Patents

Literature

220 results about "Aircraft manufacturing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

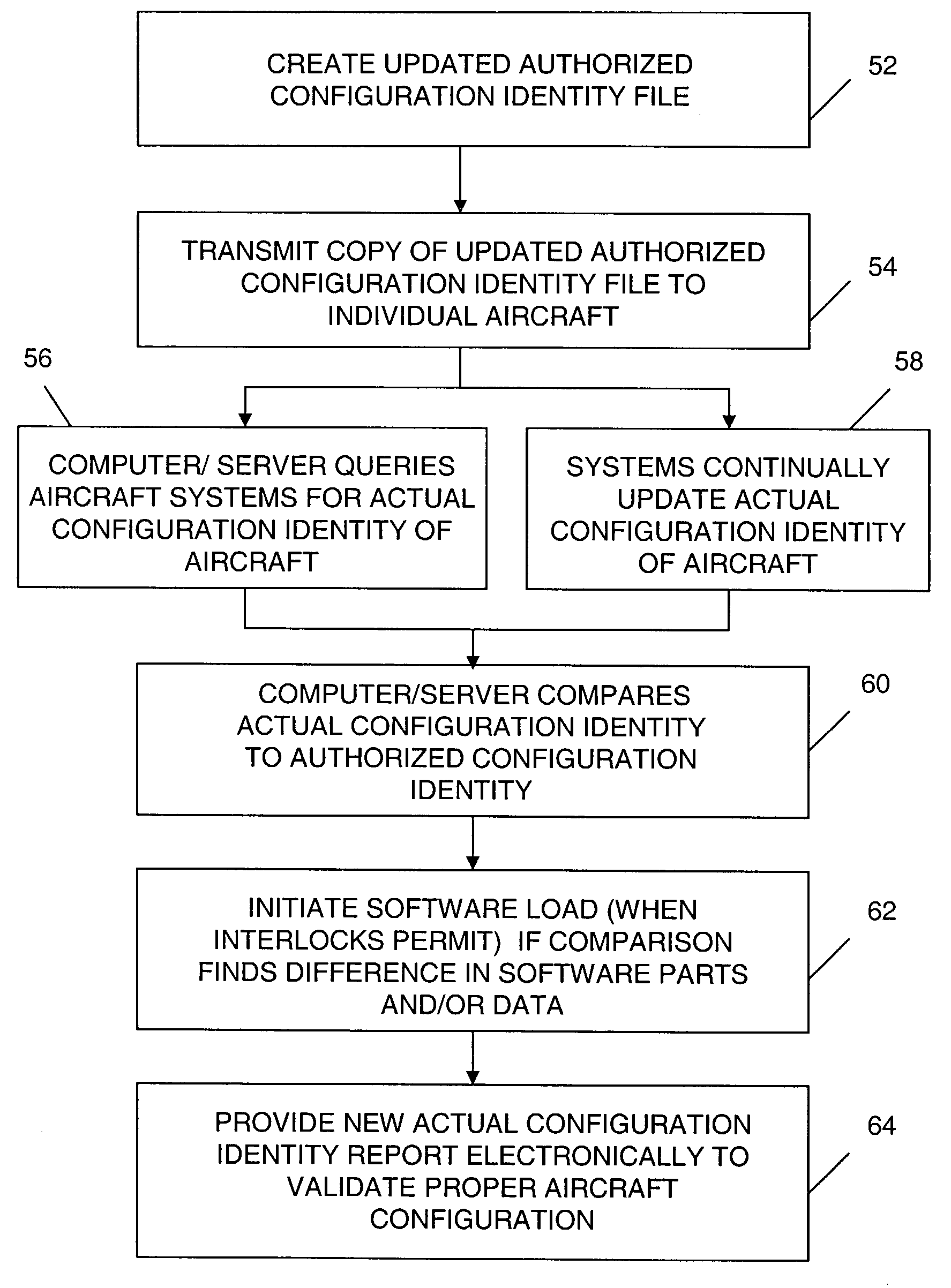

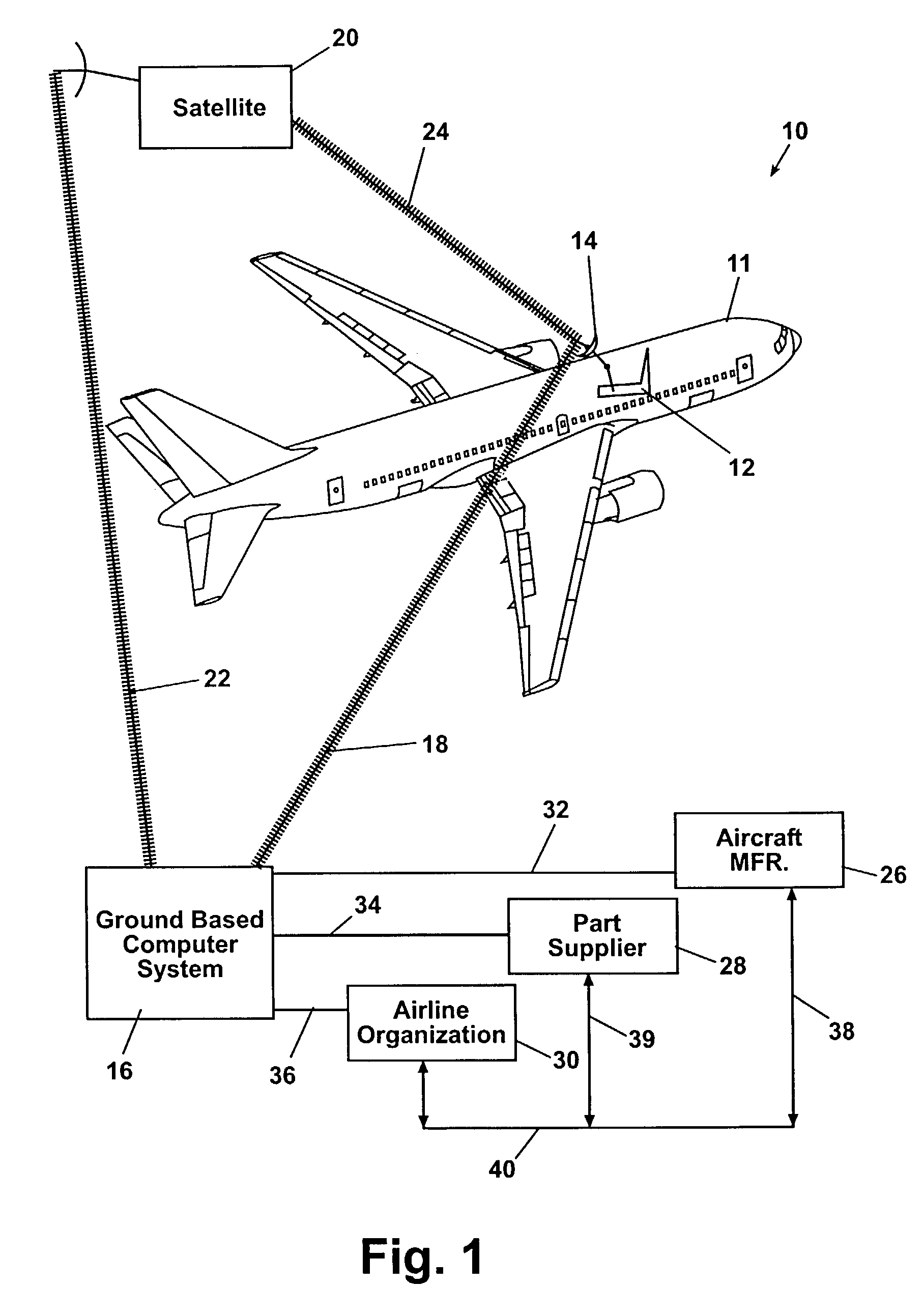

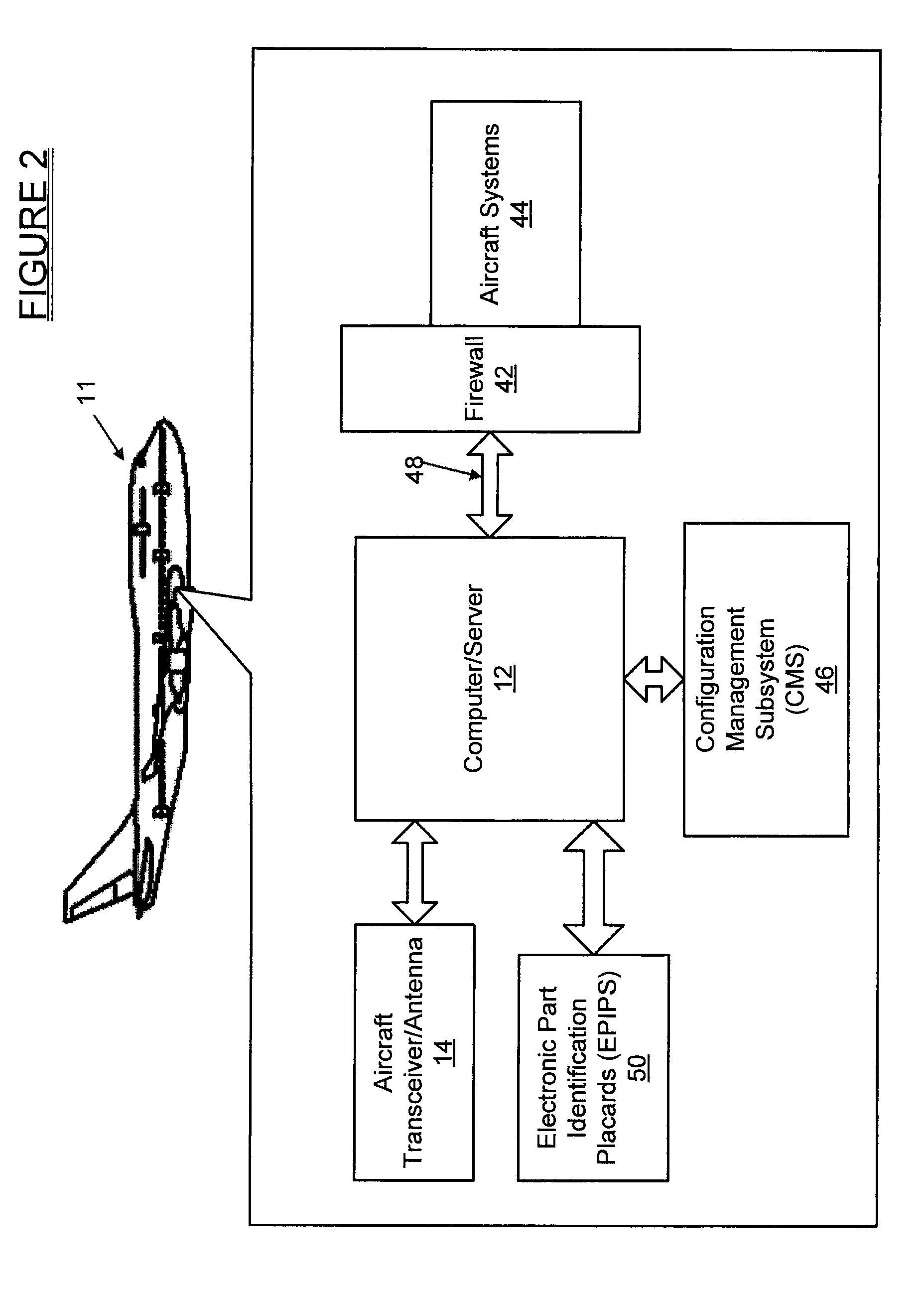

Remote aircraft manufacturing, monitoring, maintenance and management system

An aircraft wireless data communication system includes an aircraft computer / server in communication with a plurality of aircraft systems. Access to the aircraft systems via the computer / server is available in real-time via wireless communication with a ground-based computer system. The ground-based computer system includes a computer that can be accessed from one or more networks of computers. Each authorized computer user on an airline, manufacturer, or supplier network has remote real-time access to the aircraft computer / server. Properly authorized remote users can: perform comparisons between the aircraft actual configuration identity and an aircraft authorized configuration identity; perform system diagnostic testing; view system status and parameters; collaborate with users from local and remote organizations using real-time aircraft data; and upload and download software and data to and from aircraft systems.

Owner:THE BOEING CO

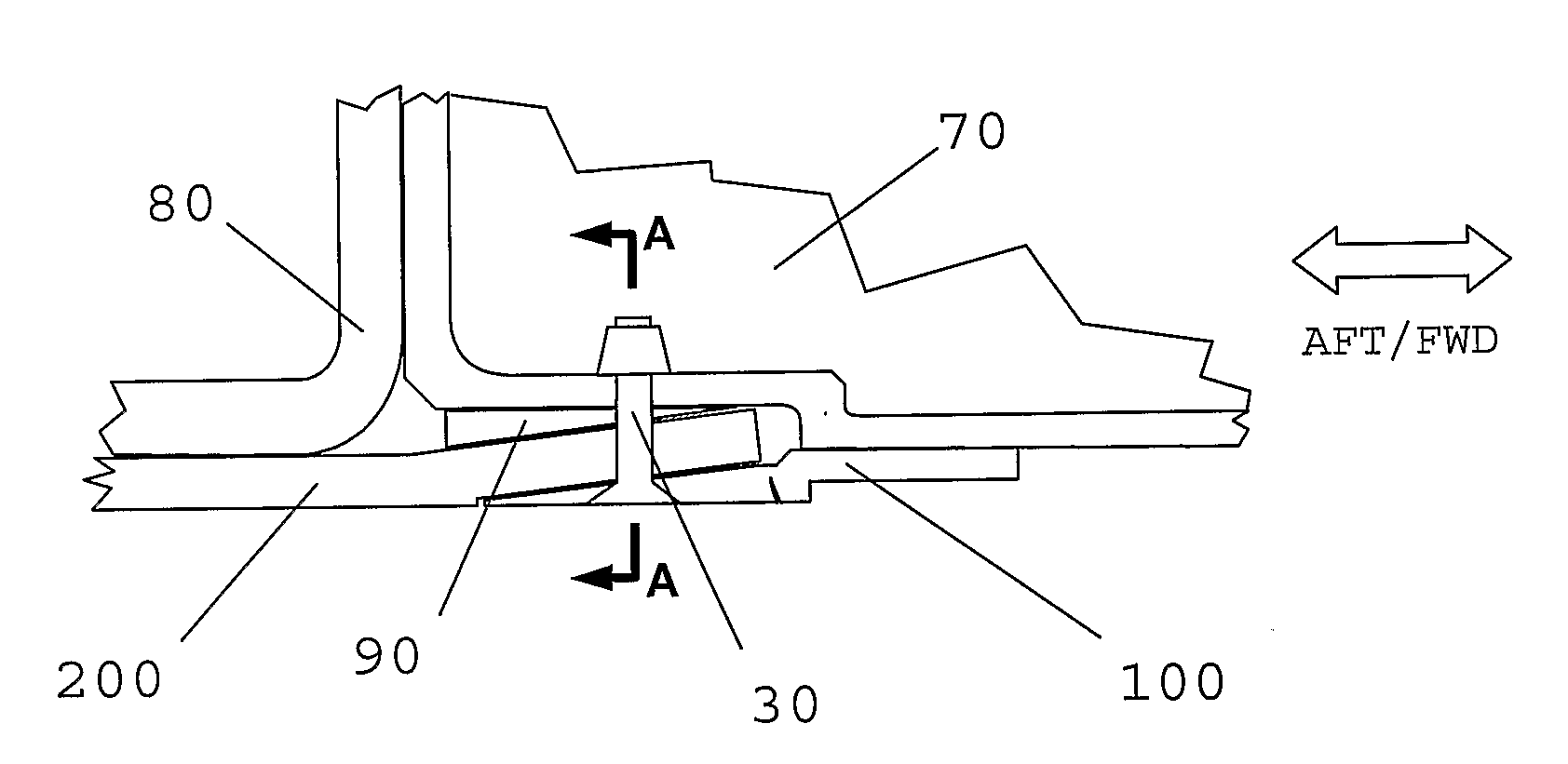

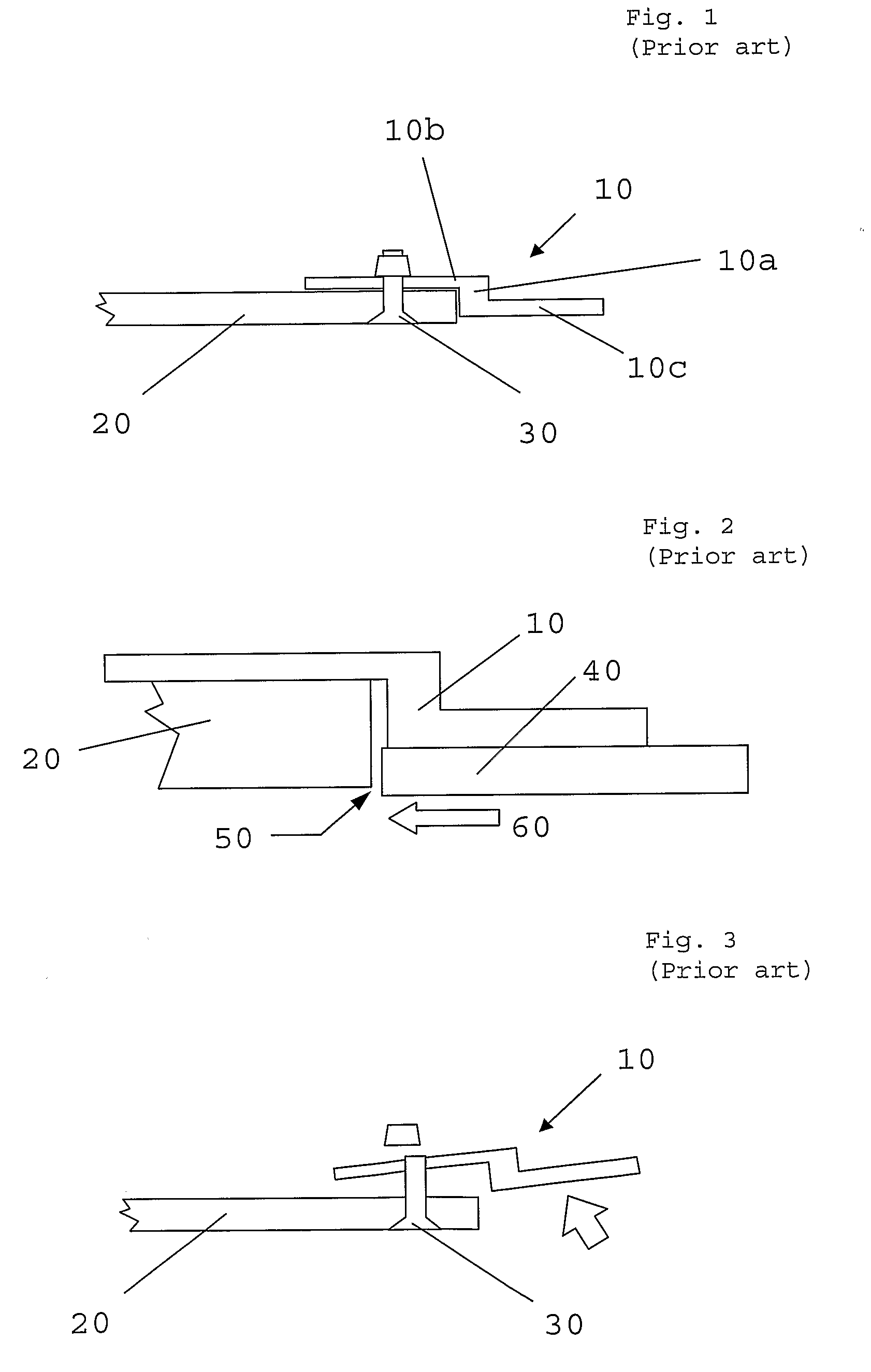

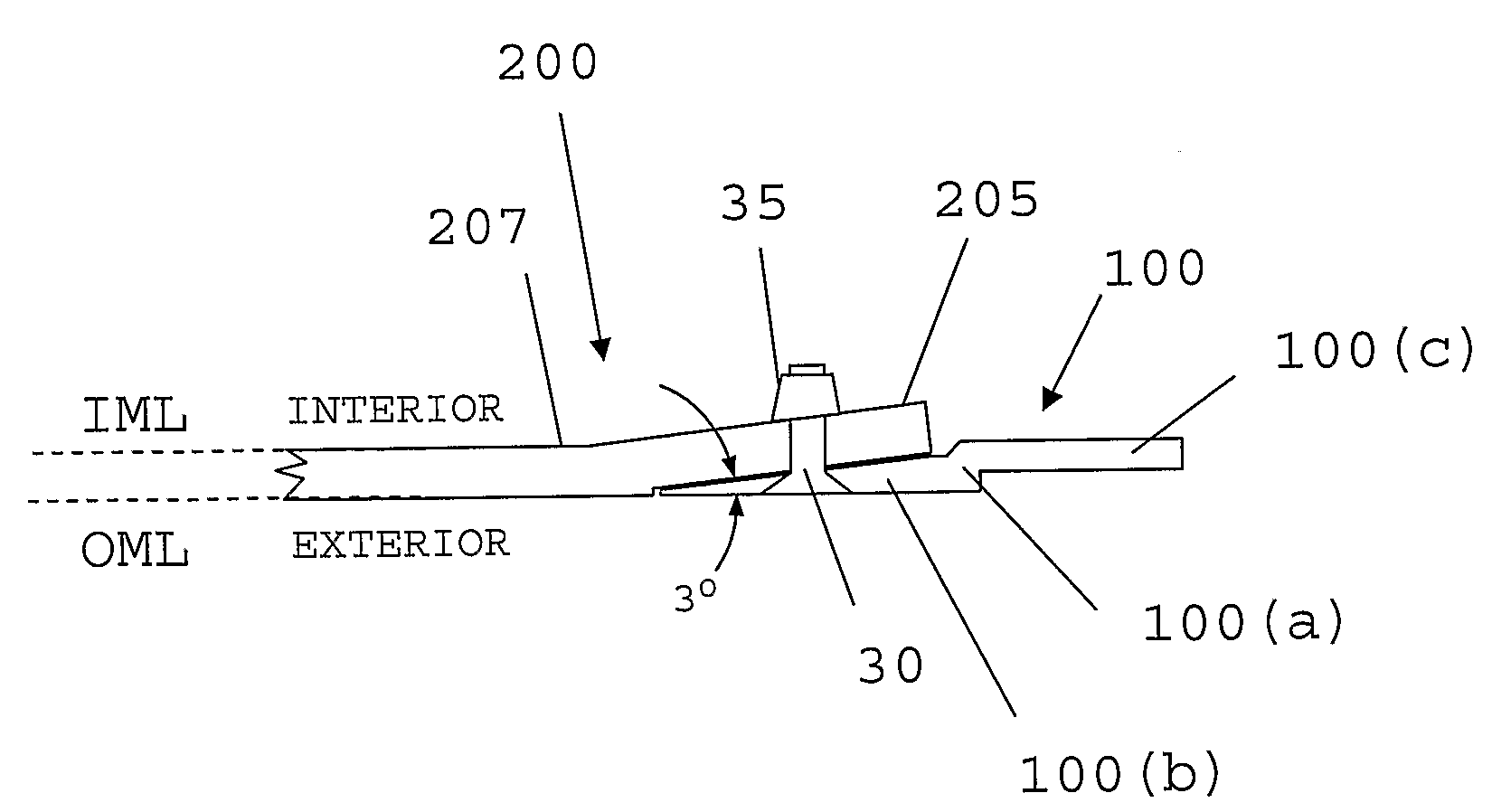

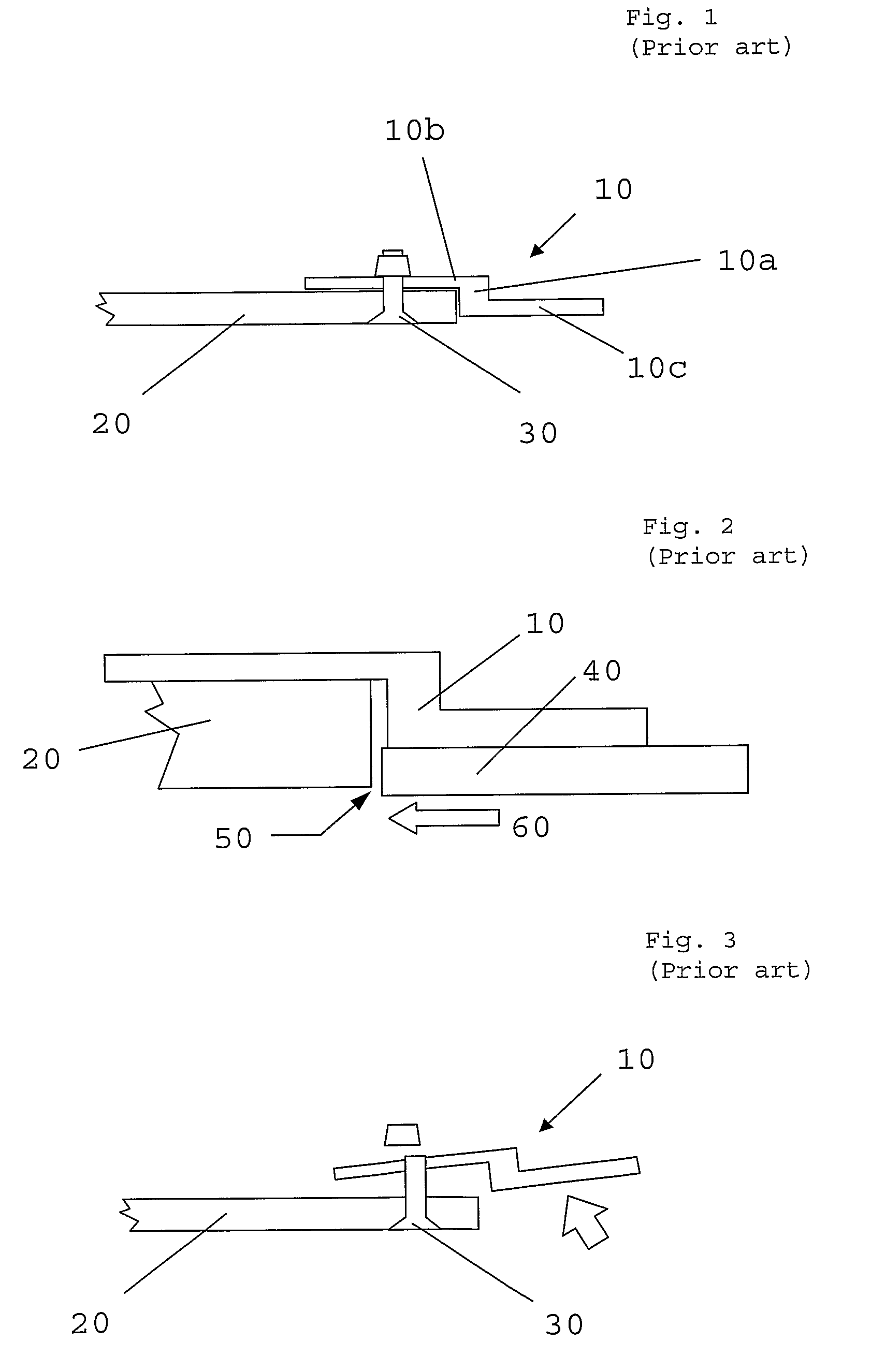

Joint for Use in Aircraft Construction

A joint for use in aircraft construction, for example a wing, comprises: a cover skin having an interior surface, an exterior surface and a distal portion, said distal portion having an exterior-facing surface; and a butt-strap having a first portion for connection to the skin, said first portion having an interior surface, an exterior surface and a distal end. The first portion of the butt-strap is connected to the distal portion of the skin such that a junction is formed between the exterior surface of the skin and the exterior surface of the first portion of the butt-strap. The exterior-facing surface of the distal portion of the skin is of a shape complementary to the shape of the interior surface of the first portion of the butt-strap. The first portion of the butt-strap tapers towards its distal end such that, at said junction, the exterior surface of the skin and the exterior surface of the first portion of the butt-strap form a substantially continuous exterior surface.

Owner:AIRBUS OPERATIONS LTD

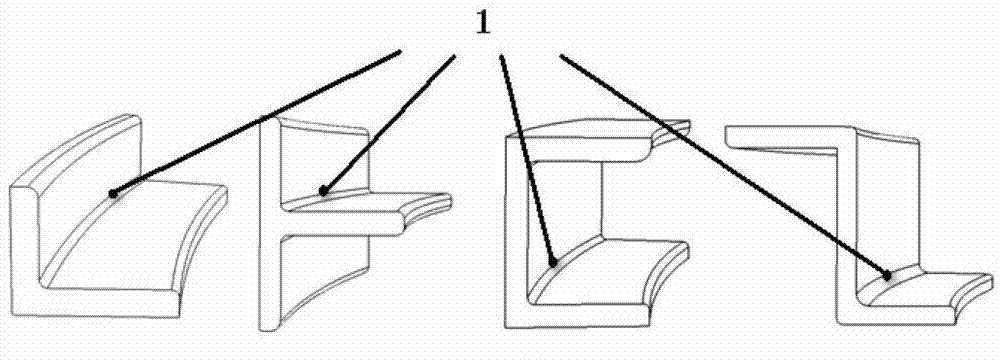

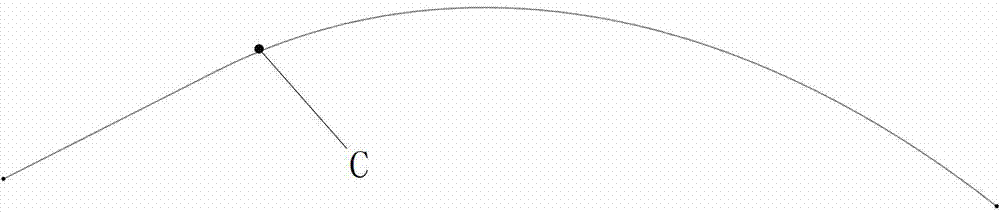

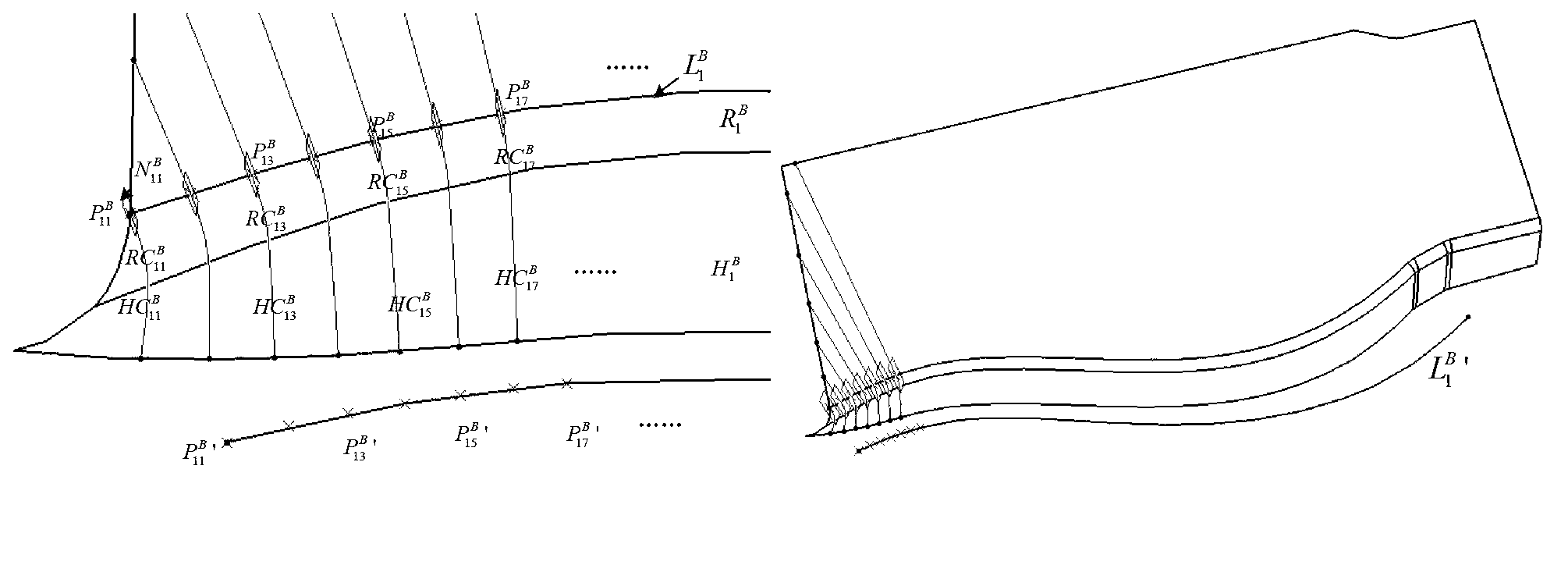

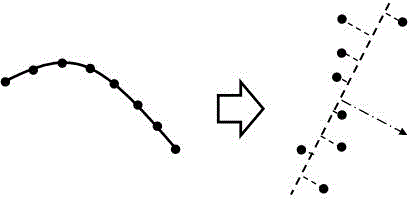

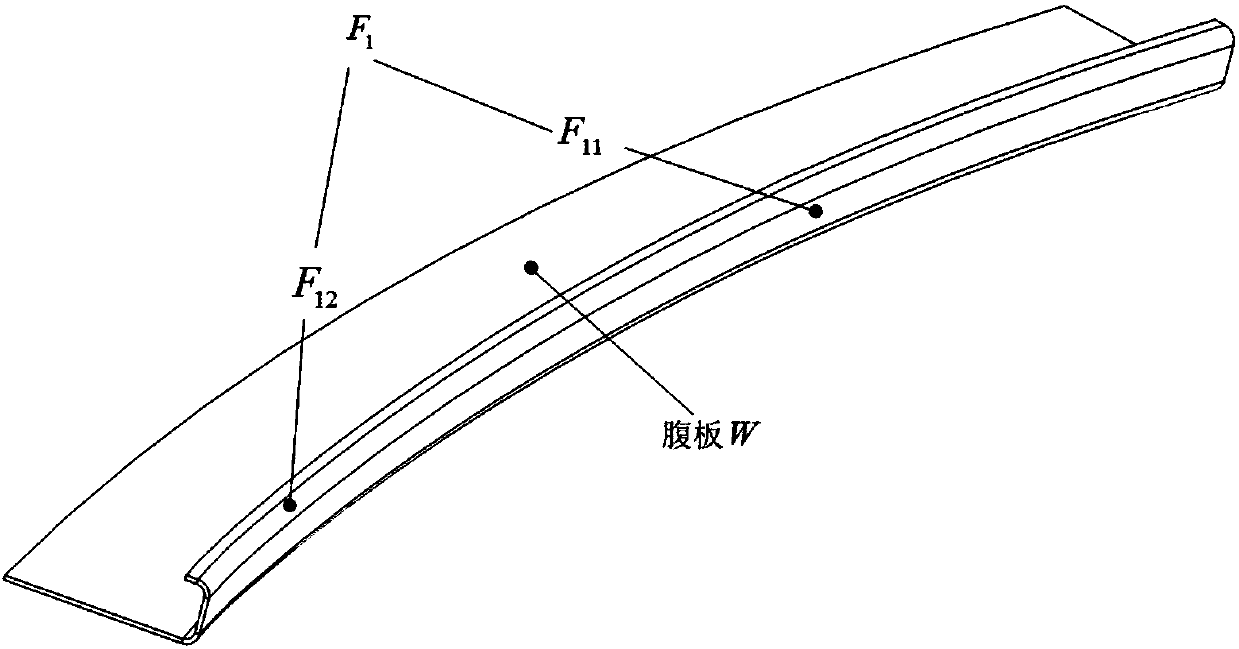

Modeling method for two-dimensional variable-curvature process model of section bar part

ActiveCN102968524ARapid designCorrectly designedSpecial data processing applicationsModel methodComputer science

The invention belongs to the technical field of aircraft manufacturing and relates to a modeling method for a two-dimensional variable-curvature process model of a section bar part. Through dispersing a contour line, the contour line is dispersed into a plurality of line segments and arc segments. By adopting finite element simulation, the recurrent magnitude of every dispersed segment is calculated; a compensated part contour curve is obtained through multiple iteration compensation; and the part contour curve is used for defining the process model of the part. The modeling method for the two-dimensional variable-curvature process model of the section bar part has the beneficial effects the process model of the section bar part can be rapidly and accurately designed, and a design used for a stretch bending mould is provided to craft personnel.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

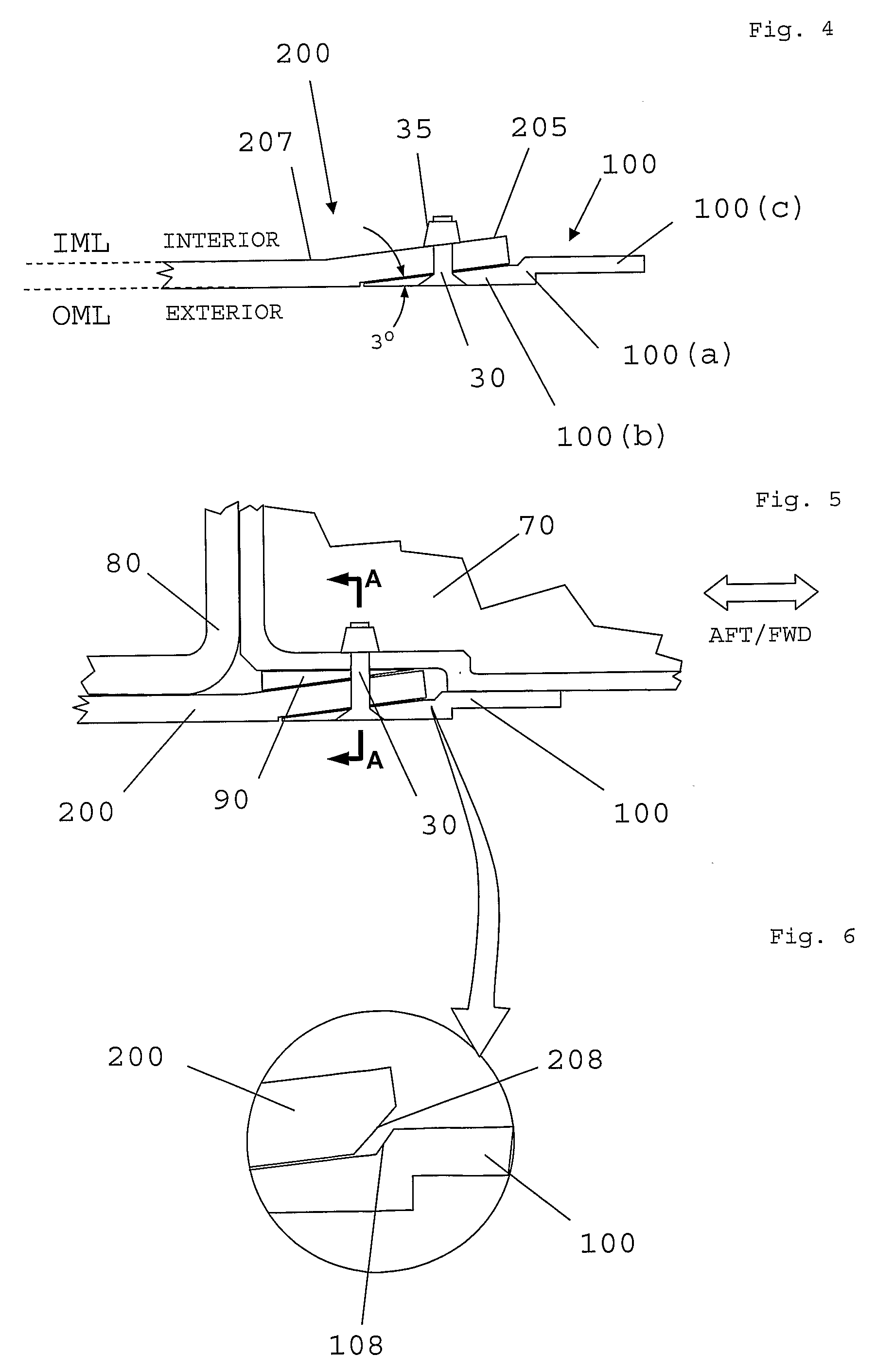

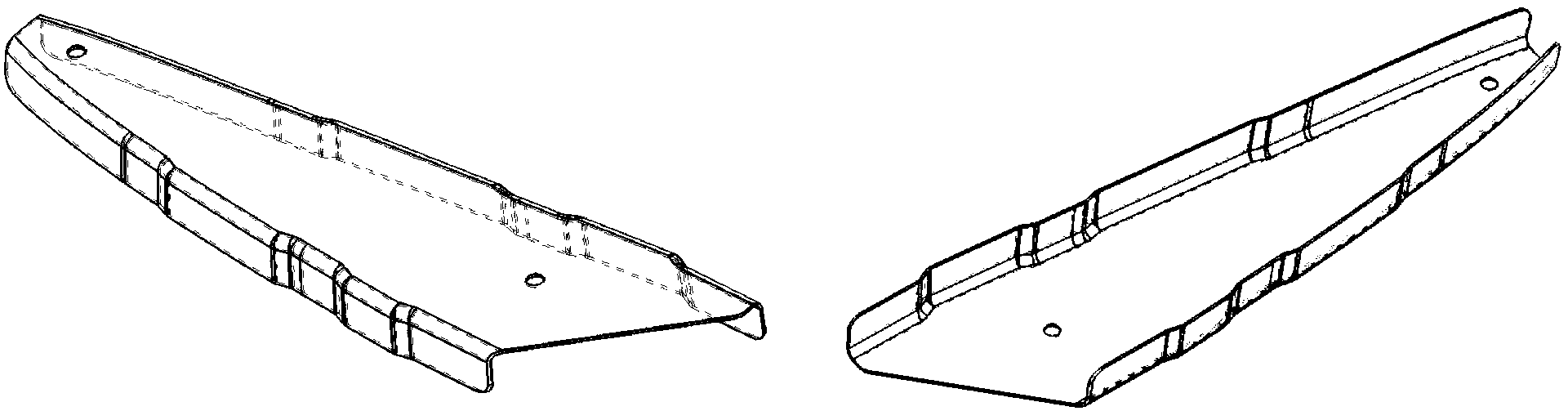

Design method of airplane frame and rib type sheet metal part processing model

The invention belongs to the technical field of aircraft manufacturing, and relates to a design method of an airplane frame and rib type sheet metal part processing model. According to design model of a part, a part processing model which can be directly applied to mold working molded surface design is designed. The design method is applicable to a frame and rib flange part with a variable camber, a variable cross-section, subsidence and a purlin notch. The design method is based on a flange reference plane, and the flange springback and compensation are taken into account.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

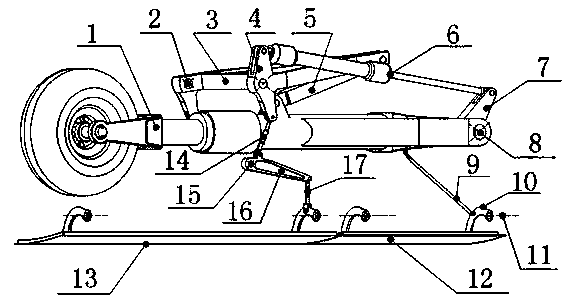

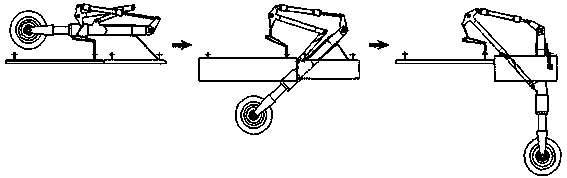

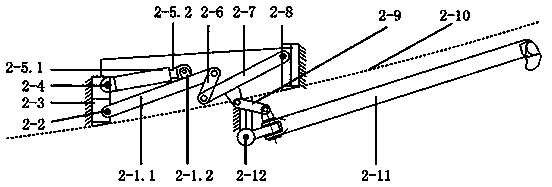

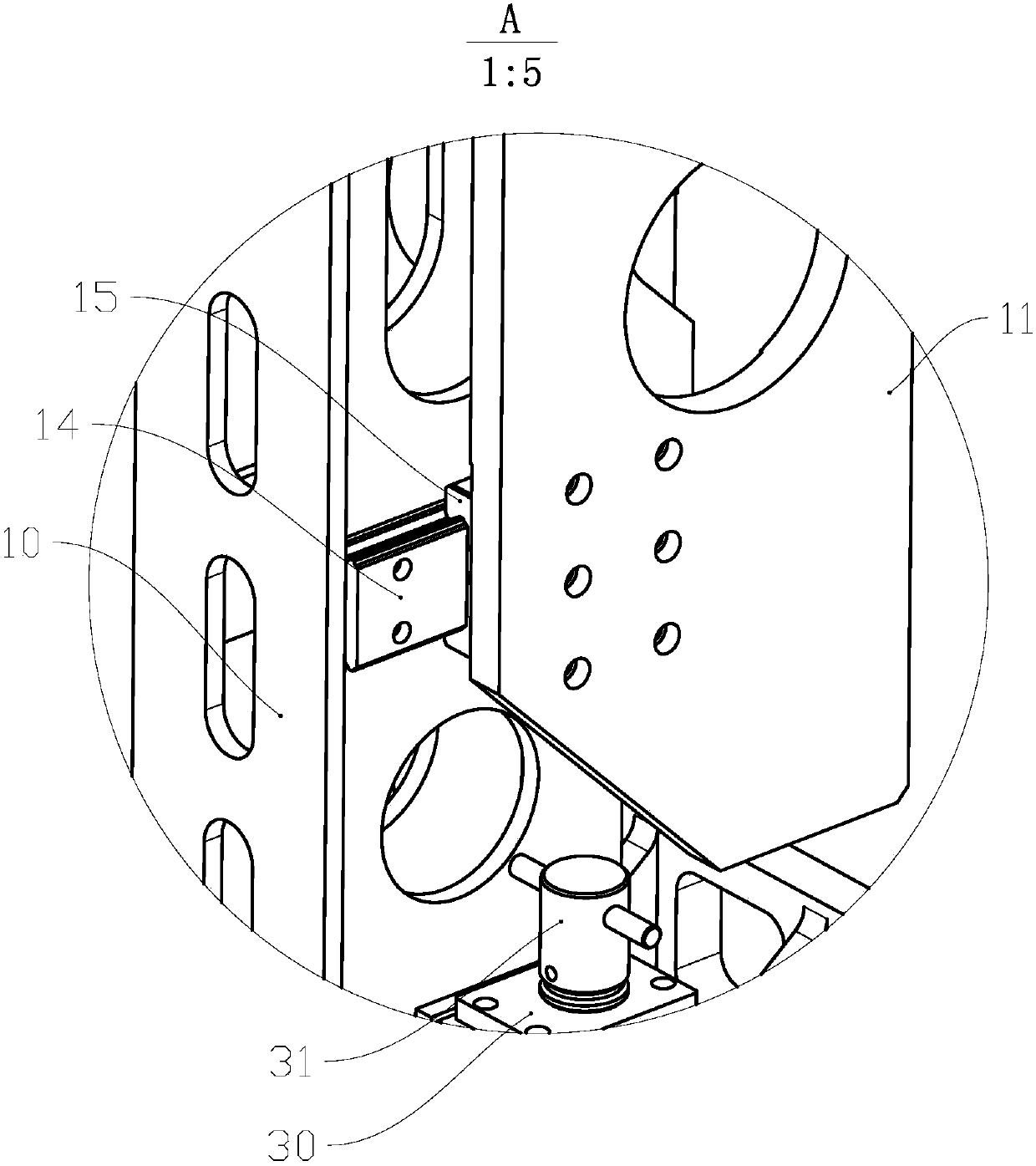

Linked landing gear cabin door folding and unfolding device

ActiveCN104176244ARealize linkage retractionSimplify retractable actuation systemWeight reductionUndercarriagesRocker armAircraft manufacturing

The invention relates to a linked landing gear cabin door folding and unfolding device and belongs to the technical field of aircraft manufacturing. The linked landing gear cabin door folding and unfolding device comprises a landing gear, a rotation shaft I, a rotation shaft II, a rotation shaft III, a rotation shaft IV, an upper supporting rod, a rocker arm I, a rocker arm II, a rocker arm III, a lower supporting rod, a folding and unfolding actuation cylinder, a connection rod I, a connection rod II, a connection rod III, a goose-shaped rocker arm, a support column protection plate and an airplane wheel protection plate. By virtue of the linked landing gear cabin door folding and unfolding device, the cabin door folding and unfolding actuation system is simplified, so that the occupying space of the device in an airplane is reduced and the structure weight is reduced; by virtue of the design of a linked mechanism, the order of folding and unfolding the landing gear, the airplane wheel protection plate and the support column protection plate is ensured, the control logic is simplified and the reliability is improved; the airplane protection plate is closed when the landing gear is unfolded, the pneumatic resistance can be reduced; the takeoff and landing performances of the airplane are improved; the damage to the airplane, caused by entrance of foreign materials in a landing gear cabin, can be avoided.

Owner:JIANGXI HONGDU AVIATION IND GRP

Joint for use in aircraft construction

A joint for use in aircraft construction, for example a wing, comprises: a cover skin having an interior surface, an exterior surface and a distal portion, said distal portion having an exterior-facing surface; and a butt-strap having a first portion for connection to the skin, said first portion having an interior surface, an exterior surface and a distal end. The first portion of the butt-strap is connected to the distal portion of the skin such that a junction is formed between the exterior surface of the skin and the exterior surface of the first portion of the butt-strap. The exterior-facing surface of the distal portion of the skin is of a shape complementary to the shape of the interior surface of the first portion of the butt-strap. The first portion of the butt-strap tapers towards its distal end such that, at said junction, the exterior surface of the skin and the exterior surface of the first portion of the butt-strap form a substantially continuous exterior surface.

Owner:AIRBUS OPERATIONS LTD

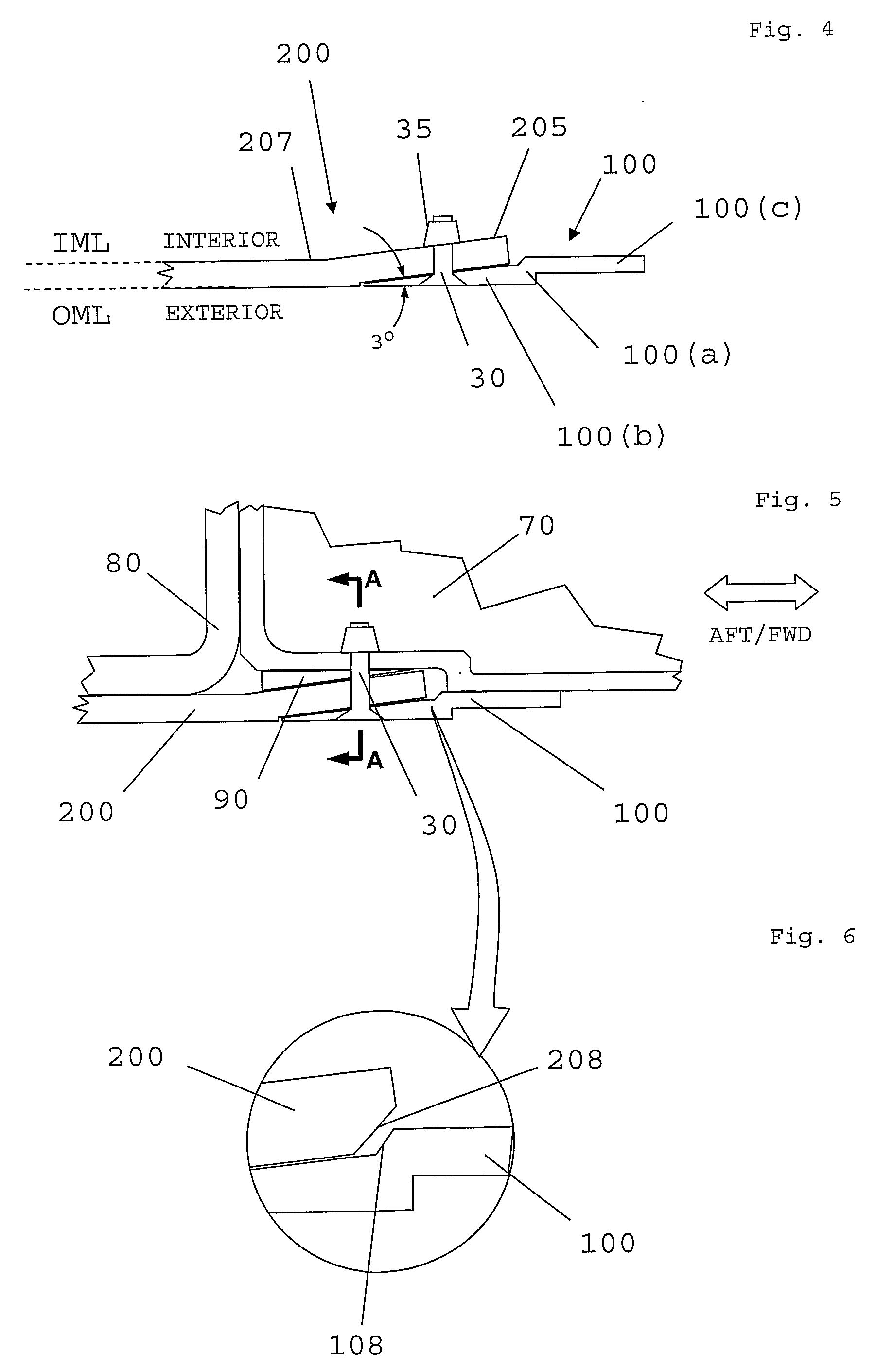

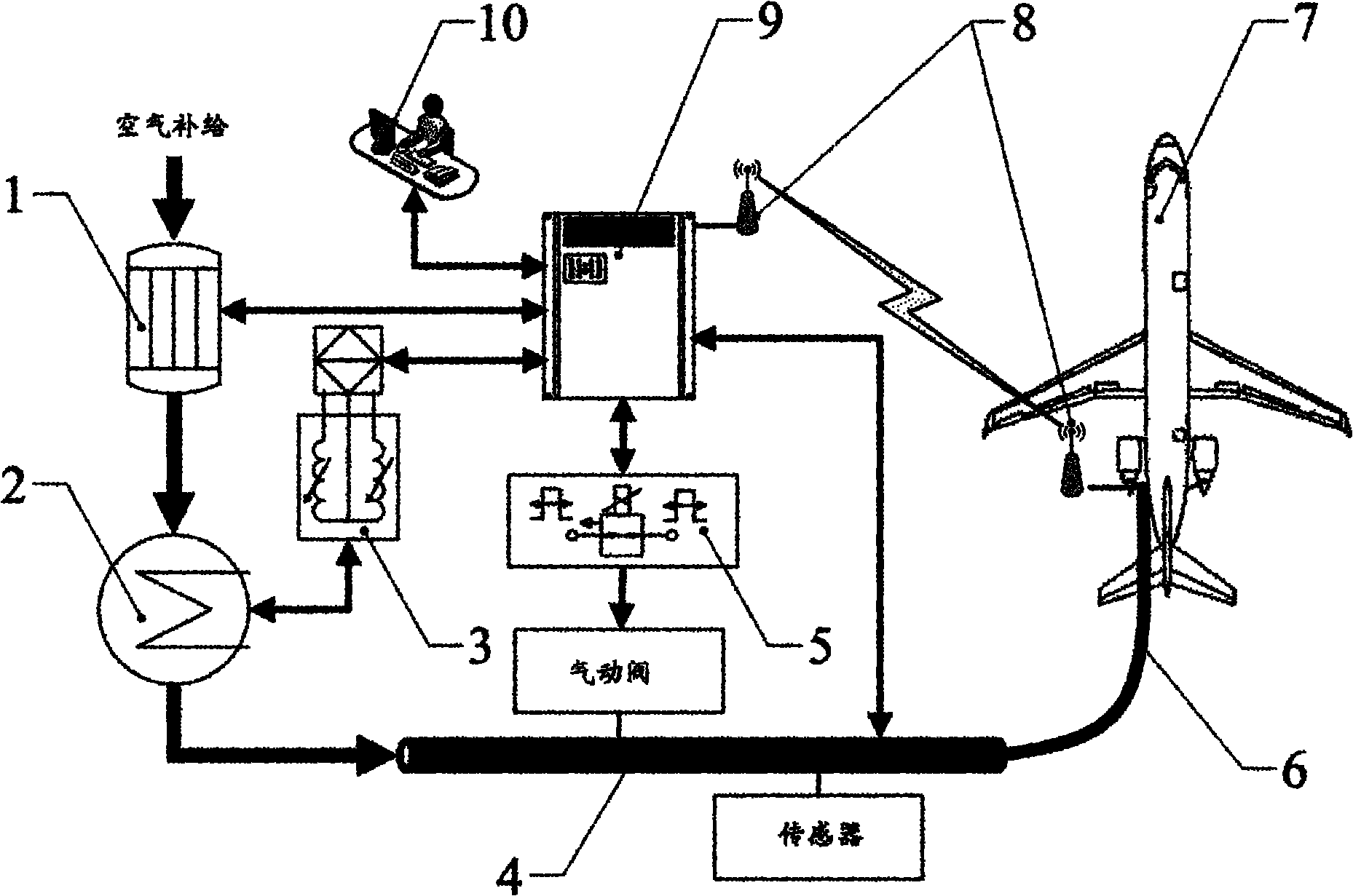

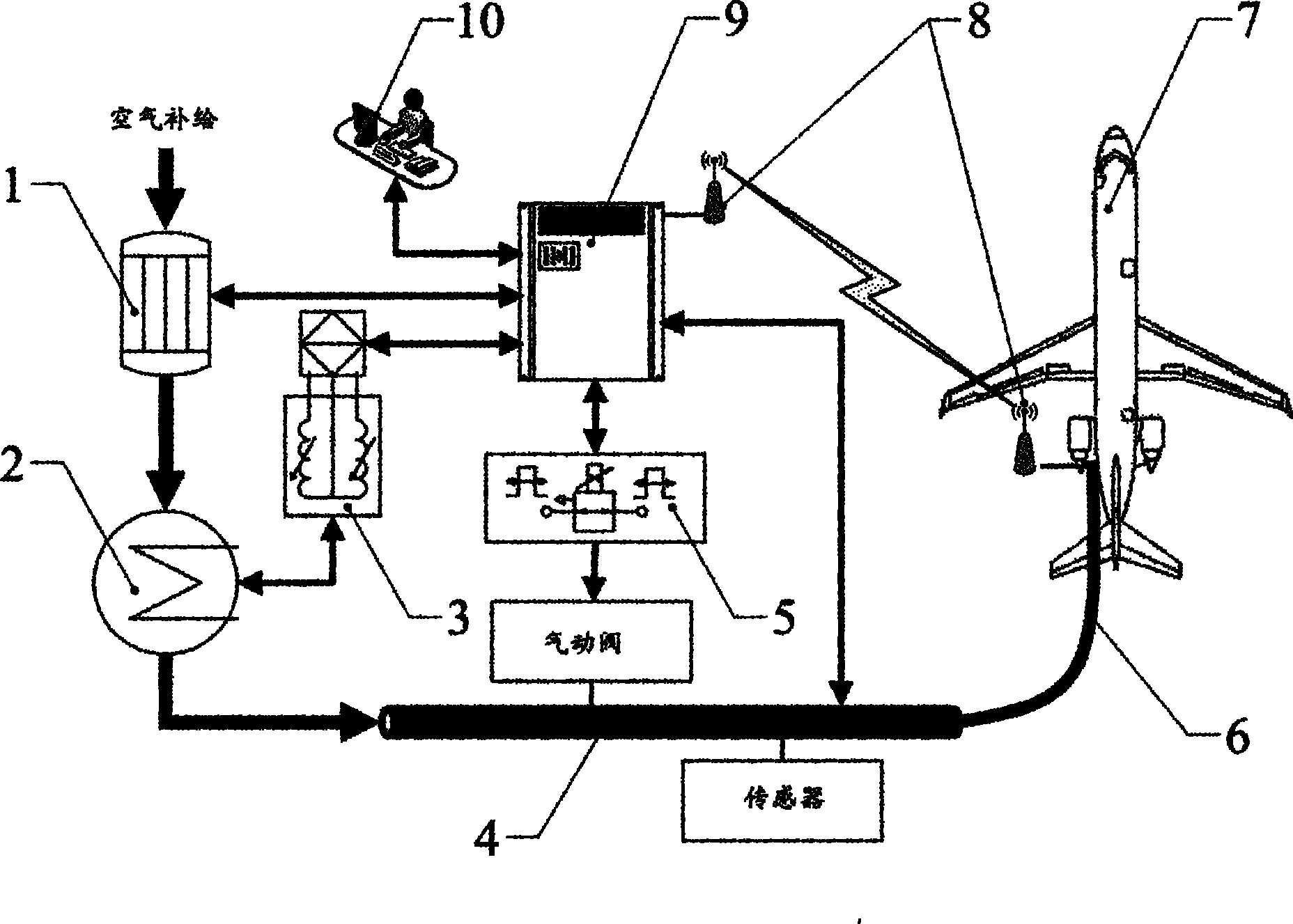

Automation device for use in civil aircraft environment control system function test

InactiveCN101916108AImprove test efficiencyRealize automatic collectionElectric testing/monitoringControl systemProgrammable logic controller

The invention relates to an automation device for use in a civil aircraft environment control system function test, which belongs to the technical field of aircraft manufacturing. The automation device comprises an air source processing component, an electric air heating furnace, an air heating furnace controller, a main pipeline system, a pneumatic valve control component, a metal hose component, a wireless sensing communication module, a programmable logic controller (PLC) control module and an upper machine monitoring computer. In the invention, an aircraft pressure cabin and air conditioner pipeline leakage amount test, a cabin pressure regulating system test, a cabin air temperature regulating system function test and an anti-ice system function test are carried out by using an on-spot air source of an aircraft assembly plant in place of an engine or an auxiliary power unit (APU) unit, so that a plurality of test items in the aircraft environment control function test can be completed, and the requirements of aircraft mass production on the quality and efficiency improvement on the environment control function test in a final assembly process are met.

Owner:SHANGHAI JIAO TONG UNIV +1

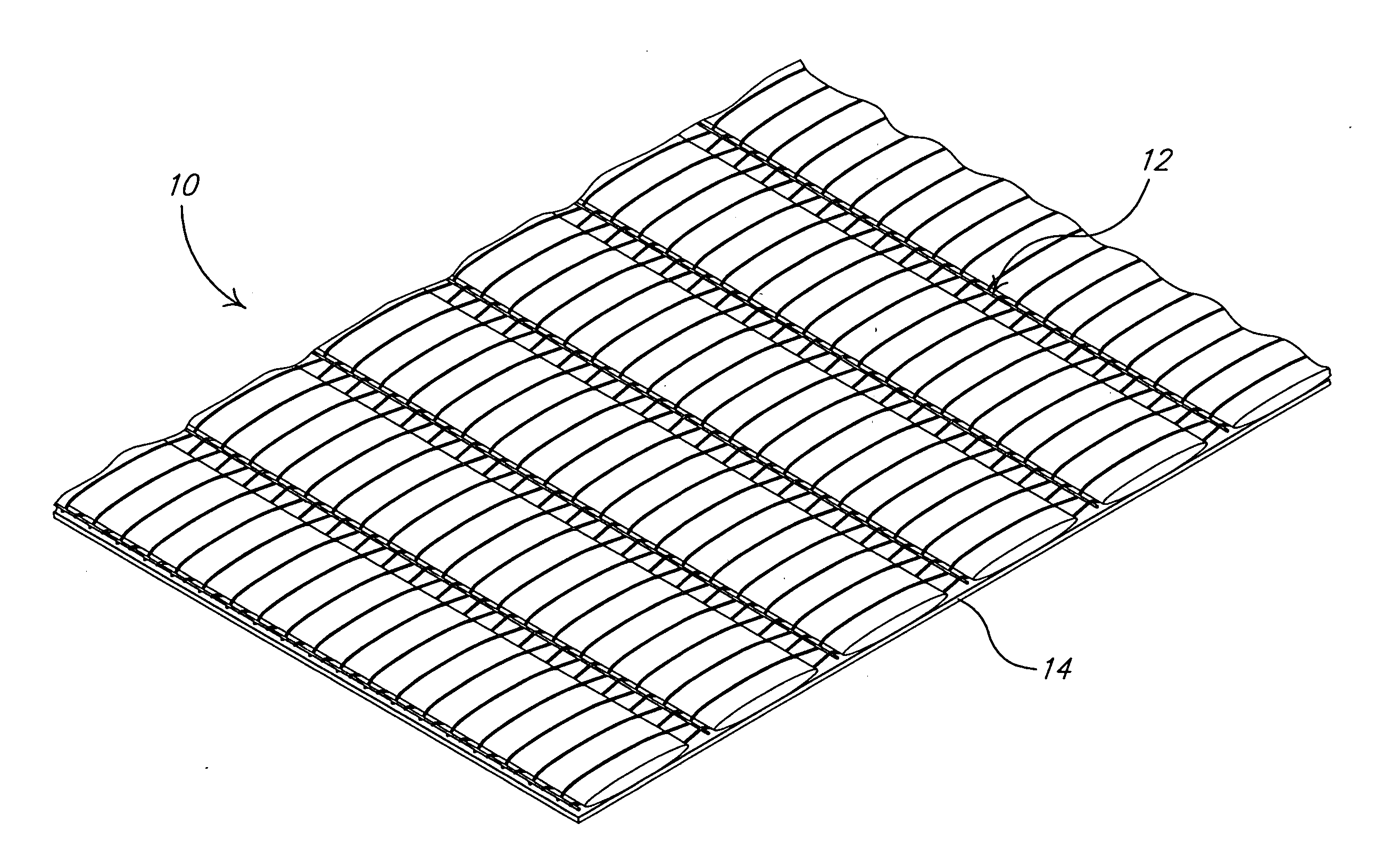

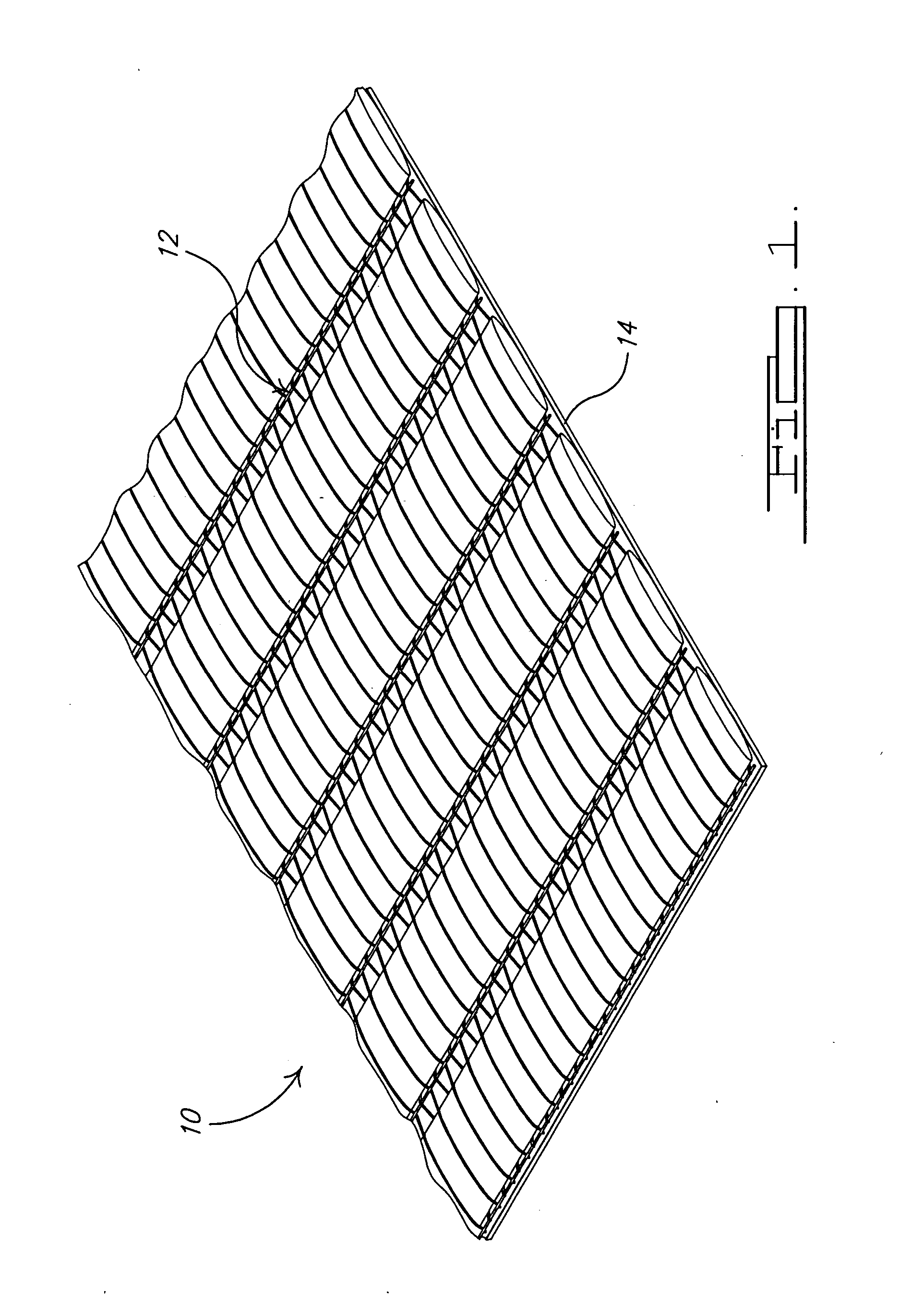

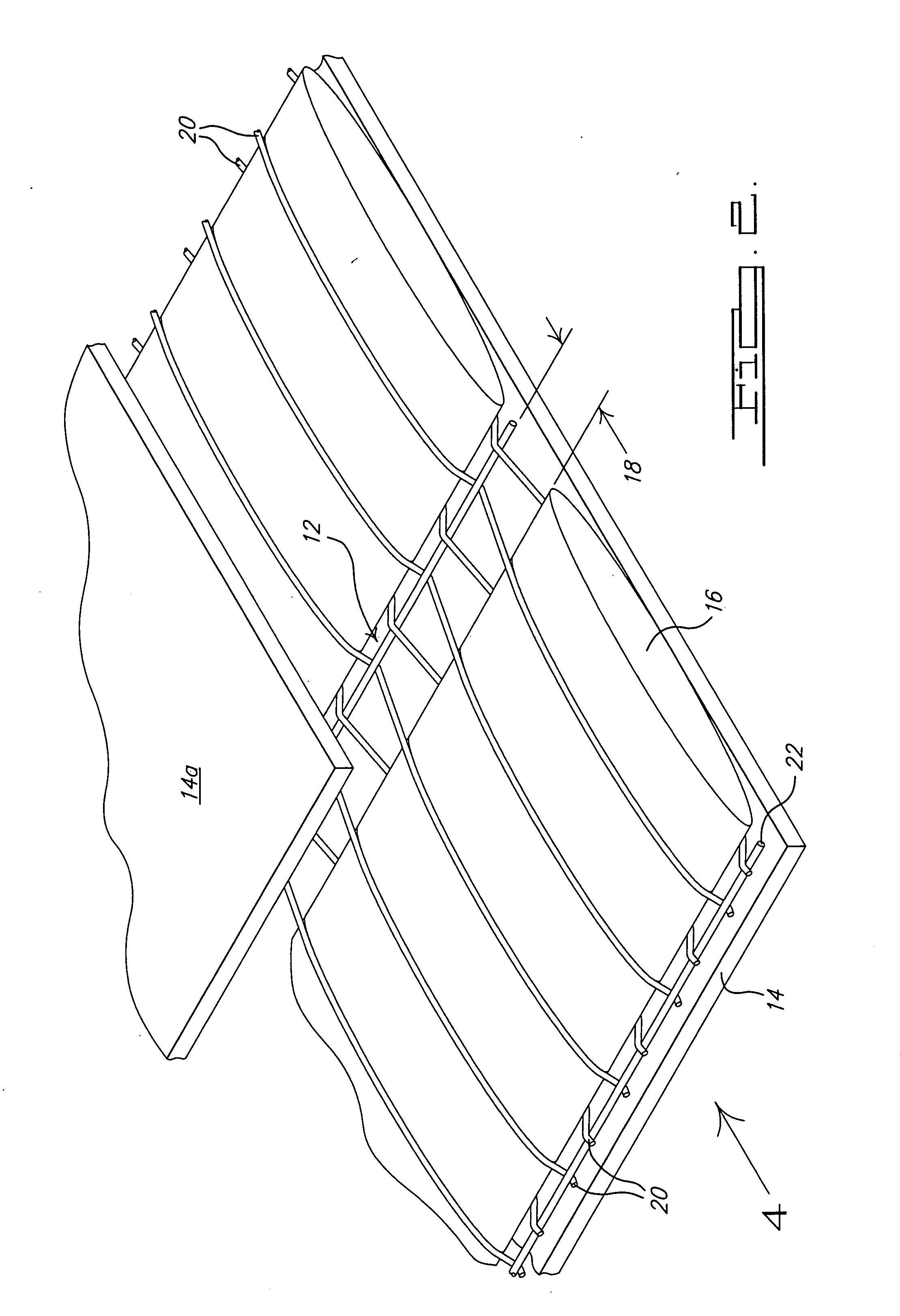

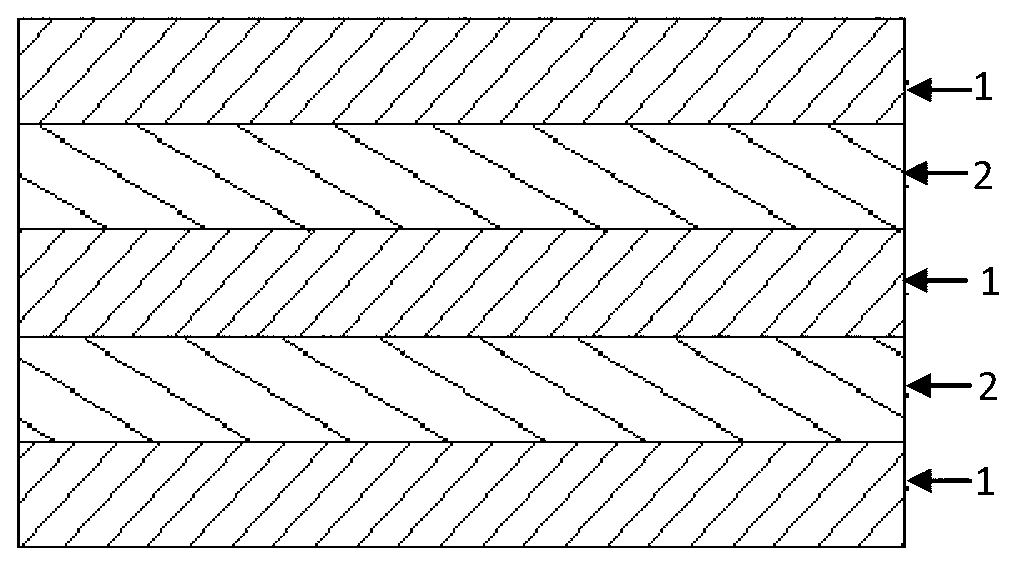

Toughened, non-crimped unidirectional fabric apparatus and method of making same

InactiveUS20060154545A1Easy to optimizeImprove impact resistanceSynthetic resin layered productsPaper/cardboard layered productsFiberEngineering

A non-crimped, unidirectional fabric. The fabric includes a plurality of non-crimped, unidirectional fibers arranged parallel to one another. Weft fibers are arranged perpendicular to the non-crimped, unidirectional fibers. Warp fibers are arranged parallel to the non-crimped, unidirectional fibers. The weft fibers are woven around the non-crimped, unidirectional fibers and around the warp fibers without crimping the unidirectional fibers. A non-woven thermoplastic fabric is secured, such as by melt bonding, to the non-crimped unidirectional fibers to act as a toughening layer and improve the impact resistance of the fabric after it is molded into a part. The resulting fabric has excellent end-to-end uniformity, excellent resistance to fluids often encountered in aerospace and commercial aircraft applications, is readily adapted for use with conventional liquid-molding operations, and is ideally suited to aerospace and aircraft manufacturing applications where lightweight yet structurally strong component parts are needed.

Owner:THE BOEING CO

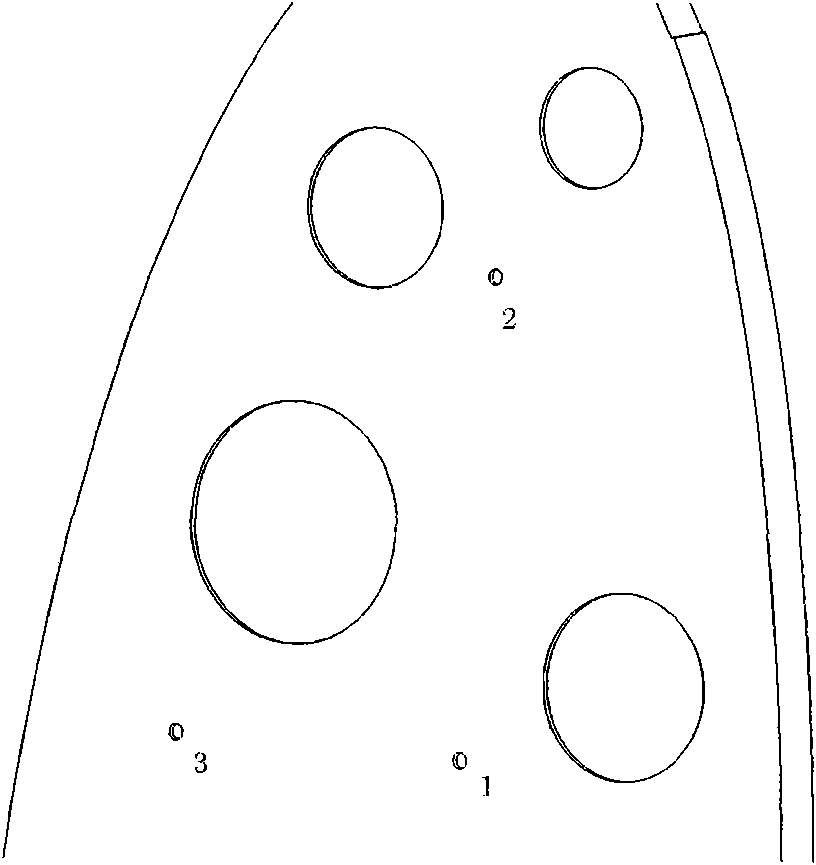

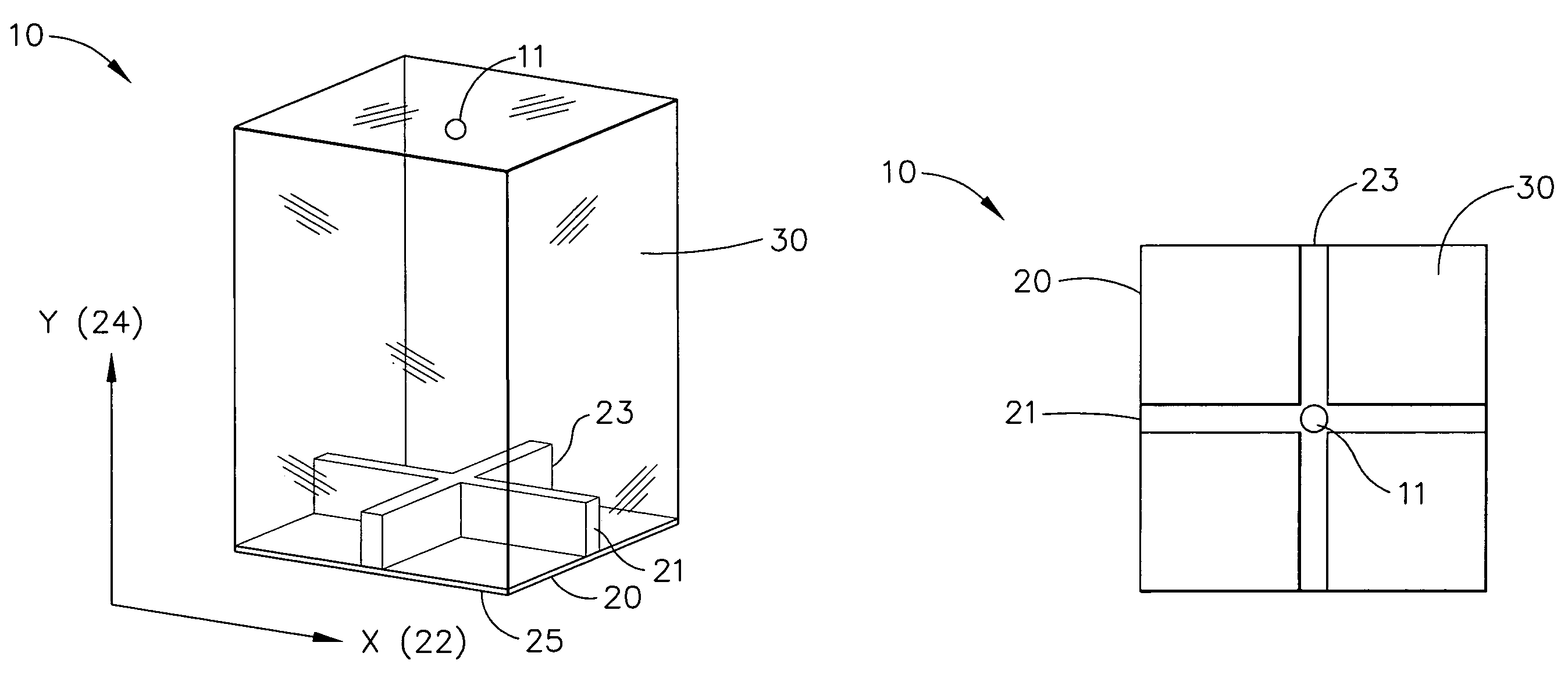

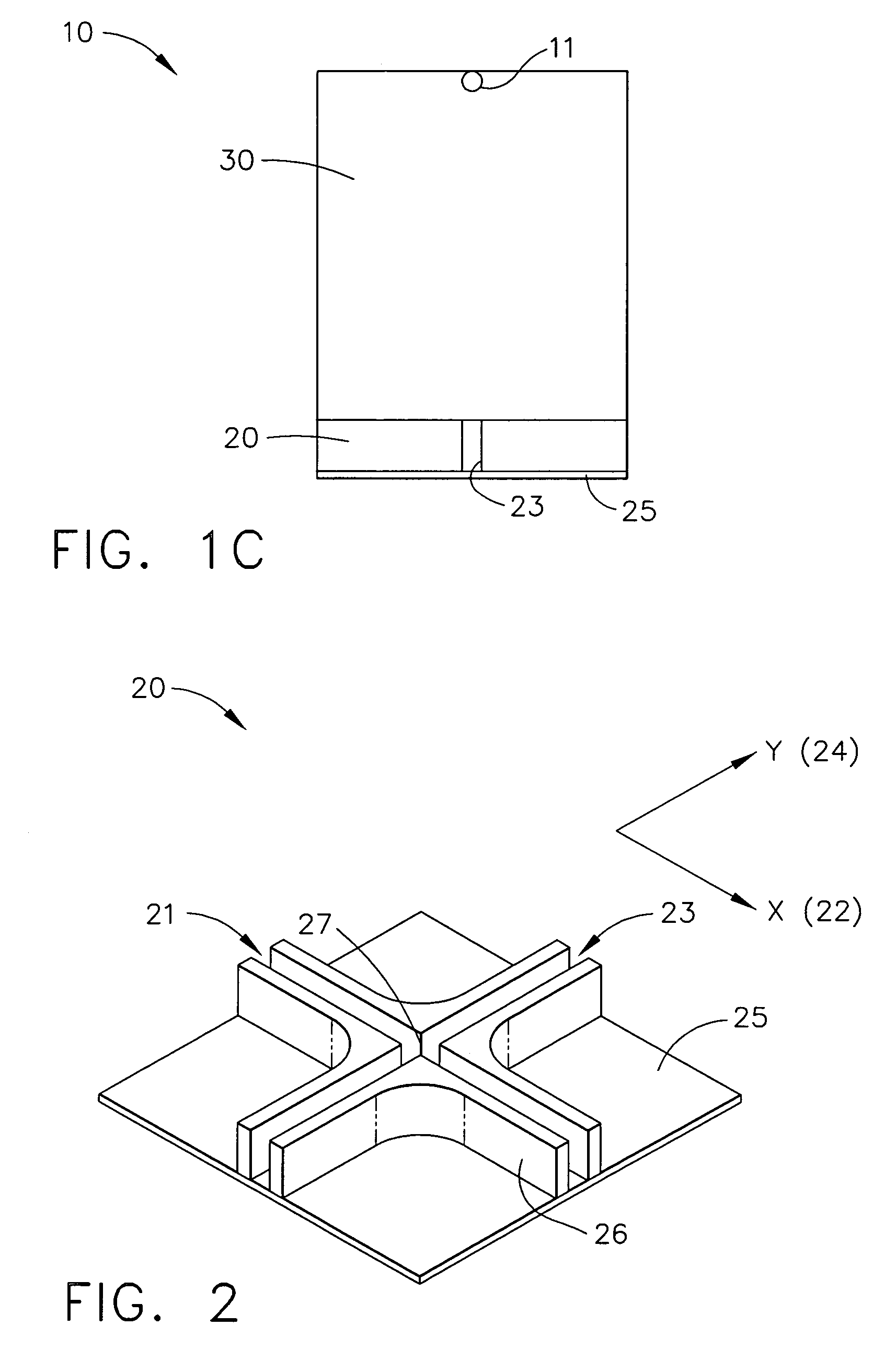

Method for assembling and locating web-type wing ribs on basis of laser measurement

InactiveCN101776440AReduce in quantityImprove assembly accuracyUsing optical meansAircraft manufacturingLaser

The invention provides a method for assembling and locating web-type wing ribs on the basis of laser measurement. The method comprises the following steps: 1. mounting a drone base on the three reference holes of the wing rib; 2. fixing the wing rib onto the clamp of an assembling unit; 3. clamping the wing rib to the position of an assembling space by the assembling unit; 4. measuring the coordinates of the circle centers of the three reference holes on the wing rib by a laser; 5. calculating the deviation and compensation of the current spatial position of the wing rib; 6. generating the adjustment command according to the deviation and compensation of the spatial position calculated in step 5; 7. driving the assembling unit to carry out the micro-adjustment of the spatial position according to the adjustment command of the spatial position; 8. repeating the process from step 4 to step 7 until the deviation of the spatial position of the wing rib is allowable; and 9. repeating the process from step 1 to step 8, so as to complete the assembly of other wing ribs of the group. The invention can solve the problems that the existing analog-dependent method for assembling and locating the web-type wing rib in a dedicated assembling tool has the disadvantages of lower precision, lower efficiency and higher cost. Therefore, the invention has good application prospect in aircraft manufacturing.

Owner:BEIHANG UNIV

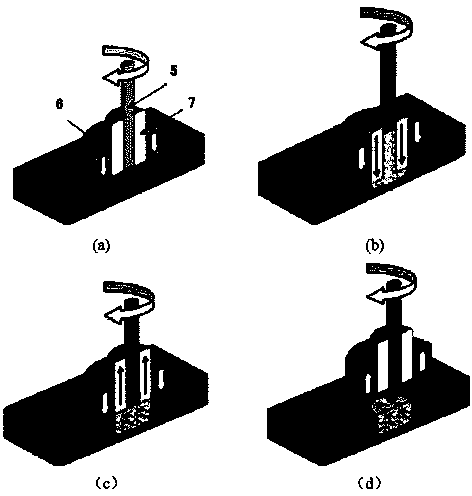

Agitation friction point braze welding method for metal plate overlap joint combination

ActiveCN104227225AEliminate wear and tearSimple design and manufactureSoldering apparatusNon-electric welding apparatusNeedle freeElectric vehicle

The invention discloses an agitation friction point braze method for a metal plate overlap joint combination. The method comprises the following steps: placing a brazing filler metal at a to-be-welded position in advance, starting a needle-free tool to rotate, and melting the brazing filler metal by virtue of frictional heat between a shoulder and the surface of an upper plate; after in-situ friction is performed for few seconds, shutting down, and applying upset forging, thereby finishing a large-area spot welding process under the condition of no abrasion and no key holes. By virtue of the twisting effect of a tool on an interface in a friction stage, the dissolution effect of the brazing filler metal on a mother metal in an in-situ friction stage and the upset forging effect of the tool on the interface in a shutdown stage, an oxidation film is easily broken, and oxidation film fragments are easily extruded along with the molten brazing filler metal which is alloyed; meanwhile, the interface wetting property and final compactness are improved, crystal structures containing brittle phases are eliminated, the soldering seam tenacity is improved, and the method can be used in occasions such as electric power fittings, electric contacts, cookers, hybrid electric vehicle series welding and overlap joint welding of thin aluminum plates in automobile and aircraft manufacturing.

Owner:咸阳瞪羚谷新材料科技有限公司

Unfolding method for complex flange of frame rib sheet metal part

ActiveCN103008497ASolve unrolled puzzlesAircraft componentsStructural engineeringDigital manufacturing

The invention relates to an unfolding method for a complex flange of a frame rib sheet metal part and belongs to the technical field of aircraft manufacturing. A digital manufacturing technology is adopted for dividing the flange of the frame rib sheet metal part into a bent area and a sunken area, respectively unfolding and then jointing and shearing, so that an unfolded outline of the flange is obtained. The unfolding problem of the frame rib sheet metal part with the complex flange is solved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

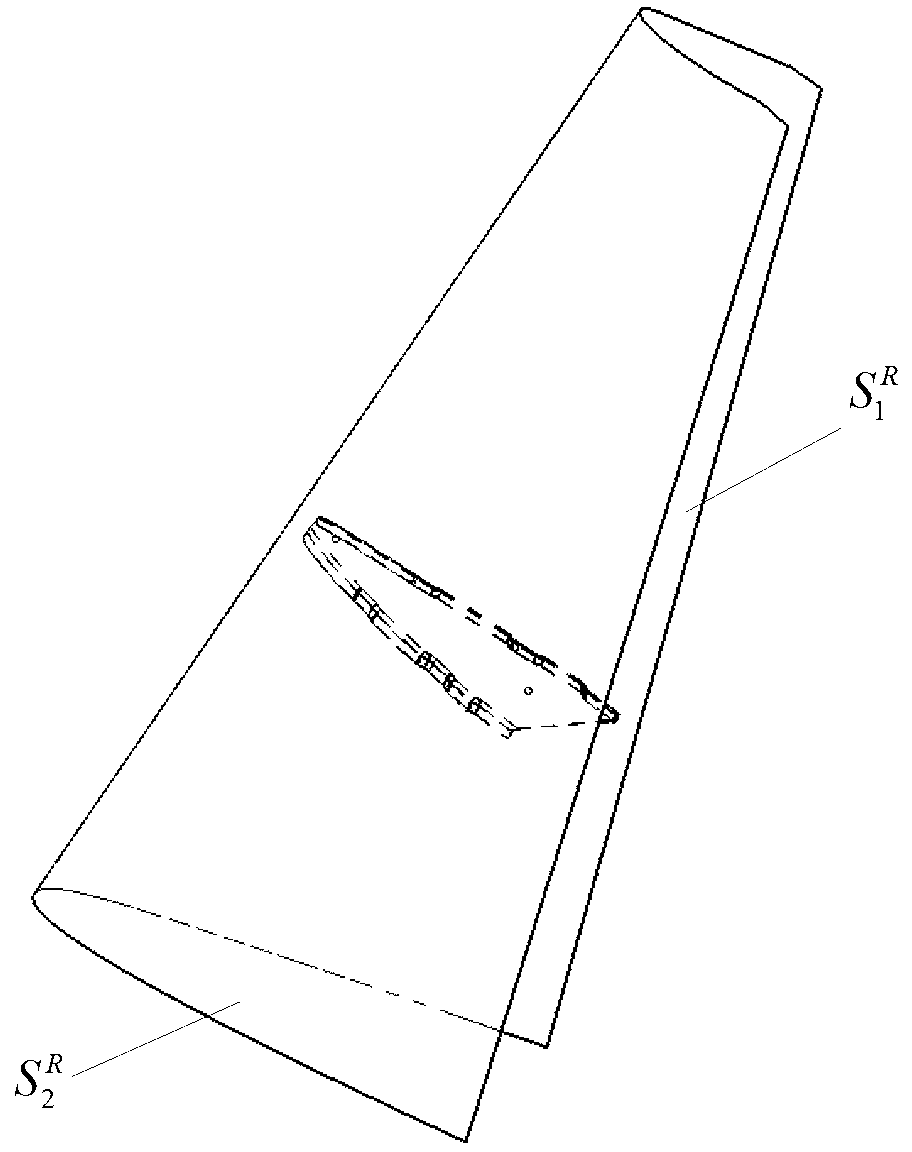

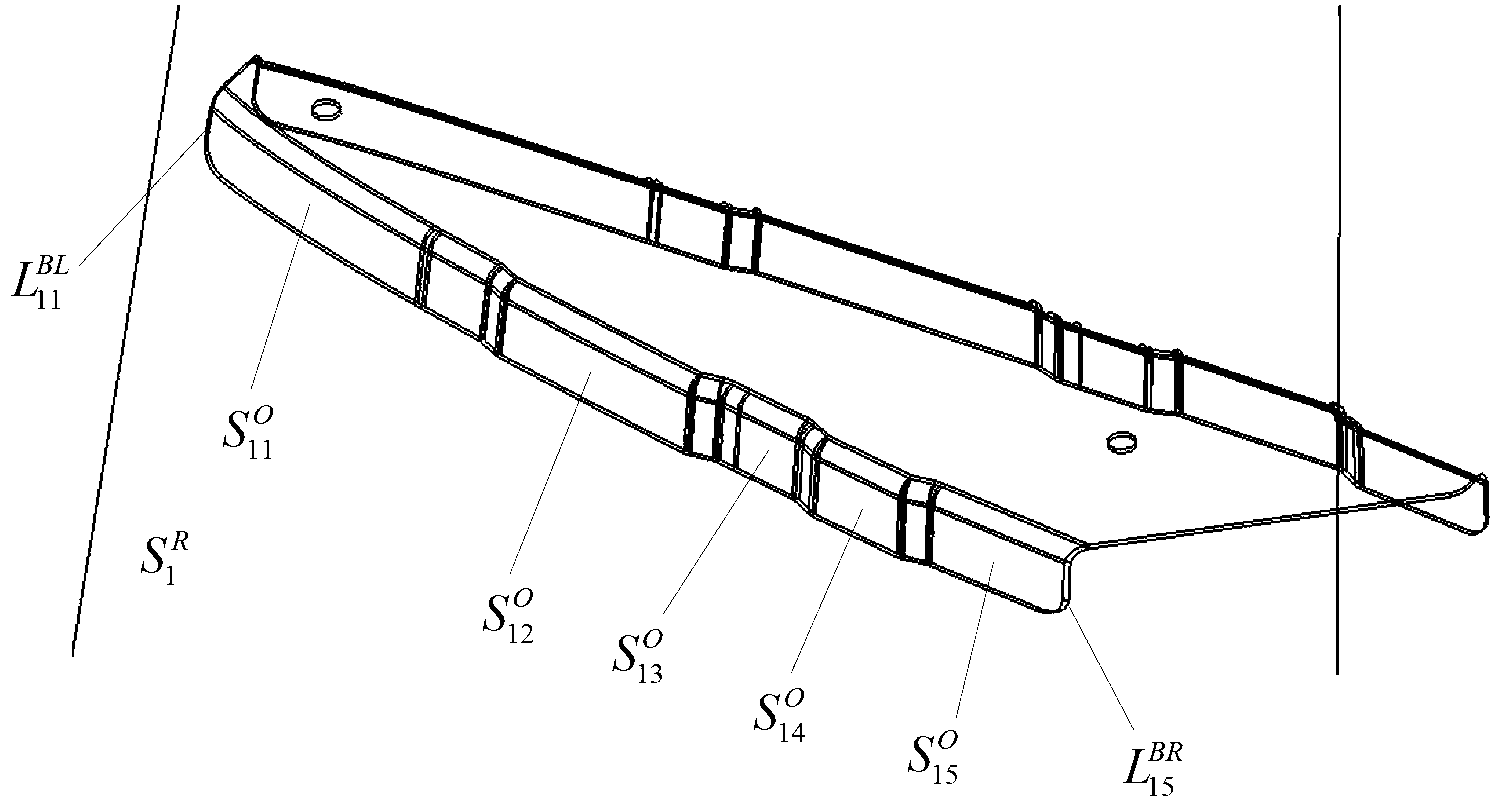

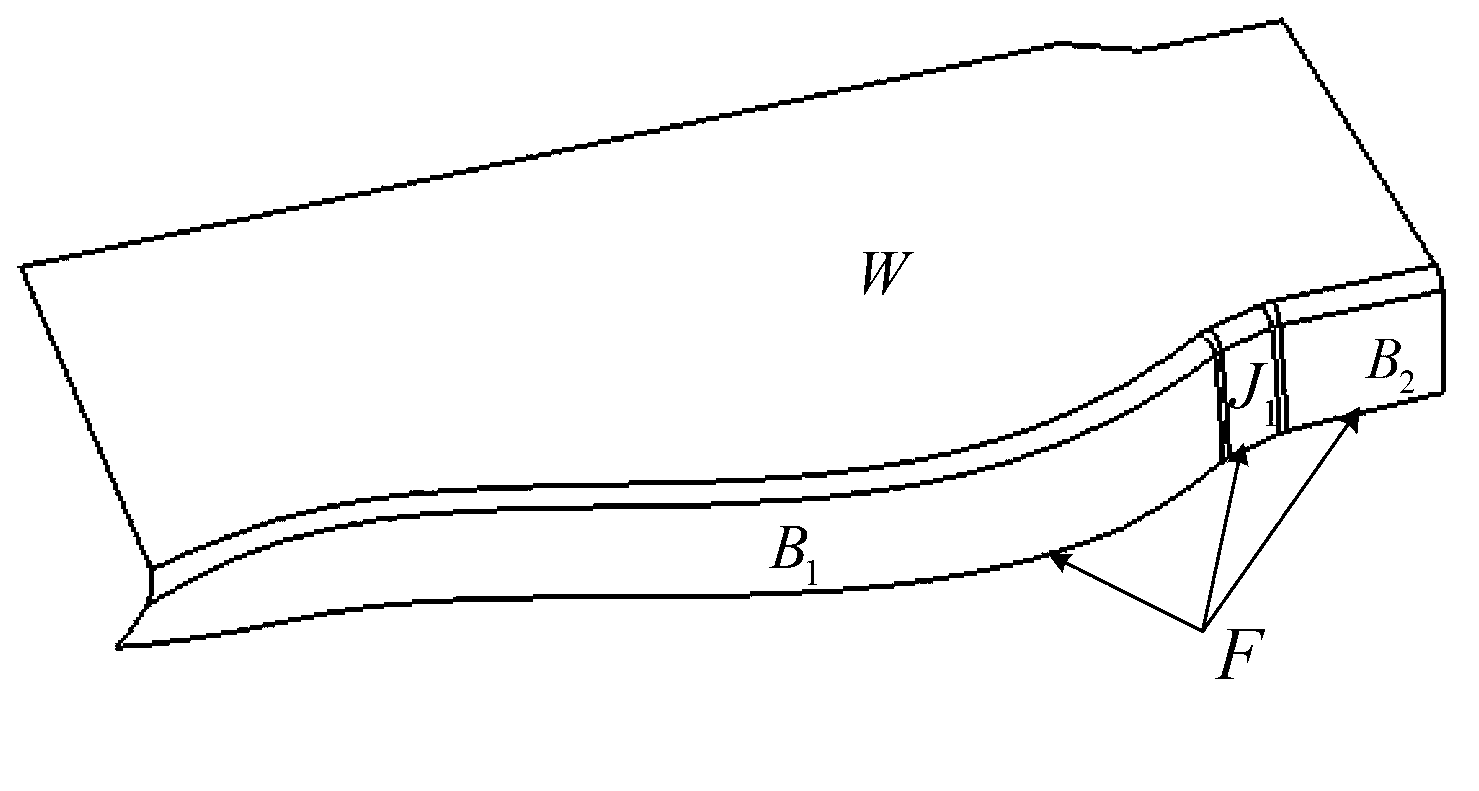

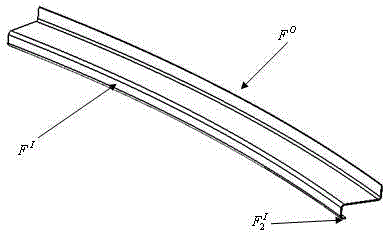

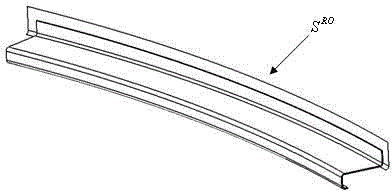

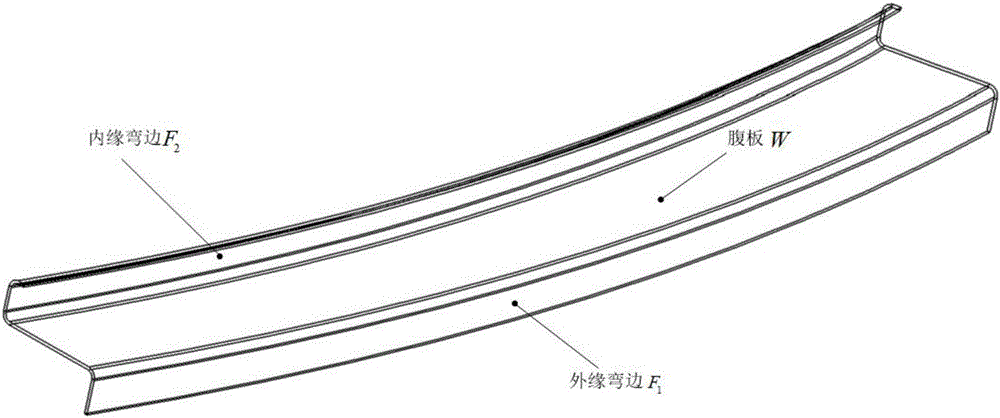

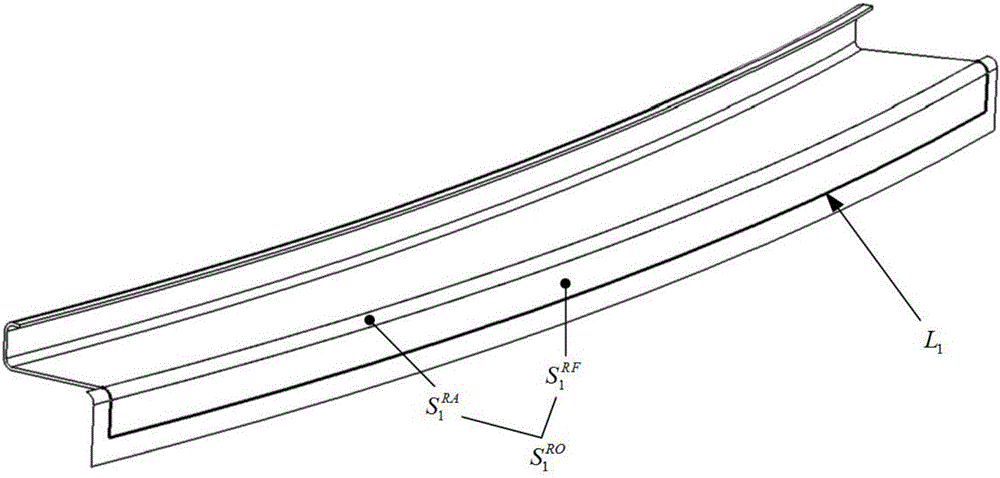

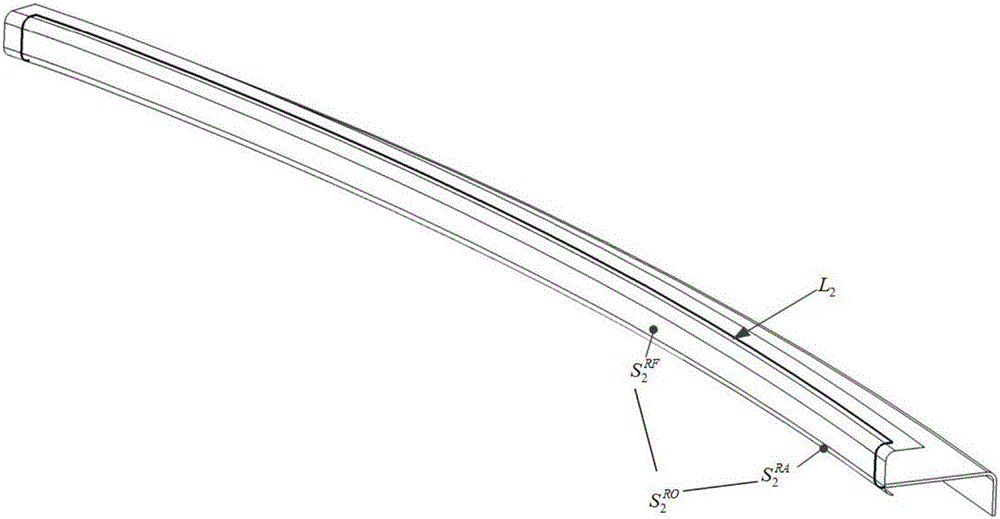

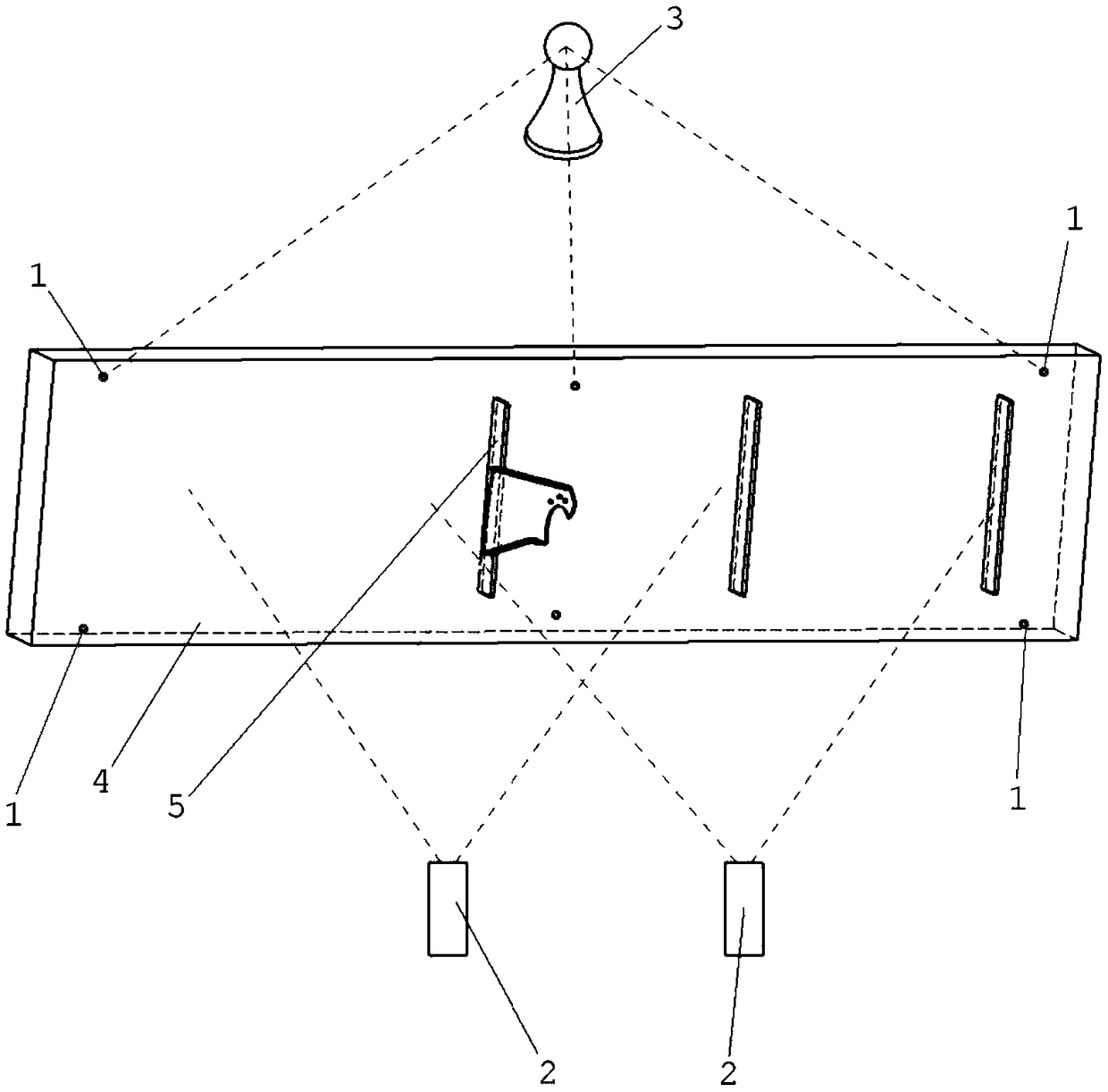

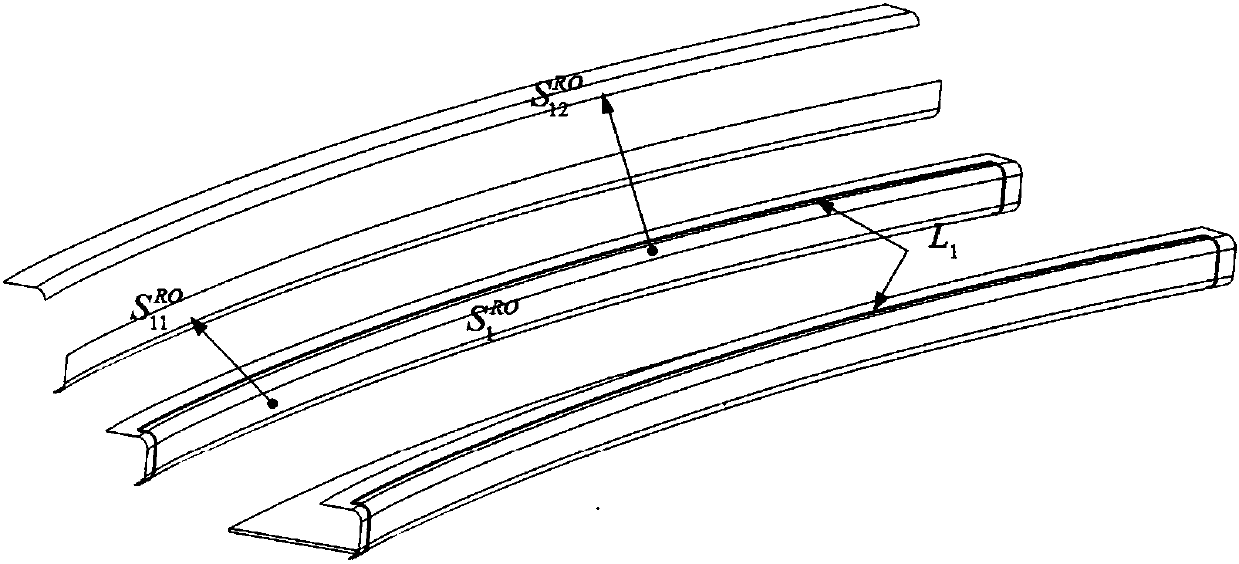

S-section sag-free aircraft frame and rib sheet metal part springback compensation calculation method

The invention relates to the field of aircraft manufacturing and design, in particular to an S-section sag-free aircraft frame and rib sheet metal part springback compensation calculation method. The method includes the steps: firstly, reconstructing a profile surface after springback compensation calculation on the basis of an outer-edge flange enlarged surface S<RO> established based on a part outer-edge flange F(O); secondly, subjecting a profile enlarged surface of a part inner-edge flange stiffened edge F2<1> to springback compensation calculation and constructing an inner-edge flange stiffened edge springback compensation profile surface S2<RI'>; thirdly, jointing the inner-edge flange stiffened edge profile surface S2<RI'> after springback compensation with the profile surface of a part inner-edge flange F1, and performing springback compensation calculation and reconstruction on the basis of a joint profile surface. The method which adopts single compensation values based on the flange profile surface is applicable to S-section sag-free variable-curvature frame and rib flange parts.

Owner:JIANGXI HONGDU AVIATION IND GRP

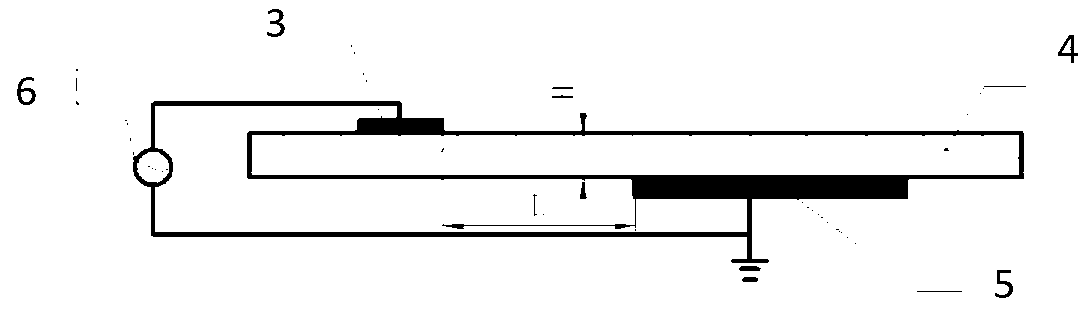

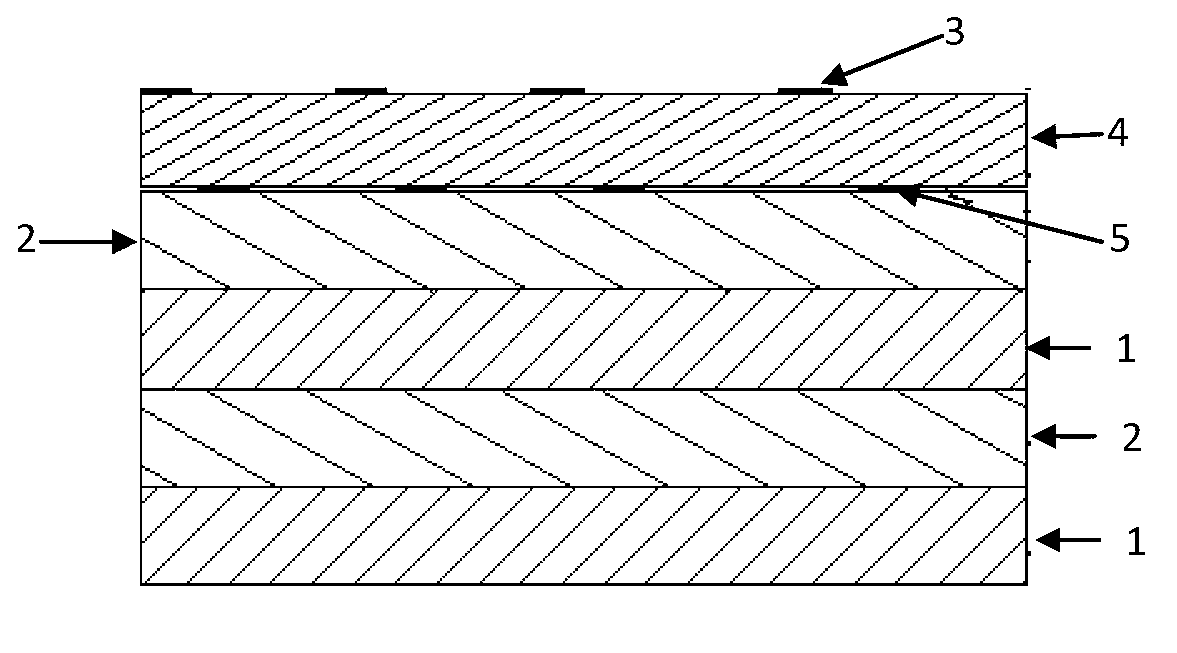

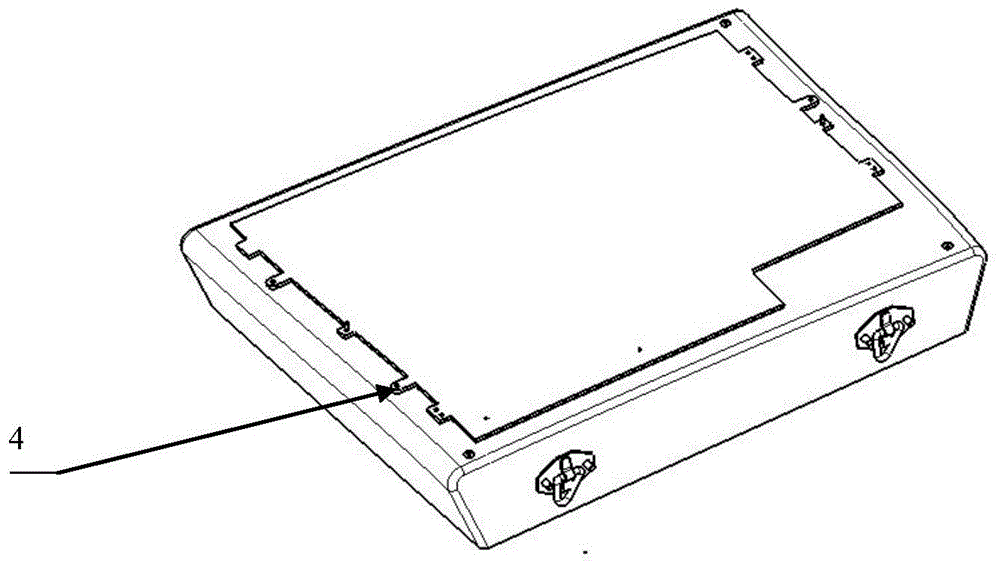

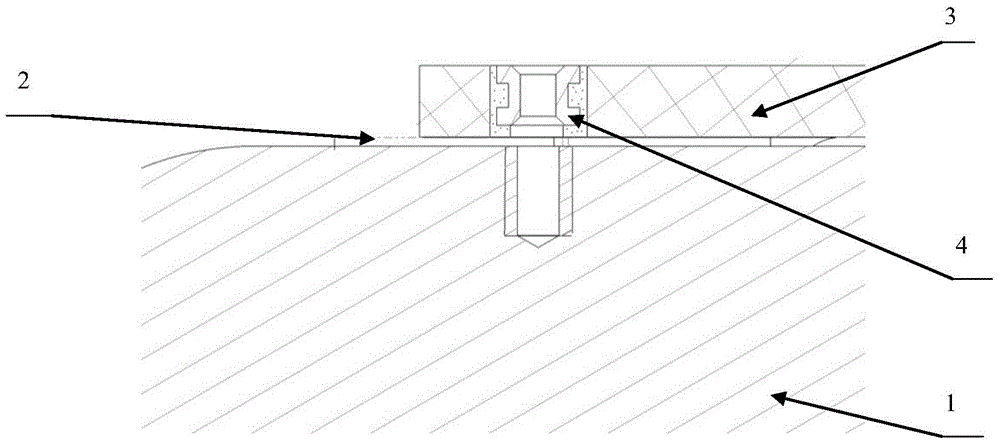

Laminated plate aircraft skin with flow control and deicing prevention functions

InactiveCN102991666AEffective controlDelayed stallSynthetic resin layered productsDe-icing equipmentsGlass fiberAlloy

The invention discloses a laminated plate aircraft skin with lift augmentation, resistance reduction, flow control and deicing prevention functions. The laminated plate aircraft skin comprises a glass fiber layer (2) and an aluminum alloy (1), wherein the glass fiber layer (2) and the aluminum alloy (1) are alternative; the surface of the skin is provided with an insulating material layer (4) and an electrode layer; the electrode layer is divided into an upper layer and a lower layer; the upper layer and the lower layer are respectively positioned on two sides of the insulating material layer (4) and are asymmetrically distributed; the upper electrode layer (3) is exposed in air and is connected with an alternating current power supply; and the lower electrode layer (5) is positioned below the insulating material layer (4) and is grounded. The laminated plate aircraft skin can be directly applied to aircraft manufacturing engineering, cannot be damaged by high-speed airflow and cannot bring parasite drag due to the damage of the original pneumatic shape. The deicing prevention function is realized by utilizing plasma heating on air and the pulse expansion wave function, the flow separation can be effectively controlled, the stall is delayed, the highest lift coefficient is increased, and the pressure difference resistance is reduced.

Owner:COMAC +1

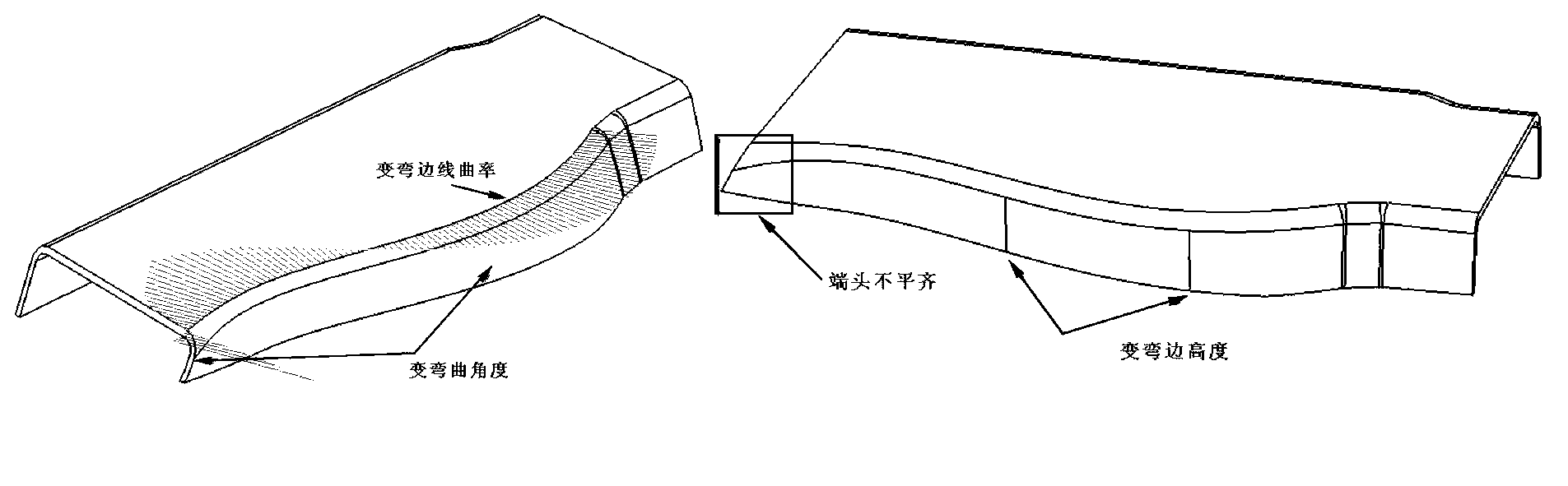

Method for controlling warping of web of large frame type sheet metal part

ActiveCN105081133AControlled reboundControl warpingAircraft componentsAircraft manufacturingIndustrial engineering

The invention provides a method for controlling warping of a web of a large frame type sheet metal part, and belongs to the technical field of aircraft manufacturing. For a large frame type sheet metal part of which the variable curvature, the variable section and the length are more than 1m, the method is that a technological rib groove structure is added to the outer flank of bent edge of the outer side of frame type rib part, so as to enable uniform distribution of the stress on the bent edge of the outer side of such parts after forming. The method is applicable to further control of the warping of the web of the large frame type part of which the bent edge section is complex and the curvature and the sectional linear dimension are changed constantly according to the bent edge line after forming and unloading, on the basis of springback compensation. With the adoption of the method, the springback of the part can be controlled, and the warping of the web of the part can be effectively controlled; after being formed, the part can simply meet the requirement on accurate formation without or with little manual repair by tapping, so that the forming quality and the production efficiency of the large frame type part can be obviously improved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

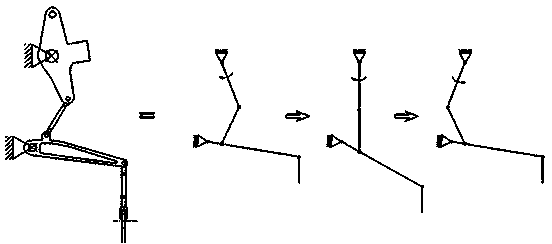

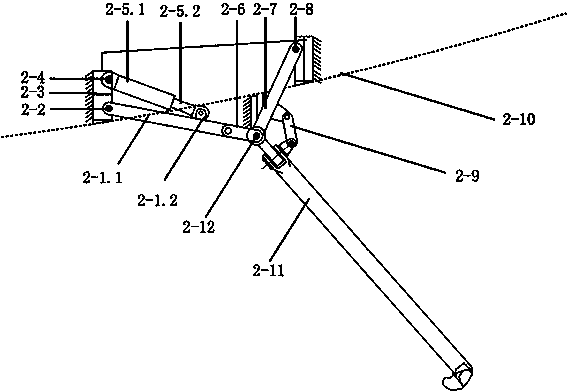

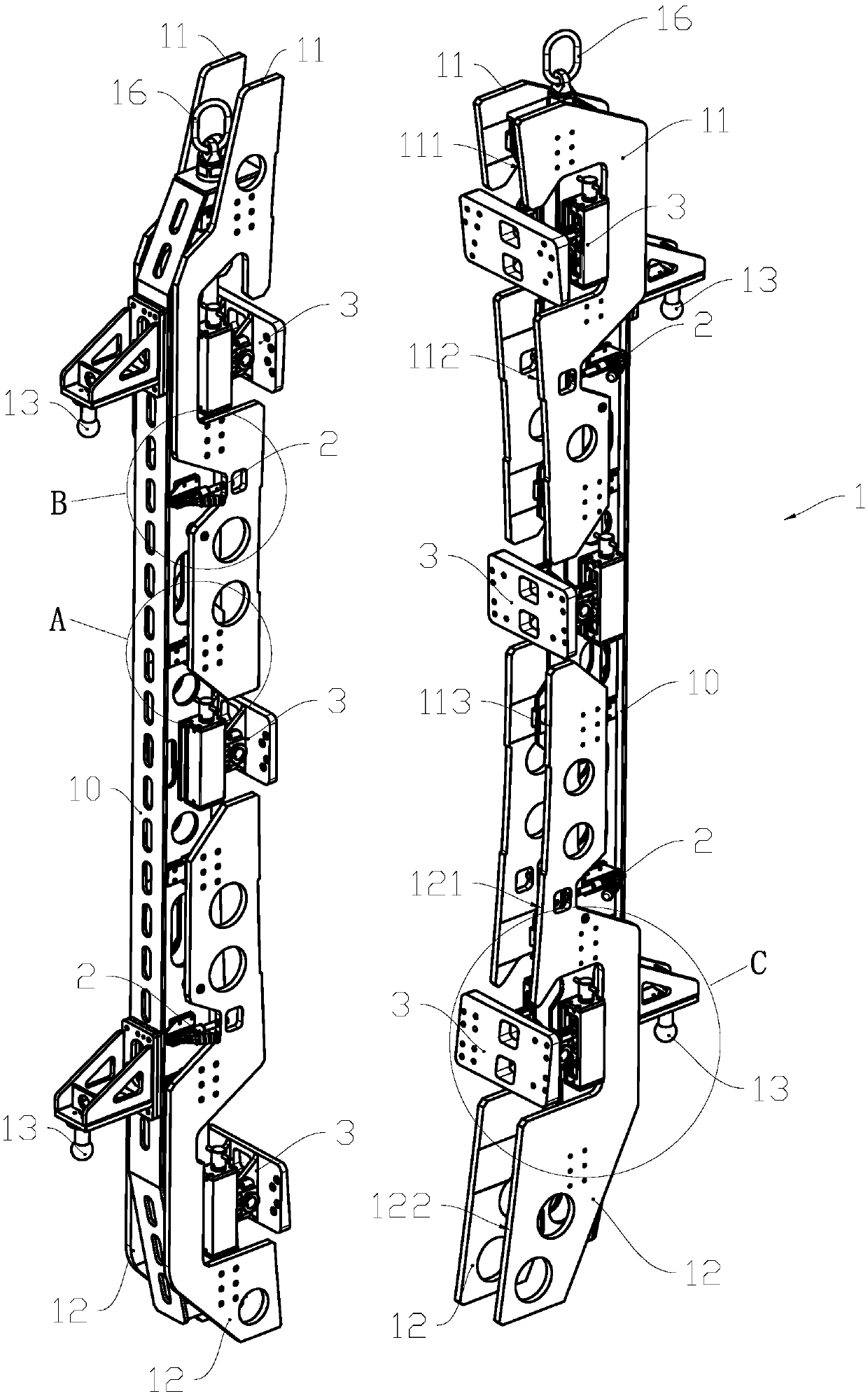

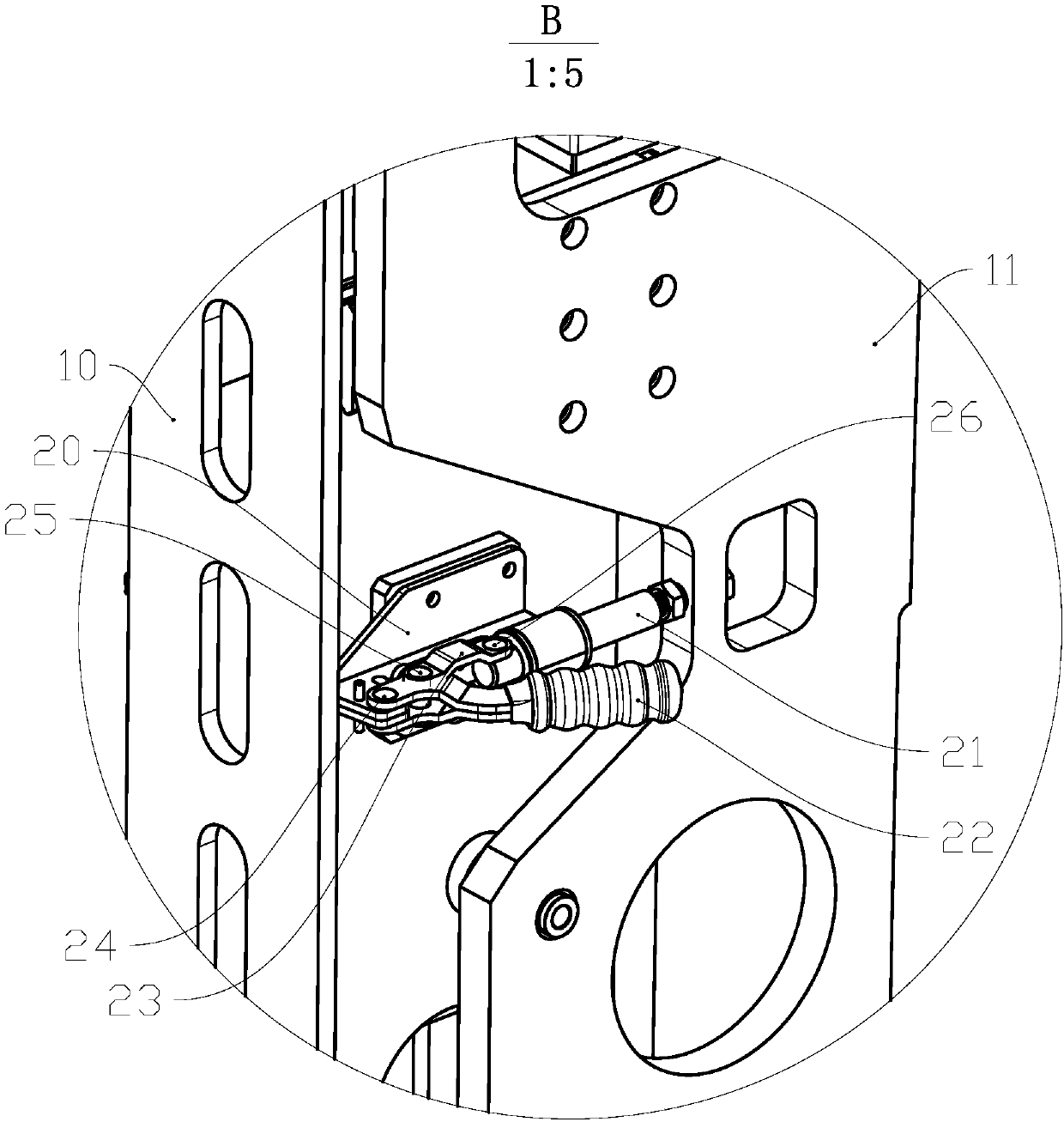

Arresting hook retracting and releasing mechanism

ActiveCN104176246AReduced strength requirementsShort action distanceArrester hooksPull forceUpper joint

The invention relates to an arresting hook retracting and releasing mechanism, belonging to the technical field of aircraft manufacturing. The arresting hook retracting and releasing mechanism comprises a connecting rod I, an upper joint, a fixed rotating shaft I, a rotating shaft support, a fixed rotating shaft II, an actuator cylinder, an expansion link, a connecting rod II, a connecting rod III, a fixed rotating shaft III, a connecting rod IV, an aircraft body surface, an arresting hook and a fixed rotating shaft IV; a transmission mechanism can enable the arresting hook to be released and retracted stably, the mechanism is reliable, and the actuator cylinder can realize long force arm by a short actuating distance; in addition, when the arresting hook is released to a working position, the connecting rod I 2-1.1, the connecting rod II 2-6, the connecting rod III 2-7 and a shipboard aircraft fixed structure form a triangular force-bearing structure, pulling force generated by arresting during aircraft landing is directly dispersed to an aircraft body structure by a connecting rod mechanism, and therefore, the strength requirement on the actuator cylinder can be reduced.

Owner:JIANGXI HONGDU AVIATION IND GRP

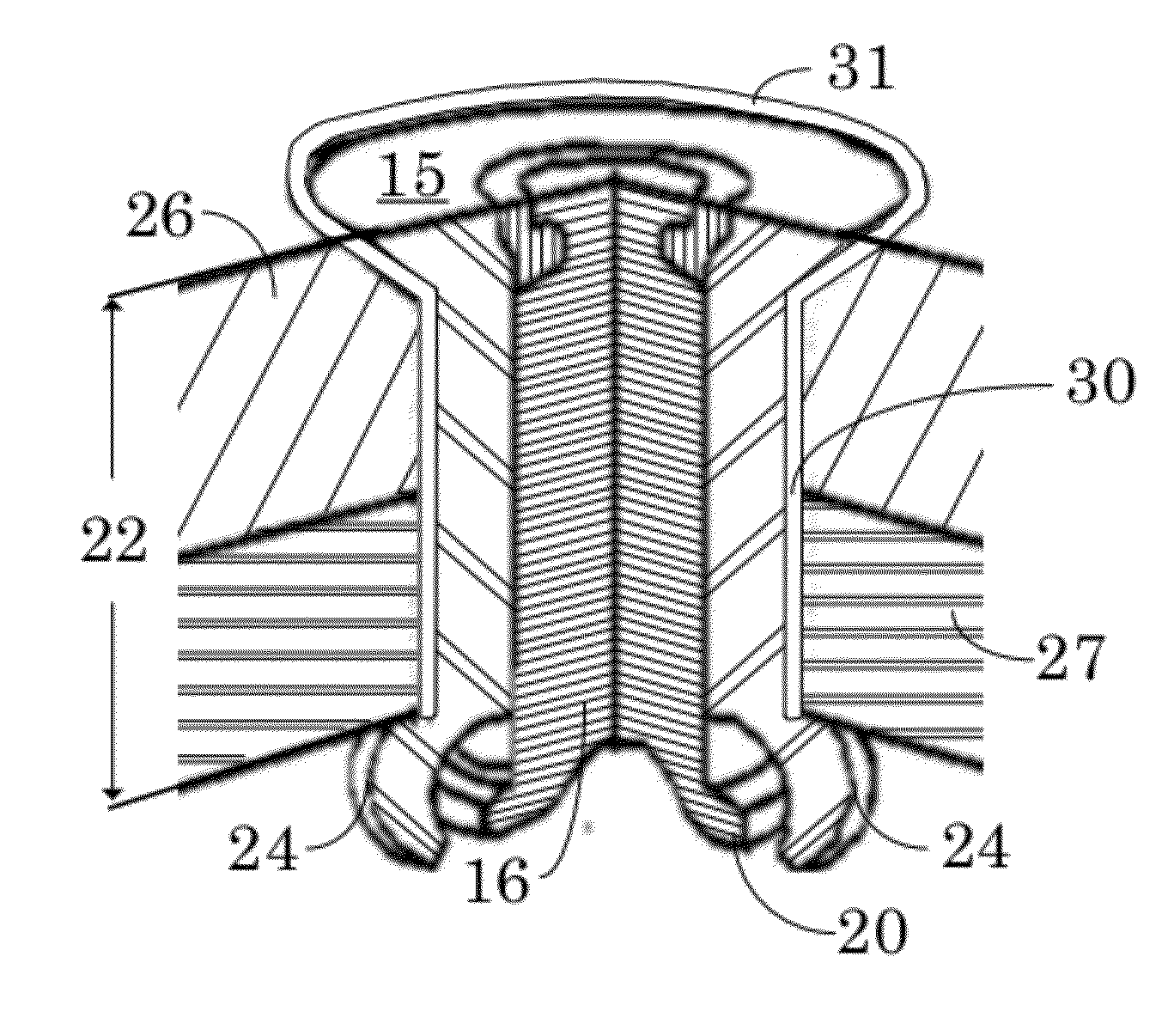

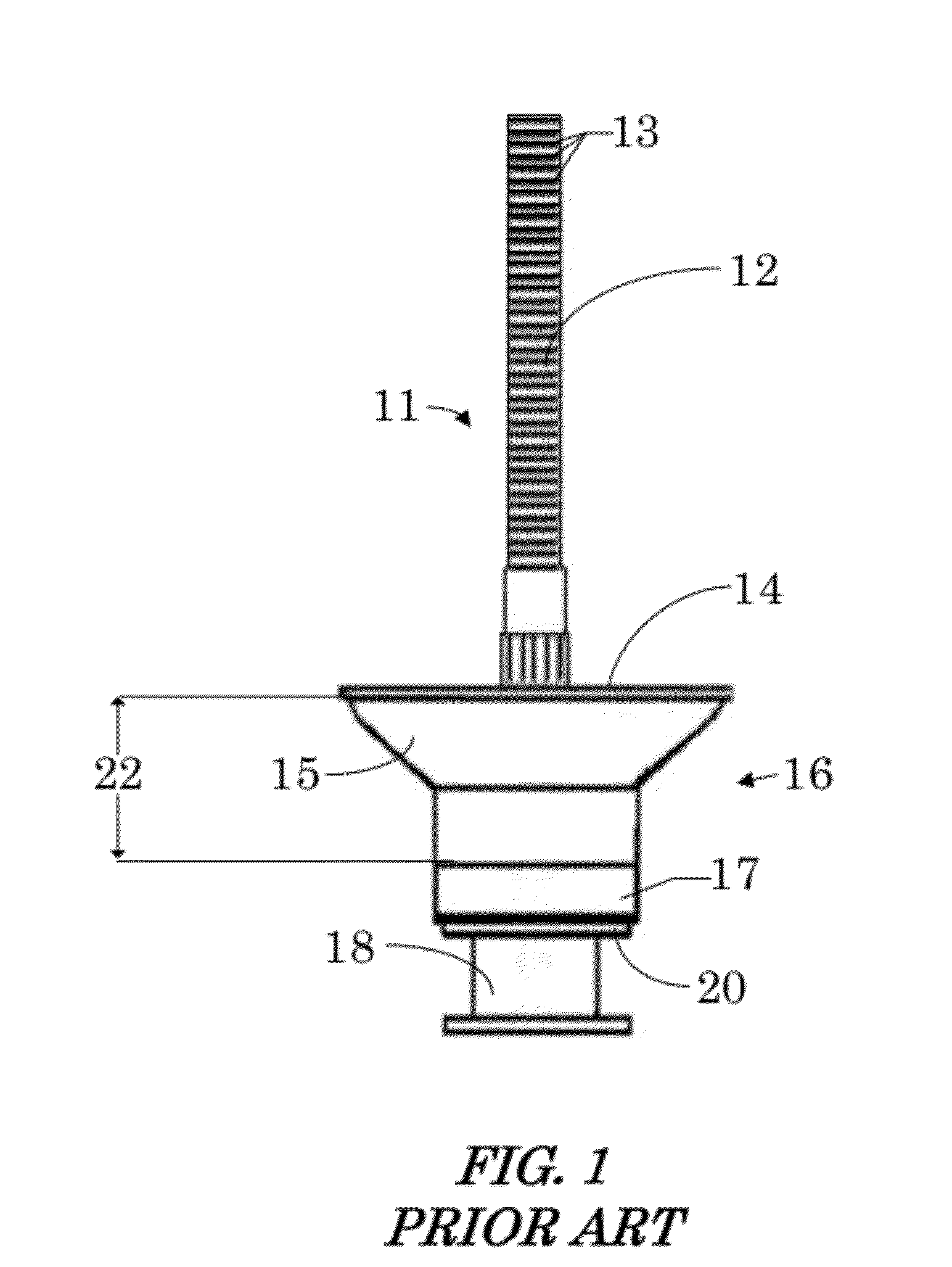

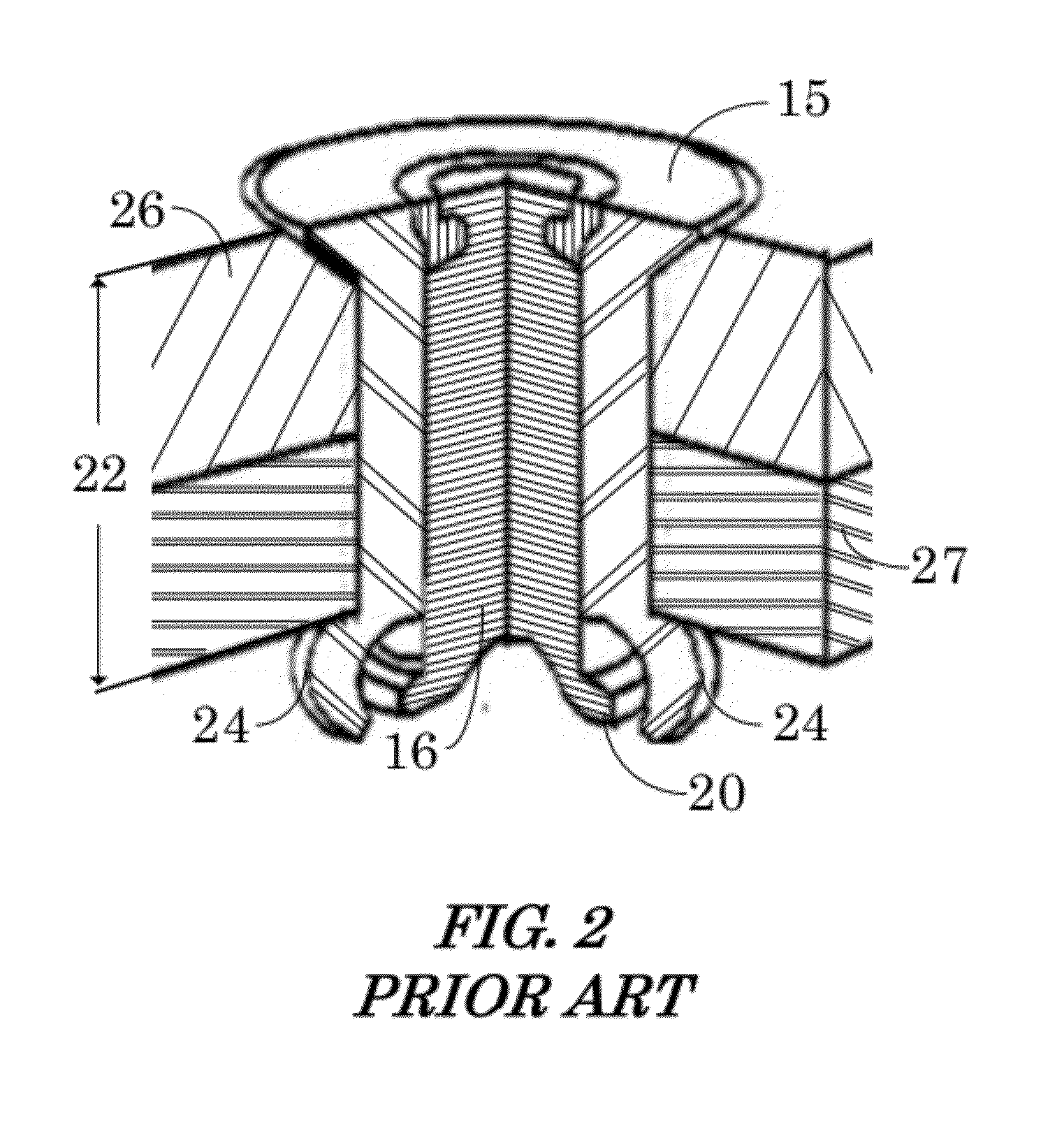

Self-Sealing Fastener

A fastener suitable for use in airplane manufacture or repair that is coated with a pre-mixed moisture cure sealant. The sealant layer is coated with a frangible moisture barrier that will break apart when the fastener is installed, thus exposing the sealant to atmospheric moisture. Once exposed to moisture, the sealant will begin to cure. Preferred embodiments also provide a moisture indicator that provides a visual indication that the outer moisture resistant layer has been damaged.

Owner:SYST & MATERIALS RES

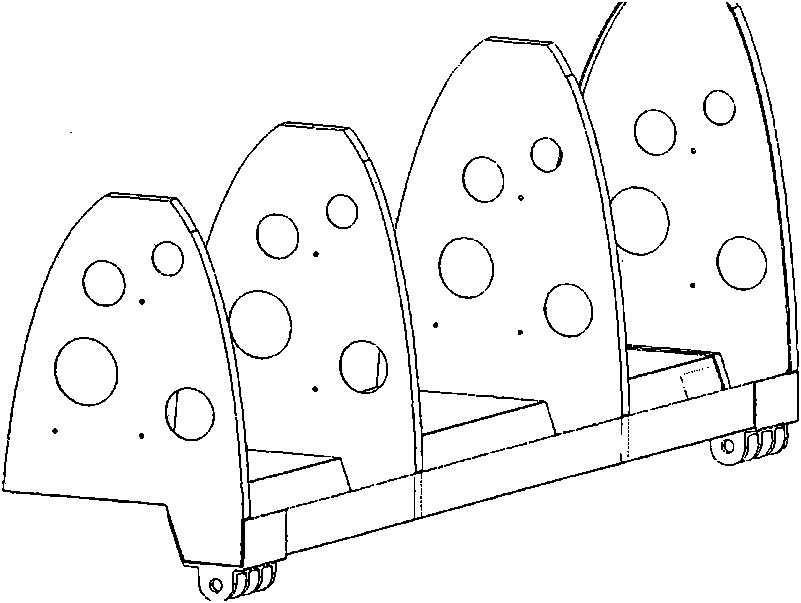

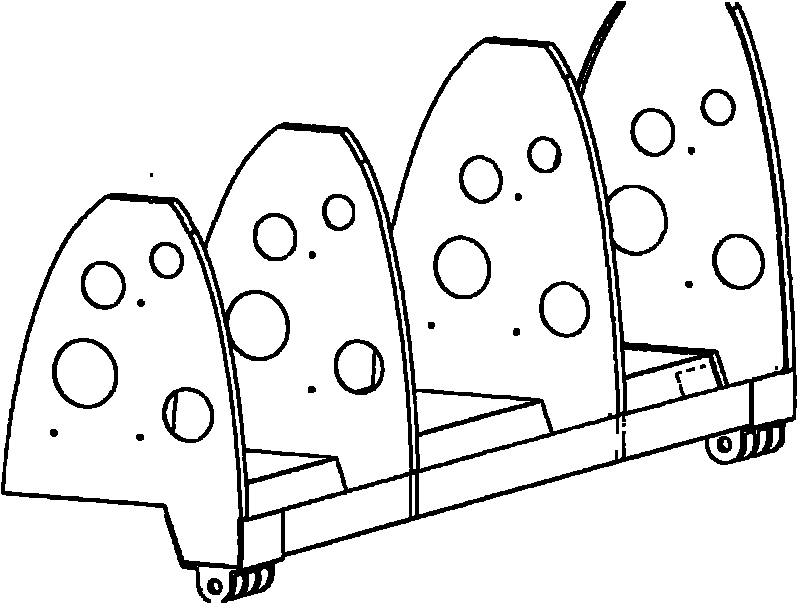

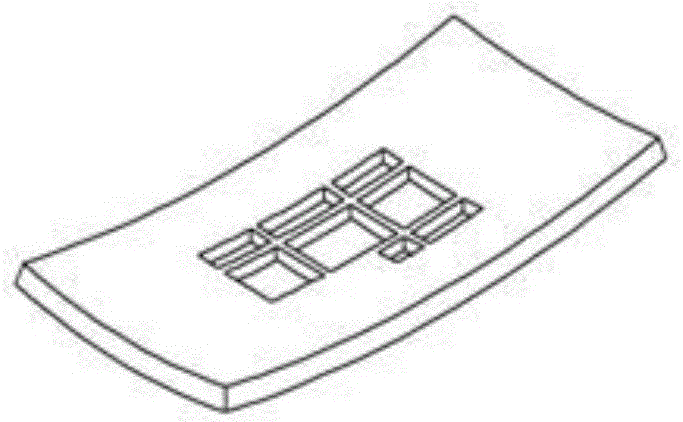

Conformal compressing tool of wing wallboard

ActiveCN107719692AImprove installation efficiencyQuality improvementAircraft assemblyEngineeringAircraft manufacturing

The invention discloses a conformal compressing tool of a wing wallboard, and belongs to the technical field of digital aircraft assembly. The conformal compressing tool comprises a conformal frame, the conformal frame comprises a supporting frame, wallboard connecting parts and a wallboard compressing part, wherein the wallboard connecting part and the wallboard compressing part are installed onthe supporting frame, the face, where the wallboard compressing part exerts pressure, of a wallboard is a curved face adaptive to the face of a pressure bearing plate of the wallboard; the two or morewallboard connecting parts are arrayed in the wallboard heading at intervals; a pushing and pressing mechanism is arranged between the wallboard compressing part and the supporting frame and used forforcing the wallboard compressing part to move relative to the supporting frame and compressing the wallboard. The conformal tool is connected with the wallboard, not only wallboard rigidity can be improved, the wallboard and a wing rib skeleton can be compressed to improve the wallboard installing efficiency and quality, and the conformal compressing tool can be widely applied to the aircraft manufacturing field.

Owner:ZHEJIANG UNIV

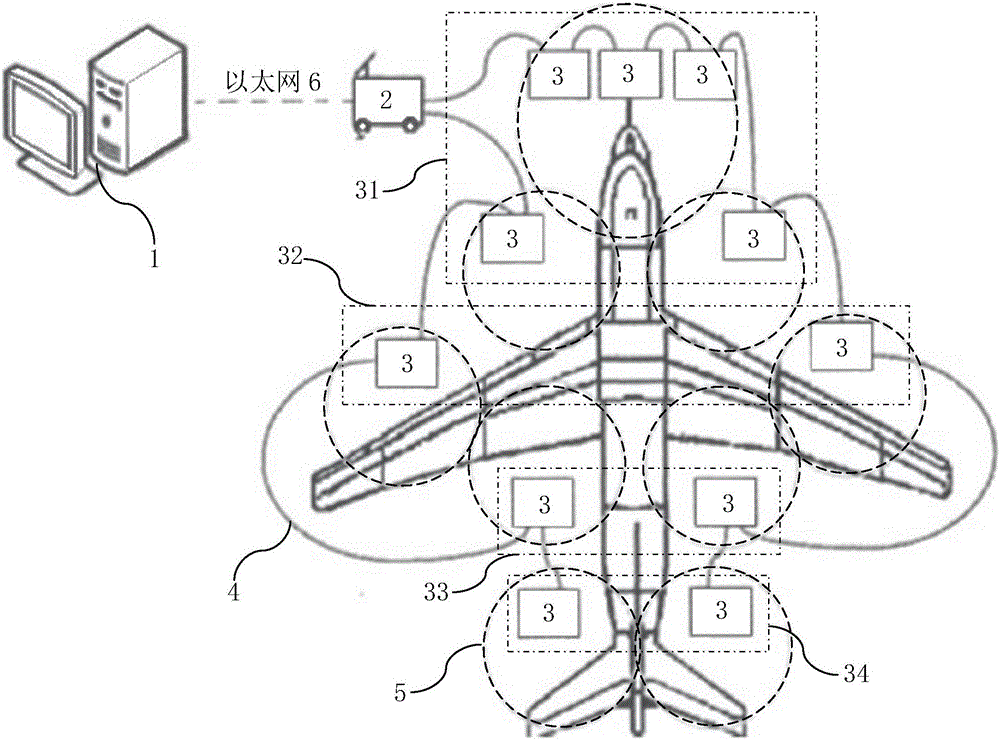

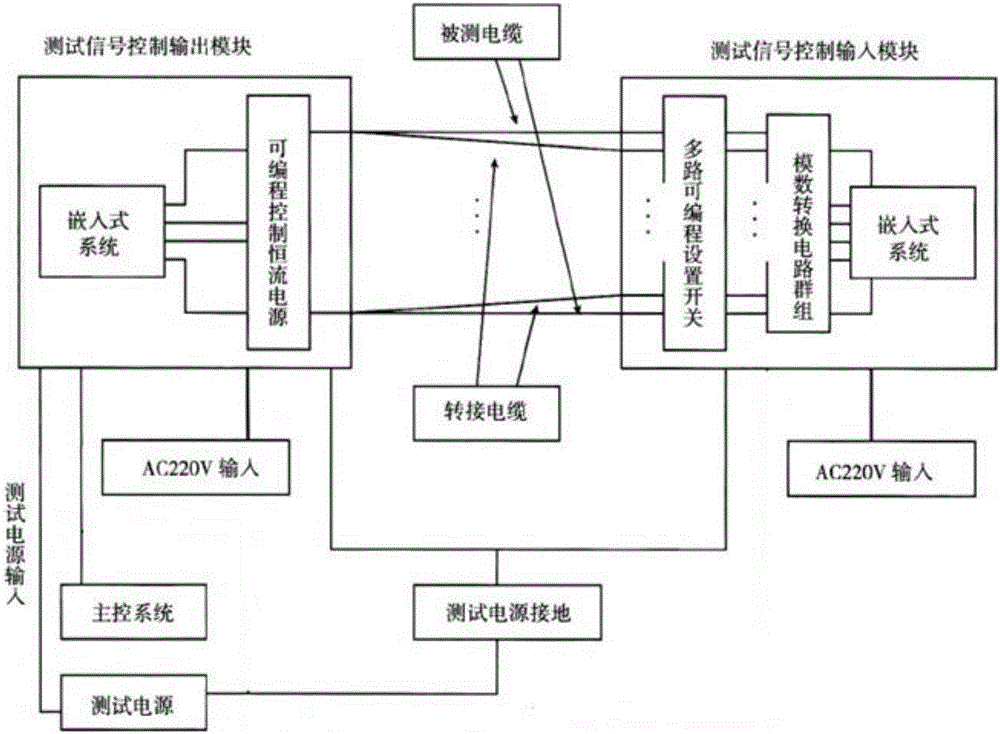

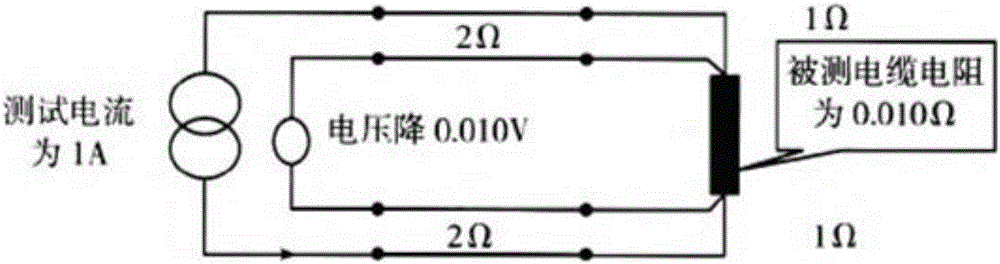

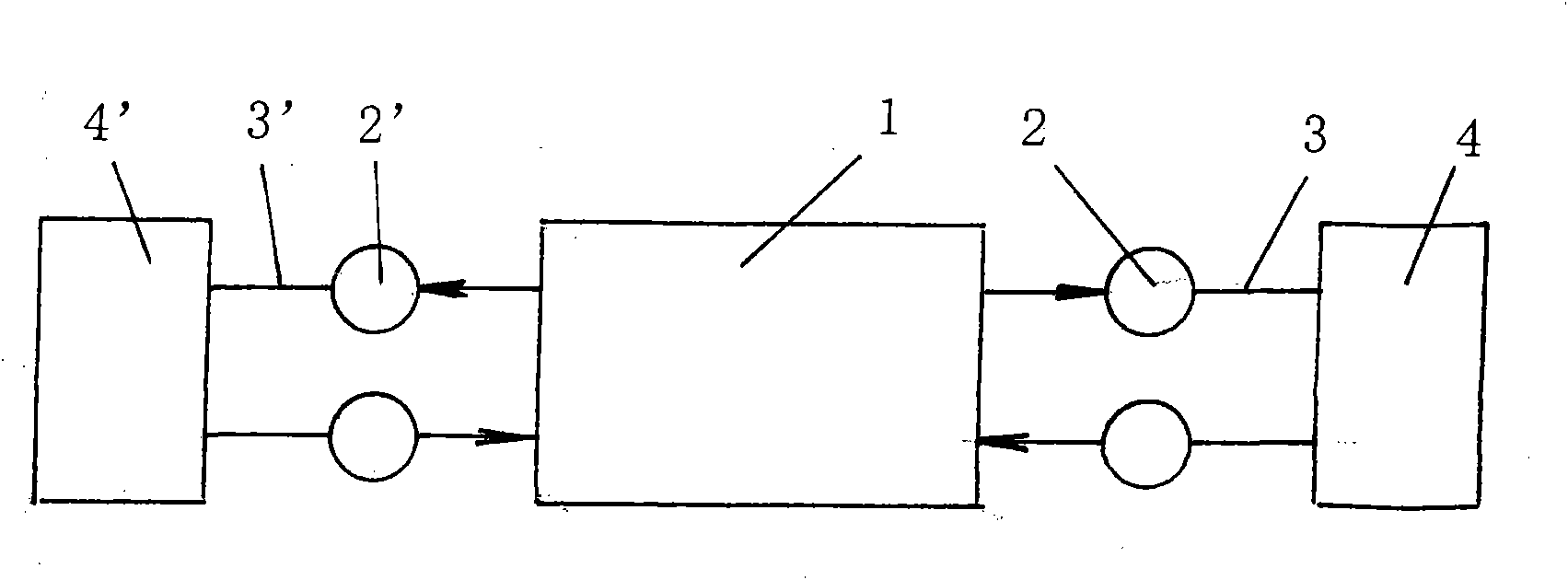

Conduction and insulation test system and method of large aircraft automatic system

InactiveCN106443311AShorten the lengthLow costTesting electric installations on transportTesting circuitsAviationFast measurement

The invention relates to a conduction and insulation test system and method of a large aircraft automatic system. The test system comprises an upper computer, a test host and distribution type test terminals; the test host is integrated with a distribution type aviation cable automatic detection system and an electric bridge measurement circuit and is in communication connection with the upper computer; the distribution type test terminals are a plurality of test terminals which are divided and distributed according to aircraft systems and are in conduction connection with the test host after being connected in series with a bus; and each test terminal is provided with a transfer cable used for being connected with a test point. According to the conduction and insulation test system, one point to multi-points simultaneous operation can be automatically realized, rapid measurement for many times is realized, test command and speed are increased, and the cost is also considered; the distribution type test terminals are distributed at a part, needing test, of an aircraft, so that the length of the transfer cable can be shortened, the cost of the transfer cable is lowered, huge economic benefit of million level is brought to an aircraft manufacturing plant, and wide popularization and spreading use are facilitated.

Owner:中航通飞华南飞机工业有限公司

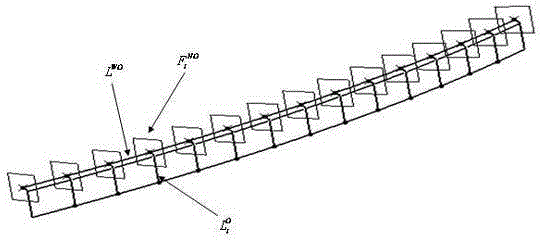

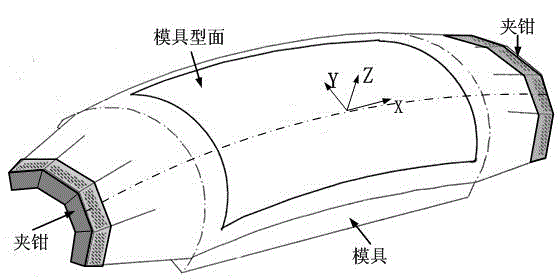

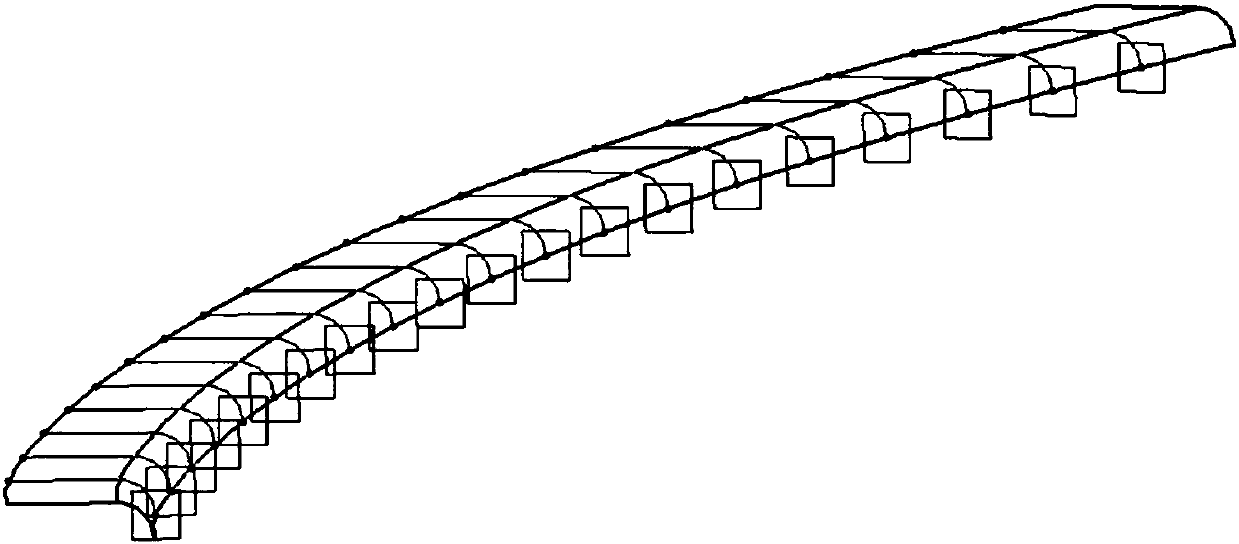

Longitudinal tensile loading trajectory design method based on mold surface extension

The invention relates to the aviation aircraft manufacturing field and relates to a longitudinal tensile loading trajectory design method based on mold surface extension. The method includes the following steps: 1, extending the mold surface, the wollens covers the mold surface via the action of the clamp during the forming process, and the material has the shape having the part curved surface; 2, calculating the jaw position and space posture, obtaining the final covering condition of the wollens during the forming process in the mold surface extending process, respectively processing the curves at two ends of the extending curved surface; (1) jaw curve scattering, (2) calculating clamp plane, (3) calculating curved clamp angle; 3, solving the movement of pulling device, designing loading trajectory of the pulling middle step, calculating according to the final device parameter; (1) calculating the pitching angle of clamp, (2) calculating the extending part of the pulling action cylinder. The longitudinal tensile loading trajectory design method based on mold surface extension can offer the guiding function for the skin longitudinal shape trajectory design and trajectory optimization.

Owner:JIANGXI HONGDU AVIATION IND GRP

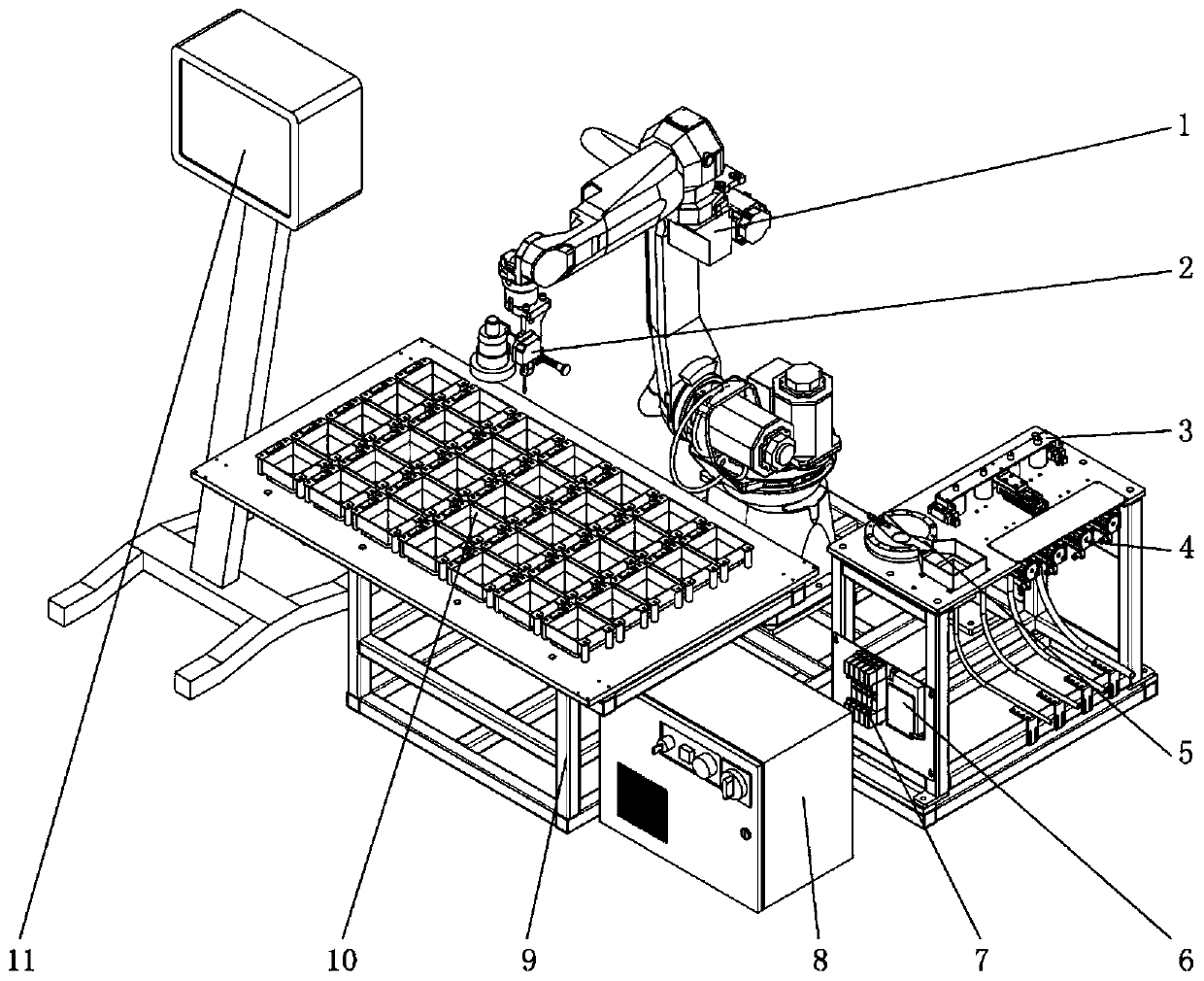

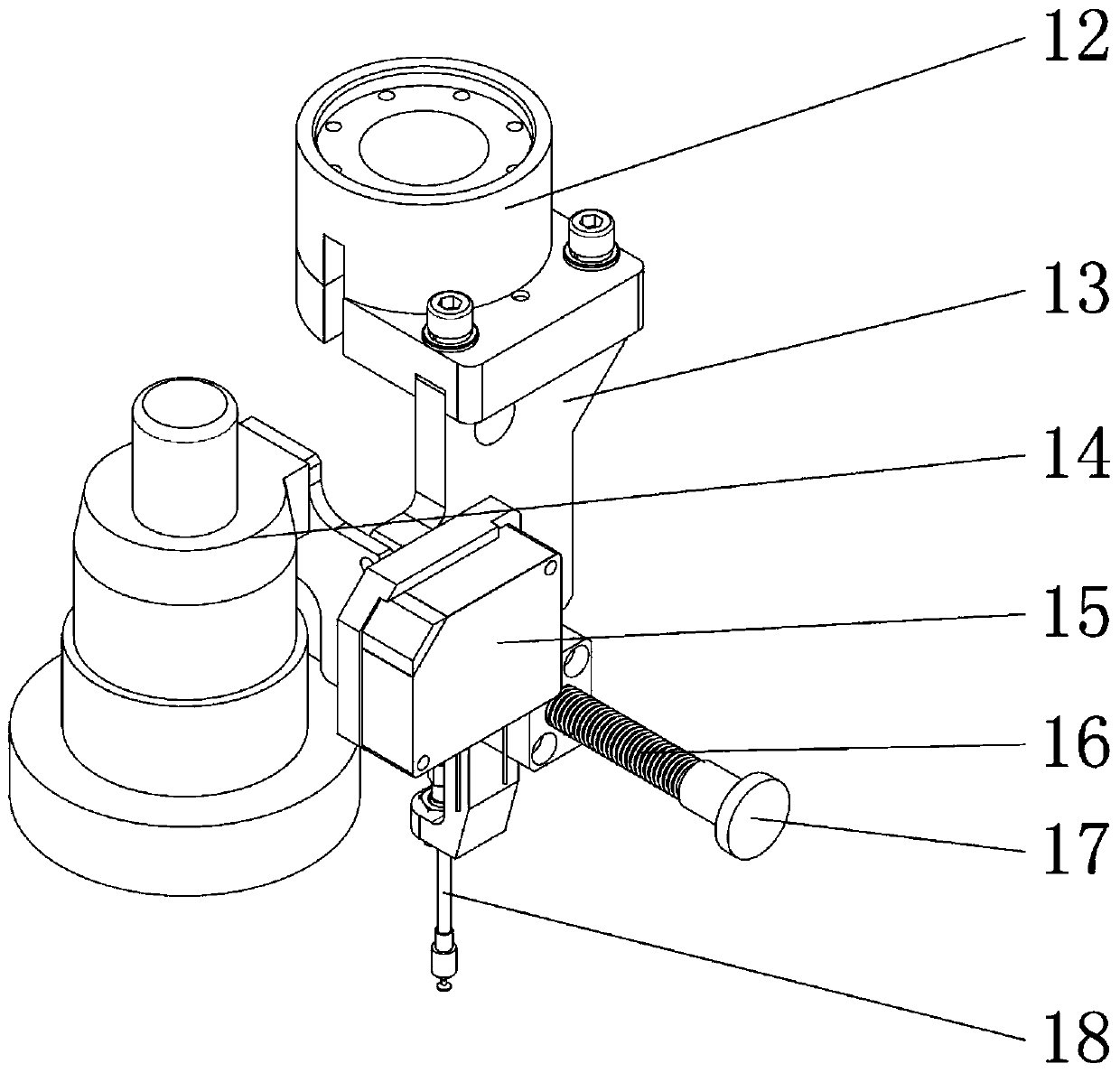

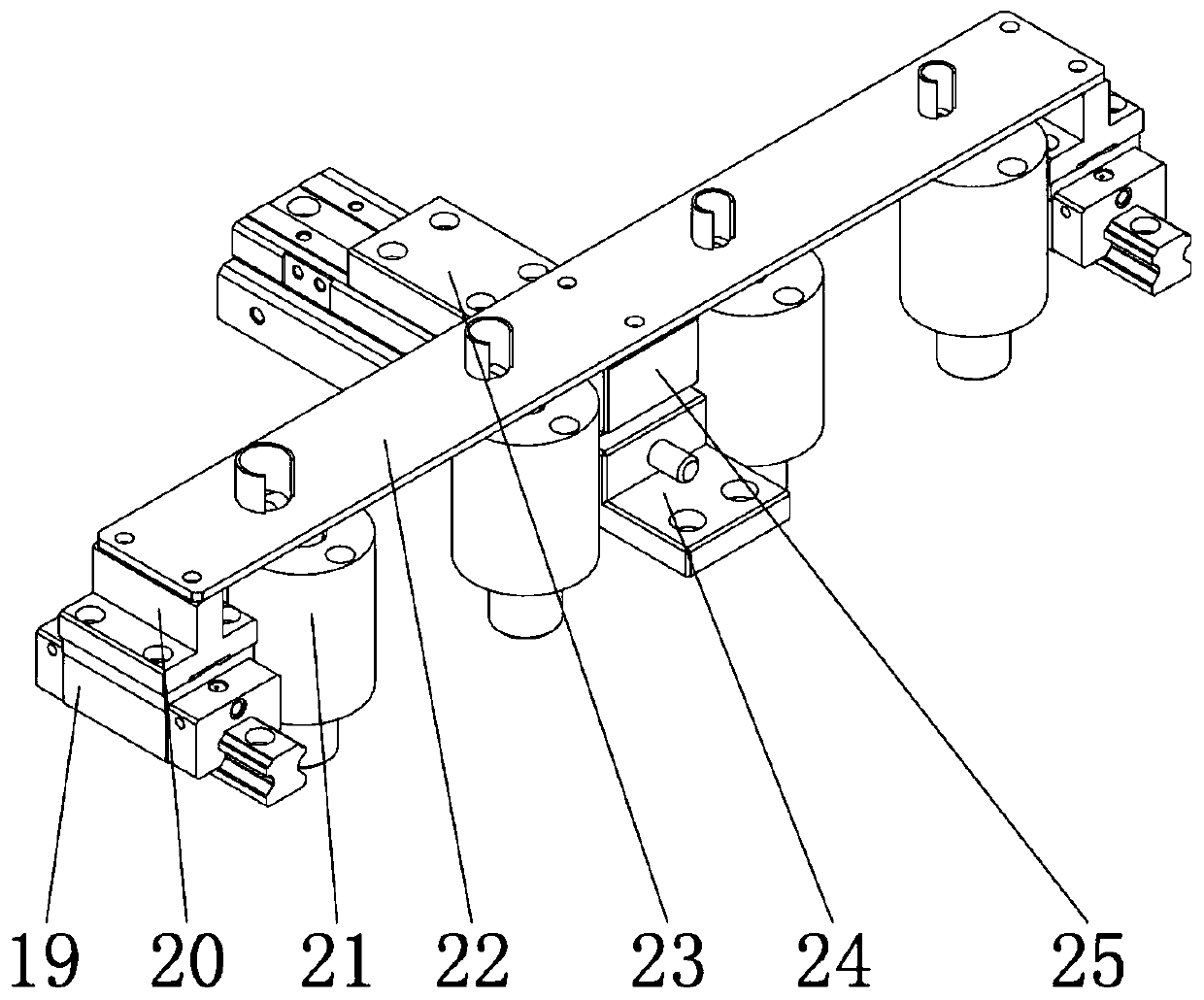

Automatic rivet feeding system and method based on robot vision

The embodiment of the invention discloses an automatic rivet feeding system and method based on robot vision, relates to the field of intelligent manufacturing, and can solve the problems that in theprior art, rivets are difficult to take out in a scattered mode, the rivet feeding efficiency is low, and more kinds of rivets cannot be conveyed. An industrial robot, a cover plate assembly, a rivetblowing mechanism, a detection disc, a vacuum generator, a valve group and a rivet storage disc are mounted on a fixture; the multifunctional end effector is composed of a flange plate, a support, anindustrial CCD camera, a laser displacement sensor, a spring, a stirring rod and a vacuum suction nozzle. The multifunctional end effector is connected with the tail end of the industrial robot through a flange plate; the bracket is used for fixing an element on the multifunctional end effector; the industrial CCD camera is installed right in front of the support and used for obtaining rivet images. The laser displacement sensor is installed on the side face of the support and used for measuring the depth of rivets. The vacuum suction nozzle is installed below the support and used for grabbingor putting rivets. The automatic nail feeding device is suitable for automatic rivet feeding in the aircraft manufacturing process.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

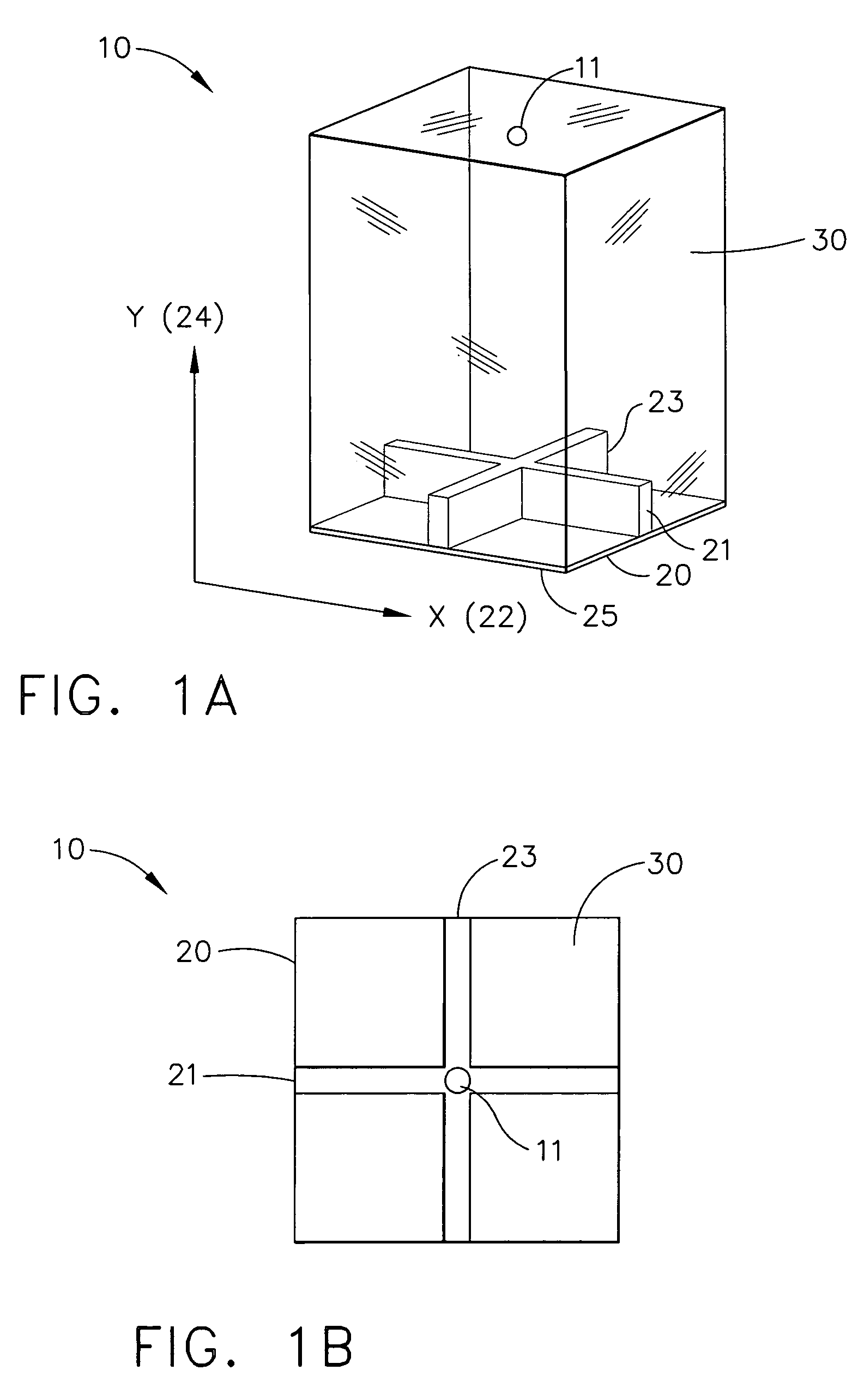

Alignment quality indicator

InactiveUS7197830B2ConfidencePrecise alignmentAngles/taper measurementsSurveying instrumentsNon destructiveEngineering

An alignment tool includes a base, a column, and a ball. The base is manufactured from a material with a high material density and includes a crosshair. The column is machined out of an optical transparent material and is attached to the base. The ball is positioned within the column at the end opposite to the base and above the center of the crosshair. The alignment tool may not only be used to properly align a radiation source with an area of interest of a part to be inspected but also as an alignment quality indicator providing information of proper alignment to an interpreter of the radiograph taken. Therefore, the need to take multiple exposures can be eliminated. The alignment quality indicator is suitable for, but not limited to, applications in the aerospace industry, such as nondestructive testing and evaluation of airframes during aircraft manufacturing, maintenance, and repair.

Owner:THE BOEING CO

Installing method of airplane component based on laser positioning

ActiveCN108981677AHigh precisionSolve the problem of difficult installationAircraft assemblyReference line/planes/sectorsManufacturing technologyMeasurement point

The invention belongs to the technical field of aircraft manufacturing, particularly relates to an installing method of an airplane component based on laser positioning, and relates to an airplane system guide pipe support frame installing and detection method. An airplane coordinate system is built by mainly using an airplane entity and a laser tracking instrument; the projection equipment coordinate system building is completed by using measuring points on the entity; then, the guide pipe support frame shape and position under the airplane coordinate system are projected out by using a projection instrument; finally, a guide pipe is installed according to the projection shape and position. The method mainly solves the technical problem that the installing position of an airplane system guide pipe support frame is frequently changed, and cannot be fixed. The method is mainly used for the quality control of the airplane system guide pipe support frame installation.

Owner:SHAANXI AIRCRAFT CORPORATION

Springback compensation method for recess-free continuous bending edge in frame and rib part

The invention provides a springback compensation method for a recess-free continuous bending edge in a frame and rib part, and belongs to the technical field of aircraft manufacturing. According to the method, the recess-free continuous bending edge of the frame and rib part is subjected to fractionated compensation, and a springback compensation correction coefficient of the continuous bending edge is determined, so that the problems that overcompensation is caused and a bending angle of the formed part is smaller than a designed bending angle of the part when the continuous bending edge is subjected to springback compensation with an existing springback compensation calculation method for a single bending edge can be solved; and accurate forming is realized through springback compensation calculation of the continuous bending edge.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

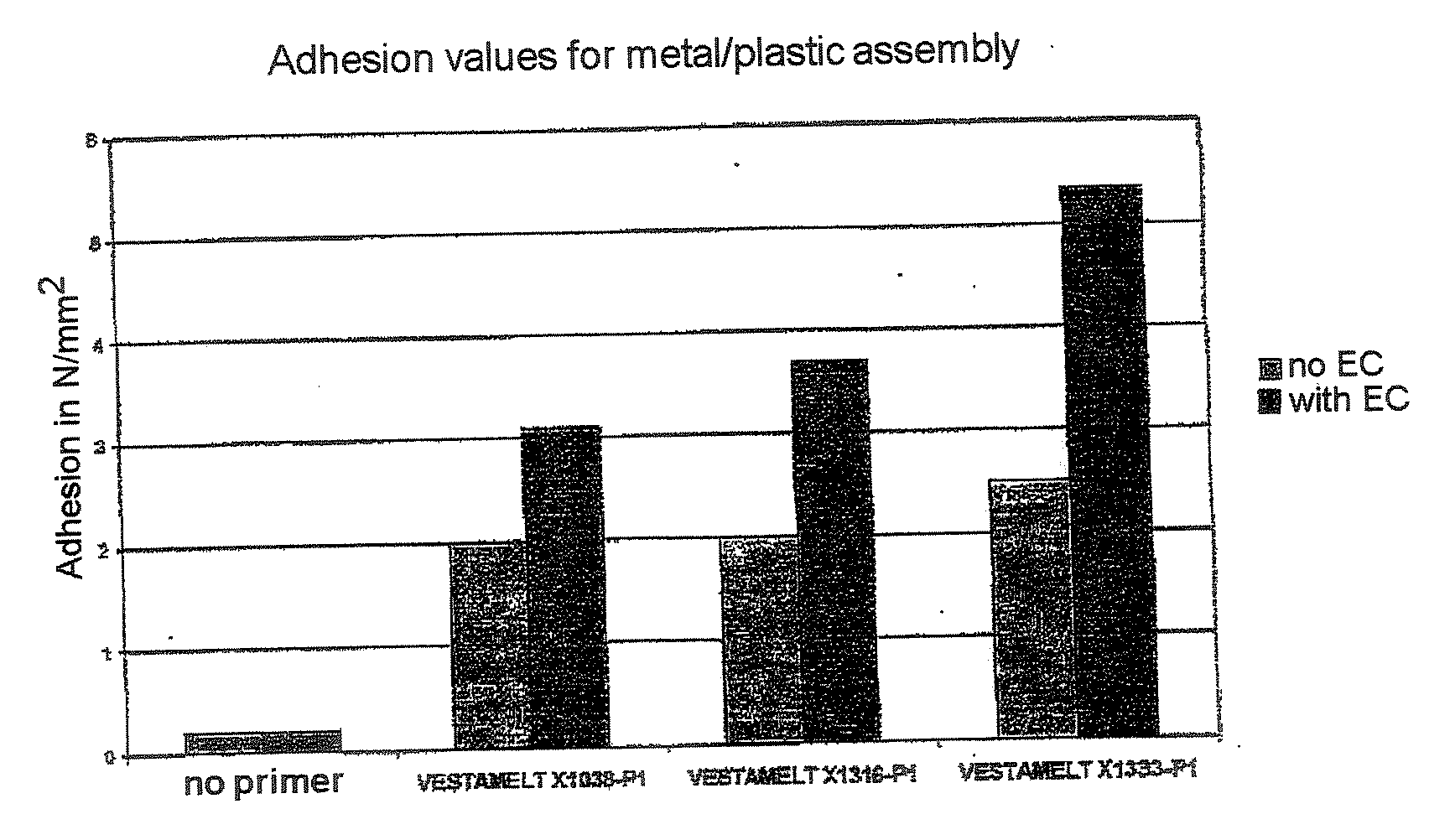

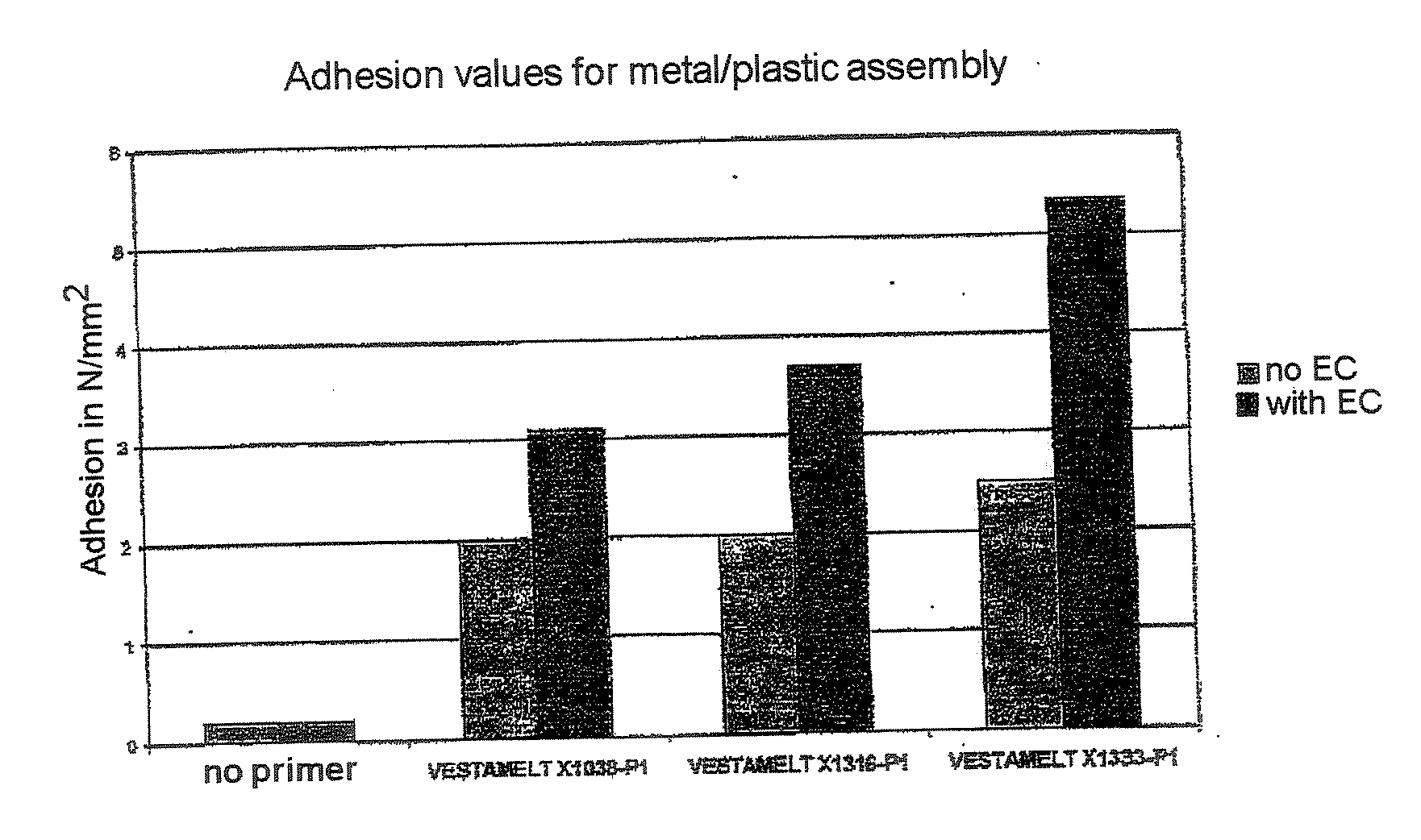

Hybrid components containing reactive hotmelt adhesives

ActiveUS20070163709A1Overcome disadvantagesAdhesive processes with adhesive heatingPretreated surfacesHot-melt adhesiveAirplane

Owner:EVONIK OPERATIONS GMBH

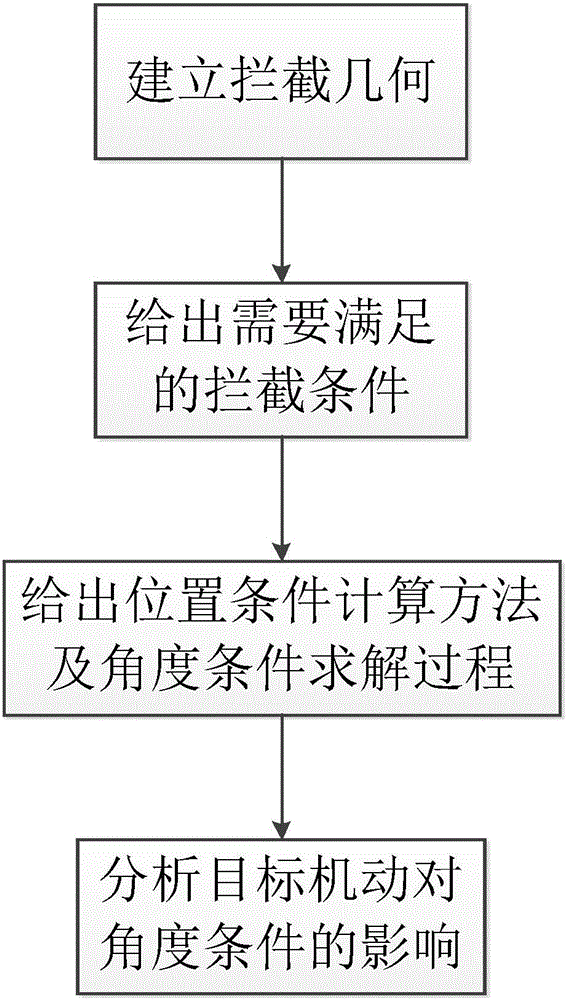

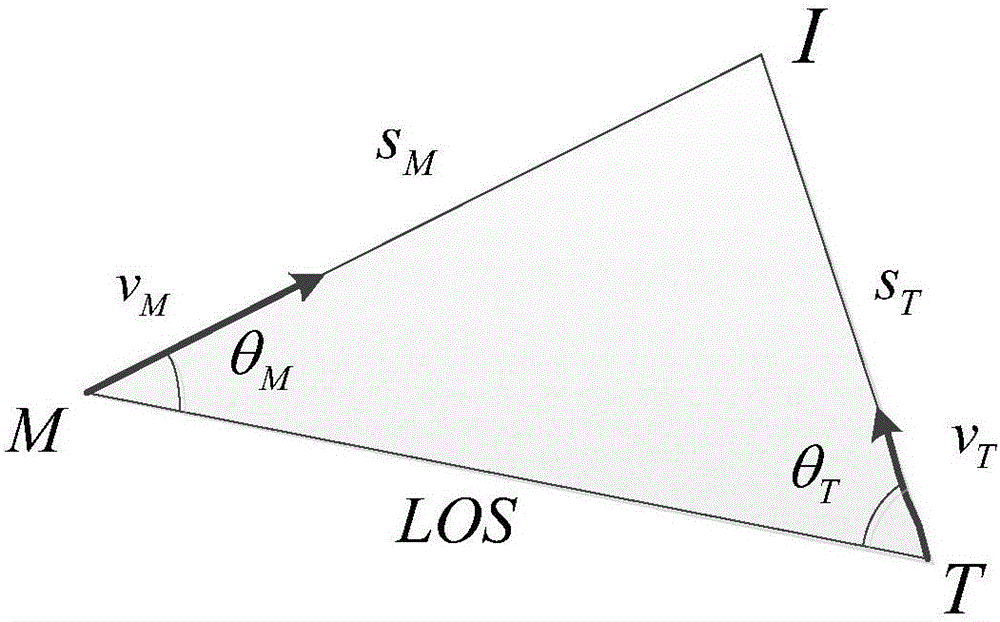

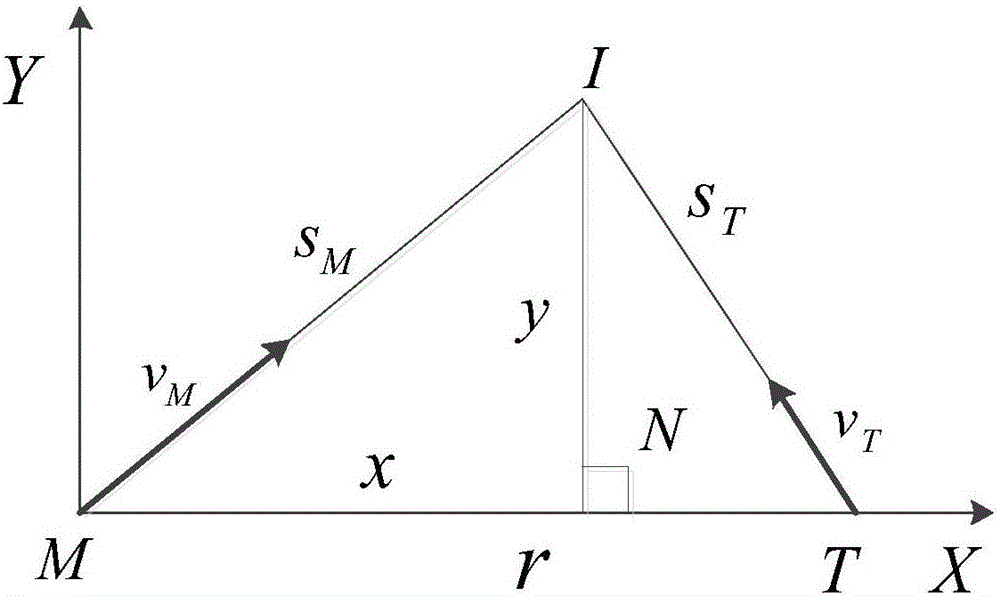

Analysis method of handover conditions of hypersonic-velocity target interception missile based on interception geometry

ActiveCN106529073ALow requirements for detection accuracySolve the difficult problem of interceptionDesign optimisation/simulationSpecial data processing applicationsRelative motionAnalysis method

The invention provides an analysis method of handover conditions of a hypersonic-velocity target interception missile based on interception geometry and belongs to the field of aircraft manufacturing technology. The method is technically characterized in that by considering all possible velocity direction of a target and according to the relative motion relation between the interception missile and the target, positions of all possible impact points are obtained through derivation, and the interception geometry is built; according to a research result of the interception geometry and the positional relation among the interception missile at the midcourse and terminal guidance handover moment, the target and the interception geometry, interception conditions required to be met for intercepting the hypersonic-velocity target are given; on the basis that the interception conditions are met, a calculation method of the positional condition and the solving process of the angle condition of the interception missile at the midcourse and terminal guidance handover moment are given, and the influence of maneuvering of the target on solving the angle condition of the interception missile is analyzed. Through the method, the problem that the hypersonic-velocity target cannot be intercepted through an existing interception method is solved.

Owner:HARBIN INST OF TECH

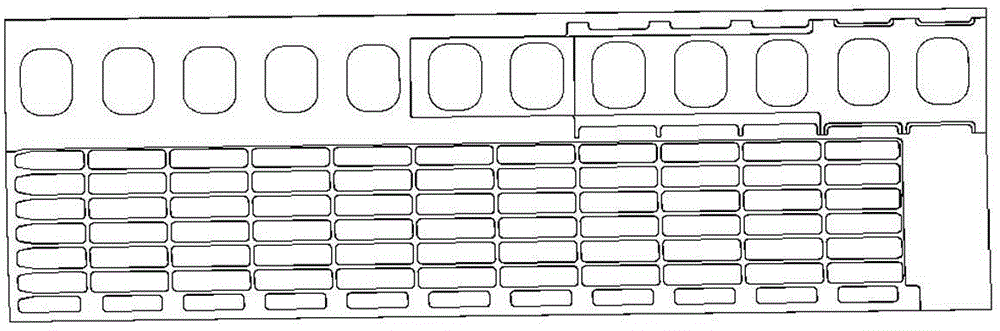

Aluminum alloy skin digital assembly method

InactiveCN104816837AImprove assembly efficiencyImprove assembly qualityAircraft assemblyButt jointEngineering

The invention relates to an aluminum alloy skin digital assembly method, and belongs to the field of aircraft manufacturing. In the prior art, when skin is assembled, the position is adjusted by workers according to experience, so that assembly accuracy is low; when the position of skin is not accurate, the skin and a framework will be staggered in shape, moreover, because of the shape error of the skin, riveting deformation is big, and the appearance of an aircraft body is poor; the quality of butt joints of the skin is poor; manual lineation is big in error and low in repeat accuracy and efficiency; when no tools are provided, allowance is polished manually on the site of riveting, the efficiency is low, the quality is poor, and the noise is high. According to the aluminum alloy skin digital assembly method, the digital technological lug positioning technology is adopted, skin can be clamped in place at a time, and repeated adjustment is not needed; besides technological lugs, the edges of the skin are net edges, and on-site allowance polishing is not needed; the assembly efficiency and the assembly quality can be greatly improved.

Owner:HARBIN

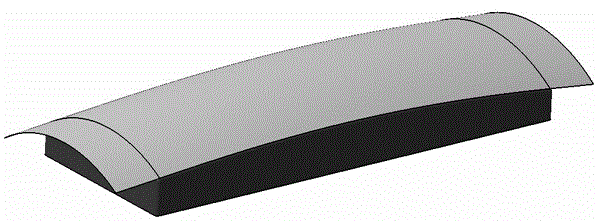

High rib aluminum alloy wallboard manufacturing method

ActiveCN106180247AGuaranteed preparation efficiencyGuaranteed manufacturing accuracySheets/panelsThick plateDouble curvature

The invention relates to the field of metal molding, in particular to a high rib aluminum alloy wallboard manufacturing method. Firstly, upper and lower multipoint molds are adopted to oppositely press an aluminum alloy plane thick plate to mold a needed curved surface shape; and then, a high-speed milling method is used for milling a needed rib structure on the curved surface thick plate in a processing path parallel to the curved surface, so that a designed high rib aluminum alloy wallboard is obtained. The method applies the characteristic of quick and adjustable reconstruction of profile surfaces of the multipoint molds, uses one set of multipoint molds for molding double-curvature aluminum alloy thick plate parts with different geometric shapes, different thicknesses and different materials, and can control the rebound in molding of the aluminum alloy thick plate through multiple times of correction so as to improve the molding precision; and the high rib aluminum alloy wallboard manufacturing method can obtain high-precision high rib aluminum alloy wallboard parts without damaging fiber structures of the aluminum alloy plate materials, guarantees the strength requirements of the wallboard parts, solves the technical difficulties in large aircraft manufacturing, and can be popularized and applied to manufacturing of such other parts as spacecrafts and rockets.

Owner:JILIN UNIV

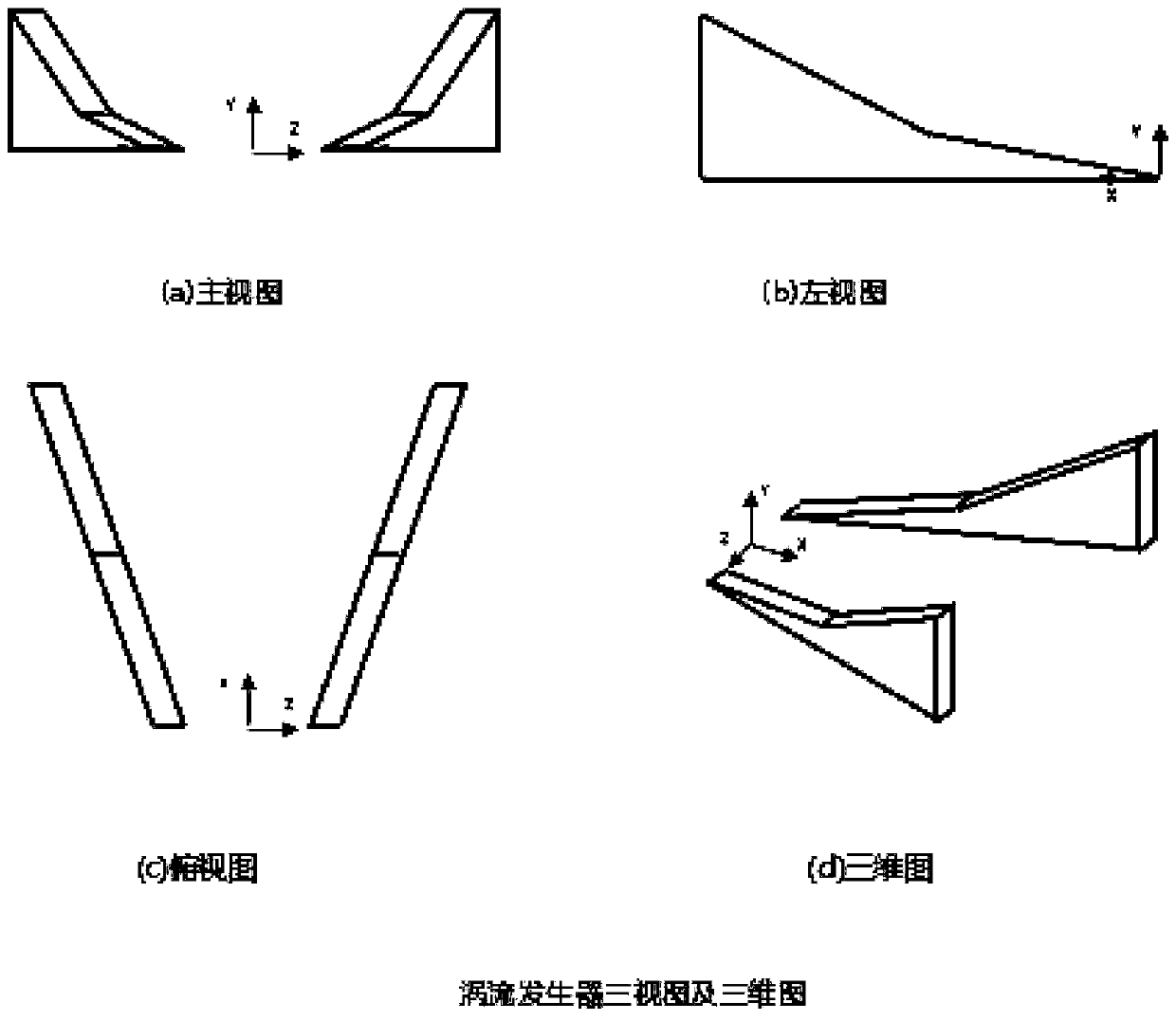

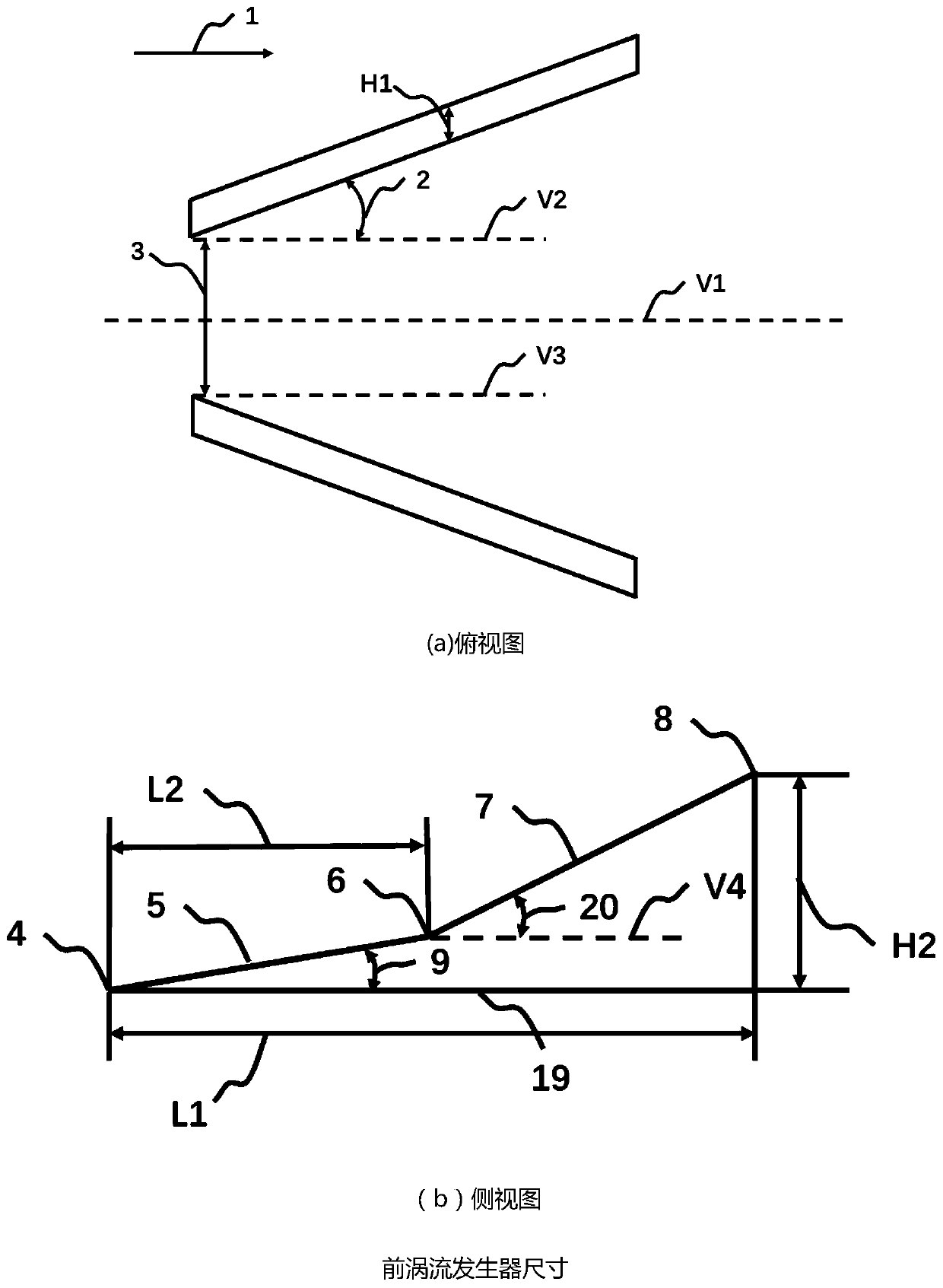

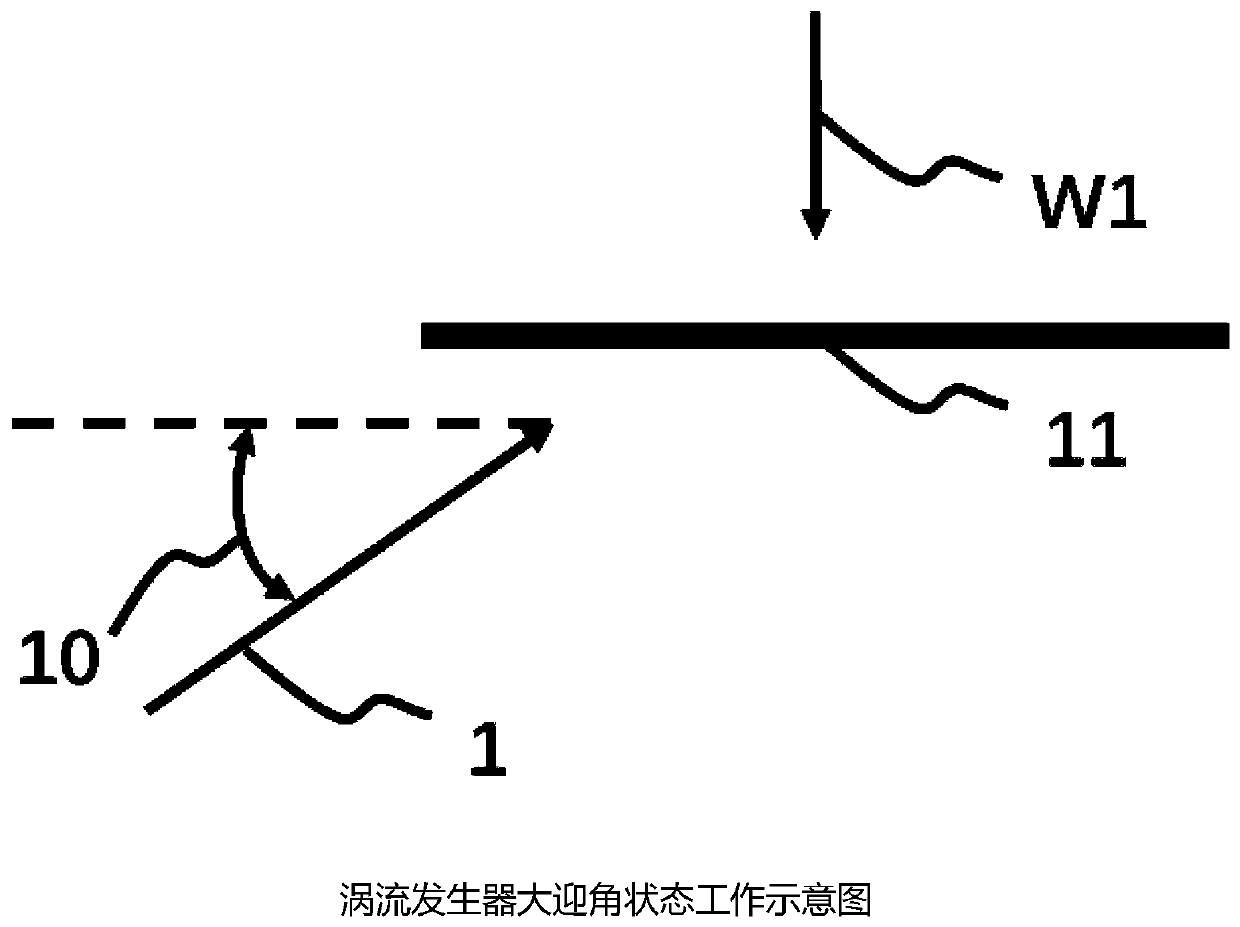

Vortex generator for reducing resistance of fuselage and delaying airflow separation

PendingCN110450942ATo achieve the purpose of drag reductionEasy to separateInfluencers by generating vorticesBoundary layer controlsFailure rateSingle chip

The embodiment of the invention discloses a vortex generator for reducing resistance of a fuselage and delaying airflow separation, and relate to the technical field of rotor aircraft manufacturing. According to the vortex generator, the passive control for the flowing of a flow field near the fuselage can be realized when a rotor aircraft encounters strong cross-wind or carries out side flight, so that the resistance of the rotor aircraft is reduced, and meanwhile, the implementation cost and the failure rate are reduced. The vortex generator provided by the invention comprises an installation angle (2) of the vortex generator, a first corner (9) of a single-chip vortex generator and a second corner (20) of the single-chip vortex generator, wherein a value of the installation angle (2) ofthe vortex generator is larger than or equal to 10 degrees and less than or equal to 45 degrees; the second corner (20) of the single-chip vortex generator is an included angle between an upper surface (7) of the second section and a connecting section (19) of the vortex generator and the object surface; a value of the first corner (9) of the single-chip vortex generator is less than 30 degrees;and a value of the second corner (20) is larger than or equal to 40 degrees and less than or equal to 60 degrees. The vortex generator is suitable for the passive control for the flow of the flow field near the fuselage when the rotor aircraft encounters the strong cross-wind or carries out side flight.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

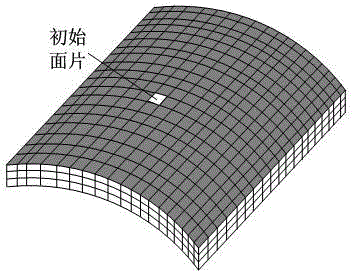

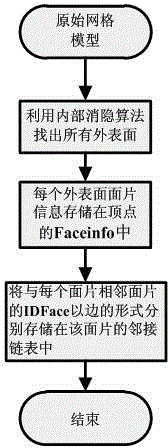

Skin roll-bending part sectional curvature analysis method

InactiveCN104392053AImprove developmentRealize automatic calculation and analysisSpecial data processing applicationsAviationAnalysis method

The invention relates to the technical field of aviation aircraft manufacturing, in particular to a skin roll-bending part sectional curvature analysis method. The method includes: treating digital-analog discrete grids of a skin roll-bending part, and rapidly obtaining a part datum plane by a part grid surface segmentation method; then, generating and automatically connecting part section segments so as to obtain a part section characteristic curve; finally, subjecting the section characteristic curve to curvature analysis so as to obtain curvature information of the roll-bending part. The skin roll-bending part sectional curvature analysis method has the advantages that the method is a rapid part curvature analysis method, can be convenient for development of independent programs and can achieve automatic computational analysis of part section information; workload of workers can be reduced, technology analysis efficiency can be improved greatly and errors caused by man-made faults can be decreased.

Owner:JIANGXI HONGDU AVIATION IND GRP

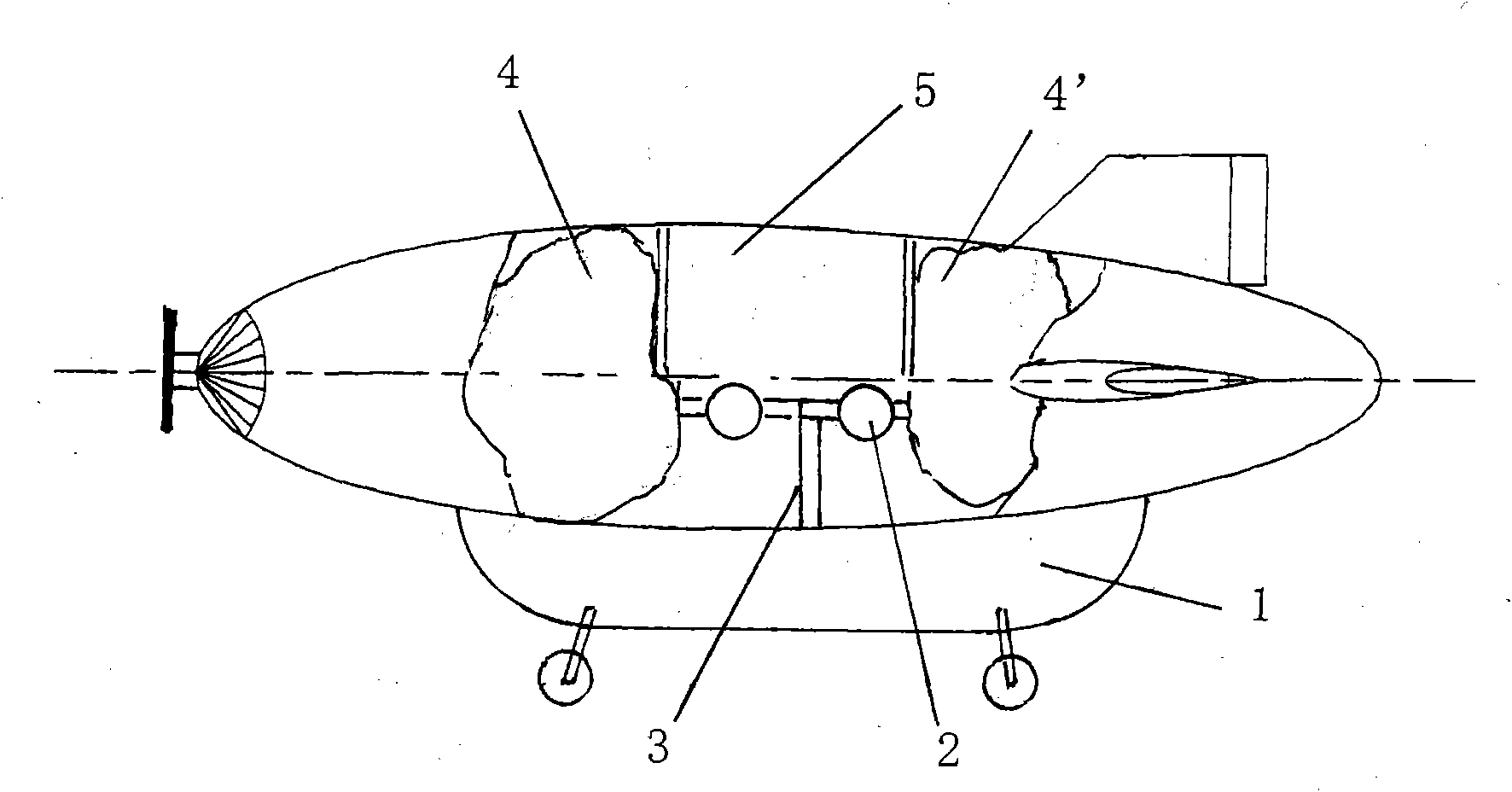

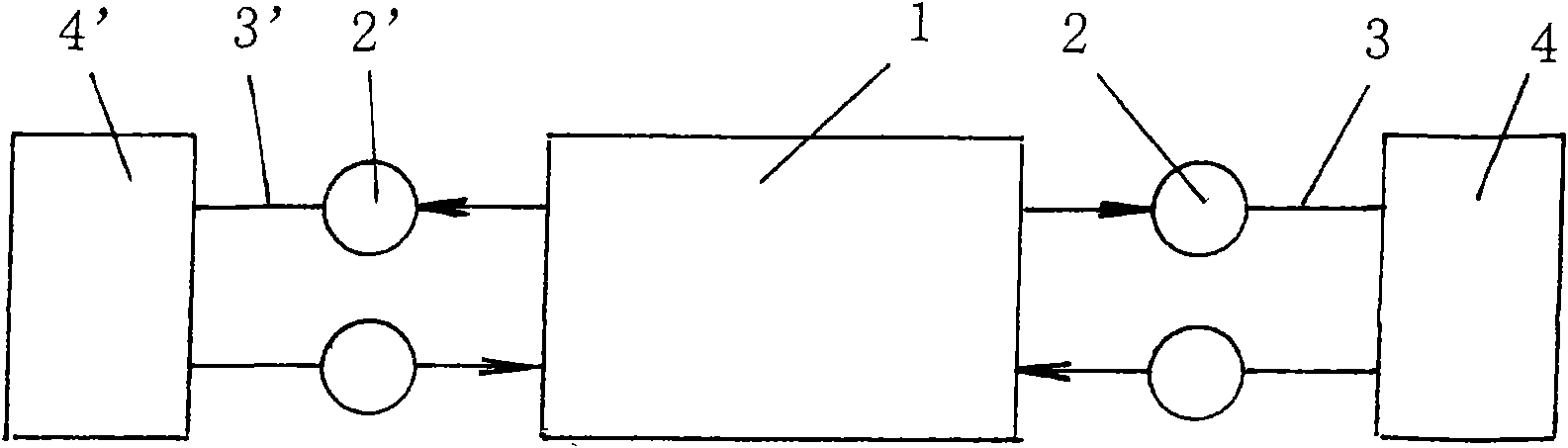

Inflation airship

InactiveCN101885378ASimple structureIncrease in sizeGas-bag arrangementsVacuum pumpingAir compression

The invention belongs to the technical field of aircraft manufacturing, and relates to an inflation airship. The inflatable airship is characterized in that a plurality of buoyancy lift air bags are sequentially connected with an inflation and deflation control device and an air storage cabin through pipelines; and the inflation and deflation control device comprises a sealing valve and an air compression pump or a vacuum-pumping pump or a combination thereof. The inflation airship has the advantages that: the structure of the airship is simple, the flow direction of helium gas can be controlled by hands or electronic switching programs with convenient operation, the expansive helium gas transfers between the air storage cabin and the buoyancy lift air bags without external leakage, and the running cost is low. When the helium gas in the air storage cabin transfers to the buoyancy lift air bags through the sealing valve and the inflation and deflation control device, the volume of the air bags is increased, the buoyancy is increased, and the airship ascends; and otherwise, the helium gas in the buoyancy lift air bags transfers to the air storage cabin, the volume of the buoyancy lift air bags is reduced, the buoyancy is reduced, and the airship descends. The inflation airship also can be used in rural areas with poor road conditions, and when meeting barriers or swamps in the direction of forward motion, the inflation airship can bypass roadblocks through levitation and continue to land and go forward.

Owner:张朝林

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com