Transporting system, transporting carriage and method for transporting metal coils

A transportation system and transportation vehicle technology, applied in transportation and packaging, transportation center control system, railway system with propulsion equipment, etc., can solve problems such as takt time coil damage, metal strip manufacturing quality damage, etc., to achieve stability and The effect of reliable data transmission and lossless information transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

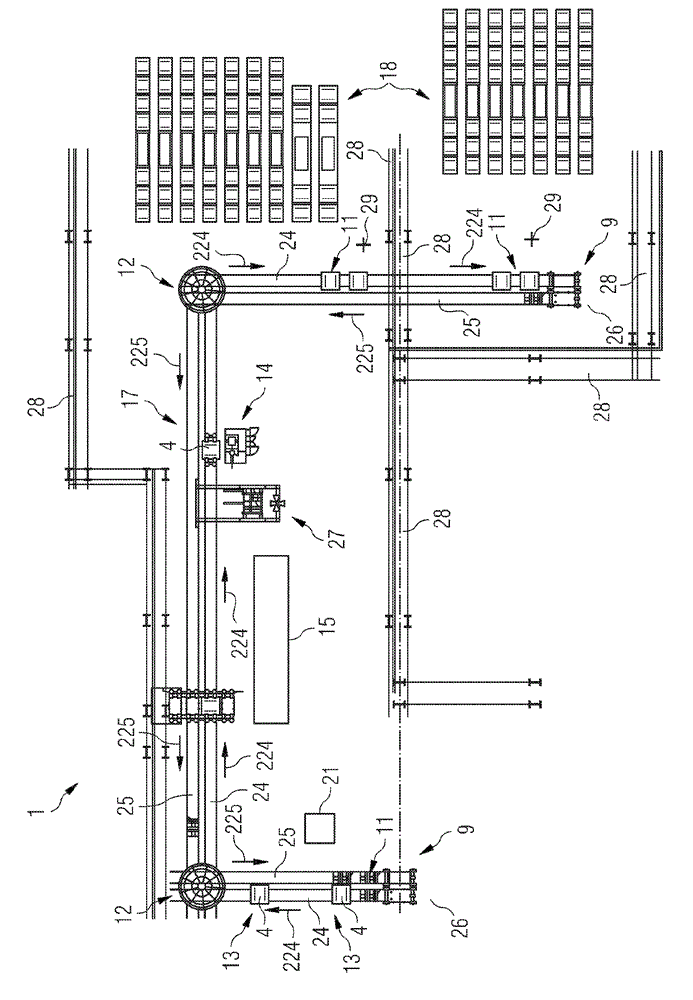

[0041] FIG. 1 schematically shows an exemplary embodiment of the transport system 1 according to the invention for transporting metal strip coils 4 . In the top view, a section of the course of the rail system 17 can be seen within the workshop in which the metal strip coils 4 are transported. The plant boundary 28 is delineated in the illustration in FIG. 1 with a thinner dotted line.

[0042] A sheet metal strip (not shown in detail) is fed to two coiler devices (down coiler) 13 (loading area) in each case and is wound up into a coil 4 . This coil 4 is loaded onto a transport trolley 11 and transported away. According to the invention, the track system 17 is formed from two lines or tracks 24 and 25 . Depending on the state of loading, the transport vehicles 11 are assigned to rails 24 , 25 . In the exemplary embodiment shown, the transport vehicle 11 travels on a rail 24 in the loaded state and on a rail 25 in the unloaded state.

[0043] The following description begin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com