Preparation method of functional magnetic absorbent used for treating industrial wastewater

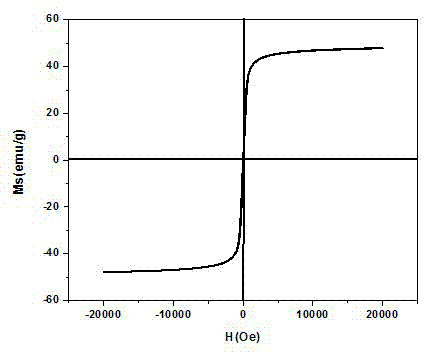

A magnetic adsorbent, industrial wastewater technology, applied in the fields of adsorption water/sewage treatment, chemical instruments and methods, alkali metal oxides/hydroxides, etc. Uniformity, slow magnetic separation speed, etc., to achieve the effect of controllable structure, controllable magnetic content, and fast magnetic response performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

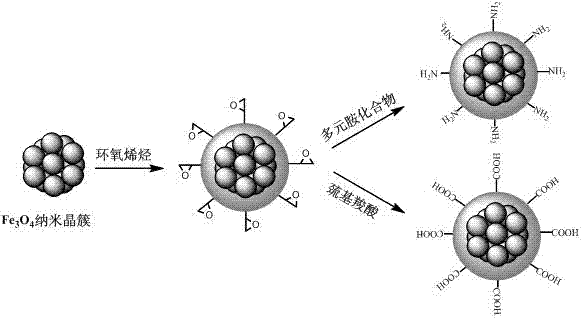

[0027] Example 1: Preparation of Amino Functional Magnetic Adsorbent

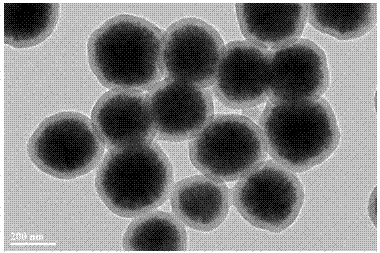

[0028] Step 1, ferric oxide nanocrystal clusters with high magnetic saturation

[0029] Take 2.2 g of iron sulfate (Fe 2 (SO 4 ) 3 ), 1.8 g of sodium citrate, and 5.6 g of sodium acetate (NaAc), were dissolved in 80 mL of ethylene glycol, and then transferred to a 250 mL three-neck flask, mechanically stirred at room temperature for 1 h, and then the flask was The liquid was transferred into a high-pressure reactor with a capacity of 100 ml and lined with polytetrafluoroethylene, and then the reactor was placed in an oven at 180 °C for 12 h, and then it was taken out and quickly cooled to room temperature with tap water. Finally, the product was washed by magnetic separation, and unreacted reactants were removed by washing with absolute ethanol and deionized water, respectively, until the supernatant was colorless, and then the product was dispersed in absolute ethanol for subsequent use;

[0030] Ste...

Embodiment 2

[0036] Example 2: Preparation of Carboxyl Functional Magnetic Adsorbent

[0037] The preparation of step 1, iron ferric oxide nanocrystal cluster is described in step 1 in embodiment 1;

[0038] Step 2, modifying the double bond functional group on the surface of ferric oxide nanocrystal clusters is as described in step 2 in Embodiment 1;

[0039] The preparation of the magnetic microspheres modified by step 3, surface epoxy functional group is described in step 3 in embodiment 1;

[0040] Step 4, preparation of carboxyl functional magnetic adsorbent;

[0041] Add 50 mg surface epoxy-modified magnetic microspheres, 15 ml water and 0.4 g mercaptoacetic acid into a three-neck flask, control the pH of the solution to 11, control the temperature to 25 °C, and stop the reaction after mechanical stirring for 12 h. The washing product is separated by a magnetic separation method, and the amino functional magnetic adsorbent is obtained after being washed several times with absolut...

Embodiment 3

[0042] Example 3: Preparation of Amino Functional Magnetic Adsorbent

[0043] Step 1, ferric oxide nanocrystal clusters with high magnetic saturation

[0044] Take 5.2 g of ferric chloride hexahydrate, 3 g of sodium citrate, and 15.6 g of ammonium acetate, dissolve them in 150 mL of ethylene glycol, transfer them to a 250 mL three-necked flask, and stir them mechanically at 160 °C After 6 h, transfer the liquid in the flask to a 200 ml high-pressure reaction kettle with a polytetrafluoroethylene liner, then put the reaction kettle in an oven at 200 ° C for 32 h, take it out, and make it dry with tap water. Cool quickly to room temperature. Finally, the product was washed by magnetic separation, and unreacted reactants were removed by washing with absolute ethanol and deionized water, respectively, until the supernatant was colorless, and then the product was dispersed in absolute ethanol for subsequent use;

[0045] Step 2, modifying the surface of ferric oxide nanocrystal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Maximum adsorption capacity | aaaaa | aaaaa |

| Maximum adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com