Patents

Literature

45results about How to "Improve lateral performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

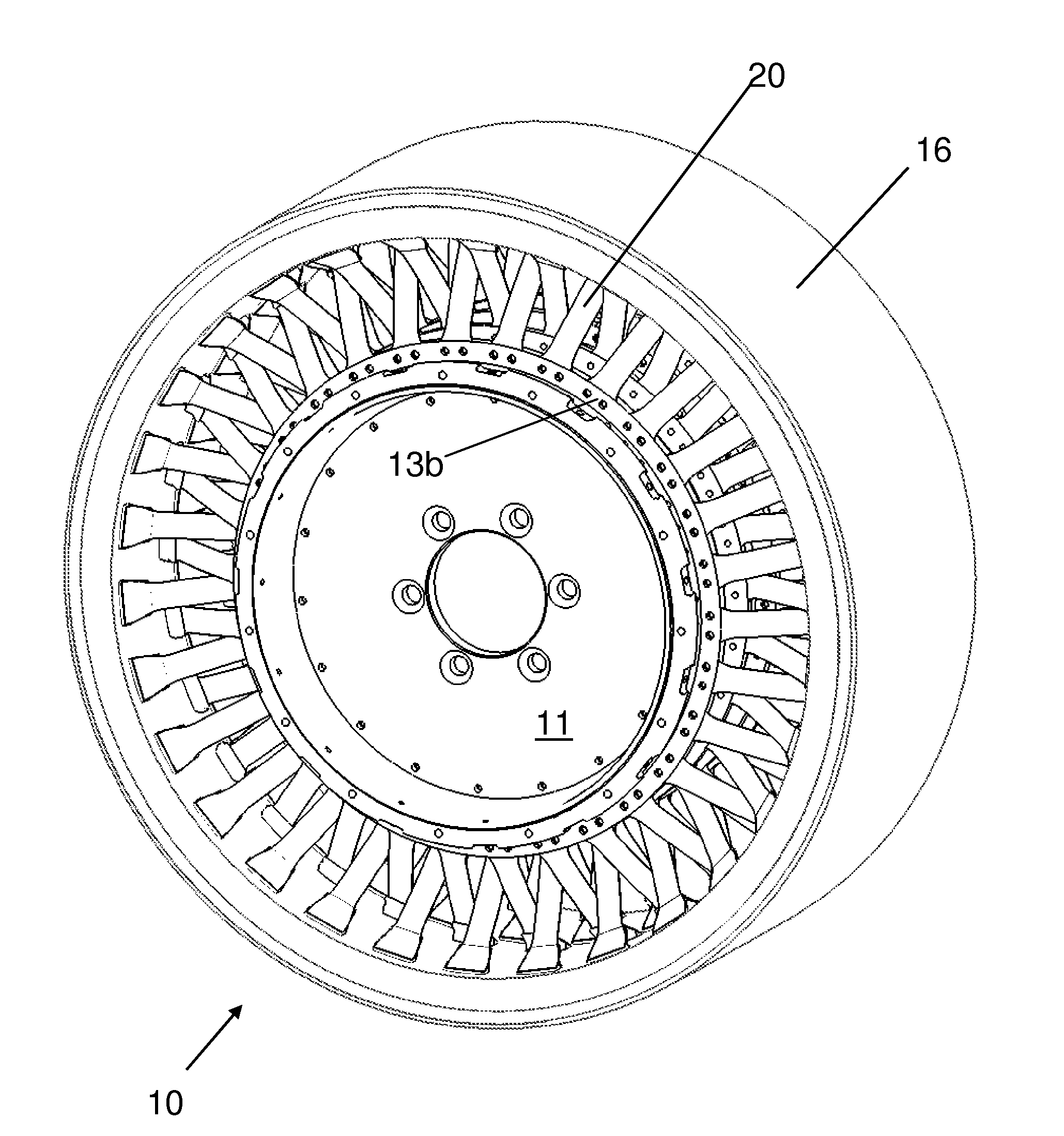

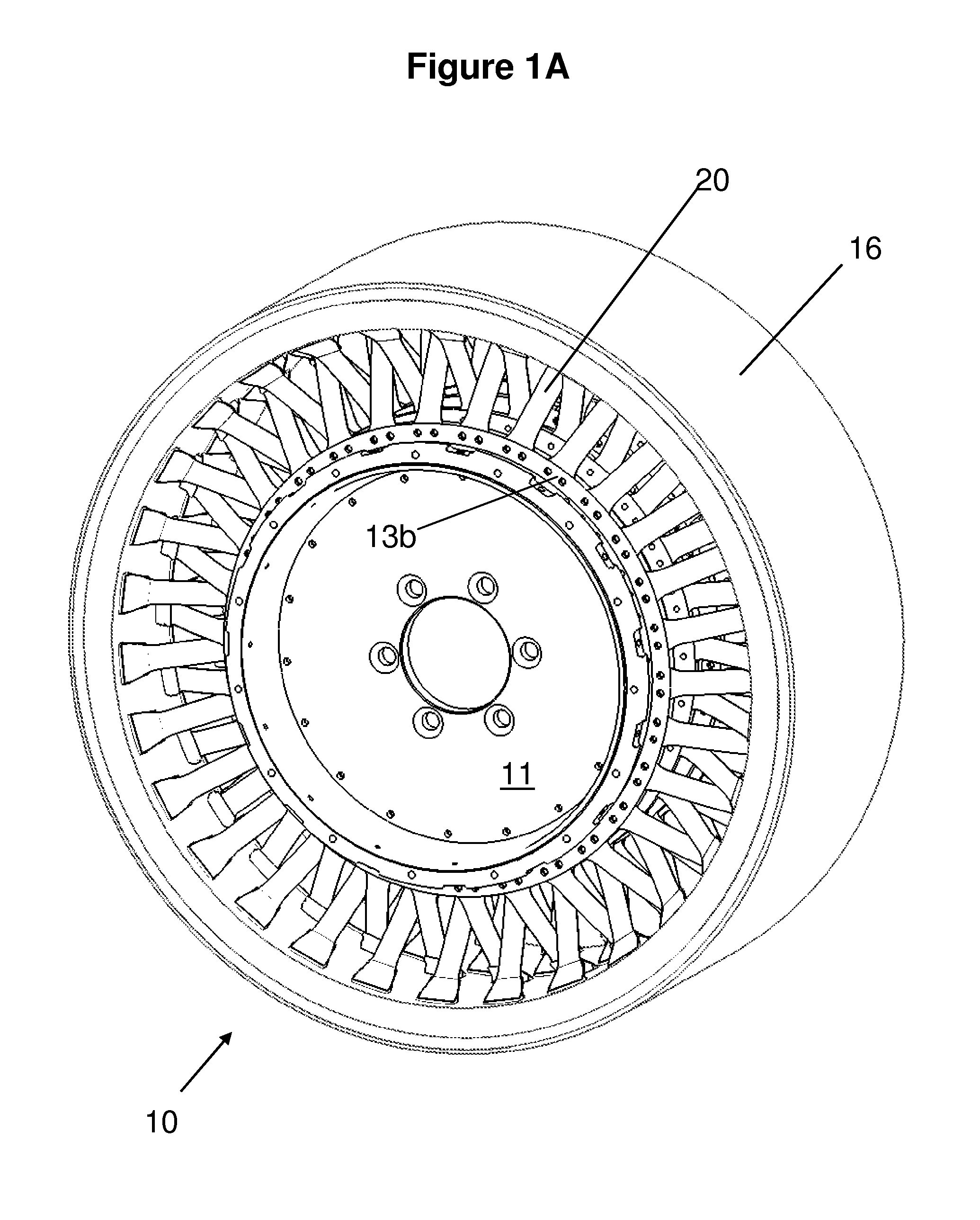

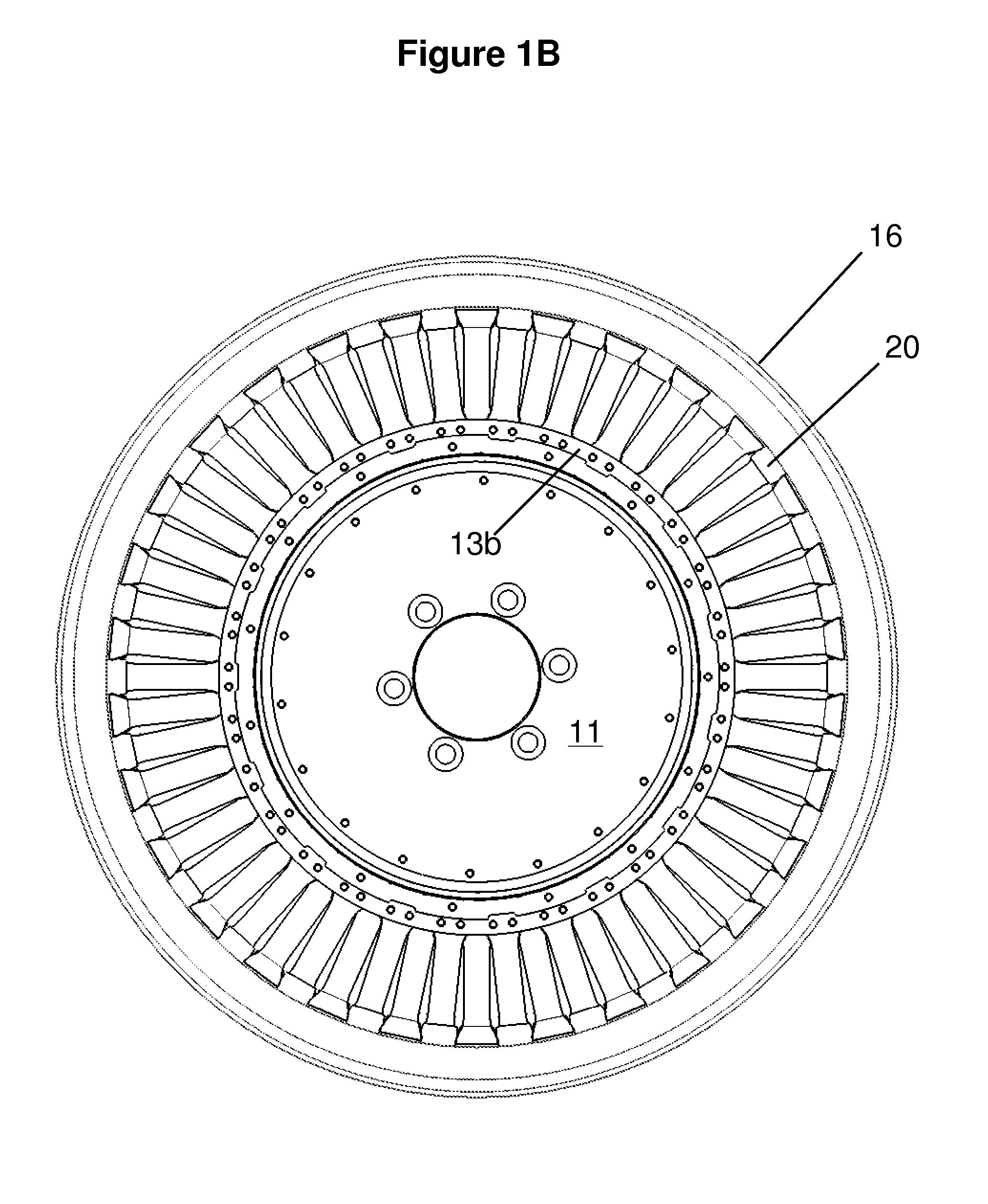

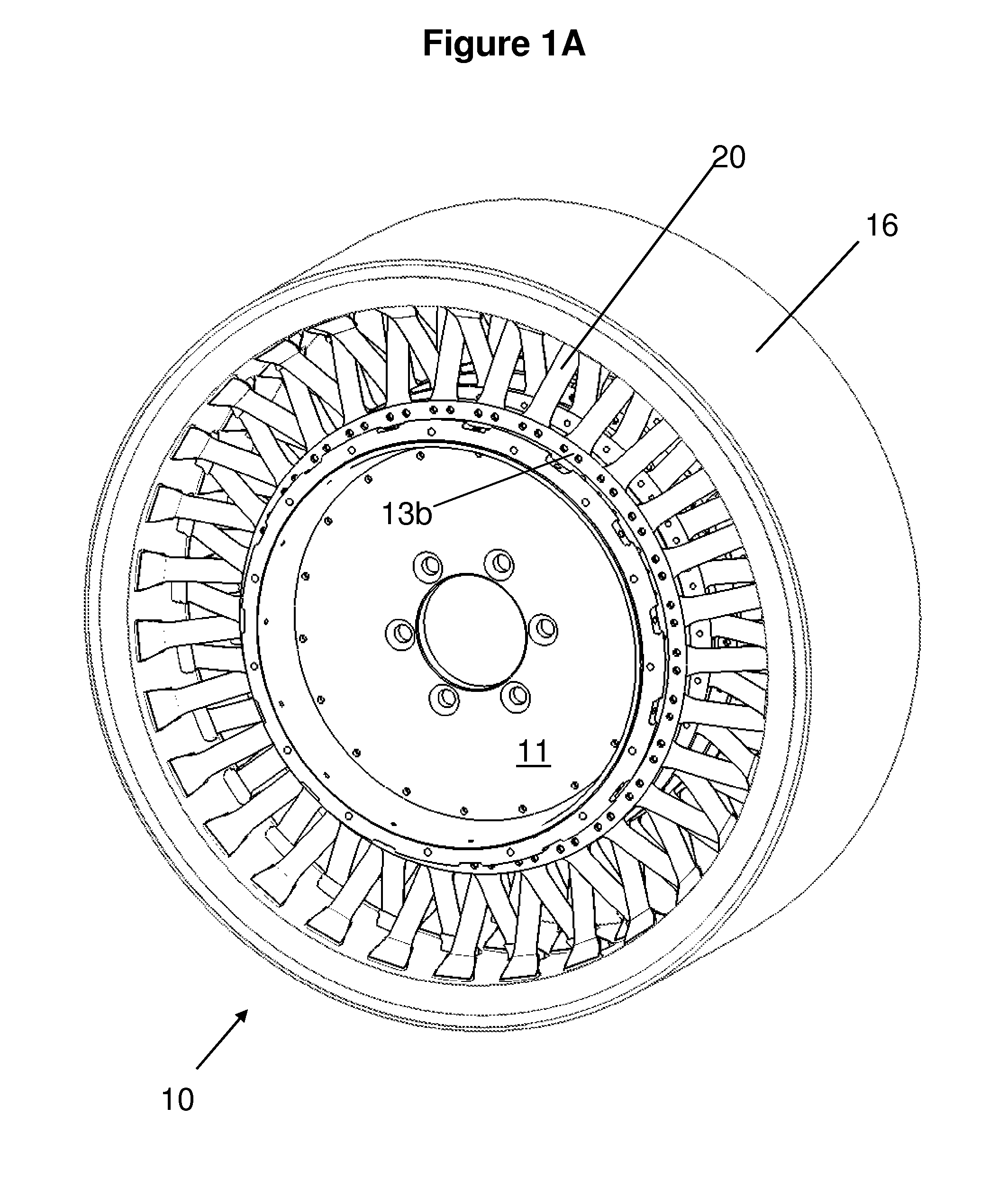

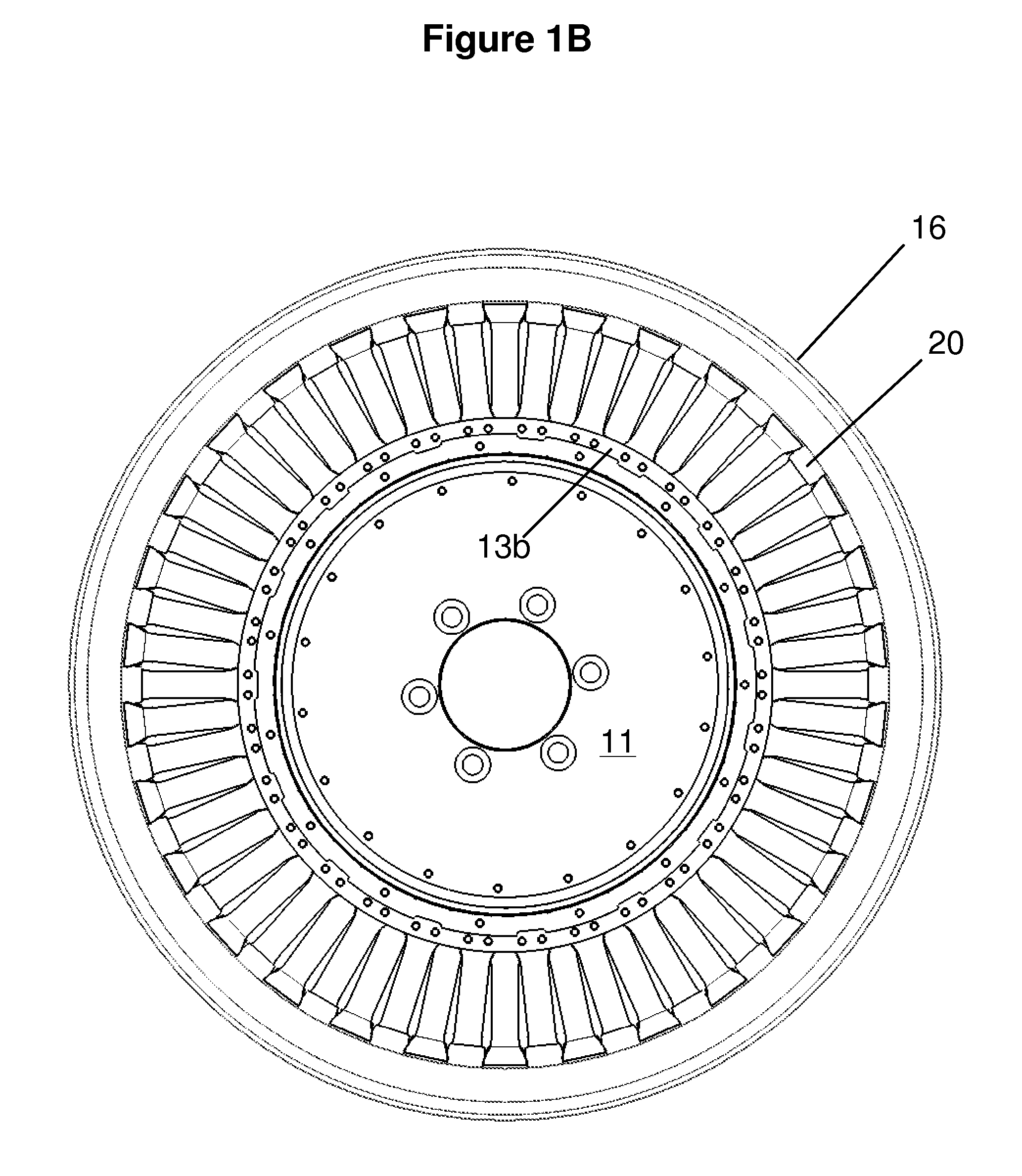

Variable Compliance Wheel

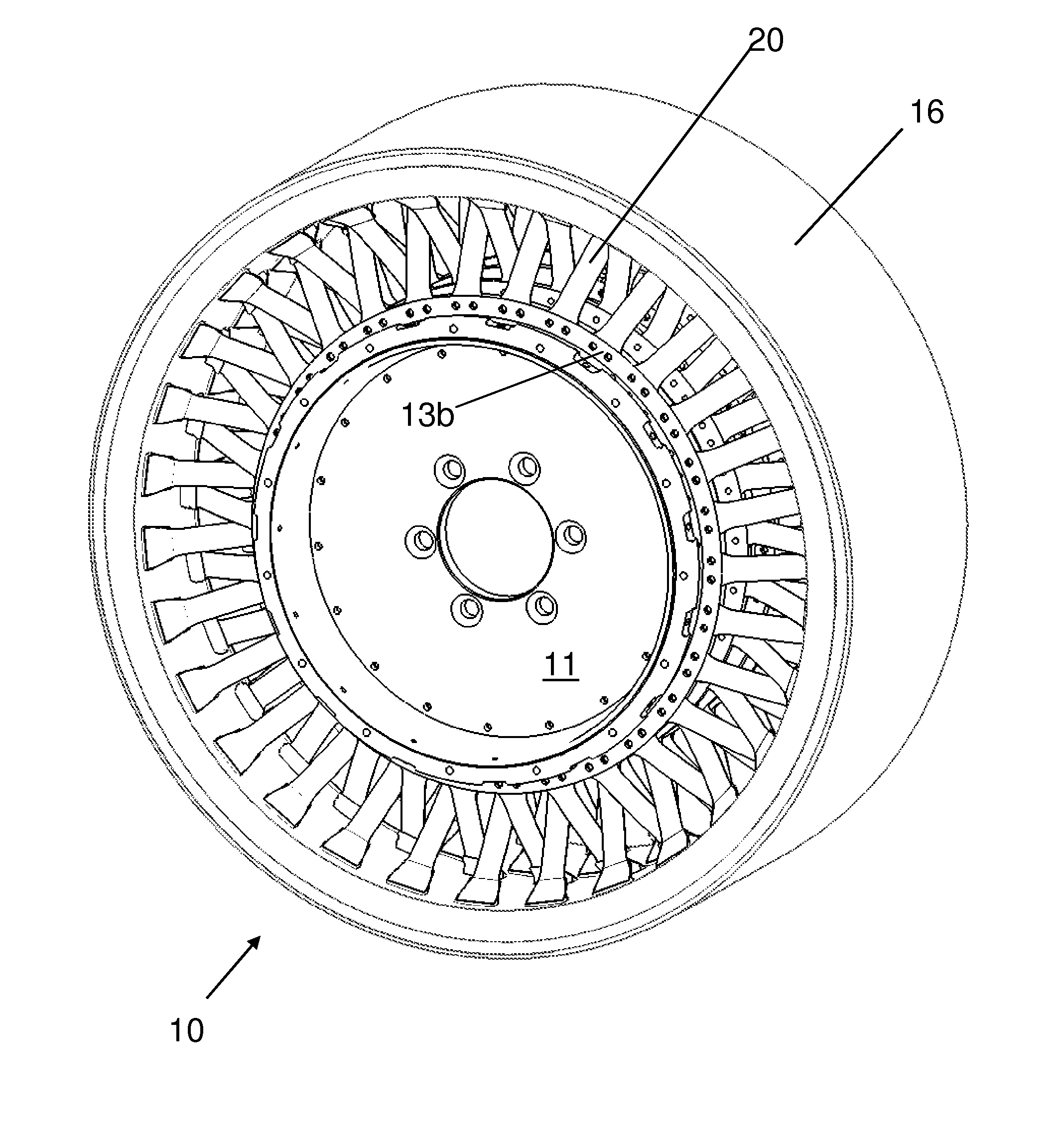

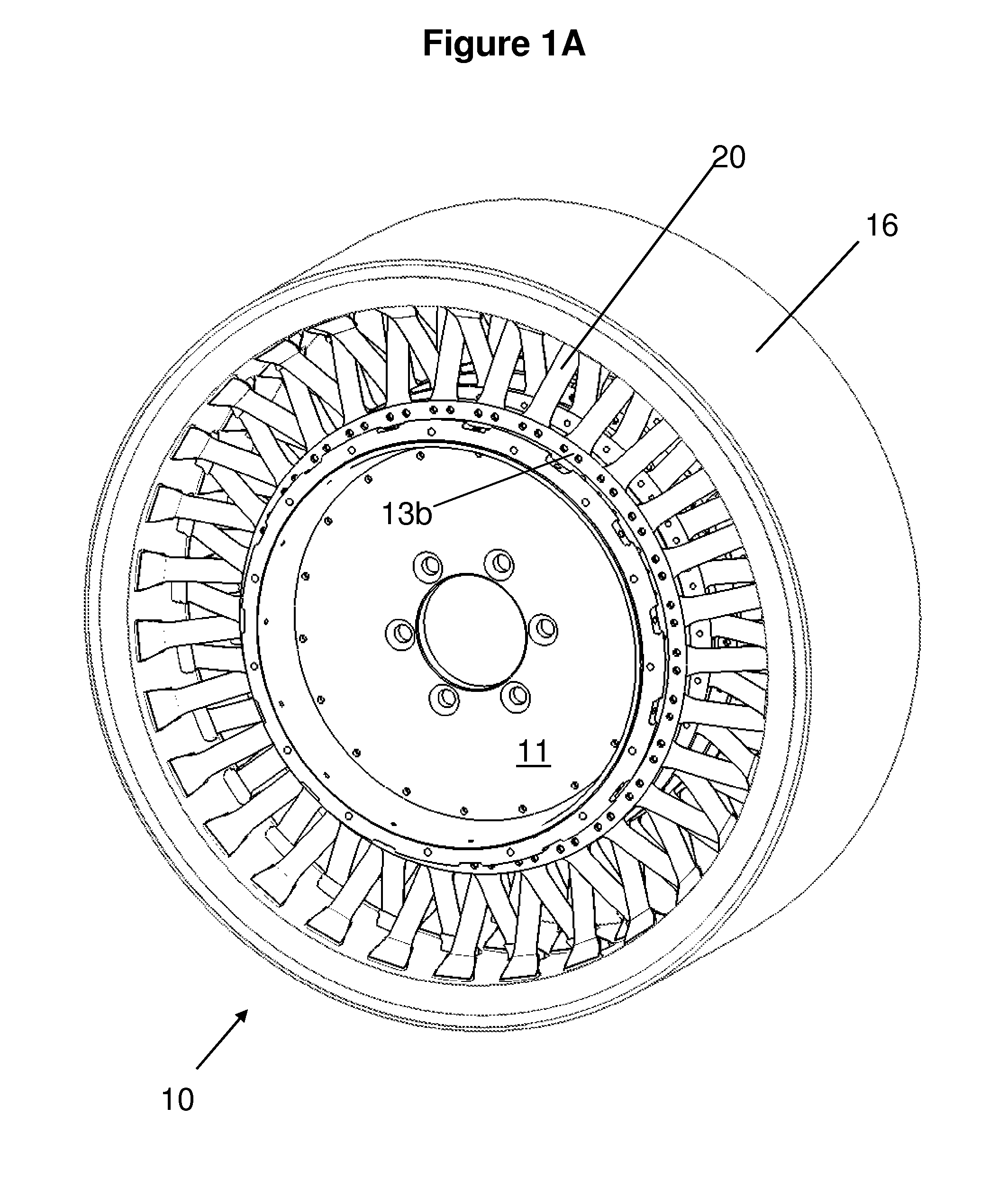

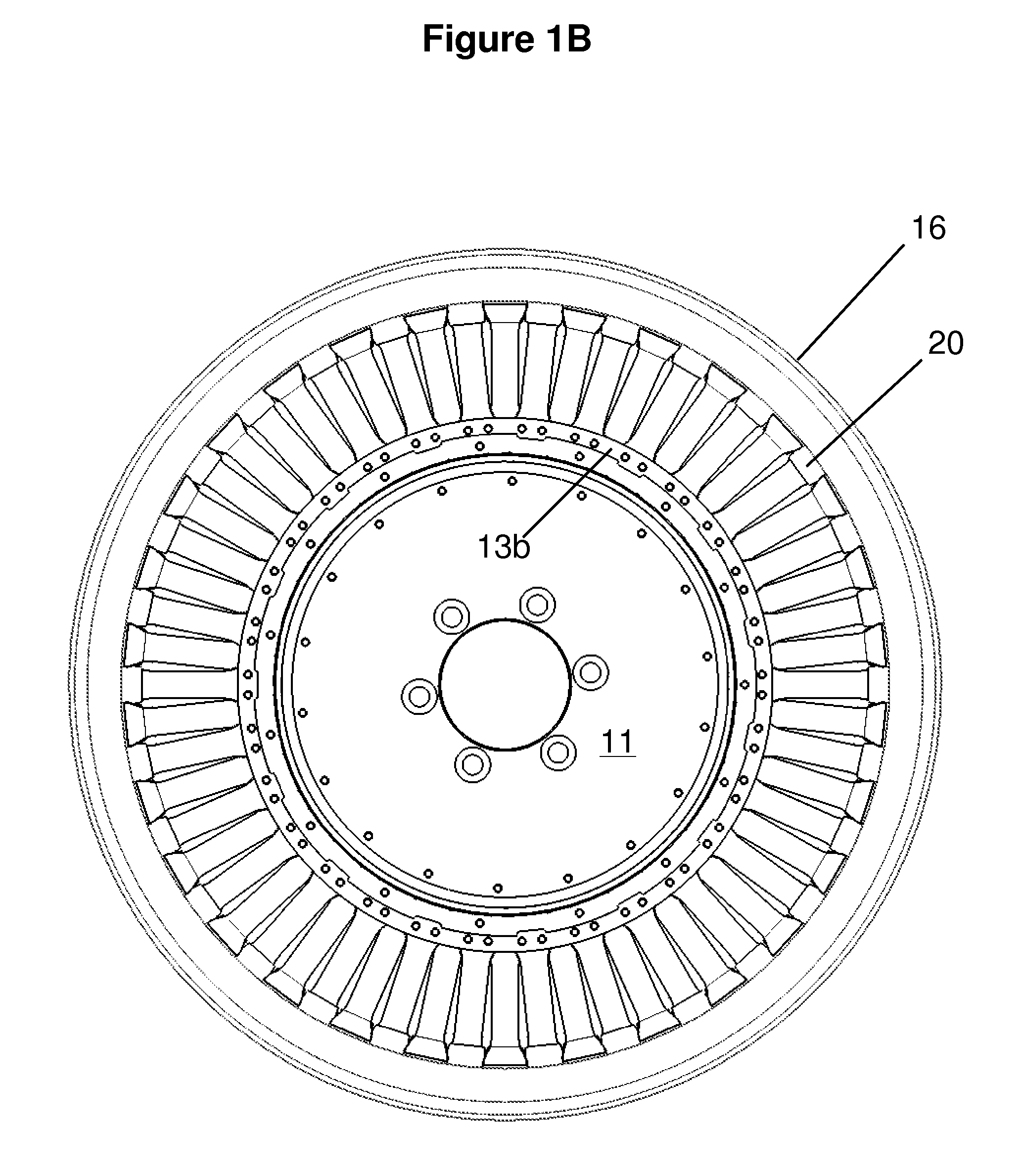

ActiveUS20110272254A1Improve lateral performanceReduce wasteShaft and bearingsNon-inflatable tyresEngineeringMechanical engineering

A system for adjusting the compliance of a wheel is provided. In one embodiment, wheel segments are adjusted, causing the stiffness of the wheel to change. Such adjustments can be made while the wheel is rotating, allowing the wheel compliance to be changed while a vehicle is in motion.

Owner:MILLENWORKS

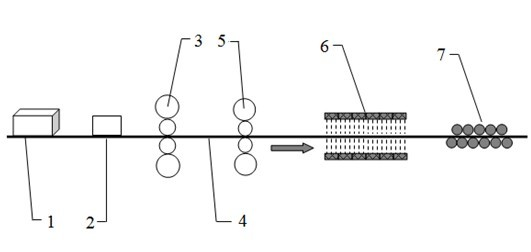

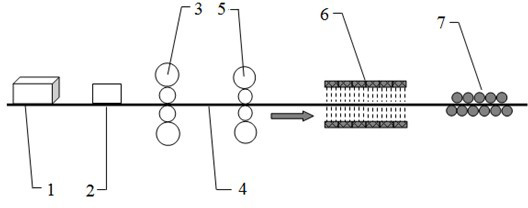

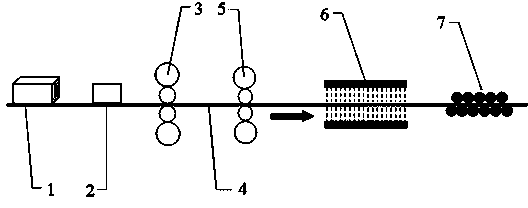

Process for producing thin gauge pipeline steel by using double-stand medium and heavy plate mill

ActiveCN102671941AGuaranteed Dynamic RecrystallizationImprove lateral performanceTemperature control deviceWork treatment devicesMetallurgyLaminar cooling

The invention discloses a process for producing thin gauge pipeline steel by using a double-stand medium and heavy plate mill. A plate blank with the thickness of 180 mm is used for producing the thin gauge pipeline steel with the thickness less than 10 mm. On the basis that the performance of a rolled piece meets requirements, the thin gauge pipeline steel with a good plate shape can be obtained by controlling the tapping temperature of the plate blank, the rough rolling broadening pass pressing rate, the longitudinal rolling pass pressing rate after rough rolling broadening pass, the rough rolling finishing temperature, the thickness of a middle blank, the finish rolling ending pass pressing rate, the finish rolling finishing temperature, the roller gap inclination and sled function in the rolling process, a high pressure water descaling system, the water entry temperature, the re-reddening temperature, and the head and tail shielding and straightening process of a laminar cooling system. The deformation rate is reduced, and the economic benefit is increased.

Owner:NANJING IRON & STEEL CO LTD

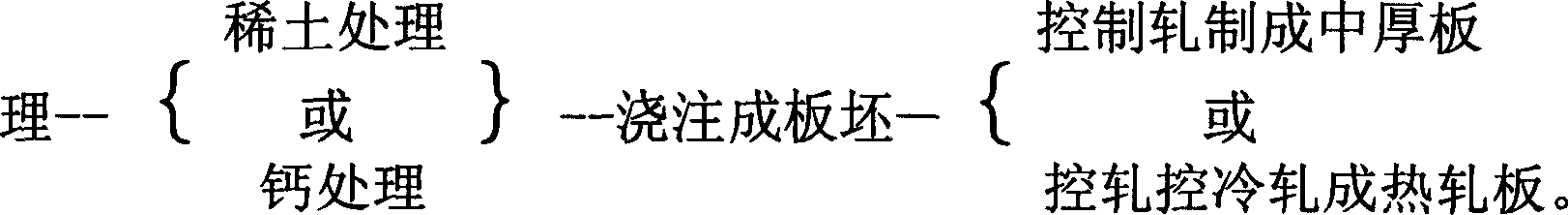

Manufacturing method of cold forming high intensity steel for welded structure

InactiveCN1563468AThe vertical and horizontal performance differences are narrowedImprove corrosion resistanceCold formedRare earth

This invention relates to a production method for cold forming high intensity welded construction steel taking low carben-Mn as the basis, added by Nb, Ti microalloy as the main composition and applying melted iron desulfurization technology, converter top and bottom combined blowing and vacuum process, among which, the melted steel is casted to slab after rare earth or Ca to be casted to slab process then to be rolled to cut deal or hot rolled plate by cut deal production technology or the hot tandem rolling technology.

Owner:武钢集团有限公司

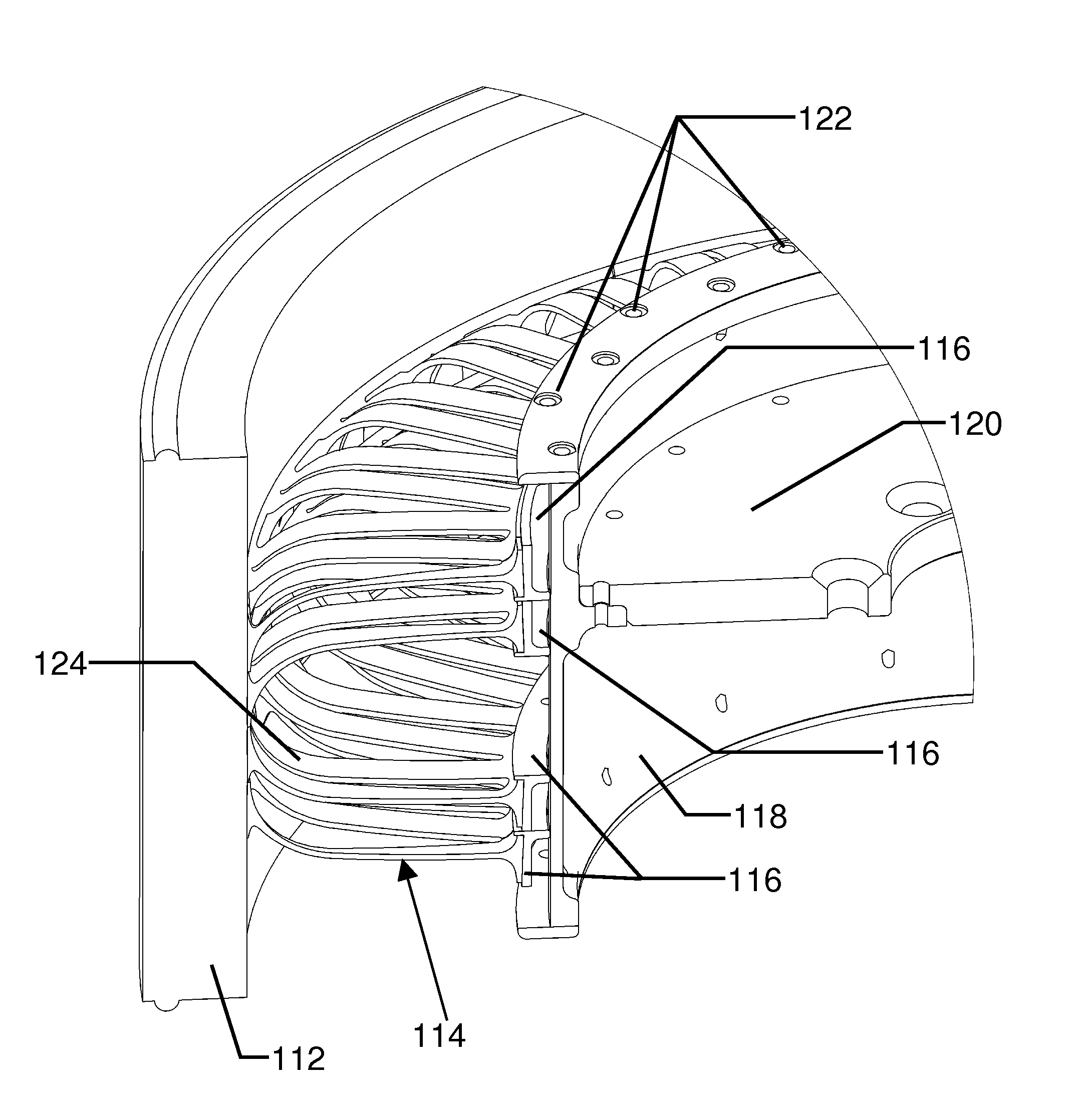

Variable Compliance Wheel

InactiveUS20140110024A1Increase vertical stiffnessIncrease stiffnessNon-inflatable tyresHigh resiliency wheelsEngineeringMechanical engineering

A system for adjusting the compliance of a wheel is provided. In one embodiment, wheel segments are adjusted, causing the stiffness of the wheel to change. Such adjustments can be made while the wheel is rotating, allowing the wheel compliance to be changed while a vehicle is in motion.

Owner:MILLENWORKS

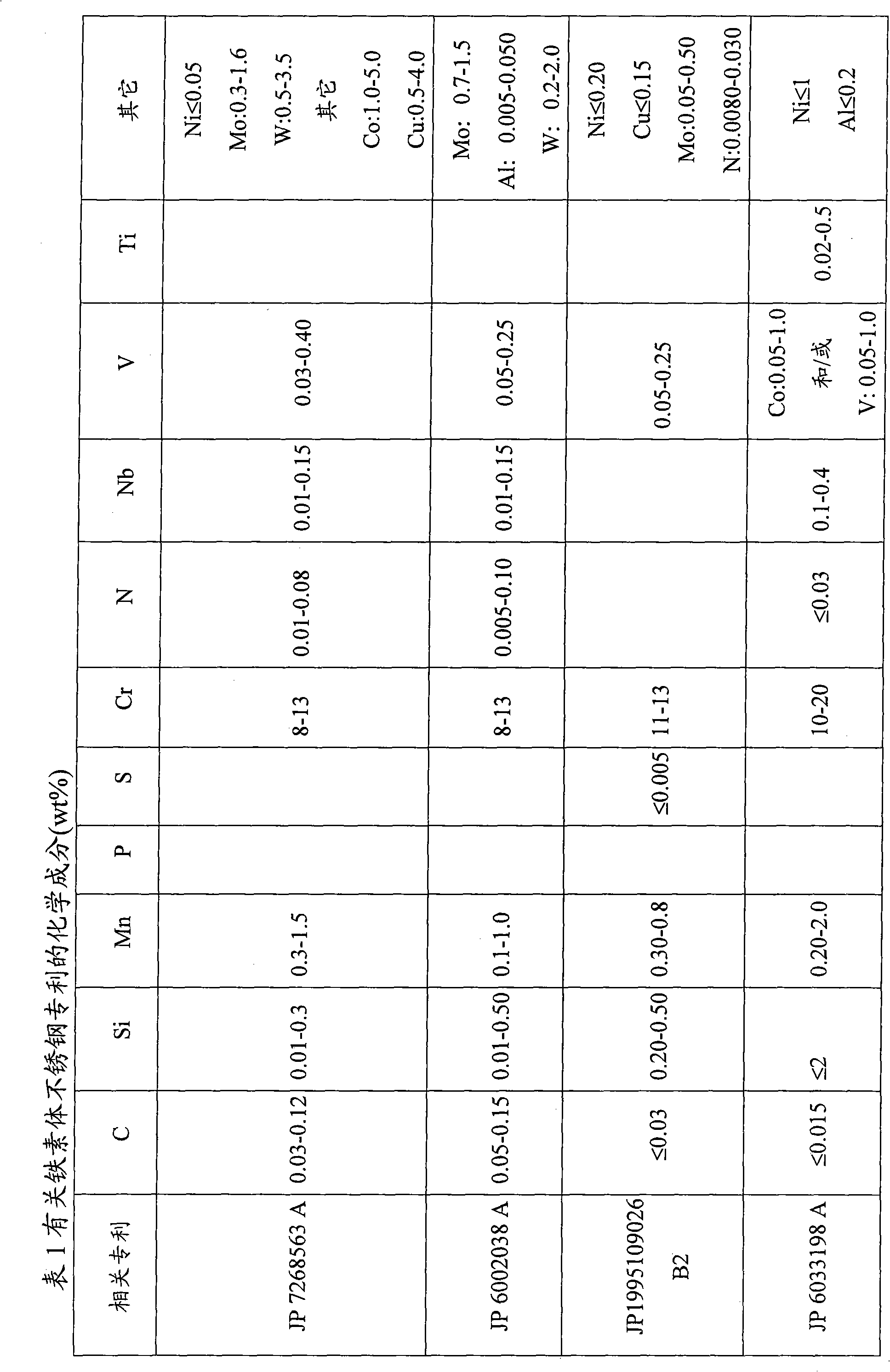

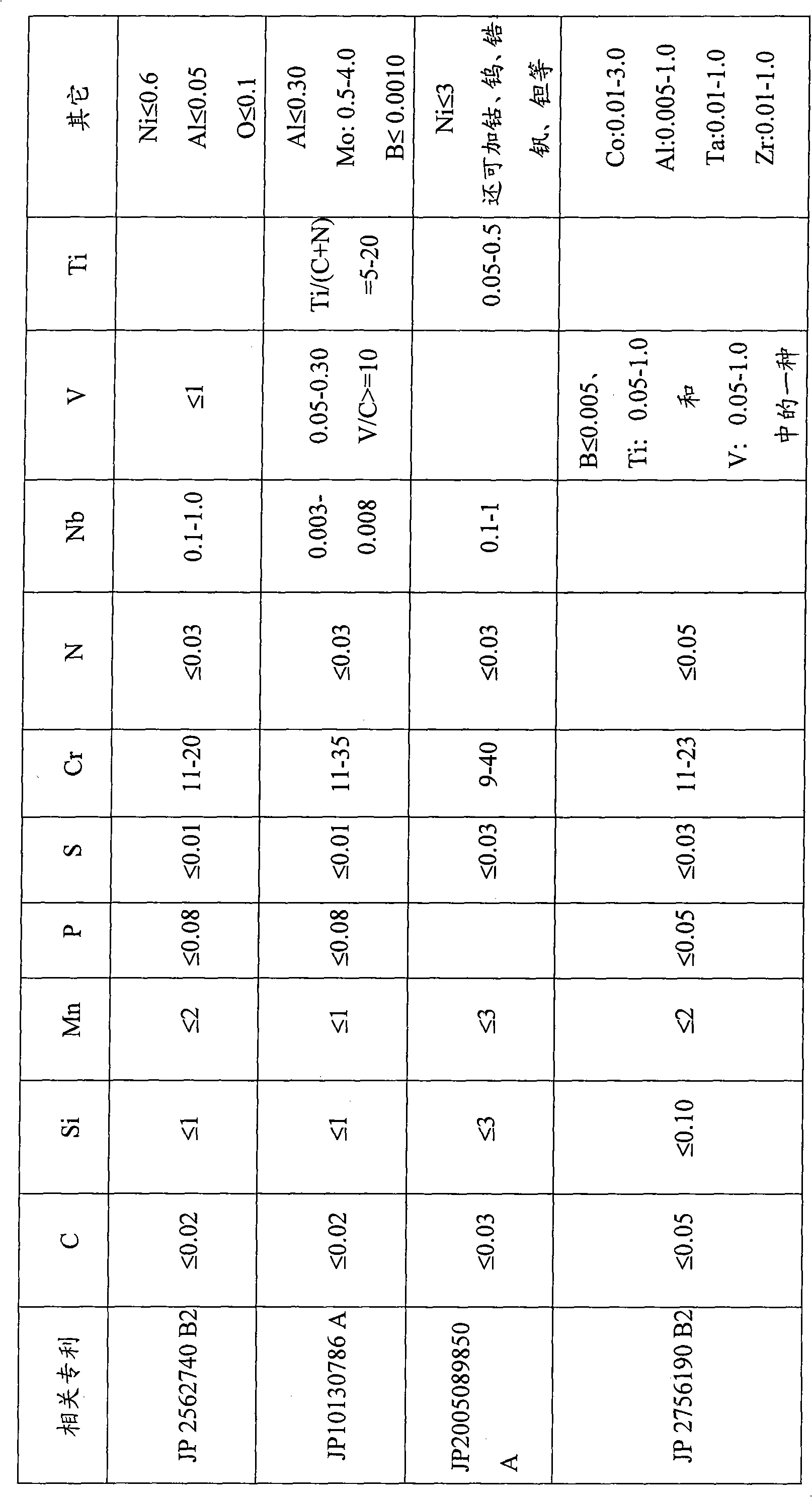

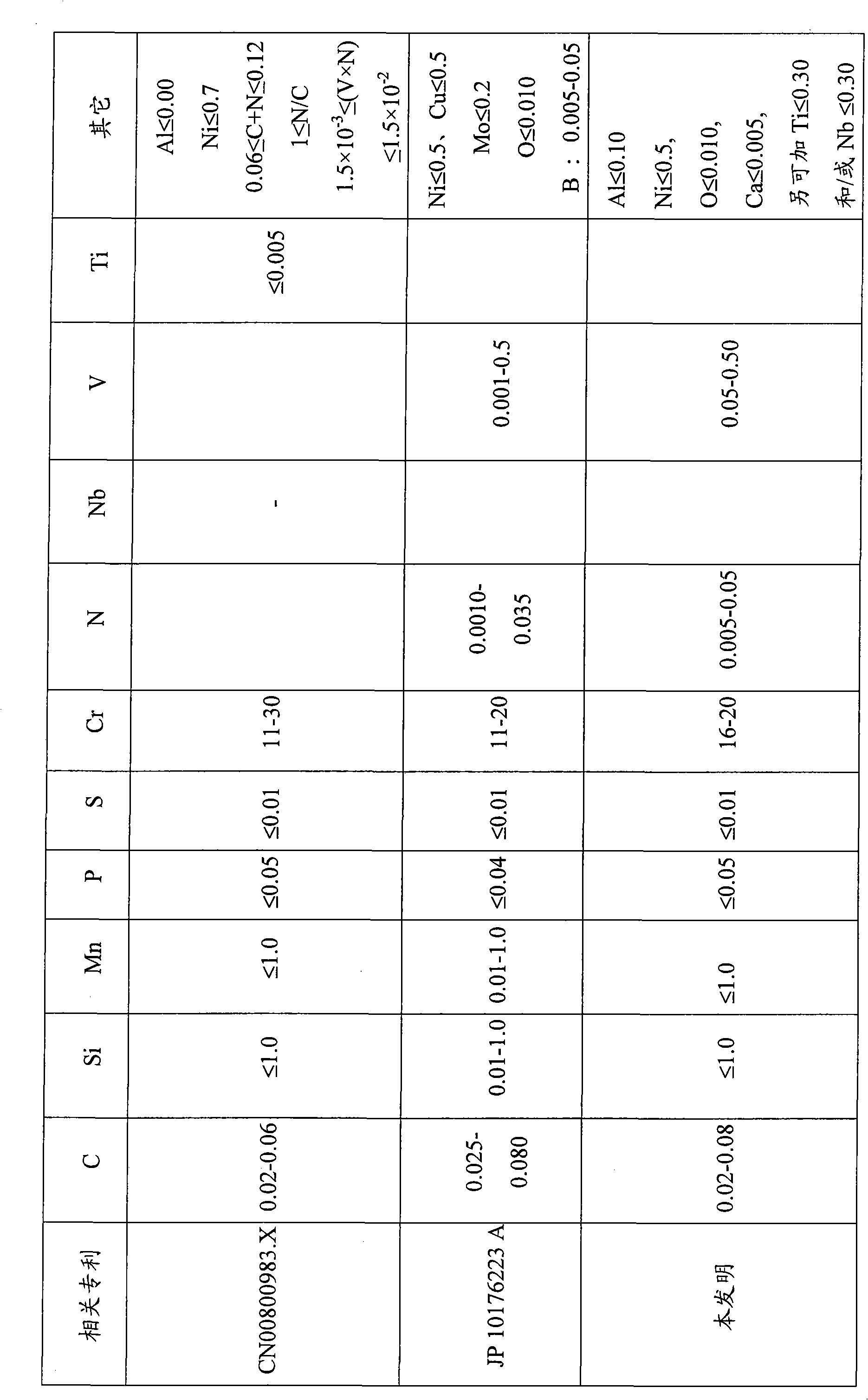

Medium chromium ferrite stainless steel and making method thereof

InactiveCN102041452AImprove strong plasticityImprove corrosion resistanceRoll force/gap control deviceTemperature control deviceChemical compositionImpurity

The invention provides medium chromium ferrite stainless steel which comprises the following chemical compositions in percentage by weight: 0.02-0.08 percent of C, not more than 1.0 percent of Si, not more than 1.0 percent of Mn, not more than 0.05 percent of P, not more than 0.01 percent of S, 16-20 percent of Cr, 0.05-0.50 percent of V, 0.005-0.05 percent of N, not more than 0.10 percent of Al, not more than 0.5 percent of Ni, not more than 0.010 percent of O, not more than 0.005 percent of Ca, additional not more than 0.30 percent of Ti and / or not more than 0.30 percent of Nb, and the balance of iron or other inevitable impurities. The invention also provides a making method of the medium chromium ferrite stainless steel, comprising the following steps of, firstly, heating a billet or a cast blank with the heating temperature of 1000-1250 DEG C; secondly, carrying out hot rolling; thirdly, annealing and pickling; fourthly, carrying out cold rolling; and fifthly, annealing and pickling. By adopting the composition design and the making method, a steel plate with good strength and plasticity, corrosion resistance and transverse performance is produced, thereby the machining needs of household appliances and products are met.

Owner:BAOSHAN IRON & STEEL CO LTD

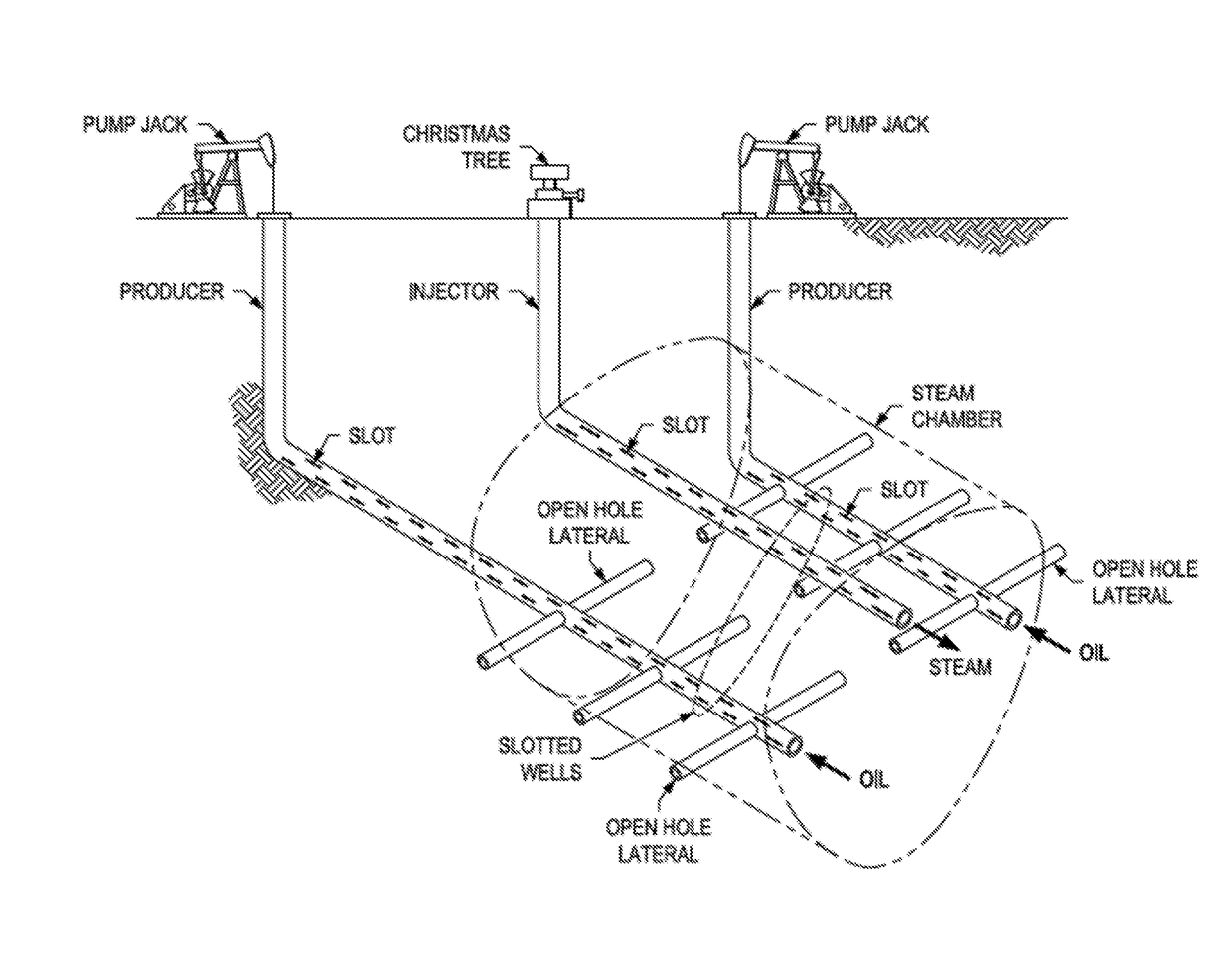

Thermal conditioning of fishbones

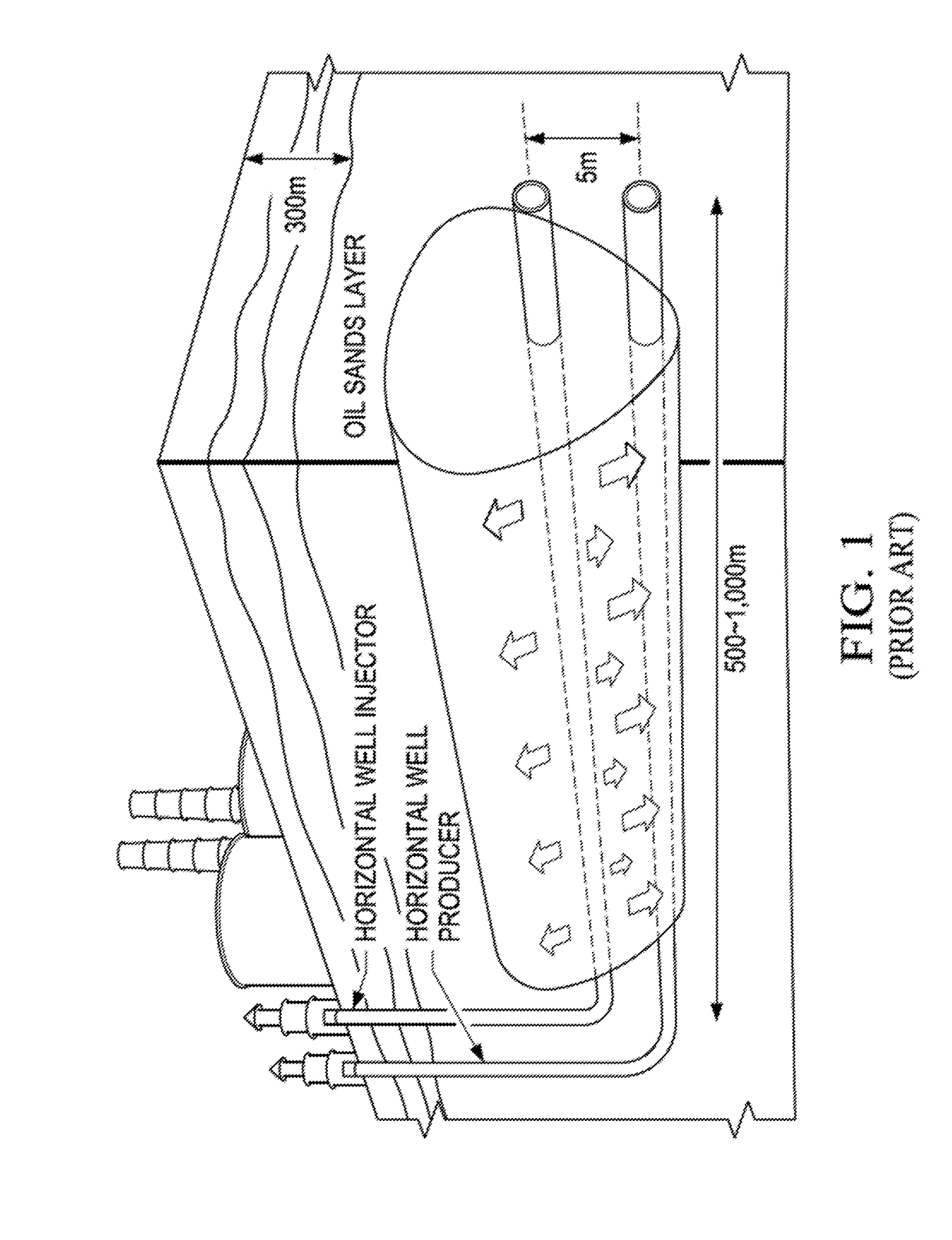

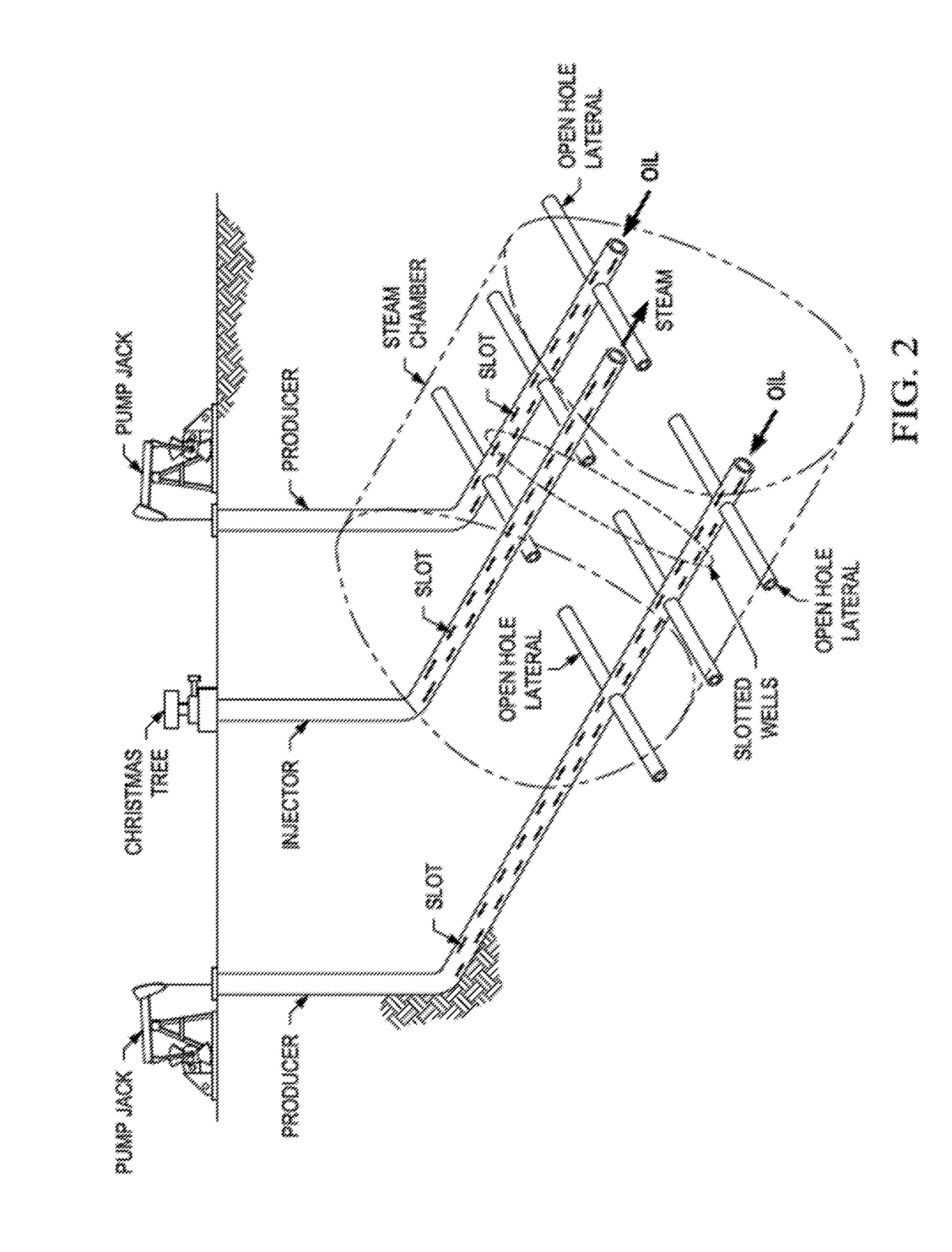

ActiveUS20170081950A1Reduce conventional steam circulationImprove lateral performanceInsulationFluid removalRecovery methodEngineering

The present disclosure relates to a particularly effective well configuration that can be used for SAGD and other steam based oil recovery methods. Fishbone multilateral wells are combined with SAGD, effectively expanding steam coverage, but the fishbones are preheated to mitigate plugging problems, with e.g., resistive heating, EM heating or chemical heating.

Owner:CONOCOPHILLIPS CO

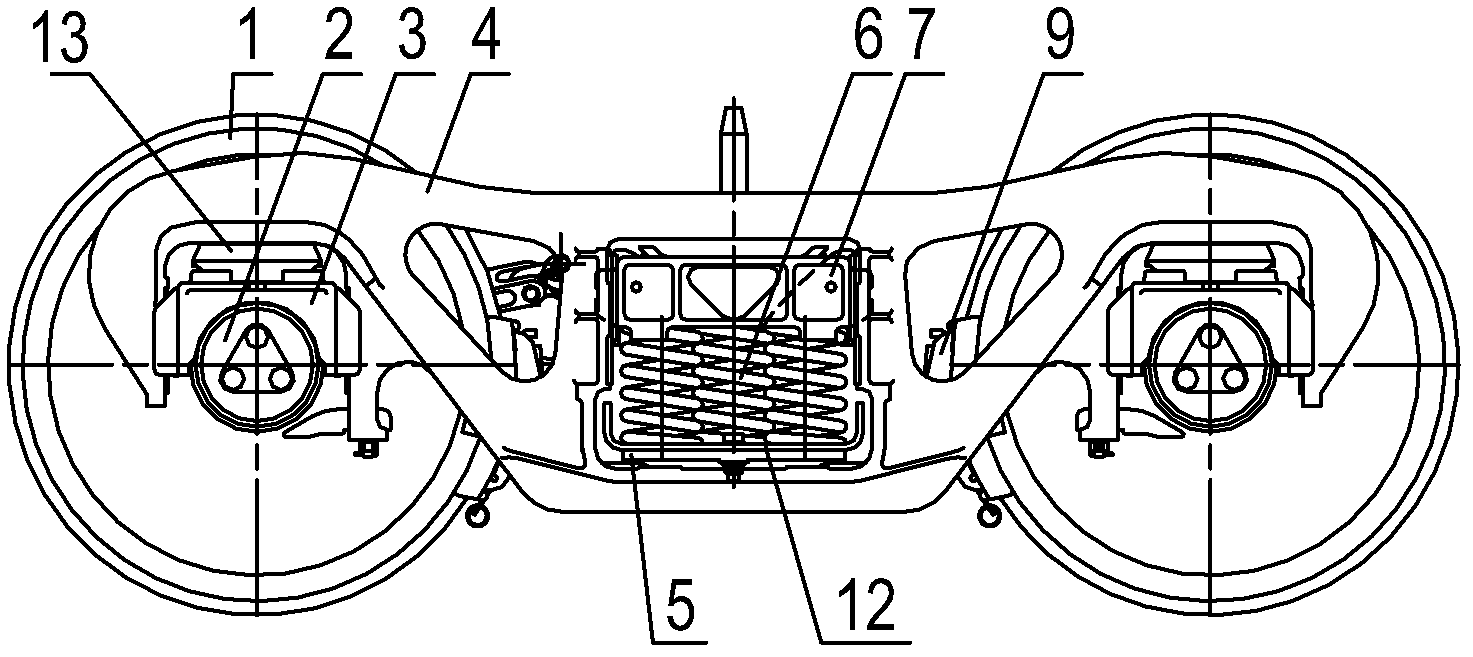

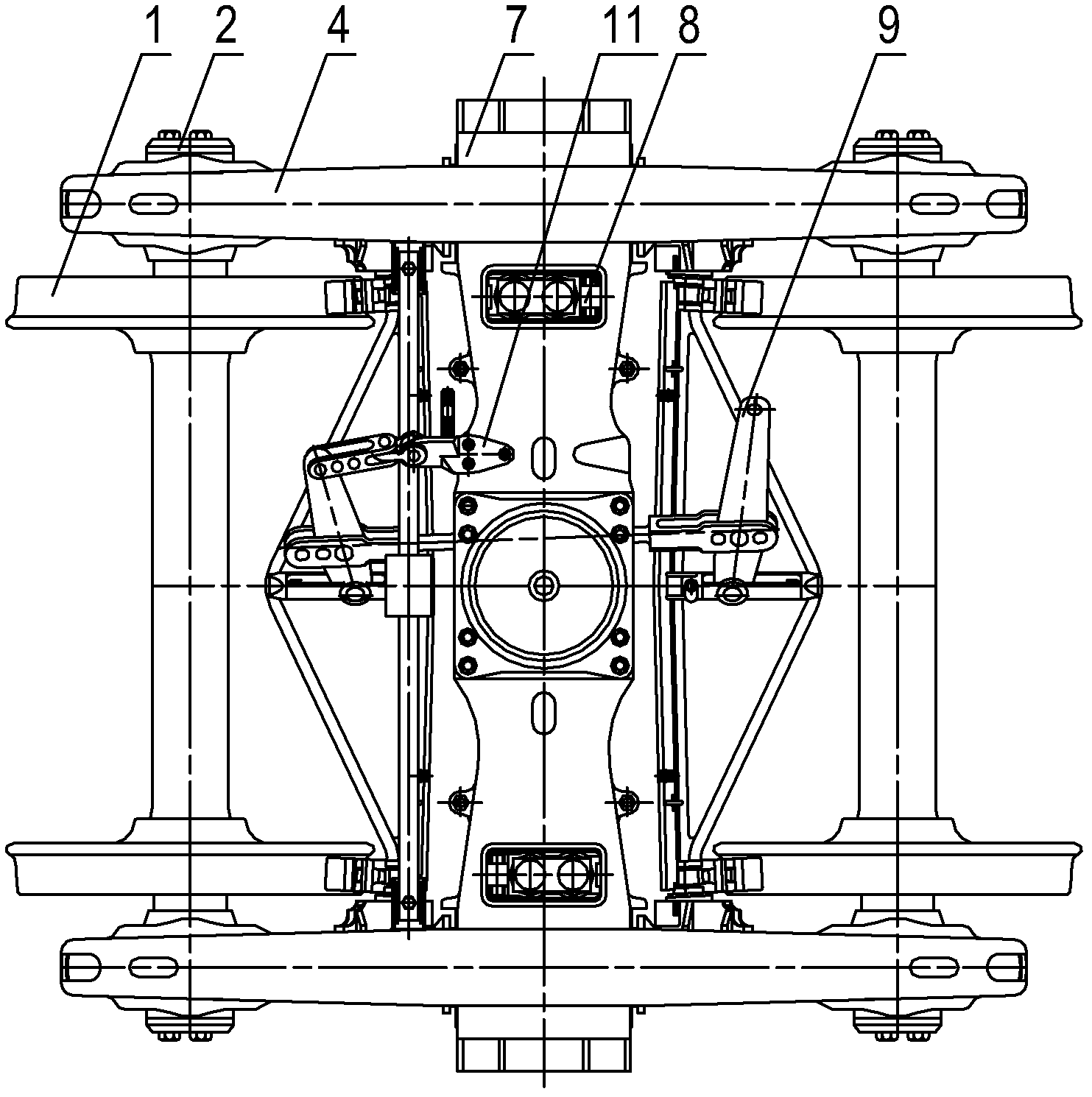

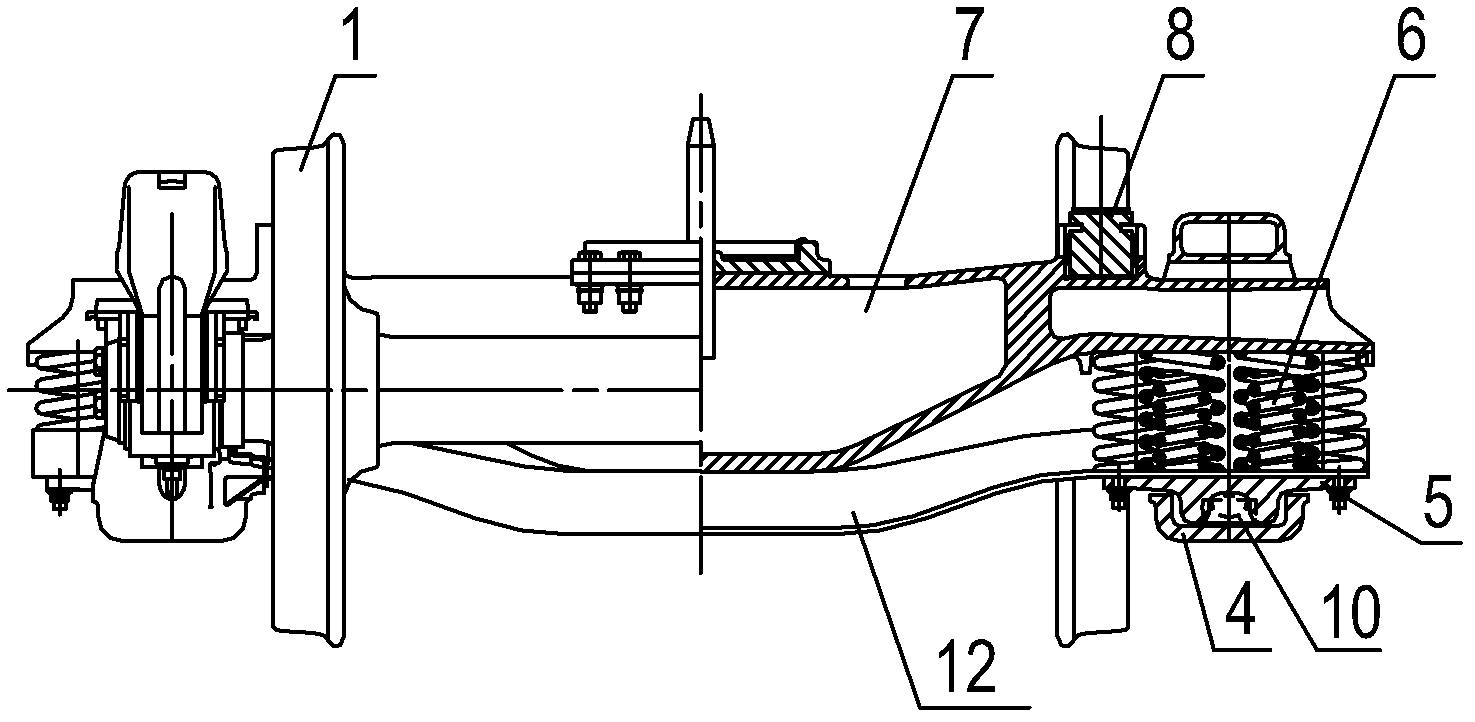

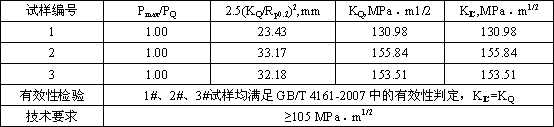

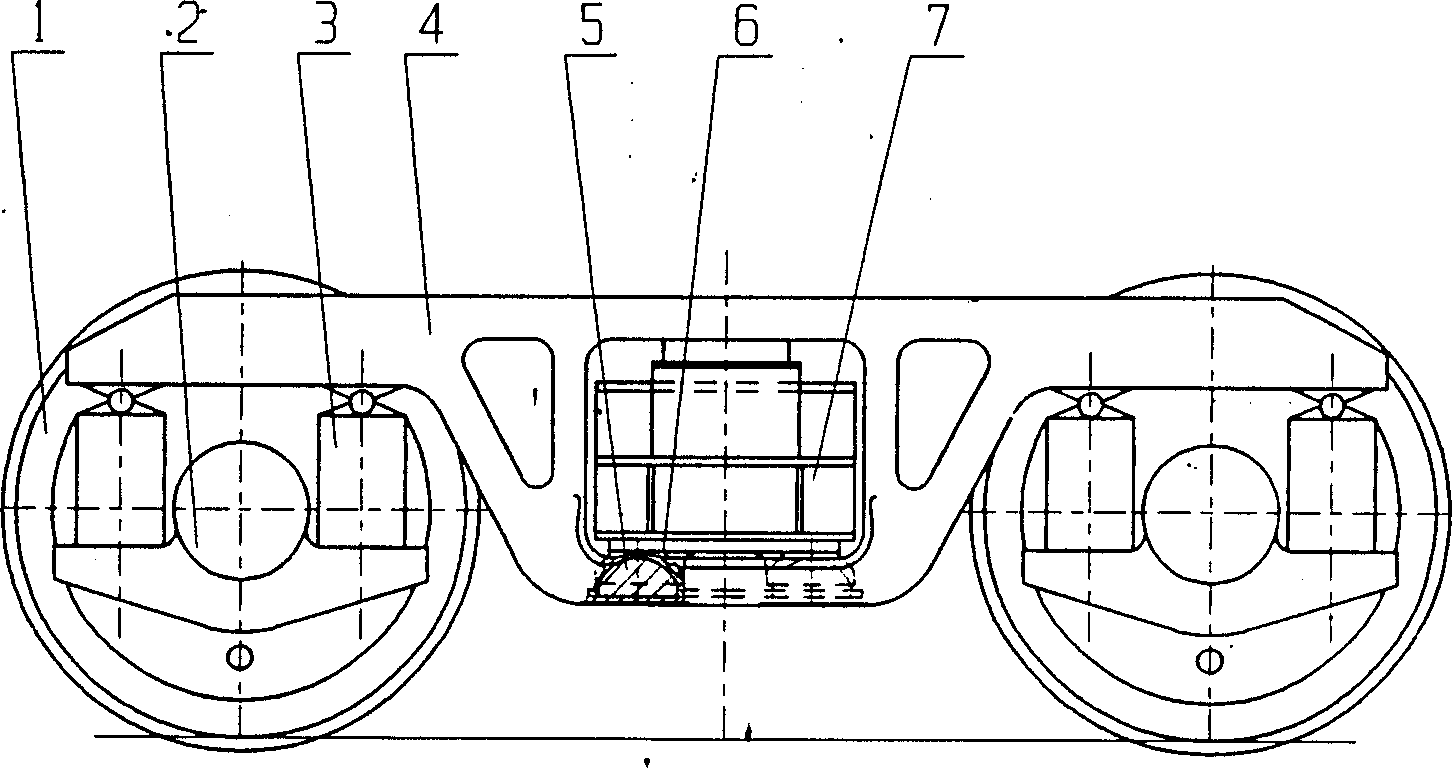

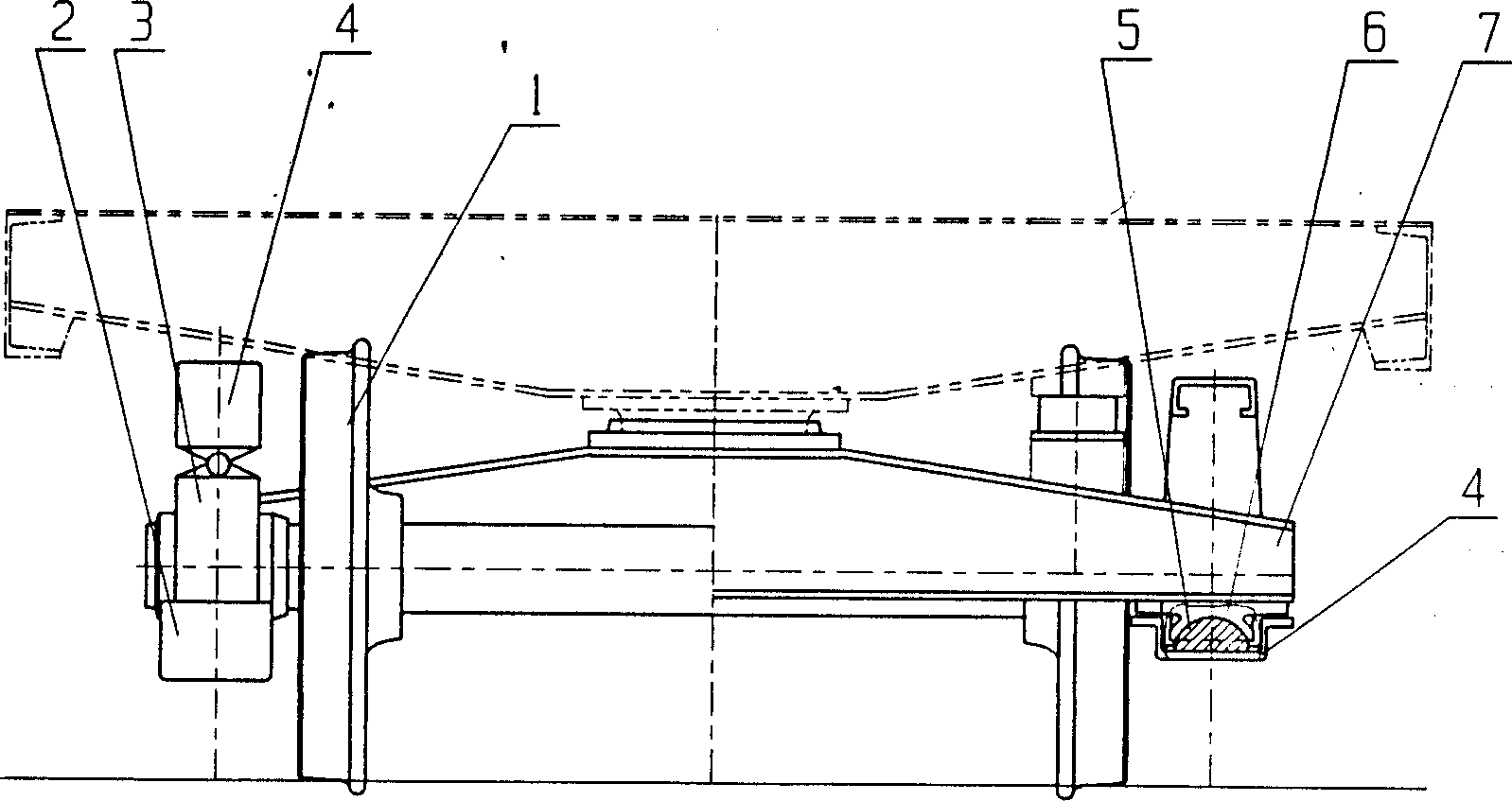

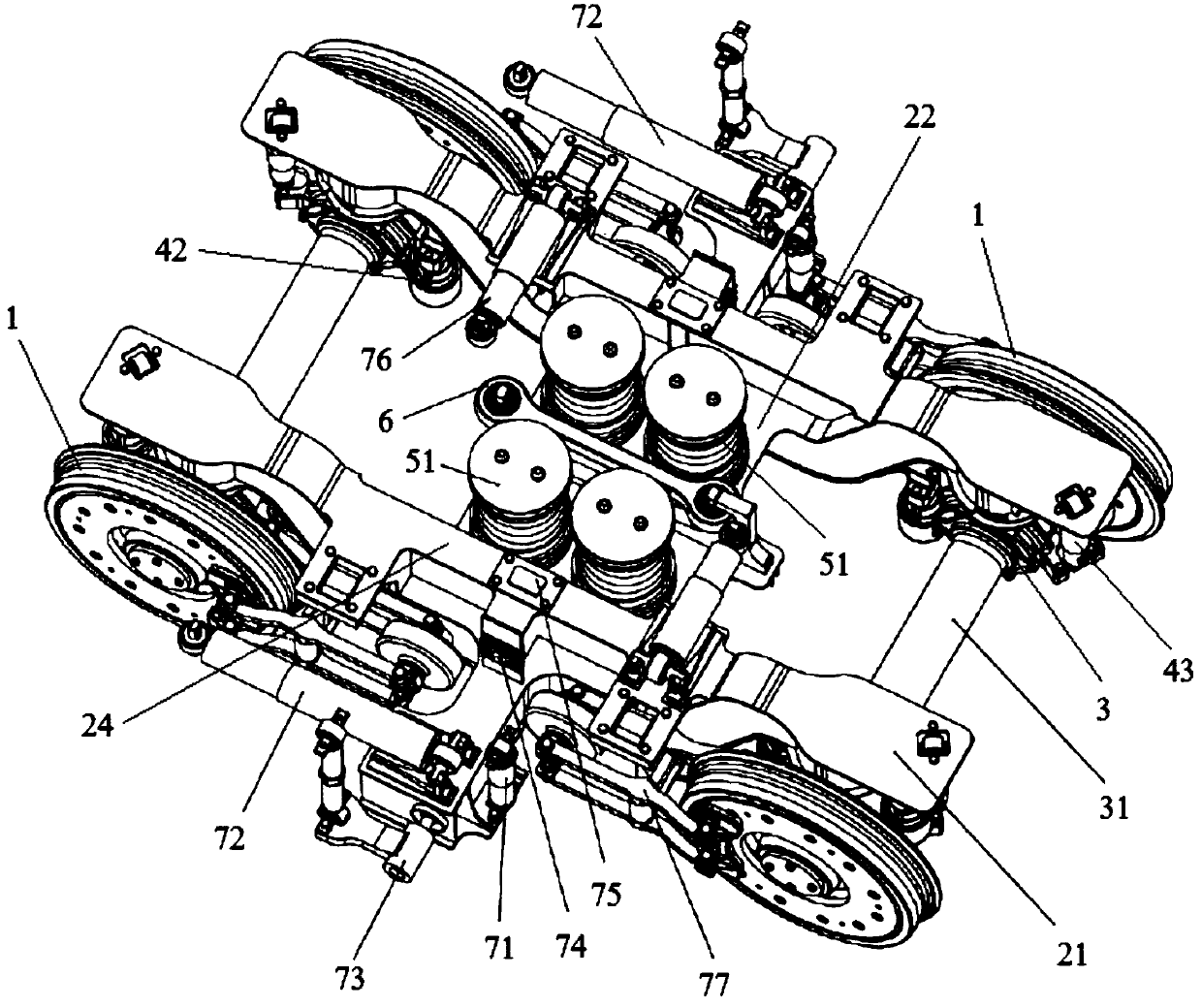

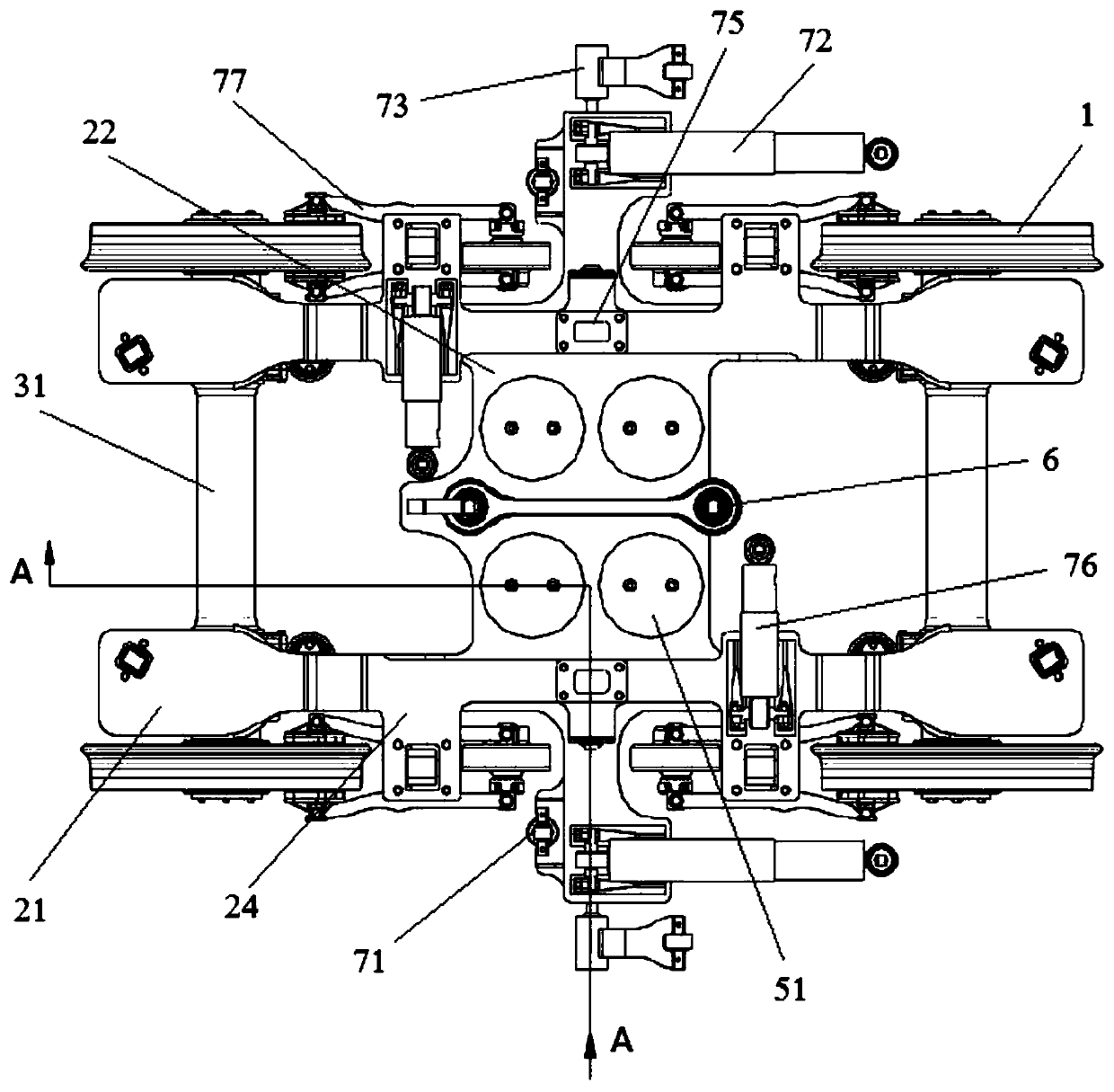

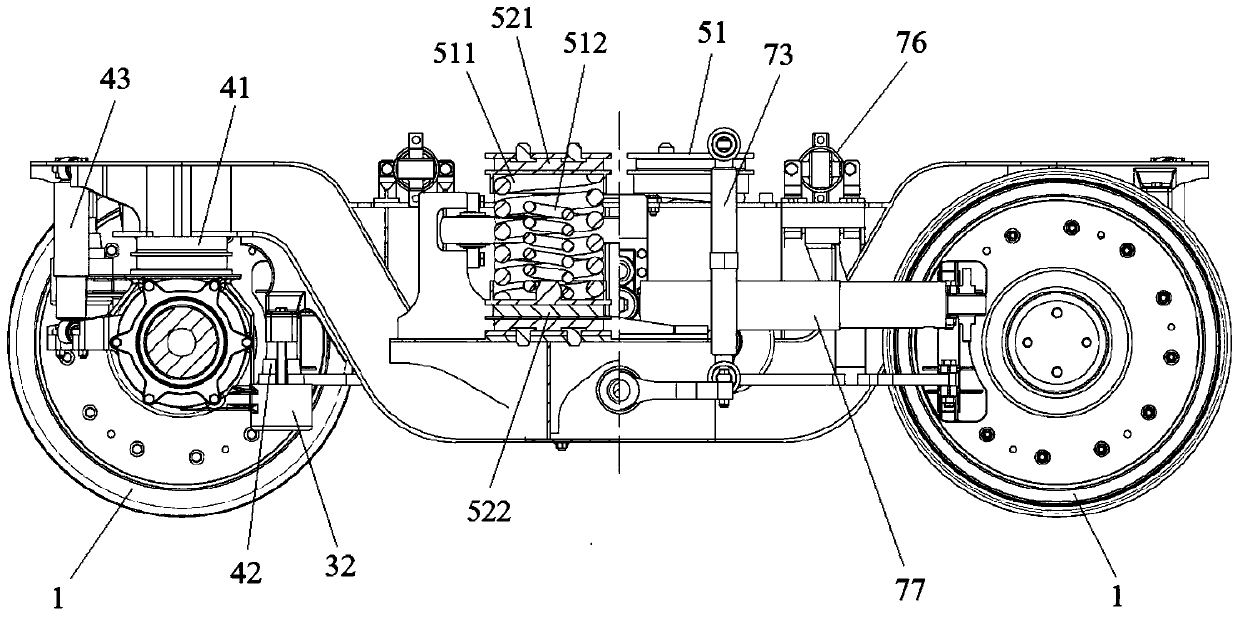

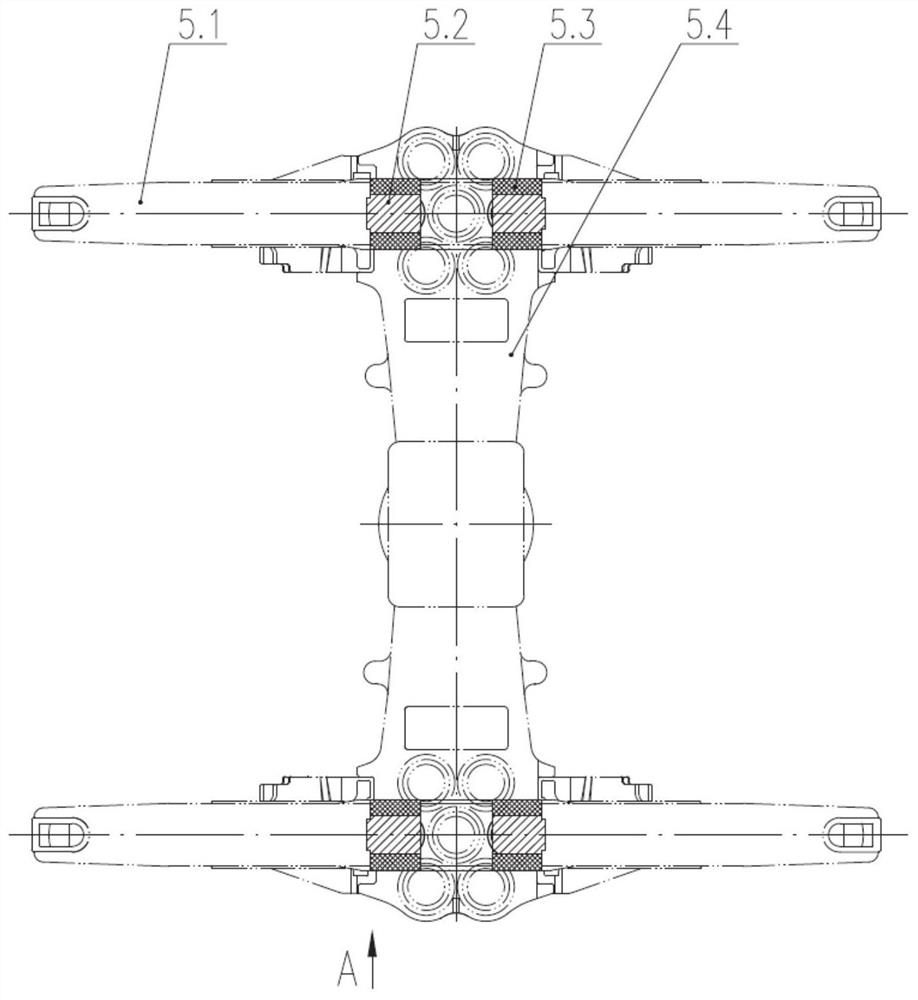

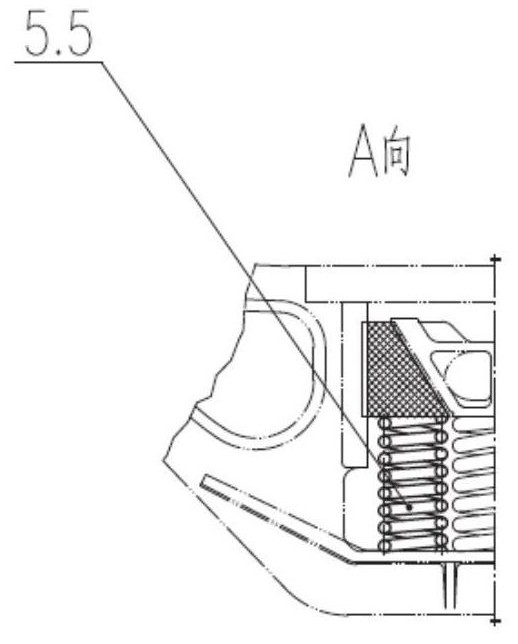

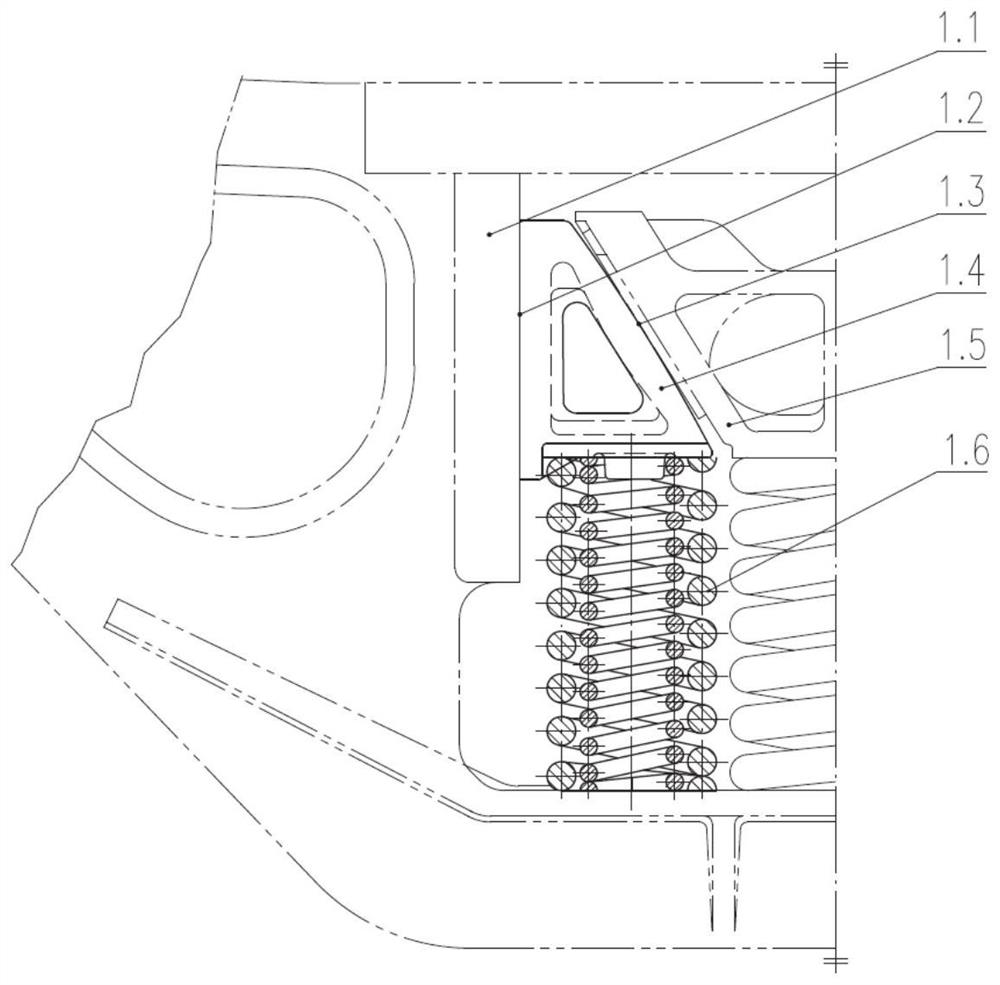

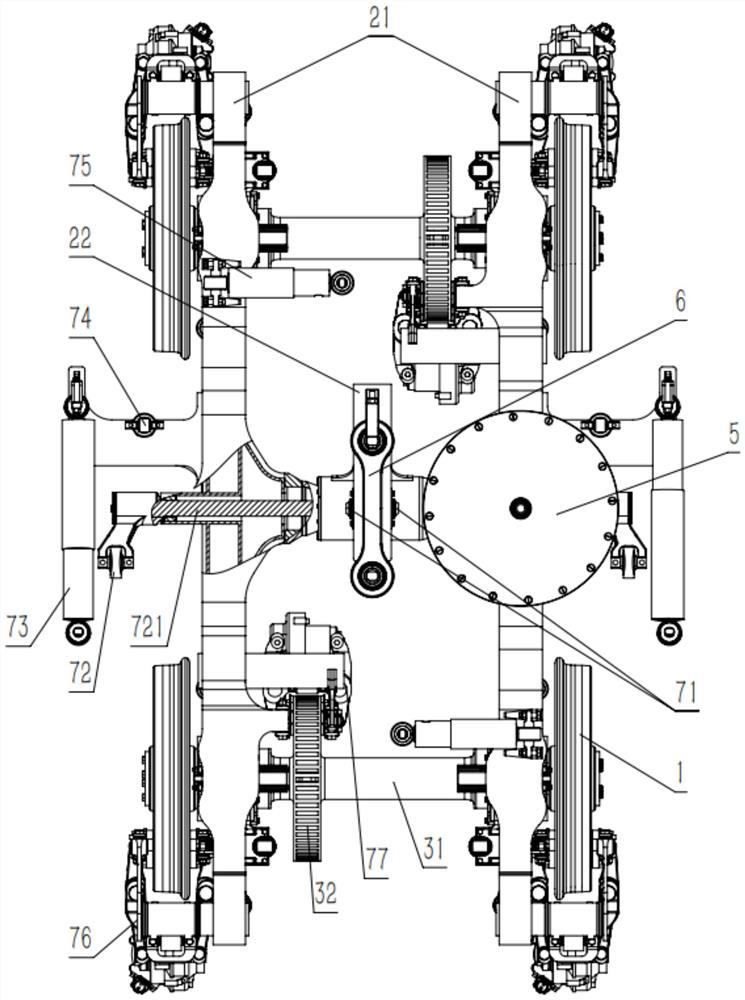

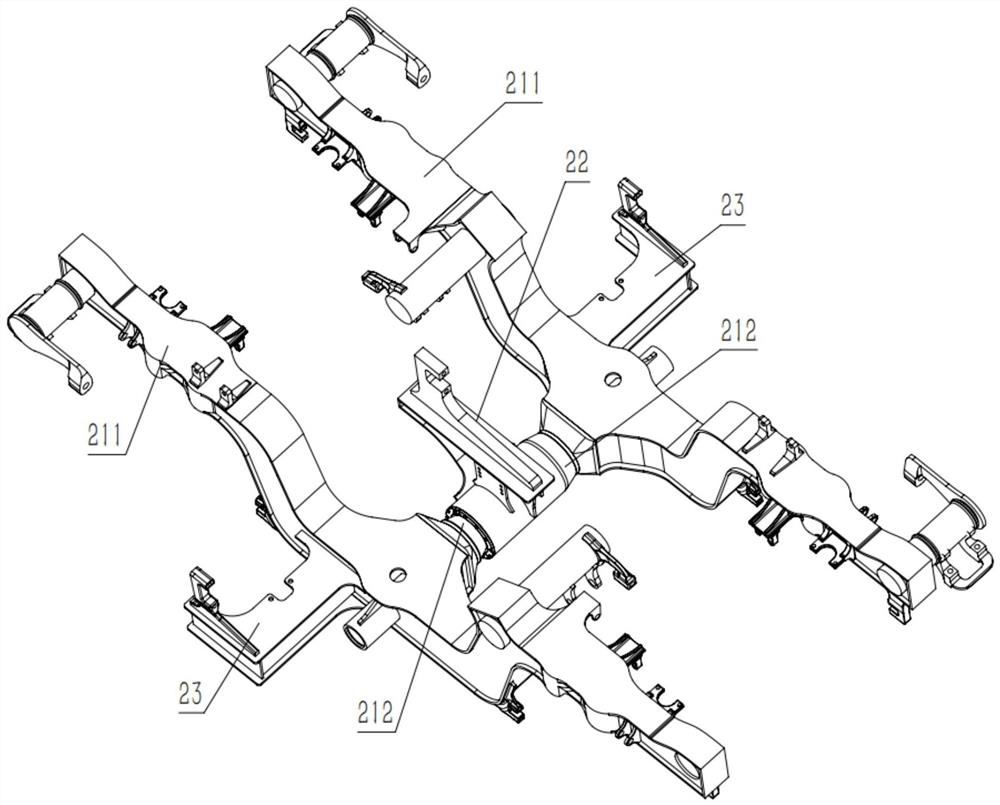

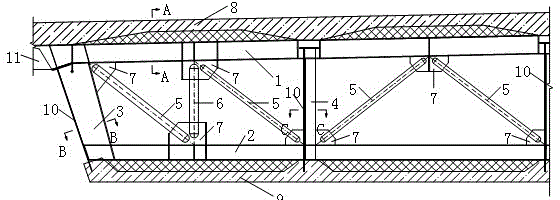

Shaft box suspension swing type bogie for rail wagon

The invention discloses a shaft box suspension swing type bogie for a rail wagon. The bogie comprises a wheel set, a shaft box, a side frame, a swing bolster, a side bearing and a foundation brake device, wherein a bearing saddle is arranged between the shaft box and the side frame; central suspension devices are arranged below two ends of the swing bolster; a fixed lever fulcrum seat is arranged on the swing bolster; a rubber spring is arranged between the side frame and the bearing saddle; a spring supporting plate is arranged below the central suspension devices at the two ends of the swing bolster in a connection mode; shaking seats are arranged below two ends of the spring supporting plate and are connected with the side frame through a shaking seat bearing; a falling prevention cylinder is arranged on an outer surface at the rear end of a bearing body of the shaking seat bearing; and a brake pull rod support is arranged on one side of a fulcrum seat body of the fixed lever fulcrum seat. The horizontal performance and the vertical performance of the bogie can be improved, speed increasing requirements of the rail wagon are met, and parts have high connection reliability.

Owner:CRRC YANGTZE CO LTD

Variable compliance wheel

ActiveUS8631844B2Increase vertical stiffnessIncrease stiffnessNon-inflatable tyresHigh resiliency wheelsMechanical engineeringEngineering

A system for adjusting the compliance of a wheel is provided. In one embodiment, wheel segments are adjusted, causing the stiffness of the wheel to change. Such adjustments can be made while the wheel is rotating, allowing the wheel compliance to be changed while a vehicle is in motion.

Owner:MILLENWORKS

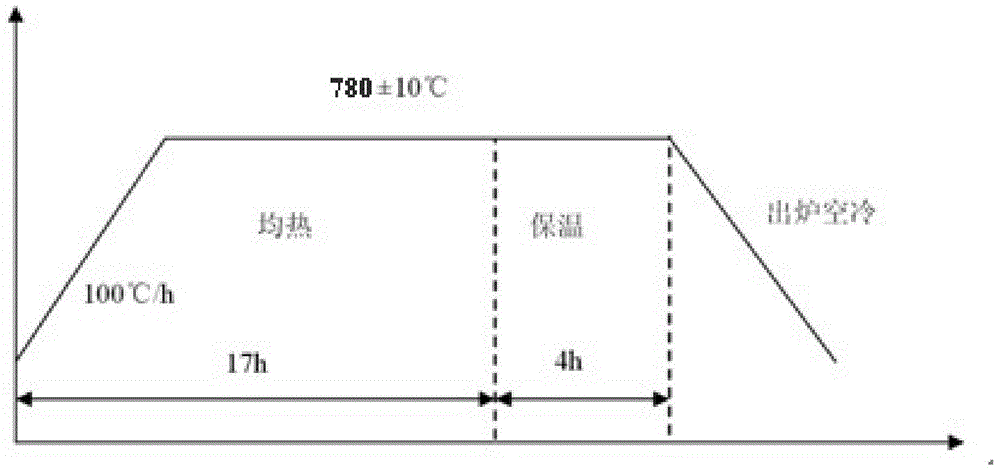

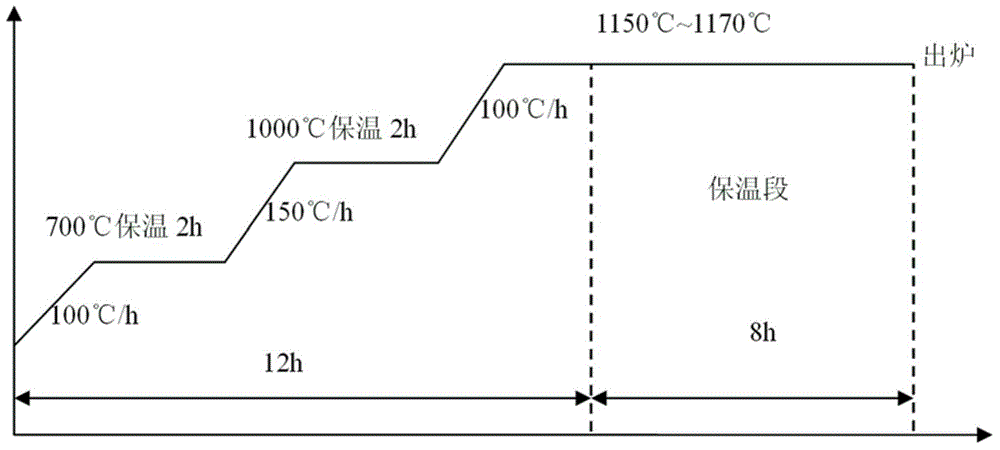

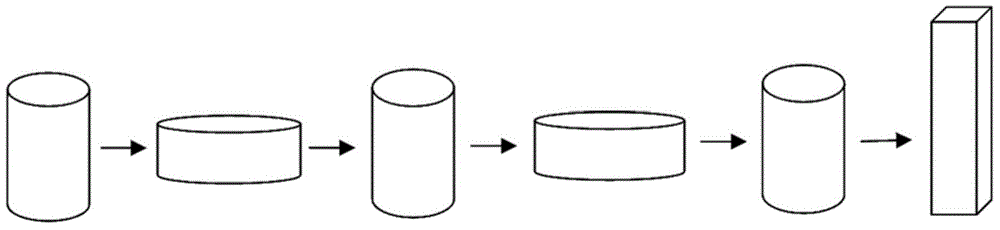

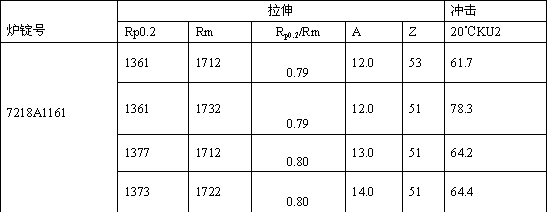

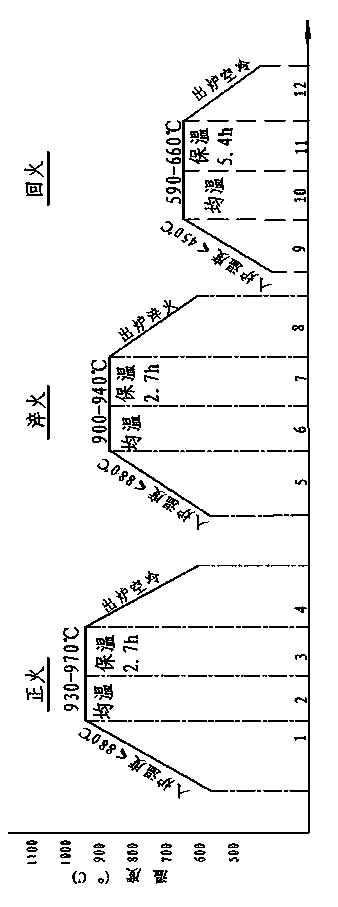

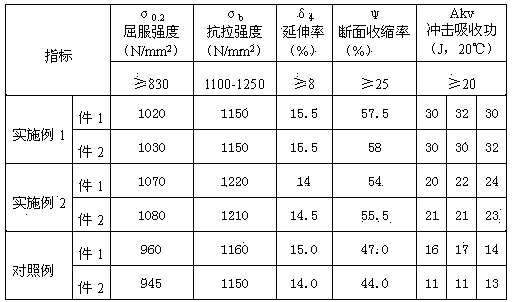

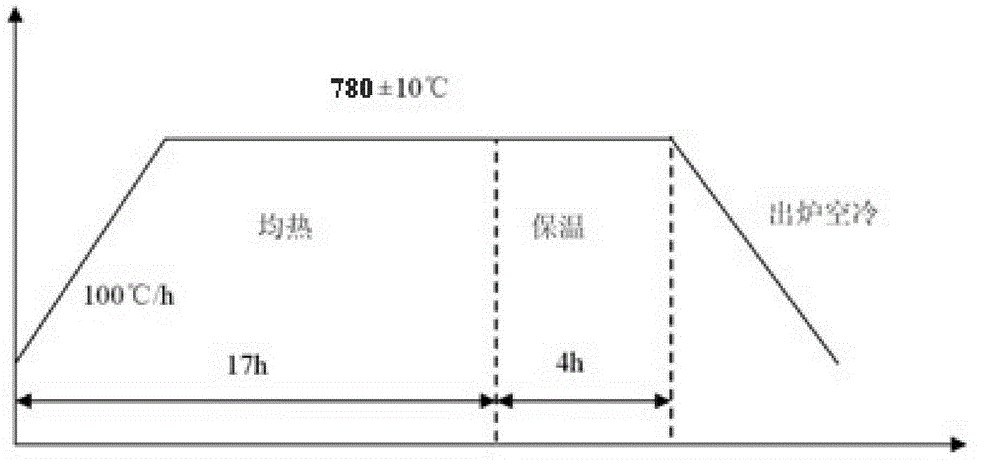

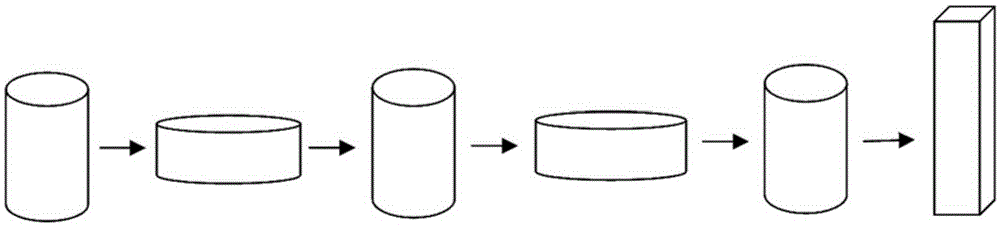

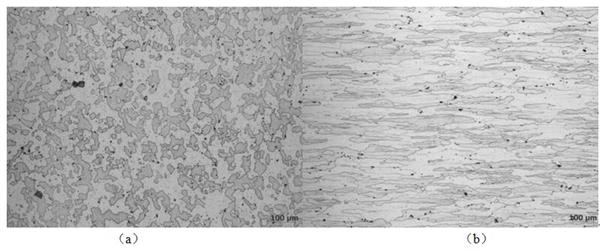

Forging method for improving lateral impact performance of steel material

ActiveCN104399854ALongitudinal performance does not degradeImprove lateral performanceMetal-working apparatusIngotSingle pass

The invention discloses a forging method for improving the lateral impact performance of a steel material. The forging method is characterized by comprising the following steps: (1) remelting an electroslag ingot; (2) producing forged steel by electroslag ingot forging, wherein the step of producing the forged steel by the electroslag ingot forging comprises the following steps:1) firstly, heating the electroslag ingot, and then, carrying out forging cogging according to a two-tampering two-pulling technology; (2) annealing a process blank; (3) after the process blank is heated and kept warm, forging a production material, wherein the total forging ratio of the production material is controlled to be above 4.0. The forging method has the beneficial effects that the electroslag ingot is subjected to single-pass big-reduction two-tampering two-pulling forging cogging, the isotropy and the lateral and longitudinal tissue evenness of the steel material can be drastically improved since tampering pulling forging is carried out for multiple times before the production material is forged, and the lateral performance of the steel material is drastically improved while the longitudinal performance of the steel material is not lowered. Since remelting heating heat insulation is carried out immediately when the forging pulling is finished one time, a forging pulling blank restores recrystallization by remelting so as to be favorable for next-time tampering pulling forging and grain refinement.

Owner:XINING SPECIAL STEEL

Polymerization method capable of effectively controlling phase transformation in PPTA (poly-p-phenylene terephthamide) synthesis process

InactiveCN103467736AImprove mechanical propertiesIncrease confusionMonocomponent copolyamides artificial filamentTurbidityThymolphthalein

The invention relates to a polymerization method capable of effectively controlling the phase transformation in a PPTA (poly-p-phenylene terephthamide) synthesis process. The polymerization method comprises the following steps of firstly dissolving LiCl in a solvent NMP (N-methyl-2-pyrrolidone) under the condition of nitrogen atmosphere protection, then adding comonomer p-phenylenediamine, terephthaloyl chloride and trace comonomer, adding acid absorbent pyridine, stirring so as to completely dissolve the acid absorbent pyridine, then adding PPD ((Para Phenylene Diamine), stirring so as to completely dissolve the PPD, then feeding condensing oil bath, maintaining the temperature of the condensing oil bath at -15 DEG C to -5 DEG C, adding TPC (Thymolphthalein Complexone) in three times, and stirring so as to fully react the TPC, thus obtaining modified PPTA resin, wherein the logarithmic viscosity number of the modified PPTA resin is in the range of 5.0-8.0, and the trace comonomer is a diamine monomer containing a flexible chain structure. The polymerization method is a method of effectively increasing the molecular weight by using the phase transformation; and according to the method, the phase transformation time of transforming a liquid phase into a solid phase can be delayed in the polymerization process, so that the molecular weight is effectively increased and the turbidity of a liquid crystal spinning solution is improved.

Owner:DONGHUA UNIV +1

Medium alloy ultrahigh strength and toughness rare earth steel and preparation method thereof

The invention provides a kind of medium alloy ultrahigh strength and toughness rare earth steel and relates to the technical field of rare earth steel, in particular to medium alloy ultrahigh strengthand toughness rare earth steel and a preparation method thereof. The medium alloy ultrahigh strength and toughness rare earth steel is characterized by comprising, by mass, 0.26%-0.31% of C, 0.50%-0.80% of Mn, 1.25%-1.60% of Si, less than or equal to 0.005% of S, less than or equal to 0.010% of P, 3.25%-3.60% of Cr, 0.80%-1.20% of Ni, 0.35%-0.60% of Mo, 0.40%-1.00% of W, 0.02%-0.04% of Nb, 0.20%-0.40% of V, 0.0045%-0.006% of La and 0.0105%-0.014% of Ce. The medium alloy ultrahigh strength and toughness rare earth steel has the characteristics of being high in strength, hardness, toughness andthe like, can also reduce the production cost and achieves a lot of positive effects meeting the application requirements.

Owner:日照市质量检验检测研究院(国家碳素结构钢产品质量检验检测中心(山东)日照市药品不良反应监测中心日照市纺织纤维监测中心

Suspension swing type bogie of axle box for railway vehicle

InactiveCN1333151ASmall unsprung massImprove lateral performanceAxle-boxes mountingBogieElastic component

The axle housing suspended swinging bogie includes wheel pair, axle housing, axle housing elastic component, side frame, positioning ball block, rocker seat and rocker beam. The rocker beam can be used to press to the positioning ball blocks which are respectively positioned on lower wing panels of mid-sections of left and right two side frames by means of rocker seats which are respectively positioned under the two ends of rocker beam. The side frame also is hinged and supported on the axle housing elastic component, and the axle housing elastic component is supported on the axle housing. Said invented special structure can mave left and right two side frames like to wing bars to drive rocker beam and make it implement transverse swing. Said invention adopts the sprung suspended special swinging mechanism so as to ensure light unsprung mass of steering frame, small wheeltrack acting force, high critical speed and excellent transverse property of vehicle, so that it can meet requirements for developing high-speed freight carrier.

Owner:CRRC YANGTZE CO LTD

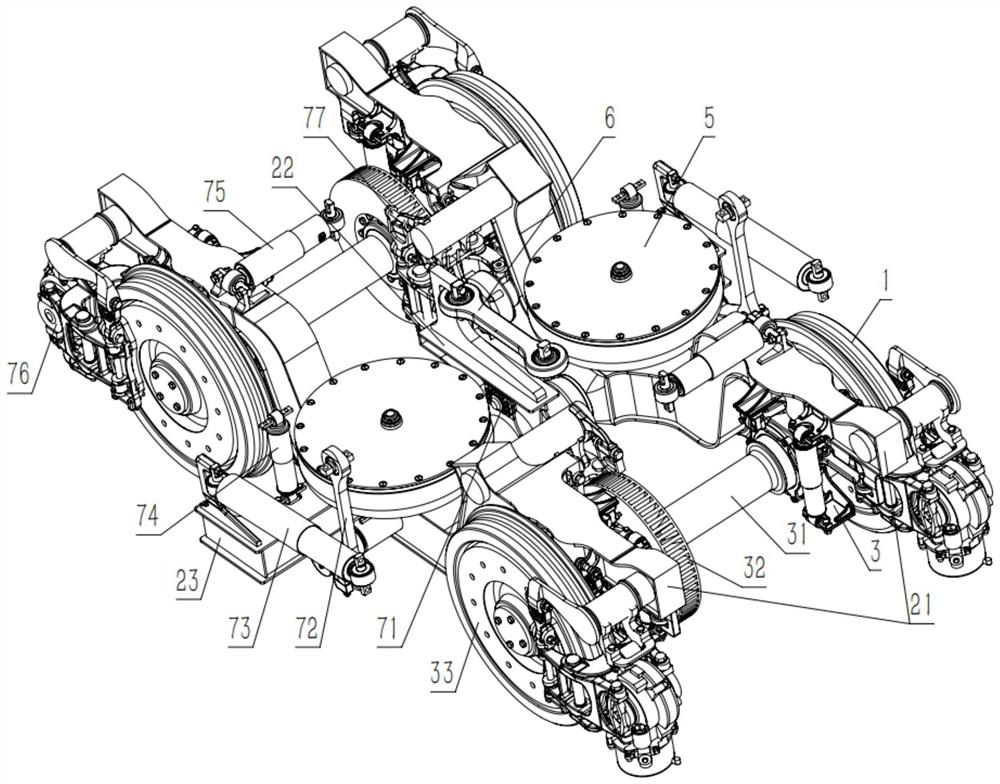

Railway vehicle bogie

PendingCN111301471ARun fastReliable speedBogiesBogie-underframe connectionsBogieTorsional deformation

The invention discloses a railway vehicle bogie. The bogie is arranged in an internal axle box manner, and frameworks are supported on the inner sides of wheel sets, so the axle length is effectivelyshortened, the unsprung mass and dead weight of the bogie are reduced, and the curve passing performance is improved; the arrangement of downward concave sections of side beams and the connection of cross beams to the downward concave sections can effectively reduce the height of the gravity center of the bogie and reserve a high longitudinal space for a vehicle body, and web plates and cover plates can be adopted to enhance the strength of the side beams and improve the bearing capacity of the side beams; two primary positioning components are adopted for positioning, so that the axle distance of the bogie can be further reduced; and a secondary suspension device is additionally arranged to improve the vertical and transverse performances of the bogie and increase the running speed of thebogie, and secondary spring sets are arranged in a centralized mode to reduce torsional deformation of the secondary spring assemblies. The bogie is compact and reasonable in structural arrangement,reliable in performances and beneficial to improving the running stability, stability and running speed of a vehicle.

Owner:SOUTHWEST JIAOTONG UNIV

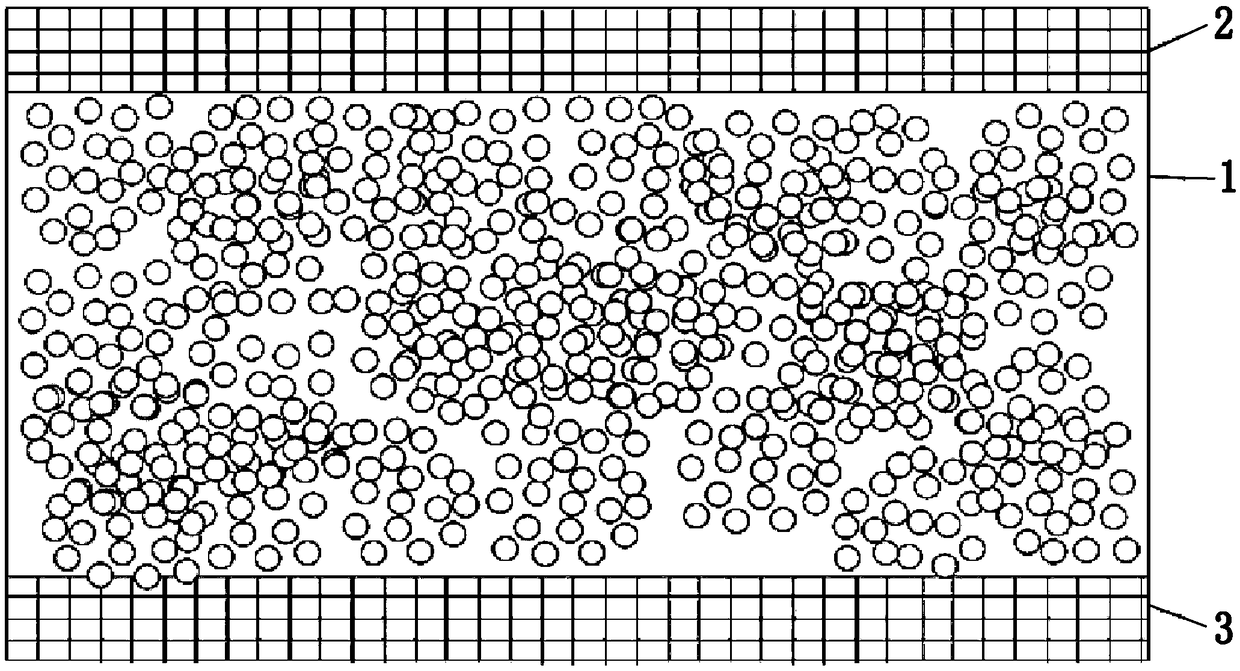

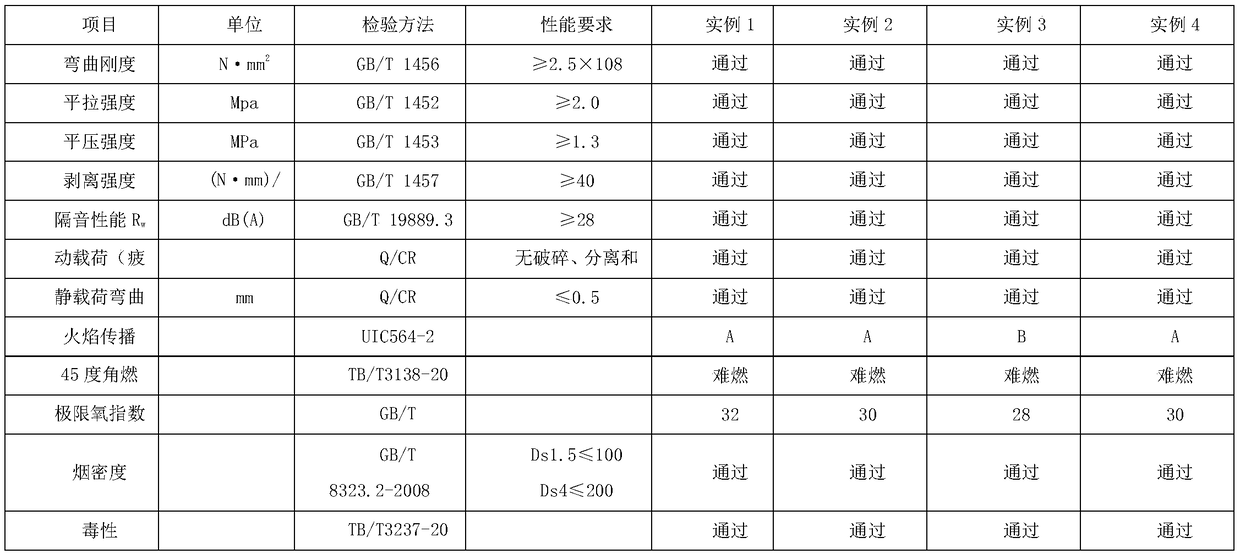

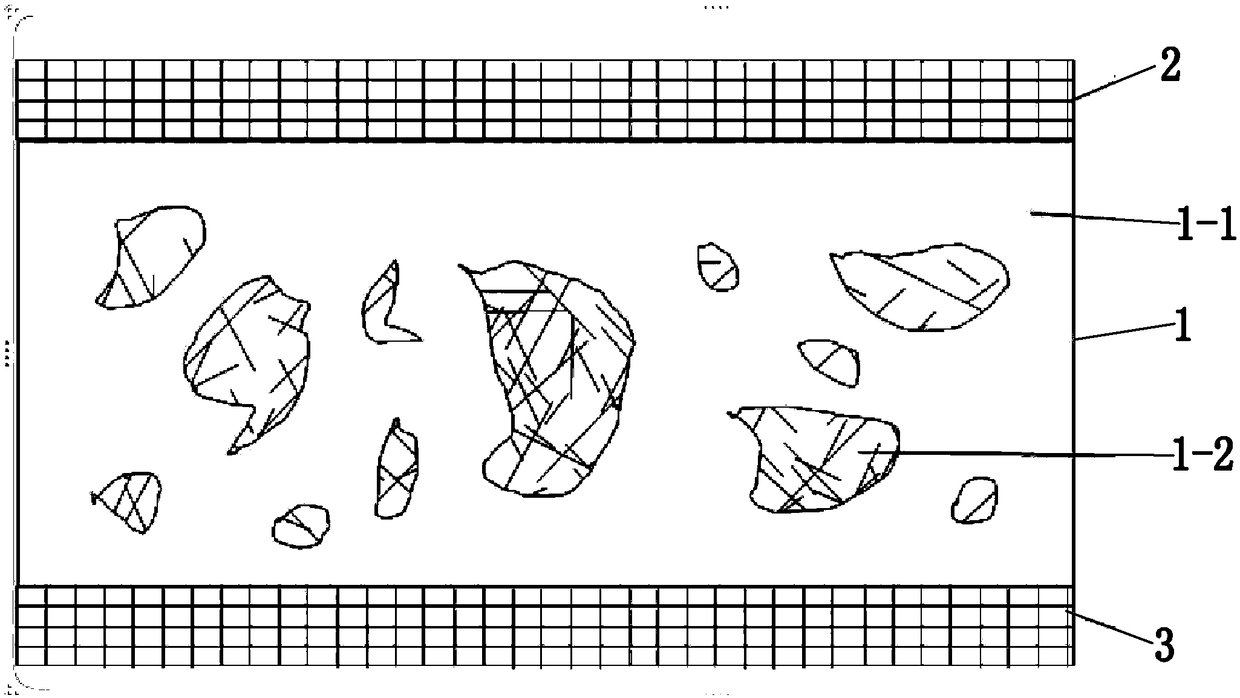

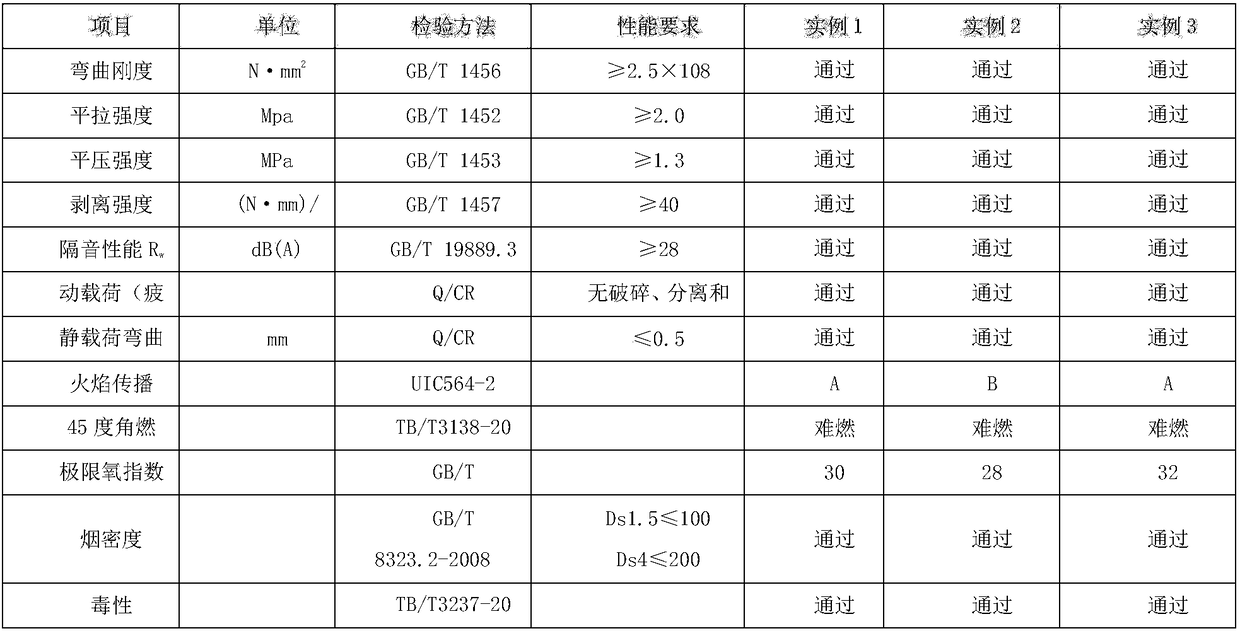

Method for preparing flame retardant rail transit vehicle interior floor based on foaming process

InactiveCN108943923AHigh vertical and horizontal performanceGood impact resistanceSynthetic resin layered productsLaminationEngineeringFiber

The invention relates to a method for preparing a flame retardant rail transit vehicle interior floor based on a foaming process. The interior floor comprises an upper surface layer, a core material and a lower surface layer arranged in sequence. The upper surface layer, the core material and the lower surface layer are compounded through heating and pressing to form the interior floor. The core material is a foam sheet. The upper surface layer and the lower surface layer are prepared from fabrics obtained by weaving multilayer unidirectional continuous glass fiber reinforced thermoplastic resin prepregs and / or glass fiber fabric-reinforced thermoplastic resin prepregs and / or glass fibers and thermoplastic resin co-extruded fibers. The polymer resin foams to form a lightweight foamed sheetas the core material through a physical or chemical foaming process. The lightweight composite core material has light weight and can absorb noise. The surface layers and the core layer are preparedfrom the same polymer. The base layer materials can be bonded through a direct practical hot pressing process and the base layer materials can be bonded with the surface layers directly through a hotpressing process without glue so that the glue spraying process is avoided. The floor materials can be recovered, is environmentally friendly and is easy to process.

Owner:嘉兴领科材料技术有限公司

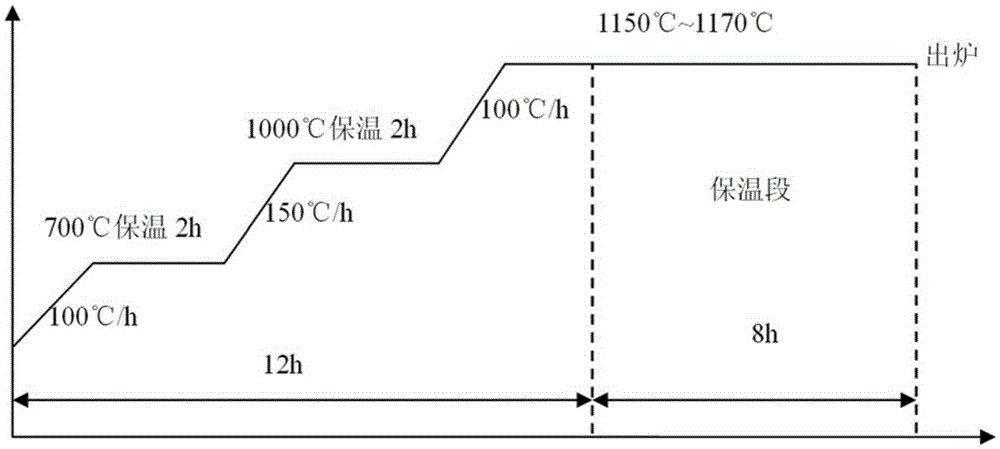

A Ni-Cr based precipitation hardening type deformable high-temperature alloy material and a preparing method thereof

InactiveCN106167862AImprove lateral performanceImprove heat resistanceSurface finishingInduction furnace

The invention discloses a Ni-Cr-based precipitation-hardening deformable superalloy material and a preparation method thereof. Required elements are melted in a vacuum induction furnace at a melting temperature of 1450-1460°C; the content of each element is adjusted during the melting process, Make the weight ratio meet the design requirements, pour the solution into a consumable electrode; remelt and refine the poured consumable electrode in an electroslag furnace, and remelt it into an electroslag ingot; heat and forge the electroslag ingot to make a steel rod ; Air-cool the steel rod to room temperature after forging; treat the surface of the steel rod; take samples from the finished steel rod to check the mechanical properties, and carry out the corresponding mechanical property test. The beneficial effects of the present invention are: the Ni-Cr-based precipitation-hardening deformed superalloy material and the alloy material prepared by the preparation method make the transverse performance and longitudinal performance relatively close, while improving the transverse performance, the alloy can also be improved The heat resistance performance in the use process can improve the service life of the products made of this kind of alloy, and has good economic and social benefits.

Owner:SICHUAN JIANGYOU LIUHE STEAM TURBINE MATERIAL

Flame retardant rail transit vehicle interior floor

InactiveCN108544812AReduce weightEasy to handleFlame-proof filament manufactureSynthetic resin layered productsFiberGlass fiber

The invention relates to a flame retardant rail transit vehicle interior floor, comprising an upper surface layer, a core material and a lower surface layer which are arranged in sequence; the upper surface layer, the core material and the lower surface layer are compounded by heating and pressurizing to form the floor; the core material is compounded from thermoplastic polymer fibers and glass fibers; the upper surface layer and the lower surface layer are compounded from fabrics which are woven by a plurality of layers of unidirectional continuous glass fiber reinforced thermoplastic resin prepreg and / or glass fiber fabric reinforced thermoplastic resin prepreg and / or glass fiber and thermoplastic resin co-extrusion fibers; according to the rail transit vehicle floor provided by the invention, the upper surface layer and the lower surface layer are fabrics which are woven by a plurality of layers of unidirectional continuous glass fiber reinforced thermoplastic resin prepreg and / or glass fiber fabric reinforced thermoplastic resin prepreg and / or glass fiber and thermoplastic resin co-extrusion fibers, and a layer by layer manner is adopted, so that the fibers form a staggered grid, thereby ensuring high longitudinal and lateral properties, and better strength, impact resistance and durability of a product.

Owner:嘉兴领科材料技术有限公司

Method for producing core rod by utilizing 30Cr3MoV steel as raw material

The invention belongs to the technical field of core rod production, and particularly relates to a method for producing a core rod by utilizing 30Cr3MoV steel as a raw material. The method for producing the core rod by utilizing the 30Cr3MoV steel as the raw material comprises the following steps of material selection, refining, electro slag, forging, rough machining, heat treatment and finish machining. The method disclosed by the invention can be used for refining by selecting the 30Cr3MoV steel as the raw material and adopting an EAF+LF / VD mode, enhances the purity and compacts the crystal structure, thereby obtaining higher impact toughness.

Owner:HENAN ZHONGYUAN SPECIAL STEEL EQUIP MFG CO LTD

Rare earth treatment method of continuously cast 20 steel crack-free tube blank

The invention relates to a rare earth treatment method of a continuously cast 20 steel crack-free tube blank, belonging to the ferrous metallurgical field. The method is as follows: the cored wire feeding speed of the rare earth metal wire changes with the casting speed of a continuous casting machine, rare earth is distributed uniformly in the casting blank; the cored wire of a rare earth wire is inserted from one side of a submerged entry nozzle, the optimum insertion depth is 150mm; the optimum weight ratio of rare earth (RE / S) to sulfur in molten steel is 4.2; when the RE / S is 1.7, rare earth can be used to increase the equiaxed crystal rate of the 20 steel tube blank, reduce the columnar zone, disorder the first interference direction turbulence, decrease the secondary interference space, improve the central refraction and reduce the subsurface cracks; and when the RE / S is 4.2, rare earth can be used to completely change the morphologies of the inclusions in steel, convert manganese sulfide, silica, aluminium oxide and other inclusions to rare earth sulfide, rare earth oxysulfide, rare earth silicate, rare earth aluminate and the like, eliminate the inner cracks in the 20 steel tube blank and increase the transverse properties of the tube.

Owner:BAOTOU SHENRUI SPECIAL ALLOY

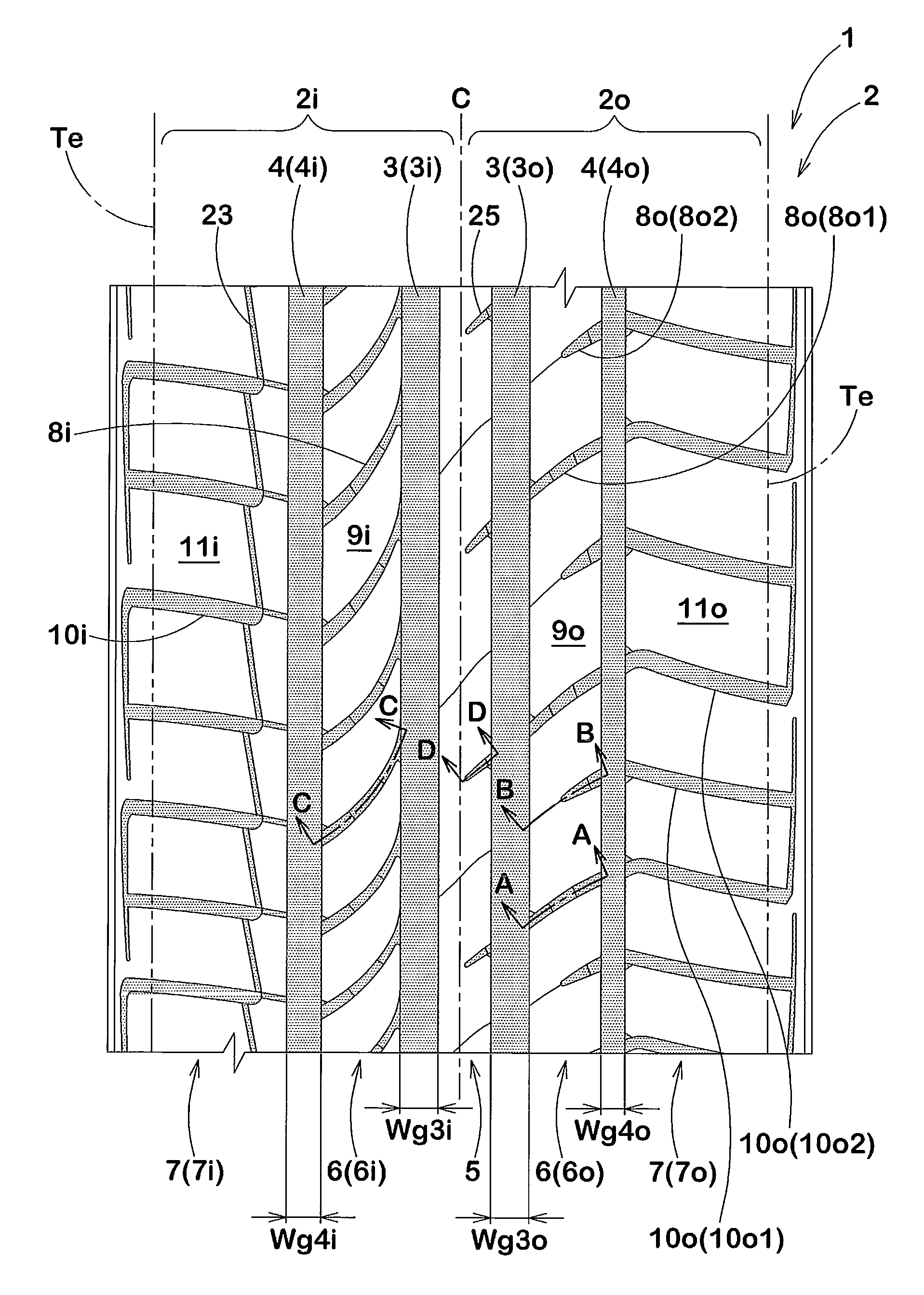

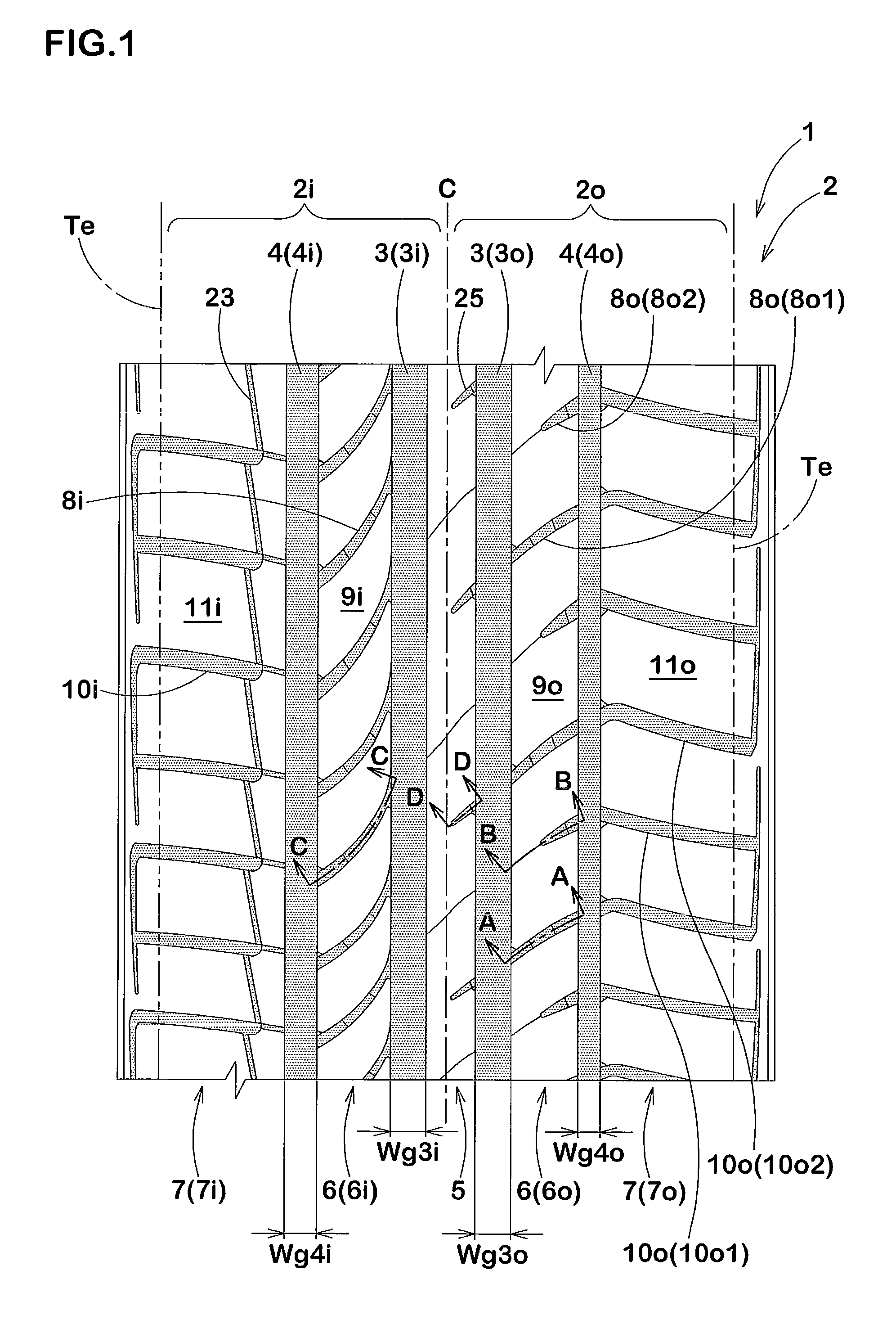

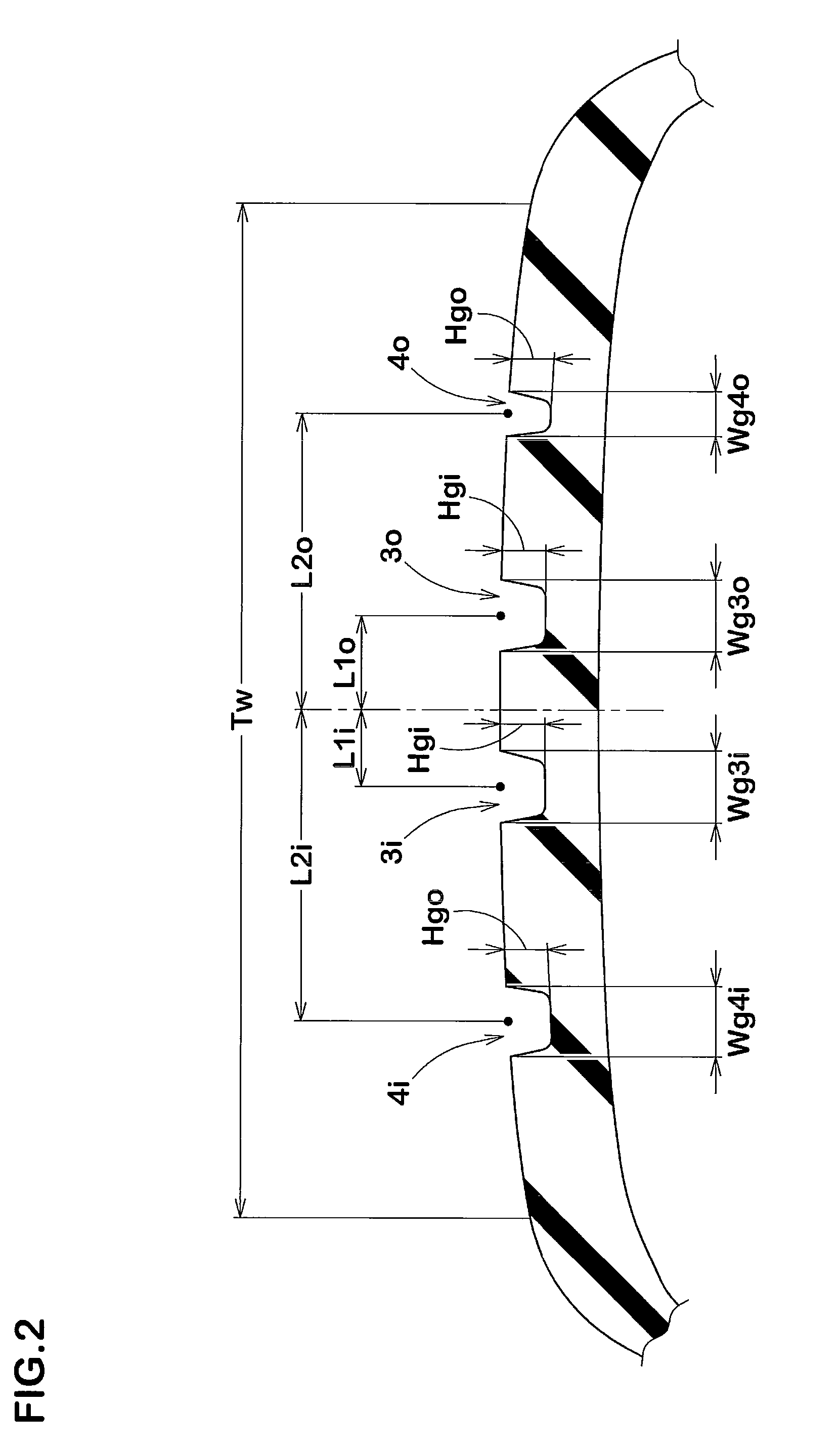

Pneumatic tire with asymmetric tread pattern

ActiveUS8550133B2Large influenceDifference in performanceTyre tread bands/patternsNon-skid devicesEngineeringTread

A tire having an asymmetric tread pattern that land proportion of outer side area 2o is larger than inner side area 2i, but having a reduced difference in drainage performance between tires on right and left wheels, the tire having tread surface 2 divided by four circumferential grooves 3 and 4 into center land 5, middle lands 6, 6 and shoulder lands 7, 7, wherein middle land 6o and shoulder land 7o in the outer side area 2o are divided respectively by outer middle lateral grooves 8o and outer shoulder lateral grooves 10o into blocks 9o and blocks 11o, inclination direction of the middle lateral grooves 8o is opposite to that of the shoulder lateral grooves 10o with respect to tire axial direction, and the lateral grooves 8o and 10o are inclined at an angle θmo between 5° and 45° and at an angle θso between more than 0° and not more than 40°, respectively.

Owner:SUMITOMO RUBBER IND LTD

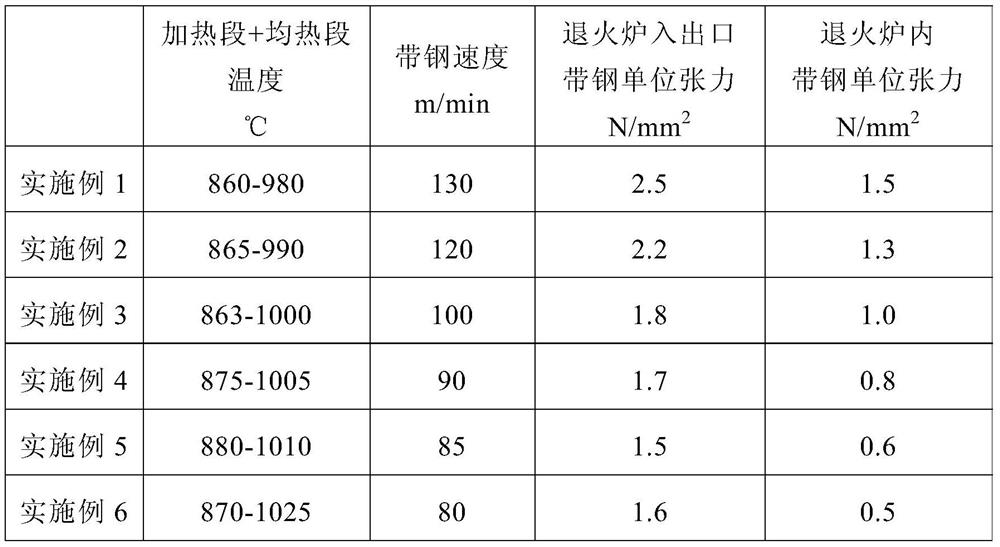

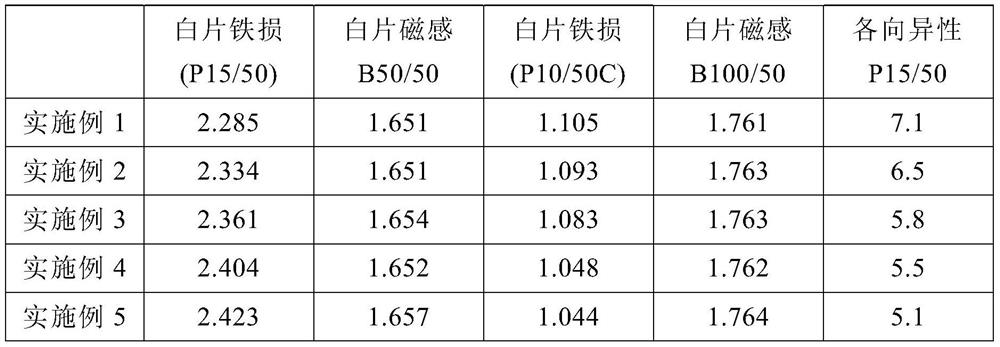

Production method of ultra-low anisotropic non-oriented silicon steel for oversize generator

ActiveCN114318127AEliminates the effects of opposing forcesRolling stress reliefFurnace typesHeat treatment process controlSteelmakingTemperature control

The invention discloses a production method of ultra-low anisotropic non-oriented silicon steel for an oversize generator. The production method comprises the steps of molten iron pretreatment, converter steelmaking, RH refining, continuous casting of molten steel into a plate blank, hot rolling, normalizing pickling, cold rolling, annealing, coating and finishing. Wherein the non-oriented electrical steel comprises the following components in percentage by weight: less than or equal to 0.003% of C, 2.80-3.60% of Si, 0.15-0.45% of Mn, less than or equal to 0.04% of P, 0.4-1.2% of Als, less than or equal to 0.002% of S and the balance of Fe and other inevitable impurities; a continuous annealing furnace is adopted for annealing, the annealing temperature of a heating section and a soaking section is controlled to be 860-1030 DEG C, the speed of the strip steel is 90-130 m / min, the unit tension of the strip steel at an inlet and an outlet of the annealing furnace is smaller than 2.5 N / mm < 2 >, and the unit tension of the strip steel at the soaking section in the annealing furnace is smaller than 1 N / mm < 2 >. According to the non-oriented silicon steel, the iron loss P15 / 50 is smaller than or equal to 2.5 W / kg, the magnetic induction B50 is larger than or equal to 1.65 T, the magnetic induction B100 is larger than or equal to 1.76 T, the iron loss P15 / 50 anisotropy is smaller than or equal to 8%, and P10 / 50C is smaller than or equal to 1.12 W / kg.

Owner:BAOSHAN IRON & STEEL CO LTD

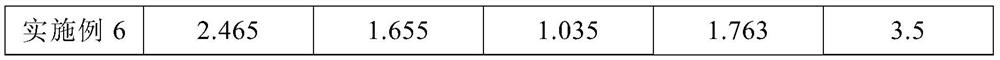

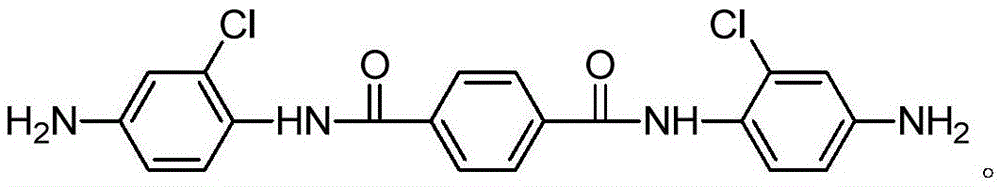

Aromatic diamine monomer and preparation method thereof

InactiveCN105646267AMaintain liquid crystal performanceLoose structureOrganic compound preparationMonocomponent copolyamides artificial filamentNitrobenzeneStructural formula

The invention relates to an aromatic diamine monomer and a preparation method thereof. The aromatic diamine monomer is N,N'-bis(4-amino-2-chlorphenyl) terephthalamide and has a structural formula shown in the specification. The preparation method comprises steps as follows: 2-chloro-4-nitroaniline, alkali and tetrahydrofuran are mixed, a tetrahydrofuran solution of paraphthaloyl chloride is dropwise added, the mixture reacts for 8-12 h at the temperature of 25-35 DEG C, N,N'-bis(2-chloro-4-nitrobenzene) terephthalamide is obtained, ethanol and Pd / C are added to N,N'-bis(2-chloro-4-nitrobenzene) terephthalamide under the protection of argon, the mixture reacts for 5-12 h at the temperature of 80-100 DEG C under the protection of hydrogen, and the aromatic diamine monomer is obtained. The aromatic diamine monomer is simple in structure, has good development prospect and is an important constituent part for PPTA (poly(p-phenylene terephthalamide)) copolycondensation modification in the future. The preparation method is simple, and the yield is high.

Owner:DONGHUA UNIV

Smelting method based on nickel-based heat-resistance alloy

The invention discloses a smelting method based on a nickel-based heat-resistance alloy. The method comprises specific steps that molten steel is prepared, and the quantitative amount of metal nickel, the quantitative amount of metal chromium, the quantitative amount of metal cobalt, the quantitative amount of ferrocolumbium, the quantitative amount of ferrovanadium and the quantitative amount of ferrotitanium are loaded in an EAF electric arc furnace, and heated to the high temperature until all kinds of metal are molten; impurities of the molten steel are removed, the prepared molten steel is subject to temperature adjustment and refining for a period, and then, electrolytic aluminum and ferroboron are added to be subject to sufficient stirring and deoxidation treatment; the molten steel is poured, the prepared alloy molten steel is put into an LF ladle furnace to be cooled for a period, and then the molten steel is poured into a shaping mold, wherein a heating agent is added into a riser of the mold; alloy phase change treatment is carried out, the poured alloy is subject to heat preservation for 24 h to 30 h at the temperature of 1280 DEG C to 1300 DEG C, after the alloy is annealed, the alloy is rapidly cooled to 800 DEG C, then the alloy is shifted into a heat preservation furnace to be subject to phase change, and after the temperature rises to a certain temperature, forging heating is carried out; and the alloy is re-machined, and the forged alloy is subject to discharging, quenching and medium-temperature tempering. The manufactured alloy is low in cost.

Owner:SICHUAN JIANGYOU LIUHE STEAM TURBINE MATERIAL

Forging Method for Improving Transverse Impact Performance of Steel

ActiveCN104399854BLongitudinal performance does not degradeImprove lateral performanceMetal-working apparatusIngotSingle pass

The invention discloses a forging method for improving the lateral impact performance of a steel material. The forging method is characterized by comprising the following steps: (1) remelting an electroslag ingot; (2) producing forged steel by electroslag ingot forging, wherein the step of producing the forged steel by the electroslag ingot forging comprises the following steps:1) firstly, heating the electroslag ingot, and then, carrying out forging cogging according to a two-tampering two-pulling technology; (2) annealing a process blank; (3) after the process blank is heated and kept warm, forging a production material, wherein the total forging ratio of the production material is controlled to be above 4.0. The forging method has the beneficial effects that the electroslag ingot is subjected to single-pass big-reduction two-tampering two-pulling forging cogging, the isotropy and the lateral and longitudinal tissue evenness of the steel material can be drastically improved since tampering pulling forging is carried out for multiple times before the production material is forged, and the lateral performance of the steel material is drastically improved while the longitudinal performance of the steel material is not lowered. Since remelting heating heat insulation is carried out immediately when the forging pulling is finished one time, a forging pulling blank restores recrystallization by remelting so as to be favorable for next-time tampering pulling forging and grain refinement.

Owner:XINING SPECIAL STEEL

Tapered wedge and swing bolster elastic connection damping device for wagon bogie and bogie

ActiveCN111976771AImprove lateral performanceConvenient relative friction coefficientBogiesBogie-underframe connectionsVertical vibrationMortise and tenon

The invention discloses a tapered wedge and swing bolster elastic connection damping device for a wagon bogie and the bogie, solves the problems of low rhombus deformation resistance of the bogie andweak control capability between a swing bolster and a side frame due to vertical vibration and transverse vibration on a main friction surface in the prior art, and has the benefits of effectively improving the transverse performance of the bogie and improving the rhombus deformation resistance of the bogie. According to the specific scheme, the tapered wedge and swing bolster elastic connection damping device for the wagon bogie comprises the swing bolster, side frames and tapered wedges, the swing bolster is connected between the two side frames, the tapered wedges are arranged at the positions, where the side frames are arranged, of the swing bolster, and the tapered wedges are arranged between the swing bolster and the side frames; the tapered wedges are connected with the inner sidesof the side frames through mortise and tenon structures so that the tapered wedges can only move vertically, elastic pieces are arranged between the two side faces of each tapered wedge and the swingbolster and make contact with the tapered wedges and the swing bolster respectively, and damping springs are arranged on the bottom sides of the tapered wedges and the bottom side of the swing bolster.

Owner:CRRC SHANDONG CO LTD

High-speed rail vehicle bogie

PendingCN112356870ALight in massShortened axle lengthBogiesBogie-underframe connectionsSuspension (vehicle)Torsional rigidity

The invention discloses a high-speed rail vehicle bogie which is arranged in an inner axle box mode, a hinged framework is supported on the inner side of a wheel set, the curve passing performance ofthe bogie can be effectively improved, the hinged framework is of a double-T-shaped structure, the central axes of cylindrical beams of two T-shaped side beams coincide, one cylindrical beam stretchesinto the other cylindrical beam. Two bearings with a certain transverse span are arranged between the two T-shaped side beams, the two T-shaped side beams can rotate freely, the torsional rigidity ofthe bogie is zero, the uniform load capacity, the line adaptability, the curve trafficability and the high-speed operation stability of the bogie are enhanced. The contradiction between the operationstability and the curve trafficability of a traditional bogie is fundamentally solved, the two primary suspension devices are adopted, the positioning rigidity of the primary suspension devices in all directions can be determined by independent components, the positioning rigidity of the primary suspension devices in all directions can be optimal at the same time, and parameters are more accurateand reliable.

Owner:SOUTHWEST JIAOTONG UNIV

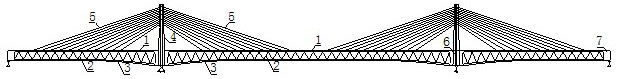

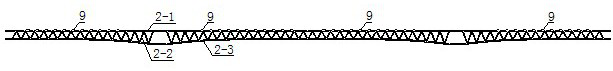

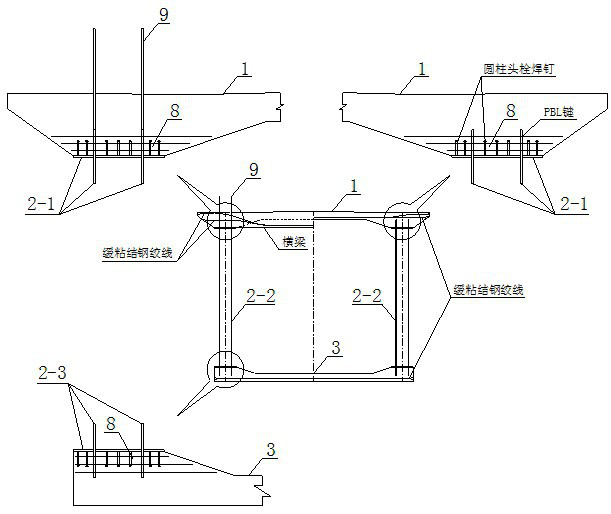

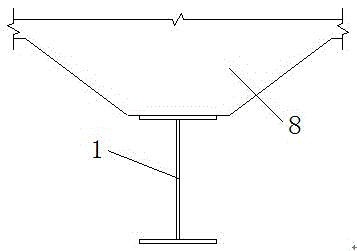

Partial cable-stayed bridge of steel truss web type concrete composite beam and construction method thereof

PendingCN111893861AImprove lateral performanceStrong self-respectCable-stayed bridgeTruss-type bridgePre stressArchitectural engineering

The invention discloses a partial cable-stayed bridge of a steel truss web type concrete composite beam and a construction method thereof. The cable-stayed bridge comprises main beams, each main beamcomprises a tower beam consolidation area, a beam end area and a steel truss web area, a main tower is arranged at the tower beam consolidation area, stay cables are arranged between the main tower and the main beams, each main beam steel truss web area comprises a concrete top plate and a concrete bottom plate, and a steel truss web is arranged between the concrete top plate and the concrete bottom plate. The construction method comprises the steps of assembling the steel truss web sections; hanging stay cables between the main tower and the main beams, and completing initial tensioning; pouring a concrete top plate by taking the steel truss web sections as supports of a cast-in-place platform; pouring a concrete bottom plate by taking the steel truss web sections as a support of the cast-in-place platform; curing the concrete top plate and the concrete bottom plate; tensioning the transverse retard-bonded prestressed steel beams; and carrying out next section construction. The earthquake working condition applicability of a traditional concrete partial cable-stayed bridge is broadened, and the cable-stayed bridge has wide application prospects in large-span bridges in high-intensity earthquake areas.

Owner:CHINA RAILWAY DESIGN GRP CO LTD

A method for manufacturing a 7-series aluminum alloy profile for the upper girder of a civil aircraft wing

ActiveCN111676399BImprove lateral performanceReduce residual stressExtrusion control devicesIncreasing energy efficiencyStructural engineeringIngot

Owner:SHANDONG NANSHAN ALUMINUM +1

Process for producing thin gauge pipeline steel by using double-stand medium and heavy plate mill

ActiveCN102671941BGuaranteed Dynamic RecrystallizationImprove lateral performanceTemperature control deviceWork treatment devicesMetallurgyLaminar cooling

The invention discloses a process for producing thin gauge pipeline steel by using a double-stand medium and heavy plate mill. A plate blank with the thickness of 180 mm is used for producing the thin gauge pipeline steel with the thickness less than 10 mm. On the basis that the performance of a rolled piece meets requirements, the thin gauge pipeline steel with a good plate shape can be obtained by controlling the tapping temperature of the plate blank, the rough rolling broadening pass pressing rate, the longitudinal rolling pass pressing rate after rough rolling broadening pass, the rough rolling finishing temperature, the thickness of a middle blank, the finish rolling ending pass pressing rate, the finish rolling finishing temperature, the roller gap inclination and sled function in the rolling process, a high pressure water descaling system, the water entry temperature, the re-reddening temperature, and the head and tail shielding and straightening process of a laminar cooling system. The deformation rate is reduced, and the economic benefit is increased.

Owner:NANJING IRON & STEEL CO LTD

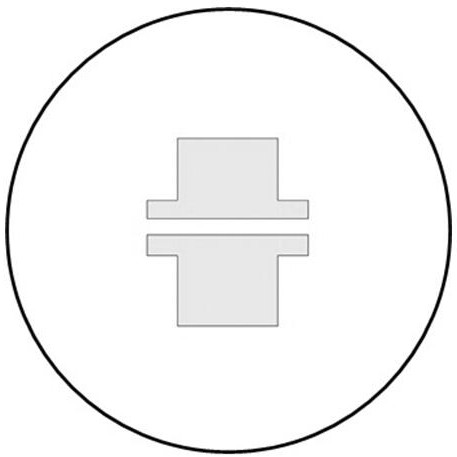

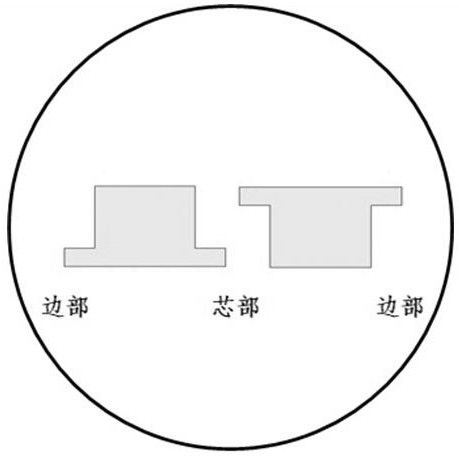

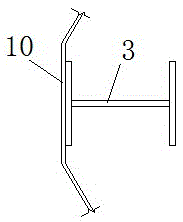

A truss-type steel transverse diaphragm of a corrugated steel web cable-stayed bridge

ActiveCN104631305BFirmly connectedEnhanced lateral connectionsCable-stayed bridgeTruss-type bridgeGusset plateCable stayed

The invention discloses a truss-type steel diaphragm plate of a corrugated steel web cable-stay bridge. An upper steel beam of the truss-type steel diaphragm plate is connected with concrete in the upper portion a top plate of a box beam through a shear stud. The two ends of the upper steel beam of the truss-type steel diaphragm plate are hinged to a steel anchor box in a cable anchor area. The bottom of a lower steel beam is connected with concrete in the lower portion of a bottom plate of the box beam through a shear stud. Corrugated steel webs are arranged between the upper steel beam and the lower steel beam. A box chamber structure is formed by enclosing the corrugated steel webs, the upper steel beam and the lower steel beam. The two ends of inclined webs and a vertical web are welded to the upper steel beam and the lower steel beam respectively. One sides of the inclined webs and the vertical web are connected with the corrugated steel webs in a welding mode. Due to the fact that inclined webs and a vertical rod are welded to gusset plates, the truss-type structure is formed by the inclined webs and the vertical rod. The truss-type steel diaphragm plate is arranged on a stayed-cable of the steel web cable-stay bridge and the main beam anchoring area, the horizontal connection of the corrugated steel web cable-stay bridge is enhanced, the torsional stiffness of a main beam is enhanced, the horizontal whole performance is effectively improved, the construction is convenient, the quality is guaranteed, and the bridge service life is prolonged.

Owner:ZHENGZHOU COMM PLANNING SURVEY & DESIGN INST

Manufacturing method of cold forming high intensity steel for welded structure

InactiveCN1273635CEasy to operate in large productionAdapt to mass production requirementsCold formedRare earth

This invention relates to a production method for cold forming high intensity welded construction steel taking low carben-Mn as the basis, added by Nb, Ti microalloy as the main composition and applying melted iron desulfurization technology, converter top and bottom combined blowing and vacuum process, among which, the melted steel is casted to slab after rare earth or Ca to be casted to slab process then to be rolled to cut deal or hot rolled plate by cut deal production technology or the hot tandem rolling technology.

Owner:武钢集团有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com