Iron catalyst containing titanium deposition for catalyzing Fischer-Tropsch synthesis reaction and method for producing the same

An iron catalyst, Fischer-Tropsch synthesis technology, applied in physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, and hydrocarbon production from carbon oxides, etc., to achieve enhanced anti-sintering performance, high specific surface area, The effect of the simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

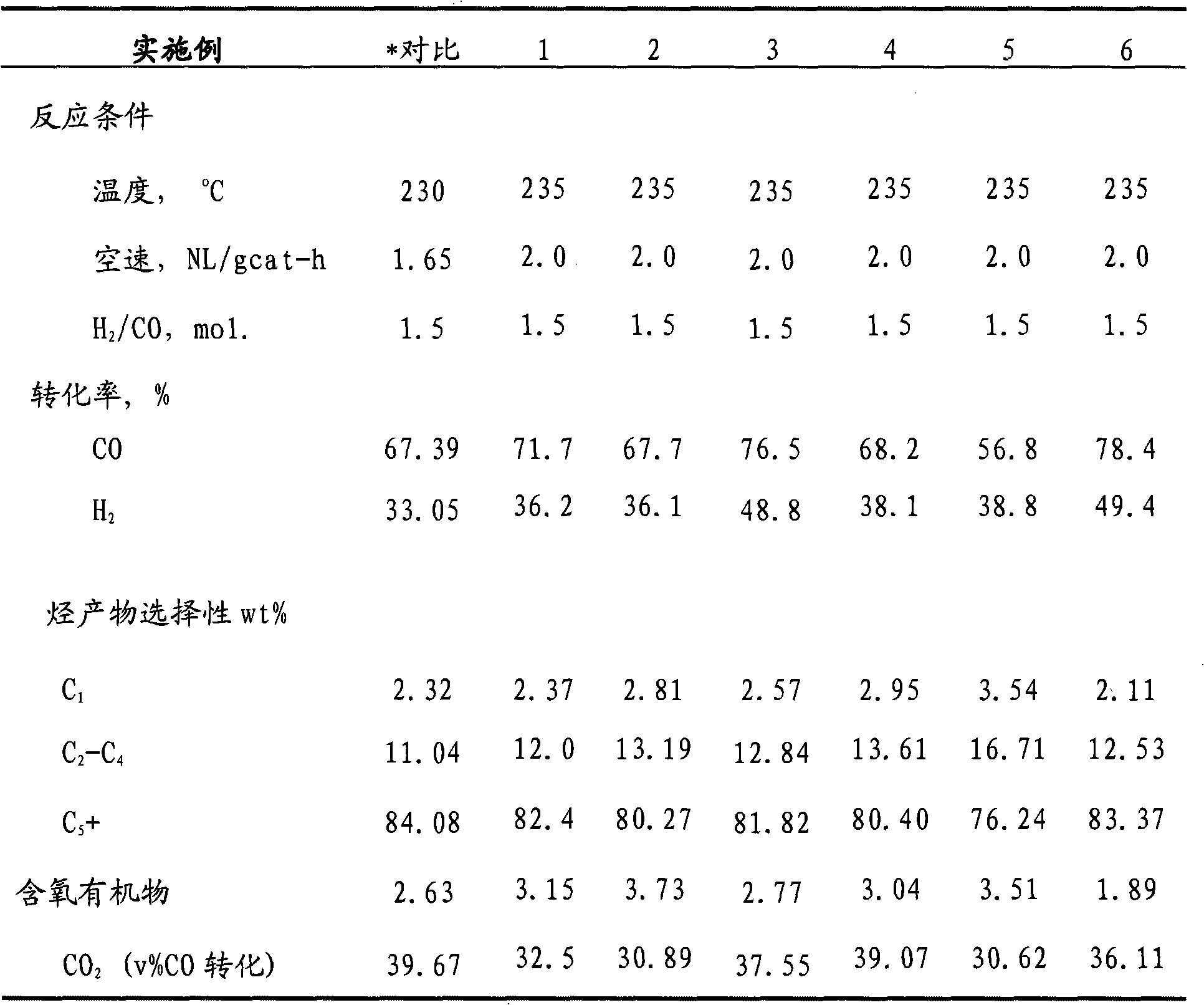

Examples

Embodiment 1

[0043] 4 kg of Fe(NO 3 ) 3 ·7H 2 O, 120 g Cu(NO 3 ) 2 ·3H 2 O and 250 grams of titanium nitrate-nitric acid solution (16%) are dissolved (diluted) in distilled water respectively, are mixed with 5% ferric nitrate solution, mix with 5% copper nitrate solution afterwards, dilute titanium nitrate-nitric acid solution simultaneously to form Dissolve 15% titanium nitrate aqueous solution at the same time to obtain 10% sodium carbonate solution. Use a peristaltic pump to add the above-mentioned solutions to a 20L stirring tank. The jacket heating temperature is maintained at 80°C. The transmission speed of the peristaltic pump should be According to the metering ratio of acidic and alkaline solutions, the precipitation was completed under the conditions of a stirring rate of 120 rpm and a pH value of 7.5, and the temperature was lowered to 60° C. for aging for 1 hour. The slurry after the sedimentation obtained was washed with a vacuum filter and deionized water for 4 times, an...

Embodiment 2

[0047] 4 kg of Fe(NO 3 ) 3 ·7H 2 O, 200 g Cu(NO 3 ) 2 ·3H 2 O and 500 grams of titanium nitrate-nitric acid solution (16%) are dissolved (diluted) in distilled water respectively, are mixed with 5% ferric nitrate solution, mix with 5% copper nitrate solution afterwards, dilute titanium nitrate-nitric acid solution preparation simultaneously into 800 grams of 10% titanium nitrate aqueous solution, and dissolve at the same time to obtain a sufficient amount of 10% sodium carbonate solution. Use a peristaltic pump to add the above-mentioned various solutions to a 20L stirred tank. The jacket heating temperature is maintained at 85 ° C. The peristaltic pump The transmission speed should be carried out in accordance with the metering ratio of acidic and alkaline solutions. Under the conditions of a stirring rate of 120rpm and a pH value of 7.8, the precipitation is completed, and the temperature is lowered to 60°C for aging for 2 hours. The slurry after the sedimentation obtai...

Embodiment 3

[0051] 4 kg of Fe(NO 3 ) 3 ·7H 2 O, 120 g Cu(NO 3 ) 2 ·3H 2 The O solution was dissolved in distilled water respectively, mixed and prepared to contain 5% ferric nitrate and 5% copper nitrate solution, and 750 ml of propanol solution containing 210 grams of tetraisopropyl titanate was prepared at the same time, diluted in deionized water, and then separately Prepare a sufficient amount of 10% sodium carbonate solution in the container, and use a peristaltic pump to add the above-mentioned solutions to a 20L stirred tank. The heating temperature of the jacket is maintained at 75°C. The metering ratio of the solution is carried out, and the precipitation is completed under the conditions of a stirring rate of 120 rpm and a pH value of 7.5, and the temperature is lowered to 60° C. for aging for 1 hour. The slurry after the sedimentation obtained was washed with a vacuum filter and deionized water for 4 times, and the conductivity of the filtrate was tested, and the nitrate i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com