Deep purification and recycling method for waste water containing heavy metal ions

A heavy metal ion and deep purification technology, applied in chemical instruments and methods, water pollutants, water/sewage multi-stage treatment, etc., can solve problems such as difficult treatment, achieve good treatment effect, convenient operation, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

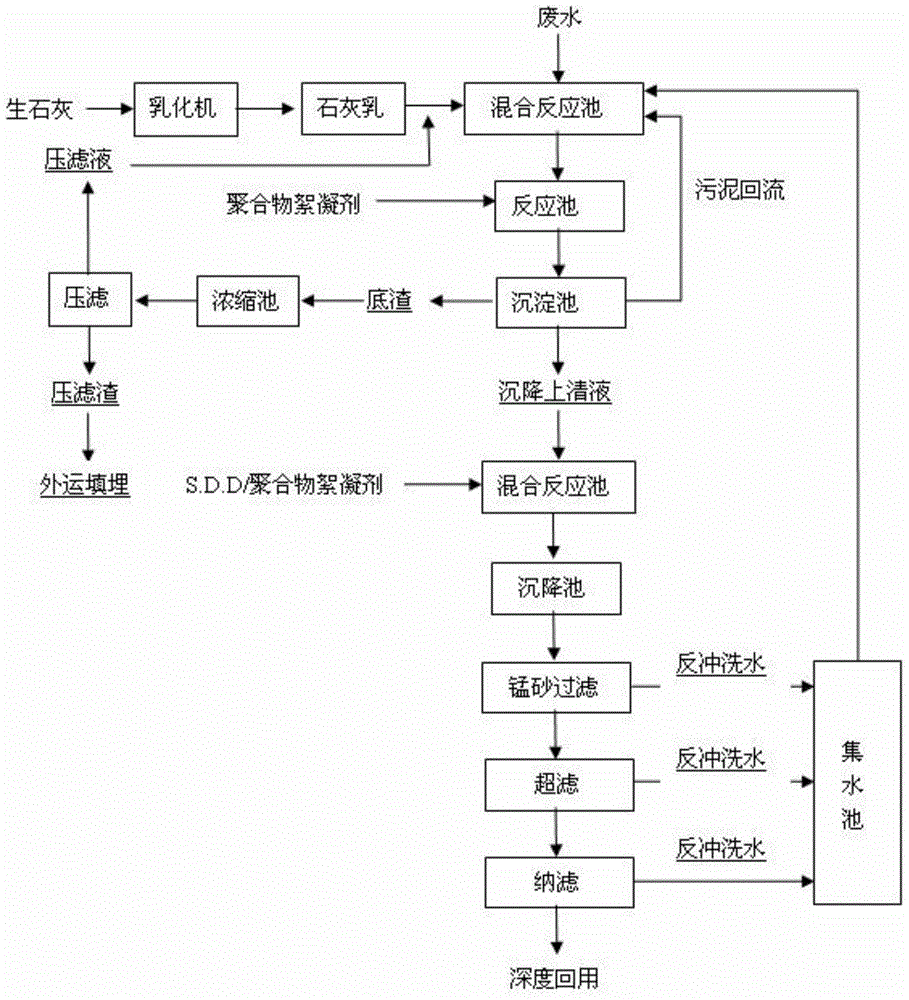

Method used

Image

Examples

Embodiment 1

[0020] The wastewater quality of a lead-zinc enterprise is as follows: the advanced treatment capacity is 500m 3 / d

[0021] project

pH

Zn

Pb

Cu

CD

As

Actual mg / L

2.0~5.4

80~120

2~8

0.5~3.0

1~3

0.5~3.0

[0022] (1) will contain Zn 2+ , Pb 2+ 、Cu 2+ 、Cd 2+ 、As 3+ Wastewater such as heavy metal ions is measured by the electromagnetic flowmeter and discharged into the mixing reaction tank. Add 5-10% lime milk or quicklime, stir for not less than 15 minutes, make the pH of the solution reach 6-8, flow into the sedimentation tank, and then add non-ionic Type polypropylene amine flocculant, the amount of flocculant added is 10-30mg / L, most of the heavy metal ions in the wastewater are converted into heavy metal hydroxides and precipitated by neutralization and precipitation, after the mud and water are separated, the effluent from the sedimentation tank is sent to the next step Wastewater treatment system....

Embodiment 2

[0028] The wastewater quality of a lead-zinc enterprise is as follows: the advanced treatment capacity is 500m 3 / d

[0029] project

pH

Zn

Pb

Cu

CD

As

Actual mg / L

2.0~4.8

75~112

2~8

0.6~2.8

1~3

0.8~3.0

[0030] (1) will contain Zn 2+ , Pb 2+ 、Cu 2+ 、Cd 2+ 、As 3+ Wastewater such as heavy metal ions is measured by the electromagnetic flowmeter and discharged into the mixing reaction tank. Add 5-10% lime milk or quicklime, stir for not less than 15 minutes, make the pH of the solution reach 6-8, flow into the sedimentation tank, and then add non-ionic Type polypropylene amine flocculant, the amount of flocculant added is 10-30mg / L, most of the heavy metal ions in the wastewater are converted into heavy metal hydroxides and precipitated by neutralization and precipitation, after the mud and water are separated, the effluent from the sedimentation tank is sent to the next step Wastewater treatment system....

Embodiment 3

[0036] The wastewater quality of a lead-zinc enterprise is as follows: the advanced treatment capacity is 500m 3 / d

[0037] project

pH

Zn

Pb

Cu

CD

As

Actual mg / L

2.0~4.4

90~120

2.5~7.8

0.5~3.5

1~3.5

0.5~3.0

[0038] (1) will contain Zn 2+ , Pb 2+ 、Cu 2+ 、Cd 2+ 、As 3+Wastewater such as heavy metal ions is measured by an electromagnetic flowmeter and discharged into the mixing reaction tank, adding 5-10% lime milk or quicklime, stirring for not less than 15 minutes, making the pH of the solution to 6-8, flowing into the sedimentation tank, and then adding polymeric sulfuric acid Iron flocculant, the amount of flocculant added is 1.5g / L. Most of the heavy metal ions in the wastewater are converted into heavy metal hydroxides and precipitated by neutralization and precipitation. After the mud and water are separated, the effluent from the sedimentation tank is sent to the next step of wastewater treatmen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com