Patents

Literature

566 results about "Industrial systems" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

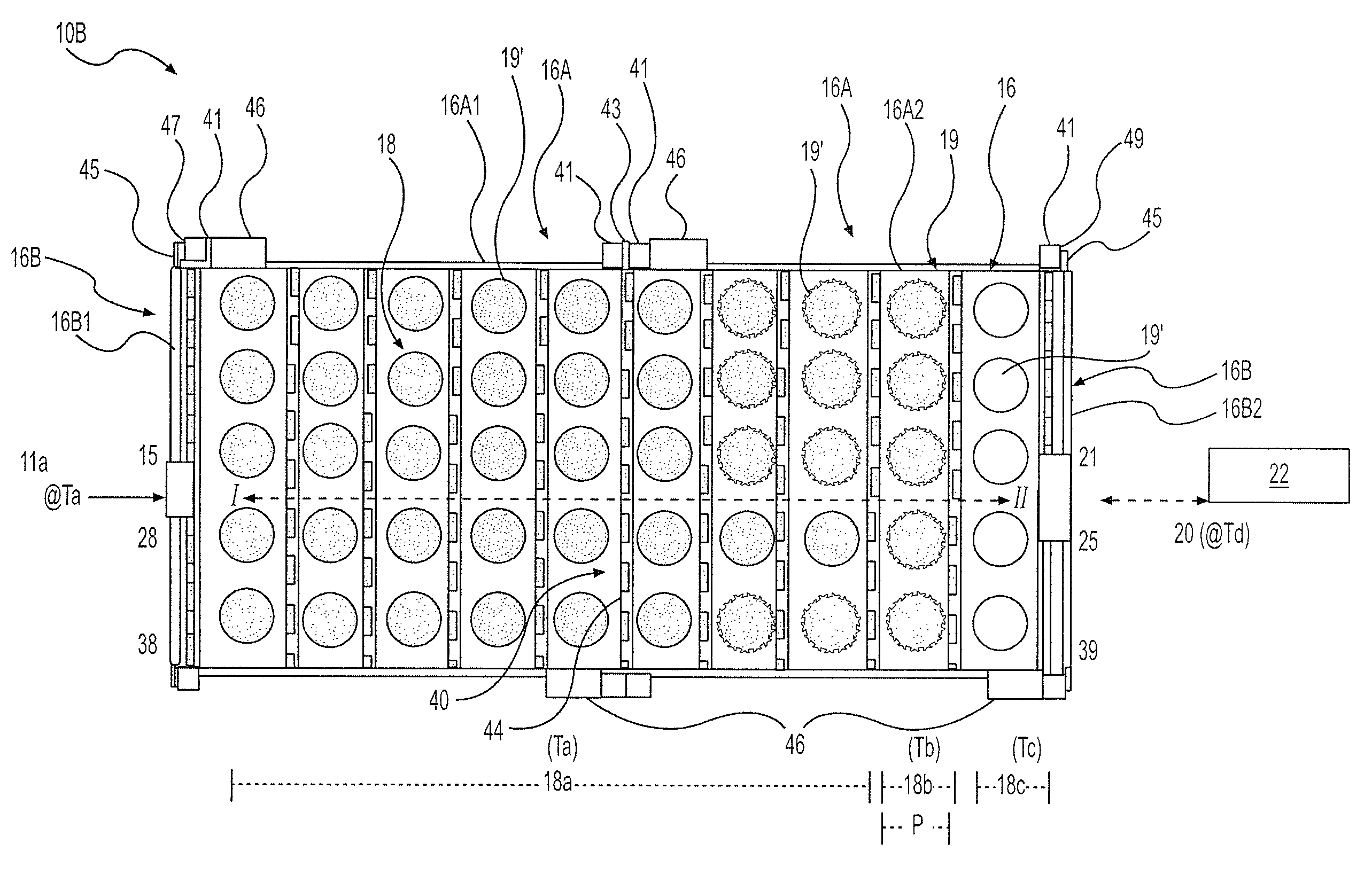

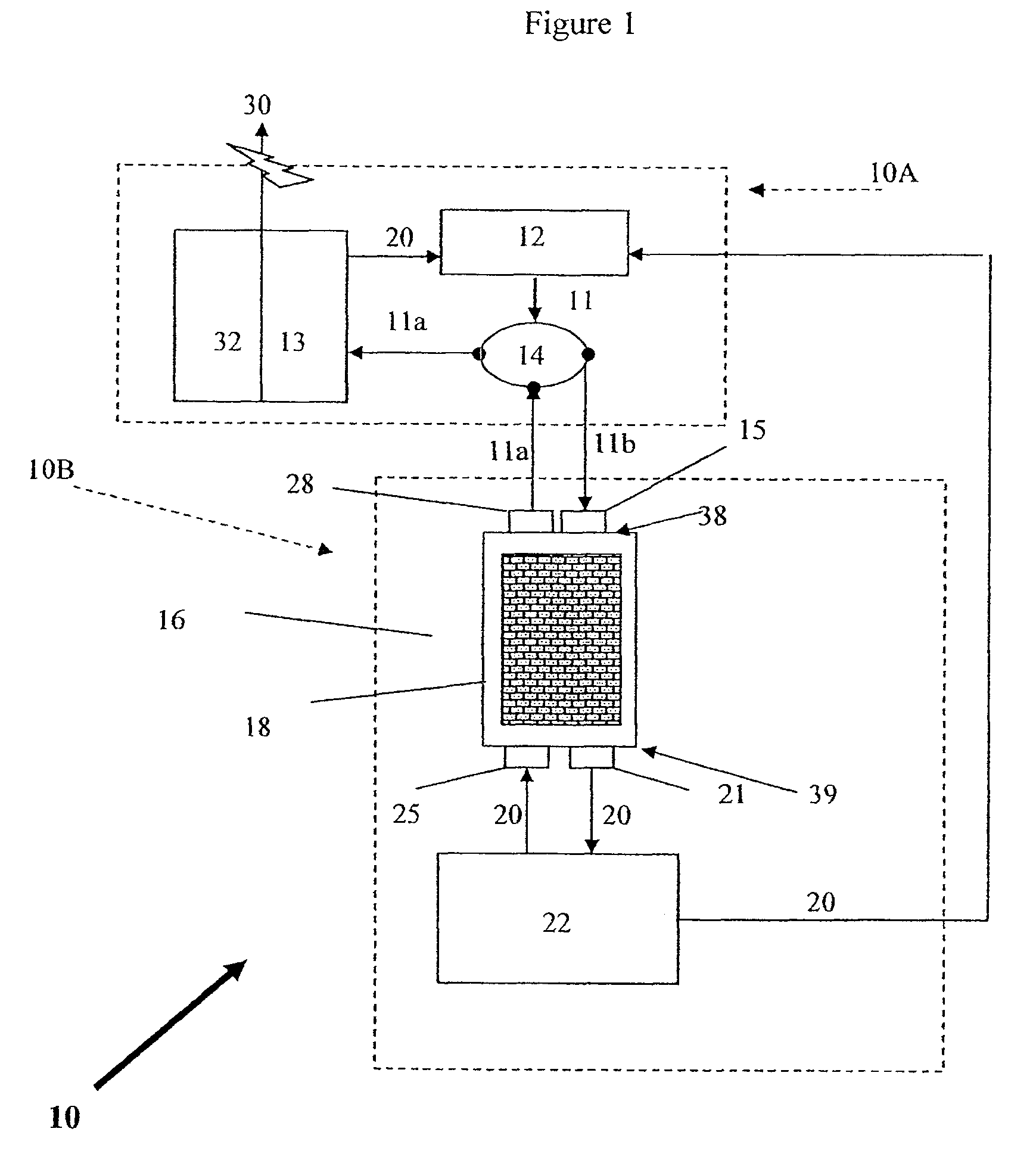

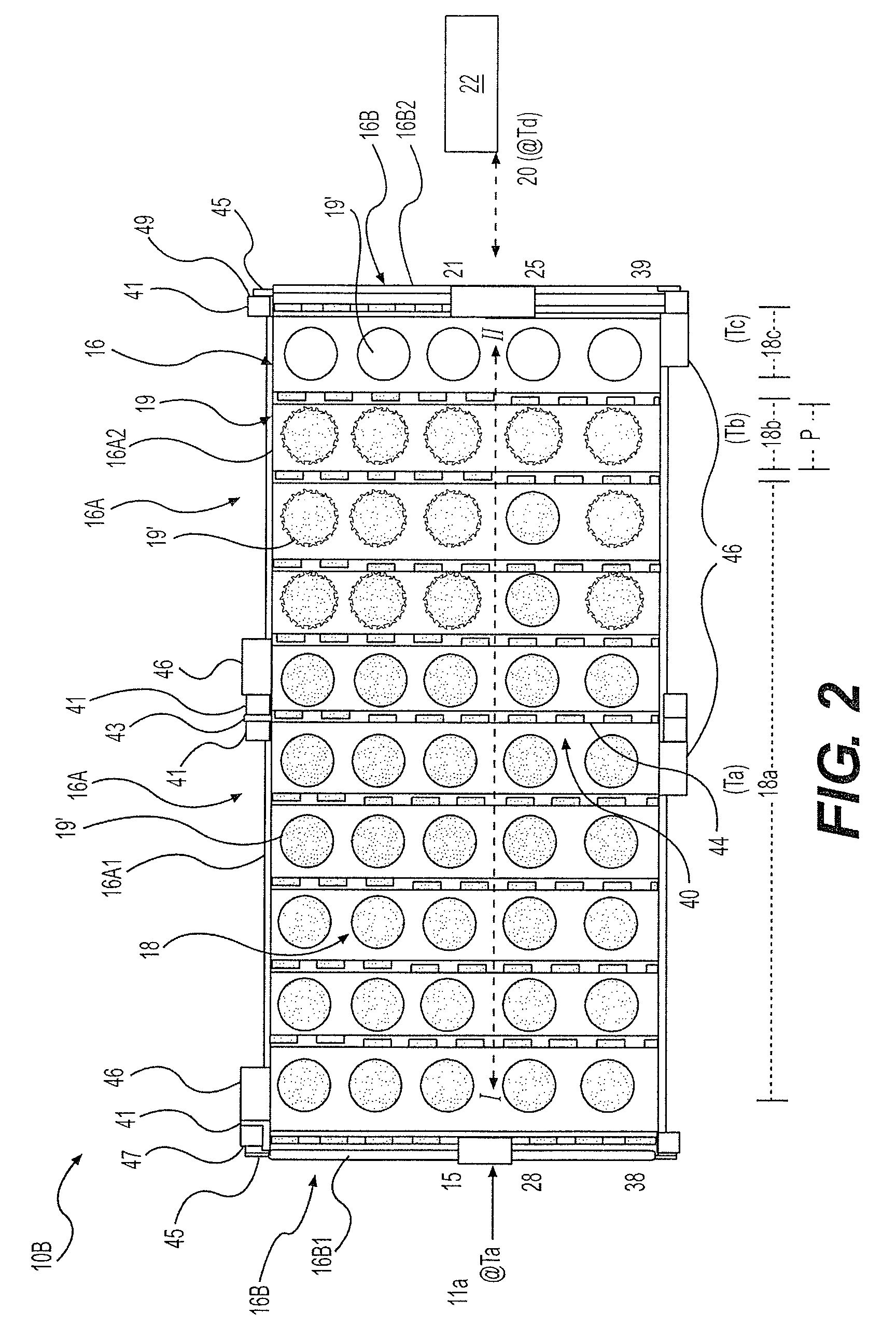

Apparatus and method for storing heat energy

ActiveUS20090178409A1Simple designLess-expensive to implementSolar heat devicesHeat storage plantsStored energyWorking fluid

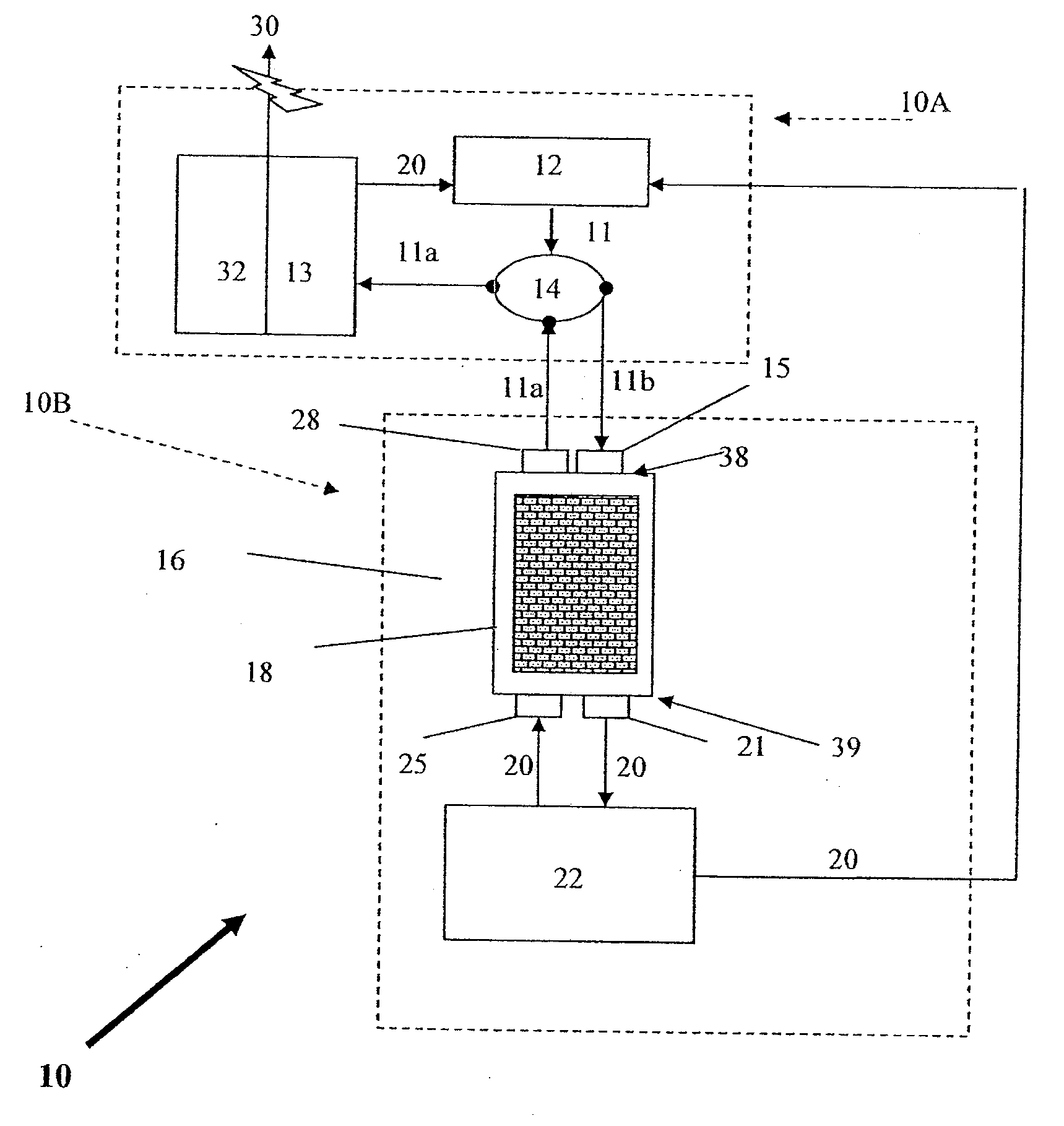

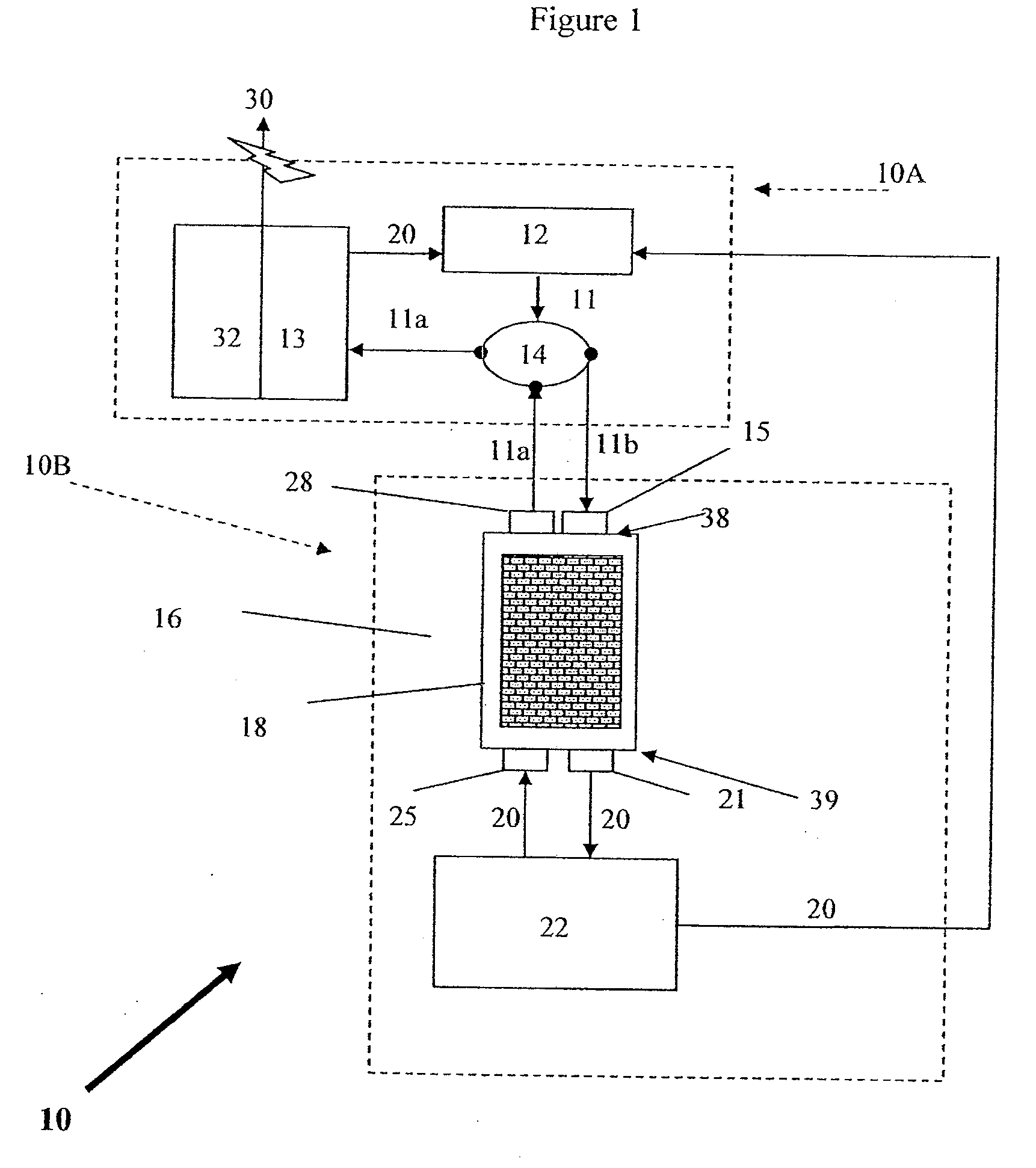

Method and apparatus for storing heat in industrial systems where large sources of stored energy are called upon to meet a work load, storing the heat content of a hot working fluid by using the hot working fluid as a heat transfer fluid in vapor form and depositing its heat content on a heat storage medium and then removing the cooled and condensed liquid phase of that heat transfer fluid, and when hot working fluid again is needed, the liquid heat transfer fluid is returned to the heated storage medium and is reheated as it passes through the hot storage medium and then is returned to the working system to be used as a hot working fluid.

Owner:RES FOUND THE CITY UNIV OF NEW YORK

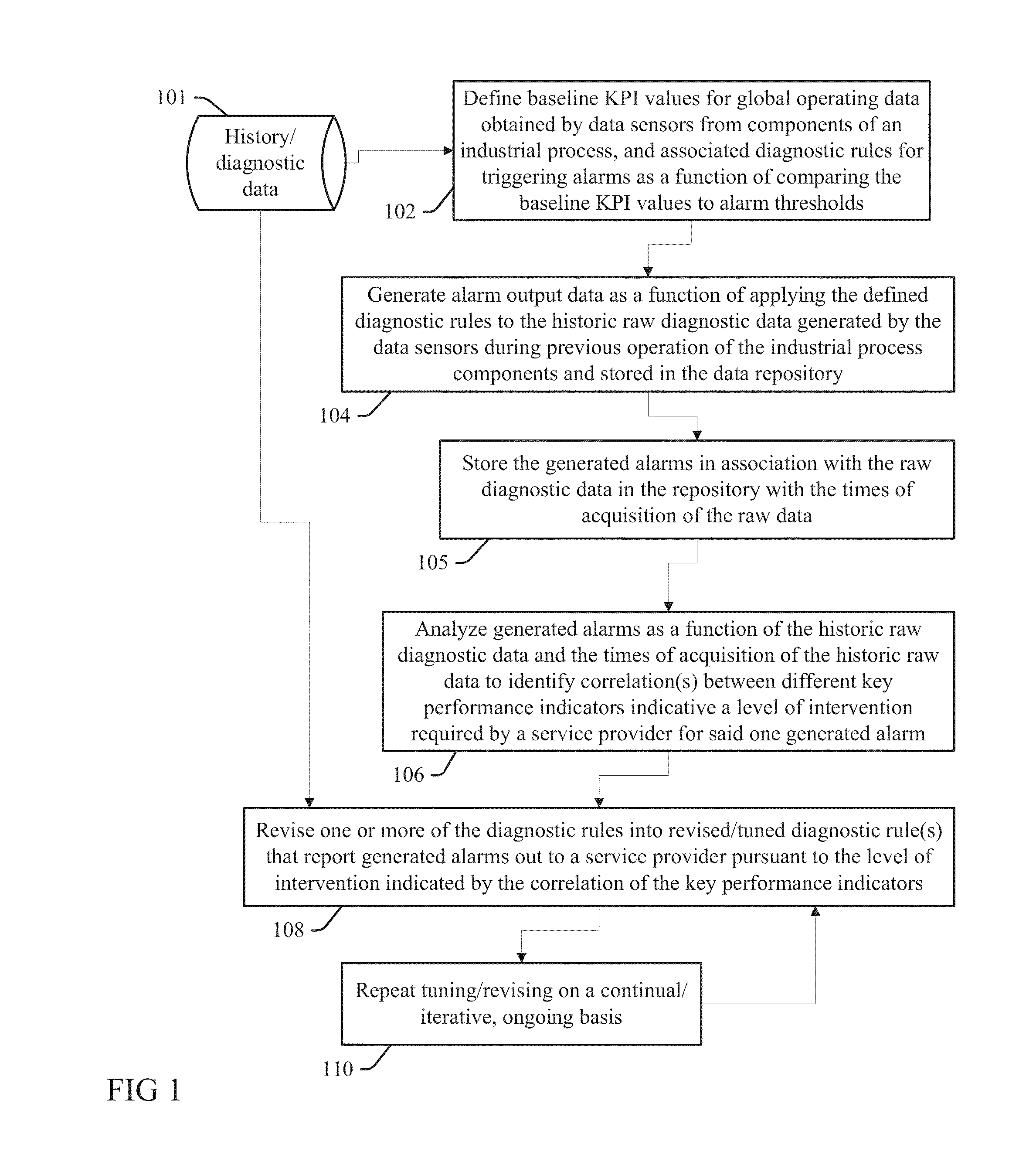

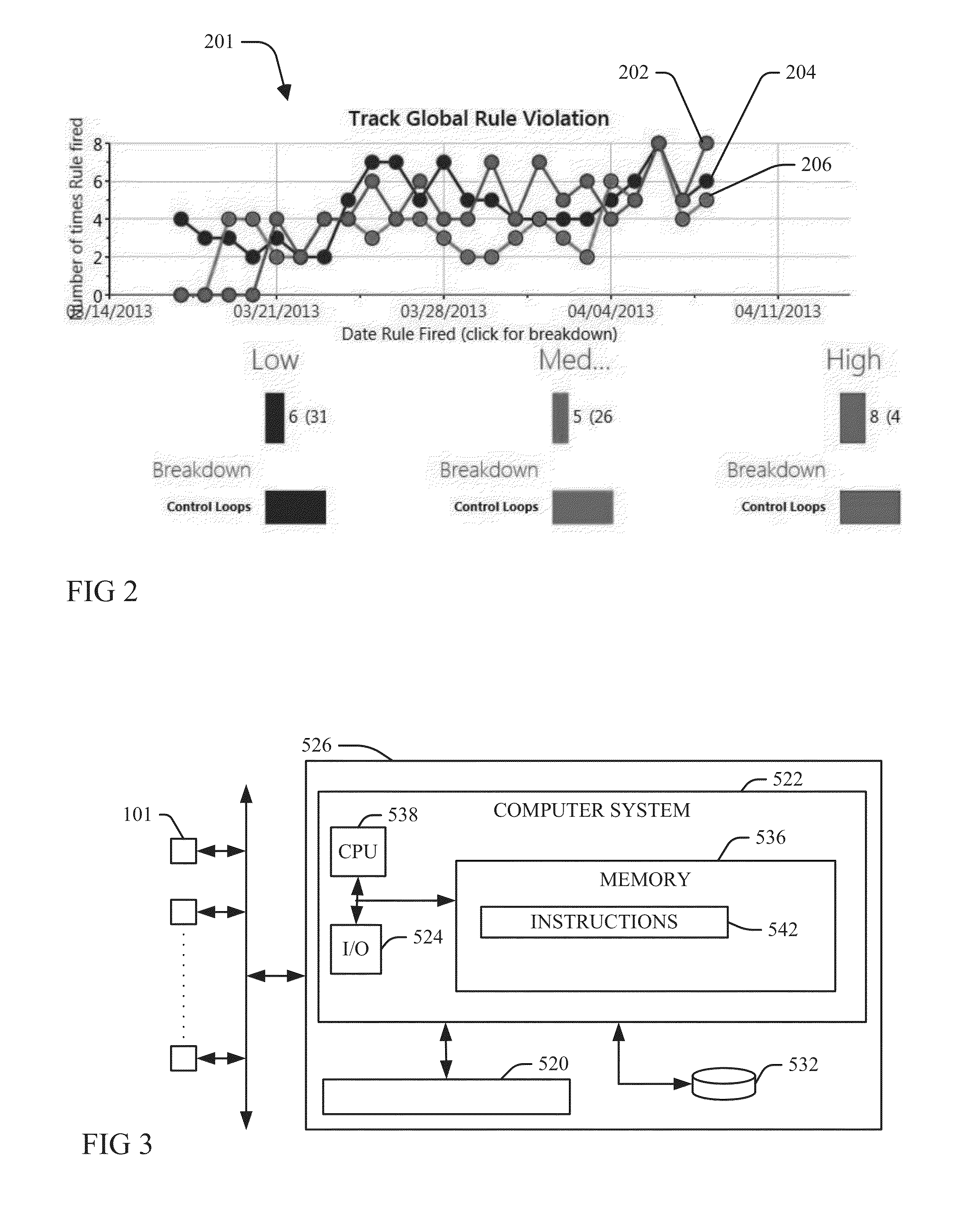

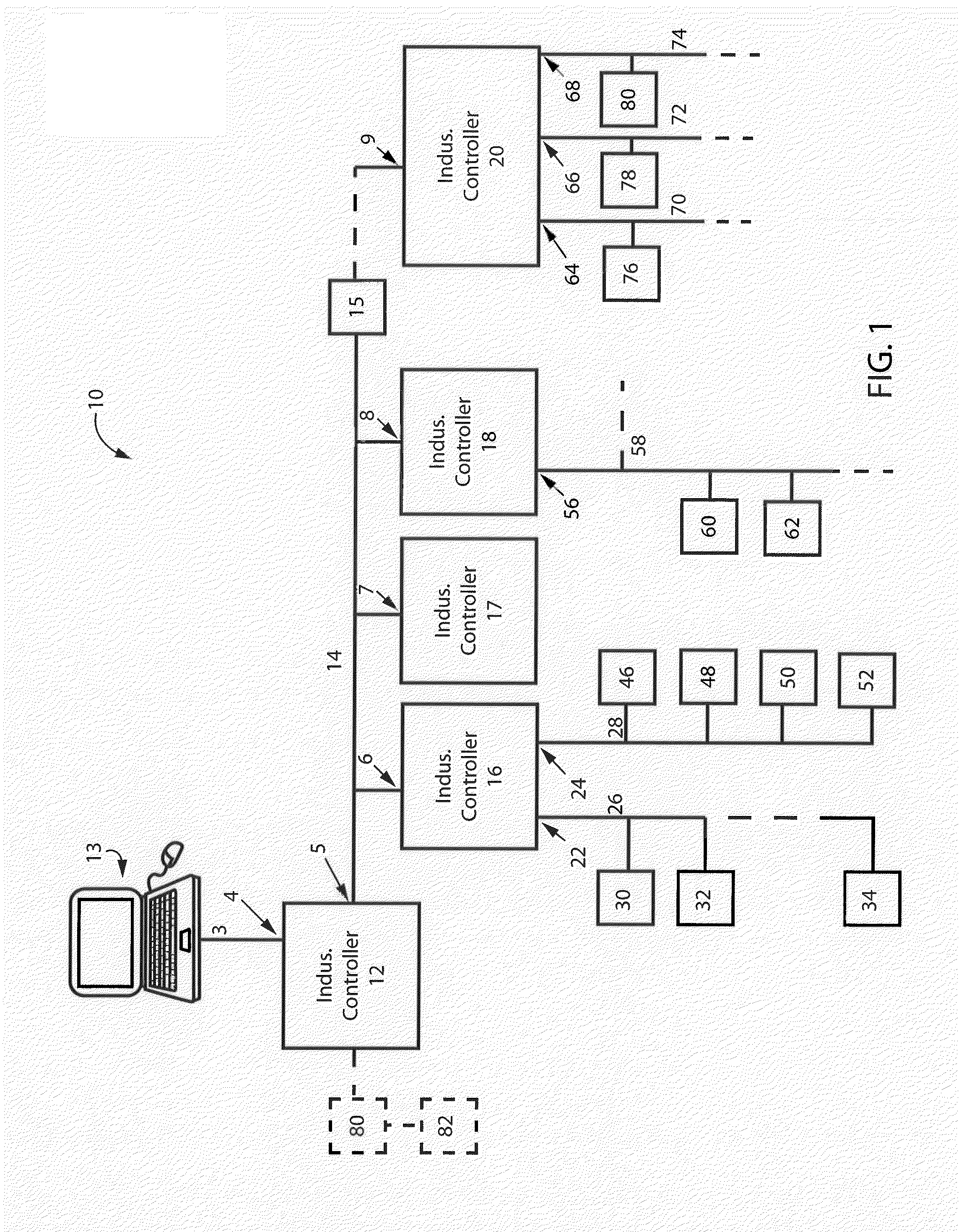

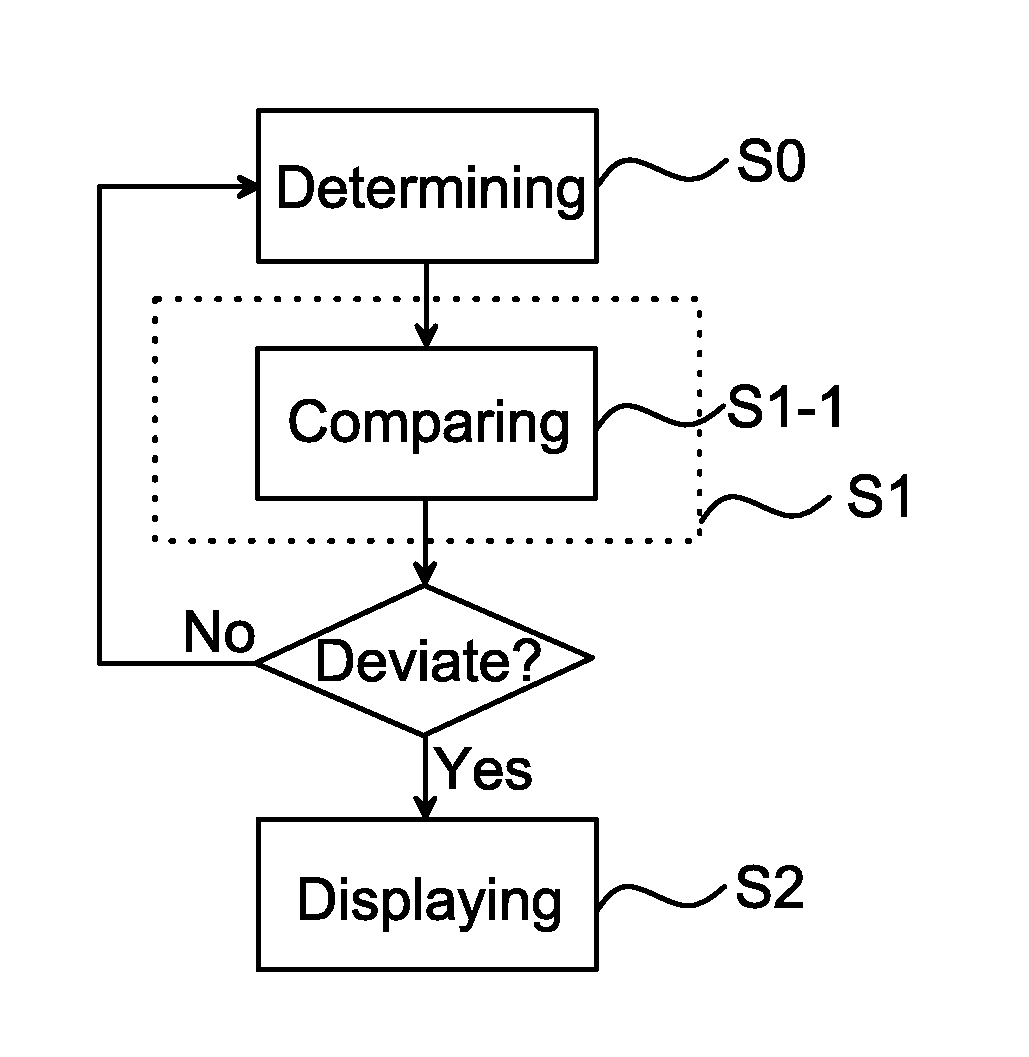

Conditional monitoring of industrial systems

InactiveUS20140336984A1Testing/monitoring control systemsNuclear monitoringDiagnostic dataIndustrial systems

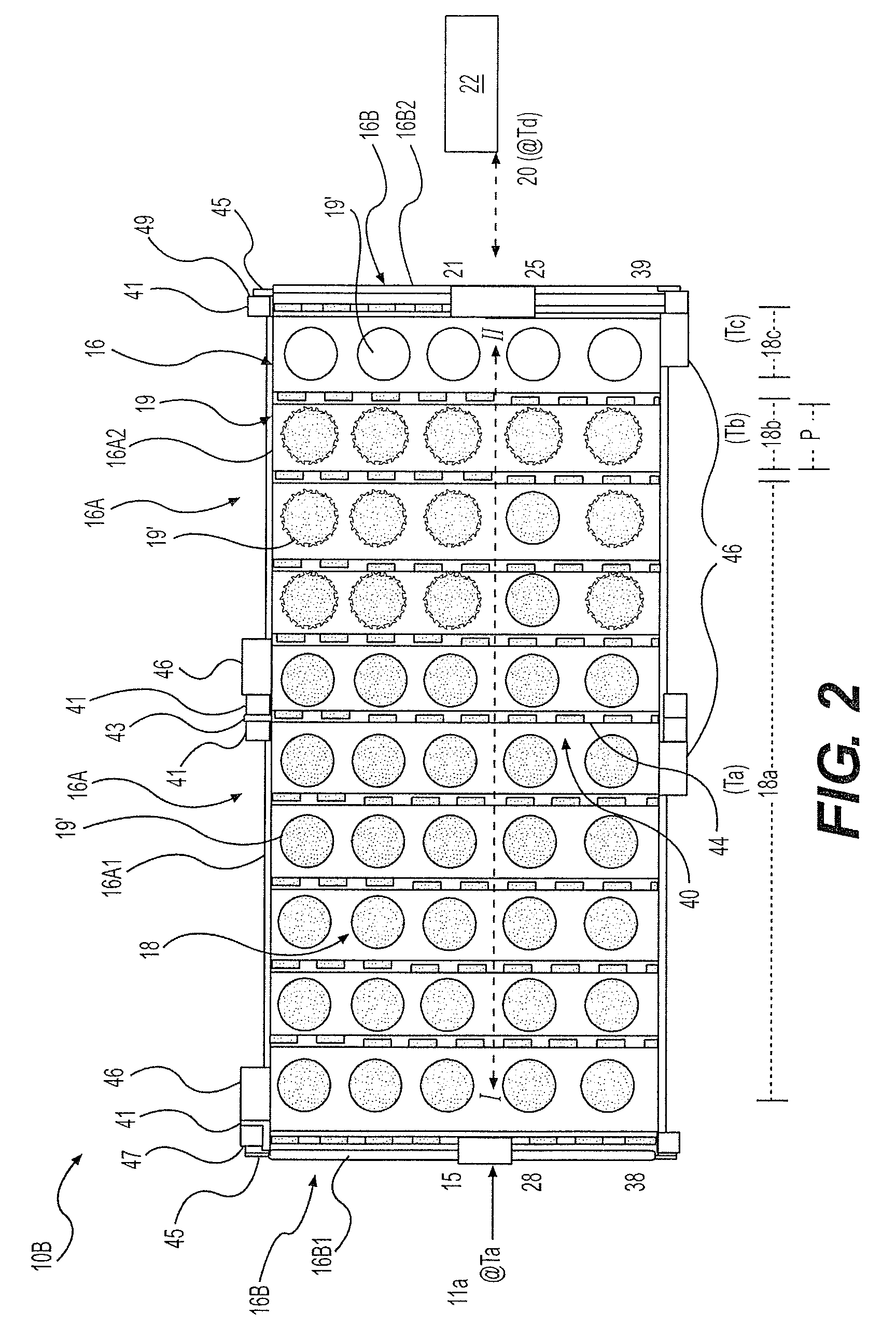

Performances of components of an industrial system are conditionally monitored as a function of key performance indicator data by defining baseline key performance indicator values for raw data obtained by data sensors from the operation of the components, and diagnostic rules to triggering alarms by comparing baseline key performance indicator values to thresholds. Generated alarms are stored in association with the historic raw diagnostic data, times of acquisition of the historic raw data and times of generation of the alarms. Generated alarms are analyzed as a function of the said stored data and times to identify a correlation between different ones of the key performance indicators that are indicative of a required level of intervention, and the diagnostic rules are revised to initiate reporting of generated alarms pursuant to levels of intervention indicated by said correlations.

Owner:ABB (SCHWEIZ) AG

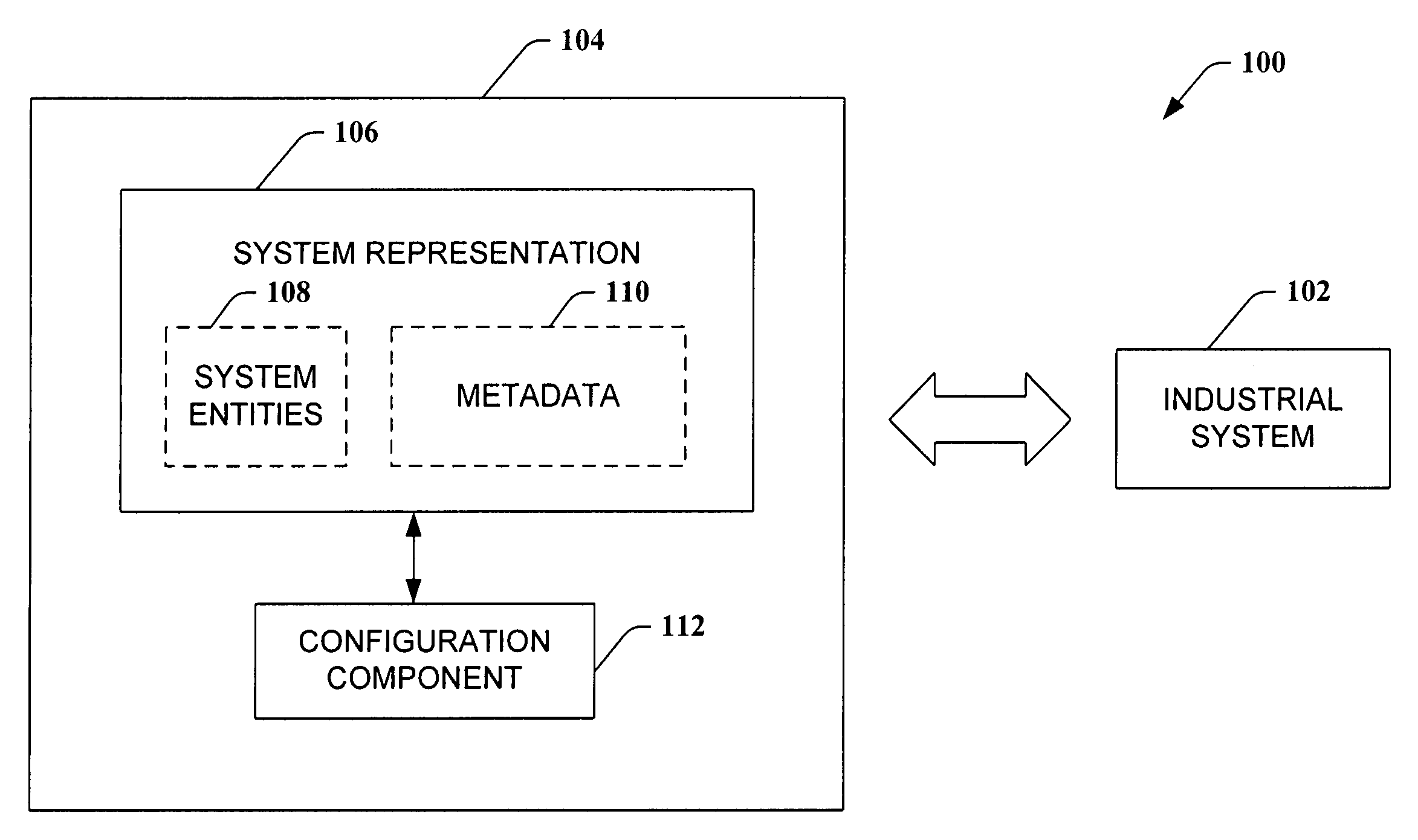

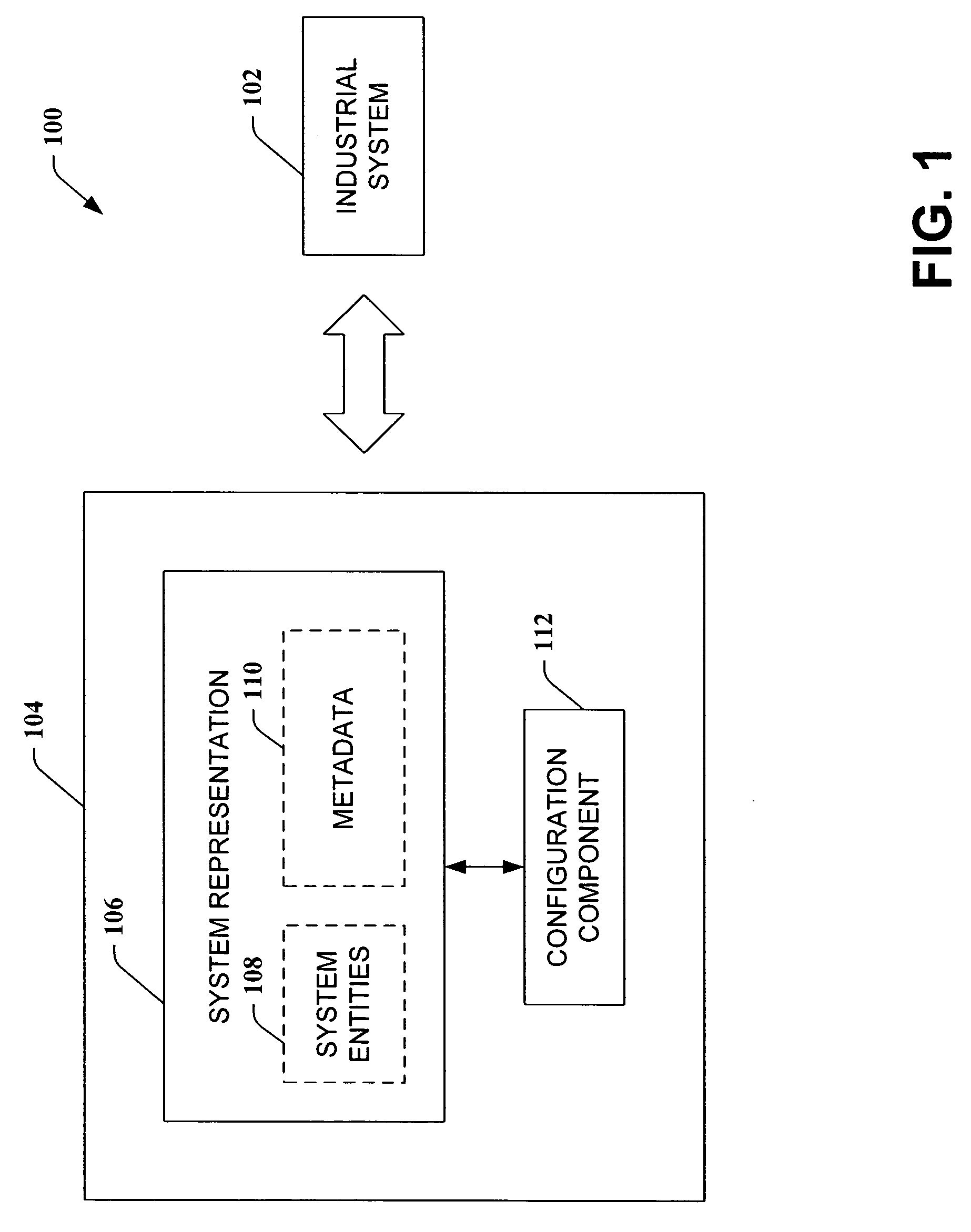

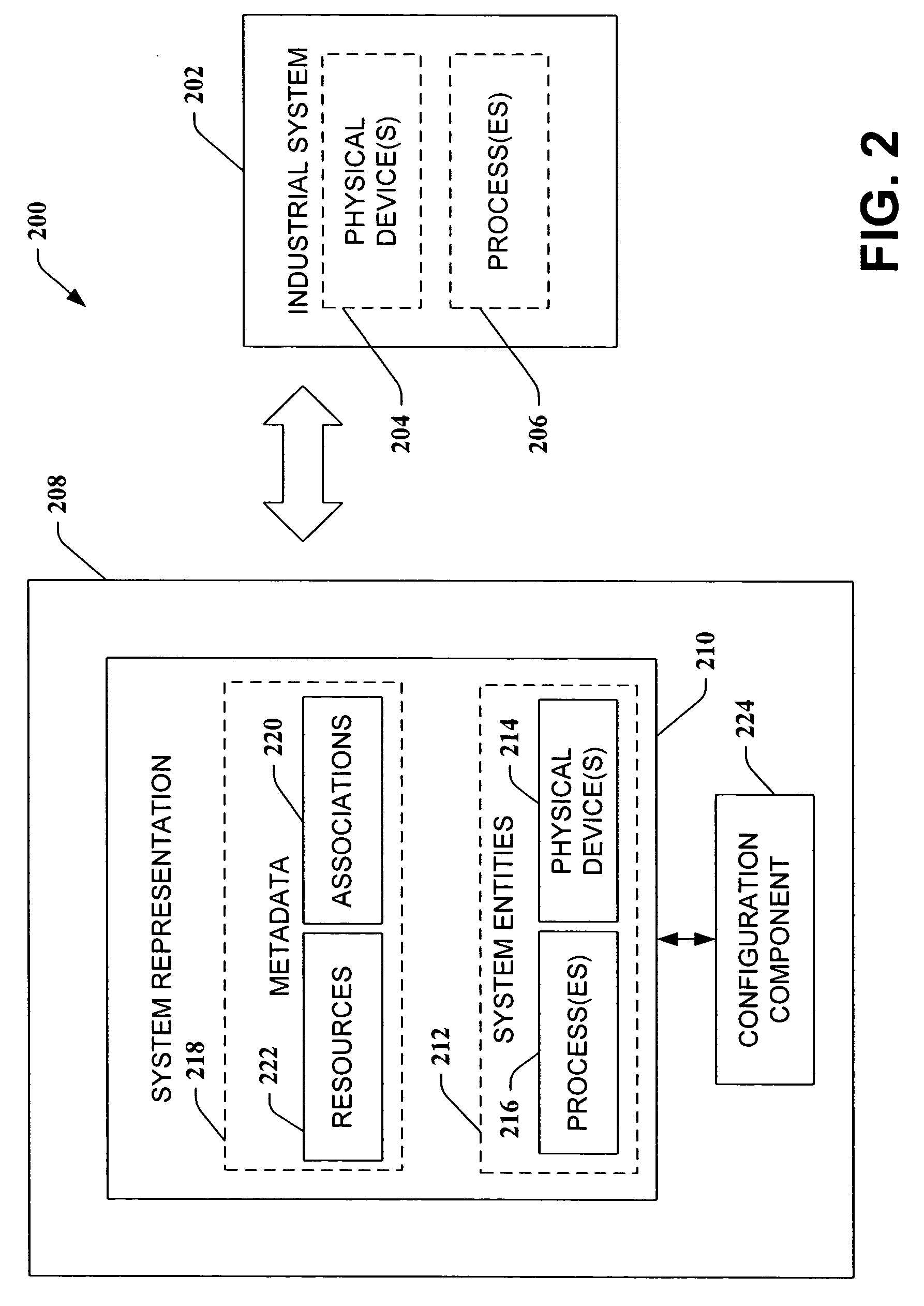

Dynamic schema for unified plant model

InactiveUS20060026193A1Robust representationIntelligent control decisionProgramme controlSpecial data processing applicationsIndustrial systemsDynamic pattern

An industrial system configuration platform facilitates automation of an industrial system. The industrial system configuration platform comprises a representation of the industrial system and a configuration component that automatically configures at least a portion of the industrial system based at least in part upon metadata that describes the representation. A physical device can be automatically configured based at least in part upon the metadata, and a database can be generated and structured based at least in part upon the metadata. The industrial system configuration platform further enables an industrial process to be implemented based at least in part upon the metadata.

Owner:ROCKWELL SOFTWARE

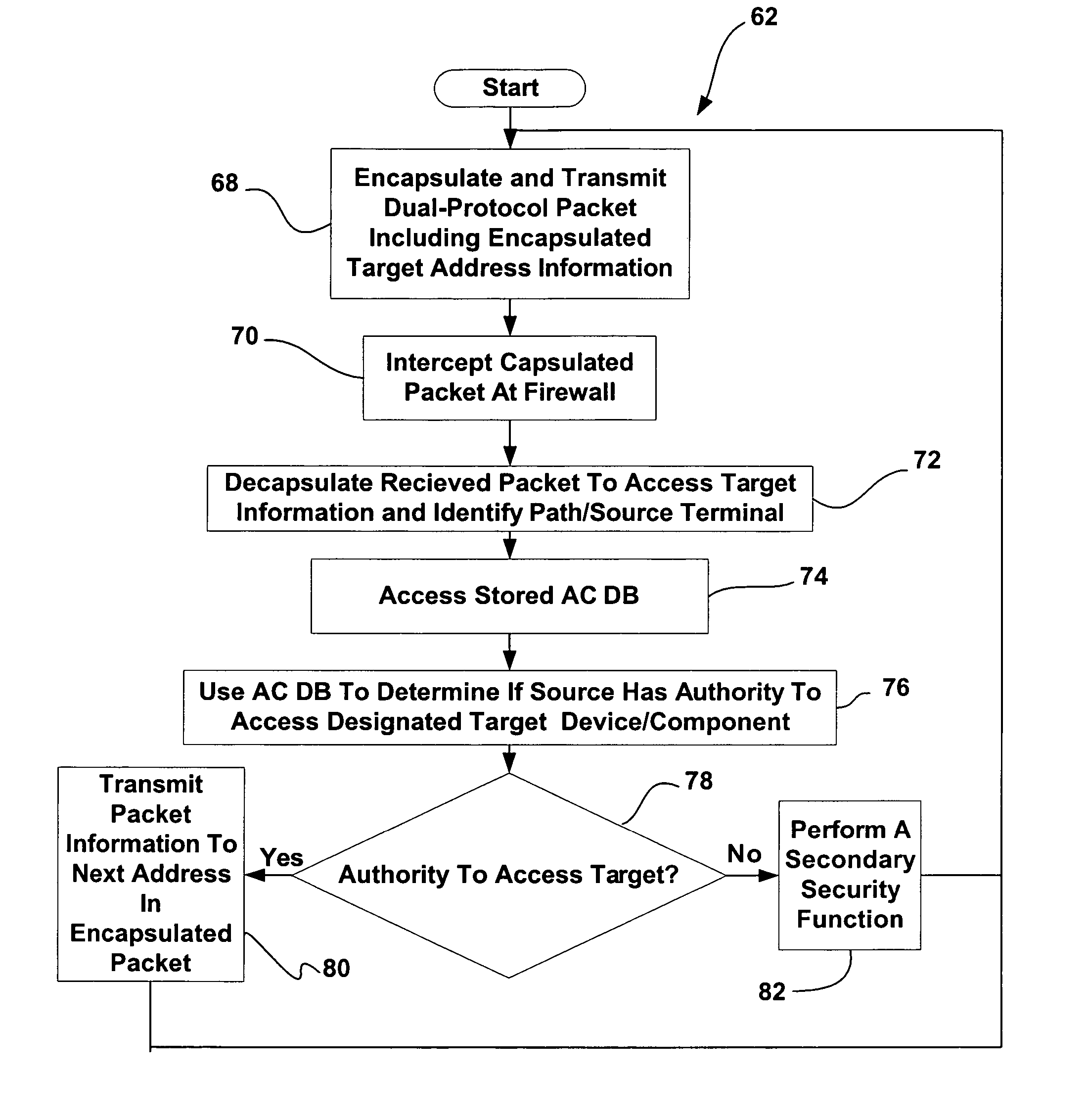

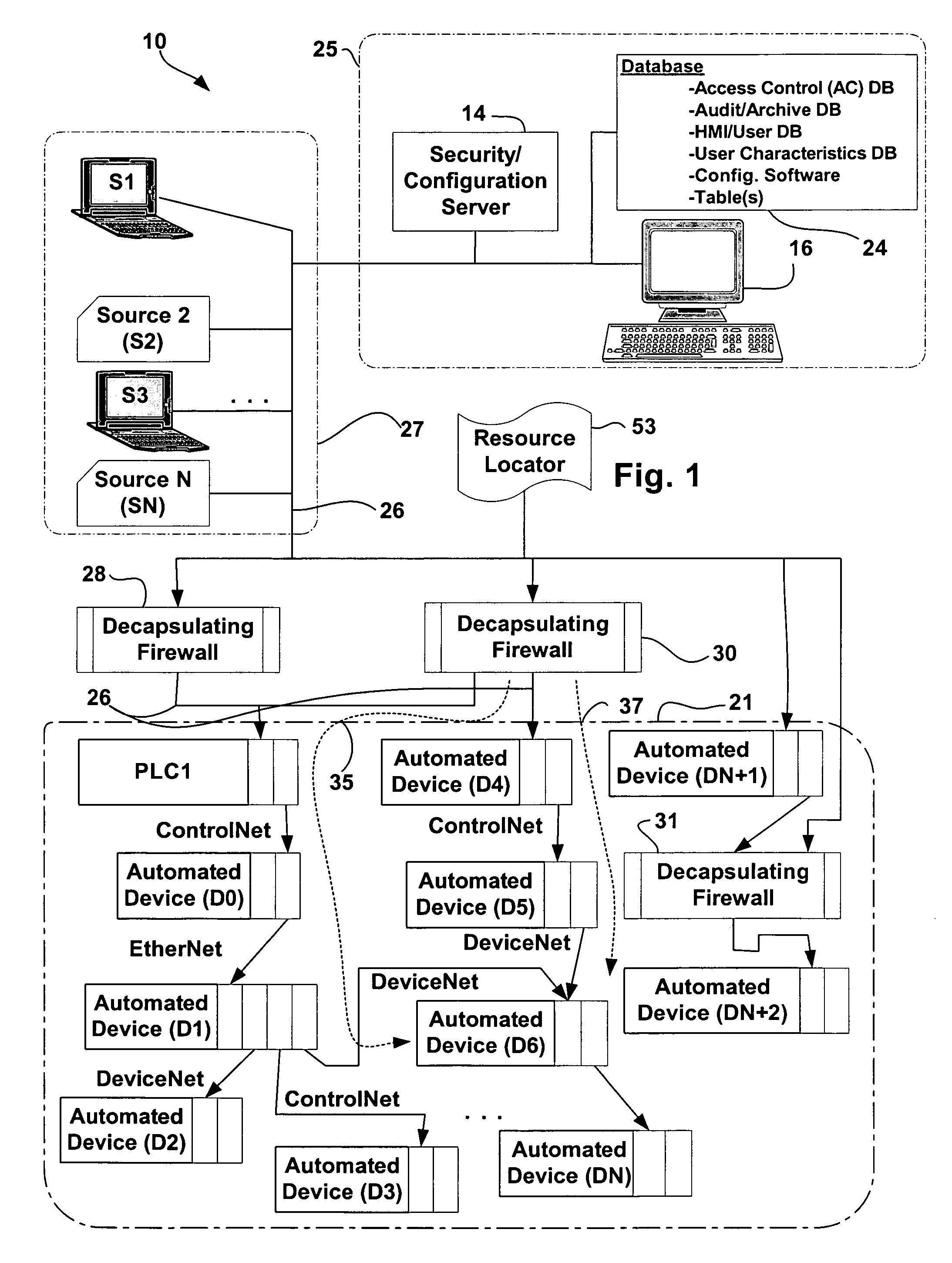

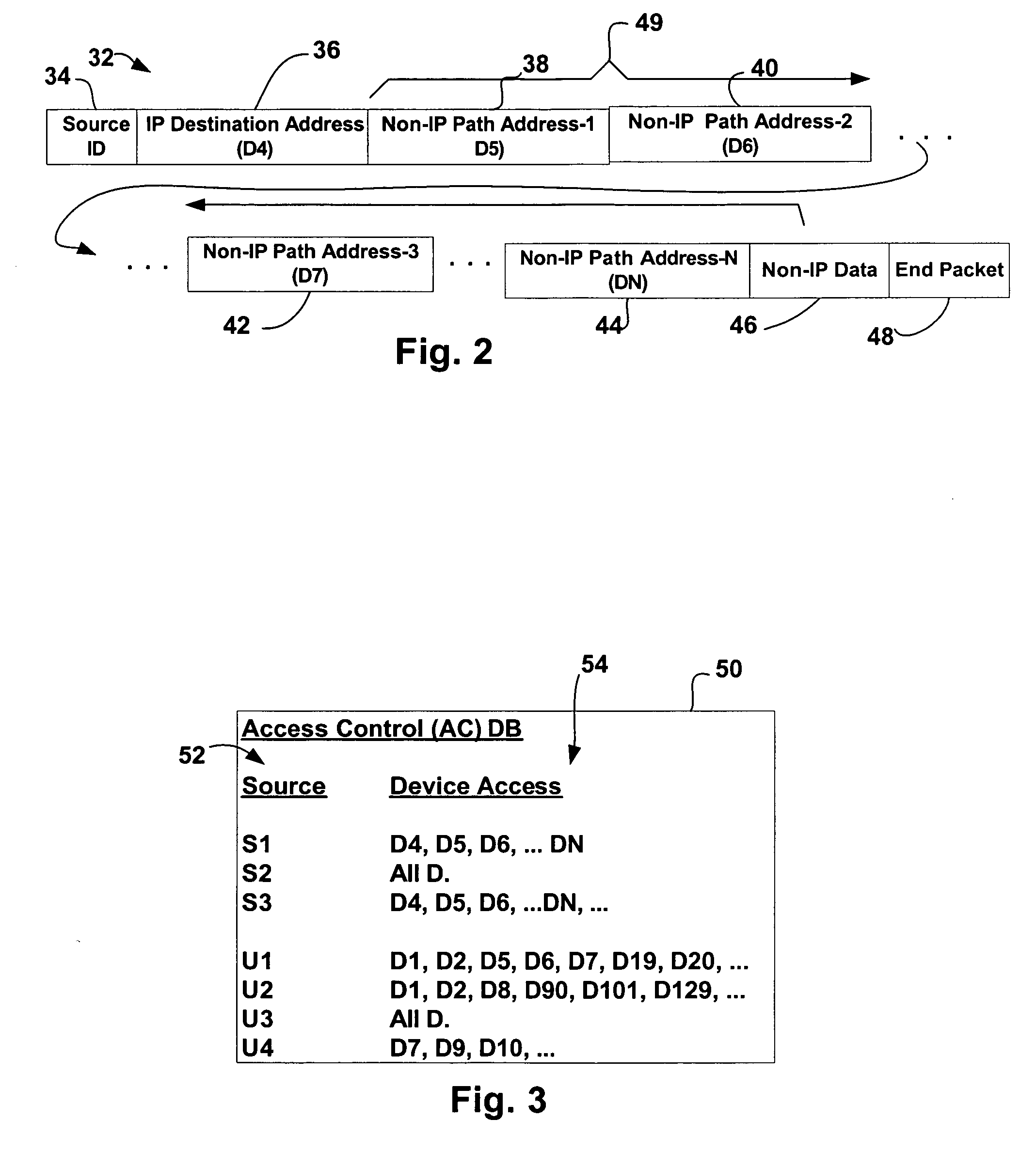

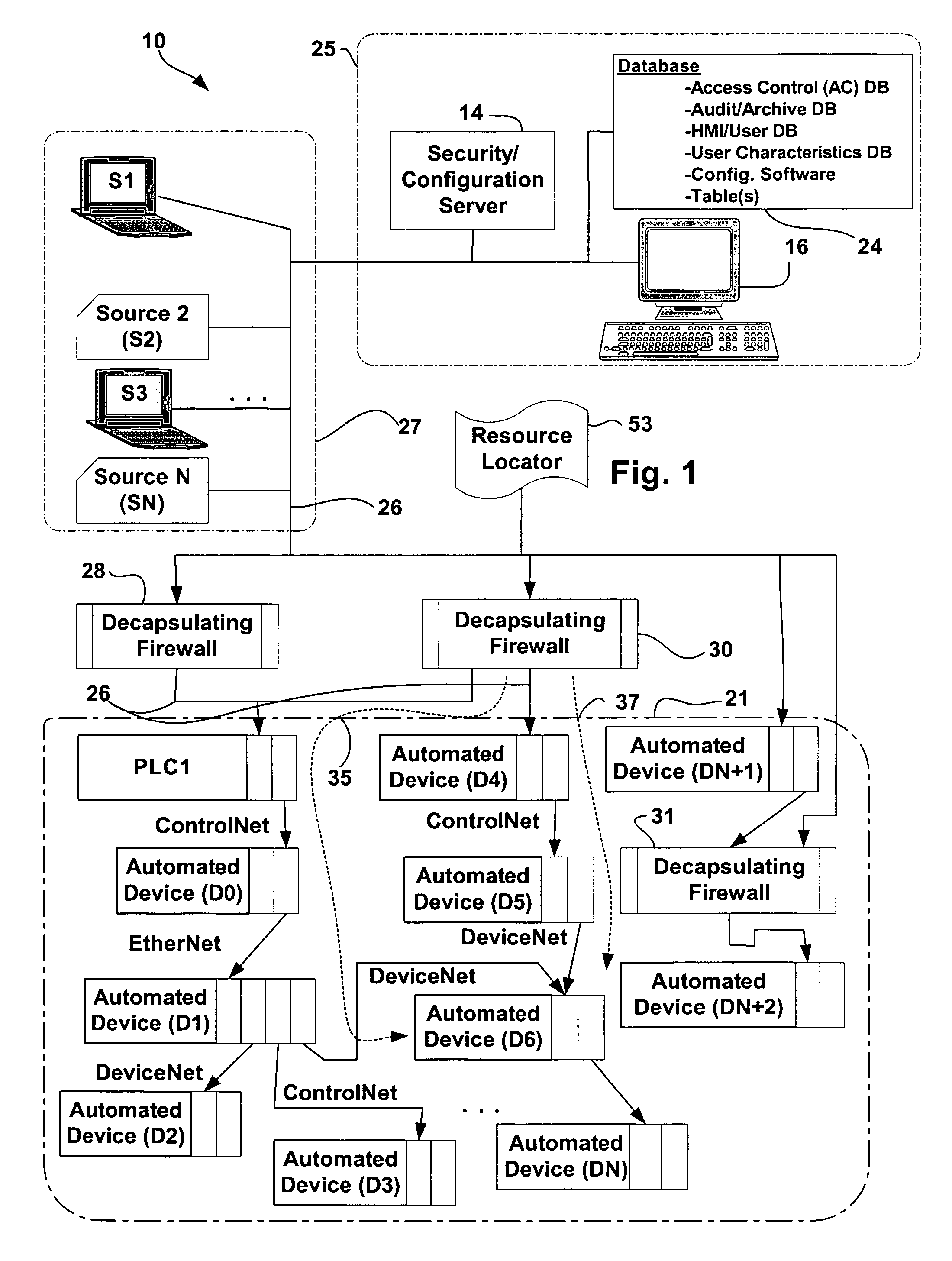

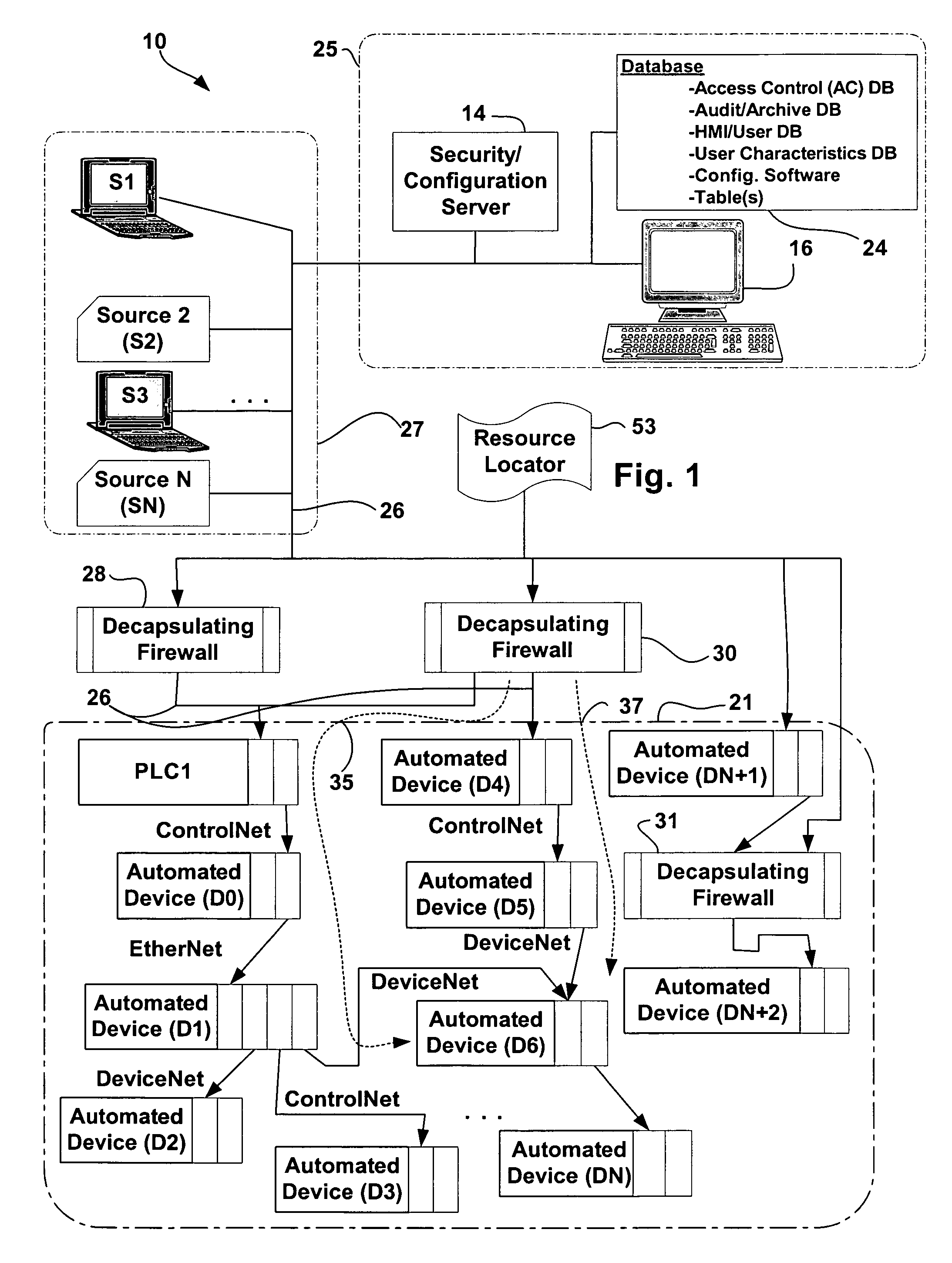

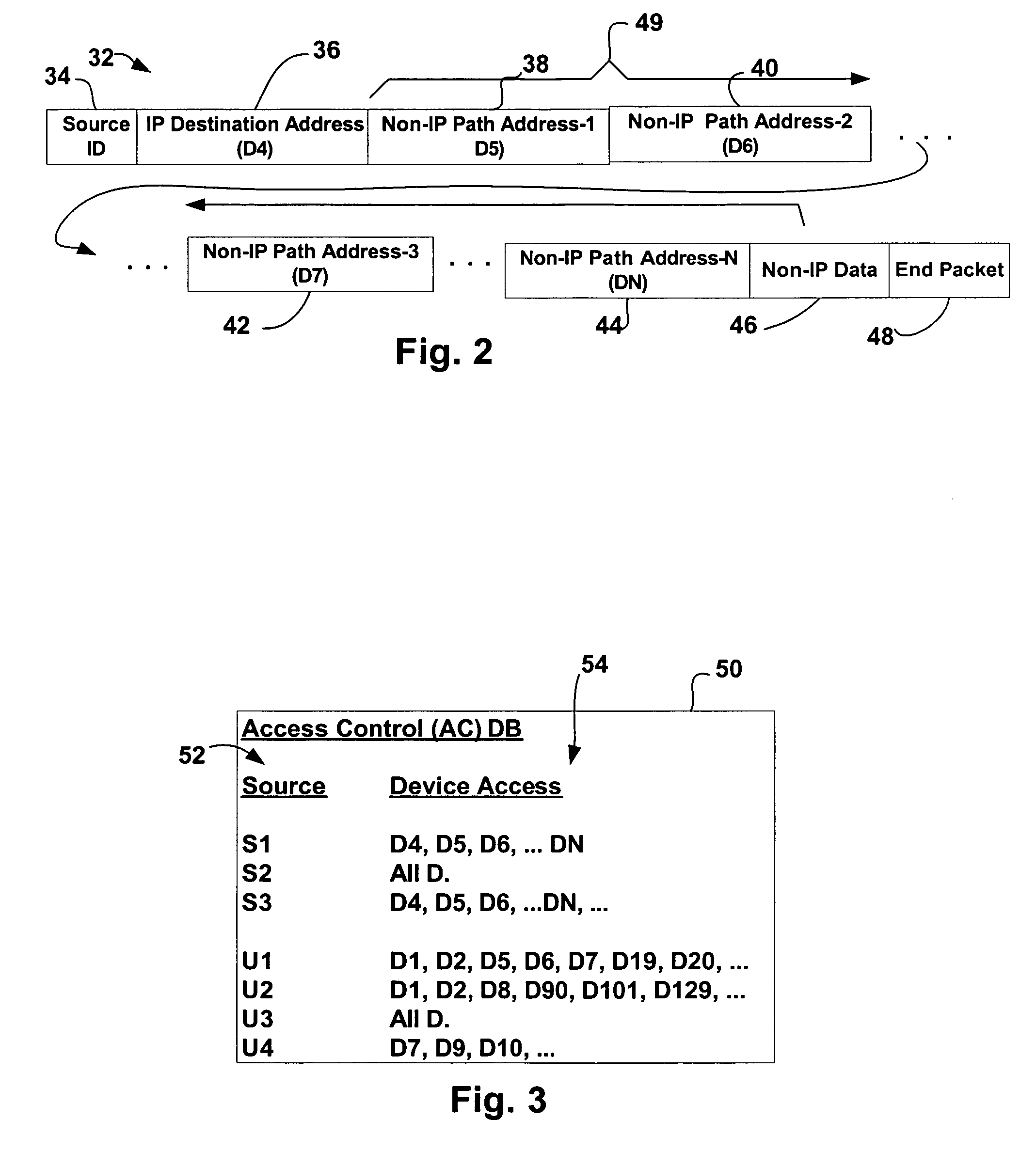

Firewall method and apparatus for industrial systems

ActiveUS20060155865A1Minimize delayData switching by path configurationMultiple digital computer combinationsIndustrial systemsData field

The invention includes a method and apparatus for use with a system including networked resources where communication between resources is via a dual packet protocol wherein a first protocol includes a frame that specifies a destination device / resource and a data field and the second protocol specifies a final destination device / resource and includes a data field and where the second packets are encapsulated in the first protocol packet frames the method including the steps of specifying access control information for resources, for each first protocol packet transmitted on the network, intercepting the first protocol packet prior to the first protocol destination resource, examining at least a subset of the additional embedded packet information to identify at least one of the intermediate path resources and the final destination resource, identifying the access control information associated with the identified at least one of the intermediate path resources and the final destination resource and restricting transmission of the first protocol packet as a function of the identified access control information.

Owner:ROCKWELL AUTOMATION TECH

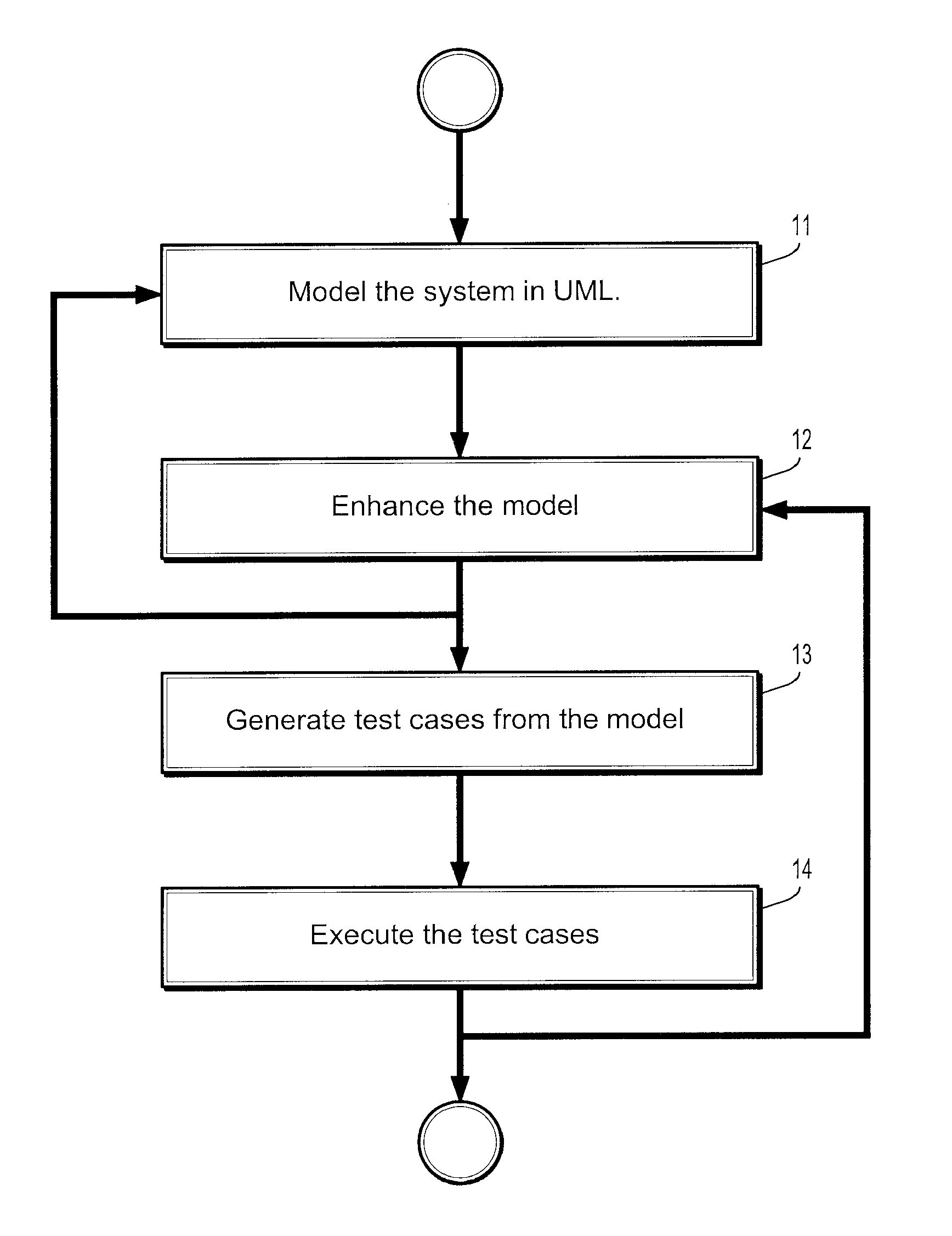

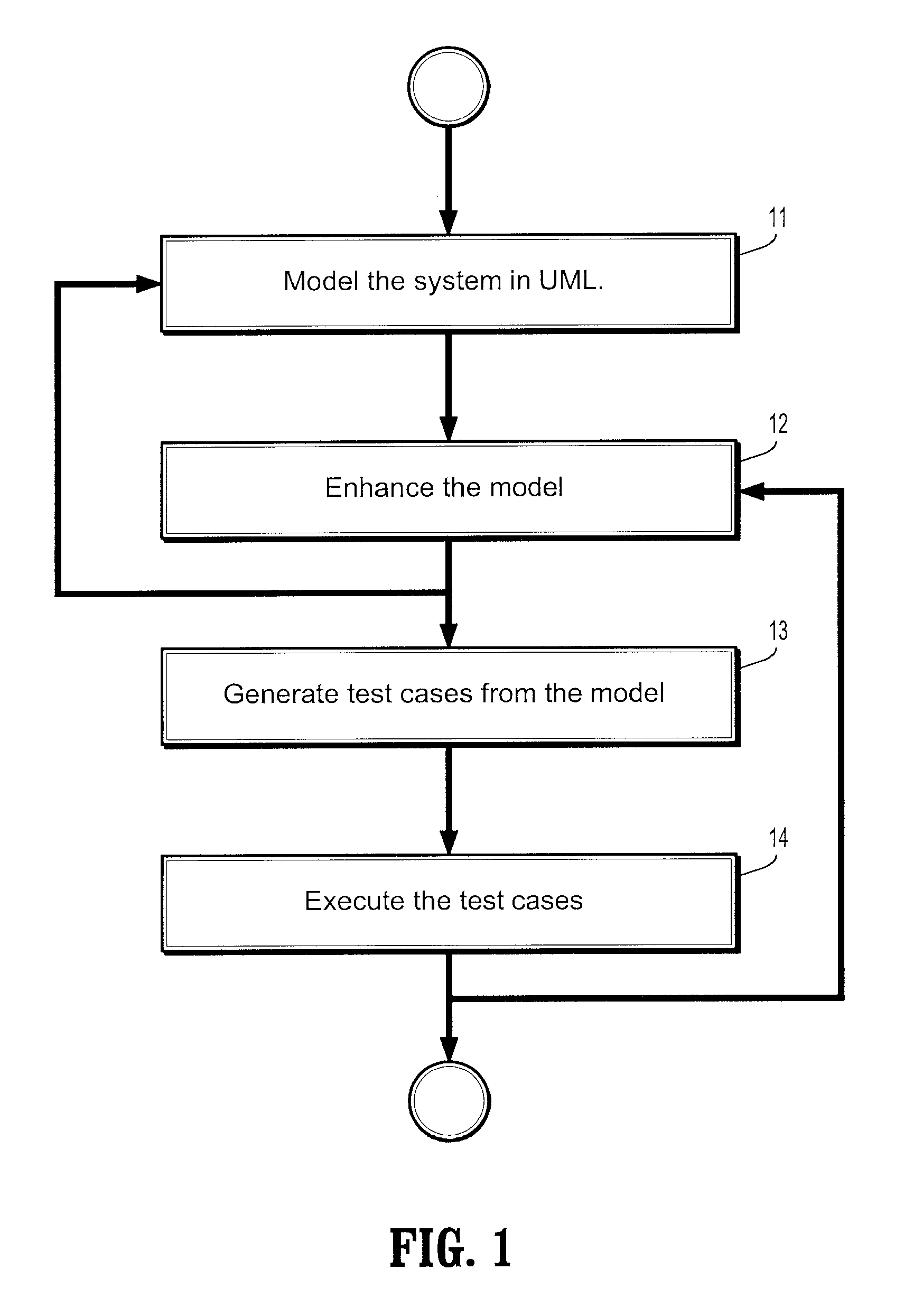

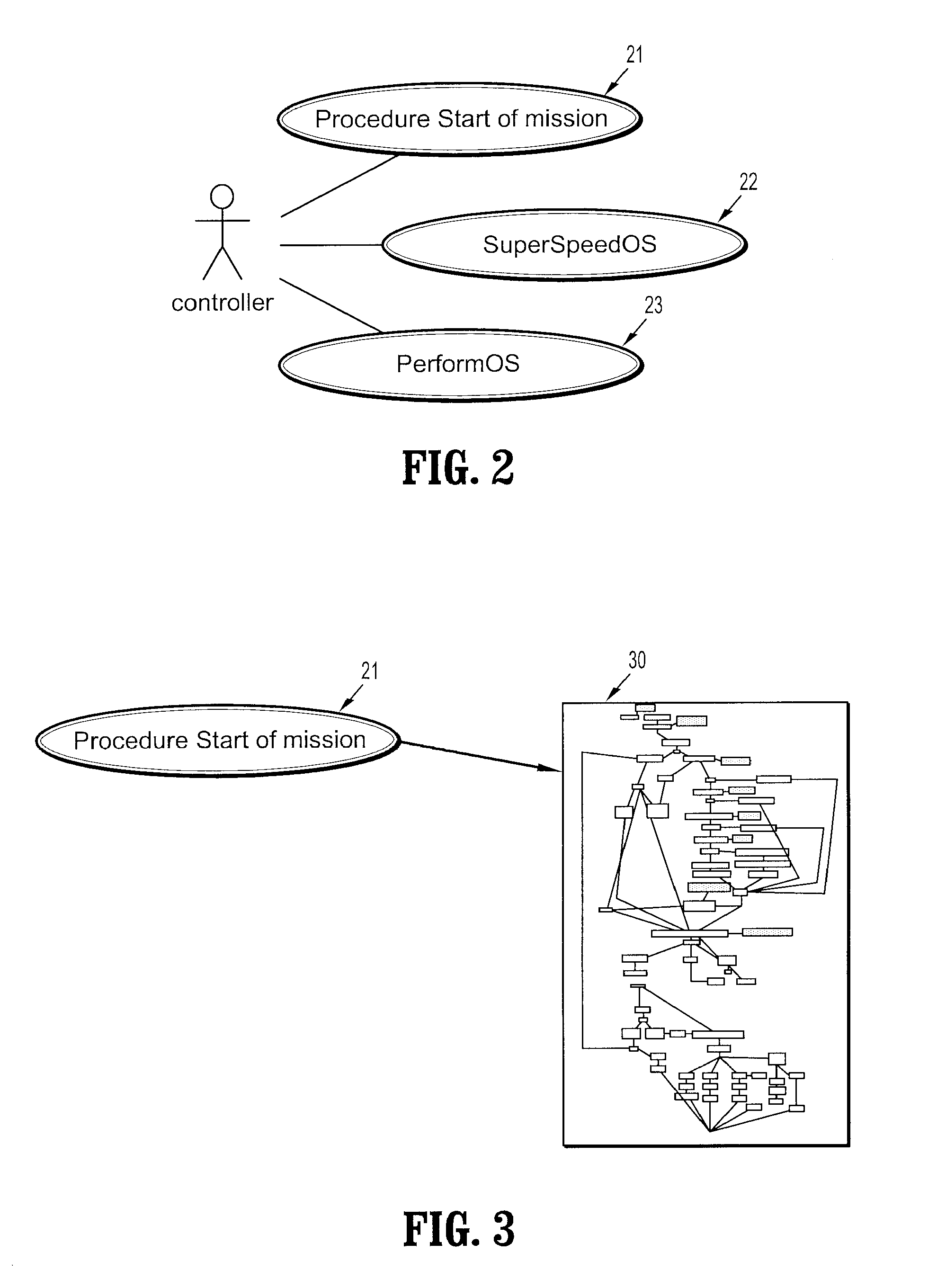

System and Method For Applying Model-Based Testing To Train Control Systems

InactiveUS20090094575A1Application to testingEnsure full coverageError detection/correctionRequirement analysisProcess logicActivity diagram

Owner:SIEMENS AG +1

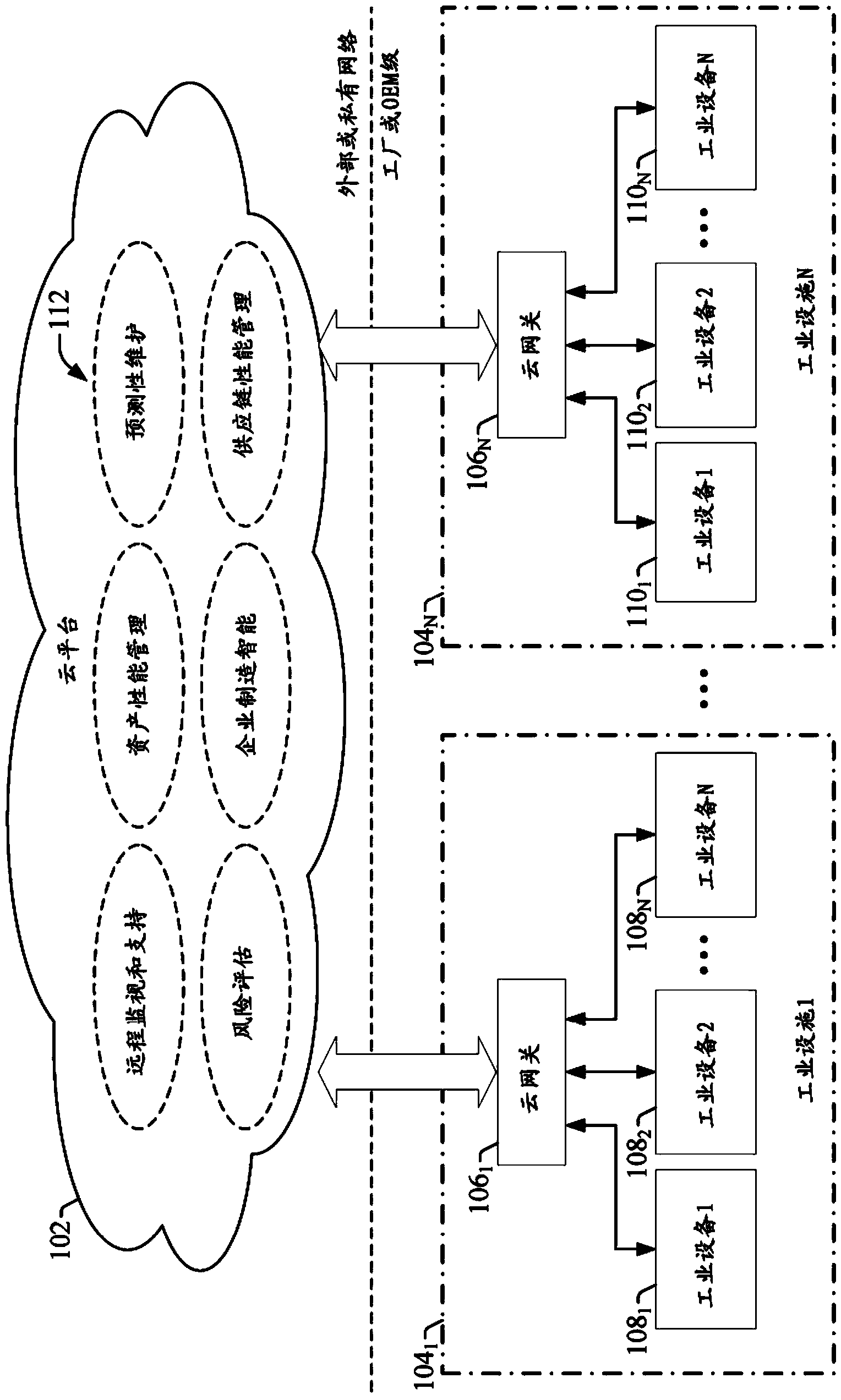

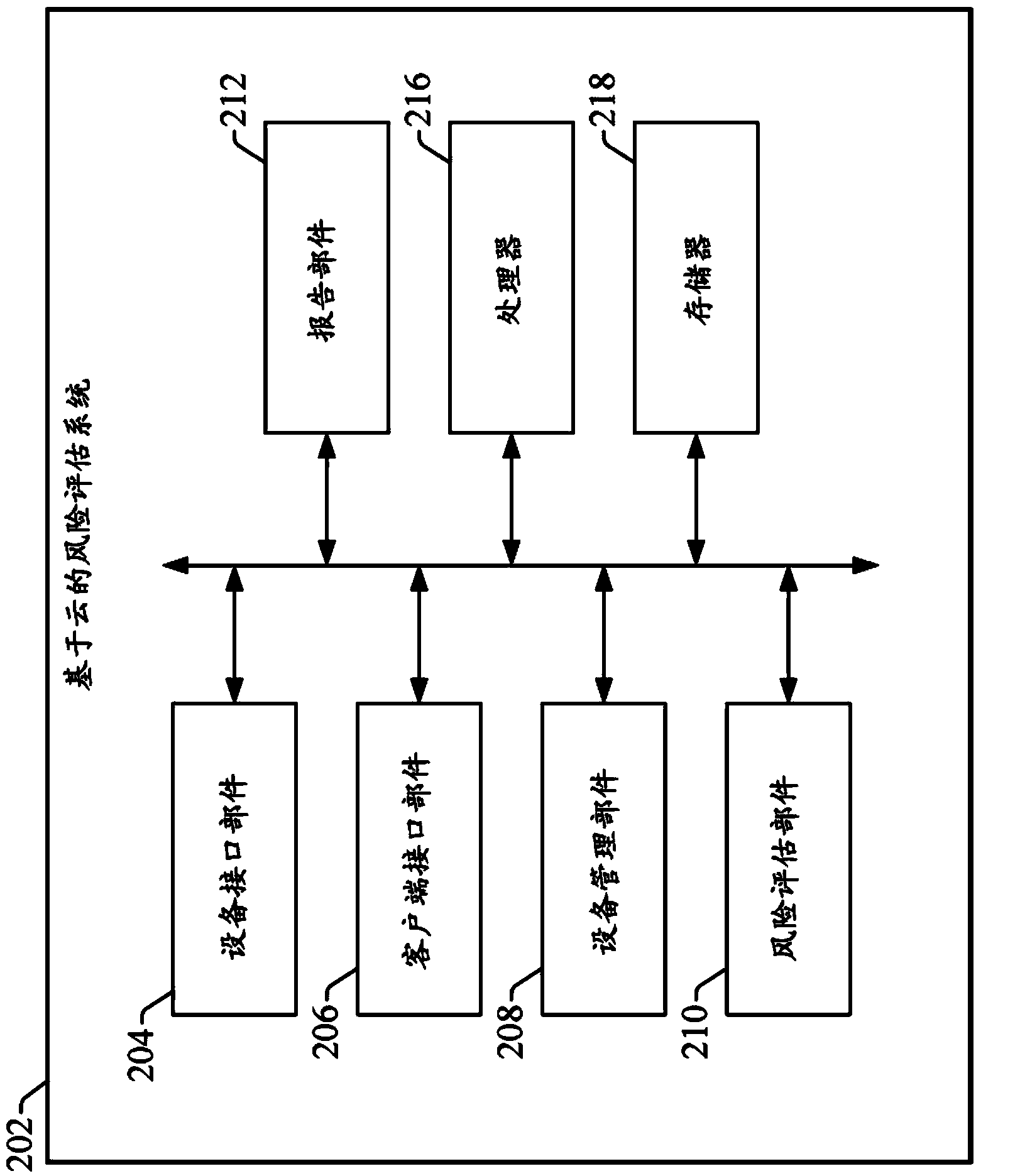

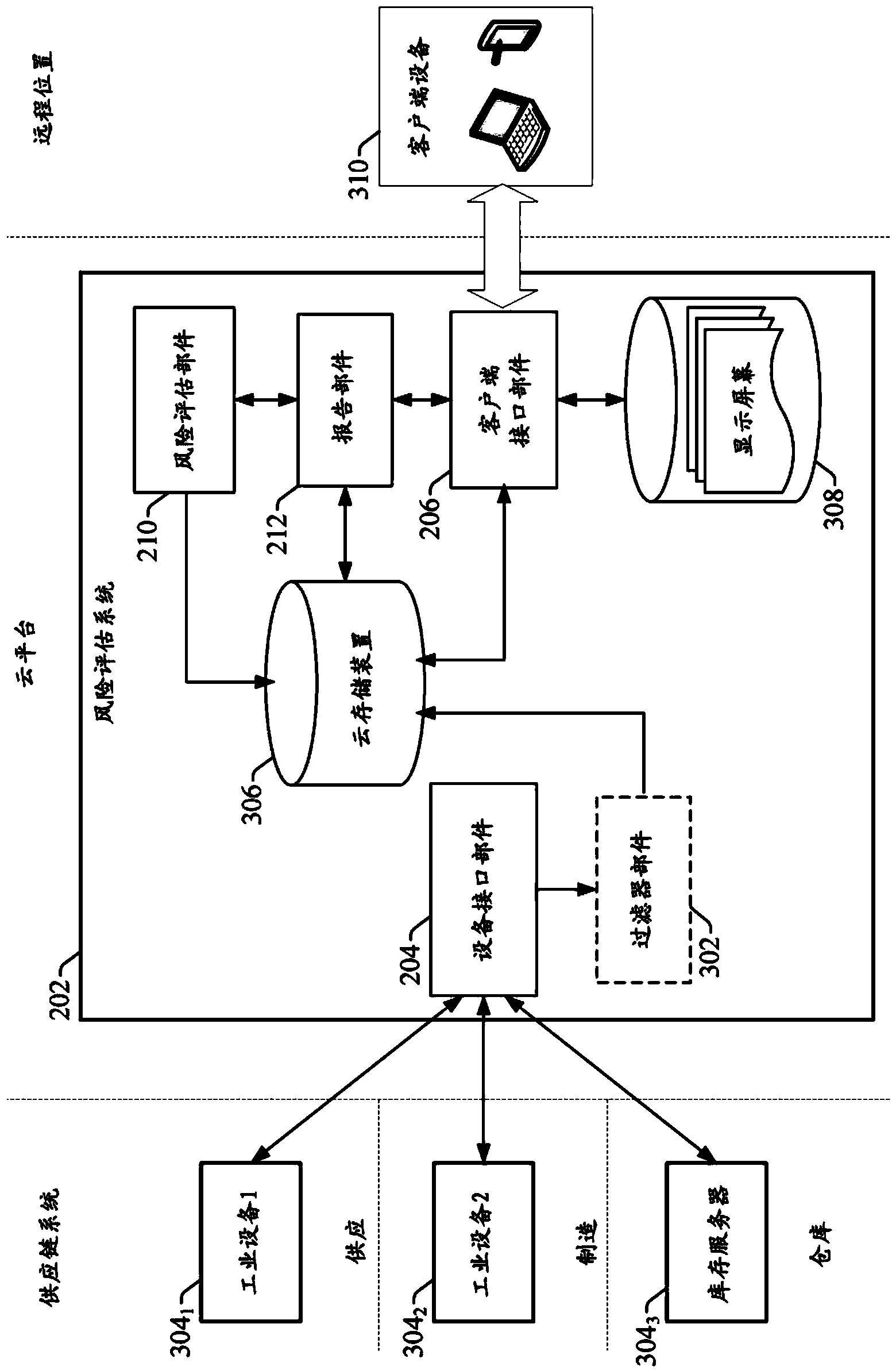

Risk assessment for industrial systems using big data

A cloud-based risk assessment service collects industrial data from multiple relevant and connected sources for storage and analysis on a cloud platform. The service analyzes gathered data from internal and external sources and customers across different industries to identify operational trends as a function of industry type, application type, equipment in use, device configurations, and other such variables. Based on the analysis, the risk assessment service identifies risk factors inherent in a customer's particular industrial enterprise. The cloud-based system generates a risk profile for the customer that identifies the determined risks and recommends risk aversion strategies based on the customer's specific profile, compared to industry standards, product information, internal business expectations, external regulatory bodies, and / or past performance. Risk profiles are tailored for both plant-level users and business-level users to provide intelligent strategies to improve performance and prevent avoidable losses.

Owner:ROCKWELL AUTOMATION TECH

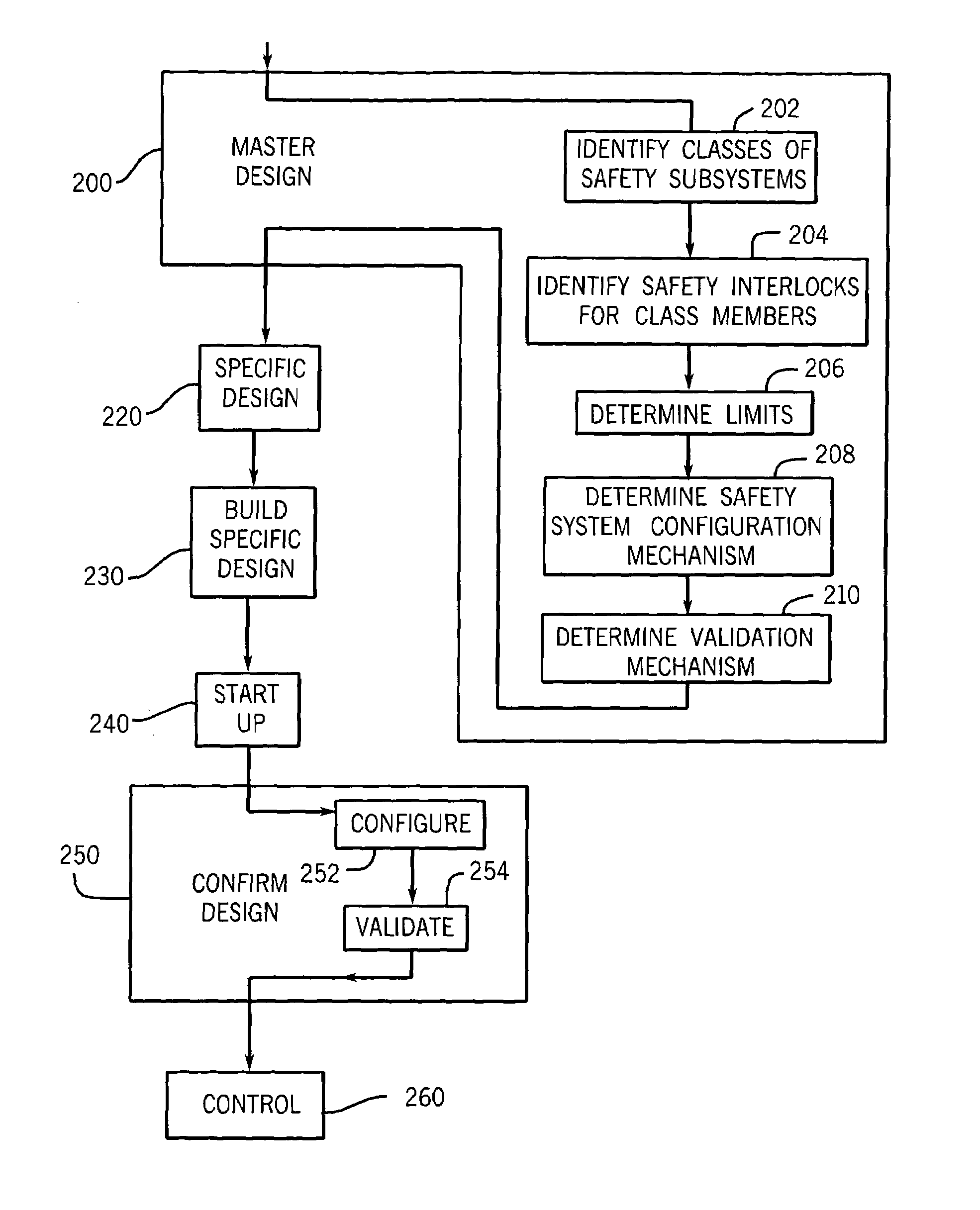

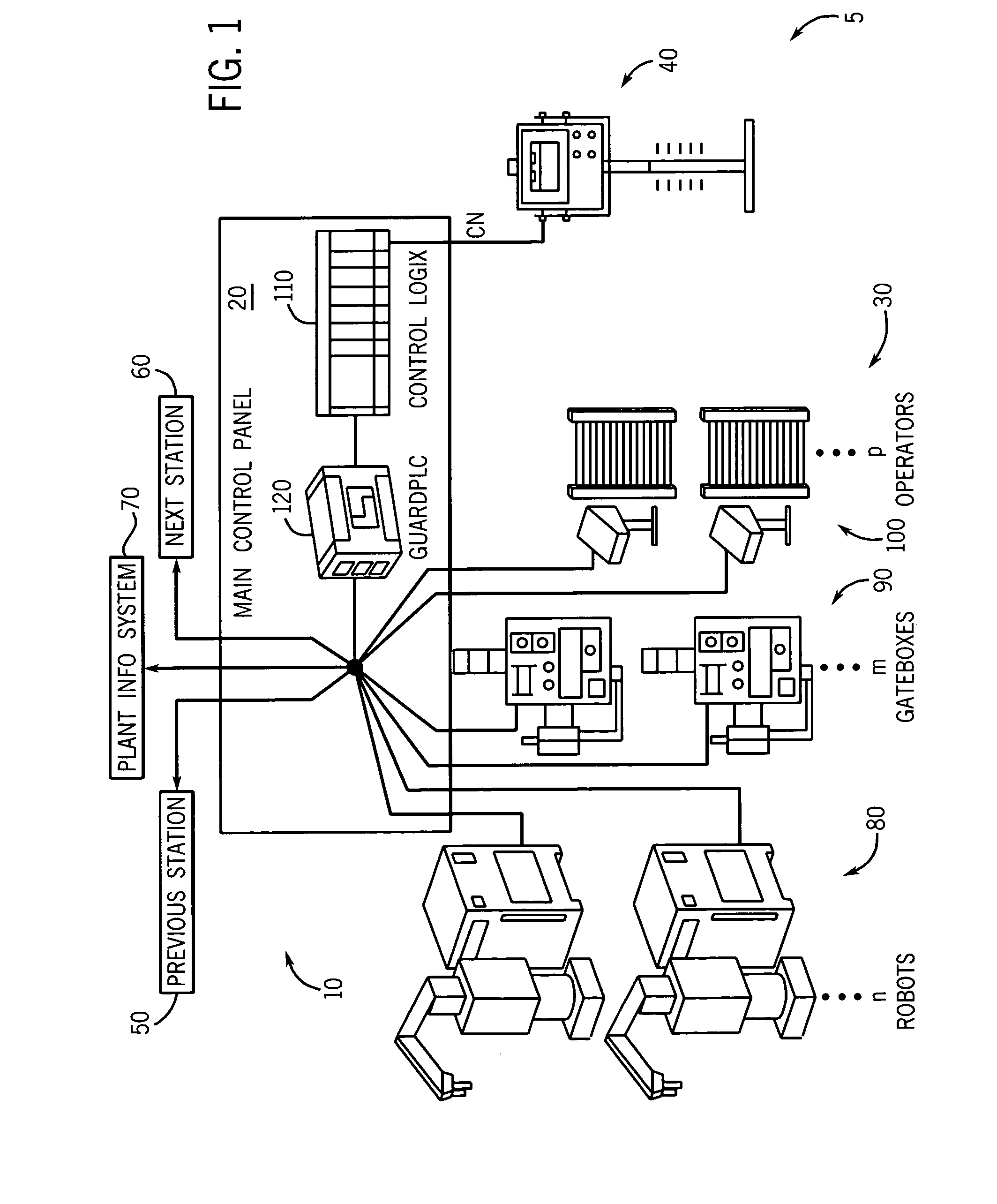

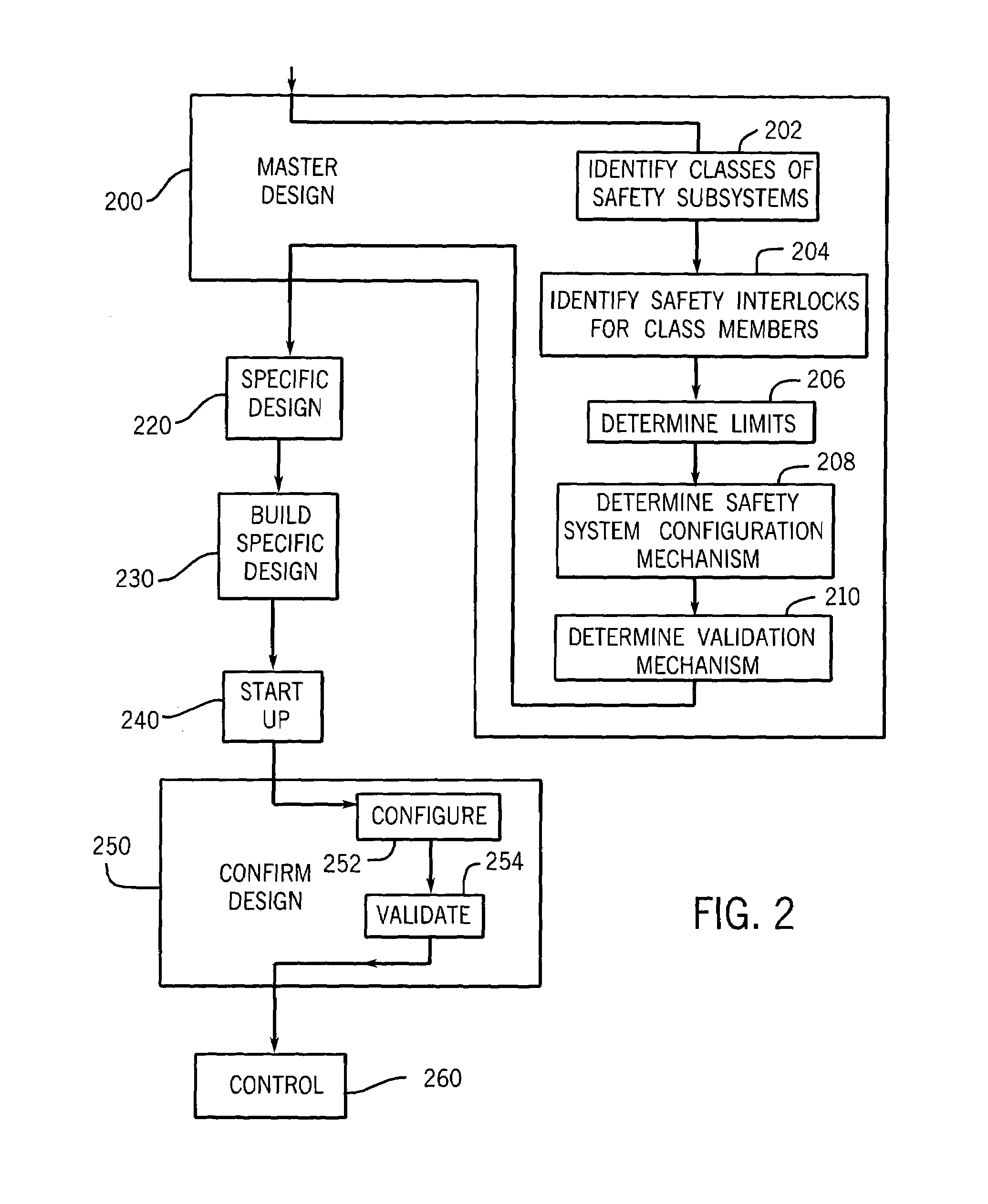

Configurable safety system for implementation on industrial system and method of implementing same

A configurable control system for operating an industrial system in a reliable, safety-enhanced manner, and method of implementing such a system in any of a variety of particular industrial systems of a given class, are disclosed. The method includes storing, onto a controller of a particular industrial system, a master program capable of being used to operate a generalized industrial system having a maximum number of safety subsystems of a given type, where the particular industrial system falls within a class defined by the generalized system. The method also includes receiving a configuration input indicative of an absence / presence of a safety subsystem of the first type; validating the input; automatically configuring the master program to arrive at a configured program capable of operating the particular industrial system; and activating the controller for operation according to the configured program, which can include activating visualization or annunciation mechanisms representing the configured system.

Owner:ROCKWELL AUTOMATION TECH

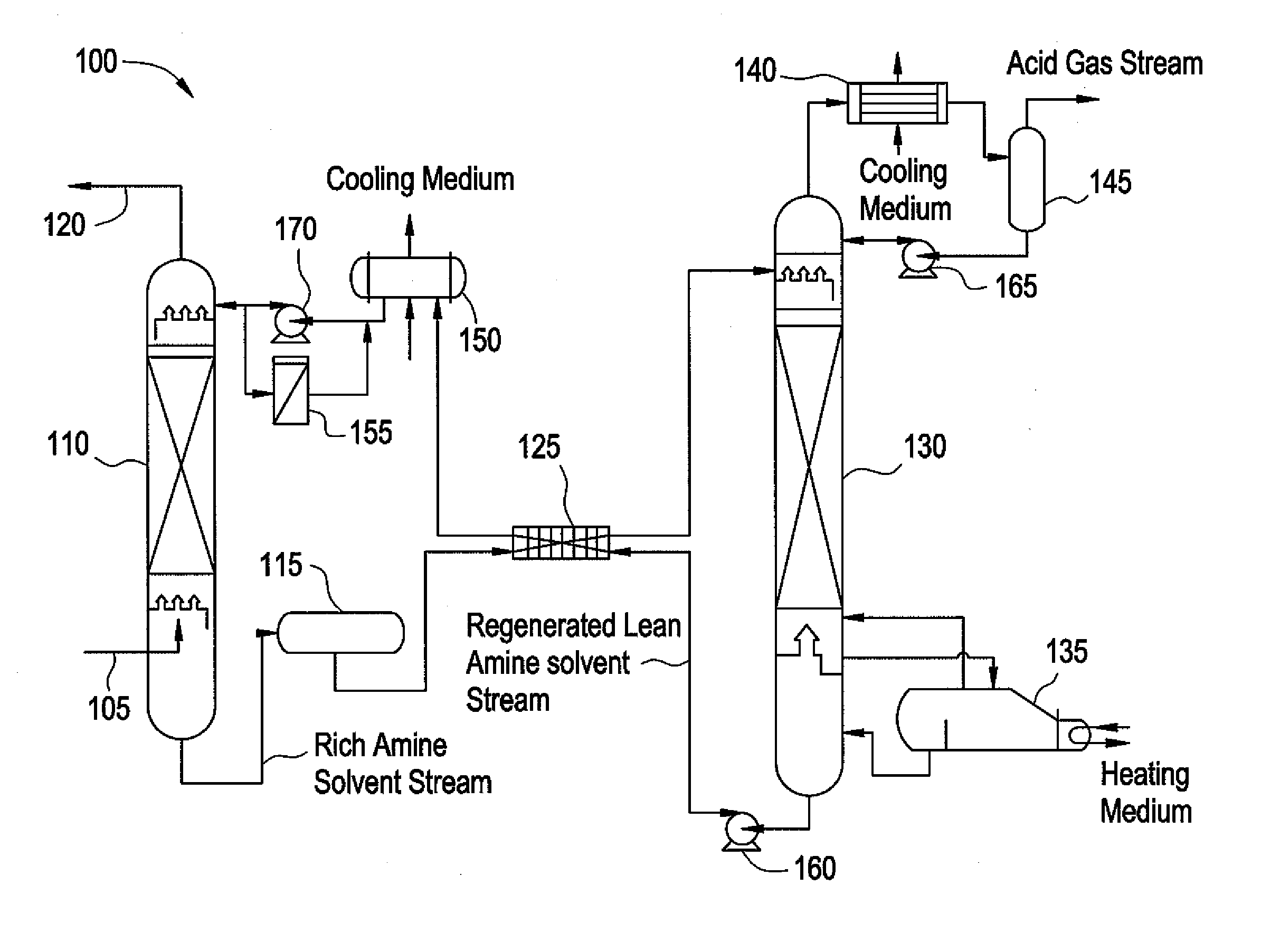

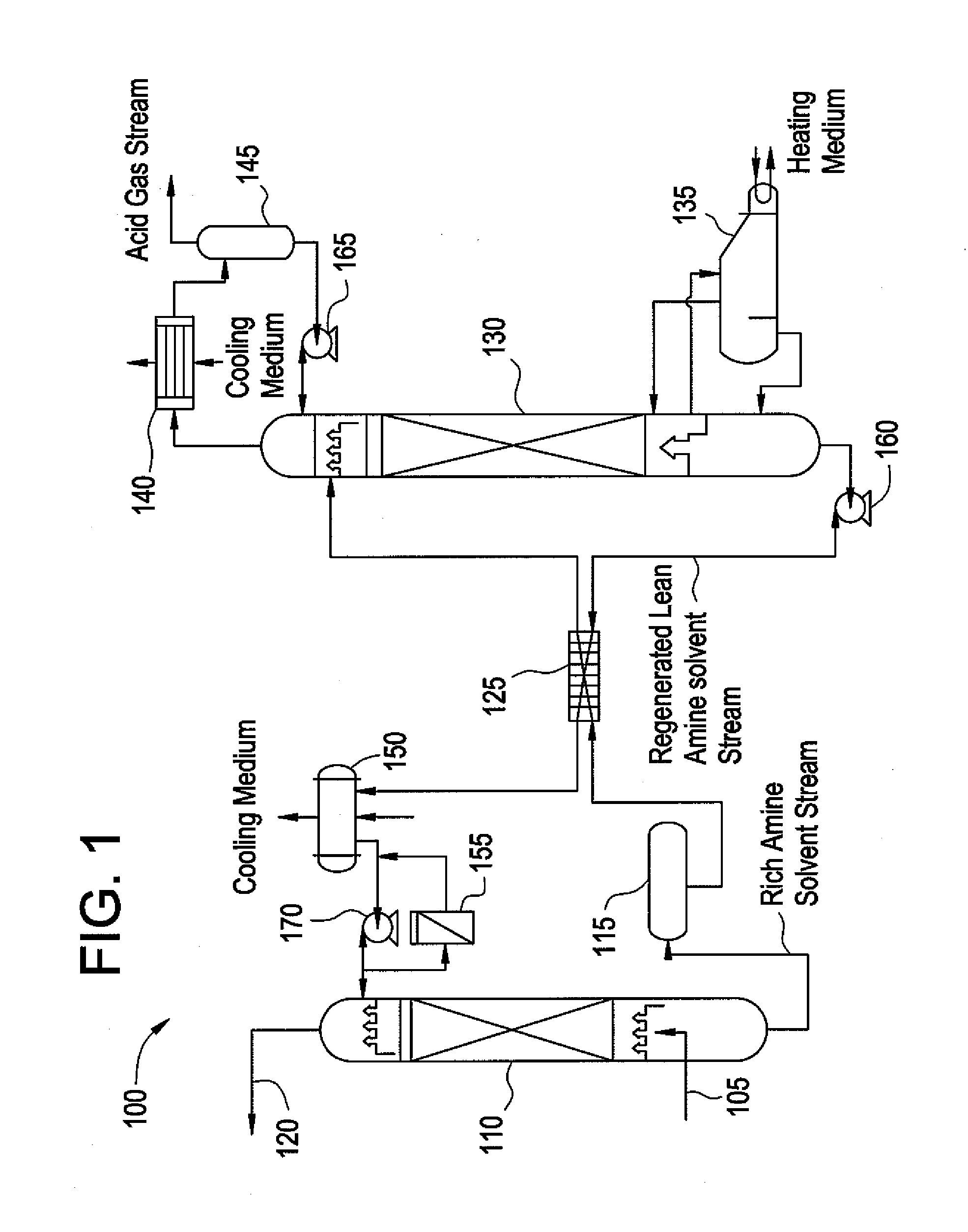

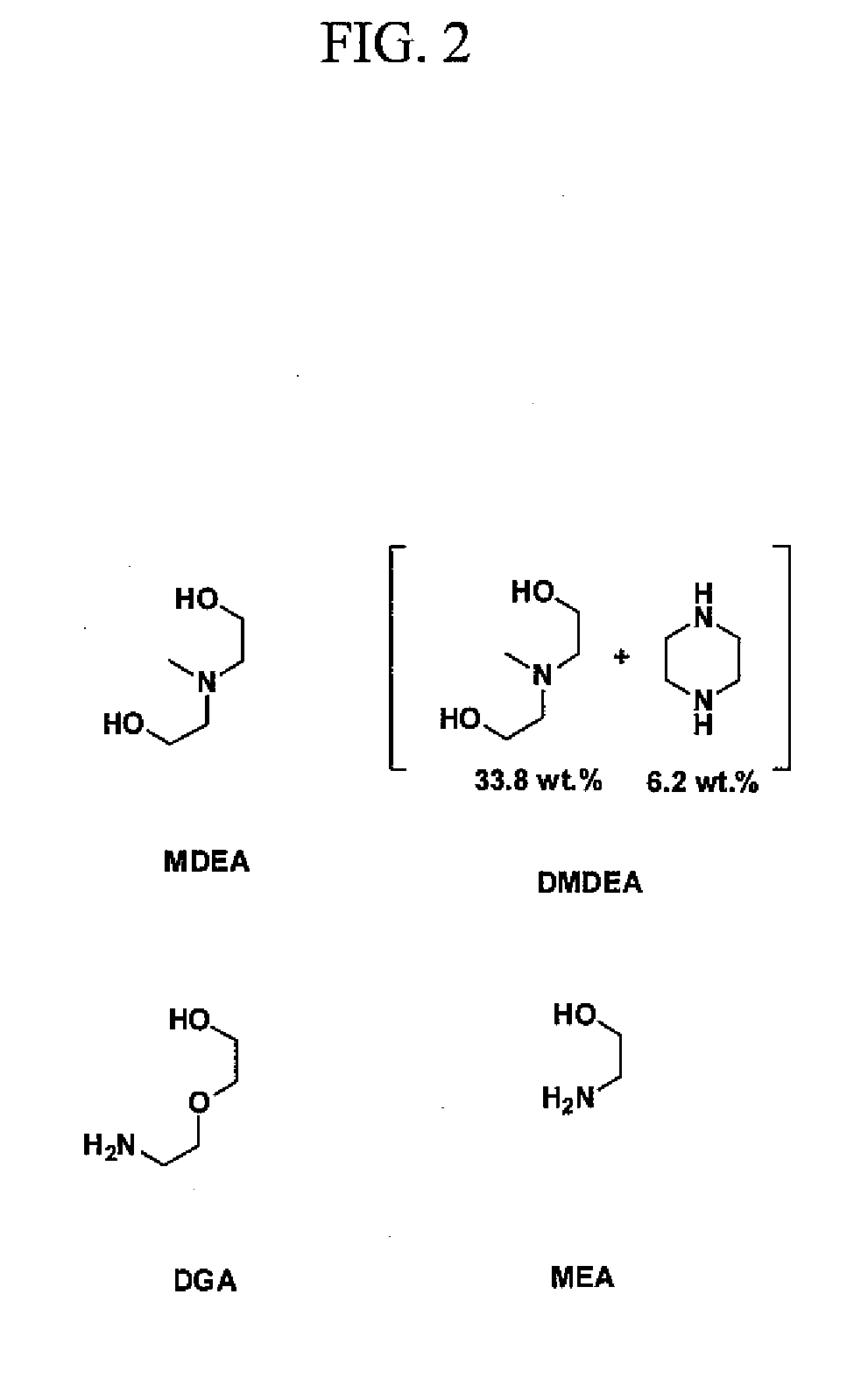

Composition for treating acid gas

ActiveUS20110256043A1Reduce volatilityConvenience to workGas treatmentOrganic chemistryPolyamine CompoundCombustion

This invention provides novel compositions comprising substituted polyamines as acid gas scrubbing solutions and methods of using the compositions in an industrial system. The invention relates to the use of such polyamine compounds in industrial processes to remove acidic contaminants from natural and industrial fluid streams, such as natural gas, combustion gas, natural gas, synthesis gas, biogas, and other industrial fluid streams. The compositions and methods of the invention are useful for removal, absorption, or sequestration of acidic contaminants and sulfide contaminants including CO2, H2S, RSH, CS2, COS, and SO2.

Owner:CHAMPIONX LLC

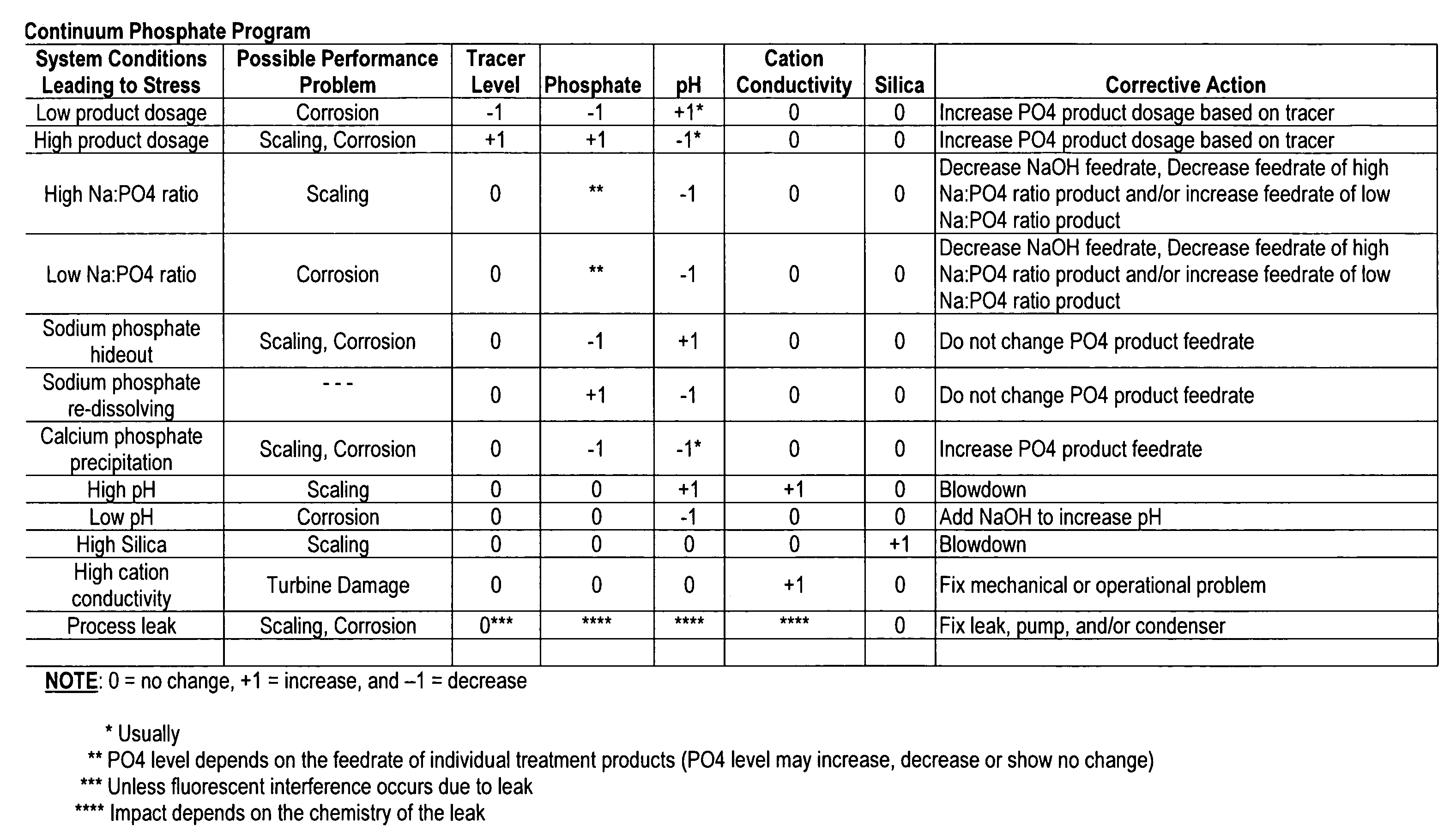

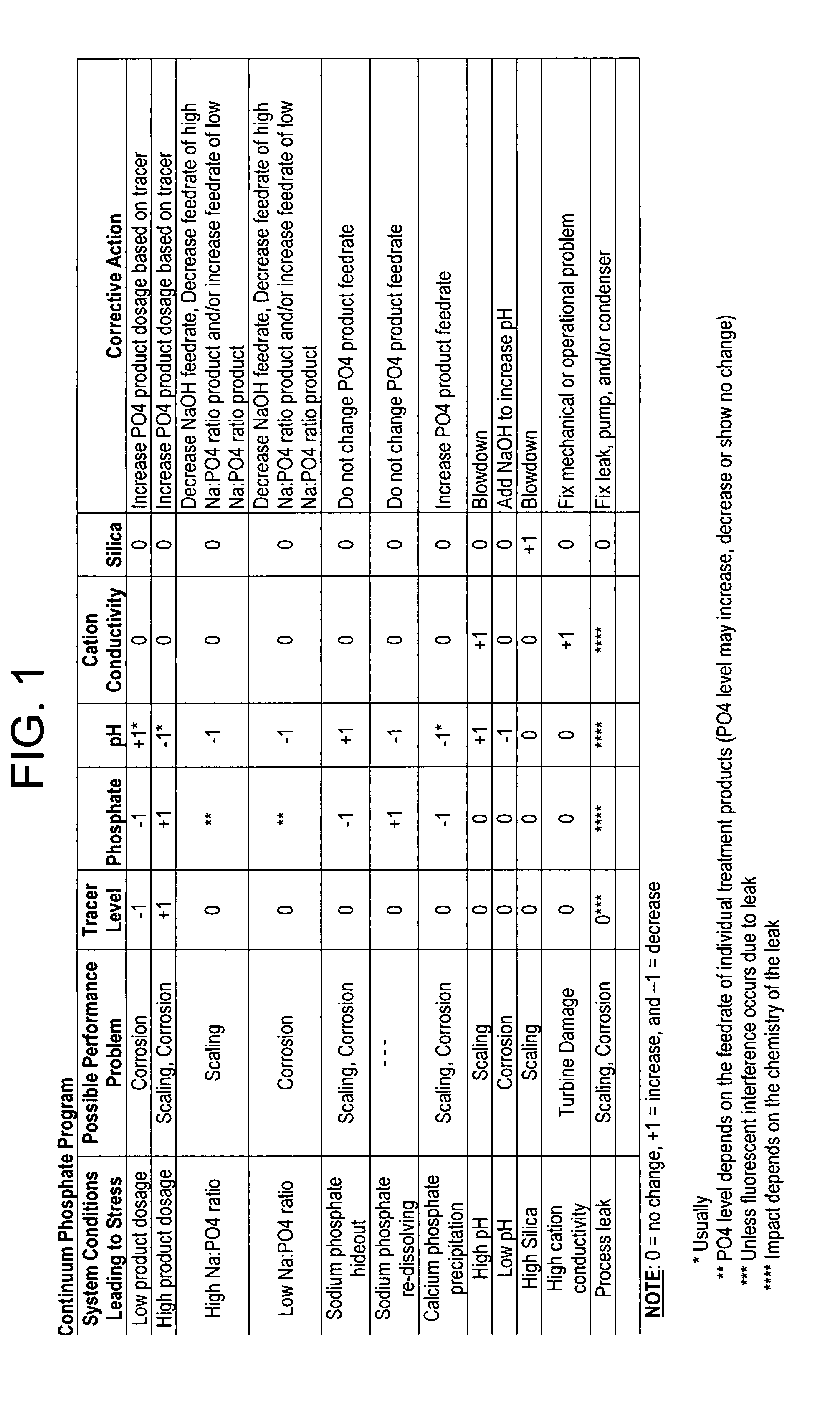

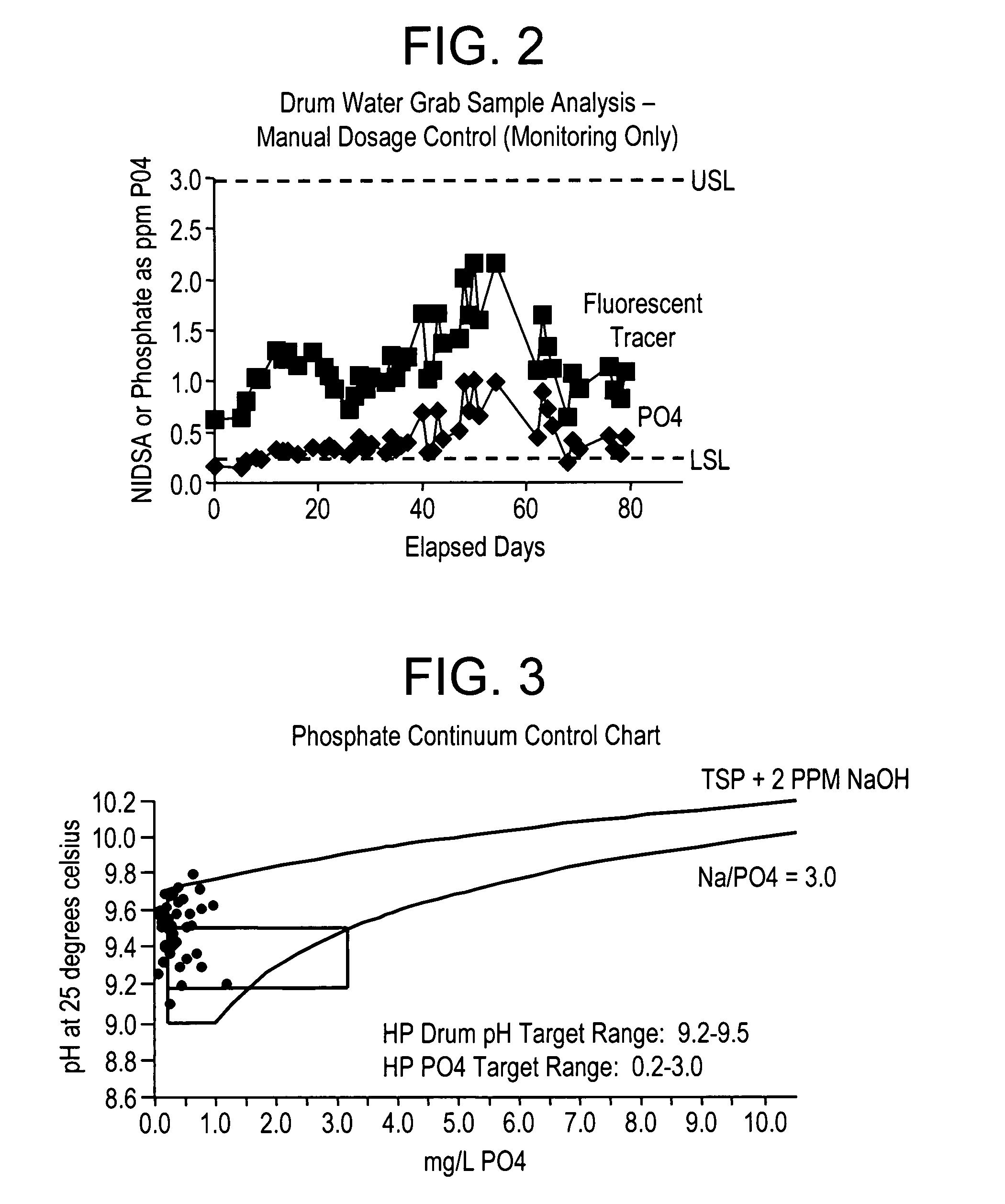

Very high-temperature fluorescent tracer and automation for boiler water applications

A method of fluorometrically monitoring dose control and leak detection, as well as boiler water system programs that occur in industrial systems containing boilers that operate between about 1500 psig and 2600 psig, and at pH from about 7.6 to 11.5.

Owner:ECOLAB USA INC

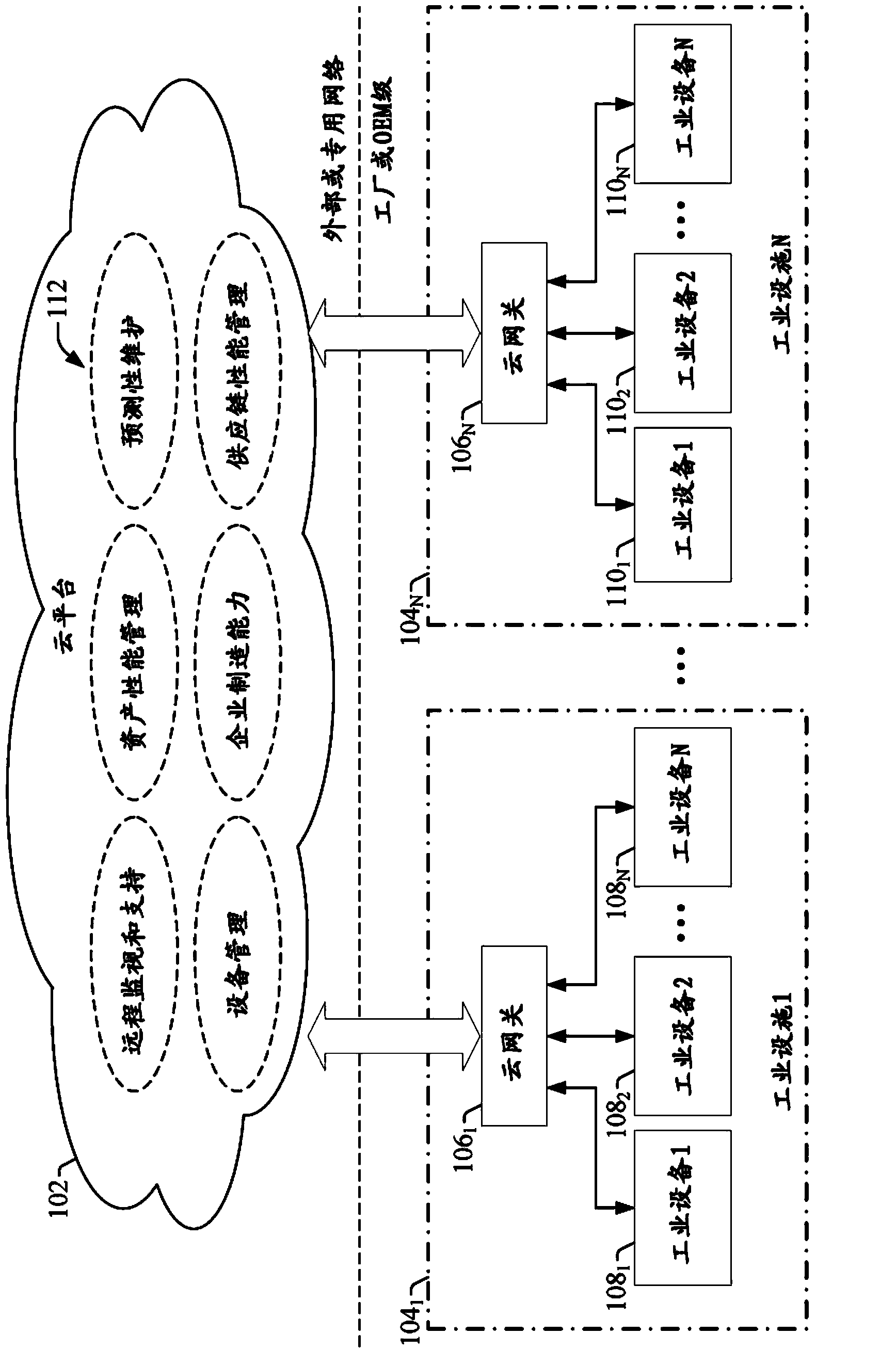

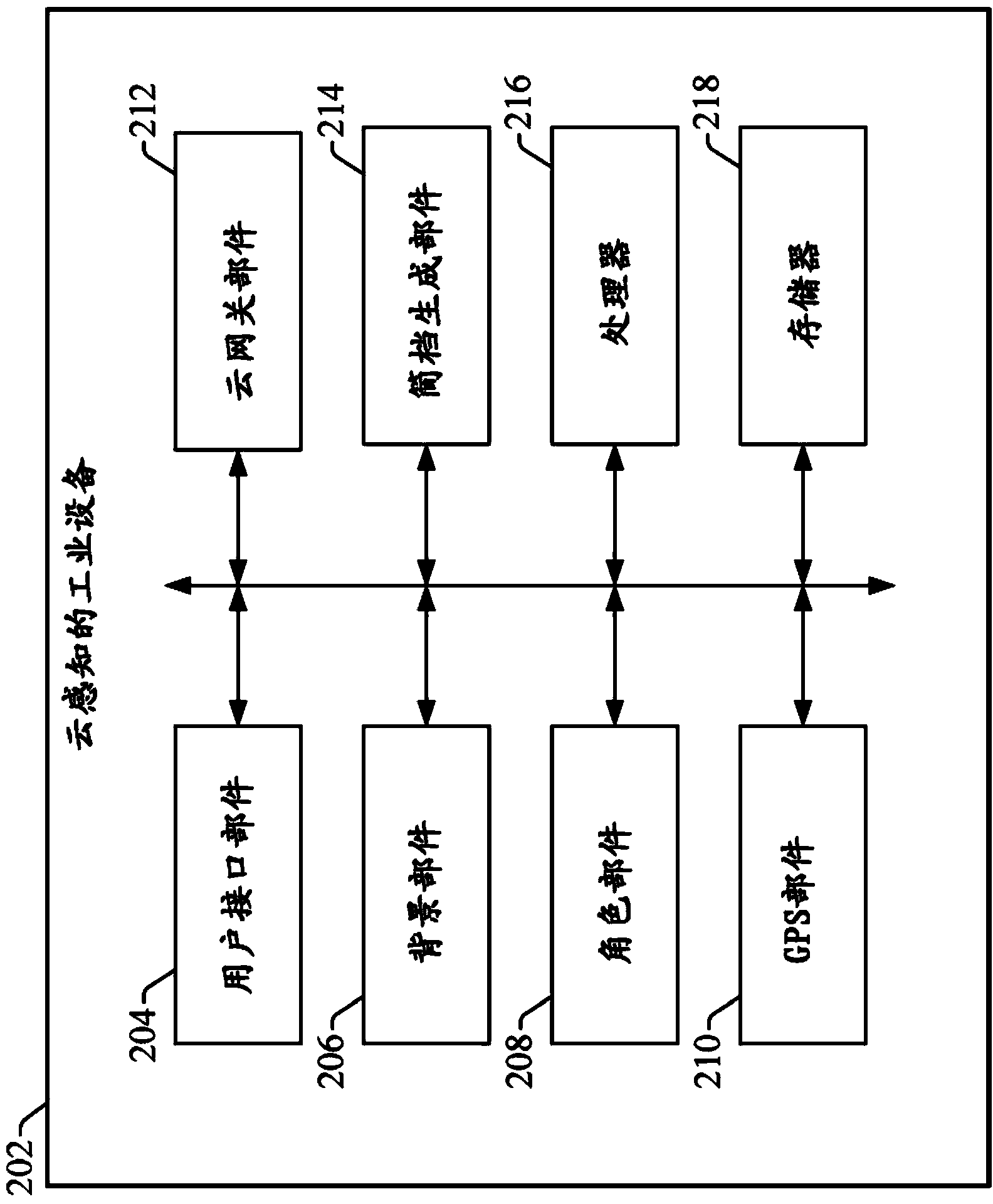

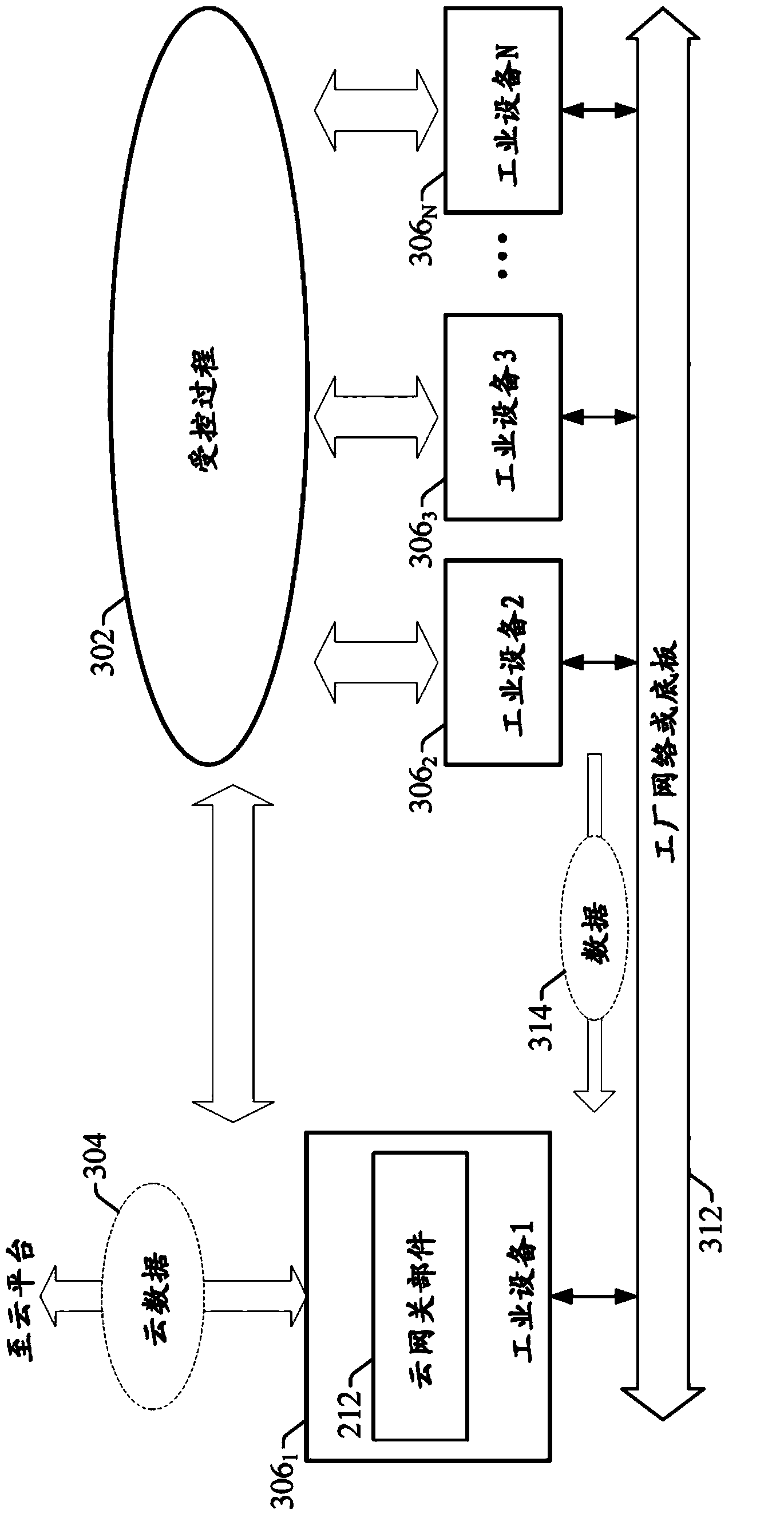

Remote assistance via a cloud platform for industrial automation

A remote technical support system leverages a cloud platform to automate technical support interactions, facilitating rapid diagnosis and solution of detected performance issues in industrial systems. The technical support system facilitates automated collection of relevant system data from a customer's industrial assets in the event of a detected performance issue requiring involvement of a technical support entity. The relevant system data can be sent to the cloud platform in response to a manual request for support at the plant floor, or automatically in response to detection of a possible device failure or performance issue. The cloud-based remote technical support system then routes the data to a suitable remote support representative, providing the representative with information about customer's industrial system and operations that may be relevant in connection with diagnosing the issue.

Owner:ROCKWELL AUTOMATION TECH

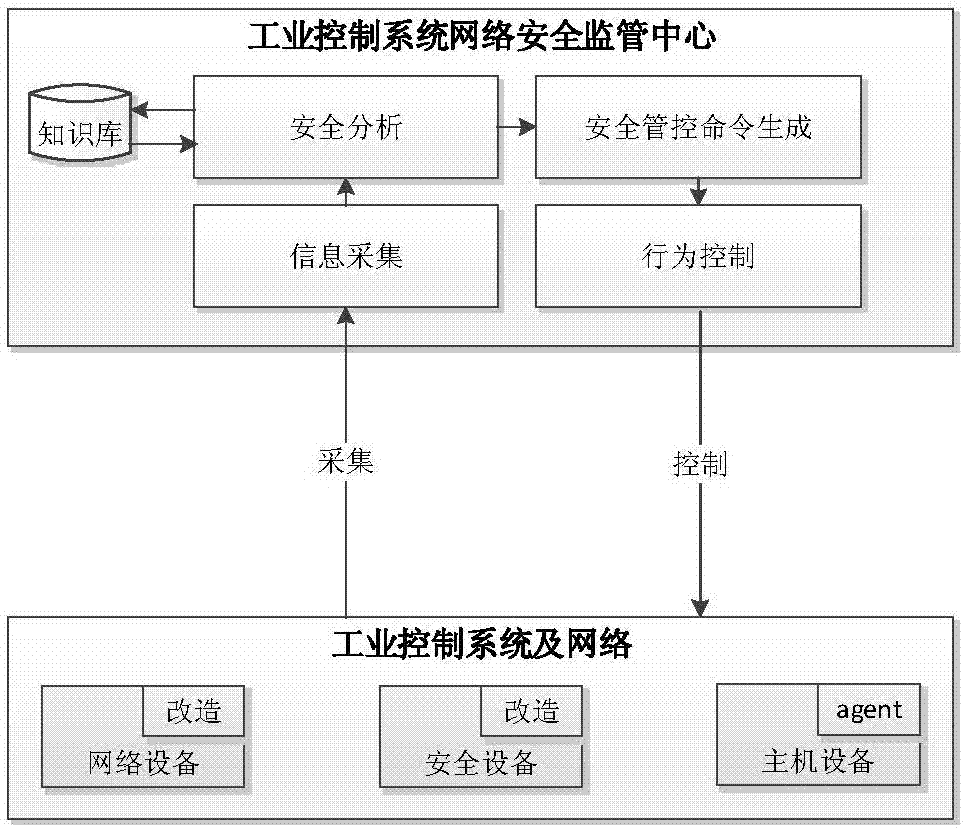

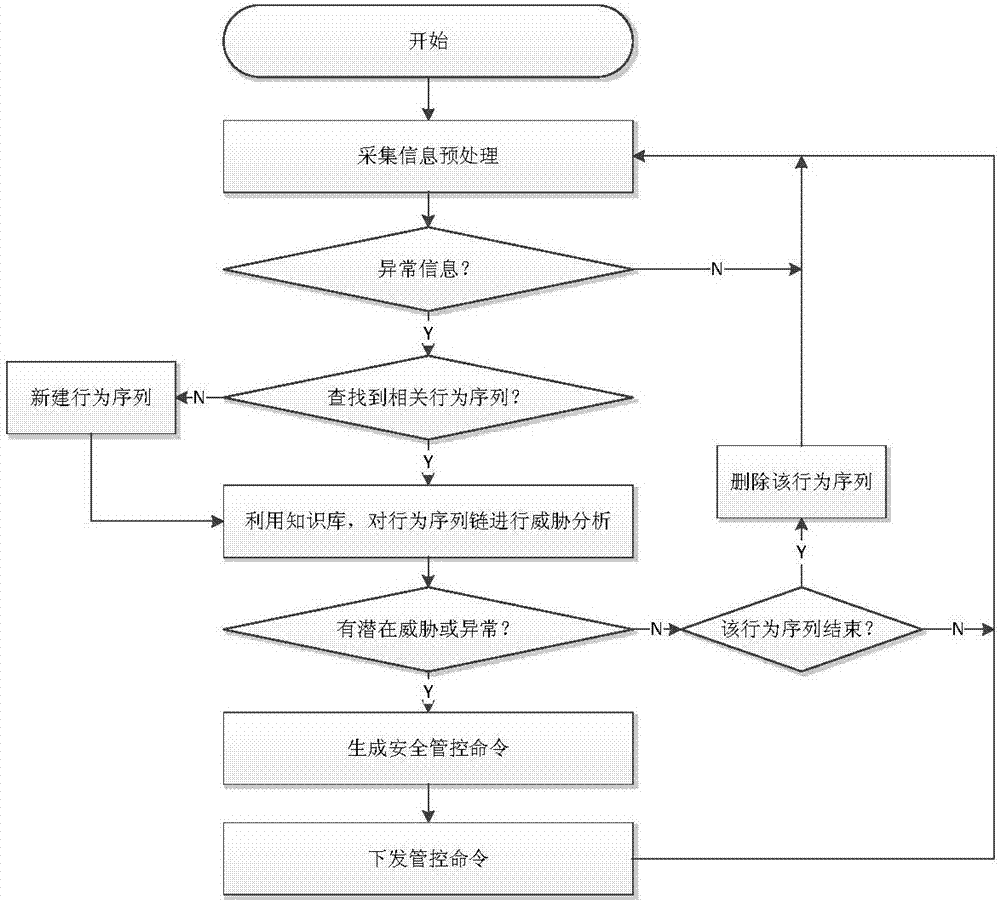

Network security monitoring method for industrial control system

ActiveCN107493265ARealize real-time monitoringRealize active defenseData switching networksRelevant informationIndustrial systems

The invention discloses a network security monitoring method for an industrial control system. The method comprises the following steps: collecting relevant information of an internal monitoring object of the industrial control system; performing security analysis on the collected relevant information; and when potential abnormal behavior is found through analysis, generating a relevant safety control order, and issuing the order to the relevant monitoring object for execution so as to block the abnormal behavior. According to the invention, real-time monitoring on major hidden security dangers of the industrial control system such as peripheral access, personnel operation, network external connection and the like is realized through abundant data acquisition of core networking equipment of the industrial control system. At the same time, through analysis processing on various behavior, the abnormal behavior is found and blocked timely, and thus real active defense of the industrial system is realized. For the current difficulty of effectively applying traditional security protection measures to the industrial control system, the major security threats to the industrial control system at present are well solved from the perspective of monitoring early warning.

Owner:NANJING NARI GROUP CORP +2

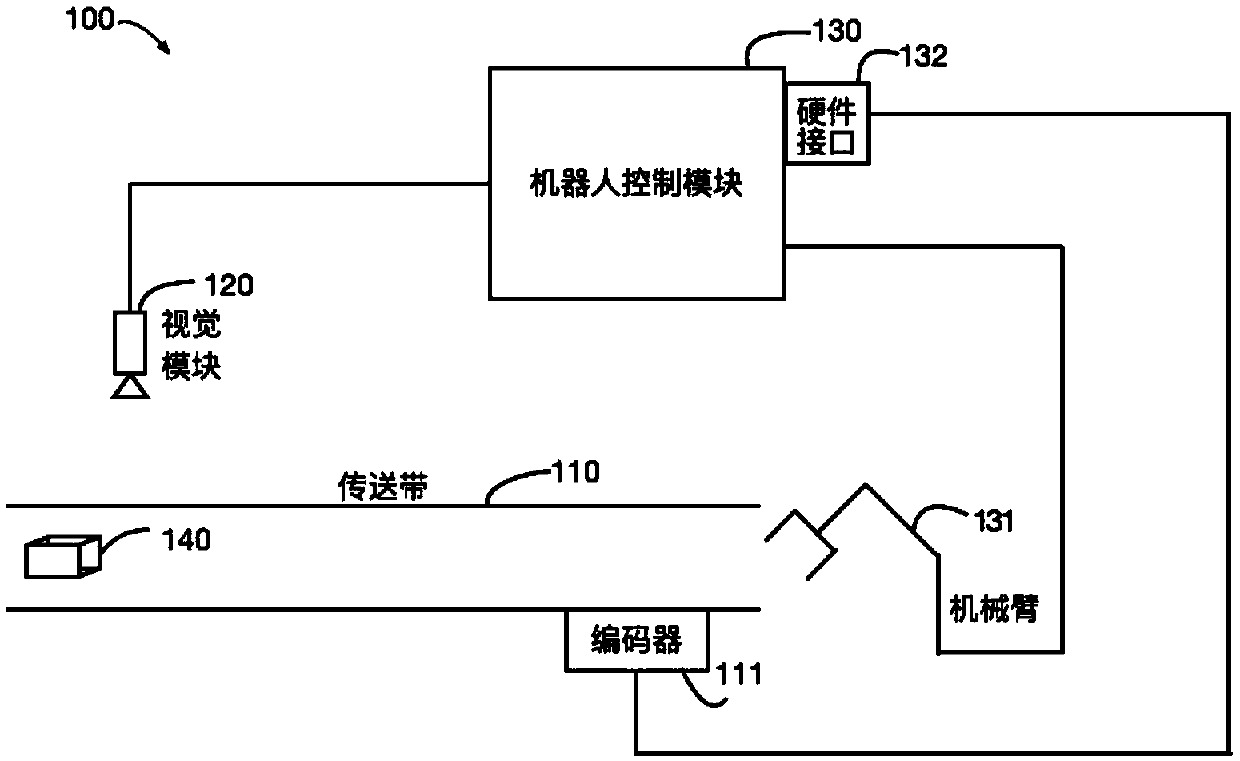

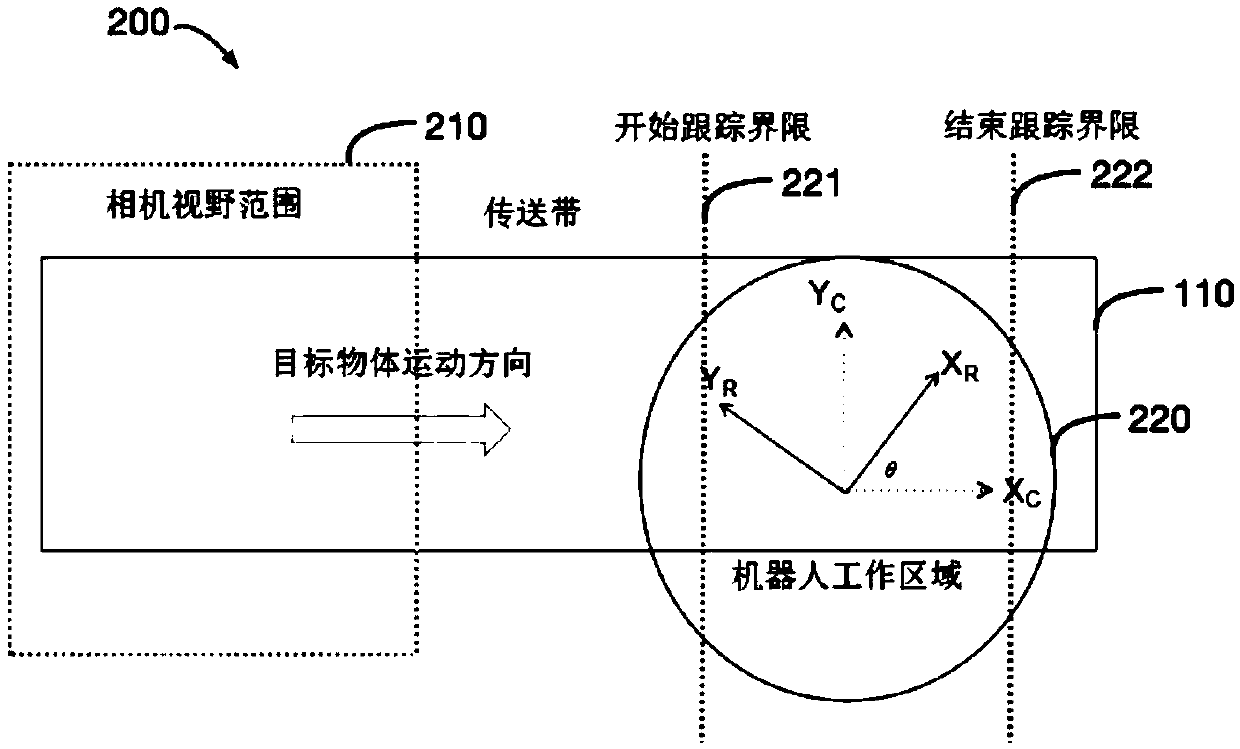

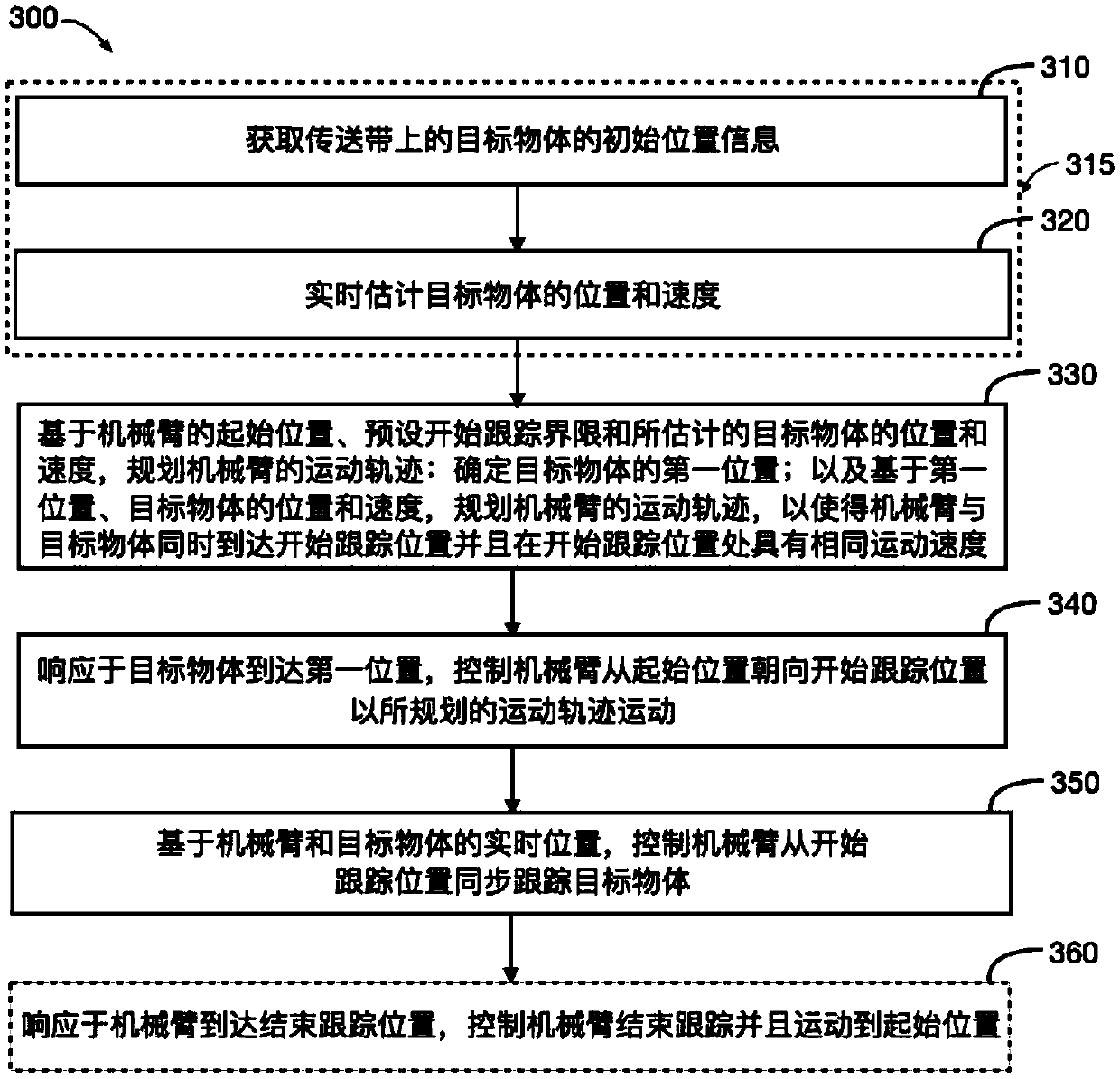

Conveyor belt synchronous tracking method, device and system for robot

ActiveCN108674922AAchieve positioningImplement trackingProgramme-controlled manipulatorConveyorsIndustrial systemsConveyor belt

The invention relates to a conveyor belt synchronous tracking method, device and system for a robot. The method comprises the following steps that initial position information of a target object on aconveyor belt is acquired, and the position and speed of the target object are estimated in real time; based on the start position of the robot, the preset start tracking limit and the estimated position and speed of the target object, the motion trajectory of the robot is planned so that when the target object reaches the first position, the robot can move from the start position to the start tracking position at the same time as the target object and have the same motion speed as the target object at the start tracking position; the robot is controlled to move in the planned motion trajectory in response to the target object reaching the first position; and based on the real-time positions of the robot and the target object, the robot is controlled to synchronously track the target object from the starting tracking position. By the adoption of the conveyor belt synchronous tracking method, device and system for the robot, fast target object positioning and tracking can be realized, the speed fluctuation is reduced, and the accuracy and work efficiency of an industrial system are improved.

Owner:GUANGZHOU SHIYUAN ELECTRONICS CO LTD

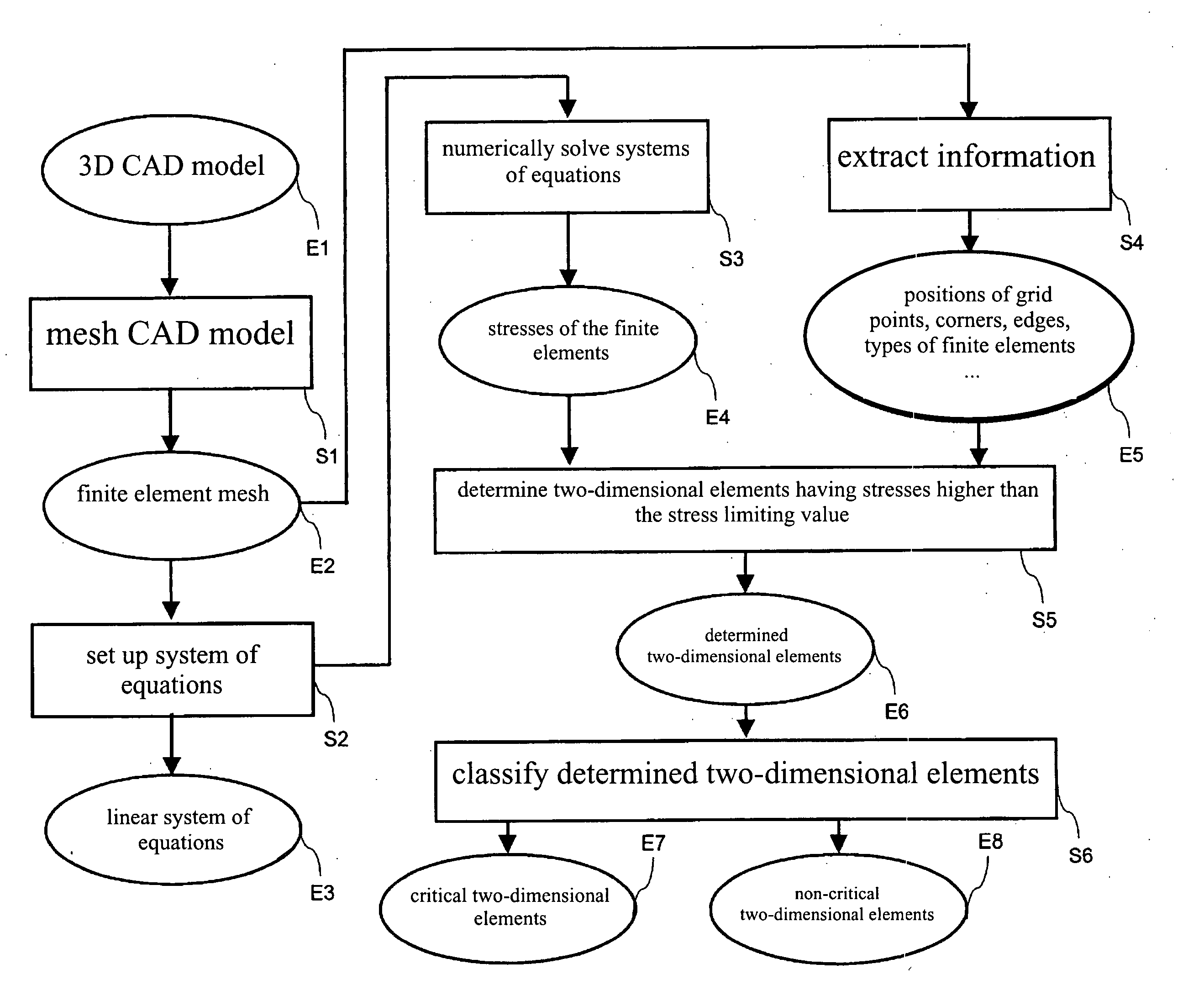

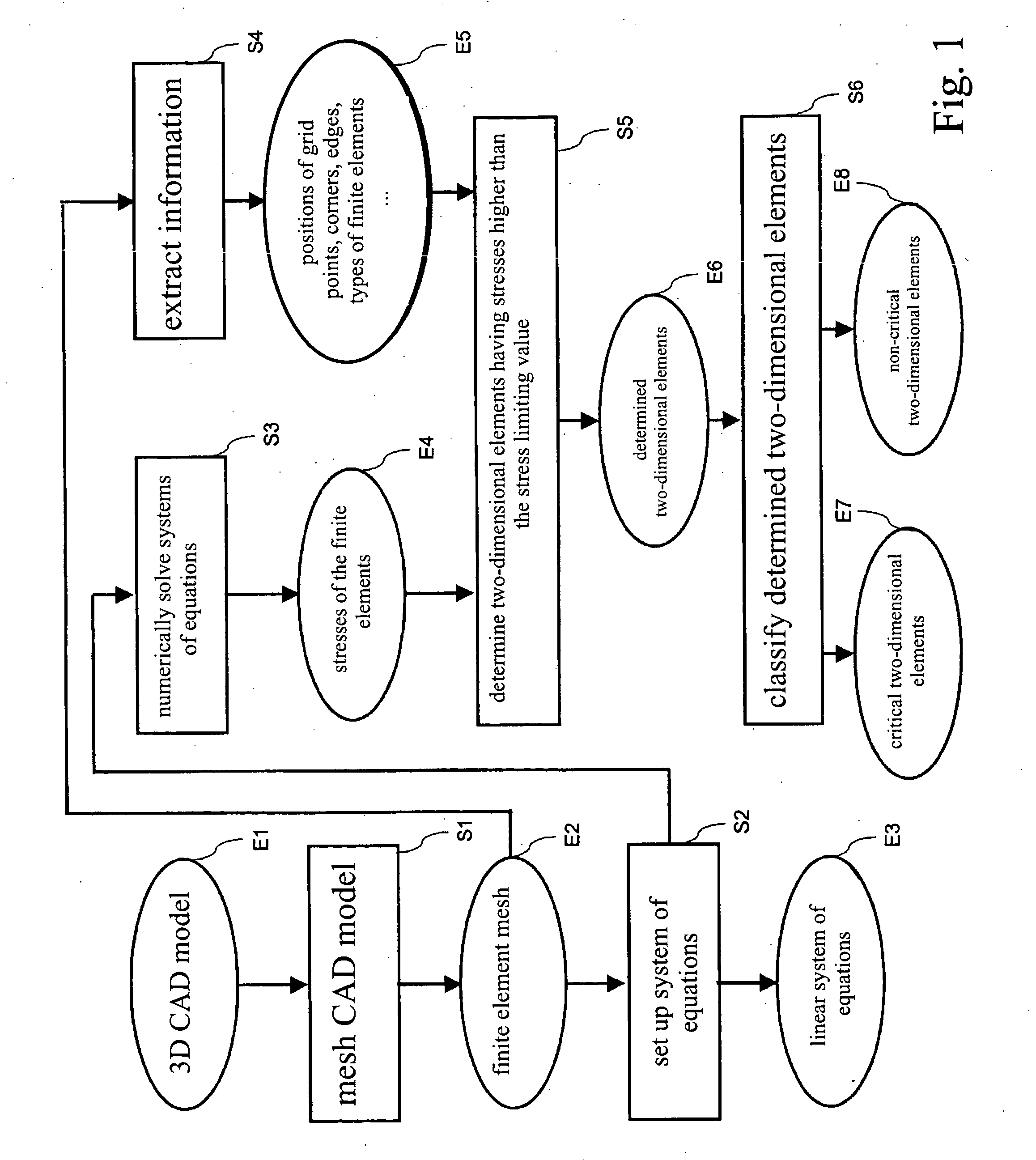

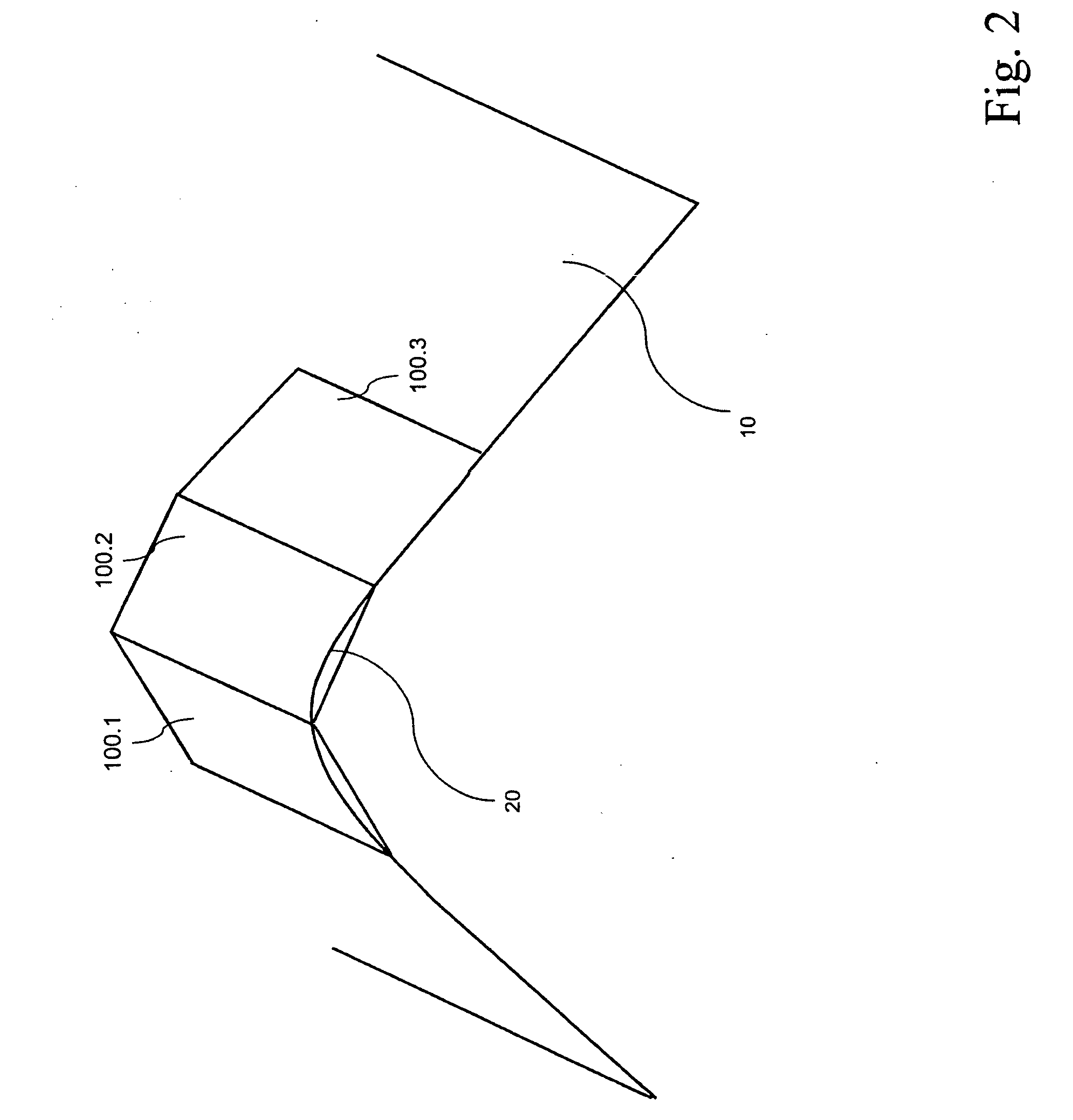

Finite element simulation

ActiveUS20050171745A1Improving critical classificationGeometric CADComputation using non-denominational number representationIndustrial systemsEngineering

A method for automatic evaluation of a finite element simulation for an industrial system such as a motor vehicle body includes predefining an electronic design model of the industrial system and generating finite elements for the model. The stresses occurring in the finite elements are determined using a finite element simulation. Each finite element, which is a two-dimensional element and not a rigid object element and whose stress exceeds a predefined stress limiting value, is determined. For each determined two-dimensional element which is not a triangle, an element limiting value is determined on the basis of the stress limiting value. Each determined two-dimensional element is classified as critical if its computed stress exceeds the established element limiting value. The method enables identification of areas of the industrial system having a high stress and reduces the effect of inaccuracies that occur on the evaluation of the finite element simulation due to the approximation of the vehicle body by finite elements.

Owner:CHEMTRON RES

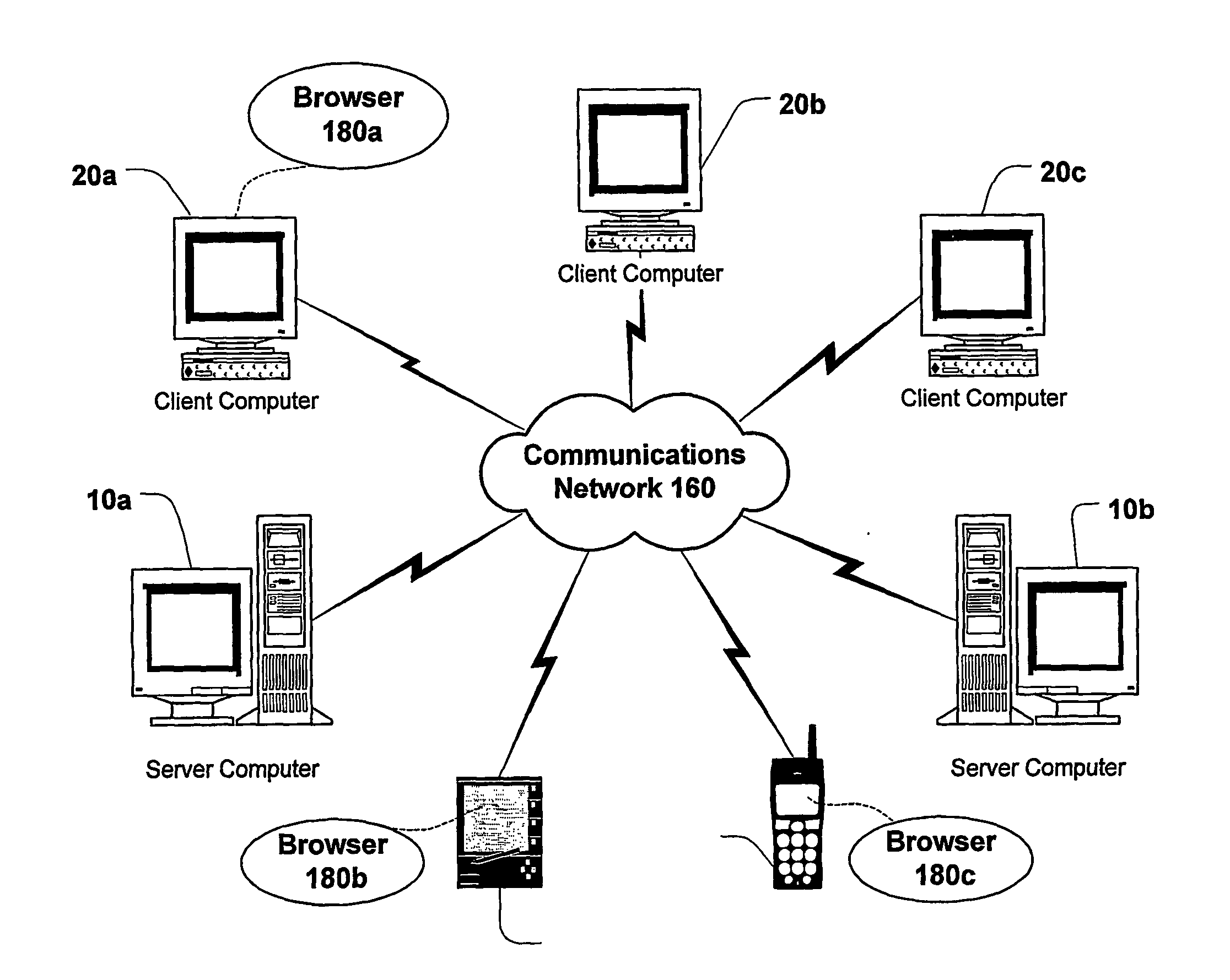

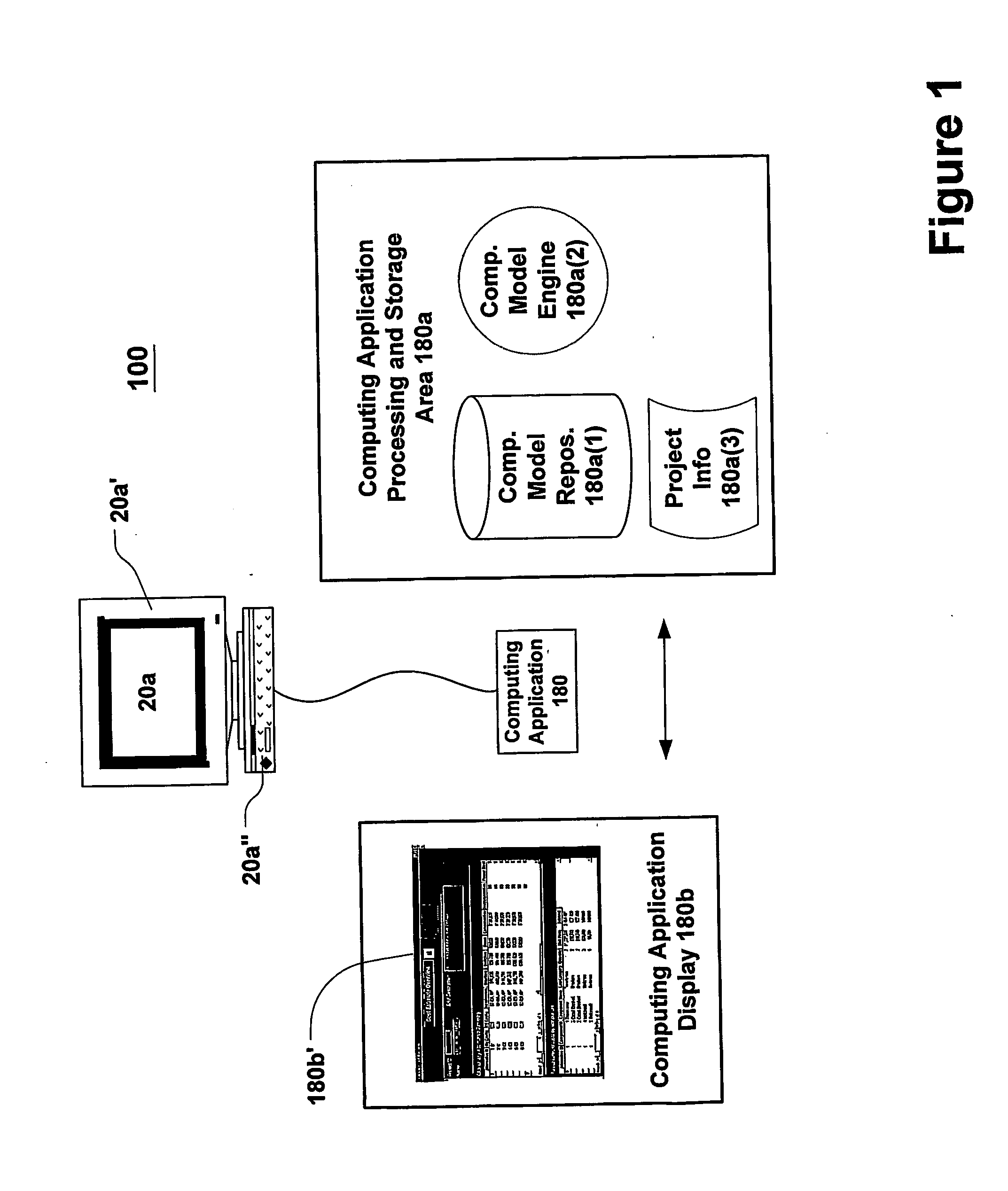

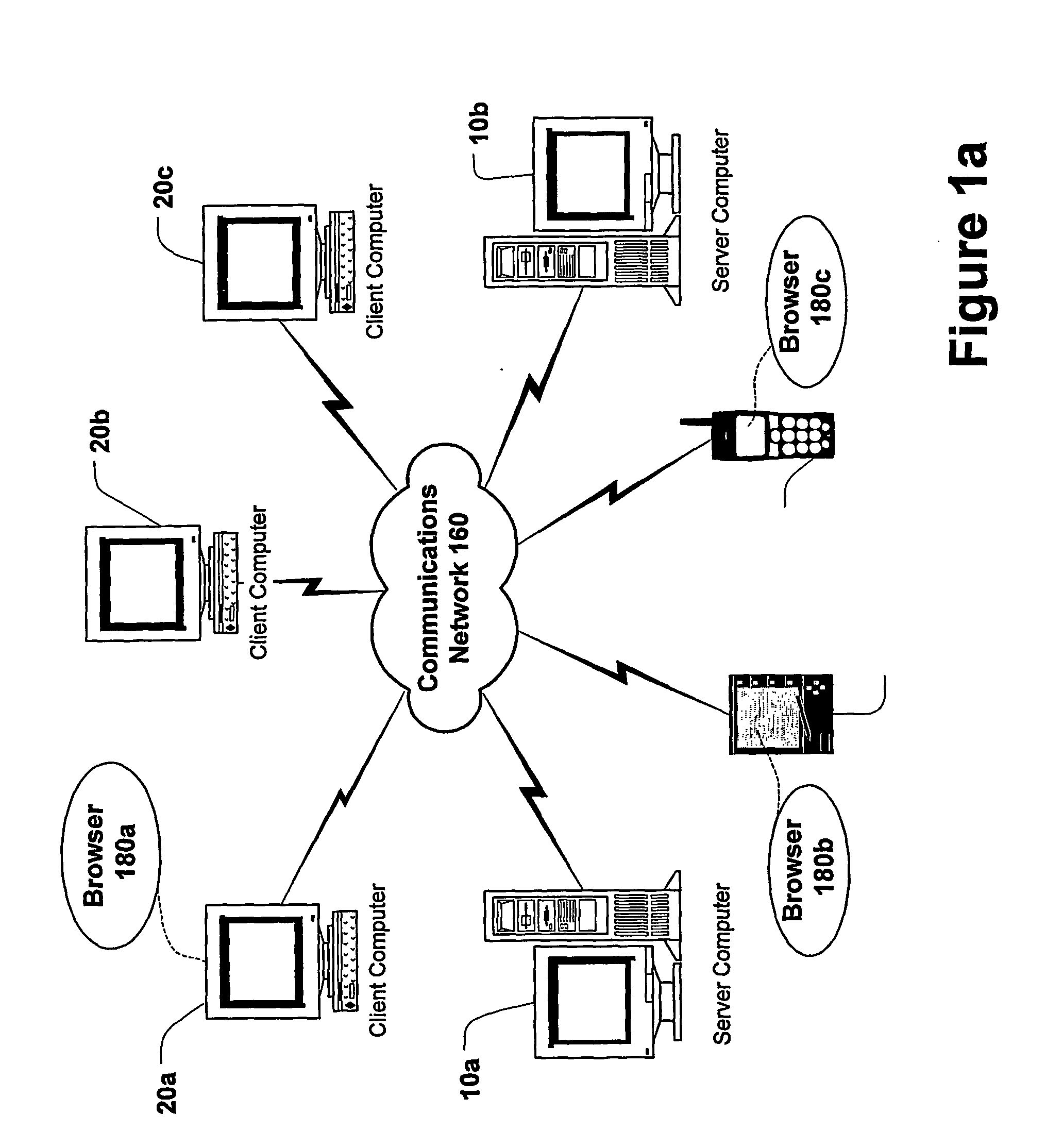

Industrial it system for distribution power transformers manufacturing material control with suppliers systems integration

InactiveUS20060052888A1ResourcesSpecial data processing applicationsDistribution transformerIndustrial systems

The invention contemplates a system and method for communicating among entities of a manufacturing process. The System (100) comprises a process tracking and workflow engine and a communications network. The process tracking and workflow engine (180a) includes at least one processing rule operating on manufacturing processing information. The communications network (160) cooperates with the process tracking and workflow engine to transmit and receive data representative of manufacturing communication information. The inventive system also may include a sales system (801) for receiving a product request, where the product request is received from a customer and / or a field sales representative.

Owner:ABB RES LTD

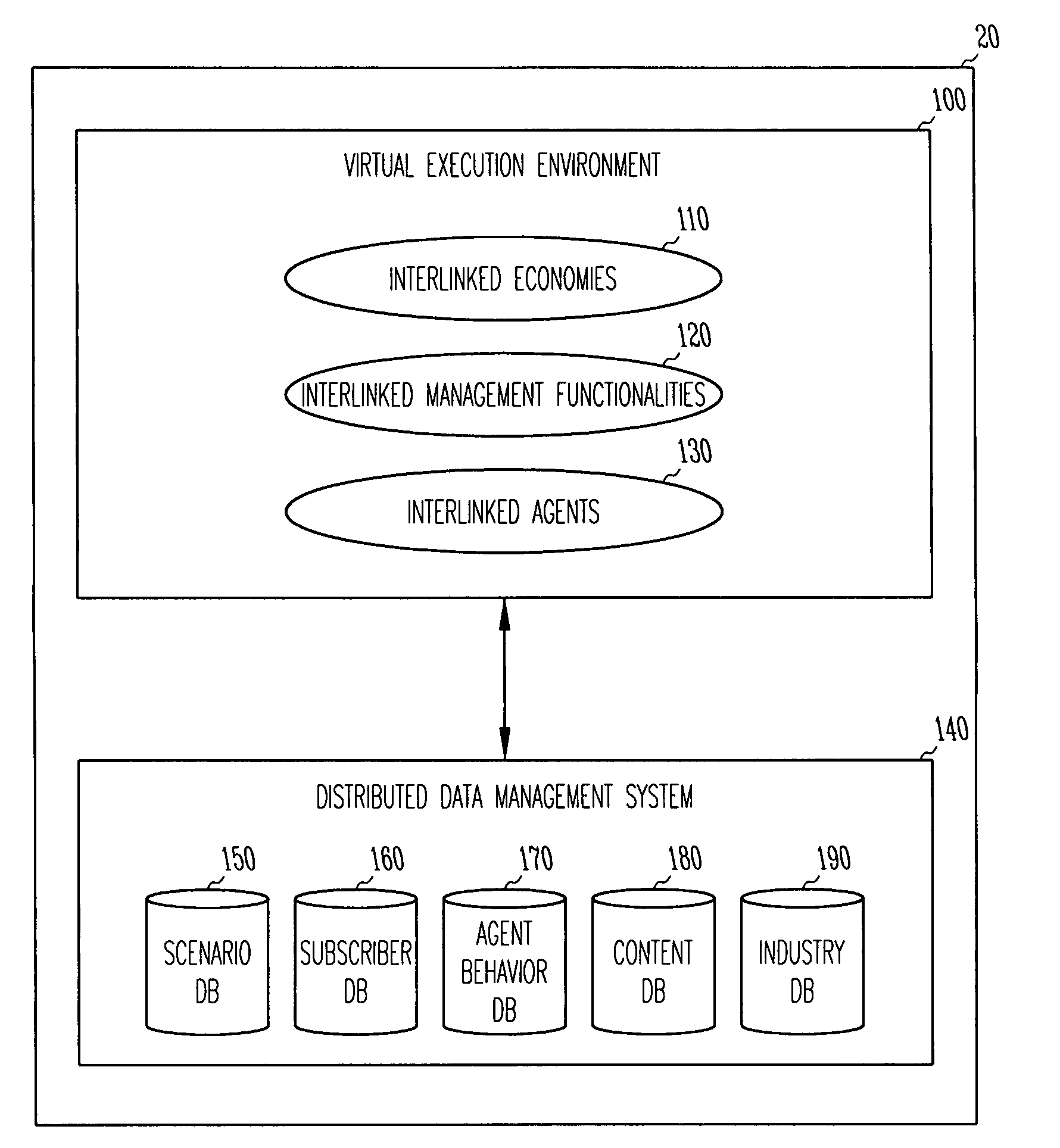

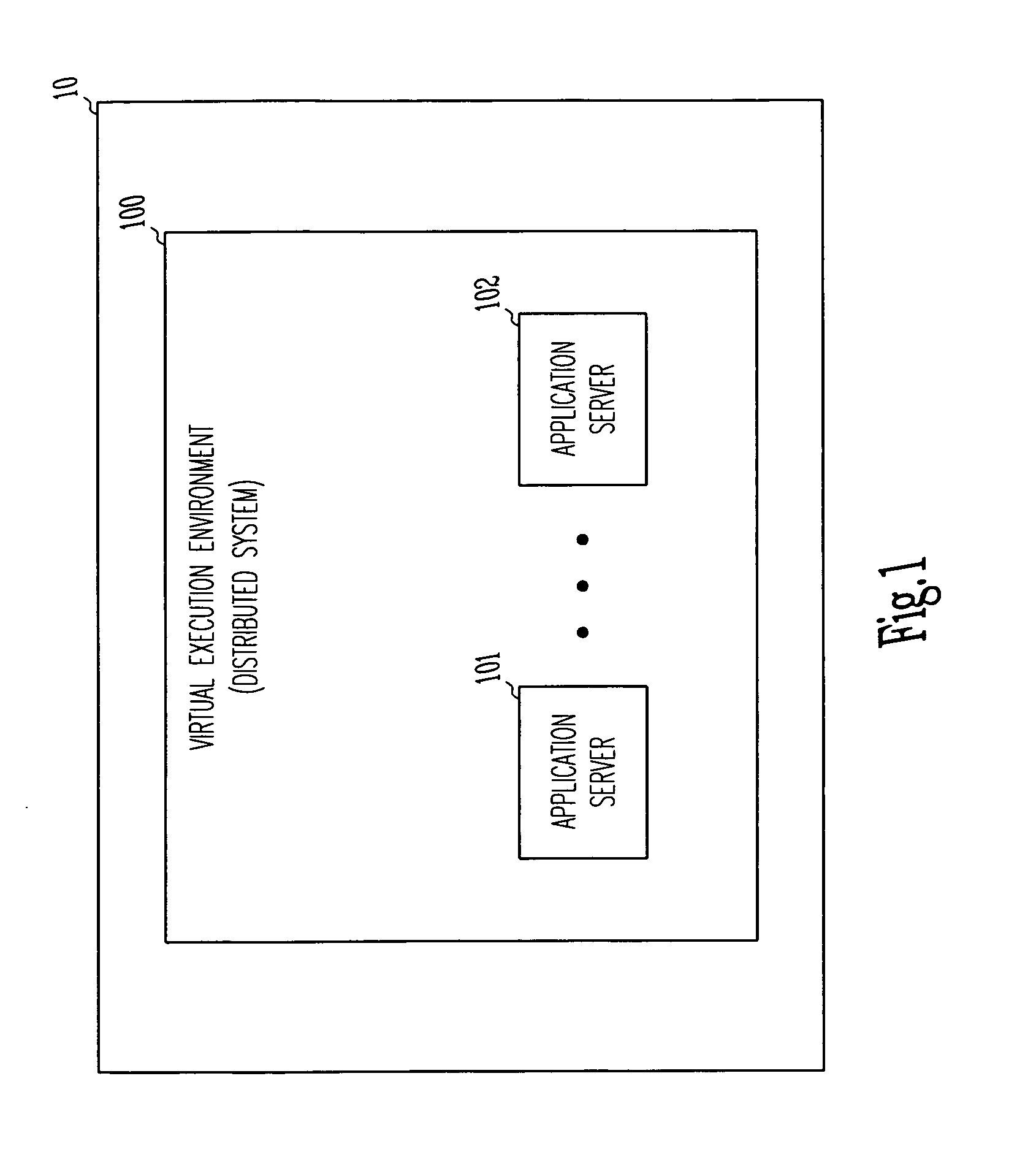

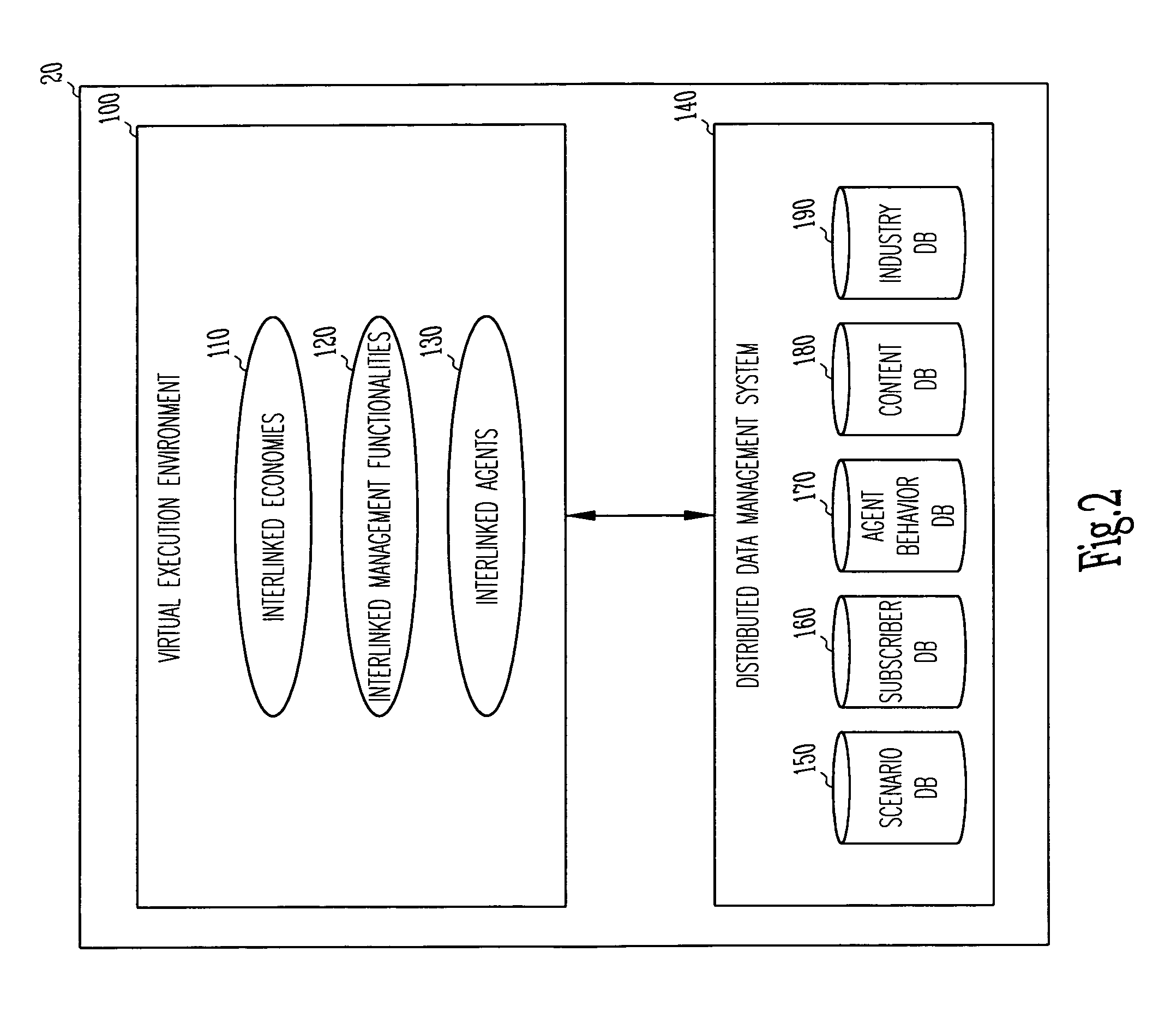

Industry simulation environment

ActiveUS6931365B1Multiprogramming arrangementsResourcesSynthetic Environment for Analysis and SimulationsIndustrial systems

An apparatus and method for simulating a global industrial environment. In one embodiment, the global industrial environment models a global economy as a set of interlinked economies, models a management framework as a set of interlinked management functionalities, and models both individual and organizational behaviors through a use of a set of interlinked agents. In another embodiment, operational data independent from the interlinked economies, interlinked management functionalities, and interlinked agents is customized at run-time. In another embodiment, individuals are electronically trained in a synthetic environment for analysis and simulation of a global industrial system. In this embodiment, the environment includes a virtual execution environment, a pre-exercise briefing, one or more rounds of exercise-time activity, and a post-game analysis.

Owner:PURDUE RES FOUND INC

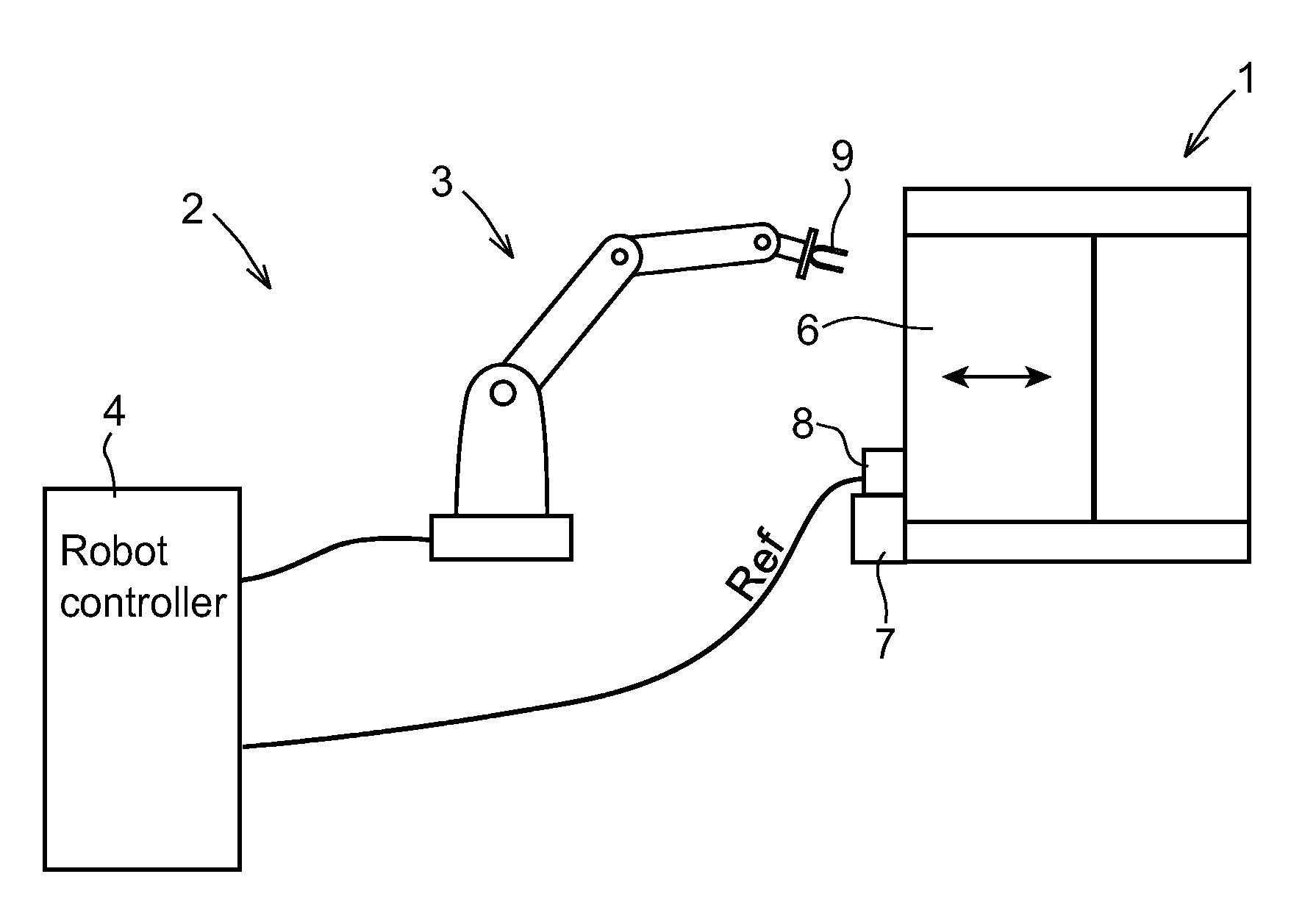

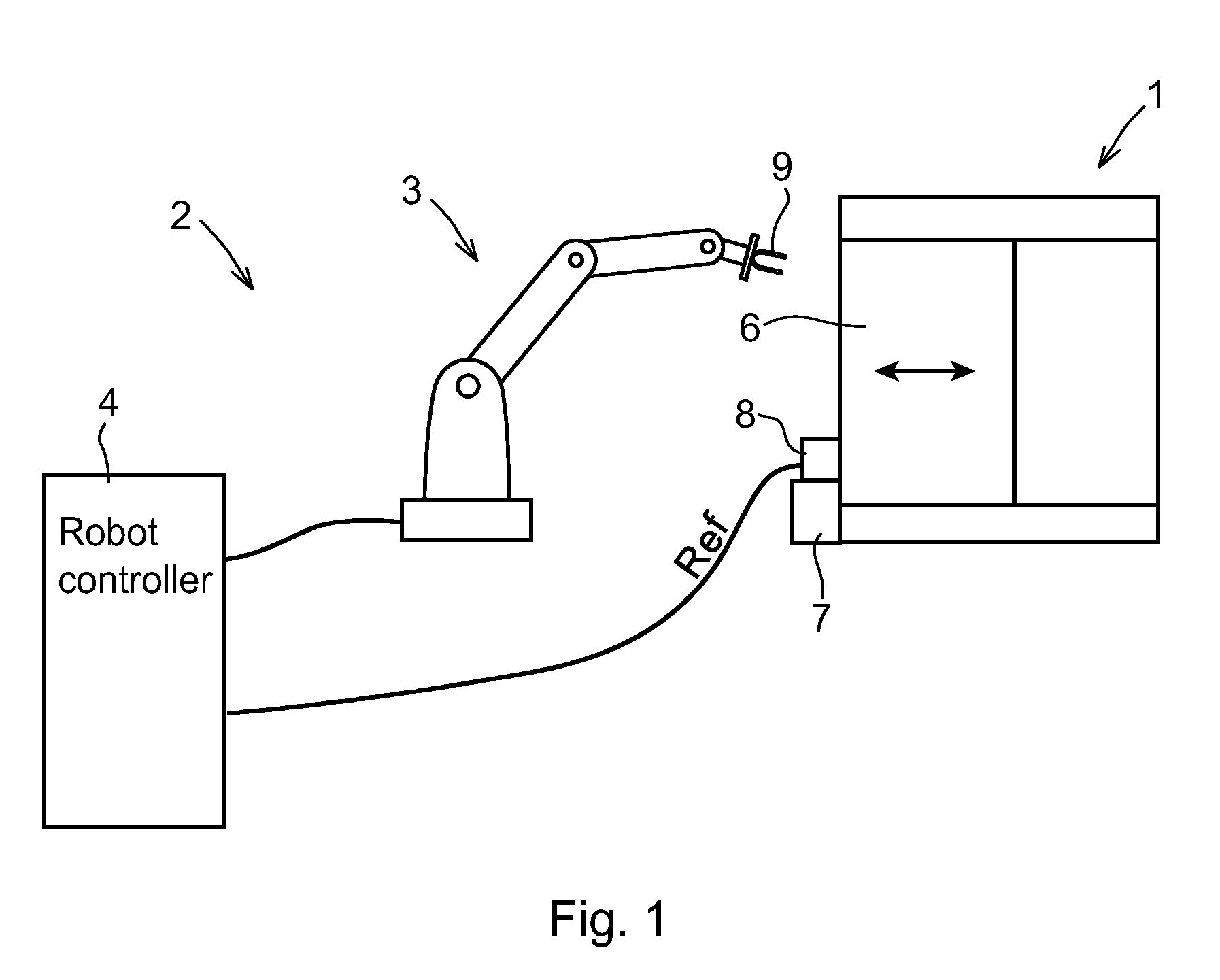

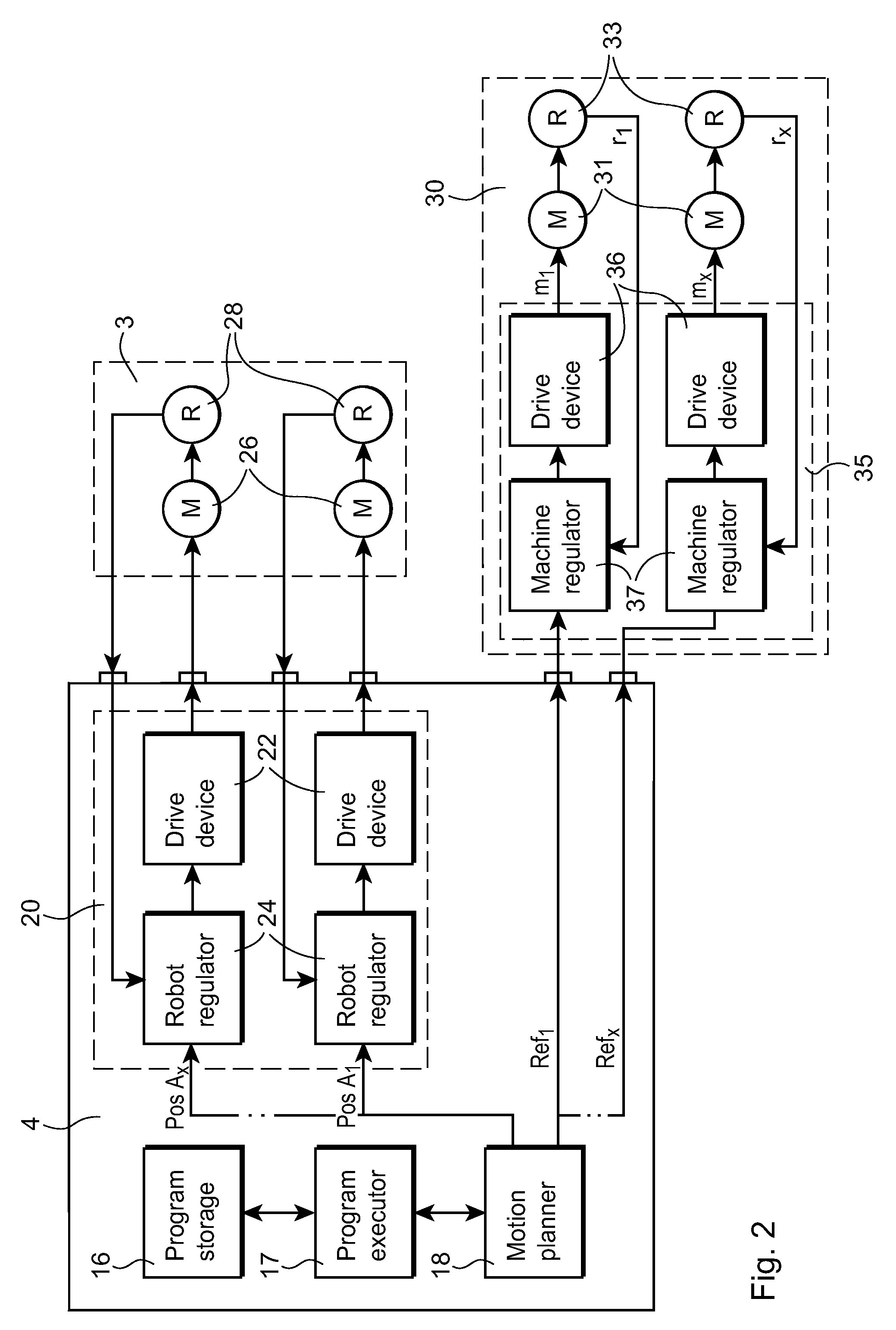

Industrial System Comprising an Industrial Robot and a Machine Receiving Movement Instructions From the Robot Controller

InactiveUS20080275593A1Shorten cycle timeTotal factory controlSpecial data processing applicationsRepetitive SequencesMachine parts

An industrial system including a machine for processing or producing a product. The machine includes at least one actuator providing a repetitive sequence of movements of a machine part, and a regulator controlling the movements of the actuator in response to a reference value. An industrial robot is adapted to tend the machine. The robot includes a drive unit and a robot controller adapted to generate control signals to the drive unit based on a control program including movement instructions for the robot. The robot controller is adapted to generate the reference value to the regulator based on a control program including movement instructions for the machine part. The regulator may also be an integrated part of the robot controller.

Owner:ABB (SCHWEIZ) AG

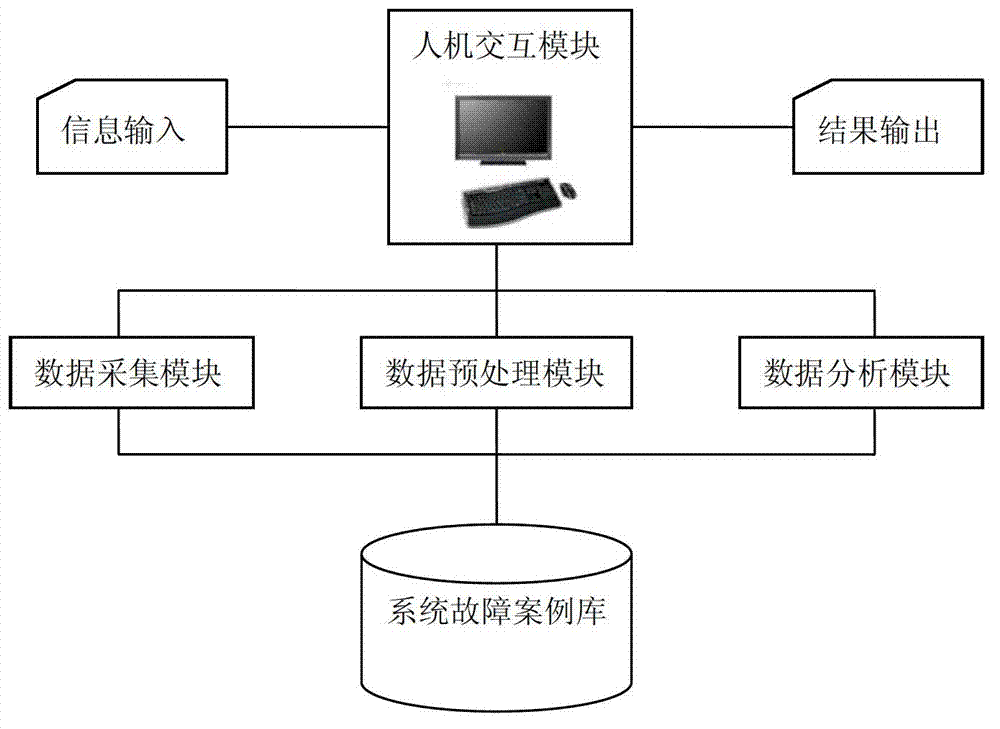

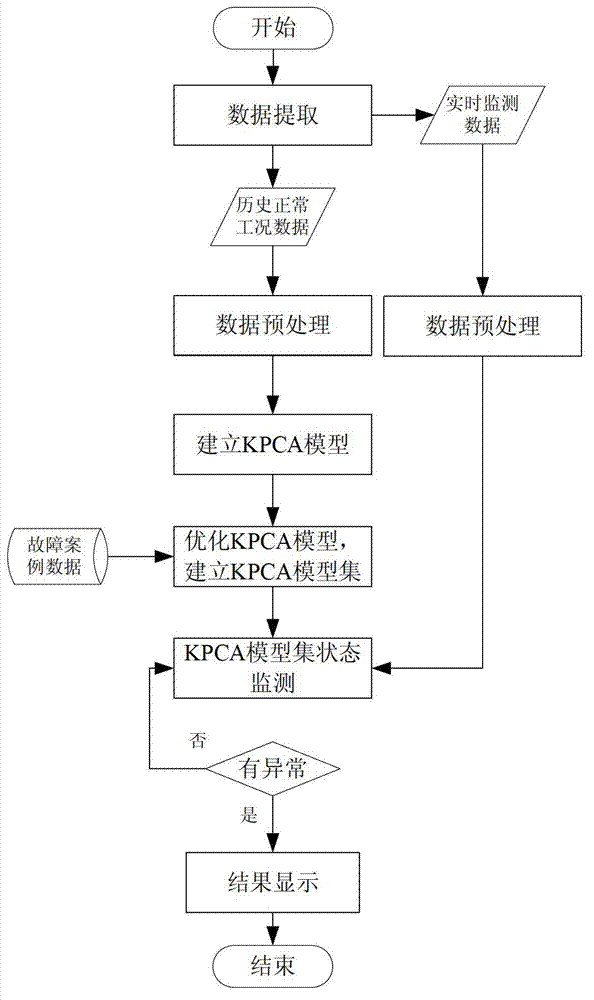

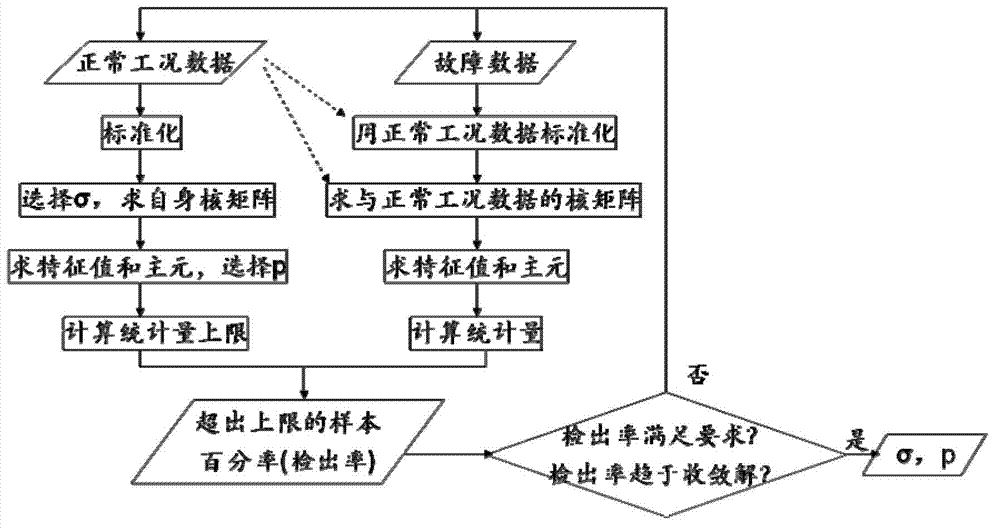

State monitoring device of complex electromechanical system for flow industry and method

ActiveCN102736546AEasy fault detectionTimely and accurate monitoringProgramme controlComputer controlKernel principal component analysisIndustrial systems

The invention relates to a state monitoring device of a complex electromechanical system for a flow industry and a method. The device comprises a man-machine interaction module, a data collecting module, a data preprocessing module, a data analyzing module and a failure case library. According to the device and the method provided by the invention, whether the system fails or is in abnormal states or not can be monitored and early warming for tripping accidents or other accidents of the flow industry system can be made. Meanwhile, a KPCA (Kernel Principal Component Analysis) method with double parameter optimization is used to overcome the deficiency that parameters are selected by empirical formula in conventional KPCA methods, thereby improving the state monitoring ability. Furthermore, the failure case database is adequately used in the historical production process so that failures of the system can be monitored more immediately and accurately.

Owner:HANGZHOU HOLLYSYS AUTOMATION

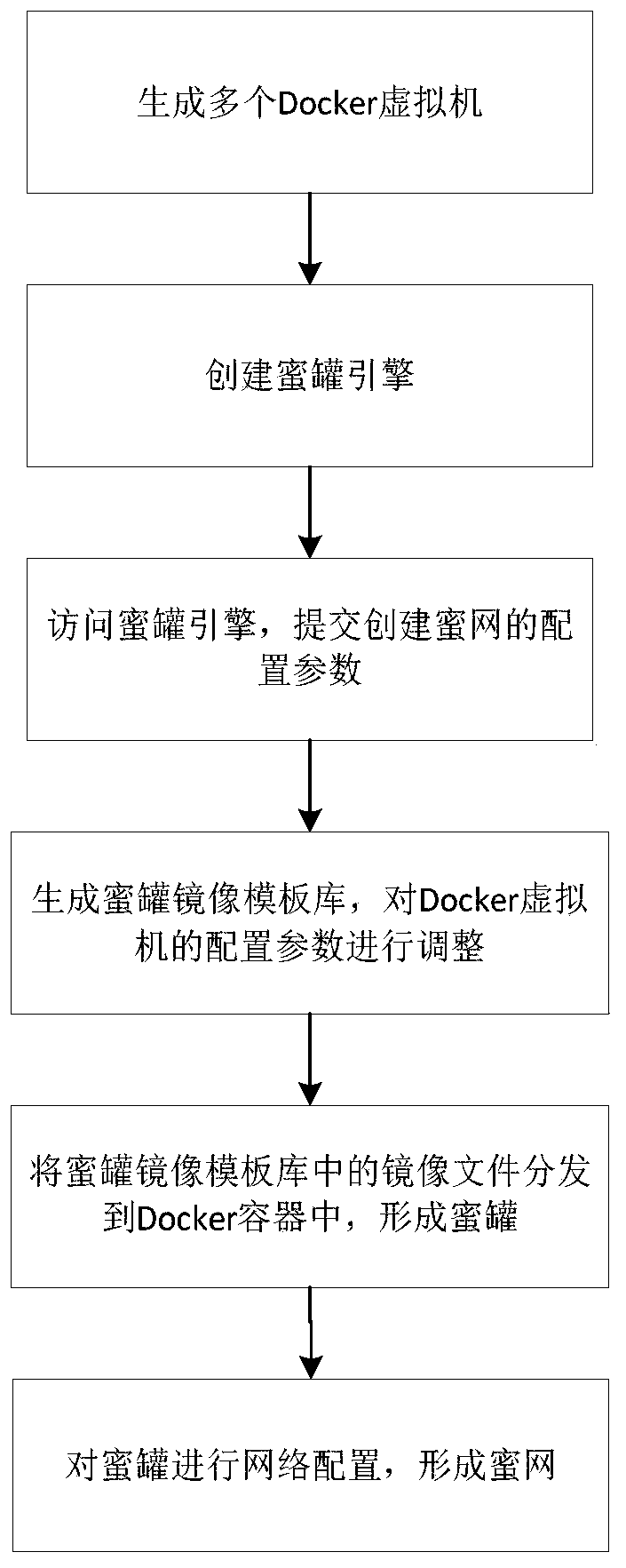

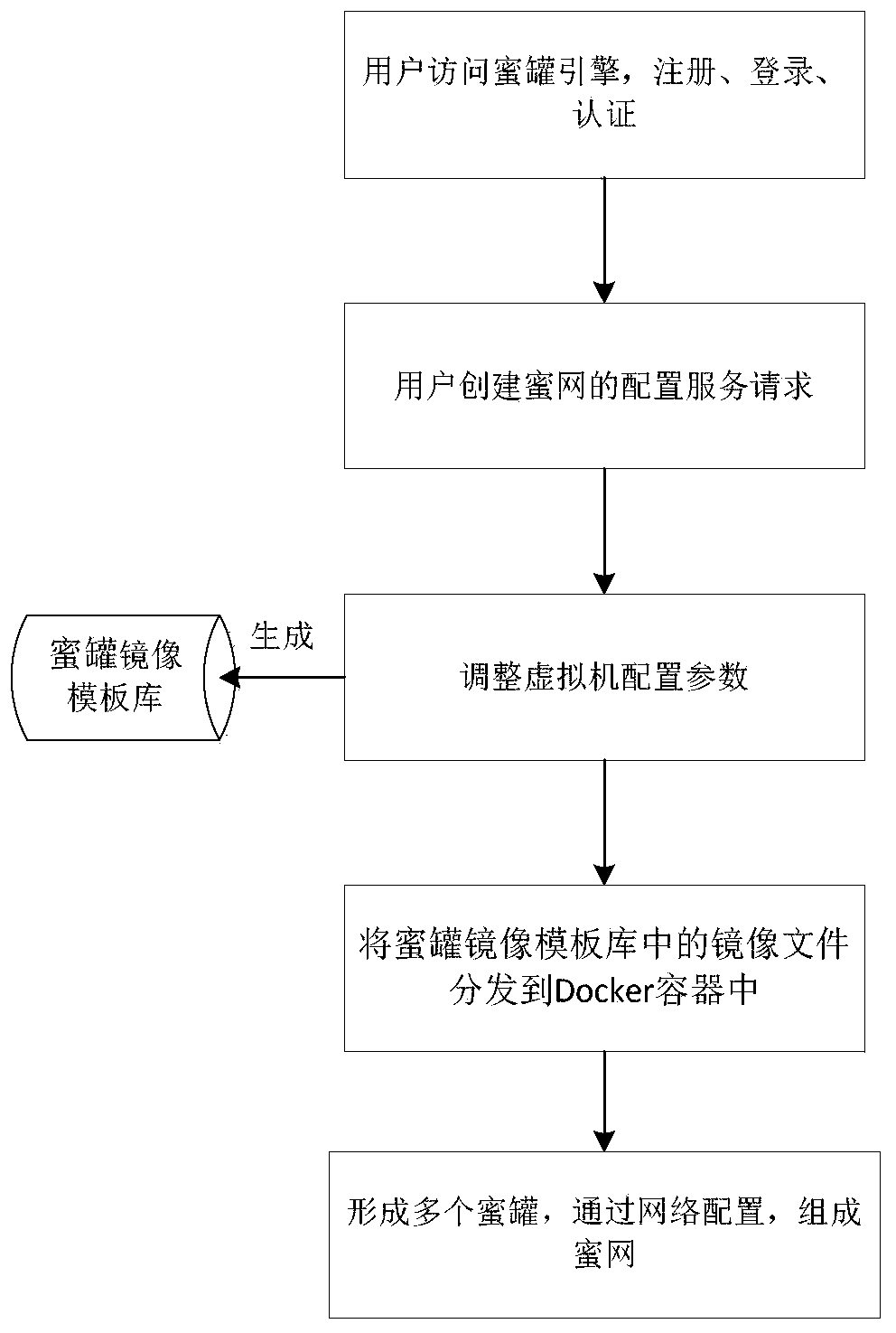

Virtual cloud honeynet deployment method, device and system and computer readable storage medium

InactiveCN110784361ALow costAchieve maximum utilizationData switching networksVirtualizationIndustrial systems

The invention relates to a virtual cloud honeynet deployment method, device and system and a computer readable storage medium. The method comprises the steps of (1) generating a plurality of Docker virtual machines; (2) creating a honeypot engine; (3) submitting configuration parameters for creating the honeynet; (4) generating a honeypot mirror image template library, and adjusting configurationparameters of each Docker virtual machine; (5) distributing the mirror image files in the honeypot mirror image template library to containers of the Docker virtual machines to form a plurality of honeypots; and performing network configuration on the Docker virtual machine corresponding to each honeypot to form a honeynet. The method is simple in configuration and high in starting speed, meanwhile, the cost of honeypot deployment in the aspect of physical host hardware resources in an industrial system is reduced, and the problems that in a traditional virtualization technology, configurationis tedious, the starting speed is low, and the hardware resources are wasted can be solved.

Owner:STATE GRID HENAN ELECTRIC POWER ELECTRIC POWER SCI RES INST +2

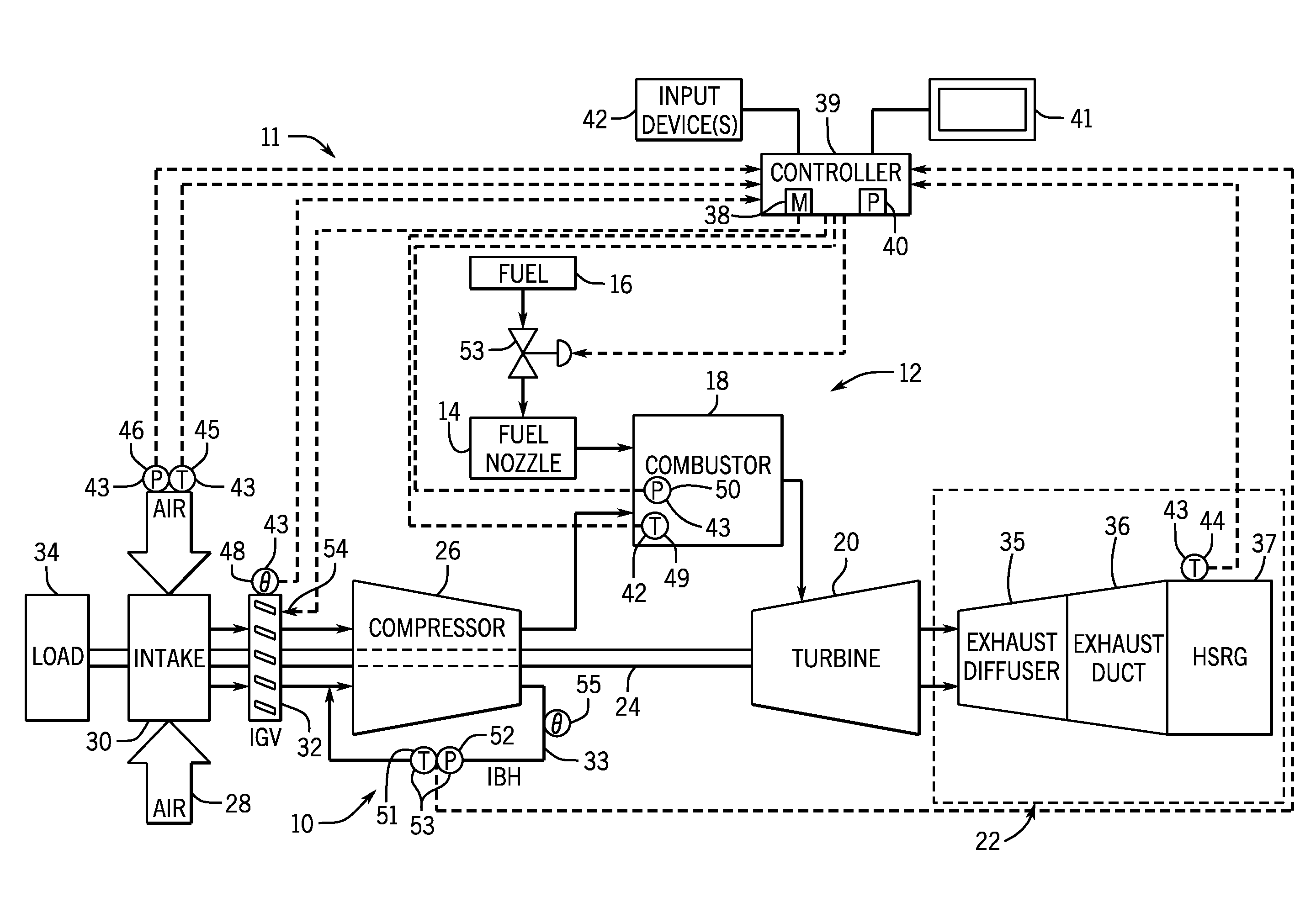

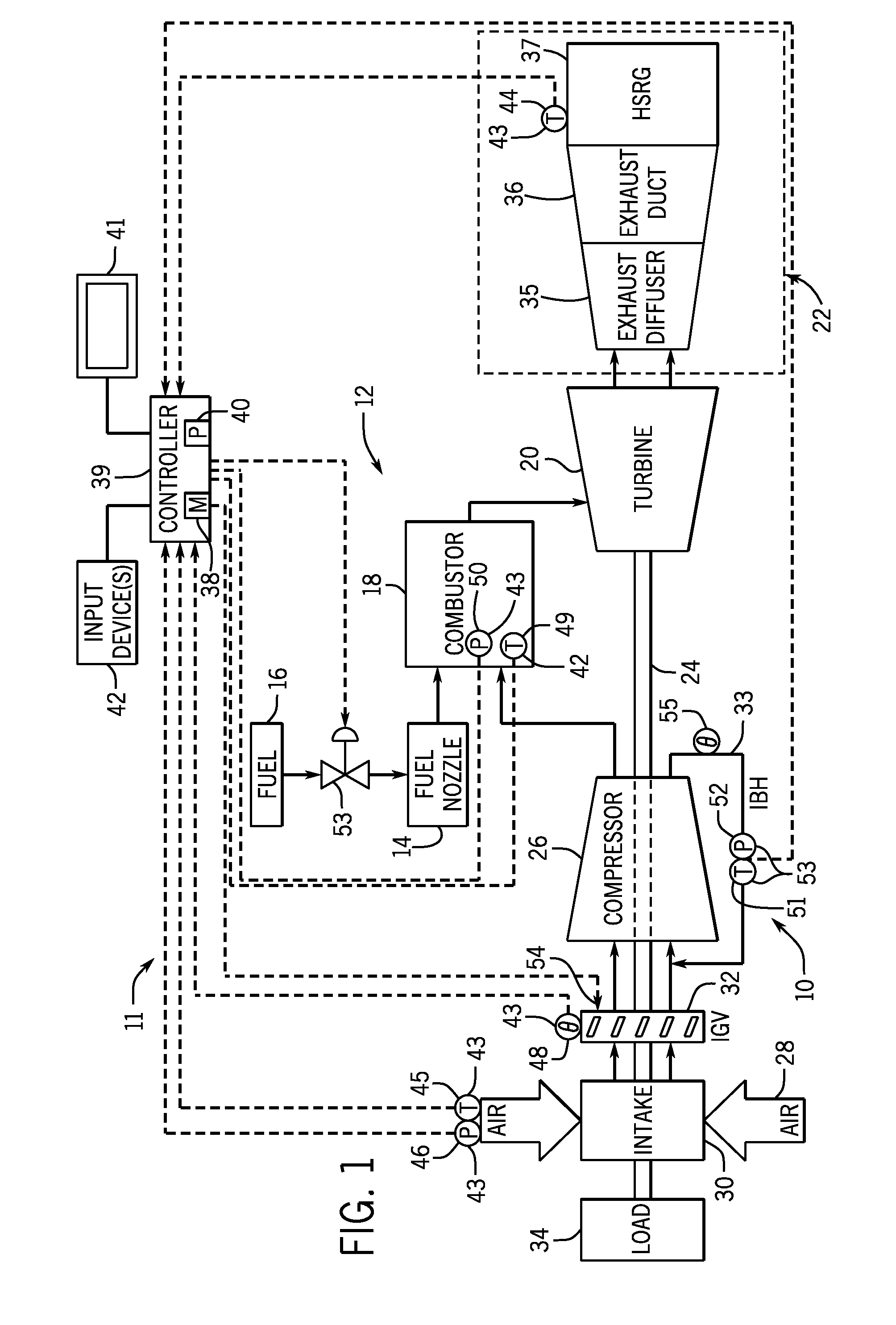

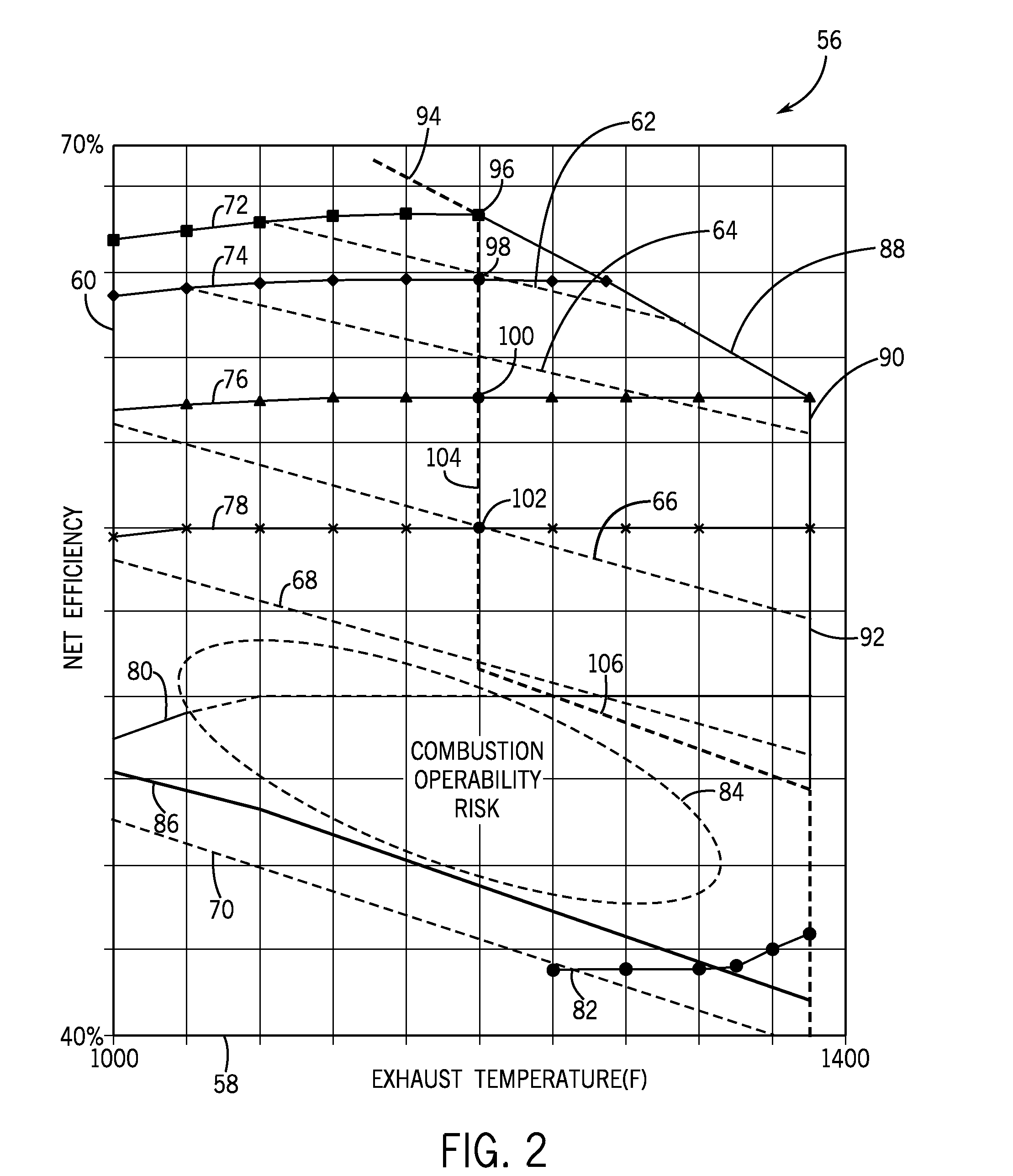

Gas turbine load enhancement

ActiveUS20140260177A1Gas turbine plantsTurbine/propulsion fuel controlIndustrial systemsControl theory

An automated industrial system is provided that includes a sensor system configured to monitor multiple parameters. The automated industrial system also includes a controller. The controller is configured to determine if any of the multiple parameters has surpassed a respective constraint threshold of multiple constraint thresholds. If any of the parameters has surpassed a respective constraint threshold, the controller is configured to classify a parameter of the multiple parameters which has surpassed the respective constraint threshold by the highest degree as the most constrained parameter. The controller is also configured to calculate a minimum temperature load path based on the most constrained parameter, with the minimum temperature load path configured to transition the automated industrial system from a base load to a part load via a minimum temperature load path.

Owner:GENERAL ELECTRIC CO

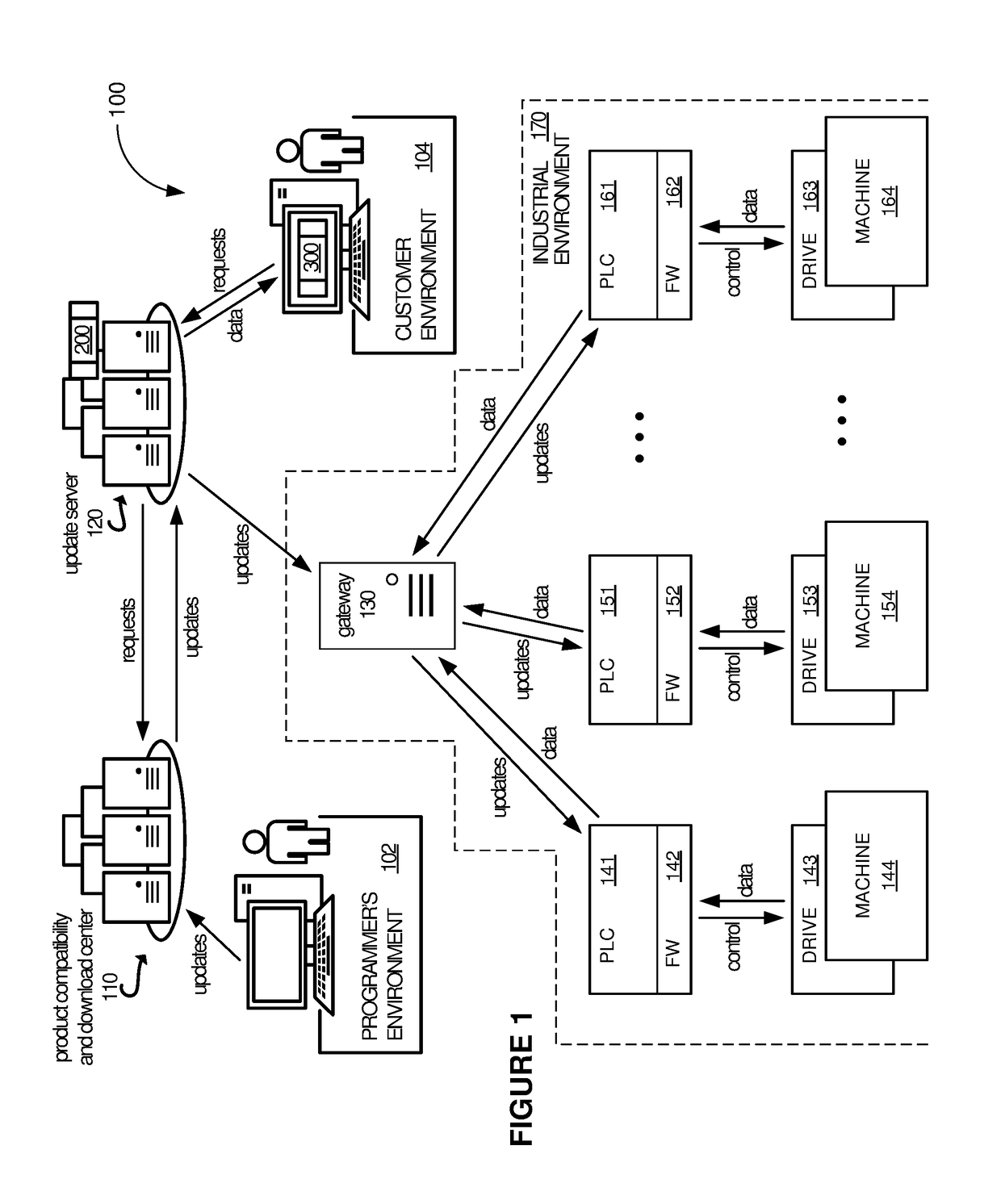

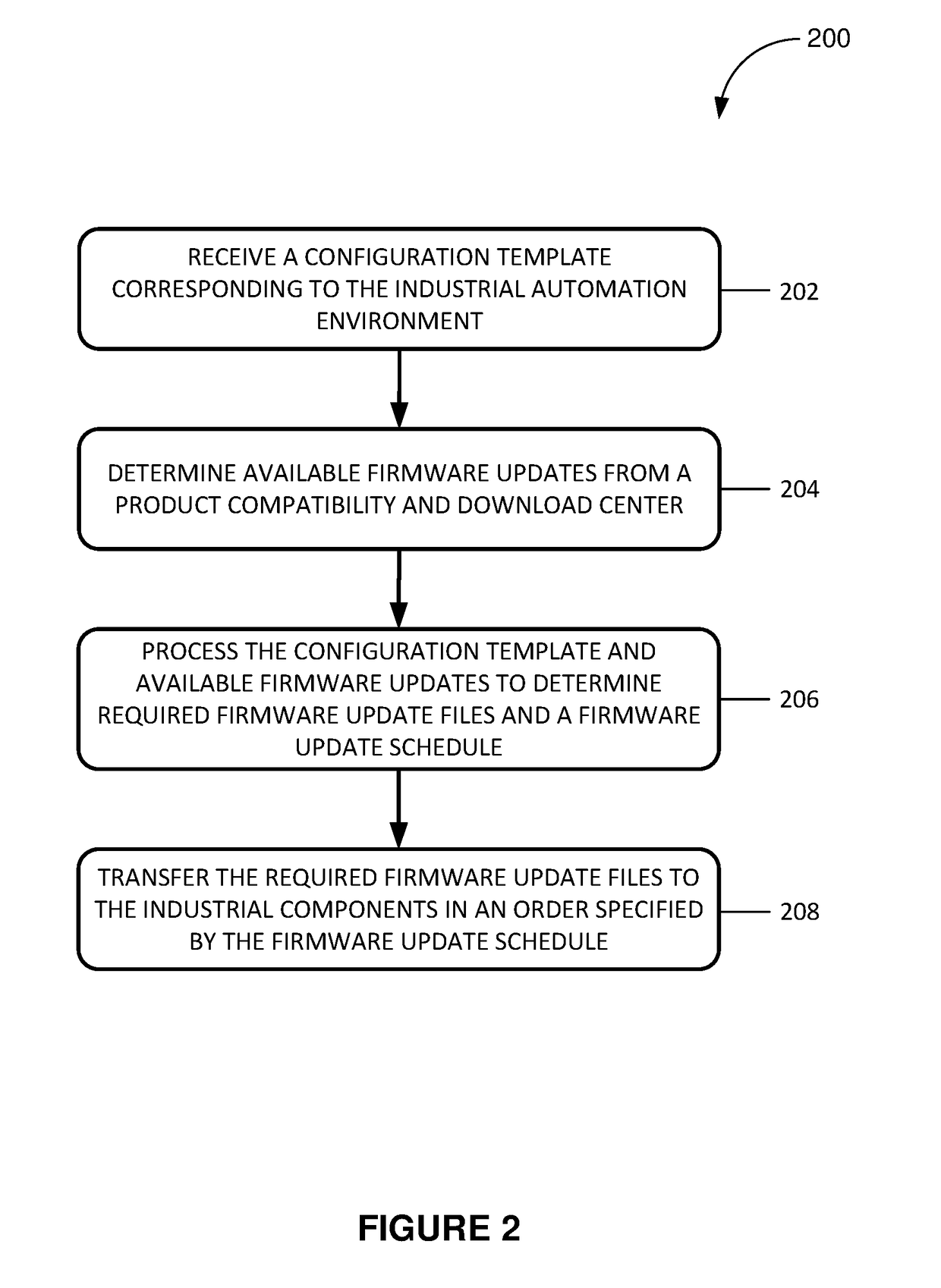

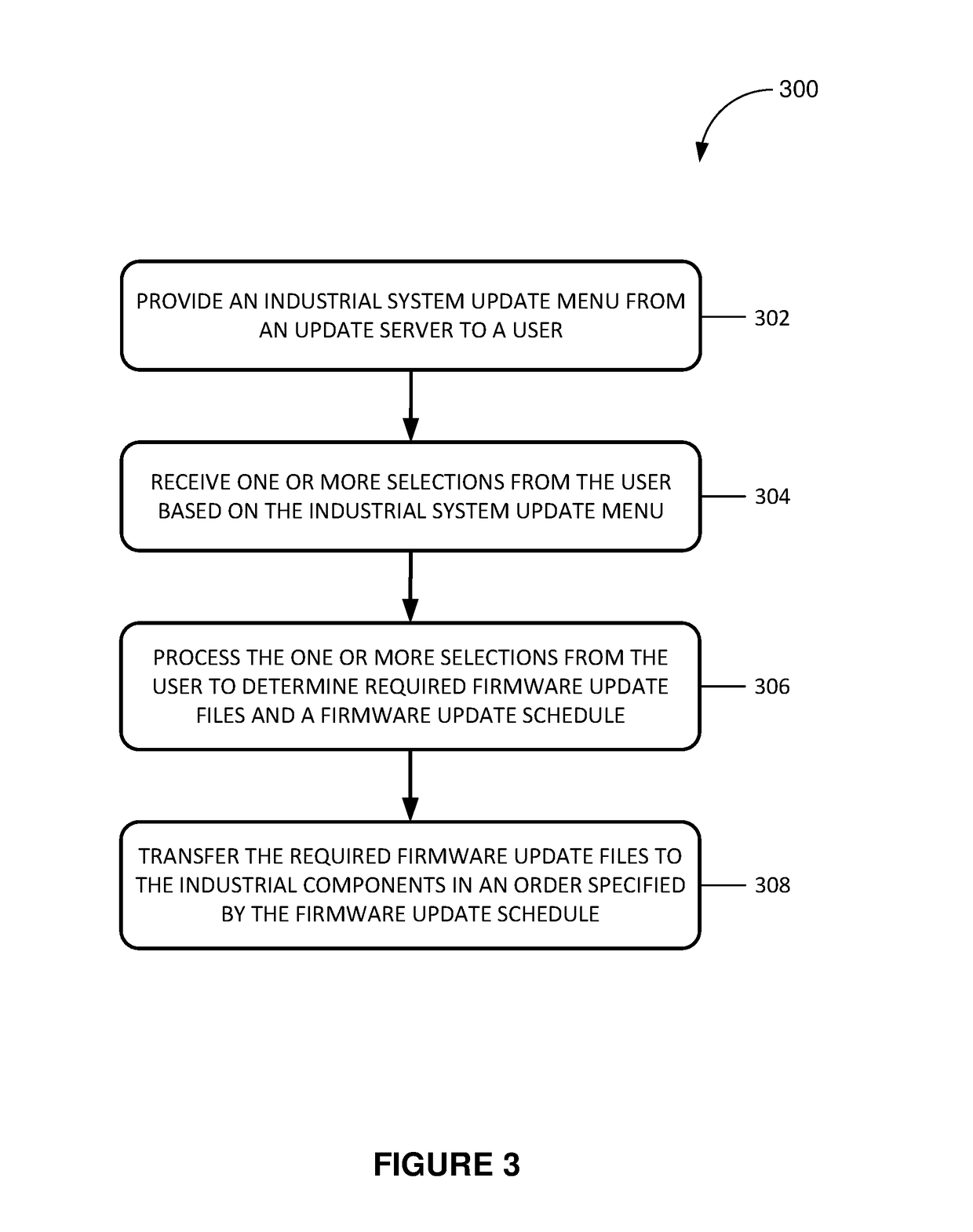

Launch multiple devices firmware update operation from another application with device list context

ActiveUS20180359144A1Small toleranceQuality improvementProgramme controlProgram loading/initiatingIndustrial systemsApplication software

A method for updating firmware within an industrial automation environment comprising a plurality of industrial components is provided. The method includes providing an industrial system firmware update menu from an update server to a user through a web interface within an application running on a user device, and receiving one or more selections of the industrial system firmware update menu from the user through the web interface. The method also includes processing the one or more selections of the industrial system firmware update menu to determine required firmware update files and a firmware update schedule, and transferring the required firmware update files to the industrial components in an order specified by the firmware update schedule.

Owner:ROCKWELL AUTOMATION TECH

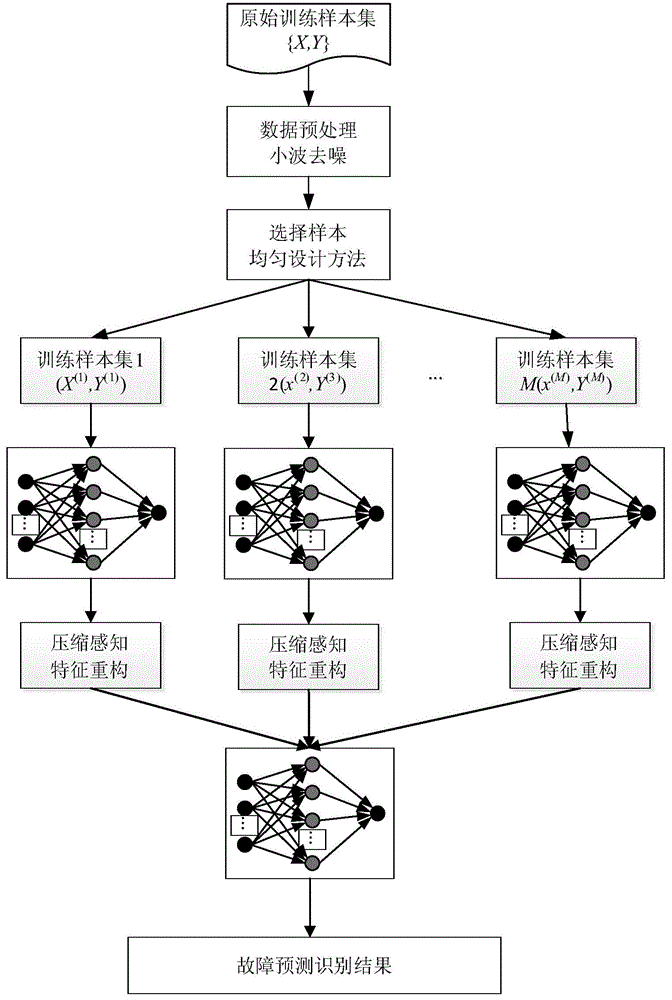

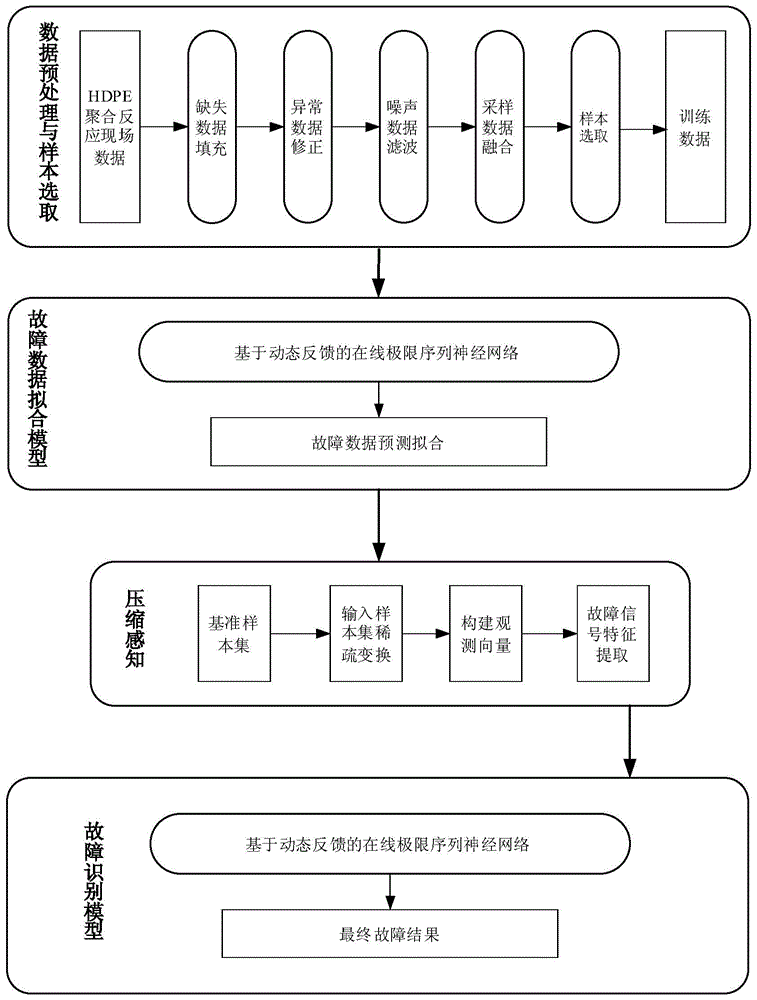

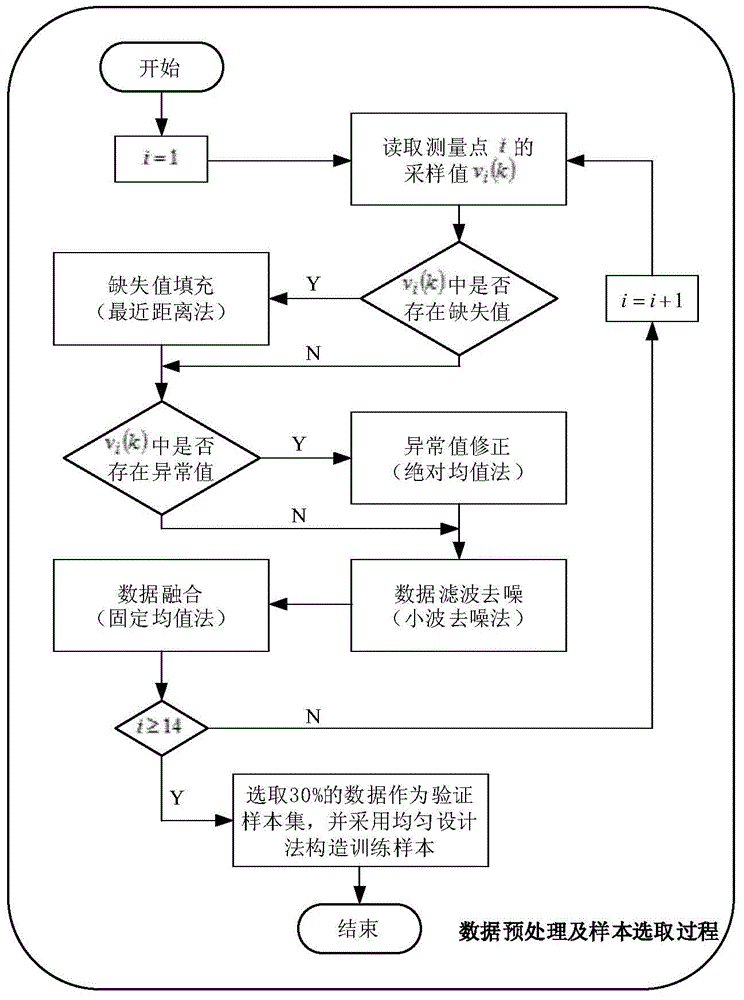

Non-linear process industrial fault prediction and identification method based on compressed sensing and DROS-ELM

ActiveCN104537415AFast learningFew adjustable parametersNeural learning methodsSpecial data processing applicationsFeature extractionIndustrial systems

The invention relates to a non-linear process industrial fault prediction and identification method based on compressed sensing and dynamic recurrent online sequential-extreme learning machine (DROS-ELM). According to the high-performance non-linear process industrial fault prediction and identification method, a problem of shortage of the on-line fault prediction and identification during the non-linear production process of the complicated industrial system can be solved. The compressed sensing and the artificial neutral network are applied to the industrial field and thus fault prediction and identification models based on the compressed sensing feature extraction and dynamic feedback OS-ELM neutral network technology is respectively constructed, thereby realizing fault prediction. Therefore, a technical support can be provided for guaranteed safety production, improved production efficiency, and saved production cost of the enterprise.

Owner:BEIJING UNIV OF CHEM TECH

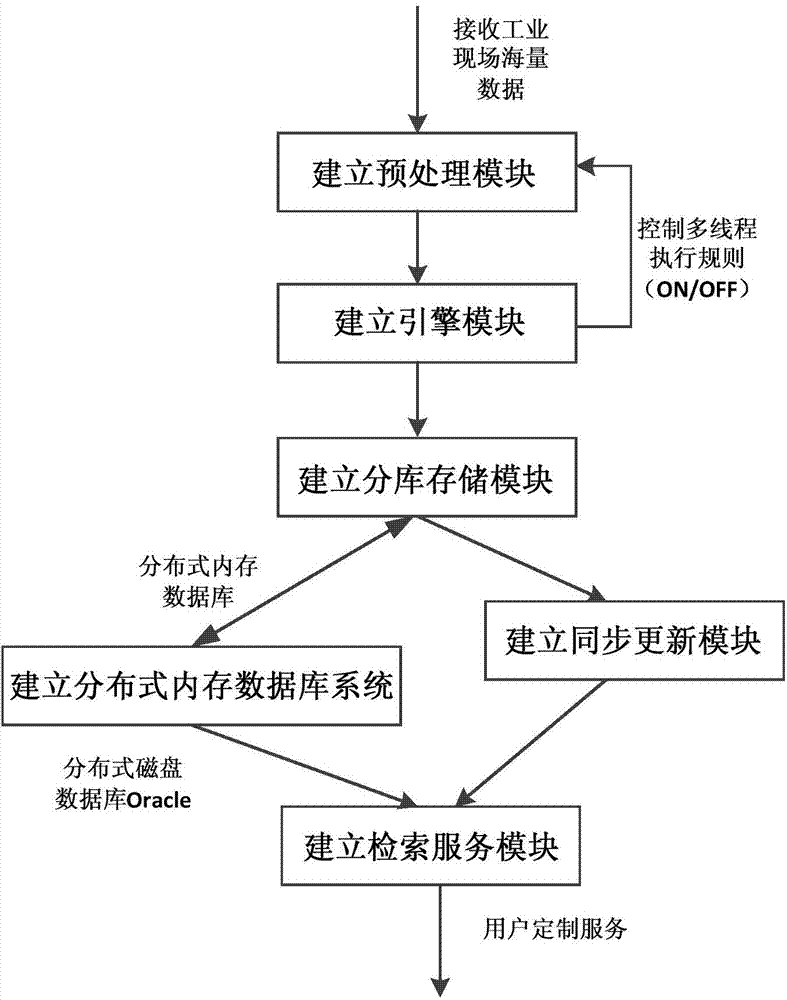

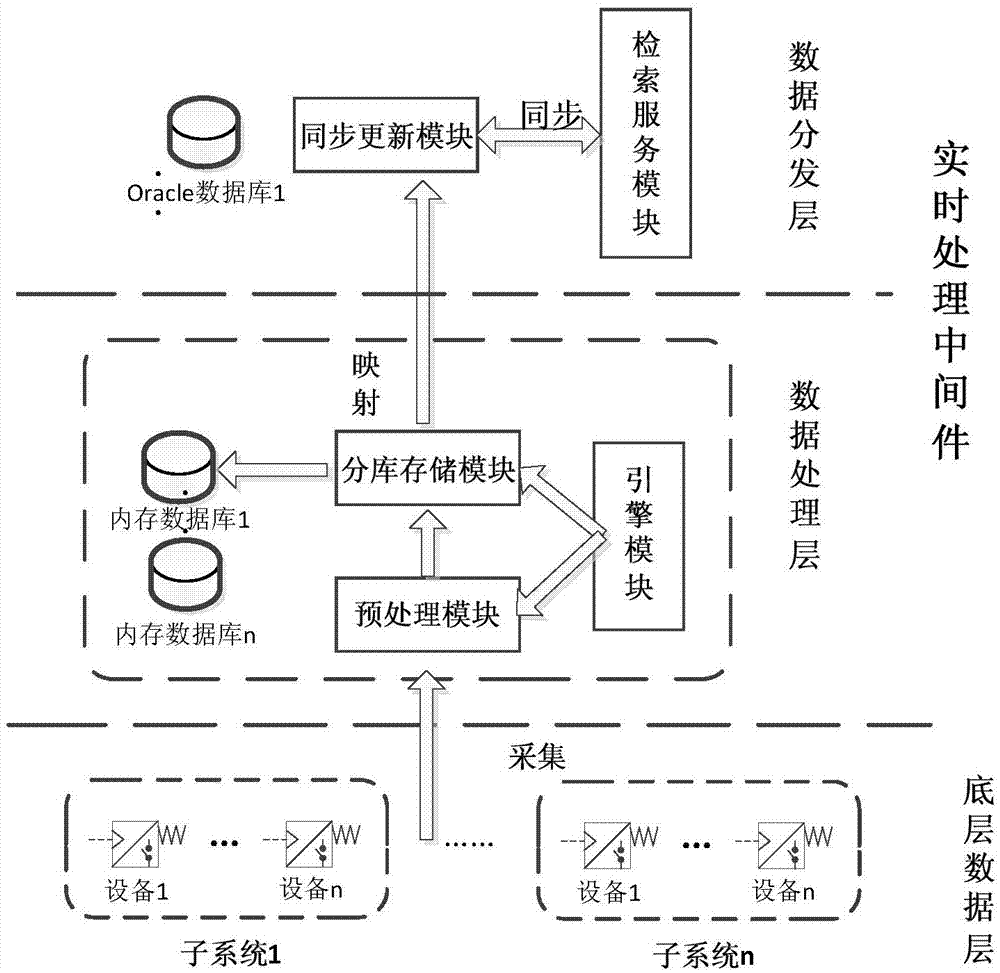

Large industrial system feedback data real-time processing method and system based on Web

ActiveCN103970903AAffect operationAffect accessDatabase management systemsSpecial data processing applicationsIndustrial systemsOriginal data

The invention discloses a large industrial system feedback data real-time processing method based on Web. The large industrial system feedback data real-time processing method based on Web comprises the steps of firstly establishing a bottom layer data layer for acquiring industrial system original data of an industrial field device; then establishing a data processing layer for processing distributed data on the acquired industrial system original data, meanwhile establishing time stamps of data access and historical data; finally establishing a data distribution layer for performing dynamic paging storage on the industrial system original data and establishing a synchronous update module and a retrieval service module in the data distribution layer. The large industrial system feedback data real-time processing method enables system functions to be subdivided and prevents problems of a certain module from influencing all of server operation and user access. User's customization is achieved, and the user experience is improved. A large industrial system data processing system is good openness and high in expansion and meets real-time data as-required processing requirement. A memory database and a magnetic disk database are efficiently combined, the real-timeliness of the whole system is improved, and the operation load of the system is reduced.

Owner:CHONGQING UNIV

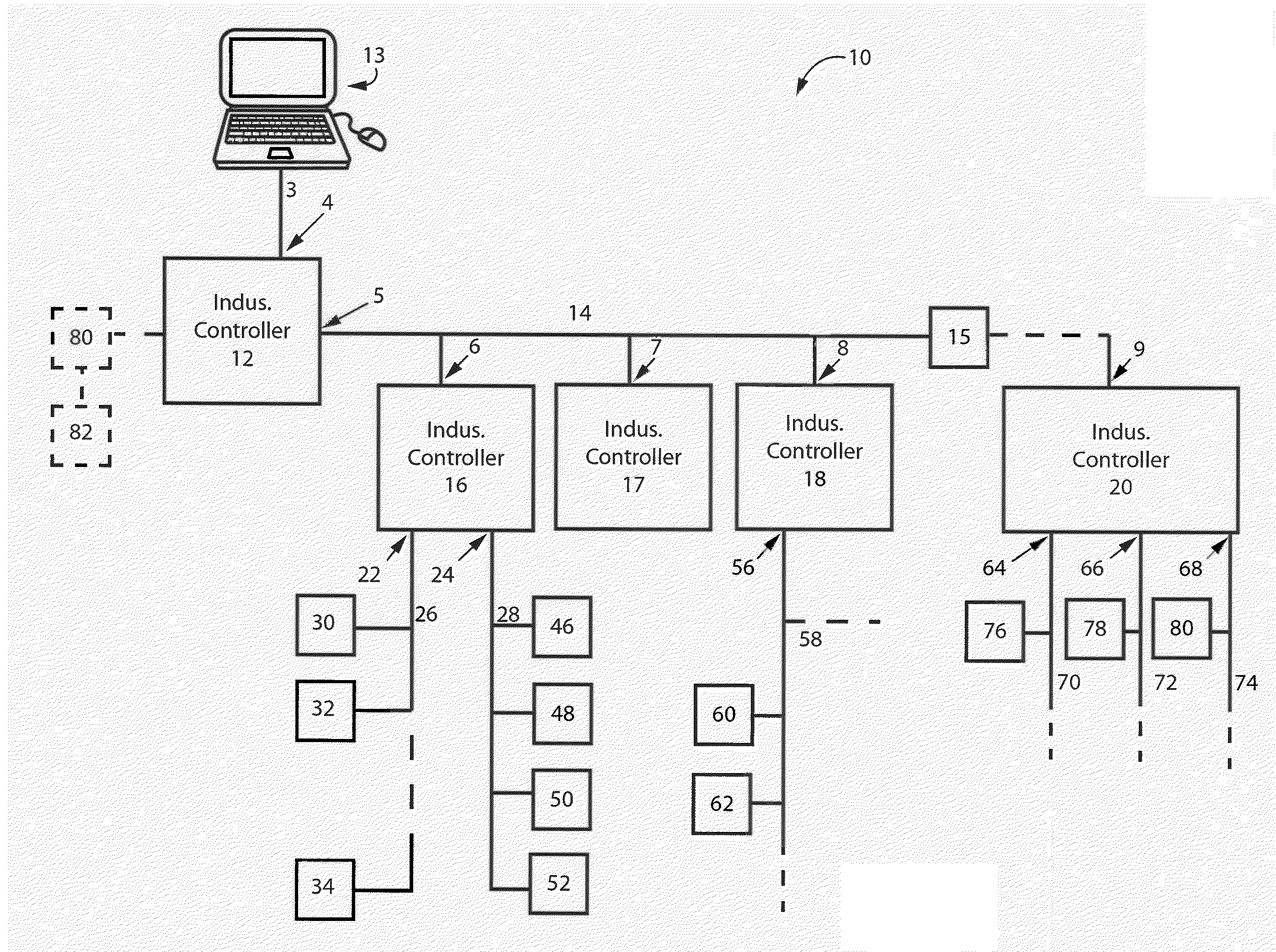

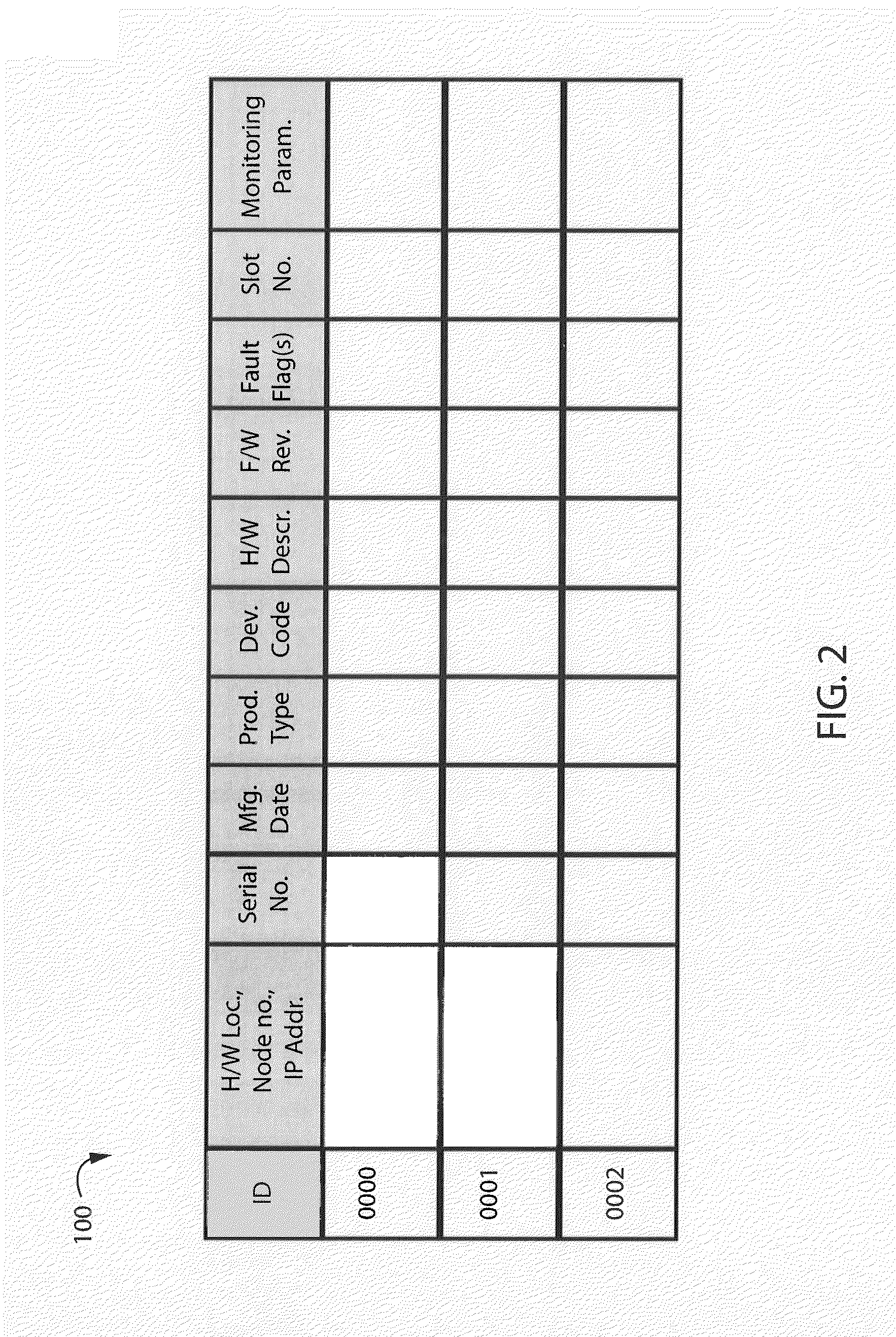

Industrial Hardware Installation Base Reporting And Failure Monitoring

ActiveUS20130345829A1Quick understandingComputer controlSimulator controlIndustrial systemsIndustrial control system

An industrial control system includes an industrial controller with a processor executing a program stored in a non-transitory computer-readable storage medium and having a user interface and a network interface for communicating over a first control network with another industrial controller having a network interface. The other industrial controller has an additional network interface for communicating over a second control network with an industrial device. The program instructs the processor to retrieve installation information contained in the other industrial controller and the industrial device; build a data structure comprising the retrieved information; periodically monitor for a hardware failure; and send a message alarm in response to detection of a hardware failure. As a result, the installation base of the industrial system and any hardware failures are quickly understood and martial data collection is avoided.

Owner:ROCKWELL AUTOMATION TECH

Apparatus and method for storing heat energy

ActiveUS8544275B2Simple designMore robustSolar heat devicesHeat storage plantsStored energyWorking fluid

Method and apparatus for storing heat in industrial systems where large sources of stored energy are called upon to meet a work load, storing the heat content of a hot working fluid by using the hot working fluid as a heat transfer fluid in vapor form and depositing its heat content on a heat storage medium and then removing the cooled and condensed liquid phase of that heat transfer fluid, and when hot working fluid again is needed, the liquid heat transfer fluid is returned to the heated storage medium and is reheated as it passes through the hot storage medium and then is returned to the working system to be used as a hot working fluid.

Owner:RES FOUND THE CITY UNIV OF NEW YORK

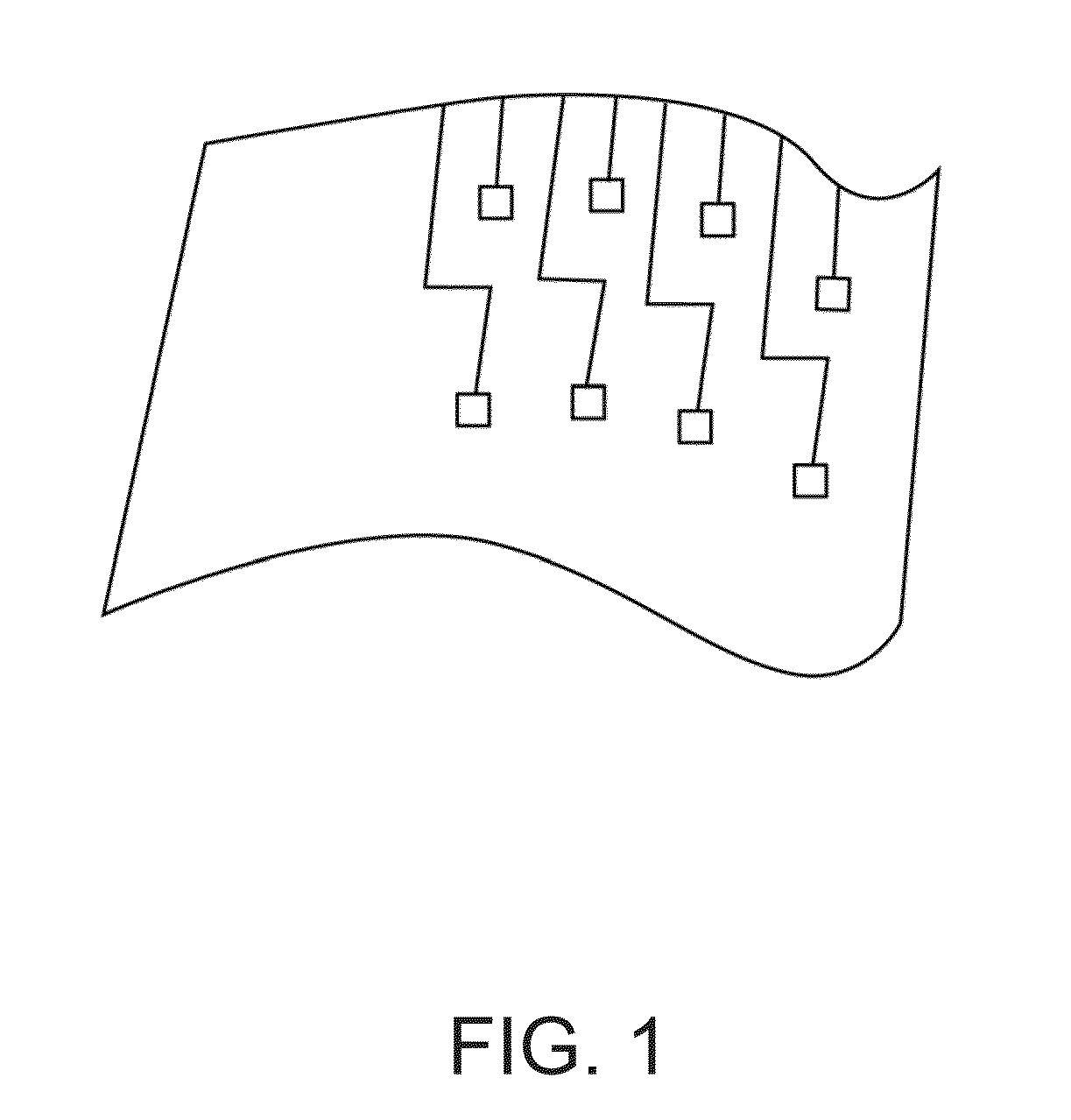

Flexible substrate sensor system for environmental and infrastructure monitoring

InactiveUS20110283821A1Realize automatic adjustmentRapidly and efficiently and informationSimultaneous indication of multiple variablesMaterial analysisAnalyteIndustrial systems

A sensor system utilizing flexible electronics for on-line real-time high-sensitivity sampling, monitoring, and analysis of a parameter or analyte of interest in a fluid or in or on a solid is provided. The flexible substrate sensor system comprises a plurality of sensors, a flexible substrate, a network, and a connection between the sensors and the network, wherein the network reads out or collects information from the sensors. The network can be onboard, connected by via a physical connection to the sensors and the flexible substrate, or external to the sensors and flexible substrate, connected via a telemetric or wireless connection to the sensors. The flexible substrate sensor system can be deployed in systems that conduct or distribute fluids or solids, such as distribution systems (municipal water systems, oil or gas pipeline systems), industrial systems (production facilities, piping, and storage systems), and large structures (dams, bridges, walkways, buildings).

Owner:HEALTH RES INC +1

Antimicrobial mixtures comprising iodopropynyl compounds and dimethyldithiocarbamate derivatives

InactiveUS20050049224A1Inhibit microbial growthBiocideAnimal repellantsIndustrial systemsCompound (substance)

This invention is directed to an synergistic antimicrobial composition which comprises a mixture of an iodopropynyl compound and a dimethyldithiocarbamate compound, said mixture provided in an amount sufficient to protect a substrate from attack by one or more microbial organisms. The composition can be used broadly in industrial systems and more particularly with substrates such as paints, coatings, plastics, wood and wood composites.

Owner:TROY TECH CORP INC US

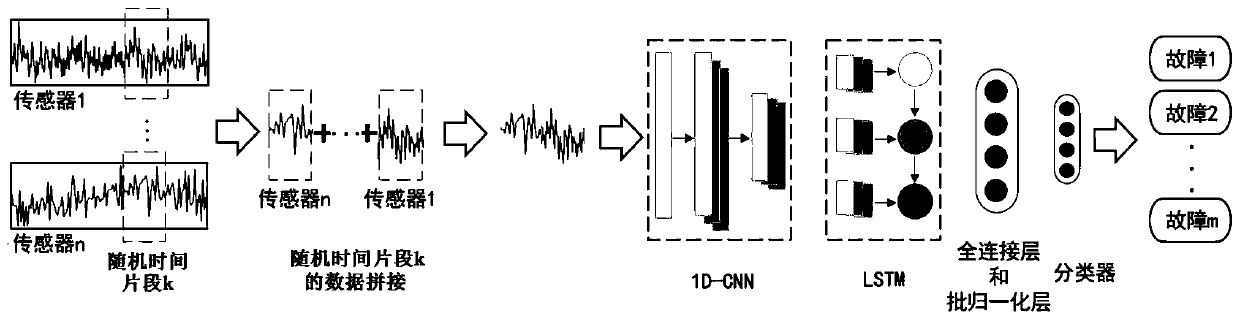

Fault diagnosis method, device and equipment for industrial system and storage medium

PendingCN111340238ASolving Difficult-to-Model ProblemsImprove accuracyMachine bearings testingElectrical testingIndustrial systemsOriginal data

The invention discloses a fault diagnosis method, device and equipment for an industrial system and a storage medium. The method comprises the following steps: obtaining historical original sequencesoutput by a plurality of sensors preset in an industrial system and corresponding industrial system fault types; splicing the data of different sensors in the same time slice in sequence, and normalizing the reconstructed sequence obtained by splicing to obtain a preprocessing sequence corresponding to the time slice as a training sample; training a deep learning model by using all the training samples to obtain an industrial system fault diagnosis model; and obtaining a diagnosis sample from the original sequence obtained in real time according to the same obtaining method as the training sample, and carrying out online diagnosis on the industrial system by using the industrial system fault diagnosis model and the diagnosis sample. The method has no requirements for the sampling rates ofdifferent sensors, can reserve most original data of the sensors, and improves the accuracy of fault diagnosis.

Owner:CENT SOUTH UNIV

Firewall method and apparatus for industrial systems

The invention includes a method including the steps of specifying access control information for resources, for each first protocol packet transmitted on the network, intercepting the first protocol packet prior to a first protocol destination resource, examining embedded packet information to identify at least one of the intermediate path resources and the final destination resource, identifying the access control information associated with the identified at least one of the intermediate path resources and the final destination resource and restricting transmission of the first protocol packet as a function of the identified access control information.

Owner:ROCKWELL AUTOMATION TECH

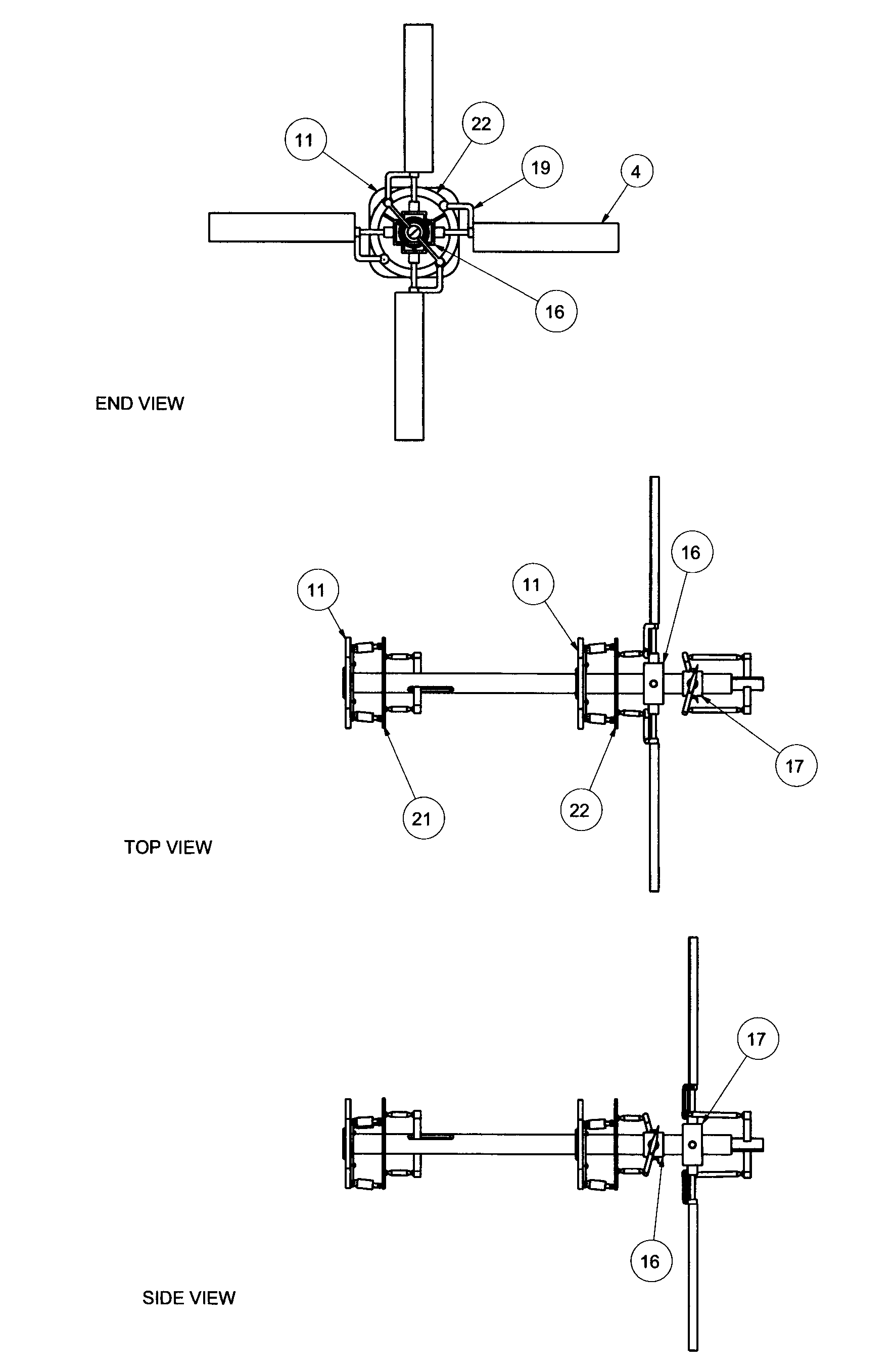

Omni-Directional Thrust Vectoring Propulsor

A propulsion system comprising independent rotor sub-systems producing a thrust force of a desired magnitude in any desired radial direction from the centre of the propulsion system, driven from a single driveshaft that may be fixed in its position in the vehicle. When the propulsion system is fitted, for example, to a single-main-rotor helicopter in place of the convention anti-torque tail rotor, the helicopter is thereby equipped with a propulsion system that can produce yaw, pitch, the anti-torque lateral thrust for stability in hover, aft thrust or drag as well as the direct forward thrust that will enable the helicopter to fly at higher speeds. The propulsion system may also be applied in other aeronautical systems as well as to marine and industrial systems to impart energy into a fluid and thereby induce movement in that fluid.

Owner:ADAM MARTIN LEON

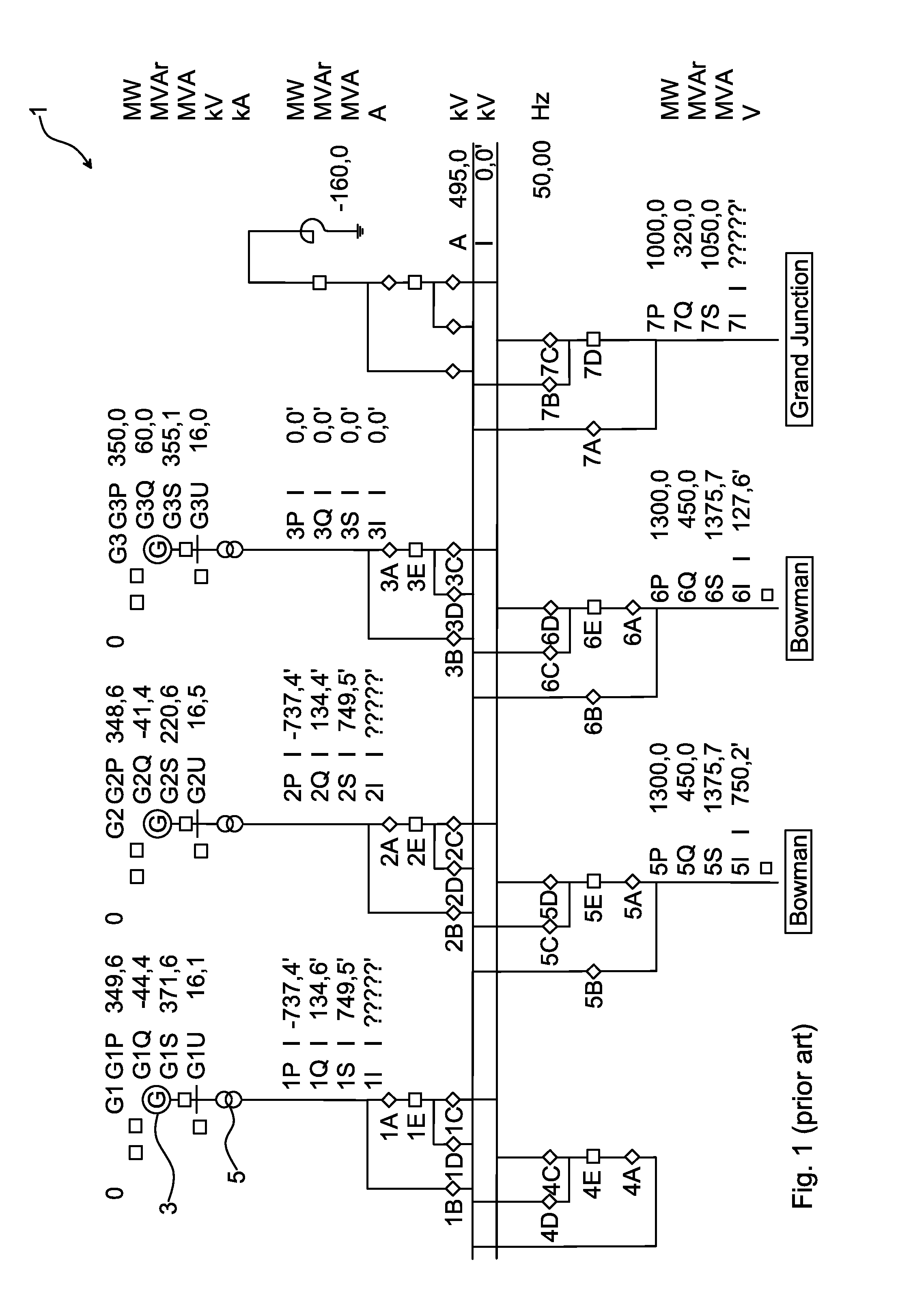

Method And System For Facilitating Control Of An Industrial System

ActiveUS20130257863A1Facilitates for operatorEasy to detectComputer controlTesting/monitoring control systemsComputer graphics (images)Industrial systems

A method for displaying a two-dimensional image in a three-dimensional view. The two-dimensional image is formed by a plurality of objects representing elements of an industrial system. The three-dimensional view is displayed on a display of a control system of the industrial system, wherein at least one object is associated with a parameter value pertaining to a state of a corresponding element in the industrial system. The method includes determining the parameter value for the object; mapping the parameter value to a depth layer, which depth layer defines part of the three-dimensional view; and displaying the object in the depth layer. A corresponding control system is also presented herein.

Owner:HITACHI ENERGY SWITZERLAND AG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com