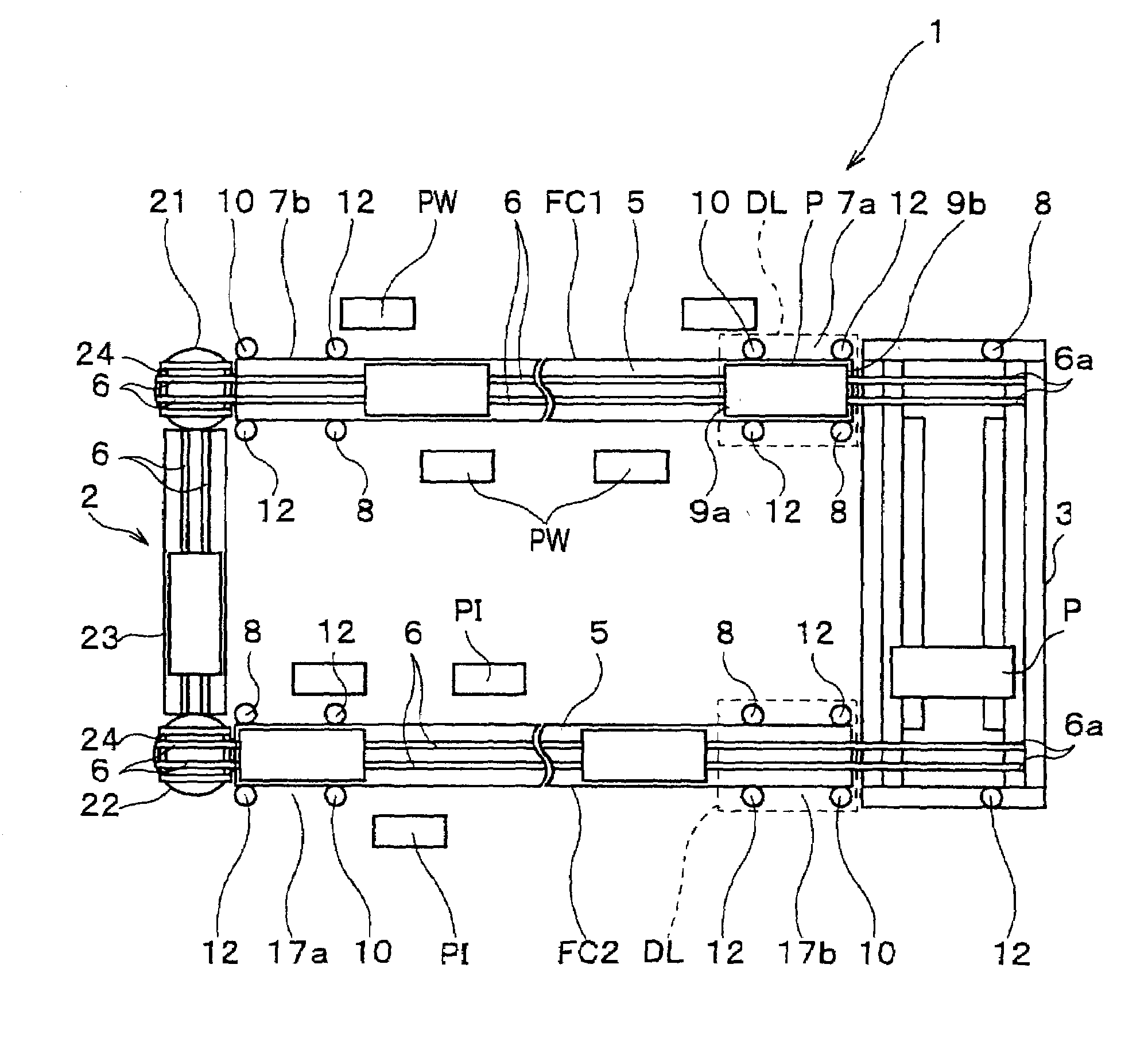

Patents

Literature

205results about "Propulsion railway systems" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

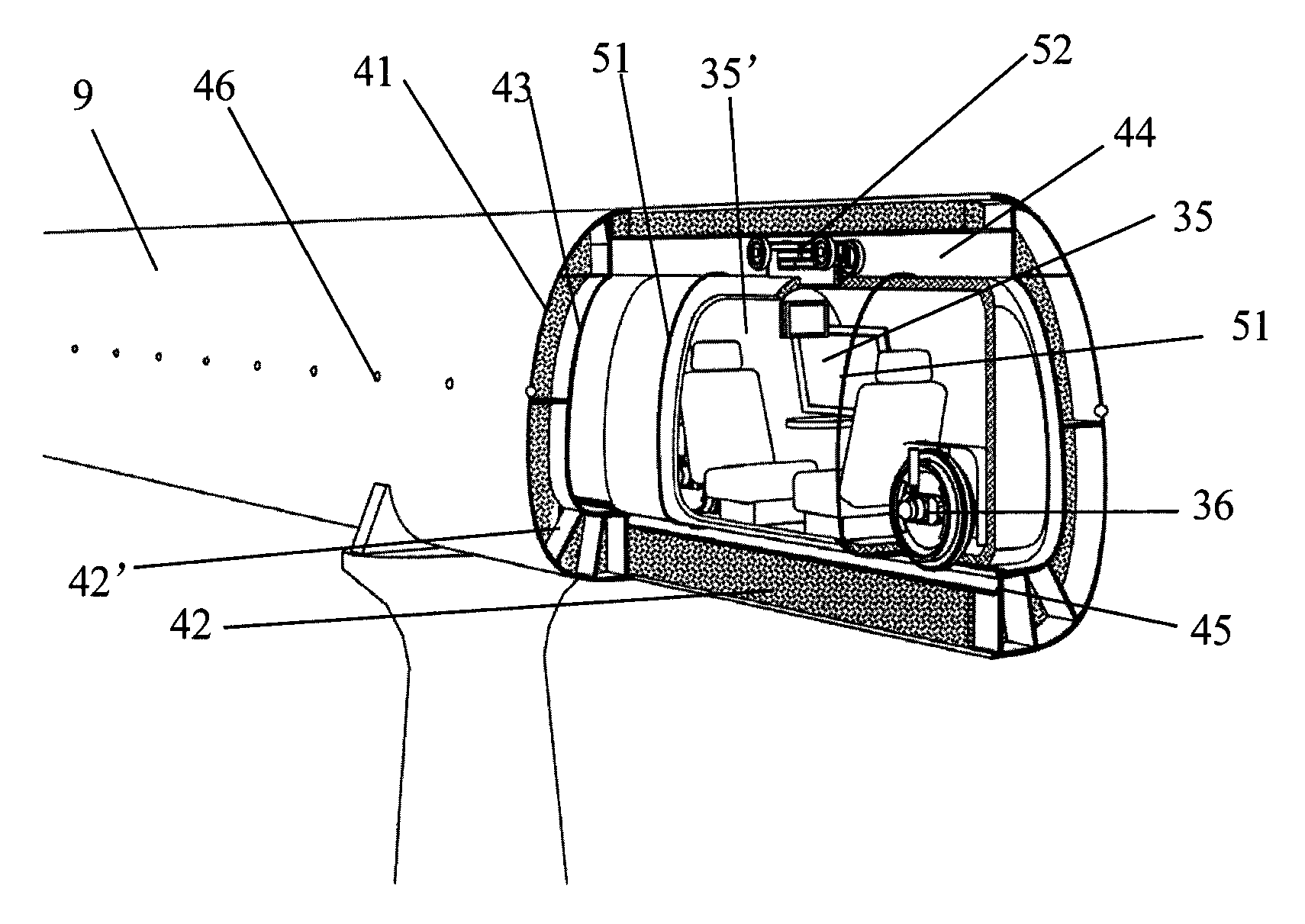

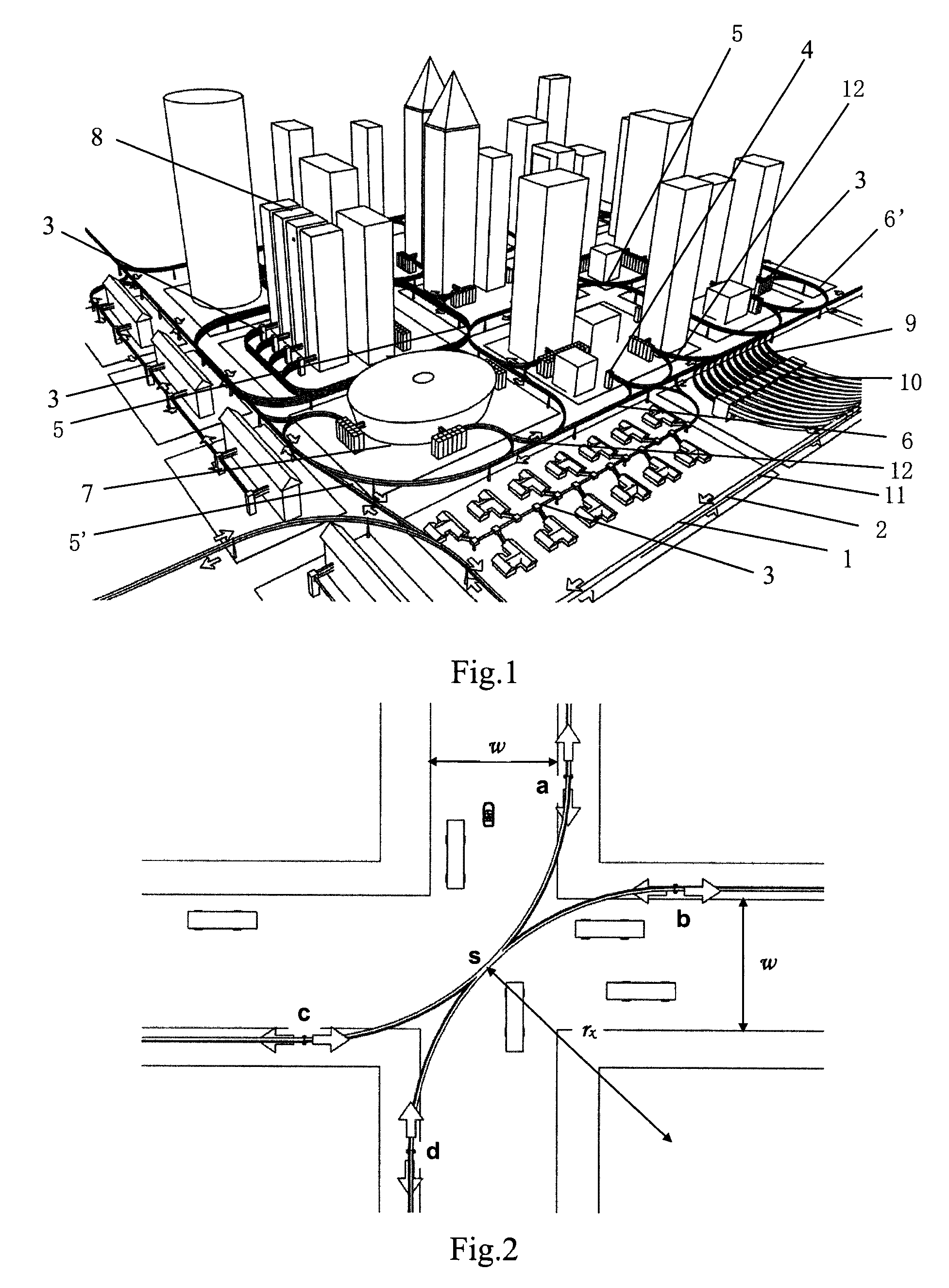

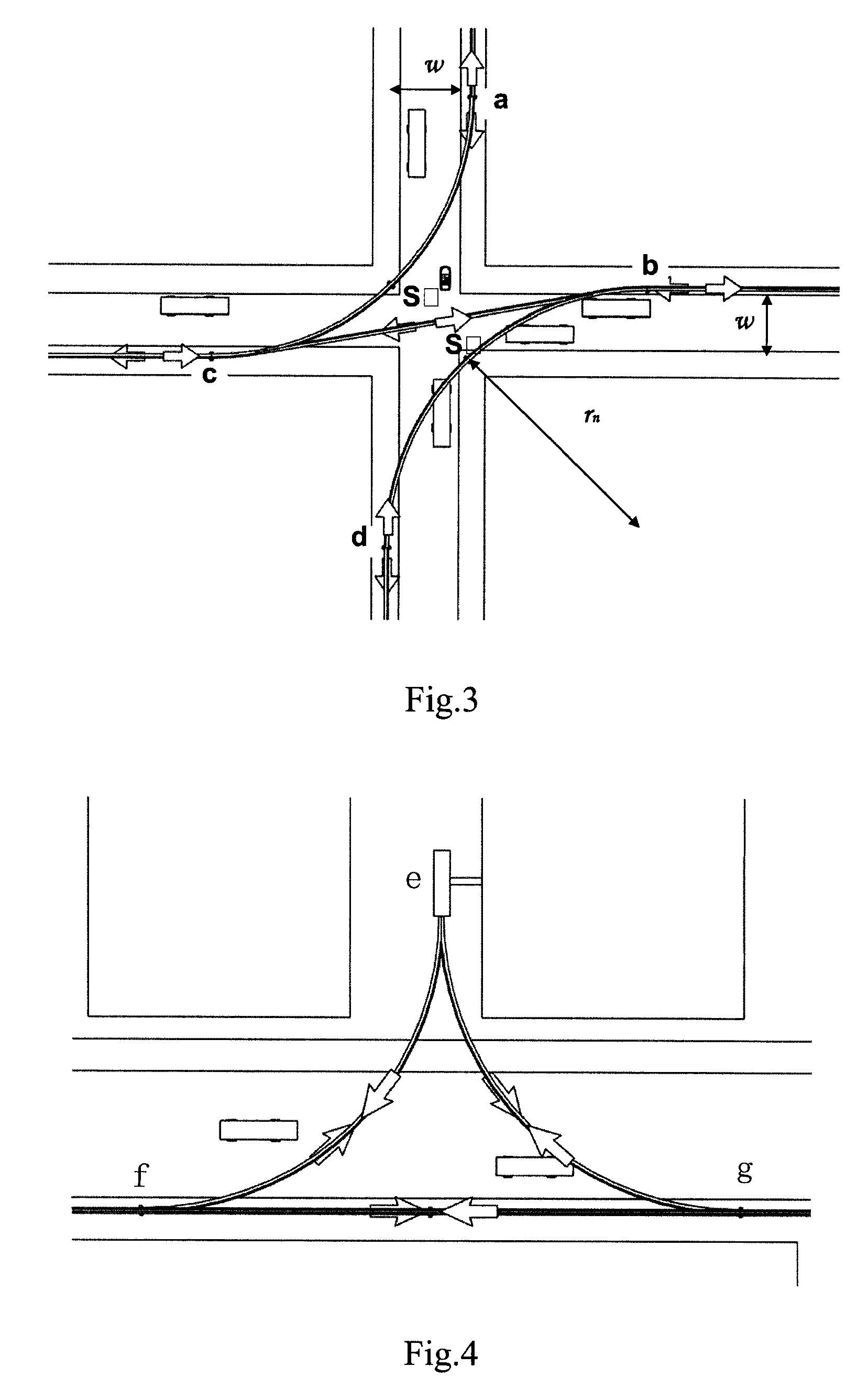

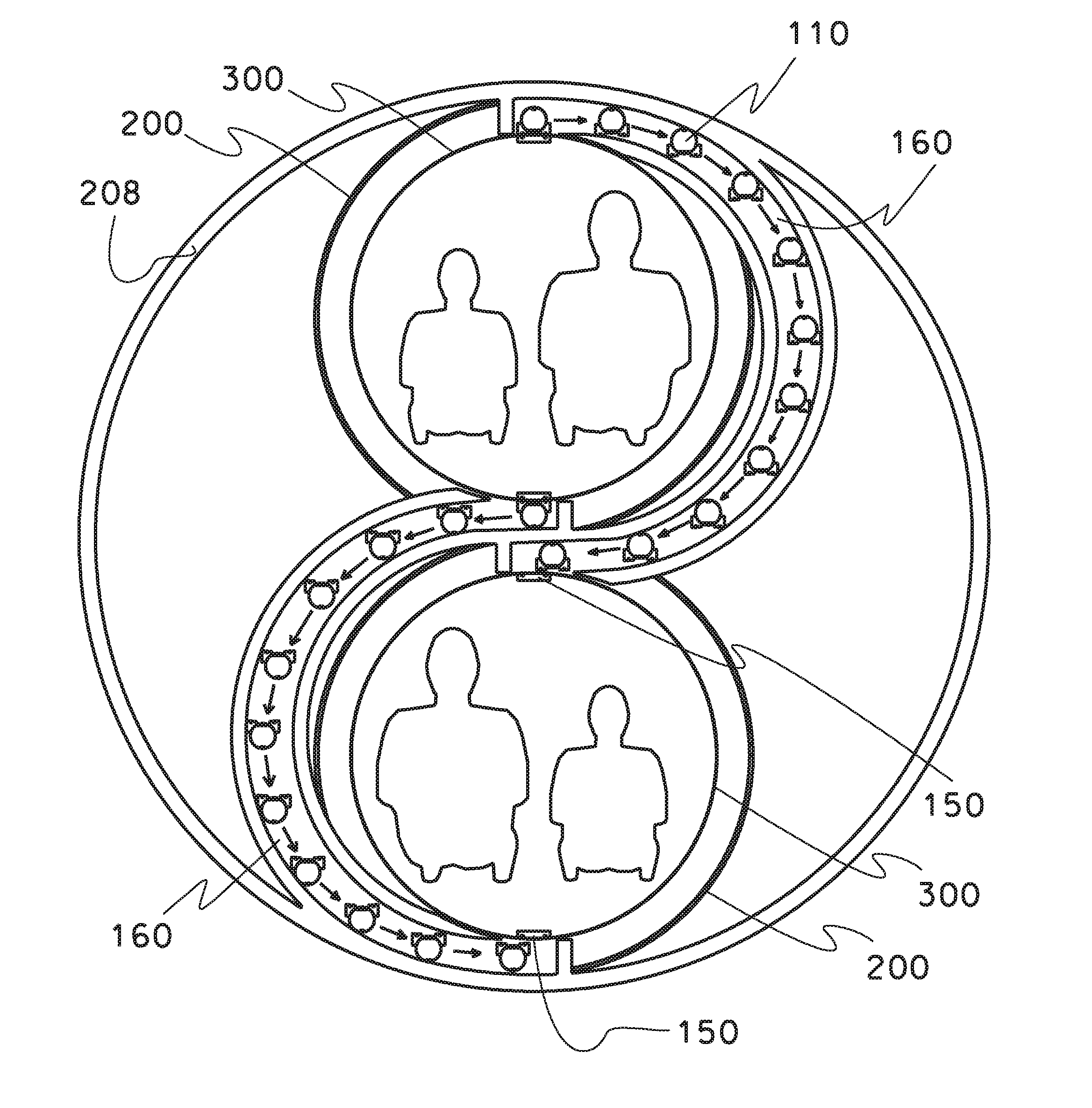

Tube car, network of tubes, personal transport system, and control system and control method thereof

InactiveUS20090101040A1Easy to removeAbility muchRailway tunnelsDigital data processing detailsOperational costsTransport system

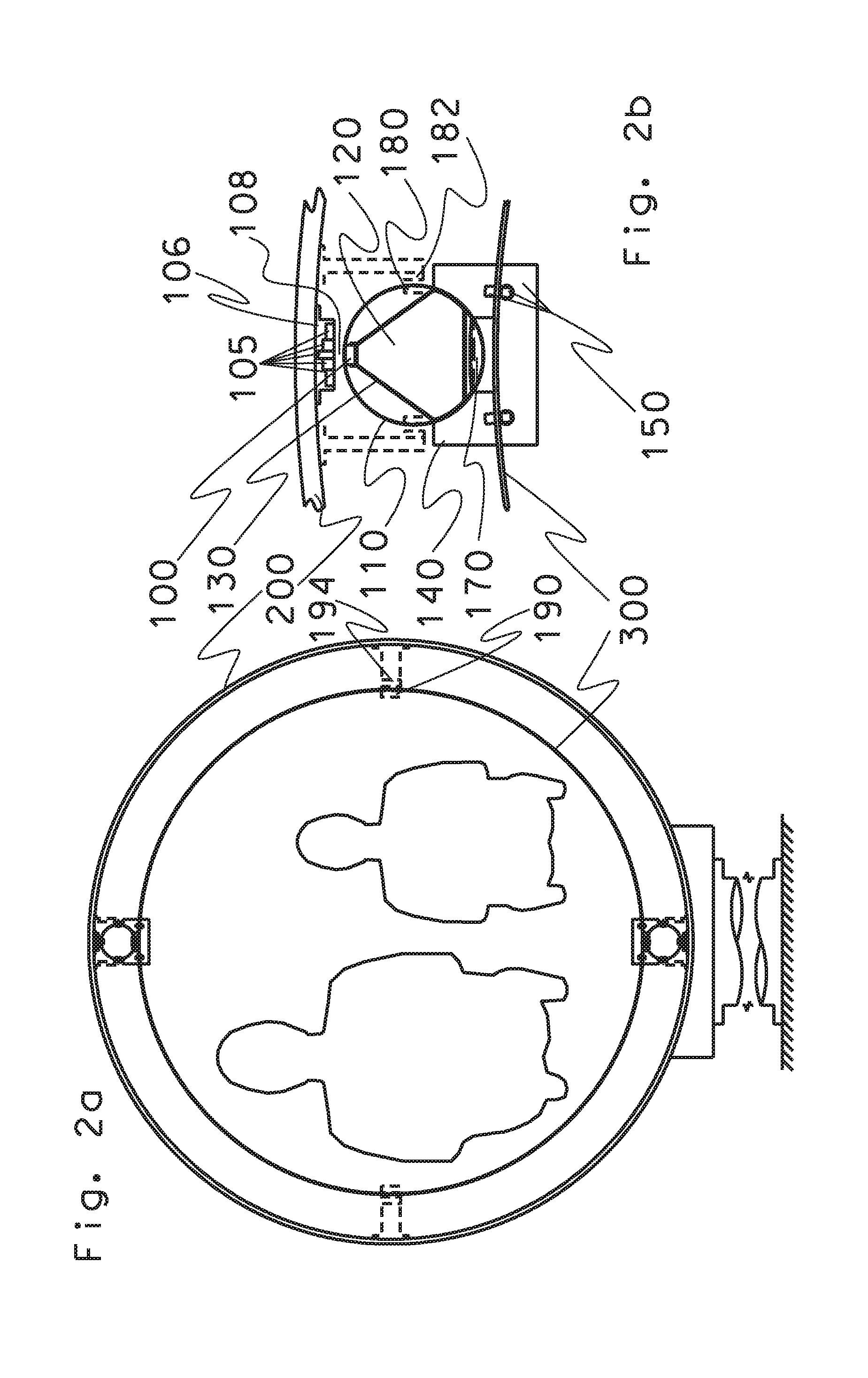

The present invention provides a new personal transport system for passengers and goods, which comprises: a tube car comprising a self-powered closed tube car carrying passengers or goods from door to door; and a network of tubes comprising a plurality of tubes, the said network of tubes combined with the existing blocks or buildings, with each tube in the network of tubes provided with an upper rail and / or a lower rail for supporting and / or guiding the said tube car carrying passengers or goods. According to the invention it is possible to achieve a door-to-door transport between two buildings. In comparison to other traffic systems, the inventive system's velocity, line capacity, safety and reliability, ability of resisting disasters and comfortableness are much increased while its consumption of energy, construction cost, occupied space, operating cost, noise and visual pollution are greatly reduced. Furthermore, the transport system of the invention is easy to put into a standardized production, quick to be laid, removed and reused.

Owner:YANG NANZHENG

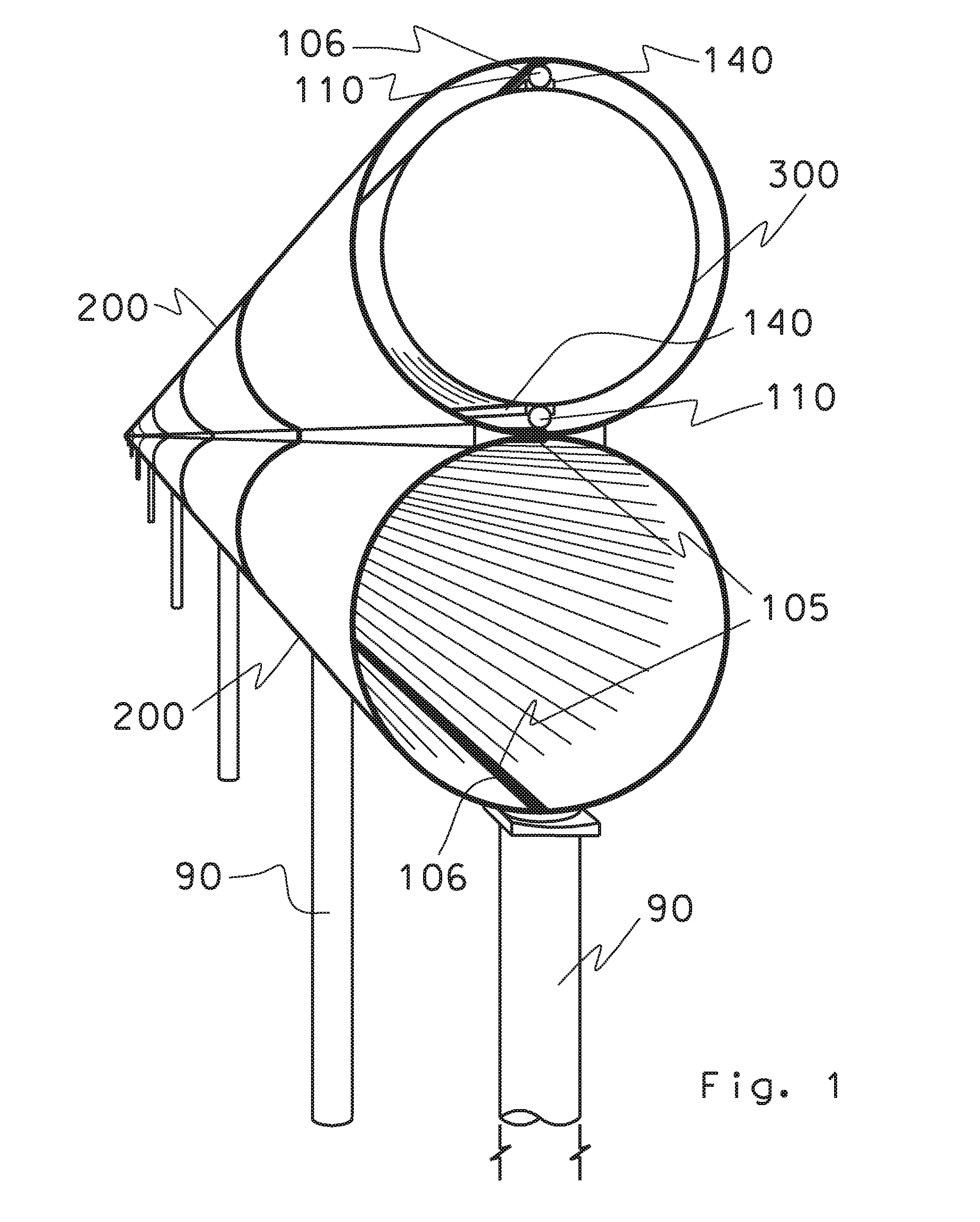

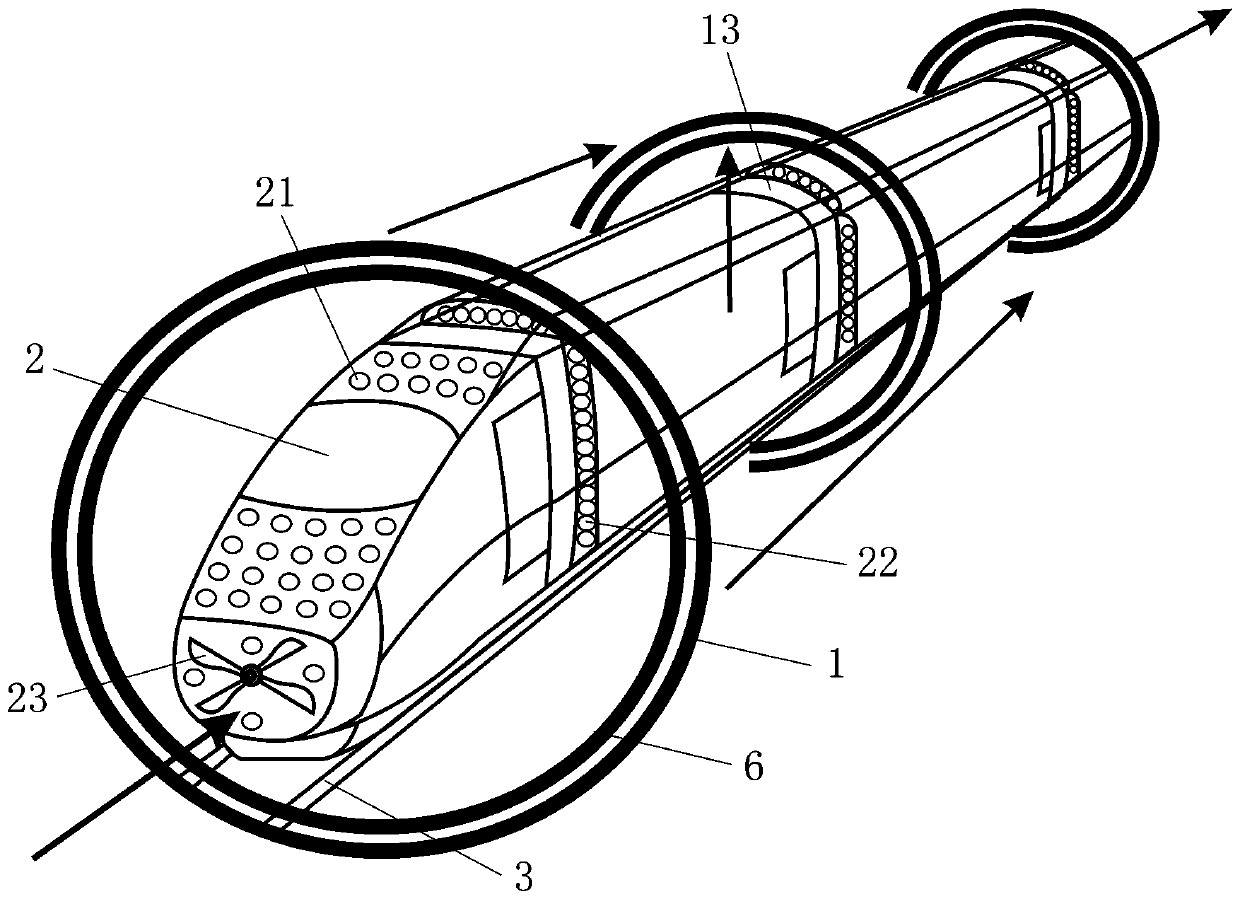

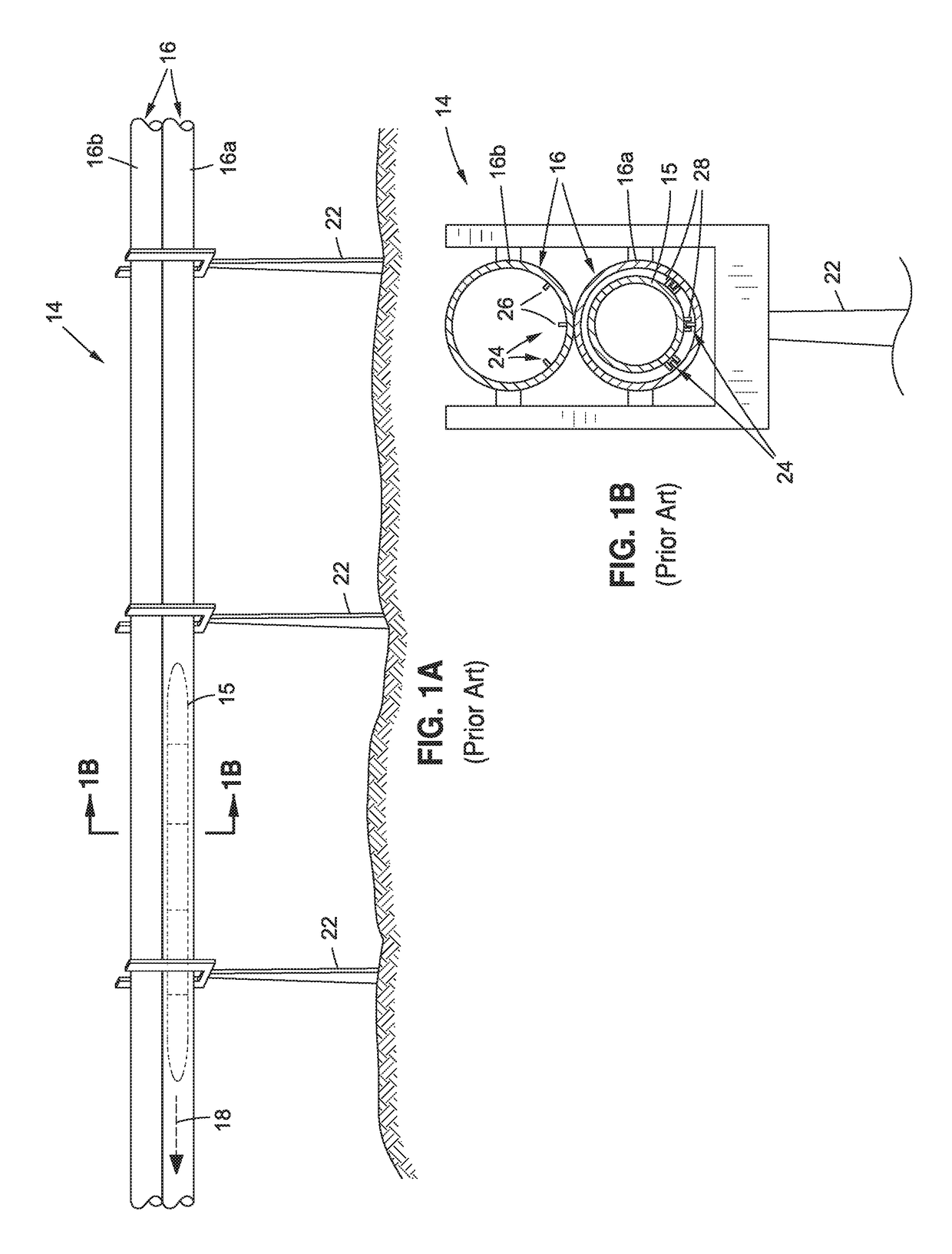

Magnetic/air transportation system

A transportation system uses a carrier conduit in the form of a long tube or channel in order to drive a vehicle by air pressure. A carrier having end plates obstructs the travel of air through the carrier conduit. Pressure differentials formed within the carrier conduit serve to propel the carrier through the carrier conduit. By rollably supporting the carrier within the carrier conduit, friction is reduced between the carrier conduit and the carrier. The carrier may be magnetically coupled to a vehicle having vanes and a set of track- or rail-engaging wheel assemblies on vanes. The vanes may pivot upon the vehicle and serve to allow the vehicle to rollably or slidably couple to the carrier conduit track. The motion of the carrier serves to propel the vehicle along the carrier conduit track as the vehicle is magnetically coupled to the carrier. Composite materials used to construct the carrier conduit may allow for such magnetic coupling without the interference that might occur through the use of ferromagnetic materials or the like. The carrier conduit may be mounted upon pillars or pylons and sources of pressure may either be present at either end of the carrier conduit, distributed at propitious points there along, or incorporated into the carrier.

Owner:HARDING LOU O

Tube car, network of tubes, personal transport system, and control system and control method thereof

InactiveUS8006625B2Easy to removeAbility muchRailway tunnelsDigital data processing detailsOperational costsTransport system

The present invention provides a new personal transport system for passengers and goods, which comprises: a tube car comprising a self-powered closed tube car carrying passengers or goods from door to door; and a network of tubes comprising a plurality of tubes, the said network of tubes combined with the existing blocks or buildings, with each tube in the network of tubes provided with an upper rail and / or a lower rail for supporting and / or guiding the said tube car carrying passengers or goods. According to the invention it is possible to achieve a door-to-door transport between two buildings. In comparison to other traffic systems, the inventive system's velocity, line capacity, safety and reliability, ability of resisting disasters and comfortableness are much increased while its consumption of energy, construction cost, occupied space, operating cost, noise and visual pollution are greatly reduced. Furthermore, the transport system of the invention is easy to put into a standardized production, quick to be laid, removed and reused.

Owner:YANG NANZHENG

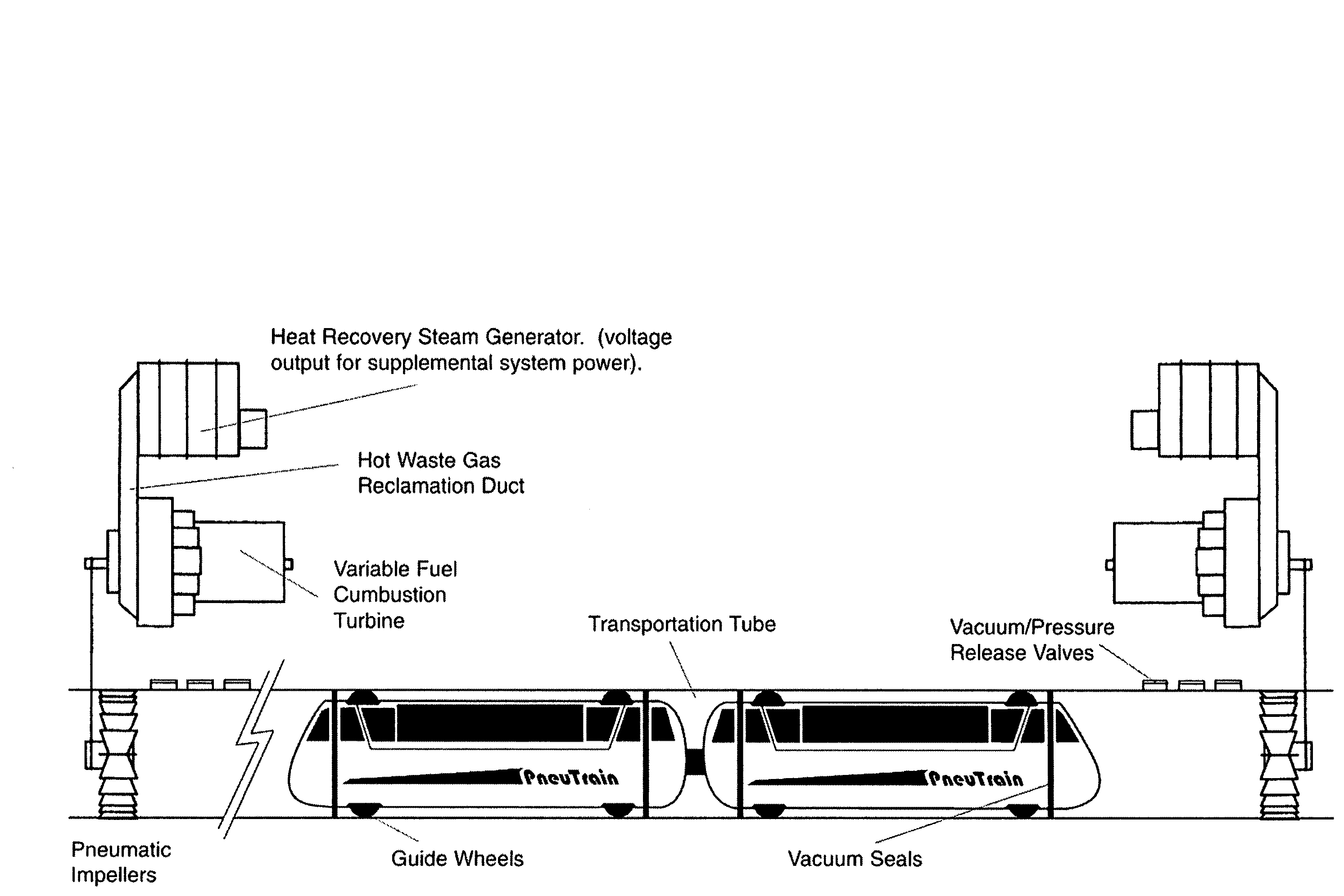

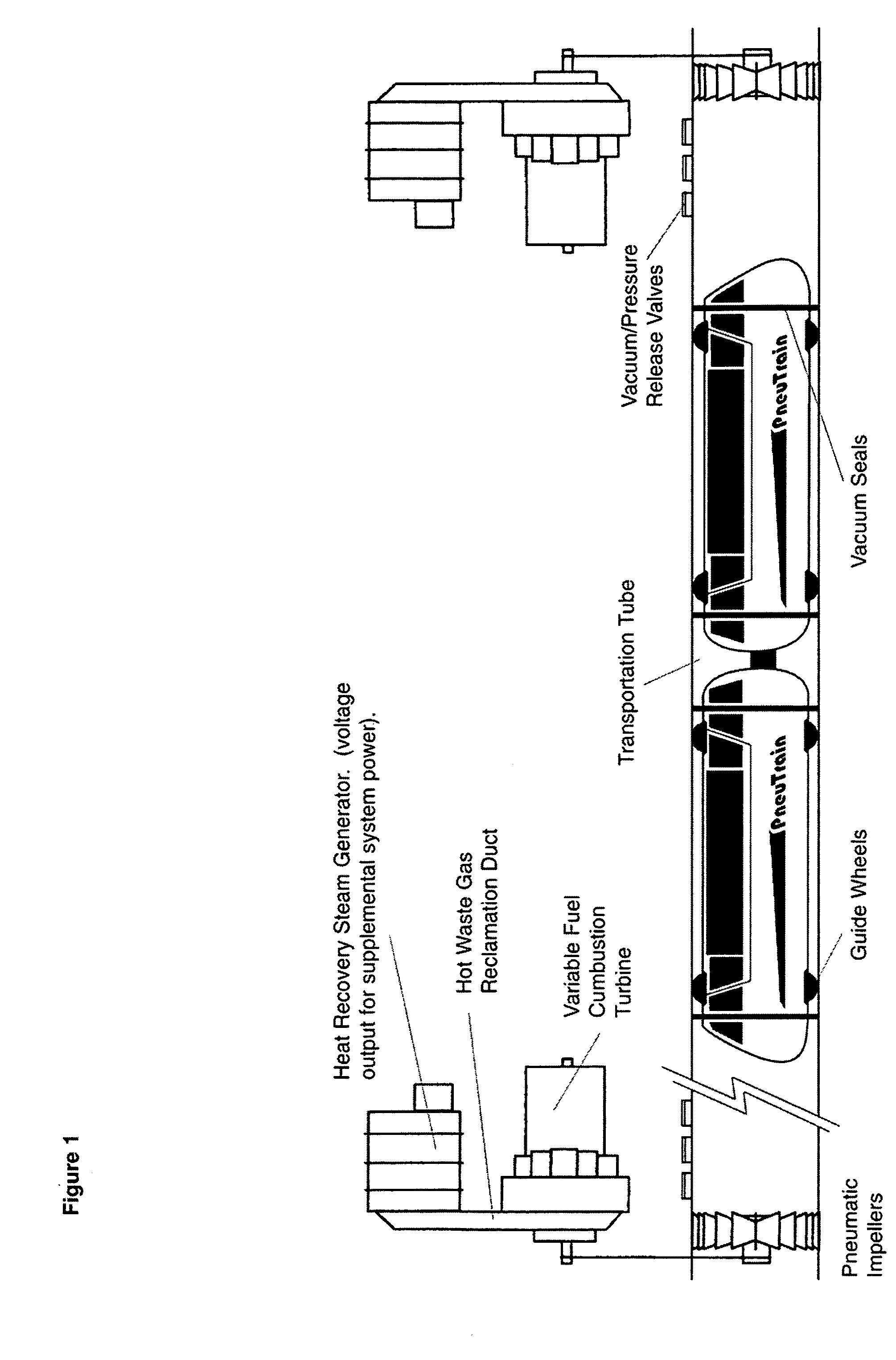

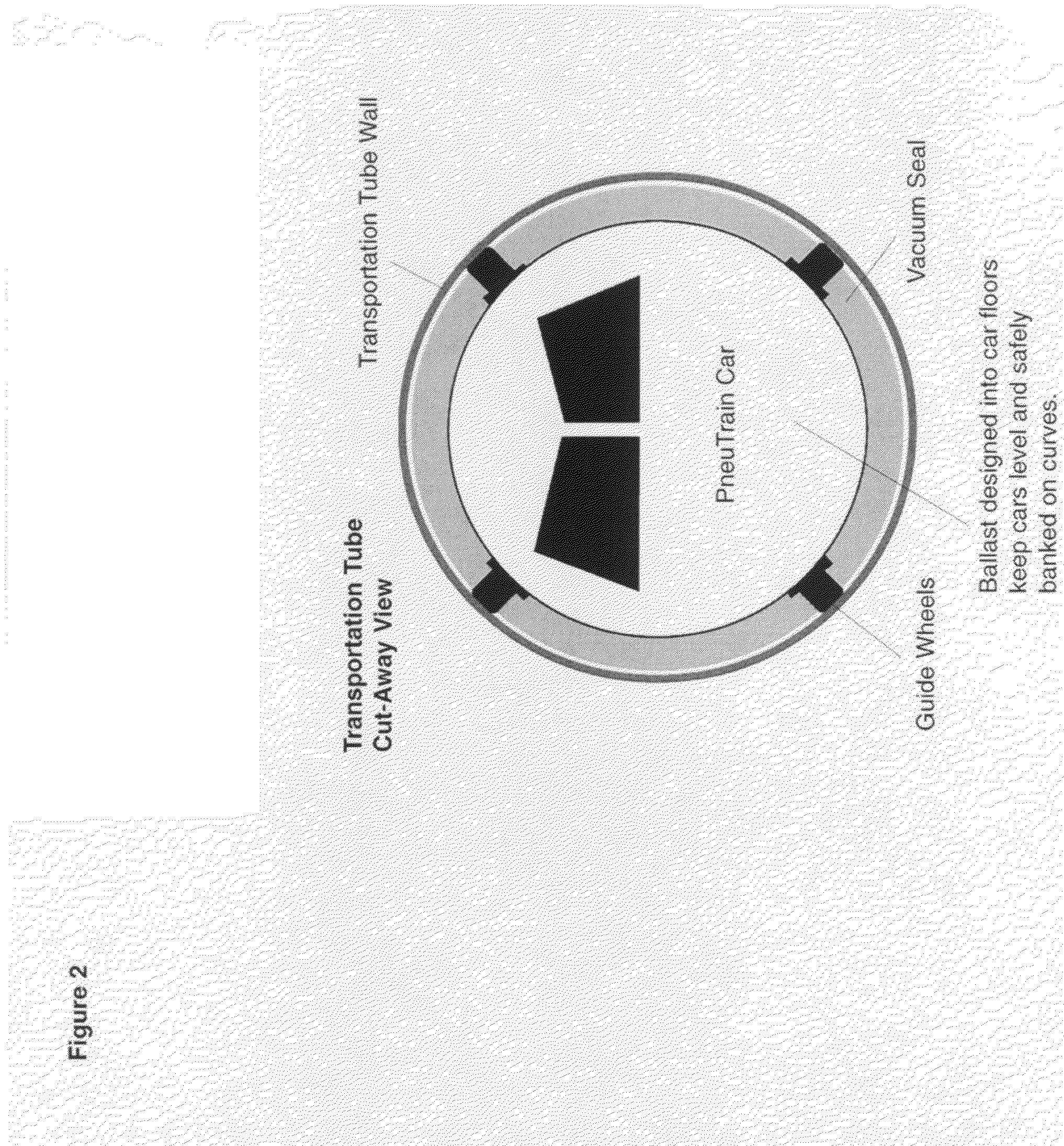

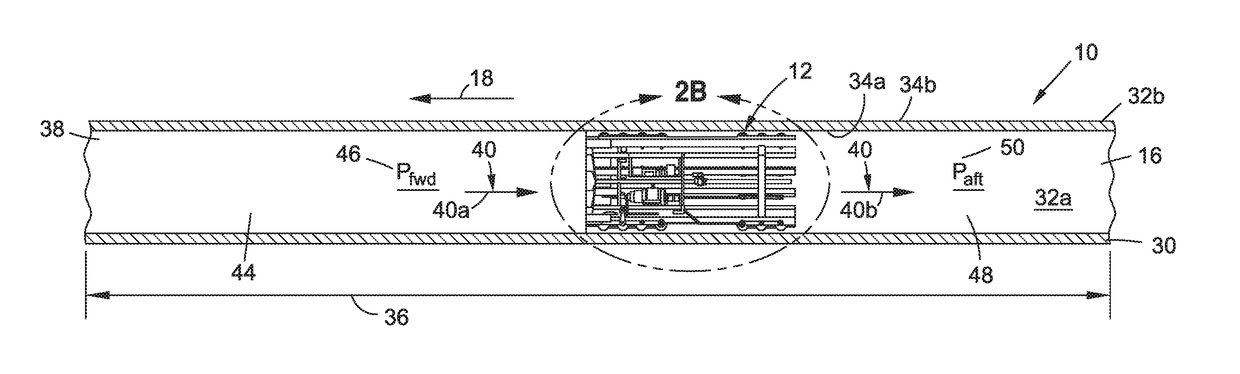

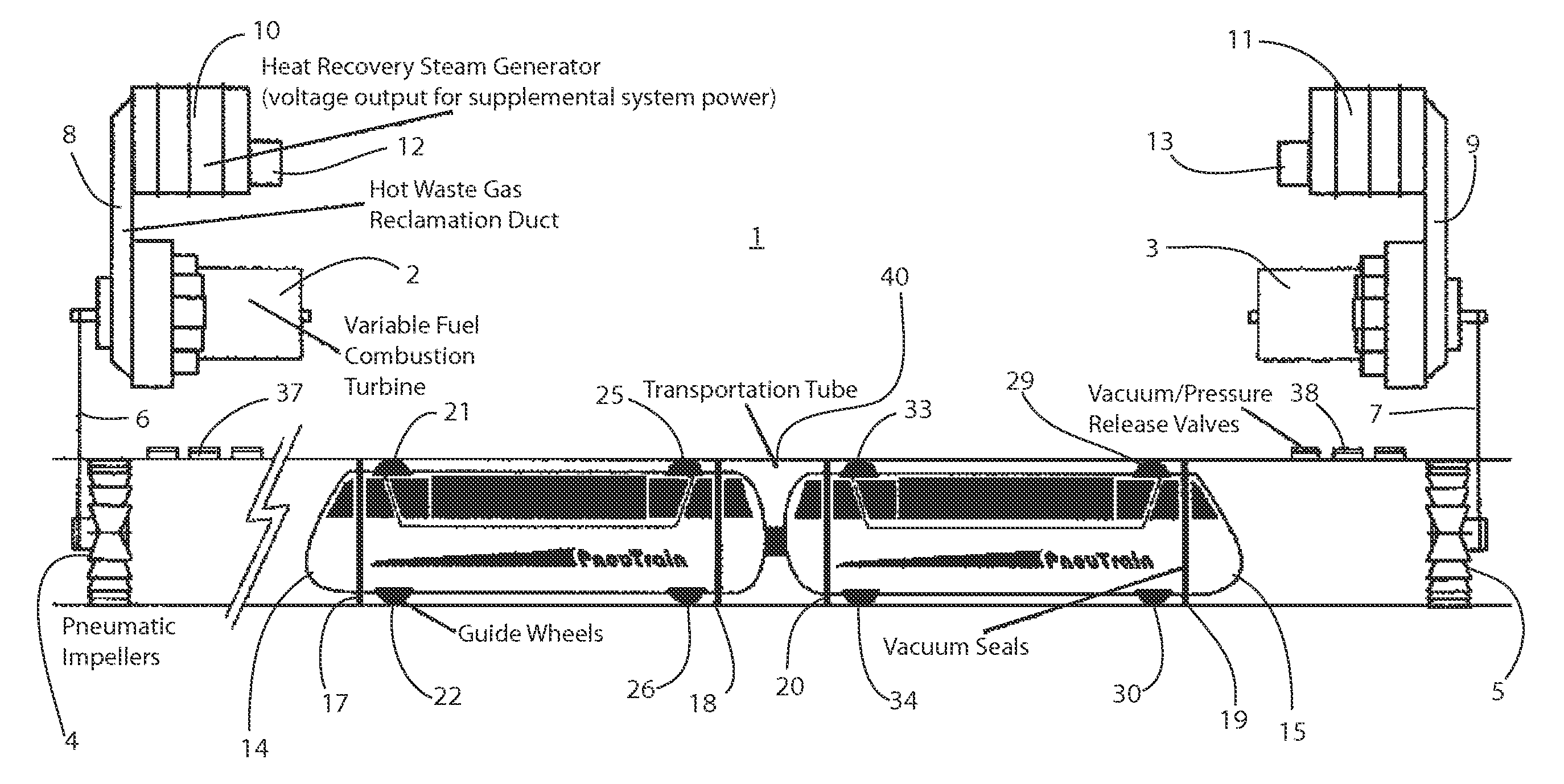

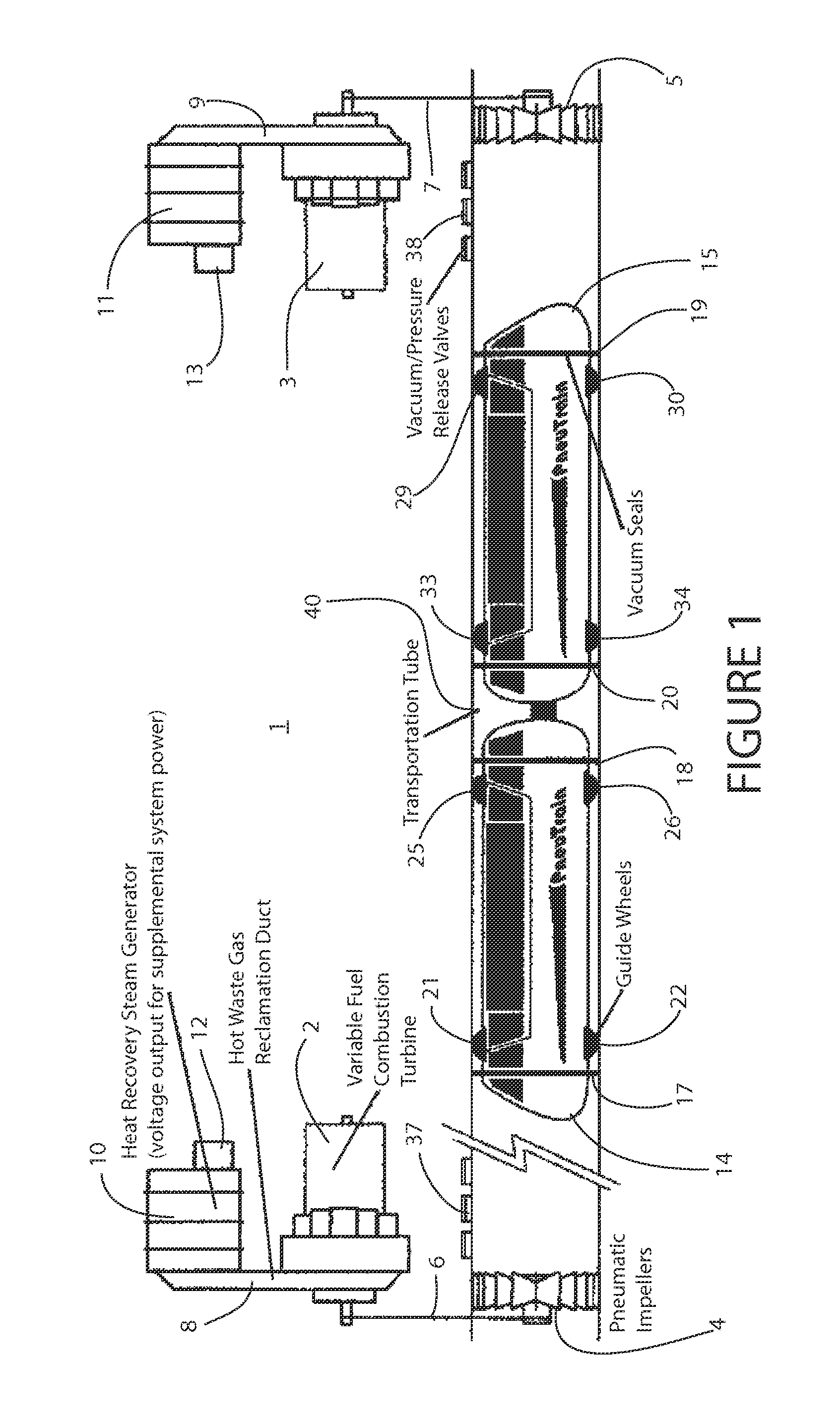

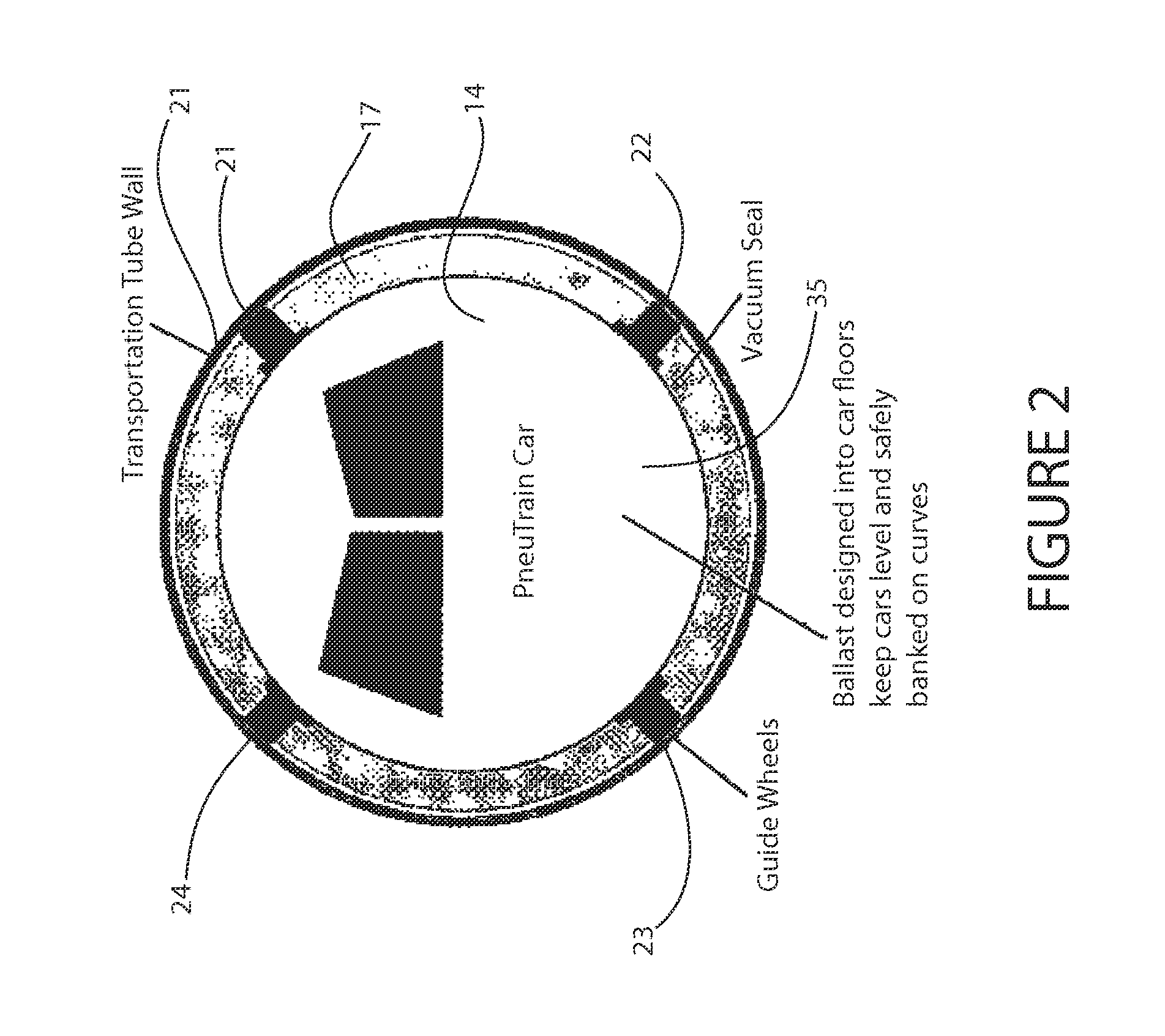

Pneutrain pneumatic mass transportation system

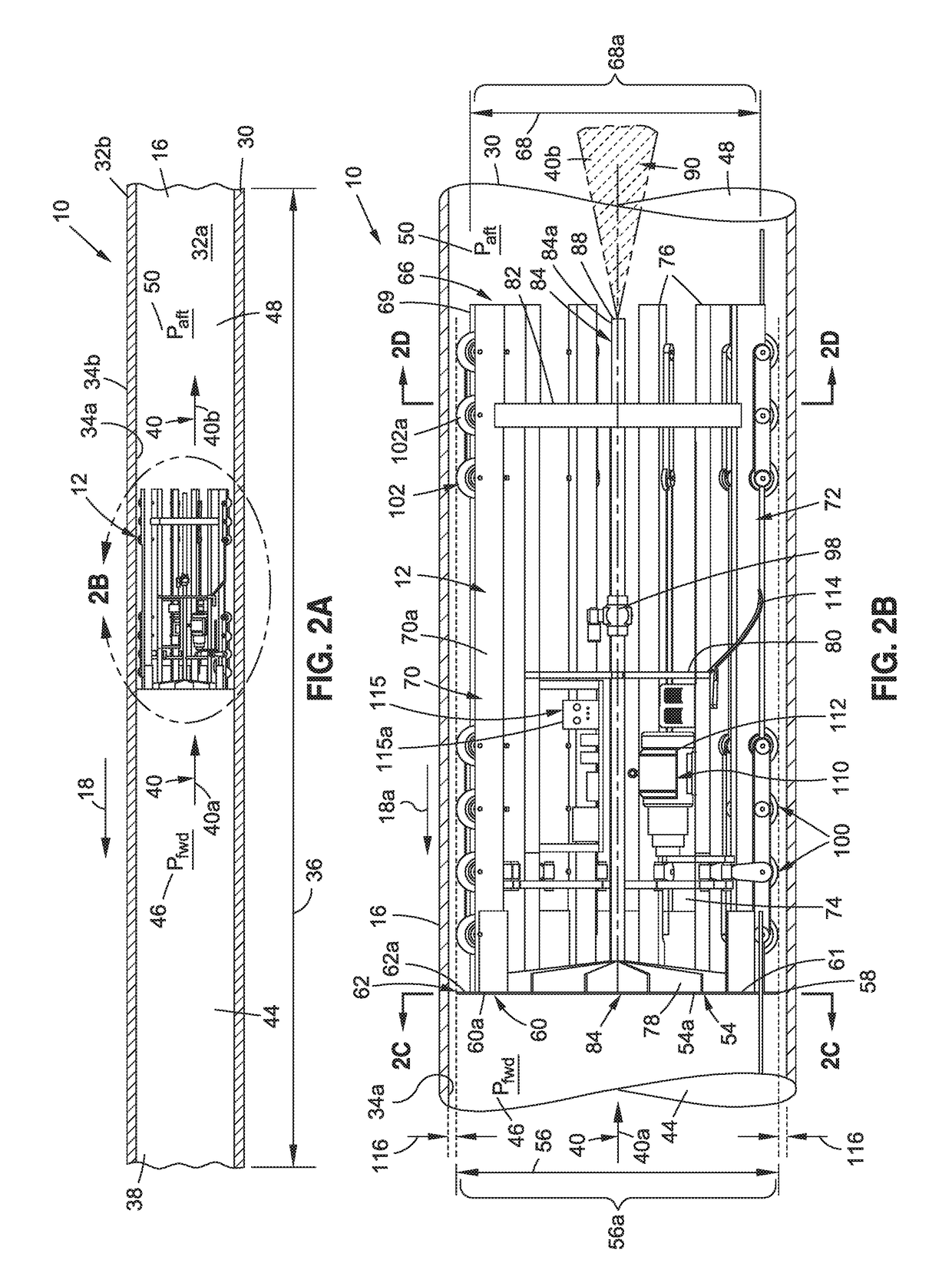

This invention is a pneumatic mass transportation system on the cutting edge of technology employing a combined cycle turbine power system with digital controls to effect acceleration, deceleration and train propulsion. The combustion turbines can be adapted to use alternative fuels including bio fuels as they are developed. The heat recover steam generator will recycle the hot exhaust gasses from the turbines to generate electricity to be used by the system. The multi-car train is propelled by differential air pressure forward and aft of the vehicle in the pneumatic tube. Air propulsion is achieved by large in-tube impellers driven by the turbines. A digital control system will operate the pitch of the impeller blades and the vacuum / pressure release valves in the tubes to produce full movement control of the trains.

Owner:FLYNN PATRICK JOSEPH

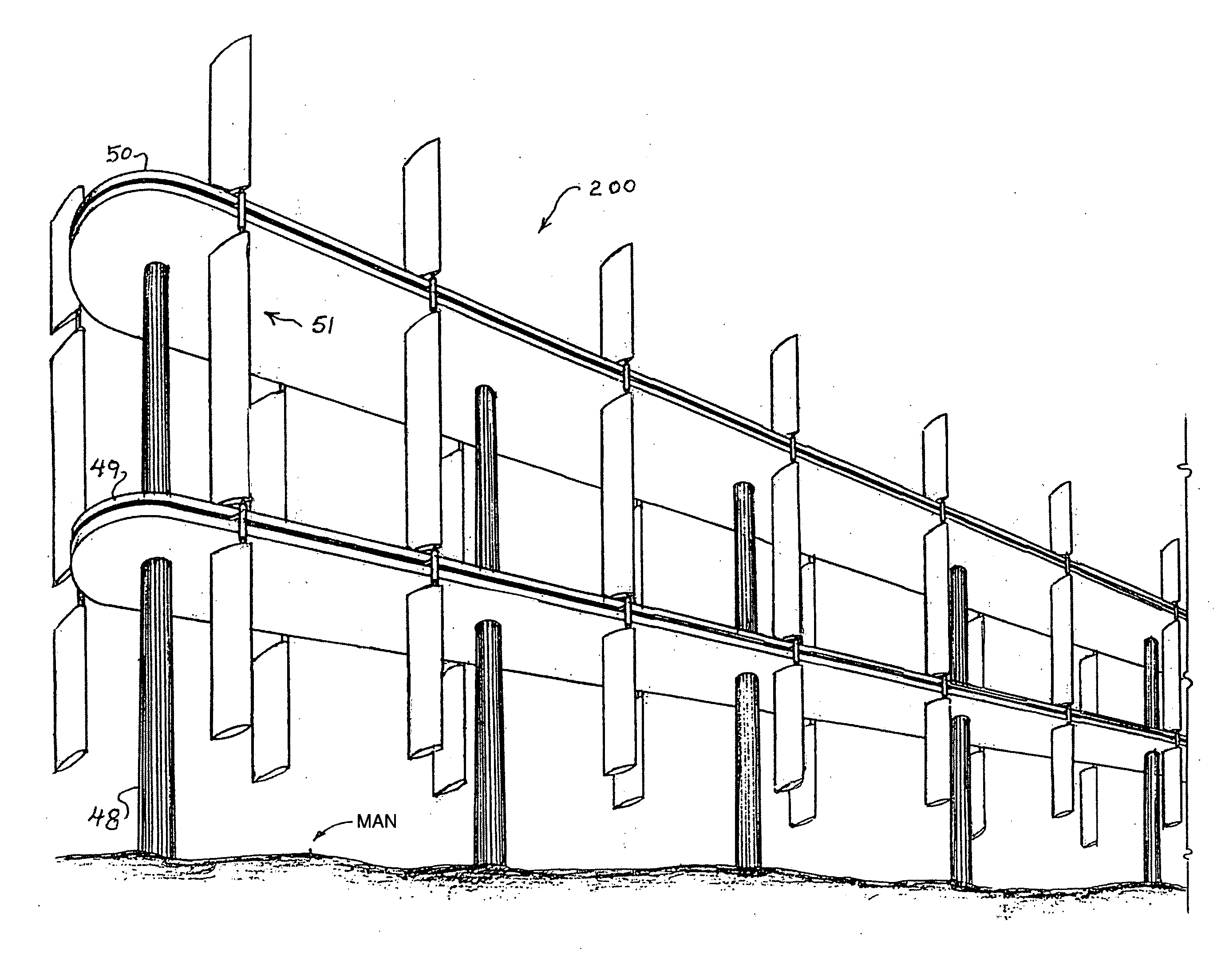

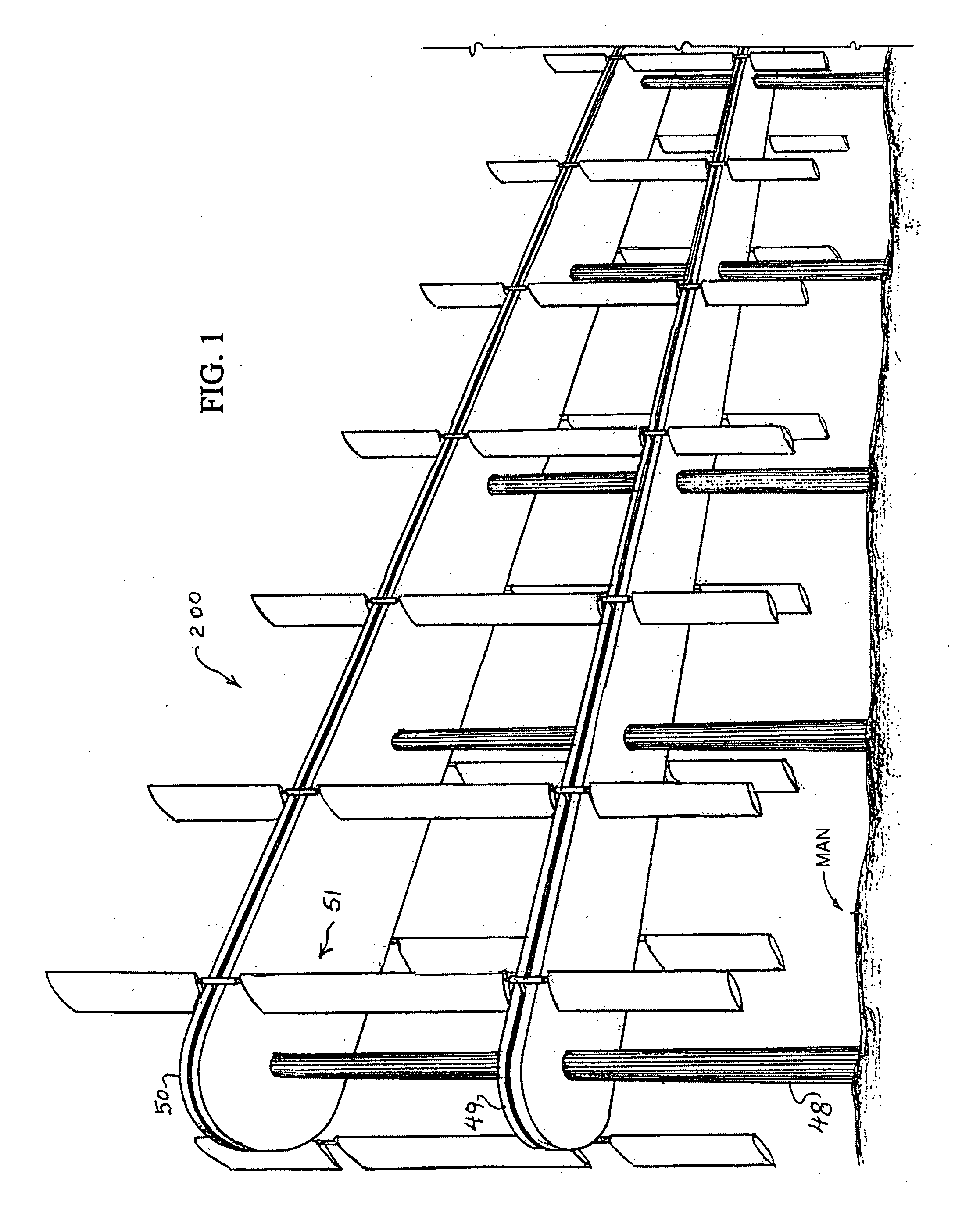

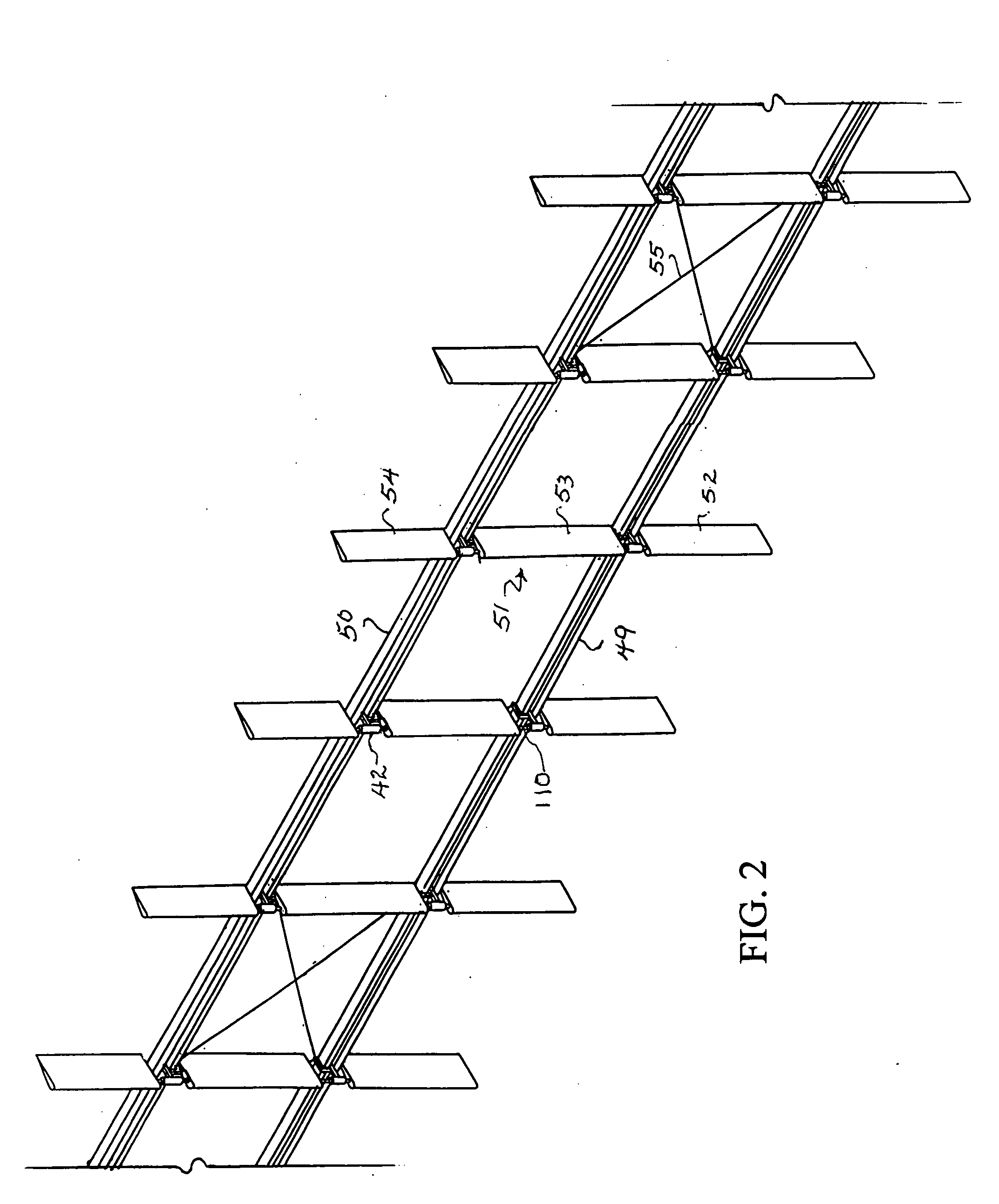

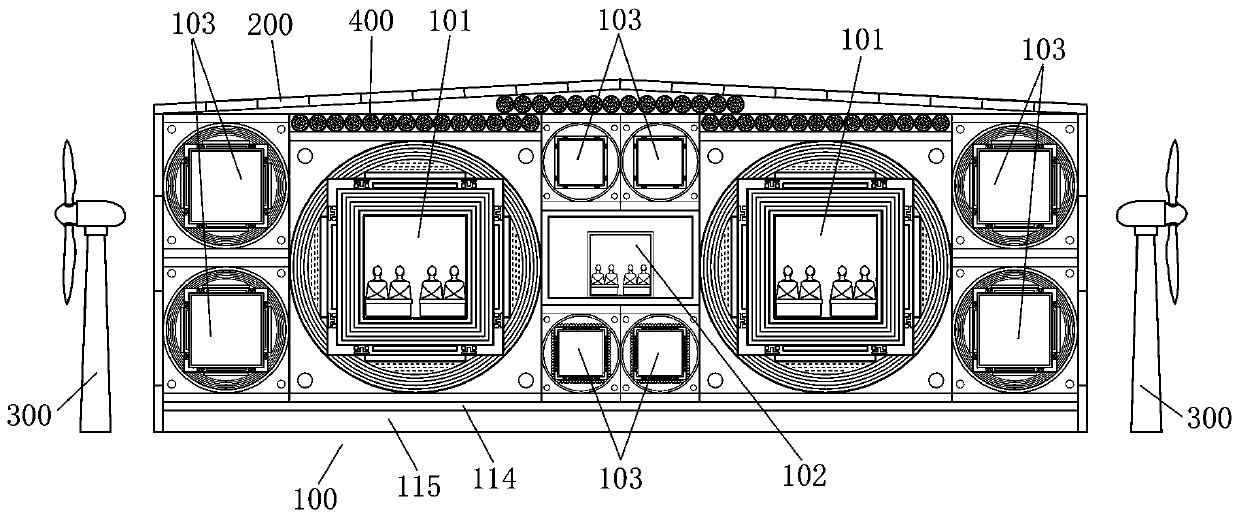

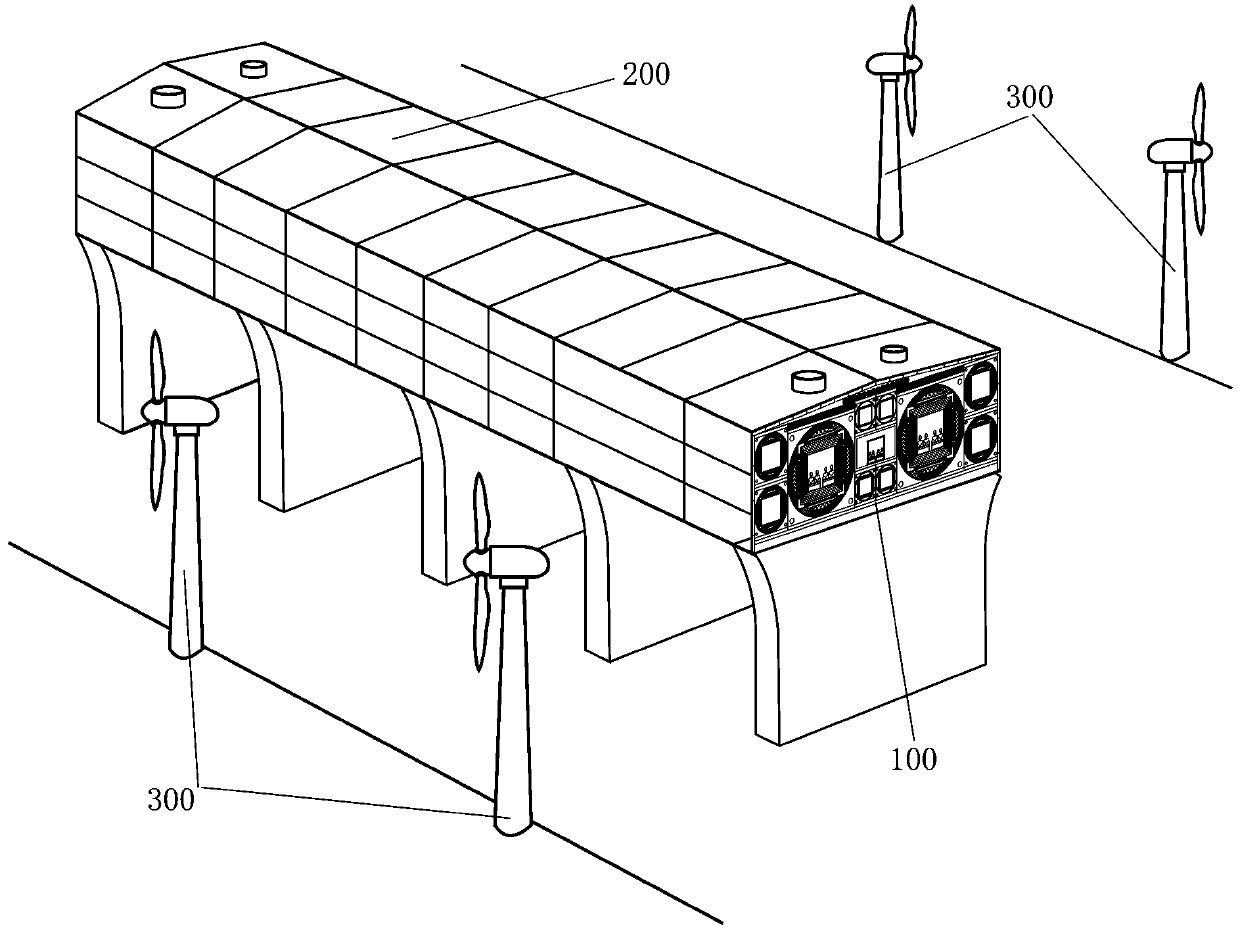

Wind and water power generation device using a tiered monorail system

A power generation assembly for use in generating electrical power from air or water currents includes a tiered rail system forming elongated loops, a vane assembly having a frame and at least one vain, and car assemblies sidably mounted to each rail, including linkage portions coupled to the frame of the vane assembly and a power-take-off arrangement includes an element that is operatively coupled to the car assembly and a drive wheel coupled to a generator and configured to take power off the moving car assembly by the drive wheels being rotated by the passing power-take-off element or a power-take-off system using a cable and clamps.

Owner:LANDERS ENERGY INC

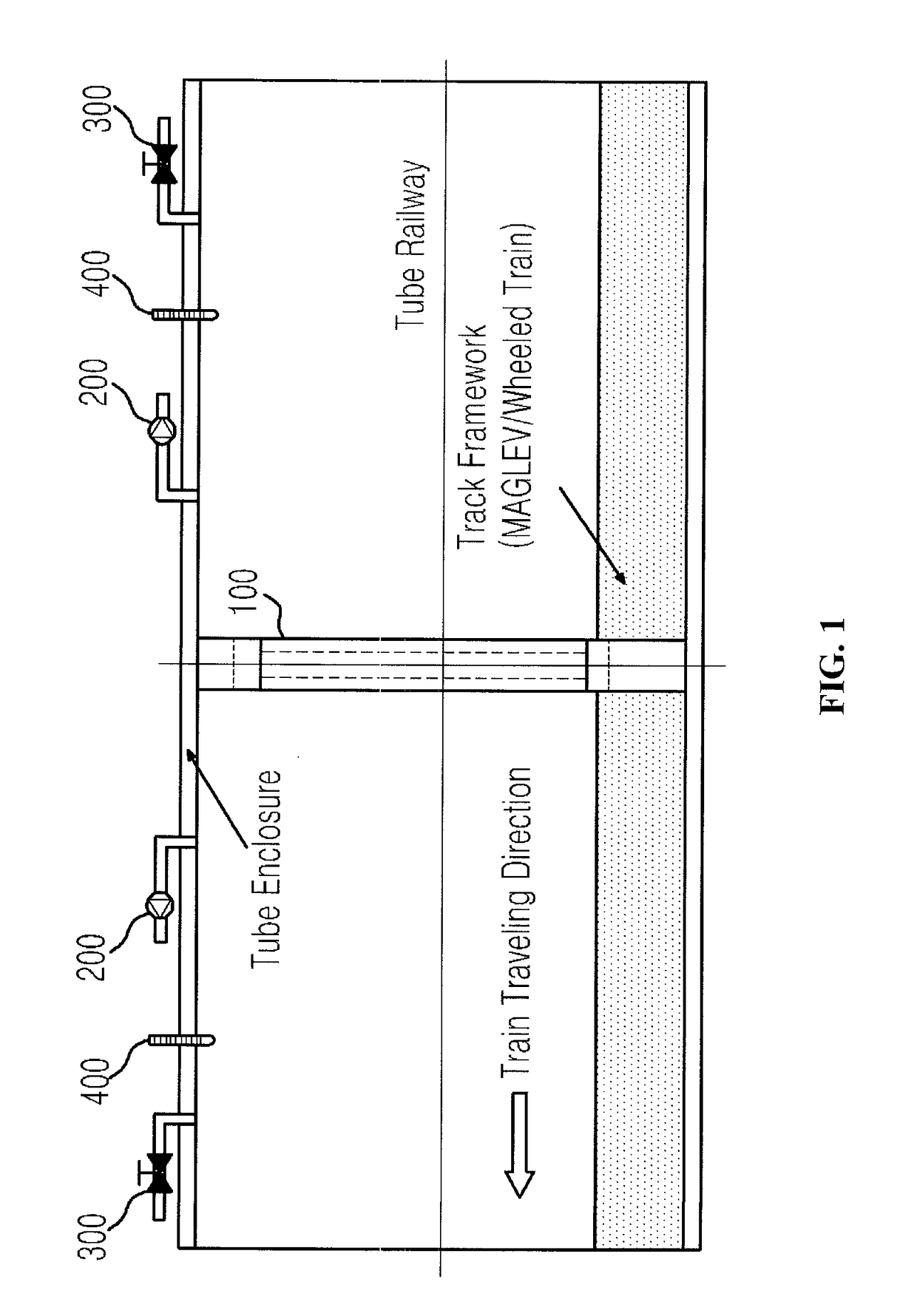

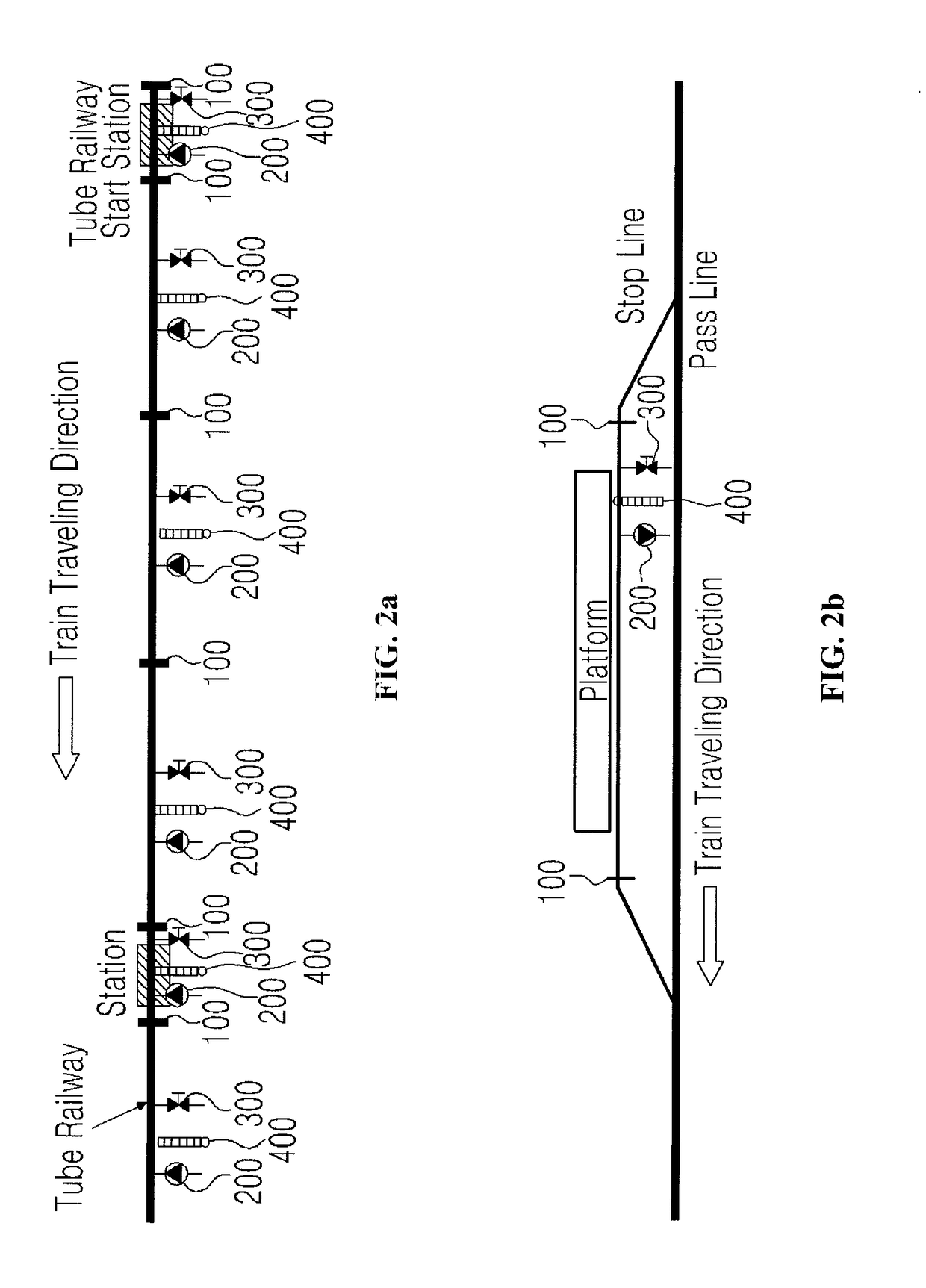

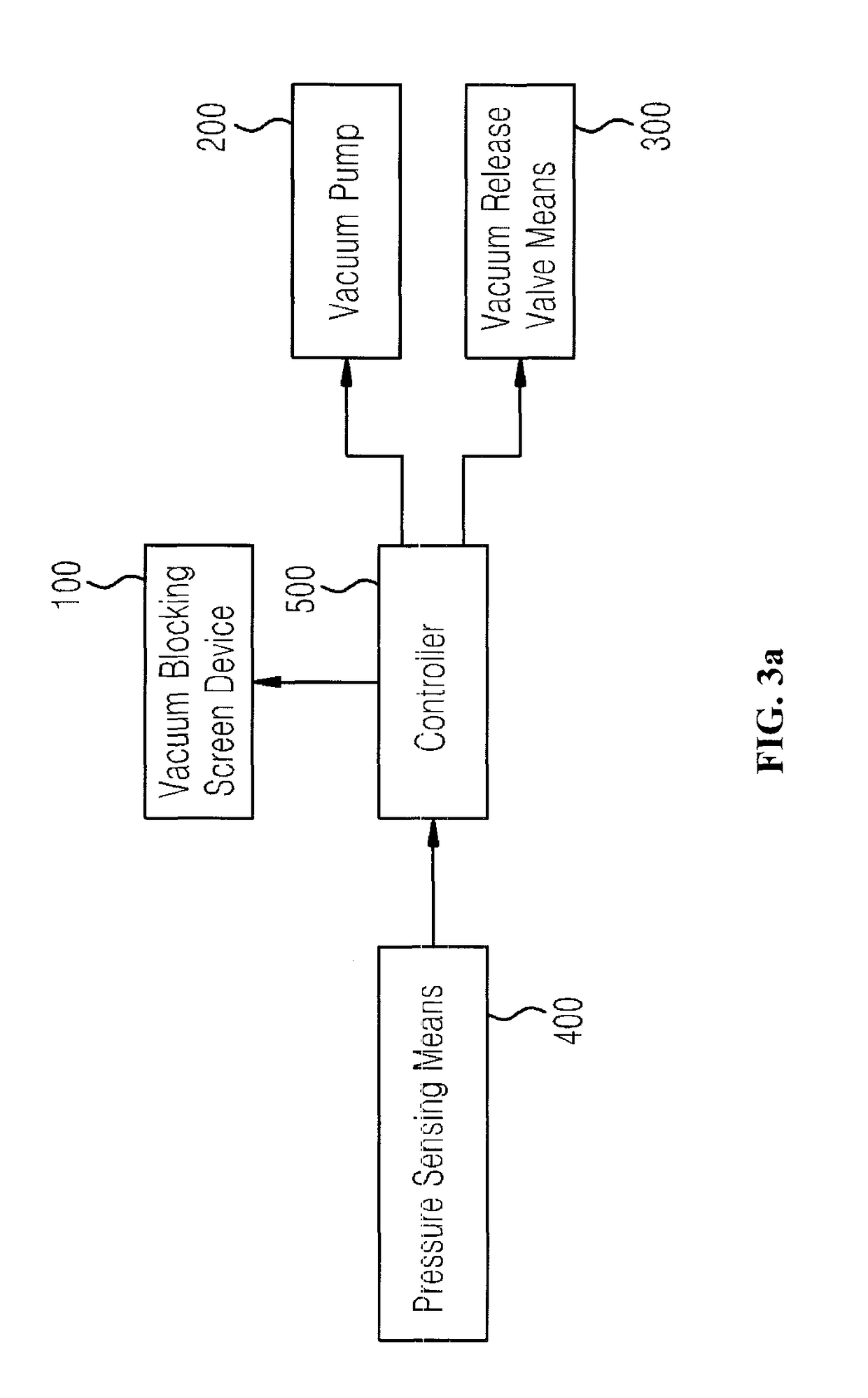

Vacuum division management system and vacuum blocking screen device for tube railway system

ActiveUS8468949B2Improve maintenance efficiencyFor quick maintenanceRailway tunnelsRailway componentsAerodynamic dragManagement system

Provided is a tube railway system that reduces noise and air resistance using a sealed evacuated tube as a passage for a tube railway, thereby allowing a train to run at a higher speed. A vacuum division management system and a vacuum blocking screen device for a tube railway system required to maintain vacuum are provided, in which the vacuum blocking screen device is operated to rapidly block a passage for a tube railway in response to an operation signal, is installed at every certain section or at a designated section of the tube railway, and is operated in a specific section when a vacuum maintenance problem occurs, or when the vacuum needs to be released, or when the train needs to stop immediately, thereby allowing the specific section to be isolated from other sections to have a degree of vacuum different from those of the other sections.

Owner:KOREA RAILROAD RES INST

Evacuated tube transport system with improved cooling for superconductive elements

InactiveUS20140261055A1Reduce constructionLow costRailway tunnelsRailway componentsHigh-temperature superconductivityTransport system

A High Temperature Superconductor Maglev (HTSM) for Evacuated Tube Transport (ETT) with a magnetic levitation structure for ETT capsule vehicles traveling in an evacuated tube. At least one ETT capsule travels within an evacuated tube, an upper and a lower cryostat respectively mount at the top and bottom of said ETT capsule along the length thereof, at least a plurality of superconductor levitation force elements divided between said upper and lower cryostats. The levitation force being spread over the length of capsule, however substantially concentrated in a compact cross-sectional area. At least a pair of permanent magnetic elements mounted at the top and bottom of the evacuated tube to cooperate with the superconductor elements to levitate the capsule.

Owner:OSTER DARYL

Conveying apparatus

InactiveUS6814218B2Effectively actPractical to useRailway componentsCharge manipulationEngineeringMechanical engineering

A conveying apparatus suitable for driving a number of carriers in such a manner that the front end of each carrier thrusts the rear end of the preceding carrier is provided. The conveying apparatus comprises a guide rail and carriers. The rail includes a U-turn path section. Each carrier includes a load bar assembly including at least three load bars connected end-to-end by vertical pivot shafts in such a manner that the bars can pivot horizontally relative to each other. Each carrier also includes a load support supported by the associated middle load bar. Each carrier further includes a front trolley supporting at least the front end load bar and a rear trolley supporting at least the rear end load bar. The trolleys are supported movably on and guided by the guide rail. The trolleys are fixed to and in parallel with the end load bars. The free ends of the end load bars protrude from the front end of the front trolley and the rear end of the rear trolley so that the free end of the front end load bar of each carrier and the free end of the rear end load bar of the preceding carrier can contact together in the U-turn path section.

Owner:DAIFUKU CO LTD

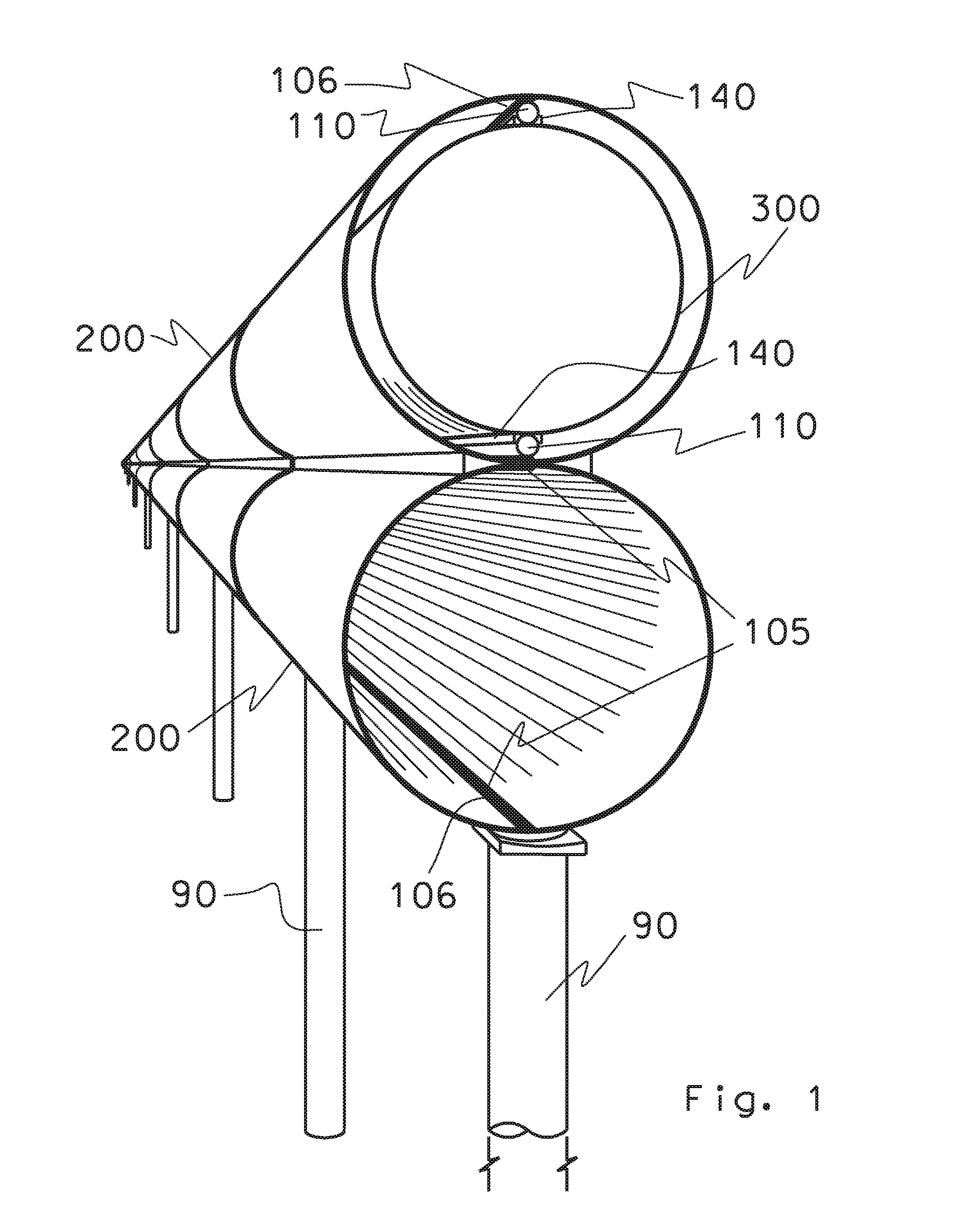

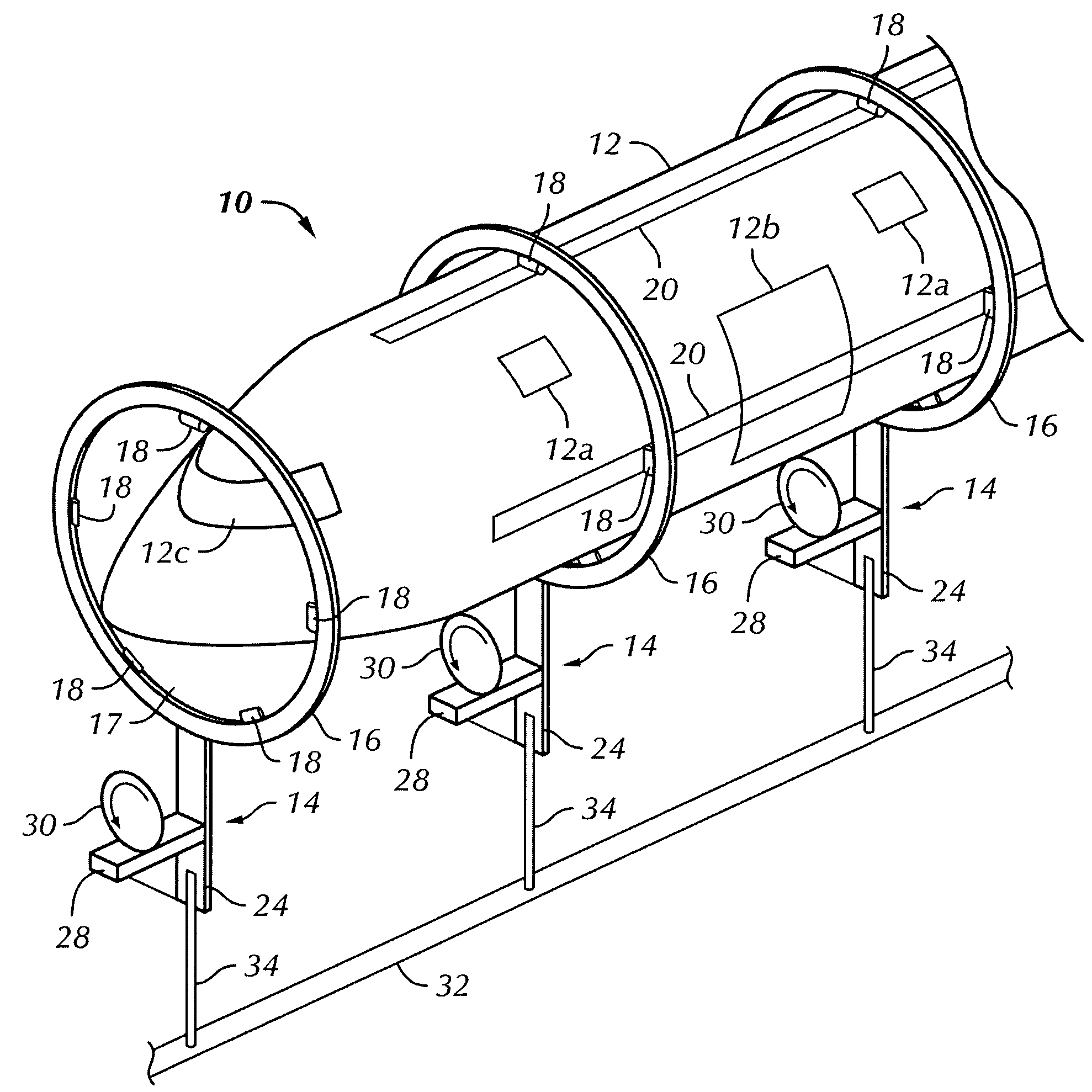

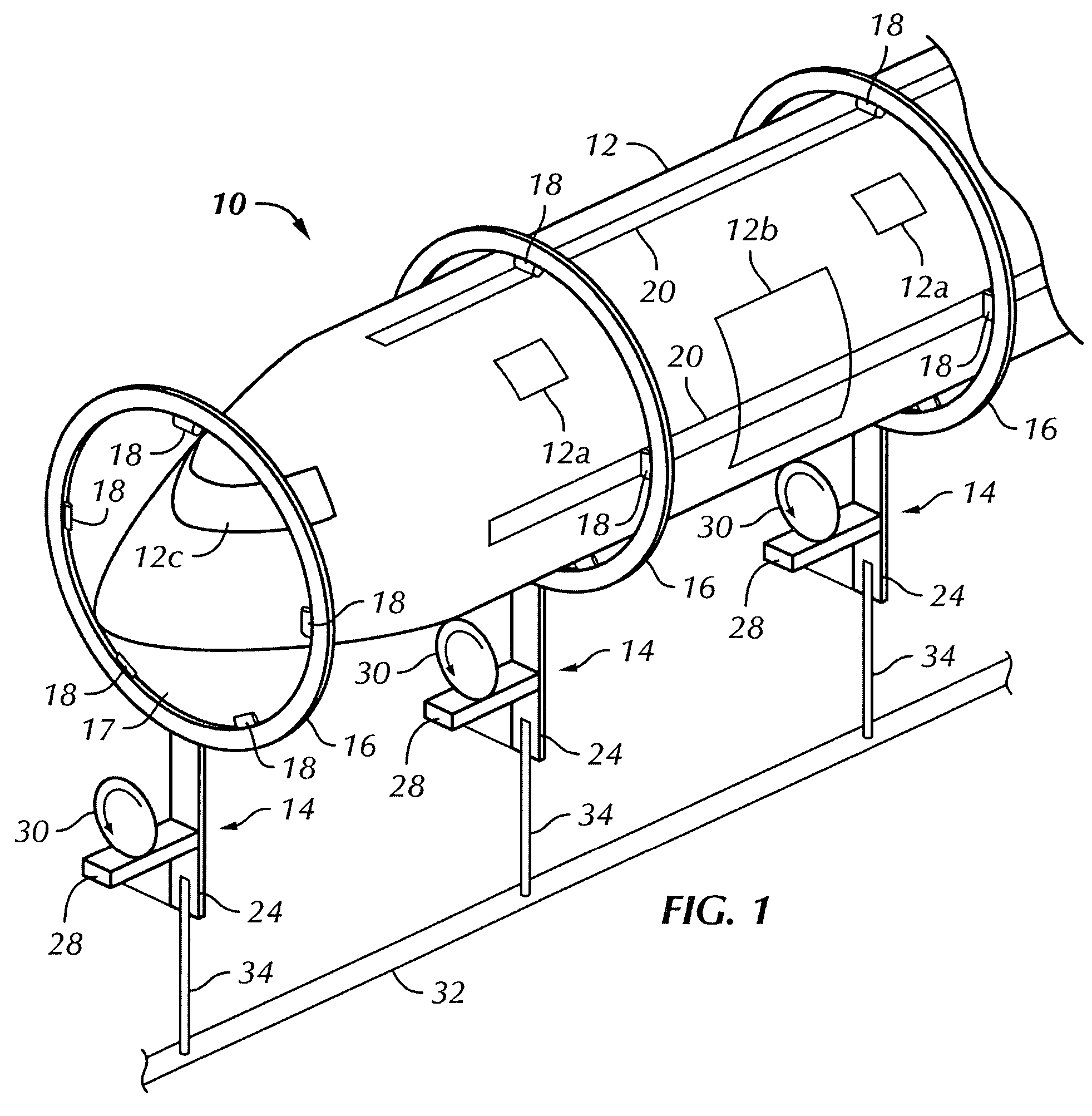

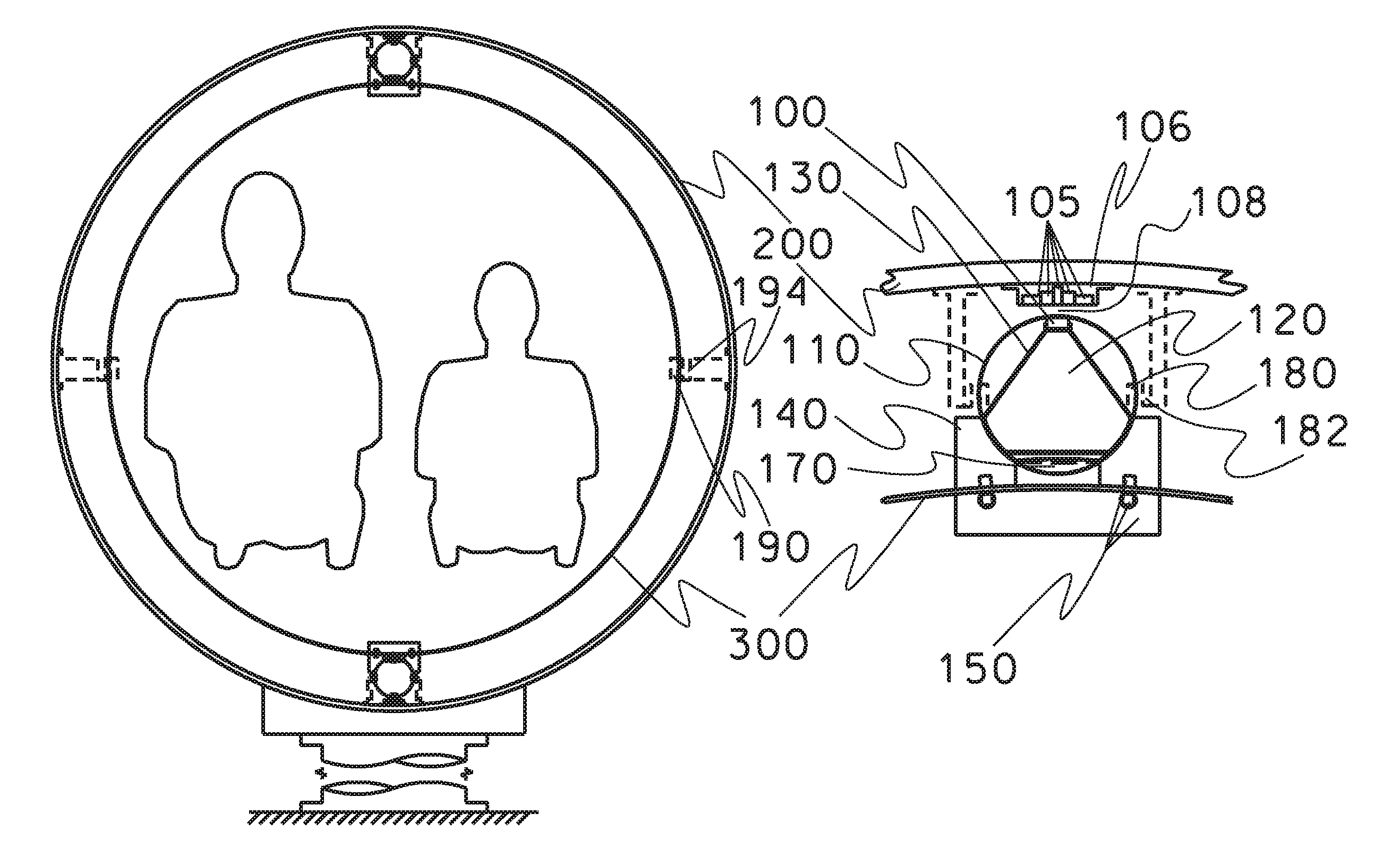

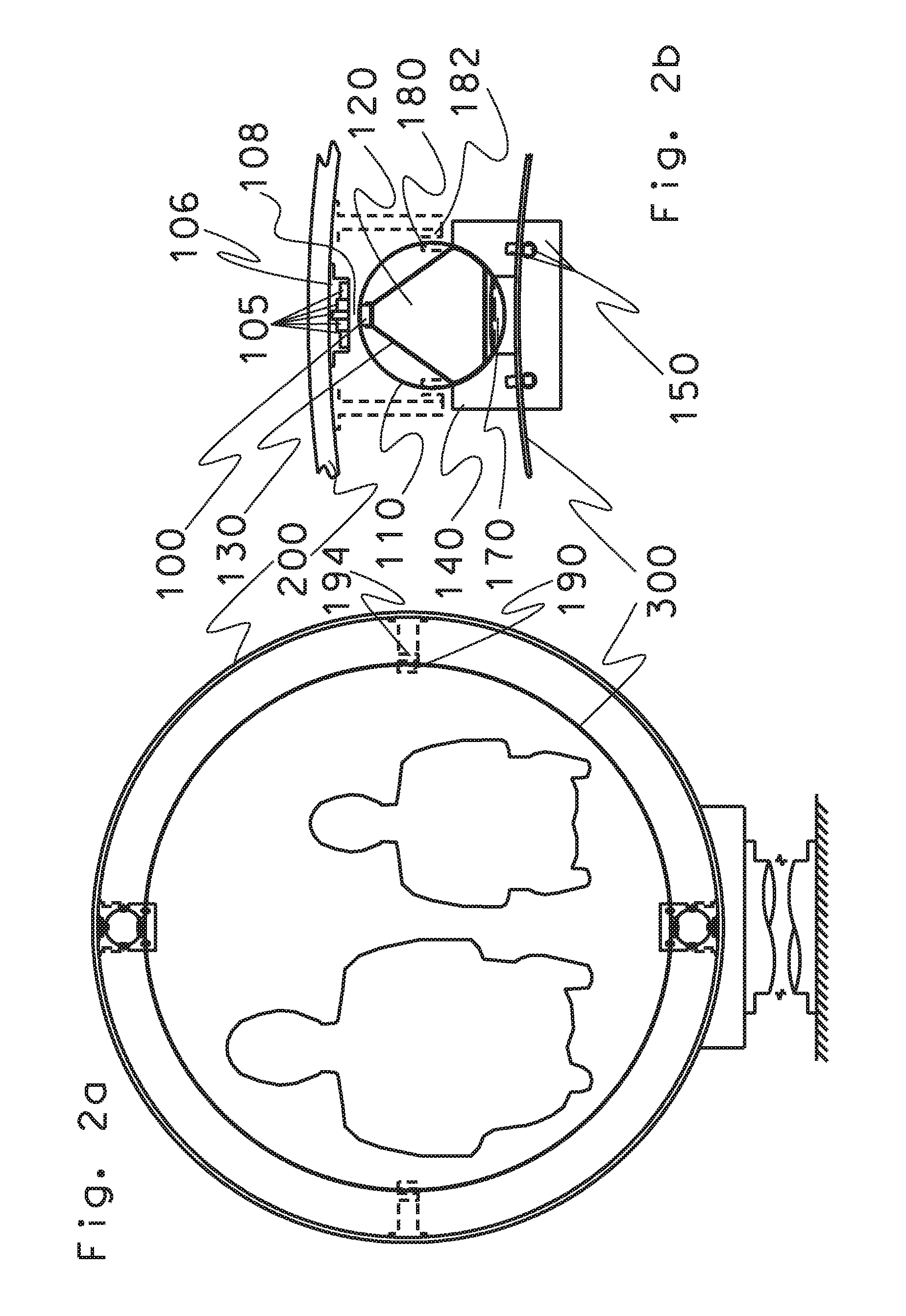

Transportation system

ActiveUS20050076802A1Stable supportSufficient clearanceTrain hauling devicesRailway tracksFreewheelLow speed

A mass transit system includes a plurality of pedestal-mounted rings which provide a support through which a vehicle travels. The pedestals are spaced apart on the ground, but no rail or connecting structure on or above ground is required. An underground conduit carries electrical and communications cable that connects the pedestals together. The rings include a plurality of rollers to drive, guide and stabilize the vehicle at lower speeds. For higher speeds flywheels are mounted on the pedestals. The flywheels are preferably driven by an electrical motor, which engages a friction or clutch plate on the vehicle separate from the rings. The friction plate or linear clutch is mounted separate from the rings on the vehicle and is lowered to engage and disengage the flywheel. The flywheel is also mounted on a shock absorber to smooth the travel of the vehicle.

Owner:TUBULAR RAIL INC

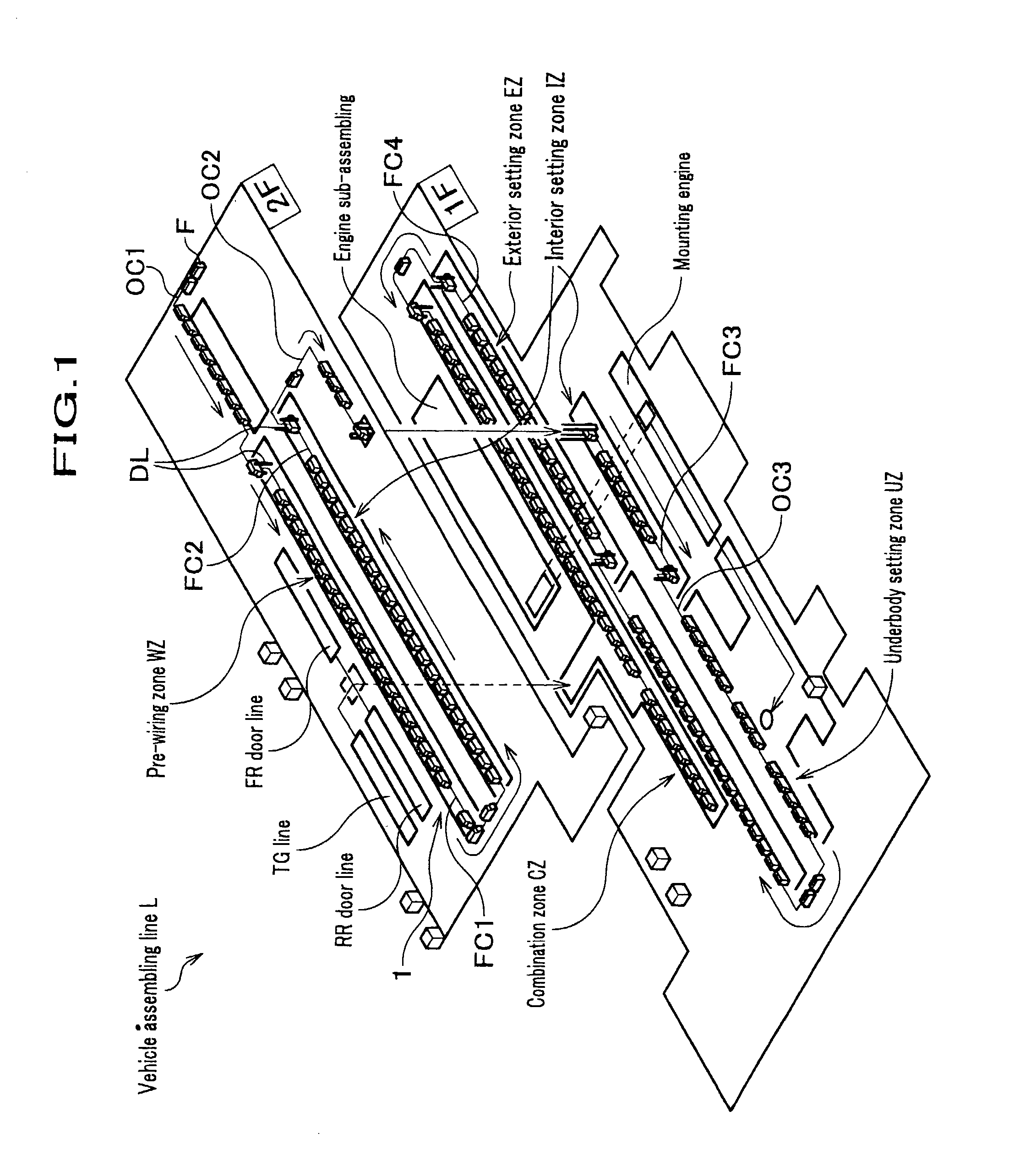

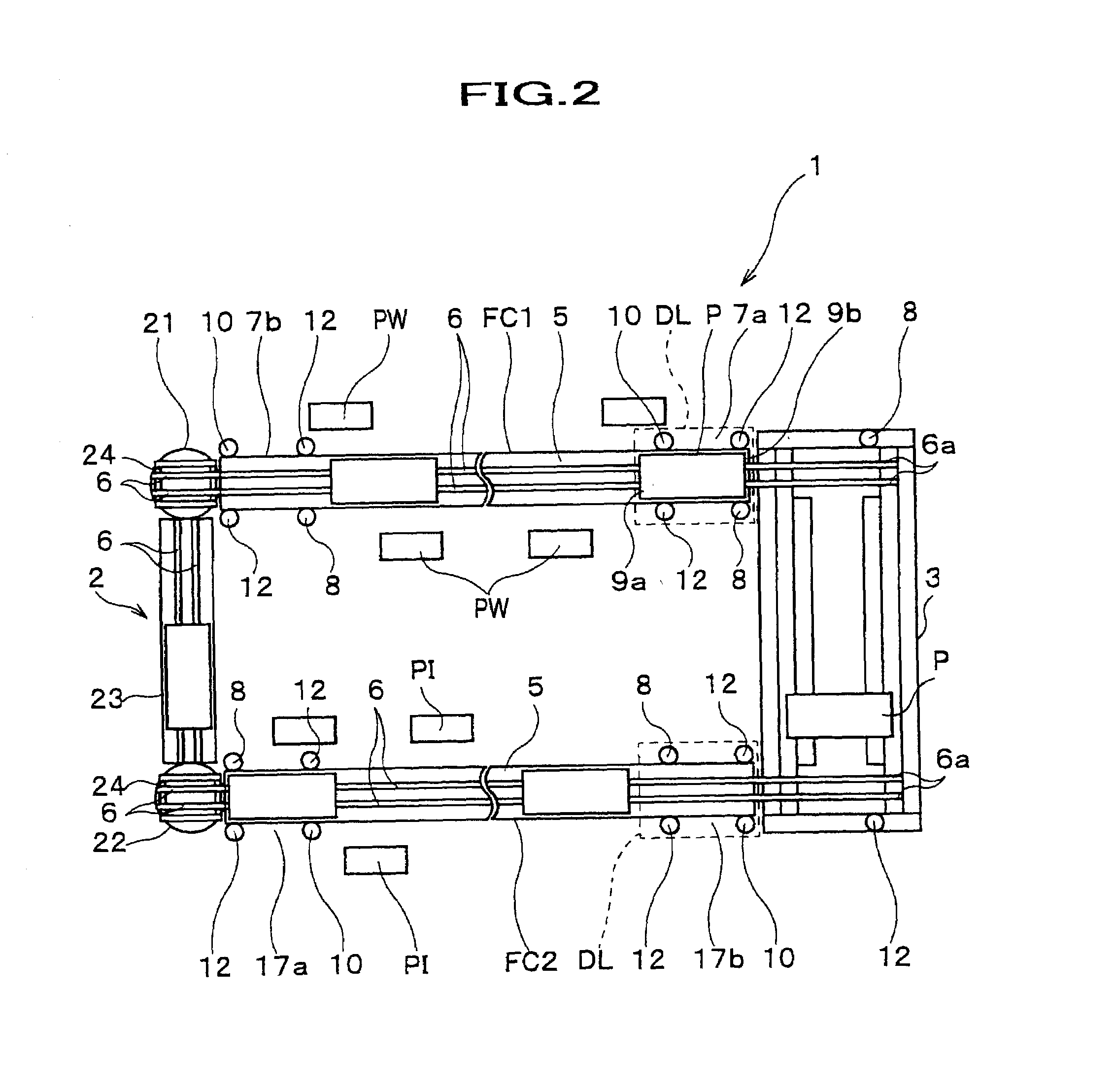

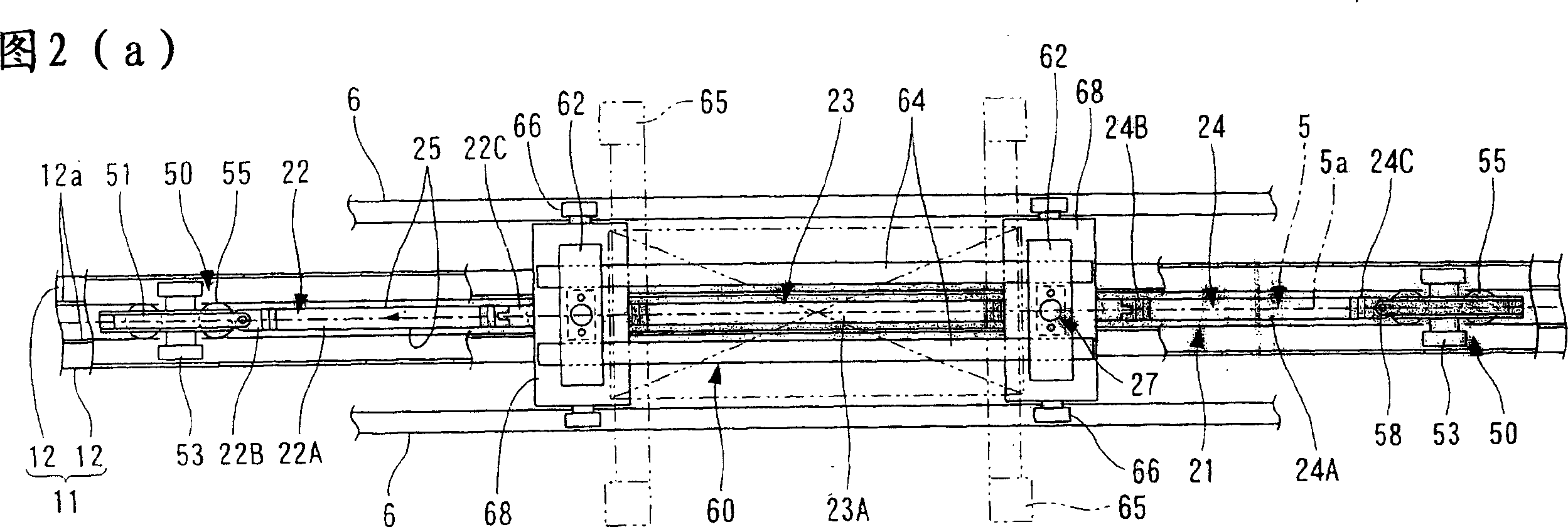

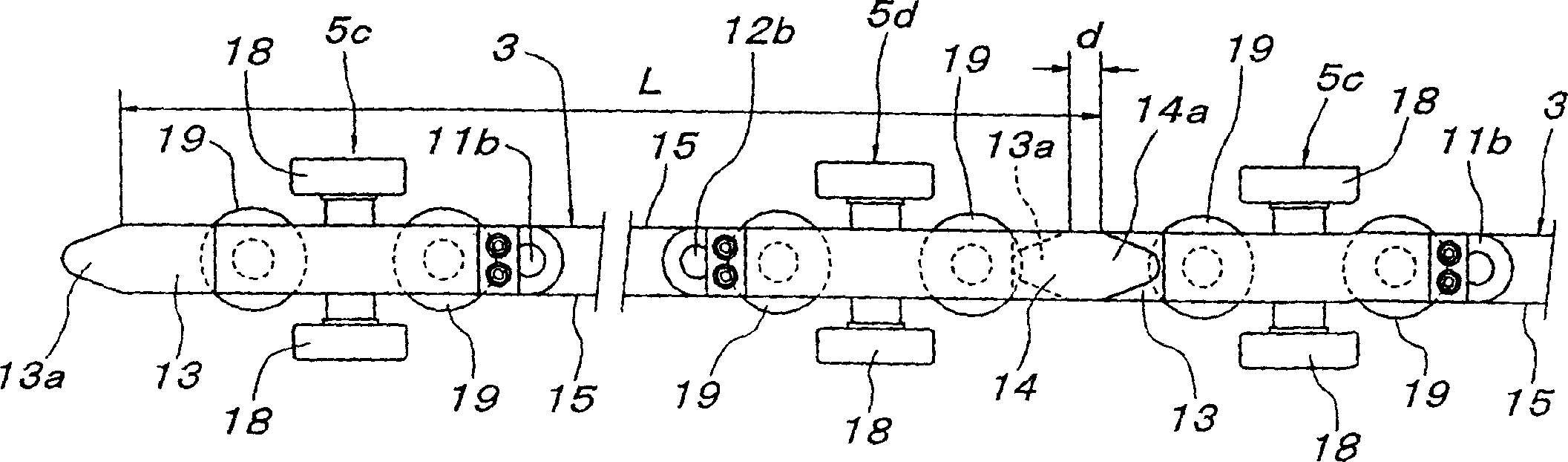

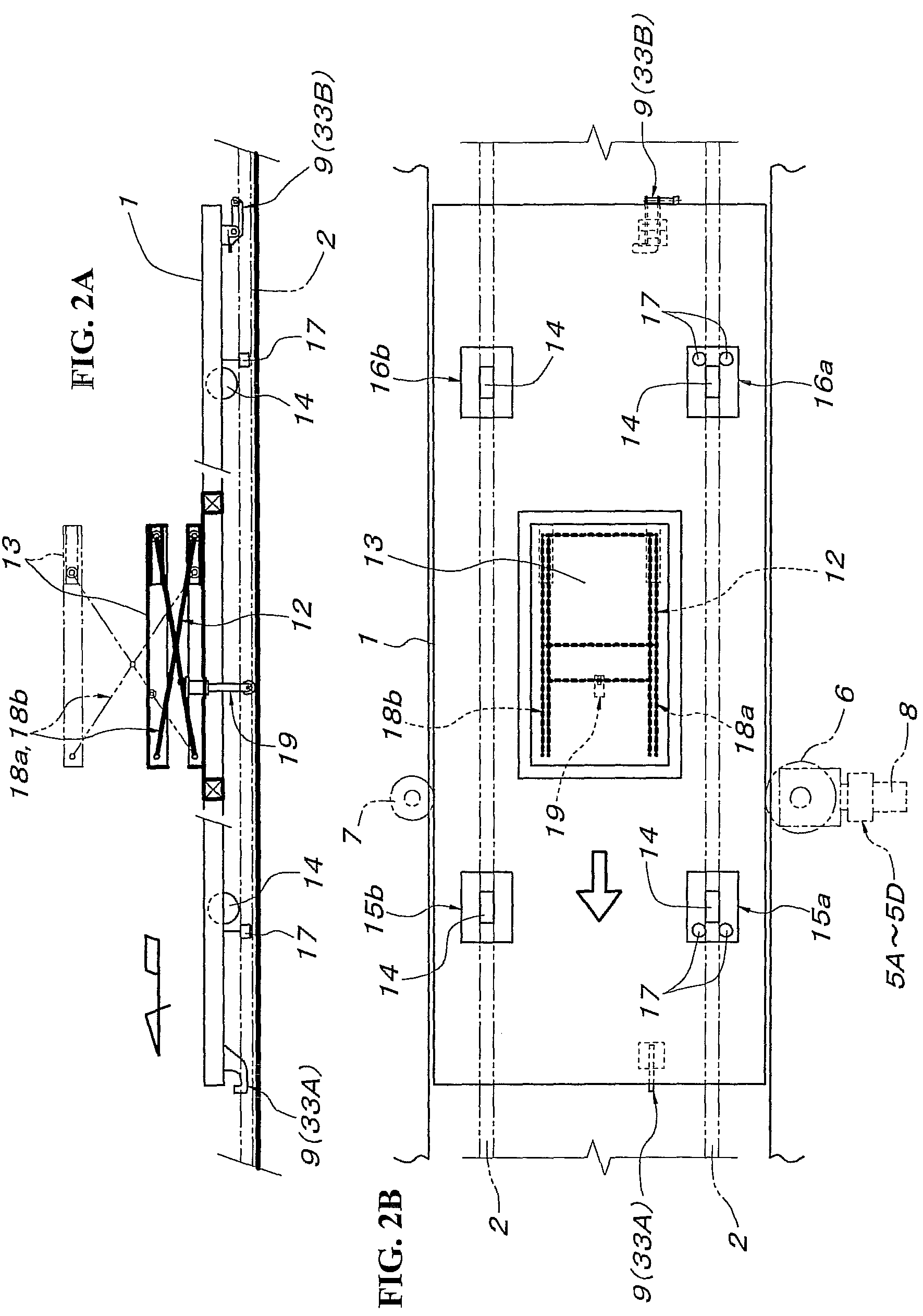

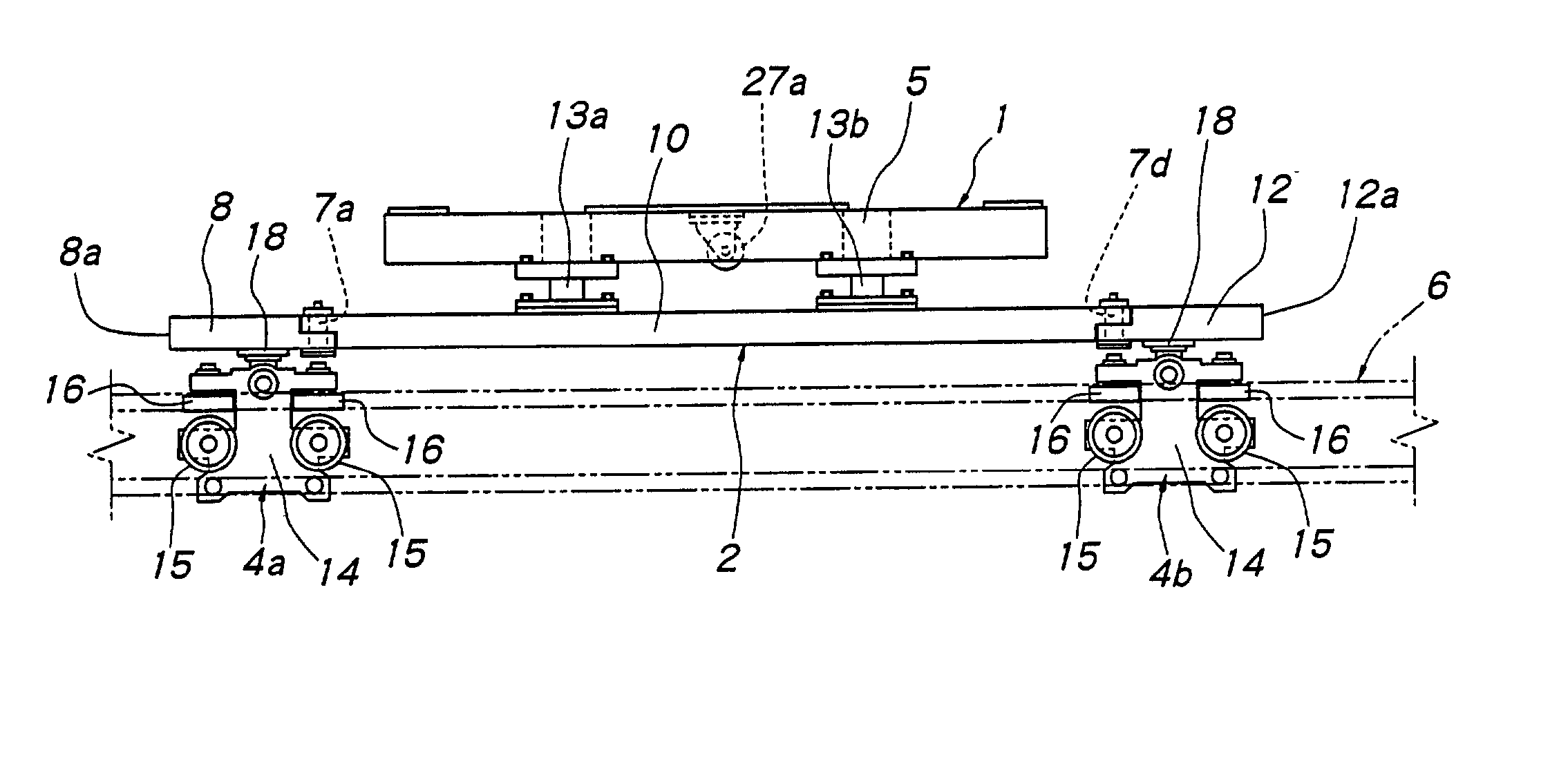

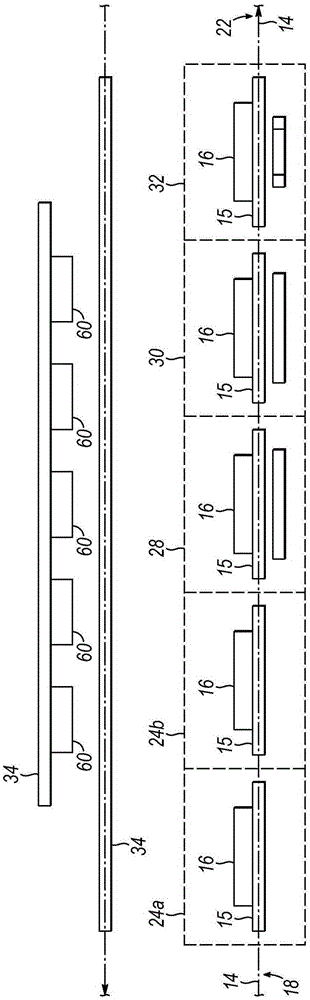

Palette conveyance mechanism and assembling line using it

InactiveUS7090068B2Fast circulationOptimization mechanismMonorailsCharge manipulationEngineeringFlange

It is the pallet conveying mechanism to move a pallet P arrived at an end point 17b of a friction conveyer FC2 to a starting point 7a of a friction conveyer FC1 in just as it is the direction without turning. The pallet conveying mechanism is comprised of rollers 34 having a flange portion 34a to contact with the pallet P by arranging along a main frame 31 provided so as to connect the friction conveyer FC 1 and FC 2 with each other and a drive mechanism 35 for driving rollers 34.

Owner:HONDA MOTOR CO LTD

Evacuated tube transport system with improved cooling for superconductive elements

InactiveUS9085304B2Reduce constructionLow costRailway tunnelsSliding/levitation railway systemsHigh-temperature superconductivityTransport system

A High Temperature Superconductor Maglev (HTSM) for Evacuated Tube Transport (ETT) with a magnetic levitation structure for ETT capsule vehicles traveling in an evacuated tube. At least one ETT capsule travels within an evacuated tube, an upper and a lower cryostat respectively mount at the top and bottom of said ETT capsule along the length thereof, at least a plurality of superconductor levitation force elements divided between said upper and lower cryostats. The levitation force being spread over the length of capsule, however substantially concentrated in a compact cross-sectional area. At least a pair of permanent magnetic elements mounted at the top and bottom of the evacuated tube to cooperate with the superconductor elements to levitate the capsule.

Owner:OSTER DARYL

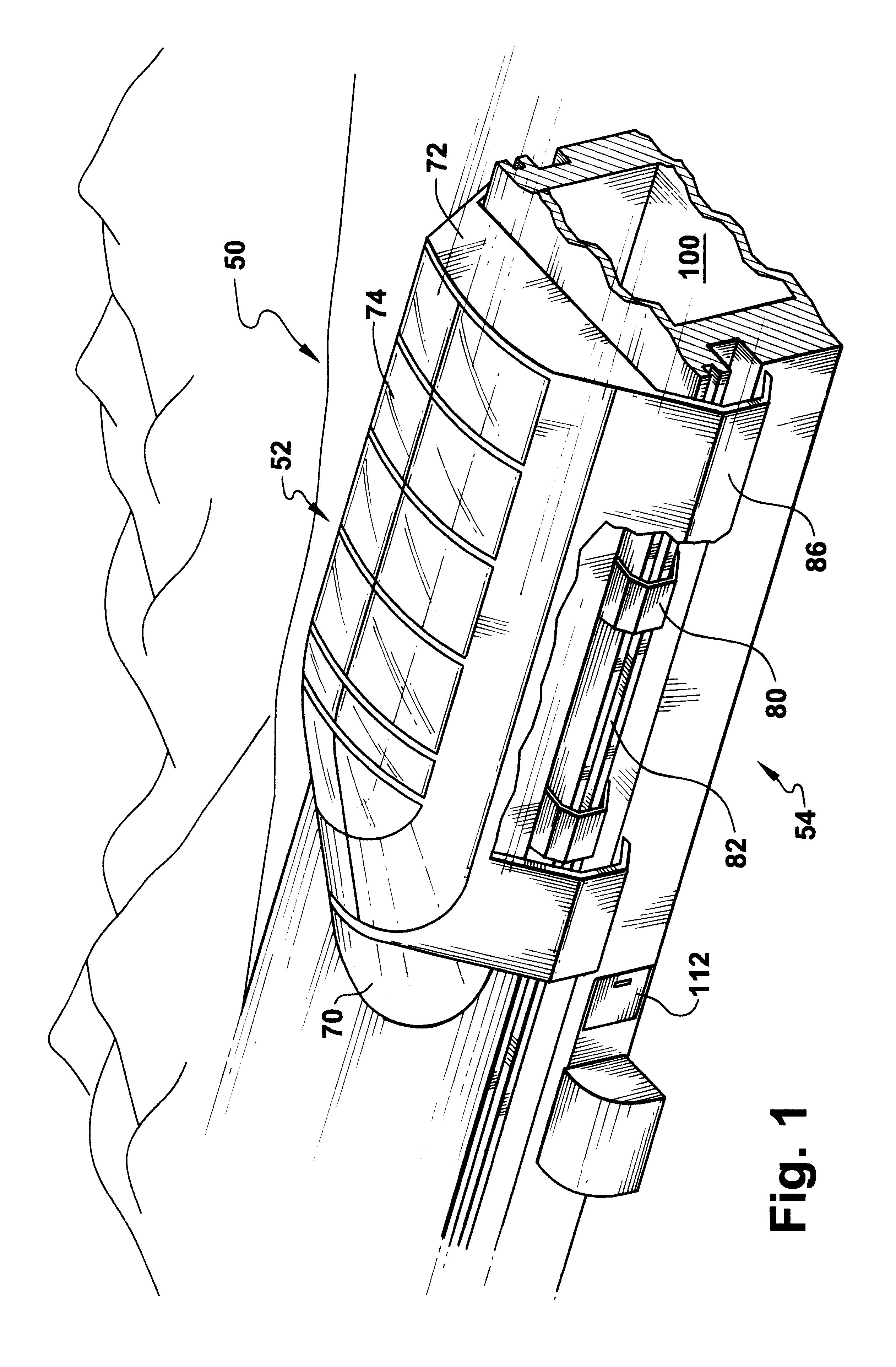

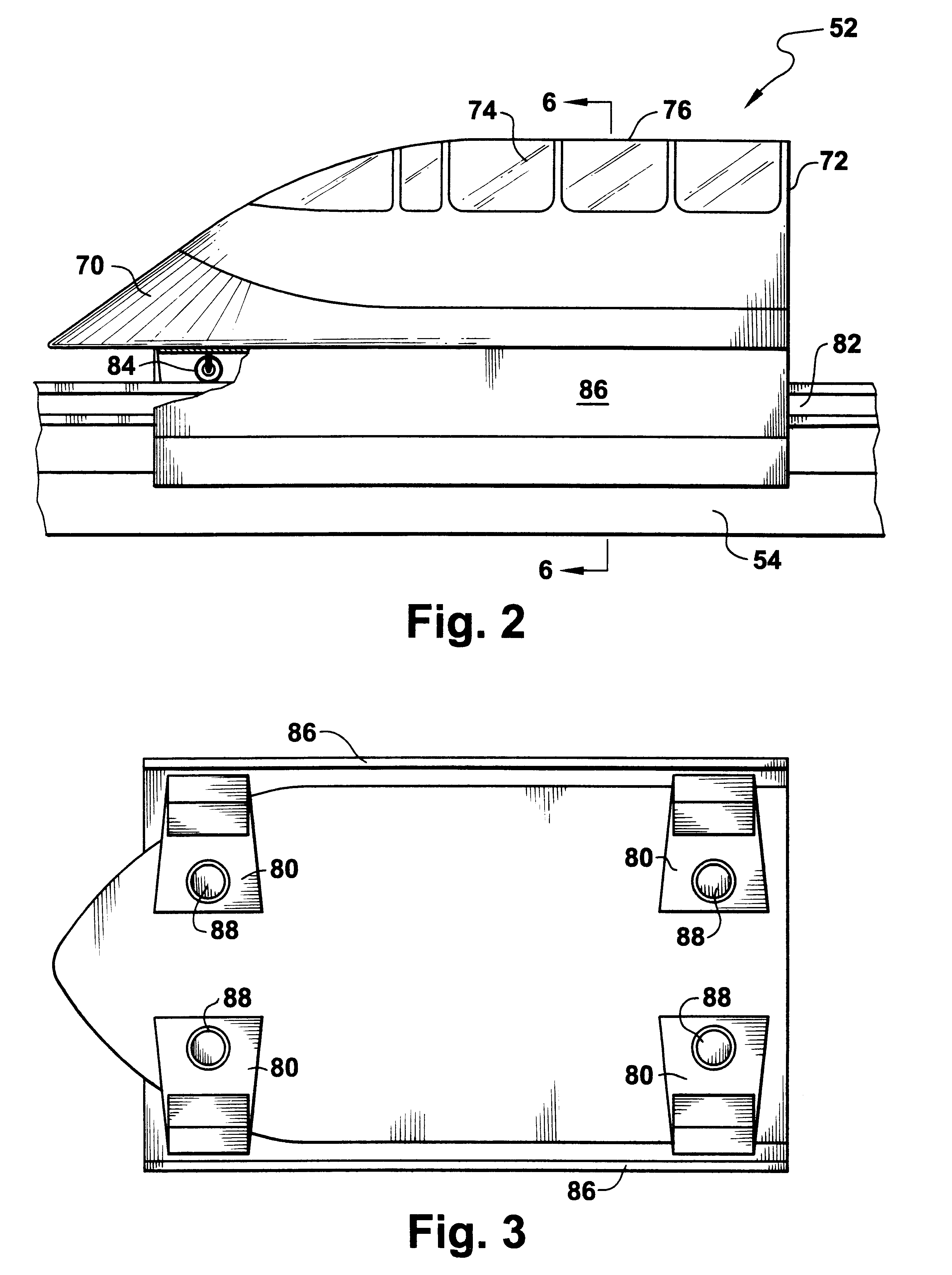

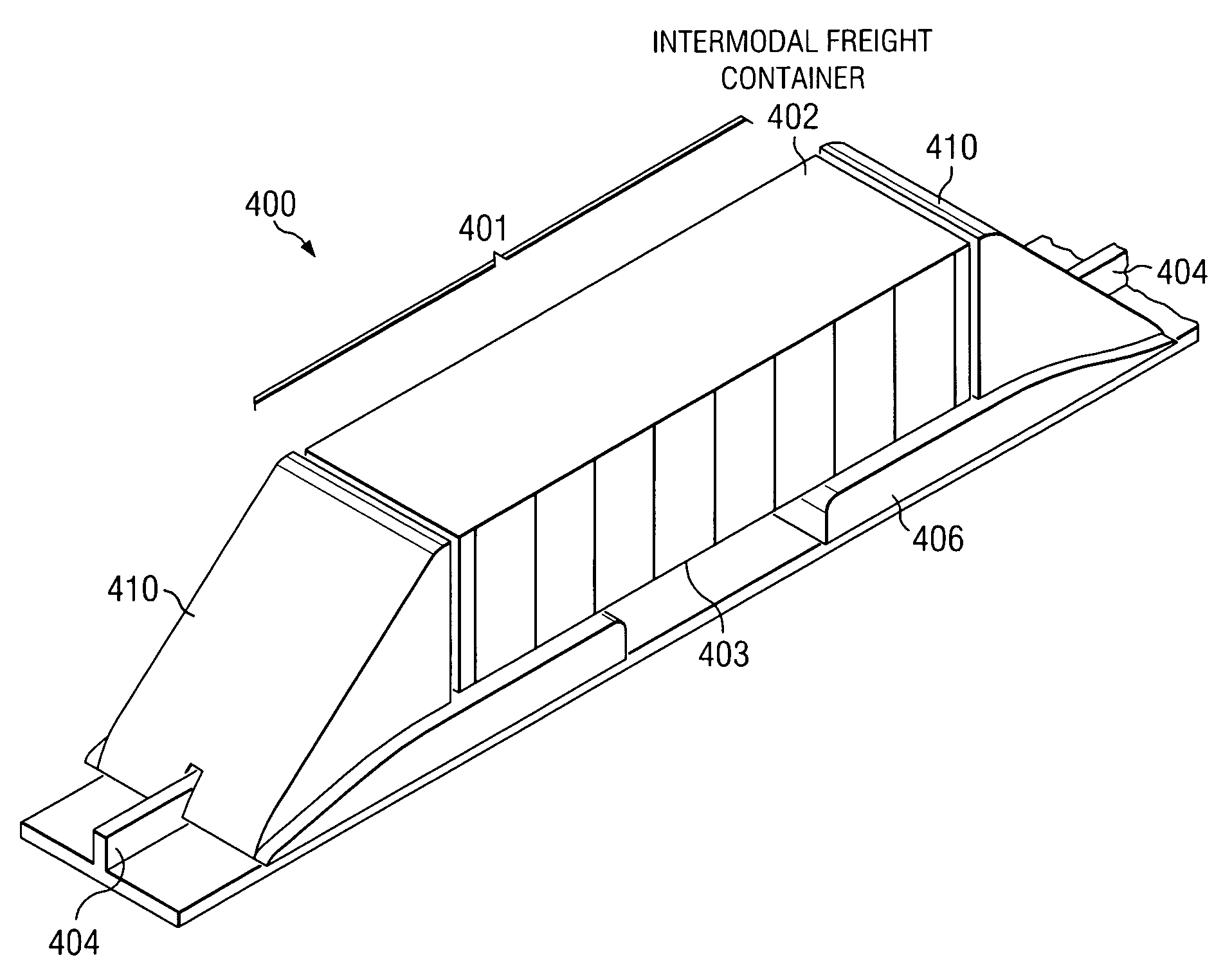

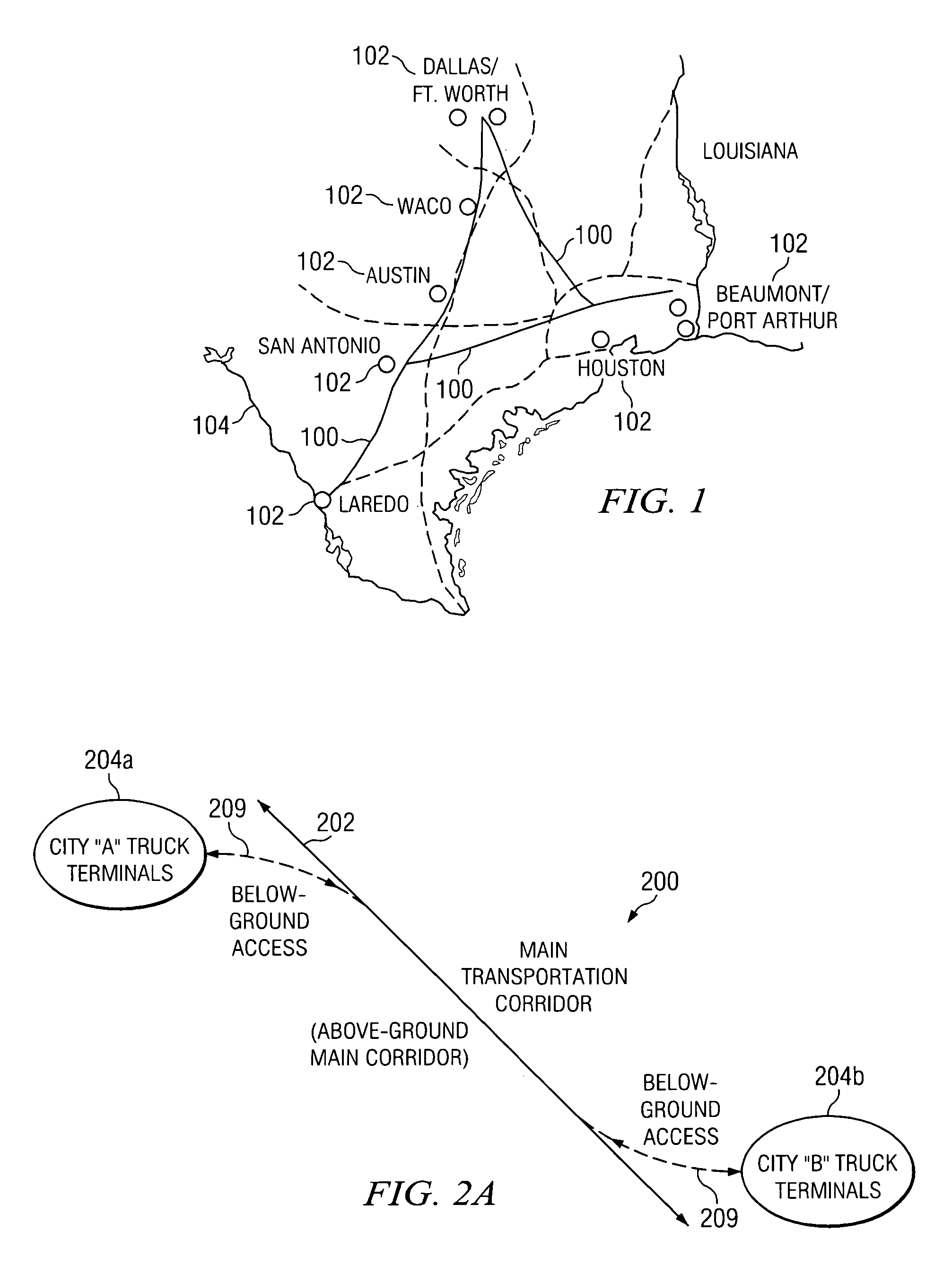

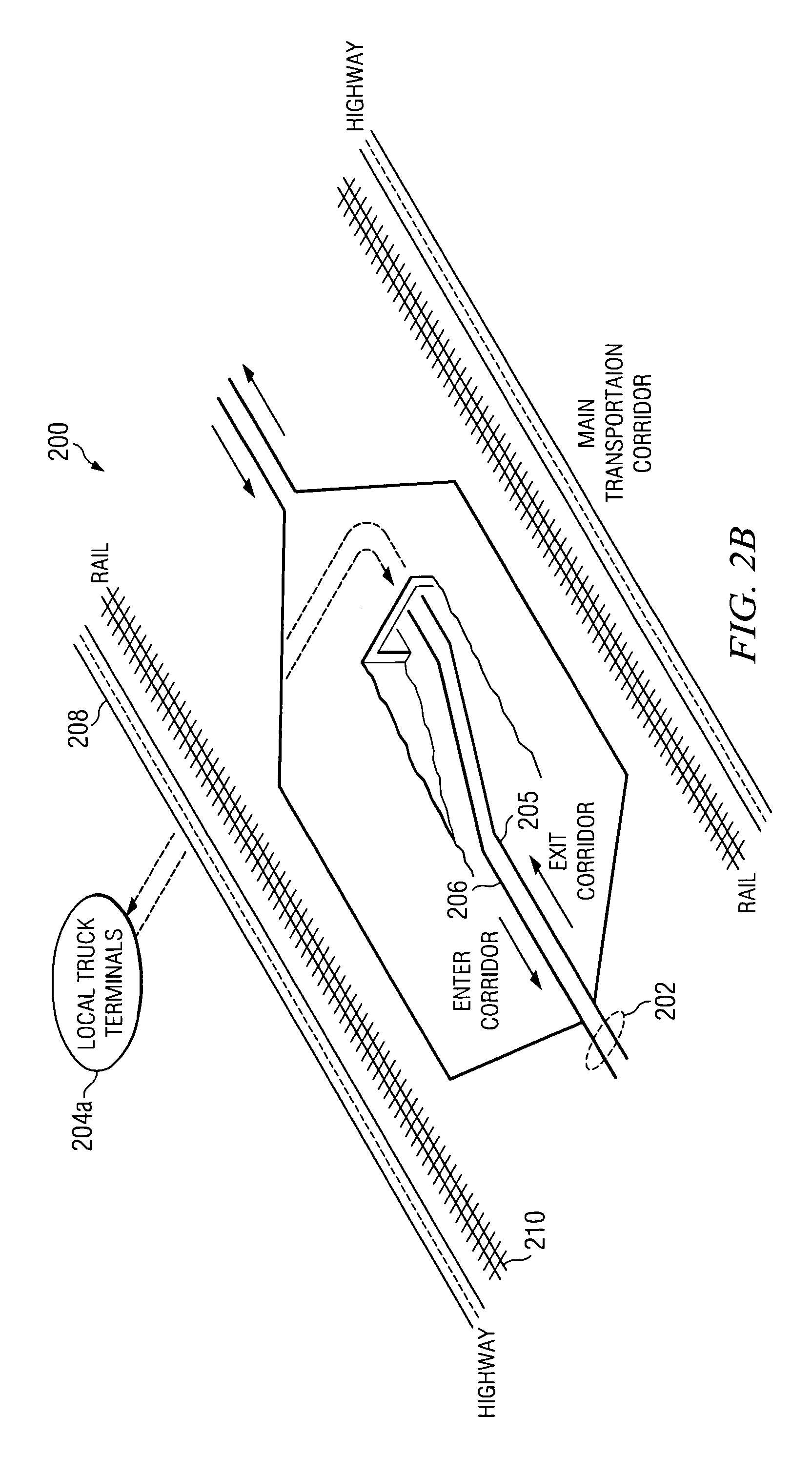

Freight transportation system and method

ActiveUS7654203B2Reduce the burden onReduce capacityPropulsion railway systemsRailway transportTransit systemControl system

According to one embodiment of the invention, a freight transportation system includes a track comprising a pair of rails and a linear motor reaction plate disposed between the rails and a transport vehicle having a universal intermodal container bay configured to accommodate a plurality of containers. The transport vehicle includes one or more suspension systems each having a plurality of steel wheels engaged with the rails. The freight transportation system further includes a linear induction propulsion system coupled to the transport vehicle and operable to work in conjunction with the linear motor reaction plate to move the transport vehicle, and a control system coupled to the linear induction propulsion system and operable to control the movement of the transport vehicle.

Owner:TEXAS A&M UNIVERSITY

Friction drive trolley conveyor

ActiveCN101503095AReduce in quantityLow costRailway componentsPropulsion railway systemsEngineeringFriction drive

A friction drive trolley conveyor has a conveying traveling body provided with a friction drive load bar having traction purpose engaging means at both ends thereof and allows traction drive to be easily conducted without fail even at the time of conveying a heavy object. The traction purpose engaging means is composed of an engaged shaft arranged in the horizontal direction within a vertical notched portion formed at one end of the load bar, a hook member vertically swingably pivotally supported at an intermediate position in vertical height of the load bar at the other end of the load bar and a holding means holding the hook member in an engaged posture or a disengaged posture, and on a traveling route side, a first switching means switching the hook member from the engaged posture to the disengaged posture and a second switching means switching the hook member from the disengaged posture to the engaged posture.

Owner:DAIFUKU CO LTD

Conveyance apparatus using movable bodies

ActiveCN1541916AEasy to moveRailway componentsPropulsion railway systemsEngineeringFrictional resistance

Guided devices are connected to the front and rear ends of the main body of a moving body. Each guided device is connected in a relatively rotatable fashion about a lateral axle to the lower part of a vertical shaft. A lateral roller supporting body is connected to the vertical shaft, and idle wheels supported and guided by guide bodies disposed in prescribed positions in a fixed path are provided on the right and left-hand ends of the roller support body. The roller supporting body is connected to the vertical shaft to rotate with it so that during movement the axis of the pair of right and left-hand idle wheels can be orientated orthogonally to the fixed path, so that they are able to rotate smoothly without causing slipping or frictional resistance. Thereby, the supporting unit can always be supported and guided smoothly even in curved path sections.

Owner:DAIFUKU CO LTD

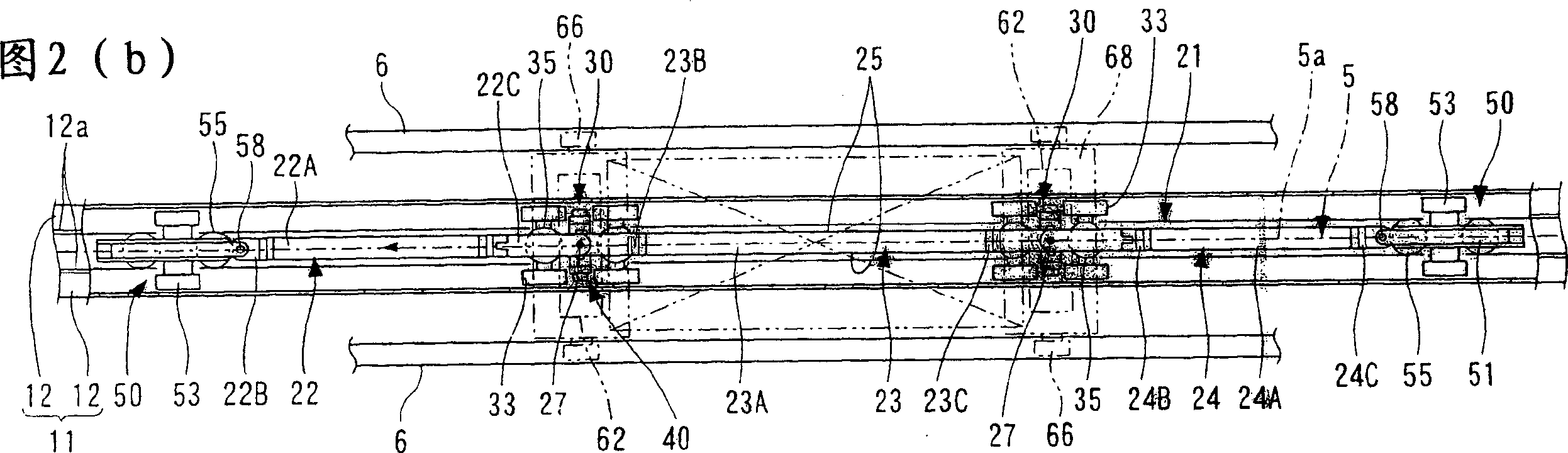

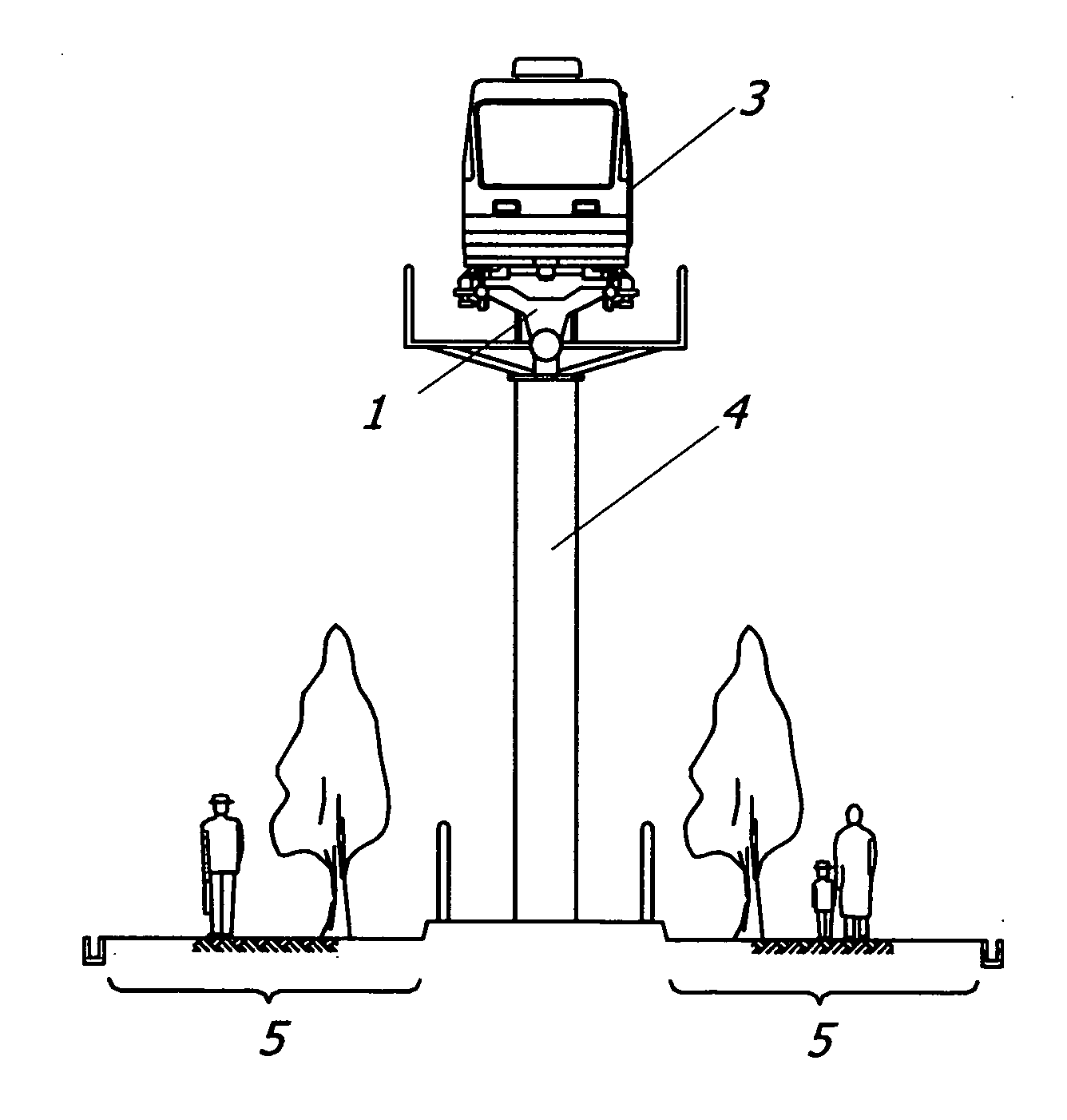

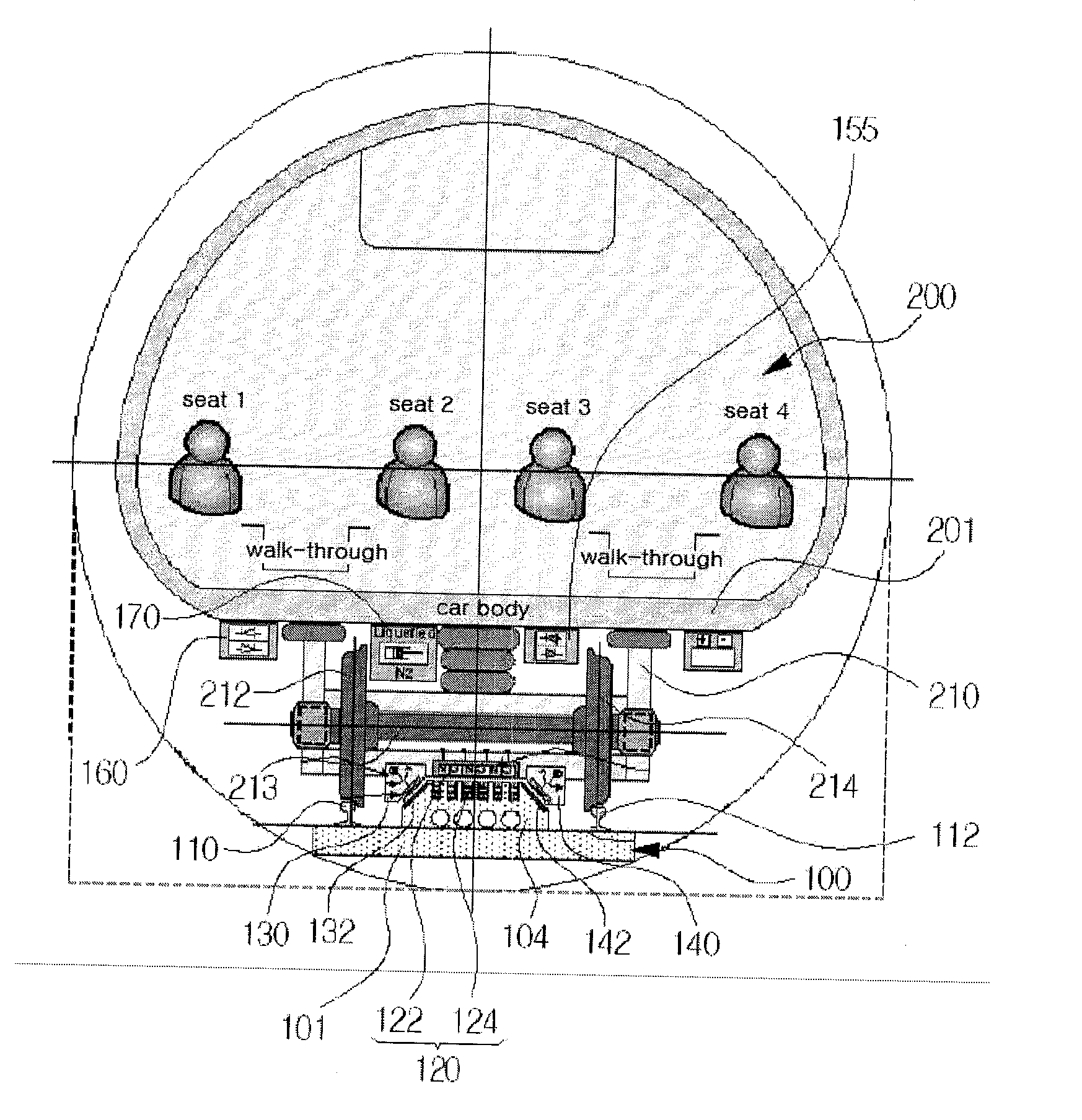

Transportation system

InactiveUS20060042497A1Reduce weight and sizeSaving cost for constructingMonorailsSliding/levitation railway systemsTransit systemAutomotive engineering

A transportation system is provided, in which a light-weight, small-sized vehicle can be used. This transportation system comprises a rail extending between stations, vehicle capable of running on the rail and carrying a drive unit, first zone for accelerating the vehicle from a stopped condition to a required speed by a propulsion force supplied from a propulsion supply unit provided from one of the stations toward the other station by a predetermined distance, and a second zone not having the propulsion supply unit, in which the vehicle accelerated in the first zone travels on the rail by the propulsion force supplied from the drive unit.

Owner:SENYO INDS

Electromagnetic vacuum ultraspeed railway system

InactiveCN108674421AGuaranteed operational safetyReduce the impactRailway hydrostatic brakesRailway hydrodynamic brakesElectromagnetic propulsionEngineering

The invention discloses an electromagnetic evacuated ultraspeed railway system. The electromagnetic evacuated ultraspeed railway system comprises a housing and at least one transporting line which isarranged in the housing; the transporting line comprises an evacuated transportation tube and a train which is positioned in the evacuated transportation tube; and active collision avoidance devices are arranged between compartments of the train and the train head and the compartments. An external electromagnetic propulsion layer is arranged on the internal wall of the evacuated transportation tube; an internal electromagnetic propulsion layer is arranged on the external wall of the train; when the train penetrates through the evacuated transportation tube, homopolar magnetism pushes the trainto advance; and meanwhile, a power generation closed lead configured for the train cuts a magnetic induction line of the external electromagnetic propulsion layer to generate electric energy needed by running. The electromagnetic evacuated ultra-speed railway system is a people and object carrying integrated transportation system with a certain power generation capacity; and according to the electromagnetic evacuated ultra-speed railway system, requirements on external power supply are extremely low; under a mutual effect of an electromagnetic tube and an evacuated environment, the train running speed is highest, the energy consumption is lowest, no fear of influence from any weather is realized, the cost is lowest, and the input-output ratio is highest.

Owner:邱洪武

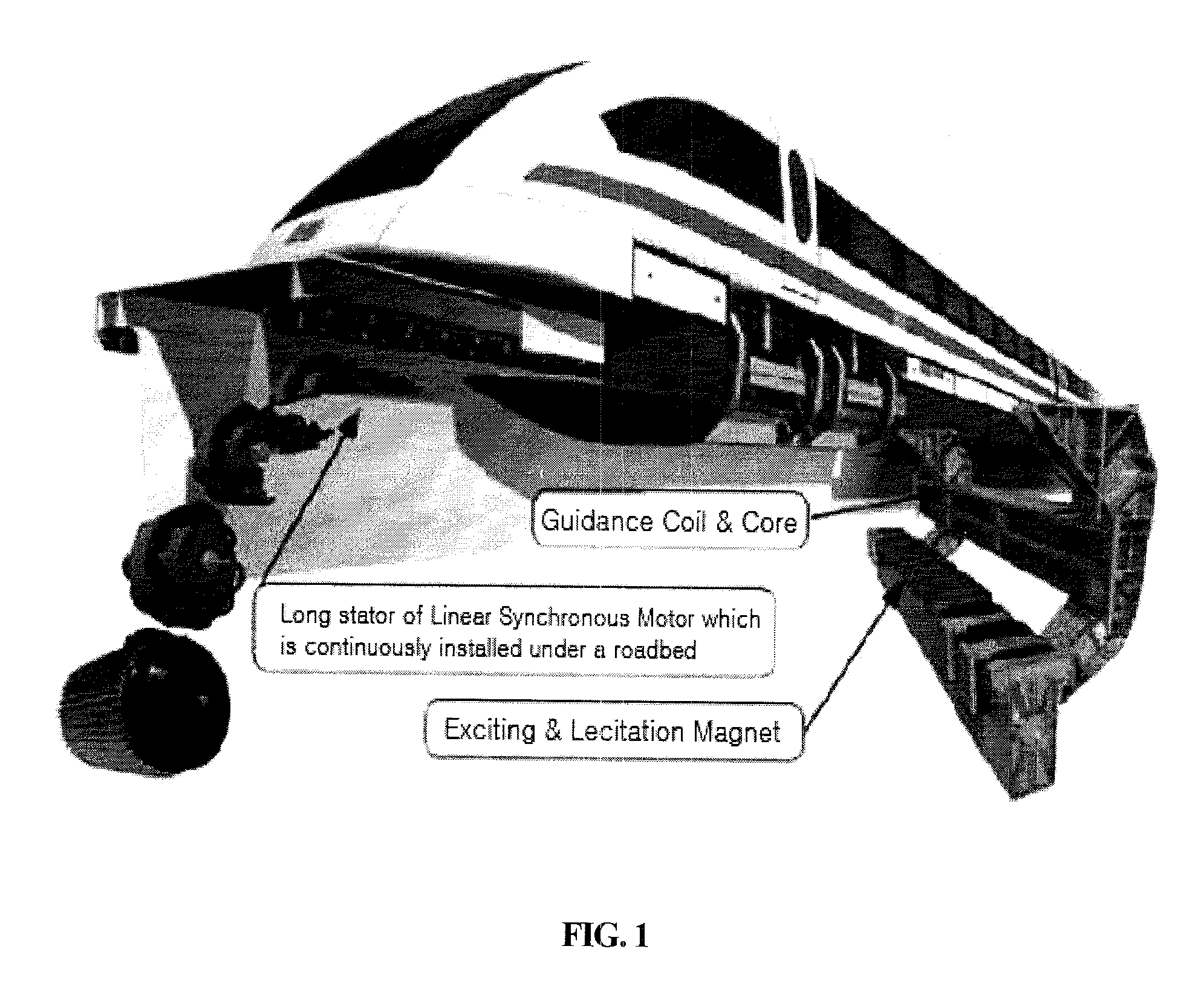

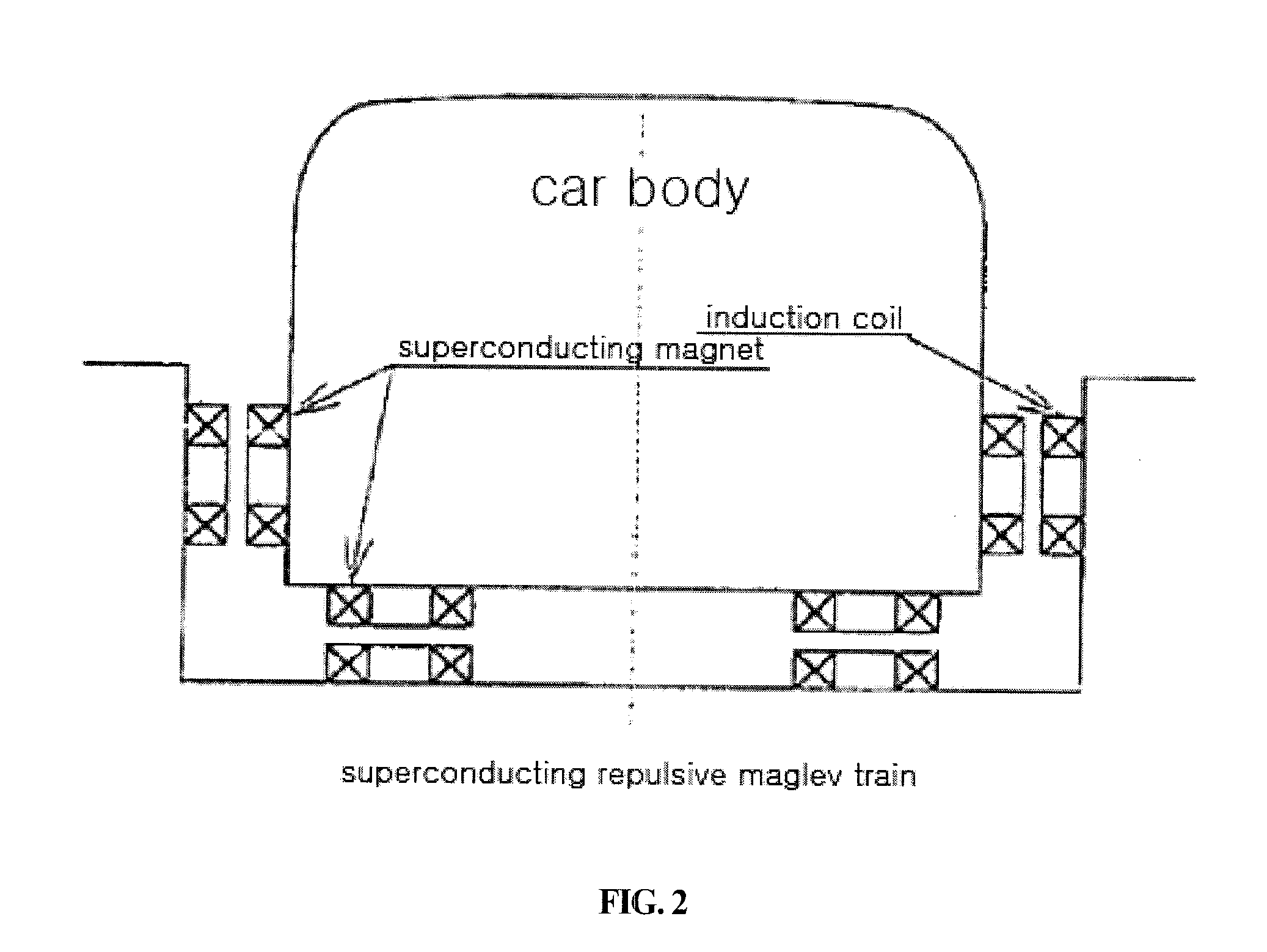

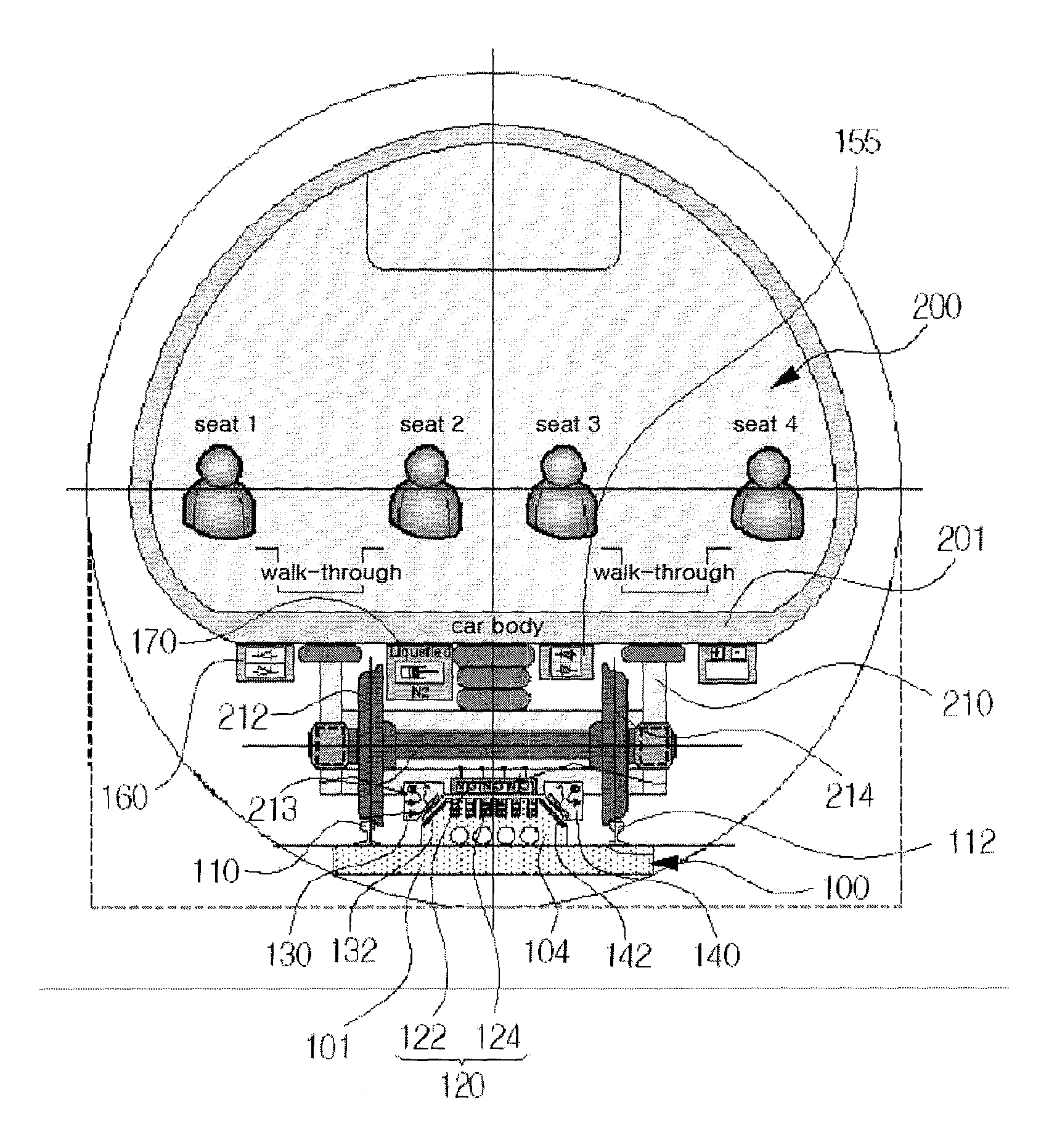

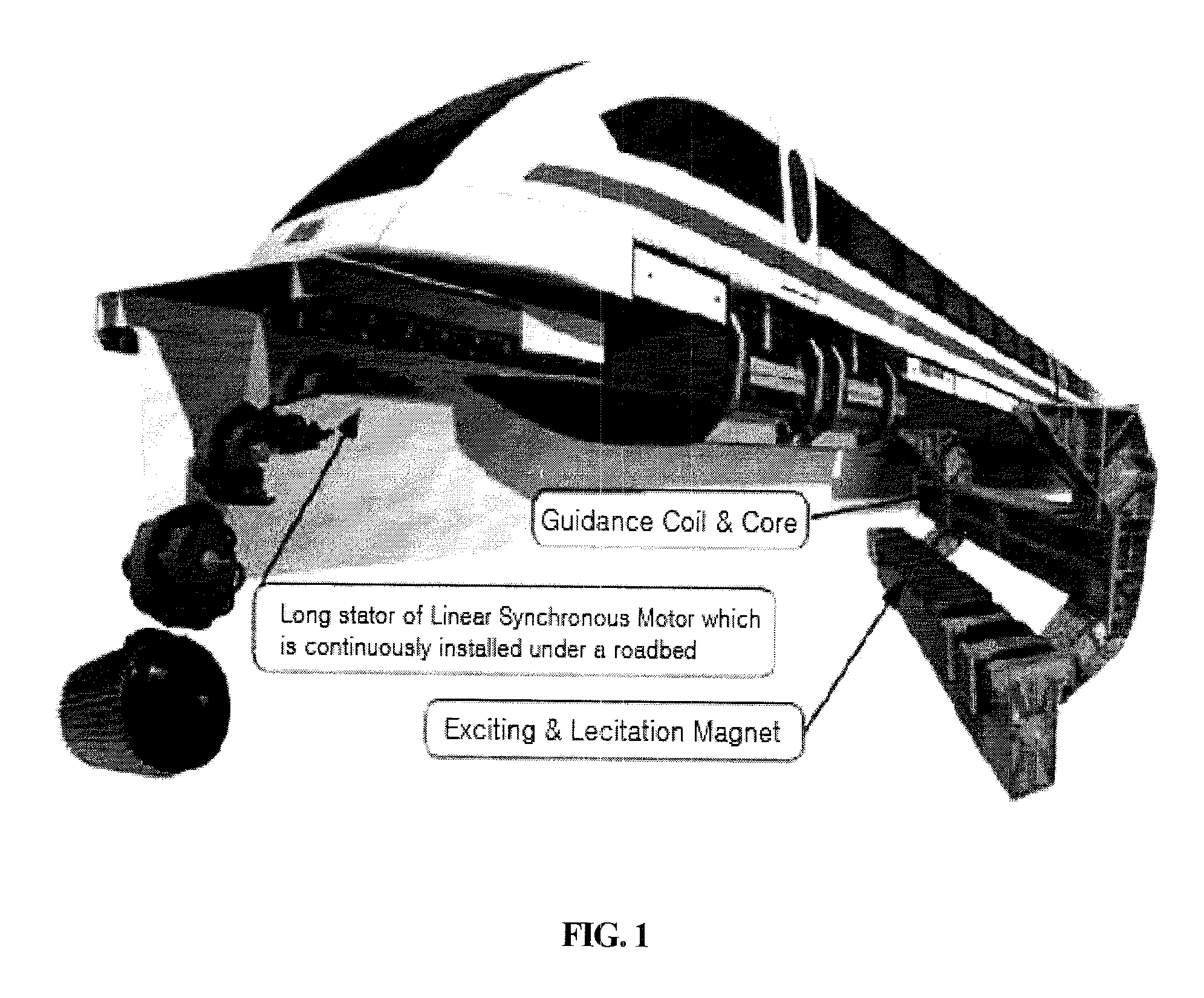

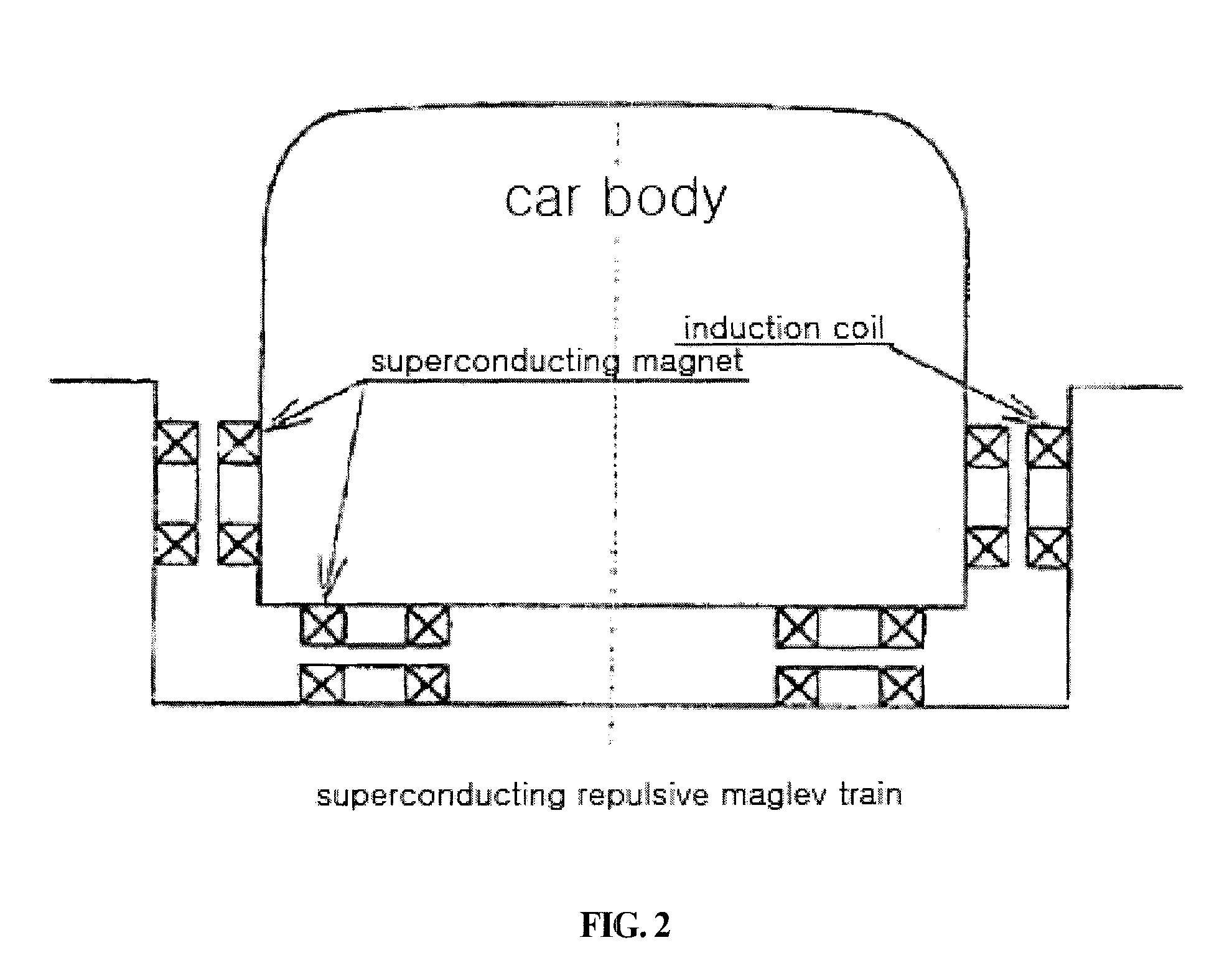

Wheel-type ultra high speed railway system

ActiveUS20110259236A1Smooth rideMinimizing rangeElectric devicesRailway tunnelsBogieUltra high speed

The wheel-type high-speed railway system includes rails provided on a railroad track and configured such that wheels provided in a bogie of a vehicle come into contact with them, a support provided on a tread surface of a railroad track between the rails, a repulsive Linear Synchronous Motor (LSM) provided between the bogie and the support and configured to improve traveling performance by reducing axle load in a high-speed region, first and second steel plates mounted on both sides of the support in inclined positions, and first and second attractive Dynamic Motion Control (DMC) magnets mounted on the bogie of the vehicle in inclined positions to correspond to the first and second steel plates, and configured to generate attractive force.

Owner:KOREA RAILROAD RES INST

Vacuum transport tube vehicle, system, and method for evacuating a vacuum transport tube

A vacuum transport tube vehicle, system, and method for evacuating a vacuum transport tube are provided. The vehicle has a first end having a first end outer surface. An annular gap is formed between the first end outer surface and an inner surface of the vacuum transport tube. The vehicle has a second end having a second end outer diameter, and a body in the form of a piston with a structural framework. The vehicle has an orifice extending from a first inlet portion in the first end to a second outlet portion of the vehicle. The vehicle has a drive assembly coupled to the body, and a power system. The vehicle evacuates the vacuum transport tube by reducing pressure within the tube with each successive vehicle pass through the tube, until a desired pressure is obtained and a vacuum is created in the interior of the tube.

Owner:THE BOEING CO

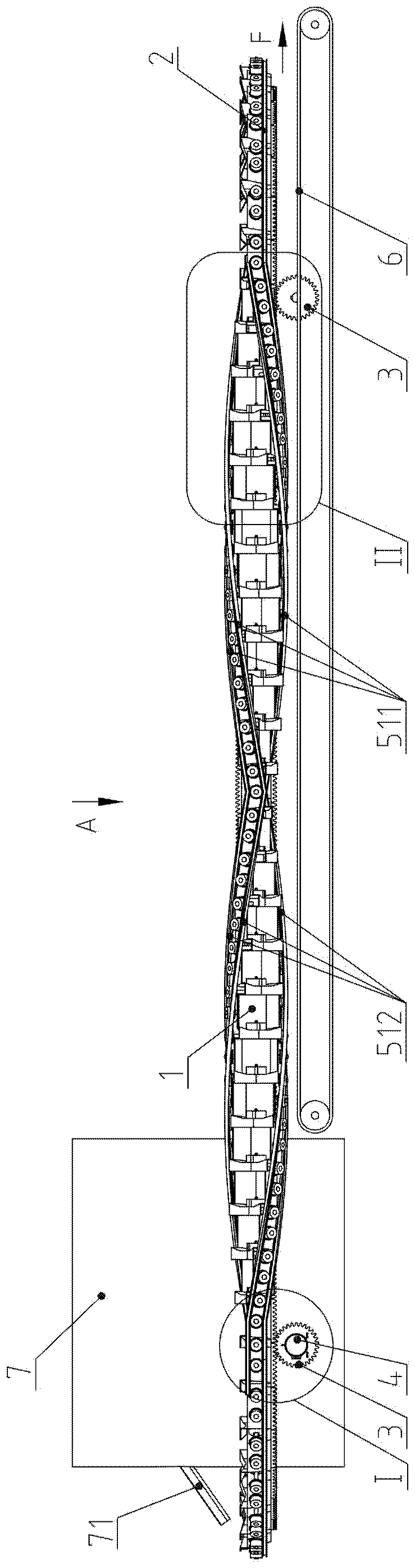

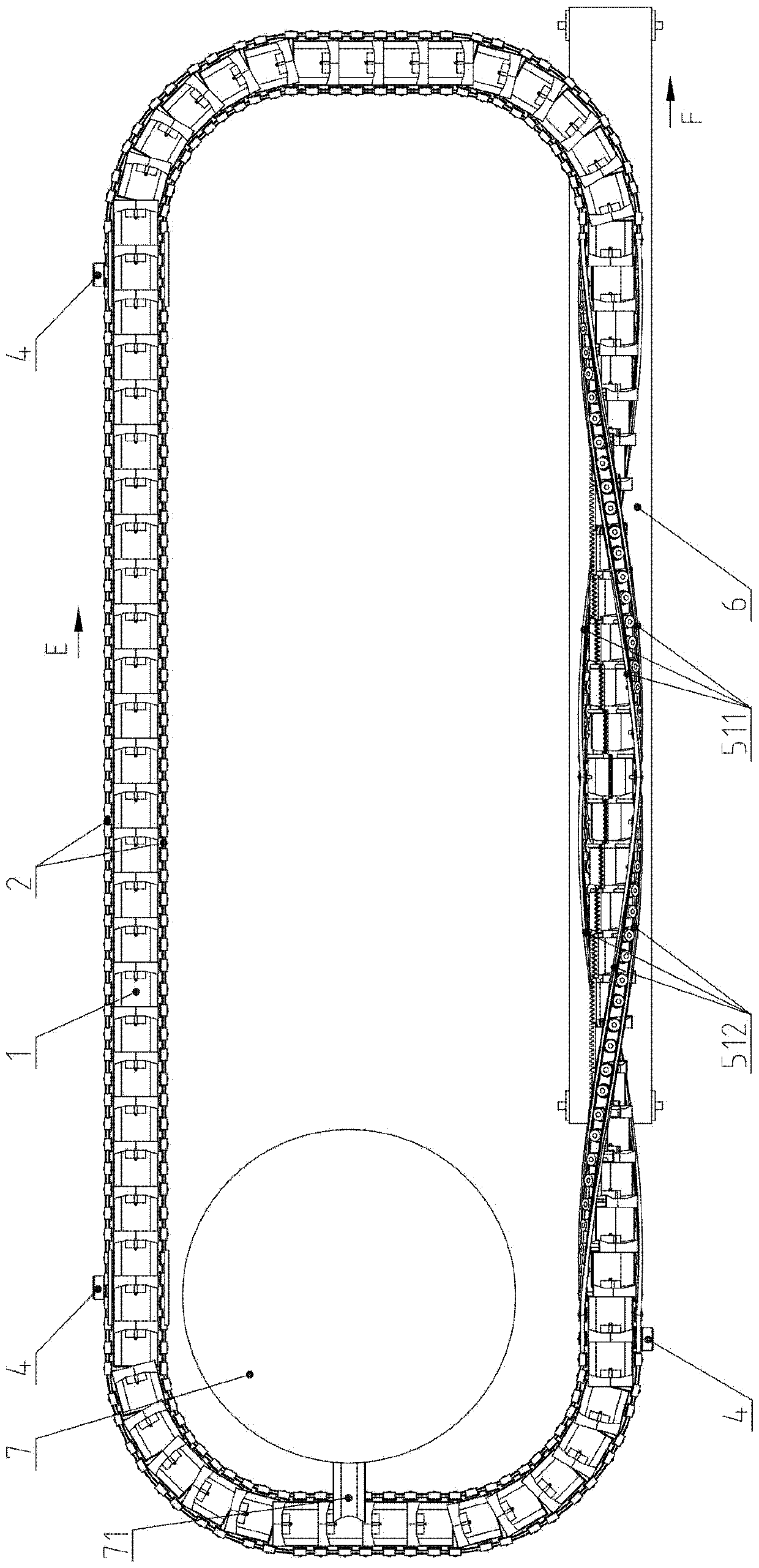

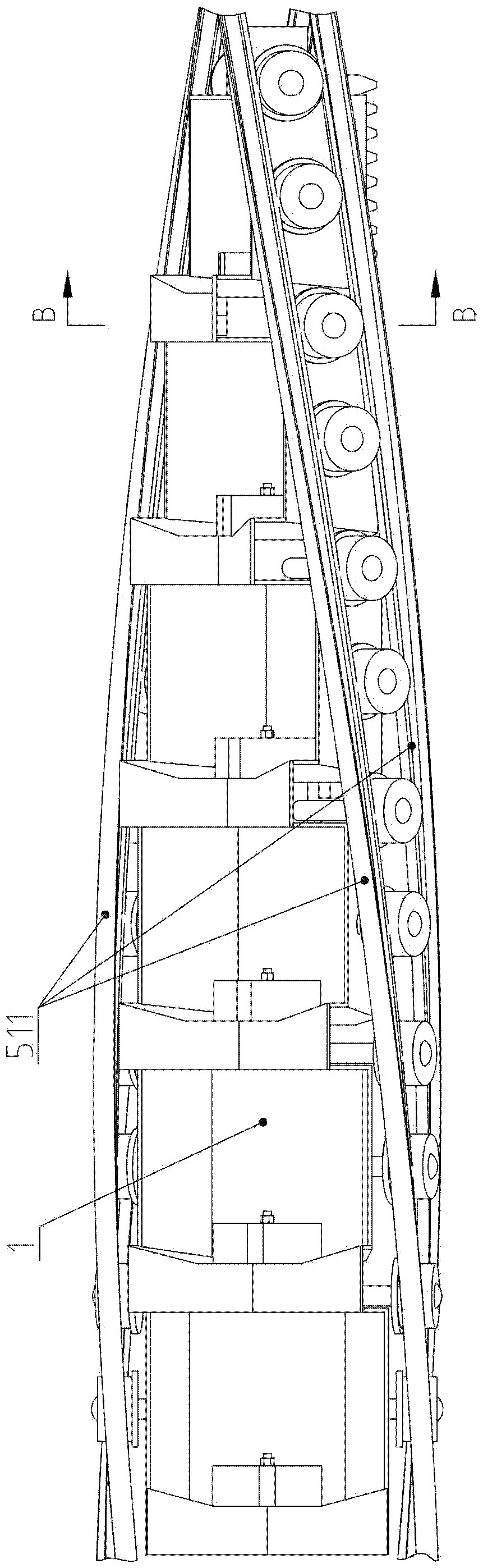

Calcium carbide conveyor train

ActiveCN104986161BImprove working environmentReduce laborPropulsion railway systemsWorking environmentCalcium carbide

The invention belongs to the technical field of calcium carbide production, relates to calcium carbide cooling and collecting equipment and concretely relates to a calcium carbide conveying train comprising a train, an enclosed loop track and a driving device. The enclosed loop is formed by a horizontal track and a spiral track; the train is formed by a plurality of calcium carbide trolleys; each calcium carbide trolley consists of a calcium carbide pot, a ball pin, a fixed wheel and a swinging wheel; a pin rod of the ball pin is connected with the front end of the calcium carbide pot; a ball is cooperated with the internal spherical surface of the back end of the calcium carbide; the plurality of calcium carbide trolleys are connected end-to-end to form the enclosed loop train; each calcium carbide trolley has the fixed wheel and the swinging wheel; the wheels roll along the tracks; the calcium carbide pot turns over along the spiral track to face downward and then turns back again; and the driving device is connected with the train. The calcium carbide conveying train possesses high automation degree and high efficiency, can continuously produce, improve work environment and can be simply operated; and the site can be flexibly arranged.

Owner:聊城研聚新材料有限公司

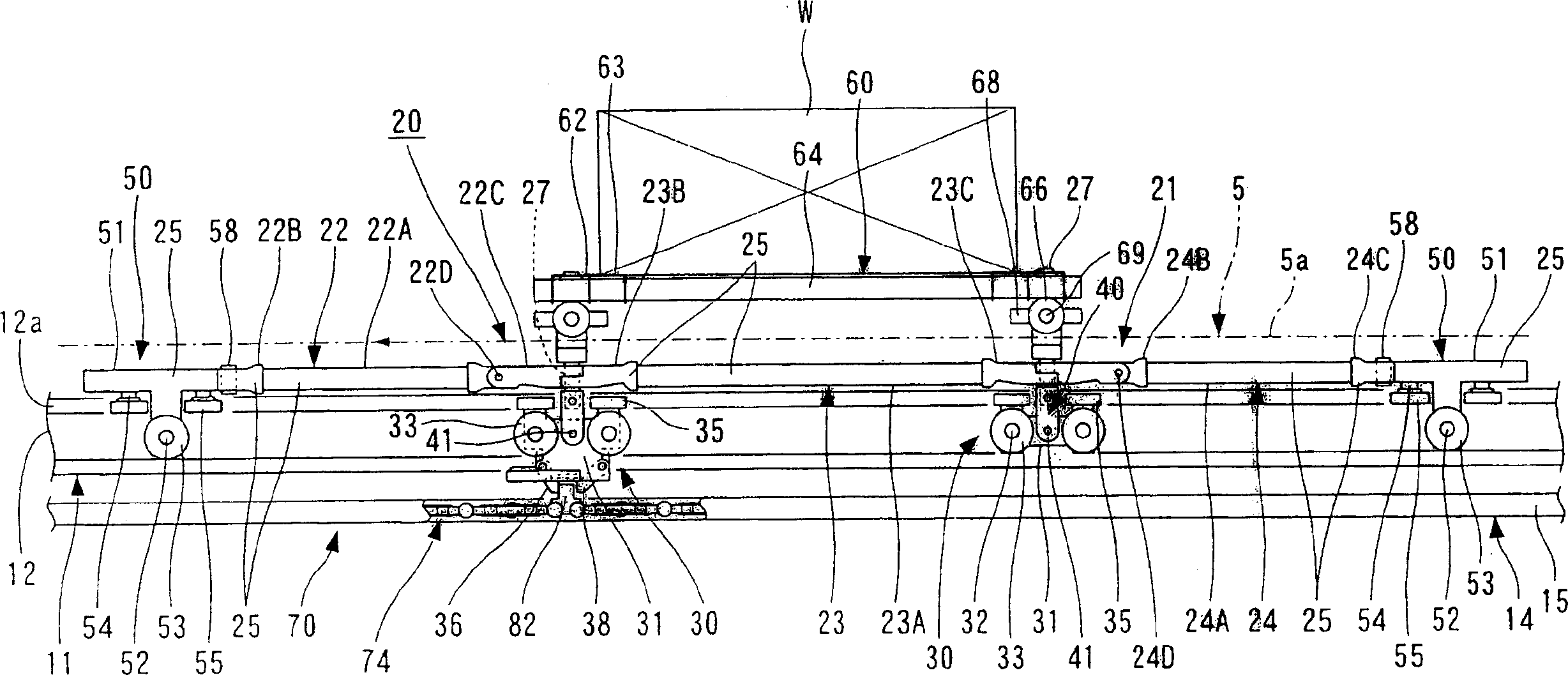

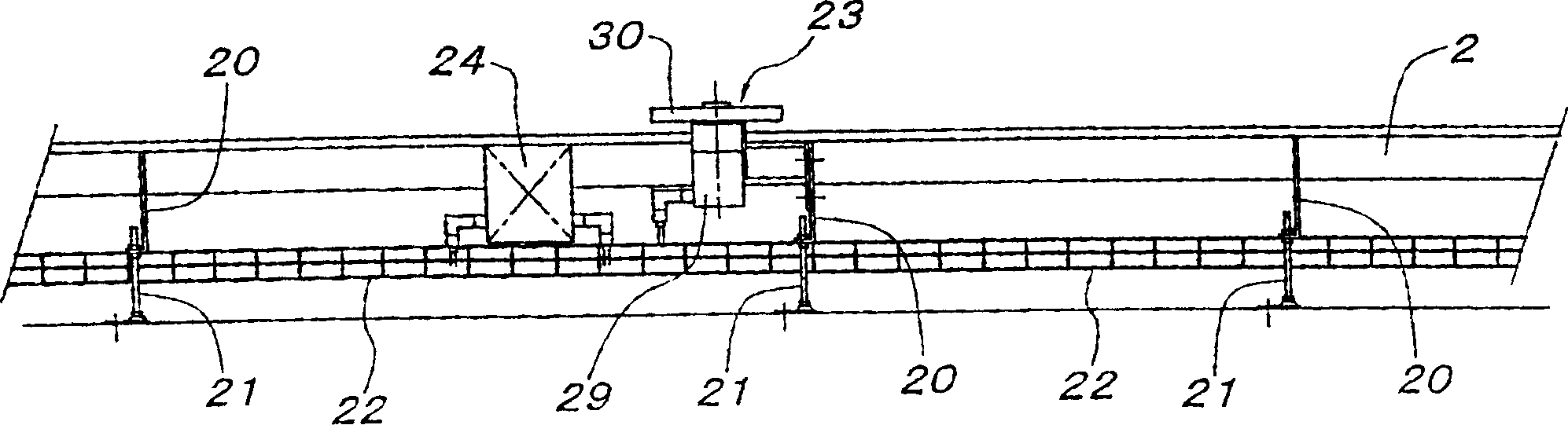

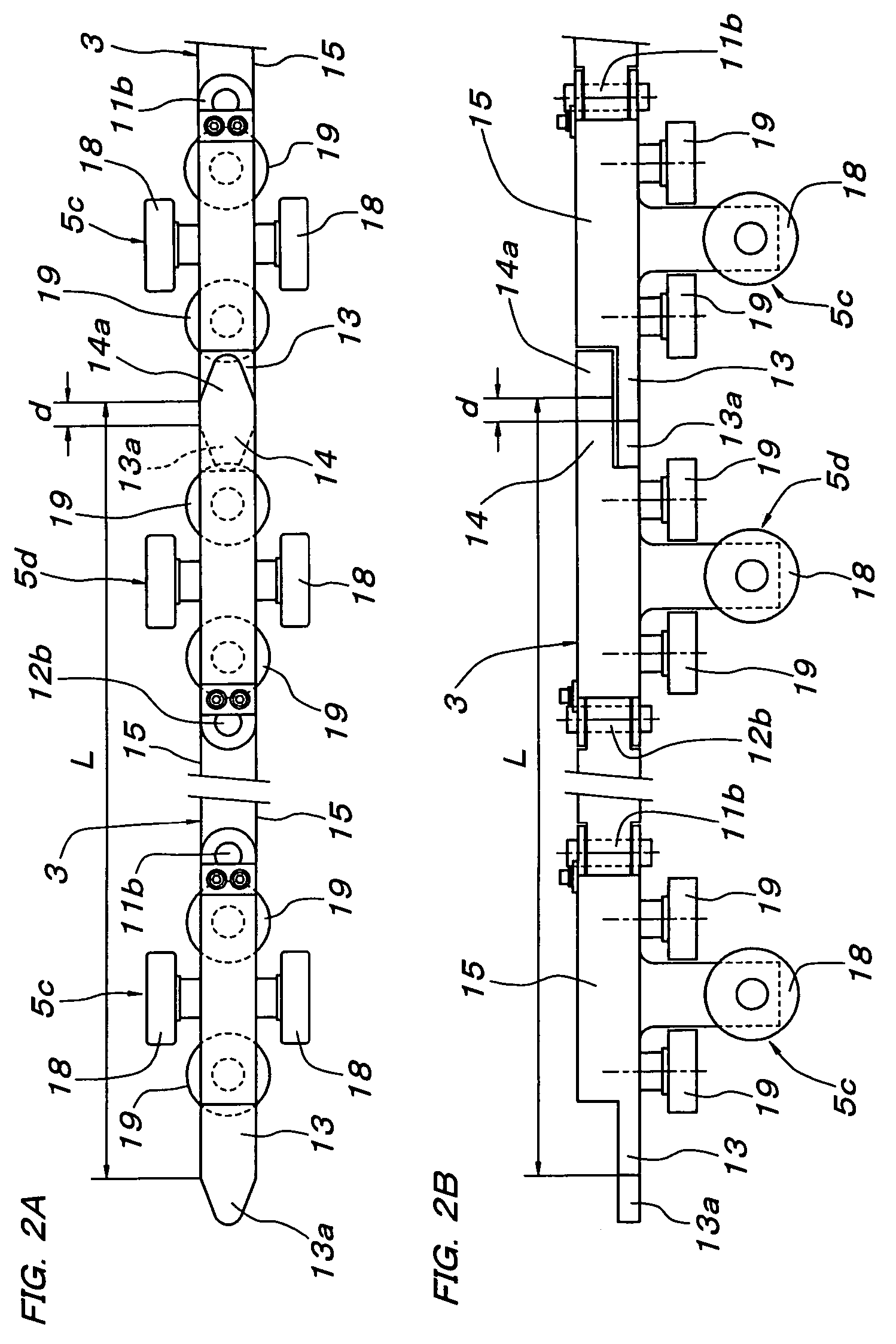

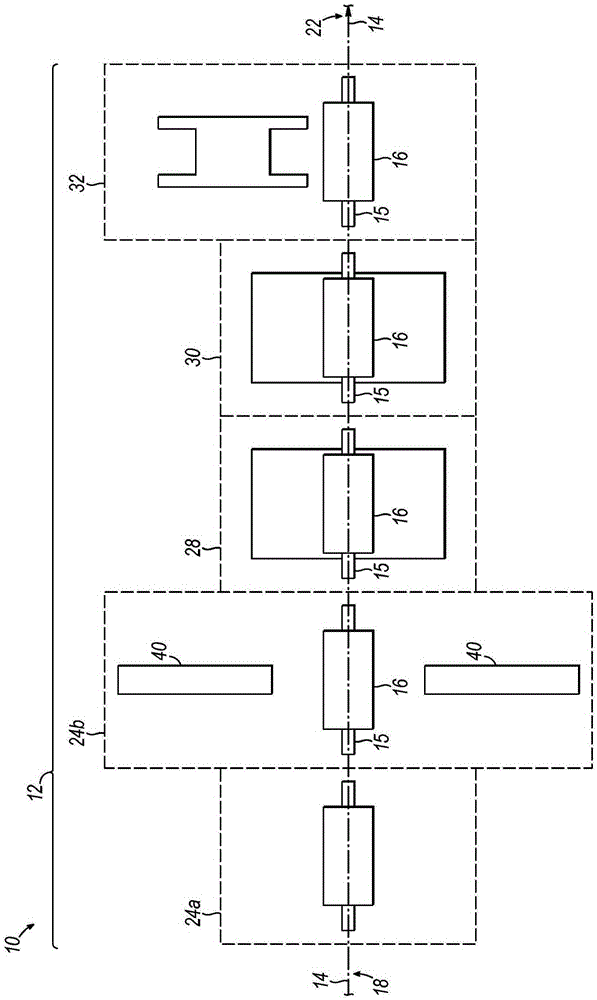

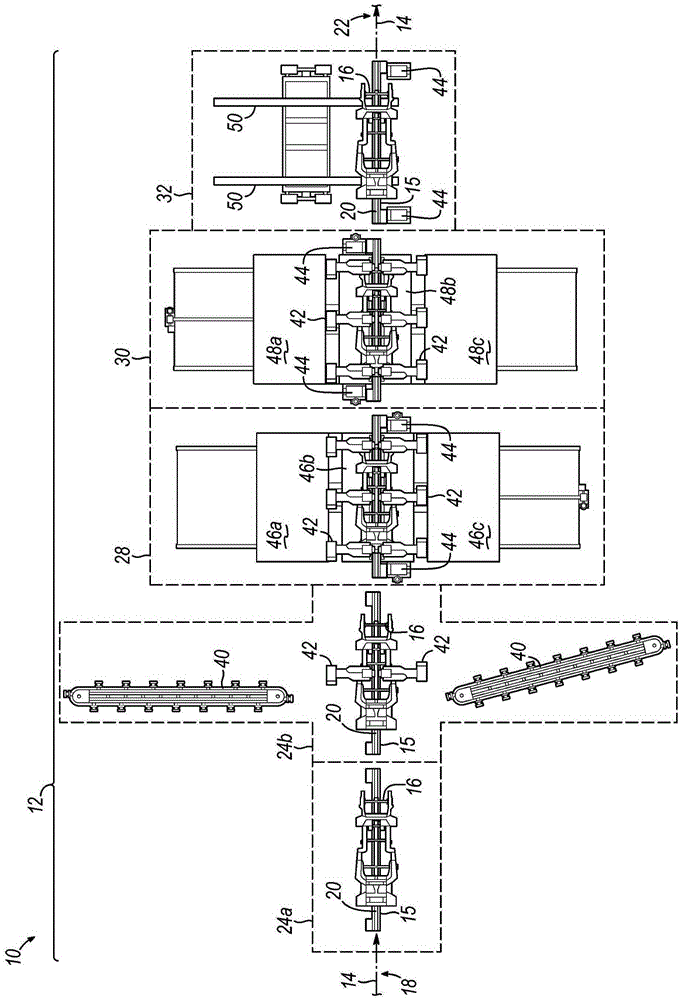

Friction drive conveyor

ActiveCN1576195AEasy to controlEasy wiringRailway componentsPropulsion railway systemsDrive wheelEngineering

Each of the friction drive wheels 30 comprises a brake-less motor 29 driving the friction drive wheel and a sensor 32 detecting the state of the contact of the friction surface 15 of the traveling body 1 for carrying on the friction drive wheel 30. The friction drive wheels 30 are disposed in an at least specified district in a carrying route at equal intervals not longer than (same or slightly shorter than) the overall length L of the friction surface 15 of the traveling body 1 for carrying. Based on the detection state of sensors 32, a control means 24 controlling the friction drive wheels 30 is controlled to start the driving of the friction drive wheel 30 in contact with the friction face 15 of the traveling body 1 for carrying when the friction drive wheel 30 on the downstream side is brought in an empty state and stop the driving of the friction drive wheel 30 apart from the friction surface 15 of the traveling body 1 for carrying.

Owner:DAIFUKU CO LTD

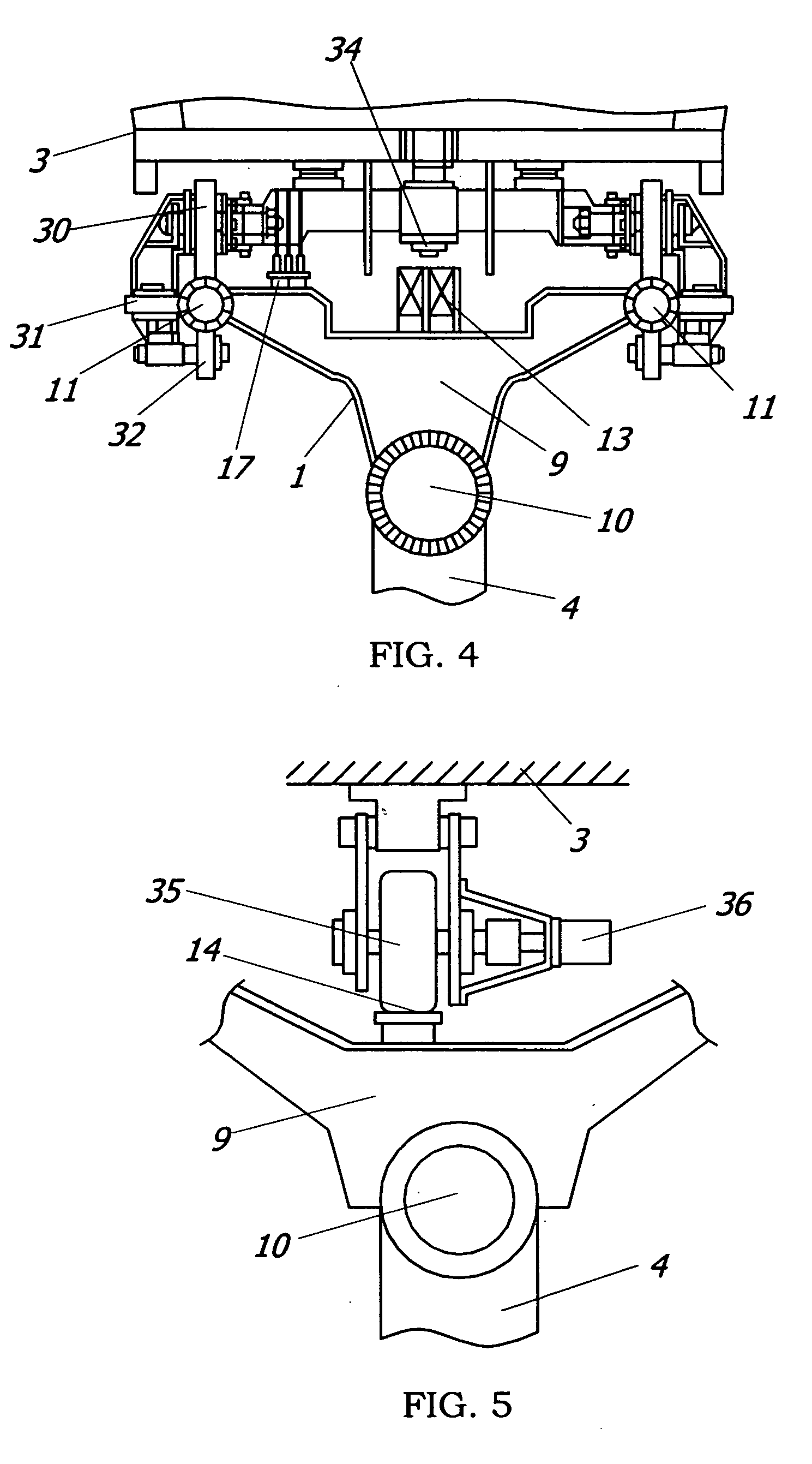

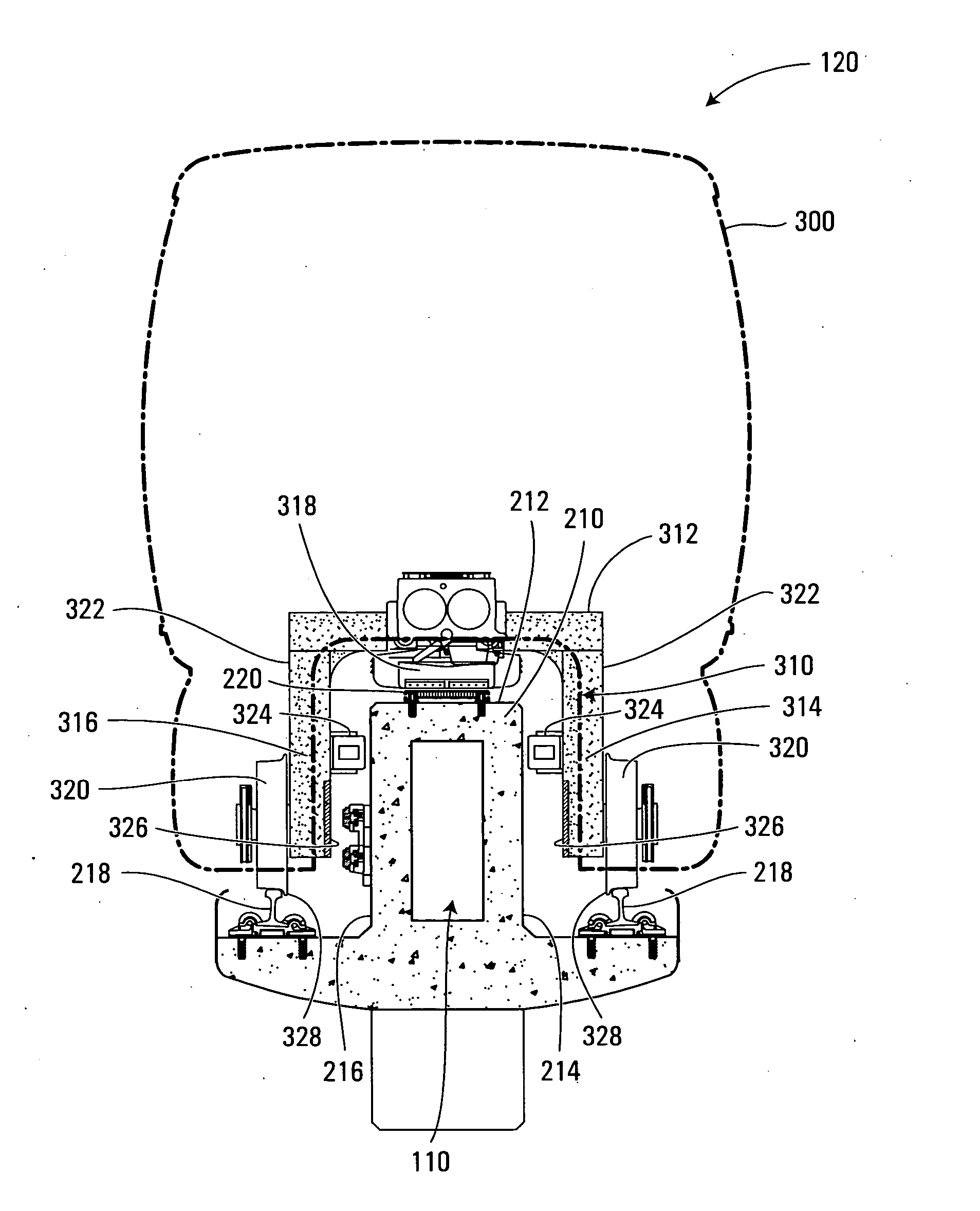

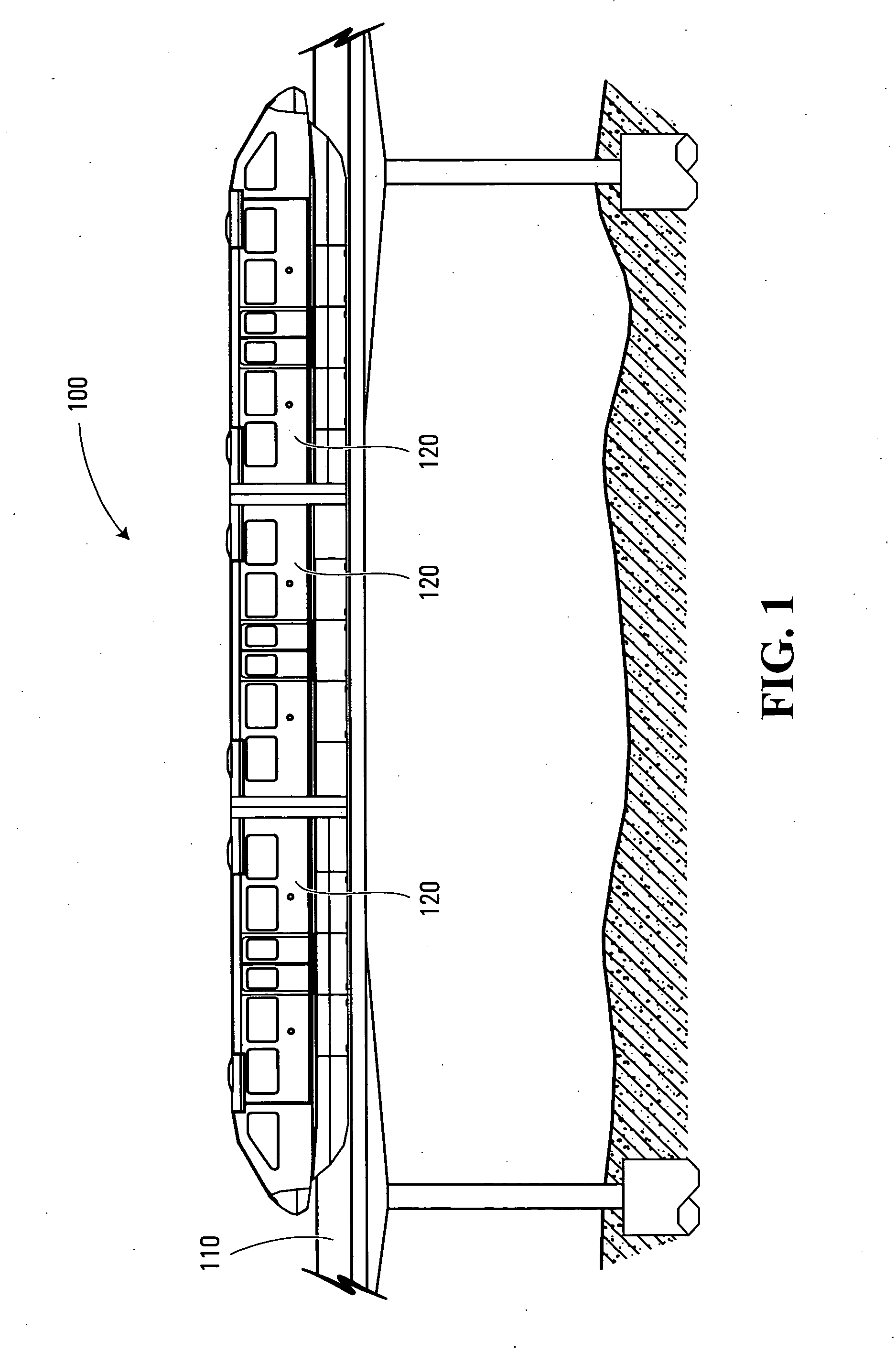

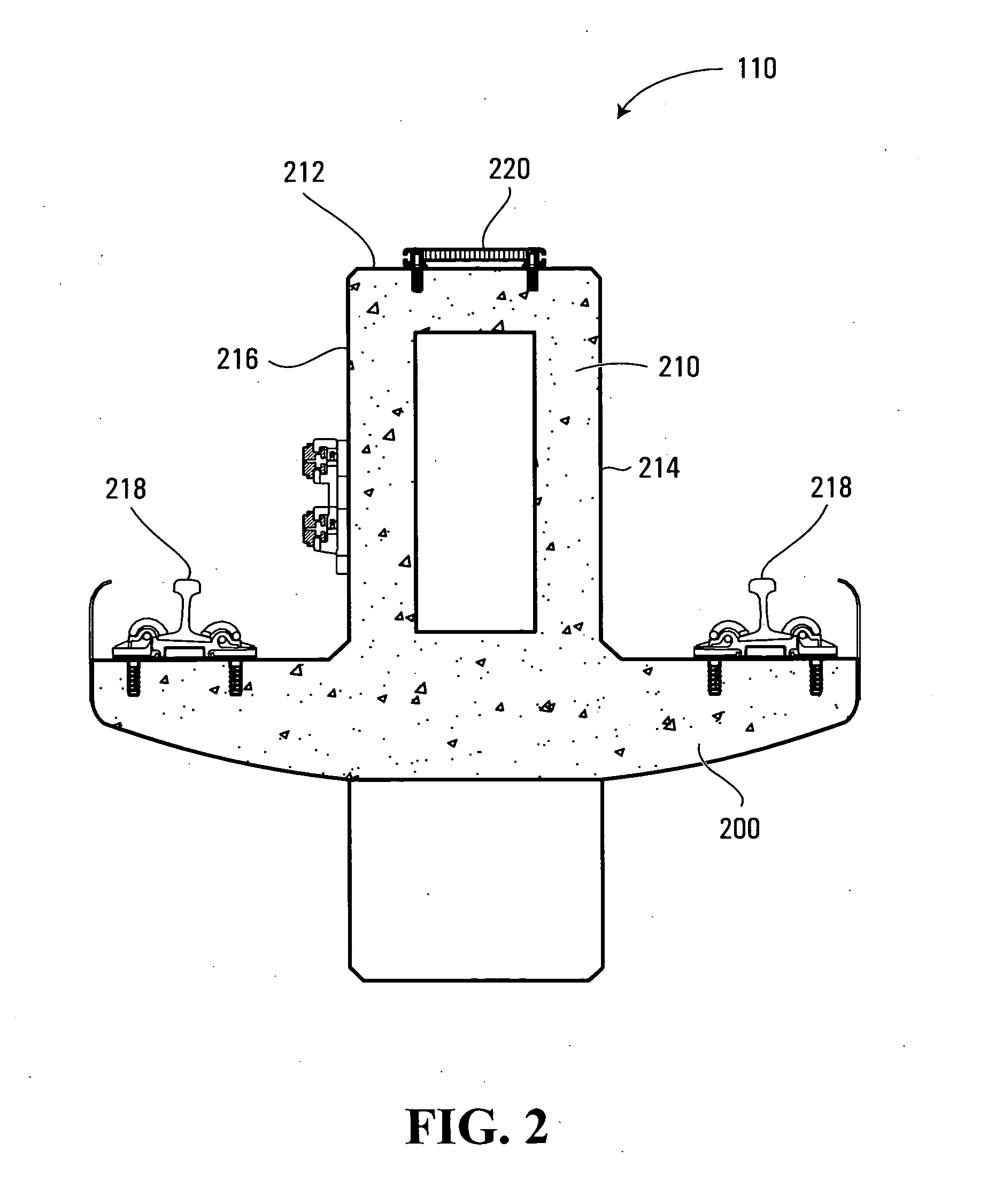

Automated people mover (APM) monorail system

A bogie assembly for supporting and guiding a vehicle car body on a monorail track, the monorail track having a guideway portion and a narrower guideway beam extending upwardly from the guideway portion. The guideway portion includes a pair of rails, while the guideway beam defines a top surface and a pair of side surfaces. The bogie assembly includes a frame operative to support the vehicle car body above the guideway beam, where this frame includes an upper surface adapted to be pivotably mounted to the underside of the vehicle car body and a pair of side members extending downwardly from the upper surface. Each side member of the frame has an inner surface and an outer surface, the inner surface of each side member adapted to be positioned adjacent a respective one of the side surfaces of the guideway beam. The bogie assembly also includes a pair of load wheels, each load wheel being mounted to a respective one of the side members of the frame and being operative to engage a respective one of the rails of the guideway portion. Each load wheel is characterized by a flange portion capable to engage the respective rail for assisting in the guidance of the vehicle car body as it travels along the monorail track.

Owner:BOMBARDIER TRANSPORTATION GMBH

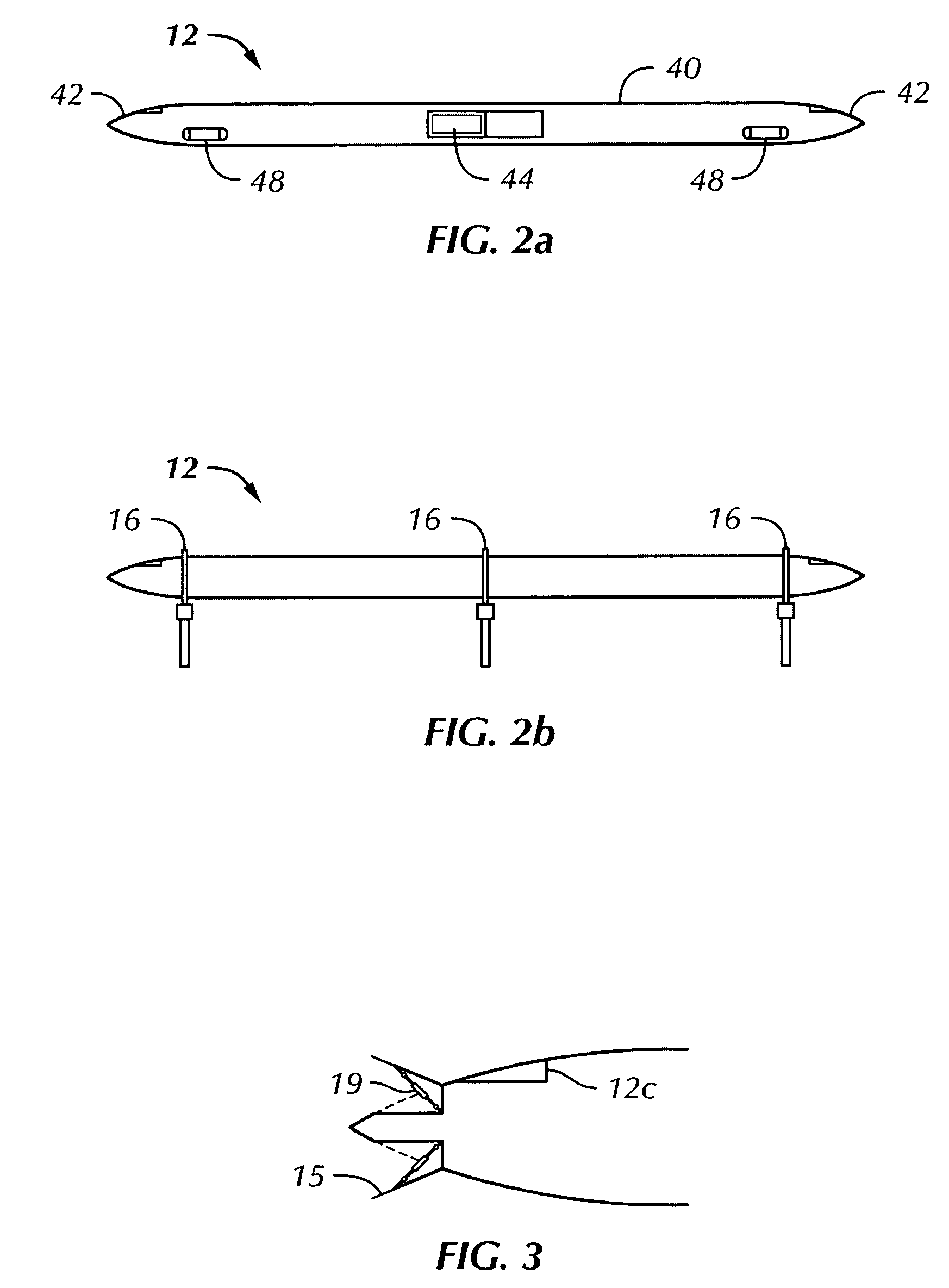

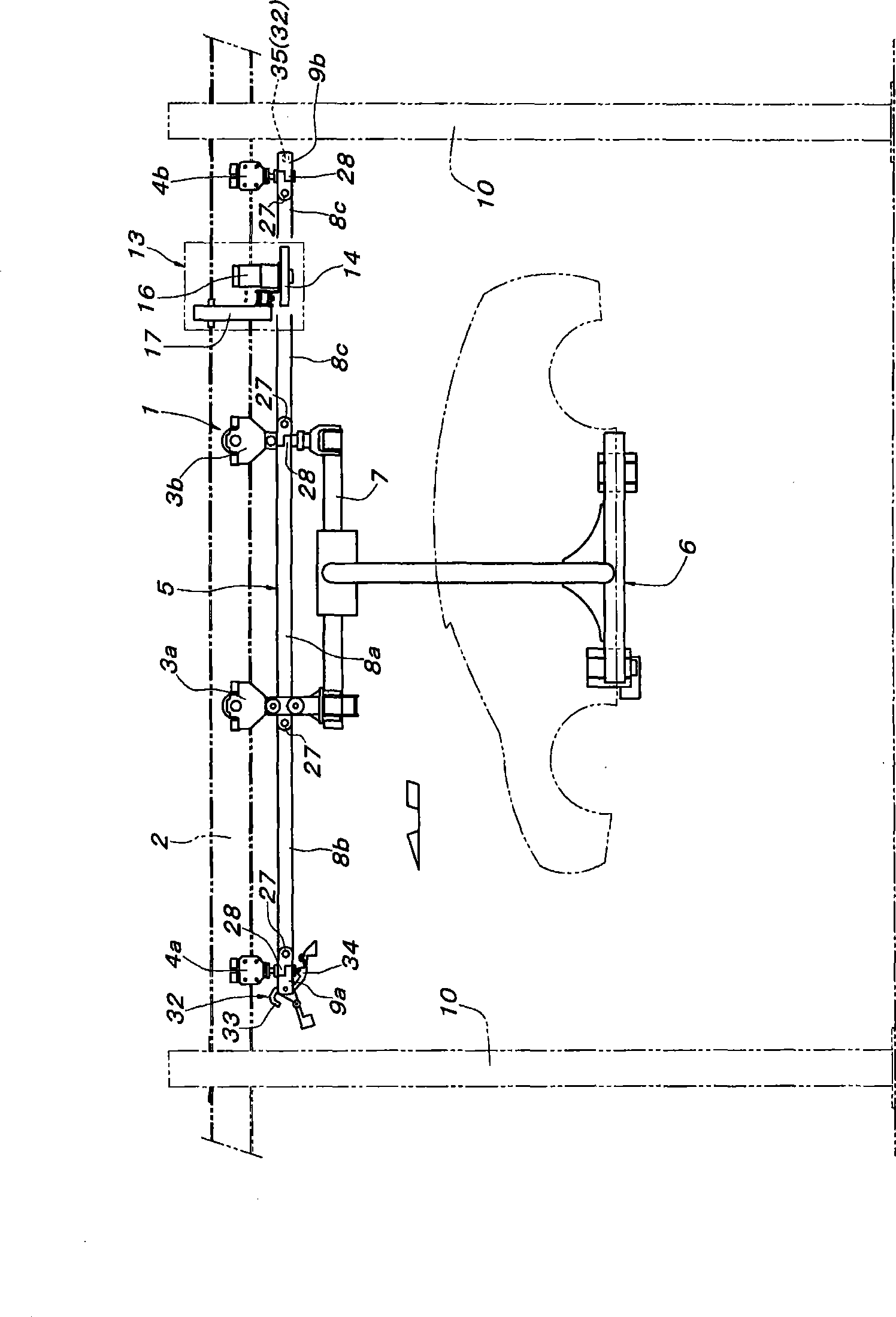

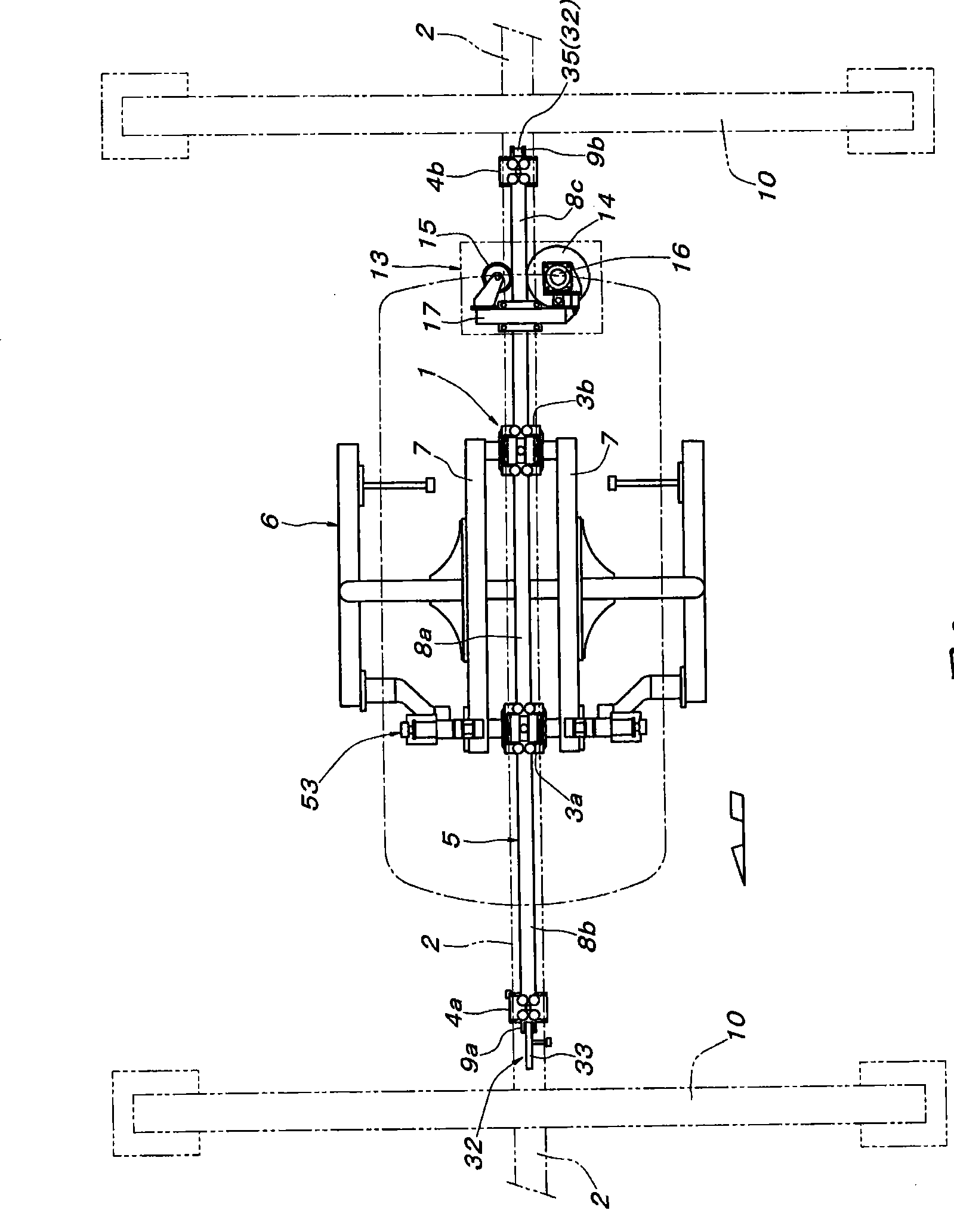

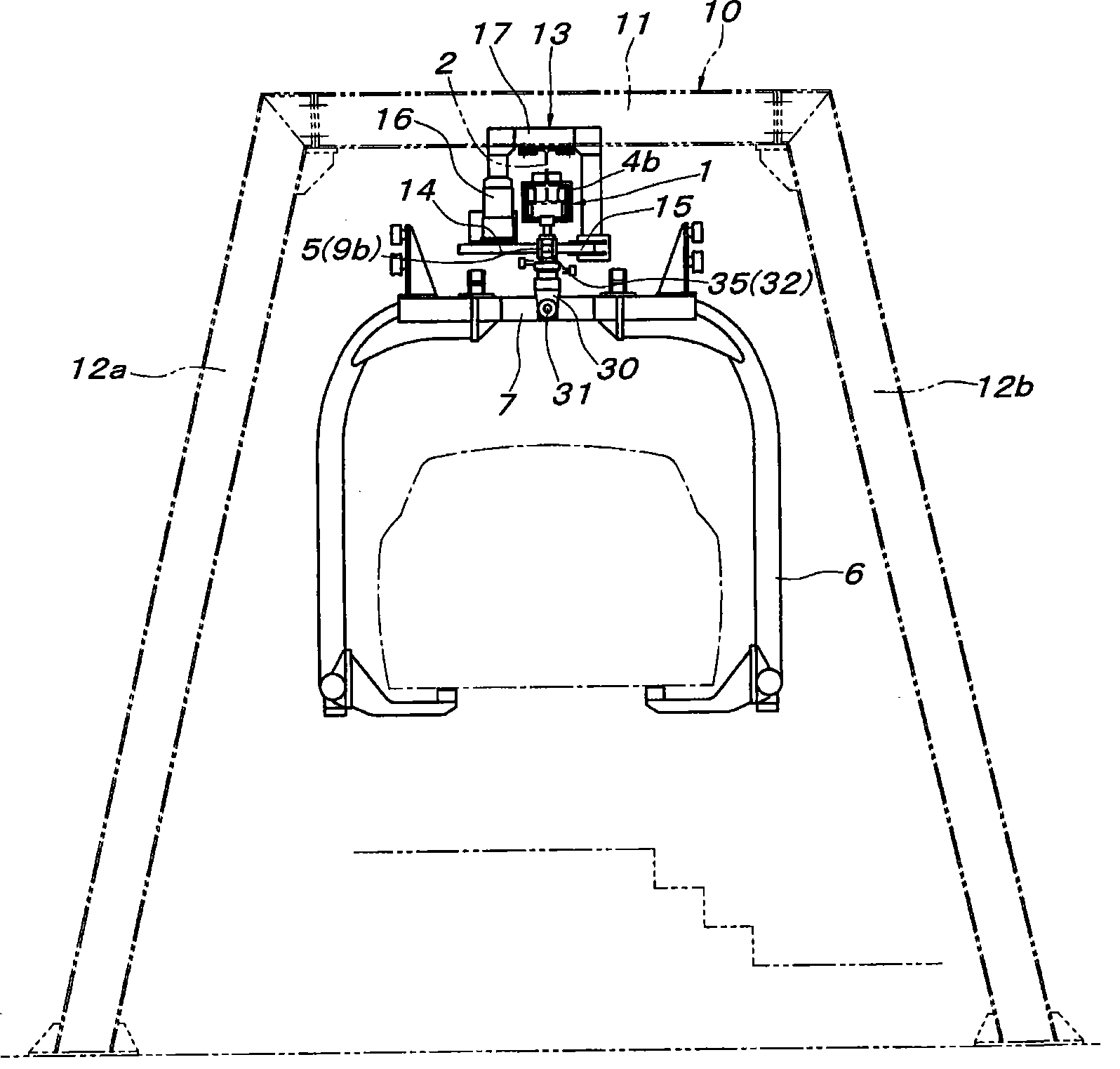

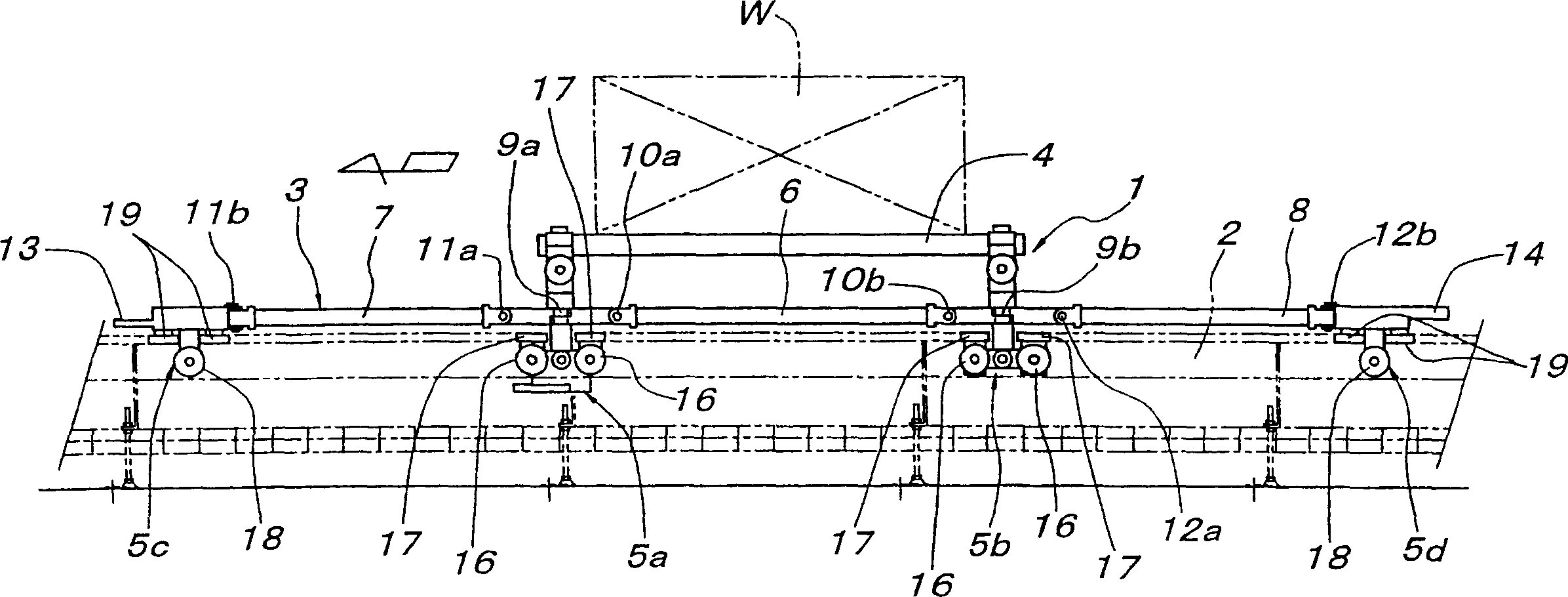

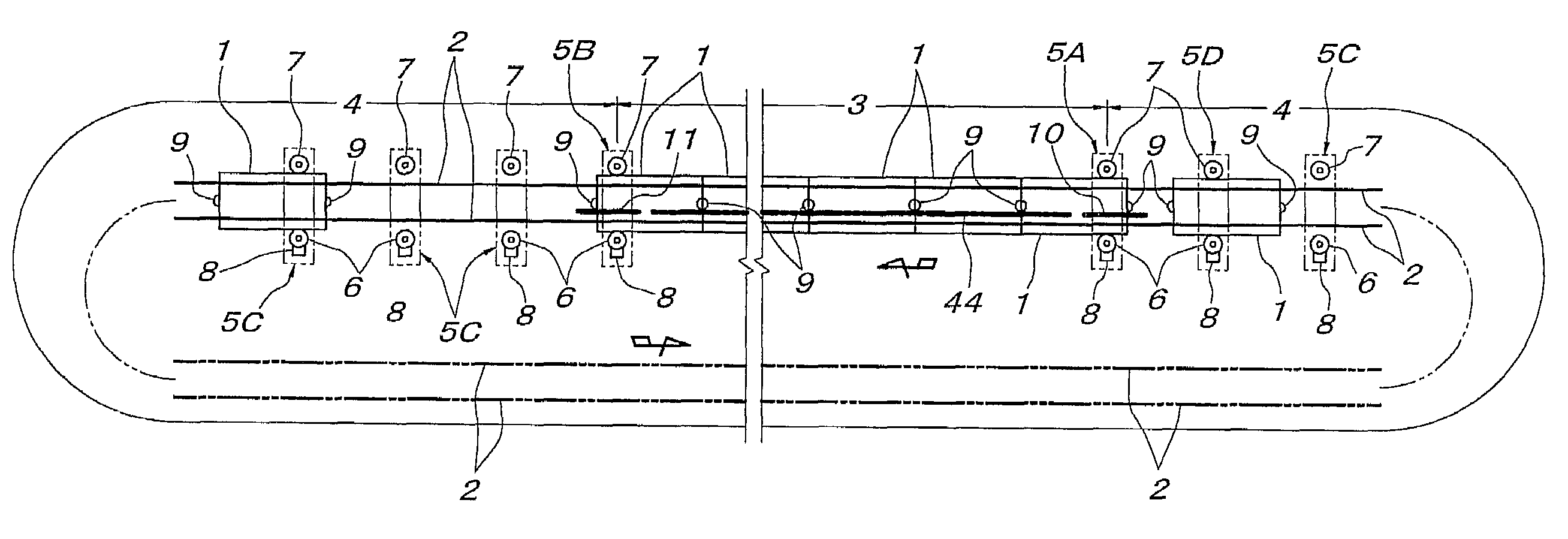

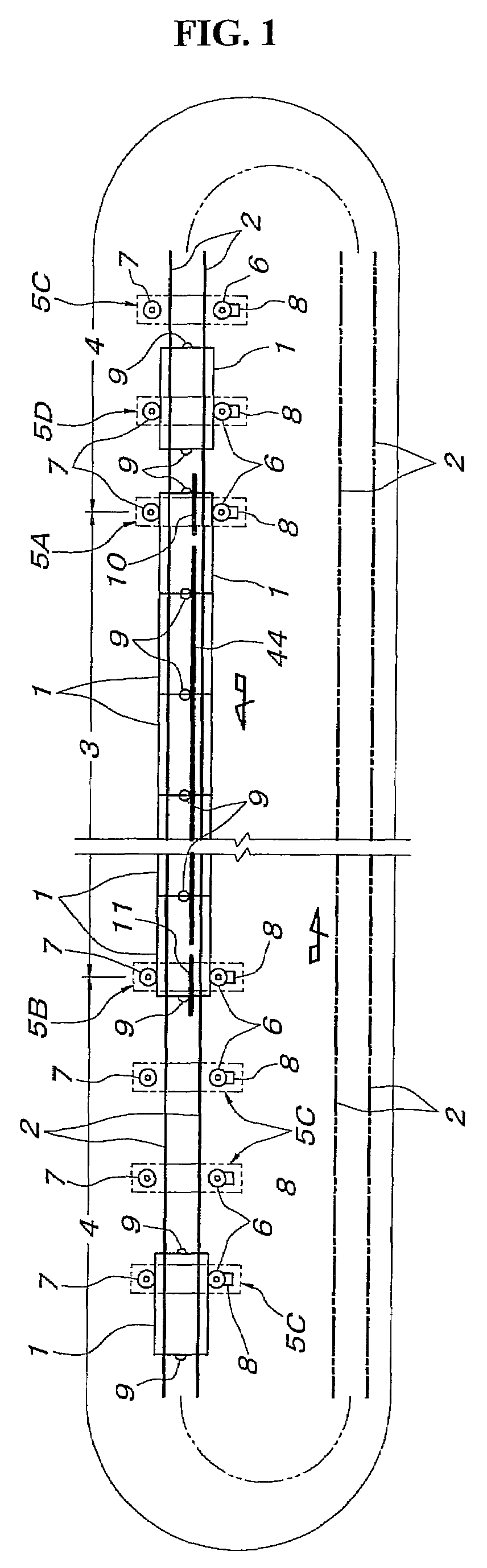

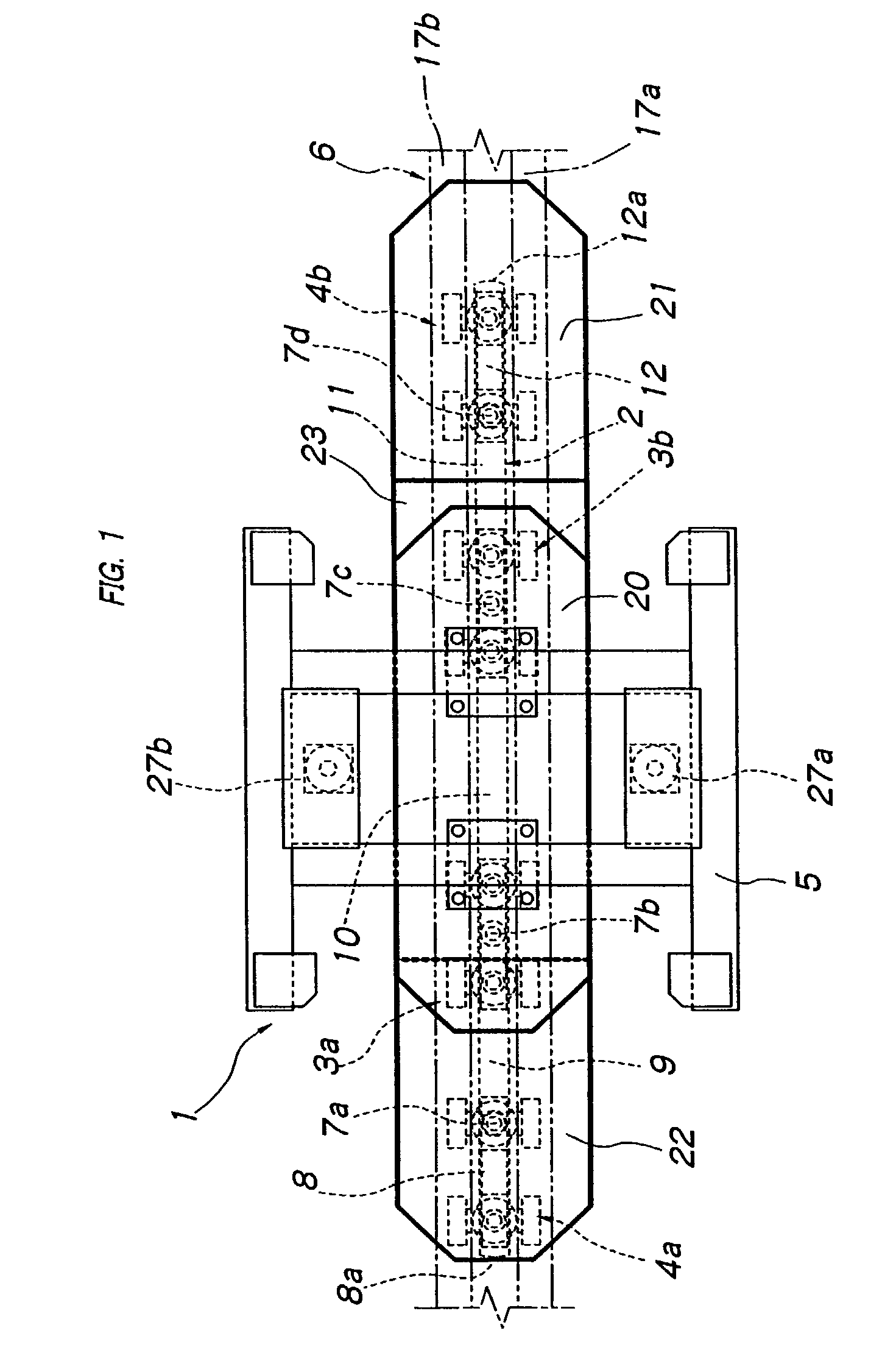

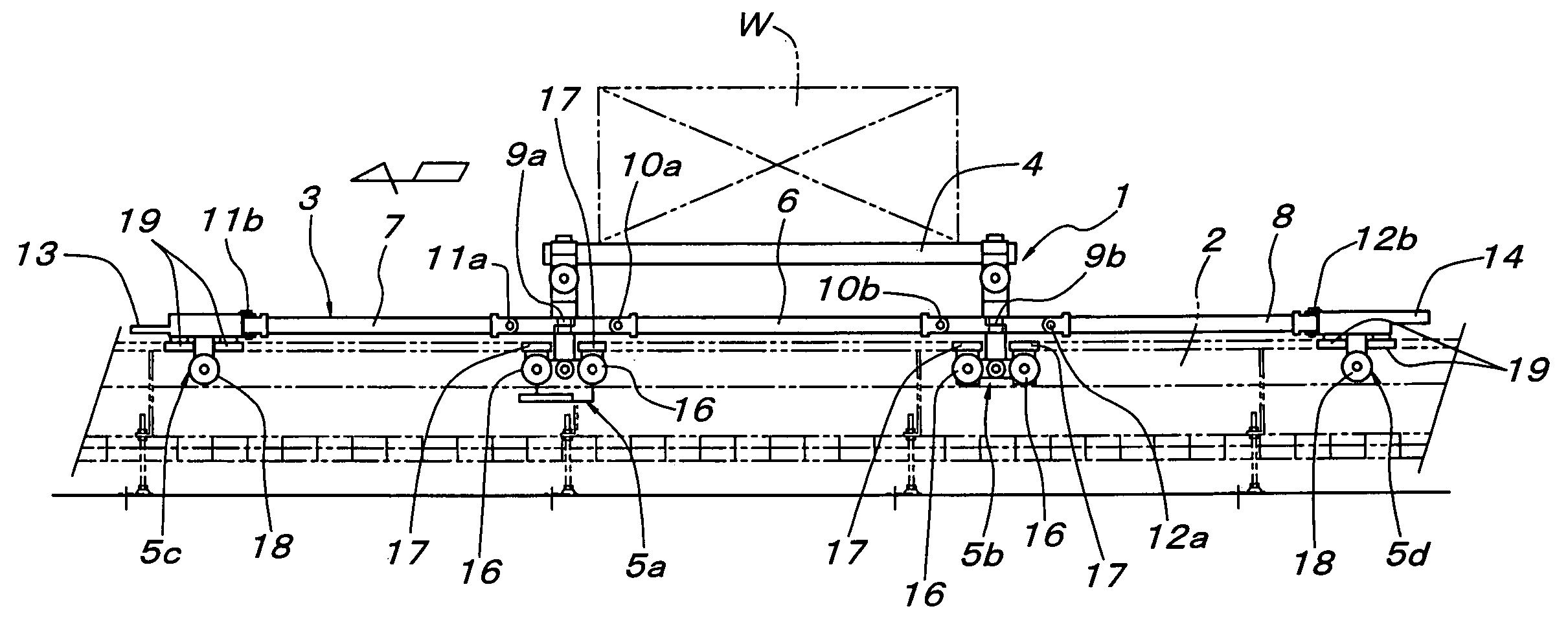

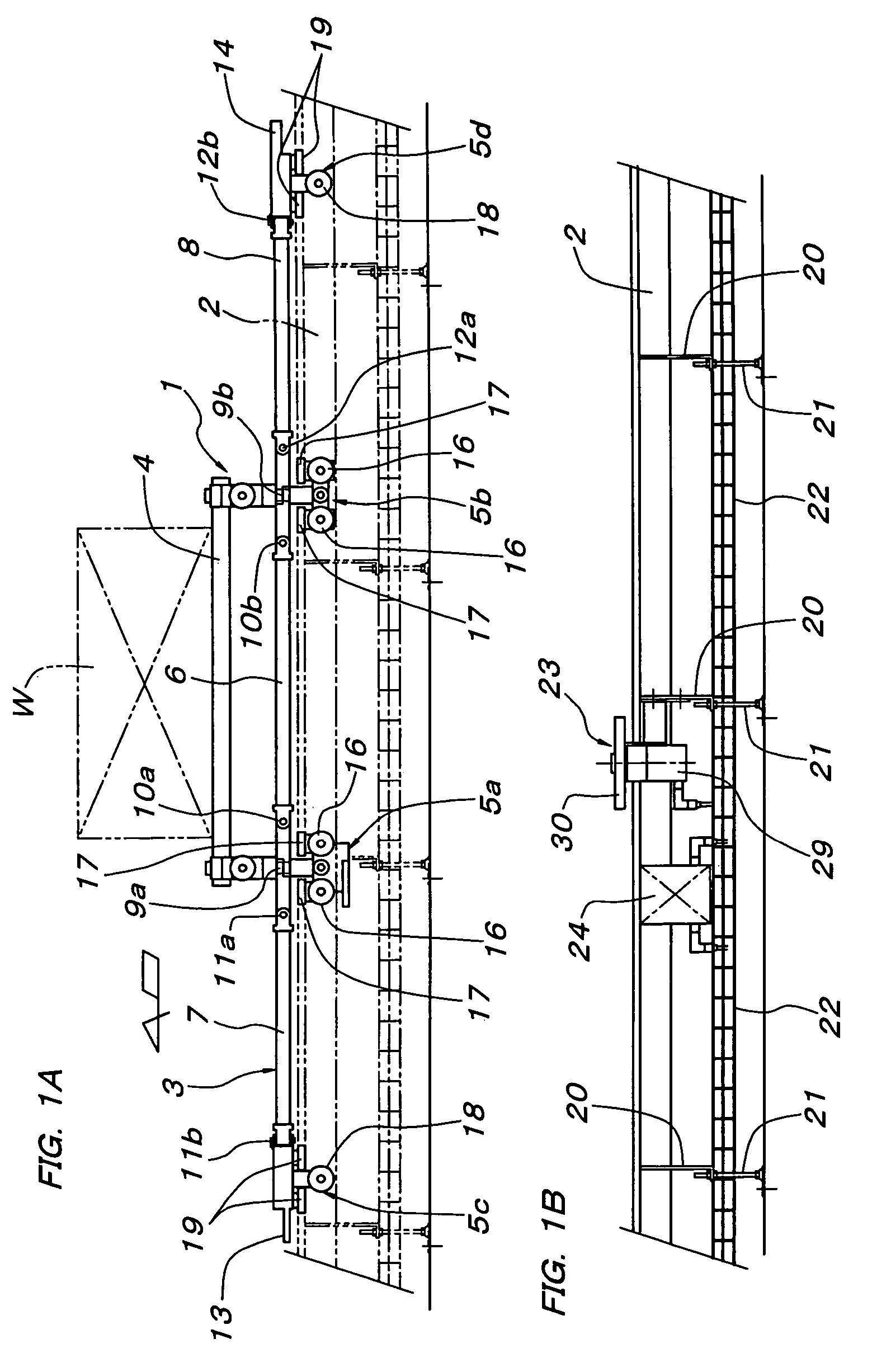

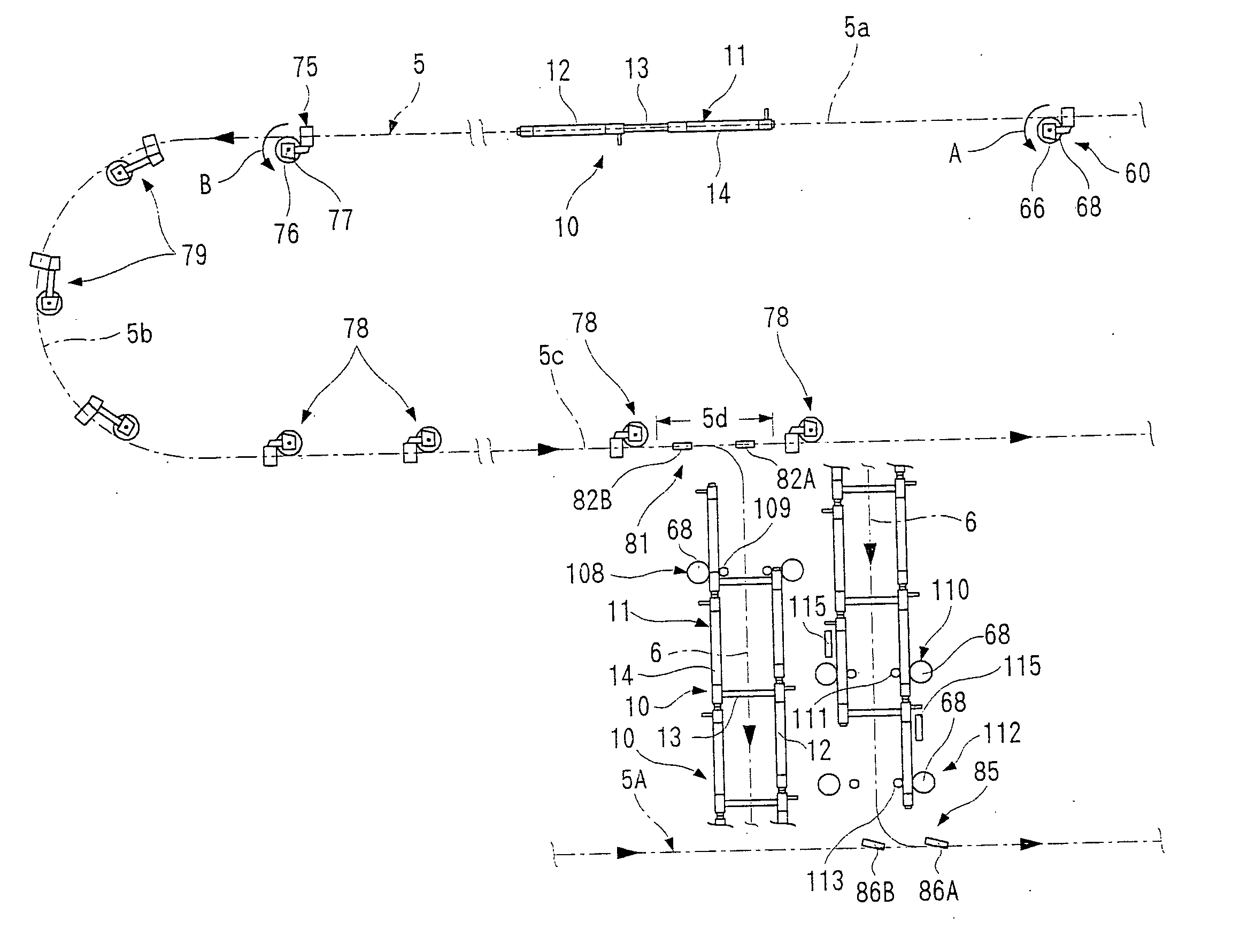

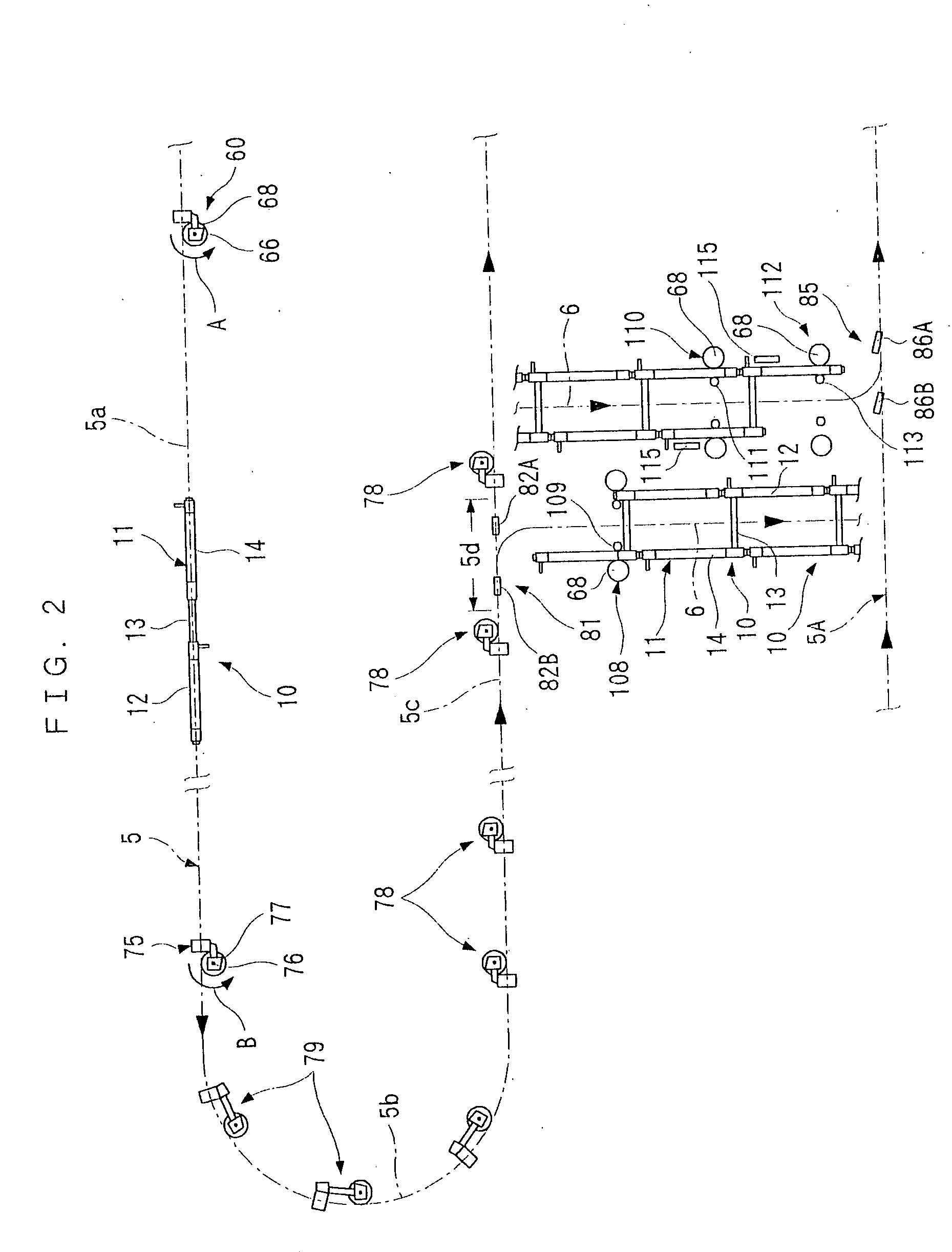

Carrier type conveying apparatus and conveying carrier connection system of the conveying apparatus

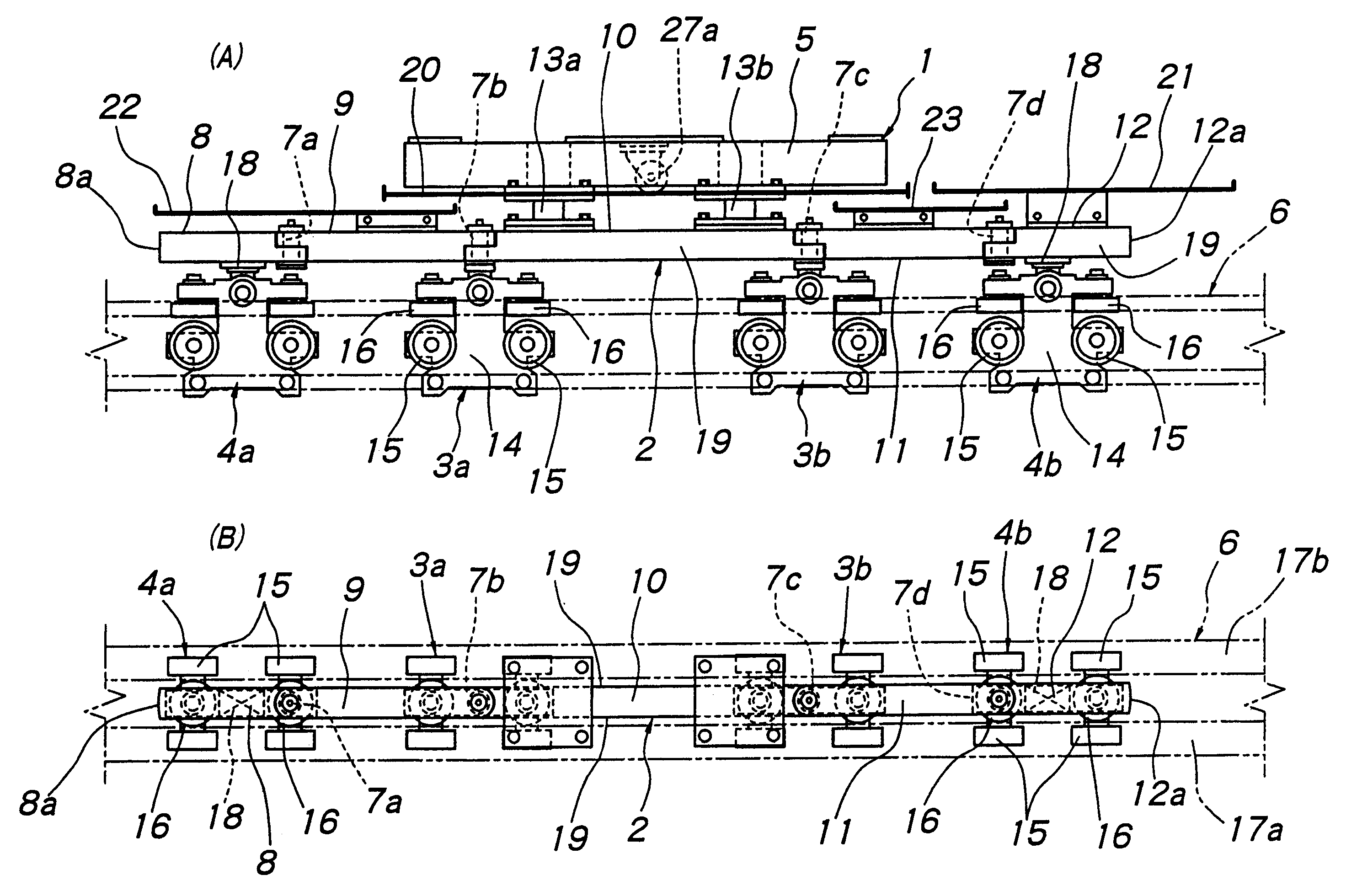

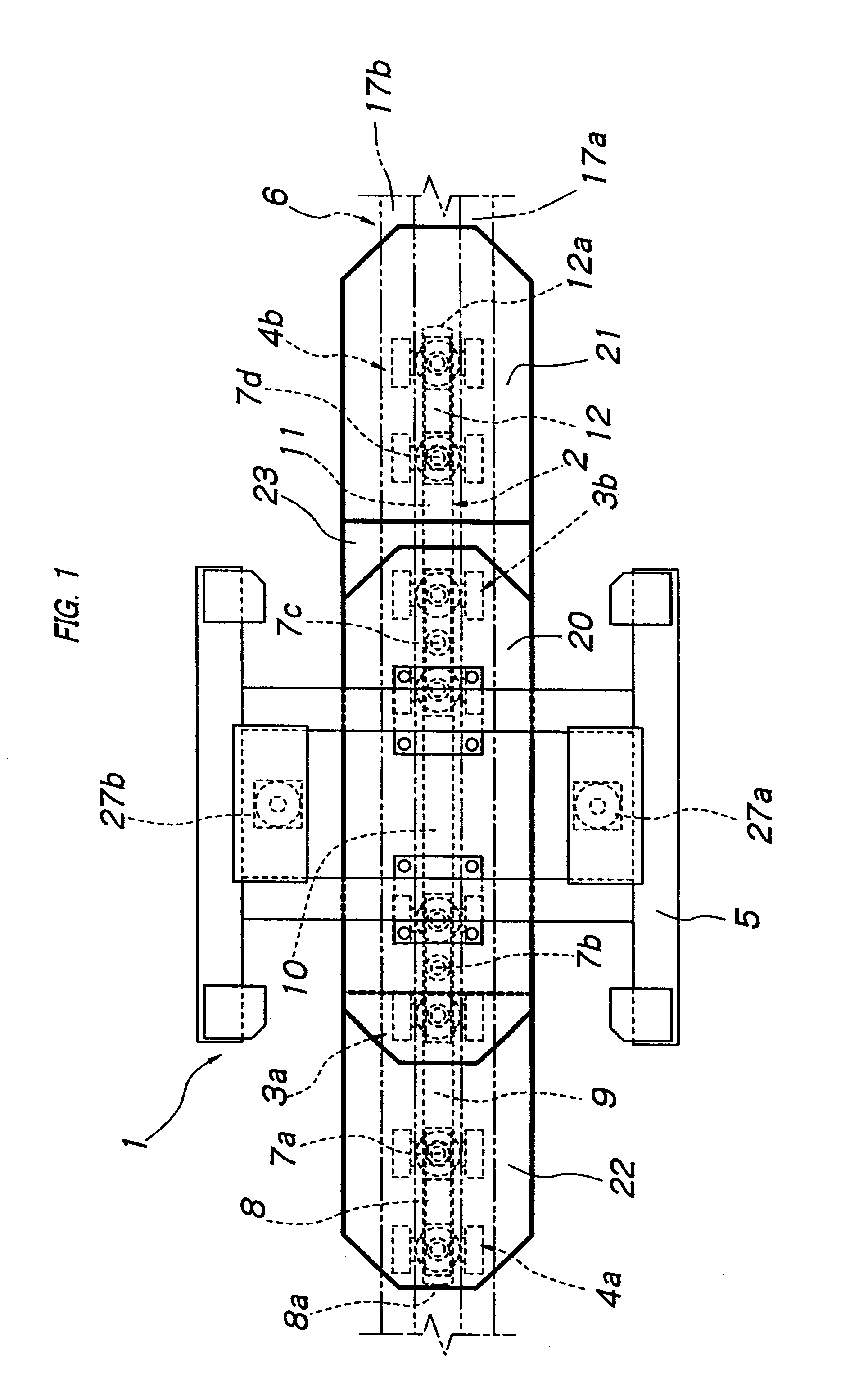

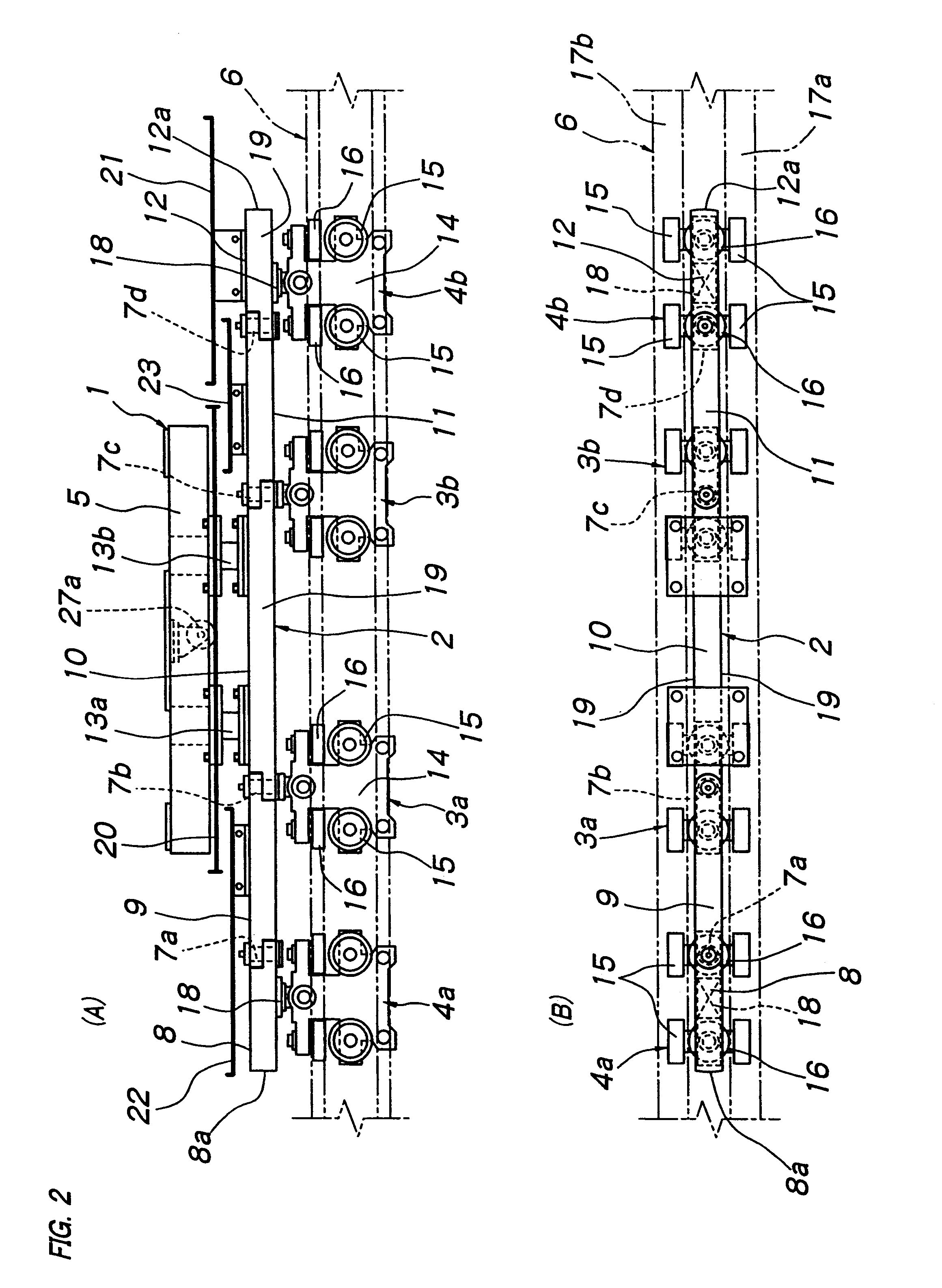

ActiveUS7658275B2Minimize workGuaranteed uptimePropulsion railway systemsRailway couplingsMechanical engineeringConstant speed

A carrier type conveying apparatus capable of solving a problem in a conventional conveying apparatus wherein a conveying carriers (1) stop abnormally, comprising a rear-pushing traveling district (3) having, at its inlet, a rear-pushing drive means (5A) propelling the conveying carriers (1) at a constant speed and, at its outlet, a speed control drive means (5B) for sending out the conveying carriers (1) at the constant speed and a high-speed traveling district (4). The conveying apparatus comprises carrier connection systems (carrier connection means (9), connection engagement means (10), connection release means (11)). When the conveying carriers (1) travel in the high-speed traveling district (4), the connection of the conveying carriers (1) adjacent to each other in the longitudinal direction by the carrier connection systems is disabled. Only when the conveying carriers (1) travel in the rear-pushing traveling district (3), the conveying carriers (1) in the longitudinal direction are connected to each other by the carrier connection system to prevent the conveying carriers (1) in contact with each other at their end parts from being separated a specified distance or longer from each other.

Owner:DAIFUKU CO LTD

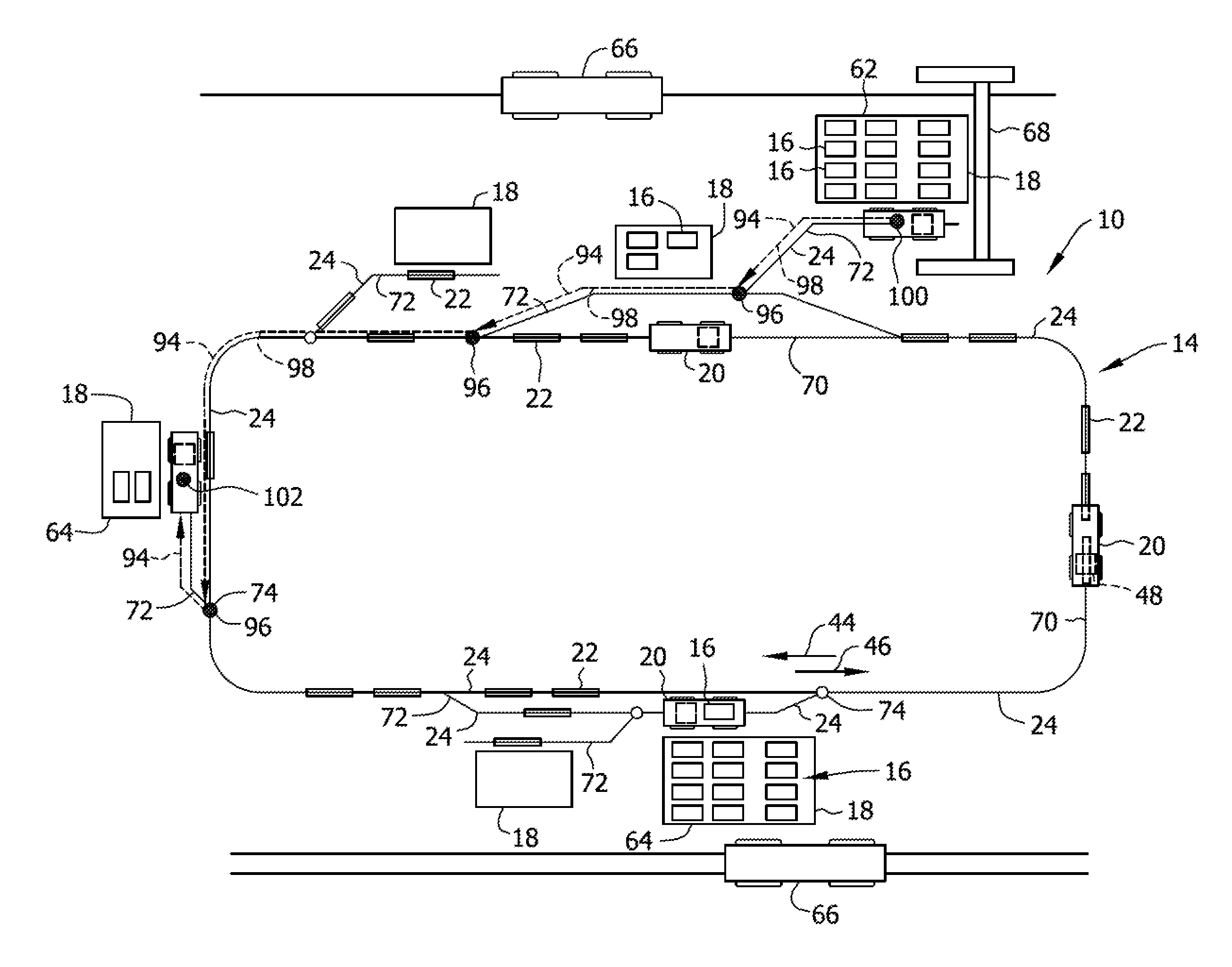

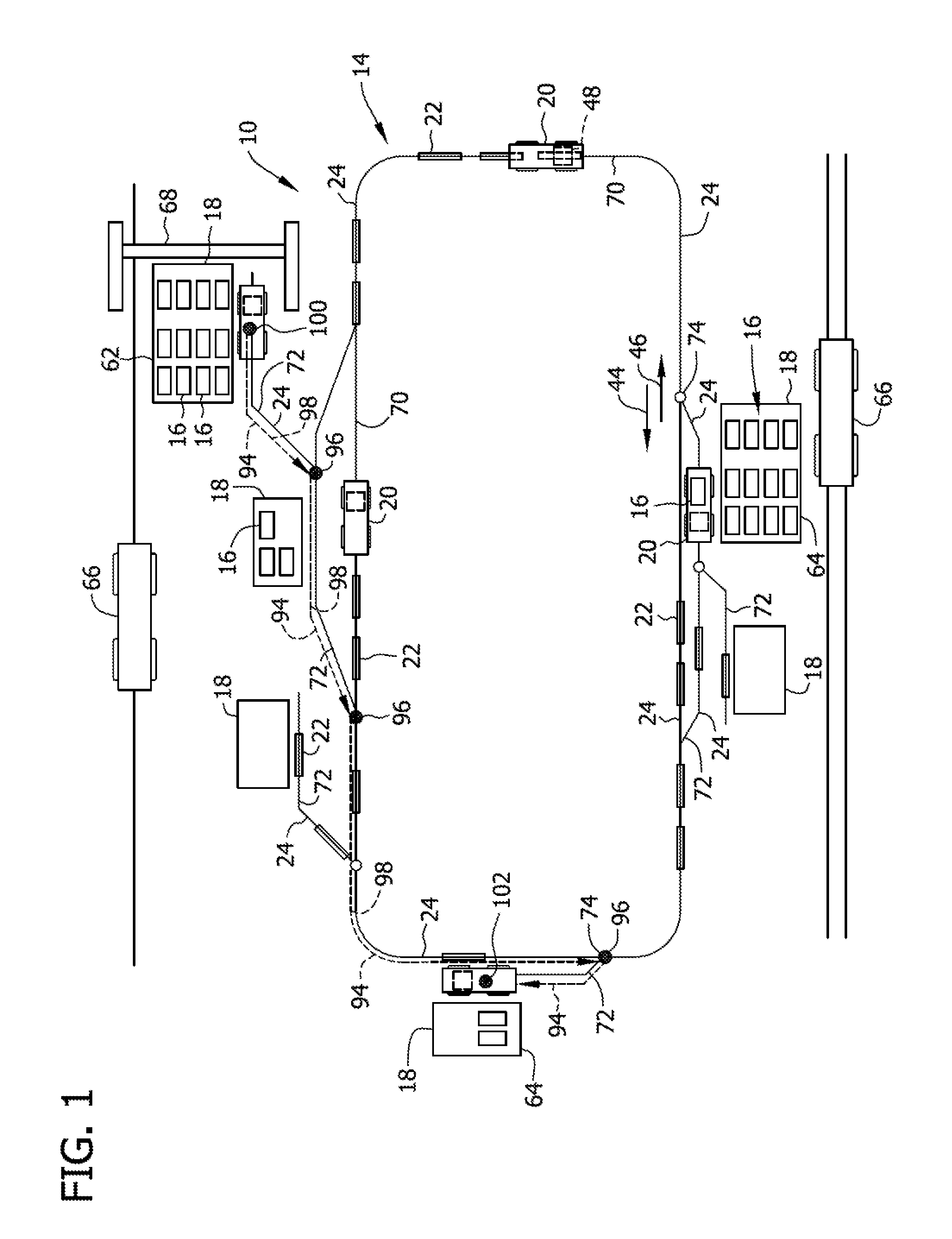

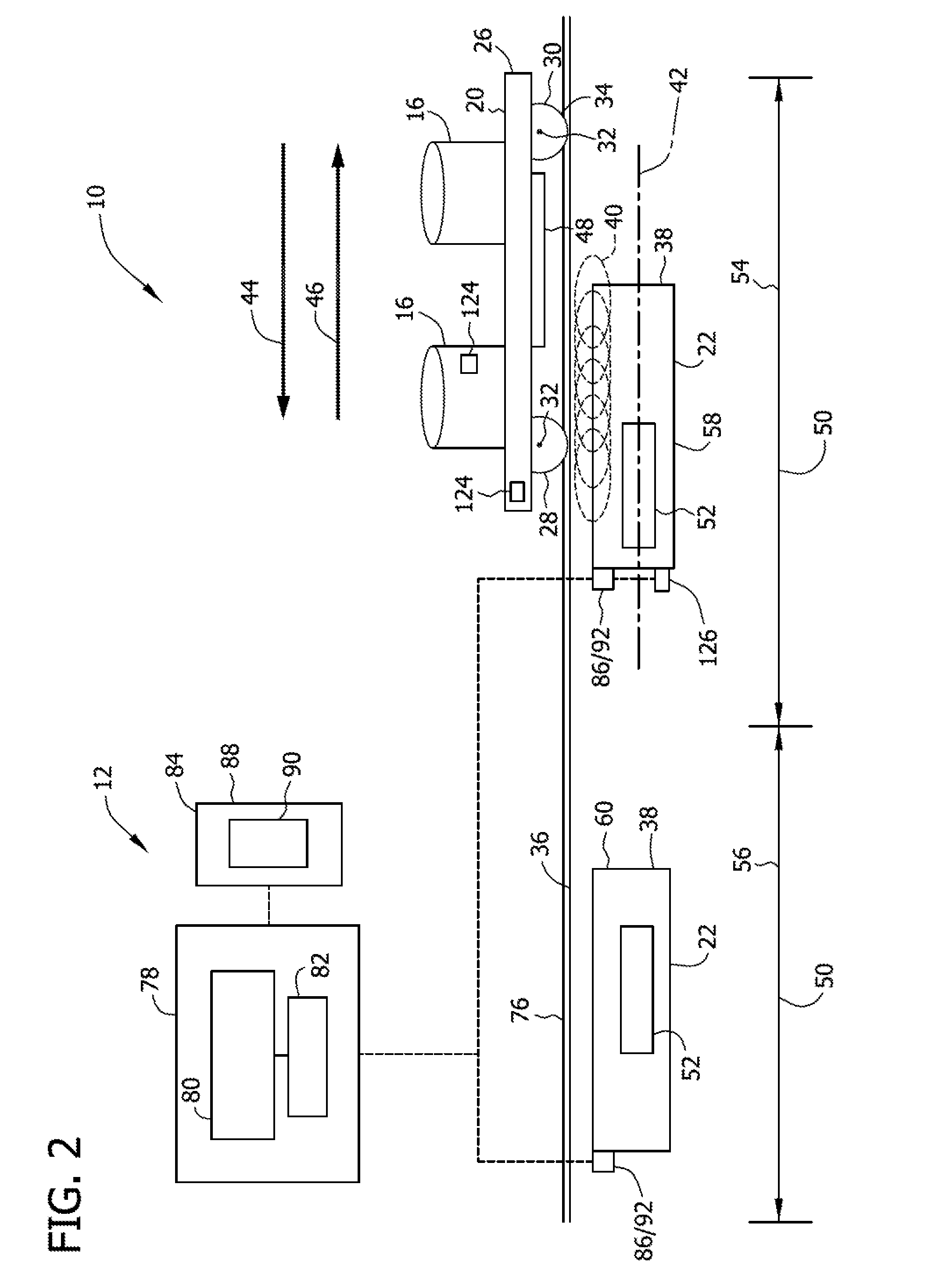

Transport and handling system and methods of transporting a commodity

ActiveUS20130173146A1Analogue computers for vehiclesDC motor speed/torque controlControl systemHandling system

A transportation system for use in transporting commodities is described herein. The transportation system includes a transportation network that includes a plurality of predefined paths of travel extending between a plurality of locations, and a plurality of transport vehicles. Each transport vehicle of the plurality of transport vehicles is configured to independently travel along the transportation network. A plurality of motor assemblies is oriented along the transportation network. Each motor assembly of the plurality of motor assemblies is oriented with respect to a predefined segment of the transportation network, and configured to move the transport vehicle along the predefined segment. A control system is operatively coupled to each motor assembly to selectively operate each motor assembly to independently convey each transport vehicle of the plurality of transport vehicles along the transportation network.

Owner:THE BOEING CO

Conveying apparatus

InactiveUS20030079967A1Effectively actPractical to useRailway componentsCharge manipulationMechanical engineering

A conveying apparatus suitable for driving a number of carriers in such a manner that the front end of each carrier thrusts the rear end of the preceding carrier is provided. The conveying apparatus comprises a guide rail and carriers. The rail includes a U-turn path section. Each carrier includes a load bar assembly including at least three load bars connected end-to-end by vertical pivot shafts in such a manner that the bars can pivot horizontally relative to each other. Each carrier also includes a load support supported by the associated middle load bar. Each carrier further includes a front trolley supporting at least the front end load bar and a rear trolley supporting at least the rear end load bar. The trolleys are supported movably on and guided by the guide rail. The trolleys are fixed to and in parallel with the end load bars. The free ends of the end load bars protrude from the front end of the front trolley and the rear end of the rear trolley so that the free end of the front end load bar of each carrier and the free end of the rear end load bar of the preceding carrier can contact together in the U-turn path section.

Owner:DAIFUKU CO LTD

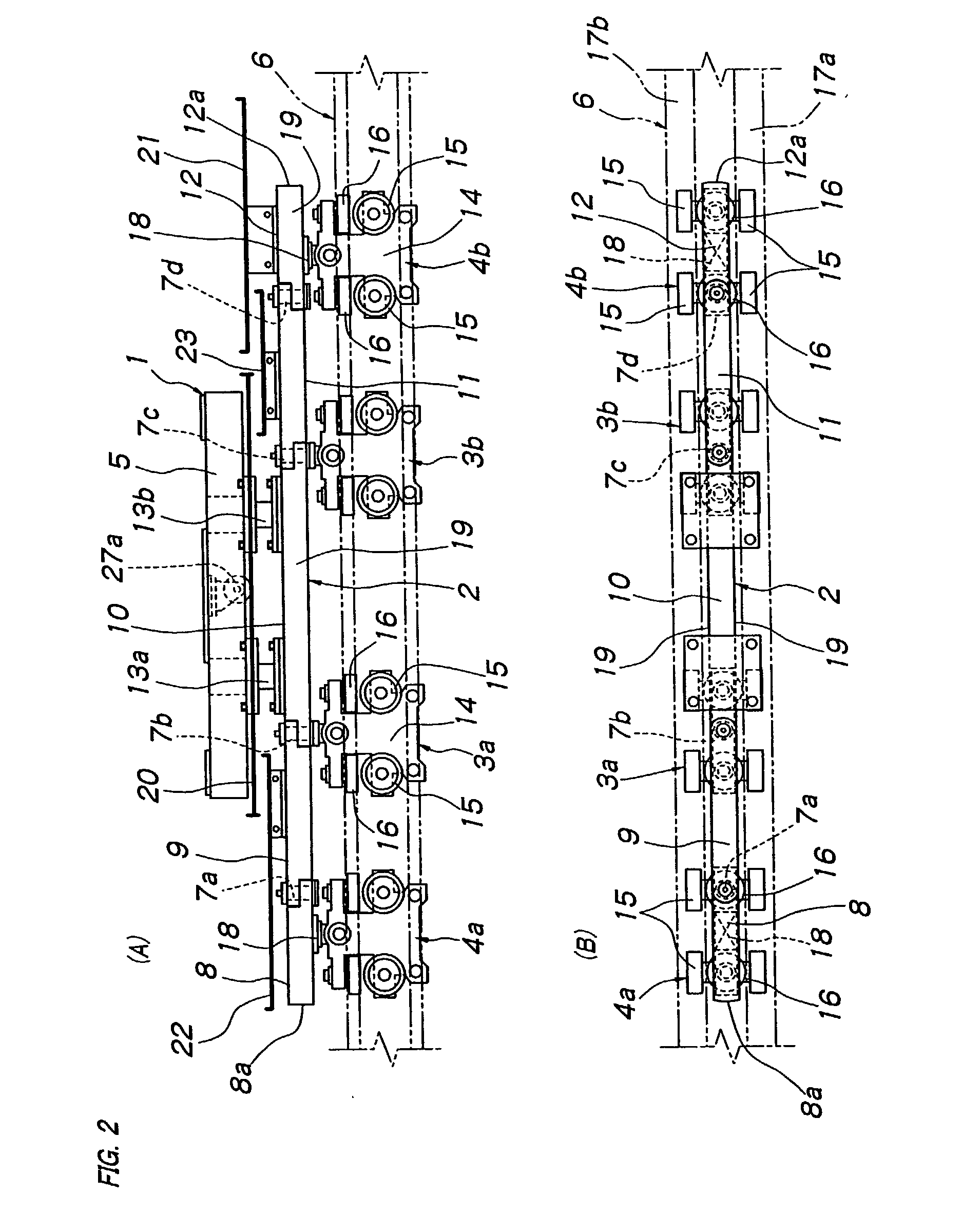

Friction drive conveyor

ActiveUS7127997B2Easily and efficiently carry-outSimple structureRailway componentsTramway railsEngineeringFriction drive

The present invention relates to a friction drive conveyor including carriers 1, which can be propelled along a track by frictional wheels 30 fitted along the track. Each frictional wheel 30 can be driven by a brakeless motor 29. A sensor 32 senses whether each frictional wheel 30 is in contact with any one frictional surface 15 of the carriers 1. The track includes a section along which the frictional wheels 30 are supported at regular intervals equal to or slightly shorter than the total length L of the frictional surfaces 15 on each side of each carrier 1. On the basis of a signal output from each sensor 32, a controller 24 so controls the associated brakeless motor 29 as to start rotating the associated frictional wheel 30 in contact with any one frictional surface 15 when the forward next wheel 30 gets free of the frictional surfaces 15, and as to stop driving the frictional wheel 30 having got free of the frictional surfaces 15.

Owner:DAIFUKU CO LTD

Flexible conveyance system

A conveyance system includes a plurality of feed-forward track segments aligned end-to end, each having an upwardly facing channel and at least one carrier drive member disposed in the channel. At least one carrier is supported for movement along the feed-forward track segments. Each carrier includes at least one drive engagement member that cooperates with the at least one carrier drive member to move the carrier along the respective feed-forward track segments. The conveyance system may further include a plurality of return track segments spaced from the plurality of feed-forward track segments.

Owner:KUKA SYST NORTH AMERICA LLC

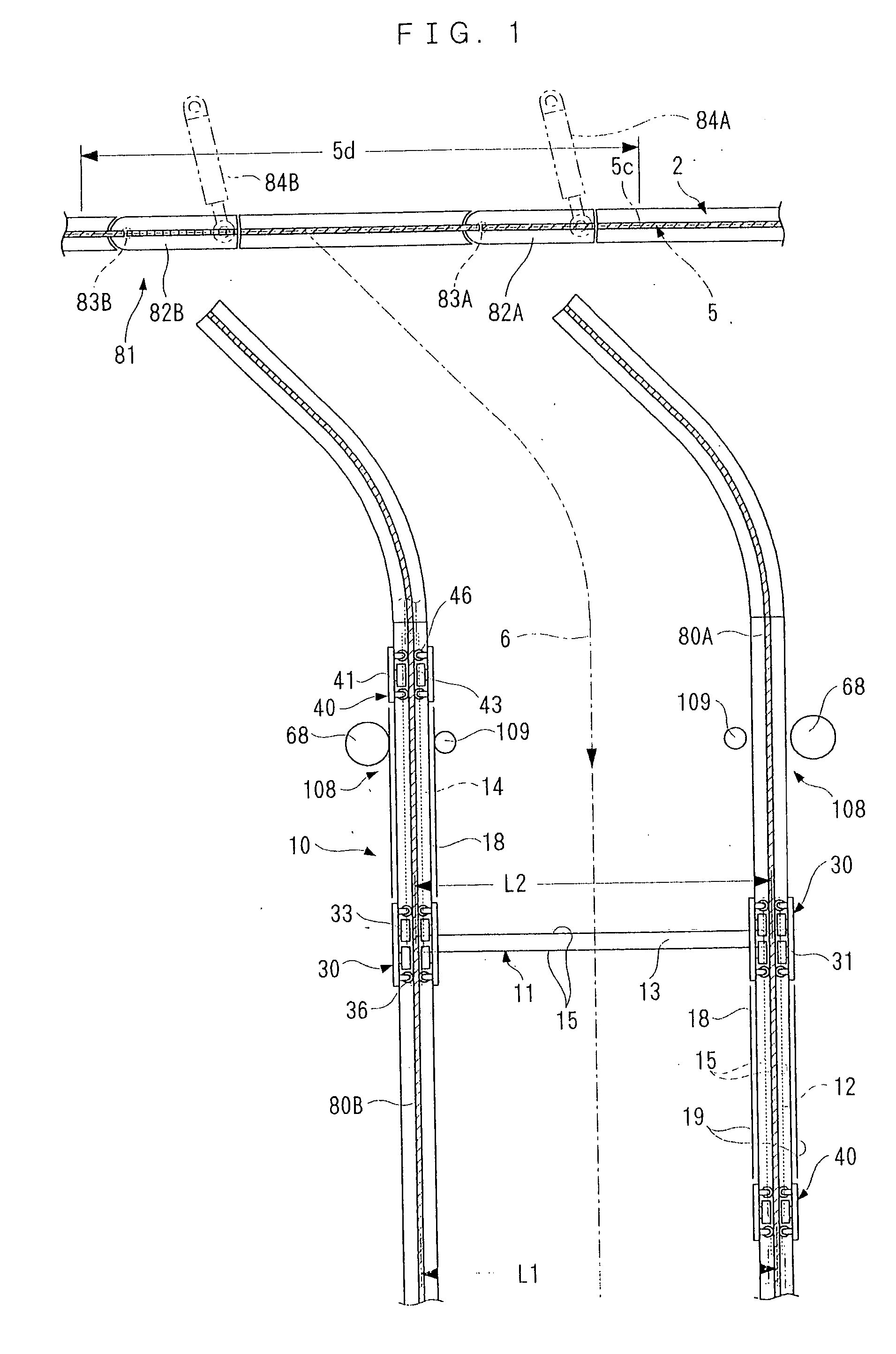

Conveyance apparatus using movable body

InactiveUS20050183620A1Simple structureEasy maintenanceTrain hauling devicesRailway tracksEngineeringMechanical engineering

A conveyance apparatus using movable bodies, in which a plurality of lateral travel rail members capable of supporting and guiding guided devices situated on a main rail are provided to the side of a prescribed region of the fixed path, in such a manner that a frame member provided with a supporting section assumes an orthogonal attitude or position with respect to a direction of travel, and the other frame members become aligned in the direction of travel, and causing the guided devices to branch off onto the lateral travel rail member group in the prescribed region. Thereby, spacing between the movable bodies in the lateral travel direction can be maintained readily by using a simple structure, and the group of movable bodies can be moved laterally in such a manner that there is no mutual contact between conveyed items.

Owner:DAIFUKU CO LTD

Wheel-type ultra high speed railway system

ActiveUS8505463B2Smooth rideTurnout is considerably simplifiedElectric devicesRailway tunnelsBogieUltra high speed

The wheel-type high-speed railway system includes rails provided on a railroad track and configured such that wheels provided in a bogie of a vehicle come into contact with them, a support provided on a tread surface of a railroad track between the rails, a repulsive Linear Synchronous Motor (LSM) provided between the bogie and the support and configured to improve traveling performance by reducing axle load in a high-speed region, first and second steel plates mounted on both sides of the support in inclined positions, and first and second attractive Dynamic Motion Control (DMC) magnets mounted on the bogie of the vehicle in inclined positions to correspond to the first and second steel plates, and configured to generate attractive force.

Owner:KOREA RAILROAD RES INST

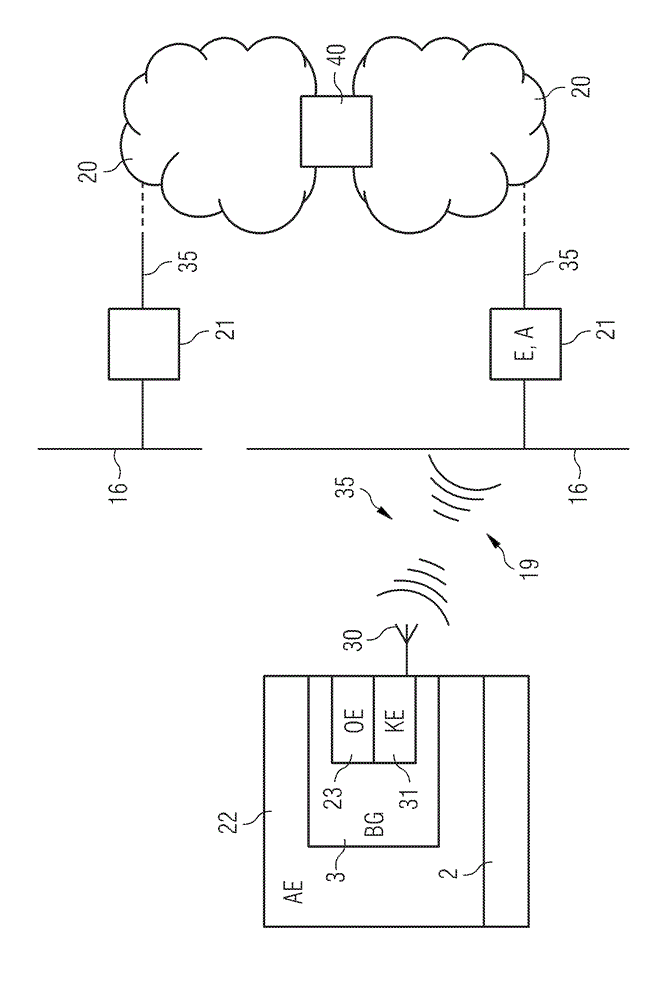

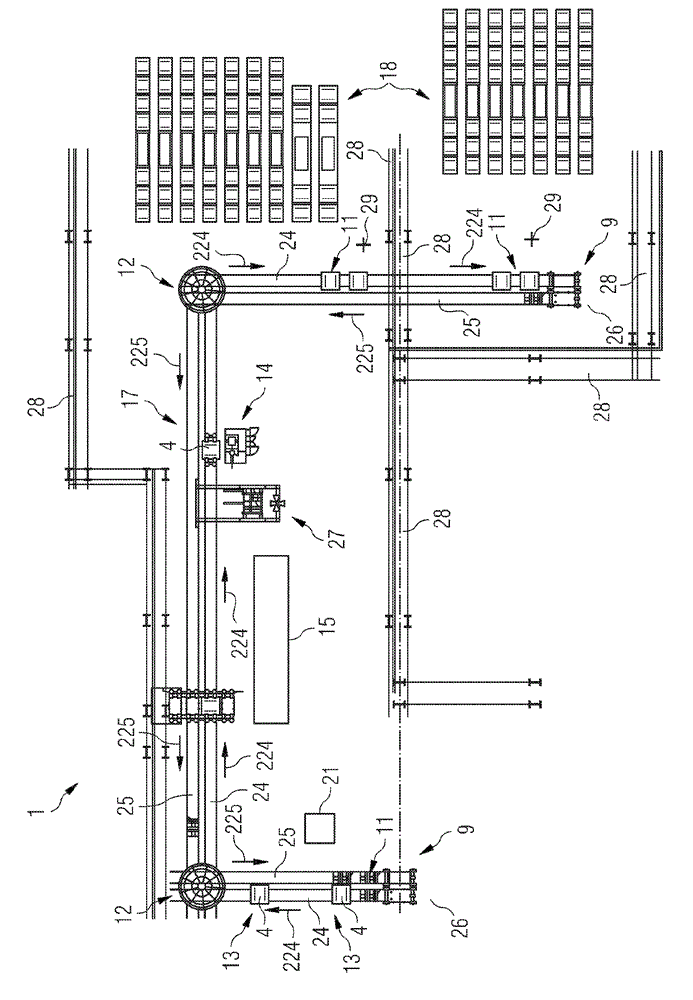

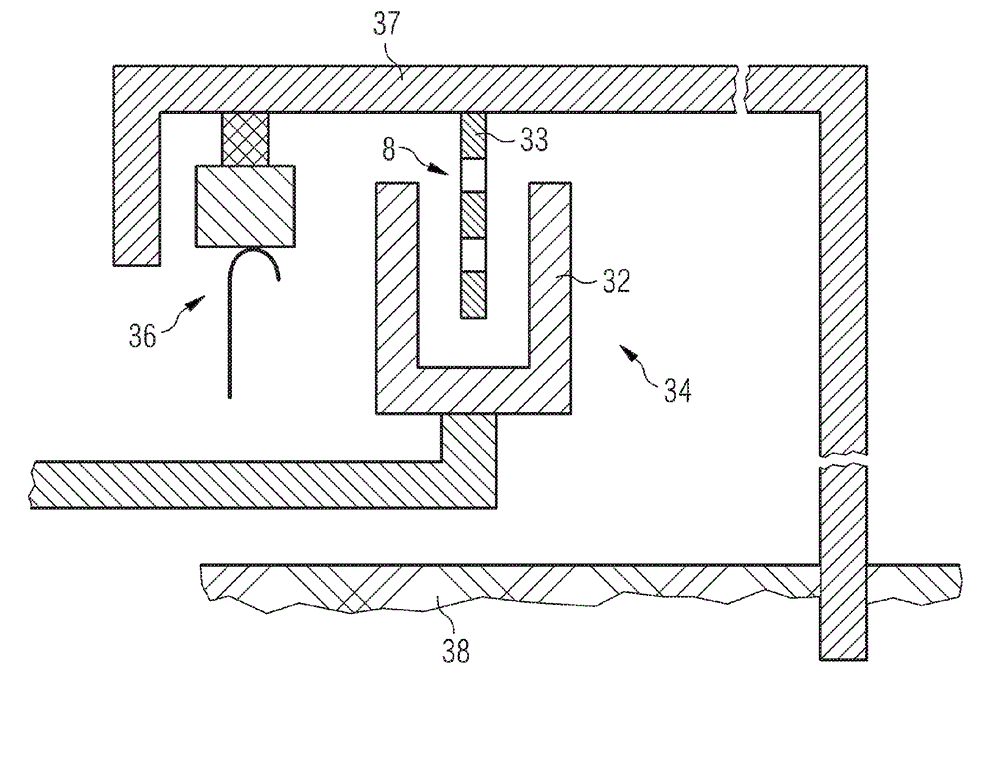

Transporting system, transporting carriage and method for transporting metal coils

A transporting system for transporting metal coils (4), in particular hot coils, comprises: - a multi-track rail system (17); - a number of driverless transporting carriages (11), which can be moved on the rail system (17) by means of a drive device (22) and are equipped with an on-board communication device (31); - a locating device (23), with which up-to-the-moment locational information can be determined for each transporting carriage (11) located on the rail system (17); - and a central control device (40), to which the locational information of each transporting carriage (11) can be fed, wherein a communication link (19), which at least in certain sections is formed without any lines, can be established between the control device (40) and the communication device (31). The invention also relates to a method for transporting metal coils and to a transporting carriage.

Owner:PRIMETALS TECH AUSTRIA GMBH

Pneumatic mass transportation system

A pneumatic mass transportation system employs a combined cycle turbine power system with digital controls to effect acceleration, deceleration and train propulsion. Combustion turbines can be adapted to use alternative fuels including bio fuels as they are developed. A heat recover steam generator recycles hot exhaust gasses from turbines to generate electricity to be used by the system. A multi-car train is propelled by differential air pressure forward and aft of the vehicle in a pneumatic tube. Air propulsion is achieved by large in-tube impellers driven by the turbines. A digital control system controls turbine speed, pitch of impeller blades and vacuum / pressure release valves in the tubes to maneuver and control the train.

Owner:FLYNN PATRICK JOSEPH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com