Patents

Literature

10219results about How to "Won't break" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

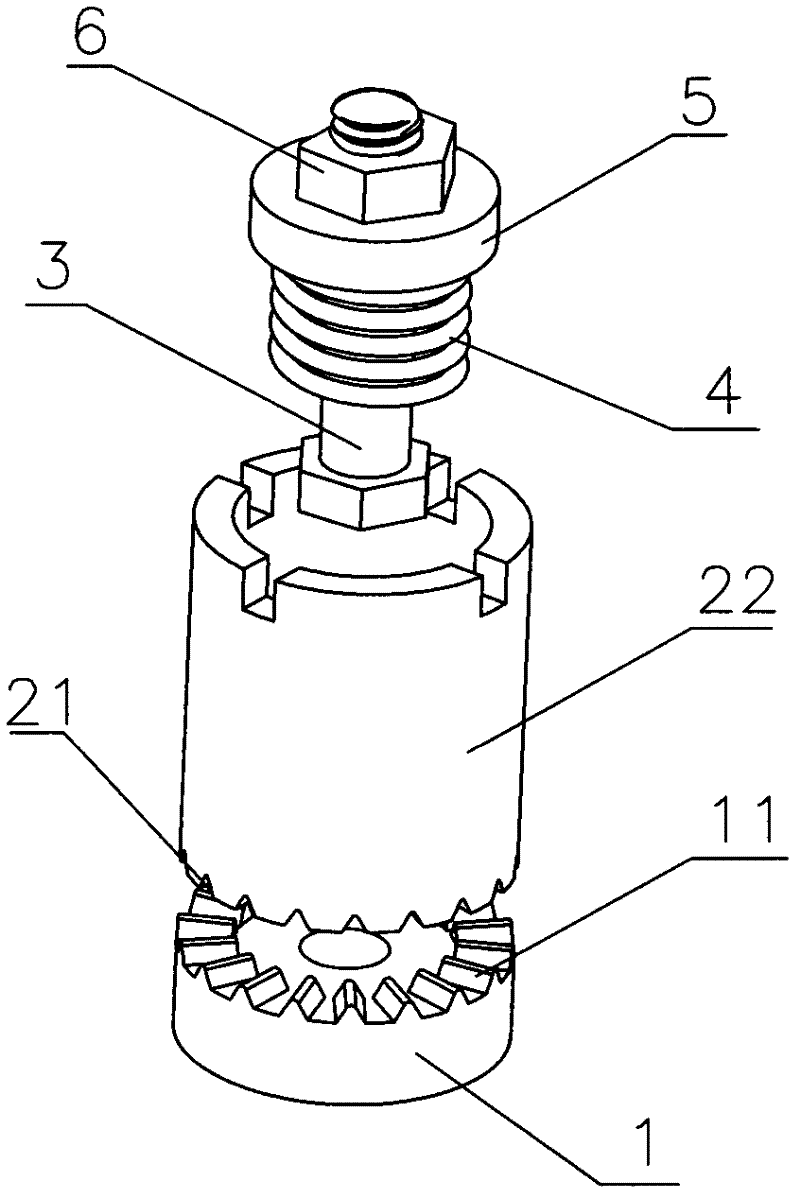

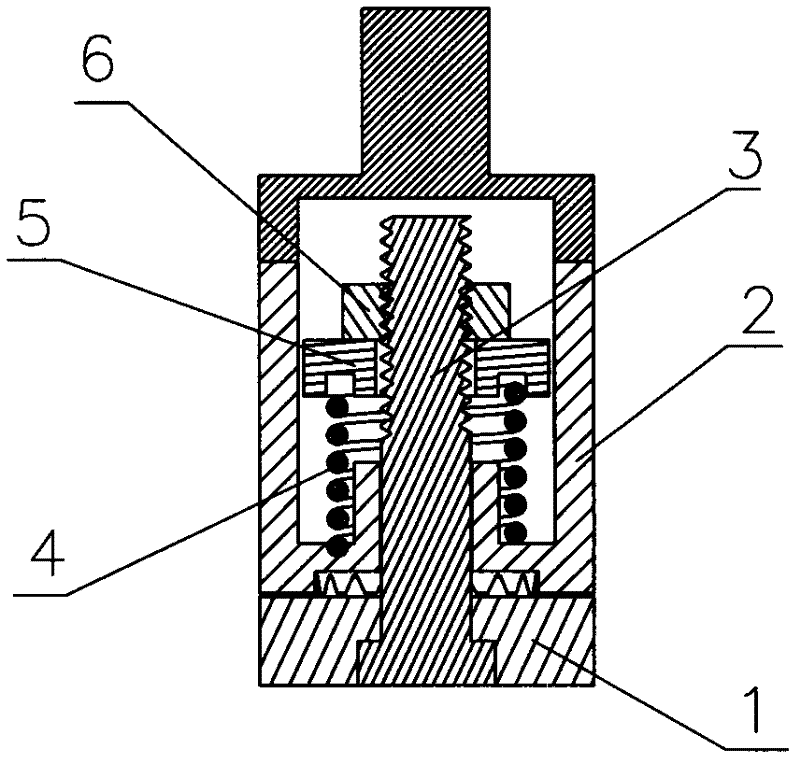

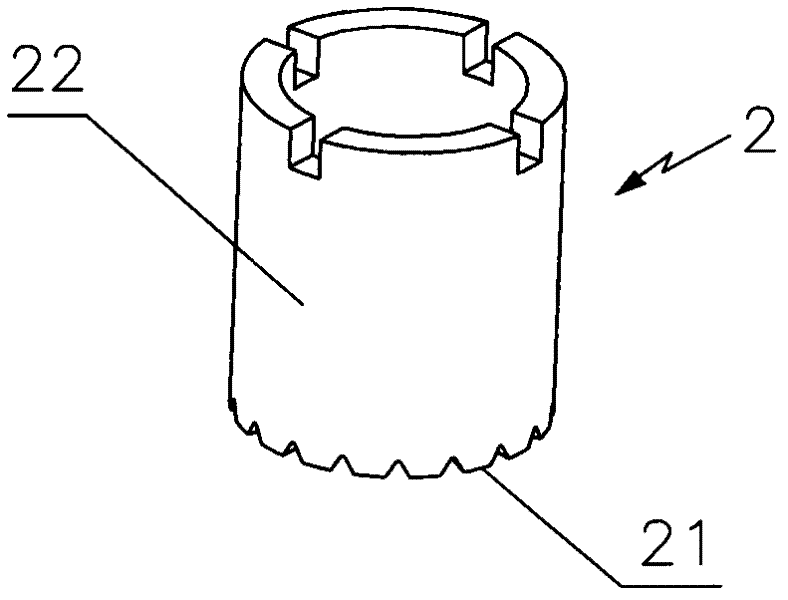

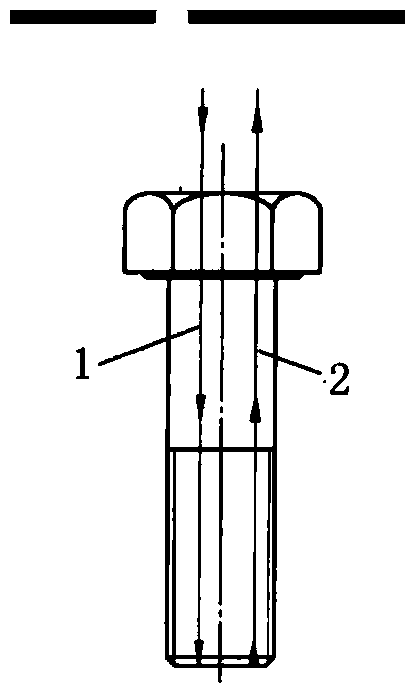

Torque limiter

InactiveCN102518690AWon't breakPlay a protective effectSlip couplingEngineeringMechanical transmission

Owner:深圳市三多乐智能传动有限公司

PVC foam wood/plastic composite material and manufacturing method thereof

The invention discloses a PVC foam wood / plastic composite material and relates to the technical field of composite materials. The PVC foam wood / plastic composite material is made from the following raw materials in parts by weight: 20-70 parts of PVC resin powder, 0-55 parts of wood flour, 5-40 parts of calcium carbonate powder, 0.1-0.5 part of sodium bicarbonate, 0.3-0.6 part of an azo-compound or hydrazine derivative, semicarbazide compound or nitroso-compound, 2-10 parts of a foaming regulator, 1.5-6 parts of a composite stabilizer, 0.7-2.1 parts of a lubricant, 0.5-1.2 part of soybean oil, 2.5-5.5 parts of an impact modifier, and 0.5-3 parts of a processing agent. The PVC foam wood / plastic composite material provided by the invention has the advantages of strong chemical stability, high strength, resistance to acid / alkaline corrosion, resistance to water seepage, flame retardancy and low cost.

Owner:山东宜群木塑科技有限公司

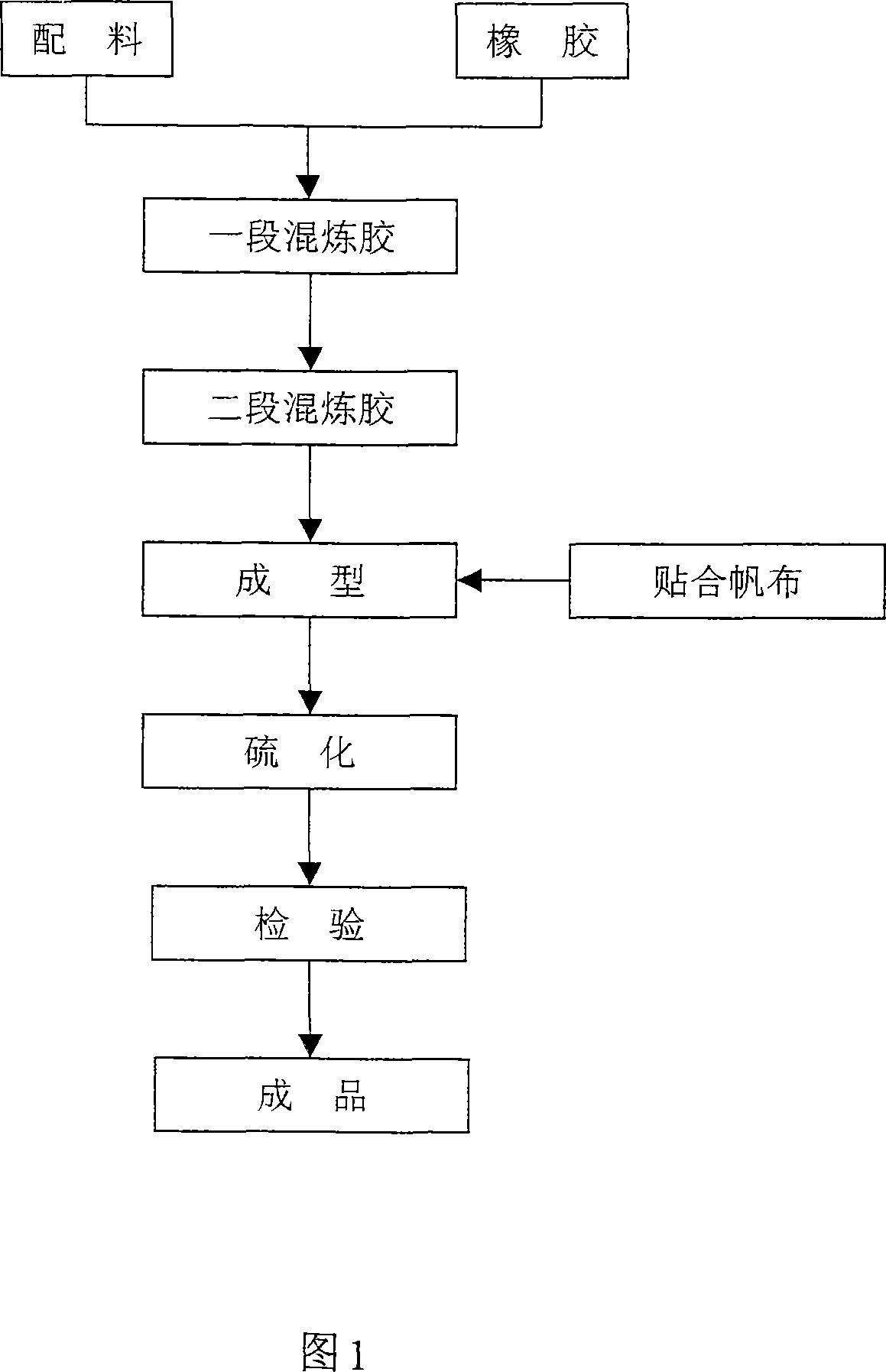

High-temperature-resisting conveyer belt

ActiveCN101028888AImprove heat resistanceExtended service lifeConveyorsBeltsCross-linkPolymer science

A refractory conveying belt is prepared from the dibasic ethylene propylene rubber, or dibasic ethylene propylene rubber and ternary ethylene propylene rubber through pre-pugging, adding heat conducting agent and anti-ageing agent, pugging, adding reinforcing agent, softening agent and short aramid fibers, pugging, adding cross-linking agent and cross-linking aid, heating, calendering to become sheet, attaching it onto tension-resistant canvas, rolling and sulfurizing.

Owner:WUXI BOTON CONVEYOR SOLUTION CO LTD

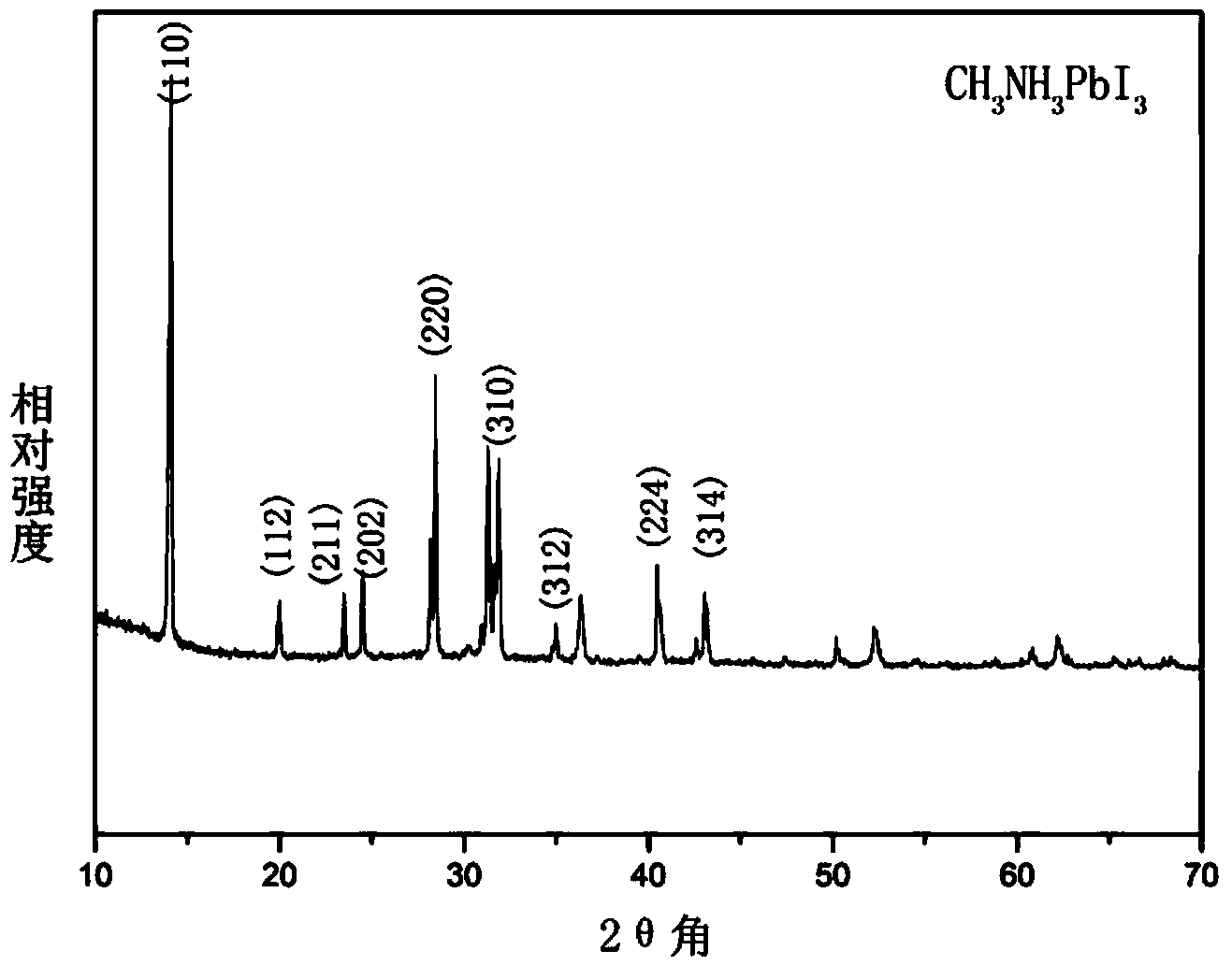

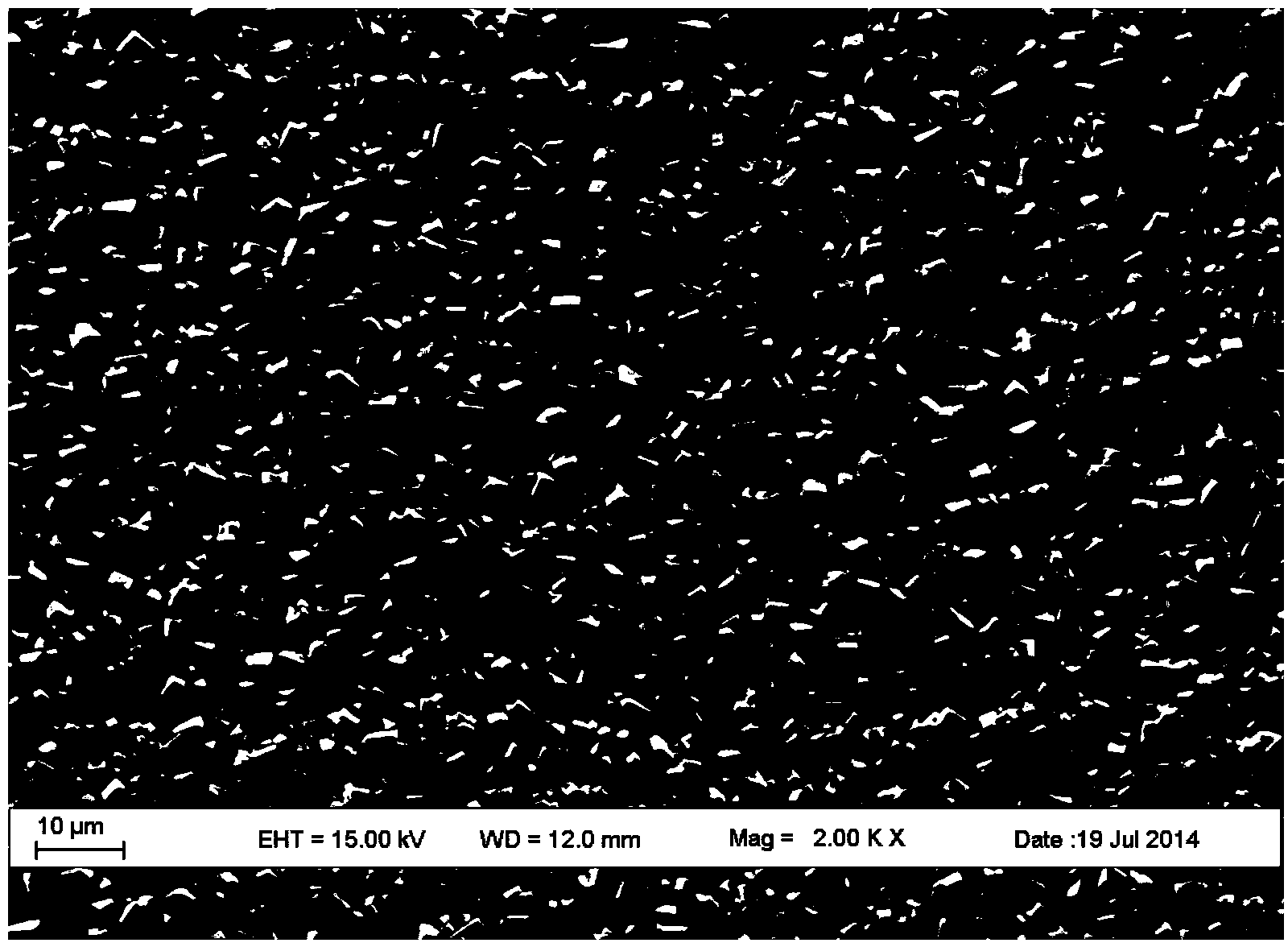

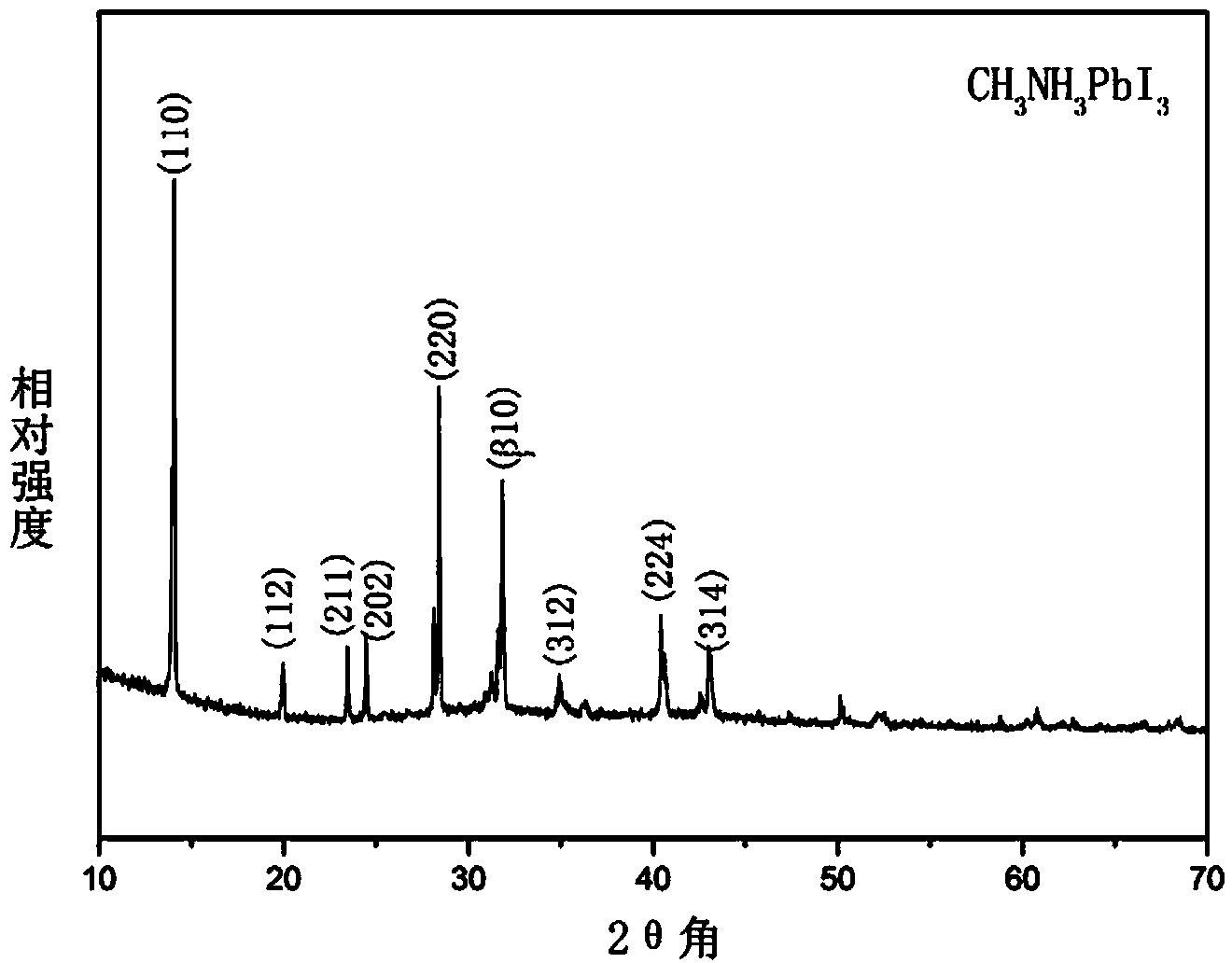

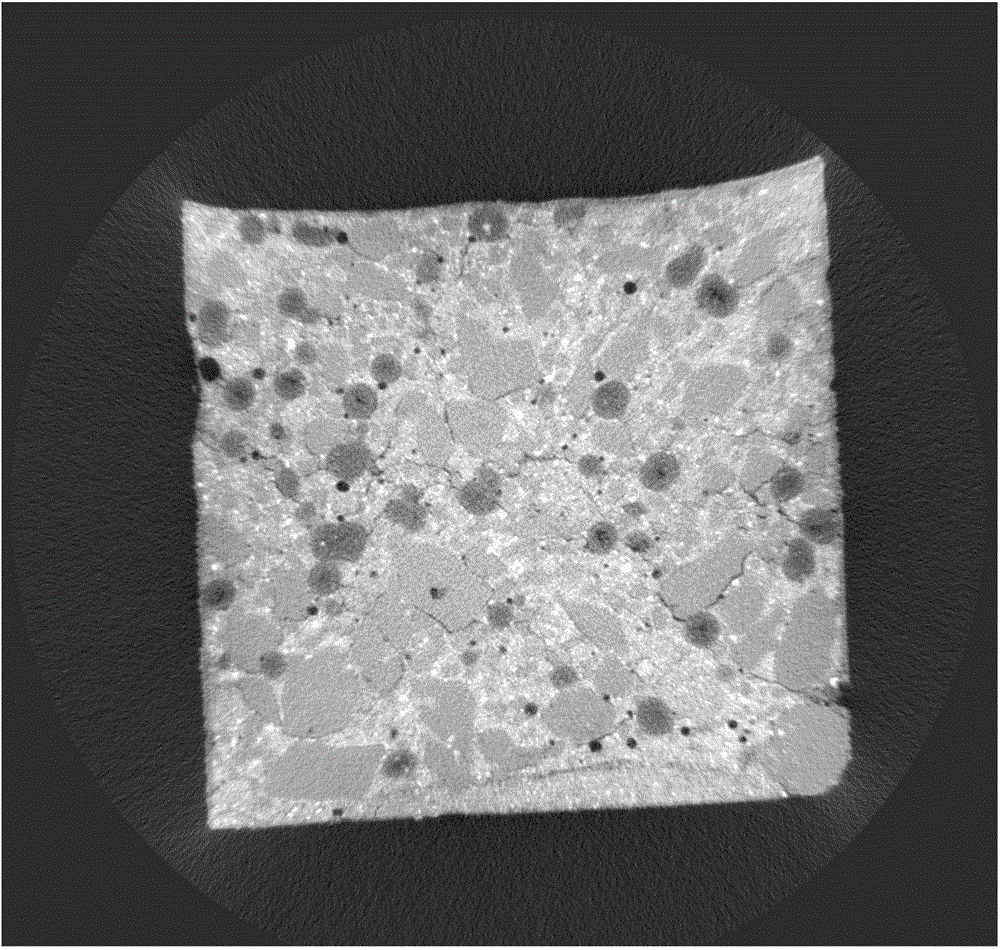

Chemical method for in-situ large-area controlled synthesis of perovskite type CH3NH3PBI3 membrane material based on lead simple-substance membrane

ActiveCN104250723AHigh purityUniform purityVacuum evaporation coatingSputtering coatingPhysical chemistryMethylamines

The invention relates to a chemical method for in-situ large-area controlled synthesis of a perovskite type CH3NH3PBI3 membrane material based on a lead simple-substance membrane. The method comprises: sputtering the lead simple-substance membrane on the surface of a substrate, then horizontally immersing the substrate material possessing the lead simple-substance membrane in an organic solution containing a simple substance iodine and iodinated methylamine, and performing a constant-temperature reaction to prepare a CH3NH3PBI3 membrane material in situ; or putting the substrate possessing the lead simple-substance membrane in a steam atmosphere of a simple substance iodine to perform iodination to generate a lead iodide membrane, then immersing in an organic solution containing iodinated methylamine, and performing a constant-temperature reaction to prepare the CH3NH3PBI3 membrane material in situ. The method is simple in operation, low in energy consumption and low in cost, and has wide industrial application prospect. The obtained CH3NH3PBI3 membrane is high in purity, uniform in membrane-surface crystal and excellent in crystallinity.

Owner:XUCHANG UNIV +1

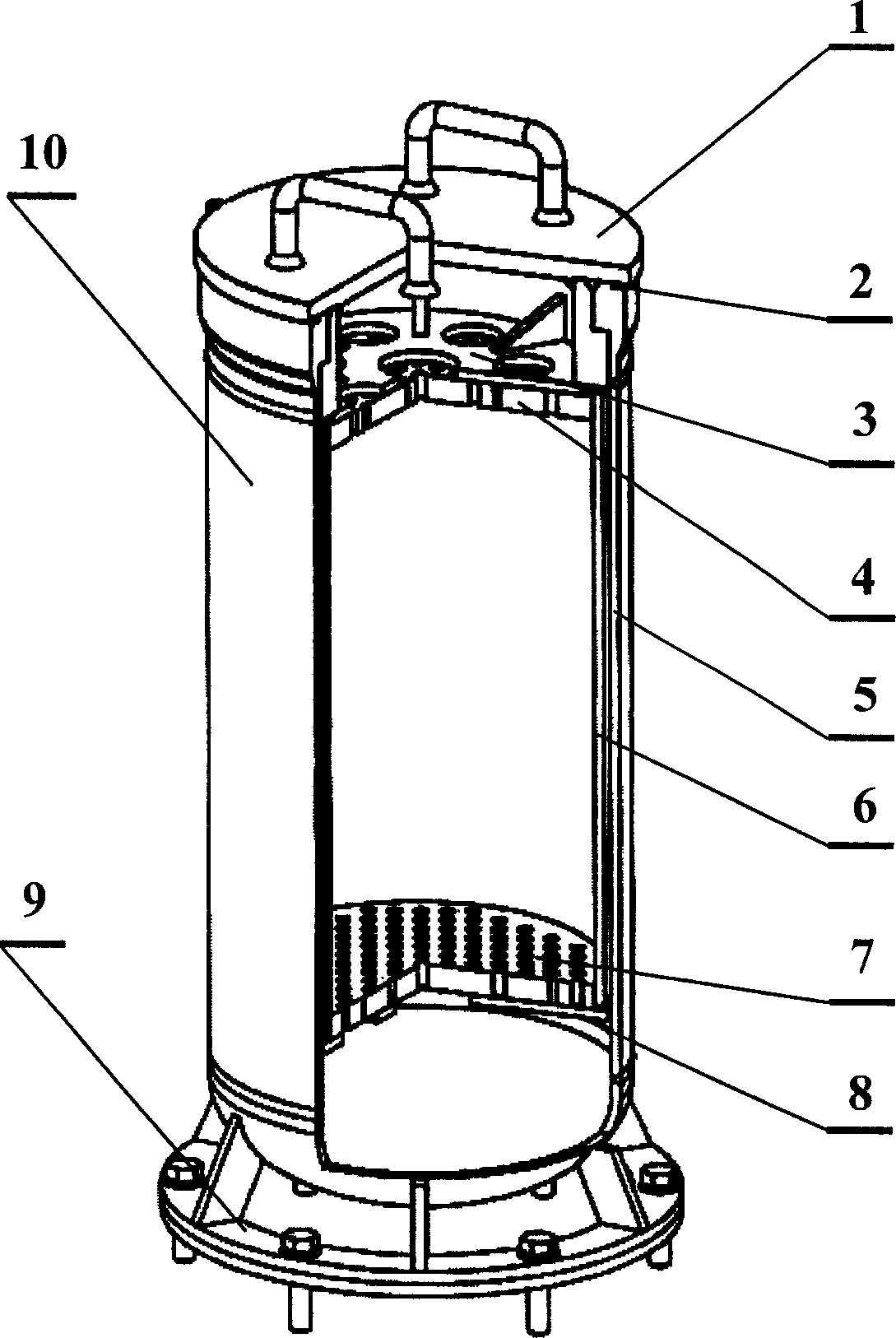

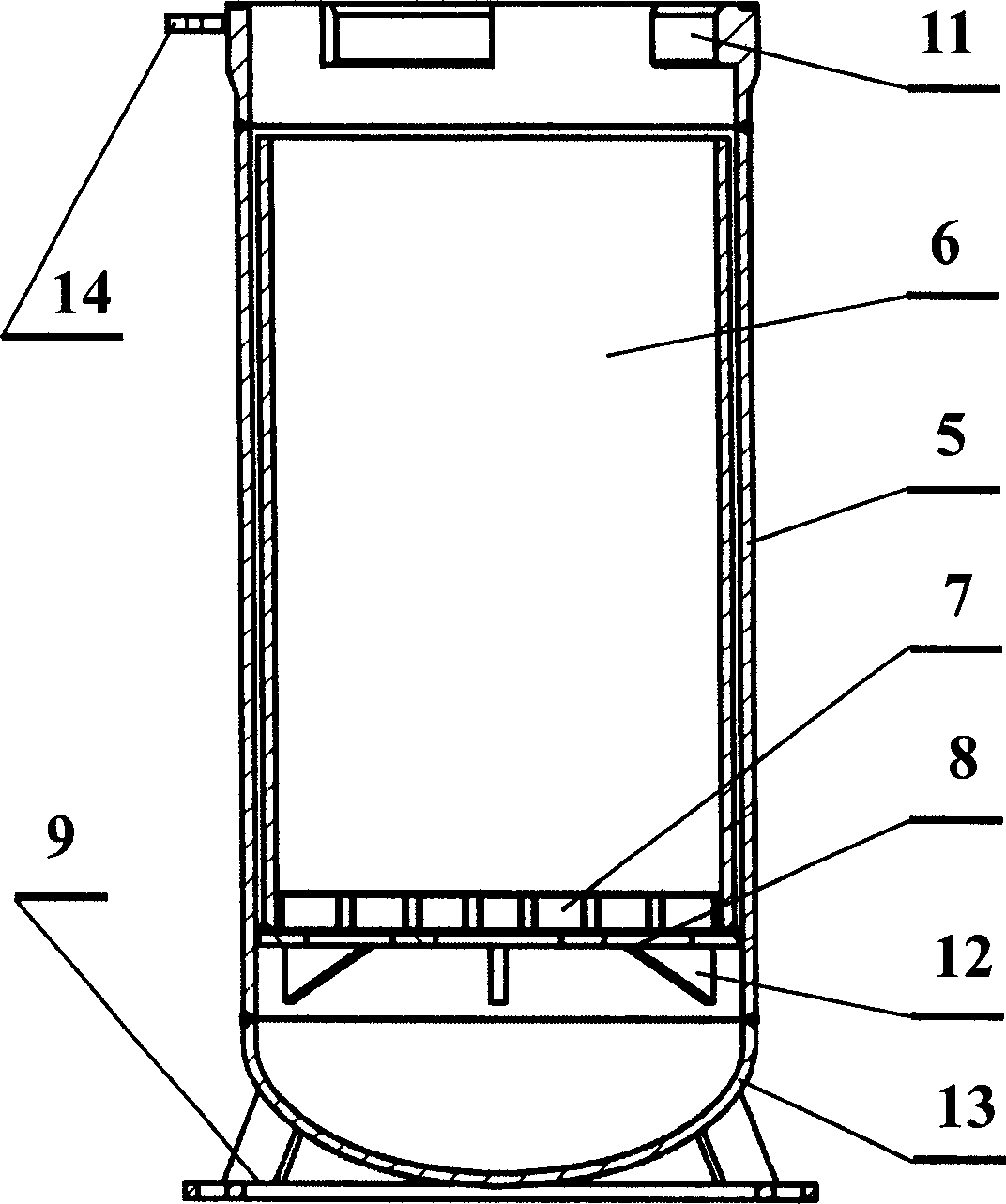

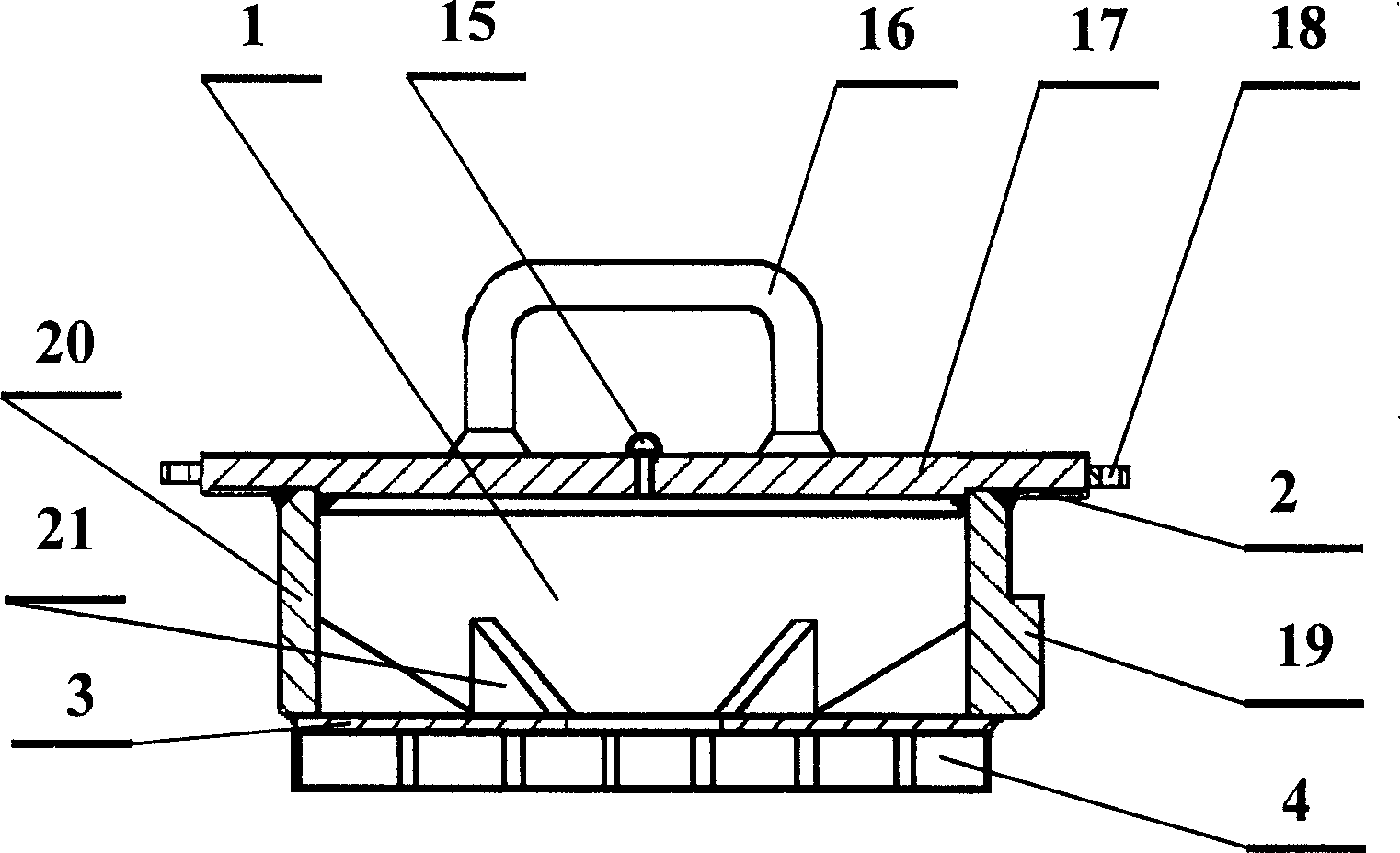

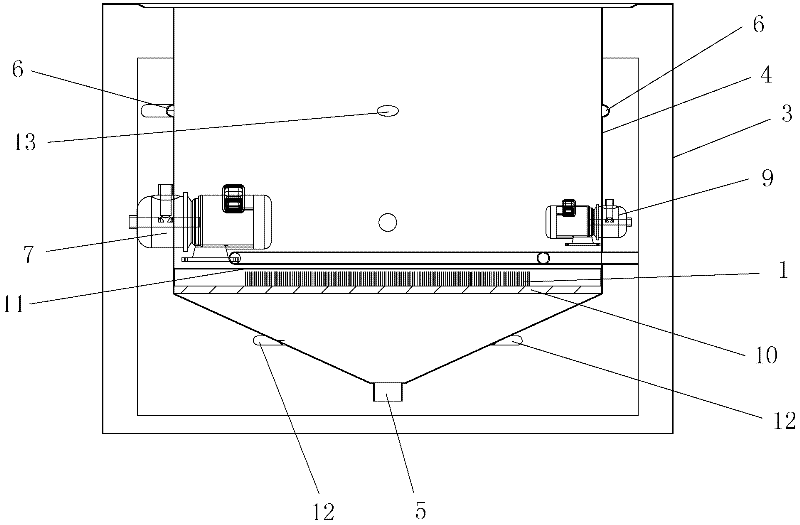

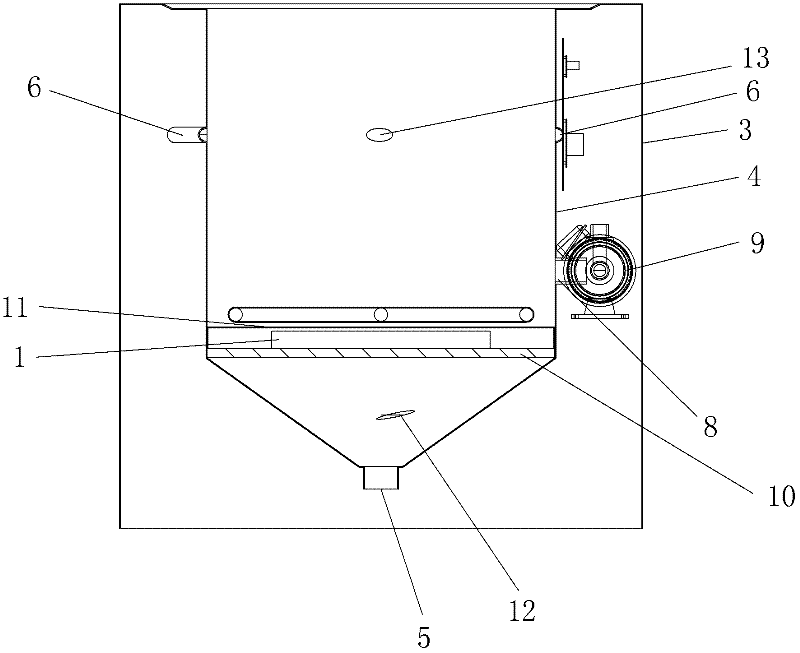

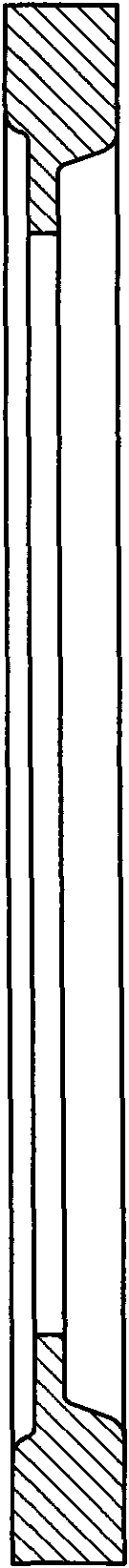

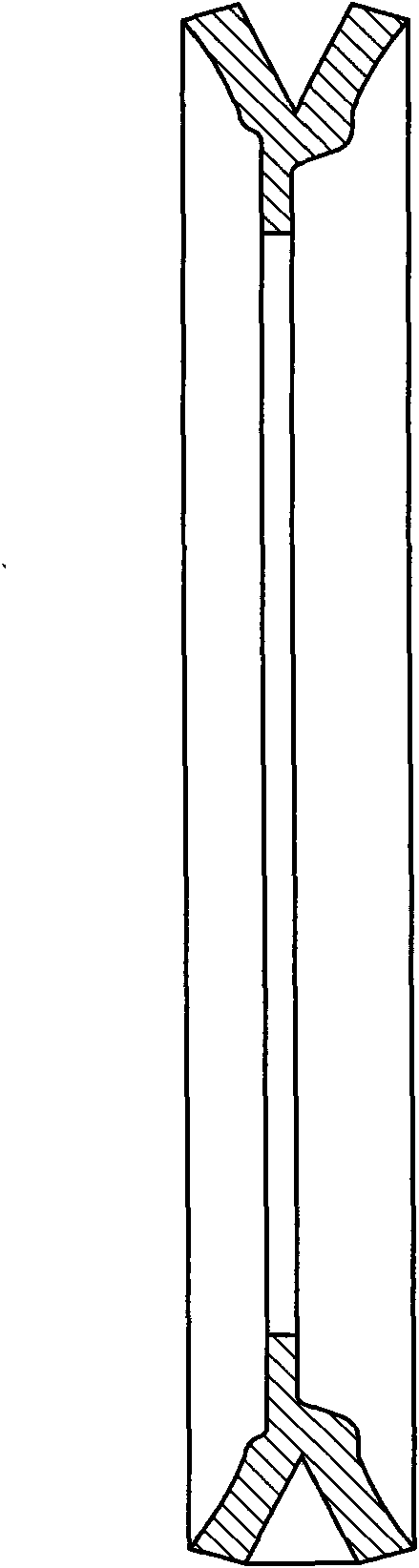

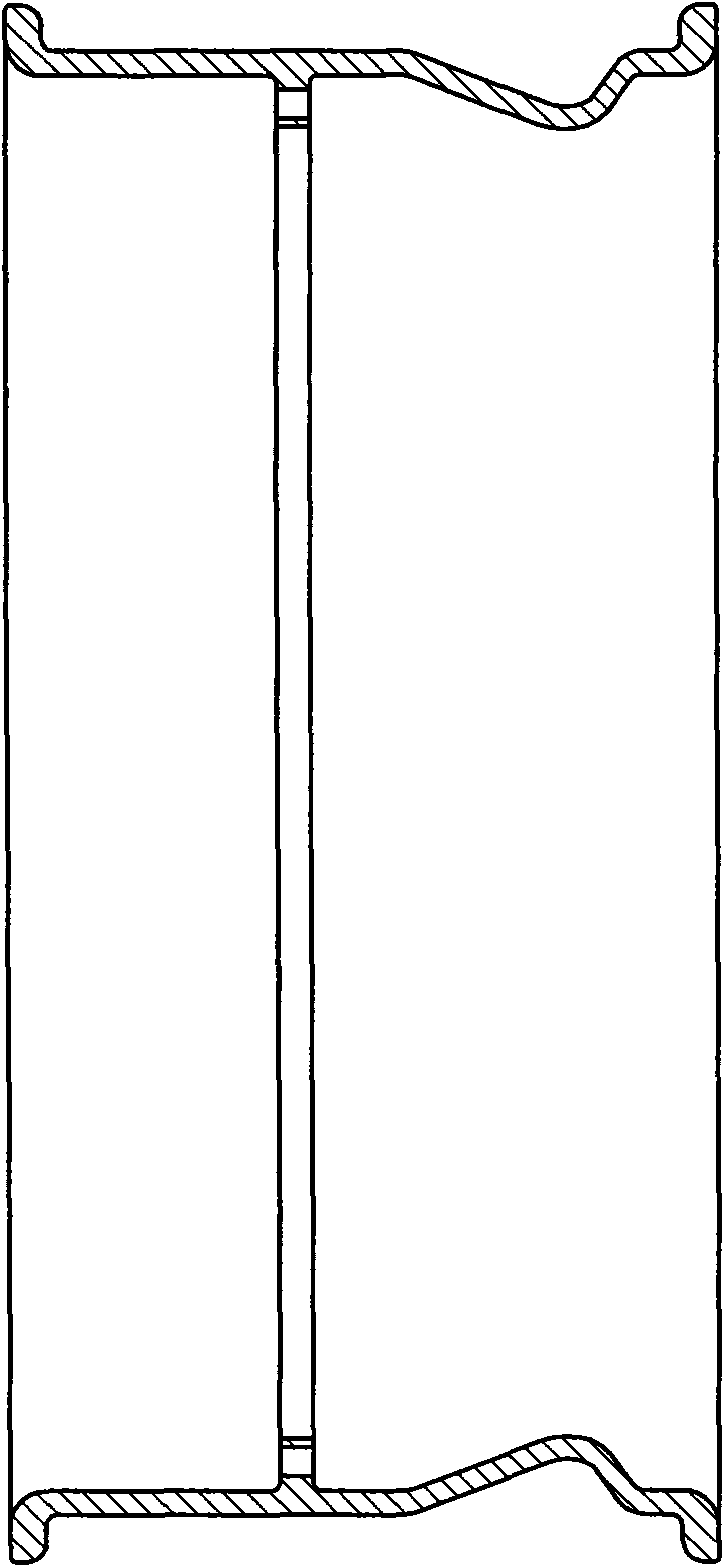

Anti-knock container

ActiveCN1632445AOpen and close flexible and convenientNot easy to wearAmmunition storageDetonatorEngineering

The invention belongs to storage and transportation equipment for detonating materials (detonators), in particular to an anti-explosion container. The anti-explosion container includes an upper cover, a cylinder and a fixed bracket. It is characterized in that the cylinder is composed of an outer cylinder and an inner cylinder, wherein the outer cylinder is a cylinder with an open upper end and a closed lower end. The lower part of the inner cylinder is provided with a lower wave breaking plate. , the upper cover is composed of a top cover plate and a cover wall, wherein the lower end of the cover wall is provided with an upper wave dissipation plate, the cover wall and the upper port of the outer cylinder are connected by splines, and the top cover plate is provided with explosion-venting bolts. The invention can not only ensure safety when the detonating equipment and explosives are transported in the same vehicle, but also can seal the harmful gas generated by the explosion in the container in case of an explosion in the container, and discharge the harmful gas after it is transported to a suitable place. In order to avoid polluting the environment and causing casualties and damage to surrounding personnel and facilities. It has the advantages of flexible and convenient opening and closing, large loading capacity, long service life, and good anti-explosion and explosion-proof performance.

Owner:蒋友明

Water catalyst sterilizing and detoxifying device and producing and using method thereof

InactiveCN102370106ASimple structureReasonable designCleaning using gasesCleaning using liquidsTitanium electrodePesticide residue

The invention discloses a water catalyst sterilizing and detoxifying device and a producing and using method thereof. The device comprises a water catalyst generator and a DC (direct current) power supply, wherein the water catalyst generator comprises an anode electrode and a cathode electrode which are both titanium electrodes; and the anode electrode is coated with a composite material coating. The producing method comprises the following steps of: (I) making electrodes; and (II) making the composite material coating: preparing composite material coating liquid, and brushing, drying and sintering the coating liquid in multiple times. The using method comprises the following steps of: a, placing the cleaned article and the water catalyst generator in the cleaning water; b, connecting the water catalyst generator with the DC power supply; and c, purifying the cleaned article with the water catalyst generator and the cleaning water. According to the invention, the design is reasonable, the producing and using processes are simple, and the purifying effect is good; and moreover, the problems of poor using effect, possible new pollution, easy damage to the nutrient components of thecleaned food and the like of the existing sterilizing and pesticide residue removing methods can be solved.

Owner:姚广兴

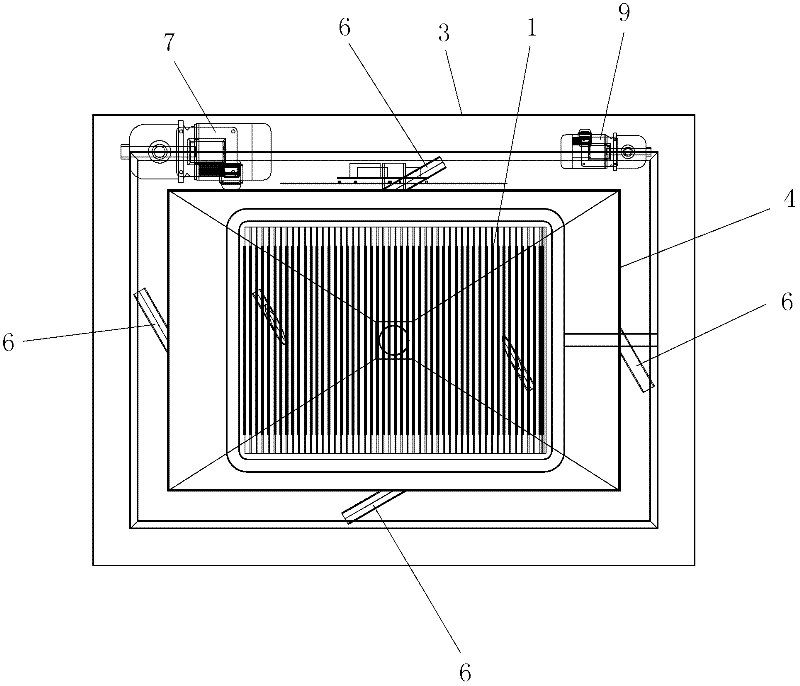

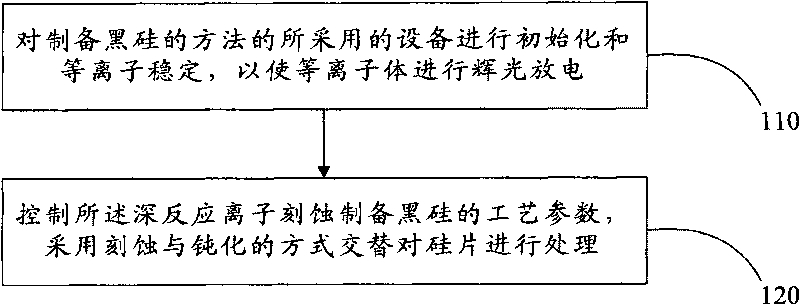

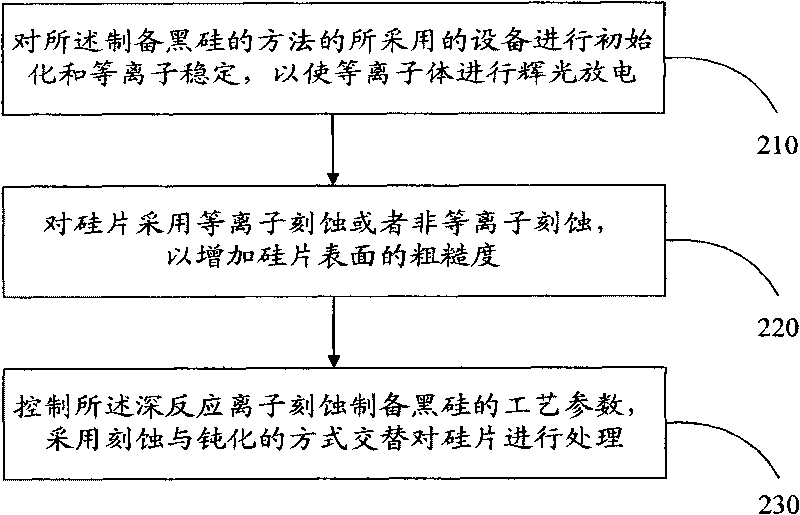

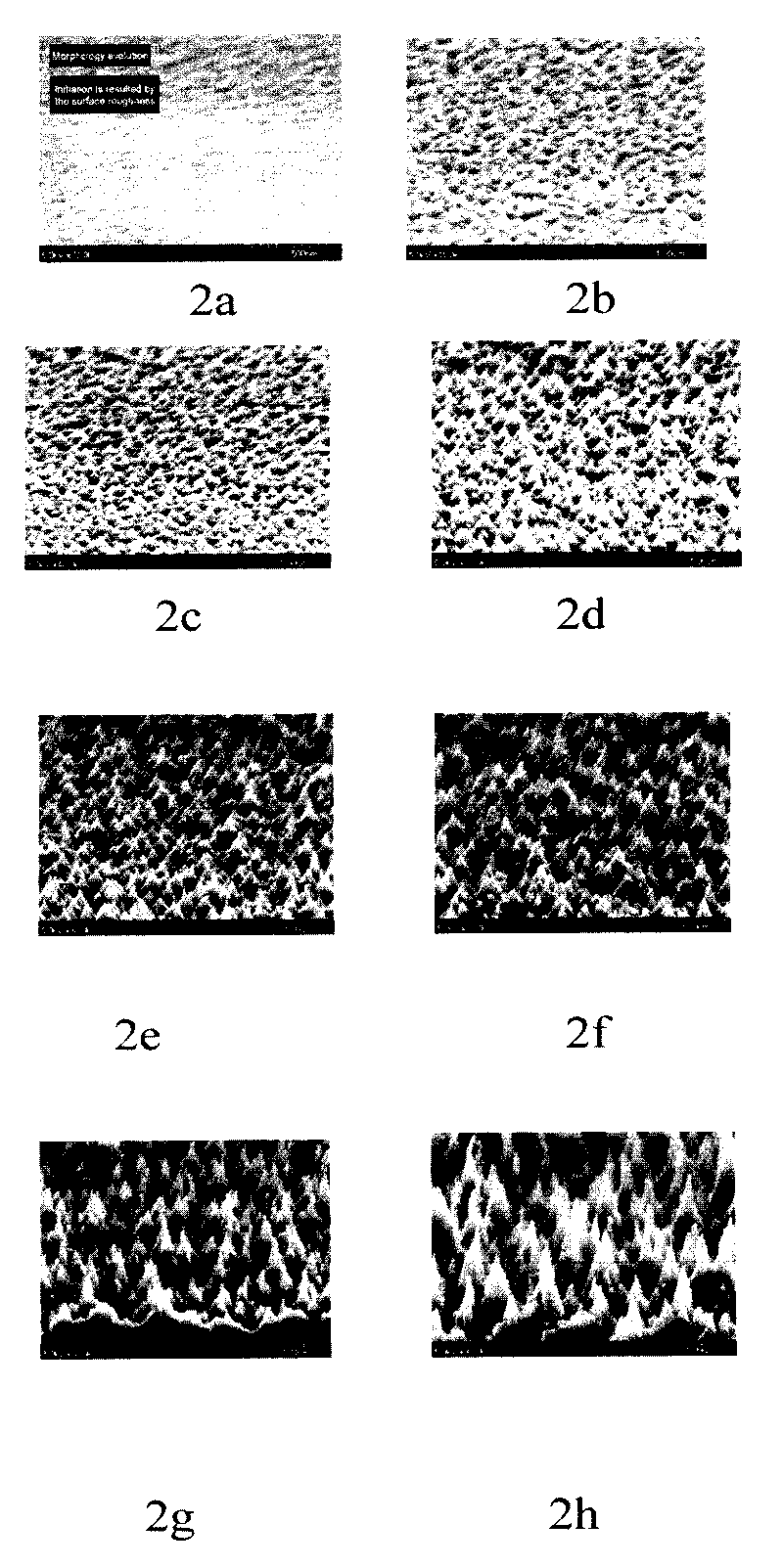

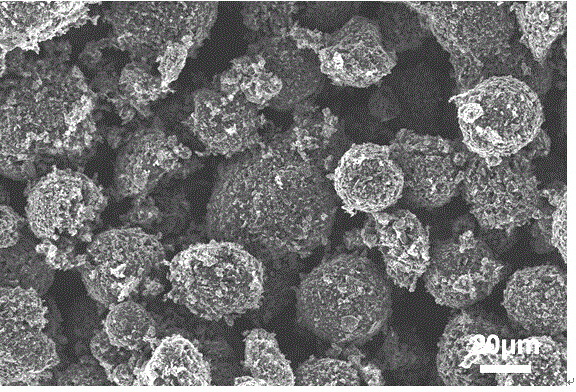

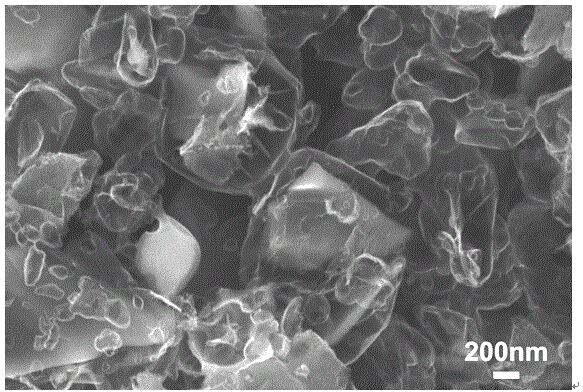

Maskless method for preparing black silicon by deep reactive ion etching

ActiveCN101734611AImprove efficiencyWon't breakNanostructure manufactureDecorative surface effectsNanostructureLarge range

The invention discloses a maskless method for preparing black silicon by deep reactive ion etching, which comprises the following steps: performing initialization and plasma stability on equipment adopted by the method for preparing the black silicon so as to make plasma perform glow discharge; and controlling technological parameters for preparing the black silicon by deep reactive ion etching, and adopting etching and passivating modes to alternately process a silicon chip, wherein the parameters comprise plasma gas flow, panel etching power, panel passivating power, coil power, and etching and passivating cycle and temperature. The maskless method directly performs plasma processing on the surface of the silicon chip, and can generate large-range high-intensity nanostructures on the surface of the silicon chip in case of no nano mask by adjusting and selecting proper etching technological parameters. Meanwhile, the method for preparing the black silicon has high efficiency and low cost, and can be integrated with other micro-fabrication technology.

Owner:PEKING UNIV

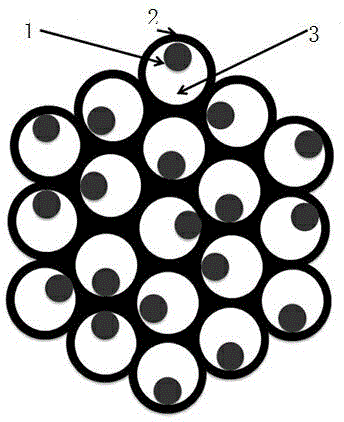

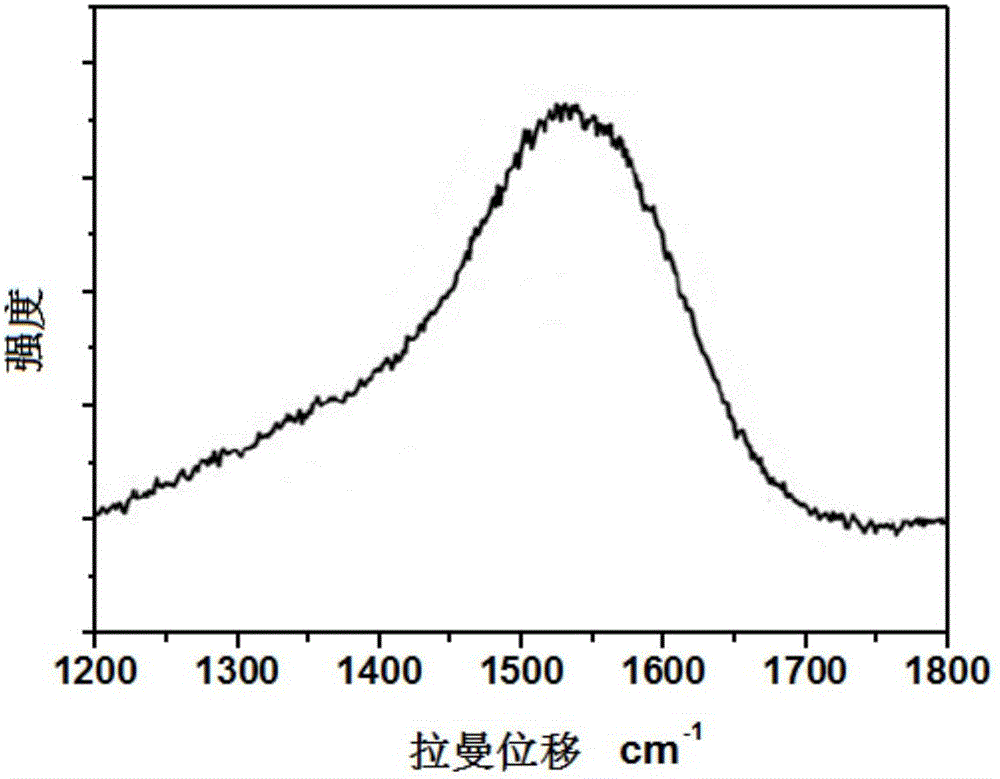

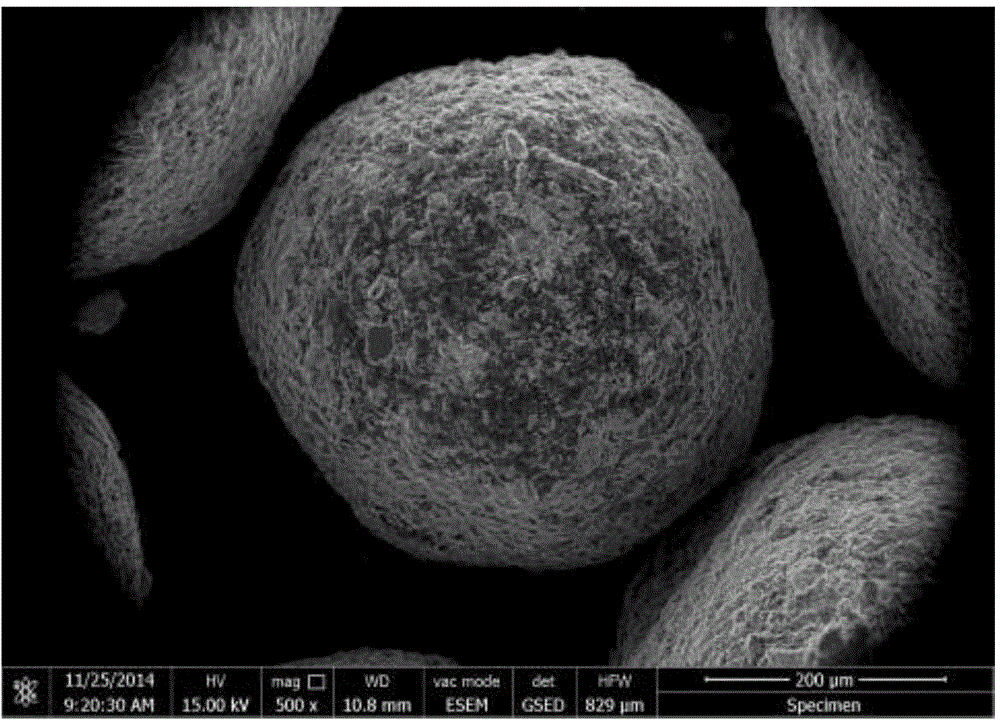

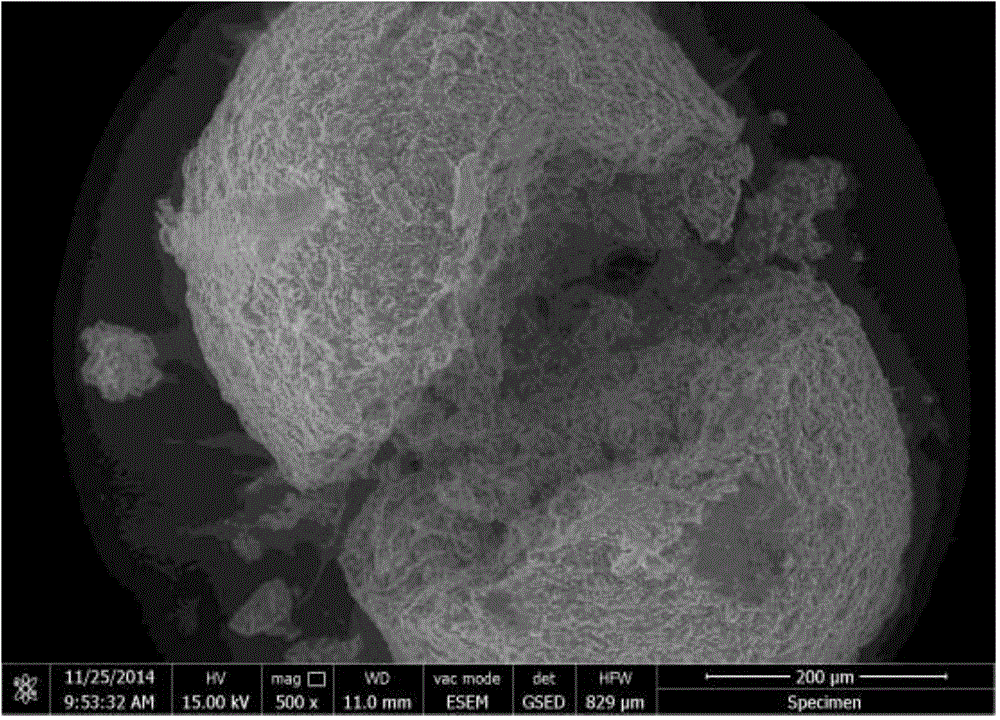

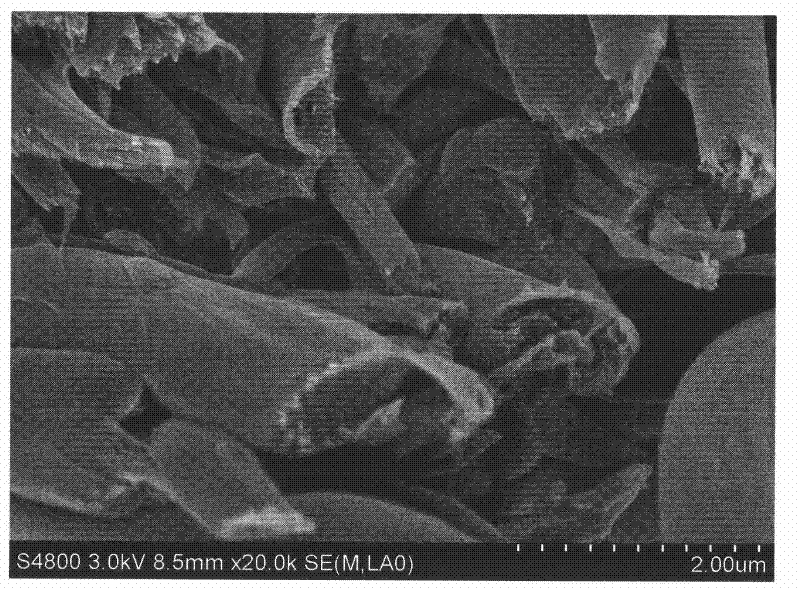

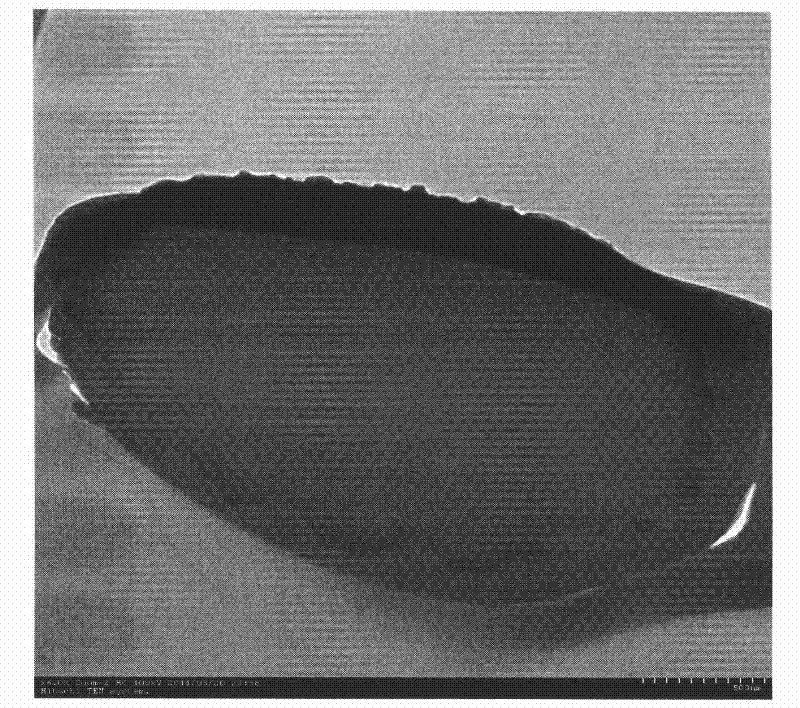

Silicon-carbon composite material and preparation method thereof and application thereof in lithium ion battery

InactiveCN106159213ASimple preparation processLow costCell electrodesSecondary cellsCarbon compositesSodium-ion battery

The invention relates to the battery field, and in particular relates to a silicon-carbon composite material and a preparation method thereof and application thereof in lithium ion battery. The following problems exist in the application of silicon-based materials in the lithium ion battery: 1. first coulombic efficiency of the lithium ion battery is low; 2, cycle life of the lithium ion battery is short; 3, the rate performance is poor; 4, the materials are low in production efficiency, and not conducive to large-scale industrial production. In order to solve the problems, the silicon-carbon composite material is provided, secondary-particles comprise a plurality of first particles containing core-shell structures, the core-shell structure comprises a carbon shell layer and silicon core particles which are completely wrapped by the carbon shell layer, and a gap is between the carbon shell layer and the silicon core particles. The preparation method of the silicon-carbon composite material and the application of the silicon-carbon composite material in the lithium ion battery are also provided.

Owner:BERZELIUS (NANJING) CO LTD

Method for preparing nano polyporous material with large specific surface area by vacuum freeze-drying process

InactiveCN101497444AAvoid damageSimple processDrying solid materials without heatTitanium dioxidePolymer scienceFreeze-drying

The invention provides a method for preparing nano porous materials with a large specific surface area by a vacuum freeze drying method with short period, simple process and non environmental pollution, which comprises the following steps: (1) taking an organosilane presursor or metal alkoxide as a raw material to synthesize wet gel; (2) allowing the wet gel to stand for 1 to 7 days, and performing aging on the wet gel; (3) using ethanol to clean the wet gel for 1 to 2 days; (4) adding a modifier into the wet gel for soakage for 1 to 2 days, performing solvent displacement, and modifying a three-dimensional network structure of the wet gel; and (5) placing the obtained product into a freeze drying box for prefreezing and vacuum drying. The method is to adopt a novel drying method, namely the vacuum freeze drying method, to dry the wet gel on the premise of maintaining the structure of the wet gel. The drying method has short period and simple process, avoids environmental pollution, cannot damage the network structure of the gel, reduces the production cost, and accelerates the large-scale commercialized application process of nano porous super heat-insulating materials, catalysts and catalyst carrier materials.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

N-type double-sided battery and manufacturing method thereof

InactiveCN104538501AImprove efficiencyIncrease production capacityFinal product manufactureSemiconductor/solid-state device manufacturingScreen printingOptoelectronics

The invention discloses an N-type double-sided battery and a manufacturing method thereof. The manufacturing method comprises the following steps that S1, texturing treatment is performed; S2, a boron source is evenly coated on the upper surface of an N-type silicon wafer in a spin coating or silk-screen printing mode, and boron diffusion is conducted in a furnace tube; S3, a mask is manufactured; S4, phosphorus diffusion is conducted on the lower surface of the N-type silicon wafer, and a high-low-junction structure is formed on the lower surface; S5, phosphorosilicate glass and the mask manufactured in the step S3 are removed; S6, a passivation anti-reflection film made from aluminum oxide and silicon nitride is manufactured on the surface of the diffused boron, and a silicon nitride passivation anti-reflection film is manufactured on the surface of the diffused phosphorus; S7, electrodes are manufactured. The manufacturing method of the N-type double-sided battery is simple in process, and the efficiency of the battery is effectively improved. In addition, a passivation layer manufacturing method of the N-type double-sided battery is a low-temperature process, and a PN junction is not damaged.

Owner:SUZHOU TALESUN SOLAR TECH CO LTD

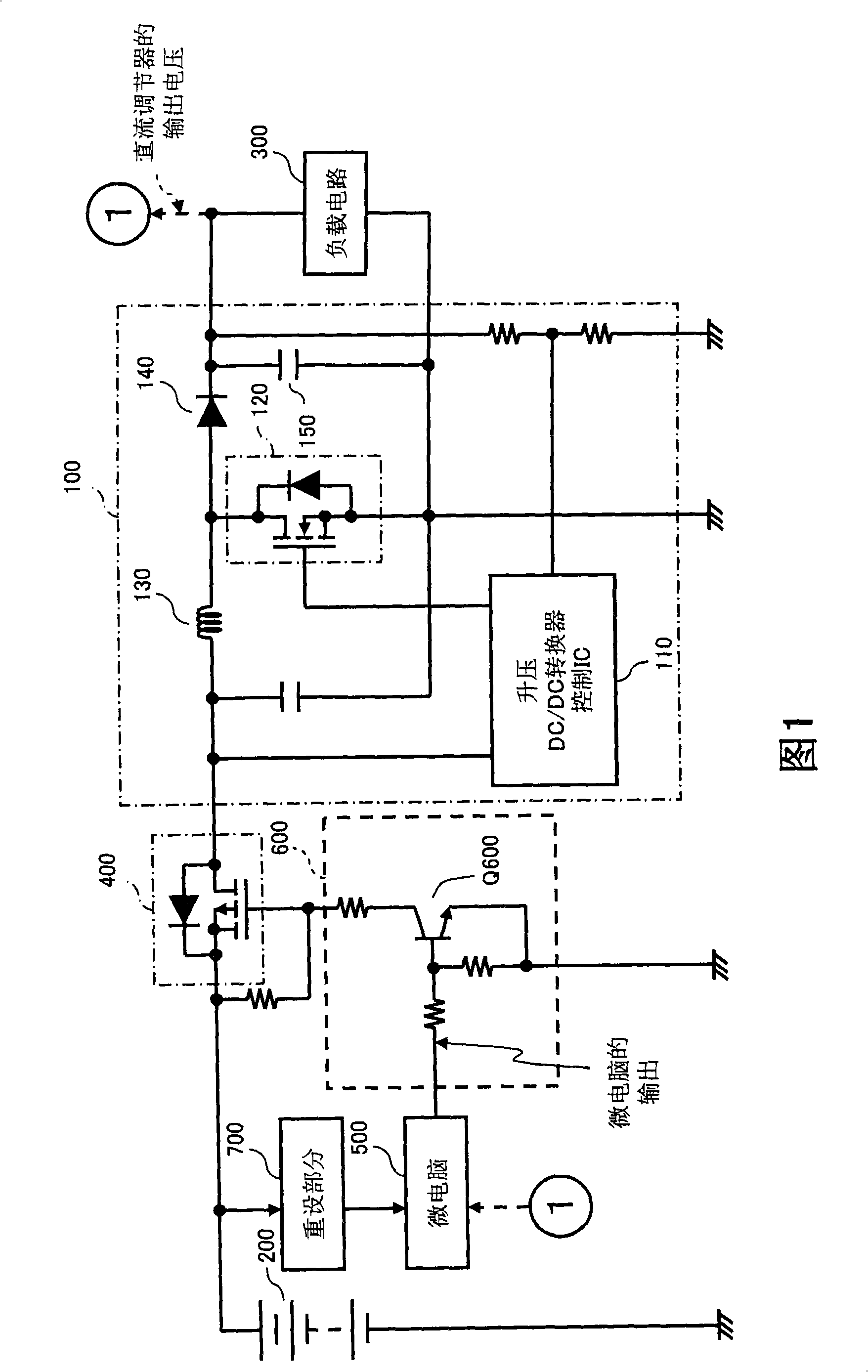

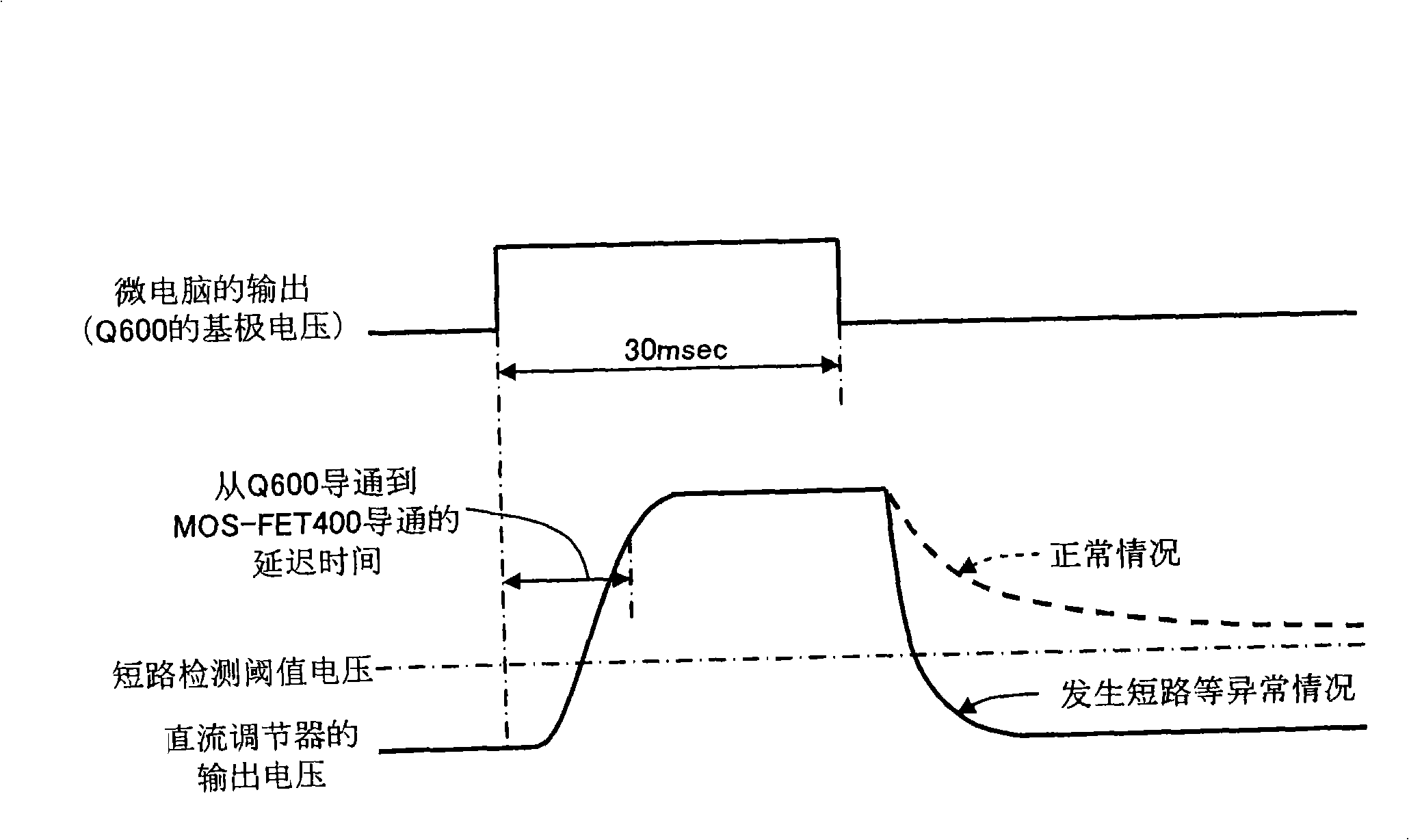

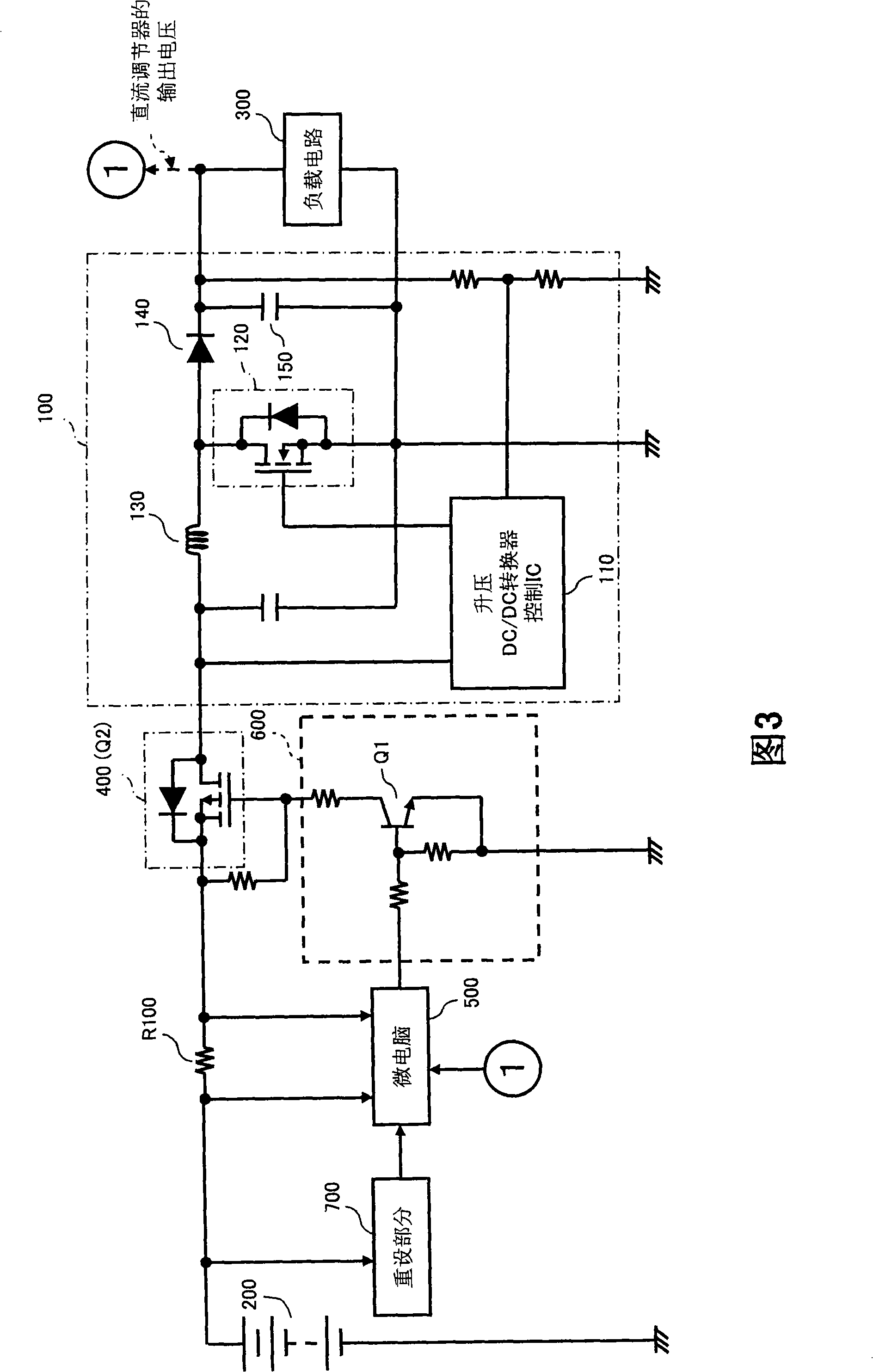

Power protection apparatus and electronic control unit

InactiveCN101335449AWon't breakWill not cause breakageTransistorEmergency protective circuit arrangementsElectronic control unitVoltage

A power protection apparatus including: a switch unit (4) connected in series in a power supply line from a power source (2) to a DC regulator (3); a first short-circuit detector (5) for detecting a short circuit based on an output voltage value of the DC regulator (3) obtained by making the switch unit (4) conductive for predetermined time and, after that, interrupting the switch unit (4); a second short-circuit detector (7) for detecting a short circuit based on a value of current flowing in the switch unit (4) when the switch unit (4) is conductive; and a switch interrupting unit (8), when a short circuit is detected by the second short-circuit detector (7), for forcedly interrupting the switch unit (4) regardless of a state of the switch unit (4) controlled by the first short-circuit detector (5).

Owner:FUJITSU GENERAL LTD

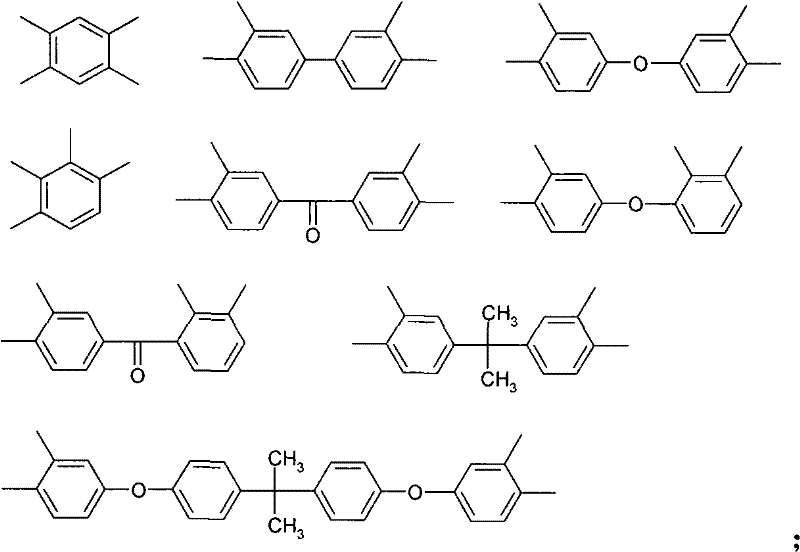

Method for preparing super-hydrophobic fabric through polyphenol modification

ActiveCN106087404AIncrease productivityGood soaping resistanceFibre treatmentTextile technologyIron(III) chloride

The invention discloses a method for preparing super-hydrophobic fabric through polyphenol modification, and belongs to the technical field of weaving. The method comprises dipping fabric successively in a ferric chloride solution and a polyphenol compound solution, so as to obtain fabric of which the surface is modified by a metal-polyphenol layer; then dipping the fabric of which the surface is modified by the metal-polyphenol layer into an ethanol-water mixed solution containing a low-surface-energy substance, reacting for 6-24 h, washing successively by deionized water and absolute ethyl alcohol, and drying the fabric at 40 DEG C in vacuum for 5-10 h, so as to obtain phenol-modified super-hydrophobic fabric. The super-hydrophobic fabric possesses extremely good soaping resistance and efficient endurable hydrophobicity, the static contact angle is still larger than 150 DEG after the fabric is washing for 20 times, the fabric variety is diversified, application is wide, and the preparation technology is simple, green, friendly to environment, low in cost and suitable for large-scale production.

Owner:DONGGUAN YIMAO FILTER MEDIA

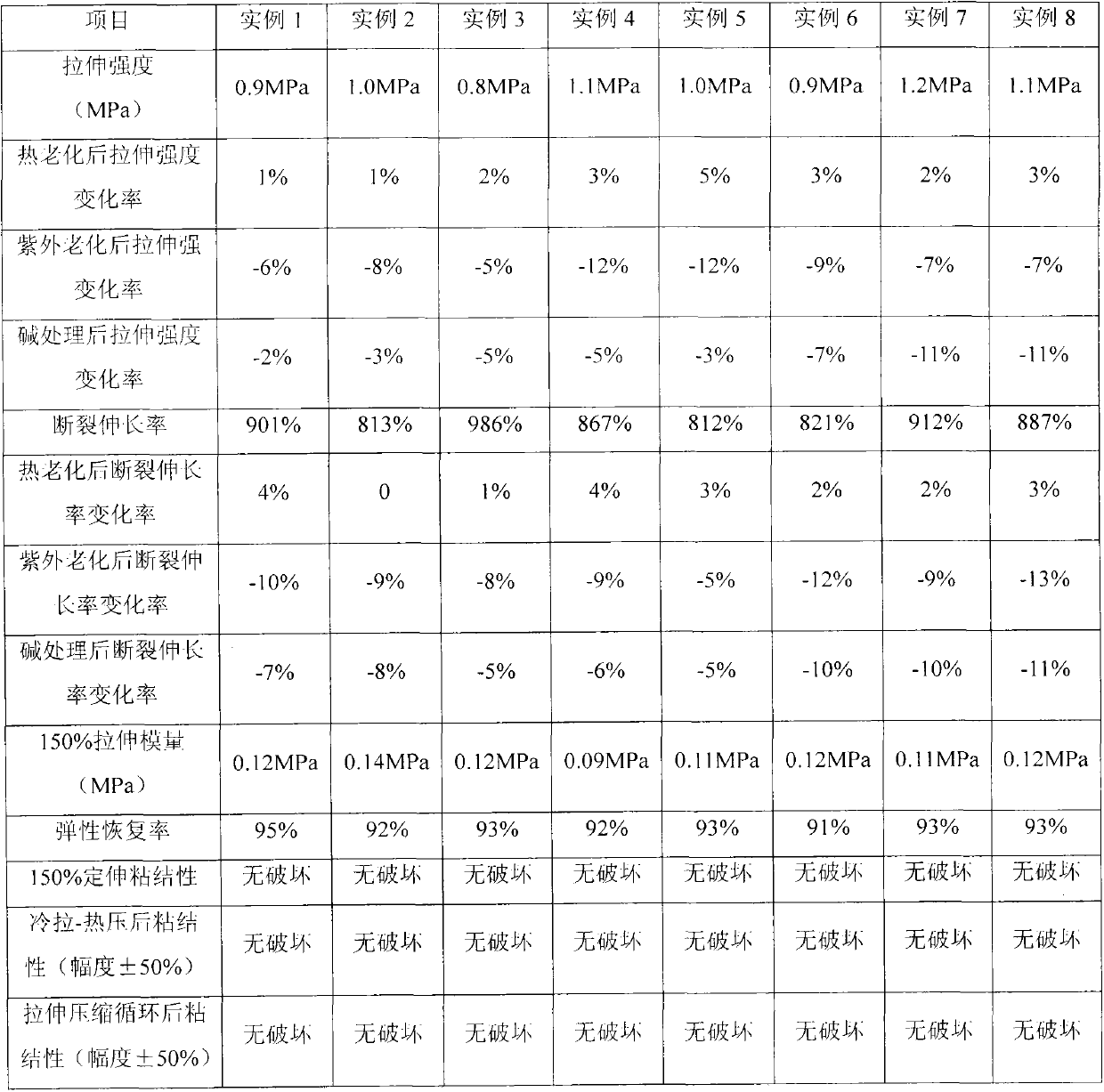

Polyurethane caulking material for expansion joints of ballastless track of high speed railway

ActiveCN103992633AImprove displacement abilityModerate mechanical strengthLow temperature curingBond properties

A polyurethane caulking material for expansion joints of a ballastless track of a high speed railway is disclosed. The caulking material is prepared from two parts A and B. the part A is composed of the following raw materials, by weight, 100 parts of isocyanate and its prepolymer, 10-150 parts of a plasticizer, 5-150 parts of a solid filler, 1-20 parts of a diluents, 1-5 parts of an adhesion promoter, 0-10 parts of a thixotropic agent and 1-3 parts of a water-removal agent. The part B is composed of the following raw materials, by weight, 10-20 parts of modified polyhydric alcohol, 1-5 parts of a diluent, 2-30 parts of a plasticizer, 5-30 parts of a solid filler, 0-5 parts of a thixotropic agent, 0.5-2 parts of an antifoaming agent, 0.1-1 part of an anti-aging agent and 0-0.01 part of a catalyst. The mass ratio of the part A to the part B is 4:1-10:1. The polyurethane caulking material has advantages of good low-temperature curing performance, high displacement capability, low tensile modulus, good bond property and excellent endurance quality and fatigue resistance, and is suitable for expansion joints of a ballastless track of a high speed railway as well as expansion joints of roads and airfield runways.

Owner:RAILWAY ENG RES INST CHINA ACADEMY OF RAILWAY SCI +2

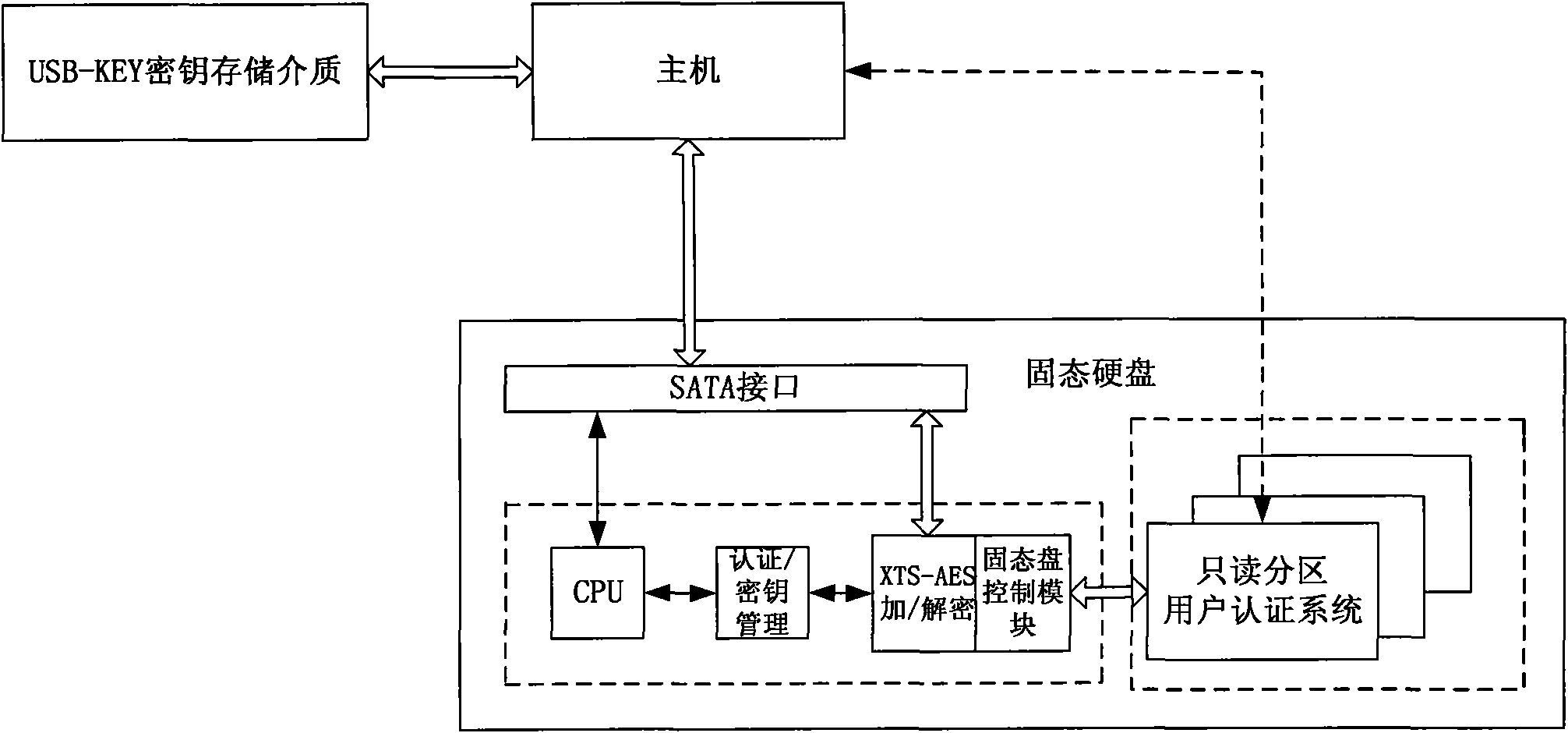

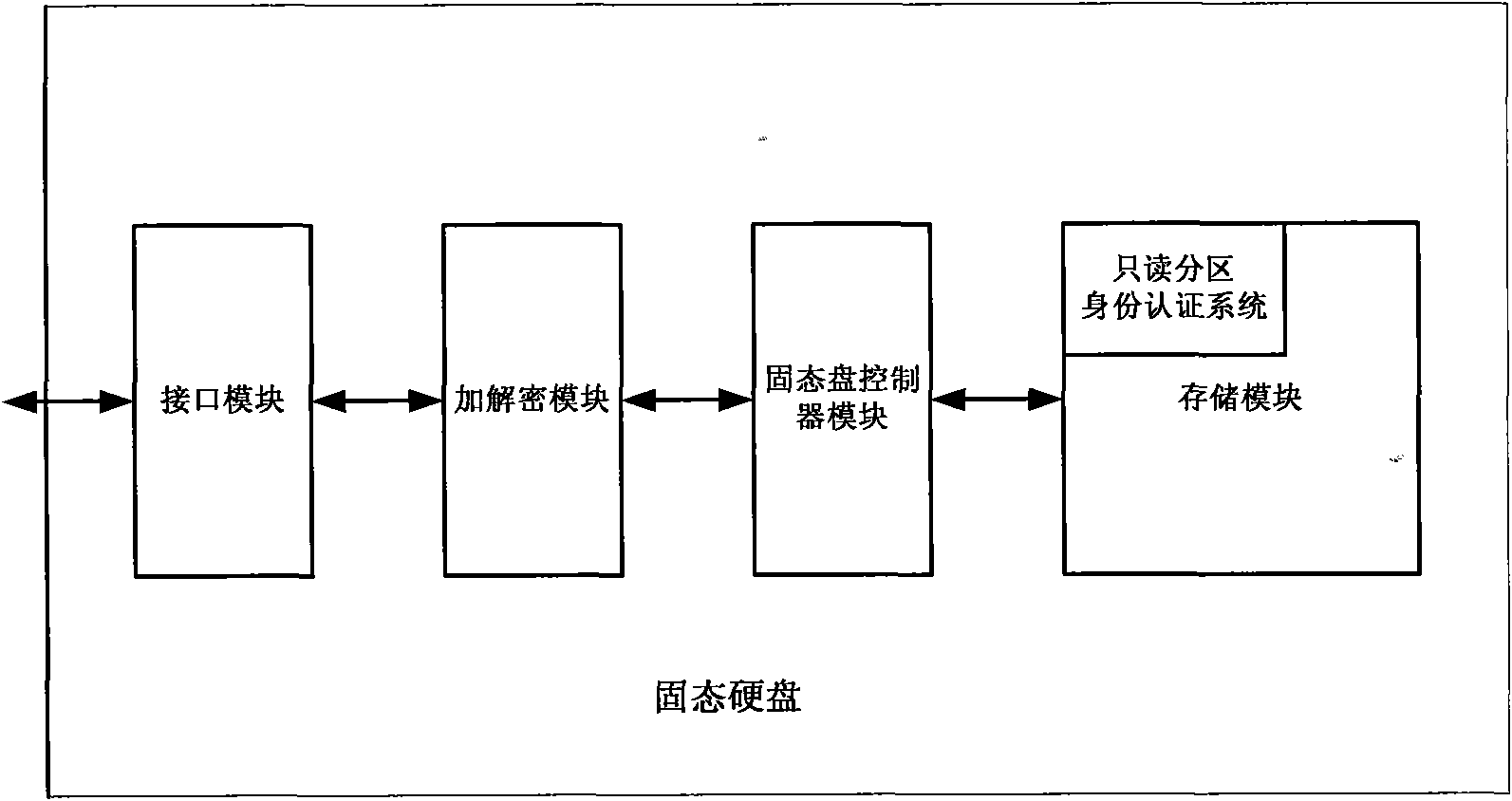

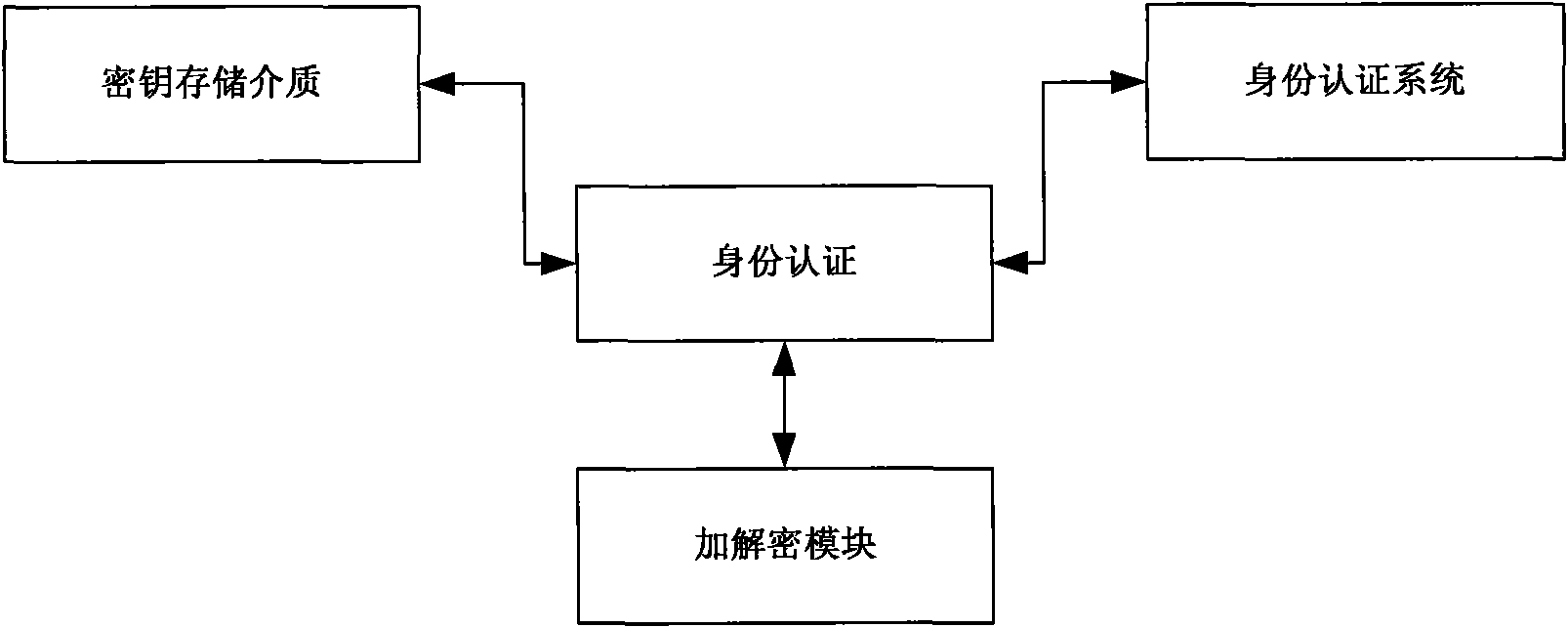

Solid state hard disk secure encryption system

InactiveCN101788959AImprove securityWill not modifyUnauthorized memory use protectionSolid-state driveKey storage

The invention relates to a solid state hard disk secure encryption system. The encryption system comprises a main engine, a solid state hard disk, and a key and identity authentication system, wherein the solid state hard disk, the key and identity authentication system are arranged on the main engine; the solid state hard disk comprises an encryption and decryption module, a solid state hard disk control module and a storage module; the identity authentication system is stored in the storage module; and the key is stored on key storage media except the solid state hard disk. Compared with the prior art, in the system, the key of the invention is stored on the key storage media (such as USB KEY, other storage devices or servers and the like) except the solid state hard disk, so that the key, the main engine and the solid state hard disk are separated, and the media for storing the key can be stored into other places, thereby improving the security of the solid state hard disk secure encryption system.

Owner:WUHAN SOLIC CZECHOSIOVAKIA DATA SCI & TECH

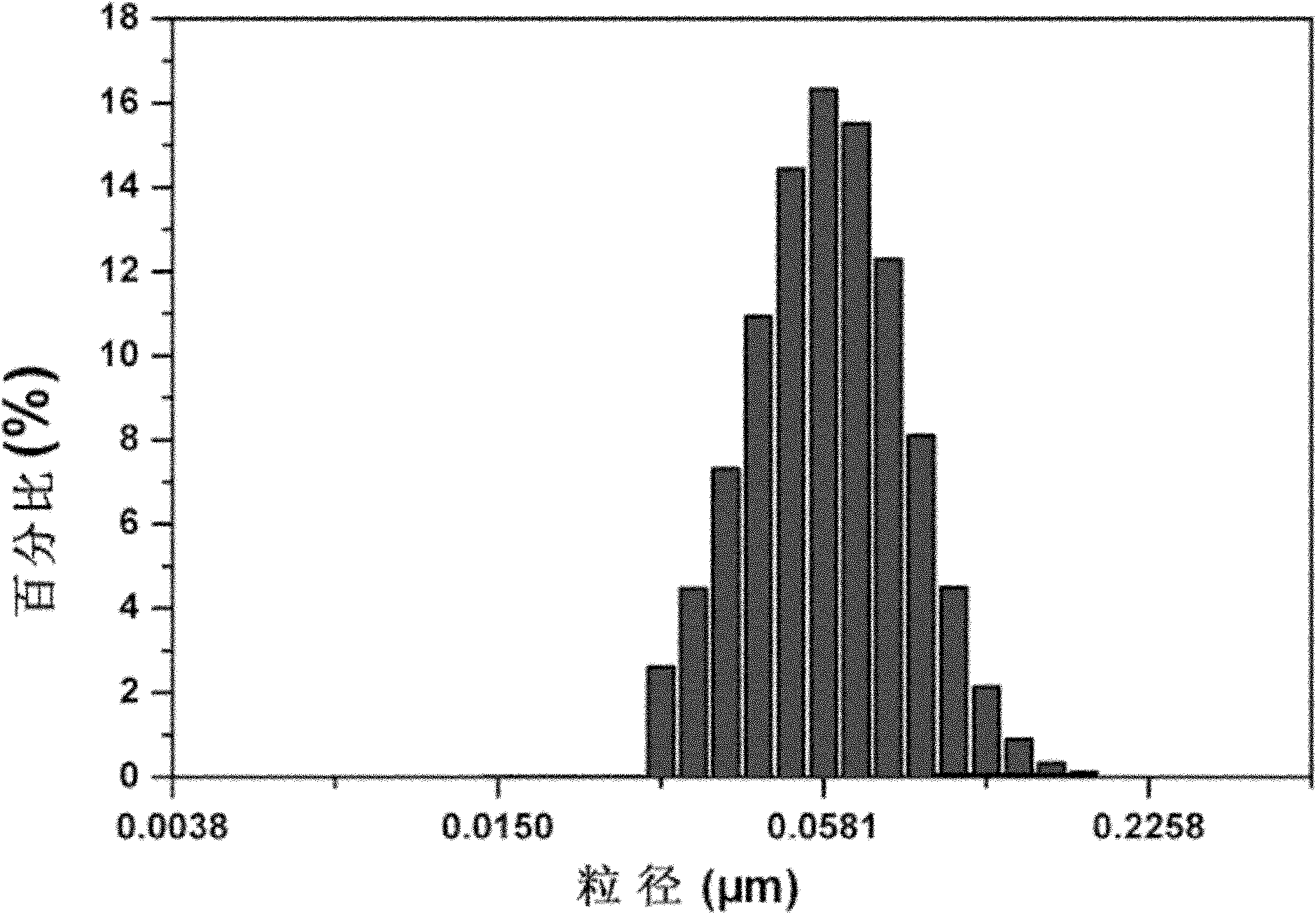

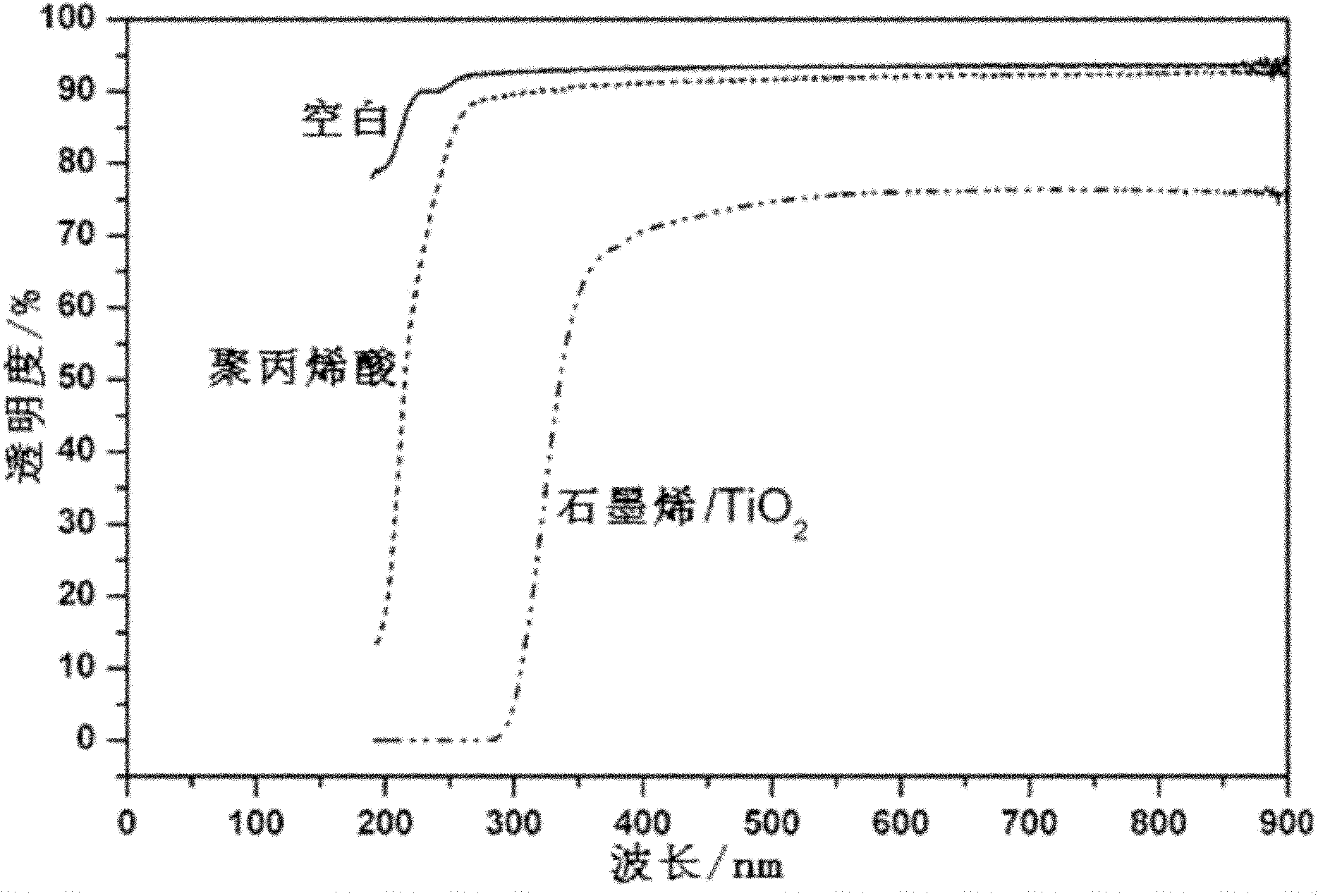

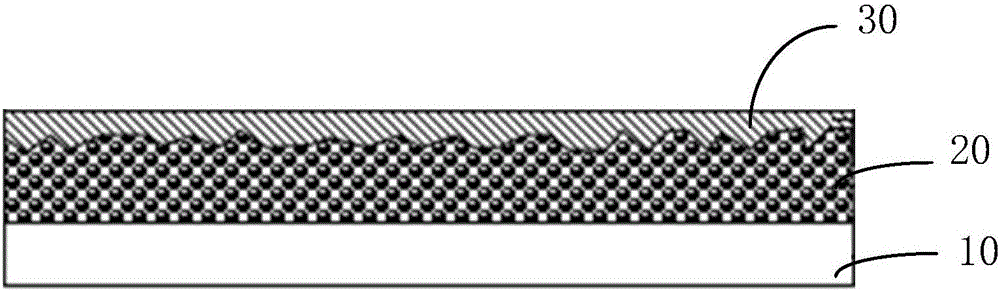

Graphene/TiO2-based near-infrared/ultraviolet radiation resistant polymer composite film and preparation method thereof

The invention relates to a graphene / TiO2-based near-infrared / ultraviolet radiation resistant polymer composite film and a preparation method thereof, relating to a near-infrared / ultraviolet radiation resistant composite film and a preparation method thereof. The invention aims to solve the problems of the existing heat reflecting material such as poor heat insulation effect, low transparency, serious light pollution and high production cost and the like. The composite film is prepared by adding the mixed liquid of graphene oxide dispersion and nano-TiO2 dispersion in the curing system of epoxy acrylate at a volume ratio of 1-10:50. The preparation method comprises the following steps: 1) preparing graphene oxide; 2) preparing TiO2 nanoparticles; 3) preparing nanometer graphene / TiO2 composite; and 4) preparing the graphene / TiO2-based near-infrared / ultraviolet radiation resistant polymer composite film. The composite film is mainly used for the glass coating of a building or means of transport for running an air-conditioning system.

Owner:HARBIN INST OF TECH

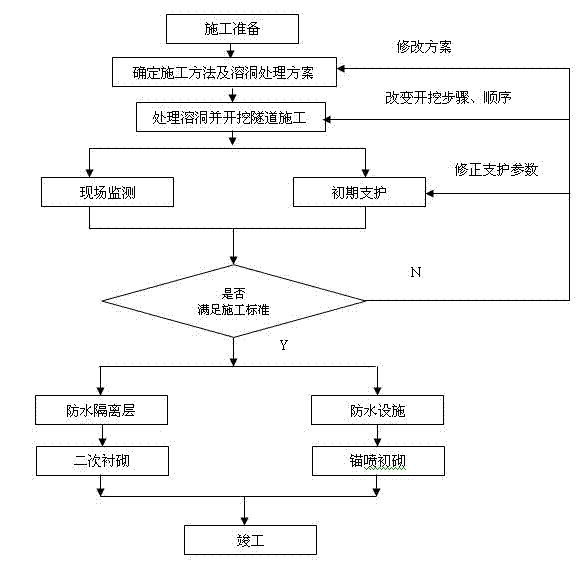

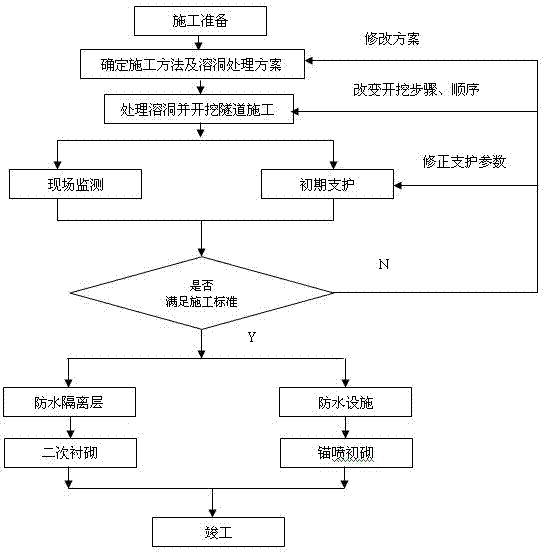

Construction technology for allowing tunnel to pass through ultra-large karst cave

ActiveCN102383806ADo not delay the construction periodQuality assuranceUnderground chambersFoundation engineeringShotcreteMesh reinforcement

The invention relates to a construction technology for allowing a tunnel to pass through a karst cave, and in particular relates to a construction technology for allowing a tunnel to pass through an ultra-large karst cave. The technology at least comprises the following steps of: 1) performing simple bridge treatment on the underground part of the karst cave; 2) performing primary support, namelyarranging a support wall at one side of the karst cave; 3) forming parallel guide holes; 4) performing bottom treatment; 5) treating the tunnel hole body at the inlet section of the karst cave; 6) filling C25 early strength sprayed concrete within 1 meter at the top of the support wall, and arranging phi 50 small grouting conduits with the lengths of 3 meters in the concrete, wherein the distancebetween the small conduits is 1.5 meters; 7) supporting the arch part and the side wall surrounding rock of the karst cave by adopting phi 22 cartridge anchor rods arranged in a plum blossom shape and at a distance of 150cm*150cm, hanging phi6 reinforcing meshes at a distance of 15cm*15cm, and spraying C25 early strength concrete with the thickness of 15 centimeters; 8) treating the accumulation of the karst cave; and 9) monitoring and measuring when the tunnel passes through the ultra-large karst cave. The construction technology for allowing the tunnel to pass through the ultra-large karst cave is simple in process, convenient for construction, low in cost, scientific, effective, energy-saving and environmentally-friendly.

Owner:CCCC SHEC DONGMENG ENG CO LTD

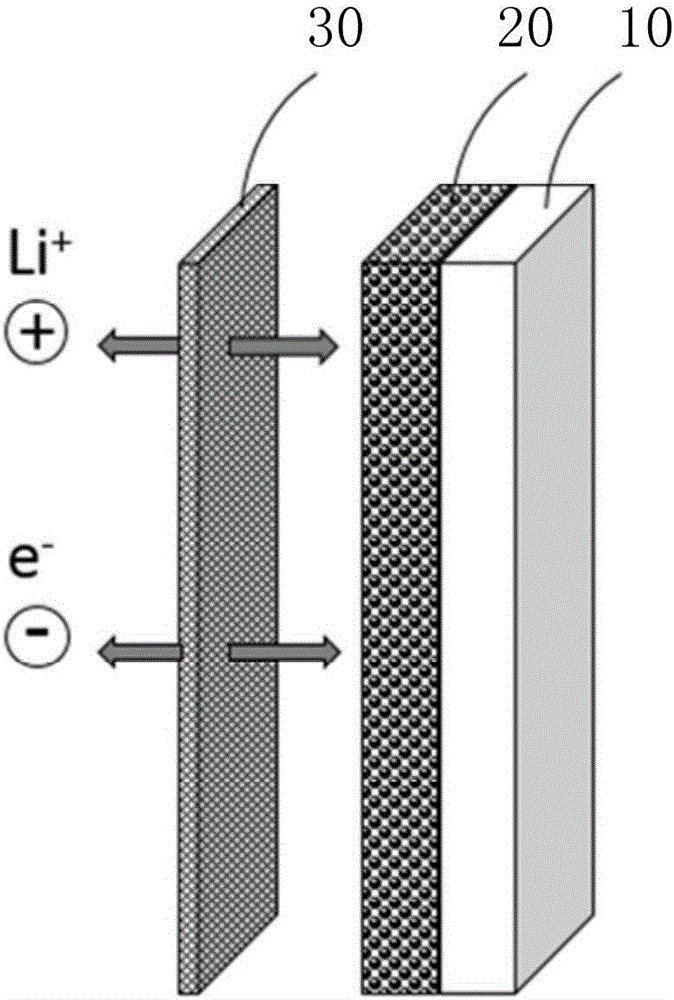

Lithium ion battery negative electrode comprising diamond-like thin film layer, preparation method for negative electrode, and lithium ion battery

InactiveCN106684387AImprove conductivityHigh mechanical strengthCell electrodesSecondary cellsElectrical batteryElectrochemistry

The invention provides a lithium ion battery negative electrode comprising a diamond-like thin film layer. The negative electrode comprises a conductive current collector, a negative electrode active material layer arranged on the conductive current collector and a diamond-like thin film layer deposited on the surface of the negative electrode active material layer; and the diamond-like thin film layer comprises doped elements, wherein the doped elements comprises one or more of Si, B, N, P, Al, Be, Mg, Ti, Cr, W, Fe, Zr, Pt, Mo, Co, Ni and Sb. According to the lithium ion battery negative electrode, the diamond-like thin film layer is deposited on the surface of the negative electrode active material layer, and the diamond-like thin film layer has excellent electrochemical inertness and conductivity and high mechanical strength, so that occurrence of an unstable SEI layer on the surface of the negative electrode active material is avoided, and the cycling stability of the electrode is greatly improved. The invention also provides a preparation method for the lithium ion battery negative electrode, and the lithium ion battery.

Owner:SHENZHEN INST OF ADVANCED TECH

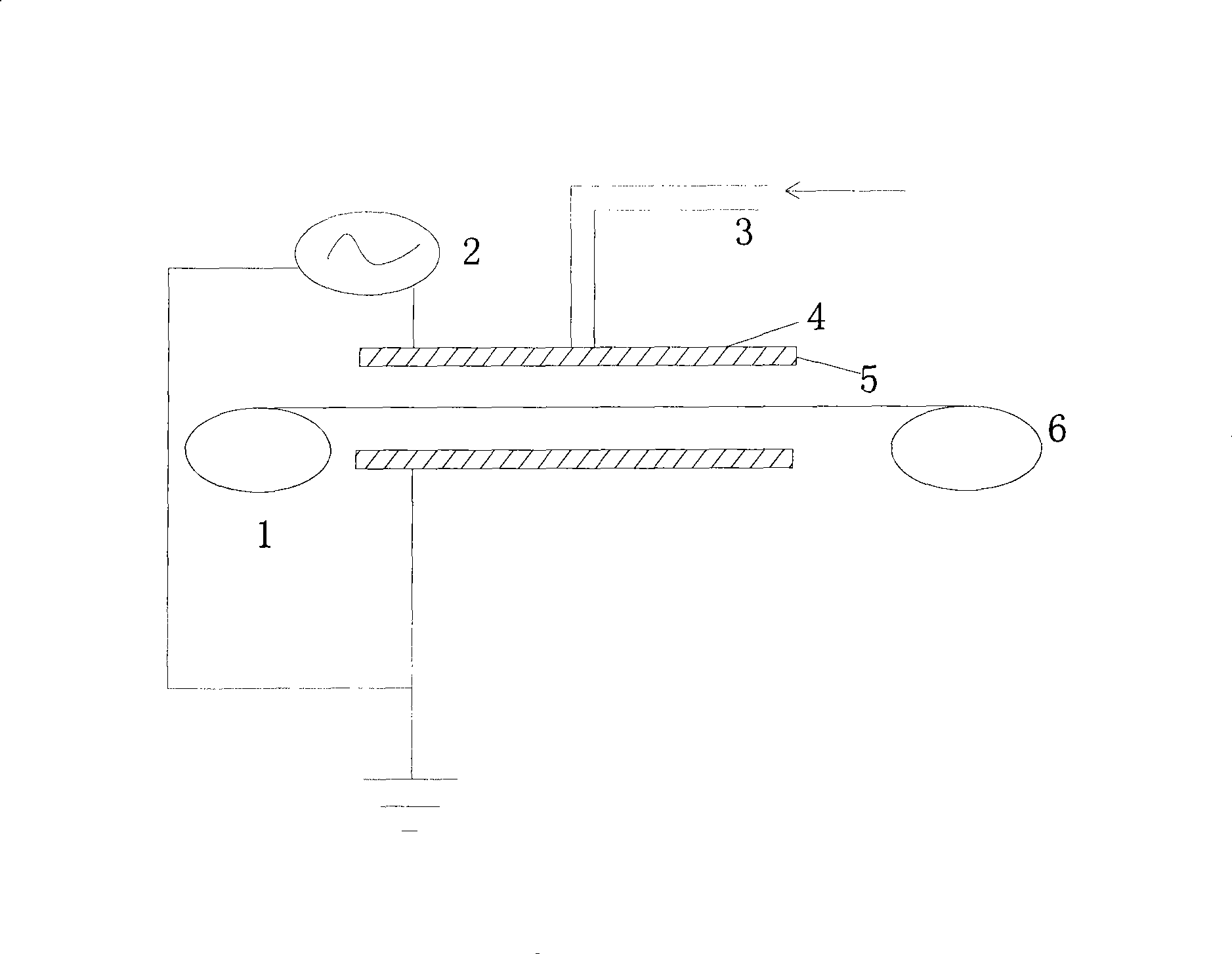

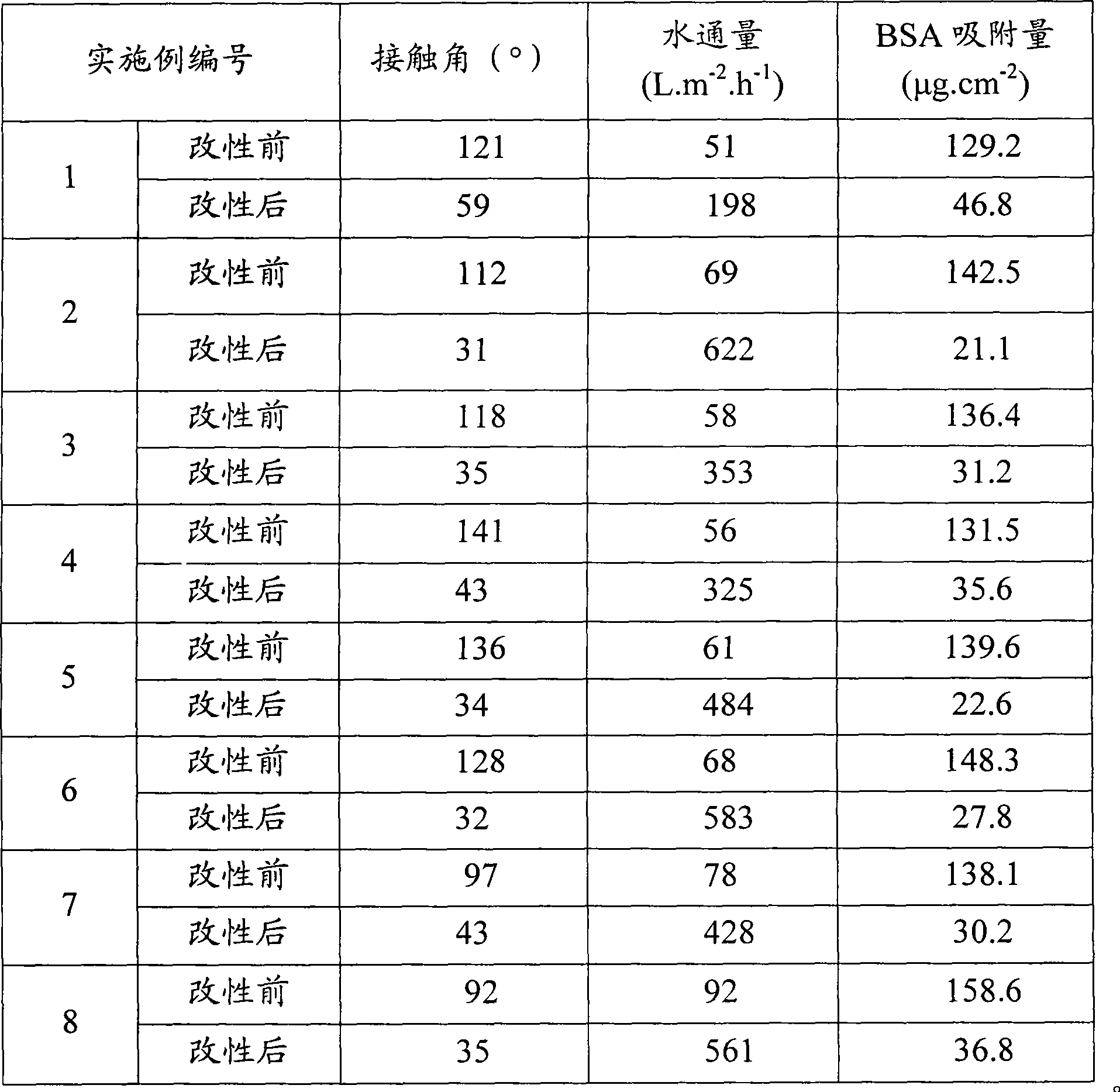

Hydrophilic modification method of polymer microporous film

InactiveCN101439265ANot easy to cause pollutionEasy to achieve continuous modificationSemi-permeable membranesPolymer scienceMonomer

The invention discloses a method of atmospheric dielectric barrier discharge plasma to carry out polymer microporous membrane hydrophilic modification. The method comprises the following steps: (1) the polymer microporous membrane is cleaned clearly, dried and then arranged into the solution of an organic monomer for dipping; after the surface of the microporous membrane absorbs the organic monomer, the microporous membrane is taken out and aired; (2) the polymer microporous membrane treated by the step (1) is arranged between the two discharge electrodes of the dielectric barrier discharge to carry out atmospheric dielectric barrier discharge plasma treatment; (3) the polymer microporous membrane treated by step (2) is cleaned and then dried. The method has the characteristics of simple technique, convenient operation, quick processing speed, good and durable processing effect, low cost, being not easy to cause environment pollution, energy saving, and the like.

Owner:ZHEJIANG UNIV

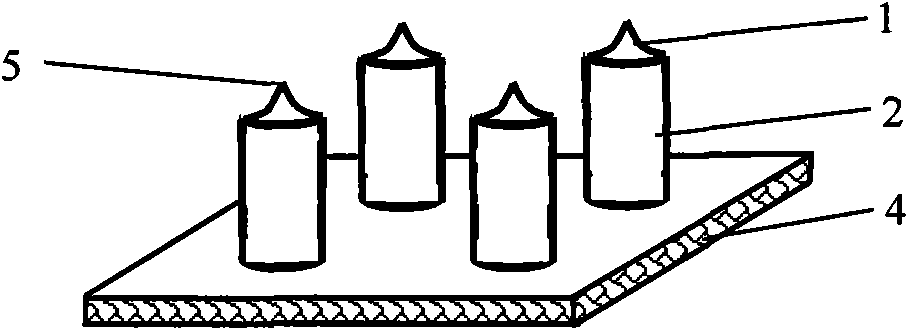

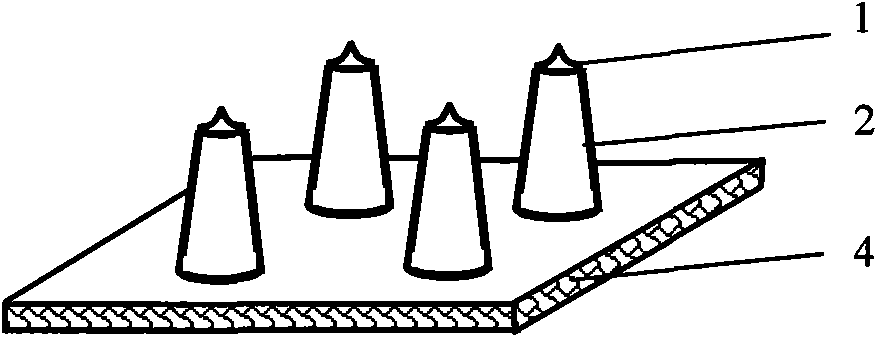

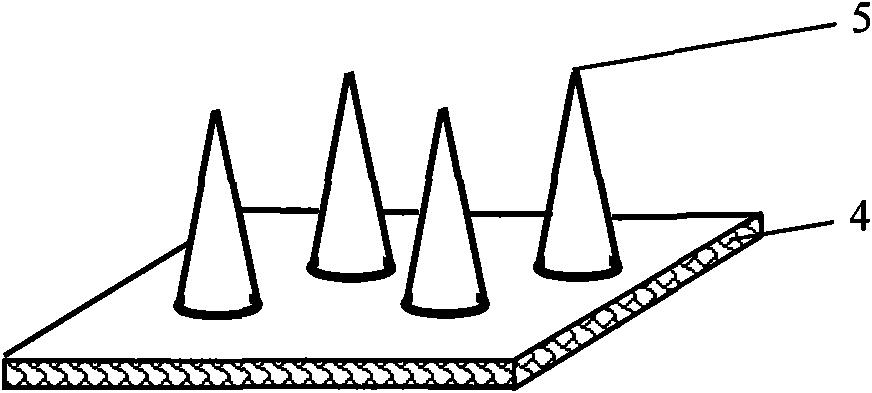

Micro-needle array chip and percutaneous administration patch using same and preparation method thereof

ActiveCN101829396AStable structureImprove consistencyMicroneedlesPharmaceutical delivery mechanismAcute angleBiomedical engineering

The invention discloses a micro-needle array chip, which comprises a micro-needle and a substrate. The micro-needle consists of a needle head, a needle rod and a needle base; the top of the needle head is provided with a needle point; the micro-needle is fixed on the substrate through the needle base; the needle rod of the micro-needle is cylindrical or conical; the needle rod is inclined to the substrate at a set angle; and the needle head is conical or the upper surface of the needle point is an elliptical plane which is parallel to the substrate or inclined to the substrate at a set acute angle. The metal micro-needle in the micro-needle array chip is firm in structure and cannot rupture; the needle point is sharp and convenient to puncture; the maximum puncture depth of the micro-needle is easily regulated and controlled; the micro-needle in the array has good consistency and are safe and reliable to use; and the hollow micro-needle has a side opening similar to that of the traditional needle. Therefore, the micro-needle array chip can effectively avoid the phenomenon that the skin blocks the infusion hole, is more favorable for rapid diffusion and absorption of medicaments, and has obvious curative effect.

Owner:TSINGHUA UNIV

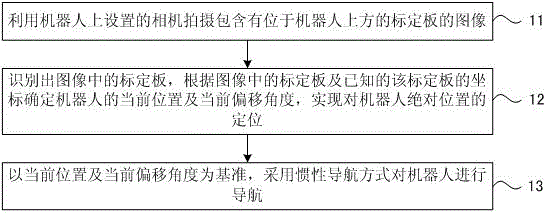

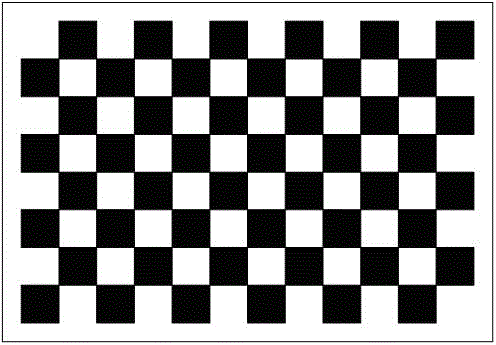

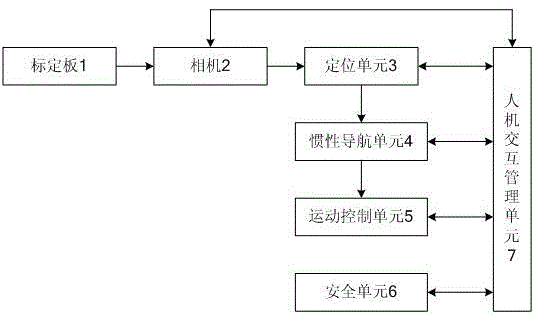

Indoor robot positioning navigation method and device

ActiveCN105486311AImprovement error is largeOvercome high costNavigational calculation instrumentsNavigation by speed/acceleration measurementsRobot positionMarine navigation

The invention discloses an indoor robot positioning navigation method and device. The method comprises using a camera on a robot to shoot an image containing a calibration plate positioned above the robot; using an image processing technology to recognize the calibration plate in the image, determining a current position and a current deviation angle of the robot according to the calibration plate in the image and known coordinates of the calibration plate, and positioning absolute positions of the robot; by taking the current position and the current deviation angle as a reference, navigating the robot by adopting an inertia navigation manner. By using the invention, problems of low positioning precision, high cost, inconvenient use and narrow use range of the existing positioning navigation method are solved.

Owner:苏州海通机器人系统有限公司

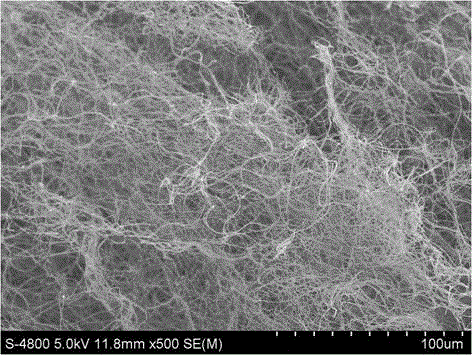

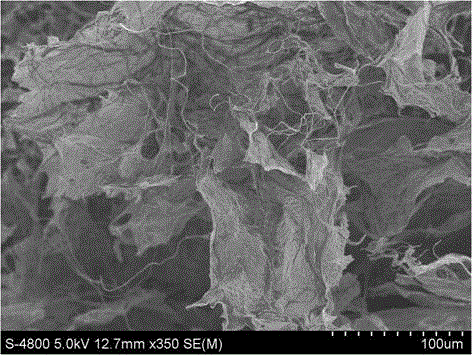

Three-dimensional oil-water separating material based on static spinning technology and preparation method thereof

ActiveCN104674384AWon't breakImprove continuityFilament/thread formingArtificial filament heat treatmentFiberPolymer science

The invention provides a three-dimensional oil-water separating material based on the static spinning technology and a preparation method thereof, belonging to the technical field of water treatment. The method specifically comprises the following steps: (a) preparing a static spinning solution; (b) selecting a proper solvent to directly receive static spinning nano fibers to obtain a nano fiber solution; (c) shaping and freezing the nano fiber solution, and drying through a freezing drying machine to obtain the three-dimensional nano fibers; (d) pre-oxidizing, carbonizing and activating the three-dimensional nano fibers to obtain three-dimensional carbon nano fibers; (e) wrapping the three-dimensional carbon nano fiber glue with lipophilic and hydrophobic films so as to obtain the final three-dimensional oil-water separating material. According to the preparation method of the three-dimensional oil-water separating material, the composition and structure of the material are easily controlled; the mechanical performance and hydrophobic performance of the materials can be effectively improved; the oil-water separating effect is good; the material can be recycled and has a wide application prospect in the oil-water separation field.

Owner:INST OF URBAN ENVIRONMENT CHINESE ACAD OF SCI +1

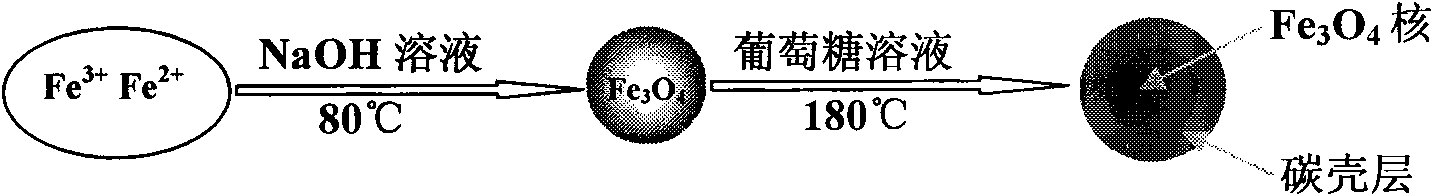

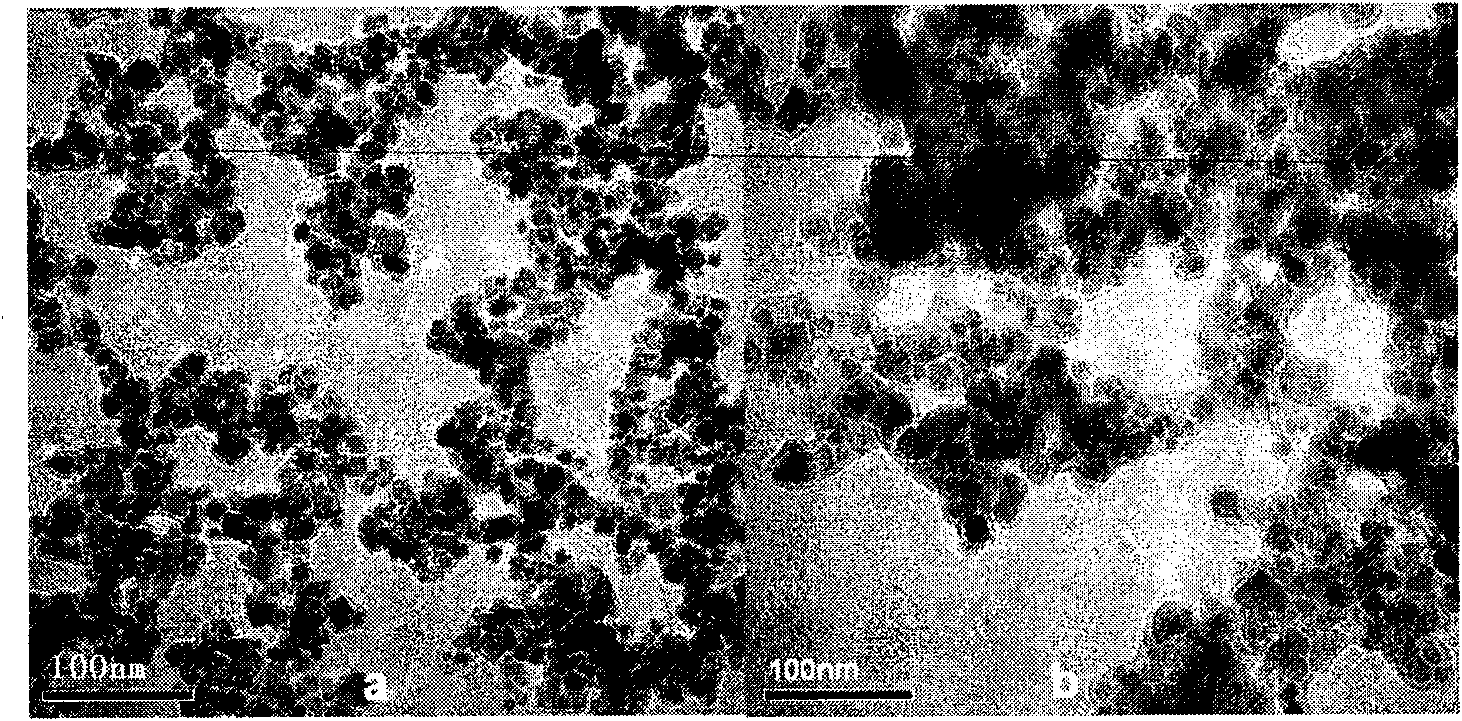

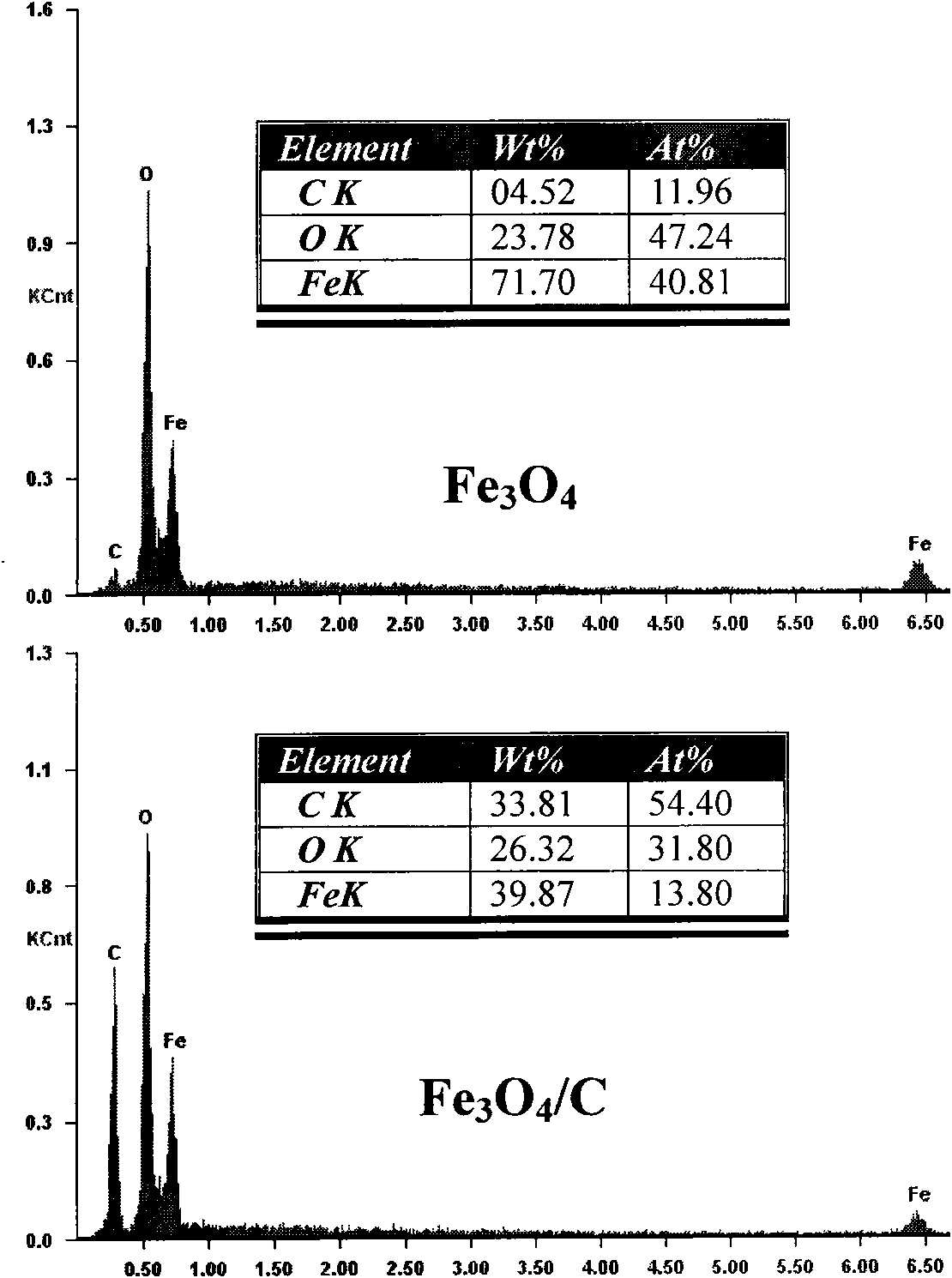

Preparation method and application of core-shell type Fe3O4/C magnetic nano solid extracting agent

InactiveCN101664668AStrong extraction abilityFast processingOther chemical processesInorganic material magnetismSolid phase extractionSorbent

The invention relates to a Fe3O4 / C magnetic nano solid extracting agent coated with a novel carbon material, belonging to the field of chemical analysis and test instruments and equipment. The extracting agent simultaneously has large special surface area of nano material, short disperse path, magnetic separation capacity of magnetic material and strong adsorption capacity of carbon material, thereby being very suitable for pretreating large-scale and large-size water samples in batch. In addition, the solid extracting agent is simple to prepare, low in raw material cost, rapid and convenientto extract and friendly to the environment and only needs using a small amount of organic solvent in the whole process.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

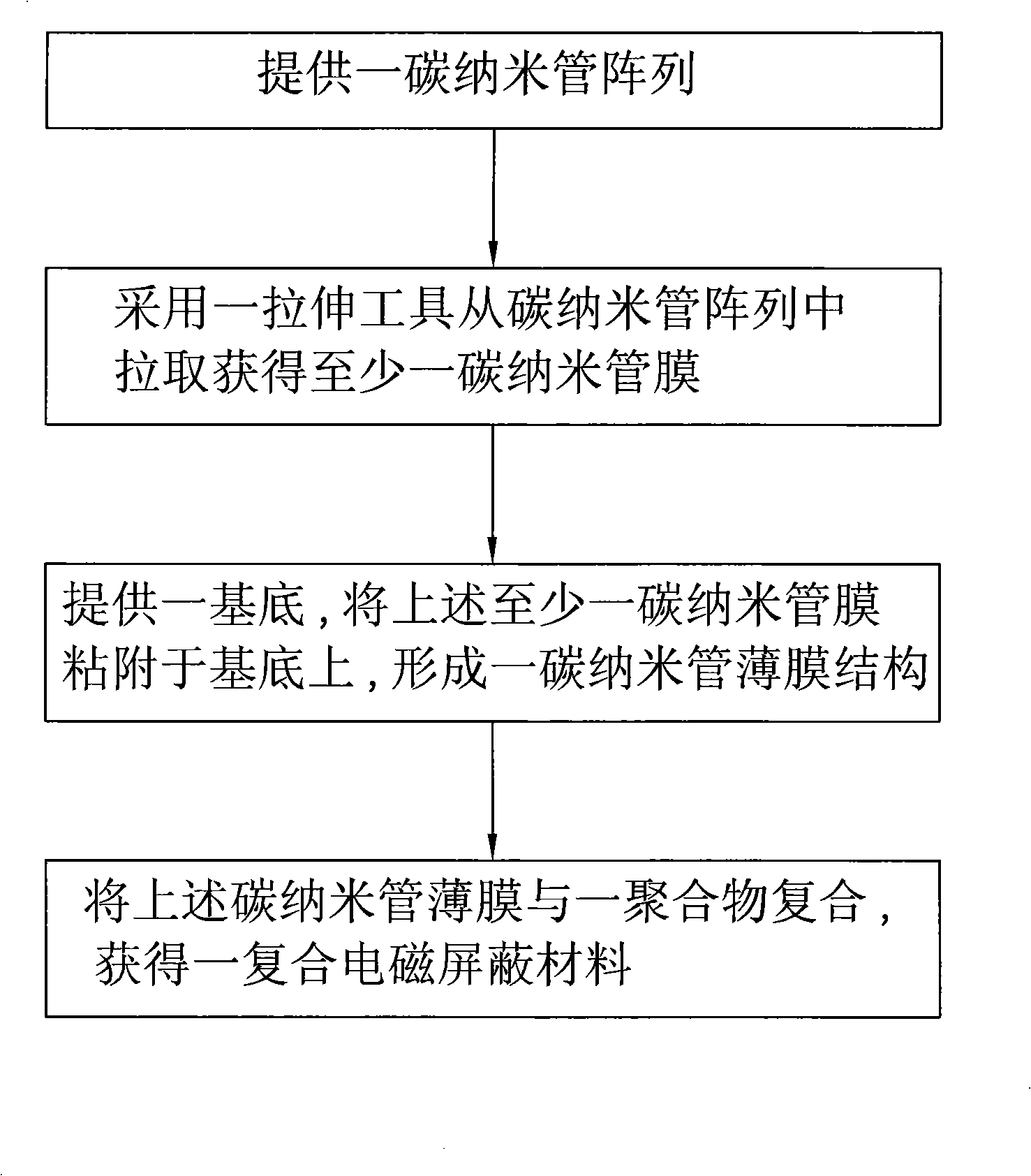

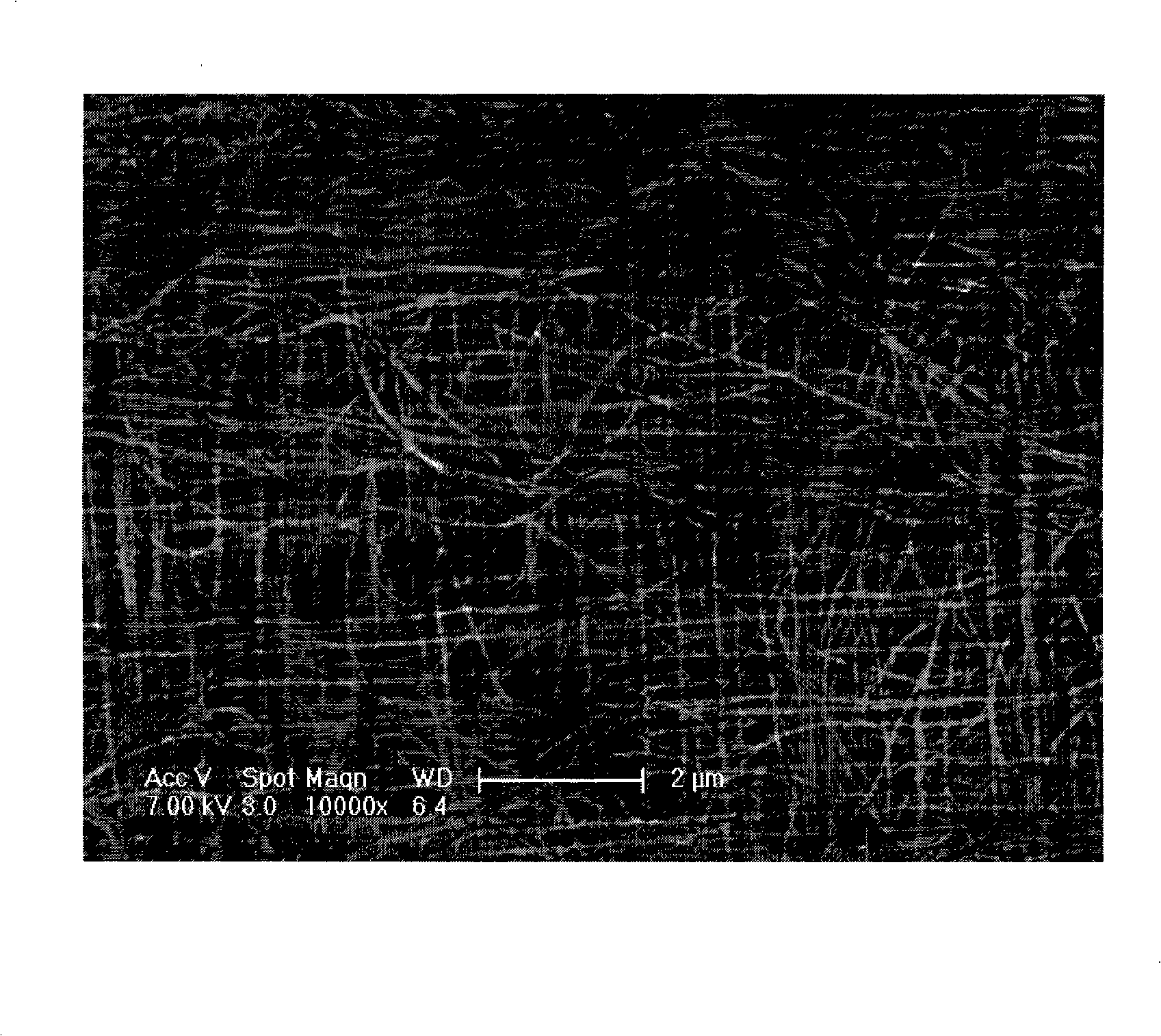

Composite electromagnetic shielding material and preparation method thereof

ActiveCN101409999AUnrestricted contentWide range of choicesLamination ancillary operationsMagnetic/electric field screeningResidual carbonCarbon nanotube

The invention provides a composite electromagnetic shielding material, comprising a polymer and a plurality of carbon nano-tubes; wherein, a plurality of carbon nano-tubes are arranged in the polymer in the form of carbon nano-tube film. A preparation method used for preparing the composite electromagnetic shielding material comprises the steps as follows: a carbon nano-tube array is provided; atleast a carbon nano-tube film is gained by the pulling in the carbon nano-tube array by a tensile tool; a substrate is provided; at least a carbon nano-tube film is attached to the substrate, thus forming the carbon carbon-tube film structure and removing the residual carbon nano-tube film structure out of the substrate; the carbon nano-tube film structure is composed with the polymer, thus gaining the composite electromagnetic shielding material.

Owner:TSINGHUA UNIV +1

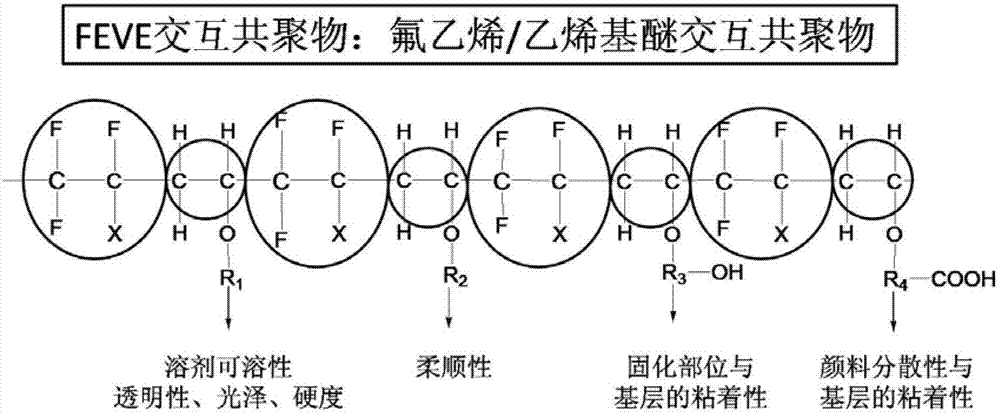

Self-cleaning super-weather-proof powder paint and preparation method thereof

ActiveCN103194140AImprove stabilityProtect against agingPowdery paintsPolyester coatingsPolyesterAging resistance

The invention belongs to the field of powder paints and particularly relates to a self-cleaning super-weather-proof powder paint. The self-cleaning super-weather-proof powder paint comprises a carboxyl-terminated polyester particle system and a fluorocarbon resin particle system in a weight part ratio of 4:1-1:4, wherein the fluorocarbon resin particle system contains TiO2 nano-particles. As carboxyl-terminated polyester is introduced into a pure fluorocarbon paint, the phase separation occurs in a solidification process, and the fluorocarbon resin floats up to the surface of a coating to serve as coating protection and ageing resistance; the carboxyl-terminated polyester and the like and a substrate can be well wetted, so that the coating and the substrate can be well adhered and can hardly crack and spall; as the TiO2 nano-particles only exist in a fluorocarbon phase, the resin on a bottom layer cannot be broken, and the excellent stability of the system is guaranteed; and the TiO2 nano-particles are scattered in a dry blending manner, and the complex preprocessing is avoided, so that the preprocessing process can be greatly shortened, the cost is lowered, and the efficiency is improved.

Owner:NINGBO SOUTH SEA CHEM

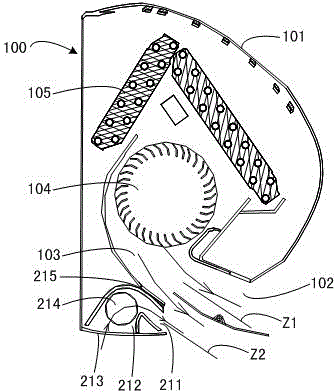

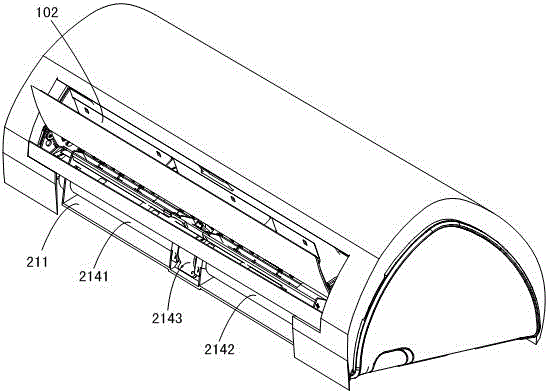

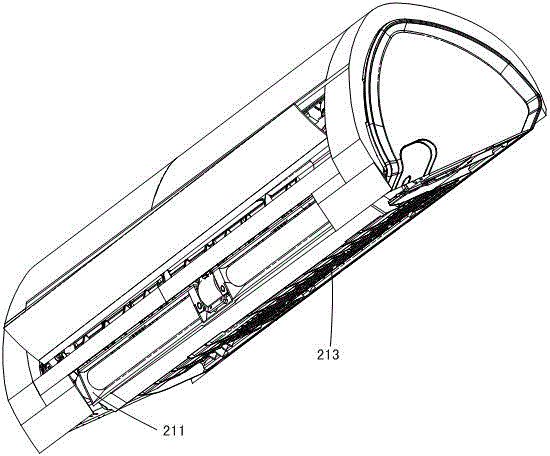

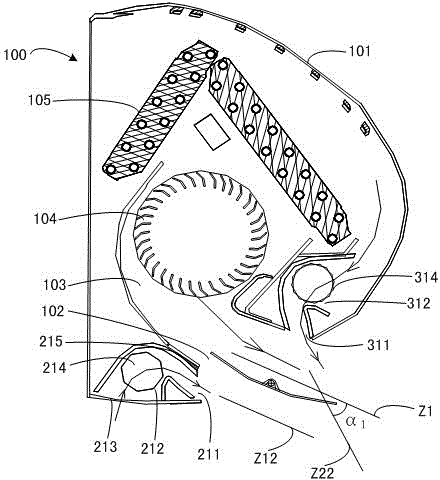

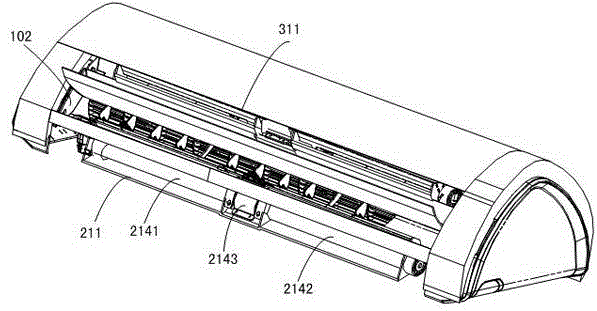

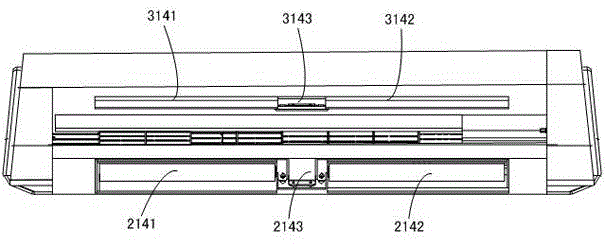

Wall-hanging type air conditioner

ActiveCN104896591AIncrease the total air volume of the air supplySpeed up the flowLighting and heating apparatusAir conditioning systemsInjection airWaste management

The invention discloses a wall-hanging type air conditioner, which comprises an indoor machine, wherein the indoor machine comprises a shell body; a heat exchanger and a main air duct are formed inside the shell body; a main air inlet and a main air outlet that is communicated with the main air duct are formed on the shell body; a main injection air blower that is used to blow out the heat exchanged air after being exchanged by the heat exchanger from the main air outlet is formed inside the main air duct; a drainage air outlet is formed on the shell body below the main air outlet; a drainage air duct separate from the main air duct is formed inside the shell body below the main air duct; the drainage air duct is communicated with the drainage air outlet; a drainage blower is formed inside the drainage air duct; and the drainage blower is used to lead the heat non-exchanged air to the drainage air duct and blow the heat non-exchanged air out from the drainage air outlet through the drainage air duct. By utilizing the wall-hanging type air conditioner provided herein, mixed air sending can be realized on the bases that the main air duct is not changed.

Owner:QINGDAO HAIER AIR CONDITIONER GENERAL CORP LTD

Microcapsule for self-repair concrete and preparation method of self-repair concrete

InactiveCN104944833AEasy to operateWon't breakMicroballoon preparationMicrocapsule preparationIntelligent controlWall material

The invention discloses a microcapsule for self-repair concrete and a preparation method of the self-repair concrete. The microcapsule comprises a capsule core and a capsule wall, wherein the capsule core is composed of a repair agent, microcrystalline cellulose and Tween 80; and the capsule wall material is a crack-stress-sensitive high-polymer organic material. The preparation method of the self-repair concrete comprises the following steps: weighing proper amounts of cement, sand, water and the microcapsule, wherein every cubic meter of concrete contains 0.05-0.08 cubic meter of microcapsule; stirring the cement, sand and microcapsule until the components are dispersed uniformly; and pouring the water into the mixture of the cement, sand and microcapsule, and stirring uniformly. The microcapsule can be doped into the concrete to form the microcapsule concrete self-repair system, thereby implementing self-repair capability of the concrete crack; and the microcapsule concrete self-repair system has the characteristic of intelligent control.

Owner:SHENZHEN UNIV

Coaxial compound nanometre fibre film as well as preparation method and application thereof

ActiveCN102230257AImprove permeabilityHigh tensile strengthFilament/thread formingCell component detailsFiberPolymer science

The invention discloses a coaxial compound nanometre fibre film composed of compound nanometre fibres of a fluorine-containing polymer skin layer and a polyimide core layer, wherein the upper and the lower surfaces and inner holes of the film are distributed symmetrically. The coaxial compound nanometre fibre film is prepared from a fluorine-containing polymer solution and a polyamic acid solution through coaxial static spinning compounding, mechanical roller pressing and thermal imidization; the nanometre fibre film provided by the invention integrates the advantages of fluorine-containing polymer and polyimide; the fluorine-containing polymer has excellent electrolyte wetting property, liquid maintaining property and ion conductivity; and the polyimide has high mechanical strength and high heat resistance. The compound nanometre film provided by the invention is fit for high-energy lithium ion energy storage batteries and high-power electrokinetic cells.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

Device and method for detecting interior initial stress of steel structural member based on ultrasonic method

ActiveCN104142195AWon't breakSimple structureAnalysing solids using sonic/ultrasonic/infrasonic wavesForce measurementPath distanceMaterials science

The invention provides a device and method for detecting the interior initial stress of a steel structural member based on the ultrasonic method. According to the method for detecting the interior initial stress of the steel structural member based on the ultrasonic method, the interior initial stress sigma of the steel structural member is solved by firstly calibrating the acoustic elasticity coefficient B of the fixed sonic path distance of a replica of the steel structural member in service and then detecting the change of the acoustic time t of ultrasonic waves in the steel structural member in service. An existing method for nondestructive detection of the stress of a steel structural member mainly has the disadvantages that only the change of the stress can be detected, and the intensity of the stress in the current state can not be detected; only the stress of the positions located on the surface of the steel structural member and the stress of the positions at most dozens of microns below the surface of the steel structural member can be detected, and the intensity of the stress of positions with depths of several millimeters can not be detected. The method for detecting the interior initial stress of the steel structural member based on the ultrasonic method can overcome the defects of the existing method and can be used for nondestructive detection of the interior initial stress of various steel structural members. Detections results are verified, the precision is high, the error requirement of practical engineering can be met, and the structural member can not be damaged during detection.

Owner:李祚华

Swaging manufacturing method of light aluminum alloy rim

InactiveCN101653901ASimple structureEasy to manufactureShaping toolsRimsPerformance indexNational standard

The invention relates to a swaging manufacturing method of a light aluminum alloy rim. The method comprises the following processing steps: (1) baiting; (2) heating; (3) carrying out ring rolling; (4)manufacturing a spinning blank; (5) carrying out hot spinning; (6) carrying out head back hot spinning; (7) carrying out heat treatment; and (8) fine machining the blank into a rim product. The performance indexes of the rim all reach national standards. The method only needs a pair of spinning moulds, i.e. an upper spinning mould and a lower spinning mould for processing, wherein the moulds havesimple structure, easy manufacture and low manufacturing cost. High temperature and high speed hot spinning processing is adopted so as to ensure that the metallographic structure of the rim has uniformity, refined crystalline grain, light weight, thin thickness, mechanical property improvement of the rim, high precision and good quality, and compared with a rim processed by cold spinning, the rim of the invention cannot crack and generate pinholes and has long service life. The blank processed by the method is annular and has high material utilization rate, less waste and processing amount reduction. Meanwhile, the invention provides a new variety for the rims in the car accessory market. Consumers can conveniently replace and adjust the rims of different shapes and types as required atany time without dismantling a tire so as to quickly change the type of the whole tire.

Owner:丁松伟

Wall-hanging type air conditioner

ActiveCN104896704AIncrease the total air volume of the air supplyStructure does not affectDucting arrangementsCondensate preventionPulp and paper industryDrainage flow

The invention discloses a wall-hanging type air conditioner, which comprises an indoor machine with a shell body, wherein a heat exchanger and a main air duct are formed inside the shell body; the shell body is provided with a main air inlet and a main air outlet; a main injection flow fan is formed inside the main air duct; a fisrt drainage air outlet is formed below the main air outlet on the shell body; a first drainage air duct separate from the main air duct is formed inside the shell body below the main air duct; the first drainage air duct is communicated with the first drainage air outlet; a first drainage flow fan is formed inside the first drainage air duct; the shell body is also provided with a second drainage air outlet; the second drainage air outlet is located on the outer side of the main air outlet next to an upper edge of the main air outlet; a second drainage air duct separate from the main air duct is also formed inside the shell body; the second drainage air duct is communicated with the second drainage air outlet; and a second drainage flow fan is formed inside the second drainage air duct. By adopting the wall-hanging type air conditioner provided herein, mixing ventilation can be realized on the basis that the main air duct is not changed.

Owner:QINGDAO HAIER AIR CONDITIONER GENERAL CORP LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com