Patents

Literature

2543 results about "Industrial wastewater treatment" patented technology

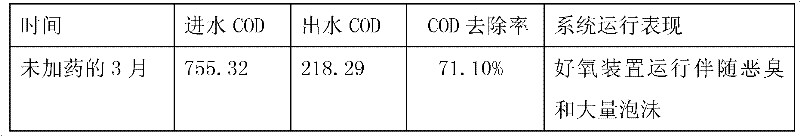

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Industrial wastewater treatment describes the processes used for treating wastewater that is produced by industries as an undesirable by-product. After treatment, the treated industrial wastewater (or effluent) may be reused or released to a sanitary sewer or to a surface water in the environment.

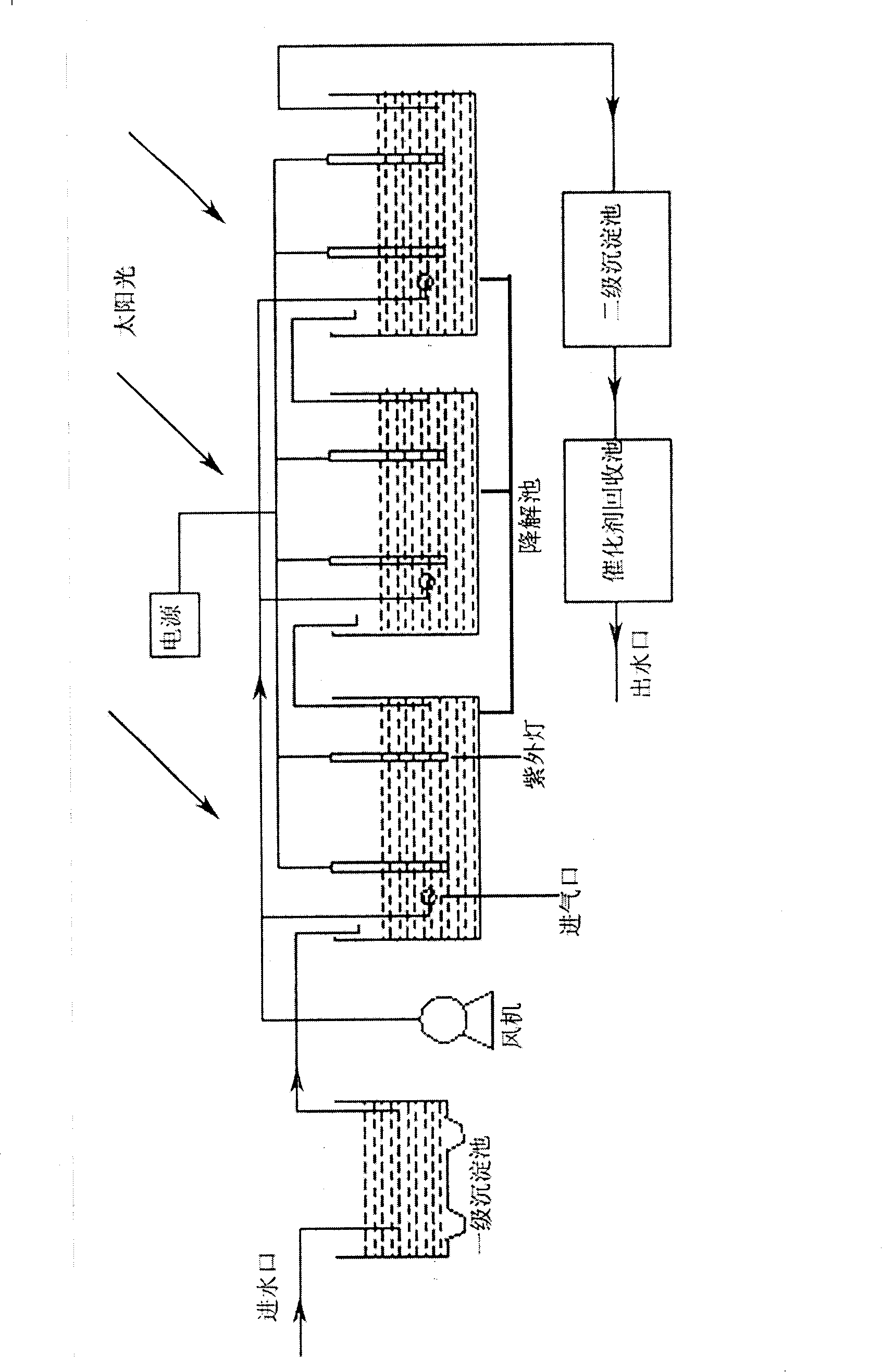

Photocatalysis oxidation treated high concentration organic trade waste

InactiveCN101219371AHigh activityImprove stabilityCatalyst carriersEnergy based wastewater treatmentHigh concentrationEmission standard

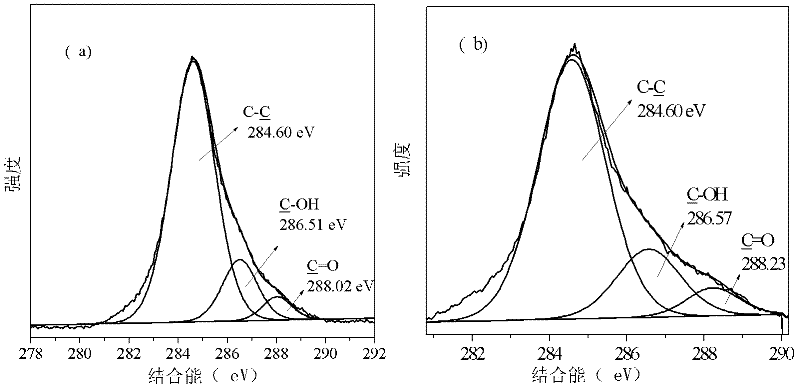

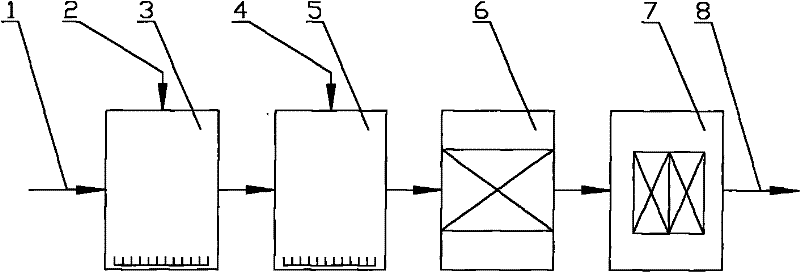

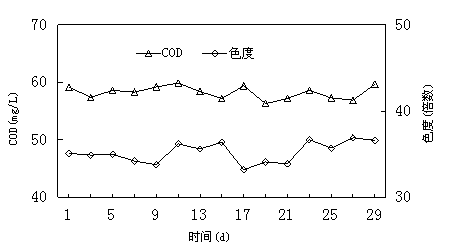

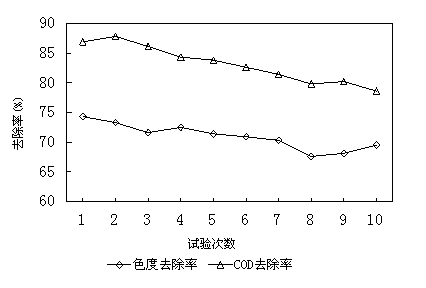

The invention relates to a modified loading nano composite photocatalyst which takes titanium dioxide as main part and adopts new reaction technique to degraded the organic industrial wastewater in a water processing system (see attached drawing 1 in Instruction). The main point on preparing the catalyst lies in that titanium dioxide active compounds loaded on different carriers are employed to prepare a loading photocatalyst with grain diameter of 5-40nm; meanwhile, different elements are mixed into the loading photocatalyst to reduce the composition between photoproduciton electron and cavity, which enables the catalyst to move the light absorbing wavelength thereof towards the visible regions, thus effectively improving the degradation rate of organic pollutants as a new environmental-friendly catalyst. As to the new technique of processing the organic industrial wastewater, the invention overcomes the defects that the present photocatalysts are only used for degrading the organic industrial wastewater with low concentration. The catalyst being irradiated respectively or simultaneously under sunbeam and ultraviolet light can decrease COD values of high-concentration organic industrial wastewater from 10000-40000mg / L to less than 100mg / L in short time, thus meeting the national emission standard.

Owner:BEIJING UNIV OF CHEM TECH

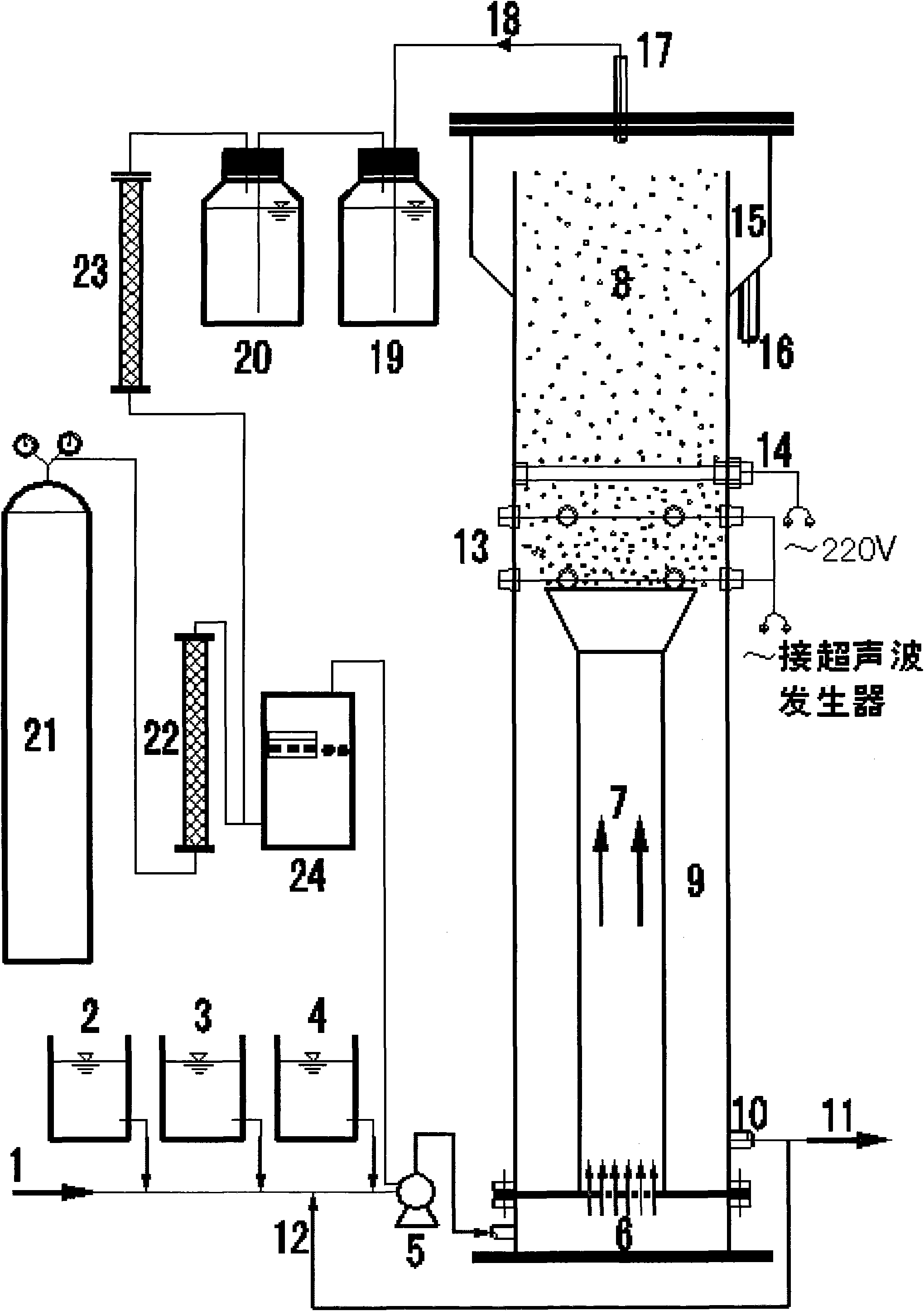

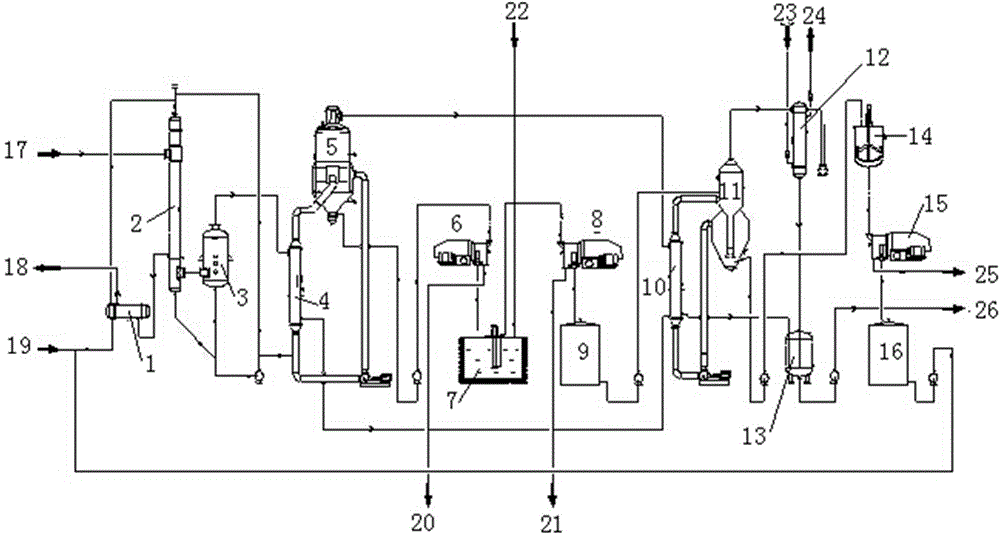

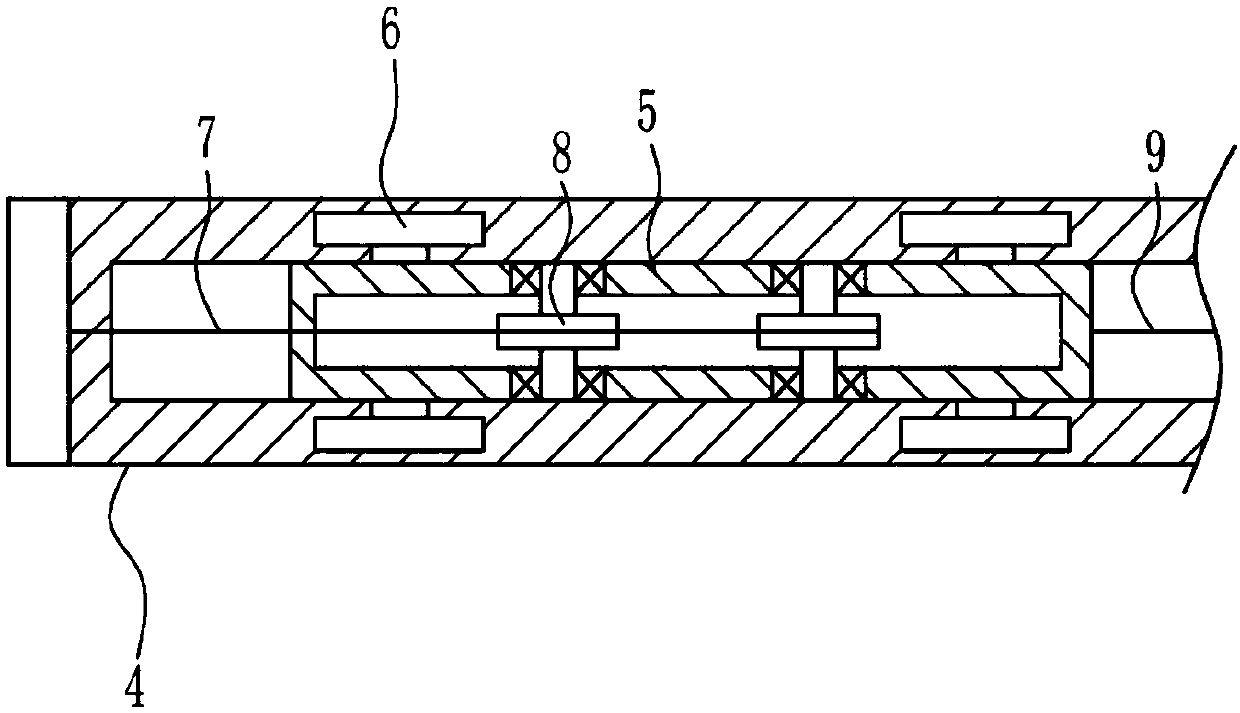

Novel multi-technology synergetic catalysis advanced micro-bubble ozone oxidation tower

ActiveCN102115253AReduce pollutionImprove efficiencyWater/sewage treatment by irradiationWater/sewage treatment with mechanical oscillationsOzone generatorActivated carbon

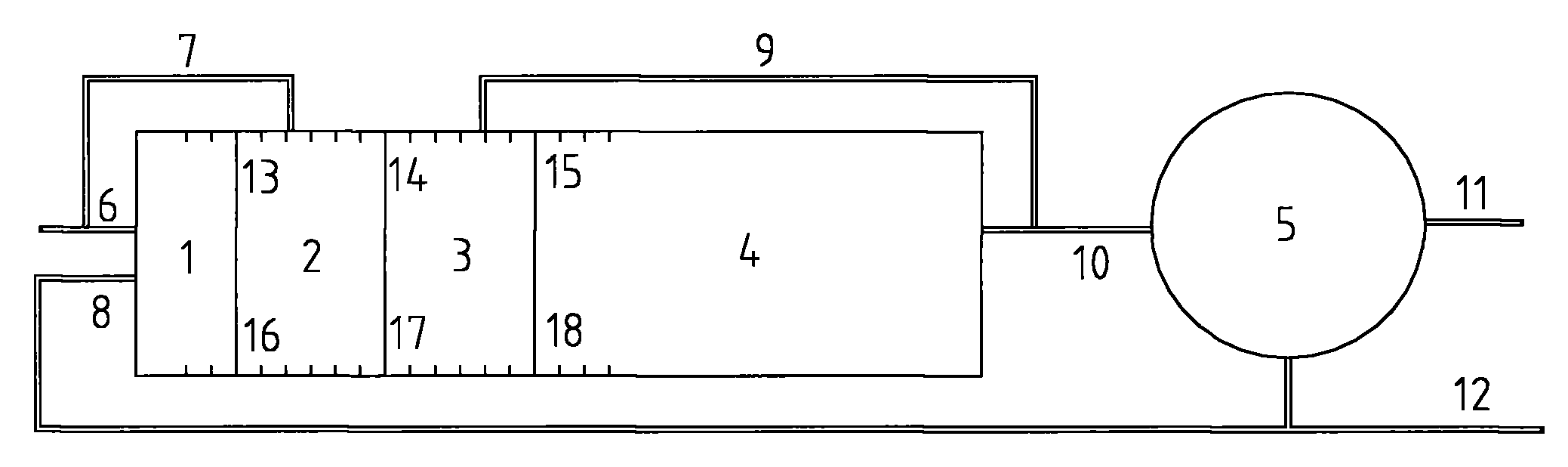

The invention belongs to a multi-technology synergetic catalysis advanced micro-bubble ozone oxidation tower mainly aiming at the treatment of refractory industrial wastewater. Influent (1) and O3 generated by an ozone generator (24) are injected into a water distribution cabin through a dissolved gas pump (5) and enter a micro-bubble release contact area (7) through a pore plate to release dissolved gas; Liquid which contains slag flows upwards and enters a floating slag separation area (8), liquid which contains no slag flows downwards and enters a gas-liquid separator (9), one part of effluent (10) is drained from a drain hole (11), and one part of the effluent (10) is refluxed to a dissolved gas pump intake pipe (12); an ultrasonic vibrator (13) and an ultraviolet light source (14) provide an ultrasonic and ultraviolet synergetic catalysis action; floating slag overflows to a collecting groove (15) and is drained through a drain hole (16); and a coagulant, powder activated carbon and hydrogen peroxide are added by adding systems (2, 3, 4) to provide a coagulation action and the synergetic catalysis action of PAC (powdered activated carbon) and H2O2. Tail gas is refluxed to the ozone generator through a drain hole (17), a one-way valve (18), gas suction tanks (19 and 20) and a dryer (23). The oxidation tower is compact in structure and has high treatment efficiency.

Owner:CHINESE RES ACAD OF ENVIRONMENTAL SCI

Granular filtering material for adsorbing and removing heavy metals in water and preparation method thereof

ActiveCN104289185AWide variety of sourcesRealize resource utilizationOther chemical processesWater contaminantsIndustrial waste waterSorbent

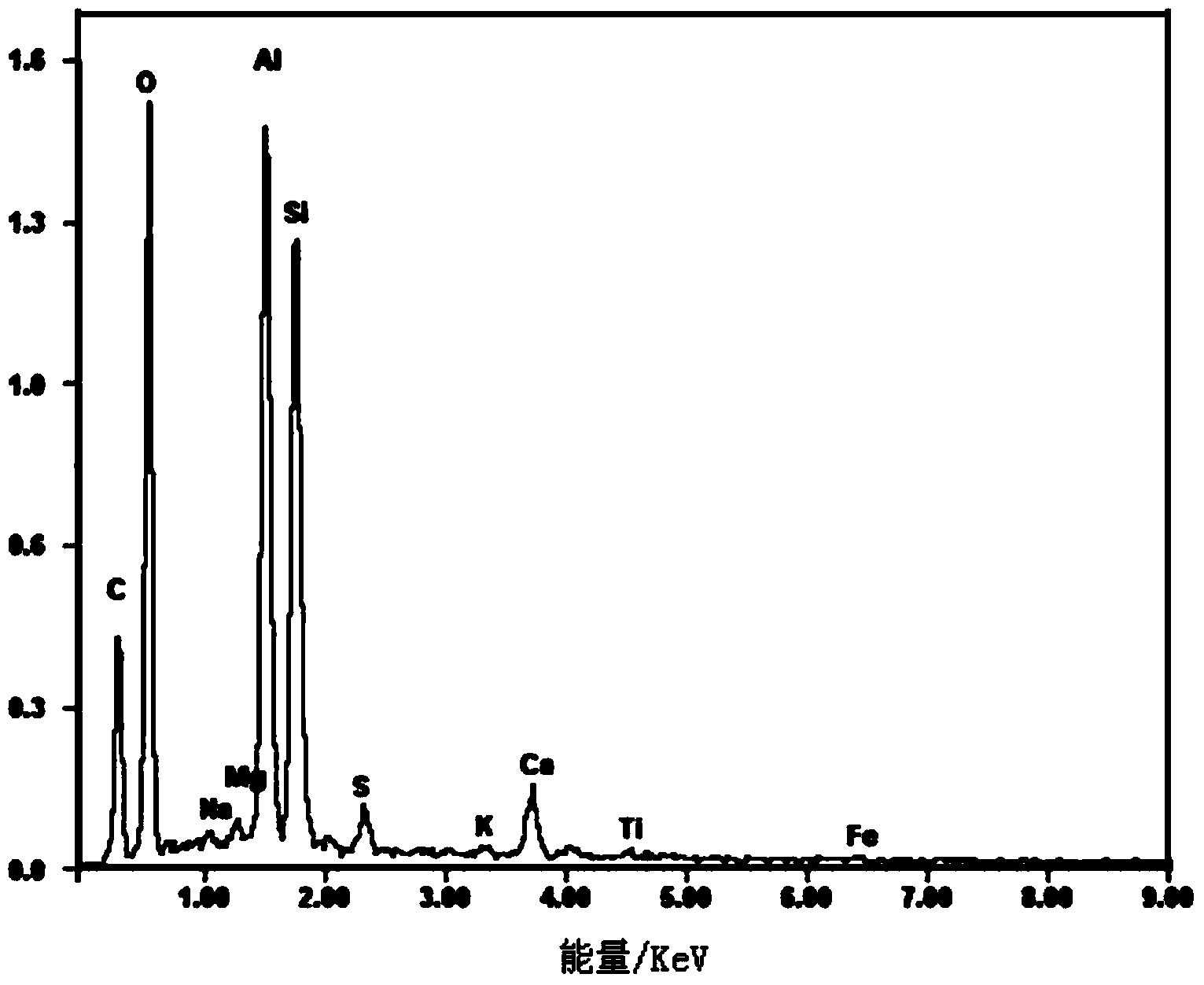

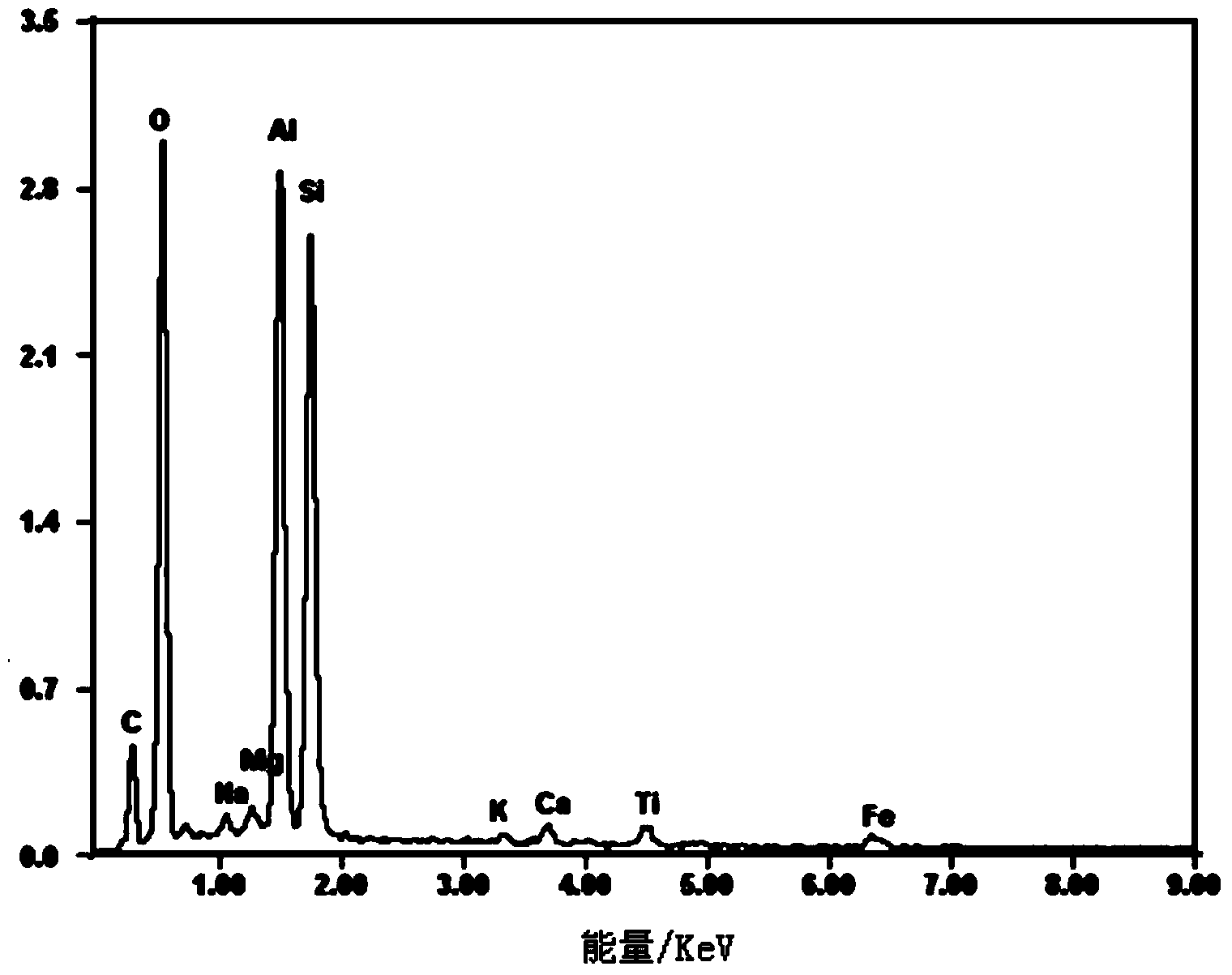

The invention discloses a granular filtering material for adsorbing and removing heavy metals in water and a preparation method thereof. The granular material consists of the following components in part by mass: 80-120 parts of an adsorbent, 7-14 pats of an additive and 0.5-3 parts of a binding agent, wherein the adsorbent consists of the following components in part by mass: 50-70 parts of coal ash and 30-50 parts of zeolite powder or sea-foam stone powder; the additive consists of the following components in part by mass: 5-7 parts of Mg-Al hydrotalcite, 2-6 parts of biochar and 0.5-1 part of magnesium Lignosulfonate; the binding agent is bentonite. The granular filtering material is prepared through the steps of adsorbent acid modification, biochar preparation, granulation and heat treatment process. According to the invention, the prepared granular filtering material is 3-6 mm in granule size, is large in adsorption capacity and excellent in adsorption effect and can effectively remove heavy metals in water, and no secondary pollutants are dissolved out, so that the granular filtering material can be applied to the treatment on heavy metal micro-polluted water and industrial waste water containing heavy metals, and has good economic and social benefits.

Owner:BEIJING FORESTRY UNIVERSITY

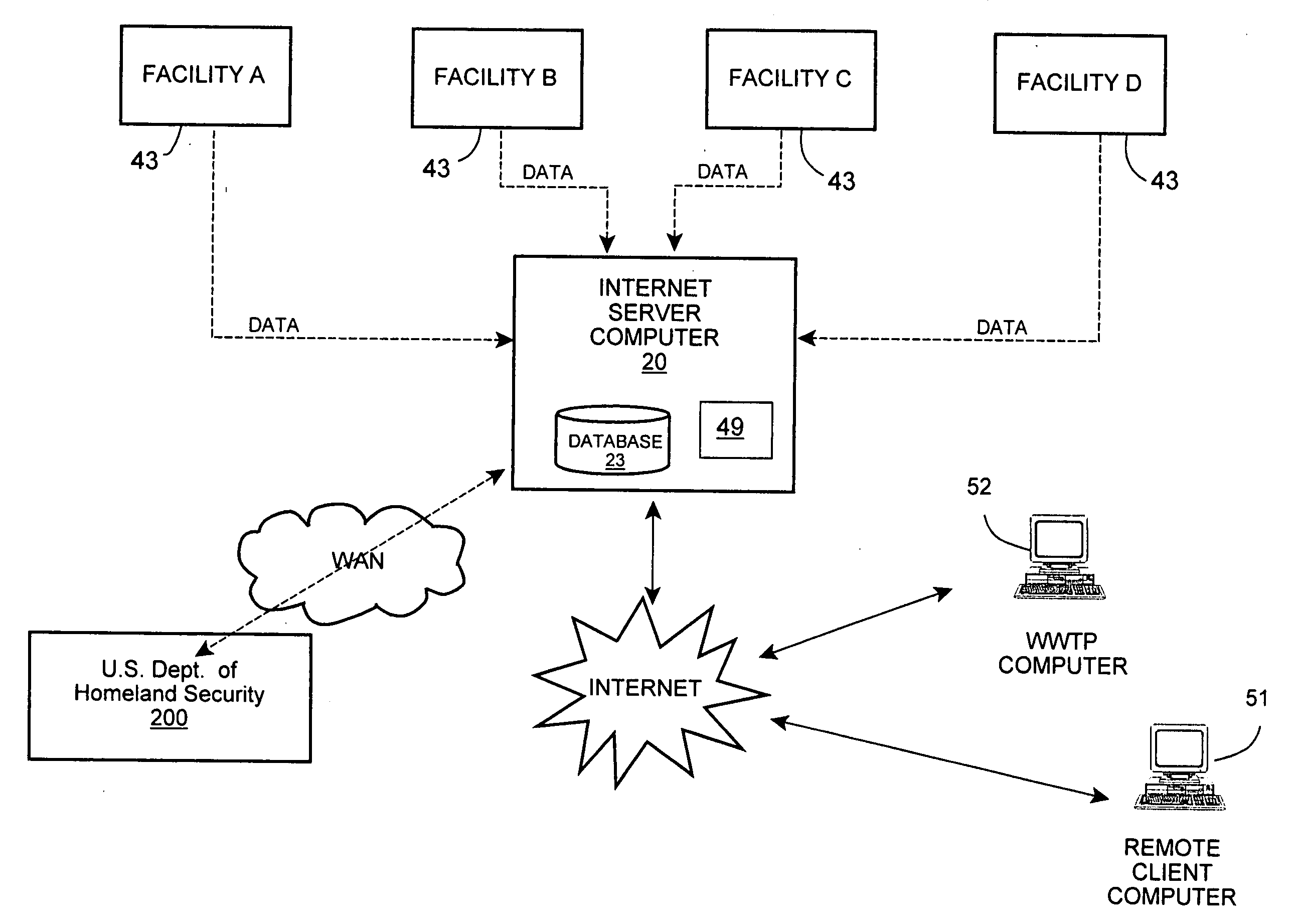

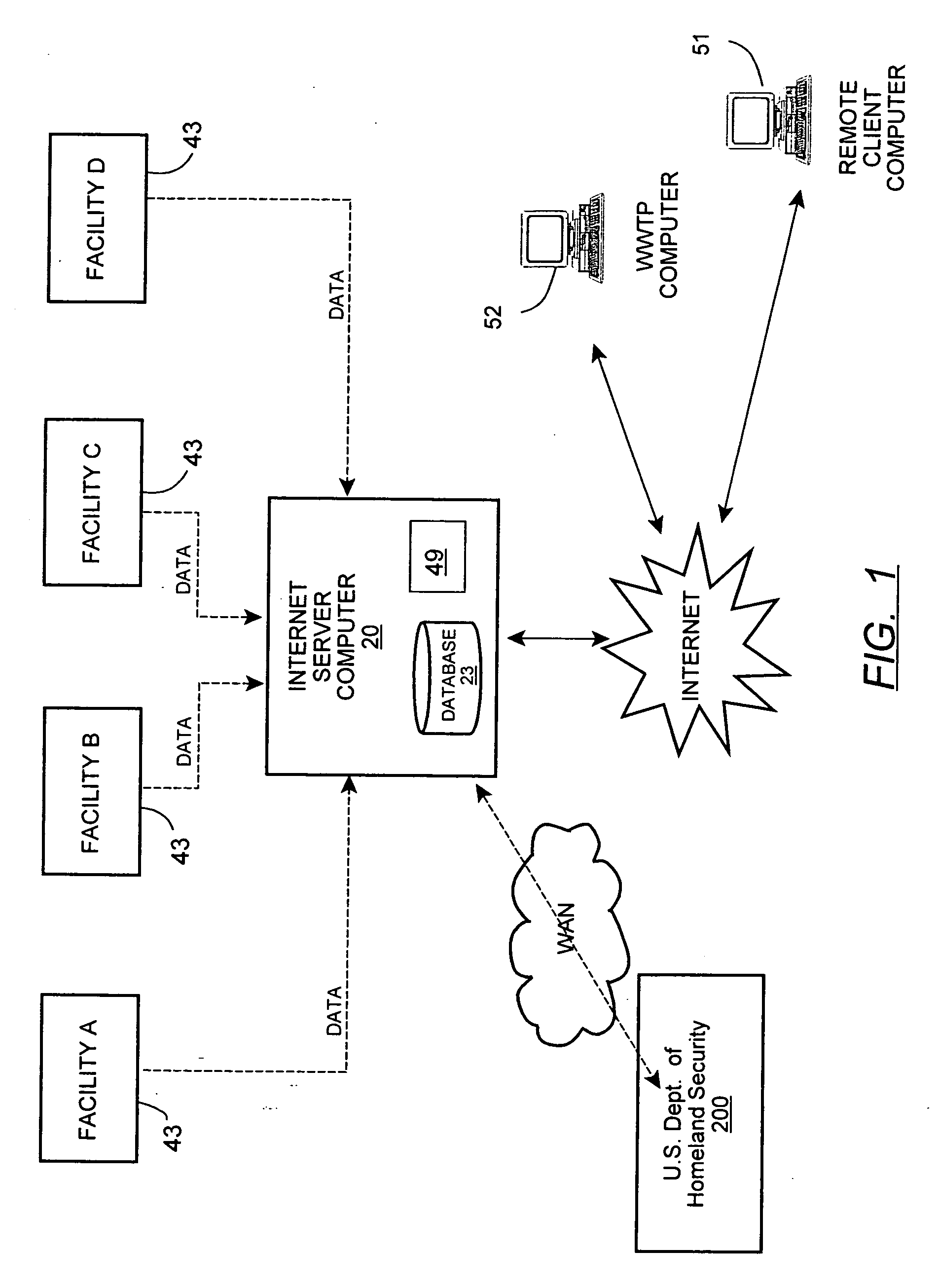

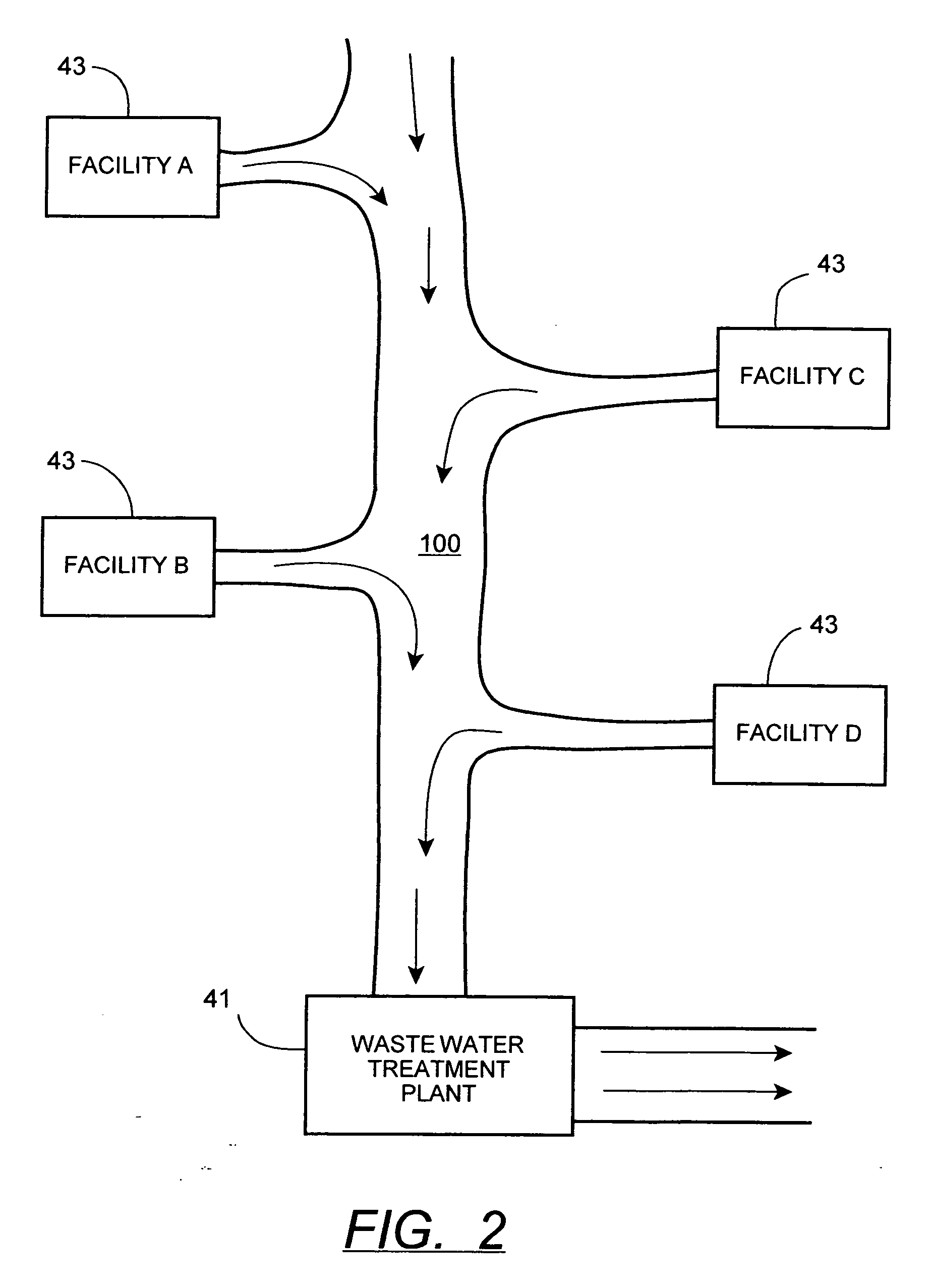

System for monitoring discharges into a waste water collection system

InactiveUS20070163965A1Prediction is simpleWater treatment parameter controlFiltration separationIndustrial waste waterCollection system

A method for monitoring the composition and flow rate of wastes discharged from industrial waste water treatment facilities into a common collection system for eventual processing at central waste water treatment plant (WWTP). The information is transmitted to a remote computer and stored in a database, and is then analyzed to prepare reports of particular interest to the receiving WWTP or treatment facility. The system includes a data collection and sending unit, a remote Internet Server computer with a database capable of receiving and storing the collected information, and a web server and reporting unit to analyze the data, prepare reports, and send out alarms. It is a further intention of this invention to correlate the incoming data from said industrial waste water treatment plants with known flows and compositions at said central WWTP to predict the flow and composition of influx water at the WWTP.

Owner:HACH CO

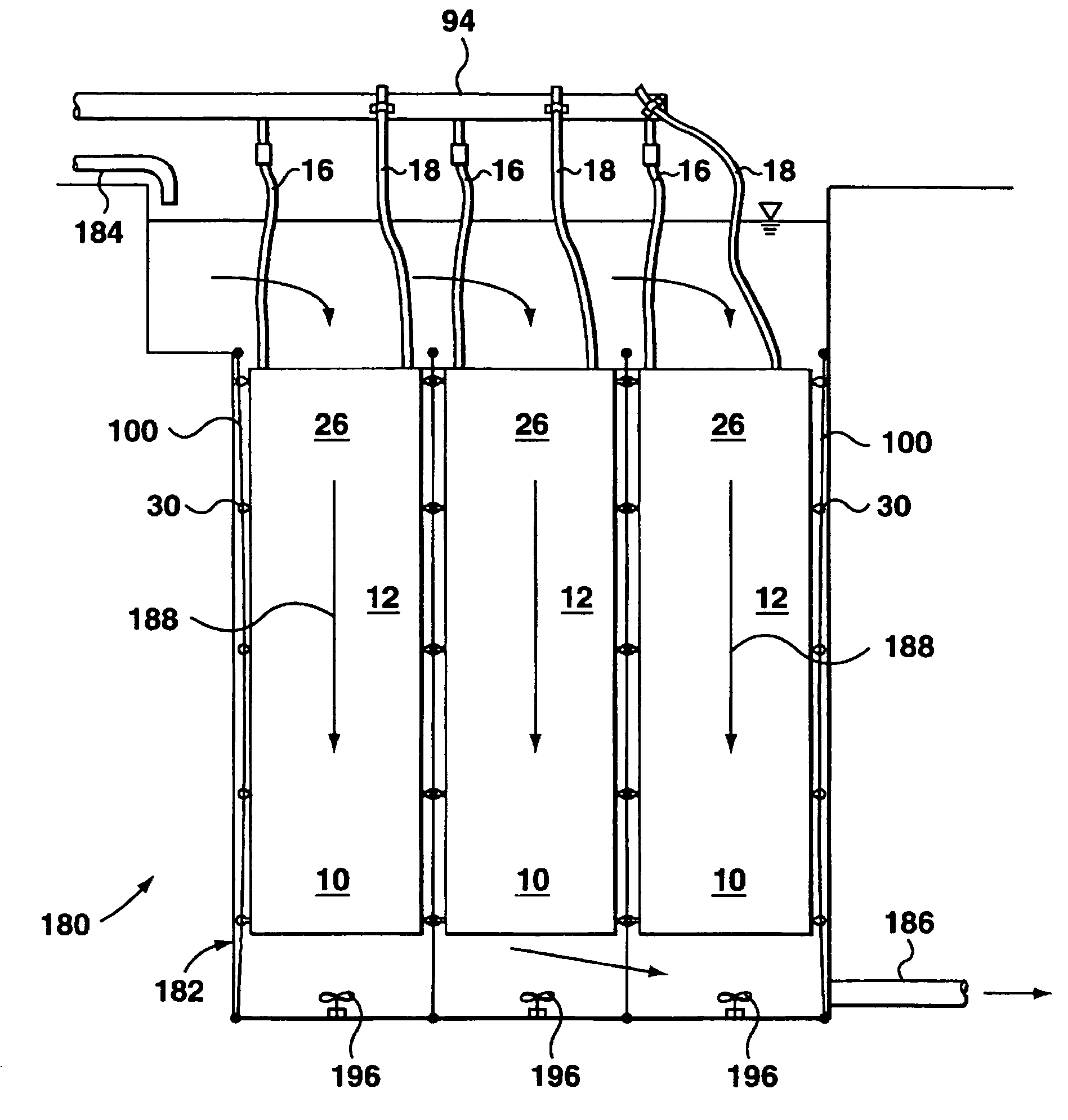

Membrane supported bioreactor for municipal and industrial wastewater treatment

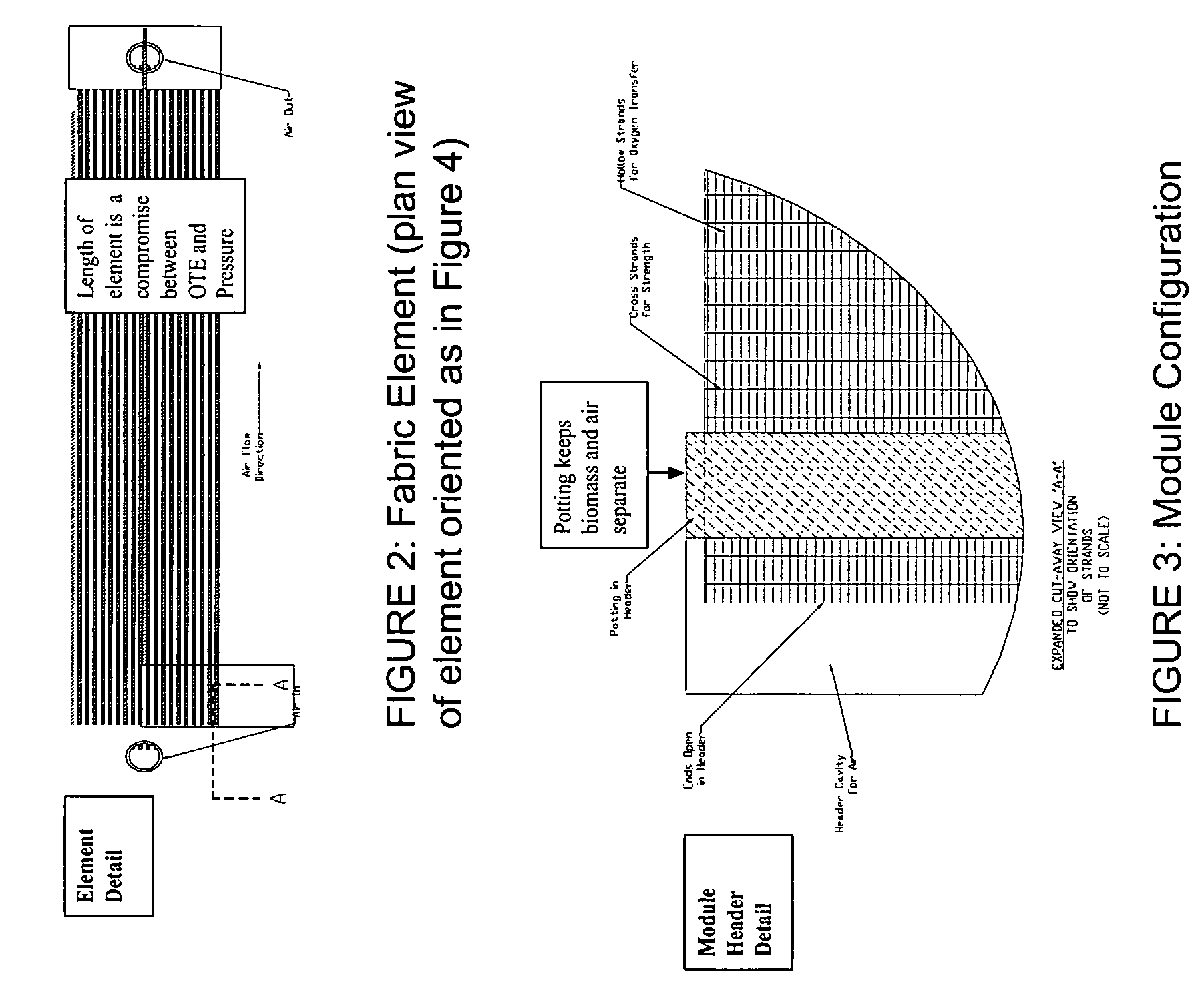

ActiveUS7118672B2Reduce operating costsIncrease surface areaCarburetting airSemi-permeable membranesBiofilmFiber

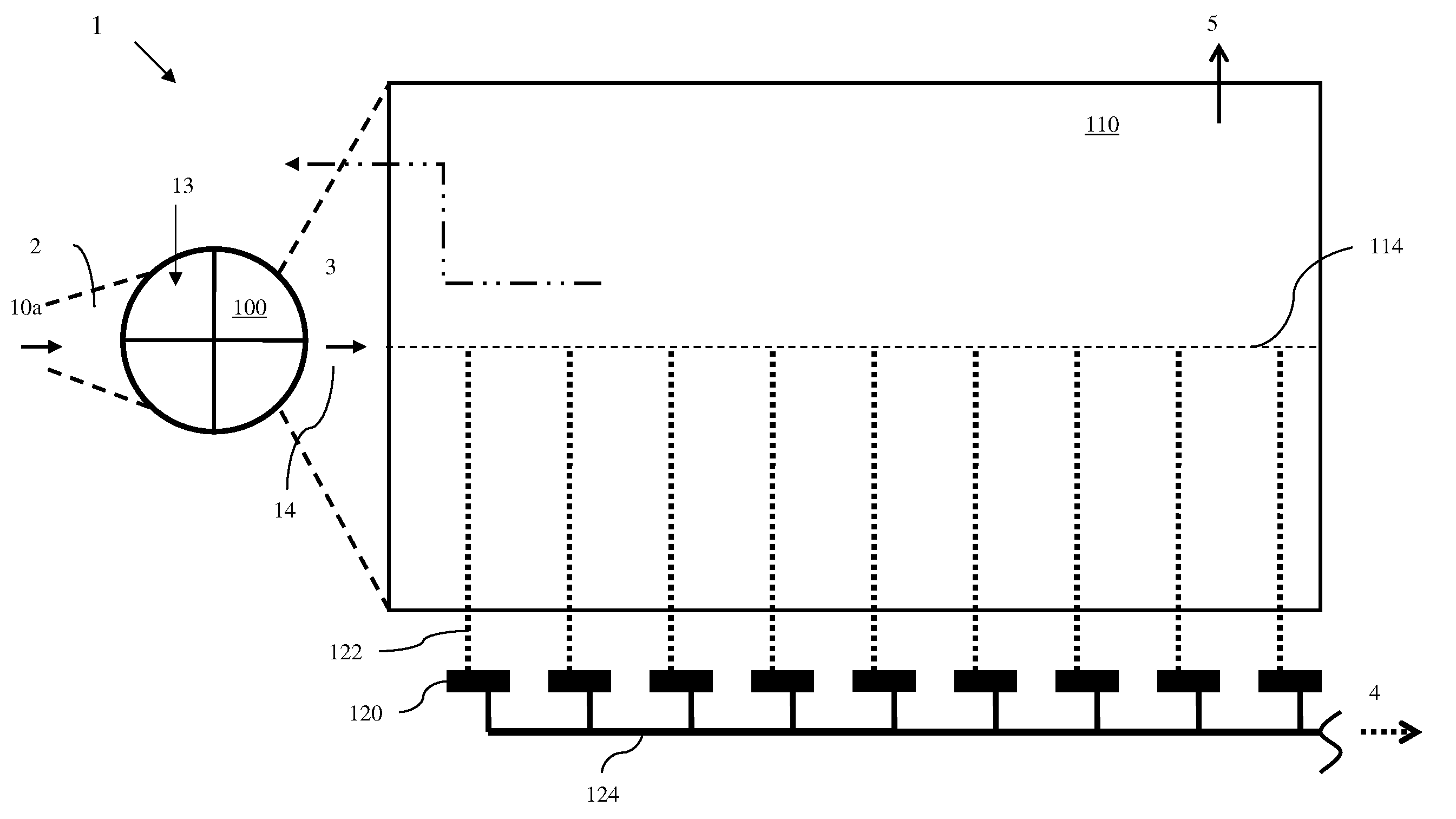

A membrane supported biofilm reactor uses modules having fine, dense, non-porous hollow fibers made from Polymethyl pentene (PMP) formed into a fabric with the PMP as the weft. One or more sheets of the fabric are potted into a module to enable oxygen containing gas to be supplied to the lumens of the hollow fibers. Various reactors using such modules are described.

Owner:ZENON TECH PARTNERSHIP

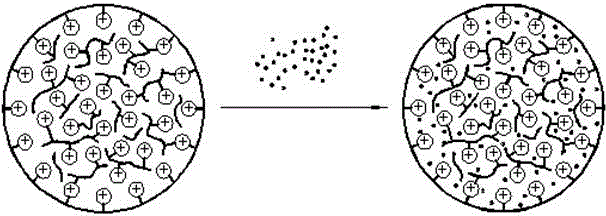

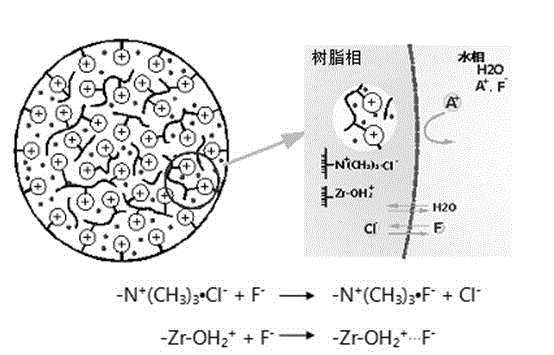

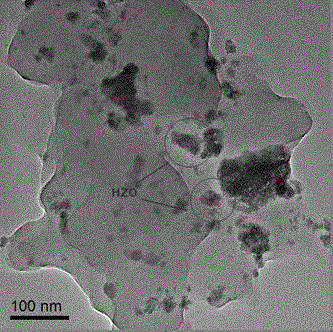

Novel polymer-based composite material and preparation method of composite material as well as method for deep fluorine removal of water body

ActiveCN102942239AHigh adsorption capacityHigh removal rateOther chemical processesAlkali metal oxides/hydroxidesIndustrial effluentDivinylbenzene

The invention discloses a novel polymer-based composite and a preparation method of the composite material as well as a method for deep fluorine removal of a water body, belonging to the fields of drinking water and industrial wastewater treatment, and environment function materials. The substrate of the composite is styrene-divinylbenzene copolymerized spheres, and nanometre zirconia hydrate particles are uniformly distributed in the holes of the spheres. The method for deep fluorine removal of the water body comprises the following steps of: (a) filtering fluorine-containing wastewater, and adjusting the pH of a filtrate to 3.0-8.0; (b) passing the filtrate through an adsorption tower in which a novel polymer-based composite material is filled; and (c) stopping adsorption in the case that the concentration of fluorine ions in effluent achieves a leakage point, performing adsorption regeneration on the novel polymer-based composite material in the adsorption tower by virtue of a NaOH-NaCl mixed solution, and then standing for recycling after regeneration. According to the invention, the pre-concentration effect of a polymer substrate and the selective fluorine removal performance of nanometre zirconia hydrate are organically combined, thus the adsorption capacity and the selectivity of the material on fluorine ions are effectively improved.

Owner:NANJING UNIV

Preparation method and application of a kind of citric acid modified rape straw adsorbent

ActiveCN102266756AGood processing effectImprove adsorption capacityOther chemical processesWater/sewage treatment by sorptionIndustrial waste waterSorbent

The invention belongs to the technical field of industrial waste water treatment and pollution treatment, in particular to a preparation method of a citric acid modified rape straw adsorbent and an application thereof. The method comprises the following steps of: firstly washing natural rape straws, drying, crashing, sieving for standby; and then modifying the surface of the rape straws with citric acid so as to prepare the novel adsorbent citric acid modified rape straws. The prepared adsorbent is used for treating industrial waste water, and removing cationic dye and heavy metal ions form the waste water. The result of a static absorption test shows the adsorbent has excellent adsorption effect for the cationic dye and heavy metal ions. By the invention, the agriculture waste resource is recycled; and cheap and efficient novel adsorbent is obtained to be used for treating the industrial waste water. The preparation process of the adsorbent is simple, and the prepared adsorbent has low cost and excellent adsorption effect.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

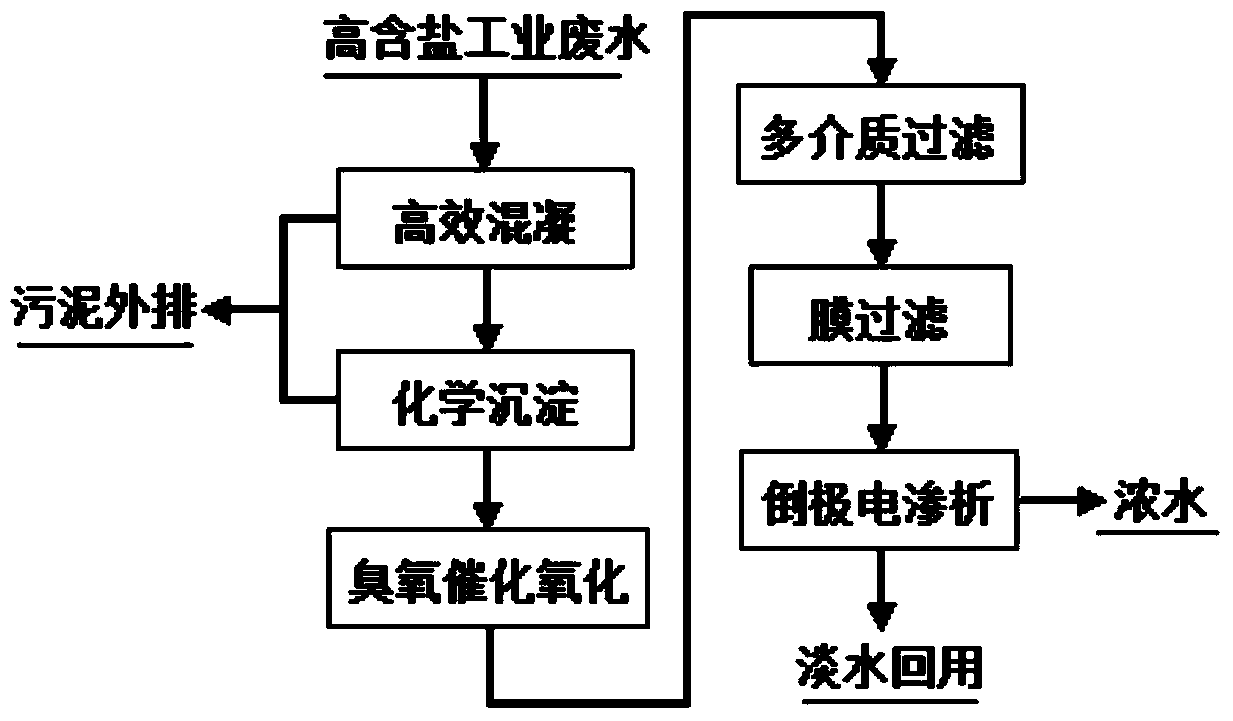

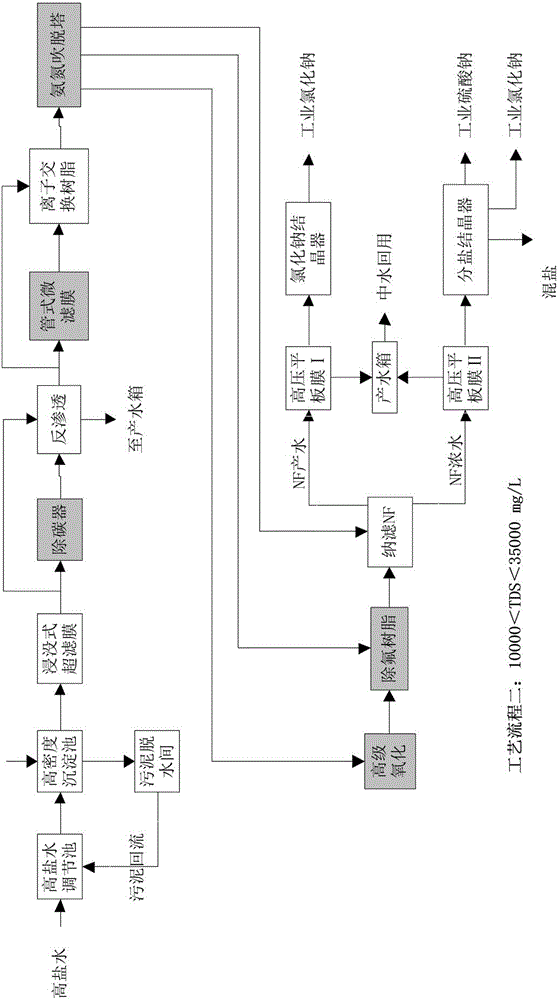

Method for deeply treating, desalting and recycling industrial wastewater with high salt content

ActiveCN104016530AImprove catalytic oxidation efficiencyGood removal effectMultistage water/sewage treatmentSuspended particlesFiltration

The invention relates to the field of industrial wastewater treatment processes and provides a method for deeply treating, desalting and recycling industrial wastewater with high salt content. The method comprises the following steps: 1) carrying out efficient coagulation treatment on the industrial wastewater with high salt content to obtain supernatant; 2) carrying out chemical precipitation on the supernatant obtained in the step 1) to remove high valence ions with valence higher than bivalence in the wastewater; 3) carrying out catalytic ozonation treatment on the supernatant subjected to chemical precipitation in the step 2); 4) carrying out multi-media filtration, precise filtration and membrane filtration treatment on the wastewater subjected to catalytic ozonation in the step 3) in sequence; and 5) carrying out electrodialysis reversal treatment on the effluent obtained after membrane filtration in the step 4). By adopting the method, organic matters, bacteria, colloids, suspended particles, Ca<2+>, Mg<2+> and high valence ions, other soluble inorganic salts and the like in the industrial wastewater with high salt content are removed by utilizing the coupling and synergistic effects of different unit technologies, thus achieving deep treatment, desalting and recycling of the industrial wastewater with high salt content.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Watersoluble polyurethane adsorption agent containing sulfhydryl group for removing hydrargyrum and preparation method thereof

InactiveCN101293196AImprove film qualityQuality improvementOther chemical processesWater/sewage treatment by sorptionHigh concentrationCross-link

The present invention pertains to the technical field of wastewater treatment, in particular to hydrophilic polyurethane absorbent containing sulfhydryl for removing Hg and a preparation method thereof. The present invention takes water and volatile non-water solvent as the mixed solvent, introduces chloromethyl thiirane monomer as the cross linking agent into hydrophilic polyurethane dispersion dope and finally carries out coating and solidification, thus obtaining the hydrophilic polyurethane absorbent containing sulfhydryl. The present invention has the advantages of simple and convenient technique, high production efficiency, high product quality and low cost. The composition of the prepared absorbent is controllable with the size of 50 to 250mm, the prepared absorbent has the advantages of large specific surface area, strong Hg-ion absorption capacity and rapid absorption rate. In addition, the present invention with excellent high-concentration Hg-ion absorption capacity and trace Hg-ion absorption capacity, good mechanical property and damage ratio lower than 0.5 percent after being used for a plurality of times can be applied to Hg, lead, cadmium and other heavy metal industrial wastewater treatment within a more extensive concentration range.

Owner:TONGJI UNIV

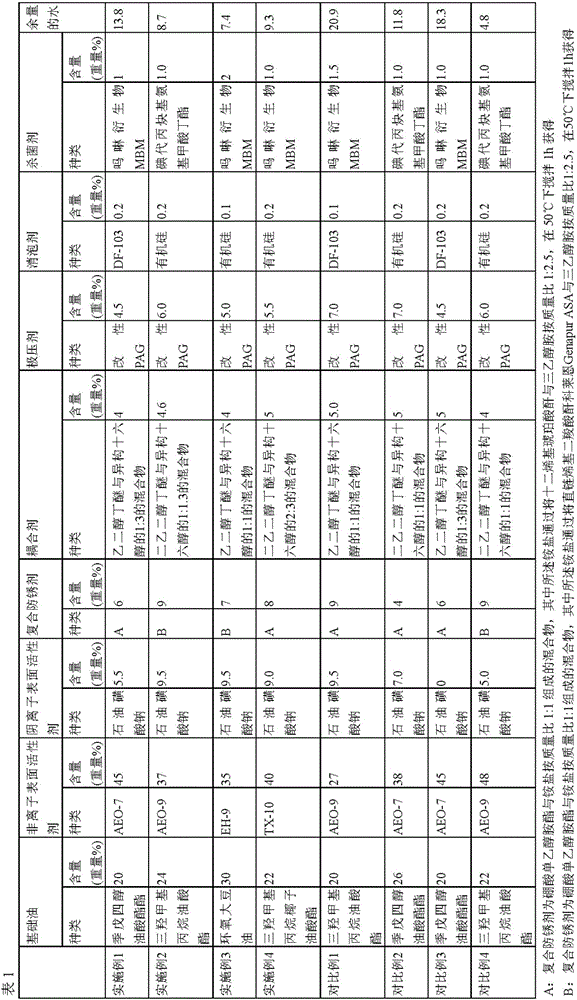

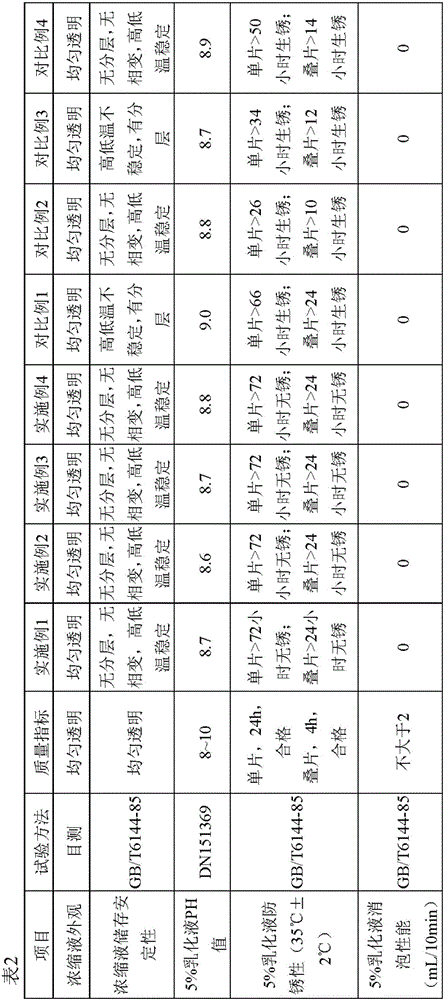

Environment-friendly metal cutting liquid and preparing method thereof

The invention relates to environment-friendly metal cutting liquid and a preparing method thereof. The environment-friendly metal cutting liquid contains, by weight, 18-30% of base oil, 30-45% of non-ionic surfactant, 5.0-10.0% of anionic surfactant, 6-11% of composite antirust agent, 3.6-5% of coupling agent, 4.5-7% of extreme pressure agent, 0.1-0.2% of defoamer, 0.8-2.5% of bactericide and the balance water. The environment-friendly metal cutting liquid does not contain nitrite, heavy metal or toxic solvent and is an environment-friendly product, has excellent cleaning ability, anti-rust property, emulsion stability and defoaming property and has unique advantages in lubrication and bacteriostasis, and liquid waste is easy to treat and can be treated like general industrial wastewater after demulsification.

Owner:SHANGHAI HITECRUN SPECIAL LUBRICATE SCI & TECH

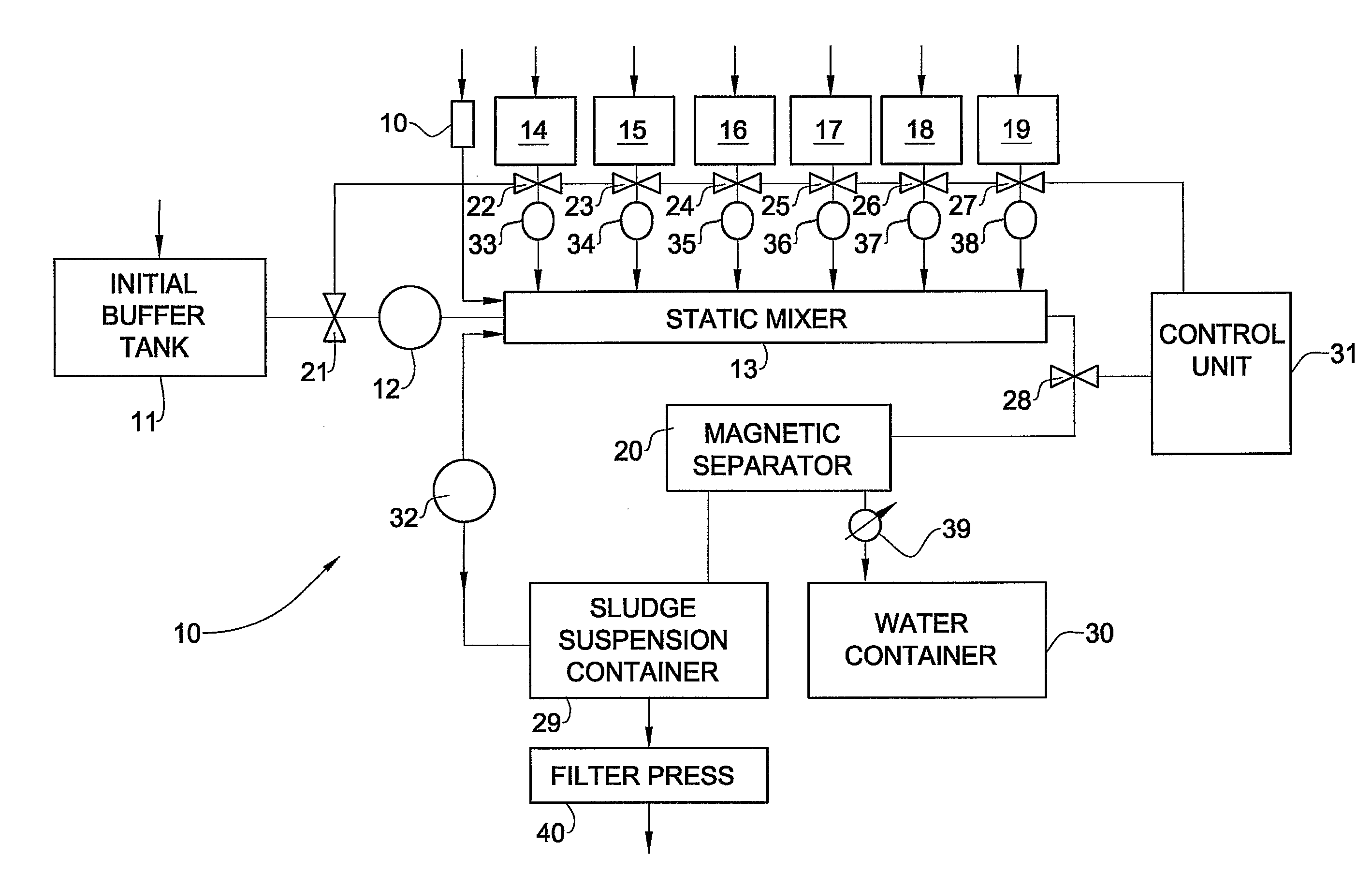

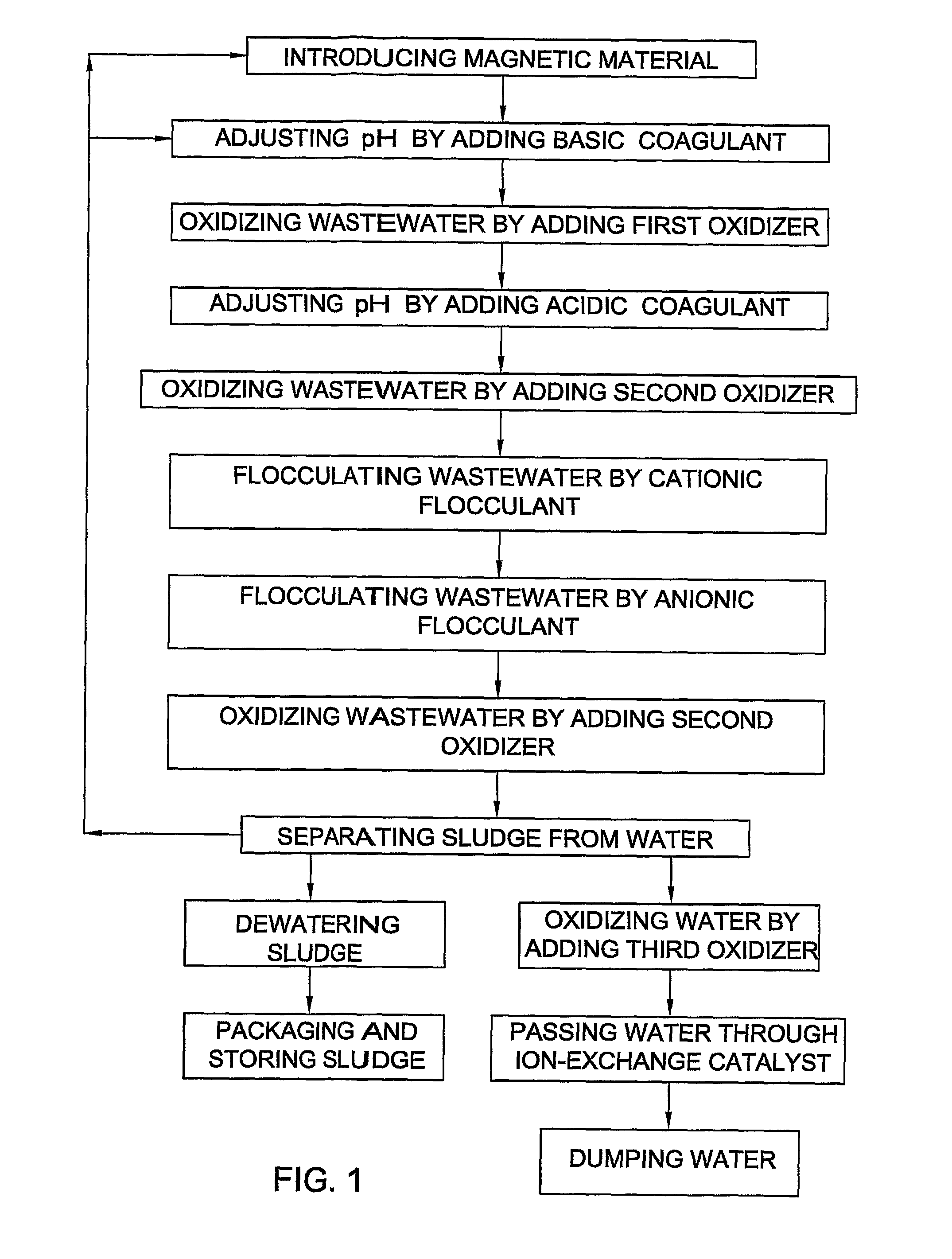

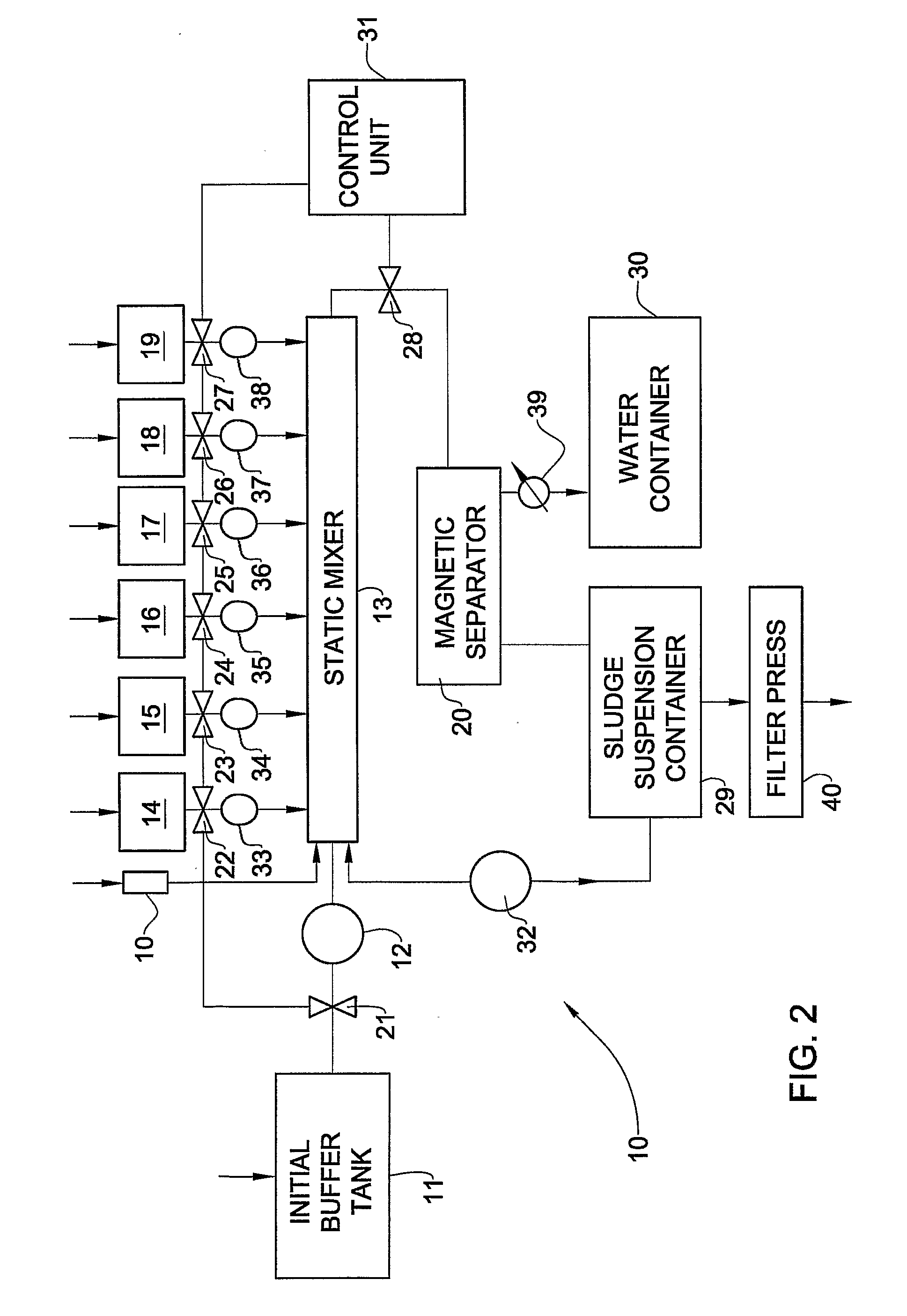

System and Method for Treatment of Industrial Wastewater

InactiveUS20080035577A1Improve efficiencyImprove standardsSolid sorbent liquid separationWaste water treatment from metallurgical processPHENOL LIQUIDSludge

Owner:UNIQKLEEN WASTEWATER TREATMENT

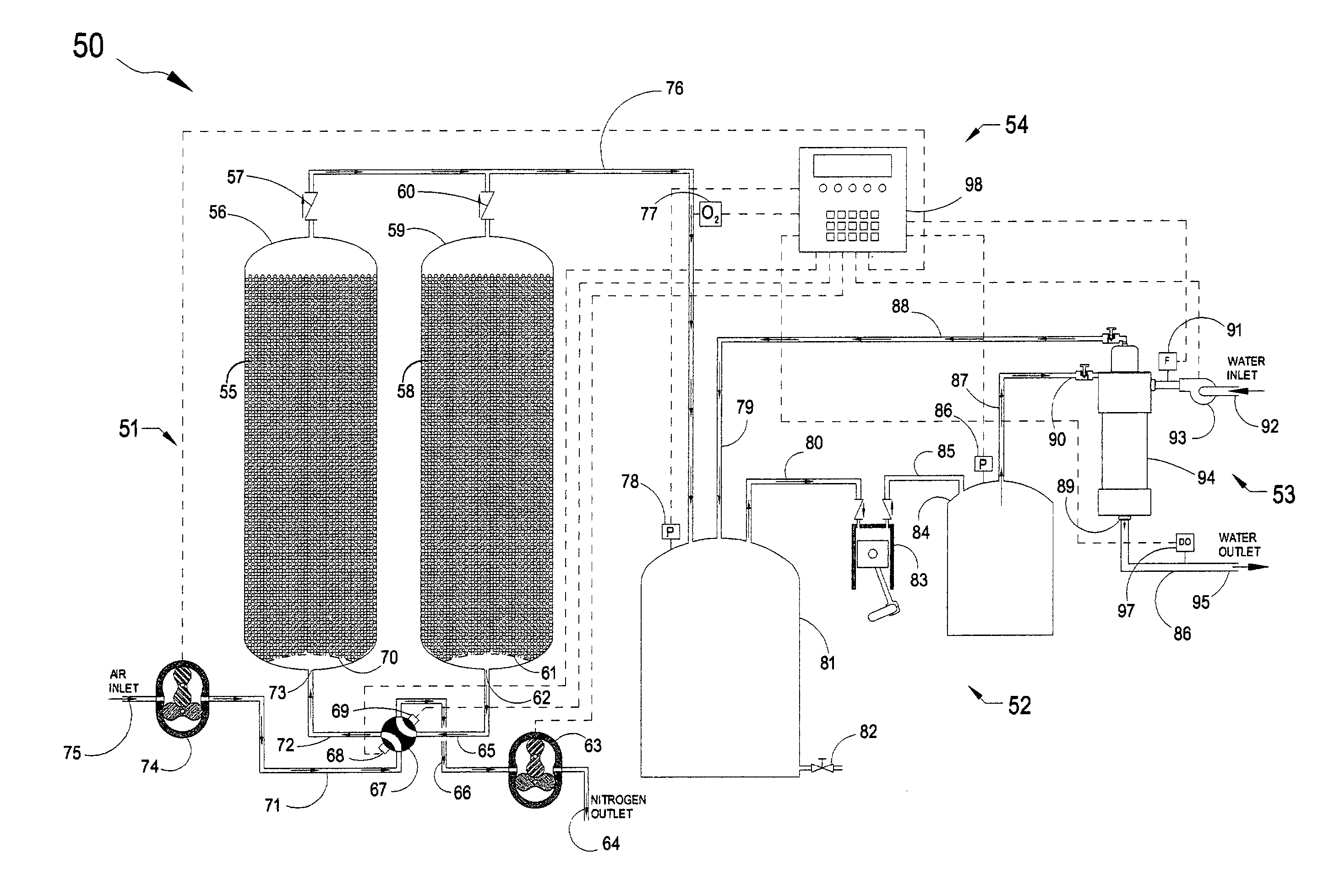

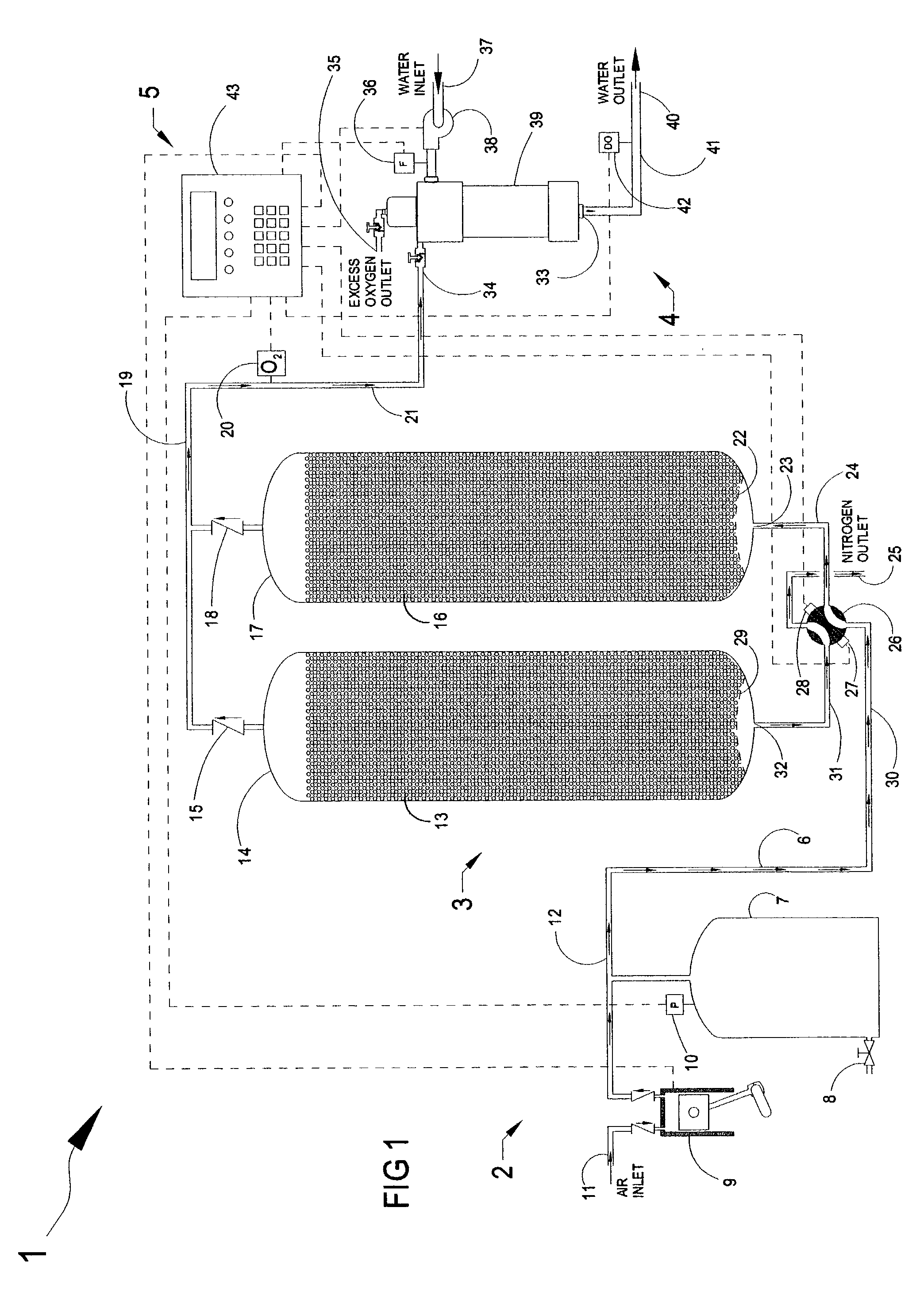

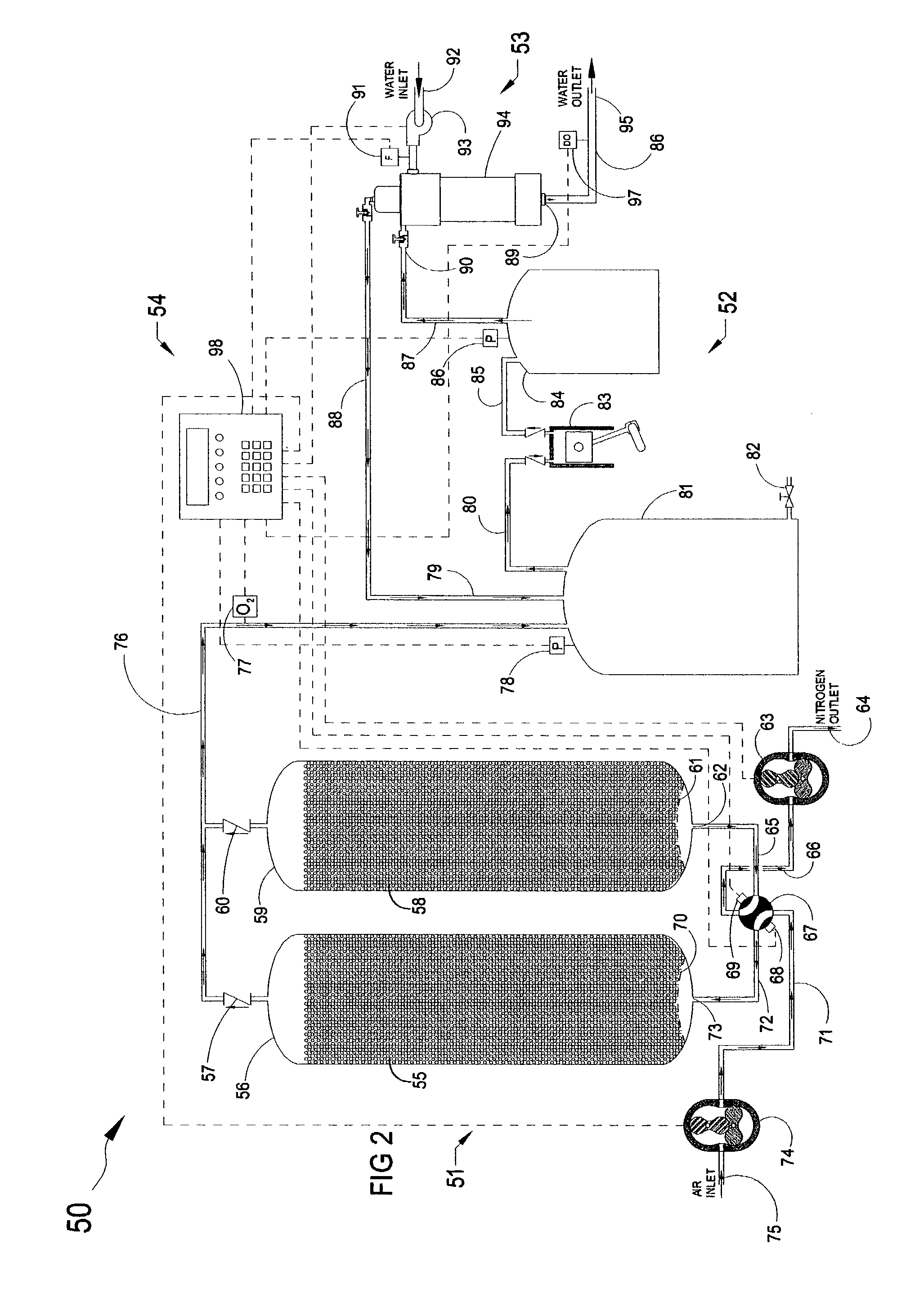

Methods and apparatus for supplying high concentrations of dissolved oxygen and ozone for chemical and biological processes

InactiveUS6962654B2Liquid separation auxillary apparatusFlow mixersHigh concentrationOrganismal Process

A method and apparatus for supplying dissolved gases (such as oxygen, ozone, chlorine etc.) for chemical and biological processes is described. The methods and apparatus described are particularly suitable for use in the biodegradation of organic matter (such as in municipal and industrial wastewater treatment), and other uses. The apparatus may comprise a dissolved gas supply system.

Owner:HYDROTREAT

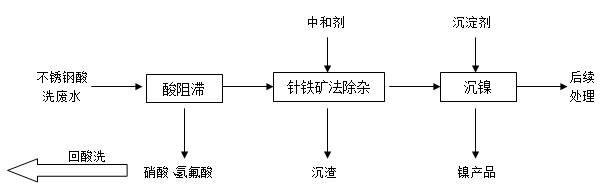

Recycling harmless treatment method of stainless steel pickling waste water

ActiveCN102659274AHigh recovery rateSmall footprintSludge treatmentSolid waste disposalIndustrial waste waterSS - Stainless steel

The invention discloses a recycling harmless treatment method of stainless steel pickling waste water, belonging to the toxic and harmful industrial waste water treatment field. The method comprises the following steps of: 1) recycling inorganic acids by an acid separation method: pumping stainless steel pickling waste water in which suspended matters are removed through filtering into a resin column so that the inorganic acids are absorbed on the resin; 2) removing impurities by a goethite method: pumping heavy metal ion solution into a reaction kettle, adjusting pH to a range from 3.5 to 5.0, and continuing reacting for 30-90 min, thereby removing iron, chromium and fluorine in the heavy metal ion solution in the form of dregs; 3) recycling nickel by a neutralized sedimentation method: feeding an alkaline liquor to nickel solution to adjust pH to a range from 9.5 to 12.5, and filtering and washing the filter residues, thereby obtaining nickelous hydroxide; and 4) performing harmlesstreatment on the dregs: after washing the dregs, adding lime powder to the dregs to realize stabilization treatment of harmful elements. The method is simple in operation and convenient for management; the high-concentration inorganic acids and nickel and the like contained in the waste water are all recycled, and simultaneously the generated dregs are harmlessly treated; and therefore the integration of economic benefit,environmental benefit and social benefit is realized.

Owner:NANJING UNIV

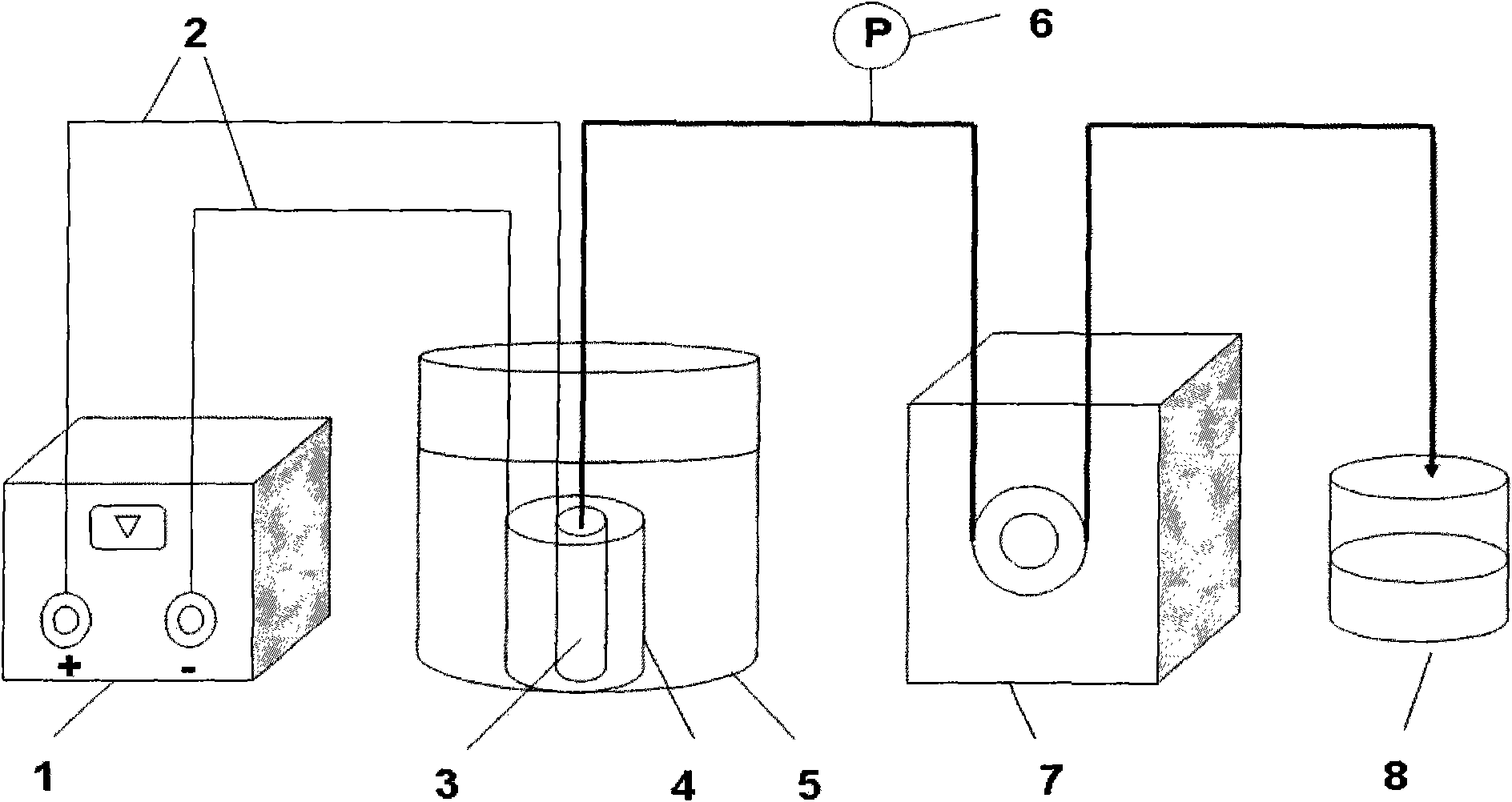

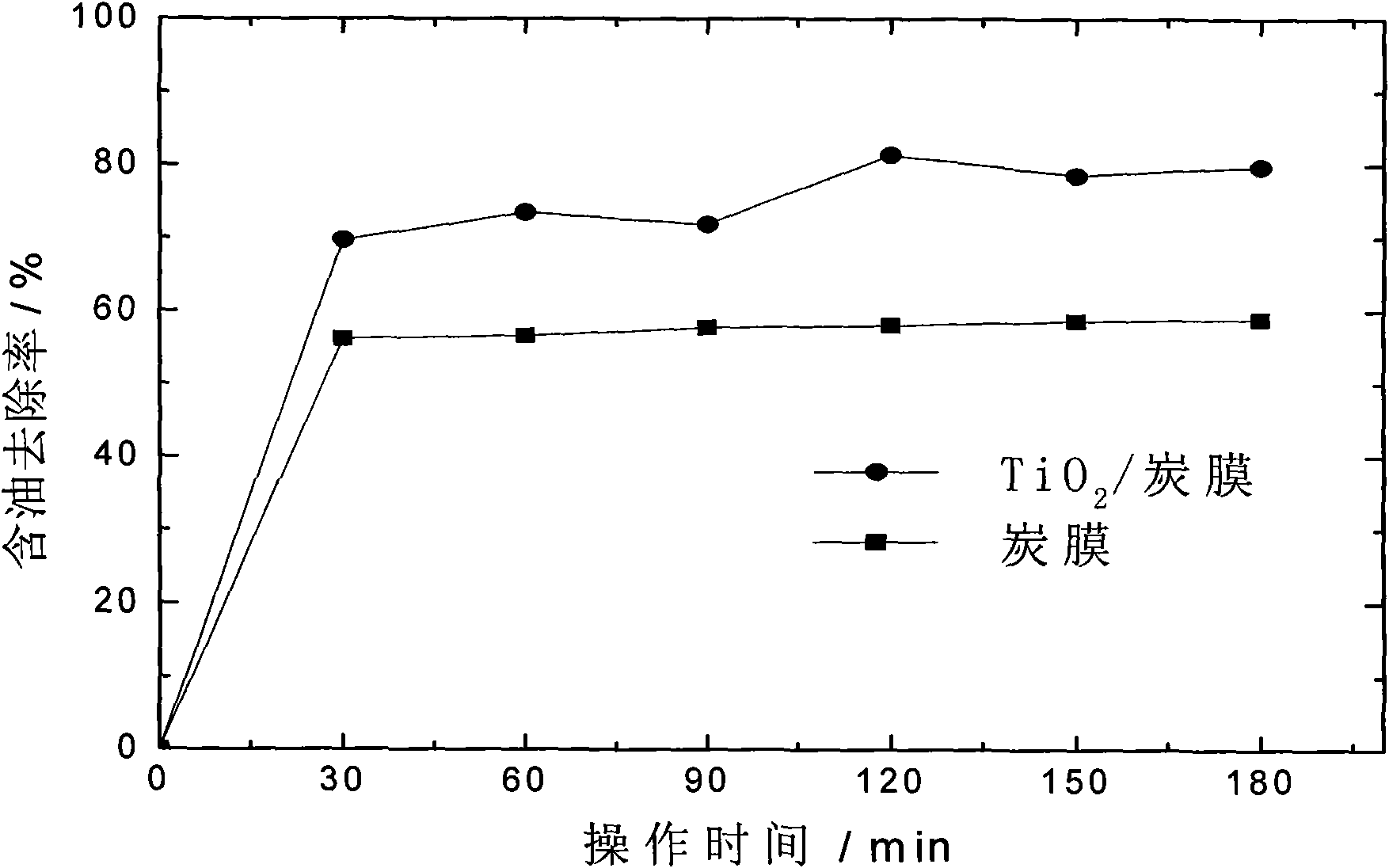

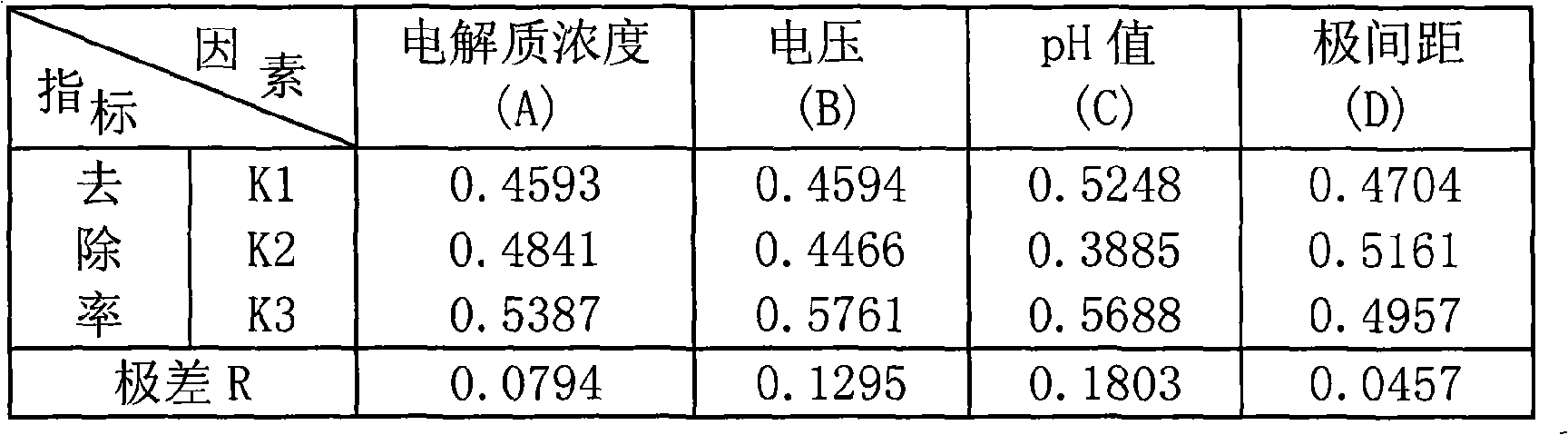

Electro-catalytic membrane reactor device

InactiveCN101597096AImprove electrocatalytic activitySimple processSemi-permeable membranesWater/sewage treatment bu osmosis/dialysisPeristaltic pumpElectrolysis

The invention describes an electro-catalytic membrane reactor device, which is characterized in that the device can couple the membrane separation technology and electro-catalysis technology for wastewater treatment, thereby solving the problem of membrane pollution and realizing self-cleaning function of the membrane. The reactor device comprises a feed liquid tank, an electro-catalytic composite membrane, an auxiliary electrode, a regulated power supply, a vacuum gauge, a peristaltic pump and the like; wherein, the electro-catalytic composite membrane is a novel membrane material prepared by taking a microporous carbon membrane as a matrix and a metal or metallic oxide as a catalytic coating layer; one end of the electro-catalytic membrane is closed and the other end thereof is connected with the peristaltic pump through a pipeline; the pump continuously supplies negative pressure so that the feed liquid permeates a separation membrane and seeps from outside to inside along the pipeline; meanwhile, the electro-catalytic composite membrane is taken as the anode and the auxiliary electrode is taken as the cathode; the electro-catalytic composite membrane and the auxiliary electrode are respectively connected with the regulated power supply by leads to form an electrolysis device. By applying voltage to the composite membrane in the process of membrane separation, the organic pollutants deposited on and adhered to the surface and holes of the membrane are electrolytically oxidized to realize antipollution of the membrane. The reactor device has the advantages of simple device, convenient operation, high efficiency, small energy consumption and the like, and can be widely used for treatment and reuse of such industrial wastewater as oily wastewater, dye wastewater, papermaking wastewater and the like.

Owner:大连华鑫源科技发展有限公司

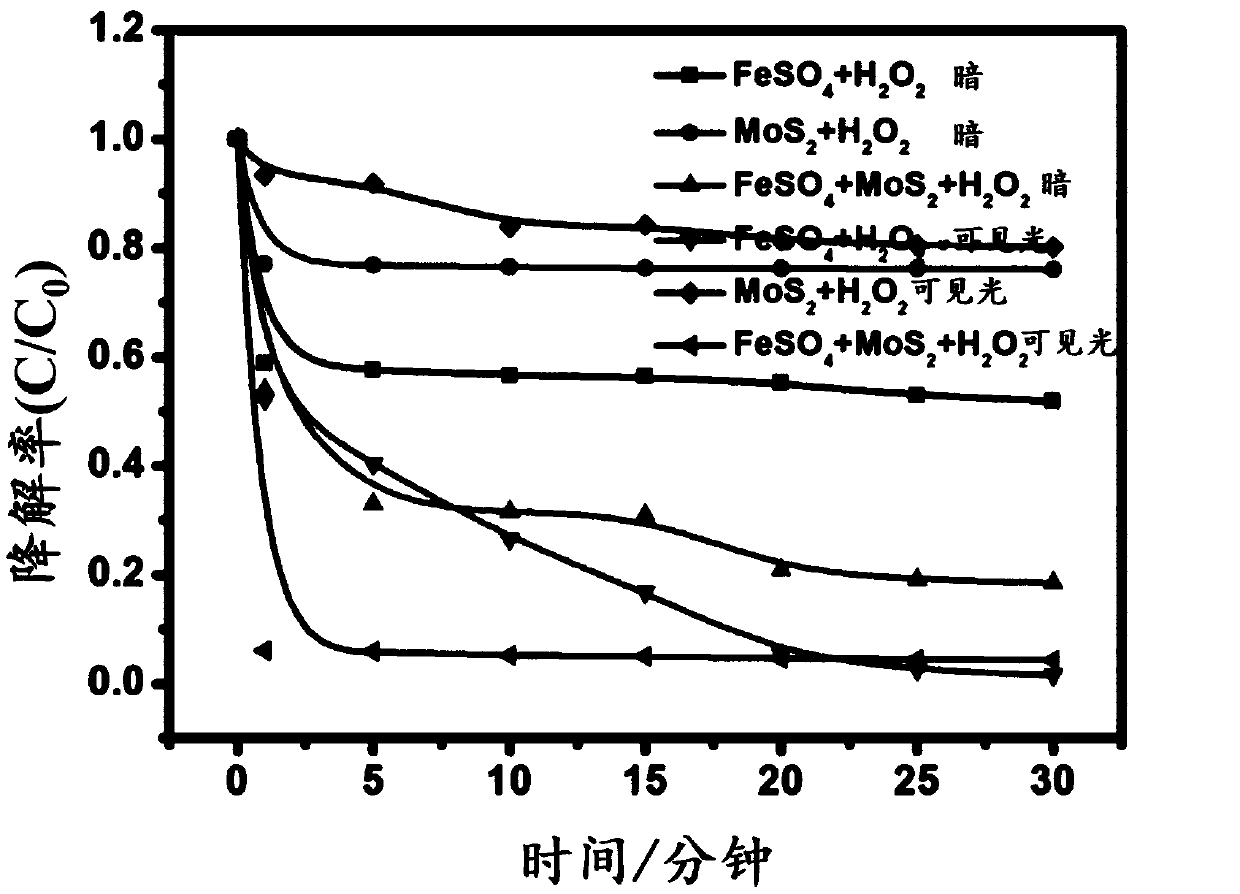

Sulfide-containing industrial wastewater treatment reagent and reaction method thereof

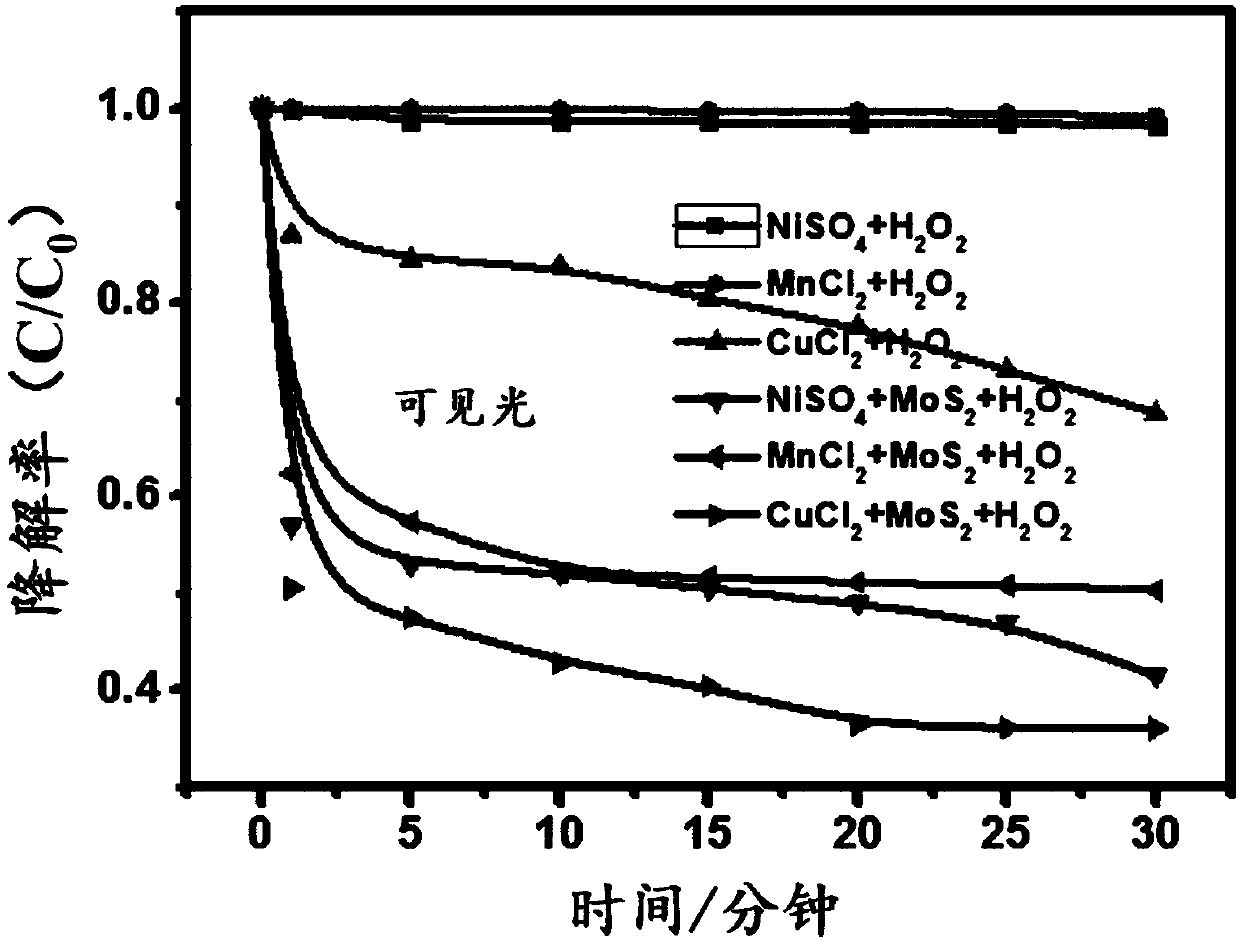

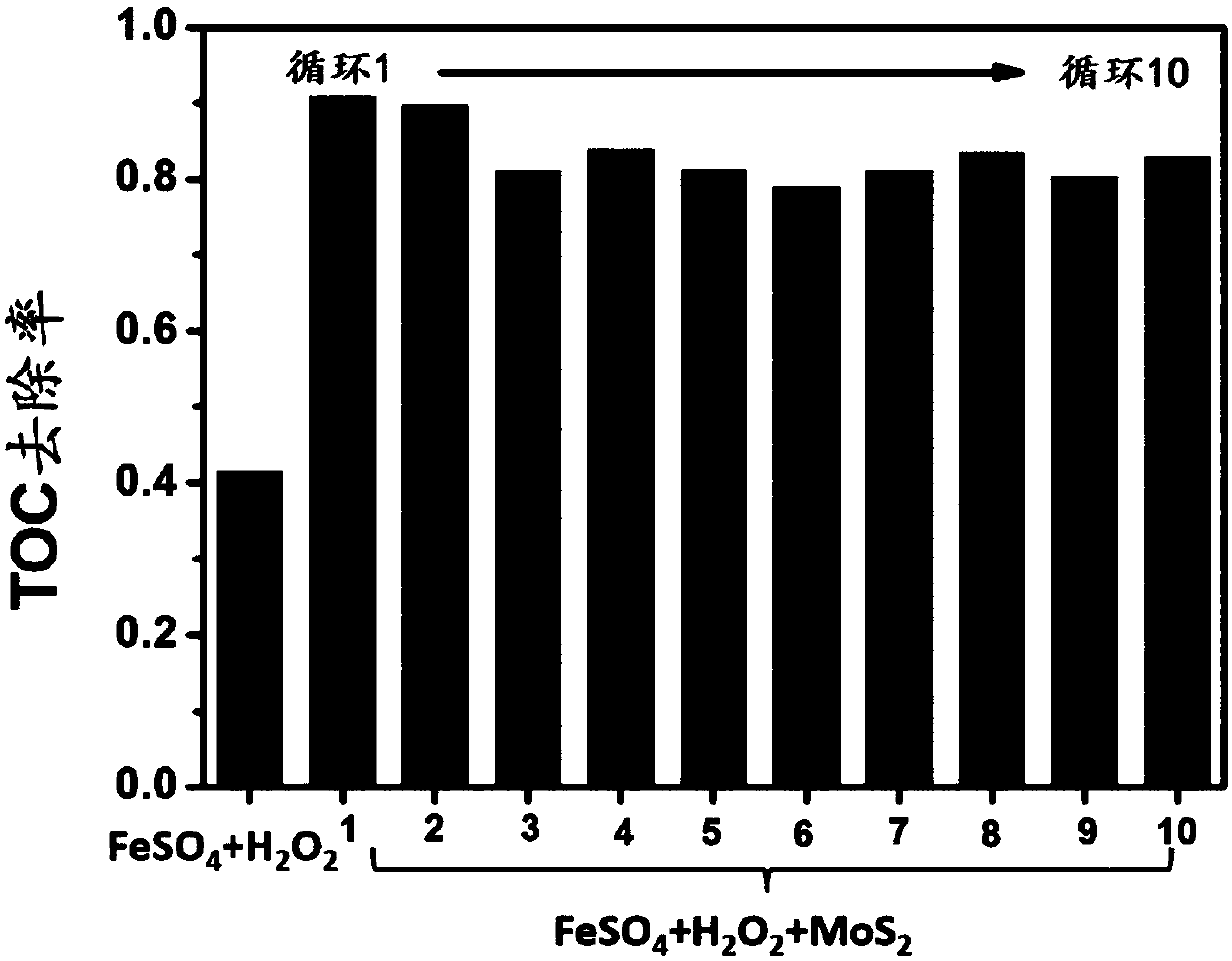

InactiveCN107720930AImprove utilization efficiencyImprove degradation efficiencyWater contaminantsWater/sewage treatment by oxidationHydrogen peroxide breakdownFenton reaction

The invention relates to the field of chemistry, in particular to the treatment of contaminants. A sulfide-containing industrial wastewater treatment reagent comprises a Fenton reagent containing an iron source and hydrogen peroxide, and also comprises sulfide, wherein the sulfide is mixed in the Fenton reagent to be used as a cocatalyst of the Fenton reagent. Compared with the traditional homogeneous Fenton reaction system, the cheap and readily available sulfide is used as the cocatalyst, so that the catalytic reaction is firstly carried out on the surface of the sulfide to improve the efficiency of decomposition of hydrogen peroxide to generate hydroxyl radicals during the Fenton reaction process and improve the degradation efficiency and the utilization efficiency of the hydrogen peroxide, and the sulfide per se can be recycled, and the problem of producing a large amount of iron sludge by homogeneous Fenton can be avoided, thereby reducing the treatment cost.

Owner:EAST CHINA UNIV OF SCI & TECH

Stereo artificial wetland system for treating sewage

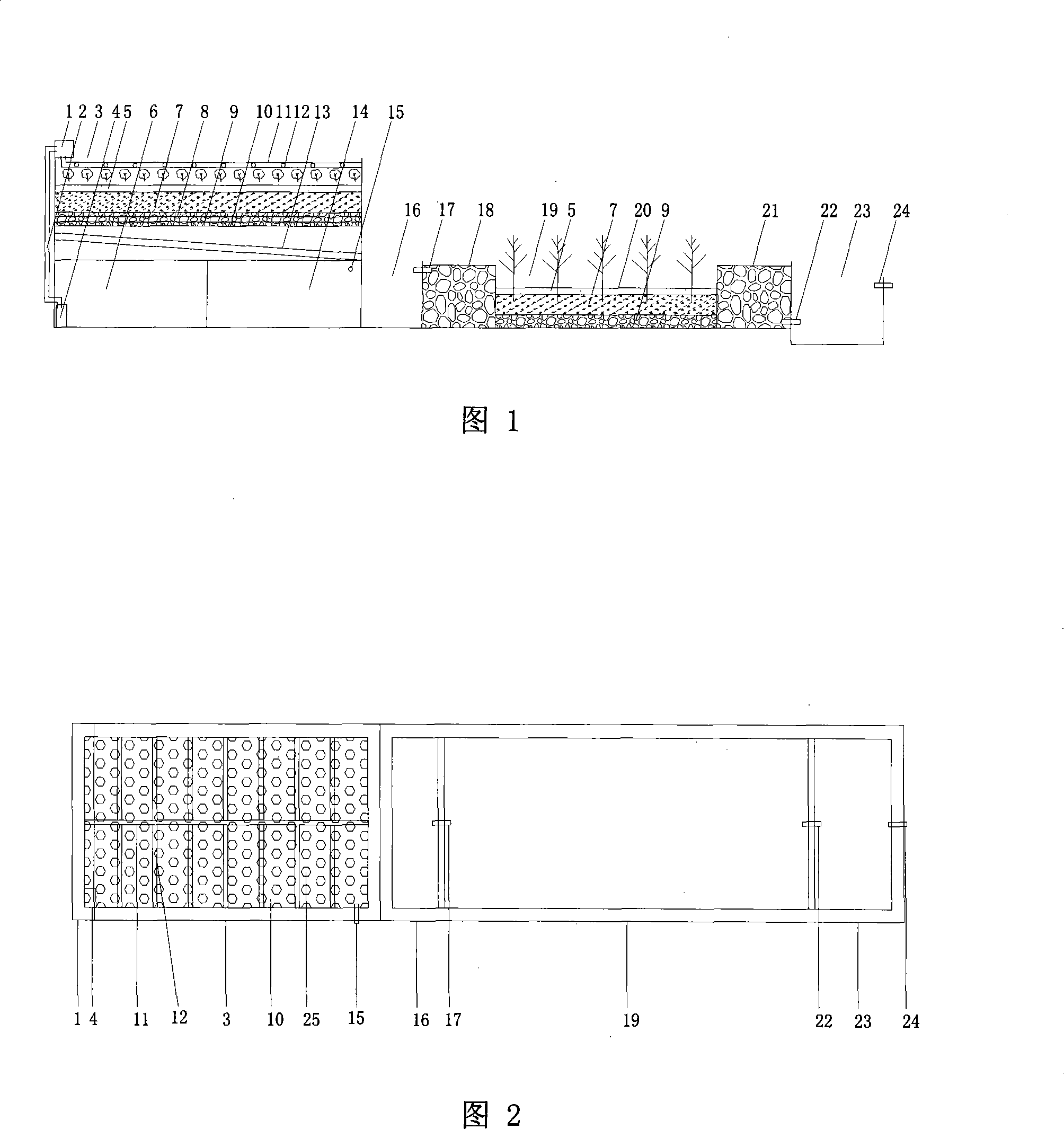

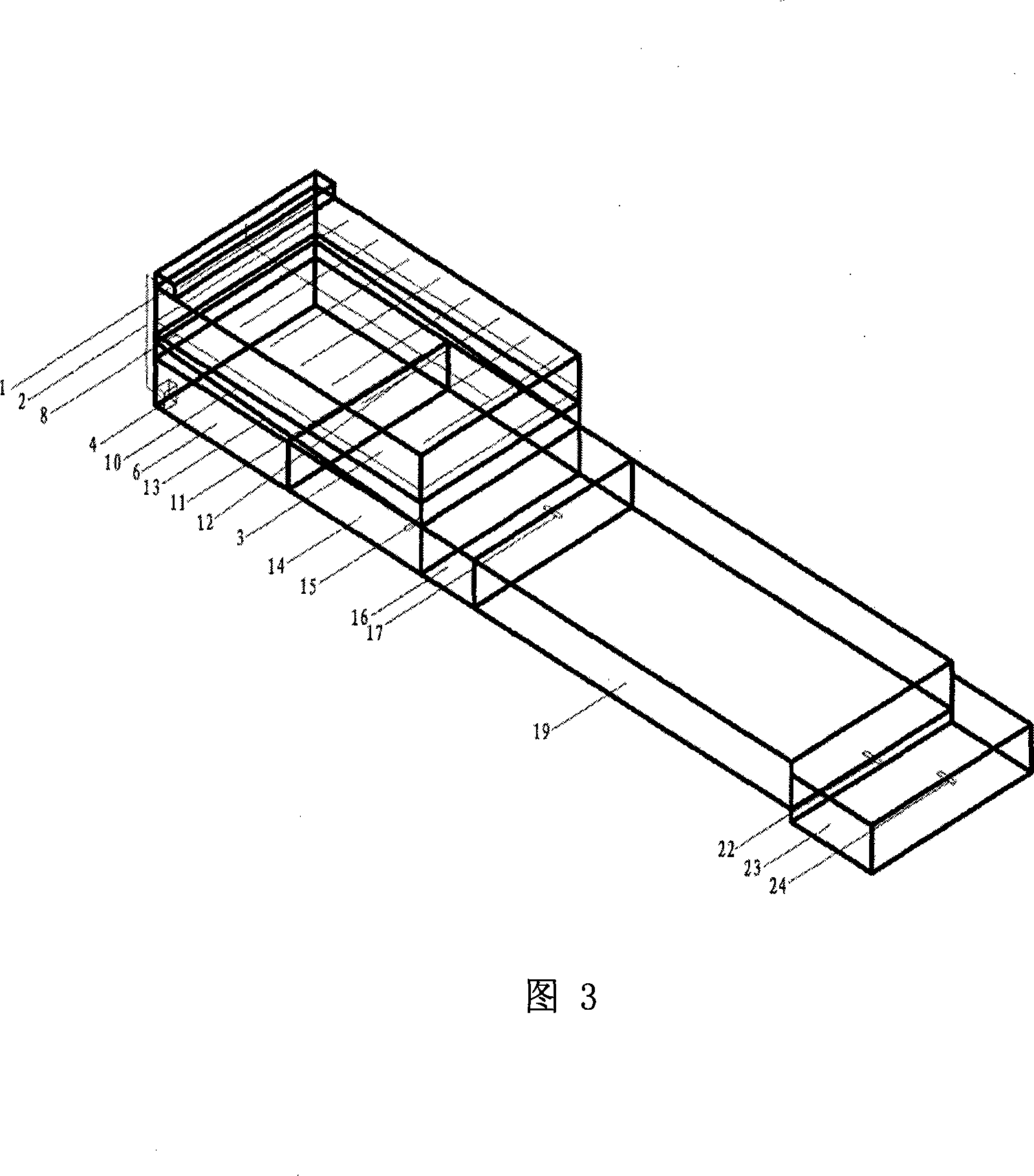

InactiveCN101186382AReduce closureHigh porositySustainable biological treatmentBiological water/sewage treatmentConstructed wetlandIndustrial waste water

The invention relates to the technical field of sewage treatment, in particular to a sewage treatment tridimensional artificial wetland system that is used for the industrial waste water treatment of small-scale isolated pollution sources. The invention aims at providing a tridimensional artificial wetland system that is used for sewage treatment and that has small floor occupancy, high hydraulic load, high pollution load and long service life so as to overcome the defects of the current sewage treatment of big artificial wetland floor occupancy, low hydraulic load, low pollution load and short system service life. The key points of the invention are that: the artificial wetland for sewage treatment adopts a tridimensional assembled structure of vertical current artificial wetland and horizontal subsurface flow artificial wetland, and base materials are filled in various directions to form the tridimensional artificial wetland system for sewage treatment; the tridimensional artificial wetland system for sewage treatment comprises a water collecting header, a porous water-filtering vertical current artificial wetland bed, a first-stage regulating tank, a water drop chute, a grid tank, a second-stage regulating tank, a horizontal subsurface flow artificial wetland bed and a water collecting tank.

Owner:ZHEJIANG NORMAL UNIVERSITY

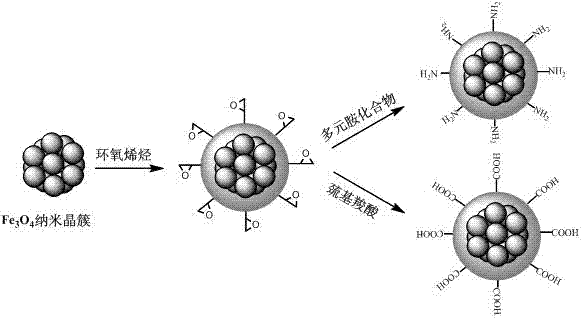

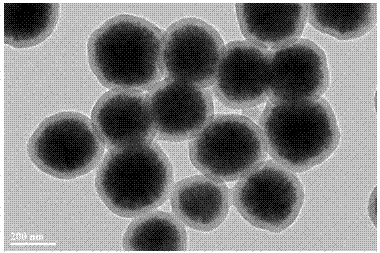

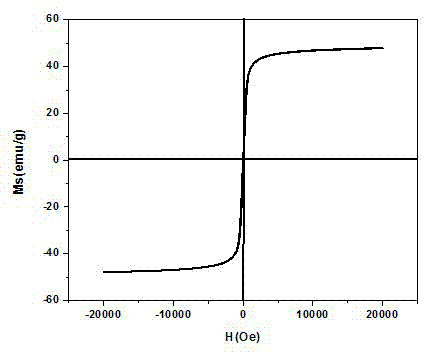

Preparation method of functional magnetic absorbent used for treating industrial wastewater

InactiveCN103285838AMagnetic content controllableUniform structureOther chemical processesAlkali metal oxides/hydroxidesEpoxyMicrosphere

The invention discloses a preparation method of a functional magnetic absorbent used for treating industrial wastewater. The method comprises the following four steps of: (1) preparing a ferroferric oxide nanocluster with a high magnetic saturation value by solvothermal synthesis; (2) modifying the ferroferric oxide nanocluster surface into a double-bond functional group by adopting a sol-gel process; (3) wrapping the ferroferric oxide nanocluster surface with a polymer shell containing an epoxy functional group in a distilling, precipitating and polymerizing manner; and (4) modifying a microsphere surface into an amino group or a carboxyl group through a ring-opening reaction of the epoxy group. The magnetic absorbent is high in functional group content, fast in magnetic responsiveness, easy for magnetic separation, regular in structure, stable in chemical and physical performances and high in dispersion stability in an aqueous solution; and the surface-modified amino and carboxyl functional groups can efficiently adsorb a plurality of heavy metals or organic pollutants, so that the magnetic absorbent can be applied to the field of industrial wastewater treatment. The preparation method is simple to operate and controllable in process and has a good application prospect.

Owner:JINGDEZHEN CERAMIC INSTITUTE

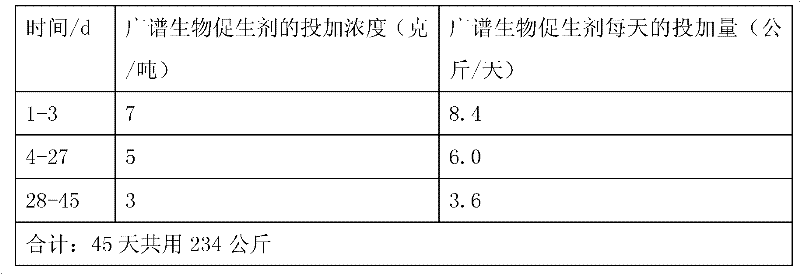

Broad-spectrum bio-energizer for industrial wastewater treatment and preparation method thereof

ActiveCN102515364AReduce processing costsPromote growthBiological water/sewage treatmentDecompositionWater quality

The invention relates to the technical field of industrial wastewater biochemical treatment and discloses a broad-spectrum bio-energizer for industrial wastewater treatment. The broad-spectrum bio-energizer contains the following components of: by weight, 1 part of enzyme, 0.15-0.4 part of a micro-element nutrition, 0.15-0.4 part of hormone, 1.5-2.5 parts of organic acid, 2.5-3 parts of a nitrogen nutrition and 0.8-1.2 parts of a phosphorus nutrition. The broad-spectrum bio-energizer can be used to promote rapid growth of various bacteria and fungi in a complex environment, promote the pollutant decomposition ability of microorganisms, raise an industrial wastewater biochemical treatment system's capability of recovering fluctuation of water quality and quantity and improve treatment efficiency of the system.

Owner:普罗生物技术(上海)有限公司

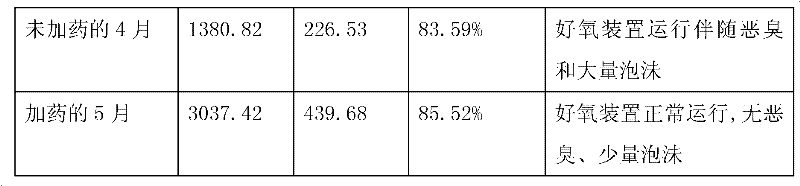

Method for recycling impurity salts generated in industrial wastewater treatment

ActiveCN106745076AEasy to handleWide operating conditionsCalcium/strontium/barium carbonatesCalcium/strontium/barium sulfatesHigh concentrationSulfate radicals

The invention provides a method for recycling impurity salts generated in industrial wastewater treatment. The method comprises the following steps: (1) calcining impurity salts generated in an industrial wastewater treatment process, cooling, dissolving in pure water, and obtaining a high-concentration sodium chloride solution; (2) performing solid-liquid separation, and removing residual organisms in the solution; (3) successively removing sulfate radicals and calcium ions, adjusting the pH of the solution to neutral, and obtaining a high-purity sodium chloride solution; and (4) crystallizing the high-purity sodium chloride solution obtained in step (3), obtaining a sodium chloride crystal product, and washing to obtain the high-purity sodium chloride crystal product. By adopting the method, the effective treatment and recycling of impurity salts generated in the industrial wastewater zero emission process of electric power, petroleum chemistry, coal chemistry and the like; moreover, the method is simple in treatment process and moderate in operation conditions, and is a high-efficiency and stable impurity salt recycling method; and a final product sodium chloride is high in recycling rate and purity.

Owner:DATANG INT CHEM TECH RESINST

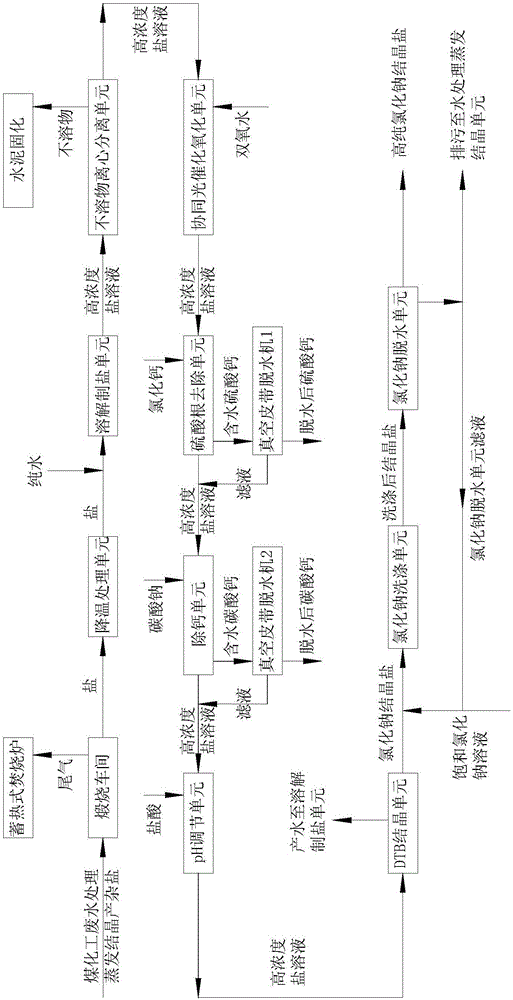

Method of manufacturing active carbon for waste water treatment using waste tyre

InactiveCN101012059AReduce qualityImprove resource utilization efficiencyOther chemical processesWater/sewage treatment by sorptionThermal energyWaste treatment

The invention discloses a making method of wastewater active charcoal through waste tyre in the processing method technical domain of environmental protective solid waste, which is characterized by the following: transmitting entire or broken waste tyre into pyrogenic stove; transmitting carbon waste in the charring activating furnace; sending non-condensed gas into combusting furnace; inducing high-hot CO2 and H2O flow into charring activating furnace to heat charring activating furnace; adopting incomplete combusting carbon black as new additional raw material; insulating the charring activating furnace from air; reducing to below 100 deg.c to obtain the product; alternating two stoves.

Owner:TSINGHUA UNIV

Method of deep desalting and recycling of industrial effluent

ActiveCN102452751AGuaranteed uptimeAvoid the problem of susceptibility to incoming water organic contaminationGeneral water supply conservationMultistage water/sewage treatmentElectricityIndustrial effluent

The invention provides a method of deep desalting and recycling of industrial effluent. The method is characterized in that industrial effluent to be treated is treated with a hardness reducing operating unit, an efficient filtering operating unit and an electro-adsorption desalting operating unit to reach a standard of recycling water. The method comprises specific steps of: a. hardness reduction, precipitation and neutralization; b. efficient filtering; and c. electro-adsorption desalting. The provided method of deep desalting and recycling of industrial effluent requires no equipment of electroosmosis or reverse osmosis membrane, or ion exchange resin, keeps stable operation of the system under a condition of water quality conductivity higher than 2500 muS / cm and does not scale; and an outlet water quality satisfies water quality requirements on recycling water replenishment. Discharge secondary industrial effluent with water quality conductivity lower than 4500 muS / cm can be treated to reach water replenishment requirements of an industrial recycling water system. The method is suitable for chemical effluent, printing and dyeing effluent, spinning effluent and oil refining effluent and has wide water quality scope of application, stable technology operation and high desalting efficiency.

Owner:CHINA PETROLEUM & CHEM CORP

Multi-stage countercurrent electrodialyzer reversal-based method for treating saline wastewater in coal chemical industry

ActiveCN104016529AAchieving processing powerRealize desalination and reuseDispersed particle separationMultistage water/sewage treatmentFiltrationInstability

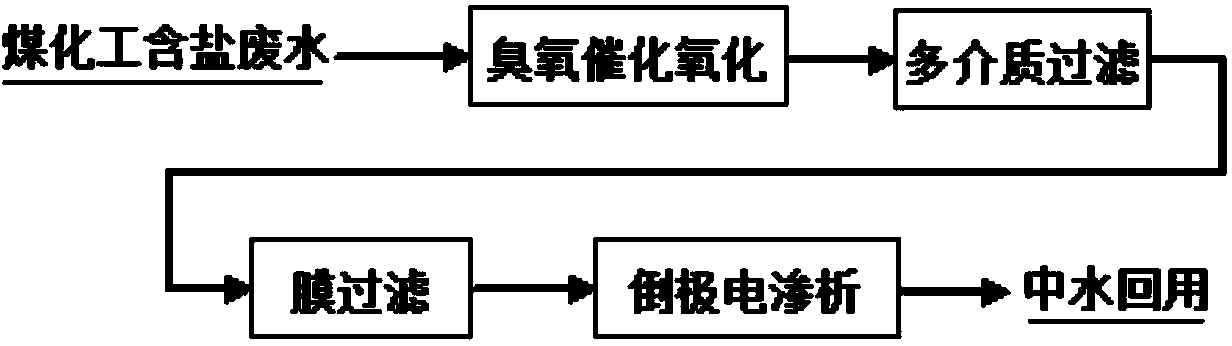

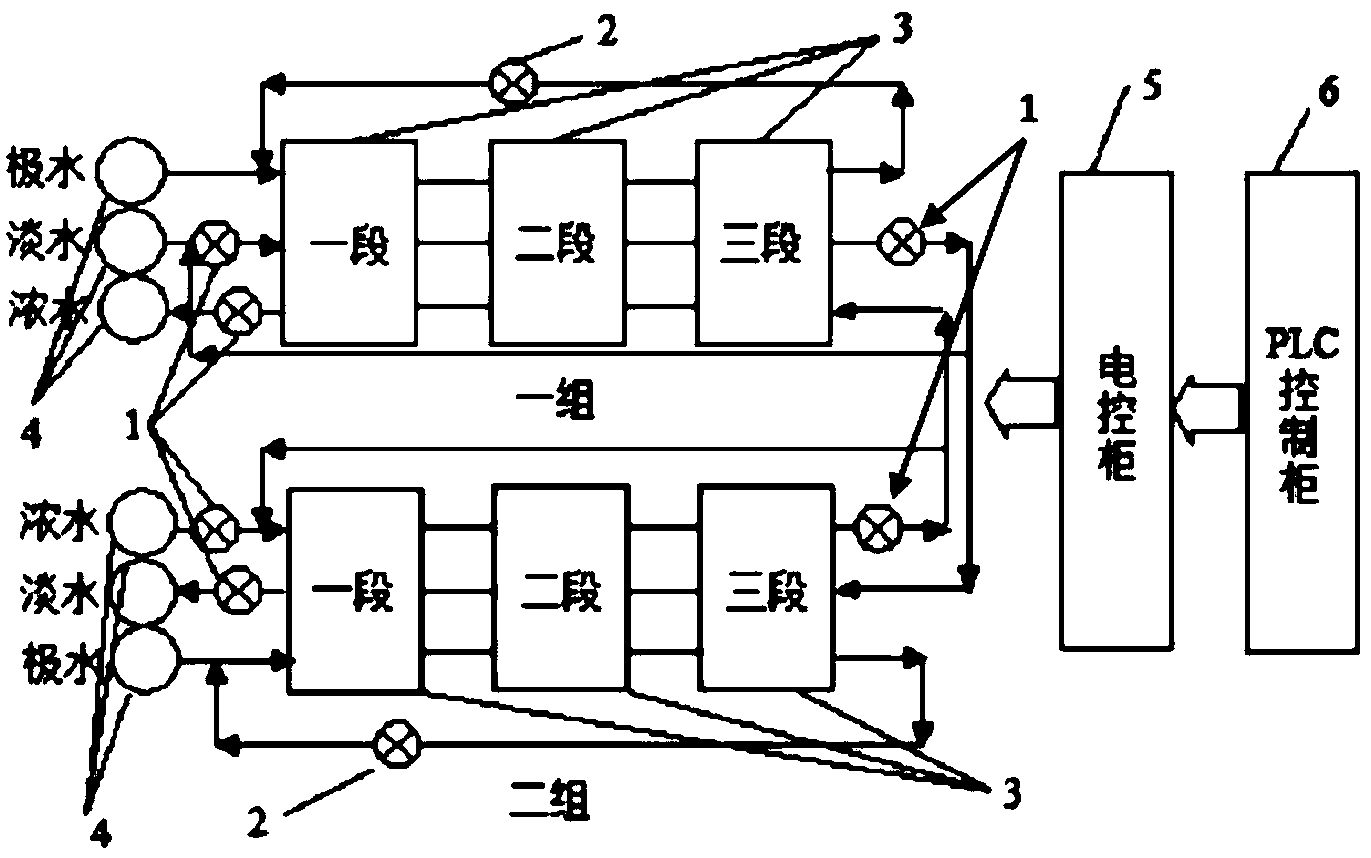

The invention relates to the field of industrial wastewater treatment processes and provides a multi-stage countercurrent electrodialyzer reversal-based method for treating saline wastewater in the coal chemical industry. The method comprises the following steps: 1) carrying out catalytic ozonation treatment on the saline wastewater in the coal chemical industry; 2) carrying out multi-media filtration and membrane filtration treatment on the wastewater subjected to catalytic ozonation in the step 1) in sequence; and 3) treating the effluent obtained after membrane filtration in the step 2) with a multi-stage countercurrent electrodialyzer reversal, thus achieving deep treatment, desalting and recycling of the saline wastewater in the coal chemical industry, wherein the multi-stage countercurrent electrodialyzer reversal comprises an electrodialysis membrane stack unit, a frequency reversal control unit and an online monitoring and process control unit. The method has the advantages of high fresh water recovery rate, low concentrated water discharge, low operating cost, stability in system operation and the like and can avoid the problems of low fresh water recovery rate, low concentration multiple, high treatment cost, serious membrane pollution, instability in system operation and the like in the routine techniques.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

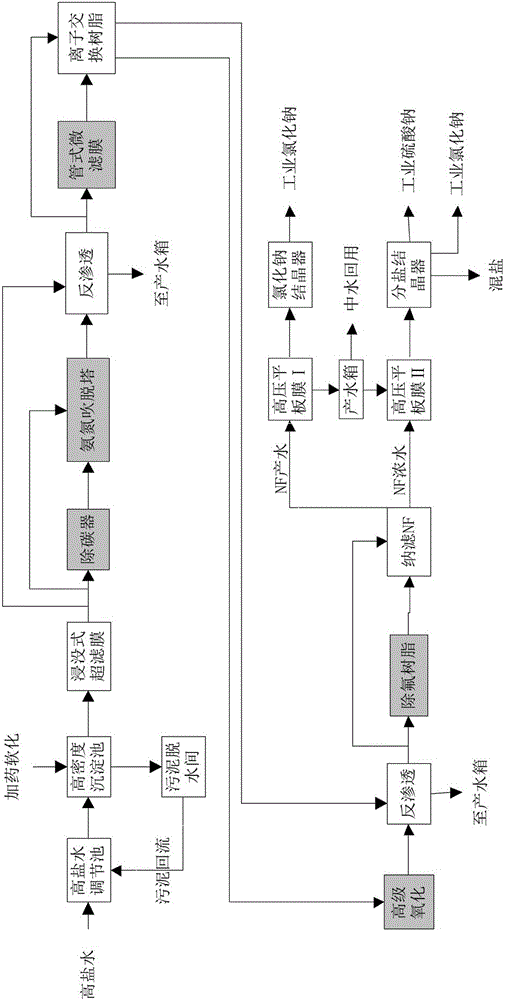

Device and method for treating industrial wastewater with high salt content

InactiveCN106396228AHigh recovery rateAchieving zero emissionsGeneral water supply conservationWater/sewage treatment by ion-exchangeFiltrationIon exchange

The invention provides a method for treating industrial wastewater with a high salt content. The method includes steps of pretreating the industrial wastewater with the high salt content, to be more specific, regulating and homogenizing the industrial wastewater with the high salt content by the aid of a high-salinity water regulating tank, then feeding the industrial wastewater into a high-density sedimentation tank, carrying out chemical softening treatment and flocculation sedimentation on the industrial wastewater, simultaneously removing most silicon dioxide and suspended matters, feeding water treated by the high-density sedimentation tank into an immersed ultra-filtration tank and further removing suspended matters and colloidal impurities in the water; carrying out separation and concentration, to be more specific, concentrating and separating the industrial wastewater with the high salt content after the industrial wastewater is pretreated at the pretreatment step, or carrying out ion exchange treatment on the industrial wastewater; recycling crystals, and to be more specific, separating the sodium chloride crystals and the sodium sulfate crystals from the water by the aid of crystallizers. The invention further provides a device for treating the industrial wastewater with the high salt content.

Owner:INNER MONGOLIA JIUKE KANGRUI ENVIRONMENTAL TECH

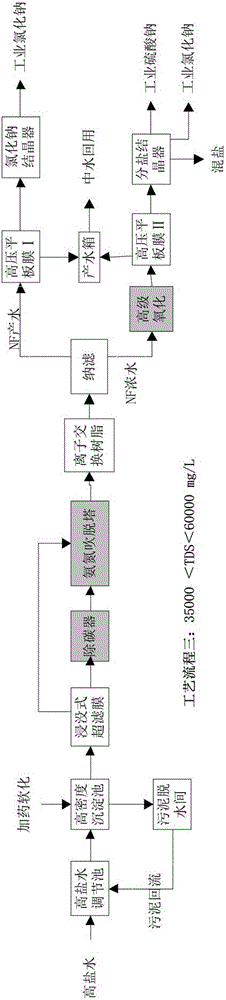

Method of liquefying microorganisms derived from biological wastewater treatment processes

InactiveUS6013183ASludge treatment by thermal conditioningSolid waste disposalActivated sludgeMicroorganism

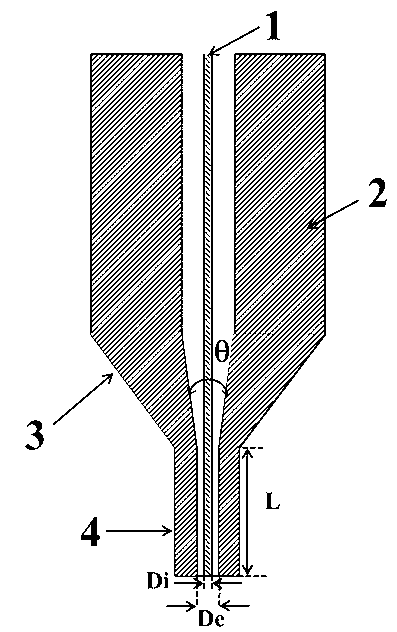

A process for liquefying microorganisms present in biosolids, such as waste activated sludge, generated by municipal or industrial wastewater treatment plants is disclosed. The process includes the step of passing a slurry of the sludge at a high pressure through a nozzle having a restricted flow area to cause liquefication of the microorganisms as they are discharged from the nozzle. The pressure drop across the nozzle preferably exceeds 5,000 psi. At least part of the liquefied microorganisms may be recirculated to the treatment facility to feed nutrients to the wastewater treatment process. Optionally, the liquefied microorganisms may be anaerobically converted to methane and carbon dioxide. For optimum results, the sludge is subjected to pH adjustment and / or maceration prior to being pumped through the high pressure nozzle.

Owner:PARADIGM ENVIRONMENTAL TECH INC

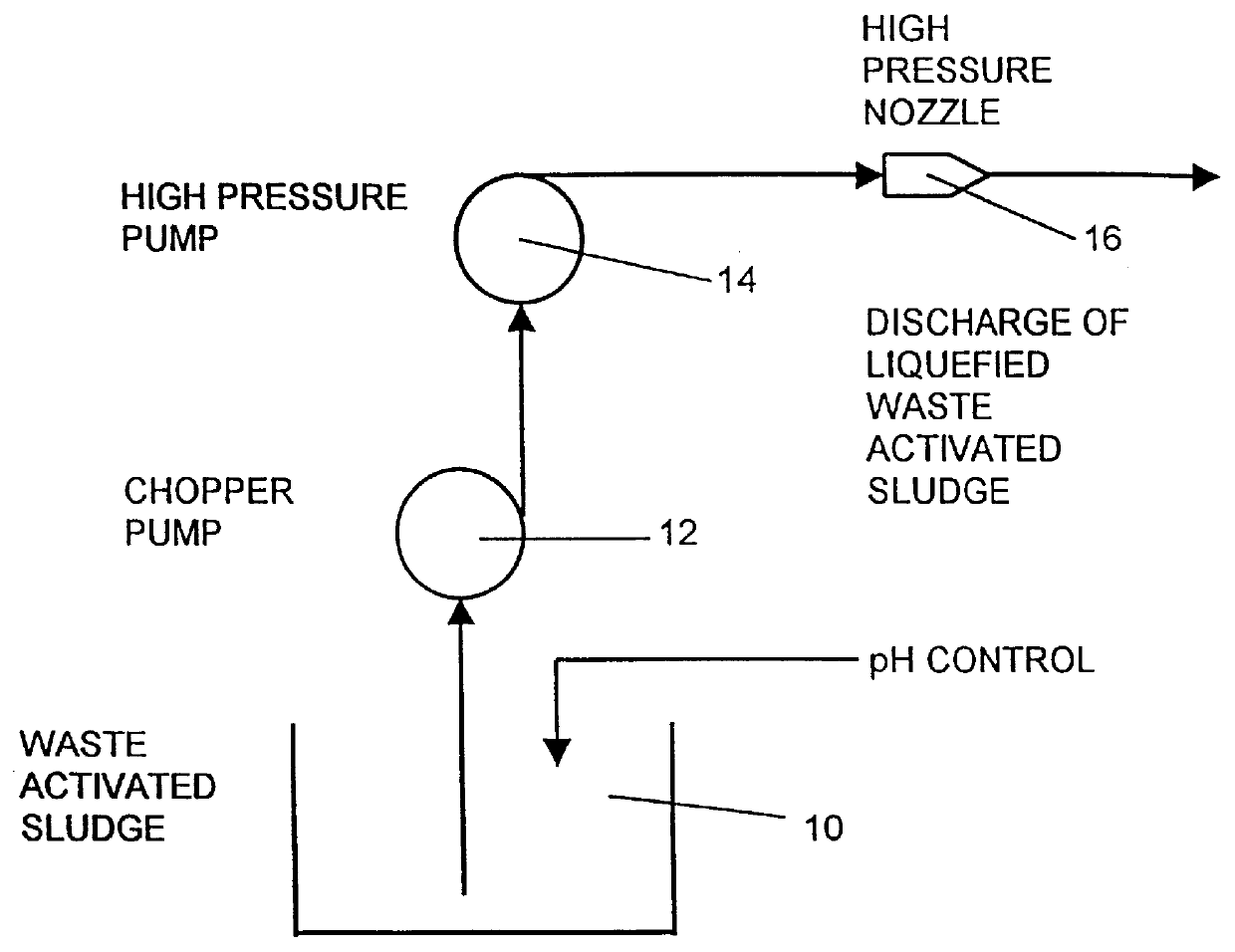

Catalytical ozonization catalyst utilizing multi-source sludge to prepare and application thereof

ActiveCN103007937ANo pollution in the processReduce manufacturing costOther chemical processesCarbon compoundsActivated carbonIndustrial waste water

The invention discloses a catalytical ozonization catalyst prepared by utilizing multi-source sludge and an application thereof, and establishes a method for preparing a sludge group active carbon catalyst for catalytical ozone oxidation organic industrial waste water. The method comprises the following steps of: utilizing multi-source sludge such as surplus sludge generated by urban sewage factory biochemical treatment and a metal sludge generated by a Fenton oxidation method, preparing a skeleton which is a sludge group active carbon through steps such as organic substance adding, actification, dehydration, drying, mixing, roasting and screening, wherein a surface layer contains a solid catalyst of metallic oxide, and the ratio of the sludge group active carbon and the metallic oxide in parts by weight is 1:(0.3-0.5). The catalyst is used for catalyzing ozone oxidation treatment organic industrial waste water and has higher catalytic activity and stability, the processing range is wide, the realization and popularization and application are easy, and the economic benefits are improved in an organic industrial waste water processing procedure.

Owner:TIANJIN UNITED ENVIRONMENTAL ENG DESIGN

Variable-volume improved A<2>/O deep nitrogen and phosphorus removal process for sewage

InactiveCN104341075AStable waterWater contaminantsTreatment with aerobic and anaerobic processesRefluxIndustrial waste water

The invention discloses a variable-volume improved A<2> / O deep nitrogen and phosphorus removal process for sewage, belongs to the field of urban sewage and industrial waste water treatment, and particularly relates to a deep nitrogen and phosphorus removal process for the sewage. Specific to the problem concerned with synchronous removal of organic matters and the problem of poor nitrogen and phosphorus removal effect in a conventional A<2> / O process, the process is characterized in that firstly, a pre-anoxic pool is arranged in front of an anaerobic pool to lower the influences of dissolved oxygen and nitric oxygen carried in returned sludge on the phosphorus removal effect, wherein 5-25 percent of sewage enters the pre-anoxic pool, and 75-95 percent of the sewage enters the anaerobic pool; and secondly, movable clapboards are arranged among the pre-anoxic pool, the anaerobic pool, an anoxic pool and an aerobic pool, and the volume ratio of each water pool can be adjusted flexibly according to the ratio of C:N:P in the sewage in order to change the hydraulic retention time of the sewage in each water pool. Meanwhile, the aim of deep nitrogen and phosphorus removal of the sewage is fulfilled under the condition that the inner reflux ratio is 100-200 percent and the sludge reflux ratio is 50-150 percent; and output water is stable, and reaches the national grade-A discharge standard.

Owner:CHINESE RES ACAD OF ENVIRONMENTAL SCI

Industrial waste water treatment process

InactiveUS7491333B1Easy to reuseFacilitated releaseSolid sorbent liquid separationWater/sewage treatment by neutralisationClean Water ActIndustrial waste water

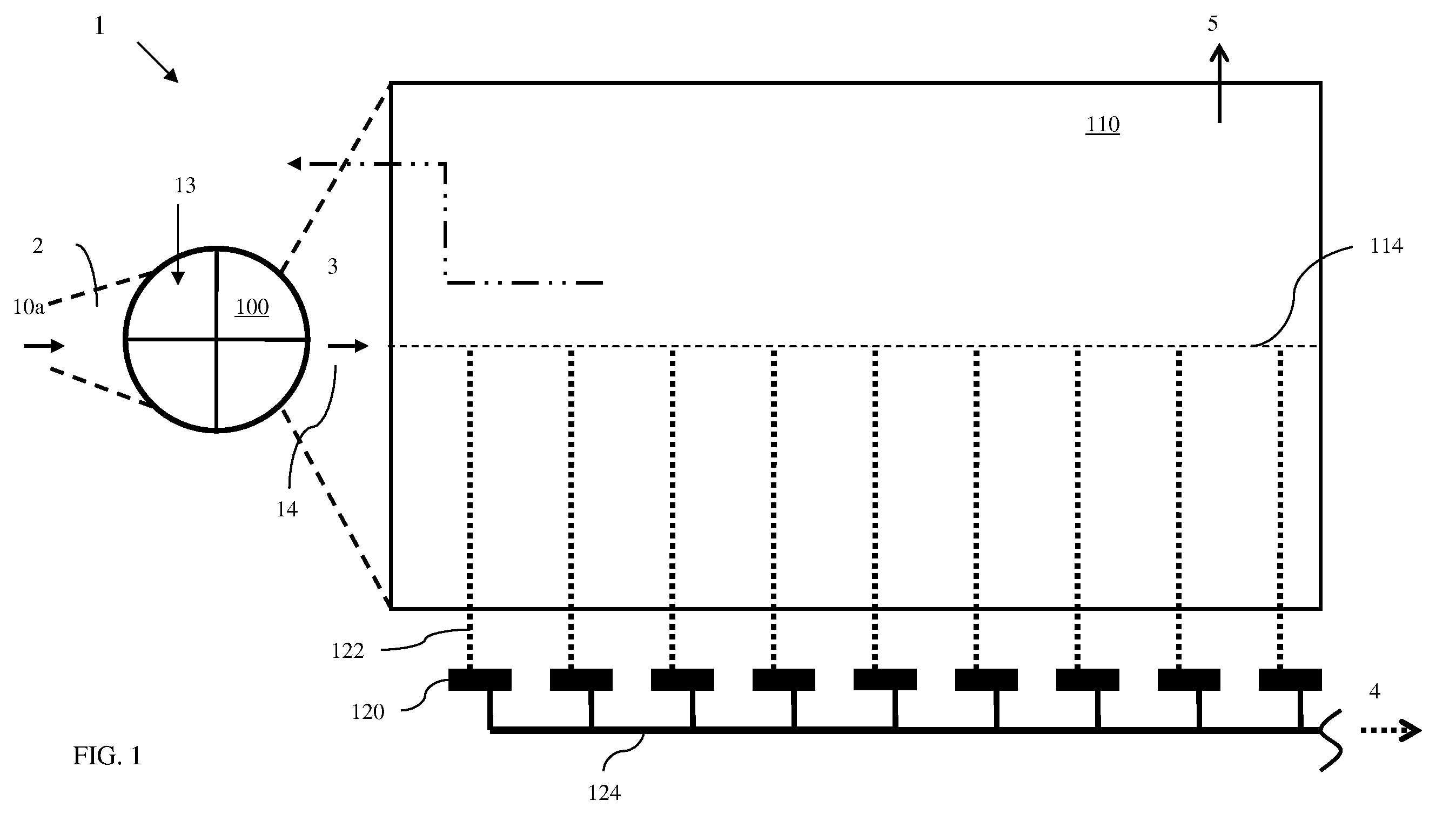

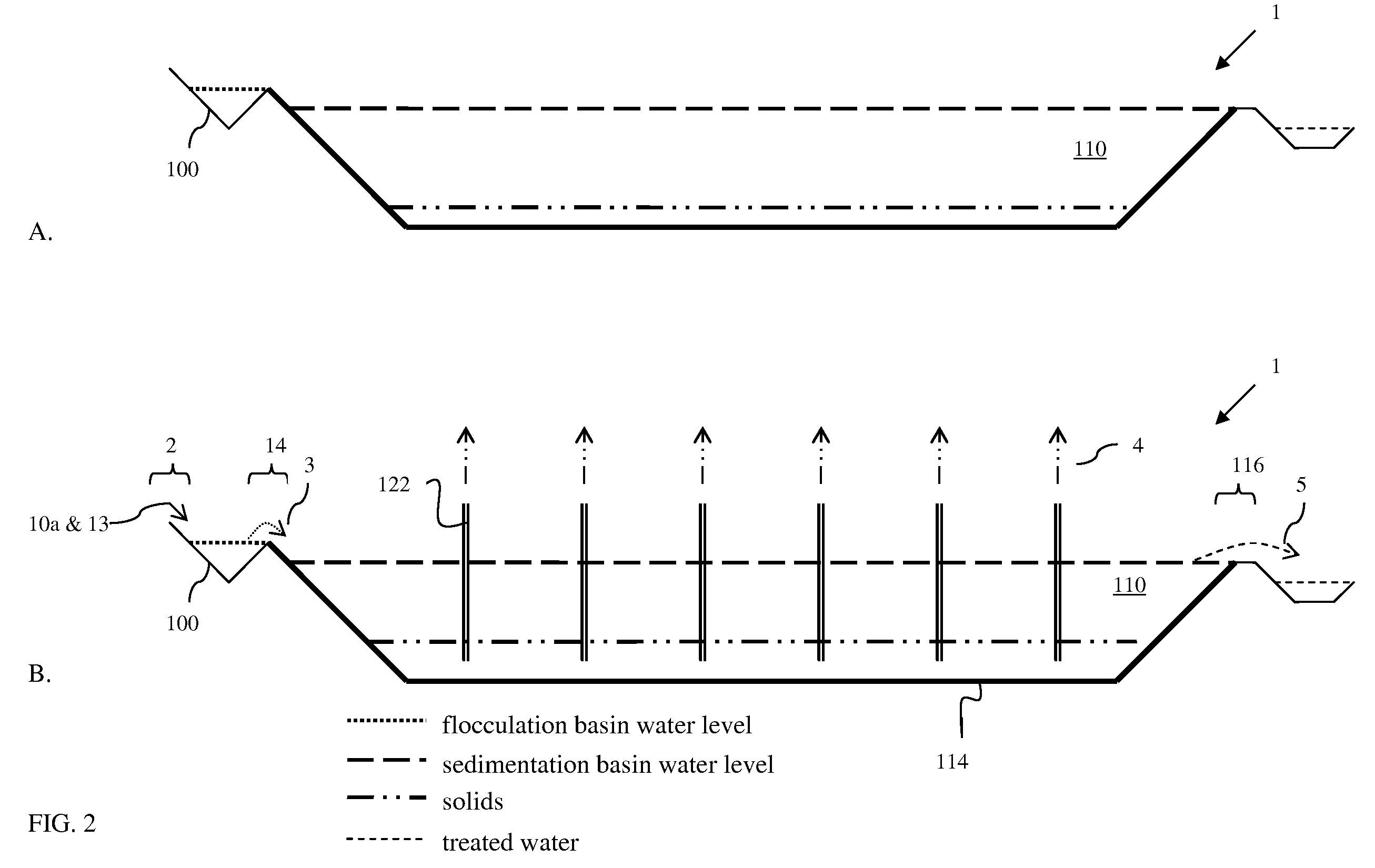

A process for the treatment of industrial waste water. The process includes the steps of admixing partially-treated waste water containing precipitated impurities with a flocculating agent in a flocculation basin, directing the admixed waste water to an elongated sedimentation basin, allowing flocculated solids in the waste water to settle to the bottom of the sedimentation basin, removing the settled solids from the bottom of the sedimentation basin and directing the treated water from the sedimentation basin. The process can further include the step of adjusting the pH of the waste water to precipitate impurities in the waste water prior to the addition of the flocculation agent. The elongated sedimentation basin can include a pair of sloped sides to consolidate the settled solids at the bottom of the basin. The settled solids can then be removed by suction. The basins can be formed from the excavation or impoundment of earth in an area adjacent to a waste water-generating facility. Furthermore, the flow of the streams between basins can be controlled by overflow, with flow rates further controlled by recycle of solids and treated water. The treatment of industrial water according to the present processes allows removal of impurities such that the water is suitable for internal re-use in an operating phosphoric acid facility or release. Additionally, the process is able to treat acidic industrial waste water by the removal of impurities as a preliminary treatment stage leading to discharge of the final treated water to natural water bodies in compliance with the Federal Clean Water Act. Moreover, treated water may be processed by reverse osmosis to remove residual impurities. By employing the processes taught herein reverse osmosis becomes possible and practicable in the context of industrial waste water treatment. Treatment of waste water in accordance with the present invention will require less expensive capital equipment for the separation stages and provide a more concentrated solids stream.

Owner:CLEANWATER TECH

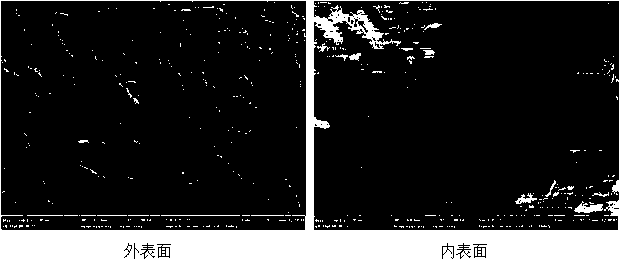

Preparation method of teflon hollow fiber membrane for membrane distillation

InactiveCN102941025ALow costAvoid loss of product water qualitySemi-permeable membranesIndustrial effluentPhysical chemistry

The invention discloses a preparation method of a teflon hollow fiber membrane for membrane distillation, which comprises the following steps of: mixing teflon dispersion powder and a extruding-aid agent, pressing a blank, extruding the blank into a teflon hollow tube through a pushing and pressing machine with a cone mould and a mouth mould, and performing longitudinal stretch, sintering and heat setting on the teflon hollow tube in a drying oven to obtain the teflon hollow fiber membrane. The processed teflon hollow fiber membrane is in an asymmetric structure, the mean pore size of an outer layer is 0.10-1.0 micrometer, the mean pore size of an inner layer is 5.0-20 micrometers, the wall thickness is 0.1-0.5 millimeter, the bubble point pressure is 0.5-2.0 kgf / square centimeter, and the water resistance pressure is 1.5-6kgf / square micrometer. The invention is mainly used for the membrane distillation separation process, and can be applied to the fields of sea water desalination, industrial wastewater treatment, cryoconcentration of food and biological products, and the like.

Owner:ZHEJIANG SCI-TECH UNIV

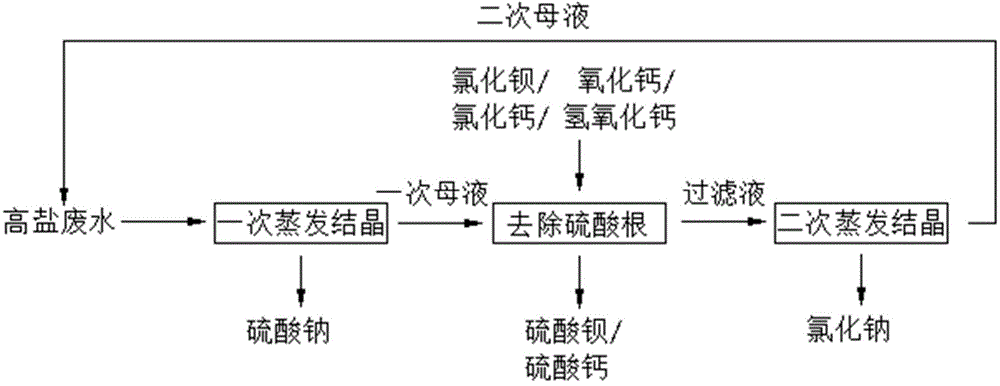

Recovery processing method of high salinity wastewater containing sodium chloride and sodium sulfate

InactiveCN104973726AHigh purityMeet quality requirementsEnergy based wastewater treatmentMultistage water/sewage treatmentResource utilizationSULFATE ION

The invention discloses a recovery processing method of high salinity wastewater containing sodium chloride and sodium sulfate, and belongs to the field of industrial wastewater treatment. According to the recovery processing method, sodium chloride and sodium sulfate are recycled via primary evaporative crystallization, removing of sulfate ions via adding of materials and generation of precipitations, and secondary evaporative crystallization. The recovery processing method can be used for effective recovery of sodium chloride and sodium sulfate in coal chemical industry high salinity wastewater; process conditions are simple and stable; the recovery processing method is convenient for industrialized popularization; recovered sodium chloride and sodium sulfate are capable of satisfying quality requirements of industrial-grade products, and can be recycled and reused directly or be sold as by-products; processing of high salinity wastewater is realized; environmental requirements are satisfied; waste is changed into valuables; salt resource utilization is realized; and factory income is increased.

Owner:SHIJIAZHUANG GONGDA CHEM EQUIP

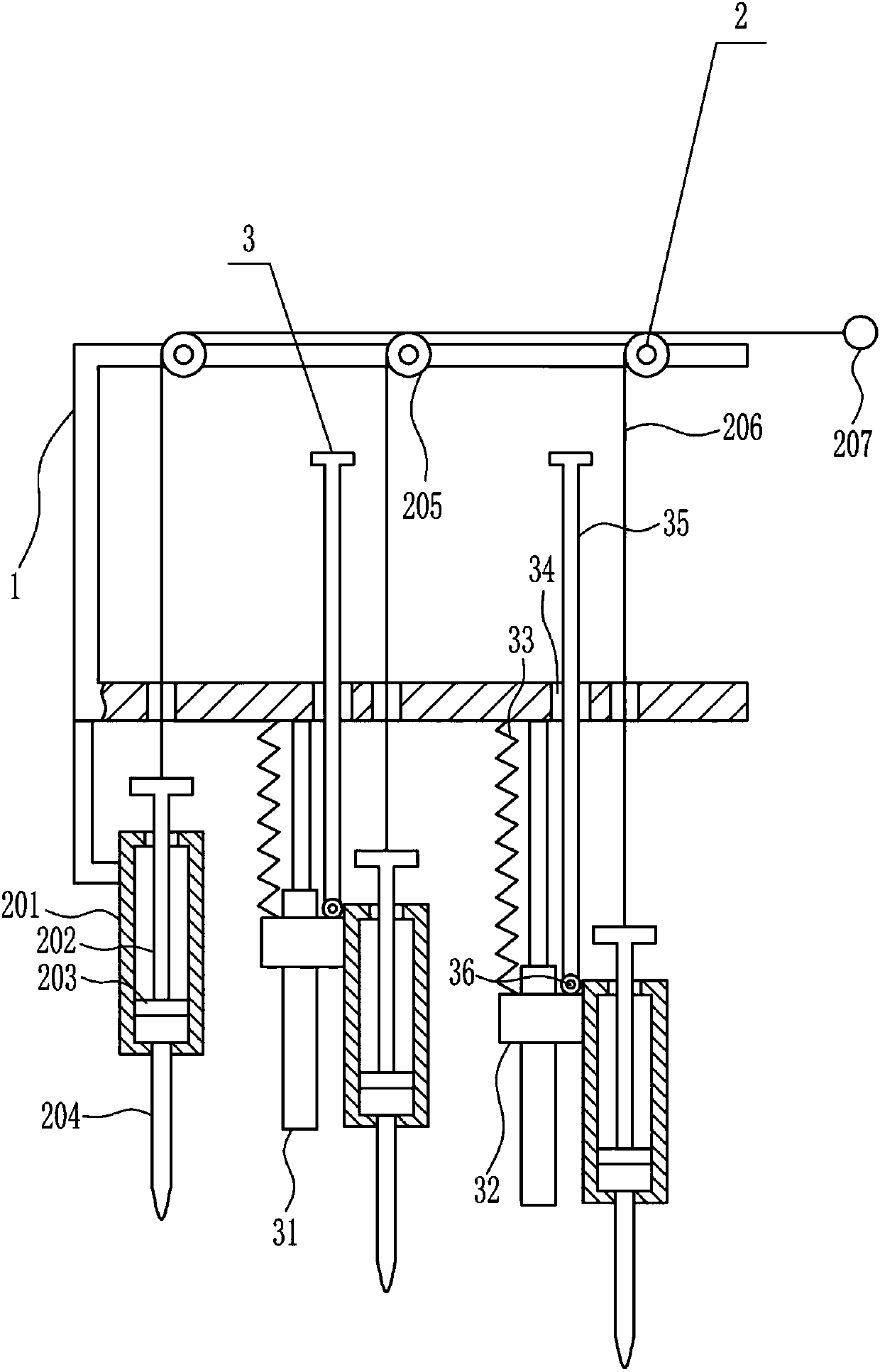

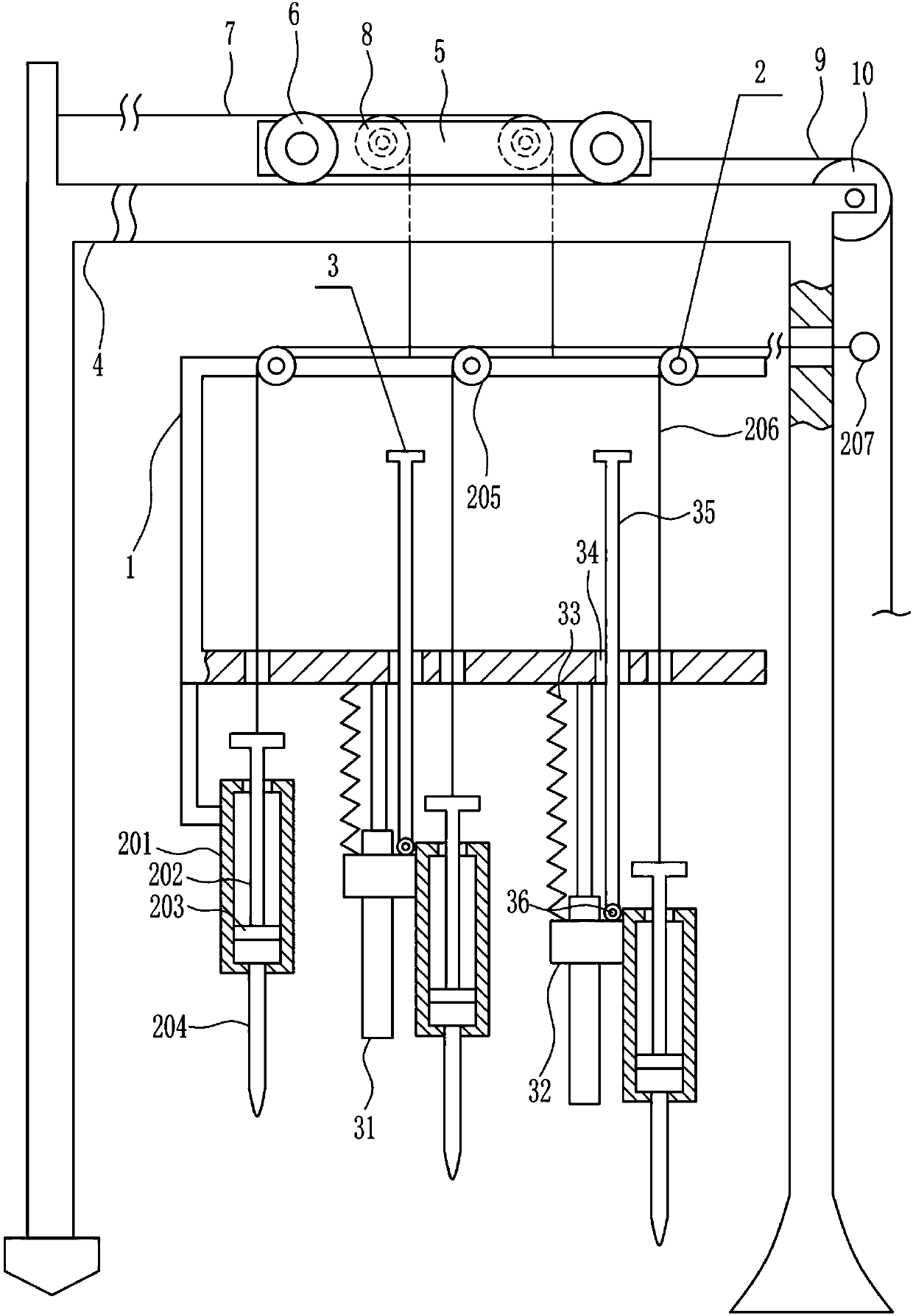

Different-depth water sampling device for treating industrial wastewater

InactiveCN107643192AConvenience to workHeight adjustableWithdrawing sample devicesSample waterSewage

The invention relates to a water sampling device, in particular to a different-depth water sampling device for treating industrial wastewater, and aims at adjusting the sampling depth according to different requirement and synchronously sampling from different places. For solving technical problems, the invention provides the different-depth water sampling device for treating industrial wastewater, and the device comprises a mounting rack and the like, wherein sampling mechanisms are uniformly arranged on the mounting rack; adjusting mechanisms which are matched with the sampling mechanisms are arranged on the mounting rack. According to the device, the sampling mechanisms are arranged and used for synchronously sampling water through a plurality of sampling pipes, which facilitates the work of workers; the adjusting mechanisms are arranged and used for conveniently adjusting the height of the sampling pipes, so that the sewage under different depth in the same place can be synchronously sampled.

Owner:韩丹

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com