Multi-point flexible positioning tool

A flexible positioning and tooling technology, applied in the field of aircraft manufacturing, to achieve a high degree of automation, improve processing efficiency and quality, and overcome the effects of high manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] This embodiment is a multi-point flexible positioning tool for positioning and supporting the upper left wall of a certain type of wing.

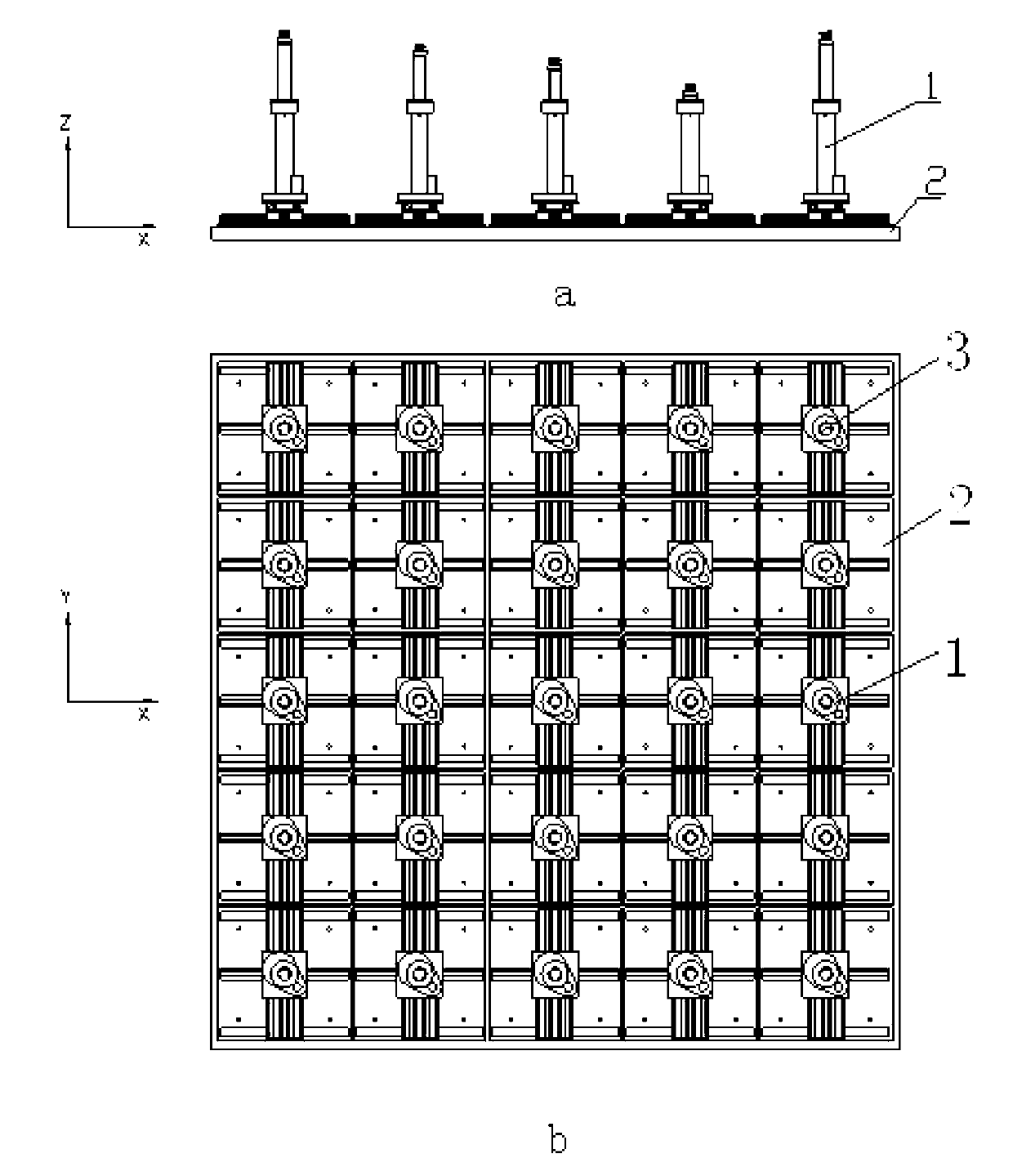

[0029] as attached figure 1 As shown, this embodiment includes a plurality of Cartesian flexible support modules 1 and bases 2 . A plurality of Cartesian coordinate flexible support modules 1 are arranged and fixed on the upper surface of the base 2 . There is a gap of 5-10 mm between the Cartesian coordinate flexible support modules 1 , and in this embodiment, the gap between the Cartesian coordinate flexible support modules 1 is 10 mm.

[0030] The base 2 is square, and its surface size is determined according to the size of the largest projected surface of the part to be clamped, and the surface size of the base 2 is larger than the maximum projected size of the part to be clamped.

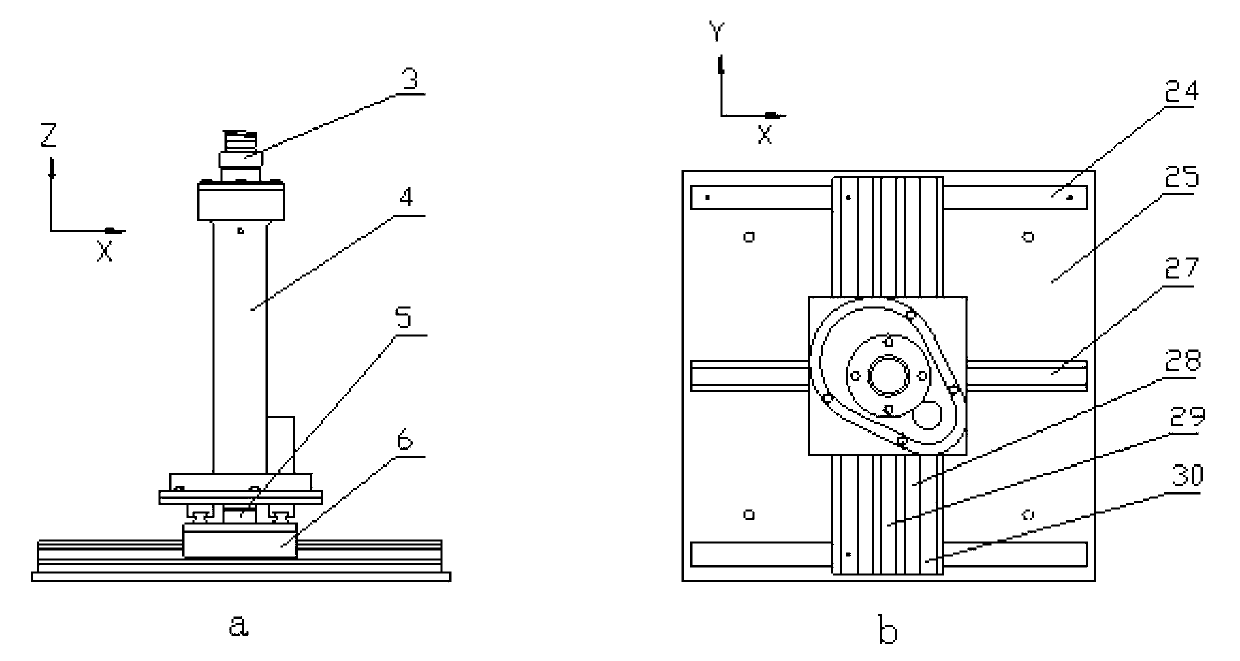

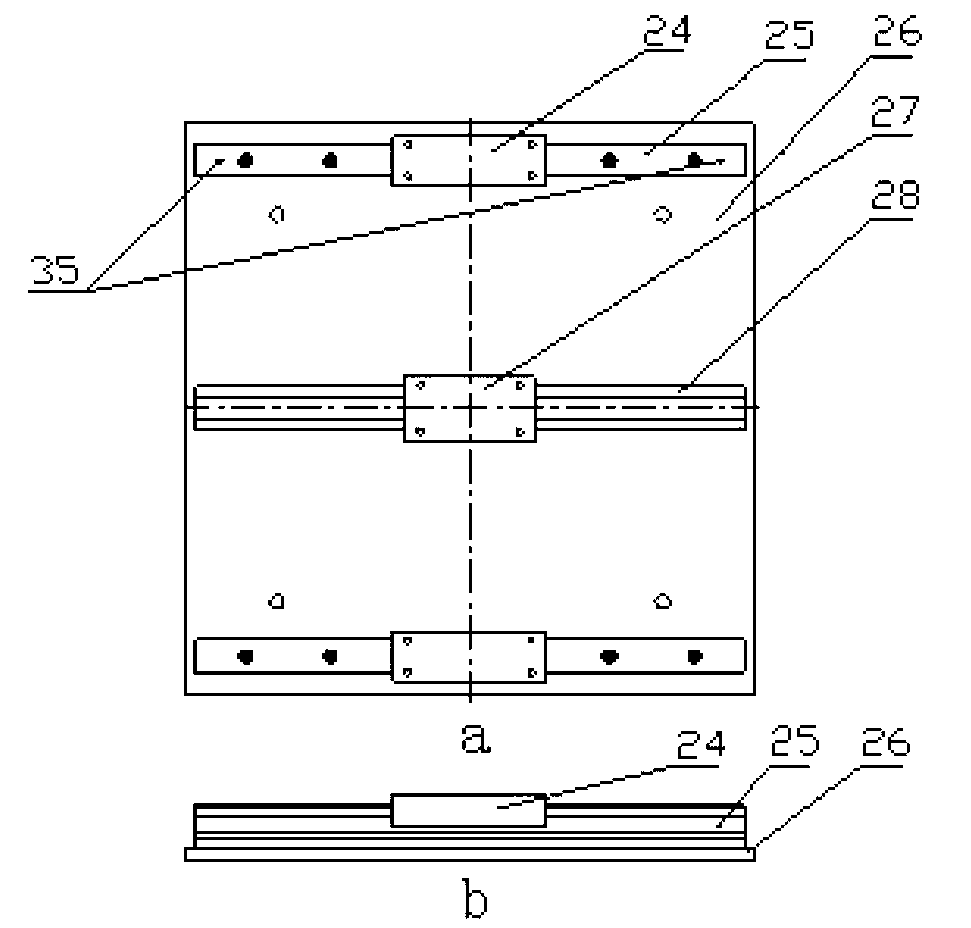

[0031] as attached figure 2 As shown, the rectangular coordinate type flexible support module 1 includes an x-direction sliding unit 6 , a y-direct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com