Patents

Literature

1441 results about "Apparent density" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Apparent density (pb) is the ratio between the apparent volume and dry specimen mass of a soil sample. The volume is limited by external specimen forces which include voids. Therefore, it is measured in kilograms per cubic meter (kg/m3).

Process for preparing olefin polymerization ball type catalytic component and carrier

The spherical catalyst carrier is prepared with alcoholated magnesium chloride containing double-ether compound in emulsifying pelletizer. Liquid titanium halide compound is carried onto the spherical catalyst carrier to form spherical solid catalyst component in the presence of electron donor. In the X-ray diffraction spectrogram, the spherical solid catalyst component has diffraction peak in 13.3 deg of 2theta angle, strongest diffraction peak in 26.5 deg of 2theta angle and no characteristic diffraction peak of alpha-anhydrous MgCl2 in 15 deg of 2theta angle. The catalyst of the presentinvention has very high activity and may be used to produce polymer with good form, high apparent density and less fine powder. The catalyst is used in homopolymerization and copolymerization of olefin and suitable for various polymerization process.

Owner:YINGKOU XIANGYANG CATALYST

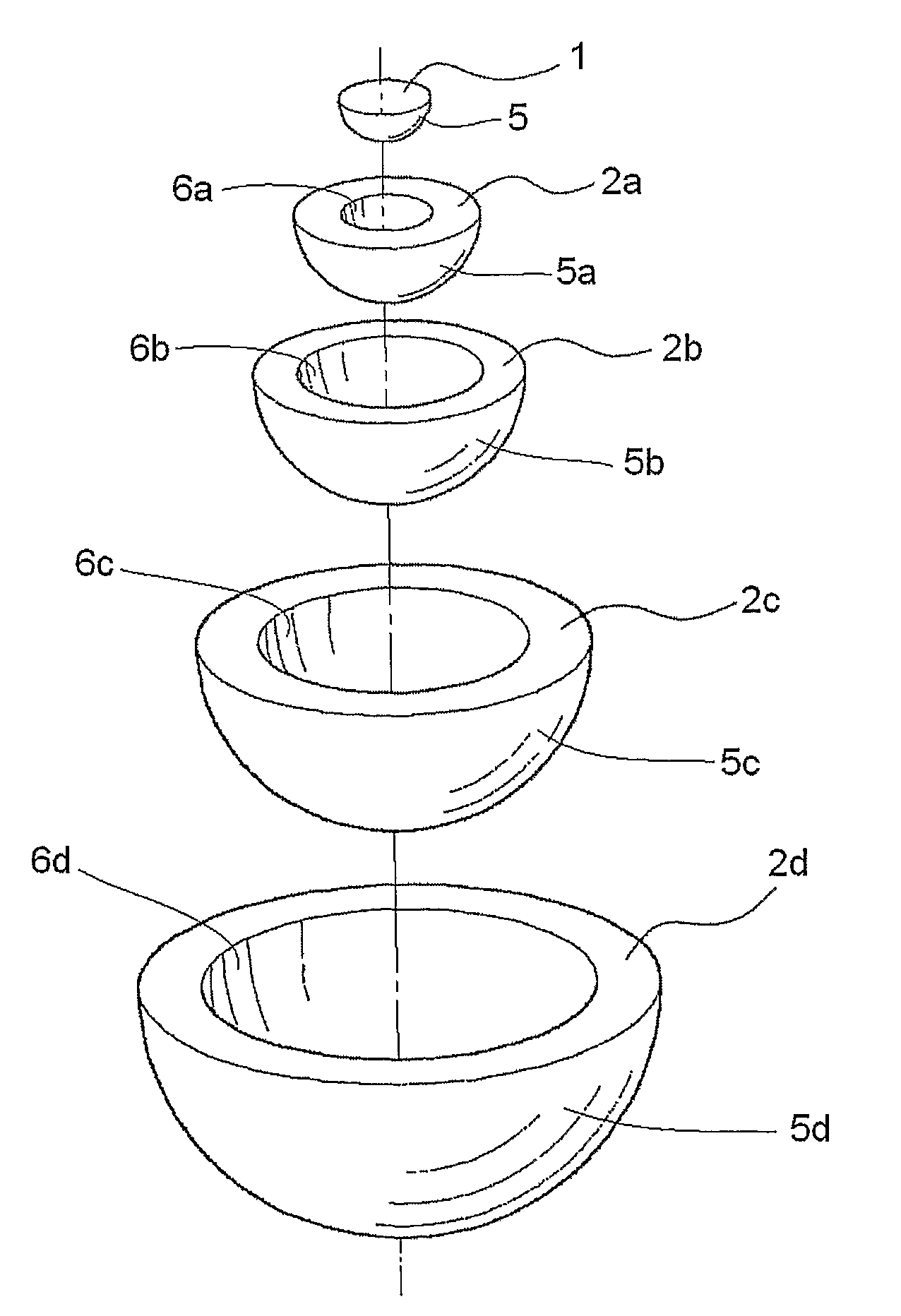

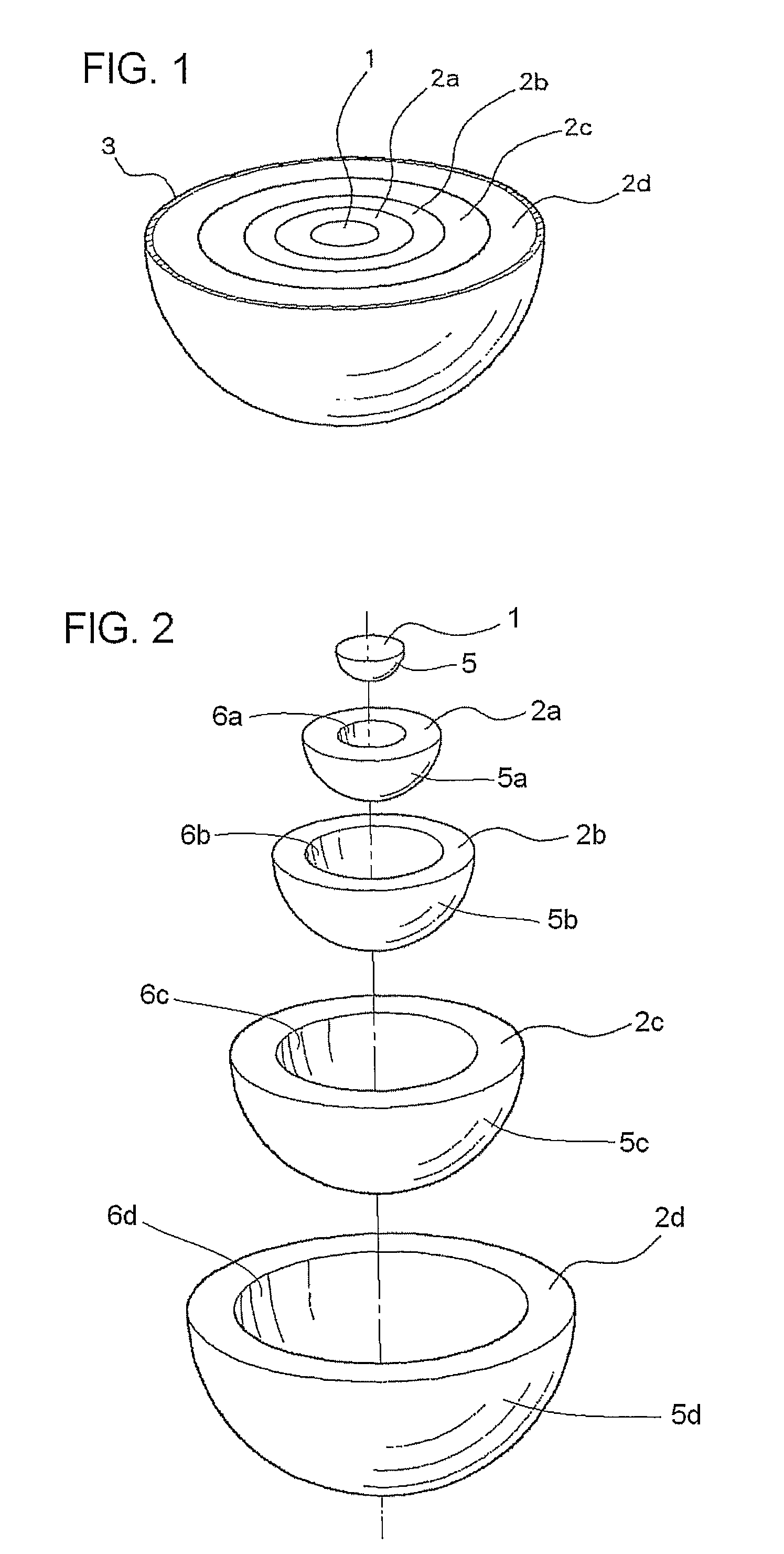

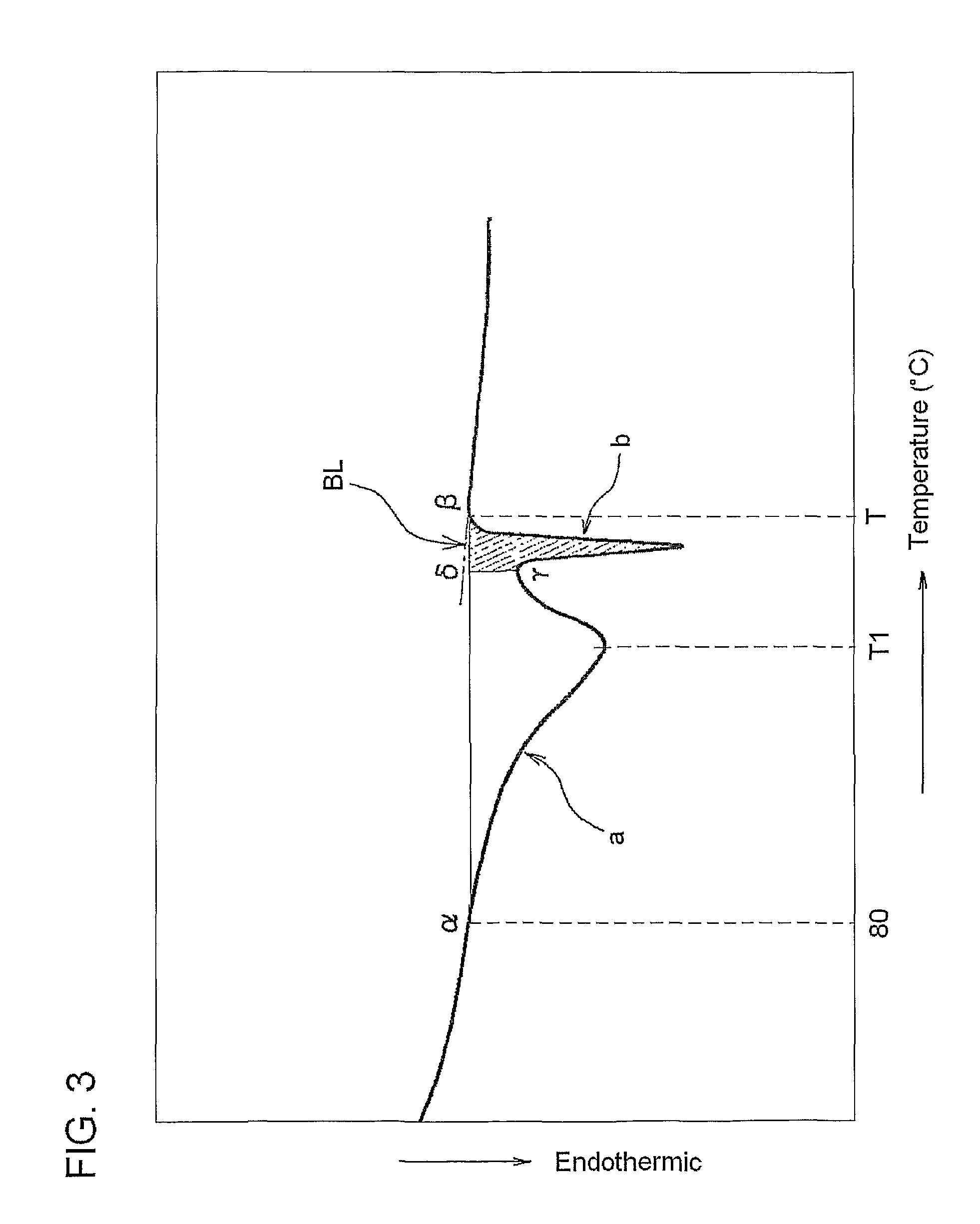

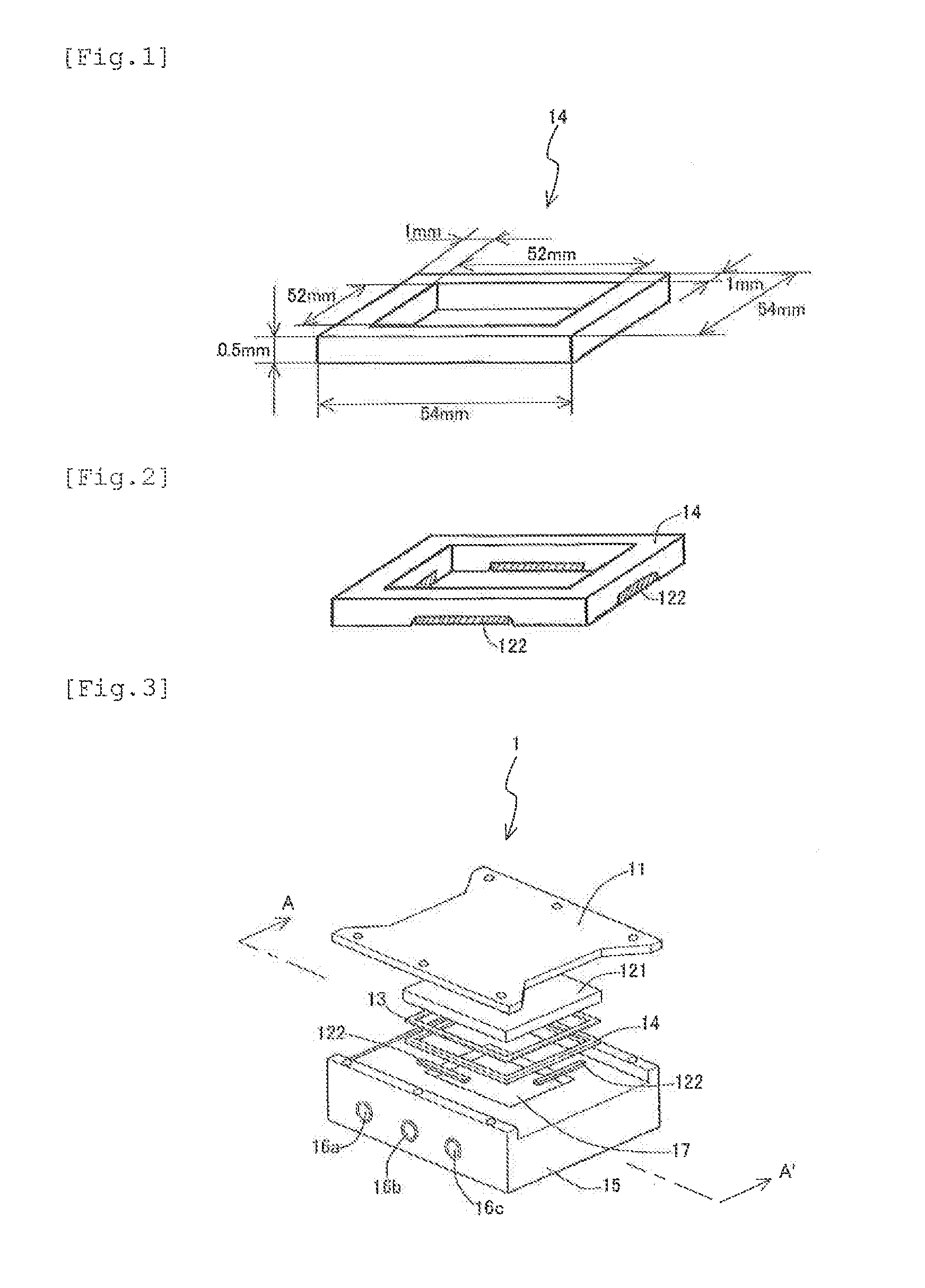

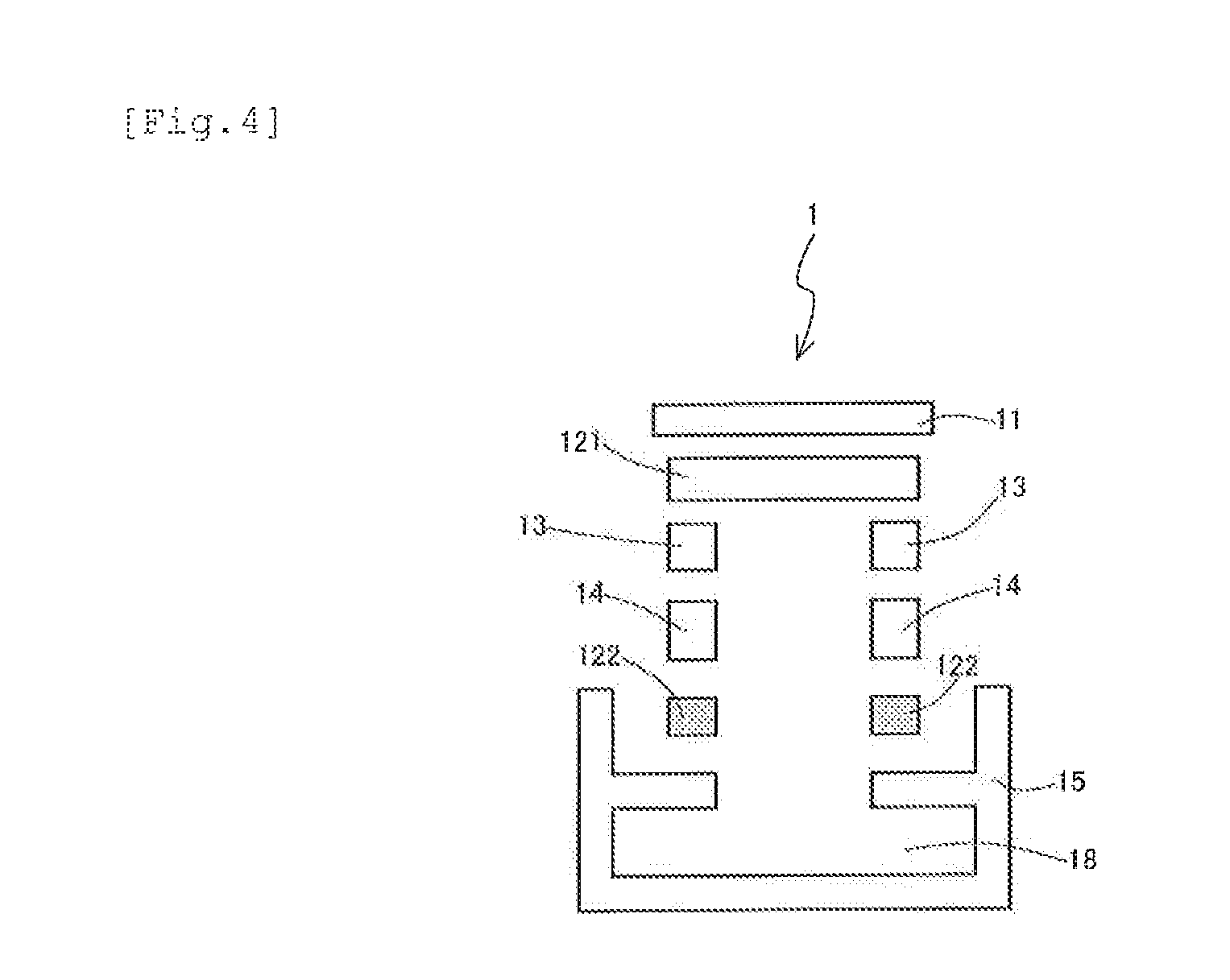

Luneberg dielectric lens and method of producing same

A hemispherical Luneberg dielectric lens including a hemispherical center layer having a hemispherical outer surface, and a plurality of hemispherical dome-shaped layers each having concentric hemispherical inner and outer surfaces, the outer surfaces of the center layer and dome-shaped layers having different diameters and the inner surfaces of said dome-shaped layers having different diameters. The center layer and dome-shaped layers are successively concentrically fitted into one another and integrated into a hemispherical shape. The center layer is a foam molding of ceramic-containing thermoplastic resin expanded beads, while each of said dome-shaped layers is a foam molding of thermoplastic resin expanded beads containing 0 to 80% by weight of a ceramic. The ceramic content per unit volume of the center and dome-shaped layers decreases from the center layer to the outermost dome-shaped layer, and the standard deviation of the apparent density of each of the center and dome-shaped layers is 0.07 g / cm3 or lower.

Owner:SUMITOMO ELECTRIC IND LTD

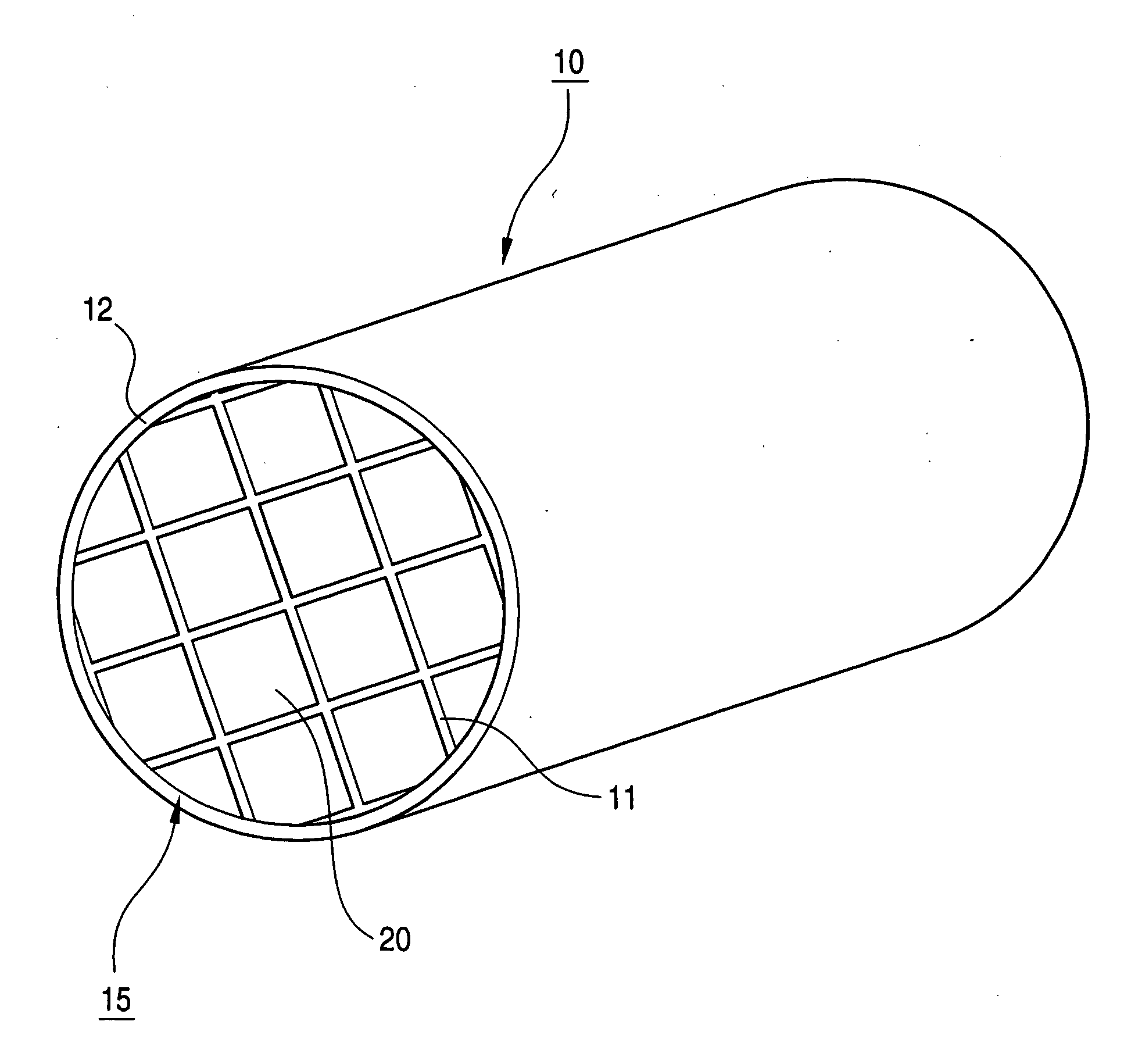

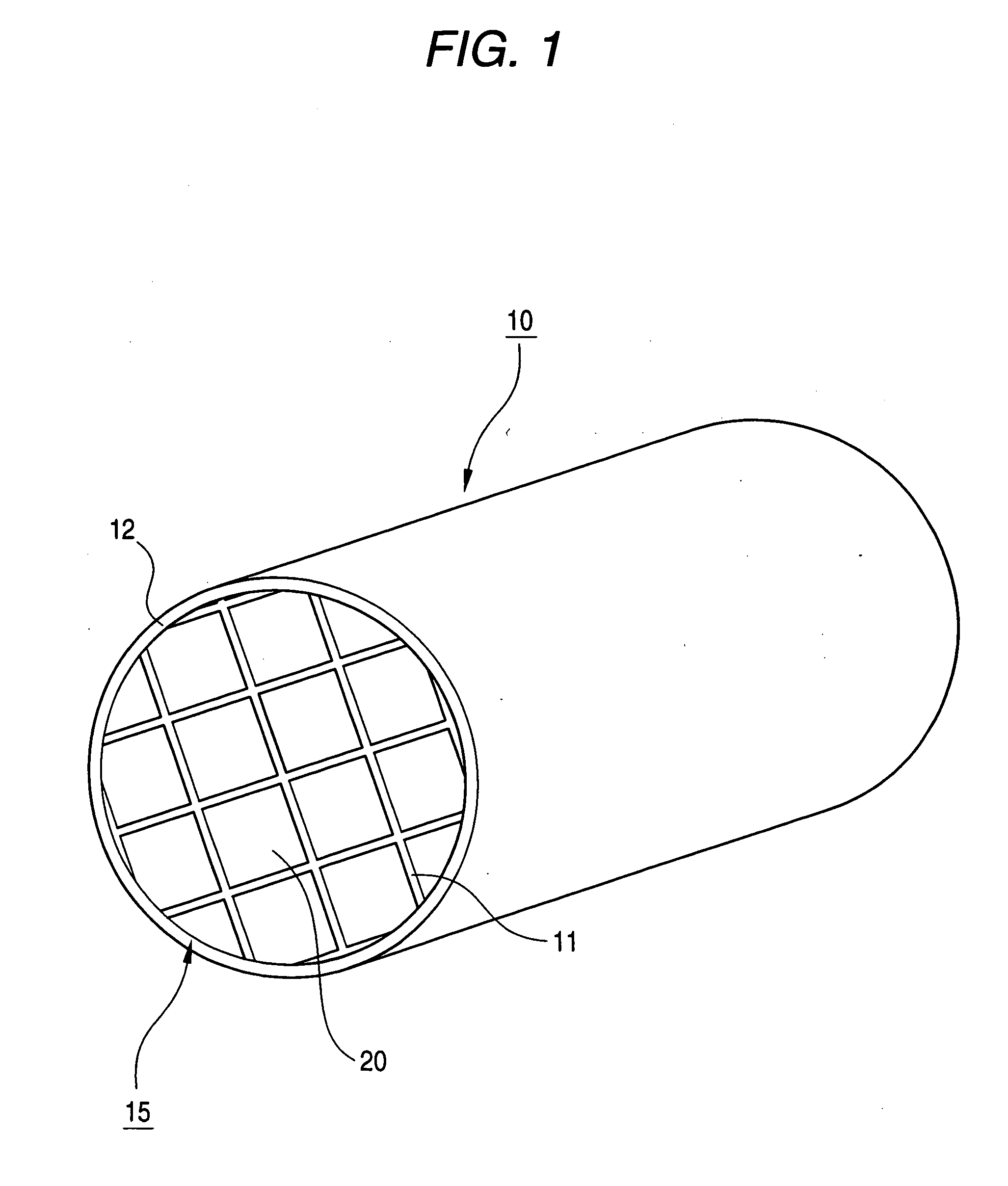

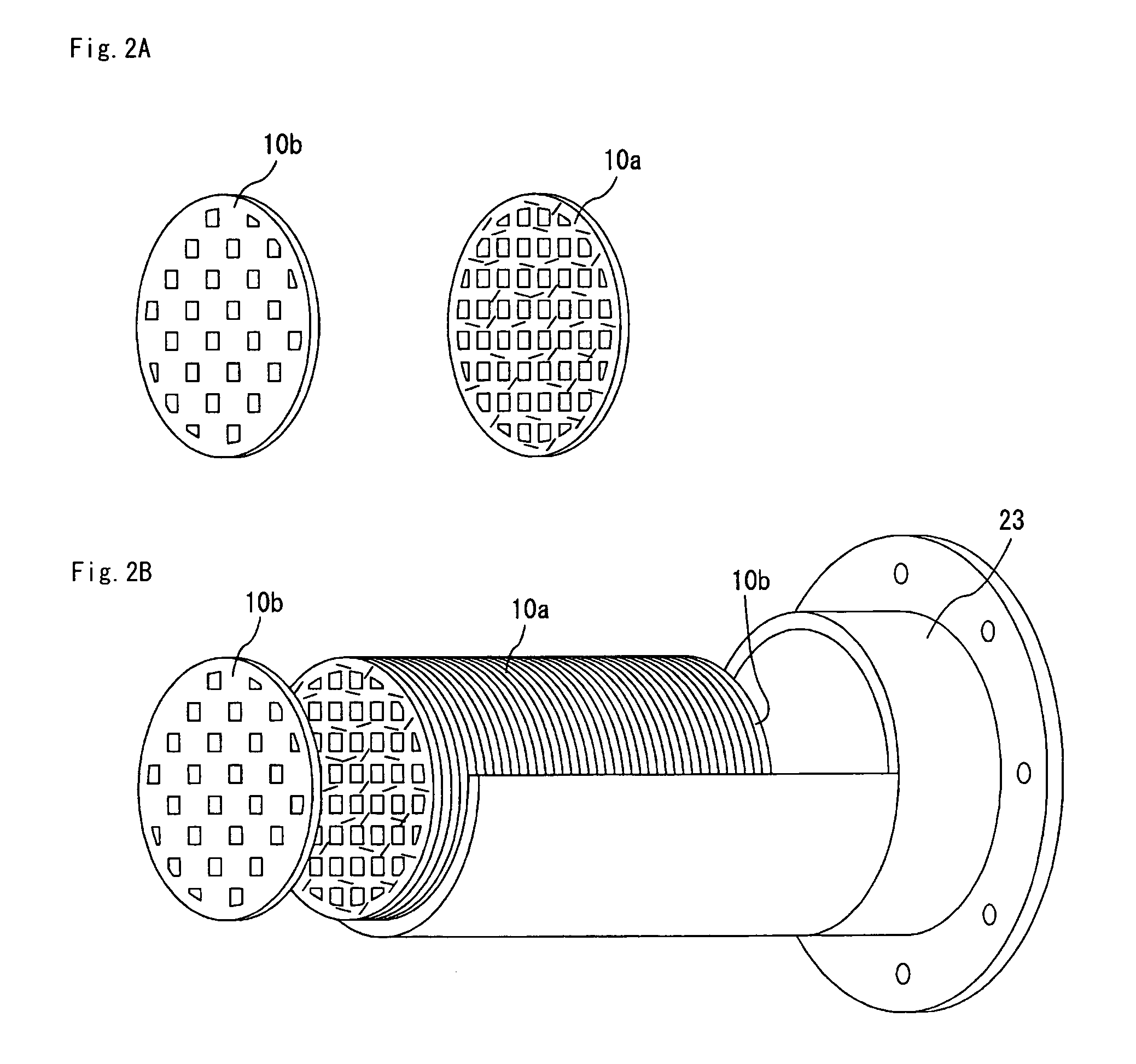

Honeycomb structure

ActiveUS20060230732A1Light weightSmall heat capacityDispersed particle filtrationOther chemical processesApparent densityYoung's modulus

A honeycomb structure including a plurality of porous ceramic members which are bonded through an adhesive layer, each of the porous ceramic members has a plurality of cells, which are arranged in parallel while being separated by cell walls. The cells extend in a longitudinal direction of the honeycomb structure. In the honeycomb structure, the following relationship is satisfied: 2≦B≦100 / 3×A−10 / 3 (1) where A (g / cm3) designates apparent density of the porous ceramic members, and B (GPa) designates Young's modulus of the adhesive layer.

Owner:IBIDEN CO LTD

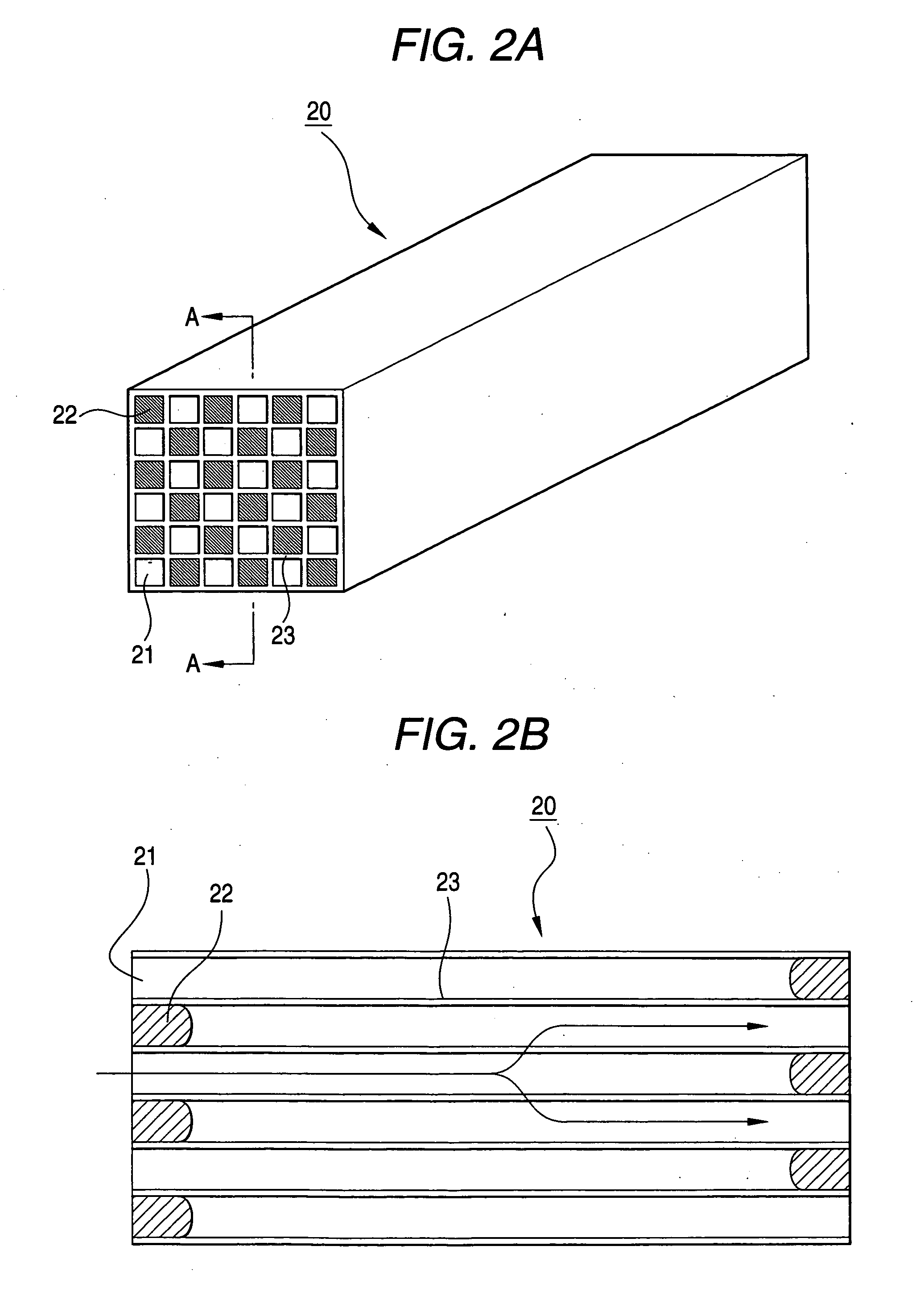

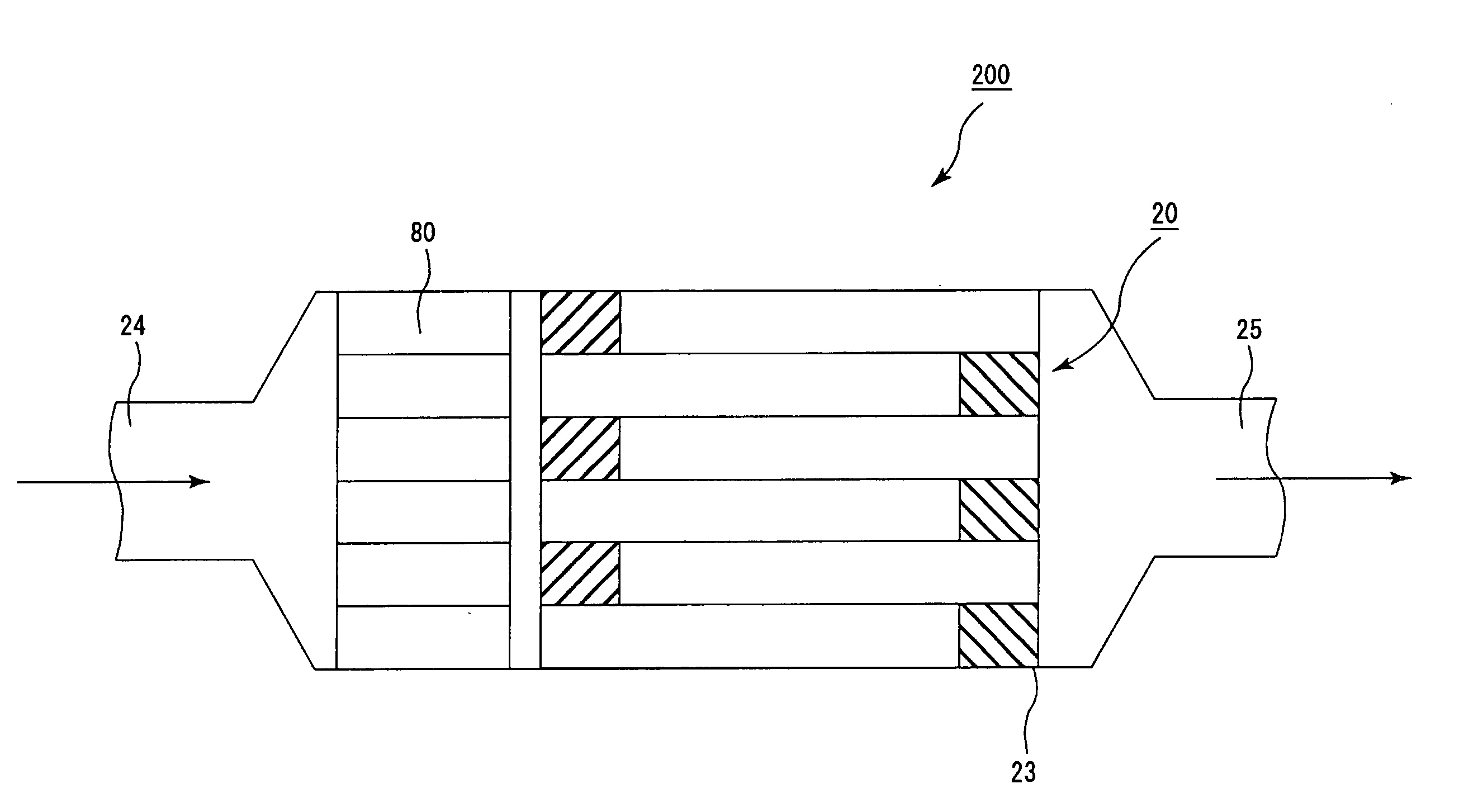

Honeycomb structured body and exhaust gas purifying device

InactiveUS20070020155A1Simple processReduce the temperatureCombination devicesGas treatmentApparent densityEngineering

A honeycomb structured body of the present invention comprises a plurality of cells placed in parallel with one another in a longitudinal direction with a cell wall therebetween, wherein an oxide catalyst is supported on at least one portion of the cell wall, and the honeycomb structured body has an apparent density of about 0.7 g / cm3 or less.

Owner:IBIDEN CO LTD

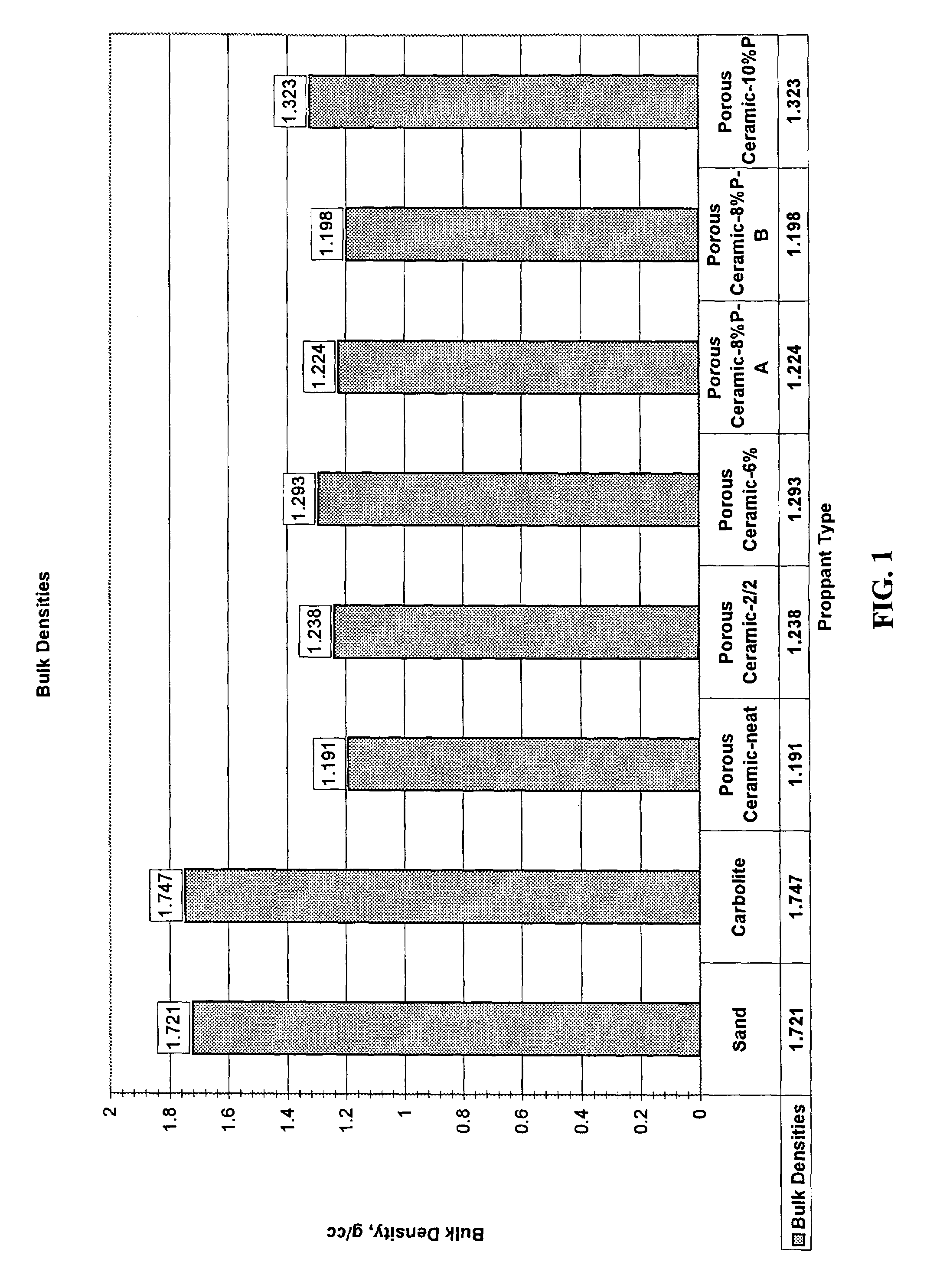

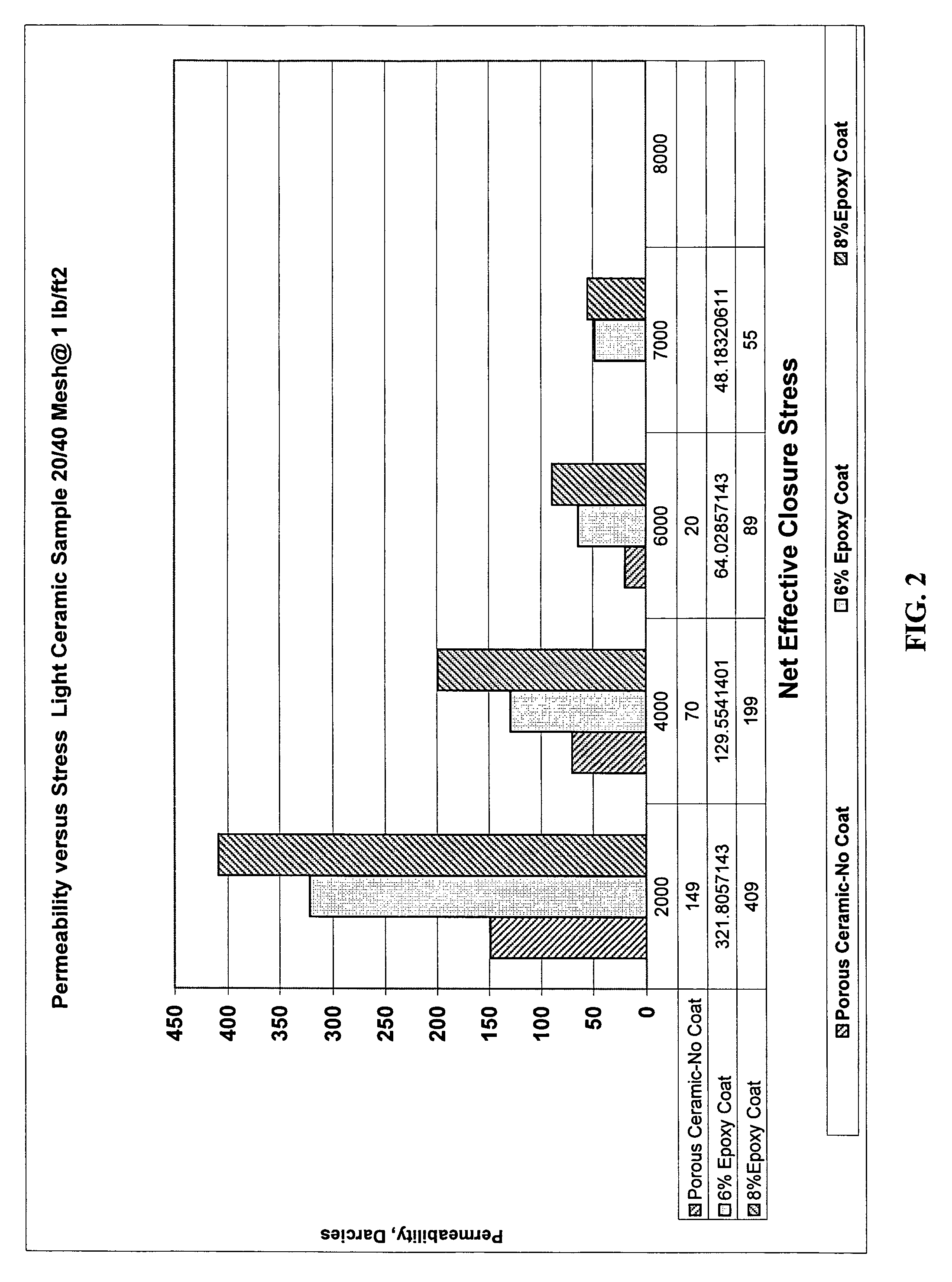

Method of treating subterranean formations with porous particulate materials

ActiveUS7426961B2Improve system performanceReduce and prevent productionFluid removalDrilling compositionApparent densityParticulates

Methods and compositions useful for subterranean formation treatments, such as hydraulic fracturing treatments and sand control that include porous materials. Such porous materials may be selectively configured porous material particles manufactured and / or treated with selected glazing materials, coating materials and / or penetrating materials to have desired strength and / or apparent density to fit particular downhole conditions for well treating such as hydraulic fracturing treatments and sand control treatments. Porous materials may also be employed in selected combinations to optimize fracture or sand control performance, and / or may be employed as relatively lightweight materials in liquid carbon dioxide-based well treatment systems.

Owner:BAKER HUGHES INC

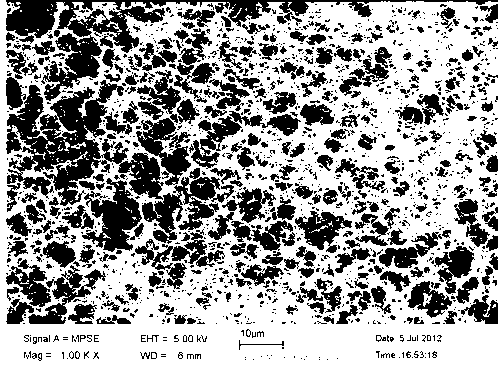

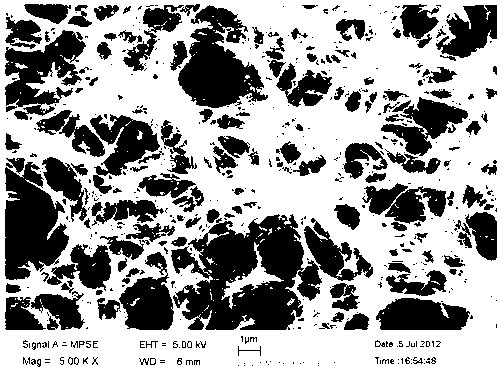

Nitrogen mixed grapheme hydrogel or aerogel and preparation method thereof

InactiveCN102874796AImprove adsorption capacityGood processing effectGrapheneApparent densityNitrogen

The invention provides nitrogen mixed grapheme hydrogel of which the water content is 90 to 99.5 percent, the electric conductivity is 10-3-100 S / m, and the molar ratio of N and C is 1 to 25 percent. The invention further provides nitrogen mixed aerogel of which the molar ratio of N and C is 2 to 20 percent, the molar ratio of C and O is 15 to 5, nitrogen atoms existing in the form of amidogen nitrogen accounts for 40 to 70 percent, pyridine type nitrogen accounts for 10 to 40 percent, graphite type nitrogen accounts for 10 to 30 percent, the specific area is 300 to 1500 m<2> / g, the apertures which are micropore account for 10 to 20 percent, the apertures which are mesoporous 20 to 50 percent, the apertures which are macropore 30 to 70 percent, the apparent density is 0.01 to 0.2 g / cm<3>, the pore volume is 5 to 20 cm<3> / g, and the electric conductivity is 1 to 1000 S / m. The nitrogen mixed grapheme hydrogel or aerogel and preparation method thereof provided by the invention has the characteristics that the operation is simple, the equipment requirement is low, the production efficiency is high, the scale-up of the technology is easy, the nitrogen mixed content is controllable and the compounding with other functional substances is simple.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

Sintered polycrystalline gallium nitride and its production

InactiveUS6861130B2Flat surfaceReadily apparentPressurized chemical processNitrogen-metal/silicon/boron binary compoundsApparent densityHardness

Polycrystalline gallium nitride (GaN) characterized by having the atomic fraction of gallium ranging from between about 49% to 55%, an apparent density of between about 5.5 and 6.1 g / cm3, and a Vickers hardness of above about 1 GPa. Polycrystalline GaN can be made by hot isostatic pressing (HIPing) at a temperature ranging from about 1150° C. to 1300° C. and a pressure ranging from between about 1 and 10 Kbar. Alternatively, polycrystalline GaN can be made by high pressure / high temperature (HP / HT) sintering at a temperature ranging from about 1200° to 1800° C. and a pressure ranging from about 5 to 80 Kbar.

Owner:SLT TECH

Lyophilized solid taxane composition, a process for preparing said solid composition, a pharmaceutical formulation and a kit for said formulation

InactiveUS20090215882A1High level of chemical degradationImprove solid solubilityOrganic active ingredientsBiocideDocetaxel-PNPDocetaxel

A lyophilized solid composition of taxane (preferably docetaxel and paclitaxel), is suitable to prepare a pharmaceutical formulation to be administered to mammals, particularly humans, comprising a taxane, a tensoactive, a lyophilizing excipient, and acid; also essentially free from organic solvents. The solid composition is free from polysorbate 80 and polyoxyethylated castor oil; it is sterile; it is soluble in aqueous solutions in the absence of organic solvent and it has an apparent density from 0.05 g / ml to 0.45 g / ml. A procedure of double lyophilization obtains a solid composition of taxane. A pharmaceutical formulation of a taxane comprises a solid composition of lyophilized taxane and a solubilizing composition. A kit comprises the compositions and a syringe.

Owner:ERIOCHEM SA

Spherical porous light haydite for treating waste water and its production method

InactiveCN1380137AHigh economic valueSolve the way outOther chemical processesSustainable biological treatmentPorosityEnvironmental resistance

The present invention relates to a kind of spherical porous loight-ceramsite produced by using industrial waste slag, steel-smelting rod mud and flyash as main raw material, using clay as binding agent, adding proper quantity of pore-forming agent and adopting high-temp., sintering process. Said invention also provides its production method, and said product can be specially used as filtration material for water treatment. Its product quality is as follows: specific surface area is 4-10 sq.m / g, average pore size is 50-250 micrometers, apparent density is 1.40-1.80 g / cu.cm and its voidage is 30-40%.

Owner:HUAQI ENVIRONMENT PROTECTION SCI & TECH

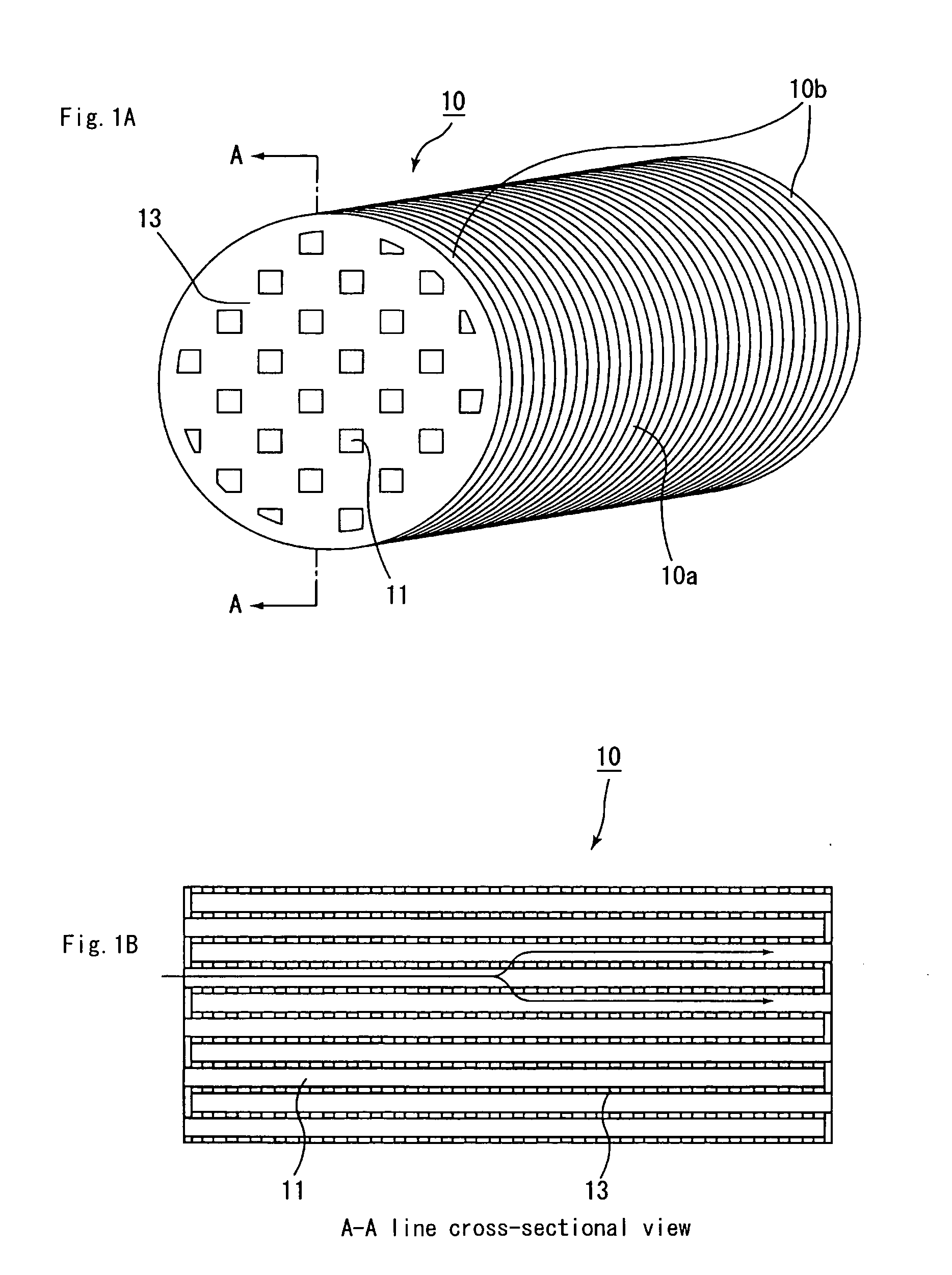

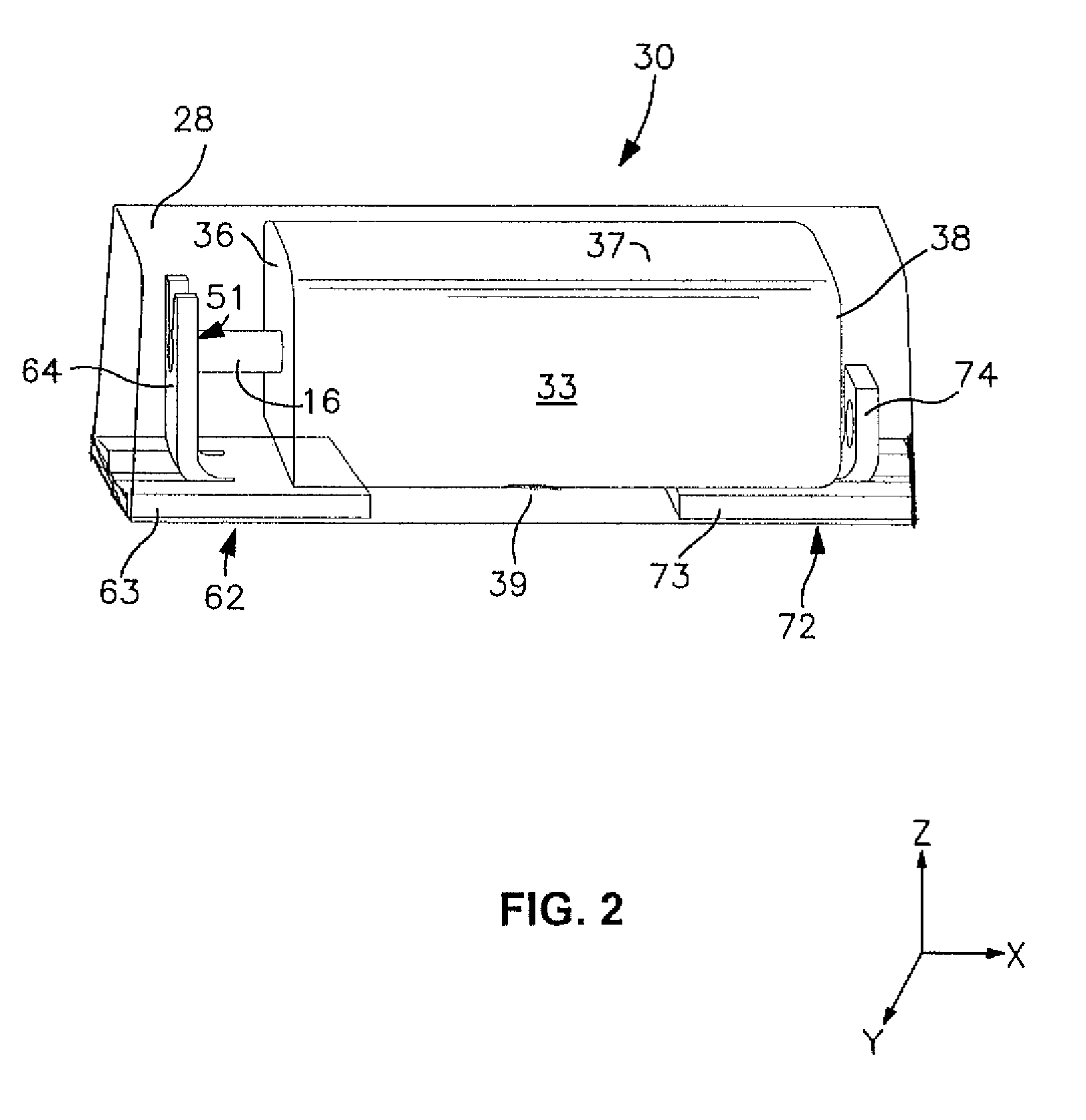

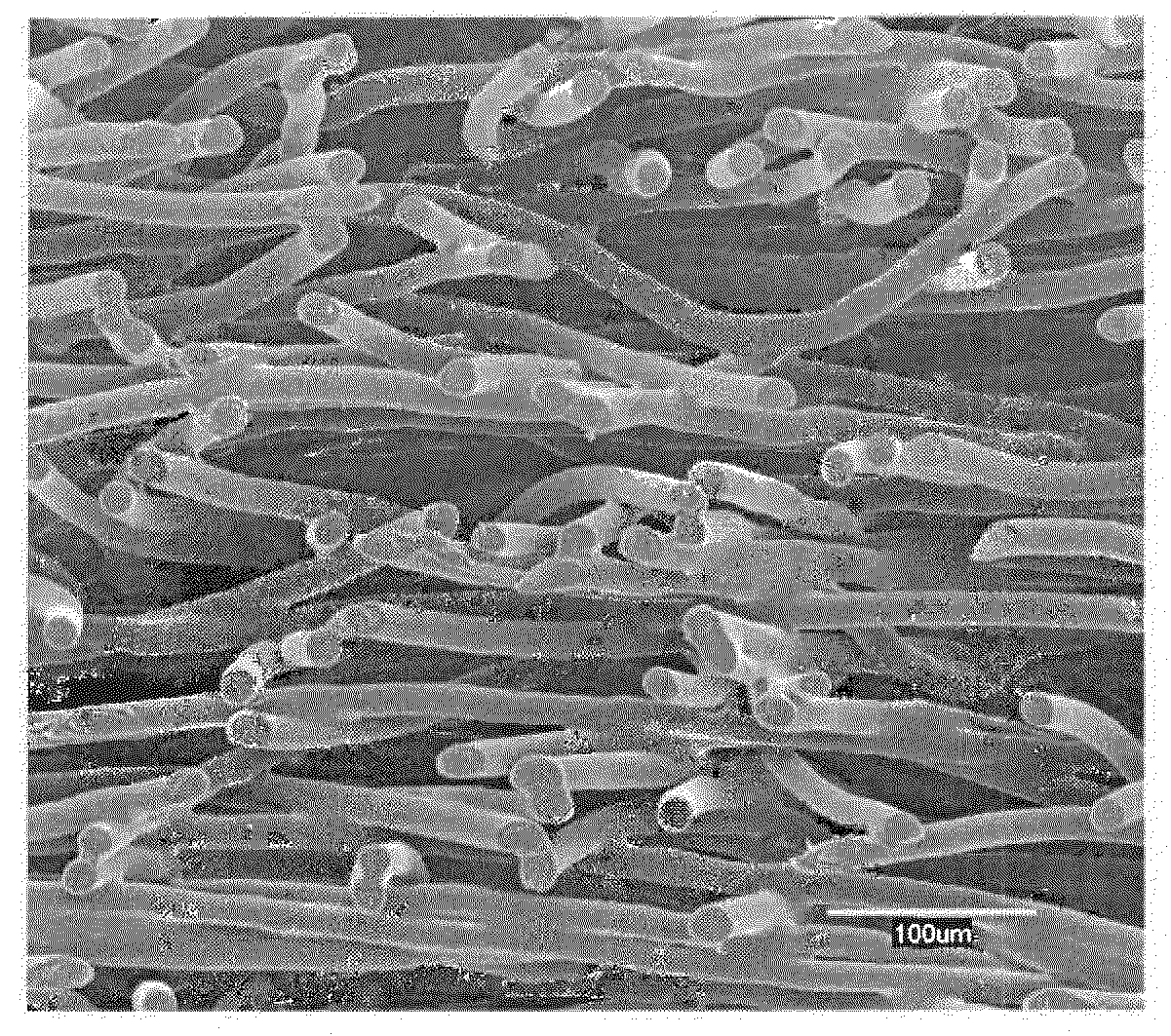

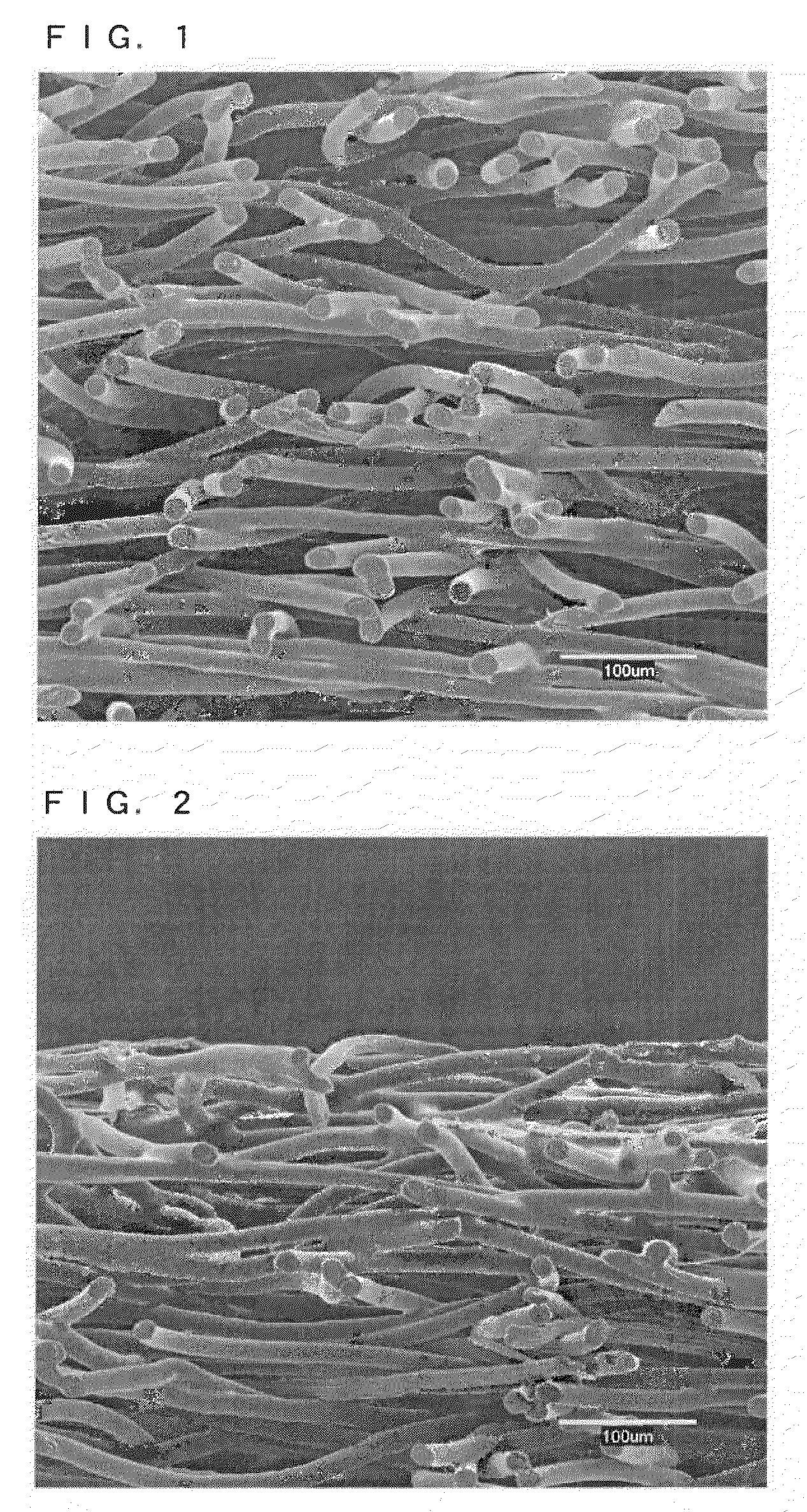

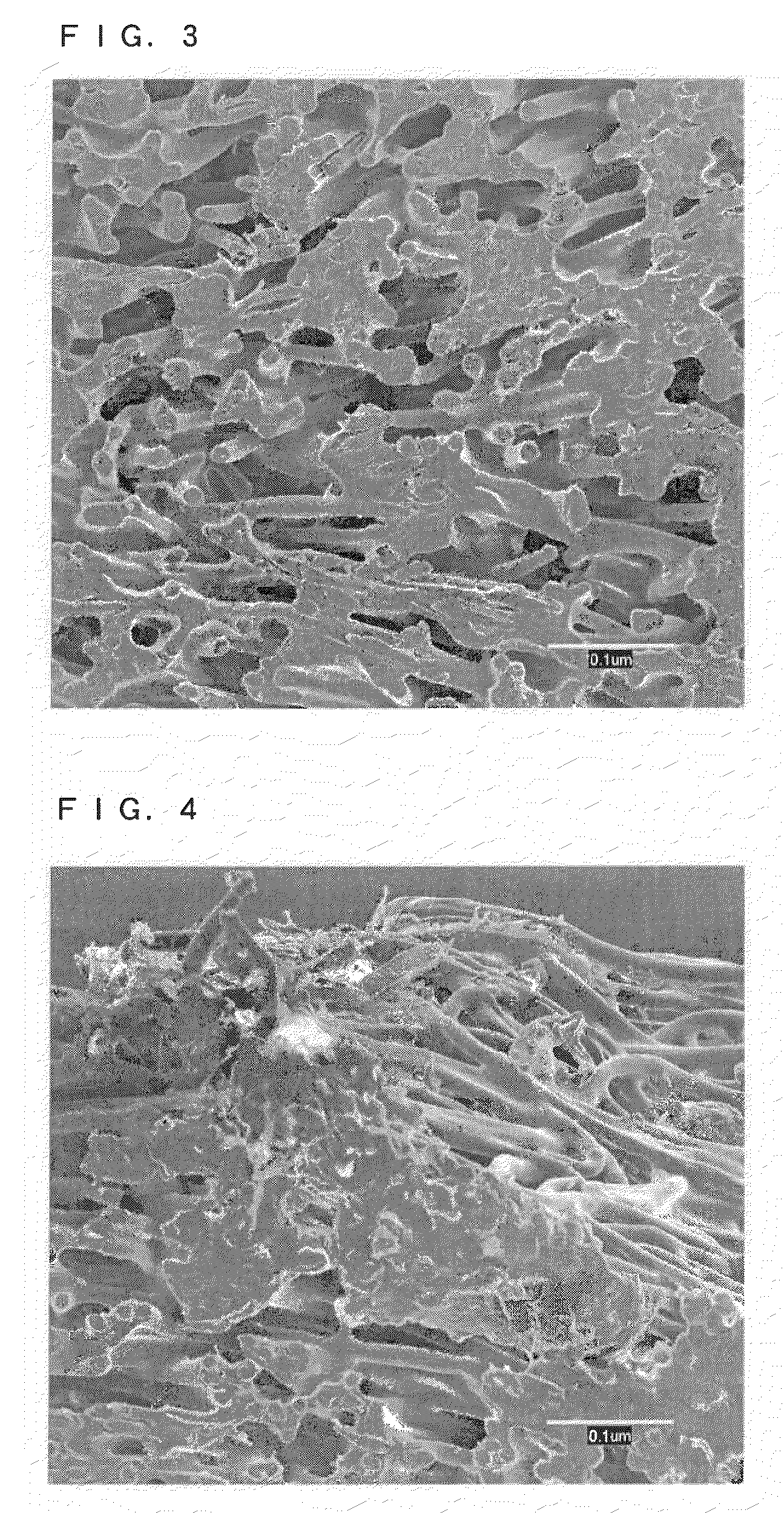

Scaffold for tissue engineering, artificial blood vessel, cuff, and biological implant covering member

InactiveUS20050107868A1Reduce foreign body reactionsImprove patencyTissue cultureBlood vesselsSubcutaneous tissueTunnel infection

The invention provides a porous scaffold for tissue engineering which allows easy cell engraftment and cell culture and thus enables stable organization and an artificial blood vessel which exhibits high patency rate even if the inner diameter is small. The scaffold for tissue engineering is made of thermoplastic resin which forms a porous three-dimensional network structure having communication property, wherein the porous three-dimensional network structure has an average pore diameter of from 100 to 650 μm and an apparent density of from 0.01 to 0.5 g / cm3. The artificial blood vessel is composed of this scaffold. The invention provides a cuff which allows easy infiltration of cells from living subcutaneous tissues, easy engraftment of cells, and neovascularization of capillary vessels so as to obtain robust bonding with subcutaneous tissues and, as a result, ensures separation of a wounded portion from the outside, thereby blocking exacerbation factors such as bacterial infection on healing and inhibiting progression of downgrowth. That is, the invention provides a cuff with none or little infection trouble such as tunnel infection. The cuff comprises a porous three-dimensional network structure which is made of thermoplastic resin or thermosetting resin and has communication property, wherein the porous three-dimensional network structure has an average pore diameter of from 100 to 1000 μm and apparent density of from 0.01 to 0.5 g / cm3. The invention provides a biological implant covering member which allows easy infiltration of cells from living subcutaneous tissues, easy engraftment of cells, and organization, thereby obtaining robust bonding with native tissues and therefore protecting a living body from adverse effect which may occur due to the insertion of a biological implantation member into the living body. The biological implant covering member comprises a porous three-dimensional network structure which is made of thermoplastic resin or thermosetting resin and has communication property, wherein the porous three-dimensional network structure has an average pore diameter of from 100 to 1000 μm and apparent density of from 0.01 to 0.5 g / cm3.

Owner:JAPAN AS REPRESENTED BY PRESIDENT OF NAT CARDIOVASCULAR +2

Low loose density sheet-like silver powder preparation method

The invention relates to a method for preparation of low apparent density sheet silver powder, which comprises five steps: choosing materials, ball grinding, one- time surface modified, drying, and secondary surface modified. With the silver powder of silver content more than 99.95% and granularity among 0.1- 1um as the material, by wet ball grinding with the existence of mill medium, mill auxiliary agent and liquid lubricant, one- time chemical modification treatment, and one- time dry ball grinding modification treatment, the low apparent density sheet silver powder is prepared. The time of wet ball grinding being among 2- 8h that is 1 / 5 of the time of mechanical ball grinding and the apparent density being only 1 / 2 of that of mechanical ball grinding, with the invented, it solves the problem of deposition and agglomeration in conductive paint; and with twice surface modified treatment, coating two- layer protective film, the first layer being dispersion film and the second being directional floating film, the dispersibility and flotation property of the silver powder are improved, and the silver powder is the required material of producing electromagnetic shielding paint and conductive paint. Every index of the silver powder can satisfy the requirement of conductive paint and shielding pain.

Owner:KUNMING HENDERA SCI & TECH

Nonwoven fabric air filter for internal combustion engine

A thin and uniform nonwoven fabric air filter for an internal combustion engine with a pleated form which comprises an air-laid nonwoven fabric obtained by forming a plurality of layers mainly composed of polyester-based binder fibers having a fiber length of 1 to 10 mm by an air-laid nonwoven fabric production process and performing heat adhesion, wherein an upper layer side (fluid inflow side) comprises large fibers, a lower layer side (fluid outflow side) comprises fine fibers, a final fluid outflow side comprises 100% of the polyester-based binder fibers, the basis weight (METSUKE) is from 100 to 350 g / m2, the apparent density is from 0.04 g / cm3 to 0.3 g / cm3, and the dry-heat shrinkage factor after 300 hours at 100° C. is 3% or less. The air filter induces no environmental pollution, is high in dust collection efficiency, and has long life.

Owner:AMBIC +1

Real time determination of gas solubility and related parameters in manufacturing processes

InactiveUS6847898B1Easy to controlEasy to handleTesting beveragesSpecific gravity by measuring pressure differencesSolubilityApparent density

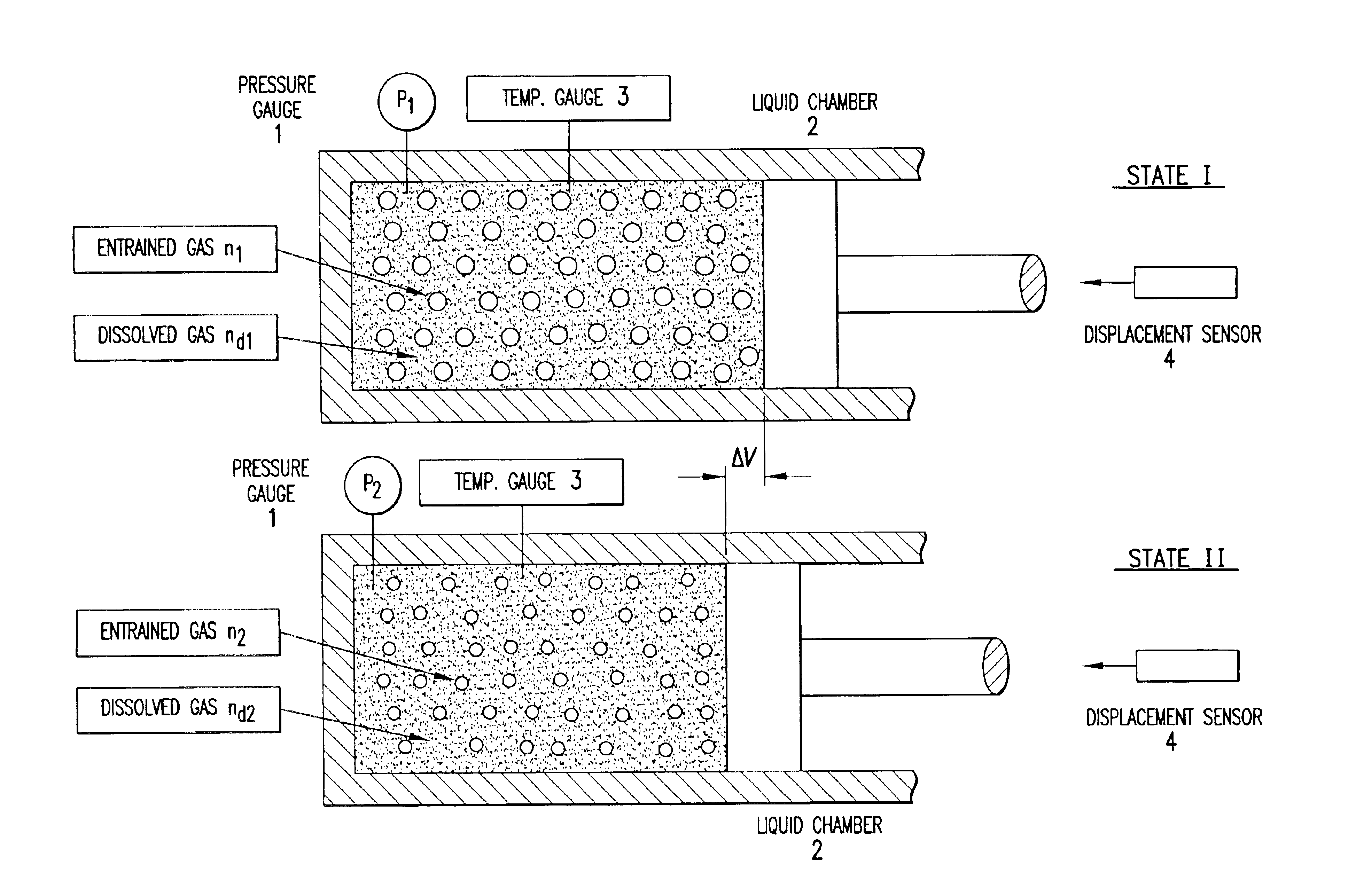

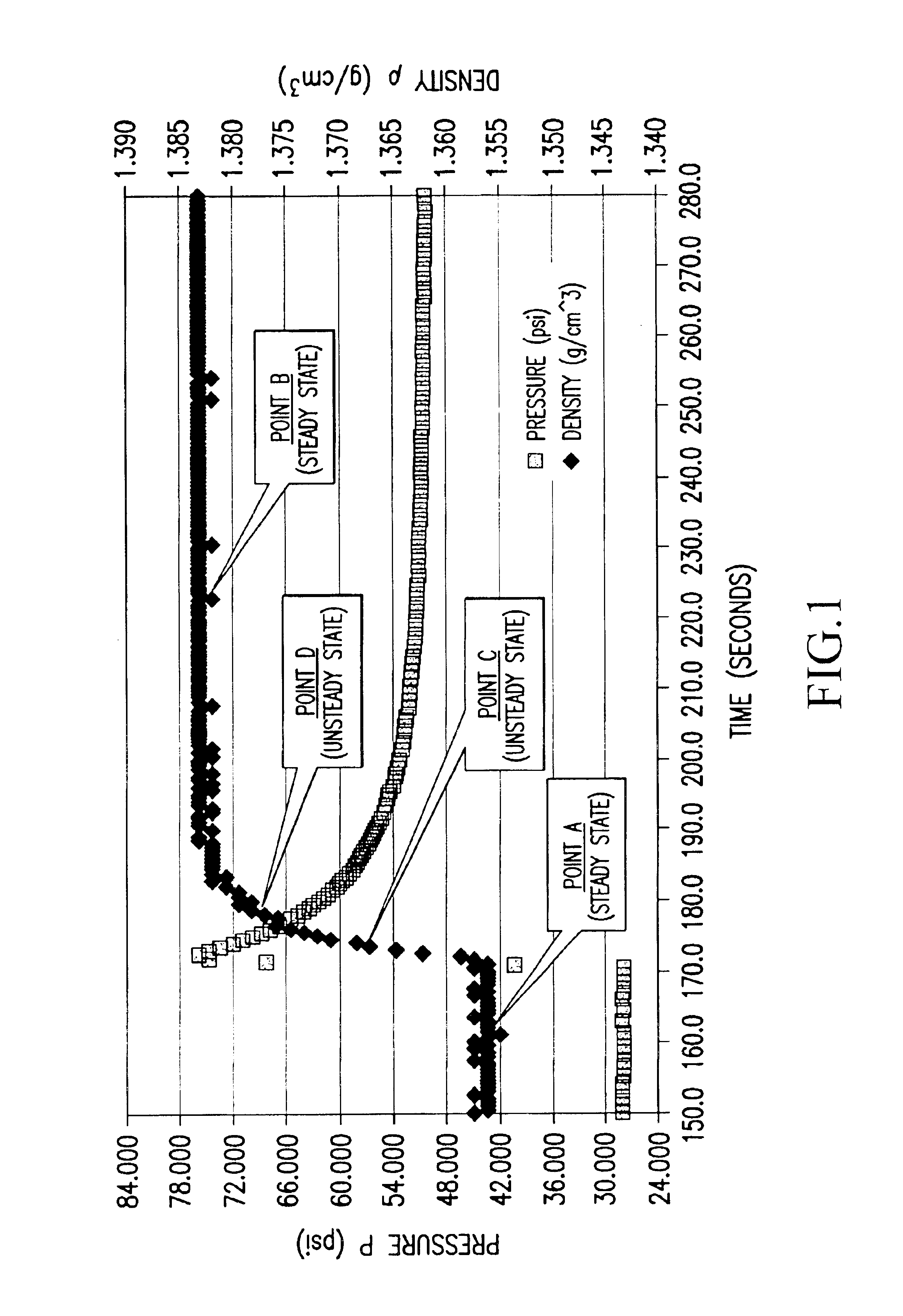

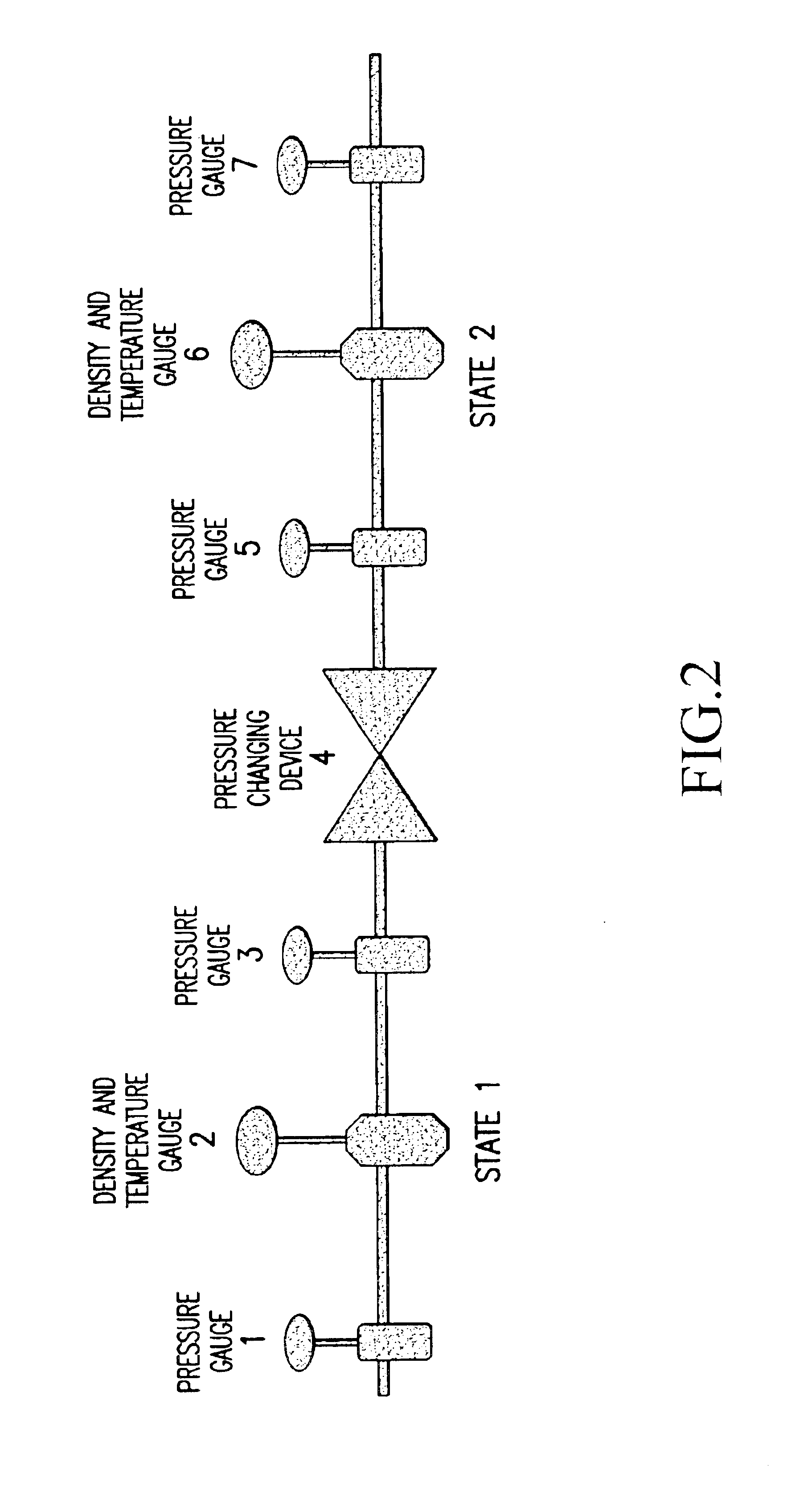

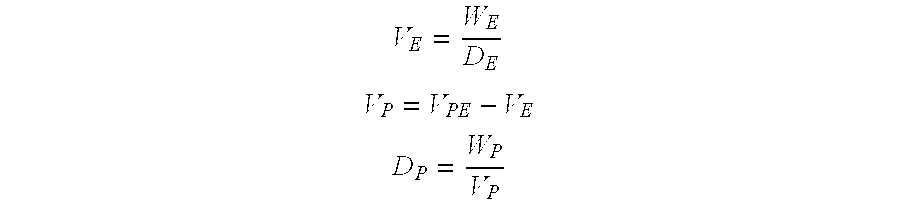

Methods and apparatuses for determining entrained and / or dissolved gas content of gas-liquid mixtures. Data generated is used to control the True (air-free) or Apparent (air-containing) Density or Entrained Air content of liquids within optimum ranges, e.g. in paper coating processes and in the manufacture of food products, personal care products, pharmaceutical products, paints, petroleum blends, etc. For example, an indirect method of continuously determining the amount of gas entrained in a liquid, by: continuously measuring the temperature, flow rate, and apparent density of the mixture at two different pressure states, and calculating the volume percentage of the gas in the liquid by using equation (28) x%=VsVs+V(28)wherein V is the volume of the gas-free liquid calculated by equation (23) V=1ρ1-[P2P2-P1(1ρ1-1ρ2)-RTP2-P1g(Δ PQa)](23)in which P1 and P2 are two different ambient pressures and ΔP=P2−P1, ρ1 and ρ2 are apparent densities of the liquid sample measured at P1 and P2, respectively, R is the constant of the Ideal Gas Law, T is the liquid temperature, Q is the flow rate, g(ΔP / Qa) is a function for determining the amount of gas being dissolved between P2 and P1, and Vs is determined by equation (27) Vs=TsTP1P2Ps(P2-P1)(1ρ1-1ρ2)-RTsPs(P1P2-P1g(Δ PQa)-g(P1-PsQa)).(27)

Owner:APPVION INC

Light-weight proppant from heat-treated pumice

InactiveUS20110118155A1High strengthLow densityPigmenting treatmentLiquid surface applicatorsParticulatesApparent density

A process for forming a strong, low-density proppant, which process includes heating pumice particulates, or shaped agglomerates thereof, so as to form heat-treated pumice particulates, or heat-treated, shaped pumice agglomerates, having an apparent density of 2.4 or less and a crush resistance of no more than 10% fines at 4000 psi. Proppants, and well treatment fluids comprising proppants, meeting these characteristics and processes for treating subterranean formations using fluids which include such proppants are also described.

Owner:BAKER HUGHES INC

Increasing buoyancy of well treating materials

ActiveUS20080277115A1Increase buoyancyHigh compressive strengthFluid removalFlushingApparent densityMetallurgy

A composite proppant having an increased buoyancy comprising a proppant substrate such as a porous ceramic or a silica sand coated with a material of a lesser actual density than the apparent density of the proppant substrate to increase the buoyancy of the composite proppant.

Owner:GEORGIA PACIFIC CHEM LLC

Polyester film for electrical insulation

InactiveUS6054224ALow densityReduce heatPower cables with screens/conductive layersInsulated cablesApparent densityPolyester

PCT No. PCT / JP97 / 02947 Sec. 371 Date May 6, 1999 Sec. 102(e) Date May 6, 1999 PCT Filed Aug. 25, 1997 PCT Pub. No. WO99 / 10417 PCT Pub. Date Mar. 4, 1999An electrical insulating polyester film has an apparent density of 1.37 to 0.85 g / cm3 and a tensile modulus of 2.0 to 4.5 GPa. A film having low oligomer content, low cost, high heat resistance, high impact resistance, superior machinability and processability, assembling stability, and superior visibility is obtained. Furthermore, leakage of current is reduced when it is used for motor insulation.

Owner:TORAY IND INC

High-fluidity powder material for selective laser sintering

InactiveCN104140668AImprove liquidityUnique Surface Interface EffectApparent densitySelective laser sintering

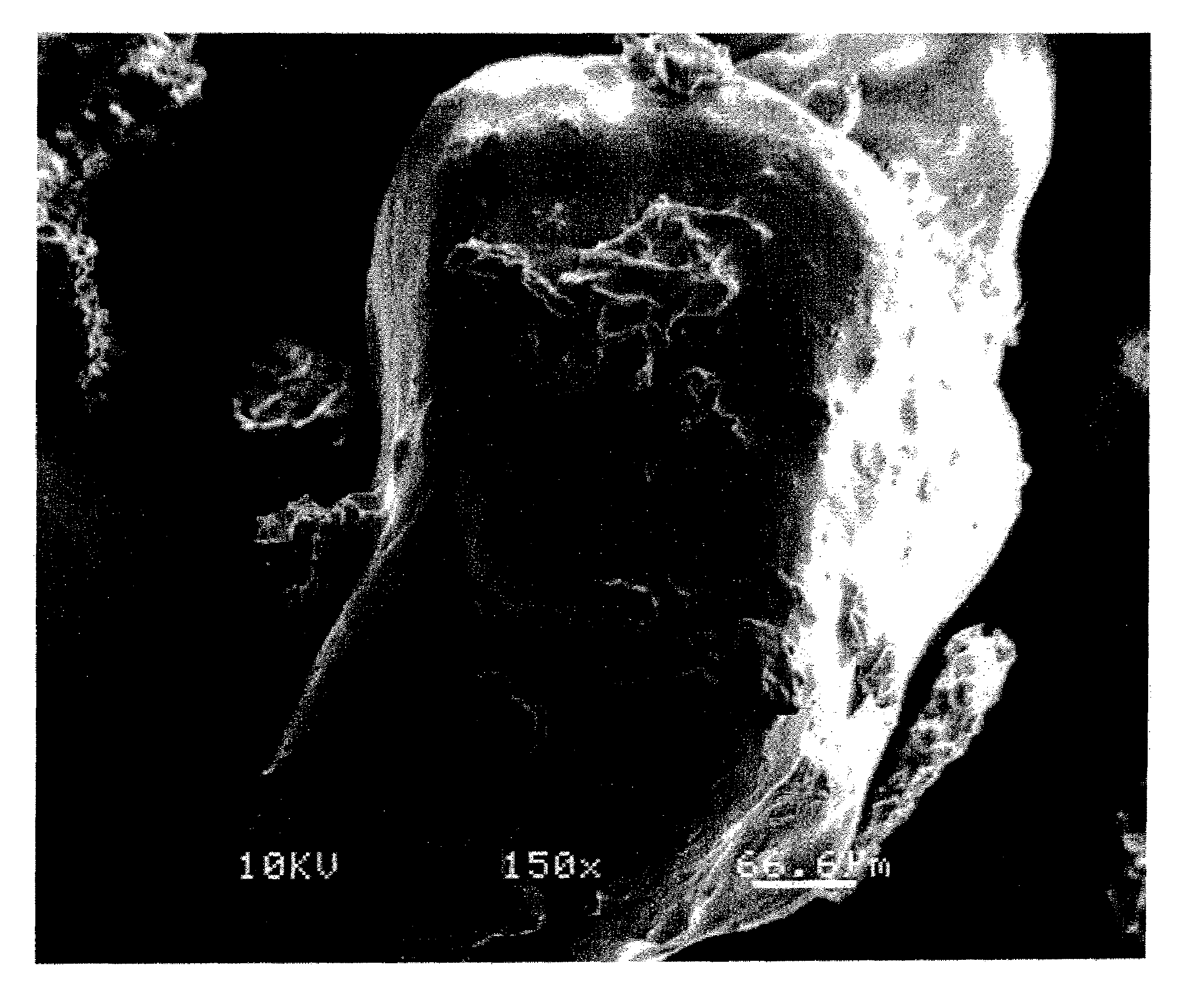

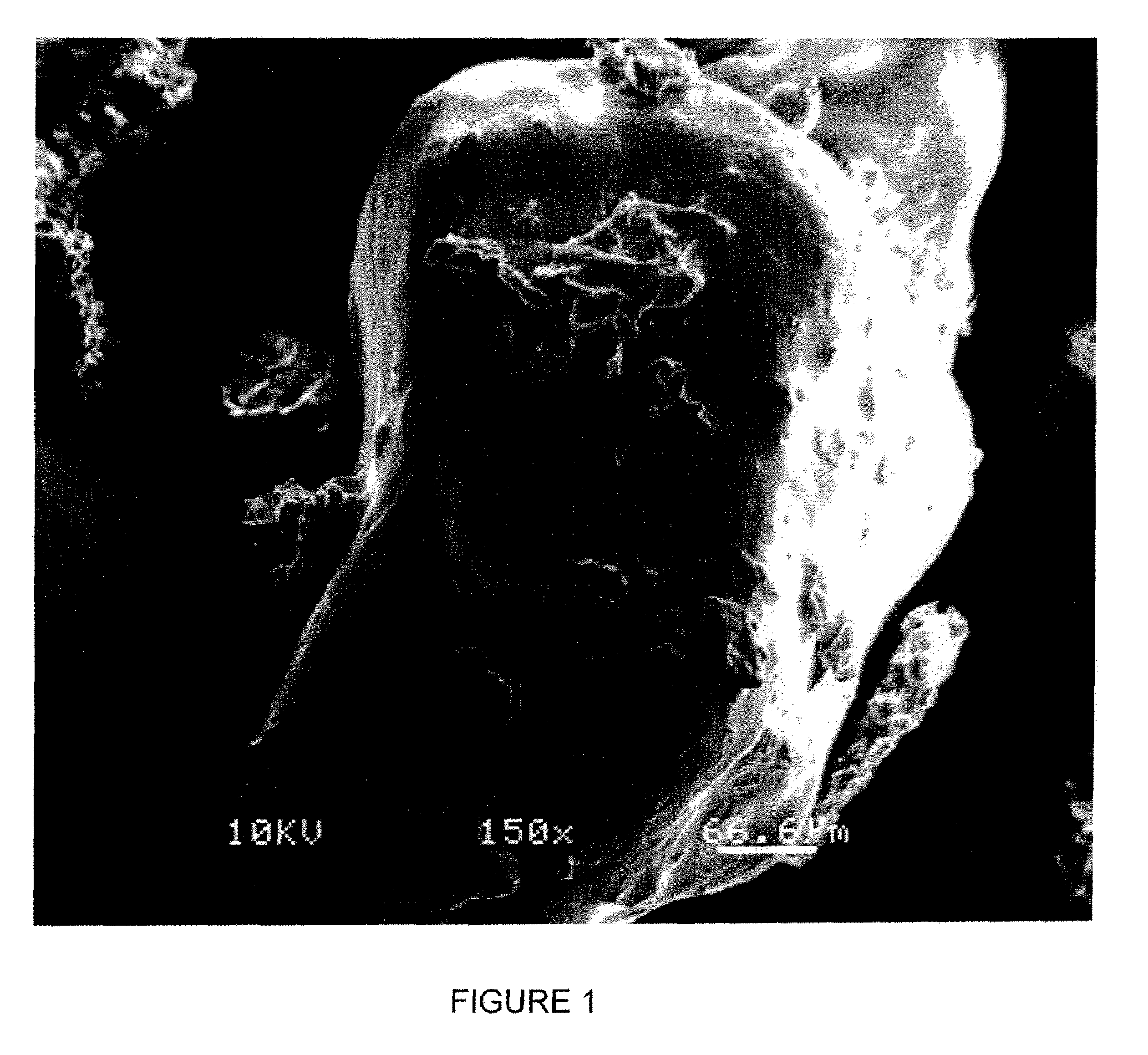

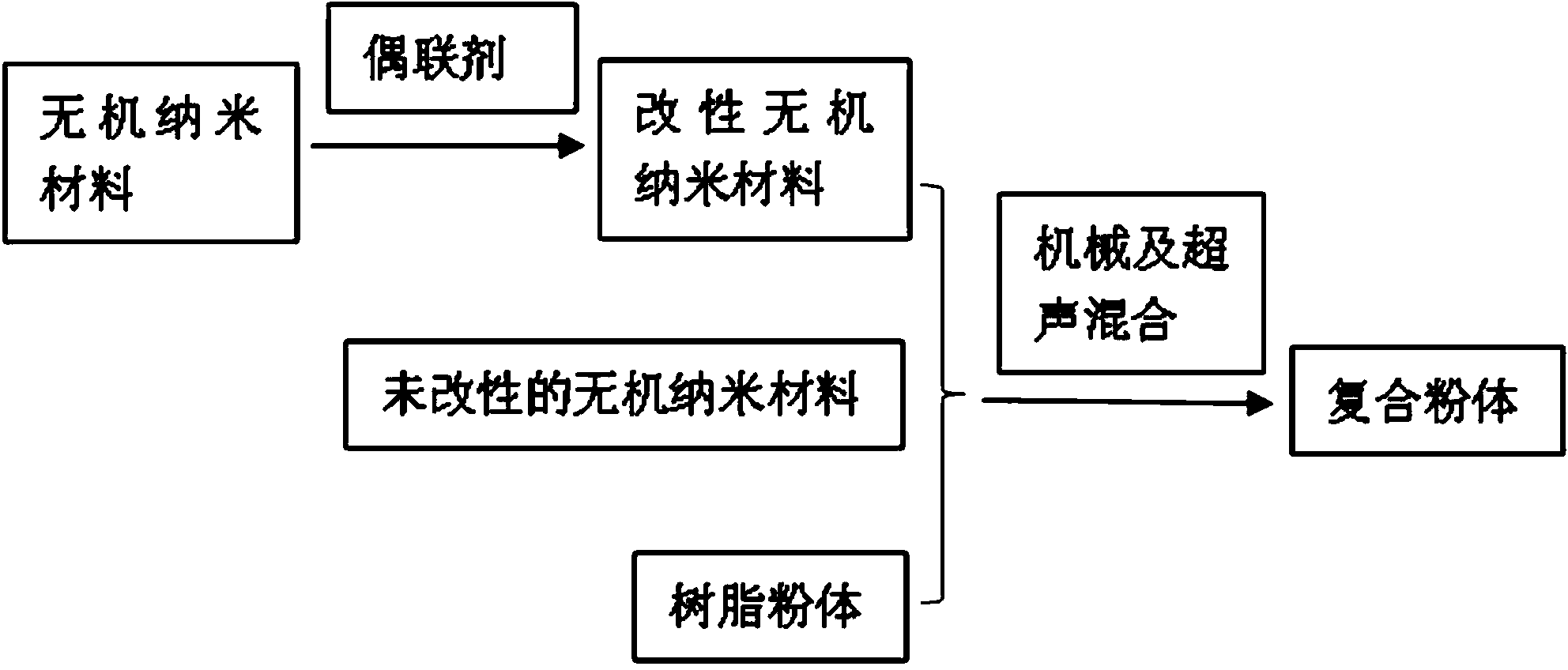

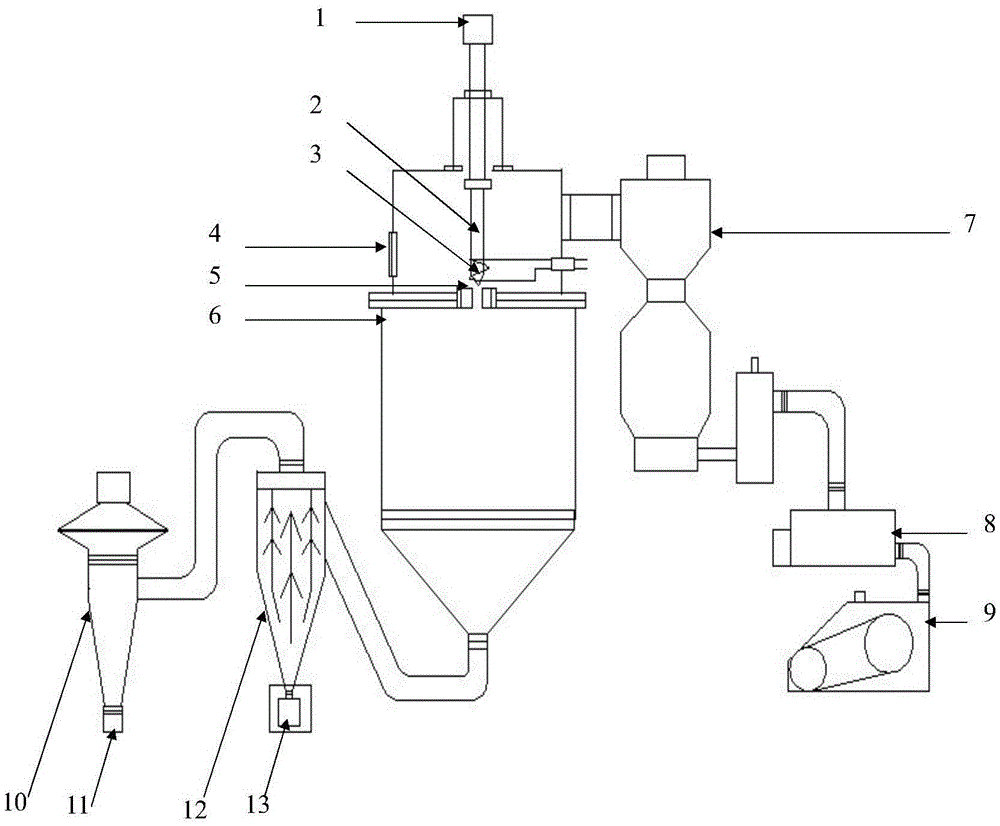

The invention discloses a high-fluidity powder material for selective laser sintering. The high-fluidity powder material comprises a plastic powder body and inorganic nanometer materials, wherein the diameter of the plastic powder body ranges from 40 micrometers to 150 micrometers, the weight of the inorganic nanometer materials accounts for 0.01% to 5% of the total weight of the high-fluidity powder material, and the inorganic nanometer materials are surface-modified inorganic nanometer particles or unmodified inorganic nanometer materials. According to high-fluidity powder material for selective laser sintering, a small number of modified or unmodified inorganic nanometer materials are added into the plastic powder body, due to the fact that the nanometer materials are special in structure, are in the unstable thermodynamics status and have the unique surface interface effect, the fluidity of the powder body and the apparent density of the powder body can be remarkably enhanced, and the high-fluidity powder material is more suitable for SLS sintering. According to the high-fluidity powder material for selective laser sintering, no special requirements for types of plastic powder bodies exist, and the application range is wide.

Owner:CHONGQING INST OF GREEN & INTELLIGENT TECH CHINESE ACADEMY OF SCI

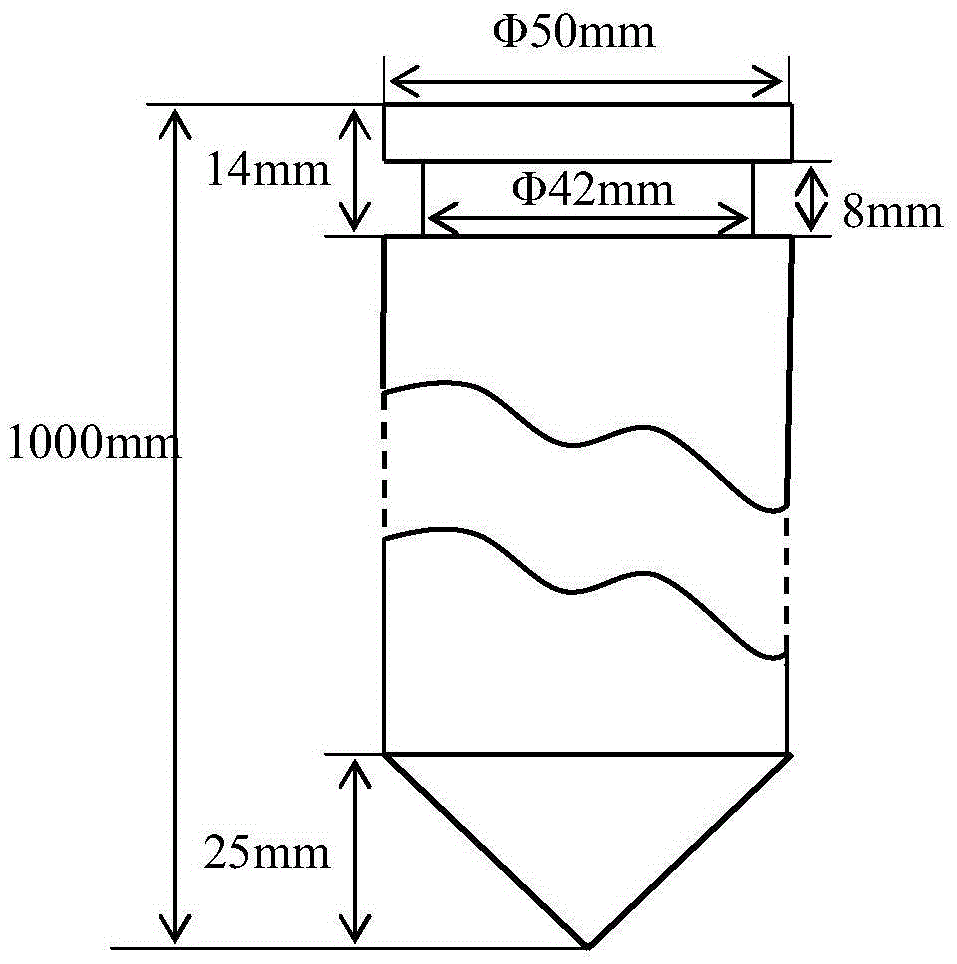

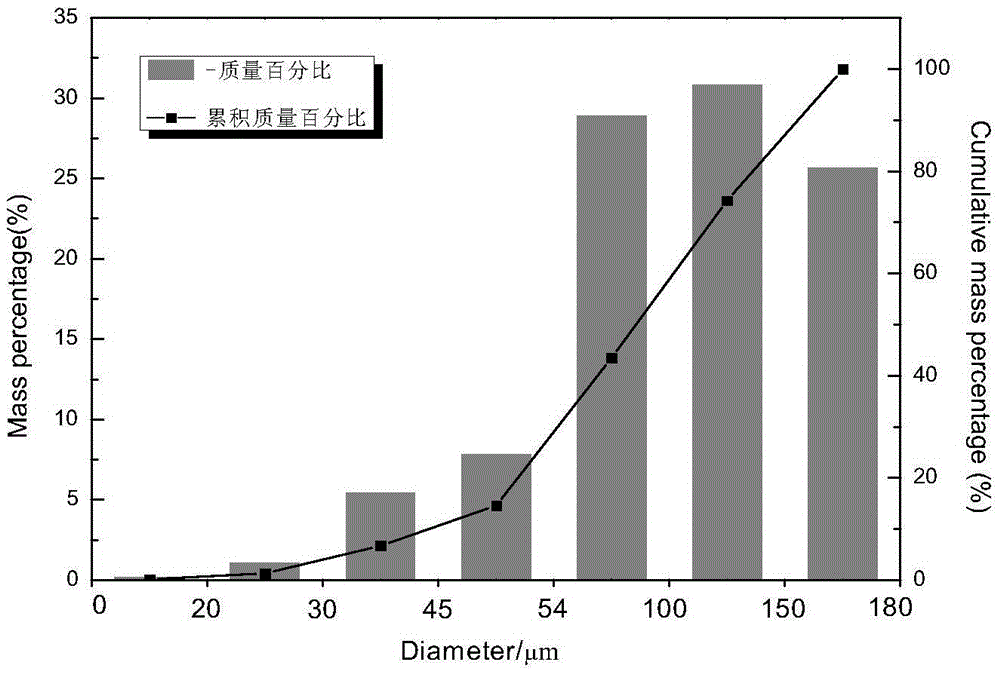

Spherical TC4 titanium alloy powder used for laser 3D printing and preparation method thereof

ActiveCN105642879AOxygen content active regulationActive control of sphericityAdditive manufacturing apparatusTransportation and packagingApparent densityVolumetric Mass Density

The invention discloses spherical TC4 titanium alloy powder used for laser 3D printing and a preparation method thereof. Titanium alloy powder particles are in a sphere shape, the grain size is 1-180 [mu]m, the oxygen content is 0.09%-0.14%, the apparent density is 2.587-2.656 g / cm<3>, and the liquidity of the powder with the grain size being 54-150 [mu]m is 20.0-30.0 s / 50g. The powder with the grain size being 1-54 [mu]m can be used for powder laying method laser 3D printing, and the powder with the grain size being 54-150 [mu]m can be used for powder feeding laser 3D printing. According to the preparation method, an electrode titanium bar of which one end is a conical tip is made from titanium alloy and is placed in a induction melting chamber to rotate, induction melting is started at the same time, and when liquid drops are formed by the tip, the titanium bar rotates and perpendicularly moves downwards; the alloy liquid drops are atomized into the powder in an atomizing chamber through inert gases by regulating and controlling the atomizing air pressure and induction parameters; and then collection is conducted through a powder collection device, and the powder with different grain sizes is screened and preserved in a vacuum mode.

Owner:ANSHAN DONGDA LASER TECH CO LTD

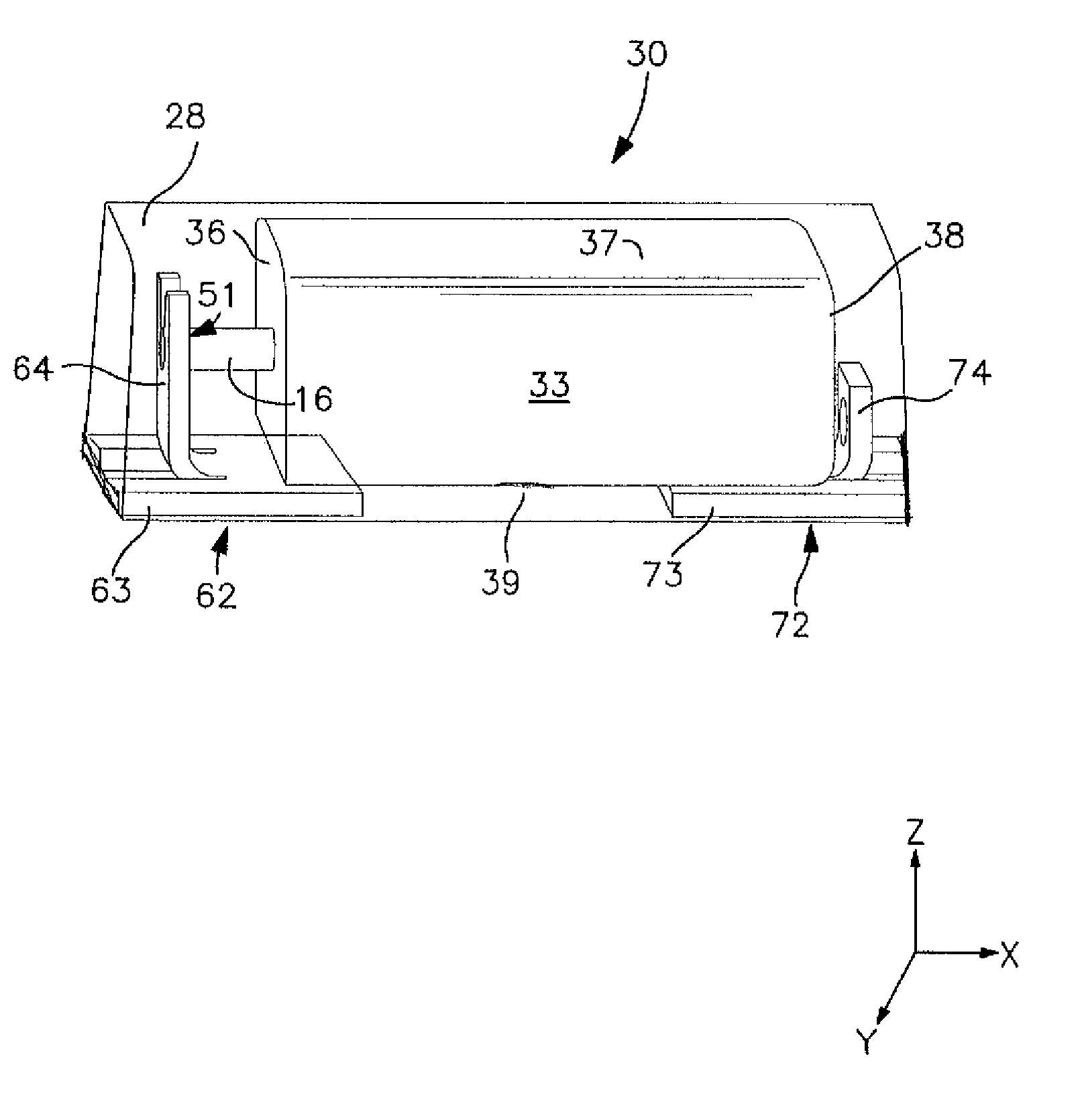

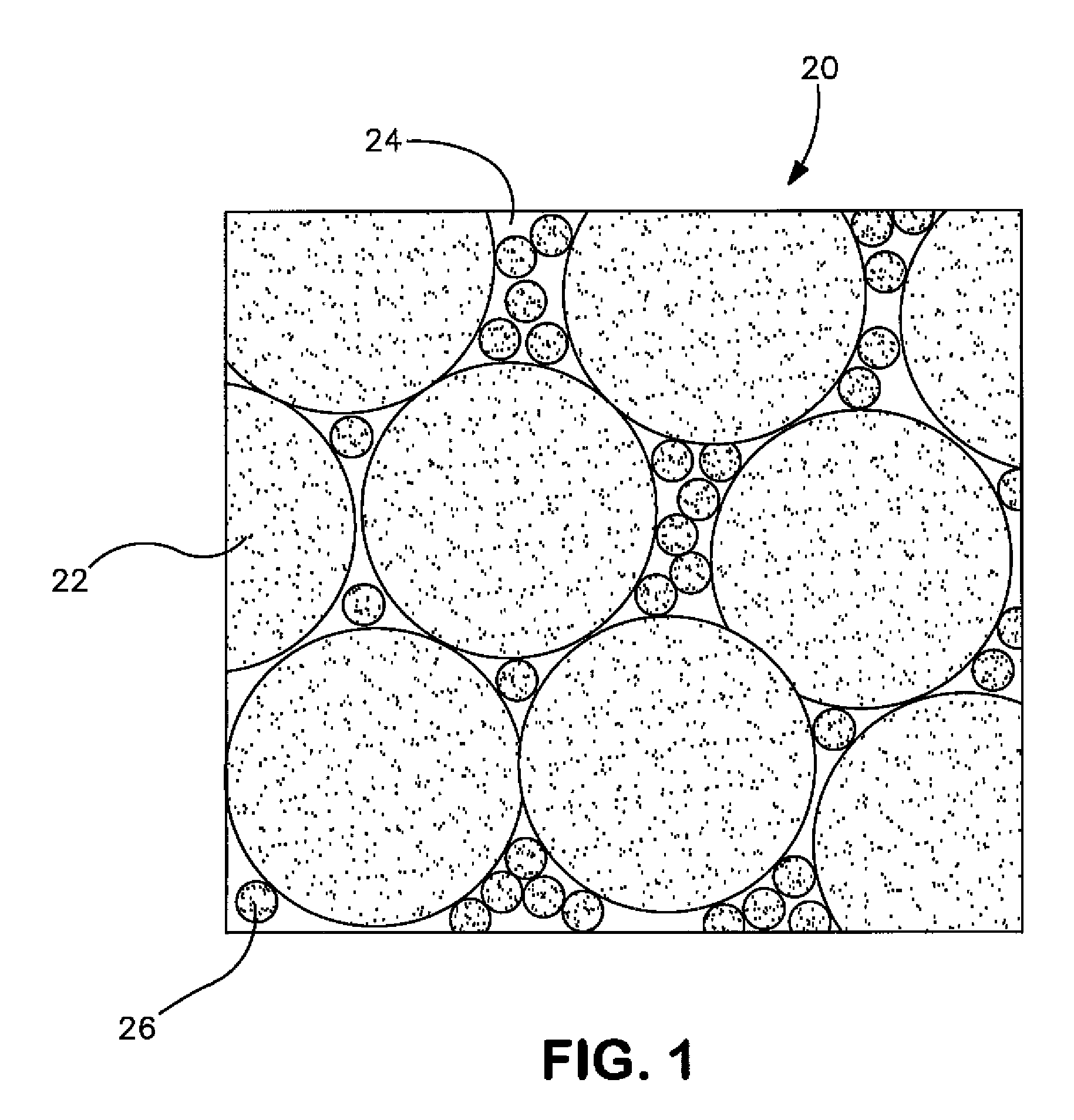

Capacitor Anode Formed From a Powder Containing Coarse Agglomerates and Fine Agglomerates

A pressed anode formed from an electrically conductive powder that contains a plurality of coarse agglomerates and fine agglomerates is provided. The fine agglomerates have an average size smaller than that of the coarse agglomerates so that the resulting powder contains two or more distinct particle sizes, i.e., a “bimodal” distribution. In this manner, the fine agglomerates can effectively occupy the pores defined between adjacent coarse agglomerates (“inter-agglomerate pores”). Through the occupation of the empty pores, the fine agglomerates can increase the apparent density of the resulting powder, which improves volumetric efficiency.

Owner:AVX CORP

Preparation method of large-mixing-amount fly ash non-autoclaved ultra-light foamed concrete

ActiveCN103524091AImprove performanceReduce dosageSolid waste managementCeramicwareFoam concreteFiber

The invention provides a preparation method of large-mixing-amount fly ash non-autoclaved ultra-light foamed concrete. The preparation method comprises the steps of preparing the following raw materials in percentage by weight: 25-35% of cement, 25-47% of fly ash, 0-5% of silica fume, 0-2% of attapulgite clay, 1-5% of a chemical foaming agent, 0.03-2% of a foam stabilizer, 0-4% of fibers, 0.5-3% of a waterproof agent, 0-2% of a reinforcing agent, 0-4% of an accelerator, 0.1-0.4% of a water reducing agent, 0.1-4% of an expansion agent, 0-3% of quicklime and 22-30% of water, and then mixing, stirring and foaming the raw materials. The main properties of the foamed concrete prepared by the preparation method are superior to those of commonly used foamed concrete, the apparent density of the foamed concrete is 160-280kg / m<3>, the thermal conductivity is lower than 0.06W / (m.K), and the specific absorption of volume is not more than 10%; besides, the ratio of fly ash doped in the foamed concrete reaches 47%, the preparation method is good in process stability and high in finished product ratio, and the foamed concrete is suitable for large-scale production and can be used for outer wall external insulation works, roof insulation works, floor heating engineering, energy-saving composite materials and the like.

Owner:BEIJING BUILDING TECH DEV

Molded object having nonwoven fibrous structure

ActiveUS20090130939A1Increased bending stressImprove toughnessErasing devicesConstruction materialPolyesterApparent density

To prepare a shaped product comprising a thermal adhesive fiber under moisture and having a fiber aggregate nonwoven structure. In the shaped product, the thermal adhesive fibers under moisture are melted to bond to fibers constituting the fiber aggregate nonwoven structure and the bonded fiber ratio is not more than 85%. The shaped product has an apparent density of 0.05 to 0.7 g / cm3, a maximum bending stress of not less than 0.05 MPa in at least one direction, and a bending stress of not less than ⅕ of the maximum bending stress at 1.5 times as large as the bending deflection at the maximum bending stress. The moistenable-thermal adhesive fiber may be a sheath-core form conjugated fiber comprising a sheath part comprising an ethylene-vinyl alcohol-series copolymer and a core part comprising a polyester-series resin. Such a shaped product can be used for a building board or the like since the shaped product has a high bending stress although the product is light and has a low density.

Owner:KURARAY CO LTD

Micro staple fiber nonwoven fabric and leather-like article in sheet form, and method for their production

InactiveUS20060234587A1Good strength performanceQuality improvementSynthetic resin layered productsAbsorbent padsApparent densityPolymer science

To provide a nonwoven fabric containing ultra-fine fibers suitable as a leather-like sheet, and also a leather-like sheet with an excellent compactness. A nonwoven fabric containing ultra-fine fibers, characterized in that it contains staple fibers with a fiber fineness of 0.0001 to 0.5 decitex and a fiber length of 10 cm or less, and has a weight per unit area of 100 to 550 g / m2, an apparent density of 0.280 to 0.700 g / cm3, a tensile strength of 70 N / cm or more, and a tear strength of 3 to 50 N.

Owner:TORAY IND INC

Gas accumulator

A gas accumulator for storing pressurized gases, in particular gaseous fuels such as hydrogen or the like, which gas accumulator has a sealed vessel which is provided with a valve-actuated feed line and outlet line for the pressurized gas and with a solid packing of carbon nanostructures. To increase the storage capacity of a gas accumulator of this type significantly, the particles of the carbon nanostructures are compacted to form larger coherent conglomerates having an apparent density which is increased in comparison with the apparent density of the originally loose particles. The compaction can be carried out, for example, by ordering the carbon nanostructures in their orientation to one another, or else by forming the conglomerates by pressing non-ordered carbon nanostructures. In each case, minimizing the interstices between the individual carbon nanostructures means that the amount of the carbon nanostructures which can be introduced into the vessel and thus the amount of the pressurized gas which can be stored in these can be increased.

Owner:MANNESMANN AG

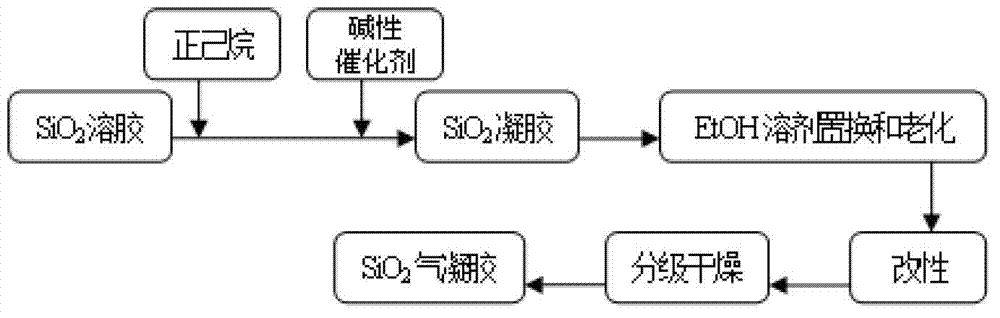

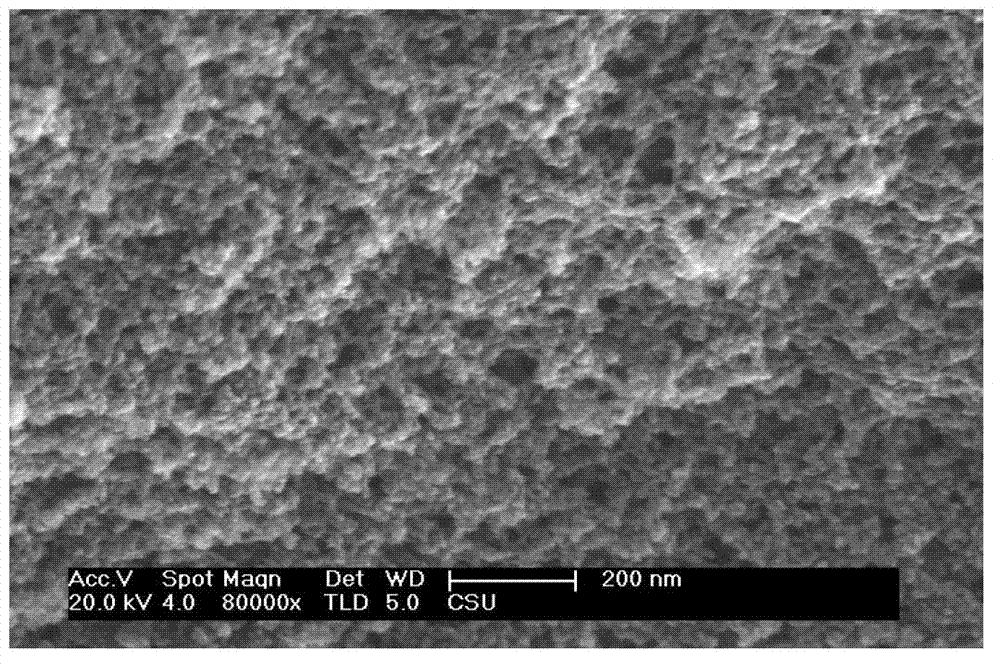

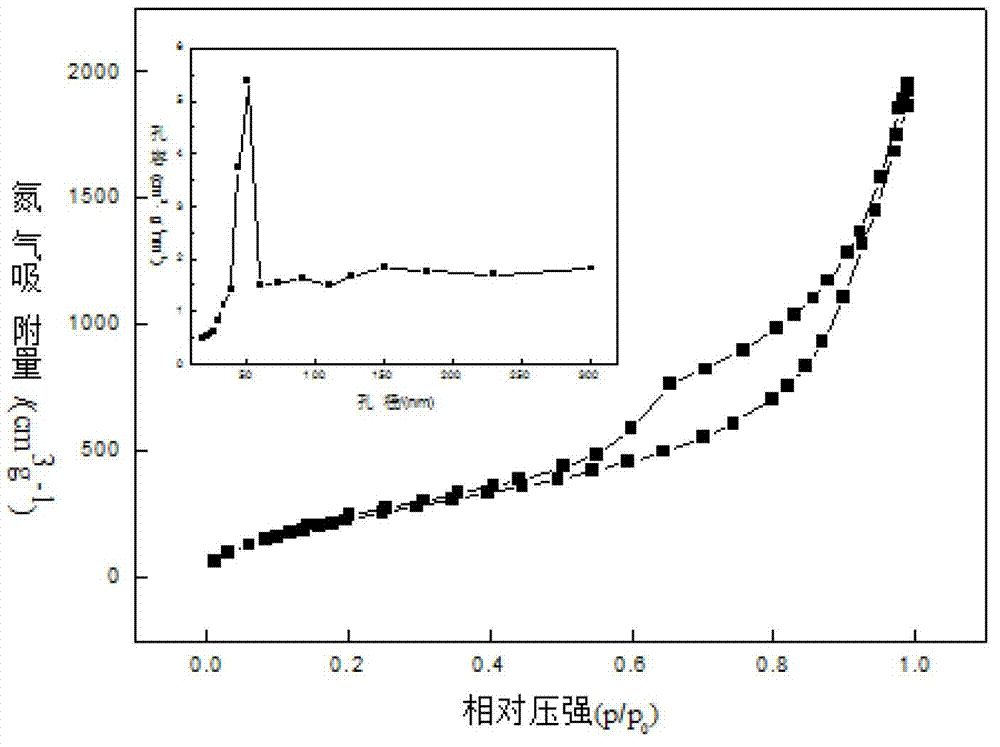

Ambient pressure drying method for rapidly preparing SiO2 aerogel

ActiveCN102951650AReduce performanceOmit the replacement processSilicon compoundsSupercritical dryingApparent density

The invention discloses an ambient pressure drying method for rapidly preparing SiO2 aerogel. Part of an alcohol solvent is replaced with a solvent with low surface tension; silica-alkoxides, the non-replaced alcohol solvent, an acidic catalyst, a basic catalyst and the solvent with the low surface tension are prepared into sol according to a certain proportion, after alcogel containing the solvent with the low surface tension is formed, ageing and surface modification processes are carried out, and then, ambient pressure drying is directly carried out, so that the complex solvent exchanging step is omitted, and the SiO2 aerogel is prepared within 30h. By using the method, not only are the defects such as high equipment investment, low efficiency, high cost of the traditional supercritical drying process overcome, but also the problems of long period, high using cost for solvent exchanging and the like in the traditional ambient pressure drying process are solved, and the prepared SiO2 aerogel has the characteristics of low surface density, large specific area, large pore volume and the like.

Owner:卢斌

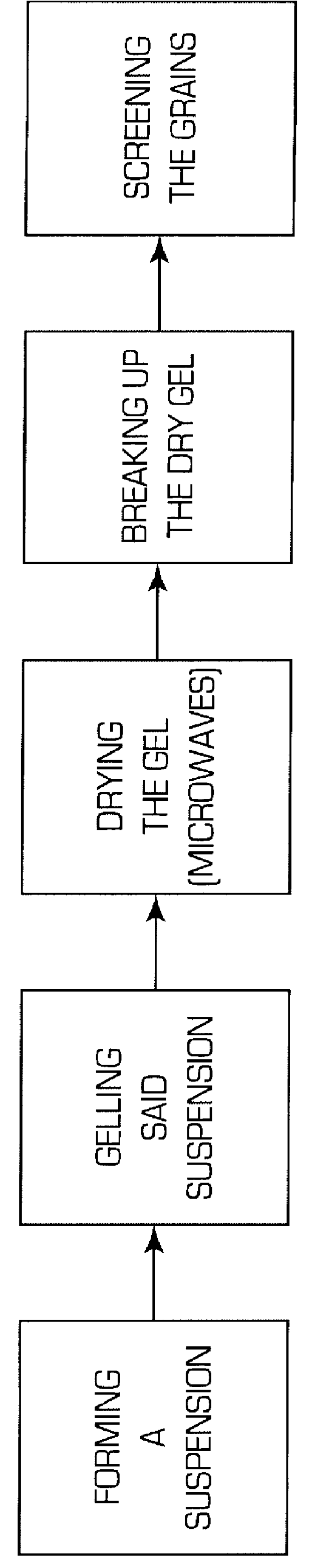

Method of manufacturing a silica powder and use of such a powder in making an optical fiber preform

InactiveUS6047568AIncrease deposition rateSilicaGlass shaping apparatusSilica particleApparent density

A method of manufacturing a silica powder using a sol-gel technique, wherein a suspension consisting of synthetic silica soot, having a specific surface area of less than 80 m2 / g, is made in water to form a concentration of 50% to 75% by weight of silica; the suspension is gelled; the resulting gel is dried without forming a crust and with microwaves and broken up into silica grains having an apparent density of 0.5 g / cm3 to 0.6 g / cm3; and screening of the dry gel is performed to provide grains having a desired size.

Owner:ALCATEL NV

Method for preparing sheet silver powder with high dispersibility

ActiveCN101279369AGood dispersionMeet different performance requirementsShaking/oscillating/vibrating mixersApparent densityMetallurgy

The invention discloses a preparation method of high-dispersion flake silver powder, which is characterized in that spherical raw material silver powder with the1 to 3Mum of particle size D50 and the more than 99.95 percent of silver content is ground into the flake silver powder by adopting a grinding machine, the dispersion is then improved by ultrasonic dispersion and airflow dispersion, and the high-dispersion flake silver powder with the 3 to 25Mum of flake diameter D50 and the apparent density of 0.5 to 1.8g / cm<3> is obtained. The preparation process has simple process flow, which is applicable to the industrial mass production of flake silver powder.

Owner:JINCHUAN GROUP LIMITED

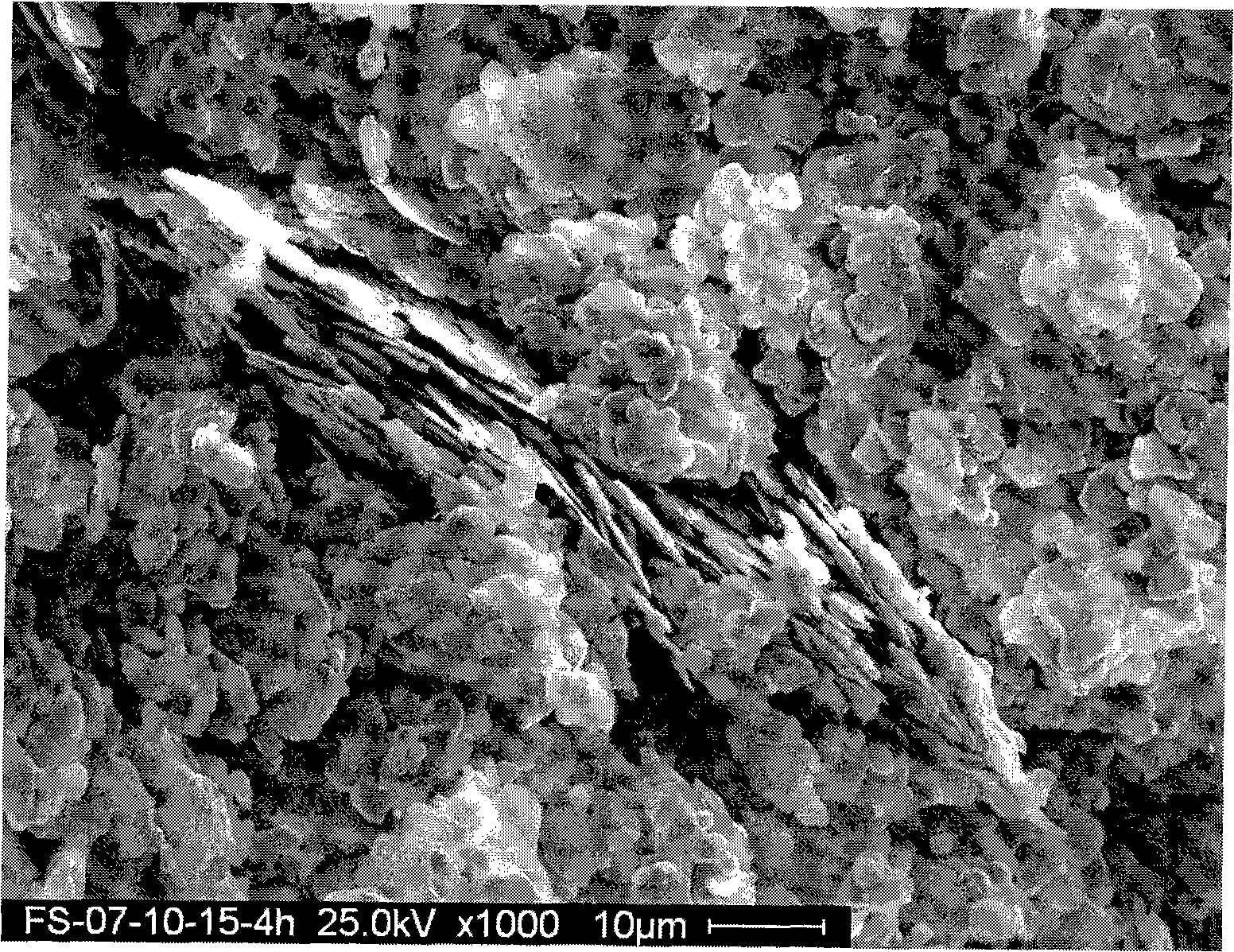

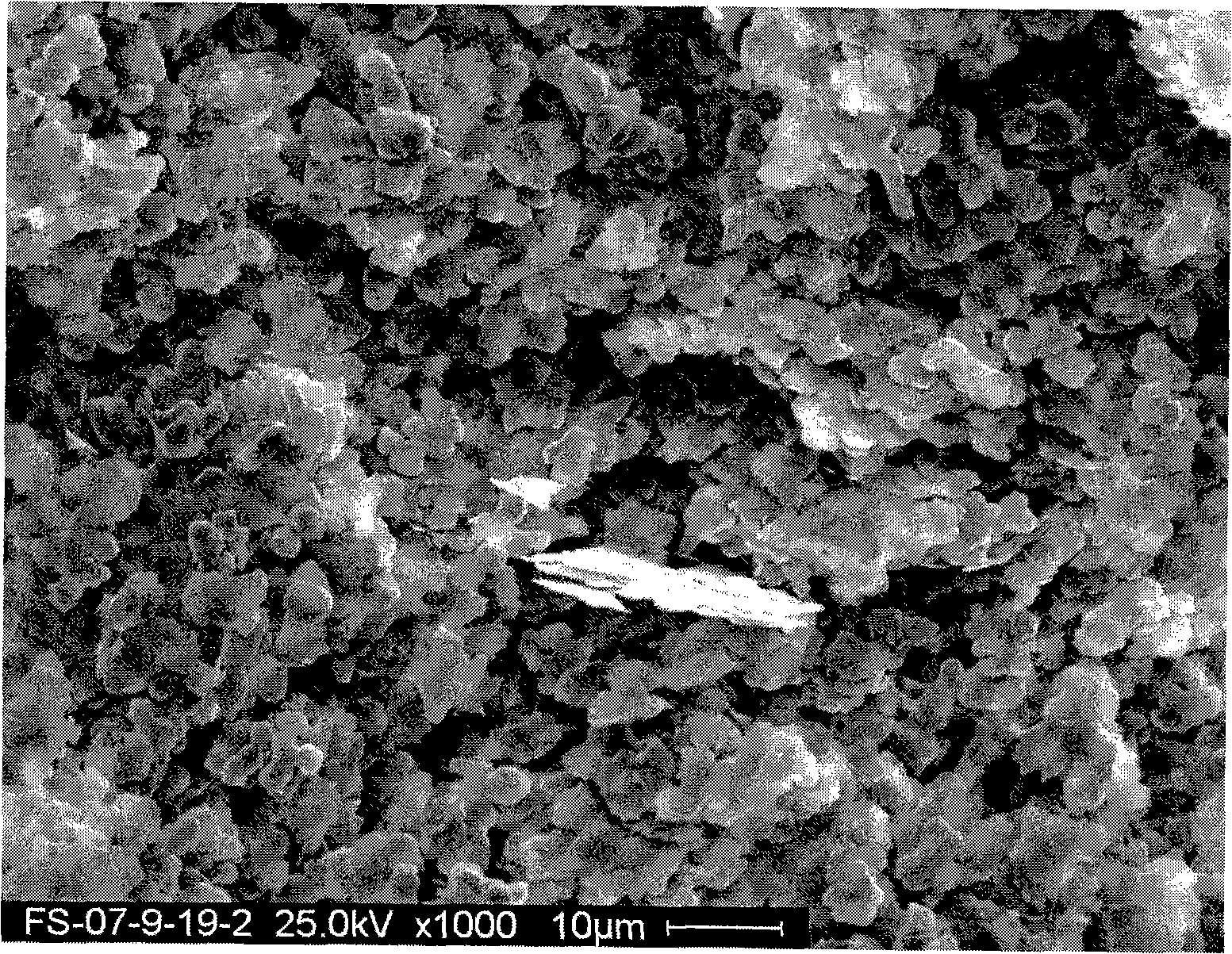

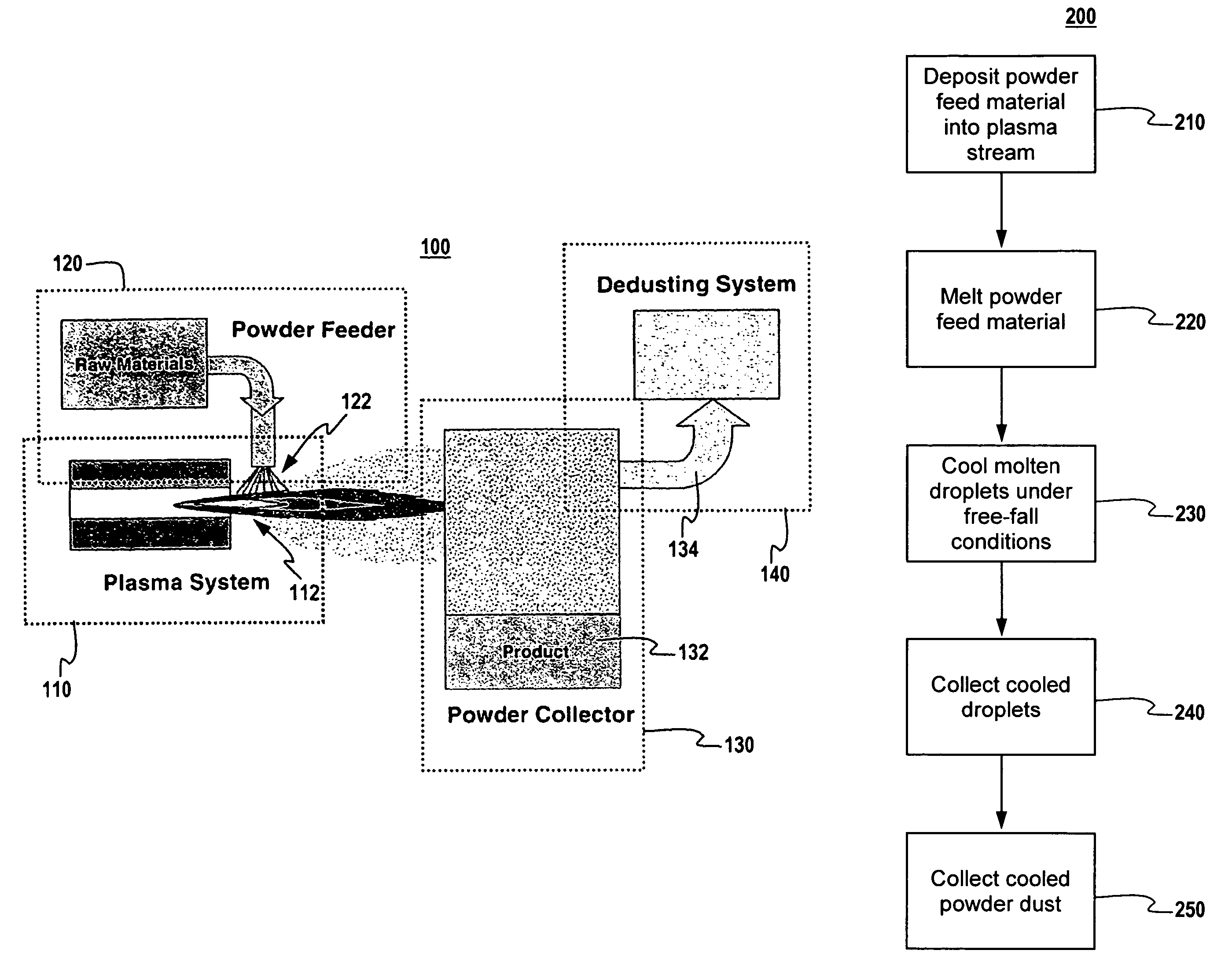

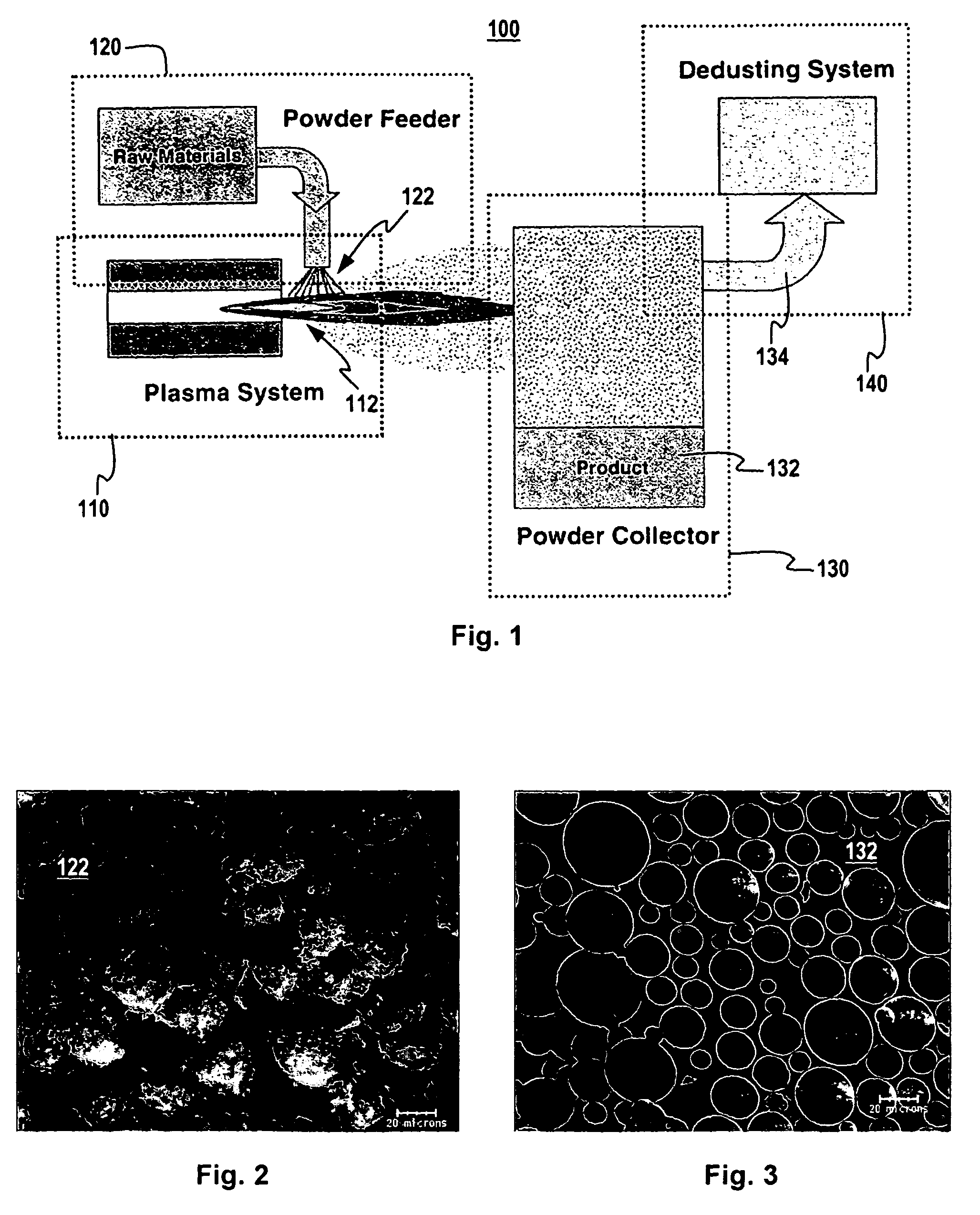

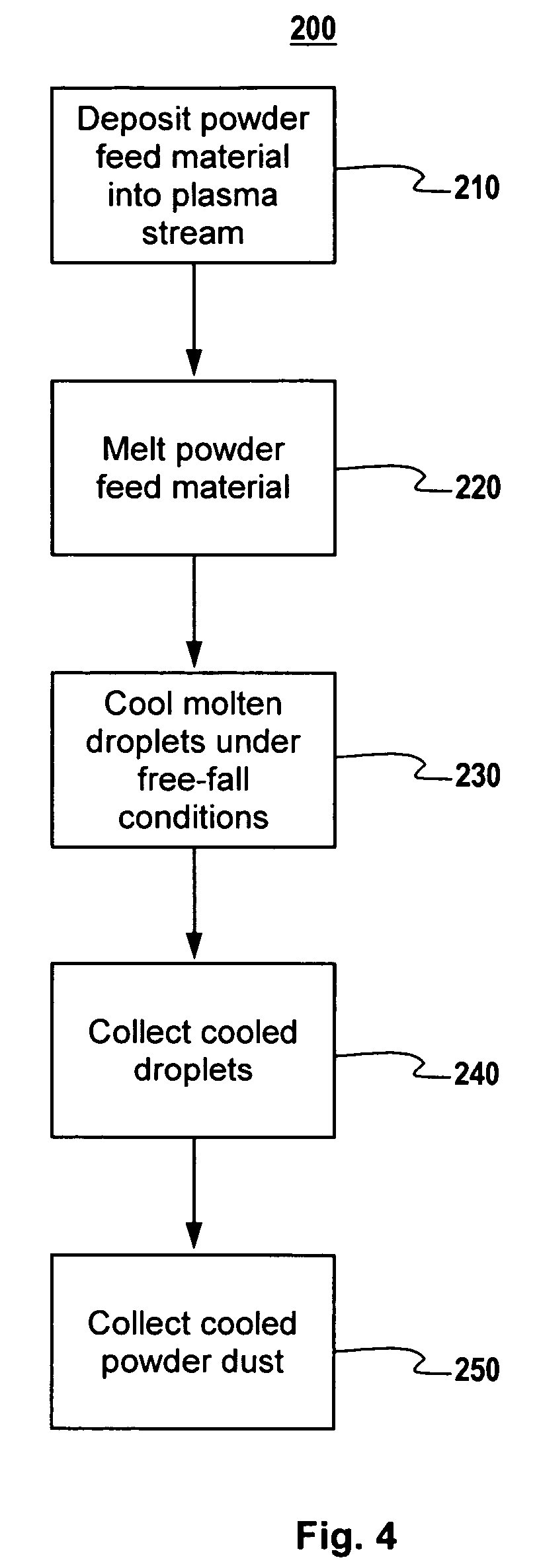

Method for making high purity and free flowing metal oxides powder

InactiveUS7931836B2Improve physical and chemical propertyImprove purification effectBurnersOxide/hydroxide preparationApparent densityFree falling

According to aspects of the present invention, metal oxide powder, such as yttria and alumina powder (feed material), is processed using a plasma apparatus. The process generally consists of in-flight heating and melting of the feed material by the plasma apparatus. The plasma apparatus contains a plasma torch with required power supply and cooling systems, a powder feeder, a chamber to collect the powder and a dedusting system. The heated powder forms molten spherical droplets that are rapidly cooled under free fall conditions. The plasma densification process removes some impurity oxides, modifies the morphology of the particle and increases the apparent density of the powder.

Owner:SULZER METCO (US) INC

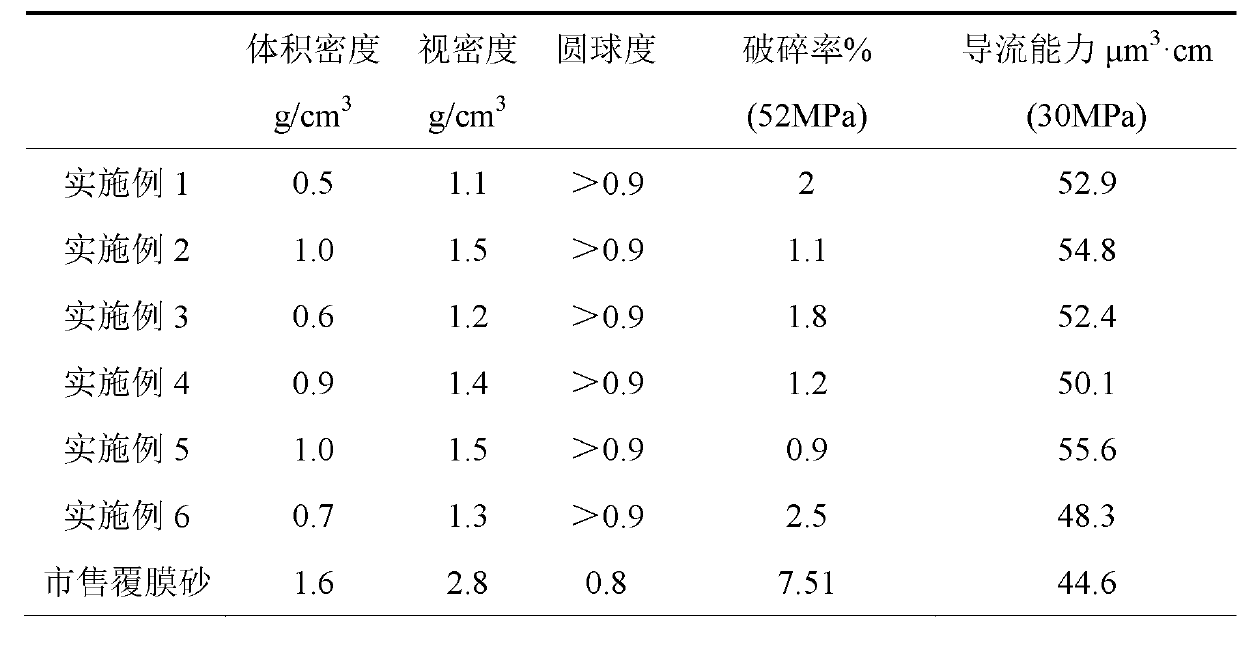

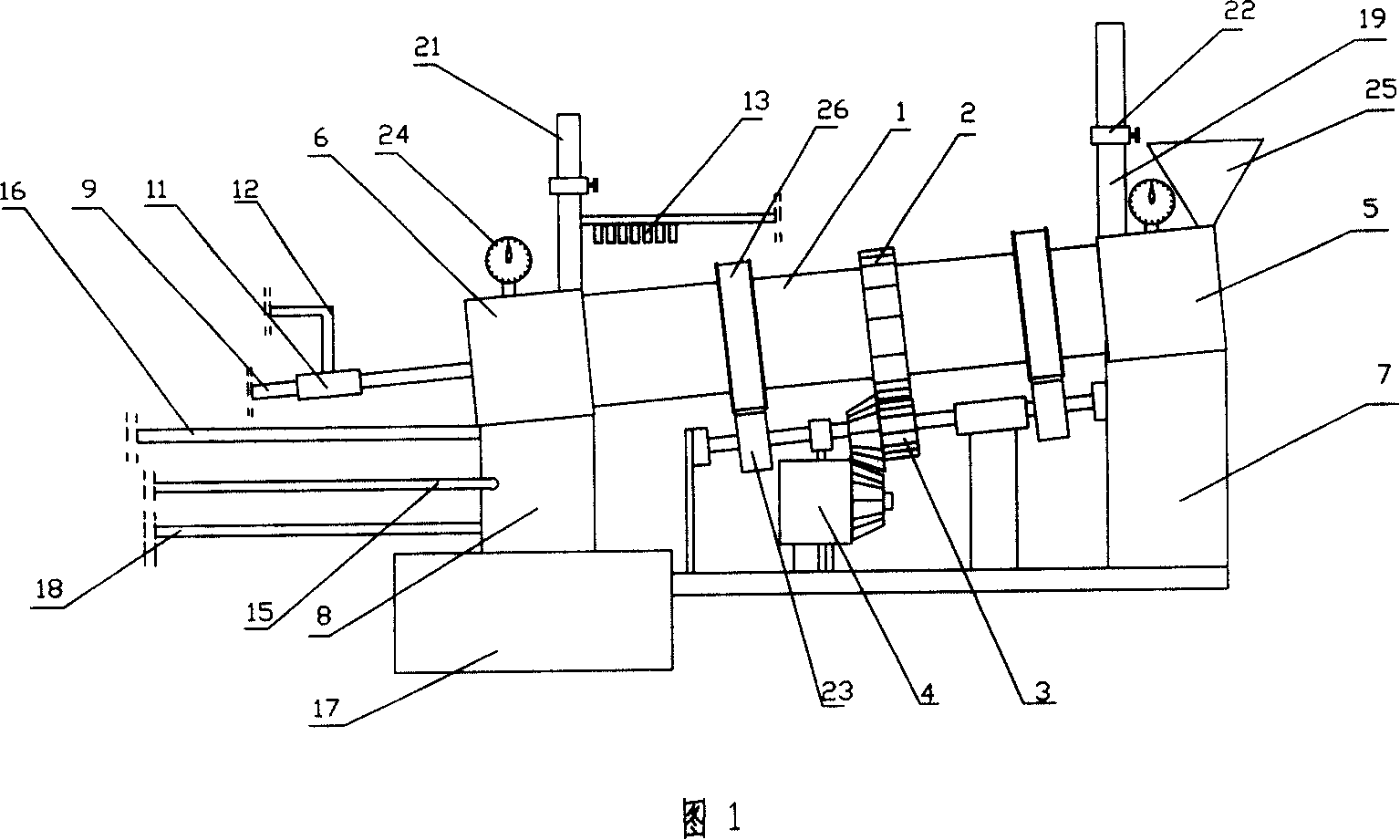

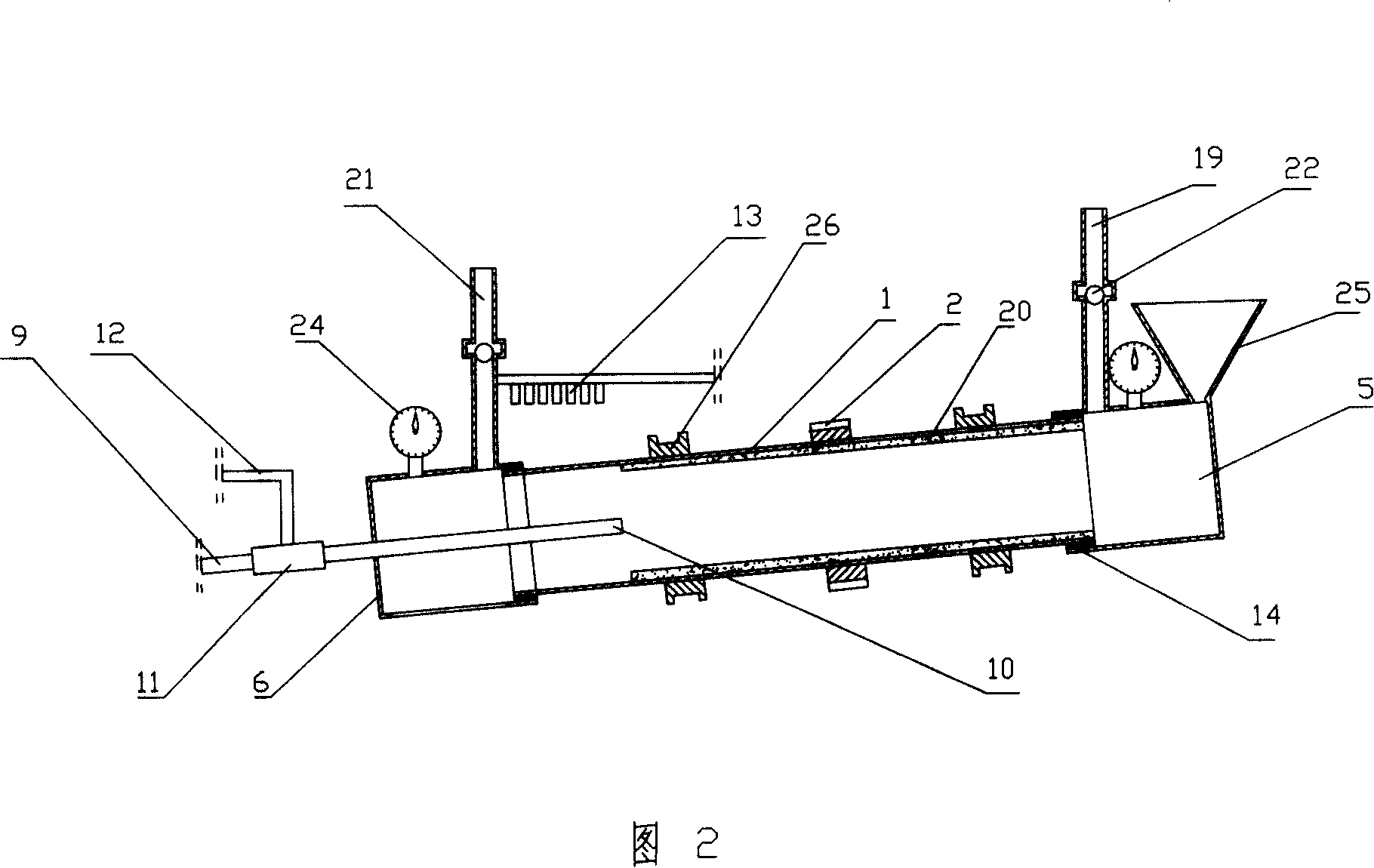

Clean-water-carrying petroleum proppant for petroleum production of low-permeability petroleum reservoir and preparation method thereof

The invention provides a clean-water-carrying petroleum proppant for petroleum production of a low-permeability petroleum reservoir. The proppant is prepared through coating macromolecular polymer particles with the particle sizes of 3-100 meshes by using macromolecular resin, wherein the macromolecular polymer particles are white polymer balls formed through polymerizing olefin monomers or polymer microspheres formed through compounding after a silane coupling agent modified mineral material is added; and the proppant has the volume density of 0.5-1.0 g / cm<3> and the apparent density of 1.1-1.5 g / cm<3>. The invention simultaneously provides a preparation method of the petroleum proppant. The clean-water-carrying petroleum proppant prepared by adopting the preparation method can greatly reduce the viscosity of sand carrying liquid, reduce the damage to strata and pumps and even realize clean fracturing. Through the low-density proppant, the entire construction cost can be reduced, and the phenomenon of proppant discharging or crack emptying is difficult to occur.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

Method for producing iron concentrate by brown hematite and siderite and reduction roaster

The present invention discloses a method for adopting the limonite and the siderite to produce iron powder and a reduction roaster. The material adopts the limonite and the siderite or the specularite, the hematite, and the sulphuric acid slag, the inclined rotary reduction roaster is used, the pressure of the furnace chamber is 250 to 350 Pa, under the deoxidizing atmosphere, the inert solid is rotated and moved to 650 to 900 DEG C from the low temperature, and is cooled and magnetized, and lastly become the iron powder through the dressing by magnetic separation. The present invention is adopted to produce the iron powder, the resources is rich and the production cost is low, and through the utilization of the powder metallurgy art, the iron content of the iron powder is controlled and the activation energy of the iron powder is reduced, and the chemical reaction ability is increased, thereby the output of iron powder is high, the quality is good, the iron powder is loose and porous, the specific surface is big, the apparent density is large, the manufacture cost of pellets sinter and steel smelting can be reduced greatly, and the iron powder can use directly to produce iron oxide red as well as H and N synthetic iron catalyst, or produce ultrapure iron powder.

Owner:郭元杰

Resin foam and foam sealing material

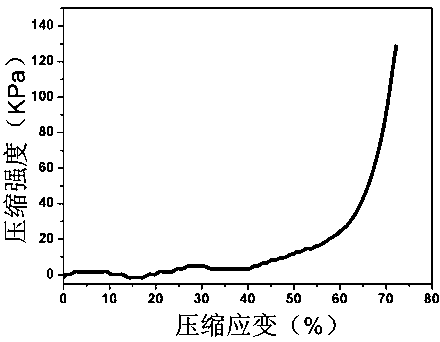

InactiveUS20130017391A1Excellent in dustproofnessImprove AssemblabilityOther chemical processesFilm/foil adhesivesApparent densityCell diameter

There is provided a resin foam excellent in dustproofness and assemblability.The resin foam has a repulsive stress at 80% compression (repulsive stress when a resin foam is compressed by 80% of the initial thickness) of 1.0 to 9.0 N / cm2 and a tensile modulus of elasticity of 5.0 to 14.0 MPa. Preferably, the resin foam further has an average cell diameter of 10 to 180 μm and an apparent density of 0.01 to 0.10 g / cm3.

Owner:NITTO DENKO CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com