Patents

Literature

1339 results about "Manufacturing quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

As customer expectations have risen over time, manufacturing quality has come to be an absolute requirement, regardless of where products are manufactured, distributed, and sold. Assuring manufacturing quality entails three principal functions: quality design and engineering, quality control, and quality management.

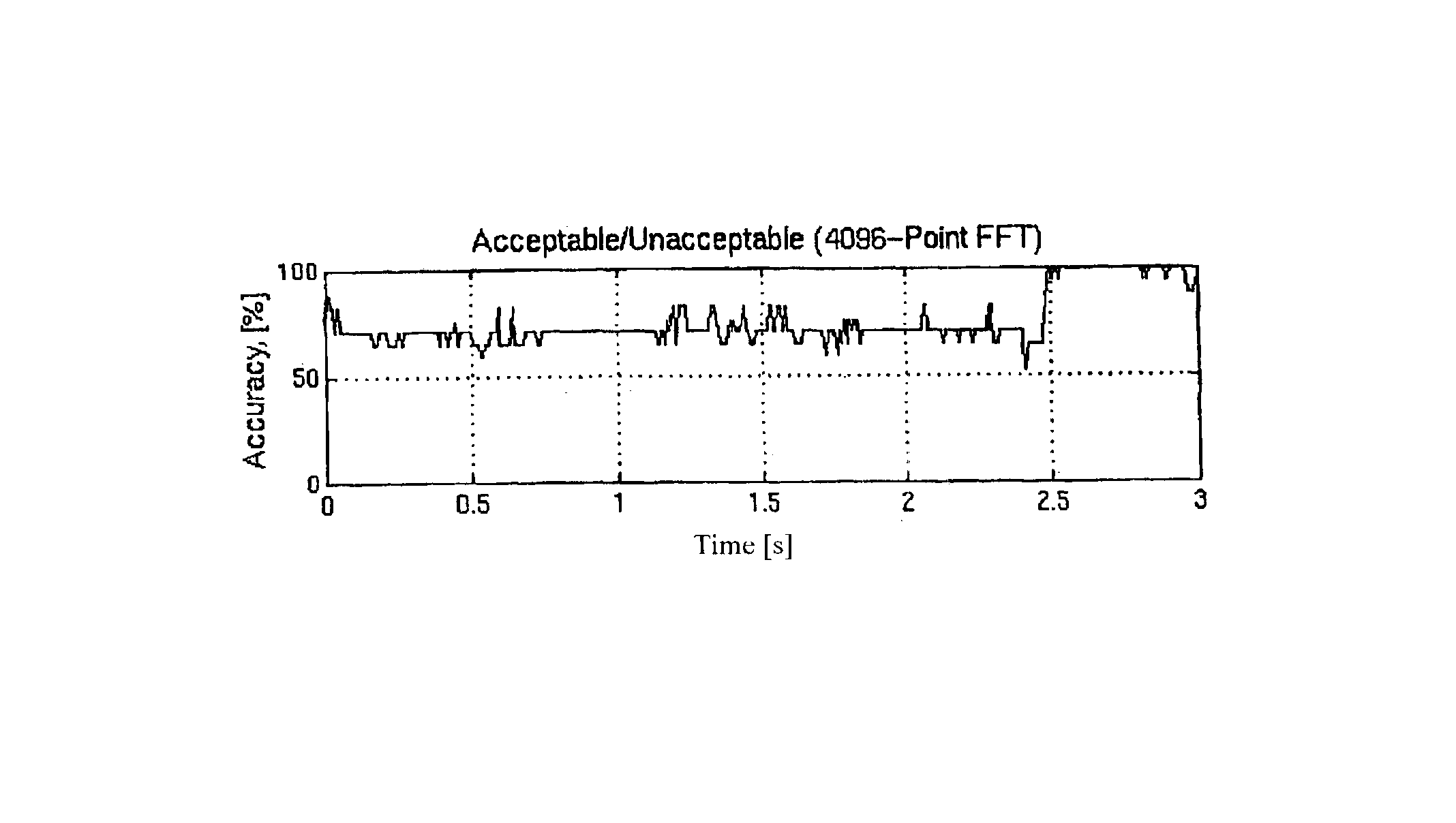

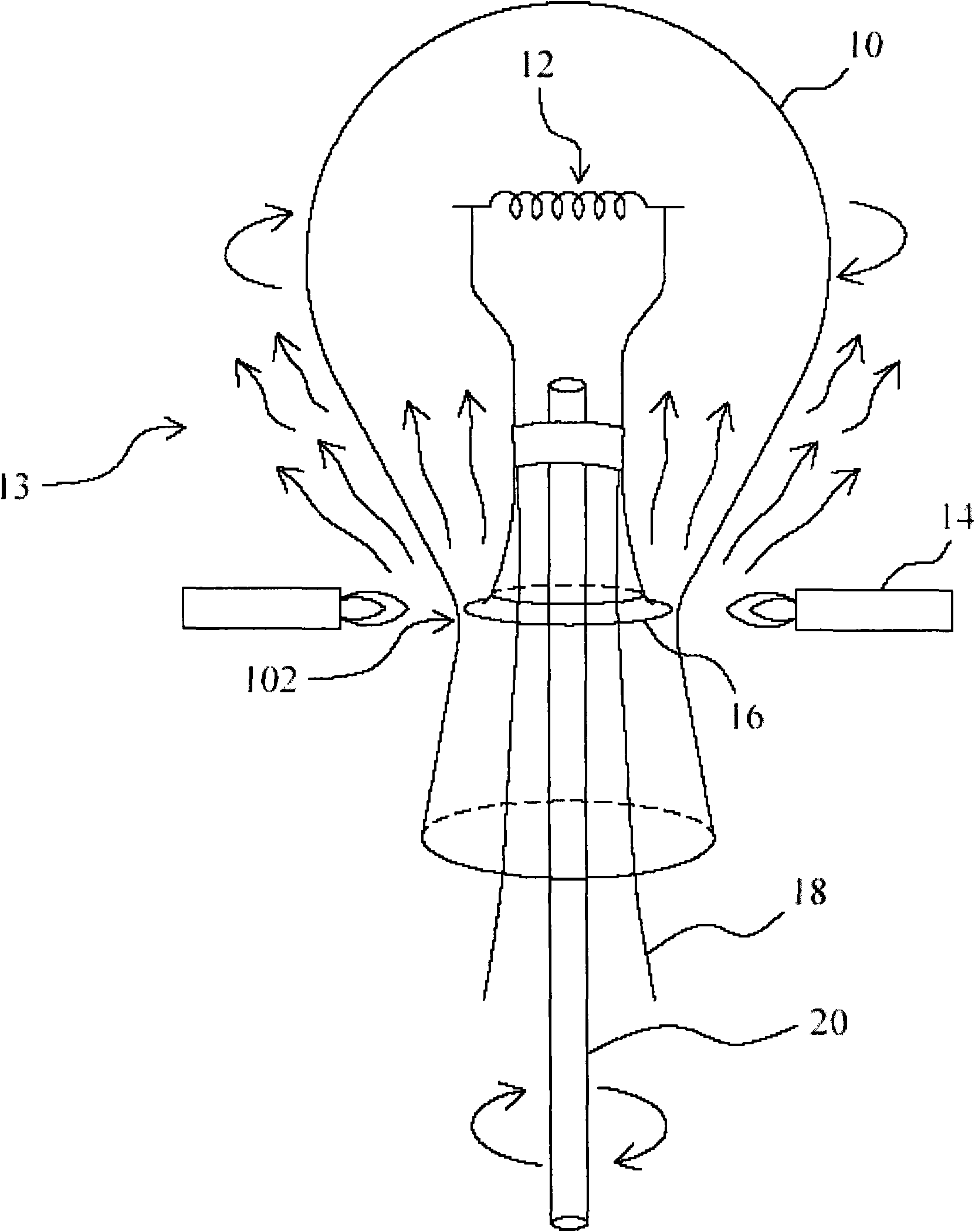

Method and apparatus for in-process sensing of manufacturing quality

InactiveUS6857553B1Low costShorten the timeAnalysing solids using sonic/ultrasonic/infrasonic wavesResonant frequencyFriction weldingAcoustics

A method for determining the quality of an examined weld joint comprising the steps of providing acoustical data from the examined weld joint, and performing a neural network operation on the acoustical data determine the quality of the examined weld joint produced by a friction weld process. The neural network may be trained by the steps of providing acoustical data and observable data from at least one test weld joint, and training the neural network based on the acoustical data and observable data to form a trained neural network so that the trained neural network is capable of determining the quality of a examined weld joint based on acoustical data from the examined weld joint. In addition, an apparatus having a housing, acoustical sensors mounted therein, and means for mounting the housing on a friction weld device so that the acoustical sensors do not contact the weld joint. The apparatus may sample the acoustical data necessary for the neural network to determine the quality of a weld joint.

Owner:THE UNITED STATES AS REPRESENTED BY THE DEPARTMENT OF ENERGY

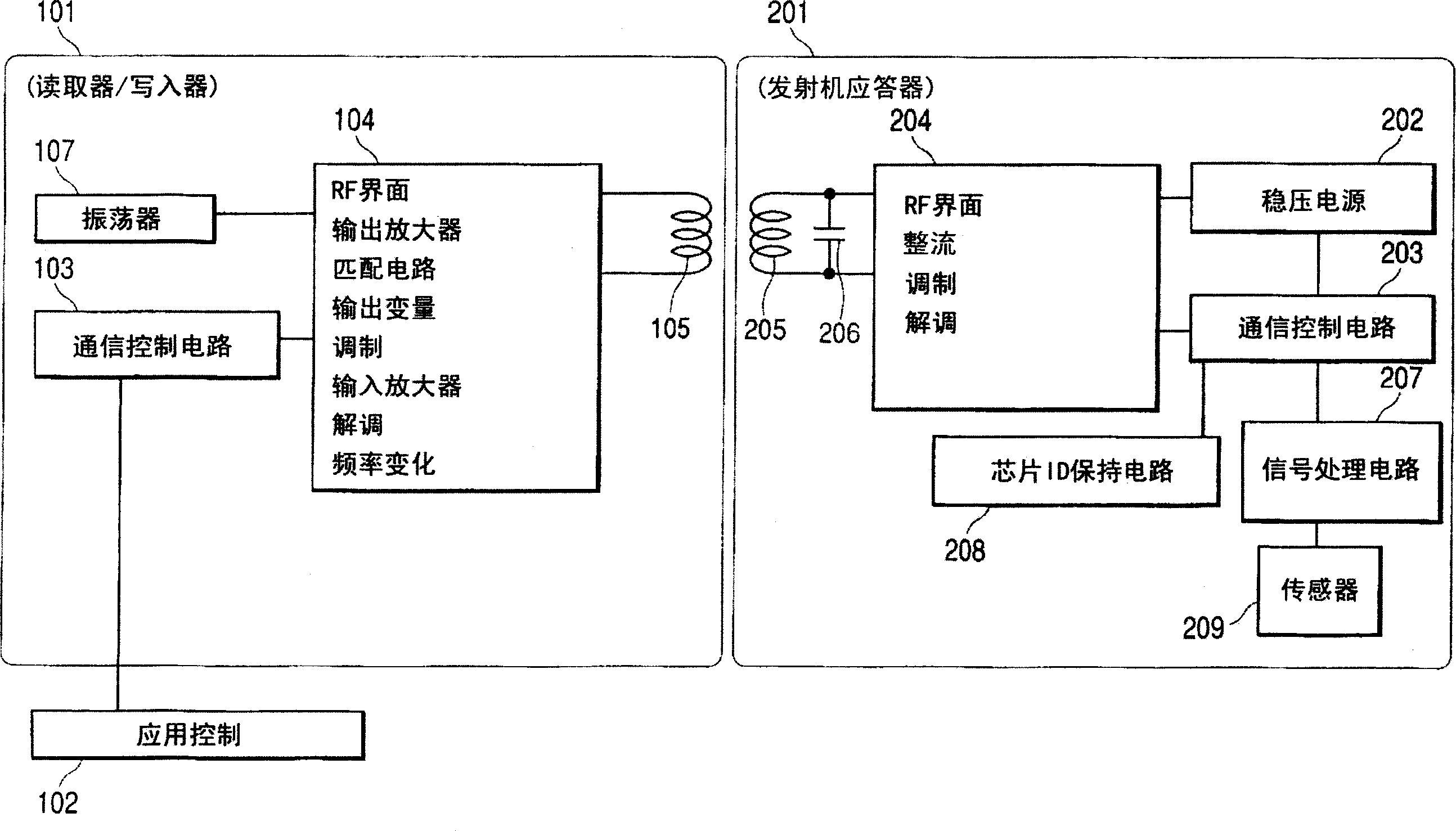

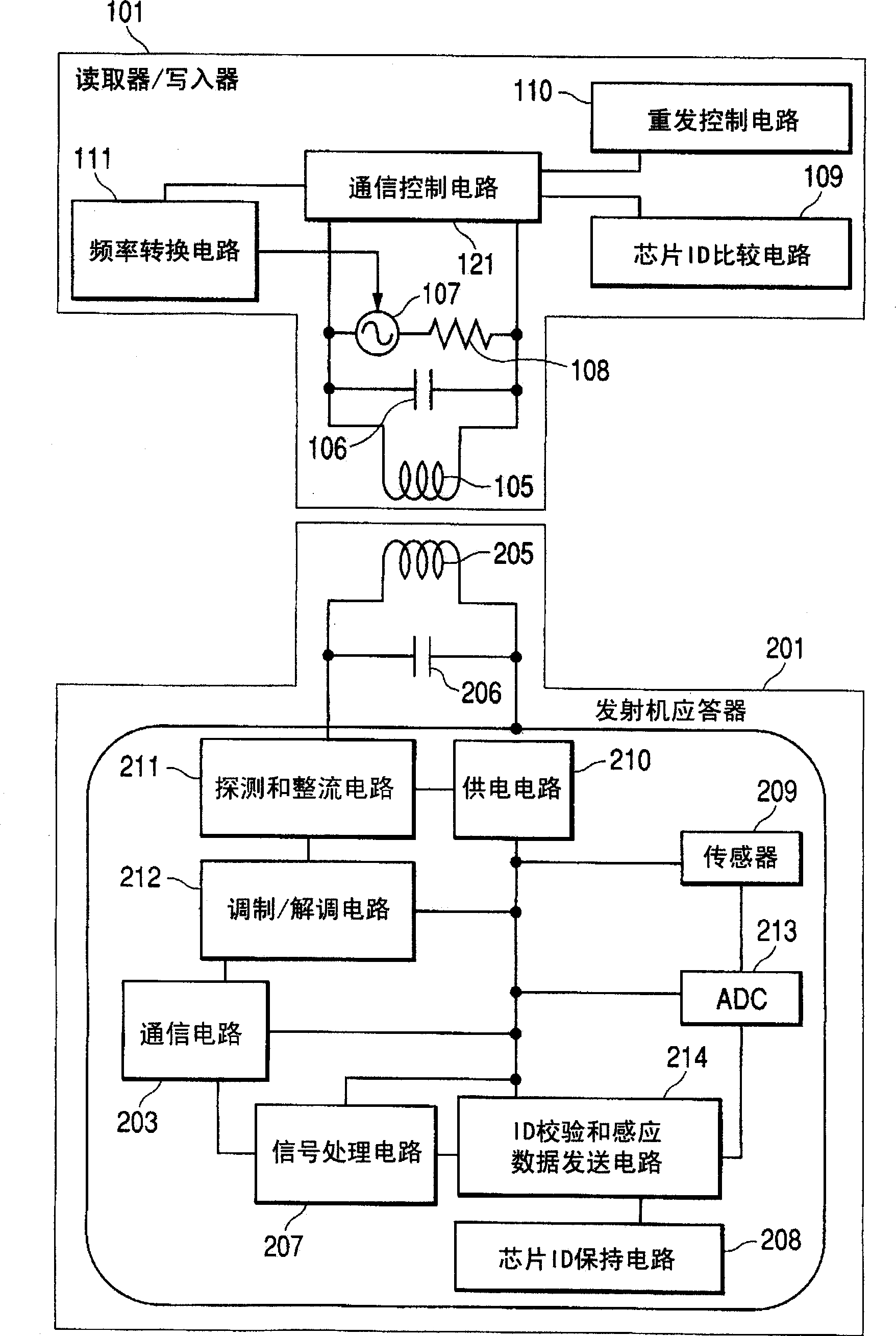

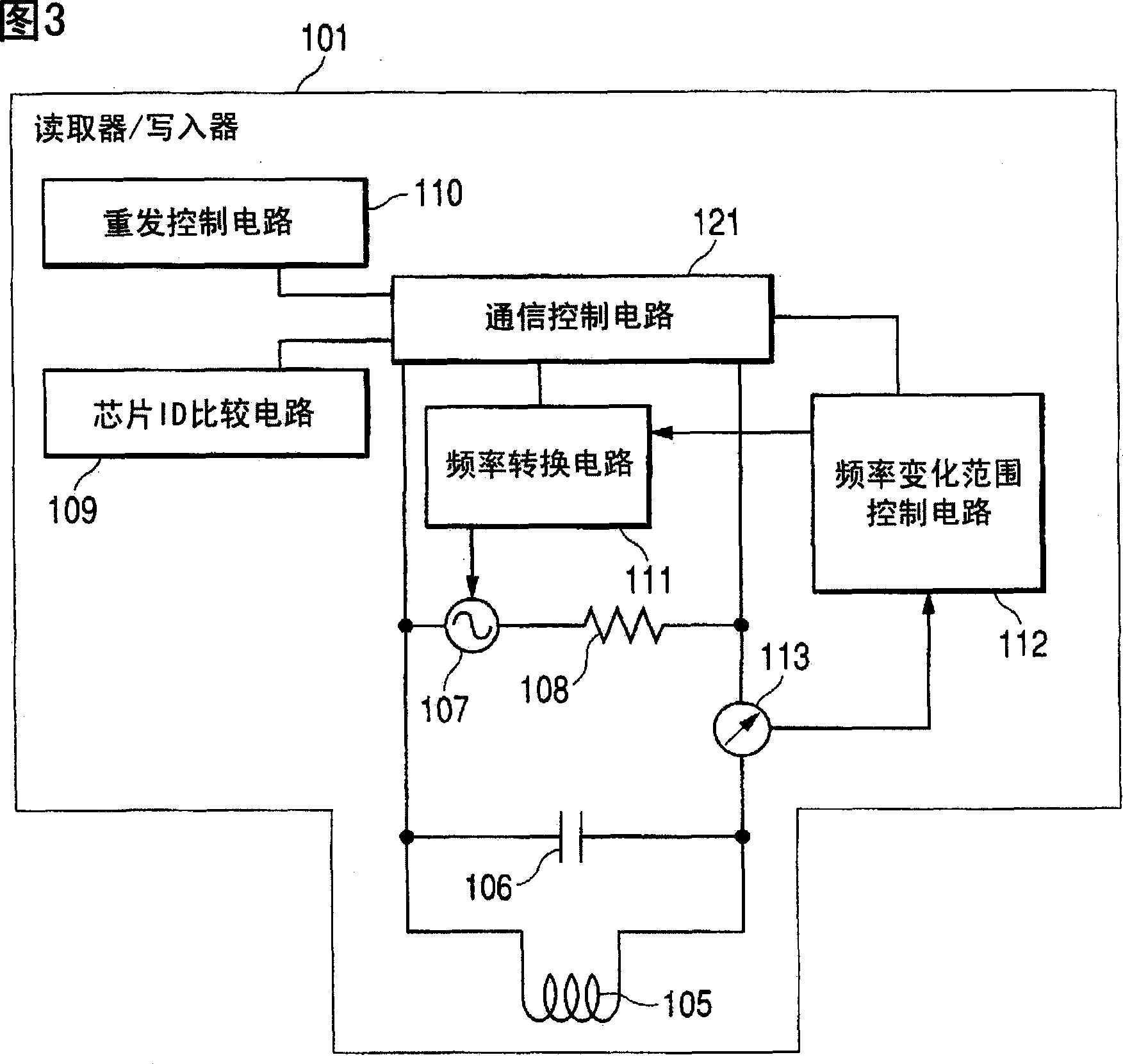

Communication system

InactiveCN1572885AStable communicationRapid detection of stabilityTransmission systemsMicrobiological testing/measurementCommunications systemResonance

A communication system is provided which enhances communication stability, using chips on which function blocks are formed including sensor, chip ID, and radio transmission / reception functions. The sensor detects biological and chemical materials and physical and stoichiometric quantities such as temperature, pressure, and pH and the sensed results are transmitted to a reader by a radio frequency (RF) function. The chip with the sensor functions at a resonance frequency which is detected by the reader initially during a frequency sweep. No dedicated power source is essential to operate the chips, but instead the chips are triggered into transmitting by the radio frequency signals transmitted from the reader. The frequency and output of transmission from the reader to the chips are variable. Stable communication can be performed without being affected by variation in the chips characteristics depending on manufacturing quality.

Owner:HITACHI LTD

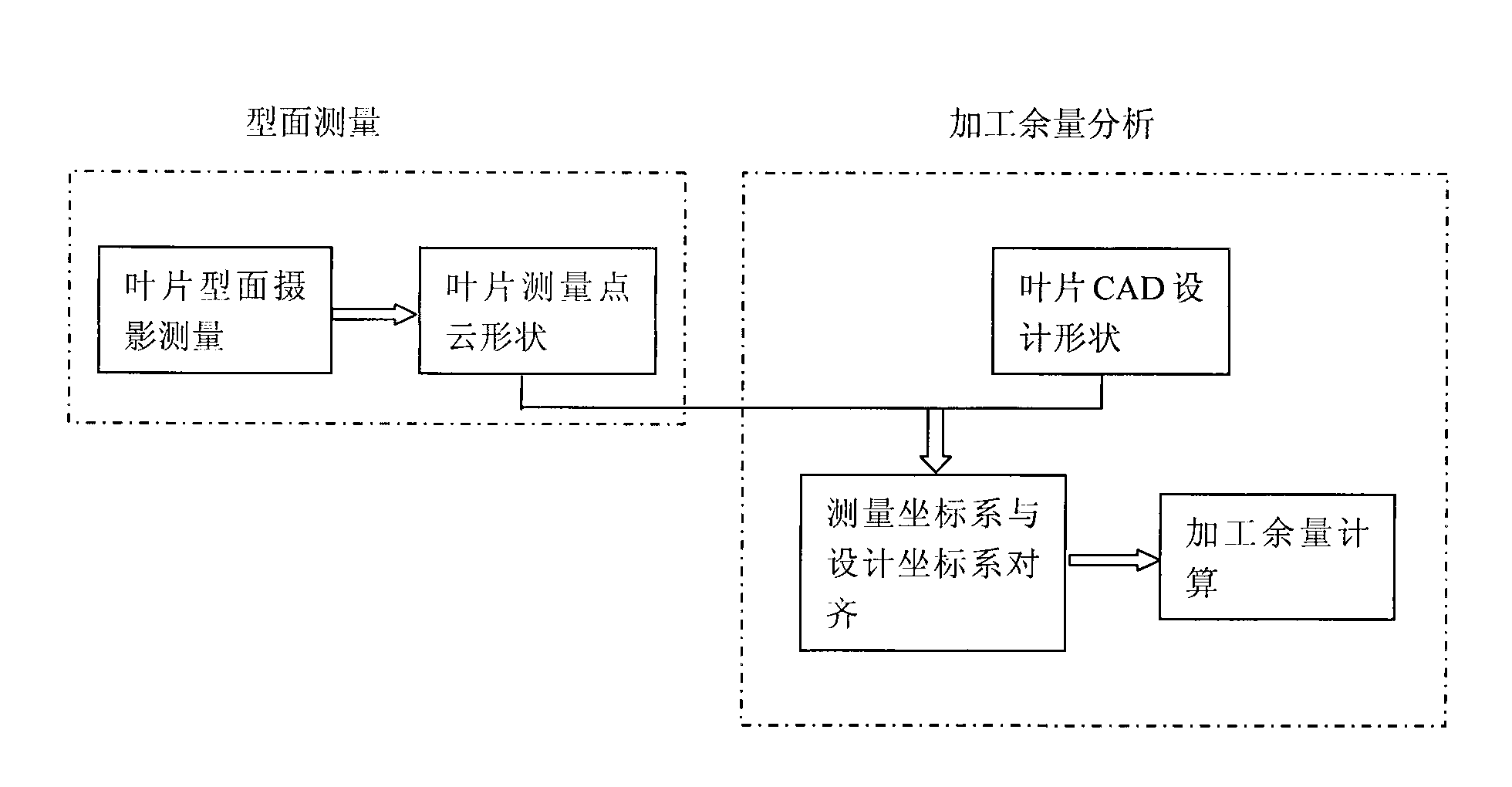

Water turbine blade blank profile measuring and machining allowance analyzing method

InactiveCN101634544AHigh speedImprove machining accuracyUsing optical meansCavitationMeasurement point

The invention relates to a water turbine blade blank profile measuring and machining allowance analyzing method capable of effectively solving the problem of water turbine blade blank profile measurement and machining allowance analysis to ensure the manufacturing quality and precision of the water turbine blades, comprising the following technical solutions: measuring the blade blanks by using a digital close range photogrammetry to obtain the measuring point cloud data shapes of the blank profiles consequently, aligning a measuring coordinate system where the measuring point clouds are located to a design coordinate system where a CAD design model is located, establishing a differential relation of free-form surface parameters with respect to rigid rotation parameters by using an analytic method derived by the multivariate of Newton iteration method to obtain a Jacobian matrix and Hessian matrix which are available for a target equation; then performing the numerical optimization calculation based on the LM method and Newton iteration method, and performing report or graphical output and print on the result. The inventive method is scientific, advanced, stable and reliable, and has high accuracy, thereby ensuring the hydraulic stability, production efficiency and cavitation property, and bringing enormous economic and social benefits.

Owner:郑州辰维科技股份有限公司

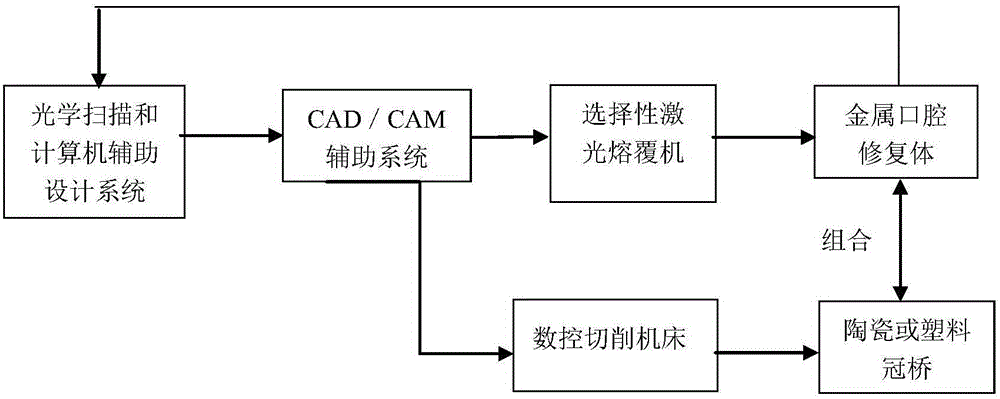

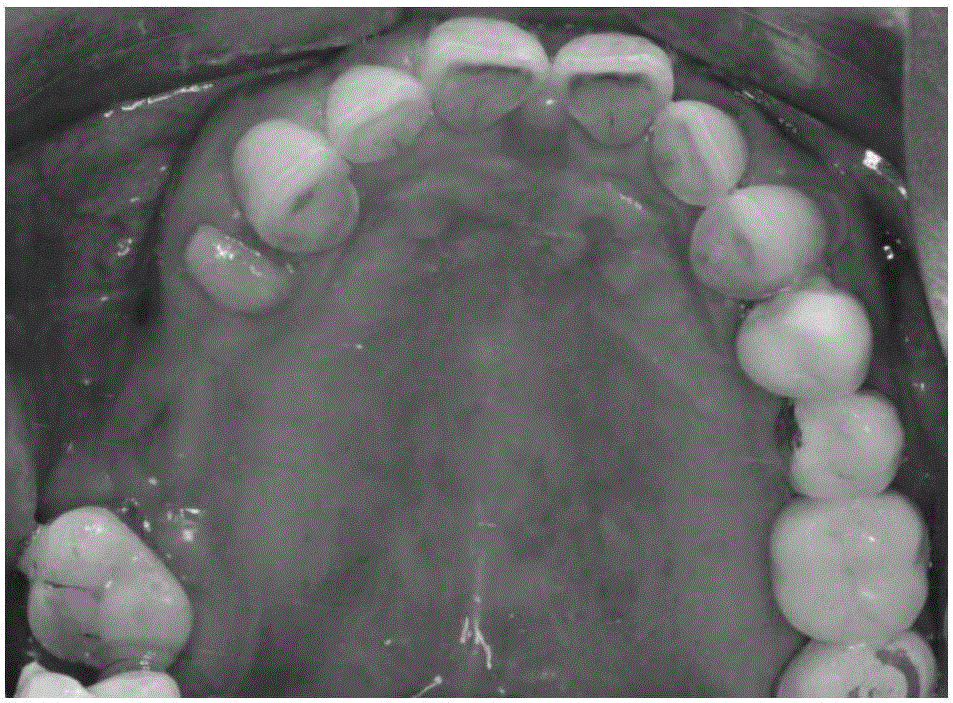

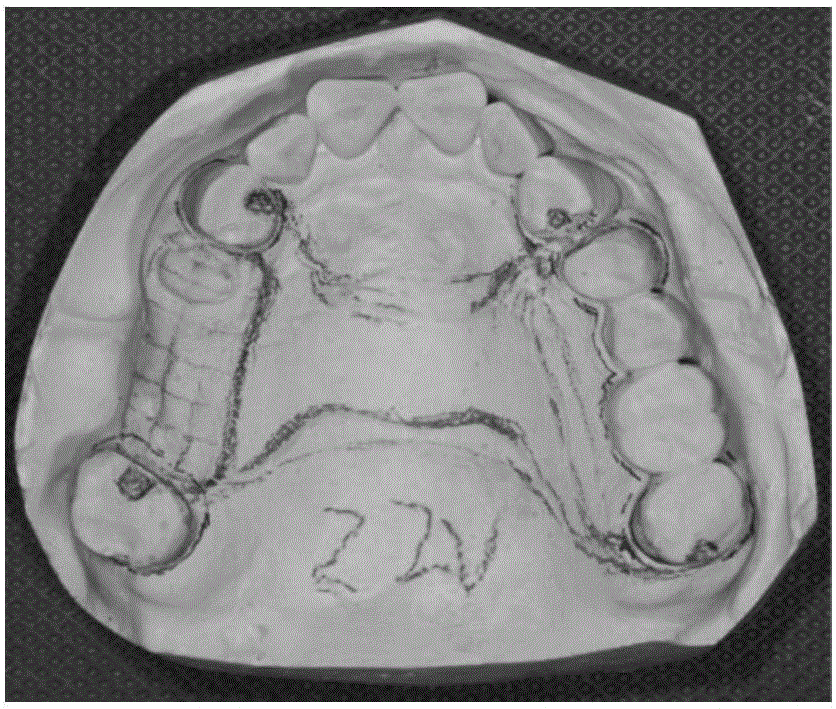

Automatic CAD/CAM/3D processing method of dental prostheses

The invention relates to an automatic CAD / CAM / 3D processing method of dental prostheses. The method comprises the step of processing dental prostheses by employing a composite system composed of an optical scanner and a computer aided design system, a CAD / CAM aided system, a selective laser cladding machine and a numerical control cutting machine tool, wherein prostheses such as removable partial dentures, fixed dentures, complete dentures and implant dentures can be rapidly manufactured. The method is characterized in that numerical control cutting (subtractive manufacturing called as subtraction) and the 3D printing technology (additive manufacturing called as addition) are organically combined and highly unified. Two aspects of the unity and opposites are merged into one uniform aspect; the automatic production efficiency of the dental prostheses, especially complex prostheses, can be greatly improved, complicated procedures of a conventional handmade dental prosthesis are eliminated, the manufacturing quality and stability of the prostheses are improved, the purposes of quickness, accuracy and individualized manufacturing are achieved, and the dental prostheses meet the urgent demands of most agomphosis patients.

Owner:维视医疗信息科技山东有限公司

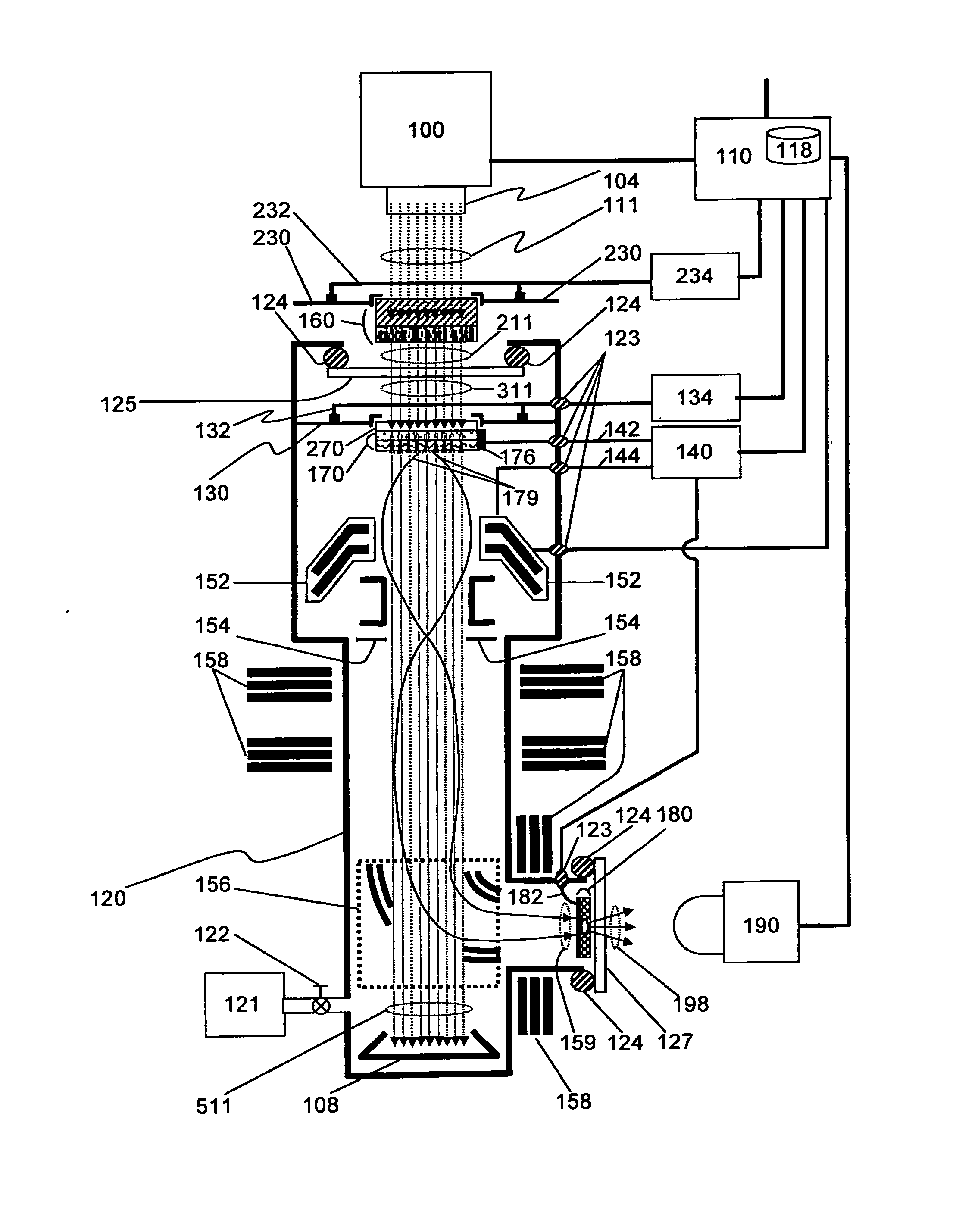

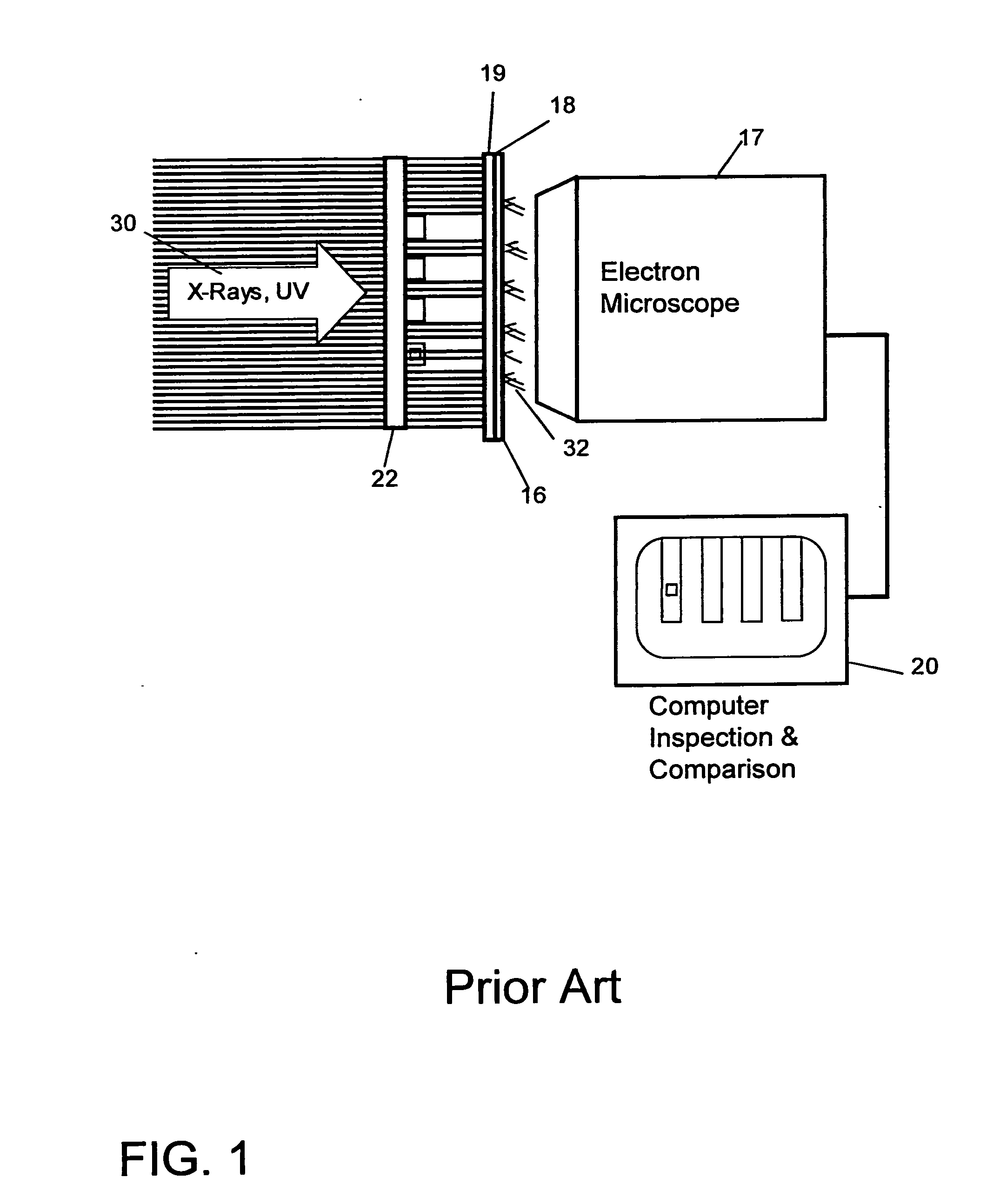

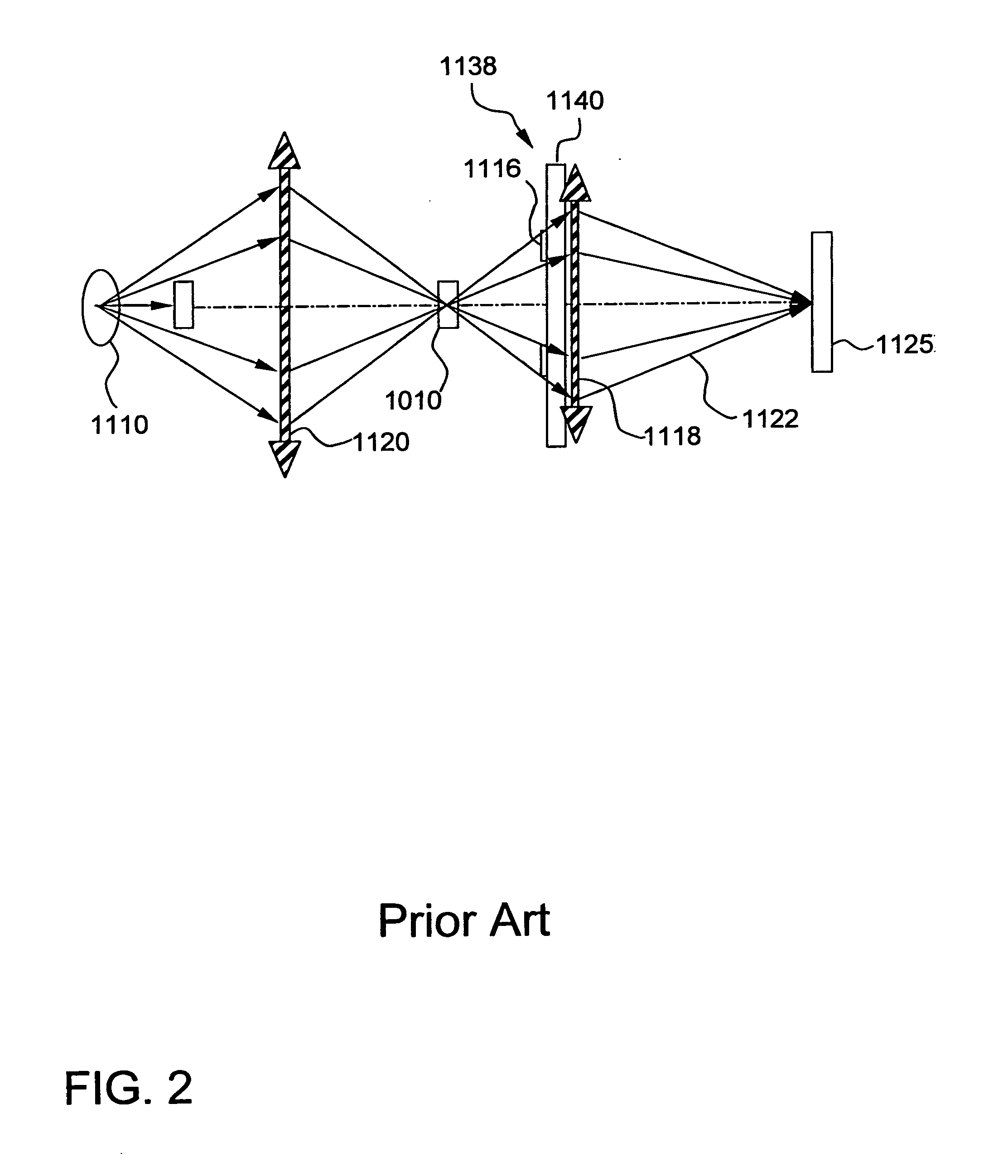

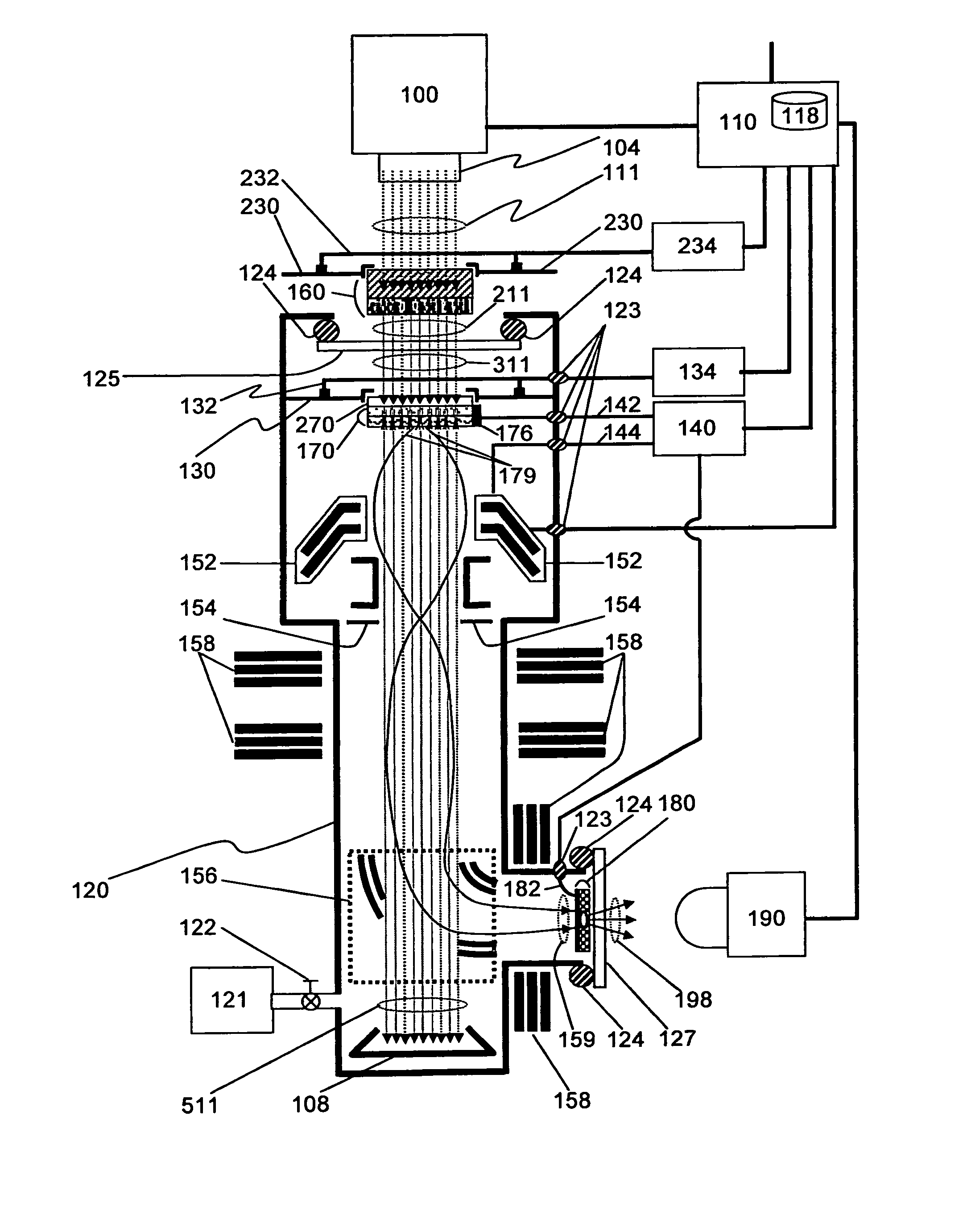

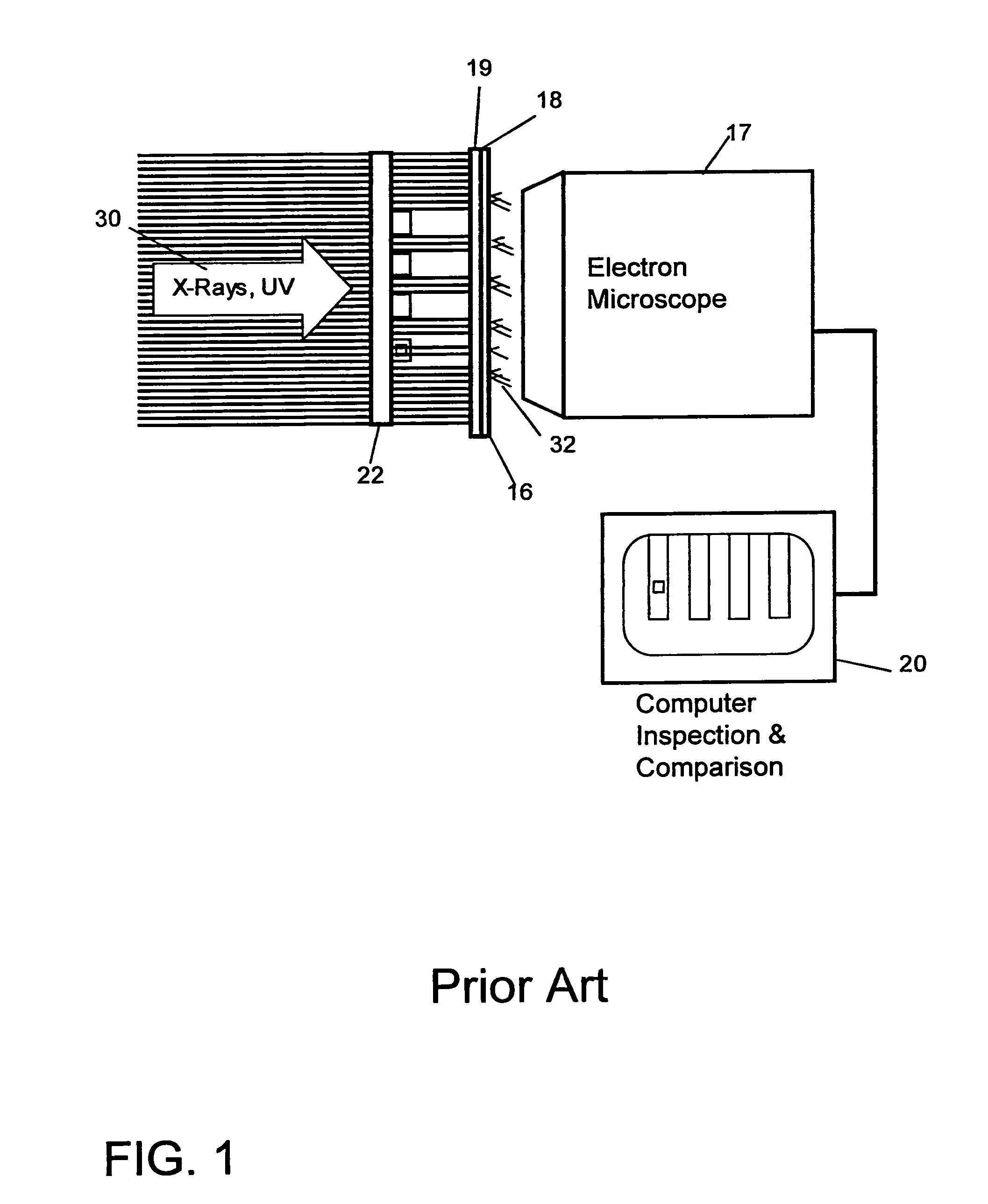

X-ray photoemission microscope for integrated devices

ActiveUS20140037052A1Reduce distanceRadiation/particle handlingSemiconductor/solid-state device detailsPhysicsManufacturing quality

An apparatus is disclosed for the examination and inspection of integrated devices such as integrated circuits. X-rays are transmitted through the integrated device, and are incident on a photoemissive structure that absorbs x-rays and emits electrons. The electrons emitted by the photoemissive structure are shaped by an electron optical system to form a magnified image of the emitted electrons on a detector. This magnified image is then recorded and processed.In some embodiments, the integrated device and photoemissive structure are independently mounted and controlled. In other embodiments, the photoemissive device is deposited directly onto the integrated device.In some embodiments, the incidence angle of the x-rays is varied to allow internal three-dimensional structures of the integrated device to be determined. In other embodiments, the recorded image is compared with a reference data to enable inspection for manufacturing quality control.

Owner:ADLER DAVID L

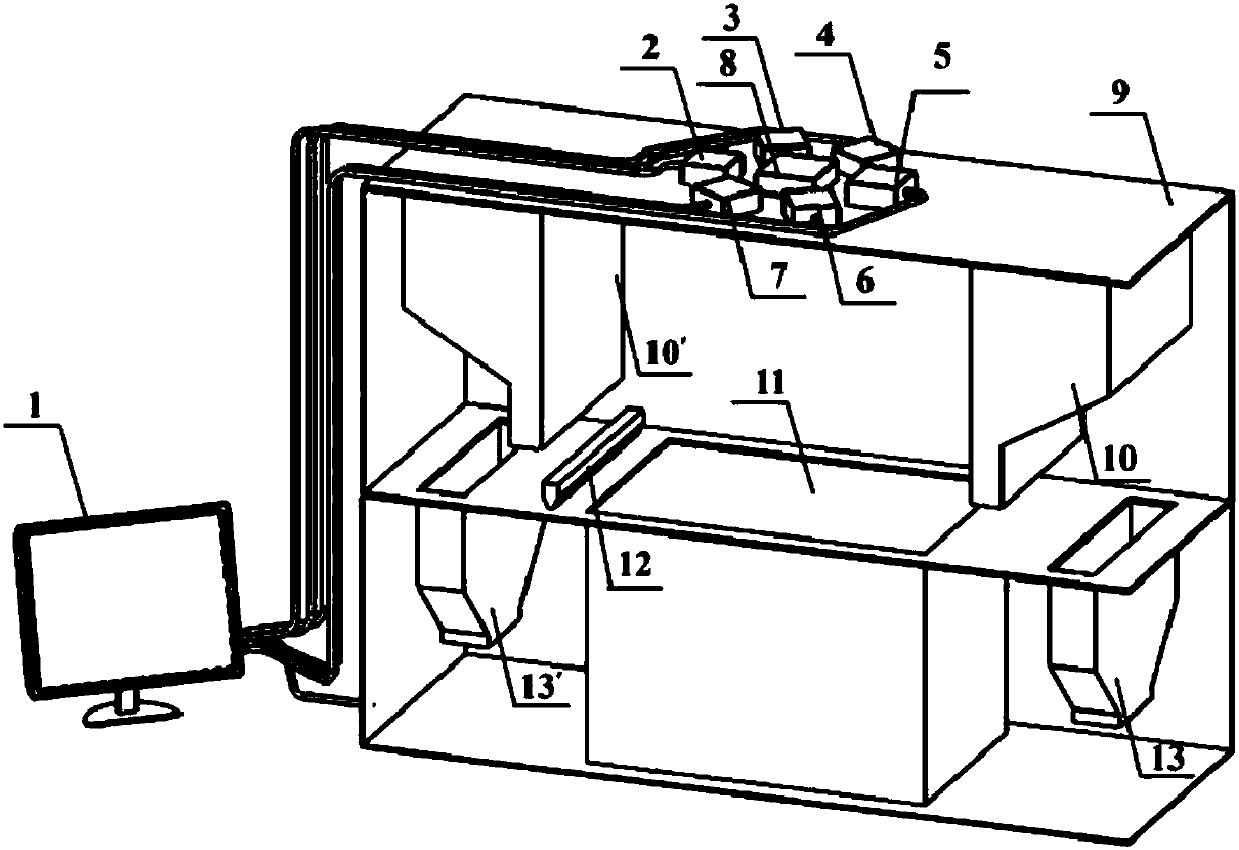

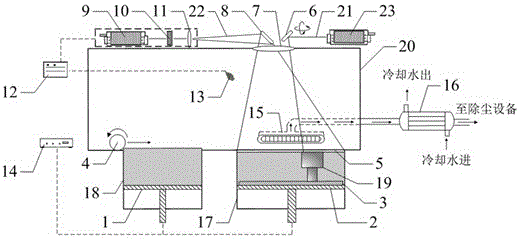

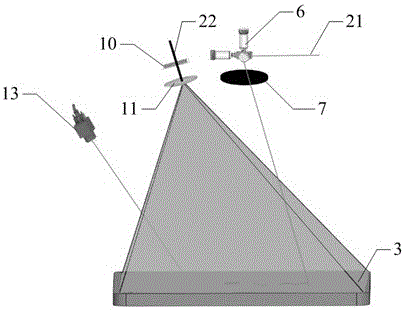

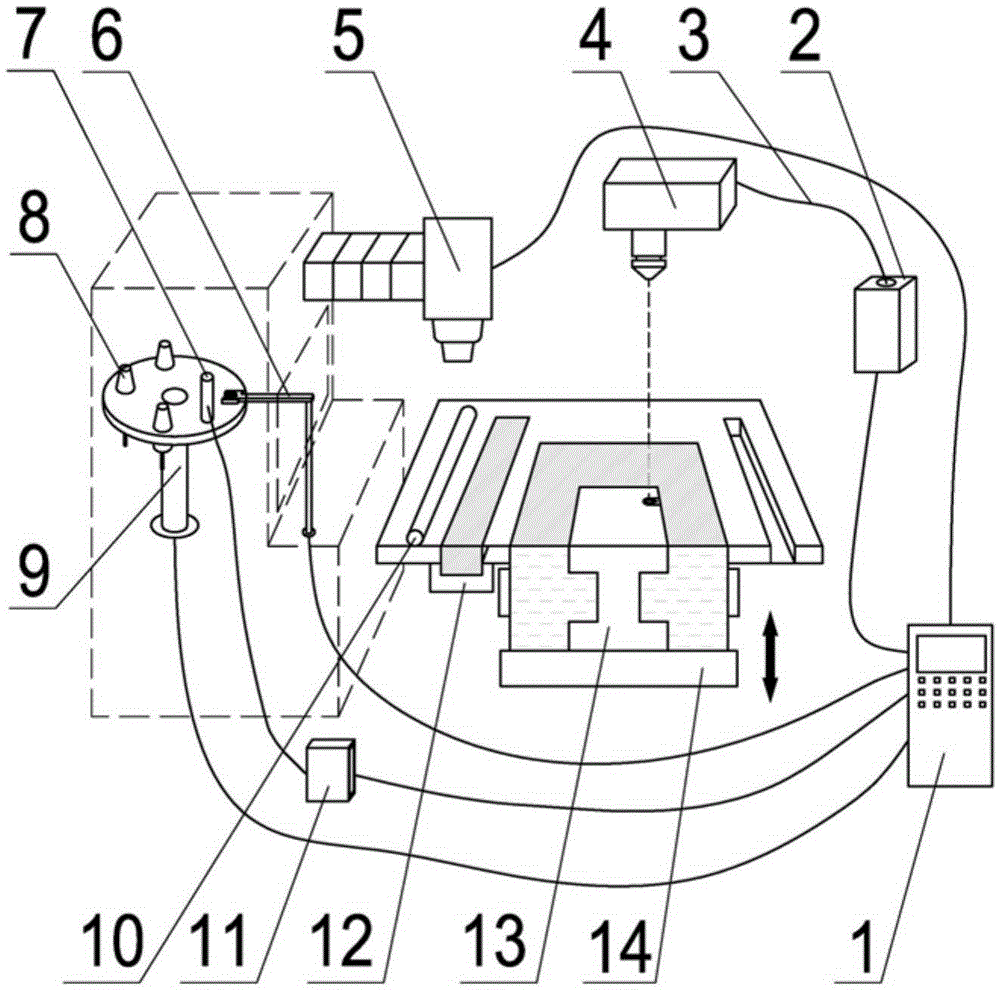

Nondestructive on-line quality inspection equipment and method applicable to powder spreading type additive manufacturing

ActiveCN107598163AFlexible combinationFlexible selectionAdditive manufacturing apparatusCeramic shaping apparatusAdditive layer manufacturingElectron

The invention discloses nondestructive on-line quality inspection equipment and method applicable to powder spreading type additive manufacturing and belongs to the field of nondestructive inspection.A forming assembly of the equipment is provided with a power spreading quality inspection module, a constituent inspection module, a defect inspection module, a deformation inspection module, a stress inspection module and a dimensional precision inspection module. All the modules can work separately and simultaneously; and the nondestructive on-line quality inspection equipment is high in use flexibility. By means of the equipment, comprehensive integrated inspection is conducted on powder spreading quality, component constituents, defects, deformation, the stress and dimensional precision in the powder spreading type additive manufacturing and forming process; powerful guarantee can be provided for the forming process of metal components of different materials, dimensions and structuresand in different shapes, and thus the excellent-quality metal components are manufactured one time efficiently; the yield can be increased to a certain extent; and economic losses are reduced. The nondestructive on-line quality inspection equipment and method can be widely applied to manufacturing of various types of powder spreading type additives of heat sources utilizing laser, electron beams,plasmas and the like.

Owner:HUAZHONG UNIV OF SCI & TECH

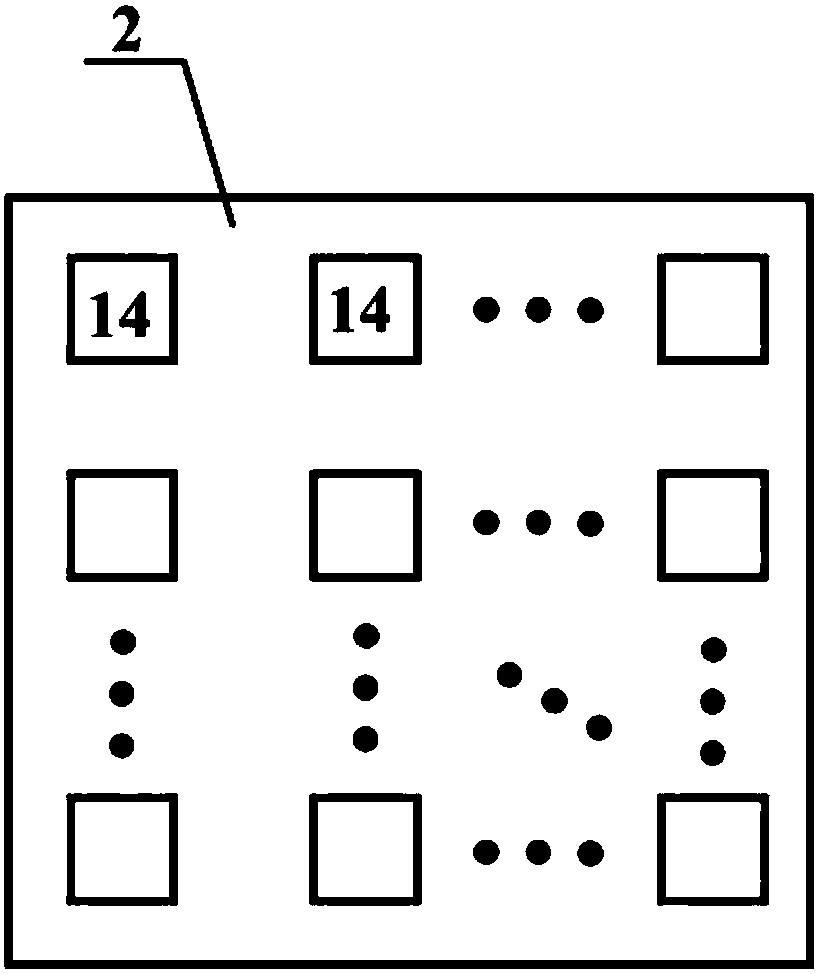

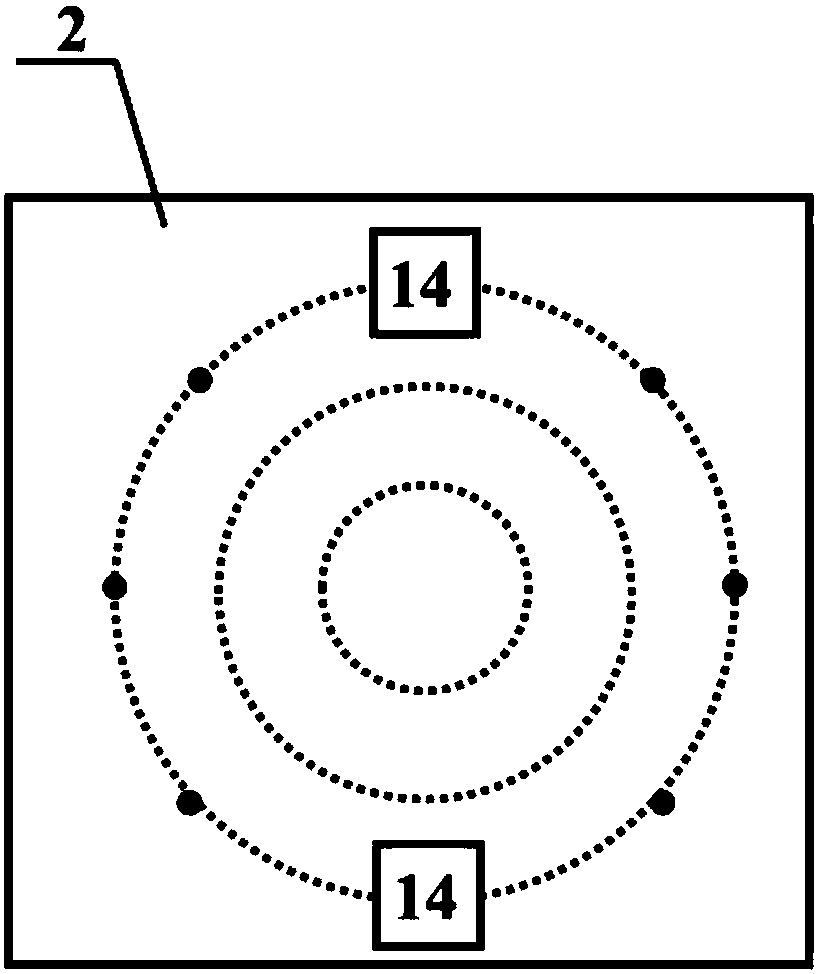

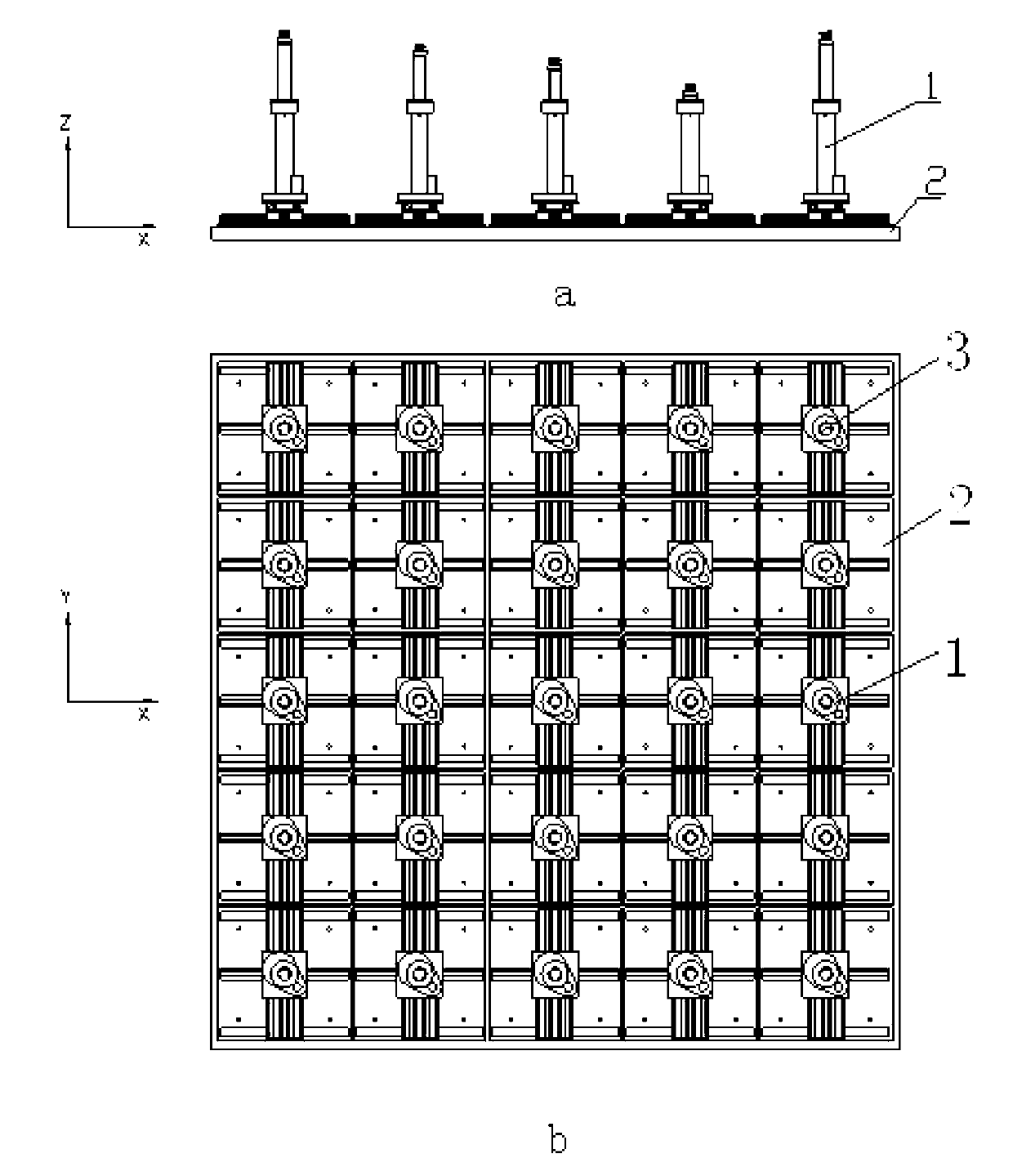

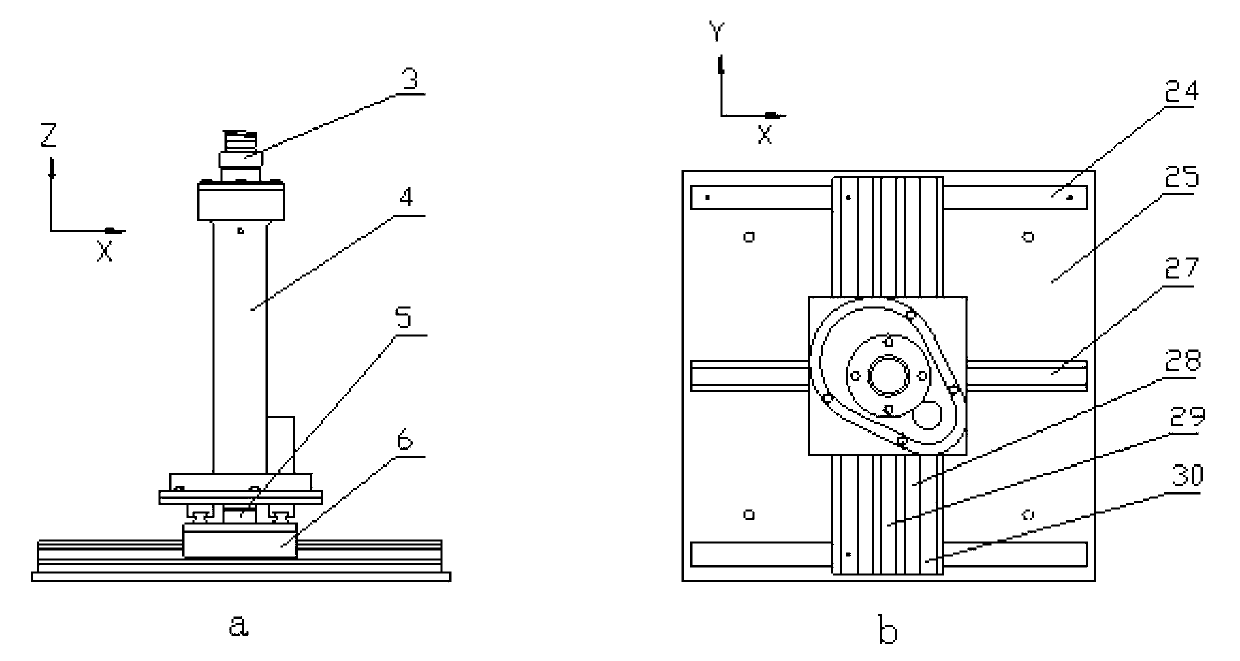

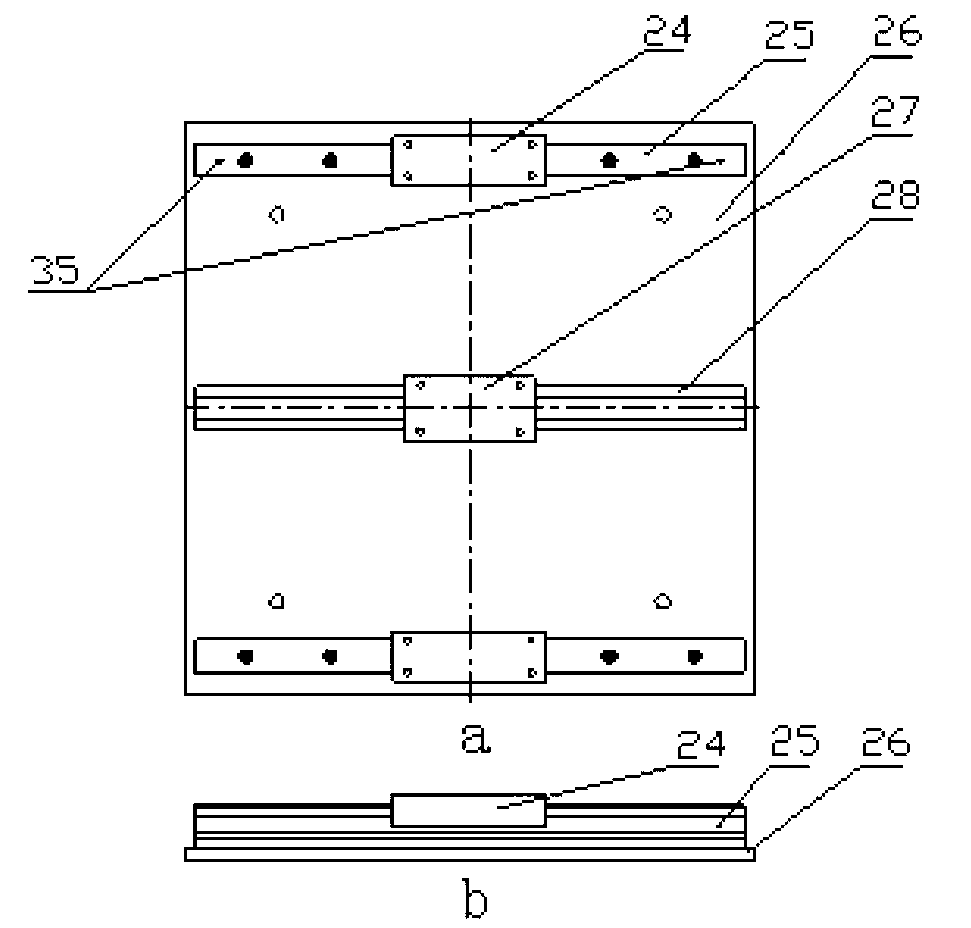

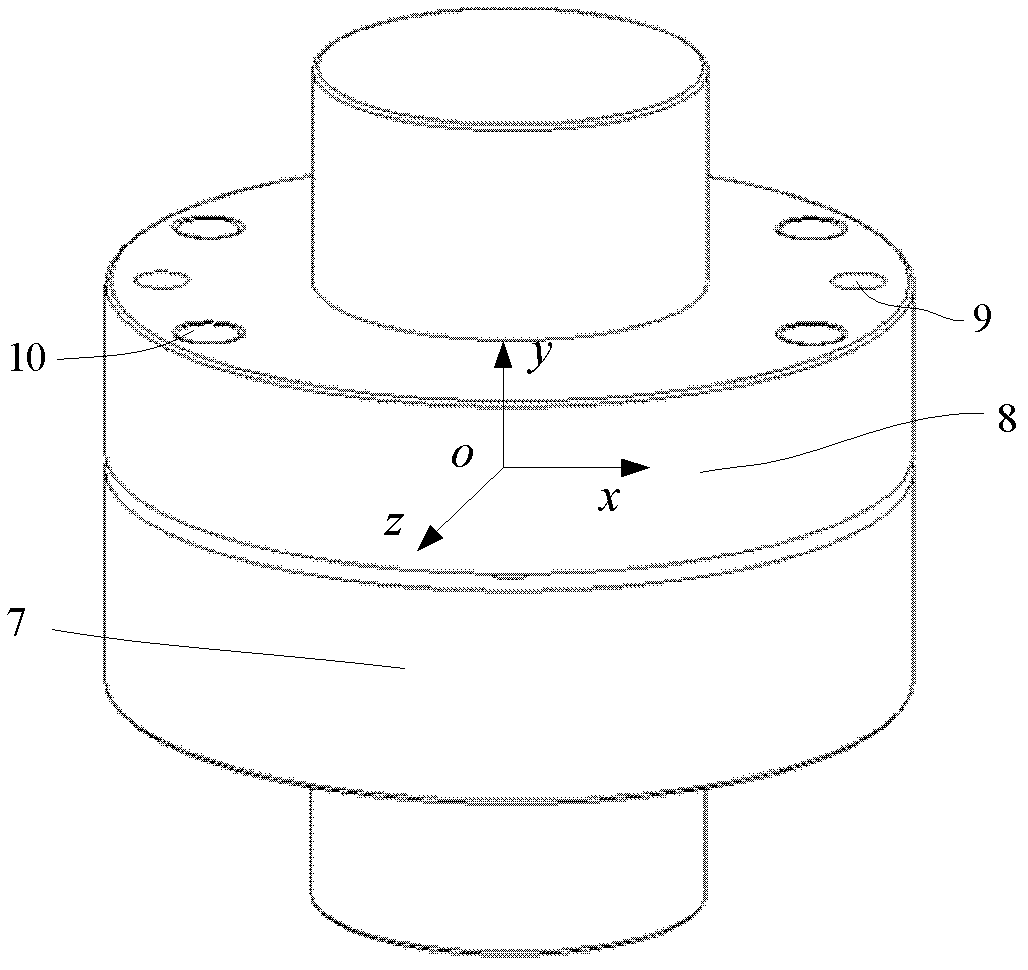

Multi-point flexible positioning tool

ActiveCN103100889APrecise positioningImprove processing efficiencyLarge fixed membersPositioning apparatusRectangular coordinatesReciprocating motion

The invention discloses a multi-point flexible positioning tool which comprises a plurality of rectangular coordinate type flexible support die blocks and a base, wherein the plurality of rectangular coordinate type flexible support die blocks are arranged and fixed on the upper surface of the base; an X-direction sliding panel in each rectangular coordinate type flexible support die block is driven by a driving mechanism to do straight reciprocating motion along an X-direction straight guide track; and a Y-direction sliding panel in each rectangular coordinate type flexible support die block is driven by the driving mechanism to do straight reciprocating motion along a Y-direction straight guide track. The multi-point flexible positioning tool can ensure precise positioning of a thin-walled curved part, rapidly form an optimal support array which is matched with the surface of the part according to three-dimensional information and machining information of the thin-walled curved part to be clamped under the control of a computer control unit, and alleviate the deformation of a workpiece which is stressed and heated in a machining state, thus improving the manufacturing quality and the manufacturing efficiency of the part; and moreover, the tool can also be taken as an assembling tool to assemble the thin-walled curved part, and can effectively improve the machining efficiency and the machining quality of the part.

Owner:XIAN WINWAY TOOLS

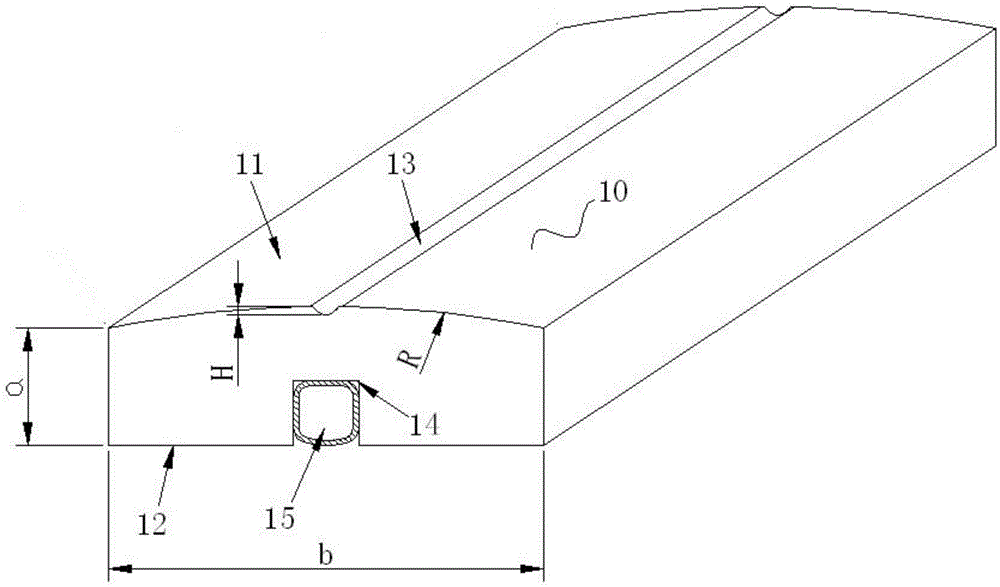

Longitudinal seam red copper liner welding process of steel sheet pressure vessel and red copper liner used by same

InactiveCN104128694AAvoid melting intoImprove product qualityWelding/cutting auxillary devicesPipeline systemsCopperWater pipe

The invention discloses a longitudinal seam red copper liner welding process of a steel sheet pressure vessel. The longitudinal seam red copper liner welding process sequentially comprises the steps of (a), aligning and splicing a longitudinal seam of a machined cylinder and carrying out point welding fixation; (b), placing the inner longitudinal seam of the machined cylinder on a red copper liner; (c), aligning the longitudinal seam of the machined cylinder to the center line of a welding groove of the red copper liner, fixing the machined cylinder and the red copper liner through an air cylinder, and guiding water into a cooling water pipe of the red copper liner; (d), carrying out welding; (e), disassembling the machined cylinder after the longitudinal seam of the machined cylinder is welded. The welding process has the advantages that automatic submerged arc welding of one-side welding and two-side forming is achieved, the RT flaw detection qualification rate is high, welding flux is saved, the manufacturing quality of the steel sheet pressure vessel is improved, and the production cost is lowered.

Owner:江门市新会区同达化工机械制造有限公司

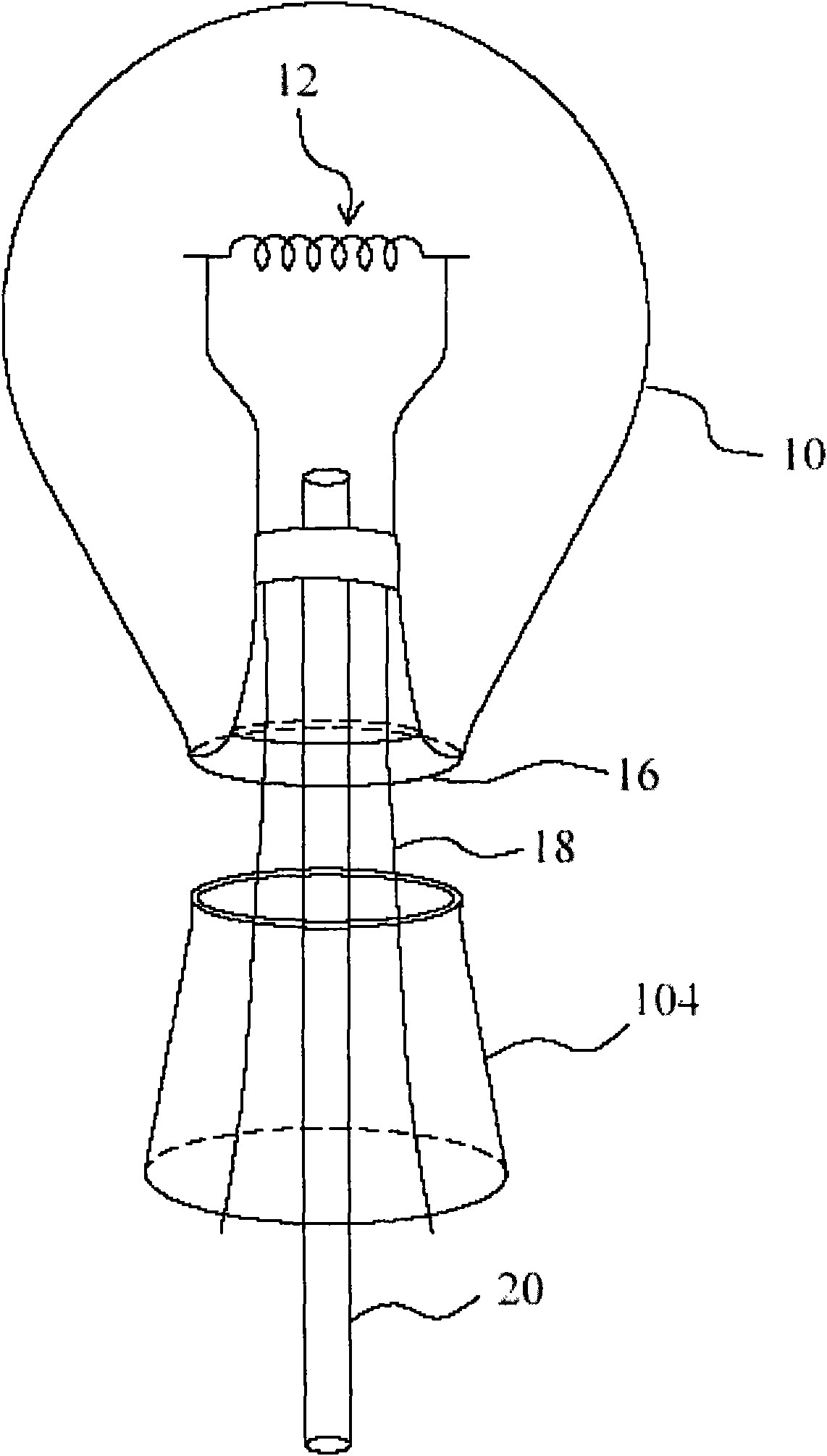

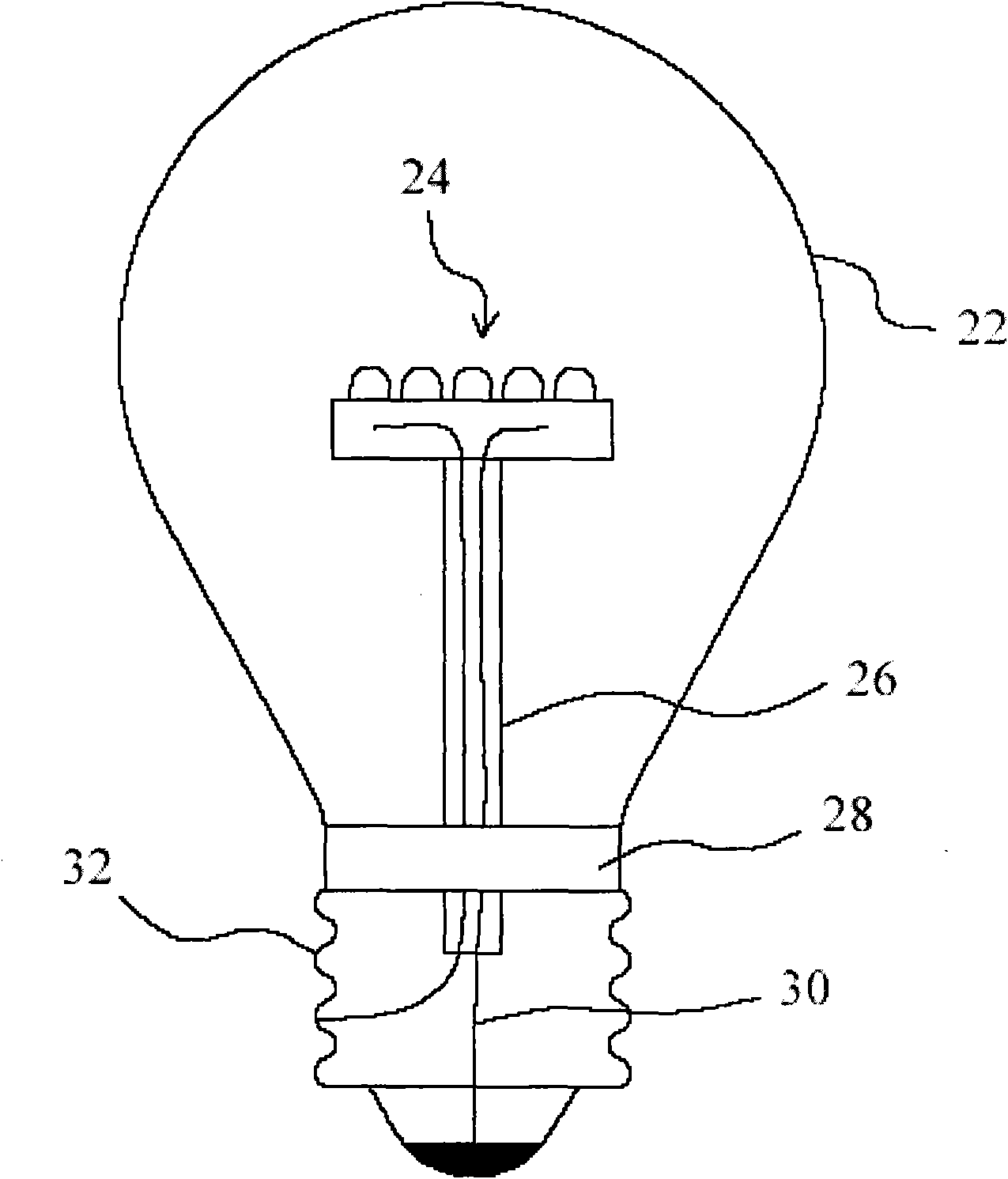

Glass packaging LED bulb and manufacturing method thereof

InactiveCN101561121AStrong resistanceLong-term reliable sealing effectPoint-like light sourceProtective devices for lightingNeck partsEngineering

The invention relates to a glass packaging LED bulb comprising a flared glass tube, a strutting piece, an LED wick, a stem assembly and a glass bulb case, wherein the flared glass tube is coated with a power lead, and one end of the power lead reversely extends to pass through the flared glass tube; the strutting piece and an exhaust tube are fixed on the flared glass tube; the LED wick is installed on the strutting piece; the stem assembly is assembled with the flared glass tube, the strutting piece and the LED wick; and the glass bulb case is provided with a neck part which is melted and connected with the flared glass tube of the stem assembly to form a chamber, the LED wick is arranged in the chamber, light-permeable liquid is injected into the chamber, and the LED wick is soaked in the light-permeable liquid. The glass packaging LED bulb has the long-term and reliable sealing effect of glass package, provides the resistance capability of serious environment, such as moisture, dust, corrosive gas, and the like, improves the manufacturing quality and speed of the LED bulb and reduces the production cost of the LED bulb.

Owner:LIQUIDLEDS LIGHTING

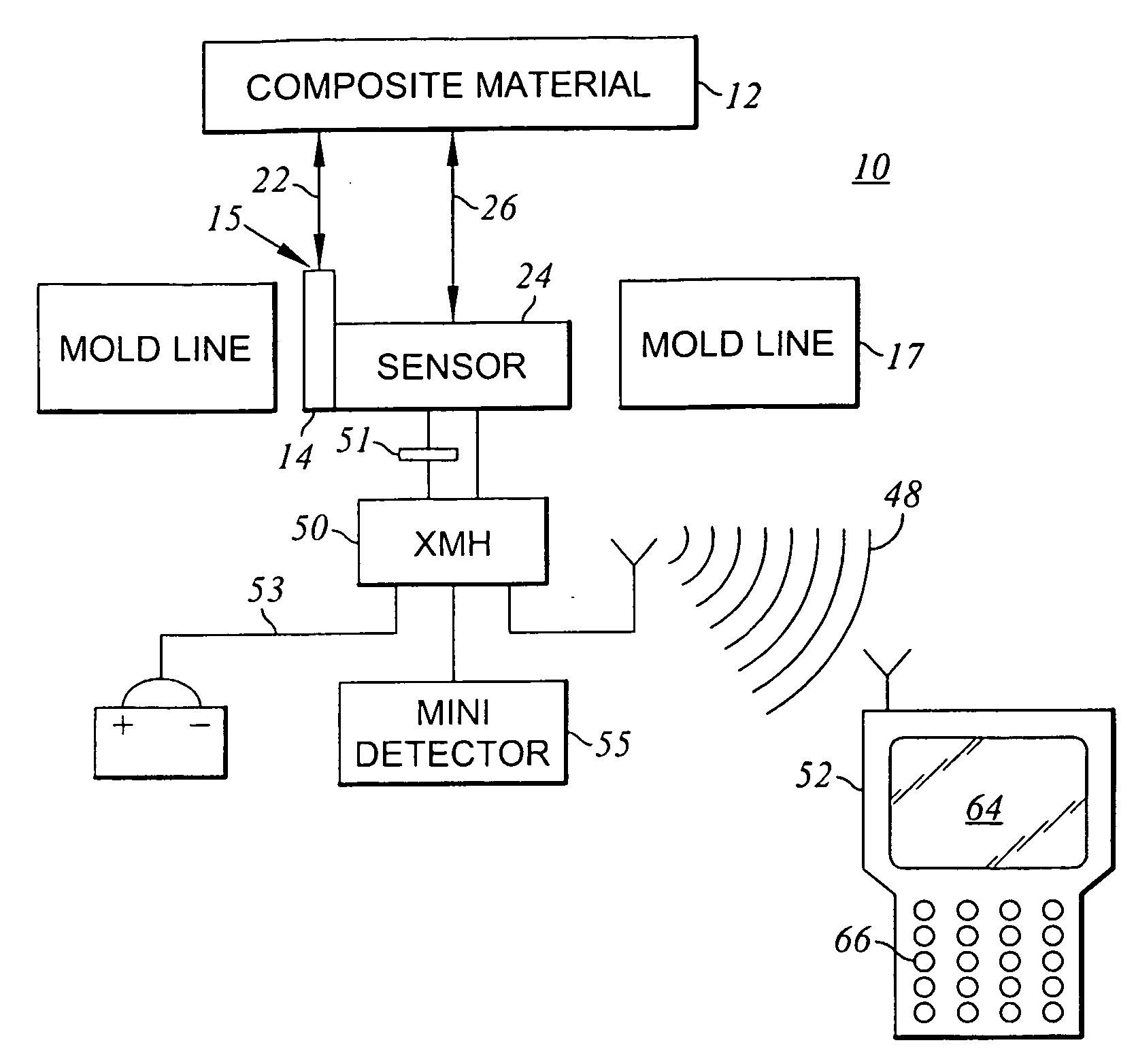

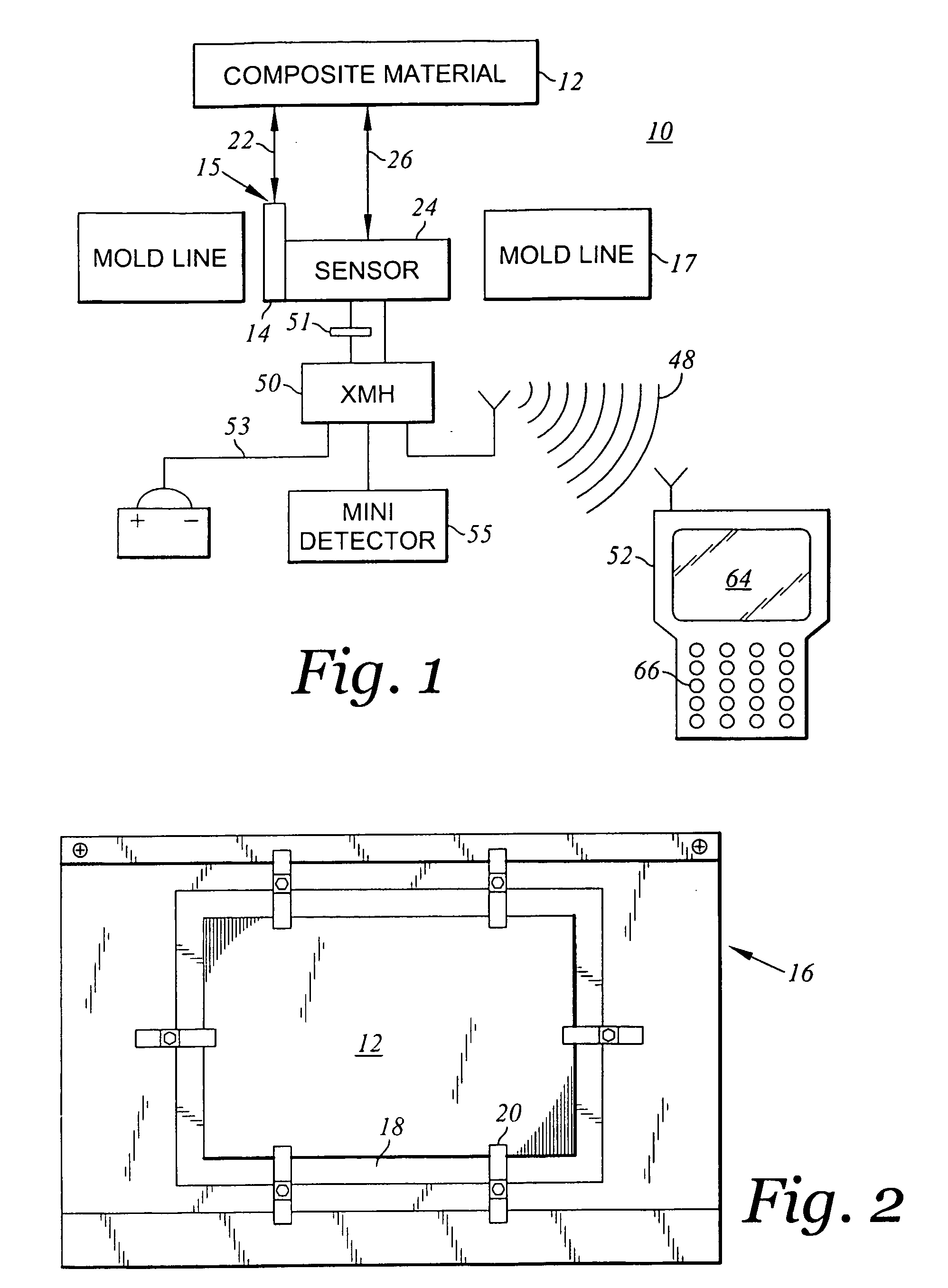

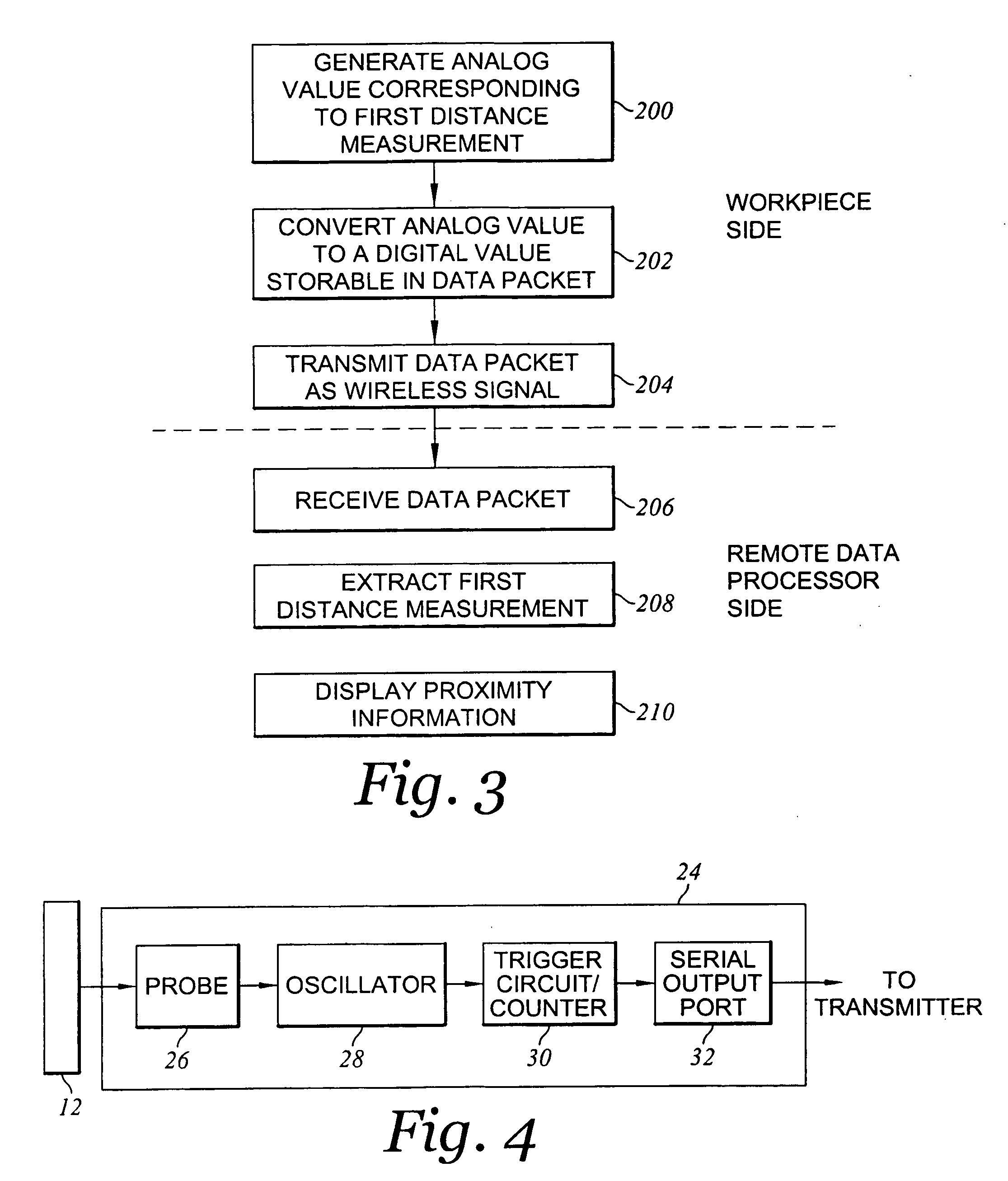

Proximity sensing systems for manufacturing quality control

InactiveUS20090198465A1Increasing manufacturing reliabilityIncreasing product throughputProgramme controlSpecial data processing applicationsControl systemRadio frequency signal

A manufacturing quality control system for monitoring the proximity of a workpiece to a machine tool is disclosed. The system includes a proximity sensor attached to the machine tool for deriving a first distance measurement based upon the distance between the workpiece and the machine tool. A wireless transmitter generates a radio frequency signal including the first distance measurement. A remote data processing device communicates with the wireless transmitter to retrieve the first distance measurement and display various derivations of sensor data.

Owner:NORTHROP GRUMAN CORP

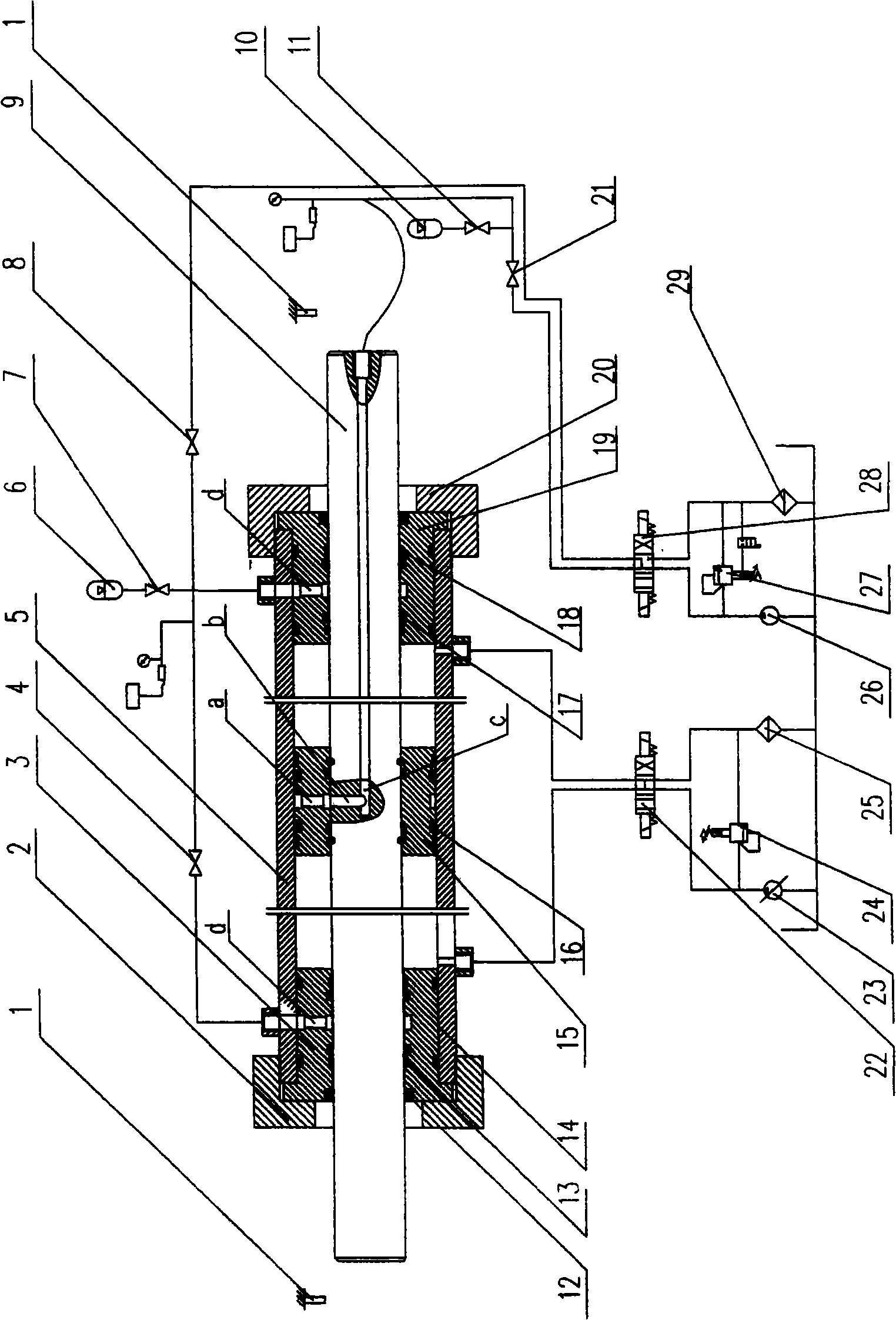

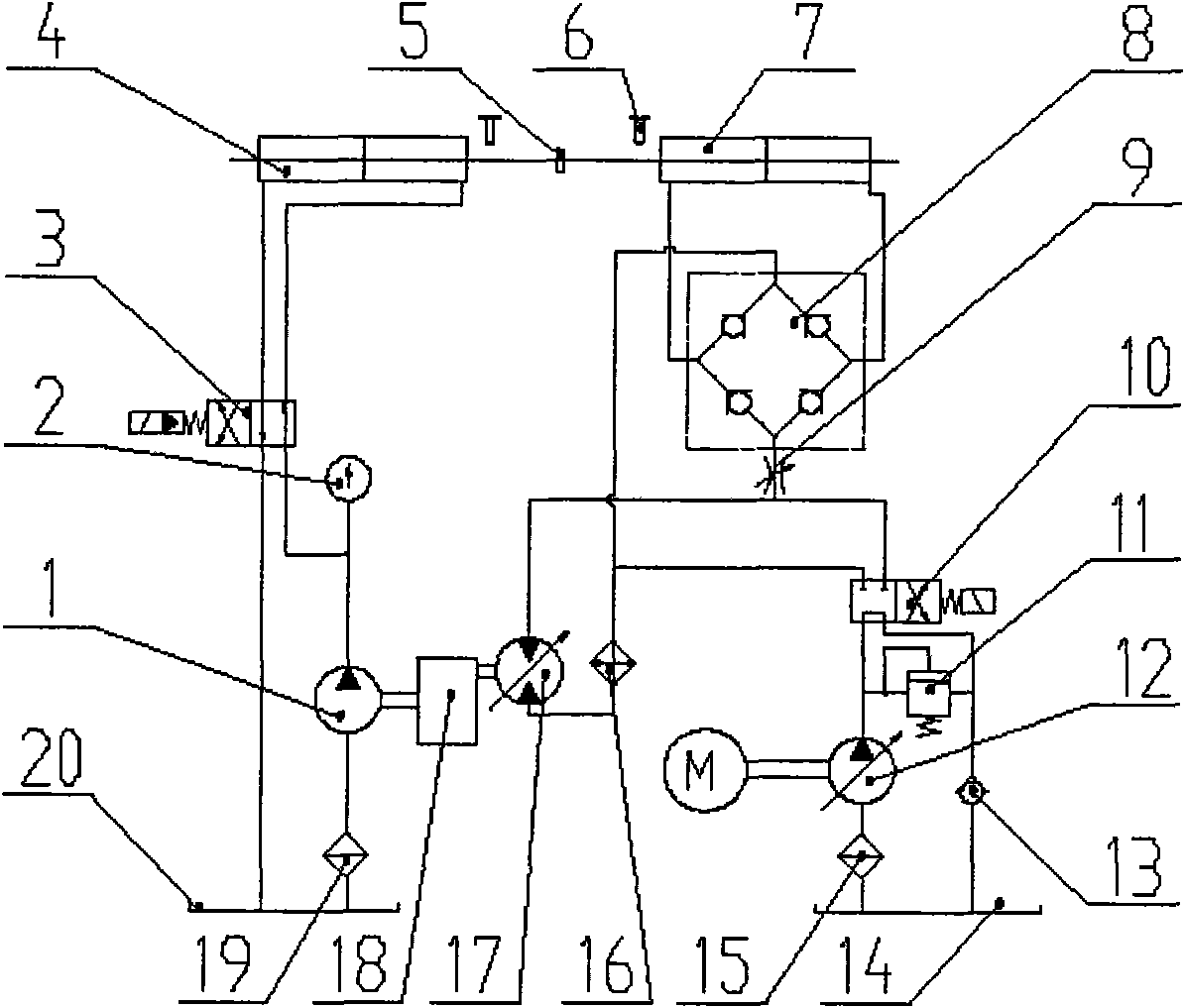

Energy-saving hydraulic sealing experimental bench and method thereof

InactiveCN101315311AIn-line inspection of manufacturing qualityOn-line detection of tribological propertiesMeasurement of fluid loss/gain rateShock testingSolenoid valveEngineering

The invention discloses an energy-saving hydraulic seal experiment table and a method thereof. The experiment table consists of an experimental cylinder, a driving loop of the experimental cylinder and a loading loop, and is characterized in that the experimental cylinder consists of a left cylinder cover, a left guide sleeve, a cylinder barrel, a piston, a piston rod, a right guide sleeve and a right cylinder cover; the driving loop of the experimental cylinder comprises a variable pump, a safety valve, a filter, a solenoid valve, etc; and the loading loop comprises a fixed displacement pump, an overflow valve, a filter, a solenoid valve, an accumulator and a stop valve. The experiment table can conduct experiments on various sealing rings of the piston and the piston rod, carry out online inspection of the sealing performance and the tribological properties of the sealing rings and the manufacturing quality of sealing elements, and perform experiments on a plurality of sealing elements to be detected simultaneously. The experiment table has the advantages of adjustable experiment speed and pressure, and excellent energy-saving effect.

Owner:徐州沃土资产管理有限公司

Method for manufacturing and installing guide rail in container ship cargo hold

InactiveCN101885368AImprove installation accuracyAvoid welding deformationVessel partsEngineeringSlipway

The invention discloses a method for manufacturing and installing a guide rail in a container ship cargo hold, which comprises the following steps of: (a) manufacturing the guide rail; (b) two-dimensional preassembly: assembling and welding a processed guide plate and the guide rail on a platform by using a doubling plate as a basal plane; (c) hoisting and boarding: installing an eye ring of the guide rail on the guide rail a quarter away from the upper end, respectively installing one eye ring at the left side and the right side of the guide plate, correspondingly reinforcing the eye rings from the back side, and hoisting the whole guide rail to a slipway; adding a toggle plate behind the doubling plate to reinforce the guide rail with low intensity; and after manufacturing the guide rail of a following ship in two segments, connecting the two segments into one guide rail after correction, and hoisting the assembled guide rail; (d) slipway installation: marking, and installing the guide rail; and (e) packaging and testing. In the method, the guide rail is firstly preassembled on the platform by using the doubling plate as the basal plane, and then, the whole guide rail is hoistedonto the slipway and installed. The invention has simple and reasonable method, convenient construction and high guide rail installation accuracy. The upward and downward hoisting and the reasonable arrangement of containers in the cargo hold can be ensured, and thus, the working efficiency and the ship manufacturing quality are increased.

Owner:YANGFAN GROUP

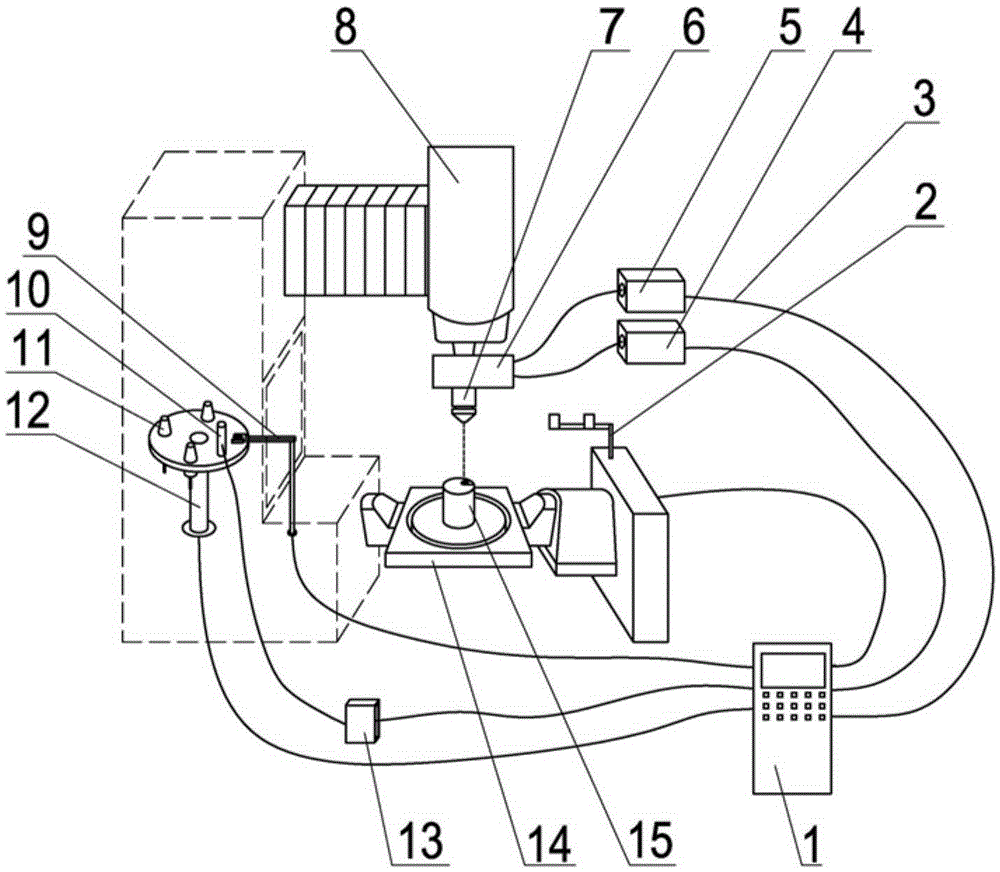

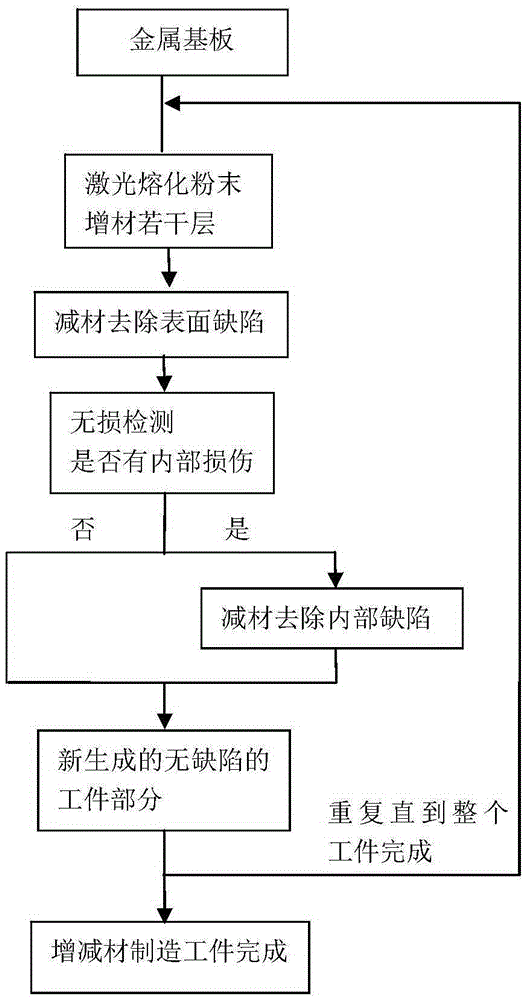

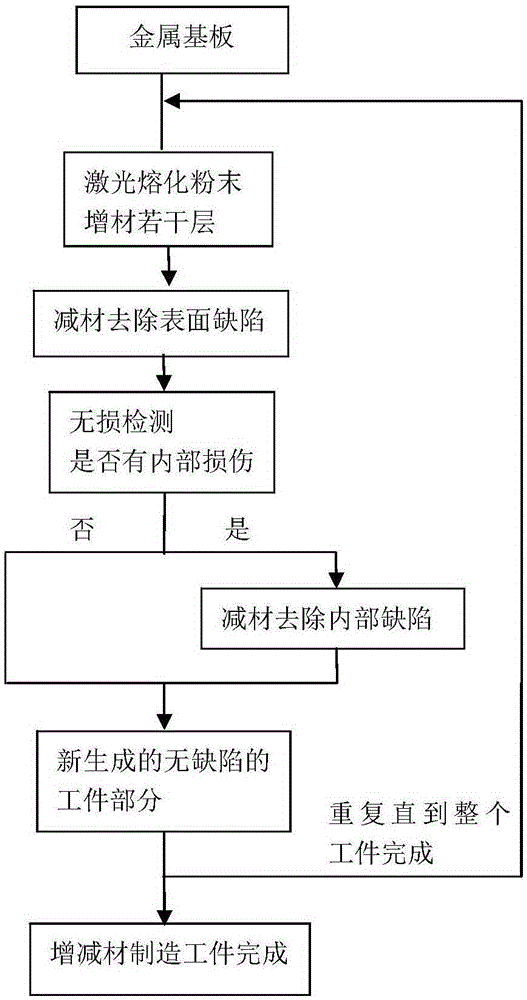

Laser coaxial powder feeding composite manufacturing machine tool and workpiece composite manufacturing method

InactiveCN105397494AReduce internal defectsHigh dimensional accuracyAdditive manufacturing apparatusMeasurement/indication equipmentsSpray nozzleMachine tool

The invention discloses a laser coaxial powder feeding composite manufacturing machine tool which comprises a cradle type workbench, a spindle, a material additive manufacturing mechanism, a material reducing machining mechanism and an online defect detection mechanism. The material additive manufacturing mechanism comprises a nozzle and a powder feeding device connected with the nozzle. A laser head is arranged at the position of the nozzle and connected with a laser generator. The material additive manufacturing mechanism is clamped by a nozzle bracket. The material reducing machining mechanism comprises a tool, a tool magazine and a tool changing bracket. The online defect detection mechanism comprises a defect detection head and a detection signal collection and analysis system. The invention further discloses a workpiece composite manufacturing method. The process of the workpiece composite manufacturing method mainly comprises the steps that material additive manufacturing, online defect detection and material reducing machining are carried out cyclically, and finally composite manufacturing is completed. By means of compounding of material additive manufacturing, material reducing machining and online defect detection, one-time forming of workpieces high in size precision and surface quality and low in internal defect is guaranteed, the production period is effectively shortened, and the part manufacturing quality and precision are guaranteed.

Owner:DALIAN UNIV OF TECH

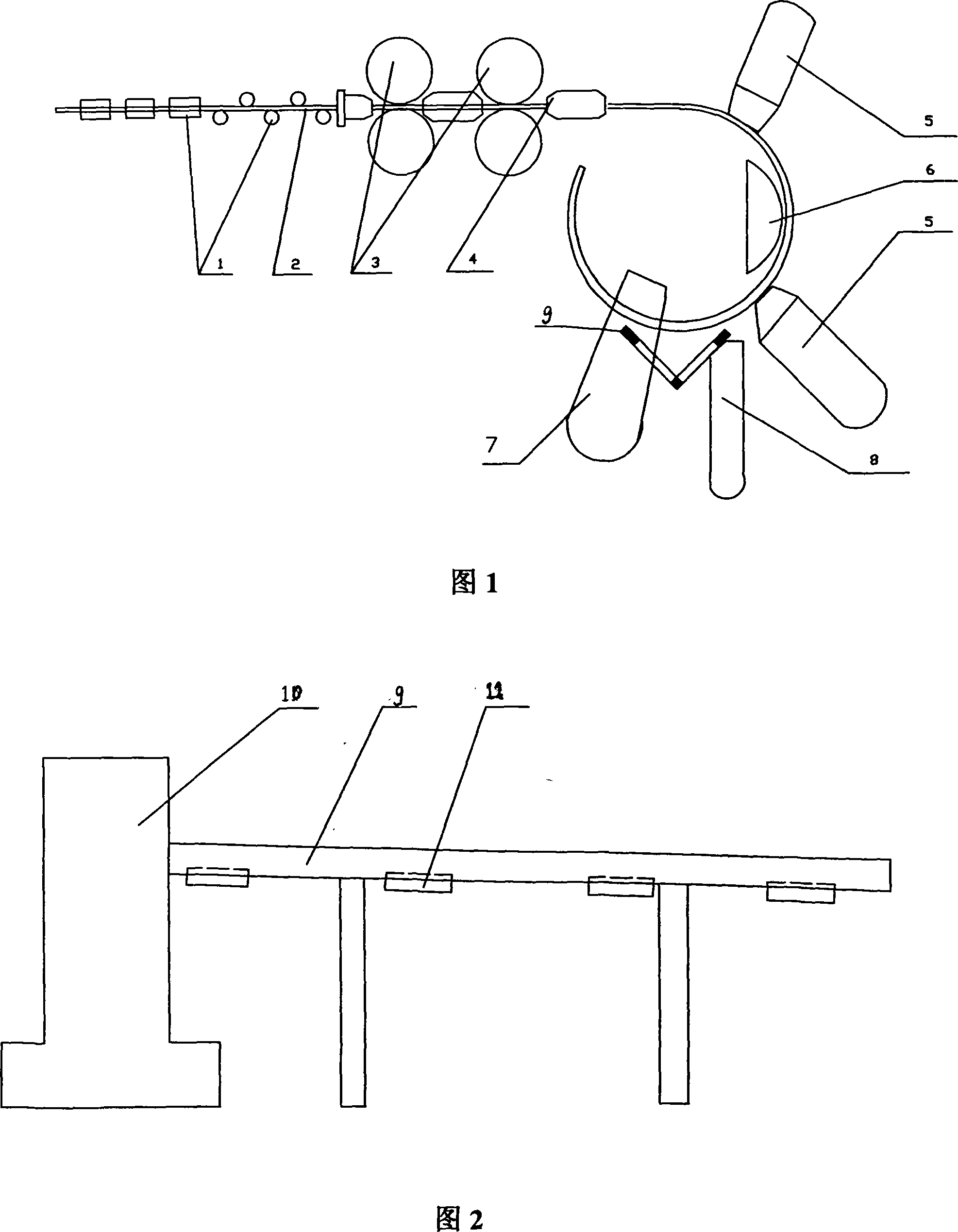

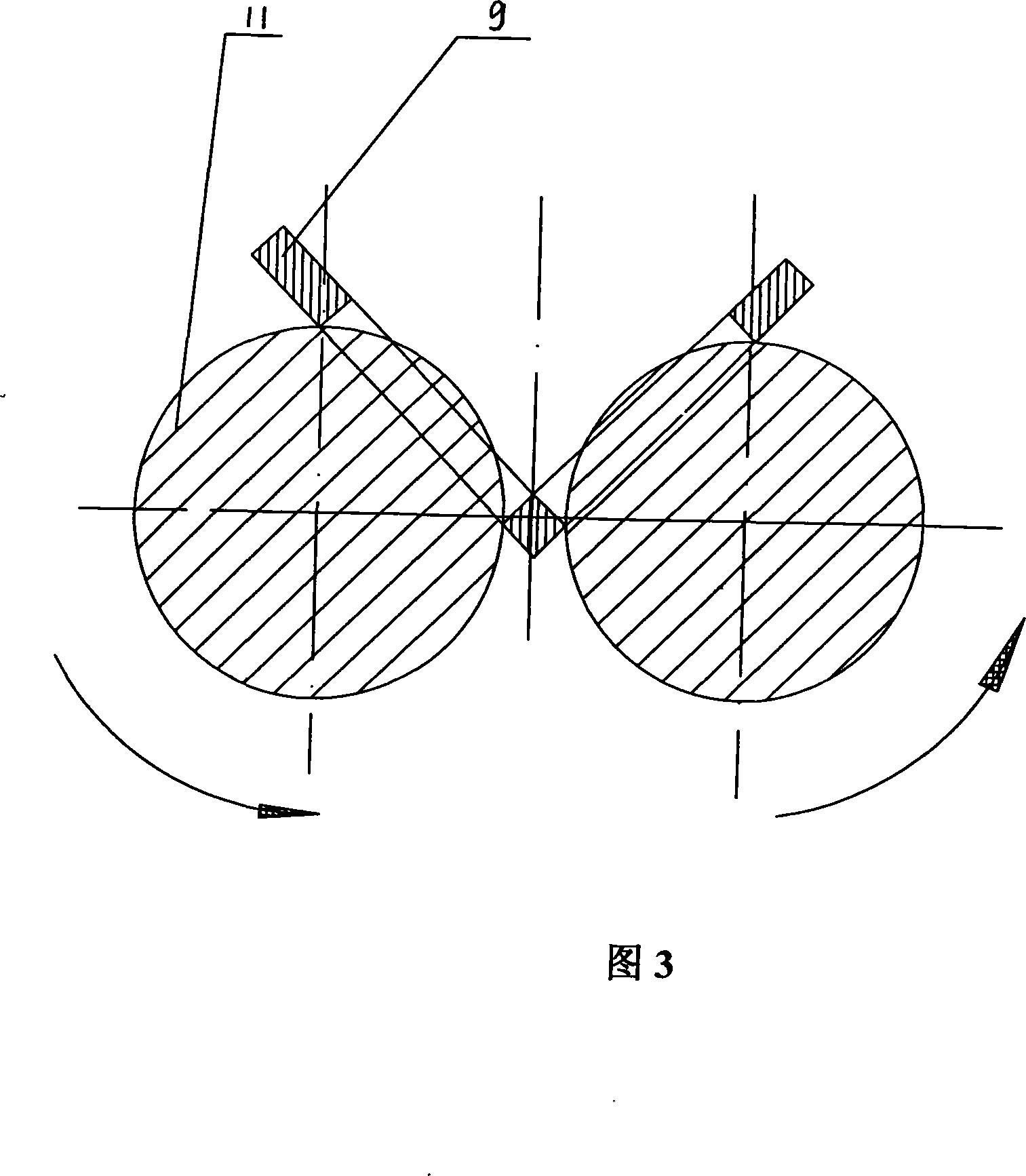

Automatically coiling method for overlength sheath spring

The invention relates to a self coiling method for an ultra-long protecting sleeve spring which leads a spring steel wire into an automatic spring coiling machine through an aligning mechanism, a rolling wheel and a guiding plate to bend and coil to make into a spiral spring ring; the spring ring that is coiled extends outward rotatably along a V-shaped slot orbit arranged in a discharge port of the automatic spring coiling machine and is driven by a plurality of pairs of rolling wheels mounted on the V-shaped slot orbit to rotate deasil along the rolling wheels or two operating workers stand at two sides of the V-shaped orbit and use hand to deasil turnover the spring that is coiled ceaselessly until the protecting sleeve spring is finished to be coiled. The coiled spring of the invention has higher automation and manufacture quality of the protecting sleeve spring, uniform node distance of the spring and higher precision on the physical dimension of the spring; compared with the adopting a manual coiling by a latch, the invention can save massive spring coiling clampers and special tools as well as greatly save the working intensity of workers.

Owner:CHANGAN AUTOMOBILE (GRP) CO LTD

Method and equipment for manufacturing three-dimensional object

ActiveCN106564187AEasy to achieve temperature balanceIncrease temperatureAdditive manufacturing apparatusIncreasing energy efficiencyManufacturing technologyLight beam

The invention describes a method for achieving manufacturing of a three-dimensional object by conducting layer-by-layer scanning on a powder layer through an energy bundle. The method comprises the steps that a powder material layer is paved on a base plate or a cured layer, so that the powder layer is formed; part of or more areas of the powder layer are preheated through a preheating light beam, so that the temperature of powder in the preheated areas reaches a set value, wherein setting of the preheating light beam is matched with absorption efficiency of the powder; selective scanning is conducted on the corresponding cross section positions, in the preheated areas, of the three-dimensional object through the energy bundle, and curing of the powder layer is completed, wherein the preheating light beam is a laser beam with the single wave length; and after homogenization is conducted and the light beam uniform in energy distribution is formed and diverged, preheating is conducted on the preheated areas. By means of the method, a powder material adopted in the powder bed additive manufacturing technology can be preheated rapidly and efficiently, and thus the temperature difference generated between the three-dimensional object and the surrounding environment when the three-dimensional object is manufactured is reduced; generation of internal stress is reduced; and manufacturing quality of the three-dimensional object is improved.

Owner:HUNAN FARSOON HIGH TECH CO LTD

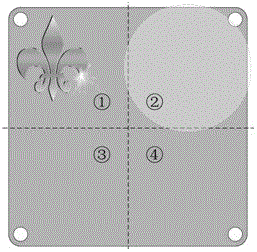

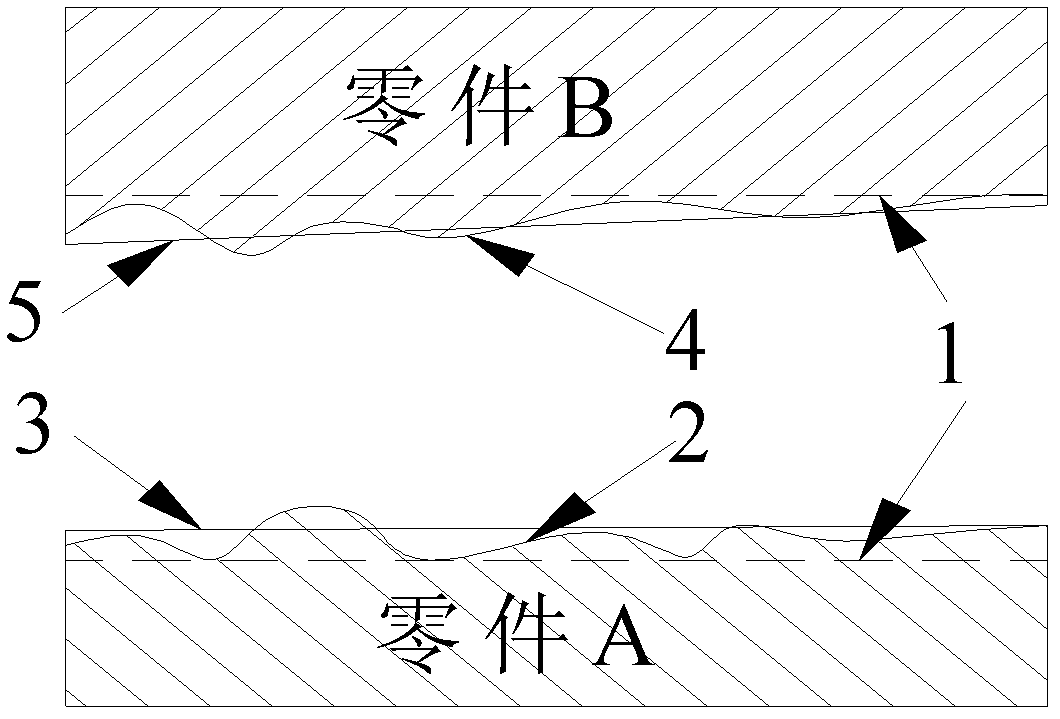

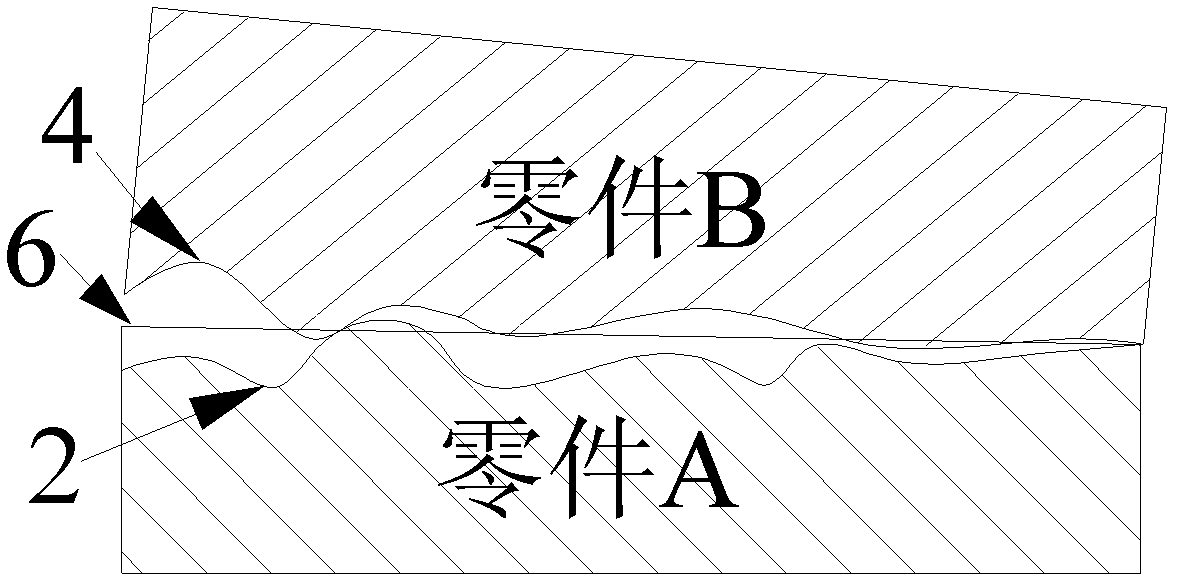

Matching error calculation method for error transfer modeling of precision mechanical system

The invention discloses a matching error calculation method for error transfer modeling of a precision mechanical system. The method comprises the following steps of: measuring shape errors D1 and D2 of two matching surfaces by applying a three-coordinate measuring machine to obtain data of a difference surface, and determining a contact point according to the data of the difference surface; calculating deformation errors delta 1 and delta 2 of the two matching surfaces of a part according to the contact point and assembly force applied to the two matching surfaces, thereby obtaining actual matching surface data D1+delta 1 and data D2+delta 2 considering the shape errors and the deformation errors of the two matching surfaces of the part; and calculating matching error component of the two actual matching surface to obtain matching error so as to be used for error transfer modeling of the precision mechanical system. In the method, the shape errors of the matching surfaces and the part deformation errors produced under the action of the assembly force are considered, a more accurate error transfer model can be established for the precision mechanical system on the basis, and the accuracy for the manufacturing quality prediction and control is improved.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Process method for manufacturing metallographic specimen

ActiveCN101692026AConvenient for metallographic sample preparationRapid metallographic sample preparation workPolishing machinesPreparing sample for investigationSurface roughnessBiomedical engineering

The invention discloses a process method for manufacturing a metallographic specimen, which comprises the following steps: a) quickly grinding a saw-cut specimen, wherein a spectrum-decommissioning specimen grinding machine changed into an abrasive wheel grinding plate is used; and a specimen grinding fixture which can clamp 8 to 10 specimens once is utilized to quickly grind the specimens and is manually held to quickly grind the specimens on the specimen grinding machine until surface roughness reaches to Ra 1.6 to 0.8 microns so as to meet the requirements on precise grinding; b) performing metallographic specimen grinding; and c) performing metallographic polishing. Compared with the prior art, the process method for manufacturing the metallographic specimen in the invention has the advantages of conveniently and quickly manufacturing the metallographic specimen, and not only ensuring the specimen manufacturing quality and analysis quality, but also saving the cost and improving the efficiency.

Owner:CHENGDE JIANLONG SPECIAL STEEL

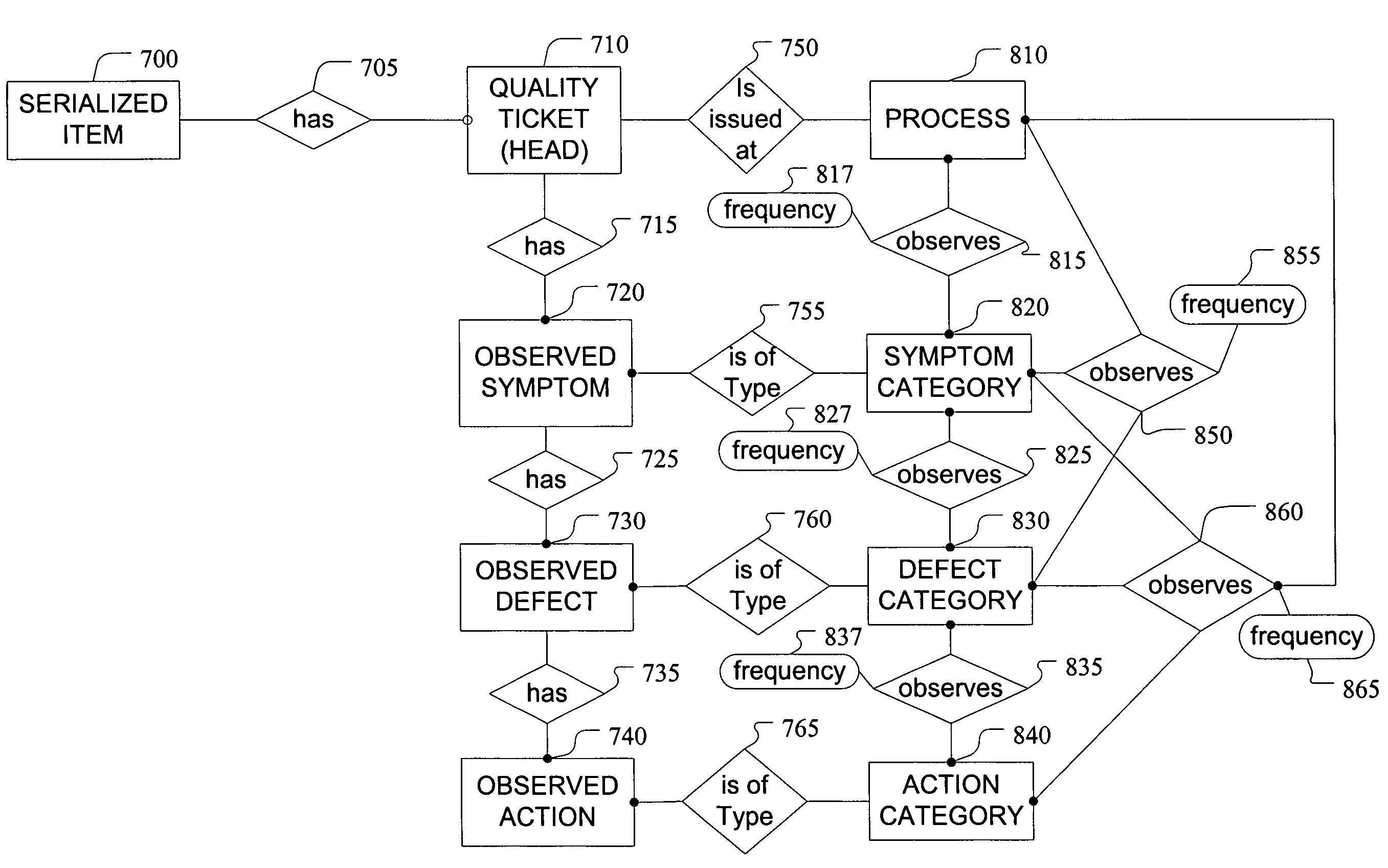

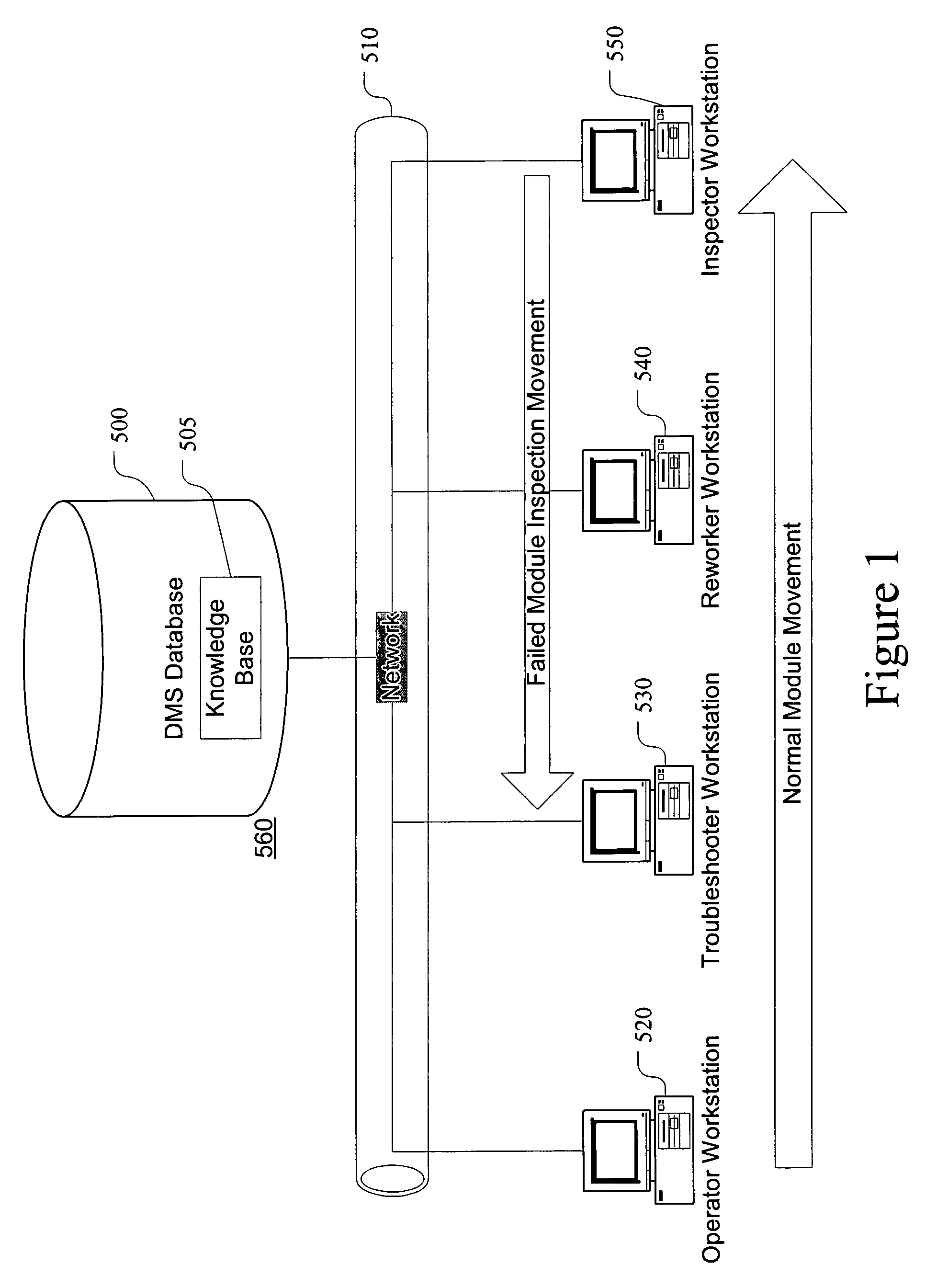

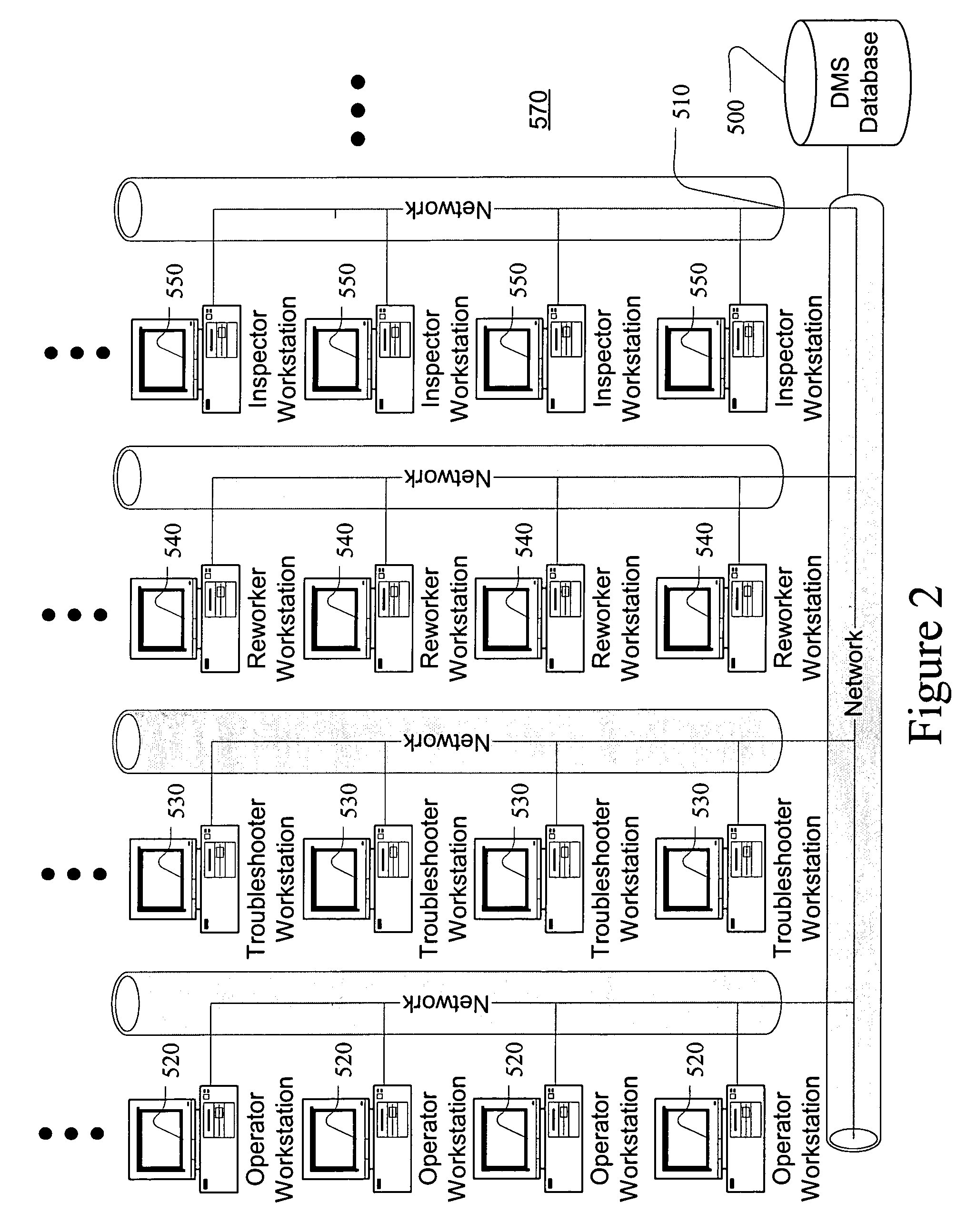

Defect management database for managing manufacturing quality information

A manufacturing quality information database structure is useful for tracking quality information relating to a manufacturing process. Accurate tracking of symptoms, defects, and actions (repairs) is achieved through data associations between symptom data entities, defect data entities, and action data entities. Further associations between symptom and symptom category data entities; defect and defect category data entities; and action and action category data entities may be used to increase the data tracking capabilities of the database. Moreover, manufacturing processes and process steps may be tracked by process and process step data entities that may also be associated with the symptom, defect and action data entities. Still further, a variety of different modules and module types may be tracked by including an item data entity that identifies each module.

Owner:CIENA

Cigarette manufacturing quality stability evaluation method

PendingCN106485422AImproving the level of cigarette rollingImprove roll levelResourcesEvaluation resultWeighted arithmetic mean

The invention belongs to the technical field of cigarette production, and particularly relates to a cigarette manufacturing quality stability evaluation method. The method mainly comprises steps of firstly, carrying out hierarchical classification on cigarette quality stability according to manufacturing processes of cigarettes; then, carrying out quantization representing on single-factor variables on a machine bench and carrying out weight assignment; evaluating manufacturing quality stability of a single machine bench, wherein the evaluation result of the machine bench is equal to the weighted average of a single-factor evaluation result; and finally, carrying out stability evaluation on batch manufacturing quality and judging the evaluation result. According to the invention, stability of a single variable in the manufacturing process can be evaluated; quality stability of the machine bench and stability of batch comprehensive quality can be evaluated; cigarette manufacturing level can be improved; and powerful support is provided for improving of product quality stability.

Owner:CHINA TOBACCO HENAN IND

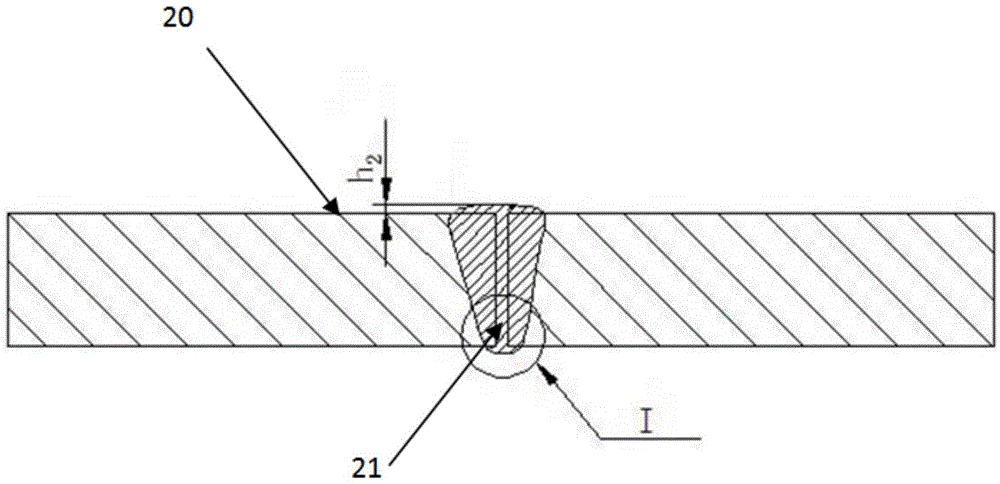

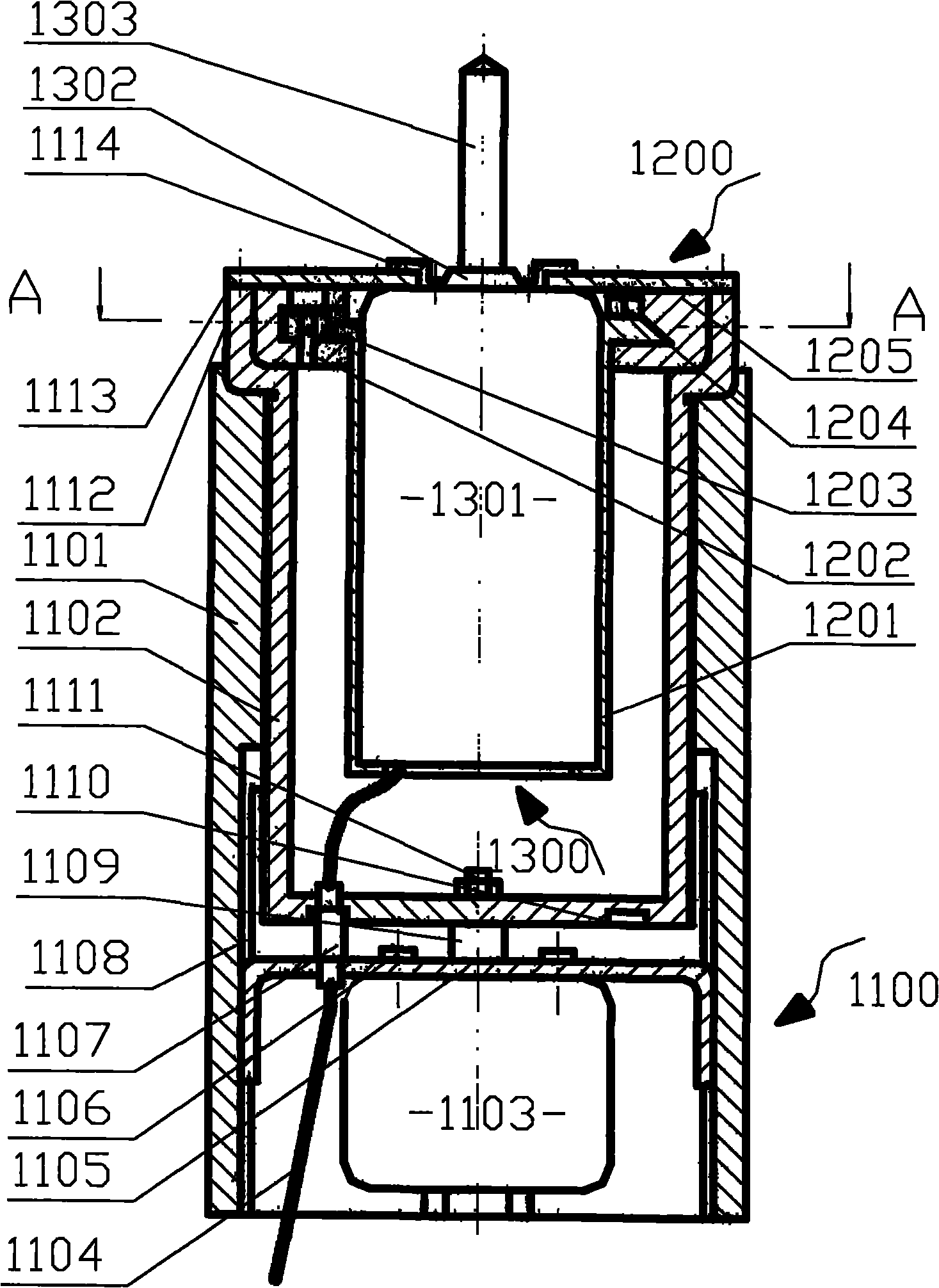

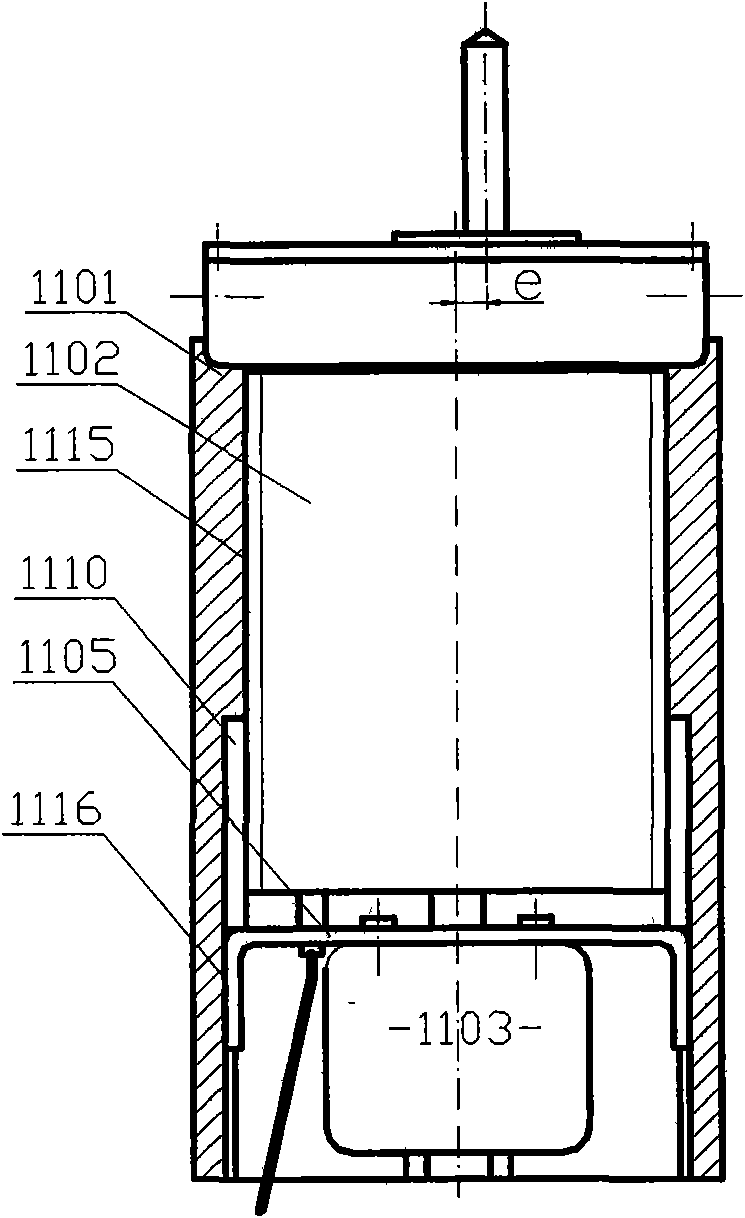

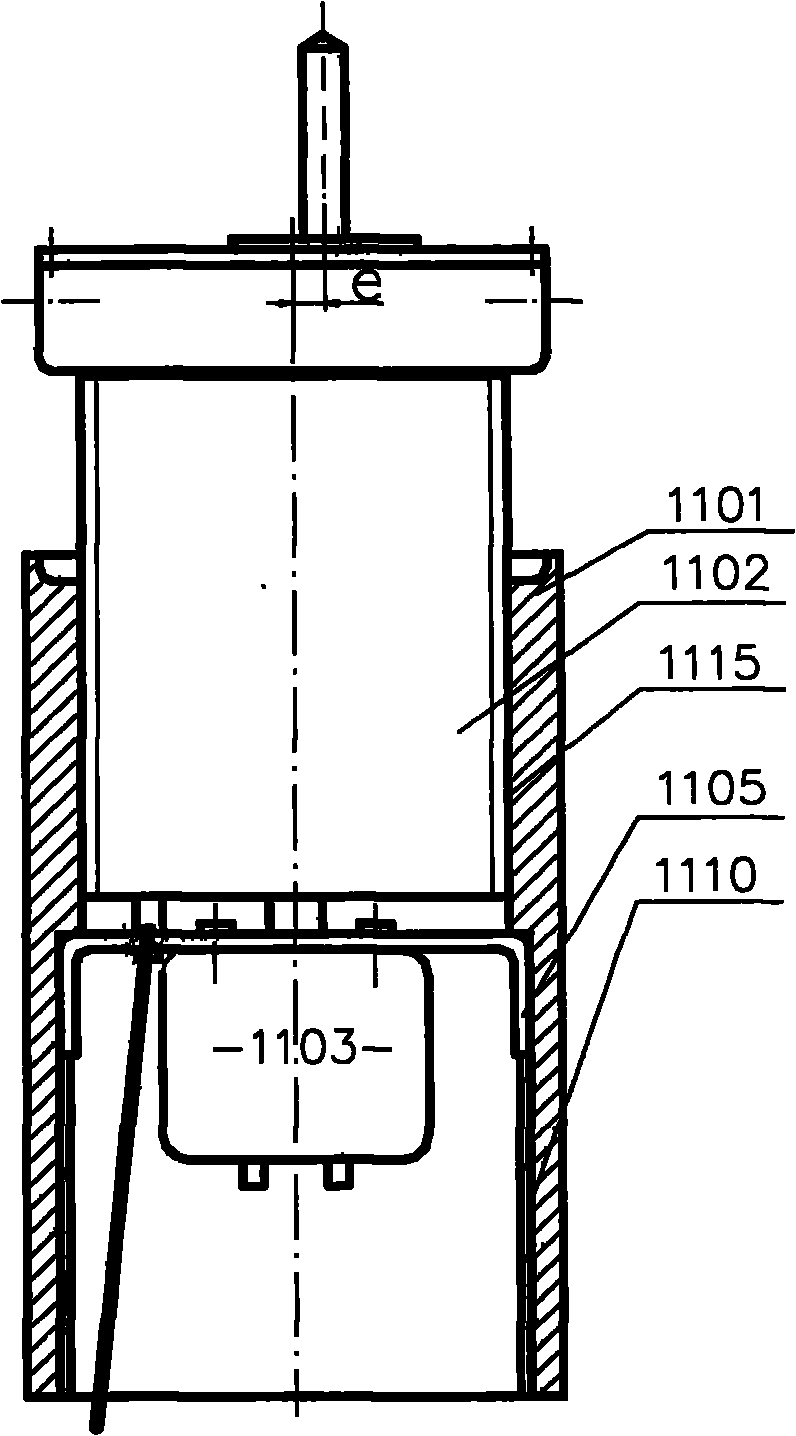

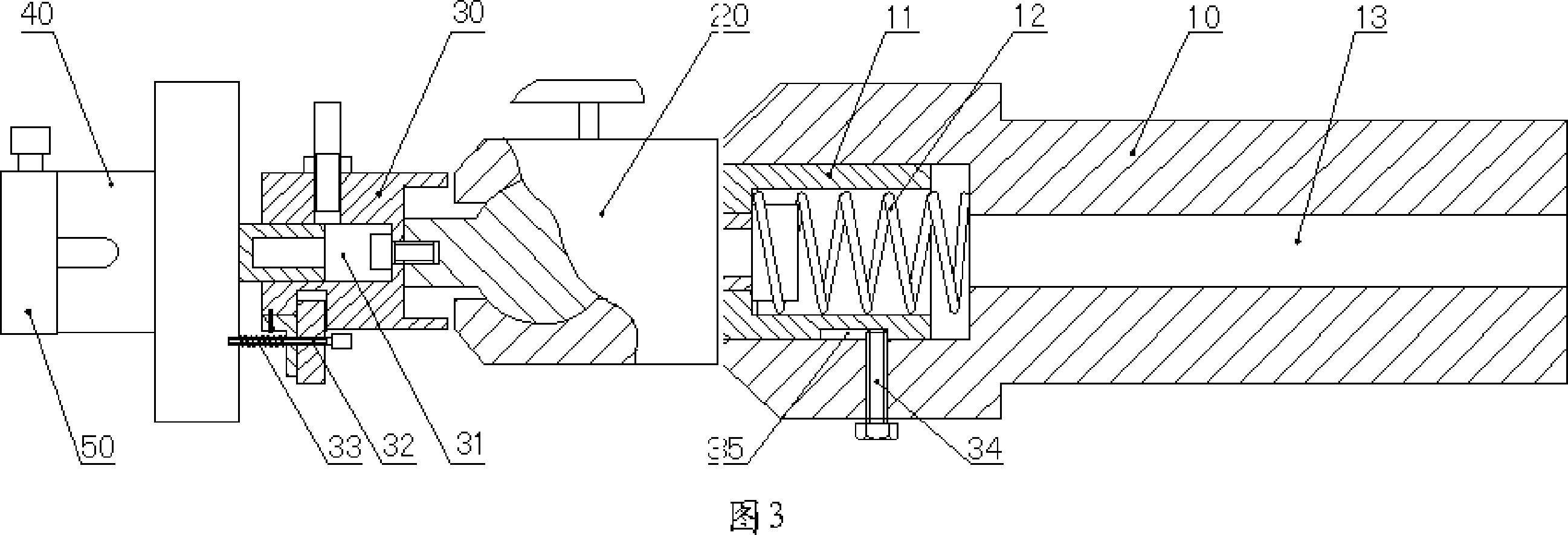

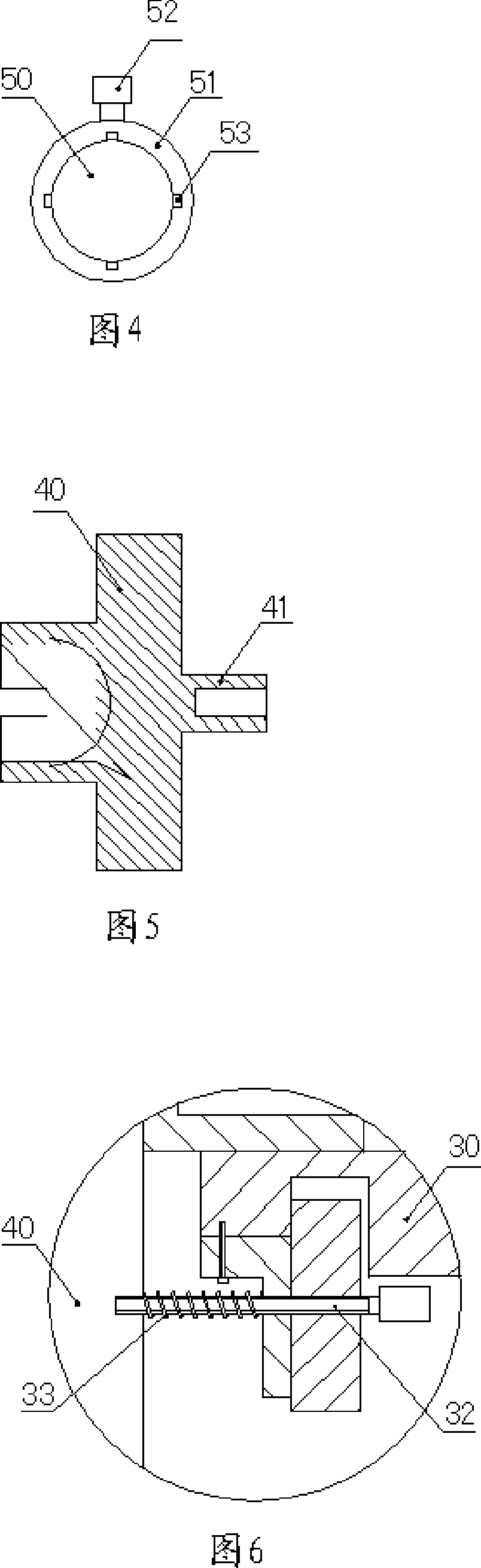

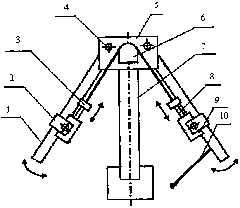

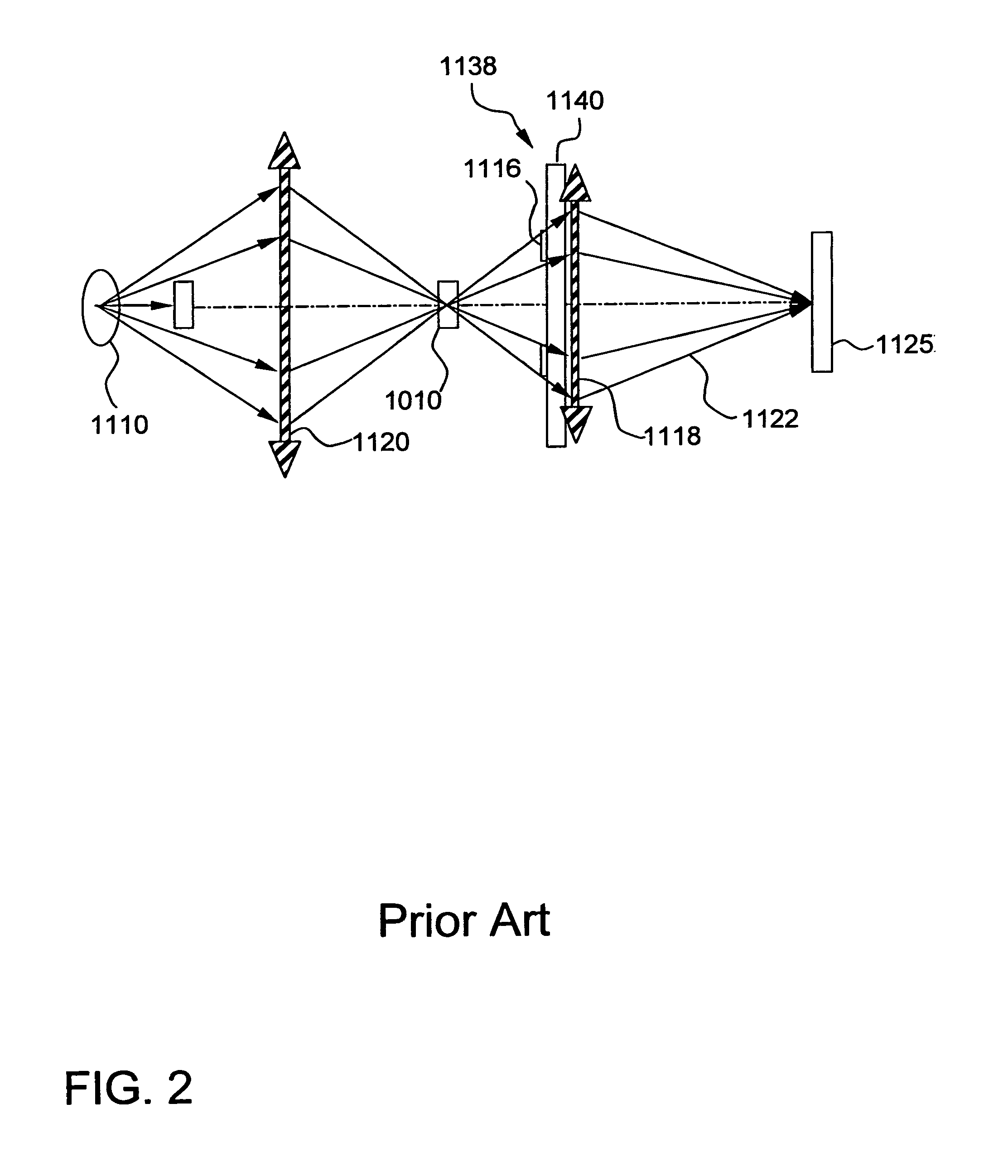

Helical milling device and method

InactiveCN101786180ASimple structureReduce weightFeeding apparatusMilling equipment detailsEngineeringRadial deviation

The invention relates to a helical milling device and a helical milling method, and belongs to the technical field of machining. The device mainly comprises a helical feed mechanism (1100) used for realizing the axial feeding and revolution of a cutter (1303), a radial deviation mechanism (1200) used for adjusting the revolution radius of the cutter (1303) relative to axes of pores and a rotation mechanism (1300) used for driving the cutter to rotate. The device and the method of the invention can greatly improve the manufacturing quality and machining efficiency of complex pore series on surfaces of large-scale workpieces.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS +1

Selective laser fusion composite manufacturing machine tool and workpiece composite manufacturing method

InactiveCN105382259AQuality improvementHigh precisionAdditive manufacturing apparatusIncreasing energy efficiencyLaser scanningHigh surface

The invention discloses a selective laser fusion composite manufacturing machine tool. The selective laser fusion composite manufacturing machine tool comprises a lifting workbench, a main shaft, a material increase manufacturing mechanism, a material decrease manufacturing mechanism and a defect detection mechanism capable of detecting workpiece defects online. The material increase manufacturing mechanism comprises a laser scanning system and a powder feeding device; the laser scanning system is connected with a laser generator; the powder feeding device comprises a powder box and a scraper plate. The material decrease manufacturing mechanism comprises a tool, a tool magazine and a tool-changing bracket. The defect detection mechanism comprises a defect detector and a detection signal collection and analysis system. The invention further discloses a workpiece composite manufacturing method. The method mainly includes the step of conducting selective laser fusion material increase manufacturing, defect detection and material decrease processing in a circulating mode till composite manufacturing is completed finally. By combination of the selective laser fusion material increase manufacturing, material decrease processing and defect detection, it is ensured that workpieces with high size precision, high surface quality and low internal defects are formed at a time, the production period is shortened effectively, and the part manufacturing quality and precision are ensured.

Owner:DALIAN UNIV OF TECH

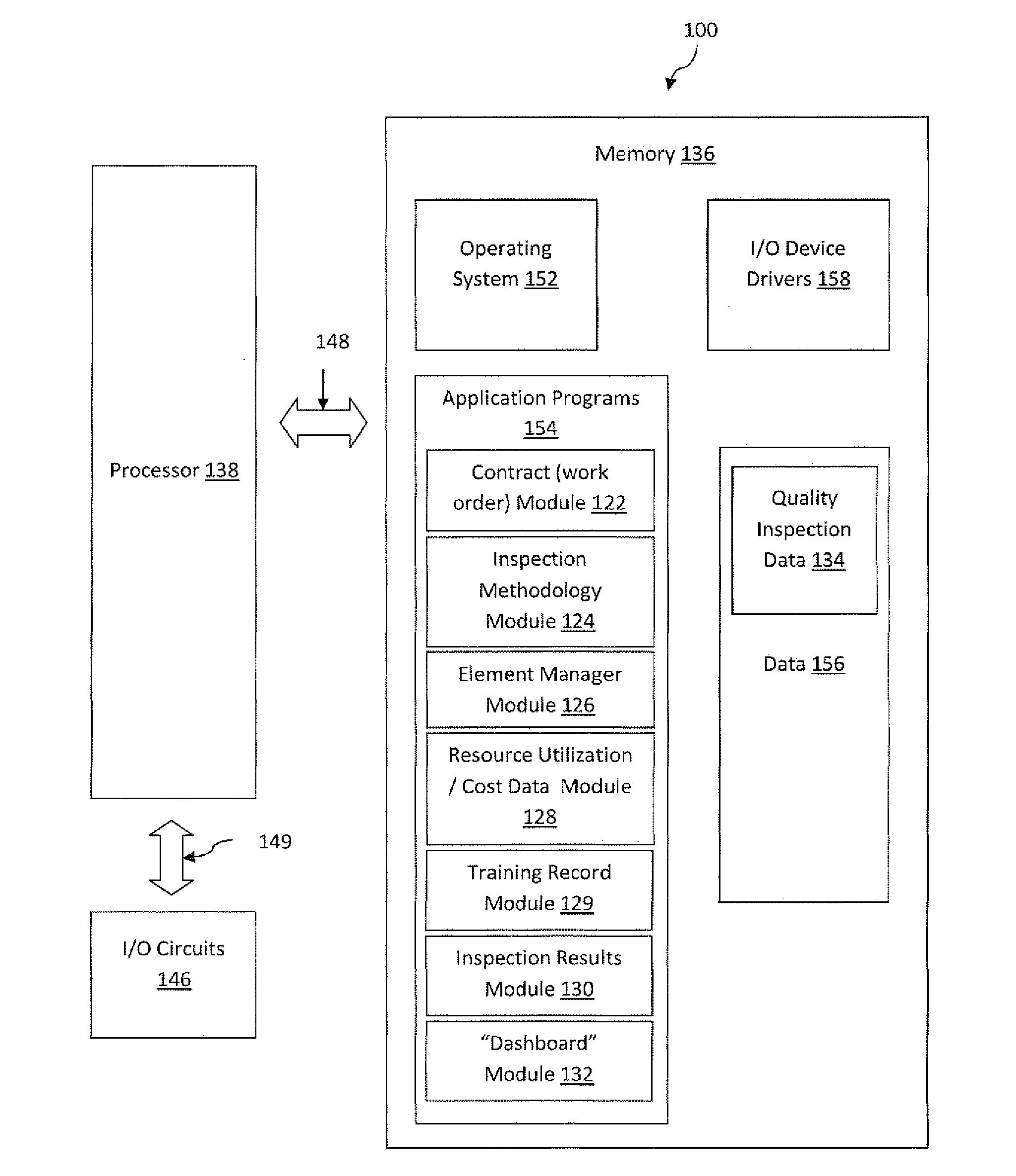

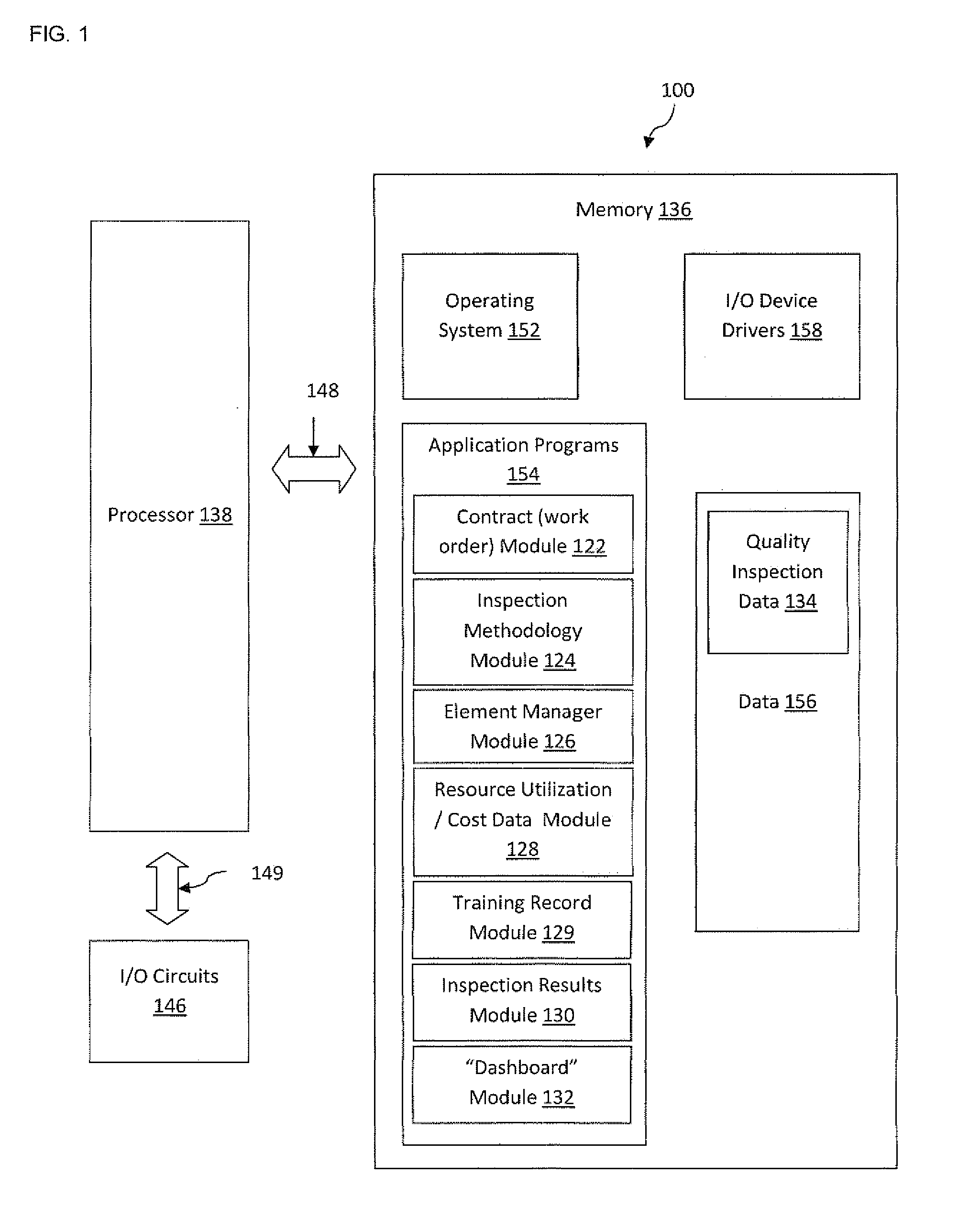

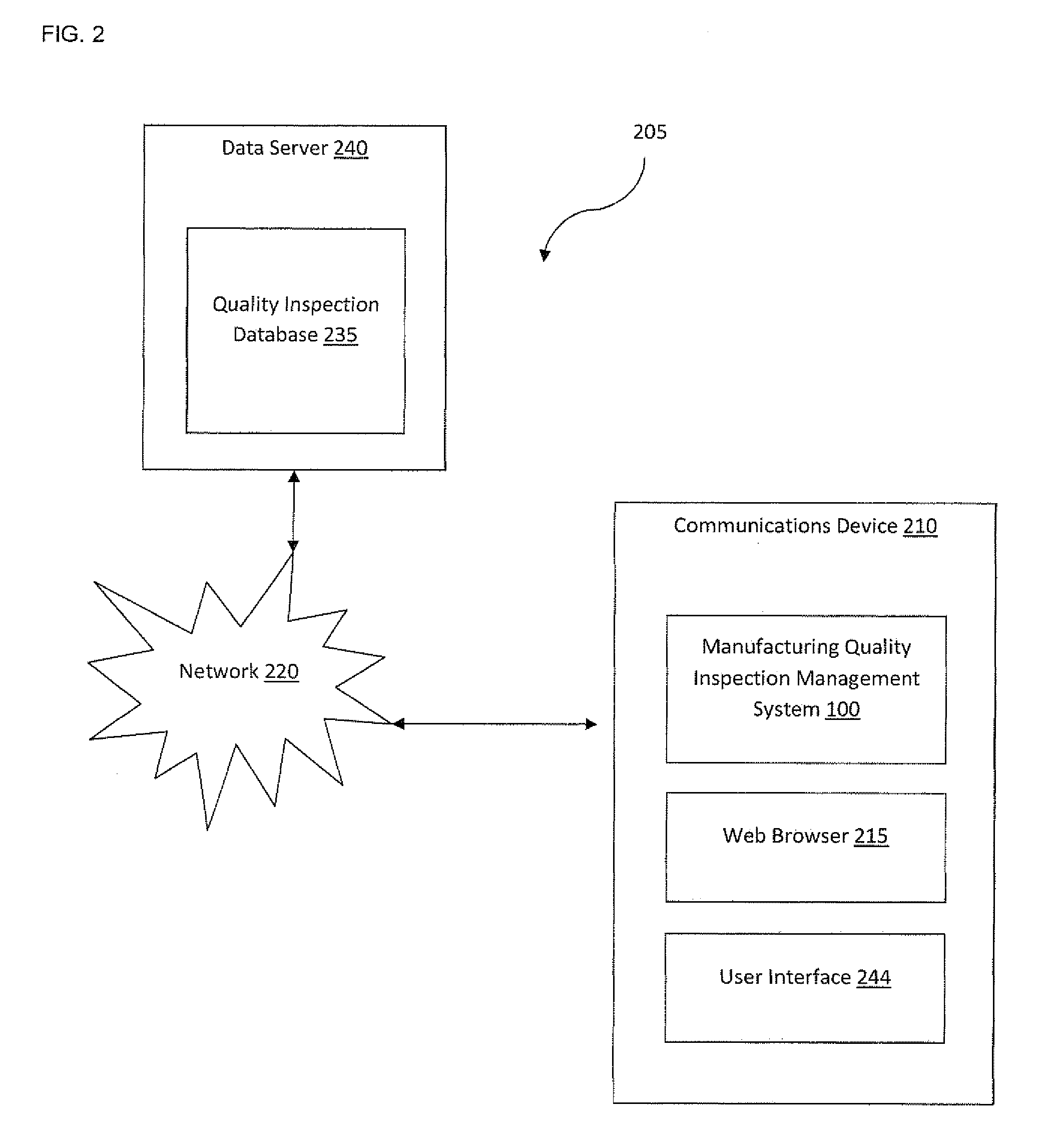

Data processing system for manufacturing quality inspection management system

InactiveUS20110055205A1Prevent wrong actionDigital data processing detailsSpecial data processing applicationsResource utilizationStatistical Report

Disclosed is a computer readable medium containing a program product provided for the development, receipt, storage, and presentation of the data necessary for delivery of quality assurance test activities. In particular, the program product allows users to create quality assurance testing criteria and procedures; define, document, and approve specific actions and allocate unique categorization codes. The program product includes a module for the creation and storage of predefined text and image elements for the provision of enterprise wide knowledge sharing. The program product applies calculations to consolidate and convert data into statistical reports utilizing a variety of user-defined criteria, including but not limited to component descriptor, quality criteria, time period and manufacturer. The program product also accepts, consolidates and calculates post-production quality resource utilization / costs, segregated periodically and / or consolidated, enabling stakeholders to determine appropriate corrective actions based on ongoing quality assurance testing outcomes.

Owner:Q2 MANAGEMENT

Emulsion pump testing system

InactiveCN101603527AReduce pressure loss along the wayImprove energy savingPump testingPositive-displacement liquid enginesHydraulic motorEmulsion

The invention relates to an emulsion pump testing system, comprising an electrical apparatus control system which is used for driving a motor to start or stop, a transmission box connected with a tested pump, an emulsion pump circulating system and a hydraulic oil circulating system for driving the transmission box; the working load of the tested pump is changed by adjusting the discharging amount of an oil hydraulic motor, hydraulic pressure output by the tested pump is compensated to the oil hydraulic motor mostly by a loading cylinder, namely, the oil hydraulic motor is not only a driving force source of the tested pump, but also is a load of the tested pump; the system can carry out reliability detecting test to the emulsion pump with different type and different power, and the comprehensive performance and manufacturing quality of the emulsion pump are detected in an on-line way, therefore, the occupying area of the equipment is not only reduced, but also the operating power can not be converted into heat energy, so as to reduce the operating cost; the most important point is that the power can be recycled, the energy consumption is greatly reduced; compared with the prior art, the energy saving can reach about 70 percent, the structure is simple and energy-saving, and has good using effect.

Owner:CHINA UNIV OF MINING & TECH +1

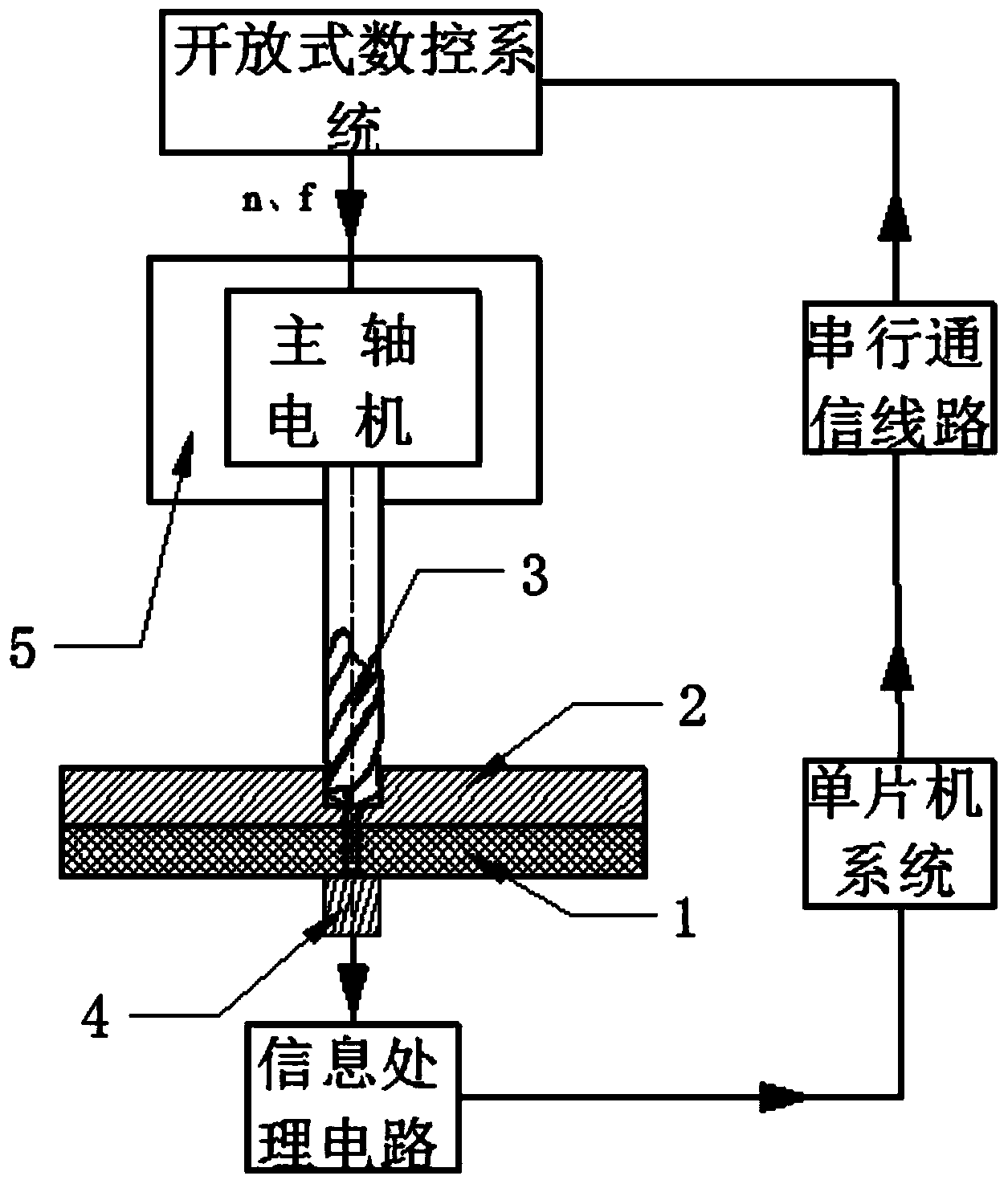

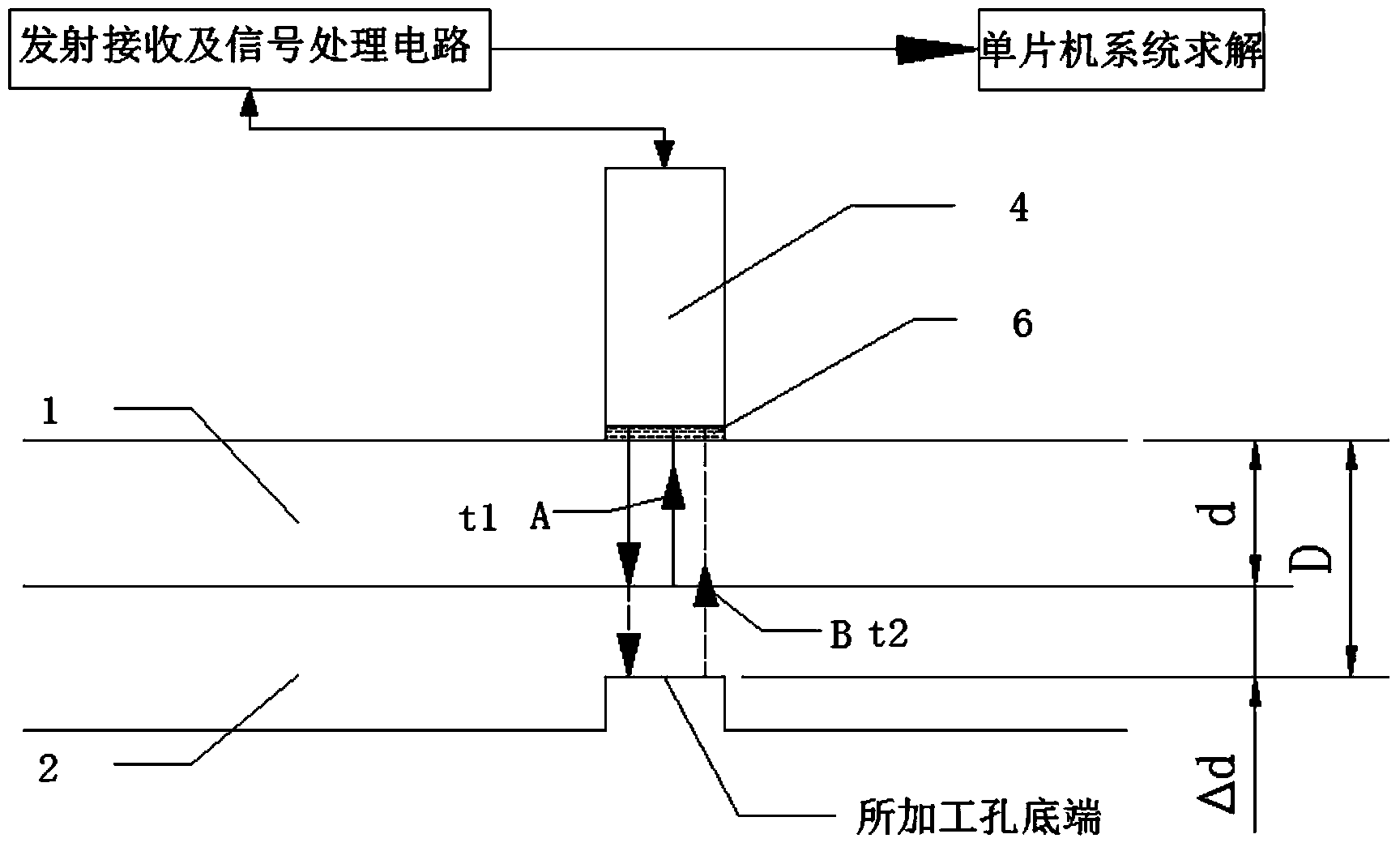

Laminated structure hole manufacturing online monitoring self-adaptive machining method

InactiveCN104289738AQuality improvementImprove efficiencyAutomatic control devicesFeeding apparatusUltrasonic thickness measurementNumerical control

The invention discloses a laminated structure hole manufacturing online monitoring self-adaptive machining method. The laminated structure hole manufacturing online monitoring self-adaptive machining method comprises the following steps that (1), a hole manufacturing cutter installed on a numerical control machine tool is adopted to manufacture holes in laminated structures of carbon fiber reinforced composite materials and alloy materials, the distance between the laminated structure hole forming position reached by the bottom end of the hole manufacturing cutter and the material interface in the laminated structures is measured through an ultrasonic thickness measurement method, and then the distance signal is transmitted to a control system of the numerical control machine tool with the hole manufacturing cutter after being processed; (2), the control system of the numerical control machine tool compares the received distance signal with a set value 0, if the distance value is greater than 0, the control system of the numerical control machine tool still outputs an initial control signal, and if the distance value is 0, the control system of the numerical control machine tool outputs a new preset control signal to change the spindle rotation speed and feeding speed of the hole manufacturing cutter. By the adoption of the method, the laminated assembly hole manufacturing quality and hole machining efficiency can be improved, and the cost is lowered.

Owner:TIANJIN UNIV

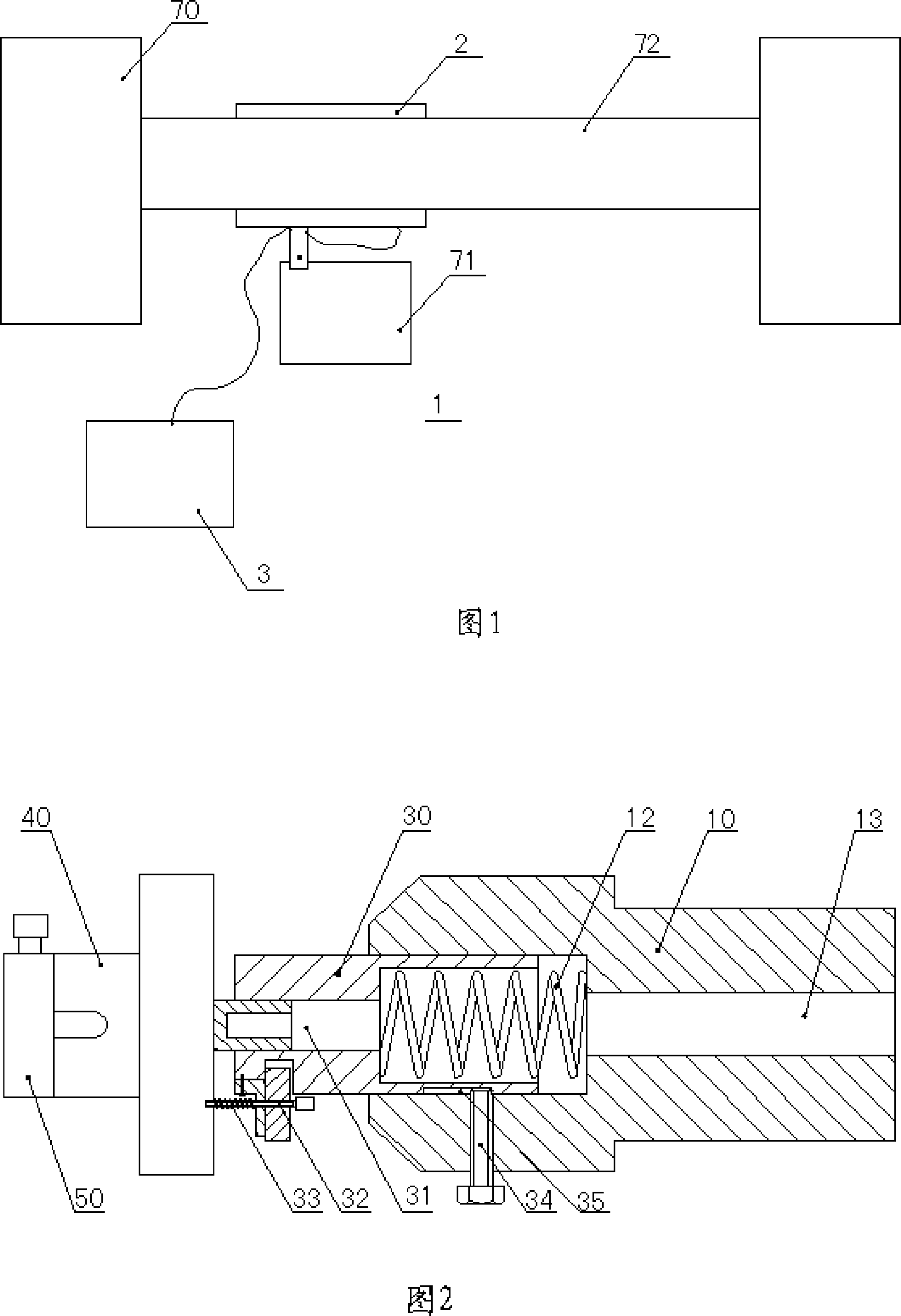

Supersonic wave on-line flaw detection method and its device

ActiveCN101122582AHigh speedImprove efficiencyAnalysing solids using sonic/ultrasonic/infrasonic wavesSupersonic wavesEngineering

The invention discloses an ultrasonic on-line flaw detection method and a device thereof. By using the method and the device, the on-line flaw detection can be conveniently carried out on rotating and non-rotating workpieces being processed. This comprises probe device (1), couplant supply device (2) and ultrasonic detection analyzer (3), and described probe device (1) is installed on the knife feeding mechanism (71) of processing machine tool (70), ultrasonic probe ( 50) is fixed on the probe device (1) and is opposite to the processing surface of the workpiece (72). The beneficial effect of the present invention is that ultrasonic flaw detection can be performed on workpieces in the process of processing to realize real-time online automatic detection, which can greatly improve the speed and efficiency of flaw detection of large workpieces, and is beneficial to ensure the manufacturing quality of large workpieces; the structure is simple , easy to set up, the position of the ultrasonic probe can be flexibly changed or adjusted precisely, and it can effectively prevent the ultrasonic probe from being damaged due to accidental collision.

Owner:CHINA ERZHONG GRP DEYANG HEAVY IND

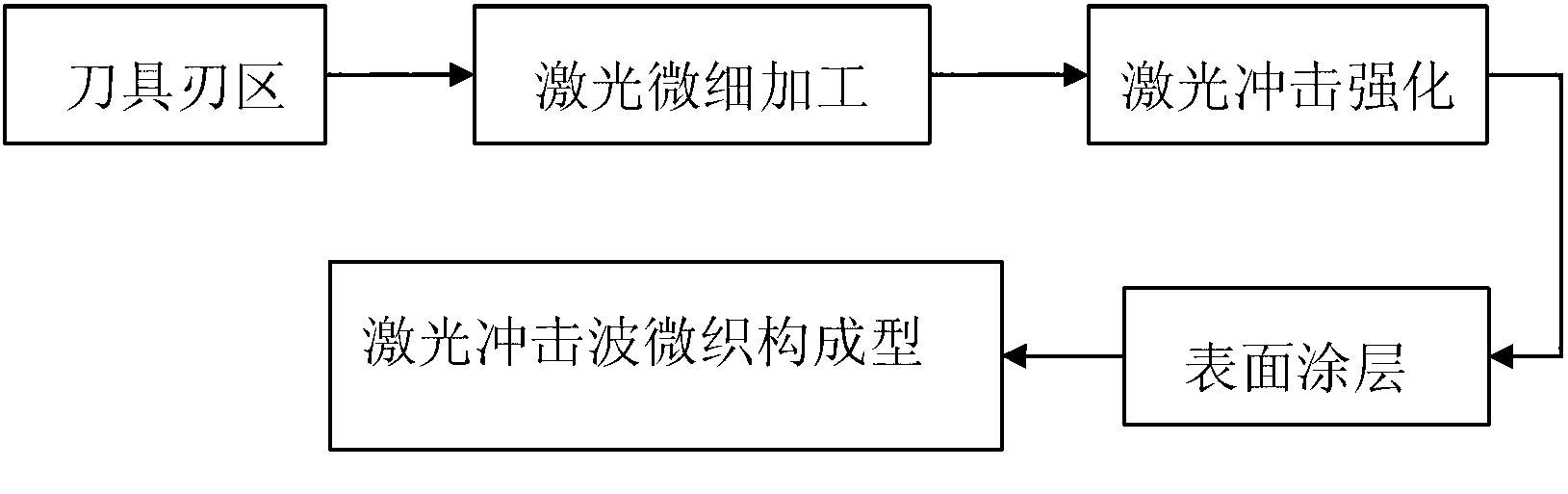

Laser compound strengthening technology

InactiveCN103060528AIncrease the residual compressive stressEase of productionFurnace typesMetallic material coating processesShock waveHeat transmission

The invention provides a laser compound strengthening technology, which comprises the following steps of (1) carrying out femtosecond laser micro machining on a blade area of a hard alloy cutter, so as to obtain pits arranged in certain sequence; (2) carrying out laser shock peening in the blade area of the hard alloy cutter; (3) coating on the surface of the cutter after laser shock peening; and (4) carrying out laser shock wave microtexture forming process on the blade area of the coated hard alloy cutter, so as to obtain a laser compound strengthening model. The laser compound strengthening technology comprises four steps, namely, laser micro machining, laser chock peening, surface coating, and the laser shock wave microtexture. According to the laser compound strengthening technology, residual compressive stress, infiltration characteristic, heat transmission, cooling and lubricating conditions of the blade area can be obviously improved, built-up edges and burrs are reduced, and nickel base material is prevented from being attached to the surface of the cutter, so that the service life of the cutter is prolonged, and the stability of the manufacture quality is improved.

Owner:WENZHOU UNIVERSITY +2

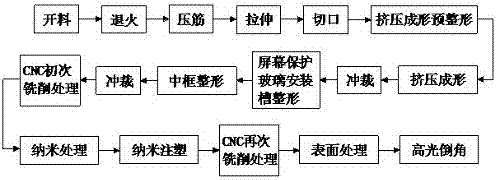

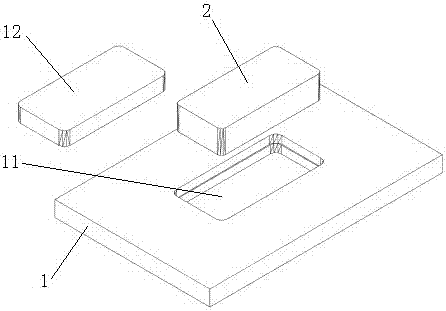

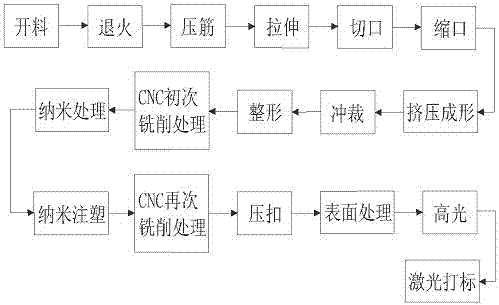

Manufacturing method of mobile phone shell and special die

ActiveCN107199287AMany structural stylesHigh strengthShaping toolsExtrusion diesNumerical controlMetal sheet

The invention relates to a manufacturing method of a mobile phone shell and a special die. The method is used for manufacturing a front shell or a back shell of a mobile phone and specifically comprises the following steps of cutting sheet metal into metal sheets first, drawing the metal sheets into concave hollow pieces, shaping notches of the concave hollow pieces, then putting in a die for extrusion forming, performing nanometer treatment and nanometer injection molding after extrusion forming, milling and trimming a workpiece through CNC (Computer Numerical Control), and then performing surface treatment on the workpiece. The die for manufacturing the front shell or the back shell of the mobile phone comprises a lower die and an upper die, wherein the upper die is matched with the lower die. The manufacturing method has the advantages of reasonable concept, simple operating process, good manufacturing quality and high efficiency and is suitable for popularization and application.

Owner:蔡振豪

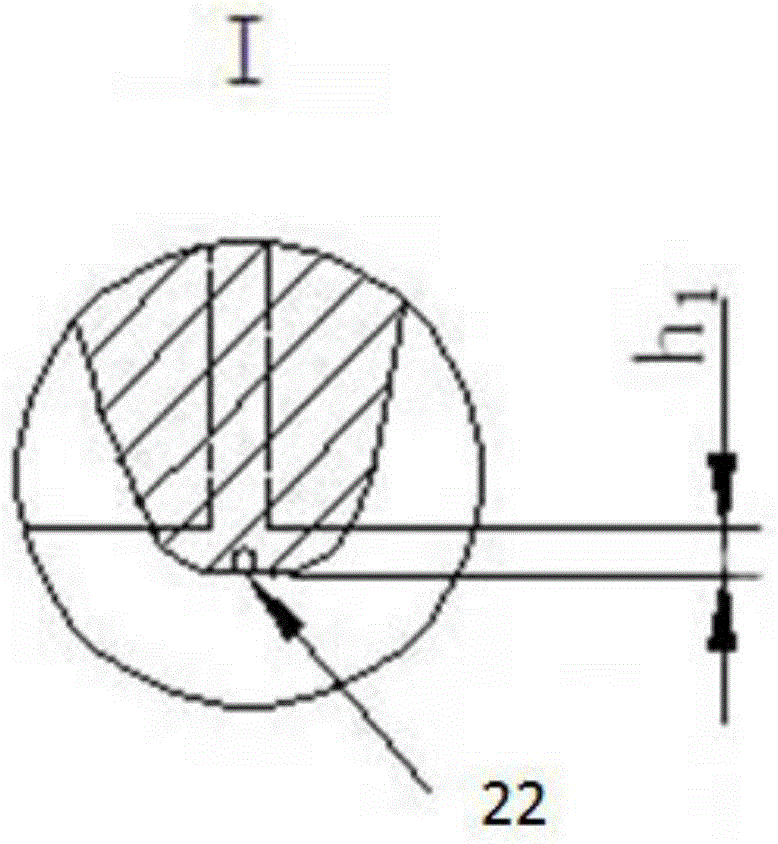

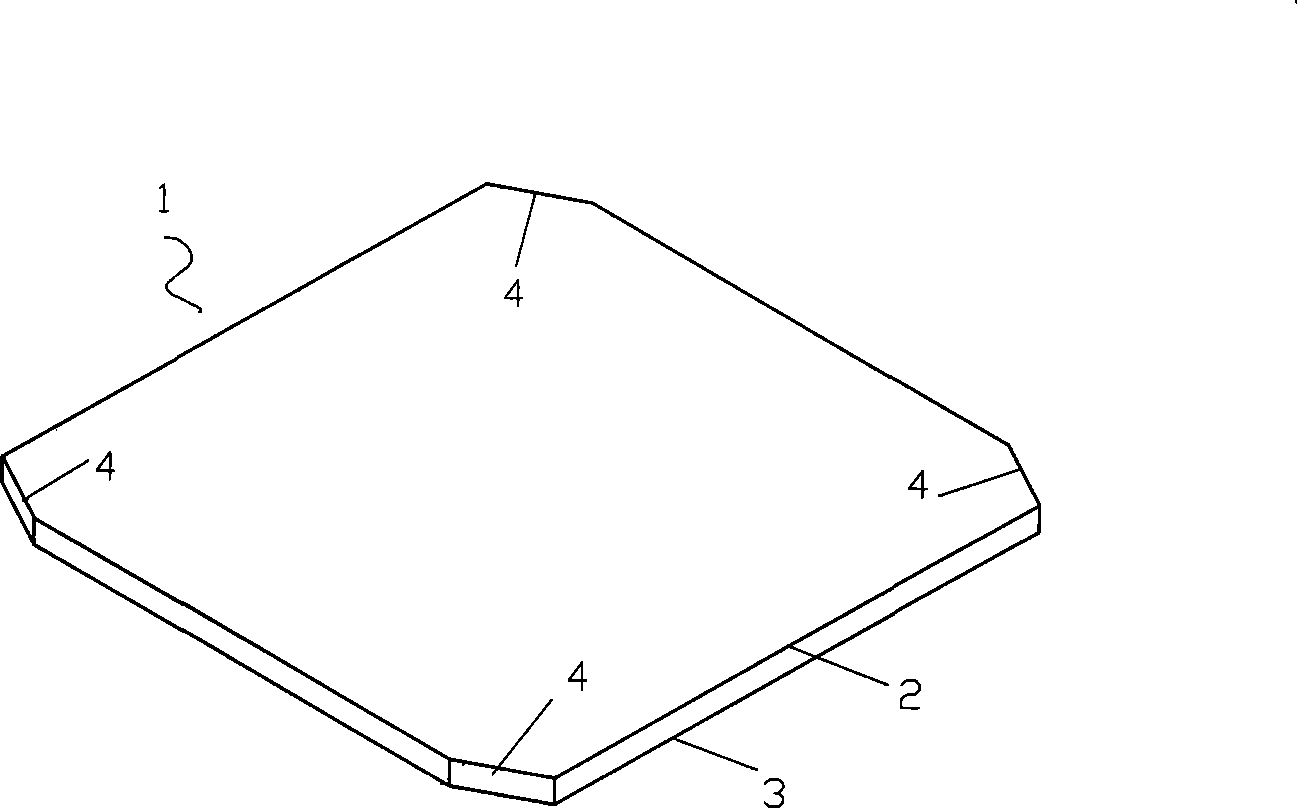

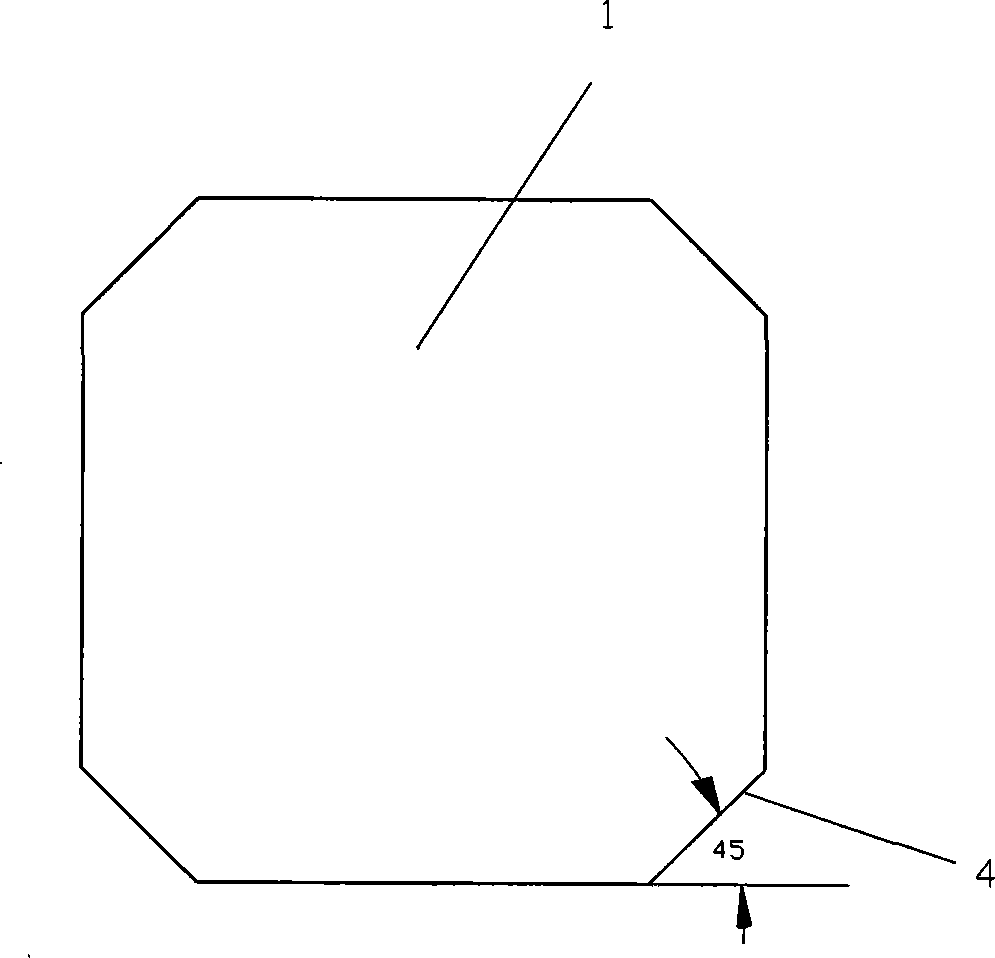

Ultra-thin solar silicon slice and its cutting technology

InactiveCN101241939AGuaranteed WarpageHigh outputFinal product manufactureFine working devicesEngineeringSolar cell

The invention relates to an ultra-thin sun energy level silicon chip and cutting technology thereof which belongs to the solar cell field. The body of the ultra-thin sun energy level silicon chip is the square slice composed of upper and lower planes in parallel, the foursquare of the square slice is four same chamfer angle of 45 DEG. The distance of the upper and lower planes is in the scope of 165-195 um, the angularity is less than 75 um, and the surface of the plane is bright, flat and flawless. The ultra-thin sun energy level silicon chip cutting technology adopts a silicon wafer stick excavator to directly cut silicon wafer stick into octagonal square cylinder whose cross-section is square and foursquare is the same chamfer angle of 45 DEG, the cutting excess stock is lump which can be reused by scrap. It also adopts optimized cutting technology to cut into the ultra-thin sun energy level silicon chip on the multi-thread cutting machine so as to guarantee the manufacturing quality of the ultra-thin sun energy level silicon chip, improve productivity, and reduce the manufacturing cost of ultra-thin sun energy level silicon chip.

Owner:江苏有则创投集团有限公司

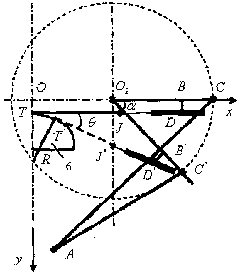

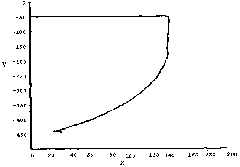

Stretch-bending molding process of angle steel component of vehicle body

ActiveCN101823092AHigh quality and precisionImprove manufacturing precisionPull forceMathematical model

The invention relates to a stretch-bending molding process of an angle steel component of a vehicle body and mainly aims to scientifically and rationally overcome the defects of overlarge rebound modulus and section bending deflection of workpieces and the like during the stretch-bending molding of the angle steel component of the vehicle body. The process realizes the emulation of pretension and post-tension corresponding to the minimum rebound modulus, provides a computing formula for the initial length of profiles and a trajectory model of a clamp, improves the forming quality, precision and work efficiency of a stretch-bending workpiece and the manufacturing quality of vehicle steel structure, reduces the manufacturing and maintenance cost, overcomes stretch-bending defects and provides basis for the stretch-bending molding precision control of profile parts. The process initially establishes a mathematical model for length rebound modulus of a multi-curvature profile, can precisely determine the initial length of a blank profile of parts, determines the optimal pretension and post-tension by a simulation method and precisely determines the trajectory of the clamp by establishing a multi-curvature profile stretch-bending module, thereby obtaining the ideal forming quality of the formed profile.

Owner:白城市瑞程汽车部件有限公司

X-ray photoemission microscope for integrated devices

ActiveUS9291578B2Reduce distanceRadiation/particle handlingSemiconductor/solid-state device detailsX-rayMicroscope

An apparatus is disclosed for the examination and inspection of integrated devices such as integrated circuits. X-rays are transmitted through the integrated device, and are incident on a photoemissive structure that absorbs x-rays and emits electrons. The electrons emitted by the photoemissive structure are shaped by an electron optical system to form a magnified image of the emitted electrons on a detector. This magnified image is then recorded and processed. In some embodiments, the integrated device and photoemissive structure are independently mounted and controlled. In other embodiments, the photoemissive device is deposited directly onto the integrated device. In some embodiments, the incidence angle of the x-rays is varied to allow internal three-dimensional structures of the integrated device to be determined. In other embodiments, the recorded image is compared with a reference data to enable inspection for manufacturing quality control.

Owner:ADLER DAVID L

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com