S-section sag-free aircraft frame and rib sheet metal part springback compensation calculation method

A technology of springback compensation and sheet metal parts, which is applied in the field of springback compensation calculation of S-section non-sagging aircraft frame rib sheet metal parts, which can solve problems such as wrinkling, cracking, and affecting the forming quality of frame rib parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0038] Example: see Figure 1 to Figure 13 .

[0039] A calculation method for springback compensation of an S-section non-sagging aircraft frame rib type sheet metal part, the method steps are as follows:

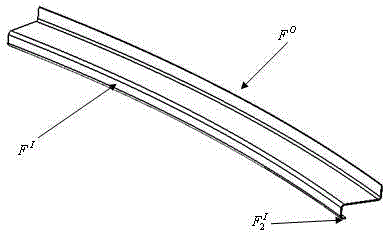

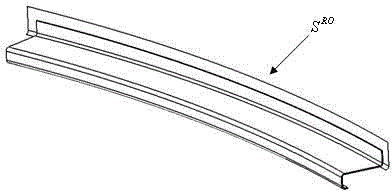

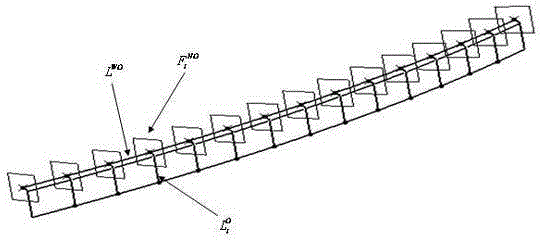

[0040] Step 1: Flange F based on the outer edge of the part O The established flange expansion surface S RO , at S RO Based on the springback compensation calculation, the outer surface is reconstructed. The specific steps are as follows:

[0041] Step a: Extract the flange F of the outer edge of the part O Fillet S of RA and flanged face S RF Constitute the outer edge of the flange flange surface S O ; extract S O Boundary line of flange area L OU , place the outer surface of the flange along the boundary line L of the flange area OU Extend 10-15mm to form the extended surface S of the outer flange of the part O' ;Extract the extension surface S of the outer edge flange O' end border line will extend the surface S 1 O along Extend outward by 10-15mm re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com