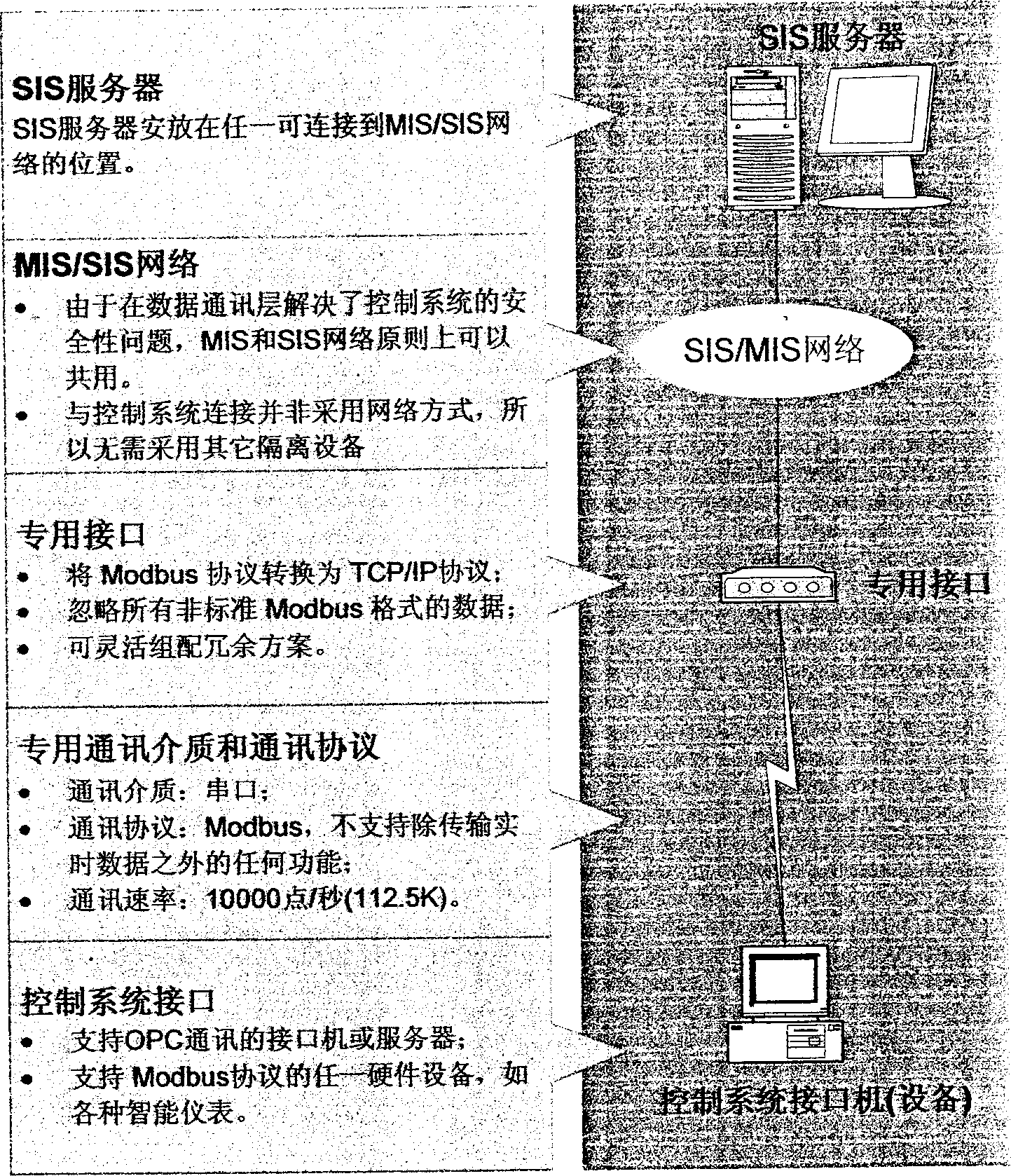

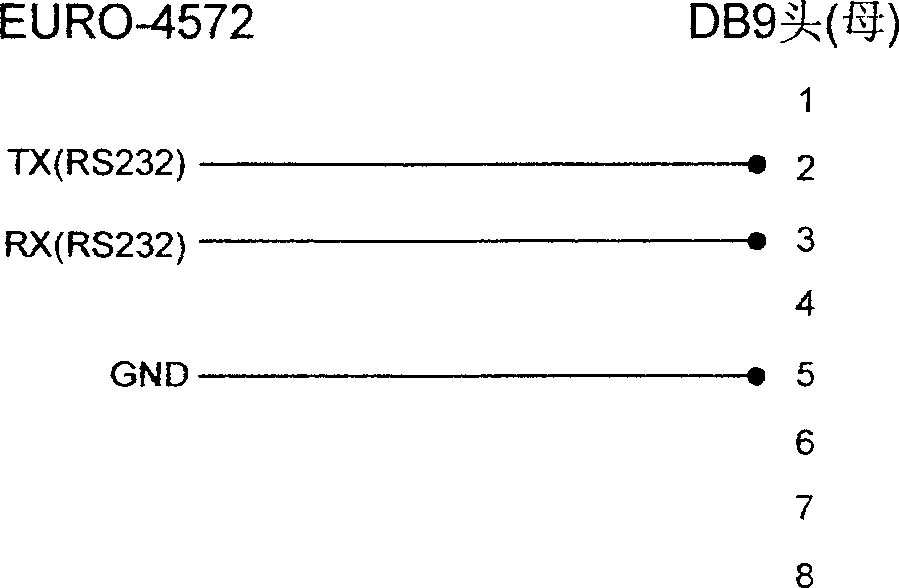

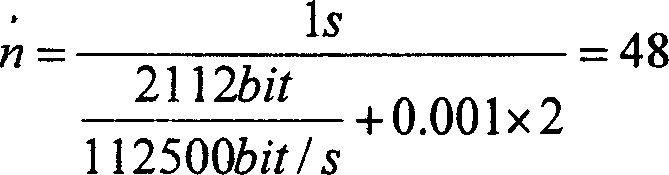

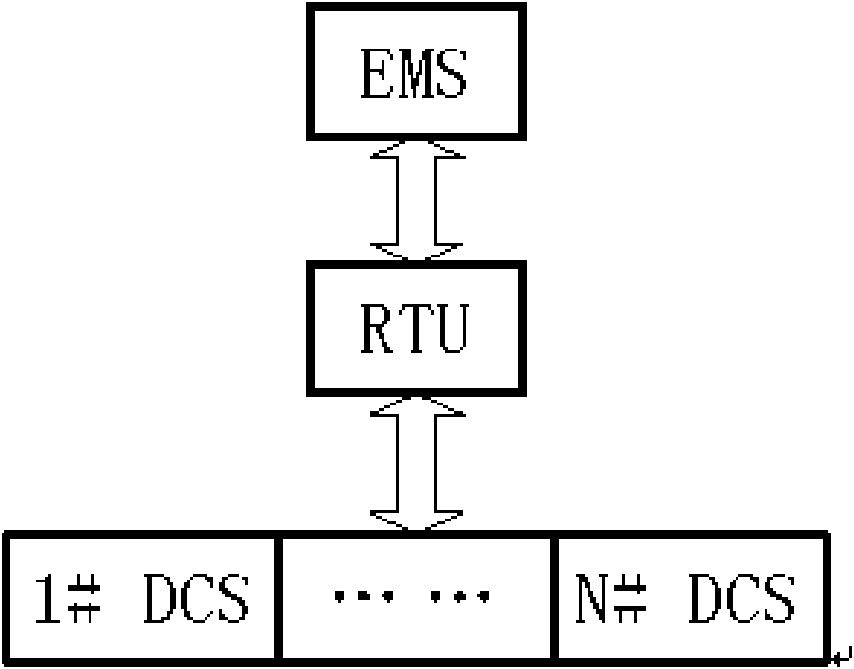

Interface method and apparatus for plant-level monitoring system and decentralized control system for power plant

ActiveCN1801018AThe communication protocol is simple and efficientNo back passTransmissionTotal factory controlModbusPlant factory

The invention discloses an interface method of power-plant factory level monitoring information system and dispersion control system (SIS and DCS), which is characterized by the following: adapting EURO-4572 mode and Modbus serial port to connect protocol; making SIS system and DCS control system accomplish data communication. The invention can transmit the data of DCS control system to SIS / MIS system effectively, which guarantees the safety of DCS control system against the attack of hacker and virus.

Owner:南京科远智慧能源投资有限公司

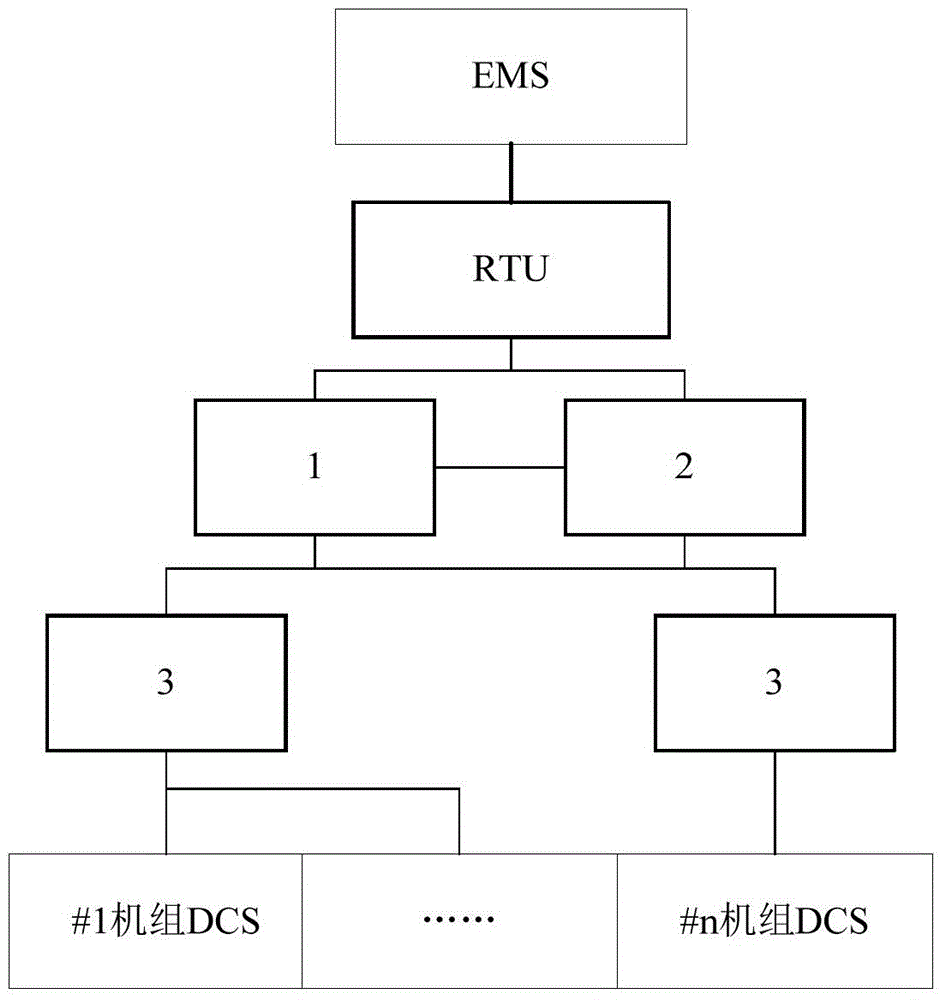

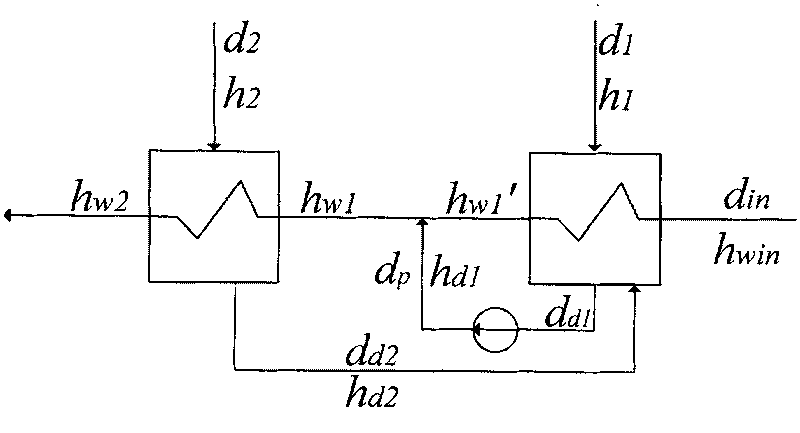

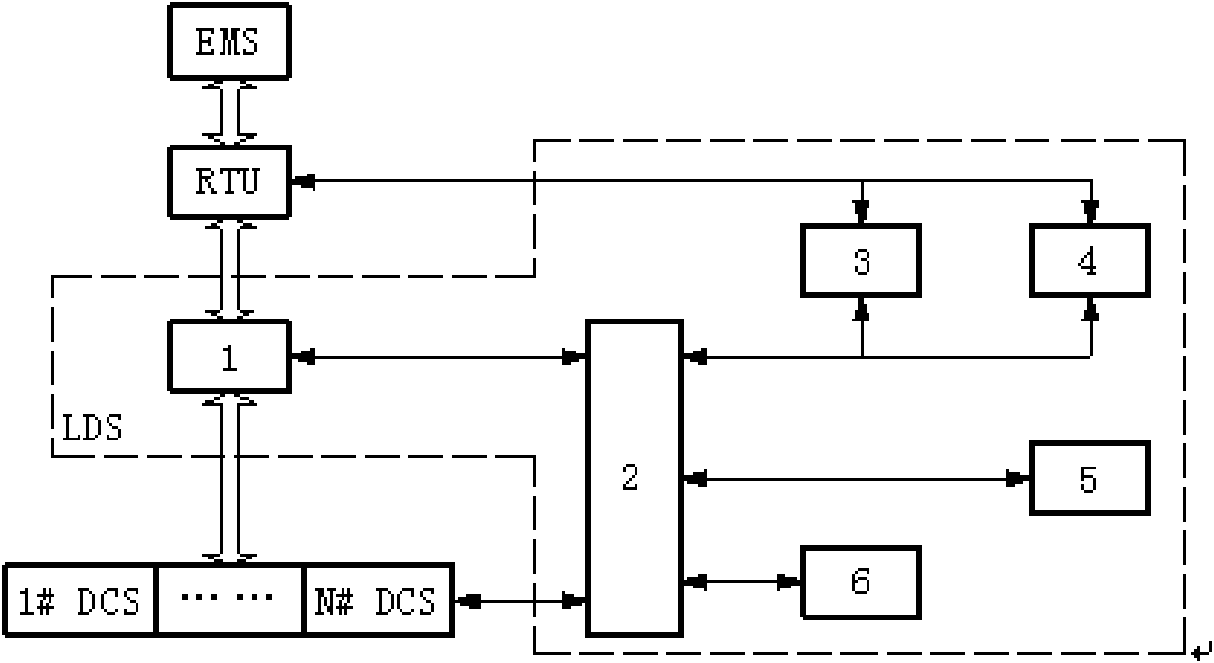

Method and device for optimally allocating plant-level load for heat power plant

InactiveCN101593979AEasy loadingGuaranteed safe operationAc network circuit arrangementsLoad following power plantHeating power

The invention discloses a method and a device for optimally allocating plant-level load for a heat power plant. The method comprises that: a load optimal allocation device is arranged between an automatical energy management system for electric network management and a group of distributed control systems of a machine set; the load optimal allocation device automatically configures a load optimal allocation proposal according to a command of the automatical energy management system for the electric network management and the load capability and machine set performance of the machine sets; and the automatical increase and decrease of the machine set loads are realized by the group of the distributed control systems of the machine set. The device is provided with the load optimal allocation device (LDS) which is arranged between a remote terminal unit (RTU) and the distributed control system (DCS) of the machine set; and the load optimal allocation device (LDS) is respectively in double-way connection with the remote terminal unit (RTU) and the distributed control system (DCS) of the machine set. In the premise of ensuring the safety operation of the device, the method and the device can realize the optimal dispatching of the load between the machine sets of the whole plant.

Owner:贵阳高新金辰软件有限公司

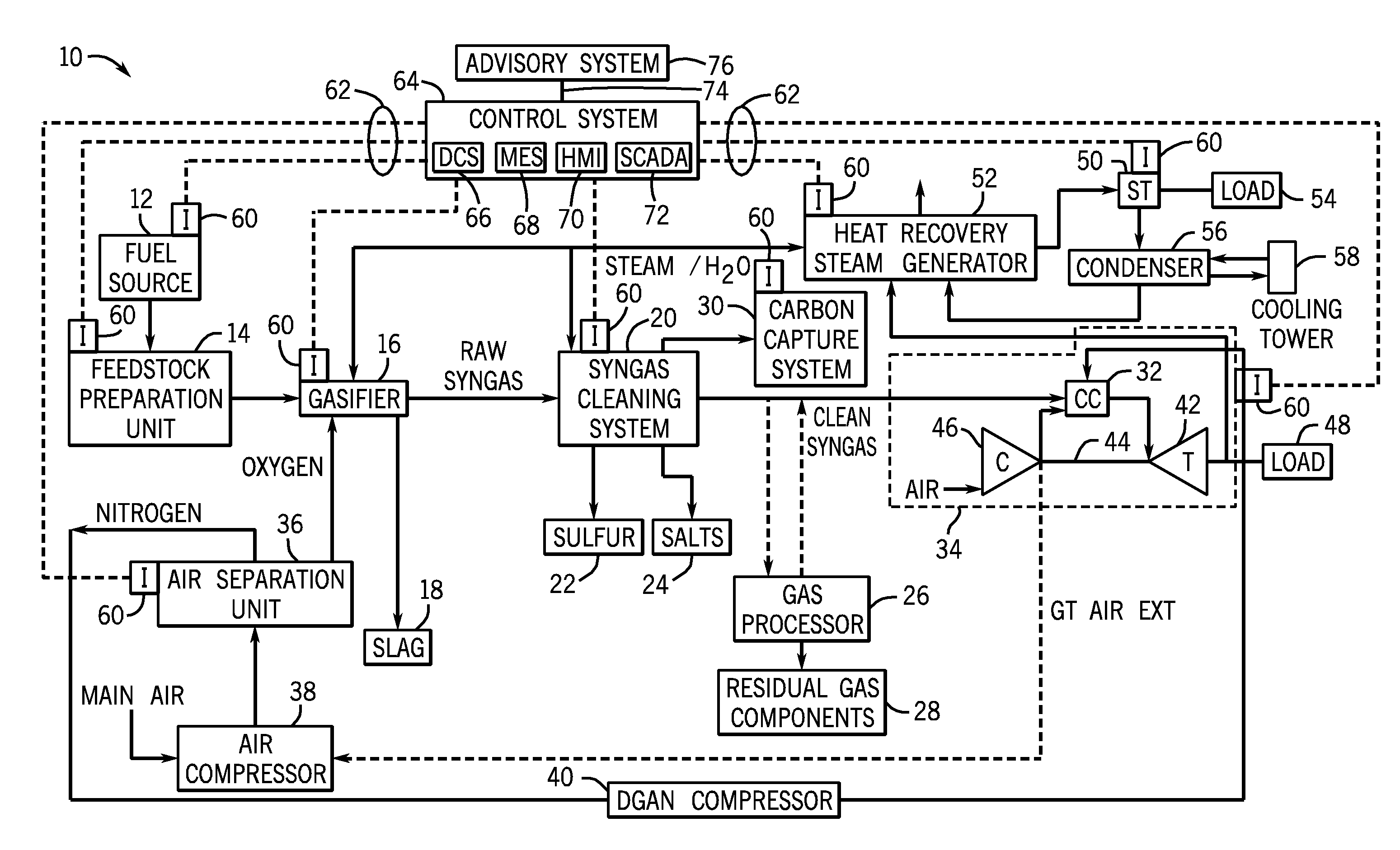

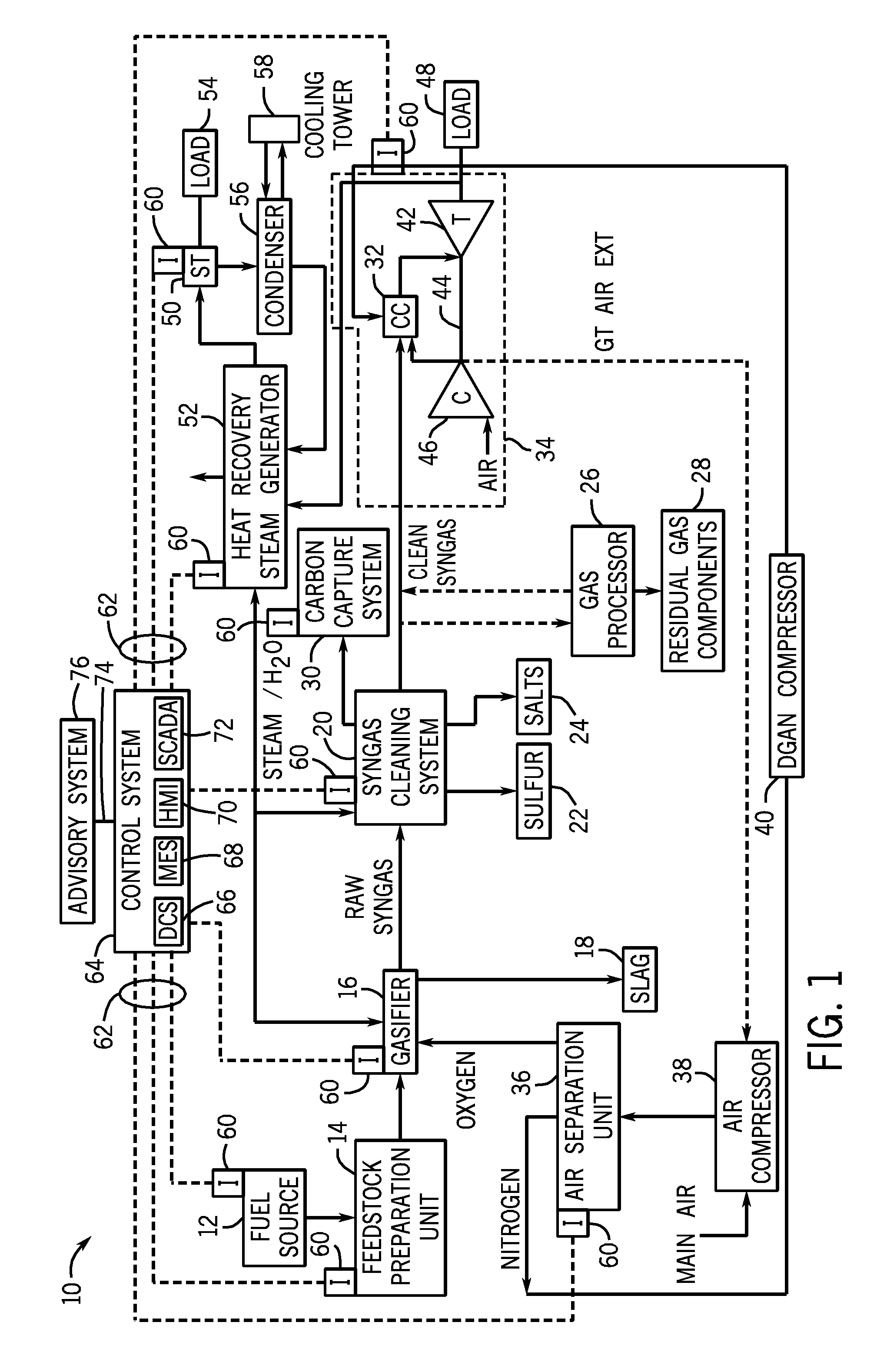

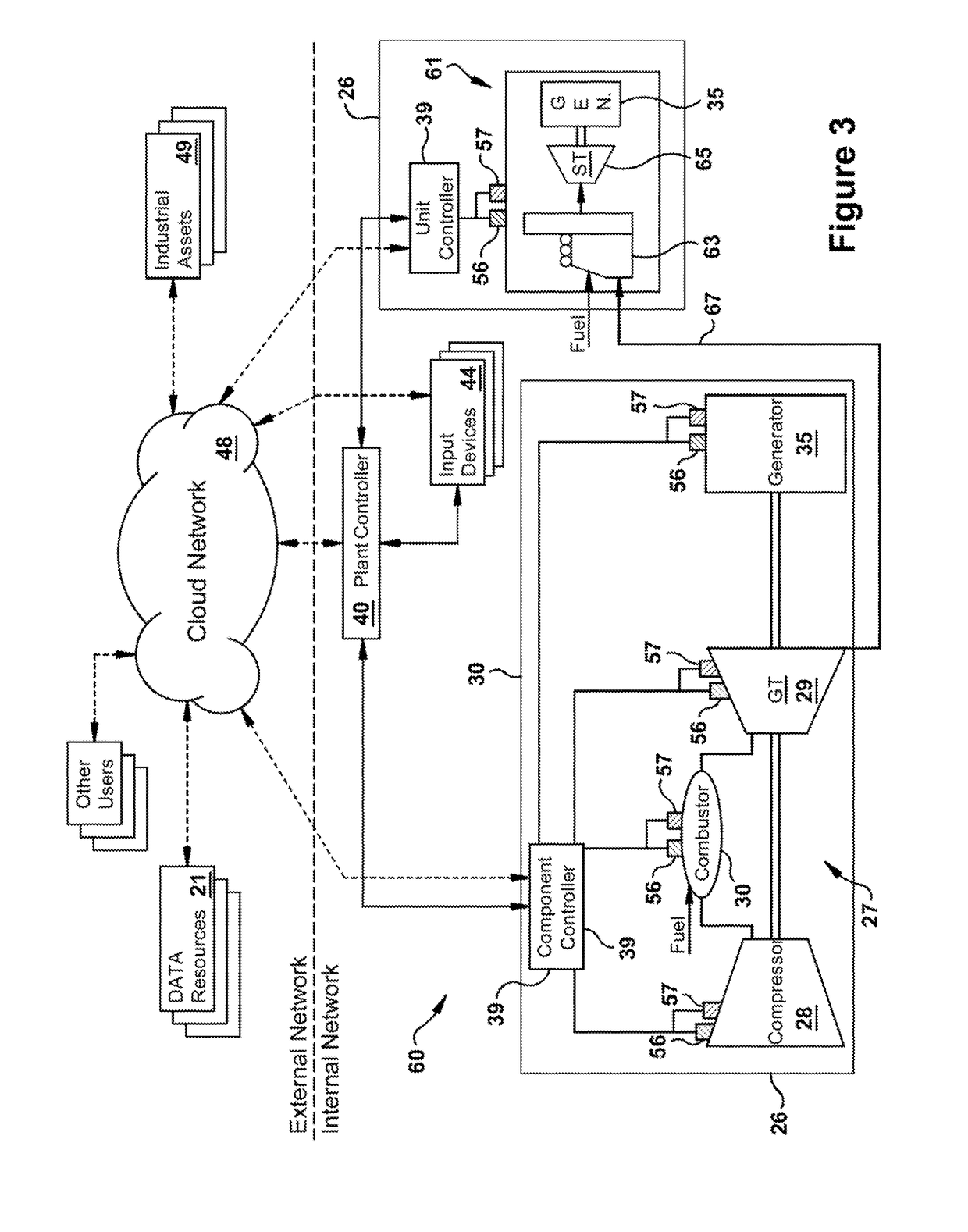

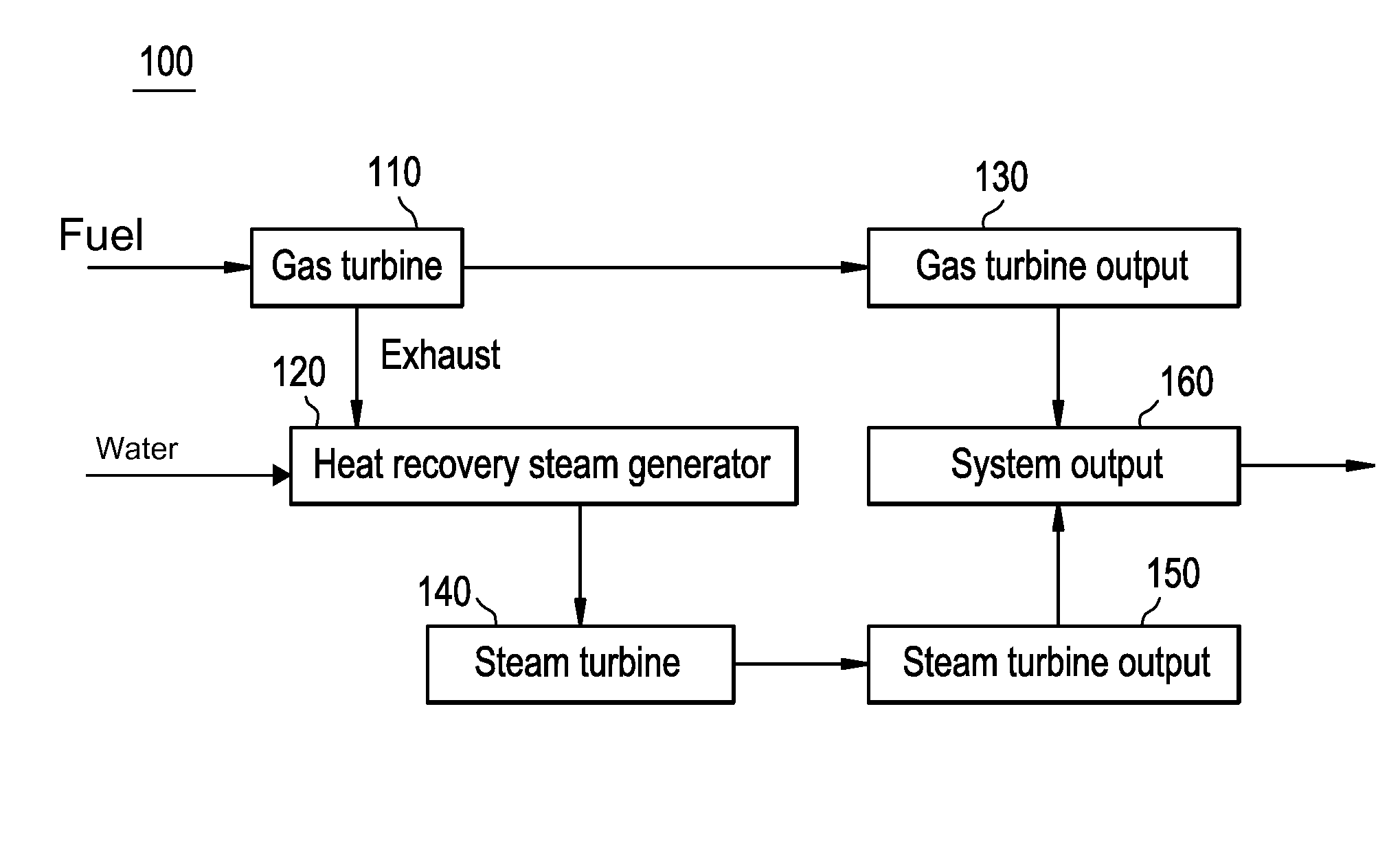

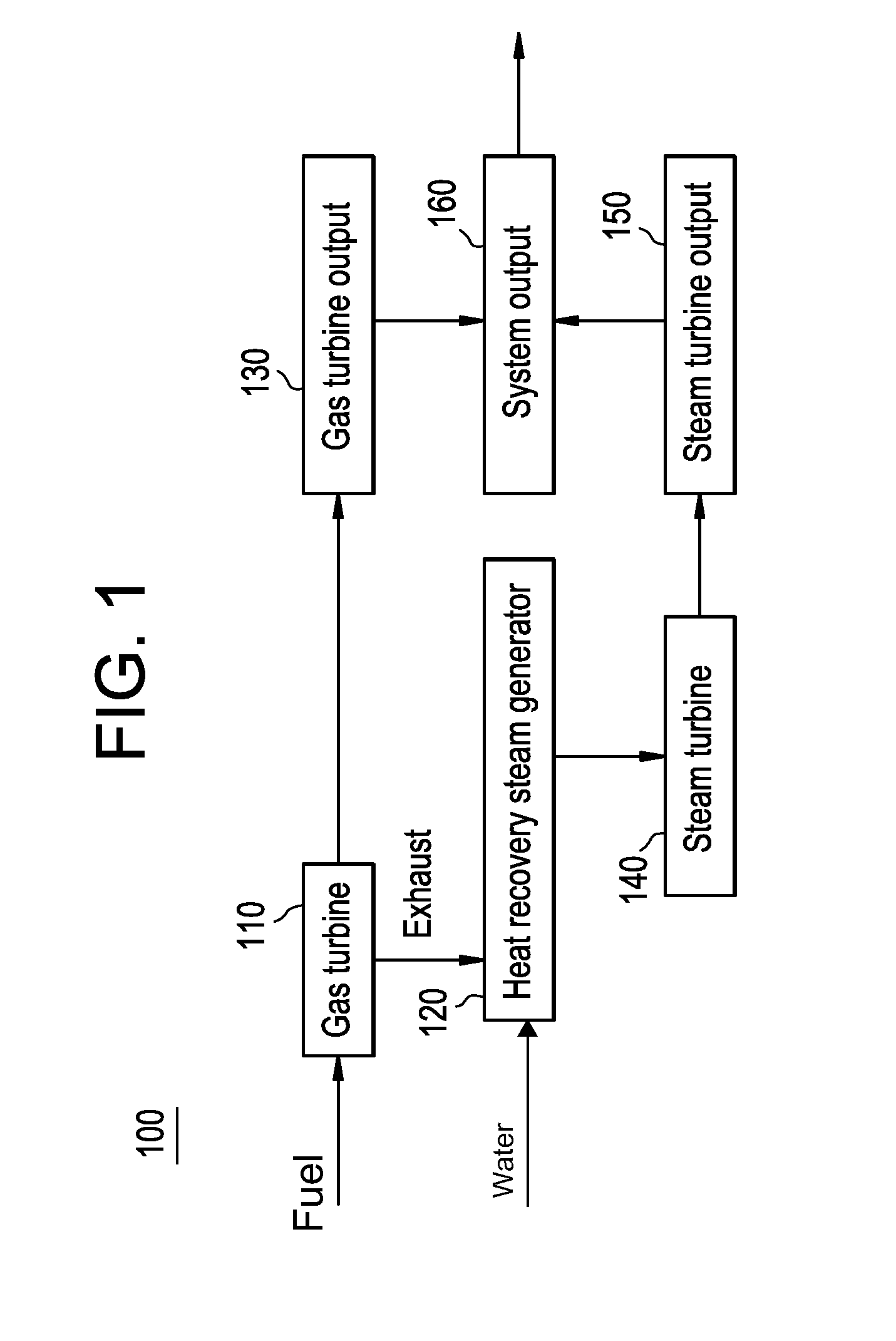

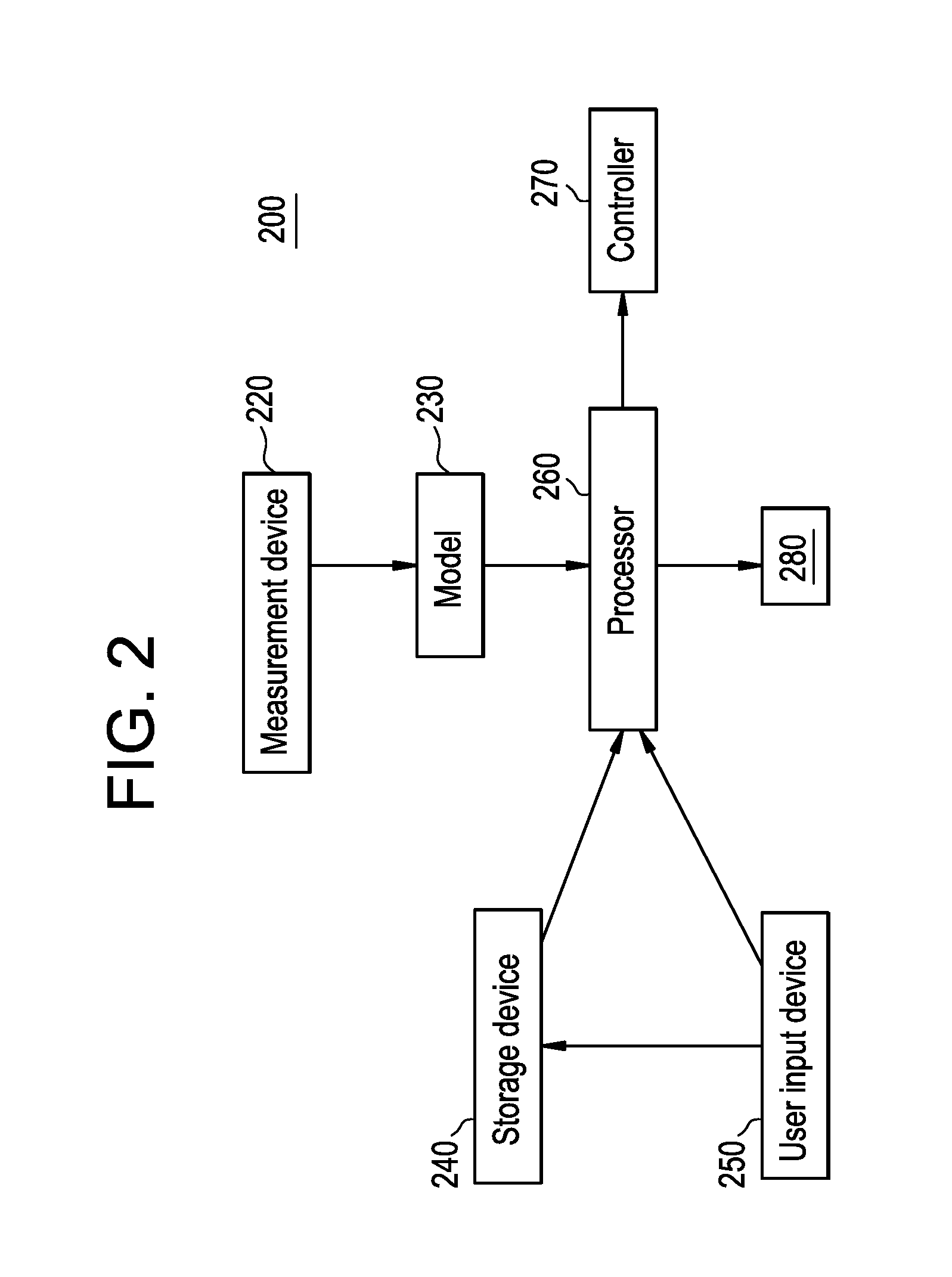

System and method for controlling and diagnosing a combined cycle power plant

A system and method in a combined cycle power plant includes a processor modeling plant level performance by considering the interrelation between outputs of the gas turbine and the steam turbine. The model can be computational, predictive, or both. The model may be used to control subsystems of the plant (including the gas turbine and the steam turbine) to achieve a target plant performance. The model may also be used to diagnose or maintain subsystems of the combined cycle power plant.

Owner:GENERAL ELECTRIC CO

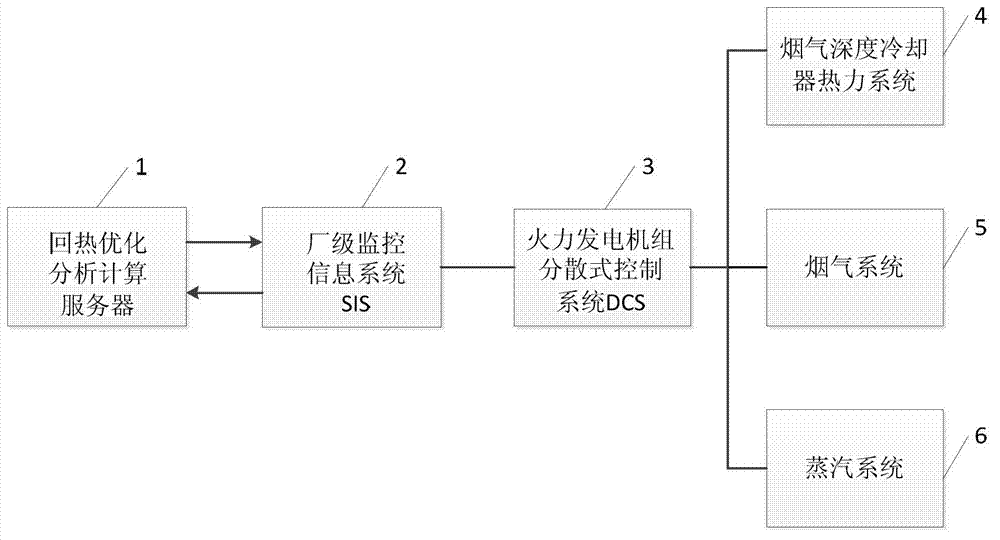

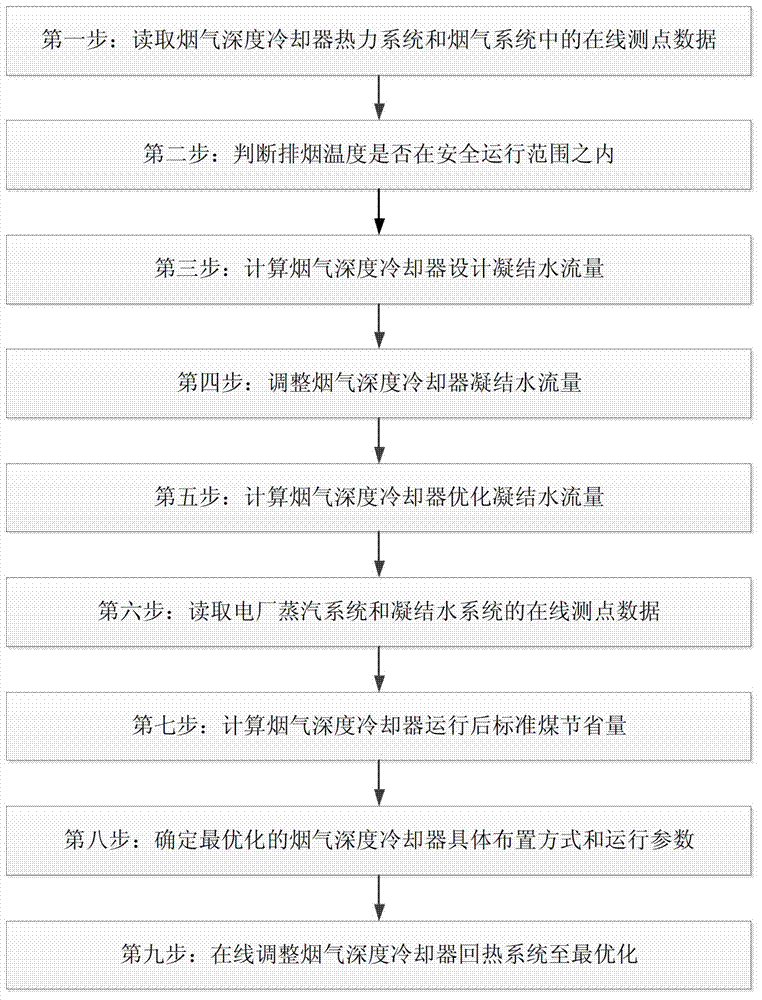

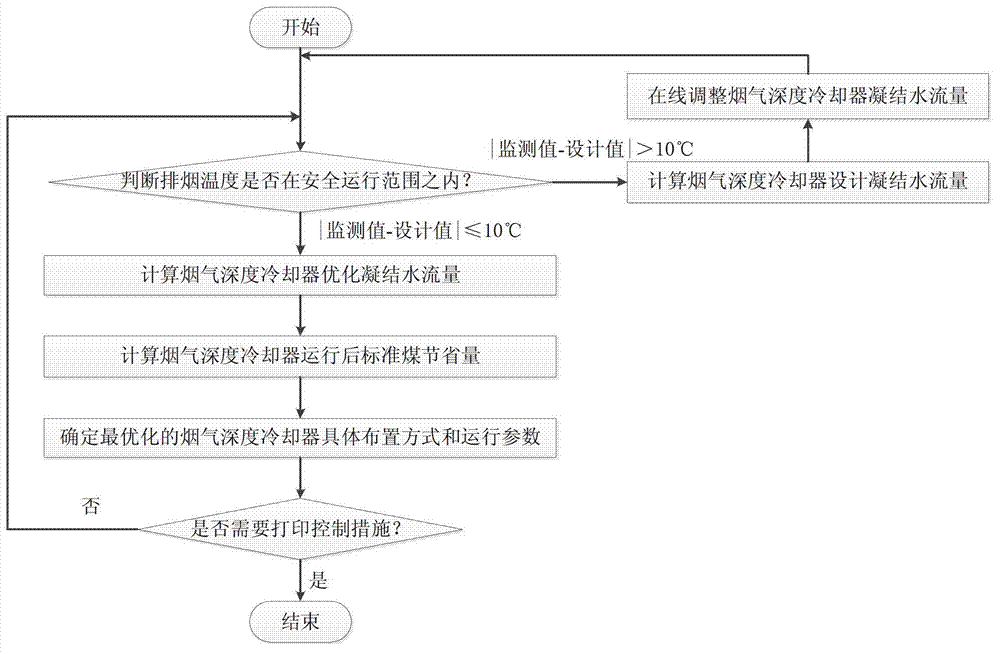

Thermal power plant smoke depth cooler heat return optimization on-line monitoring device and method

ActiveCN102759094ASafe and stable operationGuaranteed outlet smoke temperatureBoiler controlSafety instrumented systemStreamflow

The invention provides a thermal power plant smoke depth cooler heat return optimization on-line monitoring device and method. The device comprises a heat return optimization analyzing and computing server, a plant-level monitoring information system SIS (safety instrumented system) and a thermal generator set DCS (distributed control system), wherein the thermal generator set DCS comprises a smoke depth cooler thermodynamic system, a smoke system and a steam system; and the method comprises the following steps of: reading on-line monitoring data, judging whether the smoke discharge temperature is within a safe running range or not, computing the designed condensed water flow of the smoke depth cooler, adjusting the condensed water flow of the smoke depth cooler, computing the optimized condensed water flow of the smoke depth cooler, reading the on-line monitoring data of a steam system and a condensed water system in the power plant, computing the standard coal saving quantity after the smoke depth cooler runs, confirming the optimal distribution mode and running parameter of the smoke depth cooler, and adjusting a heat return system of the smoke depth cooler to be optimized on the line. According to the invention, the on-line monitoring and adjusting of a parameter-variable heat return optimization system can be realized.

Owner:XI AN JIAOTONG UNIV

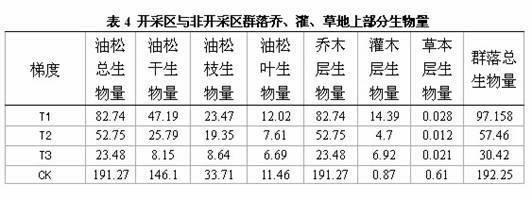

Forest vegetation degrading level evaluation method

ActiveCN102428858ASave on replanting and replanting costsImprove the survival rate of afforestationWeighing by removing componentClimate change adaptationWoodlotRevegetation

The invention belongs to the technical field of forest vegetation degrading evaluation, and is used for solving the problems of large scale range and inconvenient application of a conventional forest vegetation degrading evaluation method. The forest vegetation degrading level evaluation method comprises the following steps: 1, field investigation: 1.1, stand level degrading, and 1.2, individual plant level degrading investigation; and 2, indoor data processing and degrading level calculation: 2.1, stand level degrading level calculation, 2.2, individual plant level degrading grade calculation, and 2.3, general degrading level evaluation. The evaluation method provided by the invention has the beneficial effects that: by means of application of the evaluation method, the vegetation degrading degree of a construction area is scientifically and quantitatively divided, and different restoring technologies are selected according to the degrading degree, so that the forestation survival rate is comprehensively increased, and seedling after-culture and after-replace cost is saved. By the evaluation method provided by the invention, more remarkable social and economical benefits can be obtained along with comprehensive success of vegetation restoration and forestation construction in various regions.

Owner:山西省林业科学研究院

Unit load dispatching policy

ActiveCN101567566AImprove economyImprove securitySingle network parallel feeding arrangementsReal-time Control SystemPower grid

The invention discloses a unit load dispatching method. The method performs load dispatch of a plant level after a power plant receives an AGC command of a power grid dispatch in-time control system, so as to allow units to operate complementally and avoid load break points and to allow the power grid to increase and decrease load smoothly and achieve excellent operational safety and stability.

Owner:STATE GRID CORP OF CHINA +1

Real-time estimation method for flue gas energy of hearth outlet of thermal power generating unit boiler

The invention provides a real-time estimation method for the flue gas energy of a hearth outlet of a thermal power generating unit boiler. The method particularly comprises the steps that 1, according to the running design discipline of the boiler, a main equipment structure parameter data bank is built, and related real-time data are read from a real-time data bank of a plant-level monitoring information system; 2, according to a working medium physical property parameter bank and a flue gas physical property parameter bank, the information of a server of the plant-level monitoring information system is combined to compute the physical property parameters of the working medium on the aerated water side and the flue gas on the wind-smoke side under the given time in a real-time mode; 3, the energy Qyq of the flue gas of the hearth outlet is obtained through a heat exchanger working medium quality and energy dynamic balance model and an exhaust gas heat loss model. The method is used for online estimation of the flue gas energy of the hearth outlet, and can also be used for online recognition of the average flue gas temperature of the hearth outlet and the as-fired coal heat value and online estimation of boiler efficiency and the like.

Owner:SHANGHAI JIAO TONG UNIV

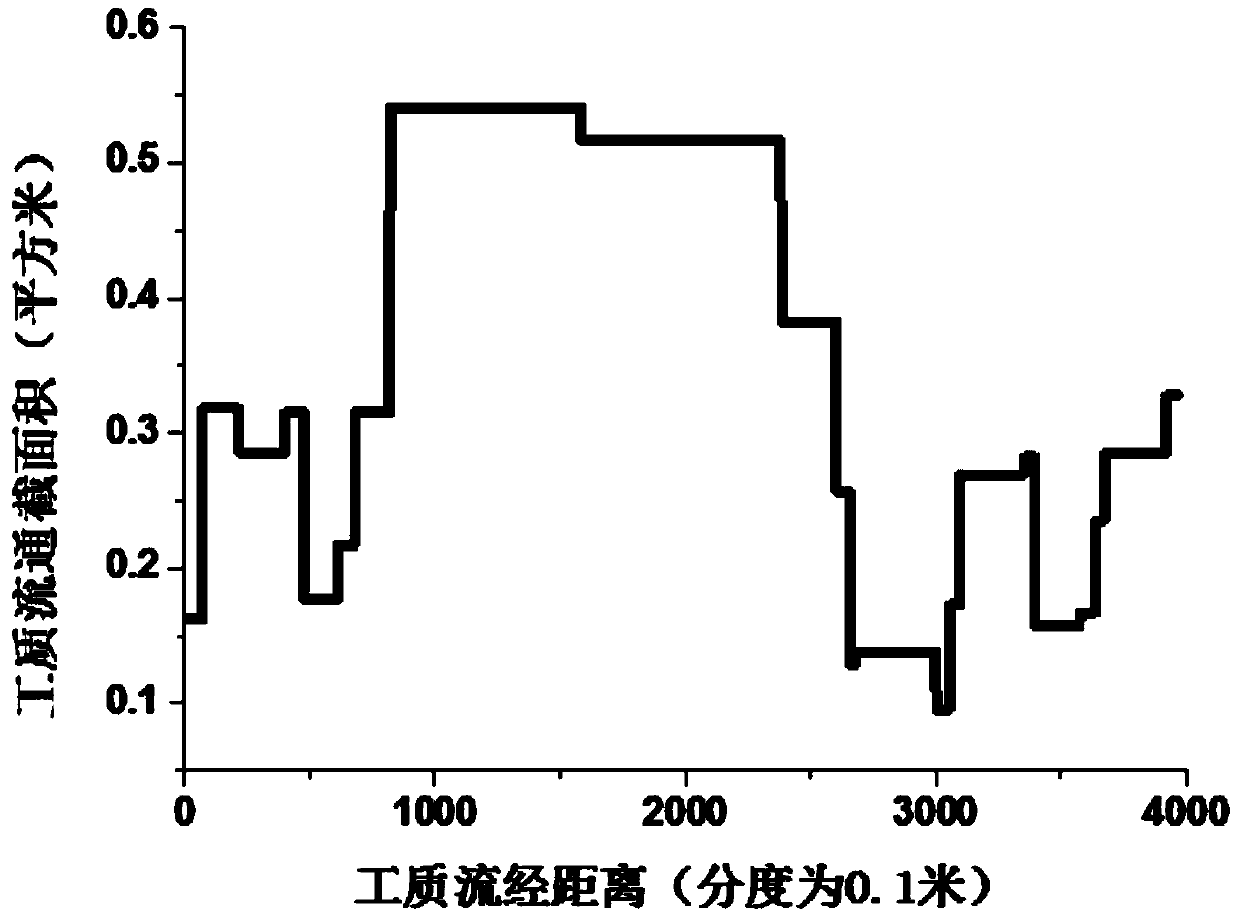

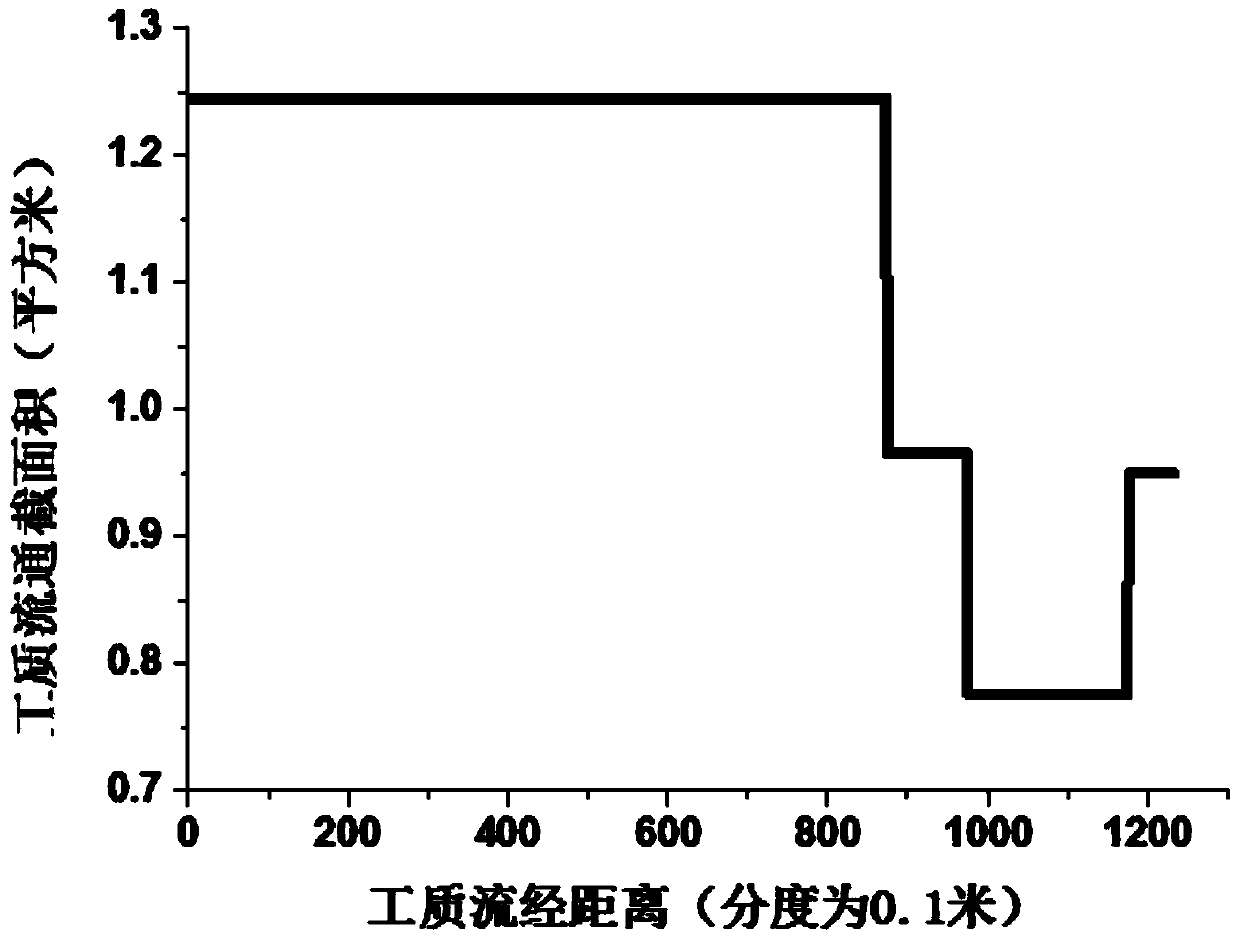

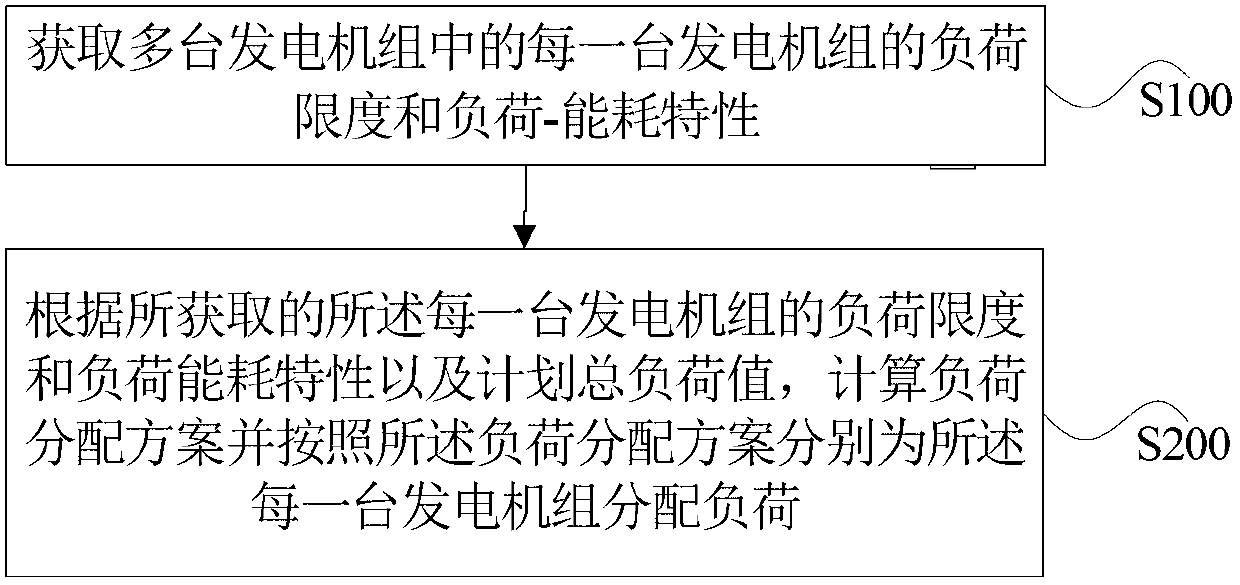

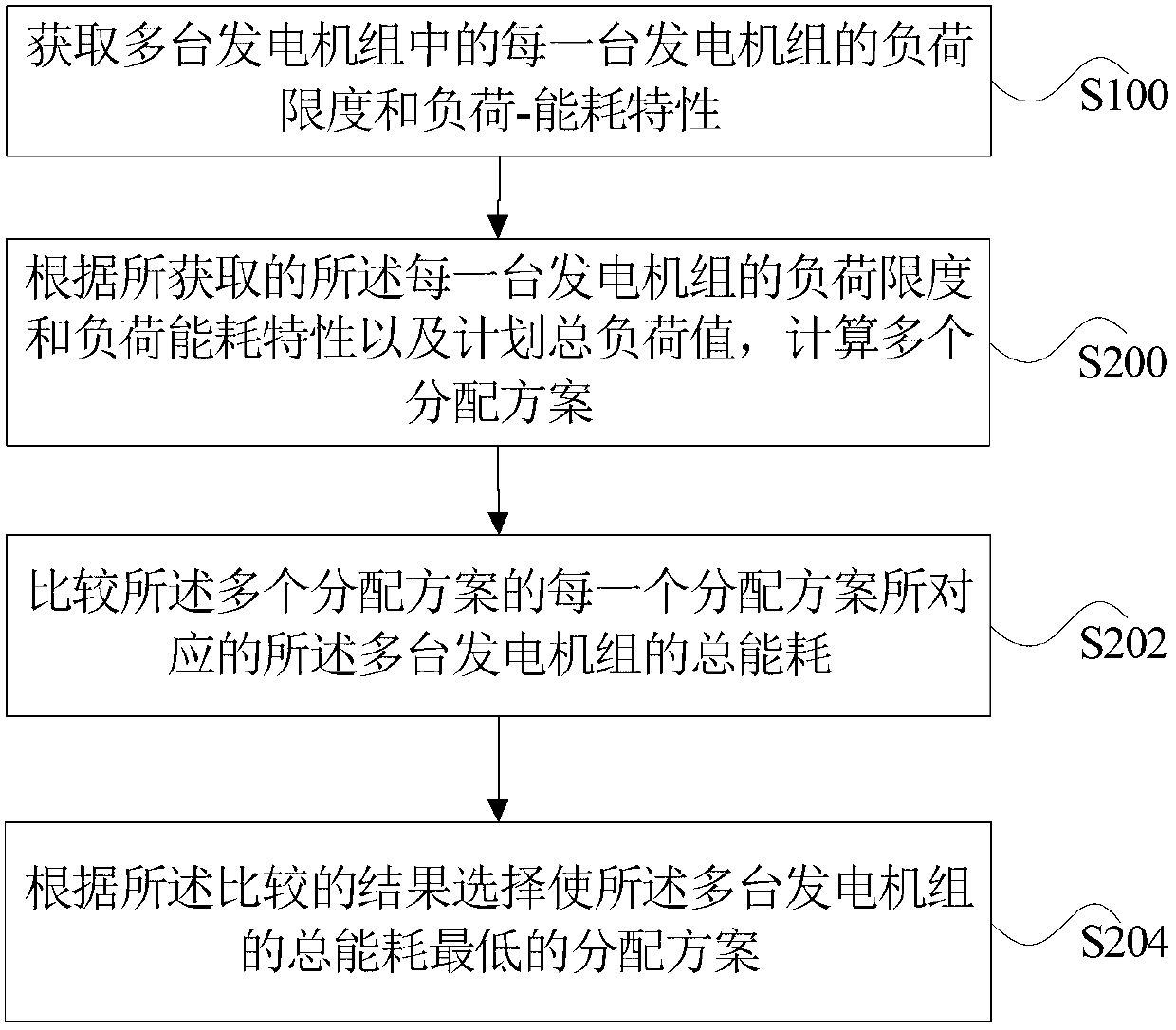

Optimal distribution method and system for heat-engine plant plant-level loads

InactiveCN103138293AAvoid frequent reciprocating adjustmentsReduce life lossSingle network parallel feeding arrangementsDistribution methodEngineering

The invention provides a distribution method and a system for heat-engine plant plant-level loads, wherein the method comprises the steps of obtaining load limit and load energy consumption properties of each generating set in multiple generating sets, according to the obtained load limit and the load energy consumption properties of each generating set and a planned total load value, calculating a load distribution plan, and according to the obtained load distribution plan, distributing loads for each generating set so as to meet the facts that the obtained loads distributed for each generating set is within the load limit of each generating set, the sum of the obtained loads of the multiple generating sets is equal to the plan total load value, and obtained total energy consumption of the multiple generating sets is the lowest. According to the technical scheme, optimization and load distribution of the plant-level generating sets can be automatically and reasonably conducted according to the load energy consumption properties, adjustment rates, load adjustment limits and operation conditions of the generating sets, and therefore the total energy consumption of the whole plant is enabled to be the lowest under the premise that the plan total load value is met.

Owner:CHINA SHENHUA ENERGY CO LTD +2

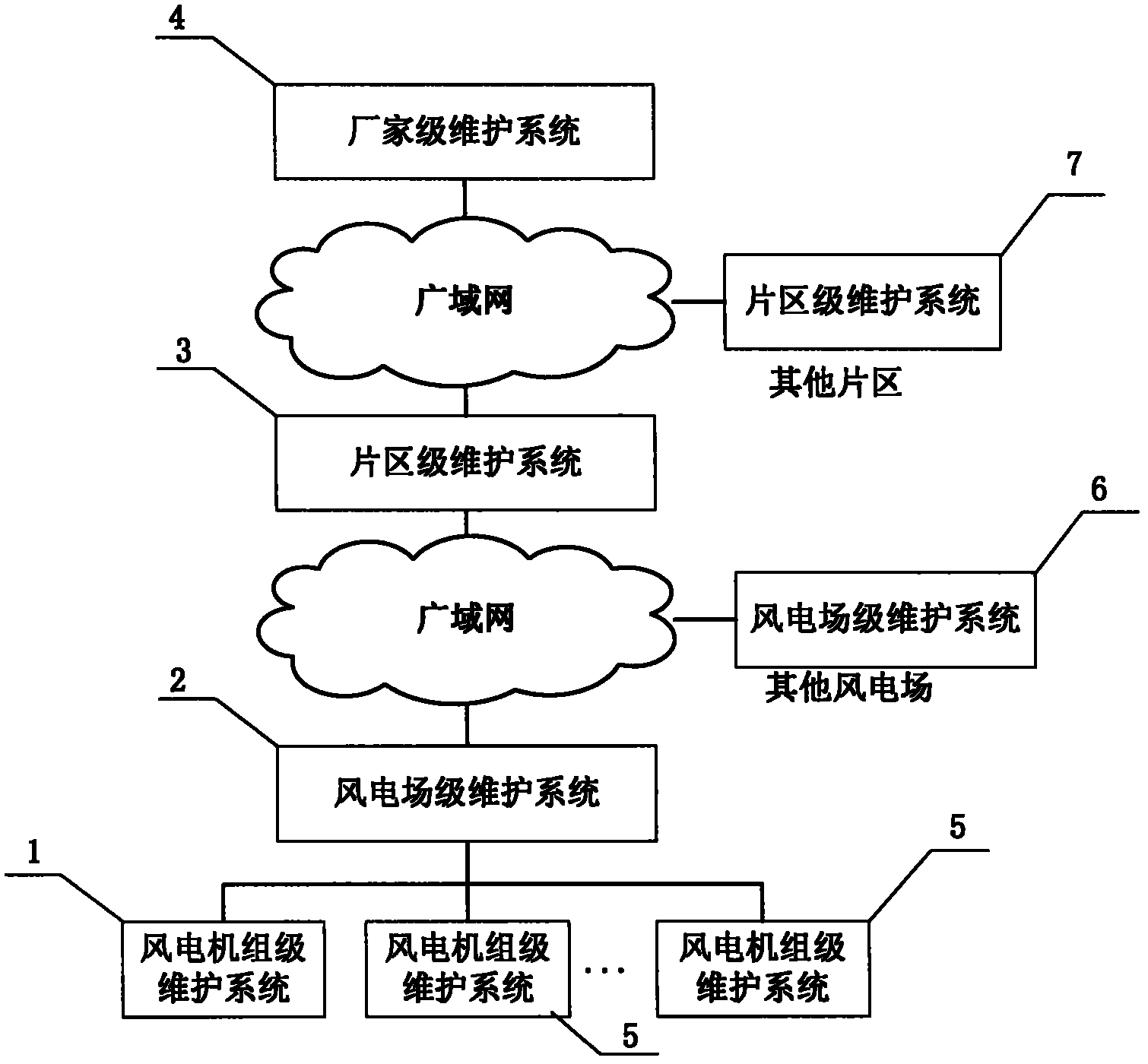

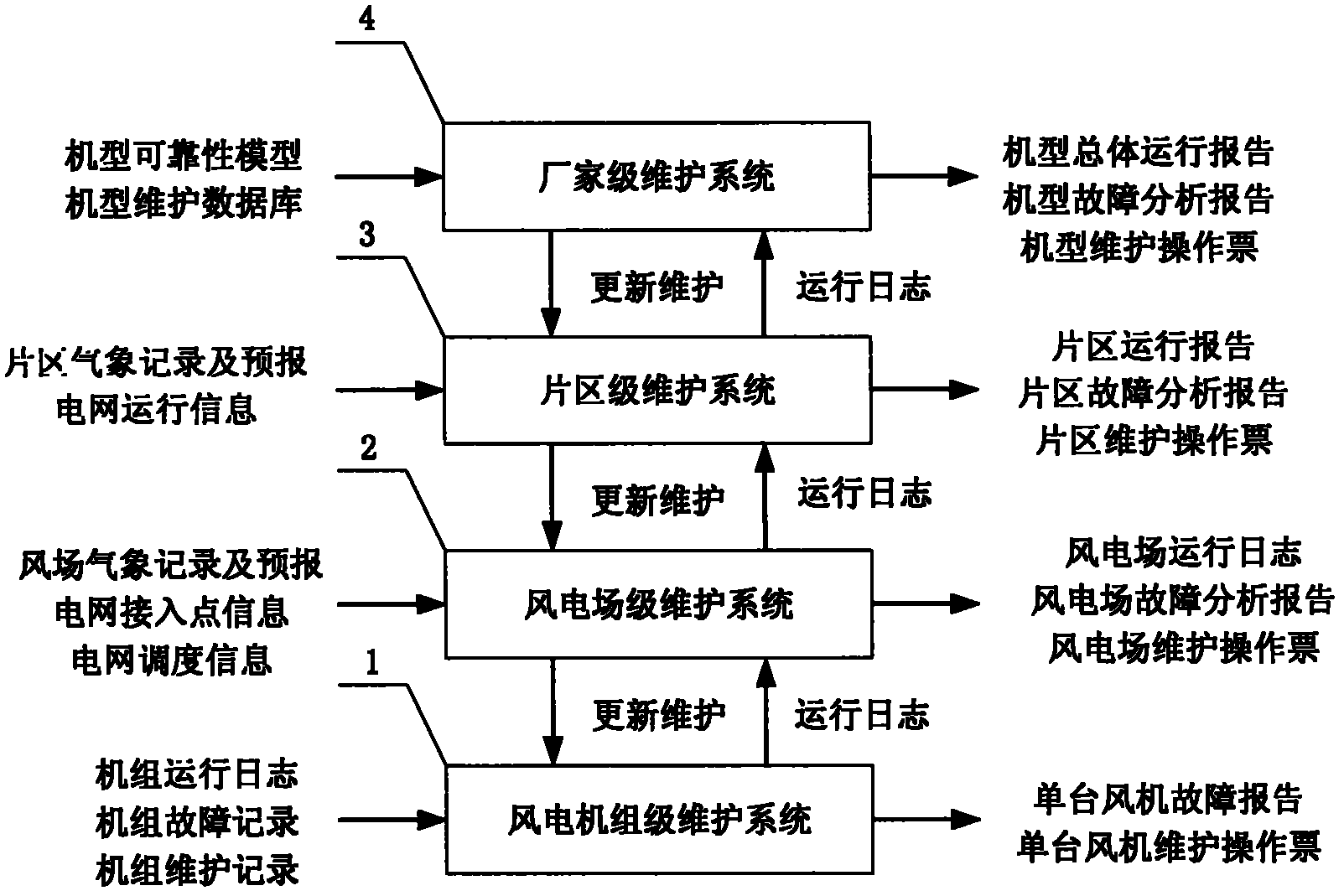

Wind generating set maintenance system based on multilevel diagnosis

ActiveCN103161681AImprove accuracyFinal product manufactureWind motor componentsElectricityControl room

The invention provides a multilevel diagnostic wind generating set maintenance system. The multilevel diagnostic wind generating set maintenance system uses a multilevel failure diagnosis mechanism. Considering influence of generic factors of different levels on a fan, the multilevel diagnostic wind generating set maintenance system is divided into a wind turbine generator level maintenance system arranged inside a wind turbine generator, a wind power plant level maintenance system arranged in a central control room of a wind power plant, a piece area level maintenance system arranged in a wind power plant cluster control centre and a manufacturer level maintenance system arranged on a device manufacturer maintenance center. With / through the method that generic influencing factors with different level ranges are brought into feature libraries of the maintenance system, and the feature libraries are updated and maintained level by level, analysis of running state and identification of failures can be achieved, running record can be provided level by level, and operation order can be maintained.

Owner:XIANGTAN UNIV

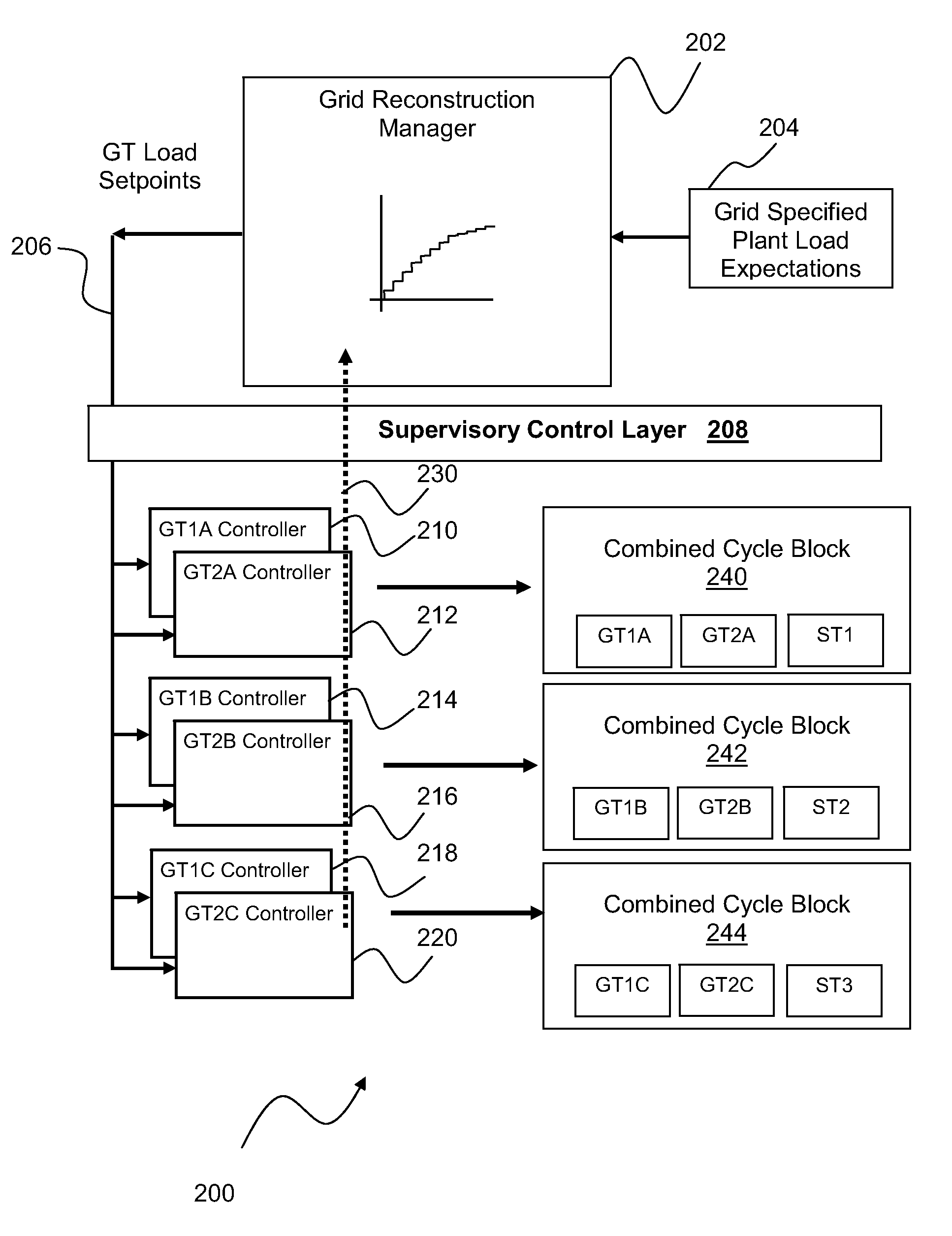

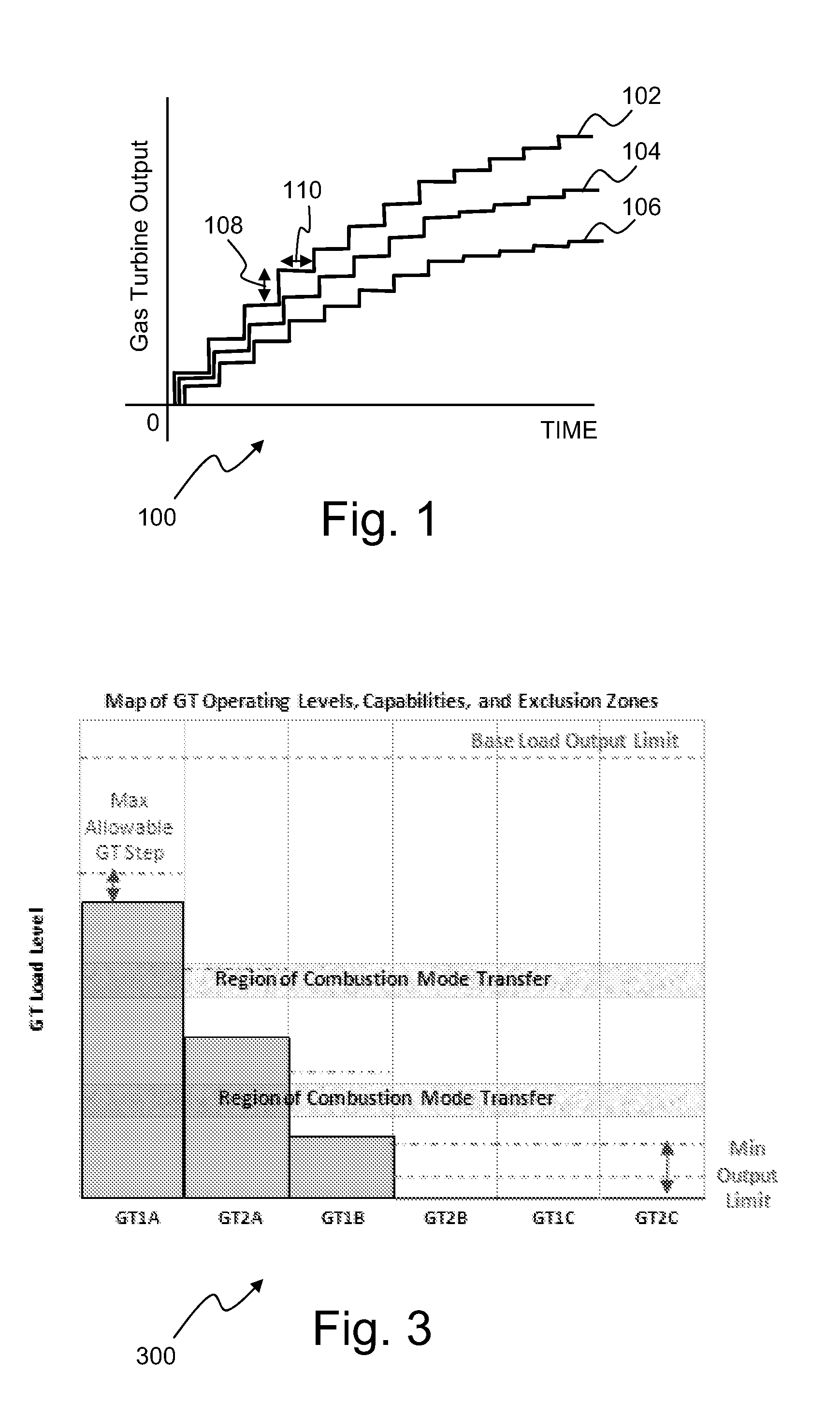

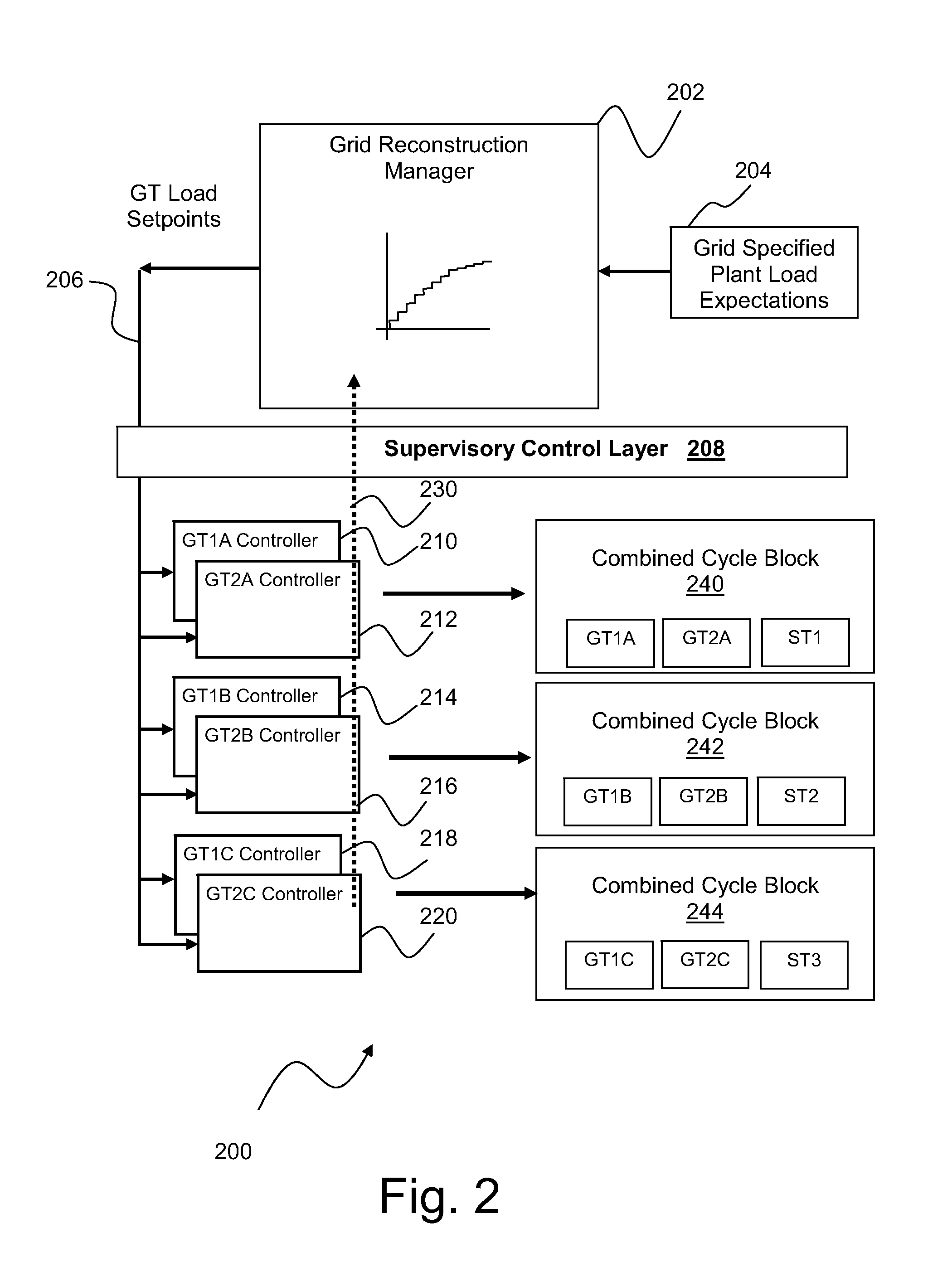

Enhanced plant level support of grid reconstruction

ActiveUS20120123601A1Maximizing abilityMaximizing capabilityMechanical power/torque controlLevel controlPower stationPower grid

Methodology is provided for enhancing plant level support for grid reconstruction following a blackout. A plant based grid reconstruction manager develops solutions for reconstruction sequence steps to be carried out automatically or to be communicated to site personnel for manual implementation. The sequence steps are based on high-fidelity modeling of the capabilities all of the power production units present in a power plant and take into consideration grid specified load expectations, ambient conditions including ambient temperature and gas turbine operating levels. The methodology also provides for consideration of possible subsequent steps in the sequence to maximize the ability to pick-up additional load in such subsequent steps.

Owner:GENERAL ELECTRIC CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com