Patents

Literature

576 results about "Iron catalyst" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Iron has received a significant amount of attention in the recent literature as a powerful catalyst for transition metal- catalyzed reactions. Due to its low cost, ready abundance, and low toxicity, iron is an ideal metal catalyst for large scale synthesis of fine chemicals.

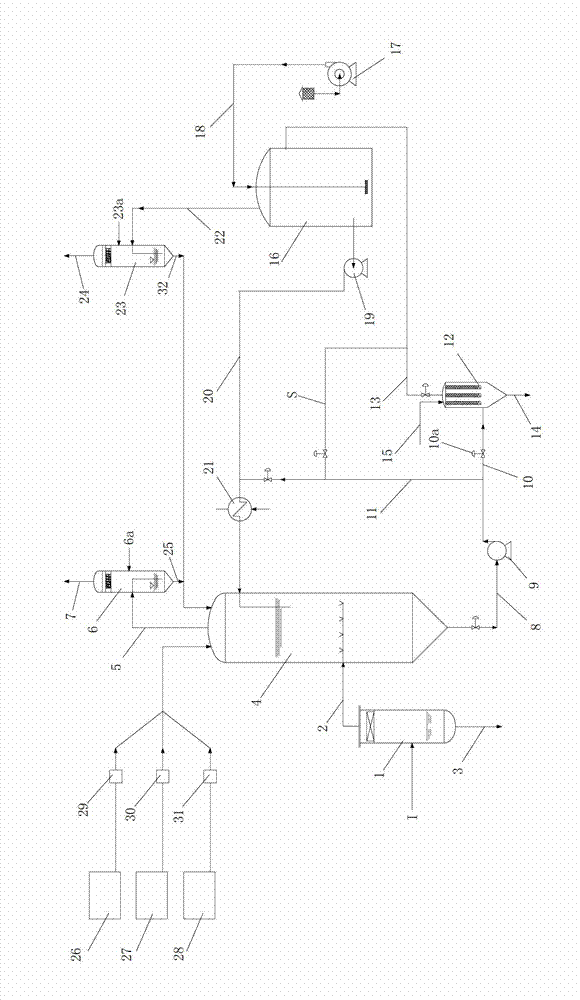

Natural gas desulfurization process suitable for offshore floating platform

InactiveCN108034466AFast regenerationImprove oxidation regeneration efficiencyGaseous fuelsChemical industryChemical reaction

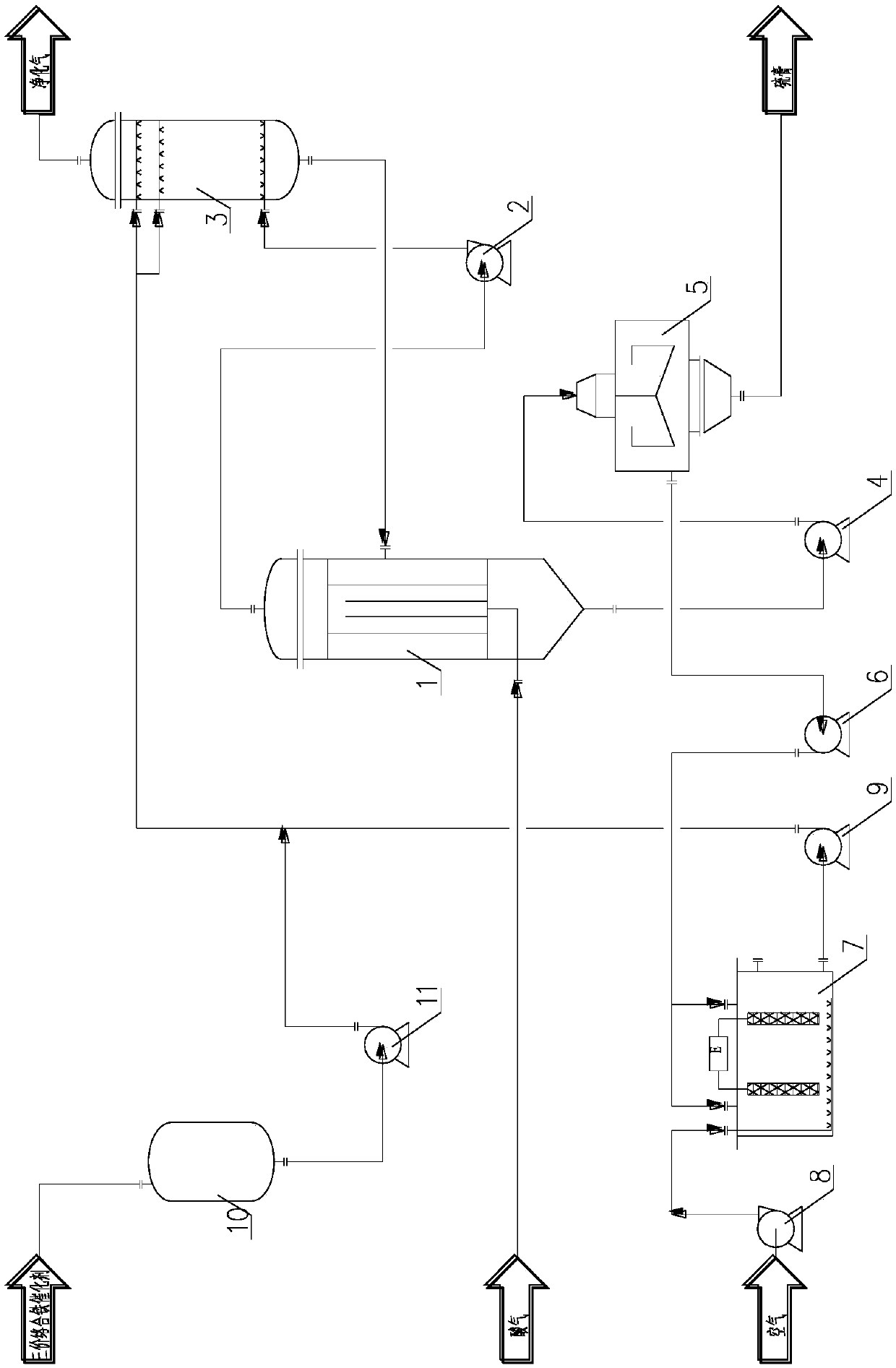

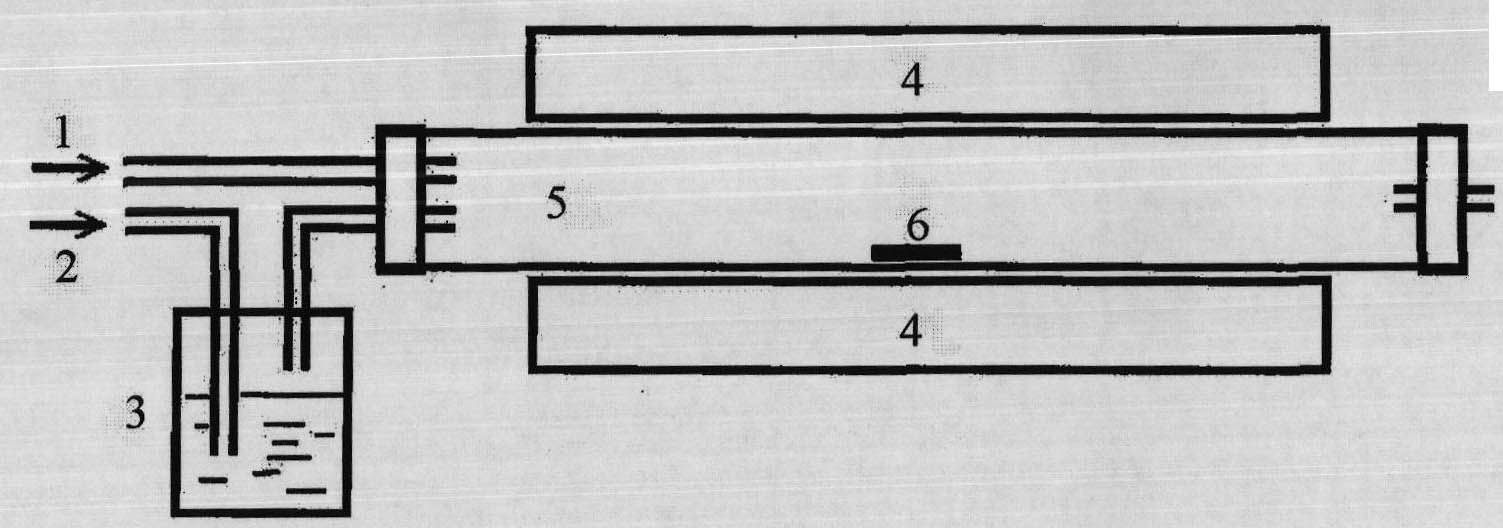

The invention relates to the field of natural gas chemical industry, in particular to a natural gas desulfurization process suitable for an offshore floating platform. The natural gas desulfurizationprocess comprises a reactor, a re-reactor and a centrifugal machine; acid gas coming from a boundary region is directly introduced into the reactor, a trivalent complex iron catalyst enters the re-reactor, the trivalent complex iron catalyst at the bottom of the re-reactor enters the reactor under the control of a valve and a pipeline, a chemical reaction is then carried out, divalent complex ironobtained by means of the reaction is centrifuged, the divalent complex iron is conveyed to an electrochemical regeneration device by means of a regenerative feed pump so as to complete the regeneration, and the regenerated trivalent complex iron catalyst is returned to the re-reactor by means of a circulation pump. The natural gas desulfurization process is simple in technological process, smallin equipment size and compact in structure, and adapts to the condition limit of limited production space of offshore floating liquefied natural gas (FLNG).

Owner:SICHUAN HENGRI GAS ENG CO LTD

Method for producing 1,1,1,3-tetrachloropropane and other haloalkanes with iron catalyst

InactiveUS20040225166A1Efficient and economical to produceHalogenated hydrocarbon preparationTetrachlorideDistillation

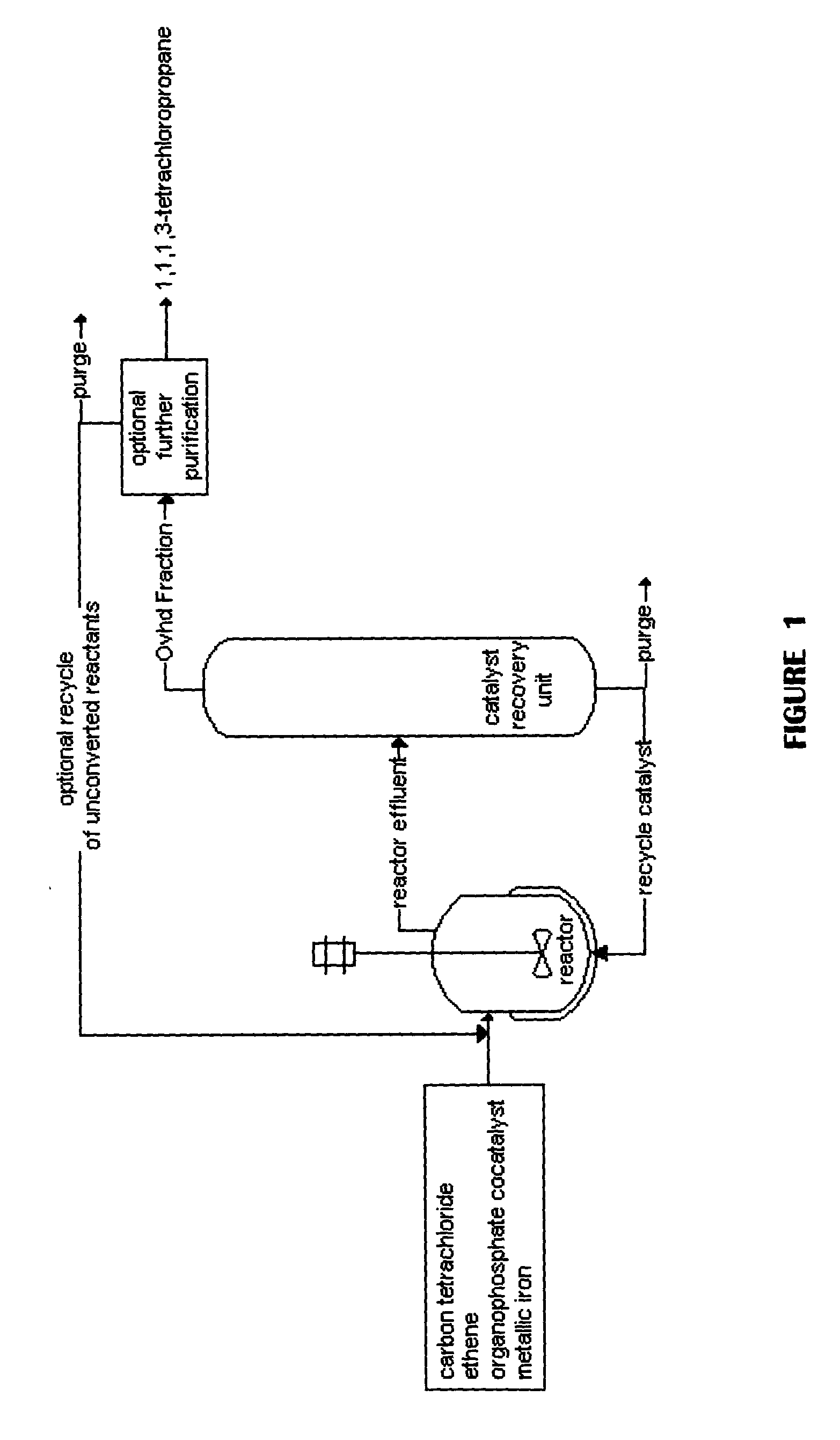

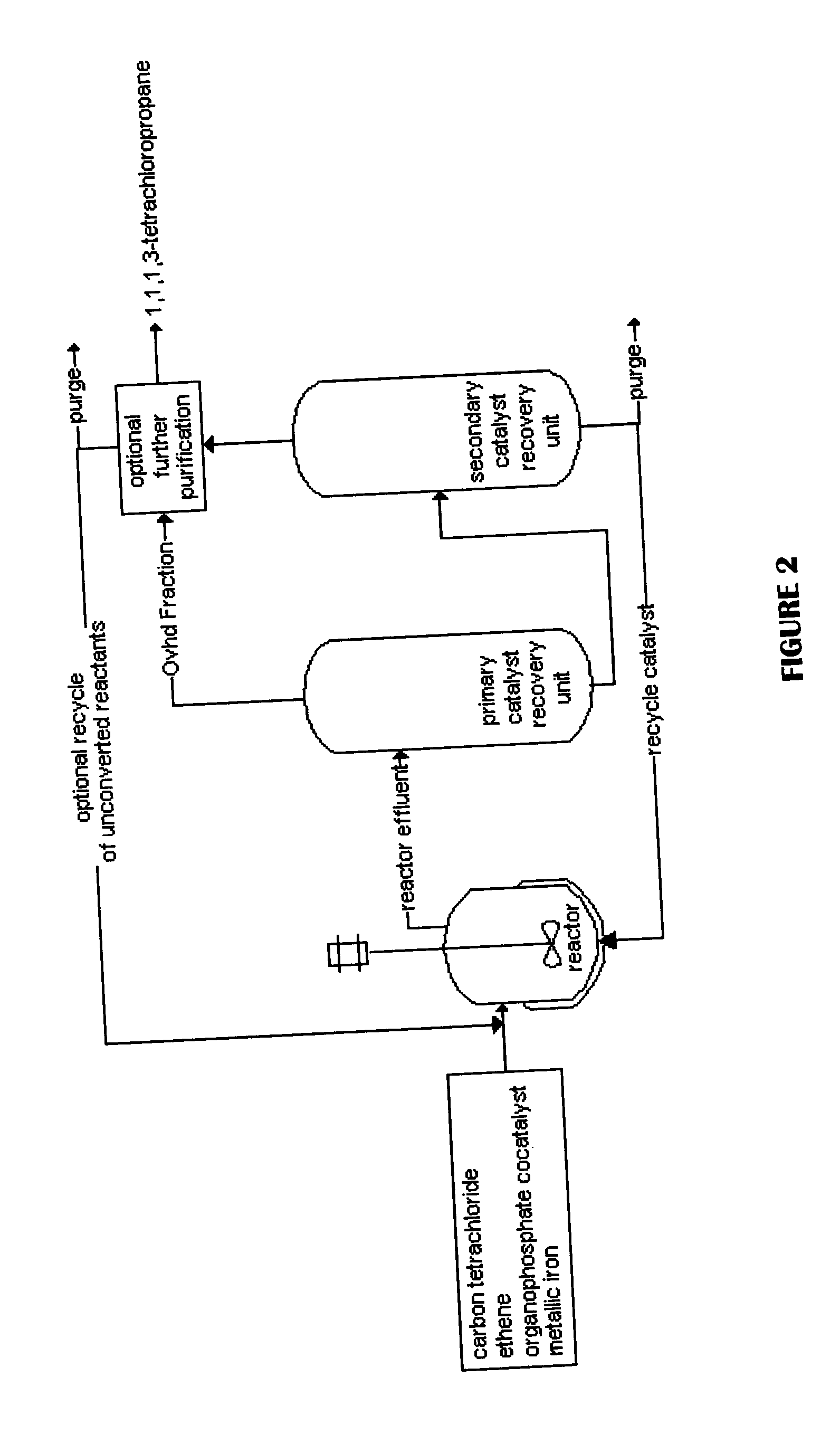

A continuous process is provided for the manufacture of haloalkanes by the reaction of carbon tetrachloride with olefins in the presence of iron metal, trialkylphosphate, and ferric chloride. A fraction of the catalyst and co-catalyst are separated after the reaction and recycled. In a preferred application, the olefin is ethene, and the haloalkane product is 1,1,1,3-tetrachloropropane. Two distillation steps take place in order to enhance the production of 1,1,1,3-tetrachloropropane.

Owner:OCCIDENTAL CHEM CORP

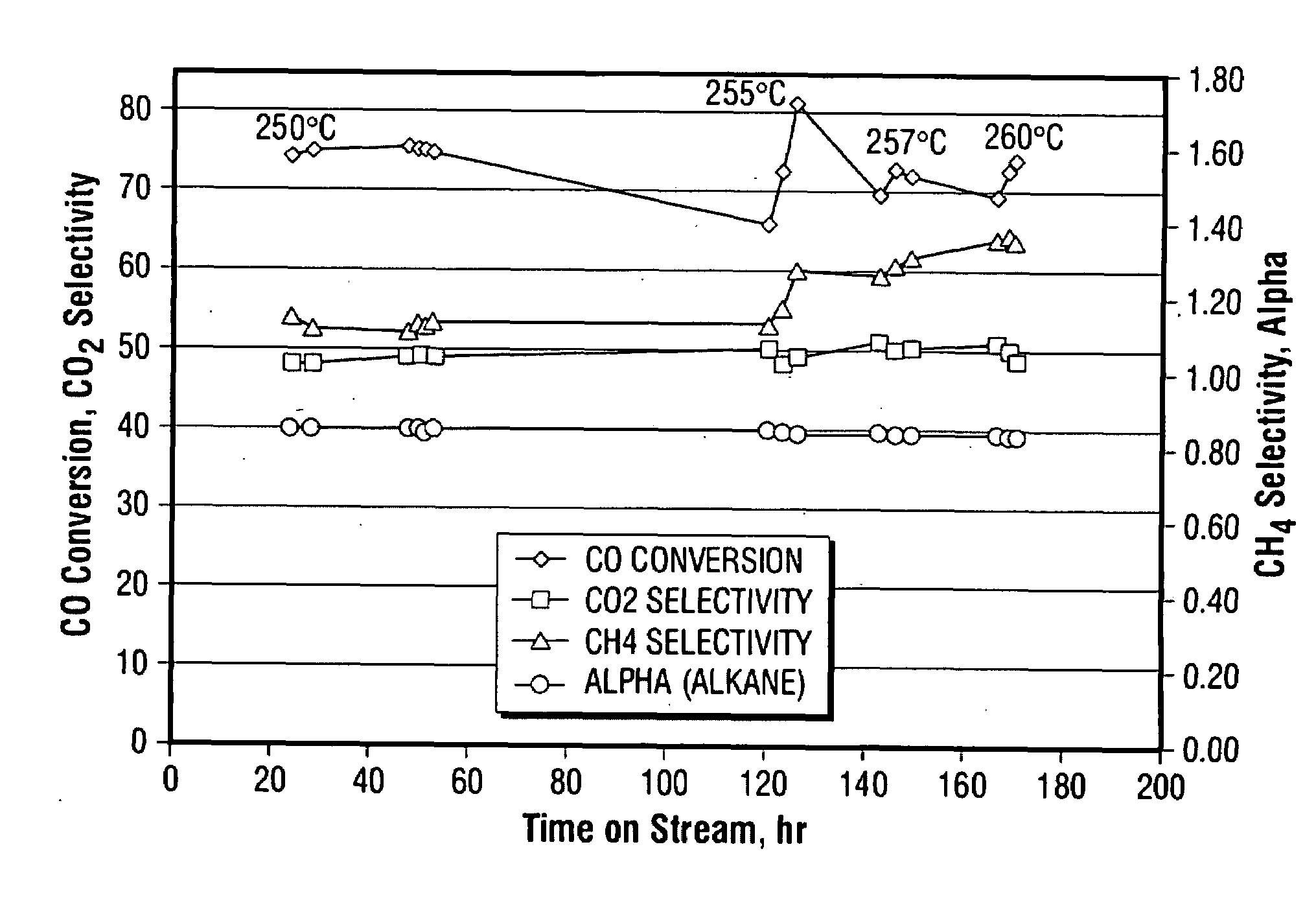

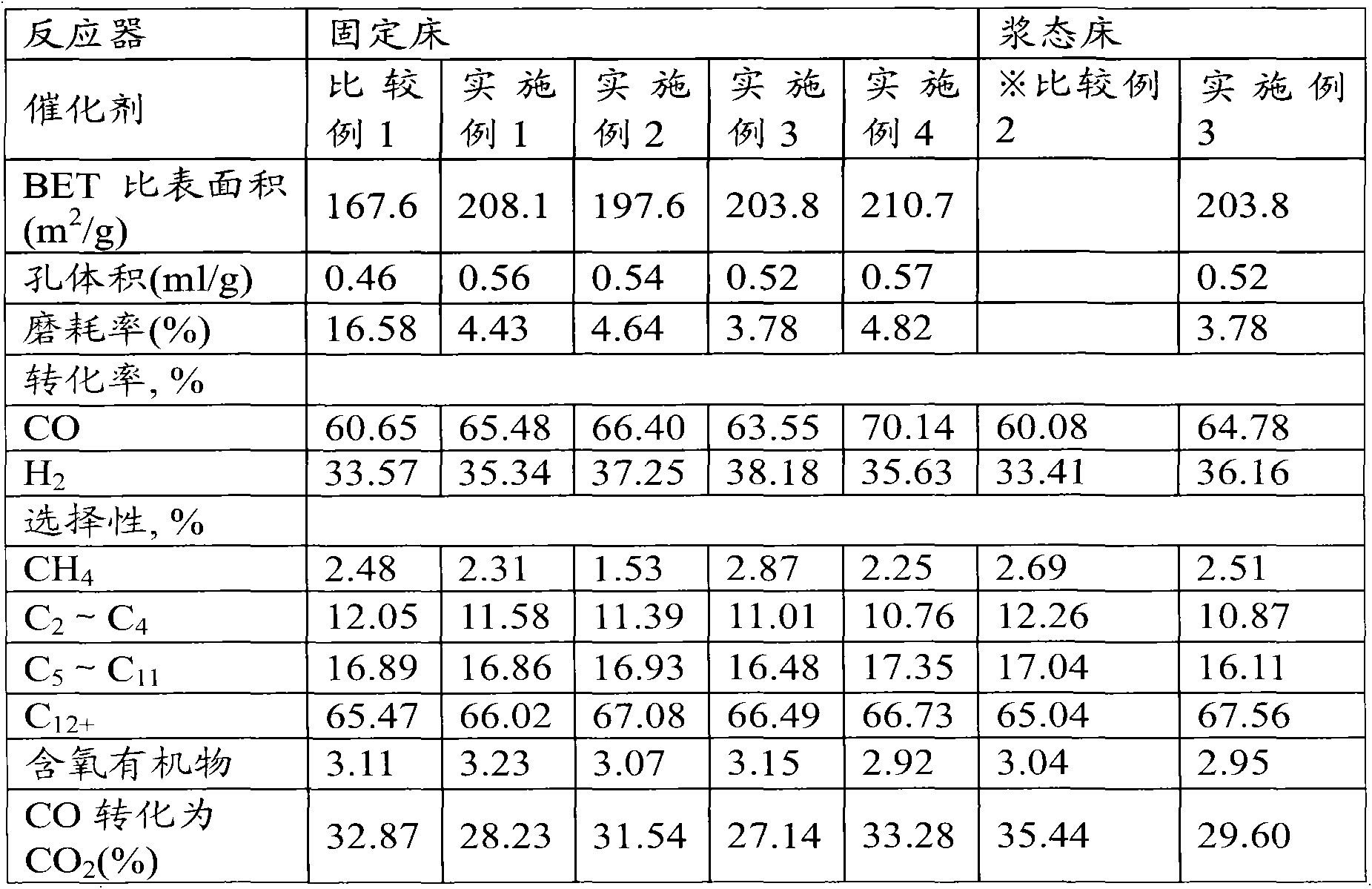

Skeletal iron catalyst having improved attrition resistance and product selectivity in slurry-phase synthesis processes

InactiveUS6277895B1High particle strengthGood attristion resistanceHydrocarbon from carbon oxidesOrganic compound preparationFixed bedSlurry

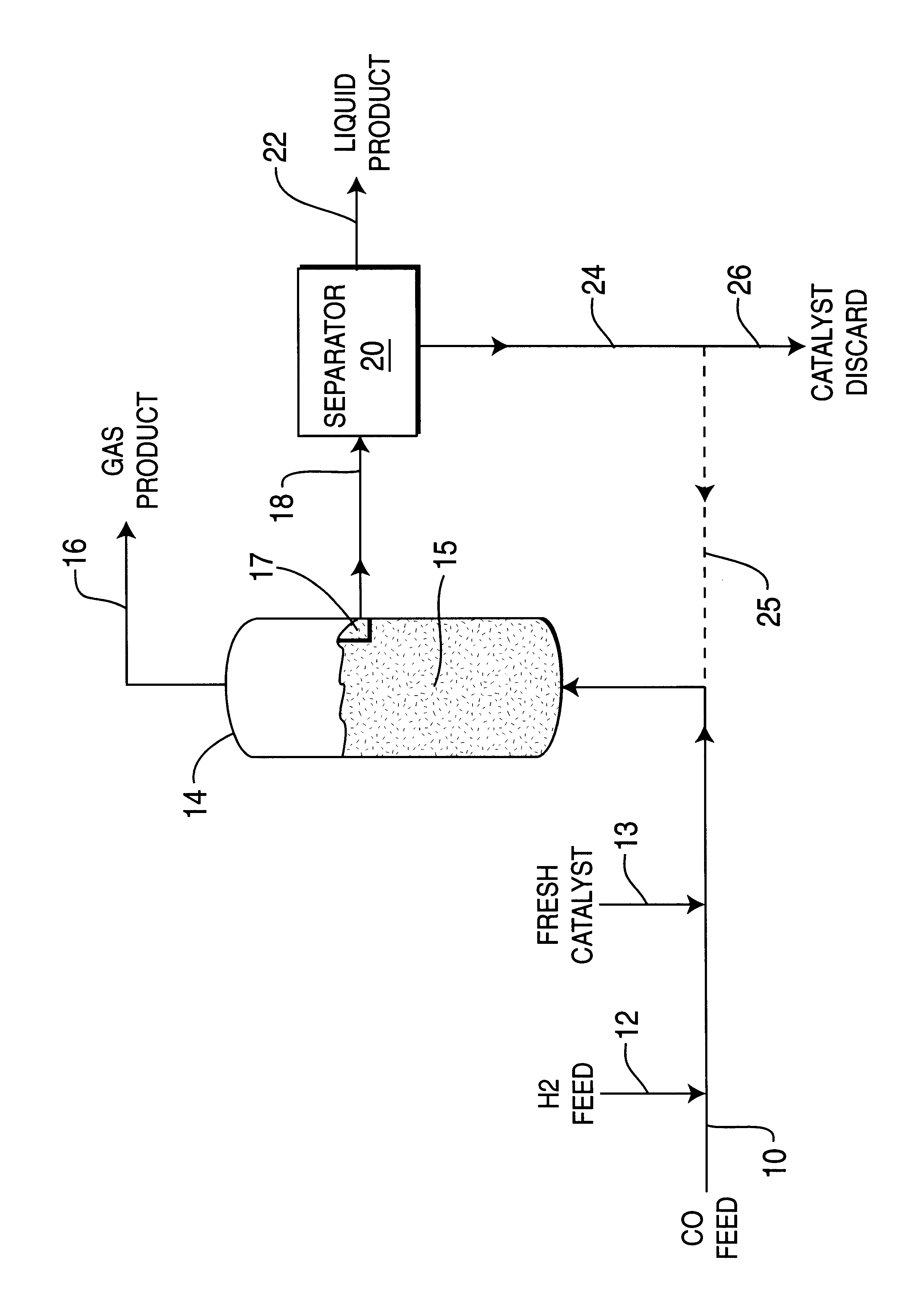

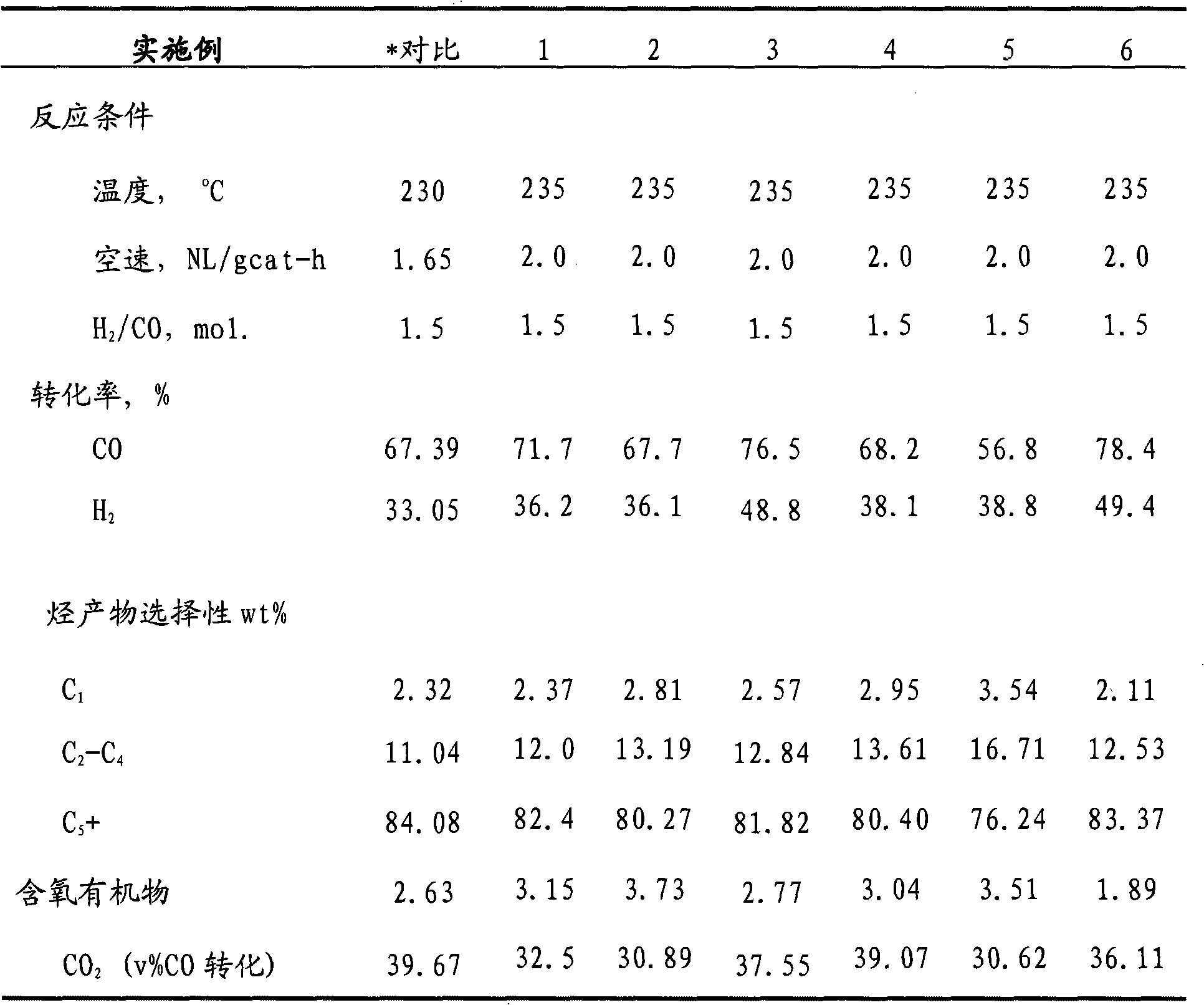

Particulate skeletal iron catalyst is provided which contain at least about 50 wt. % iron with the remainder being a minor portion of a suitable non-ferrous metal and having characteristics of 0.062-1.0 mm particle size, 20-100 m2 / g surface area, and 10-40 nm average pore diameter. Such skeletal iron catalysts are prepared and utilized for producing synthetic hydrocarbon products from CO and H2 feeds by Fischer-Tropsch synthesis process. Iron powder is mixed with non-ferrous powder selected from aluminum, antimony, silicon, tin or zinc powder to provide 20-80 wt. % iron content and melted together to form an iron alloy, then cooled to room temperature and pulverized to provide 0.1-10 mm iron alloy catalyst precursor particles. The iron alloy pulverized particles are treated with NaOH or KOH caustic solution at 30-95° C. temperature to extract and / or leach out most of the non-ferrous metal portion, and then screened and treated by drying and reducing with hydrogen and to provide the smaller size skeletal iron catalyst material. Such skeletal iron catalyst is utilized with CO+H2 feedstream for Fischer-Tropsch reactions in either a fixed bed or slurry bed type reactor at 180-350° C. temperature, 0.5-3.0 mPa pressure and gas hourly space velocity of 0.5-3.0 L / g Fe / hr to produce desired hydrocarbon products.

Owner:INST OF COAL CHEM ICCCHINESE ACADEMY OF SCI +1

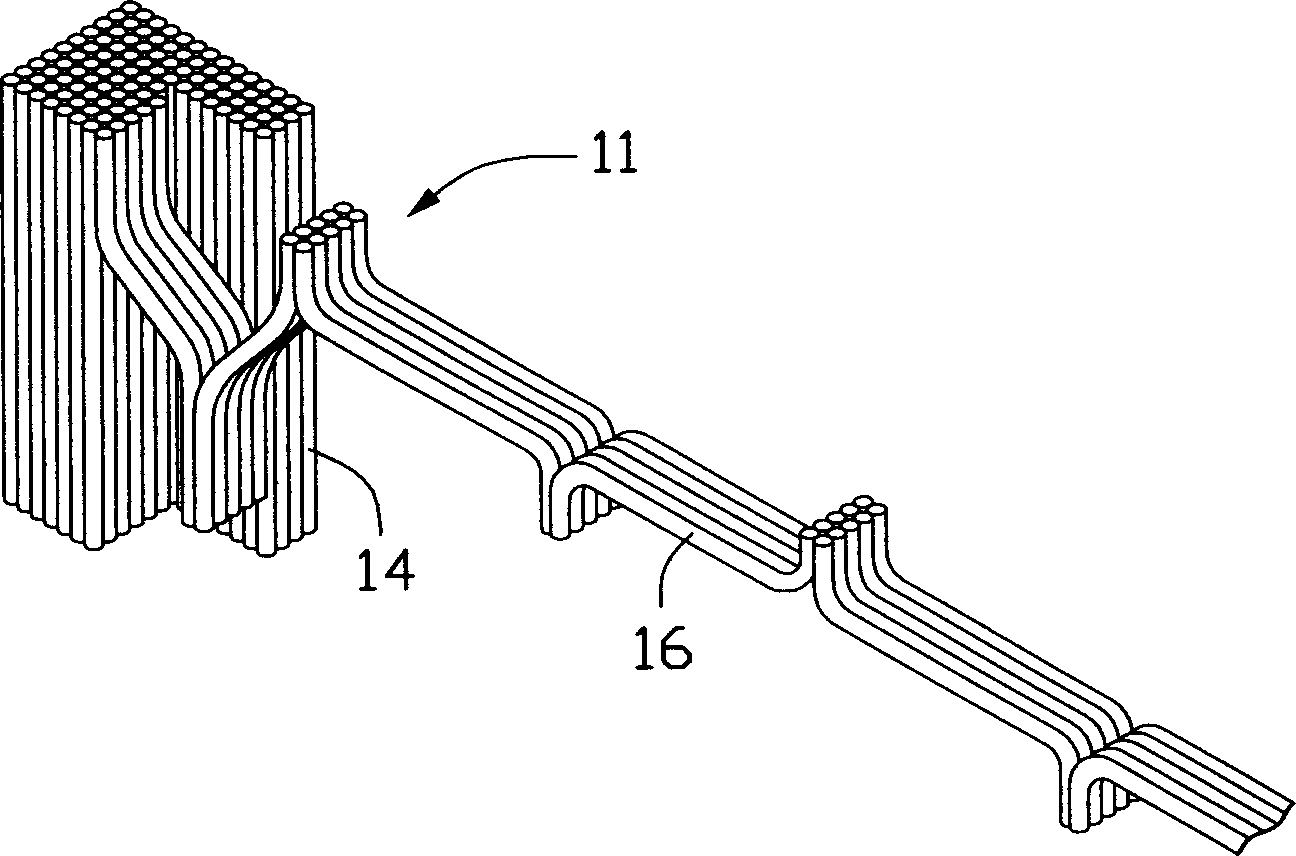

Polarized element and method for manufacturing same

InactiveCN1482472AExtended service lifeNot easy to damagePolarising elementsNanoopticsCarbon nanotubeAtmospheric pressure

The invention discloses an optical polarized light element and method for manufacturing the same, wherein the method comprises, providing a silicon base having a smooth surface, depositing iron catalyst onto the silicon base surface, feeding the silicon base into a reaction furnace, heating the reaction furnace and feeding in the mixture gas of acetylene and argon, controlling the flow capacity of the mixture gas, controlling the mixture ratio of acetylene and argon gas, gripping and pulling a bundle of carbon nanometer tubes using a clamp, arranging the carbon nanometer tubes rope compactly and parallelly onto a transparent base sheet.

Owner:BEIJING FUNATE INNOVATION TECH +1

Strengthened iron catalyst for slurry reactors

ActiveUS20090062108A1Various problemOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationSlurry reactorPotassium

A method of strengthening a precipitated unsupported iron catalyst by: preparing a precipitated unsupported iron catalyst containing copper and potassium; adding a solution comprising a structural promoter to the previously prepared catalyst; drying the mixture; and calcining the dried catalyst.A method for preparing an iron catalyst, the method comprising: precipitating a catalyst precursor comprising iron phases selected from hydroxides, oxides, and carbonates; adding a promoter to the catalyst precursor to yield a promoted precursor; drying the promoted precursor to yield dried catalyst; and calcining the dried catalyst, wherein the catalyst further comprises copper and potassium.A method of preparing a strengthened precipitated iron catalyst comprising: co-precipitating iron, copper, magnesium, and aluminum; washing the precipitate; alkalizing the precipitate; and drying the precipitate to yield a dried catalyst precursor. The dried catalyst precursor may be calcined and treated with a gas comprising carbon monoxide.

Owner:RES USA LLC

Promoted, attrition resistant, silica supported precipitated iron catalyst

InactiveUS20090075814A1Improve the immunityCatalyst activation/preparationLiquid hydrocarbon mixture productionSlurrySilicon dioxide

A catalyst support solution for improving the attrition resistance of a Fischer-Tropsch catalyst, the solution comprising: crystalline silica and at least one chemical promoter selected from alkali metal bases, wherein the support solution has a pH of greater than or equal to about 7. A structurally promoted catalyst comprising: crystalline silica; at least one basic chemical promoter; and iron; wherein the catalyst comprises SiO2:Fe in a ratio of from about 2:100 to about 24:100. A method of producing a structurally promoted precipitated iron catalyst, the method comprising: forming the structural support solution described above; stirring the support solution for a time to dissolve the silica in the solution; adding the support solution to a precipitated iron catalyst slurry to form an attrition resistant catalyst slurry; and drying the attrition resistant catalyst slurry to yield the structurally promoted precipitated iron catalyst.

Owner:RES USA LLC

Iron catalyst used in butadiene production through n-butylene oxidation dehydrogenation, and preparation method and application thereof

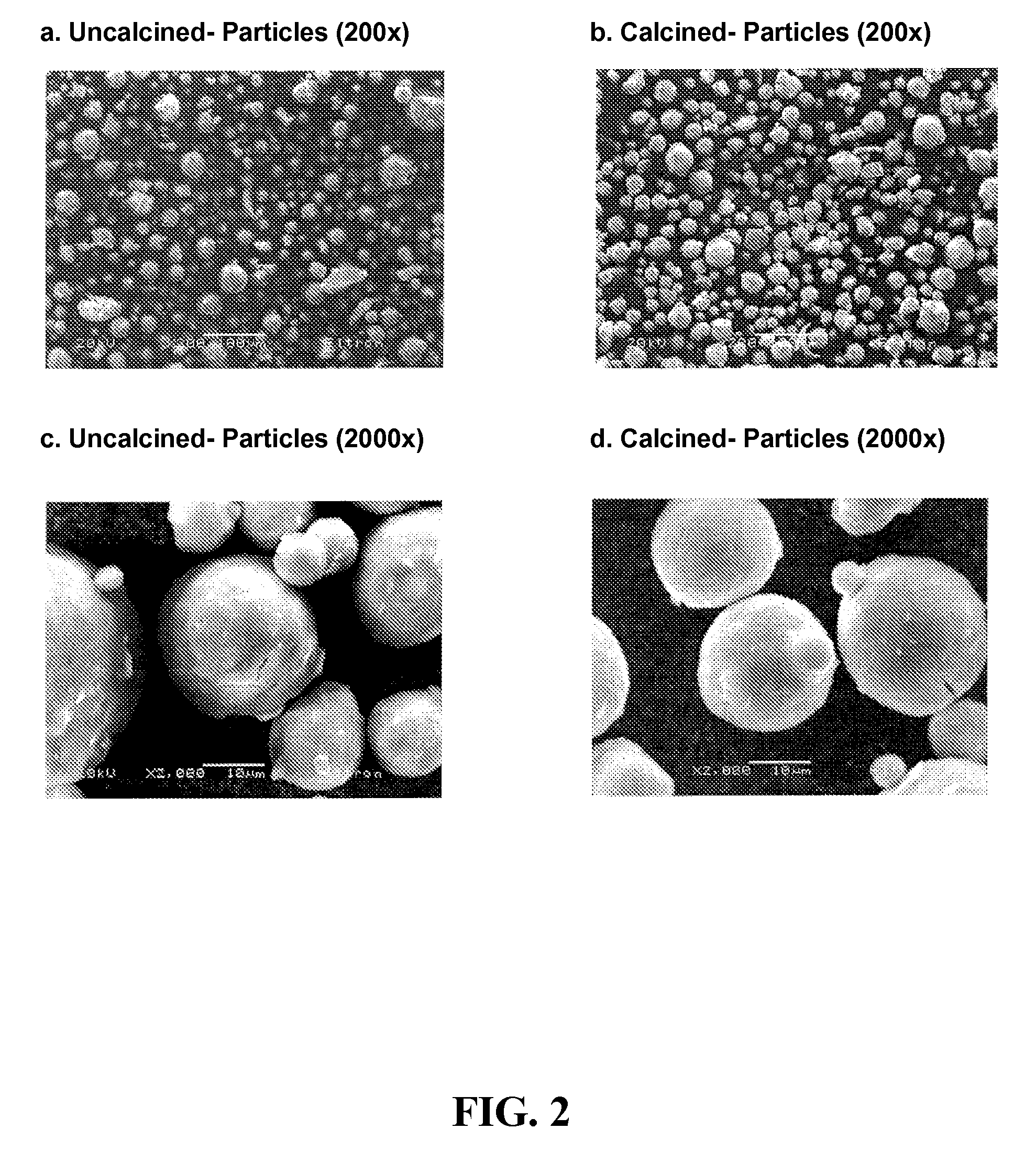

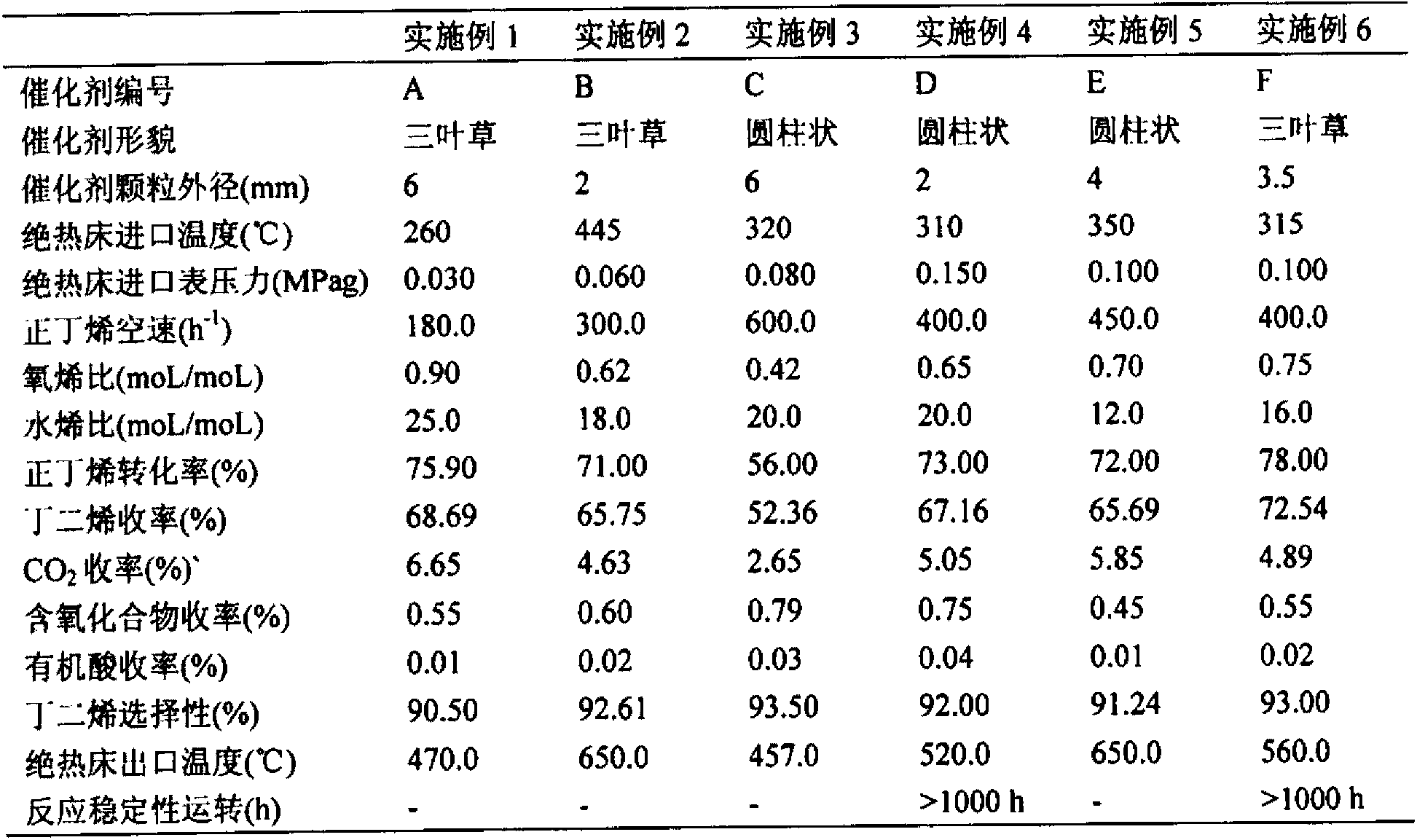

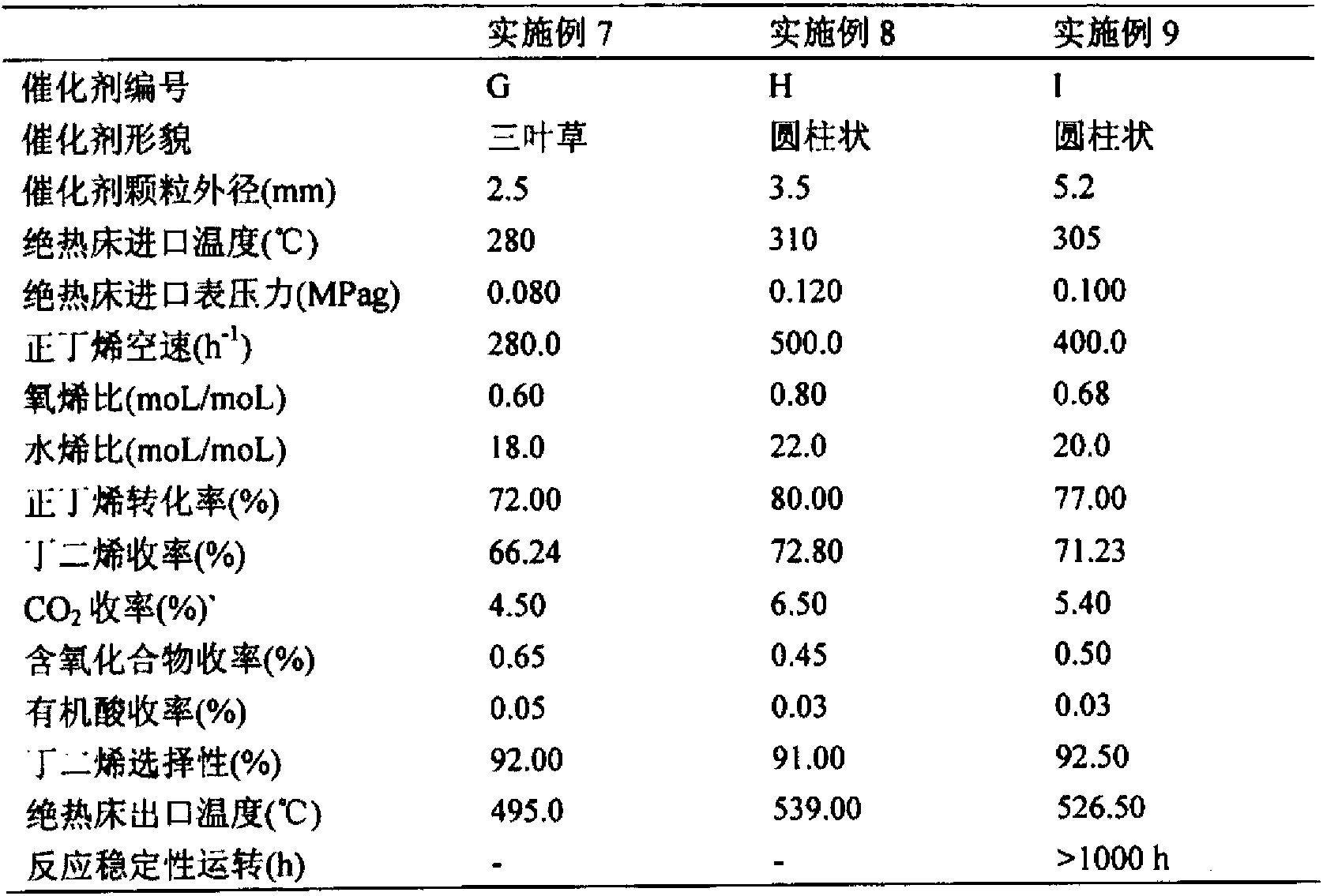

ActiveCN103055890ASimple preparation processEasy accessHydrocarbonsMetal/metal-oxides/metal-hydroxide catalystsDehydrogenationFixed bed

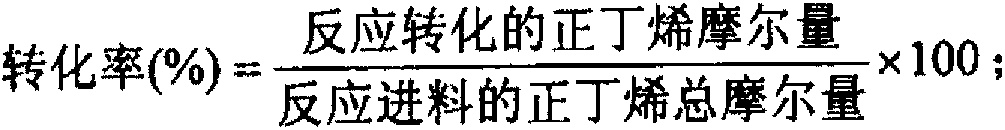

The invention relates to an iron catalyst used in butadiene production through n-butylene oxidation dehydrogenation, and a preparation method and an application thereof. The catalyst comprises Fe as a main component, and a co-catalyst comprising Mg, Zn, and other elements. The catalyst is composed of, by mass, 48.80-60.53% of Fe, 0.01-18.00% of Mg, 0-15.00% of Zn, 0-5.00% of other elements, and balance of oxygen element. The catalyst is prepared with a precipitation method. The catalyst is applied in butadiene production through n-butylene oxidation dehydrogenation by using an adiabatic fixed bed. Application conditions comprise: adiabatic fixed bed material inlet temperature is 260.0-445.0 DEG C; molar ratio of inlet oxygen to n-butylene is 0.42-0.90; molar ratio of inlet water to n-butylene is 12.0-25.0; inlet n-butylene volume space velocity is 180-600h<-1>, and an adiabatic fixed bed material outlet temperature is 457.0-650.0 DEG C. Compared with prior arts, the catalyst provided by the invention is suitable for an adiabatic fixed bed, and has the advantages such as high butadiene selectivity, good catalyst reaction stability, and the like.

Owner:WISON ENG

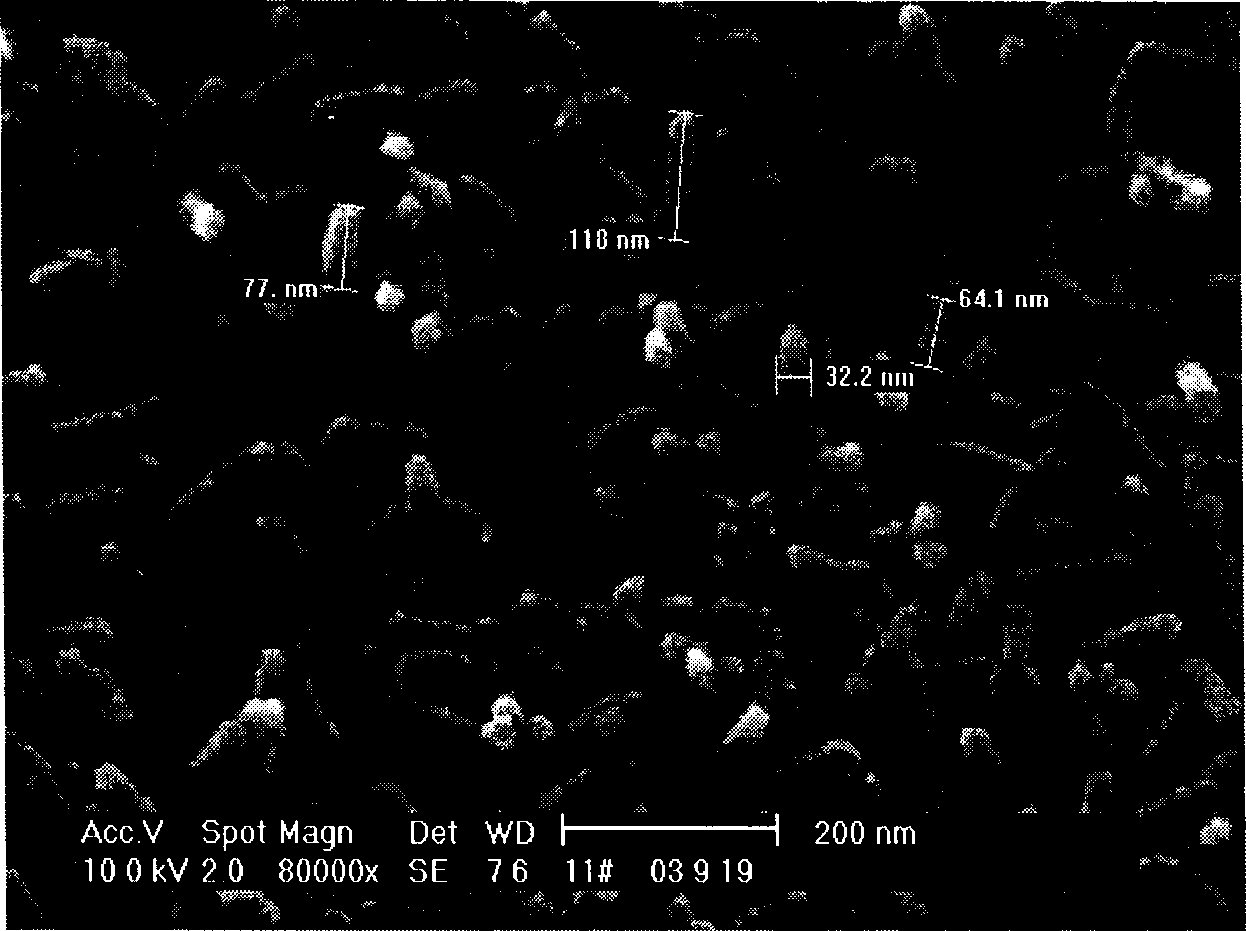

High-dispersion iron catalyst by direct coal hydrogenation liquefaction

InactiveCN1778871AHigh activityDifficult to repolymerizeLiquid hydrocarbon mixture productionActive componentCoal

A hydrogenation liquefied high-dispersion iron catalyst from coal consists of active component gamma-FeOOH with Fe content 1í½15wt%(dry base), carrier coal 50í½90wt%(dry base) and impurity water residue. The gamma-FeOOH is distributed in liquefied coal with strip shape, grain size range 60í½200nm and width 20í½100nm. It is cheap, high efficient and easy storage, has small size, high catalyst activity and various resources.

Owner:CHINA COAL RES INST

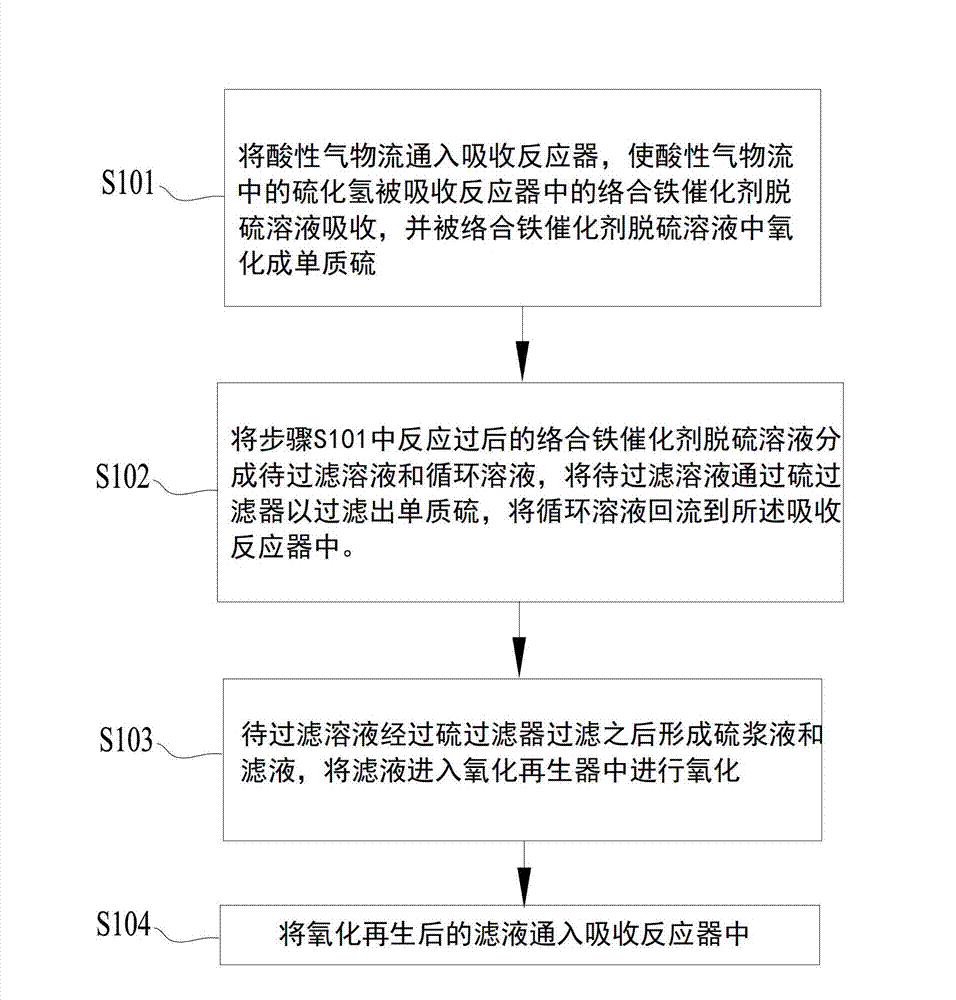

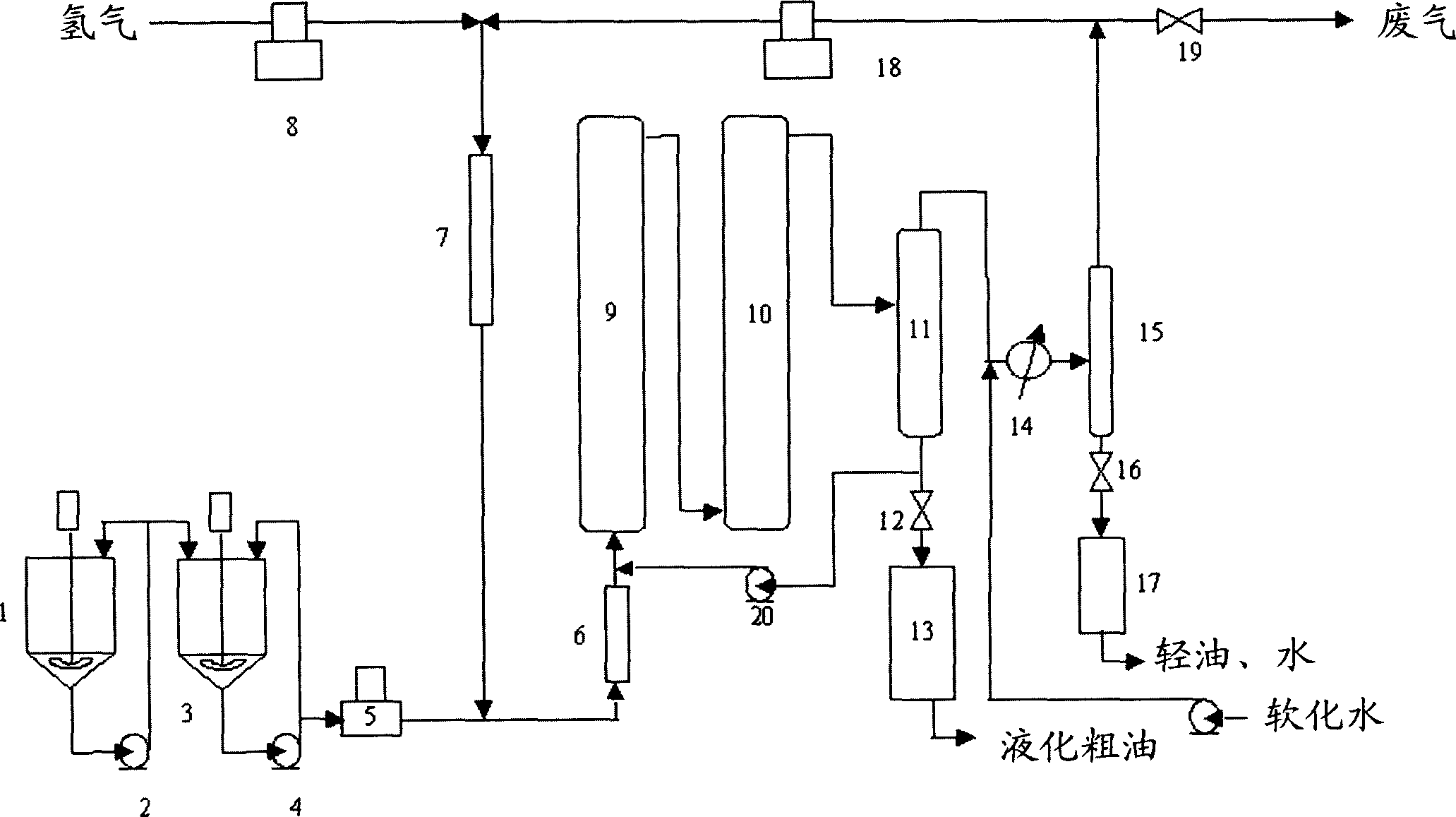

Treatment system and treatment method for removing hydrogen sulfide from acid gas

ActiveCN102895870ALow internal sulfur concentrationReduce the concentration of sulfurDispersed particle separationSulfur preparation/purificationPtru catalystPhysical chemistry

The invention relates to a treatment system and a treatment method for removing hydrogen sulfide from acid gas. The treatment system comprises an absorption reaction unit, a sulphur filtering unit, a solution regeneration unit, a temperature control unit and a medicament deliver unit, wherein the absorption reaction unit has a ferrum-catalyst desulfuration solution, is used for absorbing hydrogen sulfide contained in the acid gas introduced in the ferrum-catalyst desulfuration solution, and oxidizing the hydrogen sulfide into sulphur; the sulphur filtering unit is used for filtering the sulphur; and the solution regeneration unit is used for oxidizing and regenerating the filtered ferrum-catalyst desulfuration solution. The sulphur filtering unit is positioned between the absorption reaction unit and the solution regeneration unit. According to the system and the method, the sulphur is filtered from the solution before the step of oxidation and regeneration, so that the sulphur can not be deposited at the bottom end of an oxidization regenerator, the concentration of the sulphur in the system is low, so that the system can operate stably for a long time, and has good operational flexibility under various work conditions; the structure of equipment can be simplified; the investment is saved; and the construction period is also saved.

Owner:美景(北京)环保科技有限公司

Method of directly liquifying coal

ActiveCN1869159AHigh yieldAvoid secondary decompositionLiquid hydrocarbon mixture productionCoal dustPre treatment

The invention relates to a coal direct liquefaction method. It includes the following steps: mixing coal slurry which is made up of coal dust, hydrogenation cycle solvent, and iron catalyst with freshness or cycle hydrogen; reacting by the first and second reactor; sending the product from the second reactor to high temperature separator to separate; the weight flow ratio of the recycle and freshness materials is 2-20. The method can reduce hydrogen consumption and gas yield.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

Method for producing iron concentrate by brown hematite and siderite and reduction roaster

The present invention discloses a method for adopting the limonite and the siderite to produce iron powder and a reduction roaster. The material adopts the limonite and the siderite or the specularite, the hematite, and the sulphuric acid slag, the inclined rotary reduction roaster is used, the pressure of the furnace chamber is 250 to 350 Pa, under the deoxidizing atmosphere, the inert solid is rotated and moved to 650 to 900 DEG C from the low temperature, and is cooled and magnetized, and lastly become the iron powder through the dressing by magnetic separation. The present invention is adopted to produce the iron powder, the resources is rich and the production cost is low, and through the utilization of the powder metallurgy art, the iron content of the iron powder is controlled and the activation energy of the iron powder is reduced, and the chemical reaction ability is increased, thereby the output of iron powder is high, the quality is good, the iron powder is loose and porous, the specific surface is big, the apparent density is large, the manufacture cost of pellets sinter and steel smelting can be reduced greatly, and the iron powder can use directly to produce iron oxide red as well as H and N synthetic iron catalyst, or produce ultrapure iron powder.

Owner:郭元杰

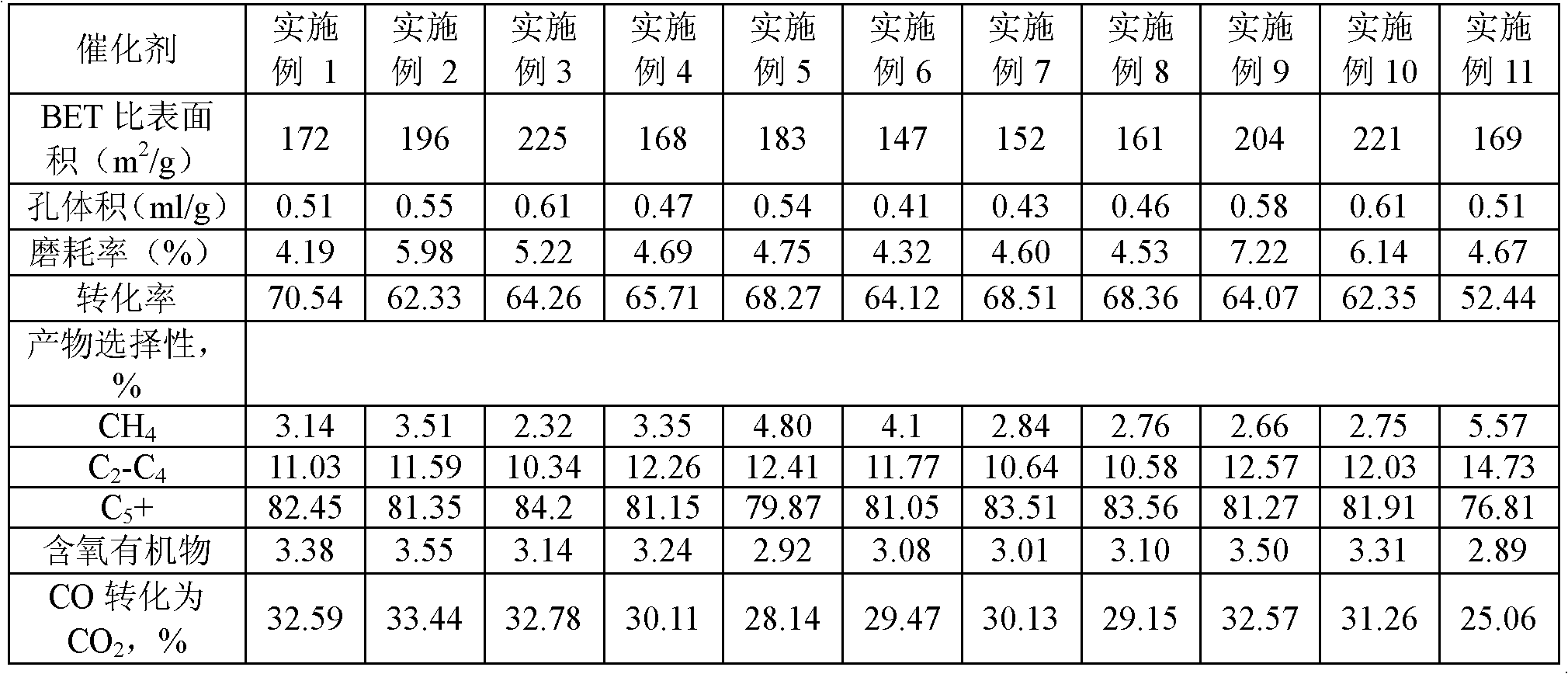

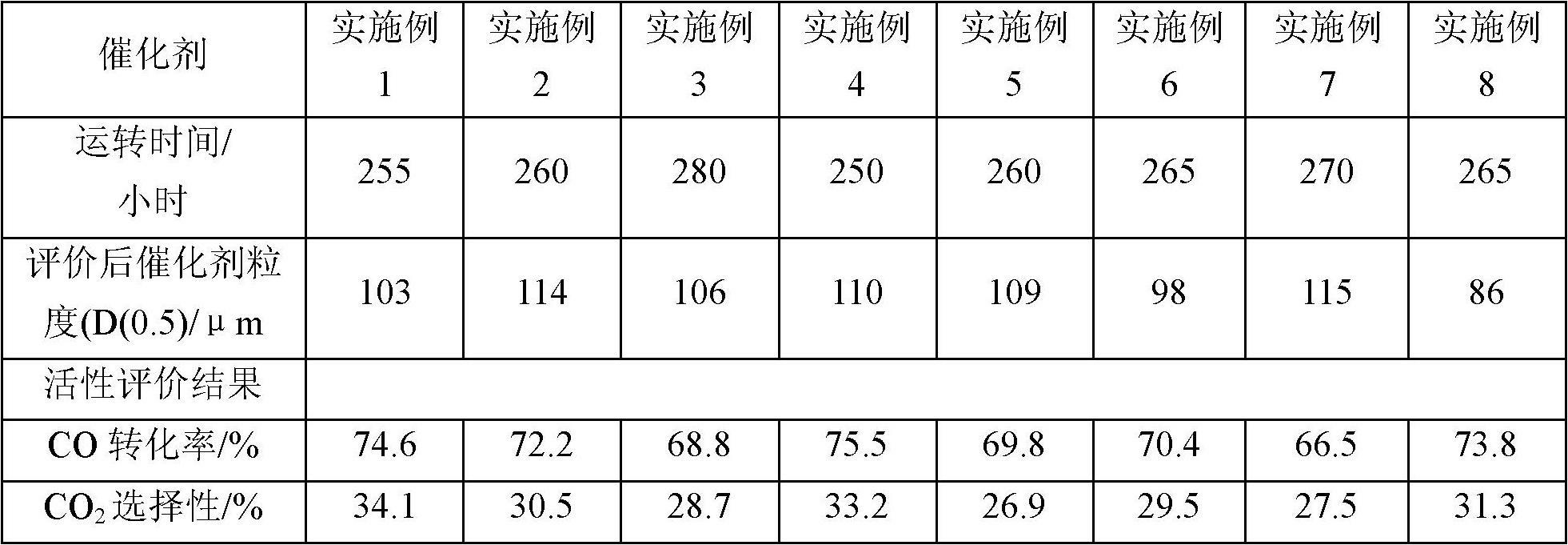

Fused iron catalyst for producing light olefins from syngas and preparation method and application thereof

ActiveCN101757925APreparation raw materials are cheapRaw materials are readily availableHydrocarbon from carbon oxidesMetal/metal-oxides/metal-hydroxide catalystsSyngasFluidized bed

The invention provides fused iron catalyst for producing light olefins from syngas and a preparation method and application thereof. The fused iron catalyst includes iron oxide and cocatalyst and the proportion of the components is as follows by weight percent: 0.1-5 alumina, 0.1-6 potassium oxide, 0.1-4.0 calcium oxide and 0.01-8.5 other oxides, and balance iron oxide. The fused iron catalyst has the beneficial effects that (1) the materials of the fused iron catalyst are cheap and easy to get, the preparation process is simple, and the fused iron catalyst is low in cost and is suitable for industrial production; (2) the fused iron catalyst is of high mechanical strength as well as good pressure resistance and abrasion resistance and is suitable for a fixed bed, a fluidized bed and a slurry bed reactor; and (3) the fused iron catalyst has high Fischer-Tropsch synthesis activity and selectivity, the conversion per pass can be more than 95%, the selectivity of the methane is less than 10% and the content of the light olefins can reach 80-90%.

Owner:ZHEJIANG UNIV OF TECH

Precipitated iron catalyst for Fischer-Tropsch synthesis reaction, and preparation method and application thereof

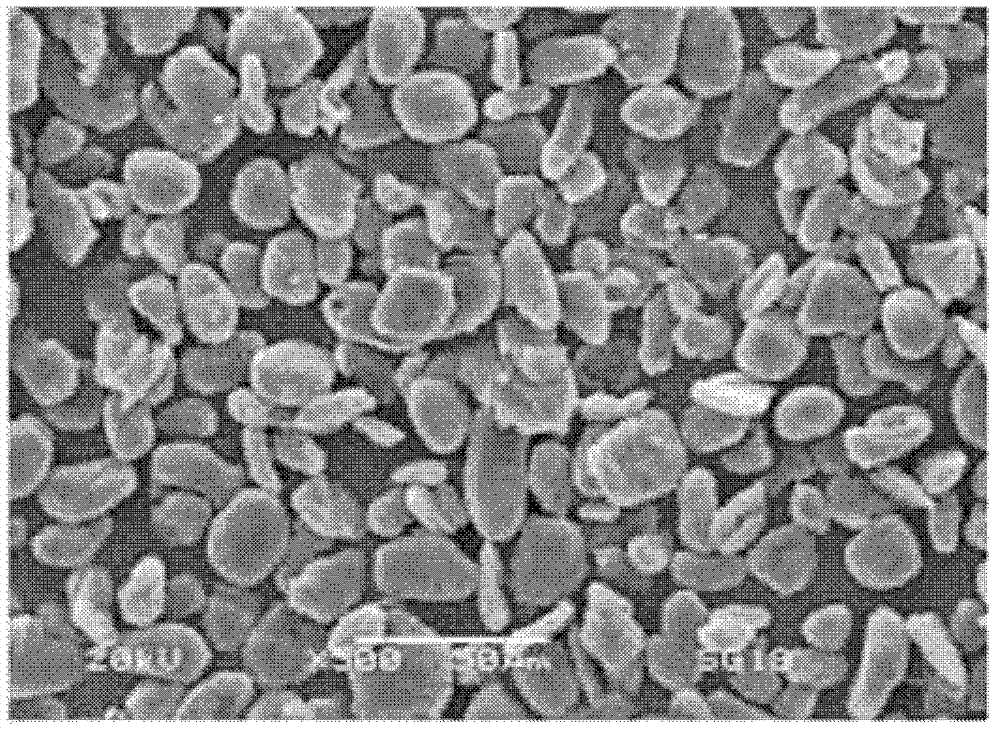

ActiveCN101884926AHigh specific surface areaIncrease the areaCatalyst activation/preparationLiquid hydrocarbon mixture productionPrecipitationIon

The invention relates to a precipitated iron catalyst for Fischer-Tropsch synthesis reaction, and a preparation method and application thereof. The preparation method comprises the following steps of: (a) feeding ferric salt solution, aid saline solution, the solution of precipitator and a small amount of solution of silicon compounds in a form of concurrent flow into a precipitation reactor; (b)performing coprecipitation reaction on the mixture under certain process conditions in the reactor, and fast cooling, filtering and rinsing pulp obtained after the precipitation reaction is finished;(c) adding a silicon compound binder into a filter cake obtained after the rinsing, adding a nitric acid into the filter cake to adjust pH and performing secondary filtration; (d) performing secondary pulping on the obtained filter cake with de-ionized water or the mixed solution of the de-ionized water and the required aid saline solution; and (e) performing spray-drying molding and baking on the obtained catalyst pulp. The catalyst prepared by the method of the invention has high specific surface area, proper pore volume, high wear strength, high sphericity and smooth surface.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

Method for activating strengthened iron catalyst for slurry reactors

InactiveUS20090111684A1Various problemOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsSlurry reactorIron catalyst

A method of activating an iron Fischer-Tropsch catalyst by introducing an inert gas into a reactor comprising a slurry of the catalyst at a first temperature, increasing the reactor temperature from the first temperature to a second temperature at a first ramp rate, wherein the second temperature is in the range of from about 150° C. to 250° C., introducing synthesis gas having a ratio of H2:CO to the reactor at a space velocity, and increasing the reactor temperature from the second temperature to a third temperature at a second ramp rate, wherein the third temperature is in the range of from about 270° C. to 300° C. The iron Fischer-Tropsch catalyst may be a precipitated unsupported iron catalyst, production of which is also provided.

Owner:RES USA LLC

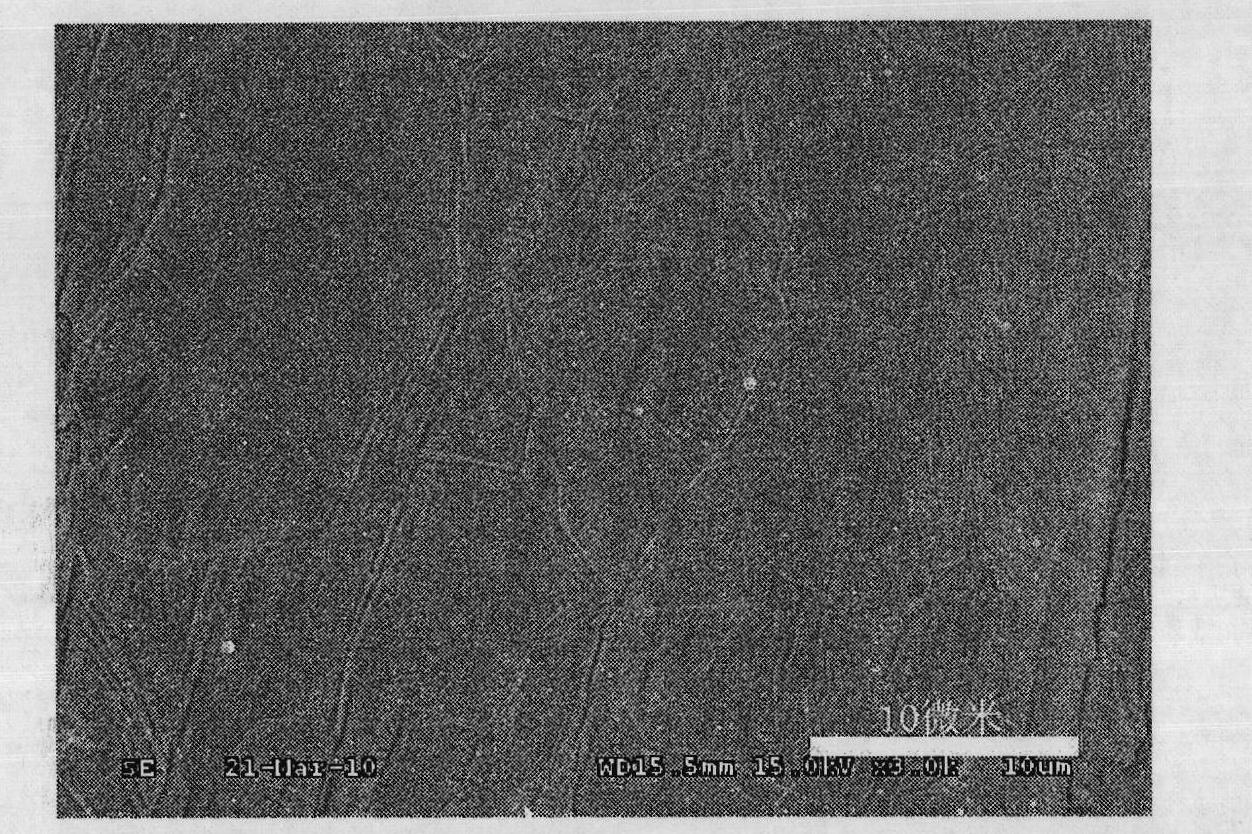

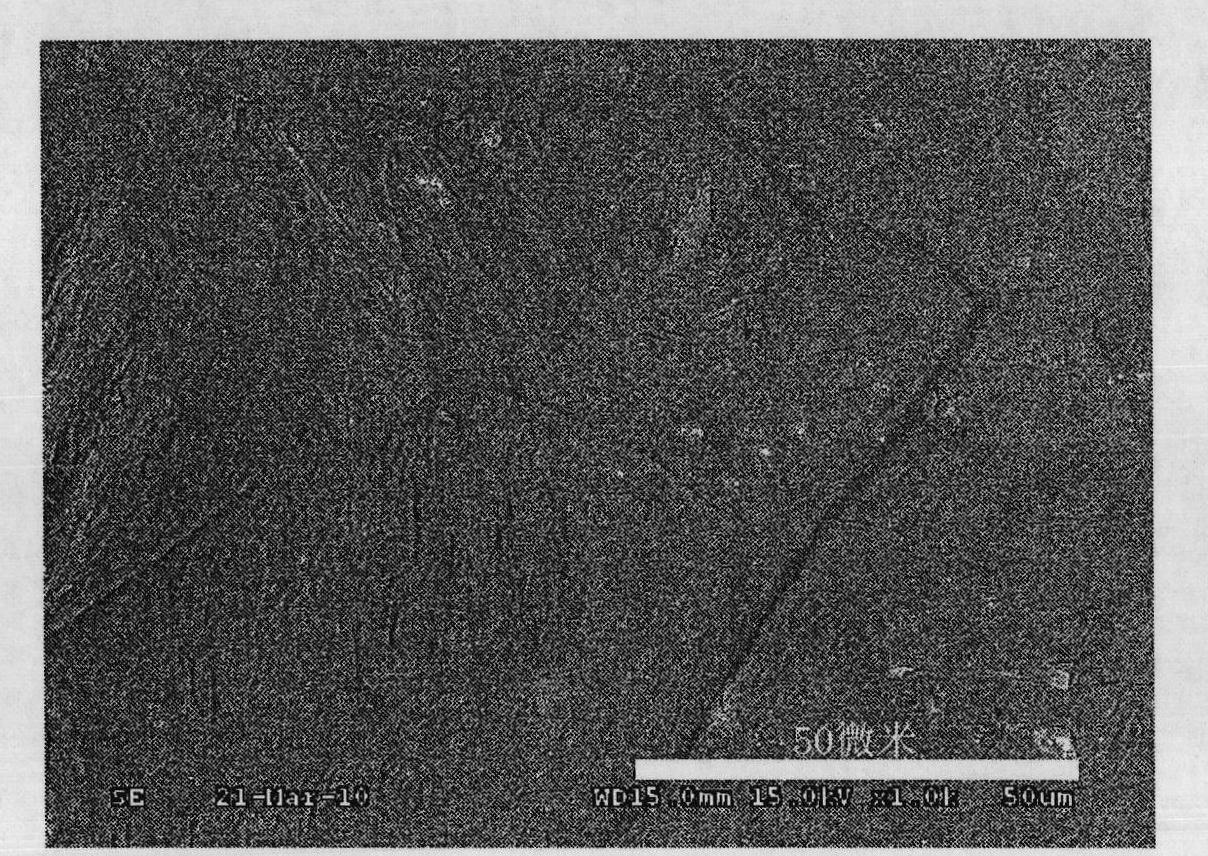

Method for preparing large-area high quality graphene on iron-based substrate

The invention discloses a method for preparing graphene. In the method, chemical vapour deposition is adopted. The method comprises the following two ways according to different carbon sources adopted in the preparation process: 1) iron catalyst is placed into an oxygen-free reactor, the temperature of the catalyst is increased to 750-1000 DEG C, then a gas carbon source is introduced into the reactor, and reaction is carried out, thus obtaining graphene; and 2) a solid carbon source is coated onto the surface of the iron catalyst or is placed on the iron catalyst and then is placed into the oxygen-free reactor, and reaction is carried out at the temperature of 750-1000 DEG C, thus obtaining graphene, wherein the iron catalyst can be a simple substance iron, iron alloy or iron compound. The method for preparing large-area high quality graphene on iron by utilizing chemical vapour deposition is easy to operate, is easy and feasible, and can be used for mass production; and the graphene prepared by the method has less defects compared with the graphene prepared by graphite oxidation.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Attrition resistant bulk iron catalysts and processes for preparing and using same

InactiveUS7259286B2Improve wear performanceReduce wear lossLiquid hydrocarbon mixture productionAdditivesFluidized bedHydrogenation process

An attrition resistant precipitated bulk iron catalyst is prepared from iron oxide precursor and a binder by spray drying. The catalysts are preferably used in carbon monoxide hydrogenation processes such as Fischer-Tropsch synthesis. These catalysts are suitable for use in fluidized-bed reactors, transport reactors and, especially, slurry bubble column reactors.

Owner:RES TRIANGLE INST +1

Method and application for synthesizing cheap nickel-iron nanosheet array high-efficiency electrocatalyst at normal temperature and normal pressure

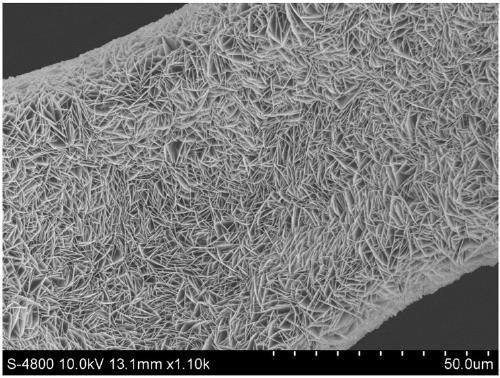

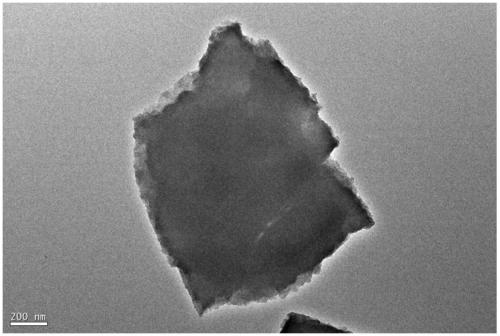

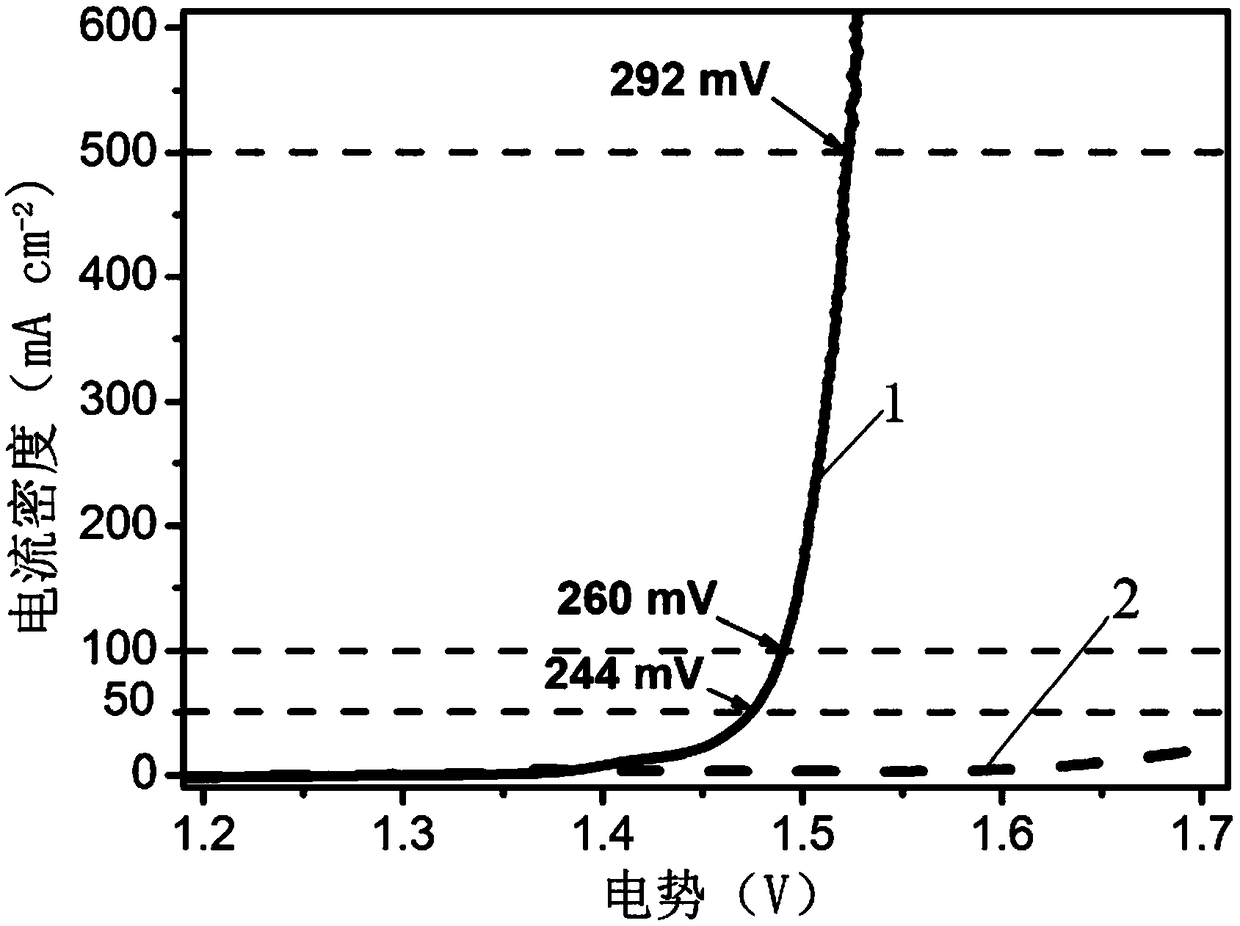

The invention discloses a method and application for synthesizing a cheap nickel-iron nanosheet array high-efficiency electrocatalyst at normal temperature and normal pressure, and relates to a methodand application for synthesizing the high-efficiency electrocatalyst. The method and application aim to solve the problems that an existing commercial oxygen evolution reaction catalyst is noble metal, high in price and poor in stability, the large-scale application is limited, the synthesis condition of an existing nickel-iron catalyst is rigorous, the process is complex, the cost is high, and the large-scale production and application of the nickel-iron catalyst are seriously restricted. The method comprises the following steps that 1, pretreatment is carried out on foamed nickel; 2, an iron solution is prepared; and 3, soaking is carried out so as to obtain the nickel-iron nanosheet array high-efficiency electrocatalyst. According to the method, the large-scale production can be achieved, the method can be used for producing the nickel-iron nanosheet array high-efficiency electrocatalysts with different specifications, is suitable for commercial application, and is more suitable for the requirements of industrial production. According to the method, the nickel-iron nanosheet array high-efficiency electrocatalyst can be obtained.

Owner:NORTHWEST A & F UNIV

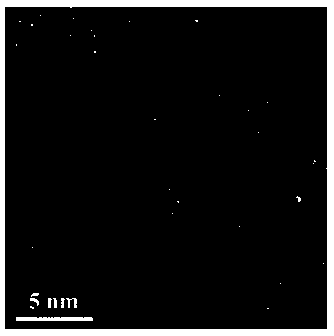

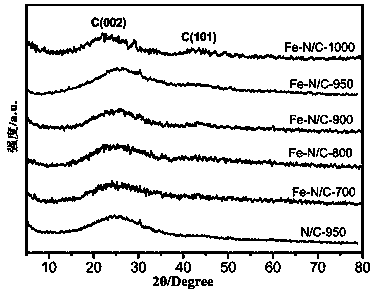

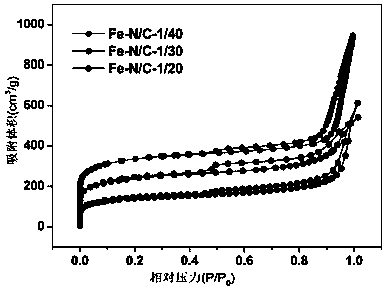

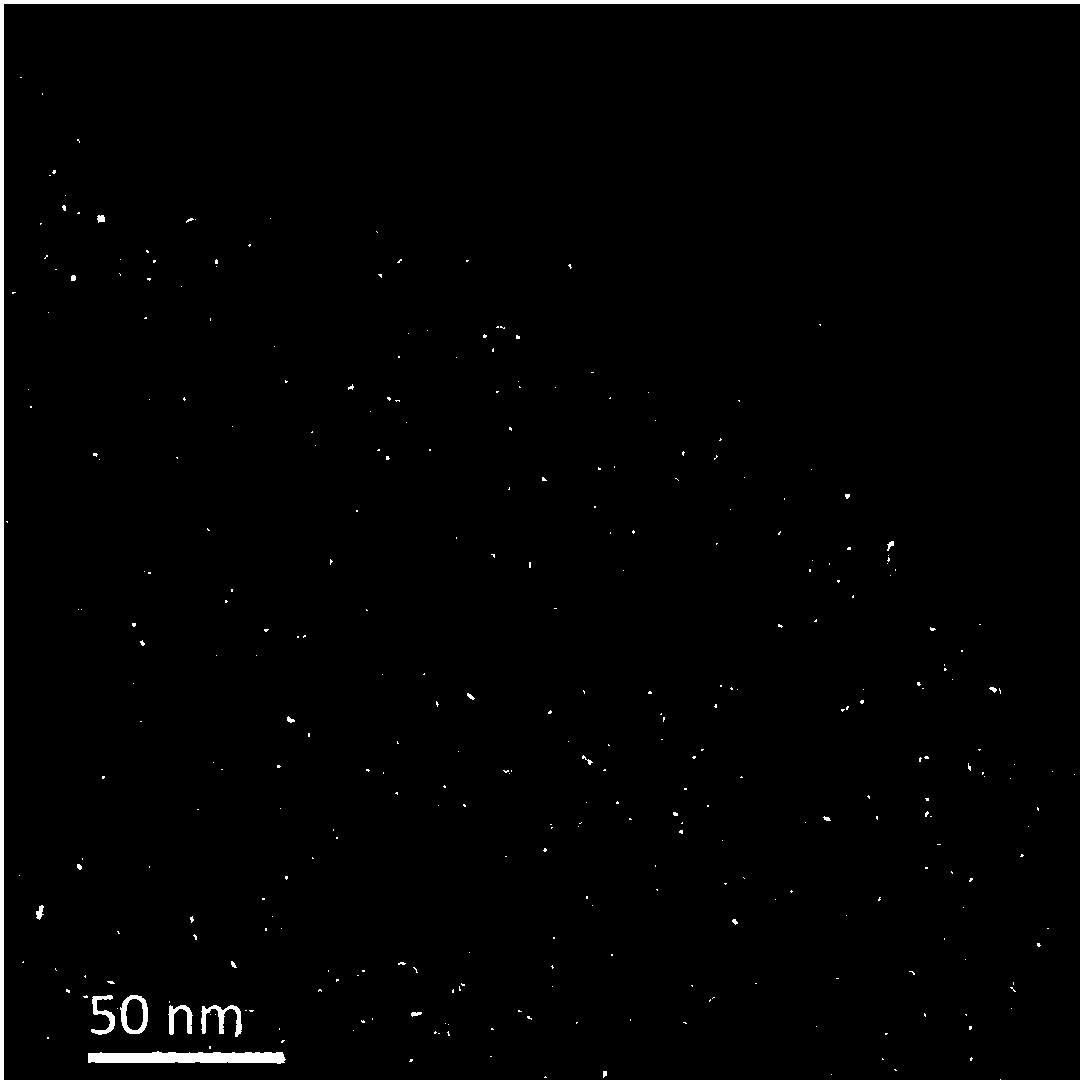

Ball-milling assisted method for preparing carbon nitrogen based monatomic iron catalyst

The invention provides a ball-milling assisted method for preparing a carbon nitrogen based monatomic iron catalyst. The method comprises the following steps: adopting a one-pot process for wrapping ferriporphyrin in a metallic organic frame hole in a monomolecular form through mechanical ball milling, thereby forming a subject-object structure; forming a nitrogen-doped porous carbon carrier by ametallic organic frame object and keeping an original porous structure, through the high-temperature pyrolytic reaction under the inert gas atmosphere; and forming a monatomic Fe-Nx structure by the ferriporphyrin molecules and fixing in the hole structure. The invention adopts a mechanical ball-milling assisted method for compounding a nanometer compound precursor; only an infinitesimal organic solvent participates in the process; the method is simple and convenient, safe, green and environment-friendly, and suitable for large-scale production; the acquired carbon nitrogen based monatomic iron catalyst has ultrahigh electrocatalytic activity and stability for the oxygen reduction reaction under an alkaline condition, and has a bright market prospect.

Owner:CAPITAL NORMAL UNIVERSITY

Preparation method of Fischer-Tropsch synthesis precipitated iron catalyst

ActiveCN102658143AFlexible control of specific surface areaFlexible control of pore volumeLiquid hydrocarbon mixture productionMetal/metal-oxides/metal-hydroxide catalystsSlurryCoprecipitation

The invention discloses a preparation method of a Fischer-Tropsch synthesis precipitated iron catalyst. The method comprises the following steps: preparing a precipitation slurry through a coprecipitation reaction; 2, filtering, washing and slurrying the precipitation slurry to obtain a catalyst precursor slurry; 3, carrying out a concurrent flow reaction on a silicon compound solution and a nitric acid solution to preparing a silicon sol; 4, mixing the catalyst precursor slurry with the silicon sol, and filtering to prepare a filter cake; 5, slurrying the filter cake to obtain a catalyst slurry; and 6, carrying out spray drying shaping and roasting on the catalyst slurry to obtain the Fischer-Tropsch synthesis precipitated iron catalyst. The preparation method of the Fischer-Tropsch synthesis precipitated iron catalyst of the invention has the advantages of flexible control of the specific surface area and the pore volume of the catalyst in a wide range according to experiment requirements, good control of the physical abrasion of the catalyst in a low level according to different preparation conditions, and simultaneous guarantee of the chemical stability of the catalyst.

Owner:CHNA ENERGY INVESTMENT CORP LTD +2

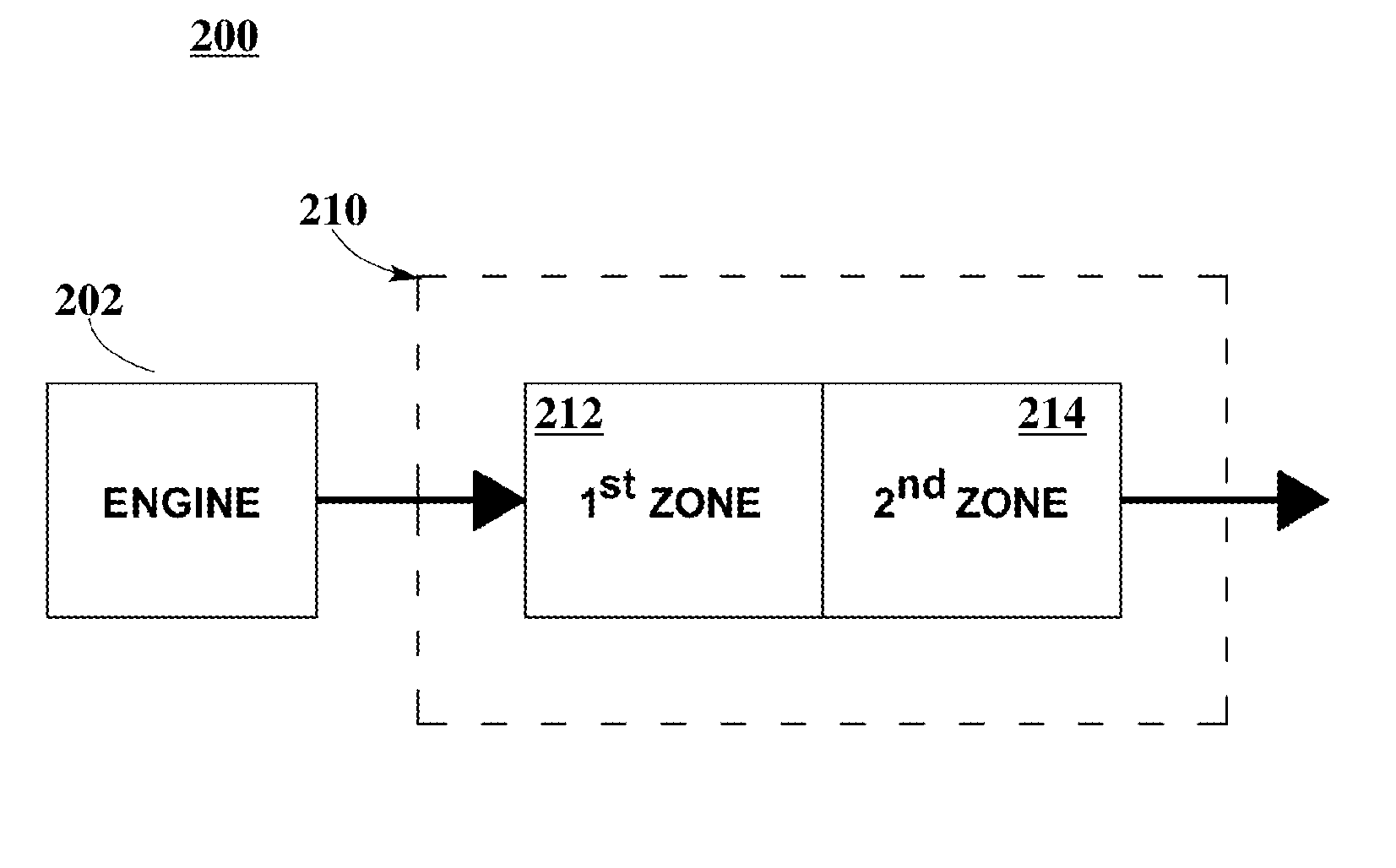

Three-way Catalyst Systems Including Nb-Zr-Al-Mixed Oxide Supports, Ba-Pd, and Rh-Fe Material Compositions

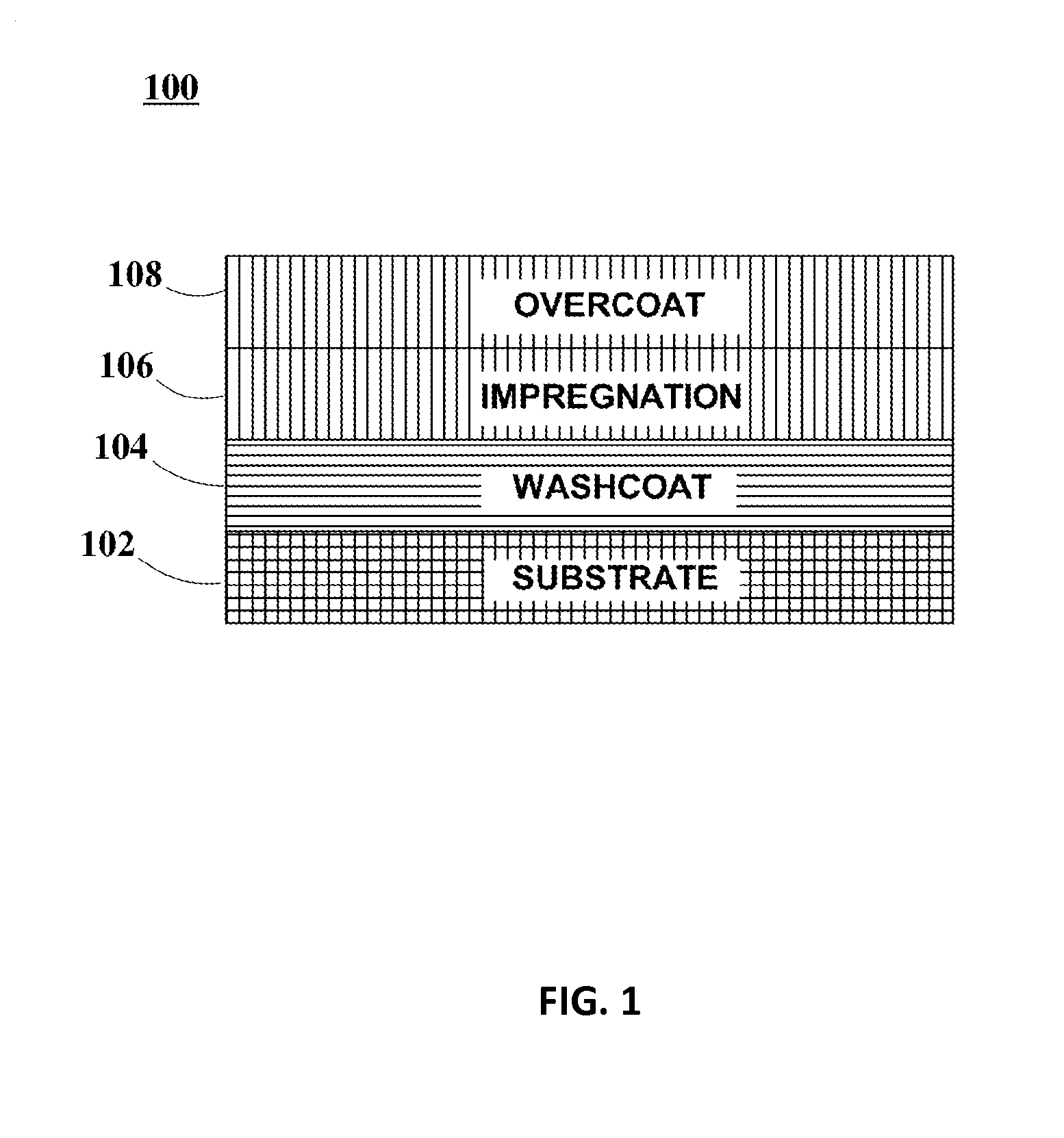

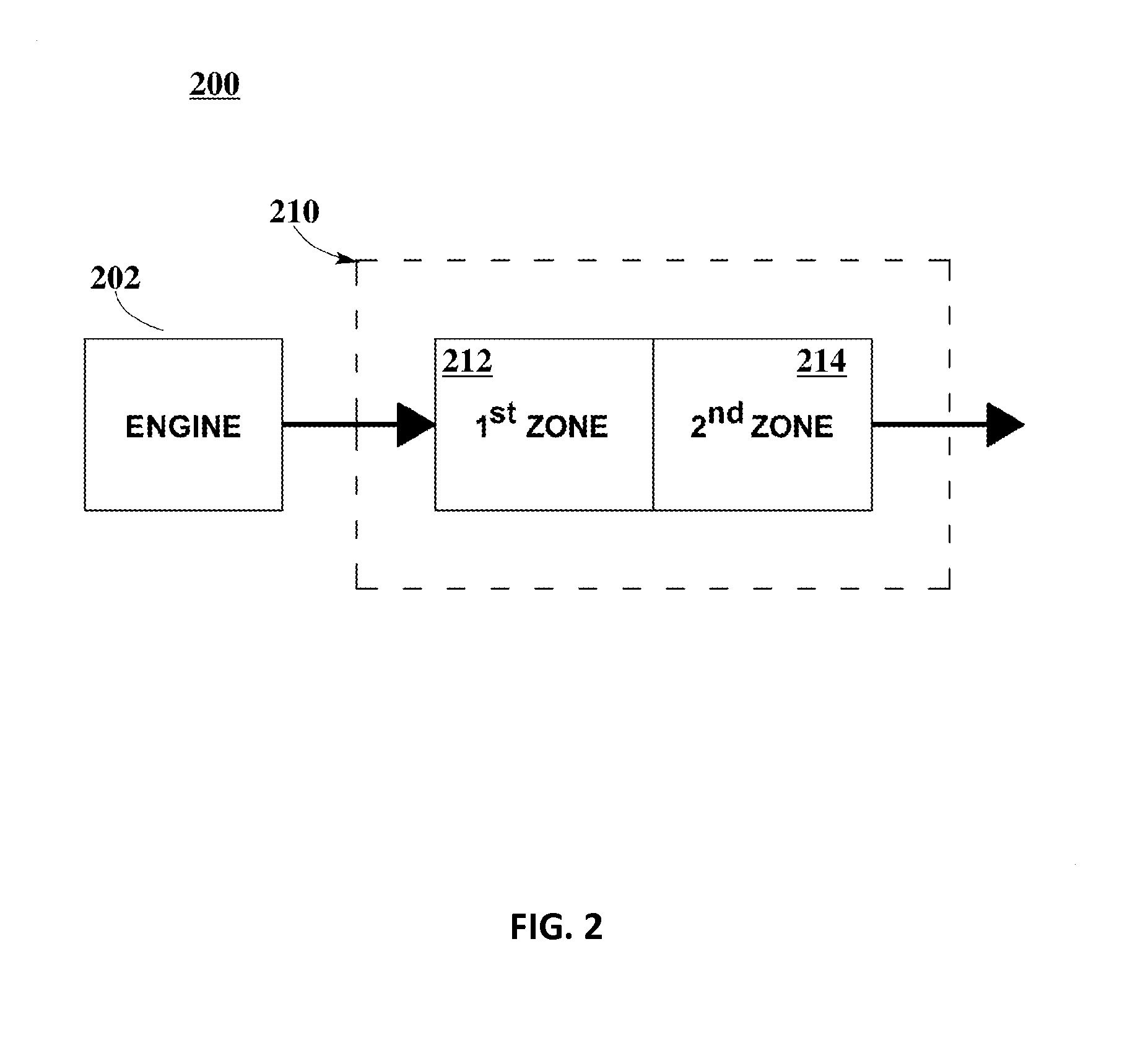

The present disclosure describes zoned three way catalyst (TWC) systems including Rhodium-iron overcoat layers and Nb—Zr—Al Oxide overcoat layers. Disclosed herein are TWC sample systems that are configured to include a substrate and one or more of a washcoat layer, an impregnation layer, and / or an overcoat layer. In catalyst systems disclosed herein, closed-coupled catalysts include a first catalyst zone with an overcoat layer formed using a slurry that includes an oxide mixture and an Oxygen Storage Material (OSM). In catalyst systems disclosed herein, oxide mixtures include niobium oxide (Nb2O5), zirconia, and alumina. Further, catalyst systems disclosed herein include a second catalyst zone with an overcoat layer formed to include a rhodium-iron catalyst. Yet further, catalyst systems disclosed herein include impregnation layers that include one or more of Palladium, Barium, Cerium, Neodymium, and Rhodium.

Owner:CLEAN DIESEL TECHNOLOGIES

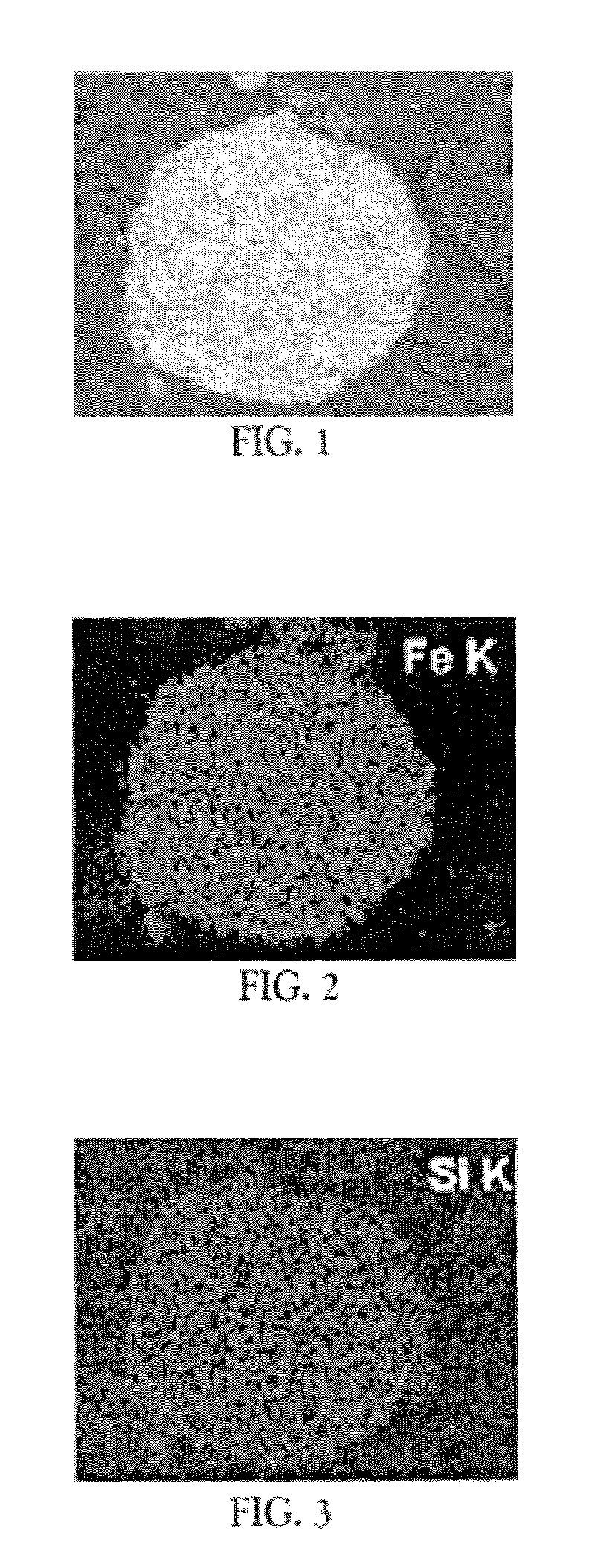

Method for manufacturing indium-tin-iron catalyst for use in production of carbon nanocoils

A method for manufacturing an indium-tin-iron type catalyst that is used to obtain carbon nanocoils that have an external diameter of 1000 nm or less, the method comprising a first process that forms an organic solution by mixing an indium-containing organic compound and a tin-containing organic compound with an organic solvent, a second process that forms an organic film by coating a substrate with the thus obtained organic solution, a third process that forms an indium-tin film by baking this organic film, and a fourth process that forms an iron film on the surface of this indium-tin film.

Owner:NAKAYAMA YOSHIKAZU +1

Iron catalyst containing titanium deposition for catalyzing Fischer-Tropsch synthesis reaction and method for producing the same

ActiveCN101298046ALarge specific surface areaGood choiceHydrocarbon from carbon oxidesMetal/metal-oxides/metal-hydroxide catalystsNitrateCopper nitrate

The invention relates to an iron catalyst which contains an assistant and used for catalyzing the Fischer-Tropsch reaction, which is characterized by comprising the components with mass ratios of Fe: Cu; K: Ti: SiO2 equal to 100: (0.1-10): (0.1-10): (0.01-5): (5-30), wherein, Fe, Cu, K and Ti exist in the form of oxides. The invention also relates to a preparation method for the catalyst, which comprises the steps that: at the presence of a precipitator with a pH value of 6-9, ferric nitrate, copper nitrate and a titanium compound are deposited in water; a deposit is separated and mixed with potassium carbonate and silica sol after being washed; a mixture obtained is dried and calcined. The iron catalyst with the assistant of titanium structure has relatively large specific surface area, CO conversion activation and antiwelding and antisulphour properties.

Owner:CHNA ENERGY INVESTMENT CORP LTD +2

High-safety lithium ion battery cathode material and its preparation method

ActiveCN102820471AImprove securityEffective isolationCell electrodesSimple Organic CompoundsHigh rate

The invention belongs to the technical field of lithium ion batteries, and concretely discloses a high-safety lithium ion battery cathode material and its preparation method. The preparation method of the high-safety lithium ion battery cathode material comprises the following steps: reacting an Al(OH)3 sol with NaOH and LiOH at 40-90DEG C to prepare LiAlO2, mixing graphite with the LiAlO2, adjusting the pH value, heating to 500-800DEG C to remove organic compounds and water, and grinding to obtain graphite / LiAlO2 composite powder; and putting the graphite / LiAlO2 composite powder under an iron catalyst in a quartz tube to prepare an LiAlO2 / carbon nanotube composite material, and ball-milling to obtain the high-safety lithium ion battery cathode material. The high-safety lithium ion battery cathode material provided by the invention has an excellent safety performance, and is especially suitable for large capacity and high rate lithium ion batteries.

Owner:中创新航科技(江苏)有限公司

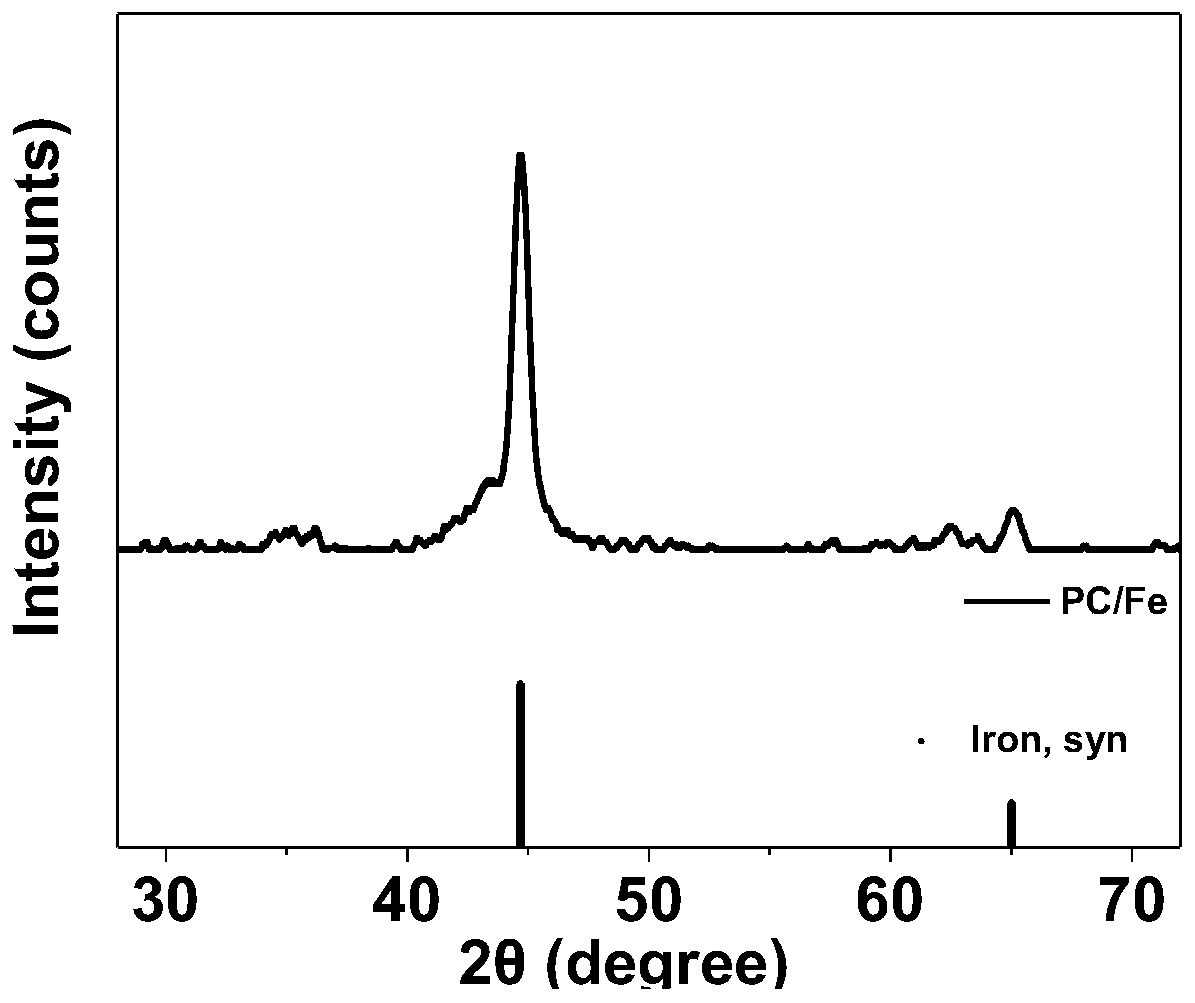

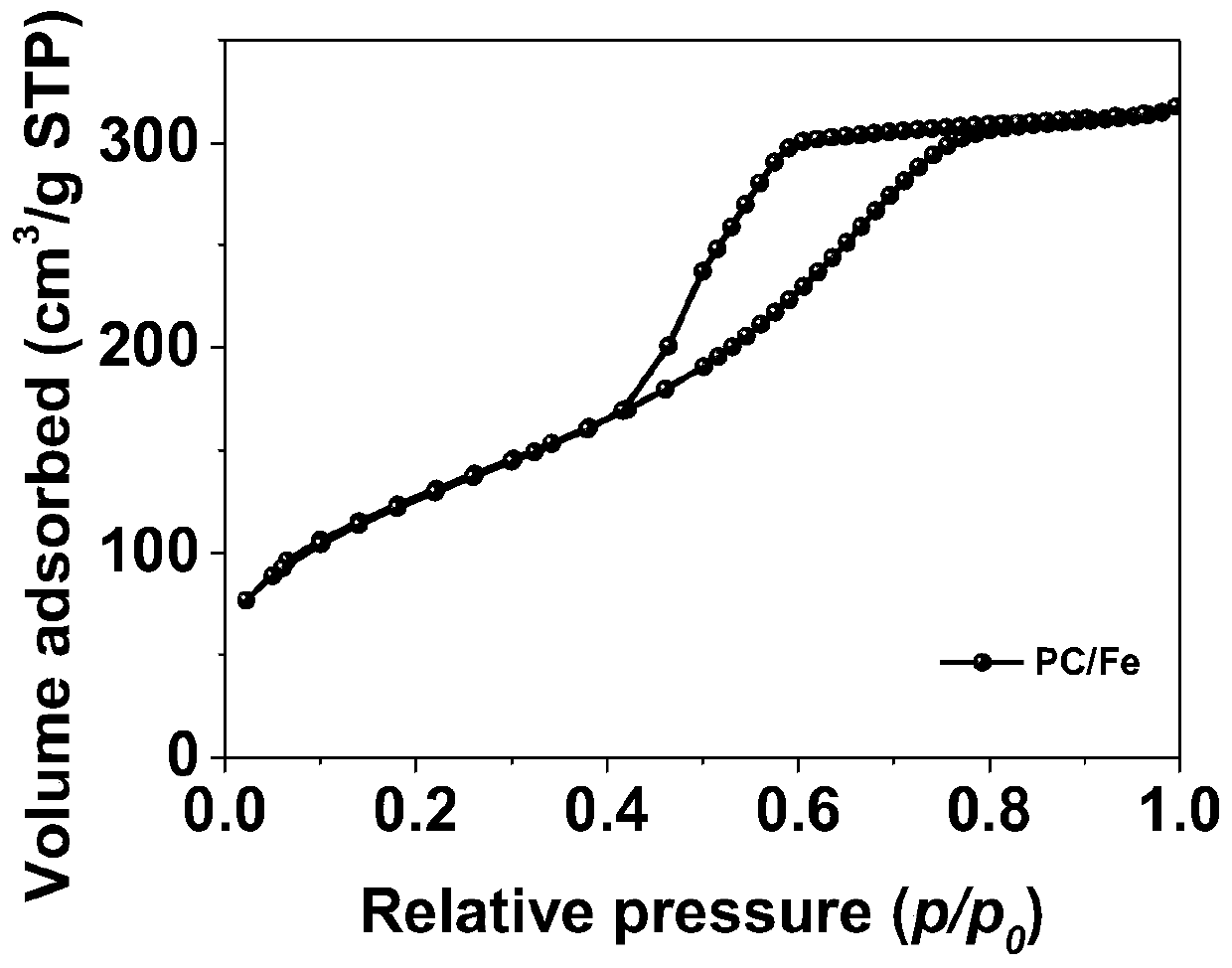

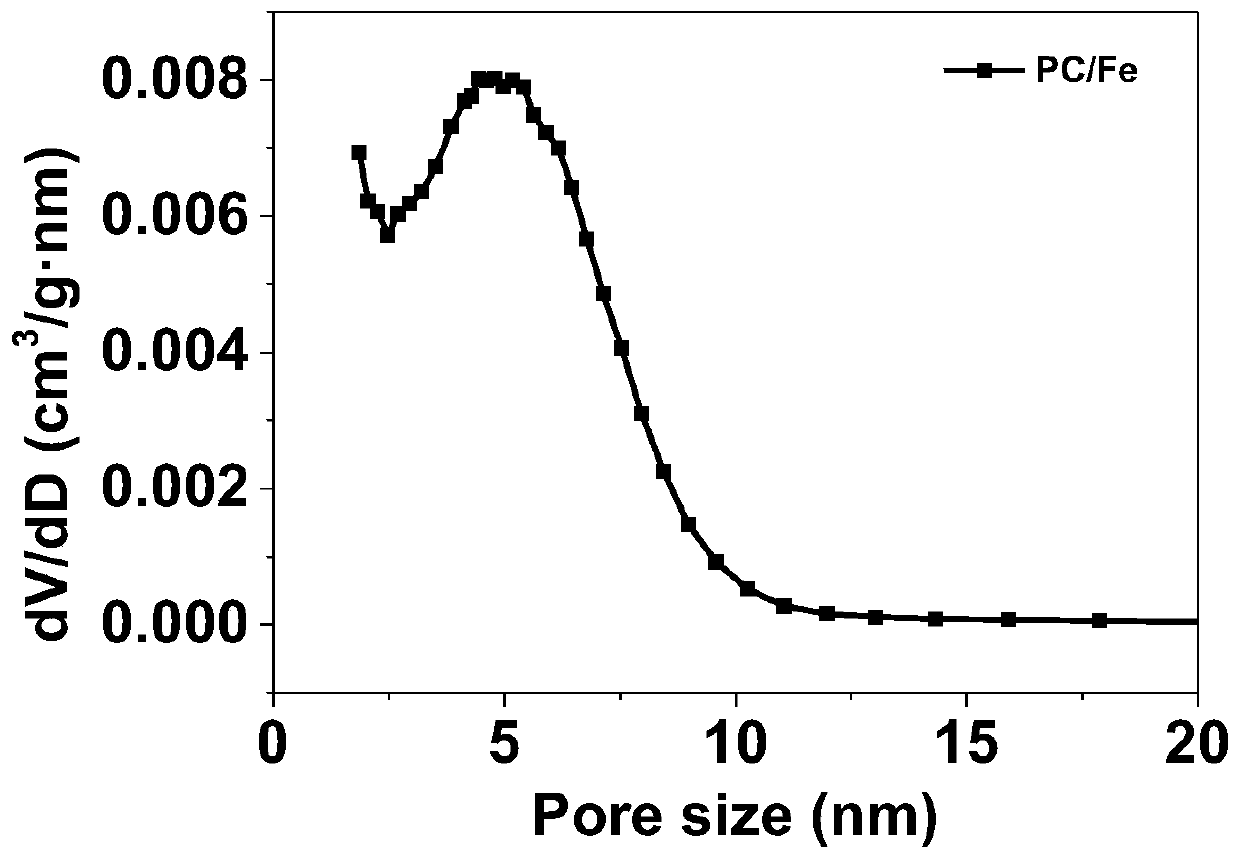

High-adsorption porous carbon supported zero-valent iron catalyst as well as preparation method and application thereof

ActiveCN109999753ALarge specific surface areaStable physical and chemical propertiesOther chemical processesWater treatment compoundsIron saltsPorous carbon

The invention discloses a high-adsorption porous carbon supported zero-valent iron catalyst as well as a preparation method and an application thereof and provides a new catalyst for an adsorbing andactivating oxidizing agent to decompose organic pollutants in soil and water. With high polymer and biomass as carbon sources, a compound catalyst with zero-valent iron supported in a porous carbon framework in a high-dispersion manner is prepared with a carbon thermal reduction one-step method. According to the prepared porous carbon supported zero-valent iron catalyst, nano zero-valent iron particles are uniformly distributed in the porous carbon framework, and the catalyst has a high specific surface area (500-1,000 m<2> / g) and large pore volume (0.3-0.7 cm<3> / g) and is magnetic. The preparation method of the catalyst can be used for batch production. The prepared catalyst can rapidly and massively adsorb organic pollutants, activate persulfate, hydrogen peroxide and other strong oxidizers, has the reaction activity higher than that of bivalent iron salt and imported commercial zero-valent iron and has broad application prospects in decomposing persistent organic pollutants in waterand soil.

Owner:SHANGHAI JIAO TONG UNIV

Carrier, inferior oil hydrogenation catalyst based on same and preparing method thereof

ActiveCN104998693AImprove conversion rateEasy accessCatalyst carriersMetal/metal-oxides/metal-hydroxide catalystsAir atmosphereSilicon oxide

The invention relates to an inferior oil hydrogenation catalyst carrier. According to a preparing method, modified natural bauxite is adopted, namely natural bauxite is roasted at high temperature in the air atmosphere and immersed in acid liquor for acid treatment to obtain the modified natural bauxite, by means of the treatment, aluminum oxide, silicon oxide and ferric oxide contained in the natural bauxite are purified, the crystallization degree is improved to form the catalyst carrier which contains aluminum, silicon and ferric and has certain cracking and hydrogenation performance, the acid activity centers of the treated natural bauxite are distributed again, and the specific area and the pore capacity are substantially increased. According to the bauxite modified and treated through the method, pore channel and pore diameter distribution in the structure are optimized, after the bauxite serves as the inferior oil hydrogenation catalyst carrier, the hydrogenation conversion performance of macromolecules such as asphaltene and colloid in inferior oil can be improved easily, and then the light distillate yield can be increased easily while the hydrogenation activity of the catalyst is improved.

Owner:FUZHOU UNIV

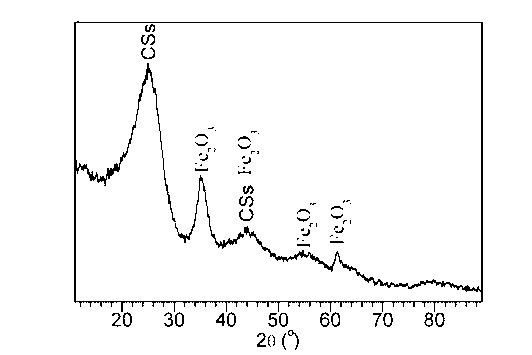

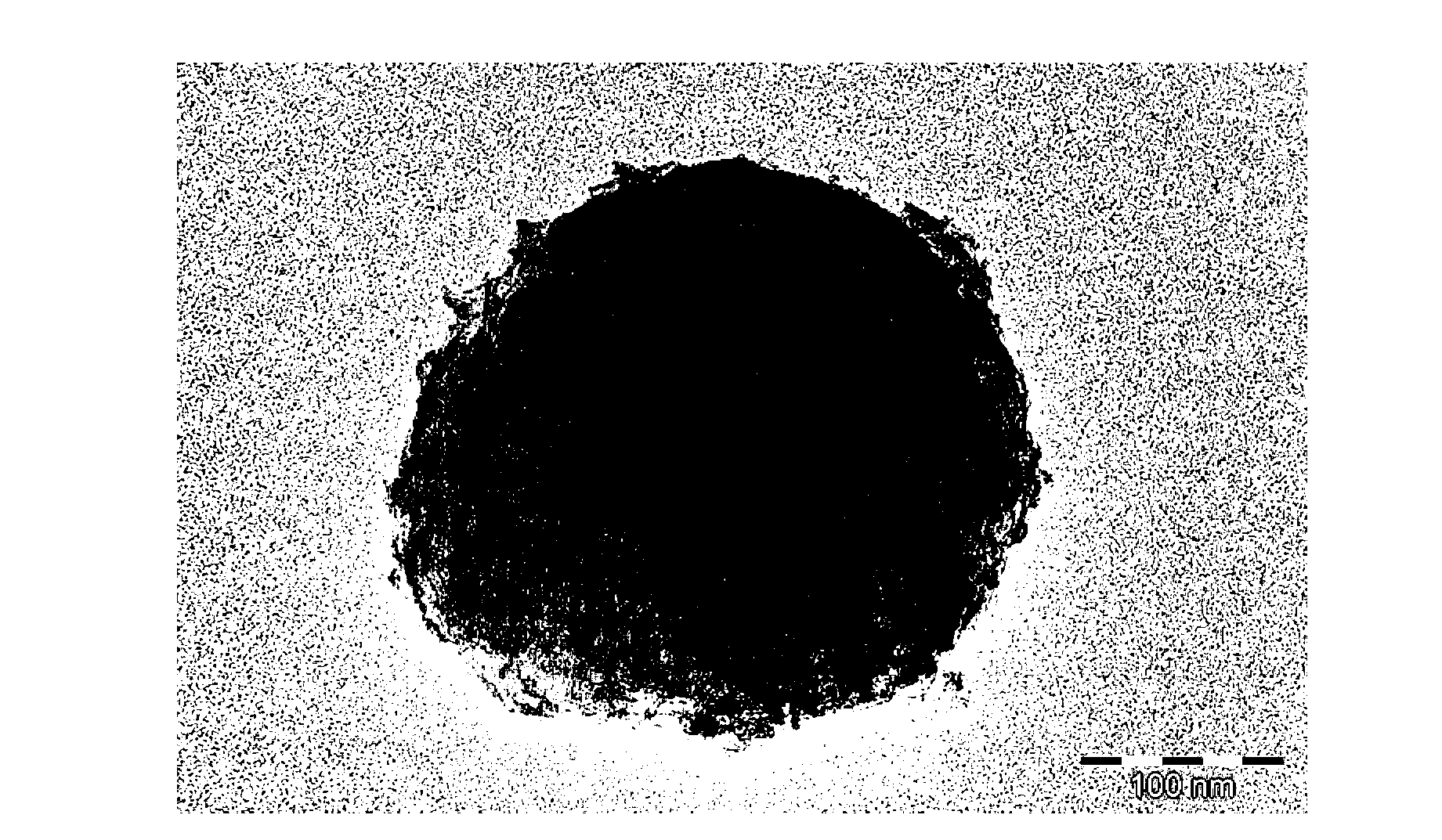

Nanometer iron oxide/carbon sphere compound catalyst and preparation method and application thereof

ActiveCN102698754ASolve serious problems such as reunionGood catalyticCatalytic crackingCatalyst activation/preparationFenton reactionCombustion

The invention discloses a nanometer iron oxide / carbon sphere compound catalyst and a preparation method and an application thereof, which belong to the technical field of catalysts. Iron oxide nano particles are uniformly loaded on the surfaces of carbon spheres. The preparation method comprises the following steps of modifying the surfaces of the carbon spheres by performing a Fenton reaction, i.e., under the strong oxidizing property in the coexistence of hydrogen peroxide and ferrous ions; and uniformly loading iron oxide on the surfaces of the carbon spheres to obtain the nanometer iron oxide / carbon sphere compound catalyst. Due to the adoption of the method, the problems of severe aggregation and the like of a nanometer iron oxide catalyst and the like are solved, and the obtained nanometer iron oxide / carbon sphere compound catalyst is taken as an efficient combustion catalyst for solid propellants, a catalyst for photo-degradation organic matters, and a catalyst for petroleum cracking.

Owner:BEIJING UNIV OF CHEM TECH

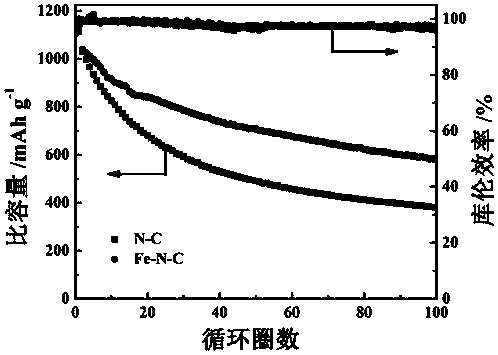

Lithium sulfur battery anode material and lithium sulfur battery utilizing same

InactiveCN107768638AInhibit shuttleImprove performanceCell electrodesLi-accumulatorsArgon atmospherePorous carbon

The invention discloses a lithium sulfur battery anode material and a lithium sulfur battery utilizing same. By adopting an in-situ doping method, iron and nitrogen are jointly added, and an iron-nitrogen exotic atom dual-doped porous carbon material is prepared by adopting a hard template method. The method comprises the following steps: preparing a precursor, a catalyst and a previous polymer ofa hard template; calcining the previous polymer to obtain solids; and etching, cleaning and drying the solids to obtain the carbon material of the invention. The prepared carbon material is uniformlymixed with sulfur powder to be heated in an argon atmosphere to form a carbon sulfur composite material which is applied to the lithium sulfur battery. The obtained carbon material is relatively highin content of nitrogen and iron, relatively high in specific surface area and yield, simple in preparation step and easy in operation. When the lithium sulfur battery anode material is applied to thelithium sulfur battery, the electrochemical performance is relatively good, compared with the iron-free carbon material, the performance is apparently improved, the sulfur can be well fixed by addingthe iron catalyst, the shuttle of the poly-sulfide can be inhibited, and the reaction dynamics can be accelerated, so that the cycling stability of the lithium sulfur battery can be improved.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Iron catalyst containing cobalt auxiliary agent for Fischer-Tropsch synthesis reaction and preparation method thereof

ActiveCN101602000AImprove responseGood dispersionHydrocarbon from carbon oxidesCatalyst activation/preparationSulfurCobalt

The invention discloses an iron catalyst containing a cobalt auxiliary agent for a Fischer-Tropsch synthesis reaction and a preparation method thereof. The catalyst comprises Fe, Cu, K, Co and SiO2 in a weight ratio of 100:(0.1-10):(0.1-10):(0.01-5):(5-30). The iron catalyst containing the cobalt auxiliary agent has higher specific surface area, CO transforming activity, sintering resistance and sulfur resistance.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

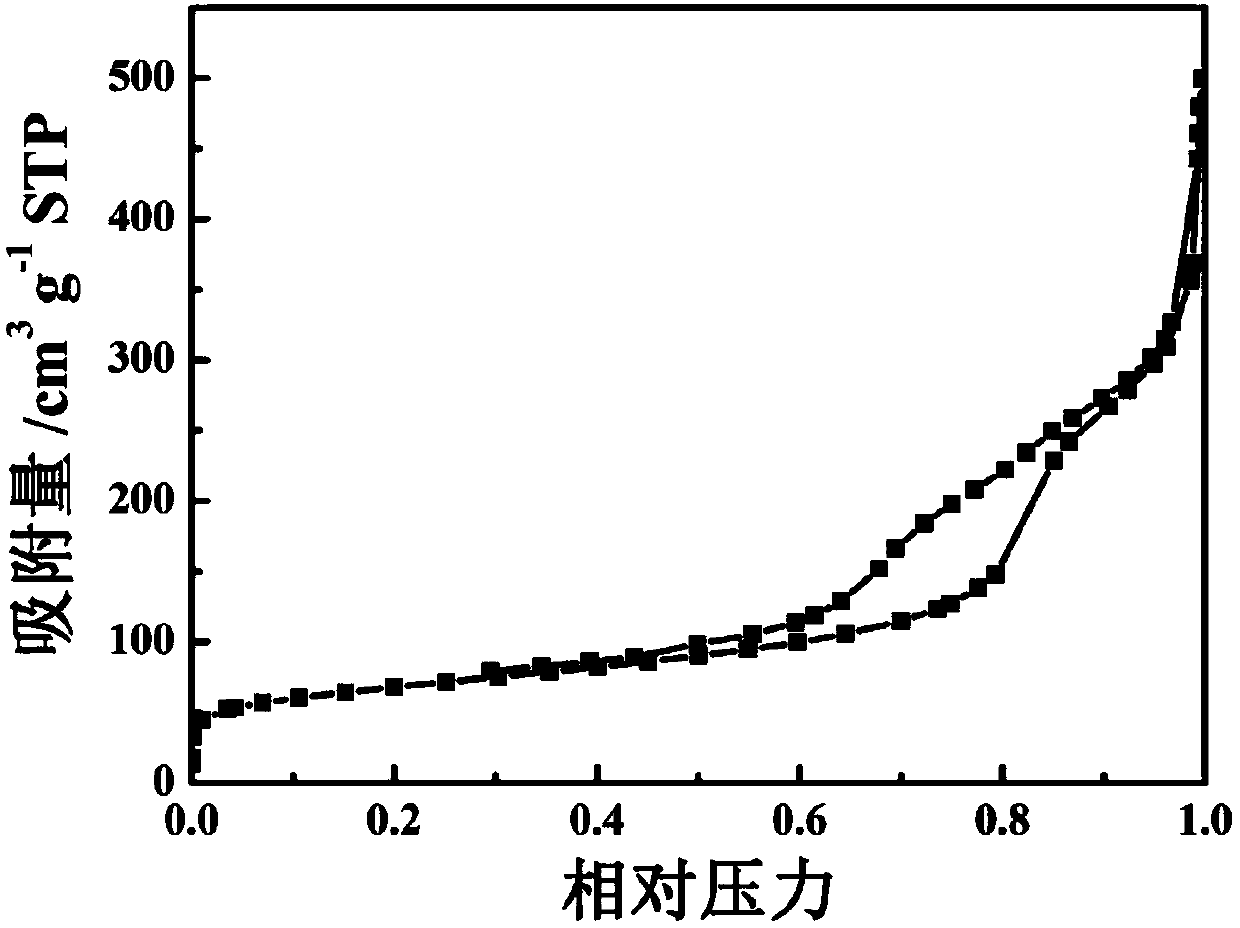

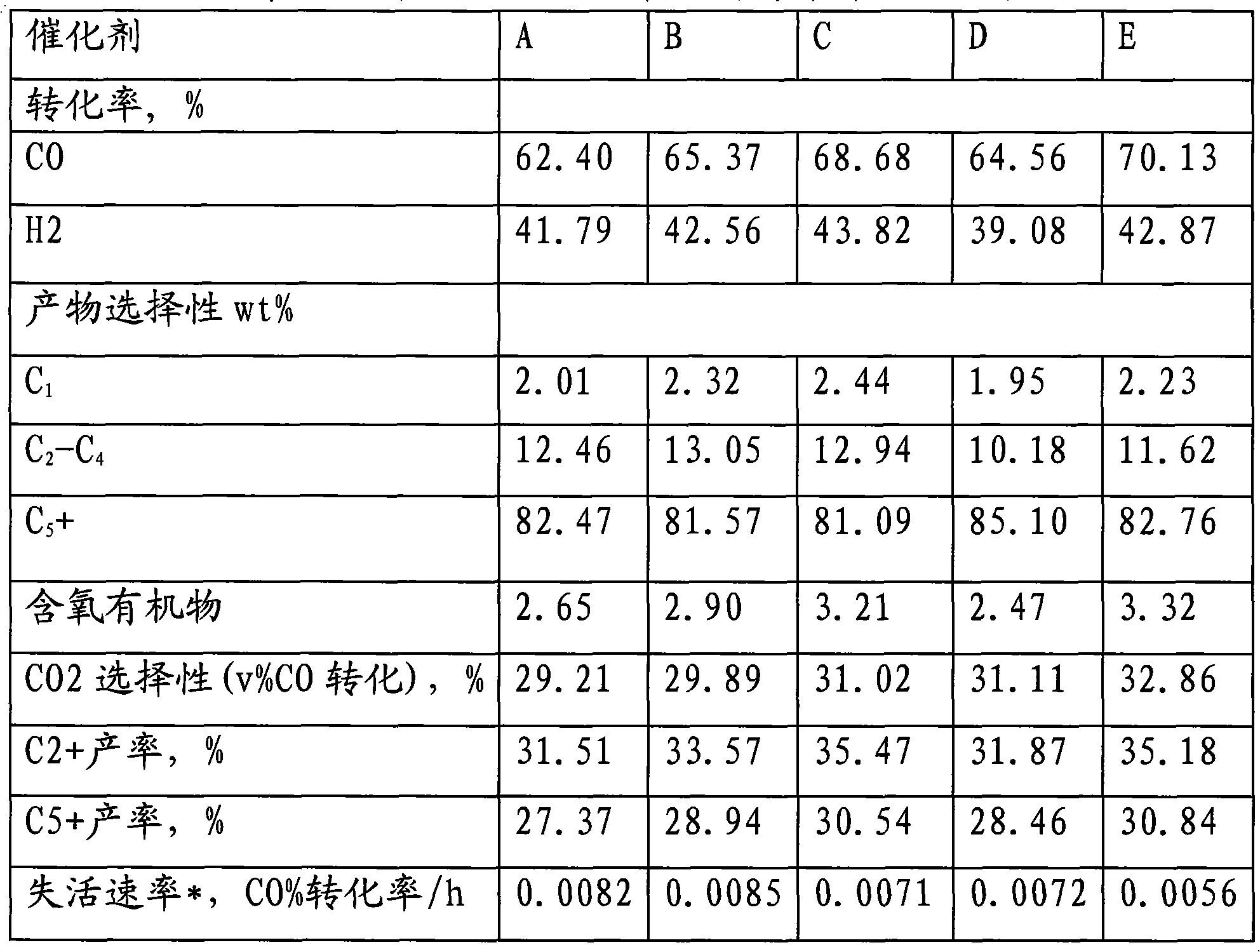

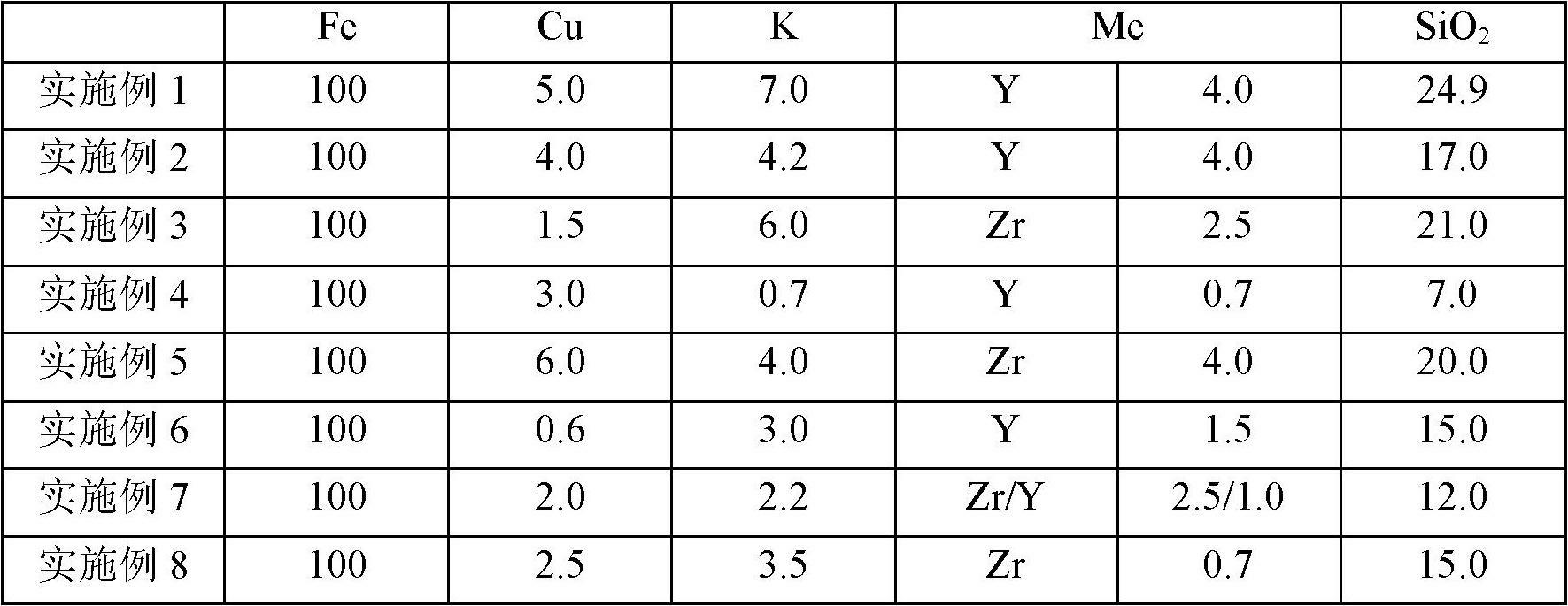

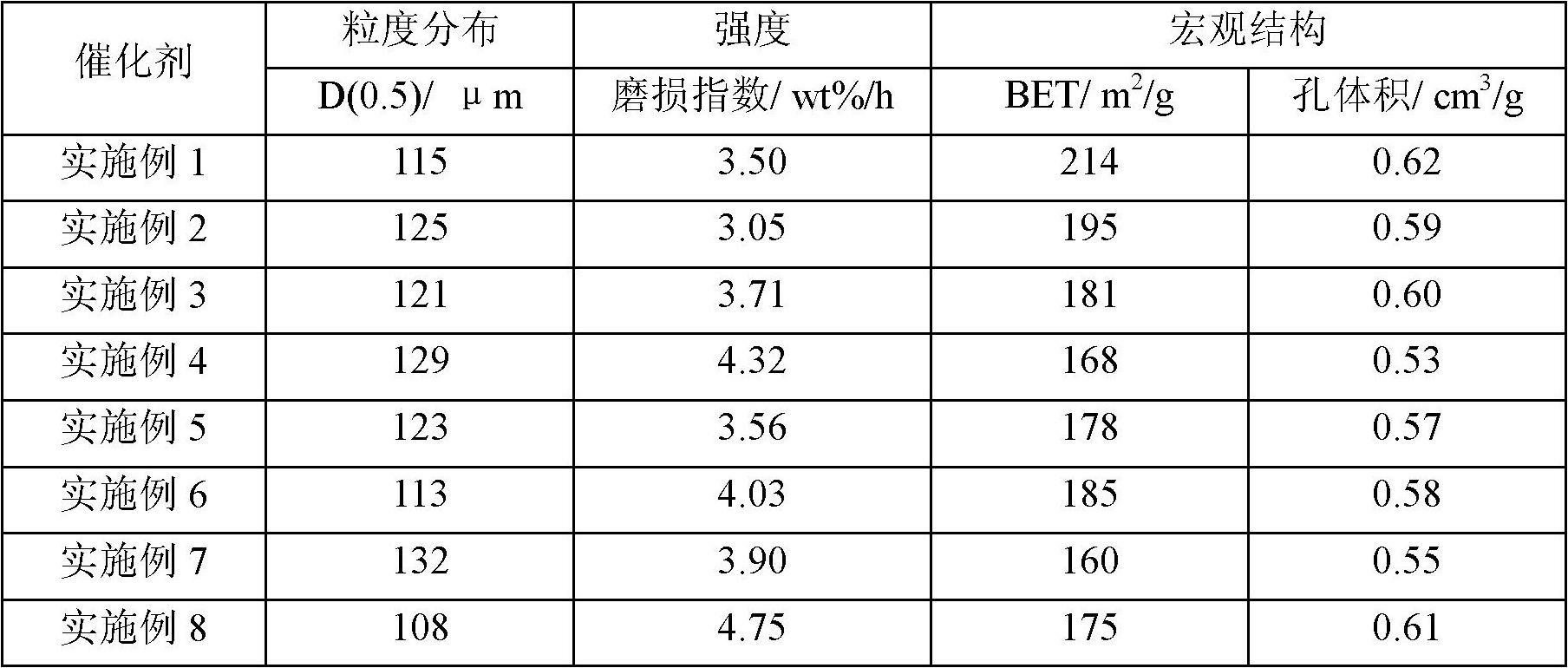

Precipitated iron catalyst for Fischer-Tropsch synthesis and preparation method thereof

InactiveCN102671667AImprove wear resistanceGood chemical stabilityCatalyst activation/preparationLiquid hydrocarbon mixture productionNano siliconSlurry

The invention discloses a precipitated iron catalyst for Fischer-Tropsch synthesis and a preparation method thereof. The catalyst comprises the following components in parts by weight: 100 parts of Fe, 0.1-6 parts of Cu, 0.5-7 parts of K, 0.1-5 parts of Me and 2.5-27 parts of SiO2, wherein Me is a transition metal Zr and / or Y, and Fe, Cu, K and Me exsist in the form of oxides. In the precipitation process of the precipitated iron catalyst for Fischer-Tropsch synthesis, proper transition metal assistants and small amounts of silicon dioxide assistant are introduced by the in-situ reaction and are organically combined with the subsequently introduced nano silicon oxide binding agent, thereby greatly enhancing the abrasion resistance of the finally prepared catalyst, improving the chemical stability and improving the problem of fine powder generated on the slurry-state bed reactor.

Owner:CHNA ENERGY INVESTMENT CORP LTD +2

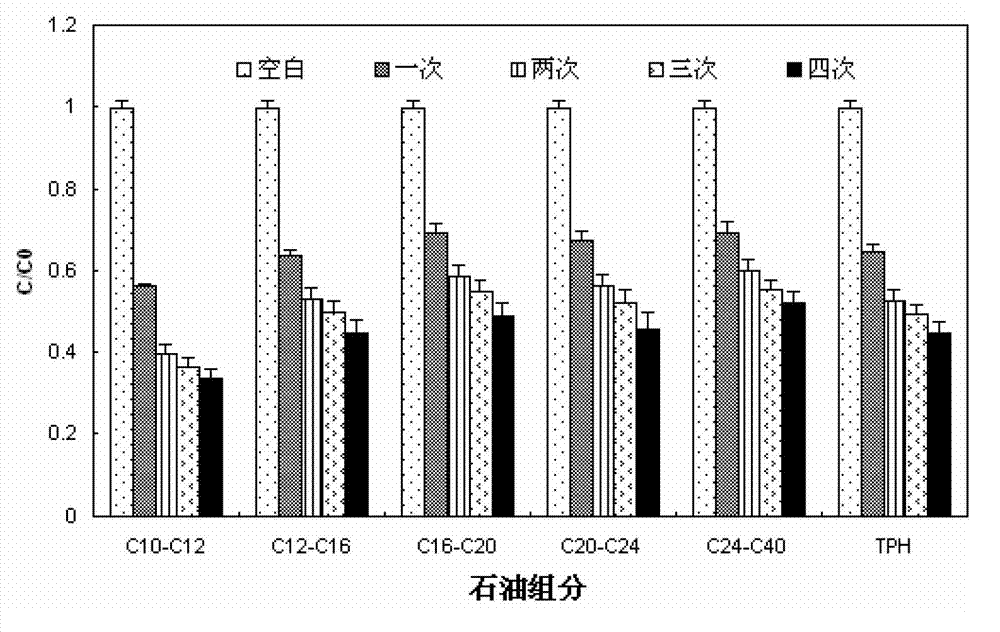

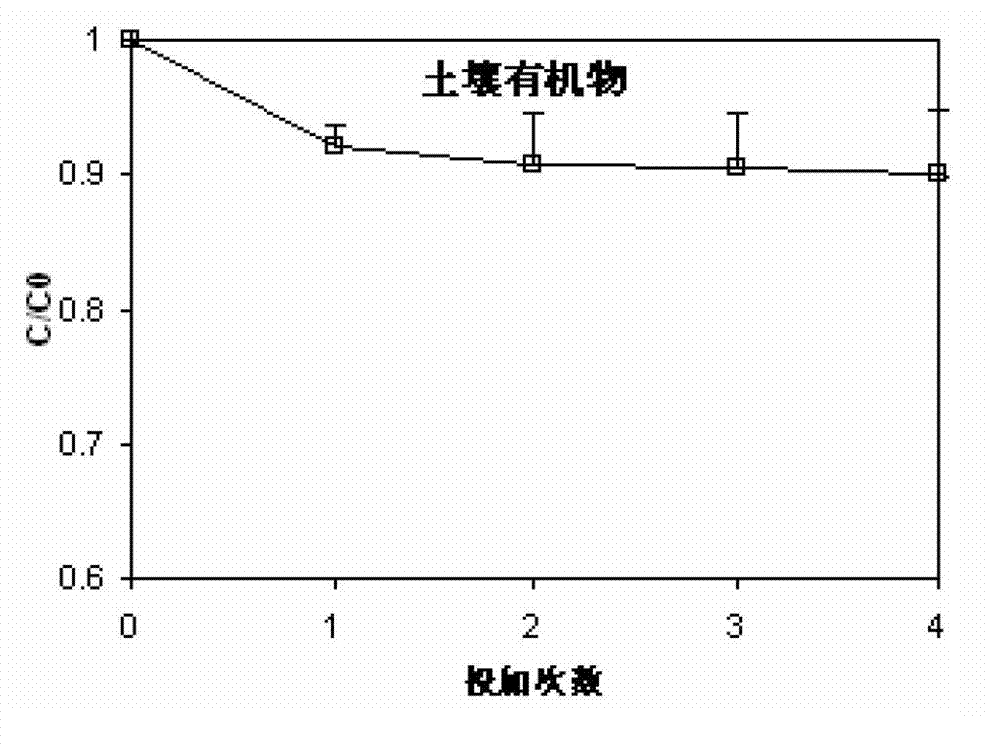

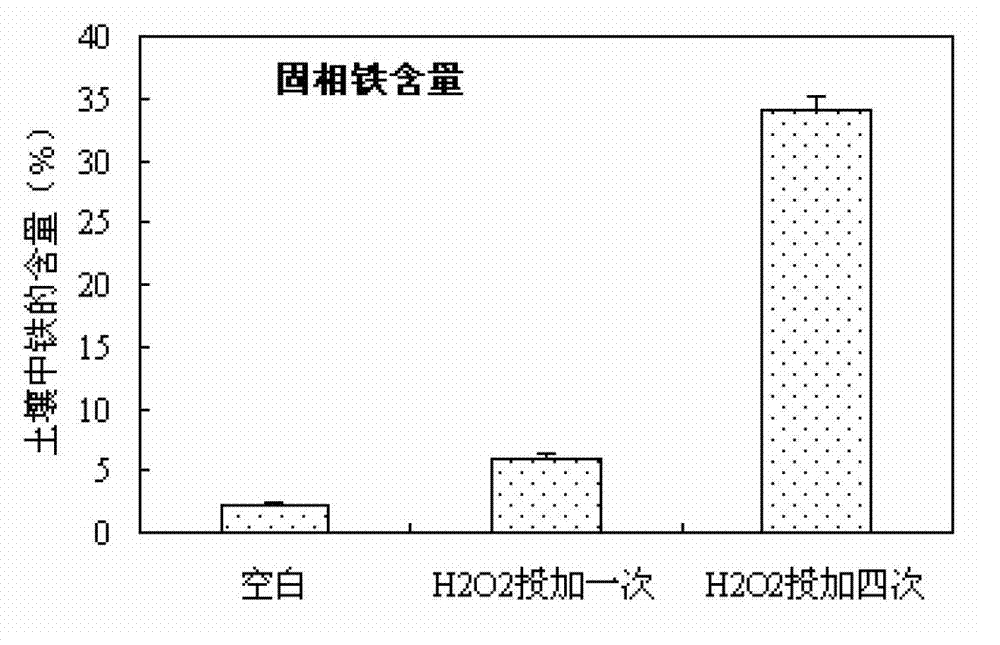

Method for degrading solid phase adsorbed state petroleum hydrocarbon in petroleum contaminated soil

ActiveCN102886378AImprove oxidation efficiencyReduce dosageContaminated soil reclamationFenton reagentBioremediation

The invention aims to provide a method for degrading solid phase adsorbed state petroleum hydrocarbon in petroleum contaminated soil. According to the method, the preparation concentration of a Fenton reagent is determined by detecting the concentration of petroleum hydrocarbon in the petroleum contaminated soil, different amounts of hydrogen peroxide in the Fenton reagent are fed for multiple times, and the concentration and the dosage of hydrogen peroxide at the next time are adjusted by the concentration of petroleum hydrocarbon after every addition for a certain time, wherein the concentration of hydrogen peroxide is 150mmol / L to 350mmol / L, and the feeding time of H2O2 is 3 to 6 times. According to the invention, a solid phase prepared iron catalyst is utilized to absorb high-activity hydroxide radicals adjacent to the petroleum hydrocarbon, and an absorption state petroleum hydrocarbon is directly oxidized, so that the oxidation efficiency is high; furthermore, the dose of H2O2 is greatly saved, and the use ratio of H2O2 is high; and the method for degrading solid phase adsorbed state petroleum hydrocarbon in petroleum contaminated soil is temperate in reaction condition, little in the heat production, low in degree of damage on the soil organic matters and the microbes, free from secondary pollution, and beneficial for subsequent biological repair.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com