Patents

Literature

107results about How to "Improve bending rigidity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

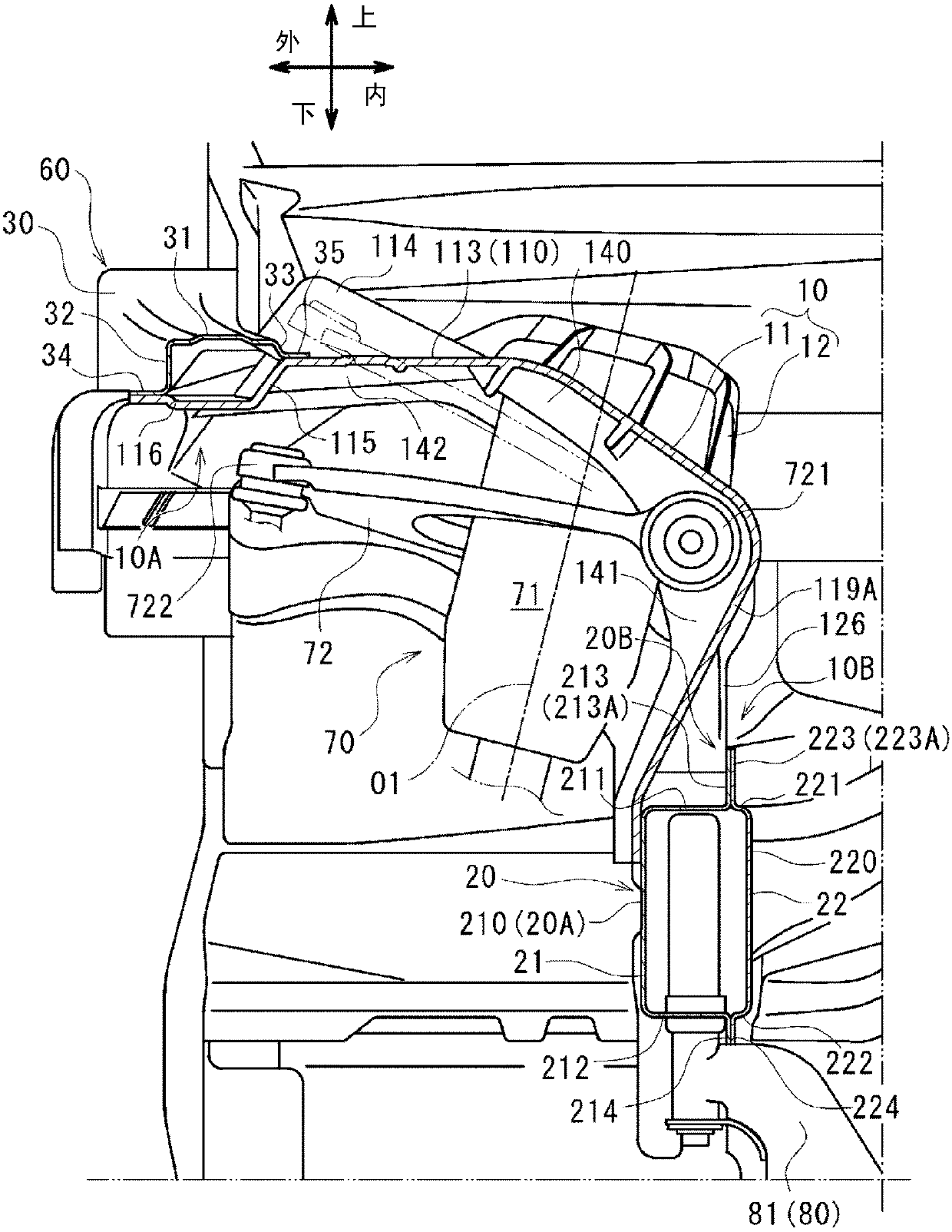

Vehicle body bottom structure

ActiveCN104114438AHigh strengthReduce the amount of backlashUnderstructuresSuperstructure subunitsDashboardGusset plate

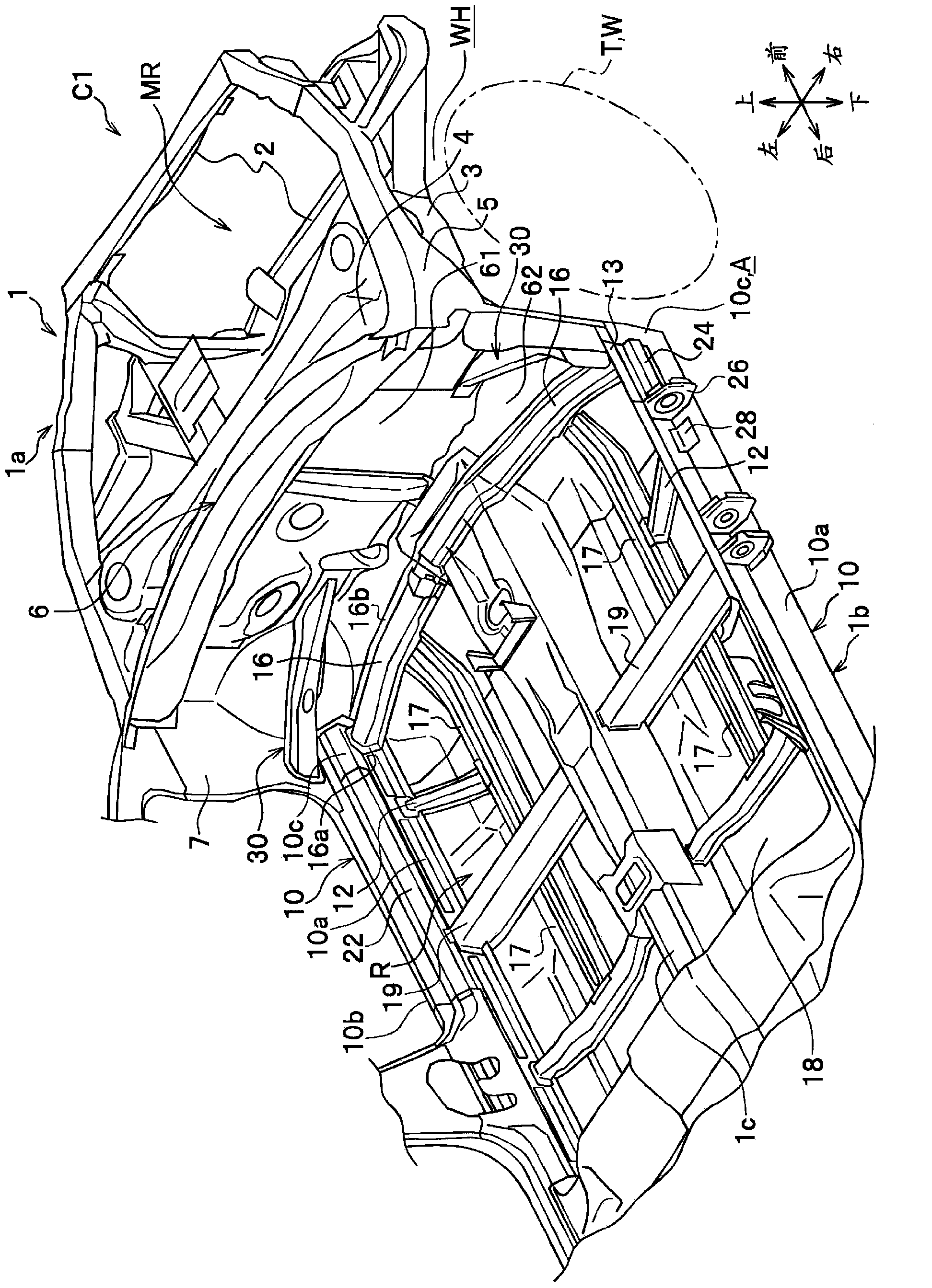

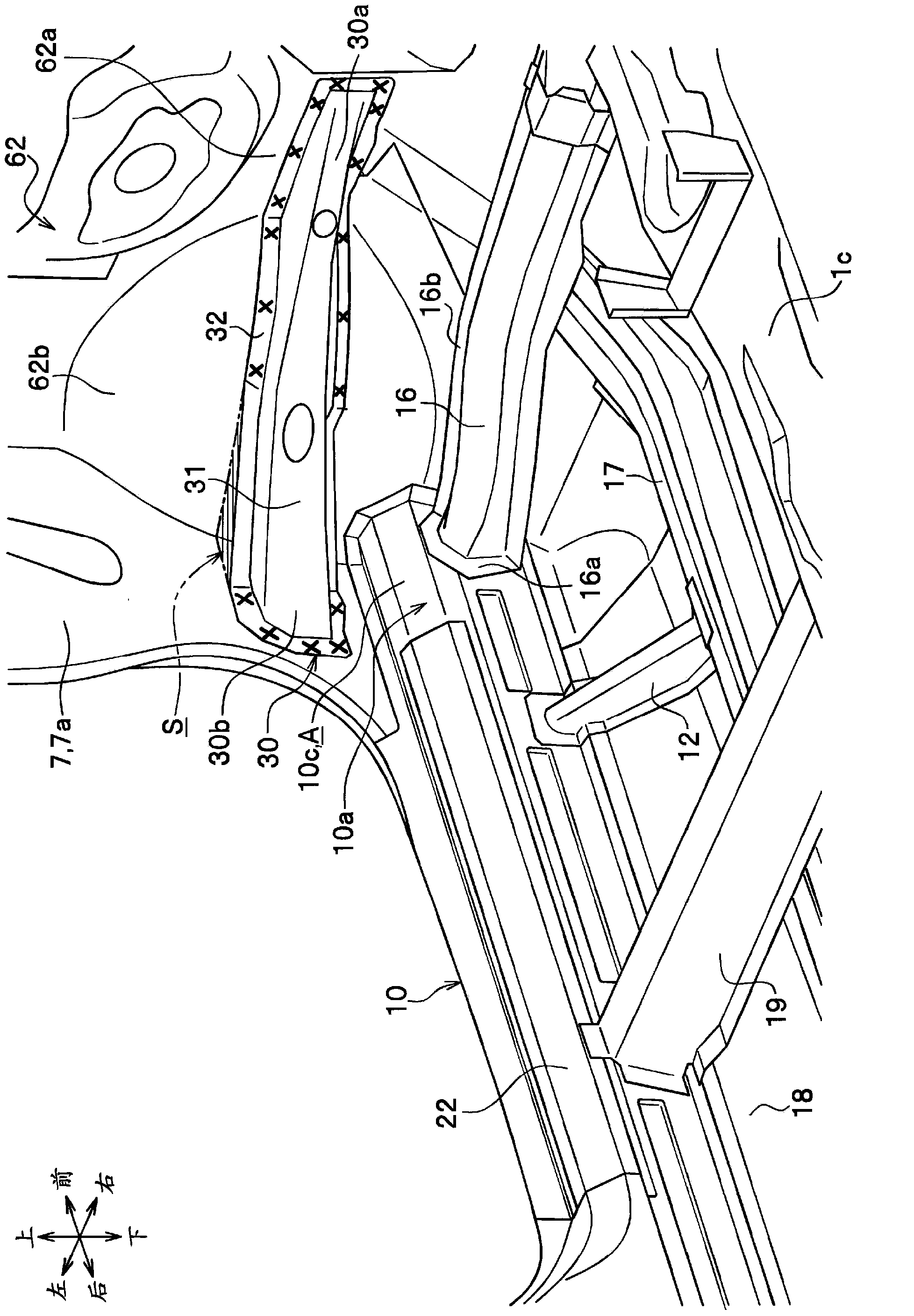

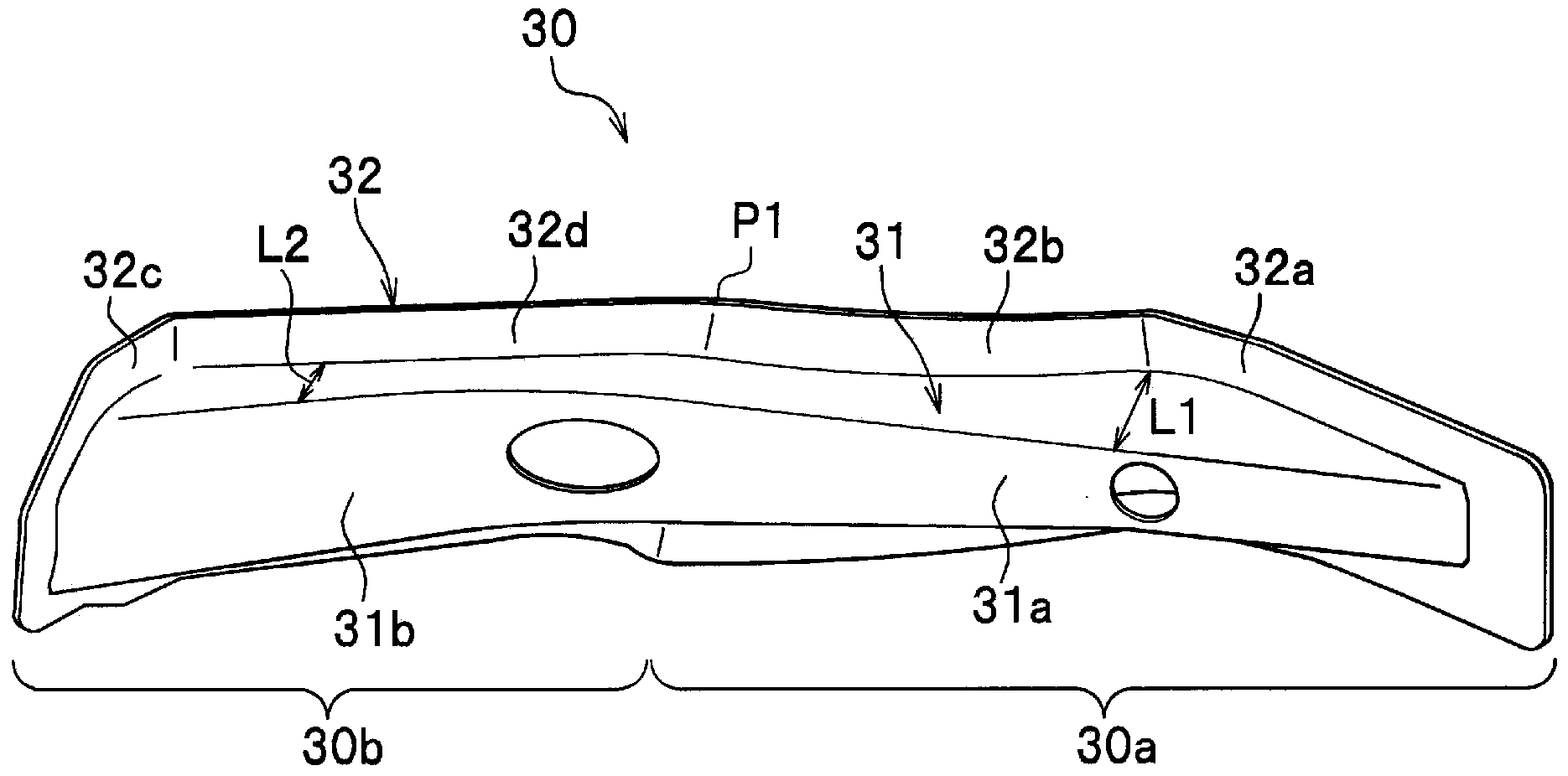

Provided is a vehicle body bottom structure whereby collision load absorption performance during a narrow offset crash can be improved and retraction of the A-pillar can be minimized. A vehicle body bottom structure comprising a dashboard lower (62) for partitioning a vehicle interior (R) and a power installation interior (MR) and also for partitioning the vehicle interior (R) and a wheel house (WH), an A-pillar (7) erected at the vehicle-widthwise end of the dashboard lower (62), and a gusset (30) spanning between the dashboard lower (62) and the A-pillar (7); the gusset (30) being designed such that one end side is bonded to the dashboard lower (62) and grows farther from the dashboard lower (62) the nearer to the A-pillar (7), the other end side is bonded to the A-pillar (7), and a collapse space (S) having a substantially triangular shape in a plan view is formed in the portion enclosed by the dashboard lower (62), the A-pillar (7), and the gusset (30).

Owner:HONDA MOTOR CO LTD

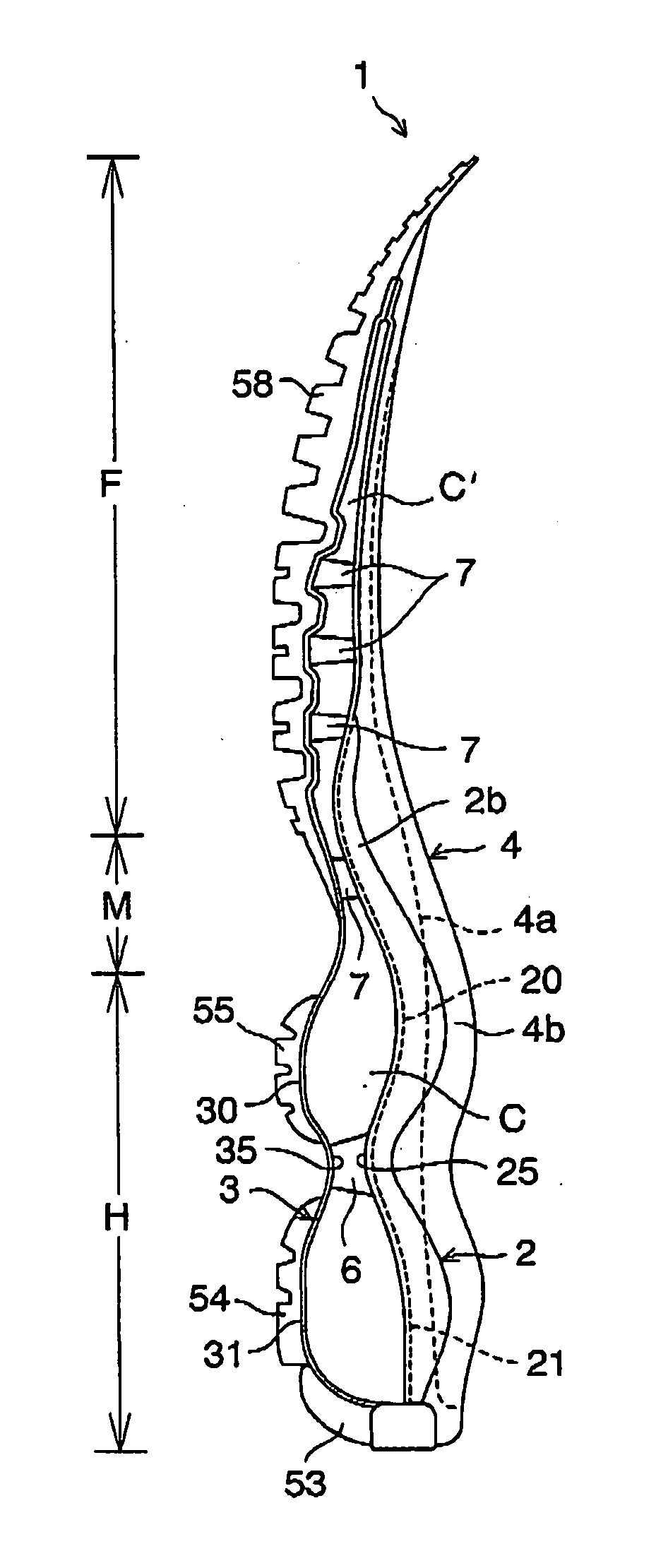

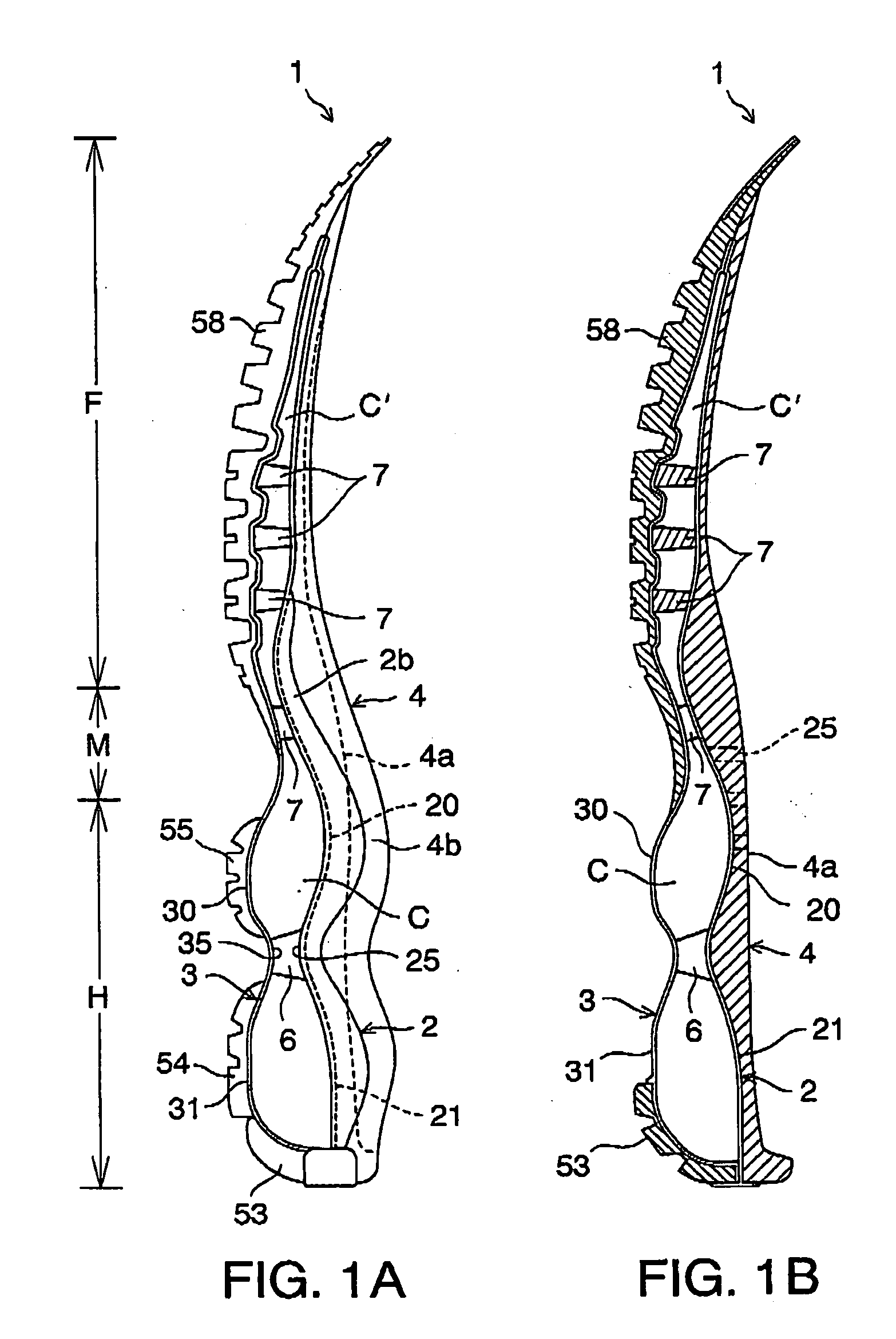

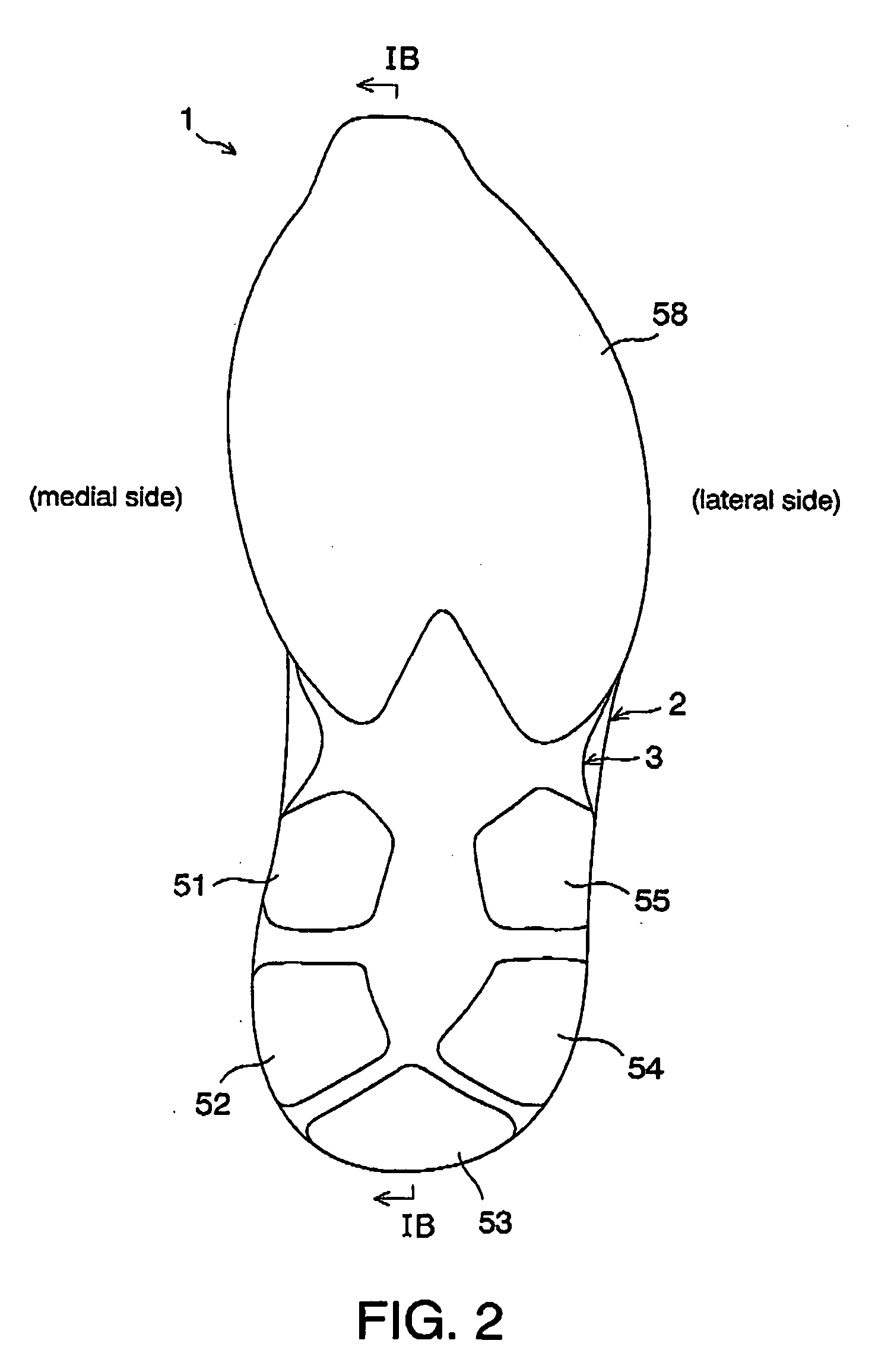

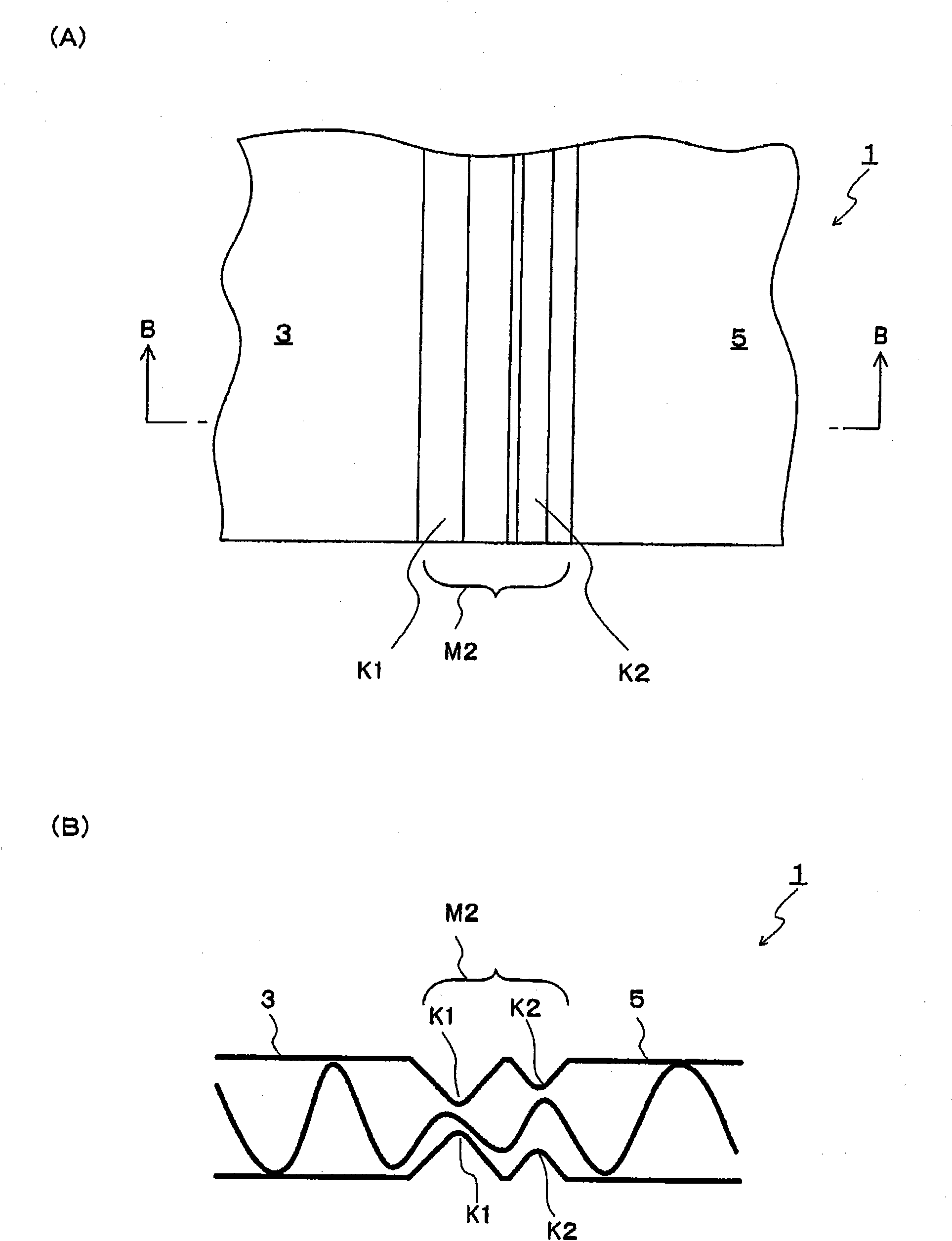

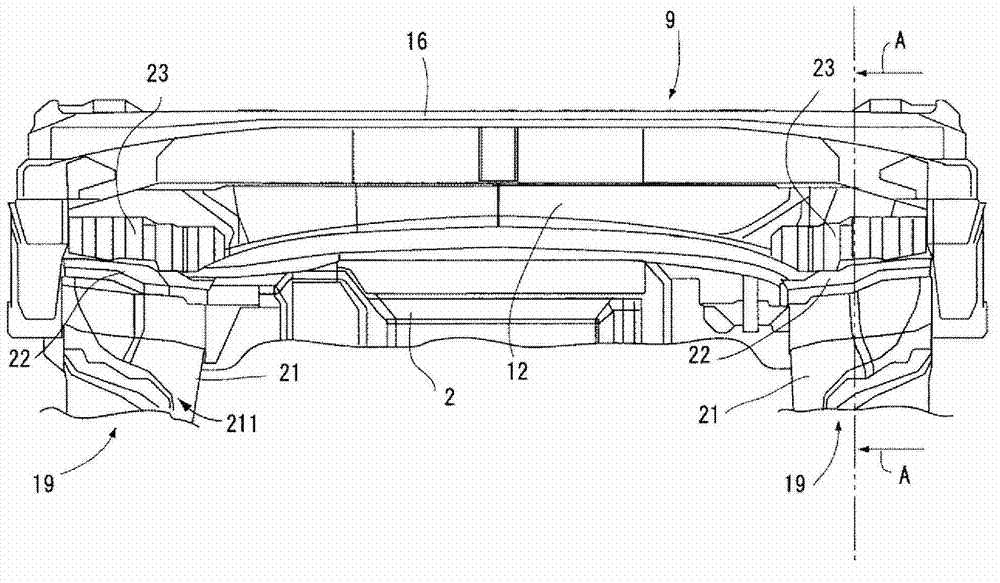

Sole structure for a shoe

A sole structure is provided that can improve cushioning and bending properties of the sole heel portion. The sole assembly 1 is formed of an upper plate 2 disposed on the upper side of the heel portion H, a wavy lower plate 3 provided below the upper plate 2 in the heel portion H and having at least two convex portions 30, 31 that protrude downwardly and that are adapted to form voids C relative to the upper plate 2, and a plurality of outsole portions 51-55 that are divided in the longitudinal direction and that are attached to the lower surfaces of the convex portions 30, 31 of the lower plate 3.

Owner:MIZUNO CORPORATION

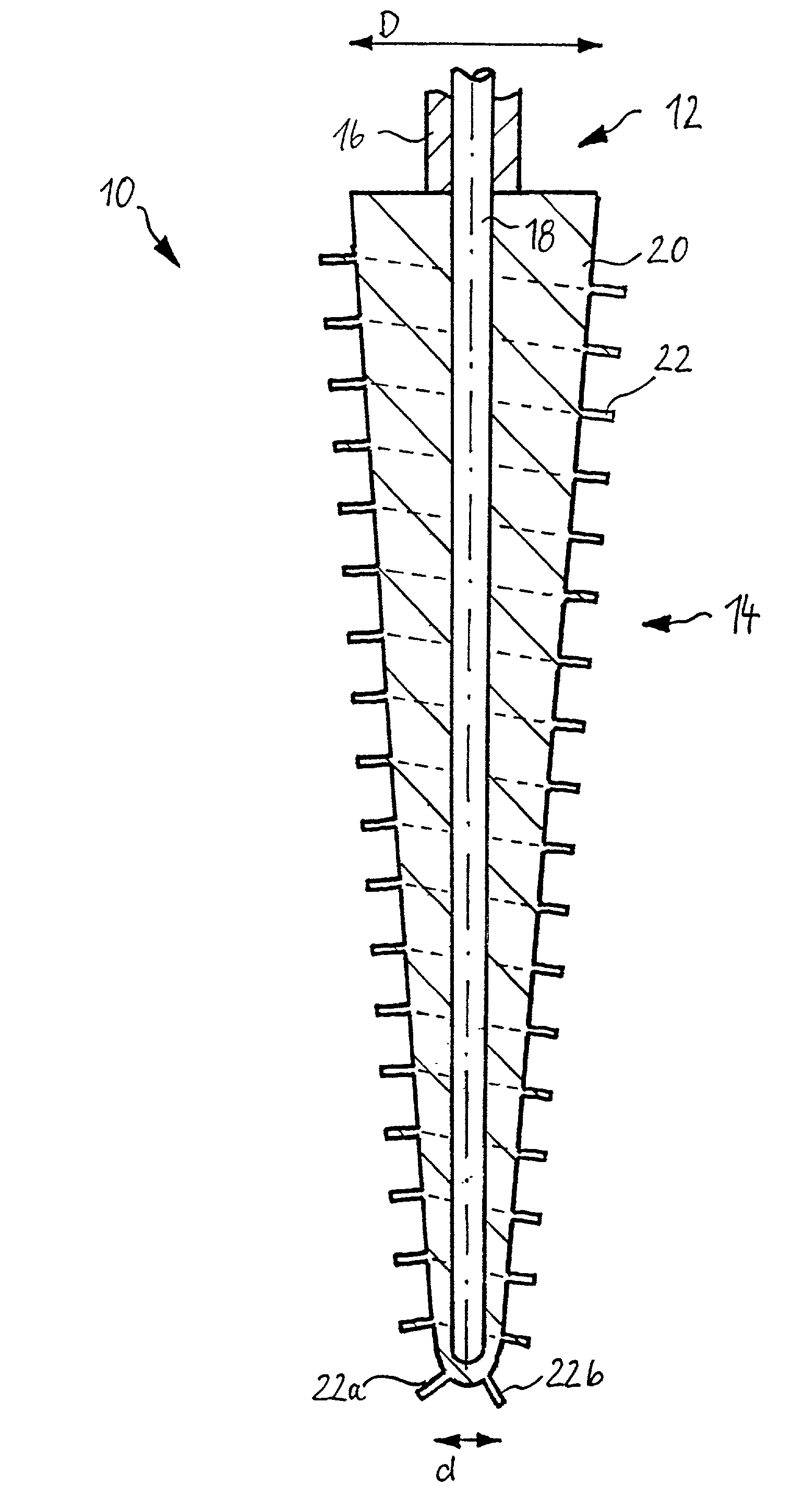

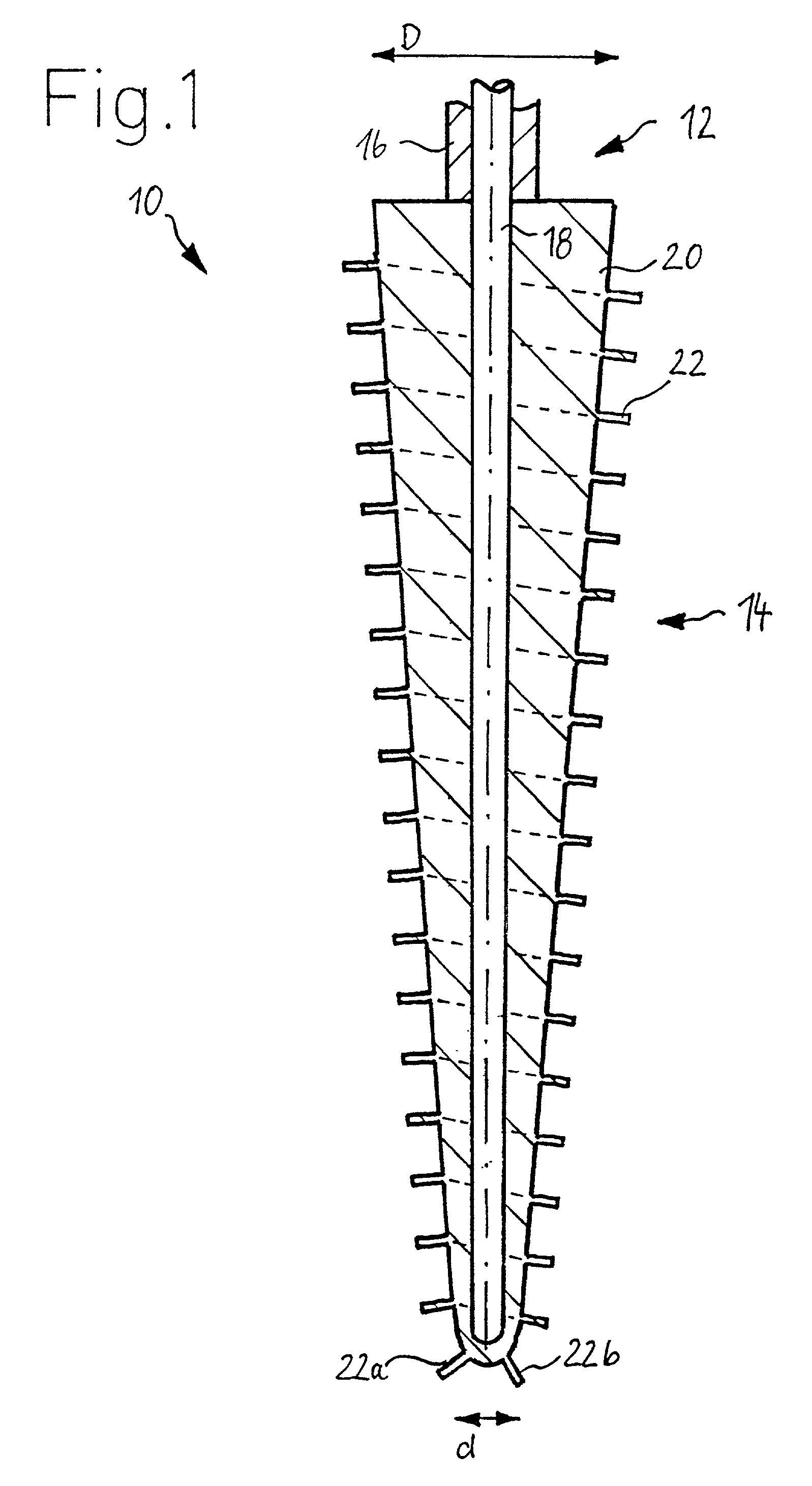

Cleaning instrument for a tooth root canal

InactiveUS20020172922A1Easy to cleanIncreased torsional rigidityGum massageBrush bodiesBristleEngineering

The cleaning instrument (10) comprises a head portion (10) and, adjacent thereto, a cleaning portion (14) having a shank (20), which is provided with bristles (22) on its external surface. In order that especially the tooth root canal or also a tooth interstice can be reliably cleaned using the cleaning instrument (10), the shank (20) is of integral construction with the bristles (22).

Owner:ROEKO & DENTALERZEUGNISSE

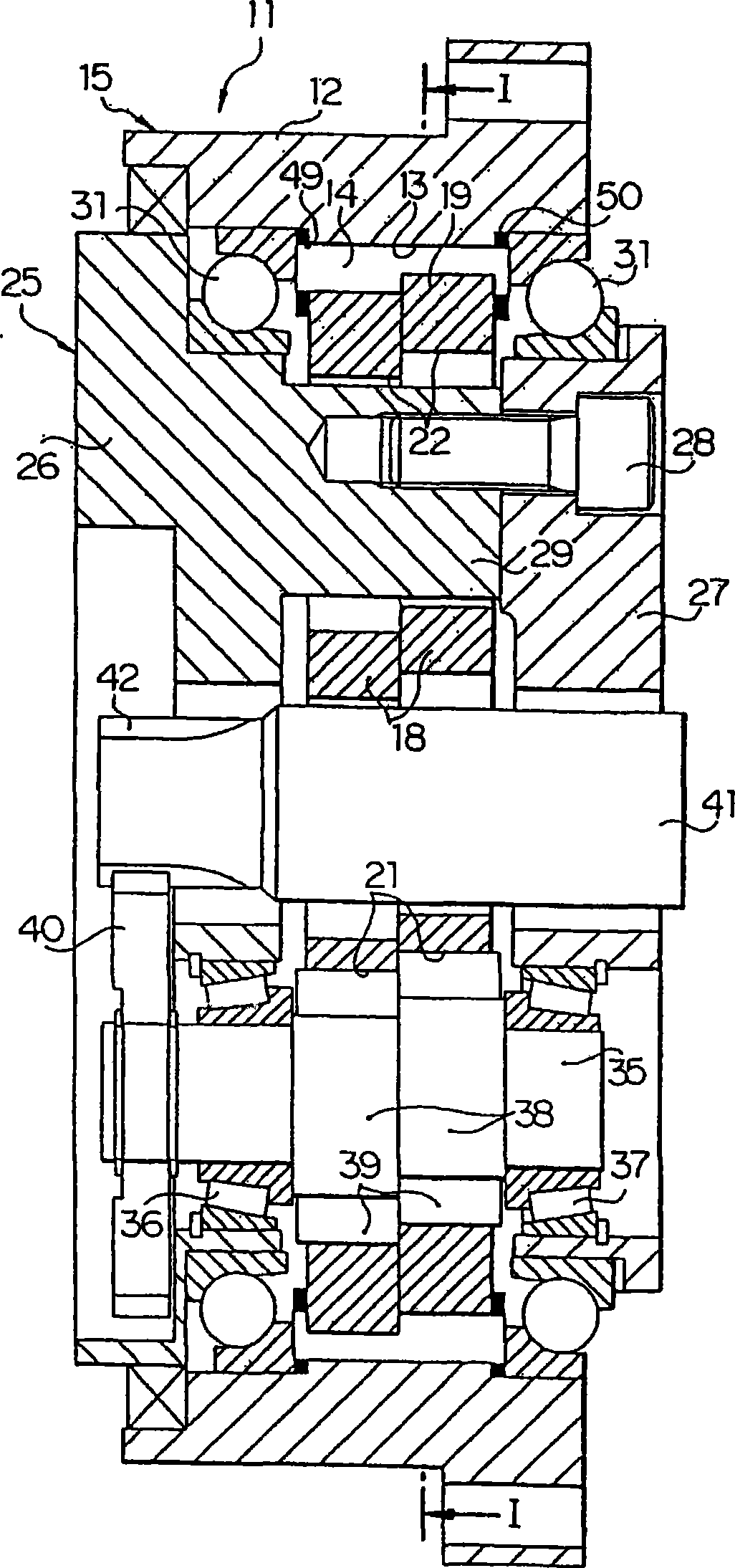

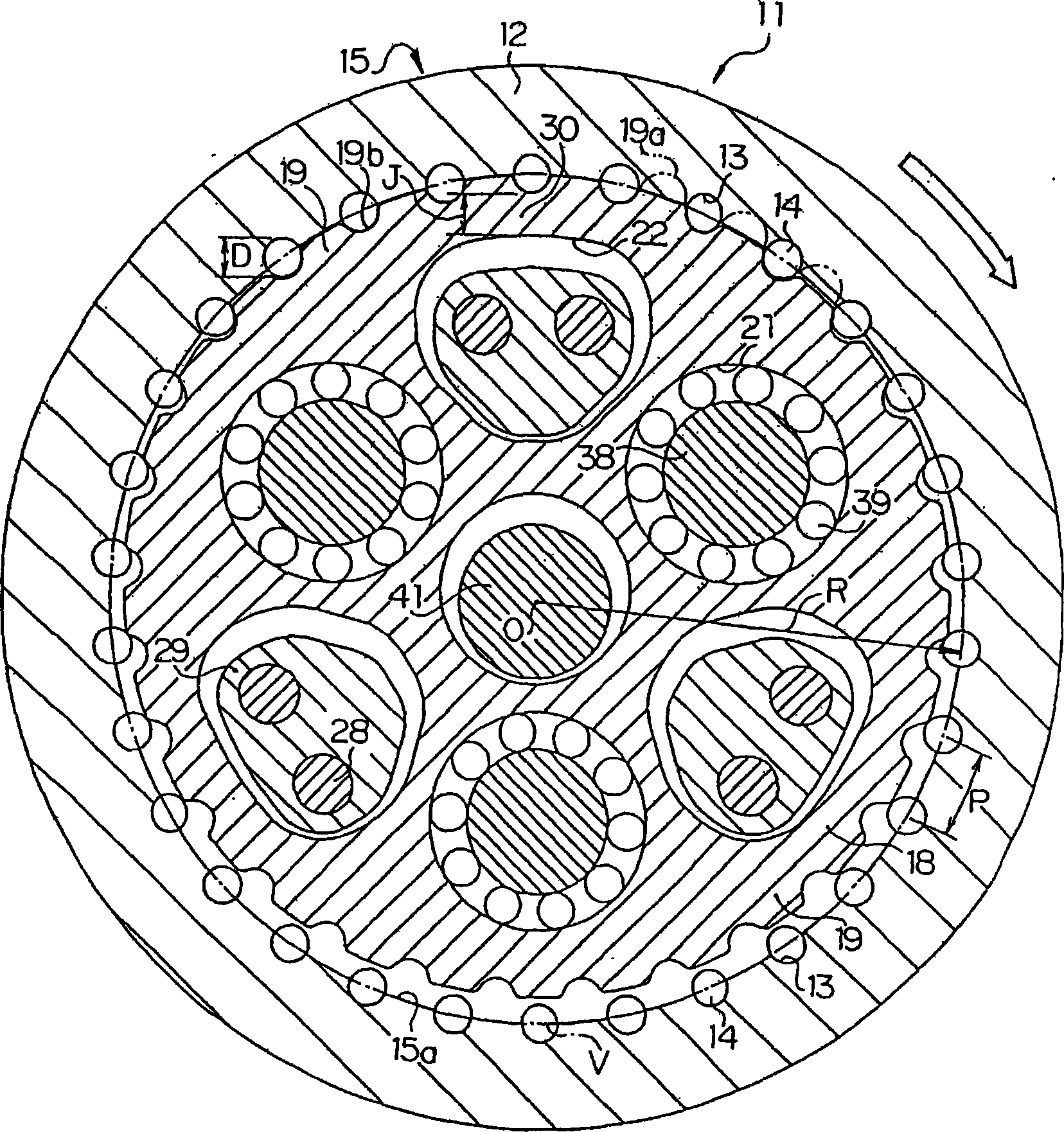

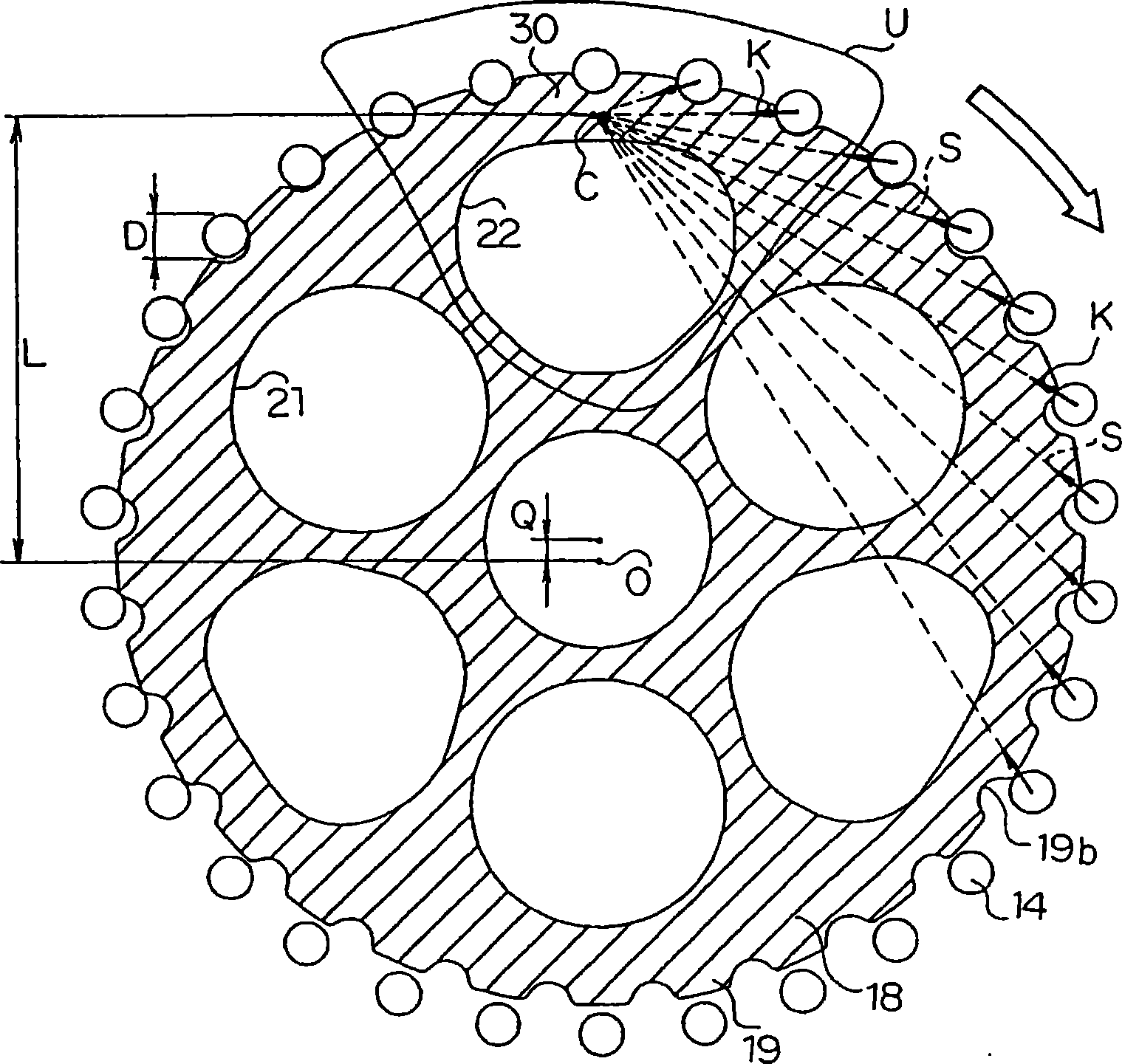

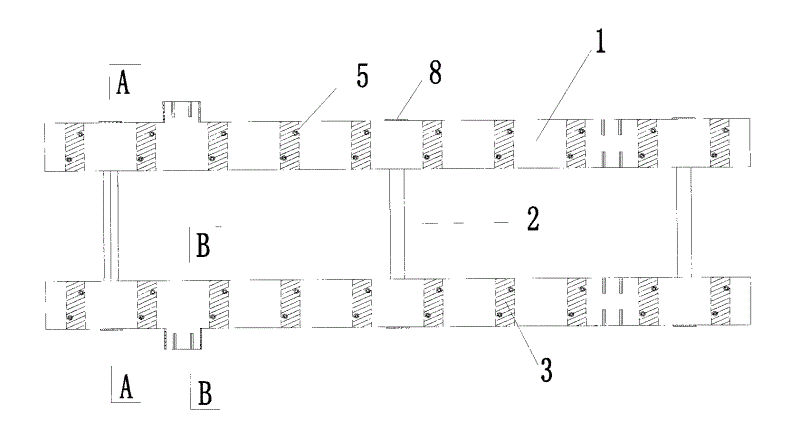

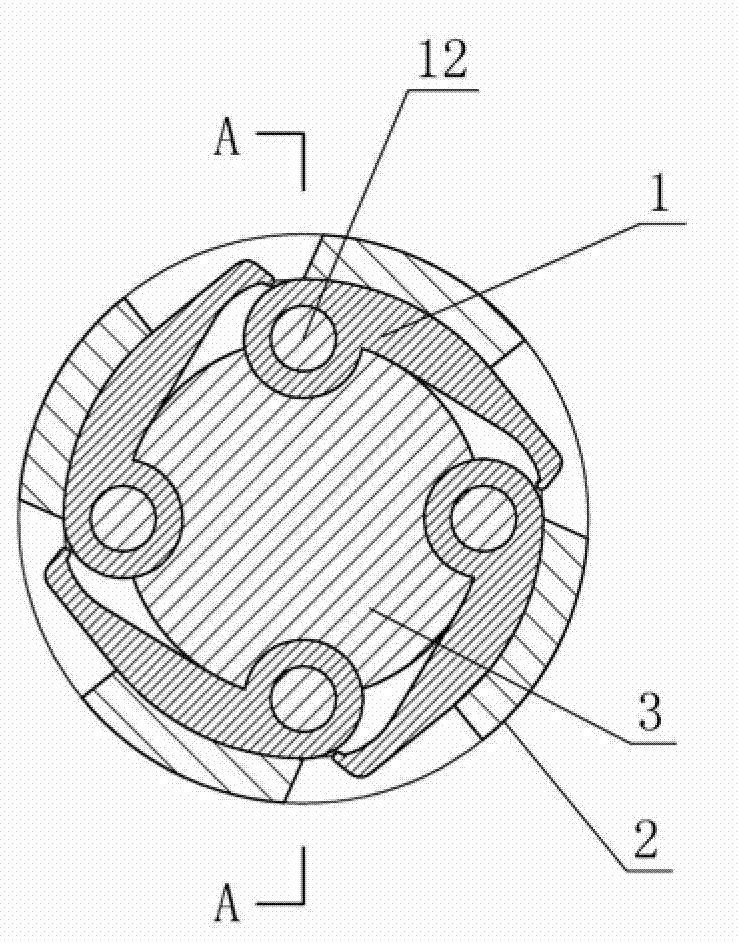

Eccentric swing type planetary gear device

ActiveCN1914438AExtend tooth surface lifeInhibition of elastic deformationToothed gearingsGear wheelEngineering

The invention provides eccentric swing type planetary gear device, deformation of bridge sections in an externally toothed gear and of outer teeth is suppressed, and this extends the life of tooth surfaces of external teeth (19), improves vibration characteristics, and drastically increases output torque while preventing a planetary gear device (11) from becoming large in size. To achieve the above, a ratio obtained by dividing the diameter (D) of pins constructing internal teeth (14) by the pitch (P) of the internal teeth (14) is made smaller to an extent where the tooth tops (19a) of the external teeth (19) are radially outside the inner periphery (15a) of an internally toothed gear (15), or alternatively, a meeting point (C) where the lines (S) of action of reaction forces (K) as drive force components meet is moved more radially outward than a conventional position so as to be positioned between a pin circle (P) passing the centers of all the internal teeth (pins) (14) and an outer end passing circle (G) passing radially outer ends of through-holes (22), or further alternatively, the amount (H) of eccentricity of an externally toothed gear (18) relative to an internally toothed gear is set not less than 0.5 times the radius (R) of the internal teeth (pins)(14).

Owner:NABLESCO CORP

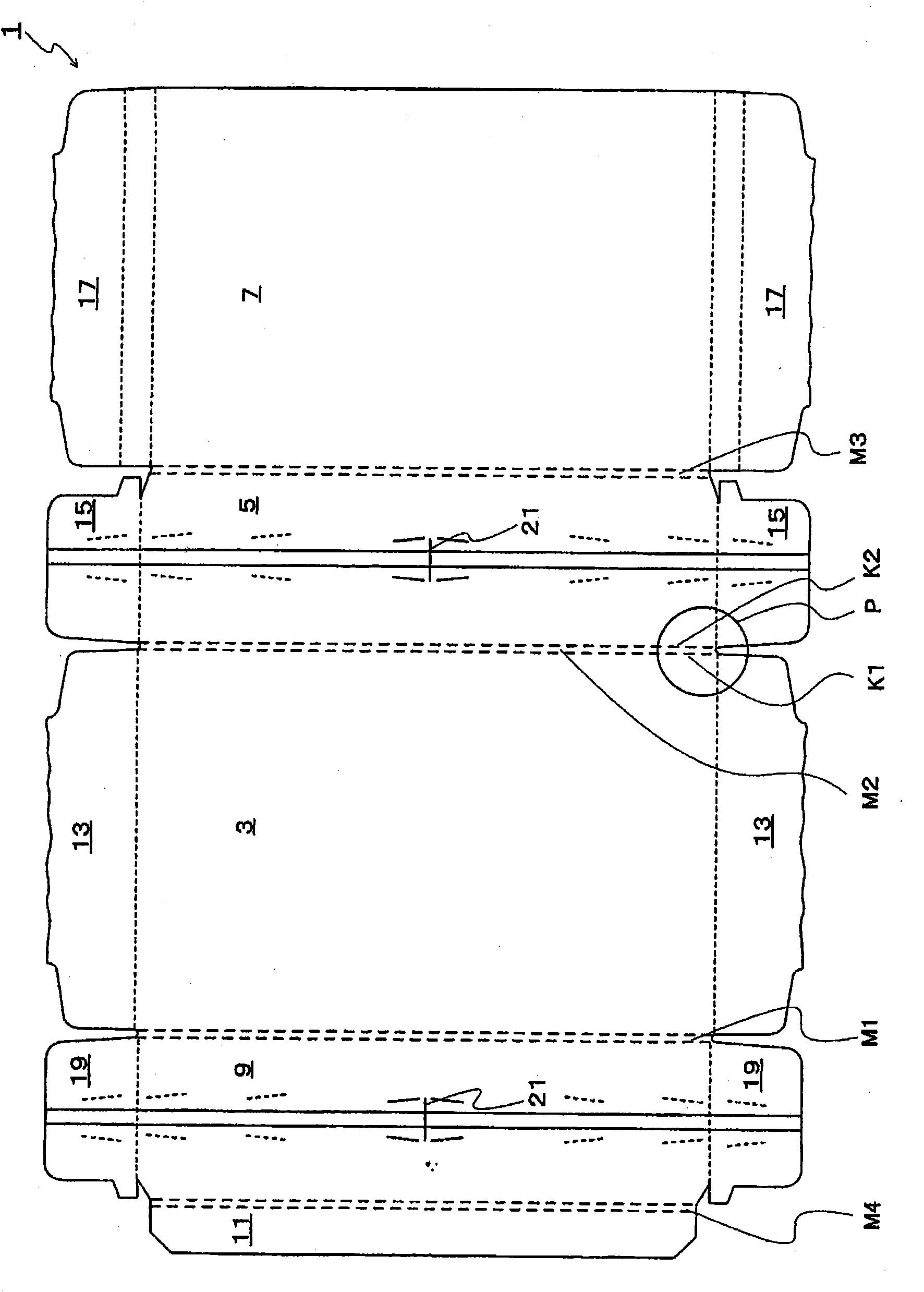

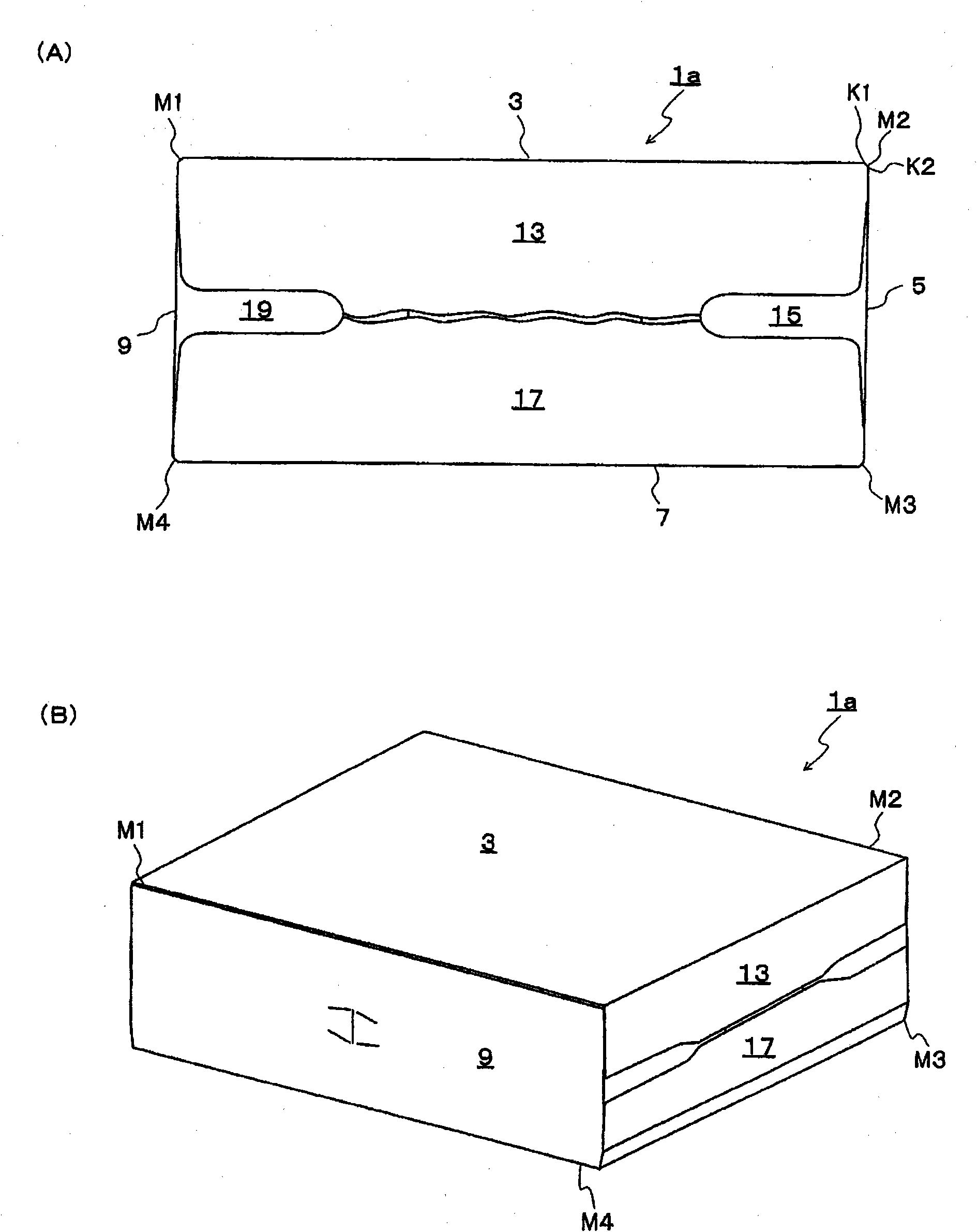

Shipping box, corrugated board blank sheet, and rule mark ring assembly

InactiveCN101772457ASuppress lumbar bulgeImprove rigidityMechanical working/deformationBoxes/cartons making machineryEngineeringWork in process

An object of the present invention is to provide a packing box having its ridge(s) collapsed so that there would be no body bulging occurring in the box and potential serpentine folding line would be avoided. Provided is a packing box having a top panel 3, a bottom panel 7, two long side panels and two short side panels, in which at least either one of a ridge defined between said top panel and said long side panel or a ridge defined between said bottom panel and said long side panel is formed by at least two parallel rules configured to be different in depth from adjacent one.

Owner:SUNTORY HLDG LTD

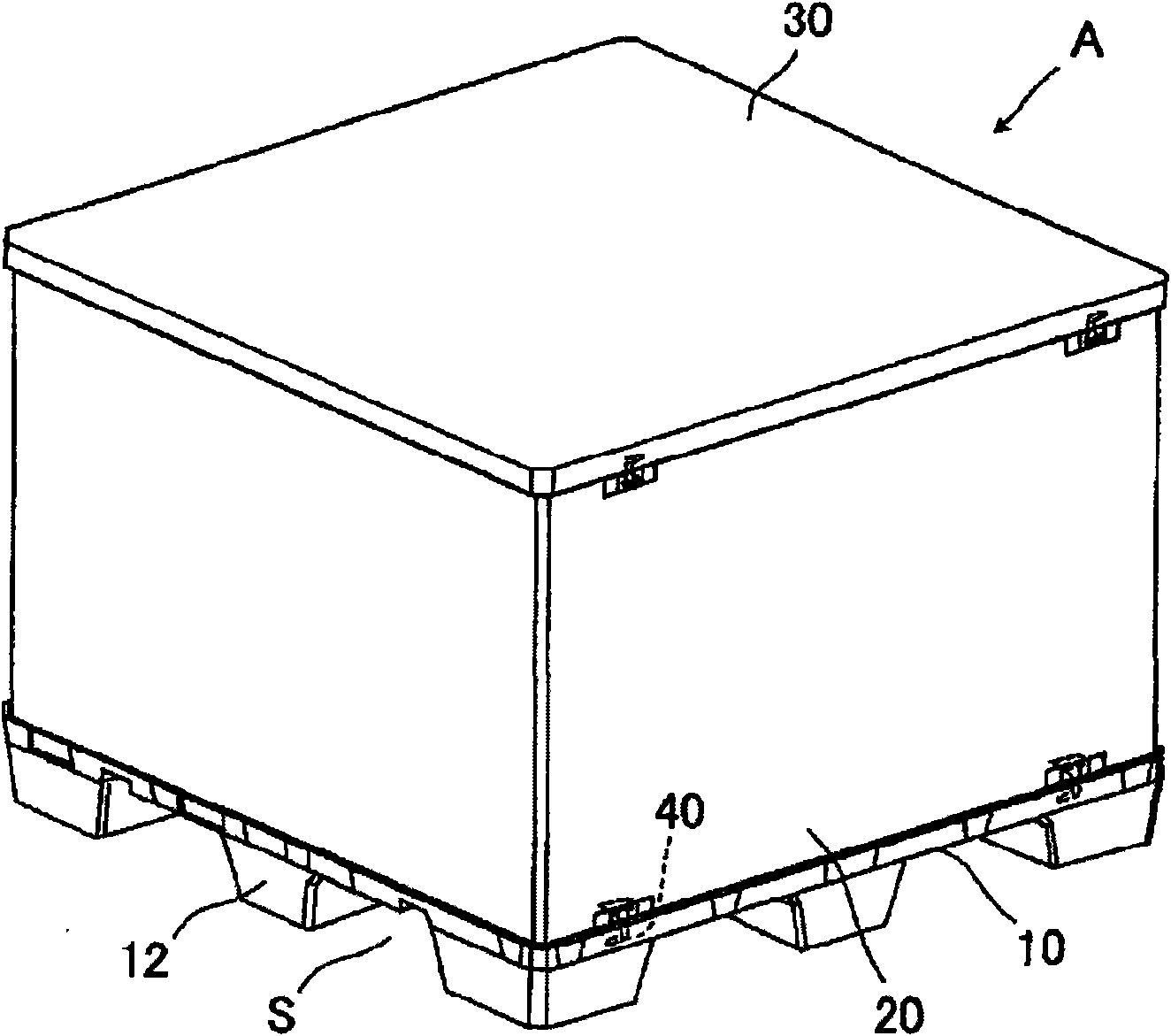

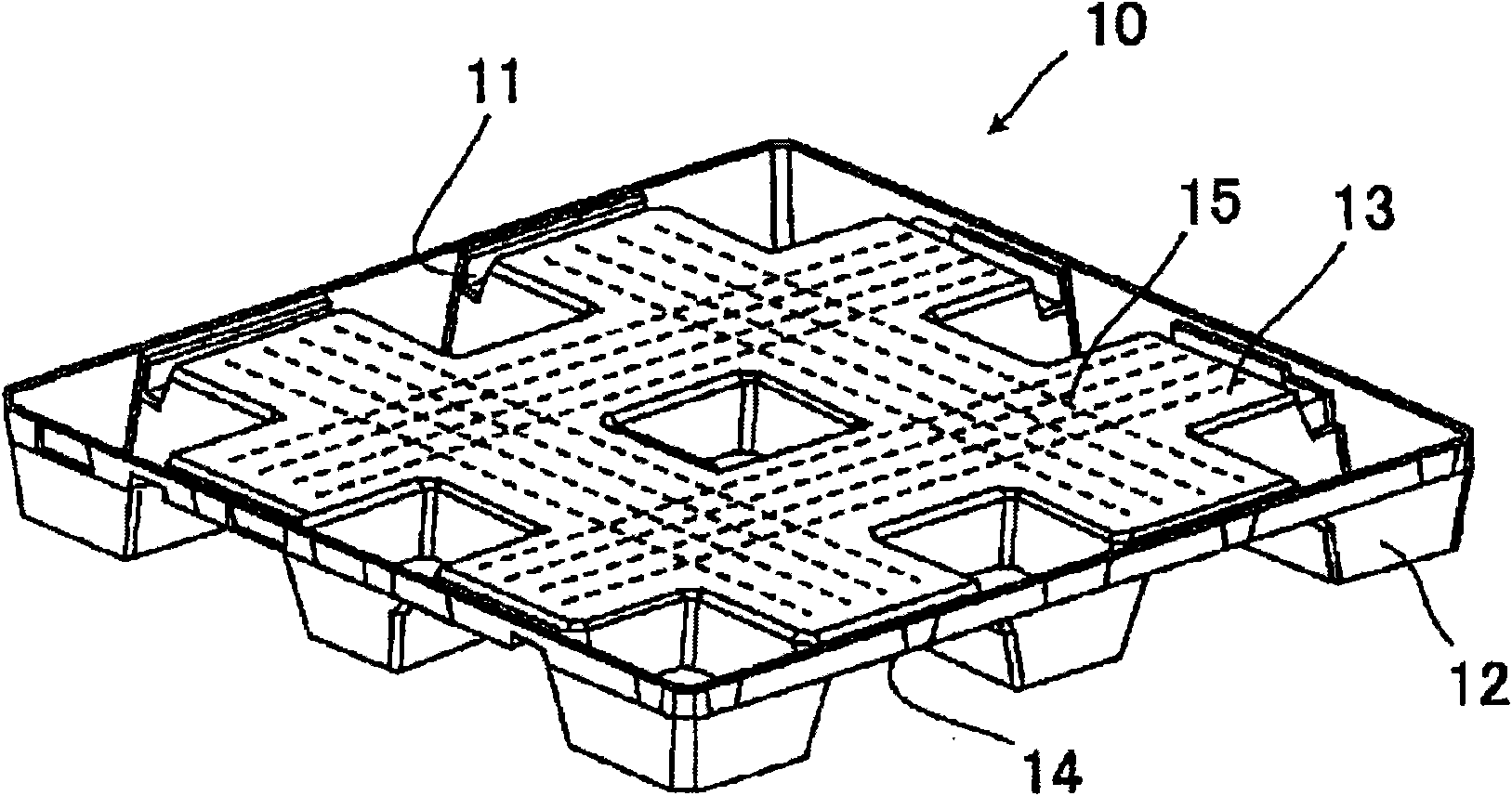

Pallet

ActiveCN101678919AAvoid destructionIncrease wall thicknessDomestic articlesRigid containersBlow moldingDouble wall

Owner:KYORAKU CO LTD

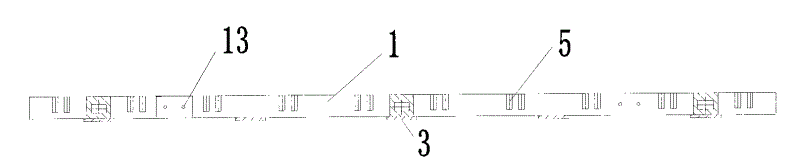

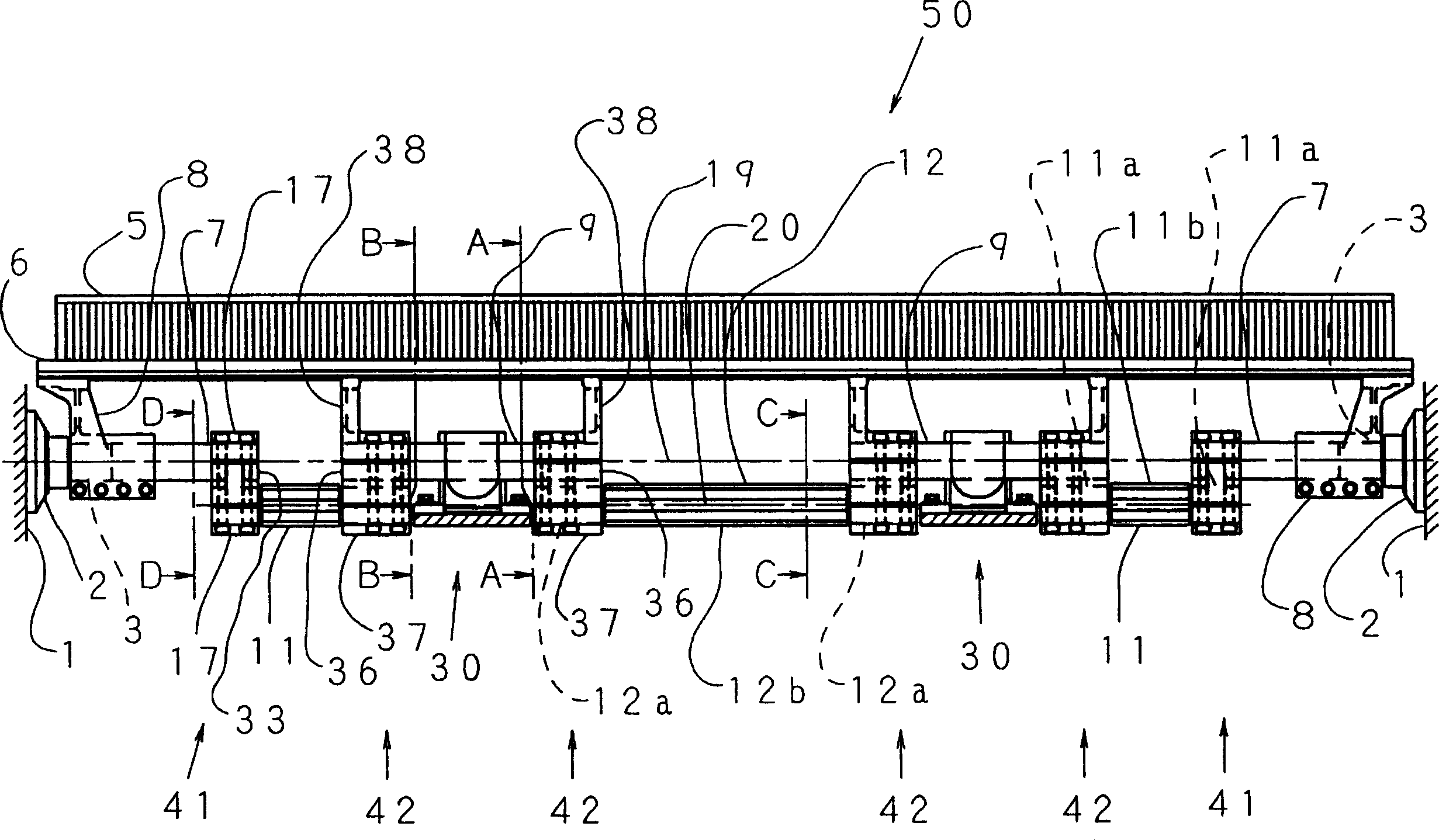

Friction drive trolley conveyor

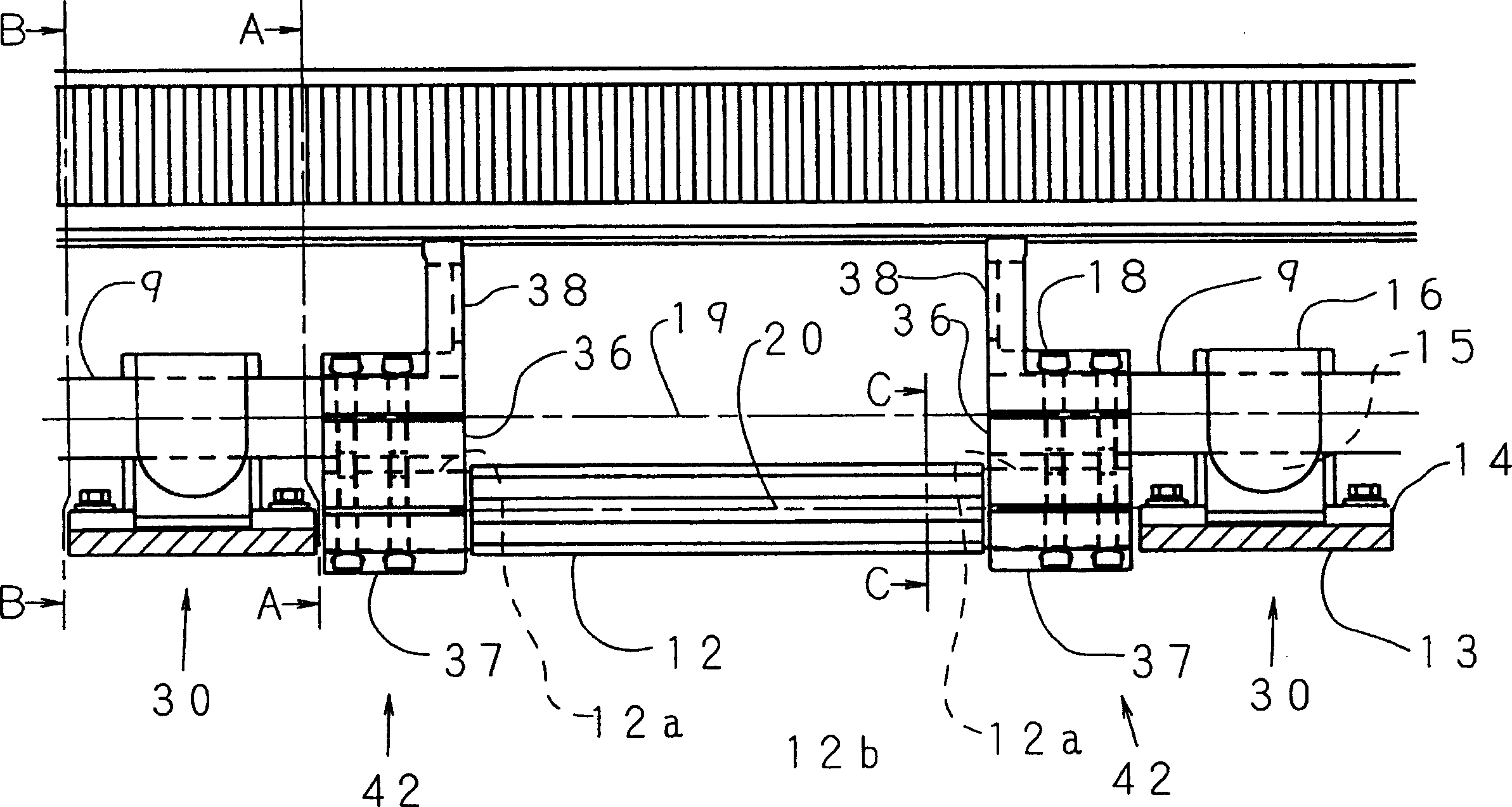

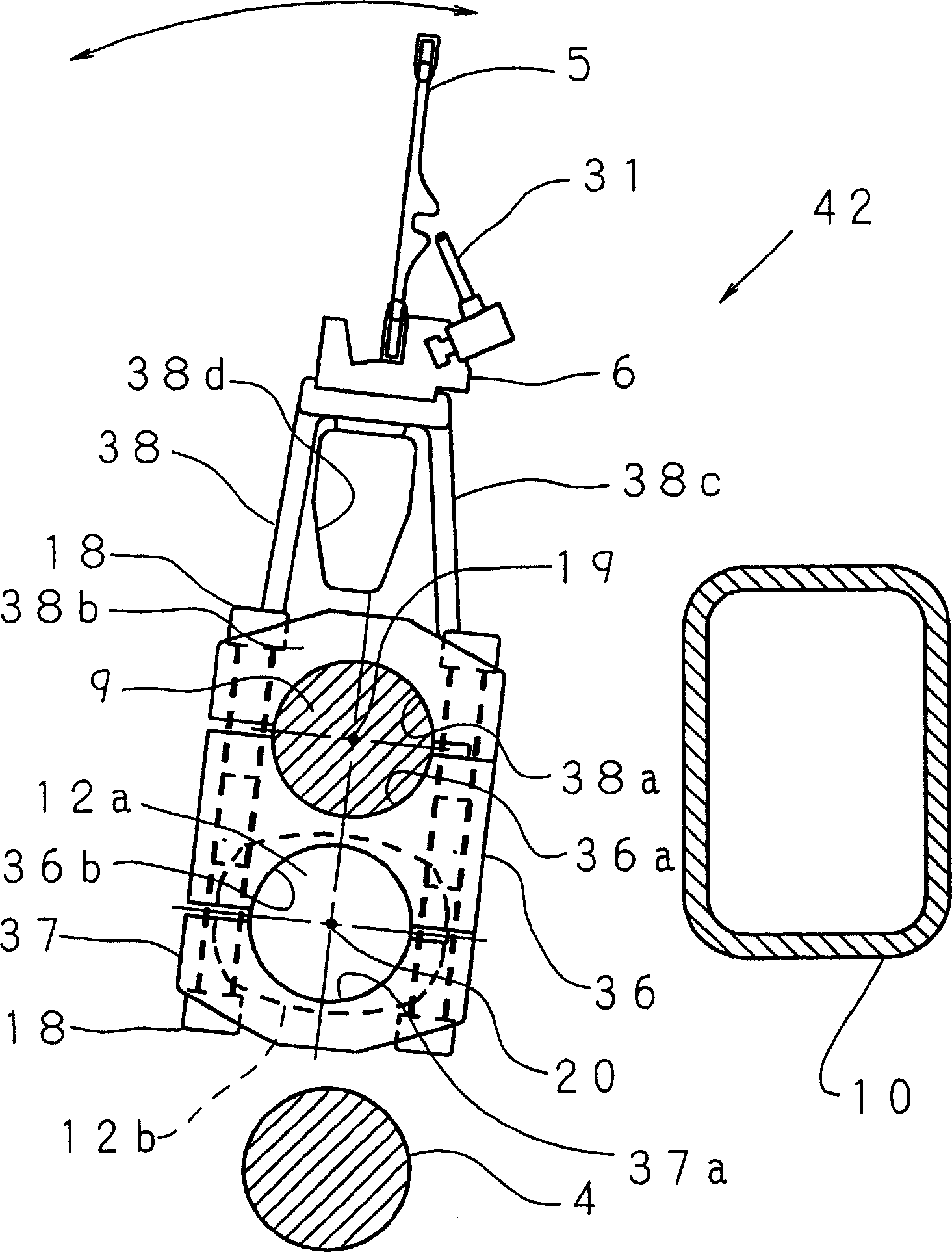

ActiveCN101503095AReduce in quantityLow costRailway componentsPropulsion railway systemsEngineeringFriction drive

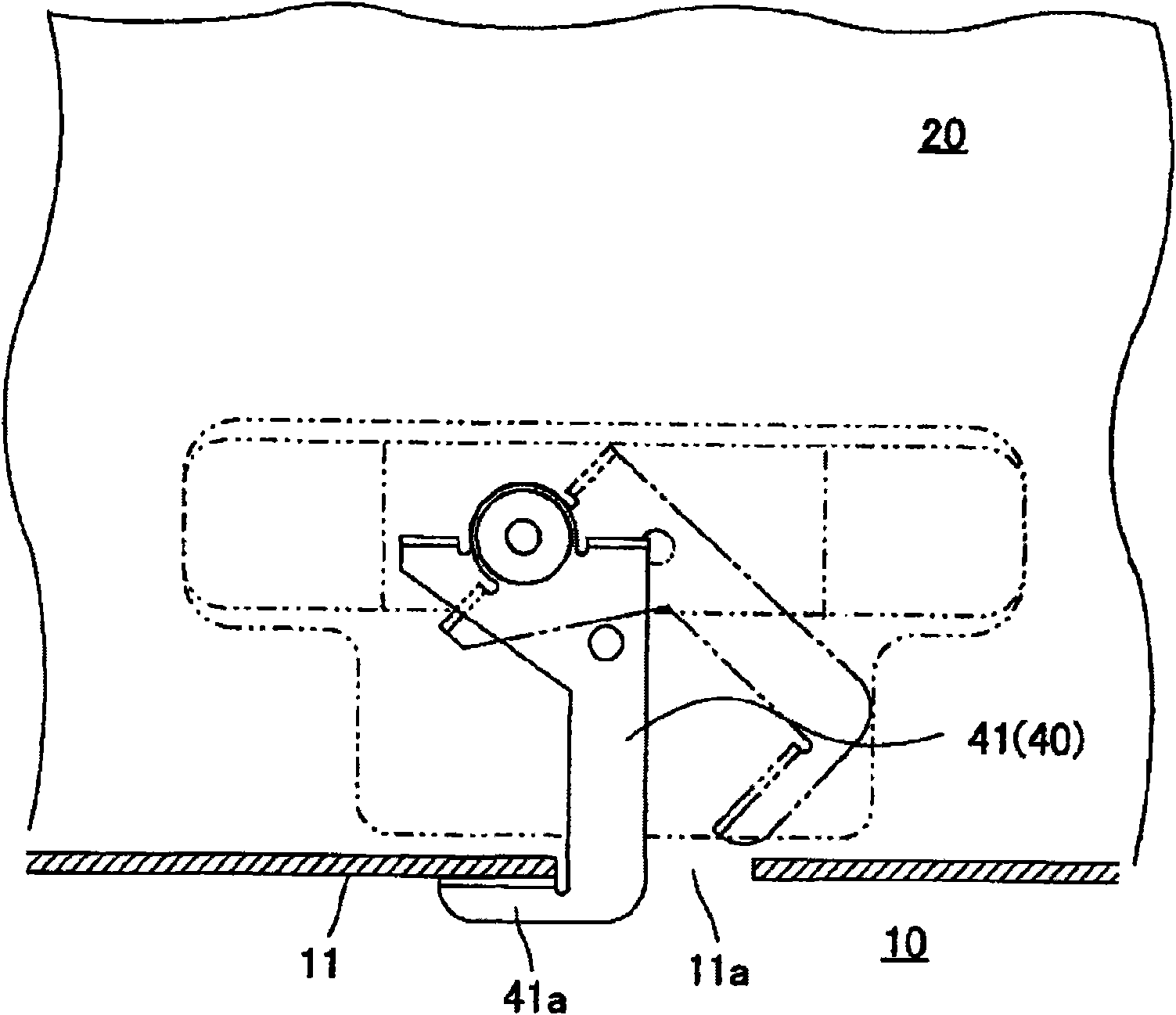

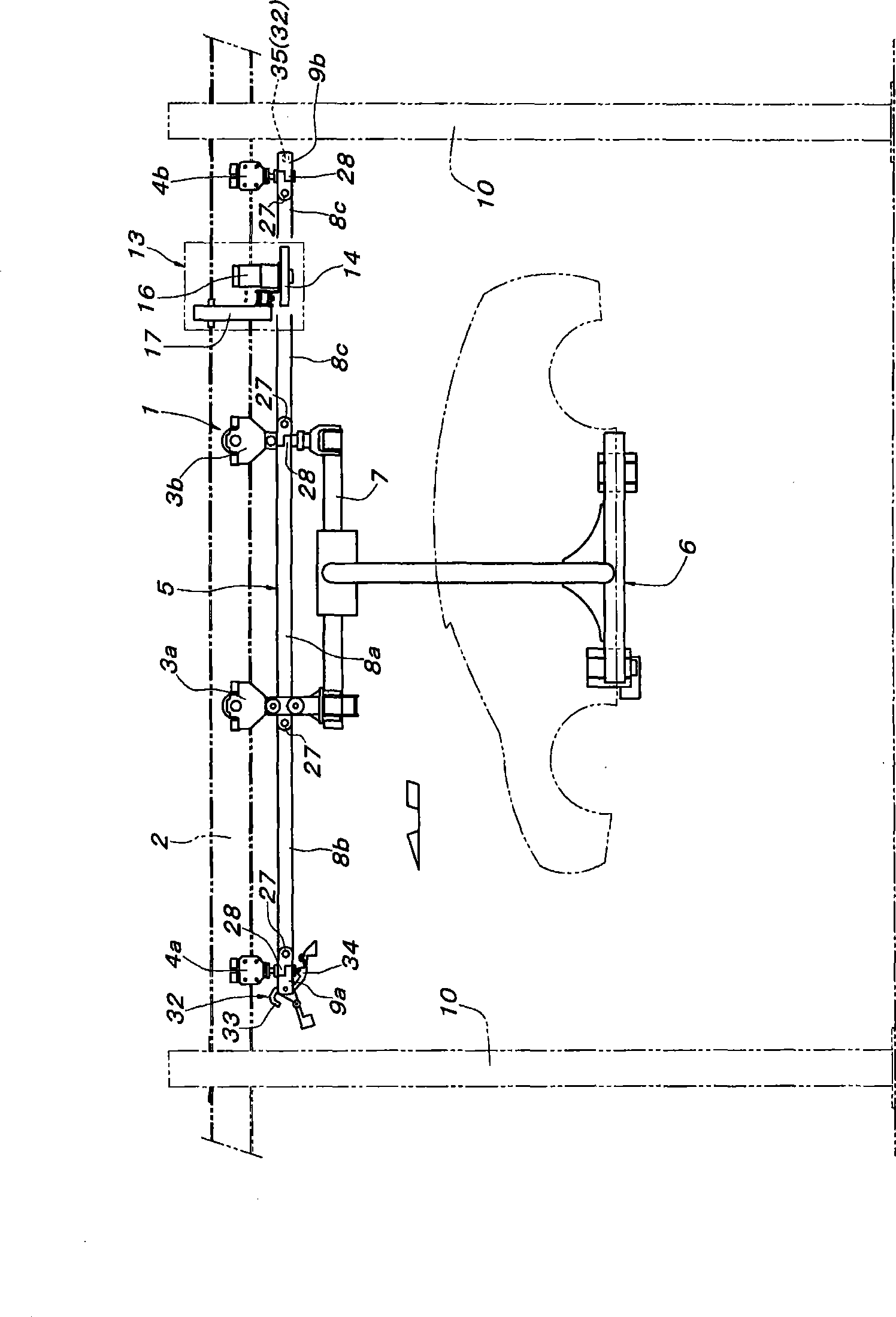

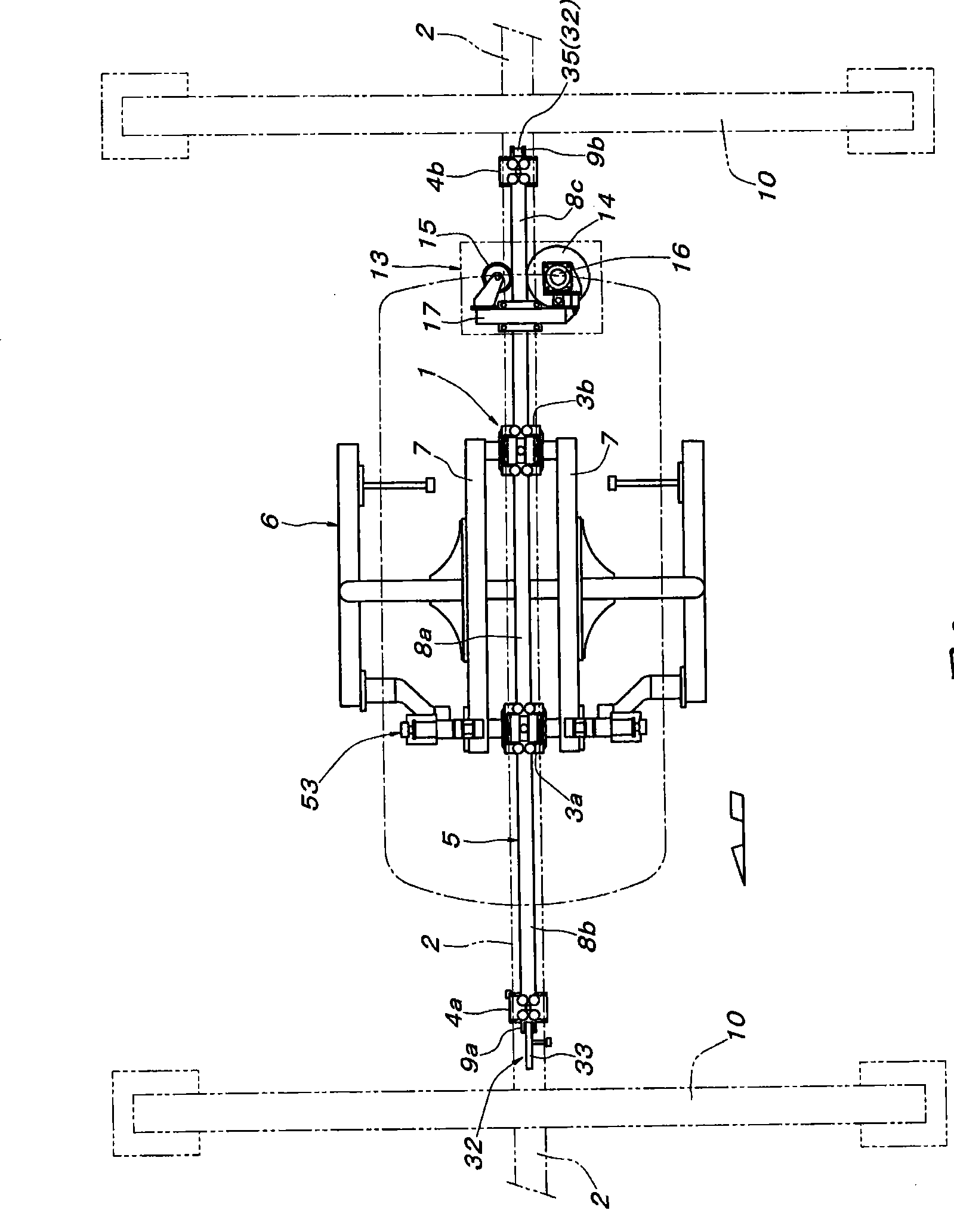

A friction drive trolley conveyor has a conveying traveling body provided with a friction drive load bar having traction purpose engaging means at both ends thereof and allows traction drive to be easily conducted without fail even at the time of conveying a heavy object. The traction purpose engaging means is composed of an engaged shaft arranged in the horizontal direction within a vertical notched portion formed at one end of the load bar, a hook member vertically swingably pivotally supported at an intermediate position in vertical height of the load bar at the other end of the load bar and a holding means holding the hook member in an engaged posture or a disengaged posture, and on a traveling route side, a first switching means switching the hook member from the engaged posture to the disengaged posture and a second switching means switching the hook member from the disengaged posture to the engaged posture.

Owner:DAIFUKU CO LTD

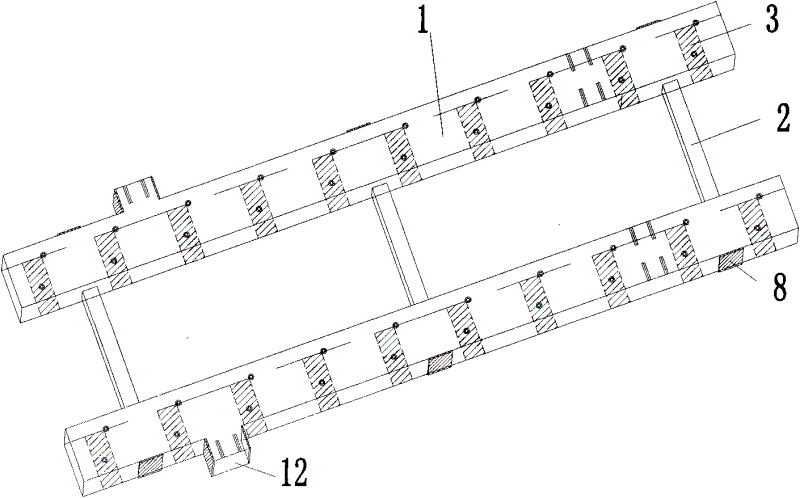

Longitudinal beam type sleeper system

ActiveCN102619145AReduce vibrationReduce rolling noiseBallastwayElastic vibrationStructural engineering

The invention relates to a novel sleeper system, and belongs to the field of railway tracks. The novel sleeper system comprises a longitudinal beam type sleeper and an elastic vibration reduction track system, wherein the longitudinal beam type sleeper is formed by connecting longitudinal beam type sleeper units one by one in series; each two adjacent longitudinal beams of the longitudinal beam type sleeper are fixedly connected with each other in the lateral direction through a connecting piece; the opposite longitudinal beam end parts of each two adjacent longitudinal beam type sleeper units are connected with each other through a sleeper connecting piece; the elastic vibration reduction track system comprises a support saddle; the longitudinal beam type sleeper is mounted on the support saddle; and a vibration reduction facility is arranged between the bottom of the longitudinal beam type sleeper and the support saddle. The novel sleeper system has the advantages that due to the longitudinal sleeper, the bending rigidity of a track is enhanced, and deformation of the track caused by repeated load is reduced; as the lateral resistance of the longitudinal beams is enlarged, the irregularity in the vertical direction of the track is reduced, and the maintenance is reduced; and as the longitudinal beams are connected with each other in the longitudinal direction, the settlement of the track at the end parts of the longitudinal beams is provided from being enlarged or damaged easily; and as rail pads are arranged continuously, foundation shake, rolling noise and wave-like deformation of the track are reduced.

Owner:BEIJING YIKE LUTONG RAILWAY EQUIPEMNT +1

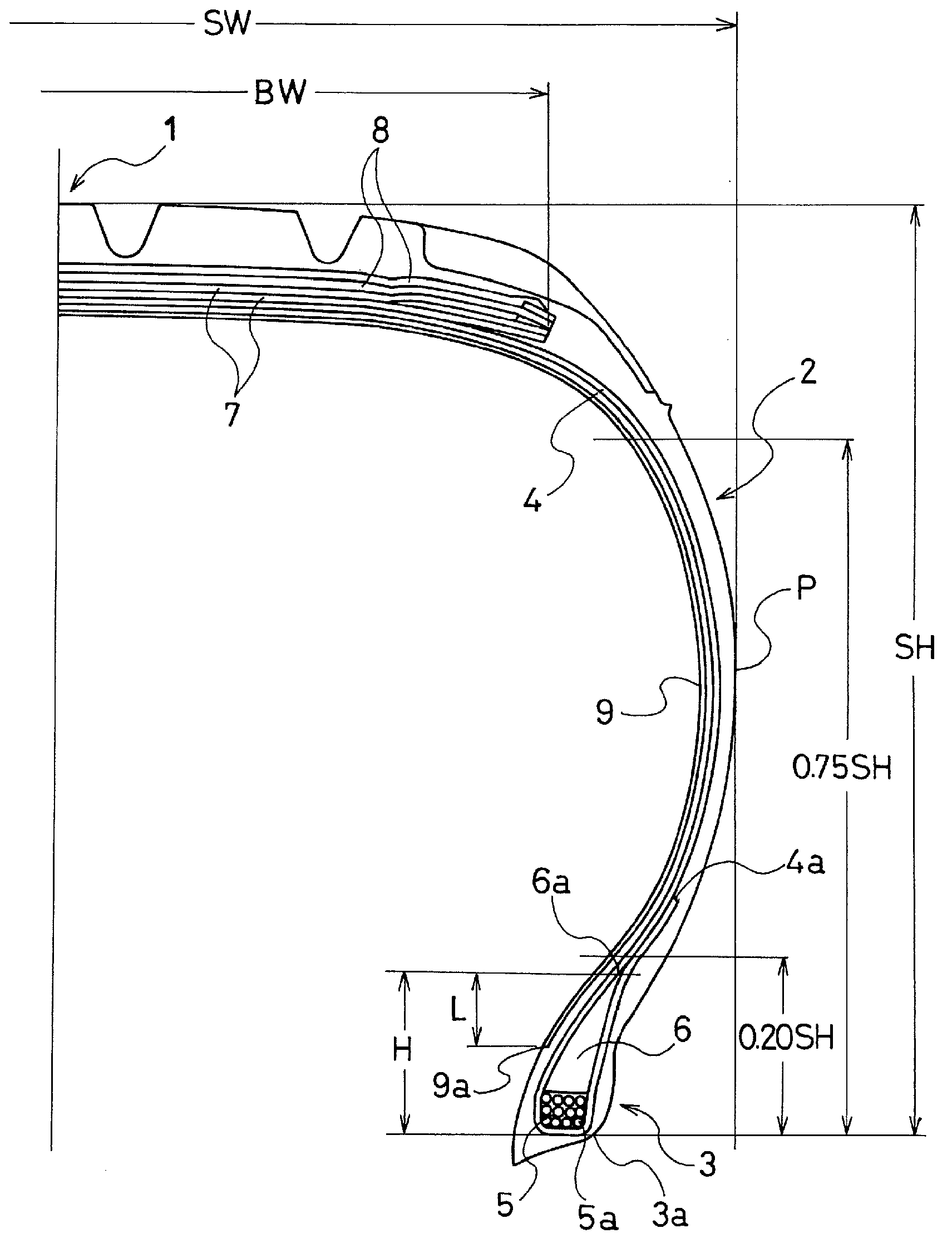

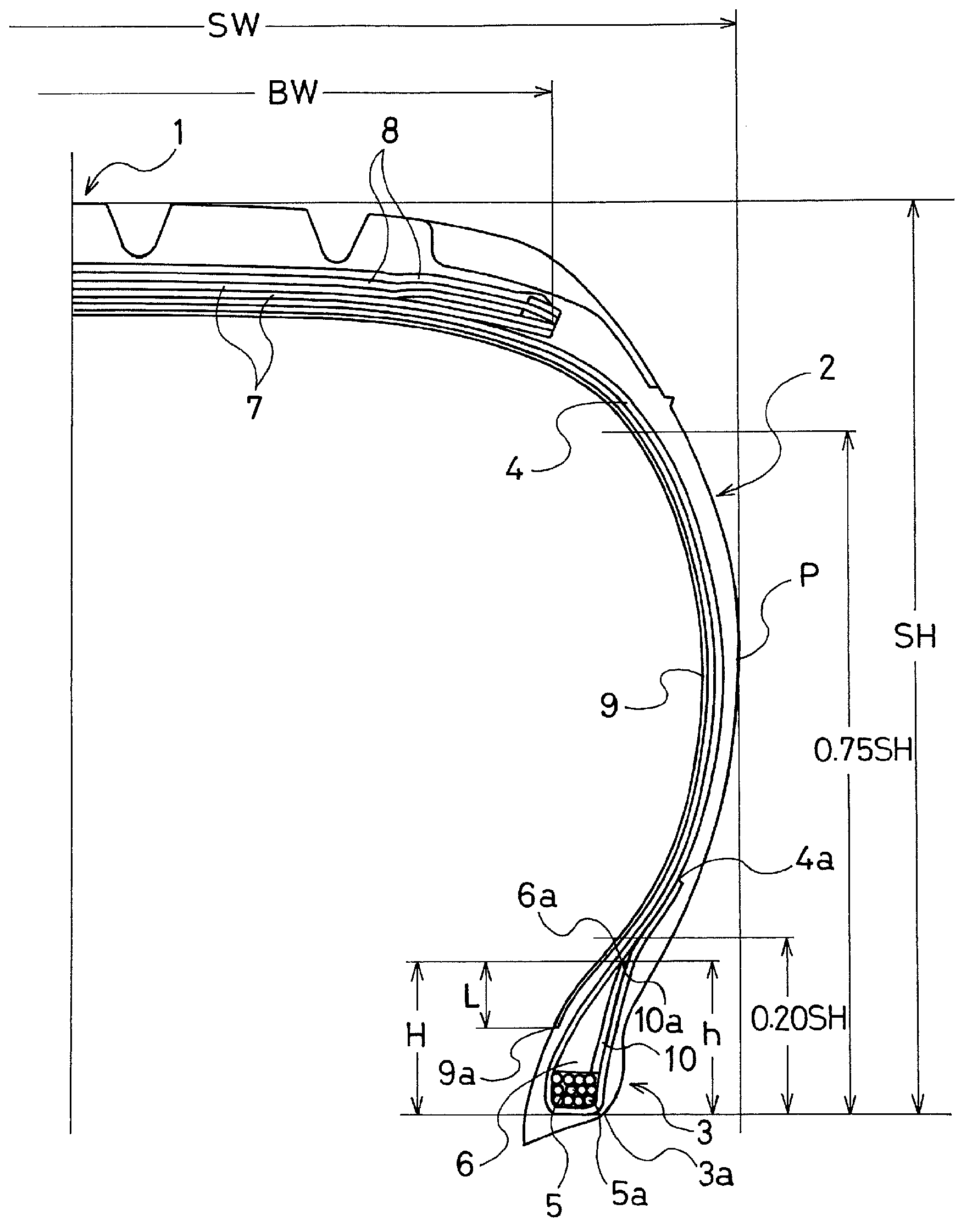

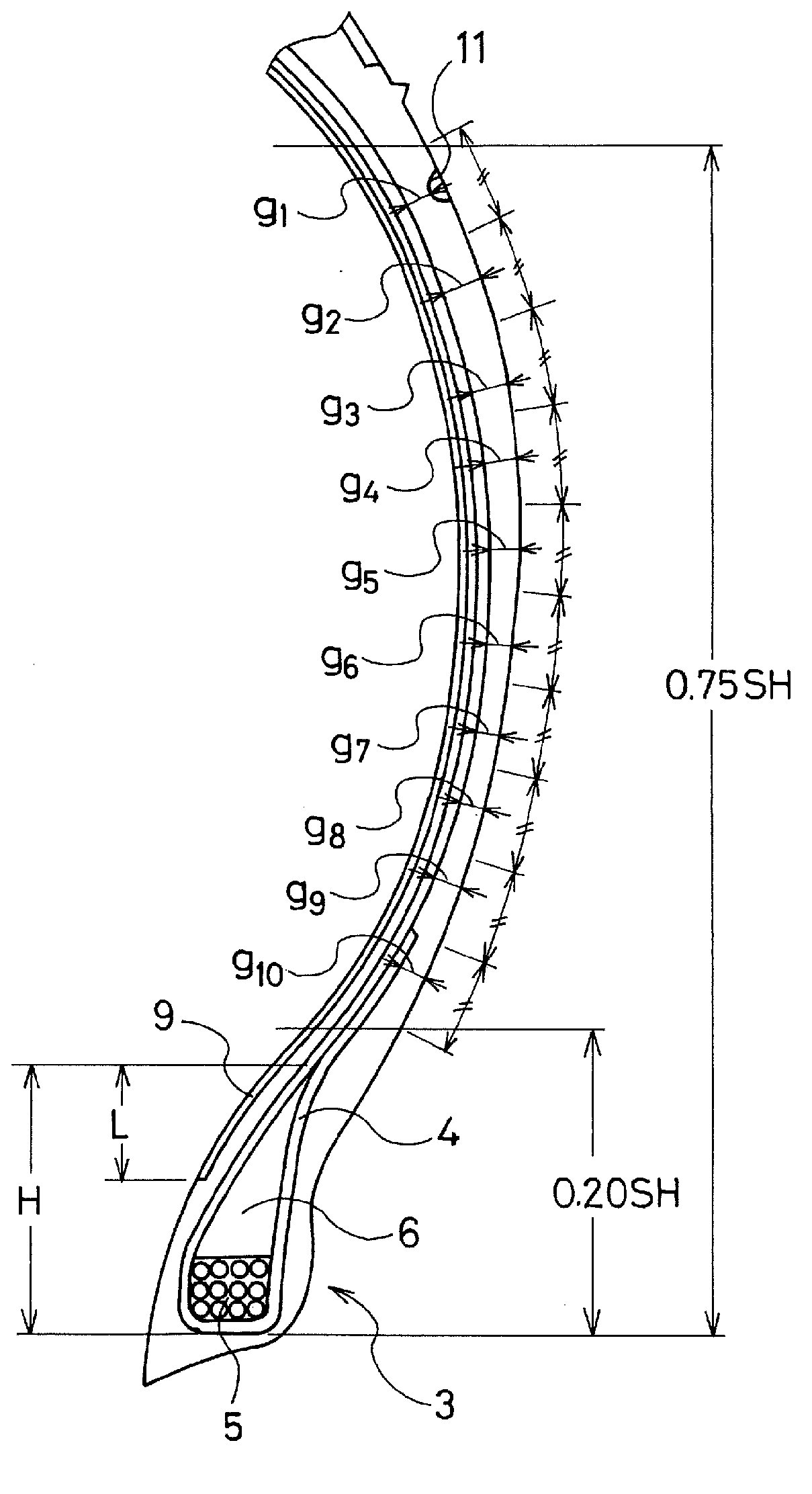

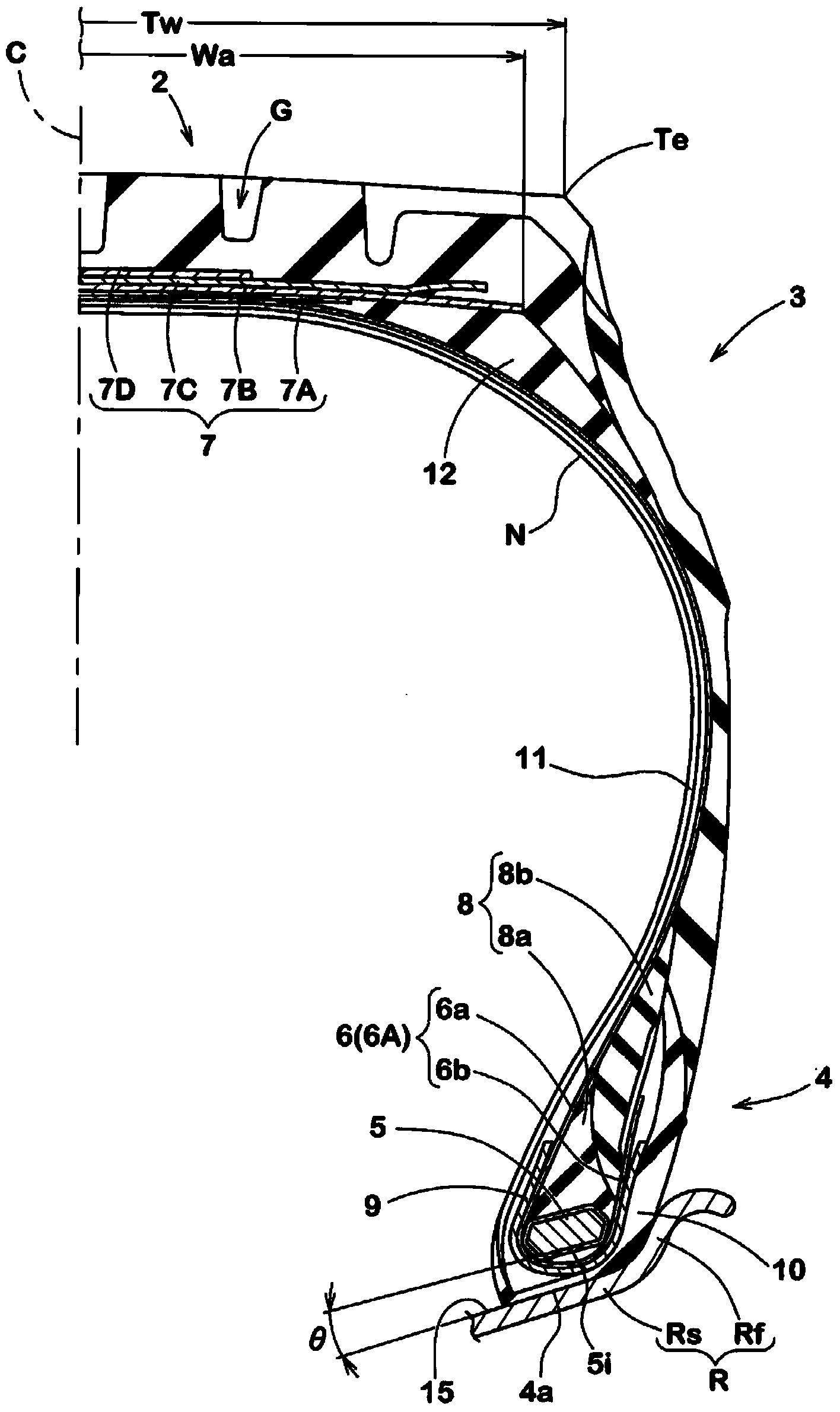

Pneumatic tire

InactiveCN103221233AModerate Rigidity VariationsMake up for driving stabilityWithout separate inflatable insertsSpecial tyresElastomerThermoplastic elastomer

Proposed is a pneumatic tire which has an excellent balance between tire weight reduction and steering stability. The height (H) of a bead filler (6) from a bead heel (3a) is set to 10-30 mm, and an inner liner (9) arranged inside a carcass layer (4) is configured of a thermoplastic resin that has a Young's modulus of 70-1500 MPa and a thickness of 0.05-0.25 mm or a thermoplastic elastomer composition that is obtained by blending a thermoplastic resin component and an elastomer component. An end portion (9a) of the inner liner (9) is positioned inside a radially outer end portion (6a) of the bead filler (6) in the tire radial direction.

Owner:THE YOKOHAMA RUBBER CO LTD

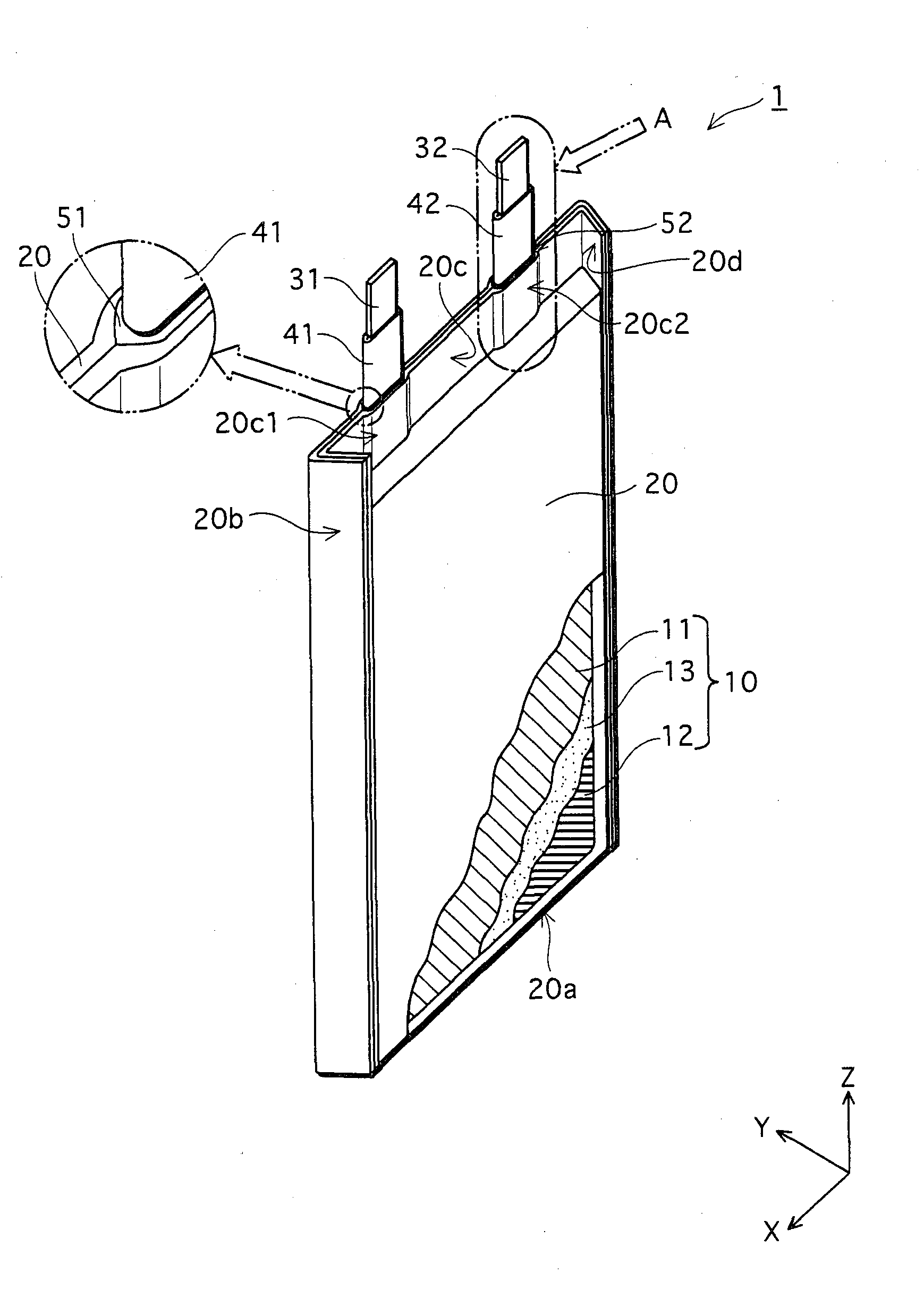

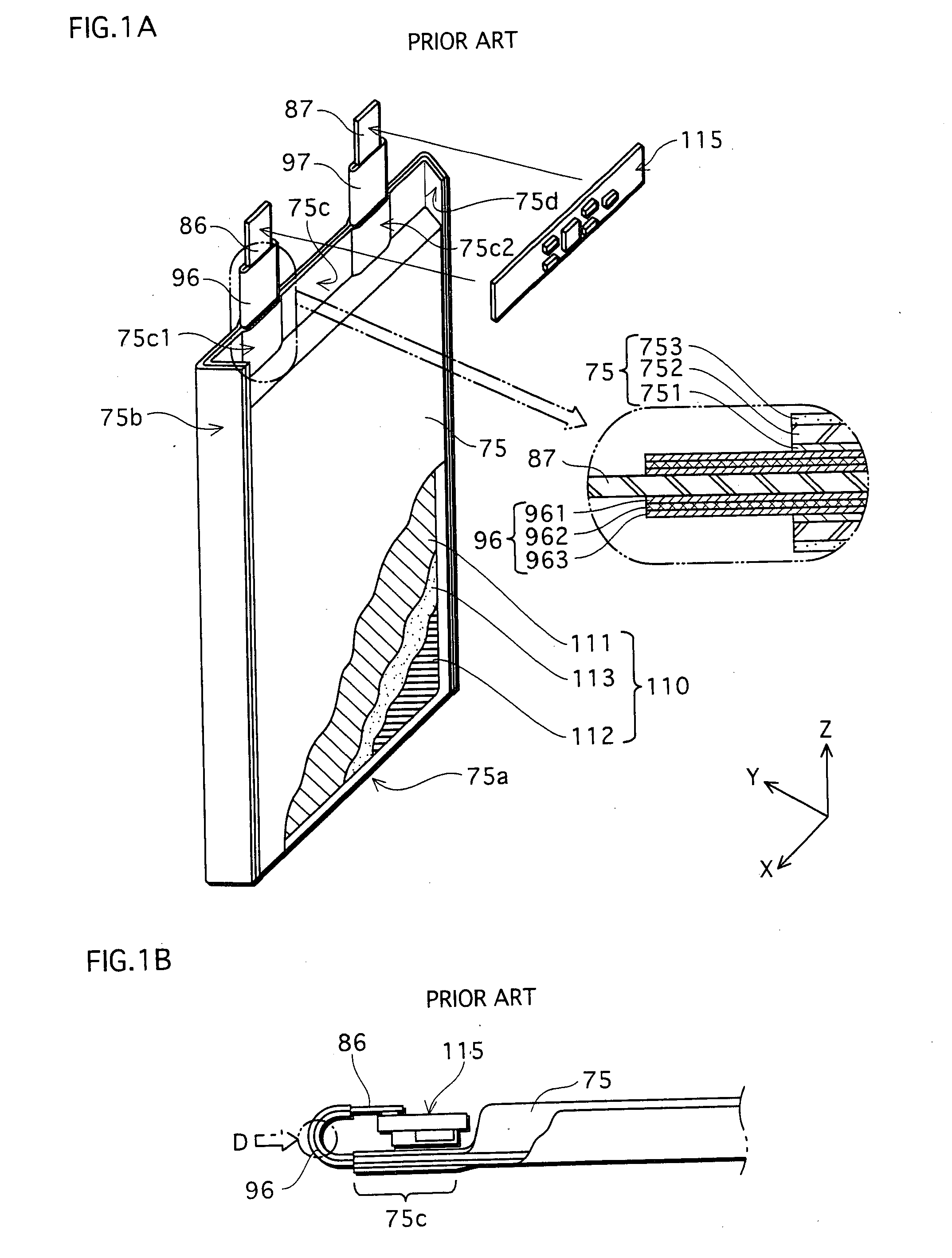

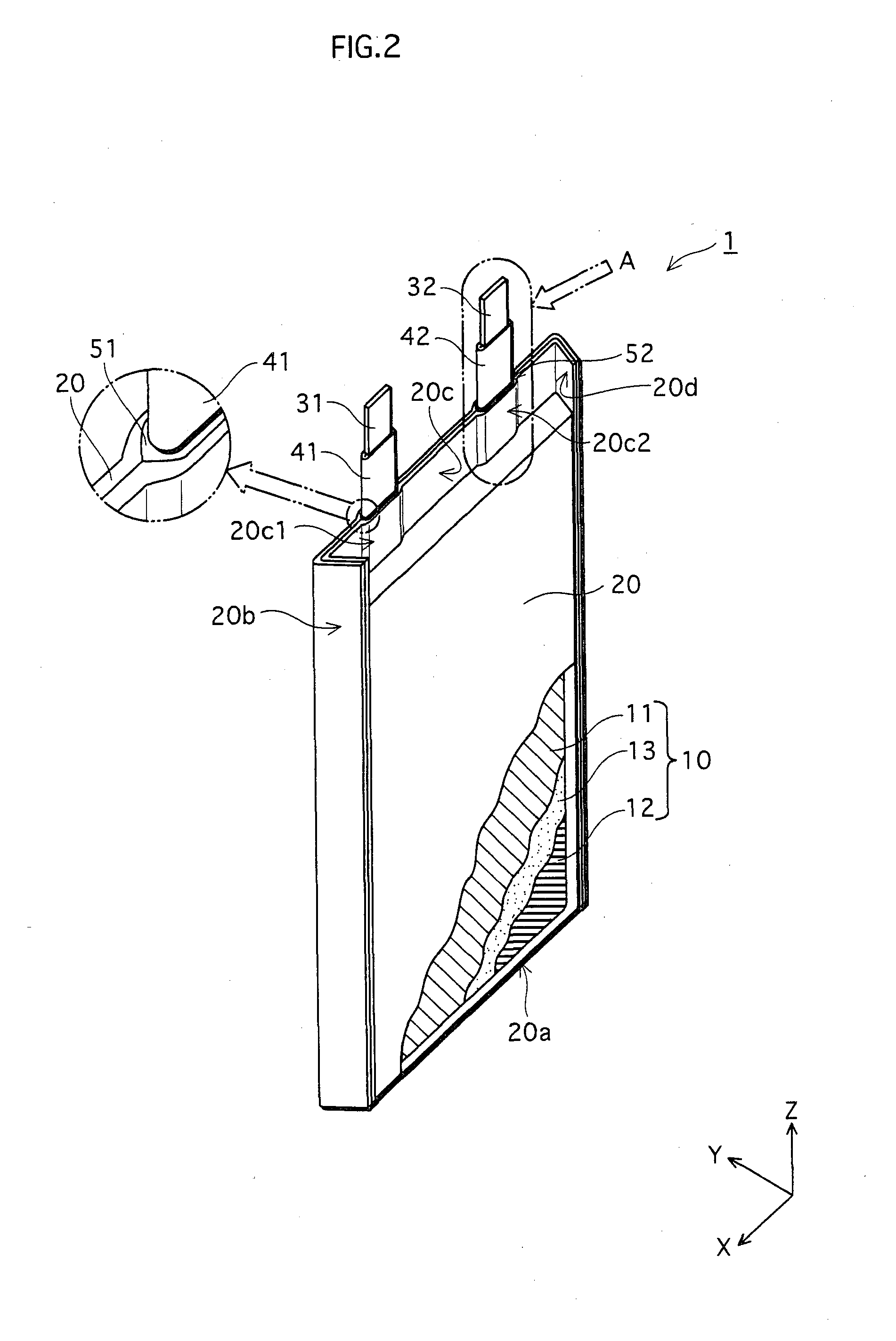

Laminate-cased battery formed with tab resin adhered to portions of tabs extended from laminate casing

InactiveUS20090035654A1Quality improvementImprove energy efficiencySmall-sized cells cases/jacketsLarge-sized cells cases/jacketsEngineeringElectrical and Electronics engineering

In a laminate-cased battery, tab resins are adhered to positive and negative tabs, except outer ends of the tabs, and inserted (i) between a casing and the positive tab and (ii) between the casing and the negative tab in areas where the positive and negative tabs cross a heat-sealed edge of the casing.Each of the tab resins has (i) a crossing area in which the tab resin crosses the heat-sealed edge and (ii) an extension area in which the tab resin extends outward from the casing, in a direction in which the positive and negative tabs extend. Each crossing area includes a high melting point resin layer whose melting point is relatively higher than a melting point of each element that constitutes the extension areas.

Owner:SANYO ELECTRIC CO LTD

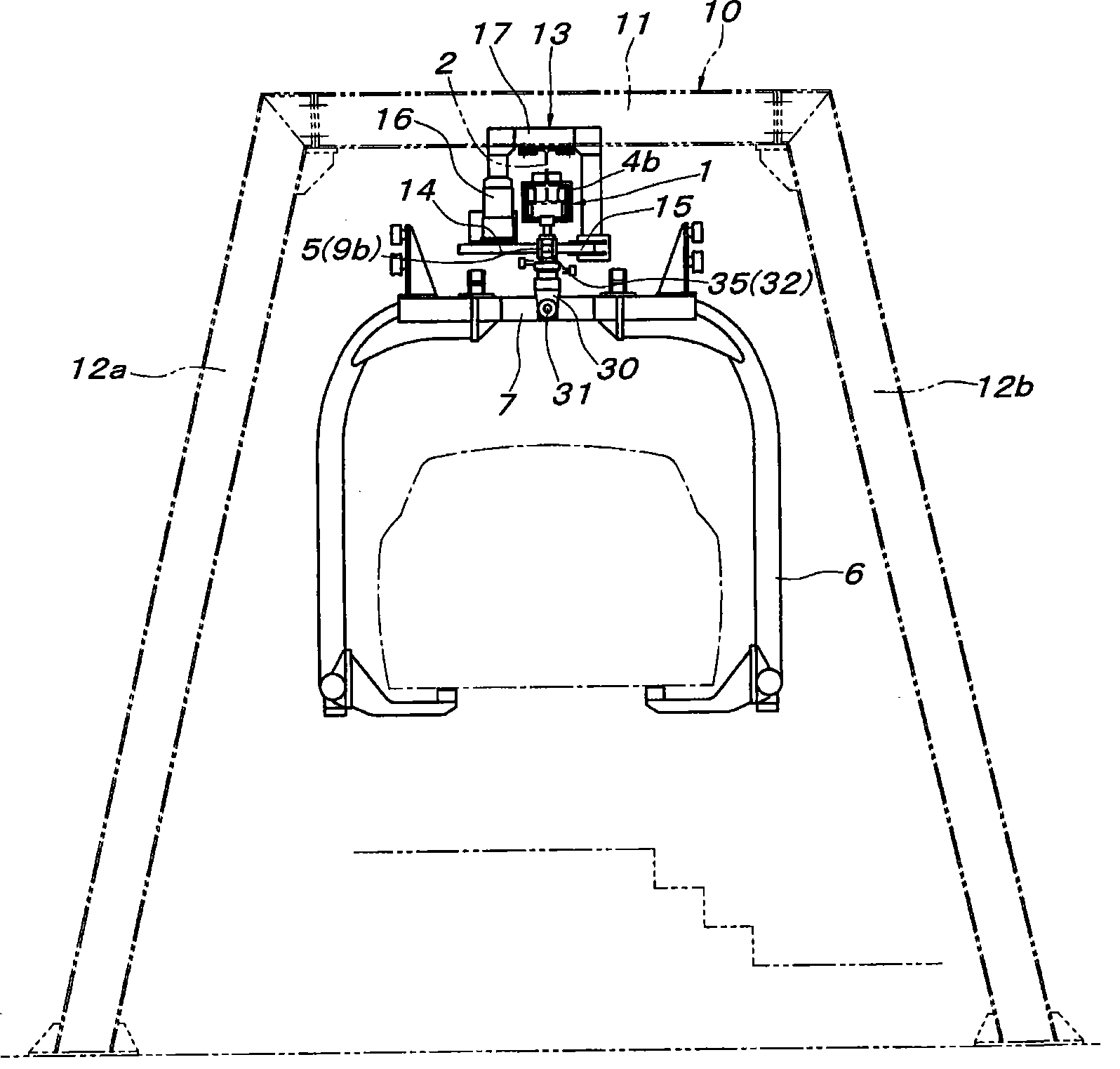

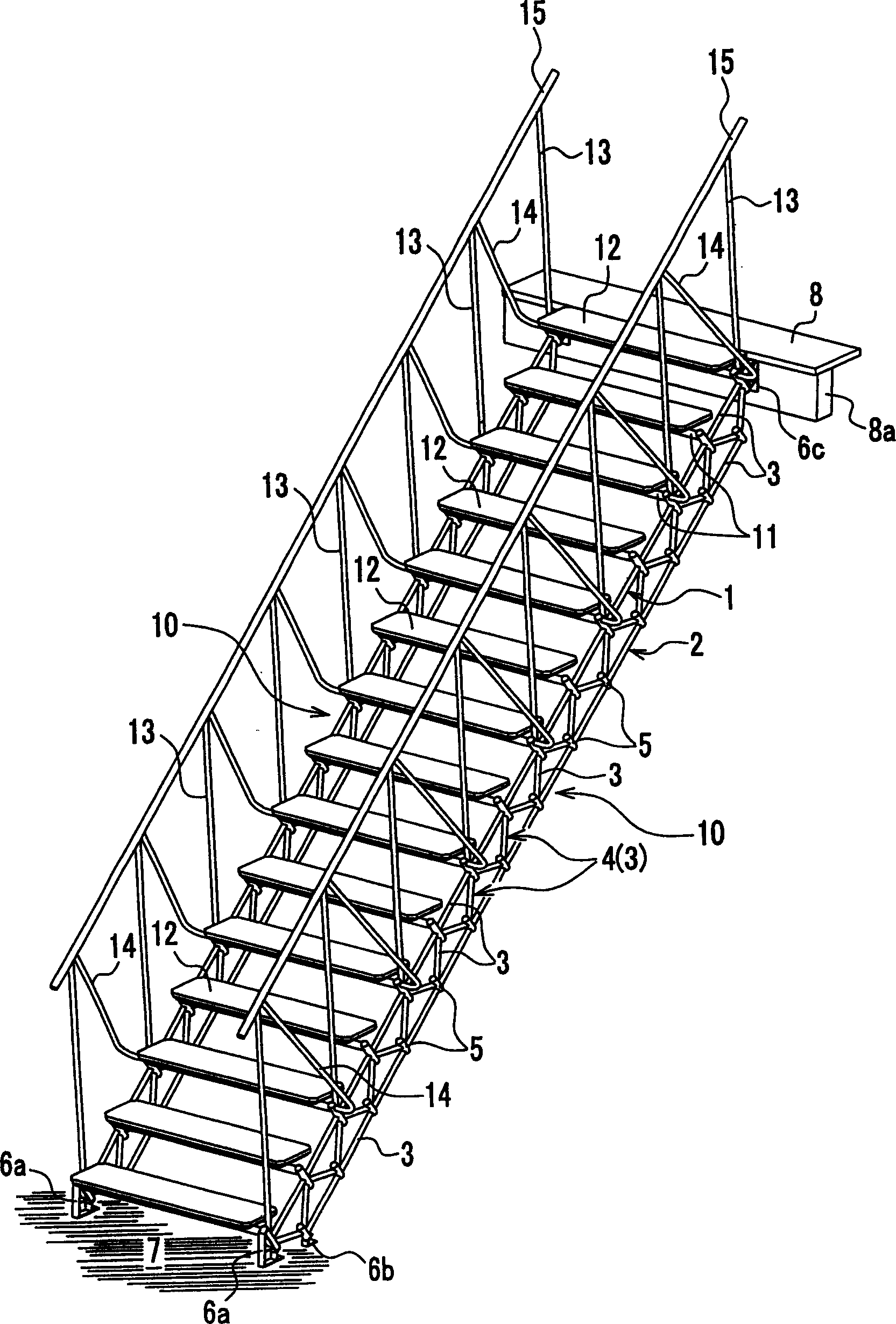

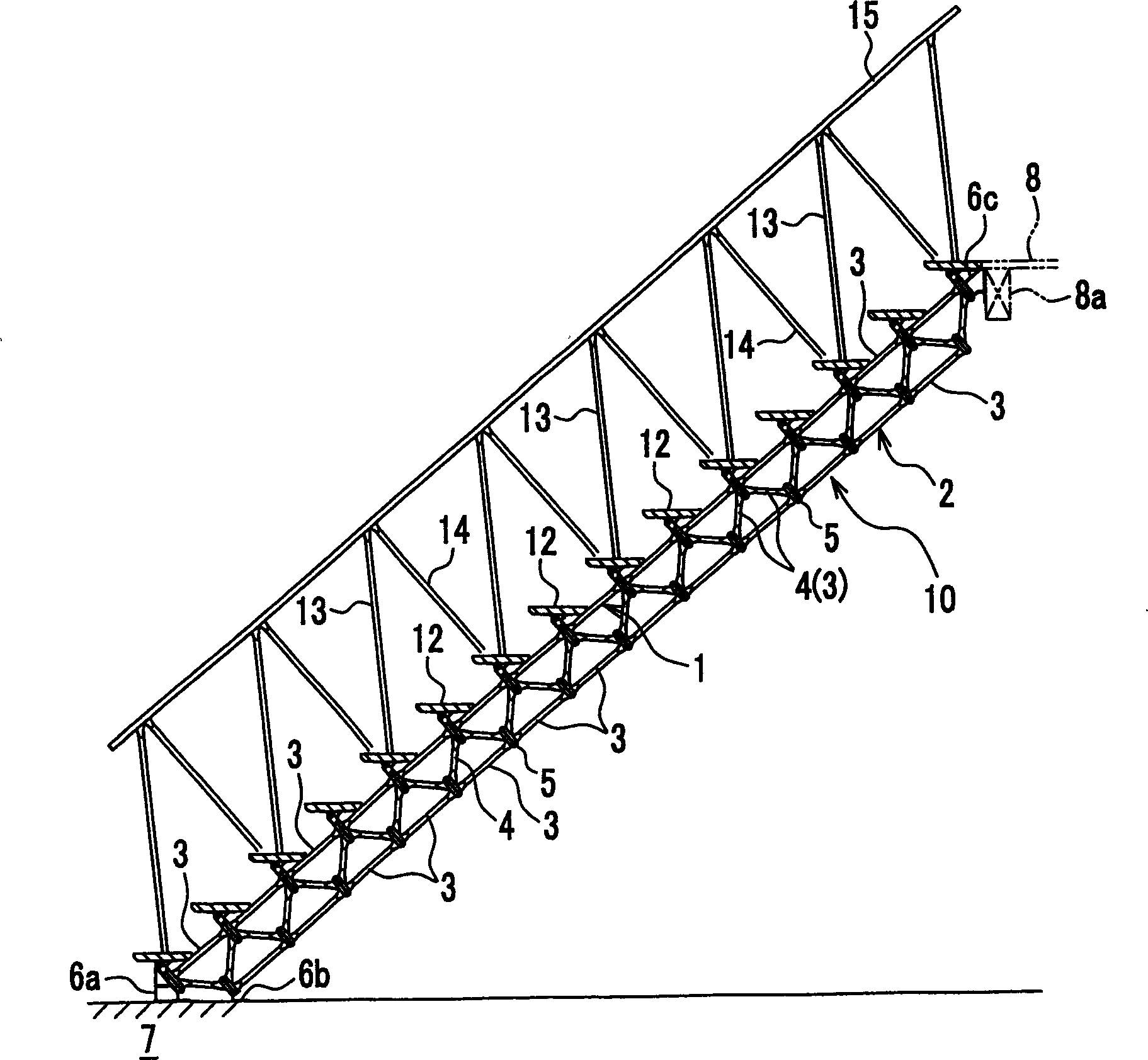

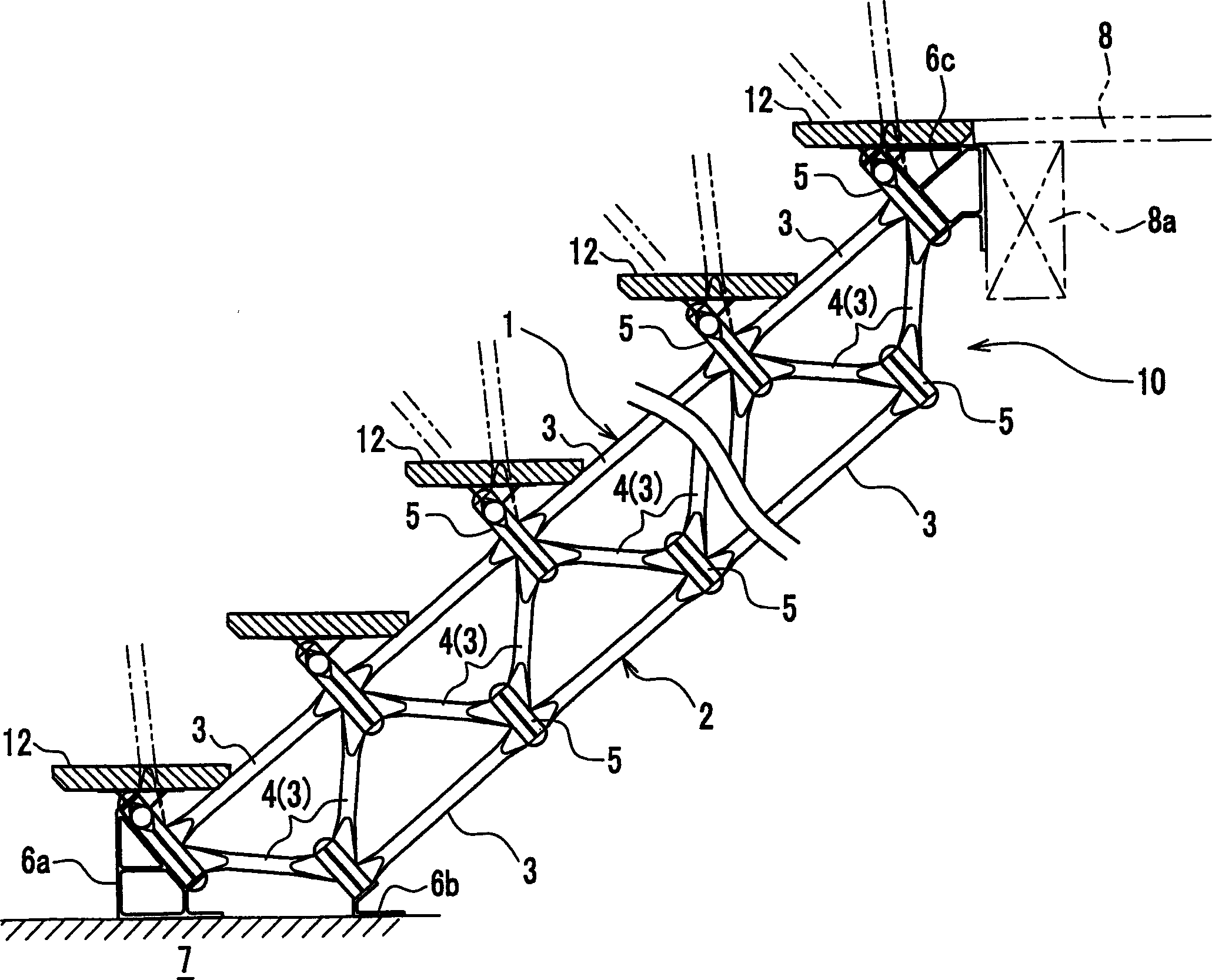

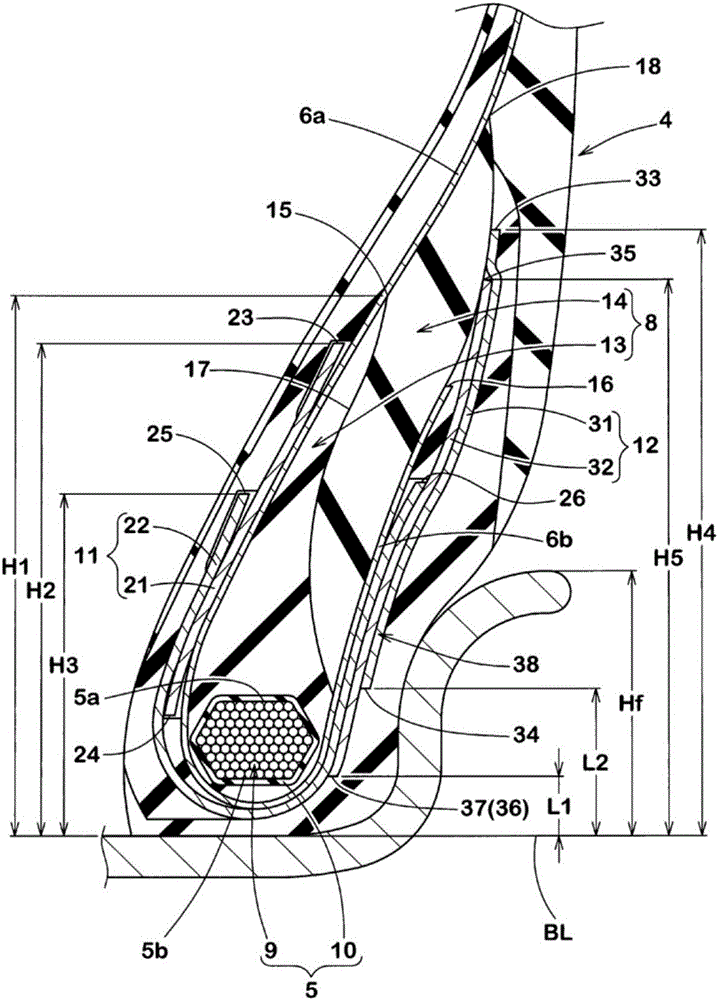

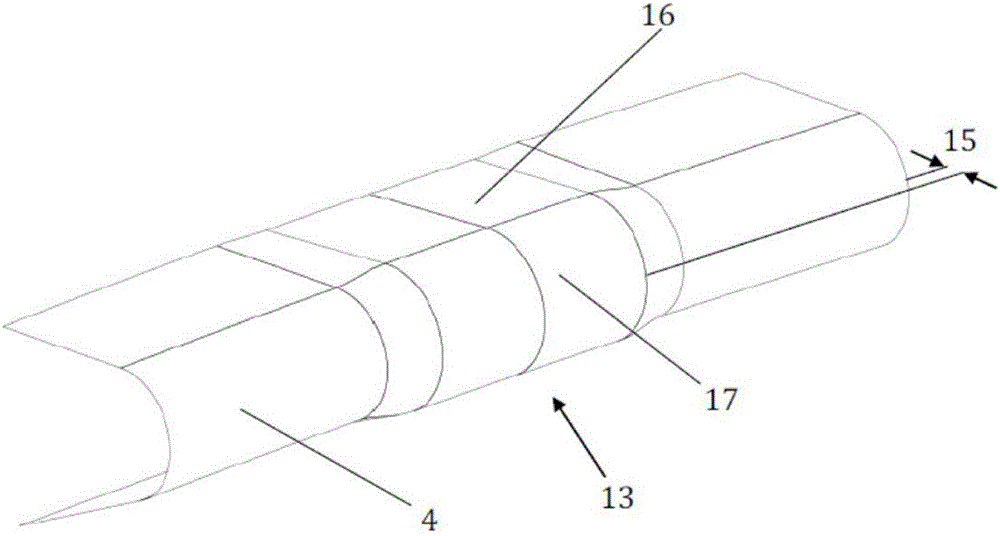

Stairway

InactiveCN1608162AIncreased torsional rigidityImprove bending rigidityTreadsLaddersEngineeringStep height

The invention provides a staircase with a light structure, high production and construction efficiency, and a sense of lightness. The staircase comprises a pair of left and right inclined beams and pedals (12) formed by truss structural parts (10). The truss structure part (10) comprises: an upper chord member (1) and a lower chord member (2) inclined with the gradient of the stairs; a plurality of grids for connecting the upper chord member (1) and the lower chord member (2) structural parts (4), between the truss structural parts (10), a plurality of connection parts (11) arranged horizontally according to each step height are fixed to connect these truss structural parts (10), and the pedals (12) are fixedly supported on these connection parts (11).

Owner:NIPPON LIGHT METAL CO LTD

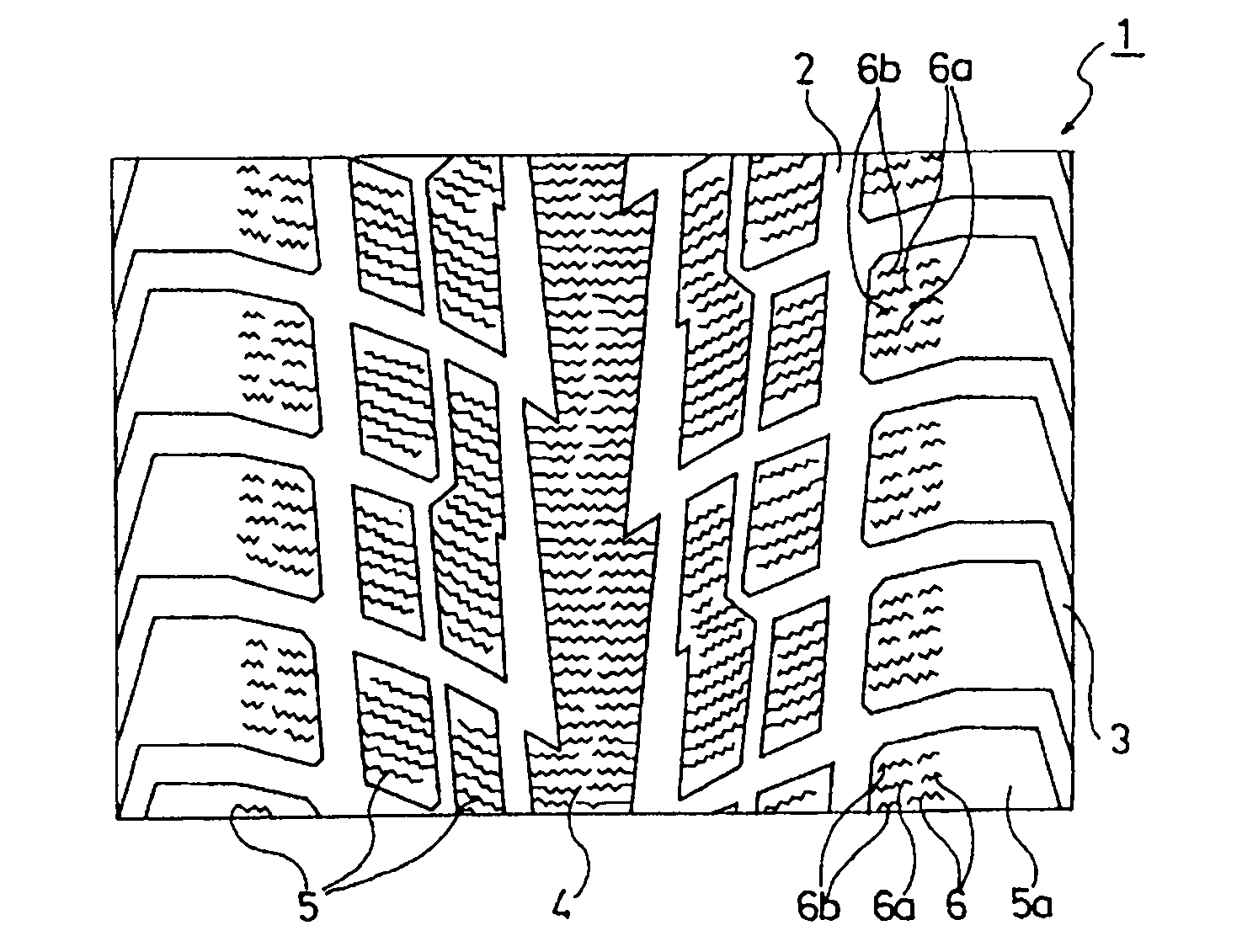

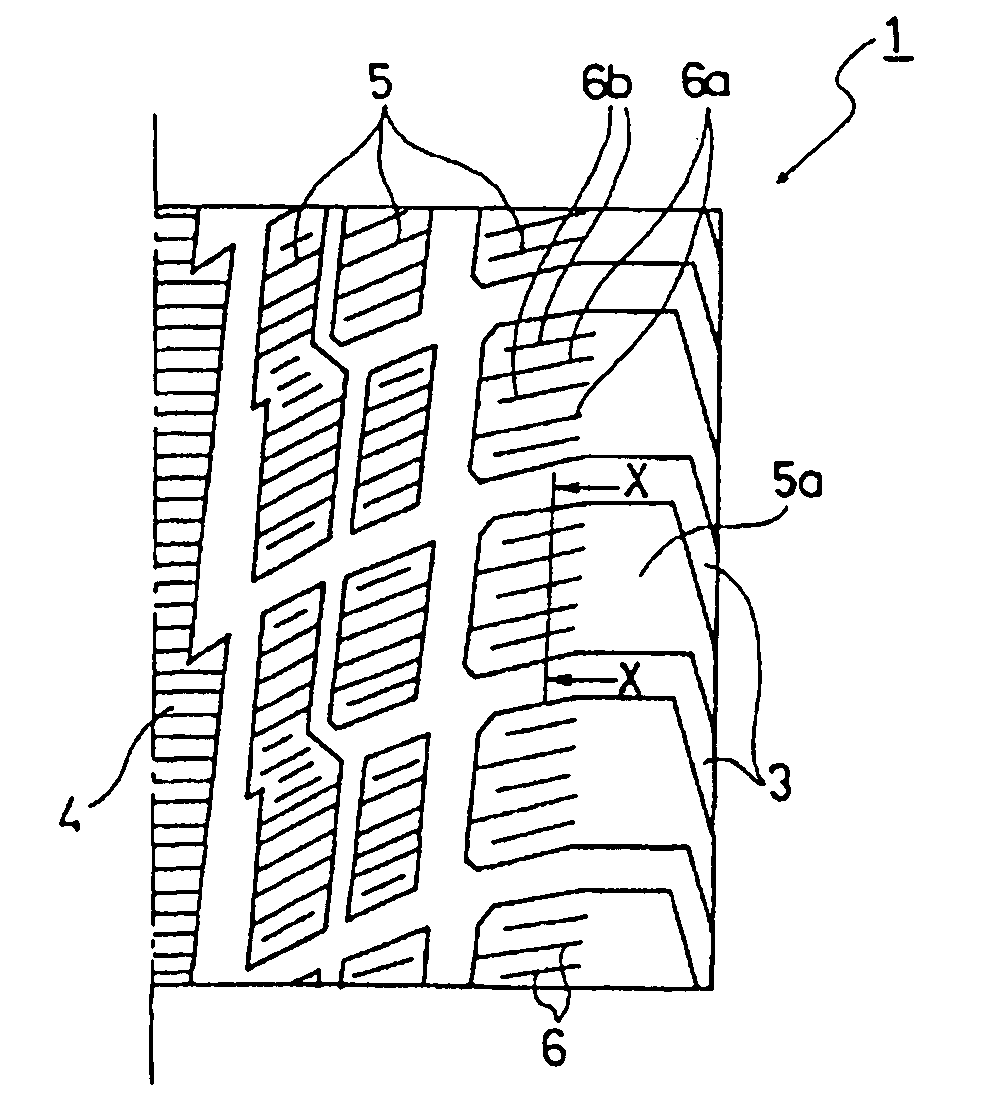

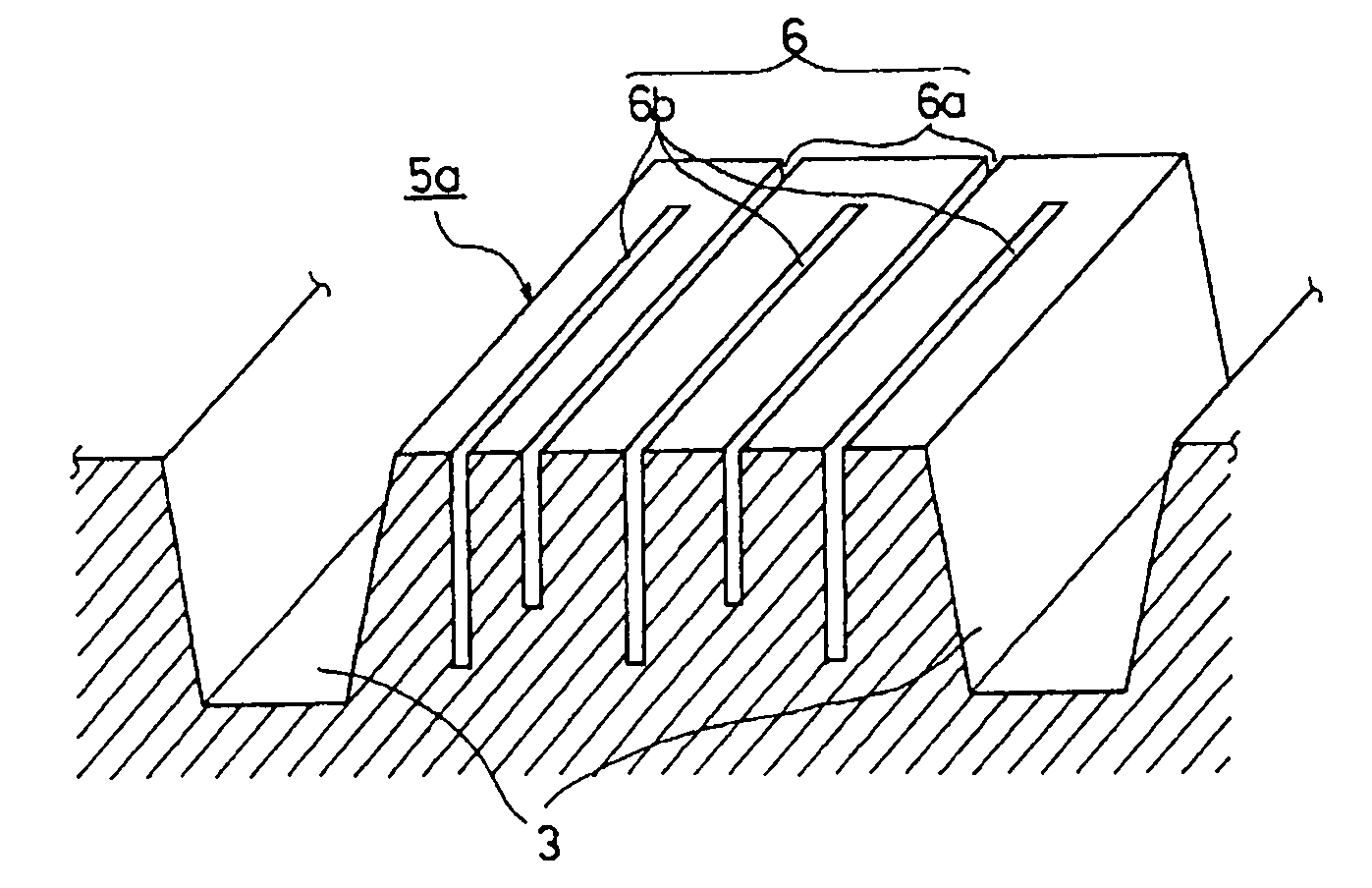

Pneumatic tire

InactiveCN102123878AImprove bending rigidityImprove performance on iceTyre tread bands/patternsMechanical engineering

Owner:THE YOKOHAMA RUBBER CO LTD

Beating device for loom

InactiveCN1704513AReduce weightReduce inertia forceLoomsSemiconductor devices for light sourcesEngineeringBending stiffness

A beating device for a loom includes a plurality of rocking shafts disposed distant from each other in a width direction of cloth to be woven by the loom; a balance shaft disposed farther away from a reed than the rocking shafts and extending in said width direction, the balance shaft being disposed between the neighboring rocking shafts; and a pair of connection units for respectively connecting two opposite ends of the balance shaft with ends of the neighboring rocking shafts. The balance shaft is non-circular in cross-section such that a rocking-direction flexural-rigidity of the balance shaft is greater than a flexural-rigidity of the balance shaft in a direction perpendicular to the rocking direction.

Owner:TSUDAKOMA KOGYO KK

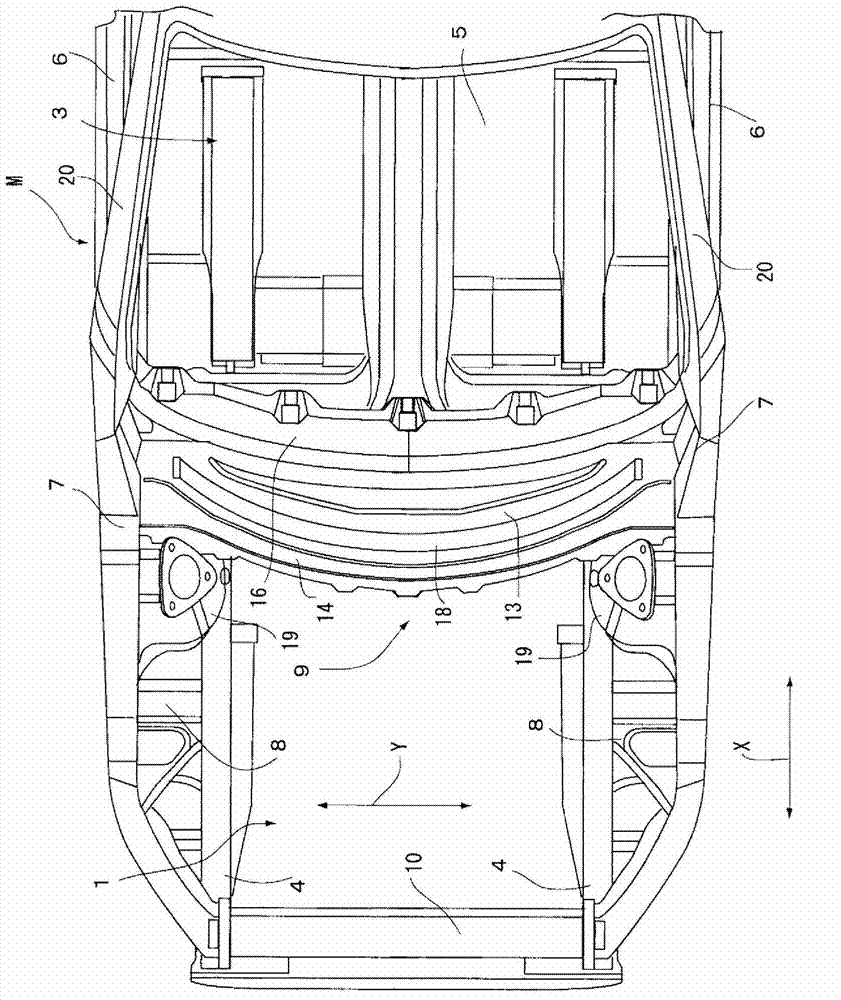

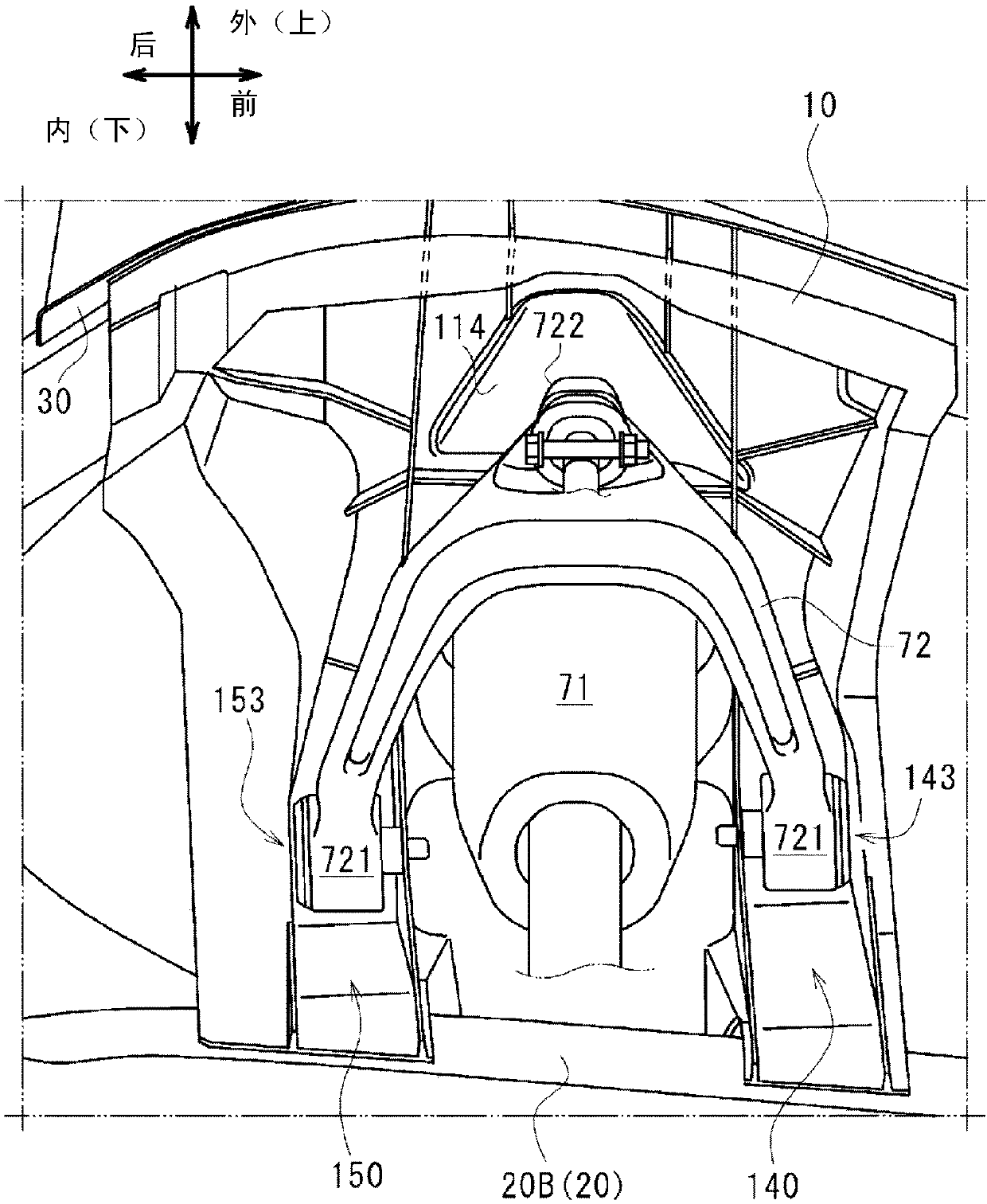

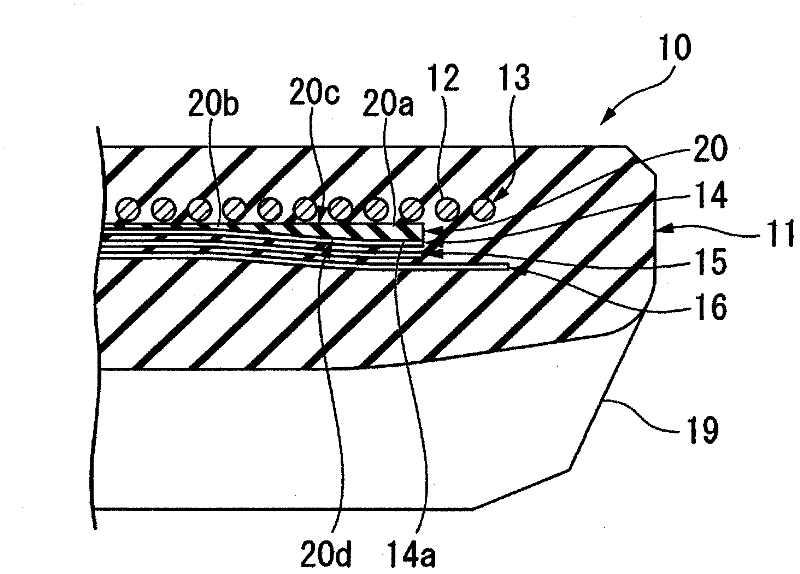

Vehicle strut tower support reinforcing structure

ActiveCN102963436AImprove bending rigidityEnsure handling stabilitySuperstructure subunitsTowerFlange

The structure has a cowl top (9) including lower wall portion (13) that is joined to upper portion of the dash panel for dividing engine compartment (1). The cowl top is bent from a front wall portion, and is formed in lower end of vacant room. A strut tower is formed along right-and left sides of inner wall of engine compartment of vehicle. A connection bracket is formed by welding flange of side wall of the housing portion and front-wall portion of cowl top. A bead (18) is formed in an area without interruption, and is configured to tie position facing right and left strut tower.

Owner:MITSUBISHI MOTORS CORP

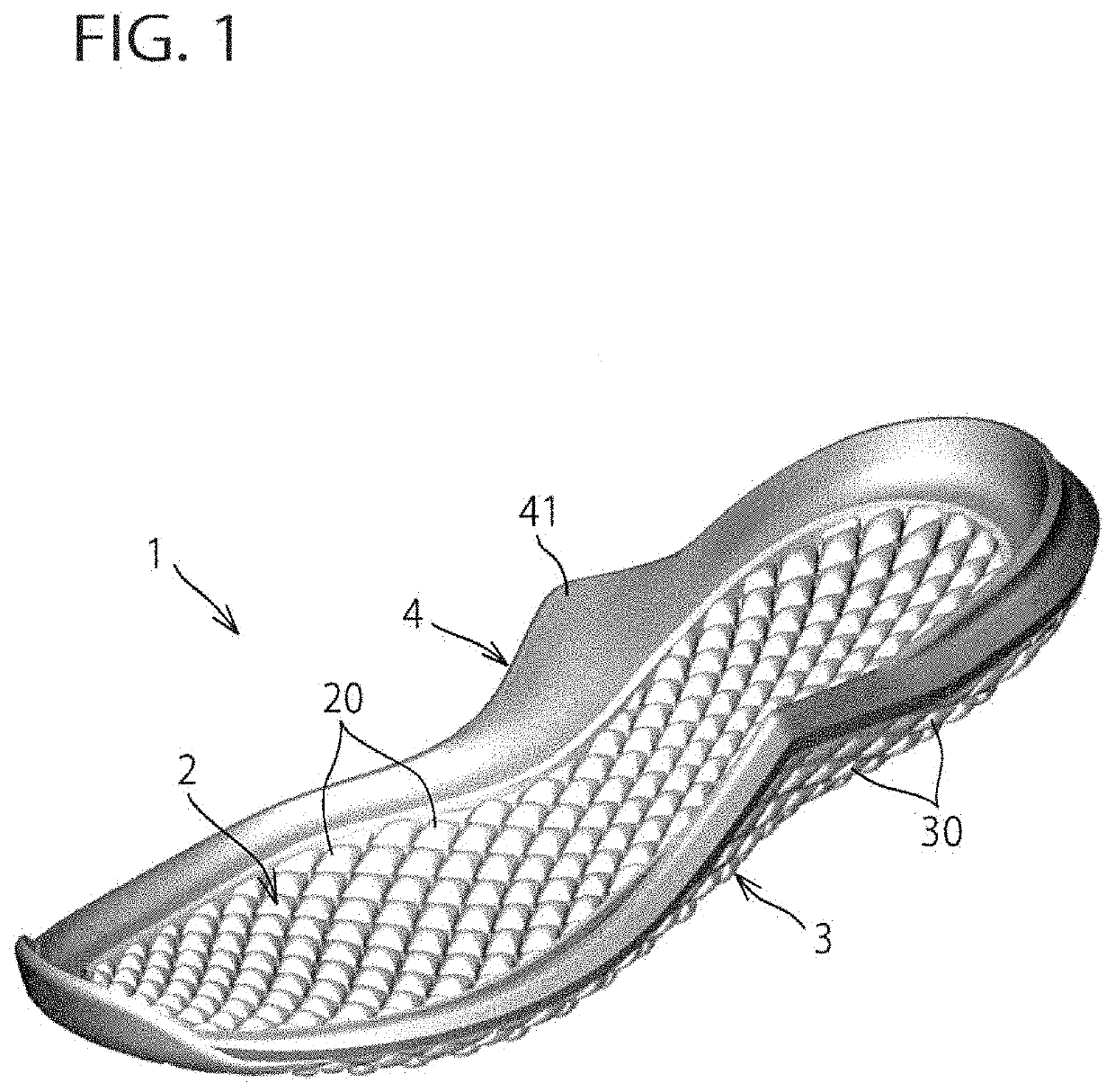

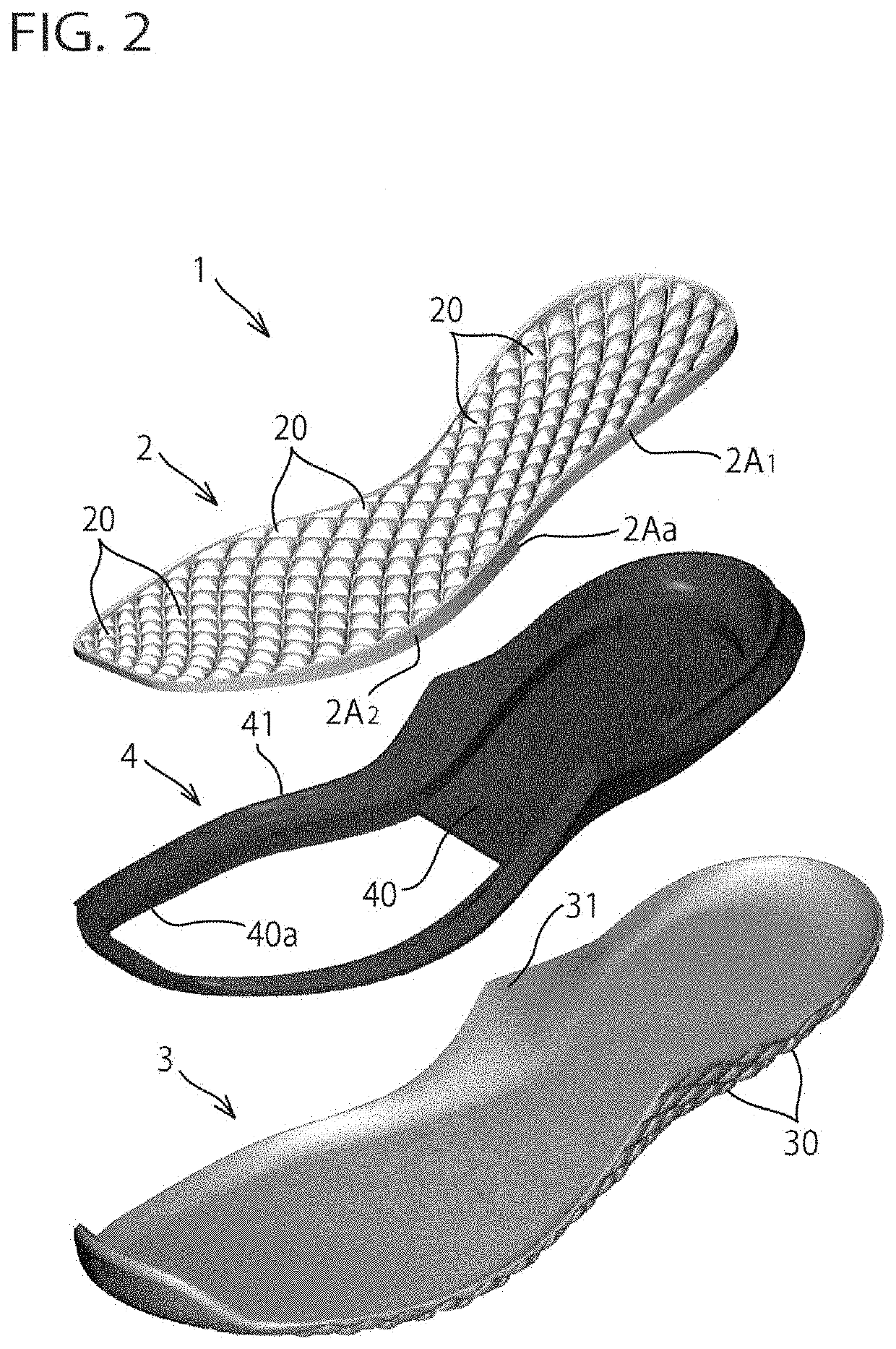

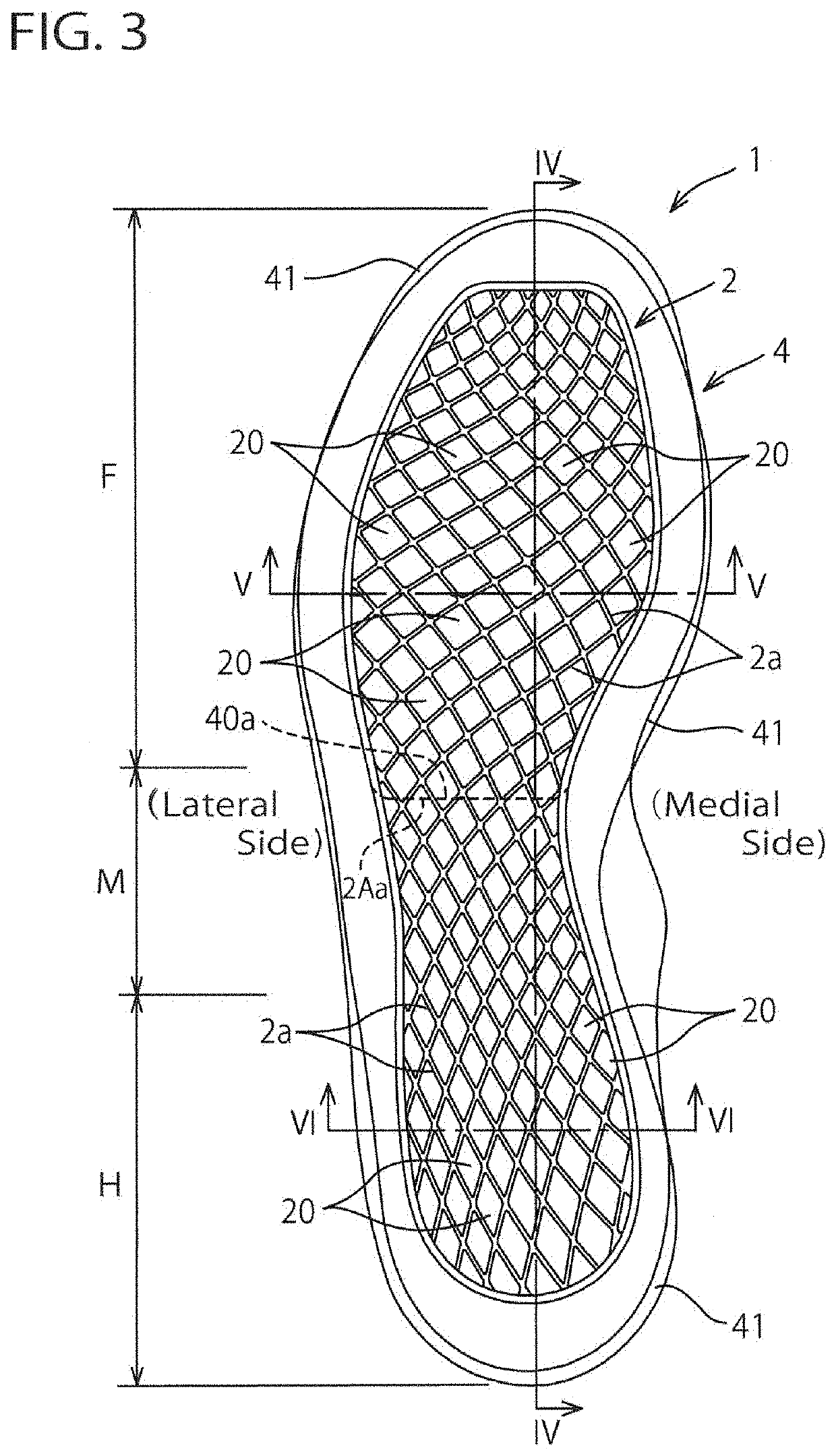

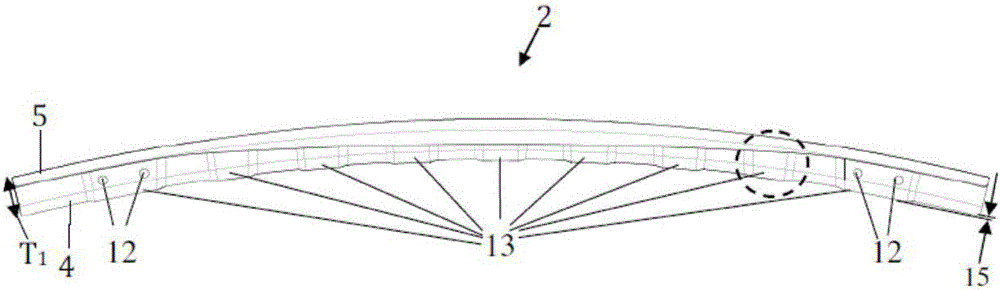

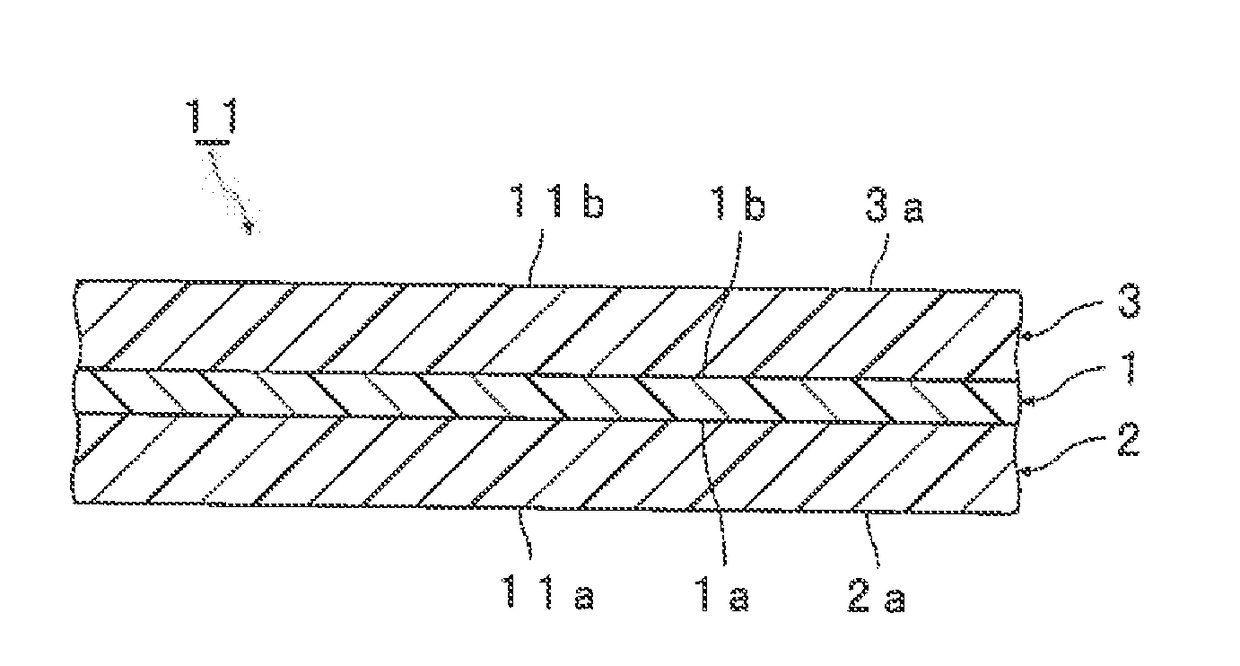

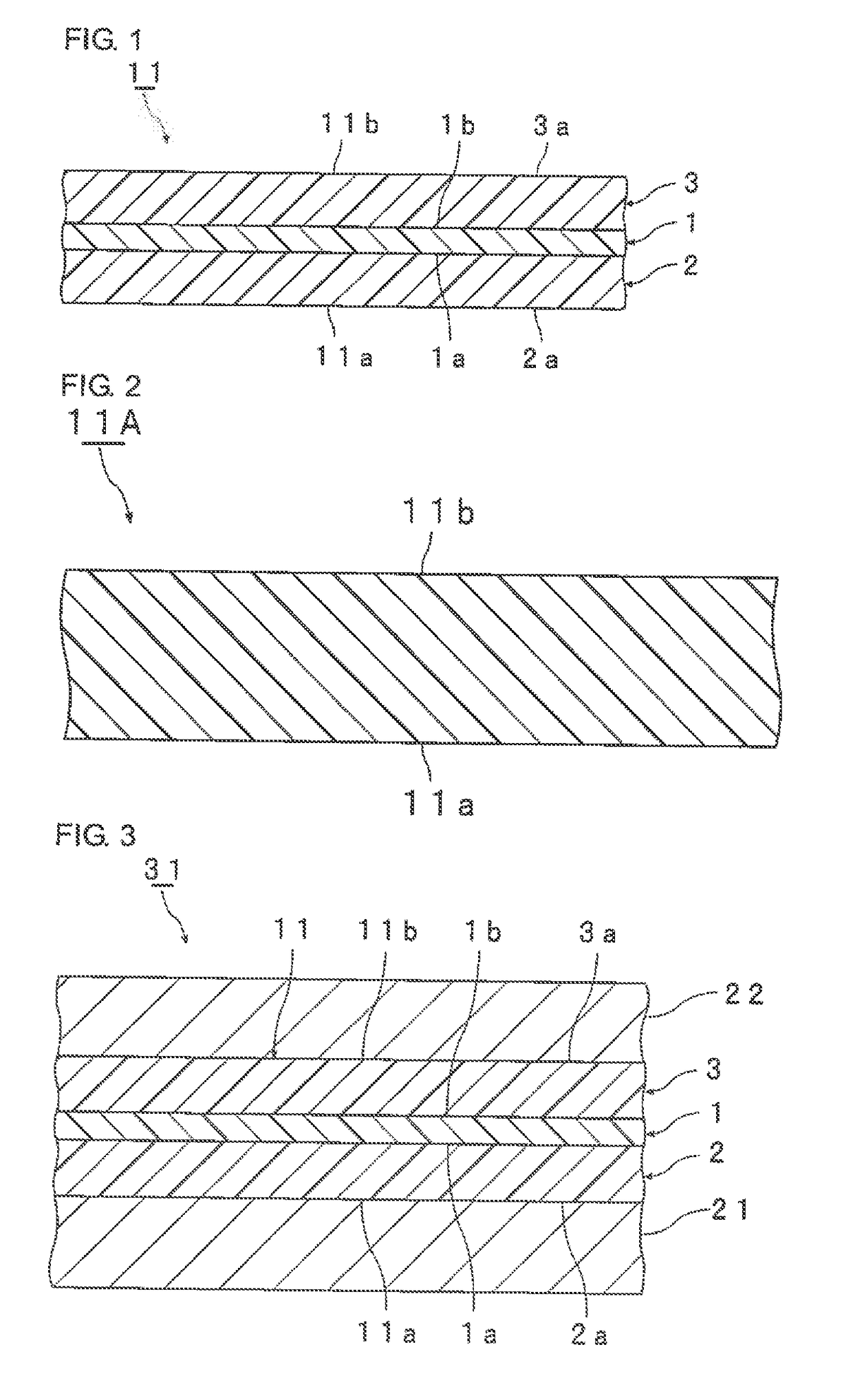

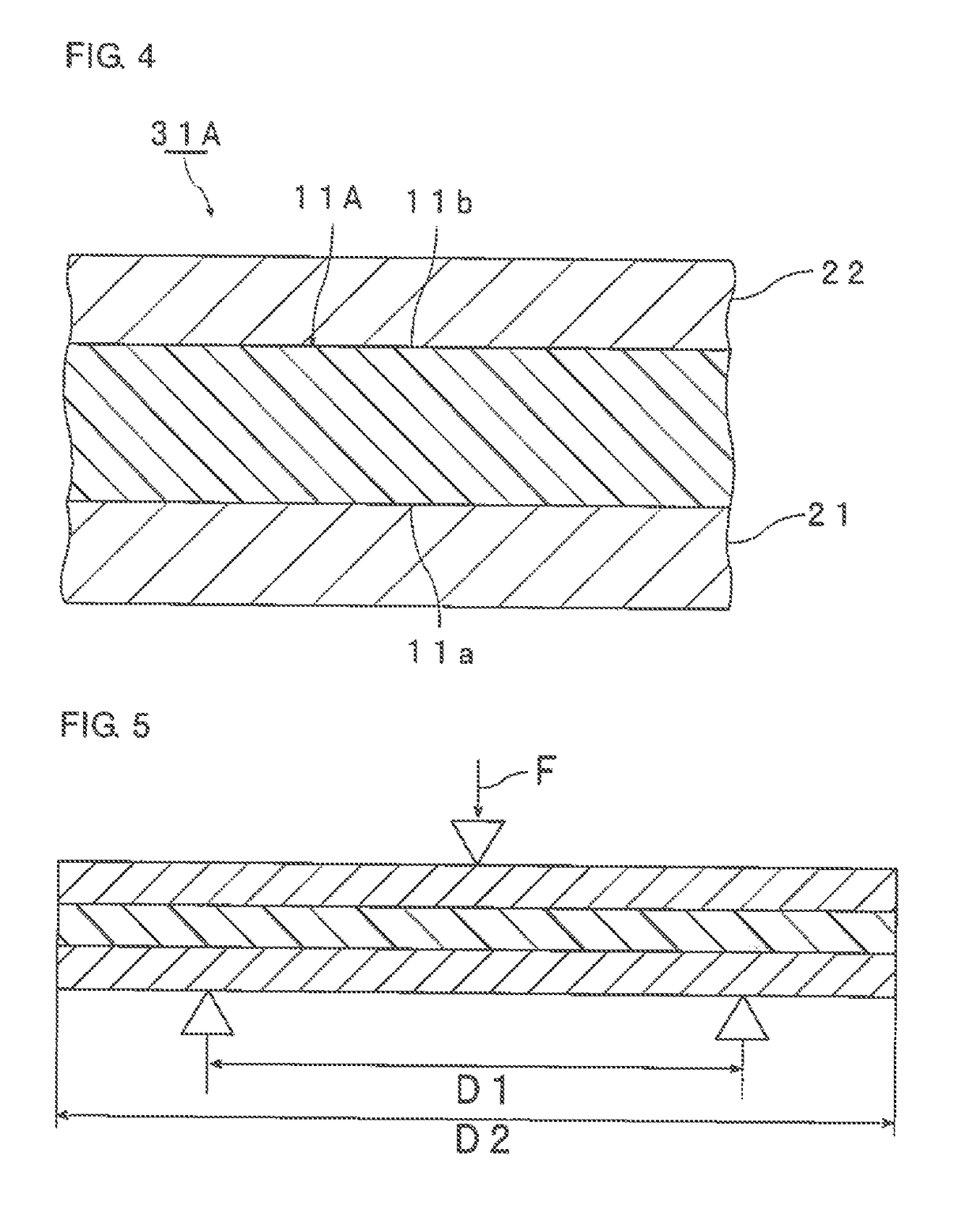

Sole Structure for a Shoe

ActiveUS20200305541A1Improve bending rigidityCushioning property can be improvedSolesPhysicsMechanical engineering

A sole structure for a shoe that can secure cushioning properties and obtain a ground surface information is disclosed. The sole structure includes a first midsole having a plurality of first protrusions on a foot-sole-contact side, an outsole having a plurality of second protrusions on a ground surface side, and a second midsole disposed at a part of a region between the first midsole and the outsole and having a lower compressive rigidity than the first midsole. At least a part of the plurality of first protrusions of the first midsole is located at a position corresponding vertically to at least a part of the plurality of second protrusions of the outsole.

Owner:MIZUNO CORPORATION

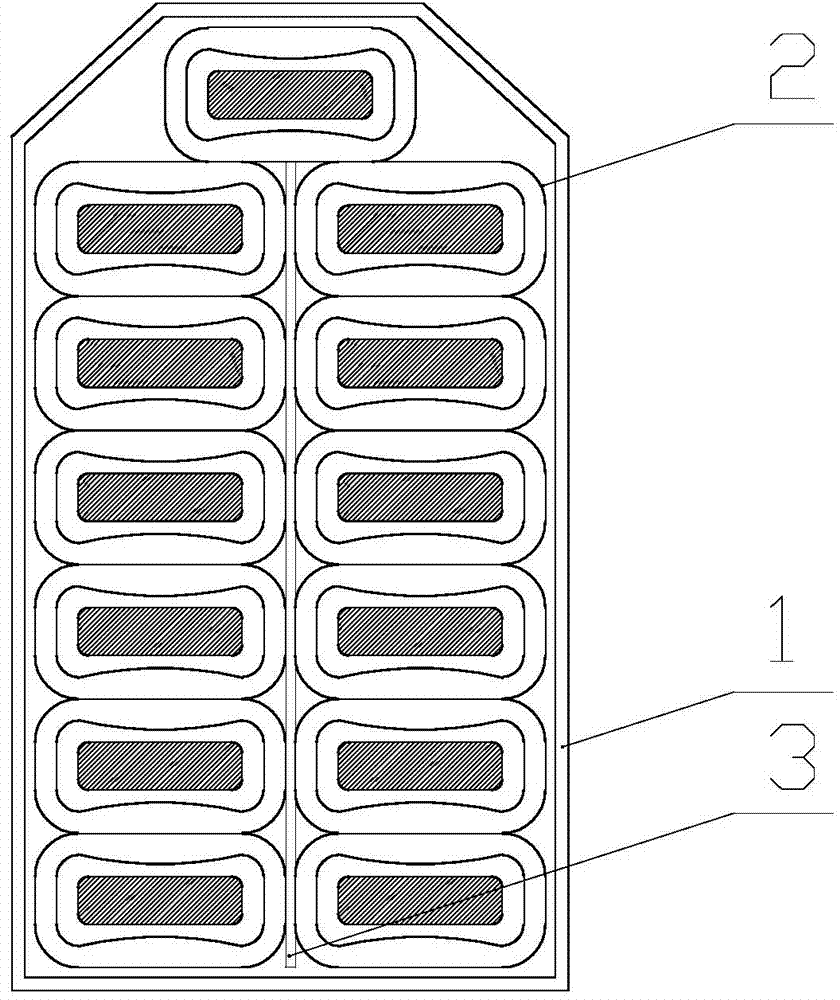

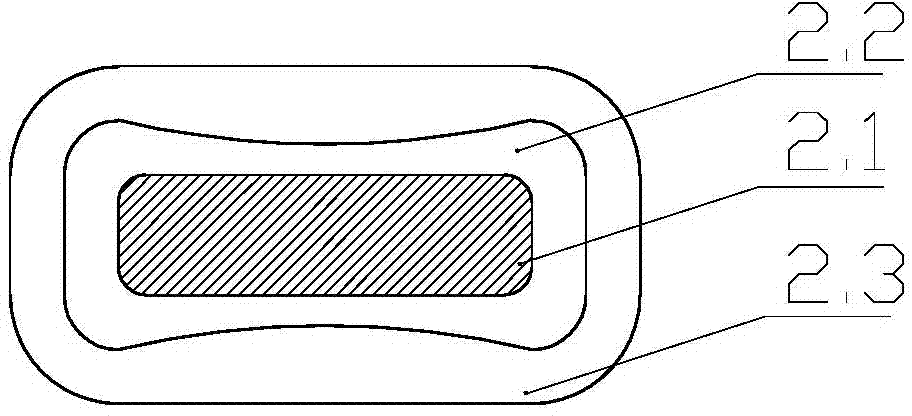

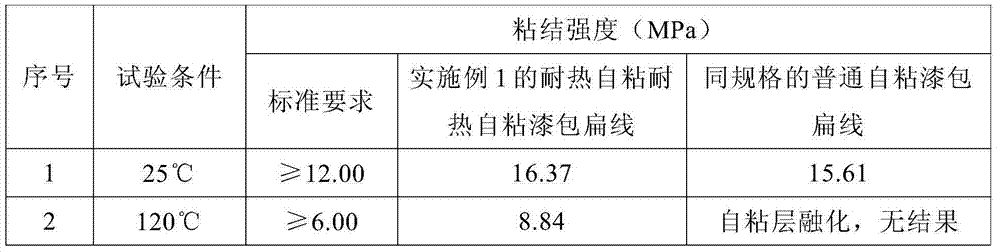

Heat-resistant self-sticking transposed conductor for transformers and manufacturing method thereof

ActiveCN104240804AHigh single line bond strengthIncreased single-line bond strengthTransformers/inductances coils/windings/connectionsInsulated cablesElectrical conductorNarrow face

The invention discloses a heat-resistant self-sticking transposed wire for transformers and a manufacturing method thereof. Two rows of heat-resistant self-sticking enameled flat wires, having mutually contacted wide faces, are arranged within an outer insulating layer. Middle lining paper is arranged between the two rows of heat-resistant self-sticking enameled flat wires in such a manner that the middle lining paper is transposed in a same direction above and below the two rows of heat-resistant self-sticking enameled flat wires along their narrow faces. Each heat-resistant self-sticking enameled flat wire comprises a rectangular conductor, the cross section of the rectangular conductor is rounded, the outside of the rectangular conductor is coated with a primer film, and the outside of the primer film is coated with a finish film. From view of the cross section of the heat-resistant self-sticking enameled flat wires, the wide side of each primer film is concavely arced, and the outline of each finish film is a rectangle rounded. The heat-resistant self-sticking transposed wire has the advantages that mechanical strength of the transformer windings under high temperature can be effectively improved, short circuit resistance of the transformer windings is improved, and the service lives of the transformer windings are prolonged.

Owner:WUXI TOLY ELECTRIC WORKS

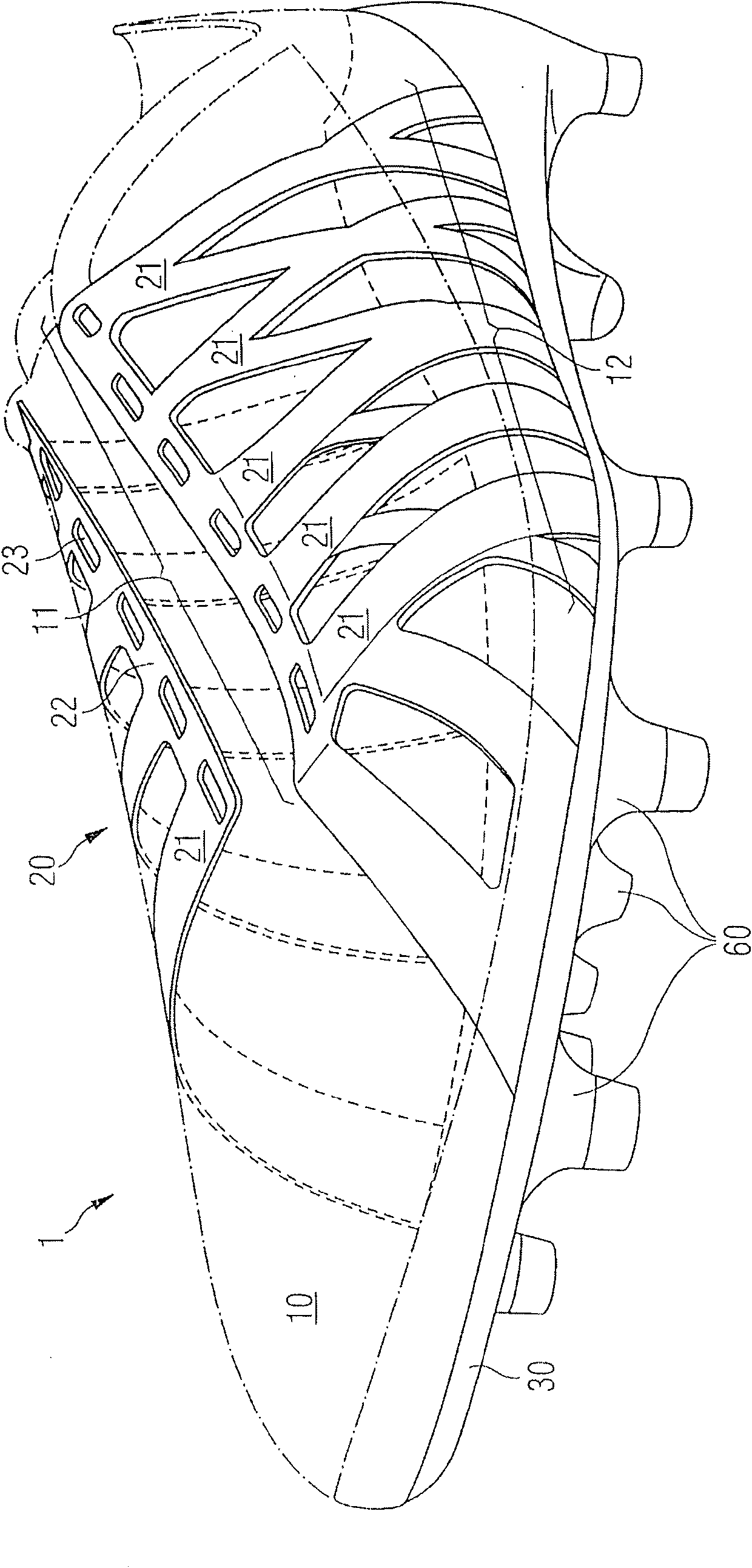

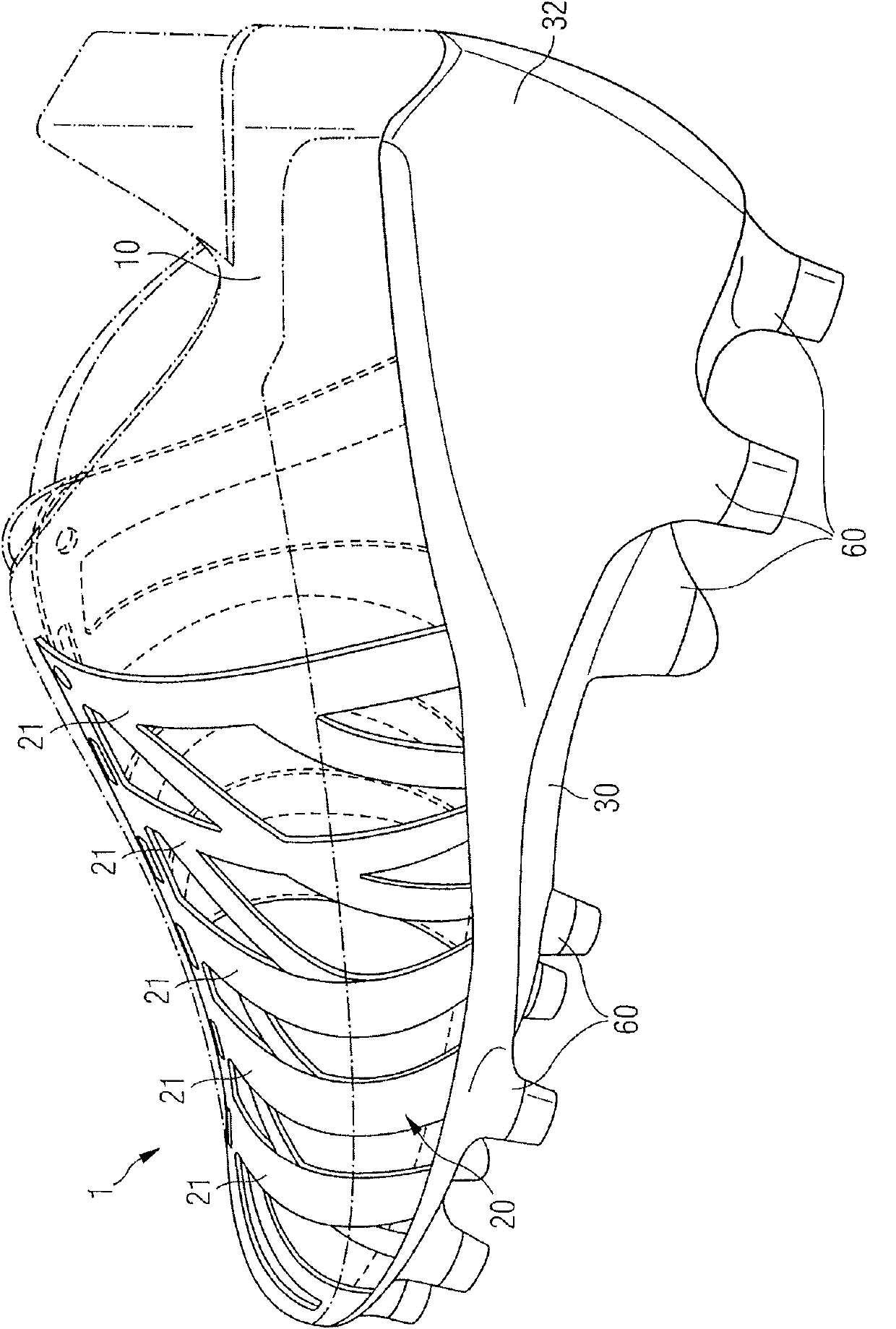

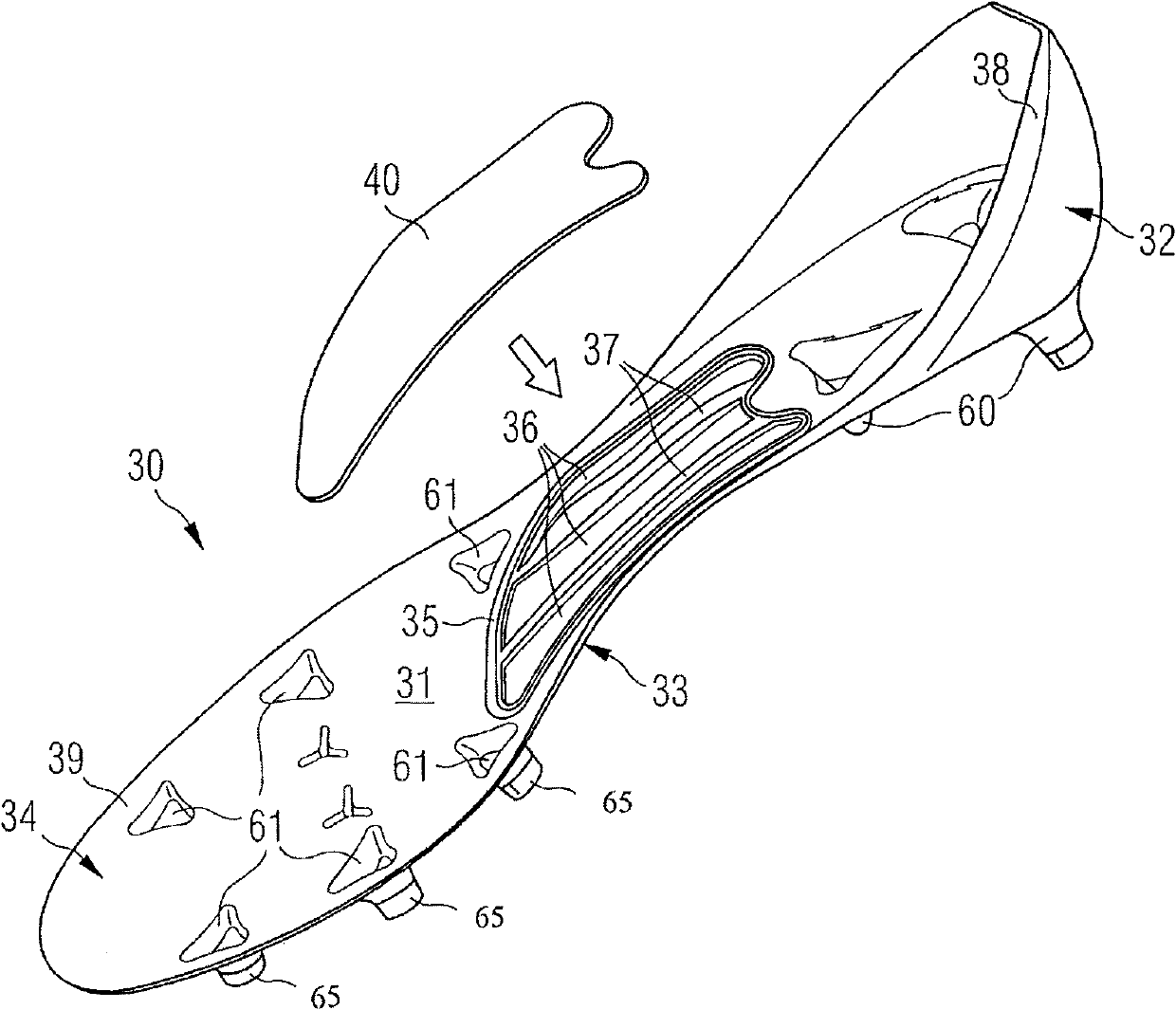

Outsole and sports shoe

The present invention relates according to a first aspect to an outsole (30) for a sports shoe (1), in particular a soccer shoe, comprising an integral sole plate (31) extending from a heel part (32) via a midfoot part (33) into a forefoot part (34) of the outsole (30), at least one first reinforcing rib (37) integrated into the sole plate (31) and a reinforcing plate (40) arranged above or below the at least one first reinforcing rib (37). According to a further aspect, the present invention relates to a sports shoe (1), in particular a soccer shoe, comprising an upper (10) of a shoe with a closure region (11) and a sole region (12) and at least one reinforcing element (20) attached to the inside of the upper (10) of the shoe and arranged in the midfoot part and comprising a plurality of flexible bands (21) extending from the closure region (11) to the sole region (12).

Owner:ADIDAS

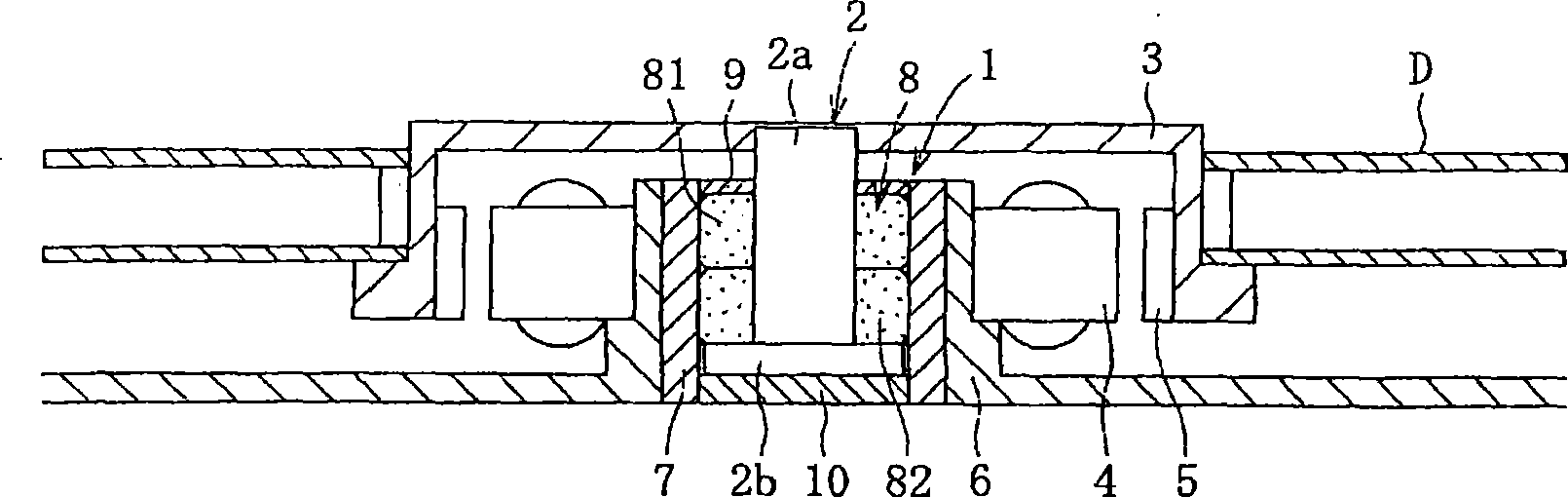

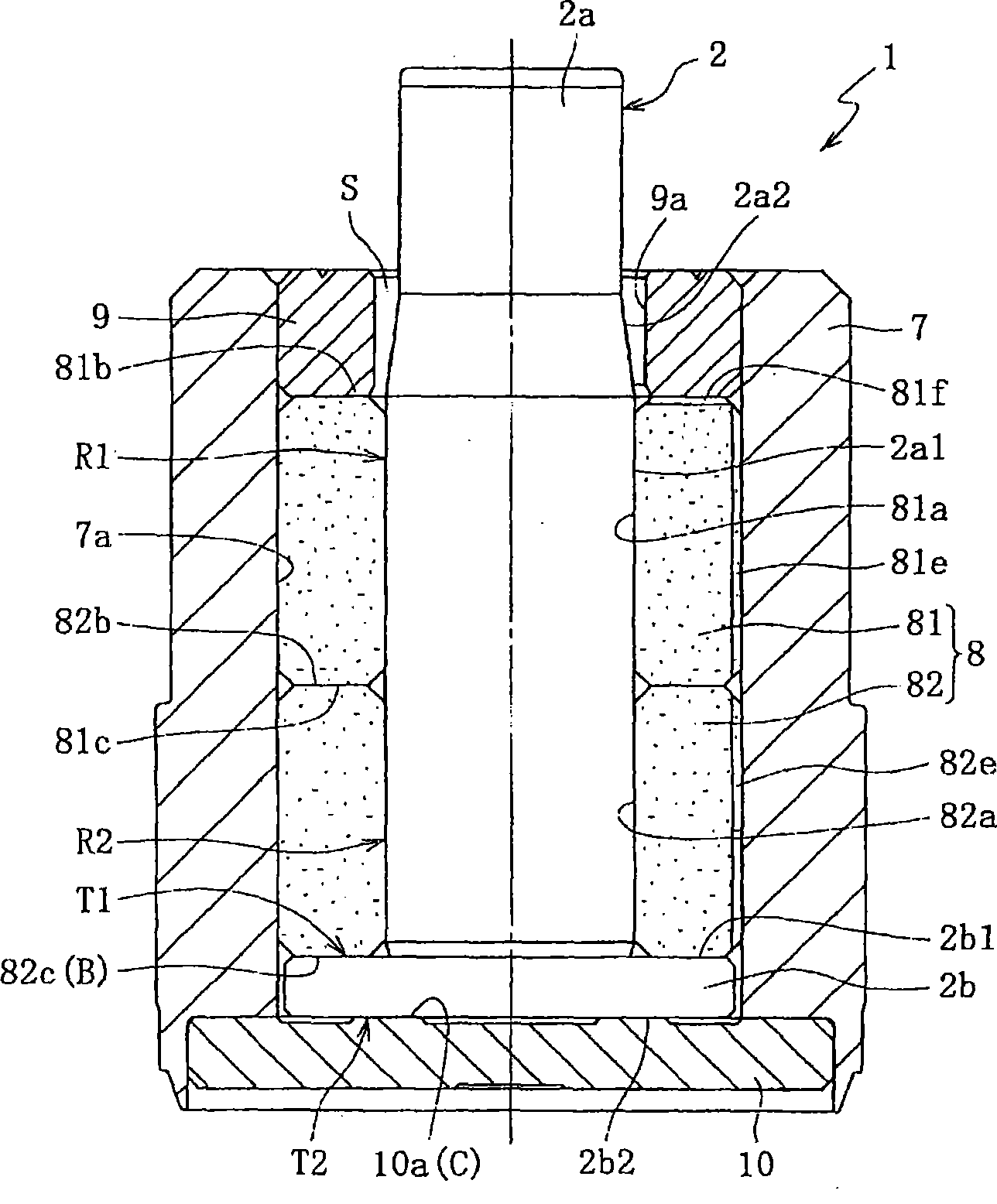

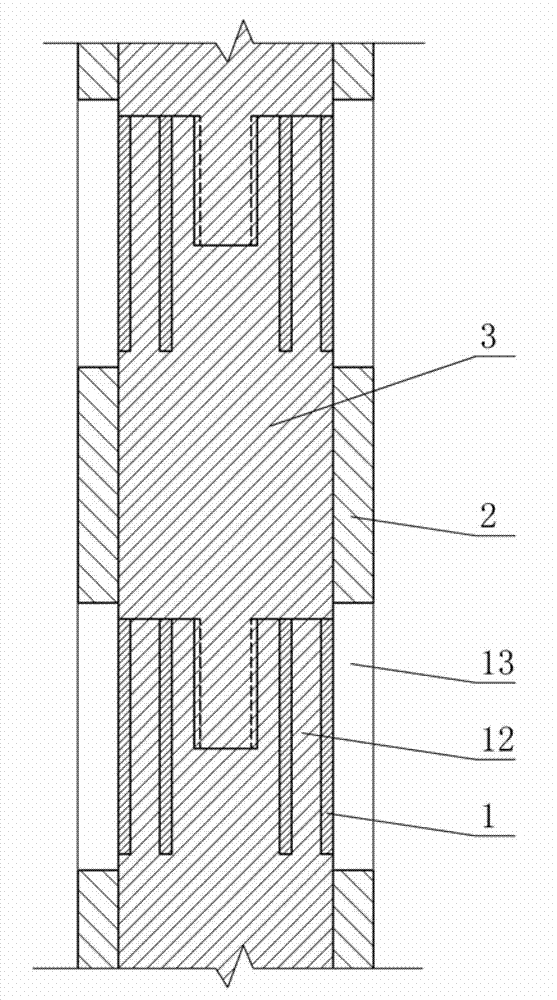

Fluid dynamic pressure bearing device and method of producing the same

InactiveCN101400904AAvoid bendingReduce assembly accuracyBearing componentsSliding contact bearingsEngineeringBearing surface

A fluid dynamic pressure bearing device that achieves high rigidity against moment without a reduction in assembly accuracy and bearing performance. In the bearing device, bearing sleeves are arranged in the axial direction and coaxiality of radial bearing surfaces formed on the inner peripheral surfaces of the bearing sleeves is set to 3 [mu]m or less. This secures width accuracy between the radial bearing gaps to prevent a reduction in bearing performance and a failure such as wear etc. caused by contact between a shaft member and the bearing sleeves. Further, a first radial bearing surface and a second radial bearing surface are provided on at least one sleeve, and this allows a sleeve assembly constructed from bearing sleeves to be supported at least three positions in the axial direction in a process of assembling the sleeve assembly. As a result, assembly work can be carried out with two bearing sleeves prevented from being bent in the middle and highly accurate coaxiality between both bearing sleeves secured.

Owner:NTN CORP

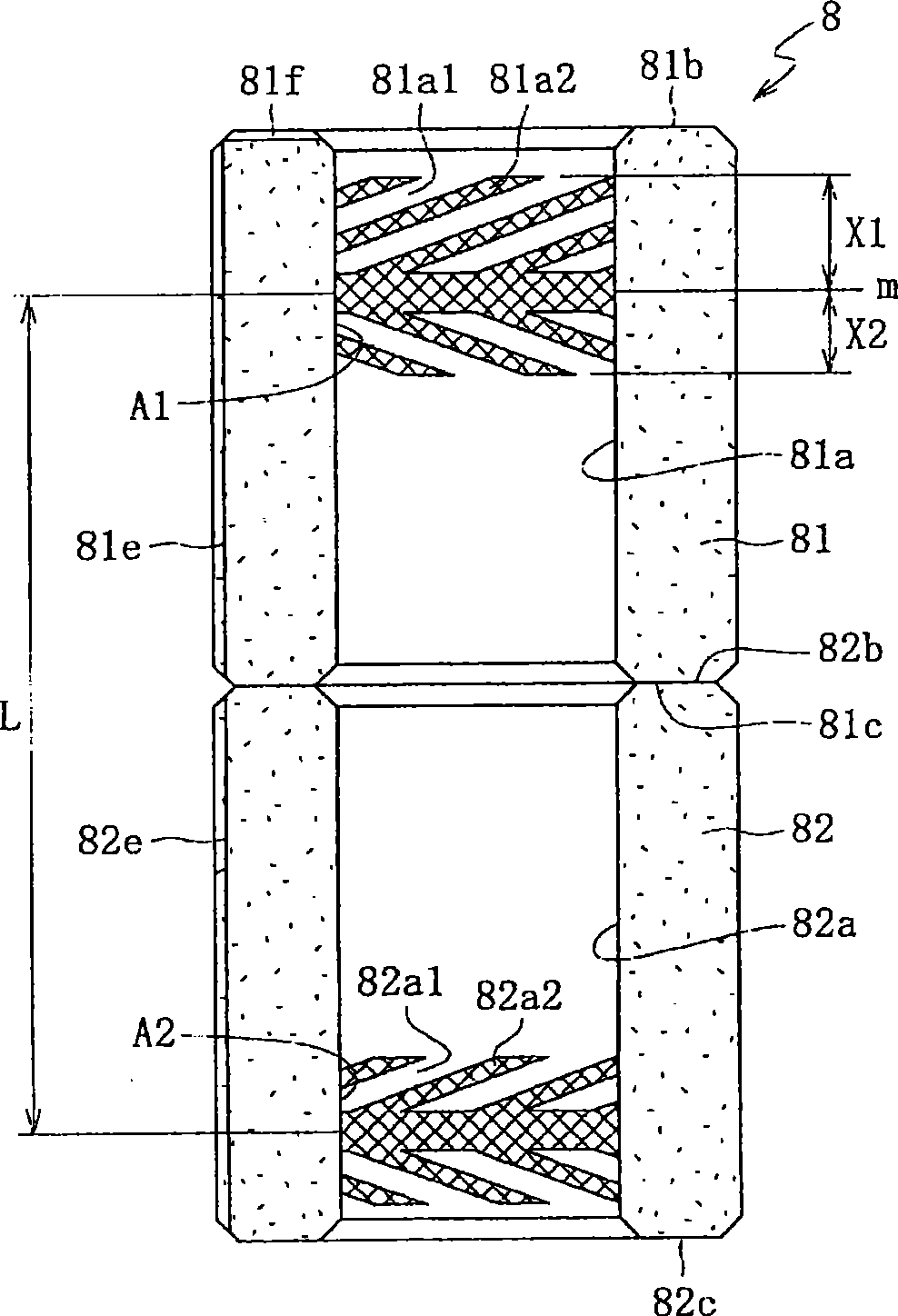

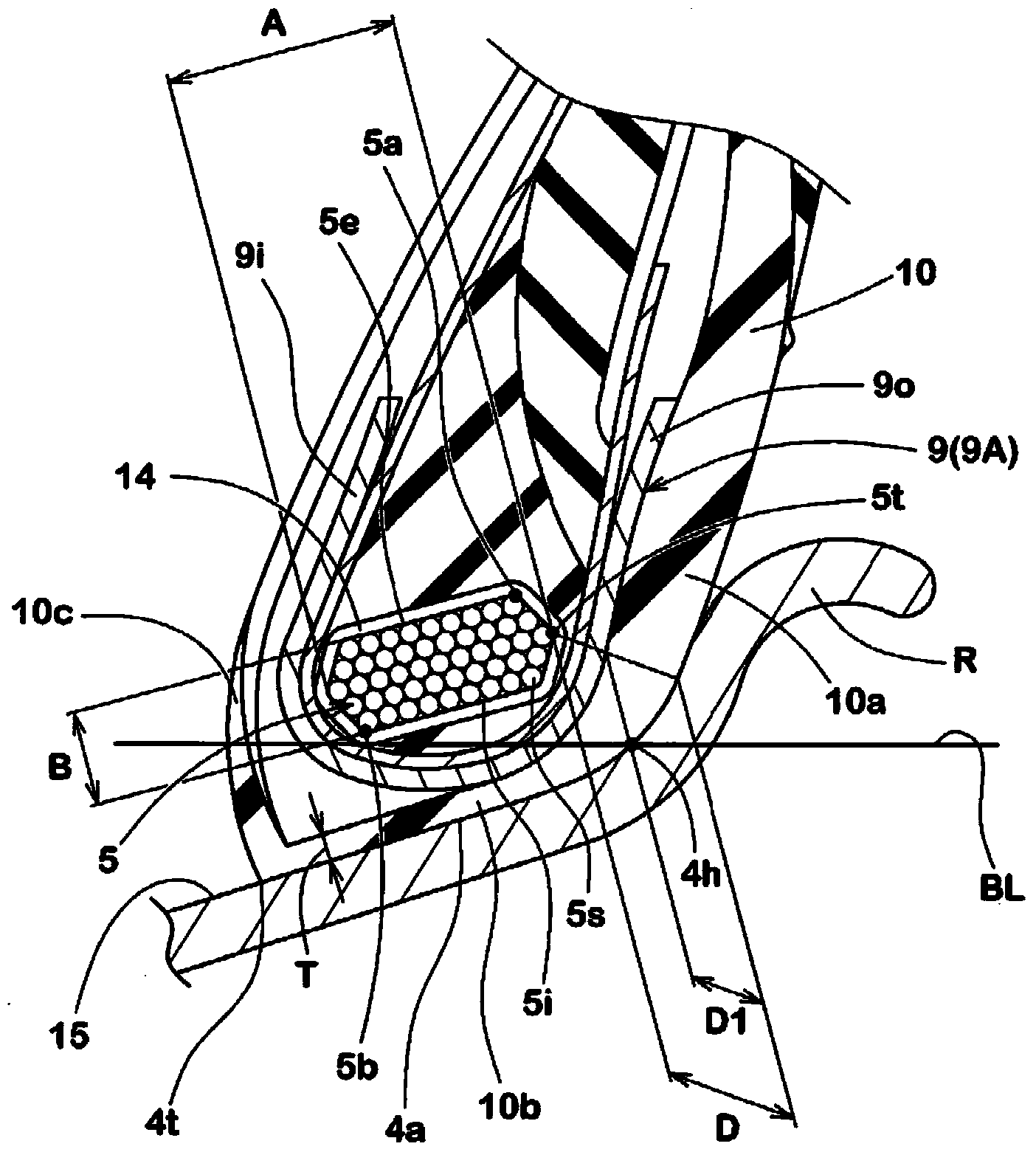

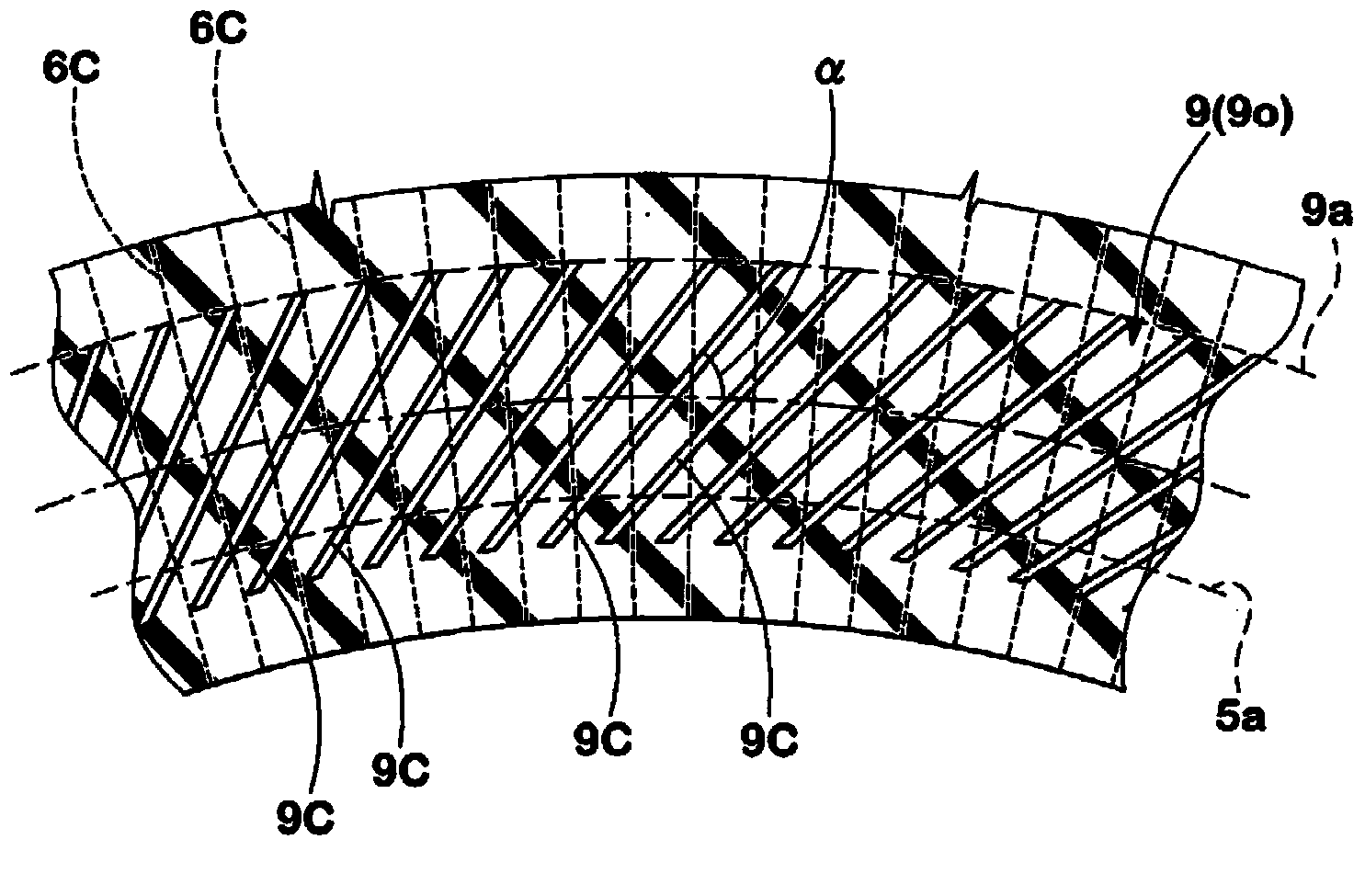

A tire for a heavy load

InactiveCN104228478AImprove bending rigidityIncreased durabilityHeavy duty tyresHeavy duty vehicleAutomotive engineeringHeavy load

A tire for a heavy load of the invention raises the durability of a tire bead portion. The tire for the heavy load comprises a tire beam core (5), a tire body (6), a tire bead filler (8), a tire bead reinforcement layer (9) and anti-rubbing rubber (10). The tire bead reinforcement layer (9) is provided with steel cords (9C) which are arranged at angles of 40-70 degrees relative to the circumferential direction of the tire. In a normal state, the ratio (B / A) of a maximum thickness (B) of a orthogonal portion between the tire bead core (5) and the inner side surface (5i) to a maximum width (A) of a parallel portion between the tire bead core (50 and the inner side surface (5i) is 0.3-0.5. In a condition that a normal load is loaded in a normal state and a normal load is grounded at an outer inclination angle of 0 degree, an angle between the inner side surface of the tire bead core (5) and a rim seat surface (15) of a normal rim (R) is 0 degree to +-3 degrees. The ratio (D / A) of the shortest distance (D) between tire axial outer end of the tire bead core (5) and the outer surface of the anti-rubbing rubber (10) to the largest width (A) of the tire bead core (5) is 0.4-0.8.

Owner:SUMITOMO RUBBER IND LTD

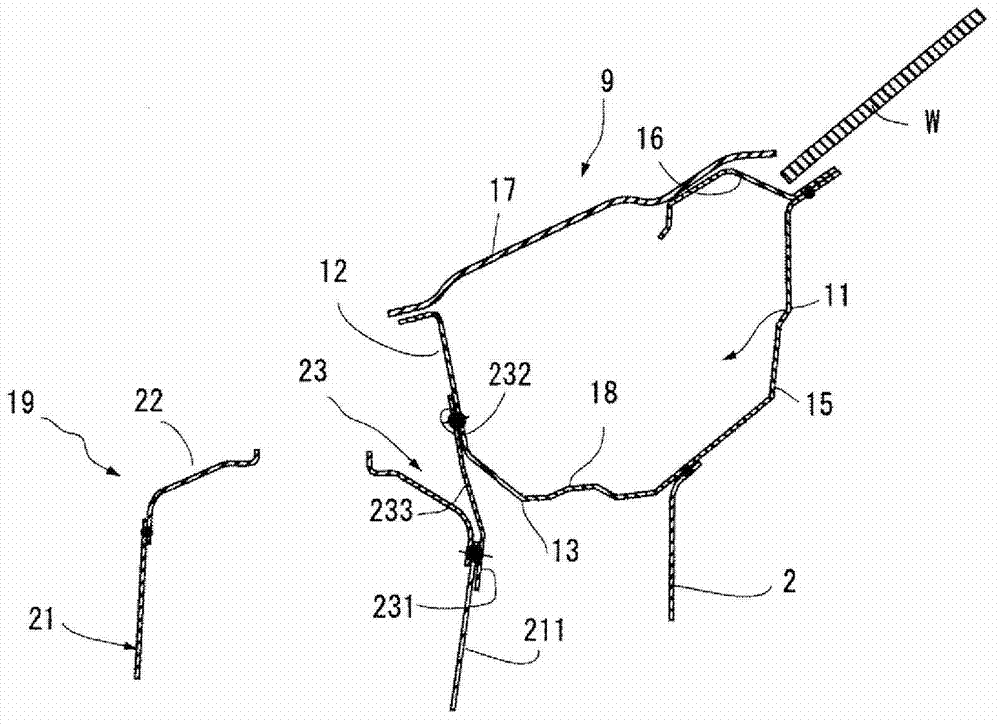

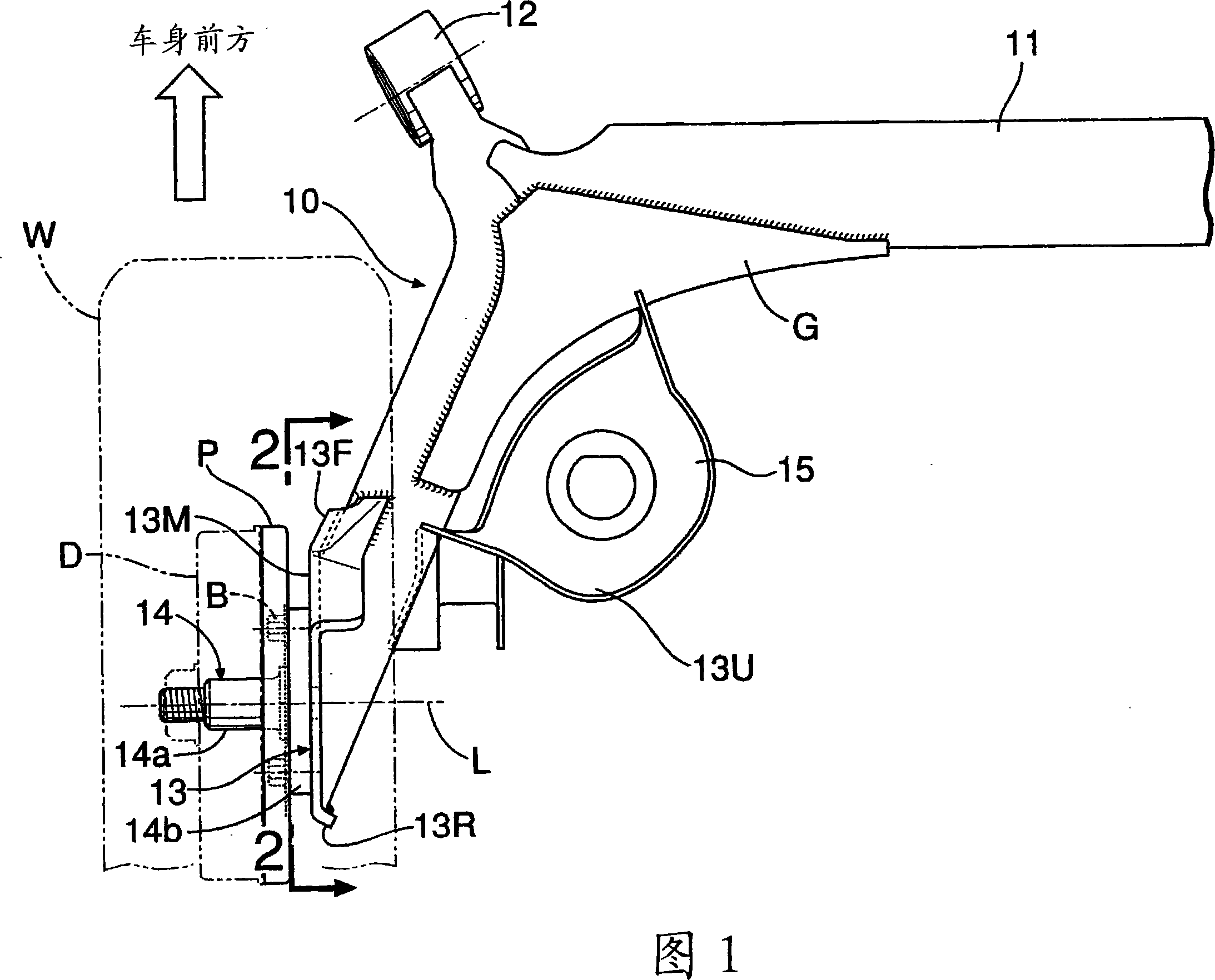

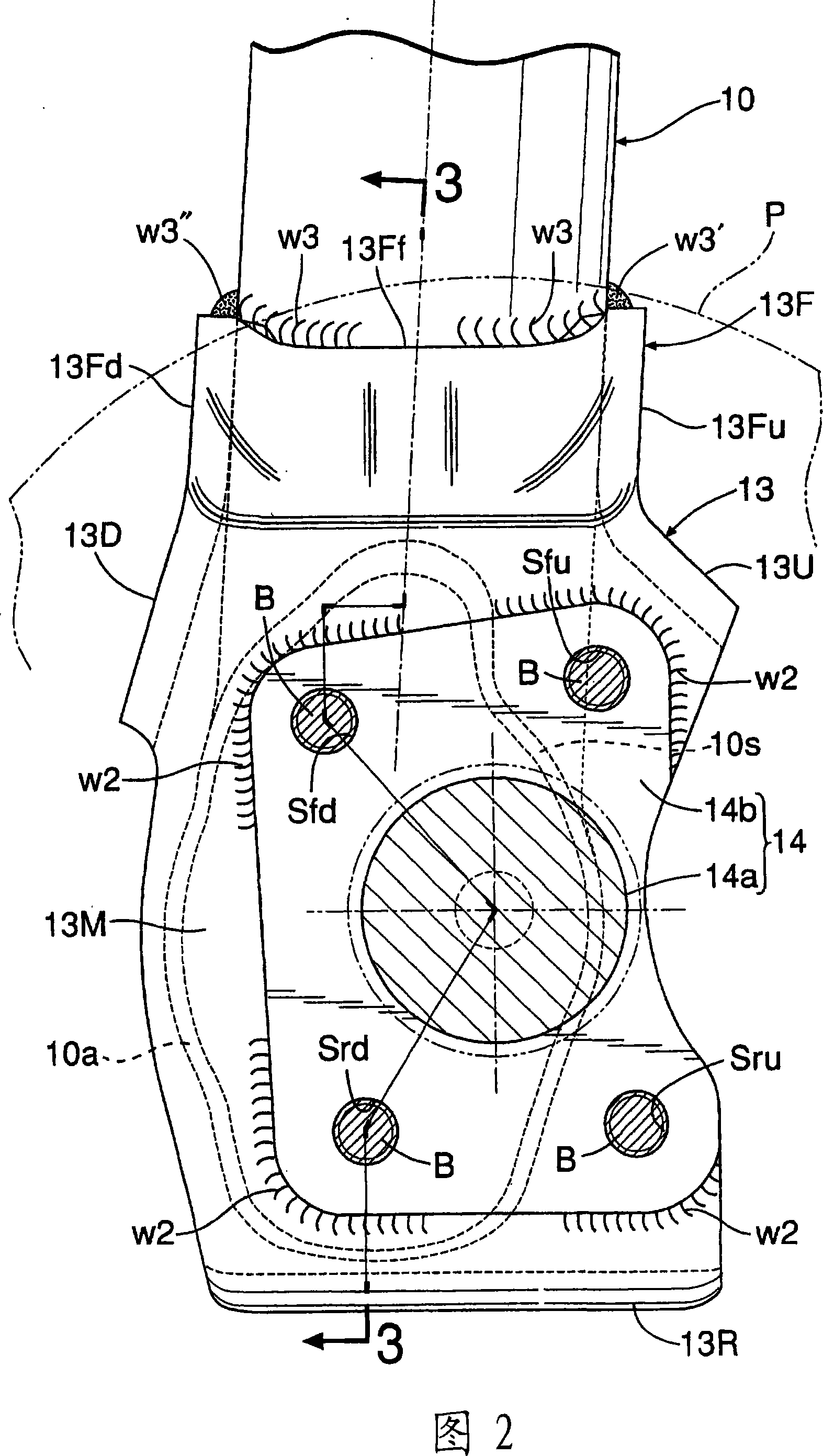

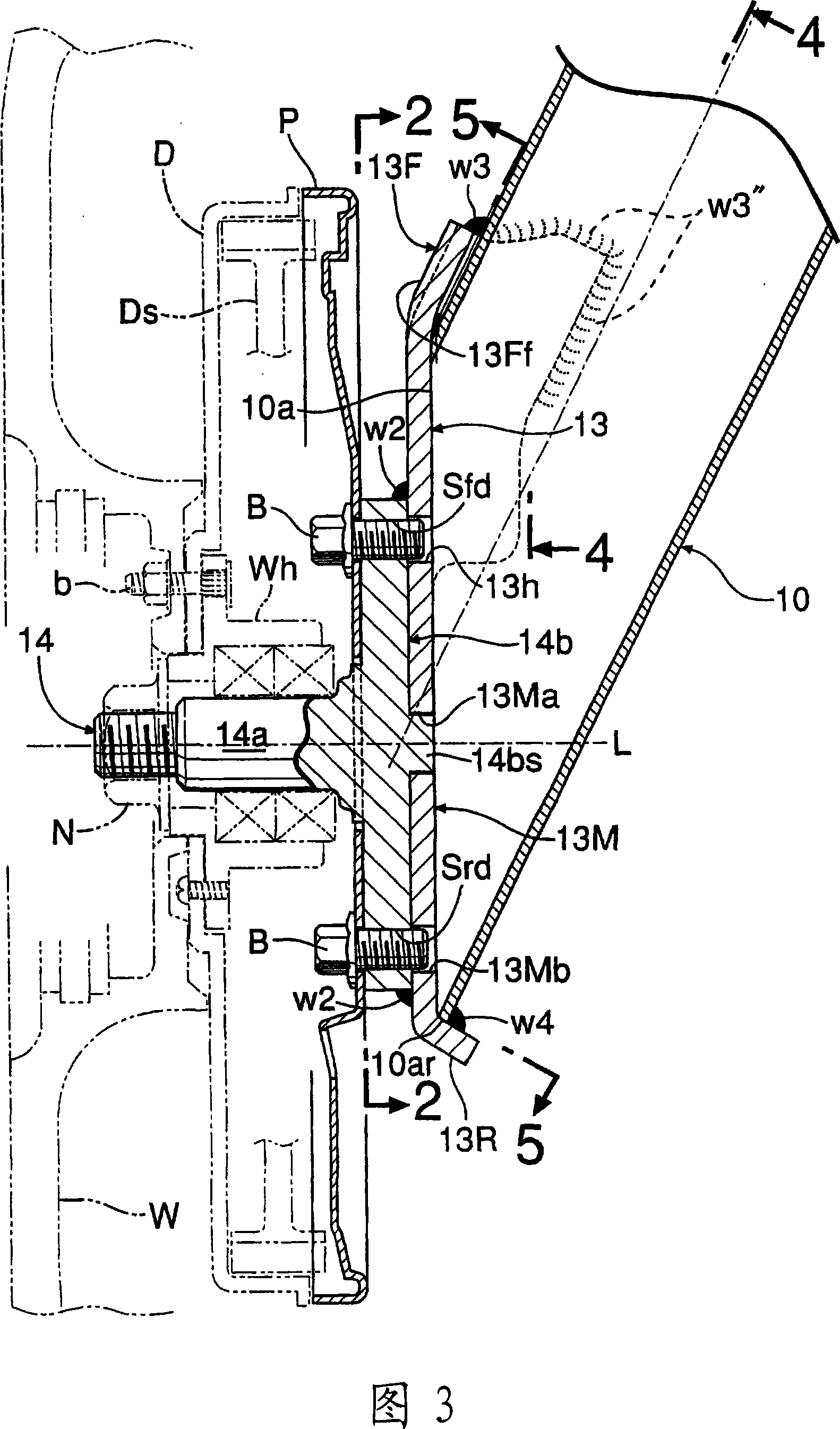

Torsion beam suspension

InactiveCN101094772APrevent thermal deformationReduced welding areaInterconnection systemsResilient suspensionsButt weldingFlange

Torsional beam type suspending rack is provided in the present invention. In the torsional beam type suspending rack making opening end face of towing arm and main shaft supporting plate butt welding, on the front end of the main shaft supporting plate (13) plate main body (13M), integrated connecting a front side bending flange (13F) extending along the back end external side of the towing arm (10) towards front and front end edge welding (W3) at the back end external side, and at the plate main body (13M) back end integrated connecting a rear side bending flange (13R) clamping and welding (4W) at the rear end edge of the towing arm (10). The main shaft substrate (14b) is overlapped and fixed (W2) on the external side of the plate main body (13M), and has four screw hole parts (Sfu, Sfd, Sru, Srd) at the front and back and un and down of the maid shaft axes separating the main shaft axes, the screw hole parts is used for combining the plate shape component (P) associated with the braking device and the bolt used for the main shaft substrate (14b), therefore, it can restrain effect of welding thermal strain, and can make the main shaft supporting plate thin-wall to realize light weight and lower cost.

Owner:F TECH INC

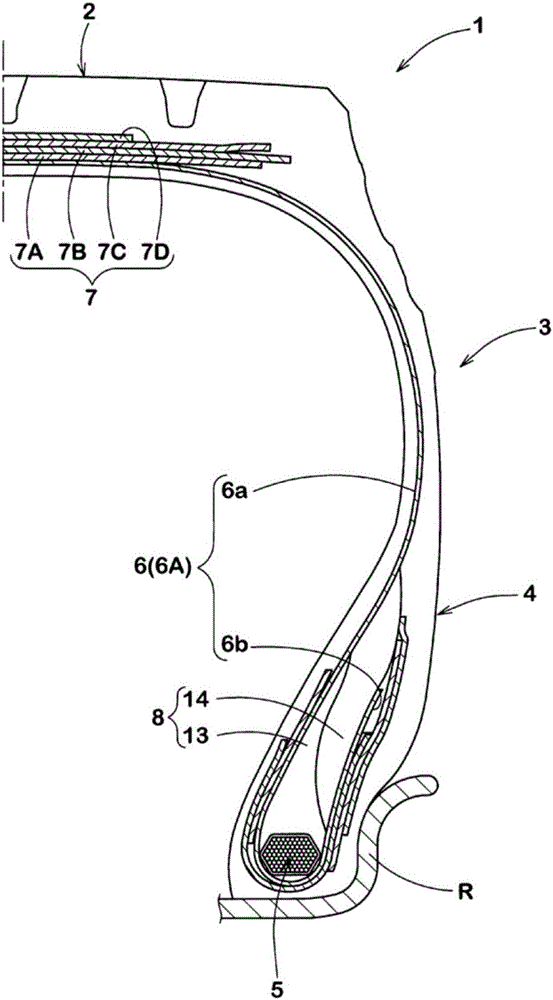

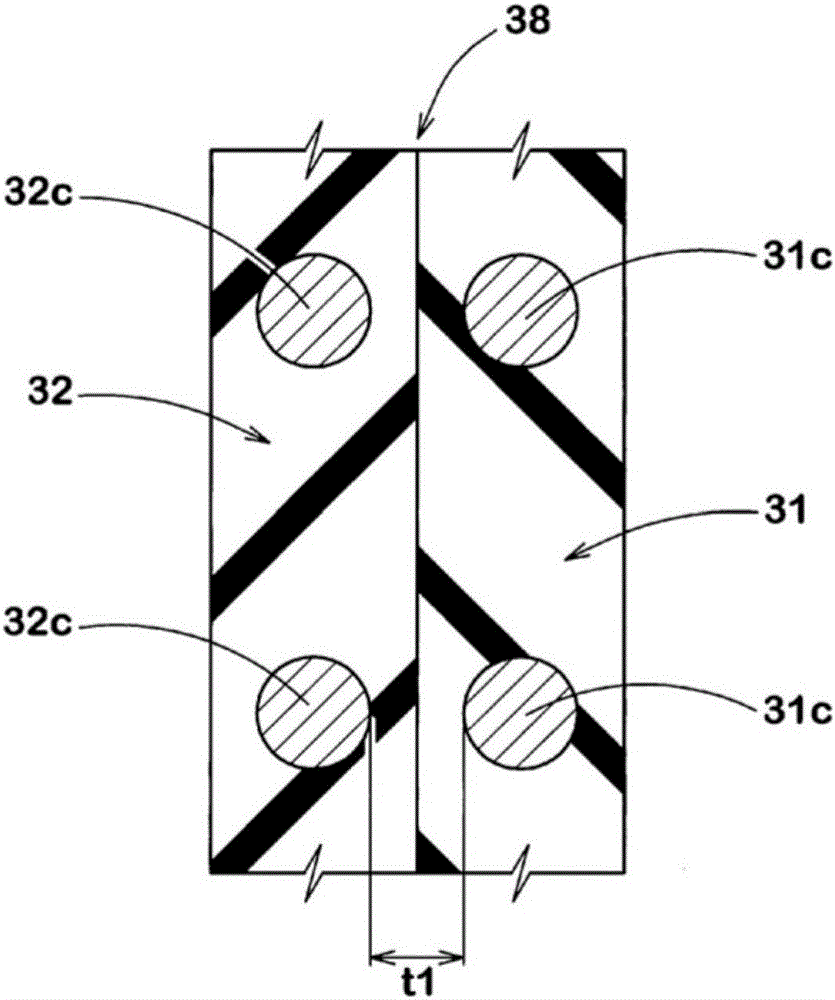

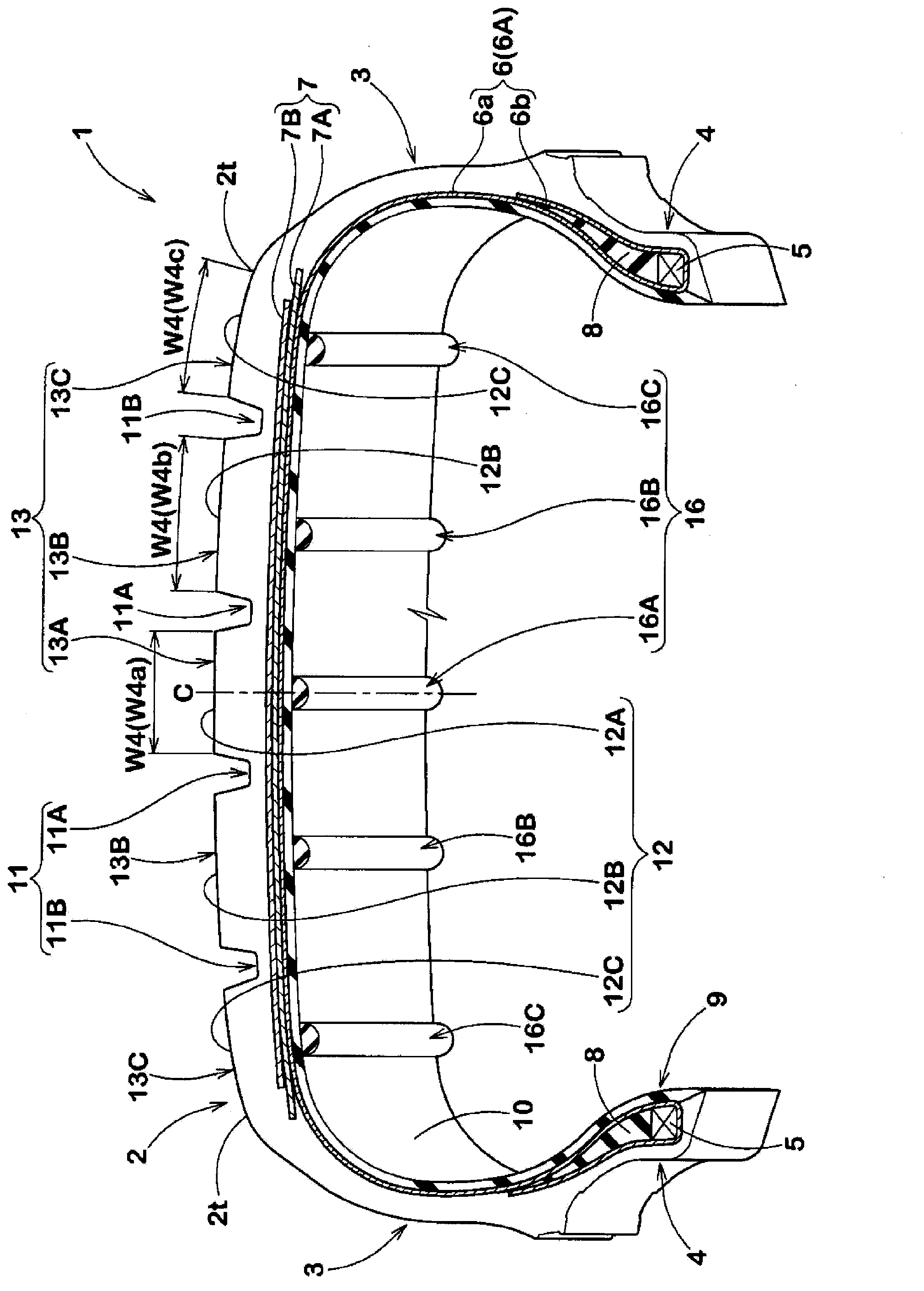

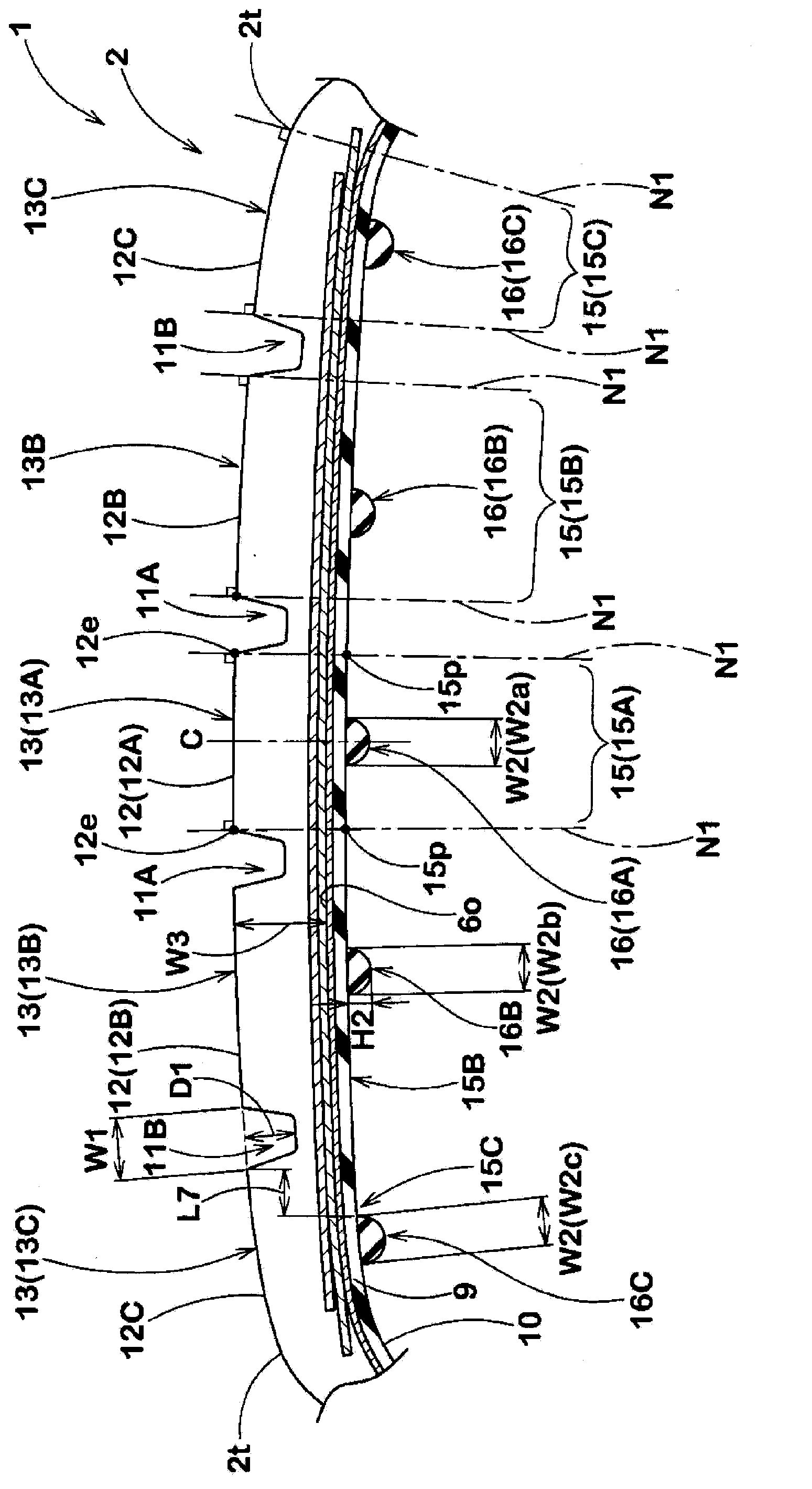

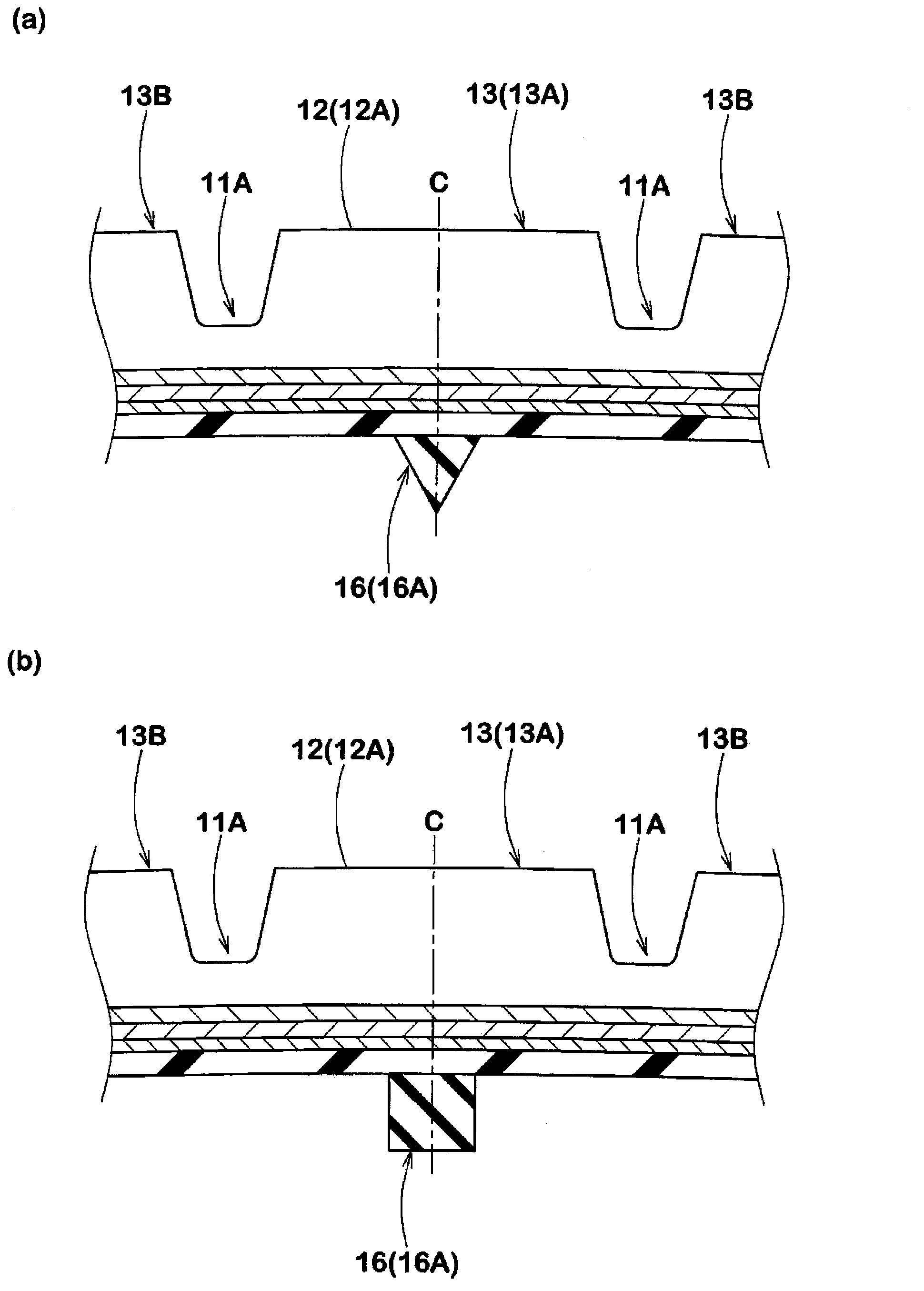

Heavy Load Tyre

The present invention provides a heavy load tyre capable of improving the durability of a tyre bead part. The heavy load tyre is equipped with a tyre 6 made of a tyre body cord fabric 6A, and the tyre body cord fabric 6A comprises a main body part 6a and a return part 6b. The tyre bead part 4 is equipped with a first reinforcing part 11 located at the side of the main body part 6a and a second reinforcing part 12 located at the side of the return part 6b, the first reinforcing part 11 comprises a first steel wire cord fabric layer 21 and a second first steel wire cord fabric layer 22 of which the cross-section is roughly U-shaped, and the second reinforcing part 12 comprises a first organic fiber cord fabric layer 31 covering the outer end at the side of the return part 6b of the second steel wire cord fabric layer from the axial outer side of the tyre and a second organic fiber cord fabric layer 32.

Owner:SUMITOMO RUBBER IND LTD

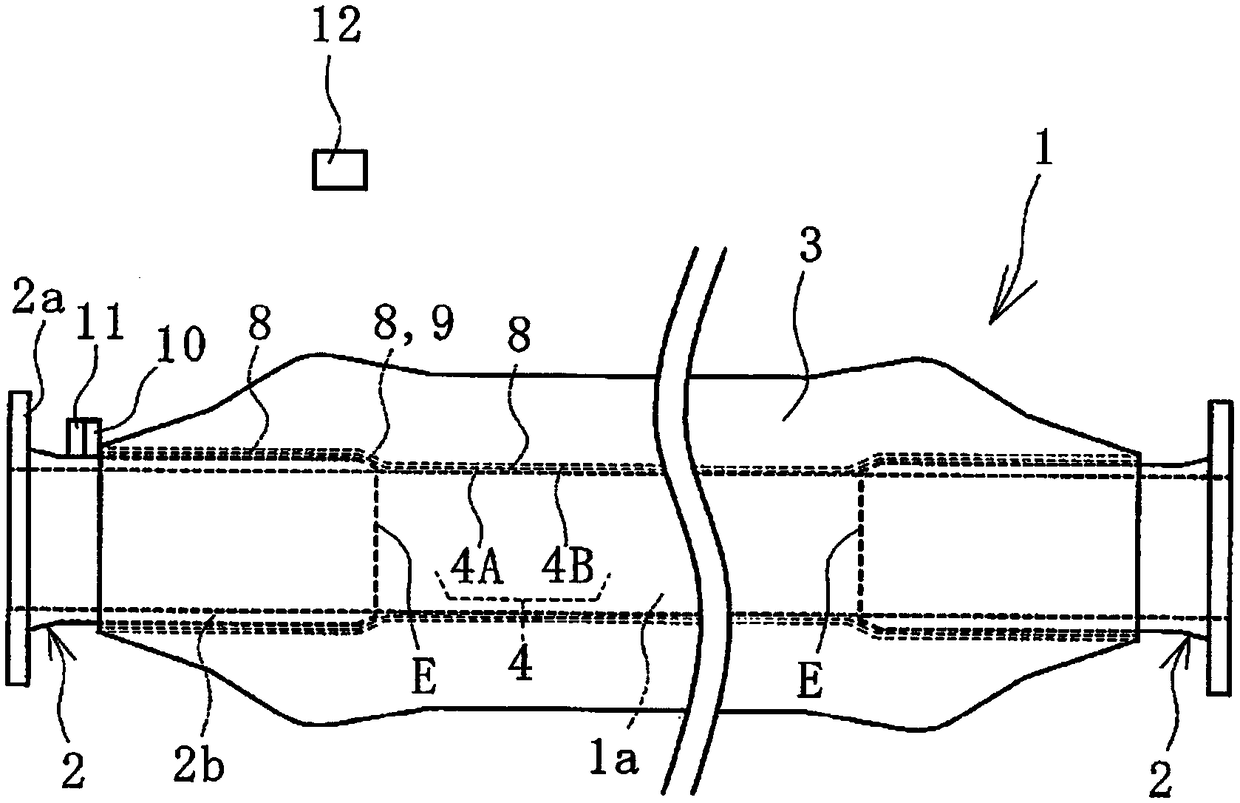

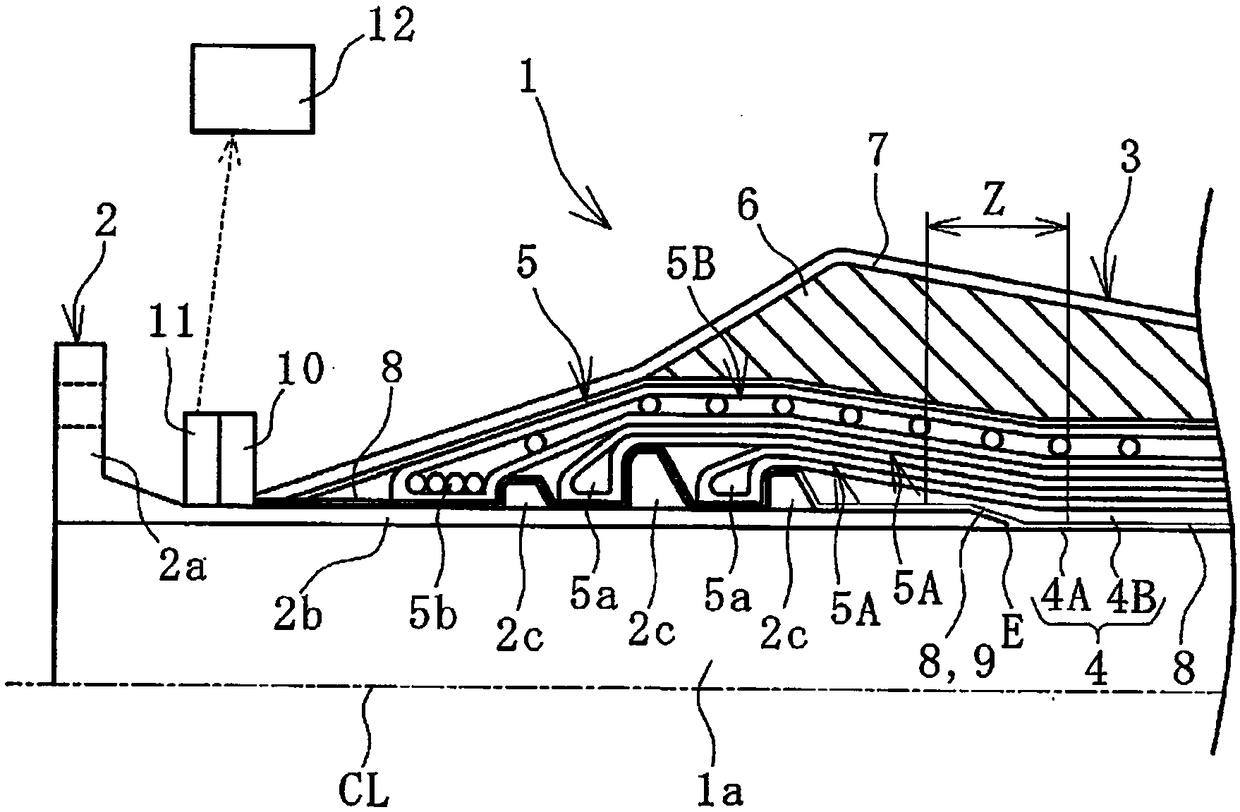

Marine hose status monitoring system

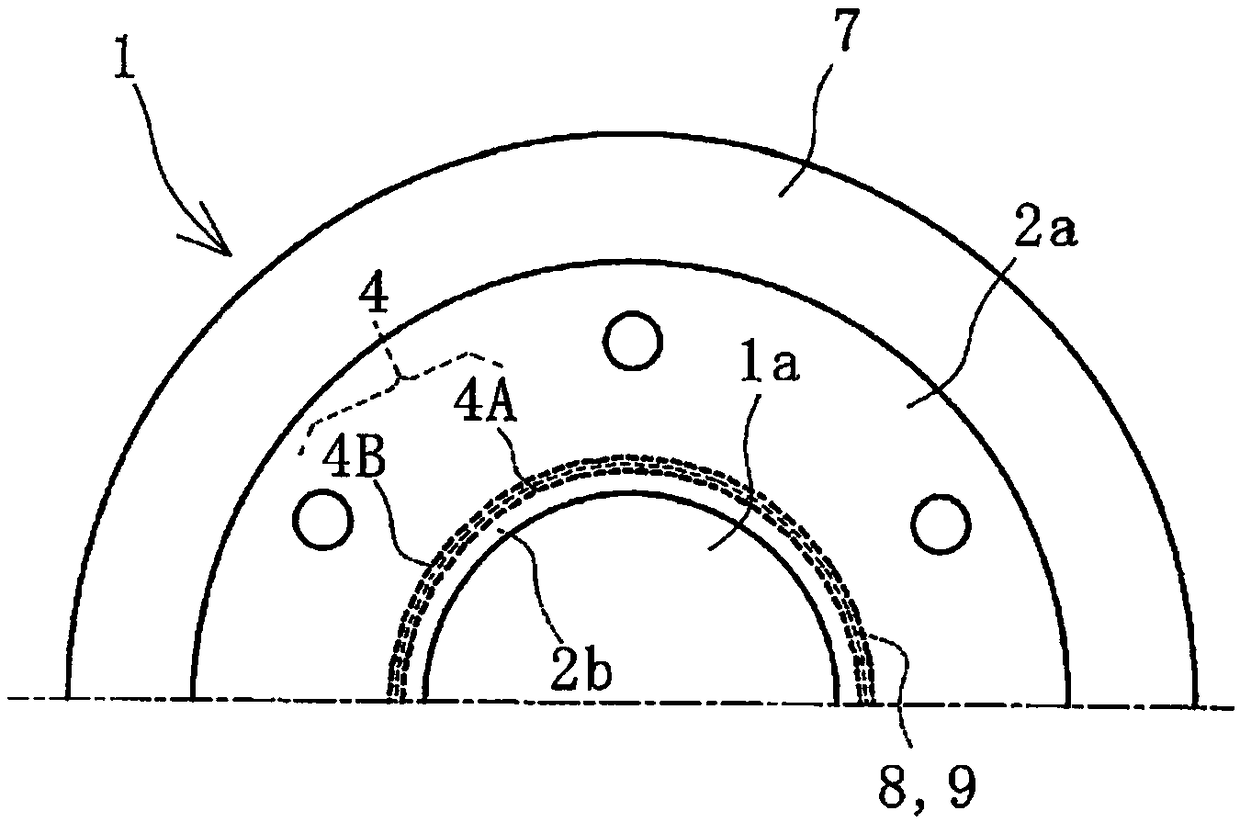

ActiveCN108700226ASensory damageSensing earlyPipe couplingsFluid-tightness measurementSurface layerFishery

Provided is a marine hose status monitoring system which makes it possible to more definitively and more quickly detect damage to the inner-surface layer of a hose body. The present invention involves: embedding a leakage detection member (8) so as to extend between a first inner-surface layer (4A) and a second inner-surface layer (4B) of a marine hose (1) obtained by connecting a connection fitting (2) to both end sections in the lengthwise direction of a hose body (3) constructed by layering an inner-surface layer (4), a reinforcing layer (5), and an outer-surface layer (7), in order from the inner-circumferential side; connecting a leakage detector (10) to the leakage detection member (8); and determining by using the leakage detector (10) that damage has occurred to the inner-surface layer (4) when a fluid (F) flowing through a fluid channel (1a) of the hose body (3) contacts the leakage detection member (8).

Owner:YOKOHAMA RUBBER CO LTD

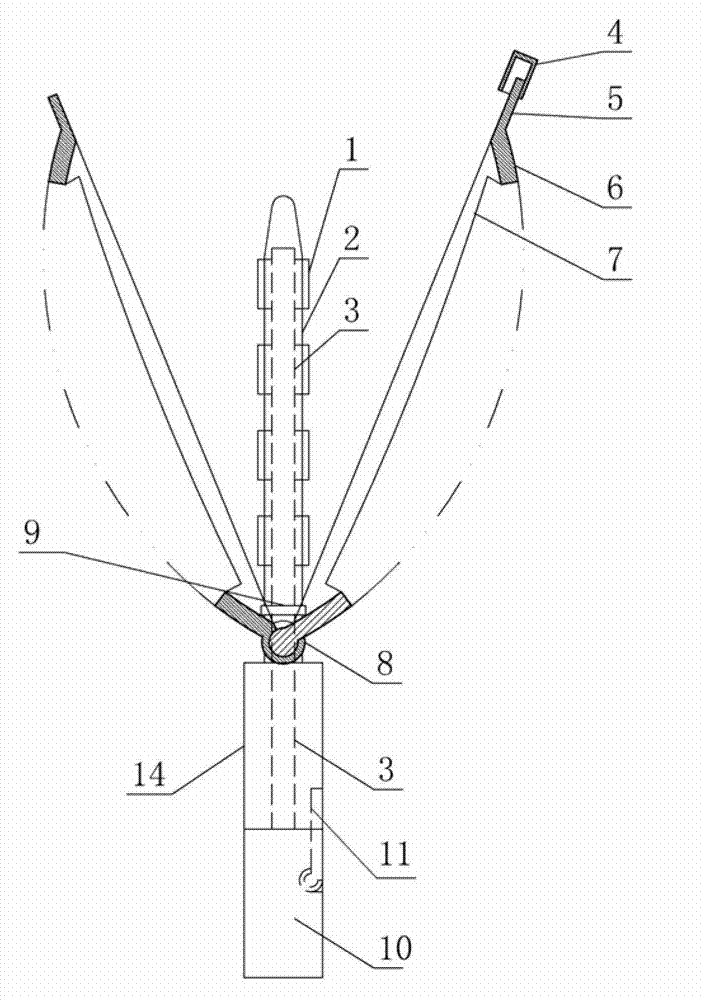

Effort-saving quick fish-scale removing mechanism

InactiveCN103109914AImprove the efficiency of scale scrapingGuaranteed straightnessFish washing/descalingAquatic productFish processing

The invention relates to the technical field of processing of aquatic products and in particular relates to an effort-saving quick fish-scale removing mechanism. The effort-saving quick fish-scale removing mechanism comprises fixed wings, a fixed barrel, a rotary rod, a locking nut, locking rods, clamping boards, a scale scraping window, a hinge, a non-return ring, a rod handle, a locking bar, wing shafts, extensible seams and a barrel handle, wherein the clamping boards are a pair of housings with elliptic and cambered outlines; the lower ends of the two clamping boards are connected by the hinges and can be freely separated and jointed; a plurality of groups of extensible seams are formed on the side wall of the fixed barrel; the rotary rod penetrates through the barrel handle from top to bottom and is positioned in the fixed barrel; a plurality of wing shafts are arranged on the side wall of the part (in the fixed barrel) of the rotary rod; the inner end of each fixed wing is provided with a cylindrical shaft sleeve; and each shaft sleeve is sleeved on one corresponding wing shaft and is capable of rotating around the wing shaft. The effort-saving quick fish-scale removing mechanism can be used for effectively improving the rigidity and the straightness of a fish body, so that the fish processing efficiency is improved.

Owner:扬州华耀生态农业有限公司

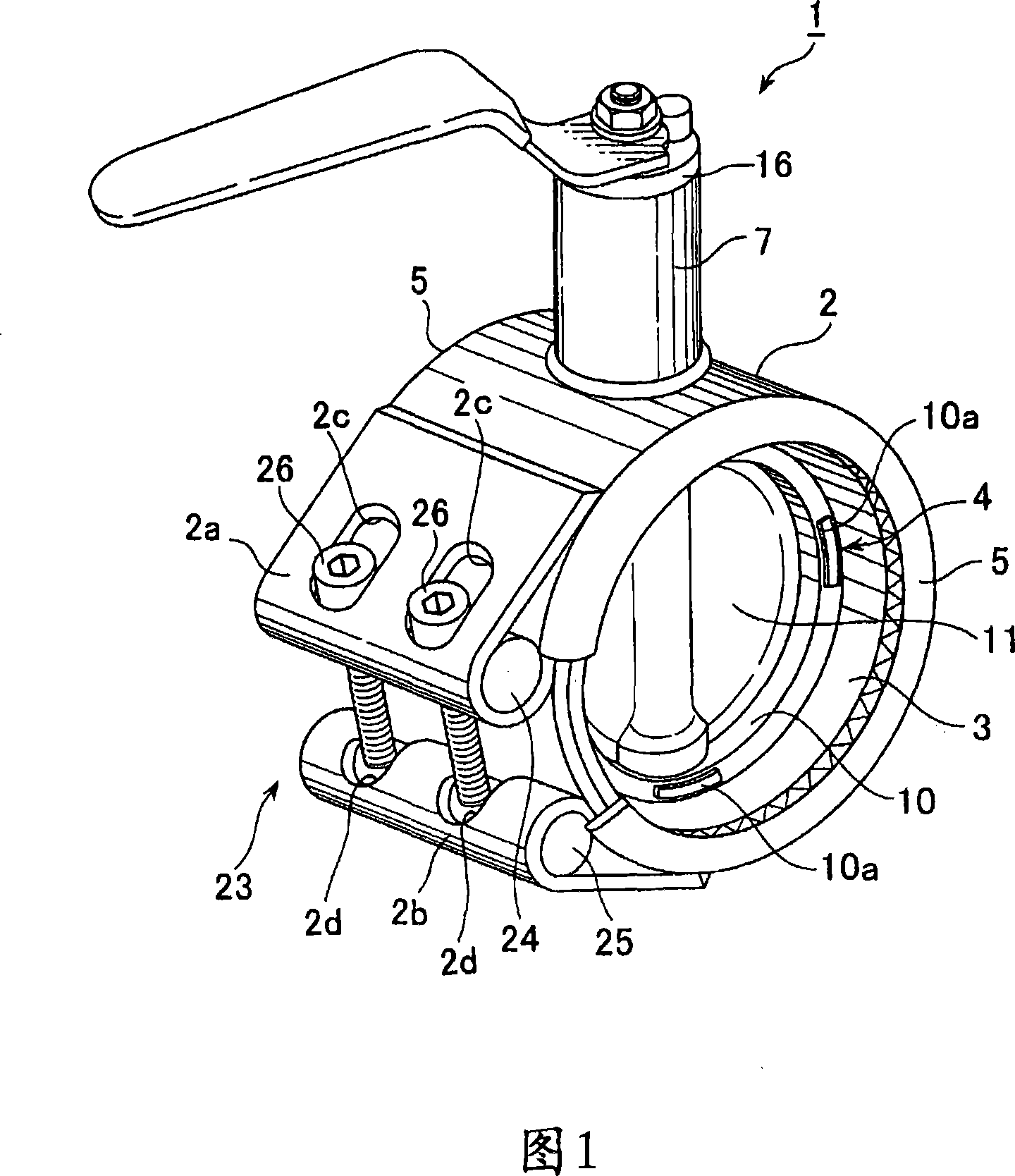

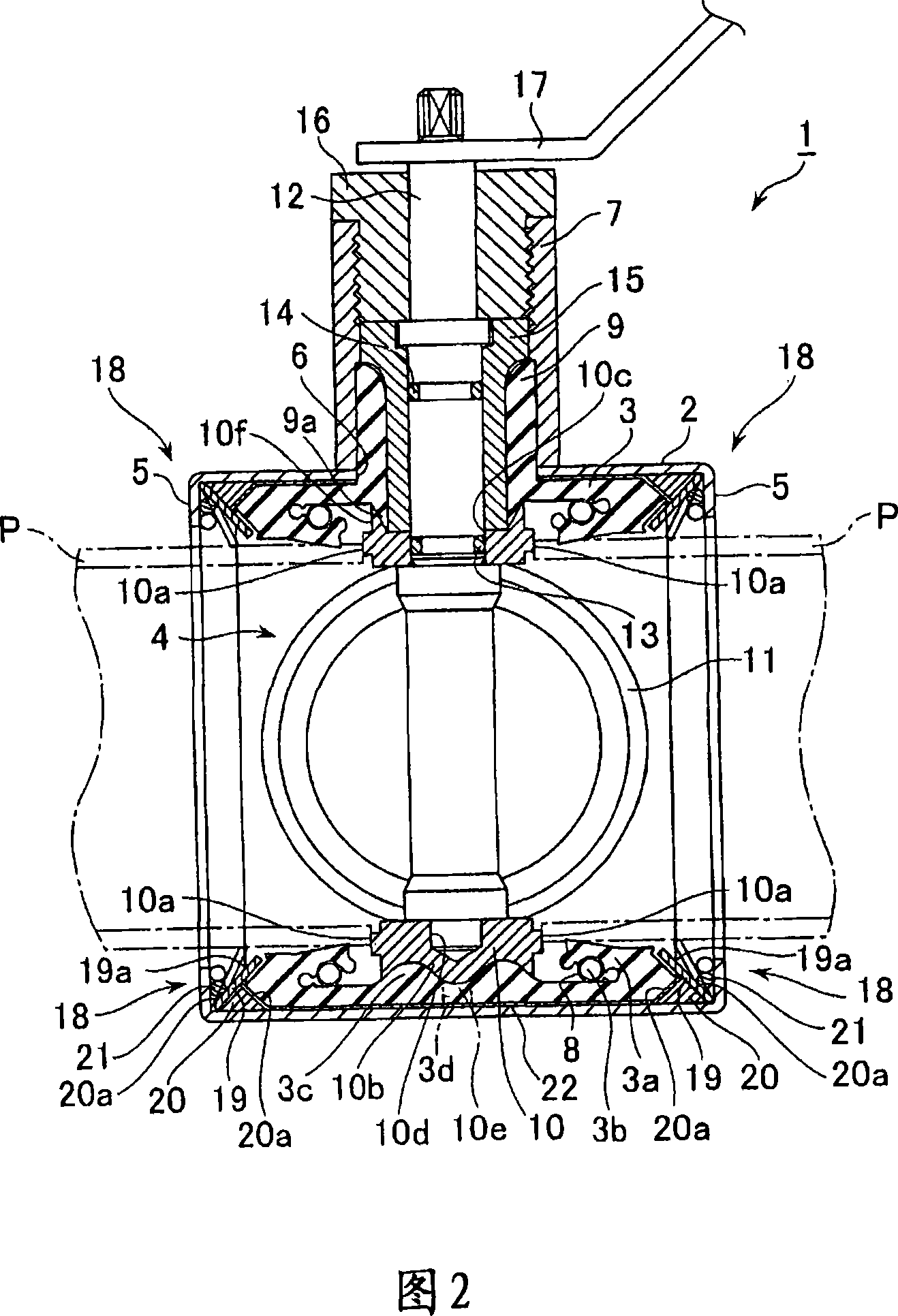

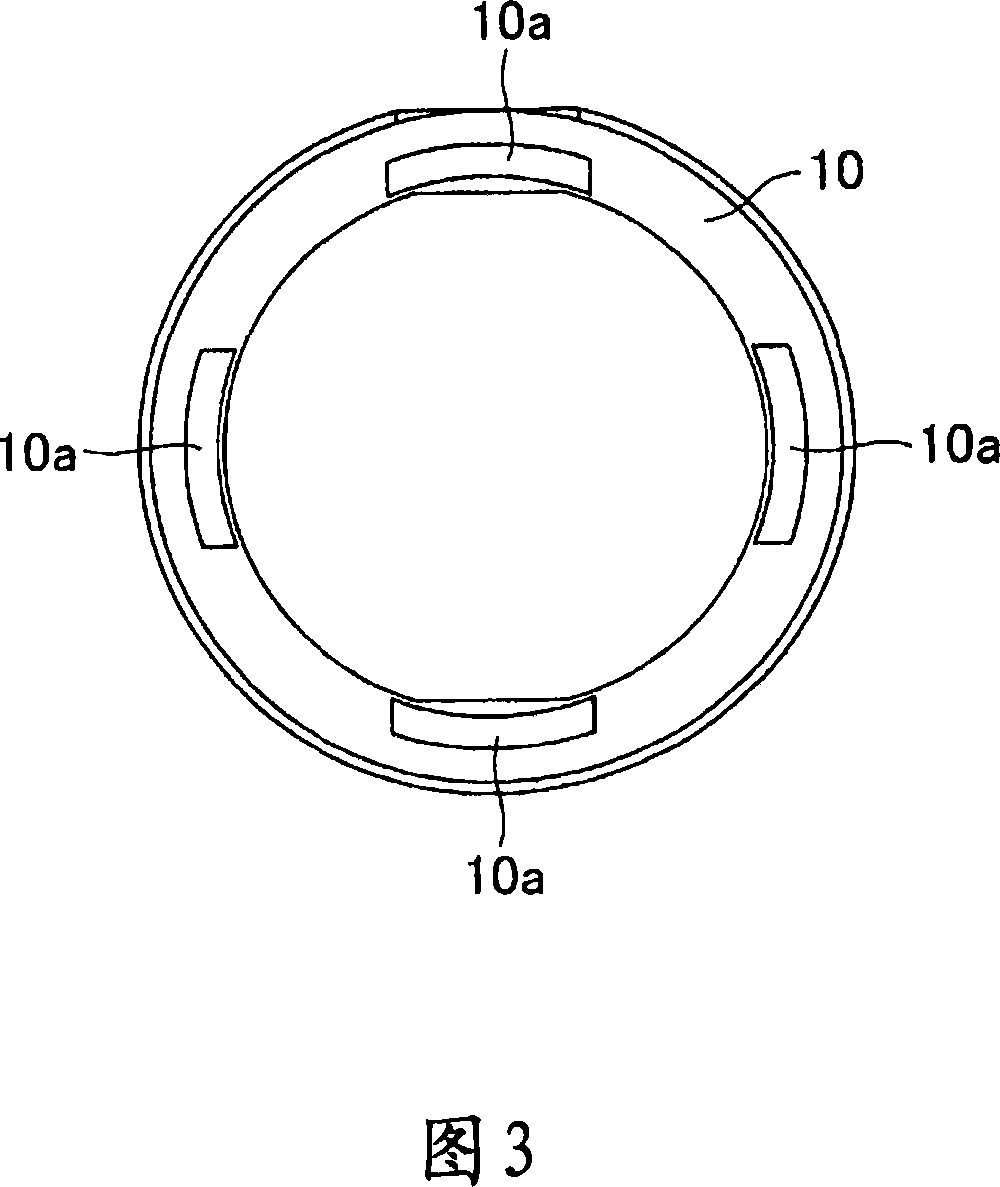

Valve with diameter-reduced joint part, joint for diameter reduction, and pipe system using these valve and joint

InactiveCN101233351AImprove sealingGuaranteed watertightnessSleeve/socket jointsPlug valvesStructural engineeringMechanical engineering

A valve easily and securely connectable to a pipe merely by tightening the housing thereof for diameter reduction without processing the connected portion of the valve, capable of absorbing vibration with a proper flexibility against the pipe joined thereto, and having excellent durability. The valve comprises a diameter-reduced joint part enabling the joining of pipes for each side independently of each other, capable of always maintaining the high sealability of the valve even when the valve is joined to and removed from the pipe, and manufacturable at advantageous cost. A sealing sleeve (3) formed of a rubber is stored in the diameter-reducible housing (2), and a valve mechanism (4) having a valve element (11) is built in the housing (2) so that flow passages in the housing (2) can be opened and closed and a flow can be controlled. The diameter-reduced joint part (18) reduces the diameter of the housing (2) to sealingly join the joining end part of the pipe (P) for joining with a sealing sleeve (3).

Owner:KITZ CORP

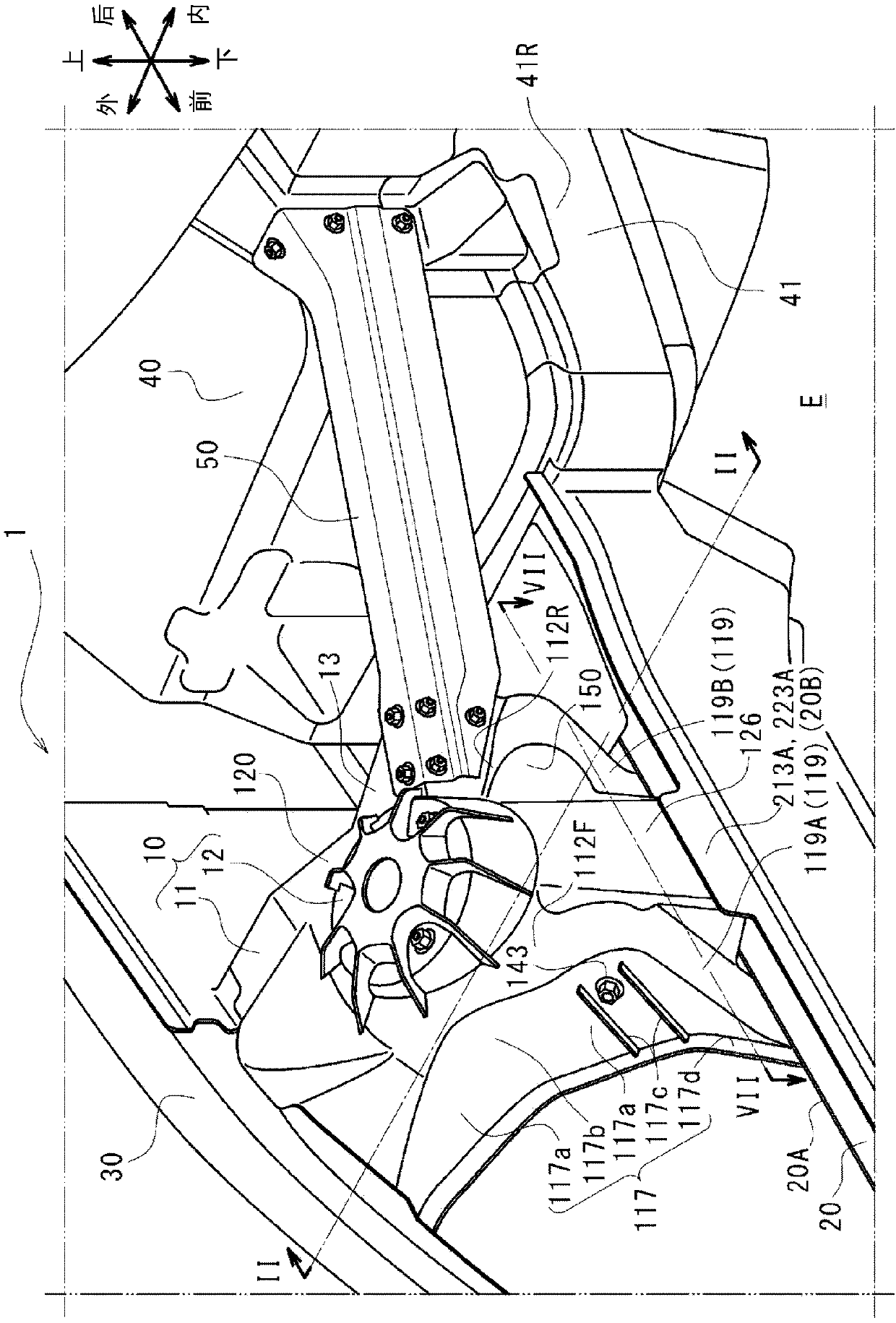

Front vehicle-body structure of vehicle

ActiveCN107662649AImprove bending rigidityEasy to assembleUnderstructuresSuperstructure subunitsFlangeEngineering

A front vehicle-body structure of a vehicle comprises a front frame, an apron reinforcement, and a suspension housing, wherein the front frame includes a frame outer and a frame inner, the frame outerand the frame inner having respective upward projection portions which are joined together to form a flange portion of the front frame, the suspension housing includes an outward-side joint portion which is joined to an outer face of the front frame and an inward-side joint portion which is joined to an outward side face, in the vehicle width direction, of the flange portion, the outward-side joint portion and the inward-side joint portion being aligned in the longitudinal direction.

Owner:MAZDA MOTOR CORP

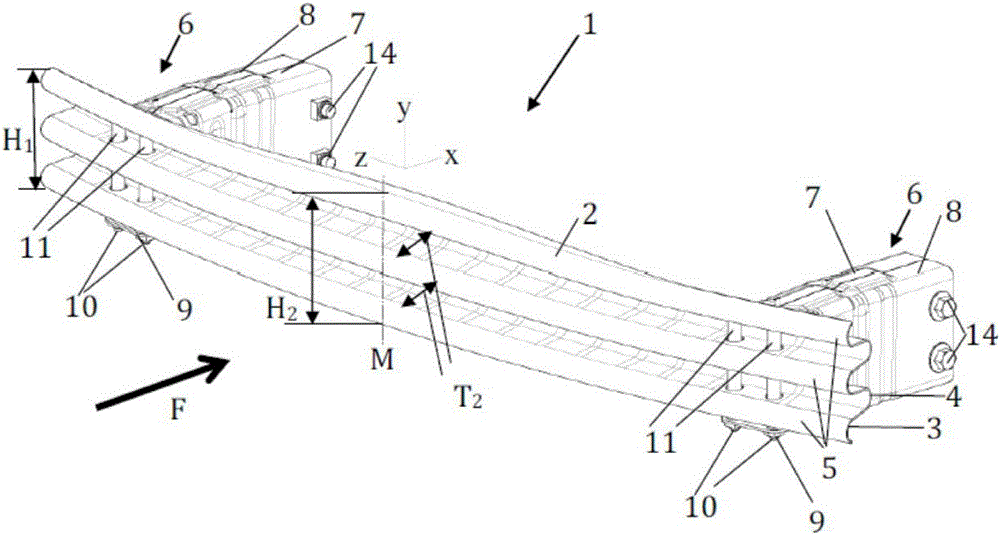

Bumper system for vehicle

ActiveCN105216722AImprove bending rigidityIncrease or decrease lengthBumpersEngineeringMechanical engineering

One bumper system for a vehicle includes a bumper bracket and a deformation element connected to the bumper bracket. The bumper bracket is composed of a metallic workpiece with an undulating form such that the bumper bracket has at least one undulation trough and at least two undulation peaks, and reinforcement zones are formed in regions of the undulation trough. Another bumper system for a vehicle includes a bumper bracket and a deformation element connected to the bumper bracket. The bumper bracket has an undulating form such that the bumper bracket has a plurality of undulation troughs and a plurality of undulation peaks, and reinforcement zones are formed in each undulation trough. In each system, a second deformation element may be connected to the bumper bracket, and at least one characteristic of the reinforcement zones may increase or decrease between the deformation elements and a middle of the bumper bracket.

Owner:THYSSENKRUPP STEEL EURO AG +1

Interlayer for laminated glass, and laminated glass

ActiveUS20170313033A1Improve bending rigidityImprove sound insulation propertySynthetic resin layered productsConstructions elementsChemistryEquivalent stiffness

An interlayer film for laminated glass that has a one-layer structure or a two or more layer-structure includes a first layer containing a thermoplastic resin, wherein the first layer has a glass transition temperature of 10° C. or lower, and wherein the interlayer film has an equivalent stiffness of 2.4 MPa or greater at 25° C.

Owner:SEKISUI CHEM CO LTD

Pneumatic tire and method of manufacturing same

The invention provides a pneumatic tire and a method of manufacturing the same, maintaining ride comfort and improving responsibility close to a neutral gear. The pneumatic tire (1) has at least one main groove continuously extending along the tire periphery and treads (12) contacted with a road surface at the outer surface (2S) of a tire surface part (2). The pneumatic tire (1) is provided with tread inward ribs (16) which are protruding toward the inner side in the tire radial direction and extend along the tire periphery at an inner cavity surface (10) of the treads (2) and in tread inner regions (15) of the inner side in the tire radial direction of the treads (12).

Owner:SUMITOMO RUBBER IND LTD

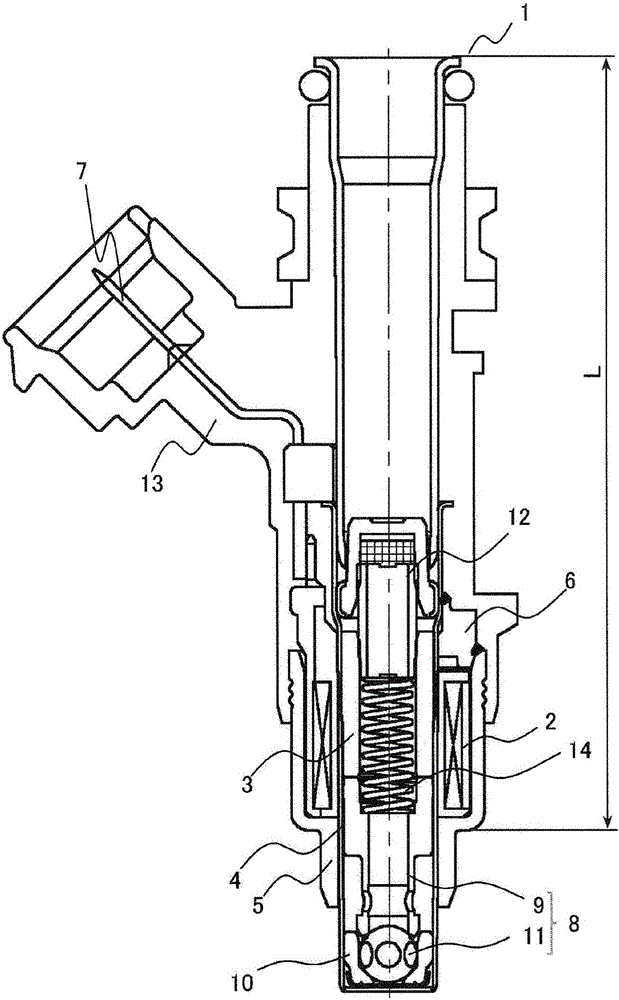

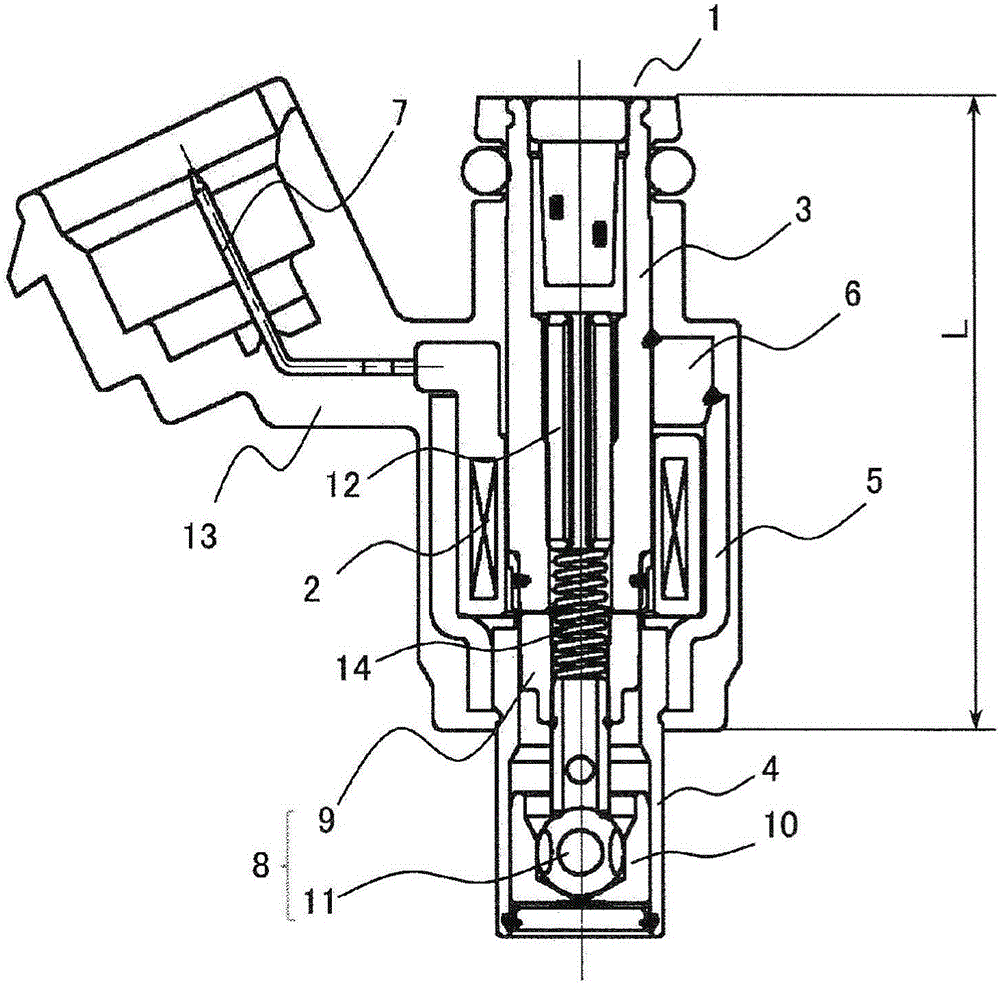

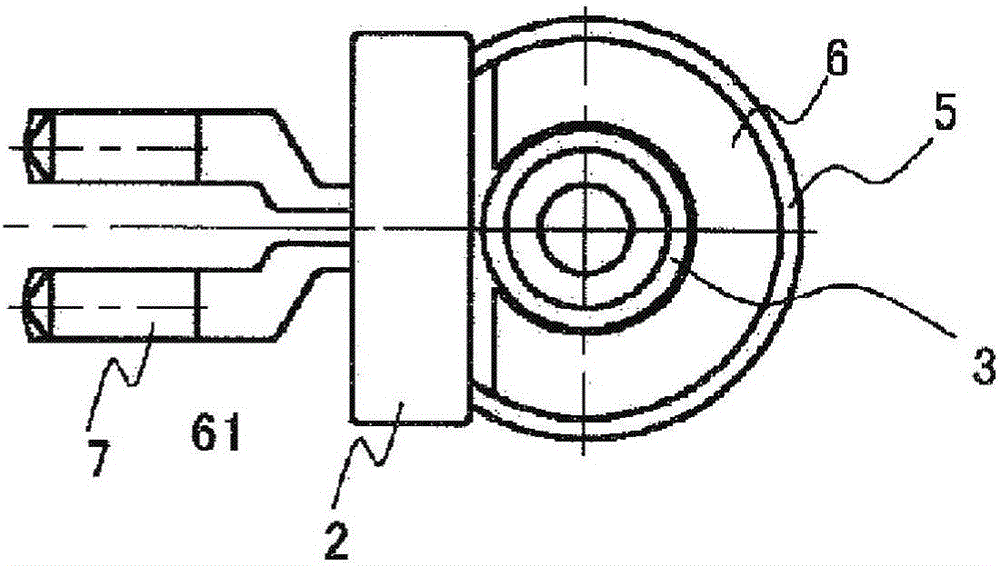

Fuel injection valve and method for manufacturing fuel injection valve

ActiveCN105745432AImprove bending rigidityShortened installation lengthMachines/enginesSpecial fuel injection apparatusEngineeringFuel injection

A fuel injection valve is provided with: a holder having a core affixed to an axial end thereof; a solenoid received between the inner peripheral surface of a housing and the outer peripheral surface of the core; a cap affixed by welding to both the housing and the core while the solenoid is in the received state; an armature disposed so as to face the axial end of the core and held on the inner peripheral surface of the holder so as to be slidable in the axial direction; a valve section affixed to the armature and capable of sitting on or moving away from a valve seat provided to the holder; a spring for always pressing the armature in the direction in which the armature moves away from the axial end of the core; and an electrode terminal disposed outside the housing and connected to the solenoid. The holder is press-fitted in and affixed to the housing. The cap has a cutout formed by cutting out a part of an annular section, and the inner peripheral surface of the cap is disposed so as to face the outer peripheral surface of the core with a gap therebetween. The electrode terminal is connected to a terminal of the solenoid through the cutout in the cap.

Owner:MITSUBISHI ELECTRIC CORP

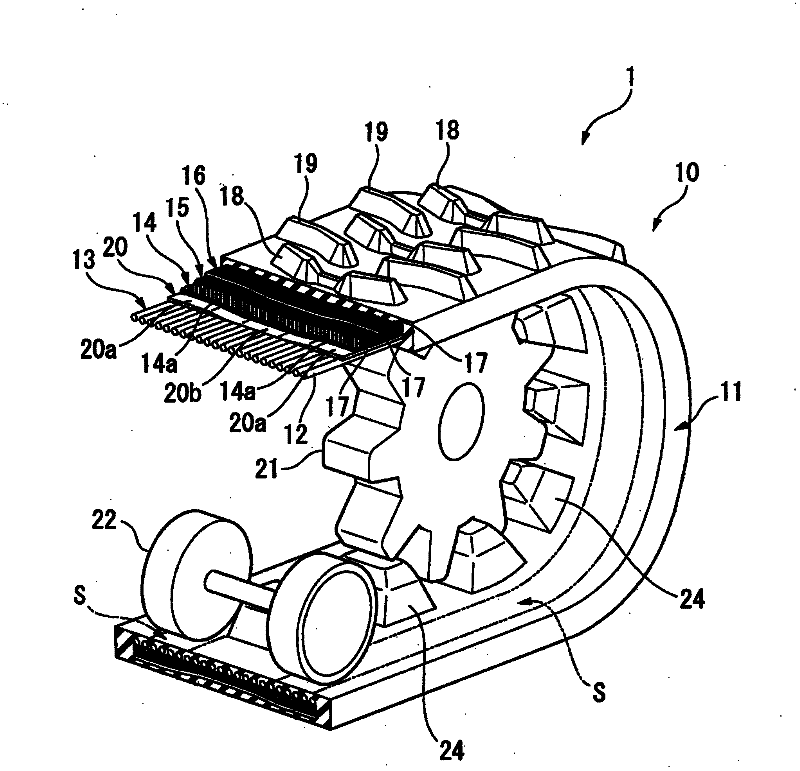

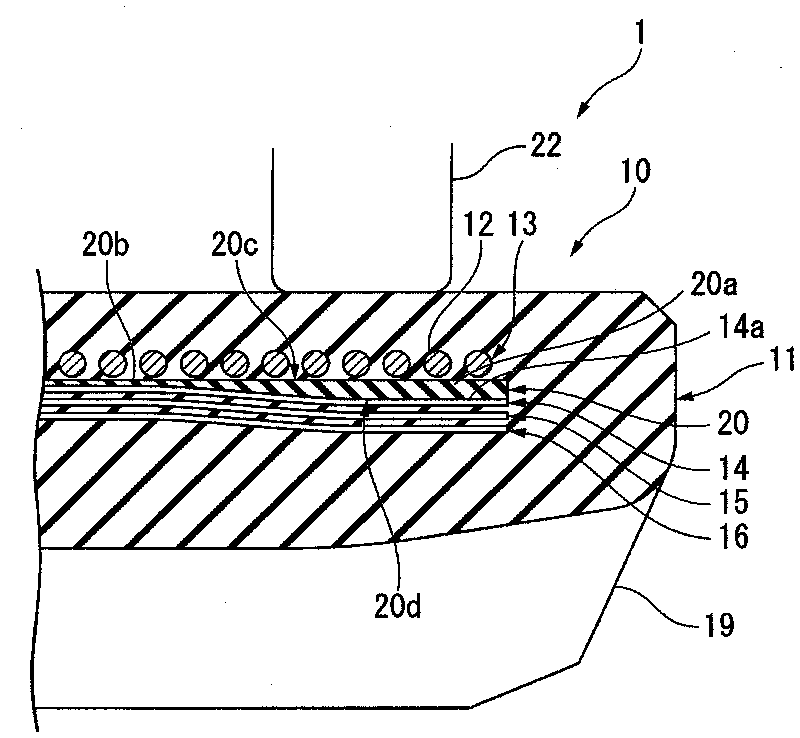

Rubber track and track type traveling body

A rubber track comprising a steel cord layer (13) formed by embedding steel cords in an endless belt-like rubber track body, the steel cords being arranged side by side in the width direction of the rubber track so as to extend in the circumferential direction of the rubber track, the rubber track body being provided, on the inner peripheral surface thereof, with at least a left and right pair ofroller path surfaces, and the rubber track also comprising biased reinforcing layers (14-16) arranged on the outer peripheral side of the steel cord layer (13). The left and right pair of roller pathsurfaces is arranged at positions which are located on the inner peripheral surface of the rubber track body and correspond to end sections of the steel cord layer (13) in the width direction of the rubber track and to end sections of each of the biased reinforcing layers (14-16) in the width direction. A rubber layer (20) is provided between the steel cord layer (13) and an innermost reinforcinglayer (14) on the innermost peripheral side among the biased reinforcing layers (14-16) so as to correspond to both the end sections of at least the innermost reinforcing layer (14) in the width direction of the rubber track.

Owner:BRIDGESTONE CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com