Preparation method and application of sulfhydryl activated carbon mercury removal agent

A technology of activated carbon and activated carbon powder, which is applied in separation methods, chemical instruments and methods, water/sludge/sewage treatment, etc., can solve the problems of poor mercury removal activity, difficulty in large-scale production and application, and promote modification treatment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

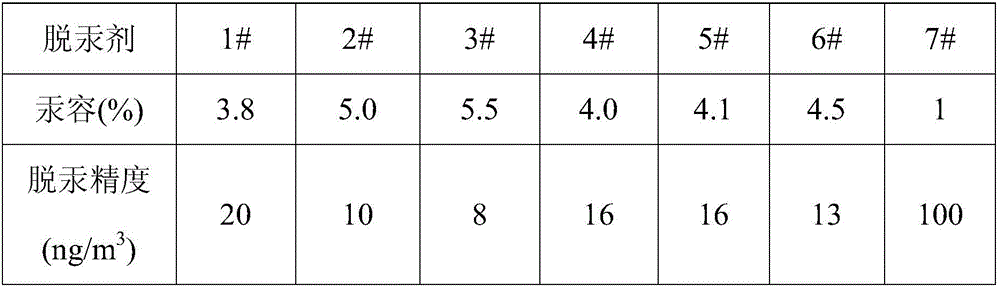

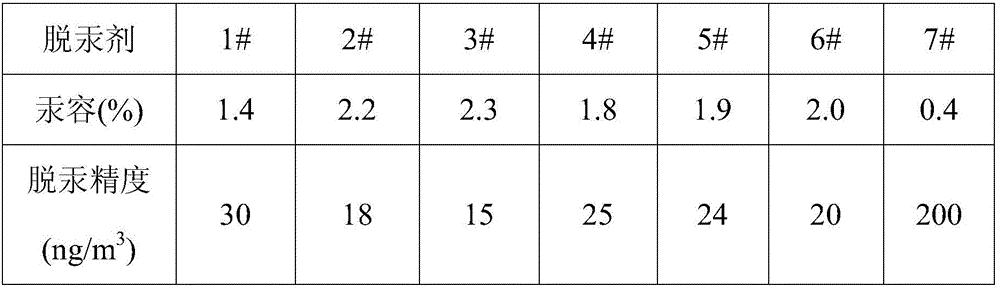

Examples

Embodiment 1

[0033] The preparation method of the mercapto activated carbon mercury removal agent described in the present embodiment comprises the following steps:

[0034] (1) the activated carbon pulverized to particle size is 100 meshes to obtain the activated carbon powder, for subsequent use;

[0035] Mix thioglycolic acid, acetic anhydride, and concentrated sulfuric acid at a volume ratio of 180:130:2 to form a mercapto-modified solution, which is set aside;

[0036] (2) Soak the activated carbon powder in the mercapto-modified solution, and let it stand at 50° C. for 24 hours, so that the mercapto-modified solution can modify the activated carbon powder to obtain modified activated carbon ;

[0037] (3) The modified activated carbon was washed to neutrality with deionized water, and dried at 80° C. until the water content was 5 wt % to obtain a mercapto activated carbon mercury removal agent, which was designated as mercury removal agent 1#.

Embodiment 2

[0039] The preparation method of the mercapto activated carbon mercury removal agent described in the present embodiment comprises the following steps:

[0040] (1) Mix mercaptoacetic acid, acetic anhydride, and concentrated sulfuric acid at a volume ratio of 220:120:1.5 to form a mercapto-modified liquid, and set aside;

[0041] dissolving polyvinyl alcohol in boiling water to prepare an aqueous binder solution with a mass percentage of polyvinyl alcohol of 10%, for subsequent use;

[0042](2) The activated carbon is crushed to a particle size of 200 meshes to obtain activated carbon powder, the activated carbon powder is uniformly mixed with the binder aqueous solution to form a mixture, and then the mixture is extruded at 8MPa to form a strip, and the formed wet The strips were dried at 110°C until the water content was 20wt%, and then heat-treated at 200°C for 0.5h to obtain activated carbon shaped products;

[0043] (3) Soak the shaped activated carbon in the mercapto-mo...

Embodiment 3

[0046] The preparation method of the mercapto activated carbon mercury removal agent described in the present embodiment comprises the following steps:

[0047] (1) Mix mercaptoacetic acid, acetic anhydride, and concentrated sulfuric acid at a volume ratio of 200:140:1 to form a mercapto-modified liquid, and set aside;

[0048] Dissolving carboxymethyl cellulose in boiling water to prepare a 5% binder aqueous solution with a mass percentage of carboxymethyl cellulose for subsequent use;

[0049] (2) Grinding activated carbon to a particle size of 200 to 300 meshes to obtain activated carbon powder, mixing the activated carbon powder with the binder aqueous solution to form a mixture, and then extruding the mixture at 4MPa to form a strip, after forming The wet strips were dried at 65°C until the water content was 15wt%, and then heat-treated at 240°C for 2 hours to obtain activated carbon moldings;

[0050] (3) Soak the shaped activated carbon in the mercapto-modified solutio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Moisture content | aaaaa | aaaaa |

| Moisture content | aaaaa | aaaaa |

| Moisture content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com