Patents

Literature

1040 results about "Gusset plate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Gusset plate is a plate for connecting beams and girders to columns. A gusset plate can be fastened to a permanent member either by bolts, rivets or welding or a combination of the three. Gusset plates not only serve as a method of joining steel members together, but also strengthen the joint. They are used in bridges and buildings, as well as other structures.

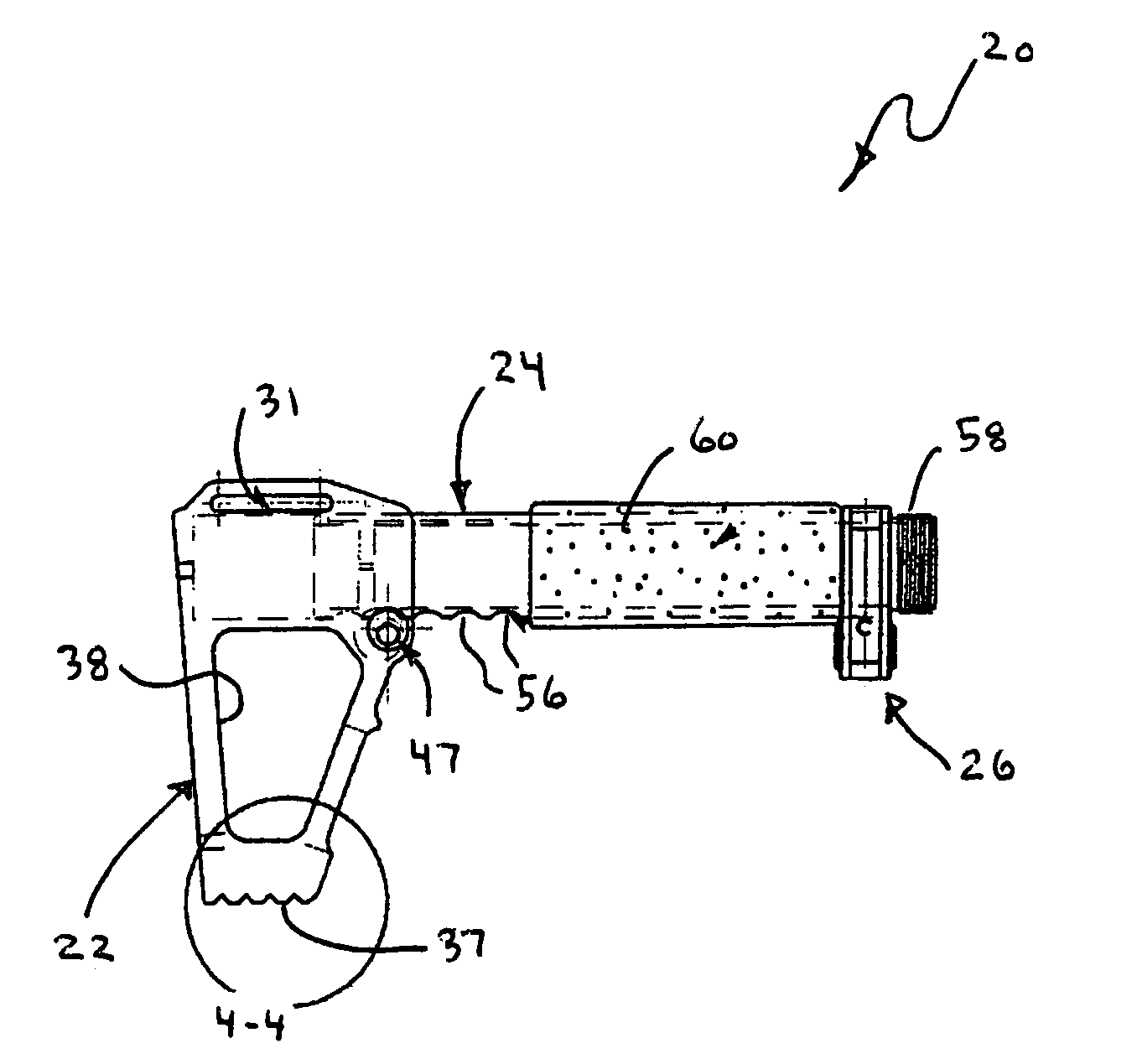

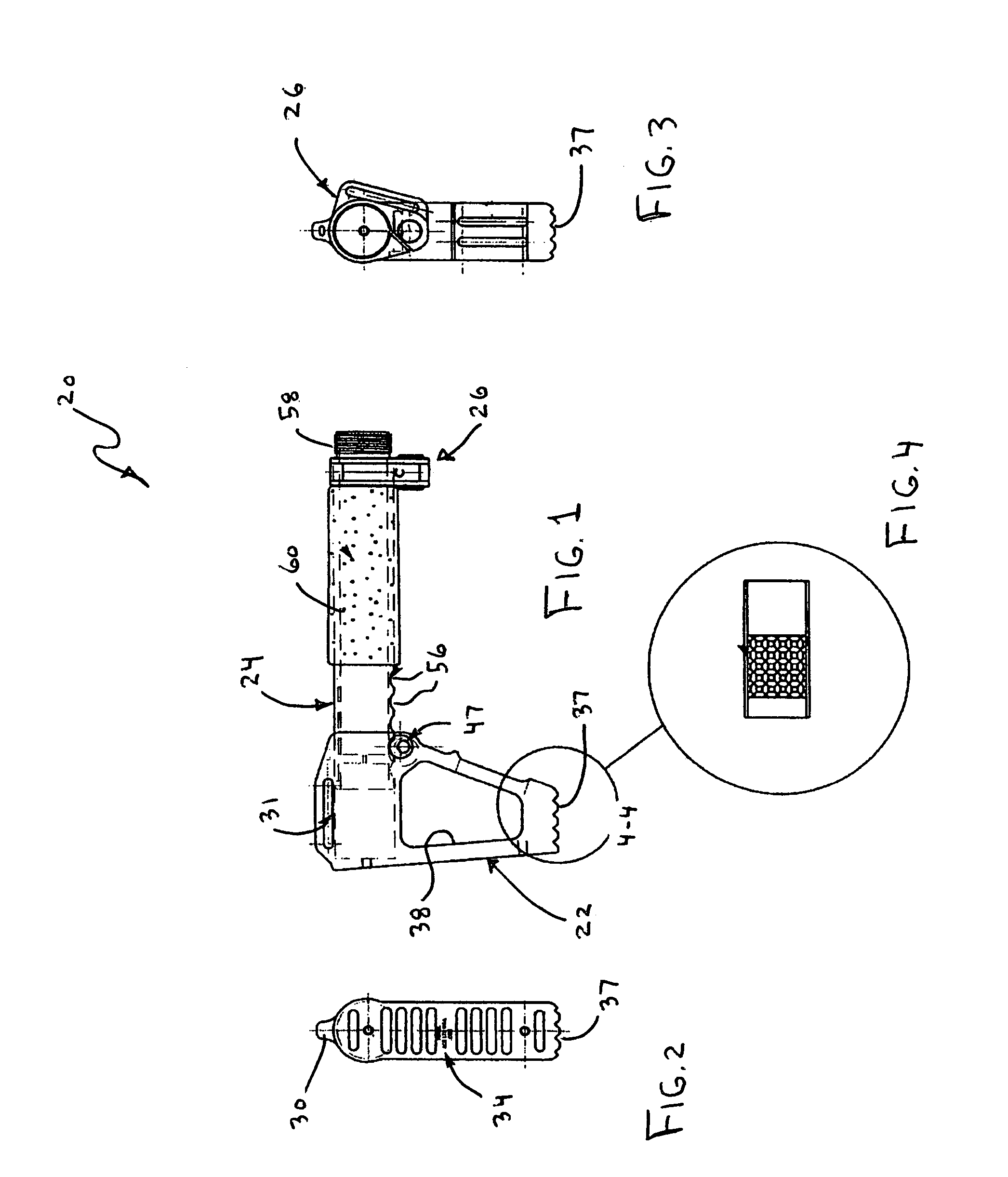

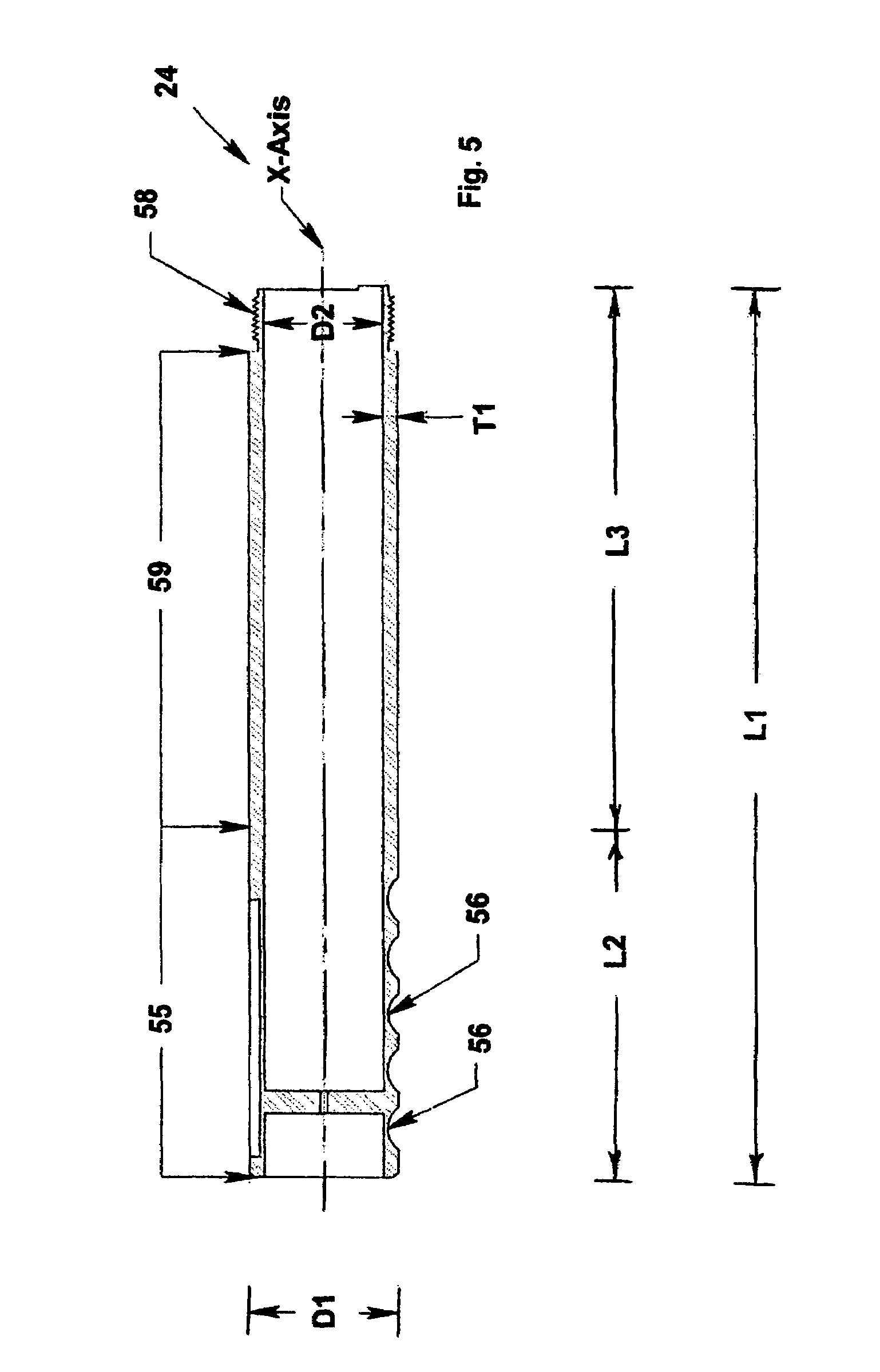

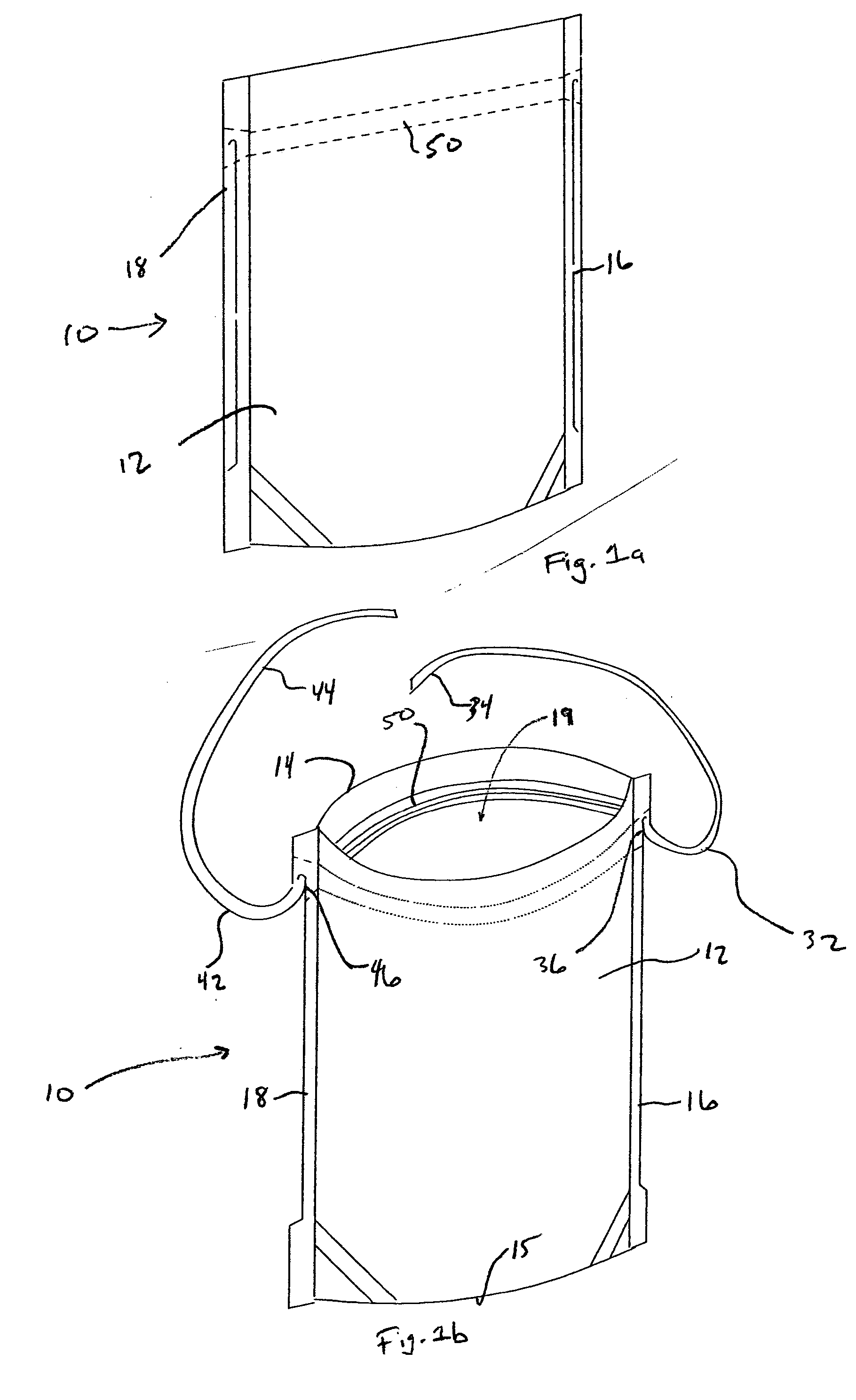

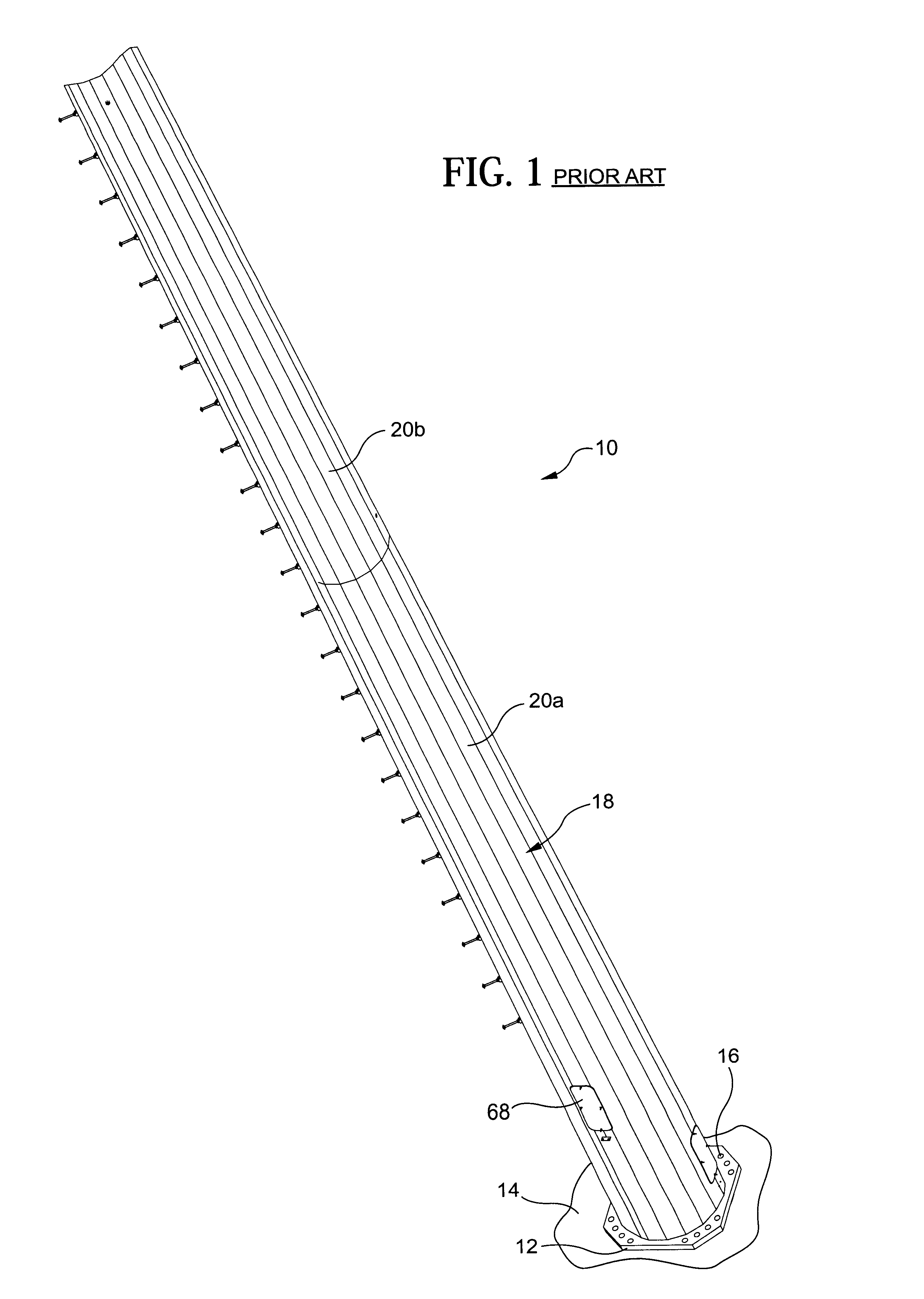

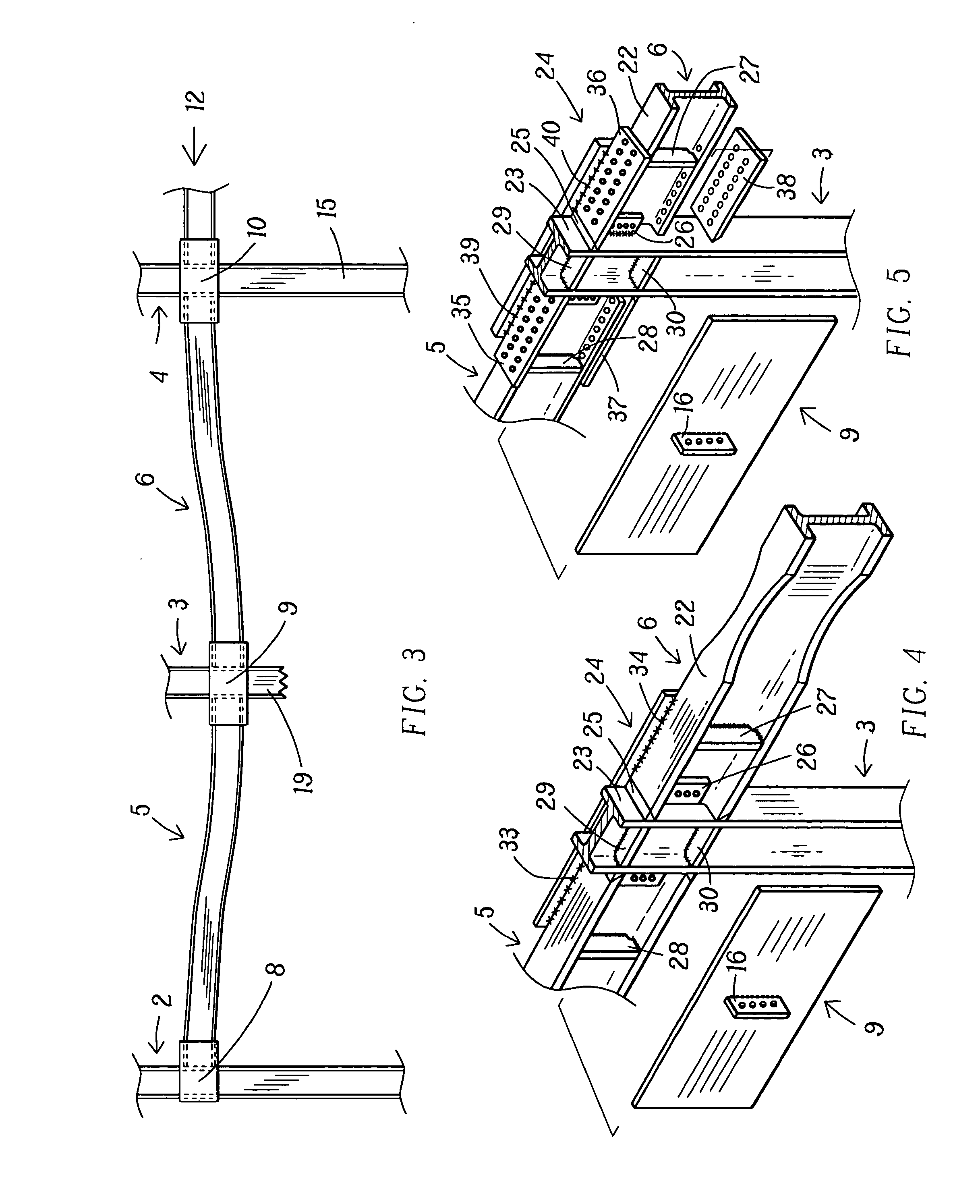

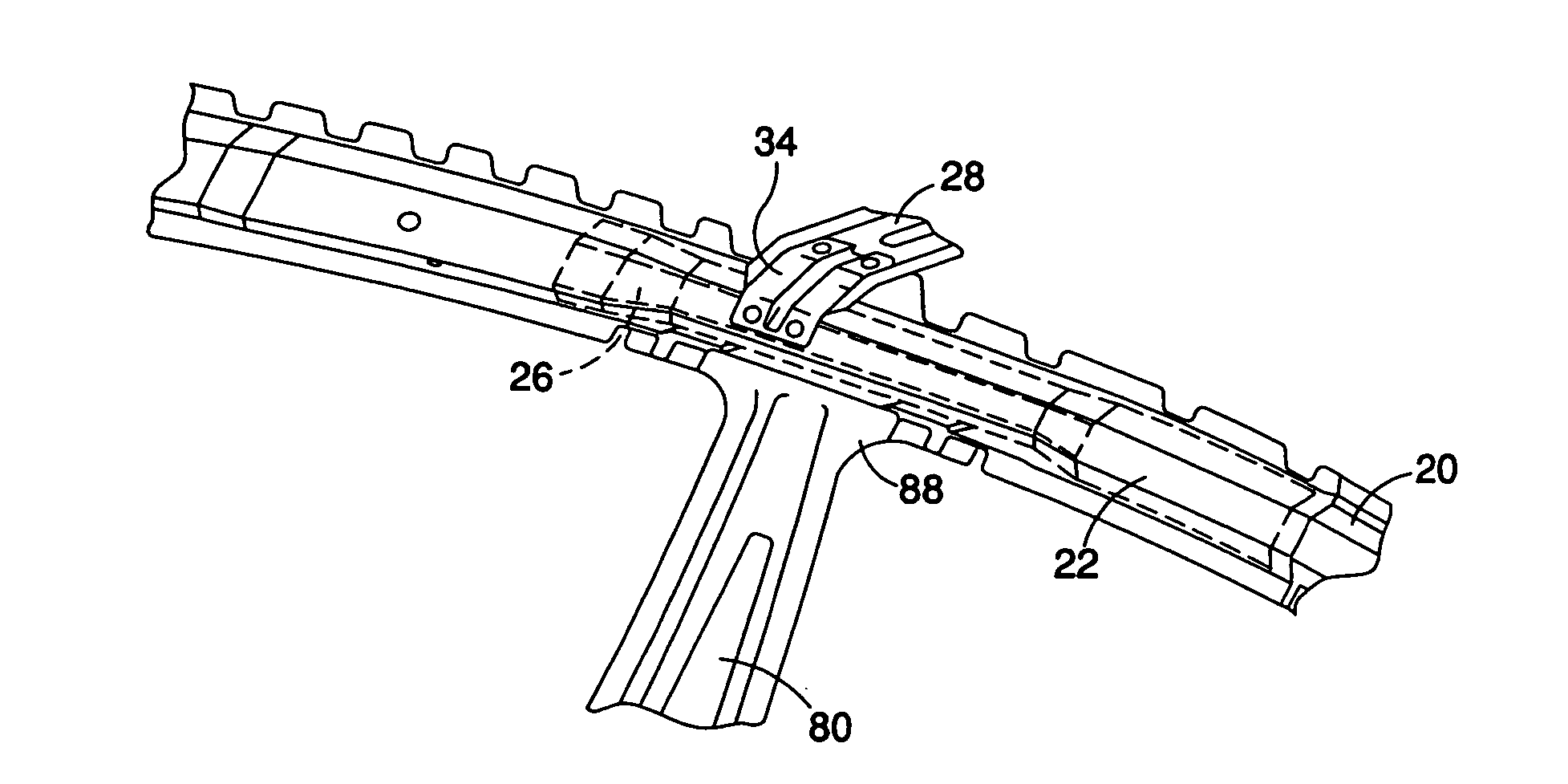

Adjustable length heavy duty butt stock assembly for a firearm

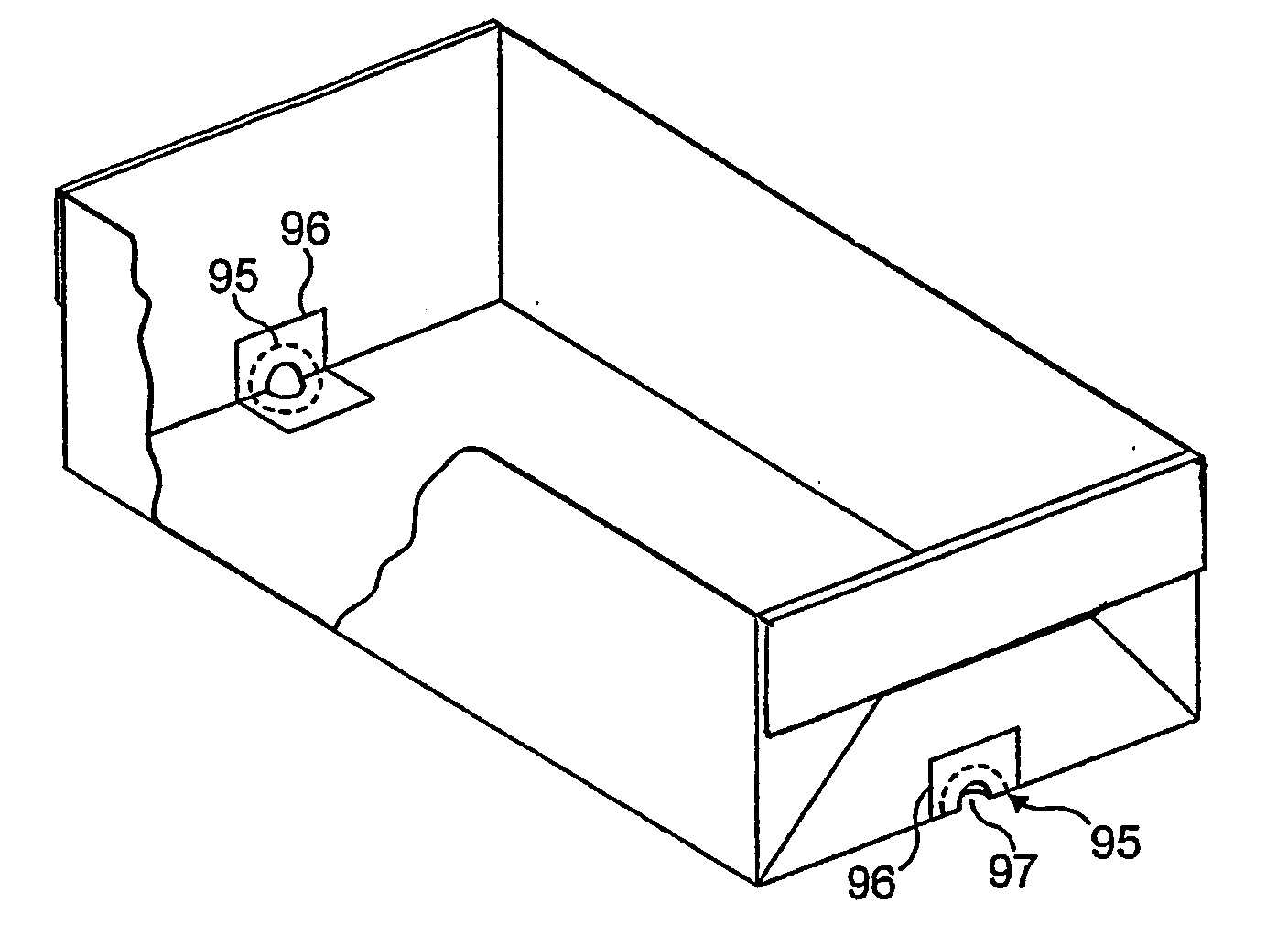

A heavy-duty adjustable length butt stock assembly for a firearm such as an AR15 rifle or any other firearm that is made to accept an AR15 butt stock. The stock is designed to be stronger than any existing production AR15 butt stock. The butt stock has three major components, the butt, the receiver extension tube and the clamping gusset The front end of the butt stock has a primary bore hole that extends inwardly from its front end to the rear end of the butt stock. The receiver extension tube is telescopically received in the primary bore hole. An adjustment push button lock extends inwardly from one of the lateral sides of the butt stock and it actuates locking plunger pin that can mate with various longitudinally spaced transversely extending grooves on the bottom surface of the receiver extension tube. Various sling mount structures can be formed on the butt stock or on a clamping gusset that is removably inserted over the receiver extension tube adjacent its front end.

Owner:J & T MUNITIONS

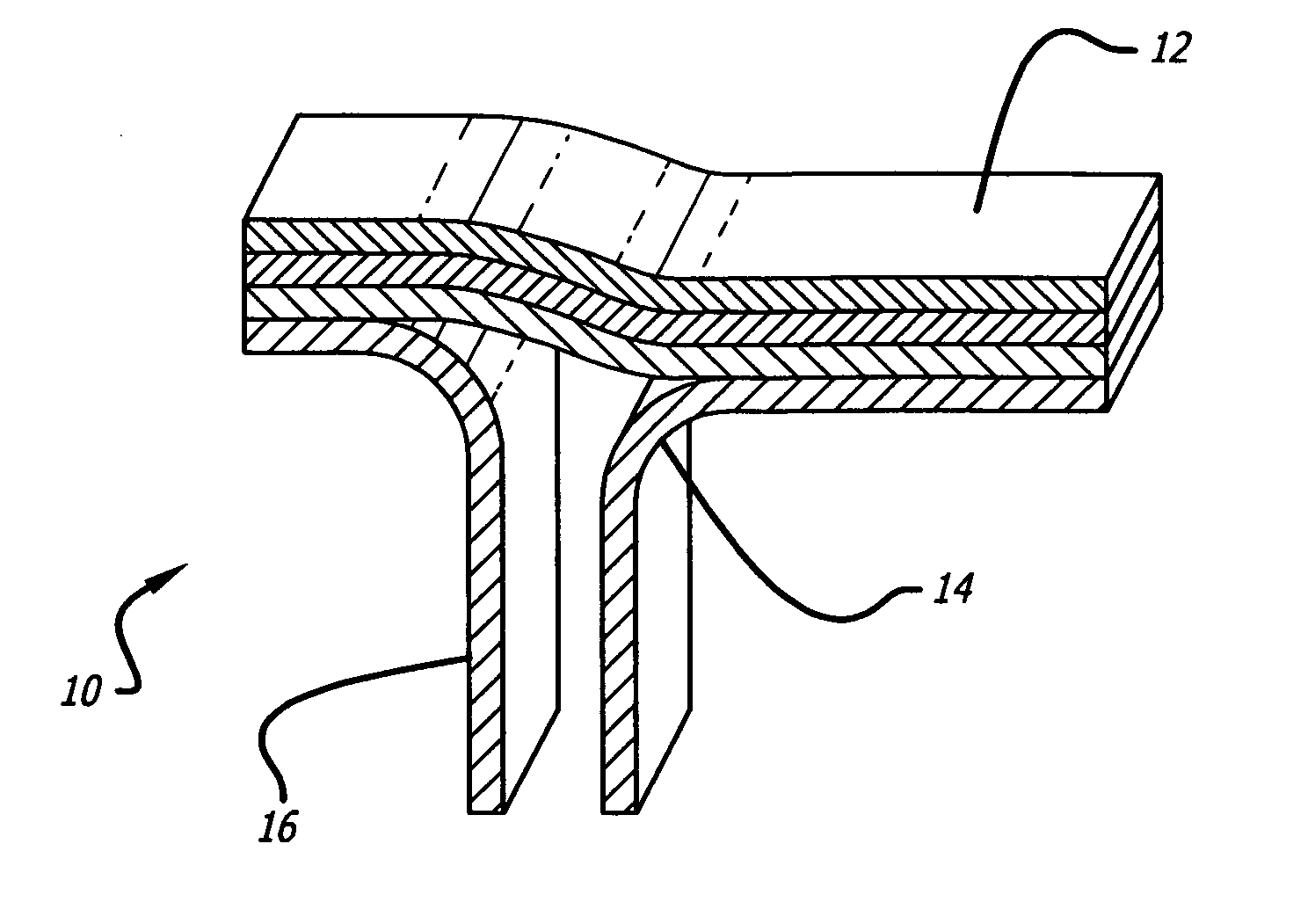

Gusset plates connection of beam to column

InactiveUS6591573B2Improve rendering capabilitiesImprove stabilityBuilding roofsArched girdersGusset plateEngineering

This invention relates to columnar, "primary support" for a building or other heavy structure, in which a beam is connected to a column in a strong, moment-resisting connection comprised of two gusset plates welded to a flange or the face of the flange of the column and welded to the beam or attached to cover plates fixedly attached to the beam.

Owner:MITEK HLDG INC

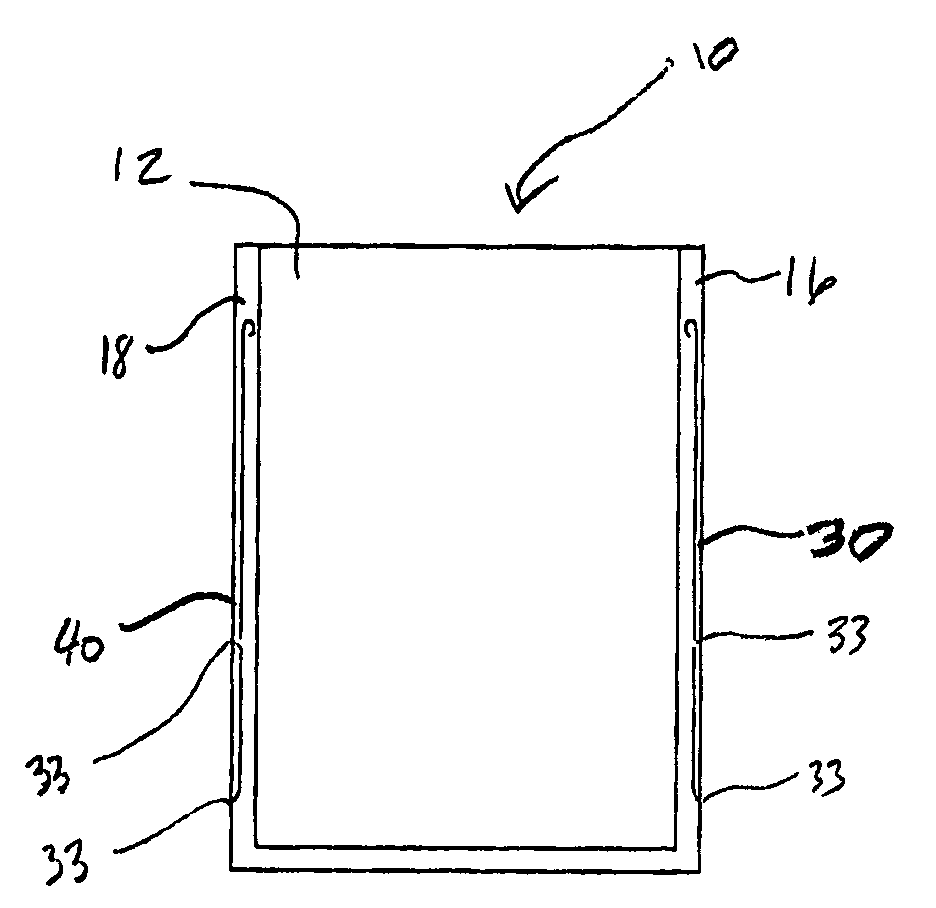

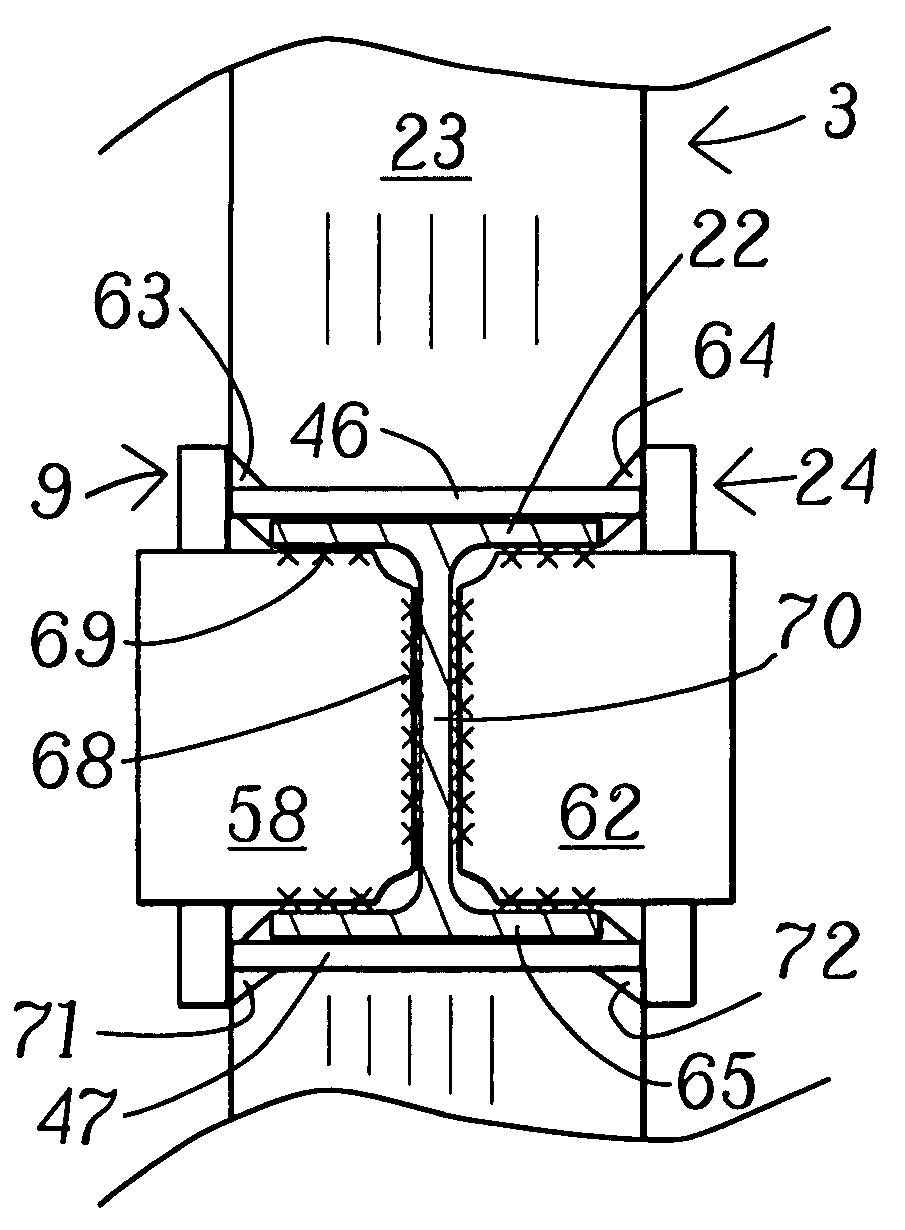

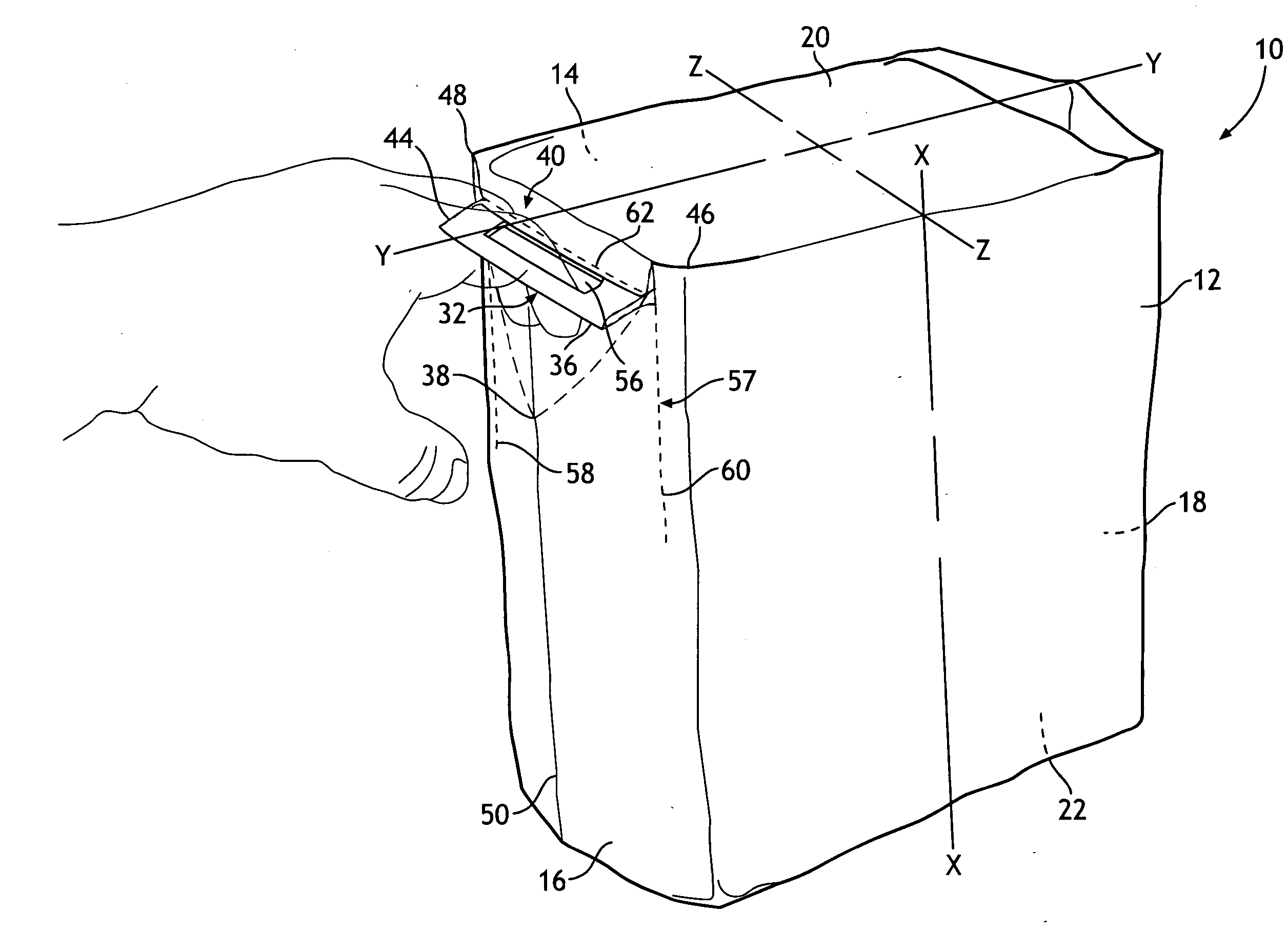

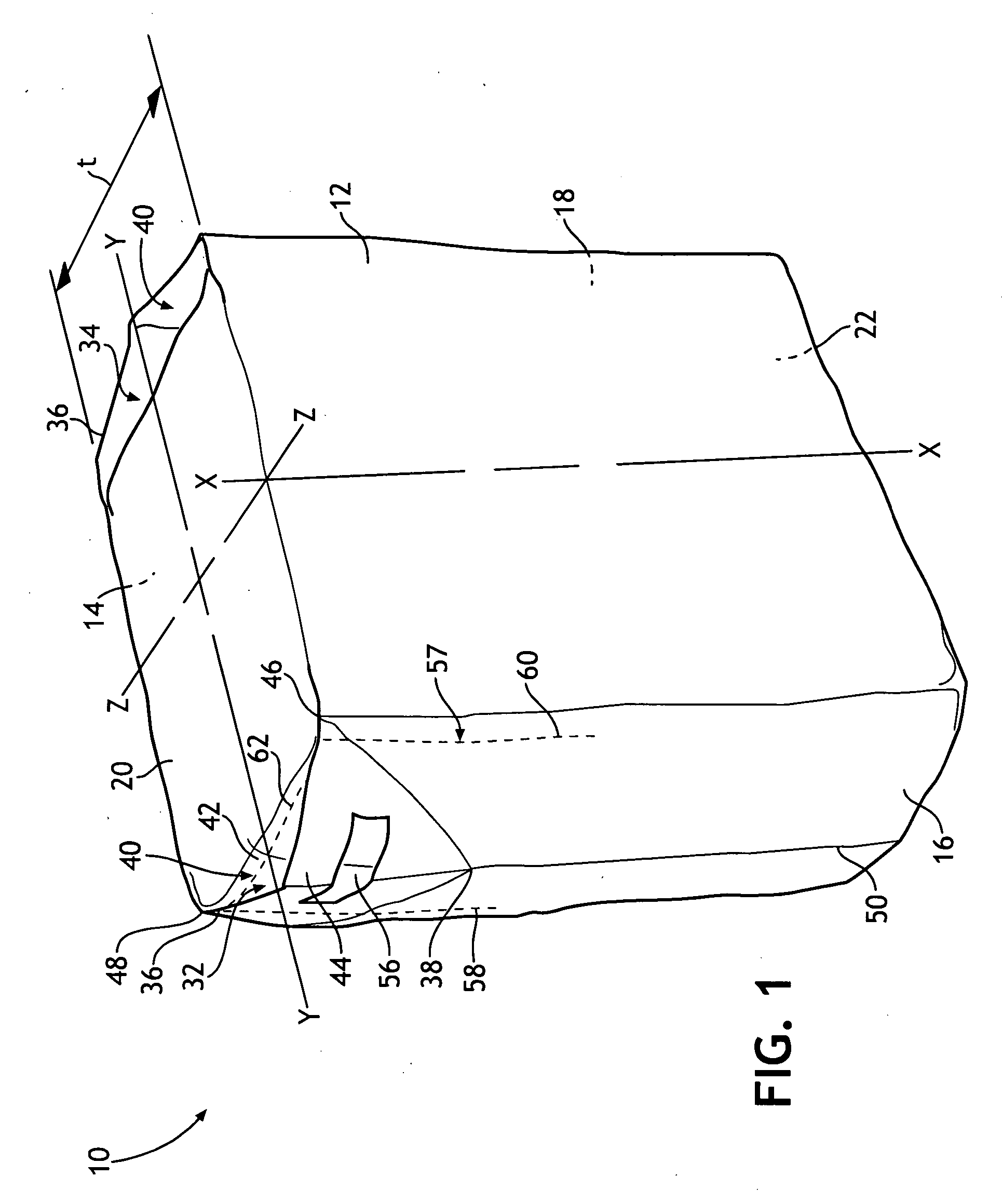

Flexible package having integrated slit member

A flexible package having front, back, and bottom panel portions (preferably gusseted). The front and back panel portions each preferably include longitudinal edges that can be joined together to create respective side seals. Each of the respective side seals can include a slit portion having a slit member. The slit member preferably includes a detachment portion and an anchor portion. The detachment portion of the slit member is detachable from a portion of the side seal to provide a tie or a looped handle for use in tying and / or handling the flexible package. The anchor portion provides support and reinforcement to prevent complete detachment of the slit member.

Owner:STEELE MARK

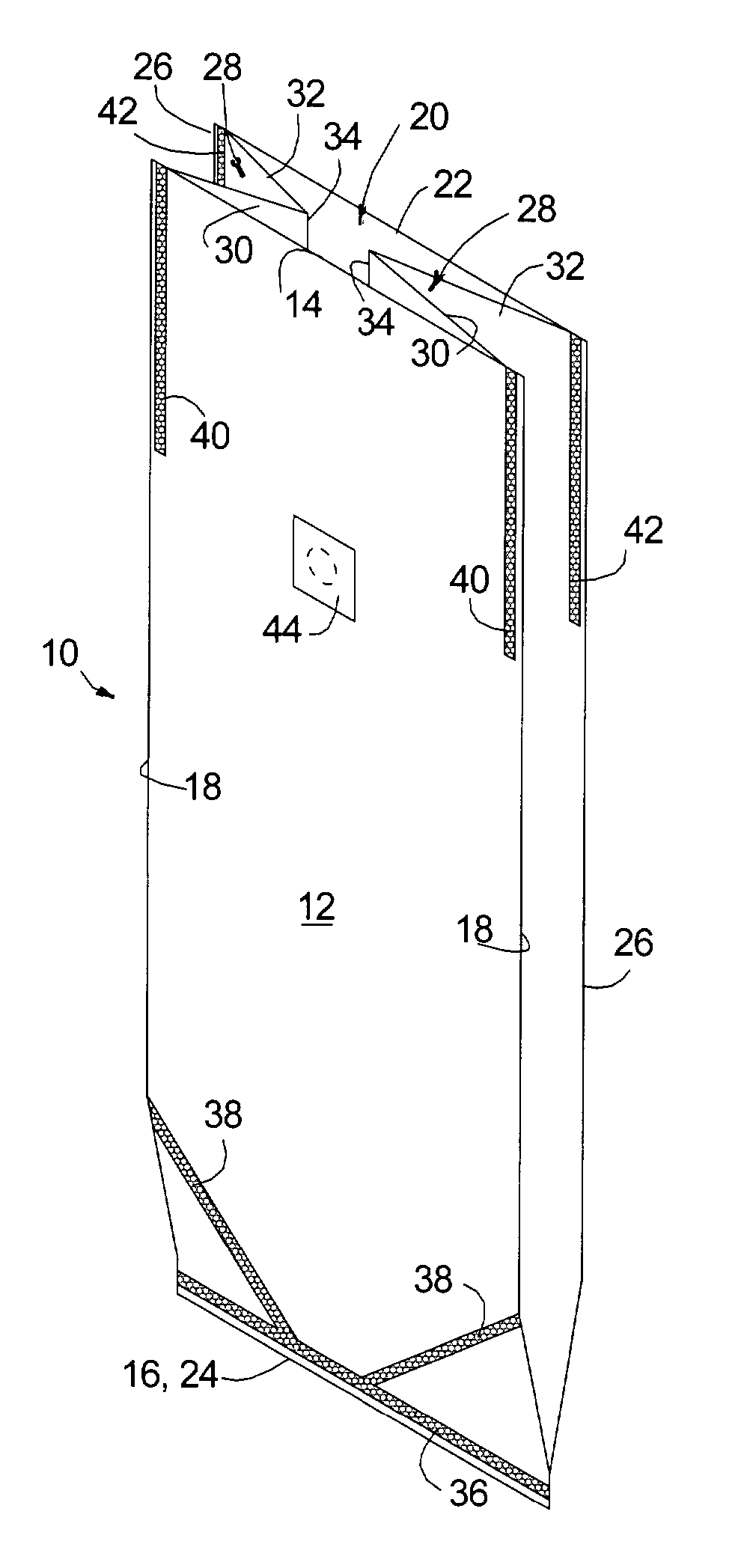

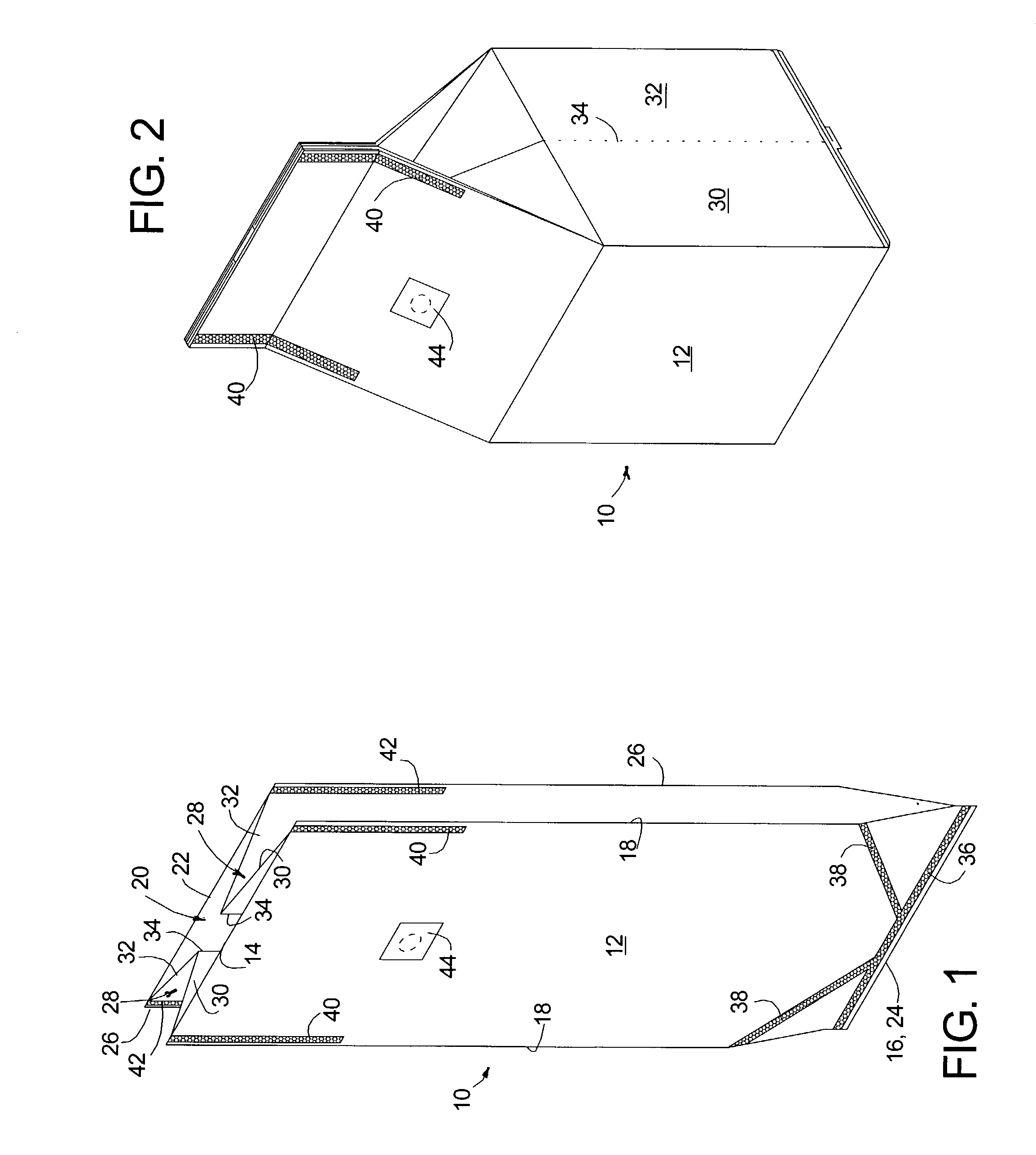

Flexi-resilient to rigid container including vertically hinged sides

An erectable and collapsible container including a plurality of side walls joined along a plurality of wall hinges providing articulation between the side walls. A bottom wall is attached to the side walls at edge hinges providing articulation between the side walls and the bottom wall. At least one flexible gusset portion is provided extending between one or more of the side walls and the bottom wall, and the gusset portion is movable with the bottom wall in response to movement of the side walls and the bottom wall between collapsed and erected configurations. Structure is provided for maintaining the side walls in the erected configuration such that the side walls define a generally rigid or semi-rigid structure. A pair of opposed flexible panels extend from the side walls and define a bag-like upper portion extending from the support structure and forming a sealable opening for the container.

Owner:THE PROCTER & GAMBLE COMPANY

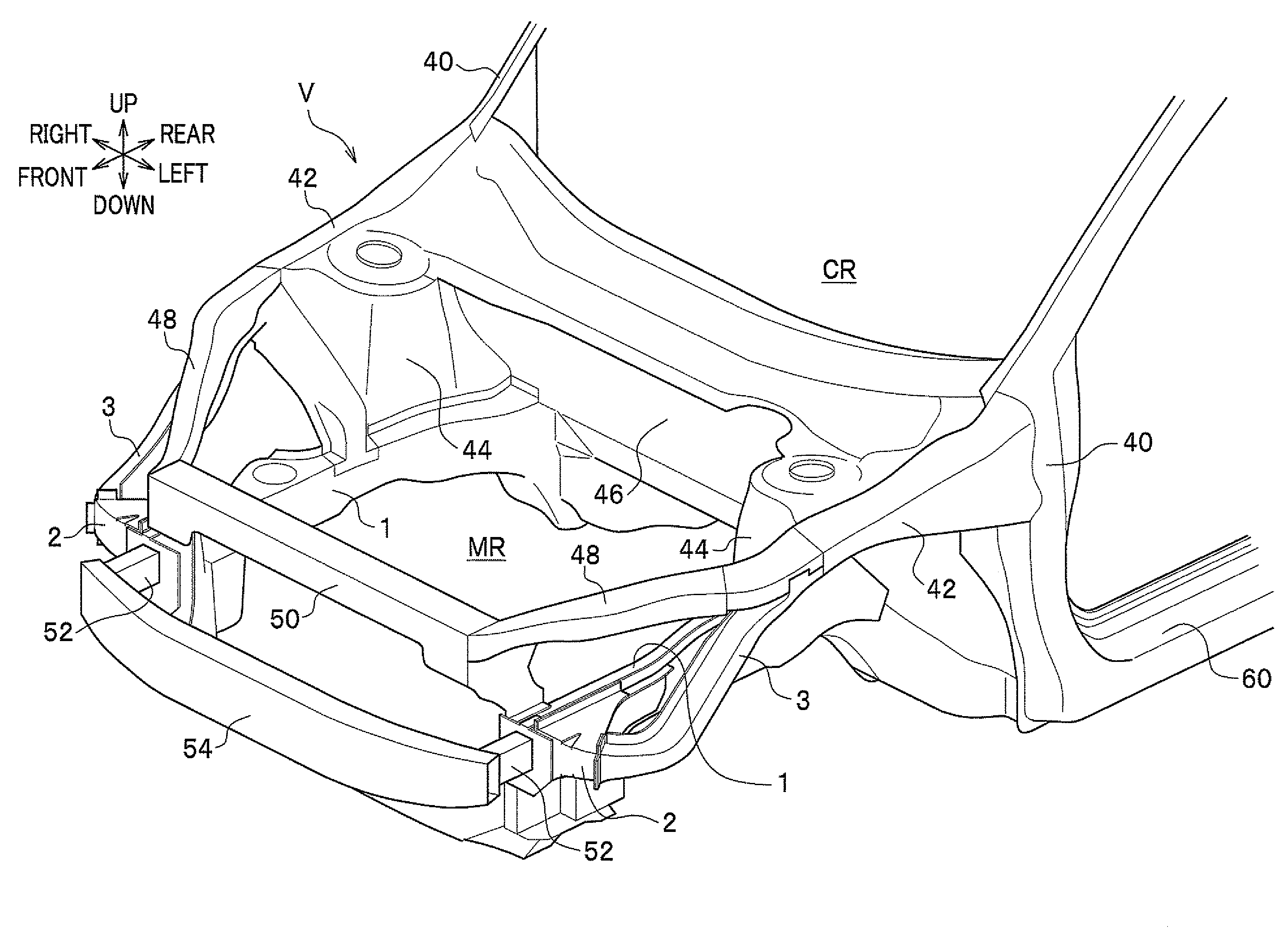

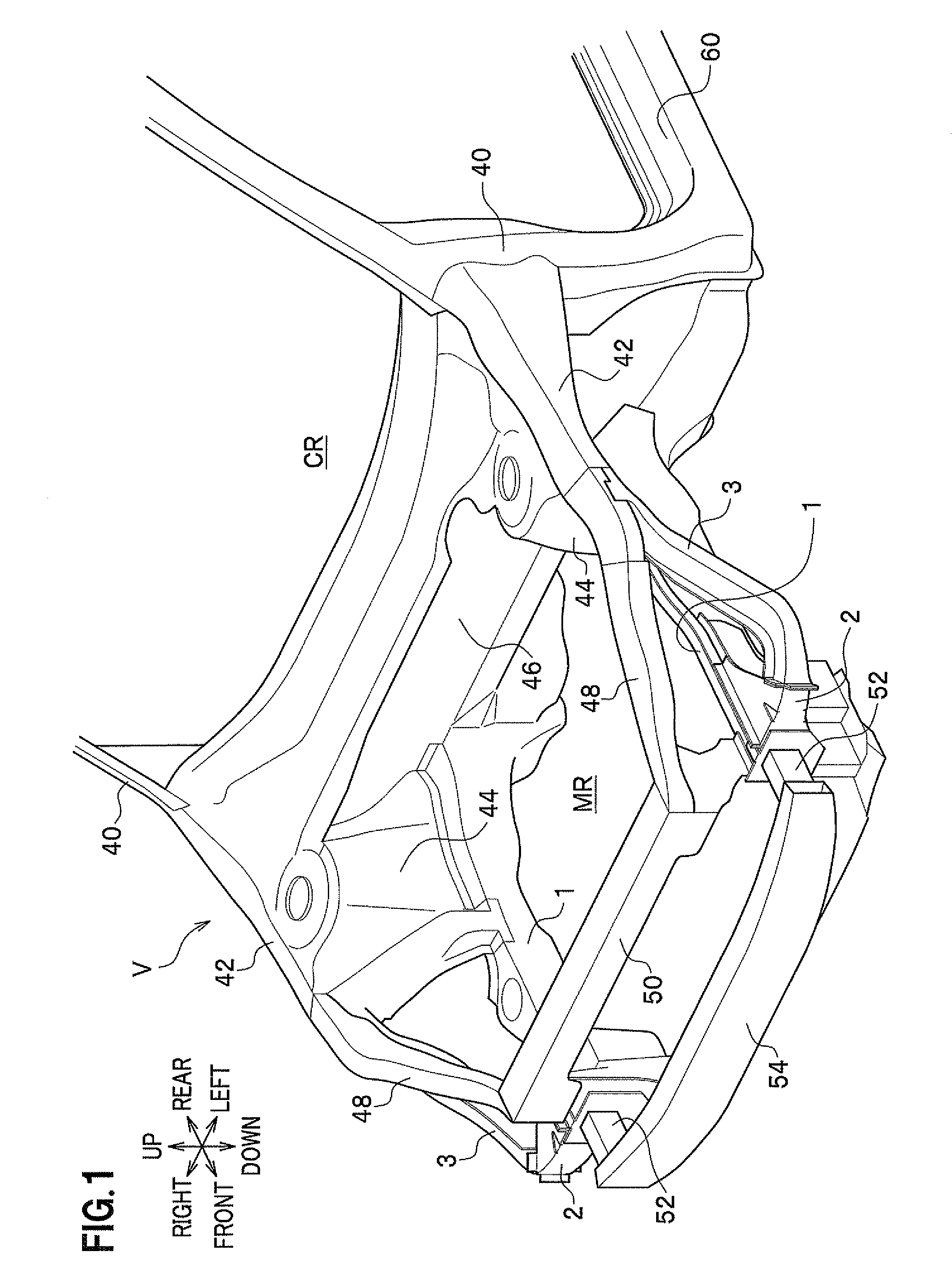

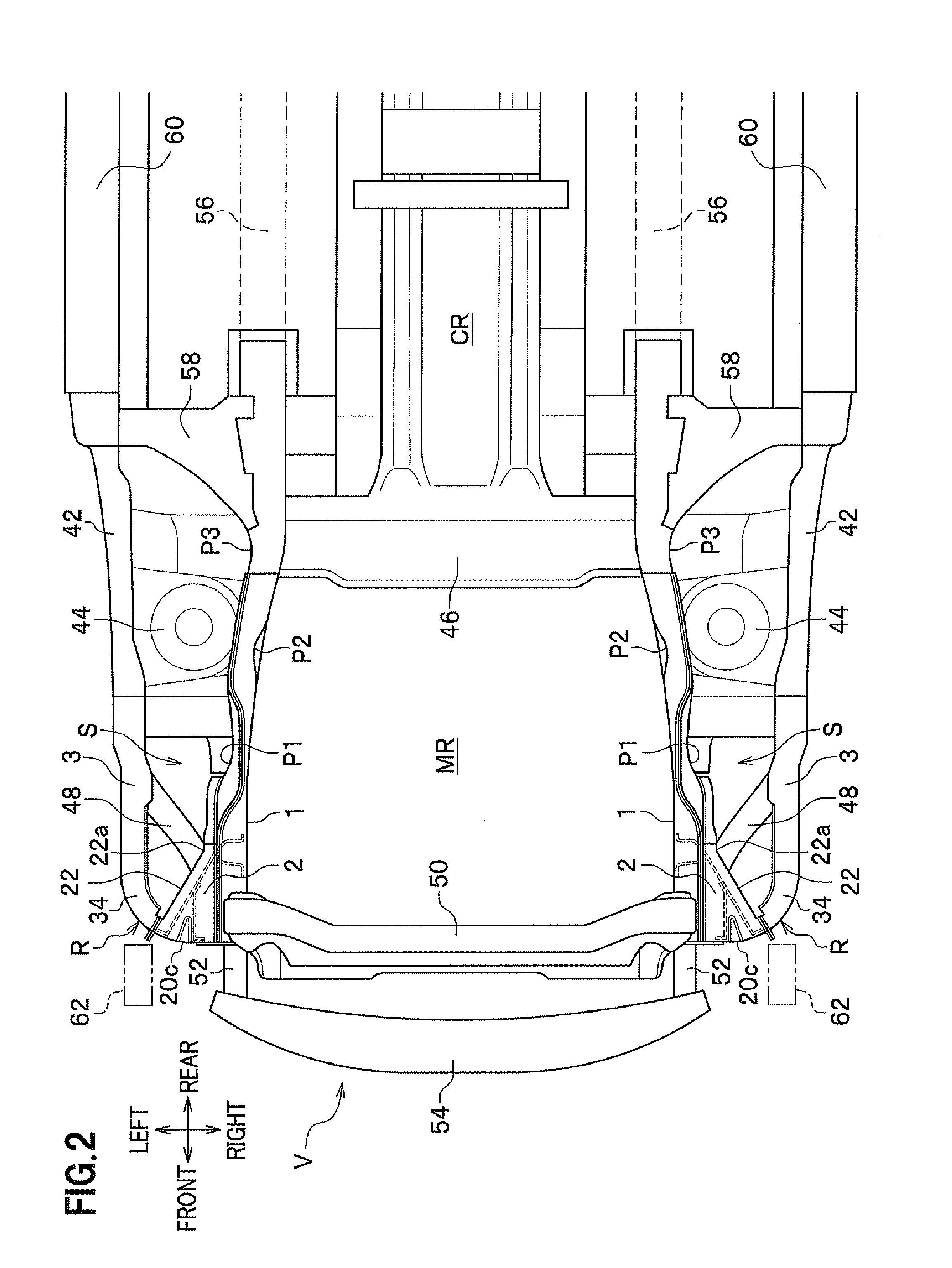

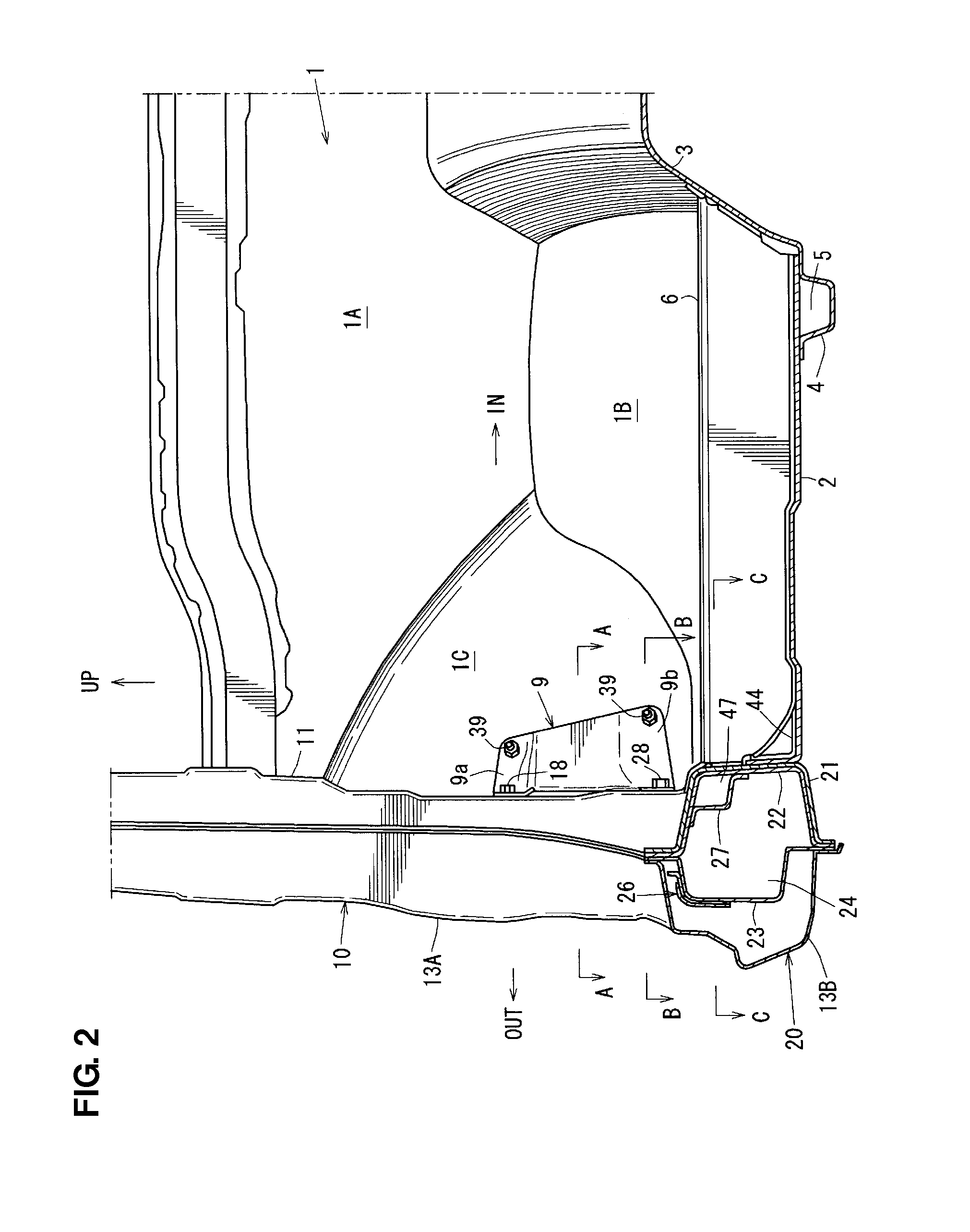

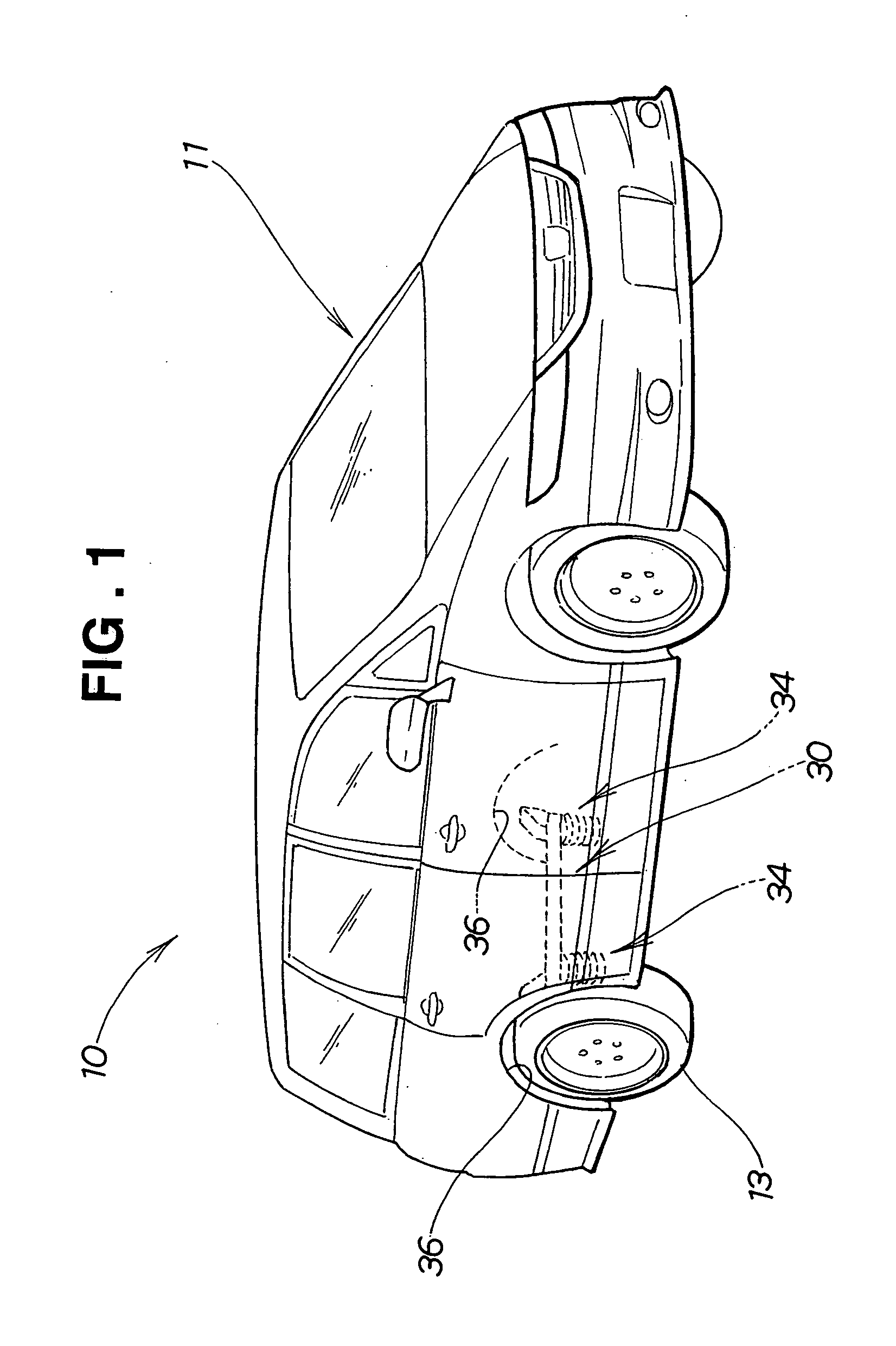

Vehicle body front structure

ActiveUS20130241233A1High strengthImprove rigidityVehicle seatsUnderstructuresGusset plateEngineering

A vehicle body front structure includes: a front side frame; a lower member placed at an outer side of the front side frame in the vehicle width direction; and a gusset placed between the front side frame and the lower member. The front side frame includes a first bending point which absorbs an impact load by being bent by receiving impact load upon a collision of the vehicle. An inner side of the gusset in the vehicle width direction is joined to the outer side of the front side frame in the vehicle width direction and extends from a front end of the front side frame to a first bending point. A tapered part which is inclined toward the front side frame as extending backward from the front end of the gusset is formed in an outer side of the gusset in the vehicle width direction.

Owner:HONDA MOTOR CO LTD

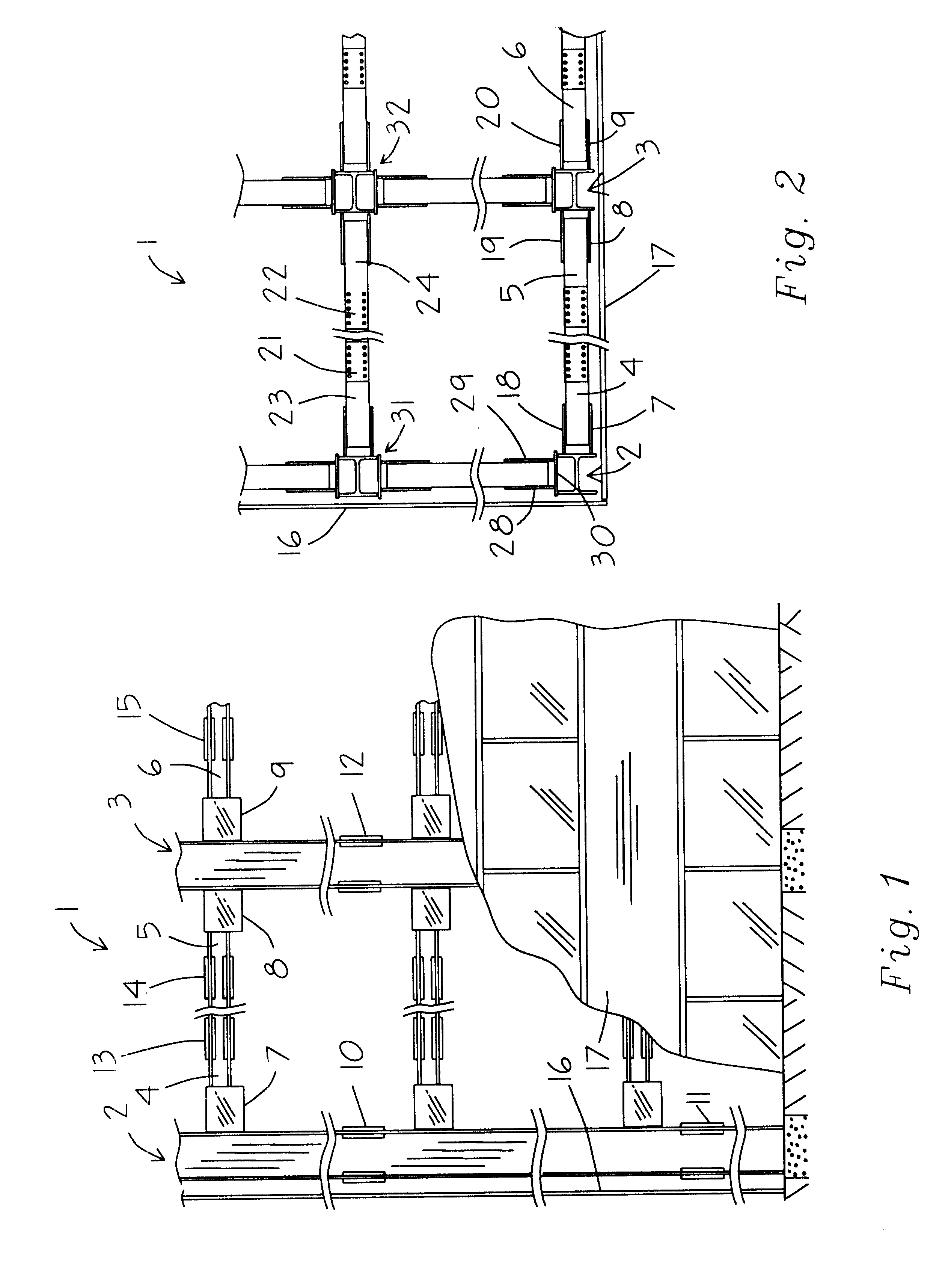

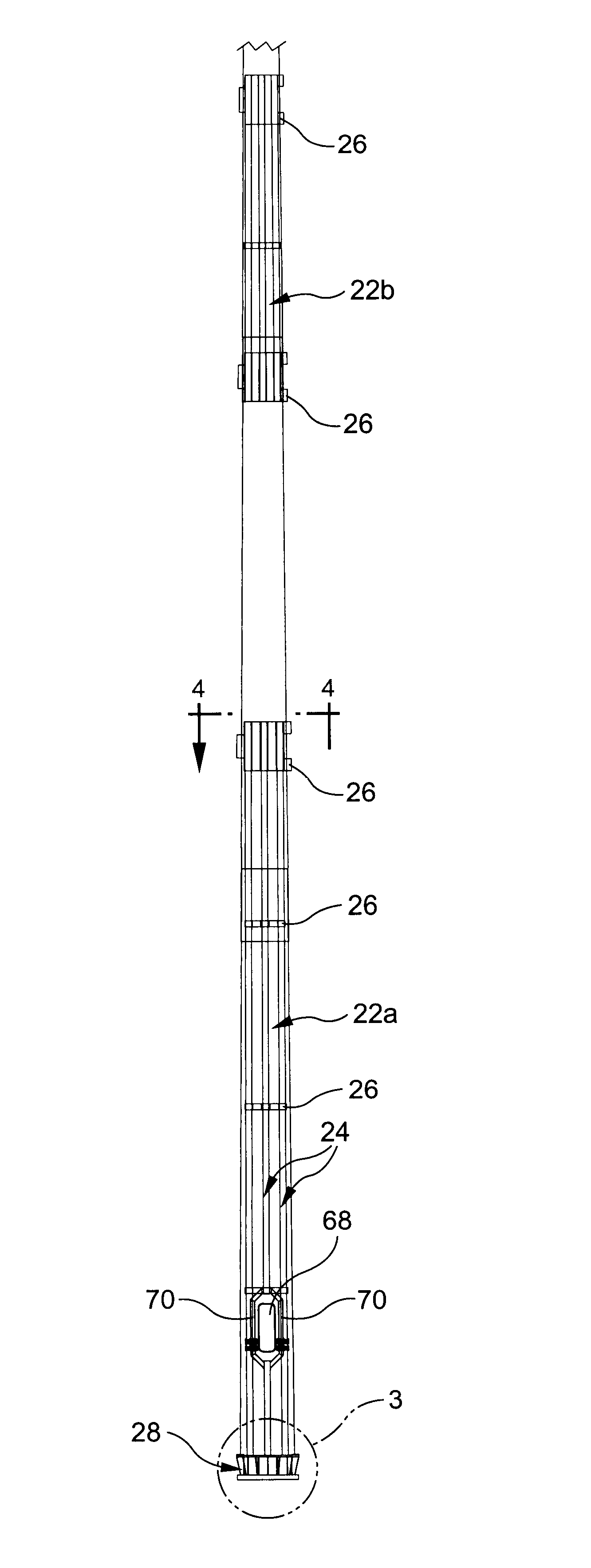

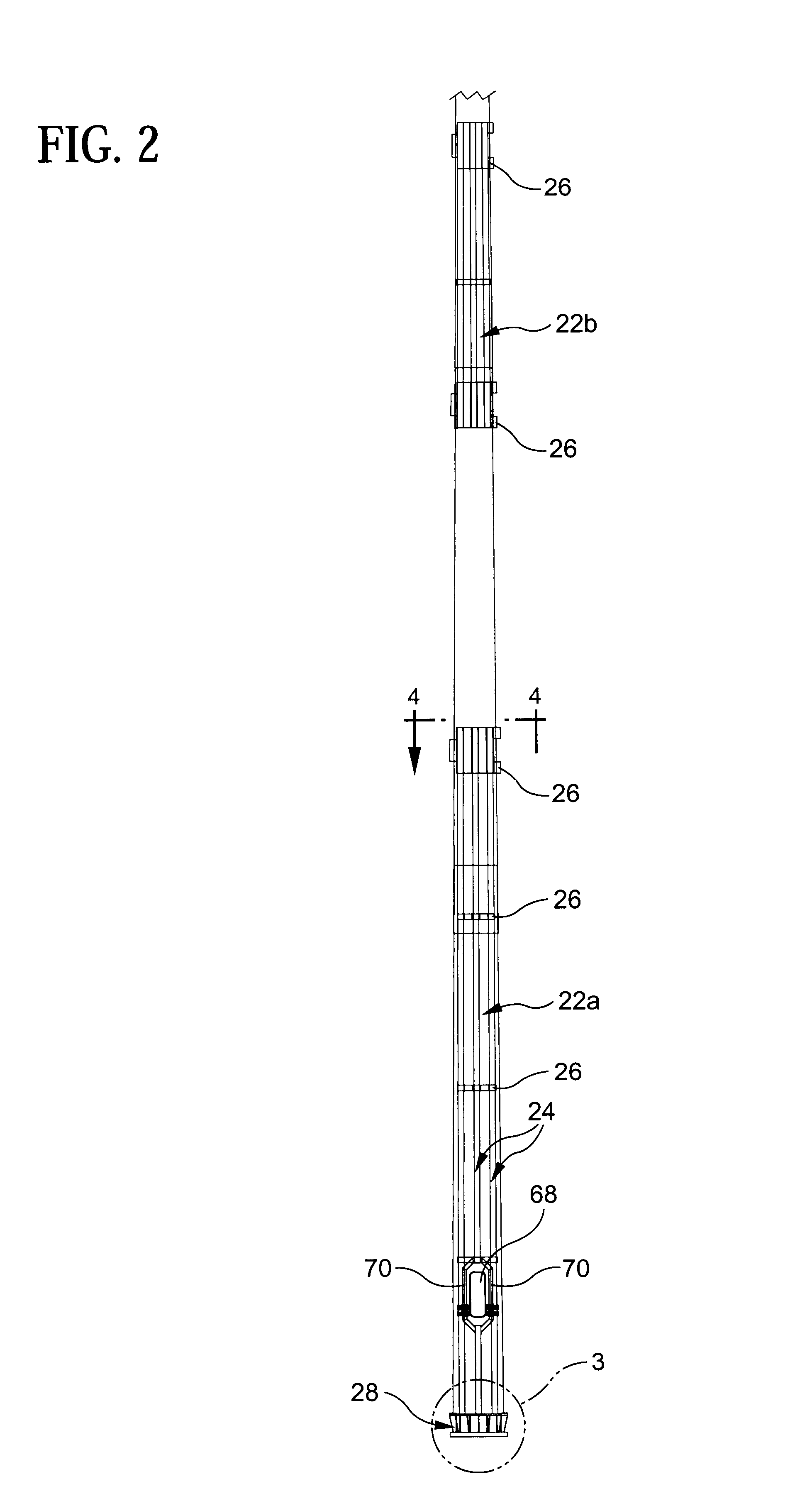

Pole reinforcing arrangement

Reinforcement arrangement for a pole including abase flange surrounding a bottom of the pole, elongate tubes connected to the base flange and arranged at discrete locations around a circumference of the pole to extend vertically alongside the pole and annular clamping collars arranged around the pole at different vertical locations. The tubes are attached to the clamping collars to thereby form a skeletal framework around the pole which provides increased load-bearing capability to the pole and enables installation of additional antennas on the pole. The base flange is supported above the base plate by gussets which are welded to the base plate and pole. The clamping collars are each formed from several collar segments, each extending partially around the circumference of the pole with adjacent collar segments being attached to one another.

Owner:PENNSUMMIT TUBULAR

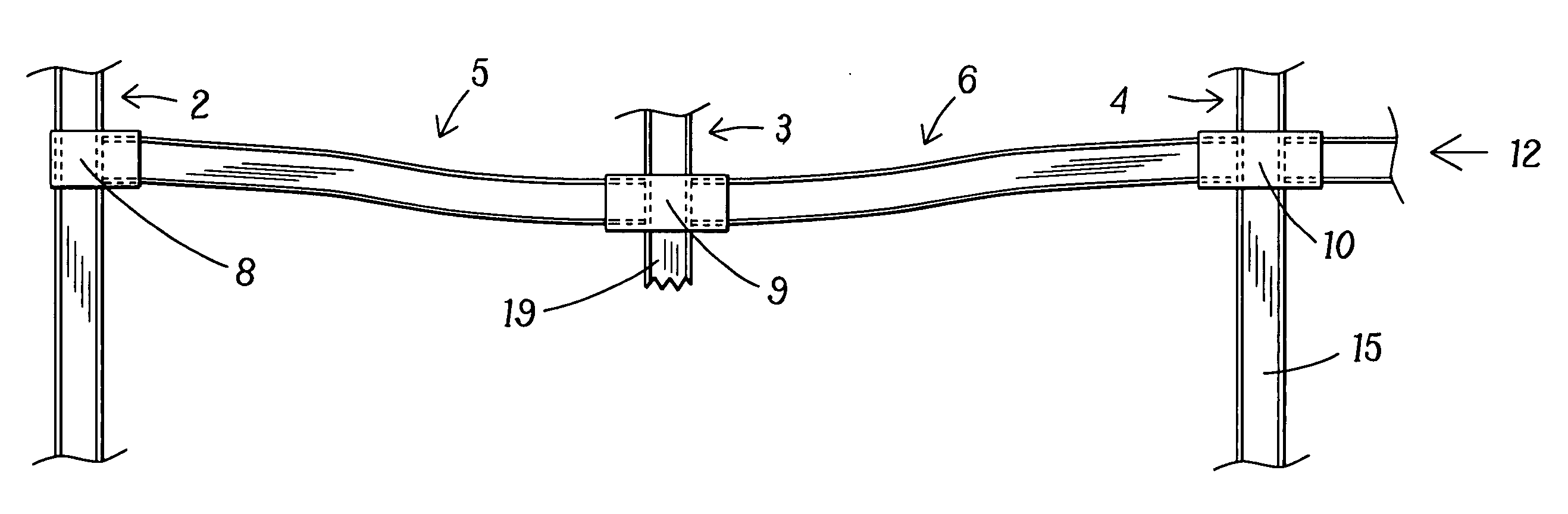

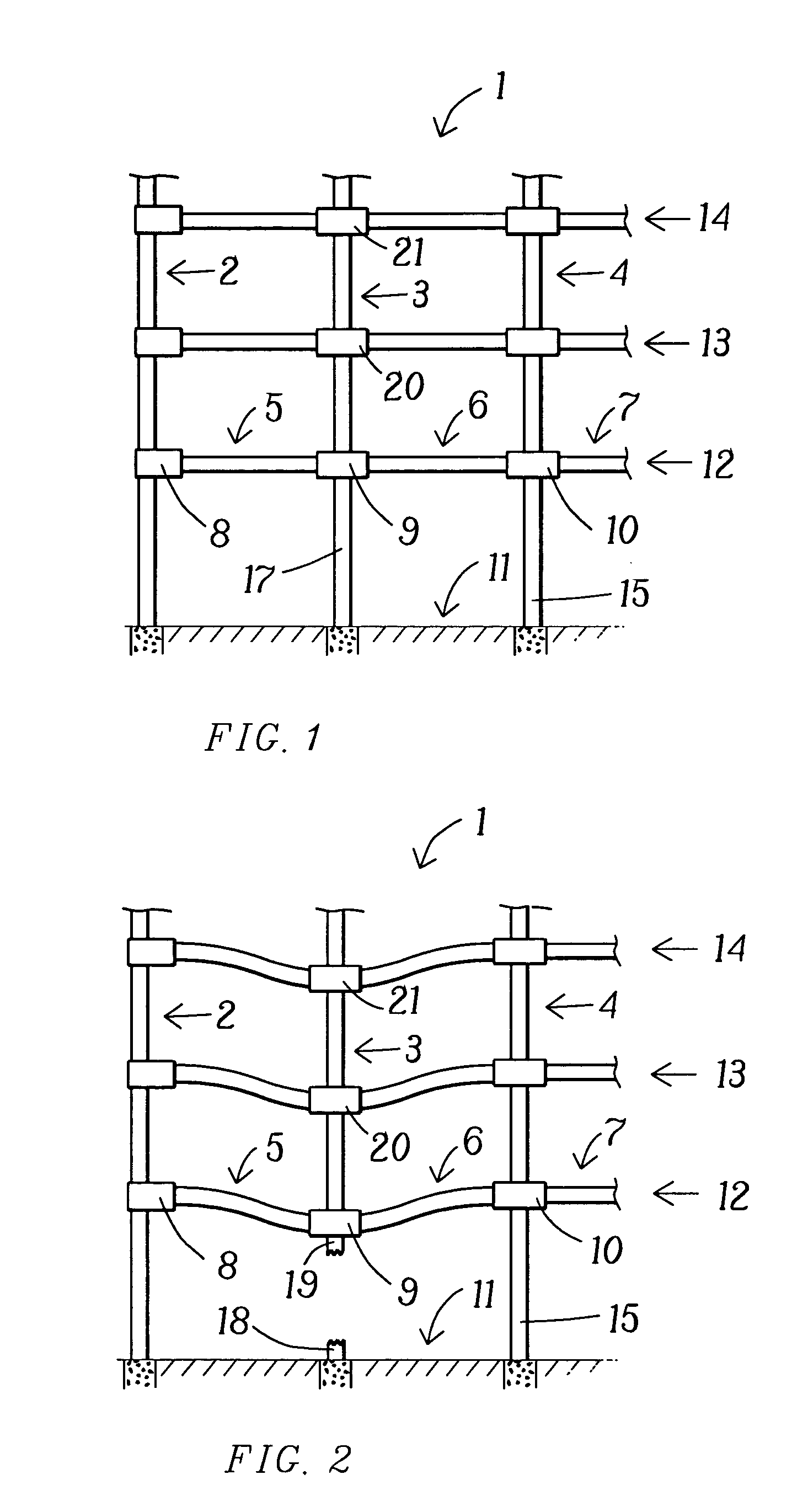

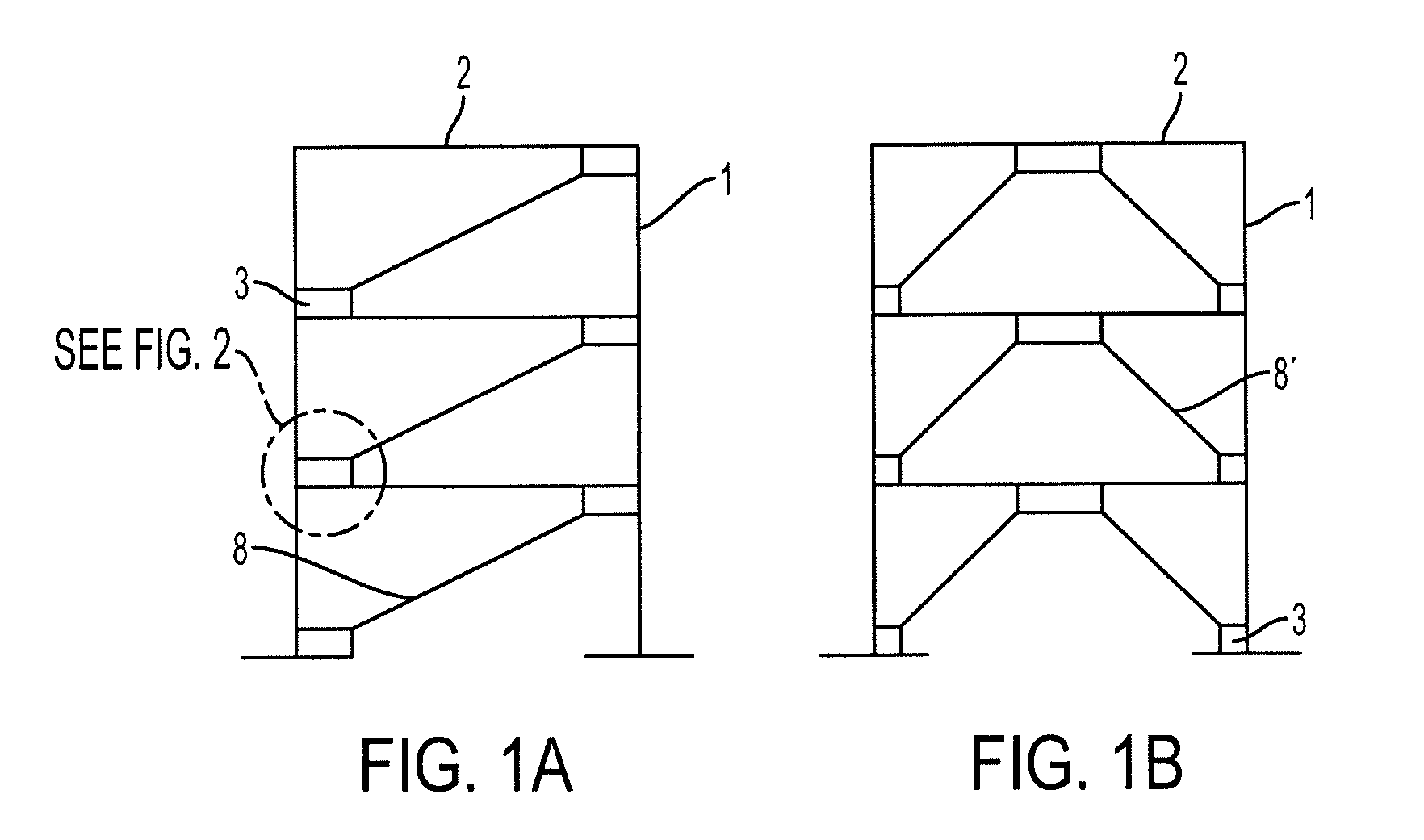

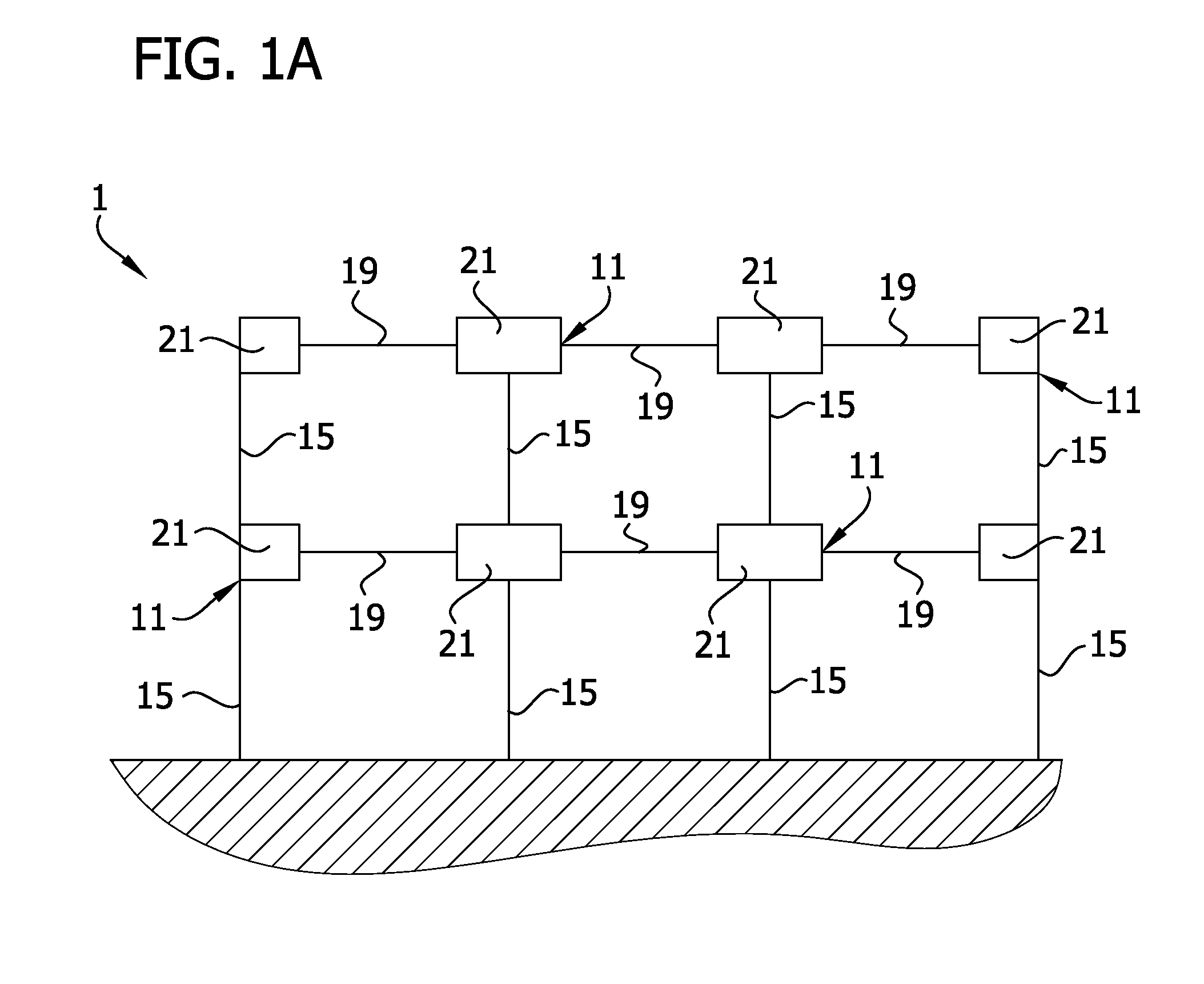

Structural joint connection providing blast resistance and a beam-to-beam connection resistant to moments, tension and torsion across a column

ActiveUS20050204684A1Mitigates likelihood of progressive collapseTremendous tensile pull and vertical moment demandBuilding roofsFloorsGusset plateEngineering

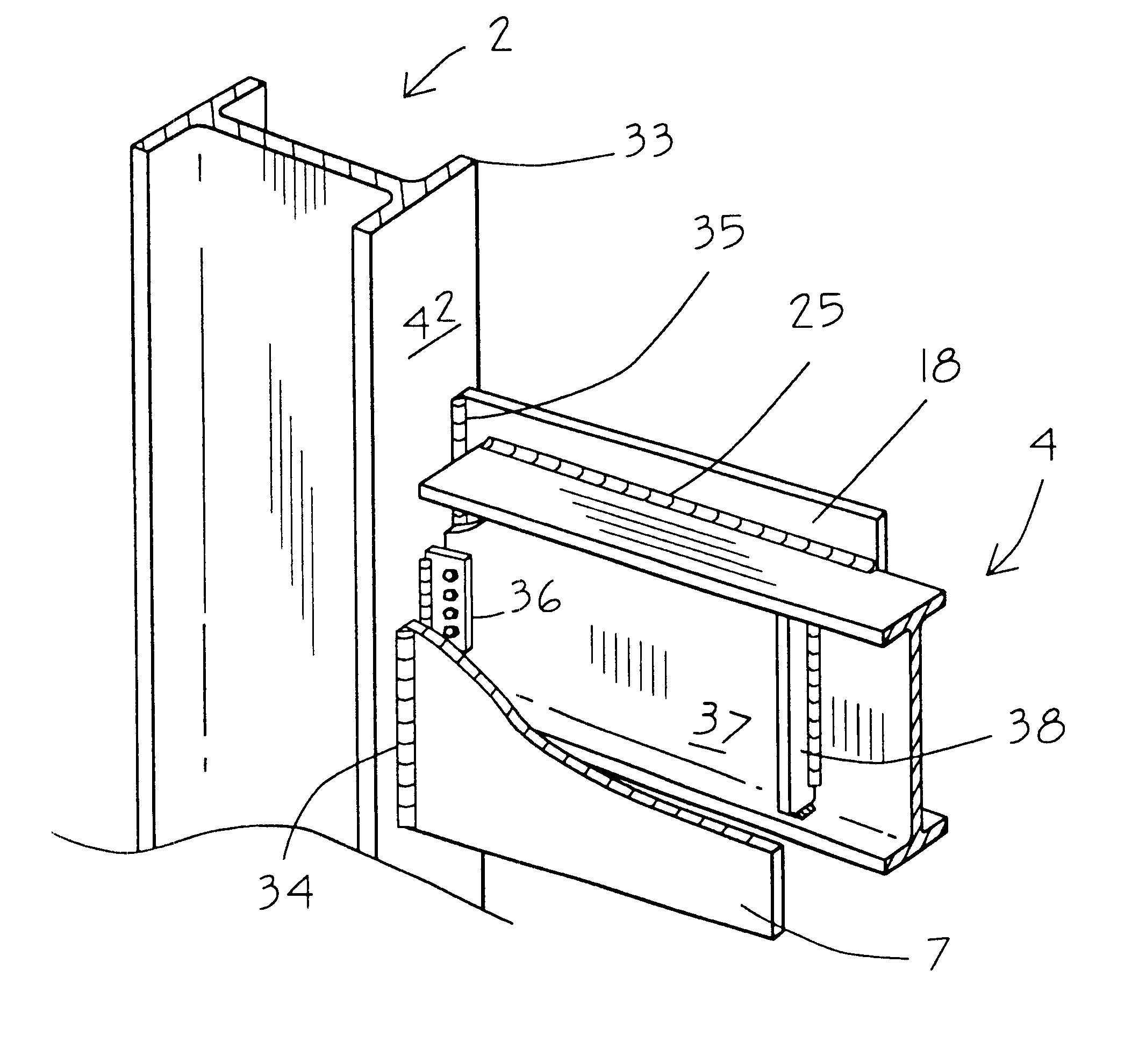

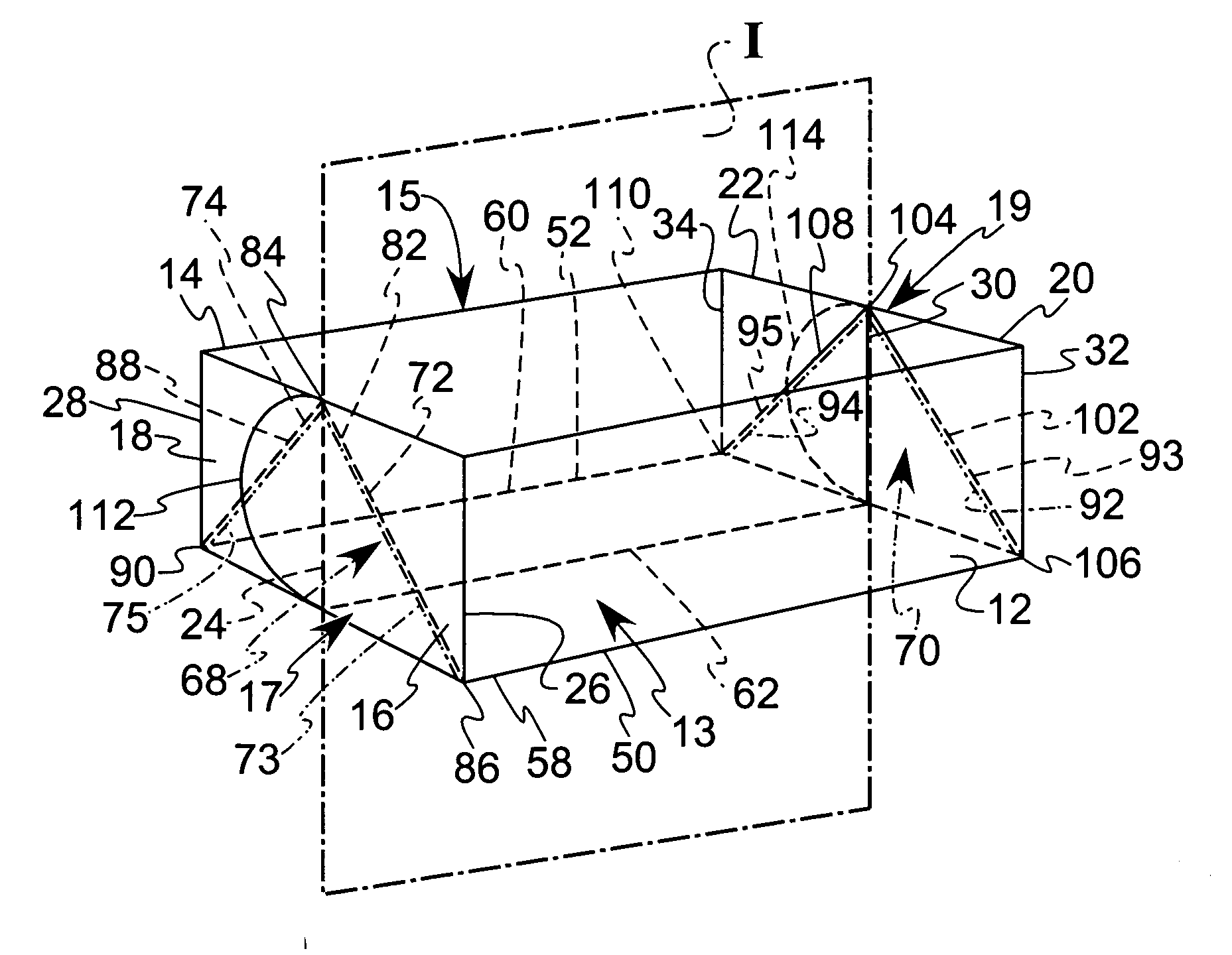

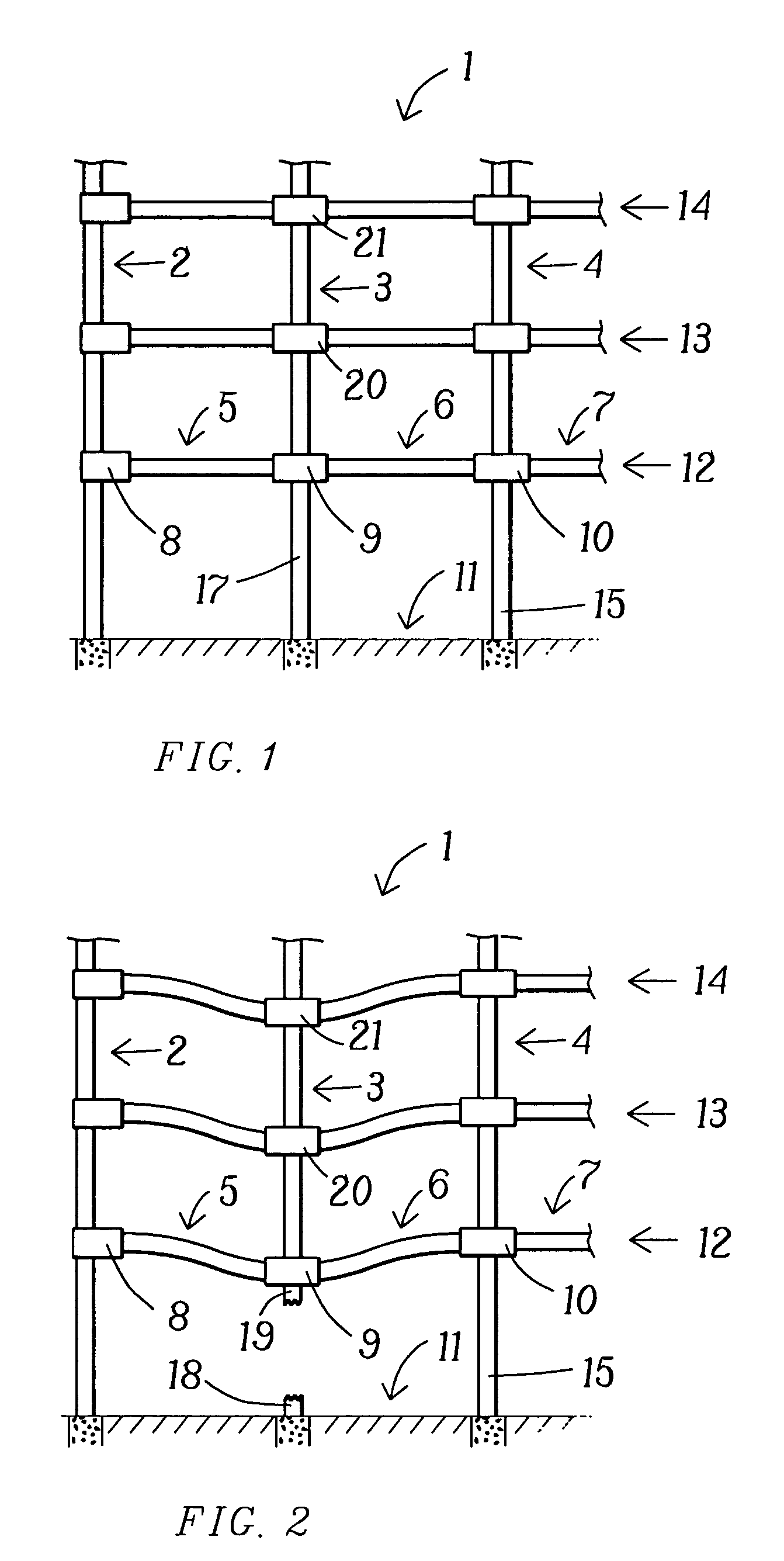

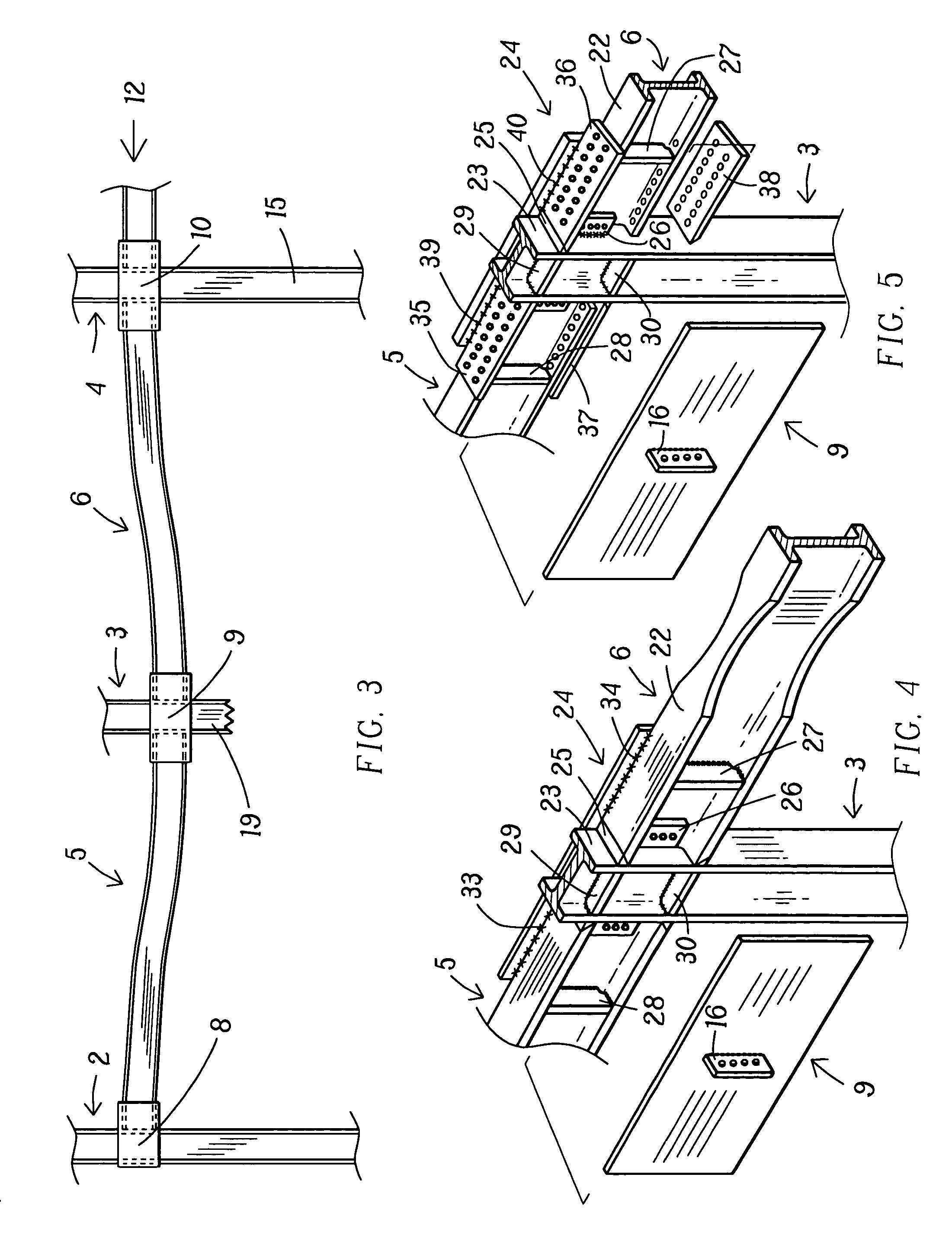

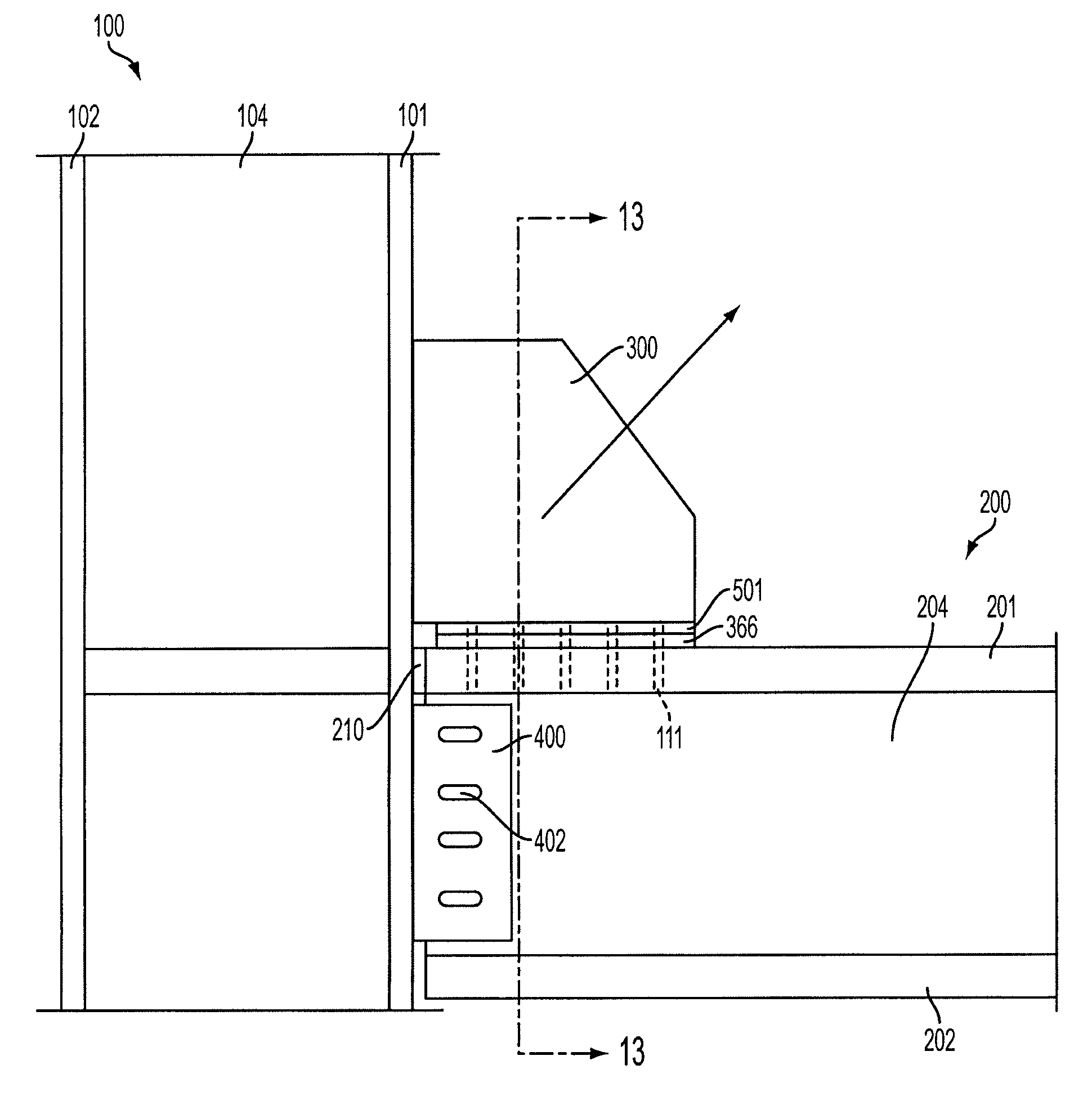

At a beams-to-column joint connection of two beams to a column, in which the joint connection comprises both a gravity load-carrying connection and a moment-resisting connection, there is added a beam-to-beam connection across the column, using two gusset plates, facing each other, on opposite sides of the joint connection. The gusset plates, which are not connected to the column in a moment-resisting connection, connect the two beams, in a tension and moment-resisting connection with respect to each other, by longitudinal welds between the gusset plates and the beams, and provide the capability of withstanding disastrous events, including loss of column support and / or loss of integrity of the beams-to-column joint connection and severe torsional and lateral inelastic deformation due to direct blast pressure. When subjected to such violent conditions and upon loss of column support, and, the likely loss of integrity of the beams-to-column joint connection, the two beams and two gusset plates provide independent beam-to-beam structural continuity, causing the two beams to act as one long beam, or, in other words, a “double-span” condition is created. Such beam-to-beam connection is capable of carrying the tension, torsional and moment loads placed upon the beams, to the ultimate capacity of the beams. Inasmuch as a gusset plate is disposed on each side of the beams-to-column joint connections, substantial shielding of those connections against blast and impact forces is also achieved.

Owner:MITEK HLDG INC

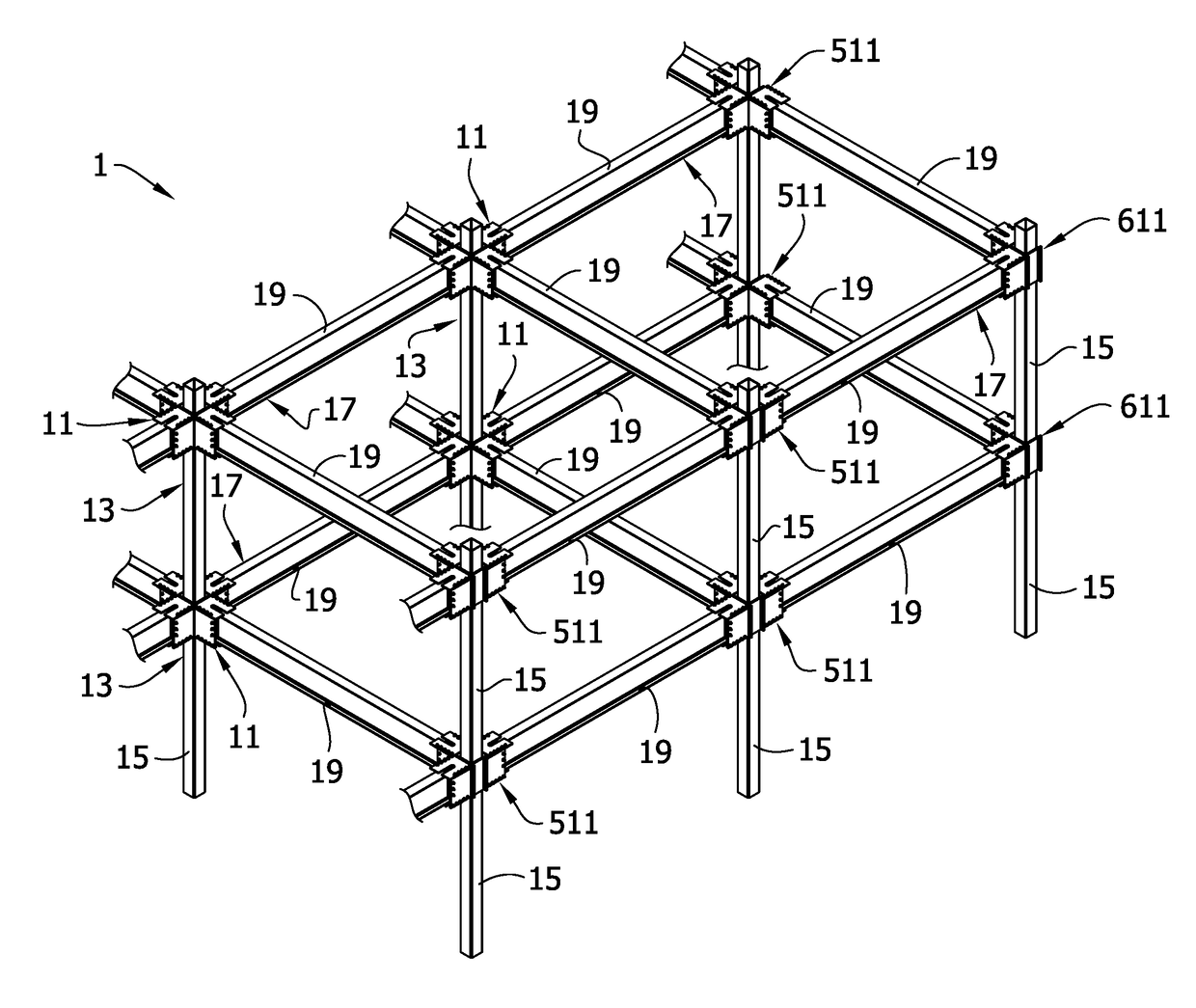

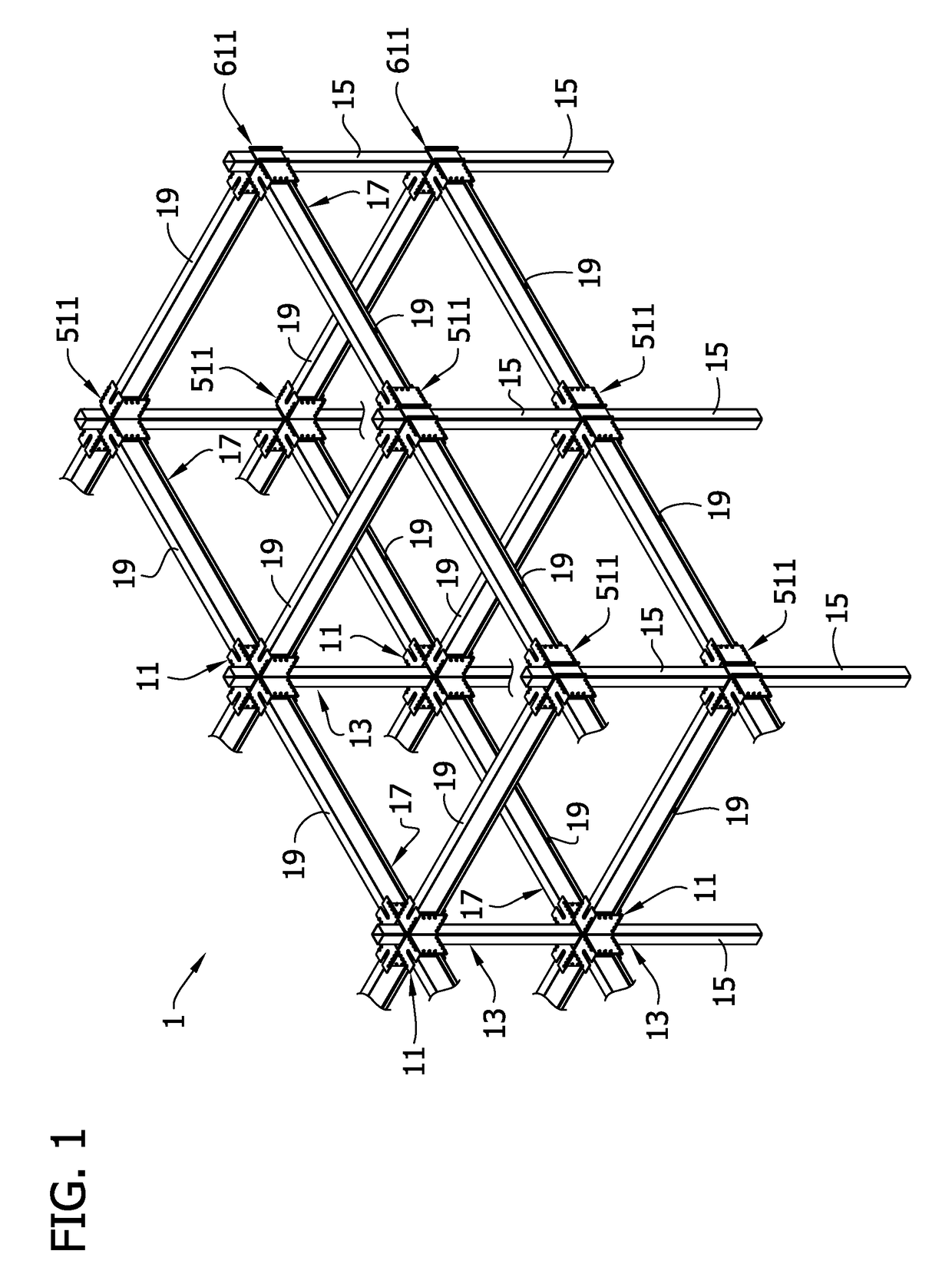

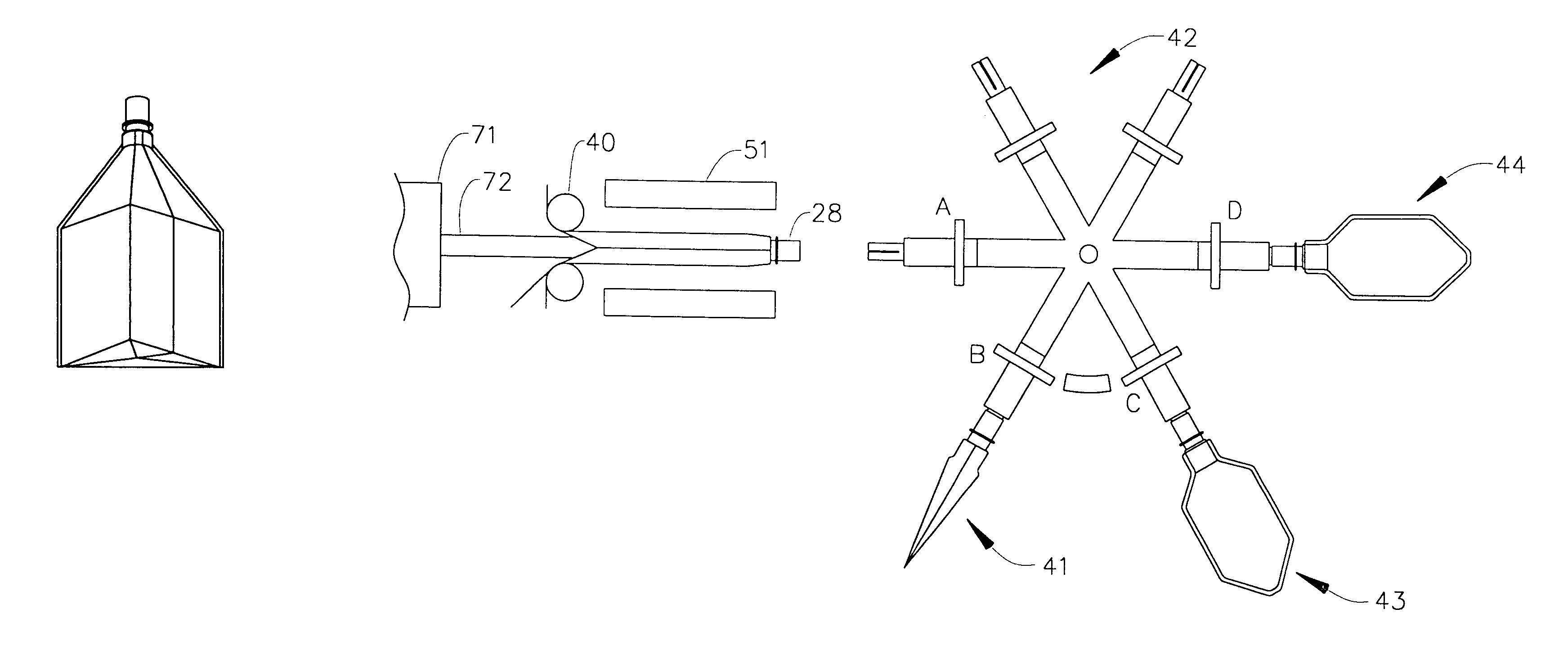

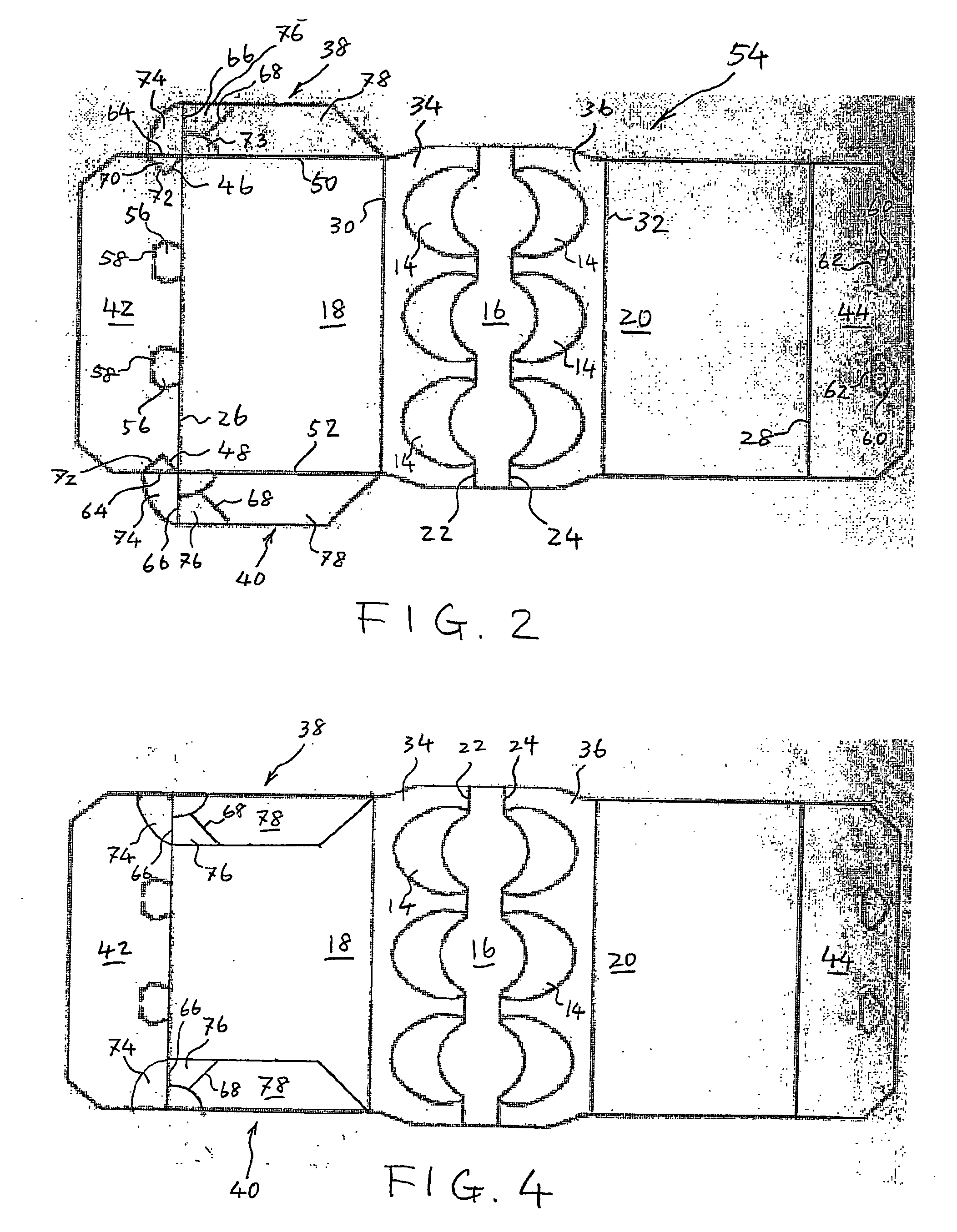

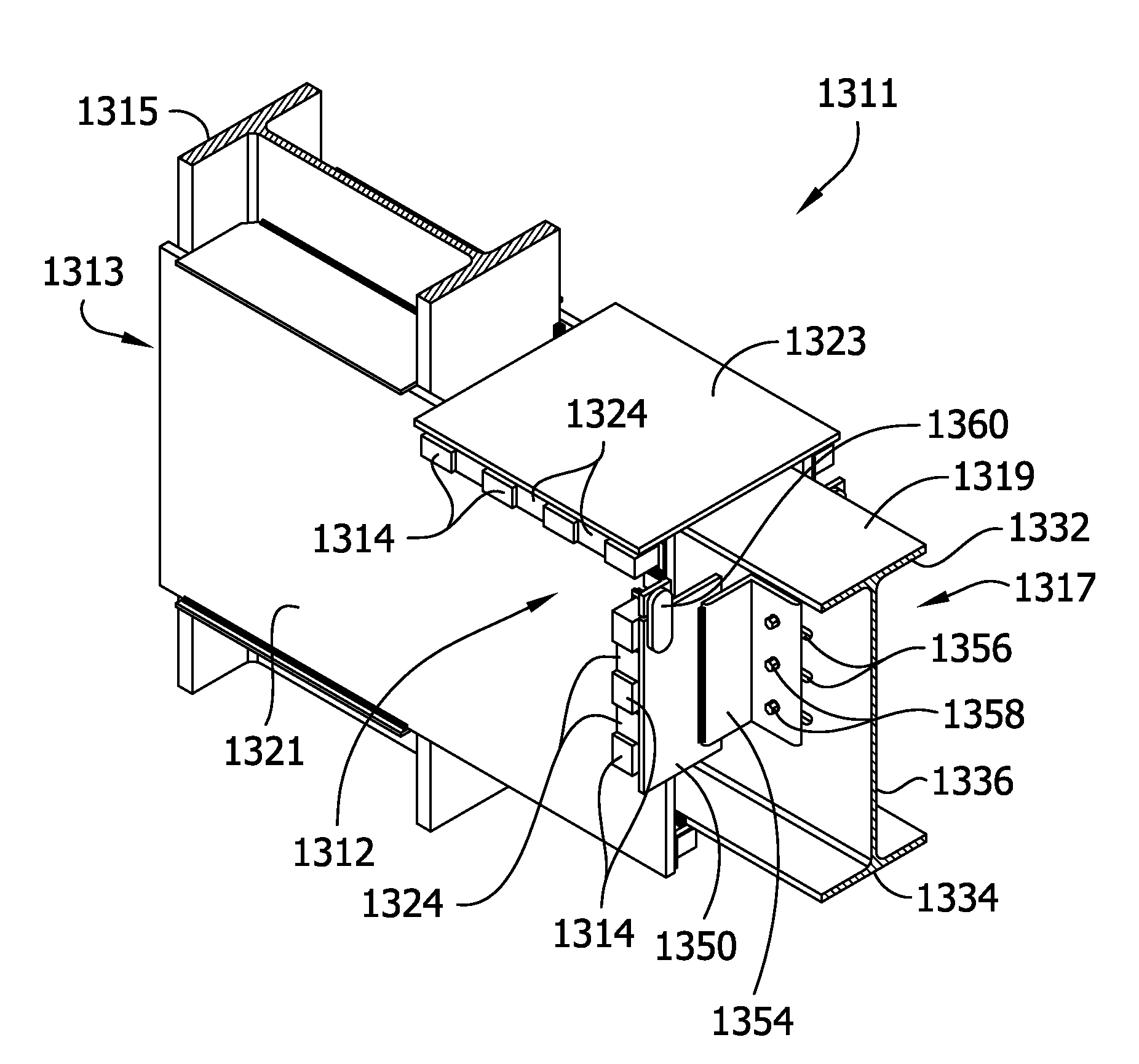

Moment resisting bi-axial beam-to-column joint connection

InactiveUS20170314254A1Building constructionsWelding/soldering/cutting articlesGusset plateAxial joints

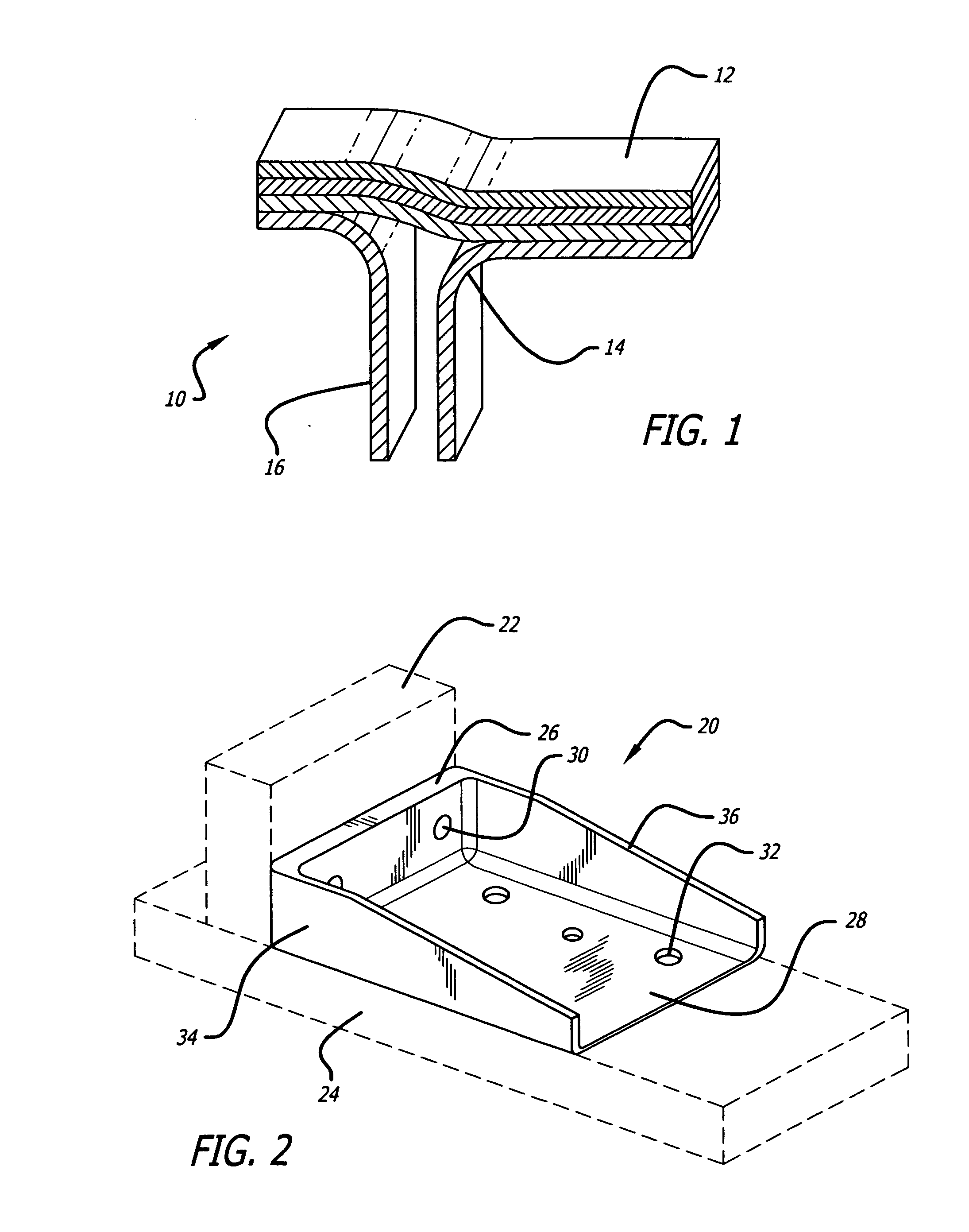

A prefabricated column assembly includes a hollow tubular column having a longitudinal axis. A gusset plate assembly includes a plurality of gusset plates connected to the column and extending laterally outward from the column in planes generally parallel to the longitudinal axis of the column. A first pair of the gusset plates extends laterally outward from the column along a first axis and defines a space for receiving an end portion of a first beam for mounting the first beam on the first pair of gusset plates. A second pair of the gusset plates extends laterally outward from the column along a second axis that is nonparallel and non-coincident with the first axis. The second pair of gusset plates defines a space for receiving an end portion of a second beam for mounting the second beam on the second pair of gusset plates to provide a bi-axial joint connection.

Owner:MITEK HLDG INC

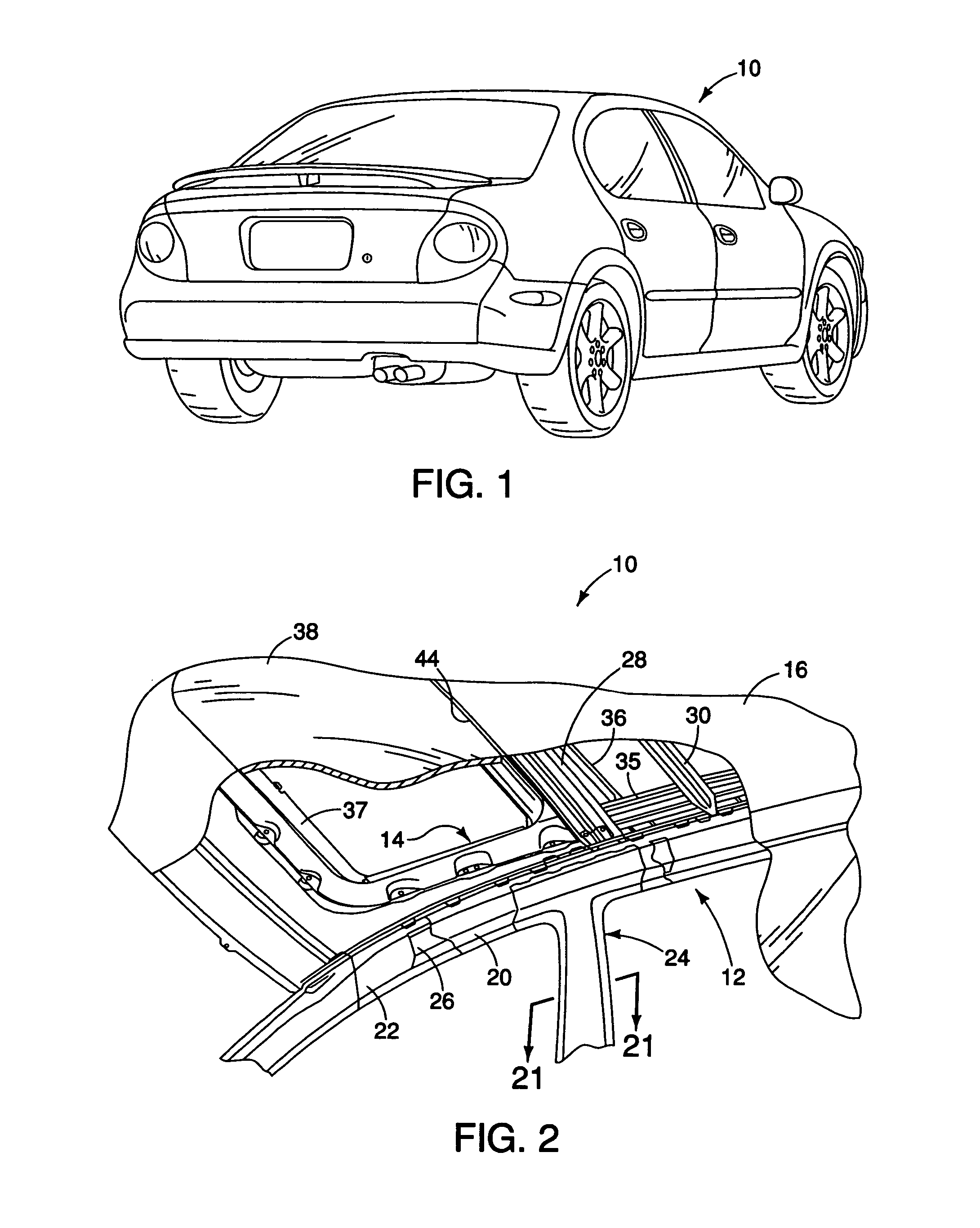

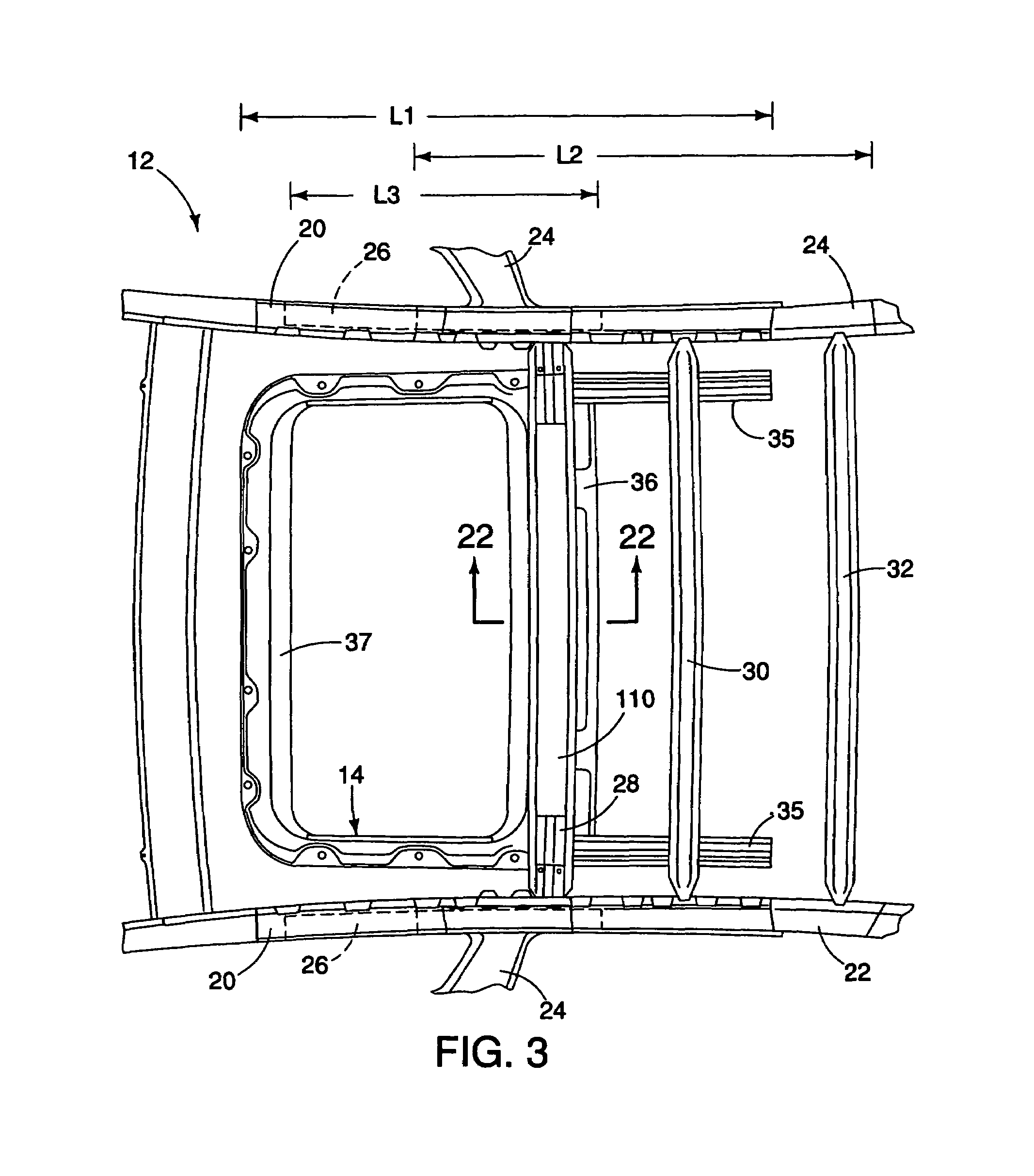

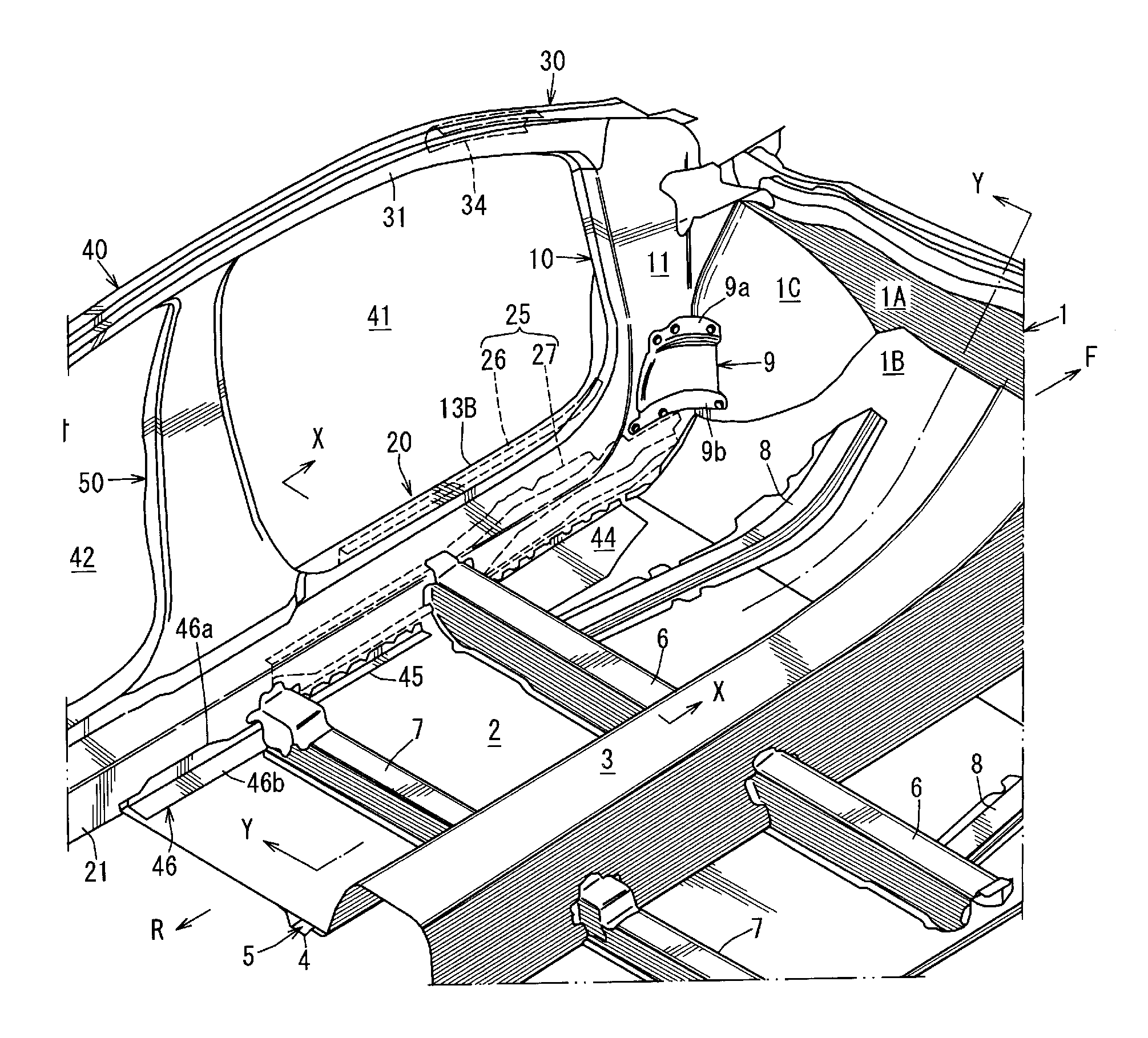

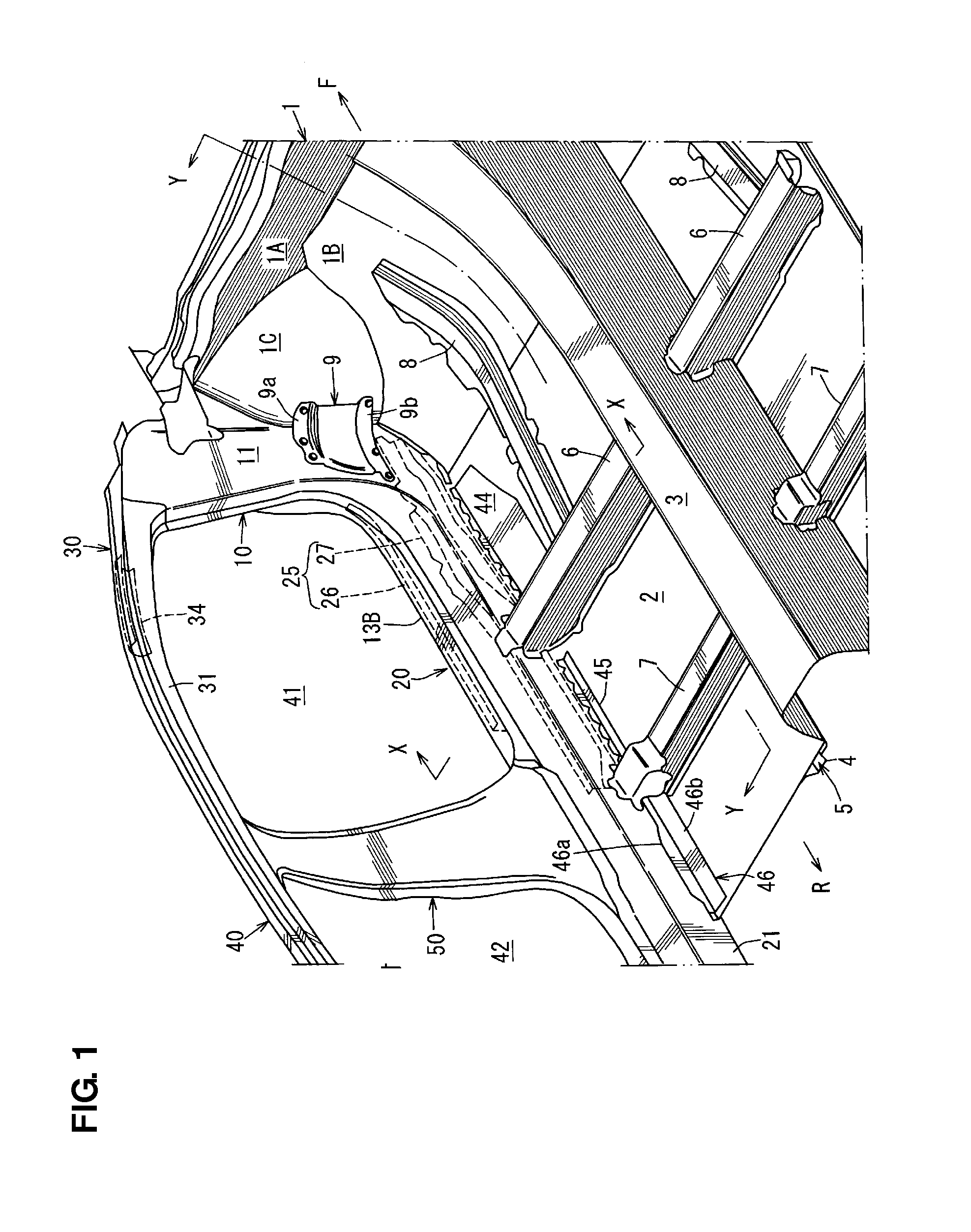

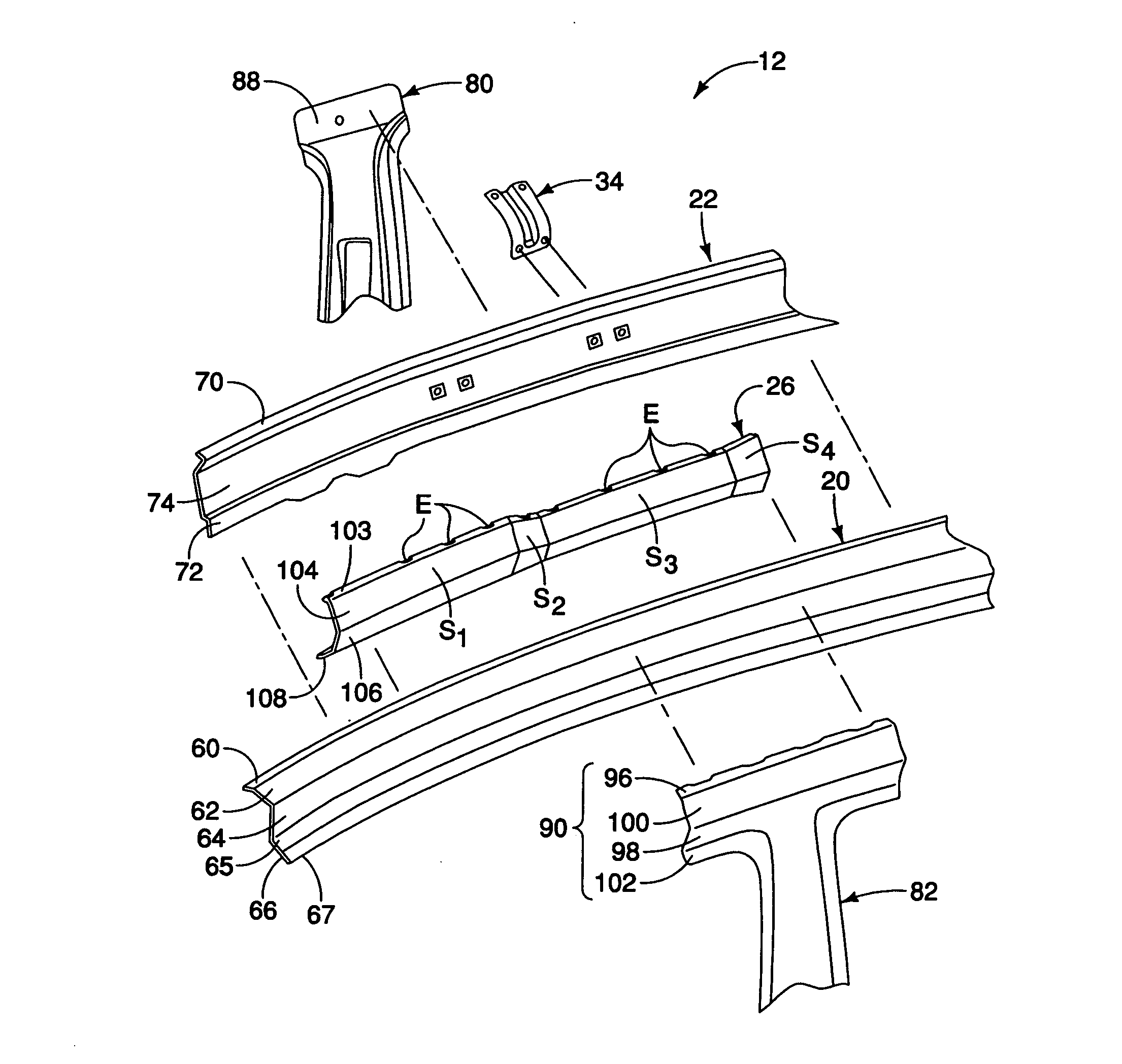

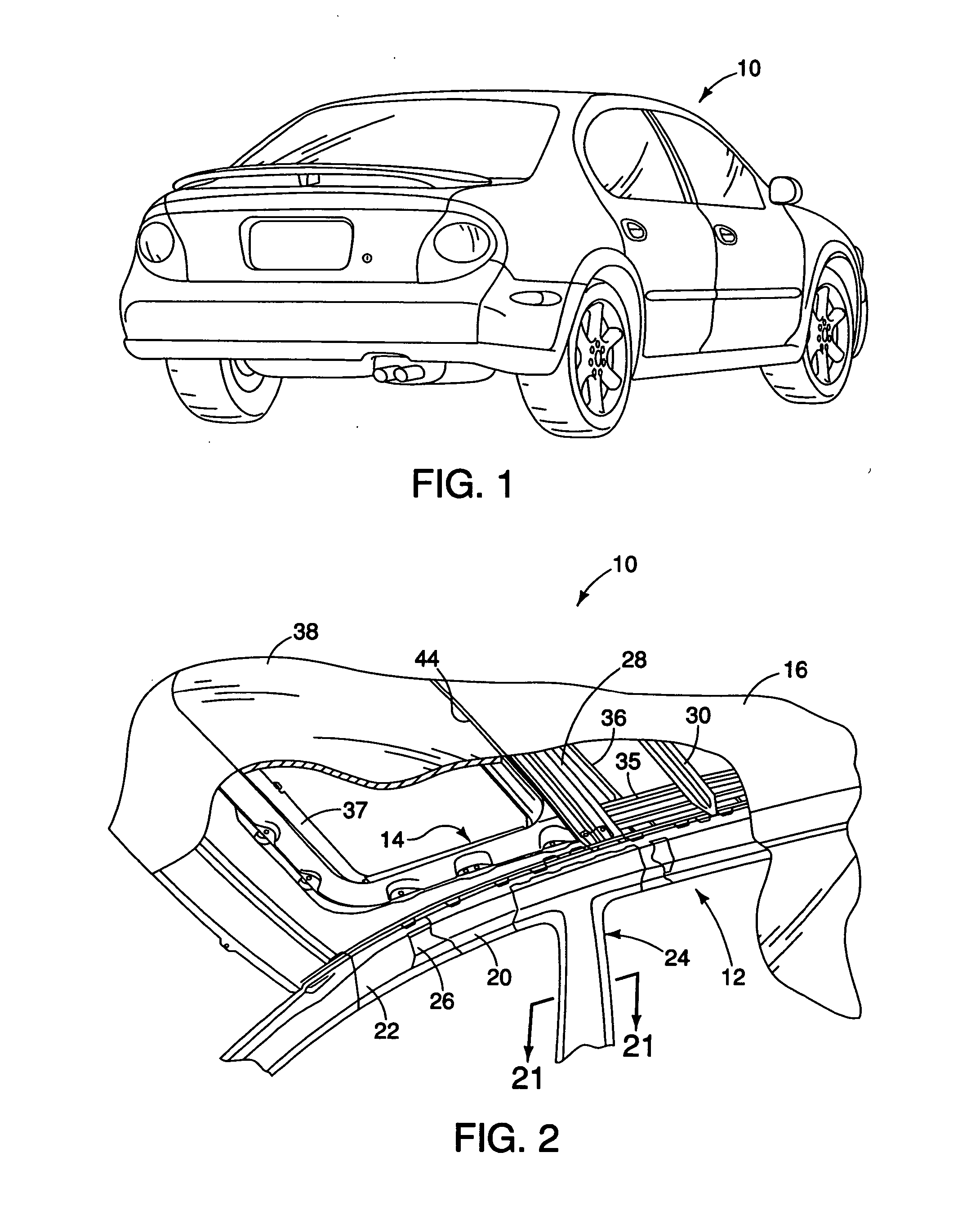

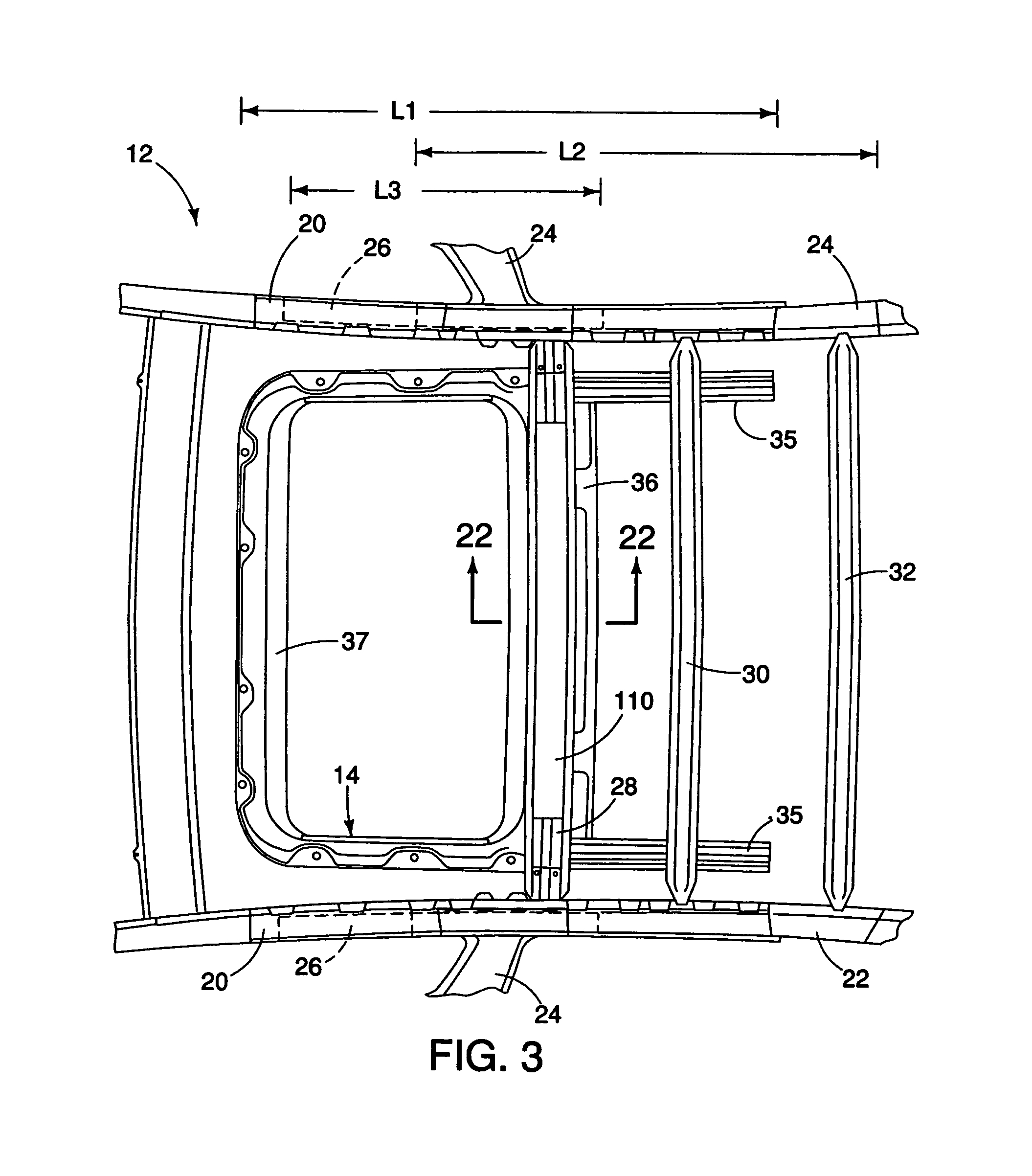

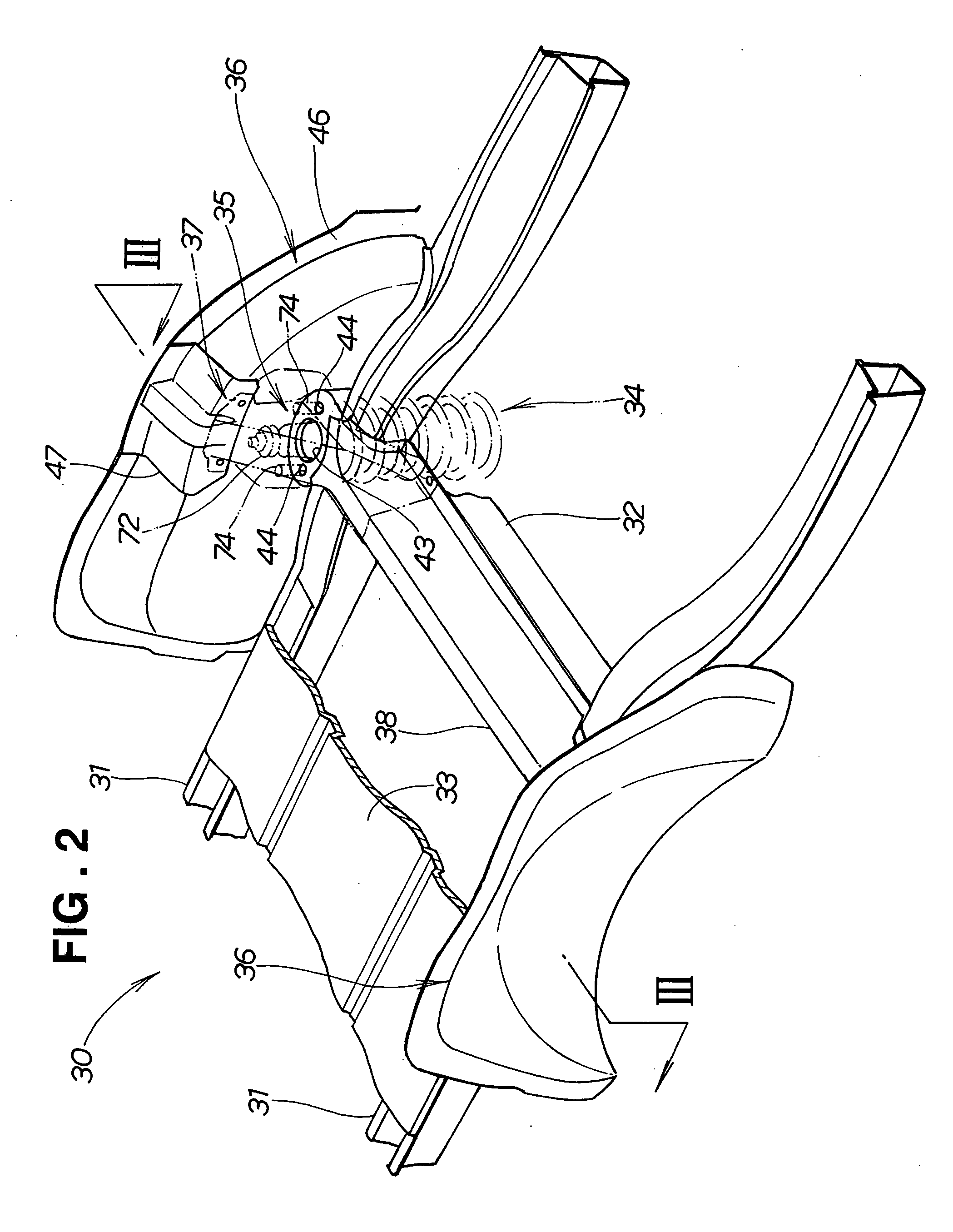

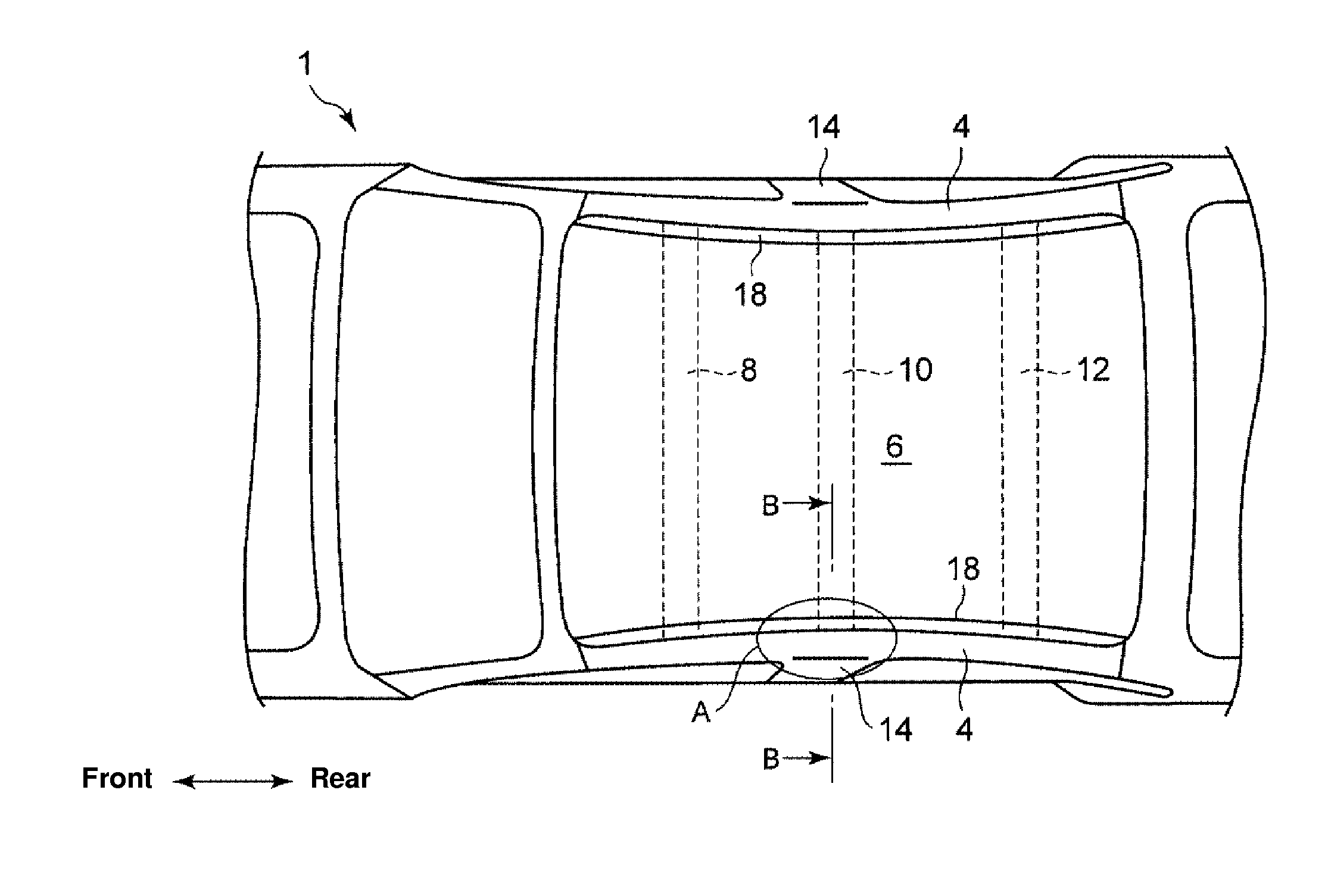

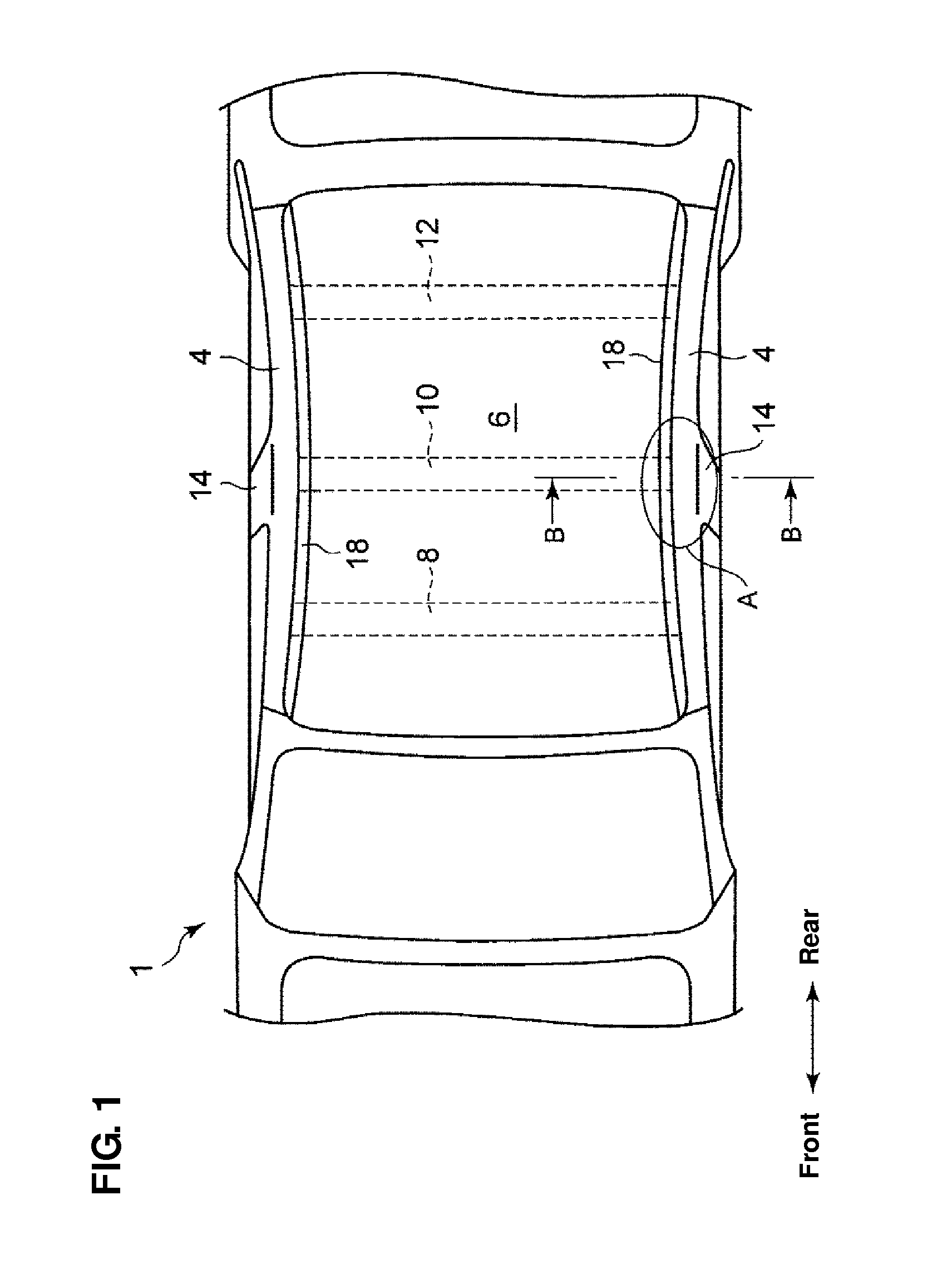

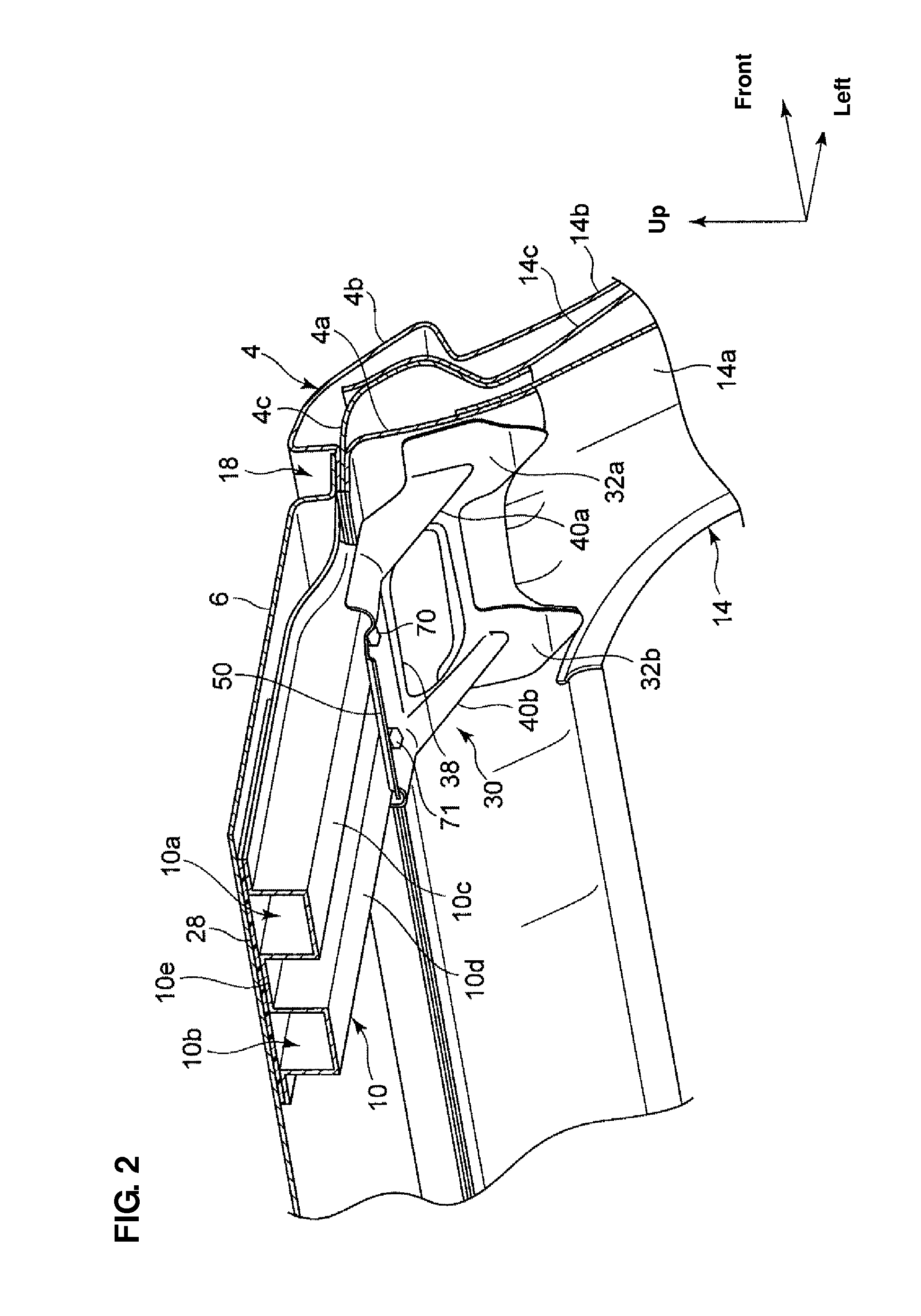

Vehicle body structure

A vehicle body structure includes longitudinally extending elements such as roof side rail outer and inner members, a reinforcement member and a gusset that are part of a side impact energy management system for vehicles that include a sunroof. A laterally extending cross member is connected to the roof side rail members, and the roof side rail members are connected to an upper portion of an approximately vertical B-pillar. The cross-member is connected to the roof side rail members approximately perpendicular to the B-pillar, but longitudinally offset from the B-pillar. The reinforcement member extends between the roof side rail members to the cross-member.

Owner:NISSAN MOTOR CO LTD

Structural joint connection providing blast resistance and a beam-to-beam connection resistant to moments, tension and torsion across a column

ActiveUS7178296B2Tremendous tensile pull and vertical moment demandBuilding roofsFloorsGusset plateEngineering

Owner:MITEK HLDG INC

Lower vehicle-body structure of vehicle

A gusset member which is provided in back of a front wheel and connects a dash panel and a hinge pillar is provided. A first reinforcing member which is connected to the gusset member to reinforce a lower portion of the hinge pillar is provided. Accordingly, a cabin deformation of a vehicle side portion as a whole can be properly restrained, thereby ensuring a sufficient space of a vehicle compartment.

Owner:MAZDA MOTOR CORP

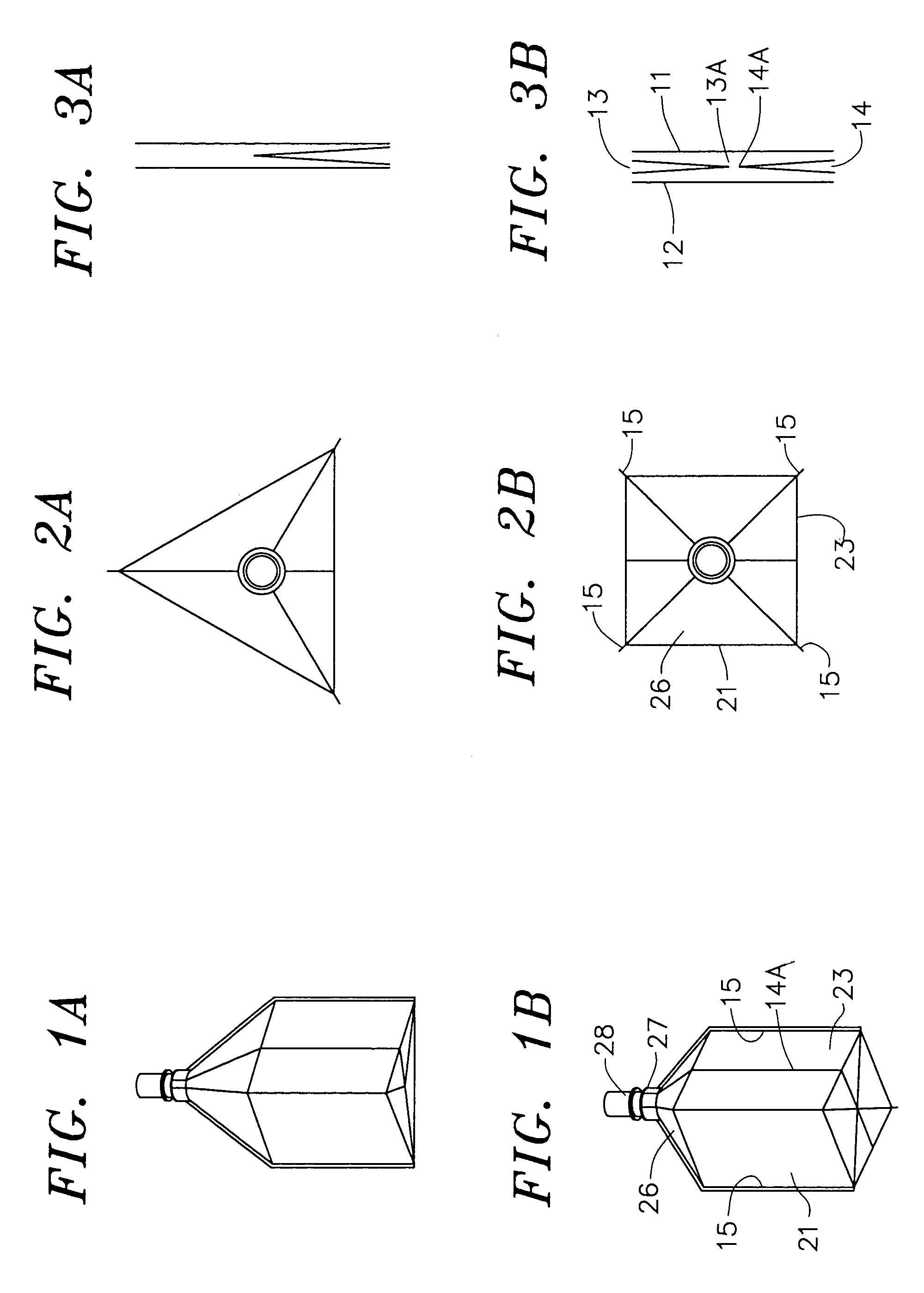

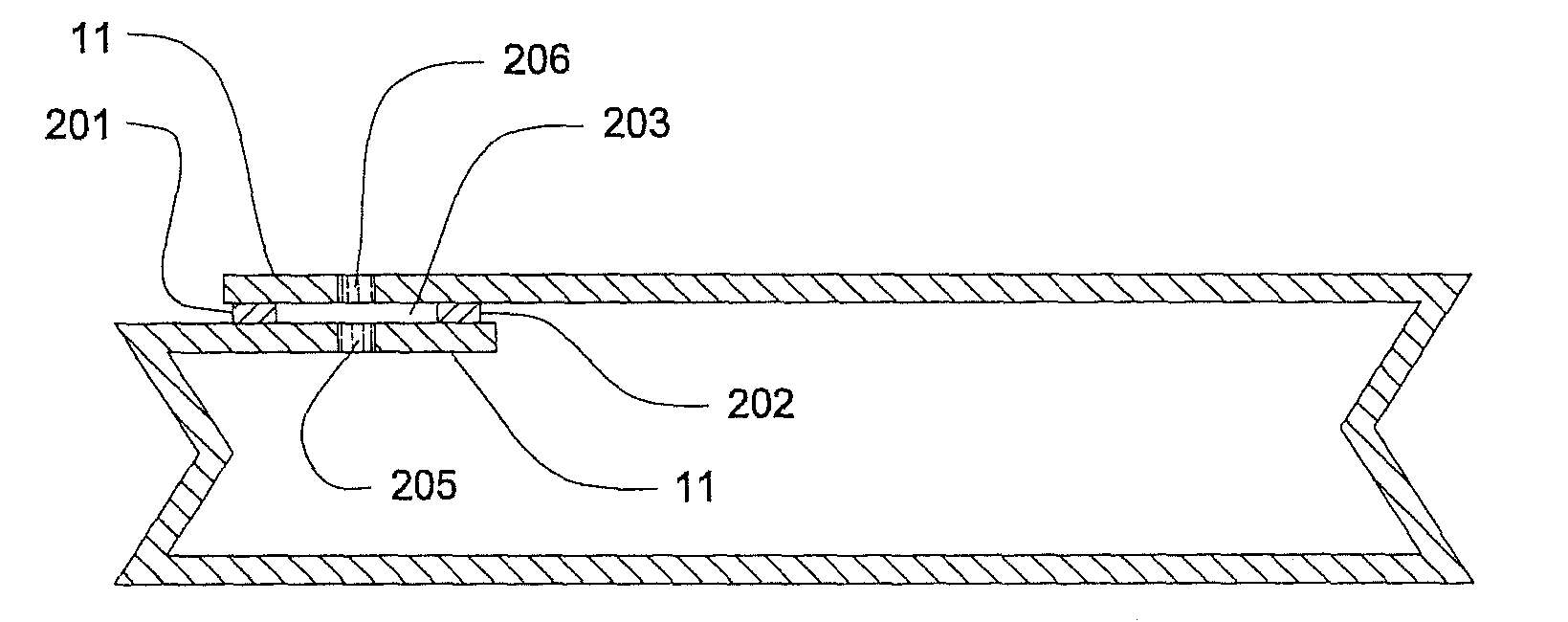

Method of fabrication of gusseted flexible bottle with fitment

InactiveUS7147597B2Avoid Insufficient SealingEnvelopes/bags making machineryBox making operationsGusset plateEngineering

A method for fabricating a fitmented flexible bottle is disclosed which involves feeding webs including one or more gussets, creating perimeter seals around only the top portion of the bottle, inserting the fitment from the input end of the machine in the direction of web travel, forming the remainder of the perimeter seams, detaching the nascent bottle from the web, and sealing the neck section of the bottle to the fitment by clamping the neck section with a heated clamp, and preferably repeating the seal operation at a different radial angle. Sealing the fitment by application of ultrasonic energy is also disclosed. In another embodiment, the fitment is sealed to the neck section of the bottle by utilizing heated wheels against the neck and rotating the bottle to create a seal all around the neck.

Owner:SMART BOTTLE

Vehicle body bottom structure

ActiveCN104114438AHigh strengthReduce the amount of backlashUnderstructuresSuperstructure subunitsDashboardGusset plate

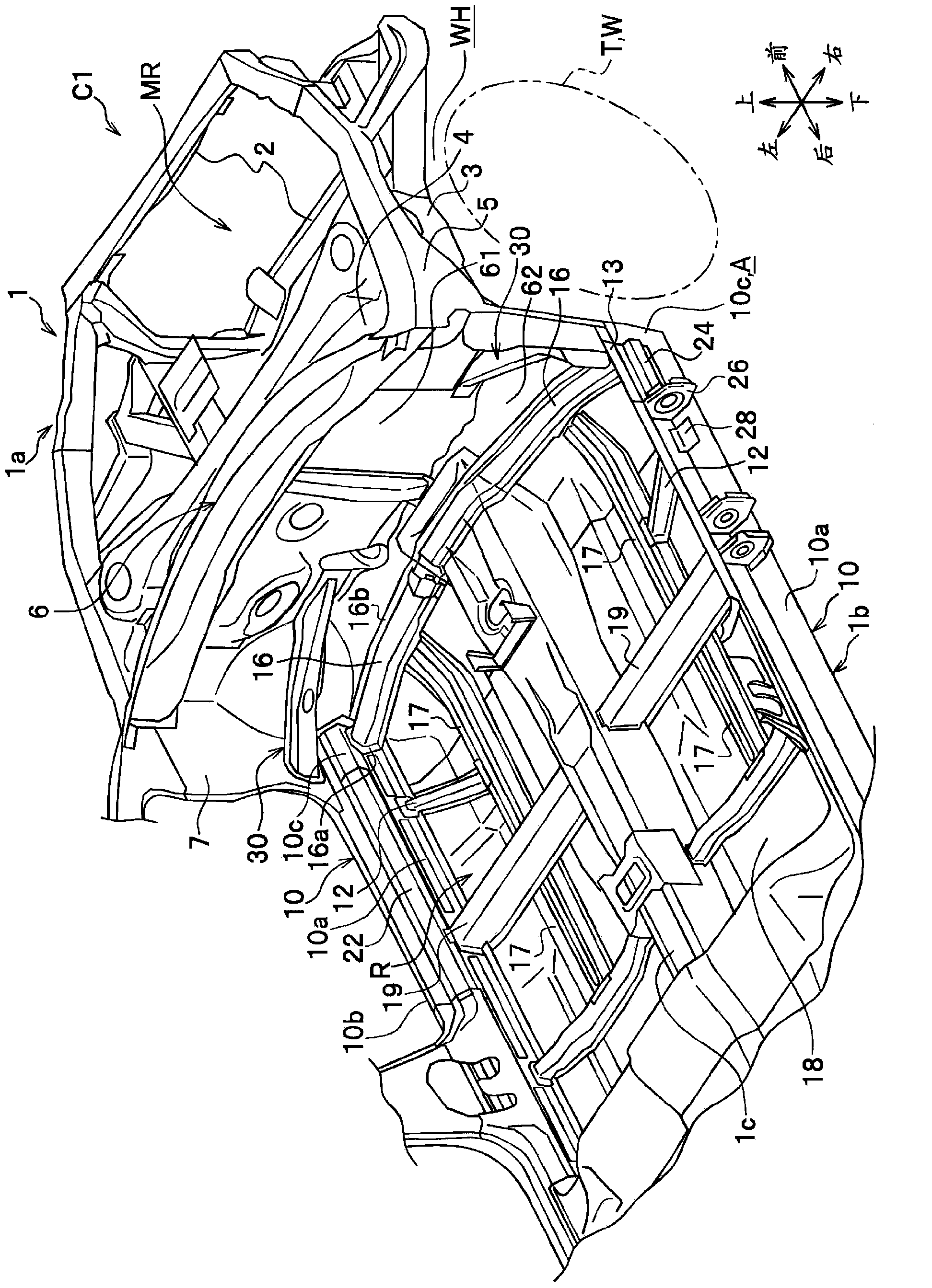

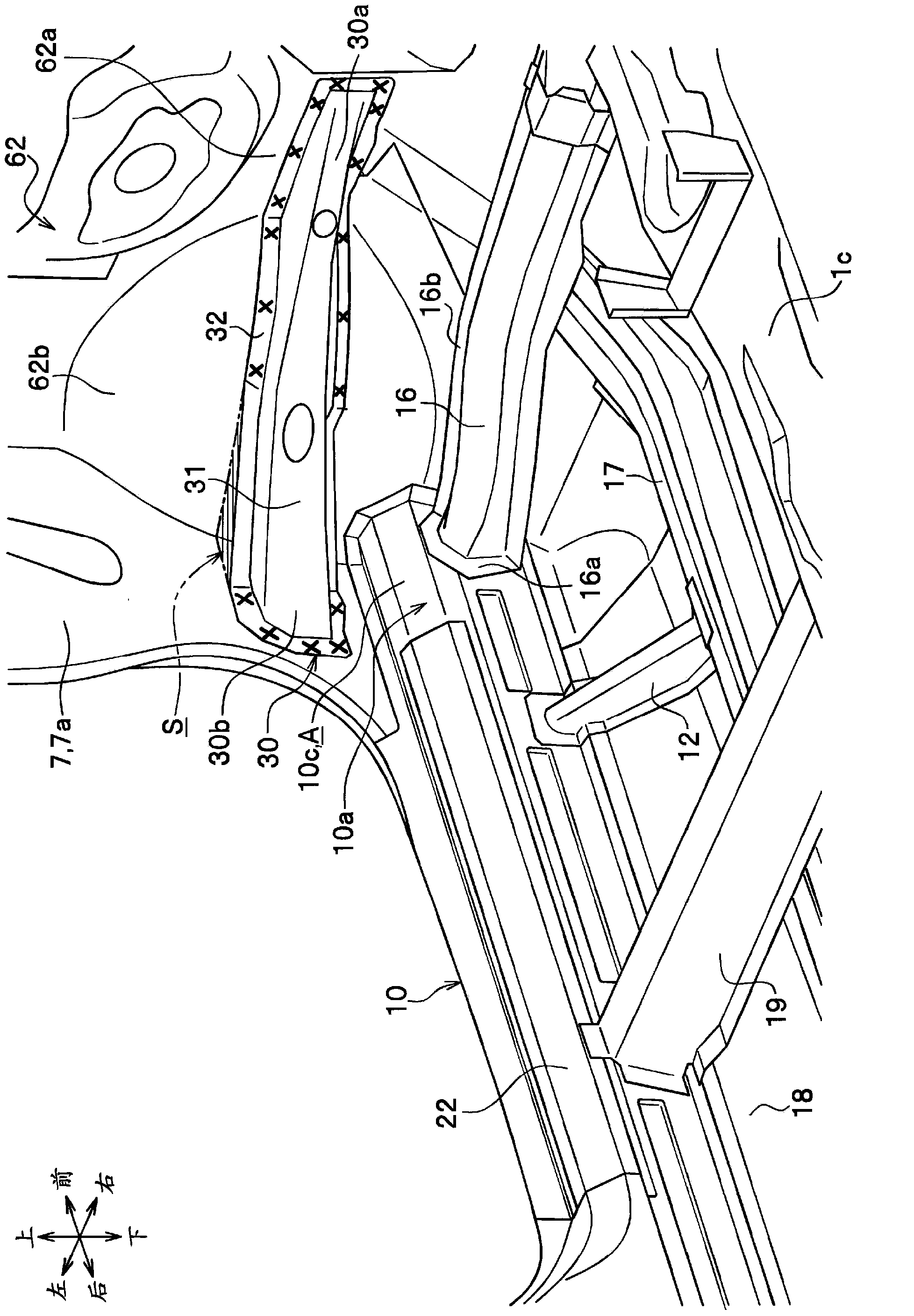

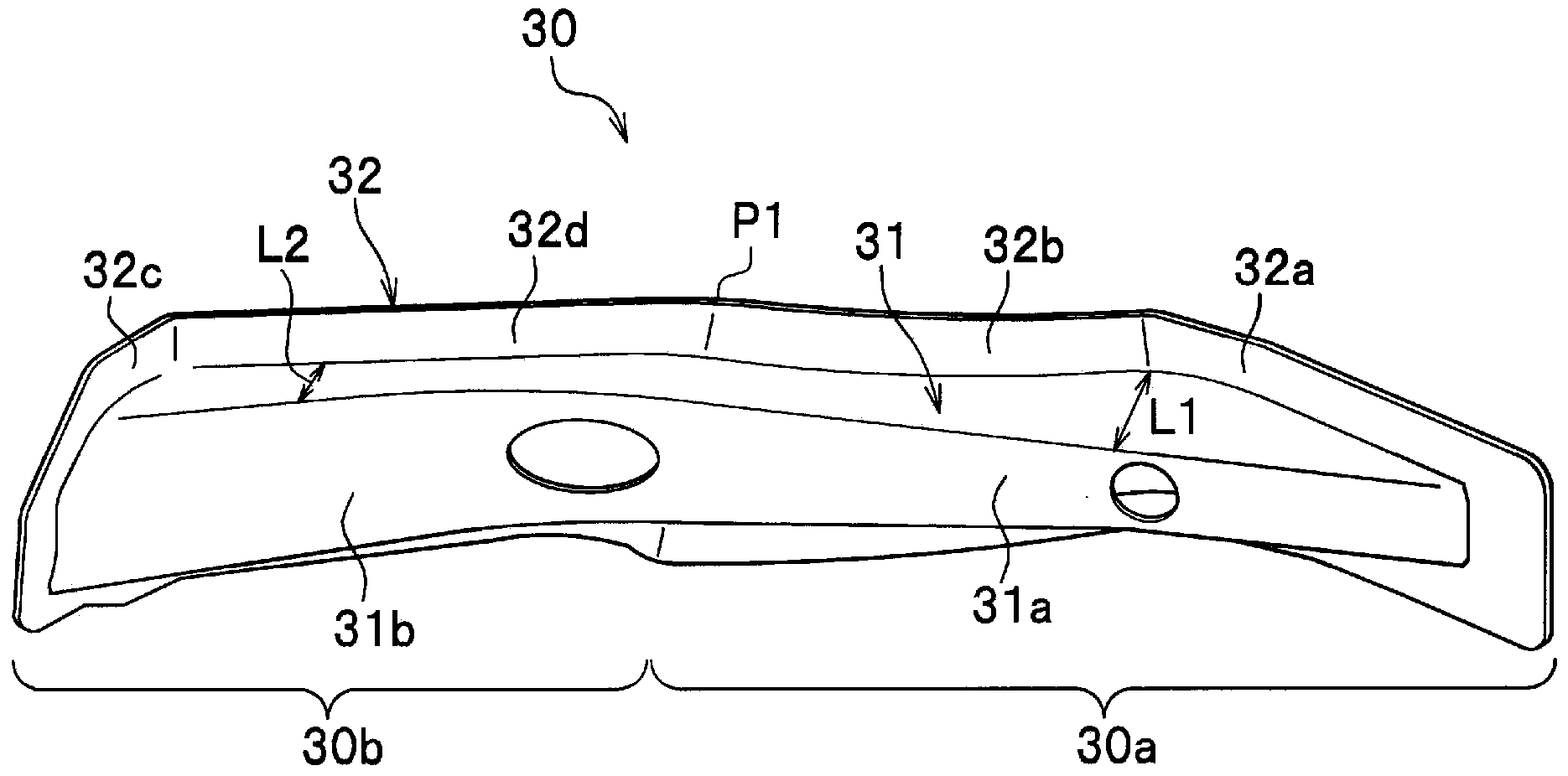

Provided is a vehicle body bottom structure whereby collision load absorption performance during a narrow offset crash can be improved and retraction of the A-pillar can be minimized. A vehicle body bottom structure comprising a dashboard lower (62) for partitioning a vehicle interior (R) and a power installation interior (MR) and also for partitioning the vehicle interior (R) and a wheel house (WH), an A-pillar (7) erected at the vehicle-widthwise end of the dashboard lower (62), and a gusset (30) spanning between the dashboard lower (62) and the A-pillar (7); the gusset (30) being designed such that one end side is bonded to the dashboard lower (62) and grows farther from the dashboard lower (62) the nearer to the A-pillar (7), the other end side is bonded to the A-pillar (7), and a collapse space (S) having a substantially triangular shape in a plan view is formed in the portion enclosed by the dashboard lower (62), the A-pillar (7), and the gusset (30).

Owner:HONDA MOTOR CO LTD

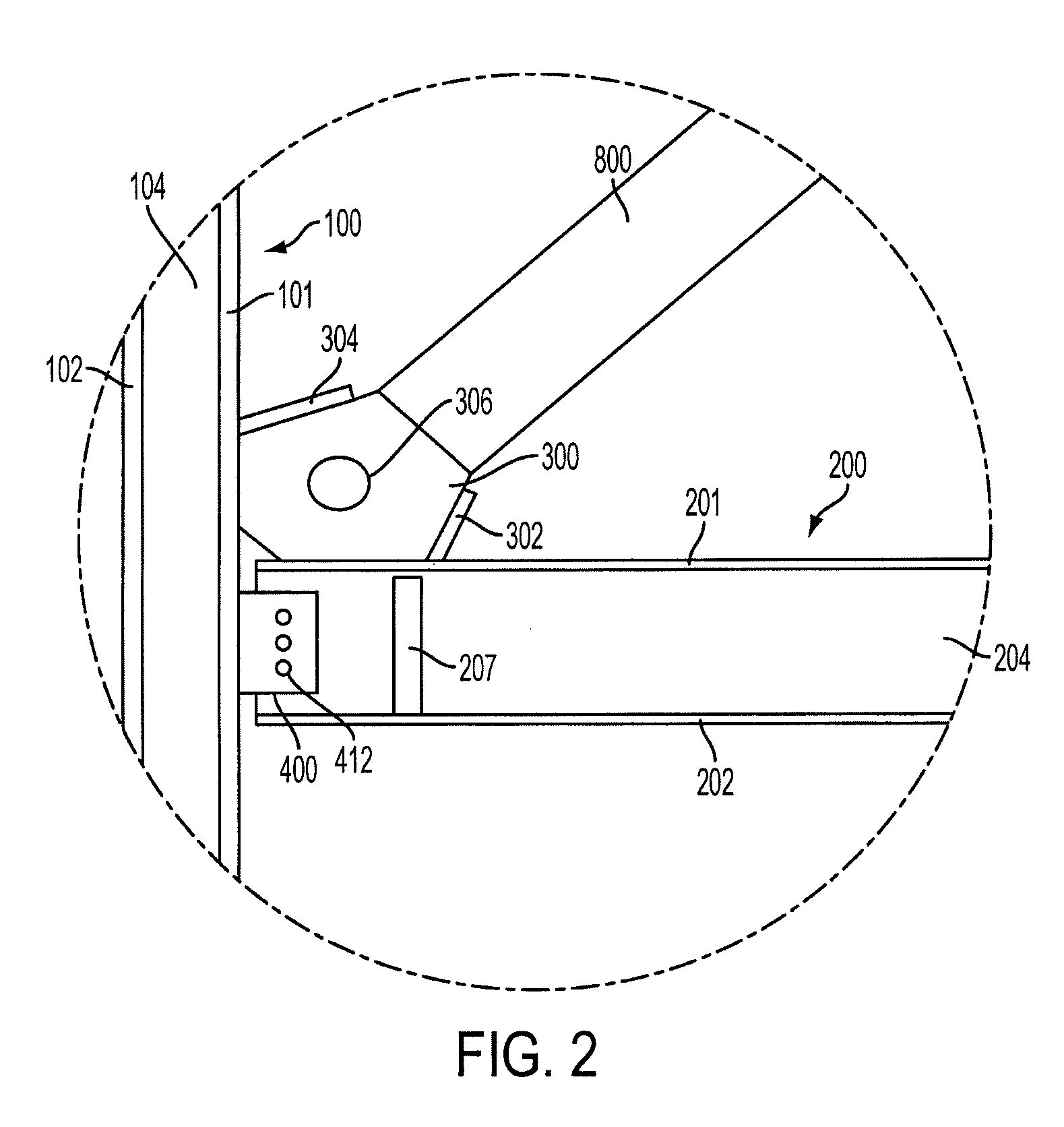

Braced frame force distribution connection

A structural framework that includes a column, a beam, a brace beam coupled at an angle to the column and the beam, and a gusset plate to connect the brace beam with the column and the beam. The framework also includes a shear plate with horizontally slotted holes to couple to the column to the beam. The structural framework may also include double framing angles or a flex plate coupled to the gusset plate and to the beam via spacer plates to provide for a semi-rigid connection.

Owner:SEISMIC STRUCTURAL DESIGN ASSOCS

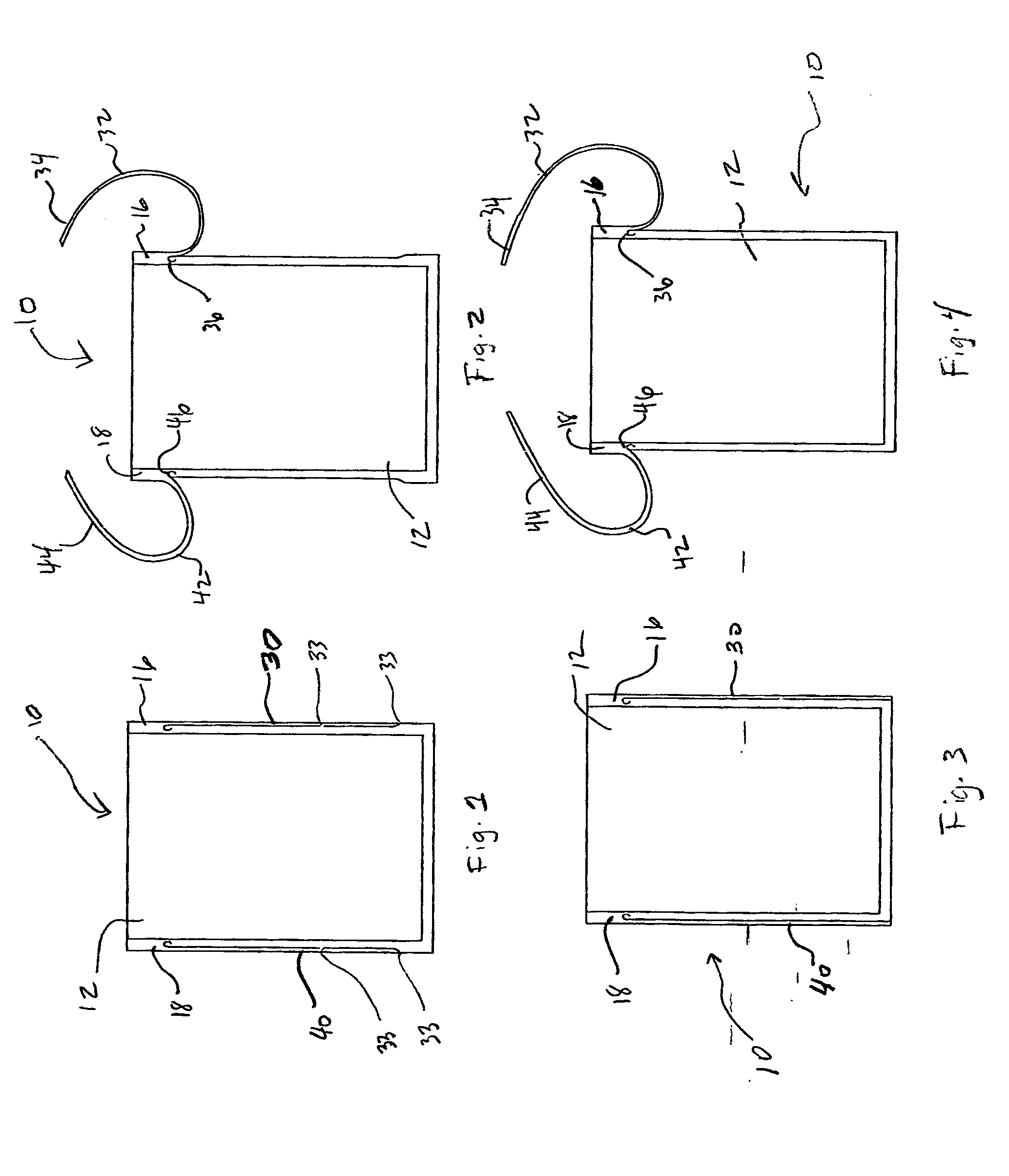

Flexible package having an easy opening feature

A flexible package is disclosed having an easy opening feature. The opening feature includes a gusset formed in at least one side wall. The gusset is aligned inward of the side wall and forms a pocket having an internal panel and an external panel. An aperture is formed through the external panel and is sized to receive at least one human finger. The package also has a line of weakness formed in the side wall containing the external panel with the aperture formed therethrough. The line of weakness has two portions, each located on an opposite side of the aperture and each extending from the first end of the gusset to a point spaced apart therefrom. The line of weakness also has a third portion which extends across the side wall and connects with the first two portions of the line of weakness. The combination of the gusset, the aperture and the line of weakness create a structure which allows the package to be easily opened.

Owner:KIMBERLY-CLARK WORLDWIDE INC

Article carrier having automatic end retention means

Owner:MEADWESTVACO PACKAGING SYST LLC

Production process method of pipe whip restraint steel structure of main power house of nuclear power station conventional island

ActiveCN101862942AImprove perforation rateReduce distortionArc welding apparatusBoring/drilling machinesNumerical controlGusset plate

The invention belongs to the technical field of pipe whip restraint steel structures of main power houses of nuclear power station conventional islands, in particular to a production process method of the pipe whip restraint steel structure of the main power house of the nuclear power station conventional island, which comprises the lofting process, the marking-off and scribing process, the cutting processing process, the bevel processing process, the hole-making process, the correction process, the polishing surface, the material splicing process, the pre-splicing process of a steel member, the assembly process, the processing process of a friction surface, the welding process of the steel structure and the anti-slip test of the friction surface of the steel member before leaving a factory, sandblasting, derusting and coating of a base coat are carried out in the factory, and the production of the steel structure is divided into the production processing of a welded H-shaped steel column, the production of a steel beam, the assembly and the welding of a support part, the production of a combined steel beam, the assembly and the welding of a girder box body and an inclined support below the girder box body, and the assembly and the welding of a pipe whip restraint key. The production process method can improve the drilling precision, utilize a numerical control planar drilling machine to complete the drilling on a gusset plate, determine a variety of processing processes and welding process parameters, and ensure the dimension of the member after the assembly and the smooth proceeding of field installation.

Owner:EAST STEEL STRUCTURE BRIDGE

Vehicle body structure

A vehicle body structure includes longitudinally extending elements such as roof side rail outer and inner members, a reinforcement member and a gusset that are part of a side impact energy management system for vehicles that include a sunroof. A laterally extending cross member is connected to the roof side rail members, and the roof side rail members are connected to an upper portion of an approximately vertical B-pillar. The cross-member is connected to the roof side rail members approximately perpendicular to the B-pillar, but longitudinally offset from the B-pillar. The reinforcement member extends between the roof side rail members to the cross-member.

Owner:NISSAN MOTOR CO LTD

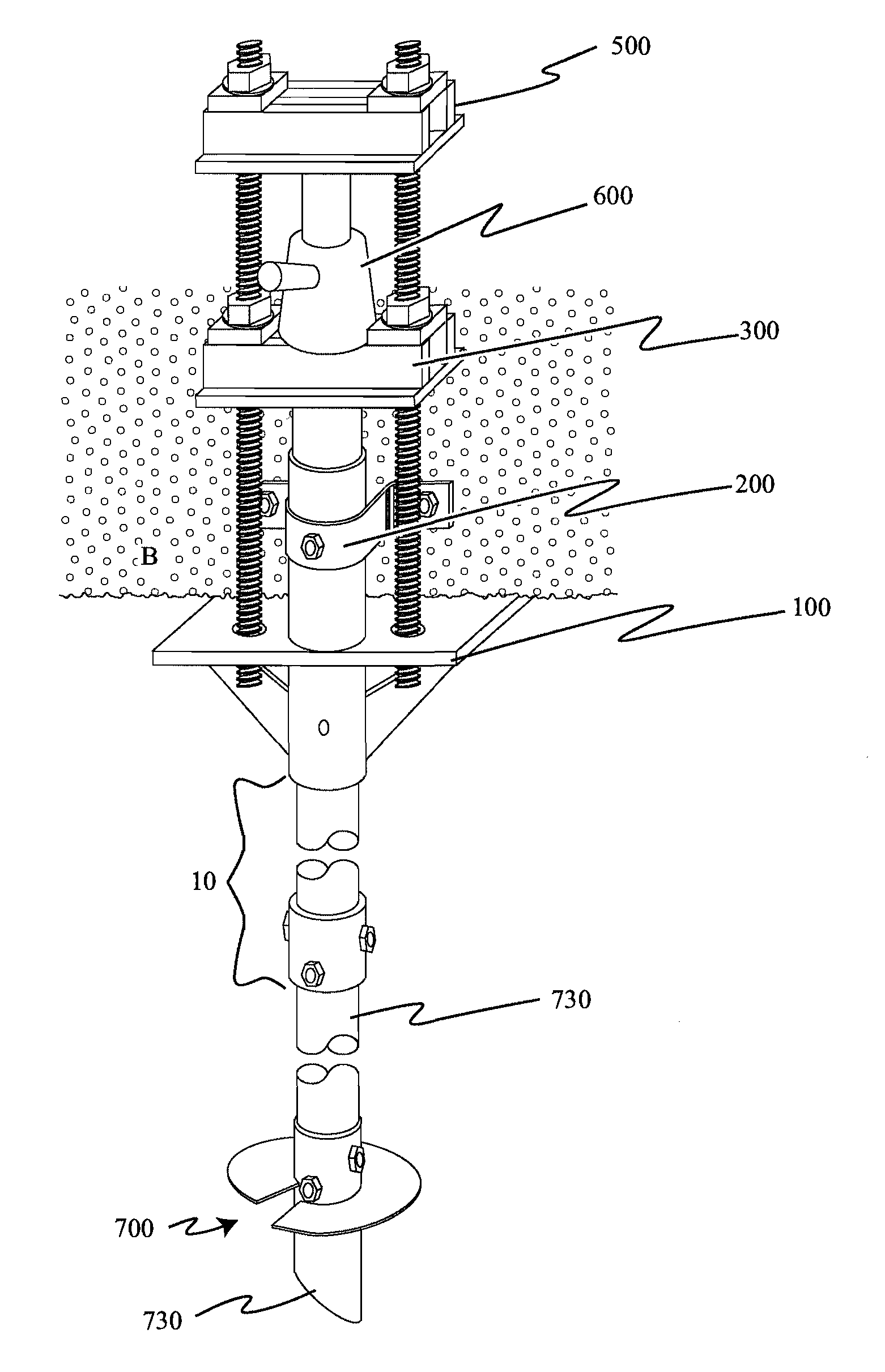

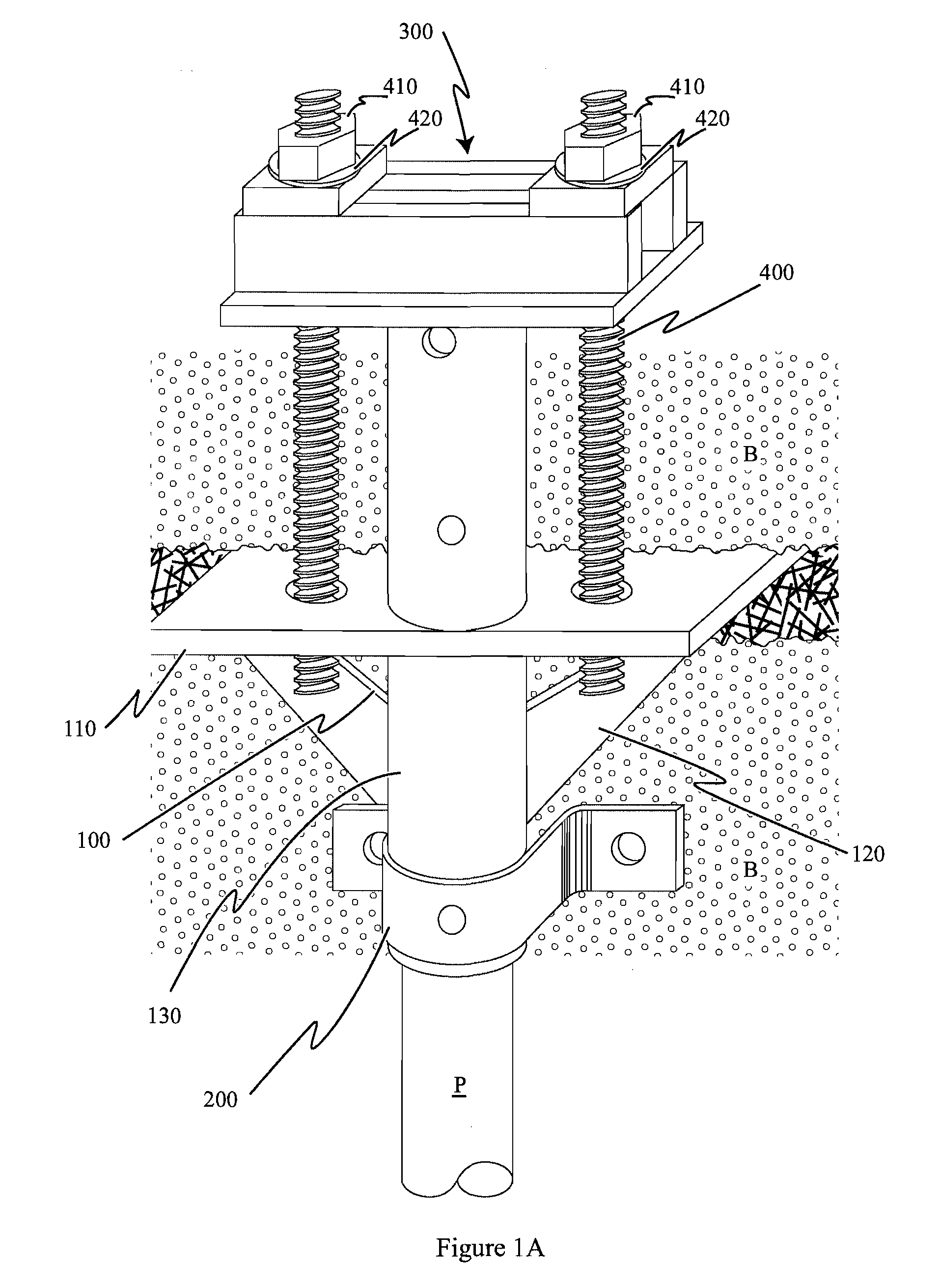

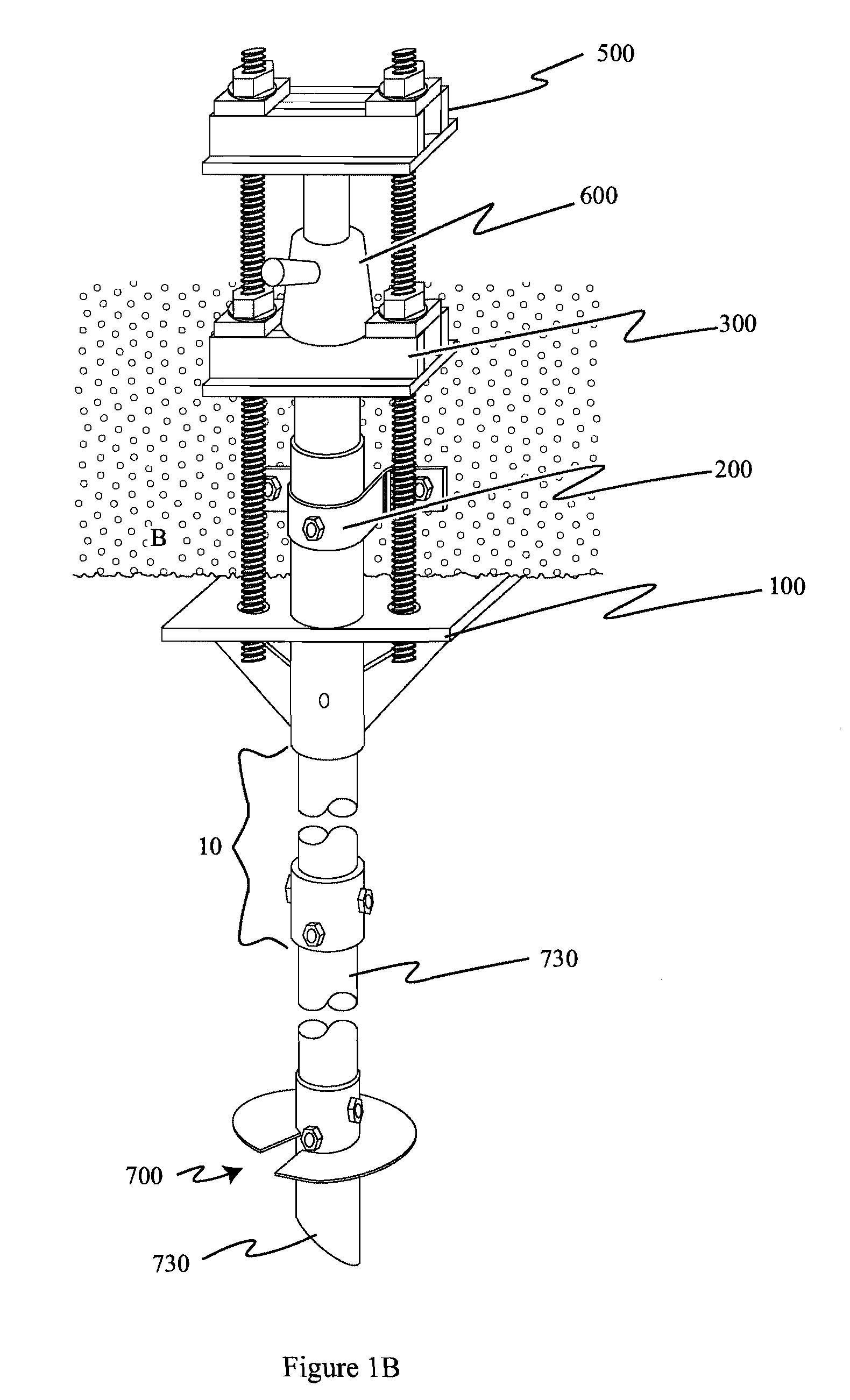

Apparatus for lifting building foundations

A lift bracket system for lifting a building structure such as a foundation and the like comprising a lift plate having a top surface and a bottom surface, the top surface for insertion under the building structure; a generally cylindrical housing affixed to the lift plate and extending perpendicularly from the top surface and the bottom surface of the lift plate, the housing defining a generally circular opening through the lift plate, the opening being disposed away from the center of the lift plate; and at least one gusset for supporting the lift plate, the gusset having a first end and a second end, the gusset disposed beneath the lift plate, wherein the first end of the gusset is attached to the bottom surface of the lift plate and the second end of the gusset is attached to the housing.

Owner:PIERTECH

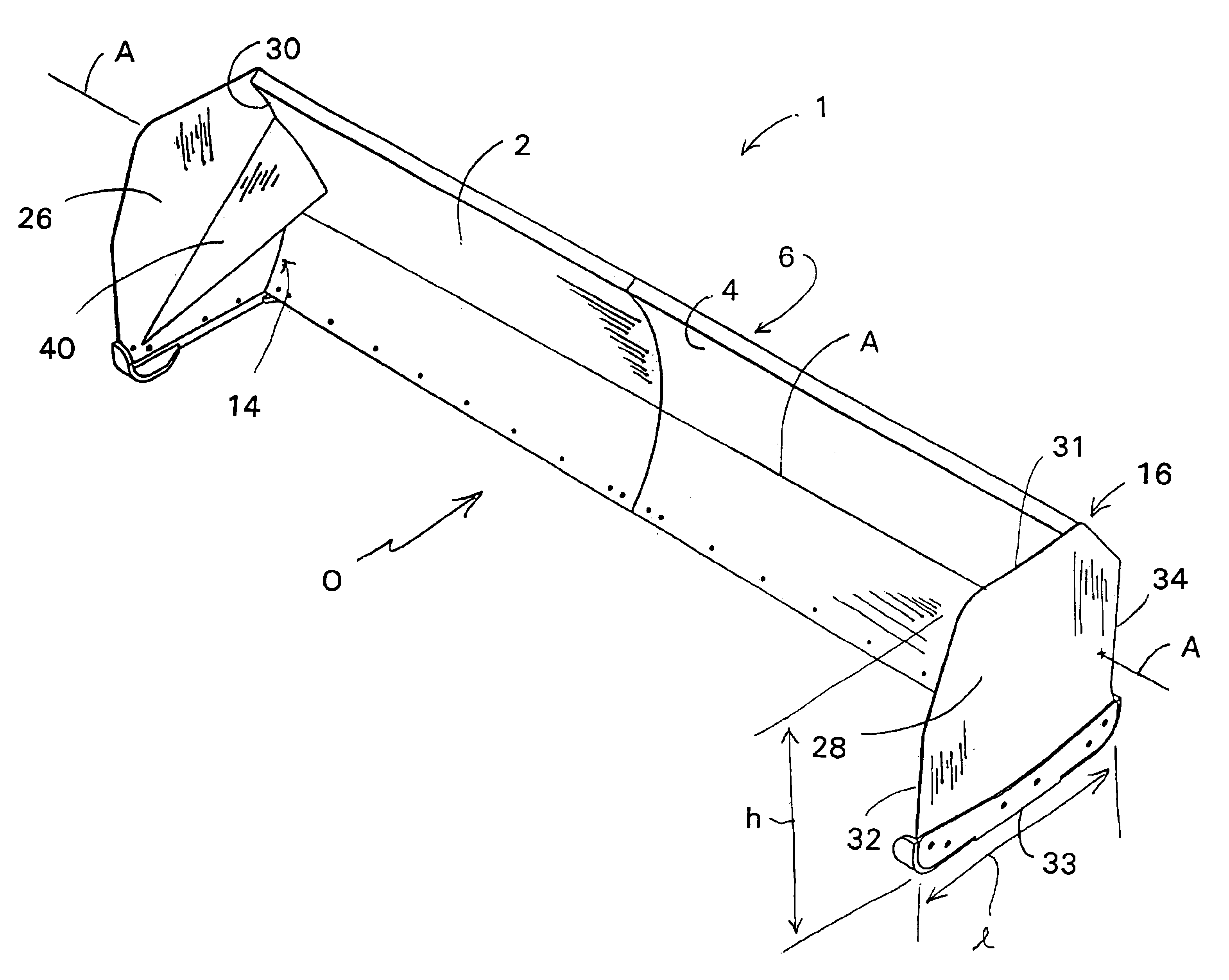

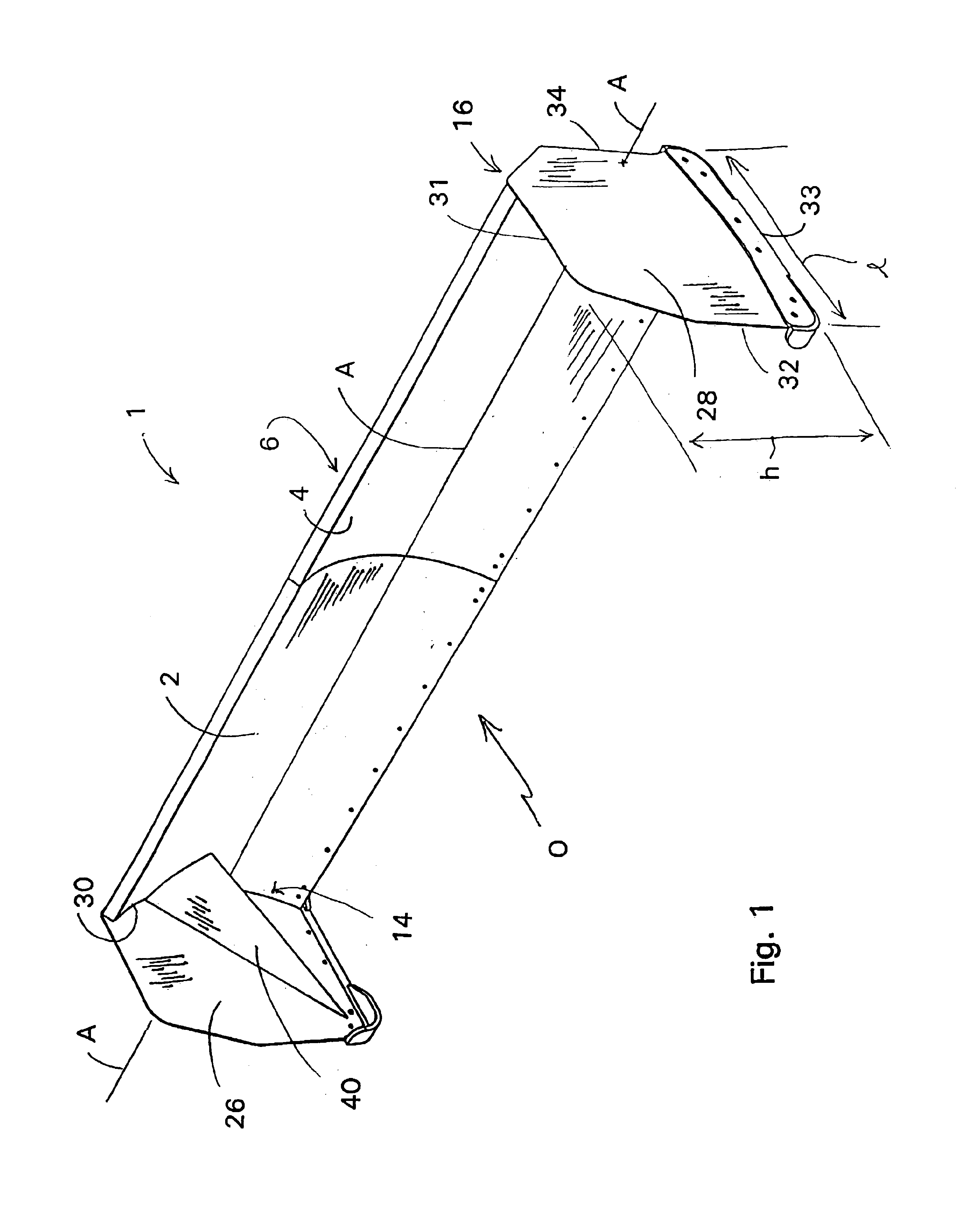

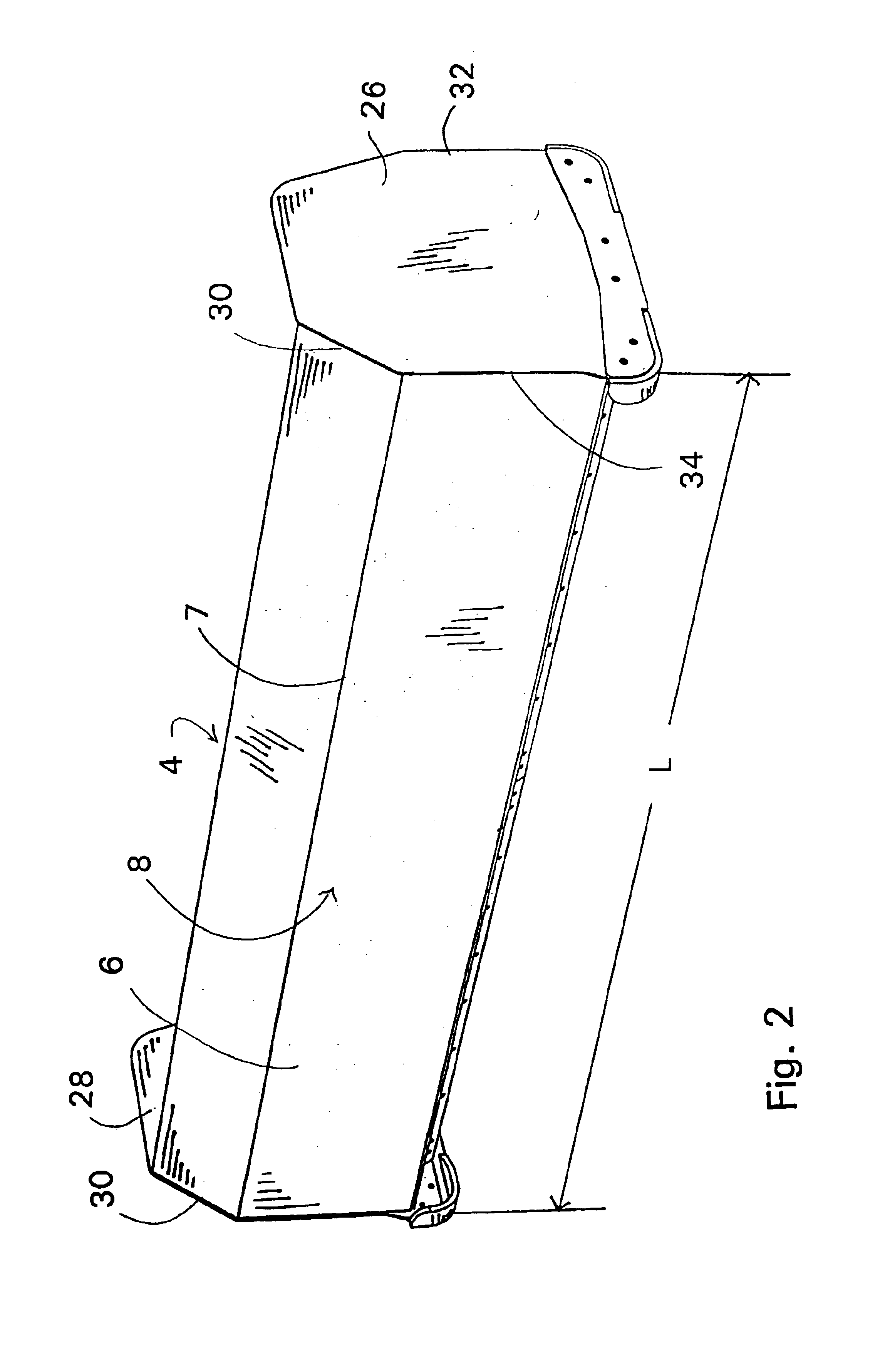

Materials moving blade

InactiveUS6845576B2Facilitate disengagementPromote sheddingMechanical machines/dredgersTilling equipmentsGusset plateEngineering

A materials pushing or moving blade for use with heavy equipment vehicles, for example, a bulldozer or loader, and more specifically to a method and apparatus for moving snow, specifically a snow moving blade having a reinforcing gusset for strengthening the extended sidewalls of the snow moving blade.

Owner:DEGELMAN IND LP

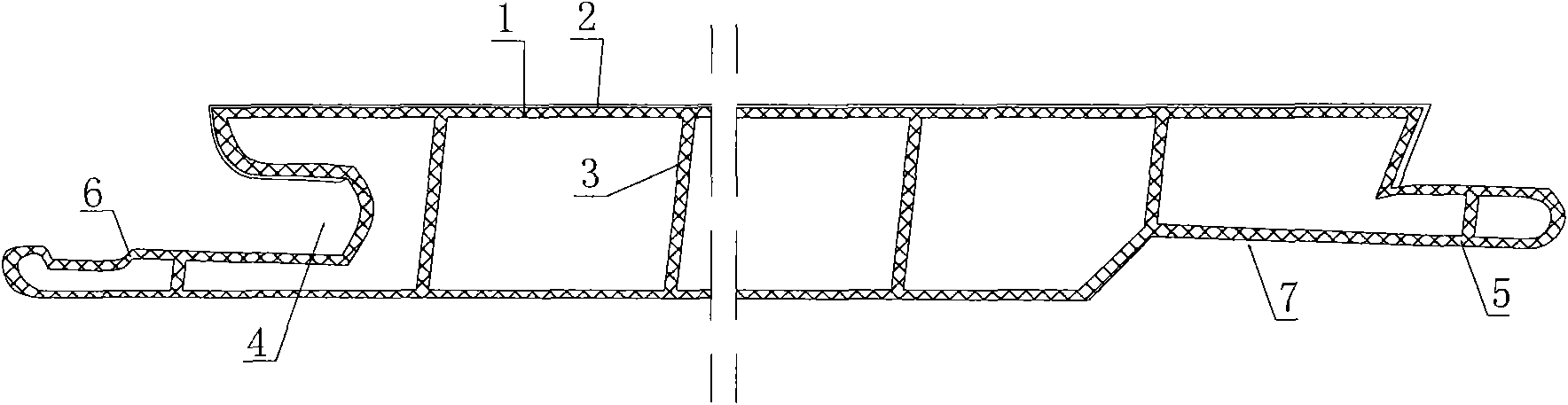

Environmental-friendly lead-free PVC ceiling sheet and manufacturing method and applications thereof

The invention relates to a ceiling sheet, in particular to an environmental-friendly lead-free PVC ceiling sheet and a manufacturing method and applications thereof. The environmental-friendly lead-free PVC ceiling sheet is obtained by blending the following components according to parts by weight and then extruding to mould: 50-100 parts of PVC resin SG-5, 15-50 parts of nano calcium carbonate, 3-10 parts of calcium zinc stabilizer, 1-3 parts of rutile titanium dioxide, 1-3 parts of CPE impact modifier, 1.5-5 parts of ACR enhancer, 0.2-0.8 part of stearic acid, 0.3-1.0 part of calcium stearate, and 0.2-0.4 part of PE wax. The PVC ceiling sheet is used as a novel environmental-friendly lead-free material of which the lead content is less than or equal to 200PPM, and is applicable to non-toxic places with high environmental requirements such as hospitals, operating rooms, baby rooms, food plants, and the like. The invention also discloses the manufacturing method of the ceiling sheet and ceiling gusset plates manufactured by the sheet.

Owner:HUAJUN PLASTIC BUILDING MATERIAL

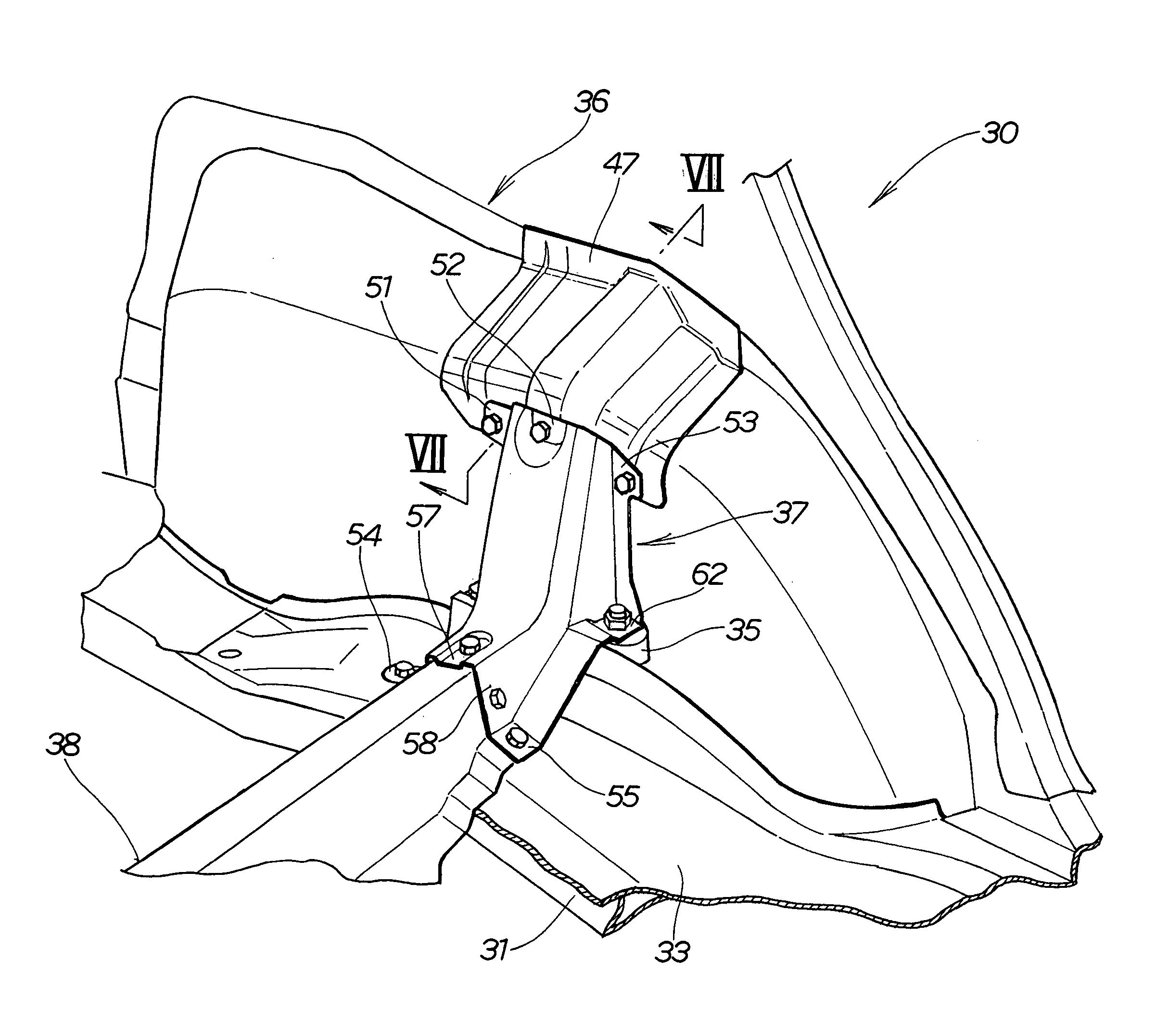

Vehicle rear body structure

InactiveUS20050073174A1Improve rigidityImprove assembly efficiencyVehicle seatsSuperstructure subunitsGusset plateEngineering

A rear body structure for a vehicle includes a gusset for reinforcing a body floor, each rear wheel house, and a damper support member disposed on the body floor adjacent to the wheel house. The gusset has a first portion connected to the wheel house, a second portion connected to the body floor, and a third portion connected to the damper support member and an upper end portion of a damper with the damper support member disposed between the third portion and the upper end portion of the damper. With this arrangement, a force applied from the damper to the damper support portion can be efficiently distributed through the gusset to the wheel house and the body floor.

Owner:HONDA MOTOR CO LTD

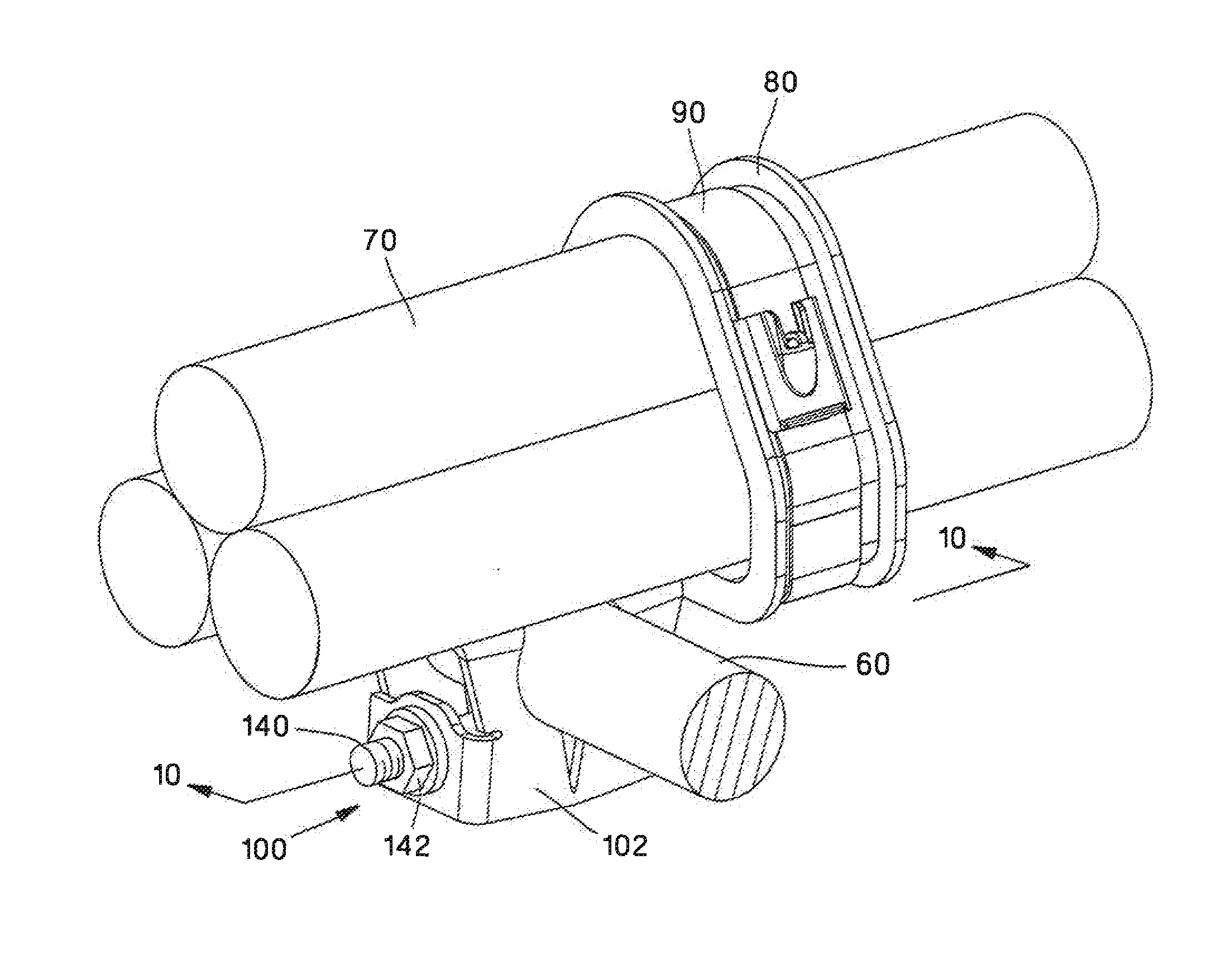

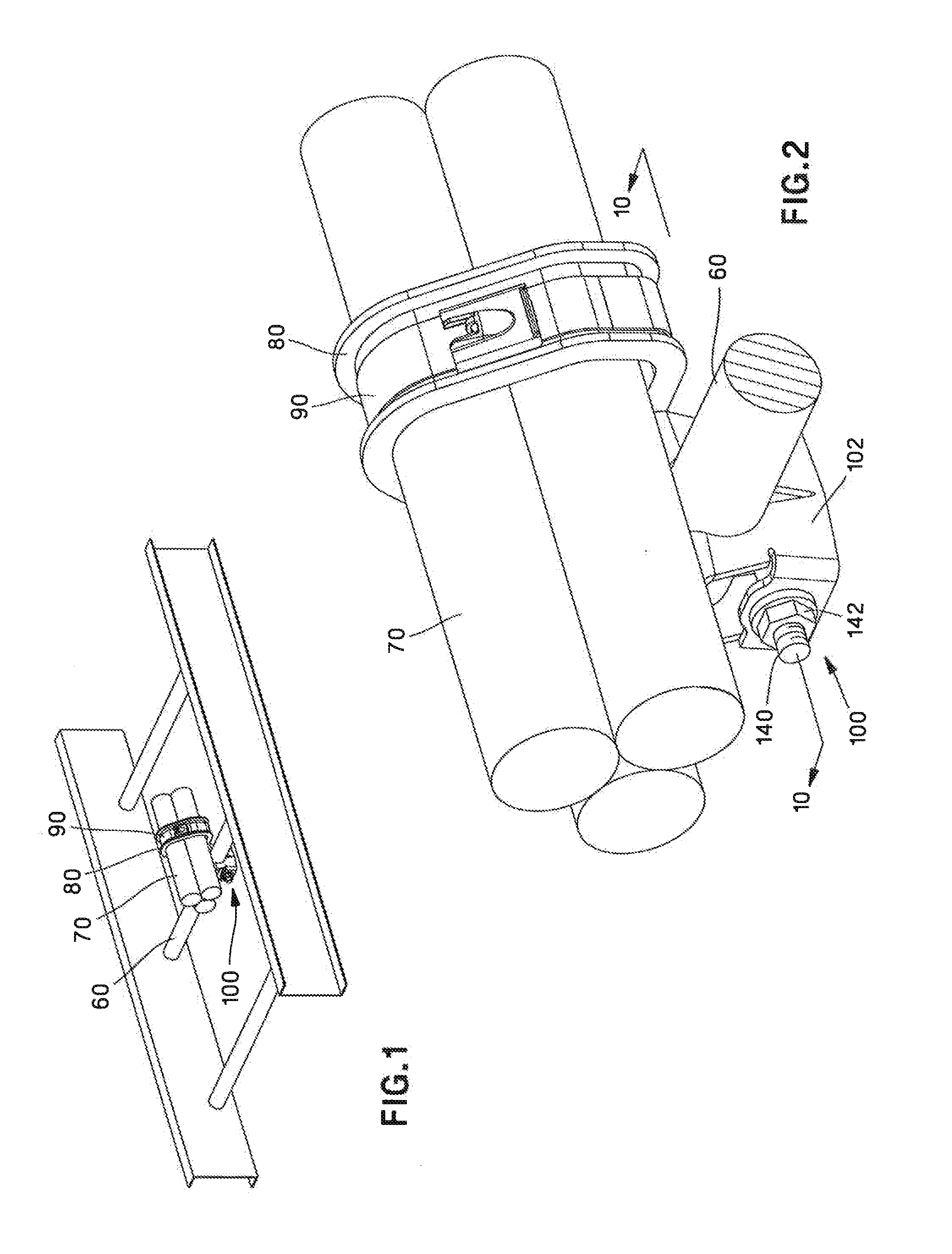

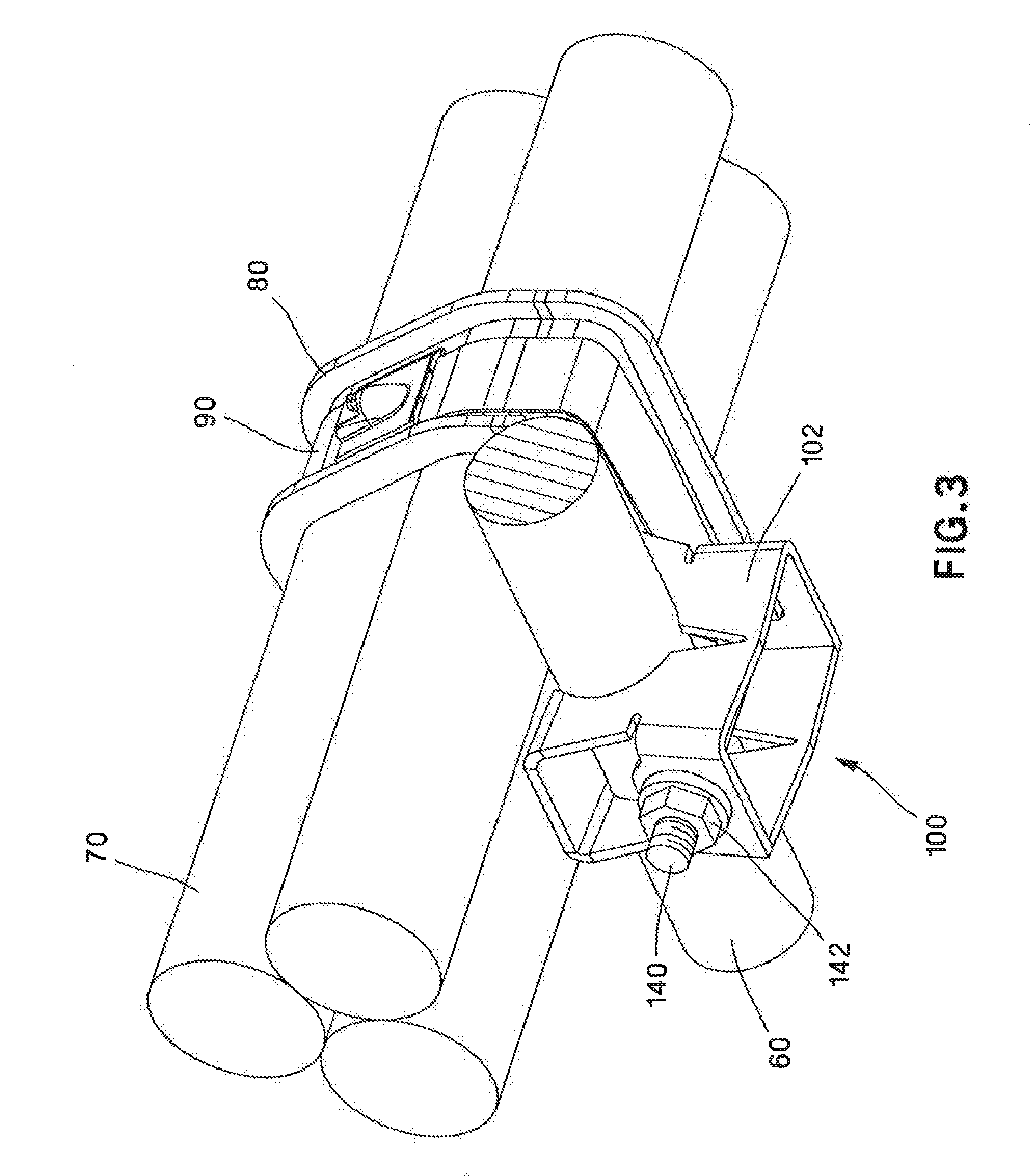

Cradle Clamp Bracket Assembly

A cradle clamp bracket assembly is disclosed. The cradle clamp bracket assembly secures cables to rungs of a ladder rack. The cradle clamp bracket assembly includes an elongated bracket having a first portion and a raised second portion. The first portion includes a slot located along the center of the first portion. The raised second portion includes a downwardly extending flange and at least one gusset to strengthen the bracket. The cradle clamp bracket assembly also includes a retainer that is received in the slot to engage the rung of the ladder rack.

Owner:PANDUIT

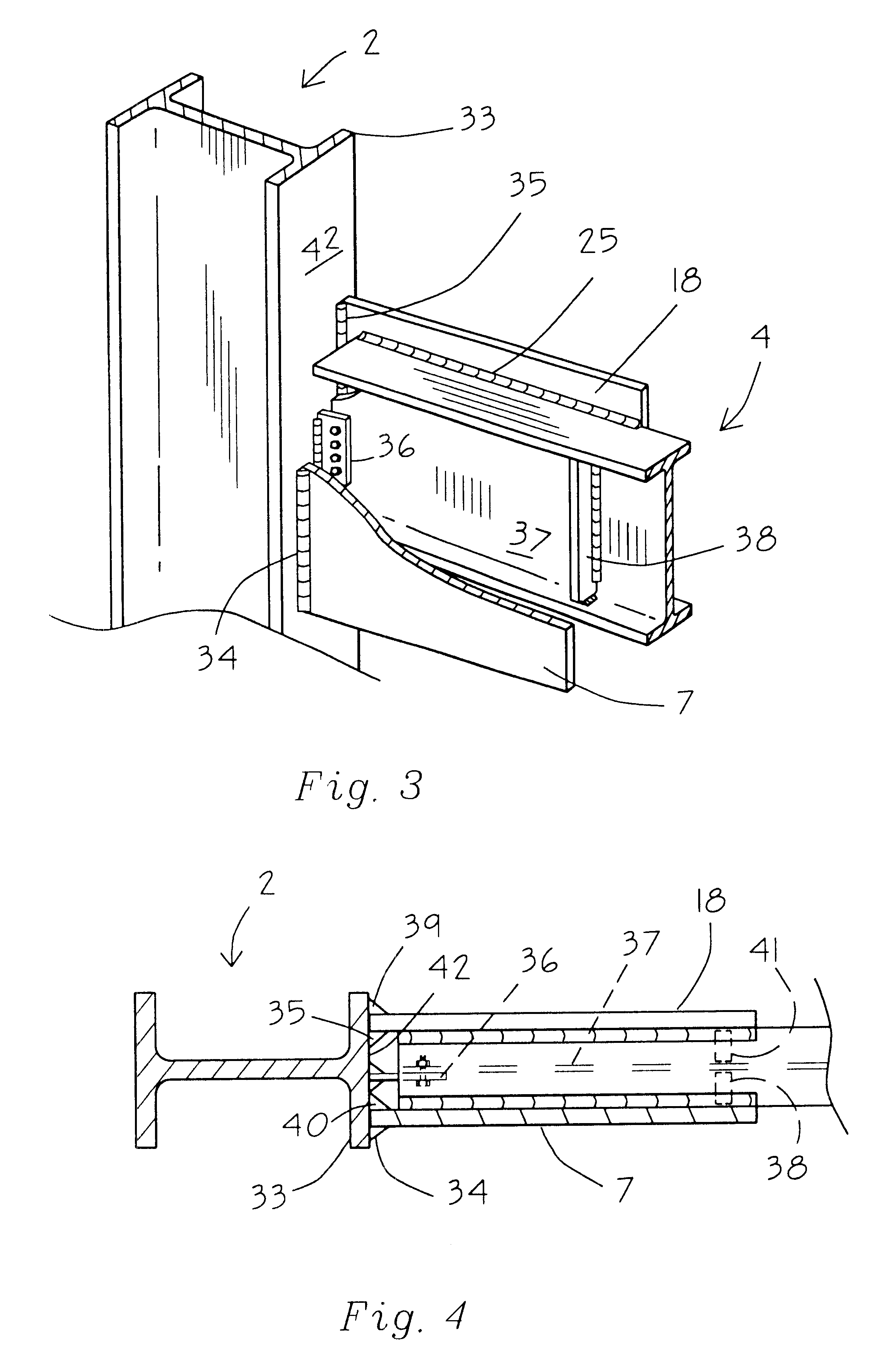

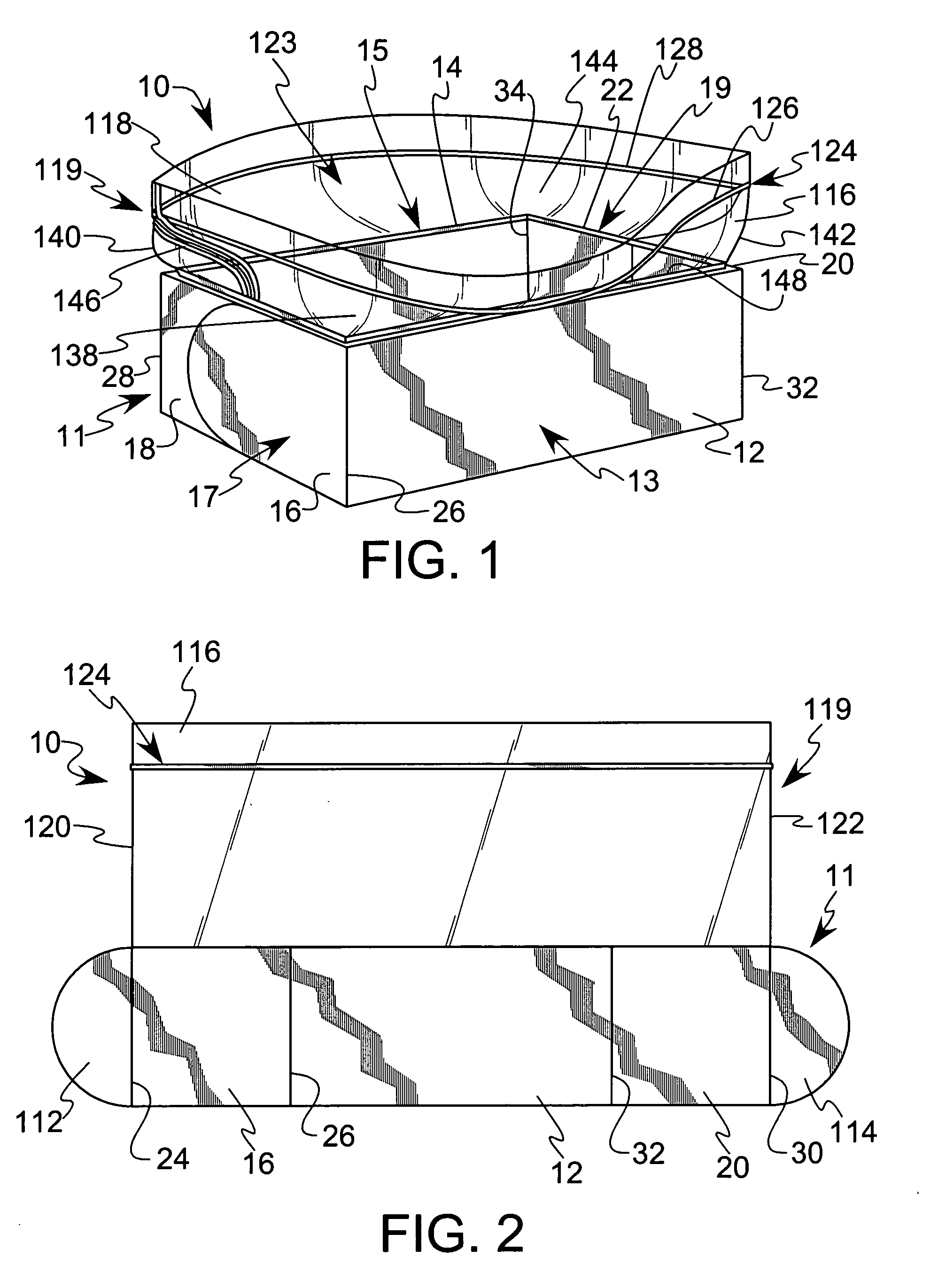

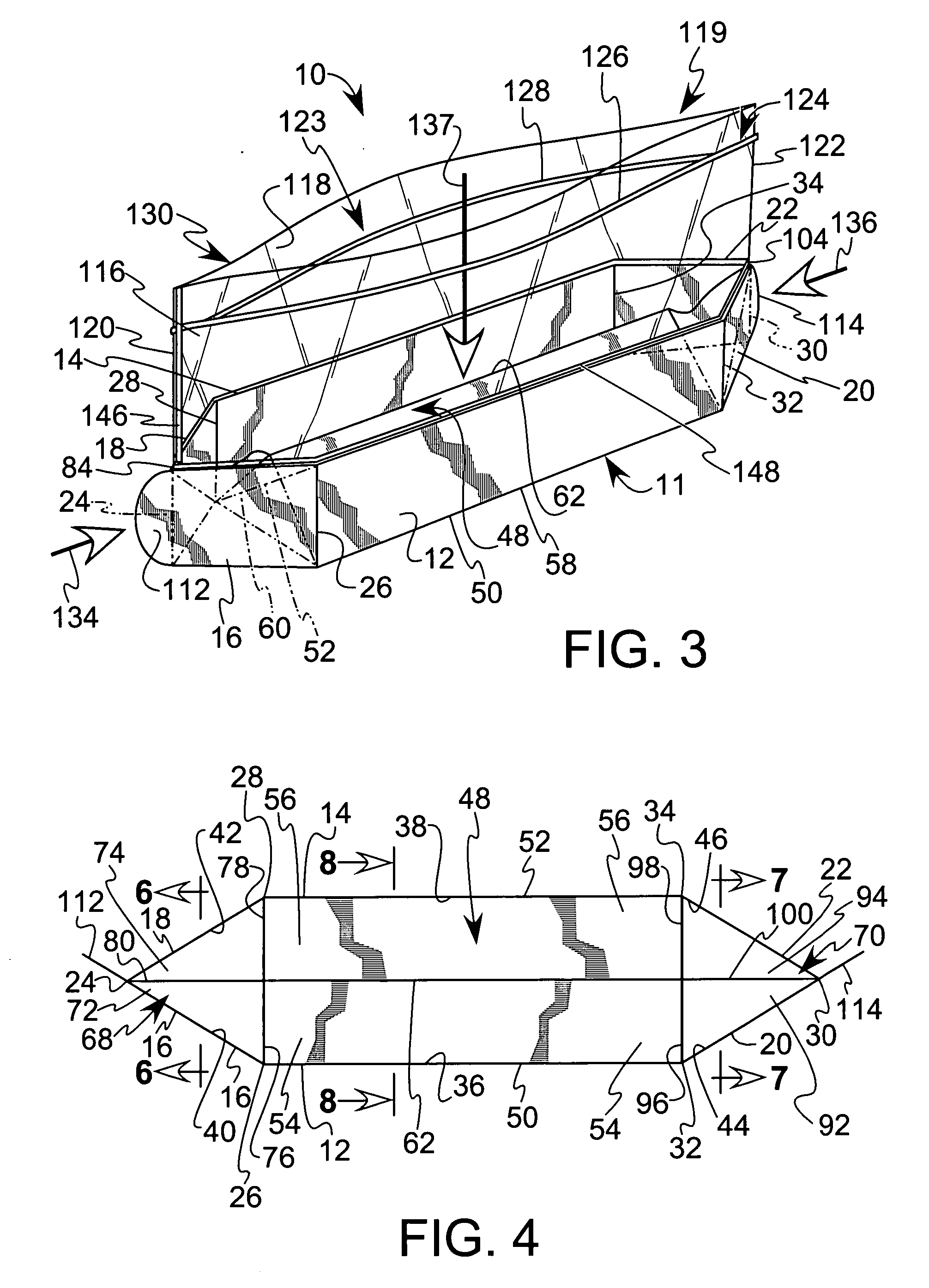

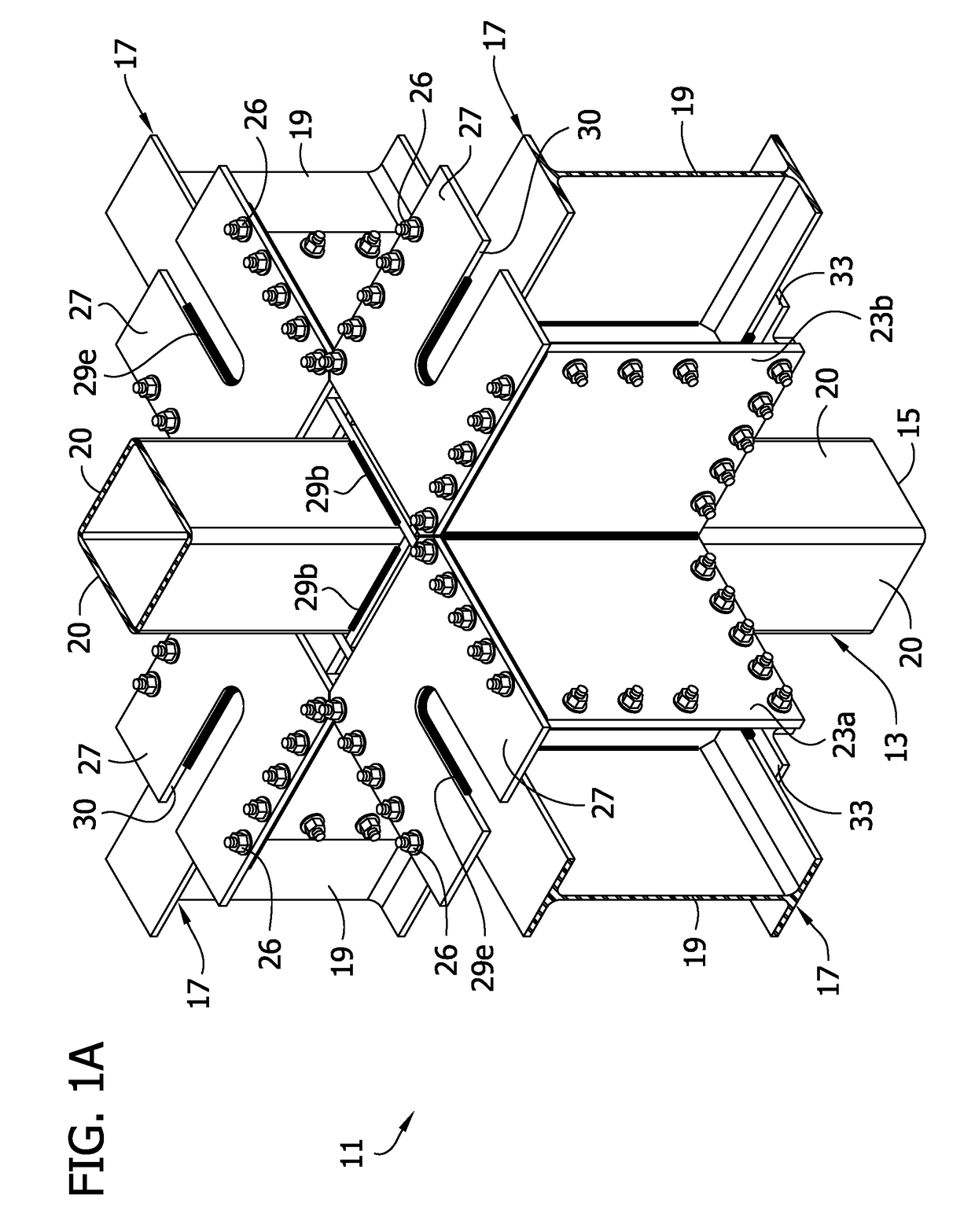

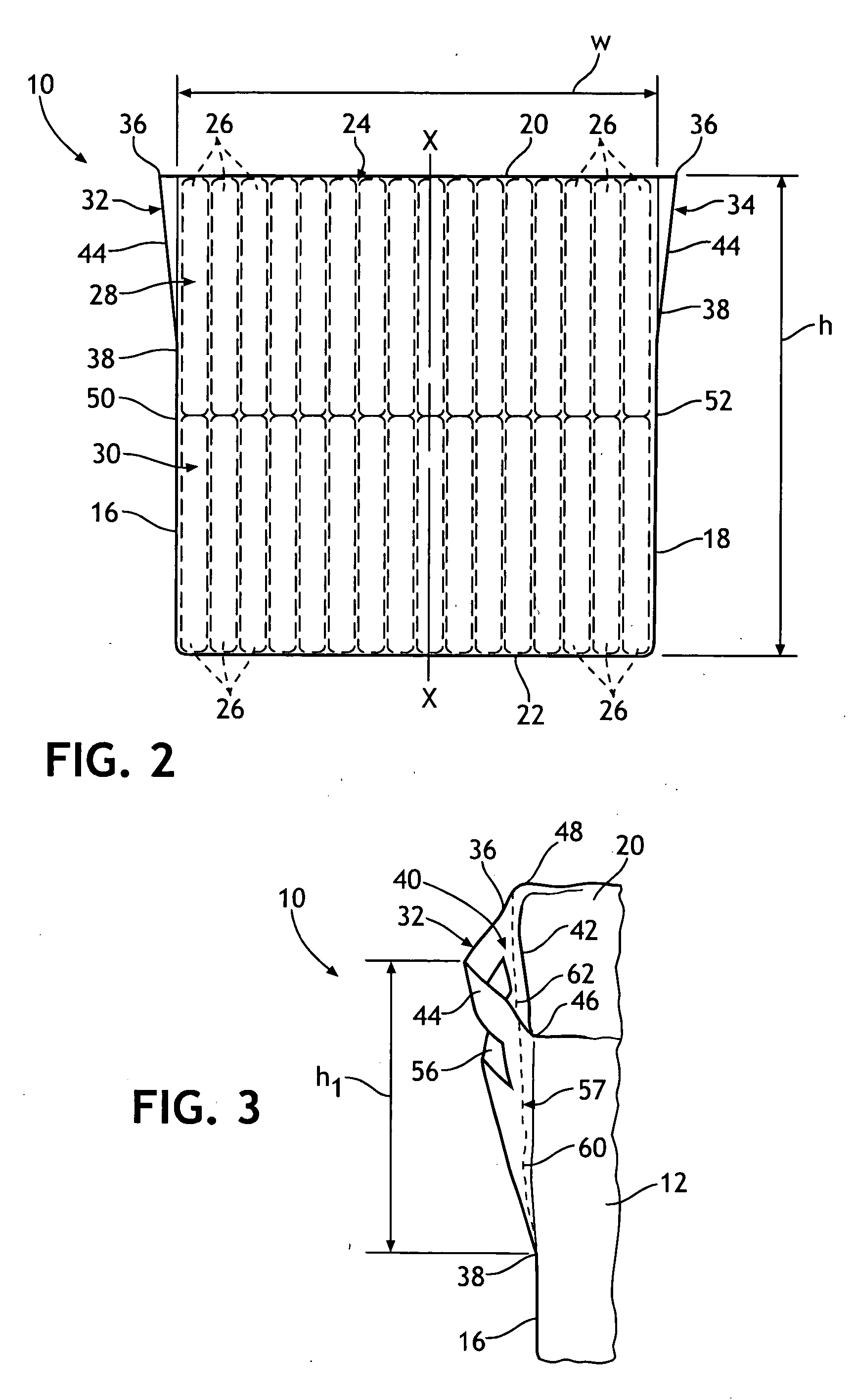

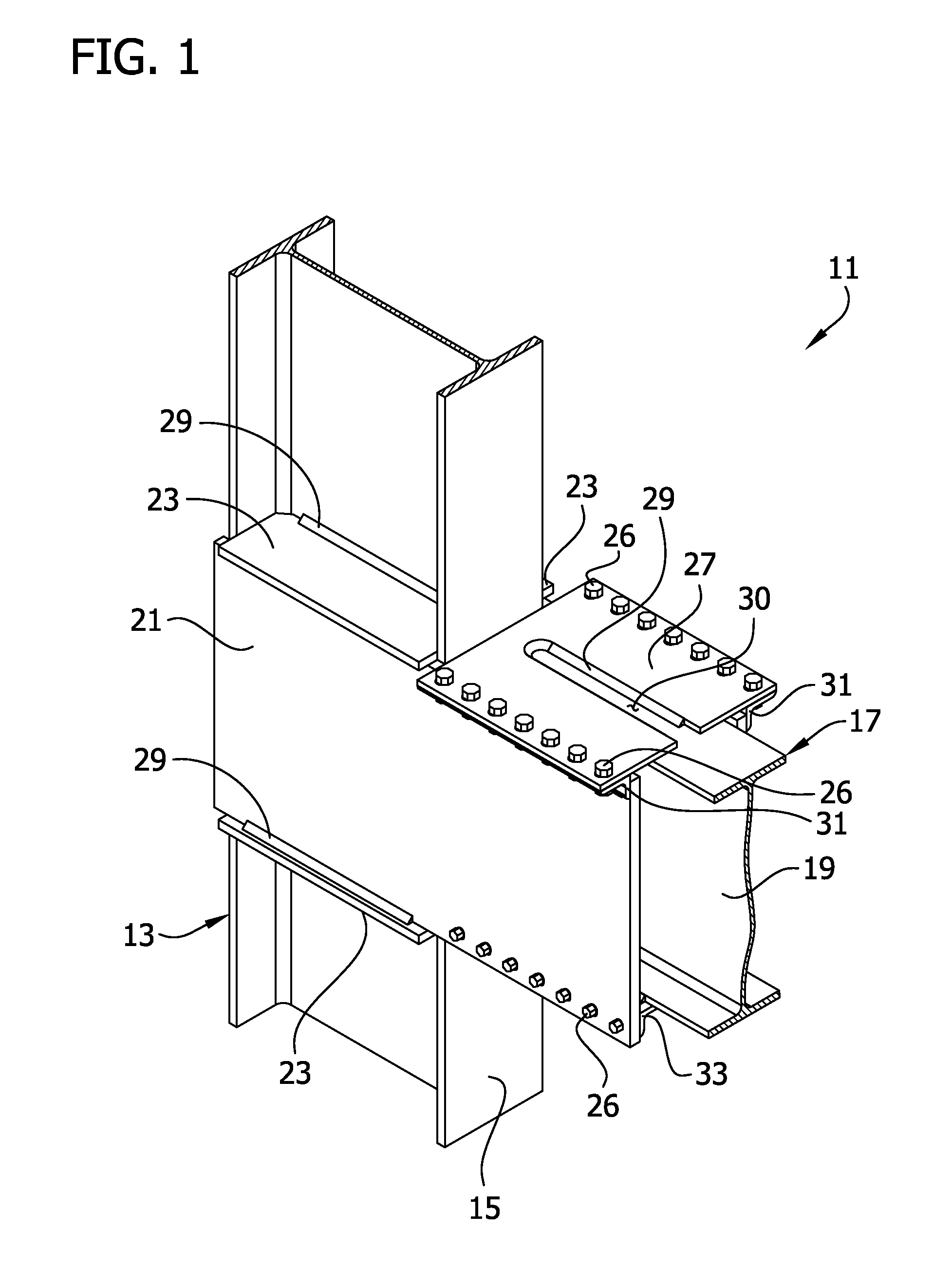

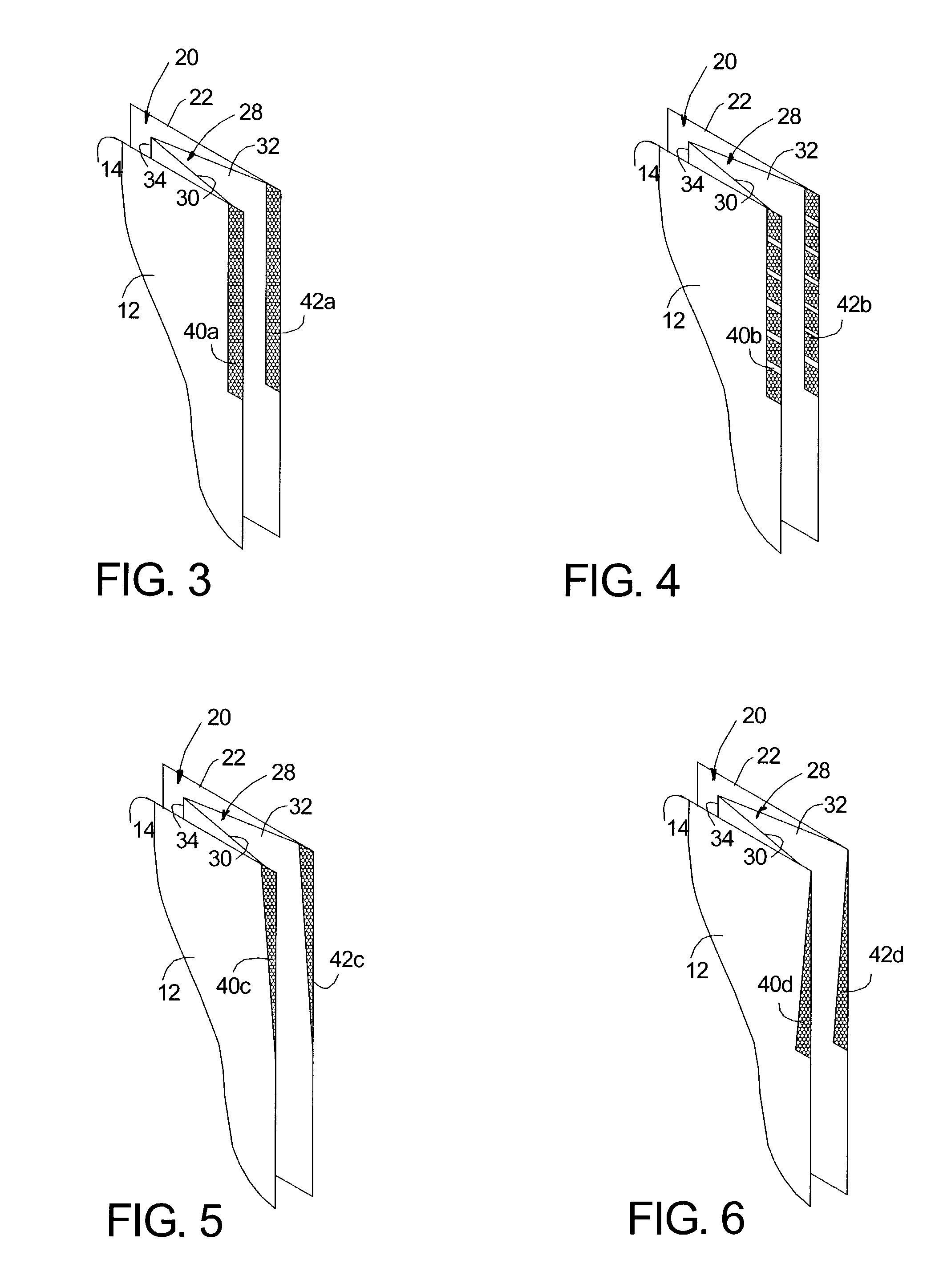

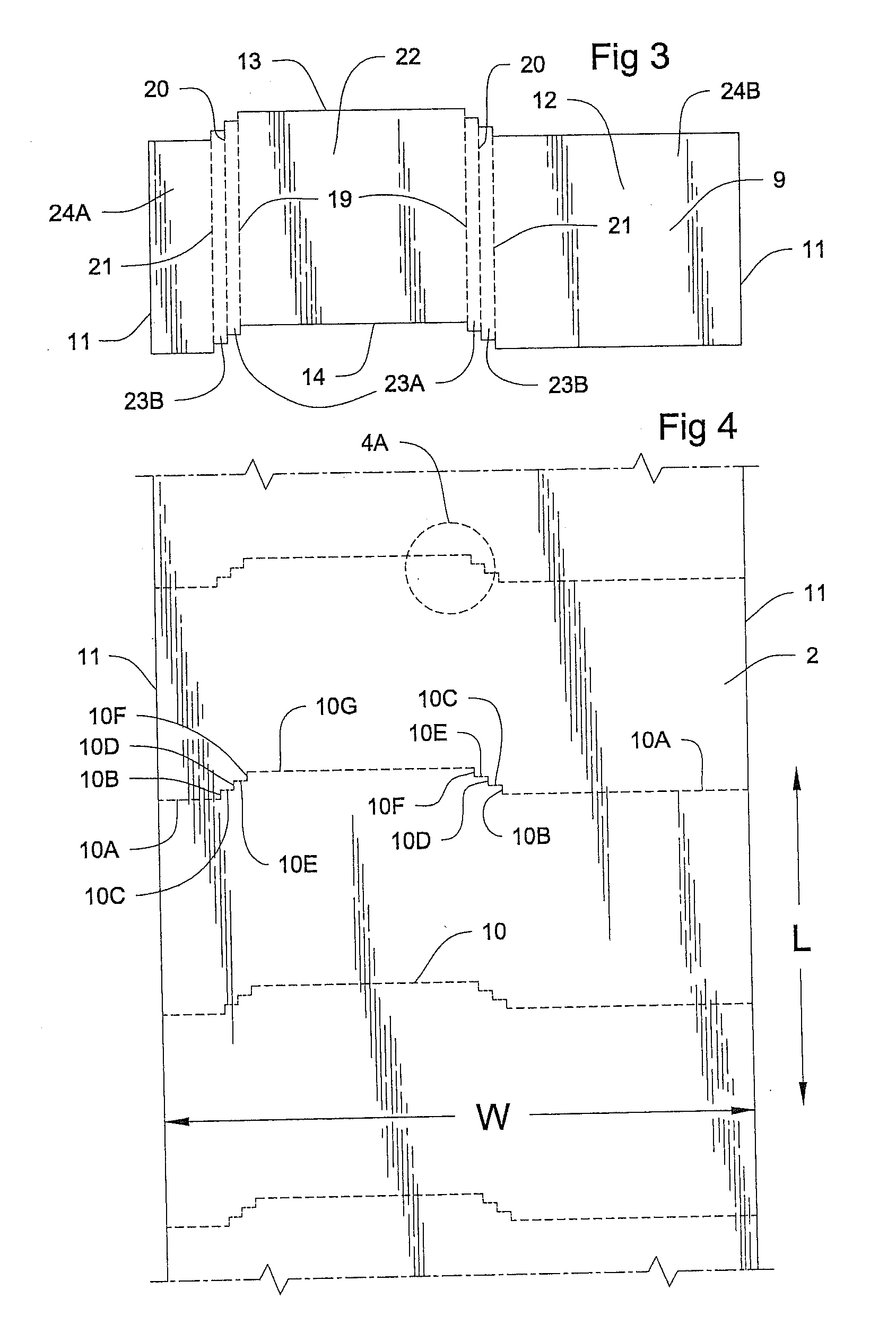

Gusset plate connection in bearing of beam to column

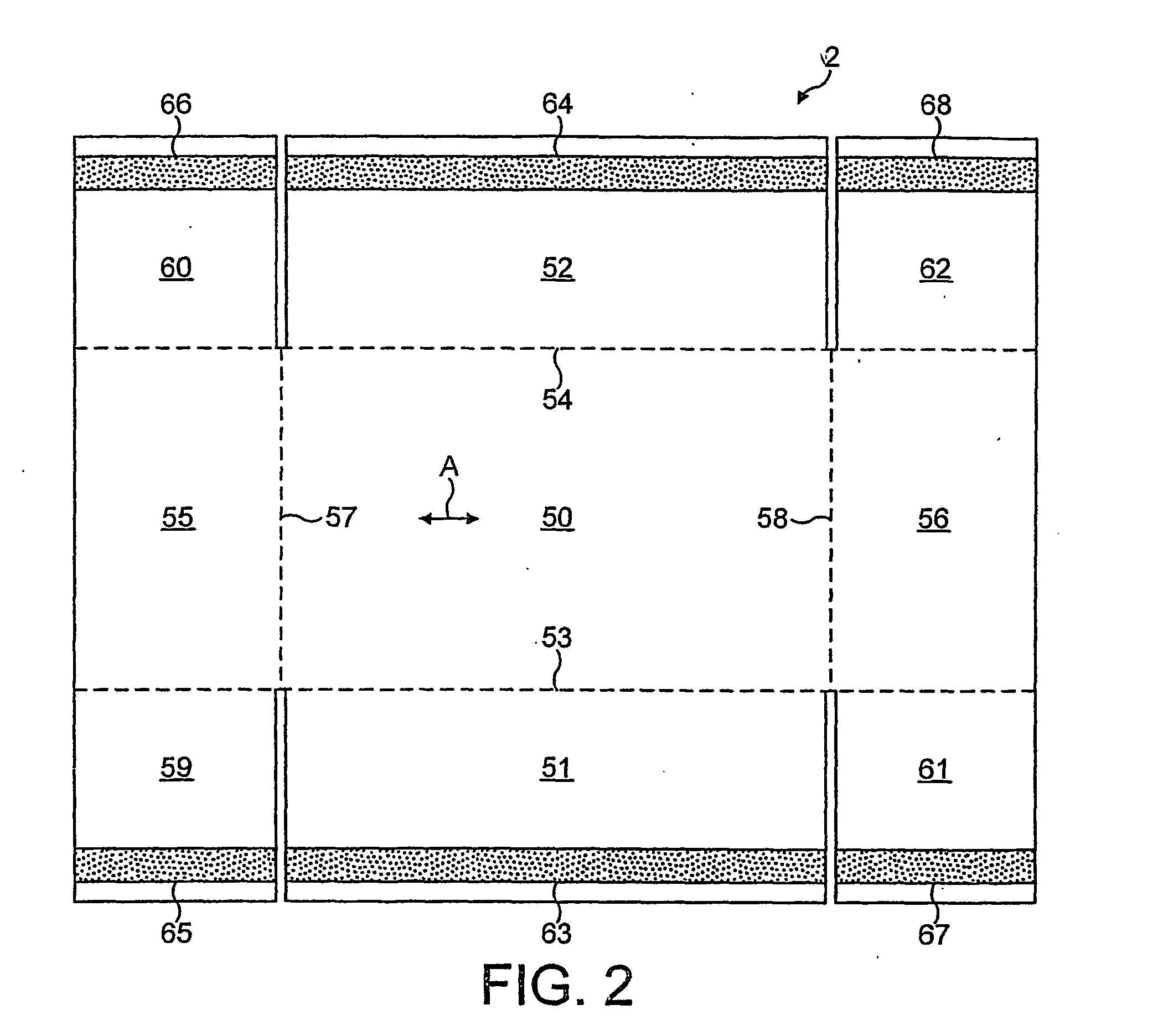

ActiveUS20150275501A1Prevent movementLoad-supporting elementsProtective buildings/sheltersGusset plateEngineering

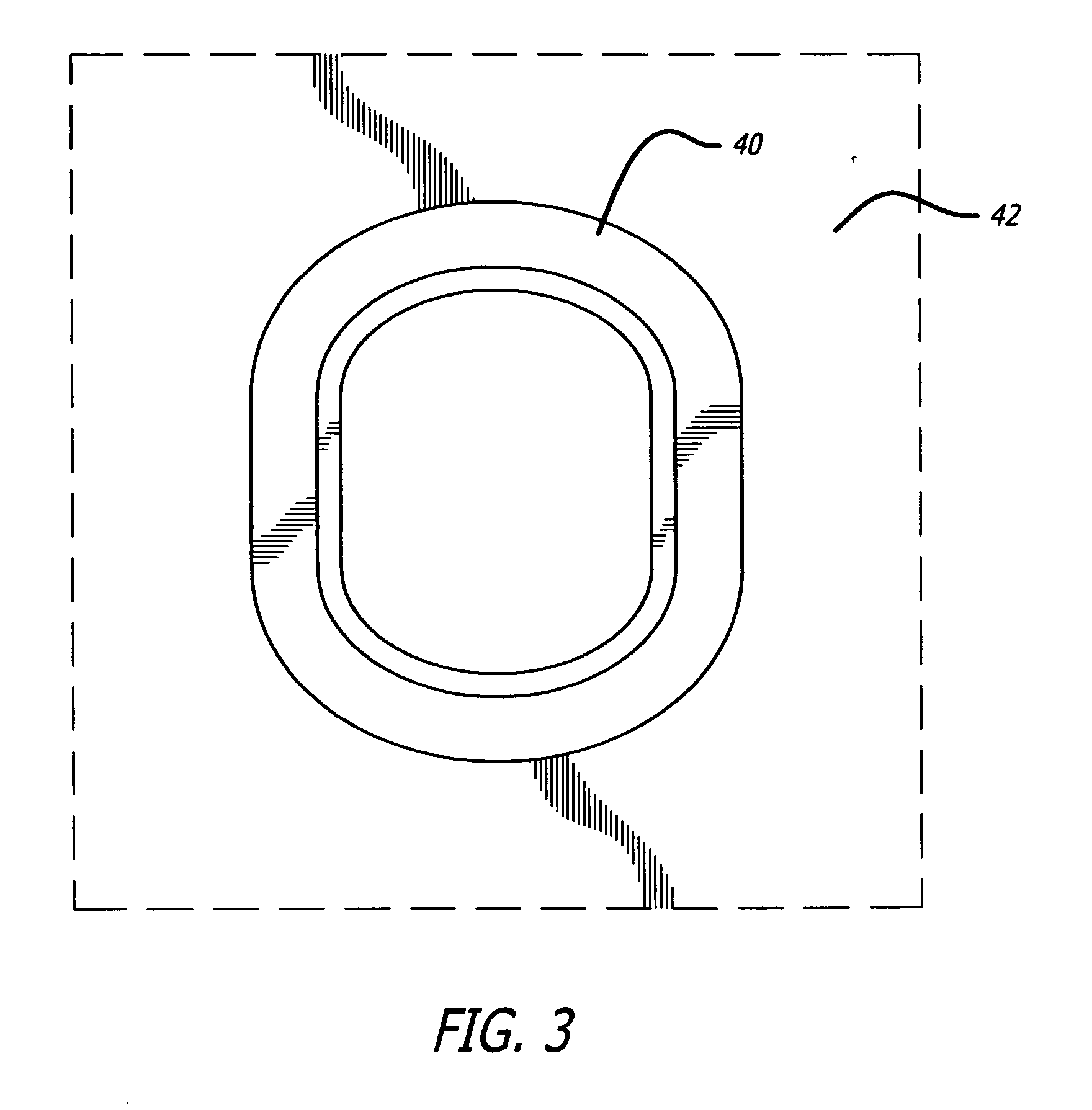

A beam to column joint connection structure of a building framework has a column assembly and a beam assembly. The column assembly includes a column, a pair of gusset plates on opposite sides of the column, and bearing elements. The beam assembly includes a beam having an end portion received between the gusset plates. The beam assembly has bearing elements. The bearing elements are positioned with respect to each other to prevent movement of the beam assembly relative to the column assembly by engagement of exterior bearing engagement surfaces of the bearing elements of the column assembly with exterior engagement bearing surfaces of the bearing elements of the beam assembly in a direction along a longitudinal axis of the beam. The beam-to-column joint connection does not require any bolts or welds connecting the beam assembly to the column assembly, resulting in an all bearing moment connection.

Owner:MITEK HLDG INC

Aerospace articles made from quasi-isotropic chopped prepreg

Quasi-isotropic chopped prepreg is used to make parts found in aerospace vehicles. Exemplary aerospace parts that are made using quasi-isotropic chopped prepreg include aircraft window frames, wing fairing supports, flange supports, frame gussets, rudder actuator brackets, shear ties, seat pedestals, cargo floor flange supports, storage bin fittings, antenna supports, torque tube pans, handle boxes, side guide fittings, wing box covers and intercostals.

Owner:HEXCEL

Container

InactiveUS20060151584A1Easy erectionImprove insulation performanceDomestic cooling apparatusLighting and heating apparatusGusset plateElectrical and Electronics engineering

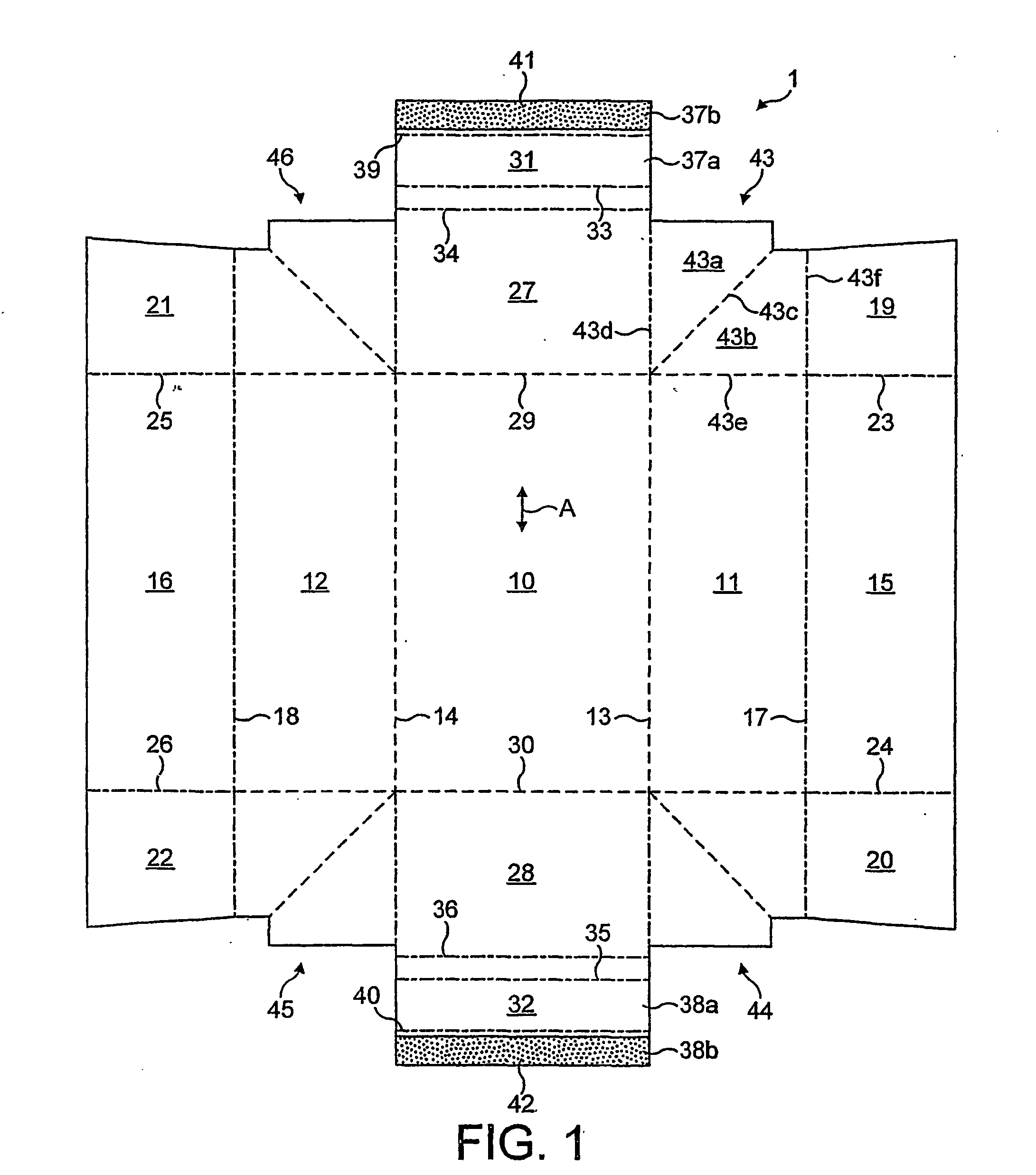

A blank (1) of stiff yet foldable sheet material erectable into a container base (3), comprising a rectangular bottom panel (10), a pair of side wall panel means foldably connected to sides of the bottom panel and provided with end flaps (19,20; 21,22), a pair of end wall panel means each comprising a first end wall panel (27,28) foldably connected to an associated end of the bottom wall panel (1) so as to be foldable upwardly therefrom and a second end wall panel (31,32) foldably connected to the first end wall panel, and foldable gusset means (43-46) at each corner of the bottom panel connecting opposite ends of each side wall panel means to opposite ones of said end wall panel means. In the erected container base the two end flaps (19,20; 21,22) are folded against the associated first end wall panel (27,28) and the second end wall panel (31,32) of each end wall panel means is folded over the underlying end flaps.

Owner:DS SMITH (UK) LTD

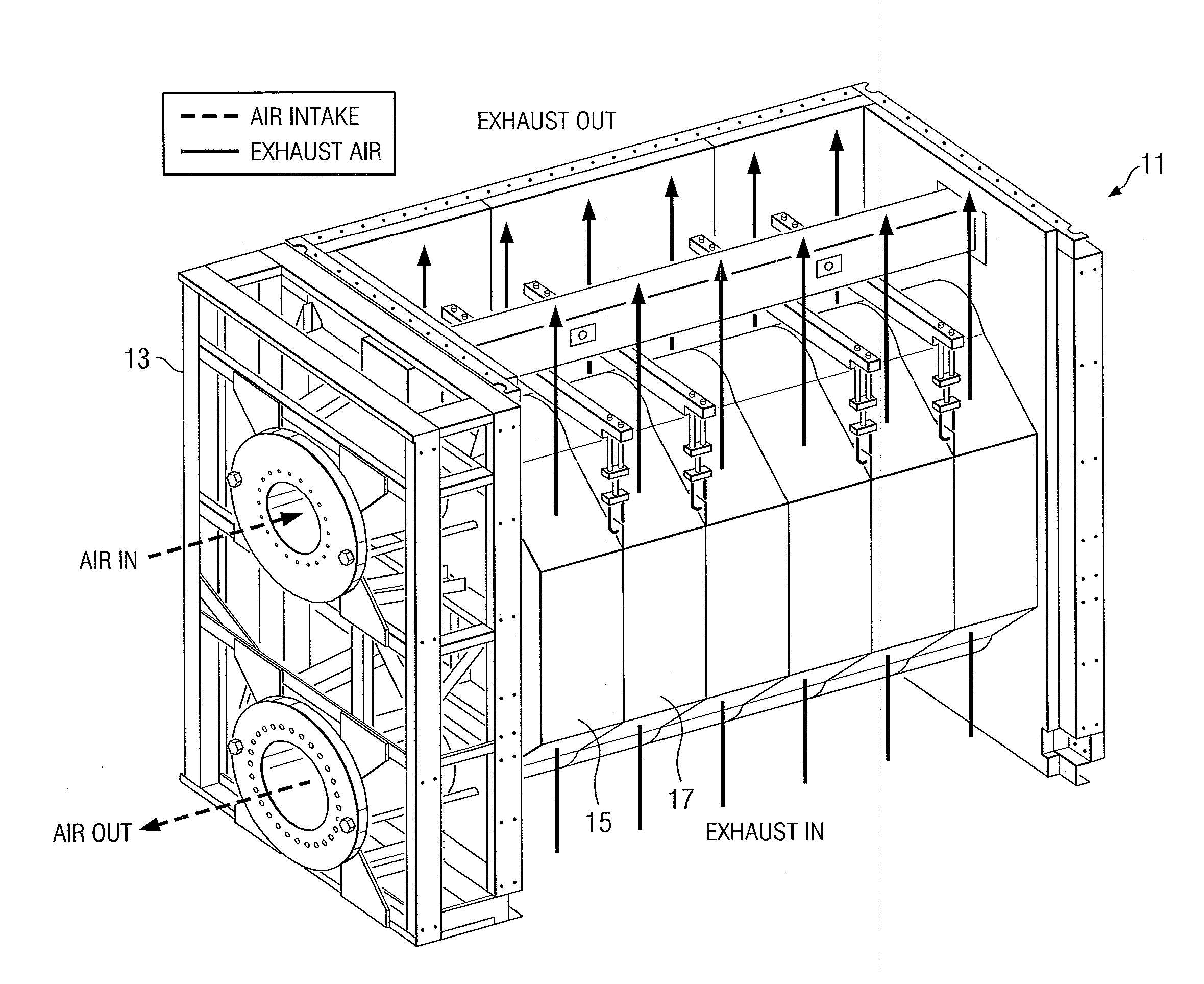

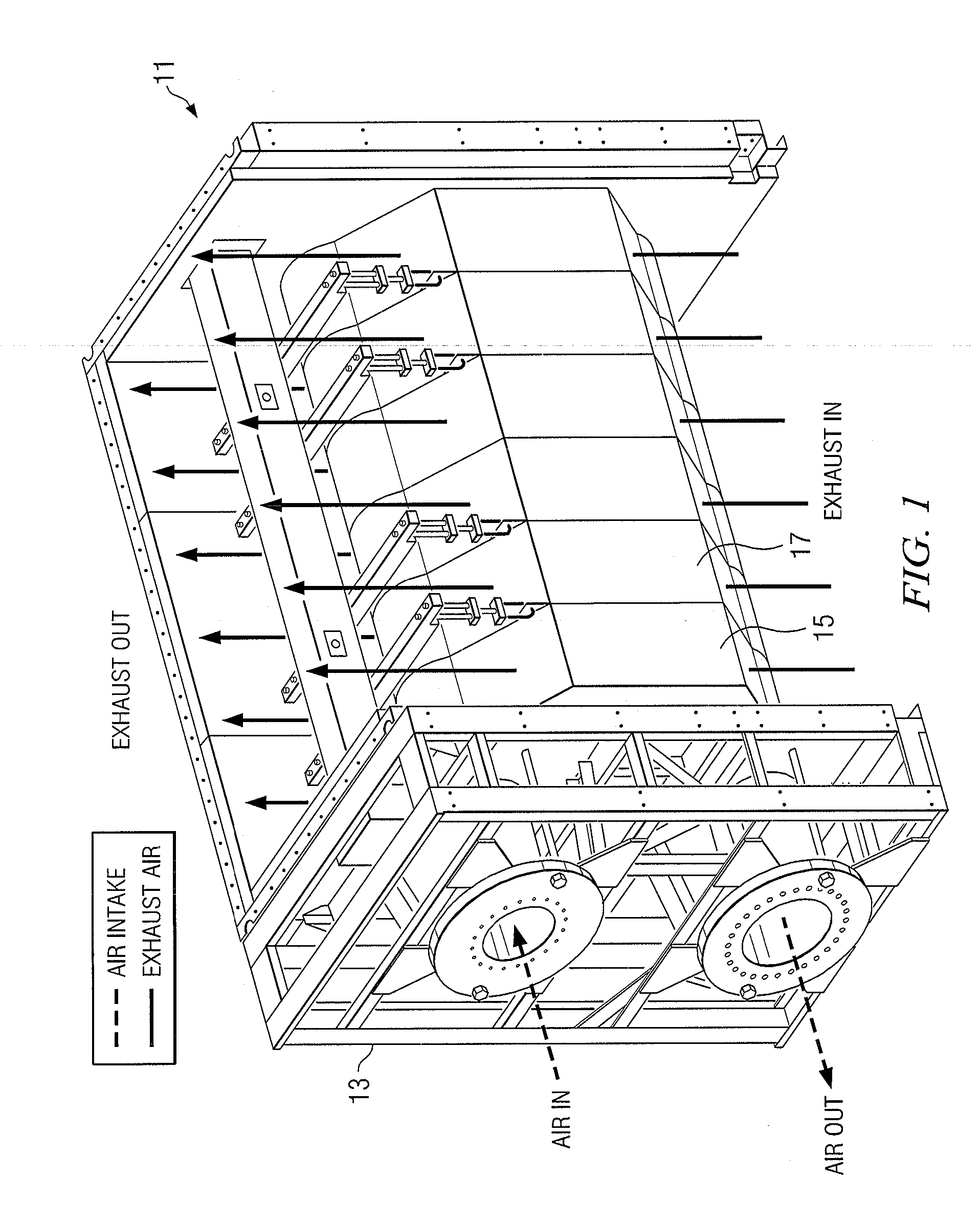

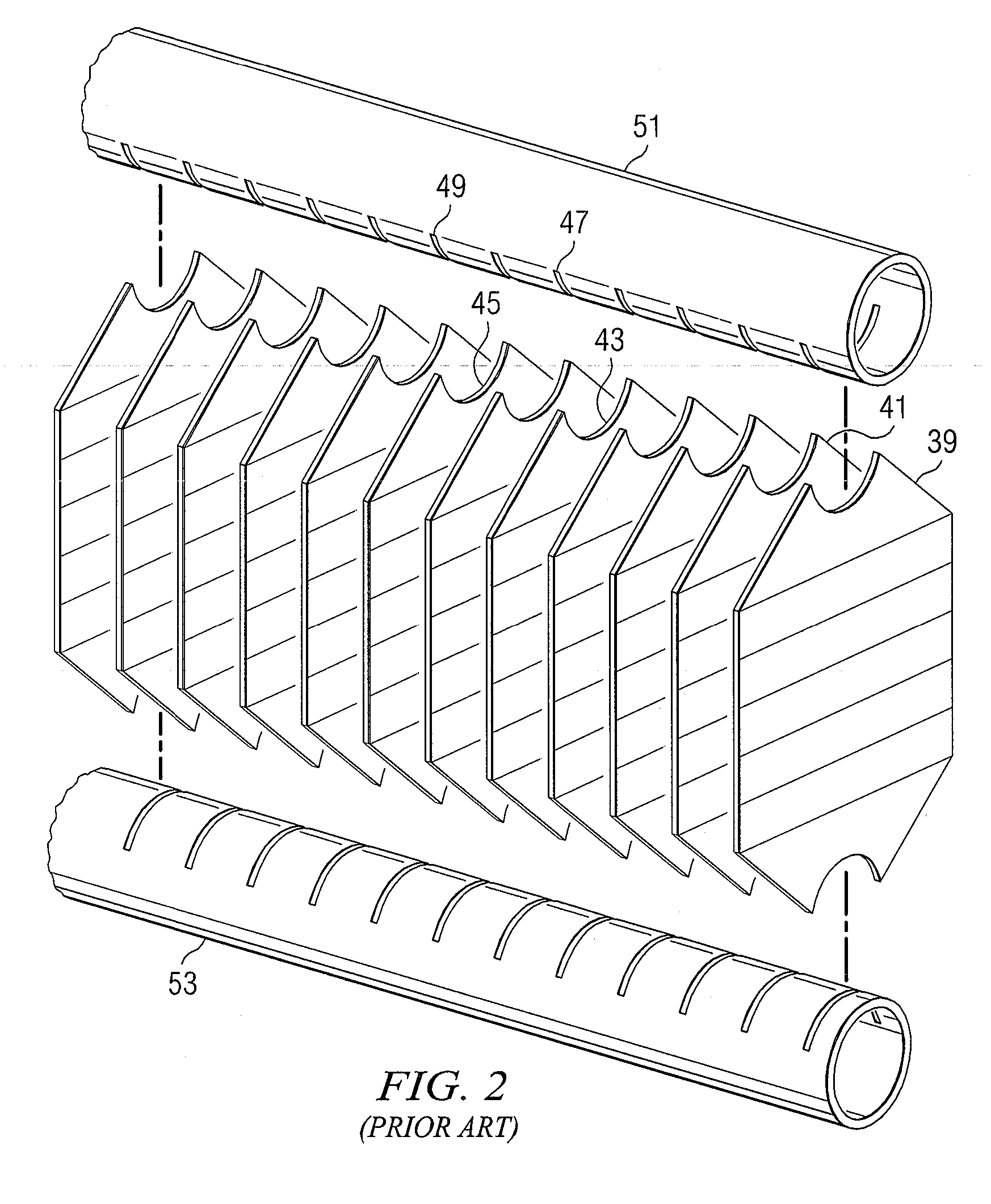

Gas Turbine Regenerator Apparatus and Method of Manufacture

A regenerator core for use in a gas turbine regenerator has integral manifold openings formed in the tube plates used to make up the core and has special reinforcing elements which provide high pressure containment in critical portions of the plate-and-fin heat exchanger construction. The reinforcing elements include a series of hoops of U-shaped cross section which are used to bridge the juncture lines of the heat exchanger manifolds. An outer channel region of the hoops is provided with a reinforcing strip of gusset material. The hoops with their reinforcing strips provide structural reinforcement in the region between the manifolds and the conventional side bar reinforcing members in the central core section.

Owner:MUND 2013 FAMILY TRUST +2

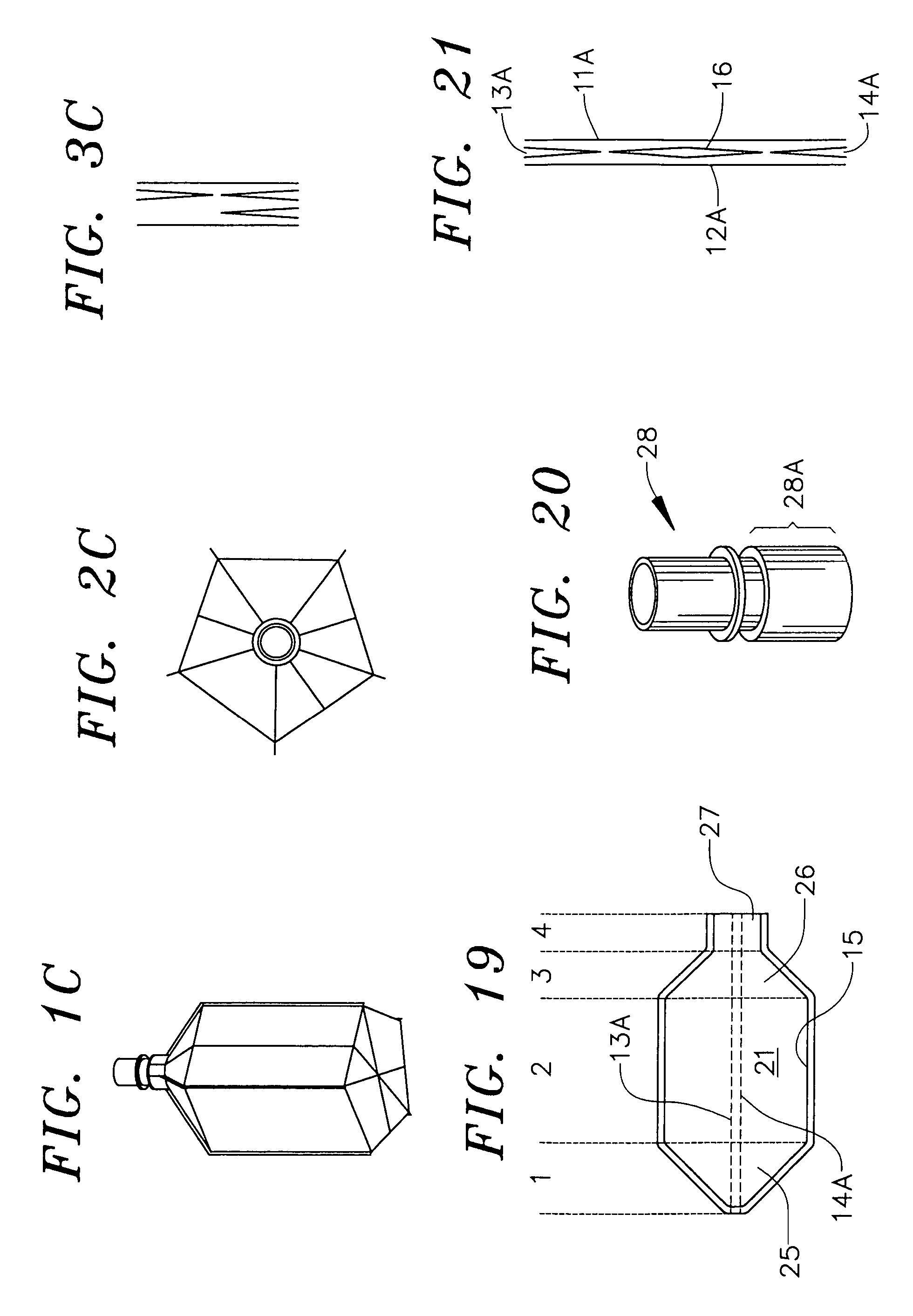

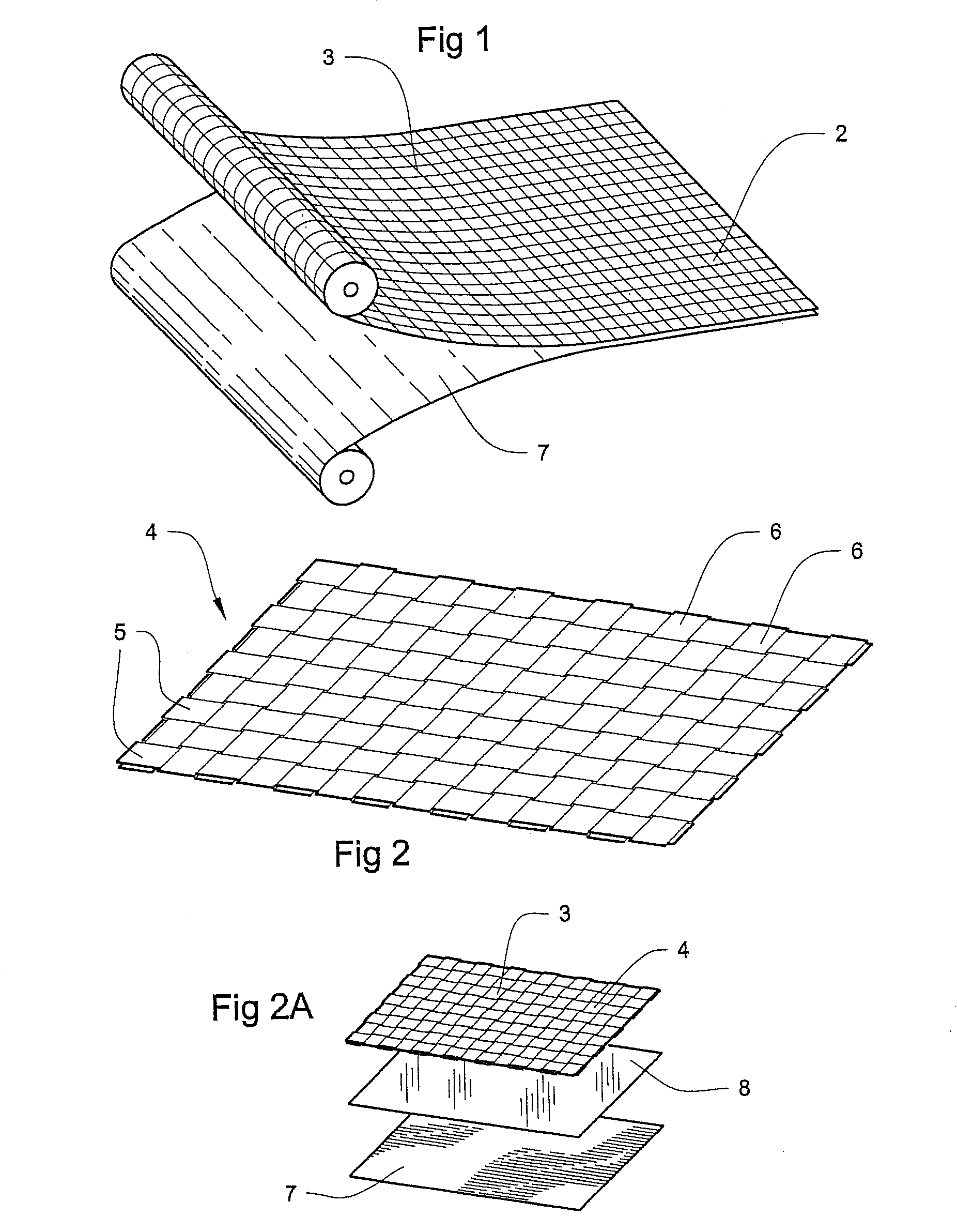

Bag for flowable materials

A bag for containing flowable materials, having a front panel, a rear panel coextensive with the front panel, and a pair of folded gussets. Each of the gussets has front and rear gusset layers joined at a central crease and a pair of outer gusset edges joined continuously along and to side edges of the front and rear panels. The bag has a bottom closure and at its initially open top portion, the front and rear gusset layers are joined to the respective front and rear panels along lines spaced from or adjacent to the joined side edges of the respective front and rear gusset layers and front and rear panels, to provide stiffened, fastened layer corner portions in the top portion of the open bag.

Owner:LIN PAC INC

Upper vehicle-body structure of vehicle

ActiveUS20140028057A1Prevent strain (deformation)Precise functionVehicle seatsSuperstructure subunitsGusset plateEngineering

Owner:MAZDA MOTOR CORP

Method of Manufacturing a Polypropylene Pinch Bag

InactiveUS20110082019A1Avoid and limit product spillBag making operationsPaper/cardboard wound articlesGusset plateEngineering

A method of manufacturing a gusseted pinch bag from polypropylene. A sheet or seamless tube of polypropylene is provided. The sheet is preferably comprised of one or more layers of axially and / or biaxially oriented polypropylene. Perforation lines in a pinch pattern are formed in the sheet or tube. Preferably a laser forms a series of small, closely spaced holes in the sheet along the perforation line. The laser heats the plastic surrounding the holes, causing the polypropylene molecules between the holes to lose their orientation. Thus, the polypropylene in the perforation line between the holes is substantially weakened. If a sheet is used, it is folded into a gusseted tube and the edges are sealed together to make a tube. If a seamless tube is used, the tube is gusseted. In either case, a lateral force is then applied to the terminal tube, breaking the perforation line and separating the terminal tube from the sheet. The bottom end of the tube is then sealed, thereby forming a bag.

Owner:BANCROFT BAG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com