Patents

Literature

3926 results about "Electron donor" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

An electron donor is a chemical entity that donates electrons to another compound. It is a reducing agent that, by virtue of its donating electrons, is itself oxidized in the process. Typical reducing agents undergo permanent chemical alteration through covalent or ionic reaction chemistry. This results in the complete and irreversible transfer of one or more electrons. In many chemical circumstances, however, the transfer of electronic charge to an electron acceptor may be only fractional, meaning an electron is not completely transferred, but results in an electron resonance between the donor and acceptor.

Process for preparing olefin polymerization ball type catalytic component and carrier

The spherical catalyst carrier is prepared with alcoholated magnesium chloride containing double-ether compound in emulsifying pelletizer. Liquid titanium halide compound is carried onto the spherical catalyst carrier to form spherical solid catalyst component in the presence of electron donor. In the X-ray diffraction spectrogram, the spherical solid catalyst component has diffraction peak in 13.3 deg of 2theta angle, strongest diffraction peak in 26.5 deg of 2theta angle and no characteristic diffraction peak of alpha-anhydrous MgCl2 in 15 deg of 2theta angle. The catalyst of the presentinvention has very high activity and may be used to produce polymer with good form, high apparent density and less fine powder. The catalyst is used in homopolymerization and copolymerization of olefin and suitable for various polymerization process.

Owner:YINGKOU XIANGYANG CATALYST

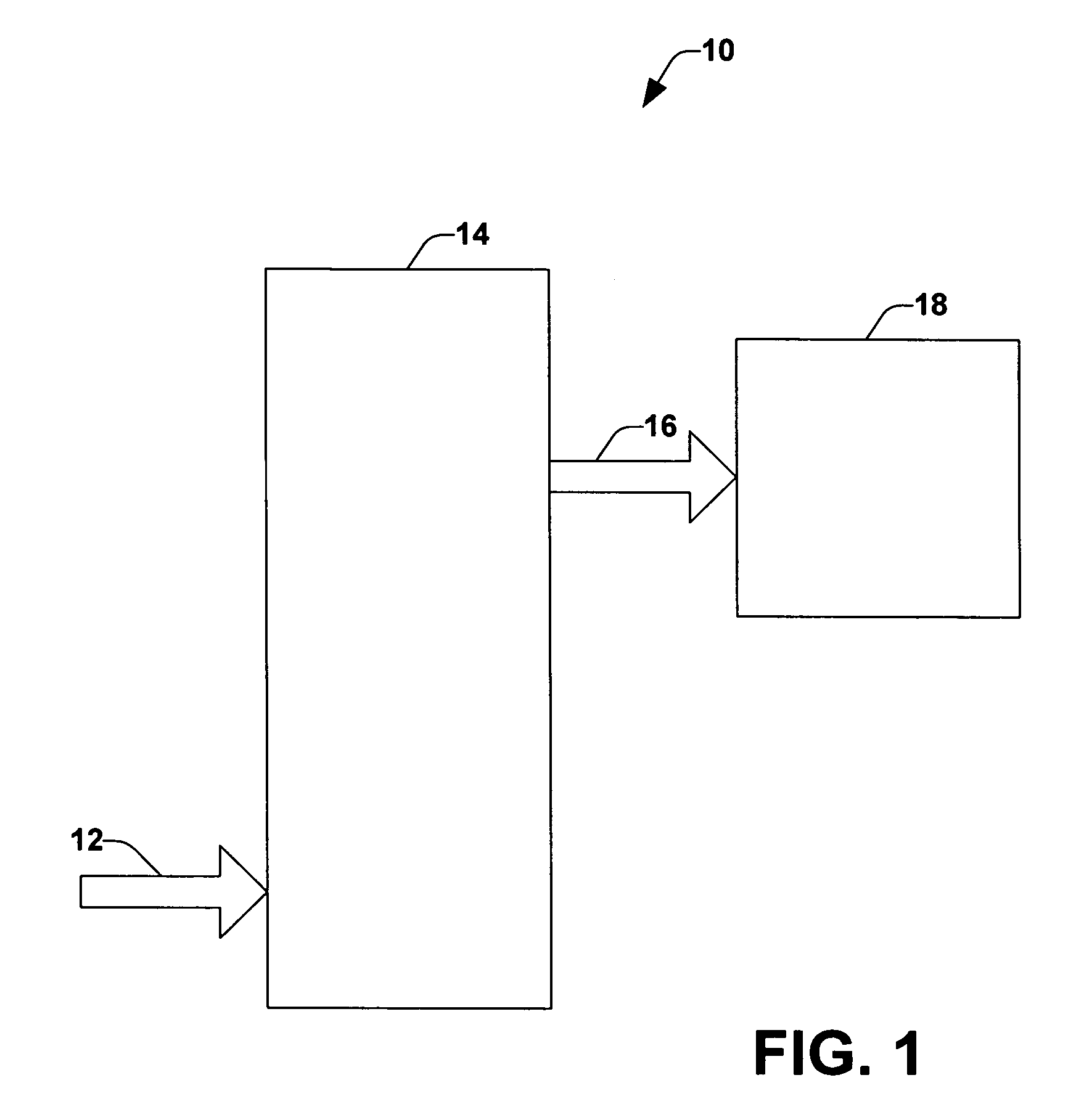

Staged reactor process

In a process for the in situ blending of polymers comprising contacting ethylene and one or more comonomers in two or more fluidized bed reactors with a catalyst system comprising (i) a magnesium / titanium based precursor containing an electron donor and (ii) a hydrocarbyl aluminum cocatalyst, the improvement comprising (A) increasing or decreasing the melt flow ratio and / or molecular weight of the blend by, respectively, decreasing or increasing the mole ratio of a precursor activator compound to the electron donor or (B) increasing or decreasing the bulk density of the blend by, respectively, increasing or decreasing the mole ratio of a precursor activator compound to the electron donor, both (A) and (B) subject to defined provisos including partial pre-activation of the precursor.

Owner:UNION CARBIDE CHEM & PLASTICS TECH CORP

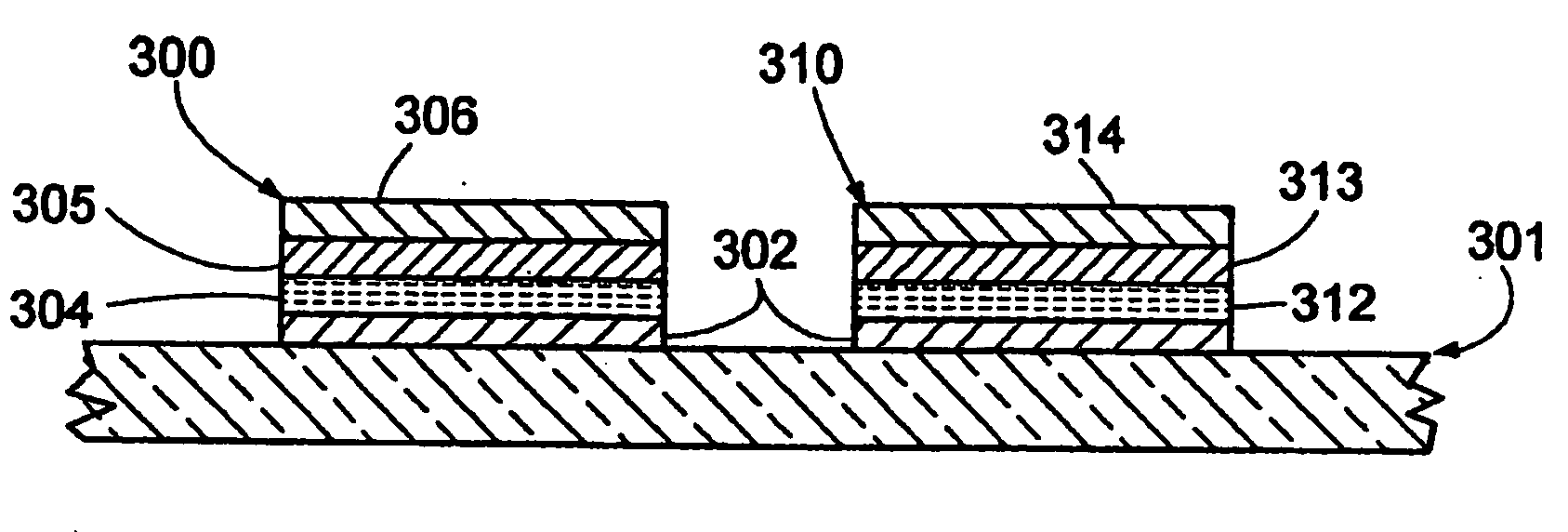

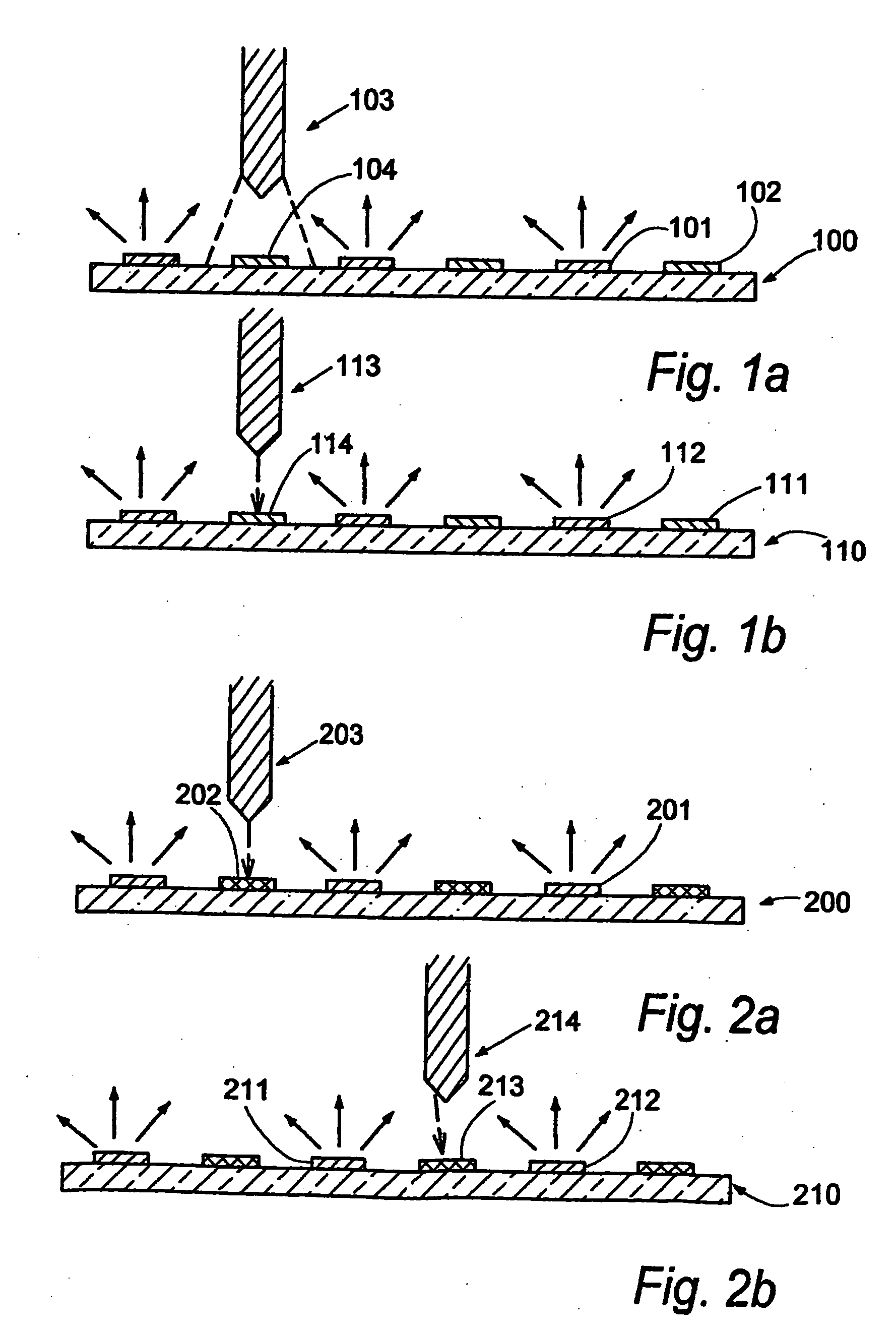

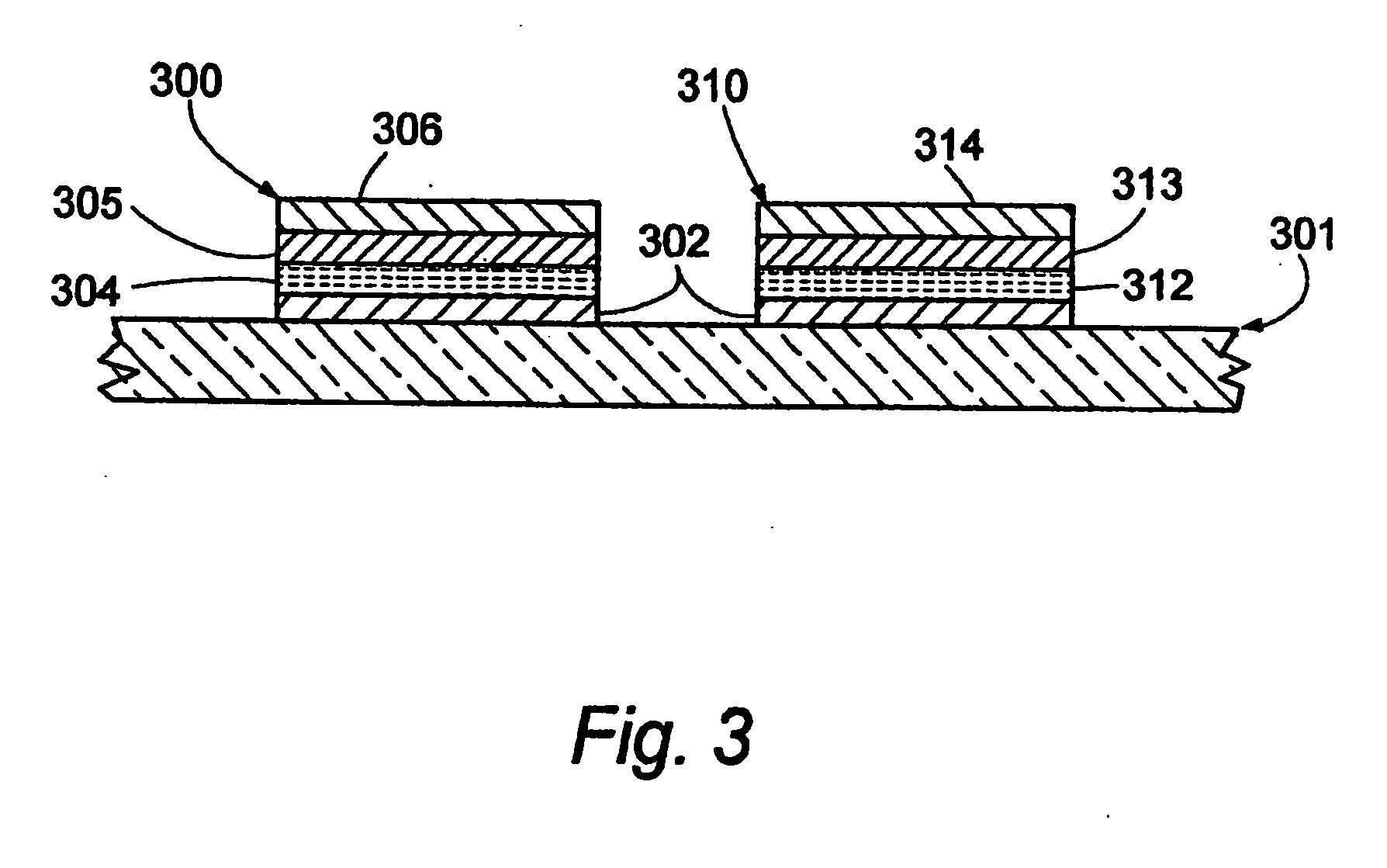

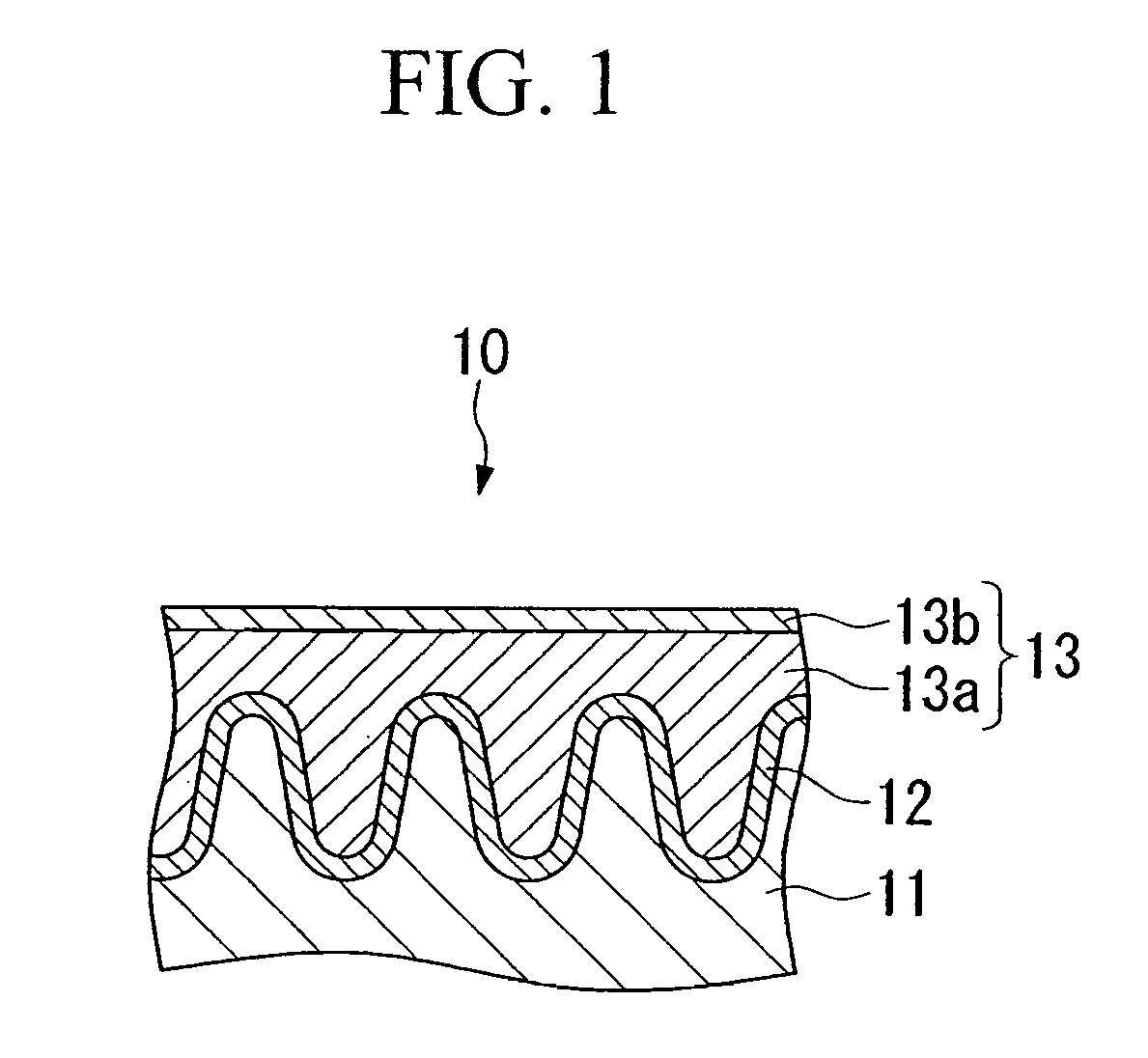

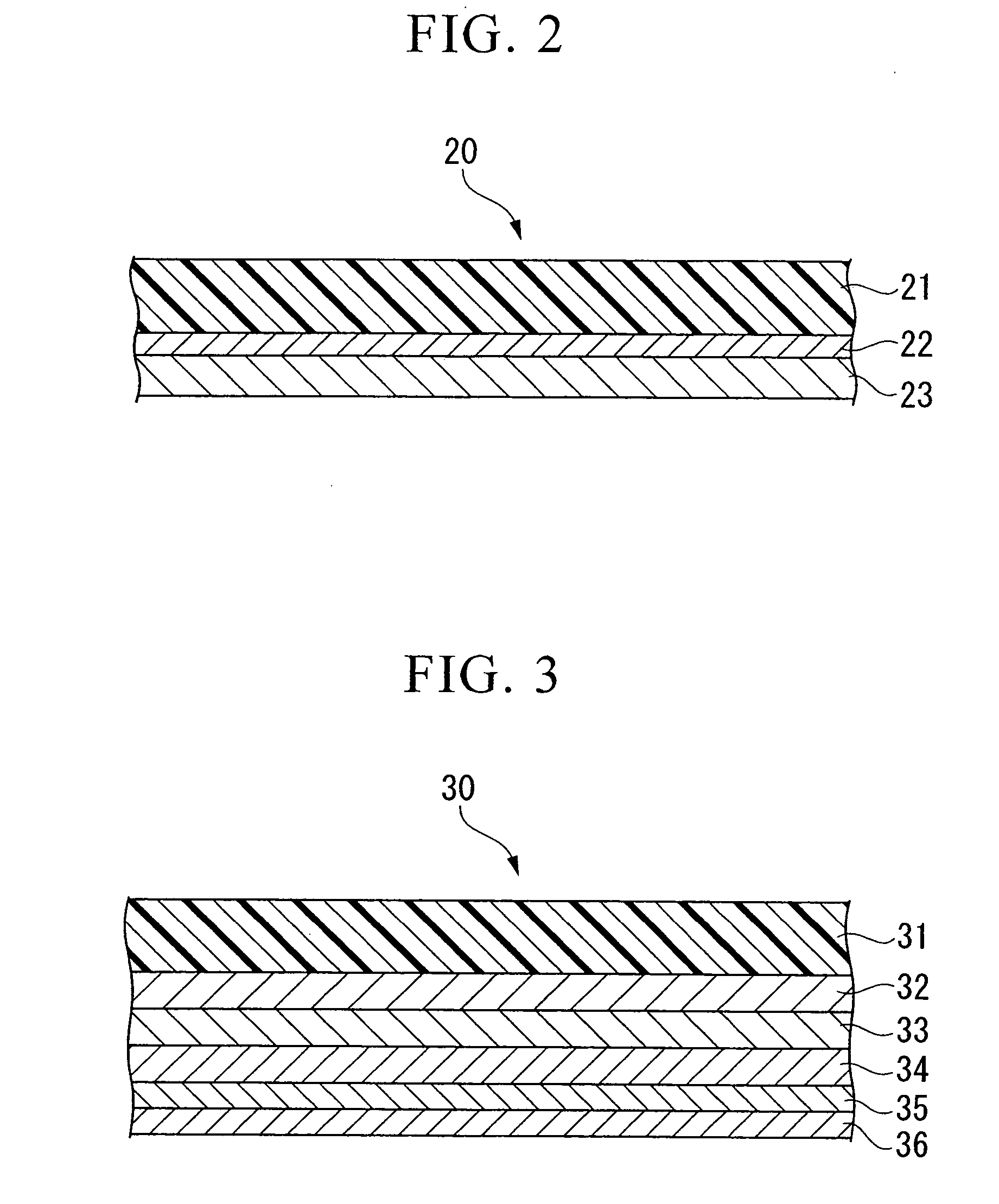

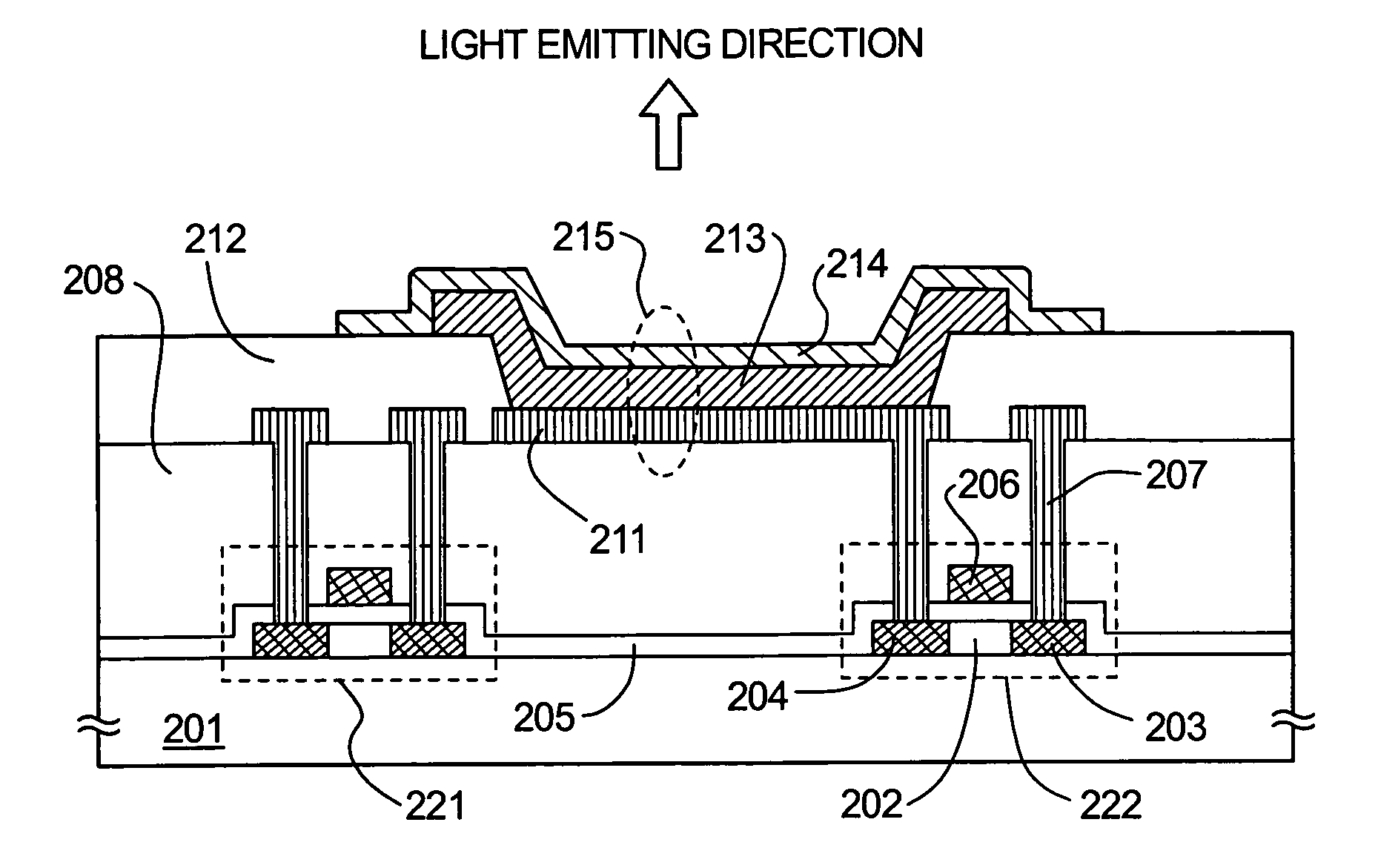

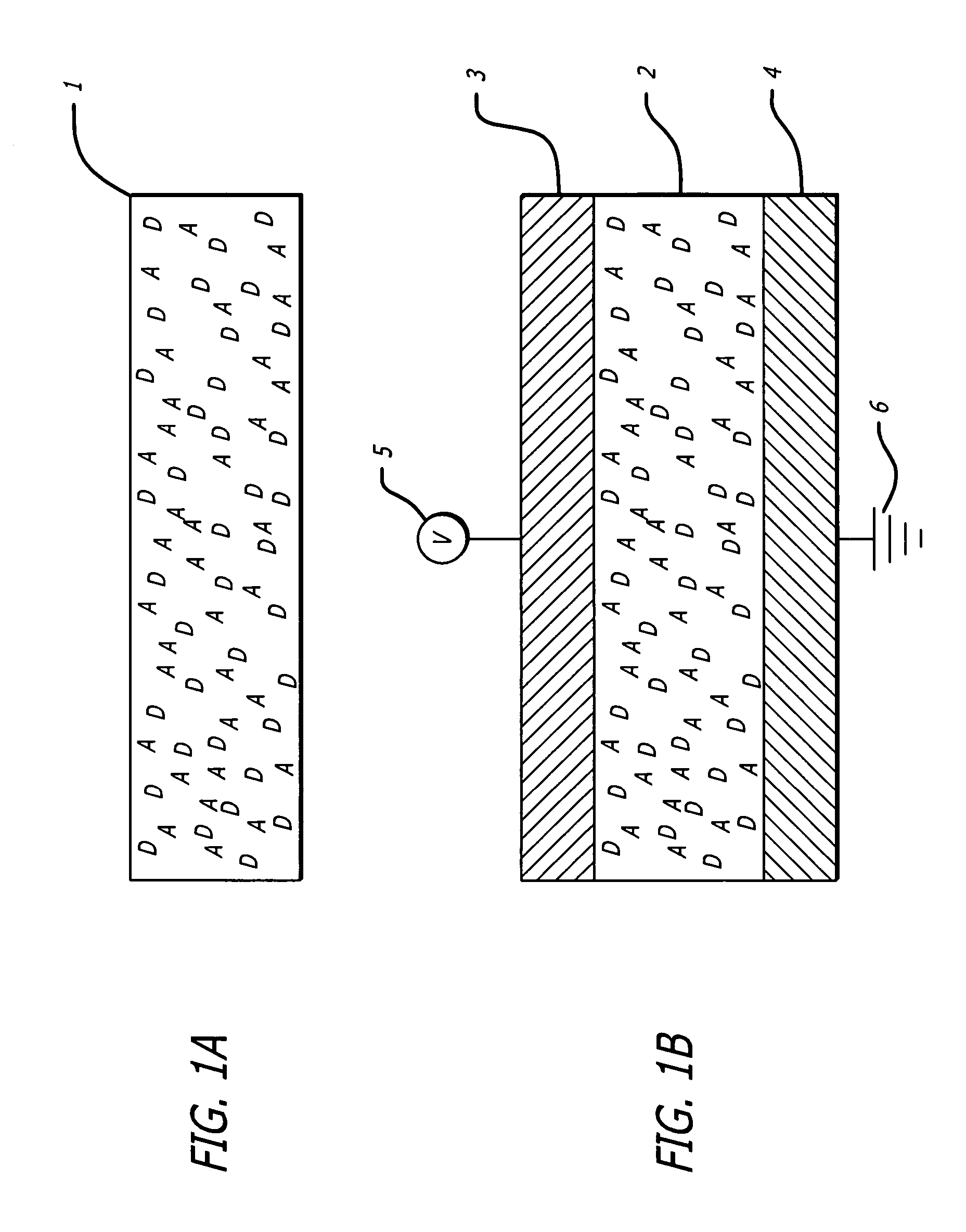

Combined information display and information input device

InactiveUS20060145365A1Better signal to noise ratioOvercome problemsNanoinformaticsSolid-state devicesElectron donorInput device

A combined information display and information input device comprising a matrix of independently addressable light emitting devices and a plurality of light sensing devices, the light emitting devices comprising organic light emitting diodes comprising organic light emitting material positioned between a low work function electrode and a high work function electrode characterized in that the light sensing devices comprise organic photovoltaic devices comprising at least an organic electron donor and at least an organic electron acceptor positioned between a high work function electrode and a low work function electrode. The combined information display and information input device has application as a touch screen, for example for a mobile communication device.

Owner:CAMBRIDGE DISPLAY TECH LTD

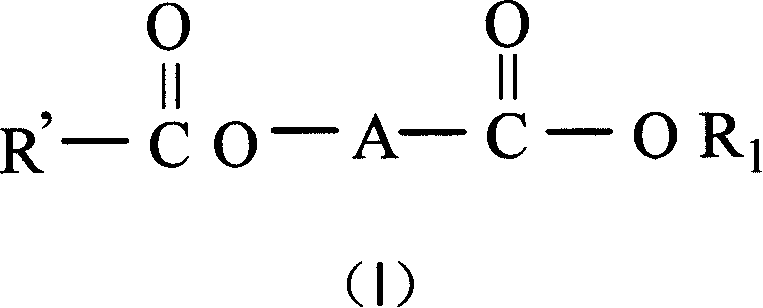

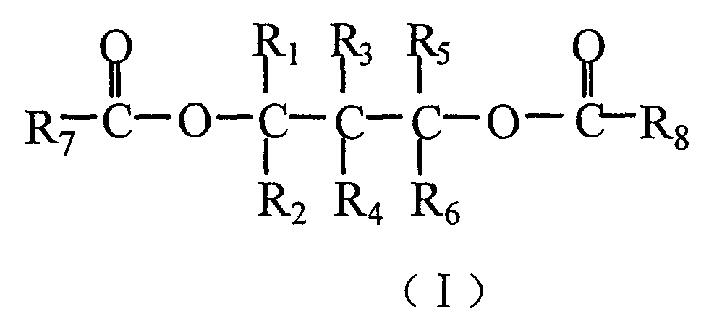

Solid catalyst component for polymerization of olefins, catalyst comprising the same and use thereof

InactiveUS7388061B2High stereospecificitySatisfactory polymerization yieldOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationPolymer sciencePtru catalyst

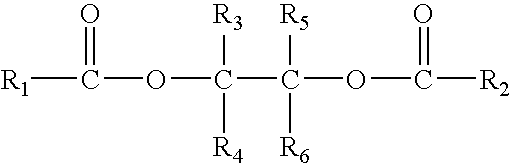

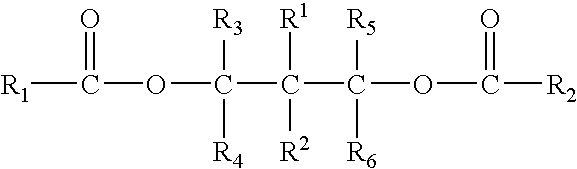

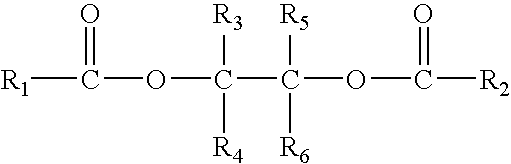

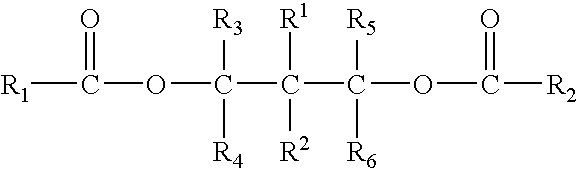

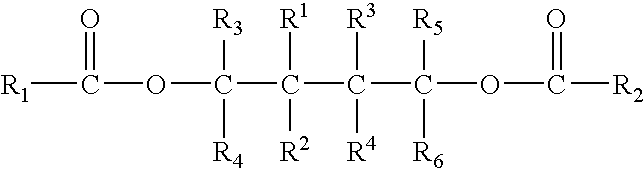

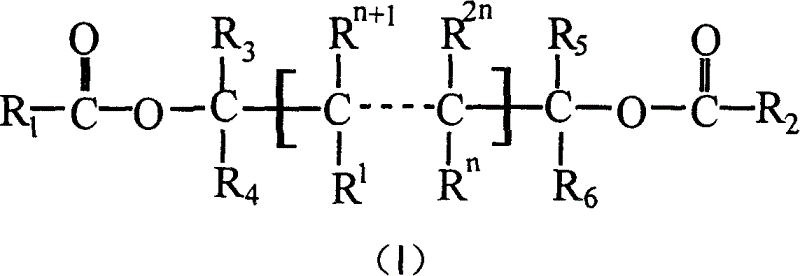

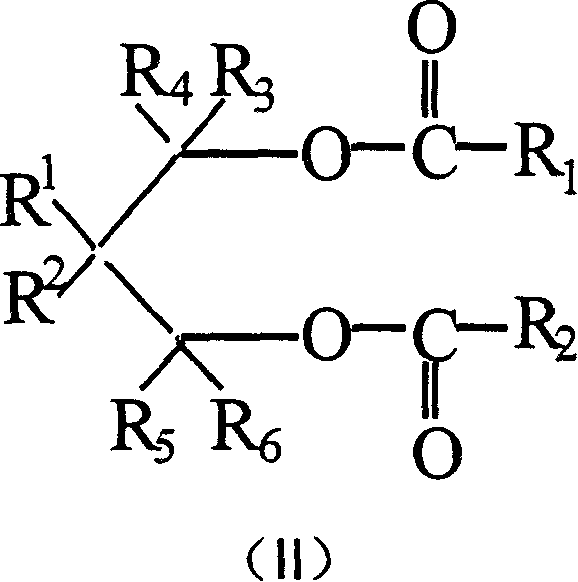

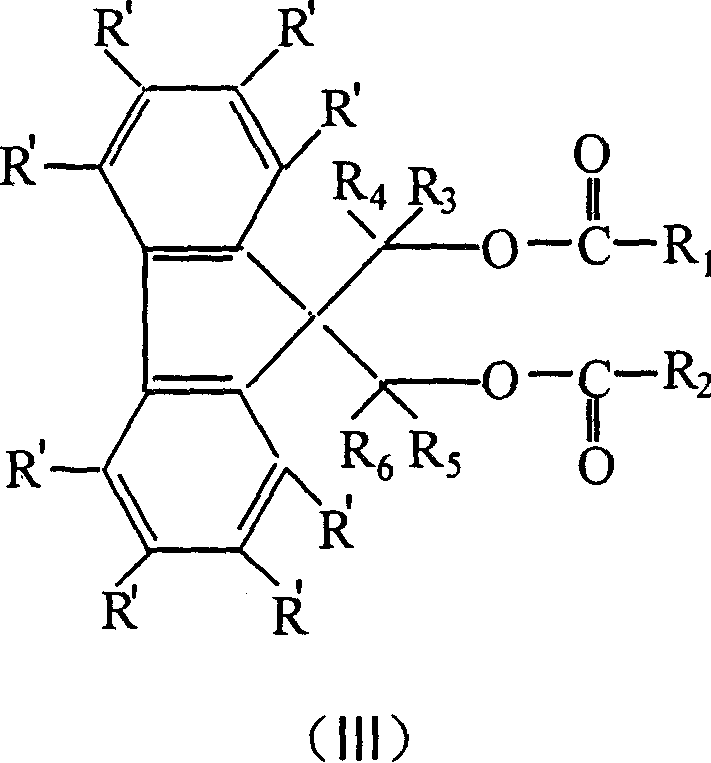

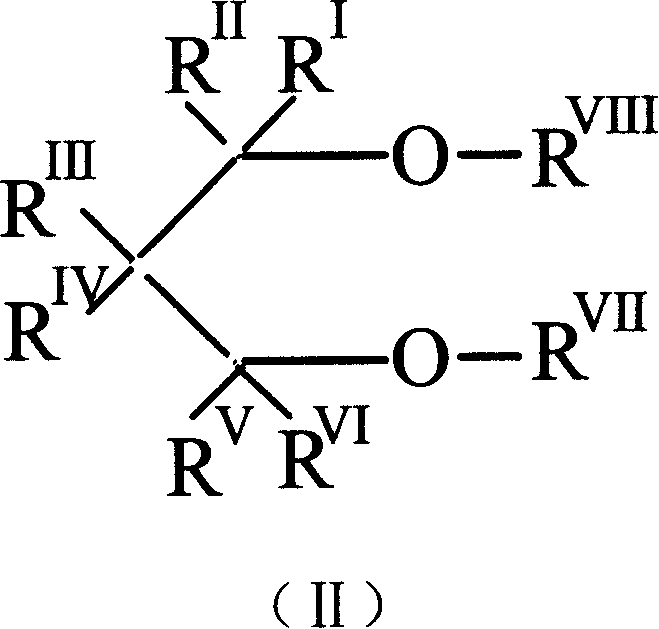

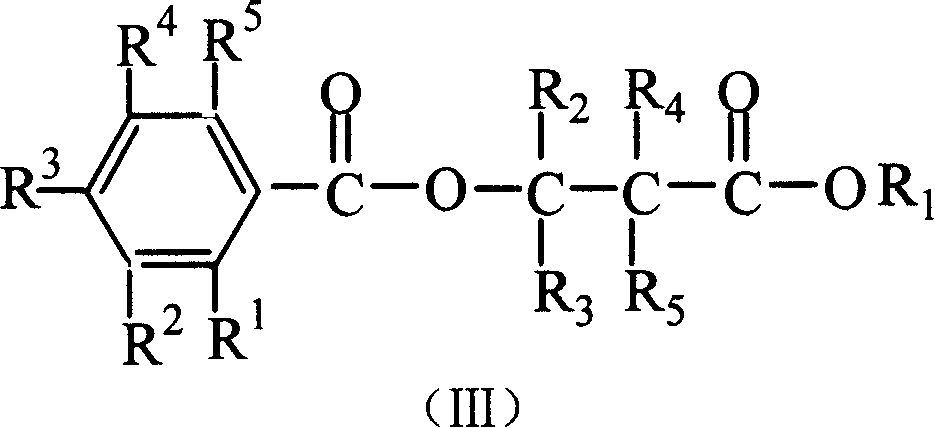

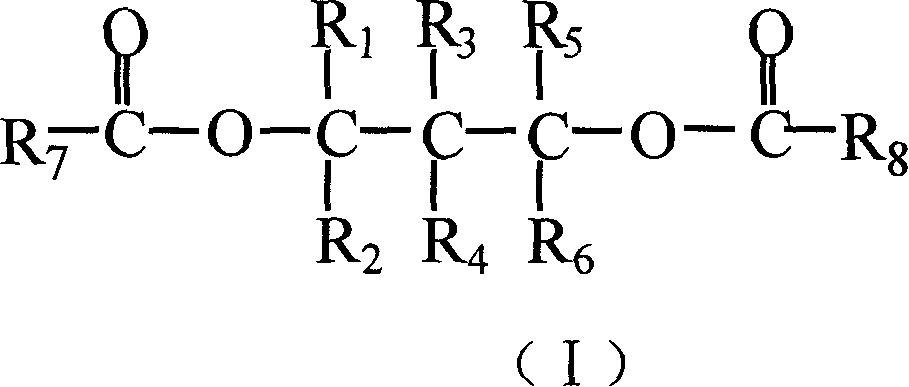

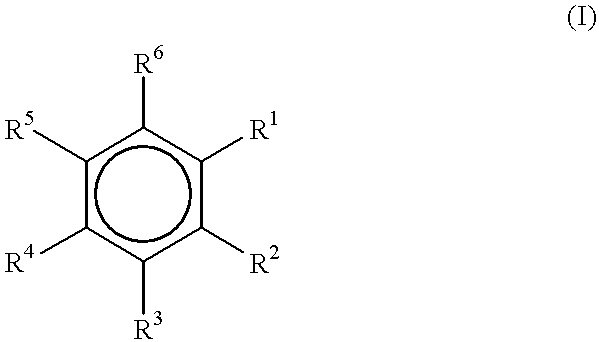

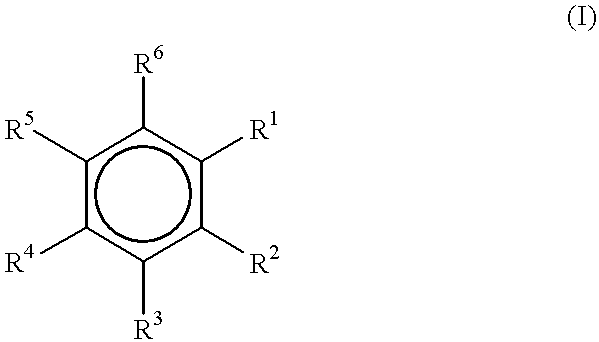

The present invention provides a solid catalyst component for the polymerization of olefins, comprising magnesium, titanium, a halogen and an electron donor, wherein said electron donor comprises at least one selected from the group consisting of ester of polyol of the formula (I):R1CO—O—CR3R4—A—CR5R6—O—CO—R2 (I)wherein, R1 and R2 groups, which may be identical or different, can be substituted or unsubstituted hydrocarbyl having 1 to 20 carbon atoms, R3-R6 groups, which may be identical or different, can be selected from the group consisting of hydrogen, halogen or substituted or unsubstituted hydrocarbyl having 1 to 20 carbon atoms, R1-R6 groups optionally contain one or more hetero-atoms replacing carbon, hydrogen atom or the both, said hetero-atom is selected from the group consisting of nitrogen, oxygen, sulfur, silicon, phosphorus and halogen atom, two or more of R3-R6 groups can be linked to form saturated or unsaturated monocyclic or polycyclic ring A is a single bond or bivalent linking group with chain length between two free radicals being 1-10 atoms, wherein said bivalent linking group is selected from the group consisting of aliphatic, alicyclic and aromatic bivalent radicals, and can carry C1-C20 linear or branched substituents one or more of carbon atom and / or hydrogen atom on above-mentioned bivalent linking group and substituents can be replaced by a hetero-atom selected from the group consisting of nitrogen, oxygen, sulfur, silicon, phosphorus, and halogen atom, and two or more said substituents on the linking group as well as above-mentioned R3-R6 groups can be linked to form saturated or unsaturated monocyclic or polycyclic ring.

Owner:CHINA PETROCHEMICAL CORP +1

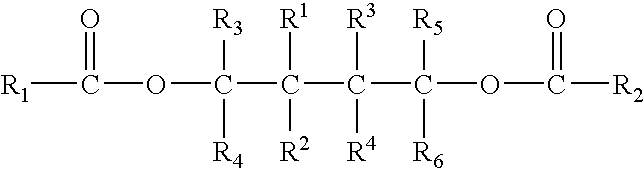

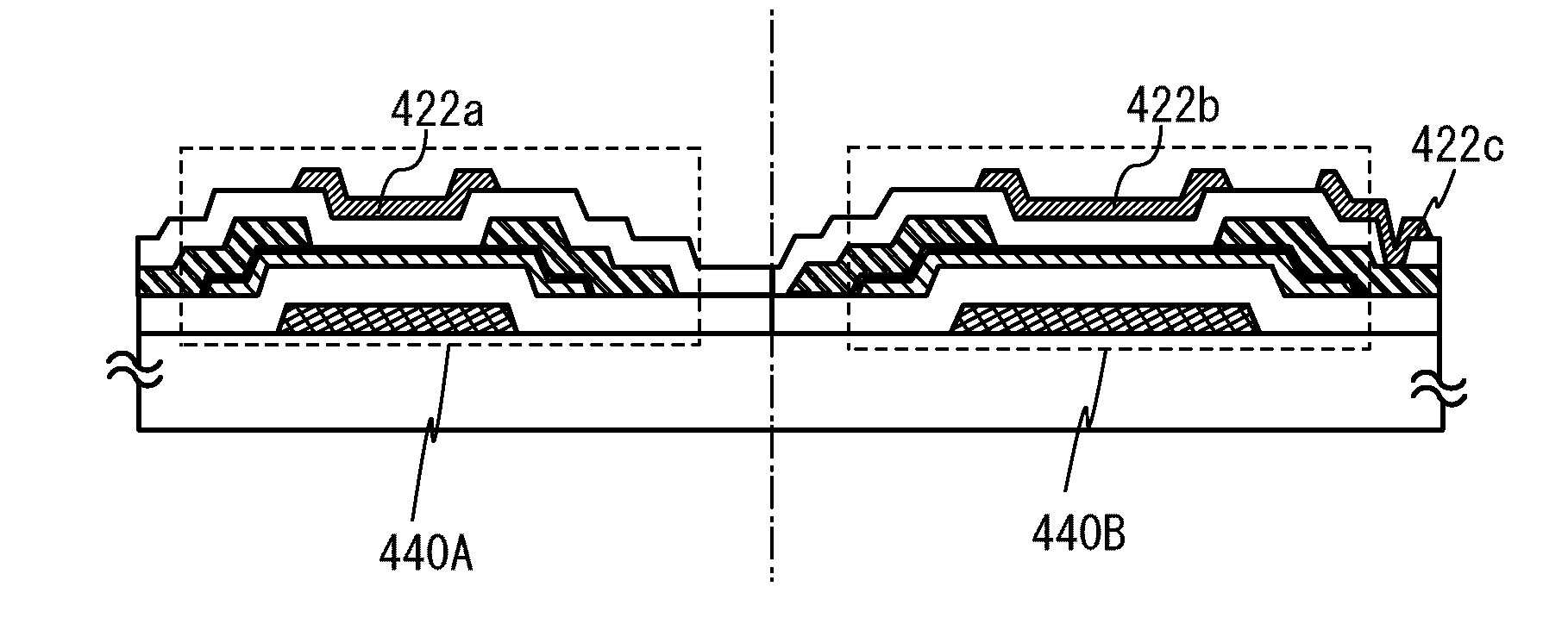

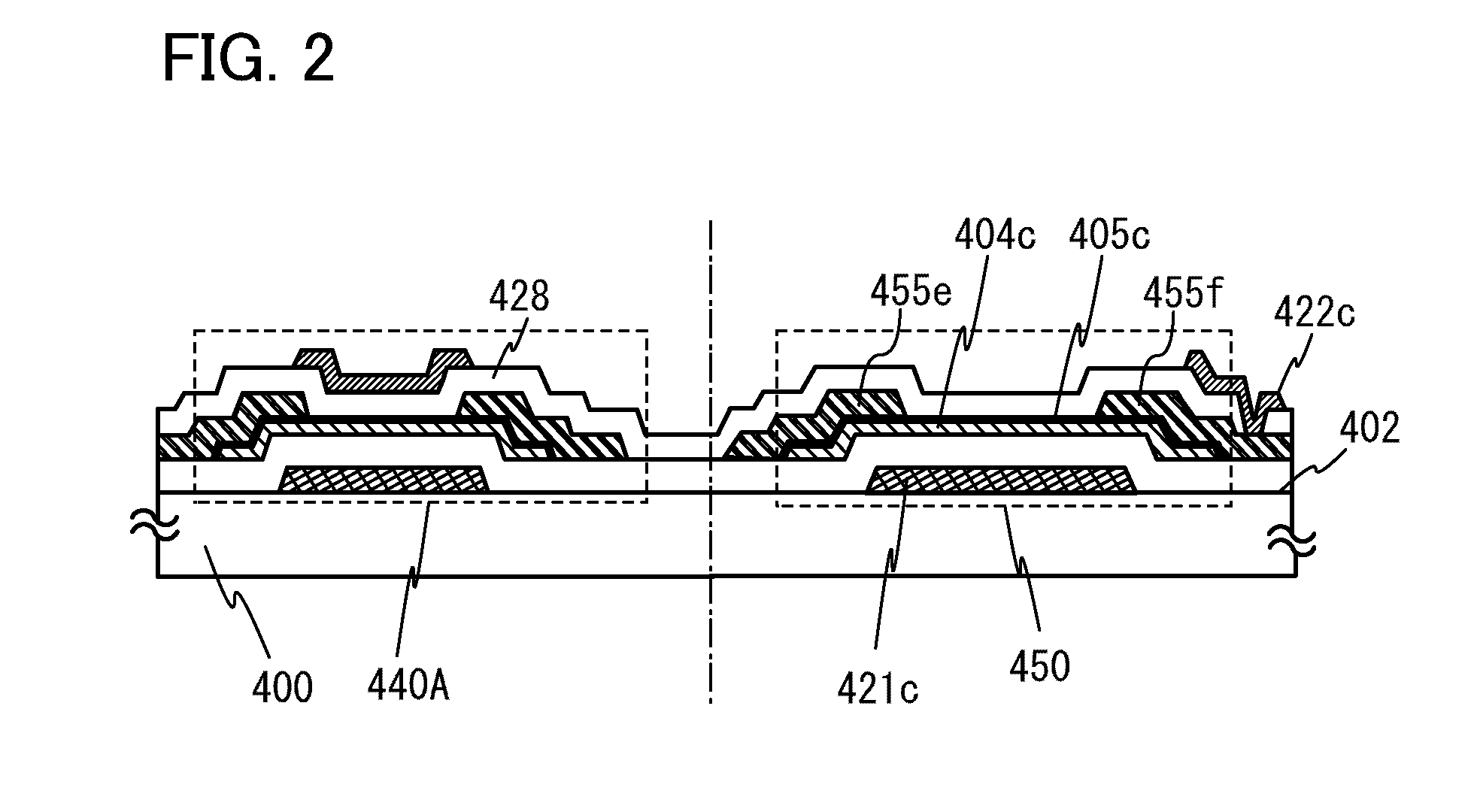

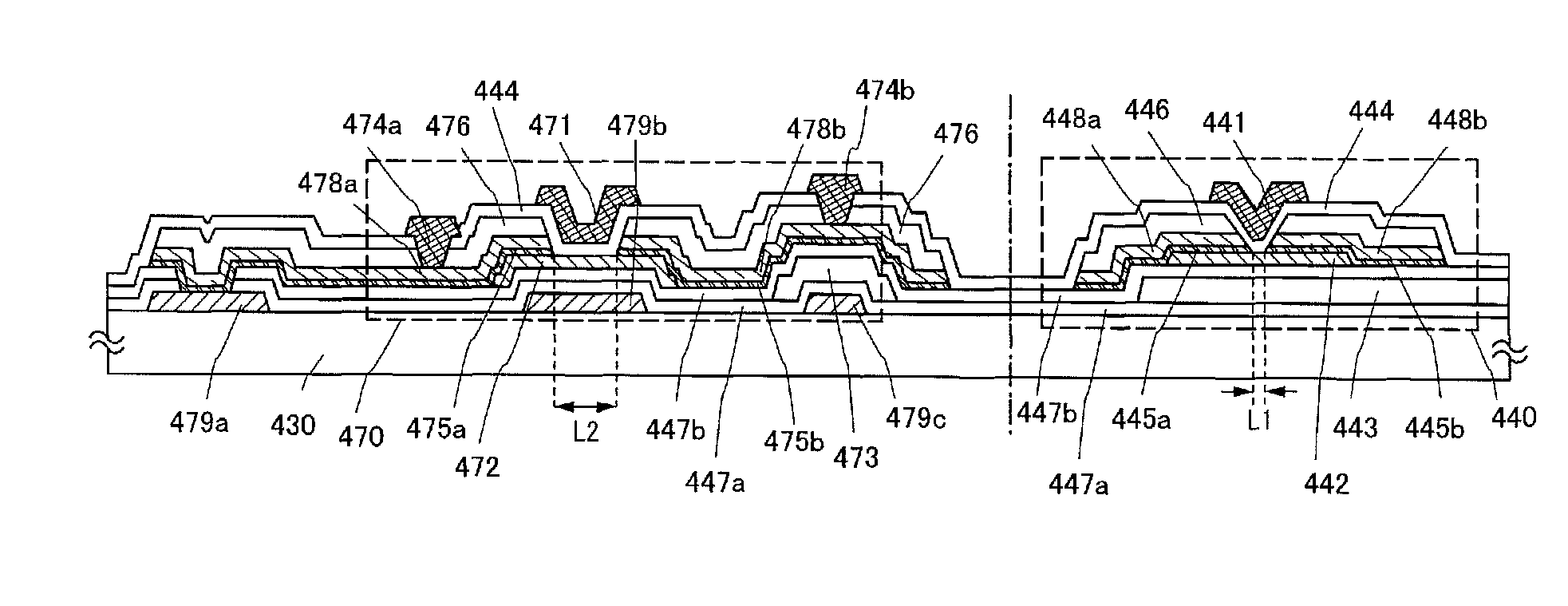

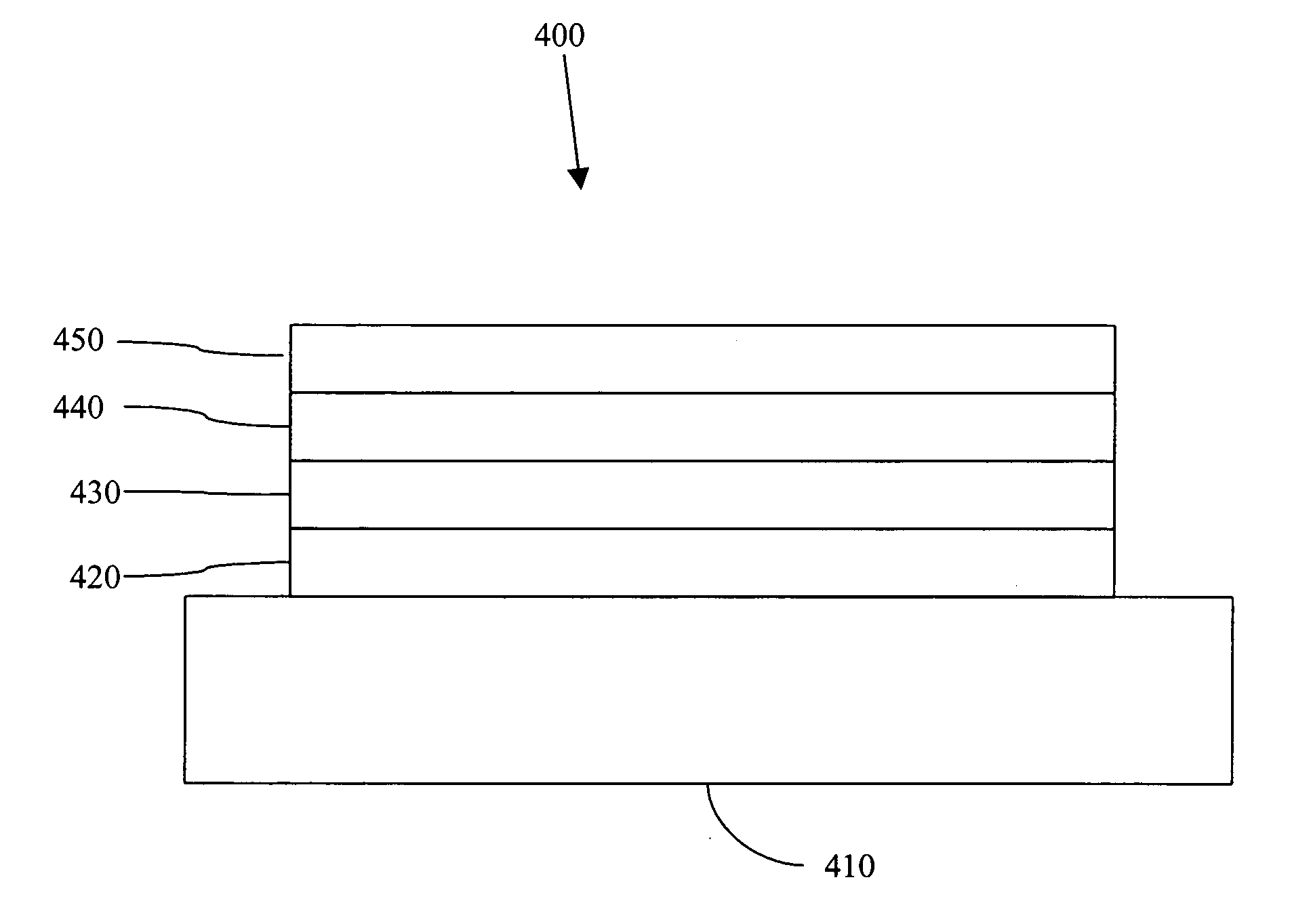

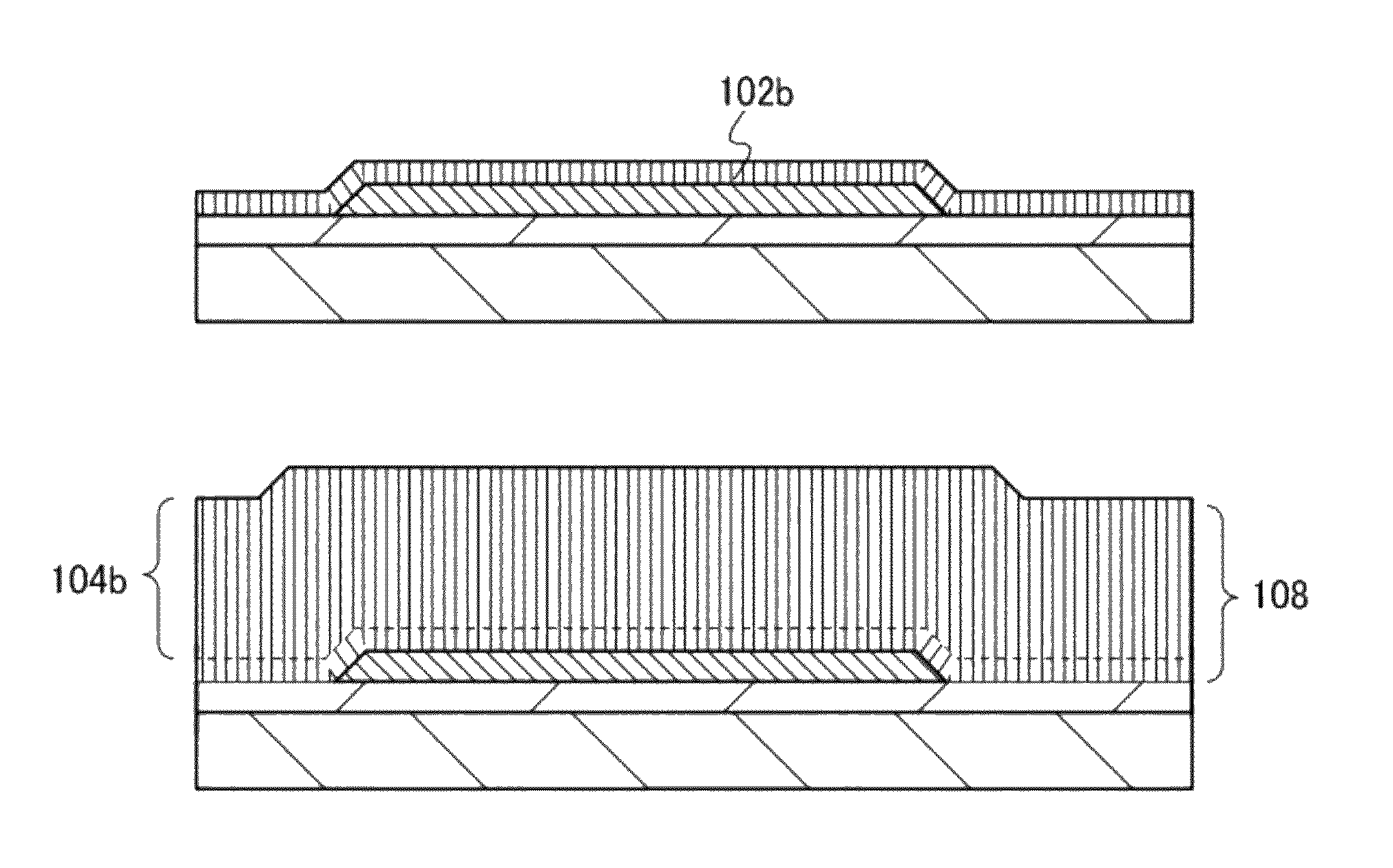

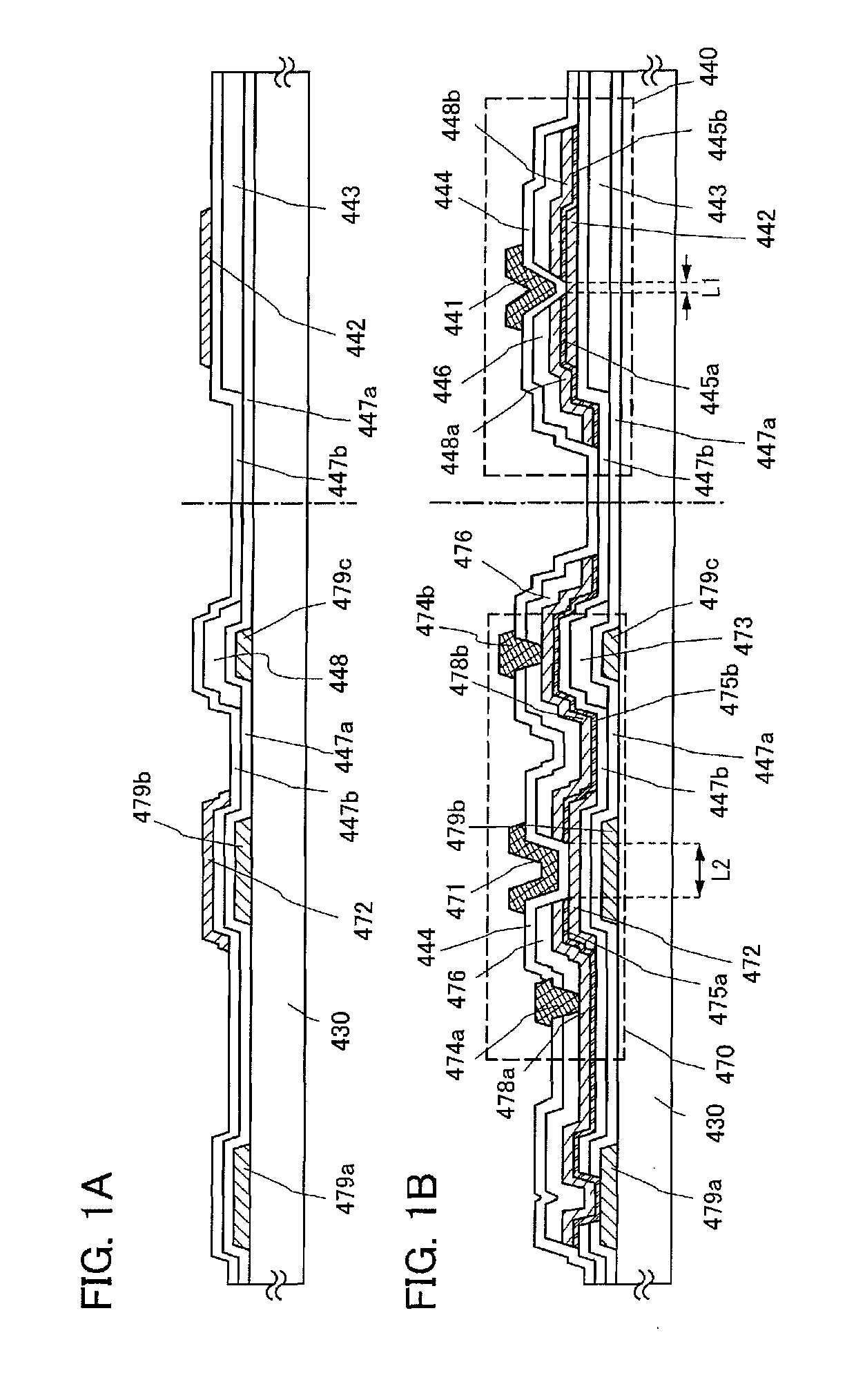

Semiconductor device and manufacturing method thereof

An oxide semiconductor layer which is intrinsic or substantially intrinsic and includes a crystalline region in a surface portion of the oxide semiconductor layer is used for the transistors. An intrinsic or substantially intrinsic semiconductor from which an impurity which is to be an electron donor (donor) is removed from an oxide semiconductor and which has a larger energy gap than a silicon semiconductor is used. Electrical characteristics of the transistors can be controlled by controlling the potential of a pair of conductive films which are provided on opposite sides from each other with respect to the oxide semiconductor layer, each with an insulating film arranged therebetween, so that the position of a channel formed in the oxide semiconductor layer is determined.

Owner:SEMICON ENERGY LAB CO LTD

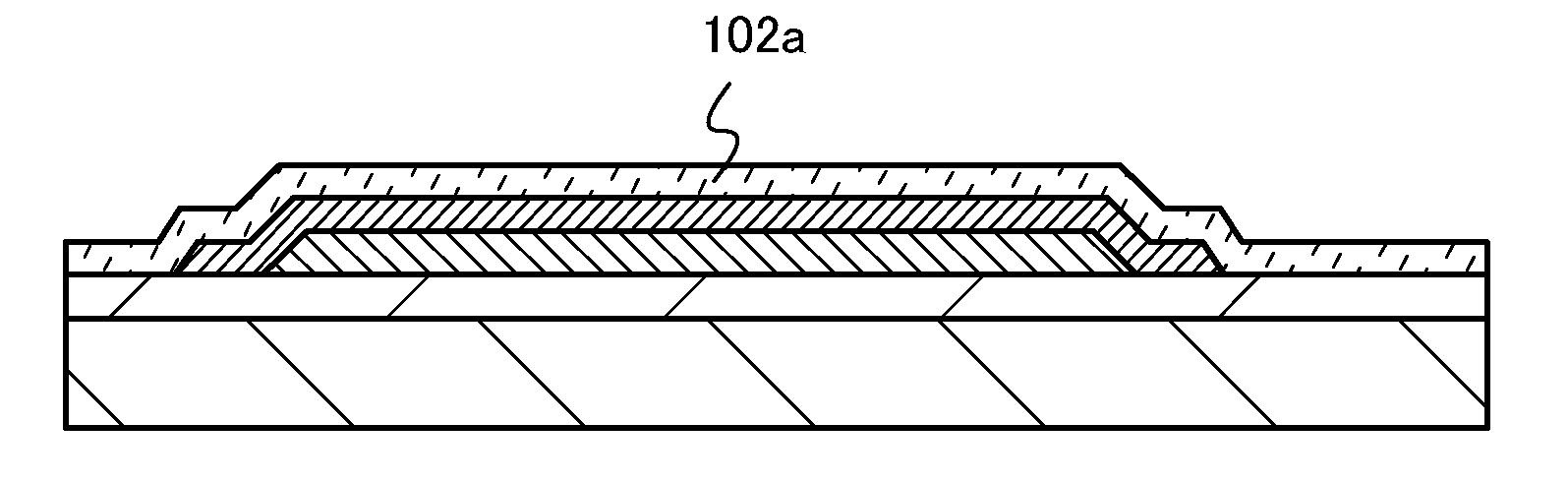

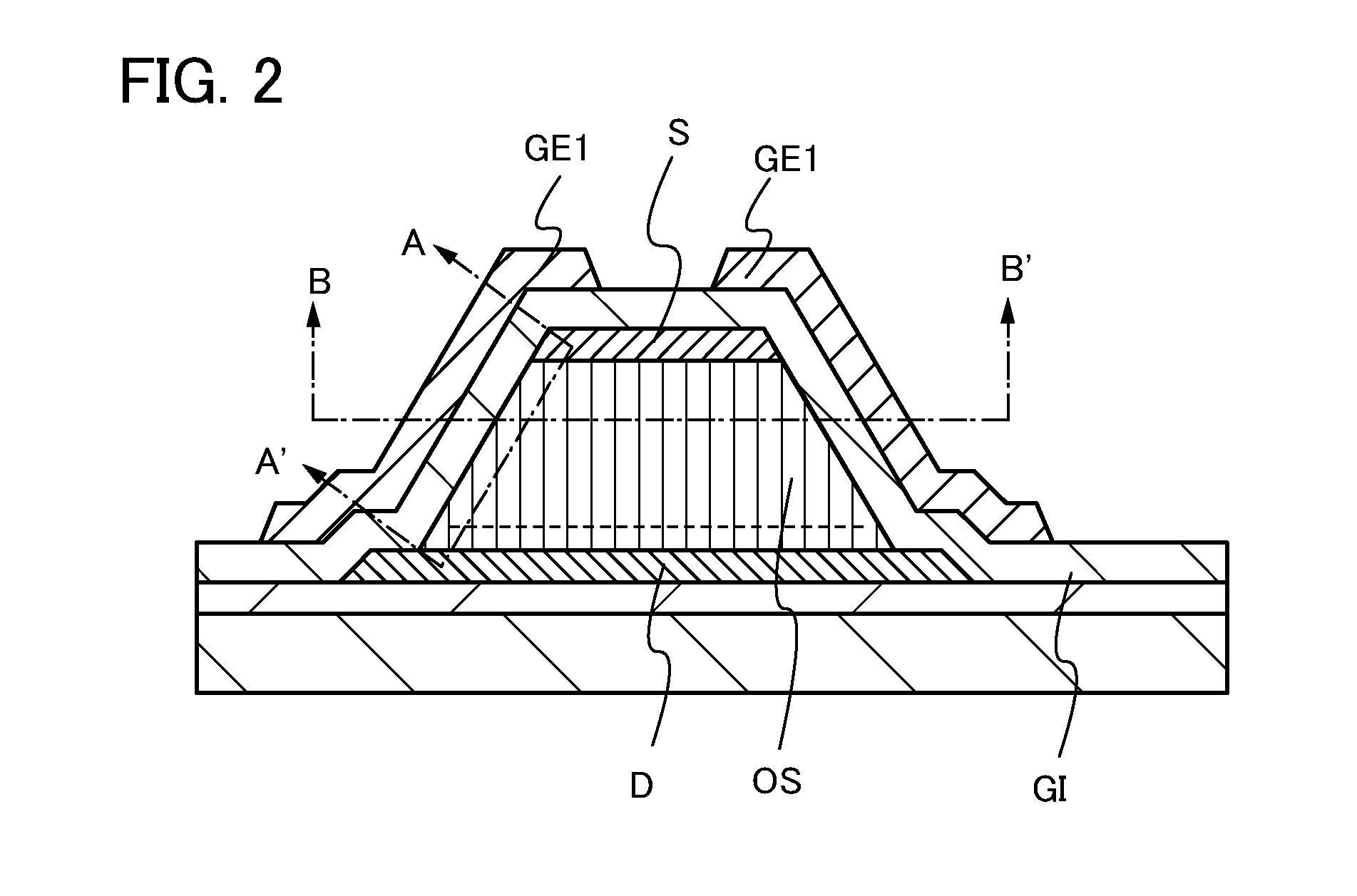

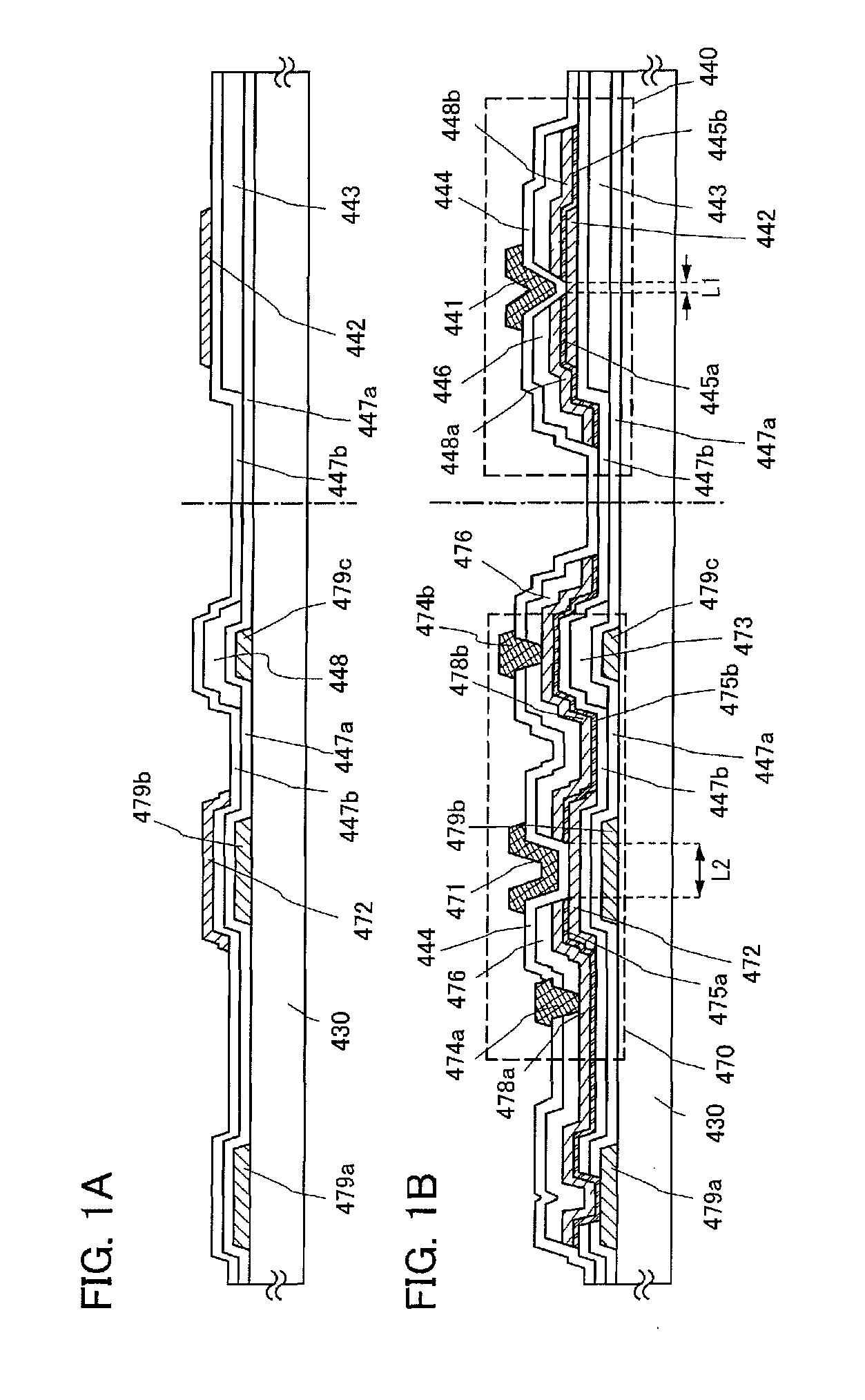

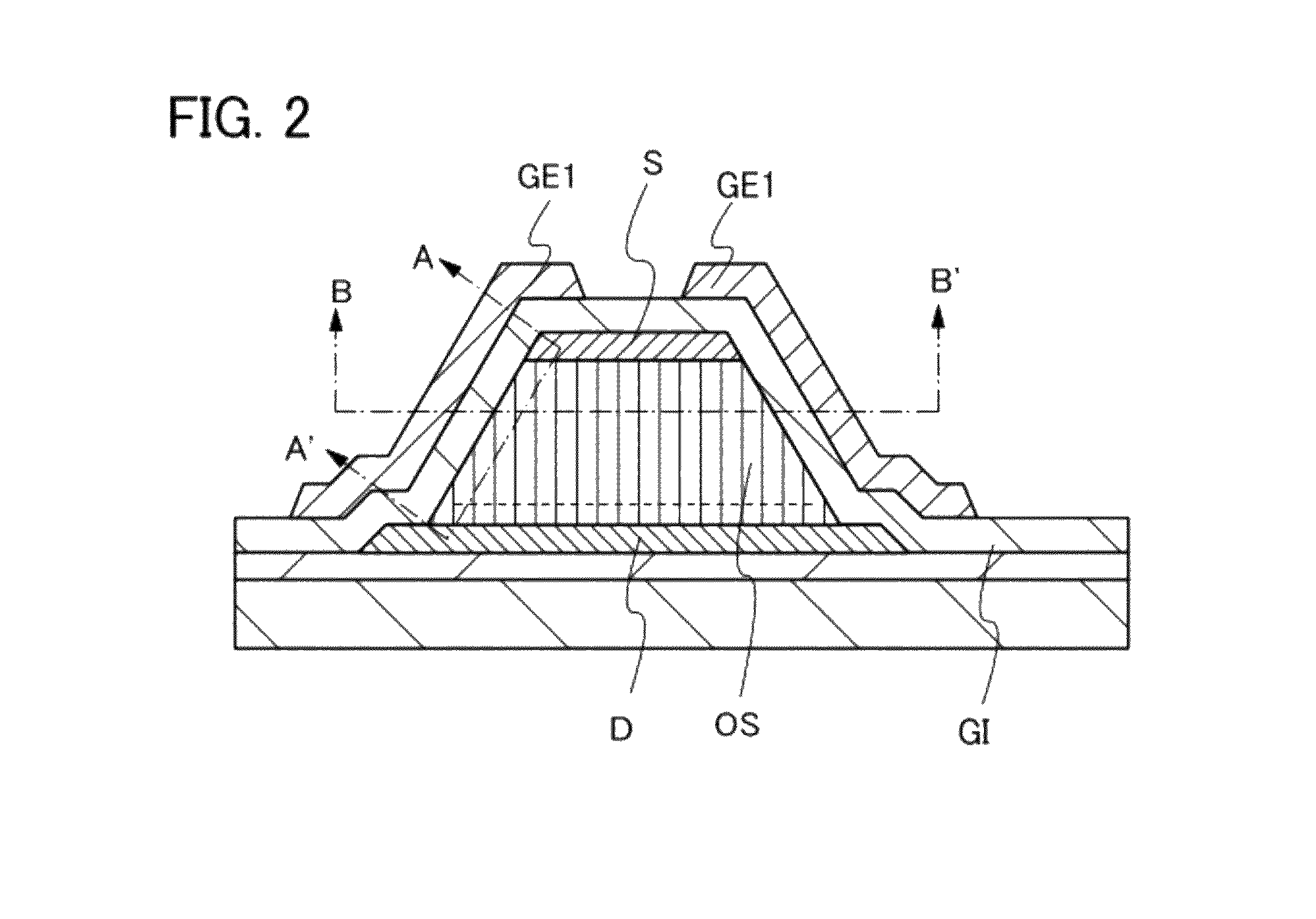

Semiconductor device and method for manufacturing the same

ActiveUS20110127522A1High on-off ratioHigh puritySolid-state devicesSemiconductor/solid-state device manufacturingSemiconductor materialsElectron donor

Objects are to provide a semiconductor device for high power application in which a novel semiconductor material having high productivity is used and to provide a semiconductor device having a novel structure in which a novel semiconductor material is used. The present invention is a vertical transistor and a vertical diode each of which has a stacked body of an oxide semiconductor in which a first oxide semiconductor film having crystallinity and a second oxide semiconductor film having crystallinity are stacked. An impurity serving as an electron donor (donor) which is contained in the stacked body of an oxide semiconductor is removed in a step of crystal growth; therefore, the stacked body of an oxide semiconductor is highly purified and is an intrinsic semiconductor or a substantially intrinsic semiconductor whose carrier density is low. The stacked body of an oxide semiconductor has a wider band gap than a silicon semiconductor.

Owner:SEMICON ENERGY LAB CO LTD

Solid catalyst component for polymerization of olefins, catalyst comprising the same and use thereof

InactiveUS20050239636A1High stereospecificitySatisfactory polymerization yieldOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationElectron donorOxygen

The present invention provides a solid catalyst component for the polymerization of olefins, comprising magnesium, titanium, a halogen and an electron donor, wherein said electron donor comprises at least one selected from the group consisting of polyol ester compounds of the formula (I): R1CO—O—CR3R4-A-CR5R6—O—CO—R2 (I) wherein, R1 and R2 groups, which may be identical or different, can be substituted or unsubstituted hydrocarbyl having 1 to 20 carbon atoms, R3-R6 groups, which may be identical or different, can be selected from the group consisting of hydrogen, halogen or substituted or unsubstituted hydrocarbyl having 1 to 20 carbon atoms, R1-R6 groups optionally contain one or more hetero-atoms replacing carbon, hydrogen atom or the both, said hetero-atom is selected from the group consisting of nitrogen, oxygen, sulfur, silicon, phosphorus and halogen atom, two or more of R3-R6 groups can be linked to form saturated or unsaturated monocyclic or polycyclic ring; A is a single bond or bivalent linking group with chain length between two free radicals being 1-10 atoms, wherein said bivalent linking group is selected from the group consisting of aliphatic, alicyclic and aromatic bivalent radicals, and can carry C1-C20 linear or branched substituents; one or more of carbon atom and / or hydrogen atom on above-mentioned bivalent linking group and substituents can be replaced by a hetero-atom selected from the group consisting of nitrogen, oxygen, sulfur, silicon, phosphorus, and halogen atom, and two or more said substituents on the linking group as well as above-mentioned R3-R6 groups can be linked to form saturated or unsaturated monocyclic or polycyclic ring.

Owner:CHINA PETROCHEMICAL CORP +1

Conductive composition and conductive cross-linked product, capacitor and production method thereof, and antistatic coating material, antistatic coating, antistatic film, optical filter, and optical information recording medium

ActiveUS20060047030A1Improve conductivityLower impedanceHybrid capacitor electrolytesHybrid capacitor electrodesCross-linkElectron donor

A conductive composition comprises a π conjugated conductive polymer, a dopant, and a nitrogen-containing aromatic cyclic compound. A capacitor comprises an anode composed of a porous material of valve metal, a dielectric layer formed by oxidizing the surface of the anode, and a cathode provided on the dielectric layer and having a solid electrolyte layer containing a π conjugated conductive polymer, which comprises an electron donor compound containing an electron donor element provided between the dielectric layer and the cathode. Another capacitor is based on the above-described capacitor, wherein the solid electrolyte layer further comprises a dopant and a nitrogen-containing aromatic cyclic compound. An antistatic coating material comprises a π conjugated conductive polymer, a solubilizing polymer containing an anion group and / or an electron attractive group, a nitrogen-containing aromatic cyclic compound, and a solvent. An antistatic coating is formed by applying the antistatic coating material.

Owner:SHIN-ETSU POLYMER CO LTD

Catalyst component for olefinic polymerization and its catalyst

This invention provides a catalys conponent and catalyst. Said catalyst comprises titanium, magnesium and at least three electron donor compounds a, b and c, in which is selected from mono-aliphatic-carboxylate or mono-aromatic-carboxylate compounds, b is selected from a special diatomic alkoxide compound, and c is selected from binary binary-aliphatic-carboxylate or binary-aromatic-carboxylate or b is ether compound. Advantages: high polymerization activity and stereospecificity when used for olefin polymerization, in particular for propylene polymerization, wide molecular weight distribution of obtained polymer and good shape of polymer granulars.

Owner:CHINA PETROLEUM & CHEM CORP +1

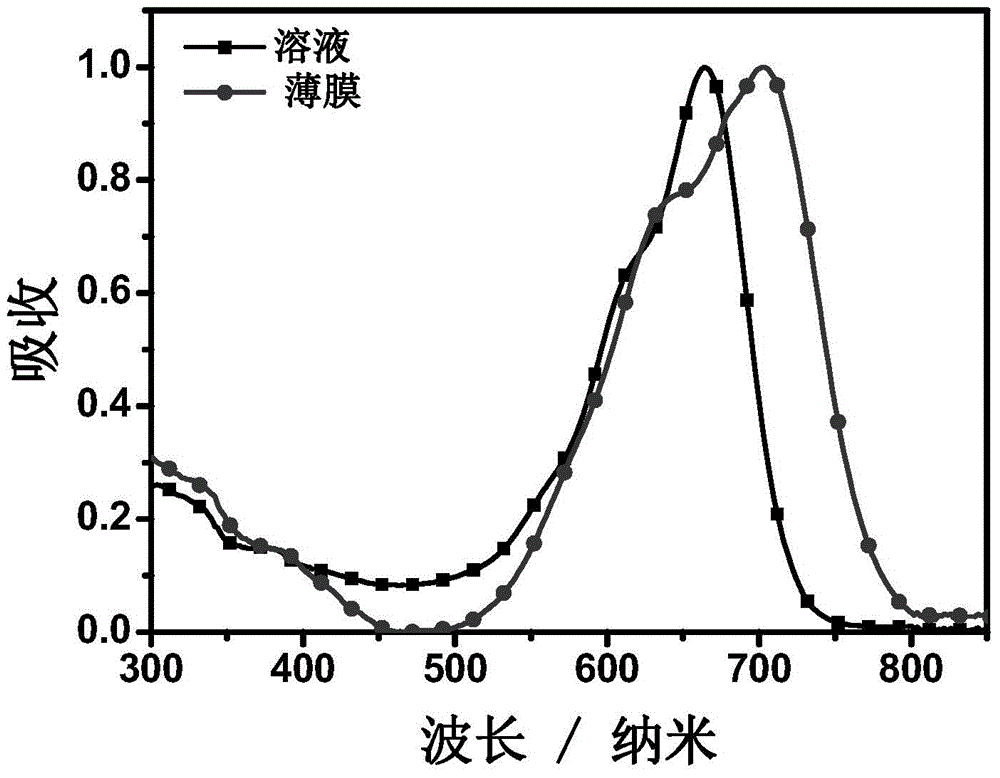

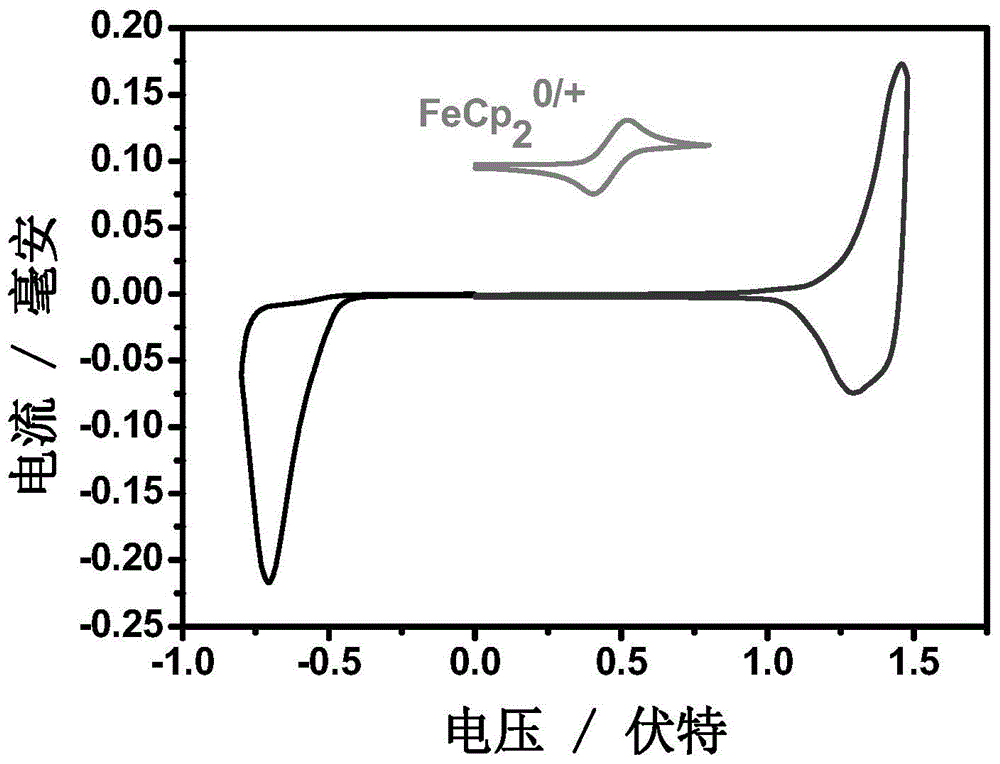

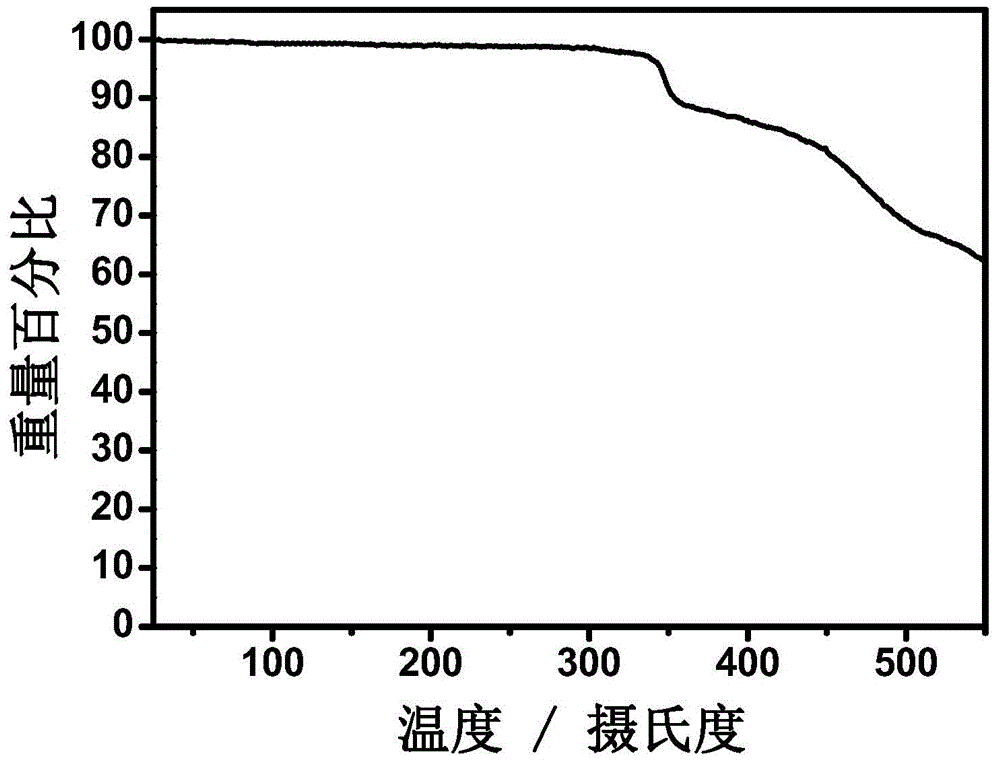

A-D-A conjugated molecules based on hepta-condensed ring units and preparation method for A-D-A conjugated molecules and application of A-D-A conjugated molecules

ActiveCN105315298AStrong visible light absorptionHigh charge transportOrganic chemistrySolid-state devicesOrganic solar cellElectron donor

Owner:INST OF CHEM CHINESE ACAD OF SCI

Catalyst components for olefinic polyreaction and catalyst thereof

Owner:CHINA PETROLEUM & CHEM CORP +1

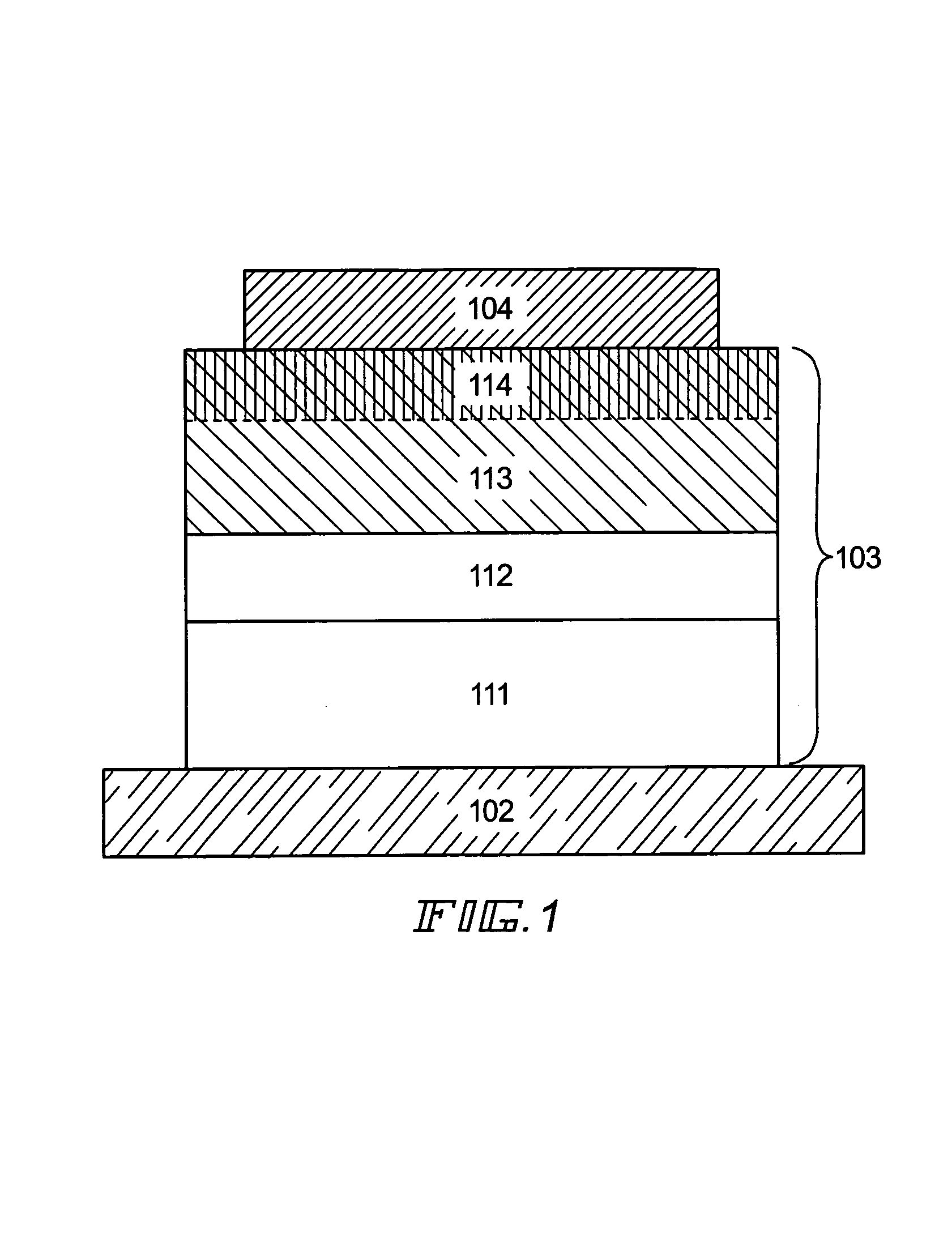

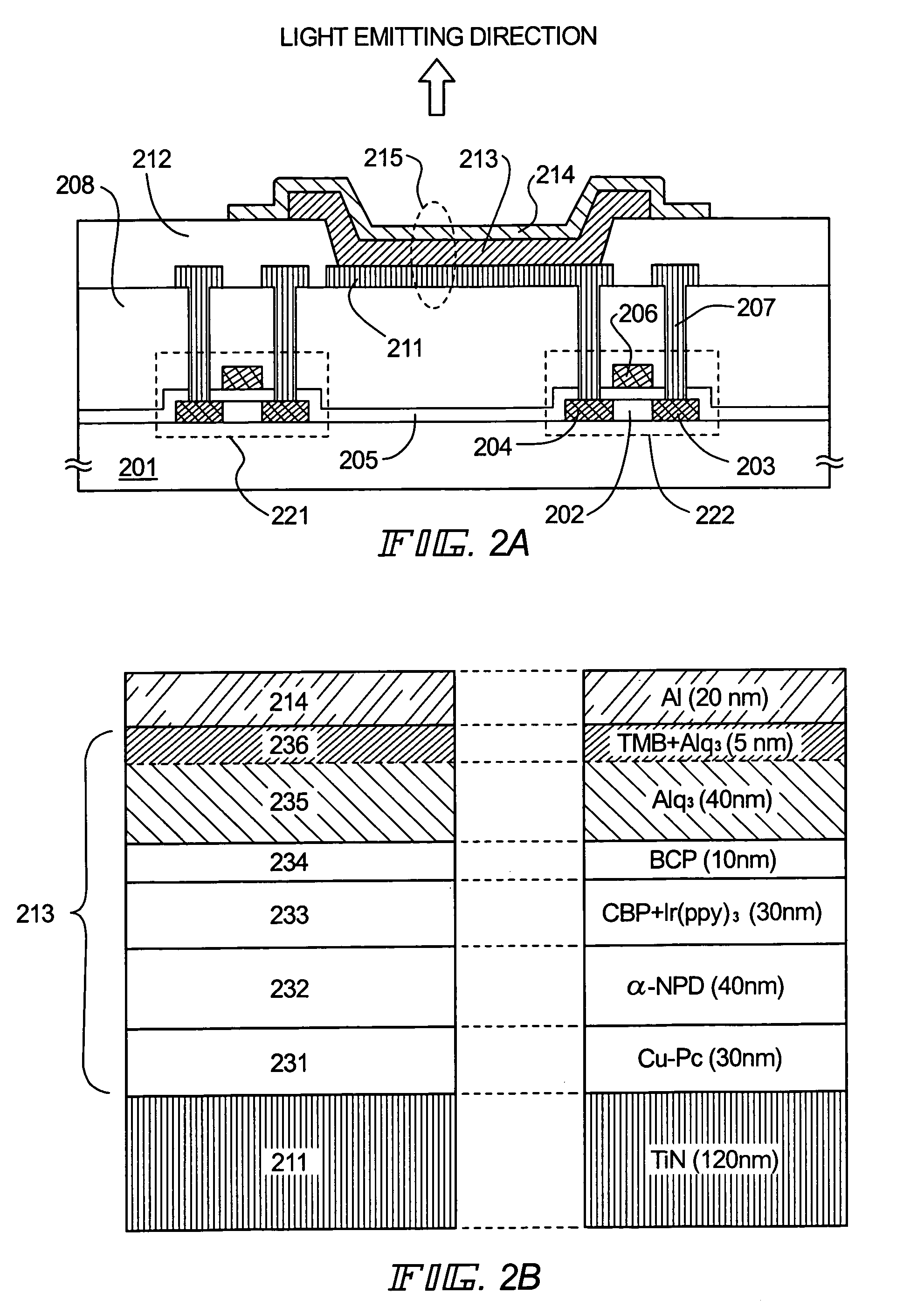

Light emitting device

InactiveUS7141817B2Improve injectionAvoid quenchingSolid-state devicesSemiconductor/solid-state device manufacturingElectron injectionElectron donor

By doping an organic compound functioning as an electron donor (hereinafter referred to as donor molecules) into an organic compound layer contacting a cathode, donor levels can be formed between respective LUMO (lowest unoccupied molecular orbital) levels between the cathode and the organic compound layer, and therefore electrons can be injected from the cathode, and transmission of the injected electrons can be performed with good efficiency. Further, there are no problems such as excessive energy loss, deterioration of the organic compound layer itself, and the like accompanying electron movement, and therefore an increase in the electron injecting characteristics and a decrease in the driver voltage can both be achieved without depending on the work function of the cathode material.

Owner:SEMICON ENERGY LAB CO LTD

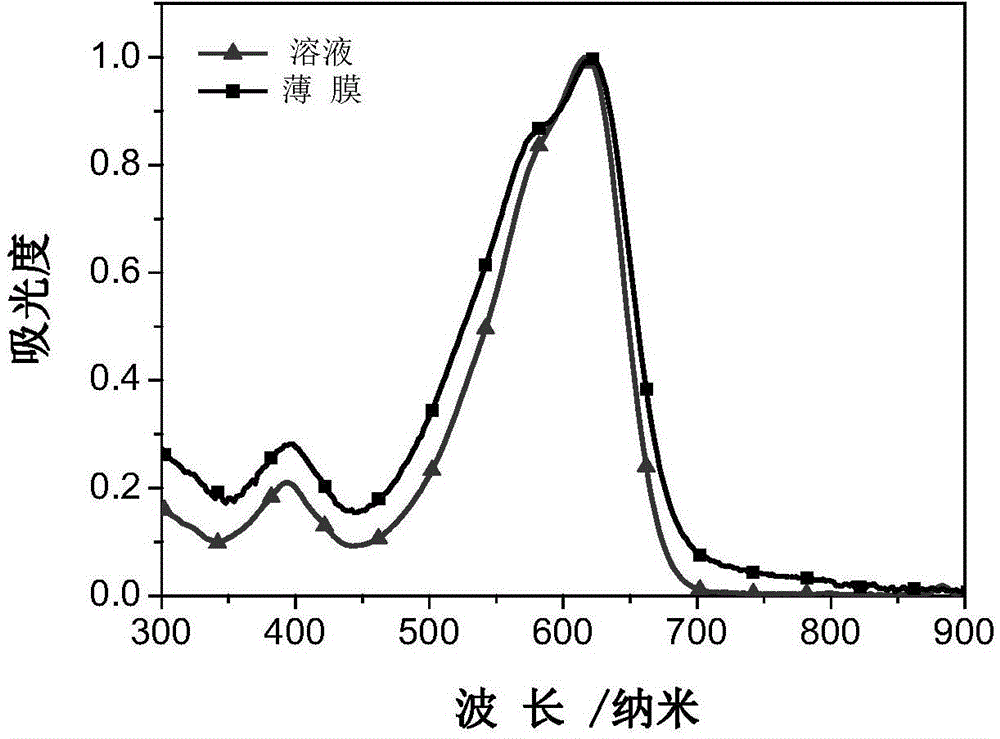

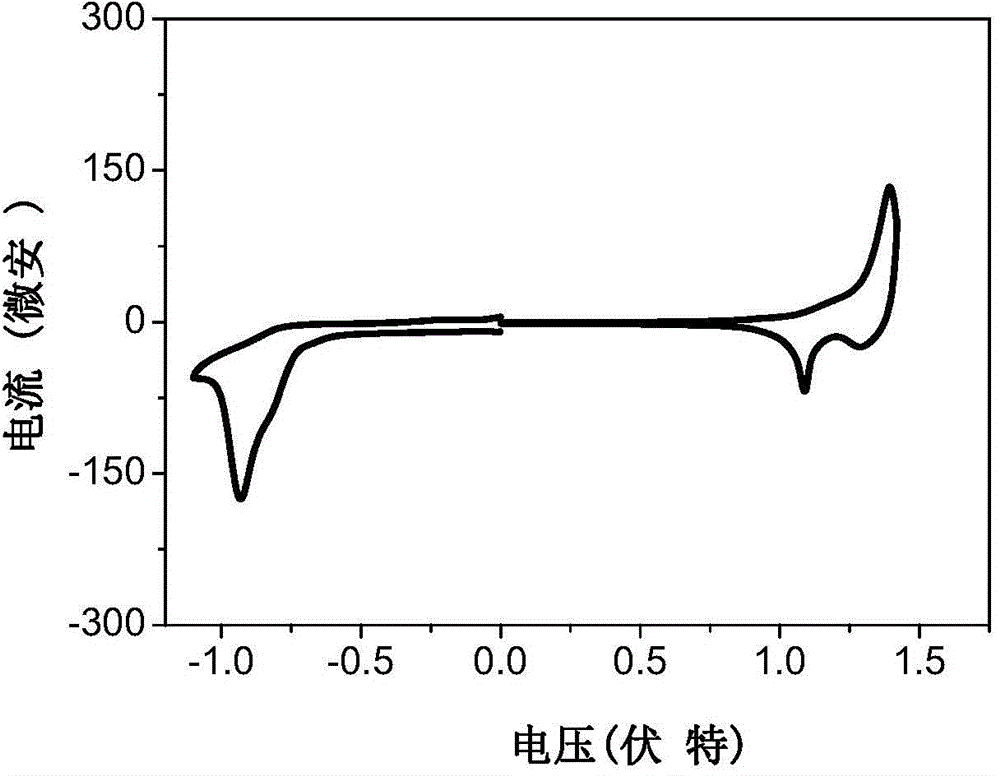

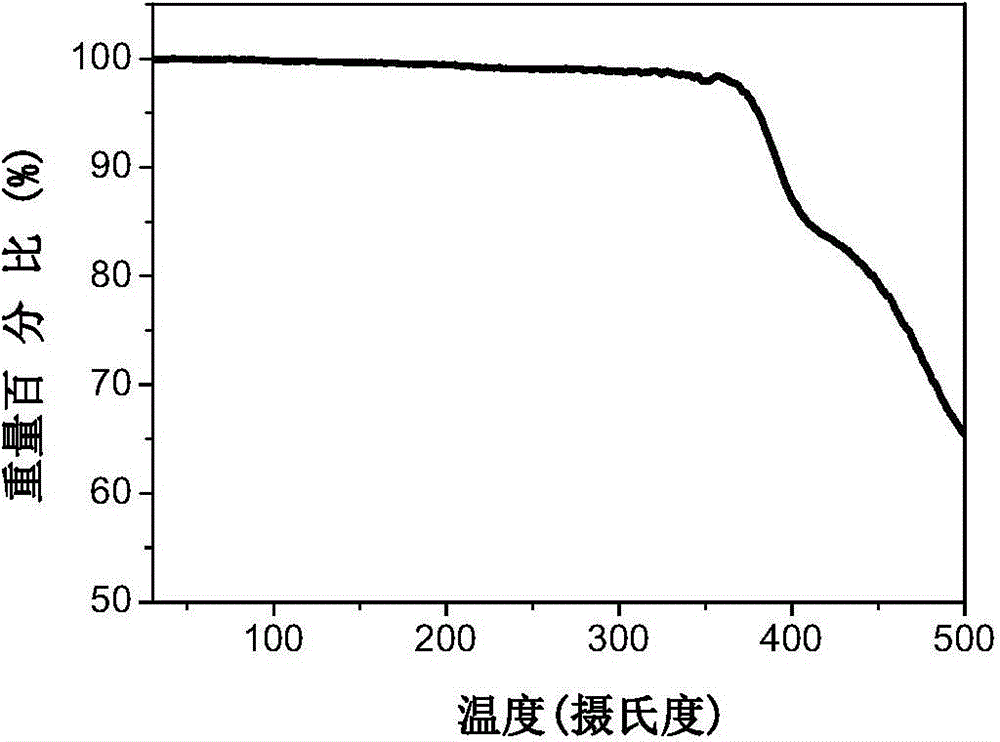

A-D-A conjugated molecule on the basis of dithiophene indacene, and preparation method and application thereof

ActiveCN104557968AStrong visible light absorptionHigh charge transportOrganic chemistrySolid-state devicesOrganic solar cellElectron donor

The invention relates to an A-D-A conjugated molecule with dithiophene indacene as a core, and oligomerizing pentatomic aromatic heterocyclic rings as a bridging unit and electron withdrawing unit at the end, a preparation method thereof and an application of the molecule, as an active-layer electron donor or electron receptor material, in an organic solar battery. The A-D-A conjugated molecule can be processed by a solution method, has proper energy level, strong sunlight trapping capability and thermal stability, is an ideal material of the electron donor or the electron receptor in the organic solar battery, and has the following general-formula structure shown in the specification.

Owner:INST OF CHEM CHINESE ACAD OF SCI

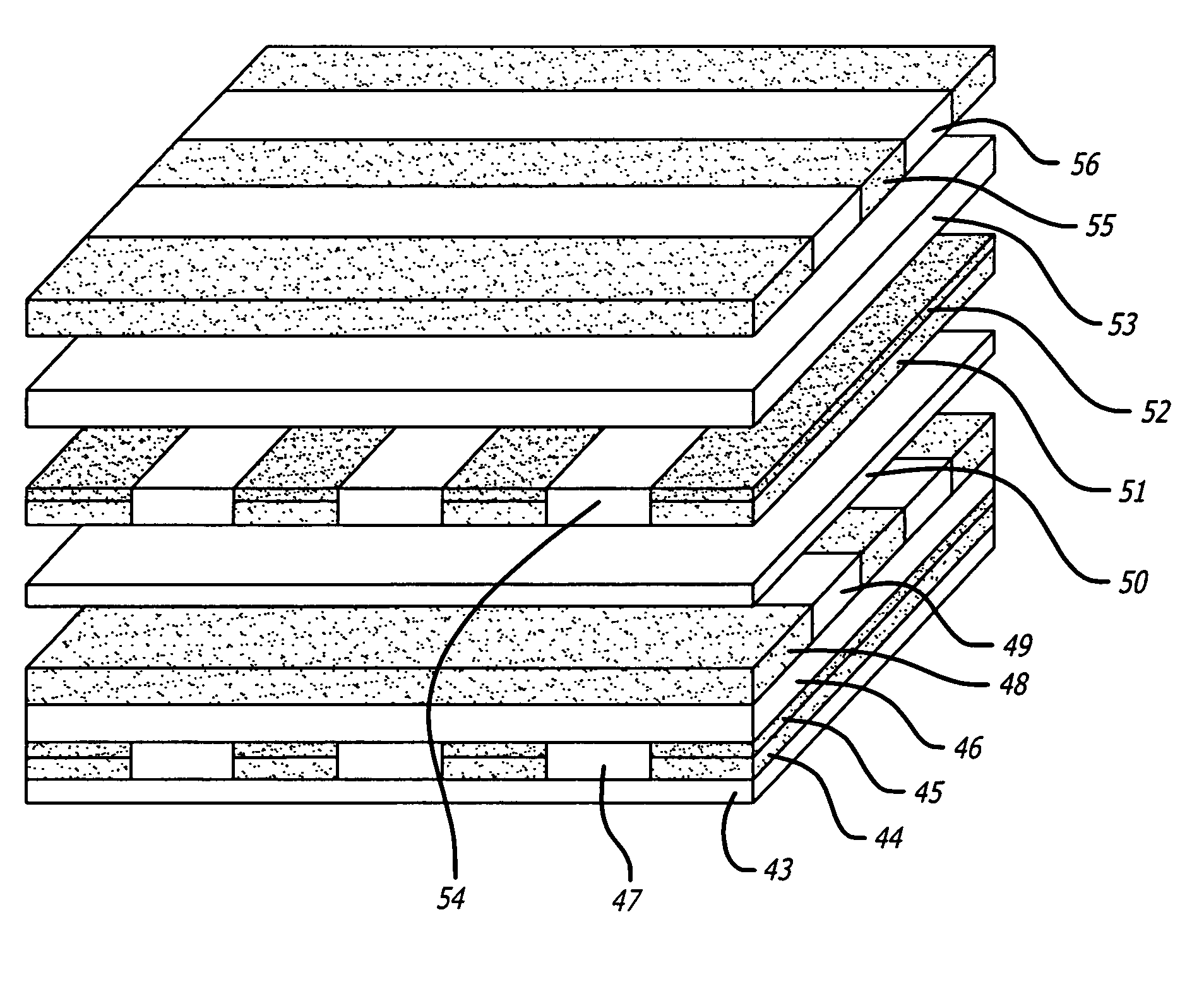

Memory devices based on electric field programmable films

InactiveUS20050058009A1Easy to manufactureImprove device densityNanoinformaticsSolid-state devicesDielectric matrixElectricity

A composition for the formation of an electric field programmable film, the composition comprising a matrix precursor composition or a dielectric matrix material, wherein the dielectric matrix material comprises an organic polymer and / or a inorganic oxide; and an electron donor and an electron acceptor of a type and in an amount effective to provide electric field programming. The films are of utility in data storage devices.

Owner:RGT UNIV OF CALIFORNIA

Catalyst for olefine polymerizing reaction and its components

The present invention provides one kind catalyst component for CH2=CHR olifine polymerization, where R is H or alkyl radical or aryl radical of C1-C6. The catalyst component contains Mg, Ti, halogen and electron donor.

Owner:CHINA PETROLEUM & CHEM CORP +1

Solid catalyst component for ethylene polymerization and catalyst therefor

InactiveCN1463991AOrganic-compounds/hydrides/coordination-complexes catalystsPolymer sciencePtru catalyst

The catalyst components for polymerization or copolymerization of ethylene includes at least one titanium compound, at least one electron donor and at least one activator carried onto one kind of Mg / Ti containing solid matter. The catalyst components has relatively narrow grain size distribution and relatively small average grain size, and the catalyst with the catalyst components has relativelyhigher activity and is especially suitable for slurry polymerization and gaseous polymerization to obtain polymer with lower fine powder content. The catalyst is especially suitable for ethylene polymerization with slurry feeding and gaseous fluidized bed polymerization.

Owner:CHINA PETROLEUM & CHEM CORP +1

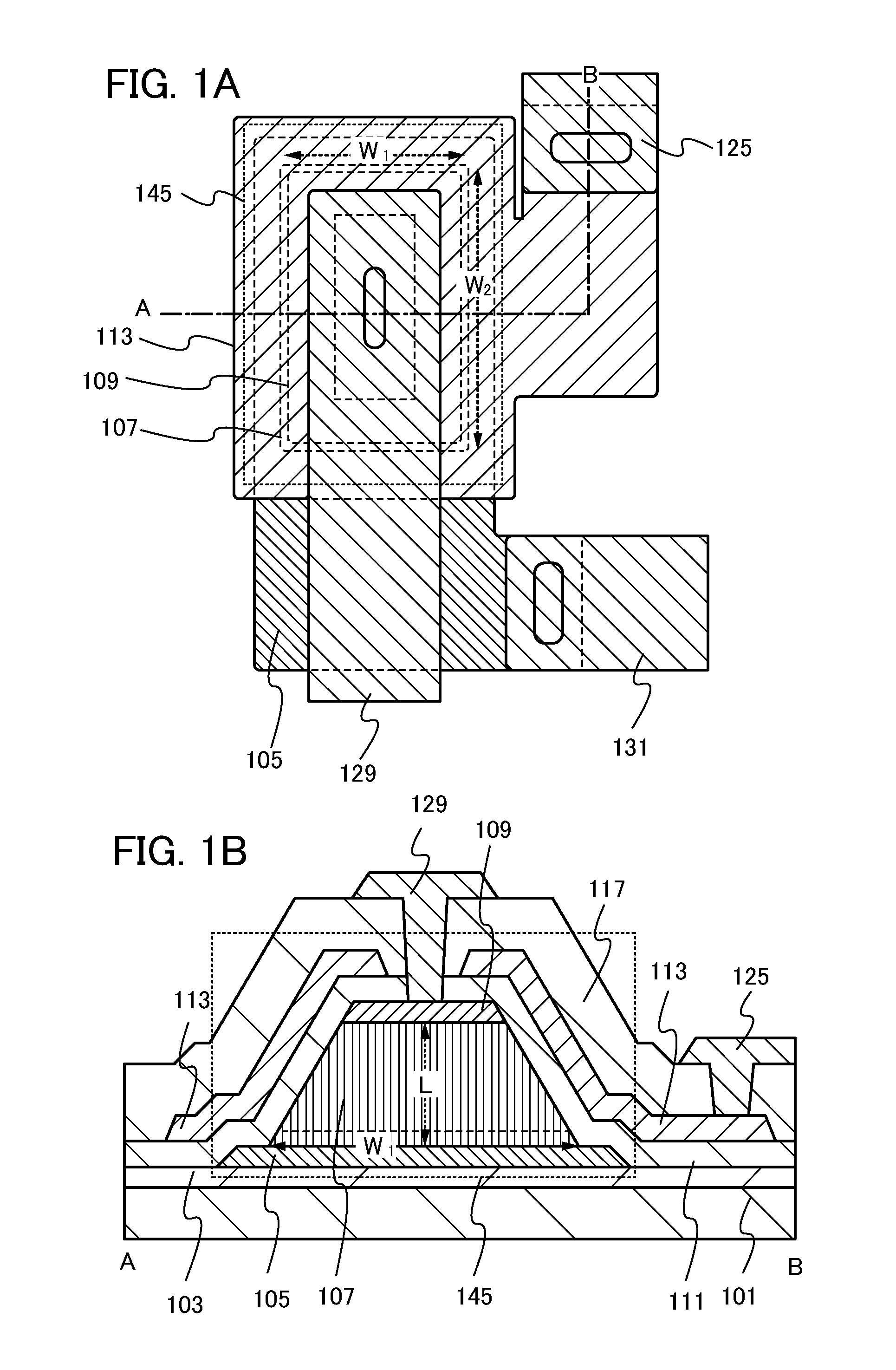

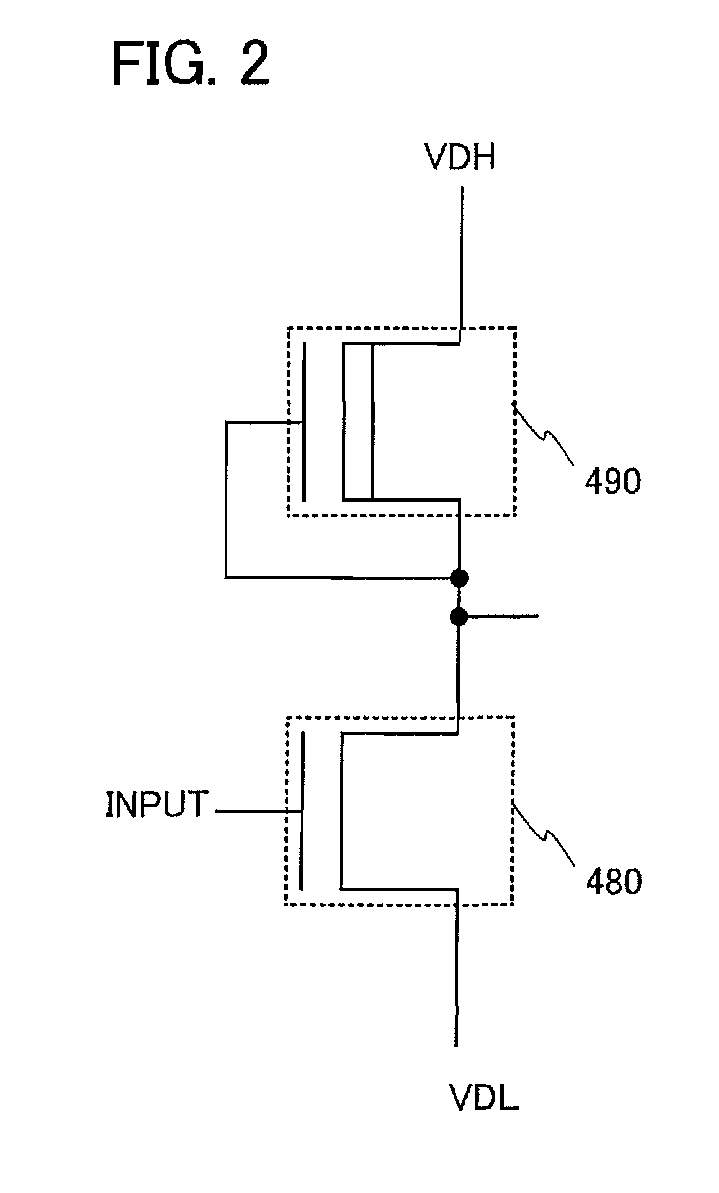

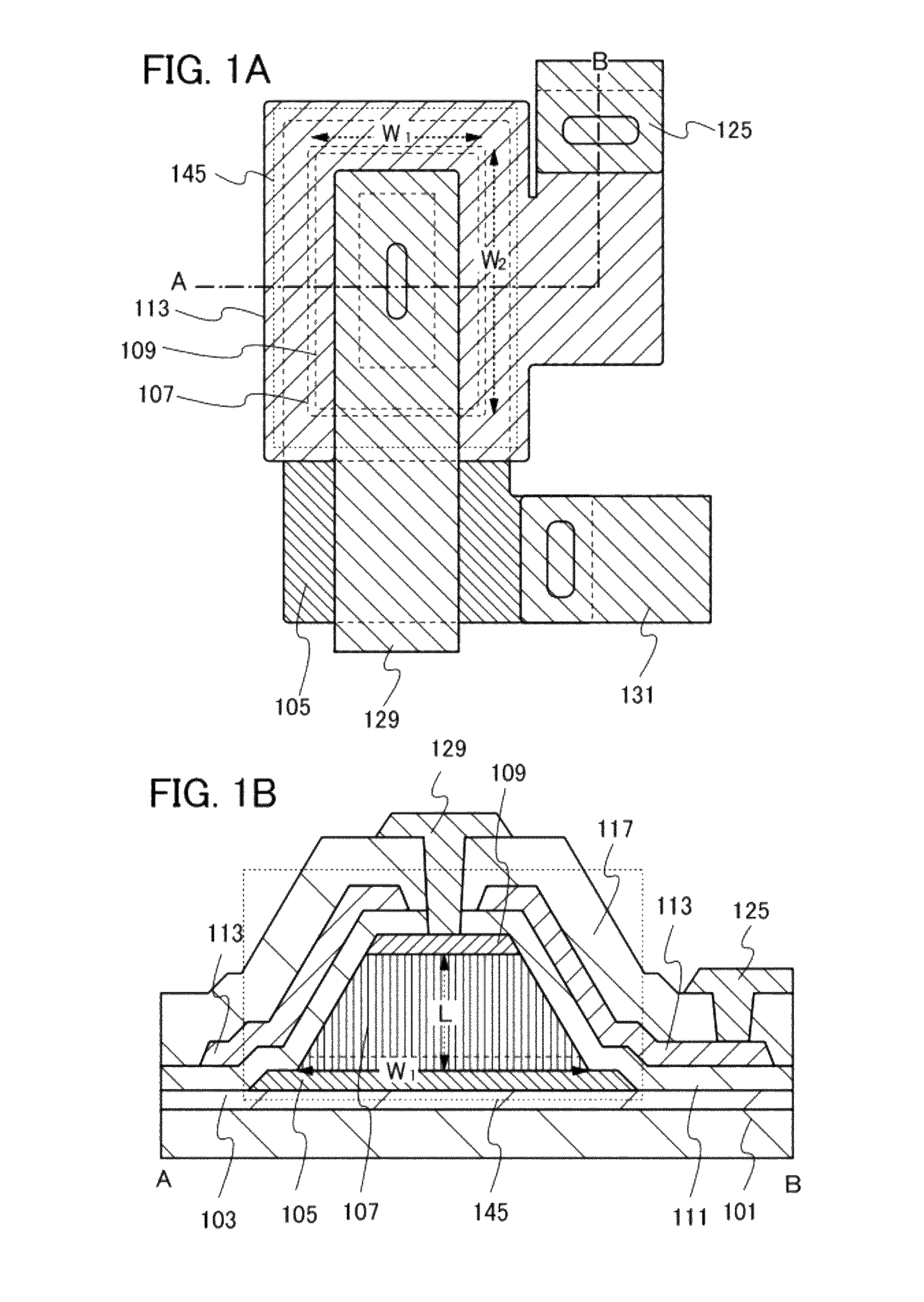

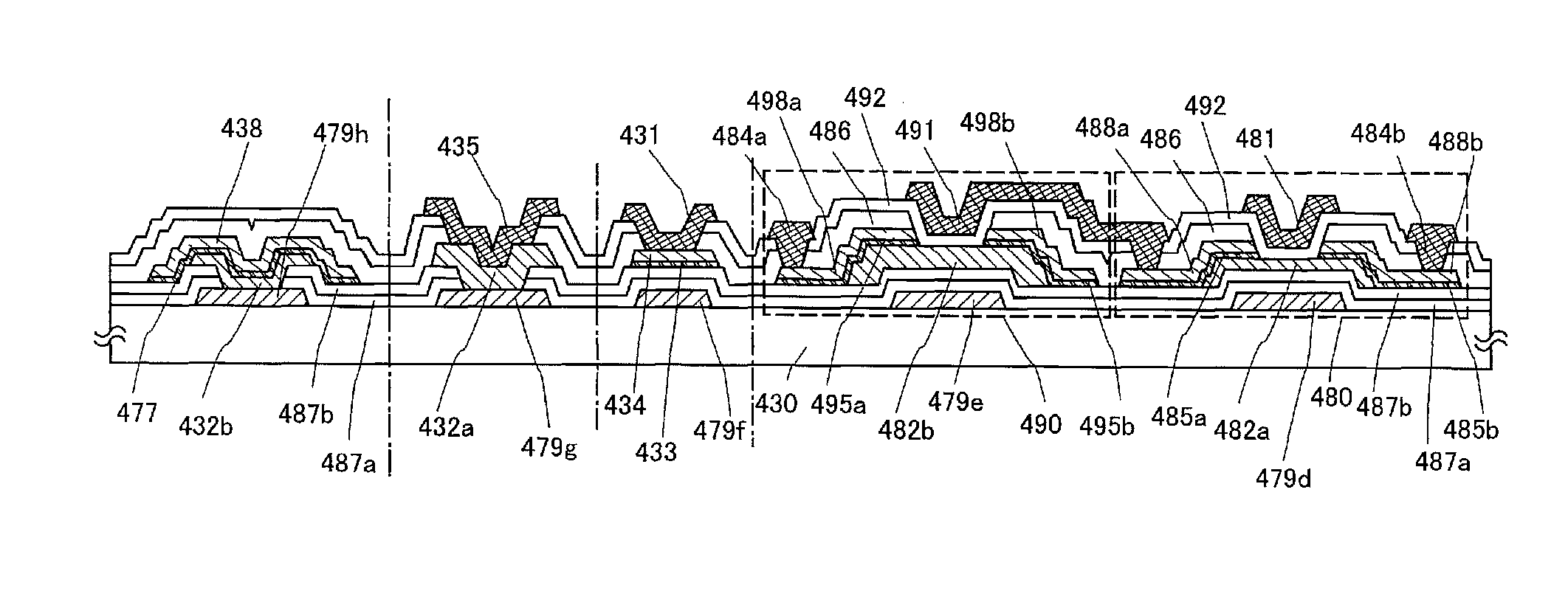

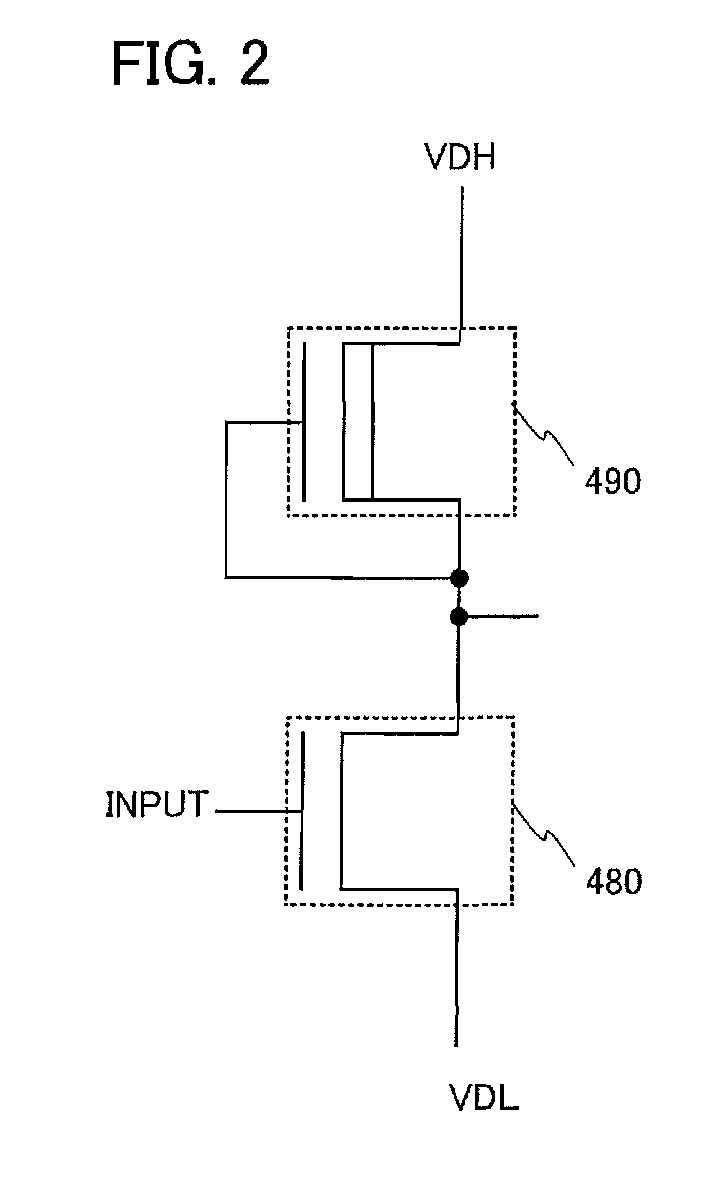

Semiconductor device and manufacturing method thereof

ActiveUS8421068B2Shorten driving distanceTimely controlSemiconductor/solid-state device detailsSolid-state devicesElectron donorElectron

An object is to reduce leakage current and parasitic capacitance of a transistor used for an LSI, a CPU, or a memory. A semiconductor integrated circuit such as an LSI, a CPU, or a memory is manufactured using a thin film transistor in which a channel formation region is formed using an oxide semiconductor which becomes an intrinsic or substantially intrinsic semiconductor by removing impurities which serve as electron donors (donors) from the oxide semiconductor and has larger energy gap than that of a silicon semiconductor. With use of a thin film transistor using a highly purified oxide semiconductor layer with sufficiently reduced hydrogen concentration, a semiconductor device with low power consumption due to leakage current can be realized.

Owner:SEMICON ENERGY LAB CO LTD

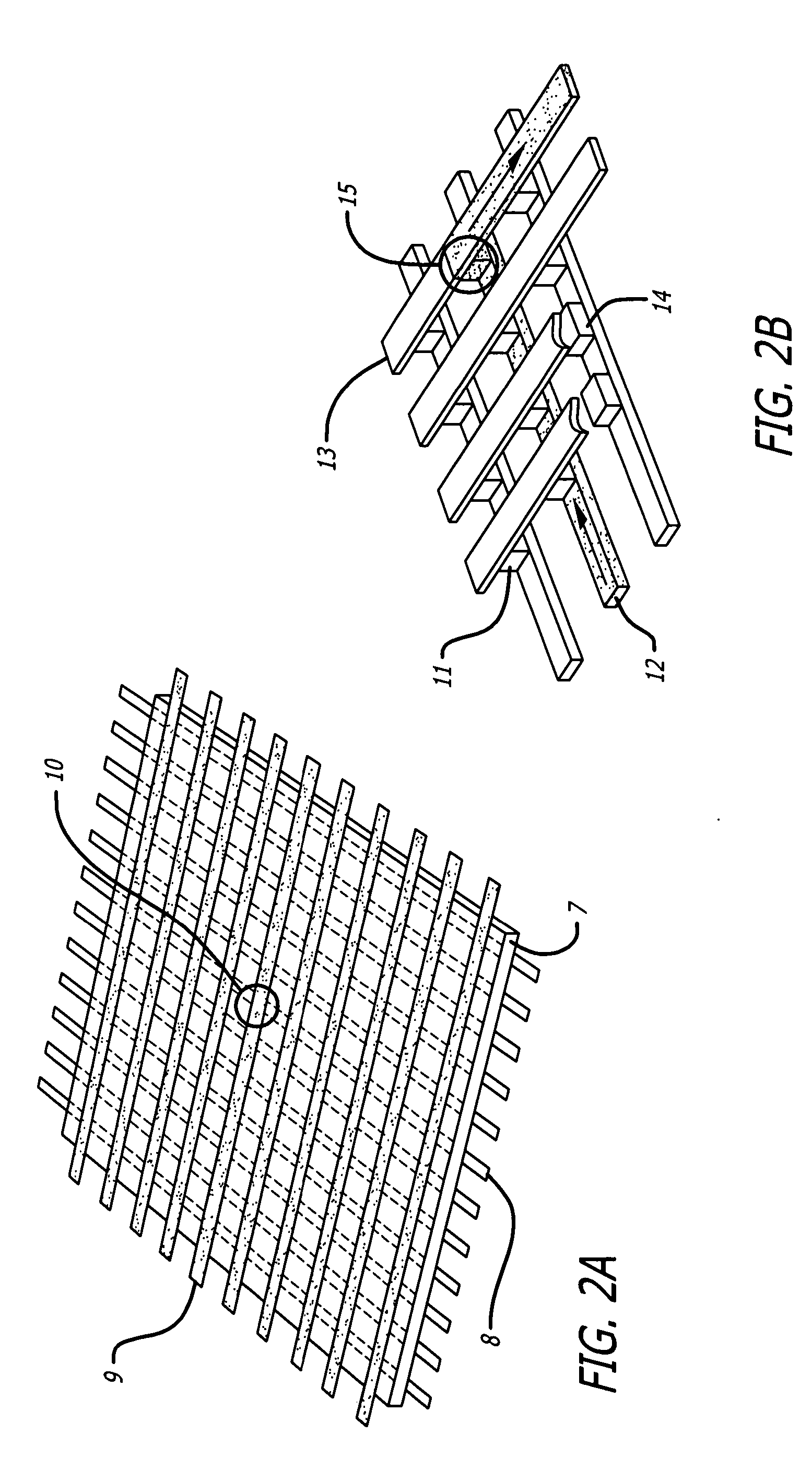

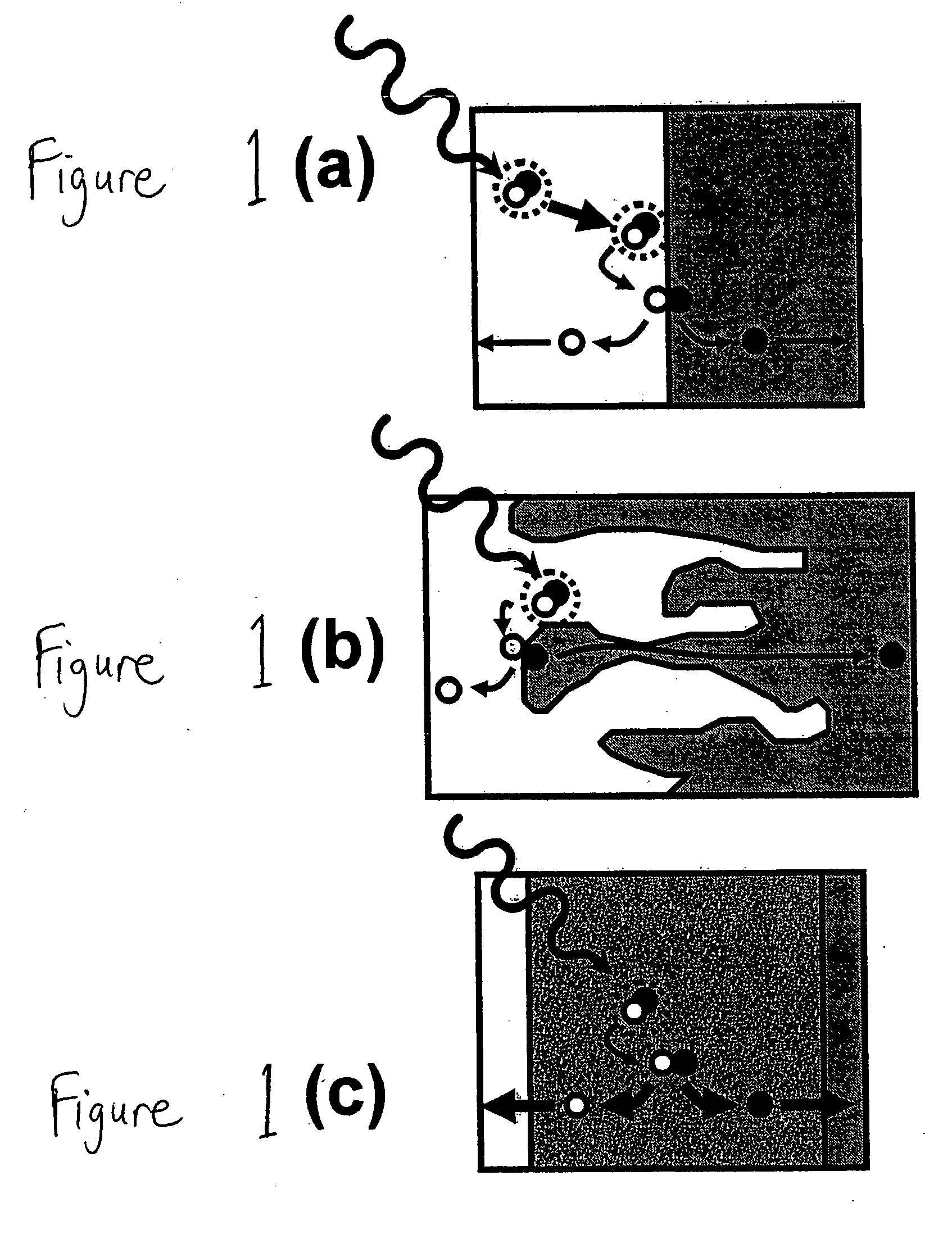

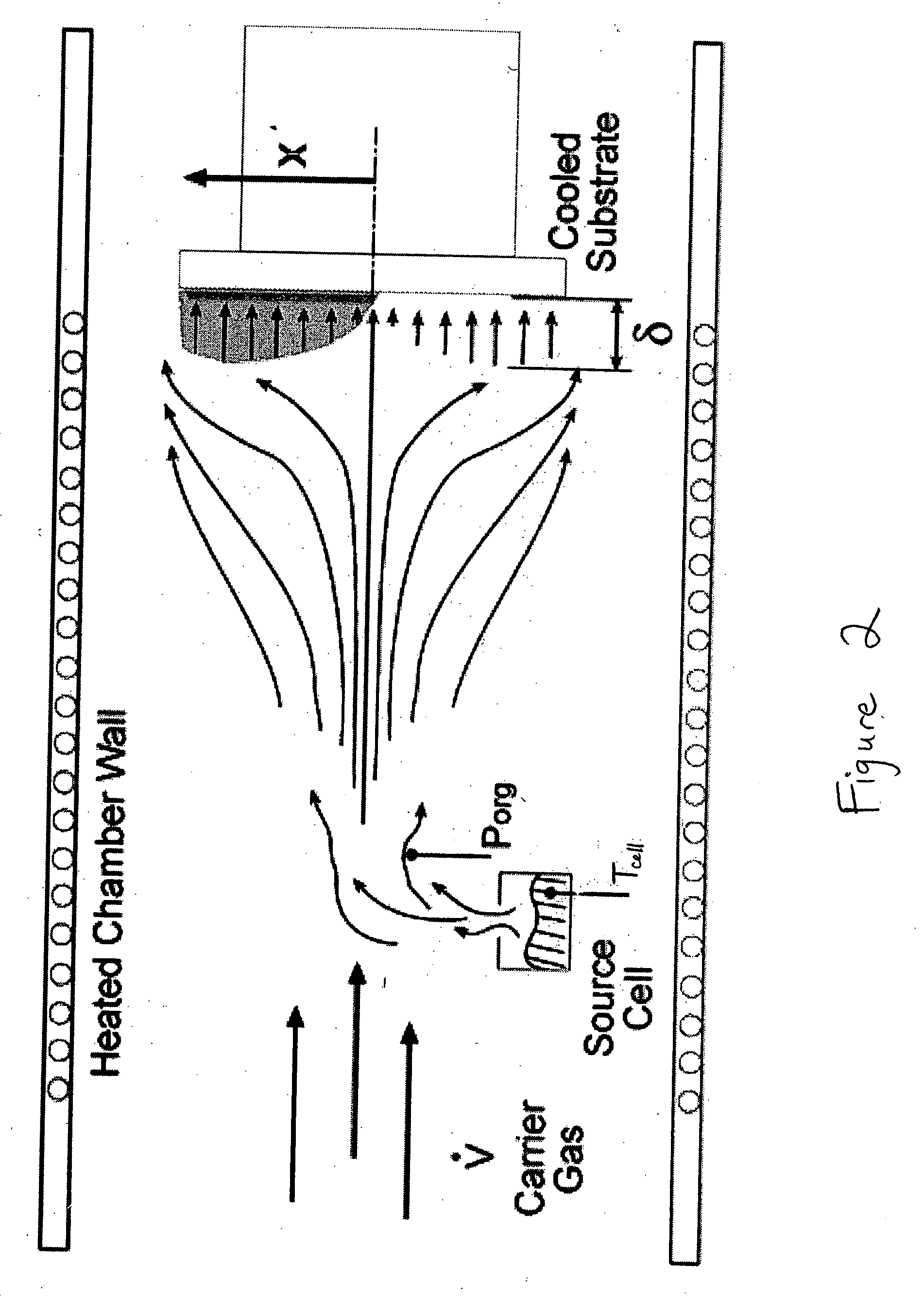

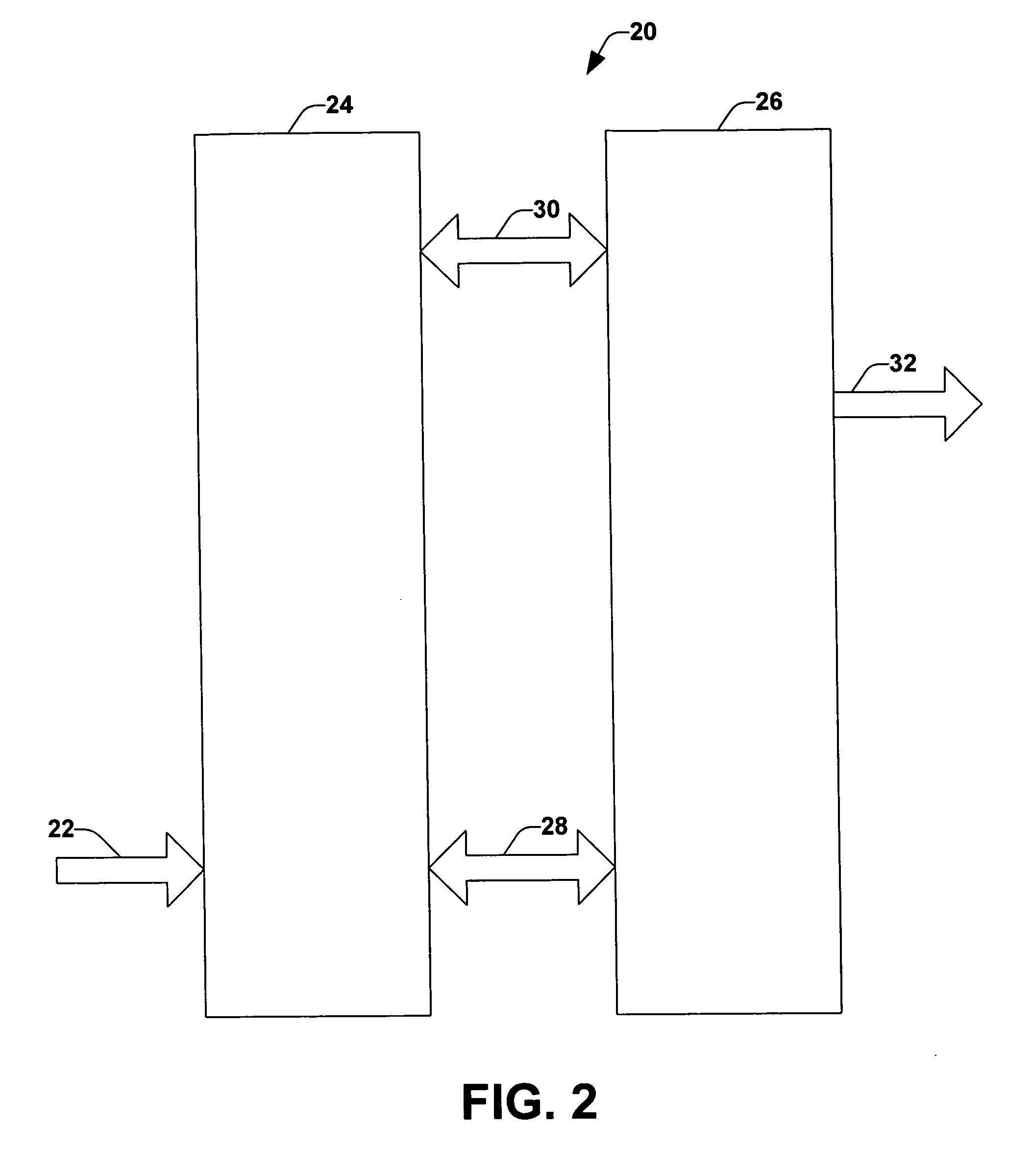

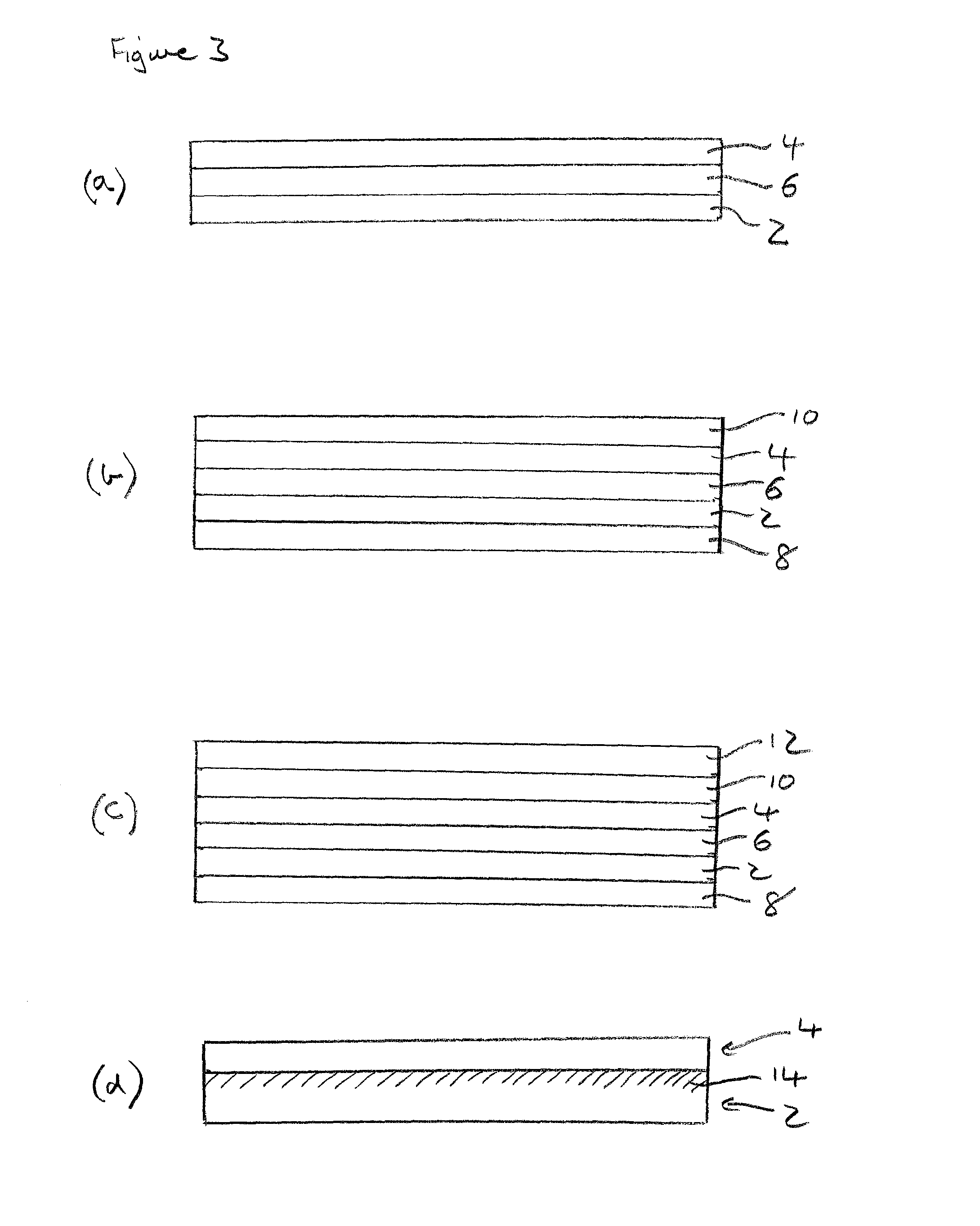

Method of fabricating an optoelectronic device having a bulk heterojunction

ActiveUS20050227406A1Acceptable power conversion efficiencyAcceptable quantum yieldMaterial nanotechnologyFinal product manufactureHeterojunctionElectron donor

A method of fabricating an organic optoelectronic device having a bulk heterojunction comprises the steps of: depositing a first layer over a first electrode by organic vapor phase deposition, wherein the first layer comprises a first organic small molecule material; depositing a second layer on the first layer such that the second layer is in physical contact with the first layer, wherein the interface of the second layer on the first layer forms a bulk heterojunction; and depositing a second electrode over the second layer to form the optoelectronic device. In another embodiment, a first layer having protrusions is deposited over the first electrode, wherein the first layer comprises a first organic small molecule material. For example, when the first layer is an electron donor layer, the first electrode is an anode, the second layer is an electron acceptor layer, and the second electrode is a cathode. As a further example, when the first layer is an electron acceptor layer, the first electrode is a cathode, the second layer is an electron donor layer, and the second electrode is an anode.

Owner:THE TRUSTEES FOR PRINCETON UNIV

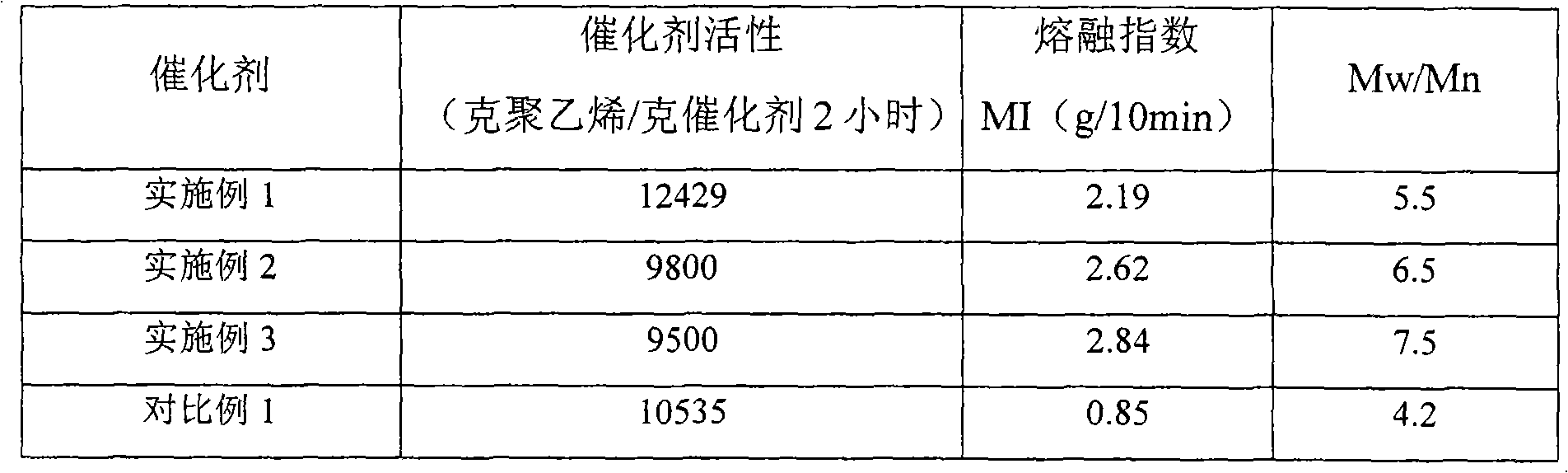

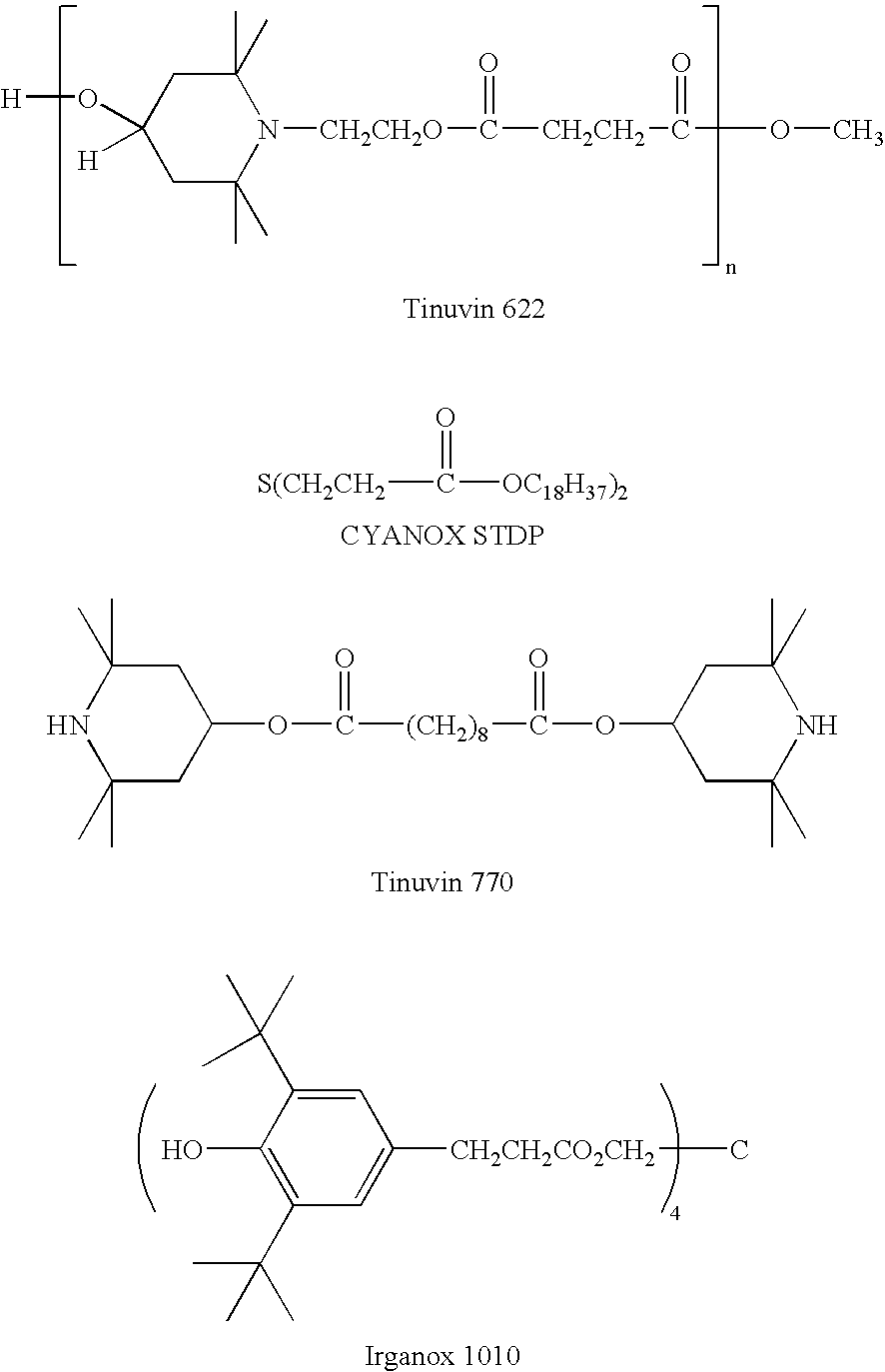

Catalyst for vinyl polymerization and method for preparing same

The invention provides a catalyst for vinyl polymerization. The catalyst contains titanium-containing active components and active agent components (organic aluminum compound), wherein an inorganic oxide carrier is loaded with at least one kind of magnesium dihalide, one kind of aluminum halide, at least one kind of titanium halide and at least one kind of electron donor, and the electron donor compound is ether, ester or ketone; and the general formula of the organic aluminum compound is AlRnX3-n, R is alkyl of which the number of hydrogen or carbon atoms is 1 to 20, X is halogen, and n is a numeral which is more than 1 and less than or equal to 3. When the catalyst is used for the vinyl polymerization, the catalyst has higher polymerization activity and hydrogen-adjusting sensitivity, and simultaneously the molecular weight distribution of the obtained polymers is wider.

Owner:CHINA PETROLEUM & CHEM CORP +1

Self limiting catalyst composition and propylene polymerization process

ActiveUS7491670B2Poor surfaceOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationSelf limitingElectron donor

A catalyst composition for the polymerization of propylene comprising one or more Ziegler-Natta procatalyst compositions comprising one or more transition metal compounds and one or more esters of aromatic dicarboxylic acid internal electron donors; one or more aluminum containing cocatalysts; a selectivity control agent (SCA) comprising at least one silicon containing compound containing at least one C1-10 alkoxy group bonded to a silicon atom, and one or more activity limiting agent (ALA) compounds comprising one or more aliphatic or cycloaliphatic carboxylic acids; alkyl-, cycloalkyl- or alkyl(poly)(oxyalkyl)-(poly)ester derivatives thereof; or inertly substituted derivatives of the foregoing.

Owner:WR GRACE & CO CONN

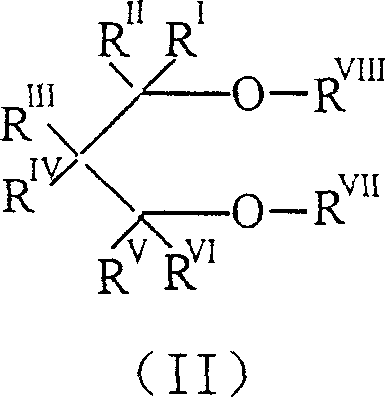

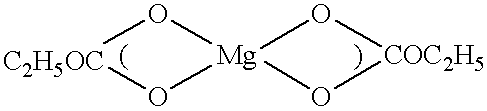

Electron donors

A method of polymerizing at least one olefin comprising contacting the olefin with a catalyst composition comprising:1) a procatalyst composition comprising a magnesium and titanium-containing component and an electron donor compound of the structure:wherein R1 is ethoxy, and R2 is an alkoxy group having from one to ten carbon atoms, and R3-R6 are each individually, hydrogen, hydrocarbyl, hydrocarboxy, nitro, a silyl group or a halogen,2) a cocatalyst and optionally3) a selectivity control agent.

Owner:UNION CARBIDE CHEM & PLASTICS TECH CORP

Method of fabricating a stacked oxide material for thin film transistor

ActiveUS8367489B2Improve conversion efficiencyImprove featuresSolid-state devicesSemiconductor/solid-state device manufacturingSemiconductor materialsElectron donor

Objects are to provide a semiconductor device for high power application in which a novel semiconductor material having high productivity is used and to provide a semiconductor device having a novel structure in which a novel semiconductor material is used. The present invention is a vertical transistor and a vertical diode each of which has a stacked body of an oxide semiconductor in which a first oxide semiconductor film having crystallinity and a second oxide semiconductor film having crystallinity are stacked. An impurity serving as an electron donor (donor) which is contained in the stacked body of an oxide semiconductor is removed in a step of crystal growth; therefore, the stacked body of an oxide semiconductor is highly purified and is an intrinsic semiconductor or a substantially intrinsic semiconductor whose carrier density is low. The stacked body of an oxide semiconductor has a wider band gap than a silicon semiconductor.

Owner:SEMICON ENERGY LAB CO LTD

Method for polymerization of an alpha -olefin

InactiveUS6066702AHigh reactivityEasy to operateOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationElectron donorAlpha-olefin

A method for polymerization or copolymerization of alpha -olefin, characterized in that the polymerization is performed using a solid complex titanium catalyst comprising magnesium, a halogen-containing titanium compound, and internal electron donors; organometallic compounds of metals belonging to Groups I and III on the periodic table of elements; and, as external electron donors, a mixture of three or more kinds of organic silicon compounds, from which homopolyolefins having MFR less than 5, MFR in the range from 5 to 20, and MFR greater than 20 are polymerized under the same polymerization conditions. By use of the present invention it is possible to produce an olefin polymer with high stereoregularity, broad molecular weight distribution, and good fluidity, at high rates of yield.

Owner:HANWHA TOTAL PETROCHEMICAL CO LTD

Semiconductor device and manufacturing method thereof

ActiveUS20110089414A1Reduce leakage currentReduce power consumptionSemiconductor/solid-state device detailsSolid-state devicesElectron donorElectron

An object is to reduce leakage current and parasitic capacitance of a transistor used for an LSI, a CPU, or a memory. A semiconductor integrated circuit such as an LSI, a CPU, or a memory is manufactured using a thin film transistor in which a channel formation region is formed using an oxide semiconductor which becomes an intrinsic or substantially intrinsic semiconductor by removing impurities which serve as electron donors (donors) from the oxide semiconductor and has larger energy gap than that of a silicon semiconductor. With use of a thin film transistor using a highly purified oxide semiconductor layer with sufficiently reduced hydrogen concentration, a semiconductor device with low power consumption due to leakage current can be realized.

Owner:SEMICON ENERGY LAB CO LTD

Spherical catalyst for olefin polymerization

InactiveUS7135531B2Large particle sizeOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationPolyolefinPolymer science

Disclosed are catalyst systems and methods of making the catalyst systems / supports for the polymerization of an olefin containing a solid titanium catalyst component having a substantially spherical shape and containing an internal electron donor, a support made from a magnesium compound, an alcohol, an ether, a surfactant, and an alkyl silicate. The catalyst system may further contain an organoaluminum compound and an organosilicon compound. Also disclosed are methods of making an impact copolymer involving polymerizing an olefin to provide a polyolefin matrix and polymerizing a polyolefin rubber using a catalyst component containing a support made from a magnesium compound, an alcohol, an ether, a surfactant, and an alkyl silicate.

Owner:ENGELHARD CORP

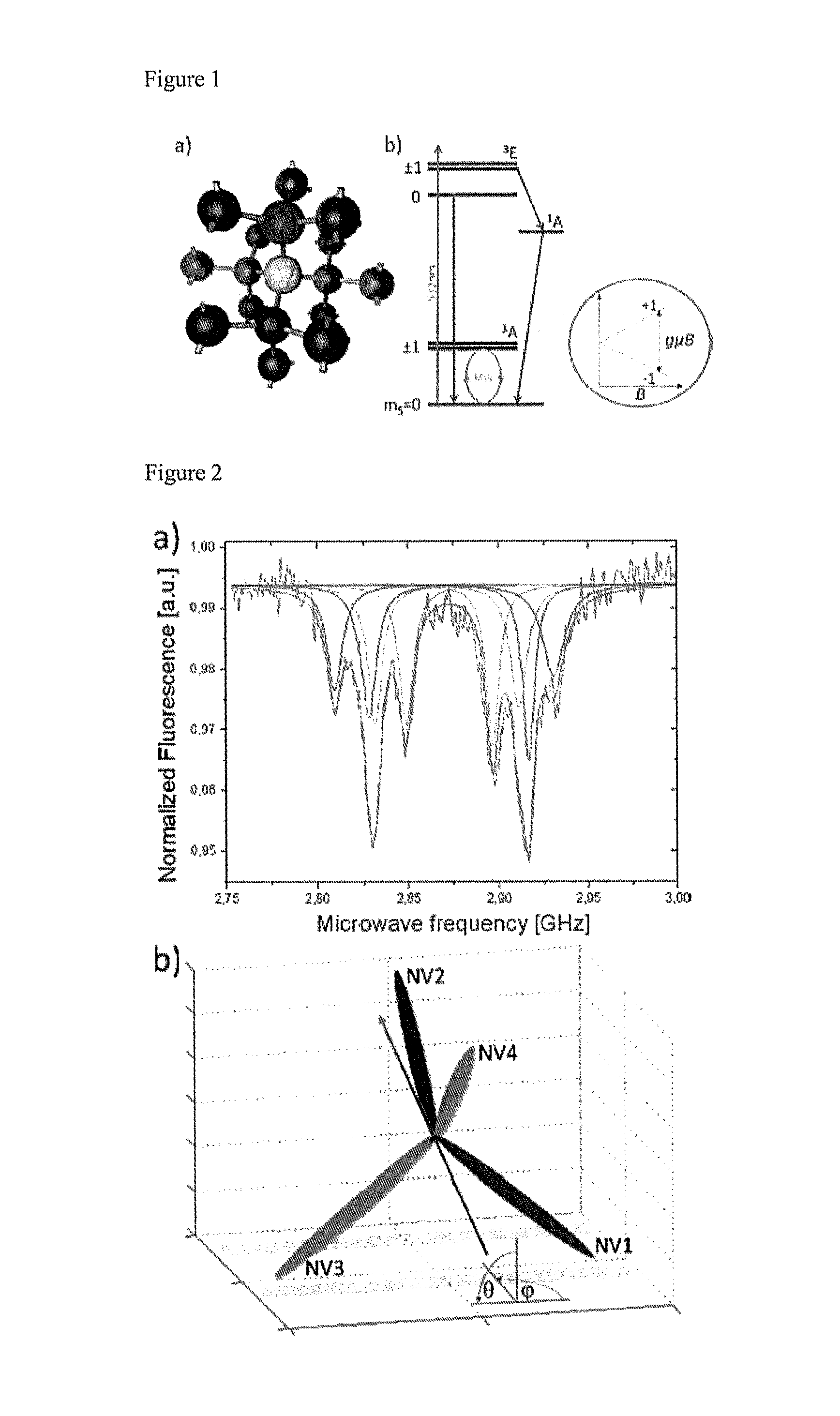

Diamond sensors, detectors, and quantum devices

ActiveUS20140037932A1High purityMinimizes strainQuantum computersPolycrystalline material growthElectron donorQuantum devices

A synthetic single crystal diamond material comprising: a first region of synthetic single crystal diamond material comprising a plurality of electron donor defects; a second region of synthetic single crystal diamond material comprising a plurality of quantum spin defects; and a third region of synthetic single crystal diamond material disposed between the first and second regions such that the first and second regions are spaced apart by the third region, wherein the second and third regions of synthetic single crystal diamond material have a lower concentration of electron donor defects than the first region of synthetic single crystal diamond material, and wherein the first and second regions are spaced apart by a distance in a range 10 nm to 100 μm which is sufficiently close to allow electrons to be donated from the first region of synthetic single crystal diamond material to the second region of synthetic single crystal diamond material thus forming negatively charged quantum spin defects in the second region of synthetic single crystal diamond material and positively charged defects in the first region of synthetic single crystal diamond material while being sufficiently far apart to reduce other coupling interactions between the first and second regions which would otherwise unduly reduce the decoherence time of the plurality of quantum spin defects and / or produce strain broaden of a spectral line width of the plurality of quantum spin defects in the second region of synthetic single crystal diamond material.

Owner:ELEMENT SIX LTD

Process for the preparation of polyethylene

InactiveUS6617405B1Avoid experimentationDisperse thoroughlyOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationElectron donorSlurry

A process of polymerizing ethylene or ethylene and one or more comonomers in one or more fluidized bed reactors with a catalyst system comprising (i) a supported or unsupported magnesium / titanium based precursor in slurry form, said precursor containing an electron donor; and (ii) an activator containing aluminum in an amount sufficient to essentially complete the activation of the precursor is disclosed. In the process, the precursor and the activator are mixed prior to introduction into the reactor in at least one mixing procedure, and then the mixture is contacted again with additional activator to essentially complete activation of the precursor. In the method, the atomic ratio of aluminum to titanium is in the range of about 1:1 to about 15:1 and the mole ratio of activator to electron donor is about 1:1 to about 2:1, and no additional activator is introduced into the reactor(s).

Owner:UNION CARBIDE CHEM & PLASTICS TECH CORP

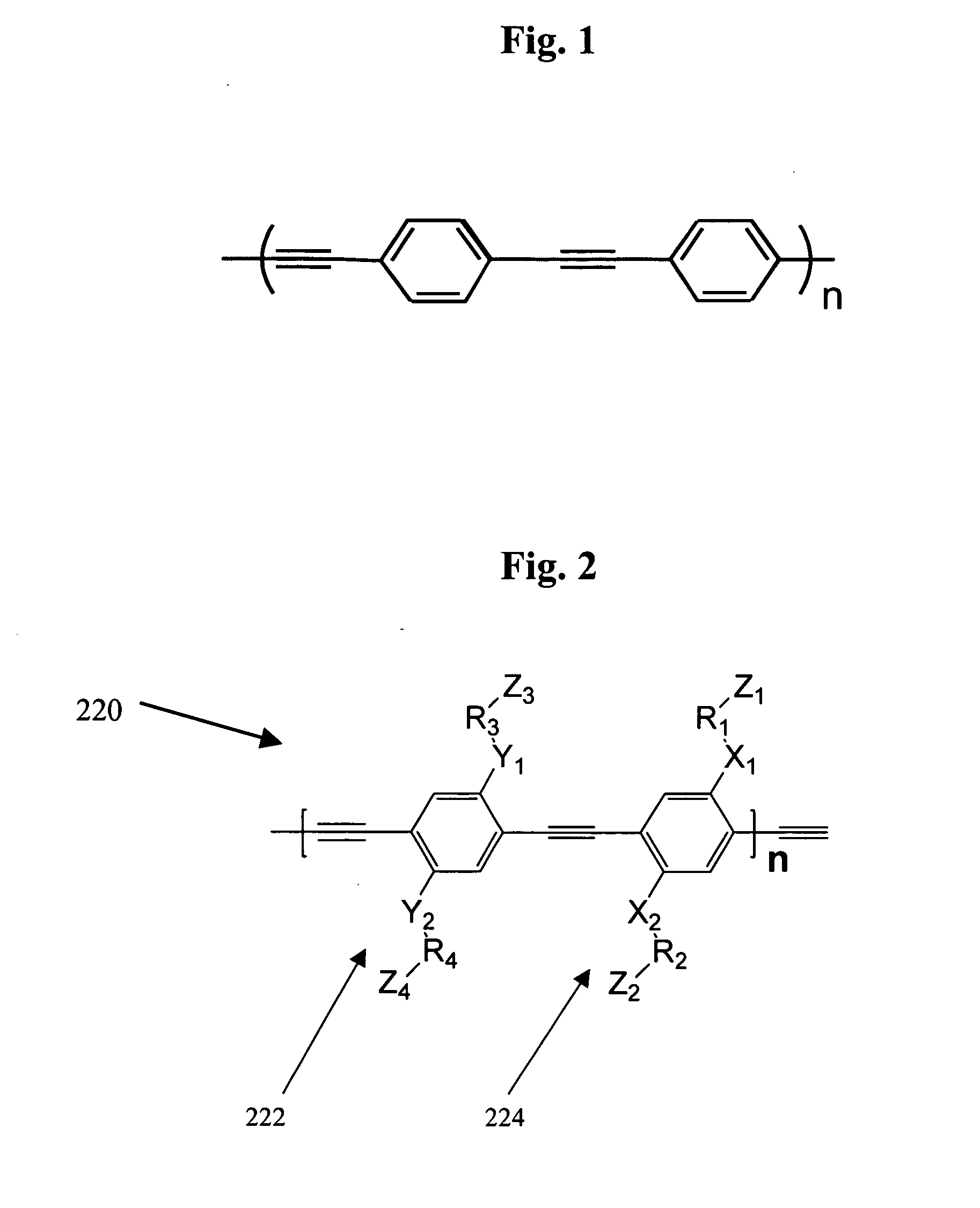

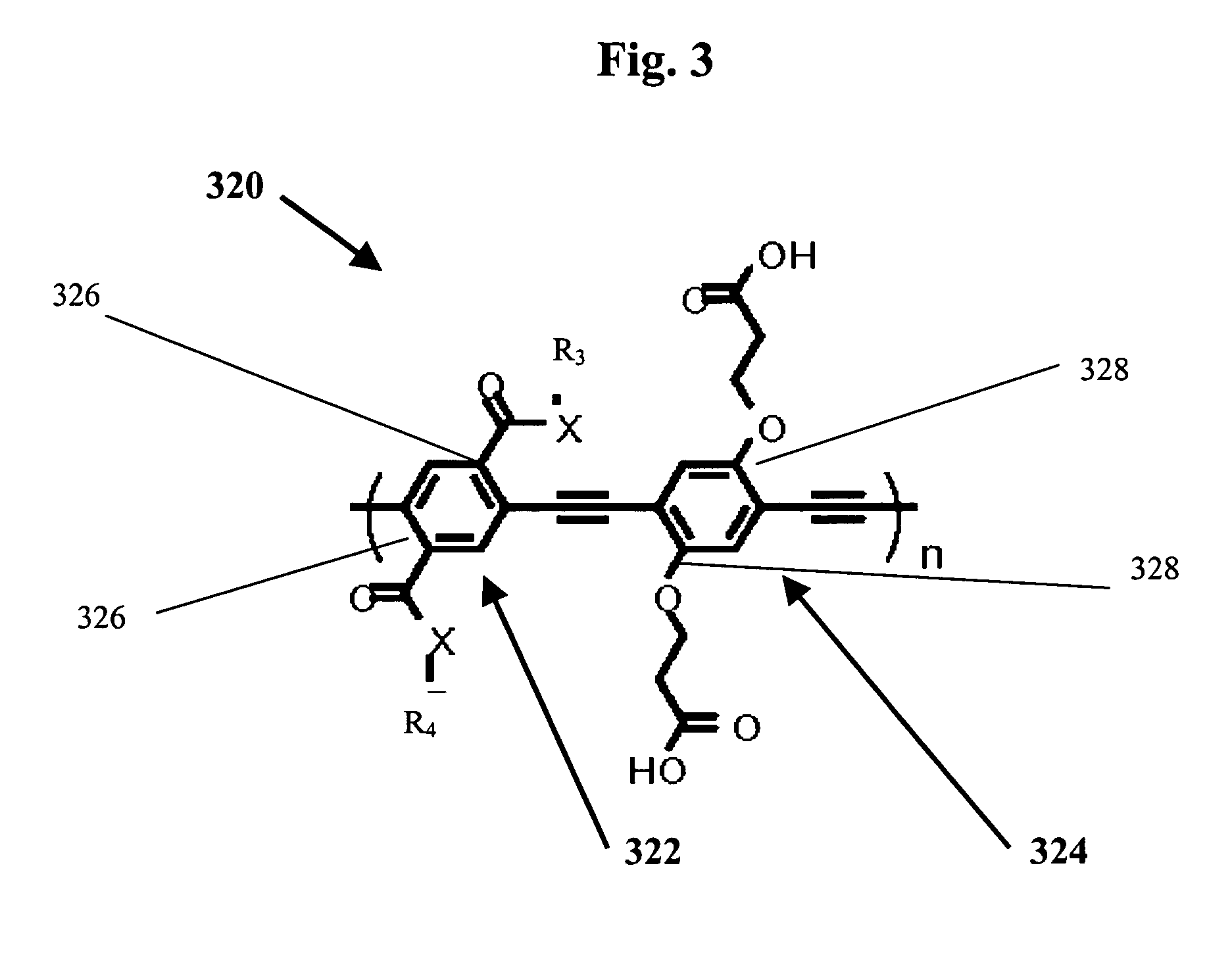

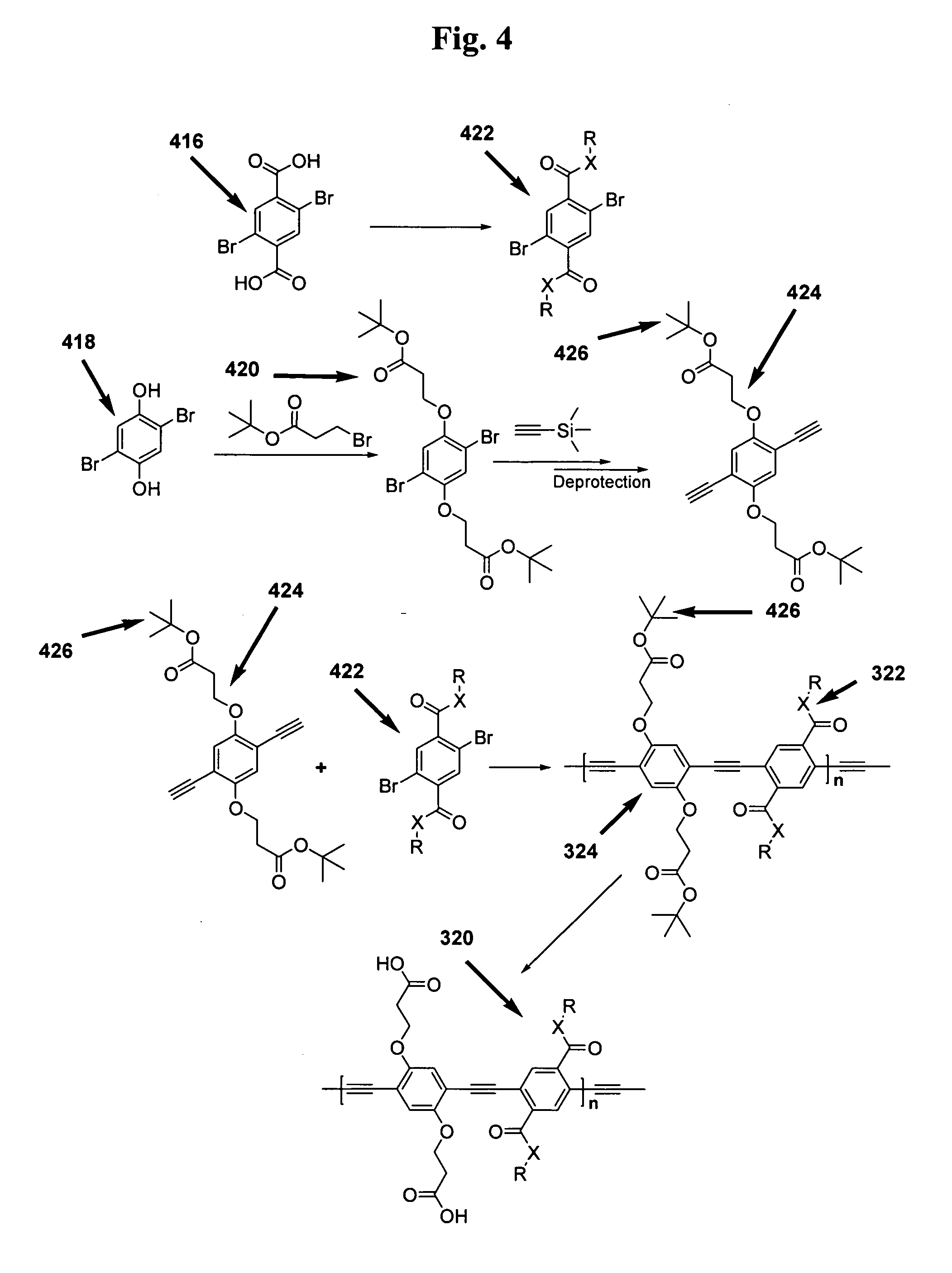

Methods for the synthesis of modular poly(phenyleneethynlenes) and fine tuning the electronic properties thereof for the functionalization of nanomaterials

Poly(aryleneethynylene) polymers for exfoliating and dispersing / solubilizing nanomaterial are provided herein. The poly(aryleneethynylene) polymers have unit monomer portions, each monomer portion having at least one electron donating substituent thereby forming an electron donor monomer portion, or at least one electron withdrawing substituent thereby forming an electron accepting monomer portion. Such polymers exfoliate and disperse nanomaterial without presonication of the nanomaterial.

Owner:ZYVEX ACQUISITION LLC

Process for the preparation of a catalyst component and components therefrom obtained

The invention provides a solid catalyst component for the polymeriztion of olefins comprising a Ti compound and an electron donor (ED) selected from alcohol, ketones, amines, amides, nitrites, alkoxysilanes, aliphatic ethers, and esters of aliphatic carboxylic acids supported on Mg dichloride in which the ED / Ti molar ratio ranges from 1.5 to 3.5 and the Mg / Ti molar ratio is higher than 5.5. The invention also provides a catalyst for the polymerization of olefins using the solid catalyst component and a process for the (co)polymerization of olefins CH2=CHR.

Owner:BASSELL POLIOLEFINE ITAL SRL

Bulk depositing synthesis process of isotactic polybutylene-1

The present invention is bulk depositing synthesis process of isotactic polybutylene-1, and belongs to the field of polymer technology. The powdered isotactic polybutylene-1 product is obtained through bulk depositing polymerization of butylene-1 as the monomer and reactant medium at 0-70 deg.c in the presence of supported titanium catalyst, and the subsequent flash evaporation to eliminate unpolymerized monomer. The catalyst system may have organic aluminum AlR3 as co-catalyst, added electron donor compound, and hydrogen as molecular weight regulator. The polymerization reaction is performed in a polymerizing kettle with stirring screw belt. The present invention has simple technological process, high efficiency and low cost, and the prepared isotactic polybutylene-1 has high stereoregularity degree, crystallization degree higher than 60 %, and smelting point of 127.5 deg.c.

Owner:SHANDONG ORIENT HONGYE CHEM +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com