A truss-type steel transverse diaphragm of a corrugated steel web cable-stayed bridge

A corrugated steel web and truss-type technology, which is applied to cable-stayed bridges, truss bridges, bridge forms, etc., can solve problems such as poor torsional rigidity, and achieve the effects of cable force transmission, enhanced torsional rigidity, and easy implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

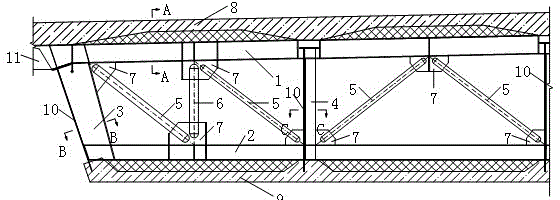

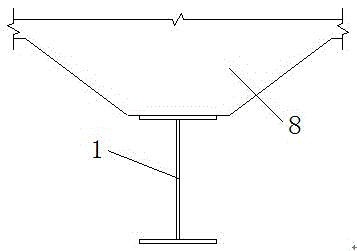

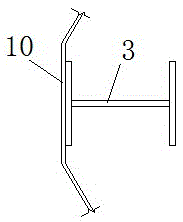

[0025] see attached figure 1 , figure 2 , image 3 and Figure 4 , The present invention provides a truss-type steel diaphragm of a corrugated steel web cable-stayed bridge, which includes an upper steel beam 1, a lower steel beam 2, an inclined web 3, a vertical web 4, an inclined web rod 5, and a vertical rod. 6 and the gusset plate 7; the top surface of the upper steel beam 1 is connected with the concrete of the box girder roof 8 through shear nails, and its two ends are welded to the steel anchor box 11 in the cable anchoring area, and the two ends of the upper steel beam 1 are anchored with the stay cables The steel anchor box in the area is welded to form a transverse force transmission system, which effectively realizes the transmission of cable force. 1. Between the lower steel beam 2, the upper steel beam 1 and the lower steel beam 2 form a box room structure, and a truss-type steel diaphragm is set at the anchorage area of the cable-stayed cable and the main b...

Embodiment 2

[0028] see attached figure 1 , figure 2 , image 3 and Figure 4 , The present invention provides a truss-type steel diaphragm of a corrugated steel web cable-stayed bridge, which includes an upper steel beam 1, a lower steel beam 2, an inclined web 3, a vertical web 4, an inclined web rod 5, and a vertical rod. 6 and the gusset plate 7; the top surface of the upper steel beam 1 is connected to the box girder top plate 8 concrete through shear nails, and both ends are welded to the steel anchor box 11 in the cable anchoring area, and the bottom surface of the lower steel beam 2 is connected to the box through shear nails. The beam bottom plate 9 is connected with concrete, and the corrugated steel web plate 10 is arranged between the upper steel beam 1 and the lower steel beam 2, and forms a box room structure with the upper steel beam 1 and the lower steel beam 2, and the inclined web 3 is connected to the vertical web. The upper and lower ends of the plate 4 are respecti...

Embodiment 3

[0031] see attached Figure 5 , The structural composition and construction process of the truss-type steel diaphragm are similar to those in Example 1, except that the beam height of the constant-section box girder is changed from 4.5m to 5.0m.

[0032] Technical effect analysis:

[0033] In order to further study the positive and beneficial effects of the present invention theoretically, taking a long-span corrugated steel web cable-stayed bridge as an example, two finite element models were established before and after the bridge was installed with truss-type steel diaphragms. Under the working conditions, the torsion angle of the main girder in the span of the two models is calculated, and its natural vibration characteristics are analyzed. The results show that the first-order transverse frequency of the bridge is increased by about 20% after the truss-type steel diaphragm is installed, and the torsion angle of the main girder in the middle of the bridge span is reduced ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com