Patents

Literature

484 results about "Mercaptoacetic acid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

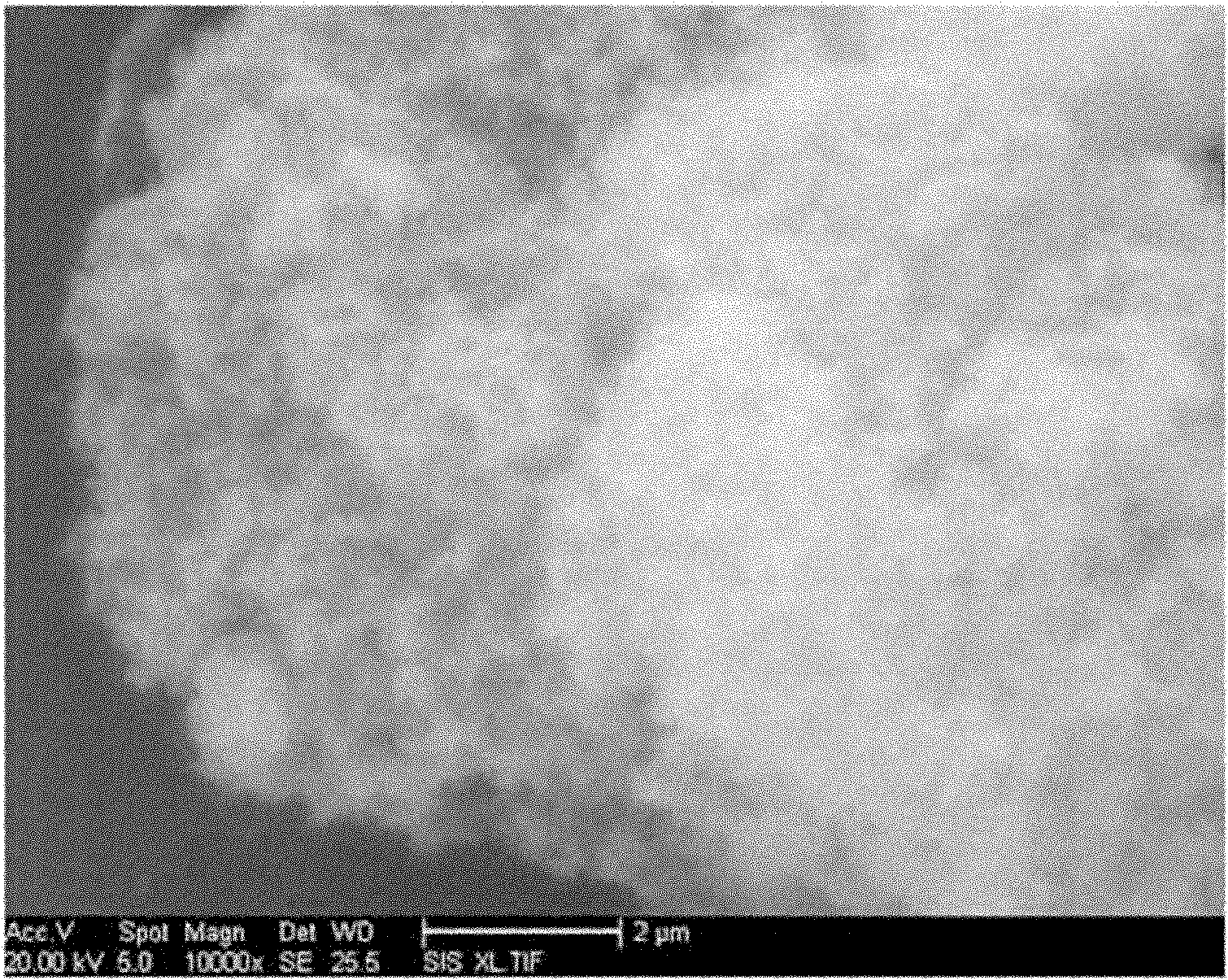

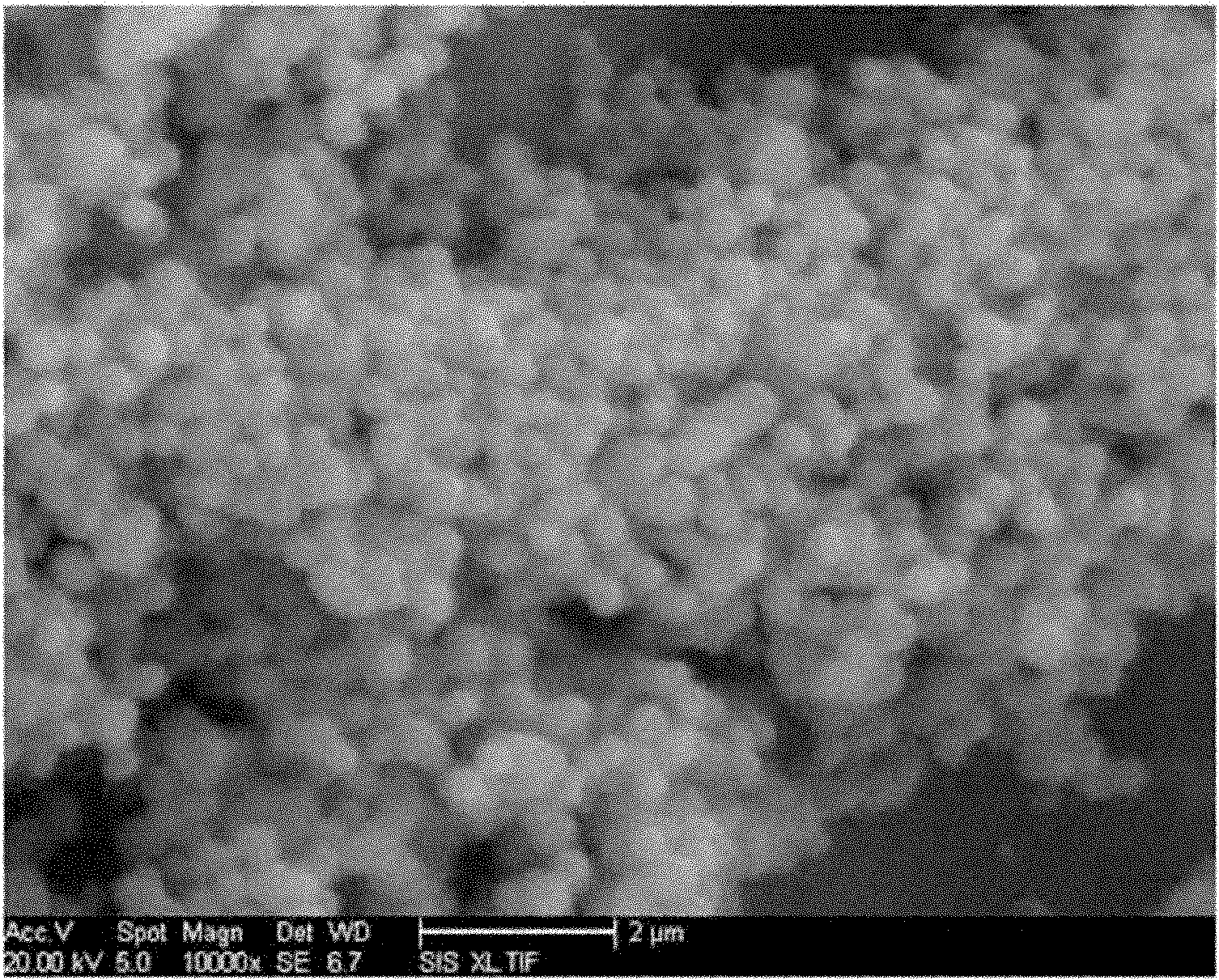

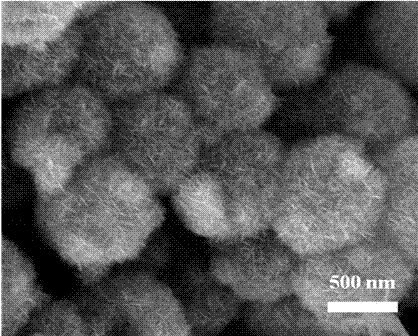

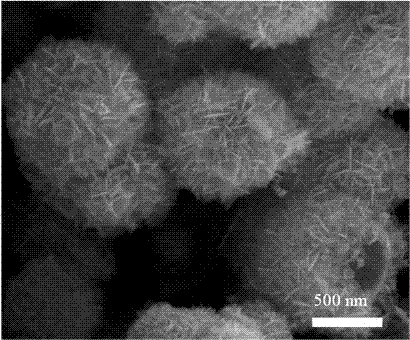

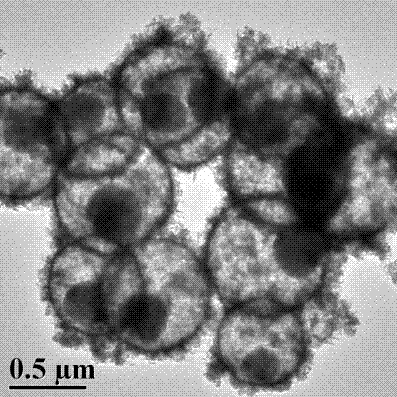

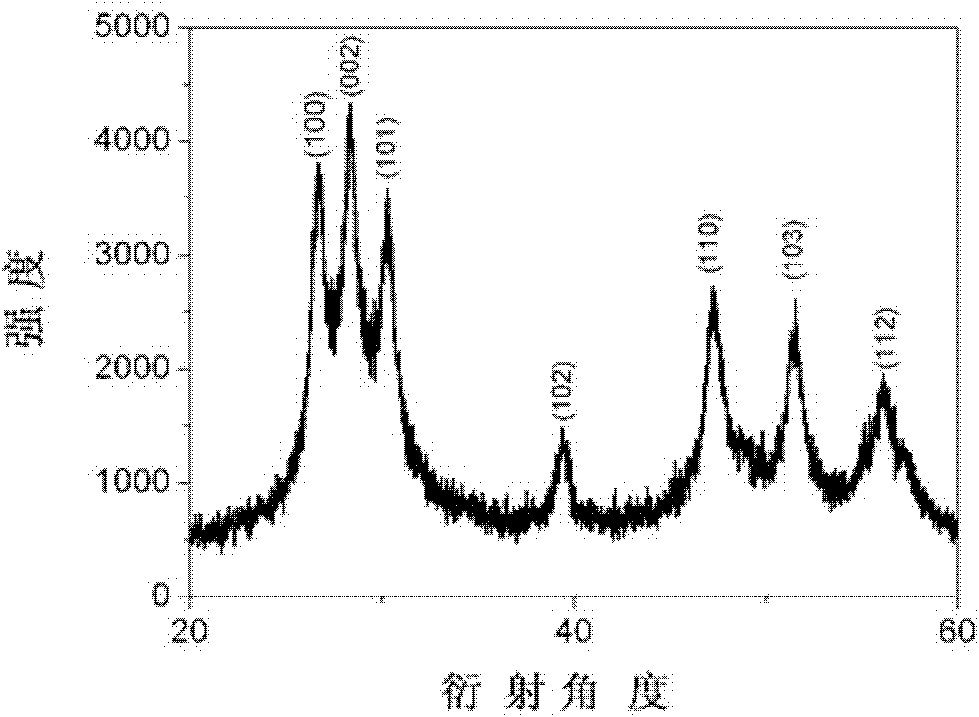

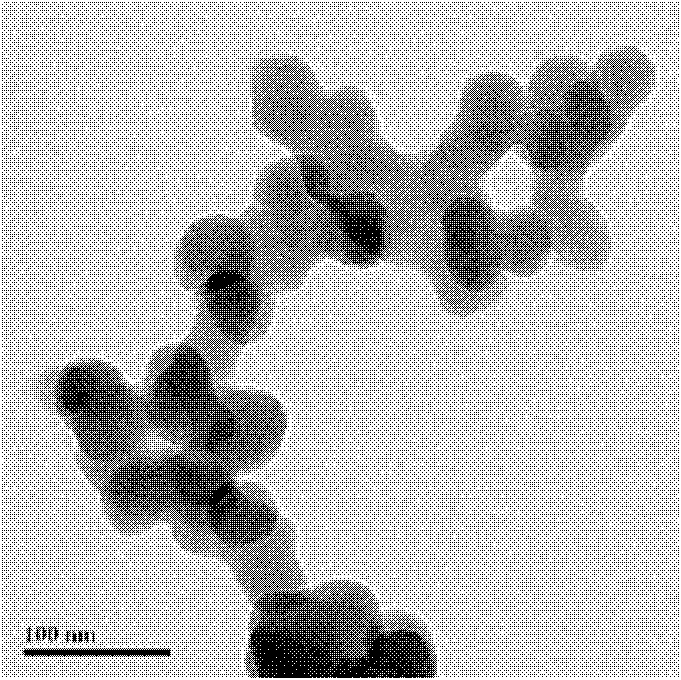

Synthetic method for magnetic metal organic framework composite material coated by [Cu3(btc)2] on surfaces of ferroferric oxide microspheres and application of composite material

InactiveCN103143331AGood magnetic responseReduce adsorptionOther chemical processesComponent separationMicrosphereMetal-organic framework

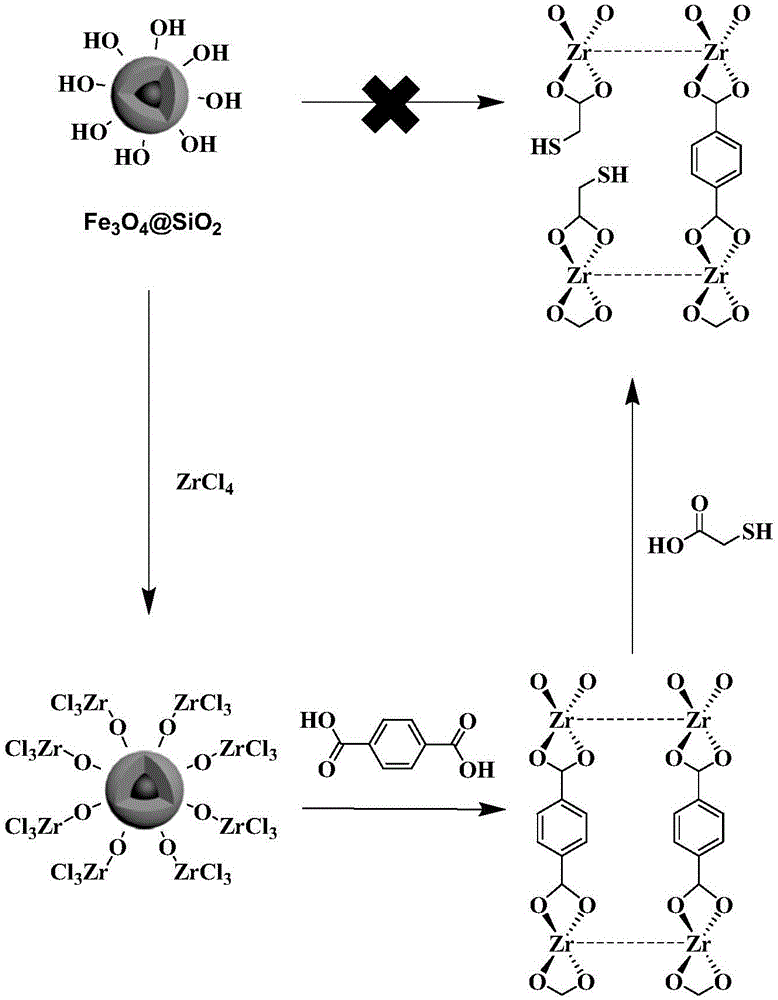

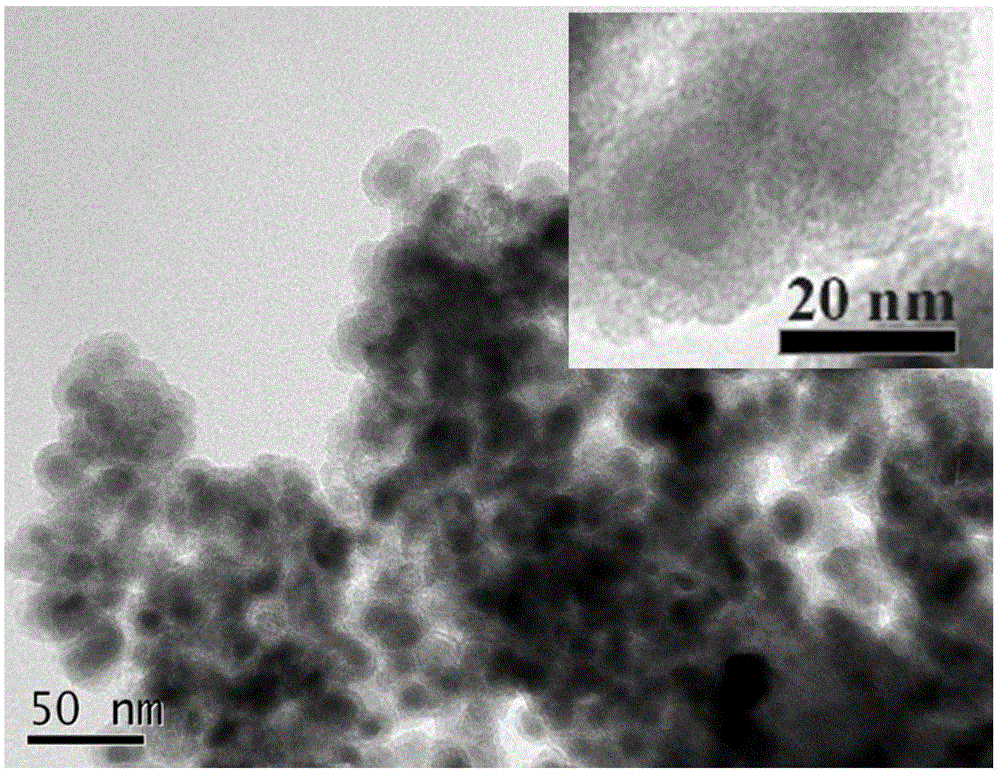

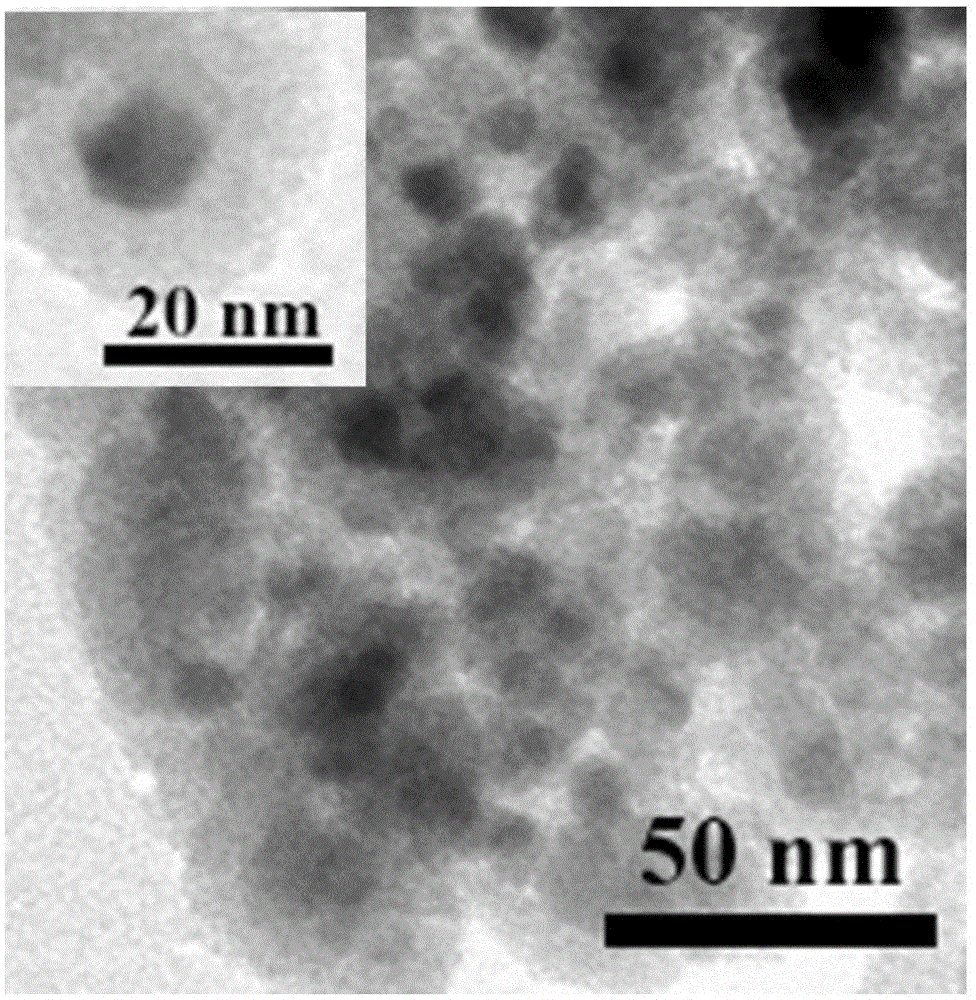

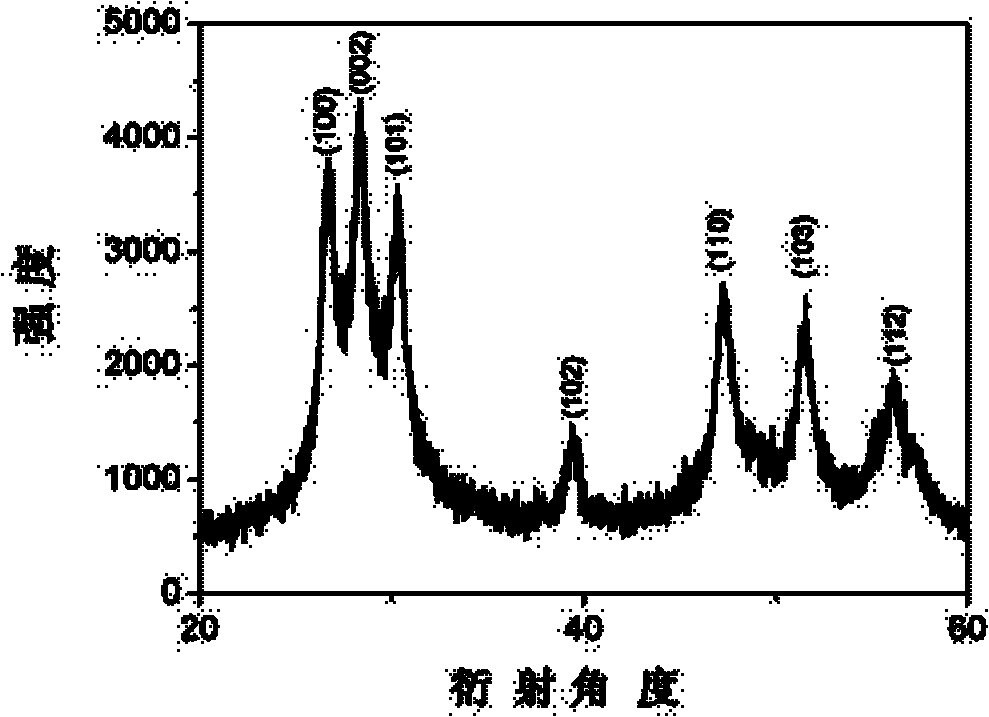

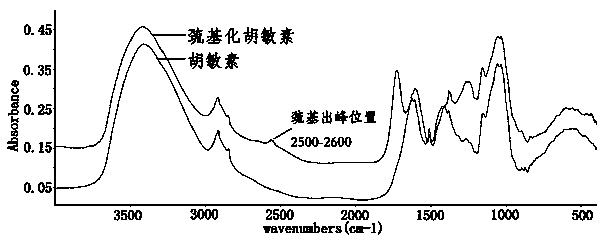

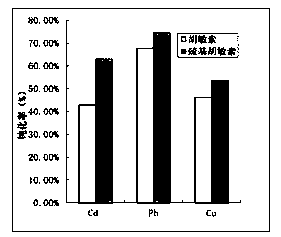

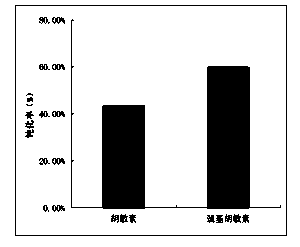

The invention relates to a synthetic method for a magnetic metal organic framework composite material coated by [Cu2(btc)2] on surfaces of ferroferric oxide microspheres and application of the composite material. The method comprises the following steps of: firstly synthesizing ferroferric oxide microspheres by a hydrothermal synthesis method; dispersing magnetic spheres in an ethanol liquid of mercaptoacetic acid, wherein hydroxyls are formed on the surface of the spheres; dispersing mercaptoacetic acid modified magnetic spheres to an ethanol liquid of copper acetate, reacting for 15 minutes at 70 DEG C, and then dispersing the product in an ethanol liquid of trimesic acid and reacting for 30 minutes at 70 DEG C; and performing alternate reaction of magnetic spheres with copper acetate and the ethanol liquid of trimesic acid to finally, obtain the magnetic metal organic framework composite material with a core-shell structure. The material has a metal organic framework shell layer and can be coordinated with peptide fragments with amino groups and carboxylic group so as to enrich low concentration peptide. Meanwhile, the enriching and separating process is fast, simple and convenient due to high paramagnetism of ferroferric oxide. The synthetic method is simple and low in cost, and can be used for enrichment and separation of low abundance peptide fragments less than 1nM and MALDI-TOFMS (Matrix-Assisted Laser Desorption Ionization-Time Of Flight Mass Spectrometer) detection.

Owner:FUDAN UNIV

Thiohydroxy-modified magnetic MOFs adsorbent and preparation method and application thereof

InactiveCN105148852AMild reaction conditionsReduce energy consumptionOther chemical processesWater/sewage treatment by sorptionThiolCoprecipitation

The invention discloses a thiohydroxy-modified magnetic MOFs adsorbent and a preparation method and application thereof. The preparation method comprises the following steps: (1) preparing magnetic Fe3O4 nanospheres with the particle size of 10-20 nm by adopting a coprecipitation method; (2) preparing Fe3O4@SiO2 with a core-shell structure by adopting a Stober silicone coupling method; (3) preparing Fe3O4@SiO2@MOF through a solvothermal in-situ growth method; (4) carrying out thiol-functionalization on Fe3O4@SiO2@MOF synthesized in the step (3) in a solvent auxiliary ligand exchange manner, and preparing the thiol-functionalized magnetic MOFs adsorbent with different proportions through adjusting the proportion of mercaptoacetic acid to Fe3O4@SiO2@MOF. According to the invention, the preparation method is mild in reaction conditions, low in cost, and simple and convenient to operate; the prepared magnetic MOFs adsorbent has the advantages of being high in adsorption speed, large in adsorption capacity and good in selectivity when removing the metal ions in water.

Owner:WUHAN UNIV

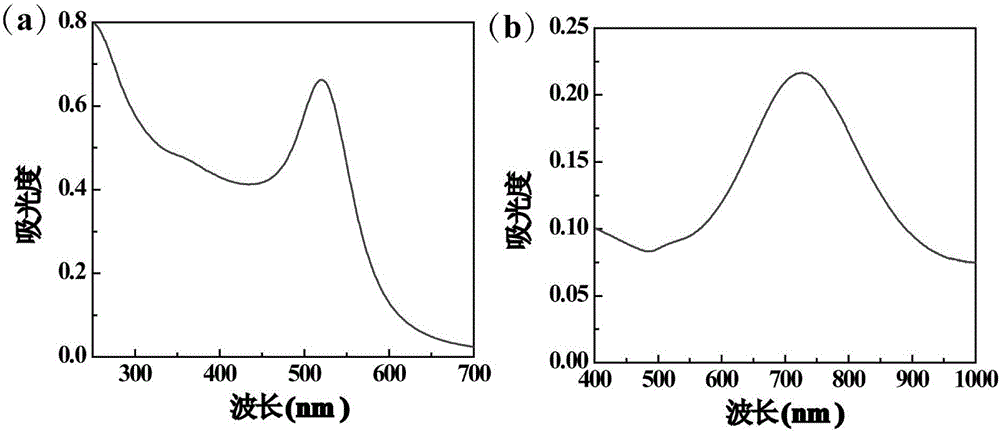

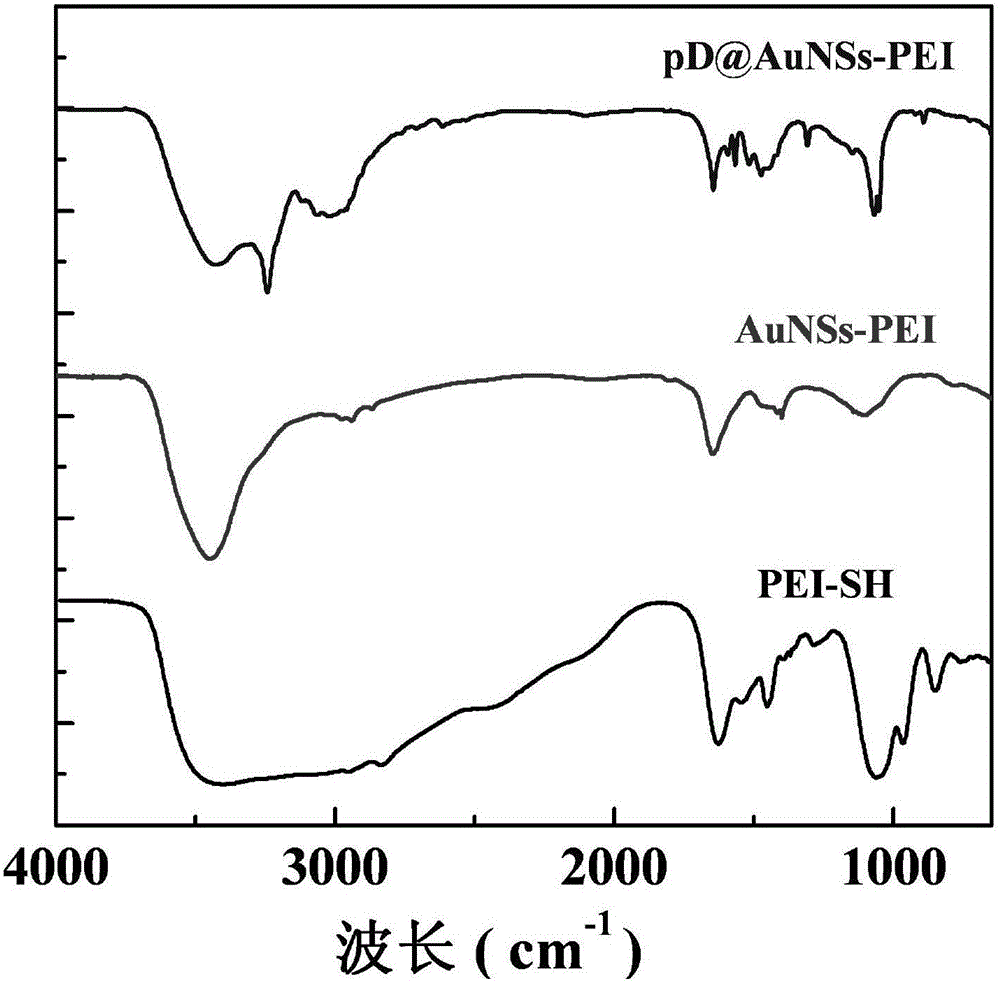

Preparation method for polydopamine-coated polyethyleneimine-stablized gold-nanometer-star photothermal treatment agent

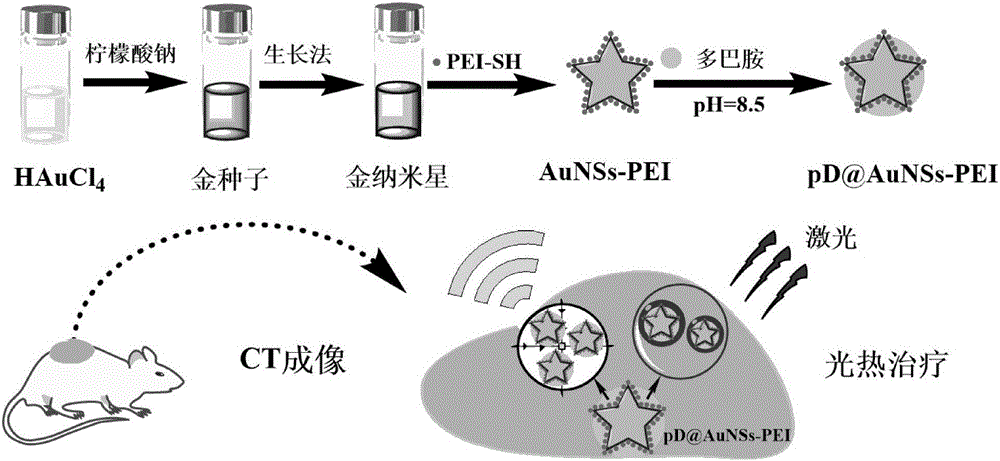

InactiveCN105031647AGood photothermal therapy effectImprove light-to-heat conversion efficiencyEnergy modified materialsX-ray constrast preparationsTreatment fieldMercaptoacetic acid

The invention relates to a preparation method for polydopamine-coated polyethyleneimine-stablized gold-nanometer-star photothermal treatment agent. The preparation method comprises the following steps: preparing a gold seed solution from chloroauric acid and sodium citrate; activating mercaptoacetic acid with EDC, then adding an aqueous PEI solution and carrying out a reaction, dialysis, cooling and drying so as to obtain PEI-SH; adding dopamine hydrochloride into a Tris buffer so as to obtain dopamine Tris buffer; adding the gold seed solution into a chloroauric acid solution, adding a AgNO3 solution and an ascorbic acid solution under stirring, adding PEI-SH after stirring reaction and carrying out a reaction so as to obtain AuNSs-PEI; and adding AuNSs-PEI into the dopamine Tris buffer and carrying out stirring and centrifugation so as to obtain the photothermal treatment agent. The preparation method has the advantages of simplicity, mild reaction conditions, easy operation and industrialization prospects; and the prepared star-like nanometer agent has application potential in the fields of CT imaging diagnosis and photothermal treatment of cancers.

Owner:DONGHUA UNIV

Animal hair solvent and preparation method and use of keratin solution

InactiveCN101979428AHigh molecular contentGuaranteed stabilityFibre treatmentAdditive ingredientSulfite salt

The invention discloses an animal hair solvent and the preparation method and use of keratin solution. The solvent is characterized in that tris(2-carboxyethyl)phosphine hydrochloride, tris(2-cyanoethyl)phosphine or trisphosphine is used as a main ingredient and is mixed with 1 to 8 percent of assistant which may be at least one of mercaptoacetic acid, mercaptoethanol, sodium hydrogensulfite, potassium bisulfate, sodium sulfite, potassium sulfite, sodium hypophosphite, ethanol, methanol and urea. The preparation method adopts the following processes: 1, preparing animal hair solution by using the animal hair solvent of the invention; 2, dissolving animal hair in the solution to prepare keratin solution; and 3, adding a proper amount of acid to perform the post-treatment of the keratin solution. The use is to use the keratin solution as textile finishing liquor or the main functional ingredient of the textile finishing liquor.

Owner:TIANJIN POLYTECHNIC UNIV +1

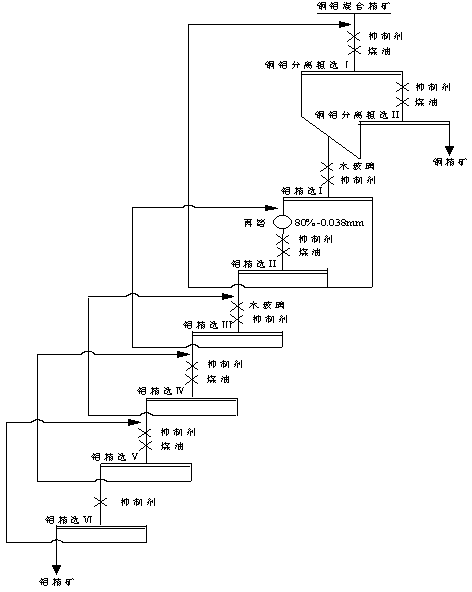

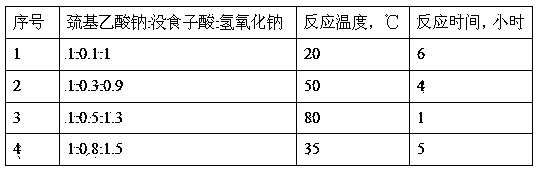

Floatation depressant and methods for preparing and using depressing agent

ActiveCN103949351AEfficient separationOvercoming a large amountFlotationGallic acid esterChemical reaction

The invention relates to a floatation depressant for obtaining molybdenum concentrate and copper concentrate by mineral separation, particularly by separation of copper-molybdenum mixed concentrate, and methods for preparing and using the floatation depressant. The floatation depressant is characterized by being an organic liquid agent obtained through chemical reaction by using mercaptoacetic acid, gallic acid and sodium hydroxide as raw materials. The floatation depressant is the organic liquid agent obtained through the chemical reaction of pyrogallic acid, the mercaptoacetic acid and the sodium hydroxide, and can be used for effectively depressing primary and secondary copper sulfide ores such as copper pyrite and chalcocite, and the copper-molybdenum mixed concentrate can be effectively separated. The defects of large usage of common sodium sulfide, severe operation environment and serious pollution are overcome, and the floatation depressant has the advantages of convenience in addition, safety in use and the like. An effective method which is small in agent usage, convenient to use and low in environmental pollution is provided for the separation of molybdenum copper sulfide mixed concentrate.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY

Thiol-containing compounds for the removal of elements from contaminated milieu and methods of use

InactiveUS20110076246A1Ability to treatLow toxicityBiocideOrganic chemistry methodsRubidiumPotassium

Sulfur-containing ligands and methods of their utilization for binding metals and / or main group elements and removing them from fluids, solids, gases and / or tissues are disclosed. The ligands are of the general structure:where R1 comprises benzene, pyridine, pyridin-4-one, naphthalene, anthracene, phenanthrene or alkyl groups, R2 comprises hydrogen, alkyls, aryls, a carboxyl group, carboxylate esters, organic groups or biological groups, R3 comprises alkyls, aryls, a carboxyl group, carboxylate esters, organic groups or biological groups, X comprises hydrogen, lithium, sodium, potassium, rubidium, cesium, francium, alkyls, aryls, a carboxyl group, carboxylate esters, thiophosphate, N-acetyl cysteine, mercaptoacetic acid, mercaptopropionic acid, thiolsalicylate, organic groups or biological groups, n independently equals 1-10, m=1-6, Y comprises hydrogen, polymers, silicas or silica supported substrates, and Z comprises hydrogen, alkyls, aryls, a carboxyl group, carboxylate esters, a hydroxyl group, NH2, HSO3, halogens, a carbonyl group, organic groups, biological groups, polymers, silicas or silica supported substrates.

Owner:HALEY BOYD E +1

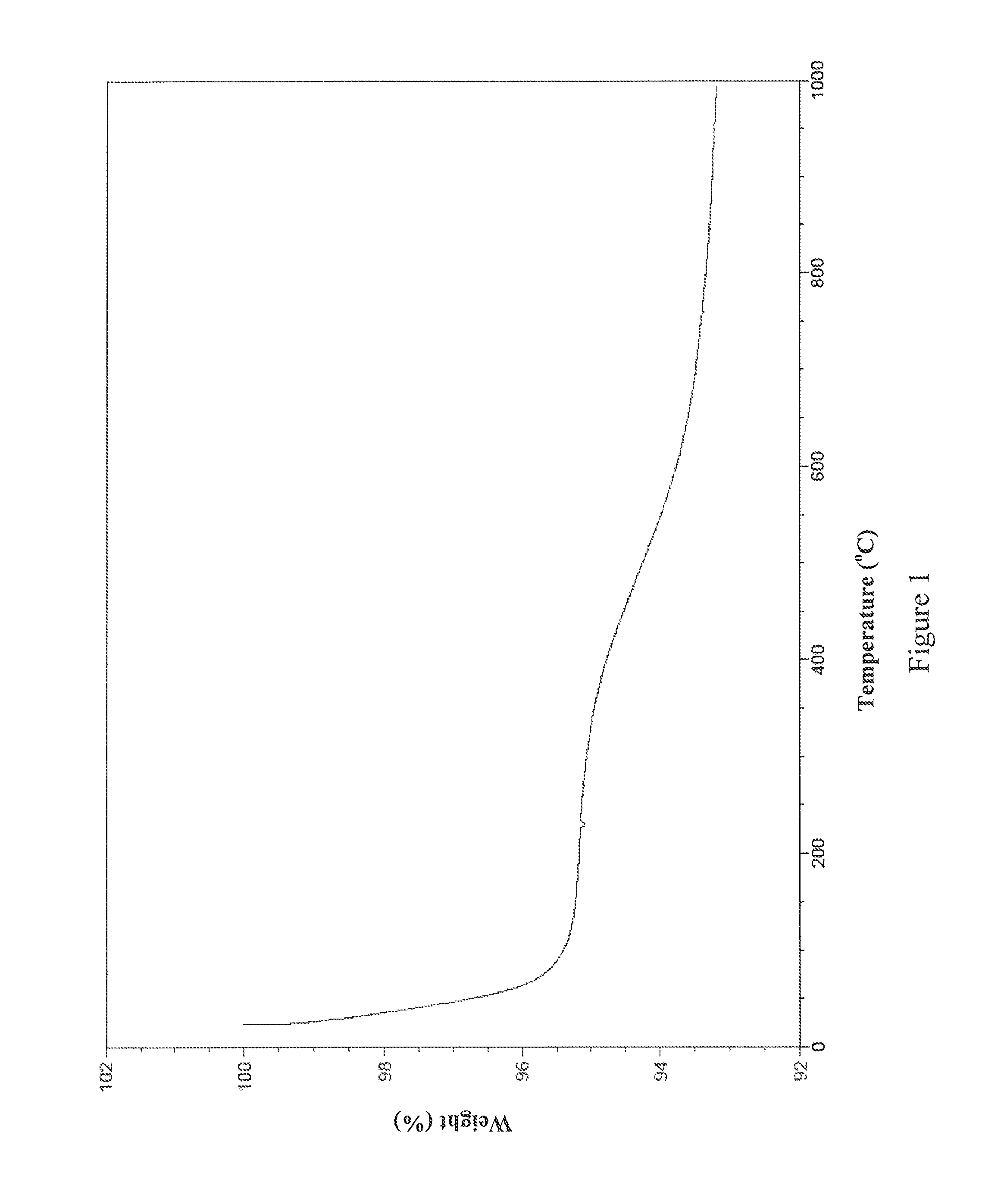

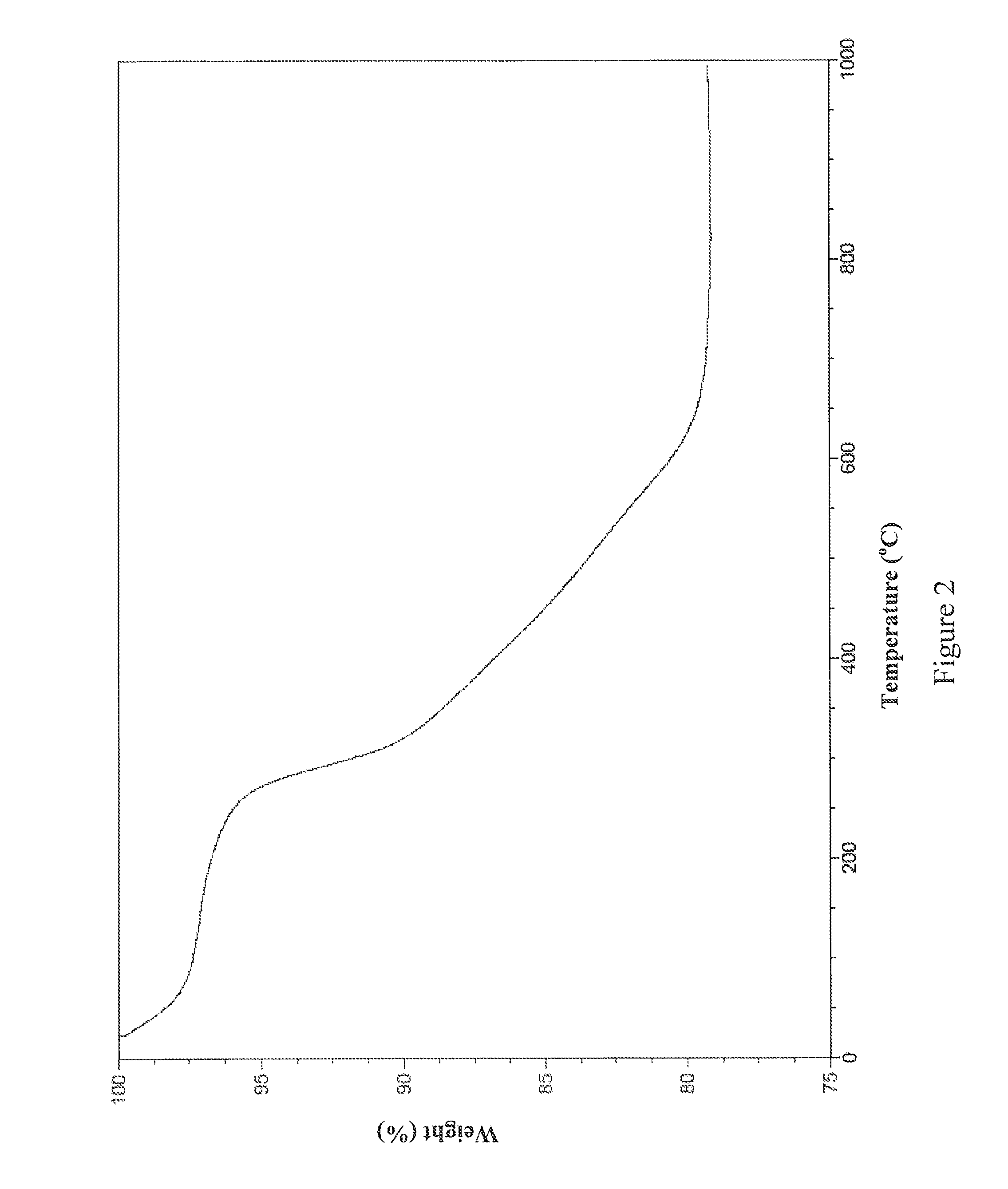

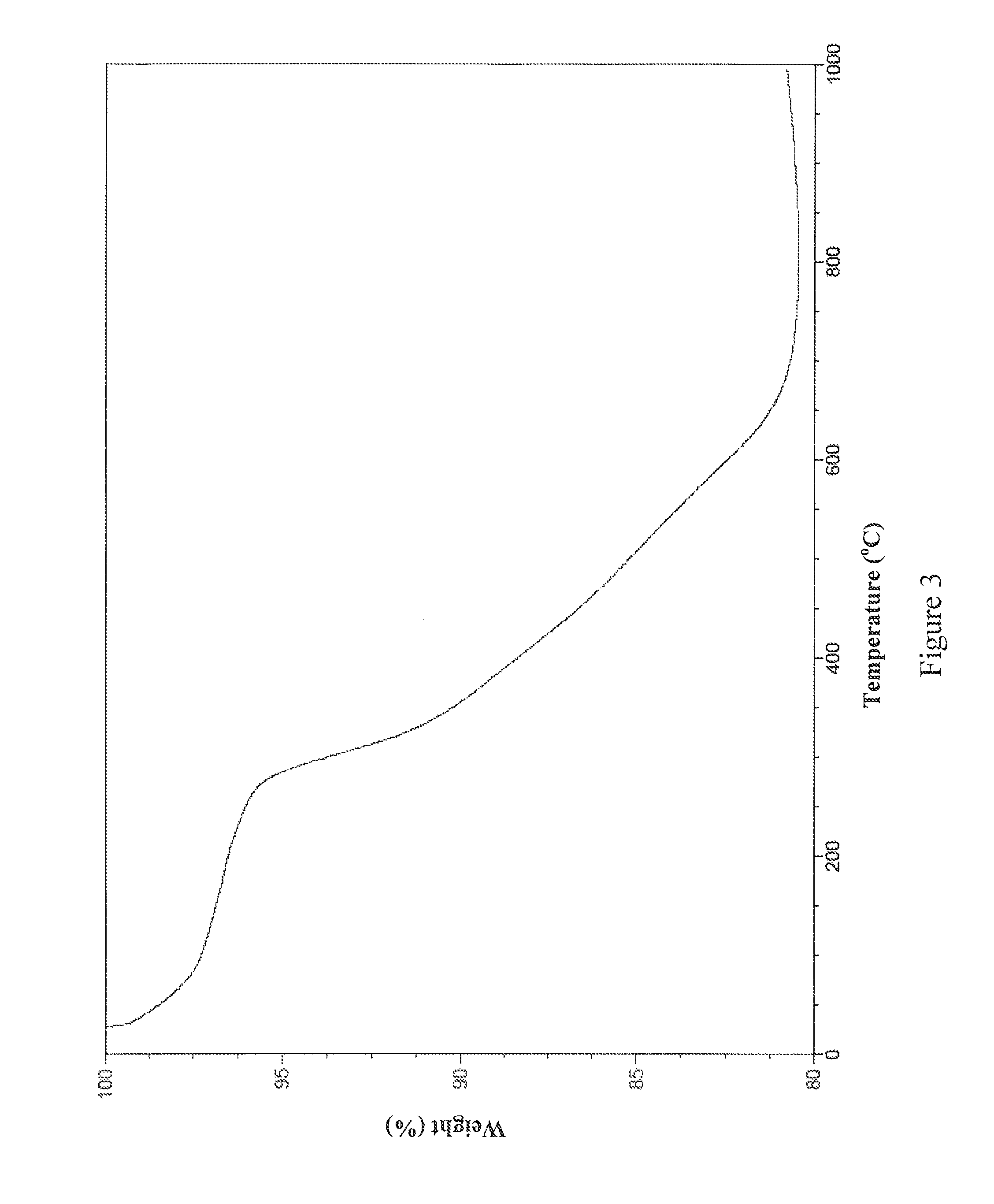

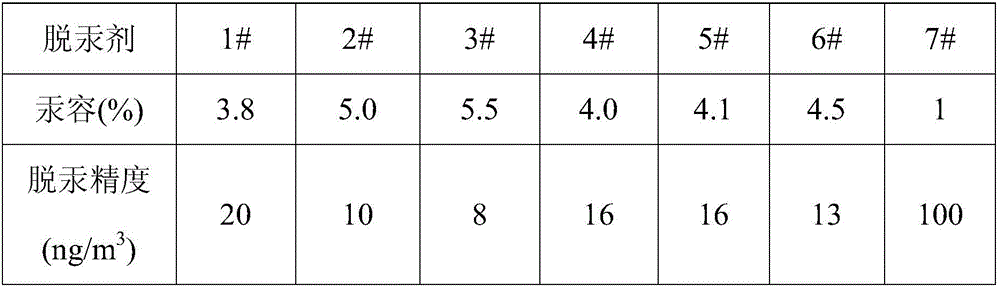

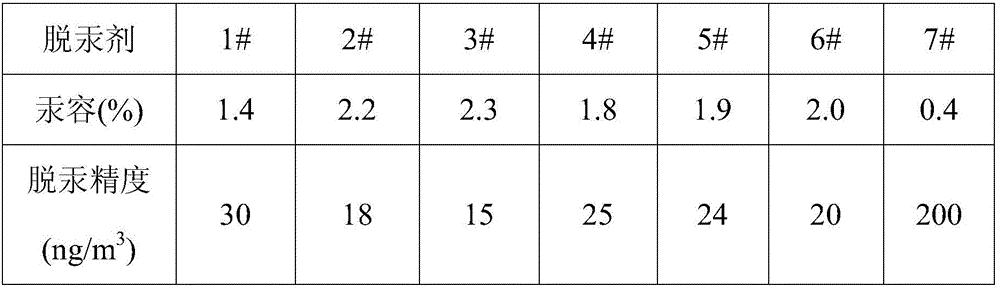

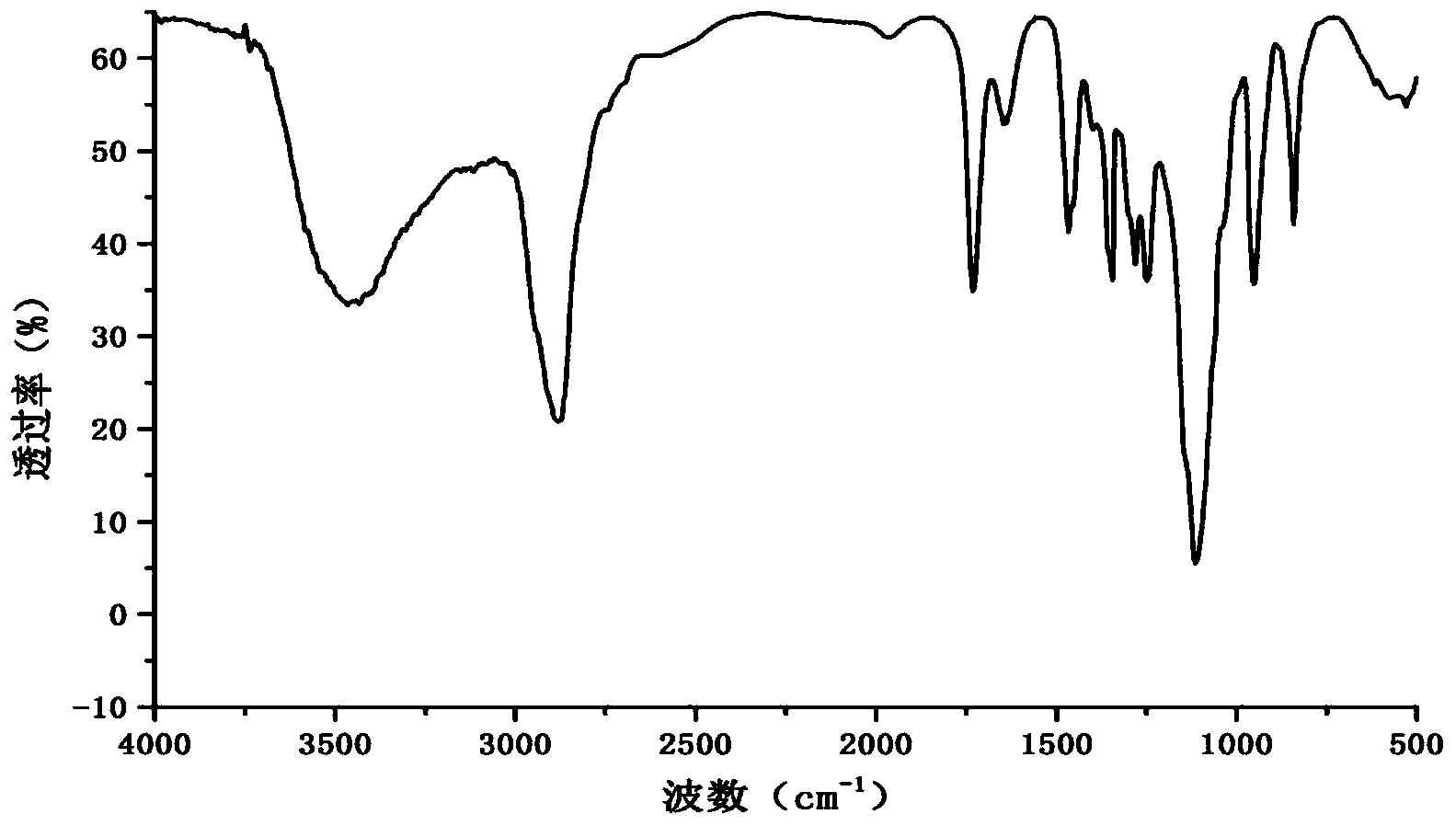

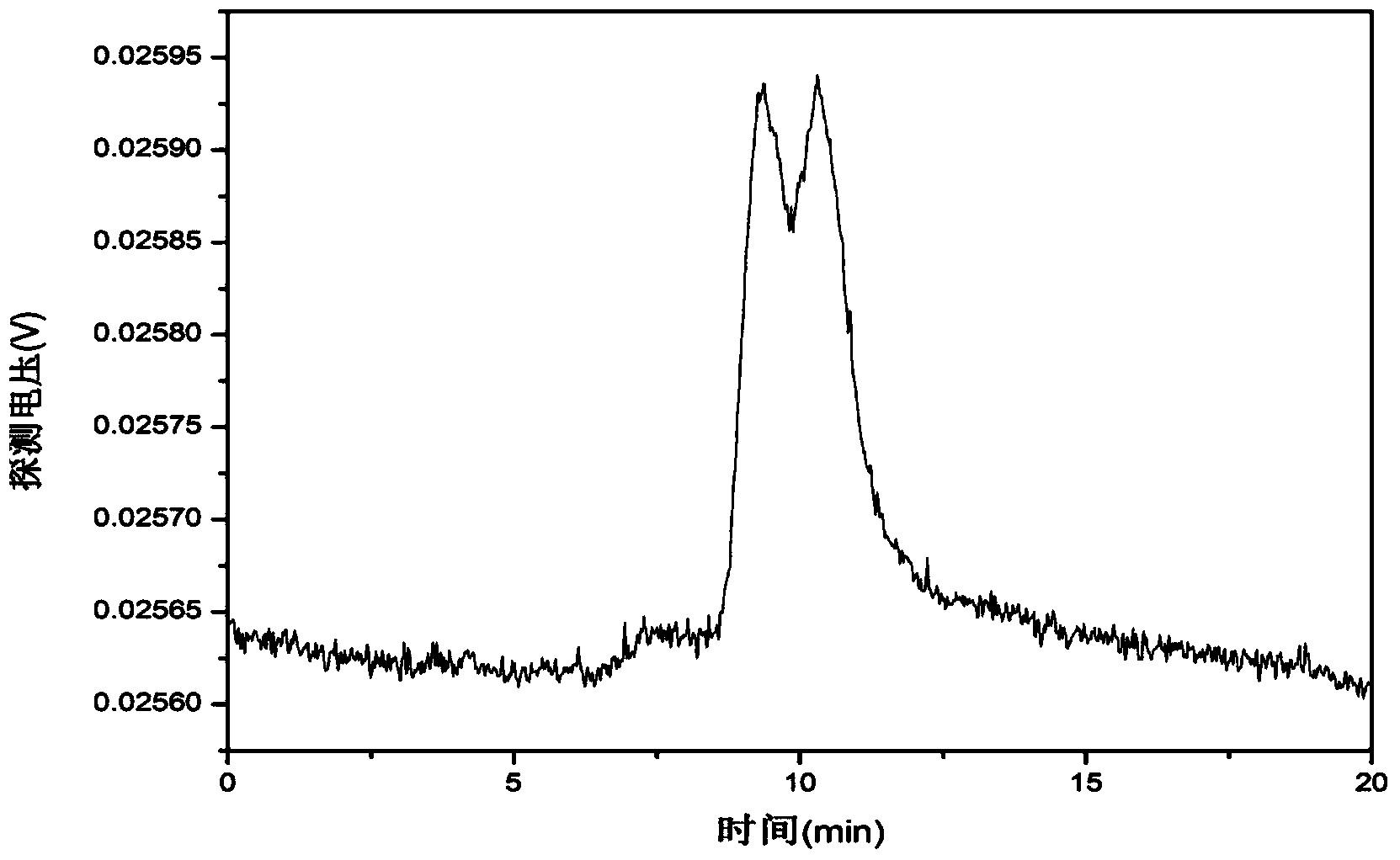

Preparation method and application of sulfhydryl activated carbon mercury removal agent

InactiveCN105771902AMercapto modification achievedPromote esterification reactionGas treatmentOther chemical processesAcetic acidActivated carbon

The invention provides a preparation method of a sulfhydryl activated carbon mercury removal agent.The preparation method comprises the steps that activated carbon is modified by initiatively adopting sulfhydryl modification liquid prepared from mercaptoacetic acid, acetic anhydride and concentrated sulfuric acid, so that hydroxyl on the surface of the activated carbon reacts with mercaptoacetic acid to immobilize sulfhydryl to the activated carbon, and then sulfhydryl activated carbon is prepared.When mercury removal treatment is performed on mercury-containing gas or liquid by adopting the sulfhydryl activated carbon prepared through the preparation method, the sulfhydryl activated carbon shows the relatively high mercury removal precision and mercury penetration capacity, and therefore the sulfhydryl activated carbon prepared through the preparation method can be used as the mercury removal agent.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD

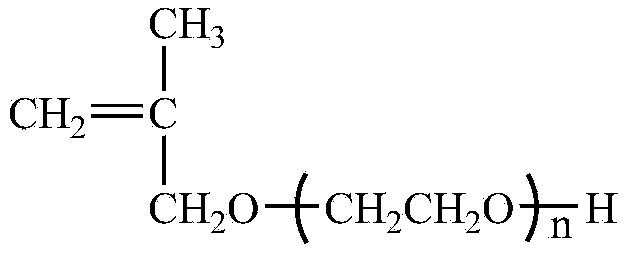

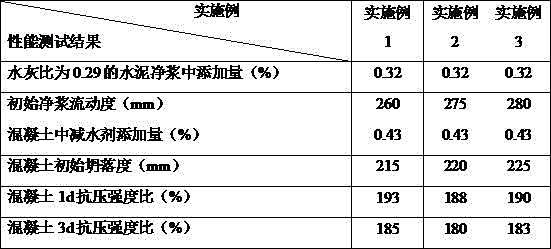

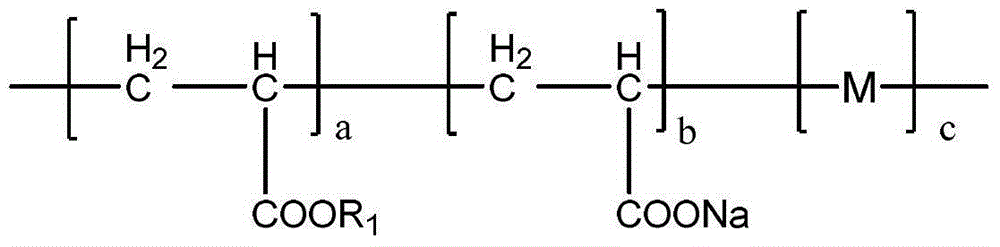

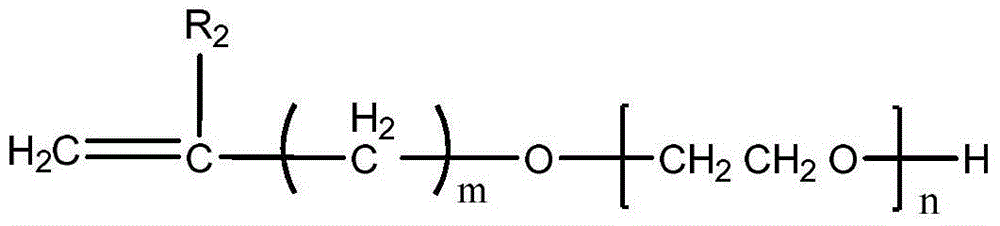

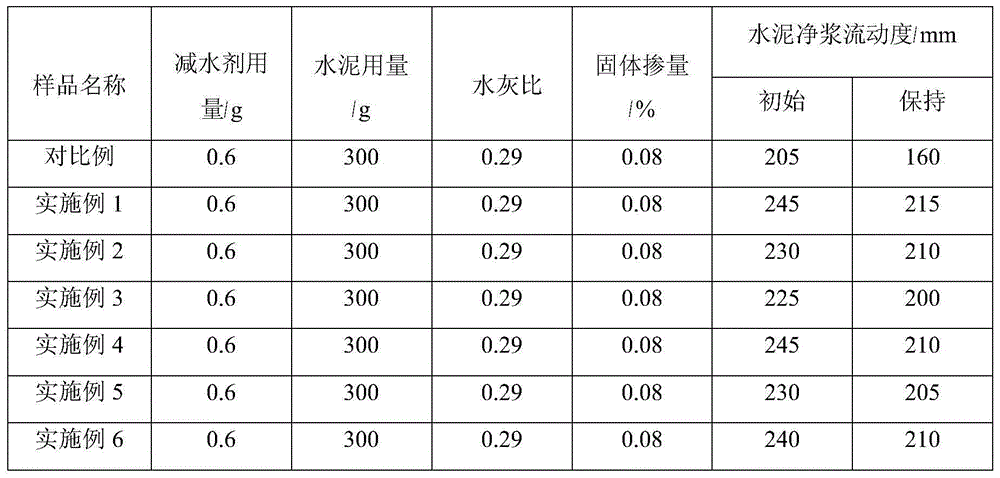

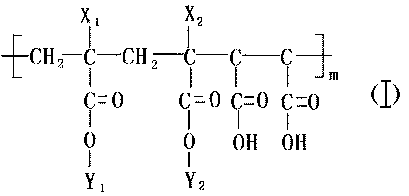

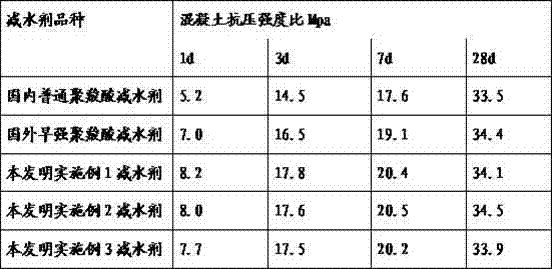

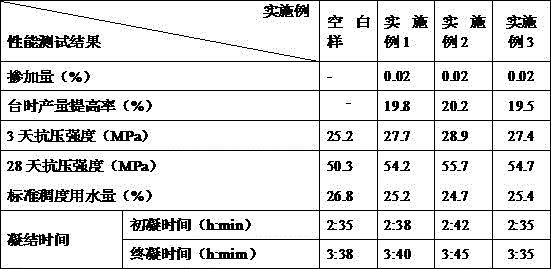

Method for preparing polycarboxylate superplasticizer by combination of polyether macromonomers of two structures

The invention discloses a method for preparing polycarboxylate superplasticizer by the combination of polyether macromonomers of two structures. The method is characterized by comprising the steps that a macromonomer A (methyl allyl polyoxyethylene ether), a macromonomer C (methyl-2-buten-1-ol polyoxyethylene ether) and water are added into a reactor and are stirred, mixed and dissolved at 40-60 DEG C, then small monomers (acrylic acid and the like) are added, mercaptoacetic acid is added, the temperature is increased to be 75-85 DEG C, an ammonium persulfate solution is added dropwise within 70-90min, heat preservation is carried out for 2-3 hours at the 75-85 DEG C to perform polymerization reaction, then materials after reaction are cooled to be at the room temperature, and the materials are neutralized through a sodium hydroxide aqueous solution of the mass percent concentration being 30% until the pH value ranges from 6.8 to 7.2 so as to prepare the polycarboxylate superplasticizer. The macromonomers and the like are combined and copolymerized, the polycarboxylate superplasticizer with high performance is compounded, and balance and performance regulation between slushing and slump retaining of existing polycarboxylate superplasticizer products are facilitated.

Owner:SICHUAN TONGZHOU CHEM TECH +1

Early-strength polycarboxylate type high-performance water reducing agent and preparation method

The invention relates to an early-strength polycarboxylate type high-performance water reducing agent and a preparation method. The early-strength polycarboxylate type high-performance water reducing agent is prepared from methyl allyl polyethenoxy ether, acrylic acid, maleic anhydride, 2-acrylamide-2-methyl propane sulfonic acid, sodium methallyl sulfonate, hydrogen peroxide, ammonium persulfate, L-ascorbic acid, dihydrate sodium formaldehyde sulfoxylate, mercaptoacetic acid, mercaptopropionic acid, sodium hydroxide and water. The newly-stirred concrete added with the water reducing agent has good workability; the water reducing rate can reach 30 percent or more; the 1d pressure-resistant intensity of the concrete can reach 185 percent to 198 percent; the 3d pressure-resistant intensity ratio can reach 176 percent to 187 percent; the concrete setting time is obviously shortened; the early strength of the concrete can be obviously improved; the rustiness effect on steel bars does not exist; no alkali-aggregate reaction occurs; a series of advantages such as concrete structure durability are practically guaranteed; the market prospects are wide. The product is widely applicable to various stages of commodity concrete and high-quality concrete for high-speed railways, high-speed highways, large-scale bridges, prefabricated components, airports, port buildings and the like, and is particularly suitable for being used for various concrete engineering constructions with the early strength requirements and concrete construction in low-temperature environment.

Owner:河南新汉材料科技有限公司

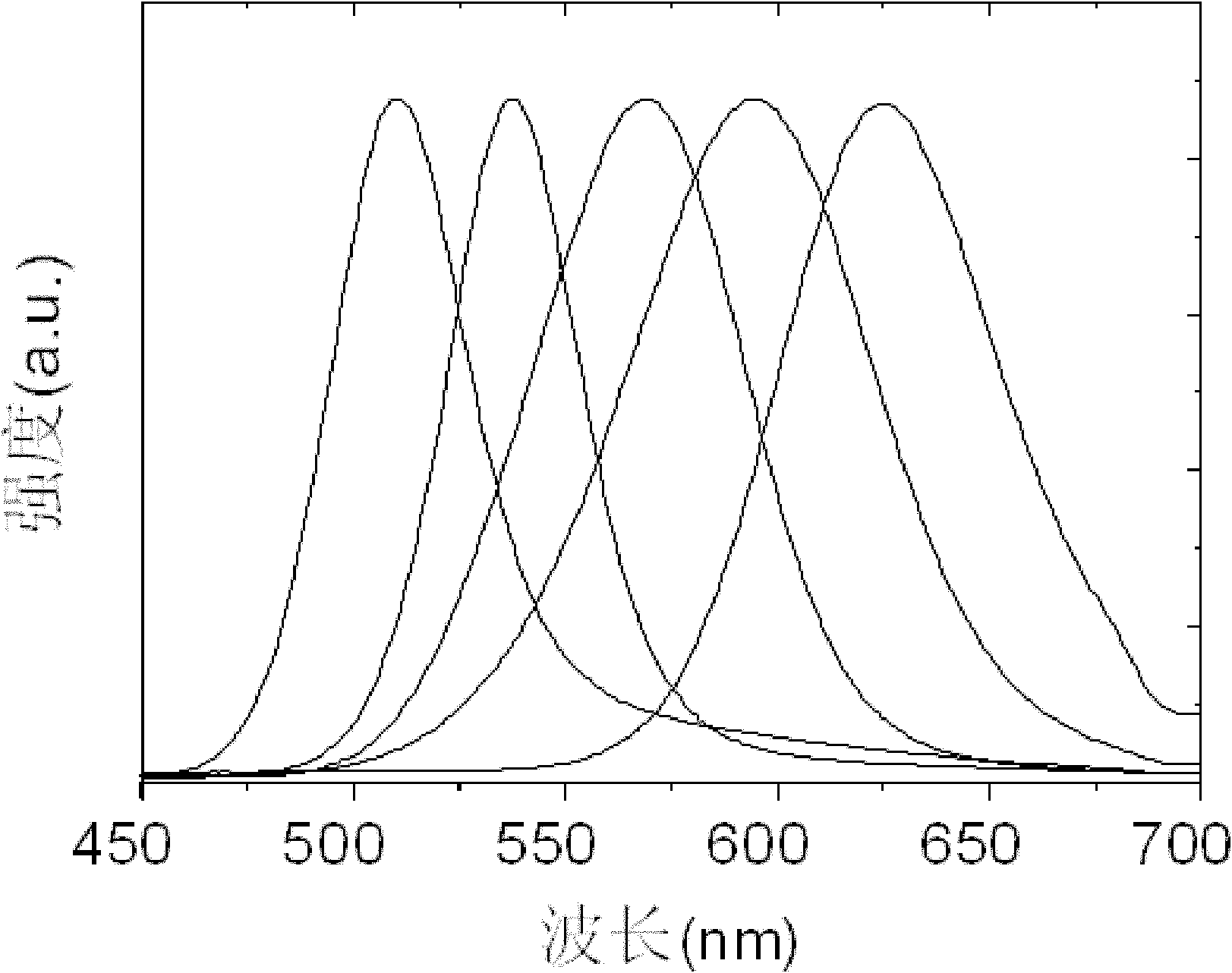

Preparation method of fluorescent submicron particle/complex multicolor fluorescent fibers

InactiveCN102094253AAvoid reunionGood biocompatibilityFilament/thread formingMonocomponent synthetic polymer artificial filamentFiberMicrosphere

The invention relates to a preparation method of multicolor fluorescent fibers, in particular to a preparation method of fluorescent submicron particle / complex multicolor fluorescent fibers. The preparation method comprises the following steps: preparing CdTe quantum dot suspension from ultrapure water, CdCl2.2.5H20, mercaptoacetic acid and a NaHTe aqueous solution; and then adding tetraethoxysilane, ethanol and ammonia water to prepare SiO2-coated CdTe quantum dot microspheres, mixing the microspheres with polyvinyl alcohol to obtain a spinning solution, and then spinning to obtain the fluorescent submicron particle / complex multicolor fluorescent fibers. The preparation method provided by the invention is simple and economic, and the obtained fluorescent submicron particle / complex multicolor fluorescent fibers have the characteristics of uniformly distributed CdTe quantum dots and no conglobation phenomenon; and the fluorescent fibers are uniform in emitted light colors and narrow in fluorescent color distribution under ultraviolet irradiation, and can emit blue, green, yellow, orange or red fluorescent light under the ultraviolet irradiation.

Owner:HEILONGJIANG UNIV

Process for preparing CdTe nanocrystal with high photoluminescent efficiency by hydrothermal technique

InactiveCN1451789AShortened thermal growth cycleImprove product qualityPolycrystalline material growthFrom normal temperature solutionsFluorescencePhotoluminescence

A process for preparing the nano CdTe crystal with high photoluminescent efficiency by hydrothermal technique includes preparing the precursor solution of water-soluble CdTe from CdCl2, NaHTe and mercaptoacetic acid or mercaptopropionic acid or mercaptoglycerine, and crystallizing growth of said solution in stainless steel reactor by heating to 100-200 deg.C, different temps can lead to differentcolors.

Owner:JILIN UNIV

Polymerizable composition for optical material, optical material and method for producing optical material

Disclosed is a polymerizable composition for o an optical material containing tolylene diisocyanate, hexamethylene diisocyanate, and one or more polythiol compounds selected from the group consisting of 4-mercaptomethyl-1,8-dimercapto-3,6-dithiaoctane,4,8-, 4,7- or 5,7-dimercaptomethyl-1,11-dimercapto-3,6,9-trithiaundecane, pentaerythritol tetrakismercaptoacetate, pentaerythritol tetrakismercaptopropionate, 2,5-bis(mercaptomethyl)-1,4-dithiane, bis(mercaptoethyl)sulfide, 1,1,3,3-tetrakis(mercaptomethylthio)propane, 4,6-bis(mercaptomethylthio)-1,3-dithiane and 2-(2,2-bis(mercaptomethylthio)ethyl)-1,3-dithietane.

Owner:MITSUI CHEM INC

Polyvinyl chloride synthetic leather for luggage and manufacturing method thereof

InactiveCN102995450AGood flexibilityHas a natural and comfortable feelPolyureas/polyurethane adhesivesSynthetic resin layered productsSurface layerGlycerol

The invention discloses polyvinyl chloride synthetic leather for a luggage. The leather comprises a surface layer, a foaming layer, a bonding layer and fluffing cloth. The surface layer is slurry prepared from the following raw materials in parts by weight: 40-50 parts of SG-3 PVC (Polyvinyl Chloride) resin, 70-80 parts of SG-5 PVC resin, 30-35 parts of glycerol triacetate, 10-15 parts of epoxidized soybean oil, 20-25 parts of glycerol triglycerate, 5-6 parts of PVC color cream, 1-2 parts of bimercapto iso-octyl acetate di-n-octyl tin, 5-10 pats of zinc oxide and 5-10 parts of modified attapulgite. Through improvement of formula and process provided by the invention, the flexibility of the synthetic leather is enhanced, and the synthetic leather has a natural and comfortable handfeel similar to that of natural leather. The synthetic leather is not easy to damage or tear within 3-5 years, and suitable for use in lug gages.

Owner:HEFEI ANSHAN COATING FABRICS

Preparation method and application of three-dimensional hollow multilevel-structured stannic oxide gas-sensitive material

InactiveCN104118904AHigh sensitivityResponse recovery time is shortMaterial nanotechnologyTin oxidesMicrosphereGas detector

The invention relates to a preparation method and an application of a three-dimensional hollow multilevel-structured stannic oxide gas-sensitive material. The preparation method comprises the following steps: preparing a precursor via a hydrothermal synthesis method by taking carbon microspheres as templates, stannous chloride as a stannum source, mercaptoacetic acid as a surfactant and urea as a precipitant, and roasting so as to obtain the gas-sensitive material with stannic oxide nanosheet self-assembled three-dimensional floriated hollow multilevel structures, wherein the gas-sensitive material is between 300nm and 500nm in diameter. The preparation method is simple in process, low in cost and environment-friendly. According to the method provided by the invention, after the gas-sensitive property of a gas-sensitive sensor prepared from the gas-sensitive material is tested, the results show that a gas-sensitive element has relatively high sensitivity to ethyl alcohol, and the gas-sensitive sensor is short in response time and recovery time, so that the gas-sensitive sensor has high stability. Thus, the gas-sensitive material provided by the invention can be applied to the gas-sensitive sensor for the ethyl alcohol.

Owner:UNIV OF JINAN

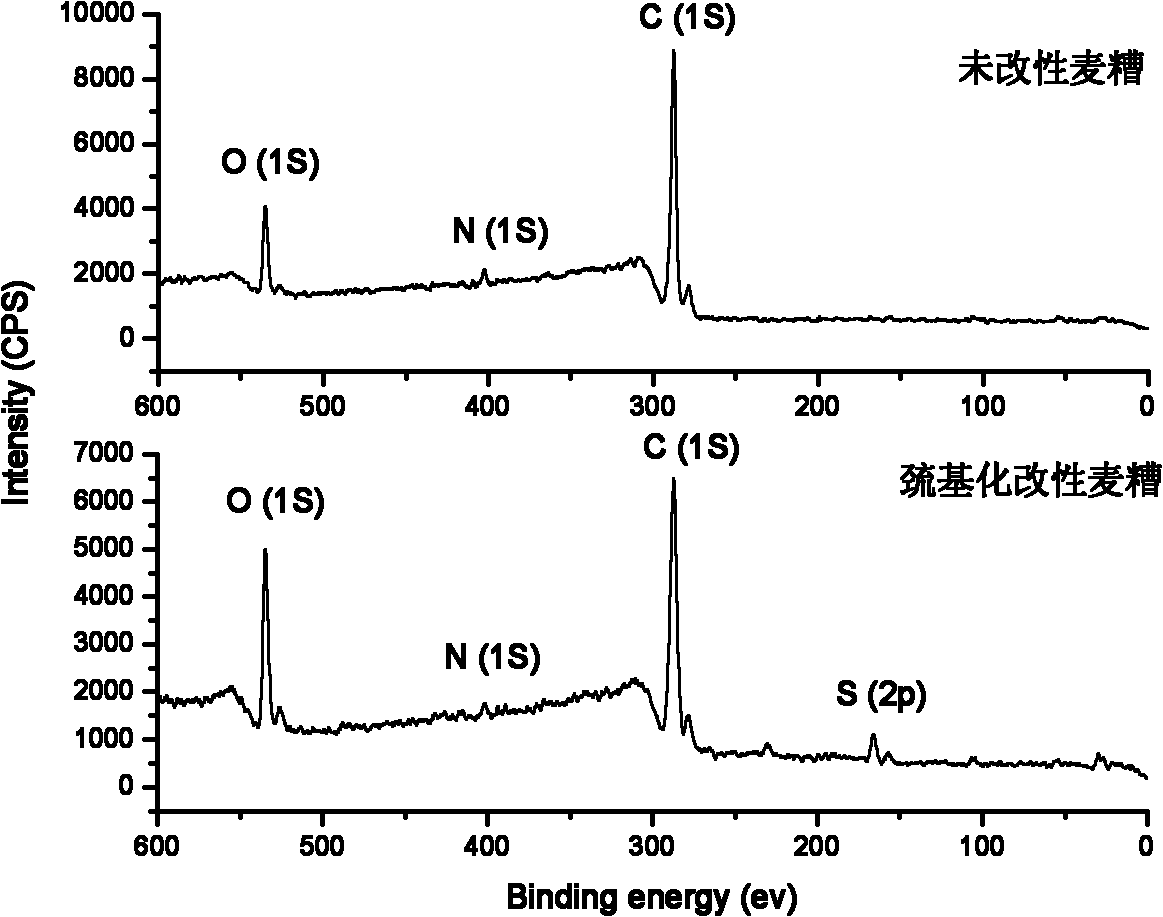

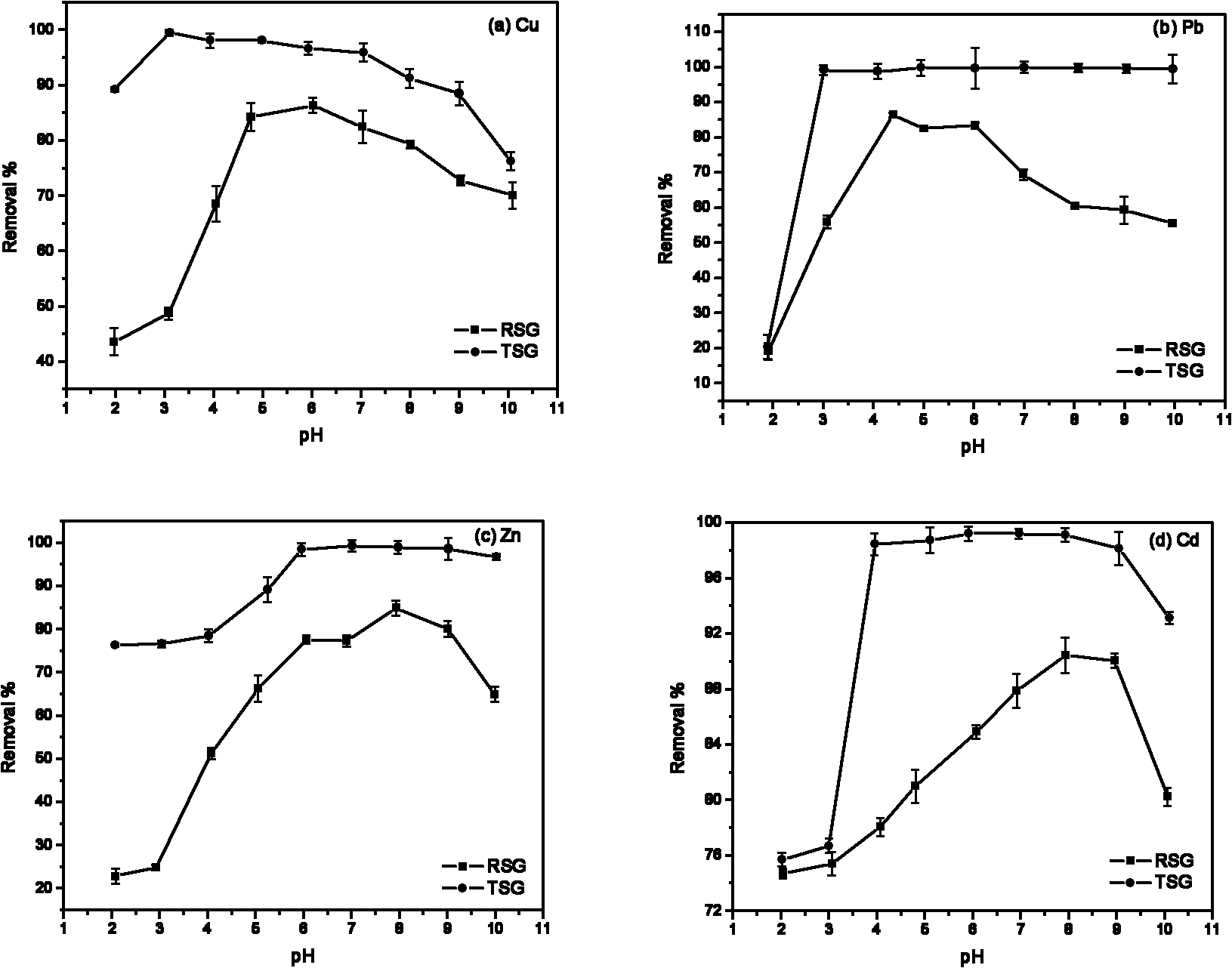

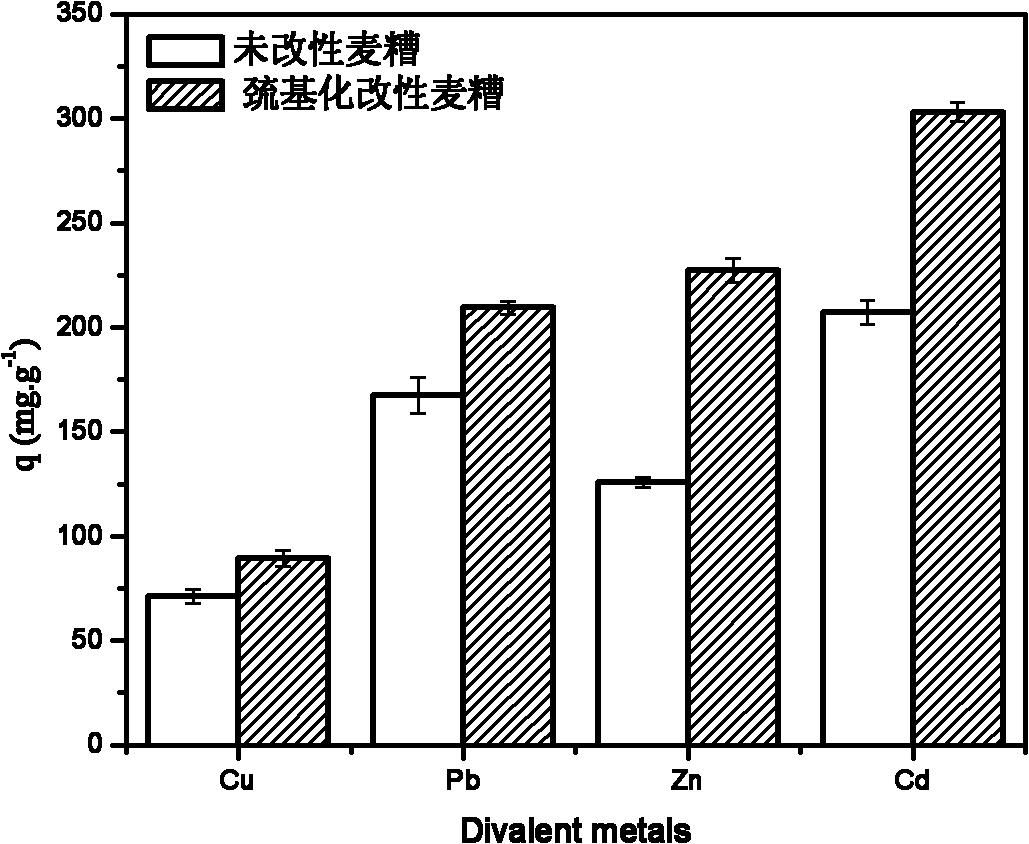

Heavy metal ion adsorbent and preparation and application method thereof

InactiveCN101804330AEasy to handleEasy to operateOther chemical processesWater/sewage treatment by sorptionPtru catalystSorbent

The invention discloses a heavy metal ion adsorbent and a preparation and application method thereof. Spent grain is adopted as material, mercaptoacetic acid is chosen as reagent for mercaptolation, NaHSO4.H2O is adopted as catalyst, N,N-dimethylformamide is adopted as reaction medium, mercaptolation is carried out, Na2S.9H2O is then added as reducing agent, aqueous ethanol is adopted as reaction medium, reduction reaction is carried out, and thereby the adsorbent is produced. Compared with the conventional sulfhydryl cotton preparation method, the method has the absolute advantages of high efficiency and quickness. The mercaptolated spend grain is rich in ester functional groups and mercapto functional groups, and can be used for the treatment of heavy metal wastewater. When the mercaptolated spend grain is used for treating mixed heavy metal wastewater containing Cu2 plus, Pb2 plus, Zn2 plus and Cd2 plus ions, effluent can meet National Integrated Wastewater Discharge Standard (GB8978-1996). The mercaptolated spend grain can be reused for at least three times, and therefore has a good application value.

Owner:CENT SOUTH UNIV

Environment-friendly waterproof and double-shielding control cable material and preparation method thereof

InactiveCN102911504AReasonable formulaEasy to prepareInsulated cablesInsulated conductorsPolymer scienceTriallyl isocyanurate

The invention discloses an environment-friendly waterproof and double-shielding control cable material and a preparation method thereof, materials in terms of parts by weight are: a mixture A: 30-40 parts of methyl vinyl silicone rubber, 10-20 parts of chloroprene rubber, 1-3 parts of semi-reinforcing carbon black, 40-60 parts of modified montmorillonite powder, 1-3 parts of ECHO.A mercapto thiadiazole derivative, 1.5-2.5 parts of triallyl isocyanurate, 1-3 parts of zinc stearate, 3-4 parts of chlorinated paraffin, 10-20 parts of magnesium hydrate and 1-3 parts of octyl ester; a mixture B: 20-30 parts of polypropylene resin, 35-55 parts of chlorinated polyethylene, 25-35 parts of ethylene-vinyl acetate copolymer, 20-30 parts of ethylene vinyl acetate, 0.3-0.5 parts of poly-4-methyl-1-amylene, 2-4 parts of anti-aging agent OD, 2-3 parts of cross-linking agent TAIC (triallyl isocyanurate), 1-3 parts of phenolic resin, 25-35 parts of talcum powder and 1-3 parts of dimethyl dimercapto tin isooctyl. The control cable material has simple preparation method and rational proportion, and drastically improves performance such as tensile strength, elongation at break, tensile strength retention rate and elongation at break retention rate after aging, and impacts brittle temperature performance while obtains excellent performances.

Owner:东莞市富庆电子线材有限公司

Polycarboxylate water reducer containing modified water-soluble acrylate and preparation method thereof

The invention provides a polycarboxylate water reducer containing modified water-soluble acrylate and a preparation method thereof. The preparation method comprises the following steps: firstly, directly carrying out esterification reaction on polyhydroxy-alcohol carbohydrates and crylic acid so as to prepare modified water-soluble acrylate micromonomers; then putting polyether macromonomers into deionized water, and fully dissolving so as to prepare a reaction base solution; dissolving the acrylate micromonomers, crylic acid, an initiator vitamin C and a chain transfer agent mercaptoacetic acid into deionized water, so as to prepare drop concentrate; putting an initiator hydrogen peroxide into the reaction base solution, dropwise adding the drop concentrate into the reaction base solution at a constant speed, reacting while stirring, then regulating the pH value of the solution to be 7-8, so as to prepare the polycarboxylate water reducer. According to the preparation method, the regulating function of the polyhydroxy-alcohol carbohydrates is directly used in the water reducer, so that the property of the water reducer is optimized; the polycarboxylate water reducer prepared by the method has high water reducing rate, and the concrete is obviously improved in fluidity retainability and has less slump loss, so that the water reducer can meet higher construction requirements.

Owner:SHANXI UNIV +1

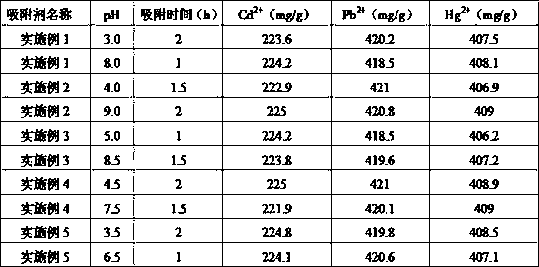

Preparation method and application of bagasse mercapto-biosorbent

InactiveCN103191703AImprove adsorption capacityHas sulfhydryl propertiesOther chemical processesWater/sewage treatment by sorptionAcetic acidFiltration

The invention discloses a preparation method and an application technology of a bagasse mercapto-biosorbent. The preparation method is characterized by comprising the following steps of: adding 35-45wt% of mercaptoacetic acid, 18-25wt% of tetrahydrofuran, 12-22wt% of alkalized bagasse and 0.15-1.0wt% of concentrated sulphuric acid in a triangular flask with a plug, performing a sealed room-temperature reaction for 2-4 hours, and adding 8-18wt% of sodium sulphide and 8-18wt% of water, wherein the sum of the percentages of all the components is 100%; plugging, and performing a static reaction for 48-60 hours at 40-45 DEG C; and then washing with deionized water, performing suction filtration until the filtrate is neutral, washing by a small amount of ethanol, placing in an oven at 55-65 DEG C and drying, so as to obtain the bagasse mercapto-biosorbent, wherein the bagasse mercapto-biosorbent is high in adsorption capacity for Cd2, Pb<2+> and Hg<2+>, fast in adsorption speed, good in physicochemical stability and mechanical stability, strong in regeneration capacity, high in repeated use times, low in cost, and capable of utilizing agricultural waste.

Owner:UNIV OF JINAN

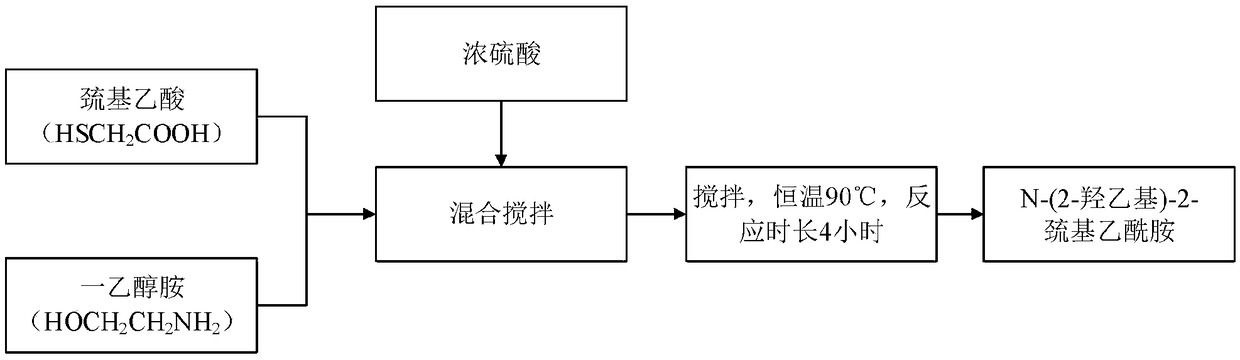

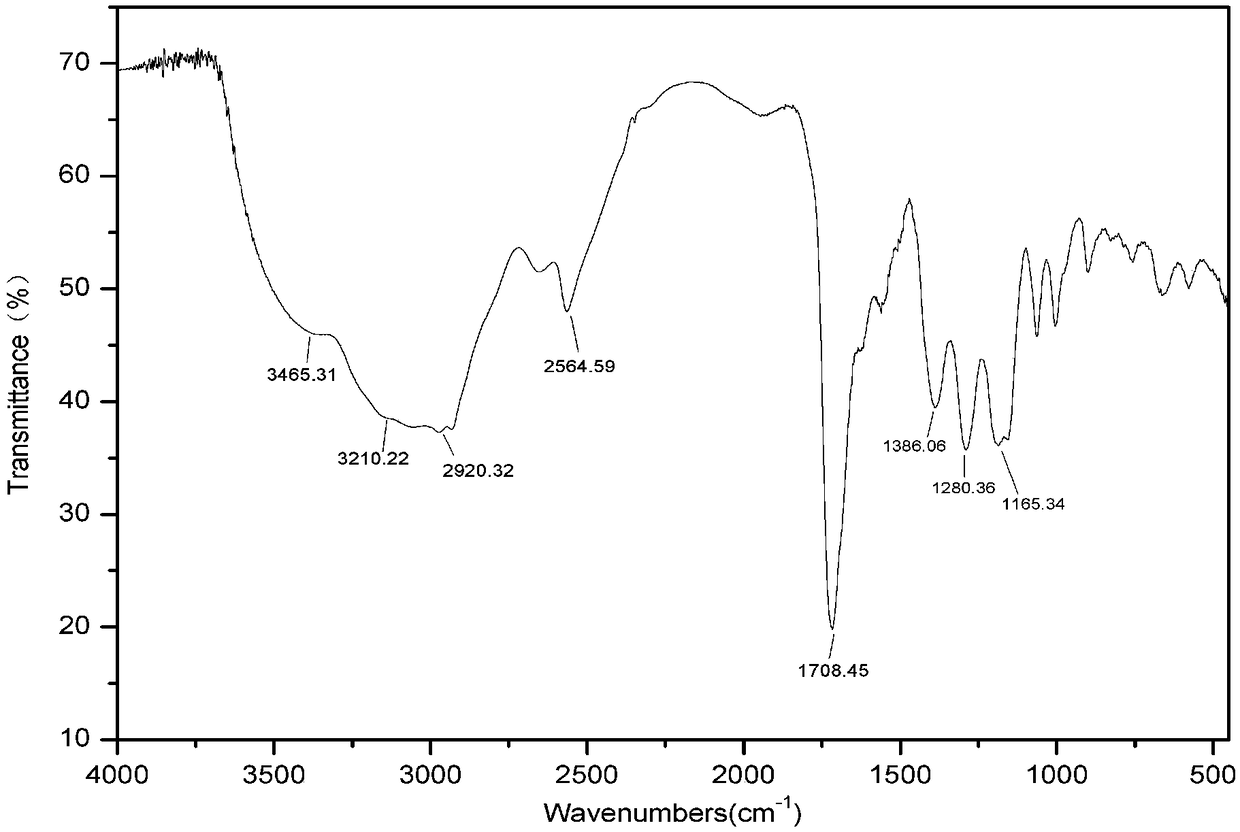

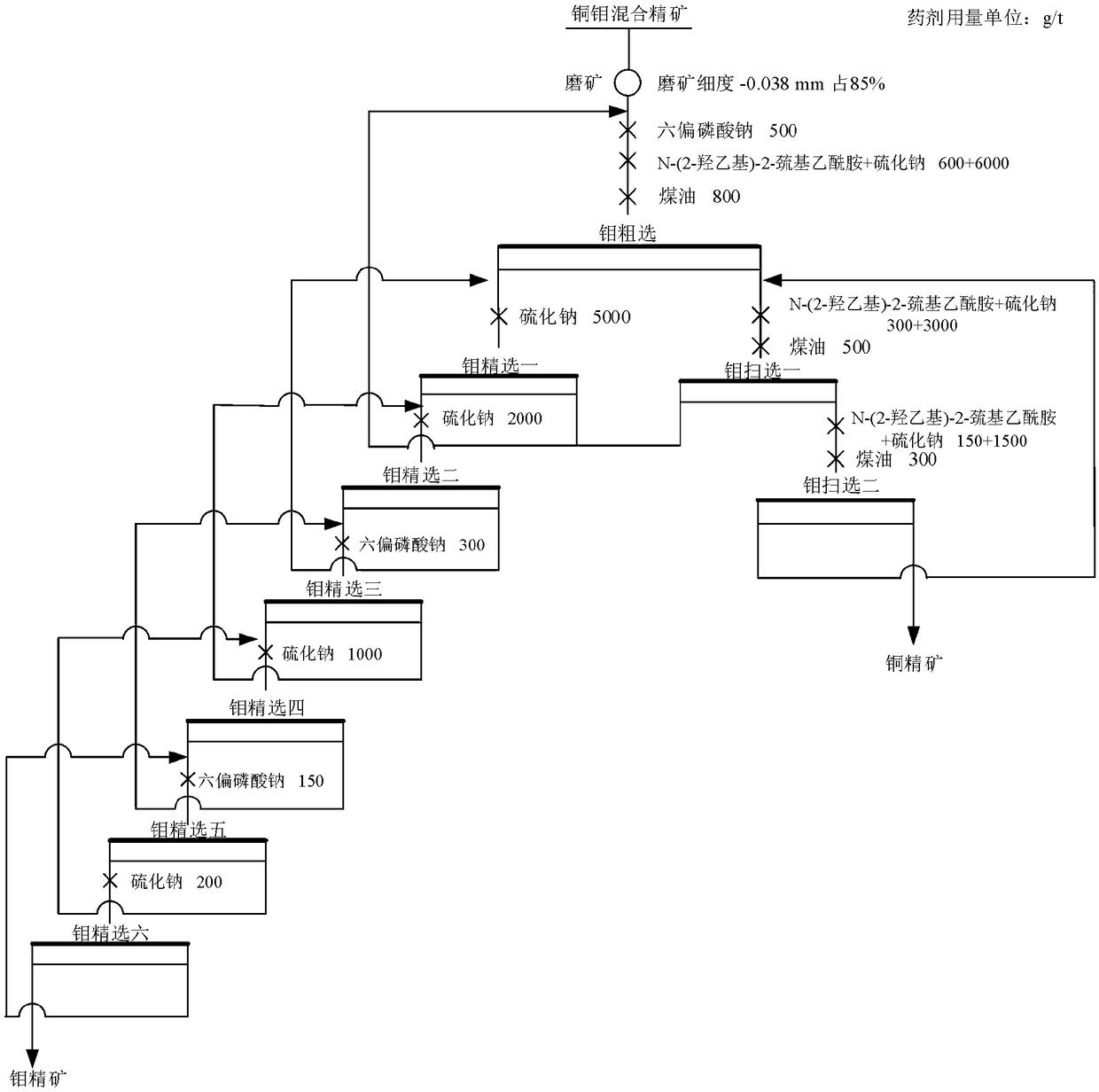

Preparation and application of copper-molybdenum separation inhibitor

The invention relates to preparation and application of a copper-molybdenum separation inhibitor. The preparation method of the inhibitor comprises the following steps that under a catalytic stirringcondition, the reaction of mercaptoacetic acid with monoethanolamine is carried out at the temperature of 90-100 DEG C, the reaction time is 4-5 hours, and the copper-molybdenum separation inhibitor,specially, N-(2-hydroxyethyl)-2-mercaptoacetamide which is subjected to dehydration condensation kneading is obtained; the application of the prepared copper-molybdenum separation inhibitor is characterized in that the copper-molybdenum separation inhibitor is applied to flotation separation of copper-molybdenum mixed concentrate, the N-(2-hydroxyethyl)-2-mercaptoacetamide is prepared, and strongparent-mine polar group (-SH) and hydrophilic polar group (-OH and -CONH) are provided, so that the copper ore can be effectively inhibited, and the copper and molybdenum separation is achieved; the inhibitor is simple in preparation method, remarkable in inhibition effect, less in use amount, free of pungent smell, stable in property, safety in addition and convenient to use; and the N-(2-hydroxyethyl)-2-mercaptoacetamide is matched with sodium sulfide to use so that the synergistic effect can be brought into full play, the copper-molybdenum separation precision is improved, and the method isparticularly suitable for flotation separation application of molybdenite and copper sulfide ore in the copper-molybdenum mixed concentrate.

Owner:ZIJIN MINING GROUP +2

Preparation and application of morphology-adjustable hollow cage-shaped Mn/Fe oxide nano material

ActiveCN108722433AShape is easy to controlReduce pollutionMaterial nanotechnologyWater contaminantsManganesePotassium ferricyanide

The invention belongs to the field of material science and environment engineering and in particular relates to preparation and application of a morphology-adjustable hollow cage-shaped Mn / Fe oxide nano material. The preparation comprises the following steps: enabling PVP (Polyvinyl Pyrrolidone), ferric sulfate, manganese sulfate, a solution system of ethanol and water, and a potassium ferricyanide solution to react at a room temperature so as to obtain a prussian blue like precursor with Mn / Fe of different morphologies; further etching the precursor with mercaptoacetic acid (TGA) so as to obtain a hollow Mn / Fe prussian blue nano material; finally calcining, thereby obtaining a hollow Mn / Fe oxide nano material. The hollow Mn / Fe oxide nano material provided by the invention is simple in synthesis process, low in cost, high in yield, green and environmentally friendly, bisphenol A pollutants can be effectively removed and can be recycled, a simple, convenient and efficient method is provided for treatment on phenol pollutants, good economic benefits and environment benefits can be achieved, and large-scale production application can be carried out.

Owner:FUZHOU UNIV

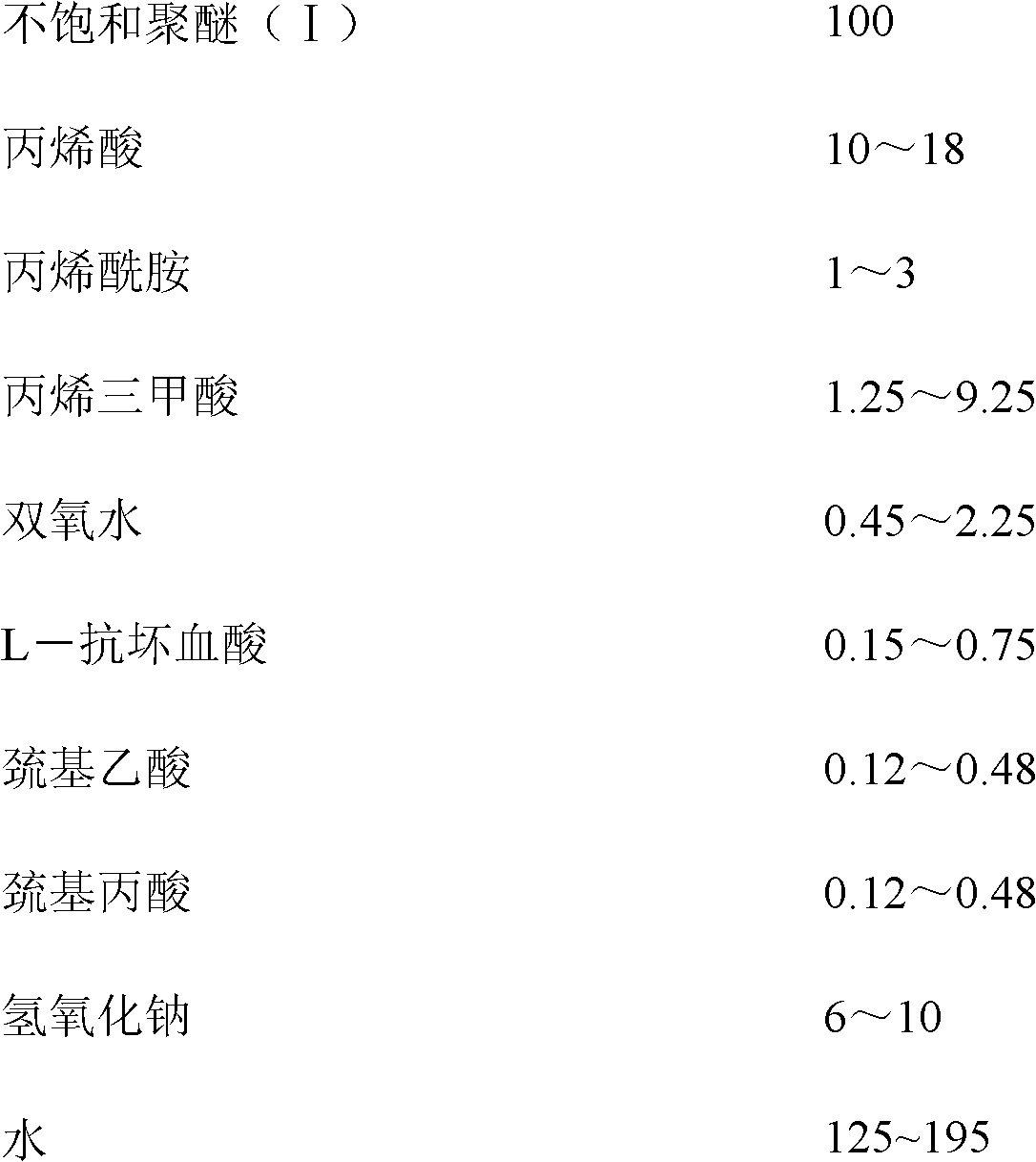

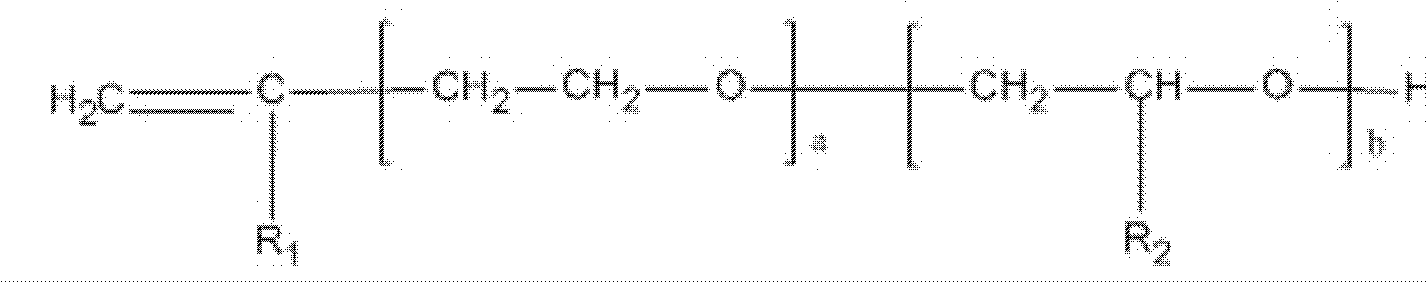

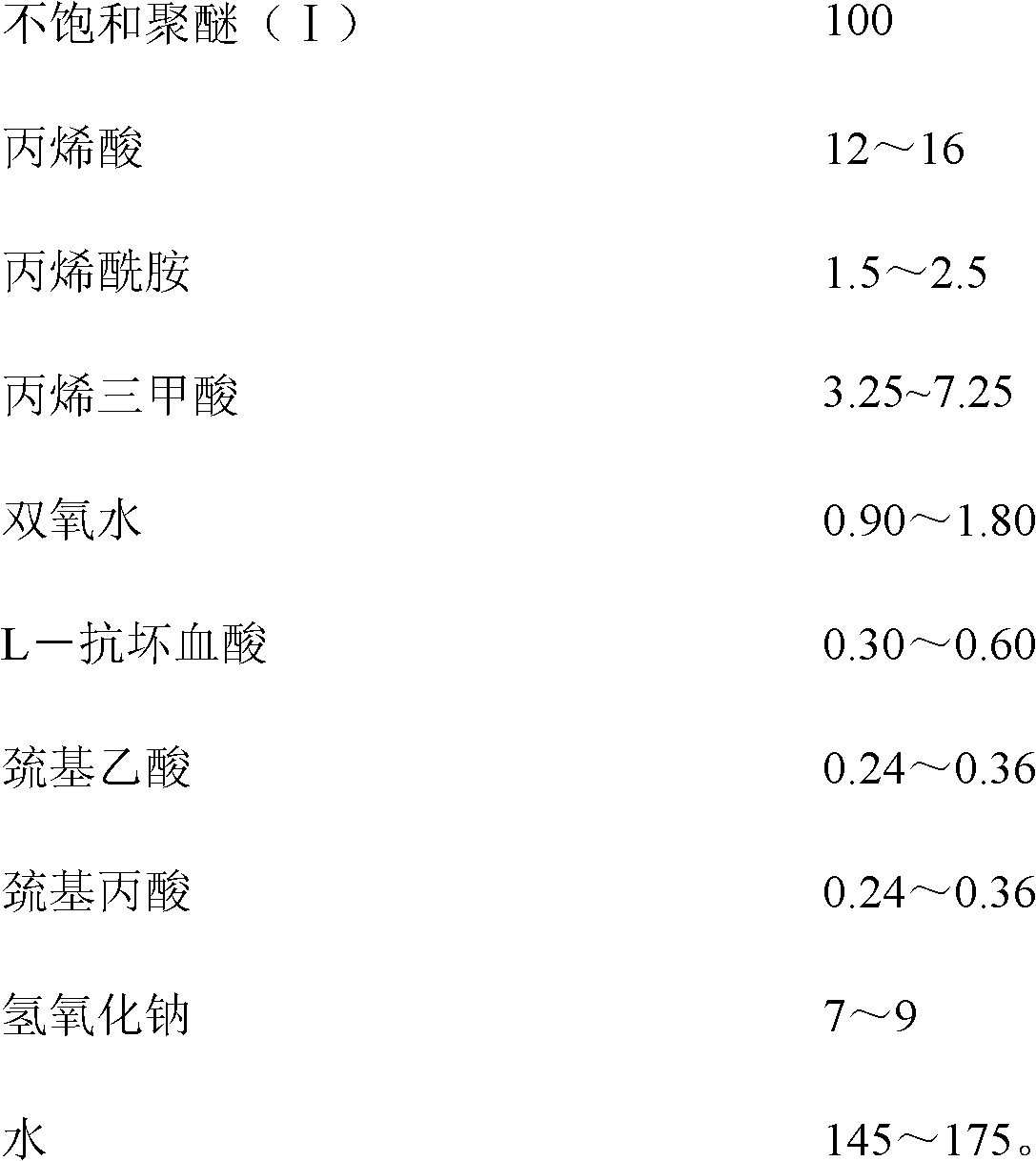

Polycarboxylic acid-series water reducing agent with ultrahigh water absorbing capacity and preparation method and use method thereof

The invention discloses a polycarboxylic acid-series water reducing agent with ultrahigh water absorbing capacity and a preparation method and a use method thereof, belonging to the technical field of building materials. The water reducing agent consists of the following raw materials in parts by weight: 100 parts of unsaturated polyether (I), 10-18 parts of acrylic acid, 1-3 parts of acrylamide,1.25-9.25 parts of aconitic acid, 0.45-2.25 parts of hydrogen peroxide, 0.15-0.75 part of L-ascorbic acid, 0.12-0.48 part of mercaptoacetic acid, 0.12-0.48 part of mercaptopropionic acid, 6-10 parts of sodium hydrate and 125-195 parts of water. The invention provides a polycarboxylic acid-series water reducing agent having the advantages of simple process, convenience for operating, low raw material cost and ultrahigh water absorbing capacity, a preparation method and a use method. Self-made unsaturated polyether (I) DD-405 is used for replacing methyl allyl polyethenoxy ether, so that the raw material supply market of the polycarboxylic acid-series water reducing agent is expanded, raw material cost is reduced, and raw material price is stabilized. The polycarboxylic acid-series water reducing agent is suitable for construction projects of high-rise buildings, large-span bridges, marine drilling platforms, tunnels, dams and airports.

Owner:SHANGHAI DONGDA CHEM

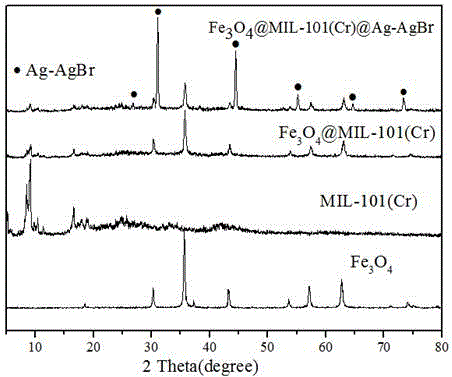

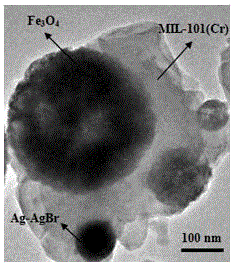

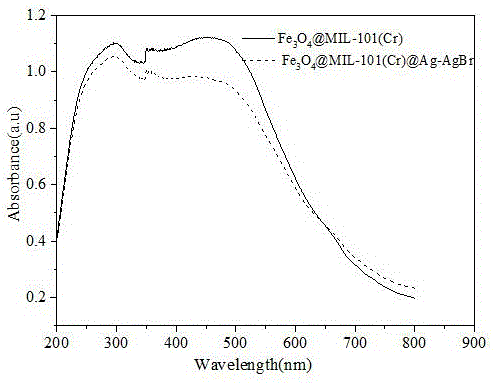

Visible-light response magnetic compound photocatalytic material and preparation method thereof

InactiveCN105728051AExcellent visible light catalytic degradation of pollutantsWater/sewage treatment by irradiationWater treatment compoundsMagnetite NanoparticlesMetal-organic framework

The invention discloses a visible-light response magnetic compound photocatalytic material and a preparation method thereof. The material is Fe3O4@MIL-101 (Cr)@Ag-AgBr. The preparation method comprises the following steps: firstly, preparing mercaptoacetic acid modified Fe3O4; adding the modified Fe3O4 to an alkali MIL-101(Cr) precursor solution and in-situ preparing a magnetic metal organic framework material Fe3O4@MIL-101(Cr) through a simple hydrothermal method; and utilizing a coprecipitation-photo-reduction method to load Ag-AgBr to the prepared Fe3O4@MIL-101(Cr), thereby acquiring a target product. The compound material prepared according to the method provided by the invention has the magnetic property of magnetic nanoparticles and excellent visible light catalytic pollutant-degradation capability and can be applied as an excellent photocatalytic material for removing environmental pollutants in a light degradation manner. An externally applied magnetic field can be adopted for simply recycling the photocatalytic material.

Owner:FUZHOU UNIV

Method for preparing doping type hexagonal system nano ZnS at low temperature

InactiveCN102079541ALow costFacilitate the realization of large-scale industrial productionZinc sulfidesNanotechnologySemiconductor materialsActive agent

The invention provides a method for preparing doping type hexagonal system nano ZnS at a low temperature, belonging to the field of semiconductor materials. The method is characterized in that transition metal and rare earth-doped hexagonal system nano ZnS is synthesized by a reversed micelle method at the temperature of less than 100 DEG C, wherein an oil phase is an organic solvent, a water phase is a zinc salt aqueous solution, N,N-dimethylformamide is used as the solvent, a zinc salt is used as an zinc ion source, thiourea serves as a sulphur ion source, and mercaptoacetic acid serves as a surface active agent; and the heating temperature is controlled by an oil bath, and the whole reaction is carried out in the air, and any air isolating measure is not needed. The method is simple tooperate, the required reactions are carried out in a liquid phase, subsequent high-temperature annealing treatment is not needed, and reaction conditions are mild; and the method is energy-saving andenvironment-friendly, and an economically feasible way is provided for producing the hexagonal system nano ZnS with high stability and good water solubility on large scale.

Owner:UNIV OF SCI & TECH BEIJING

Soil heavy metal passivator and preparation method thereof

InactiveCN103980907AHas the effect of passivating metal cadmiumSimple methodOrganic fertilisersSoil conditioning compositionsAcetic acidSoil science

The invention relates to a soil heavy metal passivator and a preparation method thereof and belongs to the technical field of soil improvement. The soil heavy metal passivator comprises humin and sulfhydrylation humin; the preparation method of the soil heavy metal passivator comprises that humin is extracted from peat soil and subjected to sulfhydrylation for obtaining the sulfhydrylation humin, and the preparation method of the soil heavy metal passivator comprises three concrete steps of pre-treating the peat soil, extracting humin and carrying out sulfhydrylation on the humin, namely carrying out air drying on the peat soil, sieving, weighing defined amount of the peat soil and mixing with sodium hydroxide solution, placing mixture on a shaking table and vibrating, standing, centrifuging and separating, washing, and carrying out air drying, so that crude humin (HM) is obtained; adding a mixed solution of mercaptoacetic acid, acetic anhydride and acetic acid, a concentrated sulphuric acid solution and the crude humin in proportion, stirring, cooling, carrying out reaction in a water bath, washing, and carrying out air drying, so that the sulfhydrylated humin is obtained. The preparation method of the soil heavy metal passivator is simple, a technology is novel; the prepared soil heavy metal passivator can increase passivation rate of Cd in polluted soil and also can be intensively combined with soil particles, migration of the passivator is reduced, and the soil heavy metal passivator is energy-saving and environmentally friendly and is applicable to large-scale popularization.

Owner:GUANGDONG UNIV OF TECH

Hyperdispersant and preparation method thereof

InactiveCN103071426AThe synthesis and preparation process is simpleLow costTransportation and packagingMixingMercaptoacetic acidMaleic anhydride

The invention discloses a hyperdispersant and a preparation method thereof. A molecular chain of the hyperdispersant comprises acrylic acid, methylacrylic acid and maleic anhydride which are copolymerized, and the molecular weight is 3,000-30,000 g / mol. The hyperdispersant is simple to prepare, short in preparation cycle and low in cost; the prepared hyperdispersant is superior in dispersion capacity; isopropanol is adopted as a chain transfer agent in copolymerization reaction in the process of preparing the dispersant, so that the non environmental protection property due to the adoption of mercaptoacetic acid as the chain transfer agent in the past is avoided; and the produced hyperdispersant is nontoxic and harmless, and accords with the green production concept.

Owner:JIAOZUO BOYANG TECH

Method for preparing sulfydryl lignocelluloses-montmorillonoid compounded magnetic biomass adsorbent

InactiveCN106984282AImprove propertiesImprove adsorption capacityOther chemical processesWater contaminantsEpoxyCross-link

The invention discloses a method for preparing a sulfydryl lignocelluloses-montmorillonoid compounded magnetic biomass adsorbent. The method is characterized in that wheat straw, ZnCl2, citric acid, N,N-dimethyl formamide, chitosan, epoxy chloropropane, ethanediamine, pyridine, triethylamine, sodium alginate, CaCl2, FeSO4, FeCl3, mercaptoacetic acid, acetic anhydride, lignocelluloses, montmorillonoid and the like are adopted as raw materials. In the N,N-dimethyl formamide, biomass granules are modified by using the citric acid and chitosan, the pyridine is adopted for catalyzing and synergizing cross-linking modification of the ethanediamine, then the biomass adsorbent is prepared, and very high adsorption capacity is achieved; as FeSO4 and FeCl3 are adopted as raw materials, magnetic Fe3O4 is synthesized, is loaded on the surfaces of the biomass granules and is wrapped by using sodium alginate, so that a magnetic biomass adsorbent is prepared; the sulfydryl lignocelluloses-montmorillonoid compounded magnetic biomass adsorbent is prepared.

Owner:凤台县双利生物科技有限公司

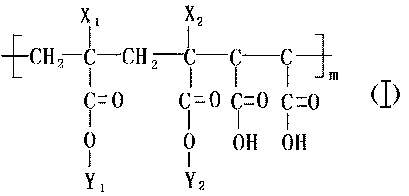

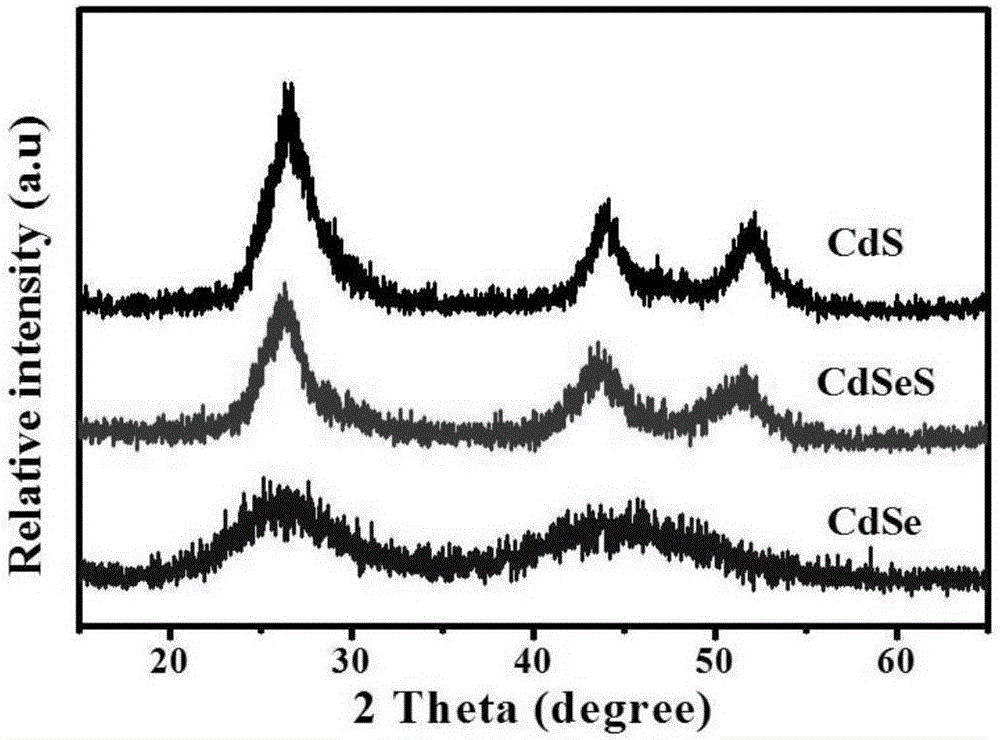

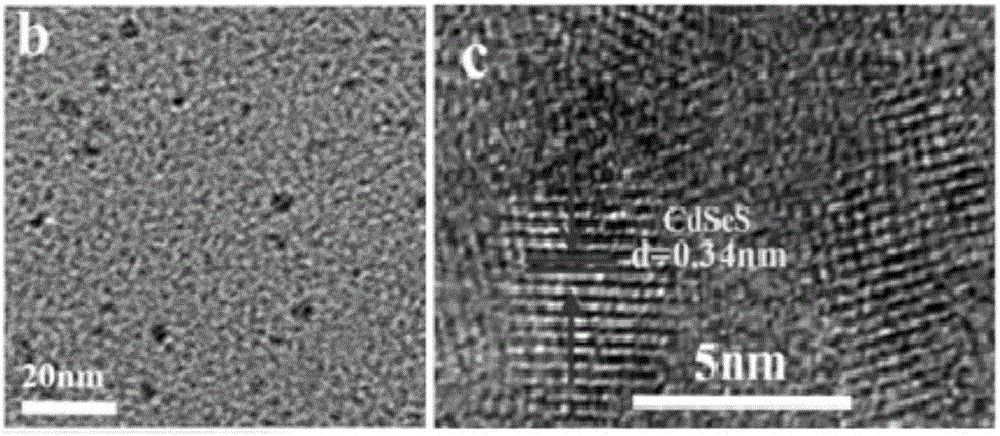

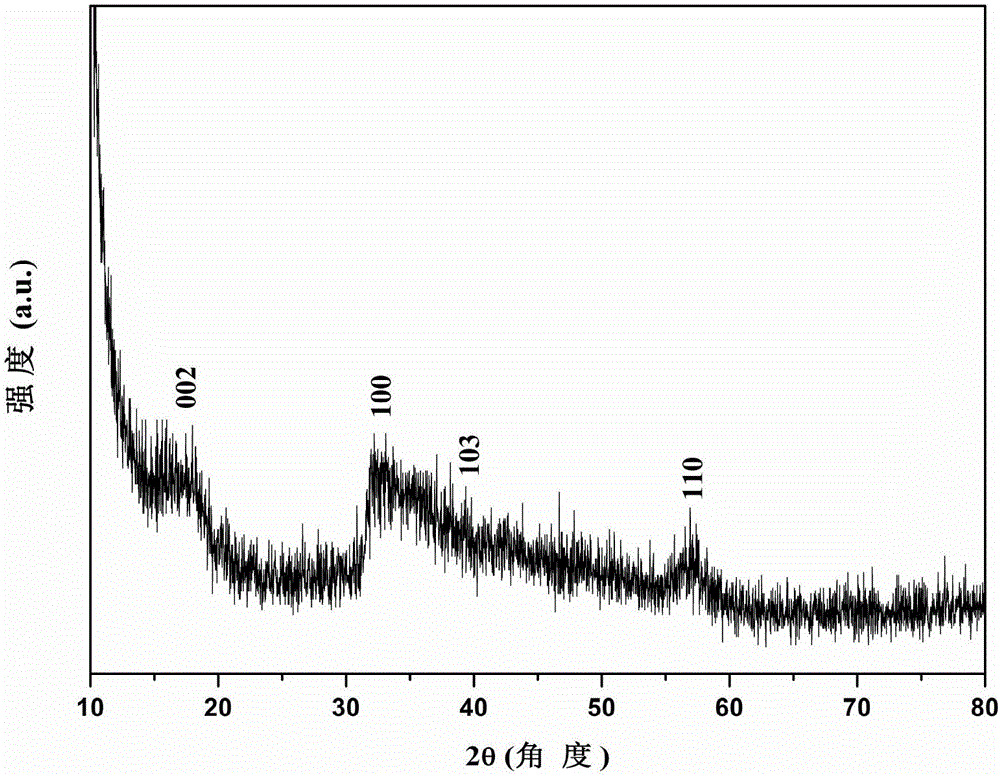

Cadmium sulphide selenide solid solution quantum dot and preparation method and photocatalytic hydrogen production application thereof

ActiveCN105885847AImprove hydrogen production efficiencyWide absorption spectrum rangeMaterial nanotechnologyPhysical/chemical process catalystsSulfite saltNitrogen gas

The invention relates to a CdSeS solid solution quantum dot and a preparation method and photocatalytic hydrogen production application thereof. The preparation method of the cadmium sulphide selenide solid solution quantum dot includes the steps that 1, a Na2SeSO3 solution is prepared, wherein selenium powder flows back in a water solution of sodium sulfite, and the Na2SeSO3 solution is obtained; 2, CdSe quantum dot suspension liquid is prepared, wherein (CH3COO)2Cd.2H2O is dissolved in distilled water, the pH value of the solution is adjusted to be 11 with alkali liquid, nitrogen is introduced for 30 min, mercaptoacetic acid and the Na2SeSO3 solution are added in the nitrogen atmosphere, a reaction is conducted for 1 h at normal temperature, the reaction is conducted for 40-60 min at the temperature of 40-60 DEG C, and the water-soluble CdSe quantum dot suspension liquid is obtained; 3, the water-soluble CdSe quantum dot suspension liquid, Na2S and Na2SO3 are added into distilled water, the obtained mixture is ultrasonically dispersed and continues to be subjected to a stirring reaction, and the CdSeS solid solution quantum dot is obtained.

Owner:WUHAN UNIV OF TECH

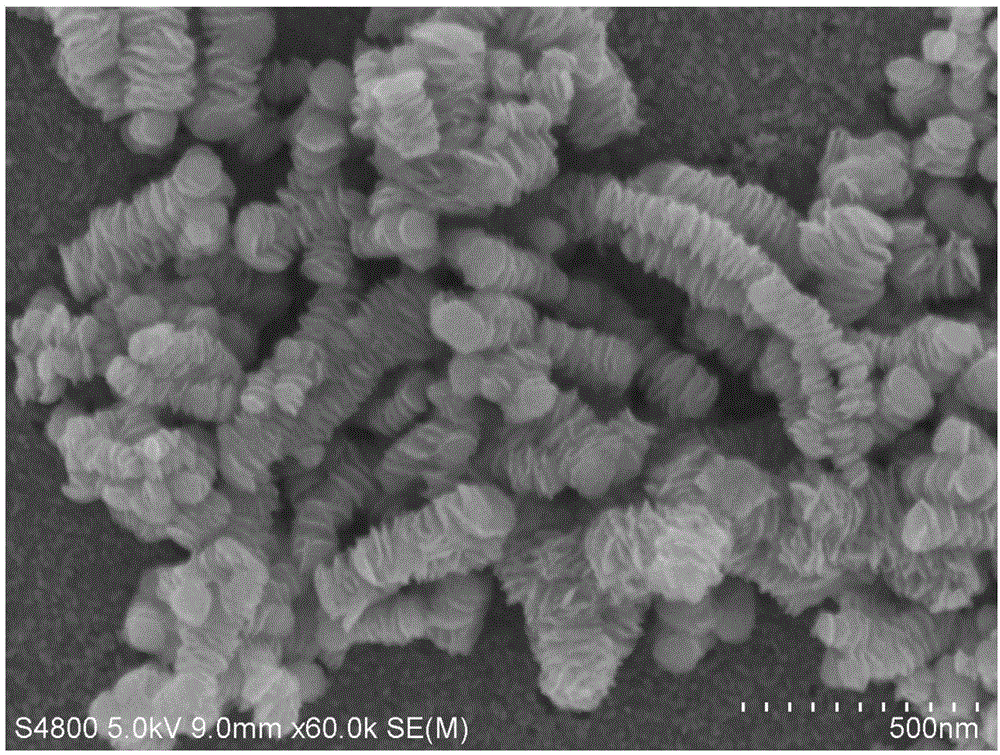

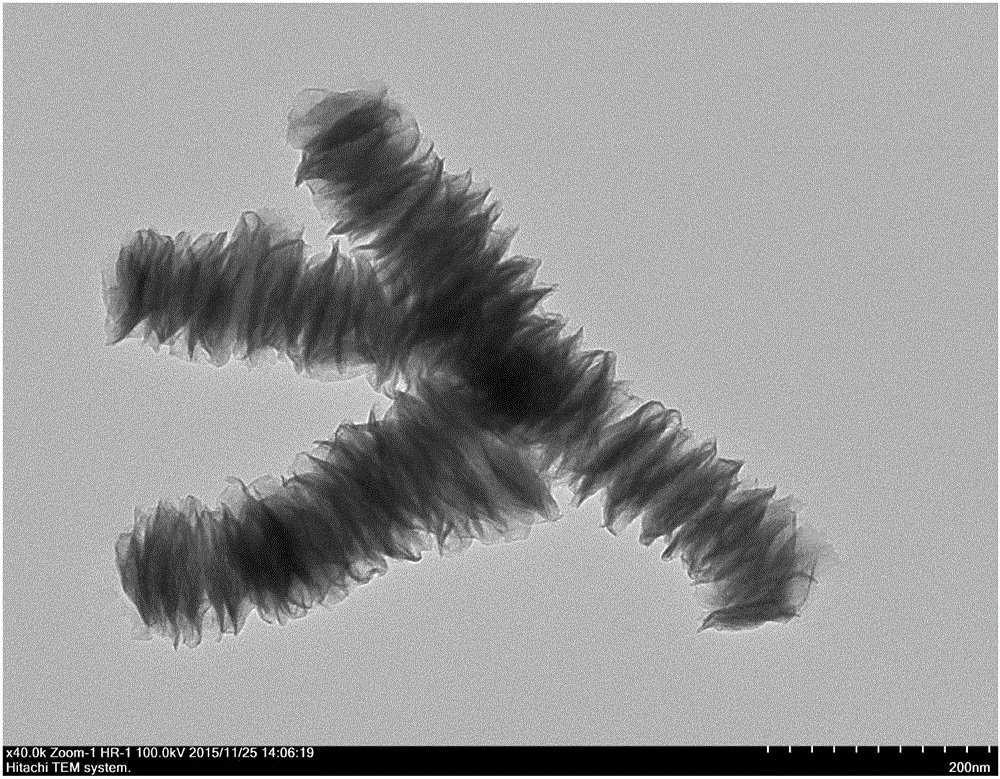

Lamella accumulated one-dimensional molybdenum disulfide nanometer material and preparation method thereof

ActiveCN106277055AImprove electrocatalytic activitySimple ingredientsPhysical/chemical process catalystsElectrolysis componentsSodium molybdateElectrolysis

The invention provides a lamella accumulated one-dimensional molybdenum disulfide nanometer material and a preparation method thereof. The molybdenum disulfide catalyst material is prepared by adopting a sodium molybdate crystal or an ammonium molybdate tetrahydrate crystal and a mercaptoacetic acid solution to react. Compared with the prior art, the lamella accumulated one-dimensional molybdenum disulfide nanometer material obtained by the invention is used as a catalyst in an electrolysis water hydrogen evolution process, shows excellent catalytic activity, and has a giant potential application value in the field of electrolysis water hydrogen production. In addition, according to the lamella accumulated one-dimensional molybdenum disulfide nanometer material and the preparation method thereof provided by the invention, the controllable preparation of morphology of the catalyst can be realized, the reaction is moderate, and the product yield is high.

Owner:ANHUI NORMAL UNIV

Super-high early-strength water reducing agent and processing method thereof

The invention discloses a super-high early-strength water reducing agent and a processing method thereof. The super-high early-strength water reducing agent is prepared from the following raw materials: a, allyl polyethylene glycol; b, either acrylic acid or methacrylic acid or a mixture of them; c, acrylamide; d, ammonium persulfate or potassium persulfate or a mixture of them; e, ammonium hydrogen sulfite; f, mercaptoacetic acid or mercaptoethanol or a mixture thereof, wherein the mole ratio of the adopted raw materials is as follows: a: b: c: d: e: f is 1: (3-4): (0.2-0.5): (0.06-0.1): (0.03-0.05): (0.03-0.05). The super-high early-strength water reducing agent disclosed by the invention obviously improves concrete strength, and specifically 1d strength of the water reducing agent is remarkably better than that of early-strength products in current market.

Owner:大连市铭源全科技开发有限公司

Polycarboxylic cement grinding aid and preparation method thereof

The invention relates to a polycarboxylic cement grinding aid and a preparation method thereof. The polycarboxylic cement grinding aid comprises isopentenol polyoxyethylene ether, acrylic acid, methacrylic acid, 2-acrylamide-2-methylpropanesulfonic acid, sodium methylacrylsulfonate, sodium allysulfonate, hydrogen peroxide, ammonium persulfate, L-ascorbic acid, sodium formaldehyde sulfoxylate dihydrate, mercaptoacetic acid, mercaptopropionic acid, sodium hydroxide and water. The preparation method comprises the following steps: adding isopentenol polyoxyethylene ether, hydrogen peroxide, ammonium persulfate, sodium methylacrylsulfonate, sodium allysulfonate and water to a reaction kettle; processing acrylic acid, methacrylic acid, 2-acrylamide-2-methylpropanesulfonic acid and water to prepare a solution A, and processing L-ascorbic acid, sodium formaldehyde sulfoxylate dihydrate, mercaptoacetic acid, mercaptopropionic acid and water to obtain a solution B; and heating the reaction kettle to 30DEG C, adding the solution A and the solution B in a dropwise manner, and carrying out a polymerization reaction to obtain the final product. The molecular structure of the polycarboxylic cement grinding aid synthesized in the invention contains various functional groups, so the grinding efficiency is effectively improved, energy consumed in the grinding process is reduced, the early strength and the later strength of cement are improved, and the compatibility of cement and a concrete additive is guaranteed.

Owner:河南新汉材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

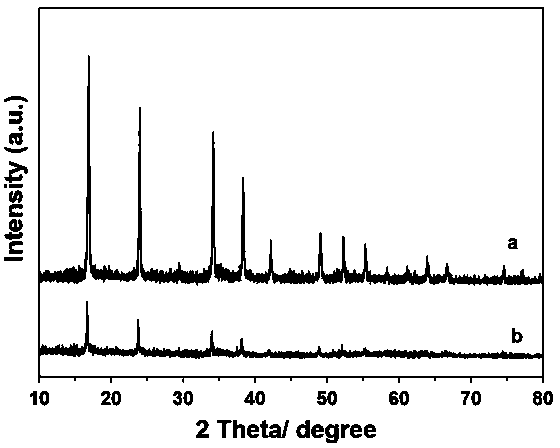

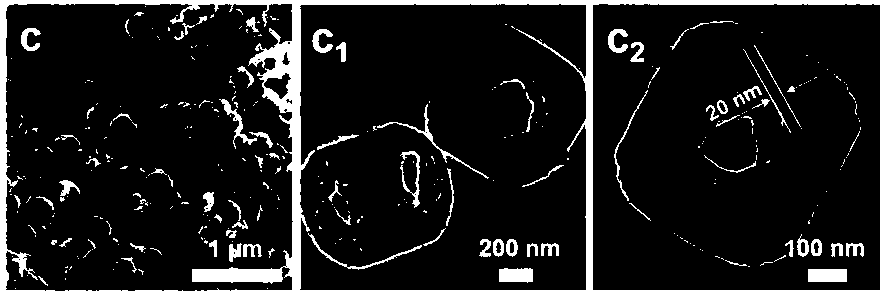

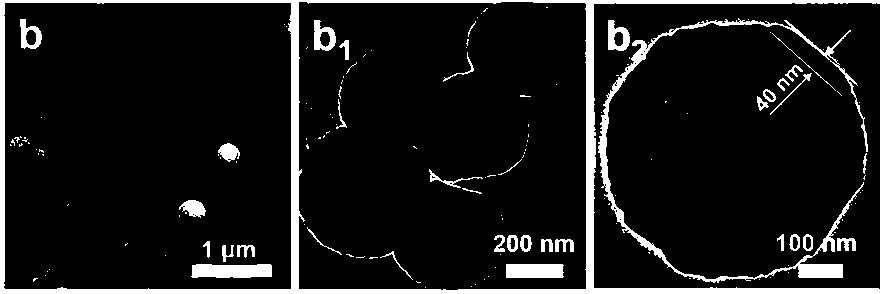

![Synthetic method for magnetic metal organic framework composite material coated by [Cu3(btc)2] on surfaces of ferroferric oxide microspheres and application of composite material Synthetic method for magnetic metal organic framework composite material coated by [Cu3(btc)2] on surfaces of ferroferric oxide microspheres and application of composite material](https://images-eureka.patsnap.com/patent_img/02083782-a159-4611-b11f-ac69b2a26ec4/130312135516.PNG)

![Synthetic method for magnetic metal organic framework composite material coated by [Cu3(btc)2] on surfaces of ferroferric oxide microspheres and application of composite material Synthetic method for magnetic metal organic framework composite material coated by [Cu3(btc)2] on surfaces of ferroferric oxide microspheres and application of composite material](https://images-eureka.patsnap.com/patent_img/02083782-a159-4611-b11f-ac69b2a26ec4/130312135520.PNG)

![Synthetic method for magnetic metal organic framework composite material coated by [Cu3(btc)2] on surfaces of ferroferric oxide microspheres and application of composite material Synthetic method for magnetic metal organic framework composite material coated by [Cu3(btc)2] on surfaces of ferroferric oxide microspheres and application of composite material](https://images-eureka.patsnap.com/patent_img/02083782-a159-4611-b11f-ac69b2a26ec4/130312135523.PNG)