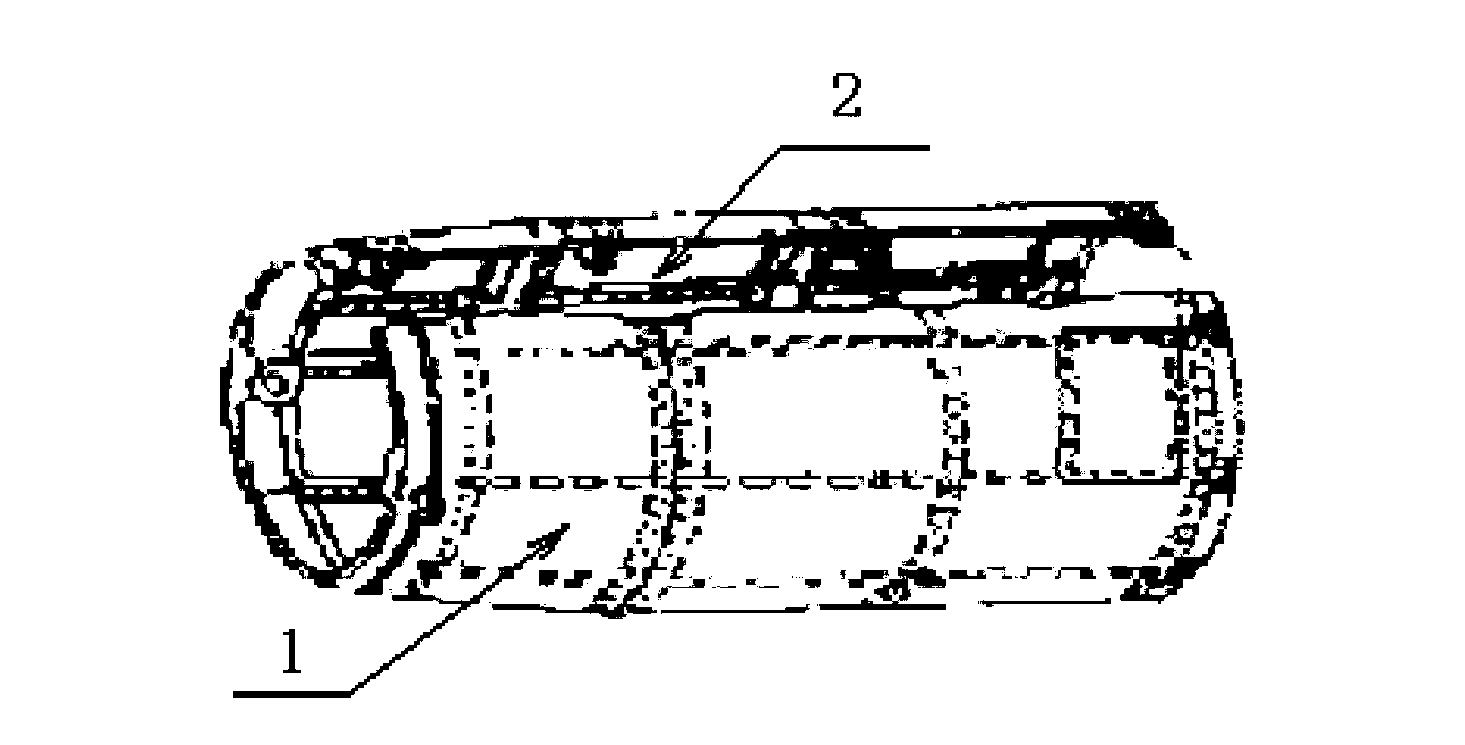

Superplastic forming (SPF)/diffusion bonding (DB) forming method of titanium alloy cylindrical four-layer structure

A technology of superplastic forming and diffusion connection, which is applied in the field of sheet metal forming, can solve the problems that the forming of rotary sandwich structural parts cannot be realized, the accuracy of the external dimension of components is difficult to guarantee, and the skin and skeleton are easy to deform, so as to achieve the freedom of structural design The effect of high strength, light structure and improved process stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

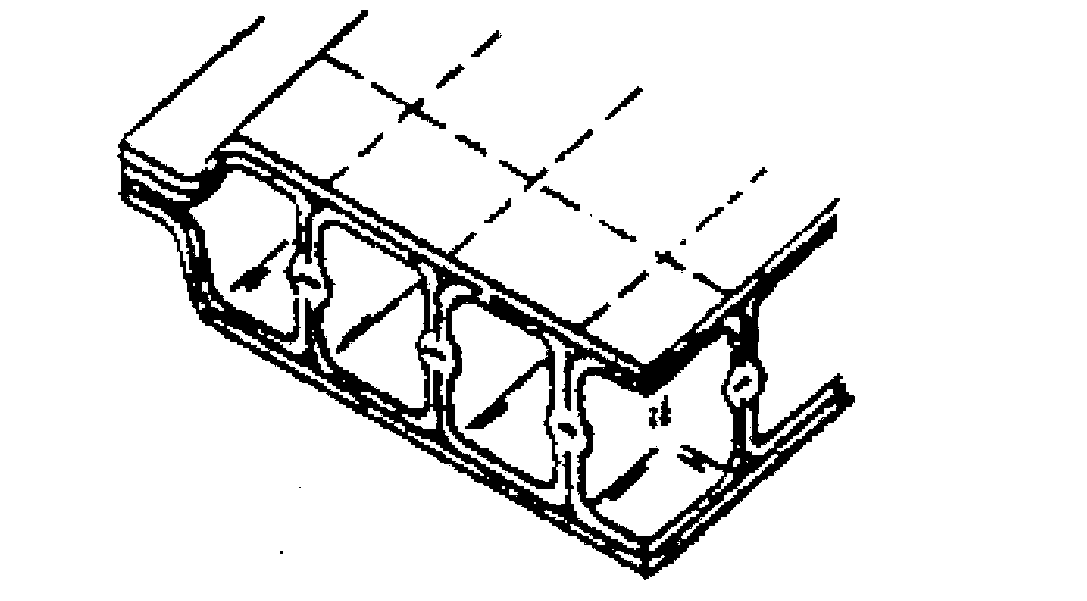

[0055] 1. The TC4 titanium alloy superplastic plate is used, and the thickness of the inner and outer cylinders and the core cylinder are both 1 mm; a single cylinder is prepared, and the inner diameter of the single cylinder is shown in Table 1.

[0056] Table 1 The inner diameter distribution of each layer of bobbins

[0057] bobbin

Outer cylinder 8

first cartridge 9

Second cartridge 10

Inner cylinder 11

the inside diameter of

207mm

204mm

200mm

197mm

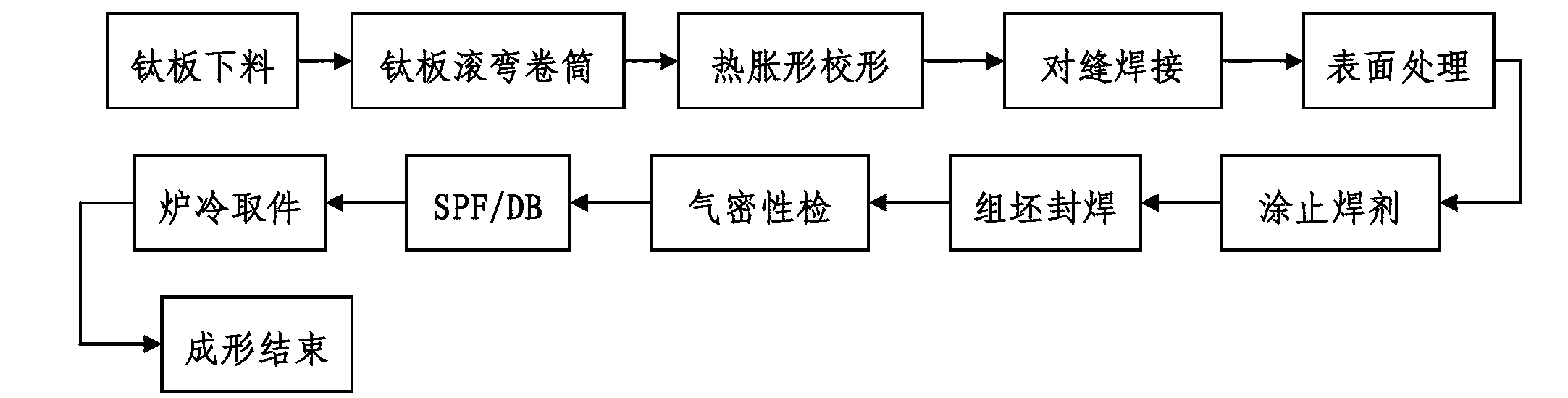

[0058] (1) Single cylinder preparation

[0059] (1.1) Prepare outer cylinder 8

[0060] According to the outer dimensions of the final formed part, the blanking size of the outer cylinder 8 is calculated to be 659×210mm, and the titanium alloy plate is cut according to the blanking size, and the plate material is rolled into a cylindrical shape, and the butt joint is welded by laser welding or argon arc welding to weld;

[0061] (1.2) Preparation of the first core barr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com