Graphene/TiO2-based near-infrared/ultraviolet radiation resistant polymer composite film and preparation method thereof

A composite film, ultraviolet radiation technology, applied in coatings, epoxy resin coatings, etc., can solve the problems of low transparency, poor heat insulation effect, light pollution preparation cost, etc., and achieves low preparation cost, easy film coating, and favorable application. and promotion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

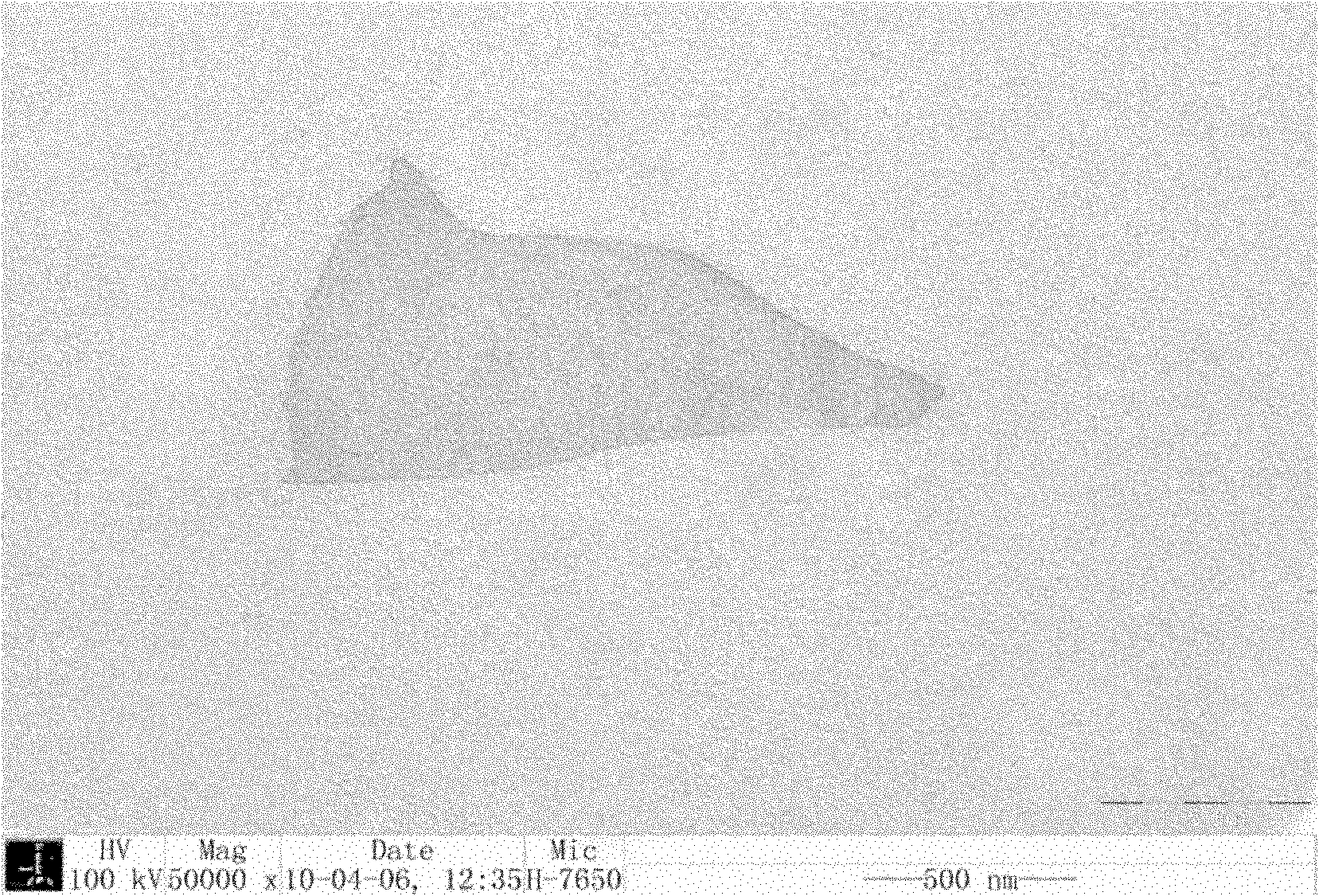

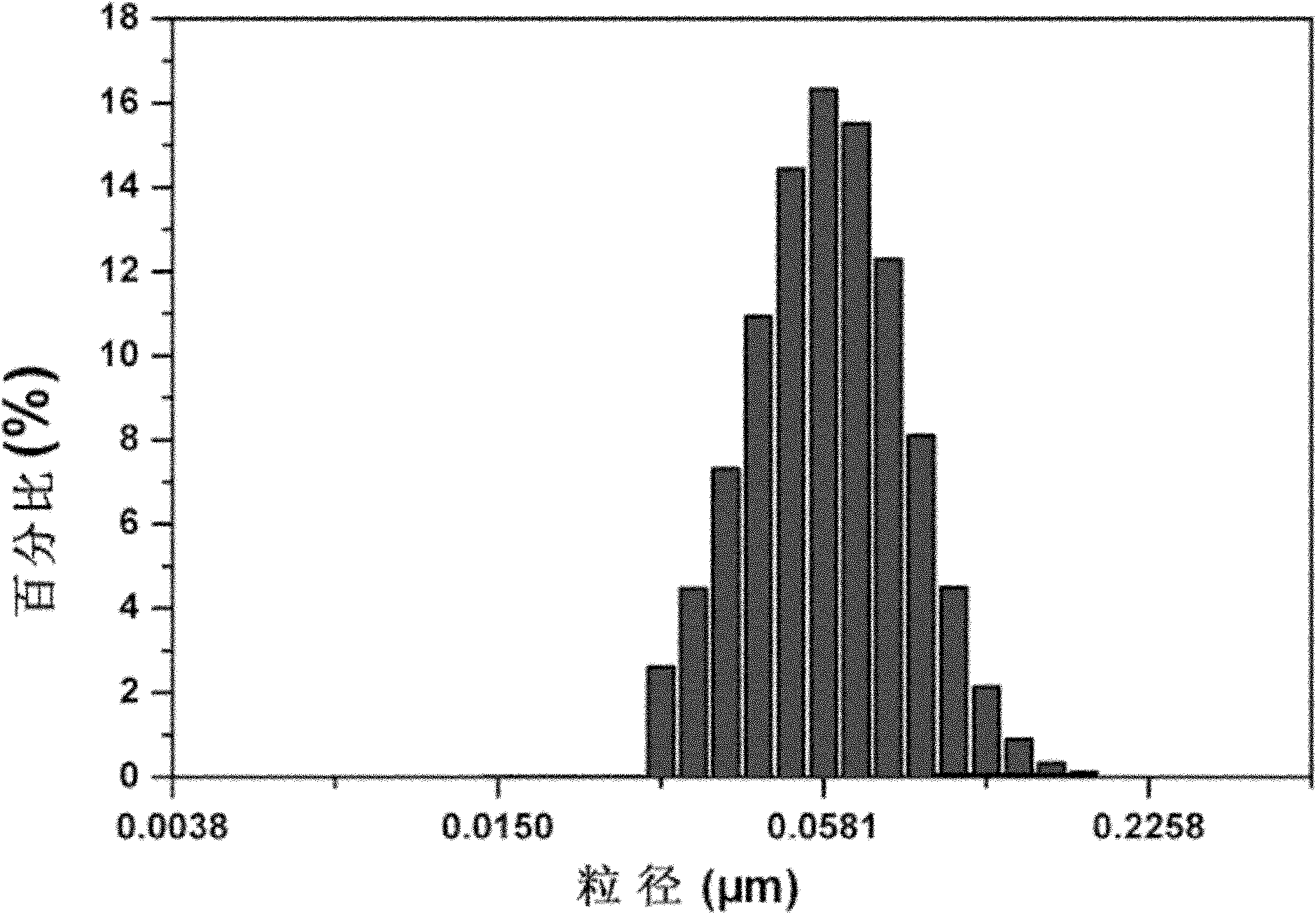

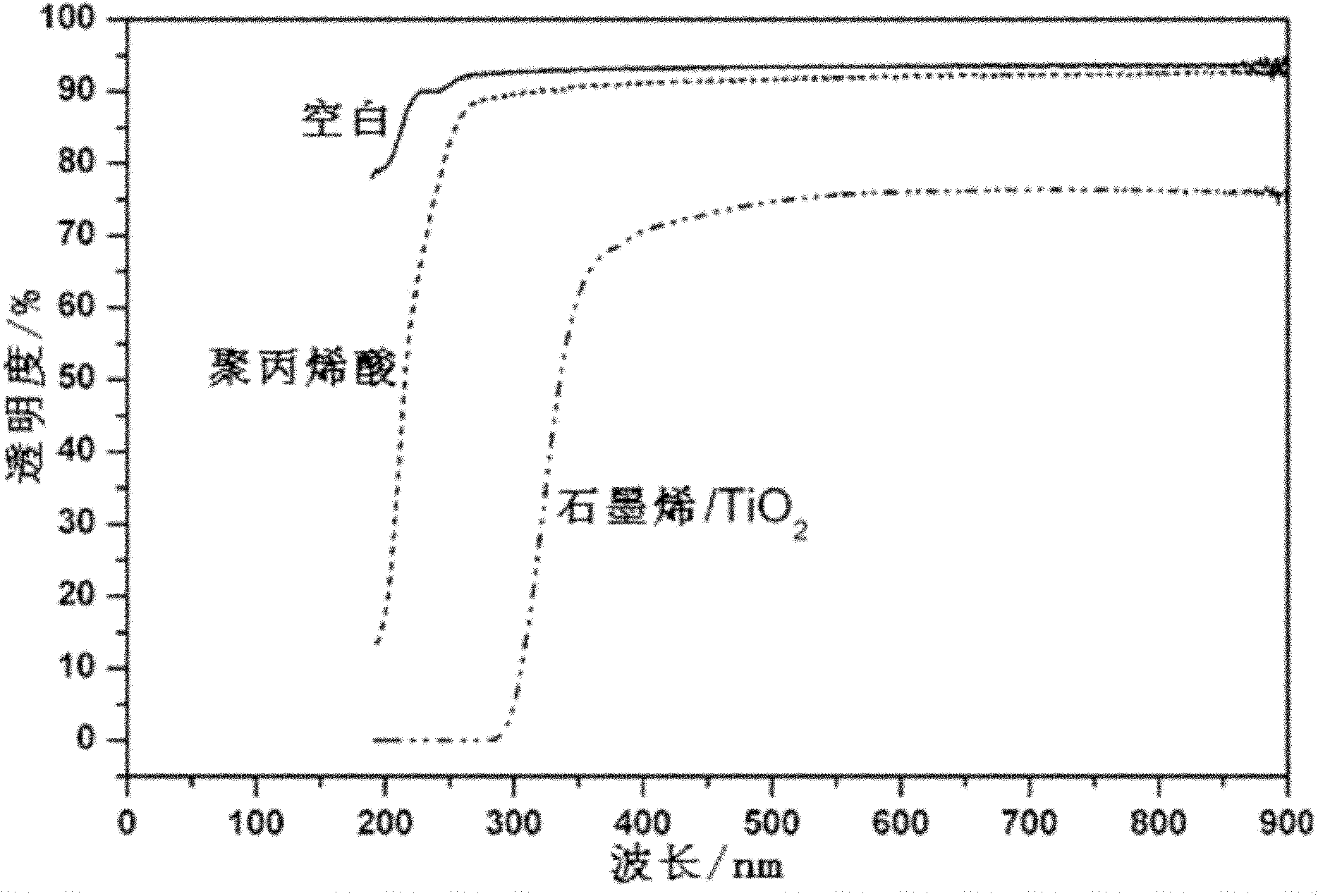

[0012] Specific implementation mode one: the present implementation mode graphene / TiO 2 The near-infrared / ultraviolet radiation-resistant polymer composite film is made by adding a mixture of graphene oxide dispersion and nano-titanium dioxide dispersion to the epoxy acrylate curing system at a volume ratio of 1 to 10:50; Wherein the mass concentration of the graphene oxide dispersion is 2% to 20%, the mass concentration of the nano titanium dioxide dispersion is 2% to 20%, and the graphene oxide dispersion and the nano titanium dioxide dispersion are mixed according to a volume ratio of 1 to 2:1 , the curing system of epoxy acrylate is mixed and stirred according to the following mass percentages: 48% to 69% of epoxy acrylate, 29% to 48% of ethoxylated trihydroxypropane triacrylate, 1-hydroxycyclohexylphenylmethanol Ketones 2% to 4%.

[0013] In this embodiment, graphene is preferred as a material with excellent photoelectric characteristics. It is also the thinnest two-dime...

specific Embodiment approach 2

[0014] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that the polymer composite film is added to the ring according to the volume ratio of 1:10 by the mixed liquid composed of graphene oxide dispersion liquid and nano-titanium dioxide dispersion liquid. Made in an oxyacrylate curing system. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0015] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is: the mass concentration of graphene oxide dispersion liquid is 10%, the mass concentration of nano titanium dioxide dispersion liquid is 10%; Graphene oxide dispersion liquid and nano titanium dioxide dispersion liquid The dispersion liquid is mixed according to the volume ratio of 1:1. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| absorbance | aaaaa | aaaaa |

| barrier rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com