Vehicle body bottom structure

A car body and structure technology, applied in the field of car body substructure, can solve the problems of increased retreat, load transmission, and low bending rigidity crushing load of upper parts, so as to achieve the effect of increasing absorption and improving bending rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach >

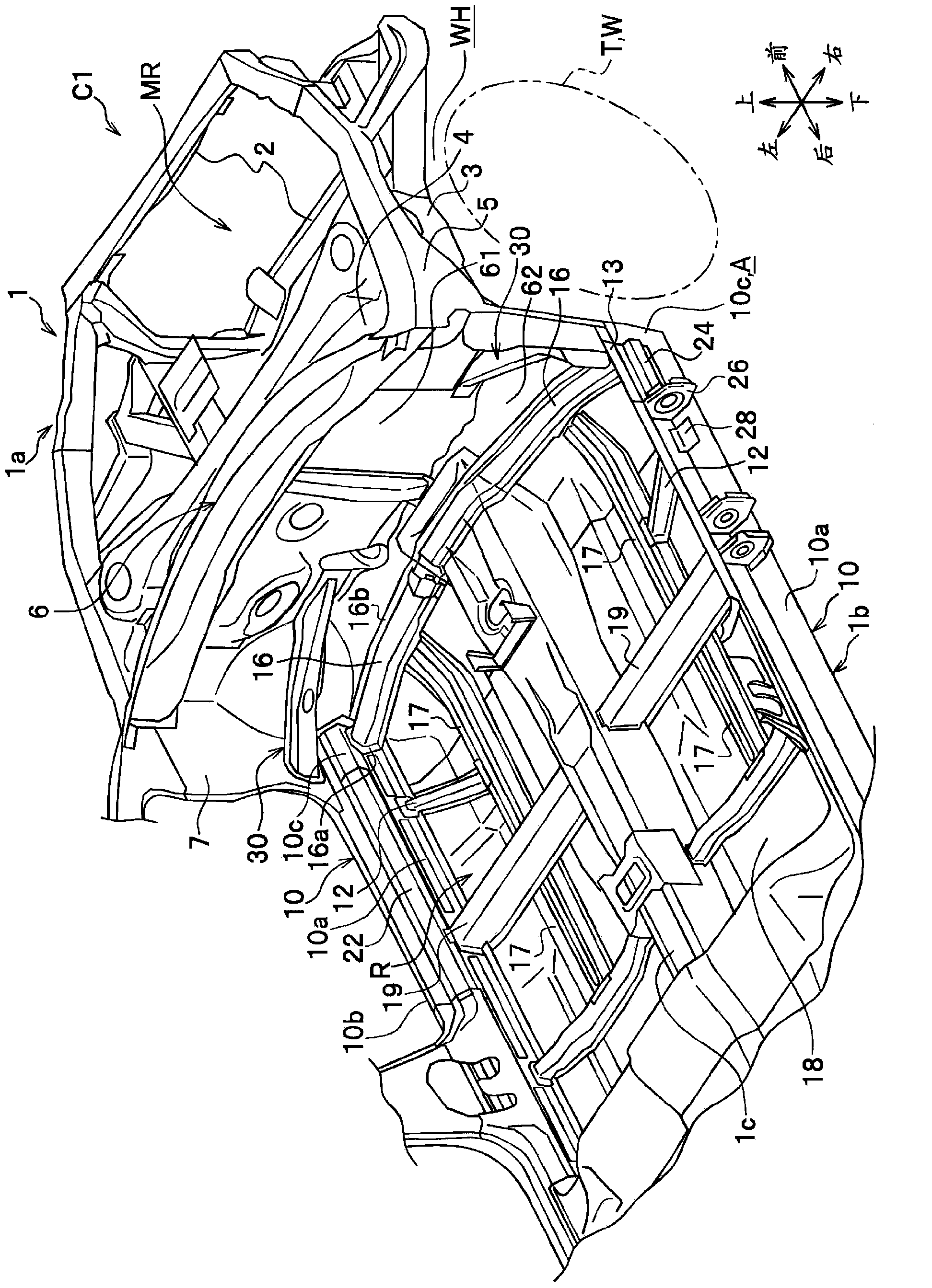

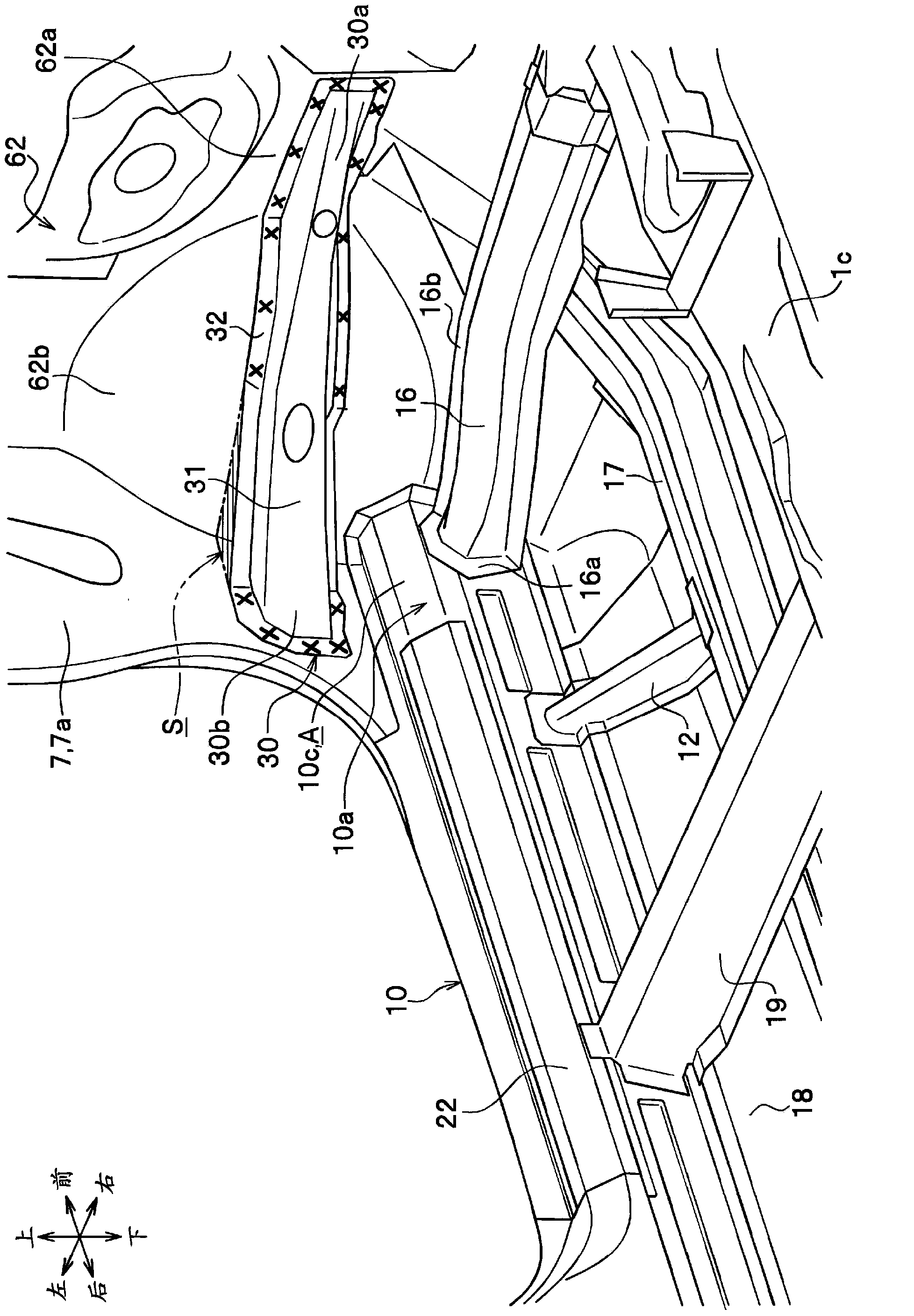

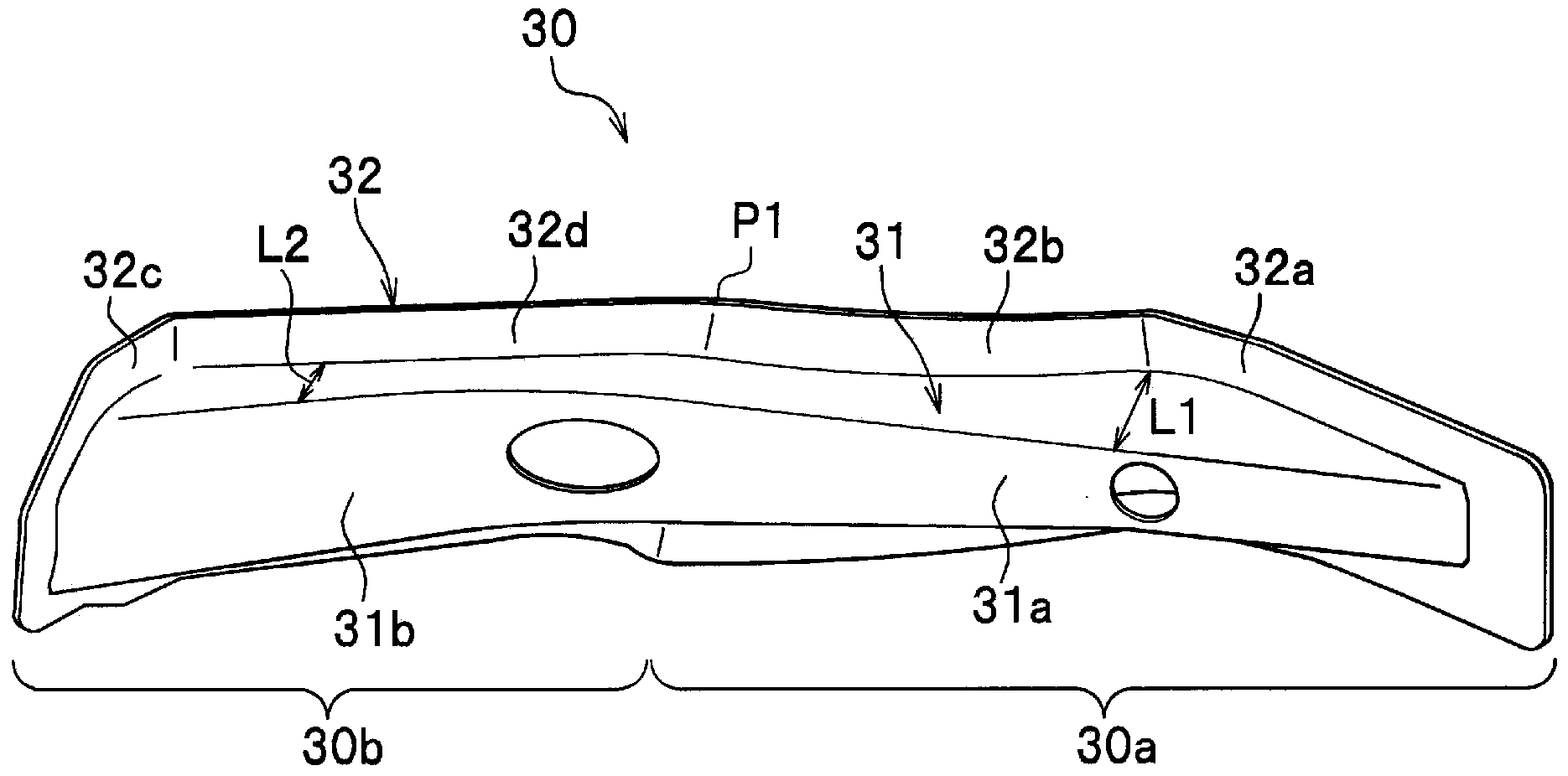

[0123] Regarding the embodiment of the present invention, refer to Figure 1 to Figure 9 Describe in detail. In the description, the same reference numerals are attached to the same elements, and overlapping descriptions are omitted. In addition, when describing a direction, it demonstrates based on front-back, left-right, up-and-down seen from the driver of a vehicle.

[0124] Such as figure 1 As shown, a vehicle C1 is constituted by an automobile having a power-mounted room MR and a front wheel room WH arranged in a vehicle body front portion 1a, and a vehicle room R arranged with a partition 6 between the power-mounted room MR and the front wheel room WH. The automobile includes, for example, automobiles of FR (front-engine, rear-wheel drive) type, FF (front-engine, front-wheel drive) type, four-wheel-drive type, and the like.

[0125] In addition, as the vehicle C1 to which the present invention is applied, only a pair of left and right front pillars 7 arranged on the le...

no. 2 approach >

[0163] Hereinafter, a second embodiment of the present invention will be described in detail with appropriate reference to the drawings. In addition, in each figure, "front and rear" and "up and down" indicated by arrows indicate the front and rear directions of the vehicle body and the up and down directions of the vehicle body, and "left and right" indicate the left and right directions (vehicle width direction) viewed from the driver's seat. In addition, in this embodiment, a vertical cross section means a vertical cross section.

[0164] In addition, since the gusset plate 30 has the same structure as that of the first embodiment, detailed description thereof will be omitted.

[0165] Such as Figure 10 As shown, a vehicle C1 is constituted by an automobile having a power-mounted compartment MR disposed at the vehicle body front portion 1 a and a vehicle compartment R disposed across the partition 6 from the power-mounted compartment MR. The automobile includes, for exam...

no. 3 approach >

[0220] Hereinafter, a third embodiment of the present invention will be described in detail with appropriate reference to the drawings. In addition, in each figure, "front and rear" and "up and down" indicated by arrows indicate the front and rear directions of the vehicle body and the up and down directions of the vehicle body, and "left and right" indicate the left and right directions (vehicle width direction) viewed from the driver's seat. In addition, a longitudinal section means a vertical section.

[0221] In addition, since the gusset plate 30 has the same structure as that of the first embodiment, detailed description thereof will be omitted.

[0222] Such as Figure 20 As shown, a vehicle C1 is constituted by an automobile having a power-mounted compartment MR disposed at the vehicle body front portion 1 a and a vehicle compartment R disposed across the partition 6 from the power-mounted compartment MR. The automobile includes, for example, automobiles of FR (front...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com