Patents

Literature

198 results about "Dimethyldithiocarbamate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Dimethyldithiocarbamate is the organosulfur anion with the formula (CH₃)₂NCS₂⁻. It is one of the simplest organic dithiocarbamate.

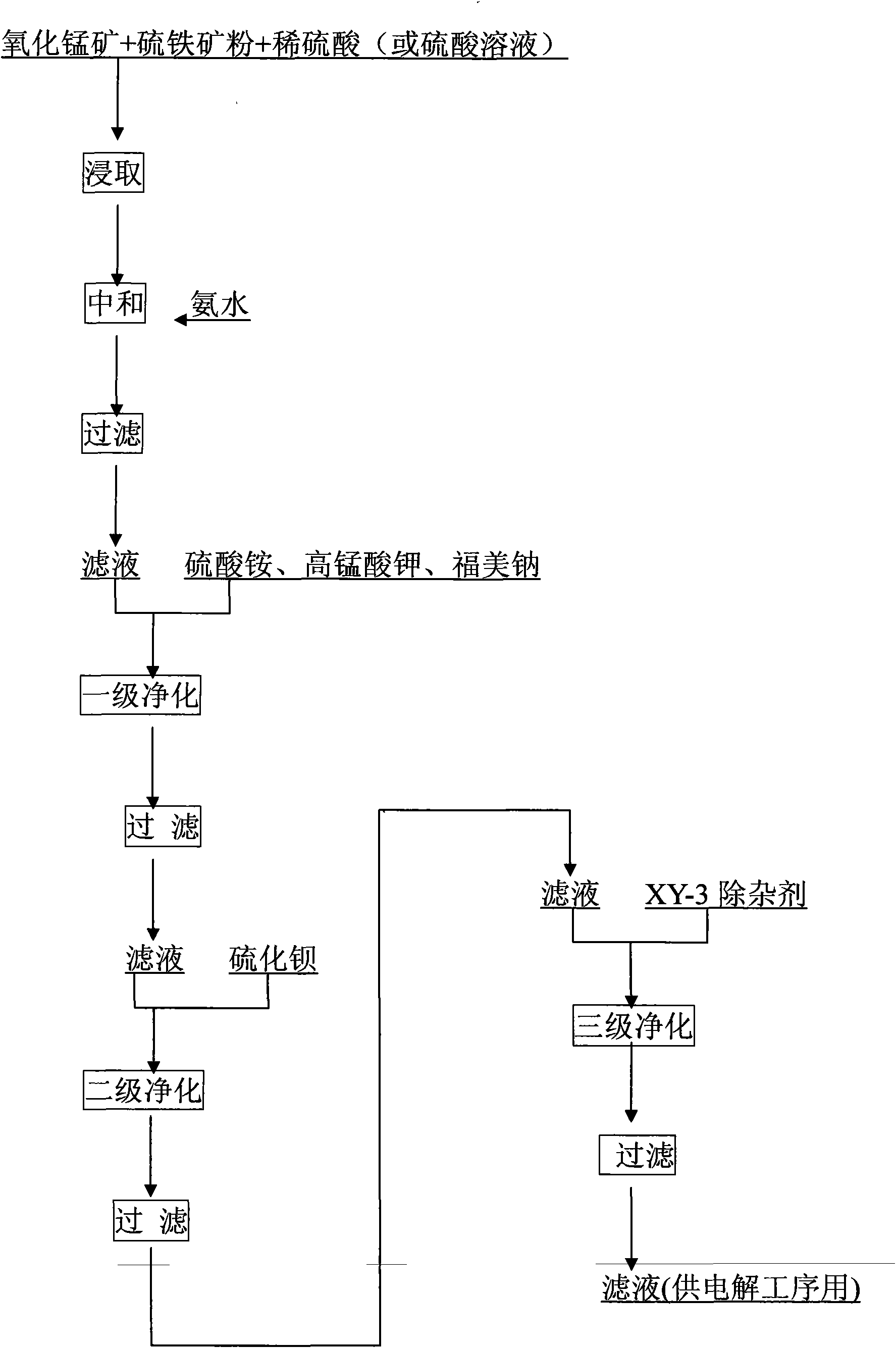

Liquid making technique for manganese oxide ore

InactiveCN101684562AAchieve outputRealization costPhotography auxillary processesElectrolysisFiltration

The invention discloses a liquid making technique for manganese oxide ore, comprising the steps of: adding the manganese oxide ore powder, pyrite powder, sulfuric acid solution into a leaching vat forleaching; adding a neutralizing agent for neutralizing after reaching leaching termination; adding ammonia sulfate, potassium permanganate and sodium dimethyldithiocarbamate into the neutralization liquid after filtration until the nickel is qualitatively removed; then, adding barium sulfide or adding barium sulfide into the filtrate after filtration, wherein the dosage of barium sulfide is 100-2000g / m<3> manganese sulfate solution; adding XY-3 impurity removal agent after filtration, wherein the dosage of XY-3 impurity removal agent is 50-400g / m<3> manganese sulfate solution, the temperatureis controlled at 30-80 DEG C, the reaction time is 0.5-3h, and the pH is 4.5-6.9; and filtrating to obtained purified manganese sulfate solution. The recovery rate of the qualified, refined and purified manganese sulfate solution is more than 90%, based on common electrolytic technique, the quality of products achieves national standard, the electrolytic yield is larger than 3kg / veneer, the powerconsumption is not more than 7500kwh / t, and the yield, cost and efficiency are all better than the traditional level of manganous carbonate production.

Owner:熊一言

Elastomeric Copolymers, Copolymer Compositions, and Their Use in Articles

A copolymer is formed from an isoolefin having from 4 to 7 carbon atoms and an alkylstyrene. The copolymer has a substantially homogeneous compositional distribution. The copolymer has from about 8 to about 12 wt % of alkylstyrene and at least 85 wt % of isoolefin. The copolymer is preferably halogenated with about 1.1 to about 1.5 wt % of a halogen. The copolymer may in elastomeric nanocomposites. To obtain a good dispersion of the nanoclay in a formulated compound, at least one cure accelerator is selected from the group consisting of mercaptobenzothiazole disulfide, mercaptobenzothiazole, cyclohexyl benzothiazole disulfide, dibutyl thiourea, tetramethylthiuram disulfide, 4-4-dithiodimropholine, zinc dimethyldithiocarbamate, and zinc dibutylphosphorodithiate.

Owner:RODGERS MICHAEL BRENDAN +4

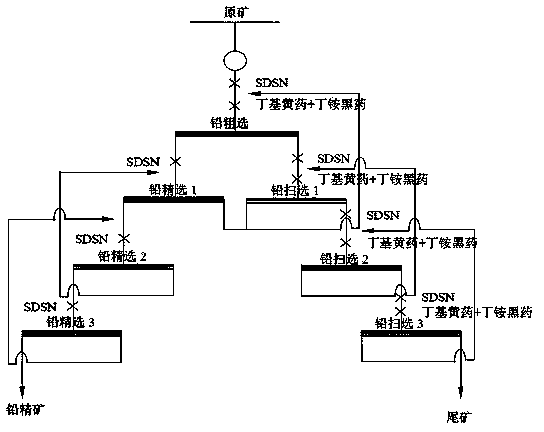

Flotation separation inhibitor and separation method of galena, pyrite and sphalerite

InactiveCN103909020AEfficient separationPlay a synergistic roleFlotationEcological environmentSeparation technology

The invention discloses a flotation separation inhibitor and separation method of galena, pyrite and sphalerite, and belongs to the technical field of mineral processing. The method includes adopting raw ores of sulfide lead-zinc mine as raw material, and adding SDSN (dimethyl dithiocarbamate : 2-(methylthio)ethylamine = 1-3:1)to serve as inhibitor of the pyrite and the sphalerite so as to perform lead and zinc sulphur flotation separation after the raw ores are grinded. Compared with an existing lead and zinc sulphur separation technology, the composite inhibitor SDSN has the advantages that selectivities of the pyrite and the sphalerite are high, inhibiting capability is high, usage is fewer, and adding is facilitated. The the pyrite and the sphalerite can be inhibited well, efficient separation of the galena and the zinc sulphur is implemented, the problems that according to the traditional lime or cyanide method, the recovery rate of associated gold, silver and other precious metals in the lead-zinc sulfide mine is low and ecological environment is seriously damaged are overcome, and an efficient and environment-friendly flotation separation method is provided for complex sulfide lead-zinc mine separation.

Owner:HUNAN RES INST FOR NONFERROUS METALS

Antimicrobial mixtures comprising iodopropynyl compounds and dimethyldithiocarbamate derivatives

InactiveUS20050049224A1Inhibit microbial growthBiocideAnimal repellantsIndustrial systemsCompound (substance)

This invention is directed to an synergistic antimicrobial composition which comprises a mixture of an iodopropynyl compound and a dimethyldithiocarbamate compound, said mixture provided in an amount sufficient to protect a substrate from attack by one or more microbial organisms. The composition can be used broadly in industrial systems and more particularly with substrates such as paints, coatings, plastics, wood and wood composites.

Owner:TROY TECH CORP INC US

Heavy metal polluted soil treatment processing agent and preparation method thereof

ActiveCN104610972AImprove biological activityPromote absorptionContaminated soil reclamationOrganic fertilisersSoil treatmentSoil heavy metals

The invention belongs to the processing agent technical field, and in particular relates to a heavy metal polluted soil treatment processing agent comprising the following components by mass: 40%-75% of dimethyl dithiocarbamate chelating agent; 20%-45% of diethyl dithiocarbamate chelating agent and 5%-15% of polyethylene imine. Compared with the existing technology, the dimethyl dithiocarbamate chelating agent can effectively fix soil heavy metal ions, and due to the biological activity of the diethyl dithiocarbamate chelating agent, the heavy metal polluted soil treatment processing agent can promote crop absorption of heavy metal ions, that is to say, the heavy metal polluted soil treatment processing agent both has the properties of heavy metal ion fixing and crop absorption of heavy metal ions, so that the treatment process of soil heavy metal ion pollution can be speeded up, and the heavy metal polluted soil treatment processing agent can thoroughly treat soil heavy metal pollution in a short period of time.

Owner:山东金鼎环保科技有限公司

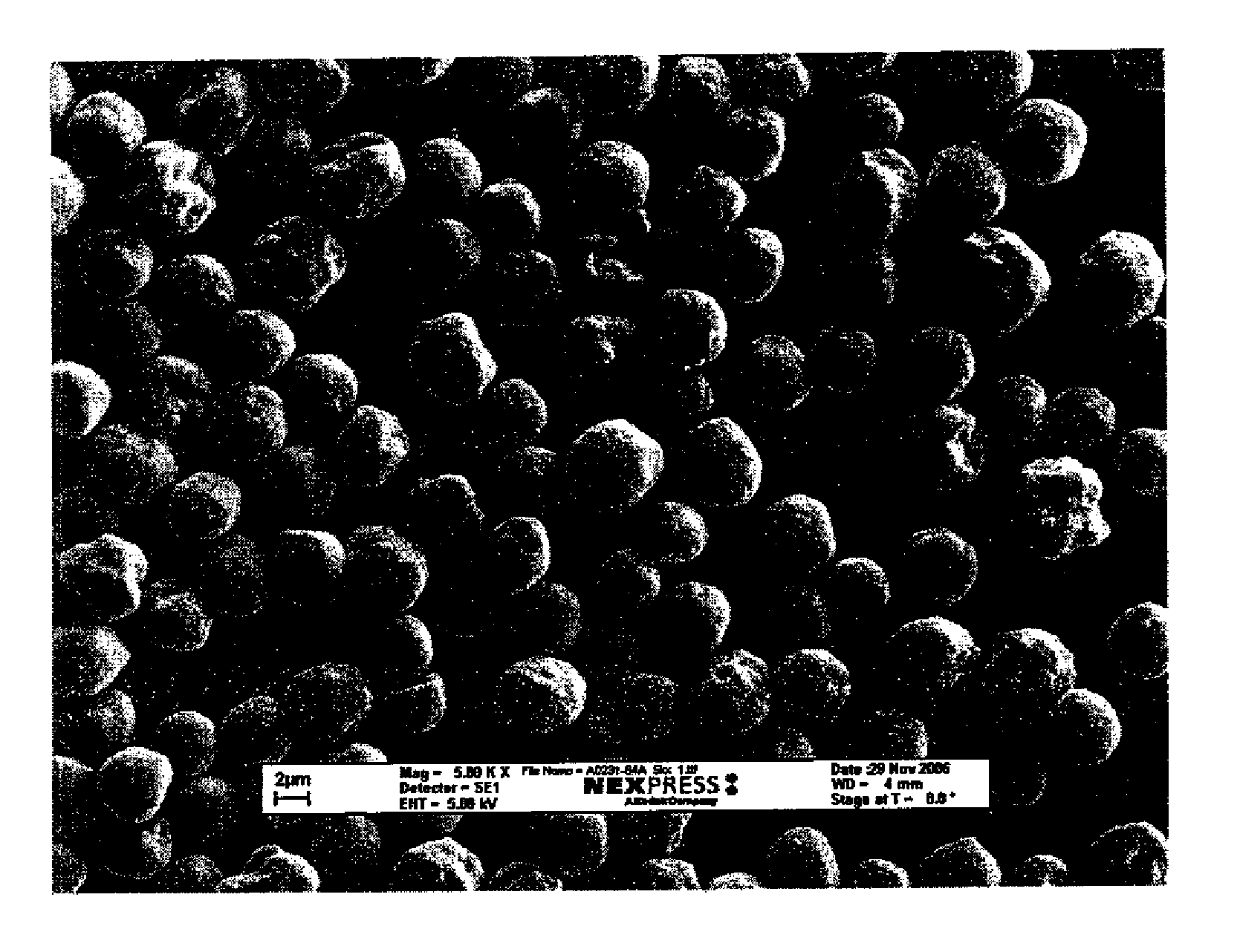

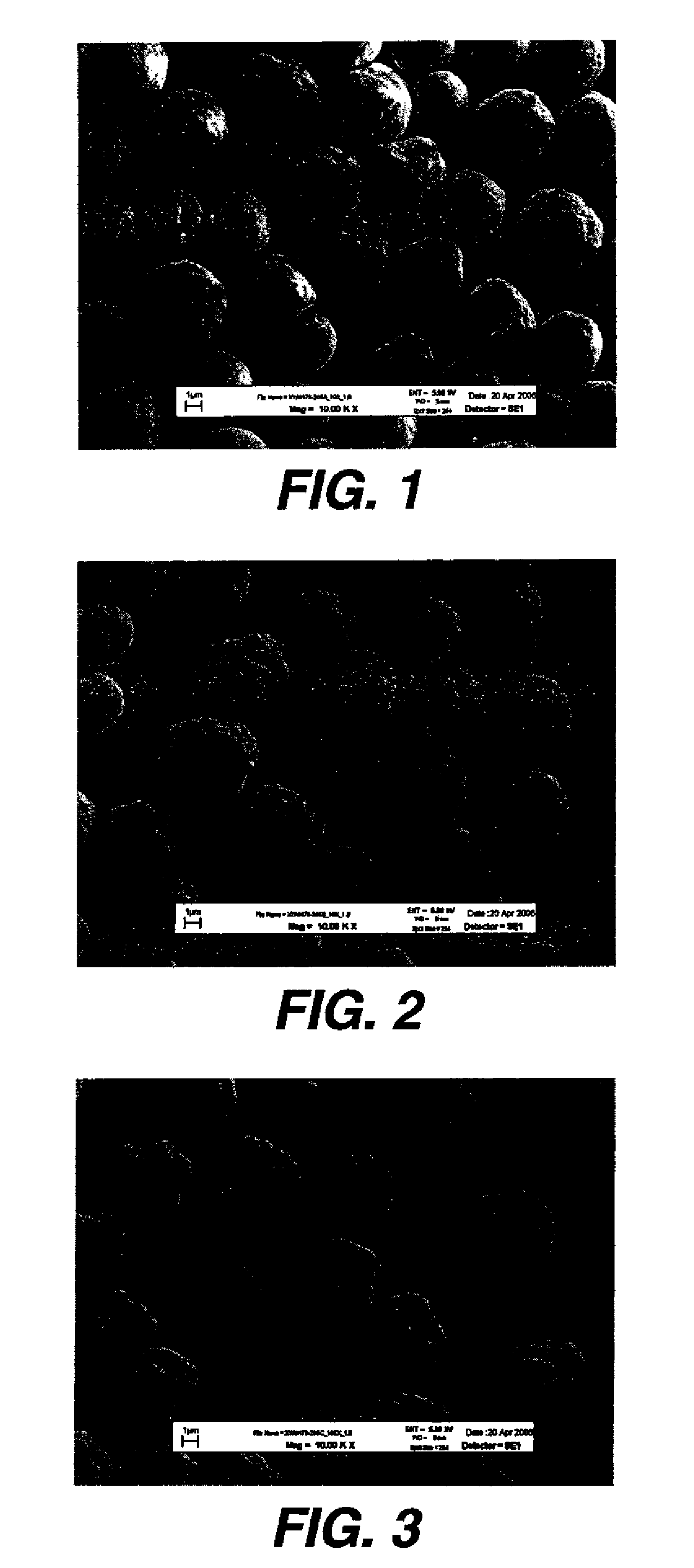

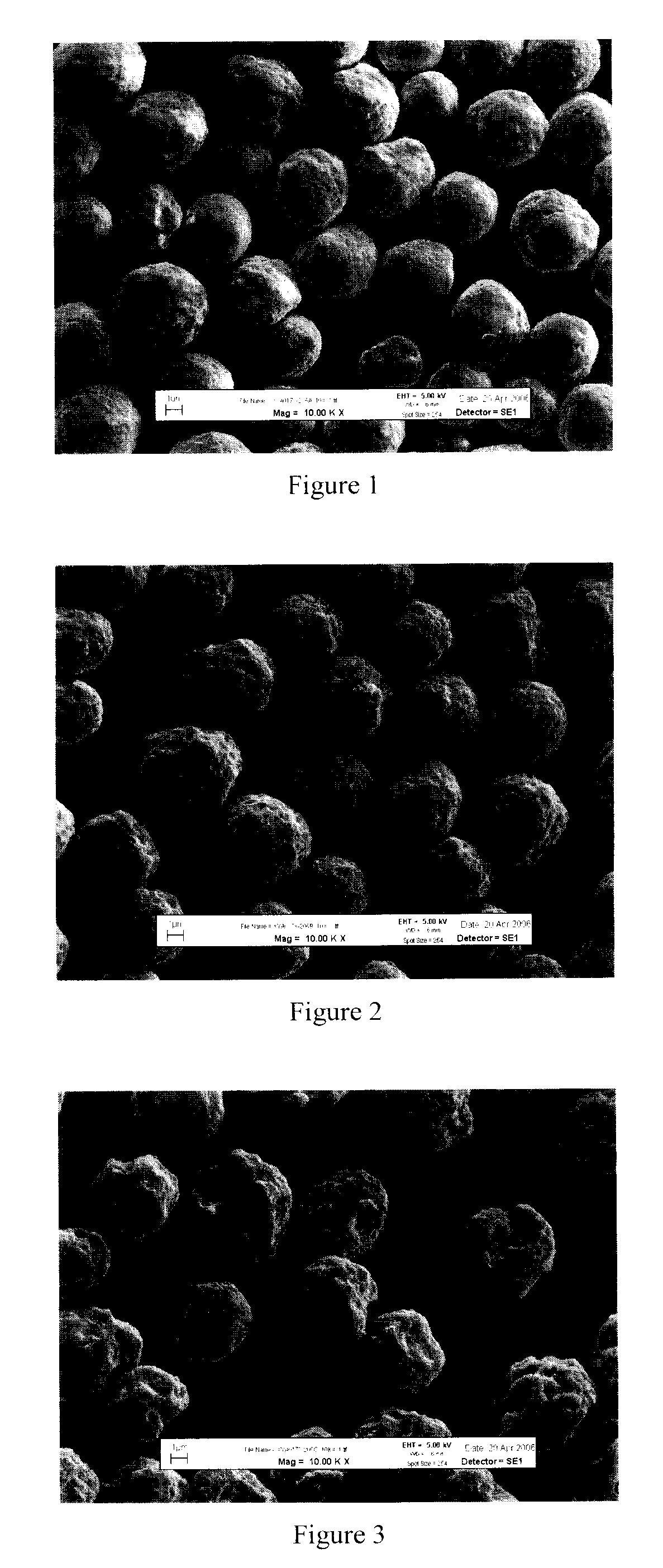

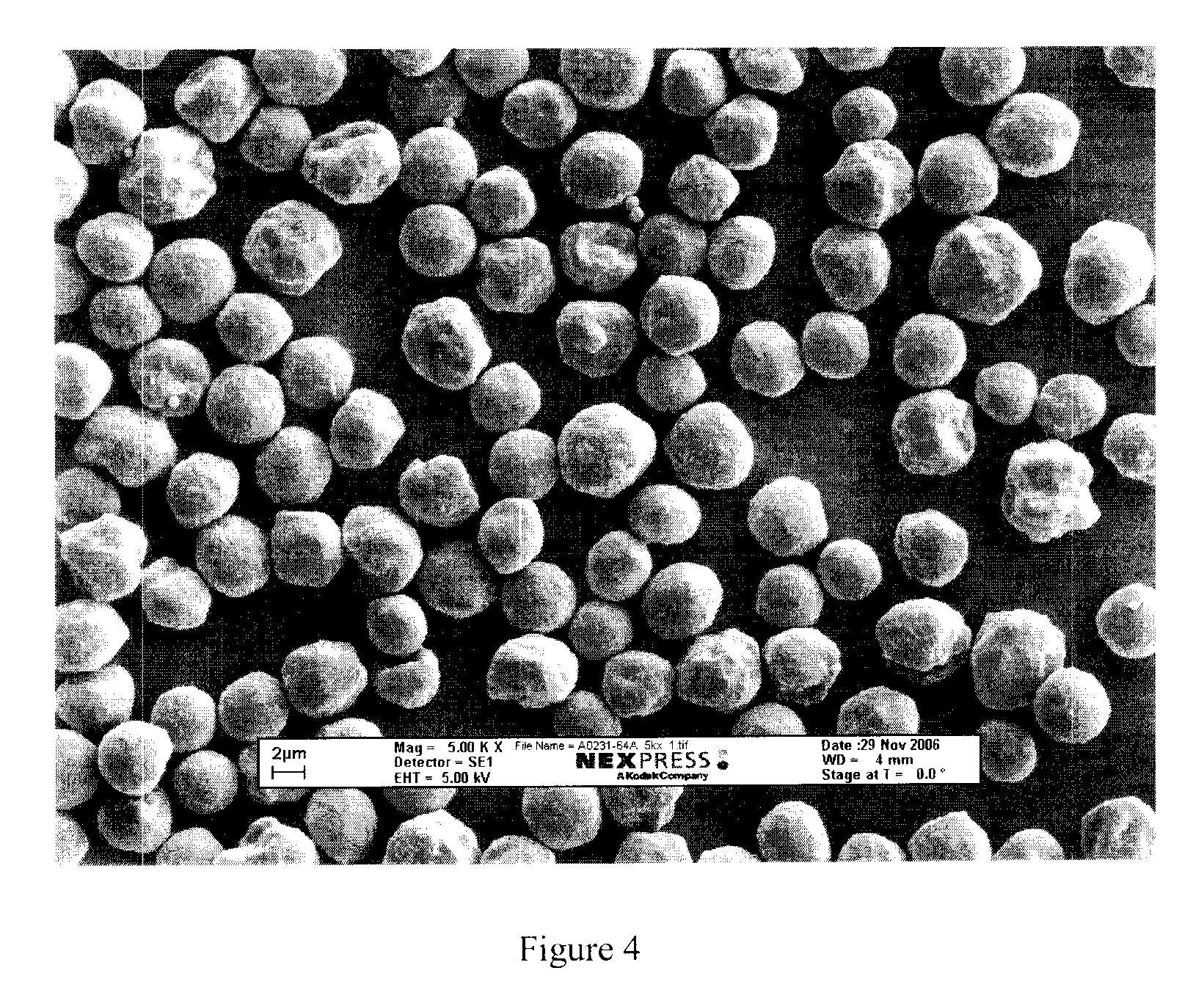

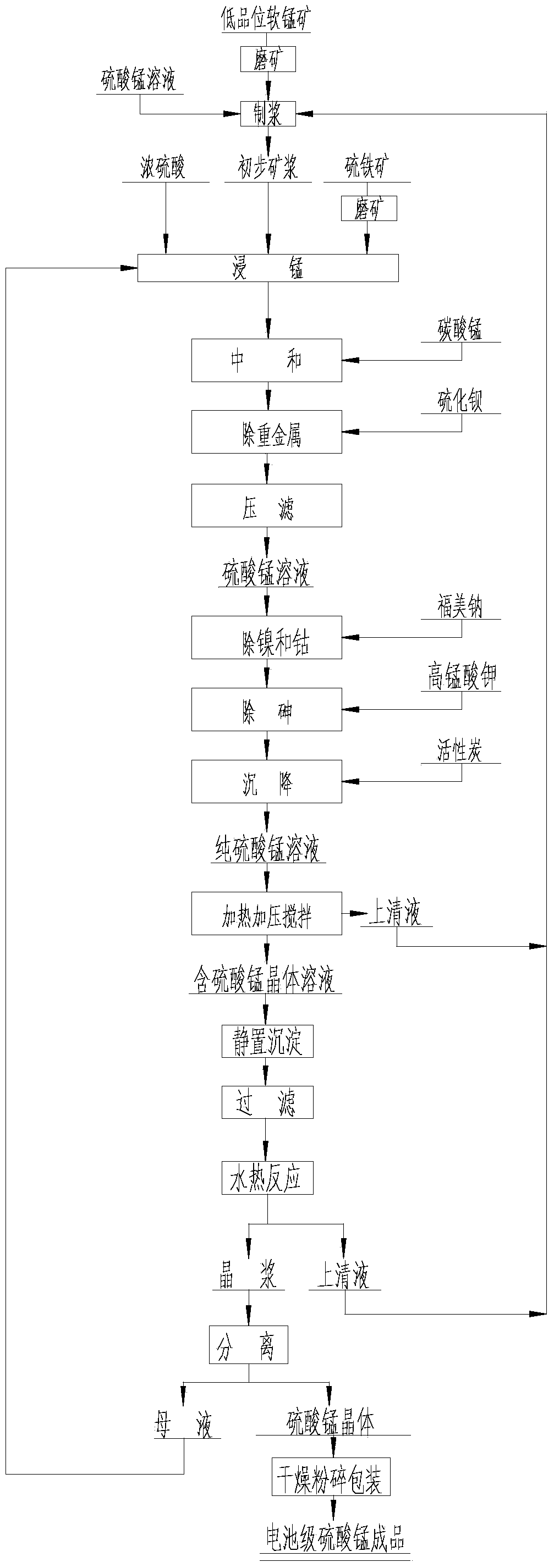

Toner particles of controlled morphology

The present invention is a method for the preparation of electrostatographic toner that includes the following steps. A polymer material is dissolved in an organic solvent to form an organic phase that includes a metal complex of zinc dimethyldithiocarbamate; zinc diethyldithiocarbamate; dibenzyldithiocarbamate, zinc di-n-butyldithiocarbamate. The organic phase is dispersed in an aqueous phase that includes a particulate stabilizer to form a dispersion and the resultant dispersion is homogenized. The organic solvent is evaporated and the resultant product is recovered, washed and dried.

Owner:EASTMAN KODAK CO

Method for integrated treatment of electroplating wasterwater

ActiveUS20200048125A1Efficient removalSolve problemsTreatment using aerobic processesGeneral water supply conservationCarboxyl radicalThio-

A method for integrated treatment of electroplating wastewater includes steps of: adjusting and maintaining pH of wastewater at 10.5-12; oxidizing pollutants such as sodium cyanide and hydroxyl-containing organic amine complexants with sodium hypochlorite; precipitating carboxyl-containing organic acid complexants with synergistic effect of ferrous and calcium ions; reducing hexavalent chromium to trivalent chromium and forming chromium hydroxide precipitate; removing precipitate by filtering; adjusting wastewater to pH of 4.5-5.5; precipitating heavy metal ions with sodium dimethyldithiocarbamate or sodium diethyldithiocarbamate; adsorbing precipitate and heavy metal capturing agents with activated carbon; filtering to remove precipitate; adjusting wastewater to pH of 6-8; and destroying aliphatic polyamine complexants and reducing COD using an available biological degradation technique. This method can effectively and economically remove the pollutants such as heavy metals in the electroplating wastewater for a good market prospective.

Owner:GUANGZHOU ULTRA UNION CHEM LTD

Latex and fiber composite foaming material and preparation method thereof

The invention discloses a latex and fiber composite foaming material and a preparation method thereof. The latex and fiber composite foaming material is prepared by mixing the following components in parts by weight: 10-30 parts of fibers, 100 parts of natural latex, 0.3-0.8 part of sodium dodecyl benzene sulfonate, 1.6-3.5 parts of sulfur, 0.6-3.5 parts of zinc dimethyldithiocarbamate, 0.8-2.3 parts of anti-aging agent RD, 15-25 parts of aluminum hydroxide, 1.5-3 pars of zinc oxide, 2.0-2.5 parts of sodium fluorosilicate, 1-8 parts of 3 mass percent formaldehyde and 5-10 parts of latex foaming agent; and the method comprises the steps of preparing the latex, molding the fibers, foaming, putting into a mold, vulcanizing, demolding, washing, drying and the like. The latex and fiber composite foaming material has good elasticity, stable foam structure and good comfort, and overcomes the defects that an un-foamed fiber elastic material is relatively hard and a sponge material is soft in supporting and poor in breathability.

Owner:GUIZHOU DAZIRAN TECH

Treatment method of cadmium ion in EDTA-free acidic non-cyanide cadmium plating wastewater

ActiveCN106336071AWater contaminantsWaste water treatment from metallurgical processCyanideWastewater

The invention discloses a treatment method of cadmium ion in acidic non-cyanide cadmium plating wastewater containing no strong coordination agent EDTA. When pH of cadmium plating wastewater is 2.47-9.34, sodium dimethyldithiocarbamate and cadmium ion react to generate cadmium dimethyl dithiocarbamate precipitate; after the precipitate is separated, content of cadmium ion in discharged wastewater meets requirements of GB 21900-2008 ''electroplating pollutant discharge standard'' Table 2. When pH of the wastewater is 4.43-6.73, sodium dimethyldithiocarbamate precipitate cadmium, cadmium ion in the wastewater meets requirements of GB 21900-2008 ''electroplating pollutant discharge standard'' Table 2.

Owner:GUANGZHOU ULTRA UNION CHEM LTD

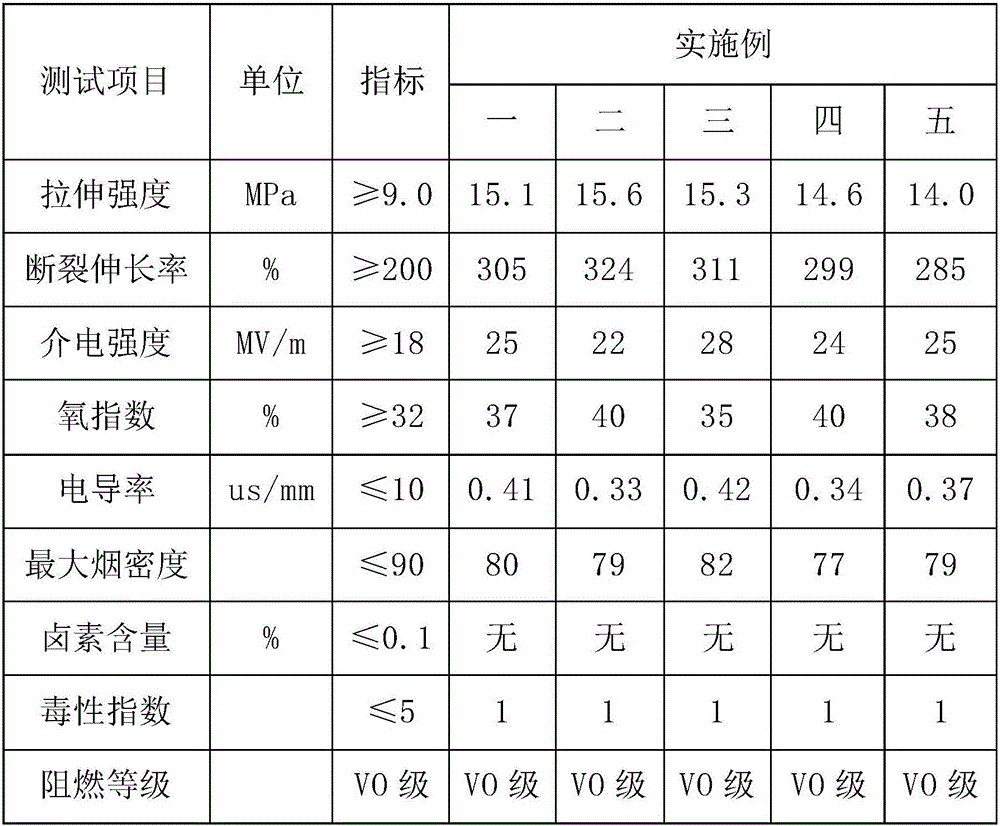

High-temperature-resistant flame-retardant cable material and preparation method thereof

InactiveCN105860425AImprove flame retardant performanceReduce hardnessPlastic/resin/waxes insulatorsAluminium hydroxidePolyvinyl chloride

The invention discloses a high-temperature-resistant flame-retardant cable material and a preparation method thereof. The high-temperature-resistant flame-retardant cable material comprises, by weight, 60-80 parts of phenolic resin, 50-100 parts of polyvinyl chloride, 20-40 parts of polyacrylate rubber, 1-3 parts of zinc dimethyldithiocarbamate, 3-6 parts of dibasic lead phosphite, 10-30 parts of antimonous oxide, 5-10 parts of aluminium hydroxide, 5-15 parts of silicon dioxide, 5-30 parts of titanium dioxide, 5-10 parts of glass fibers, 15-30 parts of dioctyl phthalate, 2-6 parts of chlorinated paraffin and 50-80 parts of filler. The high-temperature-resistant flame-retardant cable material has the advantages that on the premise of guaranteeing excellent flexibility and insulativity, combustion of internal polymers of the cable material is inhibited effectively, so that flame retardance of the cable material is improved; the high-temperature-resistant flame-retardant cable material is highly resistant to high temperature, and safety performance is improved while production cost is reduced; the preparation method is simple and easily available to raw materials.

Owner:ZIBO KUAKE MEDICINE TECH

Explosion-proof rubber sealant cover for supercapacitors

The invention relates to the technical field of capacitors, in particular to an explosion-proof rubber sealant cover for supercapacitors. The explosion-proof rubber sealant cover is characterized by comprising the following raw materials by weight part: 32-38 of high benzene rubber, 22-32 of polyacrylic rubber, 6-12 of titanium dioxide, 3-5 of zinc stearate, 3-5 of lecithin, 5-10 of graphene oxide, 5-10 of aluminum oxide, 3-5 of tea polyphenols, 5-10 of zinc dimethyldithiocarbamate, 3-5 of talcum powder, 2-4 of sulfur and 3-5 of montmorillonite. The preparation method of the explosion-proof rubber sealant cover provided by the invention is simple, and compared with the prior art, has the advantages of reduced energy consumption, green and environmental protection. The prepared product has a reasonable formula, good mechanical properties, fatigue performance, aging resistance, lower heat generation, and good comprehensive performance, and can effectively prevent burst of capacitors by installing on the shells of the supercapacitors.

Owner:宁国市裕华电器有限公司

Toner particles of controlled morphology

The present invention is a method for the preparation of electrostatographic toner that includes the following steps. A polymer material is dissolved in an organic solvent to form an organic phase that includes a metal complex of zinc dimethyldithiocarbamate; zinc diethyldithiocarbamate; dibenzyldithiocarbamate, zinc di-n-butyldithiocarbamate. The organic phase is dispersed in an aqueous phase that includes a particulate stabilizer to form a dispersion and the resultant dispersion is homogenized. The organic solvent is evaporated and the resultant product is recovered, washed and dried.

Owner:EASTMAN KODAK CO

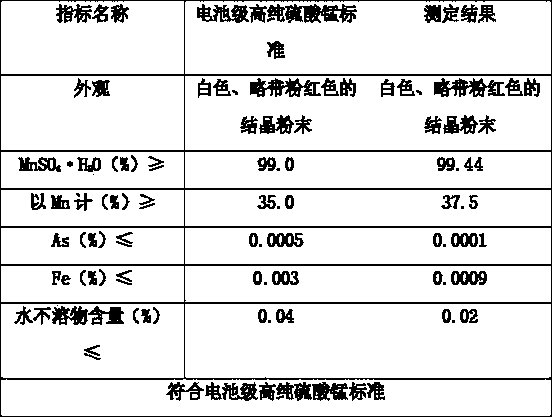

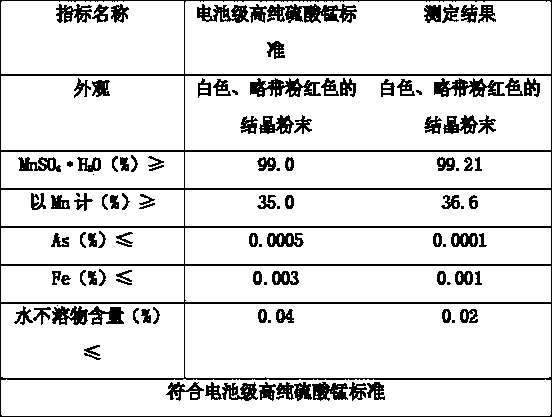

Method for preparing cell-grade high-purity manganese sulfate by low-grade manganese ore high-pressure crystallization

The invention discloses a method for preparing cell-grade high-purity manganese sulfate by low-grade manganese ore high-pressure crystallization. The method comprises the following steps of grinding low-grade pyrolusite and pyrite into powder particles, preparing a manganese sulfate solution, mixing the manganese sulfate solution and the pyrolusite powder particles to obtain preliminary pulp, mixing the preliminary pulp, concentrated sulfuric acid and the pyrite powder particles according to a certain ratio, carrying out heating, stirring and manganese impregnation on the mixture, adding a neutralizer into the mixture to adjust a pH value, adding barium sulphide and sodium dimethyldithiocarbamate into the mixture to remove impurities so that a pure manganese sulfate solution is obtained, carrying out heating pressurization stirring on the pure manganese sulfate solution, discharging a supernatant to obtain a manganese sulfate crystal-containing solution, carrying out standing precipitation of the manganese sulfate crystal-containing solution at a normal temperature, carrying out filtration to obtain a high-concentration manganese sulfate solution, adding the high-concentration manganese sulfate solution into a high-pressure autoclave, carrying out crystallization at a high temperature under high pressure, discharging a supernatant after crystallization to obtain manganese sulfate crystal-containing magma, separating the manganese sulfate crystal-containing magma to obtain high-purity manganese sulfate crystals, and drying and crushing the high-purity manganese sulfate crystals to obtain the cell-grade high-purity manganese sulfate.

Owner:CENT SOUTH UNIV +1

High-performance composite cable jacket material for cables

InactiveCN104610666ALow costDelay agingInsulated cablesInsulated conductorsStearic acidChlorinated paraffins

The invention discloses a high-performance composite cable jacket material for cables. The high-performance composite cable jacket material is prepared from the following raw materials in parts by weight: 35-45 parts of ethylene propylene terpolymer, 30-50 parts of EVA resin, 30-45 parts of modified nanokaolin, 1-2 parts of dibenzothiazyl disulfide, 1.5-2.5 parts of zinc oxide, 1-3 parts of zinc dimethyldithiocarbamate, 1-2 parts of anti-aging agent ODA, 45-55 parts of high abrasion furnace black, 25-35 parts of calcined clay, 20-30 parts of nano calcium carbonate, 1-1.8 parts of dioctyl phthalate, 1-3 parts of stearic acid, 0.5-1.5 parts of chlorinated paraffin, 2-4 parts of solid calcium-zinc stabilizer and 1-2.5 parts of anti-aging agent RD. The high-performance composite cable jacket material for cables disclosed by the invention has good ageing resistance, good mechanical properties and low cost.

Owner:ANHUI HONGYI CABLE GROUP

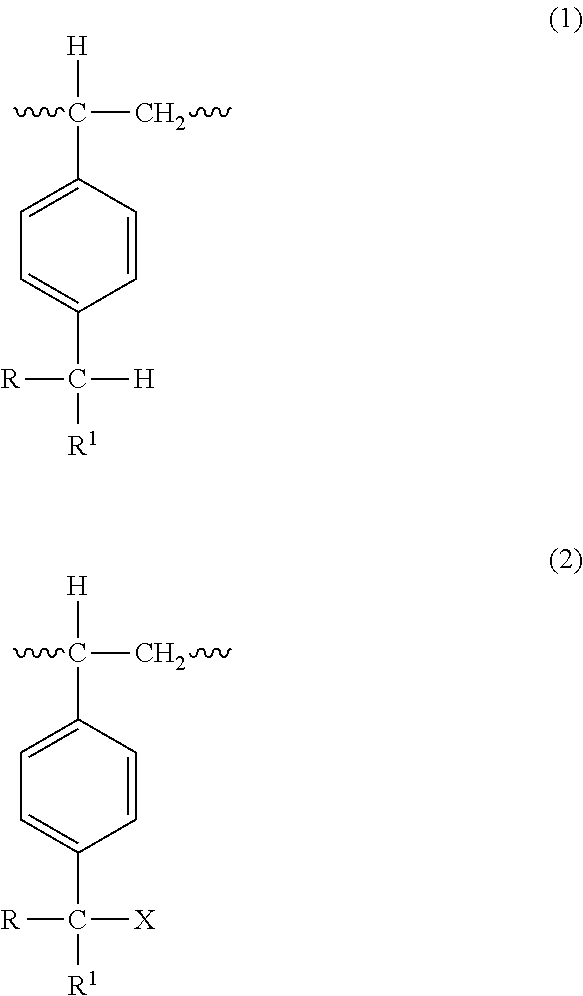

Elastomeric copolymers, copolymer compositions, and their use in articles

A copolymer is formed from an isoolefine having from 4 to 7 carbon atoms and an alkylstyrene. The copolymer has a substantially homogeneous compositional distribution. The copolymer has from about 8 to about 12 wt% of alkylstyrene and at least 85 wt% of isoolefine. The copolymer is preferably halogenated with about 1.1 to about 1.5 wt% of a halogen. The copolymer may in elastomeric nanocomposites. To obtain a good dispersion of the nanoclay in a formulated compound, at least one cure accelerator is selected from the group consisting of mercaptobenzothiazole disulfide, mercaptobenzothiazole, cyclohexyl benzothiazole disulfide, dibutyl thiourea, tetramethylthiuram disulfide, 4-4- dithiodimropholine, zinc dimethyldithiocarbamate, and zinc dibutylphosphorodithiate.

Owner:EXXONMOBIL CHEM PAT INC

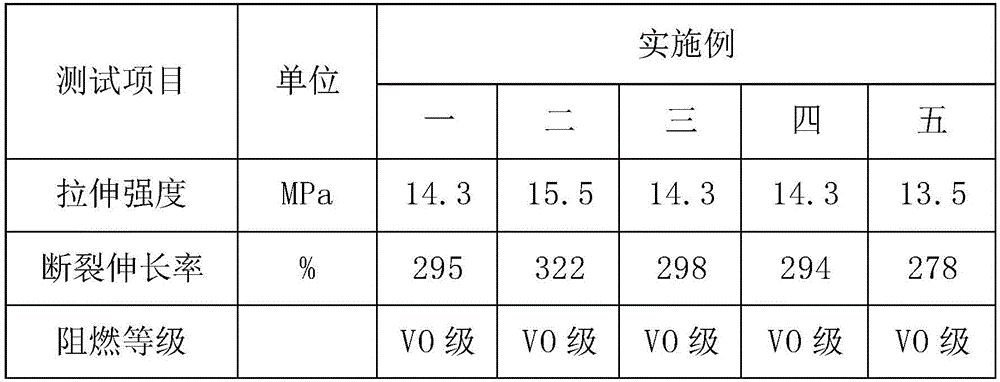

Sheathing material for power cables and preparation method thereof

InactiveCN103788517AAvoid premature vulcanizationHigh tensile strengthRubber insulatorsInsulated cablesPotassiumPolyethylene glycol

The invention discloses a sheathing material for power cables. The sheathing material comprises the following raw materials in parts by weight: 12-16 parts of chlorosulfonated polyethylene, 3-6 parts of butadiene-acrylonitrile rubber, 6-9 parts of chlorinated butyl rubber, 0.3-0.5 part of zinc dimethyldithiocarbamate, 0.3-0.7 part of dibenzothiazyl disulfide, 1.2-1.7 parts of an activator zinc oxide, 2-3 parts of stearic acid, 0.6-1 part of N-(cyclohexylthio)phthalimide, 0.5-1 part of chlorinated paraffin, 1-2 parts of a surfactant polyethylene glycol, 1.5-2 parts of potassium chloroplatinate, 1-4 parts of dioctyl phthalate, 4-7 parts of a reinforcing agent carbon black 330, 4-6 parts of a filler ultrafine talcum powder, and 2.5-4 parts of a filler calcium carbonate. The invention also discloses a preparation method of the sheathing material for power cables. According to the invention, the sheathing material for the power cables is good in mechanical properties, high in tensile strength, good in tear strength and wear resistance, excellent in aging resistance, simple in preparation process, and low in production cost.

Owner:ANHUI ZHONGTONG CABLE TECH

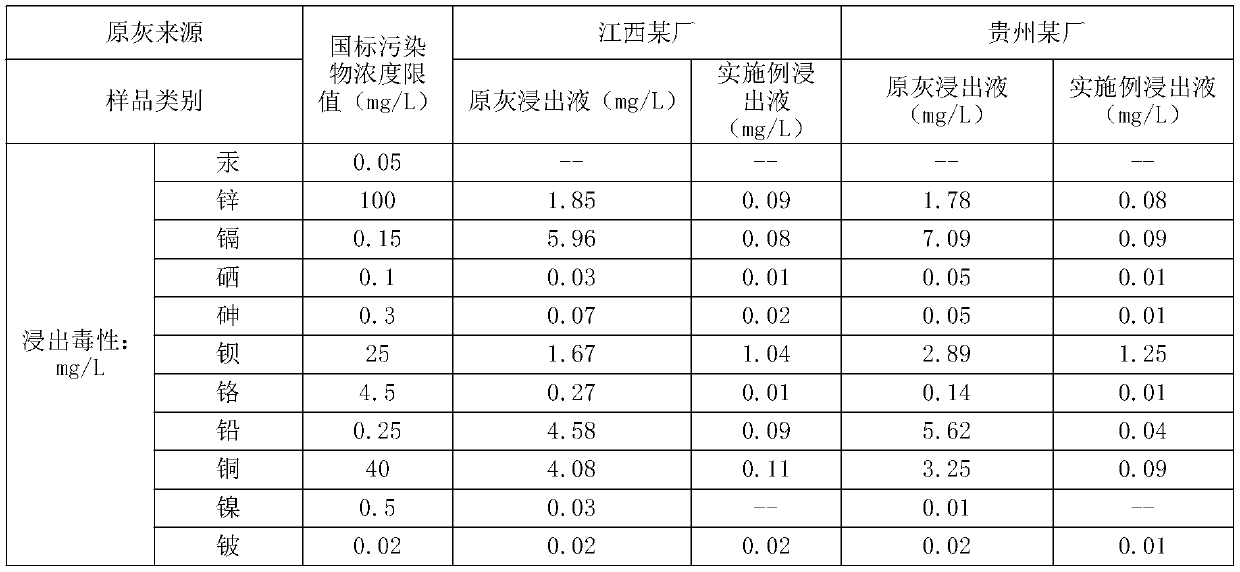

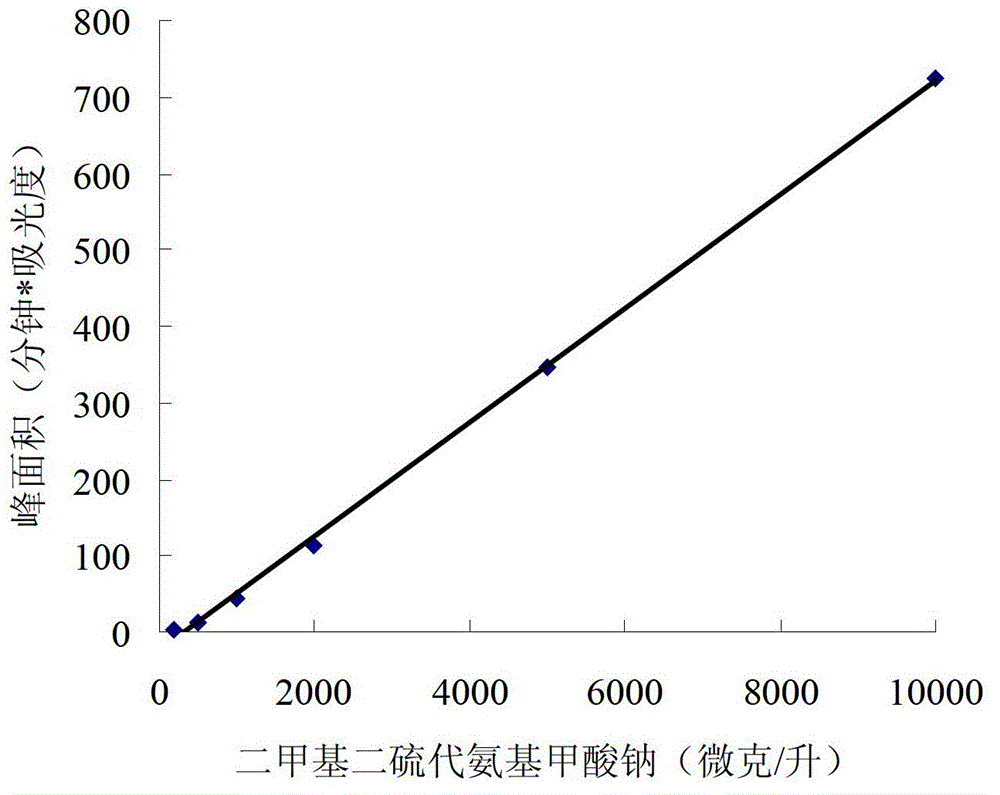

A composite heavy metal chelating agent for waste incineration fly ash and a preparation method thereof

InactiveCN110090384AStrong chelating abilityReduce processing costsChemical protectionPregnant leach solutionHeavy metal chelation

A composite heavy metal chelating agent for waste incineration fly ash and a preparation method thereof are disclosed. The composite heavy metal chelating agent includes, by weight, 15-20 parts of anorganic chelating agent, 5-10 parts of an inorganic chelating agent, 2-10 parts of an inhibitor, 2-5 parts of a dispersant and 50-80 parts of water. The organic chelating agent is a mixture of sodiumbutyl dithioxanthate and sodium dimethyldithiocarbamate. The inorganic chelating agent is sodium hexametaphosphate. The inhibitor is sodium lignosulphonate, and the dispersant is sodium silicate. Thecomposite heavy metal chelating agent is a multi-formula composite heavy metal chelating agent, has strong chelation performance for heavy metals in waste incineration fly ash through synergistic effects of organic and inorganic components, can efficiently achieve stabilization treatment of the waste incineration fly ash and can ensure that pollutant concentrations of leach liquor meet standards.The preparation method of the composite heavy metal chelating agent is also provided.

Owner:武汉古锐恩环保科技有限公司

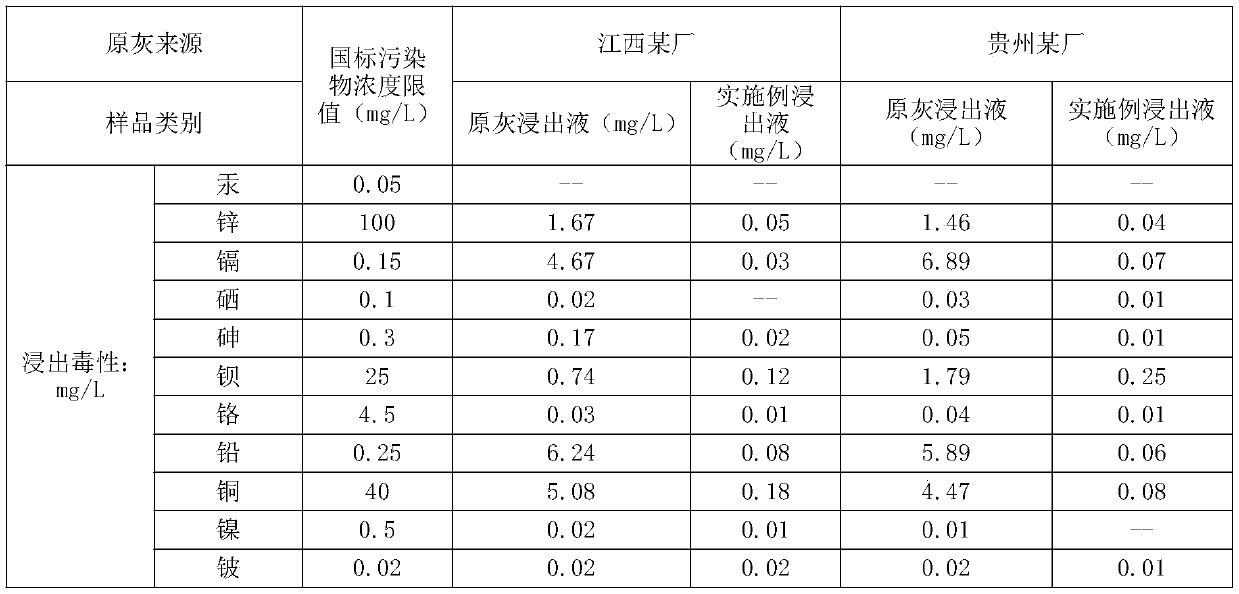

Deep purification and recycling method for waste water containing heavy metal ions

InactiveCN104973714AHigh removal rateImprove water qualityWater contaminantsMultistage water/sewage treatmentUltrafiltrationFiltration

The invention relates to a deep purification and recycling method for waste water containing heavy metal ions. The deep purification and recycling method comprises the following steps: performing chemical neutralization and sedimentation on the waste water containing one or more heavy metal ions to remove most heavy metal ions in water; adding dimethyl carbamodithioic acid or potassium dimethyldithiocarbamate and a polymer flocculating agent, and fundamentally removing the heavy metal ions in the waste water through coagulation sedimentation; adopting sand filtration, ultrafiltration and nanofiltration units to treat effluent water after sedimentation, removing suspended substances, SS, organic matters and partial heavy metal ions in the waste water, wherein the water quality reaches the water quality recycling standard of circulating cooling water after treatment. The waste water containing one or more heavy metal ions at different concentrations can be treated, the application range is large, the operation is simple, and the removal rate is high.

Owner:广西冶金研究院有限公司

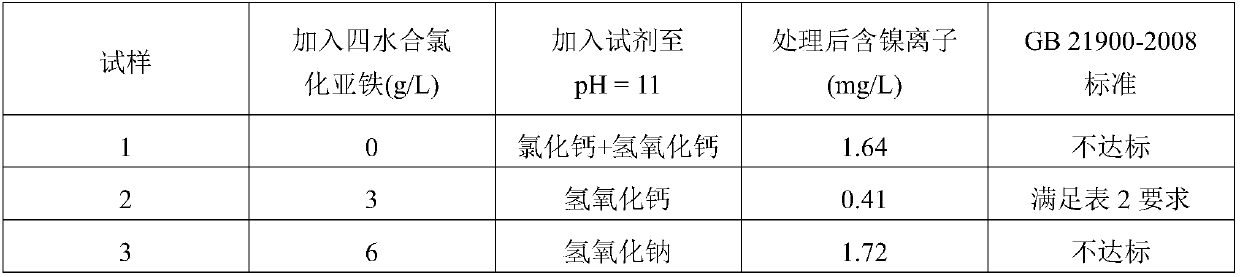

A kind of treatment method of alkaline zinc-nickel alloy electroplating wastewater

ActiveCN104961273BSolve problems that cannot be metAchieve an adequate responseWaste water treatment from metallurgical processMultistage water/sewage treatmentHydrogenNickel alloy

The invention discloses a method for treating alkaline zinc-nickel alloy electroplating wastewater. The method includes destructing strong fatty amine complex agents in the alkaline zinc-nickel alloy electroplating wastewater by the aid of hydrogen peroxide under the condition of pH (potential of hydrogen) of 8-13; enabling dimethyl carbamodithioic acid and heavy metal ions of zinc, nickel and the like to react with one another to generate precipitates of zinc dimethyldithiocarbamate, nickel dimethyldithiocarbamate and the like, and enabling residual heavy metal ions of zinc, nickels and the like in the wastewater to meet requirements of a table 2 in GB 21900-2008 Electroplating Pollutant Discharge Standards. Slow oxidation reaction needs to be carried out for longer than 10h. The method has the advantage that discharge standards can be met by the wastewater after the precipitates are separated from the wastewater.

Owner:GUANGZHOU ULTRA UNION CHEM LTD

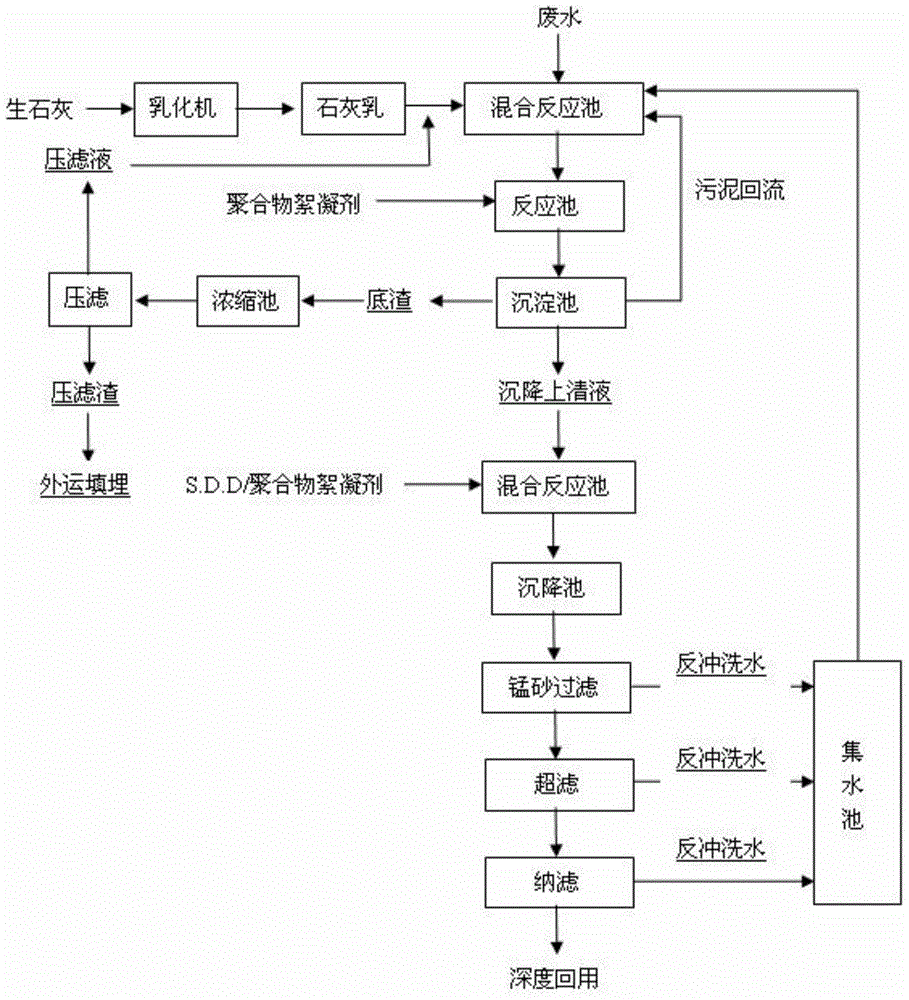

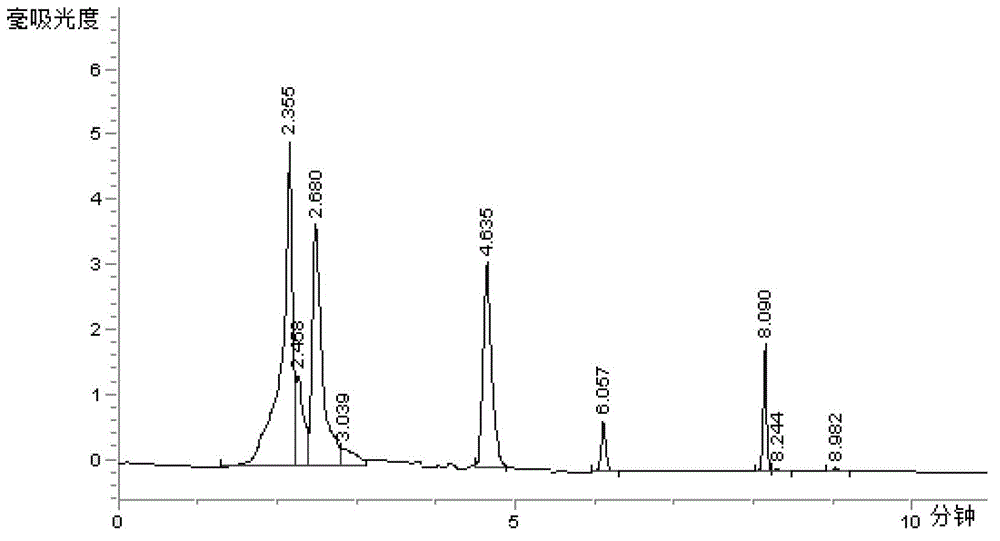

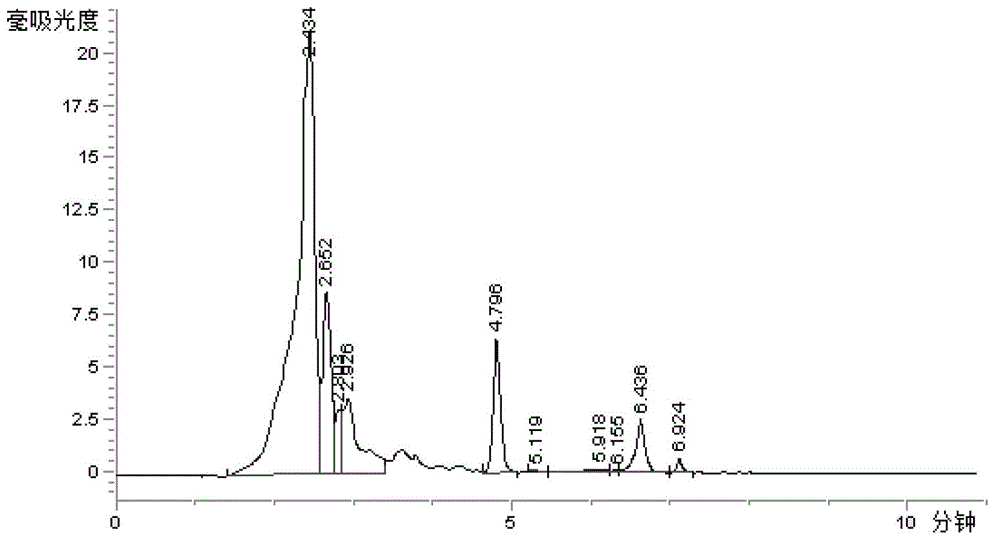

Method for detecting trace N, N-dimethyldithiocarbamate in water

The invention relates to a method for detecting trace N, N-dimethyldithiocarbamate in water. The method comprises the following steps: derivatively reacting a water sample containing N, N-dimethyldithiocarbamate with a derivatization reagent at pH value of 7.0-10.0 for 10-40 min, so as to obtain flavescent derivative tetramethyl thiuram disulfide; next, detecting tetramethyl thiuram disulfide by using an efficient liquid chromatography, so as to obtain a chromatogram; inputting a chromatographic peak appearing time into an Agilent 1200 LC chemical workstation and processing the chromatographic peak appearing time in the chemical workstation so as to obtain peak height and peak area; and finally, first finding out the peak area on a longitudinal coordinate in a standard curve graph and then finding out data on a horizontal ordinate, which represents the concentration of N, N-dimethyldithiocarbamate in the water, on a curve corresponding to the longitudinal coordinate representing the peak area. The method for detecting trace N, N-dimethyldithiocarbamate in the water, provided by the invention, has the advantages of mild and rapid derivative reaction, no interference peak, rapidness, simplicity, convenience, high accuracy and good repetitiveness; and trace N, N-dimethyldithiocarbamate in municipal sewage can be effectively detected.

Owner:TONGJI UNIV

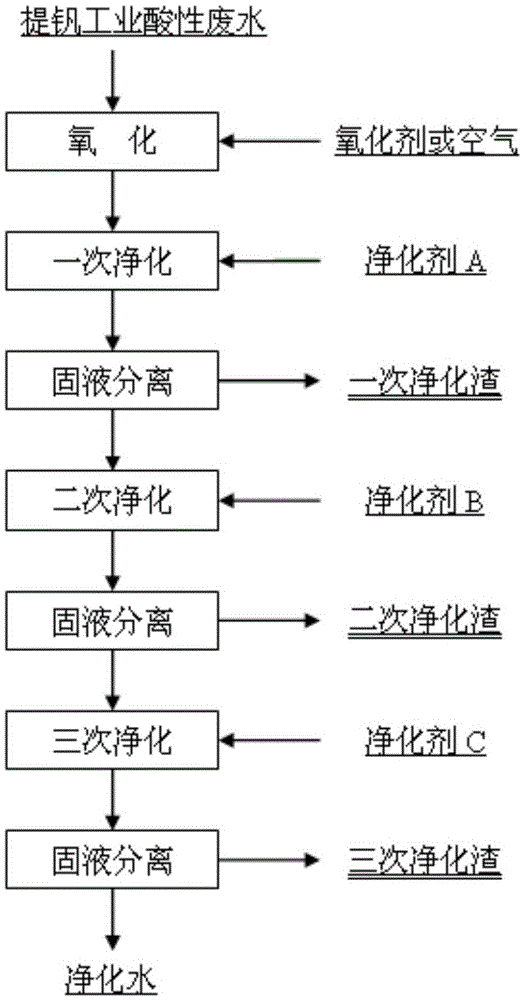

Method for treating vanadium extracting industrial acid wastewater and comprehensively recycling valuable metal

ActiveCN105567976AControl parameters are clearly definedEasy to controlCalcium/strontium/barium sulfatesCement productionWastewaterBarium sulfide

The invention discloses a method for treating vanadium extracting industrial acid wastewater and comprehensively recycling valuable metal. The method comprises the following steps that aeration and oxidation are carried out on the acid wastewater, and then a purifying agent A is added and is at least one of limestone, unslaked lime, slaked lime and lime milk; stirring is carried out for reacting, and the pH of the reaction endpoint is controlled to be equal to 4.5 to 5.0; filtering and washing are carried out, and primary purifying liquid and primary purifying residues are obtained; a purifying agent B is added to the primary purifying liquid, and is at least one of unslaked lime, slaked lime and lime milk; stirring is carried out for reacting, and the pH of the reaction endpoint is controlled to be equal to 6.5 to 7.5; filtering and washing are carried out, and secondary purifying liquid and secondary purifying residues are obtained; and a purifying agent C is added to the secondary purifying liquid and is at least one of sodium dimethyldithiocarbamate (SDD), sodium sulfide and barium sulfide, stirring is carried out for reacting, filtering is carried out, and third purifying liquid and third purifying residues are obtained. The method has the beneficial effects of being simple in process step, low in treatment cost, good in valuable metal comprehensive recovery effect and the like.

Owner:SHENGTONG YIHE TIANJIN ENTERPRISE MANAGEMENT CONSULTING CO LTD

Pre-dispersion masterbatch used as rubber ultra-fast accelerator ZDMC and preparation method of pre-dispersion masterbatch

The invention discloses a pre-dispersion masterbatch used as a rubber ultra-fast accelerator ZDMC. The pre-dispersion masterbatch used as the rubber ultra-fast accelerator ZDMC consists of the following components in parts by weight: 75-82 parts of zinc dimethyldithiocarbamate, 10-14 parts of a rubber carrier, 2-6 parts of naphthenic oil, 1 part of stearic acid, 1 part of triethanolamine, and 2-5 parts of a mixture of saturated and unsaturated fatty acid zinc soap. The zinc dimethyldithiocarbamate is prepared into the pre-dispersion masterbatch, so that the original activity of the zinc dimethyldithiocarbamate can be guaranteed effectively. The pre-dispersion masterbatch cannot be caked at room temperature, and batching is convenient and accurate, when the pre-dispersion masterbatch is used as an ultra-fast accelerator in the follow-up process, dust flying is avoided in a rubber melting process, a working environment of an operator can be improved, the use level of the accelerator is reduced, and the utilization rate of the zinc dimethyldithiocarbamate is increased; the pre-dispersion masterbatch has relatively low Mooney viscosity at the relatively low temperature of 50 DEG C, and has good dispersibility in rubber, and the quality of a rubber product can be improved.

Owner:NINGBO ACTMIX POLYMER

Combined treatment method of electroplating mixed wastewater

ActiveCN110818173AReduce CODAvoid difficultiesTreatment using aerobic processesGeneral water supply conservationWater chlorinationSodium cyanide

The invention discloses a combined treatment method of electroplating mixed wastewater. The method comprises the steps of adjusting and maintaining pH of the wastewater to 10.5-12 by using lime emulsion, and adding sodium hypochlorite sodium cyanide oxide, organic amine containing hydroxyl and like pollutants; adding a ferrous chloride solution, and precipitating an organic acid coordination agentcontaining carboxyl in the wastewater by using ferrous ions and calcium ions together, wherein the ferrous ions reduce hexavalent chromium into trivalent chromium and generate chromium hydroxide precipitate; filtering to remove the precipitate; adjusting a pH value of the wastewater to 4.5-5.5, precipitating heavy metal ions by using sodium dimethyldithiocarbamate or sodium diethyldithiocarbamate, and adsorbing precipitates and a heavy metal trapping agent by using activated carbon; filtering to remove precipitate; and adjusting the pH value of the wastewater to 6-8, and destroying the aliphatic polyamine complexing agent and reducing COD by using the existing biodegradation technology. Through the method disclosed by the invention, the heavy metal and like pollutants in the electroplating mixed wastewater can be effectively removed, the treatment cost is low, and the method has good market application prospect.

Owner:GUANGZHOU ULTRA UNION CHEM LTD

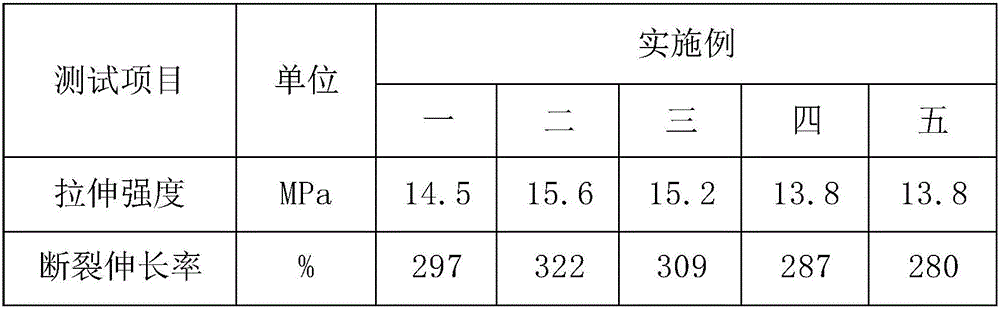

Irradiation-resistant, halogen-free and flame-retardant ethylene-propylene cable material and preparation method thereof

InactiveCN106380689AImprove insulation performanceGood weather resistanceRubber insulatorsPlastic/resin/waxes insulatorsCross-linkAntioxidant

The invention discloses an irradiation-resistant, halogen-free and flame-retardant ethylene-propylene cable material and a preparation method thereof. The cable material comprises 40-80 parts of polypropylene, 20-40 parts of ethylene propylene rubber, 0.5-1 part of dicumyl peroxide, 1-2 parts of zinc dimethyldithiocarbamate, 5-10 parts of aluminum hydroxide, 3-6 parts of magnesium hydroxide, 2-8 parts of triphenyl phosphate, 6-12 parts of p-dibenyl bisphosphate, 5-10 parts of metal fibers, 3-8 parts of silver fibers, 8-12 parts of glass fibers, 1-4 parts of 2-hydroxy-4-octyloxybenzophenone, 10-12 parts of a plasticizer, 3-6 parts of chlorinated paraffin, 0.5-1 part of an antioxidant, 1-4 parts of a cross-linking agent and 6-10 parts of a coloring agent. The cable material has the advantages of no halogen, good insulating property, good ageing resistance, good flame retardation property, good irradiation resistance, high mechanical strength and simple preparation method.

Owner:JIANGSU LINRY NEW MSTAR TECH

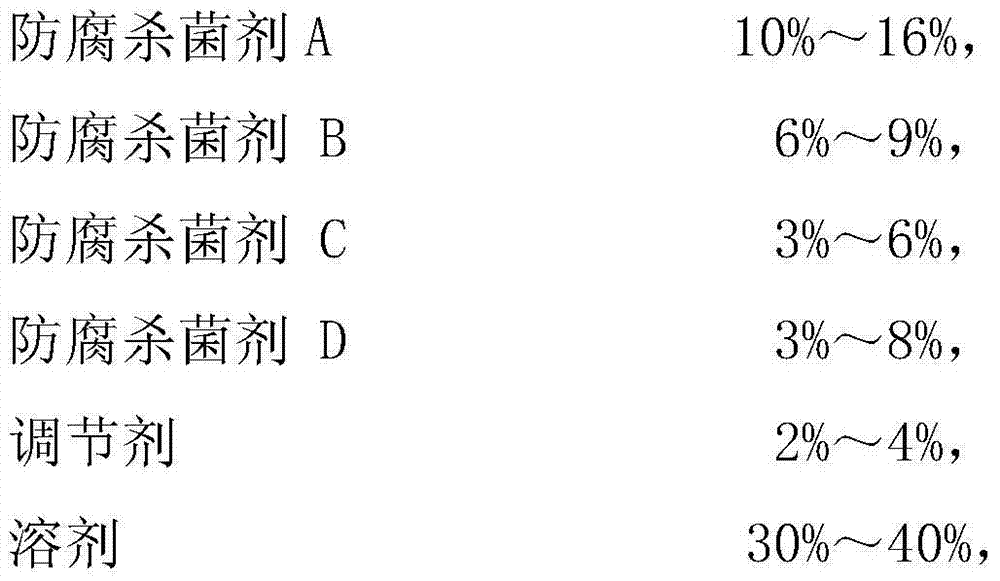

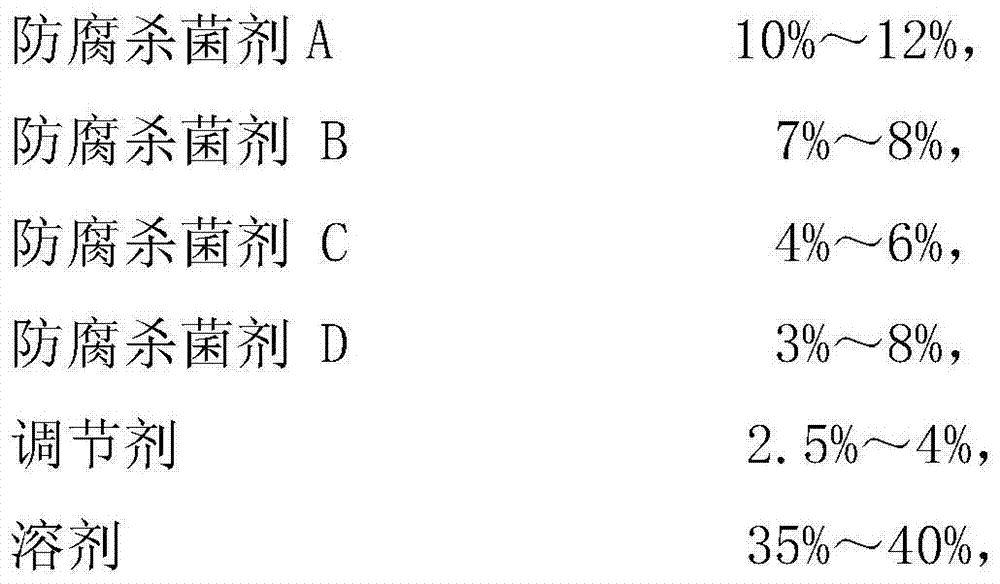

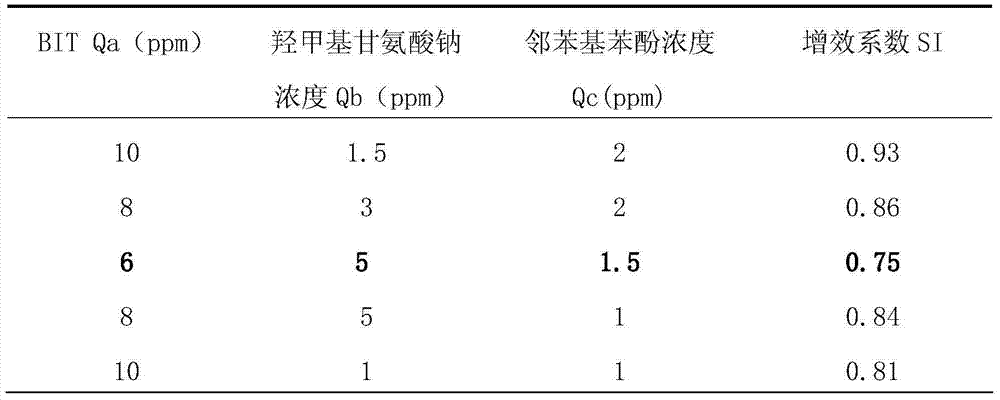

Composite synergistic bactericidal and preservative agent for organic foaming agents

ActiveCN103931627AExpand the scope of protectionHigh activityBiocideFungicidesSodium PyrithionePhenethyl alcohol

The invention relates to a composite synergistic bactericidal and preservative agent for organic foaming agents, which is prepared from 2-methylisothiazolinone and / or 1,2 benzisothiazolinone (BIT) and / or dichloroethylene based salicylamide, sodium pyrithione and / or sodium hydroxymethylglycinate, sodium dimethyldithiocarbamate and / or o-phenylphenol, phenethyl alcohol and / or phenylcarbinol, a regulator, a solvent and water. According to the invention, different bactericidal and preservative agents with various complementary bactericidal spectrums are composited, so that the products have the advantages of reasonable formula, comprehensive protection, strong synergism, good bactericidal and preservative effects and the like, and have a good application effect when being used in aqueous organic foaming agents containing large amounts of proteins and organic polysaccharides.

Owner:SHAANXI RES DESIGN INST OF PETROLEUM CHEM IND

Production process of dithiocarbamate zinc salt rubber accelerator

InactiveCN108558722AAvoid it happening againSimple production processOrganic chemistryReaction temperatureZinc dibenzyldithiocarbamate

The invention provides an environment-friendly harmless new production process of a dithiocarbamate zinc salt rubber accelerator. The process comprises the following steps of S1. putting water and zinc oxide in a clean reactor and stirring; S2. putting organic amine, stirring for half hour and then adding CS2 dropwise, and controlling reaction temperature at 40DEG C or below; S3. stopping stirringwhen PH value is detected neutral; and S4. treating the paste to obtain znic dimethyldithiocarbamate (PZ), zinc diethyl dithiocarbamaate (ZDC), zinc dibutyl dithiocarbamate (BZ), 1,5-zinc sulfinyl dithiocarbamate (ZPD) and / or zinc dibenzyl dithiocarbamate (DBZ). The process optimizes the steps, and changes an original two-step method into a one-step method, thereby improving the efficiency and simplifying the production process. The processing process does not generate sodium chloride wastewater, thereby being environmentally friendly; and the product has higher performance, and zinc oxide does not contain chloride.

Owner:宜兴市鸿远精细化工有限公司

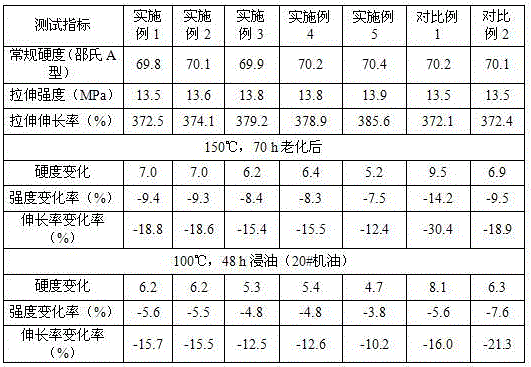

Heat-resistant oil-resistant rubber seal ring and preparation method thereof

The invention provides a heat-resistant oil-resistant rubber seal ring and a preparation method thereof. The preparation method comprises the following steps: (1) weighing raw materials according to the weight parts, and adding nitrile-butadiene rubber, zinc oxide, stearate, sulfur, bis-pentamethylenethiuram tetrasulfide, zinc dimethyldithiocarbamate, poly-hydroxy isopropyl p-phenylenediamine, a 2,2,4-trimethyl-1,2-dichloroquinoline polymer, a silane coupling agent SG-Si996, trimellitate, a hydantoin epoxy resin, a bismaleimide modified epoxy resin and a curing agent 704 into a Banbury mixer, and banburying; (2) adding the sizing material into an open mill, adding carbon black, a norbornene-terminated polyamide resin and an alkyd resin according to the weight parts, and carrying out compounding forming; (3) adding the formed rubber into a mold of a vulcanizer, and carrying out vulcanization treatment; and (4) carrying out trimming, inspection, packaging and warehousing. The seal ring has the advantages of excellent oil resistance and excellent high-temperature resistance.

Owner:珠海海源密封胶有限公司

Additive for inhibiting re-release of mercury during wet method flue gas desulfurization process and using method thereof

ActiveCN103394282AEffective combinationInhibition releaseDispersed particle separationSlurryChelation

The invention relates to an additive for inhibiting re-release of mercury during wet method flue gas desulfurization process and a using method thereof. The additive comprises the following components in percentage by weight: 30%-45% of sodium tetrasulfide, 30%-45% of dimethyl dithiocarbamate and 10%-40% of trimercapto-triazine metal salt. At normal temperature and normal pressure, the additive is added into desulfurization slurry, and the adding amount of the additive is 50-800mg / L. The additive disclosed by the invention can perform better action with Hg2+ in the slurry by utilizing the synergistic effect of the sodium tetrasulfide, the dimethyl dithiocarbamate and the trimercapto-triazine metal salt so as to form a stable HgS precipitate or a stable chelate, and the precipitate or the stable chelate and desulfurization gypsum can enter a solid phase together for being separated and removed. Simultaneously, the composite additive is more suitable for being added under operation conditions of a wet method desulfurization system.

Owner:STATE GRID CORP OF CHINA +1

Method for preparing antibacterial yarns

InactiveCN103966839AImprove antibacterial propertiesIncrease productivityVegetal fibresYarnDithiocarbamate

The invention discloses a method for preparing antibacterial yarns. The method is characterized by comprising the following steps: sequentially adding the following components in parts by weight into a container: 50-70 parts of water, 11-13 parts of nano-silver and 3-5 parts of dimethyl dithiocarbamate, and fully stirring for 60 minutes; adding a PH value regulator for regulating the PH value to 7; adding nano-modified bamboo charcoal yarns into the container for fully soaking for 30-50 minutes; taking out the soaked yarns, and drying at the temperature of 75 DEG C for 55 minutes. According to the mode, due to the method for preparing antibacterial yarns, the yarns are soaked in a prepared antibacterial solution, so that the yarns have high-efficiency antibacterial performances, the method is simple, and the production efficiency is high.

Owner:ZHANGJIAGANG WEIMEI TEXTILE

Fly ash chelating improver and preparation method thereof

The invention discloses a fly ash chelating improver and a preparation method thereof, and relates to the technical field of chelating agent preparation. The fly ash chelating improver is prepared from the following components in parts by weight: 60 to 90 parts of dimethyl dithiocarbanate, 20 to 30 parts of sodium sulphide, 15 to 30 parts of sodium phosphate, 100 to 200 parts of sodium hydroxide,50 to 60 parts of acrylamide, and 90 to 150 parts of pure water. The preparation method comprises the steps of S1, placing the 60 to 90 parts of dimethyl dithiocarbanate, the 20 to 30 parts of sodiumsulphide, the 15 to 30 parts of sodium phosphate and the 90 to 150 parts of pure water into a reactor, and stirring for 5 to 10 minutes at normal temperature; S2, adding the 50 to 60 parts of acrylamide into the step S1, and stirring for 20 to 30 minutes at normal temperature; and S3, adding the 100 to 200 parts of sodium hydroxide into the step S2, and stirring for 5 to 8 minutes to obtain the fly ash chelating improver. The fly ash chelating improver prepared through the above components and the steps has high chelating efficiency, more chelating species and fast rate.

Owner:安徽安江环保科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com