Patents

Literature

81results about How to "Improve rolling rhythm" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

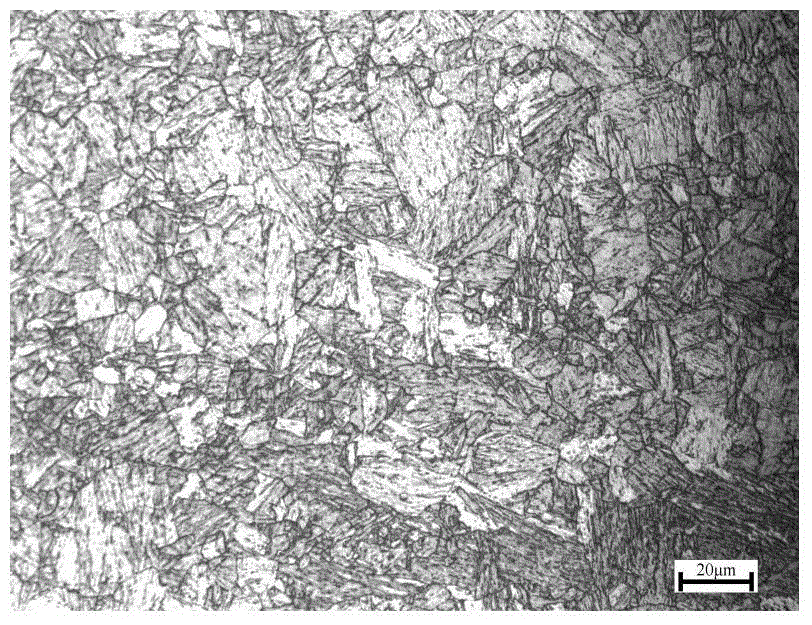

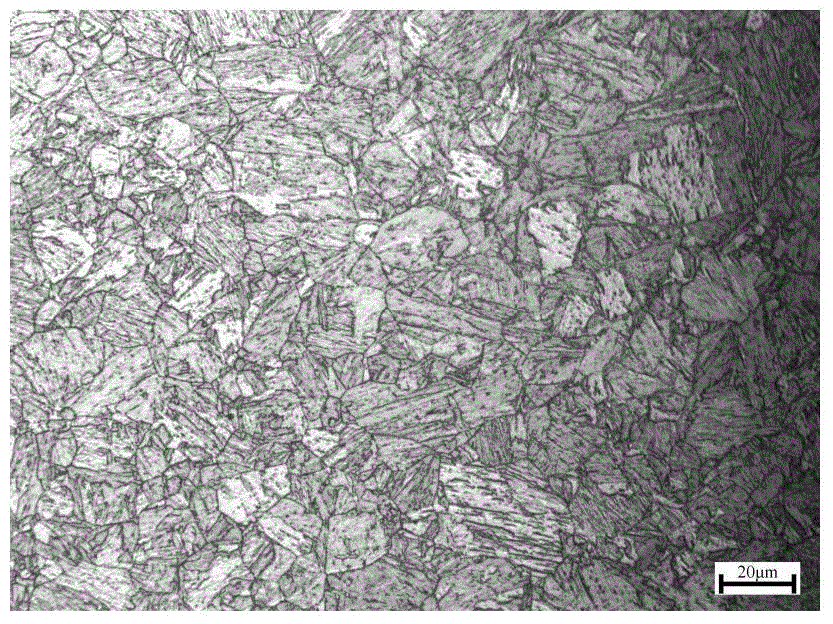

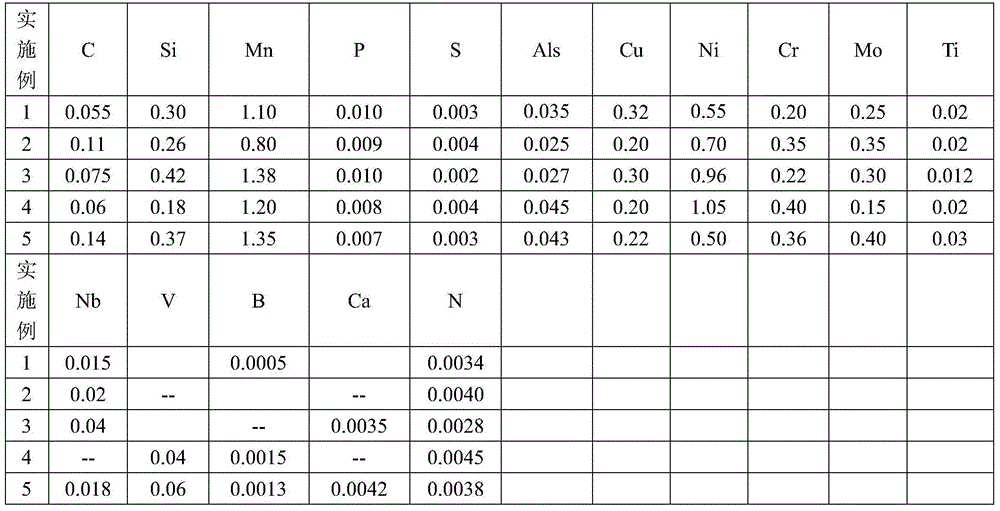

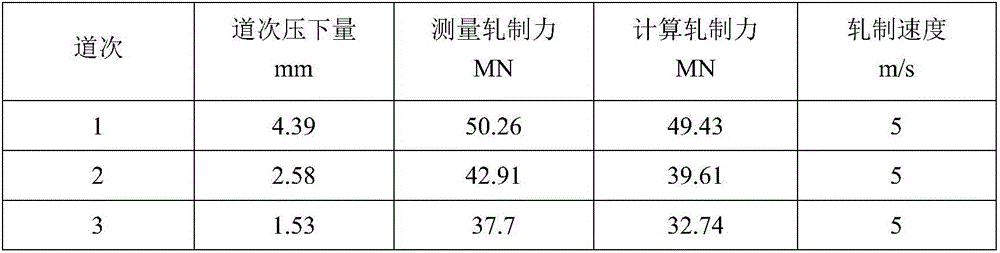

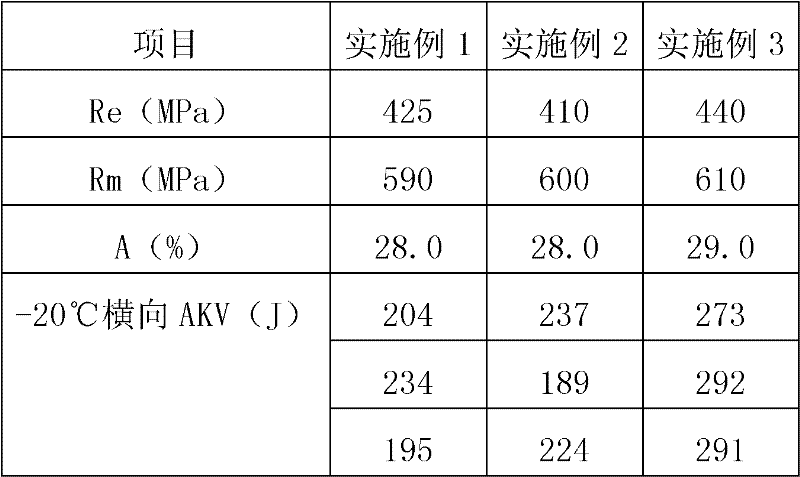

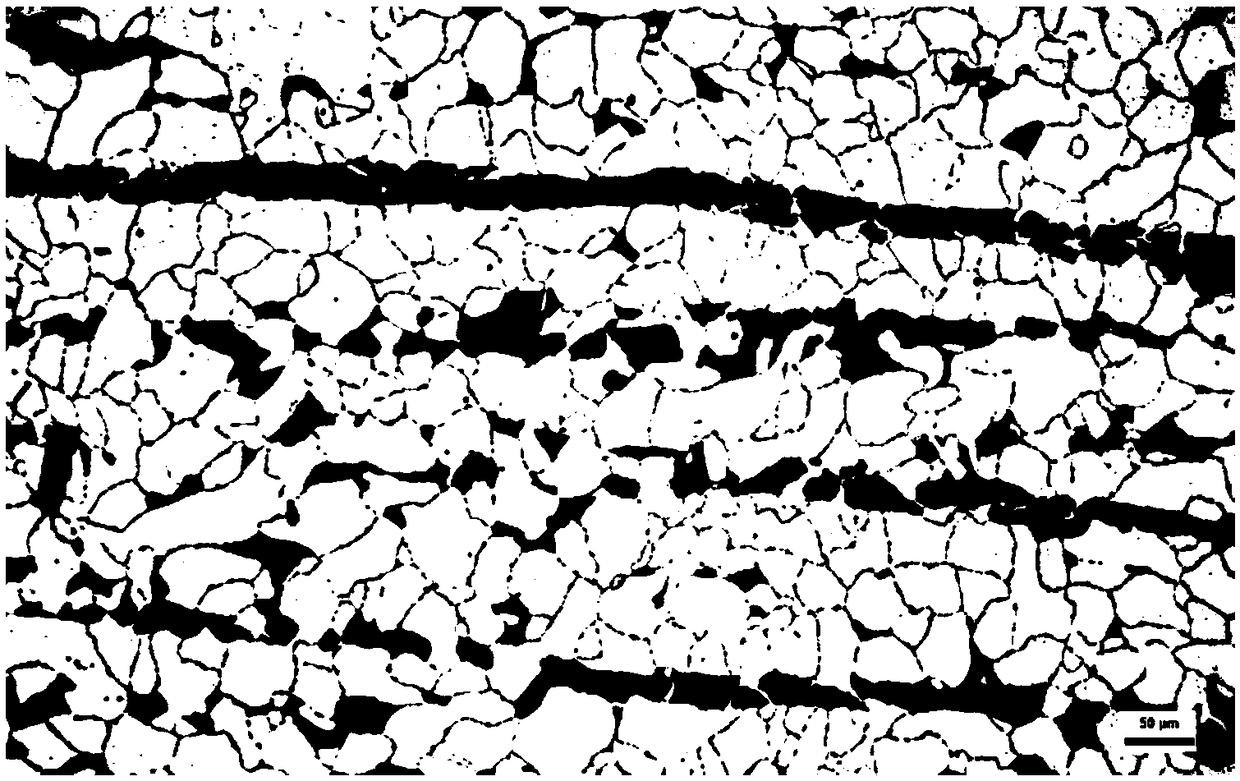

Low compression ratio 690MPa grade extra thick steel plate and production method thereof

The invention discloses a low compression ratio 690MPa grade extra thick steel plate and a production method thereof, and the low compression ratio 690MPa grade extra thick steel plate comprises the following components by weight: 0.05%-0.14% of C, 0.12%-0.45% of Si, 0.70%-1.40% of Mn, < = 0.010% of P, < = 0.005% of S, 0.025%-0.065% of Als, < = 0.005% of N, 0.10%-0.50% of Cu, 0.50%-1.00% of Ni, 0.10%-0.40% of Cr, 0.10%-0.45% of Mo, also comprises one or more than two components selected from the following chemical components: 0.03%-0.08% of V, 0.005%-0.04% of Nb, 0.005%-0.03% of Ti, 0.0008-0.004% of B and 0.002%-0.006% of Ca, and also comprises balance of Fe and inevitable impurities, wherein the total ratio of precious and strengthening elements of Cr, Mo, Ni and Cu is less than or equal to 1.5%.

Owner:ANGANG STEEL CO LTD

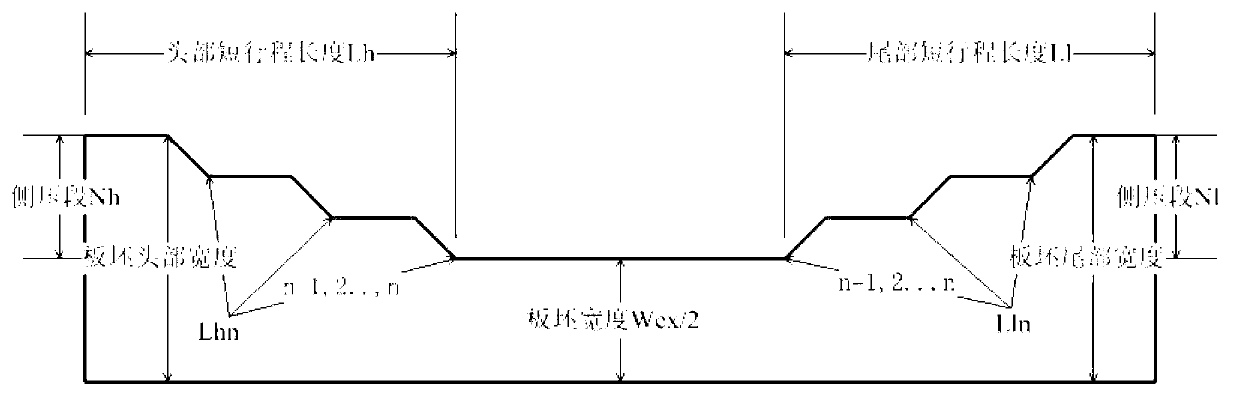

Fixed-width press plate blank width control method

ActiveCN102989784APrecise calculation of adaptive positionImplement width control methodMetal rolling stand detailsAutomatic controlEngineering

The invention discloses a fixed-width press plate blank width control method, and belongs to the technical field of steel rolling automatic control. During the process of laterally rolling the head and the tail of a plate blank by a fixed-width press, the head part and the tail part of the plate blank are in plane stress states; according to the metal flow principle of the head part and the tail part of the plate blank, and tongue and fishtail phenomena can be generated. In order to improve the condition, the widths of the head and the tail of the plate blank are controlled in short stroke by adopting the fixed-width press; under the working condition that stripe steel rolling temperature and rolling cycle are ensured, the severe width failure of the head and the tail of the stripe steel can be improved, and the final rolling target width index is ensured effectively; a pass band guarantees the width index deviation range to be 0-8mm, the yield is improved, and the production cost is saved; and when the plate blank is pressed greatly, similar to the small lateral pressing amount, the outlet width is obtained through pressing one time, the rolling temperature of the stripe steel is ensured, and the rolling cycle is improved.

Owner:BEIJING ARITIME INTELLIGENT CONTROL +1

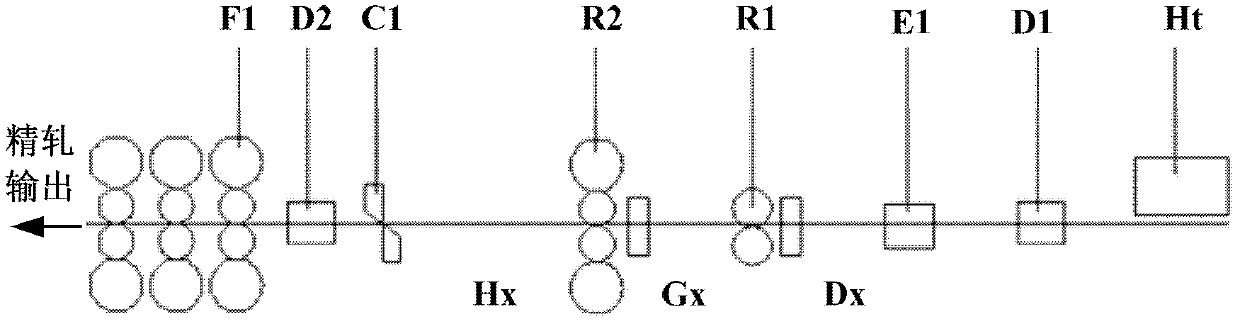

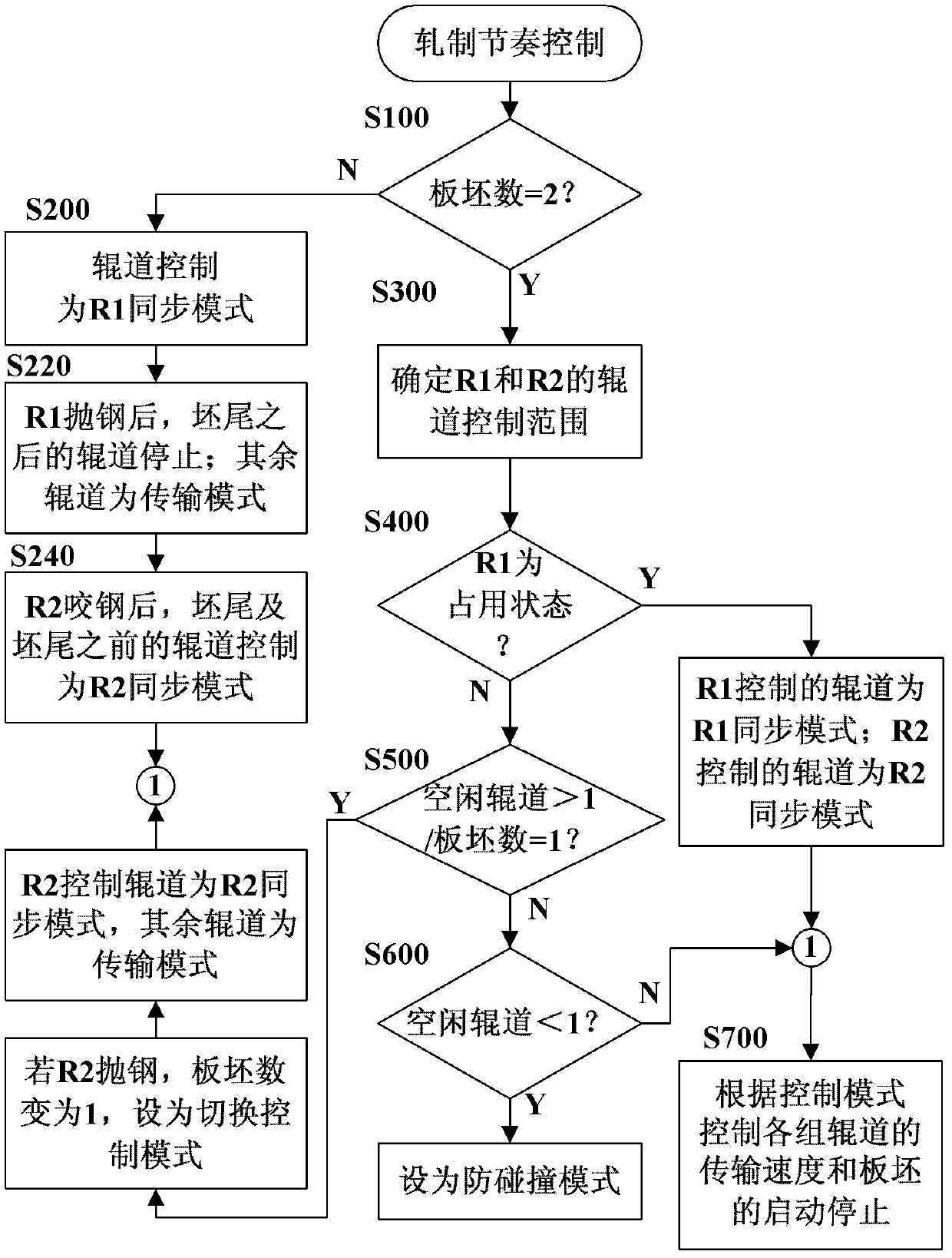

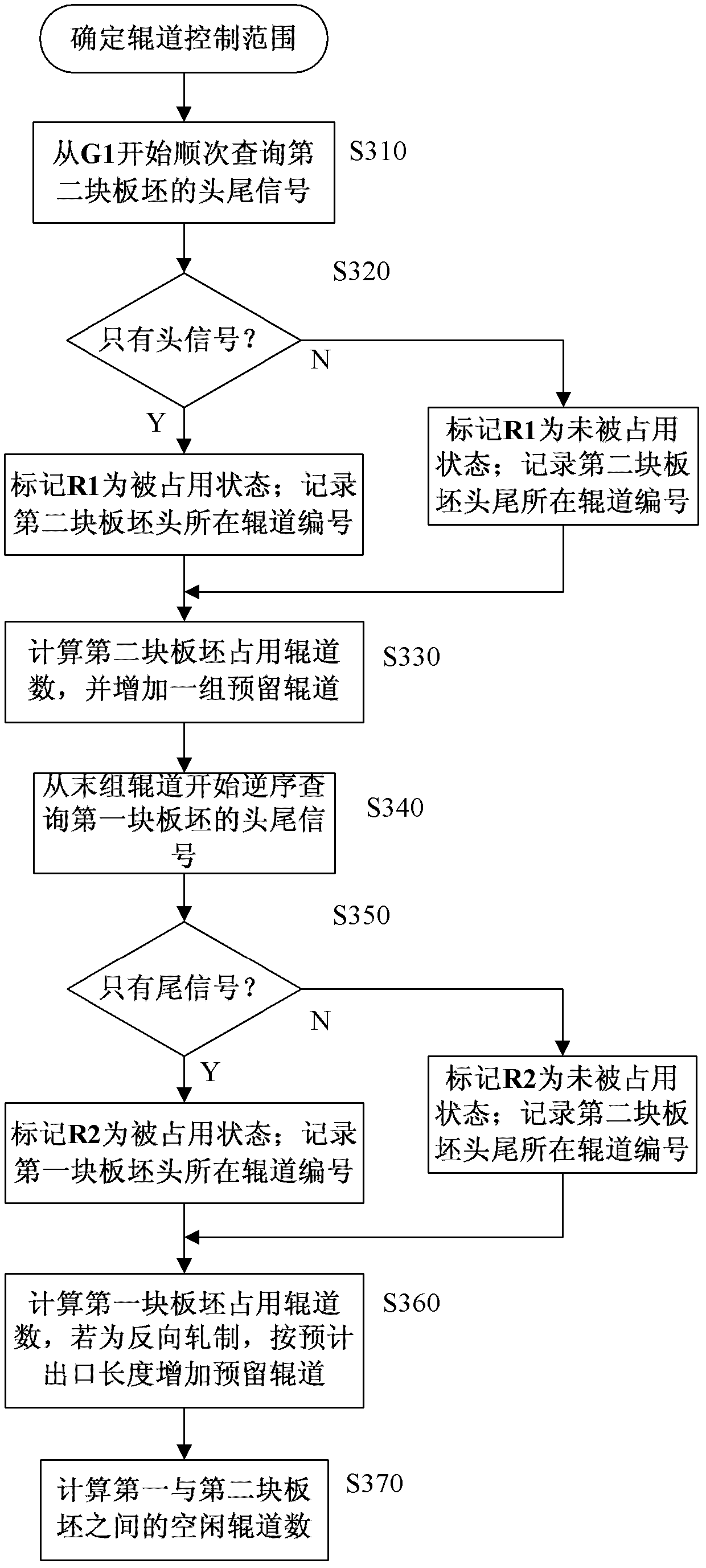

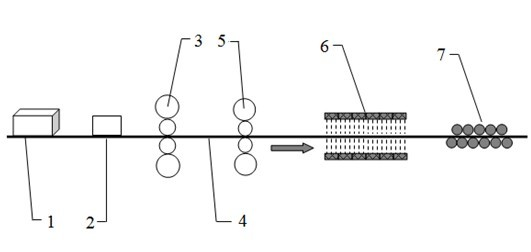

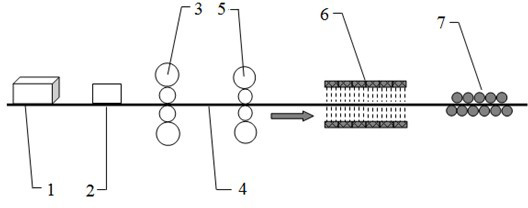

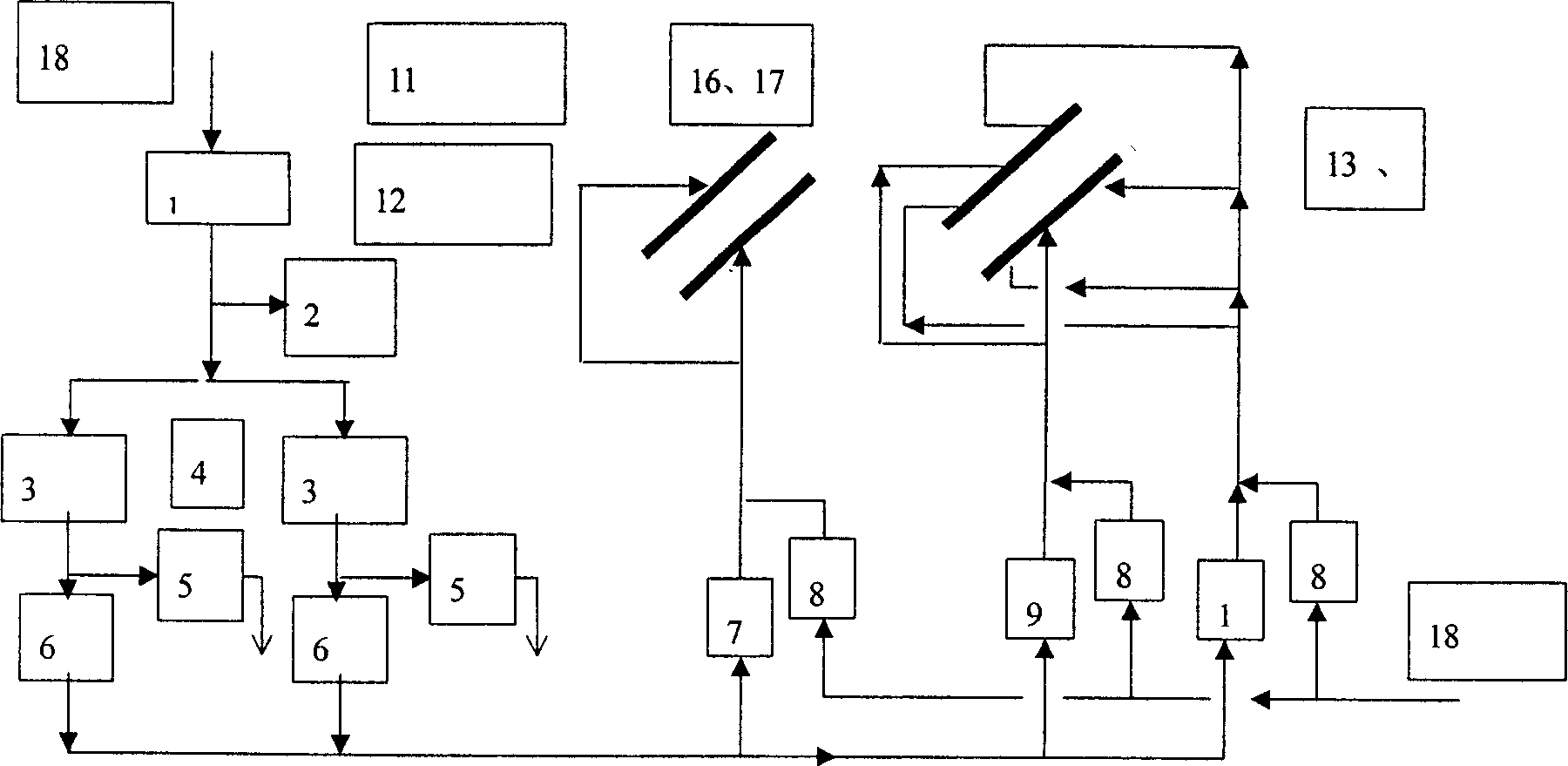

Control method for improving rolling pace of roughing mill

ActiveCN103372572AImprove rolling rhythmImprove equipment utilizationRoll mill control devicesMetal rolling arrangementsStrip millEngineering

The invention discloses a control method for improving rolling pace of a roughing mill and relates to a control device or method which is specially applicable to a metal rolling mill or machined products of the metal rolling mill. Plate blank head and plate blank tail detection devices are arranged on all groups of roller beds; according to detected plate blank head and plate blank tail signals, plate blank collision prevention conditions are set, and the occupancy state of a rack and the number of the idle roller beds are determined; according to the occupancy state of the rack and the number of the idle roller beds, control modes of the groups of roller beds are set; according to the plate blank collision prevention conditions and the control modes of the groups of roller beds, transmission speeds of the groups of roller beds are controlled respectively, and starting and stopping of a second plate blank are controlled to minimize the distance between a first plate blank and the second plate blank, so that the transmission time interval between the two plate blanks is minimized. By the aid of the method, the distance between the two adjacent machined plate blanks can be greatly shortened, so that the front and back rack production is closely connected, and the rolling pace of the rolling mill and the device utilization rate can be greatly improved.

Owner:BAOSHAN IRON & STEEL CO LTD

Process for producing thin gauge pipeline steel by using double-stand medium and heavy plate mill

ActiveCN102671941AGuaranteed Dynamic RecrystallizationImprove lateral performanceTemperature control deviceWork treatment devicesMetallurgyLaminar cooling

The invention discloses a process for producing thin gauge pipeline steel by using a double-stand medium and heavy plate mill. A plate blank with the thickness of 180 mm is used for producing the thin gauge pipeline steel with the thickness less than 10 mm. On the basis that the performance of a rolled piece meets requirements, the thin gauge pipeline steel with a good plate shape can be obtained by controlling the tapping temperature of the plate blank, the rough rolling broadening pass pressing rate, the longitudinal rolling pass pressing rate after rough rolling broadening pass, the rough rolling finishing temperature, the thickness of a middle blank, the finish rolling ending pass pressing rate, the finish rolling finishing temperature, the roller gap inclination and sled function in the rolling process, a high pressure water descaling system, the water entry temperature, the re-reddening temperature, and the head and tail shielding and straightening process of a laminar cooling system. The deformation rate is reduced, and the economic benefit is increased.

Owner:NANJING IRON & STEEL CO LTD

High-pressure water descaling system

ActiveCN1775399AImprove rolling rhythmImprove descaling efficiencyWork treatment devicesExtrusion cleaning devicesWater storage tankSystem pressure

The present invention relates to a high-pressure water scale-removing system. It includes cleaning filter and minimum flow valve group. After the described self-cleaning filter successively are set diaphragm type water storage tank and descaling pump group, and after the described minimum flow valve group successively are set low-pressure precharging valve group, on-machine descaling sprays, on-maching descaling manifold, high-effective descaling nozzle, descaling tank descaling spray valve group, descaling tank descaling manifold and descaling tank high-effective nozzle. Said invention adopts high-pressure variable frequency speed-regulating technique to raise descaling efficiency.

Owner:SGIS SONGSHAN CO LTD

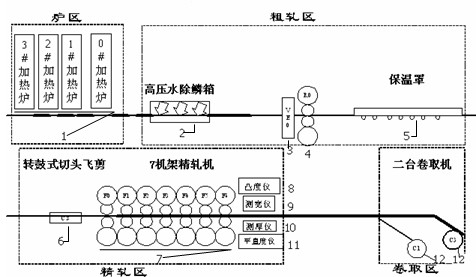

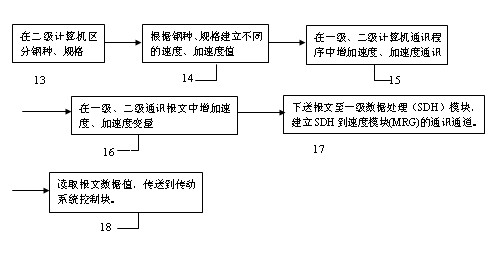

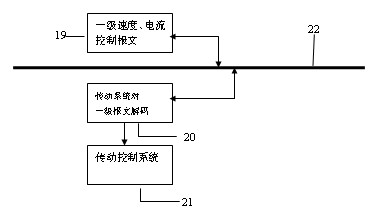

Control method of speed and acceleration of continuous hot rolling roughing rolling unit

ActiveCN102179412AAdd manual intervention functionGood descaling effectRoll speed control deviceAutomatic controlControl system

The invention discloses a control method of the speed and the acceleration of a continuous hot rolling roughing rolling unit, belonging to the technical field of continuous hot rolling. The control method is used for automatically controlling the speed and the acceleration of the continuous hot rolling roughing rolling unit through a computer system, comprising the following steps of: realizing or completing the delivery of a computing method, control values and distinguishing marks of the variable speed and the variable acceleration of the continuous hot rolling roughing rolling unit to a first-level computer through a second-level computer; implementing or carrying out continuous hot rolling automatic control on the continuous hot rolling roughing rolling unit according to the control values and the distinguishing marks of the variable speed and the variable acceleration of the continuous hot rolling roughing rolling unit through the first-level computer, wherein the variable speed is computed according to a formula: (1)V=V0(n)p1(1+p2), and the variable acceleration is computed according to a formula: (2)a=a0(1+p). The method has the advantages of developing a new control methodof the roughing variable speed and variable acceleration in a control system for solving the problems of slipping, unclean surface descaling, and the like of certain steel grade specifications and solving the problems of the slipping and improving the surface descaling effect by realizing the new control method, thereby enhancing the rolling rhythm and the rolling quality and successfully solvingthe problems during production.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

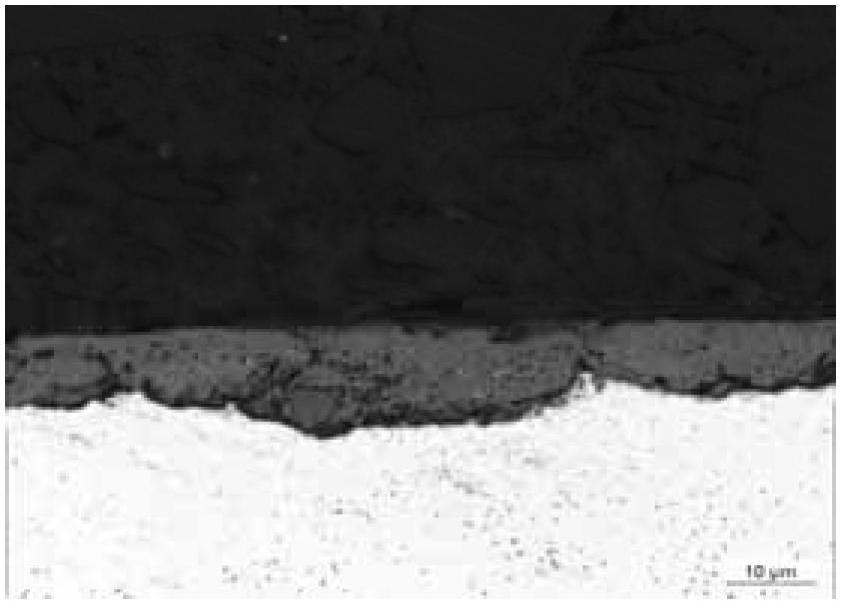

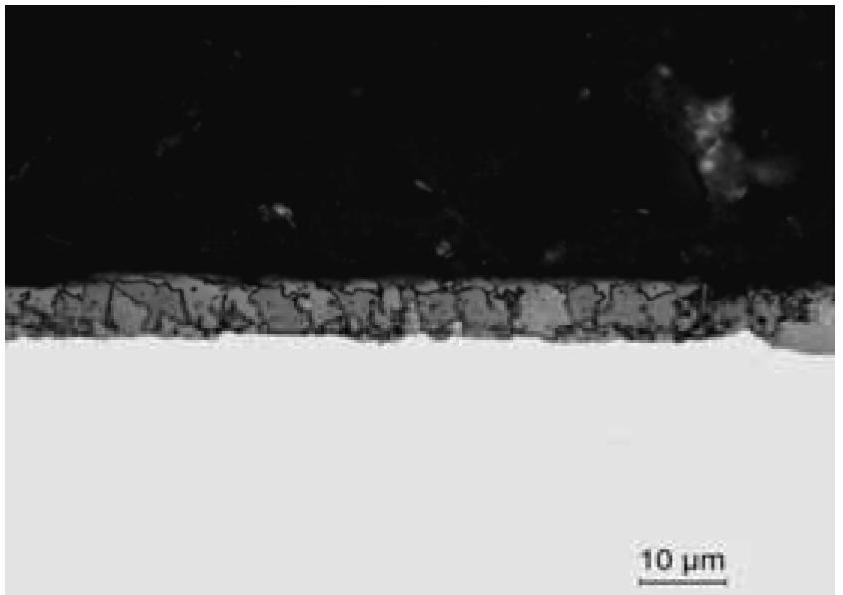

Method for making easy-to-pickle steel plate

InactiveCN102671992AIncreasing the thicknessImprove lateral uniformityRare end control deviceWork treatment devicesSheet steelStrip steel

The invention provides a method for making an easy-to-pickle steel plate and belongs to the technical field of metallurgy. The method comprises the following steps of: smelting molten steel, and making a plate blank by continuous casting; descaling by using high pressure water, performing rough rolling on the descaled plate blank, performing finish rolling, cooling to the temperature of 500 to 550 DEG C, cooling at the speed of 5 to 10 DEG C per minute to obtain the steel which is easy to pickle and in a hot rolling state and of which the content of FeO is over 25 percent; performing finish rolling, cooling to the temperature of 650 to 700 DEG C at the speed of 1 to 5 DEG C per minute to obtain the steel which is easy to pickle and in a cold rolling state and has a uniform structure and of which the content of iron oxide scale FeO is less than 10 percent. By adopting the method, the thickness of the iron oxide scale is reduced by 20 to 30 percent compared with the conventional process, the pickling speed of the strip steel is increased from 150 to 160 m per minute to 180 to 200 m per minute compared with the conventional process, not only the pickling quality of the steel plate is guaranteed, but also the pickling efficiency is effectively improved.

Owner:NORTHEASTERN UNIV +1

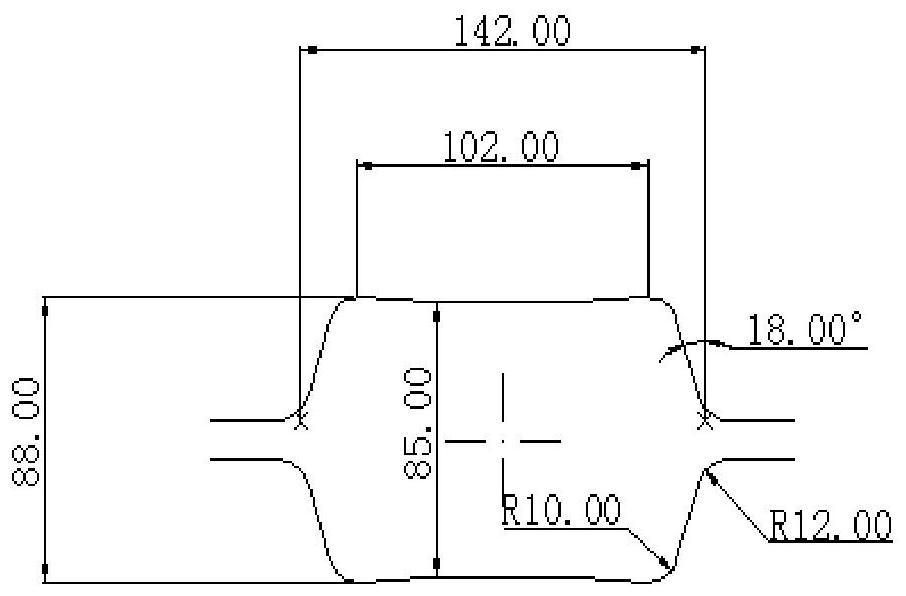

Technique for rolling figured steel for magnetic suspension train rail

ActiveCN101214494ALow costIncrease productivityRoll force/gap control deviceTemperature control deviceProduction lineThermal treatment

The invention belongs to the technology field of metal thermal treatment, which relates to the rolling technology of deformed steel used for a maglev train rail. The invention comprises the procedures in turn of rough rolling, finishing rolling, coolant-controlling and straightening, which is characterized in that two reversible mills rolling is adopted for rough rolling and the maximum rolling force of a two reversible mill is 8000 to 10000KN. And the rolling deformation should account for 60 to 90 per cent of total deformation. Three-stand universal continuous rolling line with high rolling force and high accuracy is adopted for finishing rolling to realize mixing roll under universal mode. The invention can merely use large H-shaped hot- rolling production line to produce finished products and does not require thermal treatment and machining process, with the result that the cost can be greatly reduced and the requirement of mass production can be fully satisfied.

Owner:LAIWU IRON & STEEL GRP

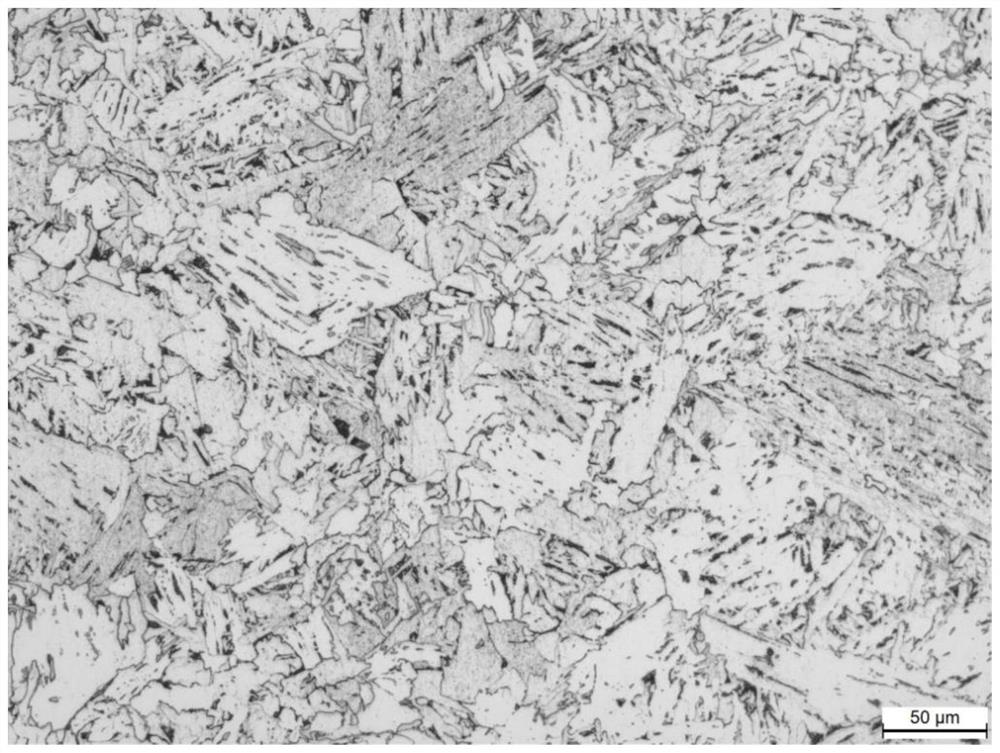

Medium plate Q345B and production method of same

The invention provides a medium steel plate Q345B and a production method of the same. The medium plate Q345B comprises the following chemical components in percentage by mass: 0.130-0.150% of carbon, 0.30-0.40% of silicon, 1.35-1.50% of manganese, less than or equal to 0.025 of phosphorus, less than or equal to 0.020 of sulfur, 0.005-0.01% of titanium, 0.05-0.07% of vanadium, and the content of the nitrogen is controlled to be 80-180 ppm. The tapping temperature of billet is 1180-1200 DEG C, the finish-rolling finishing temperature is controlled to be 1070-1100 DEG C, the cooling rate is 18-22 DEG C per second, and the final cooling temperature is controlled to be 650-750 DEG C. The method provided by the invention can effectively improve the internal structure of the steel and reach higher combination of toughness and strength under lower carbon equivalent. The steel has a yield strength of 401 MPa, a strength of extension of 536 MPa, the coefficient of elongation of 31%, and the cold bending index thereof are all qualified. Moreover, the material costs of the steel can be reduced by over 20 RMB / ton.

Owner:ANGANG STEEL CO LTD

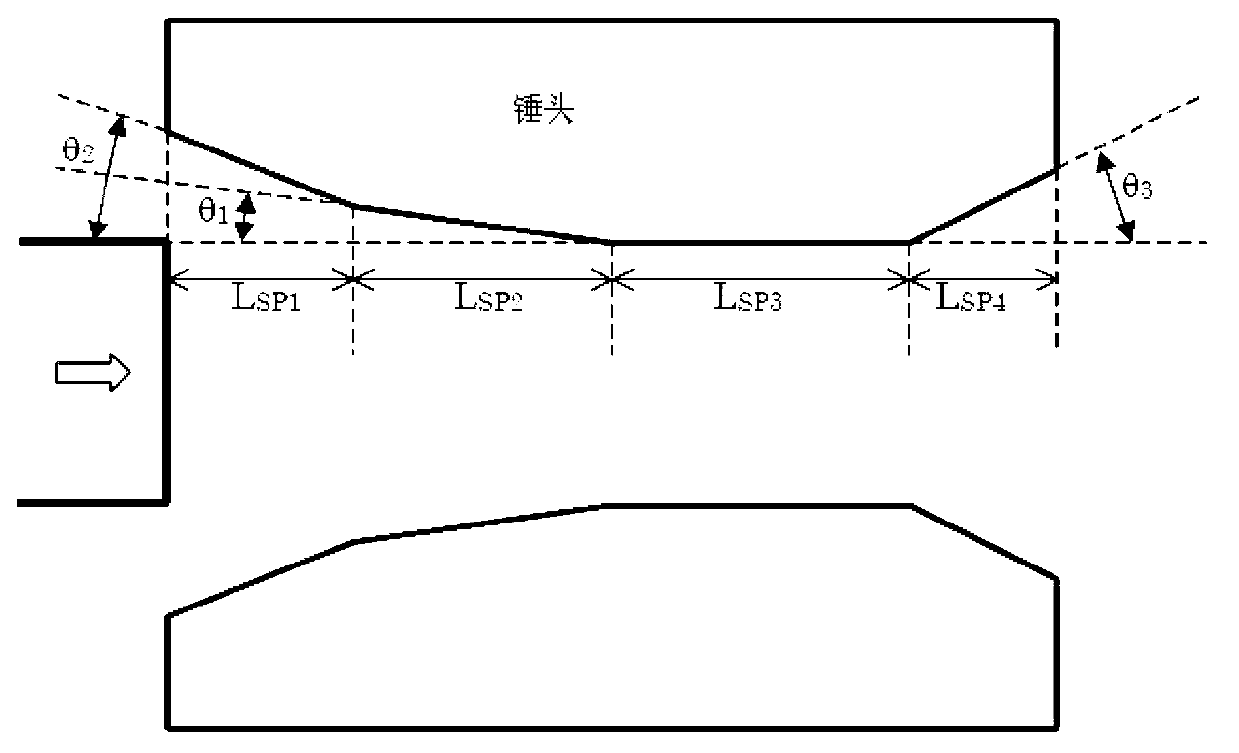

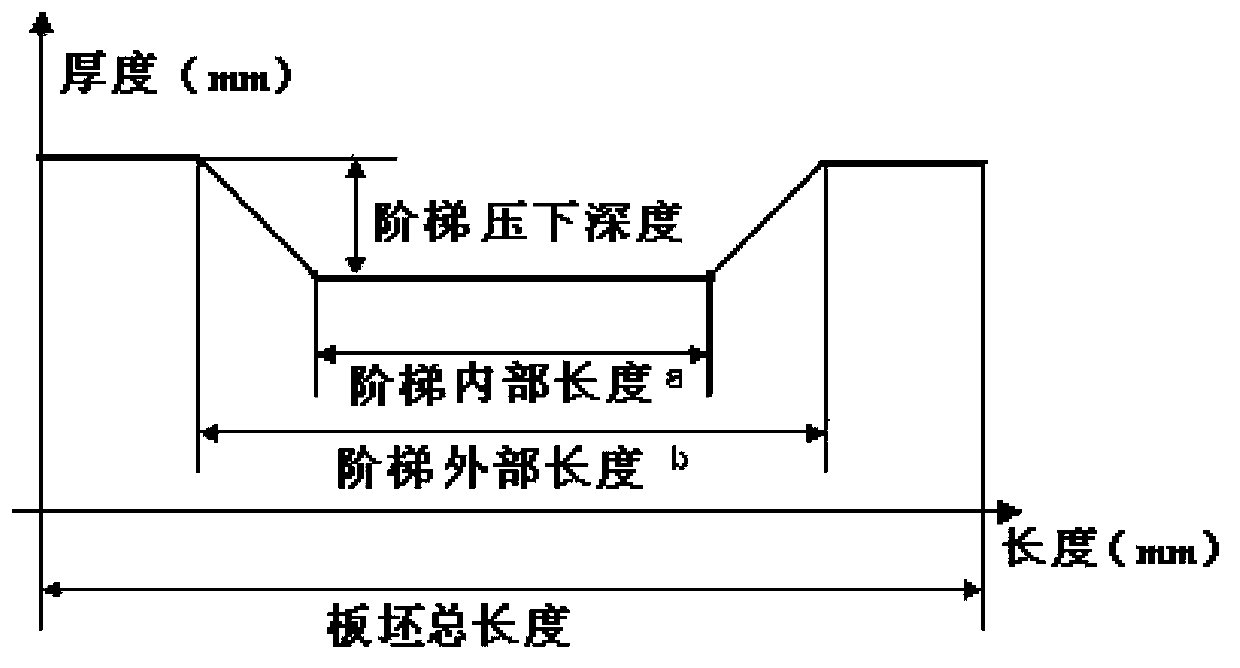

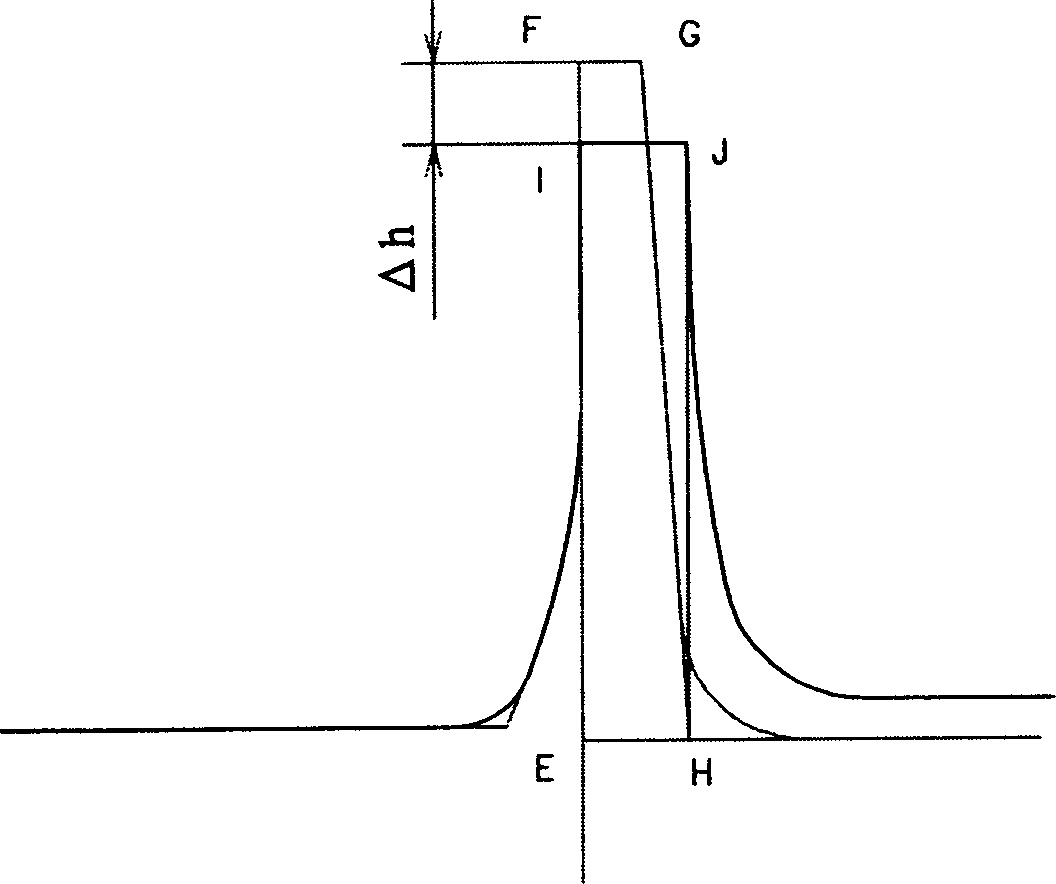

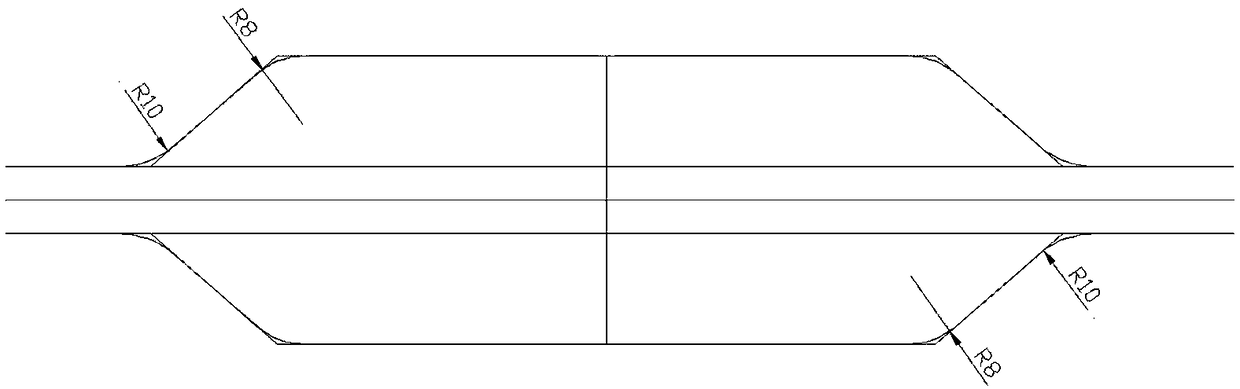

Method for controlling head-to-tail width of high broadening ratio steel plate

ActiveCN103386419AHigh yieldImprove rolling rhythmMetal rolling stand detailsMetallurgyRolling velocity

The invention discloses a method for controlling the head-to-tail width of a high broadening ratio steel plate. The method comprises a forming step, an expanding step and a longitudinal rolling step, wherein in the forming step, the rolling pass is one, the rolling reduction is 15-35mm, the ladder reduction height h is calculated according to a formula that h=2.3*(B / B'); and the rolling velocity V is calculated according to a formula that V=(b-a)*(VHGC / h) / 2. According to the method, by controlling the rolling reduction, the ladder thickness curve and the rolling velocity of the rough rolling forming pass, when the high expansion ratio steel plate is rolled, the high rolling rhythm of a roughing mill is kept, the following features of the ladder thickness curve and the set curve in the forming step can be improved, and the difference between the head-to-tail width and the middle width of the high broadening ratio steel plate is reduced, so that the trimming amount of the edge of the steel plate is reduced and the yield of the steel plate is improved.

Owner:LAIWU IRON & STEEL GRP

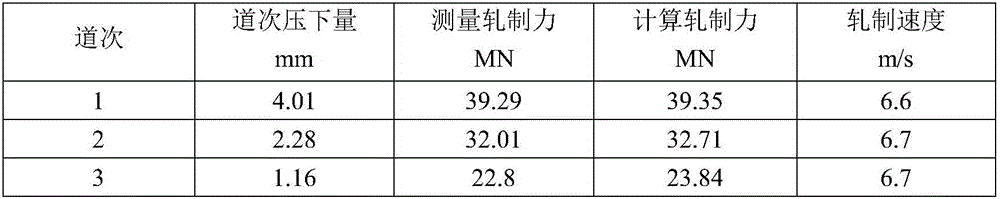

Rolling technology of producing pipeline steel of extreme specifications through wide-heavy plate mill

ActiveCN105665443ASolve the board shape problemStable productionRoll force/gap control deviceTemperature control deviceTemperature controlMetallurgy

The invention discloses a rolling technology of producing pipeline steel of extreme specifications through a wide-heavy plate mill and belongs to the technical field of steel rolling. The rolling technology comprises the steps of selecting reasonable blanks with the thickness ranging from 150 mm to 200 mm; increasing the heating temperature, improve finish rolling temperature control, optimizing the rolling schedule, adjusting cooling water distributed on roller bodies, accelerating the rolling pace, controlling the finish rolling speed to range from 4 m / s to 7 m / s, improving the straightening technology and making reasonable rolling plans. The rolling technology has the advantages that the strip shape problem of the thin-specification pipeline steel is effectively solved, the rolling hit rate and the yield are high, and qualified products can be stably produced in a batched mode.

Owner:SHOUGANG CORPORATION

Low-alloy high-strength wide and thin steel plate and production method thereof

InactiveCN102534368ALarge performance marginReduce lifting transferRoll mill control devicesMetal rolling arrangementsHigh pressure waterAlloy

Owner:WUYANG IRON & STEEL +1

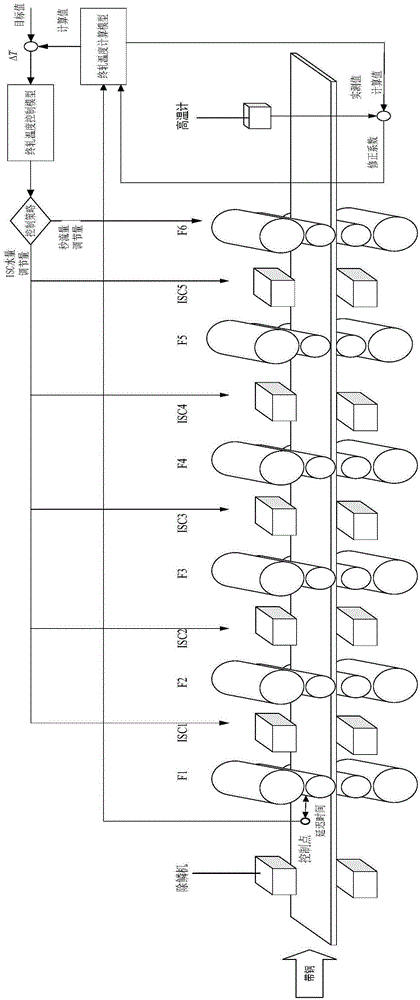

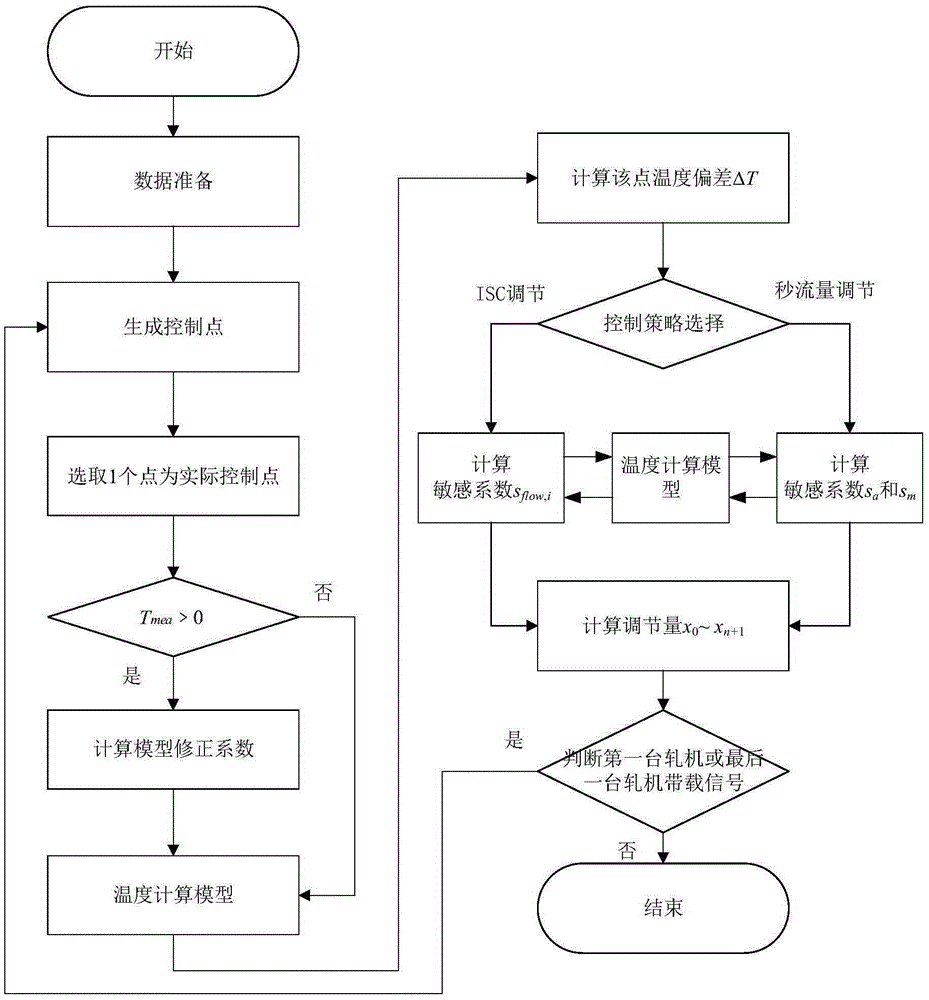

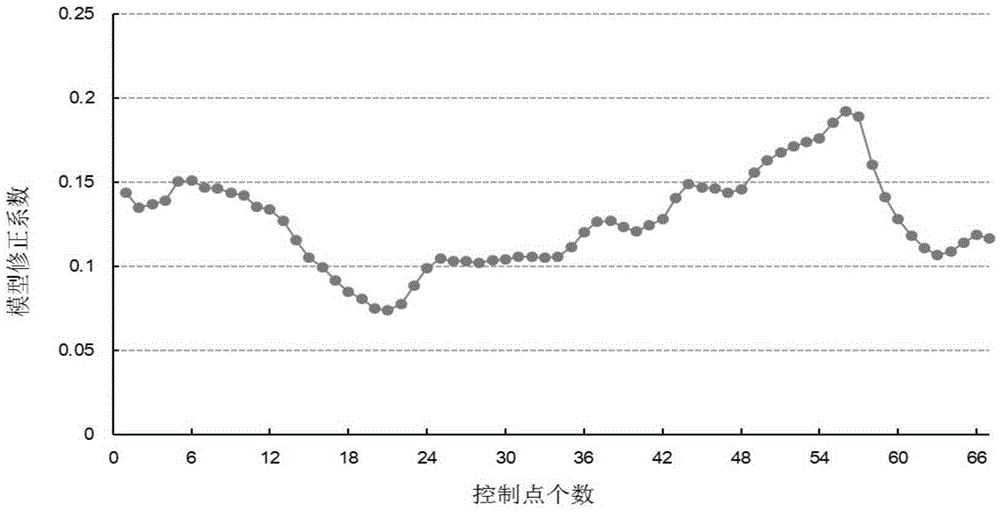

Online control method for finish rolling temperature of precision rolling strip steel

ActiveCN105344720AImprove calculation accuracyMeet control needsTemperature control deviceTraffic volumePyrometer

The invention discloses an online control method for the finish rolling temperature of precision rolling strip steel and belongs to the field of temperature control of rolling processes. The second flow regulating variable or the cooling water flow regulating variable between machine frames is subjected to online optimization through a quadratic programming optimization algorithm, and the deviation between a calculated value and a target value of the finish rolling temperature is reduced. The method comprises the steps that a plurality of control points are generated on the strip steel in the length direction according to a control period; the deviation between the calculated value and the measured value of the finish rolling temperature of all the control points is calculated according to information of all the control points and the measured value of a pyrometer at a precision rolling outlet; a temperature calculating model is corrected according to the deviation, and the calculation precision is improved, at the same time, the deviation between the calculated value and the target value of the finish rolling temperature of all the control points is calculated; and according to the deviation value between the temperature calculated value and the target value, the second flow regulating variable or the cooling water flow regulating variable between the machine frames of all the control points is subjected to online optimization through the quadratic programming optimization algorithm, and the finish rolling temperatures of all the control points are made to meet the control requirements. By means of the method, the control precision of the finish rolling temperature of the strip steel is improved, the uniformity of the total-length temperature of the strip steel is guaranteed, and the finished product quality requirements are met.

Owner:BEIJING SHOUGANG AUTOMATION INFORMATION TECH

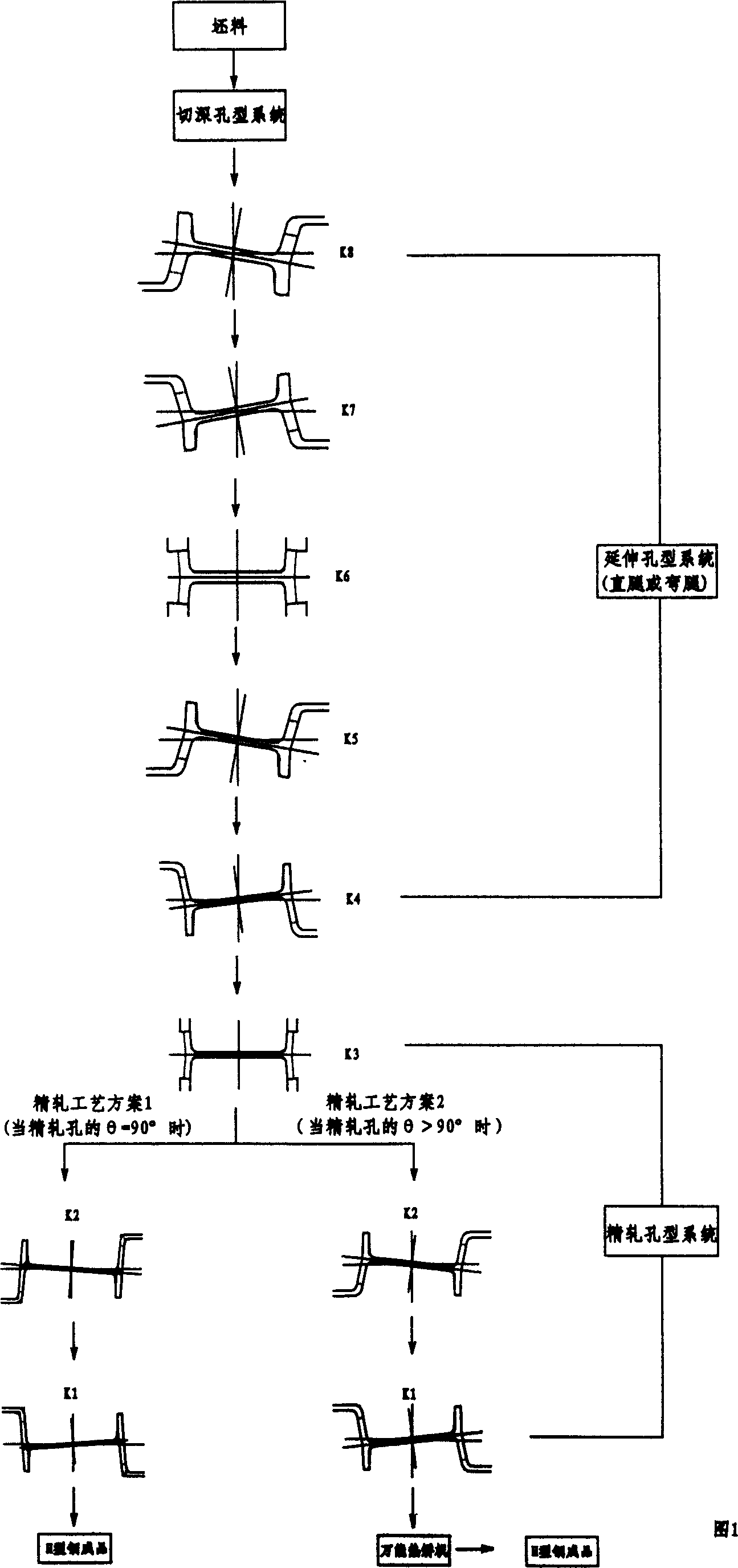

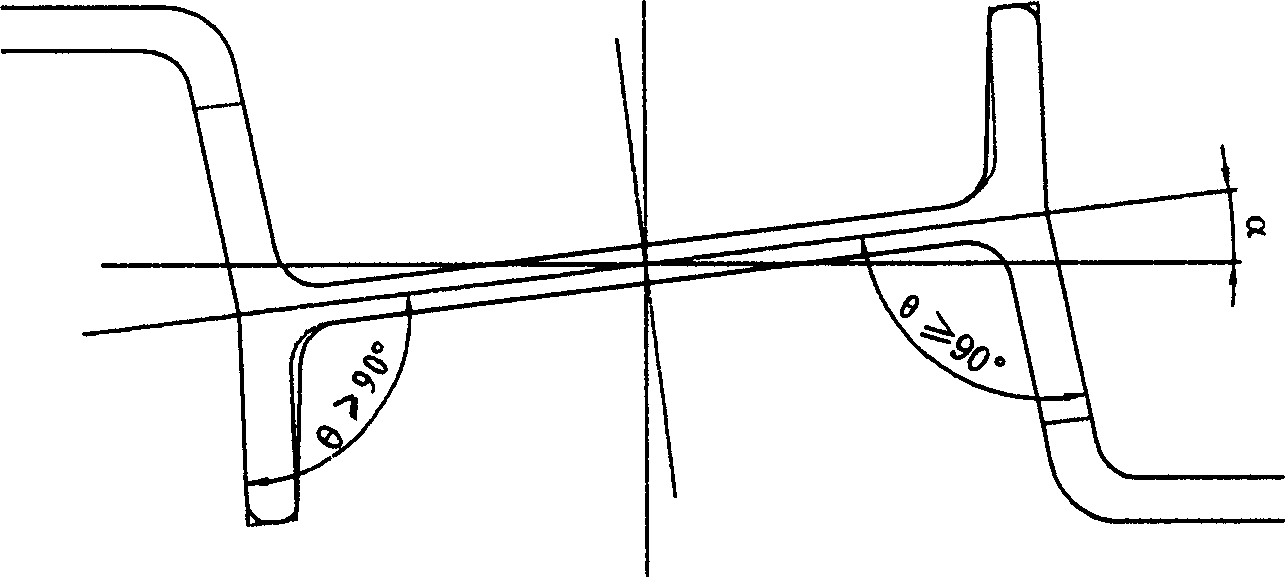

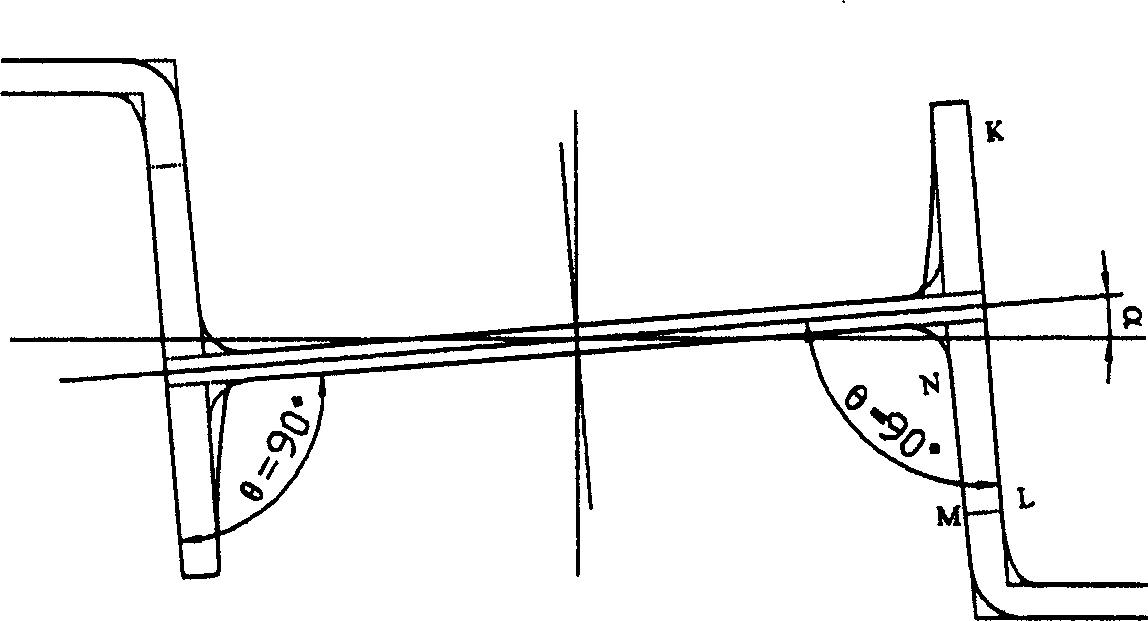

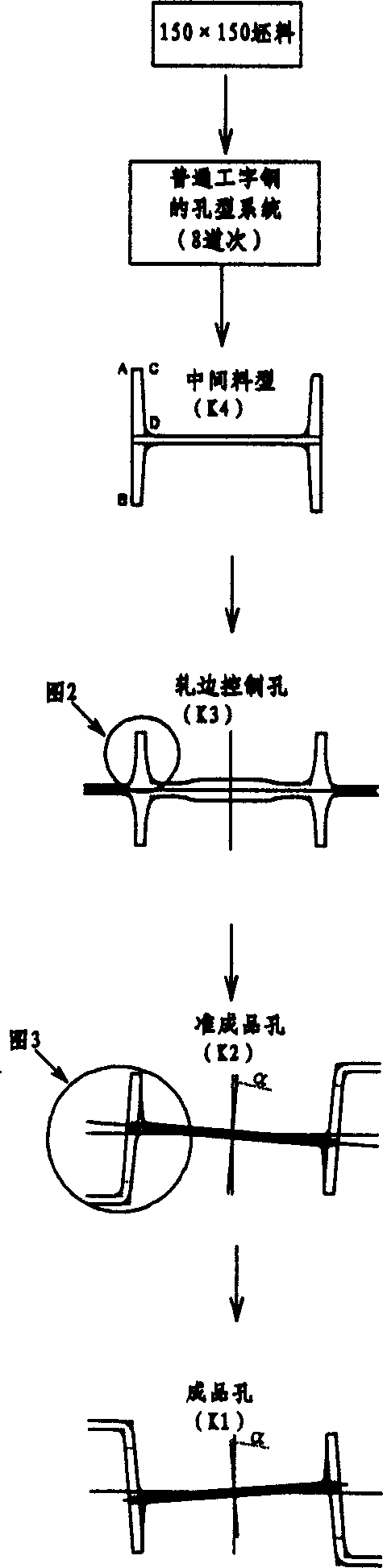

Process for rolling H steel using trio mill and heat rectification machine

InactiveCN1504277ALower the thresholdIncrease profitMetal rolling arrangementsEngineeringRoller mill

The invention relates to a process for rolling I-section steel using the three-high or two-high mills, wherein after heating square bloom, rectangular bloom etc., knifing is performed on the three-high mill, then entering the extrusion hole type system and fine rolling hole system of the common three-high or two-high roller mill for rolling, and one or two rolling lateral openings are added between the elongation pass system and fine rolling hole system, both of the elongation pass system and fine rolling hole system comprises parallel wing rim inclined rolling hole moulds.

Owner:李宝安

Method for improving rough rolling rhythm of strip steel

ActiveCN106424159AIncrease temperature dropImprove rolling rhythmTemperature control deviceWork cooling devicesStrip steelWater cooling

The invention belongs to the technical field of rough rolling and discloses a method for improving the rough rolling rhythm of strip steel. The method includes the steps that a rolling mill double-descaling water cooling step is adopted, and the temperature of plate blanks in the rolling process is lowered, wherein by adopting the rolling mill double-descaling water cooling step, descaling water is sprayed to the plate blanks at an inlet and an outlet of a rolling mill correspondingly. The method for improving the rolling rhythm by shortening the steel placement time is efficient and stable.

Owner:SHOUGANG JINGTANG IRON & STEEL CO LTD

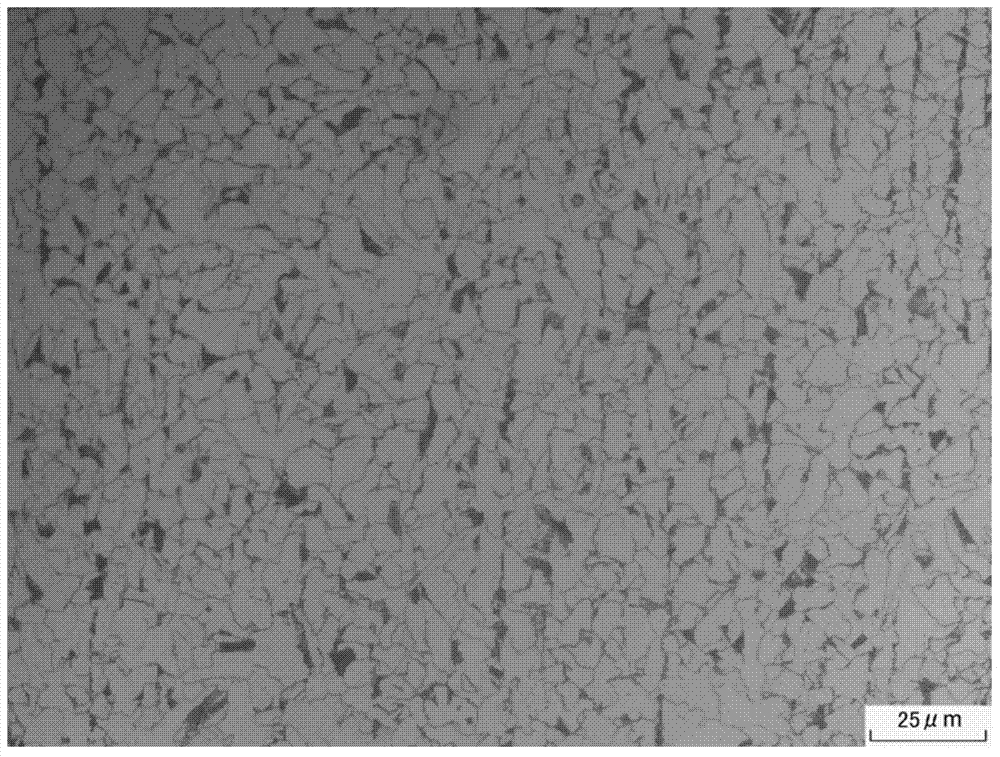

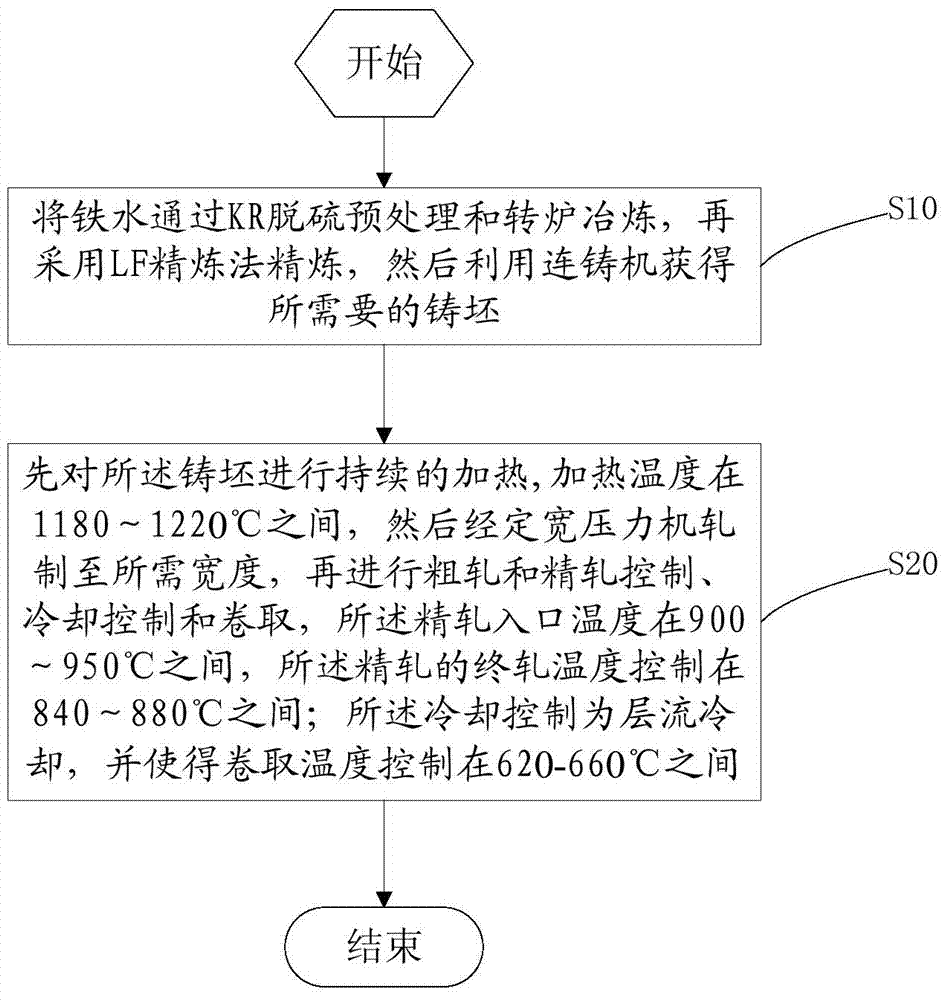

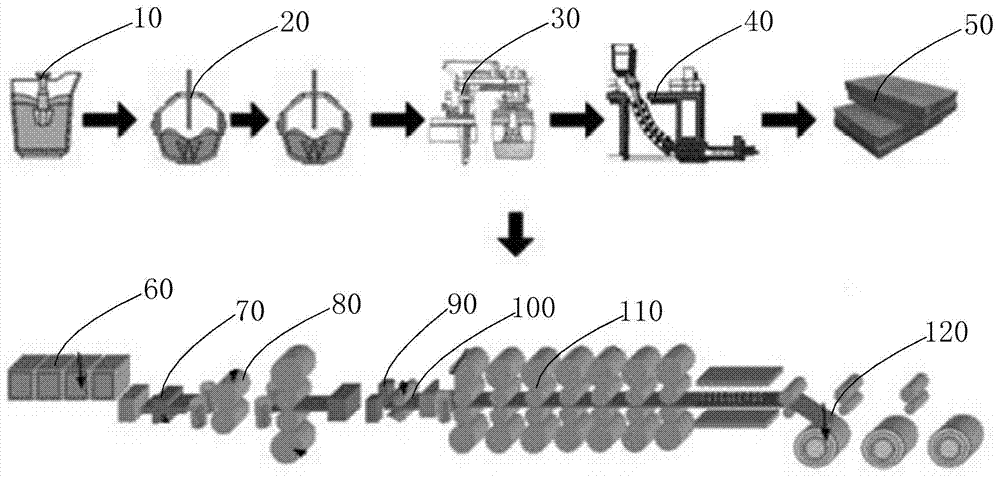

Steel for heavy-truck super-thick steel-made spokes and manufacturing method of steel

The invention relates to the technical field of steel rolling, and relates to steel for heavy-truck super-thick steel-made spokes and a manufacturing method of steel. The steel comprises the following trace elements in percent by mass: carbon, 0.07~0.12%; silicon, 0.05-0.15%; manganese, 0.7-1.1%; niobium, 0.01-0.03%; titanium, 0.01-0.03%; phosphor, <=0.015%; sulfur, <=0.005%; aluminium, 0.02-0.05%; and nitrogen, <=0.006%. The manufacturing method comprises: performing KR desulphurization and LF-method processing to obtain casting blanks, performing rough rolling and finish rolling, and performing laminar flow cooling and reeling to obtain the needed steel. By utilizing smelting to obtain the casting blanks with the above trace-element mass percentages and employing the technologies of low-temperature heating, low-temperature rolling and high-temperature reeling, the demands of heavy-truck spokes on easy spinning property, surface quality and performance stability are satisfied, and the collapsing crushing rate of heavy-truck wheels is substantially reduced.

Owner:SHOUGANG CORPORATION

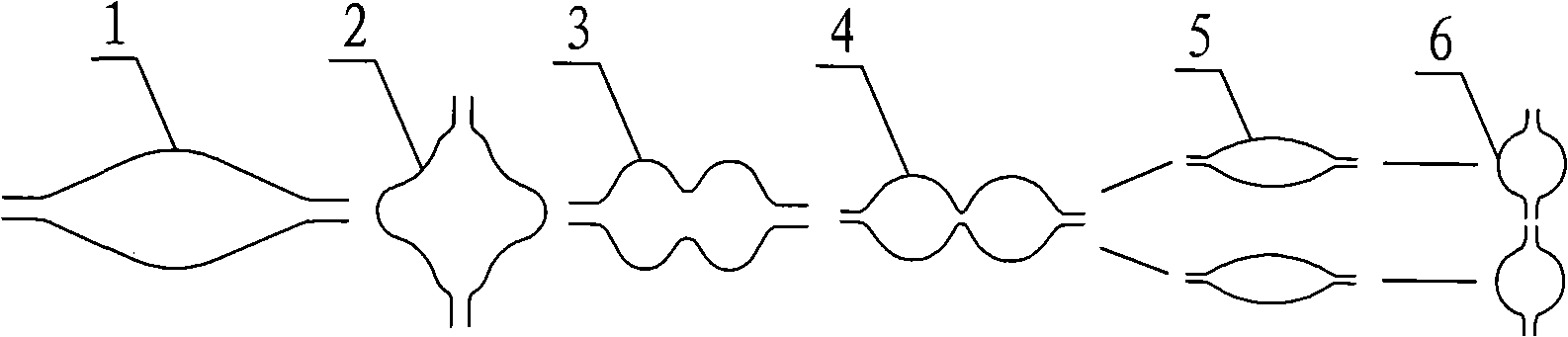

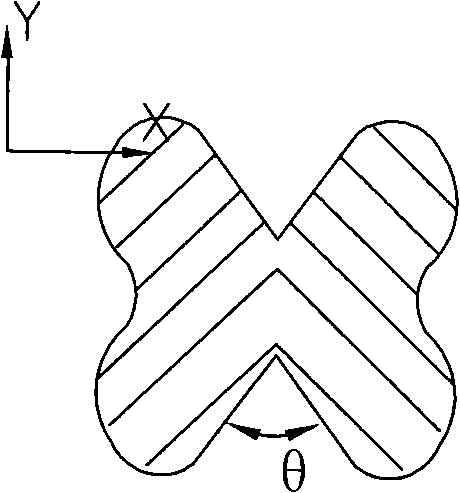

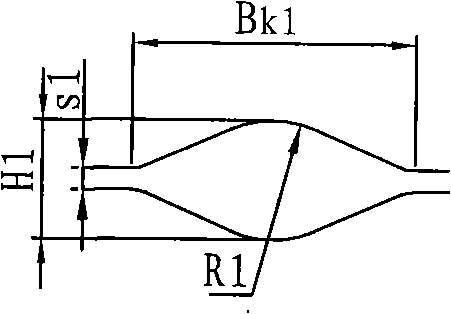

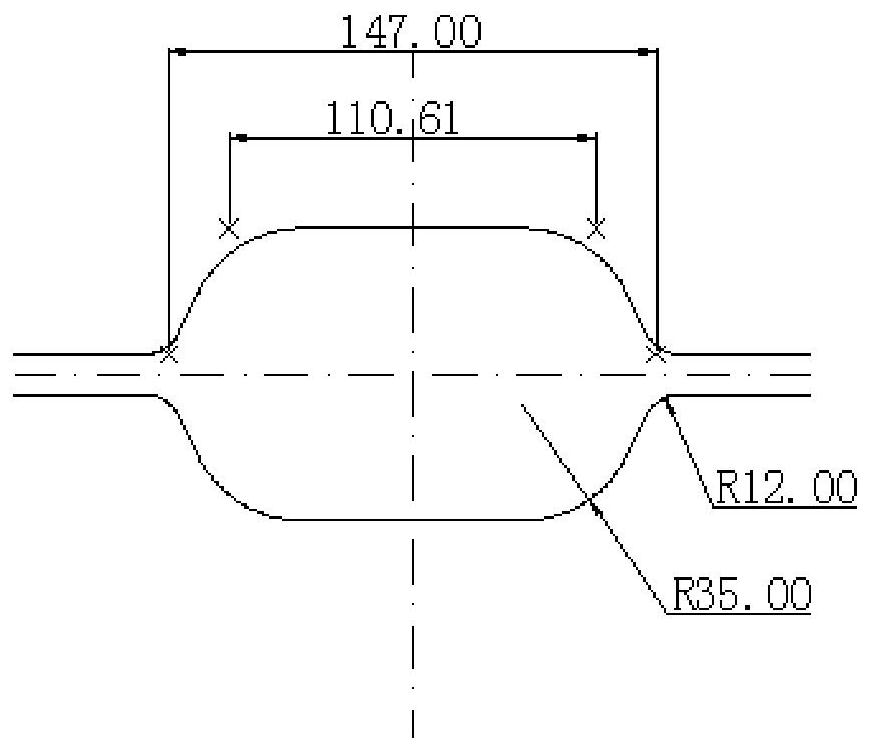

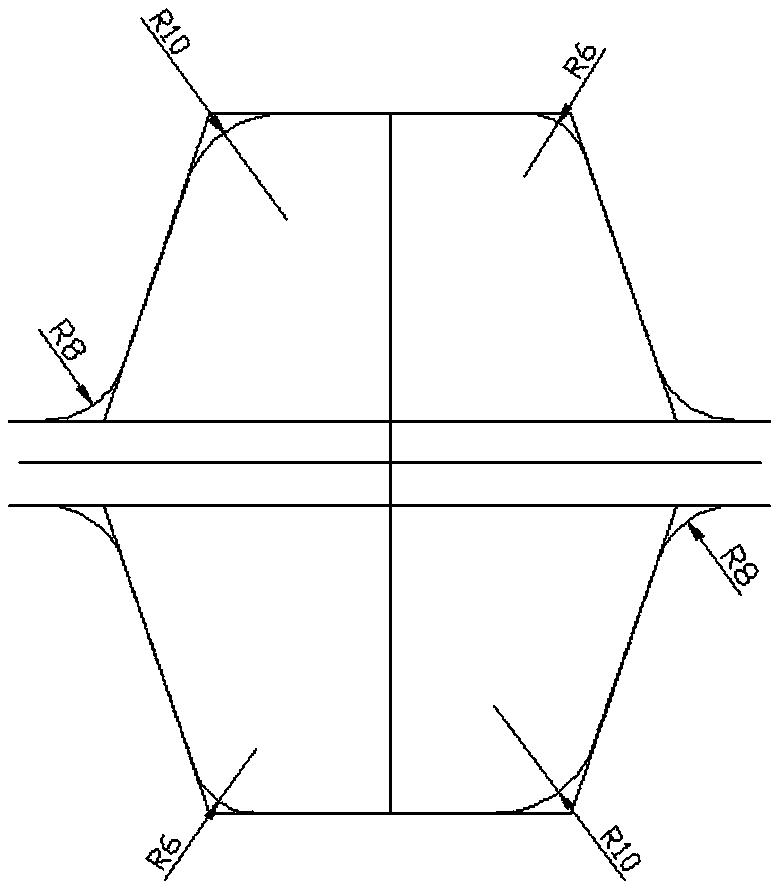

Round steel splitting rolling technique

InactiveCN101306432AHigh speedImprove machine-hour throughputRollsMetal rolling arrangementsProduction rateEllipse

The invention discloses a slit rolling technique of round steel, which comprises the following steps: a blank is rolled into parallel rolled pieces after undergoing the stages of rough rolling, medium rolling and precision rolling; the rolled pieces are slit by a slitting wheel for obtaining the round steel rolled pieces, wherein the roll passes with specific structures and sizes including the rhomboid pass, the cinquefoil square pass, the dumbbell-shaped pre-slit pass, the double-circle slitting pass, the ellipse pass and the round pass are sequentially adopted in the medium rolling and the precision rolling stages, the square rolled pieces rolled by the cinquefoil square pass require further slitting and positioning by a slitting wedge, and the point angle Theta of the slitting wedge is 60 DEG- 65 DEG; finally each thin and narrow connecting band of the rolled pieces is slit by the slitting wheel on a slitting foreplate, wherein the point angle of the slitting wheel is 90 DEG- 95 DEG. The round steel produced by adopting the slit rolling technique of the invention has good surface quality and high production rate, and the slit rolling process can effectively improve the machine-hour yield of the round steel and increase the production efficiency in a factory.

Owner:XINJIANG BAYI IRON & STEEL

Process for rolling H steel using trio mill

The invention relates to a process for rolling I-section steel using the common three-high mill, wherein after heating square bloom, rectangular bloom or special-shaped bloom, an intermediate blank similar to I-beam steel is rolled using the common three-high mill, and entering parallel wing ring hole system for rolling, then entering in turn two parallel inclined rolling hole mould with opposite opening directions, the inner and outer walls are fabricated in the open slot to make them parallel, the leg sides are processed into qualified shape in the closed end until the final I-section steel product is achieved.

Owner:李宝安

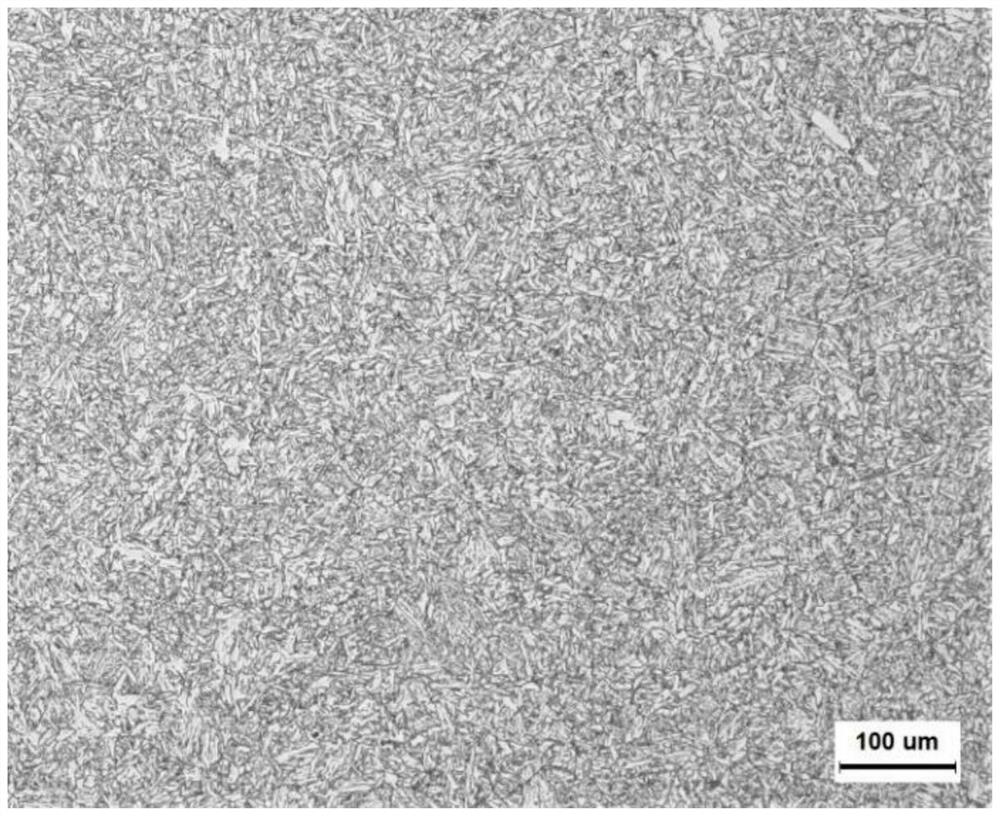

Production process of hot-rolled round steel 09CrCuSb with sulphuric acid dew point corrosion resistance

ActiveCN112792123AHigh yieldImprove corrosion resistanceMetal rolling arrangementsCrazingChemical composition

The invention discloses a production process of hot-rolled round steel 09CrCuSb with sulphuric acid dew point corrosion resistance. The round steel 09CrCuSb comprises the following chemical components in percentage by weight: 0.06 percent to 0.09 percent of C, 0.26 percent to 0.38 percent of Si, 0.48 percent to 0.60 percent of Mn, 0.90 percent to 1.00 percent of Cr, 0.30 percent to 0.40 percent of Cu, 0.07 percent to 0.09 percent of Sb, less than or equal to 0.015 percent of P, less than or equal to 0.008 percent of S, less than or equal to 0.15 percent of Ni, less than or equal to 0.0060 percent of N, less than or equal to 0.0002 percent of H, less than or equal to 0.0020 percent of O, and the balance of equivalent amount of Fe. Through scientific design of the chemical components, a passive film on the surface of steel is formed, and the corrosion resistant performance meets the using requirement; suitable and effective heating, steel rolling and cooling technologies are formulated, so that production of copper-containing steel cracks is effectively avoided, the industry breakthrough of the replacement of polished materials by corrosion-resistant steel 09CrCuSb AR(as rolled) hot-rolled materials is realized, and the material yield ratio is increased by more than 5 percent.

Owner:TIANJIN IRON & STEEL GRP

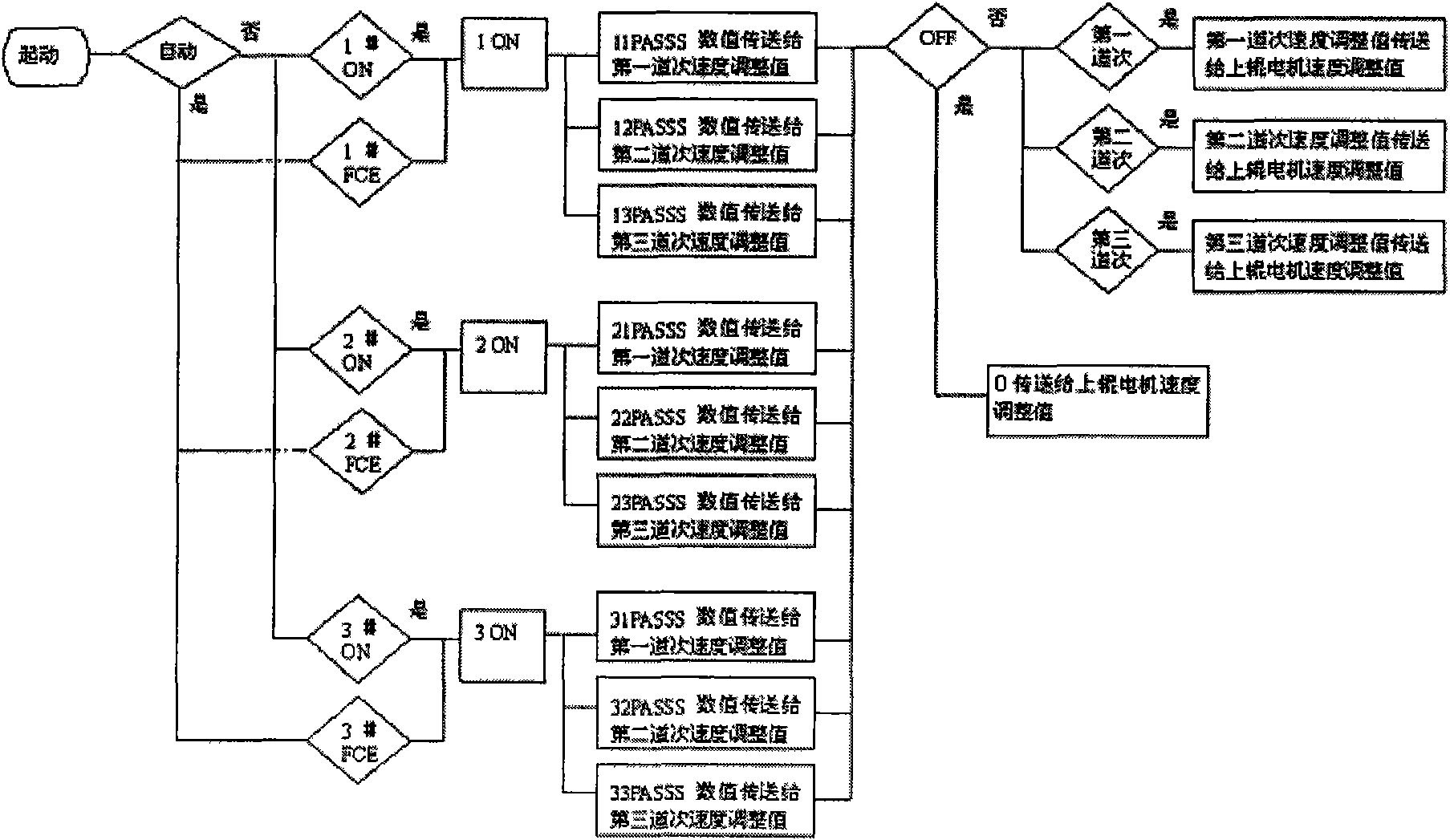

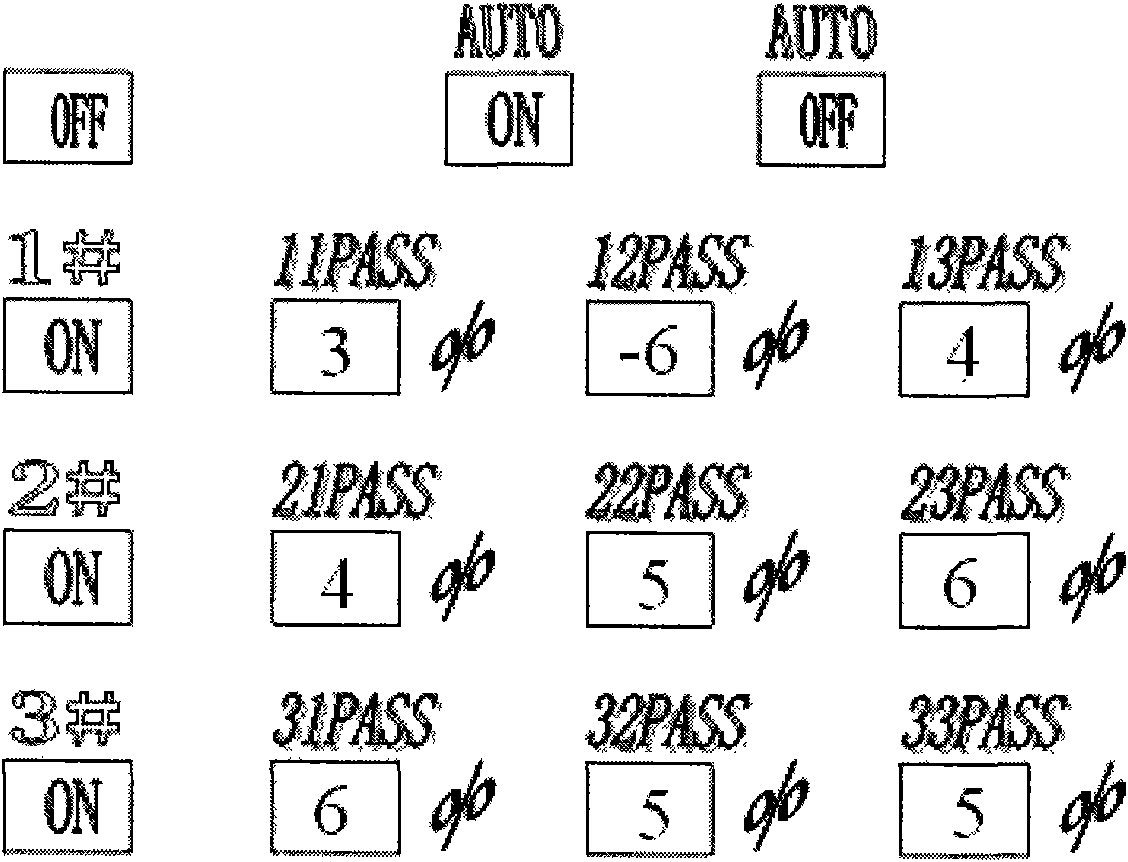

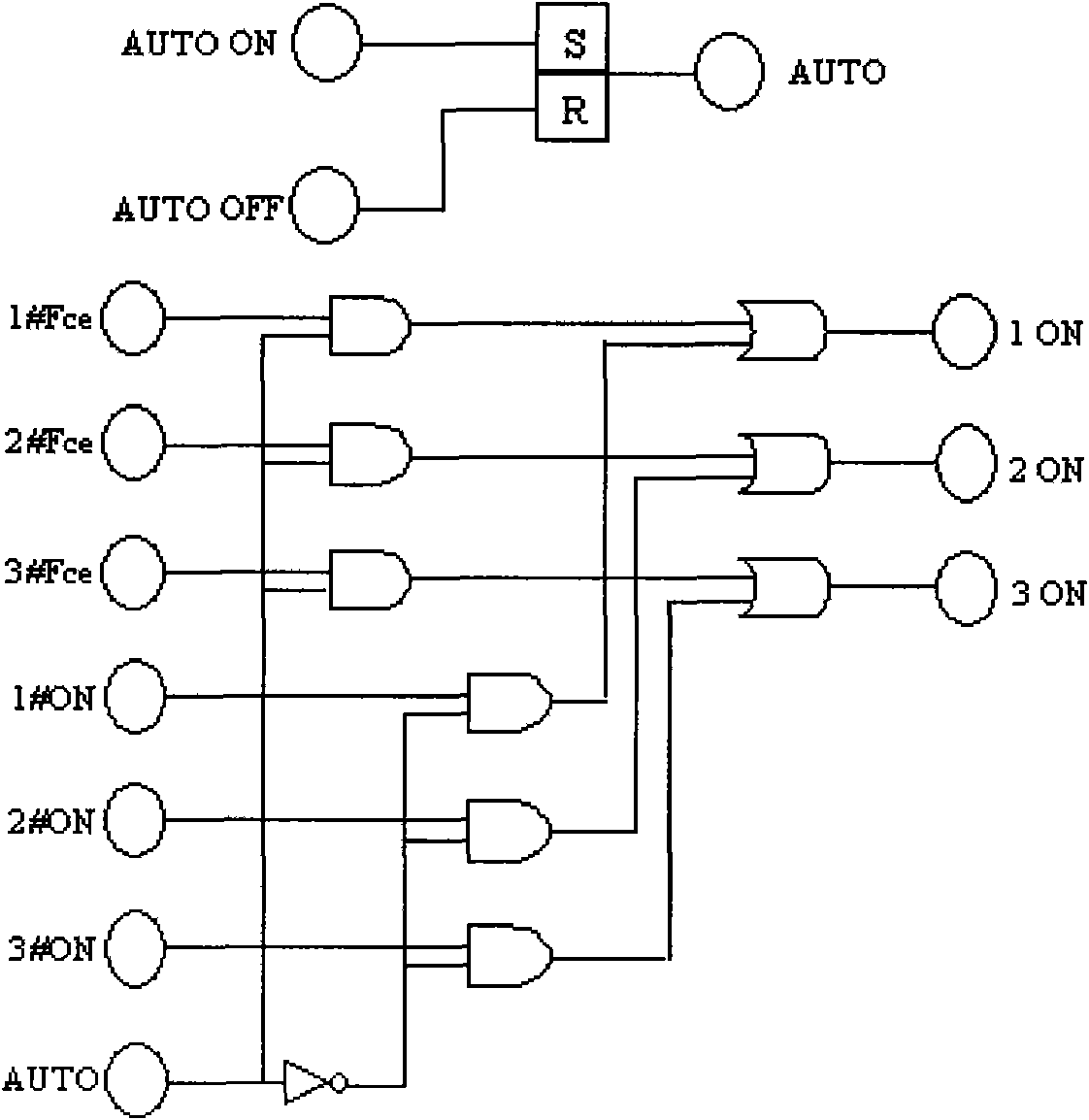

Control method for preventing bending and deformation of head of rough rolling plate blank

InactiveCN101927273AReduce workloadThe method is simple and reliableMetal rolling arrangementsRoll speed control deviceControl mannerWorkload

The invention provides a control method for preventing bending and deformation of the head of a rough rolling plate blank. An up-rolling speed of a rough rolling machine is automatically subjected to fine tuning through a human-computer operation window and a control program under the premise of constant down-rolling speed of the rough rolling machine so that the speeds of the up-rolling and the down-rolling deviate, so and the deformation of an upper surface and a lower surface of the plate blank is controlled. In the invention, the human-computer operation window is used for adjusting and setting speeds of each path of up-rolling motor of the rough rolling machine; the human-computer operation window is provided with a function put-in option button, a control way option button, a model set option button and speed regulation value input windows of each path of the up-rolling motor; and the control program consists of a function put-in option program, a control way option program and a speed given program of the up-rolling motor. The invention can automatically realize the regulation to the bending and the deformation of the head of the rough rolling plate blank through set data. The method is simple and reliable, effectively improves rolling rhythm, improves production efficiency and reduces workload and labor intensity.

Owner:ANGANG STEEL CO LTD

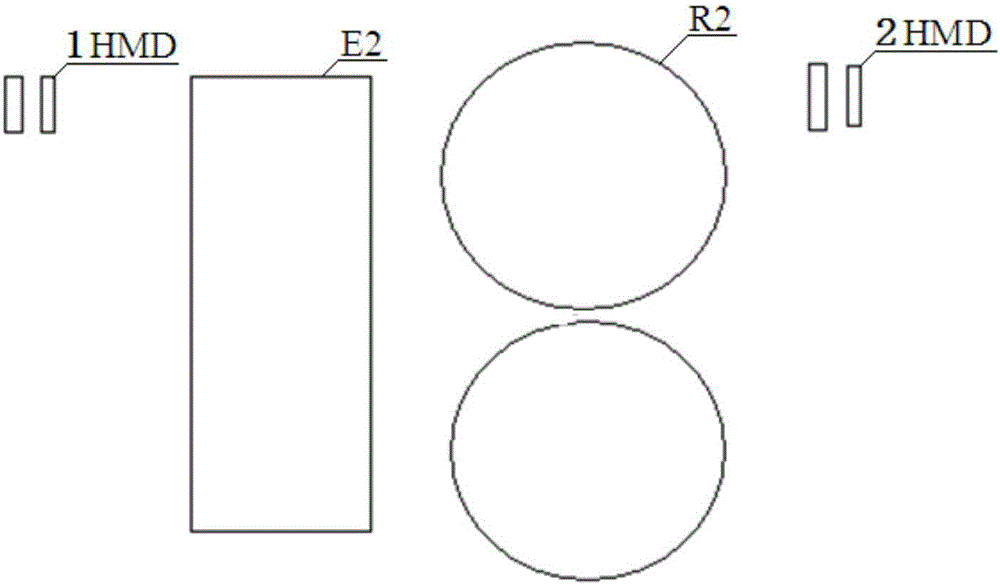

Method and device for increasing hot rolling speed of ferrite

ActiveCN106583465ALower tapping temperatureWeakening rangeTemperature control deviceWork cooling devicesRolling millRolling speed

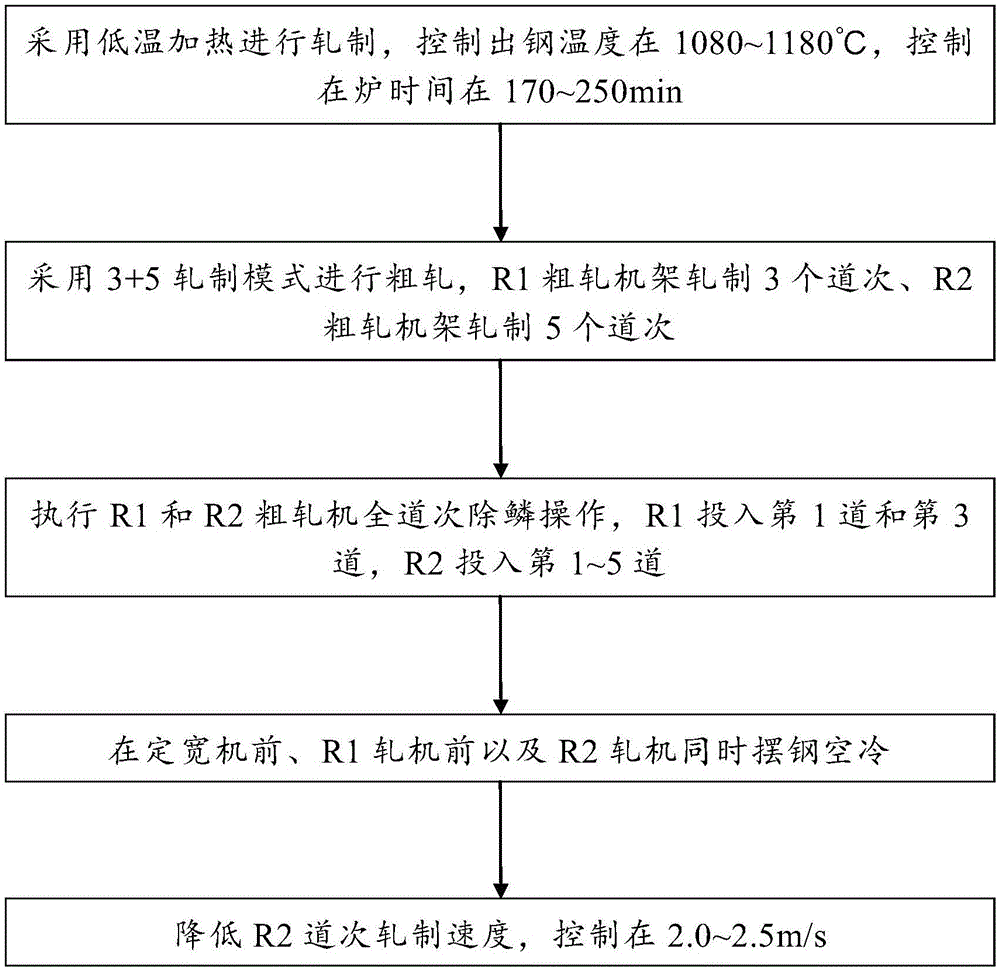

The invention belongs to the technical field of hot rolling processes, and discloses a method for increasing the hot rolling speed of a ferrite. The method comprises the following steps of rolling by adopting a low-tempreature heating method, controlling the tapping temperature to be 1,080-1,180 DEG C, and controlling the time in the furnace to be 170-250 min; conducting rough rolling by adopting a 3+5 rolling mode, forming 3 passes through rolling of a rough mill frame R1, and forming 5 passes through rolling of a rough mill frame R2; executing all-pass scale removal operations by a rough mill R1 and a rough mill R2, putting the rough mill R1 in the first pass and the third pass, and putting the rough mill R2 in the first pass, the second pass, the third pass, the fourth pass and the fifth pass; synchronously conducting steel placing and air cooling in front of a width gauge and the rough mill R1 and on the rough mill R2; and reducing the pass rolling speed of the rough mill R2, and controlling the pass rolling speed of the rough mill R2to be 2.0-2.5 m / s.

Owner:SHOUGANG JINGTANG IRON & STEEL CO LTD

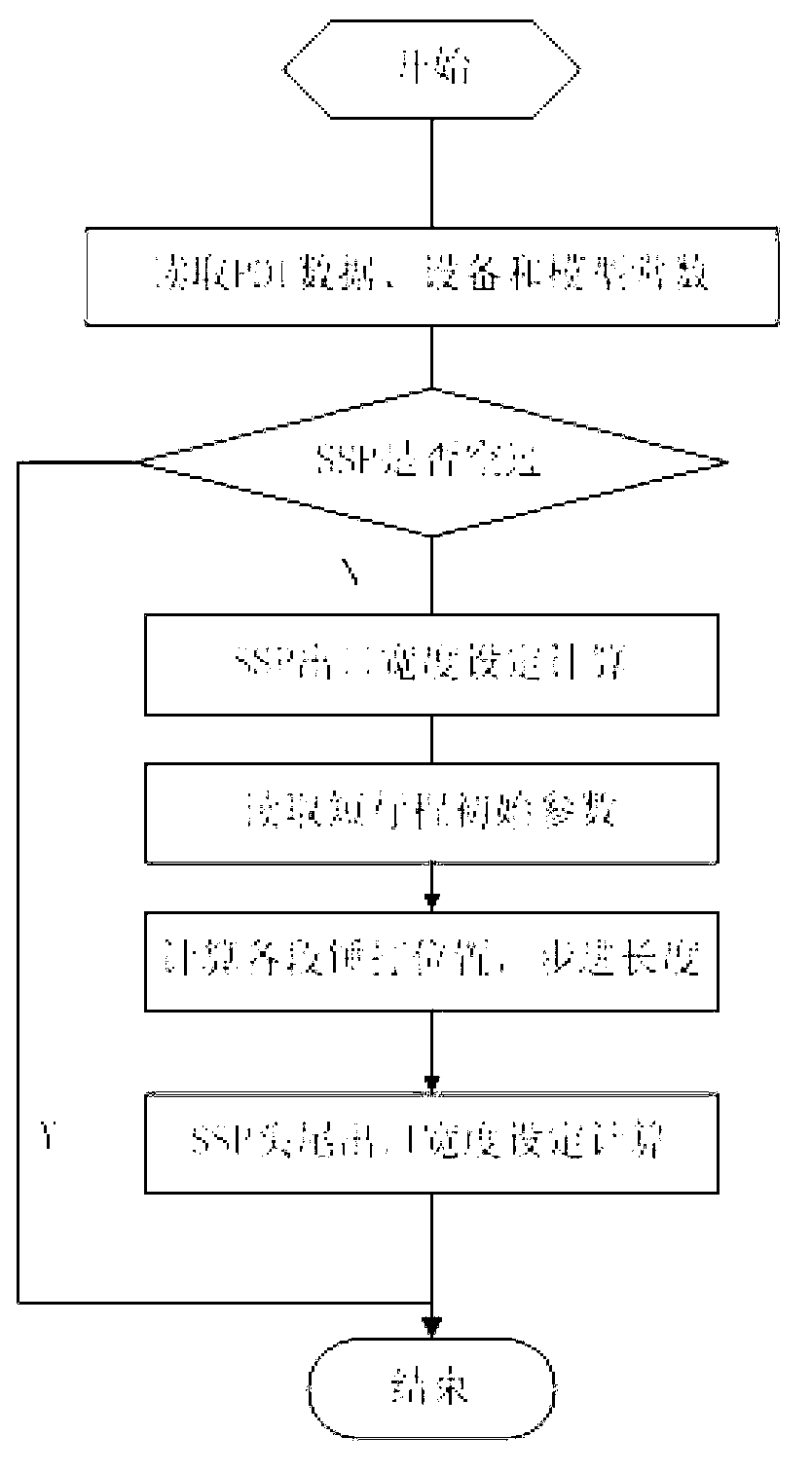

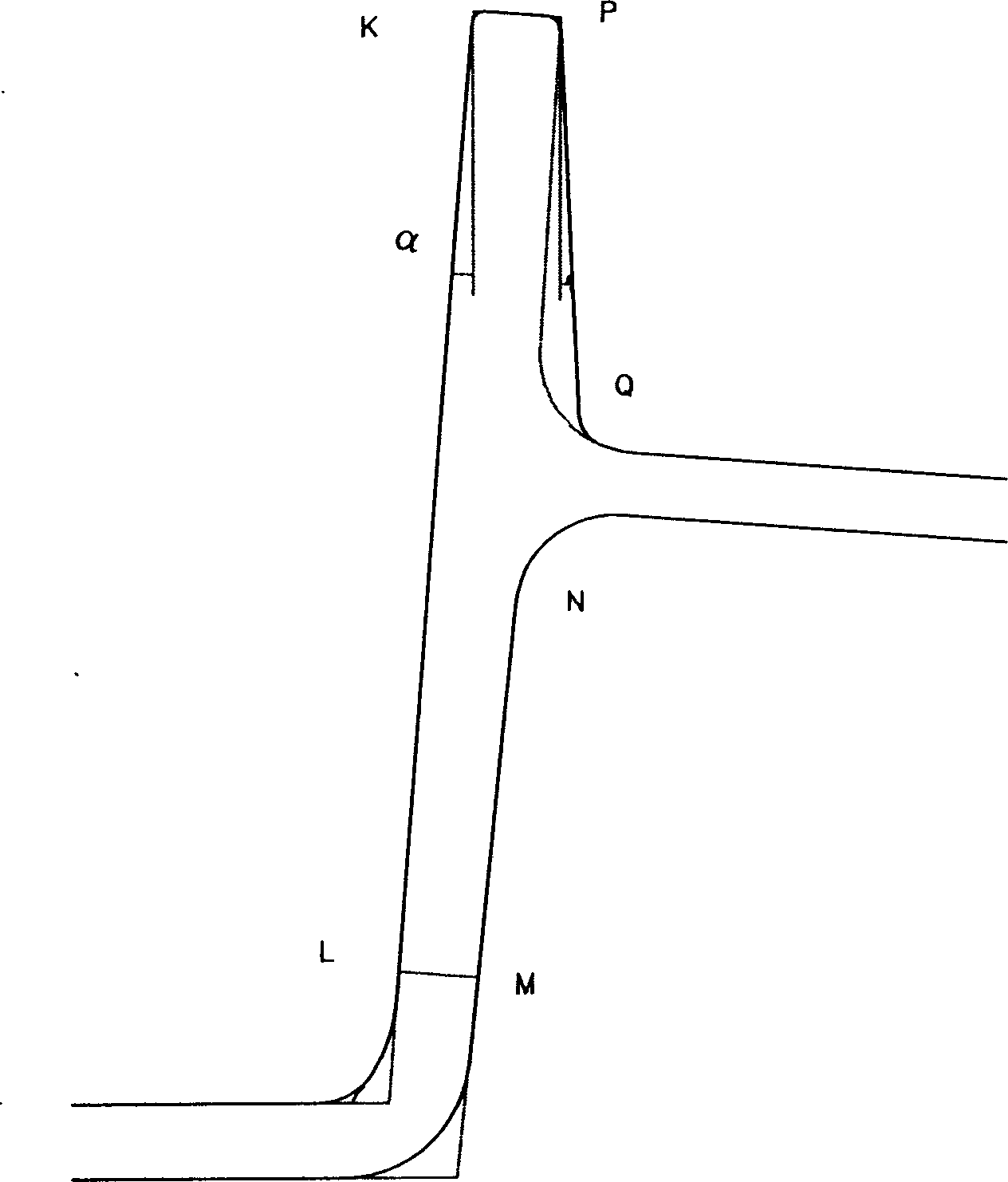

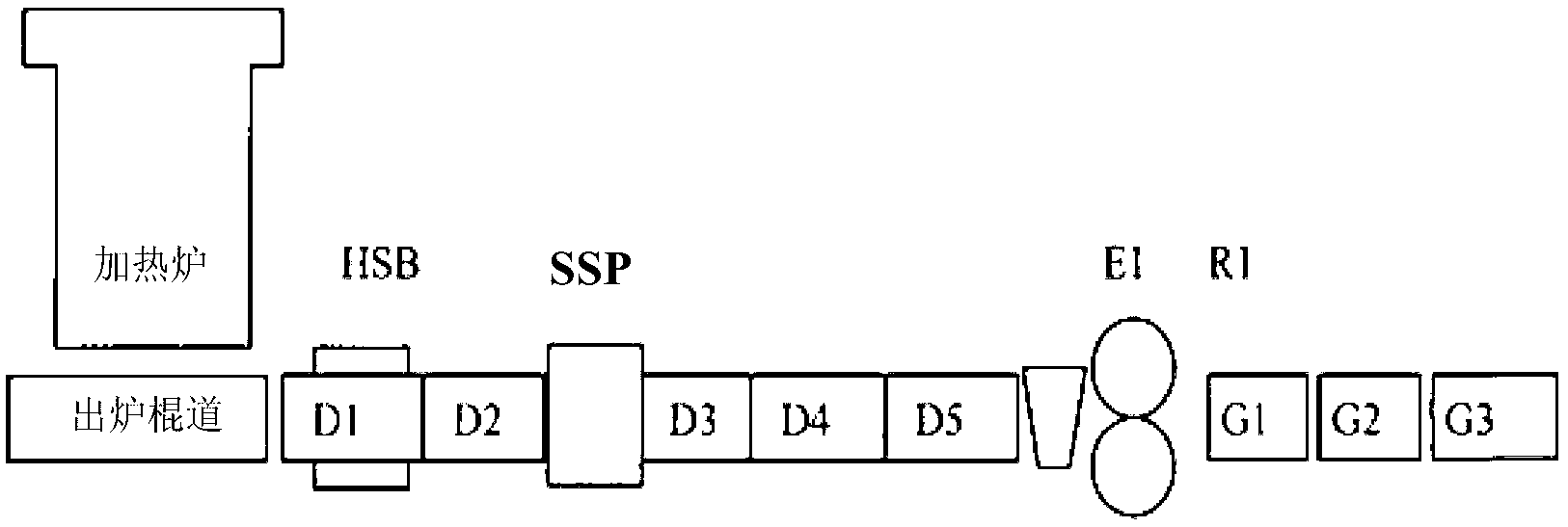

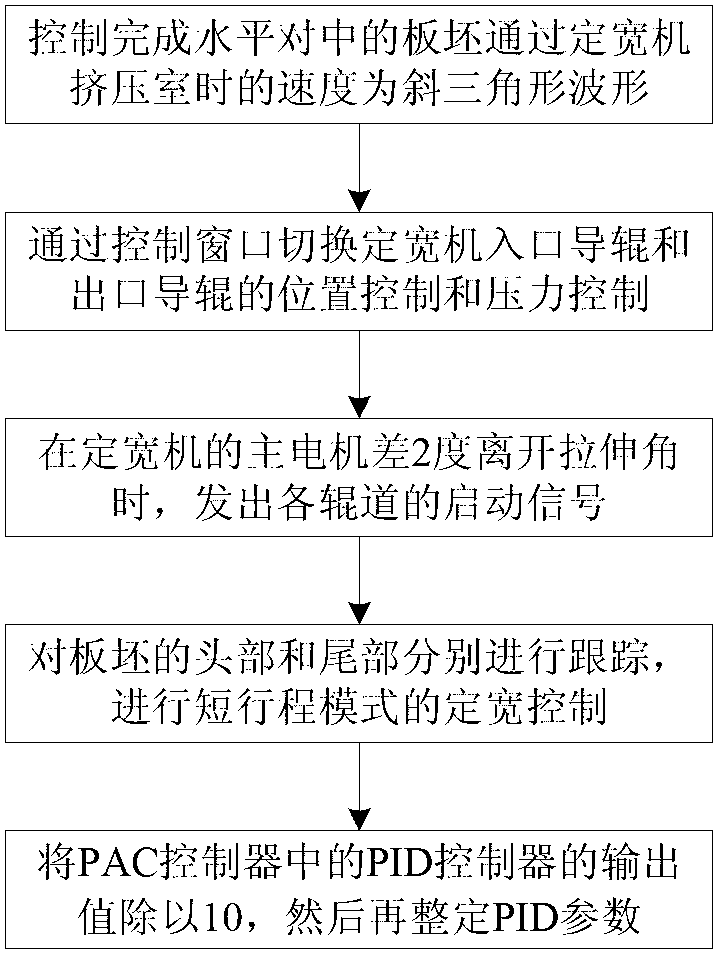

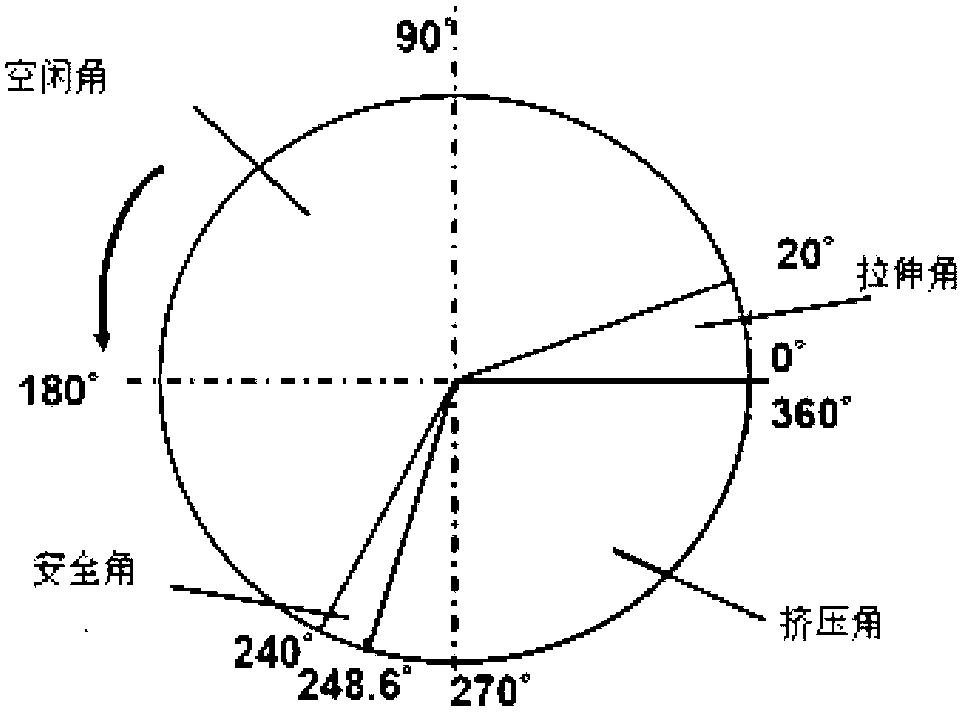

Control method for walking-stopping type high-side-pressure sizing press

ActiveCN103223423AImprove rolling rhythmImprove control accuracyRare end control deviceStart signalSizing

The invention relates to a control method for a walking-stopping type high-side-pressure sizing press. The control method is applied to a control system of a Shougang Jingtang 1580 hot rolling sizing press. The control method comprises the following steps: controlling the speed of a slab subjected to horizontal centering when the plate blank passes through an extrusion chamber of the sizing press to be oblique triangle waveform; switching position control and pressure control of an inlet guide roller and an outlet guide roller of the sizing press by a control window; sending out a starting signal of each roller way when a main motor of the sizing press departs from a stretching angle only with 2-degree superposition; tracking the heat part and the tail part of the slab respectively; when realizing pressure control by utilizing a proportion-integration-differentiation (PID) controller of an integer parameter of a PAC controller of the GE Company, dividing a control factor (actually adopting the integer 10) from the output value of the controller and setting the PID parameter, so that the control precision of the controller is improved. By the control method, the rolling rhythm and the control precision are improved. A good effect is achieved when the control method is applied to control of the Shougang Jingtang 1580 hot rolling sizing press.

Owner:BEIJING ARITIME INTELLIGENT CONTROL

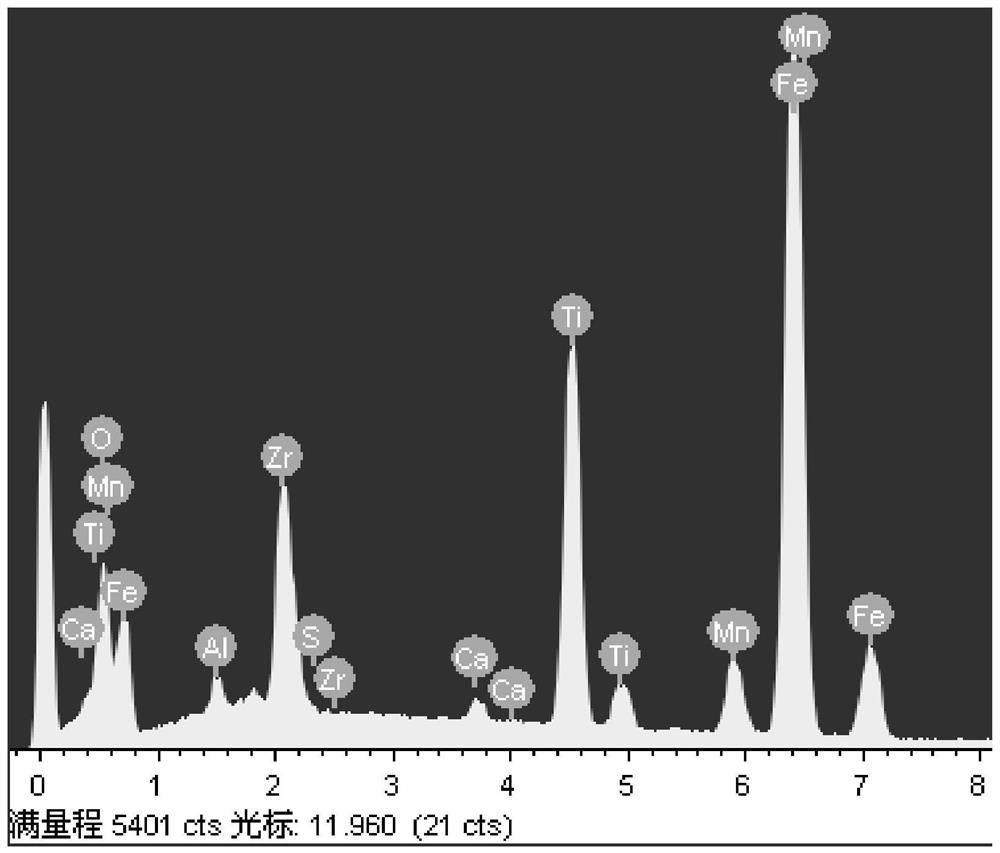

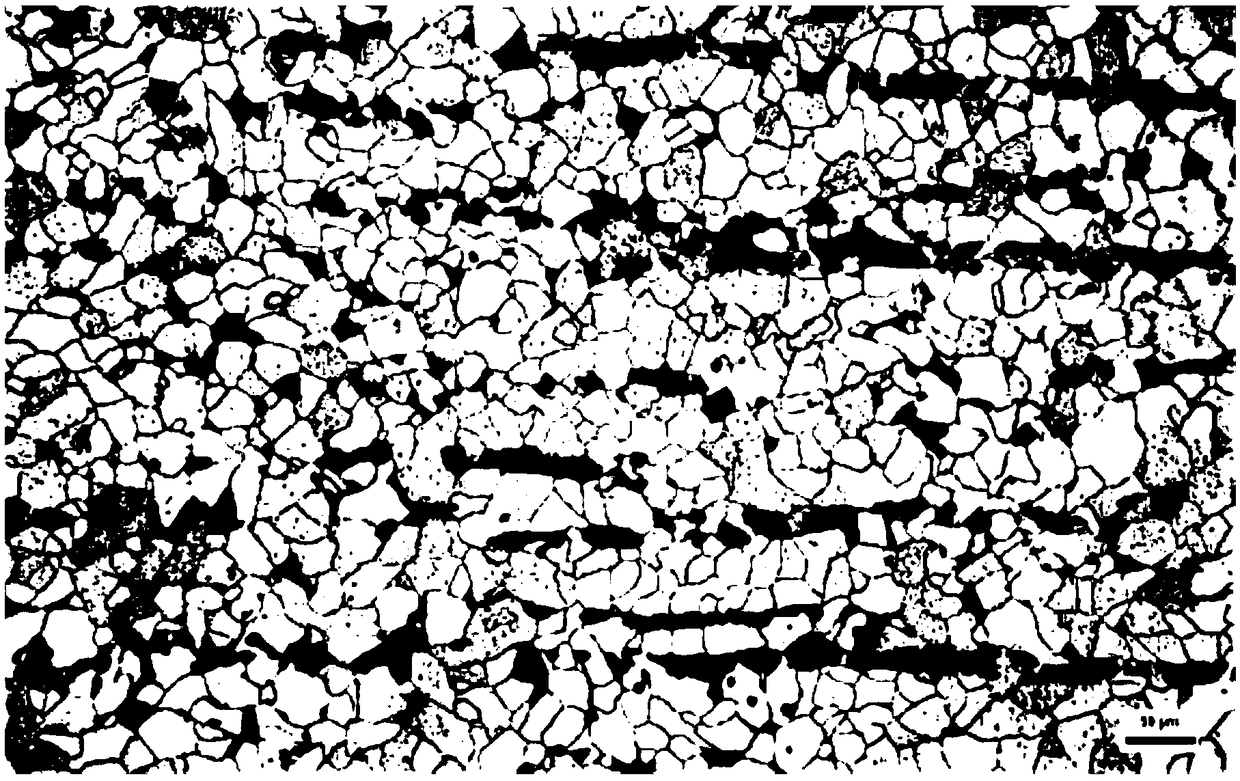

Hot-rolled seamless steel tube with excellent strength and toughness and manufacturing method thereof

ActiveCN113025902AImprove toughnessReduce consumptionProcess efficiency improvementStructure propertyToughness

The invention discloses a hot-rolled seamless steel tube with excellent strength and toughness and a manufacturing method thereof and belongs to the field of hot-rolled seamless steel tube production. The hot-rolled seamless steel tube with excellent strength and toughness comprises the following components of 0.04 to 0.25 % of C, 0.1 to 0.5 % of Si, 1.2 to 2.0 % of Mn, 0.001 to 0.015 % of P, 0.001 to 0.01 % of S, 0.001 to 0.03 % of Al, 0.004 to 0.025 % of Ti, 0.001 to 0.02 % of RE + Zr, 0.001 to 0.008 % of O, 0.001 to 0.01 % of N and the balance Fe and inevitable impurity elements. RE is one or the sum of more of Ce, La and Y. Ti, Zr and RE are core elements, and the interaction of Ti, Zr and RE obviously enhances the structure property regulation effect. According to the manufacturing method, by means of collaborative optimizing control over alloy components, a smelting method and rolling and cooling processes, the improvement effect of the inclusions on the structure and the performance is exerted.

Owner:NORTHEASTERN UNIV

Method for increasing rolling paces of 5m rolling mill

ActiveCN110773570AHigh positioning accuracyImprove tracking accuracyRoll force/gap control deviceMetal rolling arrangementsControl logicMotion control

The invention discloses a method for increasing rolling paces of a 5m rolling mill and belongs to the technical field of steel rolling. The method has the beneficial effects that through optimizationof control logics of a roll gap motion and a roll alternating motion, conversion of a steel rotation code, optimization of a rolling pass, and optimization of tracking of a to-be-rolled position of asteel plate, a steel rotation rolling pass speed and a steel throwing empty pass speed are increased, and an intra-pass steel throwing distance is shortened, so the rolling paces are obviously increased; rolling time spent on each steel plate is reduced by 18.4s on average; and significant effects are realized in increase of production efficiency and reduction of production cost.

Owner:NANJING IRON & STEEL CO LTD

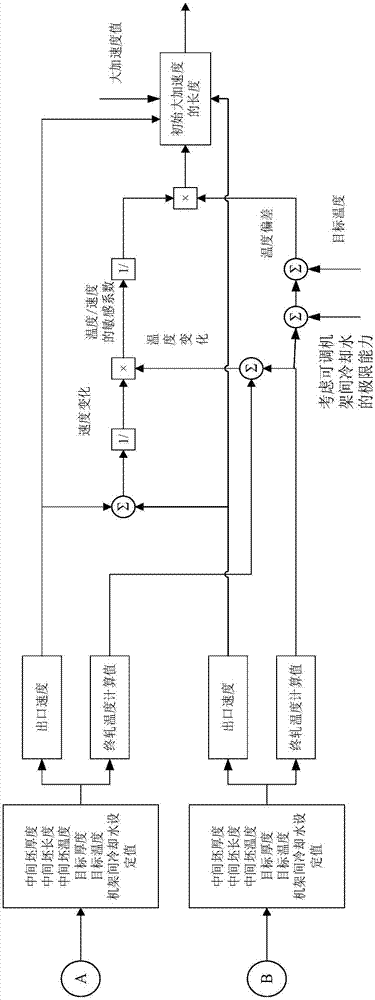

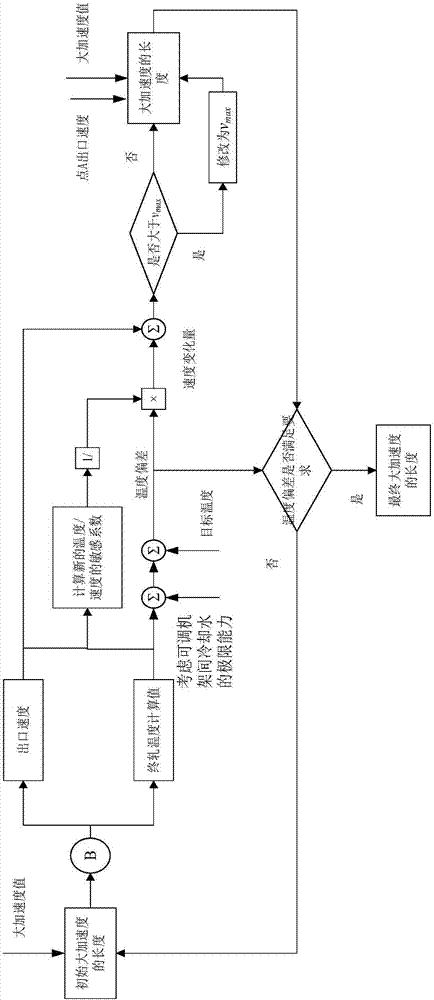

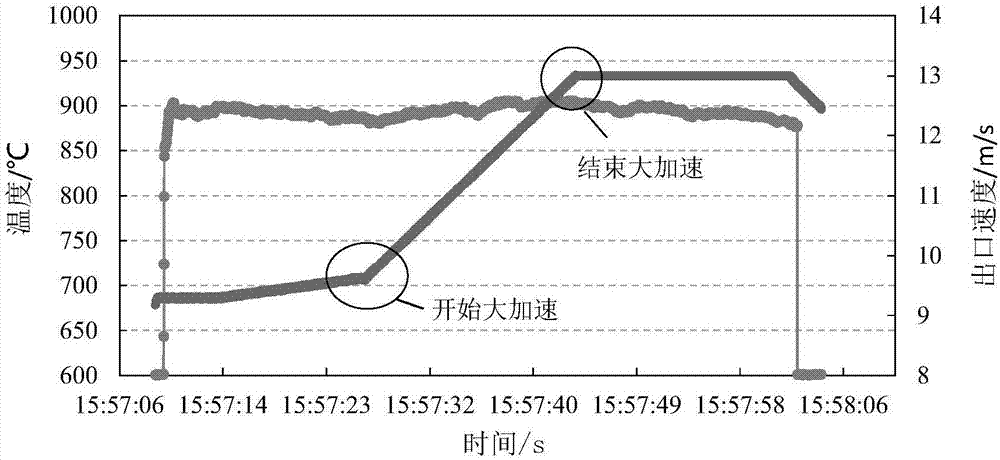

Large acceleration control method for ensuring finish rolling temperature

ActiveCN107282650AMeet control requirementsGuaranteed temperature stabilityTemperature control deviceRolling mill drivesTemperature controlStrip steel

The invention discloses a large acceleration control method for ensuring the finish rolling temperature, and belongs to the field of temperature control in the rolling process. The control method aims to meet the control requirements of different types of steel, improve the production capacity of a rolling mill, shorten the production time and ensure the stability and the uniformity of finish rolling temperature. The control method comprises the steps that two points are generated in the length direction of strip steel; according to the information of the points, a finish rolling temperature calculation value and a speed calculation value of each point are calculated, and the sensitivity coefficients of the temperature / speed are calculated; the temperature deviation between the calculated values of the finish rolling temperature of the points and the target values when considering that cooling water between adjustable machine frames reaches the limit capacity are calculated, and the speed variable quantity required by the points to reach the target temperature are calculated by combining the sensitivity coefficients of the temperature / speed; iteration calculation is carried out repeatedly until the finish rolling temperature of the points approaches the target temperature; and finally the regional length of the large acceleration of the strip steel is obtained. The method has the advantages that the contradiction between finish rolling temperature control and rolling rhythm improvement can be solved, the production time can be shortened, and the production capacity of the rolling mill can be improved.

Owner:BEIJING SHOUGANG AUTOMATION INFORMATION TECH

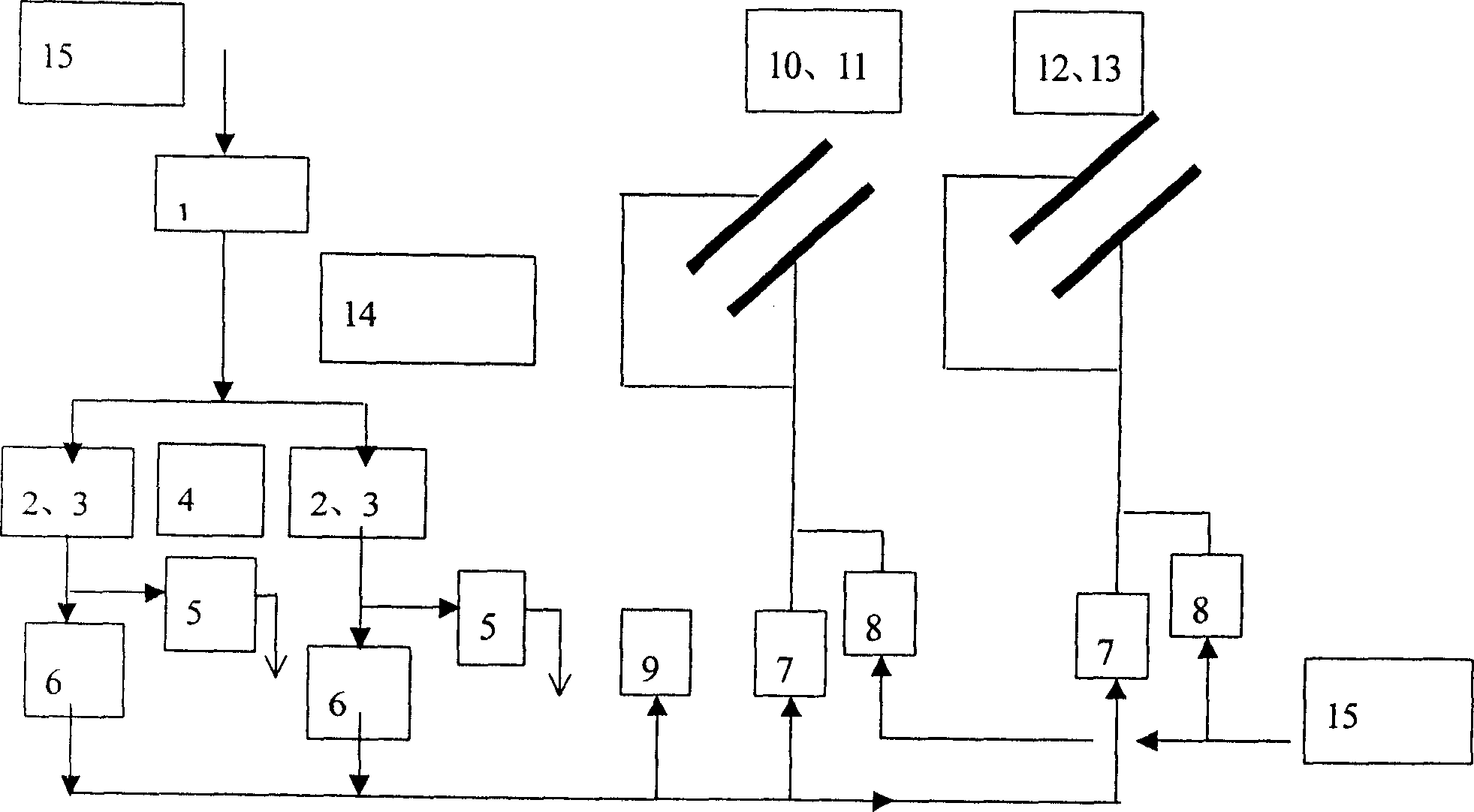

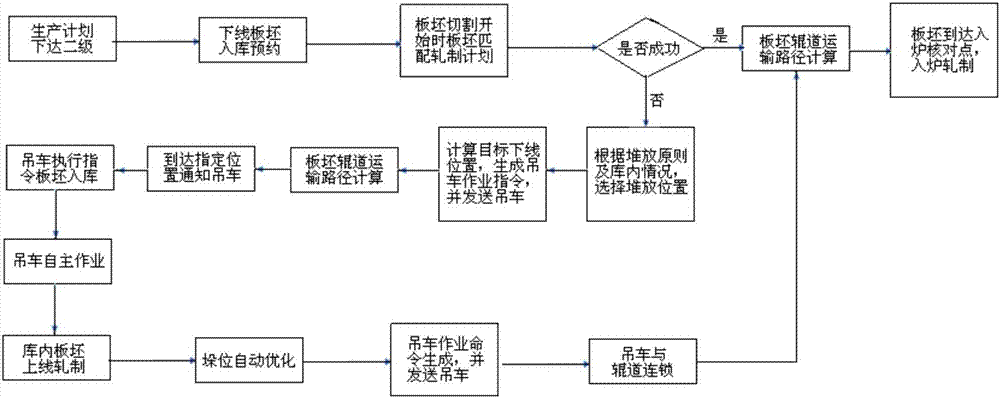

Model calculation based continuous casting and rolling logistic control method

ActiveCN107282653AGuaranteed rolling sequenceImprove rolling rhythmMetal rolling stand detailsMetal rolling arrangementsSlagProgram planning

The invention provides a model calculation based continuous casting and rolling logistic control method. The method adopts a computer management system to perform model calculation, wherein a background operation system is AIX, background program adopts C programming, a database system adopts oracie, and the model is encoded in a storage process. After the system receives slab data, a model storage process is called, a transportation path is calculated according to a slab information automatic matching production plan, a roller path automatically transports slab to a specified position, a crane operation order is automatically generated for off-line warehoused slag, and a crane operation rate is reasonably dispatched and balanced; and the crane and the roller path are sealed, buffer effect of a sidesway trolley is utilized, a rolling sequence is guaranteed, and the rhythm between a casting machine and a rolling mill is matched, so that an equipment utilization rate is increased, an occupancy rate of a raw material base is reduced, a capital turnover rate is increased, and maximization of the continuous casting and rolling yield is realized.

Owner:ANGANG STEEL CO LTD

Rolling method of small and medium shipbuilding flat-bulb steel

InactiveCN108787742ALess investmentImprove rolling conditionsMetal rolling arrangementsStrip millSteel mill

The invention relates to a rolling method of small and medium shipbuilding flat-bulb steel. A direct rolling method is used for rolling the small and medium shipbuilding flat-bulb steel, and relevantrolling equipment includes 3-5 three-roller section steel mills, and all the three-roller section steel mills are horizontally arranged. The rolling process comprises the steps of (1) rough rolling, specifically, a box-type hole is rolled, and a special-shaped flat-bulb steel section is rolled on a rolled piece; (2) intermediate rolling, specifically, metal of a bulb and a web is distributed, thespecial-shaped rolled piece subjected to rough rolling is forced to be widened through large reduction to complete metal distribution of the bulb and the web at a time, and the metal proportion is setaccording to the proportion of finished flat-bulb steel; and (3) finish rolling, specifically, the rolled piece subjected to intermediate rolling and approximate to the flat-bulb steel is variably rolled to obtain an inclination angle of the bulb, and the aspect ratio of the bulb and the web of the finished flat-bulb steel is ensured. By adoption of the rolling method of the small and medium shipbuilding flat-bulb steel, the objectives of high yield and low consumption can be achieved during batch production of the shipbuilding flat-bulb steel, the work efficiency can be improved, the marketrequirement is met, and the benefits of enterprises are increased.

Owner:ANGANG STEEL CO LTD

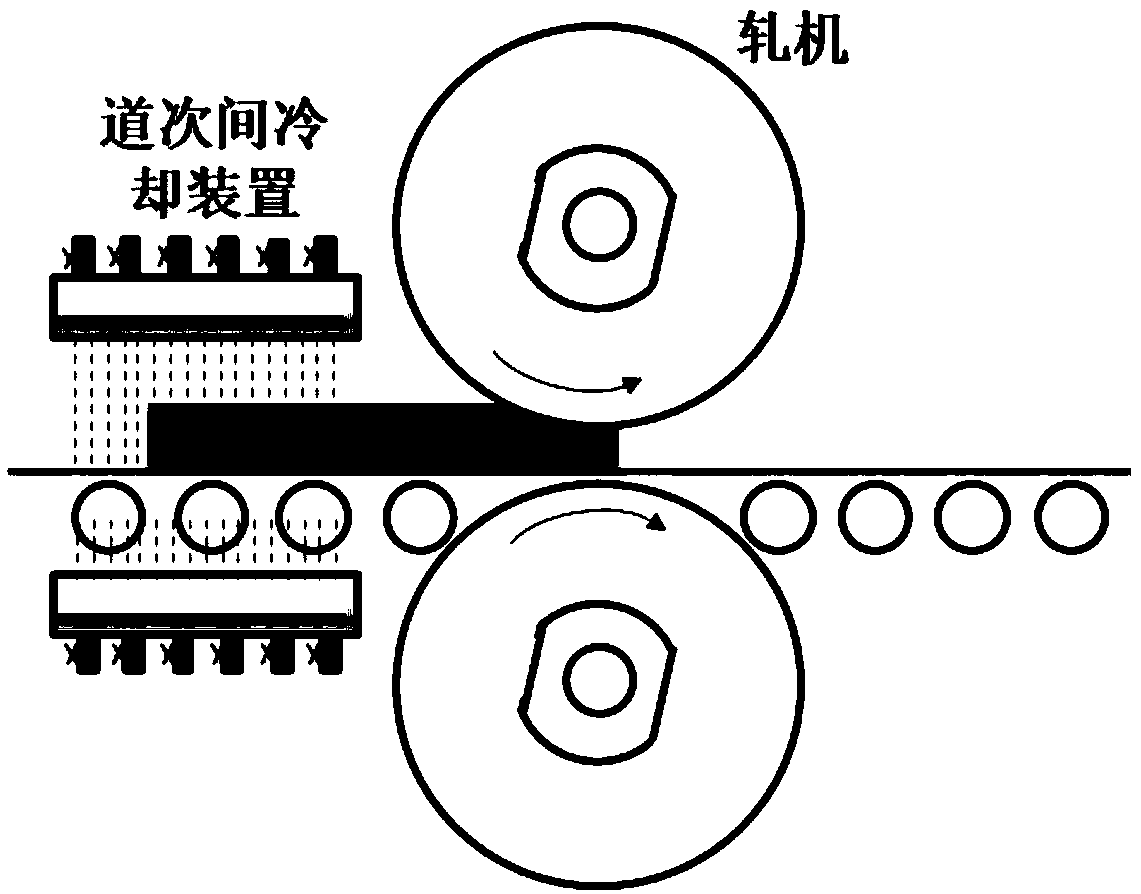

Method for improving core quality and flaw detection eligibility rate of super-thick steel plate

ActiveCN109013711ASave rolling waiting timeReduce waiting timeProfile control deviceReduction rateSteelmaking

The invention provides a method for improving the core quality and the flaw detection eligibility rate of a super-thick steel plate, and belongs to the technical field of ferrous metallurgy. The method improves the core quality and the flaw detection eligibility rate of the super-thick steel plate (greater than or equal to 80mm) based on an inter-pass on-line instant cooling system, and the methodcomprises the following specific process steps that when a continuous casting billet (greater than or equal to 200mm) is not subjected to converter steelmaking or enters into a longitudinal rolling stage after the converter steelmaking is completed, one or more passes of on-line cooling is carried out in a rolling gap by using an instant cooling system near a rolling mill, an initial surface temperature is 850-1000 DEG C, the continuous casting billet enters a cooling zone at a speed of 2-6m / s, the roll speed in the cooling zone is 1-3m / s, the water supply and drainage ratio is (1:2)-(1:6), the total flow of a single group of headers is 200-400m<3> / h, after cooling is performed, the return temperature is controlled at 750-900 DEG C for rolling, and the reduction rate after cooling is greater than 12%. The method for improving the core quality and the flaw detection eligibility rate of the super-thick steel plate enables a core part of the thick plate to be increased through temperature difference rolling, the core quality and the flaw detection eligibility rate are significantly improved, and the yield is further increased.

Owner:NORTHEASTERN UNIV

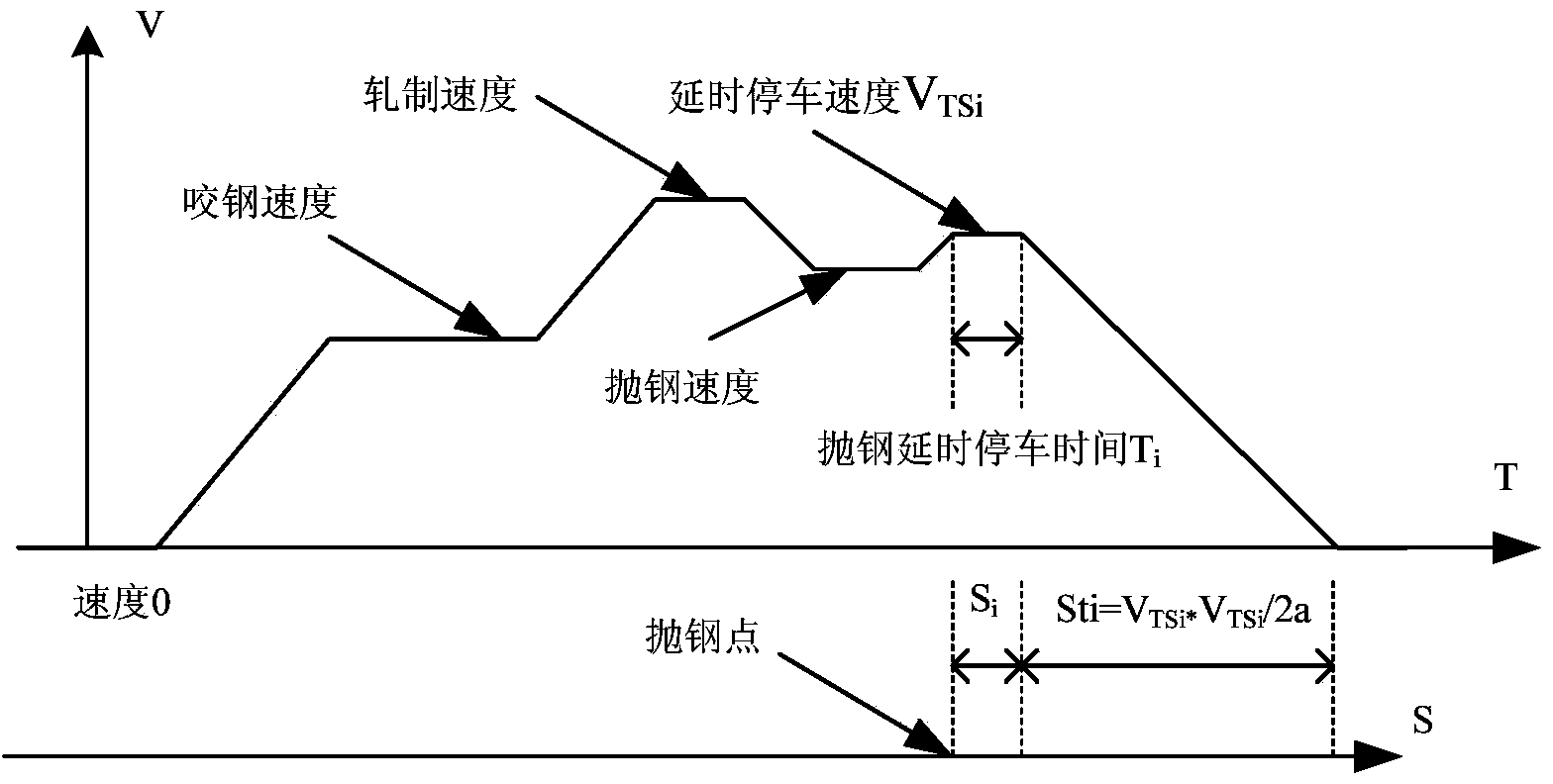

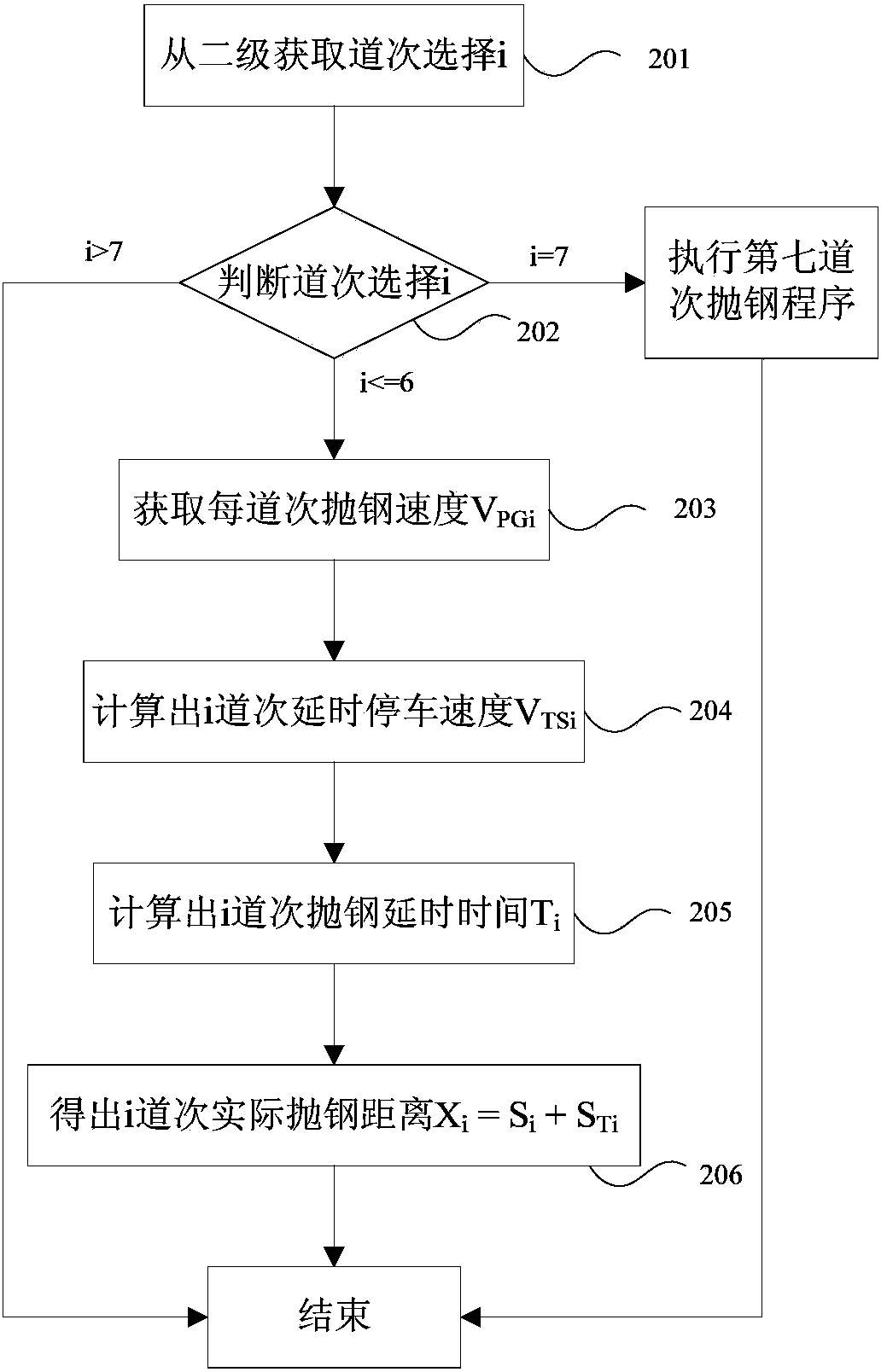

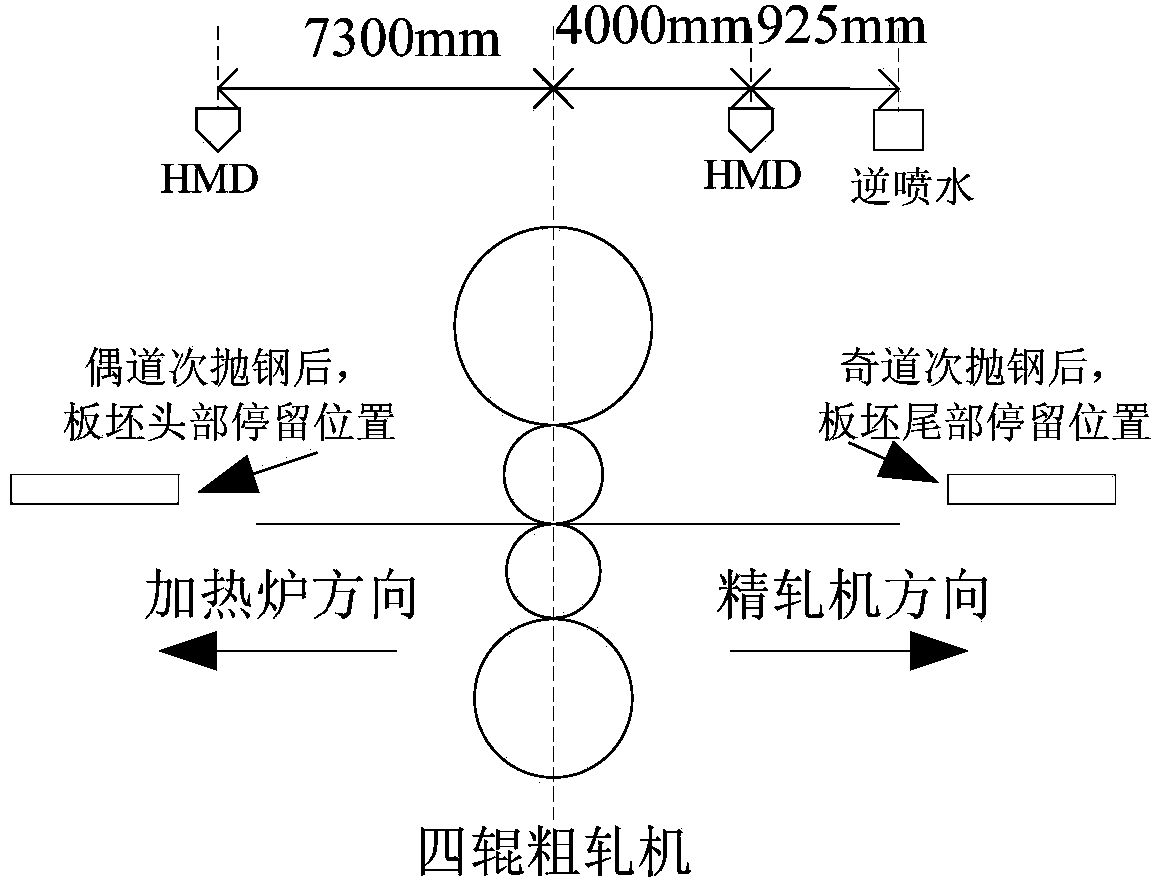

Method for controlling steel throwing distance of hot-rolling reversing roughing mill

InactiveCN103447309AAvoid Unable to Roll AccidentsImprove rolling rhythmRoll mill control devicesMetal rolling arrangementsTime delaysStrip mill

The invention discloses a method for controlling a steel throwing distance of a hot-rolling reversing roughing mill and belongs to the field of the metallurgical industry. The method comprises the following steps: a, acquiring a pass selection i from a second stage, executing the step b if i is less than or equal to 6, executing a seventh pass steel throwing program and then finishing the process if i is equal to 7, or finishing the process; b, setting a steel throwing speed in each pass into VPGi and assigning the steel throwing speed corresponding to the pass i in the variable VPGi; c, by a formula VTSi=VPGi+VC, acquiring a time-delay shutdown speed VTSi in the pass i; d, by a formula Ti=Si / VTSi, acquiring a steel throwing delay time Ti in the pass i; and e, acquiring the actual steel throwing distance Xi=Si+STi in the pass i. According to the method, the actual steel throwing distance of a slab is guaranteed to be accurately controlled in the effective range of hot detection in the front of a rolling mill and reversed water spraying behind the rolling mill; the rolling cycle of a roughing region is improved; and serious fault alarm of transmission and an accident that the slab cannot be normally rolled are avoided.

Owner:SHOUGANG JINGTANG IRON & STEEL CO LTD

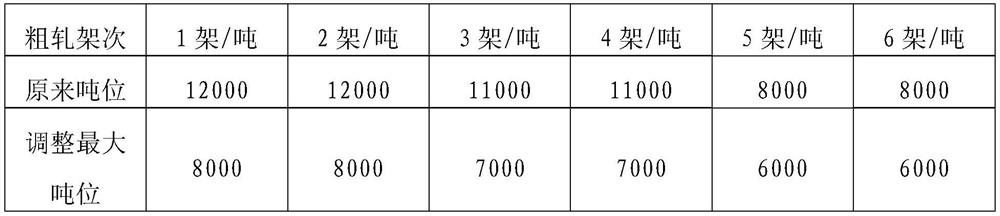

Rolling pacing-improving load distribution method of reversible single-rack four-roller rough rolling mill

ActiveCN109365544ASave rolling timeImprove rolling rhythmRoll speed control devicePower flowLimit value

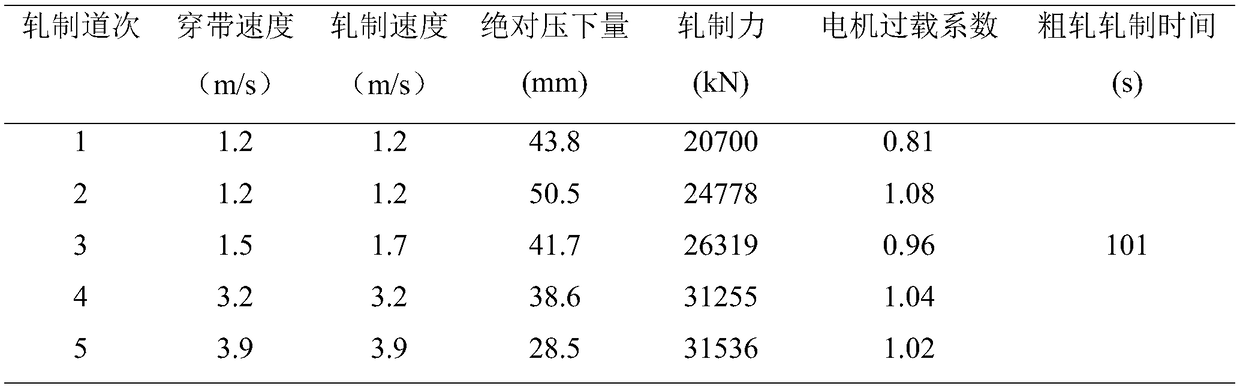

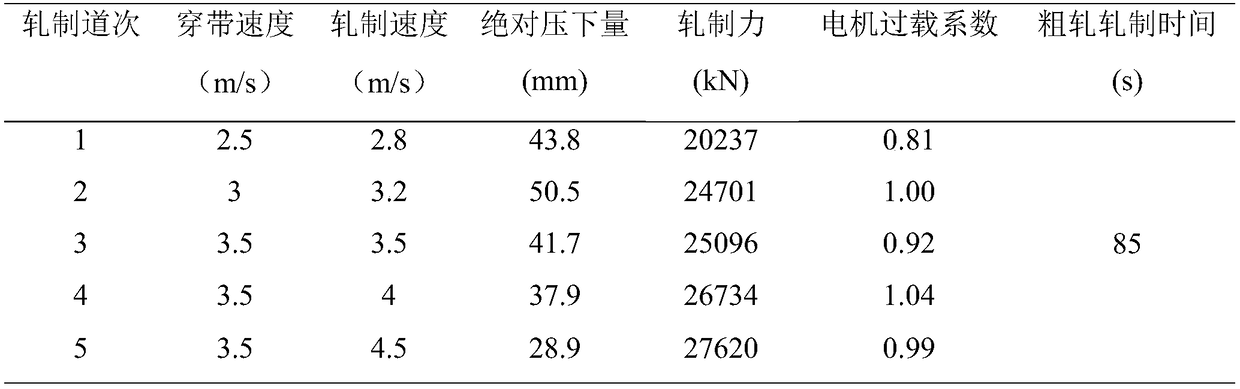

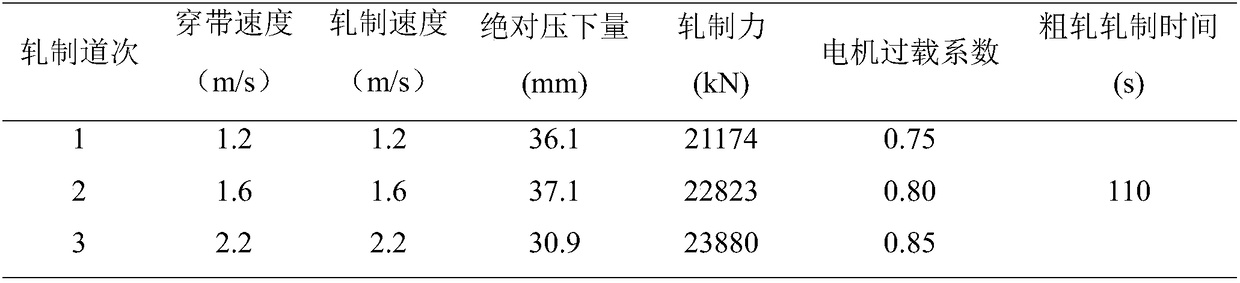

The invention provides a rolling pacing-improving load distribution method of a reversible single-rack four-roller rough rolling mill. The method comprises the following steps that a single grade of steel is stratified according to the width of plate blanks and total rolling passes of rough rolling, rough rolling setting and calculation parameters are stored, and a rough rolling load distributionmodel is established; the amplitude limiting value of a threading speed of each rough rolling pass is set according to rough rolling passes, wherein the amplitude limiting value of the threading speedof the first pass is 2.5m / s, the amplitude limiting value of the threading speed of the last pass is 4.5m / s, and the difference between the amplitude limiting values of the threading speeds of everytwo adjacent passes is not more than 1m / s; a grade of steel to be treated is provided, data of the rough rolling load distribution model are combined, and the threading speed and the amplitude limiting value of a rolling speed of the single grade of the steel are adjusted so as to satisfy the requirement that when the rolling speed of the steel of the grade is lower than the amplitude limiting value of the threading speed, the threading speed is kept consistent with the rolling speed, when the rolling speed of the steel of the grade is higher than the amplitude limiting value of the threadingspeed, the threading speed is set to be the amplitude limiting value, and meanwhile, when a current of a rough rolling motor is not overloaded, and the rough rolling mill does not slip, the actual rolling speed of the single pass reaches the maximum rolling speed.

Owner:湖南华菱涟源钢铁有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com