Patents

Literature

1072 results about "Metal forming" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

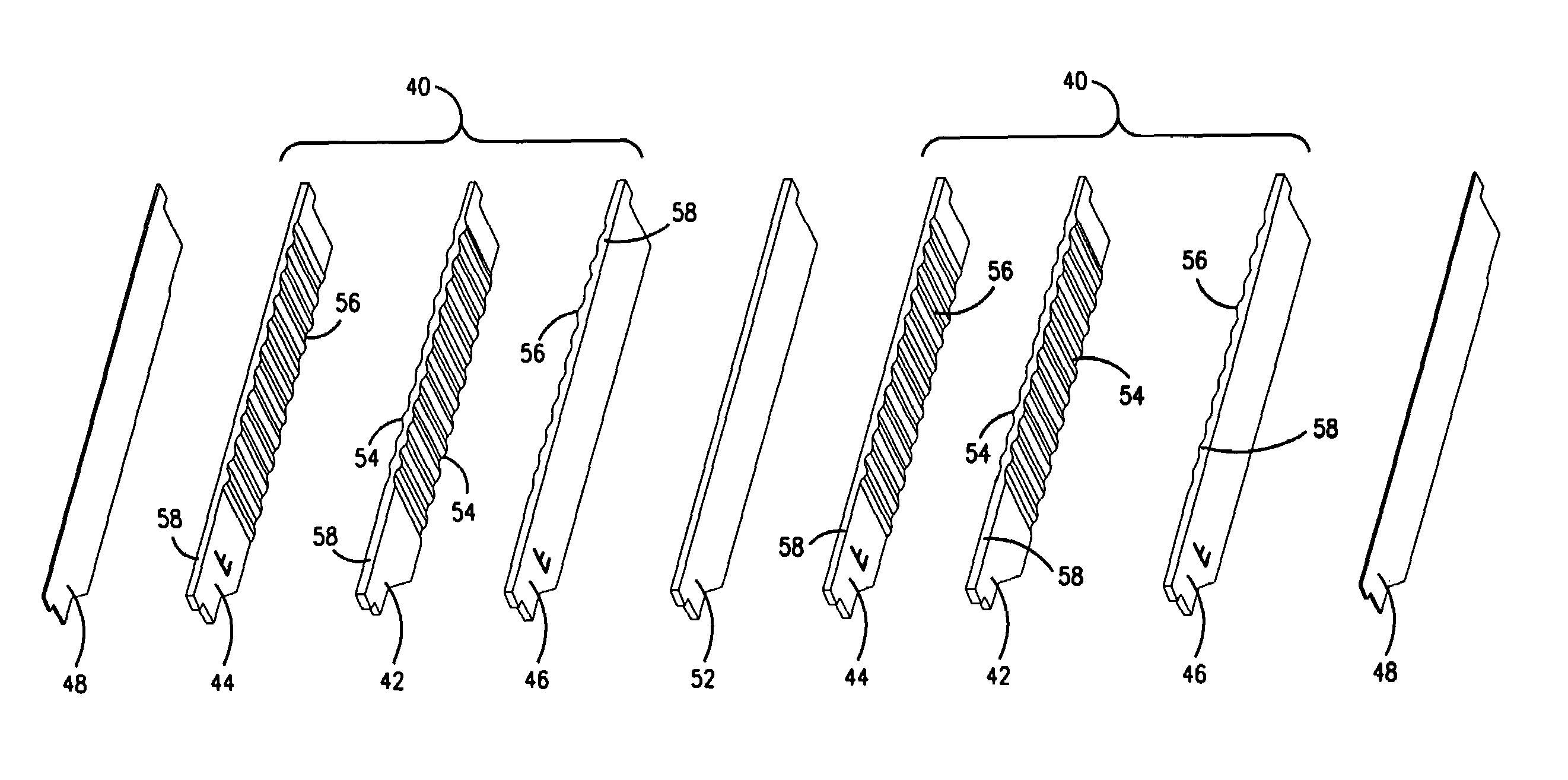

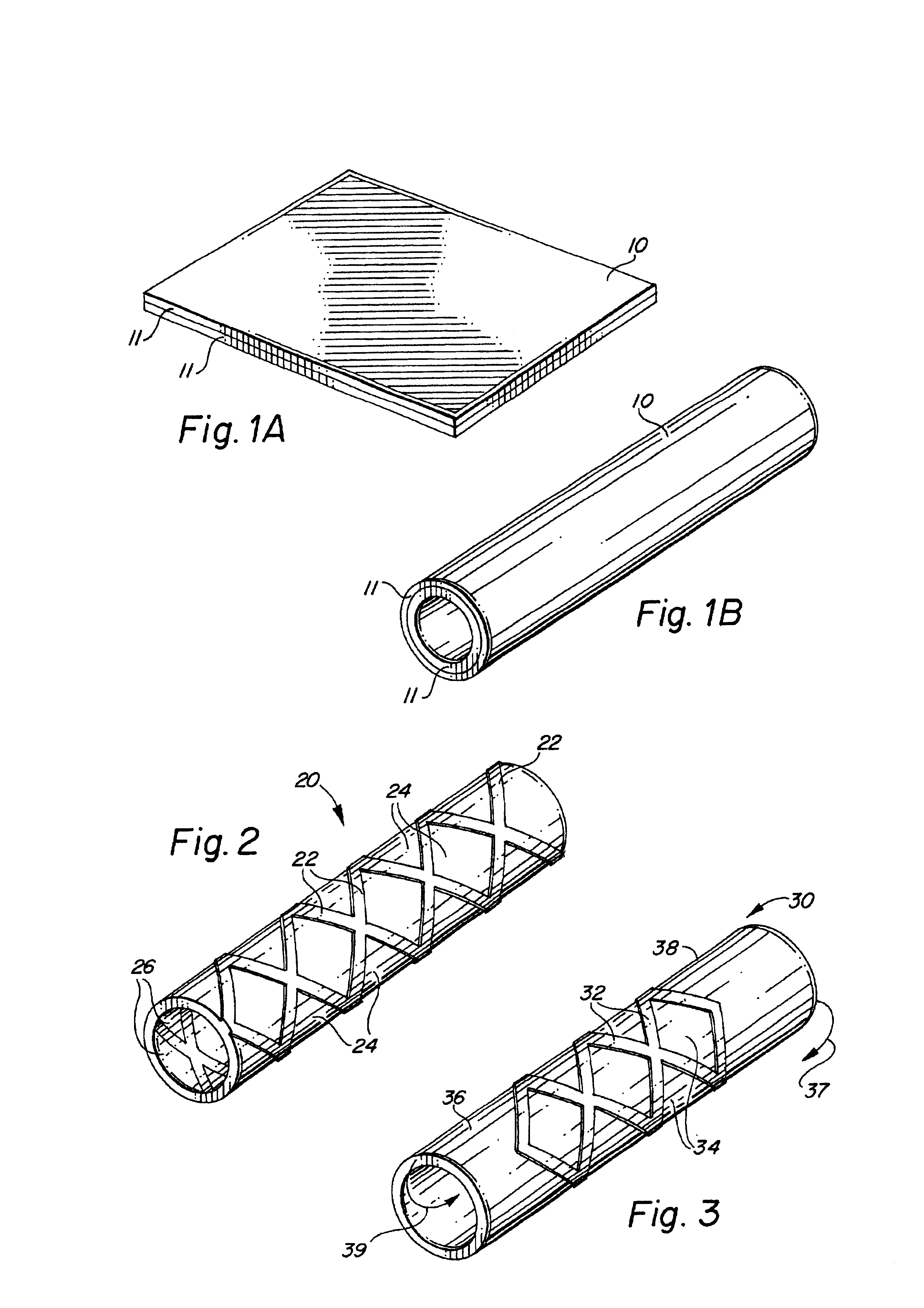

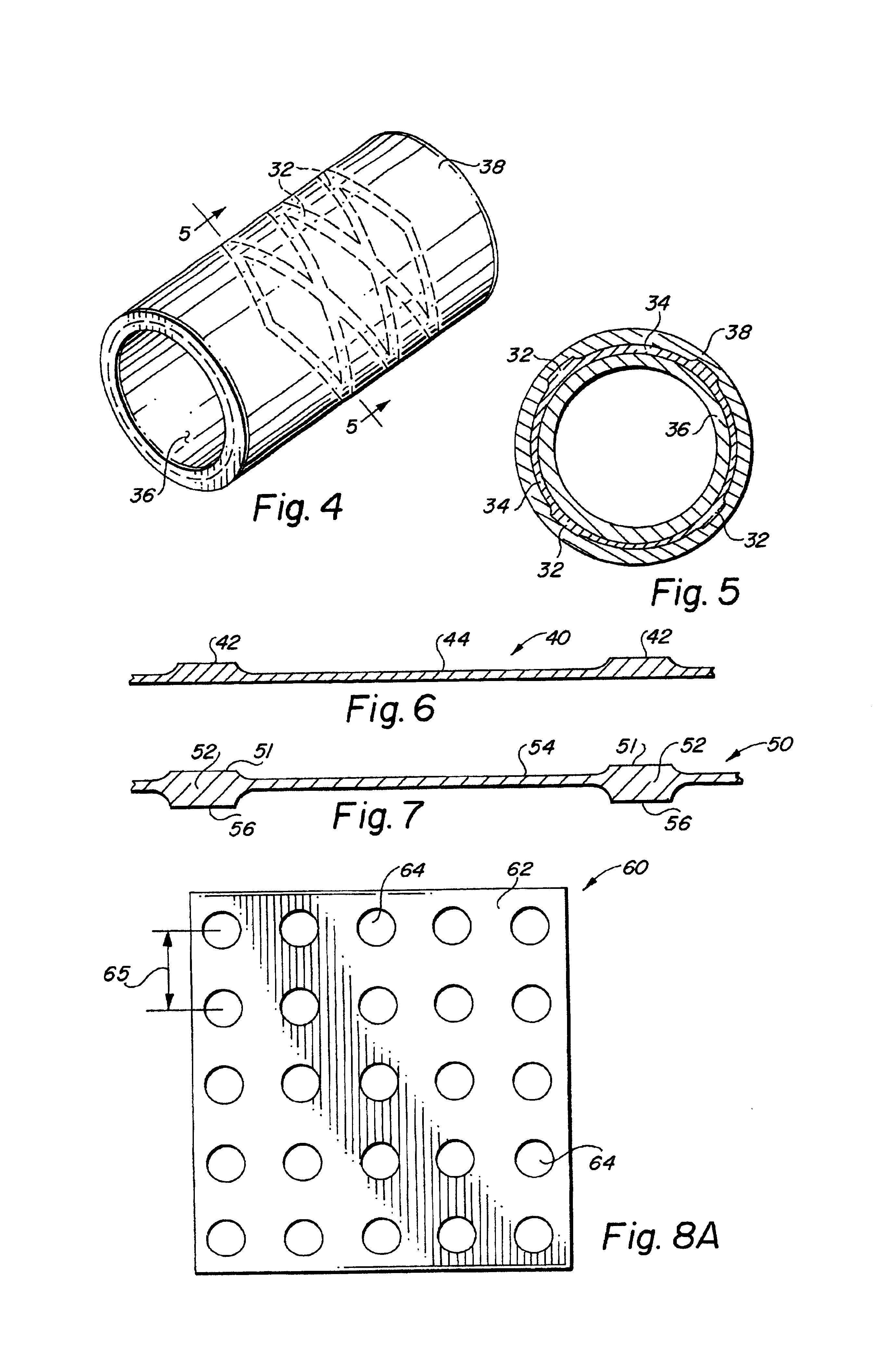

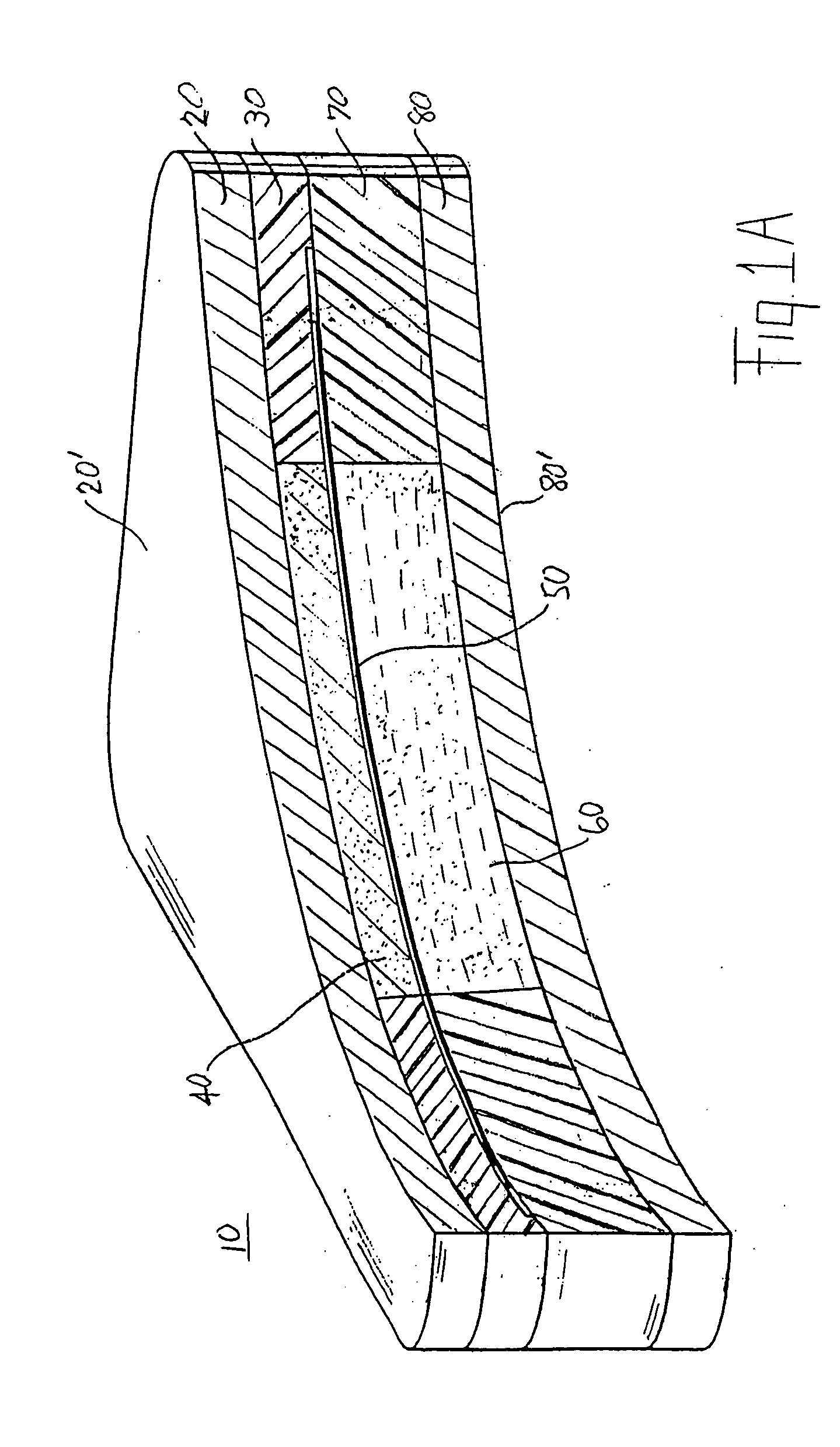

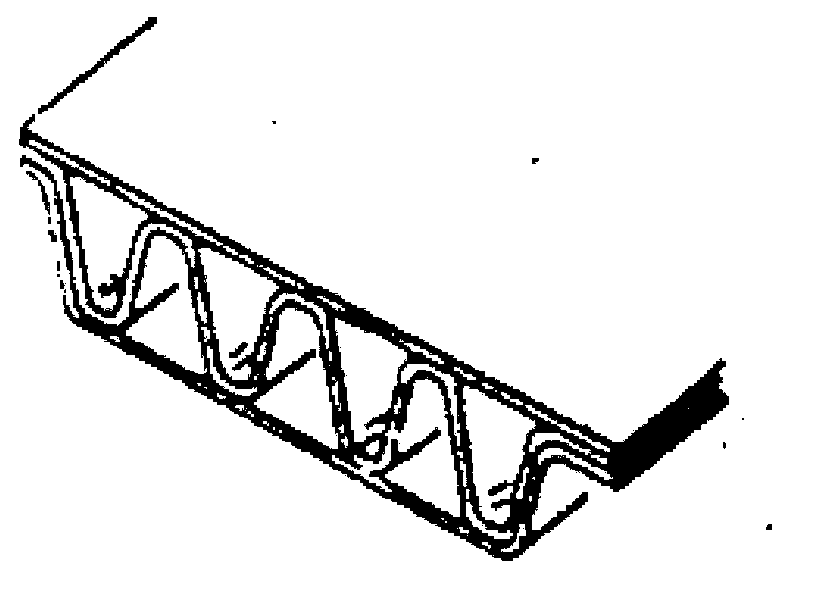

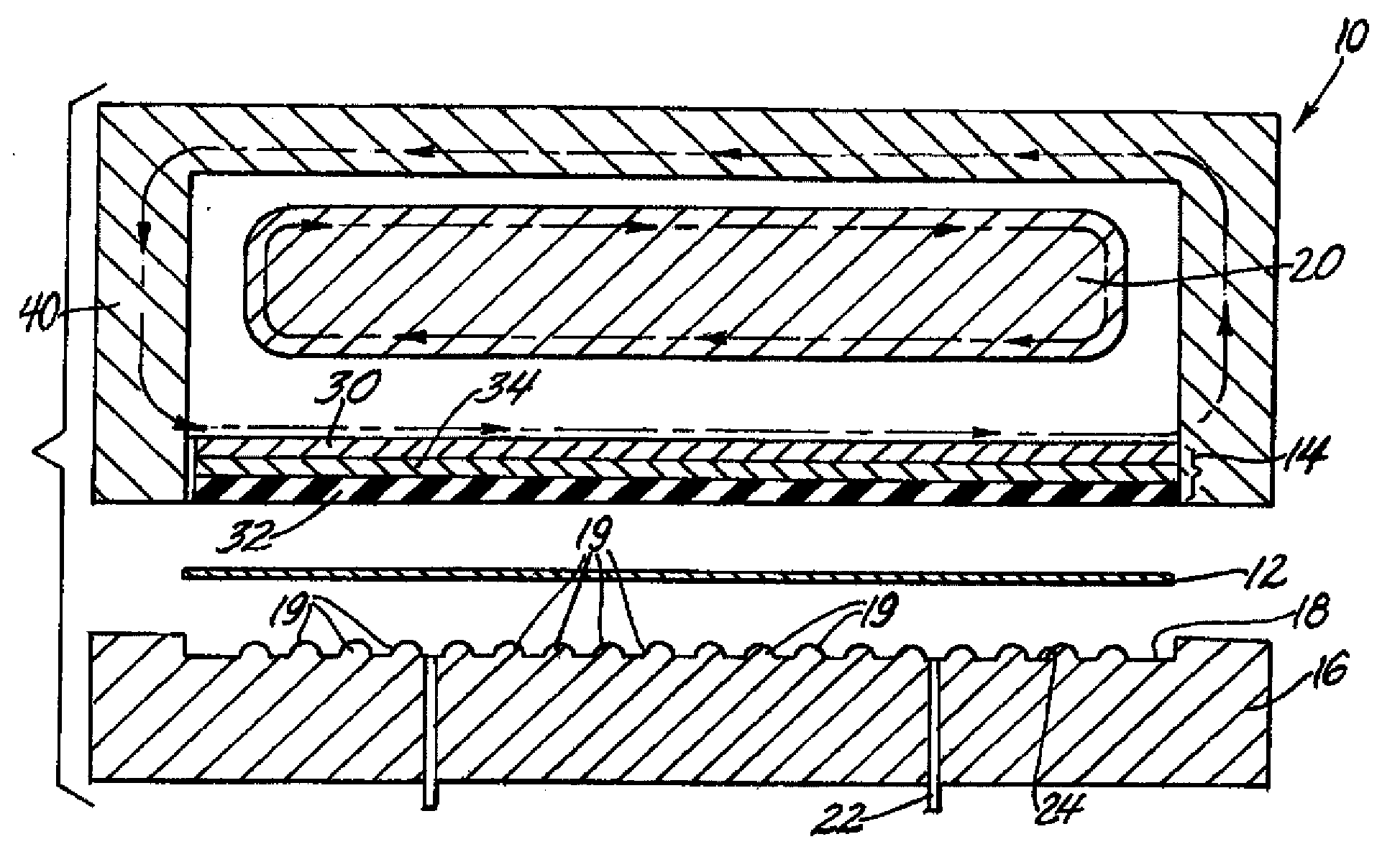

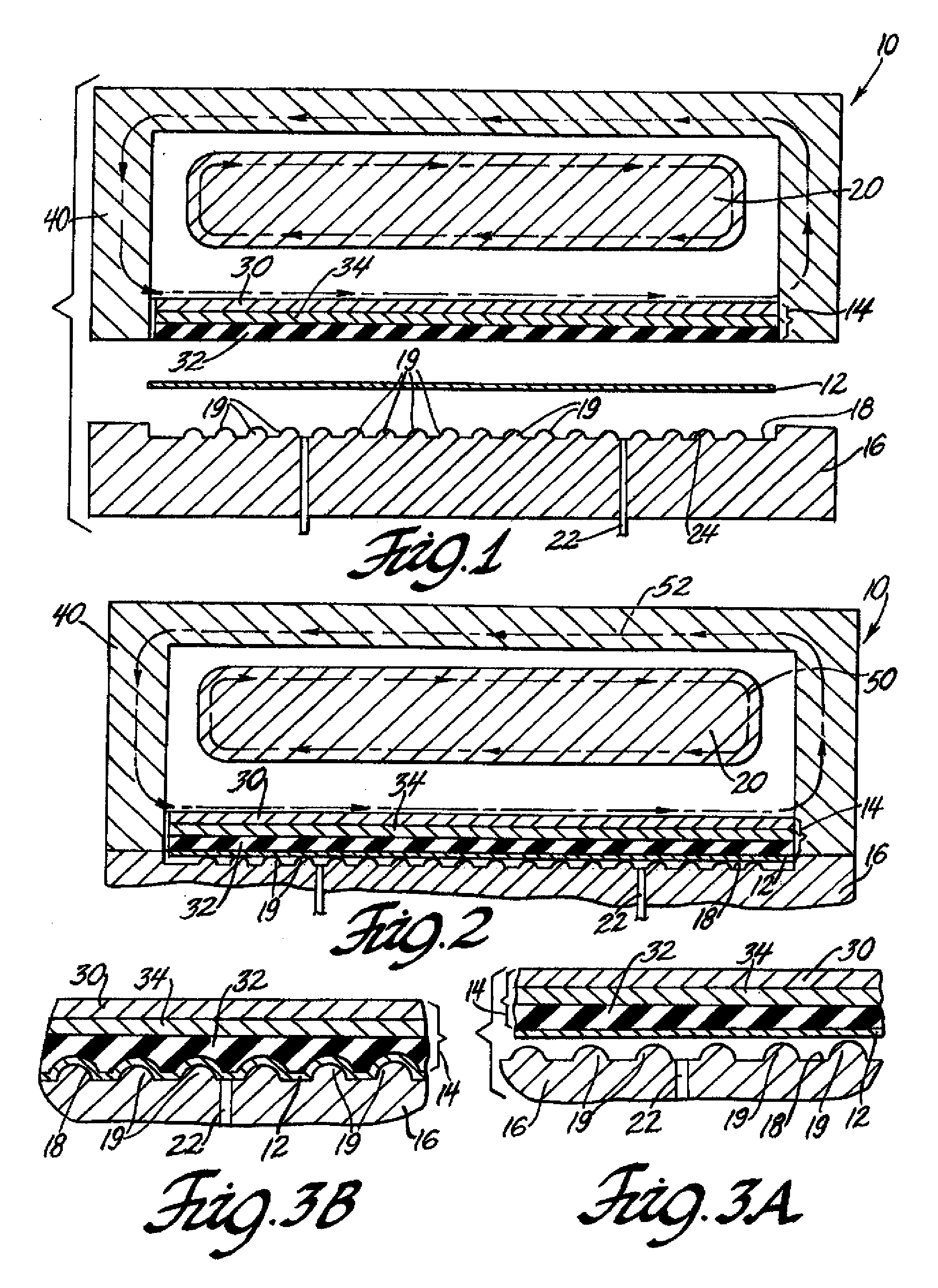

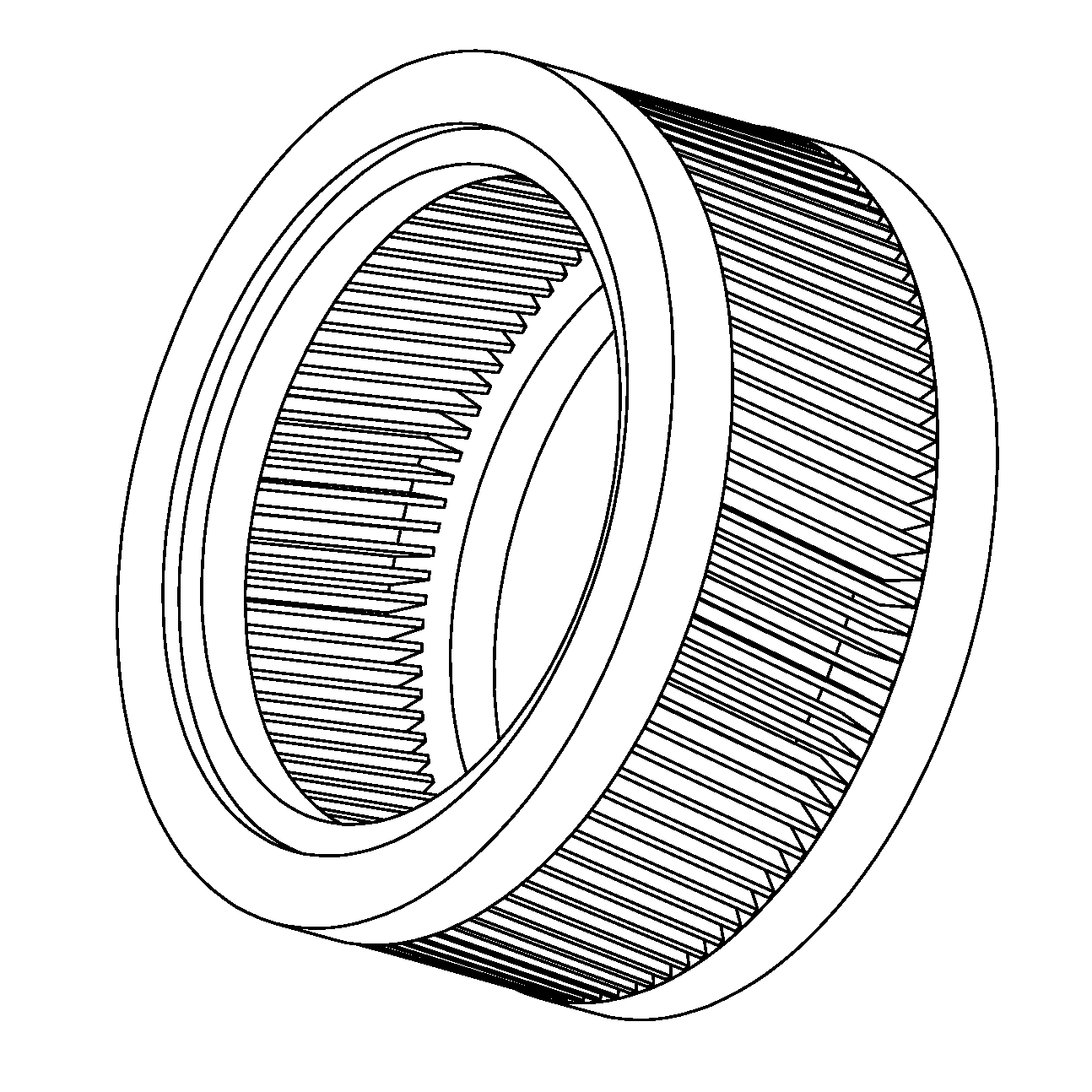

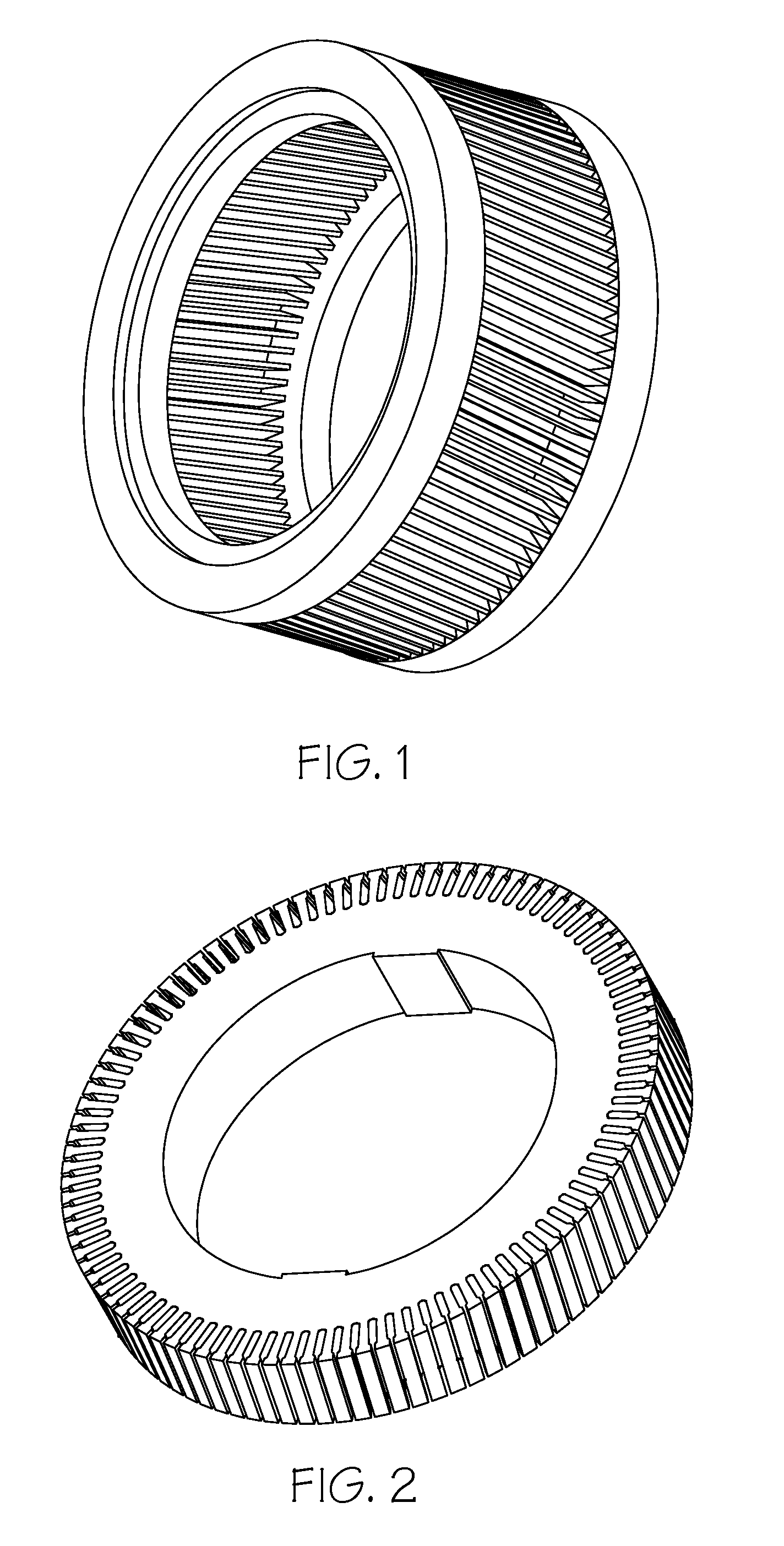

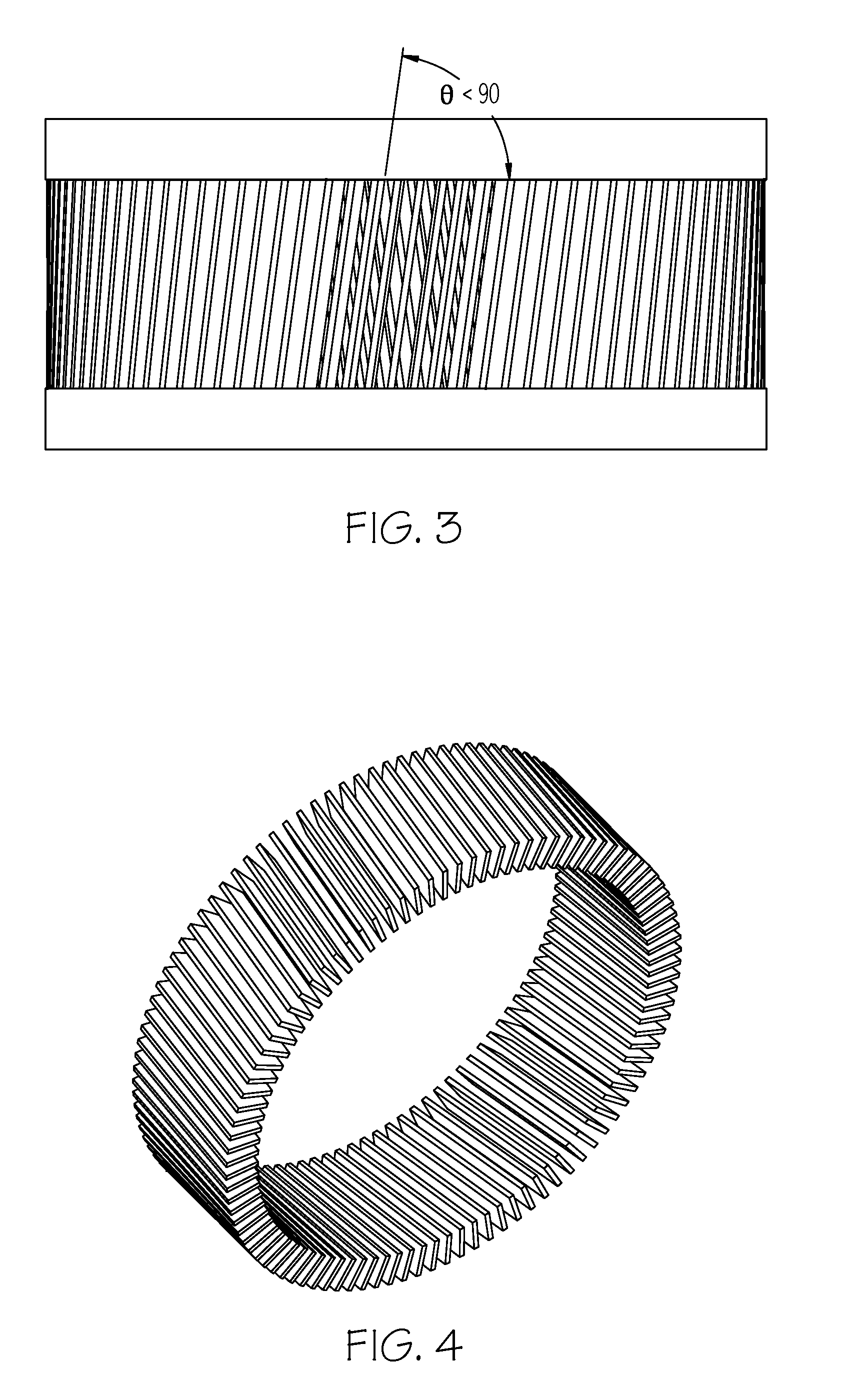

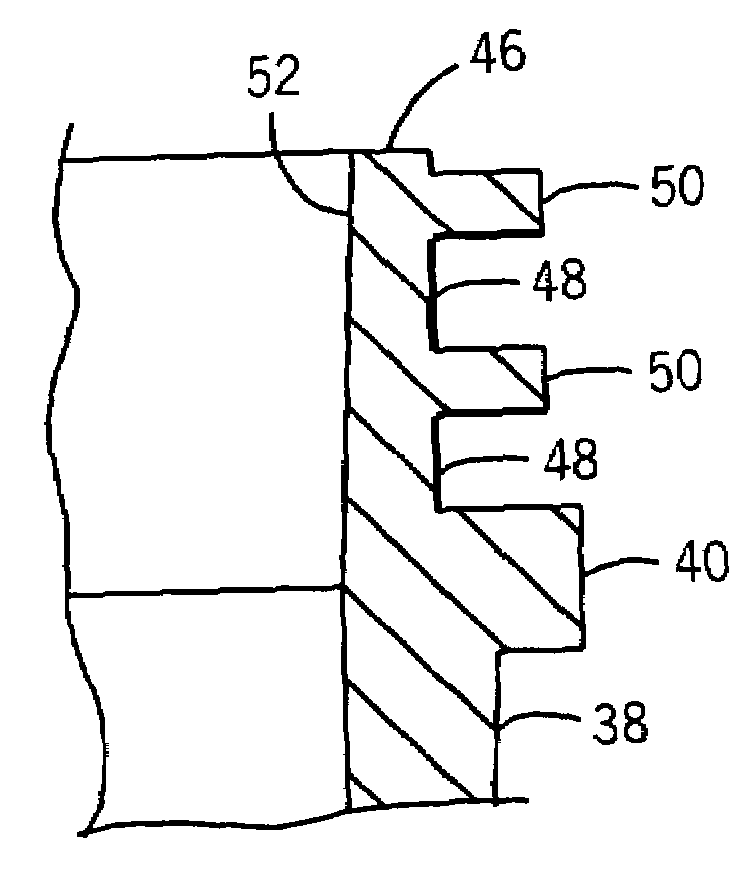

Metal-forming die and method for manufacturing same

InactiveUS7086267B2Good flexibilityIncrease flexibilitySuture equipmentsShaping toolsMetal formingEngineering

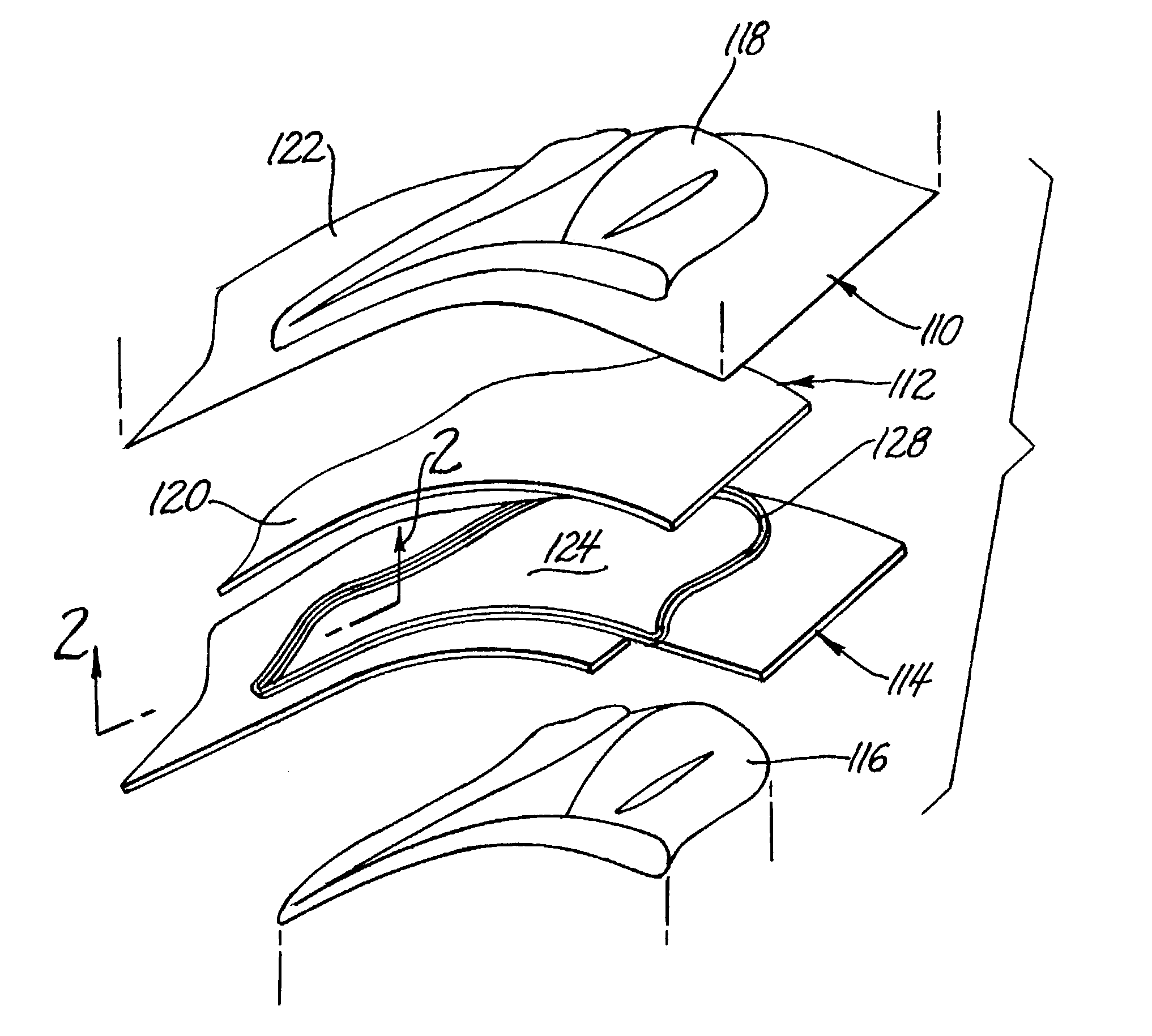

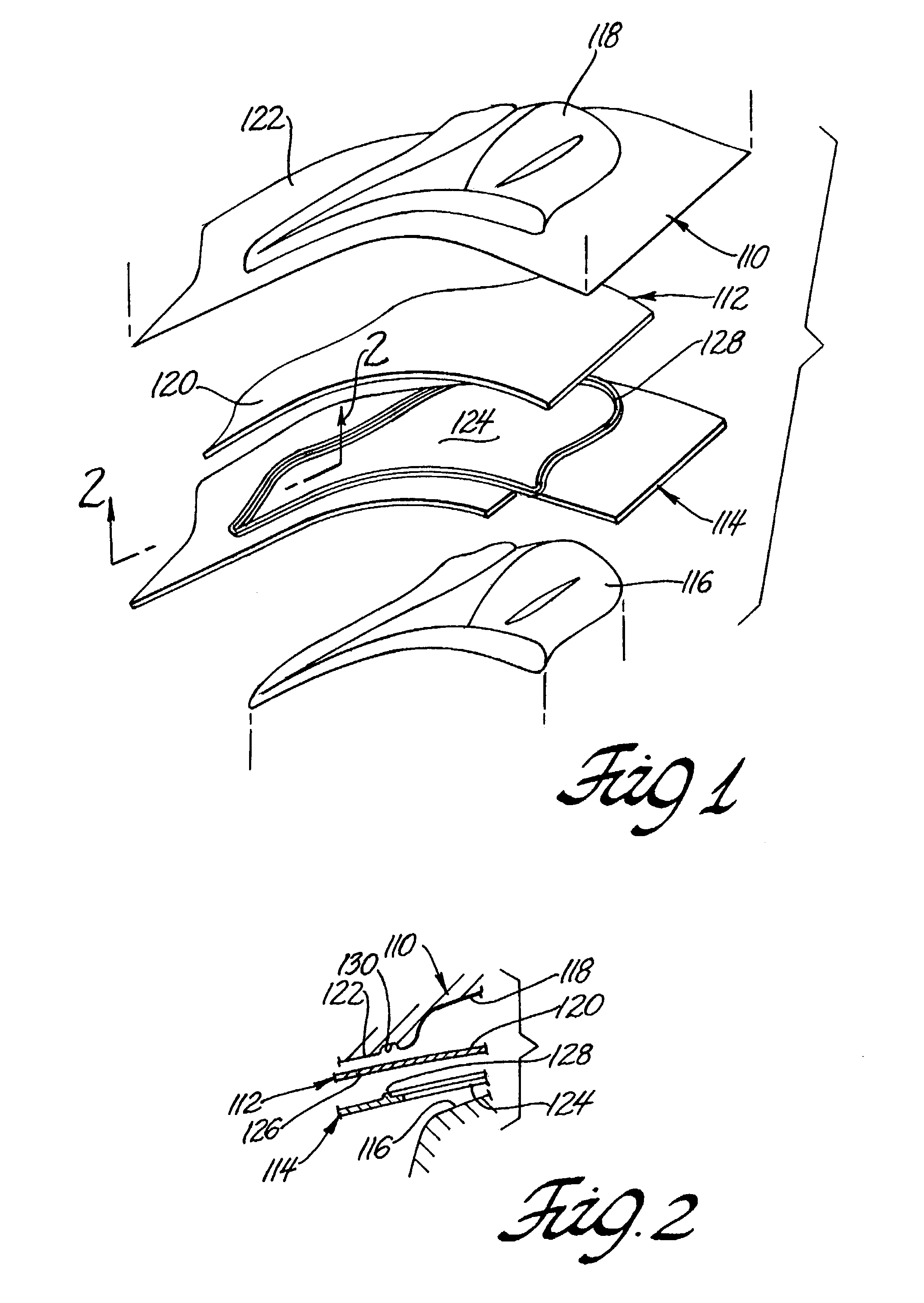

A metal-forming die according to the present invention includes die blades with convoluted opposed side surfaces that correspond to variable-width features on the working surface of the die. The convoluted side surfaces and variable-width working surface features permit the impression left by one die blade to fill space taken from an impression made by a laterally adjacent die blade. Such a die permits formation of working surface shapes not possible with flat-sided die components. The die is manufactured in discrete longitudinally extending components, or blades. Dividing the working surface of the die into longitudinally extending portions, each carried by a die blade allows conventional machining processes to be employed in forming the working surface on each die blade. An additional machining process cuts complementary shapes on the sides of the die blades. The die blades and their corresponding working surfaces interfit, or nest together.

Owner:FR W DWORAK

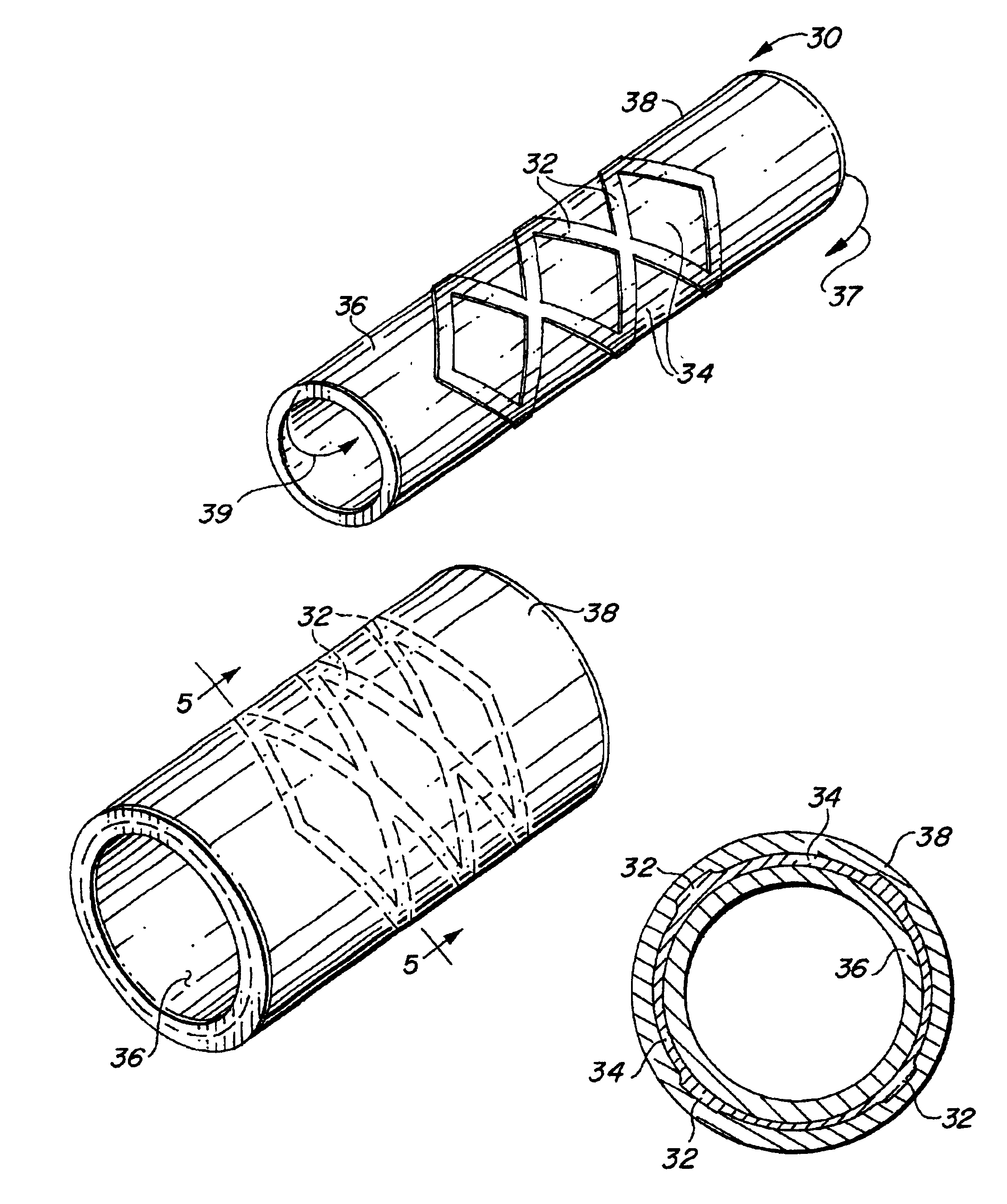

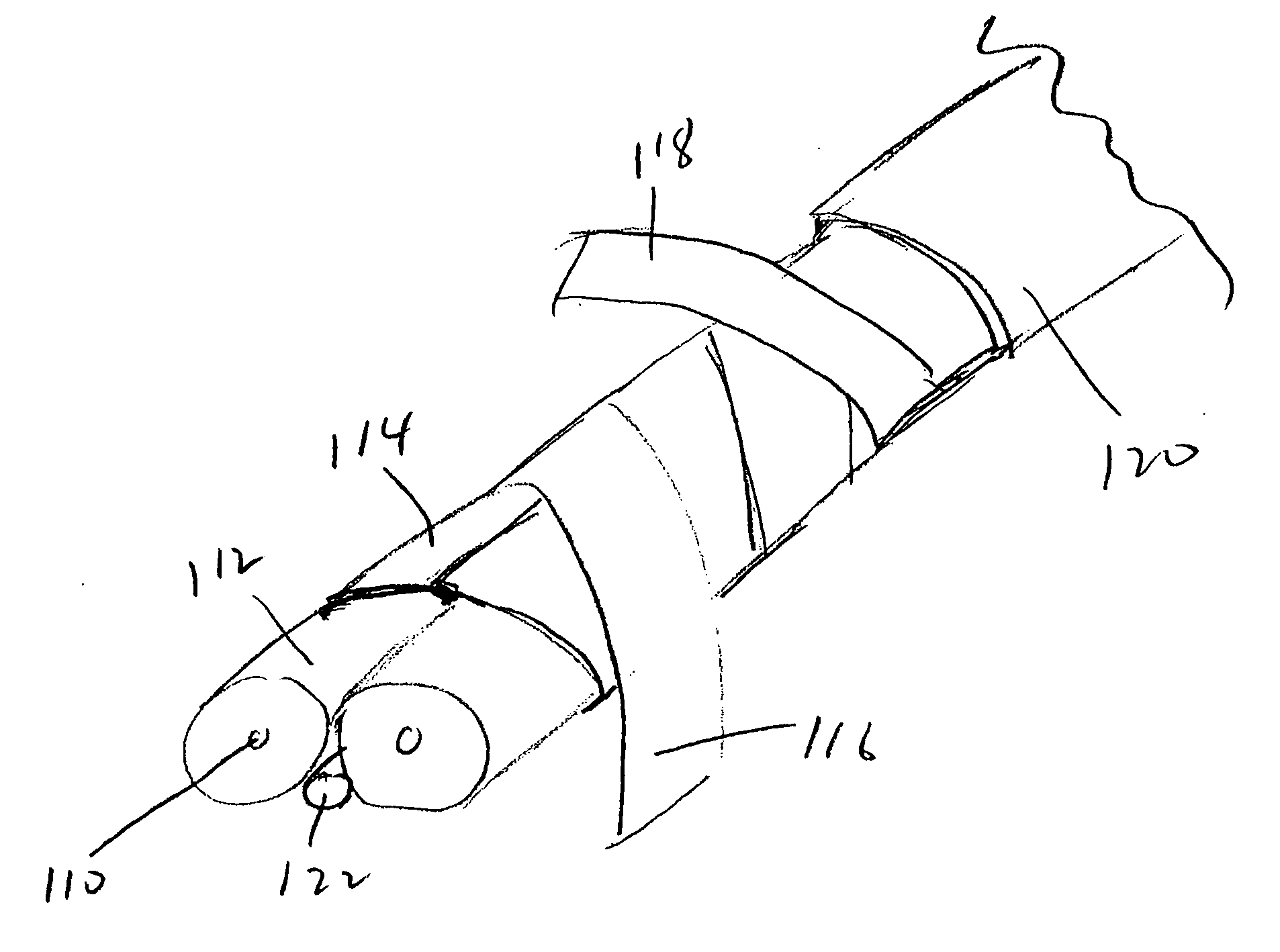

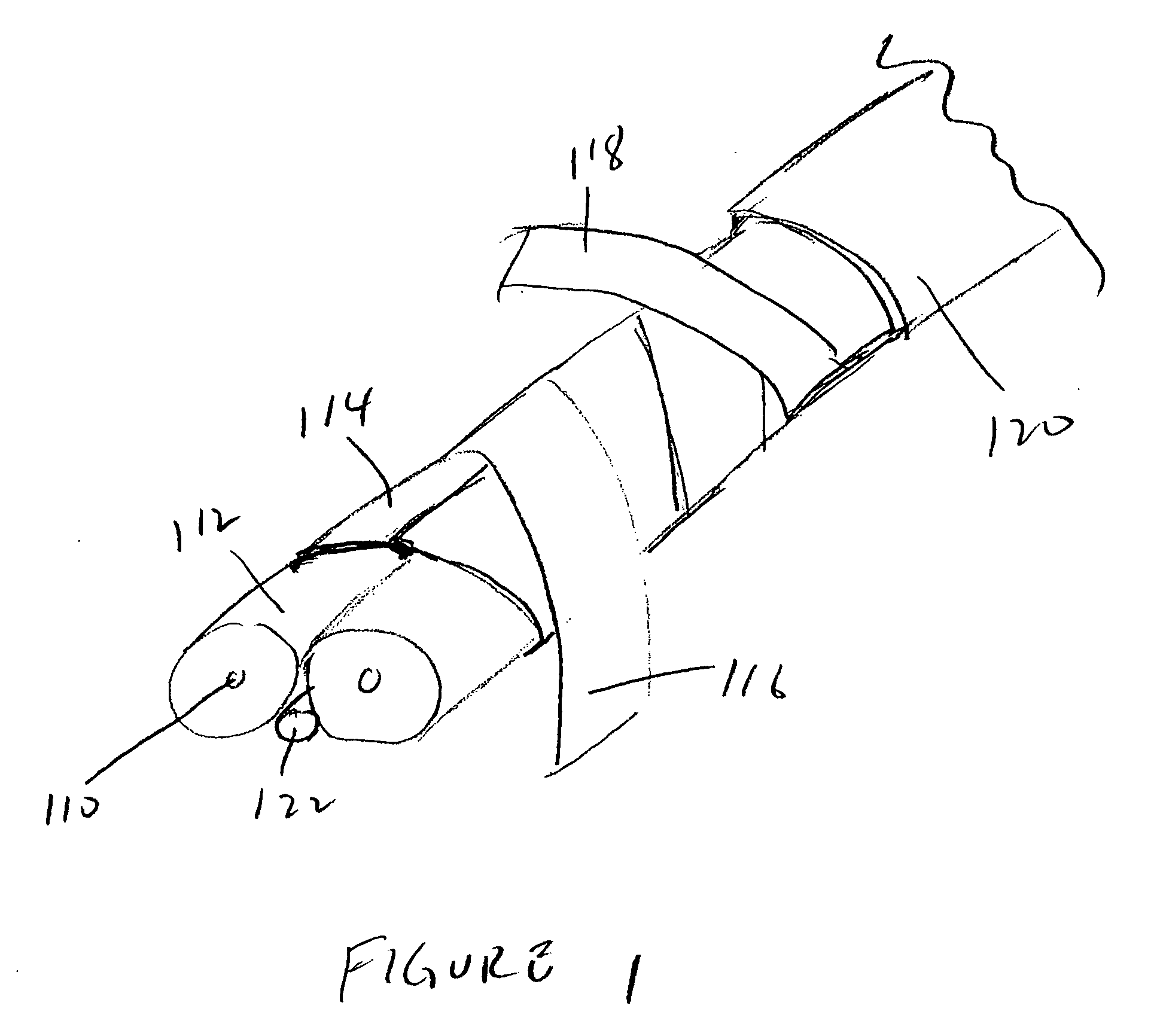

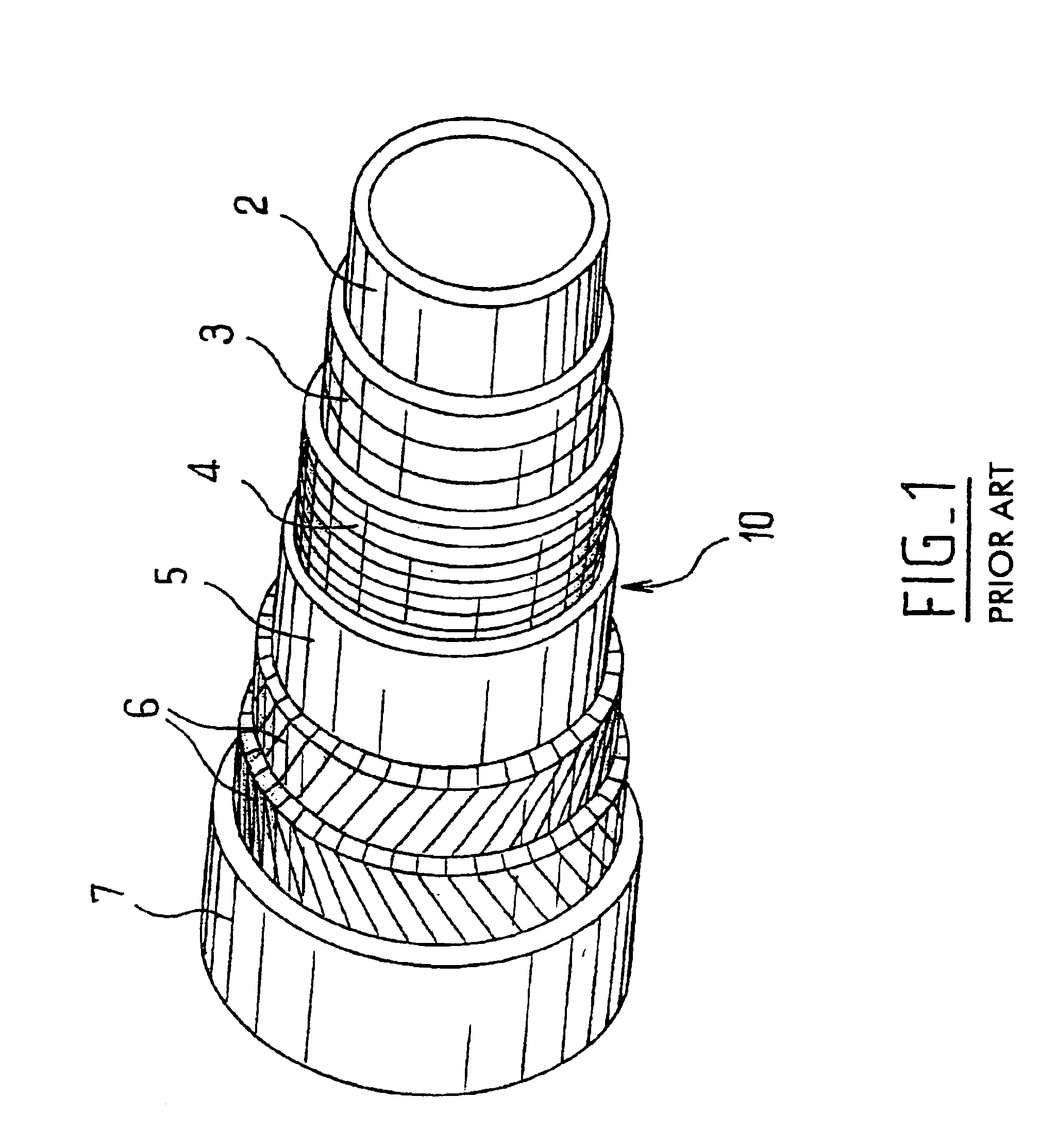

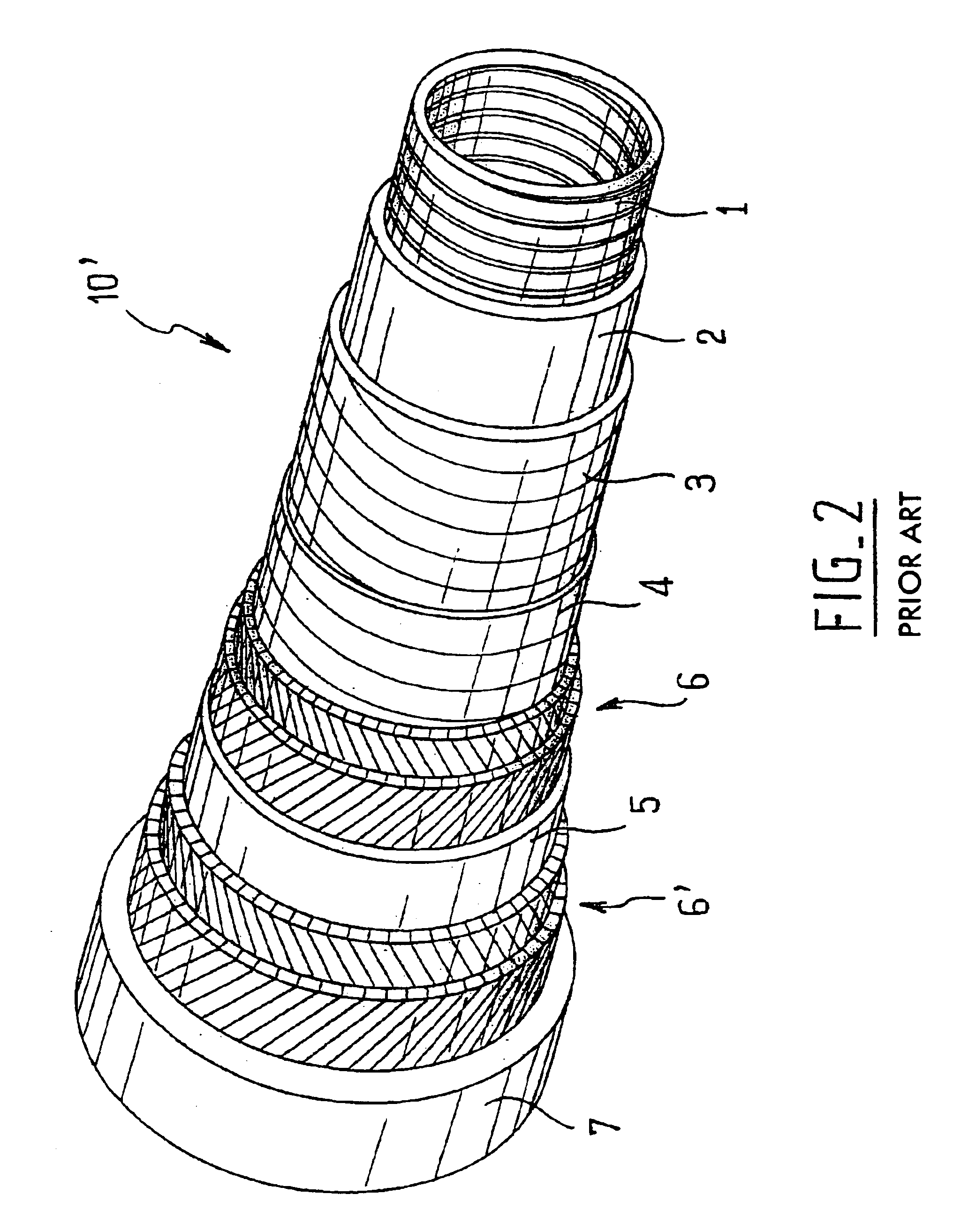

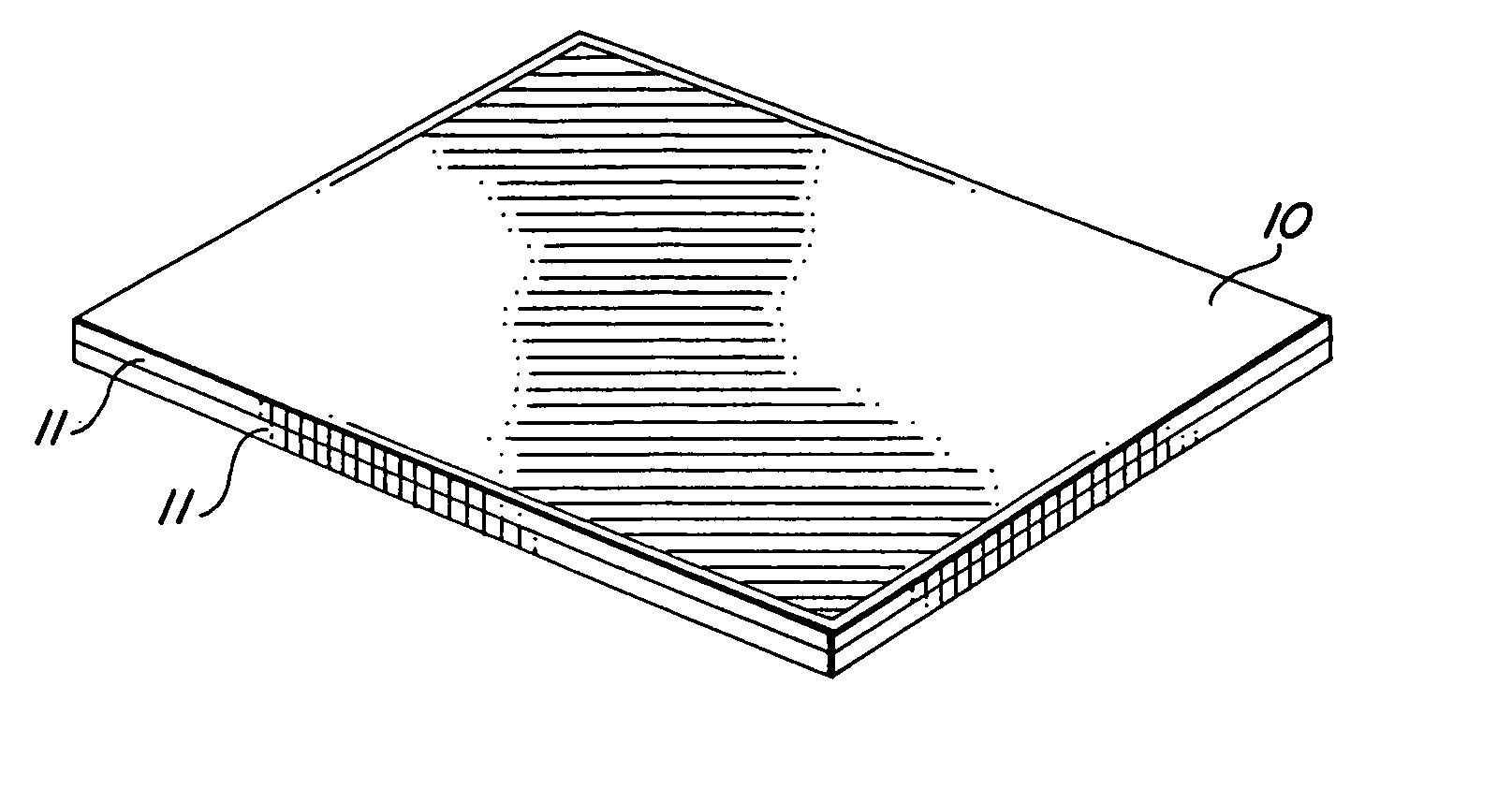

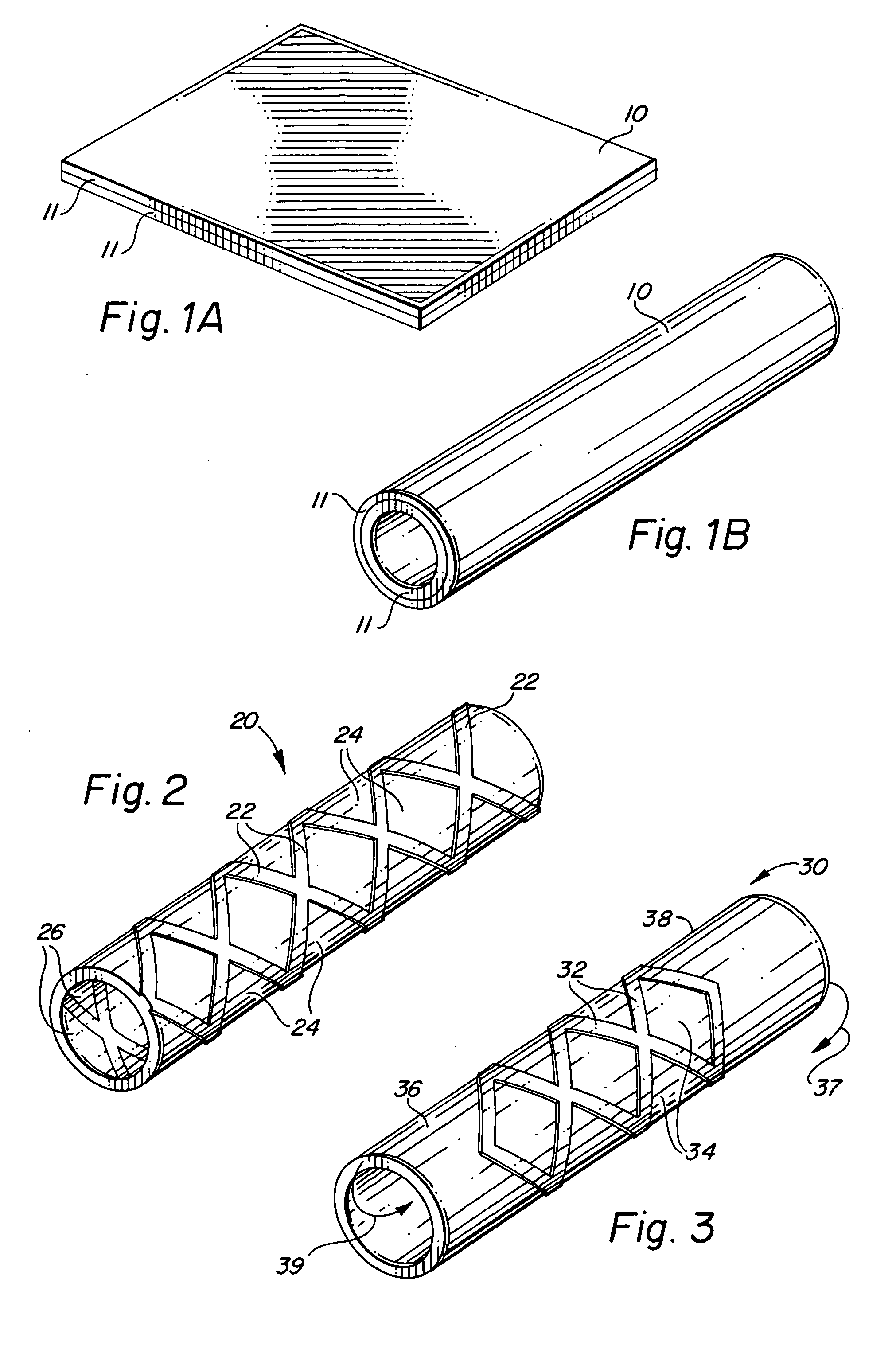

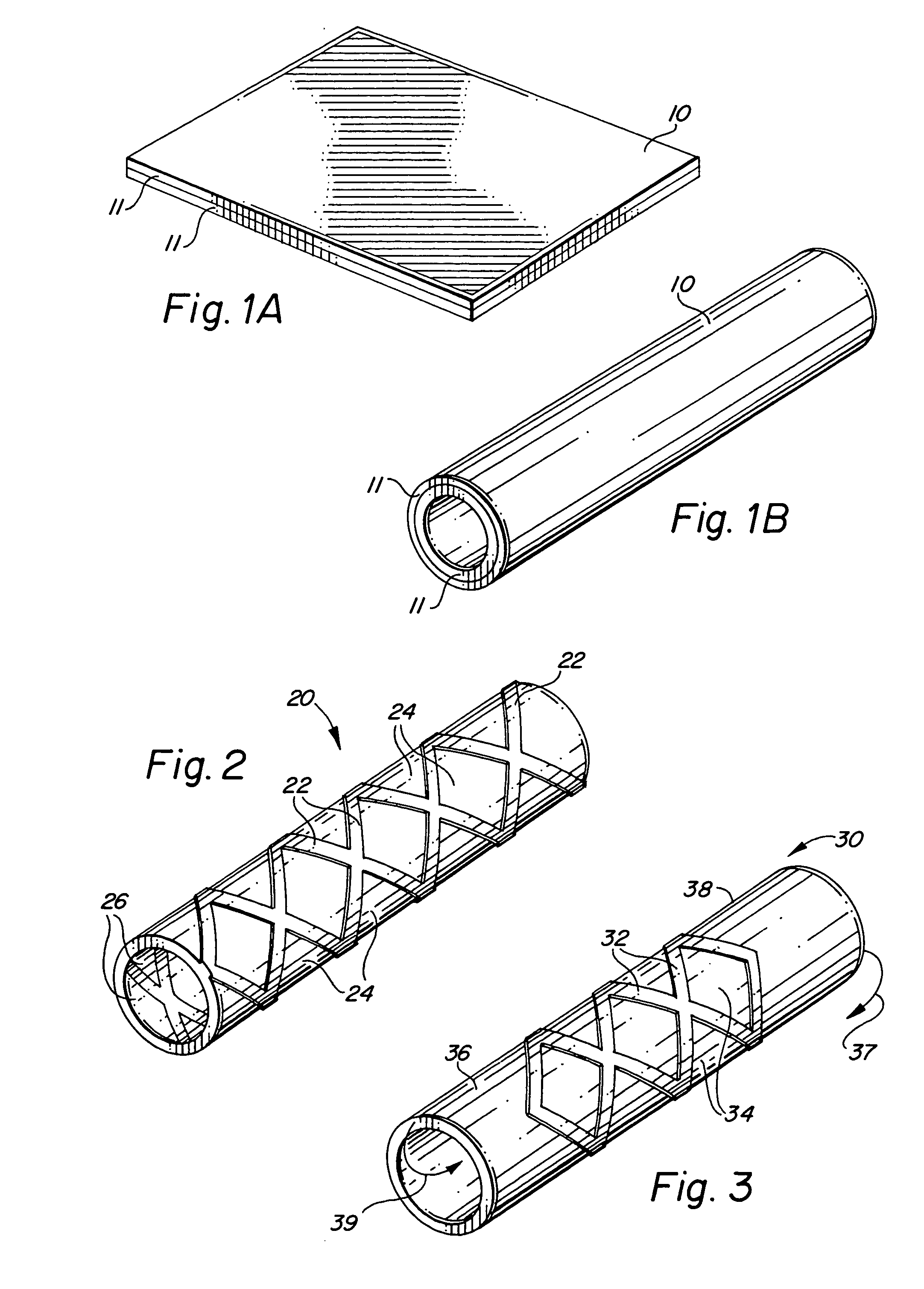

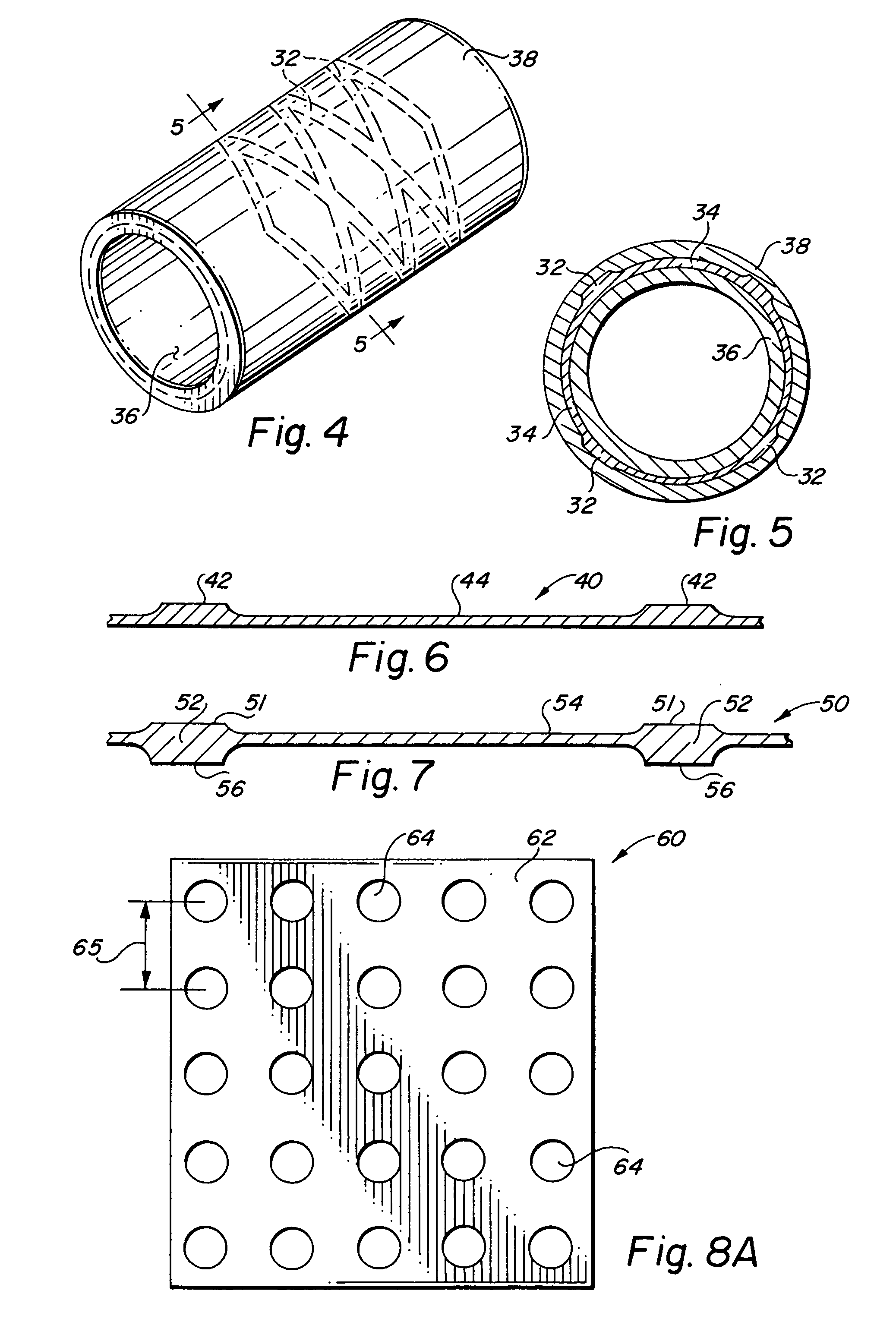

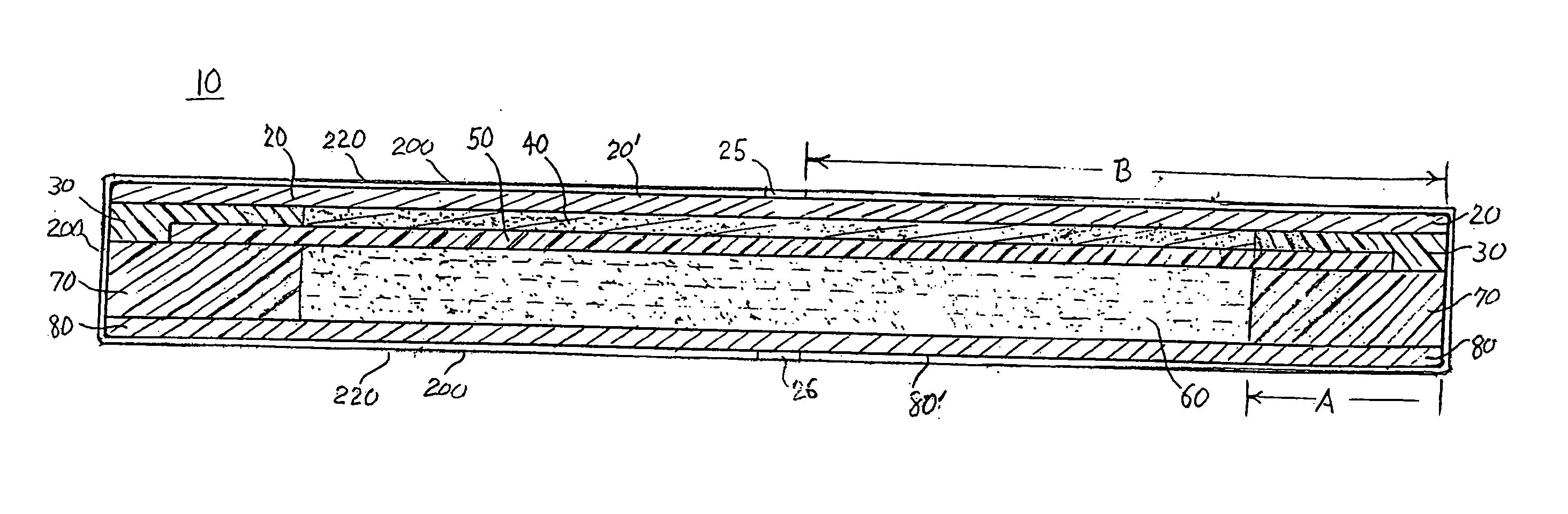

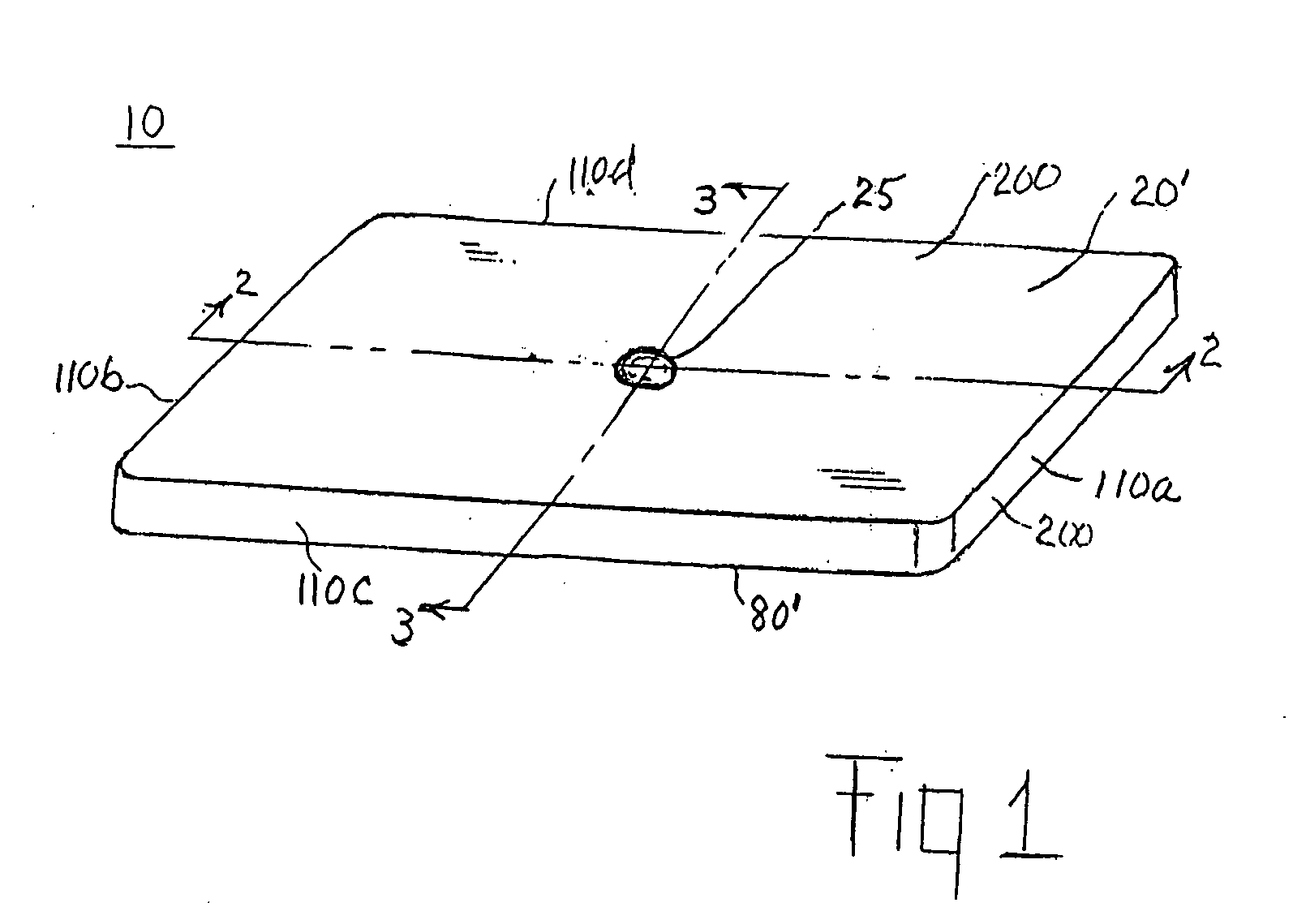

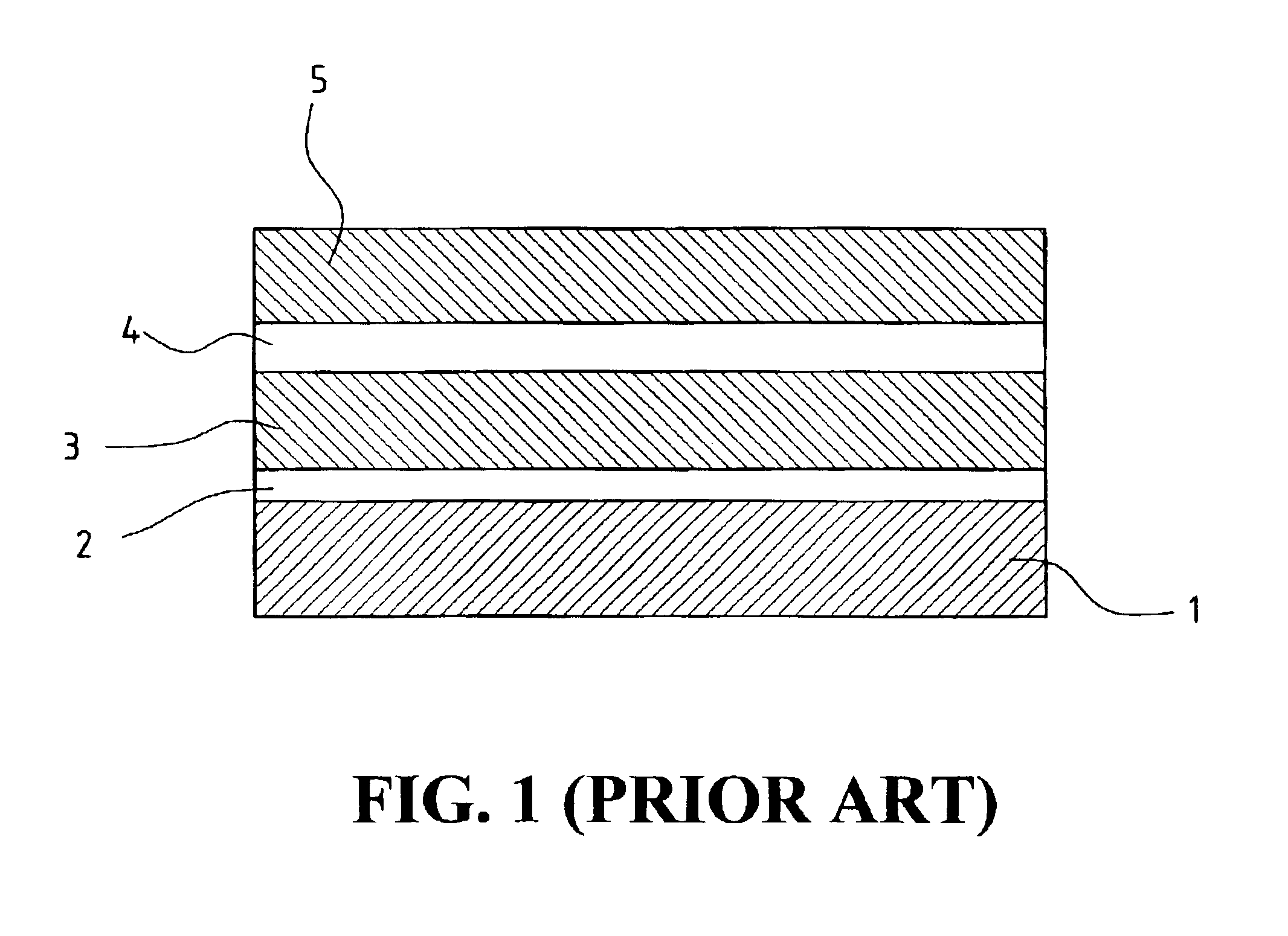

Self-supporting laminated films, structural materials and medical devices manufactured therefrom and methods of making same

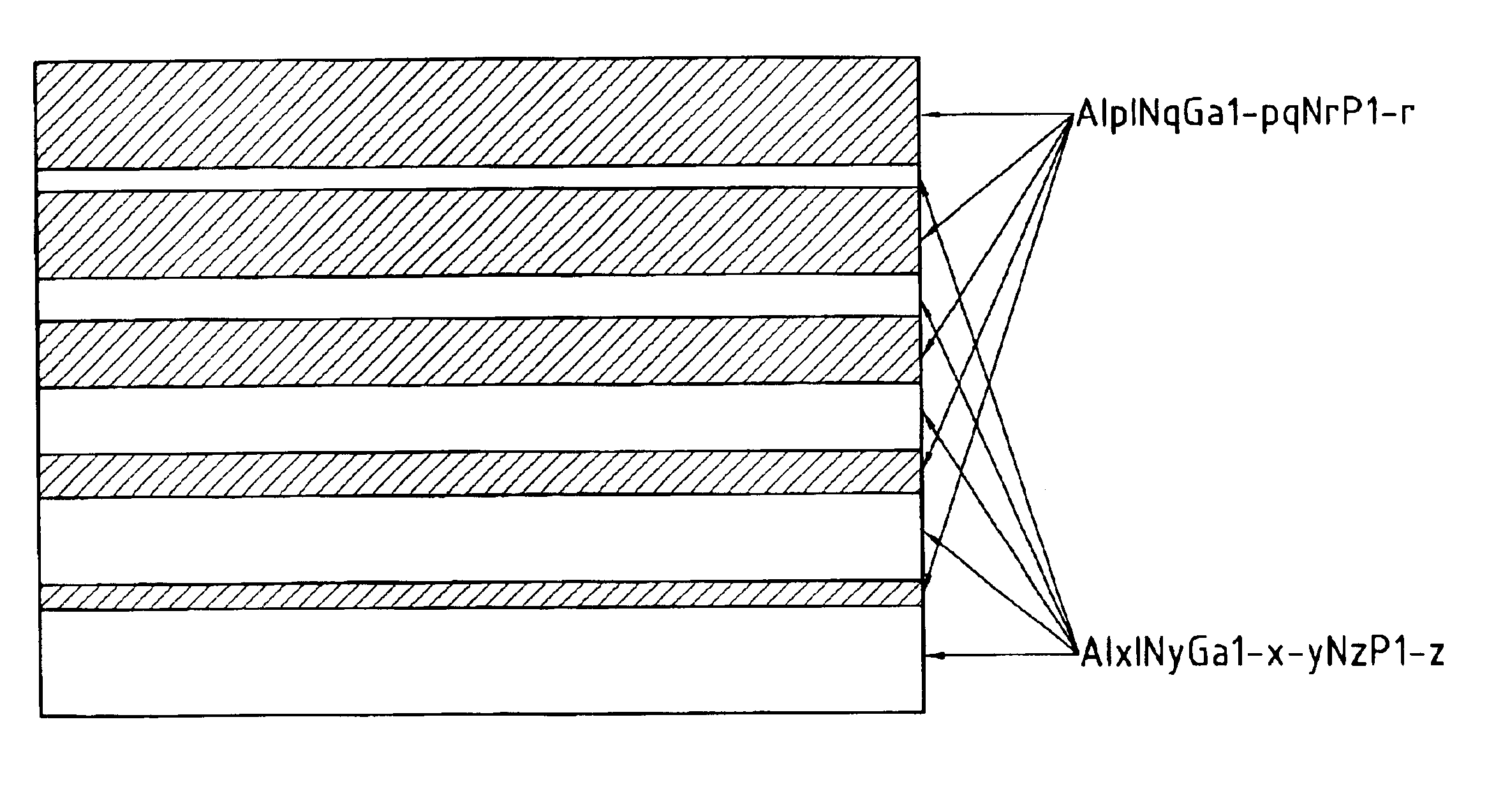

Metal foils, wires, and seamless tubes with increased mechanical strength are provided. As opposed to wrought materials that are made of a single metal or alloy, these materials are made of two or more layers forming a laminate structure. Laminate structures are known to increase mechanical strength of sheet materials such as wood and paper products and are used in the area of thin films to increase film hardness, as well as toughness. Laminate metal foils have not been used or developed because the standard metal forming technologies, such as rolling and extrusion, for example, do not lend themselves to the production of laminate structures. Vacuum deposition technologies can be developed to yield laminate metal structures with improved mechanical properties. In addition, laminate structures can be designed to provide special qualities by including layers that have special properties such as superelasticity, shape memory, radio-opacity, corrosion resistance etc. Examples of articles which may be made by the inventive laminate structures include implantable medical devices that are fabricated from the laminated deposited films and which present a blood or body fluid and tissue contact surface that has controlled heterogeneities in material constitution. An endoluminal stent-graft and web-stent that is made of a laminated film material deposited and etched into regions of structural members and web regions subtending interstitial regions between the structural members. An endoluminal graft is also provided which is made of a biocompatible metal or metal-like material. The endoluminal stent-graft is characterized by having controlled heterogeneities in the stent material along the blood flow surface of the stent and the method of fabricating the stent using vacuum deposition methods.

Owner:VACTRONIX SCI LLC

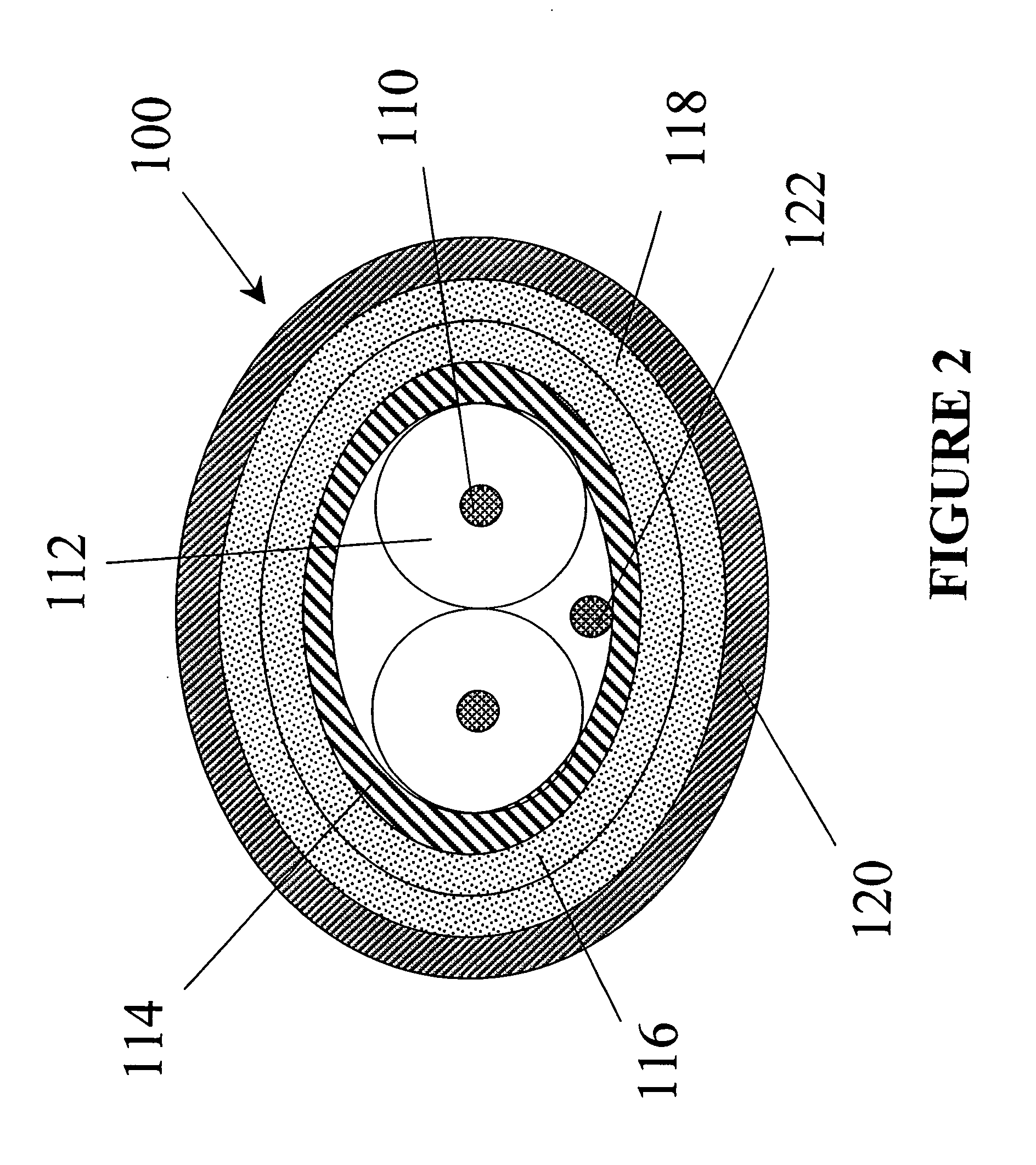

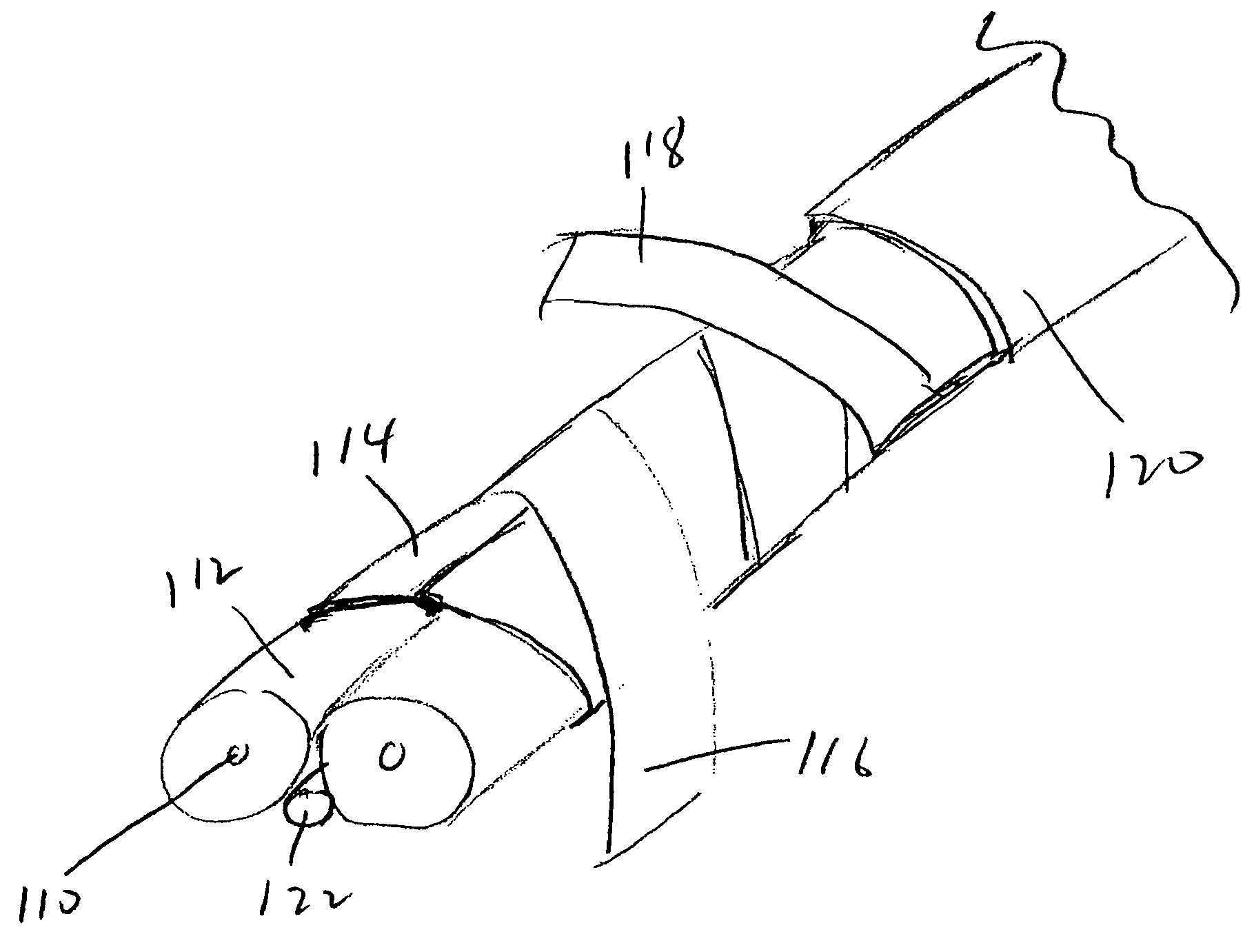

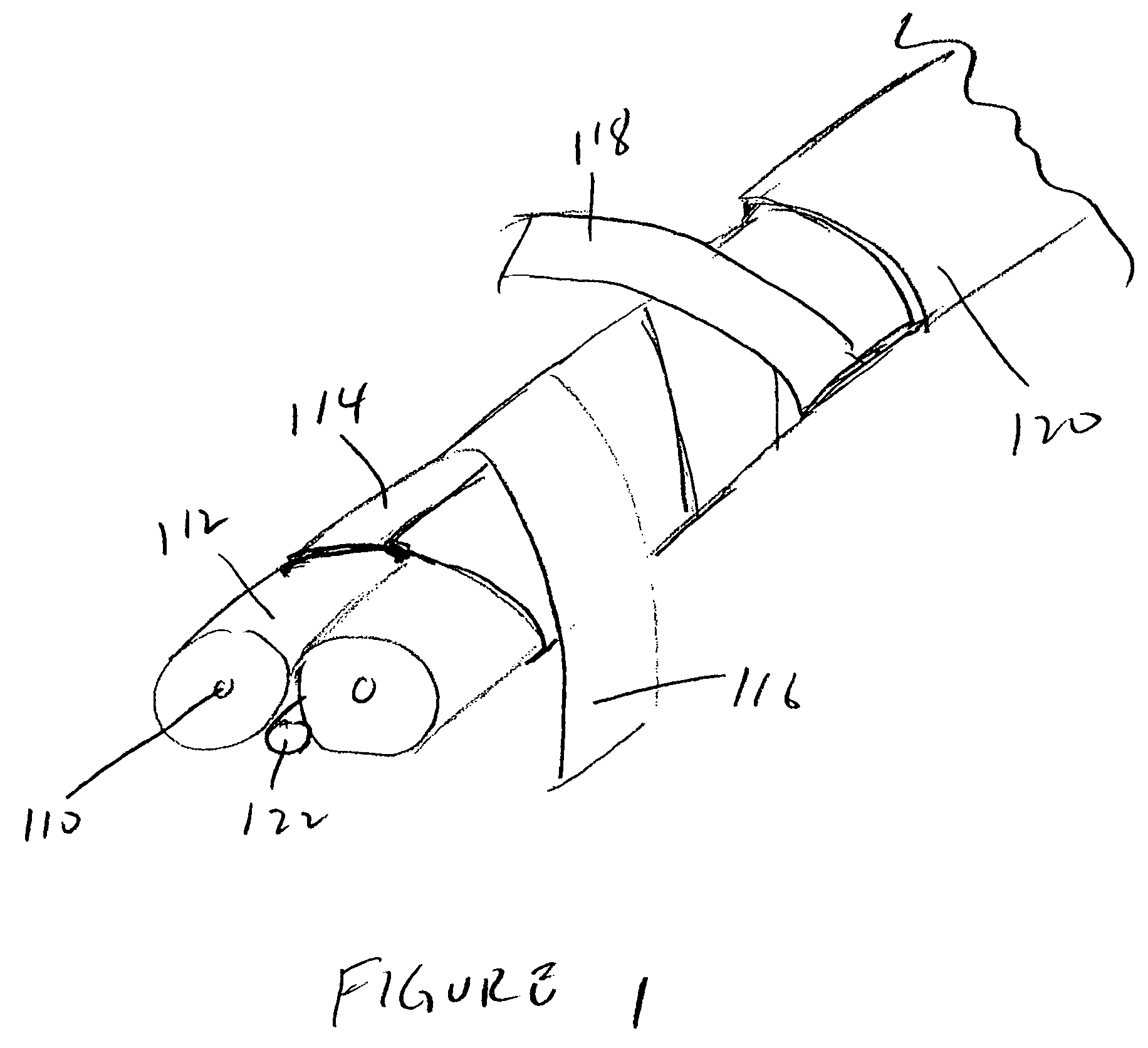

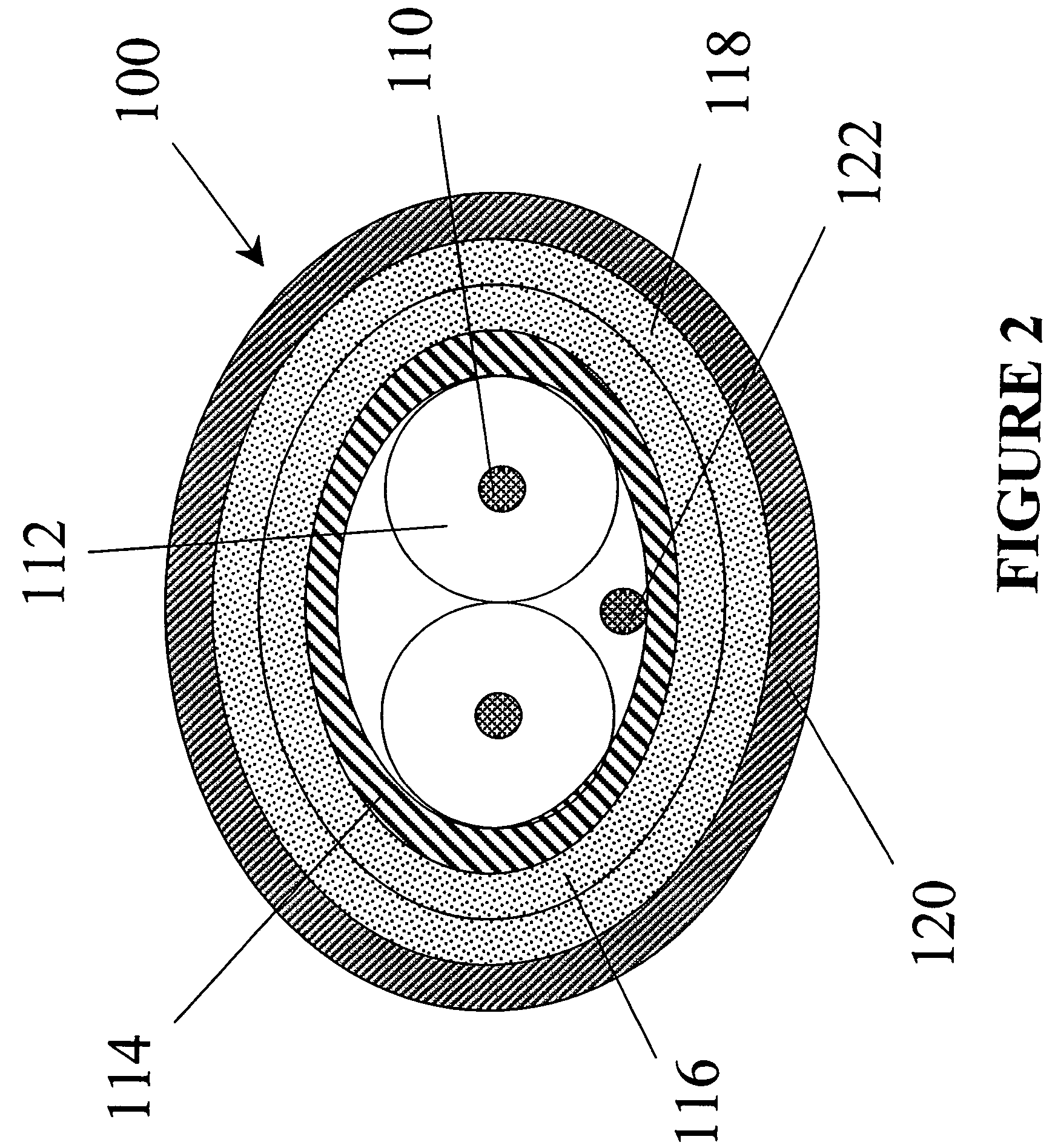

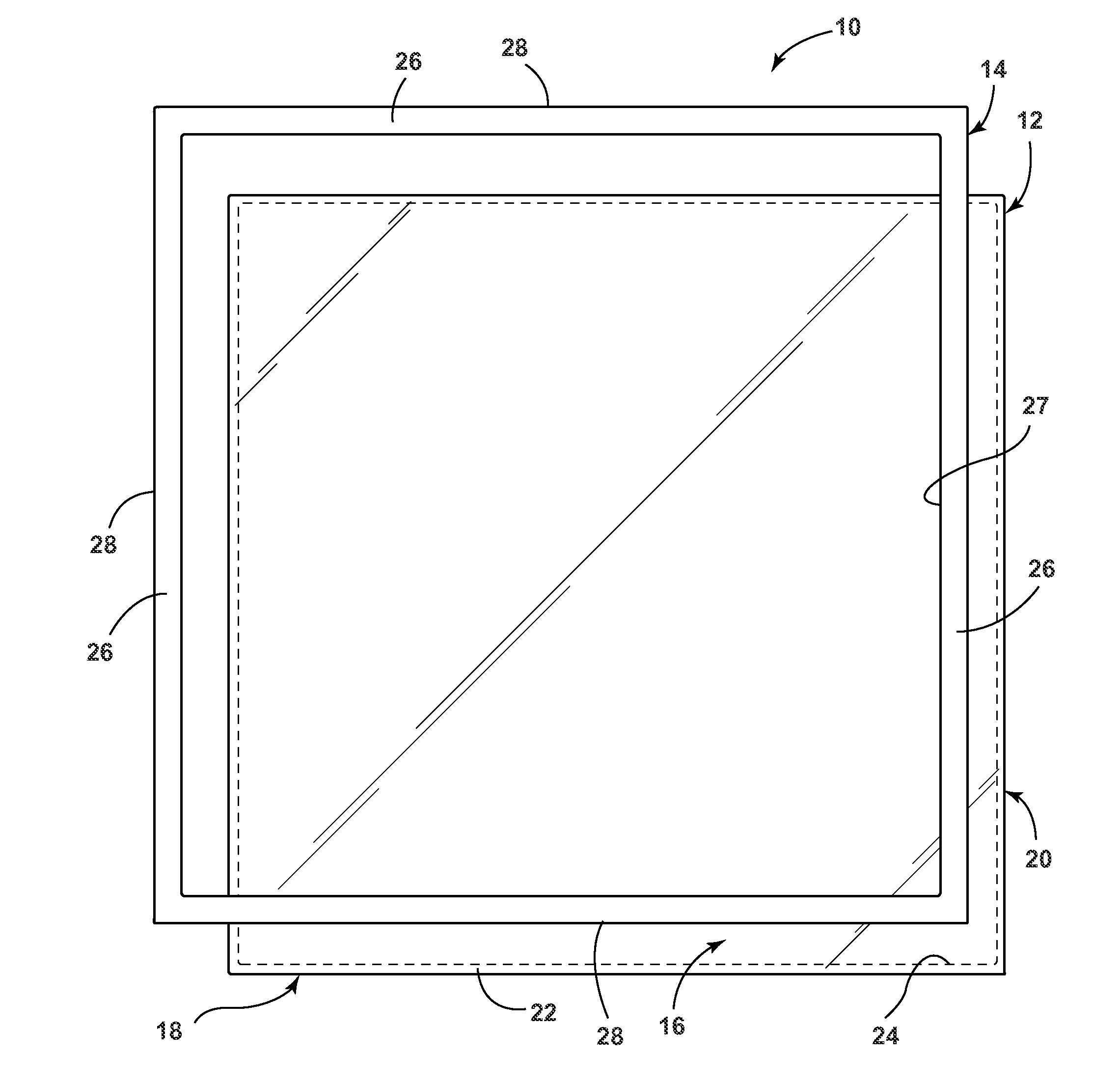

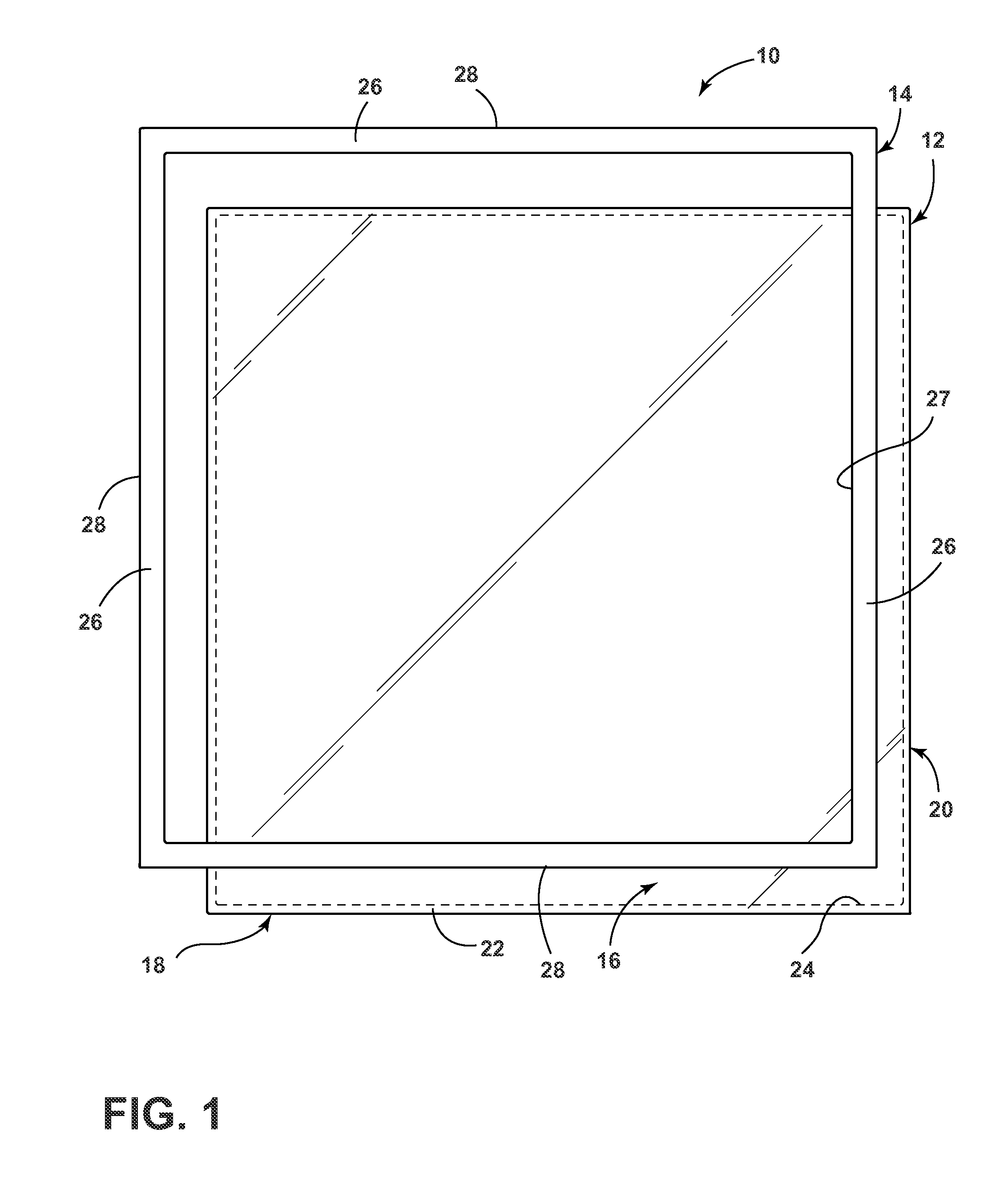

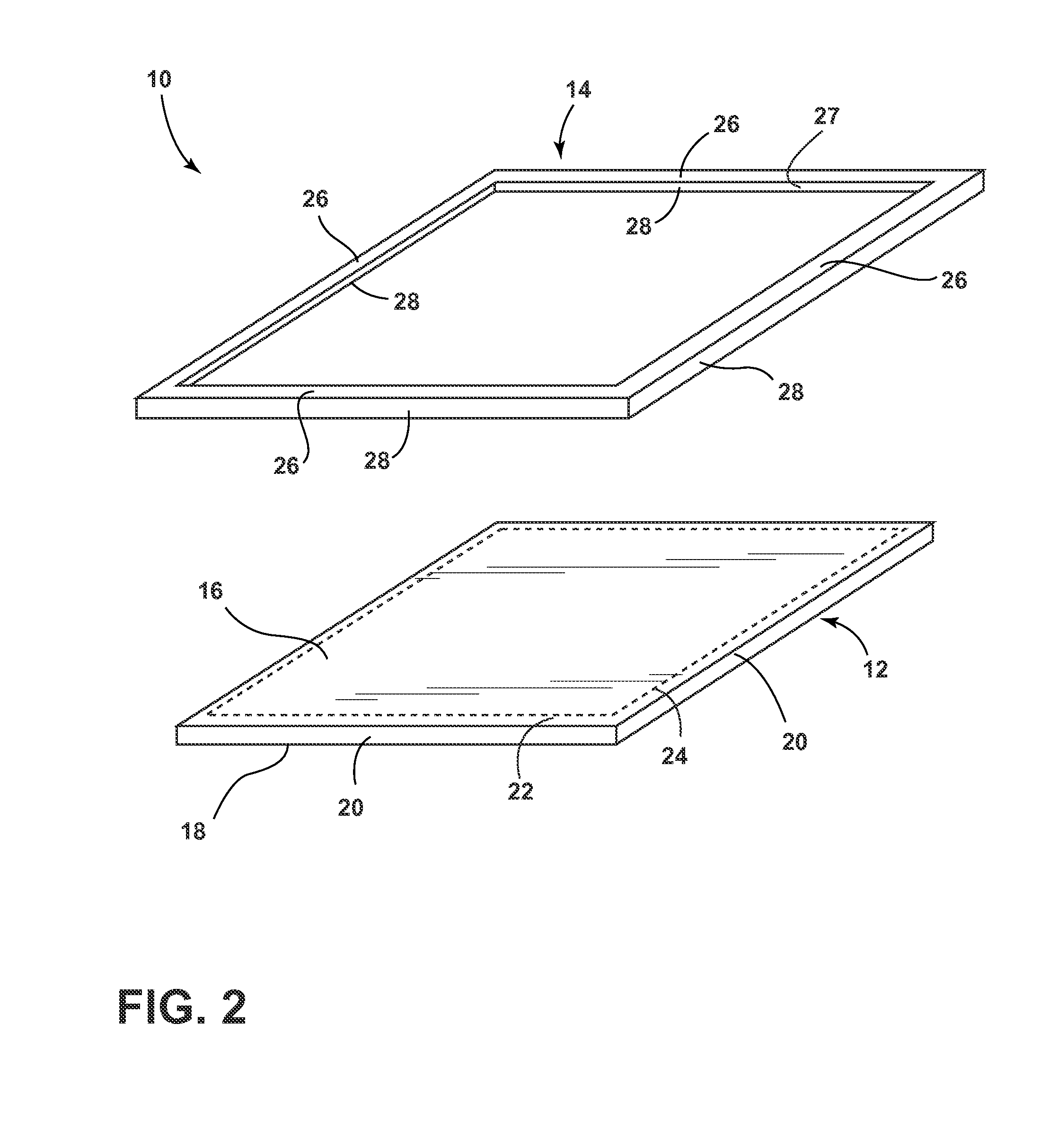

Shielded parallel cable

ActiveUS20060054334A1Low insertion loss performanceLower performance requirementsPower cables with screens/conductive layersInsulated cablesMetal formingContact pad

The cable of the present invention contains at least one pair of insulated conductors and an optional drain wire. The insulate conductors and drain wire is longitudinally covered in a shielding tape, which preferably comprises a metallic sheet having an adhesive applied on selected portions of a surface of the metallic sheet. The adhesive is preferably applied in a checker board pattern so that the surface having adhesive thereon contains areas of uncoated, exposed metal forming contact pads. The shielding tape is then covered with two layers of polymeric tapes in opposite helical directions. The polymeric tape is preferably constructed of a polymeric sheet having a layer of adhesive disposed on a surface thereof. In a preferred embodiment, the tapes are wrapped around the shielding tape in opposite directions such that the adhesive surfaces face each other. The tapes are then optionally covered with a jacket.

Owner:AMPHENOL CORP

Shielded parallel cable

ActiveUS7790981B2Lower performance requirementsInsulated cablesInsulated conductorsMetal formingContact pad

The cable of the present invention contains at least one pair of insulated conductors and an optional drain wire. The insulate conductors and drain wire is longitudinally covered in a shielding tape, which preferably comprises a metallic sheet having an adhesive applied on selected portions of a surface of the metallic sheet. The adhesive is preferably applied in a checker board pattern so that the surface having adhesive thereon contains areas of uncoated, exposed metal forming contact pads. The shielding tape is then covered with two layers of polymeric tapes in opposite helical directions. The polymeric tape is preferably constructed of a polymeric sheet having a layer of adhesive disposed on a surface thereof. In a preferred embodiment, the tapes are wrapped around the shielding tape in opposite directions such that the adhesive surfaces face each other. The tapes are then optionally covered with a jacket.

Owner:AMPHENOL CORP

End-fitting for flexible pipe

InactiveUS6923477B2Prevent leakageEasy crimpingPipe elementsFlexible pipesMetal formingConductor Coil

A fixing end-fitting for a flexible tubular pipe, the pipe comprising an inner sealing sheath, a pressure vault comprising a short-pitch helical winding of a metal forming wire, an intermediate sheath and at least a web of tensile long-pitch wound armour wires and an outer sealing sheath. The end-fitting comprises a stepped part capable of sliding into a stepped cylindrical housing of the end-fitting. Two crimping elements sealingly fix the inner sheath and the intermediate sheath. Screws enable the stepped part to be brought closer to and be fixed on the end-fitting. The stepped part and the deformable elements constitute three separate elements, thereby facilitating mounting and providing a better control of tightness.

Owner:COFLEXIP

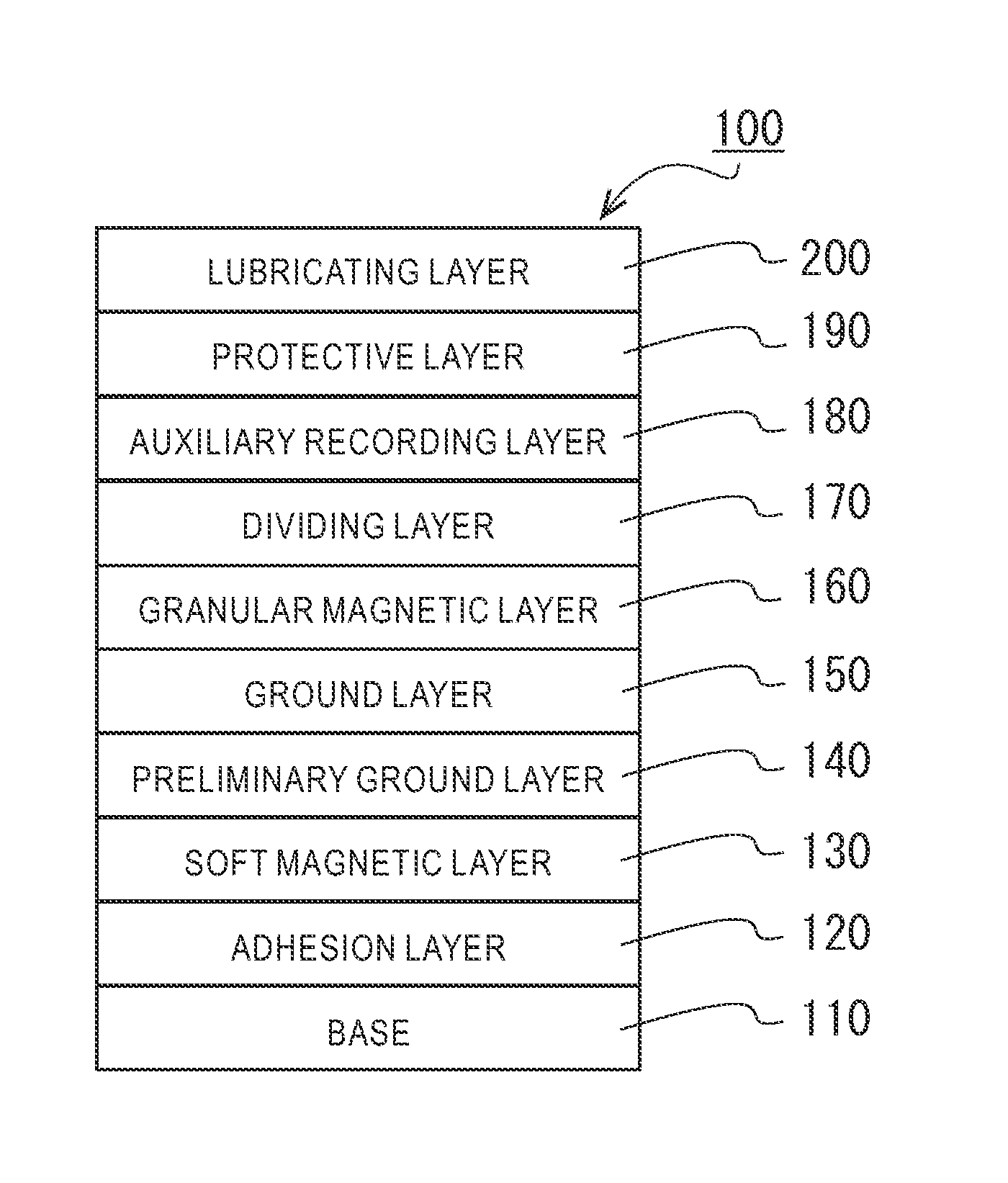

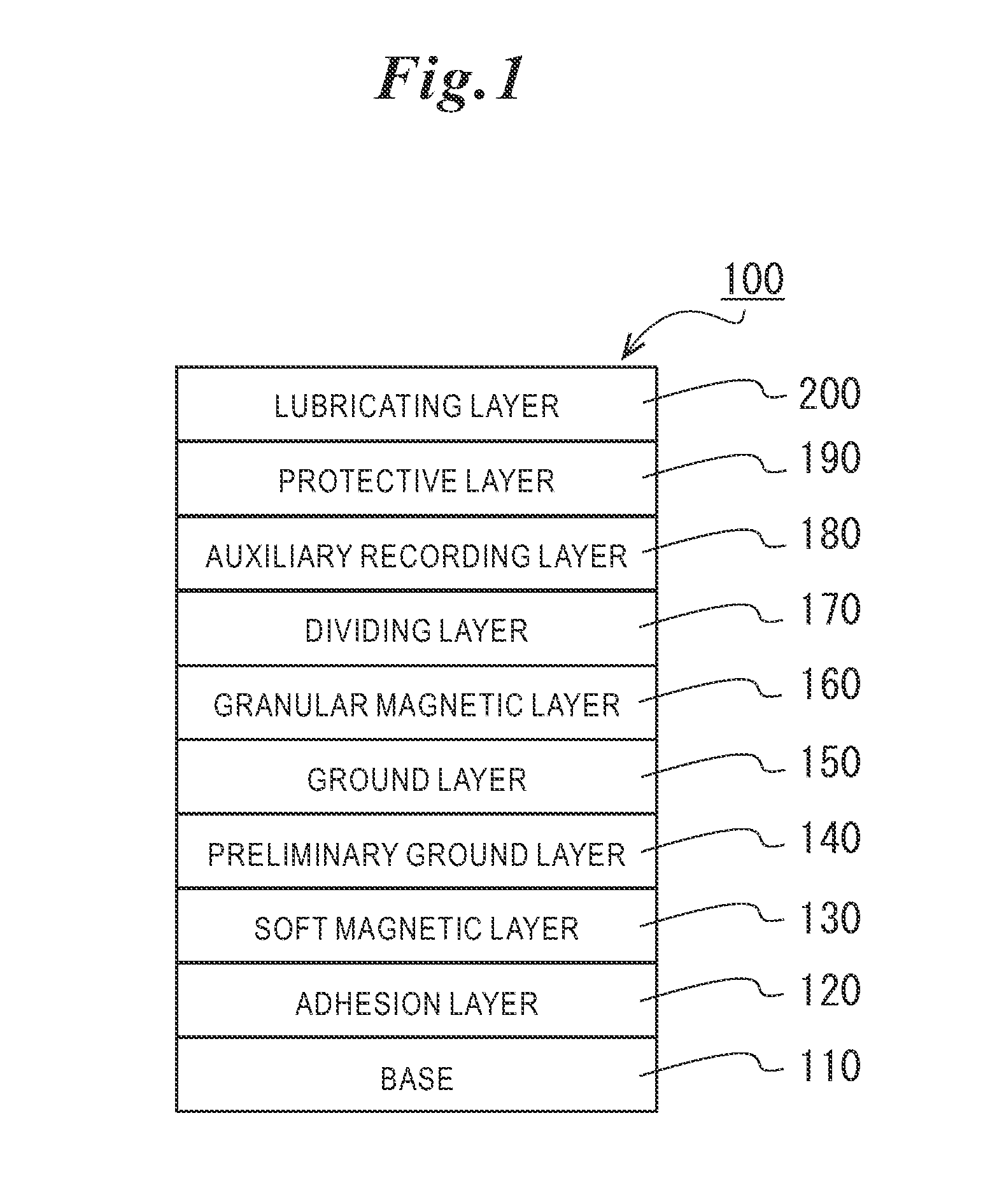

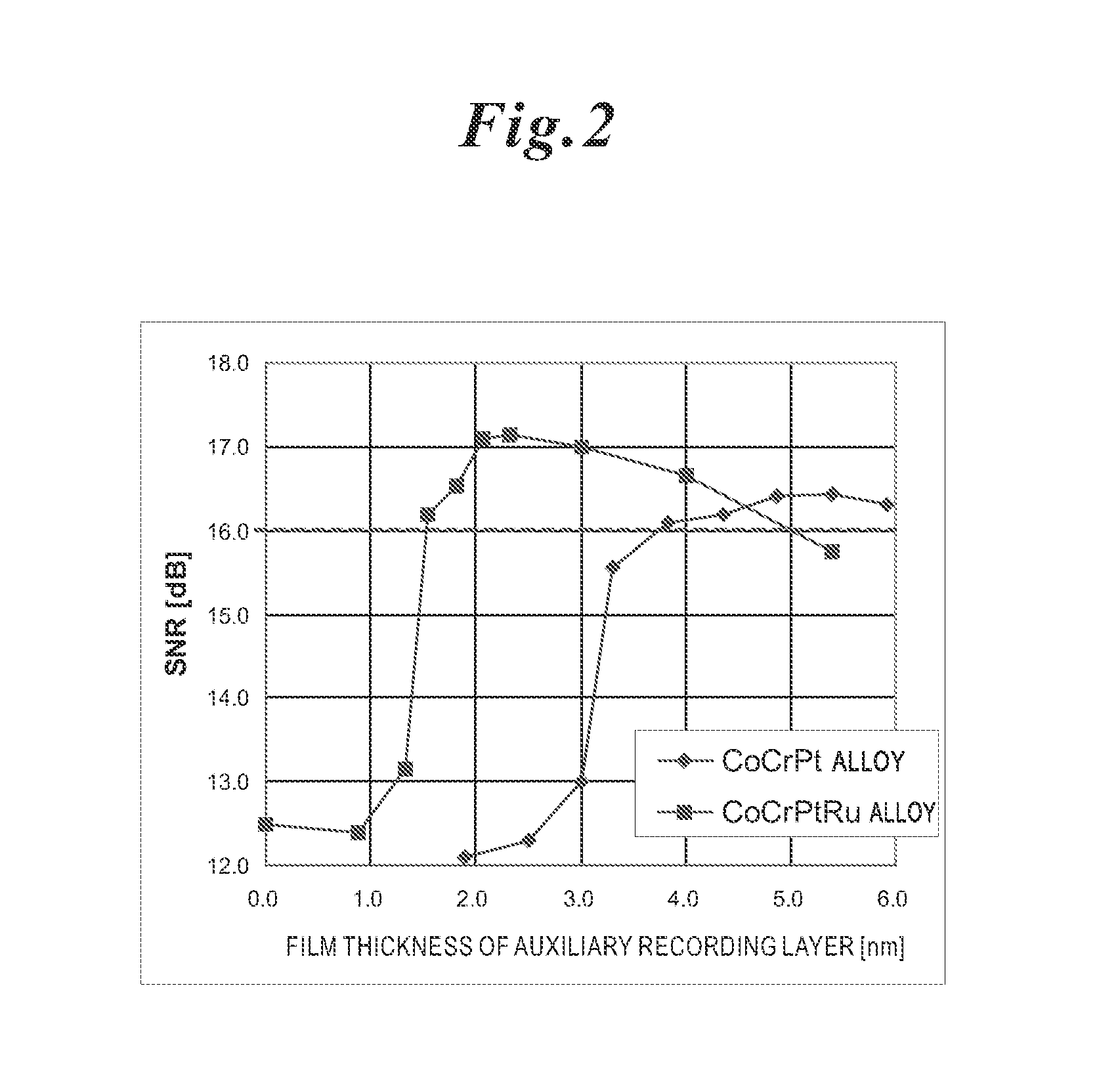

Perpendicular Magnetic Recording Disc

ActiveUS20120129009A1High crystallinityImprove signal-to-noise ratioMagnetic materials for record carriersRecord information storageMetal formingAdditive ingredient

[Summary][Problem] An object is to make a film thinner while keeping the function as an auxiliary recording layer and increase an SNR.[Solution] A structure of the perpendicular magnetic disk 100 according to the present invention includes, on a base 110, a granular magnetic layer 160 and an auxiliary recording layer 180 disposed above the granular magnetic layer, the granular magnetic layer having a granular structure in which a non-magnetic substance having an oxide as a main component is segregated around magnetic particles having a CoCrPt alloy as a main ingredient growing in a columnar shape to form a grain boundary part, and the auxiliary recording layer having a CoCrPtRu alloy as a main component and further containing, as a accessory component, a metal forming passivity and not being an antiferromagnet.

Owner:WESTERN DIGITAL TECH INC

Self-supporting laminated films, structural materials and medical devices manufactured therefrom and methods of making same

Metal foils, wires, and seamless tubes with increased mechanical strength are provided. As opposed to wrought materials that are made of a single metal or alloy, these materials are made of two or more layers forming a laminate structure. Laminate structures are known to increase mechanical strength of sheet materials such as wood and paper products and are used in the area of thin films to increase film hardness, as well as toughness. Laminate metal foils have not been used or developed because the standard metal forming technologies, such as rolling and extrusion, for example, do not lend themselves to the production of laminate structures. Vacuum deposition technologies can be developed to yield laminate metal structures with improved mechanical properties. In addition, laminate structures can be designed to provide special qualities by including layers that have special properties such as superelasticity, shape memory, radio-opacity, corrosion resistance etc. Examples of articles which may be made by the inventive laminate structures include implantable medical devices that are fabricated from the laminated deposited films and which present a blood or body fluid and tissue contact surface that has controlled heterogeneities in material constitution. An endoluminal stent-graft and web-stent that is made of a laminated film material deposited and etched into regions of structural members and web regions subtending interstitial regions between the structural members. An endoluminal graft is also provided which is made of a biocompatible metal or metal-like material. The endoluminal stent-graft is characterized by having controlled heterogeneities in the stent material along the blood flow surface of the stent and the method of fabricating the stent using vacuum deposition methods.

Owner:VACTRONIX SCI LLC

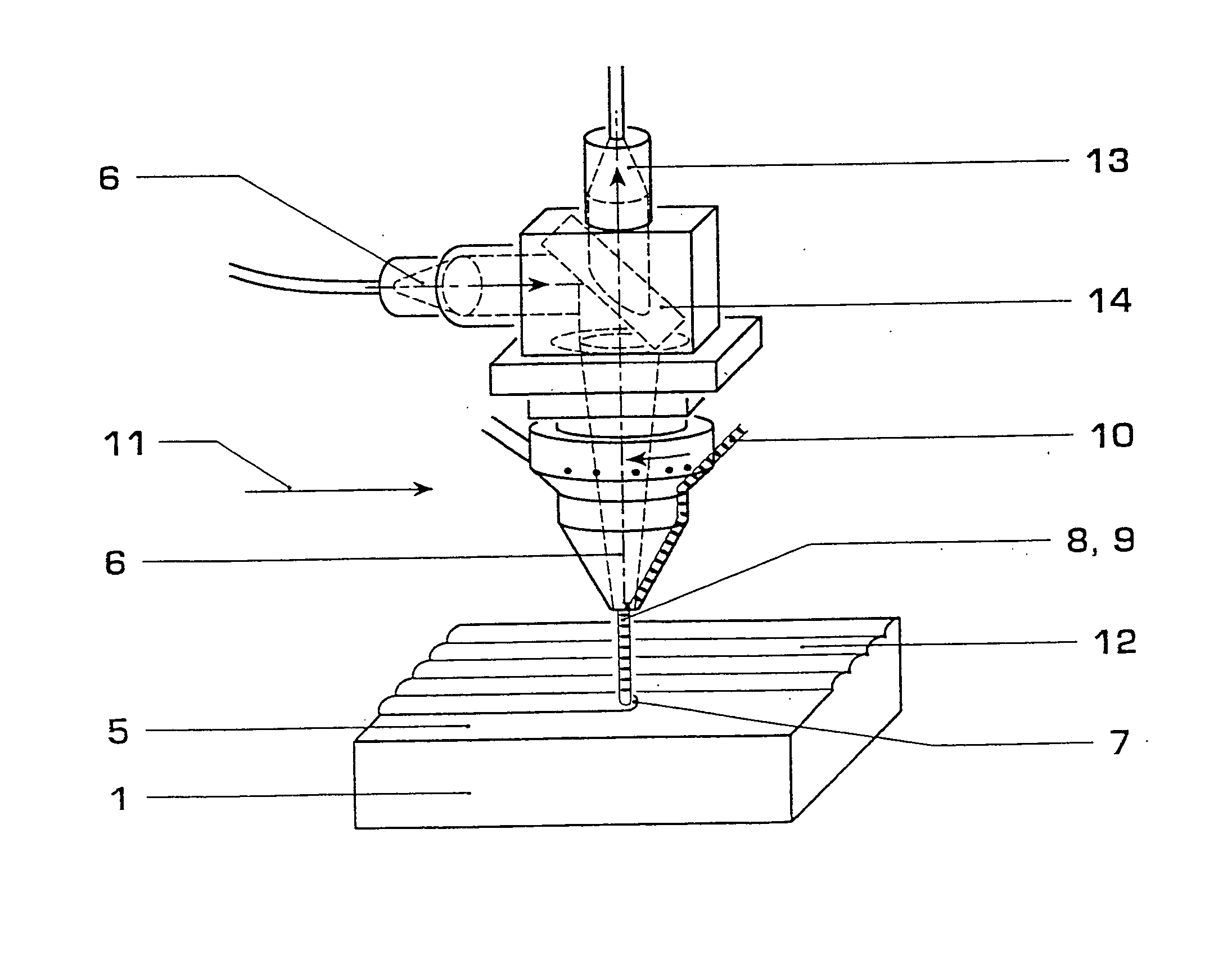

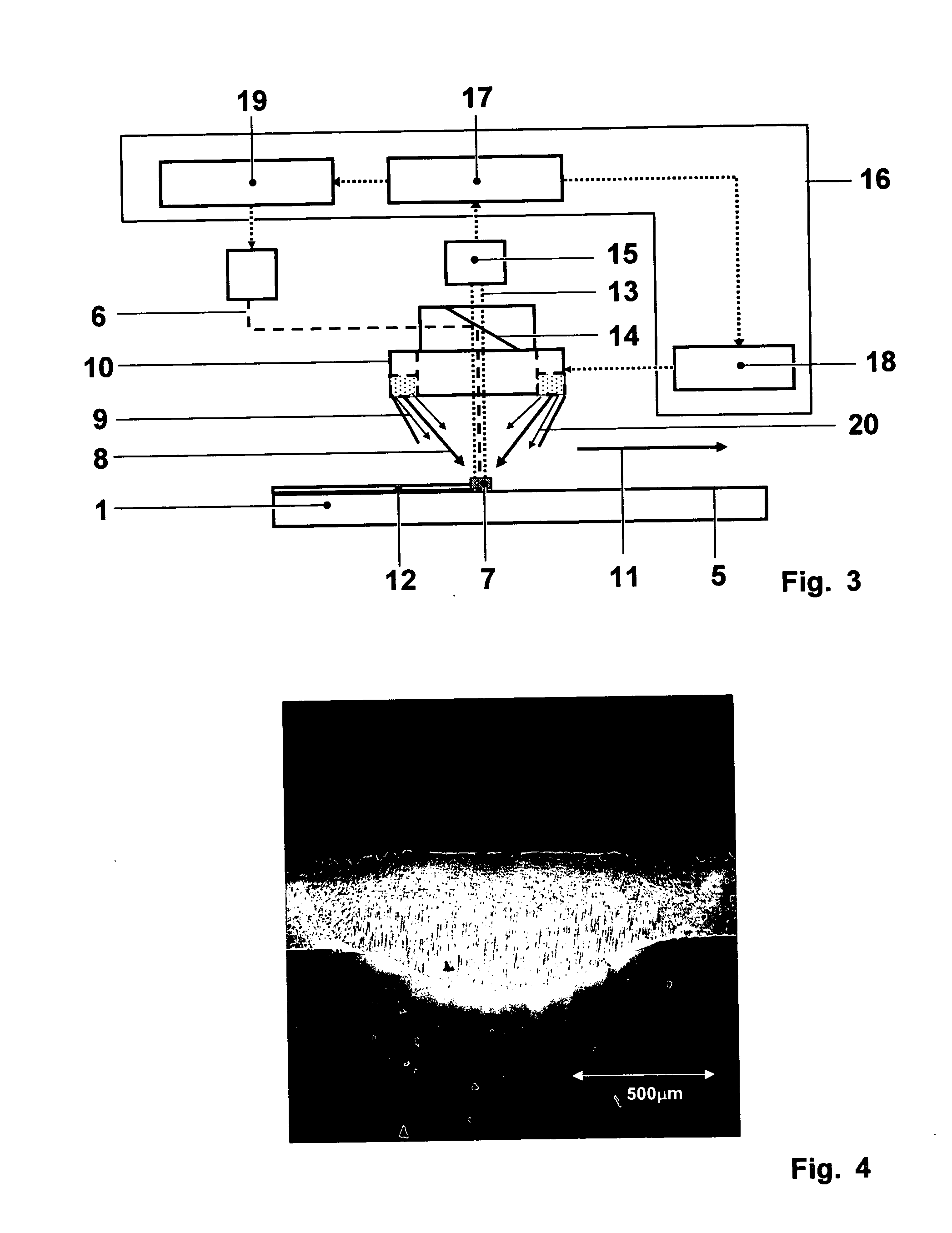

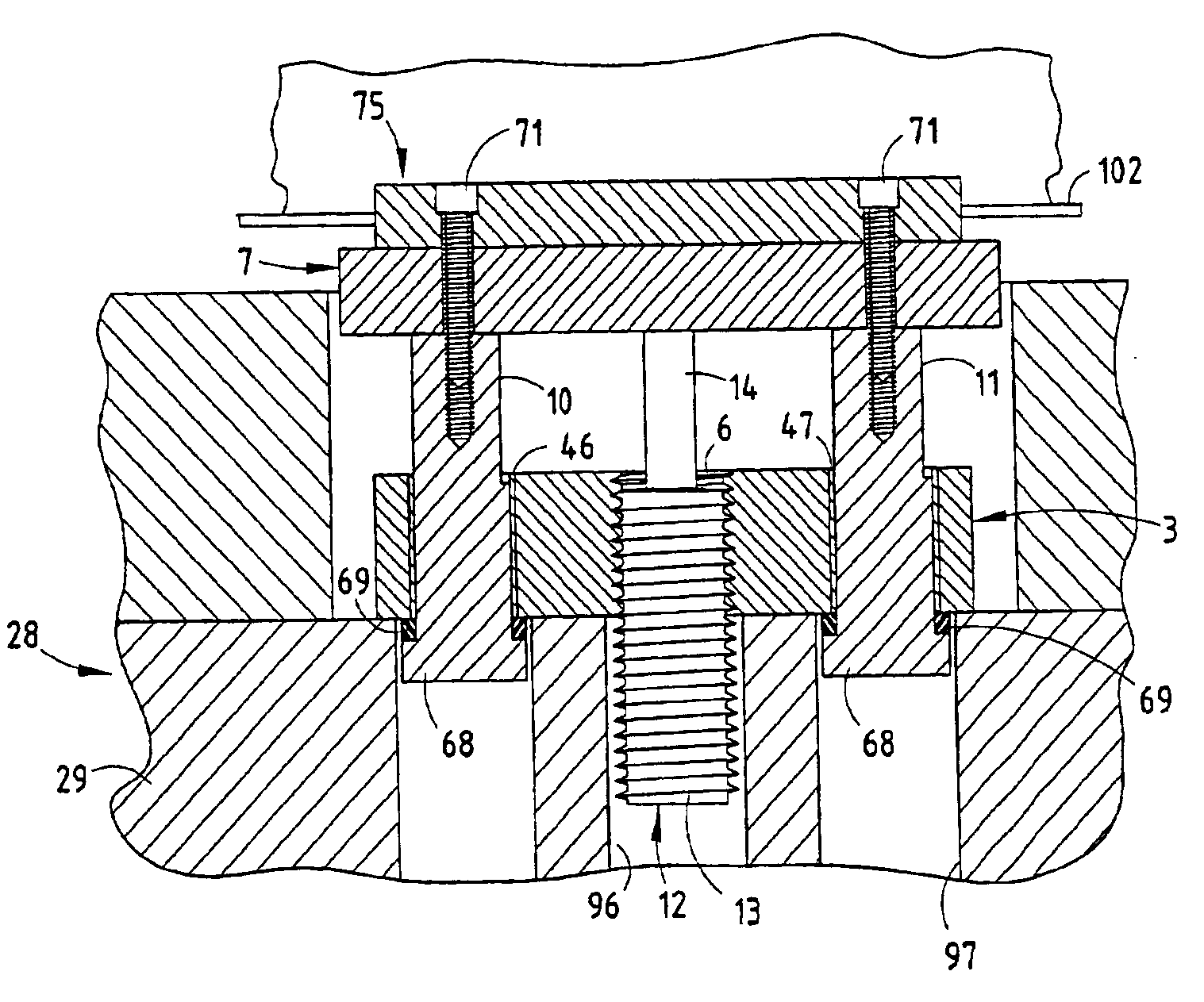

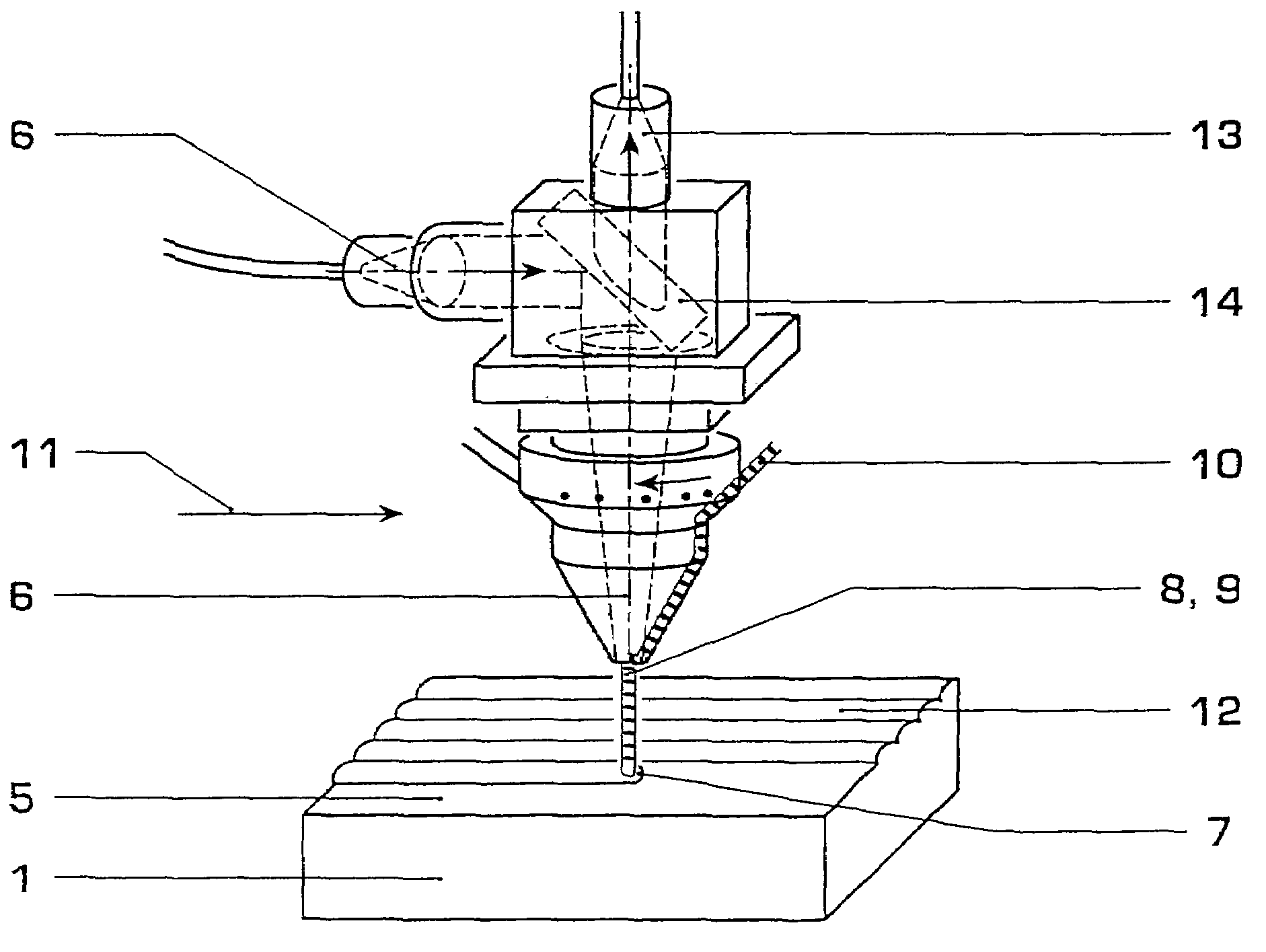

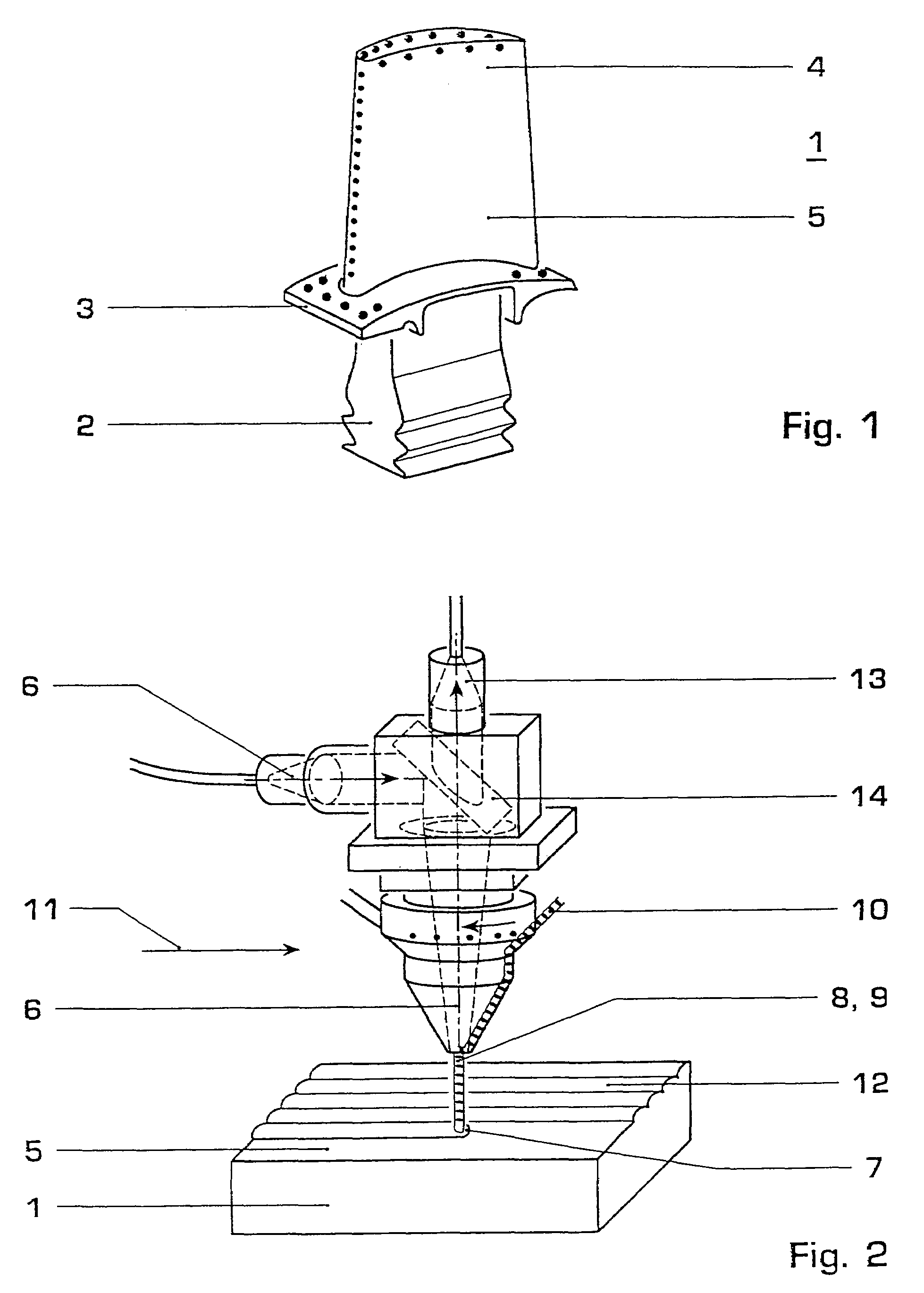

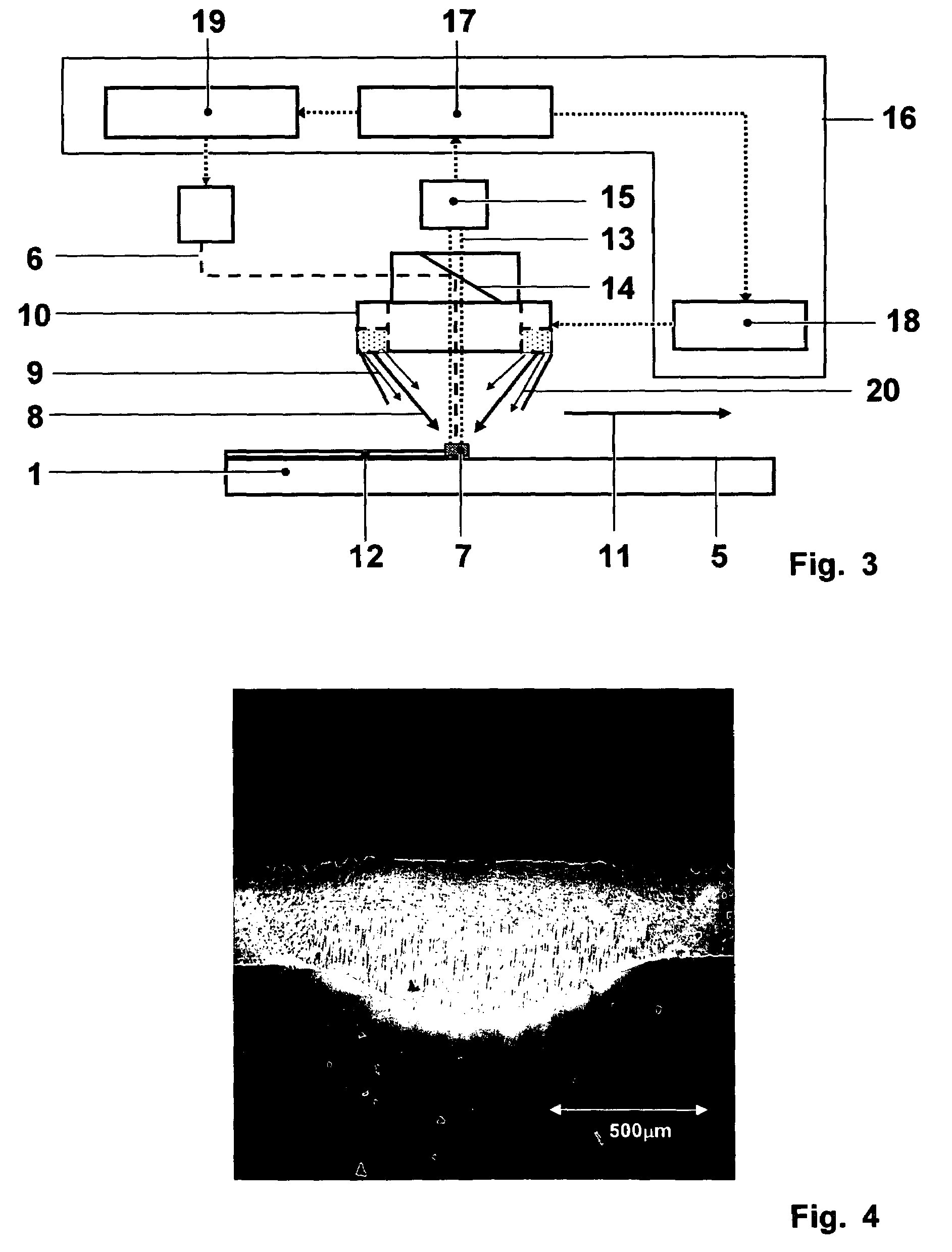

Method of controlled remelting of or laser metal forming on the surface of an article

InactiveUS20050040147A1Superior emission lifetimeRelieve pressurePolycrystalline material growthMolten spray coatingMetal formingControl system

A method for controlled remelting of or laser metal forming on the surface (5) of an article (1) can include moving a light source and a signal capturing apparatus over the article (1). The light source having a specific power can be used to melt the surface (5) of the article (1) locally and to form a melt pool (7). Thereby an optical signal (13) is captured by the signal capturing apparatus from the melt pool (7), and the monitored optical signal (13) is used for the determination of temperature and temperature fluctuations as properties of the melt pool (7). Furthermore, a control system (16) with a feedback circuit is used to adjust at least one process parameter such as the power of the light source such that desired melt pool properties are obtained. Subsequently the melt pool (7) solidifies.

Owner:ANSALDO ENERGIA IP UK LTD

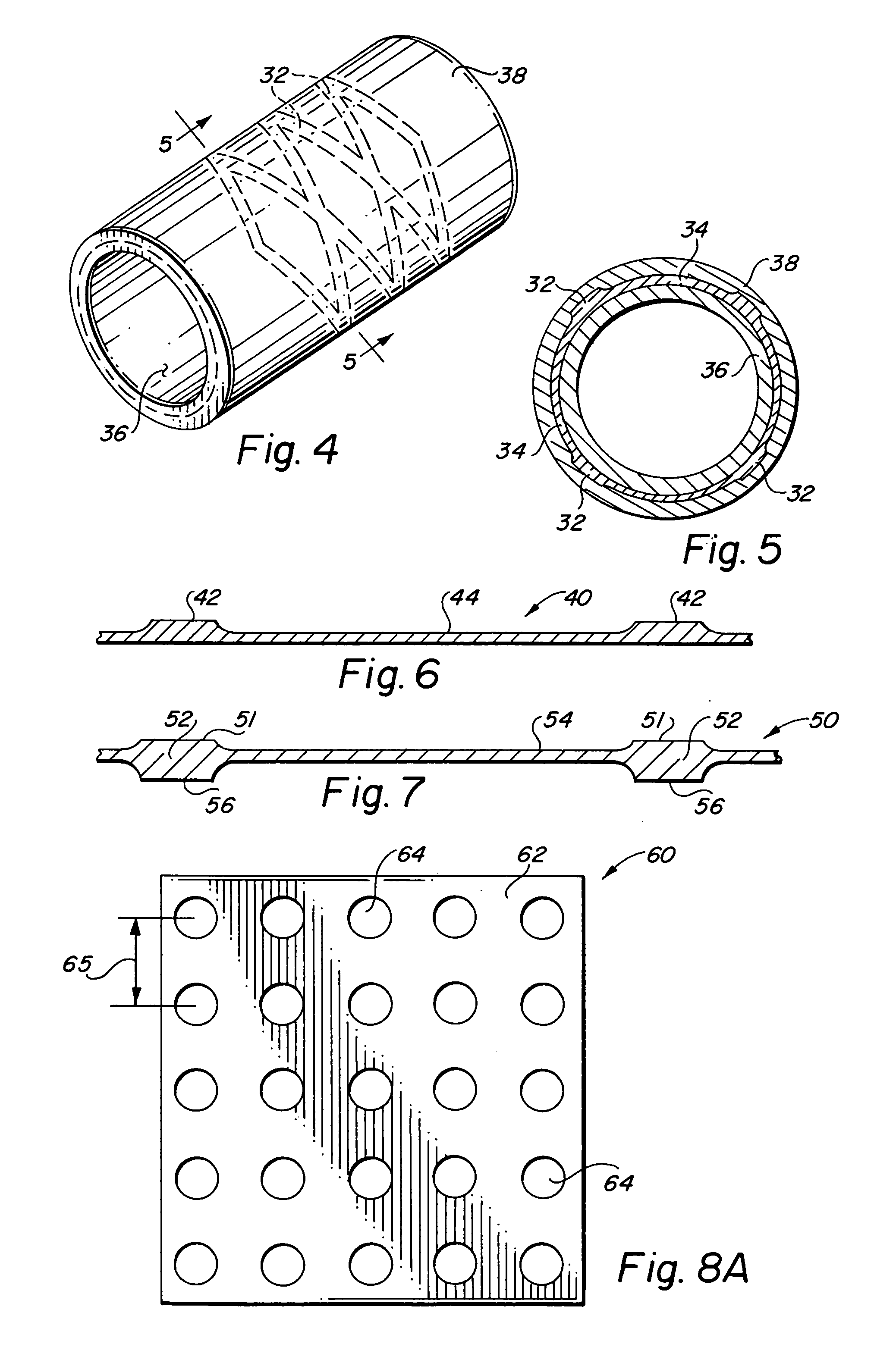

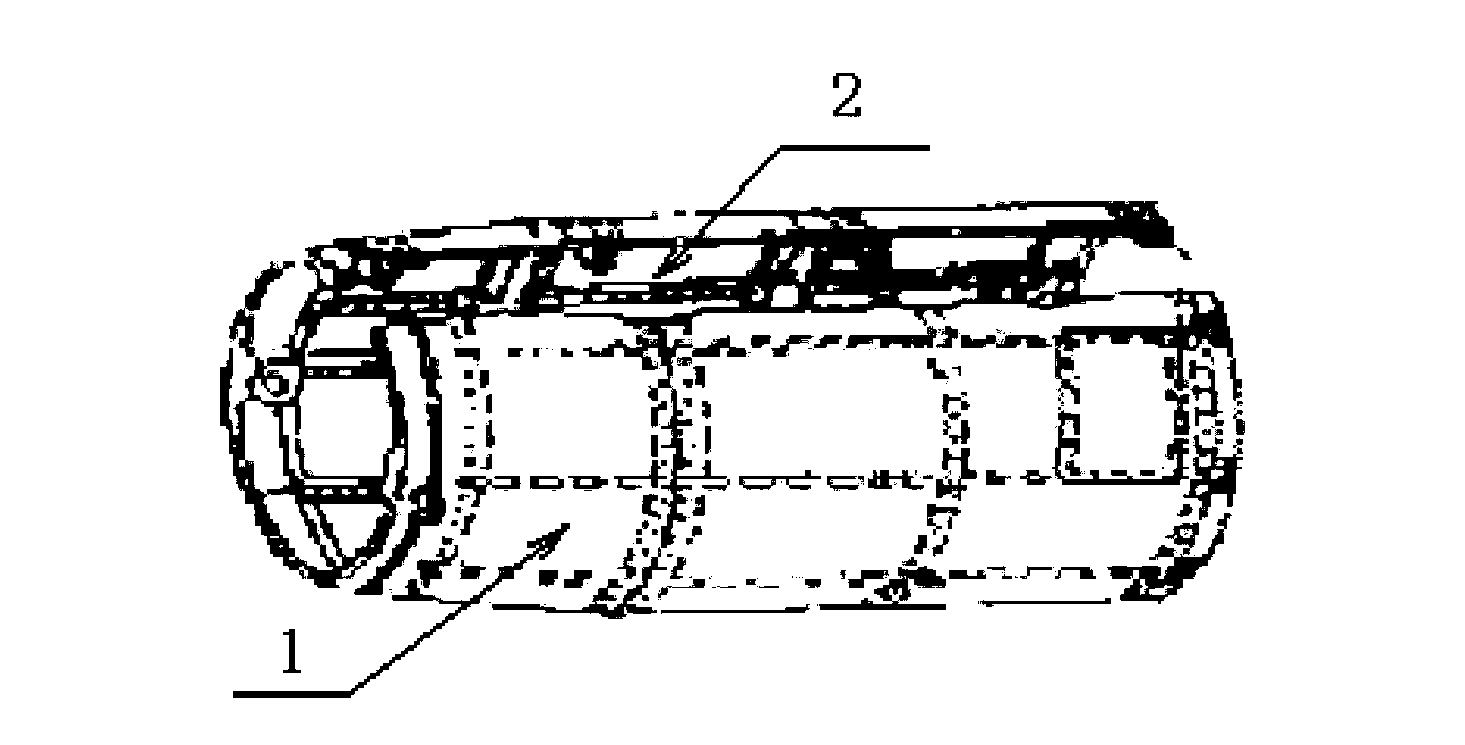

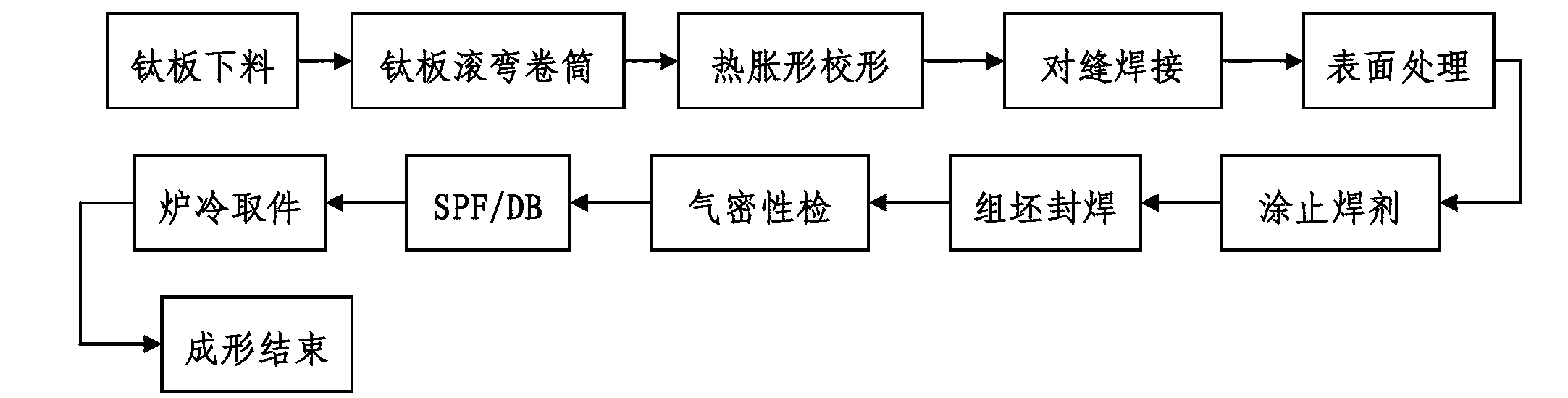

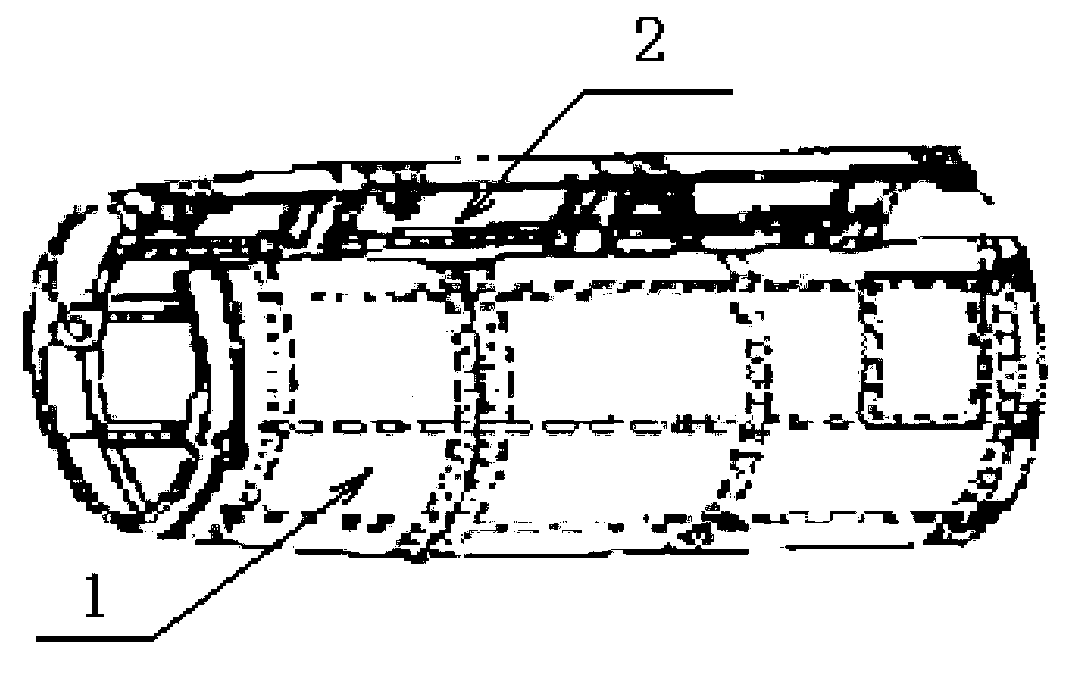

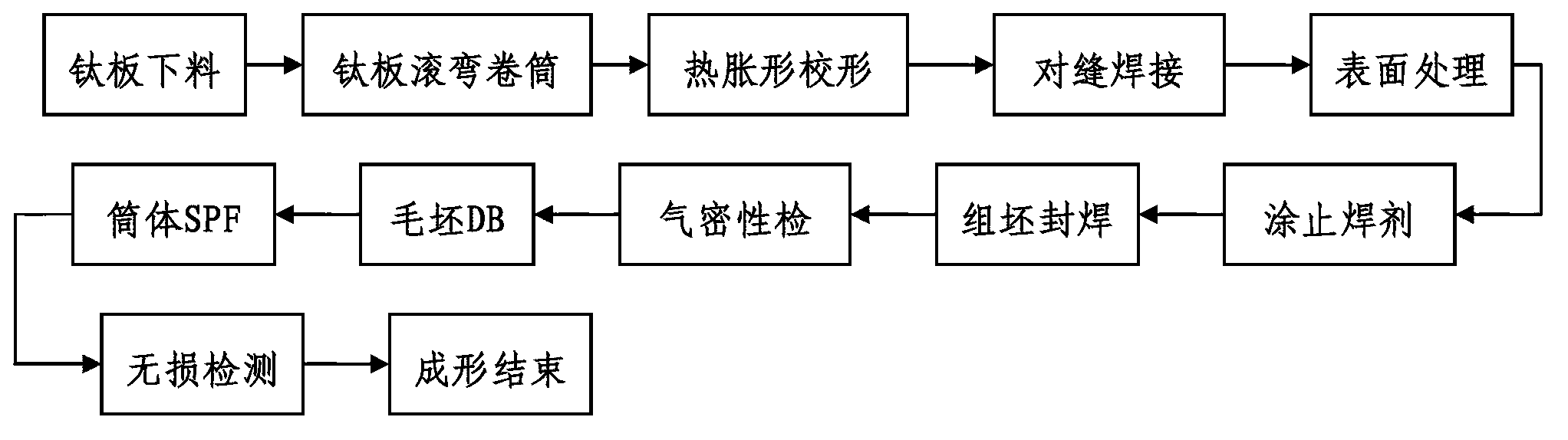

Superplastic forming (SPF)/diffusion bonding (DB) forming method of titanium alloy cylindrical four-layer structure

ActiveCN103008997AThe overall structure is light in weightImprove integrityShaping toolsMetal formingApplication areas

The invention belongs to a sheet-metal forming technology, and relates to a superplastic forming / diffusion connection forming method of a titanium alloy cylindrical four-layer structure. By adopting a novel blank structural form and a blank production method, the requirements on coating welding stopping agent and positioning a cylinder on the four-layer structure can be met, and the formation quality and the technological stability can be improved, the difficulty and complexity of a technological tool can be reduced, the SPF / DB formation of the titanium alloy cylindrical four-layer structure can be stably and reliably realized, and the formation quality and the technological stability can be improved. The SPF / DB technological method is enlarged from the formation of a flat sandwich structure to the formation of a cylindrical rotation sandwich structure, so that the application field of the process is enlarged, and good economic and technical benefit can be realized.

Owner:BEIJING AERONAUTICAL MFG TECH RES INST

Self-supporting laminated films, structural materials and medical devices manufactured therefrom and methods of making same

Metal foils, wires, and seamless tubes with increased mechanical strength are provided. As opposed to wrought materials that are made of a single metal or alloy, these materials are made of two or more layers forming a laminate structure. Laminate structures are known to increase mechanical strength of sheet materials such as wood and paper products and are used in the area of thin films to increase film hardness, as well as toughness. Laminate metal foils have not been used or developed because the standard metal forming technologies, such as rolling and extrusion, for example, do not lend themselves to the production of laminate structures. Vacuum deposition technologies can be developed to yield laminate metal structures with improved mechanical properties. In addition, laminate structures can be designed to provide special qualities by including layers that have special properties such as superelasticity, shape memory, radio-opacity, corrosion resistance etc. Examples of articles which may be made by the inventive laminate structures include implantable medical devices that are fabricated from the laminated deposited films and which present a blood or body fluid and tissue contact surface that has controlled heterogeneities in material constitution. An endoluminal stent-graft and web-stent that is made of a laminated film material deposited and etched into regions of structural members and web regions subtending interstitial regions between the structural members. An endoluminal graft is also provided which is made of a biocompatible metal or metal-like material. The endoluminal stent-graft is characterized by having controlled heterogeneities in the stent material along the blood flow surface of the stent and the method of fabricating the stent using vacuum deposition methods.

Owner:VACTRONIX SCI LLC

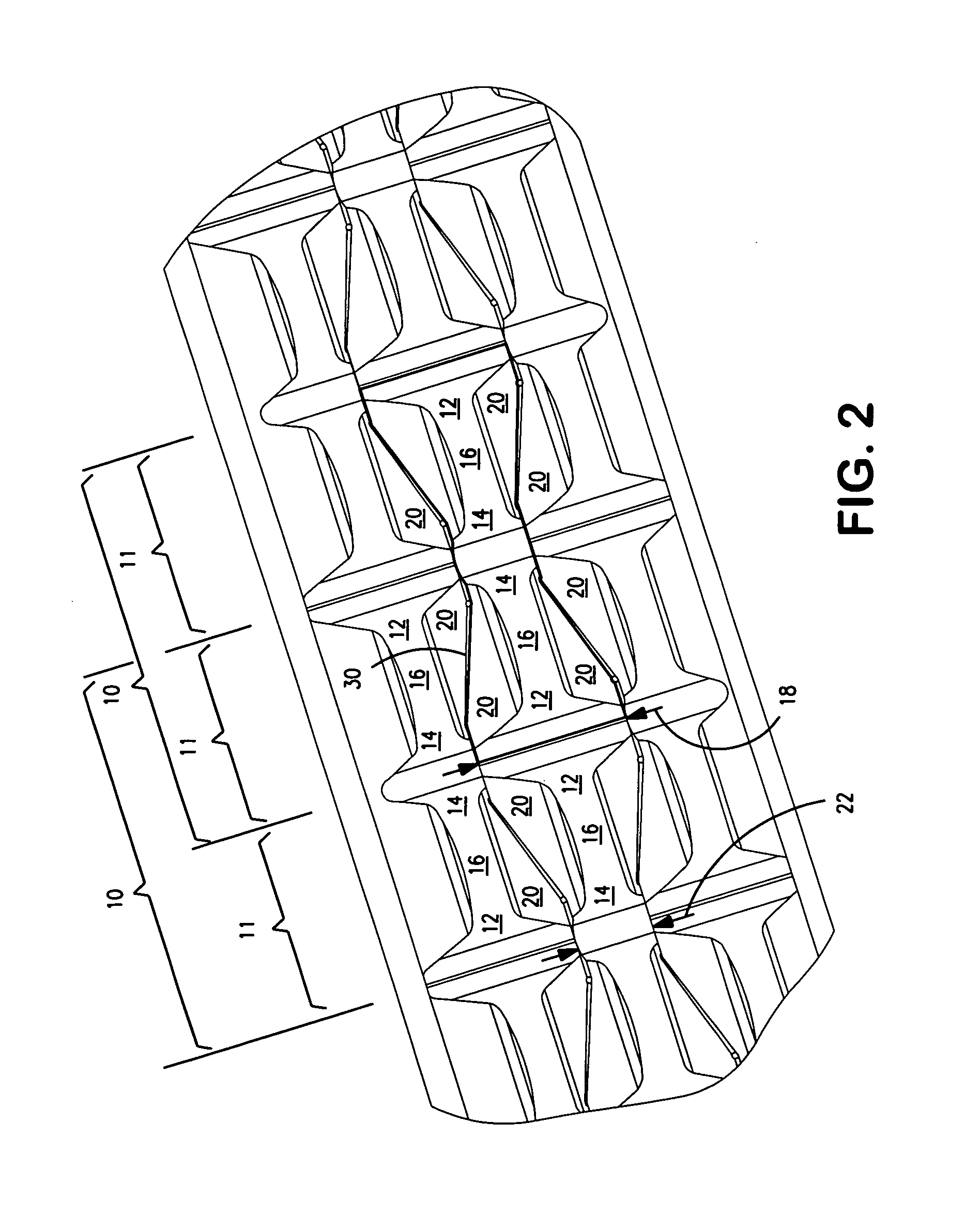

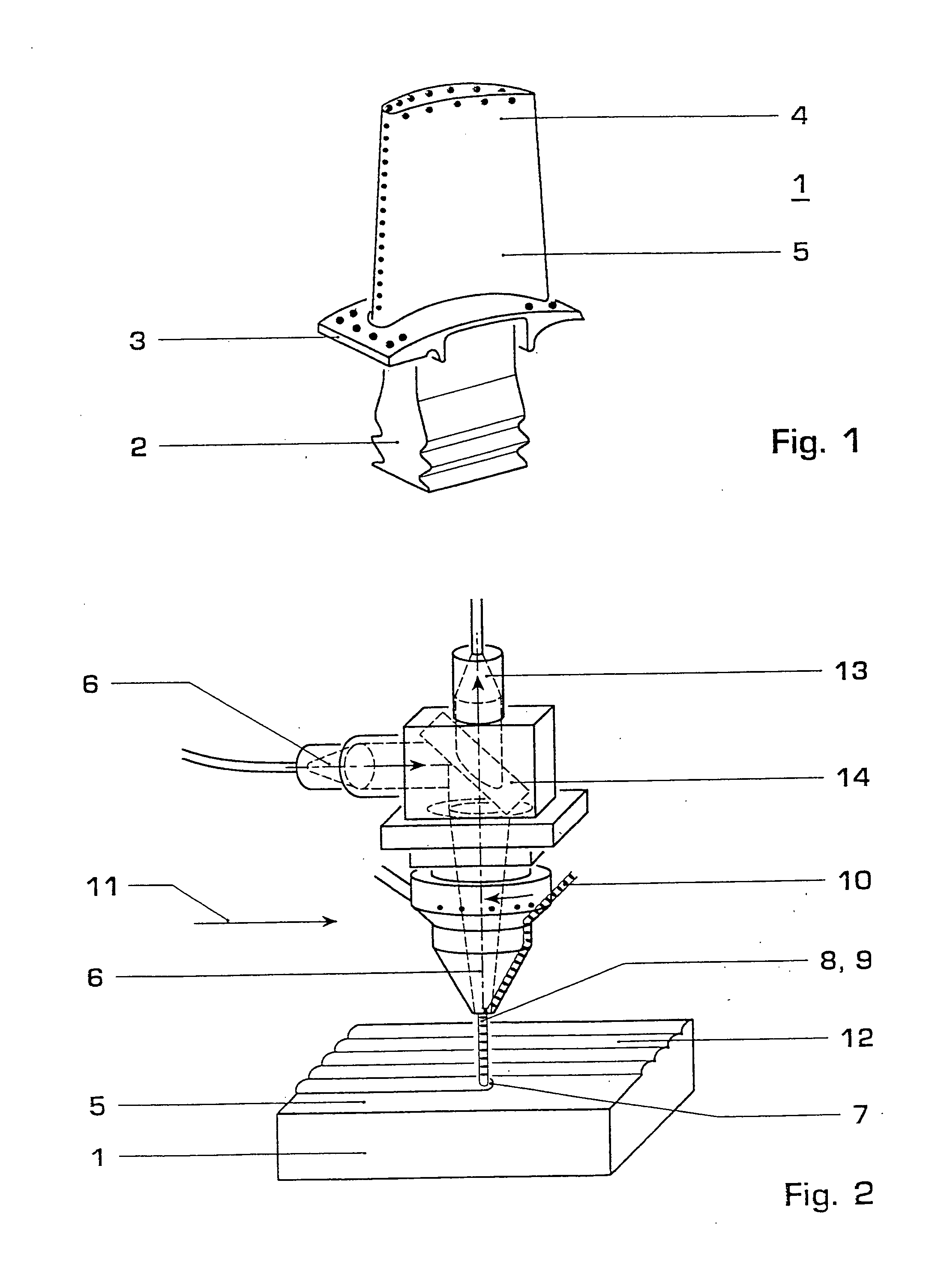

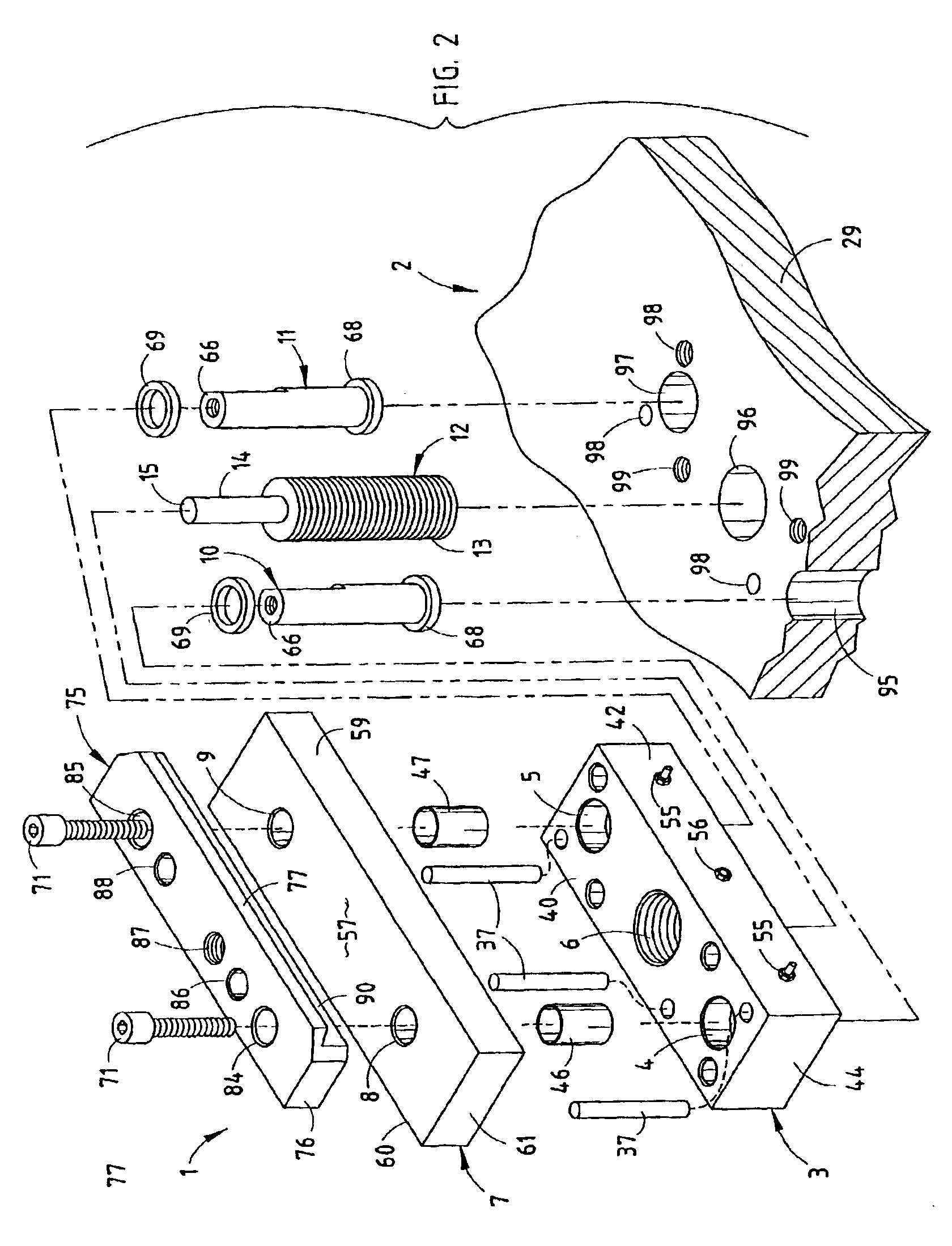

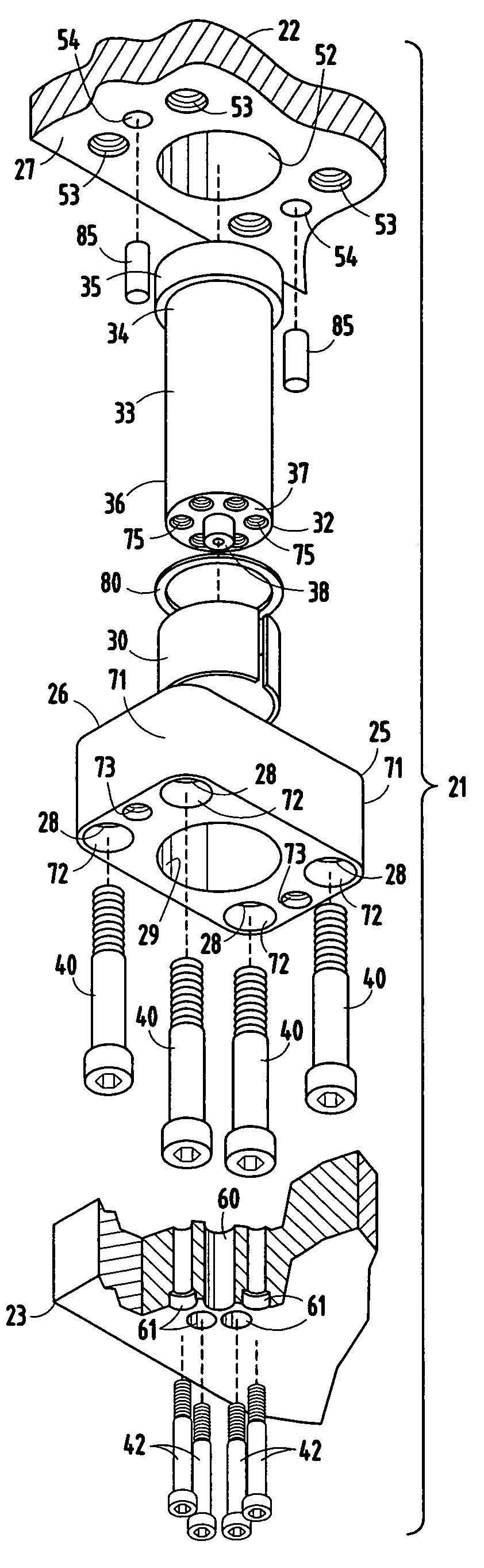

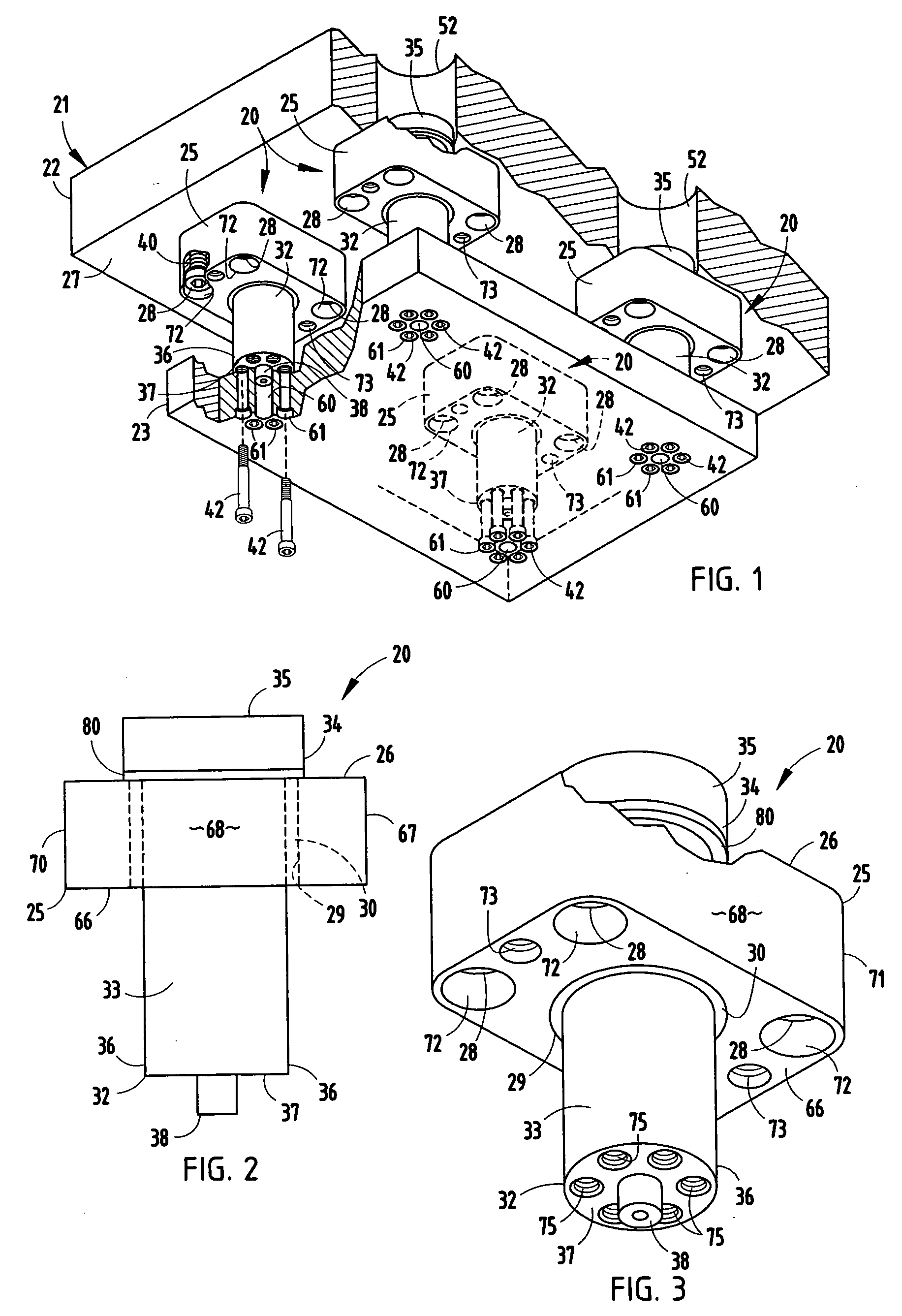

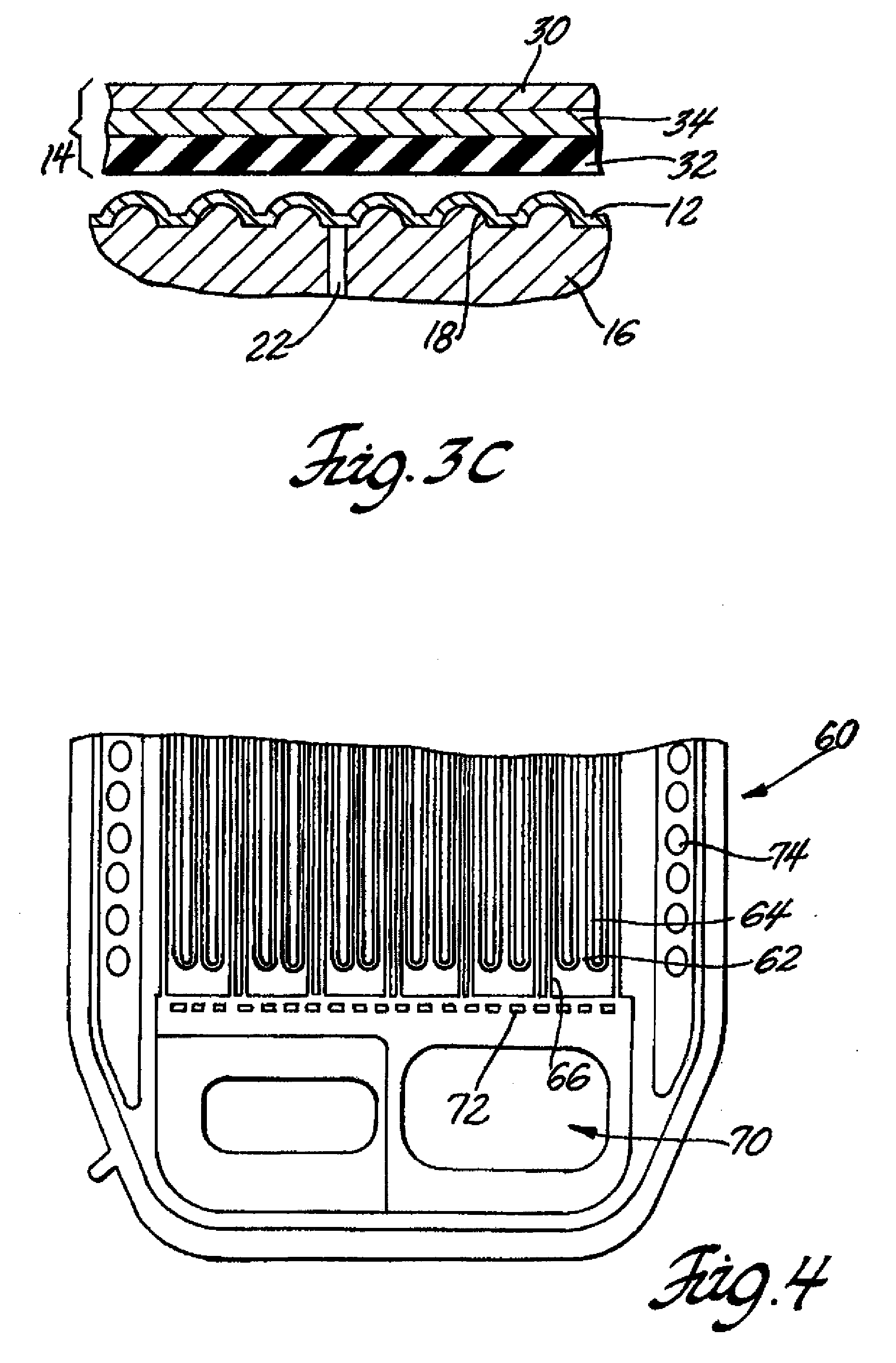

Stock lifter for metal forming dies and method for making the same

InactiveUS6848290B2Reduce design costReduce manufacturing costShaping toolsMetal-working feeding devicesMetal formingReciprocating motion

A self-contained stock lifter is particularly adapted for use in multiple station, progressive metal forming dies and the like, and includes a base plate with two vertical through holes adjacent opposite sides, and a vertical spring unit aperture located between the through holes. The stock lifter also includes a lifter bar having two vertical through holes in vertical registry with the base plate through holes. Two rigid guide shafts are mounted in the base plate through holes to permit the lifter bar to reciprocate in a manner which selectively lifts stock in the die to permit longitudinal shifting of the stock along the multiple die stations. A spring unit has a base retained in the spring unit aperture, and a reciprocating rod biased outwardly, with a free end abutting a central portion of the lifter bar to shift the lifter bar to an extended position, thereby defining a fully self-contained unit that can be readily mounted in and removed from the die to reduce manufacturing and repair costs.

Owner:PYPER TOOL & ENG

Method of encapsulating a projection and making an evacuated cabinet

The invention relates to a method of using high velocity metal forming to encapsulate a projection of a non-metallic article by a metallic article and a method of crimping terminal flanges defining an interstitial space therebetween, while trapping a vapor barrier element between the terminal flanges, thereby hermetically sealing the interstitial space.

Owner:WHIRLPOOL CORP

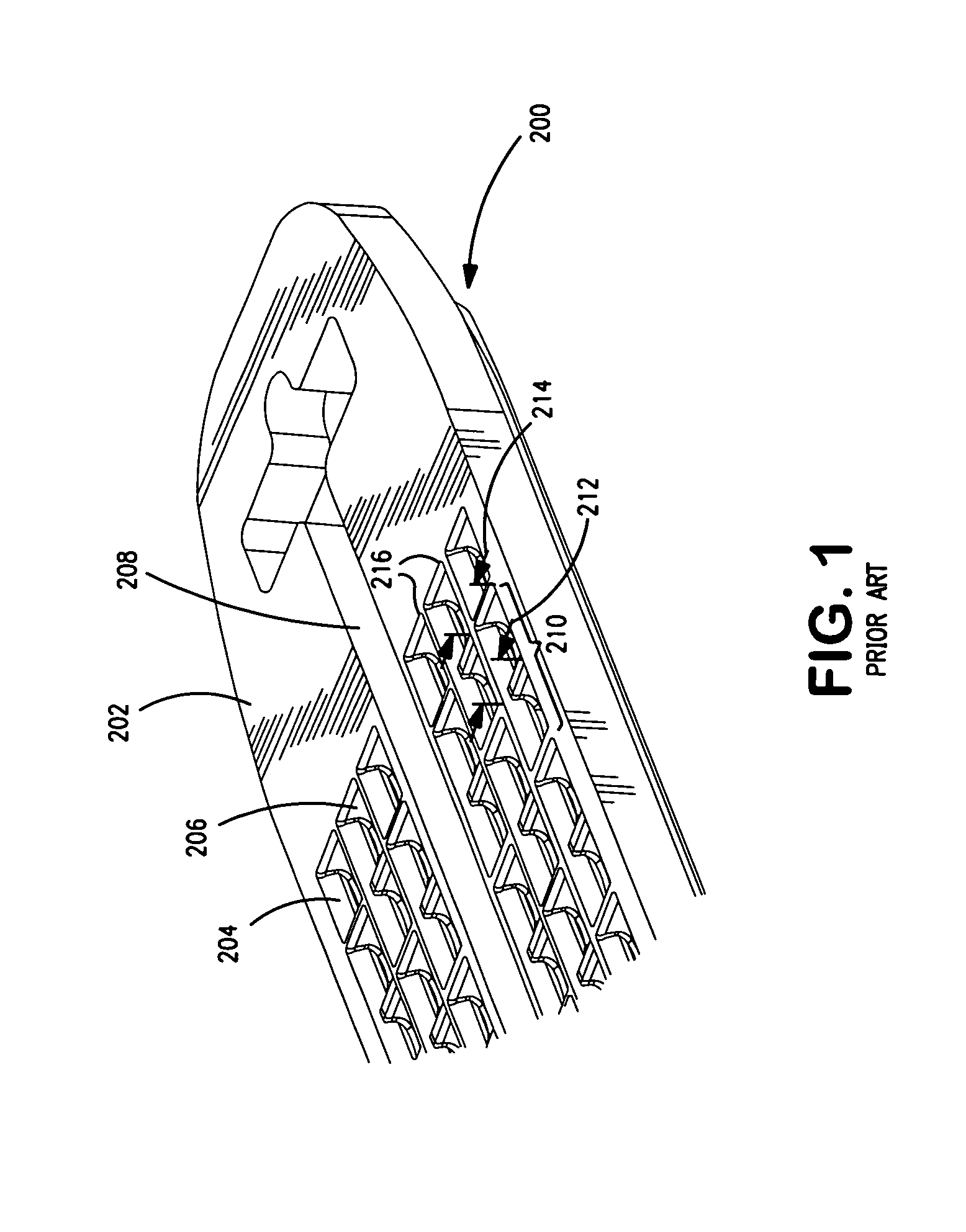

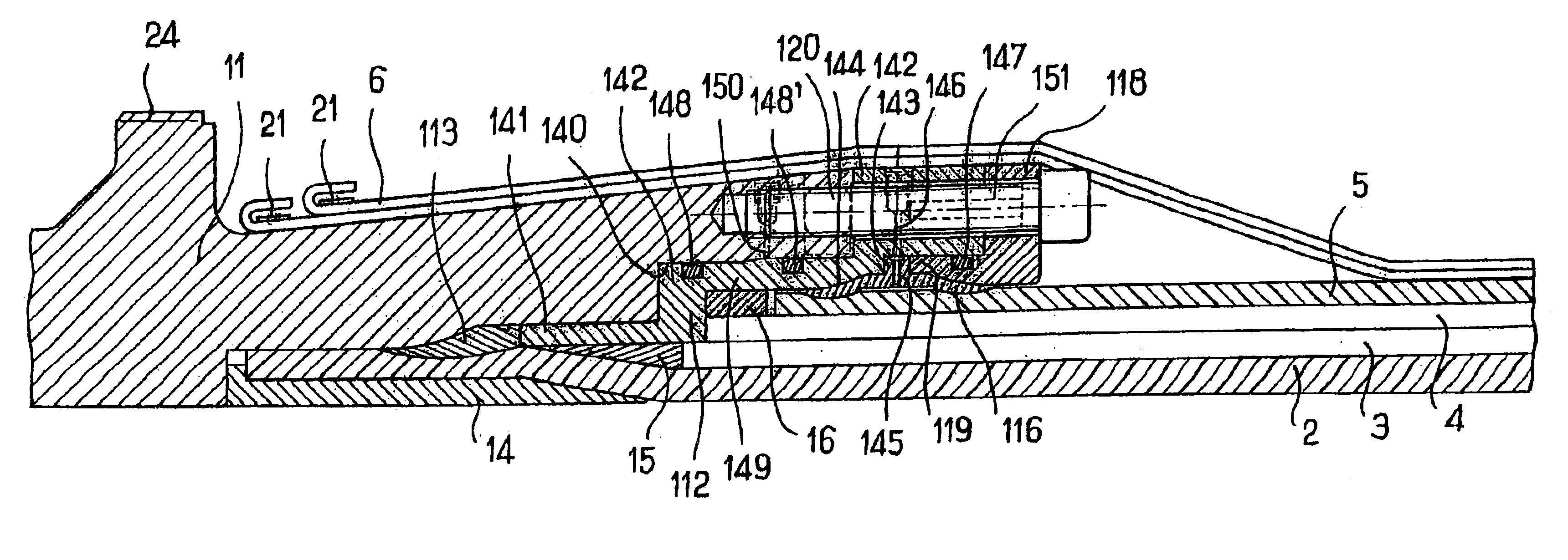

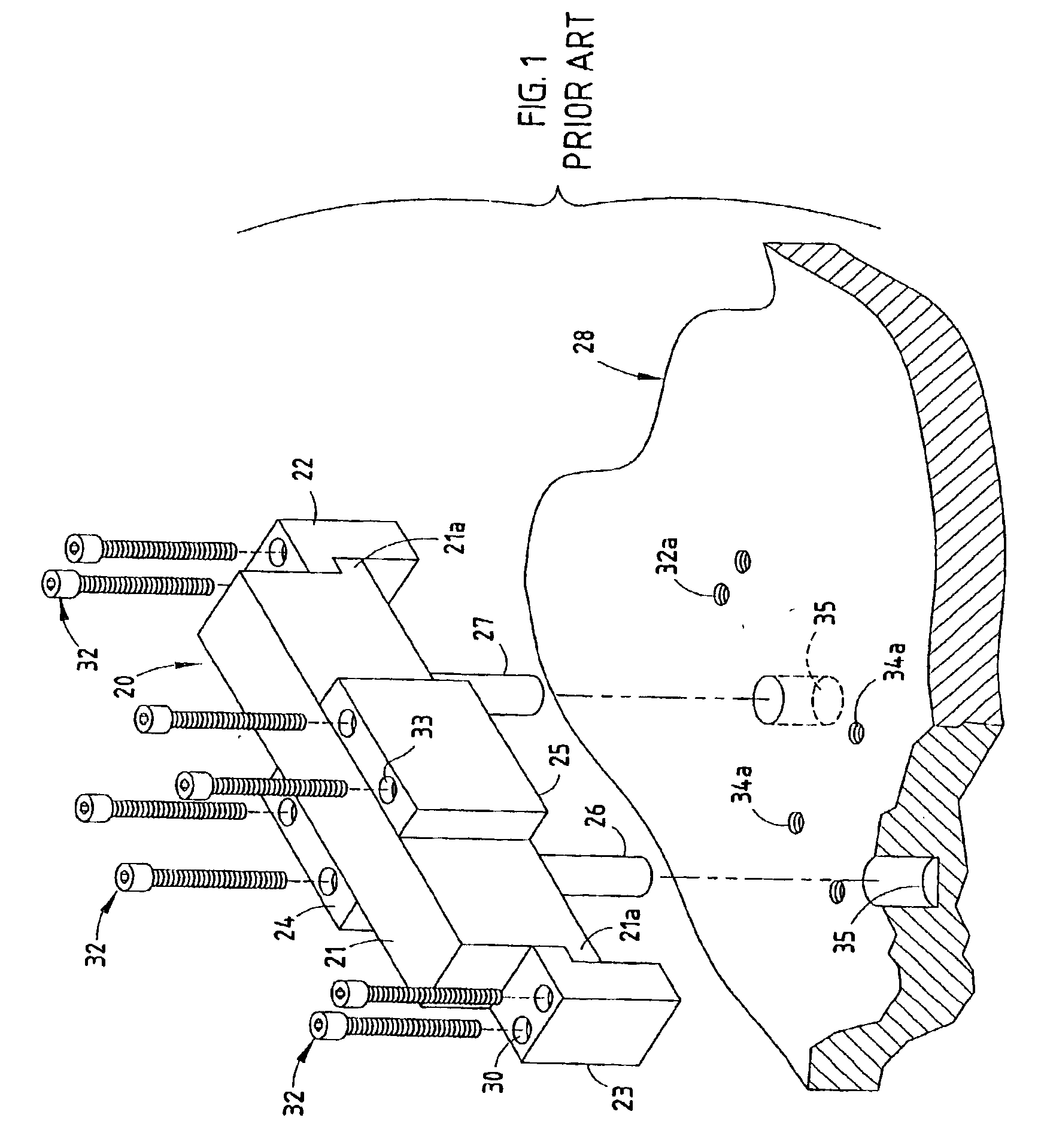

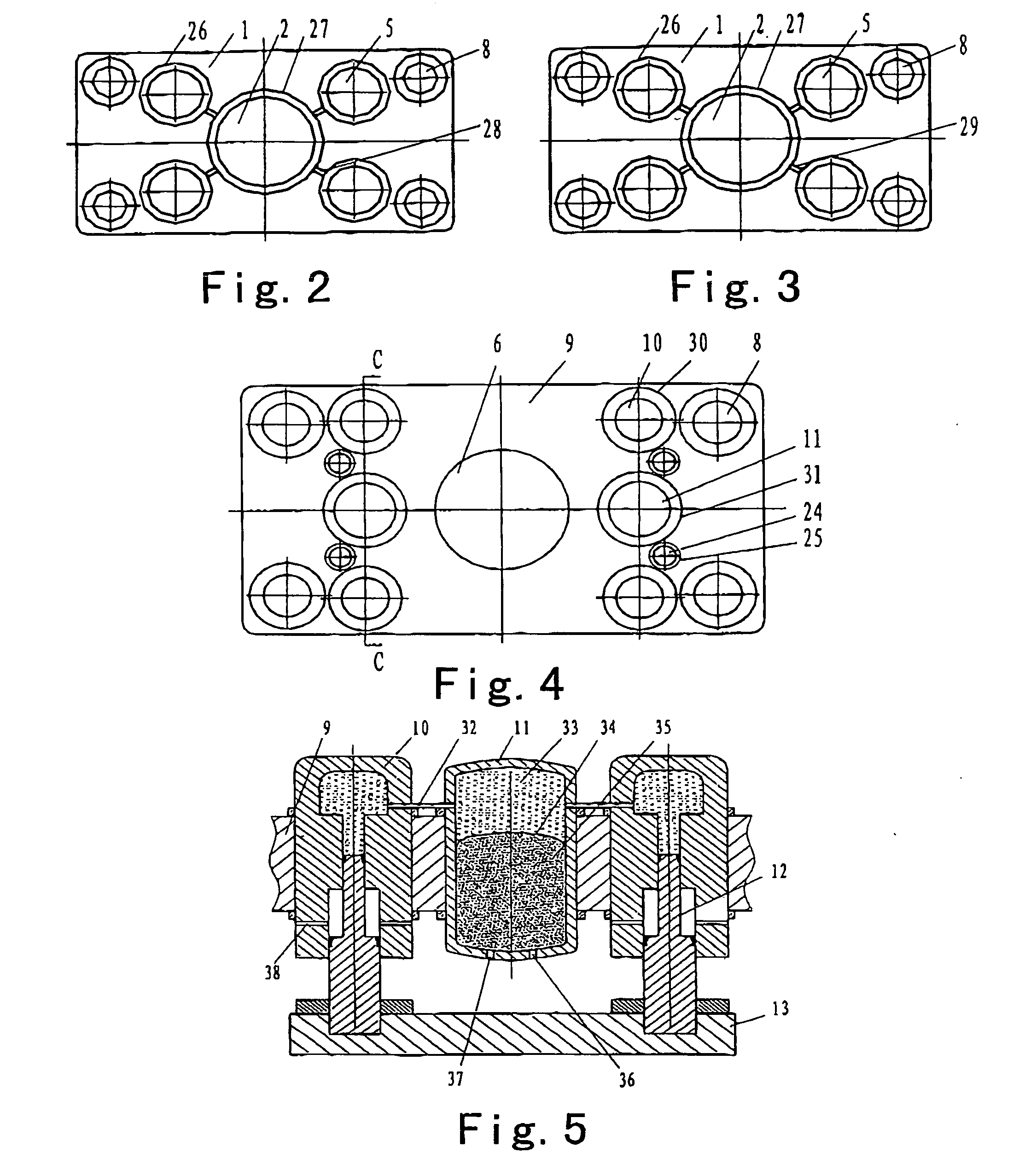

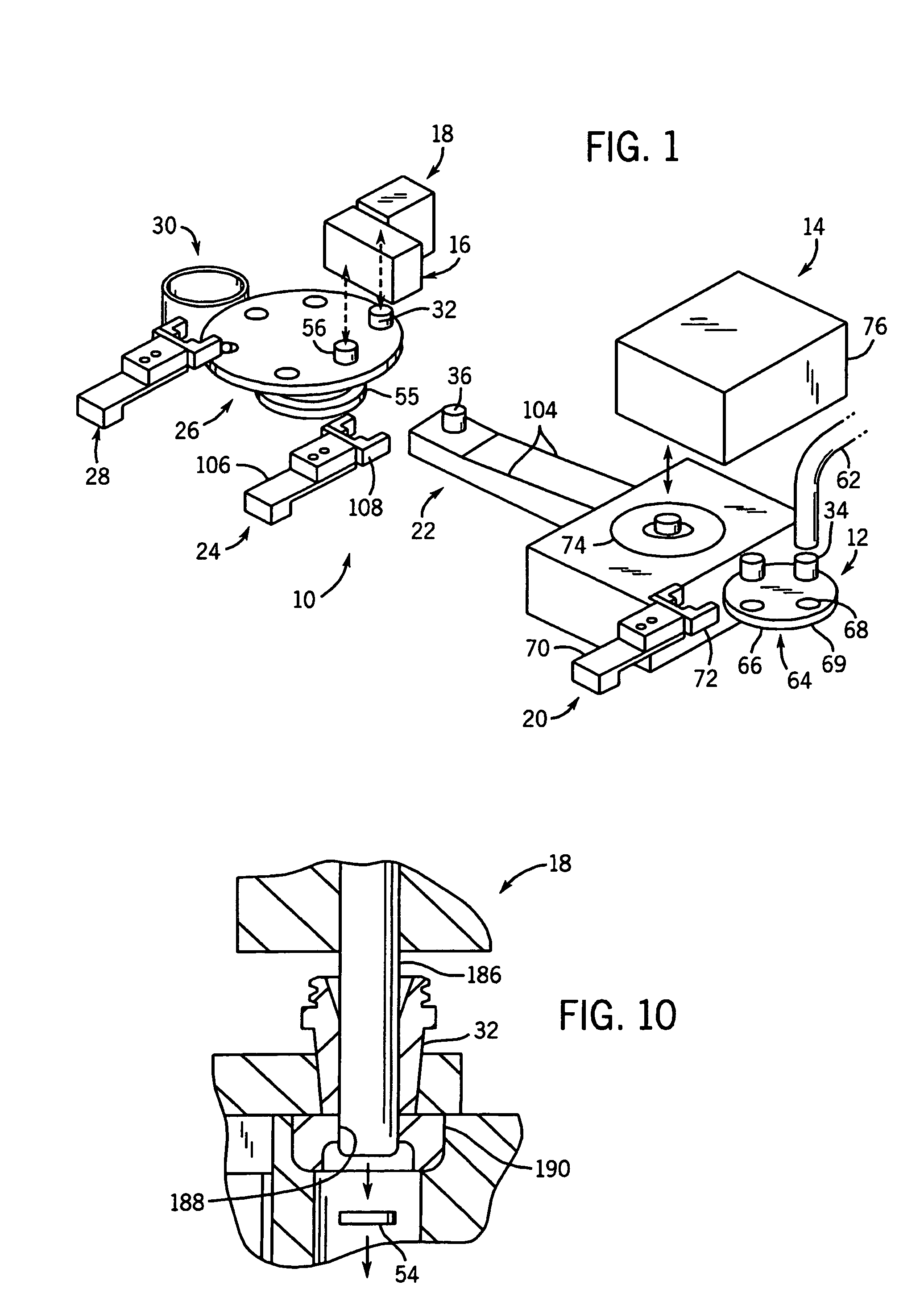

Guided keeper assembly and method for metal forming dies

ActiveUS20090193865A1Facilitate transport and mountingEasy to installShaping toolsStripping-off devicesMetal formingReciprocating motion

A guided keeper assembly and method for metal forming dies includes a base having a mounting face, a connector portion and a central aperture. A guide pin has a cylindrical center portion closely received in the central aperture of the base for reciprocation, an enlarged first end with an alignment member, and an outwardly opening circumferential groove. A retainer ring is removably mounted in and protrudes radially outwardly of the groove to securely, yet detachably, retain the base on the guide pin between the enlarged head and the retainer ring in an assembled condition to facilitate transport and mounting of the guided keeper assembly.

Owner:STANDARD LIFTERS INC

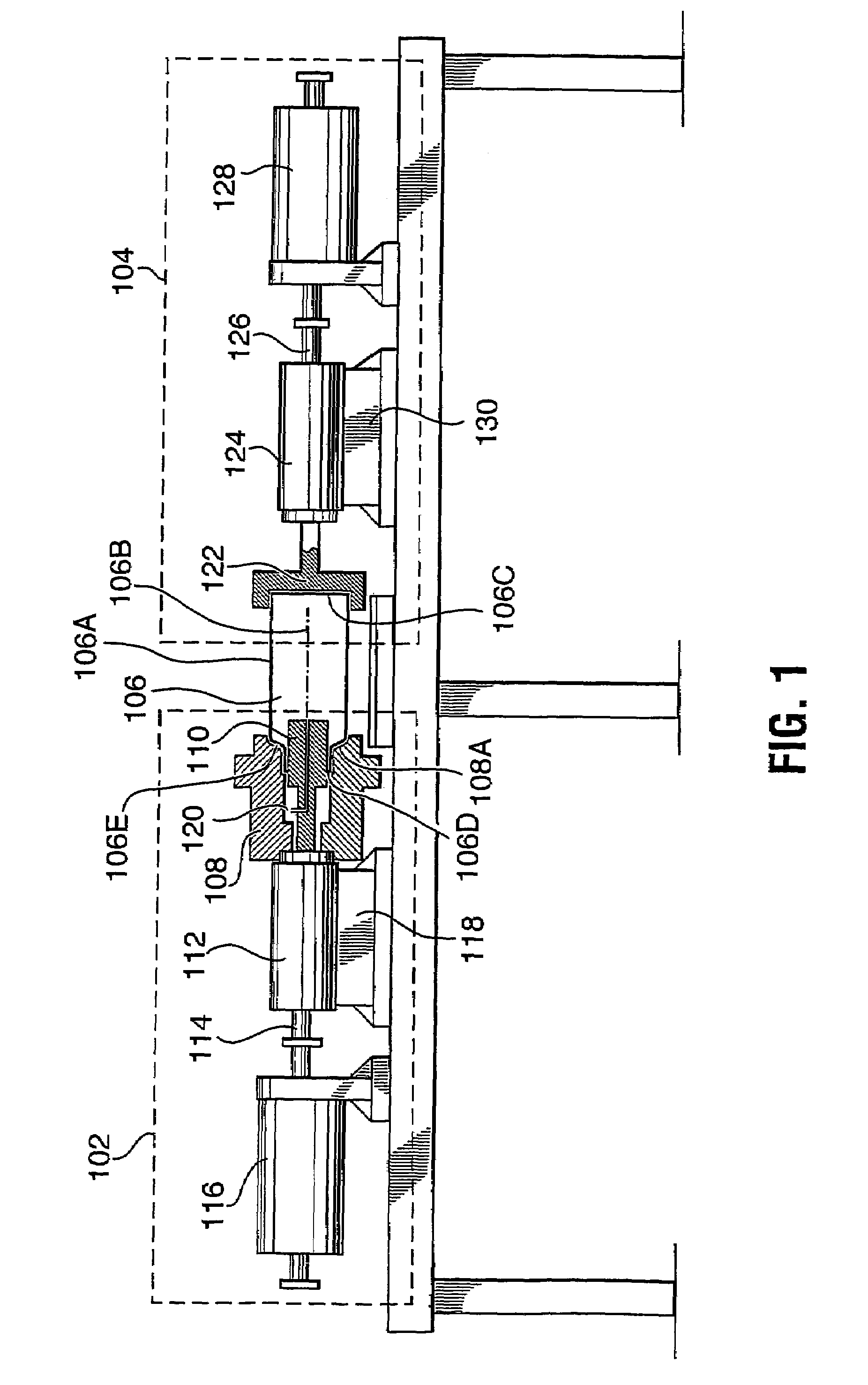

Linear drive metal forming machine

InactiveUS7073365B2Reduce the overall diameterEasy to adjustHollow articlesNumerical controlMetal forming

Owner:CROWN PACKAGING TECH

Wafer alkaline cell

ActiveUS20050208381A1Conveniently insertedAvoid the needAlkaline accumulatorsSmall-sized cells cases/jacketsElectrolyte leakageMetal forming

Owner:DURACELL U S OPERATIONS

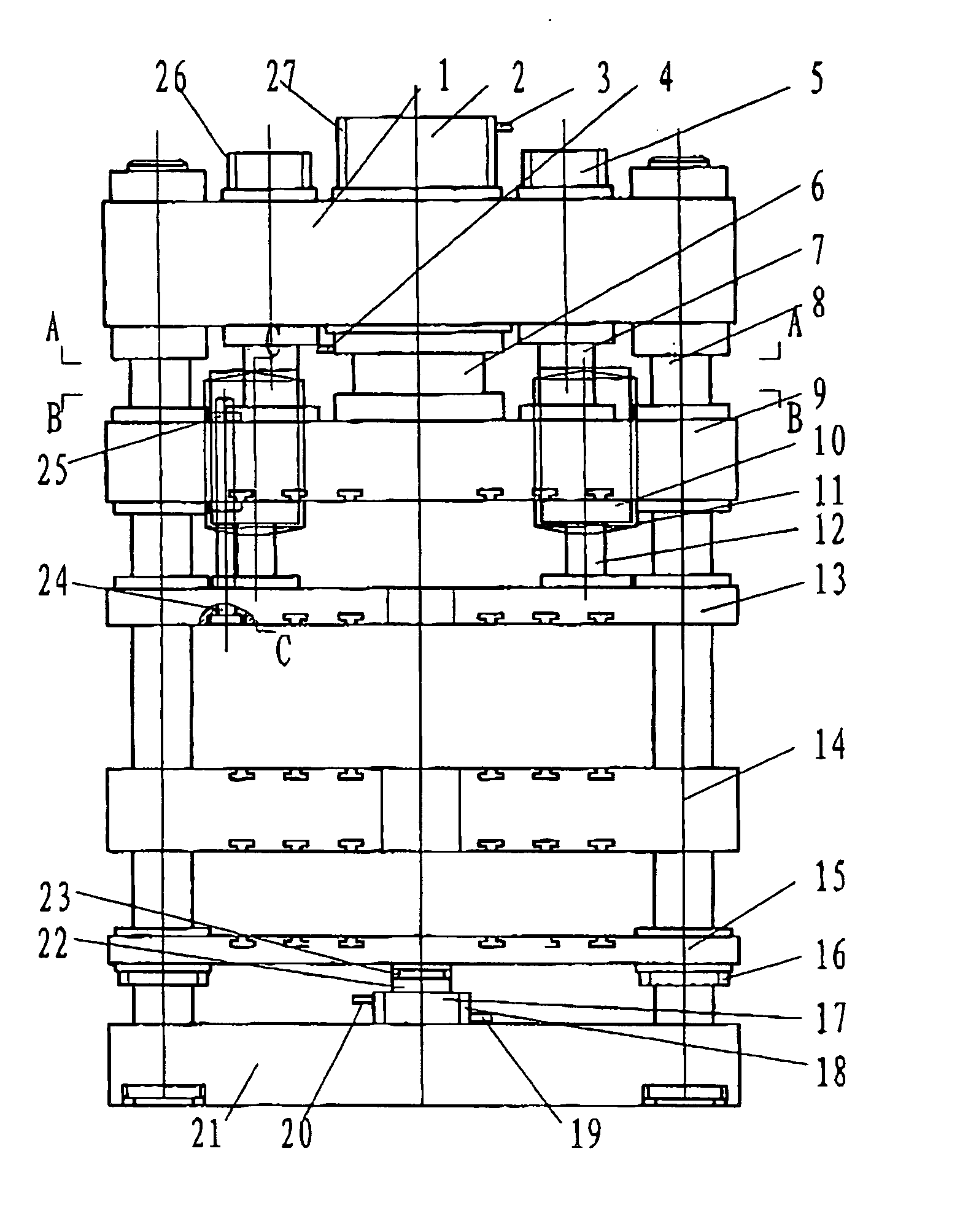

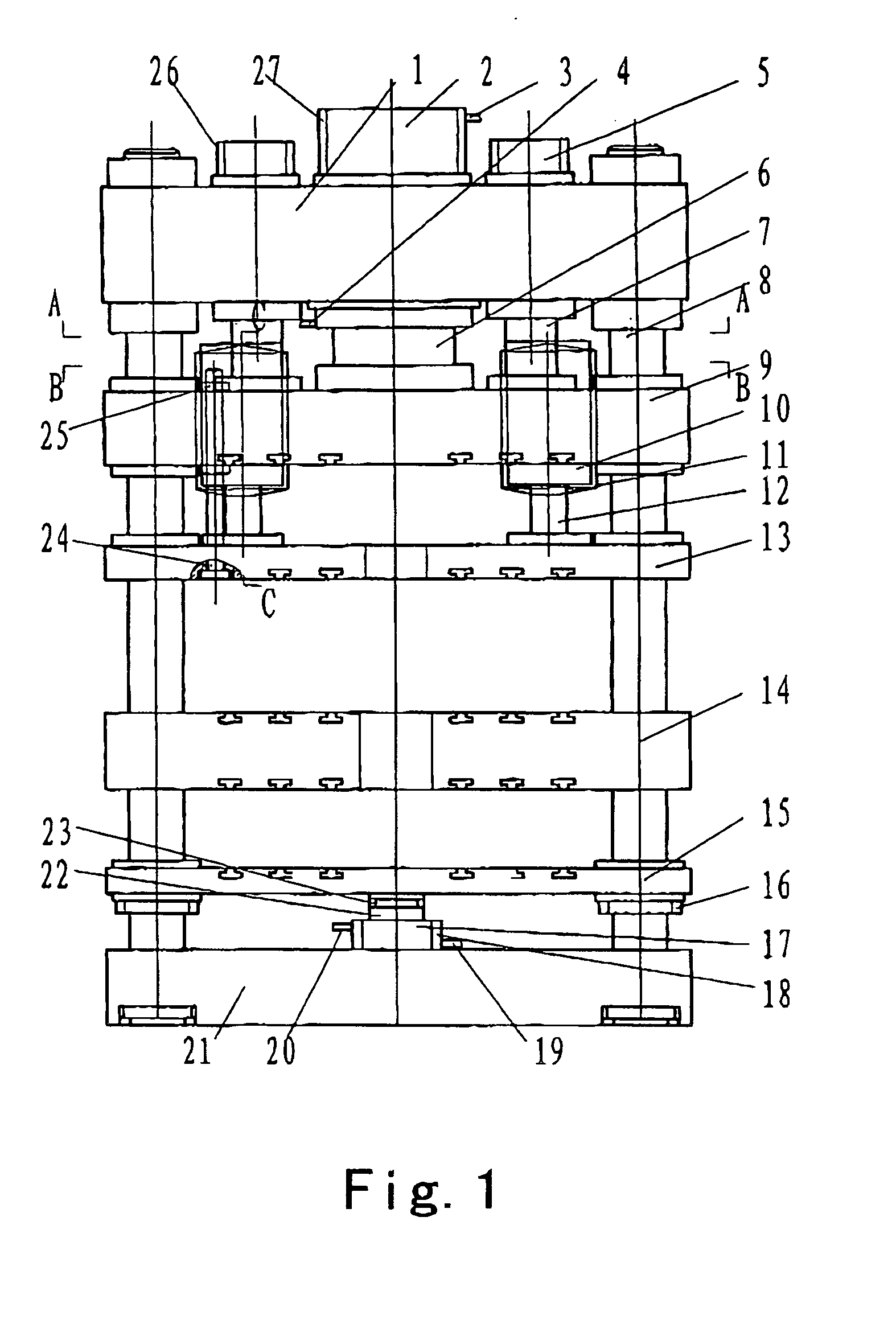

Adjustable Hydraulic Press With Both Upper And Lower Double Action

ActiveUS20080098908A1Innovative designSimple structureShaping toolsForging/hammering/pressing machinesMetal formingGear wheel

The present invention discloses an adjustable hydraulic press with both upper and lower double action, specially suitable for the cylindrical gear formed by stamping or expanding, closed forging and the metal cold forming or metal hot forming of punching, finishing, flanging and drawing of sheet materials. The press comprises four columns, an upper beam, a main slide block, a hold down slide block, a fixing worktable, a floating worktable and a lower beam. The hydraulic chamber of master cylinder fixed in the upper beam communicates to the hydraulic chamber of the auxiliary cylinder, the plunger of master cylinder is connected to the main slide block and drives it. The hydraulic chamber of gas-liquid power accumulator fixed in the main slide block communicates to the hydraulic chamber of hold down cylinder, the plunger of hold down cylinder is connected to the hold down slide block and drives it. The plunger of ejecting cylinder fixed in the lower beam is connected to the floating worktable and drives it. The hydraulic press of the invention simplifies the hydraulic system of the existing hydraulic, improves utilization rate of energy, production efficiency and working accuracy of workpiece.

Owner:JILIN UNIV

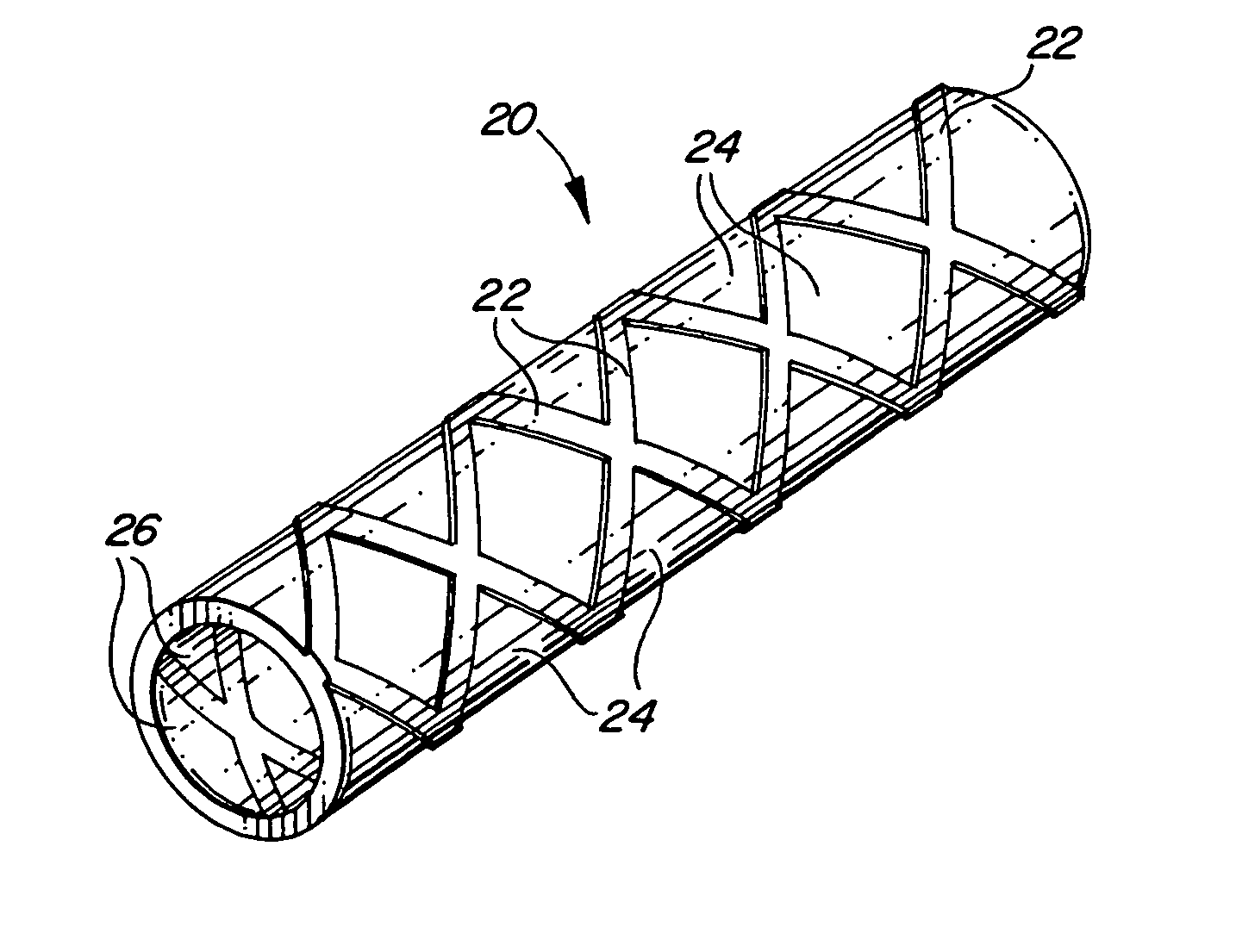

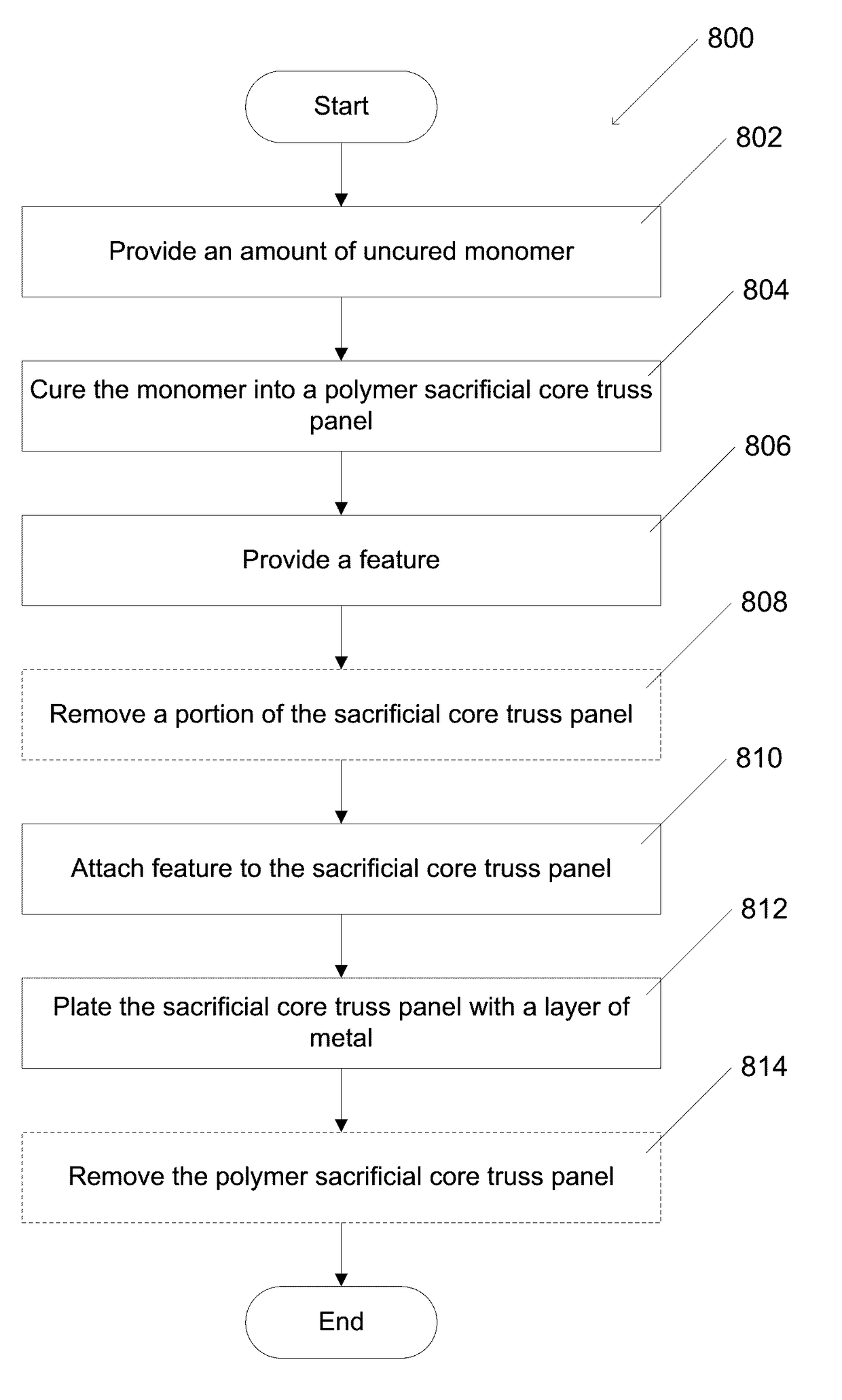

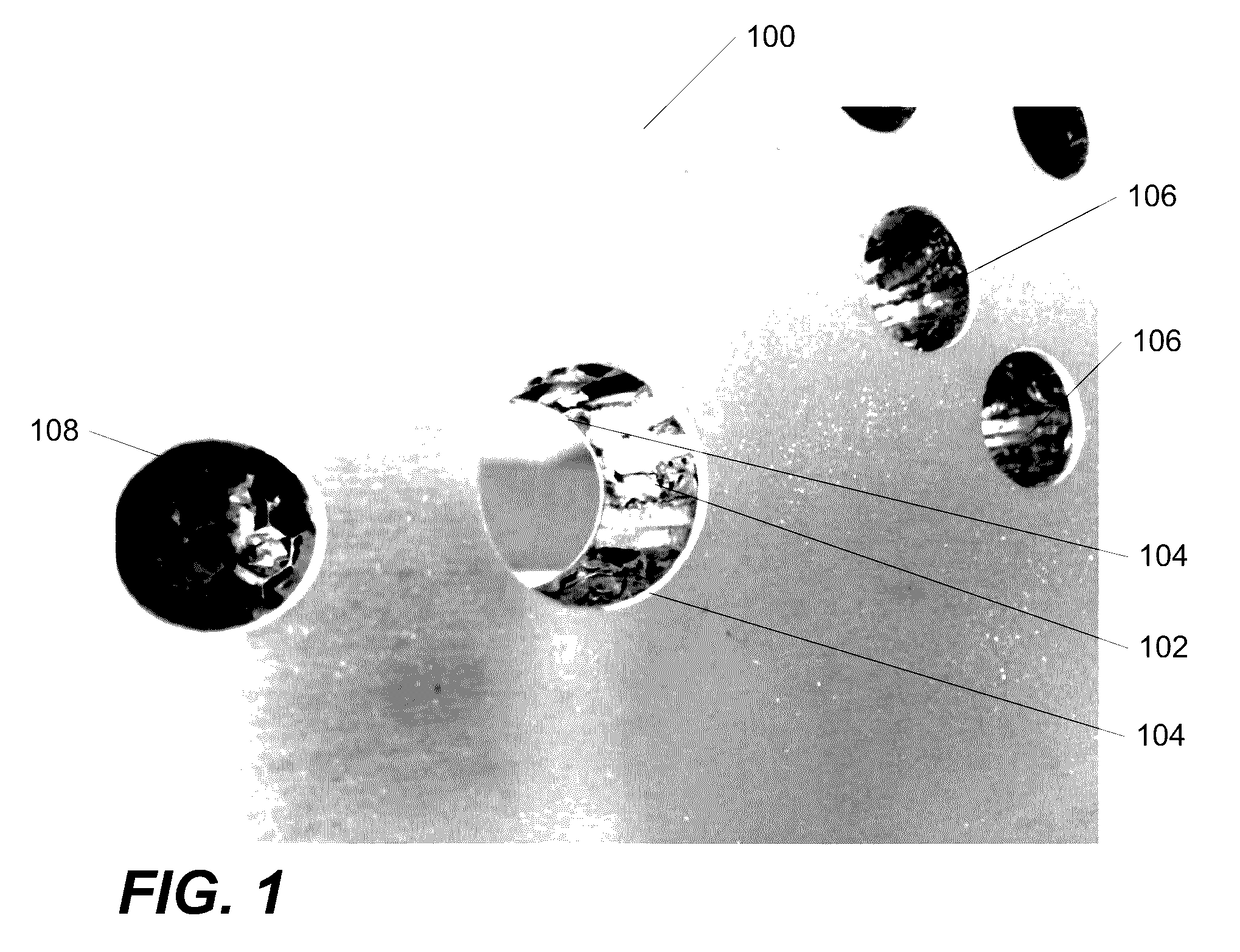

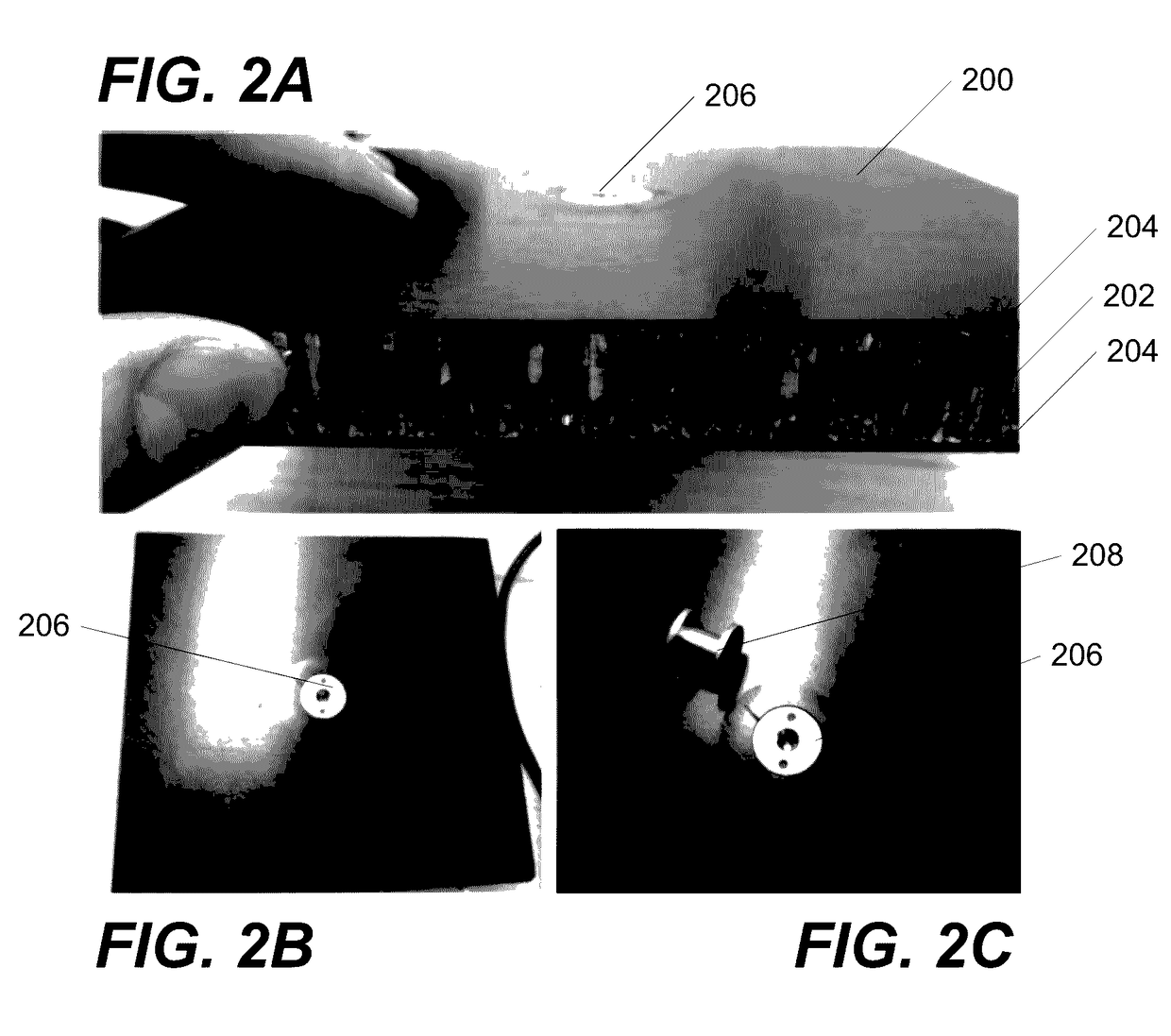

Method for Embedding Inserts, Fasteners and Features into Metal Core Truss Panels

ActiveUS20170137955A1Additive manufacturing apparatusVacuum evaporation coatingMetal formingEngineering

Systems and method for fabricating a metal core truss panel with seamlessly embedded features in accordance with embodiments of the invention are illustrated. One embodiment includes a method for producing a metal core truss panel composite, the method including fabricating a sacrificial core truss panel including a plurality of interconnected truss members and at least one embedded feature, and plating the sacrificial core truss panel with a layer of metal forming a metal core truss panel including a plurality of interconnected metal truss members and at least one seamlessly embedded metal feature.

Owner:CALIFORNIA INST OF TECH

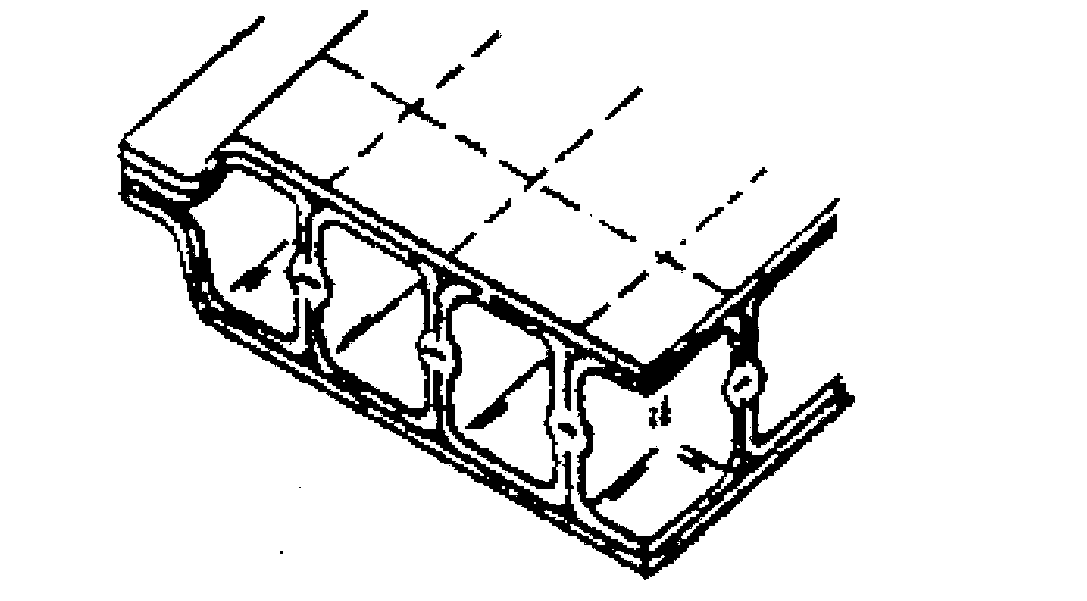

Superplastic forming (SPF)/diffusion bonding (DB) forming method of titanium alloy cylindrical three-layer structure

ActiveCN103008998AThe overall structure is light in weightImprove integrityMetal formingTitanium alloy

The invention belongs to a sheet-metal forming technology, and relates to a superplastic forming (SPF) / diffusion bonding (DB) forming method of a titanium alloy cylindrical three-layer structure. A novel blank structural form and a blank production method are adopted, the requirements on coating welding stopping agent and positioning a cylinder on a three-layer structure can be met, and a hot isostatic pressure DB and cylinder SPF step-by-step formation method is adopted for the cylinder blank, so that the technical difficulty and complexity can be reduced, and the structural flexibility can be improved. A partition ring is creatively additionally arranged among the cylinders, the dropping of the welding stopping agent, caused by the collision of the cylinders, can be avoided, an air inlet passage and an exhaust passage are directly machined and formed on the blank, no air passage needs to be machined on a mold, and the structural complexity of a tool can be reduced. The SPF / DB formation of the titanium alloy cylindrical three-layer structure can be stably and reliably realized, and the formation quality and the technological stability can be improved. The SPF / DB technological method is enlarged from the formation of a flat sandwich structure to the formation of the cylindrical rotation sandwich structure, so that the application field of the process can be enlarged, and good economic and technical benefit can be realized.

Owner:BEIJING AERONAUTICAL MFG TECH RES INST

Method of controlled remelting of or laser metal forming on the surface of an article

InactiveUS7586061B2Superior emission lifetimeRelieve pressurePolycrystalline material growthMolten spray coatingMetal formingControl system

A method for controlled remelting of or laser metal forming on the surface (5) of an article (1) can include moving a light source and a signal capturing apparatus over the article (1). The light source having a specific power can be used to melt the surface (5) of the article (1) locally and to form a melt pool (7). Thereby an optical signal (13) is captured by the signal capturing apparatus from the melt pool (7), and the monitored optical signal (13) is used for the determination of temperature and temperature fluctuations as properties of the melt pool (7). Furthermore, a control system (16) with a feedback circuit is used to adjust at least one process parameter such as the power of the light source such that desired melt pool properties are obtained. Subsequently the melt pool (7) solidifies.

Owner:ANSALDO ENERGIA IP UK LTD

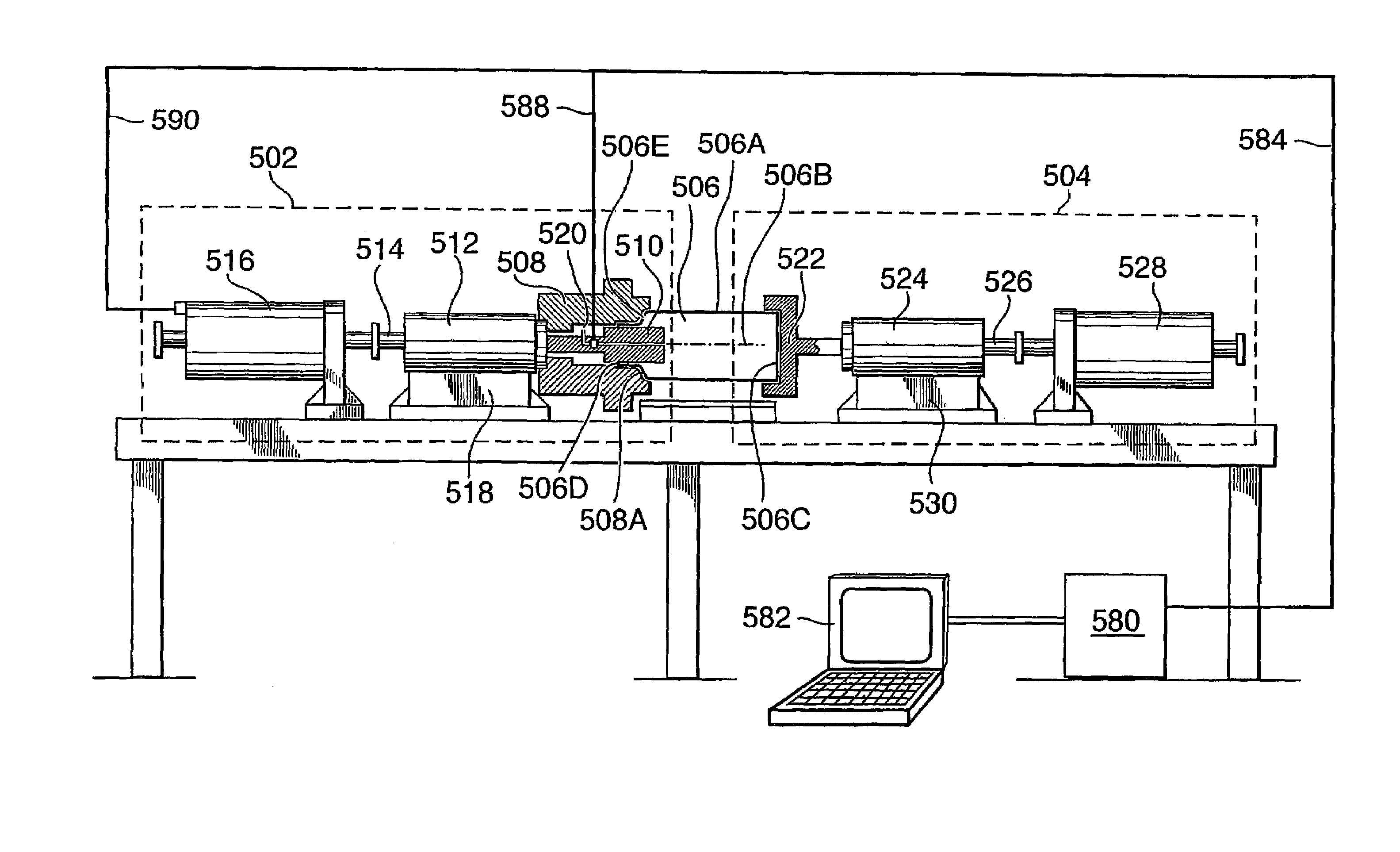

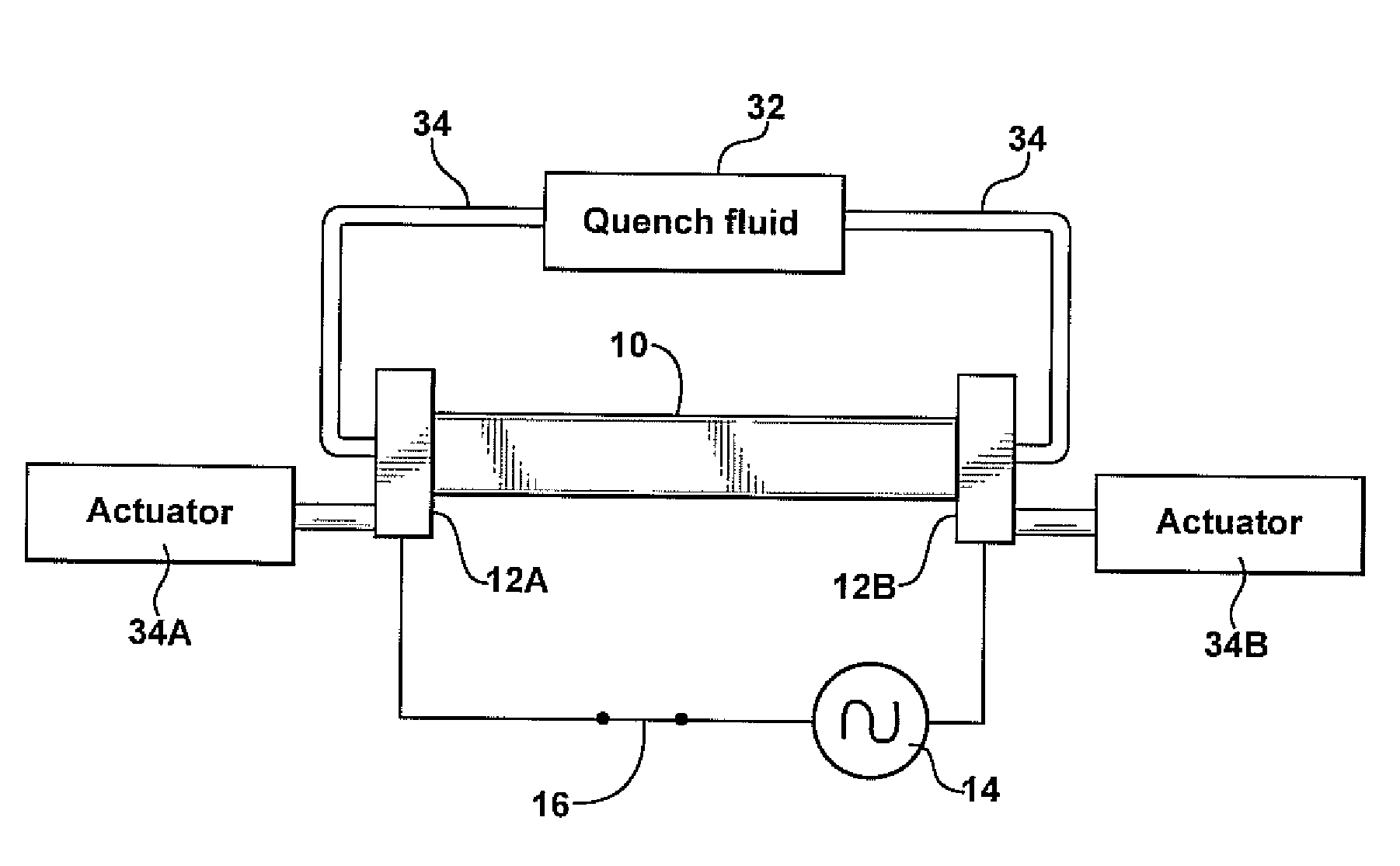

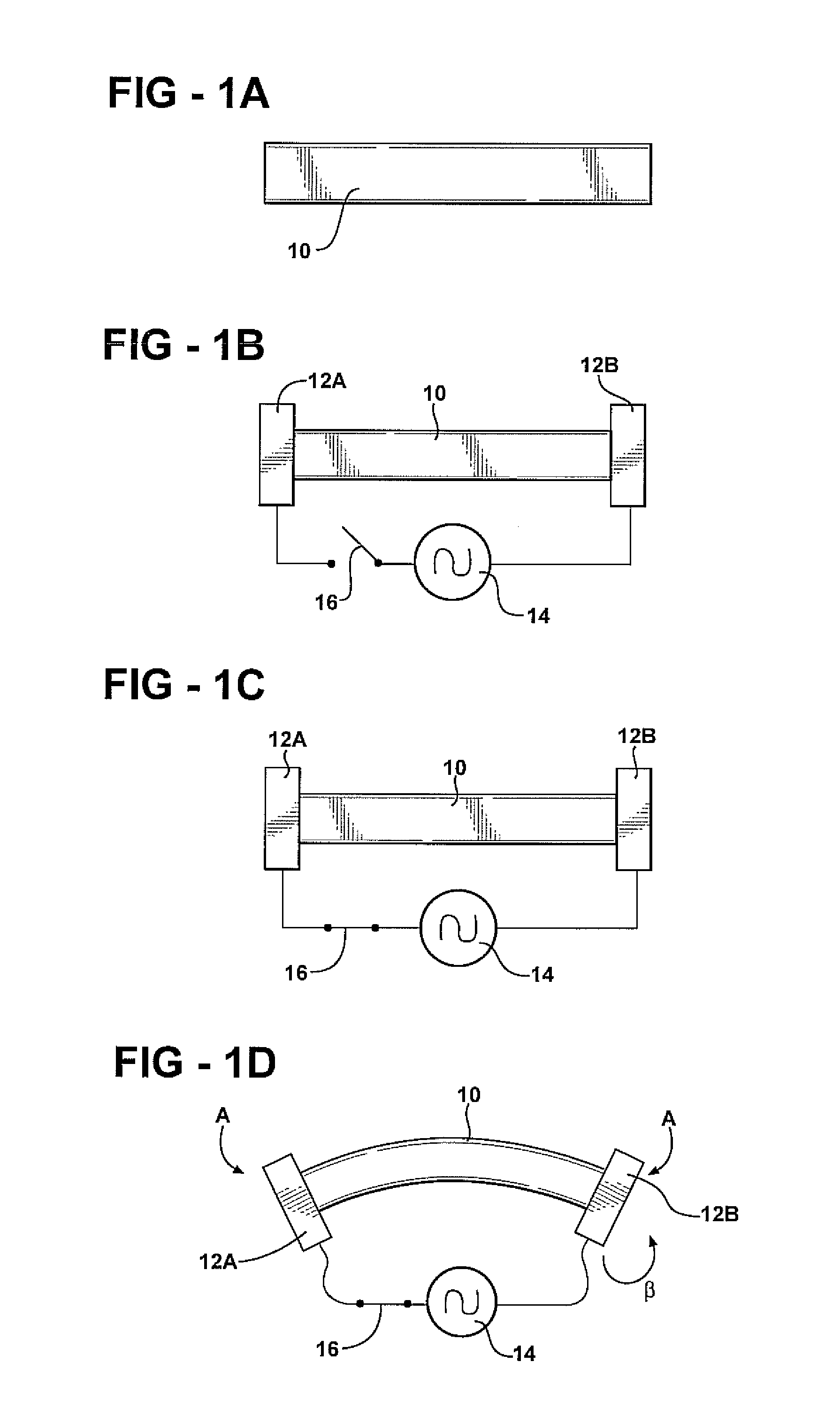

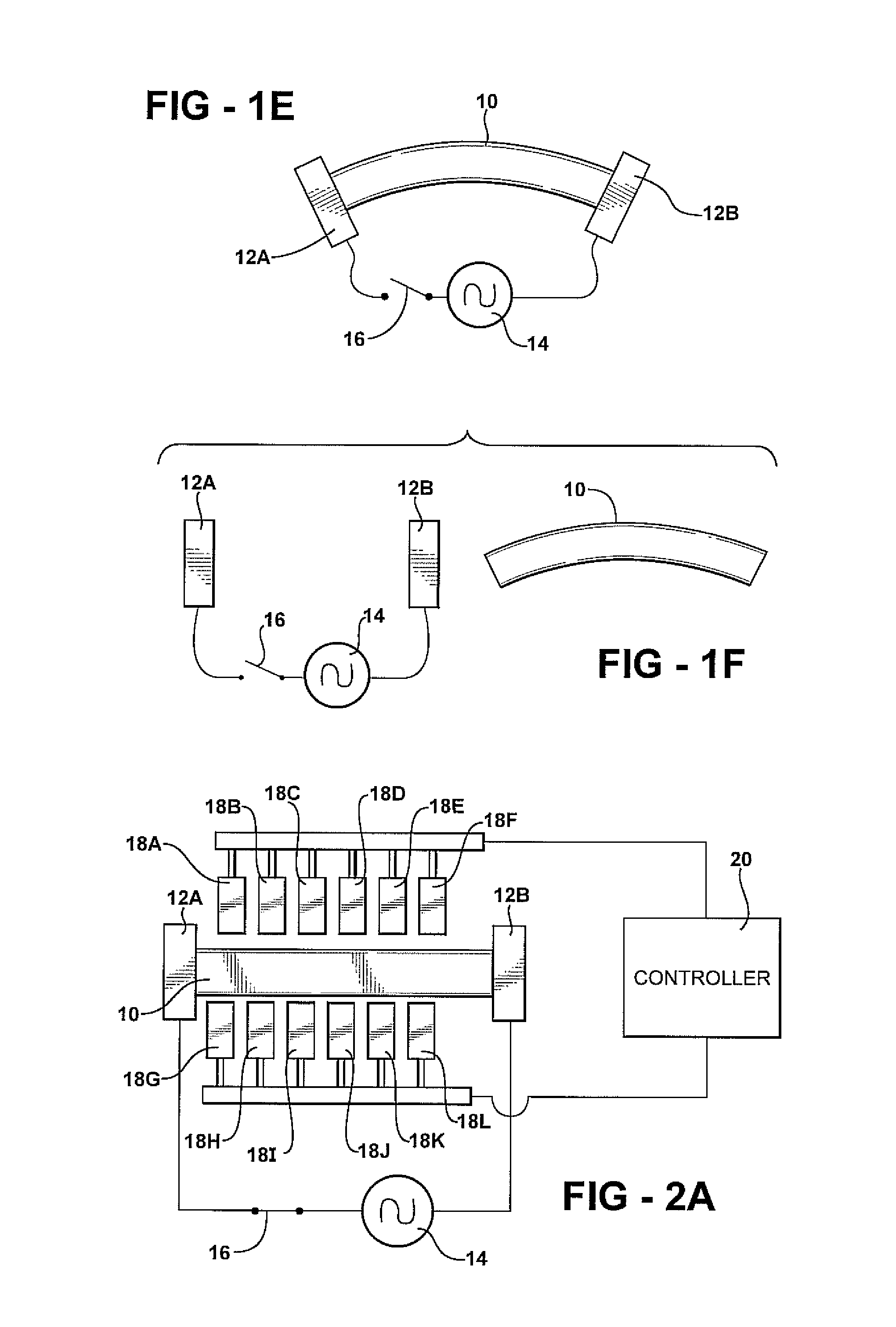

Metal forming apparatus and process with resistance heating

InactiveUS20080302775A1Easy to adaptQuickly reconfiguredElectric discharge heatingArc welding apparatusElectrical resistance and conductanceElectricity

An apparatus for forming a metal article includes a station which receives and supports a workpiece. The station has a source of electrical current and a source of a fluid. The station further includes a first and a second electrode clamp. Each clamp is in electrical communication with the source of current and in fluid communication with the source of fluid. The clamps engage a workpiece and deliver an electrical current and a fluid thereto. The system includes an actuator mechanically associated with at least one of the clamps. The actuator is operable in combination with a clamp to apply mechanical force to the workpiece. The system is operable to selectably control the temperature profile and / or ambient conditions of a workpiece during forming or processing steps. Disclosed are specific systems including modular systems. Also disclosed are methods for using the systems.

Owner:NOBLE ADVANCED TECH

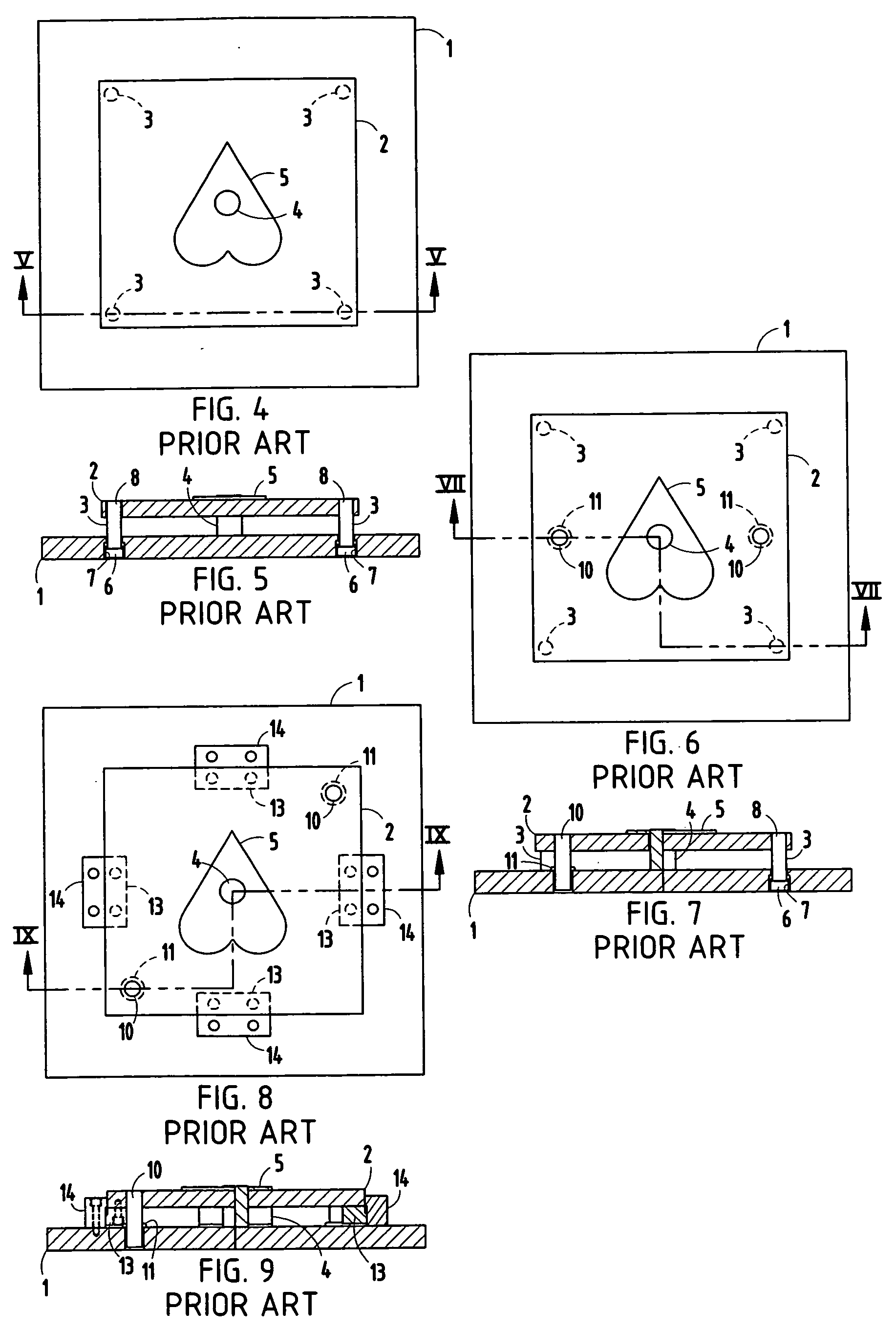

Draw-in map for stamping die tryout

ActiveUS7130708B2Rapid productionMinimum effortShaping toolsSpecial data processing applicationsMetal formingSize determination

Sheet metal forming is a manufacturing process in which flat sheet metal is drawn into a die cavity to form a product shape. Draw-in amount is the single most important stamping index that controls all forming characteristics (strains and stresses), formability failures (splits, wrinkles) and surface quality (distortions) on a panel. Adaptation of a new die set for repetitively stamping sheet metal parts to a part design specification is simplified by using a math-based simulation of the stamping operation under specified engineering stamping conditions for the specified part. The stamping simulations are used to create an engineered draw-in map comparing selected locations on the peripheral edge of the stamped part with corresponding locations on the peripheral edge of its original sheet metal blank. The resulting map of sheet metal draw-in dimensions reflect suitable displacements of the metal sheet between the binder ring and binder surface of the female die member at all such locations as the punch member of the die set executes its stamping operation. The engineered draw-in dimensions for a simulated part identify specific locations for adjustment of the binder ring / binder surface system in adapting the die set for production of parts.

Owner:GM GLOBAL TECH OPERATIONS LLC

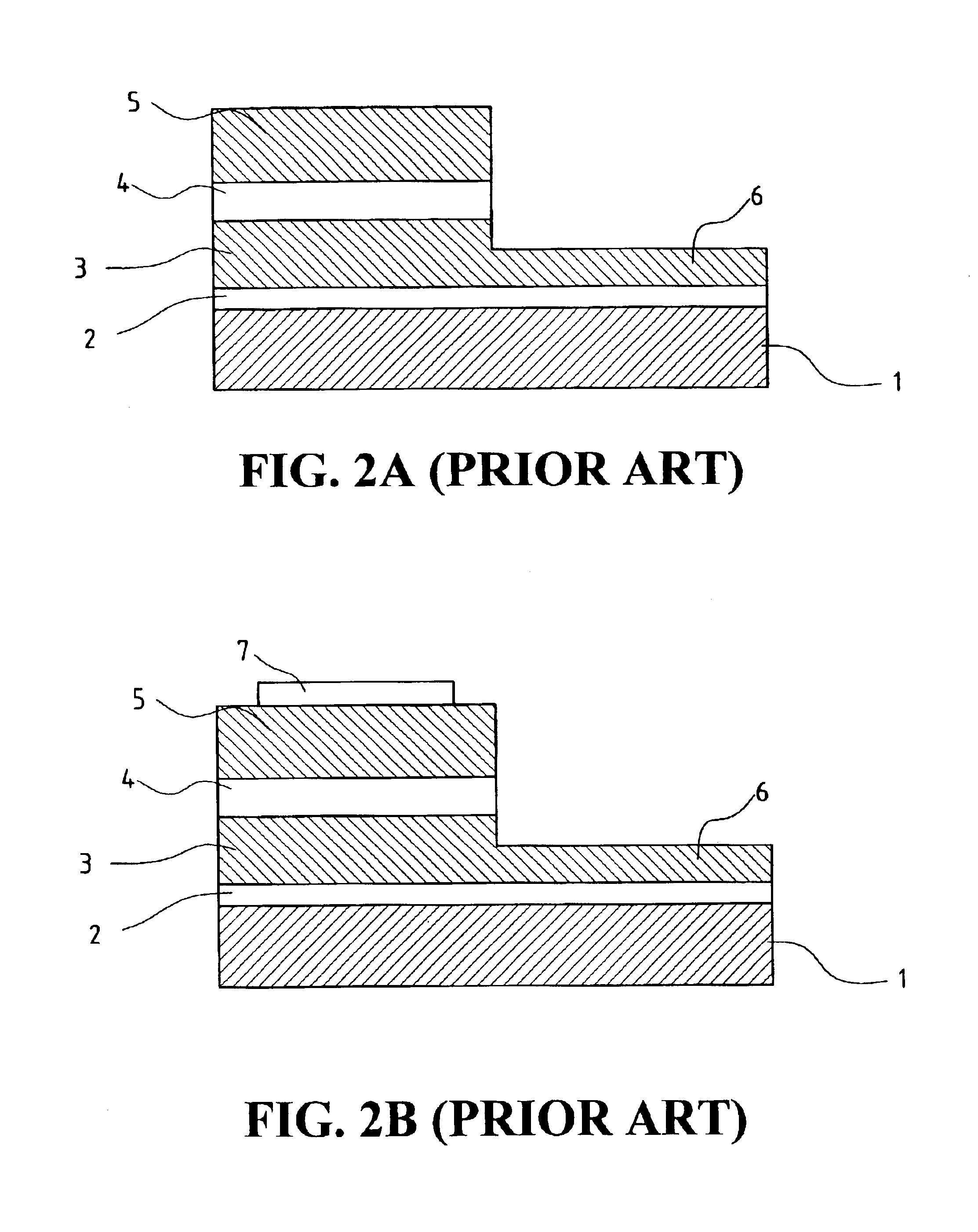

Structure and manufacturing method for GaN light emitting diodes

InactiveUS6914264B2Good light penetrationReduce resistanceSolid-state devicesSemiconductor devicesMetal formingOhmic contact

A GaN semiconductor stack layer is formed on top of a substrate for manufacturing a light emitting diode. The GaN semiconductor stack layer includes, from the bottom up, an N-type GaN contact layer, a light emitting stack layer and a P-type contact layer. The next step is to form a digital transparent layer on the P-type GaN contact layer, then use dry etching technique to etch downward through the digital transparent layer, the P-type GaN contact layer, the light emitting layer, the N-type GaN contact layer, and form an N-metal forming area within the N-type GaN contact layer. The next step is to form a first ohmic contact electrode on the P-type contact layer to serve as P-type ohmic contact, and a second ohmic contact electrode on the N-metal forming area to serve as N-type ohmic contact. Finally, a bump pad is formed on the first ohmic contact electrode and the second ohmic contact electrode, respectively.

Owner:FORMOSA EPITAXY INCORPORATION +1

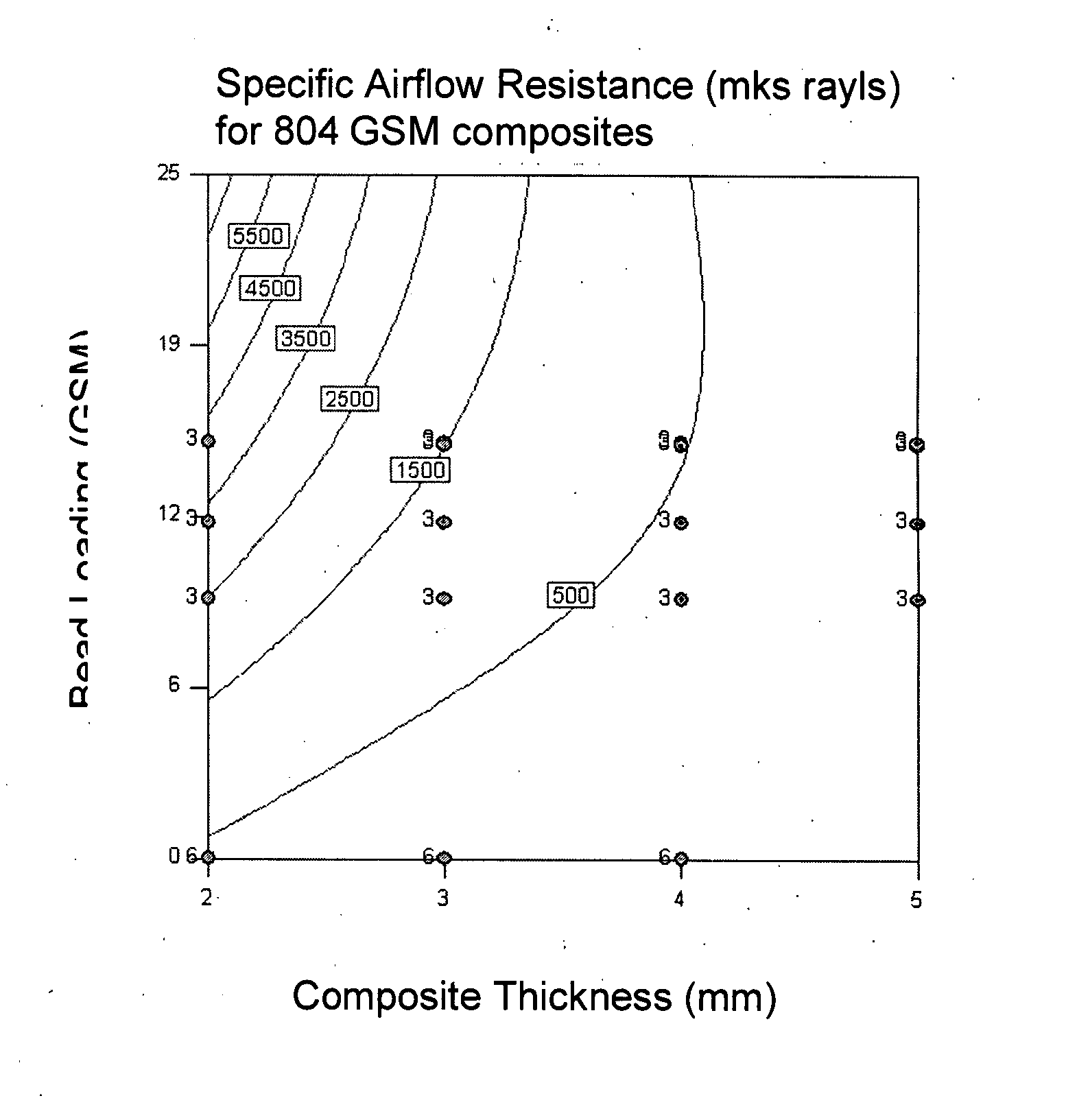

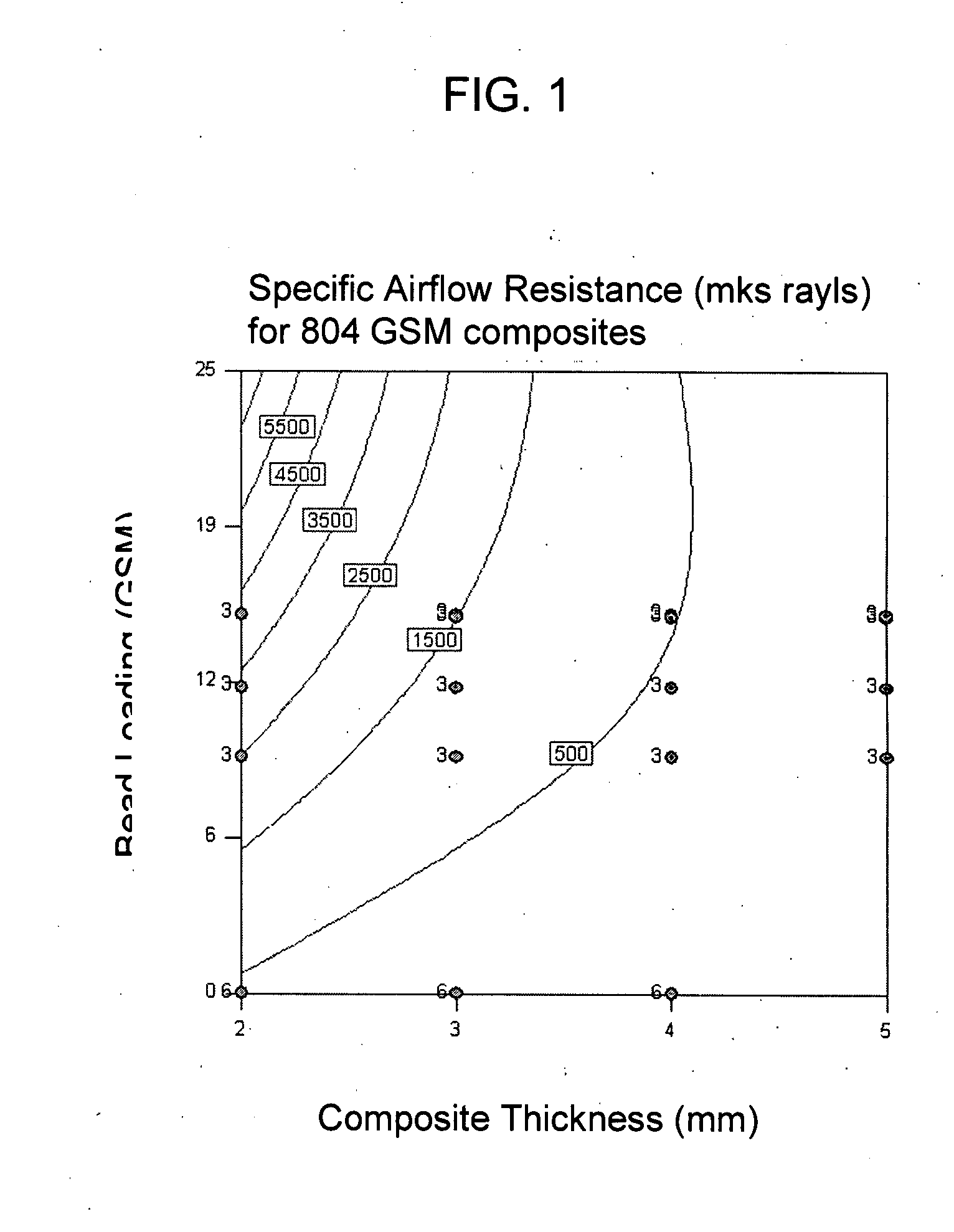

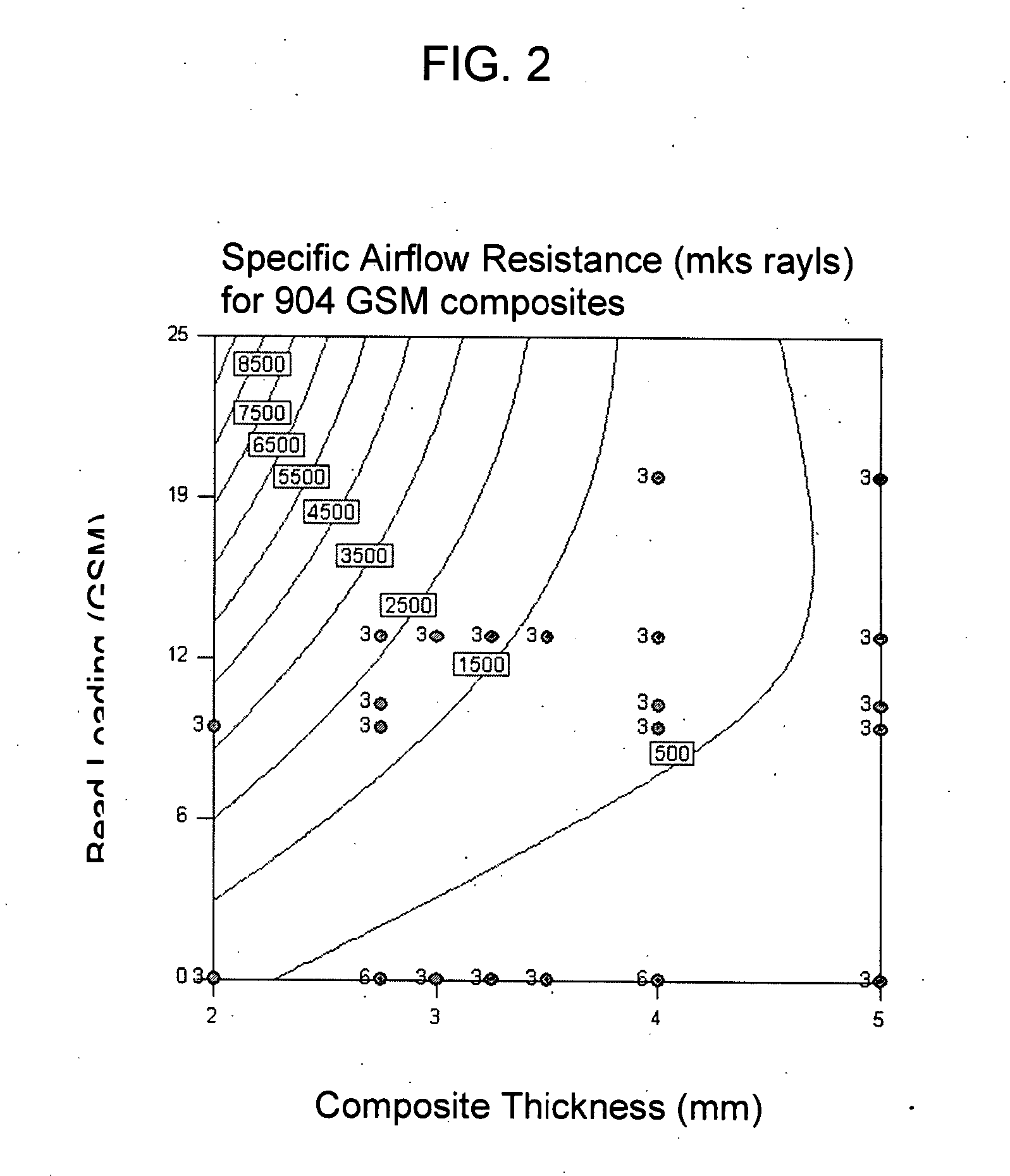

Enhanced sound absorption in thermoplastic composites

InactiveUS20080008869A1Good sound-absorbing propertiesEnhanced sound absorption characteristicNatural cellulose pulp/paperSynthetic resin layered productsMetal formingMicrosphere

A moldable composite sheet having enhanced sound absorption characteristics and attenuation of transmitted sound intensities. In one aspect, the composite sheet may be a porous fiber-reinforced thermoplastic comprising discontinuous reinforcing fibers, expandable polymeric beads such as microspheres, and, optionally, one or more thermoplastic skins. Generally, the composite sheet may have a void content or porosity from greater than 0% to about 95% by volume of the sheet, an areal weight between about 400 g / m2 to about 4000 g / m2 (gsm), a fiber content from about 20% to about 80% by weight, and an expandable polymeric bead content from greater than 0 gsm to about 25 gsm. The composite sheet can be molded via low pressure processes, such as thermoforming, match metal molding on stops, vacuum forming and pressure forming, to produce durable automotive interior trim parts and construction articles having enhanced sound absorption capabilities in addition to other beneficial characteristics.

Owner:AZDEL INC

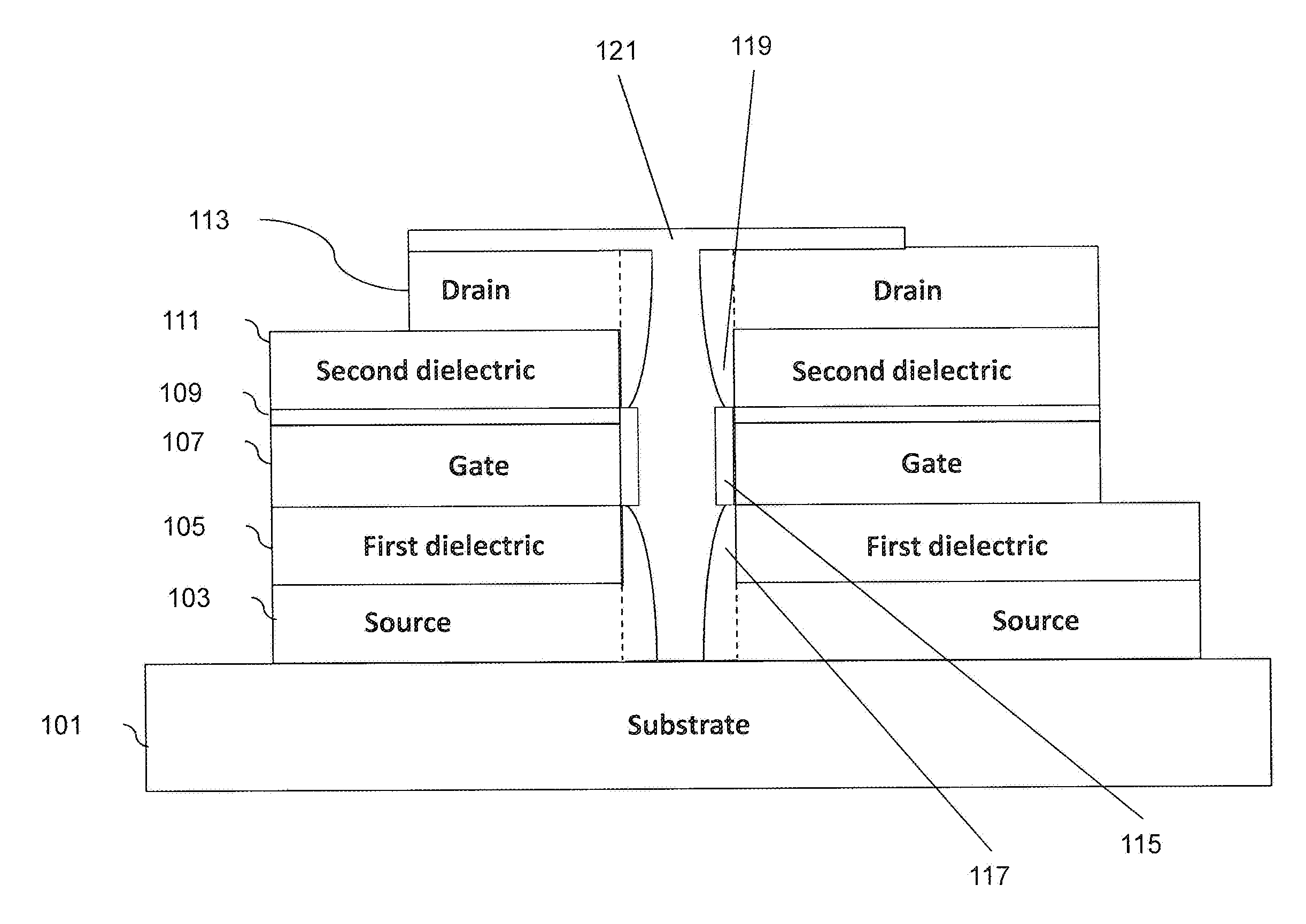

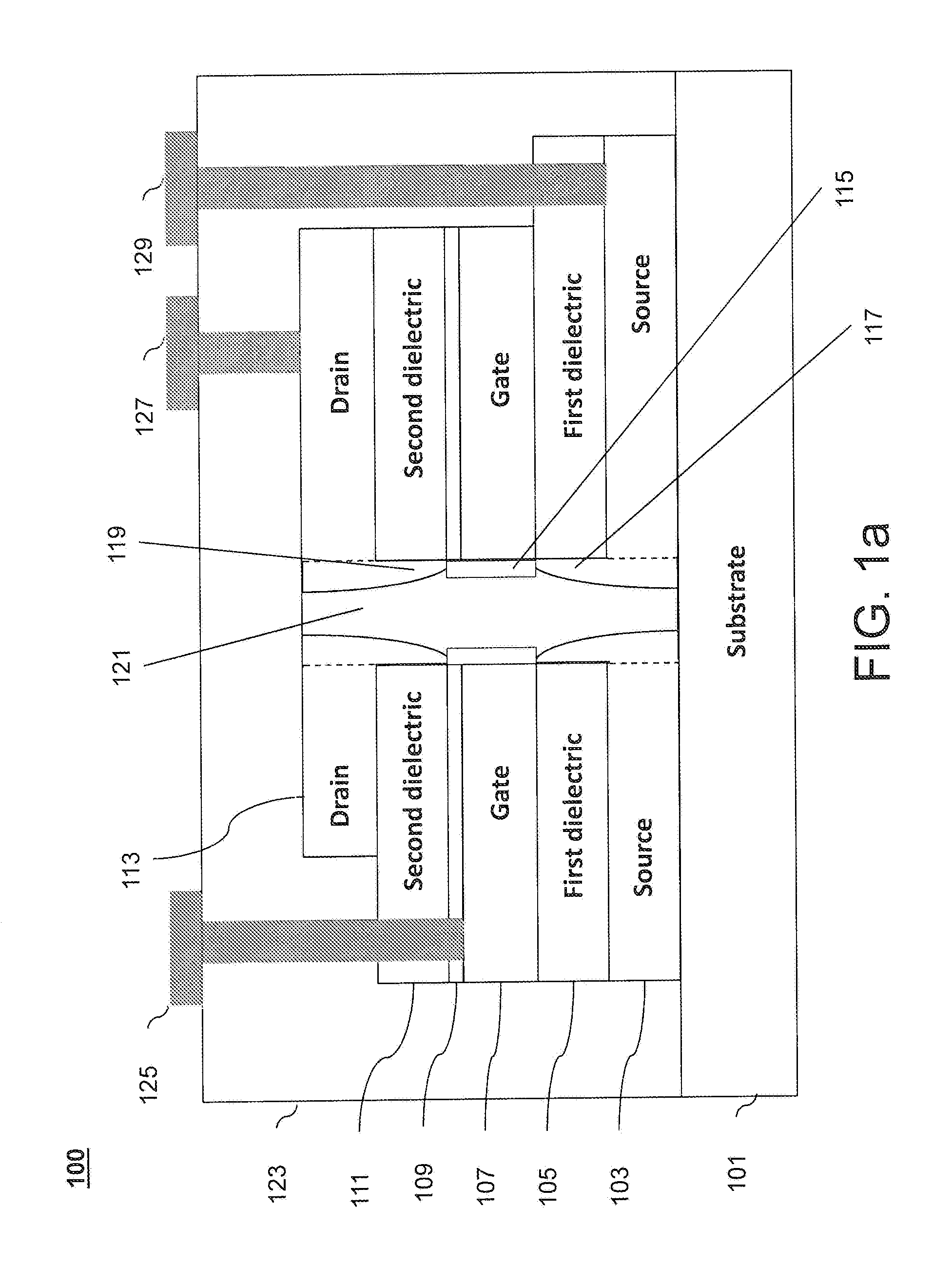

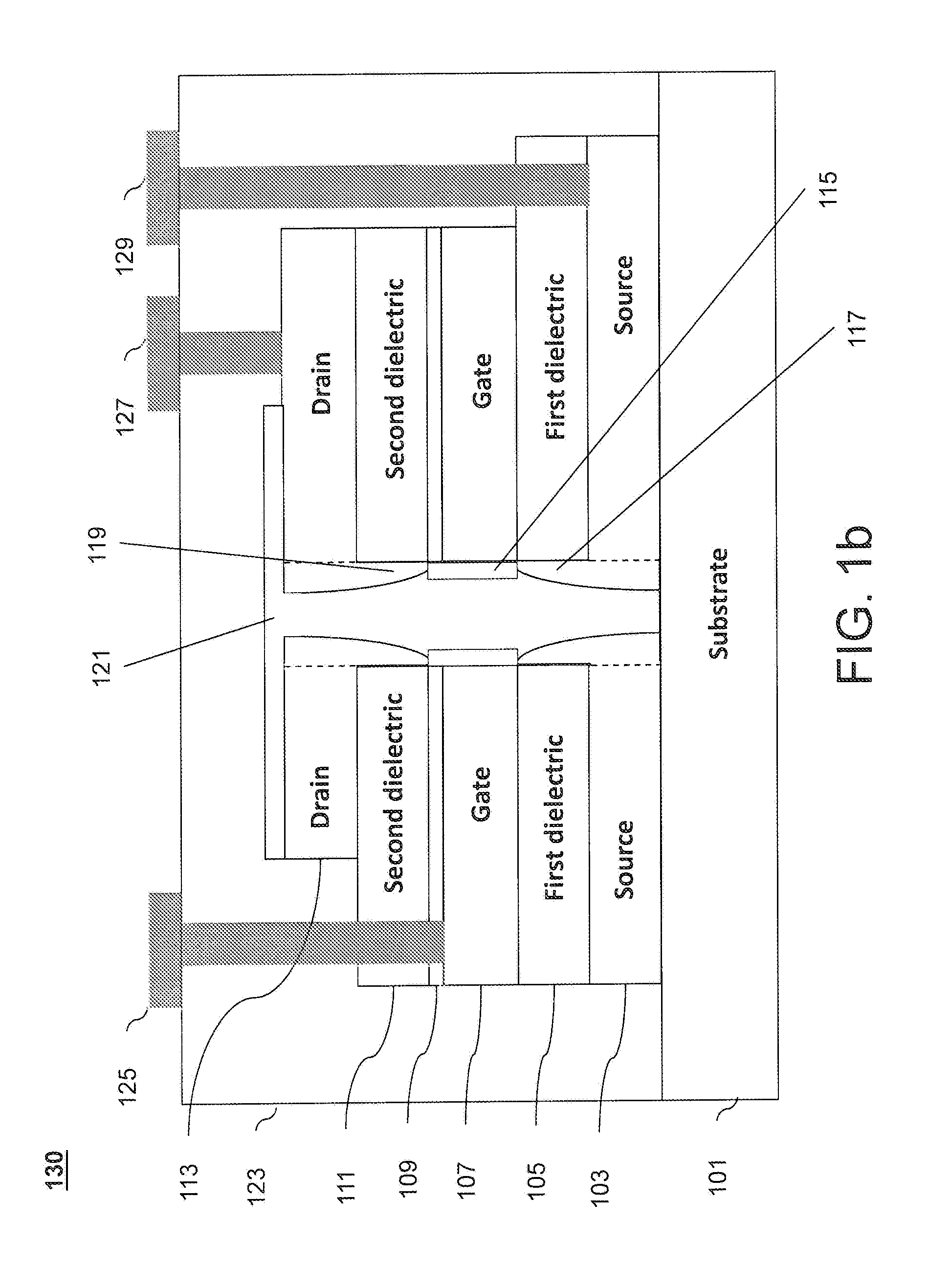

Semiconductor device with a vertical channel

Semiconductor devices and manufacturing methods are provided for making channel and gate lengths independent from lithography. Also, semiconductor devices and manufacturing methods are provided for increasing resistivity between drain and channel to allow for higher voltage operation. For example, a semiconductor device includes a first doped layer implanted in a semiconductor substrate forming one of a source or a drain and a gate metal layer disposed over the first doped layer. The semiconductor device further includes a second doped layer disposed over the gate metal forming the other the source or the drain, where the first doped layer, the gate metal layer and the second doped layer form a vertical stack of layers of the semiconductor device. The semiconductor device further includes a conduction channel formed in a trench that extends vertically through the vertical stack of layers and terminates at the semiconductor substrate.

Owner:AVAGO TECH INT SALES PTE LTD

Lubricant for metal forming

Disclosed is a solid or aqueous lubricant concentrate used for the cold forming of metals, which, with reference to the solids content, including a) 20 to 50 parts by weight polyethylene with a softening point above 120 DEG C. and a particle size int he range between 0.1 and 50 mu m; b) 20 to 8 parts by weight polyacrylate with a molecular weight of 4,500 to 10,000 and c) 2 to 8 parts by weight styrene / acrylic acid copolymer with a molecular weight of 150,000 to 250,000 and a glass transition temperature of 45 to 55 DEG C., where, under the conditions of use, the acrylic acid component of the polymers in accordance with items b) and c) is predominantly present as salt of one or more inorganic cations, and the softening points of the individuals polymers are distributed over the temperature range defined by the limiting values of ambient temperature and 200 DEG C. The lubricant concentrate may contain homo-or copolymers or acrylic acid or the esters thereof with graded molecular weights as well as surfacant. Also disclosed is a method for facilitating the cold forming, where, by means of the lubricant concentrate, a lubricant film is applied on the workpiece from a dispersion having solids content of 5 to 25 wt-%.

Owner:MG TECH CO LTD

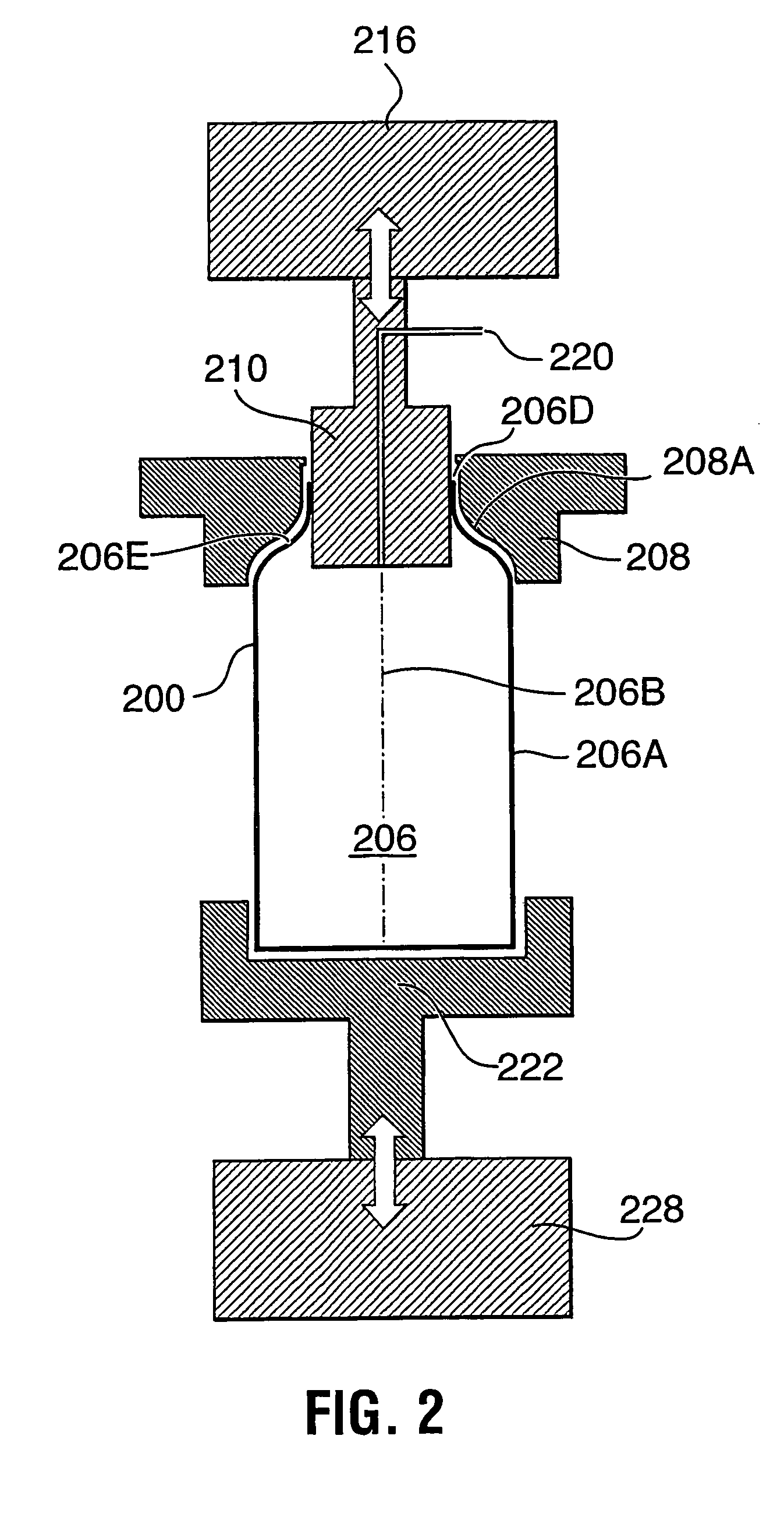

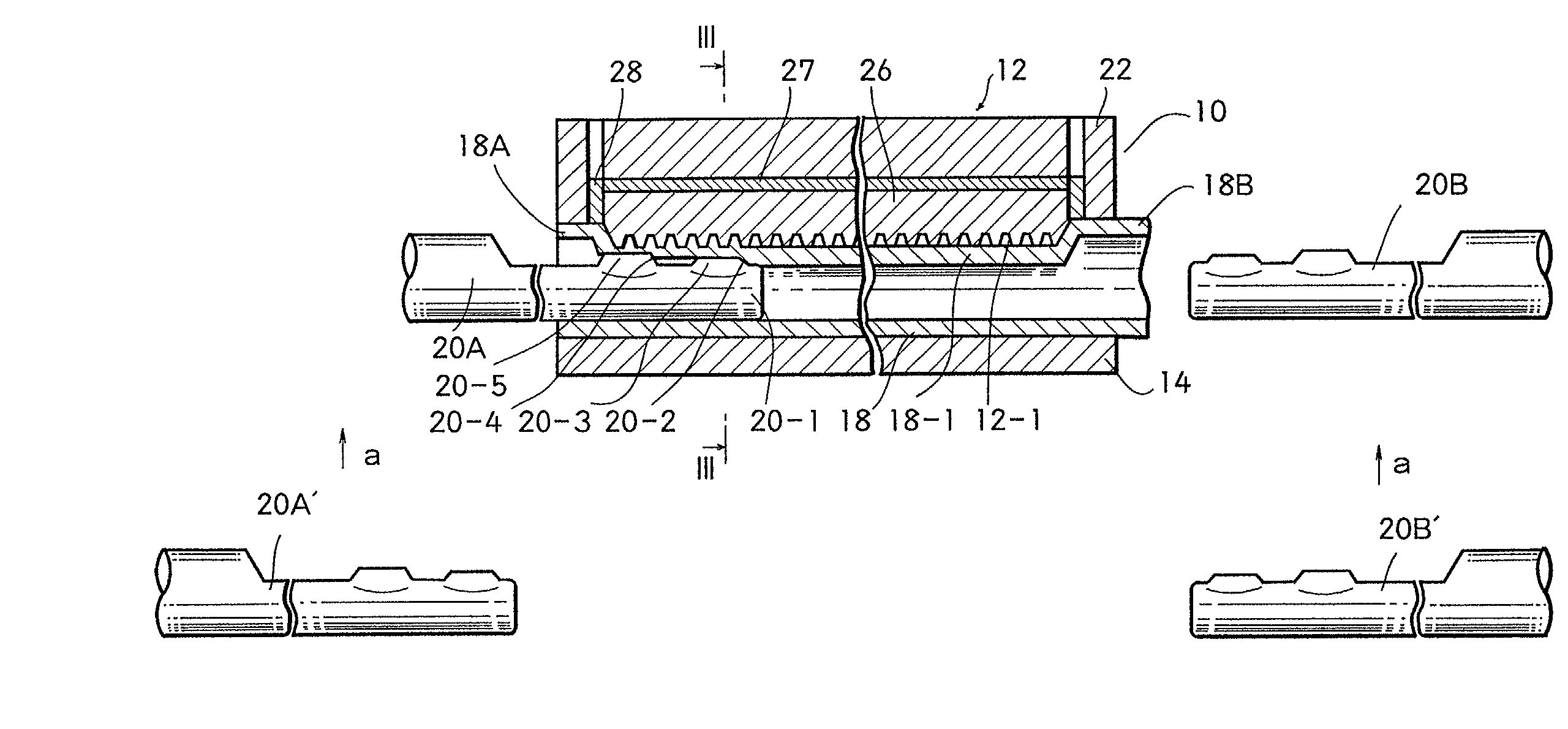

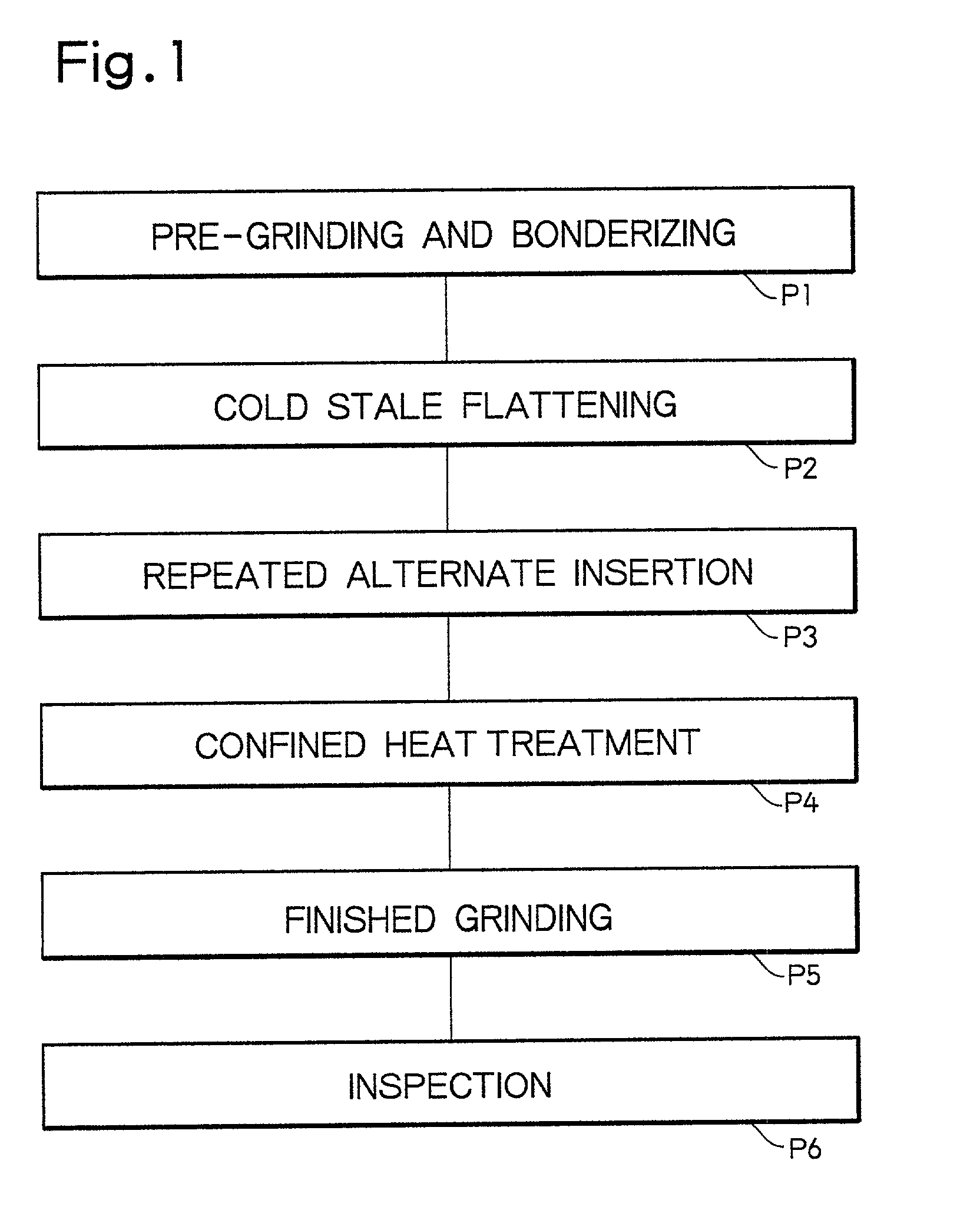

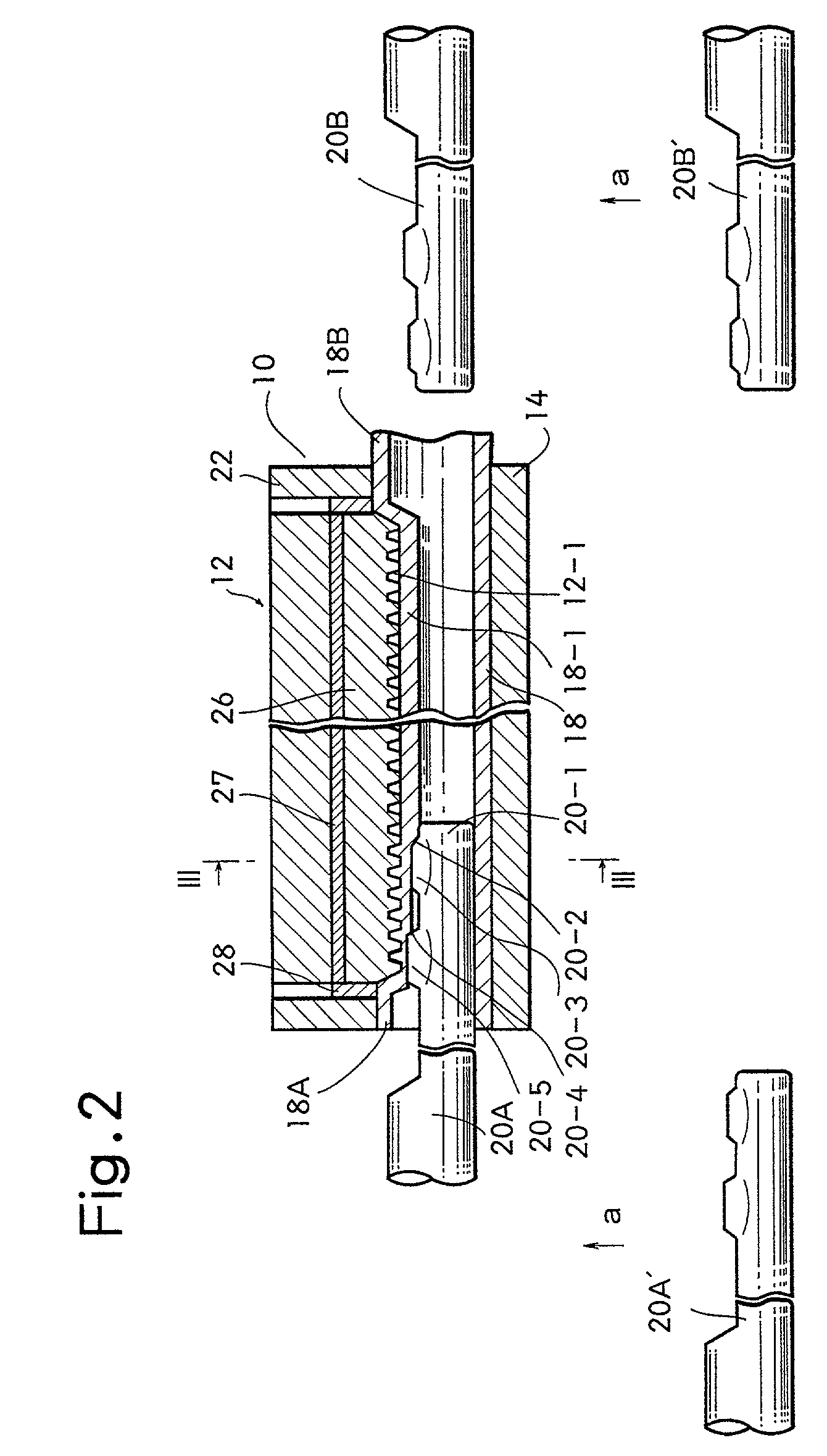

Mandrel insertion type metal forming of rack bar

InactiveUS20020044439A1High precisionReduce processing stepsFoundry mouldsMechanical steering gearsMetal formingEngineering

A method for producing a rack bar for a steering mechanism in an automobile. A blank pipe is held in a die, which has, at its inner surface, linear tooted portions. Mandrels are inserted repeatedly to the blank pipe while the direction of the insertion is alternately changed, while the insertion of the mandrel on one side of the blank pipe and the withdrawal of the mandrel on the other side are overlapped. Furthermore, lubrication is controlled so that an increased temperature of the work around 200° C. as generated under the plastic deformation of the metal is kept. An increased efficiency as well as reduced cost are obtained.

Owner:KOSHINGIKEN

Driver plate for electromagnetic forming of sheet metal

ActiveUS20090090162A1Repeat usageRelieve pressureShaping safety devicesMetal working apparatusMetal formingEngineering

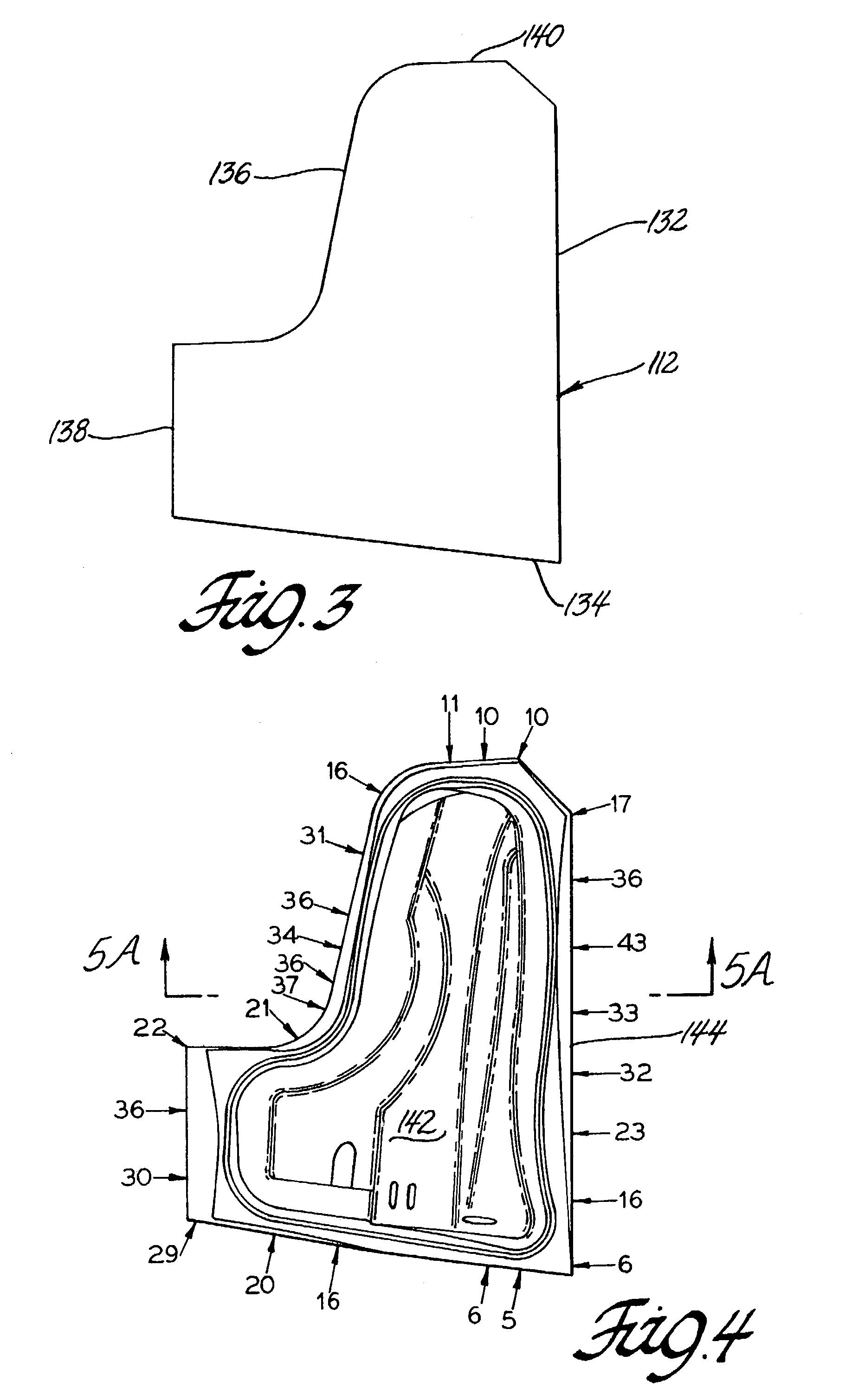

A multi-layer driver plate is disclosed for use in electromagnetic sheet metal forming operations. In one embodiment, the driver plate comprises a first layer characterized by low electrical resistivity and thickness for inducement and application of a suitable electromagnetic forming force, a second layer comprising an elastomeric material for compressing a sheet metal workpiece against a die surface and then regaining its original pre-forming structure, and a third layer interposed between the first layer and the second layer to protect the EMF force providing layer and to provide overall strength and durability to the EMF driver plate.

Owner:THE OHIO STATE UNIV RES FOUND +1

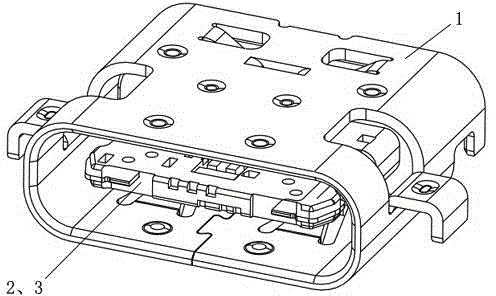

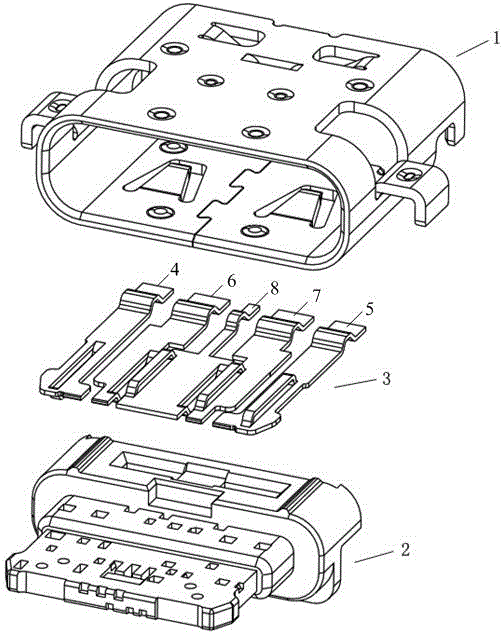

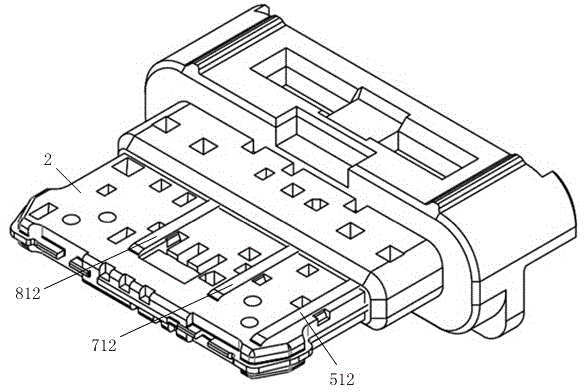

USB connector based on TypeC

InactiveCN104882705AReduce in quantityEasy to assembleCoupling contact membersTwo-part coupling devicesMetal formingInjection moulding

The invention provides a USB connector based on TypeC. The USB connector comprises a housing and plug-in assemblies. The plug-in assemblies comprise an insulating body and a row of conductive terminals which are integrated with the insulating body. The conductive terminals comprise a first grounding terminal, a first power terminal, a signal terminal, a second power terminal, and a second grounding terminal. The USB connector is formed by two components of the housing and the plug-in assemblies, and product assembly is simple, providing convenience for automation production. The product structure is reliable, and quality is stable. The plug-in assemblies comprise the insulating body and the row of conductive terminals. The row of conductive terminals are formed in a one-time manner in an injection molding process. In an assembly process, weld legs are cut off and a housing is installed, so product coplanarity is easy to ensure. The row of conductive terminals comprise the first grounding terminal, the first power terminal, the signal terminal, the second power terminal, and the second grounding terminal, and the above terminals can be made by a same metal strip through a sheet metal forming technology, so that the number of dies is saved, and production cost is reduced.

Owner:ALL BEST ELECTRONICS TECH CO LTD

Methods of manufacturing induction rotors with conductor bars having high conductivity and rotors made thereby

Squirrel cage rotors of aluminum based material end rings joined with high conductive and durable material (such as copper) conductor bars for use in electric motors and methods of making them are described. The methods include forming conductor bars by casting or other metal forming methods in the slots of laminate steel stack, or positioning the preformed or premade solid conductor bars in the longitudinal slots of the stacked laminated steel, with bar ends extending out of the laminated steel stack ends, optionally coating the extended part of the conductors (bars) with a latent exoergic coating containing Al and one or more conductor bar chemical elements, positioning the laminated steel stack having conductors (bars) in a casting mold that forms the cavity of both end rings of the rotor, filling the end ring cavities with aluminum melt, and allowing the end rings to solidify under pressure. Alternatively, the conductor bars and end rings can be made separately and mechanically joined together.

Owner:GM GLOBAL TECH OPERATIONS LLC

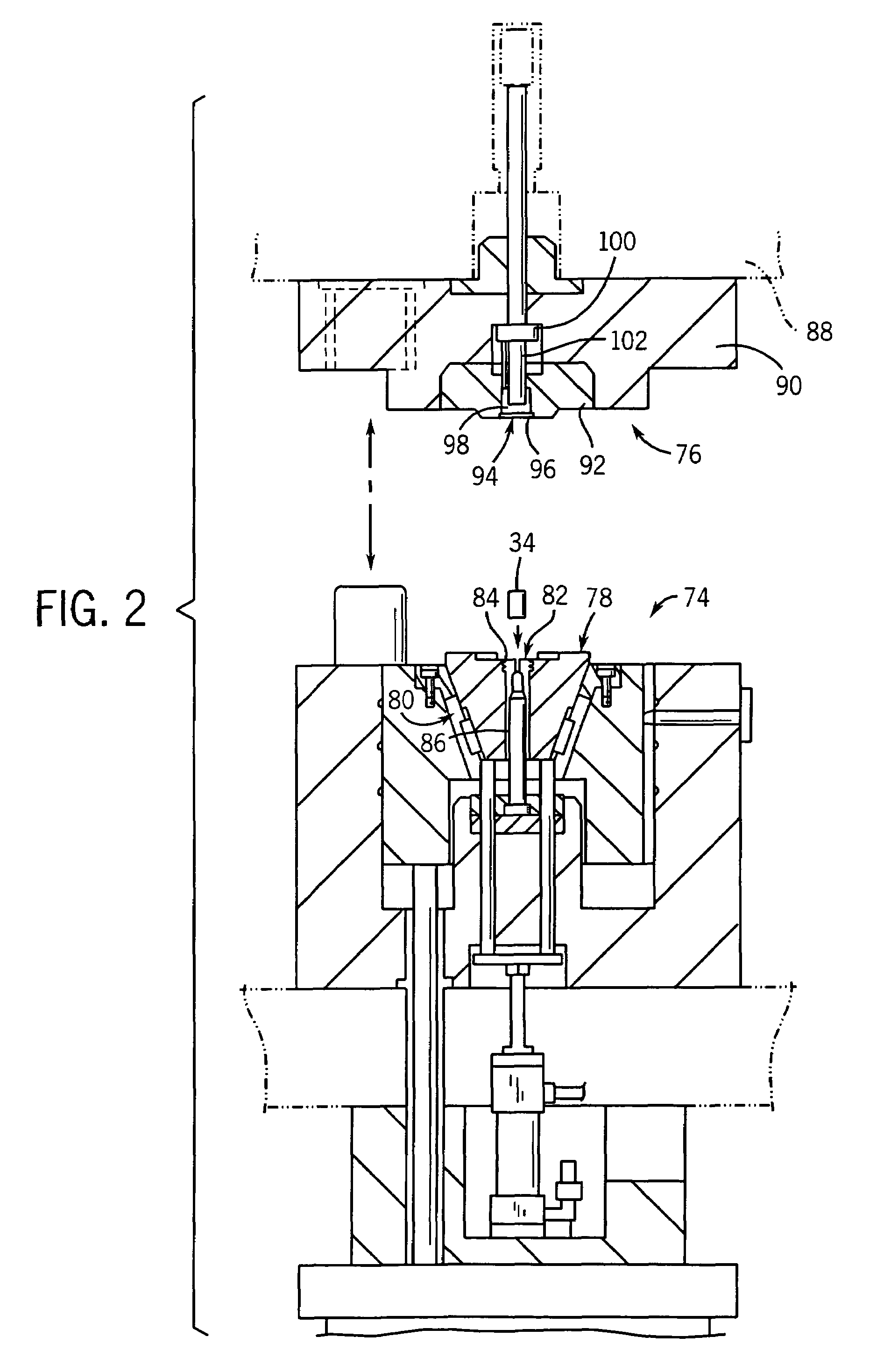

Method and apparatus for manufacturing a battery terminal with undercut rings

InactiveUS7021101B2Prevent electrolyte leakageEasy to manufactureLead-acid accumulatorsSmall-sized cells cases/jacketsCold formedMetal forming

A method and apparatus utilizing a radial rolling process to cold form rings on a lead battery terminal with undercuts or overhangs to improve the sealing properties of the rings. The apparatus includes a fixture configured to securely position the battery terminal beneath a rolling station. The rolling station includes a radial rolling spindle having a plurality of cam shaped rollers configured to transform at least one ring on the battery terminal from having an initial rectangular cross-sectional shape into a desired arrowhead cross-sectional shape when the terminal and cold metal forming member are rotated relative to each other. A drive assembly is configured to rotate the battery terminal and radial rolling head relative to each other.

Owner:TULIP MOLDED PLASTICS CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com