Patents

Literature

335results about How to "Reduce trimming" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

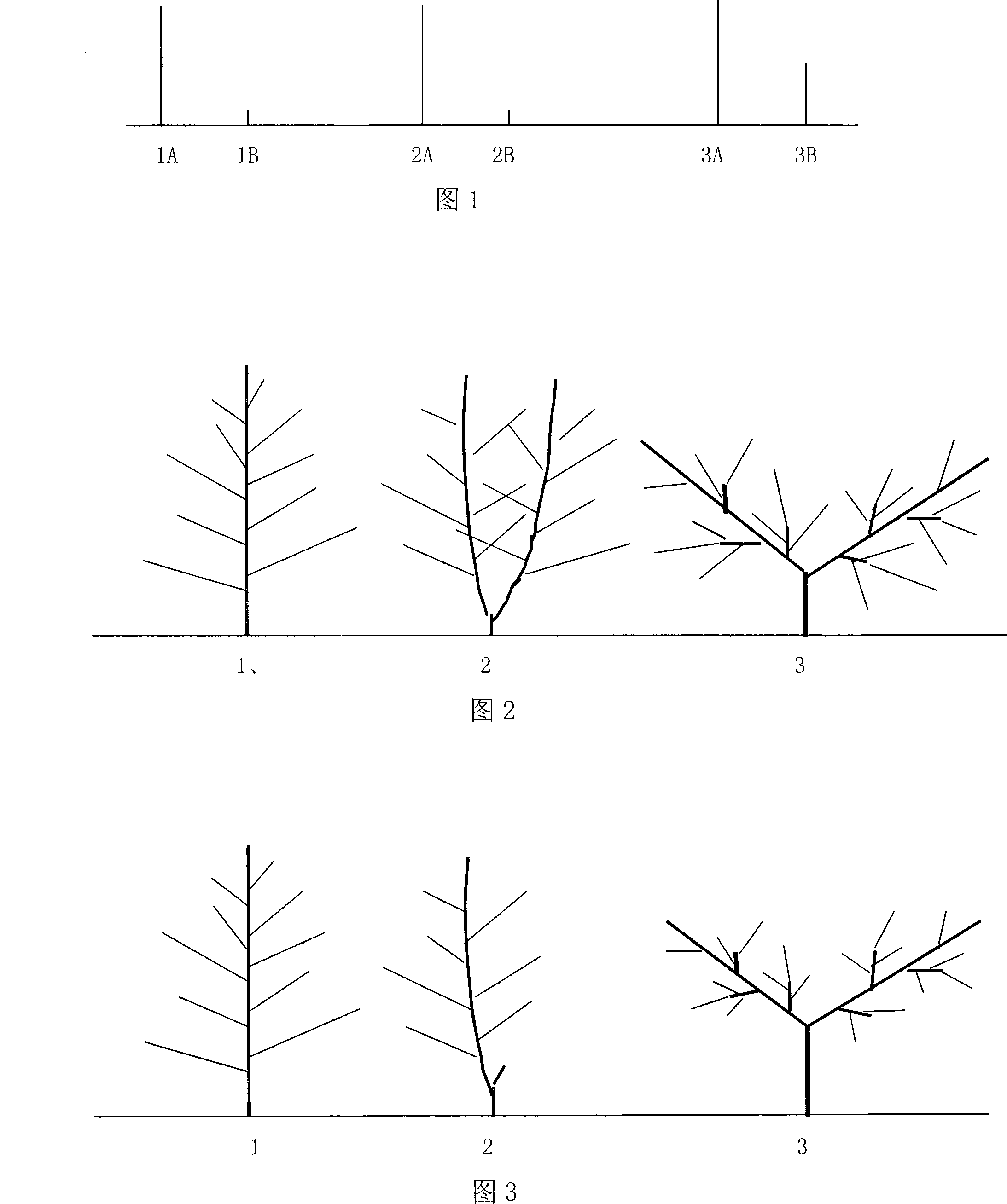

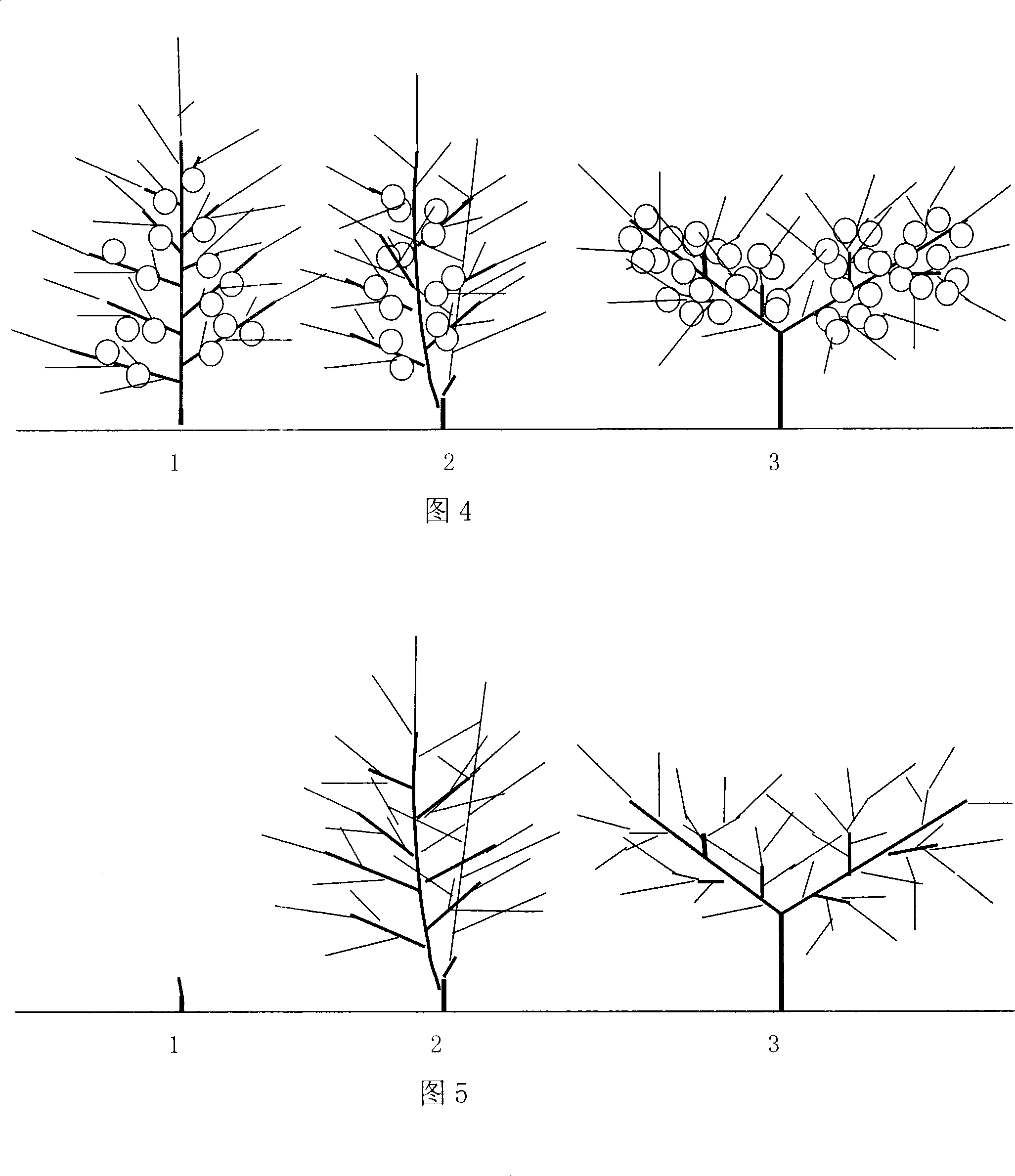

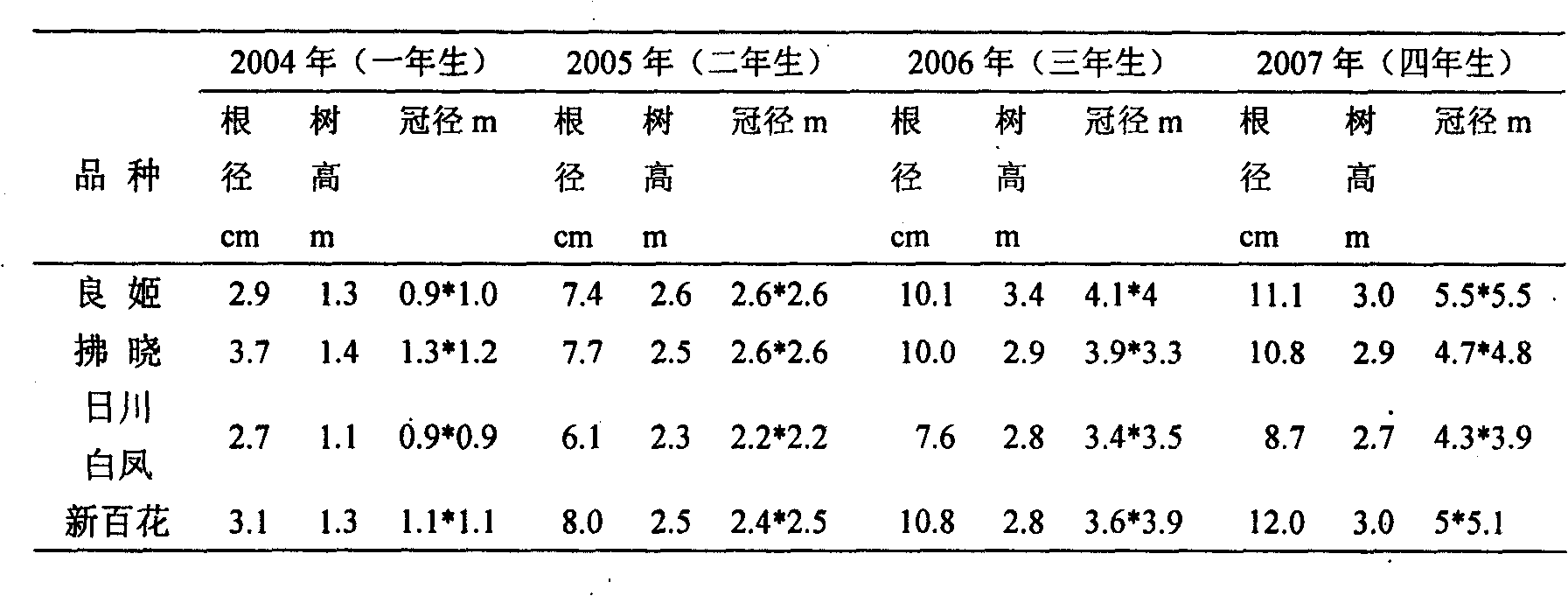

A peach shape for high-density planting and tree body controlling means

InactiveCN101156540ASmall footprintUncontrollable sizeCultivating equipmentsHorticultureHigh densityPeach orchard

The invention discloses a peach tree shape applicable for high-density planting. The peach tree shape of the invention is Y-shaped, and consists of a trunk and two large branch groups. Two large fruit branch groups can be produced on the upside of the trunk, and are arrayed oppositely in a line, and respectively extend into the two side rows; the extension direction is perpendicular to the row direction, as well as has a 45-55 degrees angle with the vertical direction. Fruit branches and small sized fruit branch groups are produced on the large fruit branch groups. The peach tree shape of the invention is applicable for high density planting, the structure of the tree is simple, the pruning is simple, the forming is quick, and the cost is low. The method of the invention is easy to be learned, the operation is simple. Standard management can be conducted for the invention to ensure that the peach orchard realize early rich and high-quality yield, high yield and stable yield.

Owner:CHINA AGRI UNIV

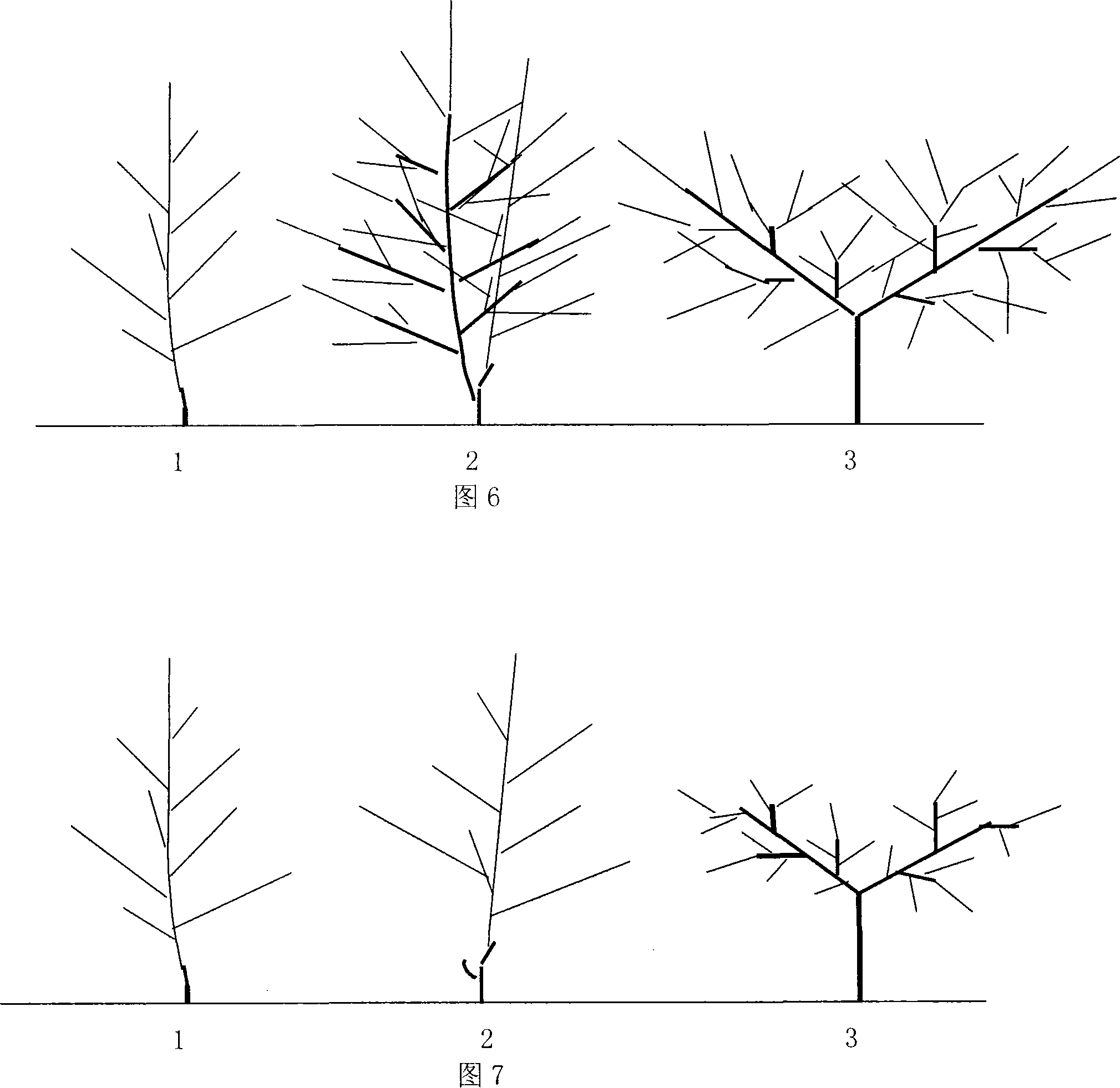

Method for preparing composite powder of nano tungsten carbide-coblt through direct reducition and carbonization

WC-CO nm composite powder is prepared by one of the three ways: 1. W-CO raw material, crystal depressor and carbon powder are mixed in proportion to be milled to mixed powder of the oxide and carbon 2. The W-CO raw material, crystal depressor are processed to oxide powder by a compound technology then to be mixed with carbon powder to be milled to a mixed powder of the oxide and carbon 3. W-CO raw material, crystal depressor and soluble carbon oxide powder with carbon by a compound technology which refers to spray pyrolytic decomposition, spray drying and spray burning. The nm WC-CO composite powder is got by putting the oxide powder in a reacting furnace, controlling temperature of recovery carburization and time and washing carbon temperature and time.

Owner:WUHAN UNIV OF TECH

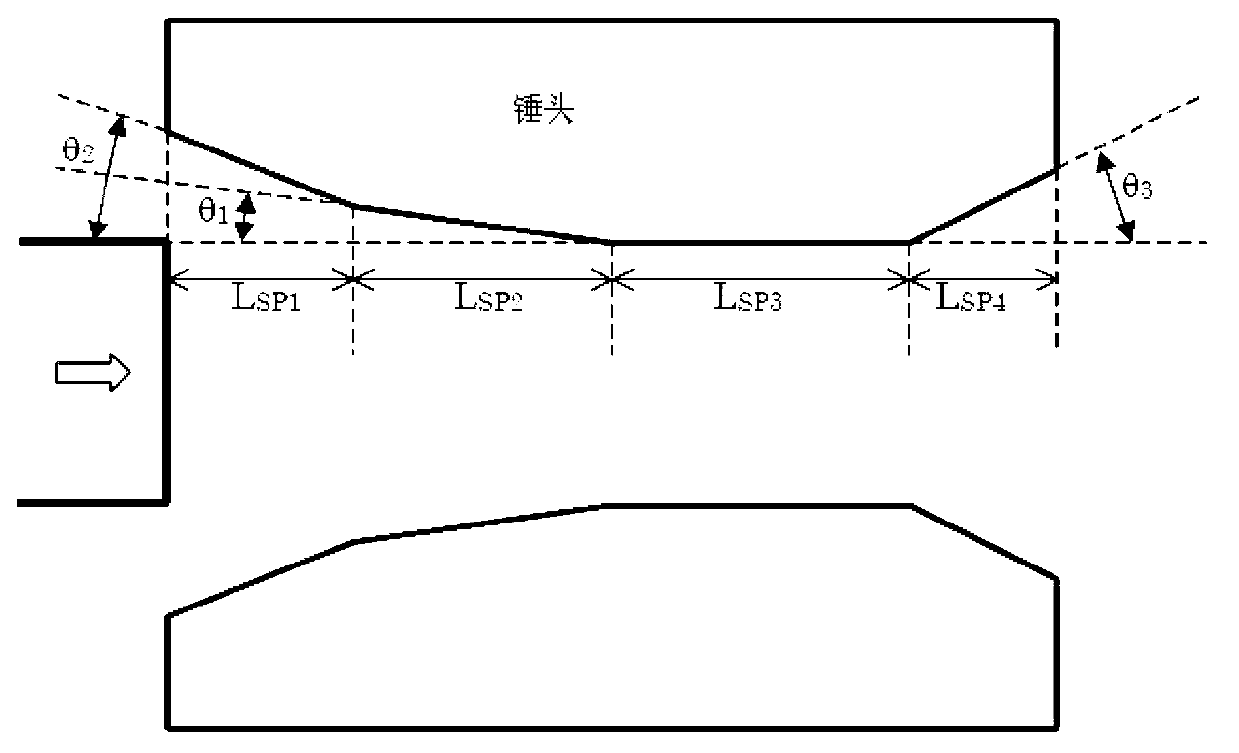

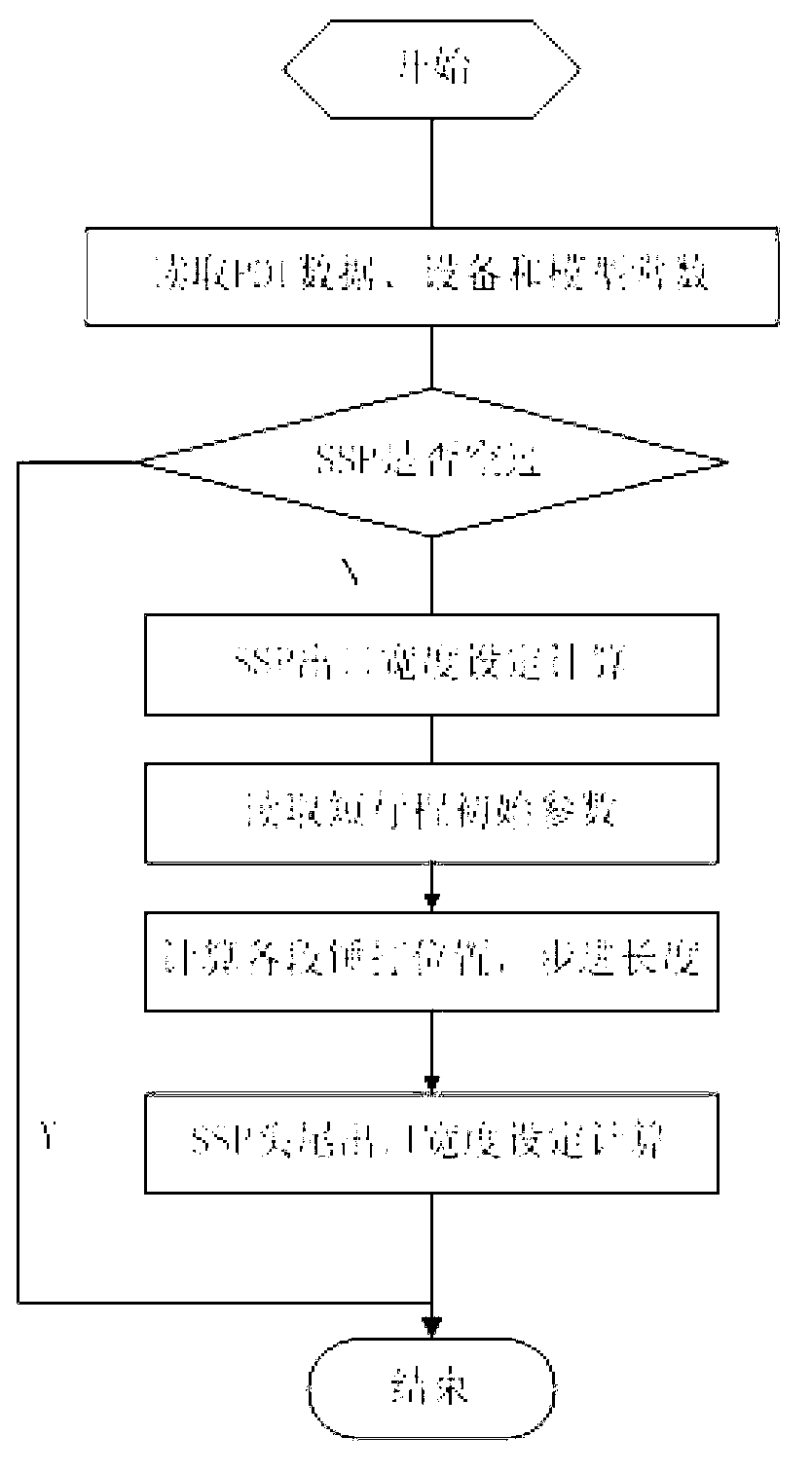

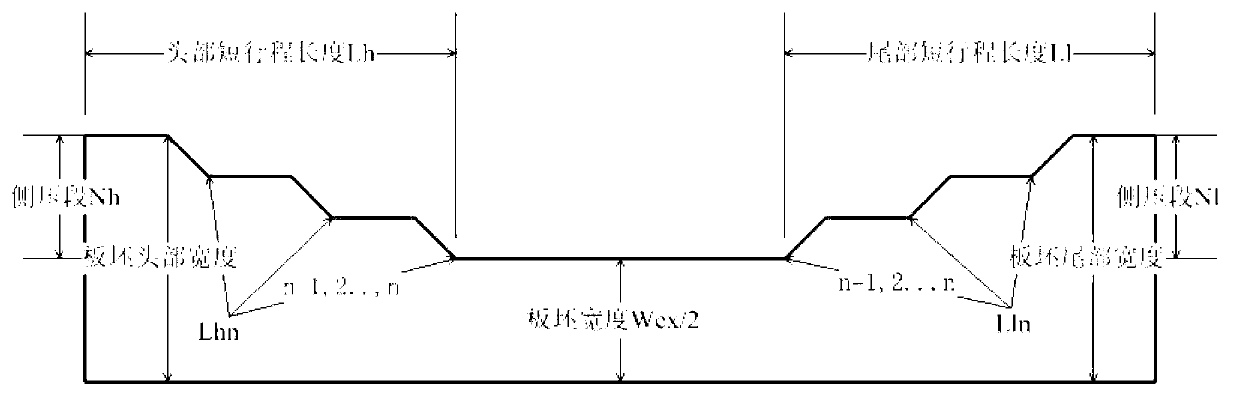

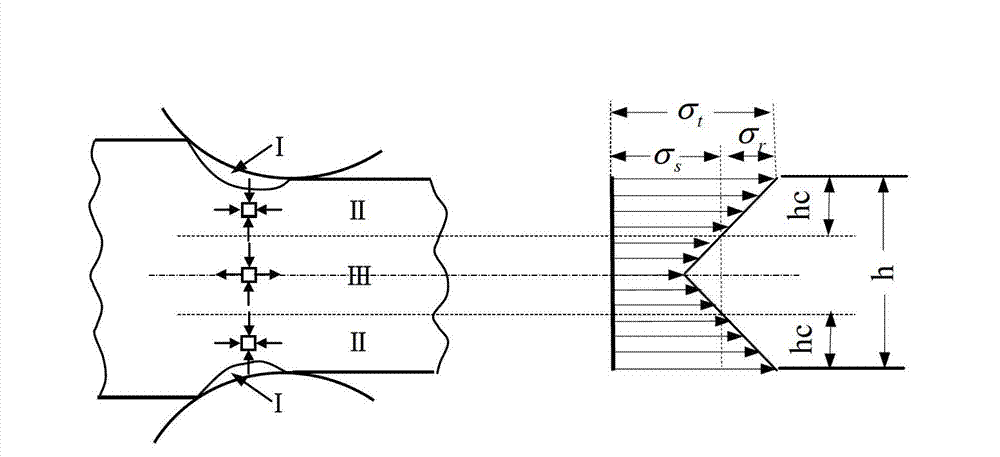

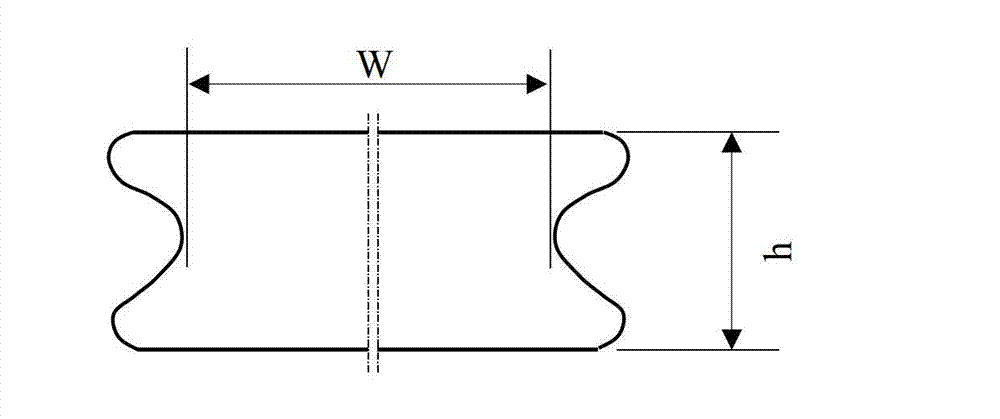

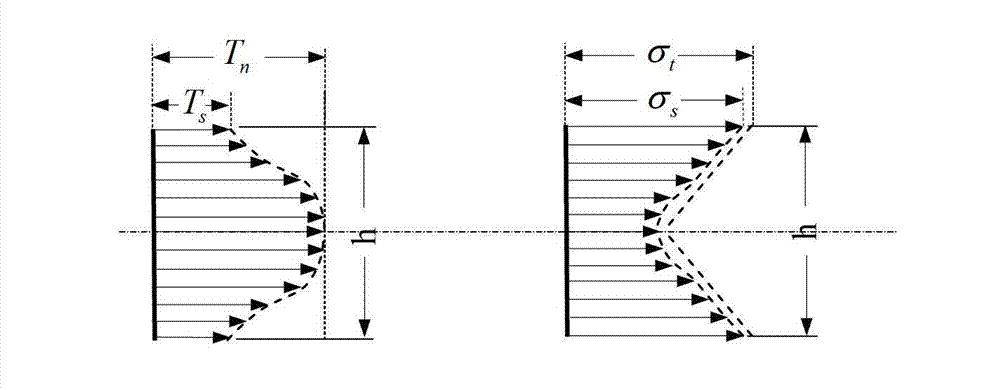

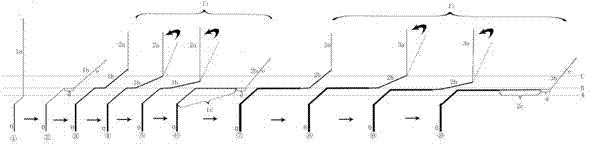

Fixed-width press plate blank width control method

ActiveCN102989784APrecise calculation of adaptive positionImplement width control methodMetal rolling stand detailsAutomatic controlEngineering

The invention discloses a fixed-width press plate blank width control method, and belongs to the technical field of steel rolling automatic control. During the process of laterally rolling the head and the tail of a plate blank by a fixed-width press, the head part and the tail part of the plate blank are in plane stress states; according to the metal flow principle of the head part and the tail part of the plate blank, and tongue and fishtail phenomena can be generated. In order to improve the condition, the widths of the head and the tail of the plate blank are controlled in short stroke by adopting the fixed-width press; under the working condition that stripe steel rolling temperature and rolling cycle are ensured, the severe width failure of the head and the tail of the stripe steel can be improved, and the final rolling target width index is ensured effectively; a pass band guarantees the width index deviation range to be 0-8mm, the yield is improved, and the production cost is saved; and when the plate blank is pressed greatly, similar to the small lateral pressing amount, the outlet width is obtained through pressing one time, the rolling temperature of the stripe steel is ensured, and the rolling cycle is improved.

Owner:BEIJING ARITIME INTELLIGENT CONTROL +1

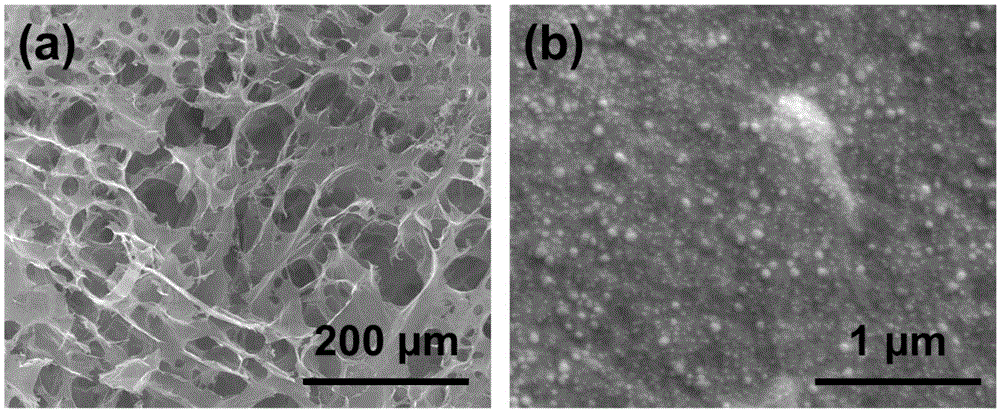

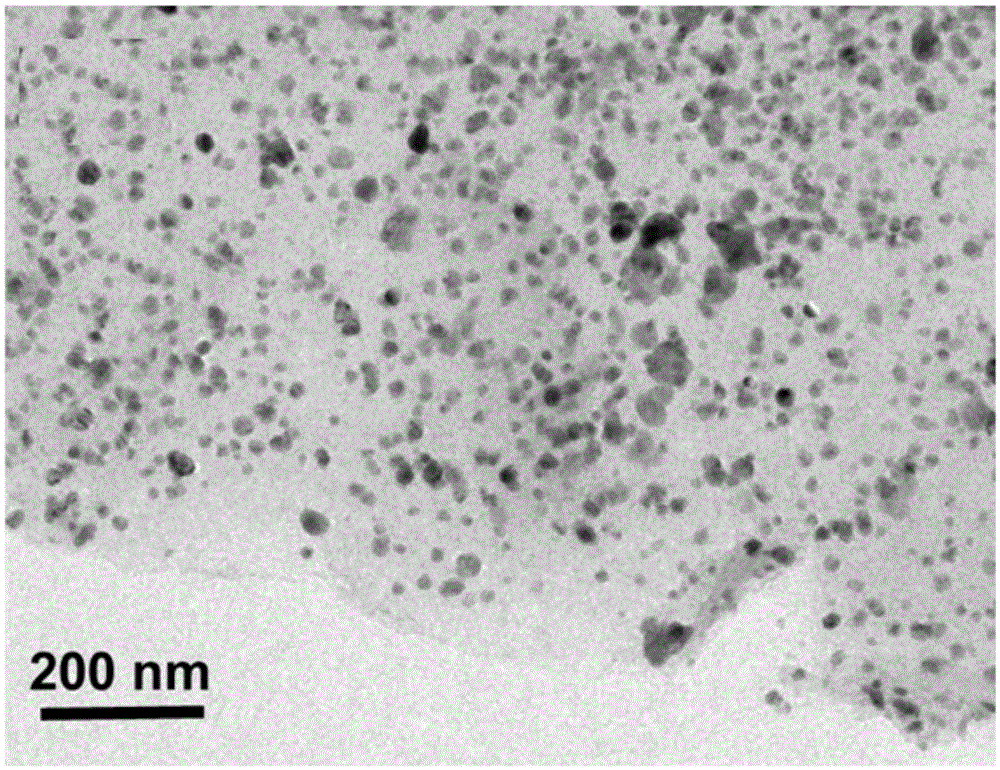

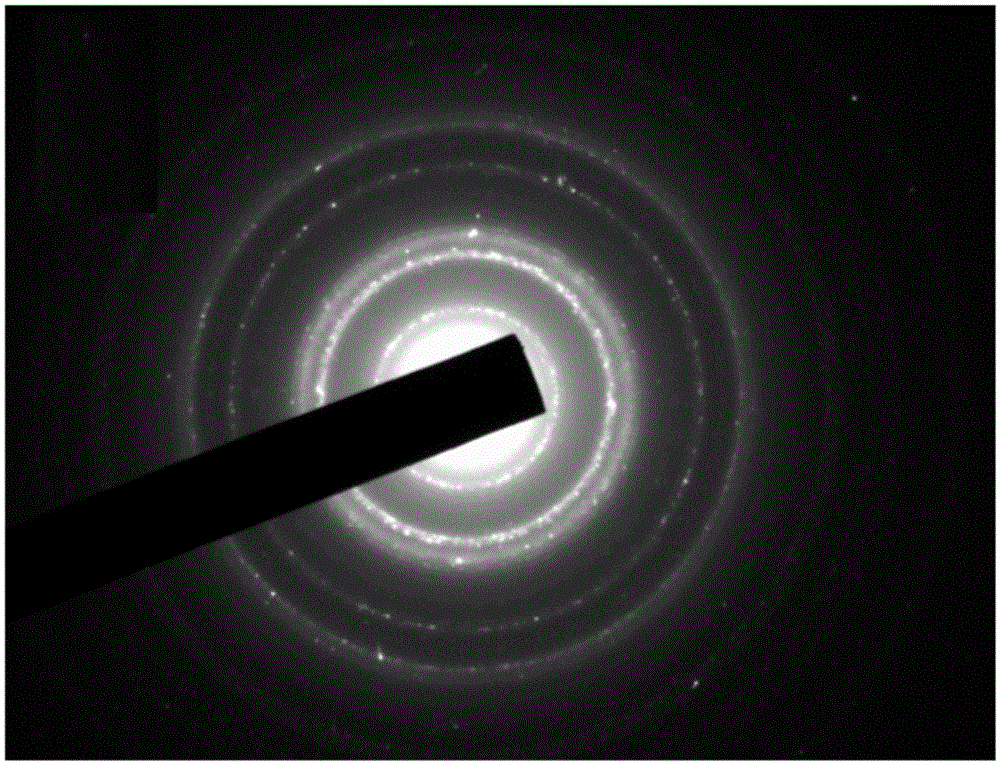

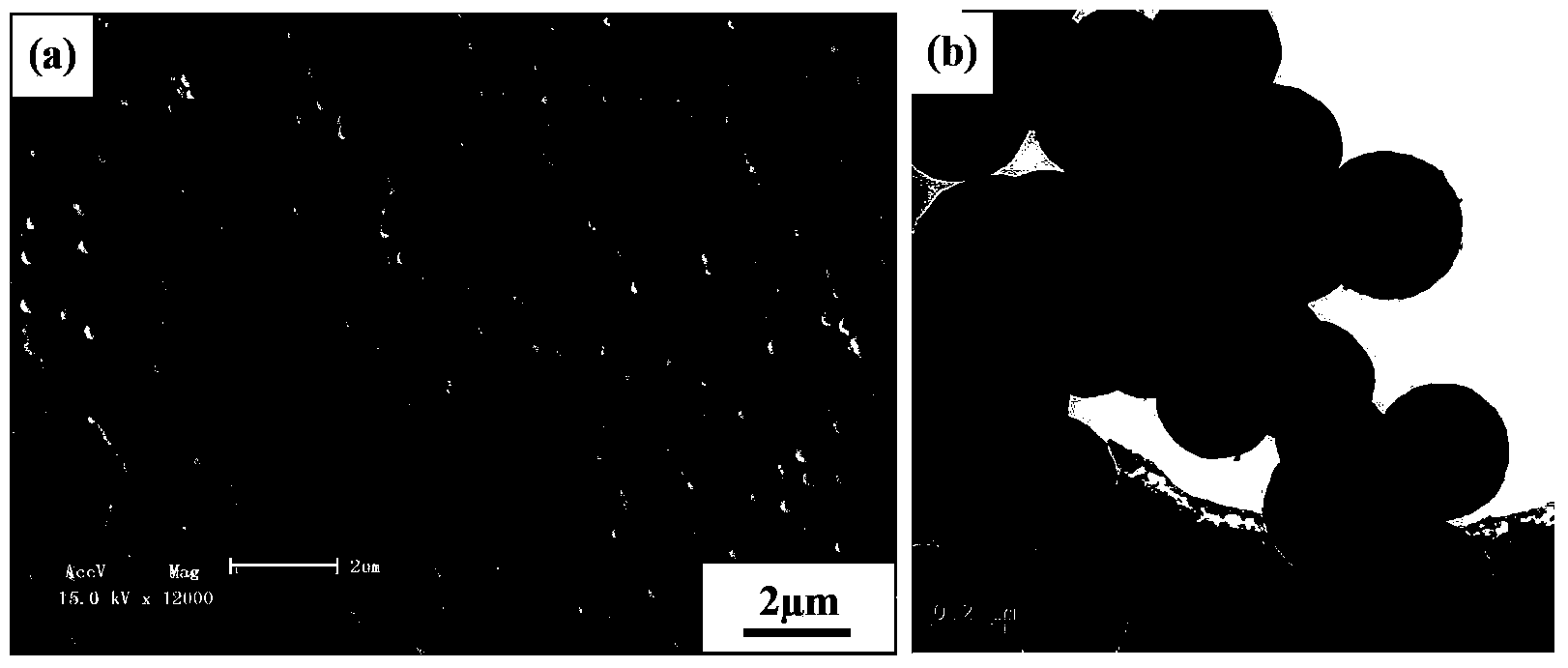

Reduction-oxidation graphene/nanometer metallic silver aerogel with three-dimensional structure and preparation method

ActiveCN105251484AIncreased reactive areaGood catalytic performanceMetal/metal-oxides/metal-hydroxide catalystsCvd grapheneGraphite oxide

The invention relates to a reduction-oxidation graphene / nanometer metallic silver aerogel with a three-dimensional structure and a preparation method thereof. The aerogel has a three-dimensional porous structure which is formed by a reduction-oxidation graphene slice layer and a polycrystal nanometer metallic sliver uniformly loaded on the reduction-oxidation graphene slice layer. The aerogel is prepared according to the preparation method which comprises the following steps: (1) uniformly mixing a soluble silver salt aqueous solution with a graphene oxide aqueous solution, thereby acquiring a pecursor solution; (2) transferring the pecursor solution into a reducing agent solution, reacting at room temperature, thereby acquiring a three-dimensional graphene / metallic silver nanometer grain hydrogel; and (3) taking out and cleaning the three-dimensional graphene / metallic silver nanometer grain hydrogel, drying, and then acquiring a target product. Compared with the prior art, the reduction-oxidation graphene / nanometer metallic silver aerogel has the advantages that the preparation method is simple, the whole reaction process is performed at a room temperature, no excessive extra energy consumption is required, and the like.

Owner:SHANGHAI JIAO TONG UNIV

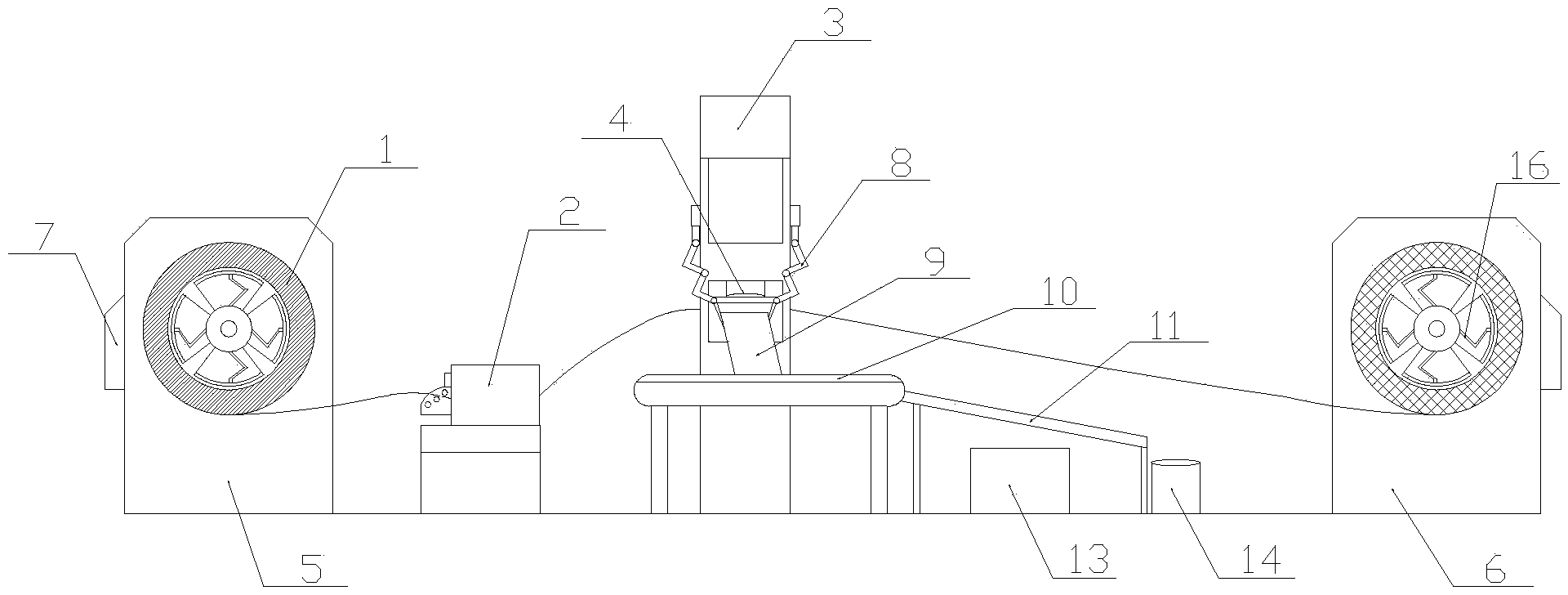

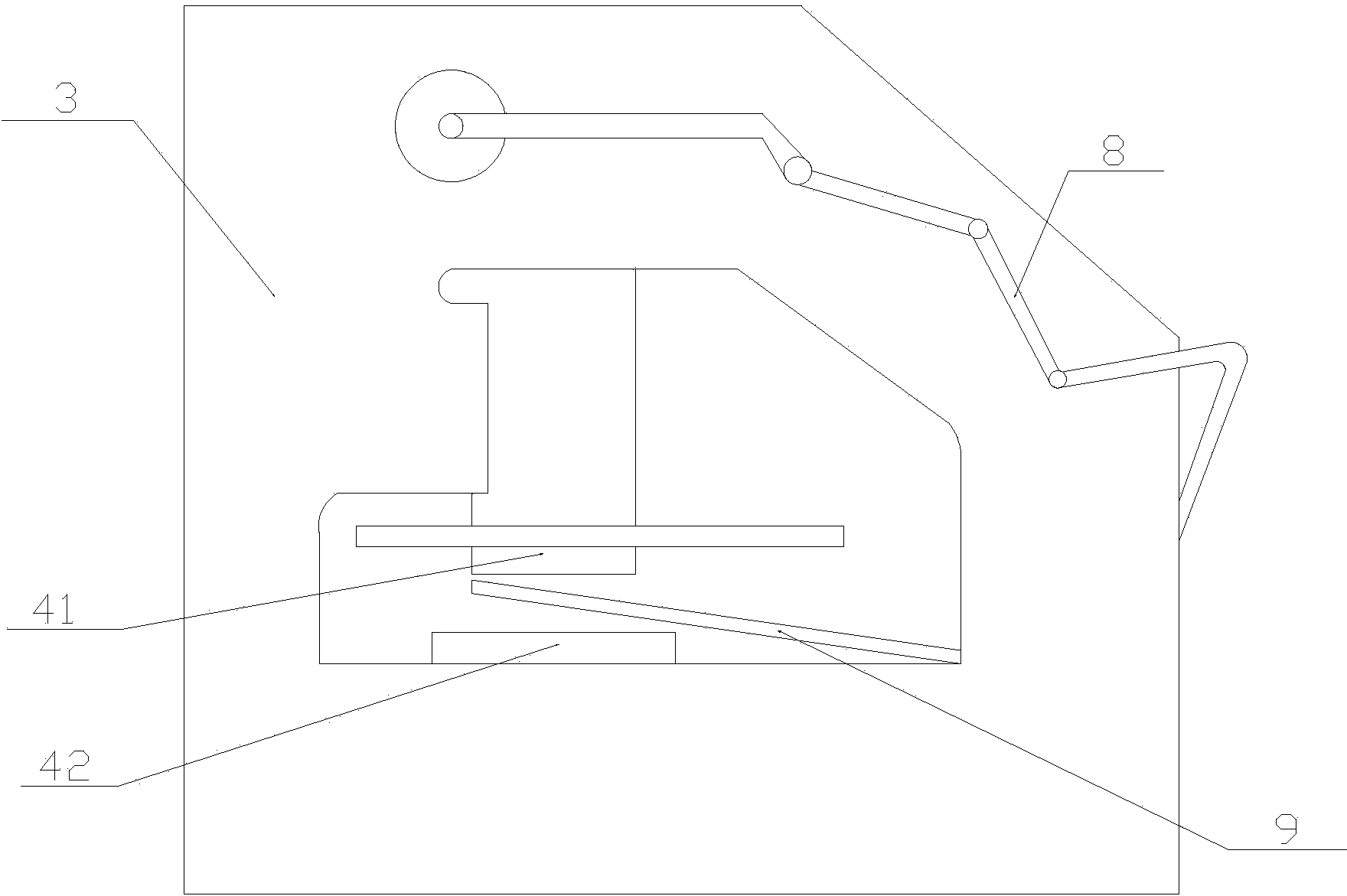

Automatic efficient motor stamped steel device and punching technology thereof

InactiveCN103962443AReduce trimmingSave materialMetal-working feeding devicesManufacturing stator/rotor bodiesSteel qualitySteel plates

The invention relates to the technical field of motor stator core manufacturing, in particular to an automatic efficient motor stamped steel device and a punching technology thereof. The automatic efficient motor stamped steel device comprises a silicon steel plate material coil, a deflection material conveying device, a customized punching machine, a one-time finished product punching die, an automatic finished product sorting mechanism, an automatic numerical-controlled discharging device and a waste recycling device. The punching machine of the improved structure can enable the material coil to freely swing without being uncoiled, and the sorting device can be additionally arranged; the punching die of the improved structure manufactures motor stamped steel finished products through one-time punching, and the automatic finished product sorting mechanism can automatically sort stamped steel. The punching technology of the automatic efficient motor stamped steel device comprises the steps that the overall coil is conveyed automatically, motor stamped steel finished products are manufactured, stator stamped steel and rotor wafers are automatically separated and sorted. The technology has the advantages that processes are few, the stamped steel finished products are smooth, and stamped steel quality is high.

Owner:江苏环球特种电机有限公司

Aluminum alloy material and production method of cast-rolling stock of decorative strip of same

The invention relates to a 3004 aluminum alloy material and a production method of a cast-rolling stock of a decorative strip of the 3004 aluminum alloy material. The compositions of the aluminum alloy material comprise smaller than or equal to 0.25 percent of Si, 0.20 to 0.60 percent of Fe, 0.10 to 0.15 percent of Cu, 1.0 to 1.20 percent of Mn, 0.85 to 1.25 percent of Mg, smaller than or equal to 0.05 percent of Ti, and the remaining amount of Al. The production method comprises the steps of smelting, refining, on-line degassing, grain refinement, filtration, cast rolling, and the like; during the smelting, 50 percent to 60 percent of electrolytic aluminum liquid and the rest of aluminum alloy waste materials are mixed and smelted; the compositions except Mg are added to the mixture; and after the steps of powder injection refining, slag skimming, magnesium ingot adding, furnace turning-down and refining are conducted, the stock of the strip is cast-rolled. A product of the production method has even and steady chemical compositions and can satisfy the mechanical property requirements of subsequent rolling, so that the yield of subsequent rolling is increased; by using the aluminum alloy waste materials as raw materials, the raw materials are saved; by directly adding the electrolytic aluminum liquid, gas loss in the melting process is reduced, and burning loss in the waste material melting process can also be decreased; and by using a cast-rolling manner to replace a hot-rolling manner, the process is simplified and the production cost is greatly reduced.

Owner:沁阳市鼎建建设发展有限公司

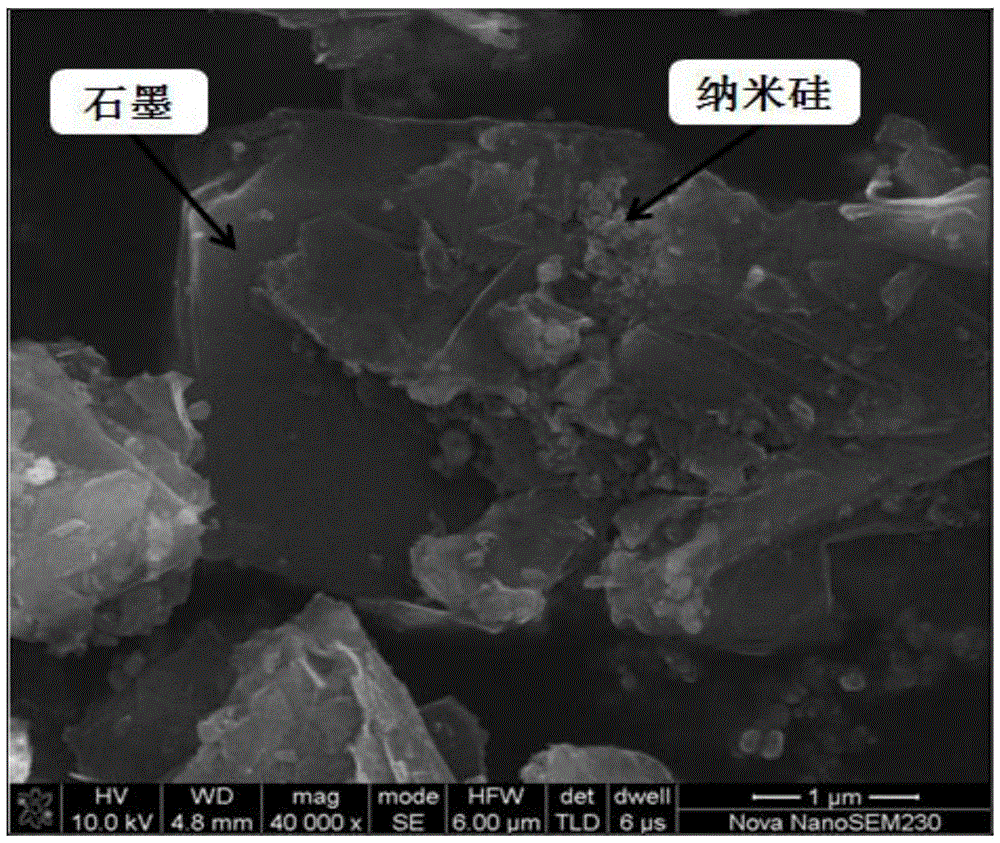

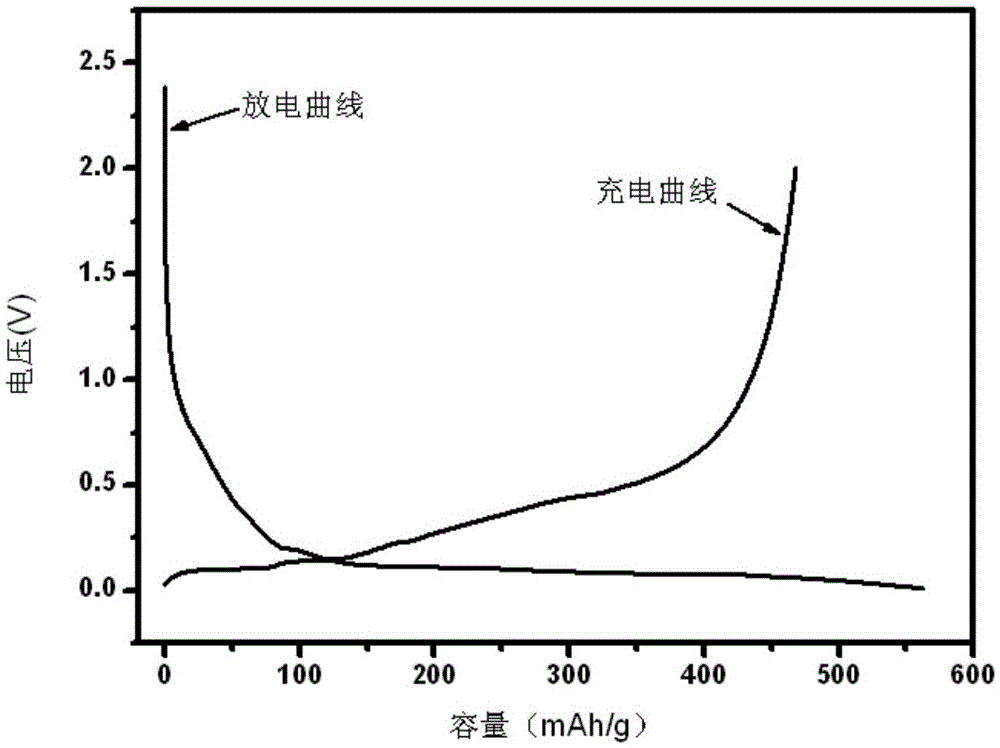

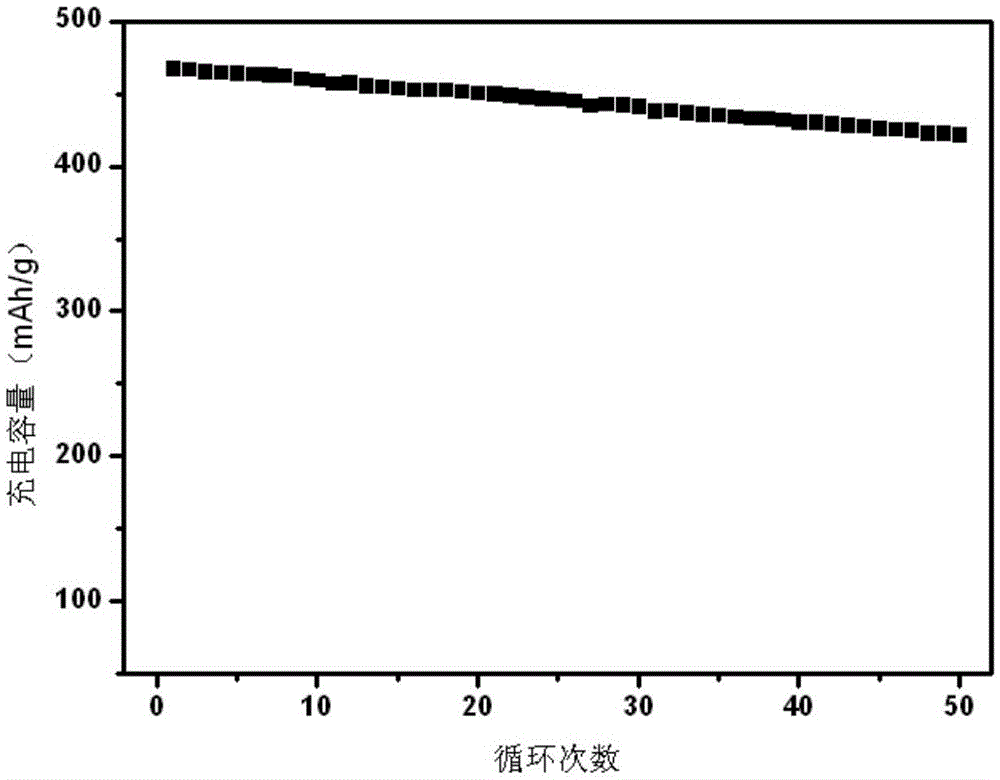

High-capacity silicon-based anode material for lithium ion battery and preparation method thereof, and lithium ion battery

ActiveCN105576209AImprove reunion effectAvoid performance degradationMaterial nanotechnologyCell electrodesIn situ reactionLithium electrode

The invention discloses a high-capacity silicon-based anode material for a lithium ion battery and a preparation method thereof, and the lithium ion battery. The material comprises nanometer silicon, graphite, organic matter pyrolytic carbon and lithium fluoride. A preparation method comprises the following steps of carrying out mixing, drying and vacuum baking on the nanometer silicon, the graphite and a pyrolytic carbon organic matter precursor to obtain a composite precursor, baking the composite precursor to obtain a pyrolytic carbon coated composite, and utilizing lithium salt solution and fluoride solution to carry out in-situ reaction on the surface of the composite to generate a lithium fluoride coating layer, namely the high-capacity silicon-based anode material for the lithium ion battery. Through in-situ generation of the lithium fluoride on the surface of the silicon-based composite, the interface characteristic of the material is effectively improved, the compactness and the stability of a solid electrolyte membrane formed by the material in the first lithium insertion process is improved, so that the electrochemical performance of the material is improved, the first charge and discharge efficiency of the battery is more than 80%, and the capacity retention ratio after 50 charge and discharge cycles is more than 85%.

Owner:CENT SOUTH UNIV

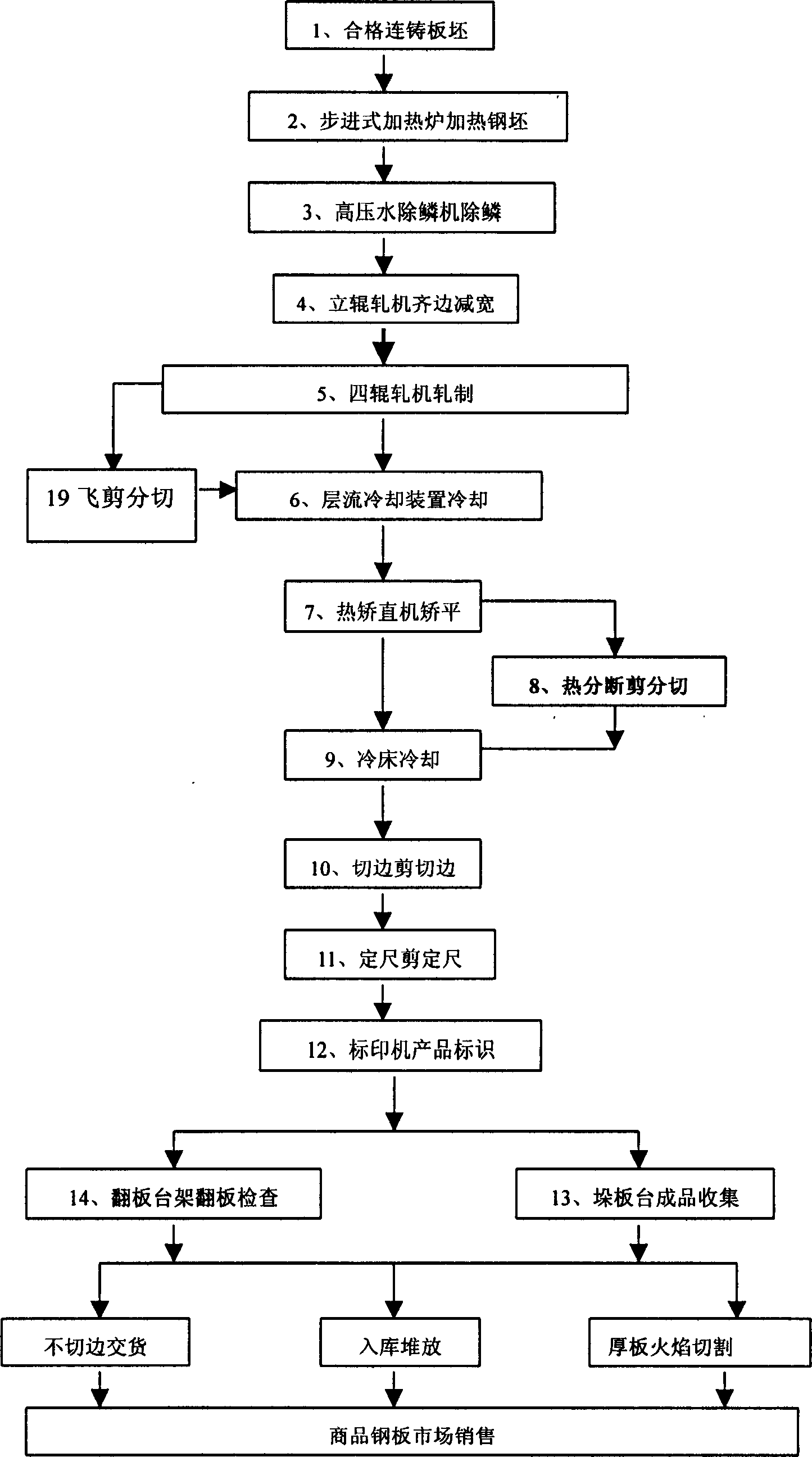

Medium-thick plate production process

InactiveCN1775390AIncrease productivityProduction adaptationMetal rolling arrangementsThick plateSheet steel

The present invention relates to a production process of heavy and medium plate. Said process includes the following steps: heating slab, removing scale, rolling by using rolling mill, laminar flow cooling, thermal straightening by using heat straightening machine, trimming by using trimming shear and cut-to-length by using cut-to-length shear.

Owner:SGIS SONGSHAN CO LTD

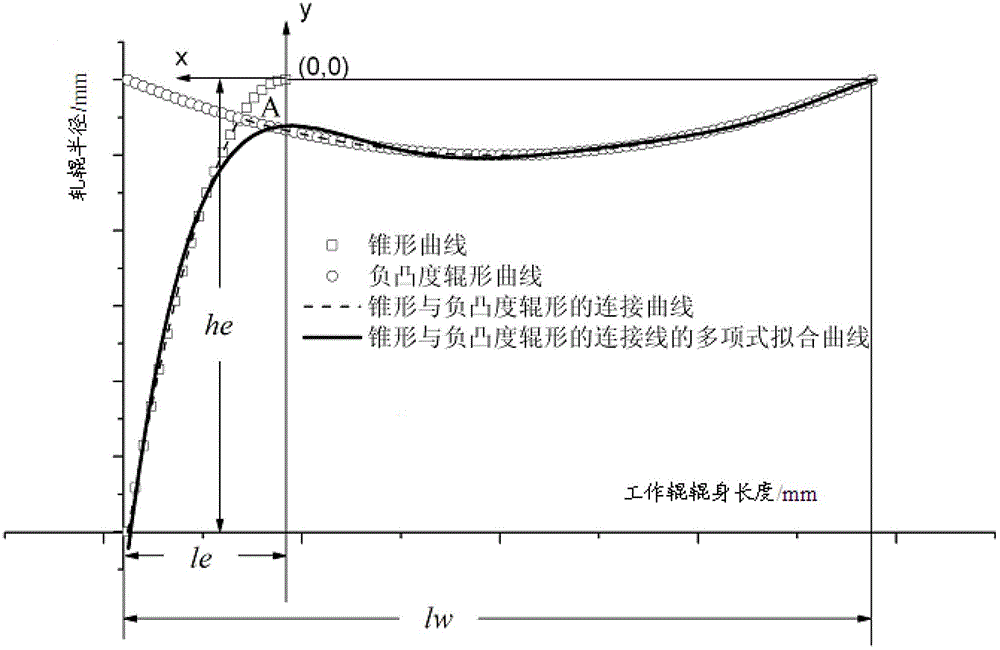

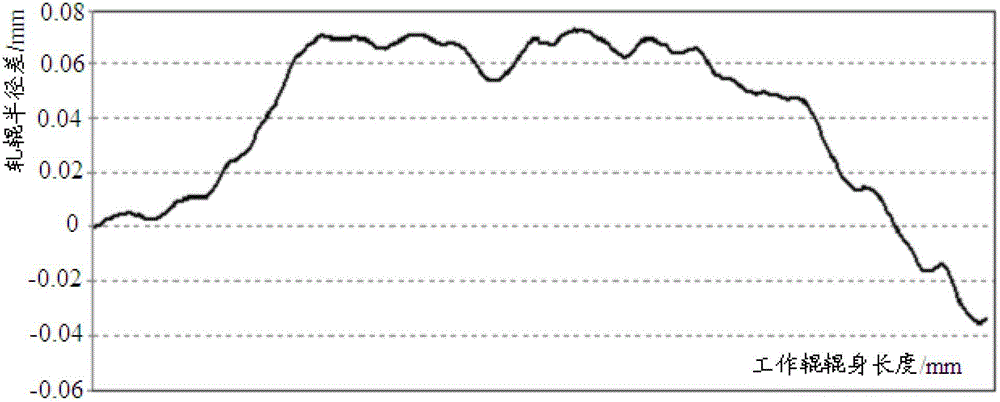

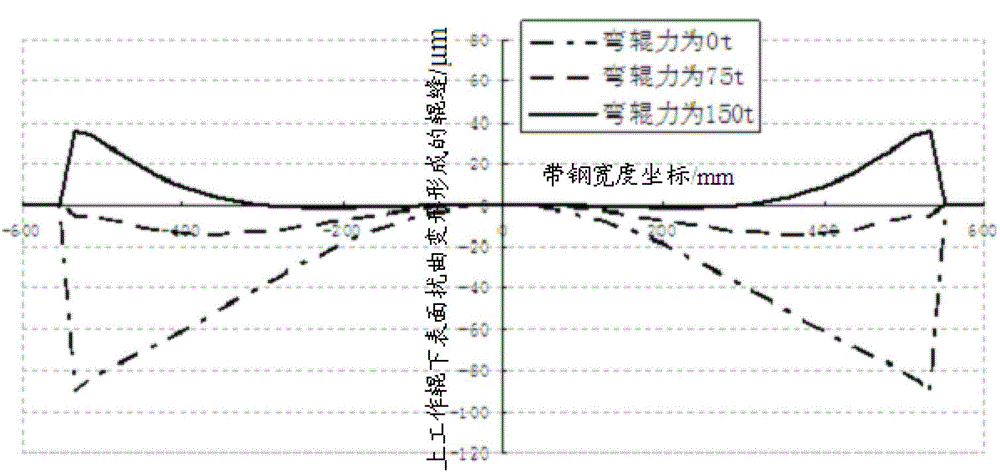

Working roller considering both convexity and edge drop control of strip steel and design method for roller shape of working roller

ActiveCN102744260AImprove shape qualityGood cross-sectional profile shapeRollsMetal rolling arrangementsProduction lineEngineering

The invention discloses a working roller considering both a convexity and an edge drop control of strip steel, belonging to the technical field of steel rolling. A curve equation of a roller shape of the working roller is that R(x)=b6x6+b5x5+b4x4+b3x3+b2x2+b1x+b0, x belong to [ 0,1w]. When the working roller is used for rolling silicon steel by the working roller on a downstream rack in a refine rolling set of a heat continuous rolling production line, a rolling hot convexity can be offset by a negative convexity segmentation of a parabolic curve, the edge drop of strip steel can be controlled by the segmentation of a conical curve, so that hot silicon steel is enabled to have a cross section with excellent profile and shape, a good board condition is provided for subsequent cold rolling, quality of silicon steel board shape is increased, edge-cutting quantity of a finished product of silicon steel is reduced, and the finished product rate is improved. Additionally, the invention further discloses a design method for a roller shape of the working roller.

Owner:SHOUGANG CORPORATION

Compartment trench controlled irrigating paddy rice water-saving culturing method

InactiveCN105248206AWide applicabilityEasy to masterRice cultivationSoil-working methodsWater levelBiology

The invention discloses a compartment trench controlled irrigating paddy rice water-saving culturing method. The culturing method comprise she following steps of ploughing the soil, digging trenches, forming compartments, direct broadcasting or transplanting paddy rice, managing moisture and managing the field. A compartment and trench mode is employed for paddy rice plantation; based on different paddy rice growth periods, a circulating irrigation process with humid compartment surface soil and formed by full trench water-half trench water or full trench water-dry trench is achieved; paddy field compartment trench water level can be visually tested and compartment surface soil humidity can be determined, so irrigating time and amount can be determined and present intermittent irrigation technology can be optimized; irrigation water can be conserved; rain water and irrigation water utilization rate can be improved; and paddy rice yield can be maintained or improved.

Owner:HUAZHONG AGRI UNIV

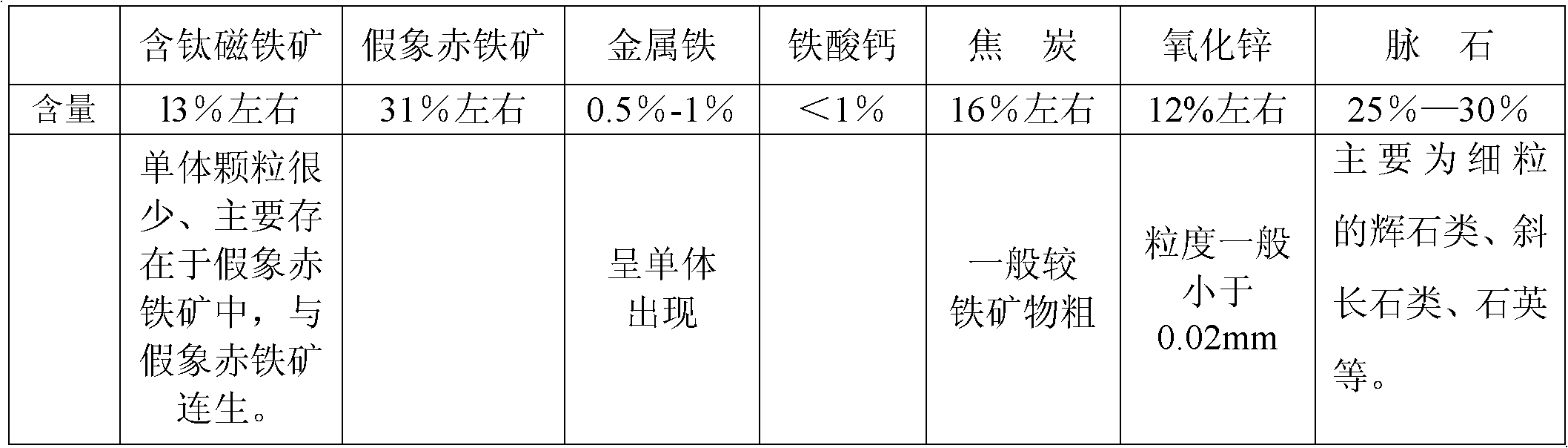

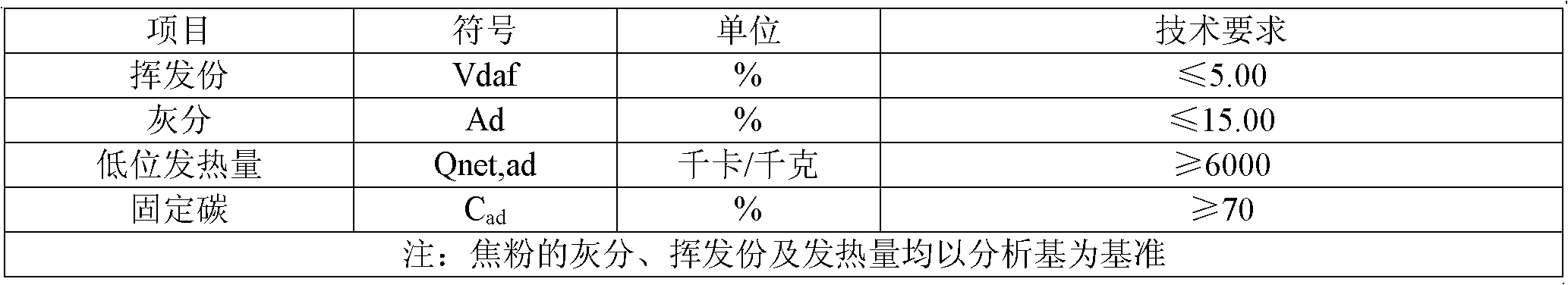

Technological method for extracting zinc by roasting blast furnace gas mud by virtue of rotary kiln

InactiveCN102127645AReduce in quantityReduce mass ratioRotary drum furnacesProcess efficiency improvementSlagZinc

The invention discloses a technological method for extracting zinc, in particular to a technological method for extracting zinc by roasting blast furnace gas mud by virtue of a rotary kiln, belonging to the technical field of metallurgy production. By applying the technological method provided by the invention, zinc oxide in the gas mud can be thoroughly reduced, and the production cost is low. The technological method comprises the following steps of: a) burdening, namely adding coke powder with the mass ratio of 16-20% into the gas mud and mixing to be uniform; b) checking, namely carrying out a sampling test on the calorific value of mixture of the gas mud and the coke powder which are uniformly mixed, wherein the acceptable calorific value is 1600-2000 kcal / kg; c) roasting and reducing, namely directly sending the qualified mixture of the gas mud and the coke powder into a kiln body of the rotary kiln to be roasted and reduced, thus zinc oxide particles and metallized slag are generated; and d) collecting, namely collecting the zinc oxide particles at the tail of the kiln and discharging residual metallized slag from the head of the kiln.

Owner:PANZHIHUA GANGCHENG GROUP

Low-mercury catalyst for hydrochlorination of acetylene

ActiveCN103203241AImprove anti-poisoning performanceExtend your lifeMolecular sieve catalystsActivated carbonPtru catalyst

The invention discloses a low-mercury catalyst and particularly relates to the low-mercury catalyst which is suitable for synthesizing vinyl chloride by hydrochlorination reaction of acetylene. The catalyst comprises a main active component, namely mercury chloride, auxiliary active components, namely at least one of oxides of cobalt, manganese, silver and copper and a carrier, namely activated carbon, wherein the mercury chloride accounts for 2-4% of the weight of the carrier of the catalyst, and the auxiliary active components account for 5-30% of the weight of the carrier of the catalyst in total. According to the prepared low-mercury complex catalyst disclosed by the invention, the auxiliary components are added, so that the anti-poisoning performance of the low-mercury catalyst is enhanced, the reduction of the mercury chloride during the using process is reduced, the loss of mercury is retarded, the service life of the low-mercury catalyst is significantly prolonged, and the low-mercury catalyst is the novel low-mercury catalyst with good activity, strong stability and high selectivity. The low-mercury catalyst has the advantages of simple production process, short production period and low mercury consumption.

Owner:XINJIANG TIANYE GRP +1

Manufacturing method of super-thick steel plate

ActiveCN103111464AReduced compression ratio requirementsLarge amount of deformationTemperature control deviceMetal rolling arrangementsThick plateIndustrial engineering

The invention discloses a manufacturing method of a super-thick steel plate (thickness is 60 millimeters) and belongs to the steel plate production field of metallurgical industry. The manufacturing method of the super-thick steel plate comprises the following steps: firstly, sending a plate blank which is heated to a certain temperature and removed an oxide scale to cooling space to conduct forced cooling, surface temperature cooling a phase transition temperature of the super-thick plate material above Ar 1, then by short time temperature returning, the surface temperature rising to the range between 780 DEG C and 880 DEG C, and sending the plate bland to a rolling mill to roll as soon as possible; when the surface temperature of the plate blank being higher than 880 DEG C, needing to conduct the forced cooling again, and then conducting the subsequent rolling. A cooling-temperature returning-rolling process can be repeated for many times if needed till rolling to the needed thickness of the super-thick steel plate. The manufacturing method of a super-thick steel plate can increase dependent variable of the central area by increasing temperature difference between a surface layer and the central area and has the advantages of being beneficial to refining central organization and improving impact toughness, beneficial to removing center porosity of the super-thick plate, and capable of reducing double strand shape on lateral sides of the super-thick plates. The manufacturing method of a super-thick steel plate further has the advantages of being saving in investment, and flexible to operate.

Owner:UNIV OF SCI & TECH BEIJING

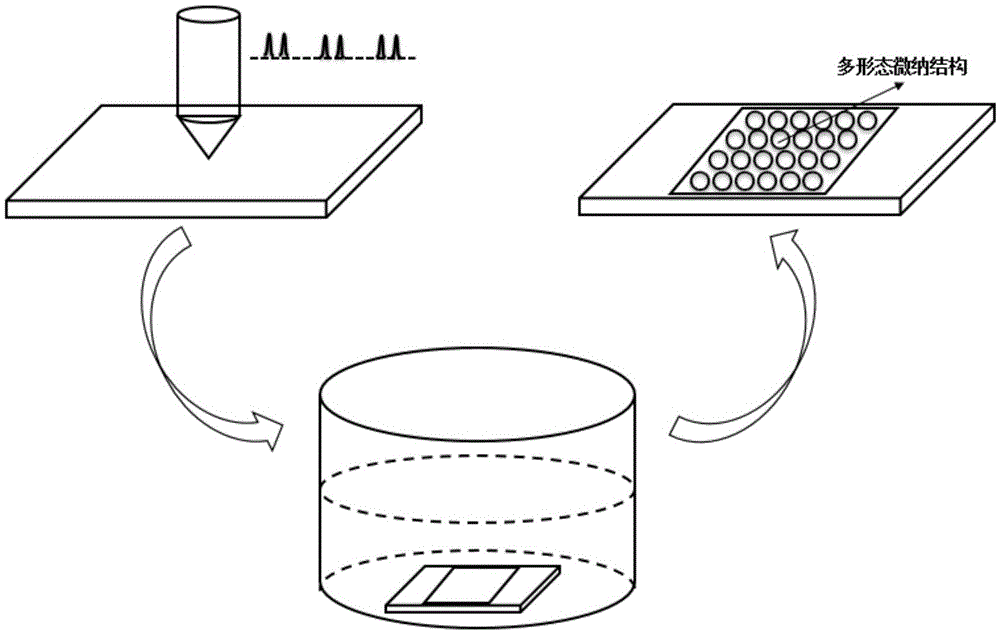

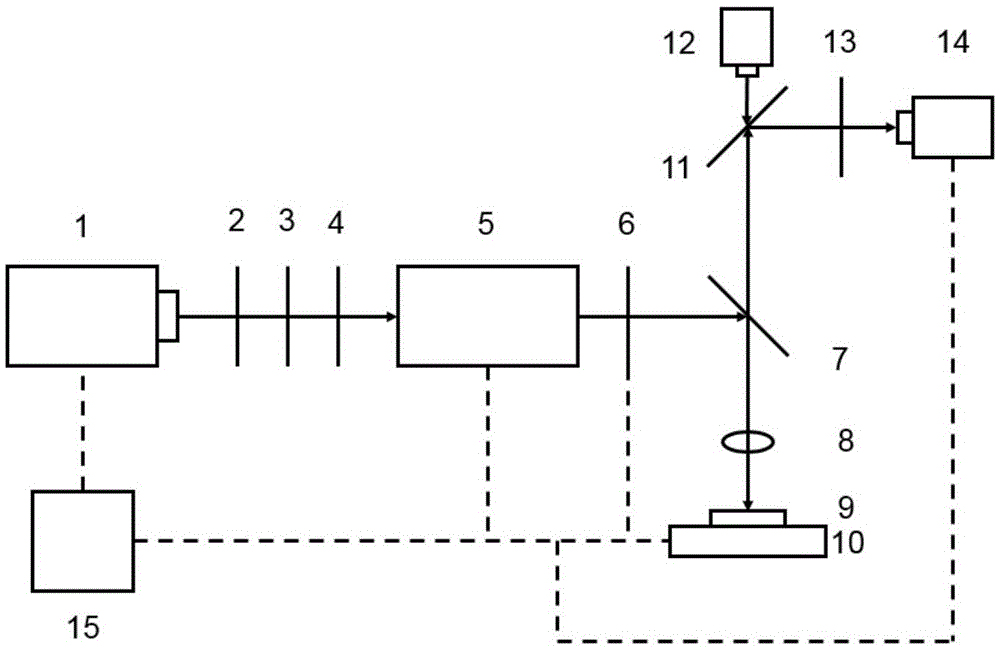

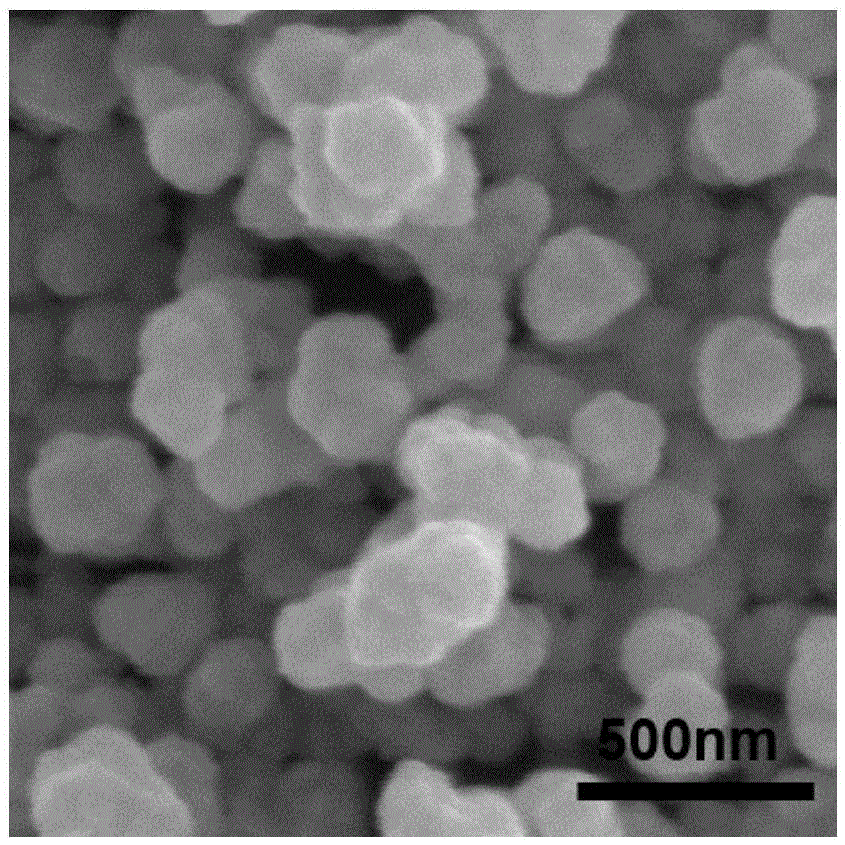

Method for preparing polymorphic gold nano-structure by using laser-inducing material through reduction

The invention relates to a method for preparing a polymorphic gold nano-structure by using a laser-inducing material through reduction and belongs to the field of micro-nano manufacture. According to the method, different degrees of reducibility of the surface of a molybdenum disulfide film are induced to obtain a modified molybdenum disulfide film by focusing a femtosecond laser pulse sequence to the surface of the molybdenum disulfide film; the modified molybdenum disulfide film is immersed into a chloroauric acid solution with the concentration of 0.2-8 mM / L, and the modified area of the molybdenum disulfide film performs reducing reaction with chloroauric acid to obtain the polymorphic gold nano-structure. The method for preparing the polymorphic gold nano-structure by using the laser-inducing material through reduction utilizes regulation and control of the femtosecond laser pulse sequence to enable the molybdenum disulfide surface to have chemical reduction activity so as to directly obtain the gold nano-structure through reduction and has the advantages that a special chemical environment and any chemical reagent are not needed, and the method is green, environmentally friendly, simple and flexible in operation and the like.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Method for controlling strip steel edge cracking

InactiveCN107626745AQuality improvementControl edge crack depthRoll mill control devicesMetal rolling arrangementsReduction rateStrip steel

The invention relates to a method for controlling strip steep edge cracking. The method is suitable for the cold rolling process after oriented silicon steel normalizing treatment. The method includesthe steps that firstly, in the shearing process before cold rolling, heating is conducted on the edge portion of strip steel, and the disc shear blade side gap and the lap amount are adjusted; secondly, the strip steel temperature is controlled to be 60 DEG C or above before cold rolling; and thirdly, in the cold rolling process, the reduction rate, the rolling temperature, the deformation speed,tension and the work roller roughness in the first gate are controlled. The above measures are adopted so that the strip breaking phenomenon caused by edge cracking can be effectively reduced, the yield of a rolling mill is increased, the waste rolling amount and the edge reduction amount are reduced, and the oriented silicon steel edge portion quality and the product yield are increased.

Owner:ANGANG STEEL CO LTD

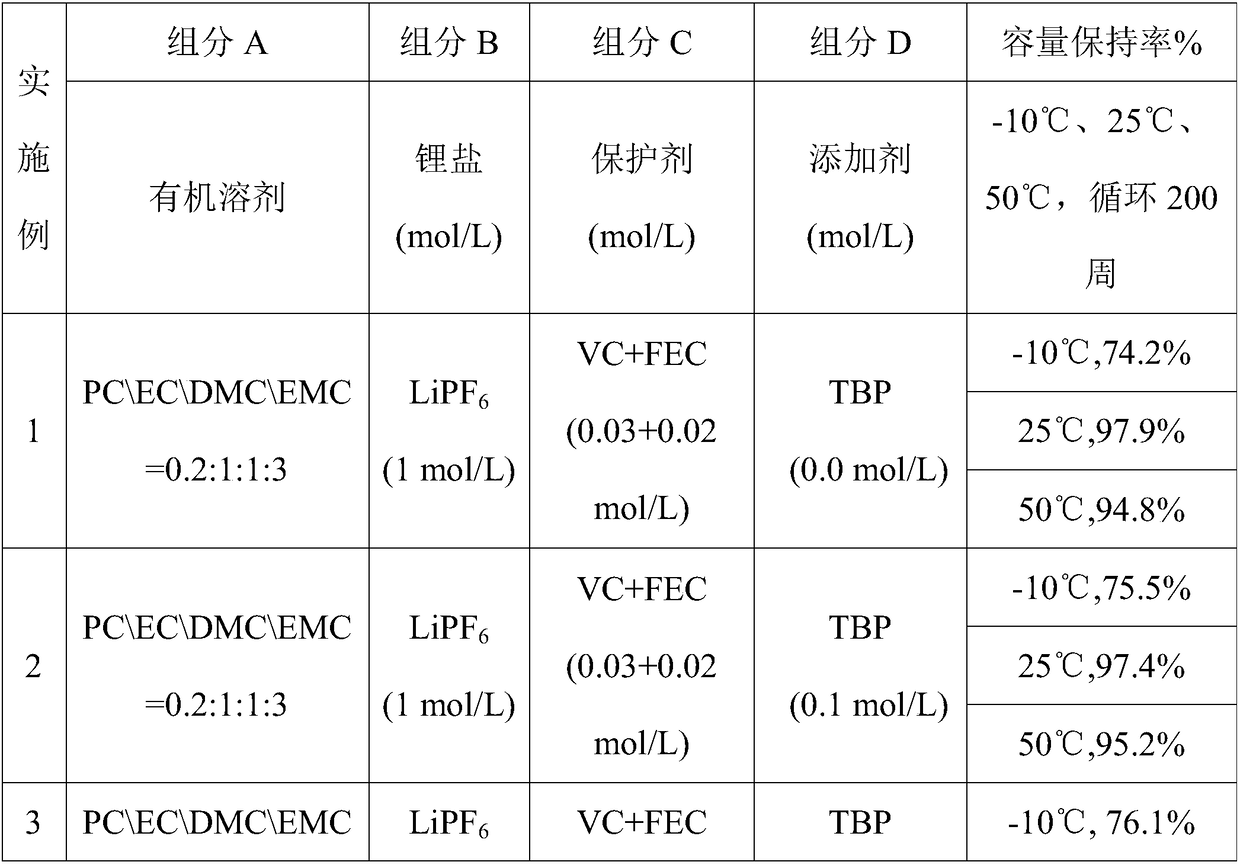

Electrolyte additive for improving low-temperature properties of lithium ion battery and electrolyte

InactiveCN108321433AImprove conductivityHigh freezing pointSecondary cellsOrganic electrolytesChemistryCharge and discharge

The invention discloses an electrolyte additive for improving low-temperature properties of a lithium ion battery and electrolyte and relates to the technical field of lithium ion batteries. The additive is pyridine with an electron donor group substitution group, and in addition, the molecular structure of the additive is free of intense electron withdrawing group substitution group. When the additive is applied to lithium ion battery electrolyte, the ion conduction velocity of the electrolyte under a low-temperature condition can be increased, the curing point of the electrolyte can be reduced, the charge and discharge capacity and the circulation performance of the lithium ion battery at a low temperature can be improved, meanwhile the wettability of an anode piece and a cathode piece can be improved. The additive does not affect the performance of a battery cell at normal temperatures and high temperatures, and is gentle to the environment.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

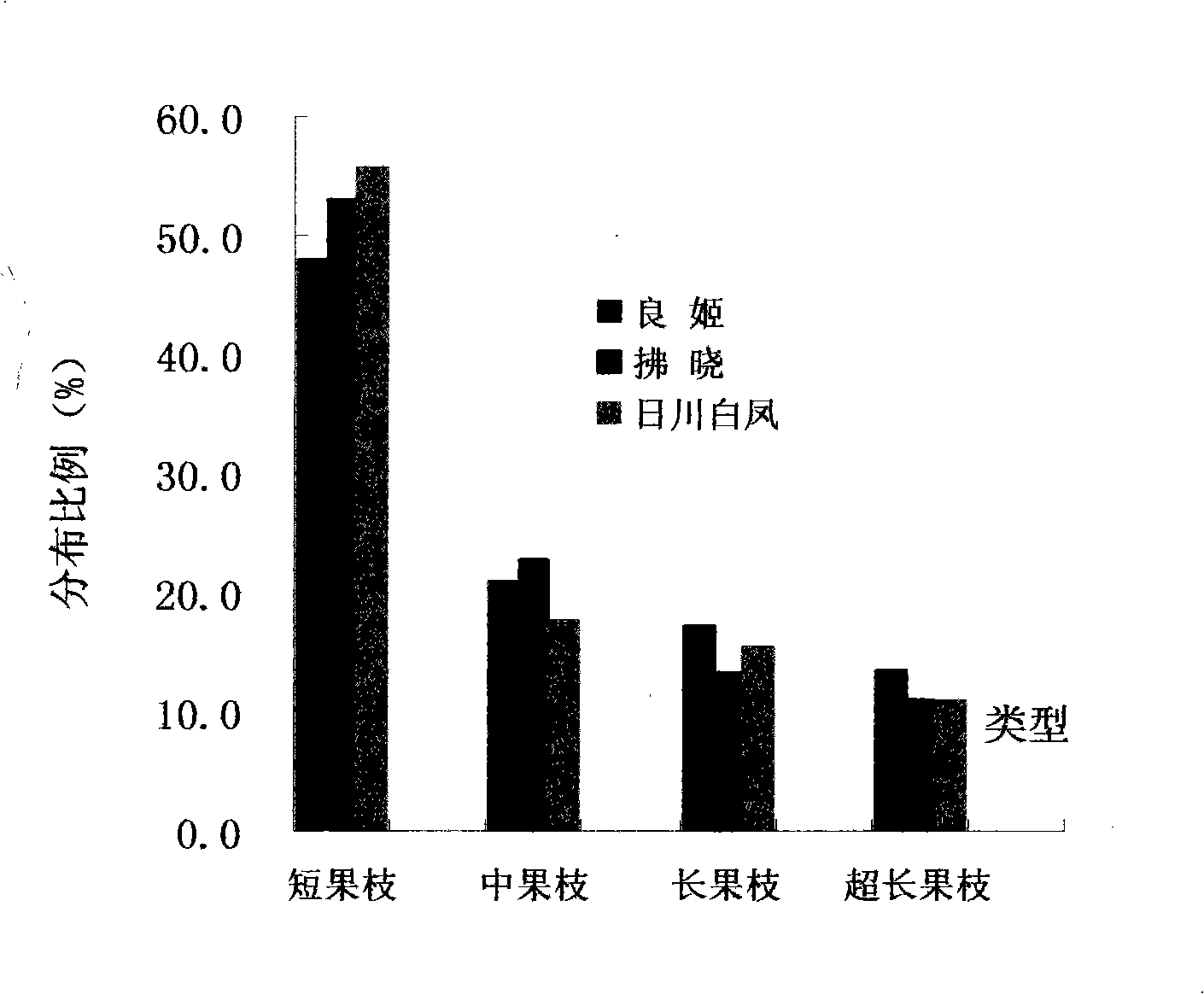

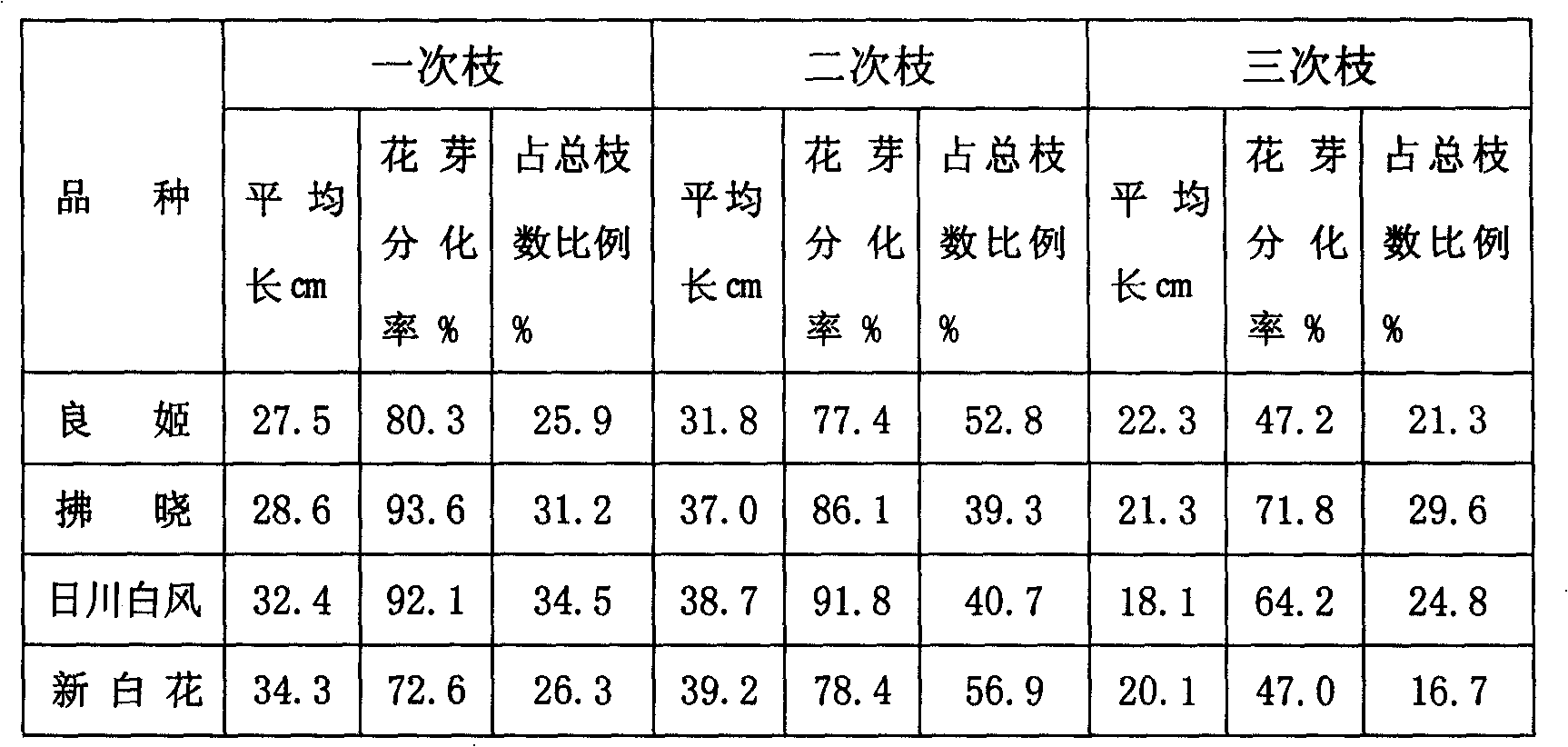

Plate-like tidying and pruning method for peach

The invention relates to a peach tree pruning method which belongs to the technical field of peach tree cultivation. After peach seedlings are colonized, 15cm to 20cm of fixed pole height is adopted; a fixed pole is provided with more than 5 to 7 good leaf buds which grow straightly upwards along a young sprout cultivating central pole on the top end; other germinal young sprouts at the matrix form wheel-shaped branches; after 3 to 4 years, 3 to 4 of the branches are selected as boughs to be cultivated; both sides of each bough are evenly provided with side branches and bearing branches; the angles formed between the boughs and the ground are kept to be about 30 degrees to 40 degrees. After 4 to 5 years of cultivation, a coiled tree shape with the 3-to-4-year boughs as the backbone is formed. The tree shape cultivated through the method makes full use of the characteristics of the natural growth of a peach tree; in the preliminary period, tree crown expands quickly, has high yield and good quality, is low in height, convenient and labor saving in operation; the light condition in the bore is fully improved, the matrix is not bald, the full bearing period is prolonged, the tree is strong, the economic life is long, and the peach tree cultivation has very good promotion and application value.

Owner:ZHENJIANG WANSHAN HONGBIAN AGRI PARK

European pear tree labor-saving early-fruiting pruning method

InactiveCN103004416AReduce invalid consumptionPromote differentiationHorticulture methodsFruit treePear tree

The invention belongs to the technical field of fruit tree pruning and particularly discloses a European pear tree labor-saving early-fruiting pruning method. In combination with actual production, by adopting a slender columnar European pear tree shape and by using techniques of bud carving, branch bending, bud picking, trunk cutting and the like, a labor-saving early-fruiting pruning technique which has the advantages that European pear trees can fruit from the third year and can yield highly from the fifth year after the European pear trees are planted, the European pear trees are not pruned basically in the first four years, the pruning quantity at a full bearing period is very small and 3-5 mu of European pear trees can be pruned per person per day. Not only can the labor force and the production cost be greatly saved, but also the cultivation goals of early fruiting and high efficiency are realized and the economic benefits are remarkable.

Owner:ZHENGZHOU FRUIT RES INST CHINESE ACADEMY OF AGRI SCI

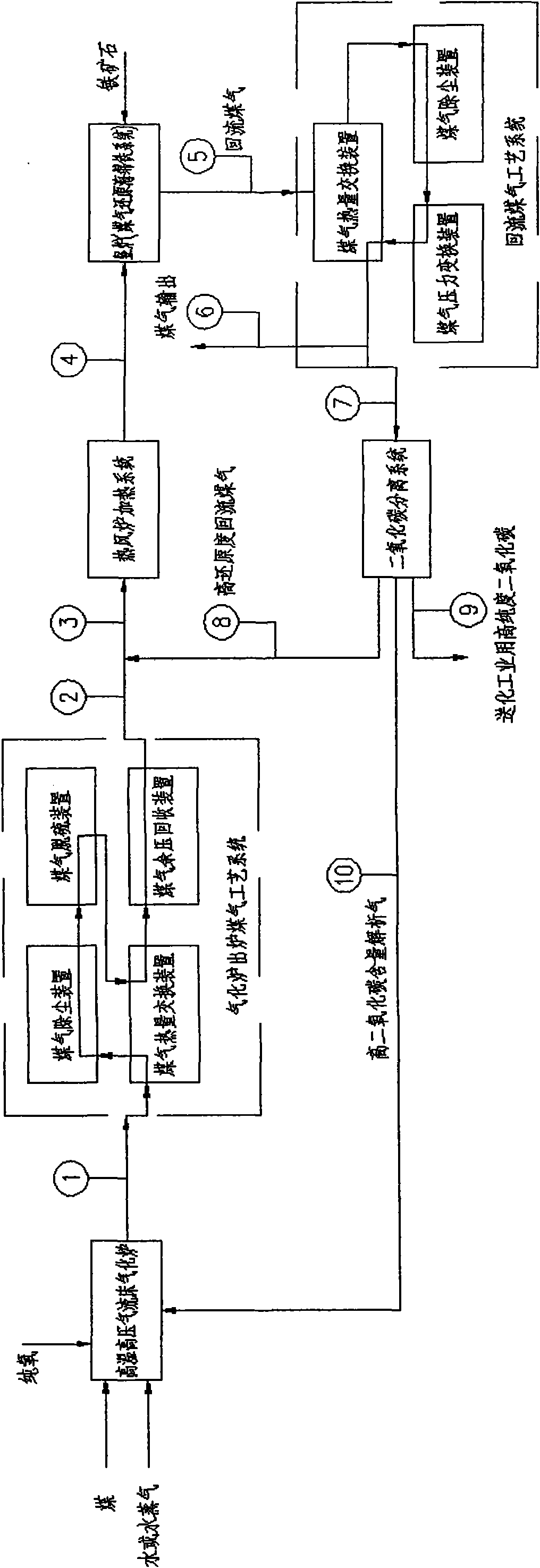

Sponge iron production technology by coal gasification

ActiveCN101643809AReduce consumptionReduce investmentProcess efficiency improvementShaft furnaceProcess systemsWater vapor

The invention belongs to the metallurgy technical field and discloses a sponge iron production technology by coal gasification. The invention is characterized in that: coal and oxygen, water or steamreact in a high temperature high pressure entrained flow gasifier to generate reducing coal gas rich in CO+H2, the reducing coal gas is subject to dust removal, desulfuration and pressure and heat transformation by a gasifier discharge coal gas process system and then mixed with decarburization gas rich in CO+H2 after shaft furnace top gas passes through a return coal gas process system and a carbon dioxide separation system, and then the mixed gas is heated to the temperature range required by the shaft furnace and then fed into the shaft furnace to reduce iron ore, so as to produce sponge iron. The invention reduces high temperature high pressure entrained flow gasifier cost; the shaft furnace top gas circulating reflux is fully utilized to reduce coal use consumed in sponge iron production, and cost is saved; and CO2 is collected and recycled.

Owner:CISDI ENG CO LTD

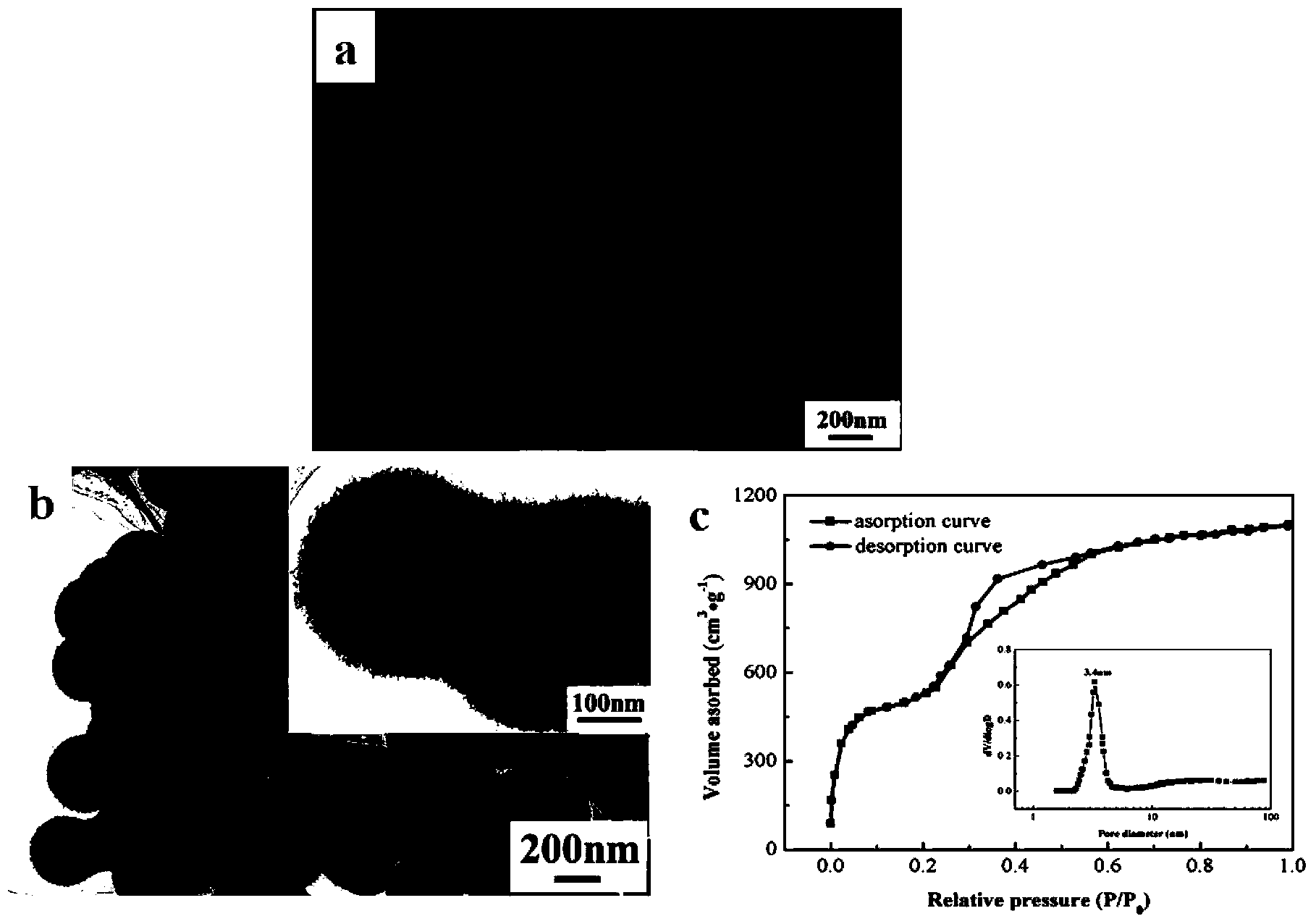

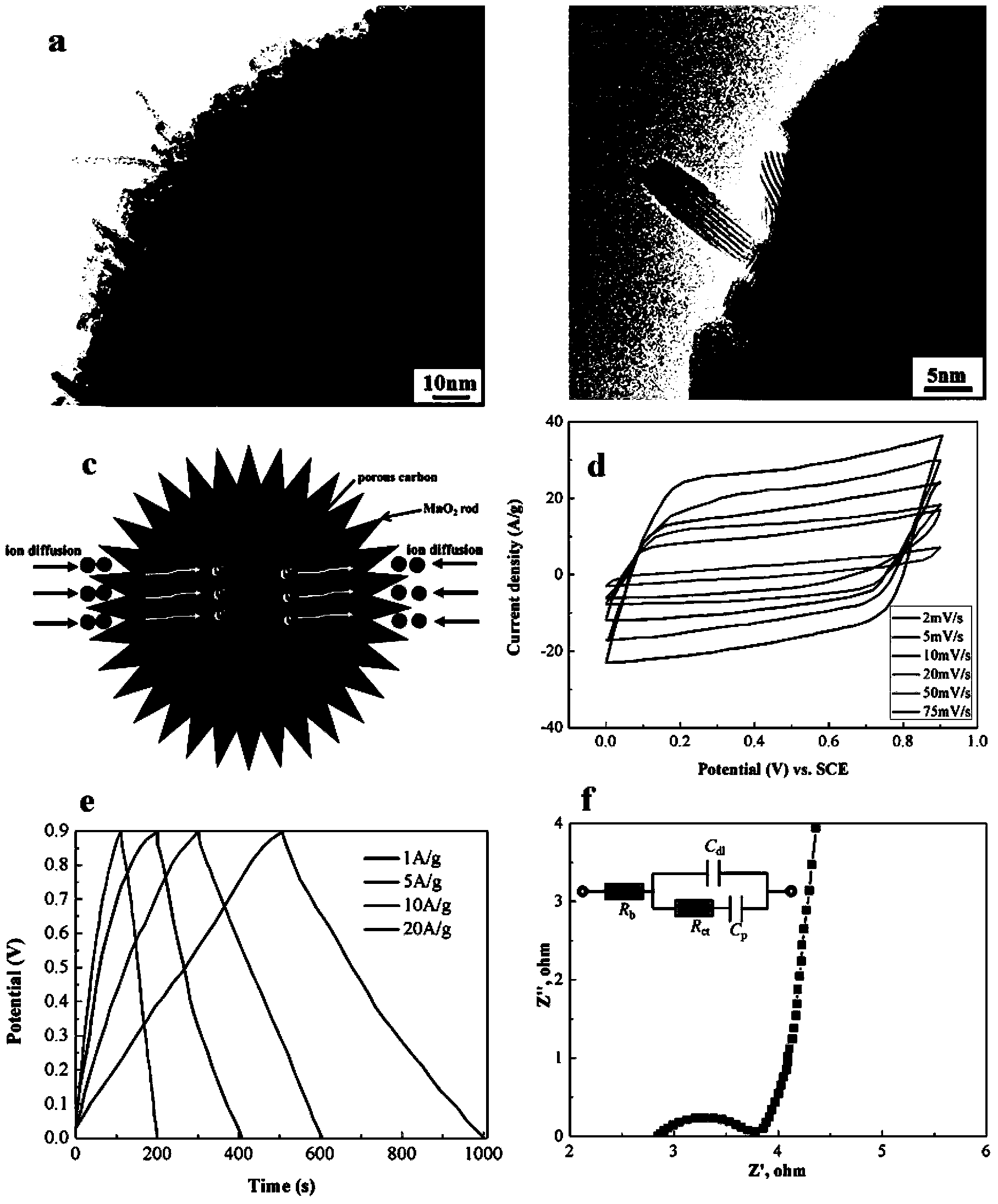

Method for preparing MnO2/carbon composite material for super-capacitor

ActiveCN103413691AReduce trimmingImprove conductivityHybrid capacitor electrodesHybrid/EDL manufactureCarbon compositesSucrose

The invention provides a method for preparing a MnO2 / carbon composite material for a super-capacitor. The method includes the steps of step one, dissolving glucose or sucrose or fructose in deionized water, stirring until a settled solution is obtained, transferring the settled solution into a hydrothermal reaction kettle, performing centrifugation, water washing, alcohol washing and drying on an obtained polymeric pecursor solution to prepare monodisperse carbon spheres; step two, taking the monodisperse carbon spheres, performing heat treatment on the monodisperse carbon spheres in a NaOH solution, then performing centrifugation, water washing and alcohol washing on a mixture solution three times, conducting drying, and performing calcination treatment in vacuum or inert atmosphere; step three, using the carbon spheres experiencing modified treatment in the step two as a template, placing the template in a KMnO4 aqueous solution, stirring and aging at the room temperature, obtaining a sediment, performing centrifugation, water washing and alcohol washing on the sediment, performing drying in a vacuum oven, and obtaining CS@MnO2 coated powder. Obtained MnO2 / carbon sphere composite powder is of a core-shell structure, the specific surface area of the powder can reach more than 778m<2> / g, the specific capacity of the powder can reach more than 439F / g, charge transfer resistance is lower than 2.1 omega, and the powder is a novel super-capacitor electrode material.

Owner:TSINGHUA UNIV

Fast frame-climbing method of shed frame pear tree boughs

ActiveCN103081676AIncrease pavedIncrease reachCultivating equipmentsHorticulture methodsShootAgricultural engineering

The invention provides a fast frame-climbing method of shed frame pear tree boughs. The frame-climbing method is carried out on a shed frame of a three-line one plane or two-line one plane mode, and frame climbing is carried out by three steps of strengthening, pulling in an inclined mode, and pulling in a level mode. The first step of strengthening is that young shoots are guided onto an elevation guide line in a vertical mode during a growing season so that the young shoots can keep a vertical growing state. The second step of pulling in an inclined mode is that base parts of the shoots growing vertically are pulled in a level mode and fixed behind the shed frame face during autumn of the same year, and then are guided onto the elevation guide line according to a 45-degree angle, namely, the base parts of the shoots are firstly pulled in a level mode and fixed and then pulled in an inclined mode. The third step of pulling in a level mode is that the shoots are pulled in a level mode and fixed on the shed frame face during autumn of the next year. The fast frame-climbing method has the advantages of being fast in frame-climbing, few in water shoots, small in trimming quantity, large in frame face fruit area, high in output and the like.

Owner:INST OF FRUIT & TEA HUBEI ACAD OF AGRI SCI

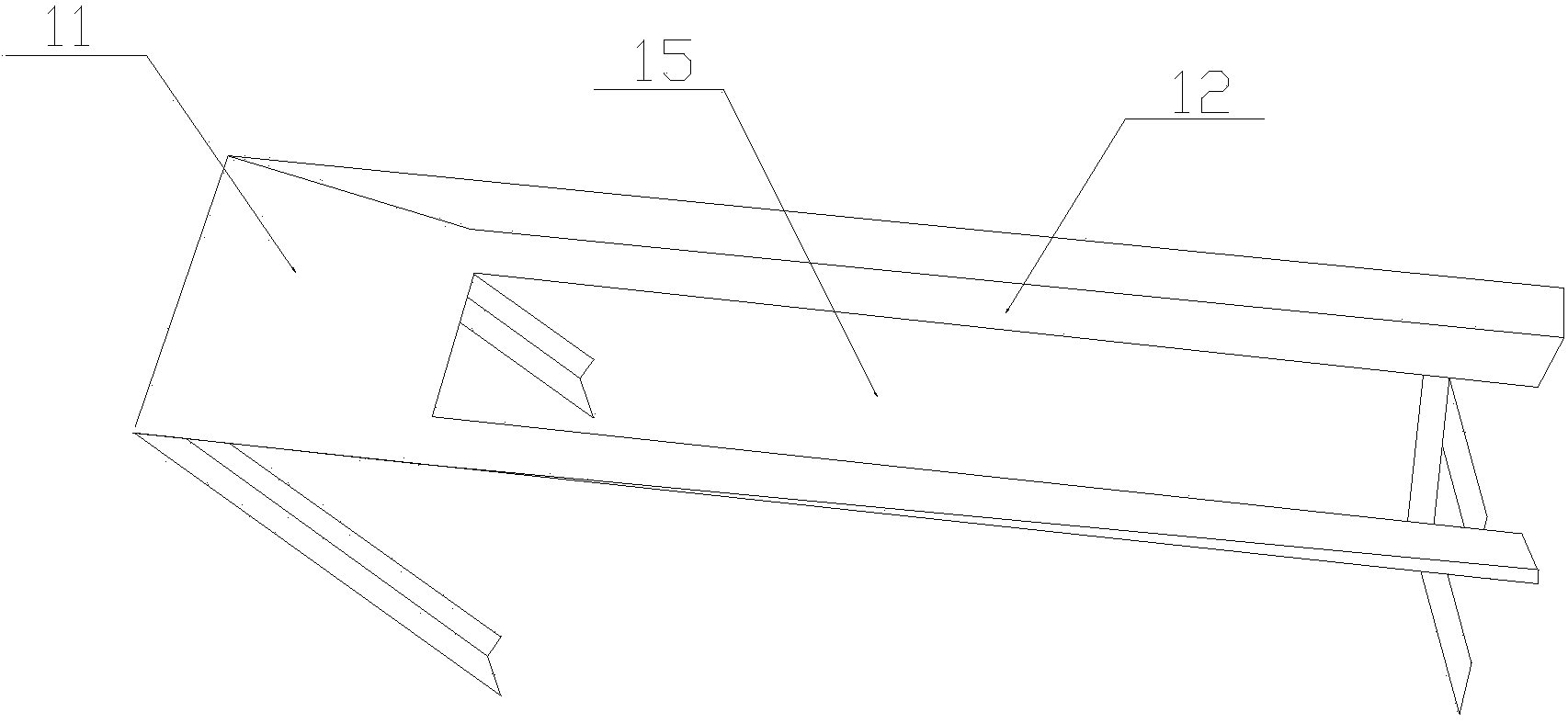

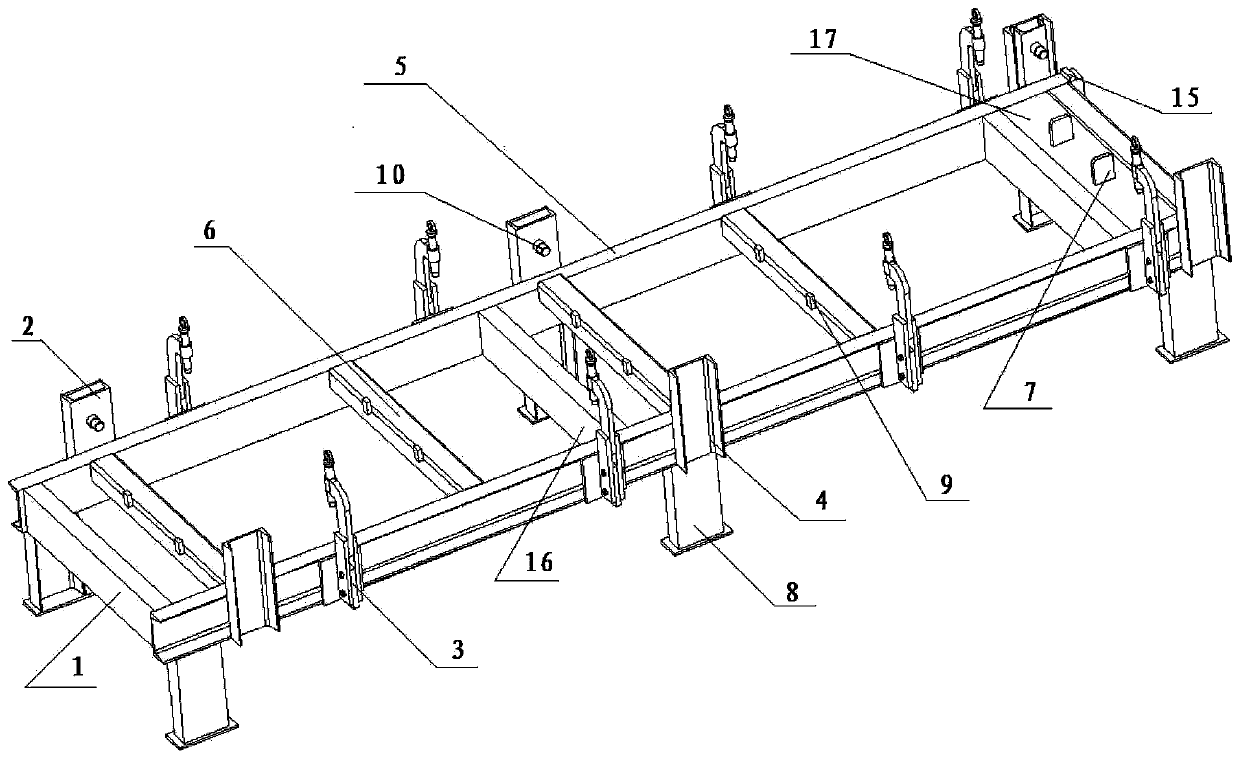

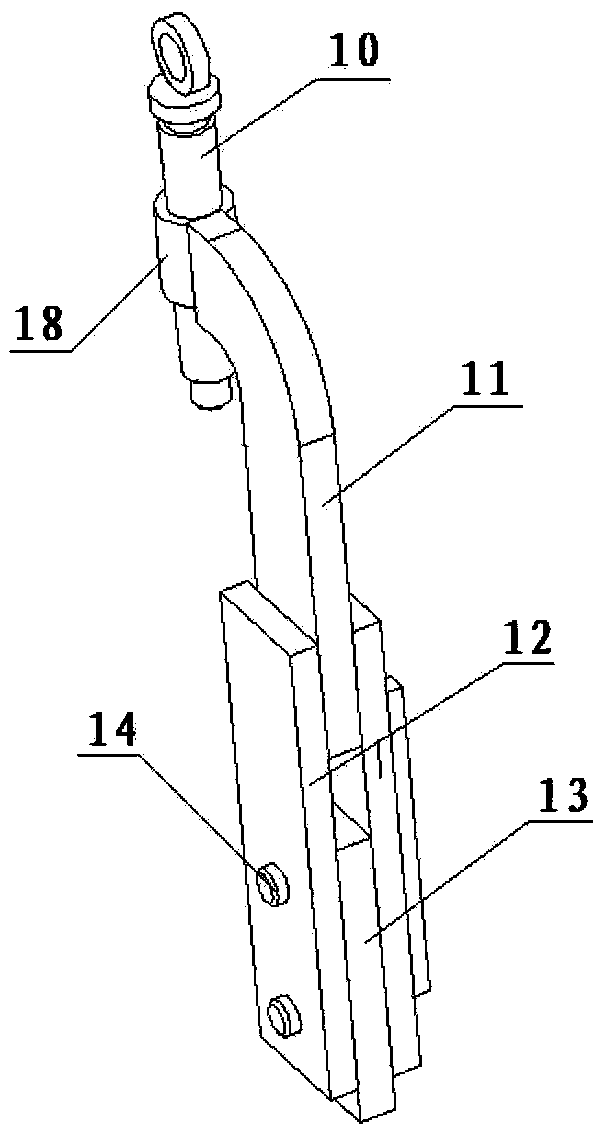

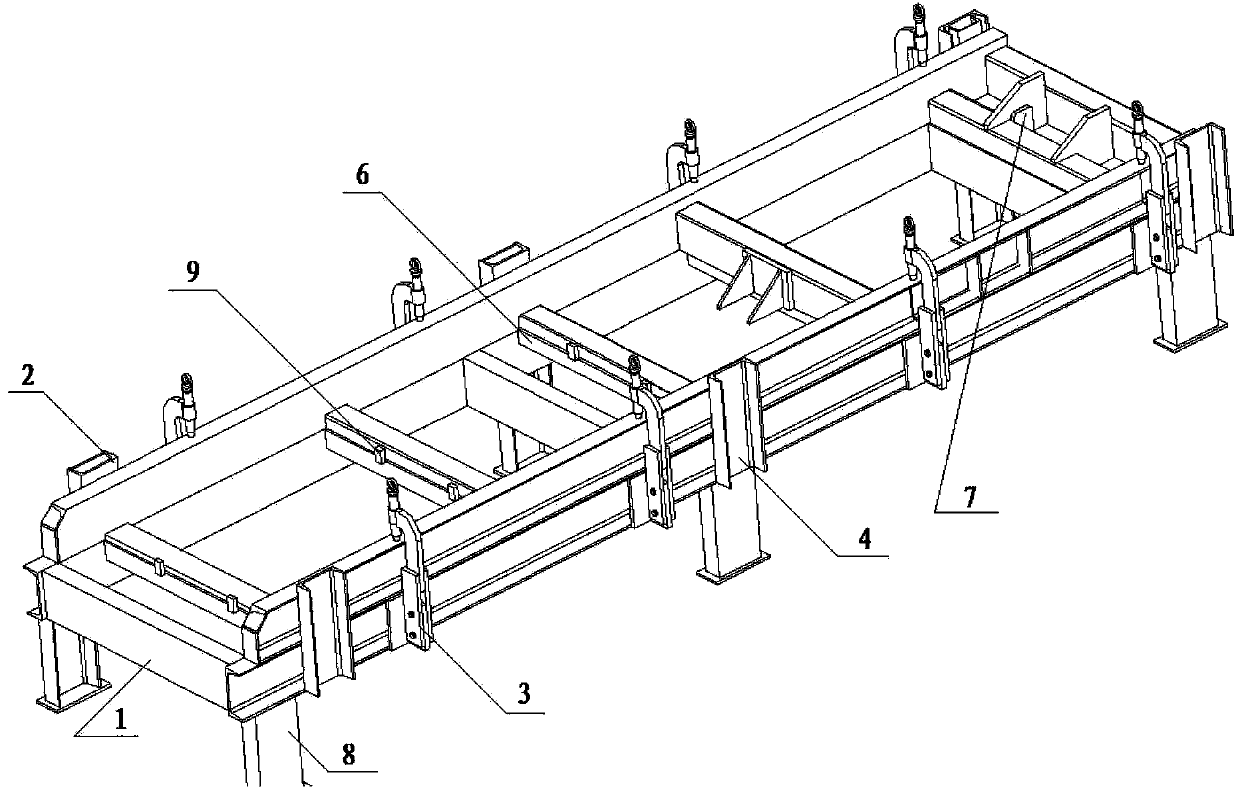

Carriage longitudinal beam tailor welding tool

ActiveCN103418965ASave adjustment timeHigh precisionWelding/cutting auxillary devicesAuxillary welding devicesEngineering

The invention relates to a carriage longitudinal beam tailor welding tool. The carriage longitudinal beam tailor welding tool comprises a fixing frame and a first stand column which is fixed on the edge of one side of the fixing frame, wherein the edge of the other side of the fixing frame is fixedly connected with the lower portion of a second stand column, a regulating rod is fixed on the edge of the position, between the first stand column and the second stand column, of the fixing frame, and a base plate is fixedly connected with the surface of one end of the fixing frame. The carriage longitudinal beam tailor welding tool has the advantages that a part to be welded is accurately located and reliably clamped, so that the part to be welded is conveniently assembled and welded, and structural accuracy of the part to be welded is improved.

Owner:广西玉柴专用汽车有限公司

Lithium-Ion Secondary Battery

ActiveUS20090274958A1Small internal resistanceExcellent force and ion conductivityAlkaline accumulatorsActive material electrodesCapacitanceCurrent collector

The purpose of the present invention is to provide a lithium-ion secondary battery with small internal resistance, excellent load characteristics and low reduction in capacitance due to repeated discharge and charge.The lithium-ion secondary battery of the present invention attaining the above purpose comprises a positive electrode, negative electrode and electrolyte; said positive electrode and negative electrode are configured by binding an active material layer, including an electrode active material and a binder, to a collector; the binder used for at least one of the positive electrode or negative electrode includes polymer particles; and the polymer particles satisfy the following properties:swelling degree in the electrolyte of a sheet-like molded body, obtained by pressure molding of only the polymer particles, is 5 to 50%, and lithium ion conductivity of the sheet-like molded body swollen by the electrolyte is 1×10−4 S·cm or more.

Owner:ZEON CORP

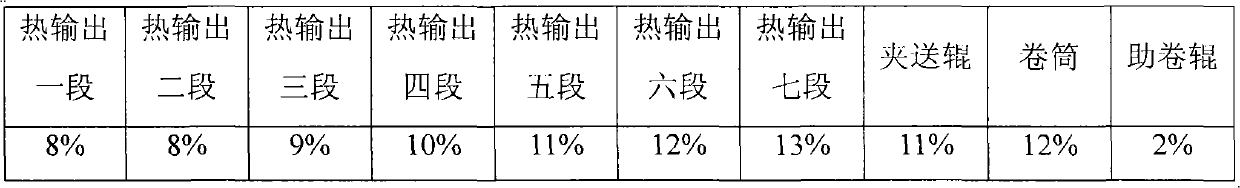

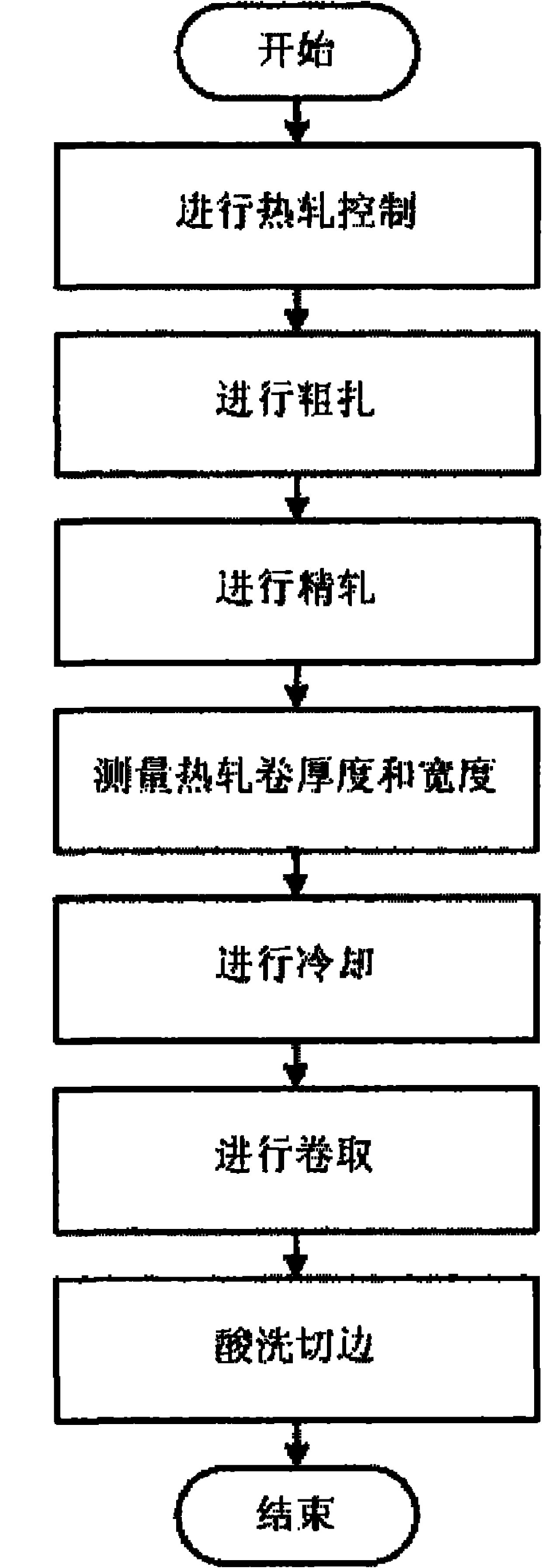

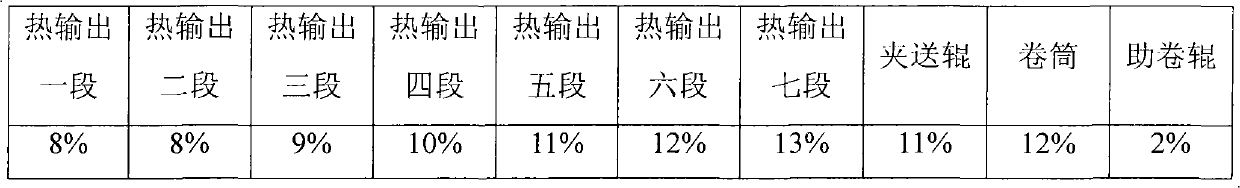

Production method of preventing from coiling and pulling narrow of hot-rolled low carbon strip steels used for cold-rolled base plates

InactiveCN101912874AReduce control difficultyReduce the probability of breakage or even broken beltTemperature control deviceMetal rolling arrangementsLaminar coolingTemperature difference

The invention discloses a production method of preventing from coiling and pulling narrow hot-rolled low carbon strip steels used for cold-rolled base plates, which comprises the following steps of: (1) controlling hot rolling, and heating plate blanks to 1190 to 1250 DEG C with temperature differences of the same plate equal or less than 40 DEG C; (2) carrying out rough rolling by adopting a 2-stage-3-point short stroke control with an outlet temperature of 1030 to 1080 DEG C; (3) carrying out finishing rolling at a temperature of 860 to 900 DEG C; (4) measuring thicknesses and widths of hot rolled steel coils; (5) carrying out laminar cooling; (6) setting each lead rate and coiling tension and coiling at a temperature of 560 to 670 DEG C; and (7) carrying out acid cleaning and cutting. The invention completely solves the problem of coiling and pulling narrow the hot-rolled low carbon strip steels used for the cold-rolled base plates by controlling hot rolling temperatures, short strokes of rough rolling, coiling lead rates, and coiling tensions.

Owner:NINGBO IRON & STEEL

Polymerizing production method for transparent amorphous copolyester

The invention discloses a polymerizing production method for transparent amorphous copolyester. The method has the advantages of low esterification temperature, short esterification time and high esterification rate. The method comprises the following steps of: carrying out an esterification reaction and a condensation reaction on dihydric alcohol and dicarboxylic acid to obtain the transparent amorphous copolyester, wherein the esterification reaction comprises the following specific procedures of: breaking various materials into pulp by using a pulping machine and carrying out the esterification reaction on the pulp at the temperature of 220-240DEG C for 1.0-1.5 hours to obtain an esterified product; the condensation reaction comprises the following specific procedures of: polymerizing the esterified product obtained by the esterification reaction at the reaction pressure of 0.2-0.5MPa and the temperature of 250-260DEG C for 1.5-2 hours; then reducing the pressure to be less than 200MPa within 0.5 hour; raising the condensation reaction temperature to be 275DEG C from 260DEG C; adding a thermal stabilizer; and after the condensation reaction, obtaining a polyester copolymer with the inherent viscosity of greater than 0.75dL / g and the carboxyl content of less than 10mol / t.

Owner:JIANGSU JINGHONG NEW MATERIAL TECH

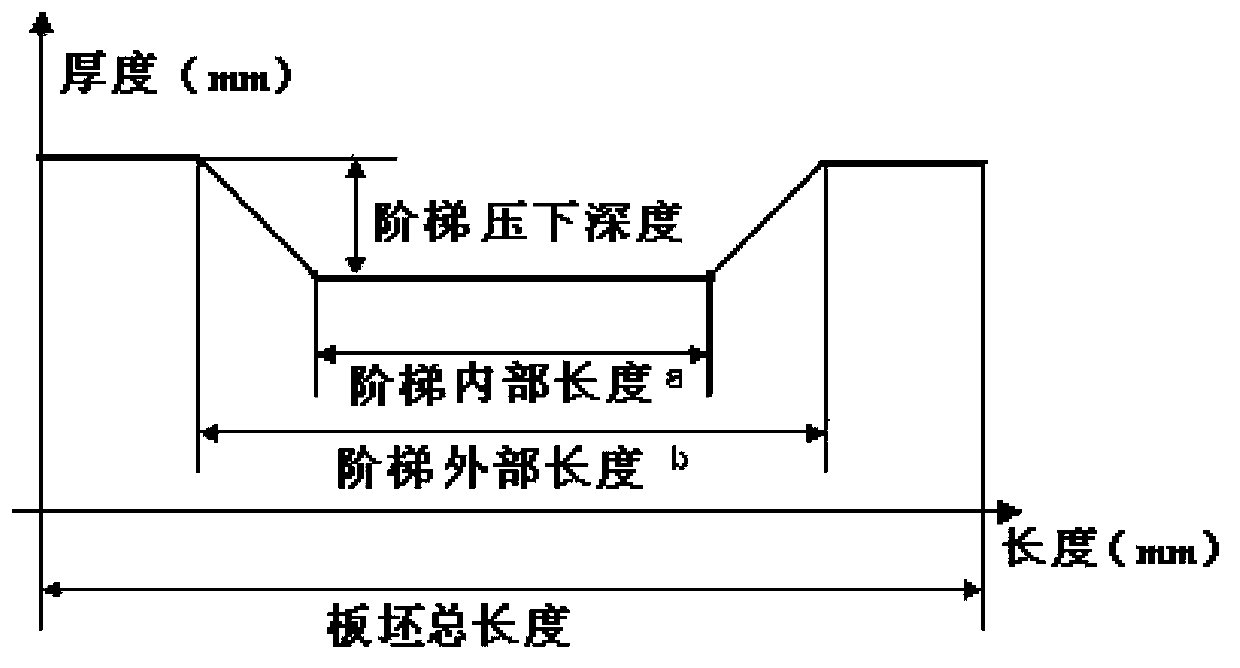

Method for controlling head-to-tail width of high broadening ratio steel plate

ActiveCN103386419AHigh yieldImprove rolling rhythmMetal rolling stand detailsMetallurgyRolling velocity

The invention discloses a method for controlling the head-to-tail width of a high broadening ratio steel plate. The method comprises a forming step, an expanding step and a longitudinal rolling step, wherein in the forming step, the rolling pass is one, the rolling reduction is 15-35mm, the ladder reduction height h is calculated according to a formula that h=2.3*(B / B'); and the rolling velocity V is calculated according to a formula that V=(b-a)*(VHGC / h) / 2. According to the method, by controlling the rolling reduction, the ladder thickness curve and the rolling velocity of the rough rolling forming pass, when the high expansion ratio steel plate is rolled, the high rolling rhythm of a roughing mill is kept, the following features of the ladder thickness curve and the set curve in the forming step can be improved, and the difference between the head-to-tail width and the middle width of the high broadening ratio steel plate is reduced, so that the trimming amount of the edge of the steel plate is reduced and the yield of the steel plate is improved.

Owner:LAIWU IRON & STEEL GRP

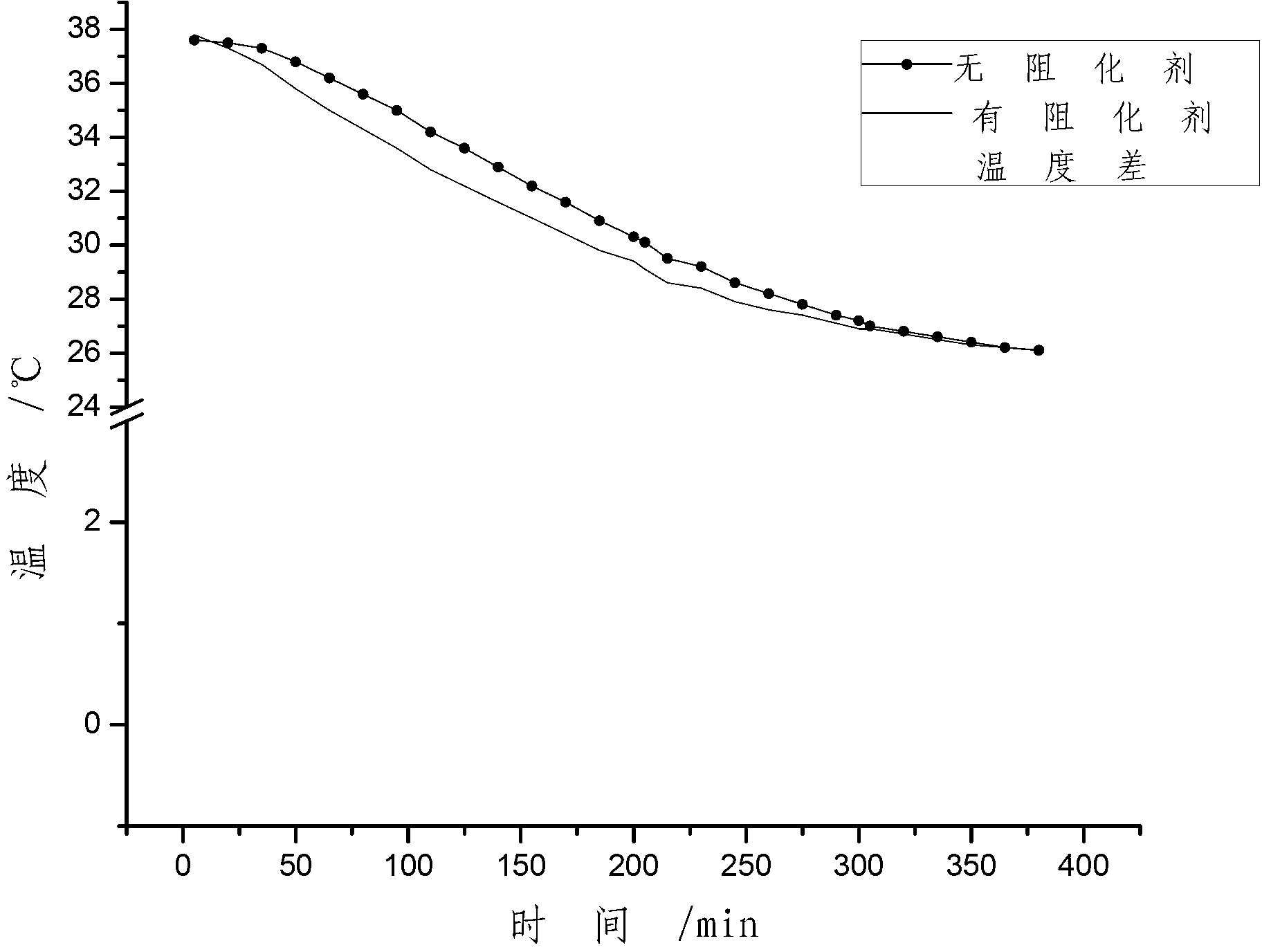

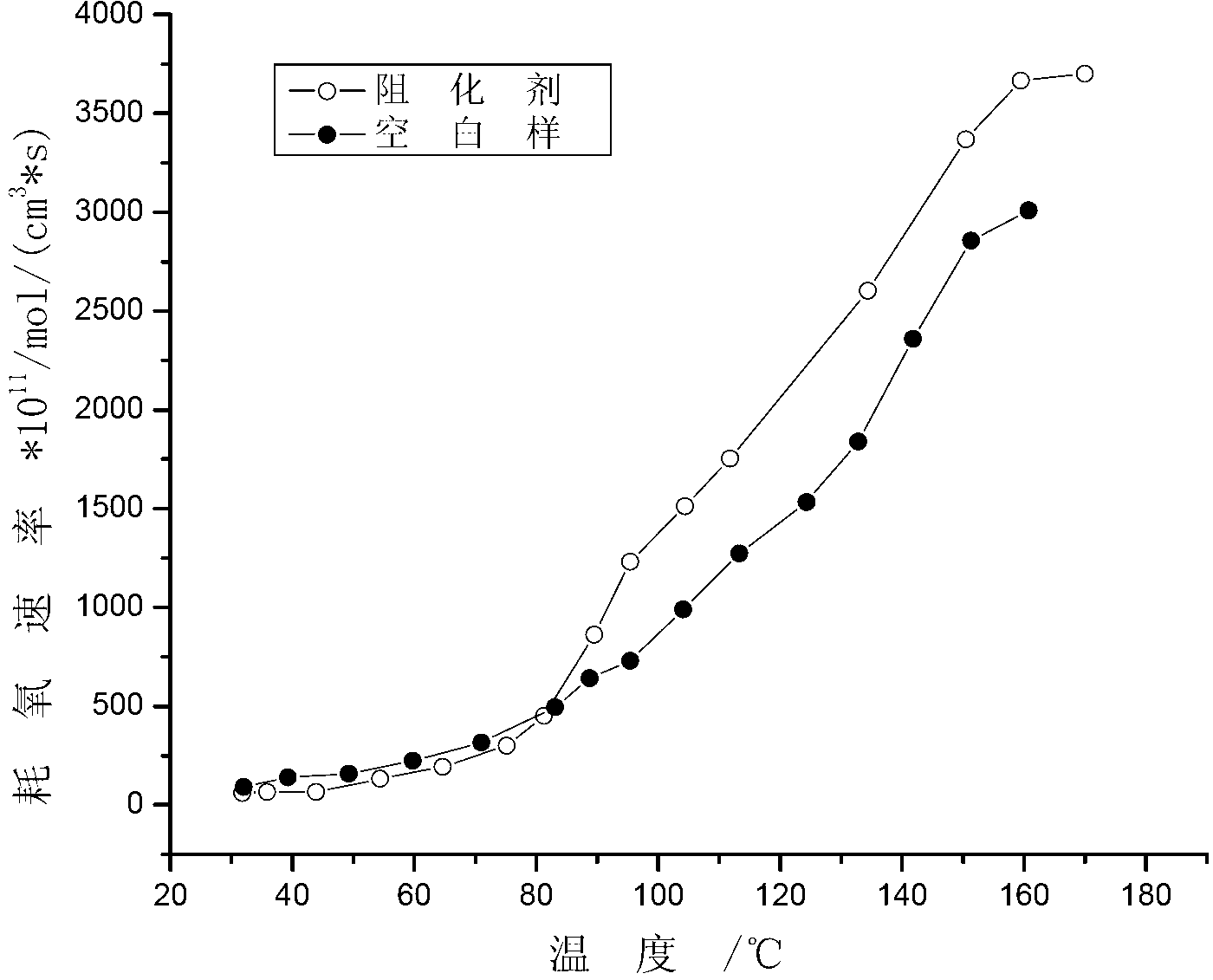

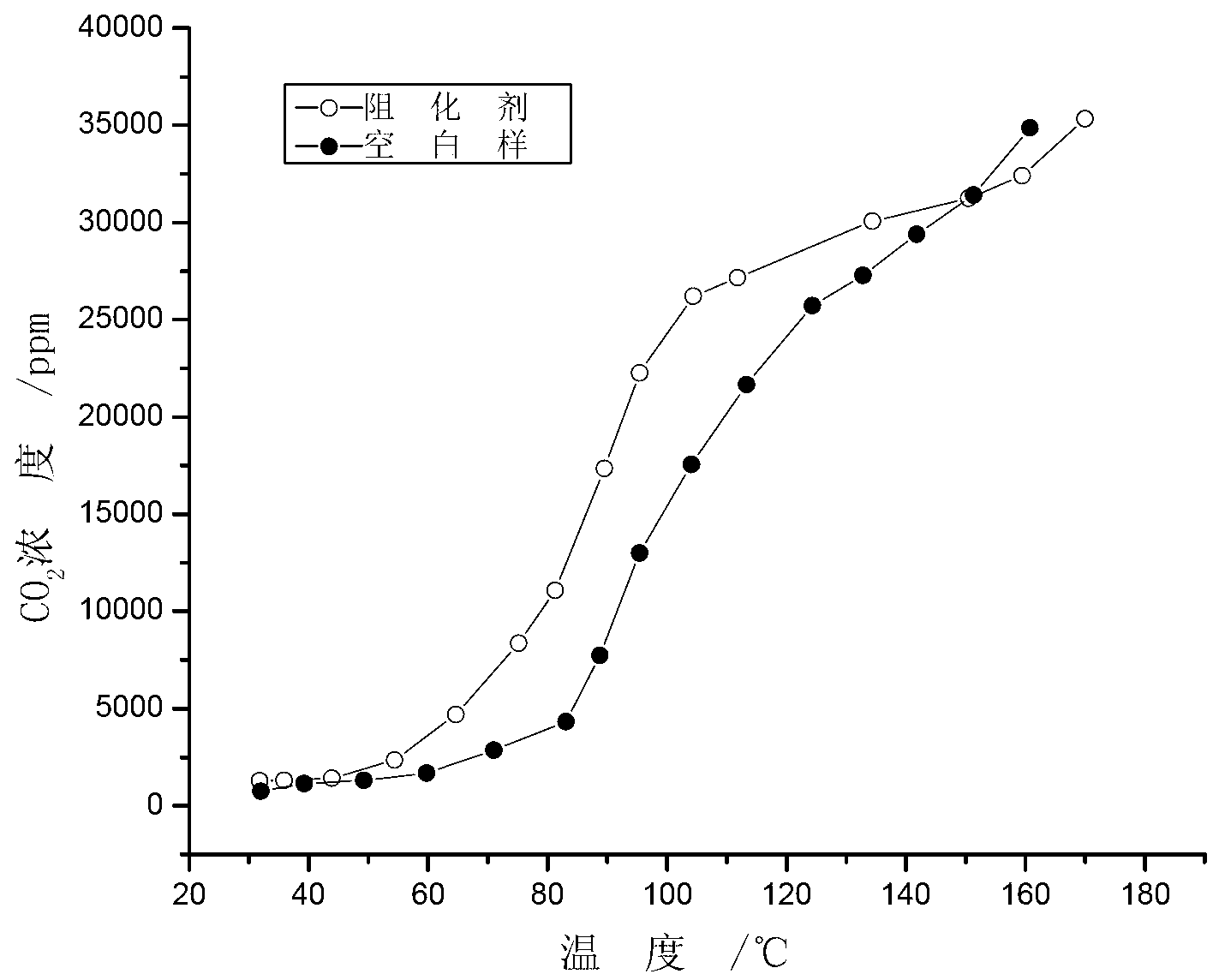

Compound stopping agent for preventing pulverized coal from spontaneous combustion

InactiveCN103306710AReduce reactivityReduce generationDust removalFire preventionInorganic saltsSpontaneous combustion

The invention discloses a compound stopping agent for preventing pulverized coal from spontaneous combustion and a preparation method of the compound stopping agent. The compound stopping agent mainly comprises a component A and a component B, wherein the component A comprises 70%-90% of a penetrant and 10%-30% of peroxide; the component B comprises inorganic salt. The component A and the component B are mixed at a weight ratio of 1:(1.5-3) and used as the compound stopping agent. The preparation method comprises steps as follows: firstly, the penetrant is prepared into an aqueous solution, then the peroxide is dissolved in the penetrant, and the mixture is stirred, so that the component A of the stopping agent is obtained; the component A is matched with the inorganic salt of the component B for use. The compound stopping agent has the characteristics of low cost and non-toxic. During the use, the component A and the component B of the stopping agent are jointly and uniformly added to the pulverized coal, the operation is simple, the stopping effect is excellent, and the compound stopping agent has a wide application prospect.

Owner:SHENMU ZHANGJIAMAO COAL MINING CO LTD OF SHAANXI COAL & CHEM IND GRP +1

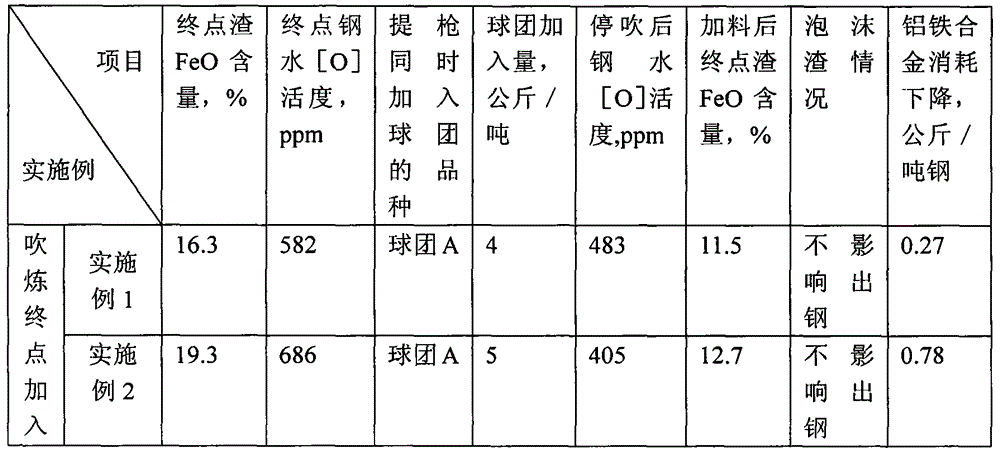

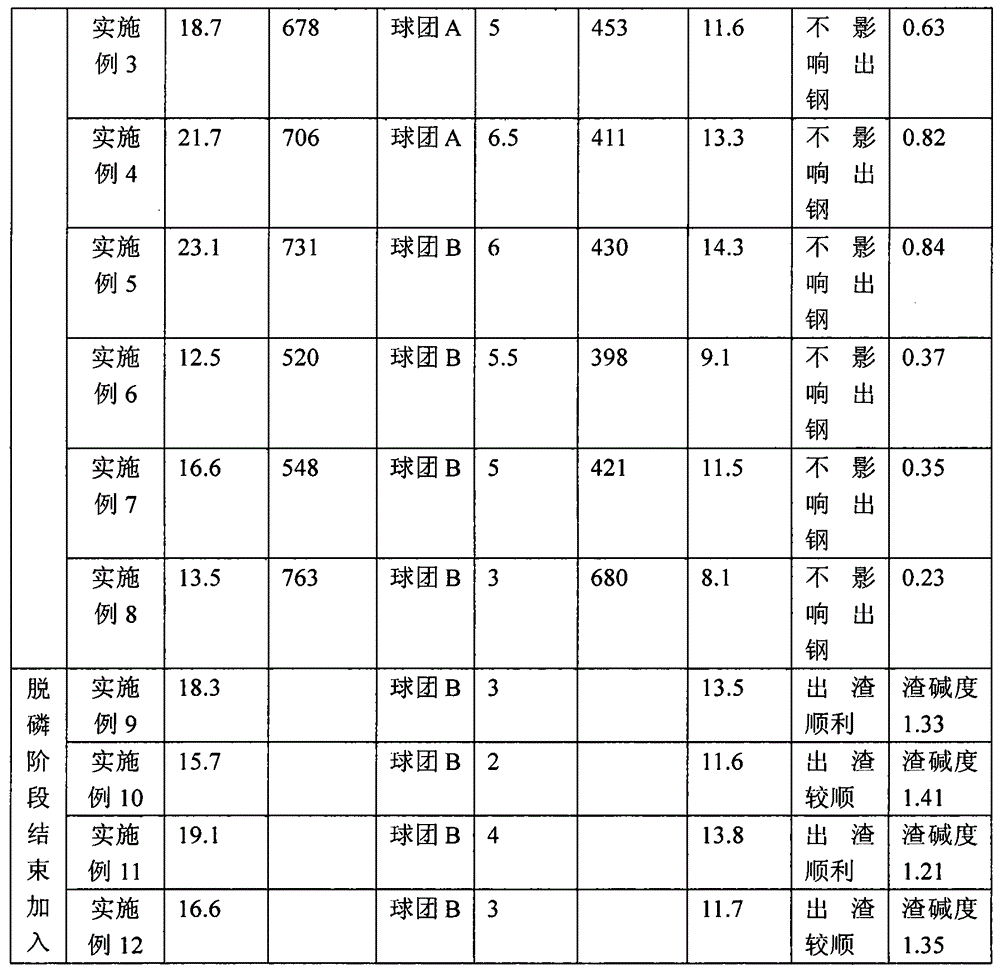

Carbon-containing slag suppression cold-bonded pellet and utilization method thereof

ActiveCN106148686AEfficient use ofSimple processManufacturing convertersProcess efficiency improvementSpecific gravityTar

The invention discloses a carbon-containing slag suppression cold-bonded pellet and a utilization method thereof. In the carbon-containing slag suppression cold-bonded pellet, the TFe content is smaller than or equal to 45%, the carbon content is larger than or equal to 5%, the content of volatile components (including decomposable gas) is larger than or equal to 10%, and the specific gravity is smaller than or equal to 3.5 g / cm<3>. The pellet is added into a converter from a high bin while lance lifting is about to be finished through blowing in the dephosphorization stage of the converter or when lance lifting is about to be finished through the blowing end point of the converter, and then deslagging or tapping is carried out. The carbon-containing slag suppression cold-bonded pellet and the utilization method have the beneficial effects that iron and carbon in gas dust sludge or other iron and carbon containing metallurgy dust sludge can be efficiently utilized, and waste paper pulp, tar slag and other waste are used as additives for pelletizing; the process is simple, and cost is low; the pellet is only used as slag, heat energy of the slag is fully utilized, and the influence of the temperature of molten steel is extremely low; foam slag can be suppressed effectively, and deslagging or tapping in the dephosphorization stage is facilitated; and by means of reduction of FeO in the pellet and FeO in the slag, the yield of the molten steel is increased, consumption of a deoxidizing agent and an alloy is reduced, and slag-splashing furnace protection work is facilitated.

Owner:王虎

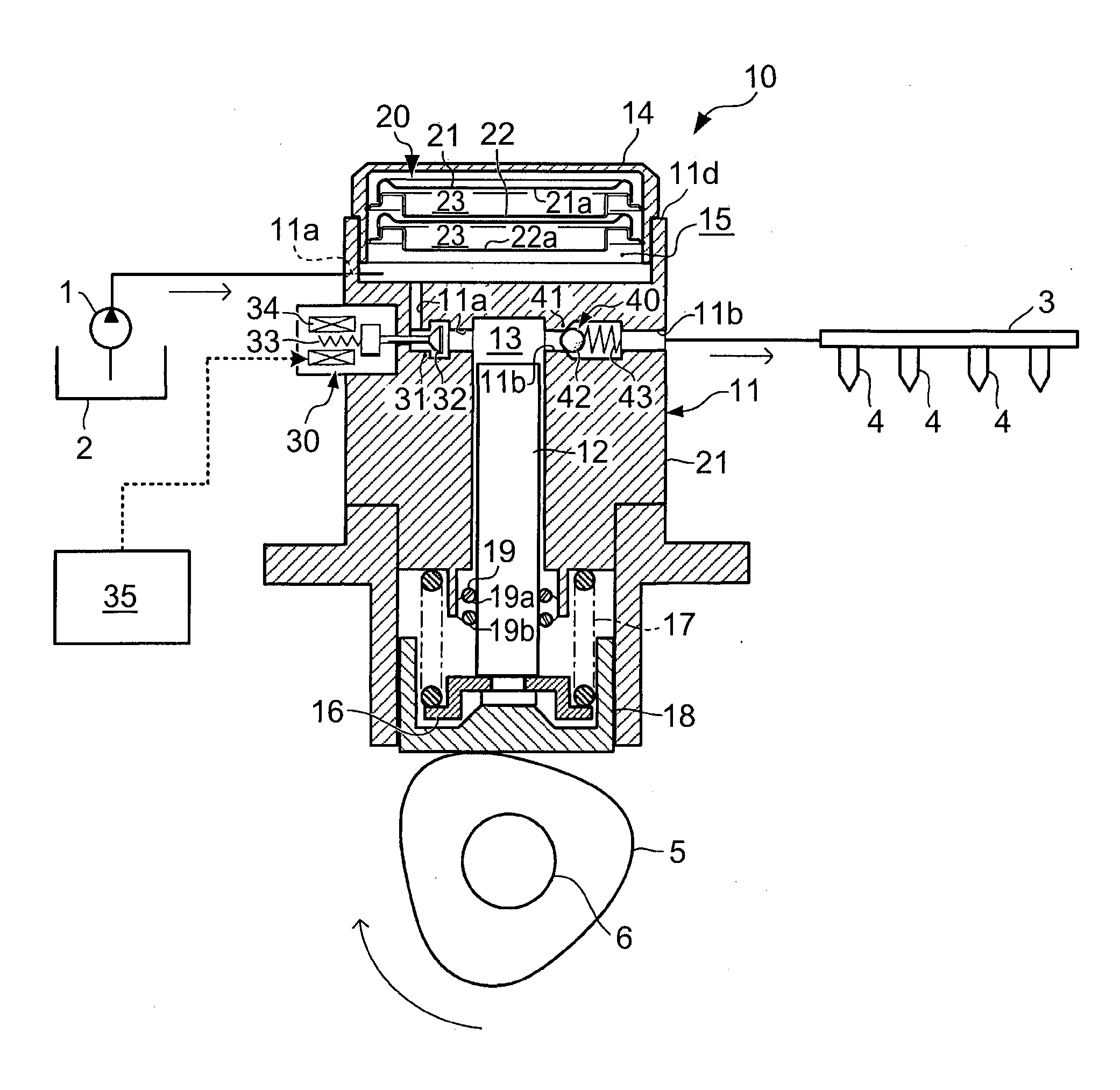

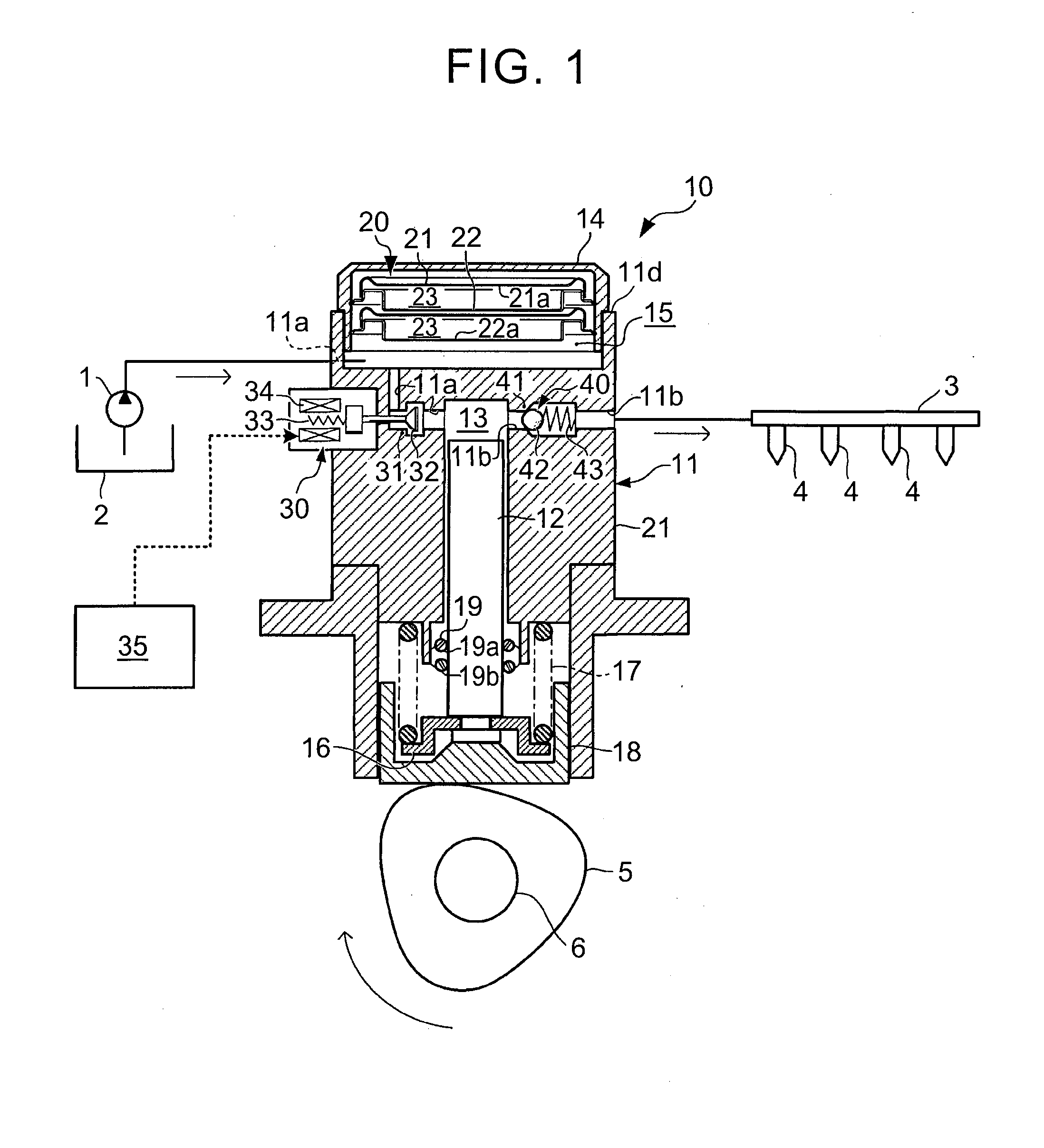

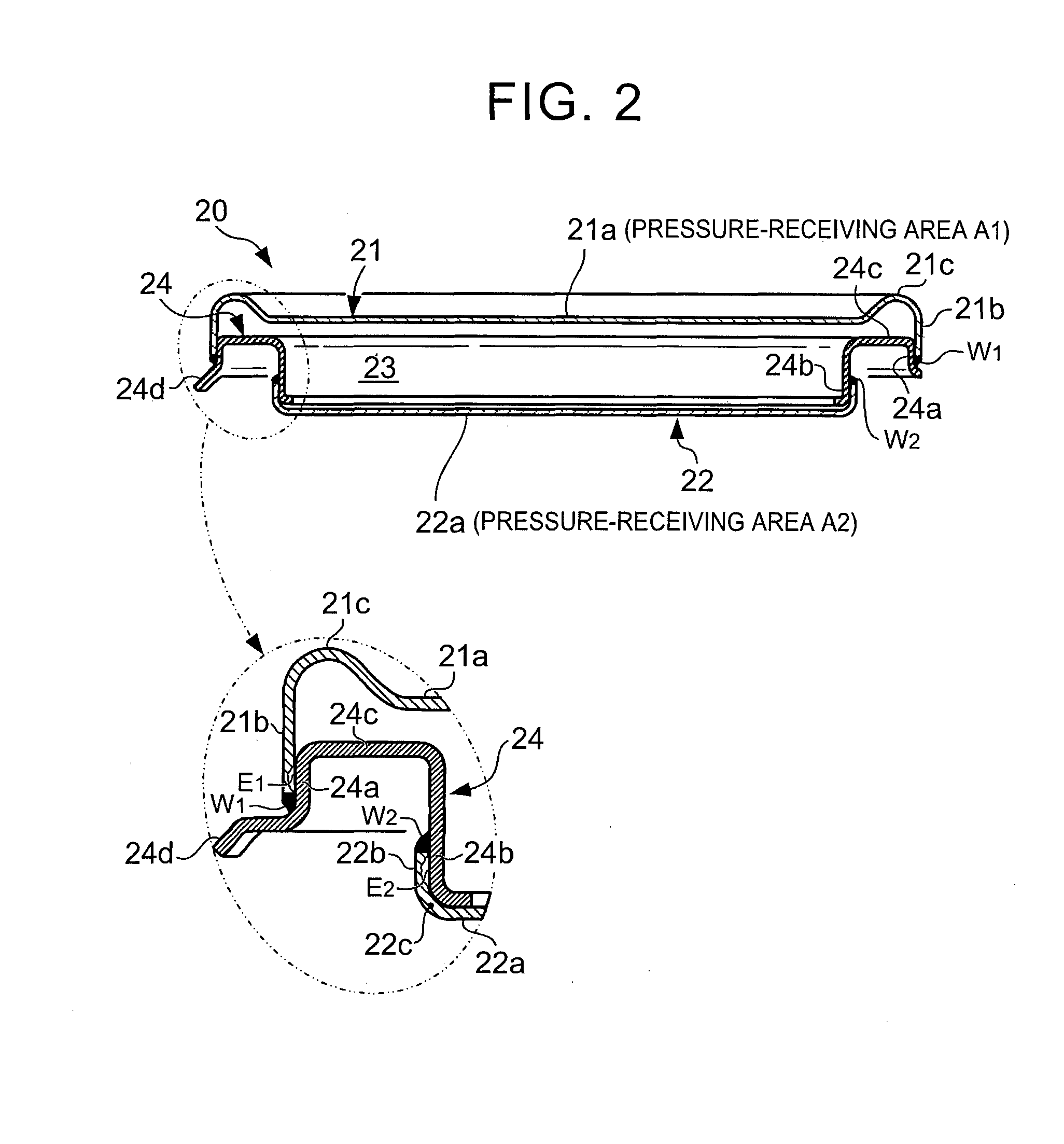

Pulsation damper and high-pressure fuel pump

InactiveUS20160169173A1Suppresses vibration transmissionSufficient damping performanceFlexible wall reciprocating enginesPositive displacement pump componentsCouplingEngineering

A pulsation damper (20) includes a first diaphragm (21) and a second diaphragm (22) having a first pressure-receiving film portion (21a) and a second pressure-receiving film portion (22a) and defining a gas chamber (23) between the first pressure-receiving film portion (21a) and the second pressure-receiving film portion (22a) and an annular attachment member (24) configured to support the first diaphragm (21) and the second diaphragm (22). Pressure receiving areas (A1, A2) of the first pressure-receiving film portion (21a) and the second pressure-receiving film portion (22a) are different from each other. The annular attachment member (24) includes a large-diameter annular support portion (24a) formed so as to surround the first pressure-receiving film portion (21a) and to support the first diaphragm (21); a small-diameter annular support portion (24b) formed so as to surround the second pressure-receiving film portion (22a) and to support the second diaphragm (22); and an annular coupling portion (24c) configured to couple the large-diameter annular support portion (24a) with the small-diameter annular support portion (24b) so as to close the gas chamber (23).

Owner:TOYOTA JIDOSHA KK

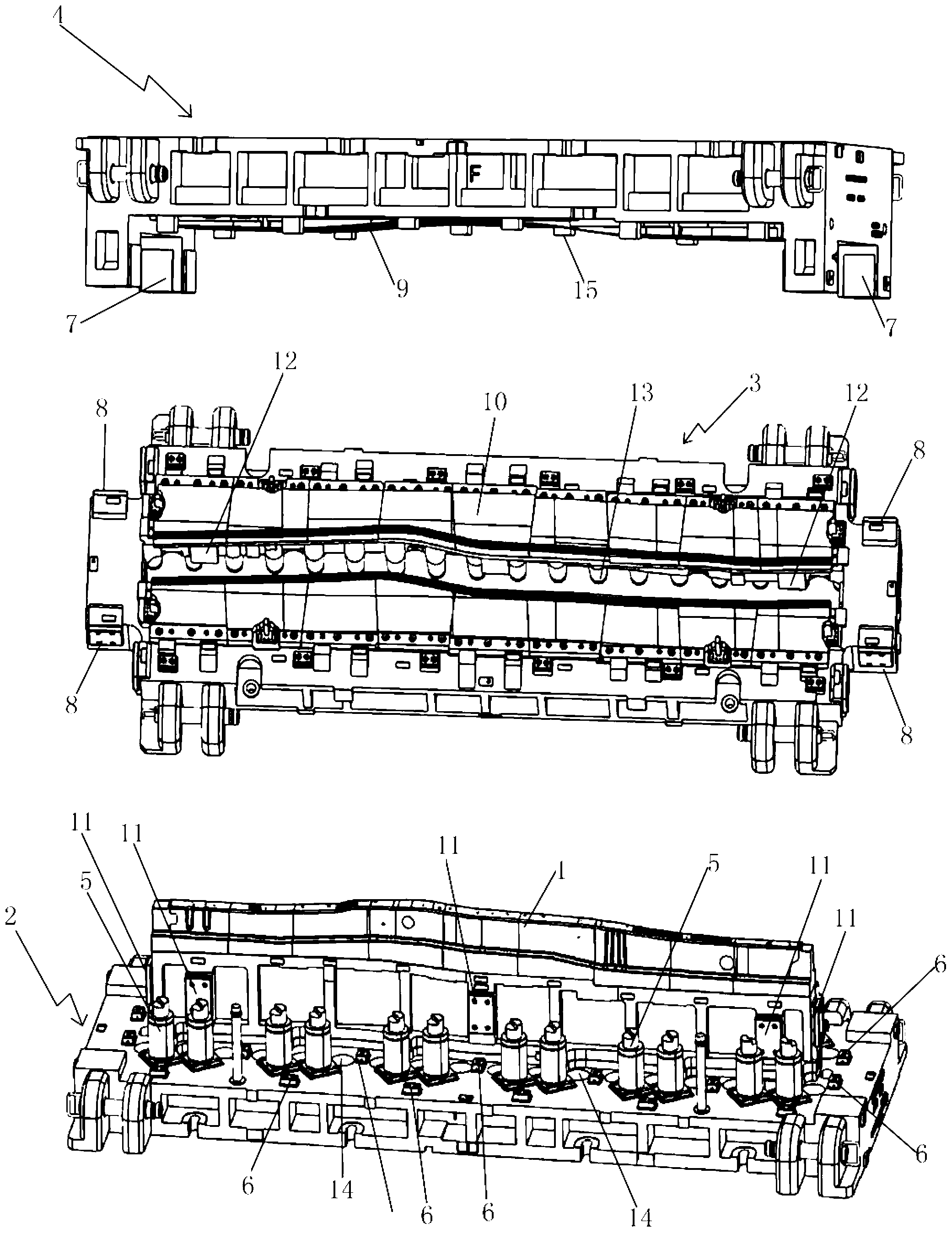

Variable-blank-holding-force beam type drawing die

InactiveCN103240339AReduce reboundResolve distortionShaping toolsInternal stressMechanical engineering

The invention discloses a variable-blank-holding-force beam type drawing die. The variable-blank-holding-force beam type drawing die comprises a concave die base, a protruding die base and a blank holder assembly, wherein the concave die base and the protruding die base are arranged in an up-and-down mode, the blank holder assembly is located between the concave die base and the protruding die base, a protruding die is arranged on the protruding die base, at least two groups of nitrogen spring assemblies are arranged on the front side and the rear side of the protruding die on the protruding die base respectively, tops of nitrogen spring assemblies contact with the lower surface of the blank holder assembly, the protruding die contacts with the blank holder assembly, and the lower surface of the concave die base contacts with the upper surface of the blank holder assembly. By the aid of the variable-blank-holding-force beam type drawing die, arc-shaped springback of cross beam side walls is reduced, the problem of beam distortions is well solved, and the wrinkling phenomena of pressing face materials are reduced, so that a cross beam is shaped and deformed fully, internal stresses of parts are reduced, and the overall springback of parts is reduced.

Owner:SAIC-GM-WULING AUTOMOBILE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com