Forging method for improving lateral impact performance of steel material

A technology of transverse impact and high performance, which is applied in the forging field of steel and improves the transverse impact performance of steel. It can solve the problems of low transverse impact and unstable transverse and longitudinal mechanical properties of bars, and achieve high transverse impact energy and isotropy. and the effect of improving the uniformity of the transverse and longitudinal structures and refining the grains

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

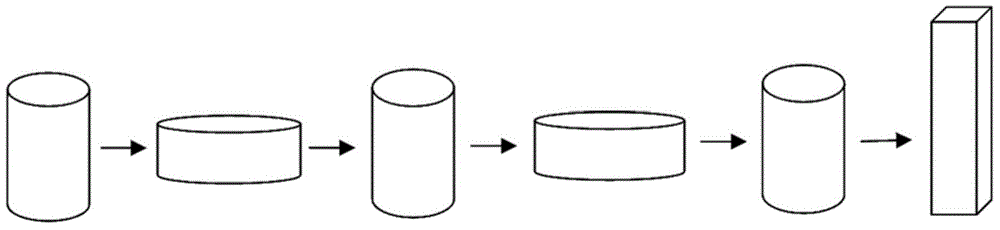

[0032] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

[0033] 1. Remelting of electroslag ingot

[0034] The blank adopts Ф240mm forged consumable electrode blank.

[0035] The heavy melting slag is pre-melting slag, and the amount of slag is 65kg.

[0036] Deoxidizer: CaC 2 300g, 300g of Al powder, and 250g of Ca-Si powder are mixed evenly, and 100g of deoxidizer is added for every 120kg of consumable electrode blank.

[0037] The remelted ingot shape is Ф430mm, the electroslag ingot is sawed at both ends, and the ingot height is controlled at 700-800mm.

[0038] Power system: voltage 68-70V, current 8500±500A.

[0039] Melting speed control: 3.5kg / min-4.0kg / min.

[0040] Electroslag remelting equipment: 10t double-arm exchange electrode electroslag furnace.

[0041] During the electroslag remelting process, an automatic feeder is used to evenly add powdered deoxidizer to the crystalli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com