Patents

Literature

2084results about How to "Improve quality stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing tobacco sheet and application thereof

ActiveCN101637298AGood physical propertiesExtract completelyTobacco preparationTobacco treatmentMaillard reactionFiber

The invention discloses a method for preparing tobacco sheets and an application of the method. In the method, enzymolysis is implemented when the tobacco stalk and the tobacco powder are soaked, solid-liquid separation is implemented after extraction, the solids are made into fiber sheet substrates, liquid is made into concentrated solution by alcohol precipitation and concentration, the concentrated solution is made into coating liquid by maillard reaction and coated on the fiber sheet substrates, and the fiber sheet substrates are dried and cut into tobacco sheets. In the invention, the macromolecular compounds that influence the quality of the tobacco sheets are sufficiently degraded by enzymolysis, the content of the impure taste in the tobacco sheets is decreased, the internal quality of the tobacco sheets is improved, and better aroma is obtained by the technical solution that produces prospective aroma by the maillard reaction to provide a rich aroma for the tobacco sheets so as to obtain tobacco sheet products fitting different types of cigarette products and having better internal quality. The tobacco sheets prepared by the method have excellent compatibility and harmonywith the conventional raw materials of the cigarettes, and have the advantages of good cigarette taste, various and rich aromas and less impure taste.

Owner:CHINA TOBACCO GUANGDONG IND

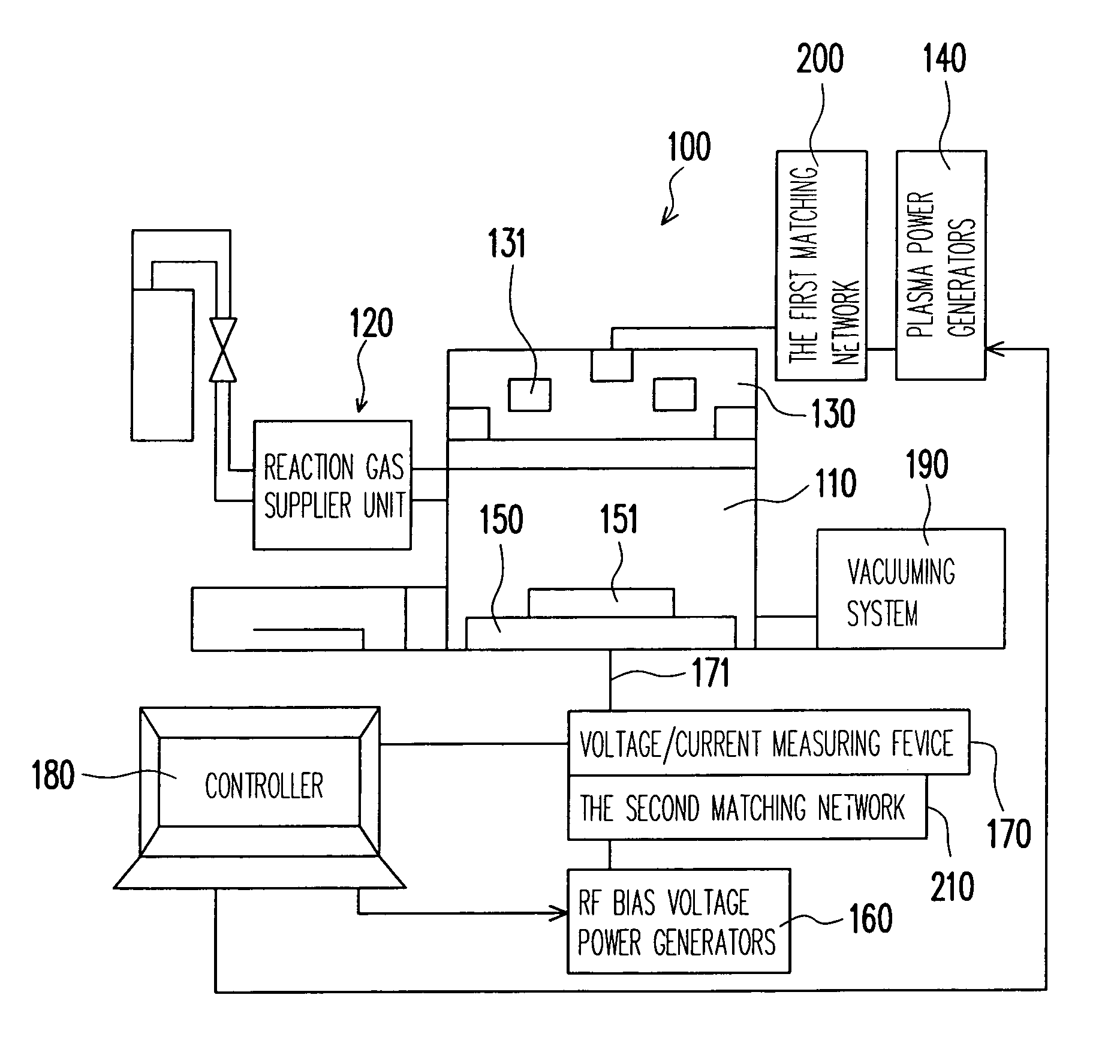

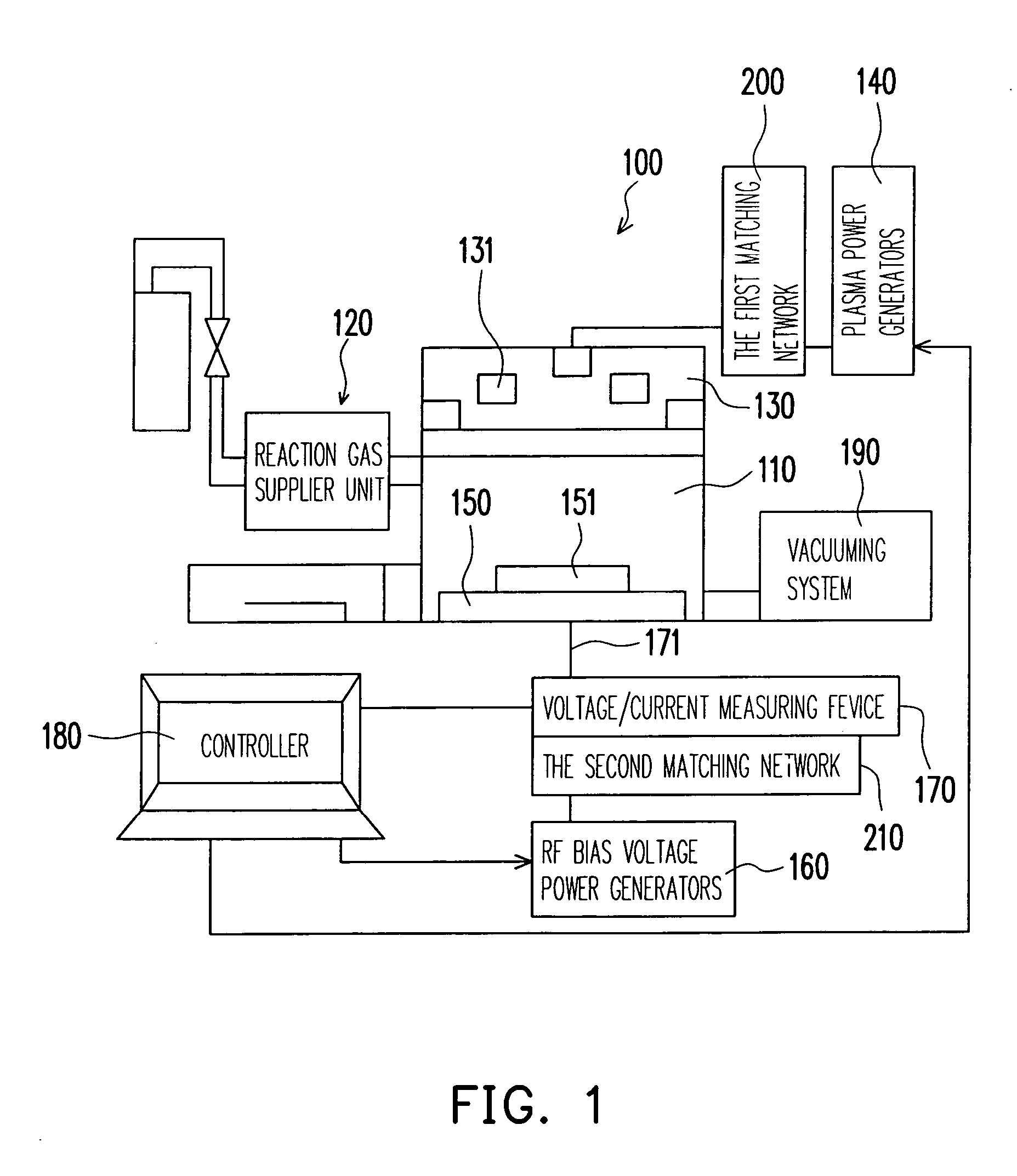

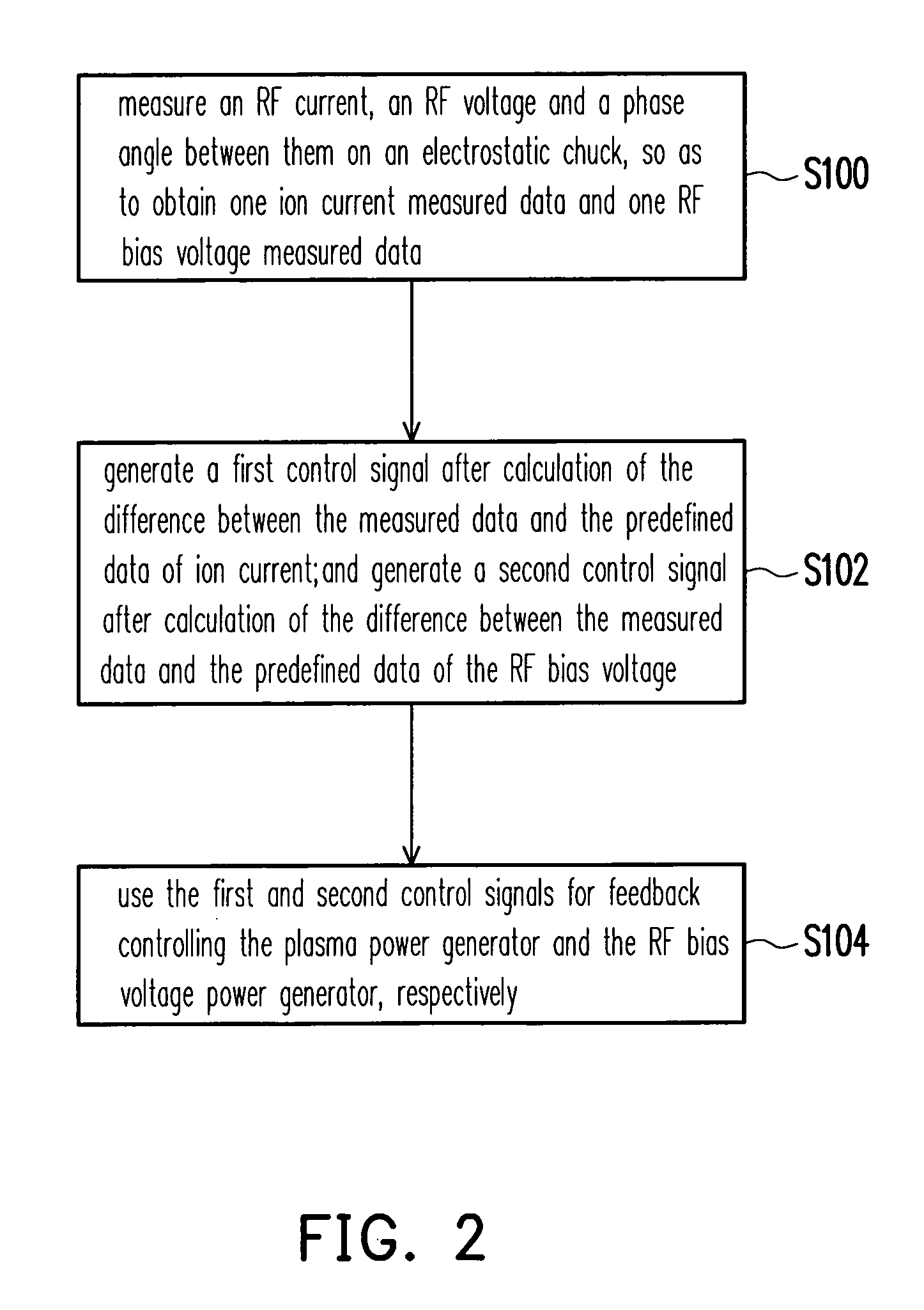

Inductively-coupled plasma etch apparatus and feedback control method thereof

InactiveUS20060226786A1Lengthy and laborious R & DImprove quality stabilityElectric discharge tubesElectric arc lampsIon currentEngineering

An inductively-coupled plasma etch apparatus and a feedback control method thereof are provided. A voltage / current measuring device is connected to an electrostatic chuck of the plasma etching apparatus, so as to measure the RF current, voltage and the phase angle between them on the electrostatic chuck. The ion current and the RF bias voltage are obtained by calculation of the RF current, voltage and the phase angle. Finally, using the obtained ion current and the RF bias voltage to feedback control the RF power generator in order to achieve the desired plasma status.

Owner:NATIONAL TSING HUA UNIVERSITY

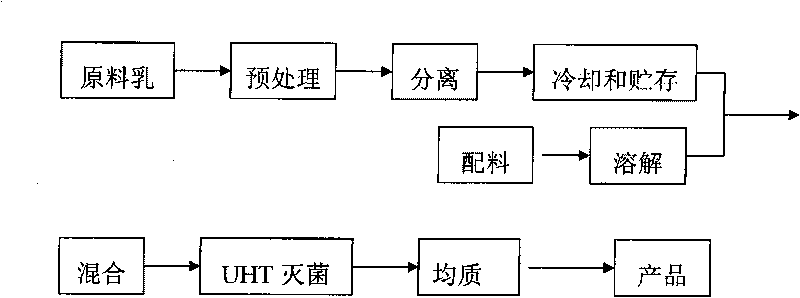

Cream and making method and use thereof

The invention discloses a cream which contains 20-45% of fat, 1-3% of protein, 0.1-0.55% of stabilizer, 0.05-0.35% of emulsifier, 0.005-0.15% of buffer salt and the balance water, and the percent is the weight percent of each component in the total weight of the cream. The invention further provides a making method of the cream. The making method can overcome the defects of short shelf life, strict preservation conditions and further limitation of the sales regions of the cream prepared by the conventional method, and the invention provides the cream and the making method thereof by improvingthe formula and the process of the cream. The cream produced and prepared by the method can be stored at room temperature, the use is convenient and fast, and the shelf life is long, thereby being suitable for long-distance transportation and being conductive to construction of a national sales network; meanwhile, the cream product has the advantages of uniformity, stability, no water separation,good whipability and thermal stability, thereby being applicable to making egg tarts, candies, cakes or cream soup.

Owner:BRIGHT DAIRY & FOOD

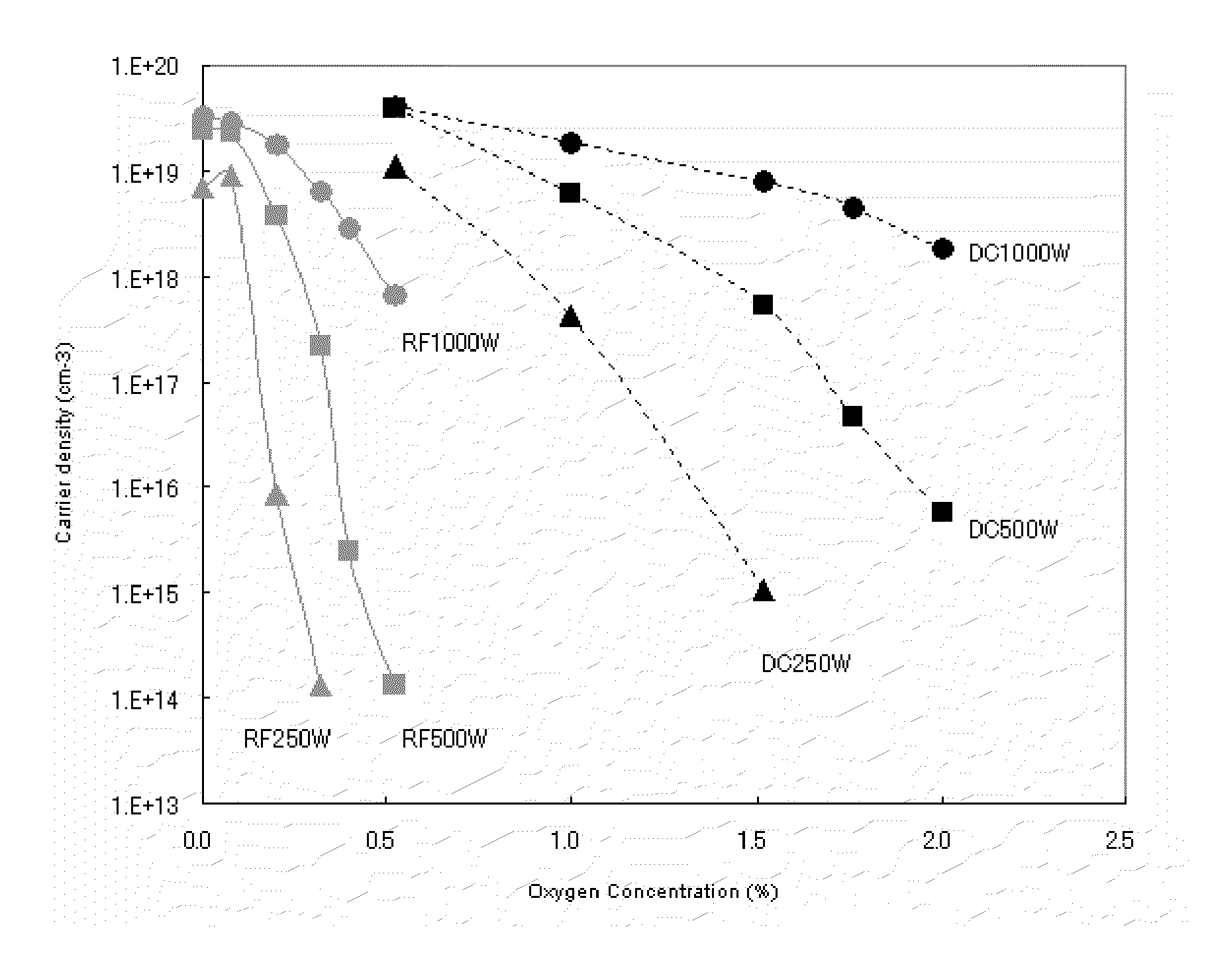

Method for producing a-IGZO oxide thin film

ActiveUS8148245B2Good reproducibilityImprove quality stabilityCellsSynthetic resin layered productsSputteringIndium

There is provided a method for producing an a-IGZO oxide thin film by sputtering, which can control the carrier density of the film to a given value with high reproducibility. The method is an amorphous In—Ga—Zn—O based oxide thin film production method including: providing a sintered oxide material consisting essentially of indium (In), gallium (Ga), zinc (Zn), and oxygen (O) as constituent elements, wherein the ratio [In] / ([In]+[Ga]) of the number of indium atoms to the total number of indium and gallium atoms is from 20% to 80%, the ratio [Zn] / ([In]+[Ga]+[Zn]) of the number of zinc atoms to the total number of indium, gallium and zinc atoms is from 10% to 50%, and the sintered oxide material has a specific resistance of 1.0×10−1 Ωcm or less; and producing a film on a substrate by direct current sputtering at a sputtering power density of 2.5 to 5.5 W / cm2 using the sintered oxide material as a sputtering target.

Owner:JX NIPPON MINING & METALS CORP

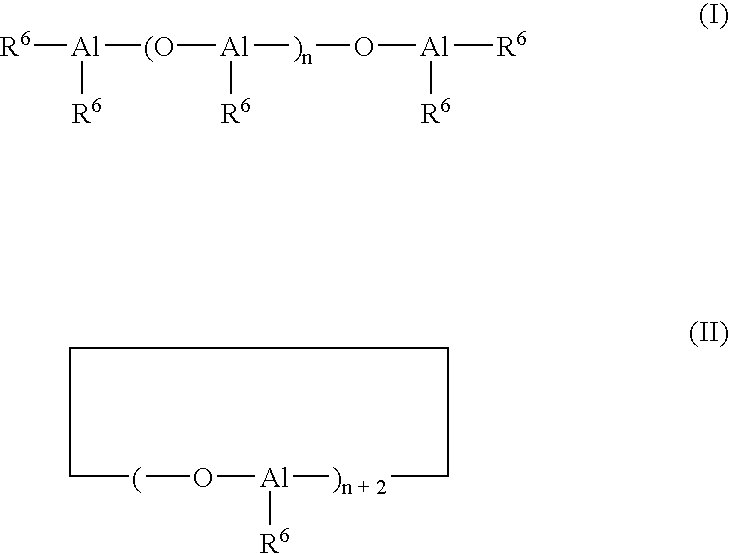

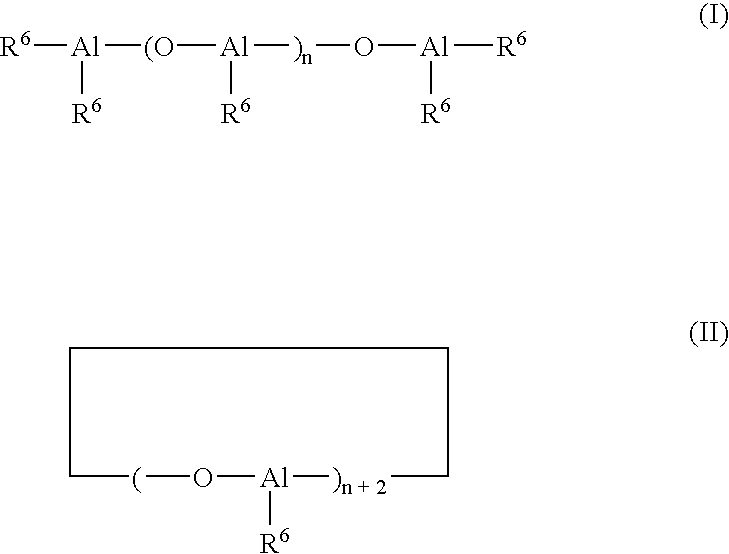

Method for producing modified conjugated diene polymer and rubber composition

ActiveUS20050009979A1Improve quality stabilityImprove abilitiesSpecial tyresPolymer scienceAqueous solution

Disclosed are a method for producing a modified conjugated diene polymer improved in quality stability, more enhanced in low heat buildup and reinforcing ability when used in a rubber composition, excellent in wear resistance, mechanical characteristics and processability, and improved in cold flow; and a rubber composition using the same. The method includes a step of modifying an active end of an active end-containing conjugated diene polymer having a cis-1,4-bond content of 75% or more with an alkoxysilane compound containing at least one functional group selected from the group consisting of (a) an epoxy group, (b) an isocyanate group and (c) a carboxyl group, and a step of adding a condensation accelerator to conduct condensation reaction of the alkoxysilane compound (residue) in an aqueous solution having a pH of 9 to 14 and a temperature of 85 to 180° C.

Owner:ENEOS MATERIALS CORP

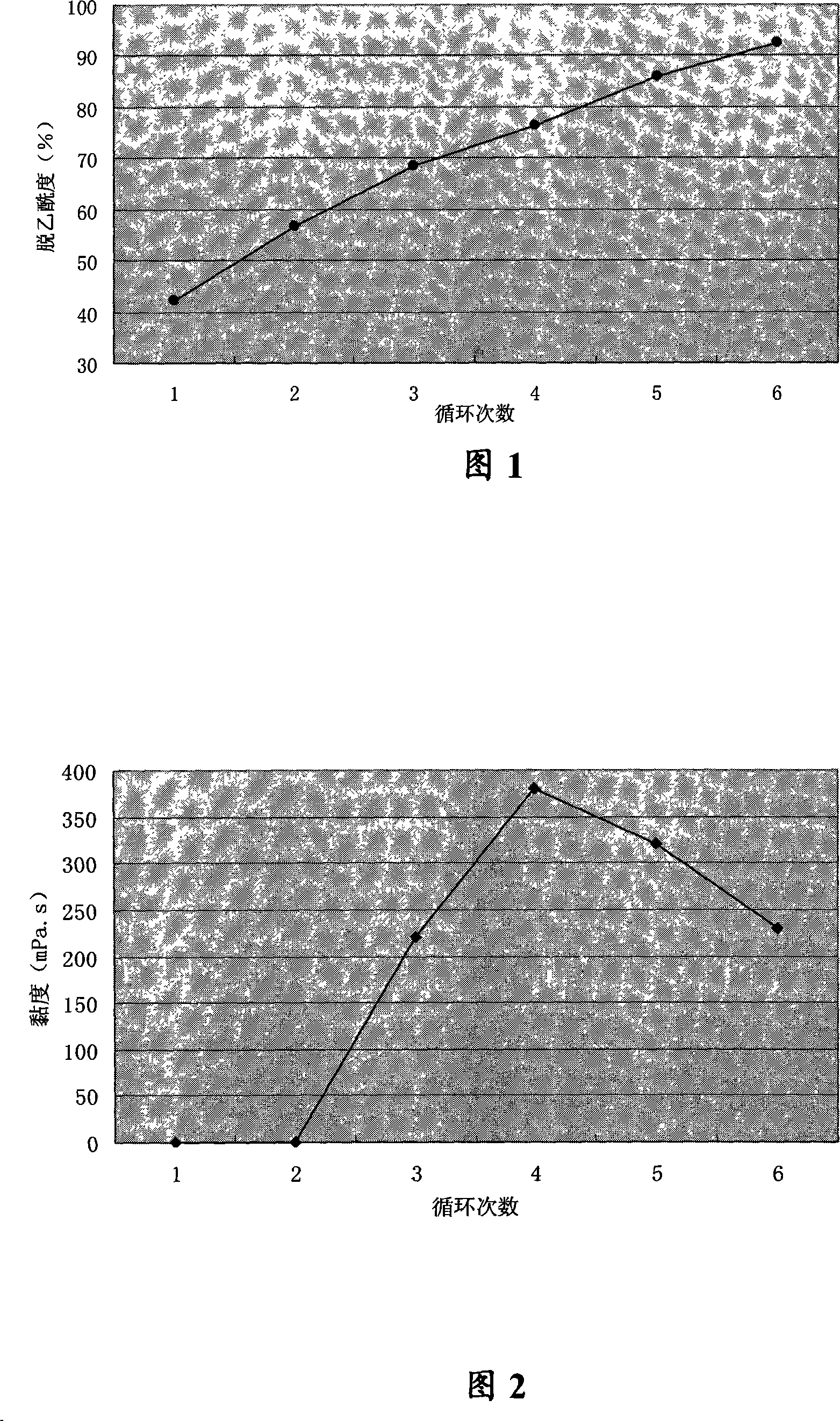

Method for preparing chitin and its chitosan and chitosan oligosaccharide

InactiveCN101144097ATake advantage ofImprove production conditionsMicroorganism based processesFermentationSolubilityBioreactor

The present invention relates to a method for preparing chitin and chitosan oligosac charide. The method comprises the steps that usual raw materials such as the crust of shrimp and crab, the insect crust or the fungal mycelia, etc. are micronized through the dry process or wet process; the carapace material of the obtained fine powder raw material is decalcified with the chemical process, and then is defatted and deproteinized with the method of micro-organism compound enzyme coarse enzyme liquid co-enzymolysis, and the insect and fungus fine powder thereof is directly defatted and deproteinized; a whole cell immobilizing bioreactor of a chitin deacetylase high-yield producing strain is prepared, to perform the circulatory deacetylation to the chitin and then obtain chitosan with corresponding degree of deacetylatoion; obligate anaerobic acid-producing bacterium and high-yield producing chitosan bacterium are utilized, the chitosan is submerged and fermented in the liquid, to obtain chitosan oligosaccharide with high water solubility. The present invention has the advantages that the method is helpful to fully utilize the resources, and makes the waste to the worth, at the same time, the default of the manufacturing process of the chemical process can be avoided, the production efficiency is improved, the energy is saved, the consumption is reduced, the byproduct with corresponding high value added can be produced, the comprehensive economic benefits of the relative secondary industry are obviously improved, the industrial development is promoted, and the multi-win effect is attained.

Owner:重庆百奥帝克微生态科技有限公司

Quick client development frame for manufacturing execution system and software development method for frame

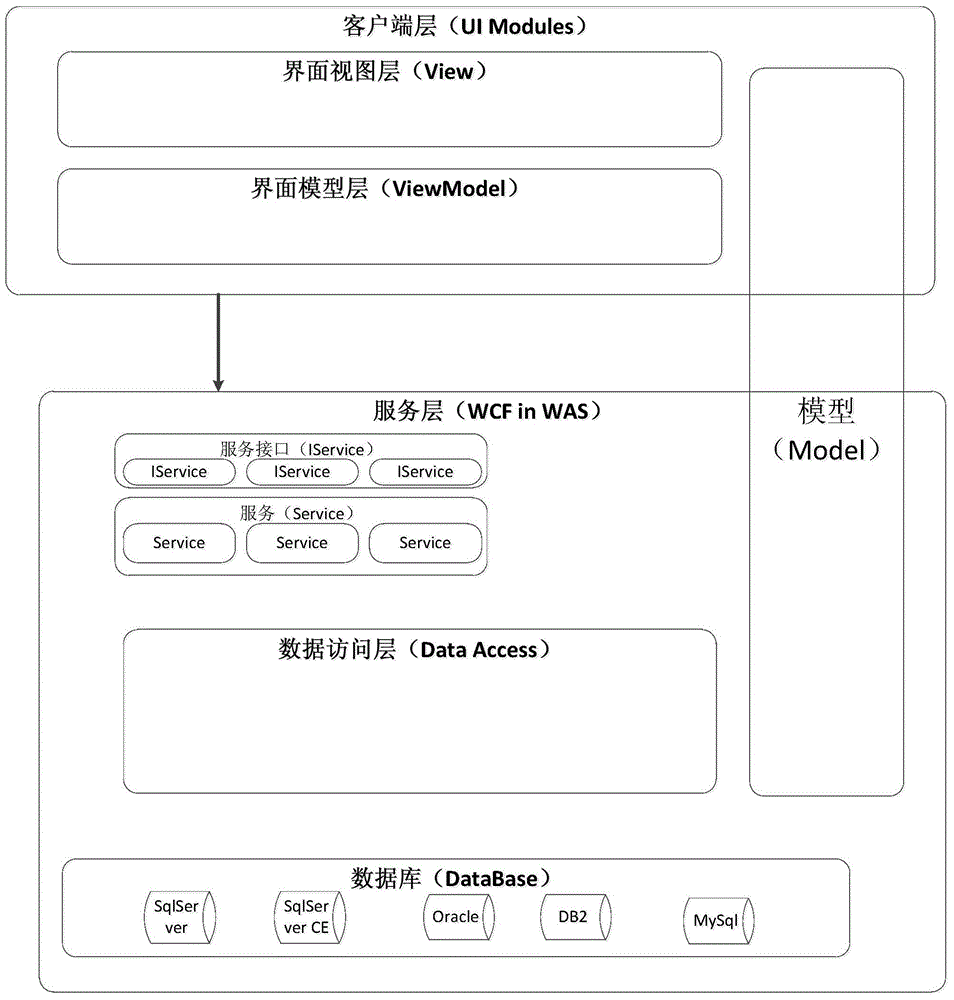

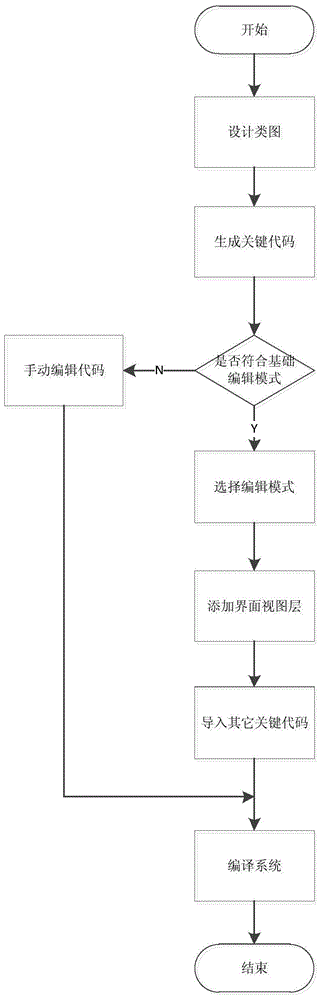

InactiveCN105630472AImprove robustnessReduce technical difficultySpecific program execution arrangementsSoftware development processCode writing

The invention relates to a quick client development frame for a manufacturing execution system and a software development method for the frame. The frame comprises a client layer and a service layer, wherein the client layer is used for realizing client interface interaction and comprises an interface view layer, an interface model layer and a model; and the service layer is used for realizing a business logic and data storage, receiving data sent by a client, reconstructing the data of the client according to a business requirement and sending the data to a database. The software development method for the frame comprises the steps of determining a data structure and the business logic of a development page as needed; designing UML class graph automatic generation codes; adding the codes into corresponding layers of project engineering in sequence; and compiling the project engineering to generate system software. According to the frame and the method, the code writing workload of the manufacturing execution system can be greatly reduced and the code quality and the system stability can be improved; and meanwhile, by applying a layered architecture and a configuration file, the software generated by the frame can be conveniently transplanted in different database systems.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

Automatic pressing-filling device for steel balls

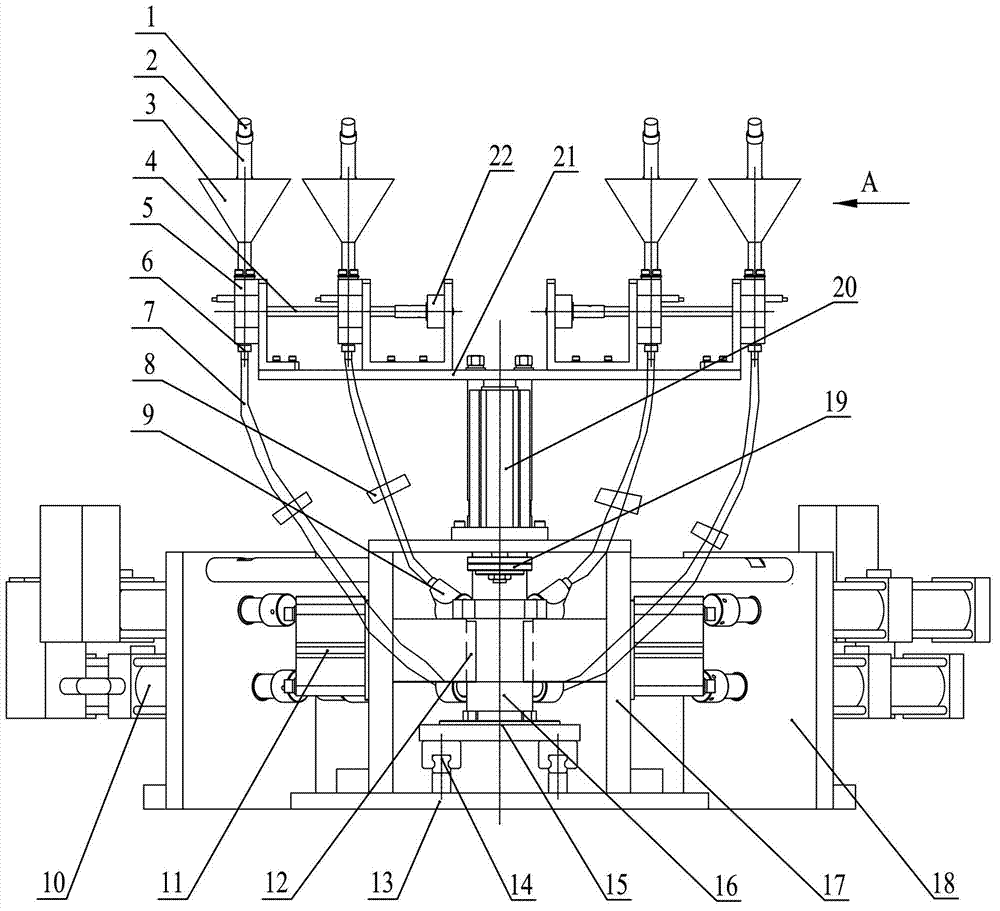

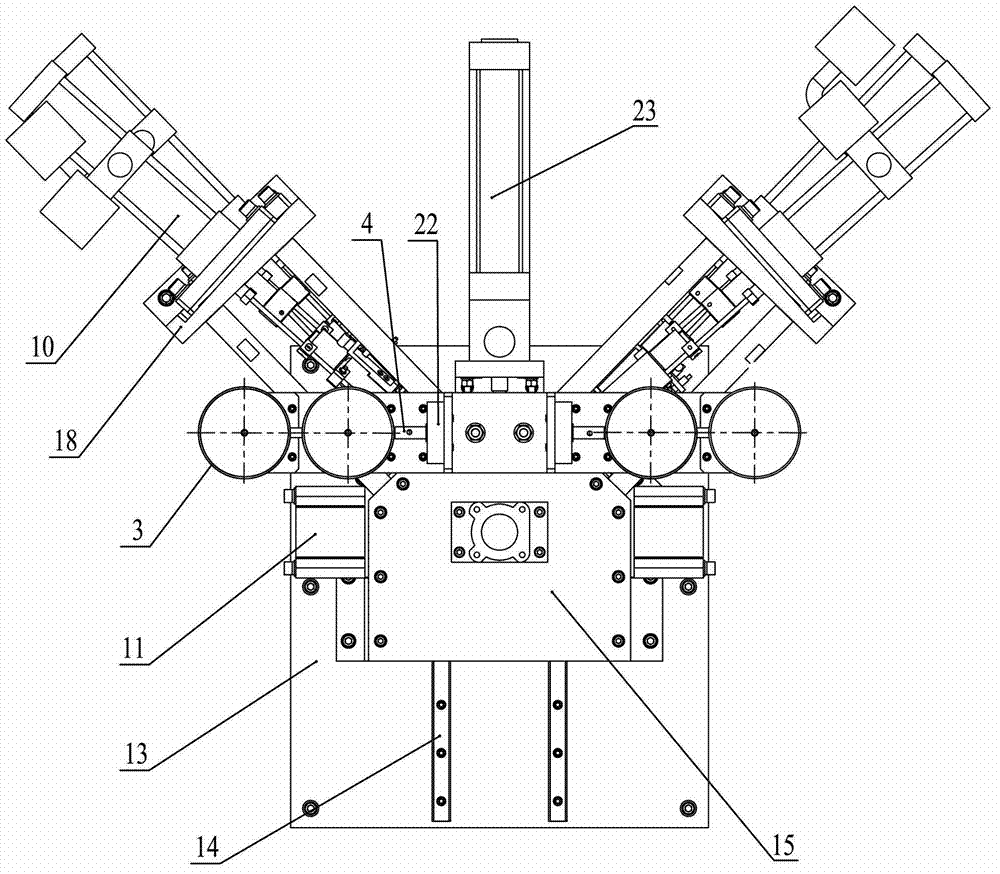

ActiveCN102729035AImprove quality stabilityReduce work intensityAssembly machinesMetal working apparatusEngineeringSteel ball

The invention relates to an automatic pressing-filling device for steel balls. The automatic pressing-filling device is characterized by comprising a base and a support, wherein a workpiece conveying mechanism is installed on the base, and a workpiece clamping mechanism, a steel ball sorting and conveying mechanism and a steel ball pressing-in mechanism are installed on the support; the workpiece conveying mechanism is used for loading and conveying a workpiece, the workpiece clamping mechanism is used for fixing the workpiece which is conveyed in place, the steel ball sorting and conveying mechanism is used for conveying the steel balls to the workpiece, and the steel ball pressing-in mechanism is used for pressing the steel balls in the workpiece. The automatic pressing-filling device for steel balls disclosed by the invention is ingenious, compact and reasonable in structure, accurate in pressing-fitting and positioning, convenient in installation and maintenance, capable of automatically conveying the steel balls and accurately pressing-filling the steel balls in the workpiece of an oil pump shell, thus improving the quality stability of a positioning and pressing-filling process for the steel balls in the oil pump shell, lightening the working intensity of operating personnel, and improving the labour production efficiency; therefore, the quality of pressing-filling for the steel balls of the oil pump shell meets the requirements of a process assembly standard.

Owner:WUXI YAZHONG PNEUMATIC HYDRAULIC

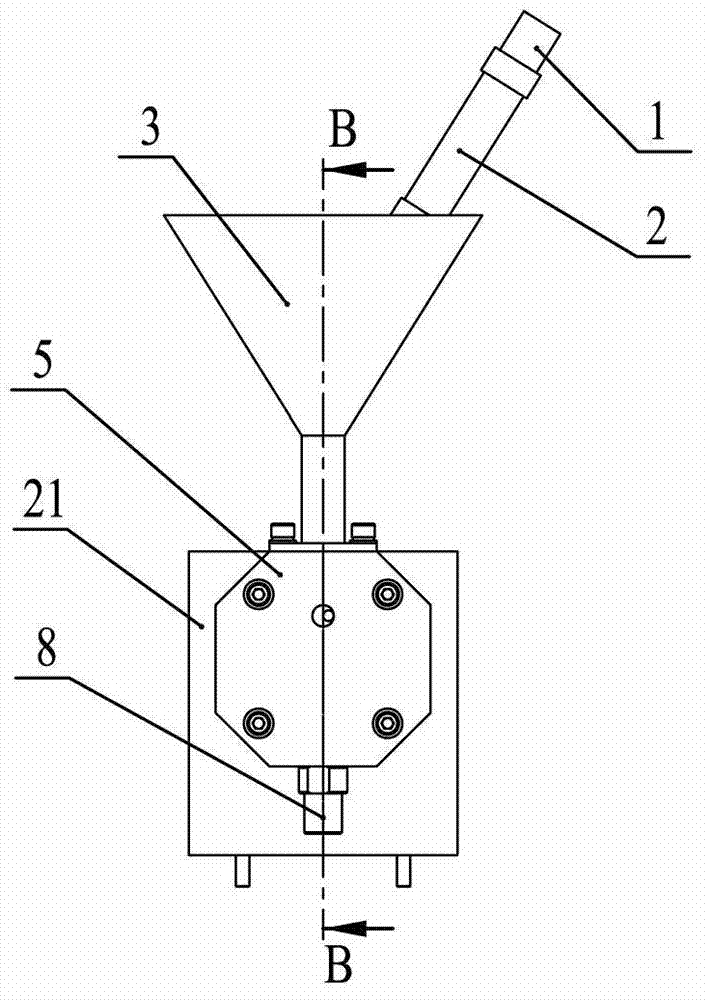

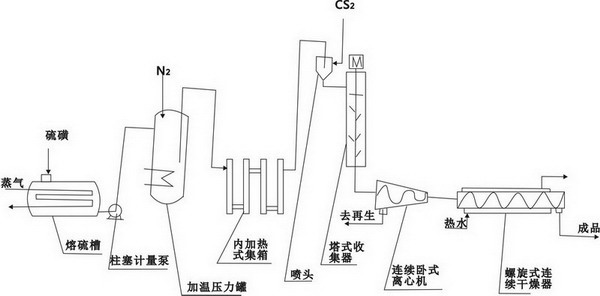

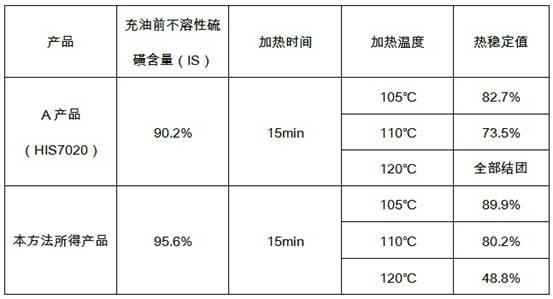

Method for producing insoluble sulfur

The invention discloses a method for producing insoluble sulfur, and belongs to the field of inorganic fine chemical engineering. The production method comprises the following steps of: (1) melting and polymerization; (2) atomization and cold quenching (3) solidification; (4) centrifugal separation; (5) continuous drying; and (6) crushing, screening and charging oil to obtain a finished product. The method is a continuous production method; by the method, the yield of the product is improved; and the product has high purity and stable quality.

Owner:四川中信华诚化工科技有限公司

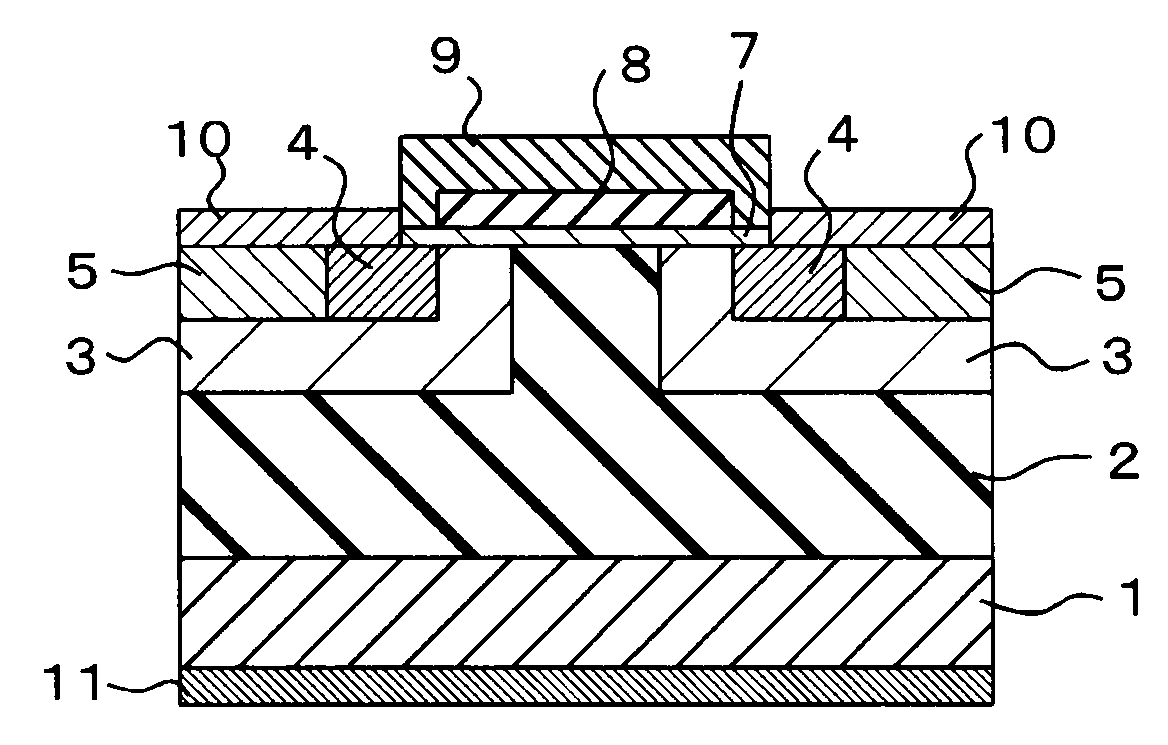

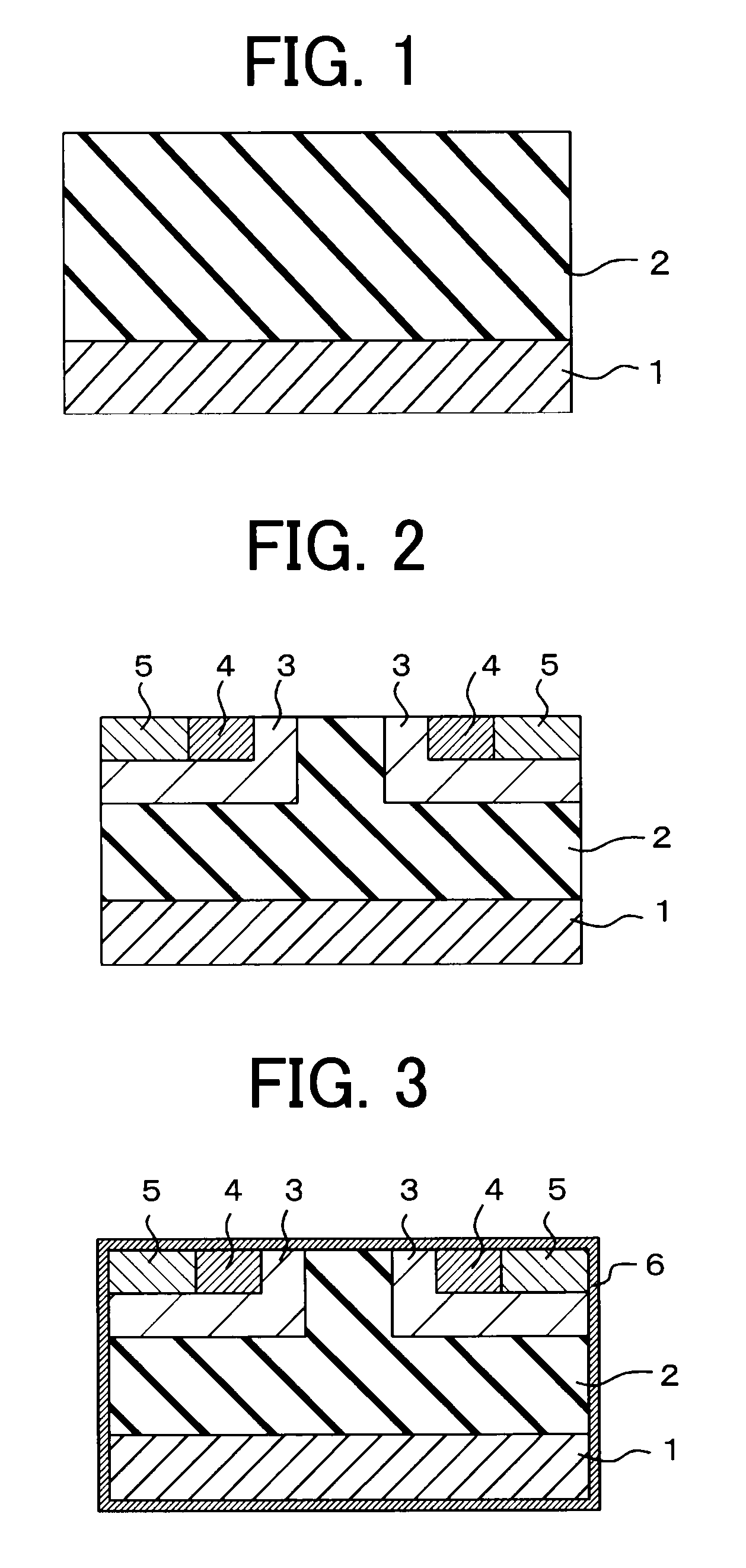

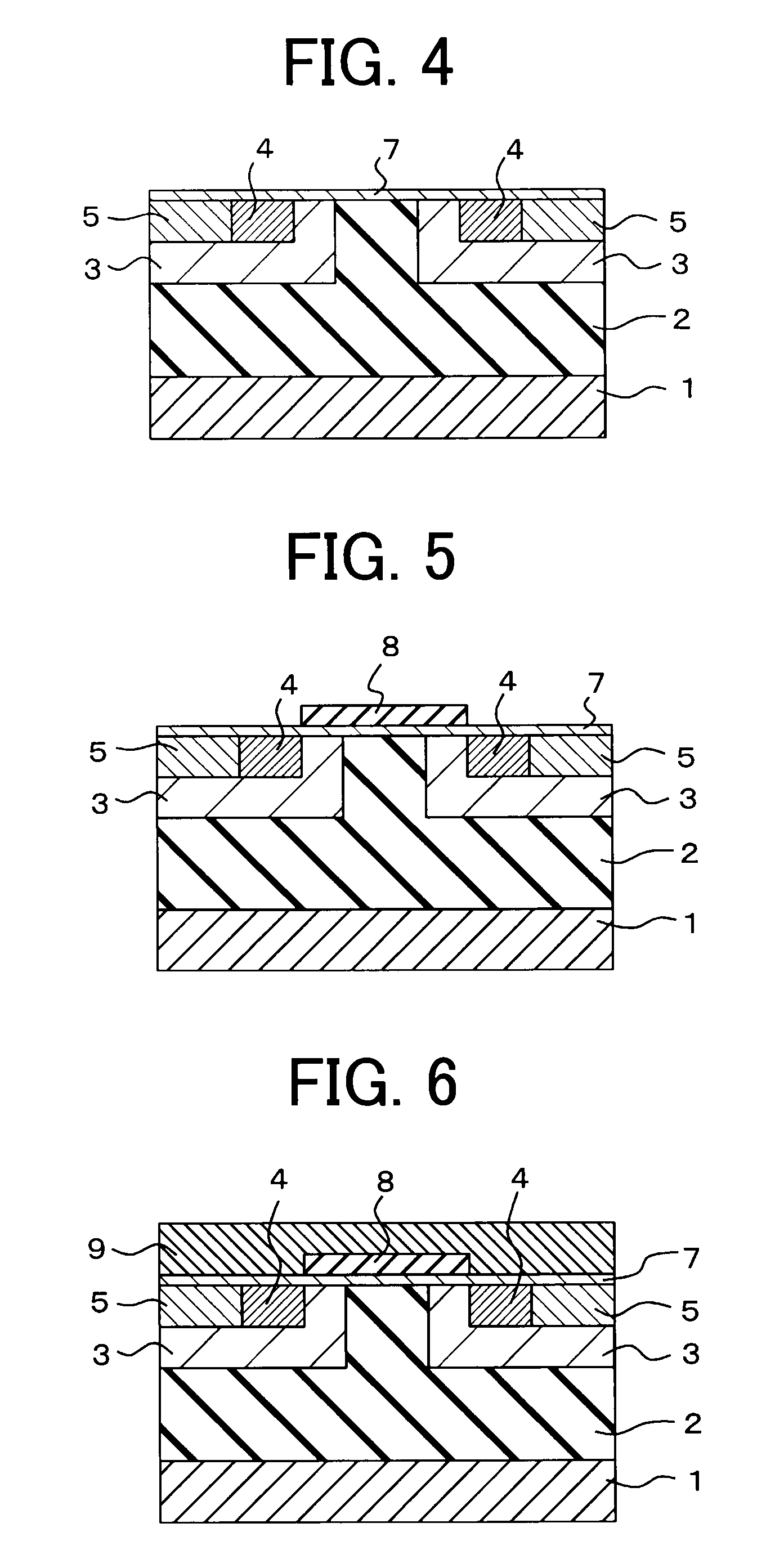

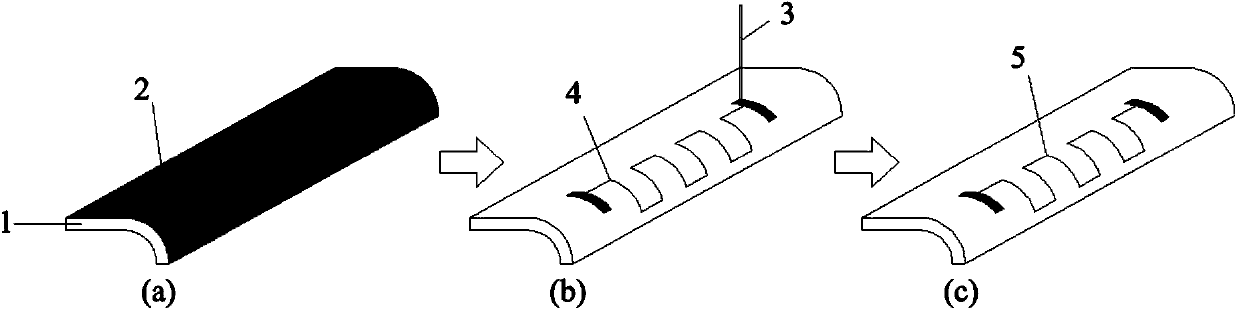

Method of manufacturing silicon carbide semiconductor device

ActiveUS20090042375A1Improve quality stabilityHigh yieldSemiconductor/solid-state device manufacturingSemiconductor devicesDevice materialGas phase

A method of manufacturing a silicon carbide semiconductor device includes a step of ion-implanting an impurity in a surface of a silicon carbide wafer (1 and 2); a step of forming a carbon protection film (6) of a predetermined thickness over the entire surface of the silicon carbide wafer (1 and 2) having been ion-implanted with the impurity, by a chemical vapor deposition method that deposits a film by pyrolyzing a hydrocarbon gas; and a step of annealing the silicon carbide wafer (1 and 2) having been formed with the carbon protection film (6). Thereby, the carbon protection film (6) can be formed that contains extremely few contaminants, and prevents step bunching from creating on the surface of the silicon carbide wafer (1 and 2) and crystal defects created therein due to unbalanced thermal stress form increasing.

Owner:MITSUBISHI ELECTRIC CORP

Long glass fibre reinforced nylon material and preparing method thereof

The present invention belongs to high polymer material and forming and processing field thereof, and provides a long glass fibre reinforced nylon material and preparing method thereof, wherein the constituents comprise: 29-67wt% of nylons, 30-60wt% of long glass fibre, 2-10wt% of compatilizer and 0.3-1.0wt% of antioxidants. The preparing method comprises the following steps: first mixing the nylons, compatilizer and antioxidants; adding the mixture into a double-screw extruder, wherein the processing temperature is 235-300 DEG C; extruding resin fondants into a dipping mould connected to the double-screw extruder; enabling the long glass fibre to pass through the dipping mould, wherein the dipping temperature of the dipping mould is 260-300 DEG C, dipping the long glass fibre completely in by the fondants, cooling, dragging and granulating the long glass fibre to obtain the long glass fibre reinforced nylon materials. The method of the present invention can strengthen the dipping effect of glass fibre in nylon fondant, eliminate or decrease harmful substances, reduce environmental pollution, and improve the dipping effect and mechanical property of materials effectively.

Owner:NANJING JULONG SCI&TECH CO LTD

Production of cryogenic direct-welding polyurethane envelope without pinhole

InactiveCN101029203AReduce direct soldering temperatureImprove adhesionPolyurea/polyurethane coatingsEngineeringPolyurethane

A low-temperature straight-welding polyurethane wire enamel without pin hole is carried out by preparing hydroxide radical component, preparing enclosed component and formulating wire enamel. It can be used for extended or bended zero pin hole below 340degree.

Owner:DANYANG STAR CHEM

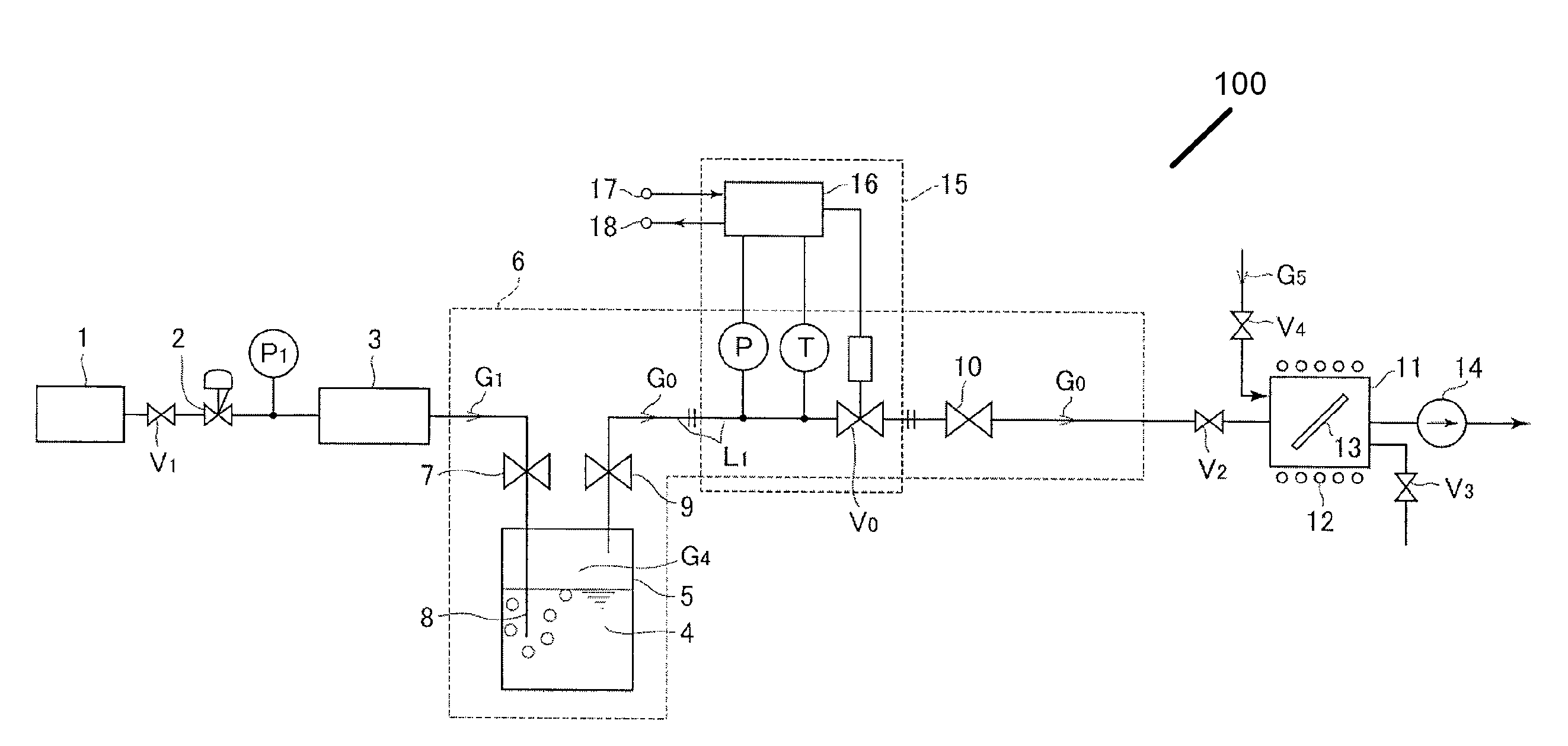

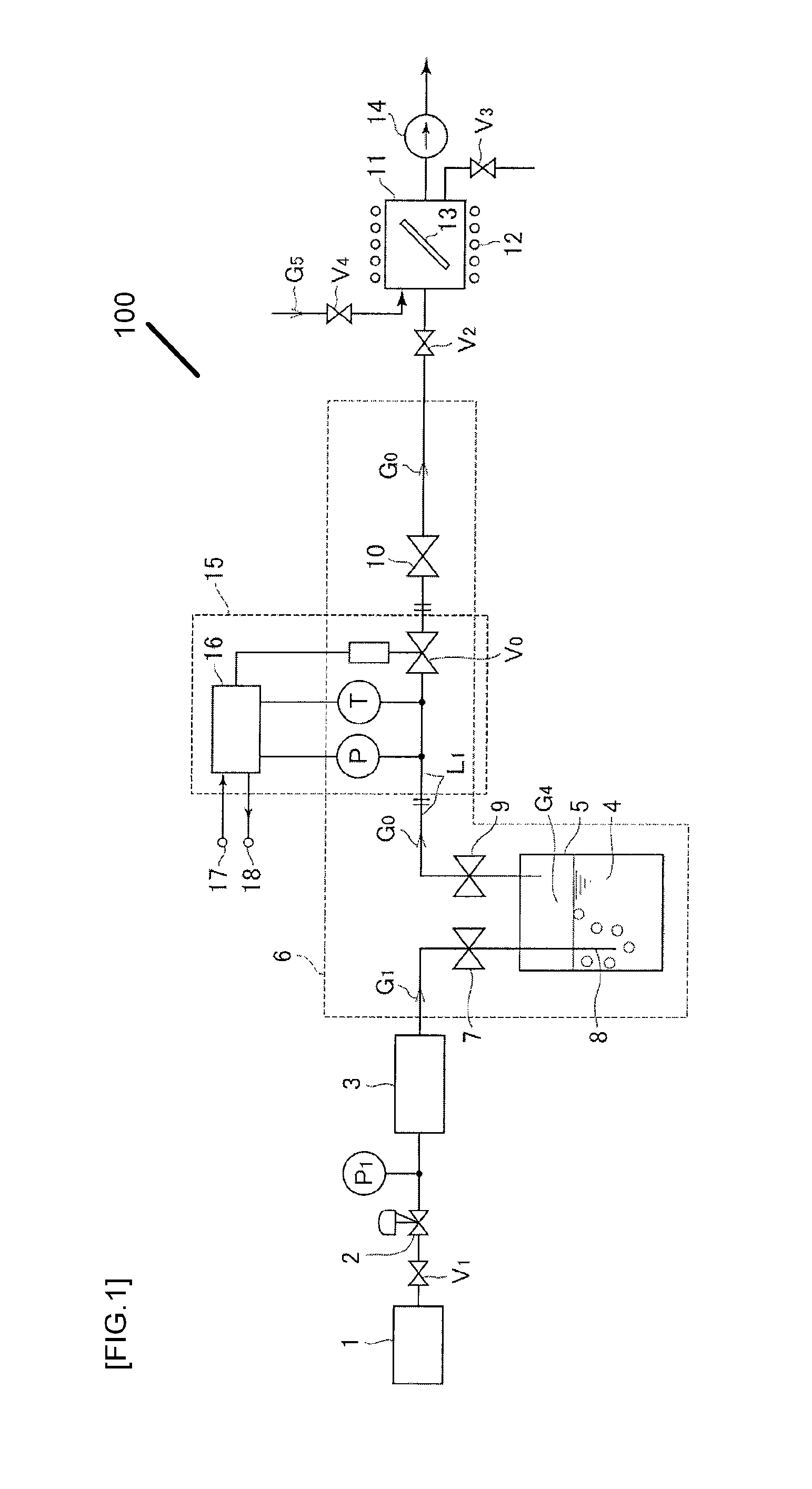

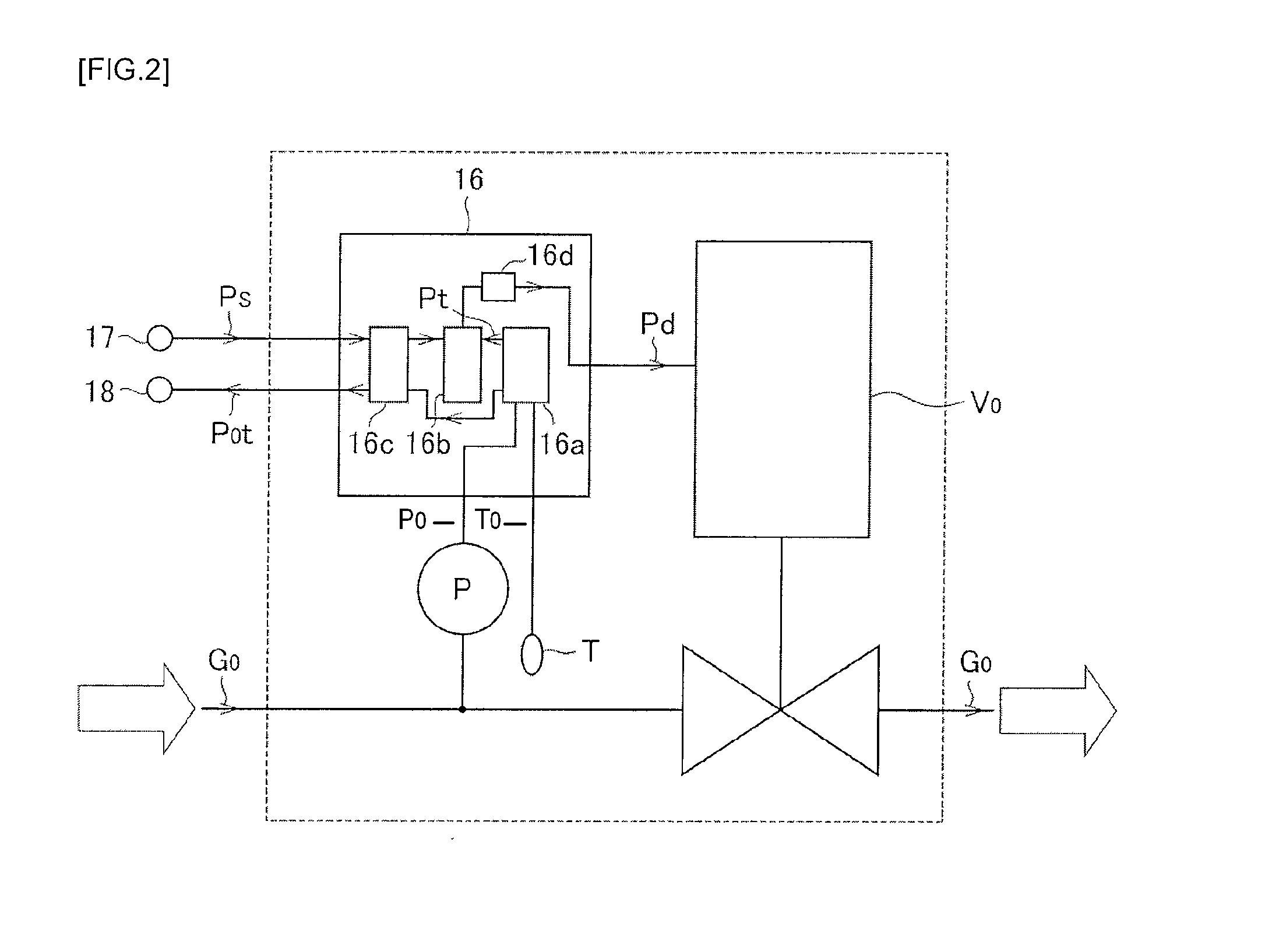

Evaporation supply apparatus for raw material and automatic pressure regulating device used therewith

ActiveUS20100012026A1Accelerate evaporationQuality improvementCarburetting airFunctional valve typesEvaporationProduct gas

An evaporation supply apparatus for raw material used in semiconductor manufacturing includes a source tank in which a raw material is pooled; a flow rate control device that supplies carrier gas at a regulated flow rate into the source tank; a primary piping path for feeding mixed gas G0, made up of raw material vapor G4 and carrier gas G1, an automatic pressure regulating device that regulates a control valve based on the detected values of the pressure and temperature of mixed gas G0 to regulate the cross-sectional area of the passage through which the mixed gas G0 is distributed so as to hold the pressure of the mixed gas G0 inside the source tank constant; and a constant-temperature heating unit for heating the source tank to a set temperature, in which mixed gas G0 is supplied to a process chamber while controlling the pressure inside the source tank.

Owner:FUJIKIN INC

Method for preparing rice bran oil from rice bran

InactiveCN1935963AImprove stabilityReduced activityFatty-oils/fats productionRice Bran ExtractRice bran oil

The invention relates to rice bran oil preparing method. It includes the following steps: processing the rice bran by micro wave with 800W power, 60s, 60mm height of layer, 7.4% humidity after processing; using supercritical carbon dioxide to extract rice bran oil at 25-60 degree centigrade, 10MPa-40MPa pressure, 15L / h-90L / h rate of CO2 flow for 30-150min. The prepared rice bran oil will not be rancidity and resolved by lipase to increase its stability. The product is easy to store. The rice bran oil yield is 20-22%.

Owner:南京远望富硒农产品有限责任公司 +1

Method for producing modified conjugated diene polymer and rubber composition

ActiveUS7202306B2Improve quality stabilityImprove abilitiesSpecial tyresWear resistanceAqueous solution

Disclosed are a method for producing a modified conjugated diene polymer improved in quality stability, more enhanced in low heat buildup and reinforcing ability when used in a rubber composition, excellent in wear resistance, mechanical characteristics and processability, and improved in cold flow; and a rubber composition using the same. The method includes a step of modifying an active end of an active end-containing conjugated diene polymer having a cis-1,4-bond content of 75% or more with an alkoxysilane compound containing at least one functional group selected from the group consisting of (a) an epoxy group, (b) an isocyanate group and (c) a carboxyl group, and a step of adding a condensation accelerator to conduct condensation reaction of the alkoxysilane compound (residue) in an aqueous solution having a pH of 9 to 14 and a temperature of 85 to 180° C.

Owner:ENEOS MATERIALS CORP

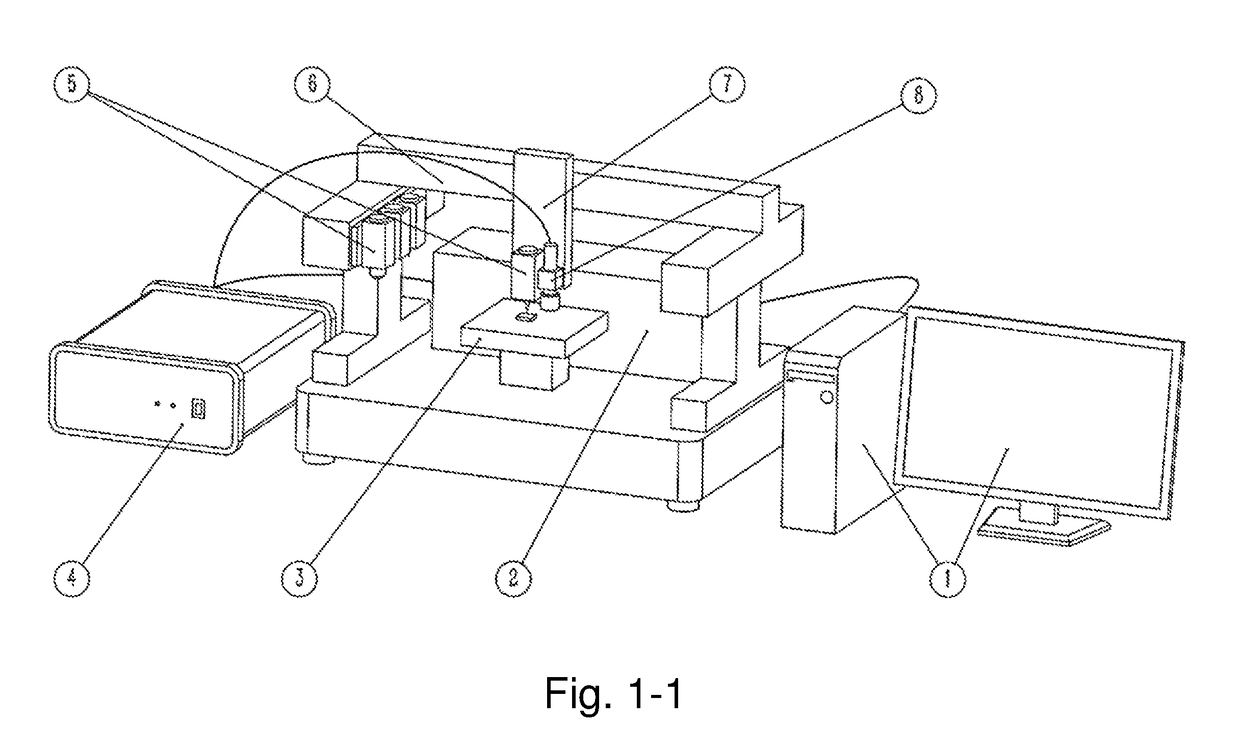

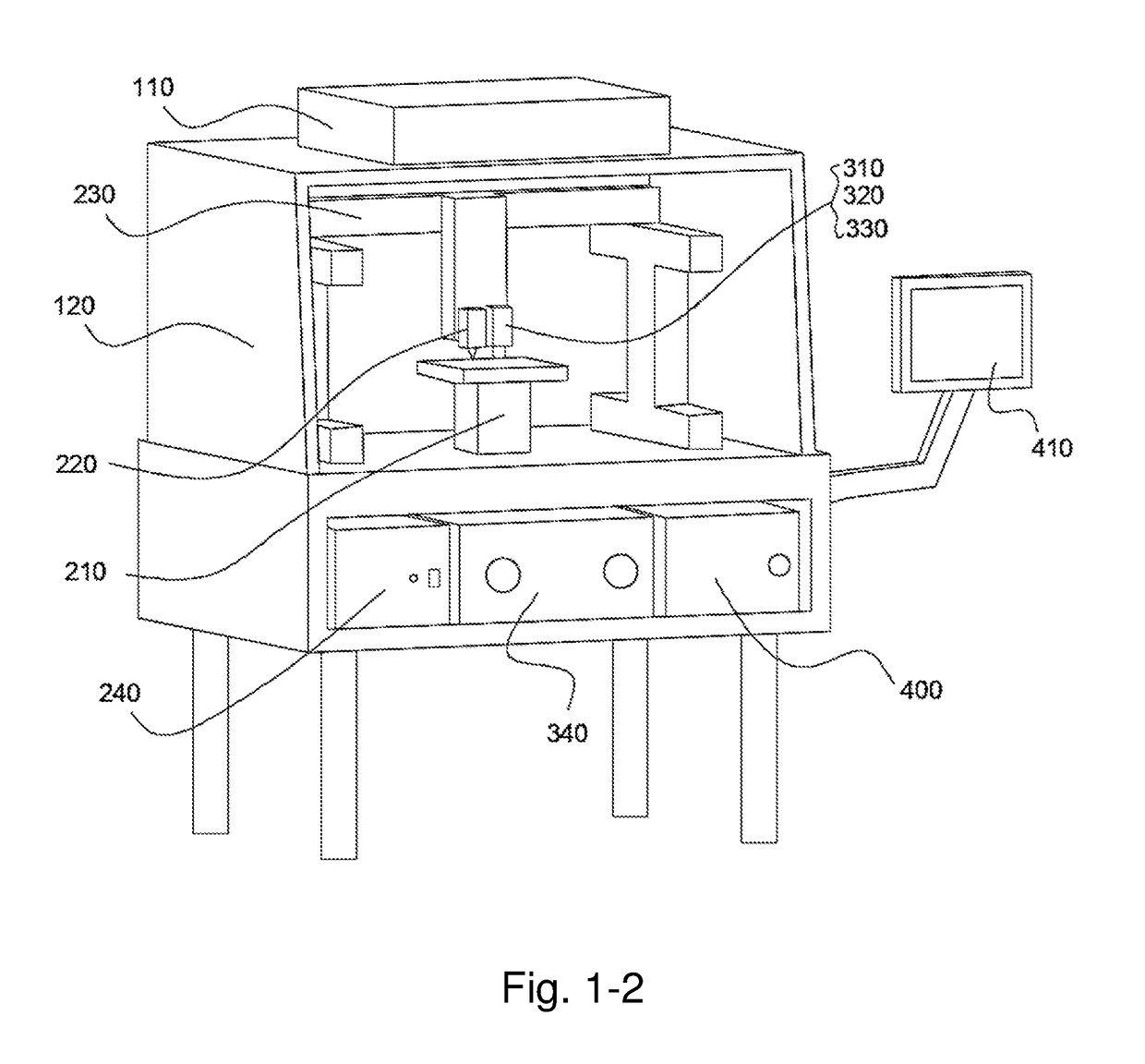

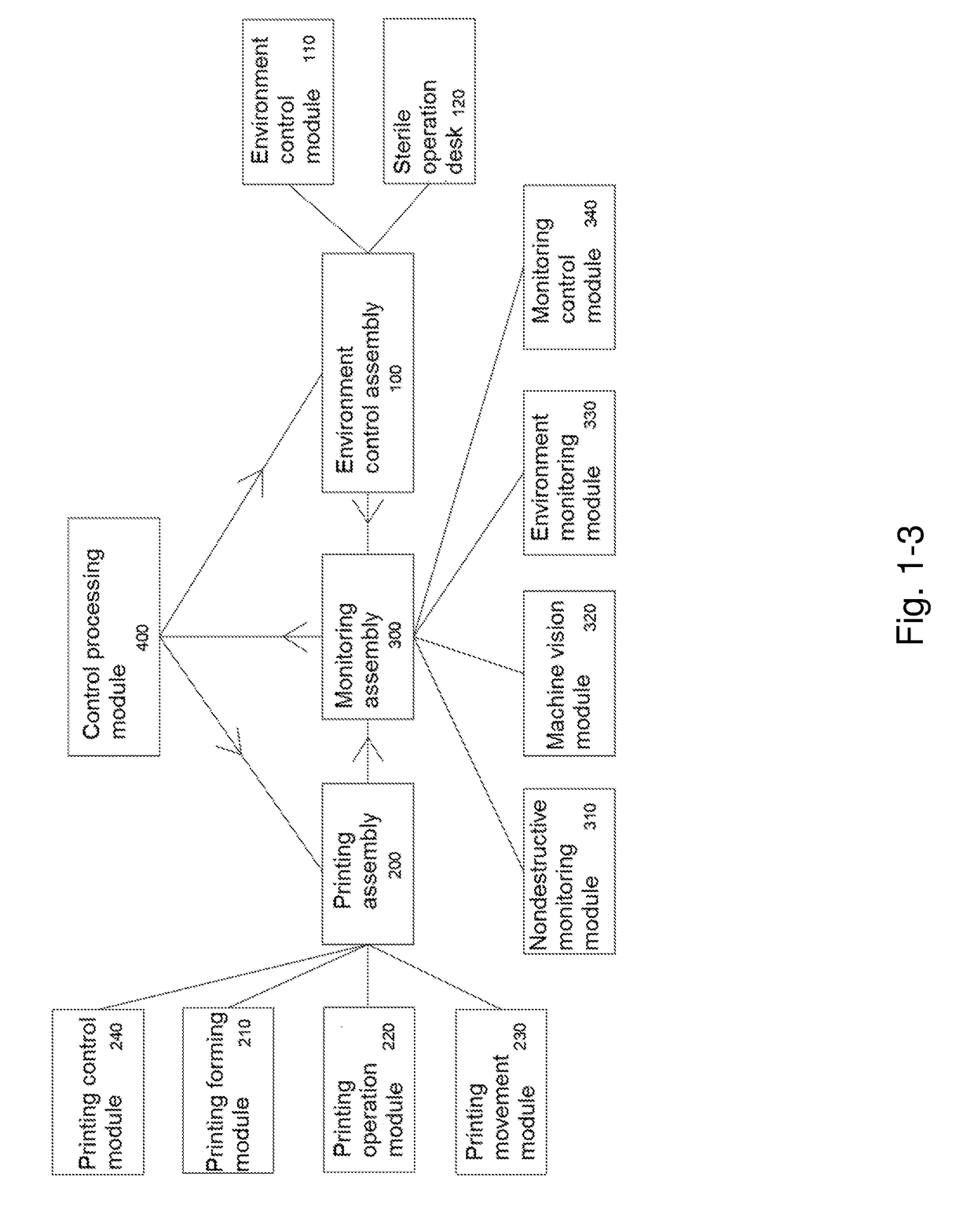

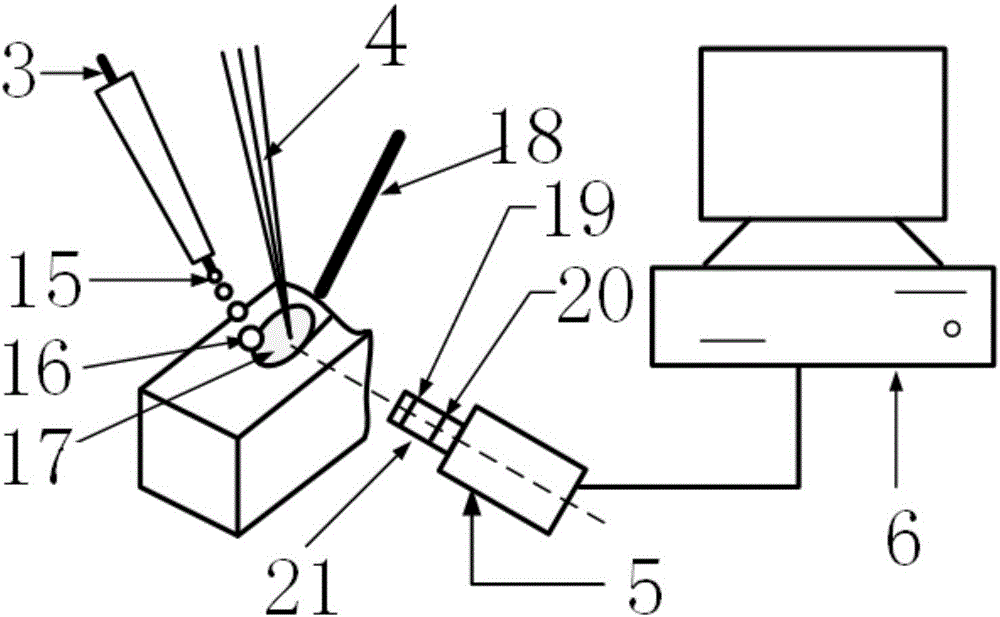

On-line Monitoring Method and System for Three-dimensional Printing

ActiveUS20190086899A1Improve consistencyImprove quality stabilityProgramme controlImage enhancementDepth imagingMonitoring system

Provided are a three-dimensional printing on-line monitoring method and system, relating to the technical field of three-dimensional printing, so as to solve the technical problem that the existing three-dimensional printing on-line monitoring systems are limited in imaging volume and cannot realize full-longitudinal-depth imaging. In the three-dimensional printing on-line monitoring method, full-longitudinal-depth imaging monitoring of the whole printing process is achieved by longitudinal-depth segmented scanning of a printing solidified layer and based on a longitudinal automatic splicing algorithm, and synchronous micro-tomography imaging on-line monitoring of the printing is achieved by guiding printing parameter optimization and control of a next depth-increased segment by using in real time a result feedback of the longitudinal-depth segmented being scanned; and at the same time of completing the manufacturing of the printed product, a three-dimensional high-resolution global image of an internal structure of the printed product is acquired, thereby completing quality control.

Owner:REGENOVO BIOTECH

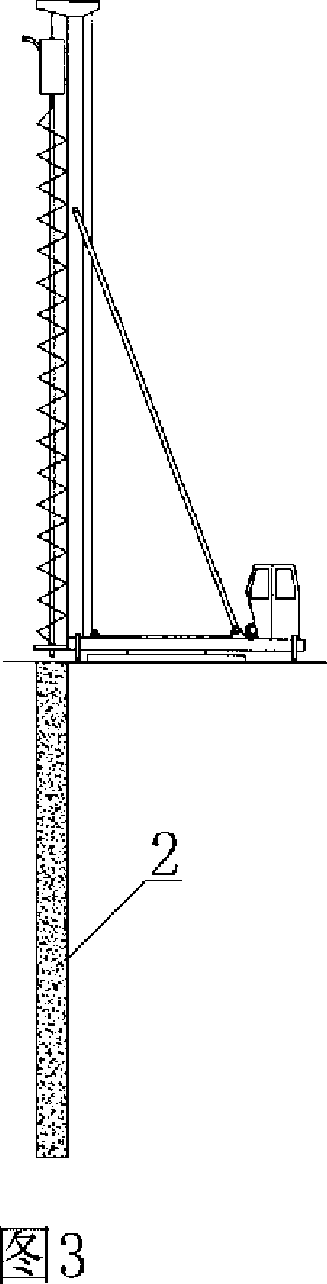

Post-grouting construction method for long helical bore grouting pile and its grouting device

ActiveCN101054799AIncrease stiffnessReduce settlementBulkheads/pilesBearing capacityBuilding construction

A long auger hole grouted pile post-grouting processing method and the postposition grouting device, which has the following step: firstly, the postposition grouting device is made; then, the long earth auger is used to drill; the plain concrete is pumped into the hole of the pile; after pouring the concrete on the pile stem, the grouting device is hung up and disposed above the pile stem before the cement is initially set; the hammer of the grouting device is started, and the postposition grouting device is immersed into the pile stem to the design elevation under the action of the exciting force and the leading of the guide member; the hammer is vibrating while being lifted and the hammer is drawn, then the hammer is closed, to set the postposition grouting device in the pile stem; after the pile stem concrete pouring is completed and the cement is finally set, the grouting is processed by the pile toe grouting pipe and the pile side grouting pipe, to make the soil mass in some distance around the pile toe and the pile cycle being reinforced. The invention greatly advances the bearing capacity of pile, reduces the engineering quality hidden danger of the long auger hole grouted pile and the amount of pile compared with the traditional technology, lowers the basic engineering invest.

Owner:JIAN YAN FOUND ENG

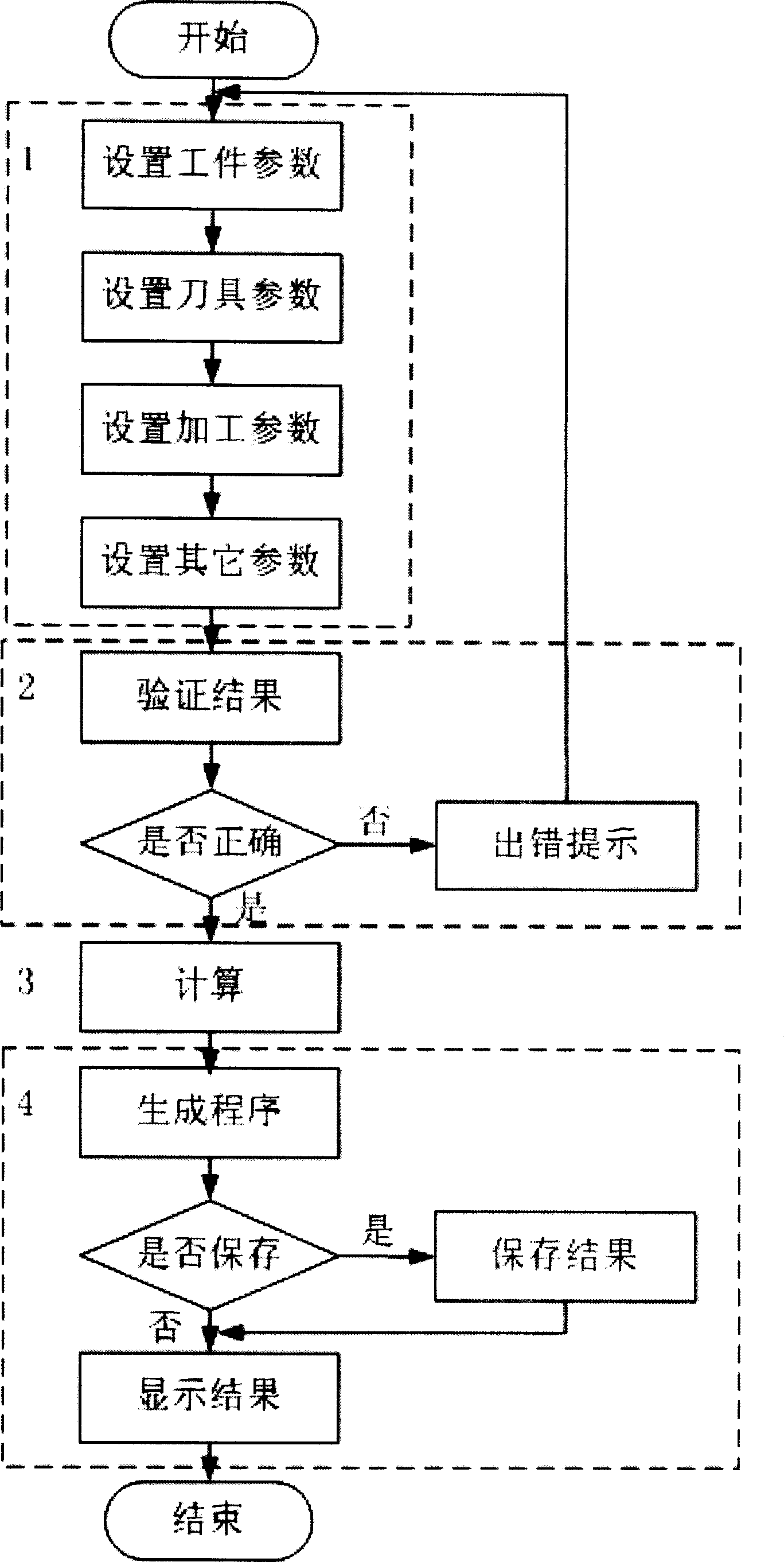

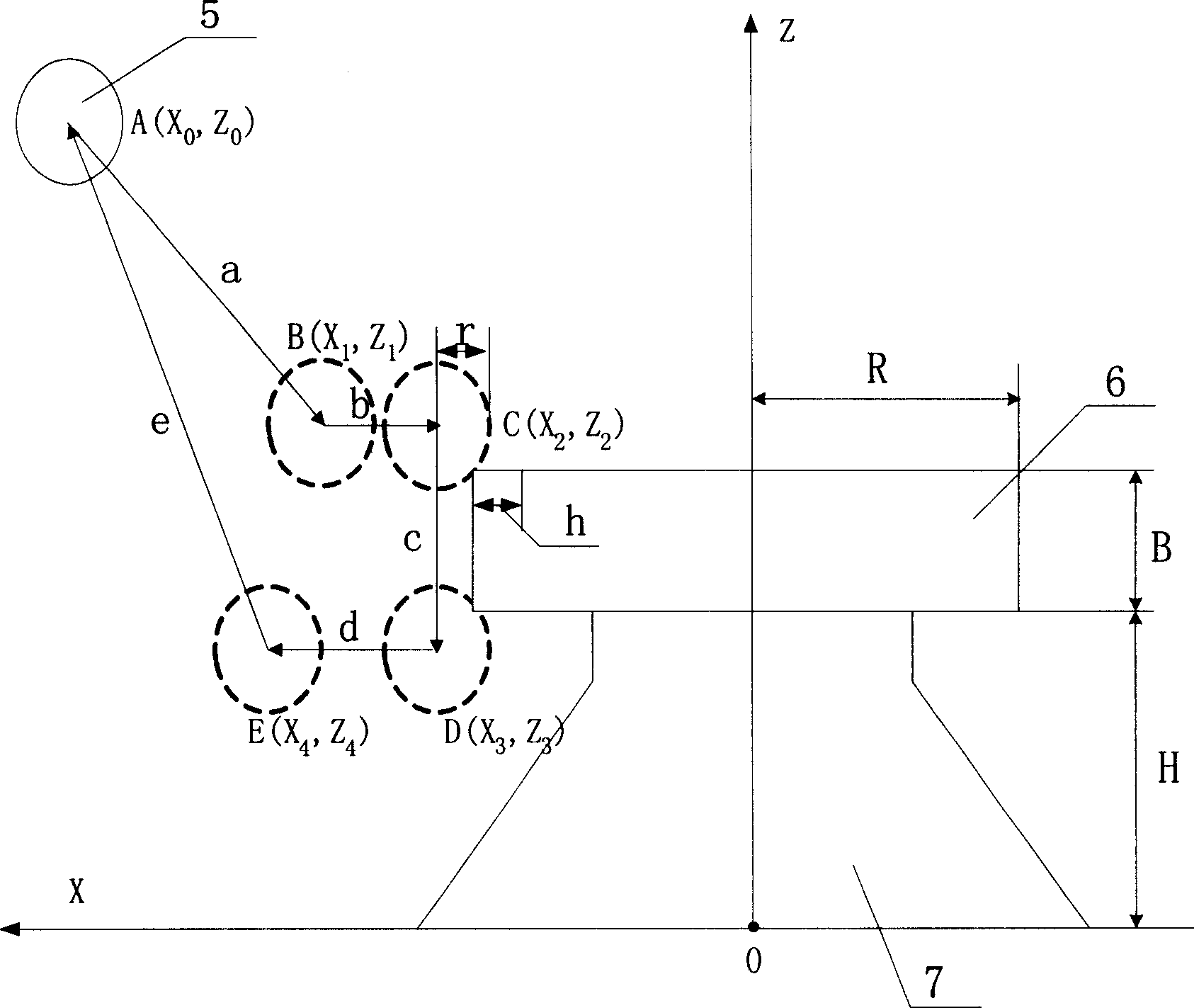

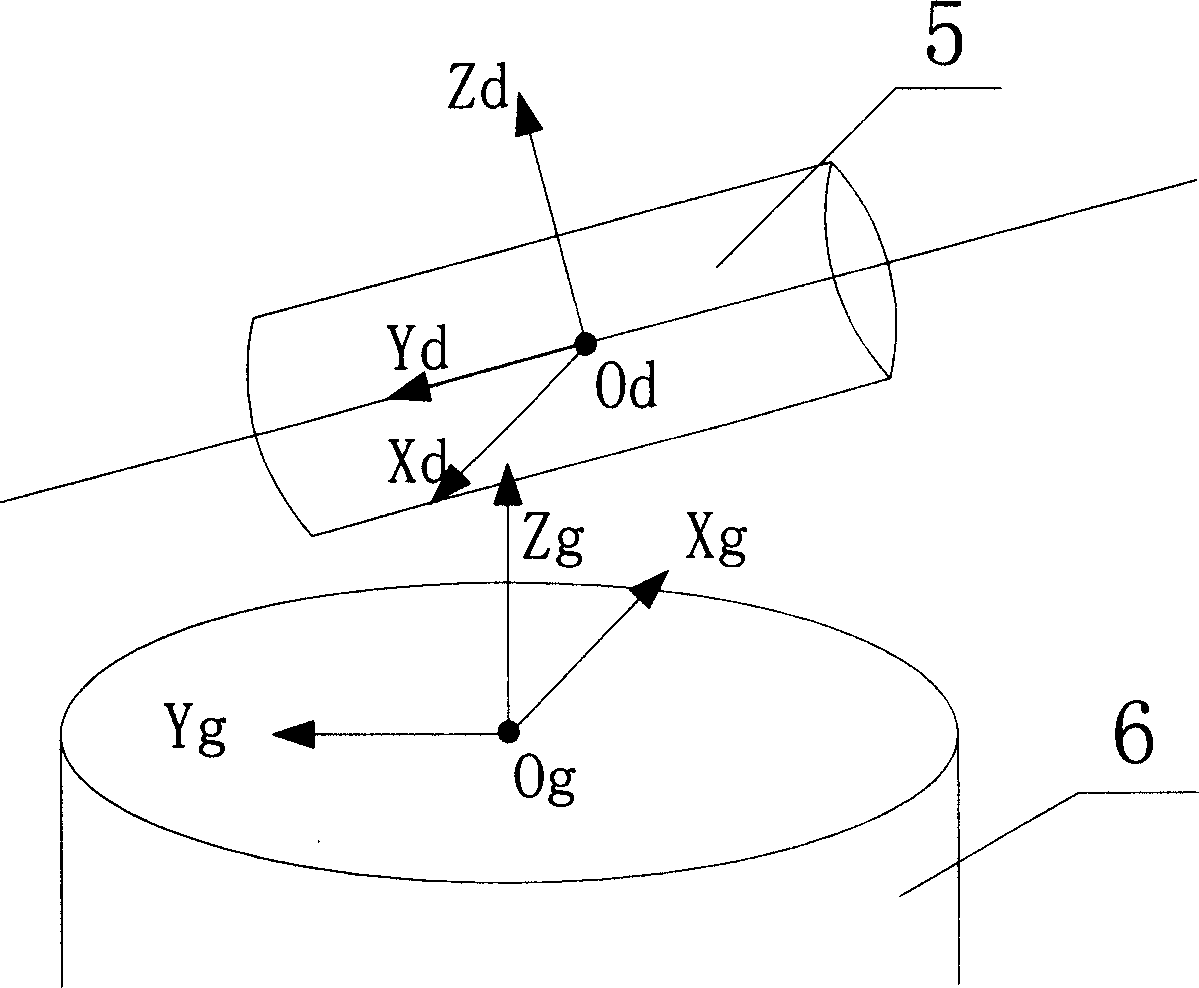

No programming method for machining of numerically controlled gear hobbing machine

InactiveCN1838008AIncrease profitLower requirementProgramme controlComputer controlHuman–machine interfaceHobbing

This invention relates to a method for machining of numerically controlled gear hobbing machine. Wherein, applying the self-carried keyboard and NC system of the system to set, compute and validate the parameters for work pieces, cutting tools, and manufacture; according to system program format, automatic producing the NC processing code.

Owner:CHONGQING UNIV

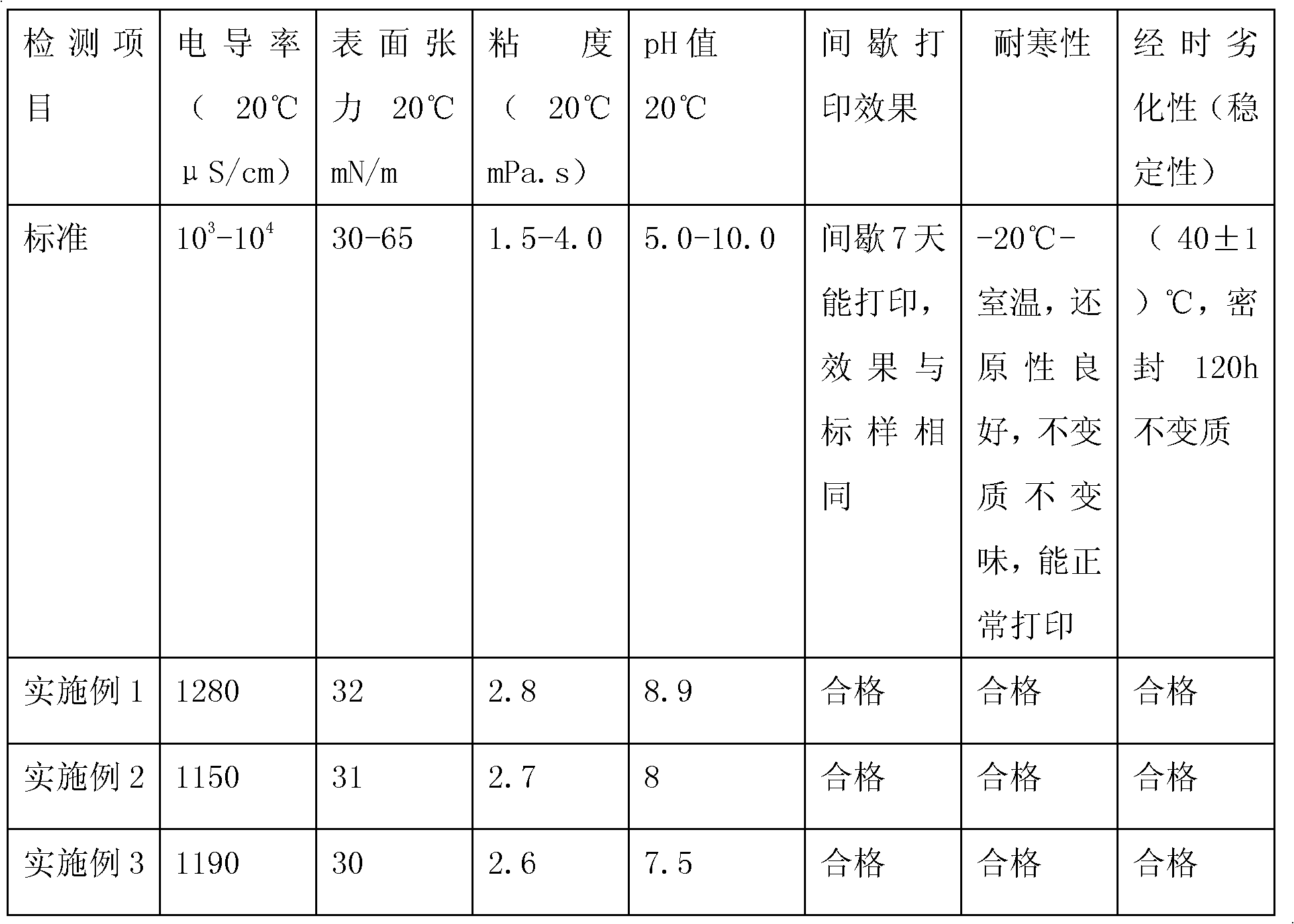

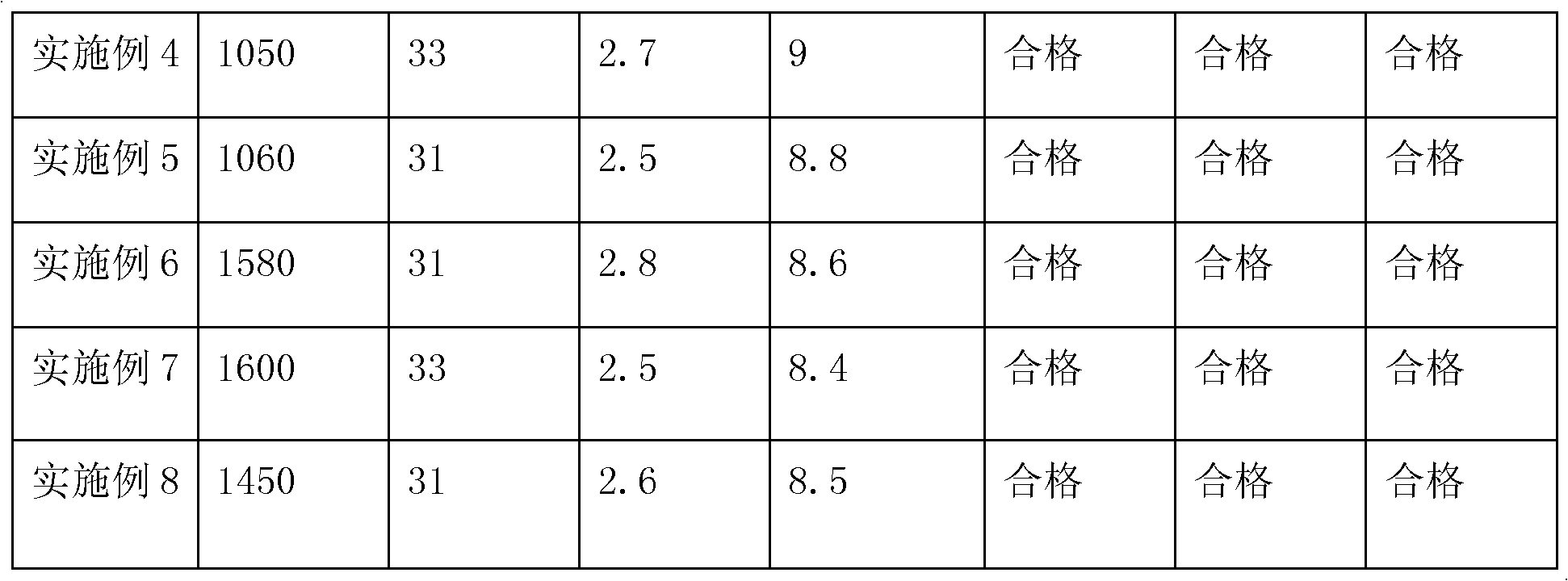

Direct ink-jet printing disperse dye ink and use method thereof

The invention discloses direct ink-jet printing disperse dye ink which comprises the following components in percentage by weight: 1.0-14 percent of disperse dye, 0.5-20 percent of dispersing agent, 0.2-2.0 percent of surface tension regulator, 0.1-1.0 percent of fungicide, 2-30 percent of viscosity regulator, 0.1-2 percent of pH regulator and the balance of deionized water. The invention also discloses a use method of the direct ink-jet printing disperse dye ink for fabric printing, comprising the following steps of: carrying out direct ink-jet printing on a fabric at 40-70 DEG C, steaming or roasting the printed fabric at 180-230 DEG C for 2-15min and carrying out color fixing. The invention has the beneficial effects that the quality stability is high, the long-term storage is realized, and the color strength and the color fastness both reach higher technical requirements.

Owner:HONGSAM DIGITAL SCI & TECH

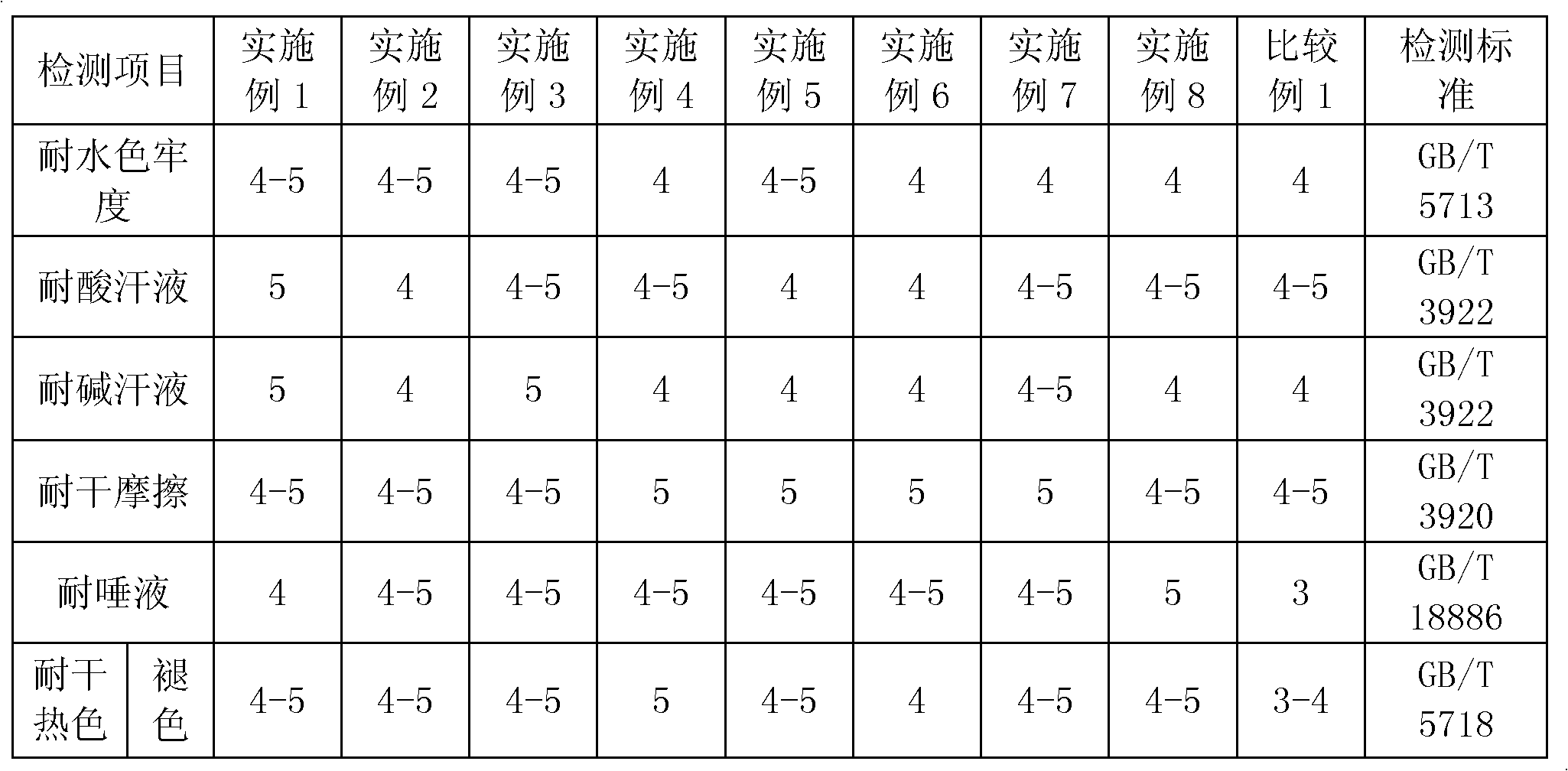

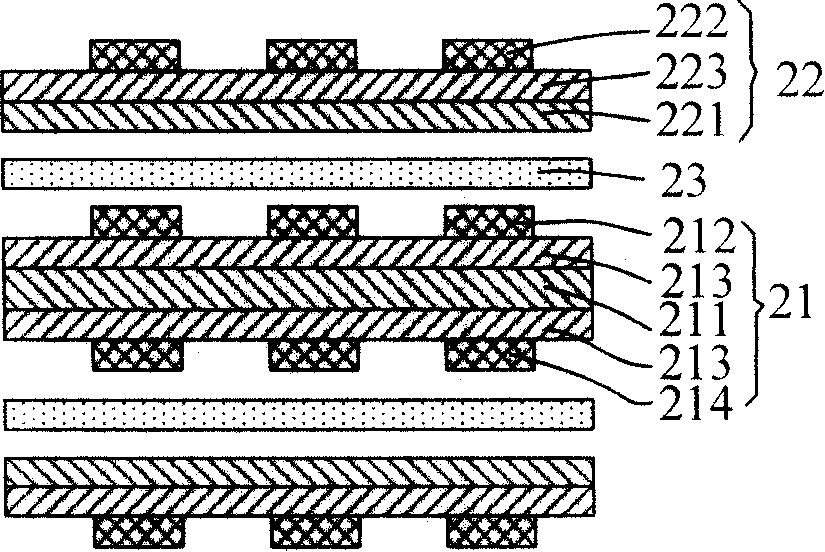

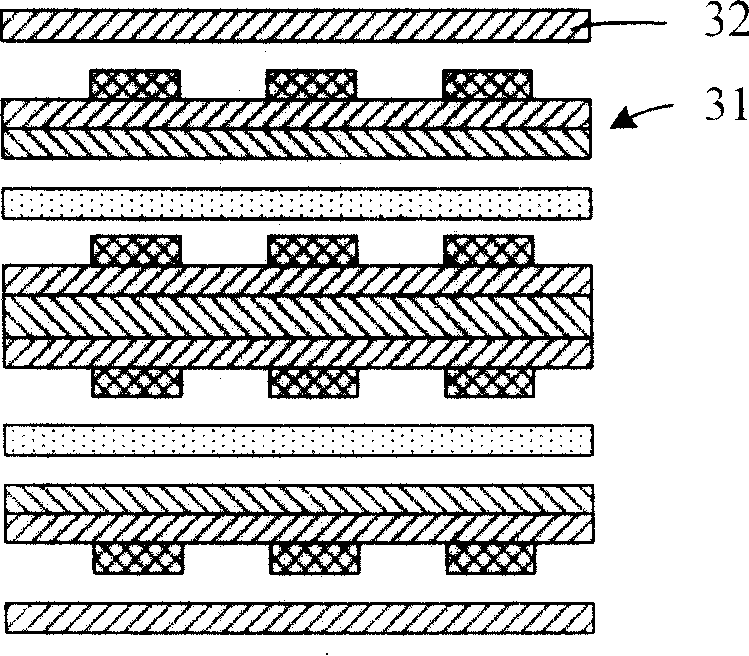

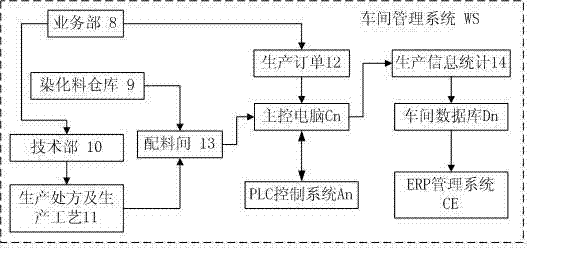

Method for preparation of multi-layer flexible circuit board

InactiveCN101203095AImprove quality stabilityImprove alignment accuracyPrinted circuit assemblingPrinted circuit aspectsInsulation layerFlexible circuits

Owner:AVARY HLDG (SHENZHEN) CO LTD +1

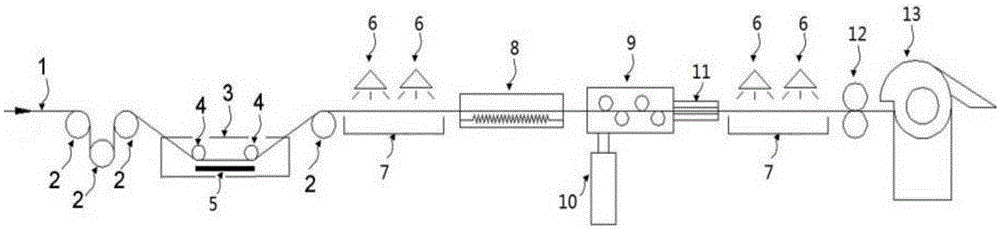

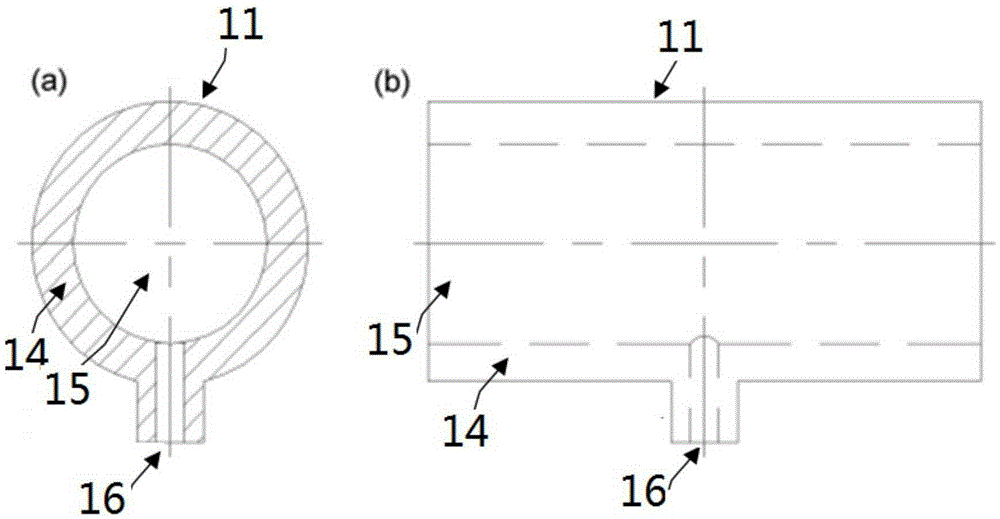

Preparation method and device for carbon fiber-reinforced thermoplastic resin composite material

The invention provides a manufacturing method for a carbon fiber-reinforced thermoplastic resin composite material. The method comprises the steps of firstly removing a sizing agent on a carbon fiber surface, then performing metallic coating treatment, water scrubbing and surface heat treatment, leading into a dipping die head containing melt thermoplastic resin in a splitting state, enabling the melt thermoplastic resin to wrap the carbon fiber surface, then performing cooling and grain-size dicing, so that the carbon fiber-reinforced thermoplastic resin composite material is prepared. The method has the advantages of simple and practical process, low cost, stable quality, good mechanical property, good electromagnetic protective property and light weight.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

Residential building system with cast-in-situ beam columns and prefabricated sandwich concrete wall panels and construction method

ActiveCN102251699AHigh bonding strengthImprove reliabilityWallsProtective buildings/sheltersSocial benefitsEngineering

The invention relates to a residential building system with cast-in-situ beam columns and prefabricated sandwich concrete wall panels and a construction method, and the construction process of a vertical load-bearing structure is as follows: mounting the prefabricated sandwich concrete wall panels in para-positions on an underbeam / foundation so as to leave certain vertical gaps at the joints between the prefabricated sandwich concrete wall panels respectively, leaving horizontal gaps between the prefabricated sandwich concrete wall panels and the underbeam / foundation, mounting clamp dies at the gaps and casting concrete in situ so as to fixedly connect inter-plate connecting columns and horizontal joints formed at the vertical gaps and the horizontal gaps respectively, cast-in-situ wall corner columns and the prefabricated sandwich concrete wall panels into a whole and further constitute the vertical force-bearing structure of the residential building system. By adopting the invention, the bearing capacity of a wall body and the integrity and the anti-seismic performance of the structure of the whole residential building system are significantly improved, the application of steel mesh frame polyphenyl sandwich panels in the load-bearing structures is powerfully pushed, and the economic and social benefits are significant.

Owner:BEIJING HUAMEIKEBO TECH DEV

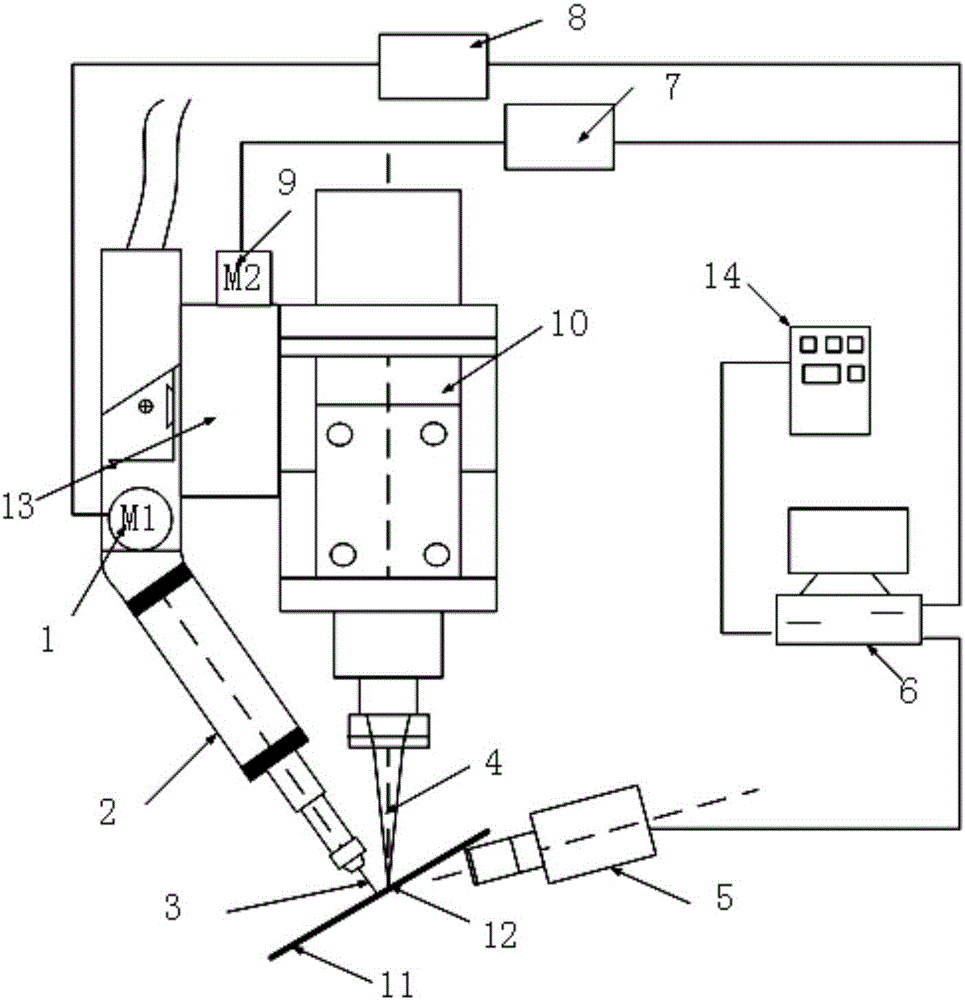

Vision sensing-based laser-electric arc hybrid welding real-time automatic control device and welding method thereof

ActiveCN106001926AImprove quality stabilityImprove welding stabilityLaser beam welding apparatusAutomatic controlEngineering

The invention discloses a vision sensing-based laser-electric arc hybrid welding real-time automatic control device and a welding method thereof. A welding gun is connected with a laser head. The fused welding wire tip of a welding wire forms a molten drop in the welding process. A laser beam is irradiated to weldment, and a laser keyhole is formed. A high-speed camera is used for filming images of the fused welding wire tip and the laser keyhole. The high-speed camera is connected with an image processing industrial personal computer. The image processing industrial personal computer is connected with a combined welding head control device of the welding gun and a welding equipment control device of the welding gun. The image processing industrial personal computer controls the distance between the central point of the laser keyhole and the central point of the molten drop through the combined welding head control device of the welding gun and controls the vertical coordinate Y value of the central point of the fused welding wire tip through the welding equipment control device of the welding gun. By the adoption of the vision sensing-based laser-electric arc hybrid welding real-time automatic control device and the welding method thereof, the problems that in the prior art, the distance between the center of a molten drop and the center of a laser keyhole cannot be adjusted in real time, visualization of the adjusting process cannot be achieved, and accordingly the distance between the center of the molten drop and the center of the laser keyhole is too large or too small are solved.

Owner:CHANGCHUN UNIV OF SCI & TECH

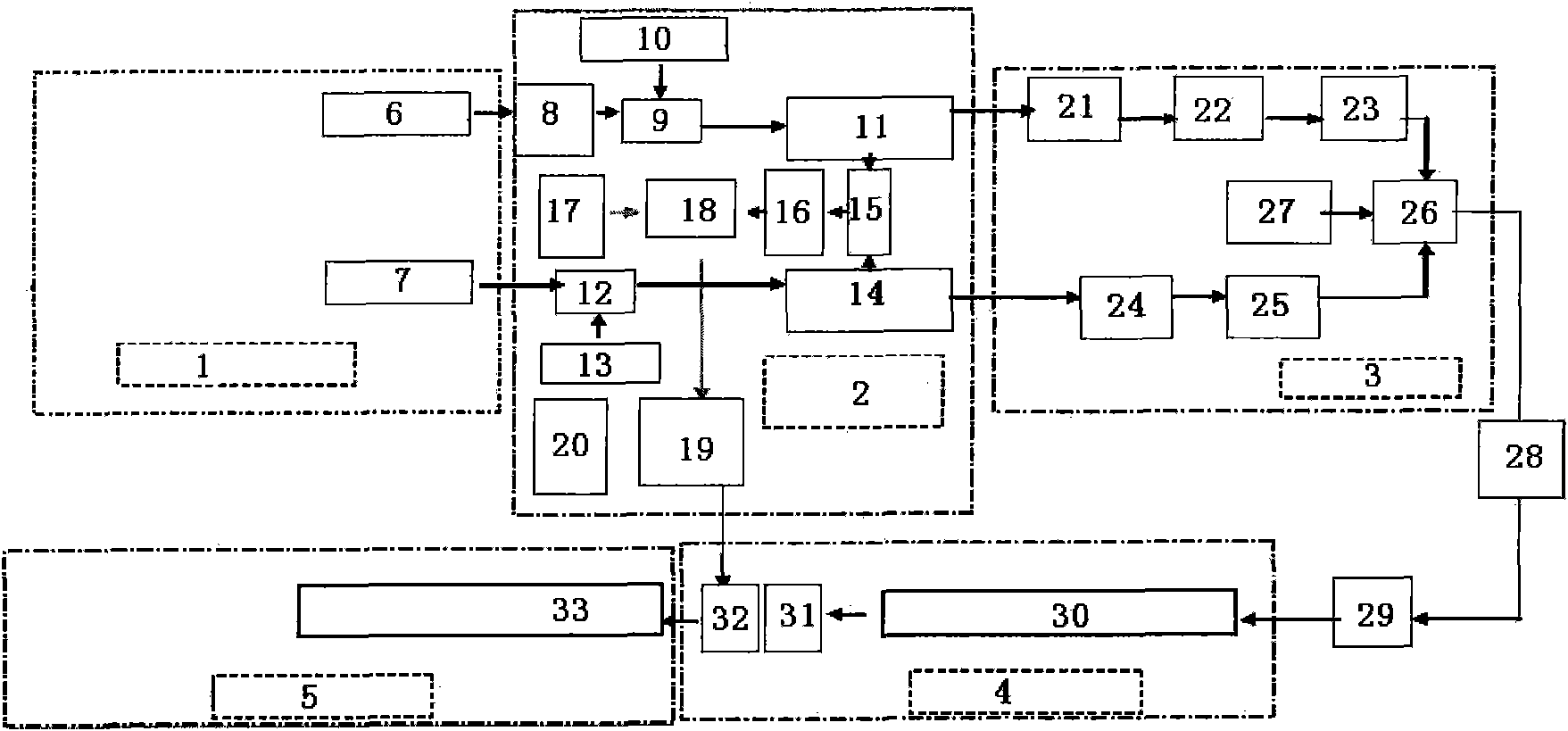

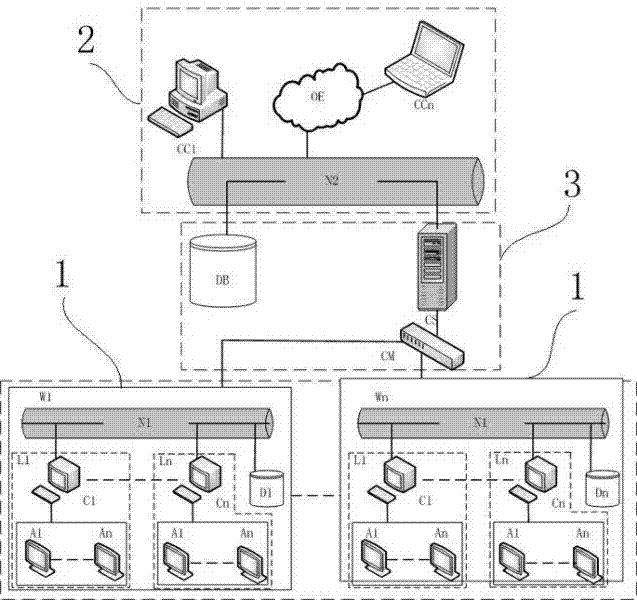

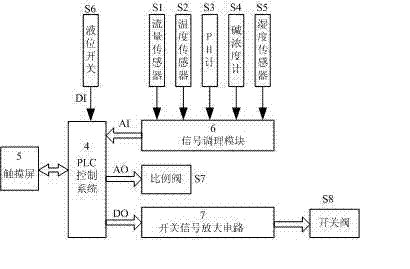

ERP-based intelligent intensive control system of continuous dyeing production line

InactiveCN102385363AImprove efficiencyReduce energy consumptionTotal factory controlProgramme total factory controlEnterprise resource planningPlant level

The invention mainly discloses an ERP-based (Enterprise Resource Planning-based) intelligent intensive control system of a continuous dyeing production line, comprising a plant-level monitoring system, an enterprise-level management system, and an intermediate information management system for connecting the two former systems. The ERP-based intelligent intensive control system establishes a process model based on orders so that the process parameters of the production process can be automatically regulated and controlled when a machine tool works; therefore, the influence of human factors onthe production process and the quality of products is effectively reduced; the quality stability of the products is improved; the unit energy consumption of the products is reduced; and the enterprise revenue is increased.

Owner:ZHEJIANG SCI-TECH UNIV +1

Method for manufacturing and repairing conducting circuits on surfaces of ceramic substrates

ActiveCN103781285ALow costLarge format 3D processingInsulating substrate metal adhesion improvementPrinted circuit secondary treatmentComplex ionsChemical plating

The invention aims at providing a universal method for manufacturing and repairing electric circuits on the surfaces of two-dimensional or three-dimensional ceramic materials. The universal method includes the steps that the surfaces of the ceramic materials which are covered with ions or complex-ions of specific metal in advance are processed through laser beams according to pre-designed circuit patterns, then chemical plating is implemented, and then the required conducting circuits can be obtained. According to the technology, the various complex conducting circuits can be rapidly and directly manufactured or repaired on the surfaces of various ceramic substrates including the planar ceramic substrates and the three-dimensional ceramic substrates, and the universal method has no special requirements for the materials of the substrates, does not need vacuum, and is low in cost and high in flexibility degree and efficiency. The obtained conducting circuits are even and compact in surface, free of cracks and good in conductivity and combining force, and therefore the universal method has the universality.

Owner:HUAZHONG UNIV OF SCI & TECH

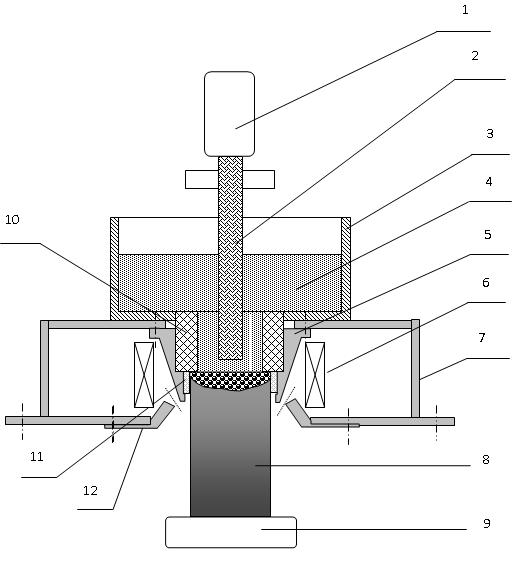

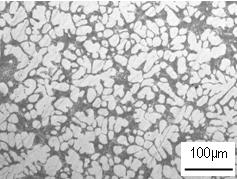

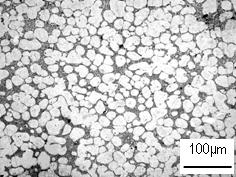

Continuous casting method for producing aluminium alloy semisolid casting ingot

The invention belongs to the technical field of metal semisolid processing and relates to a continuous casting method for producing an aluminium alloy semisolid casting ingot. The continuous casting method is characterized by comprising the following steps: firstly, a flow splitting disc, a flow guiding pipe and a stirring rod of a mechanical stirrer positioned at the central part of the flow guiding pipe are preheated at the temperature of 50-80 DEG C; then overheat aluminium liquid with qualified smelting is casted into the flow splitting disc continuously at the temperature of 100-200 DEG C higher than the temperature of a liquid phase line; when the level of the aluminium liquid in the flow splitting disc reaches the range from 50 to150mm, a dummy ingot base starts to act, the continuous casting process is started, and the level of aluminium liquid in the flow splitting disc needs to be maintained in the range from 50 to 150mm; and finally, while the process of continuous casting is started, simultaneously an electromagnetic stirrer positioned at the outer part of the flow guiding pipe and the mechanical stirrer positioned at the central part of the flow guiding pipe are started and aluminium liquid flowing through the flow guiding pipe is stirred. The continuous casting method has the advantages that the aluminium alloy semisolid casting ingot can be produced in a low-cost and large-batch manner, and the continuous casting method is especially suitable for batch production of large-diameter aluminium alloy semisolid casting ingots.

Owner:TIANJIN FLEMINGS ALUMINUM

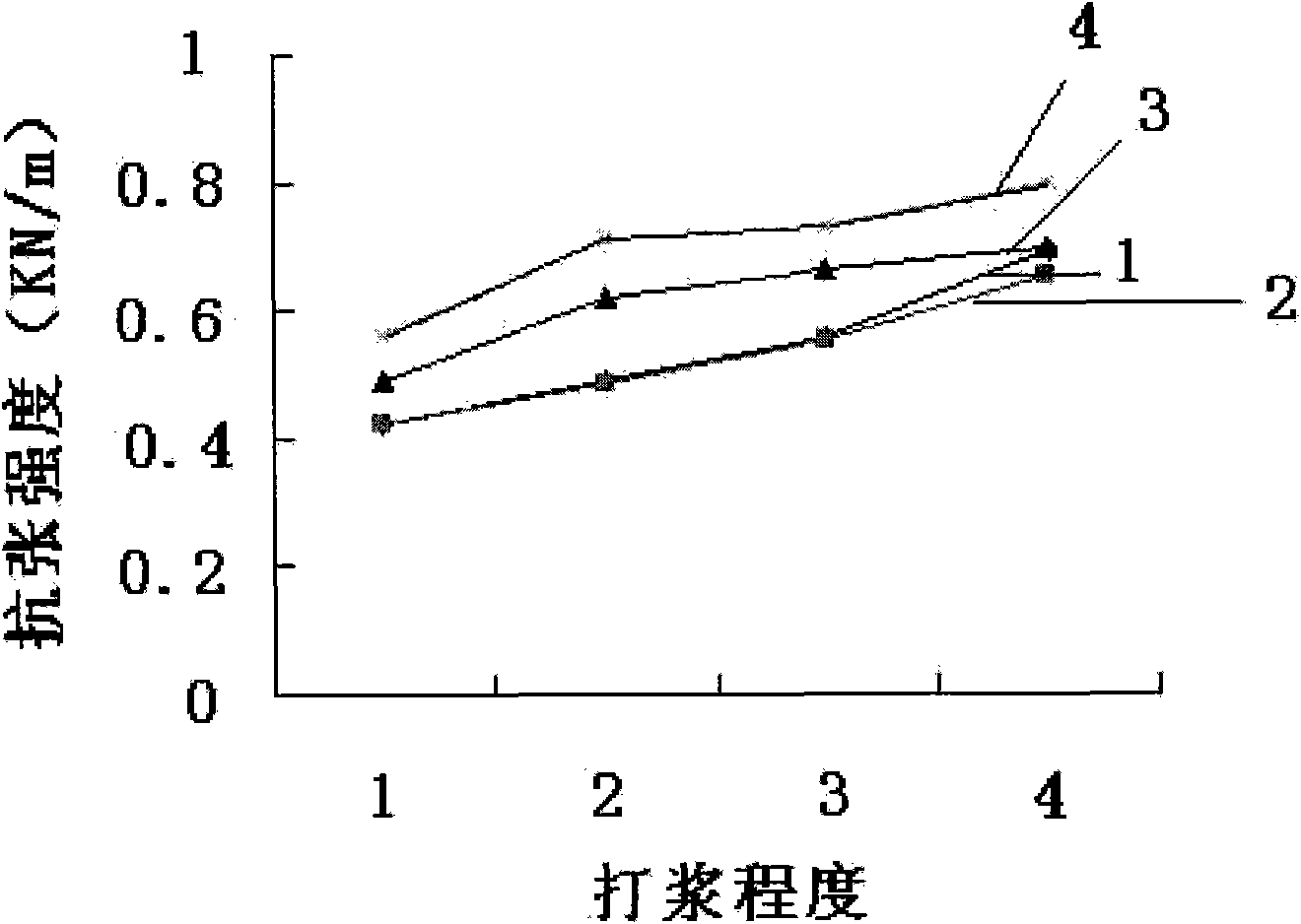

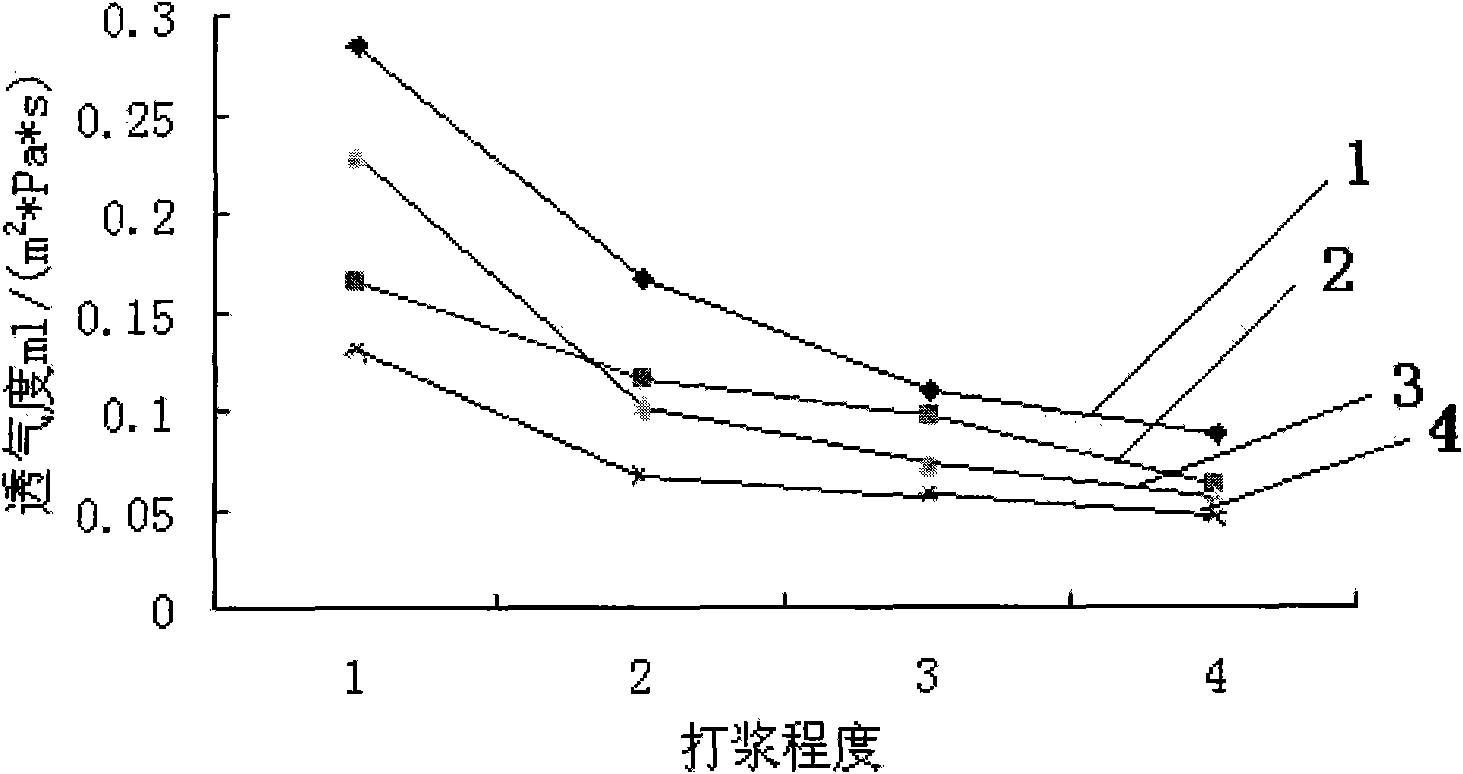

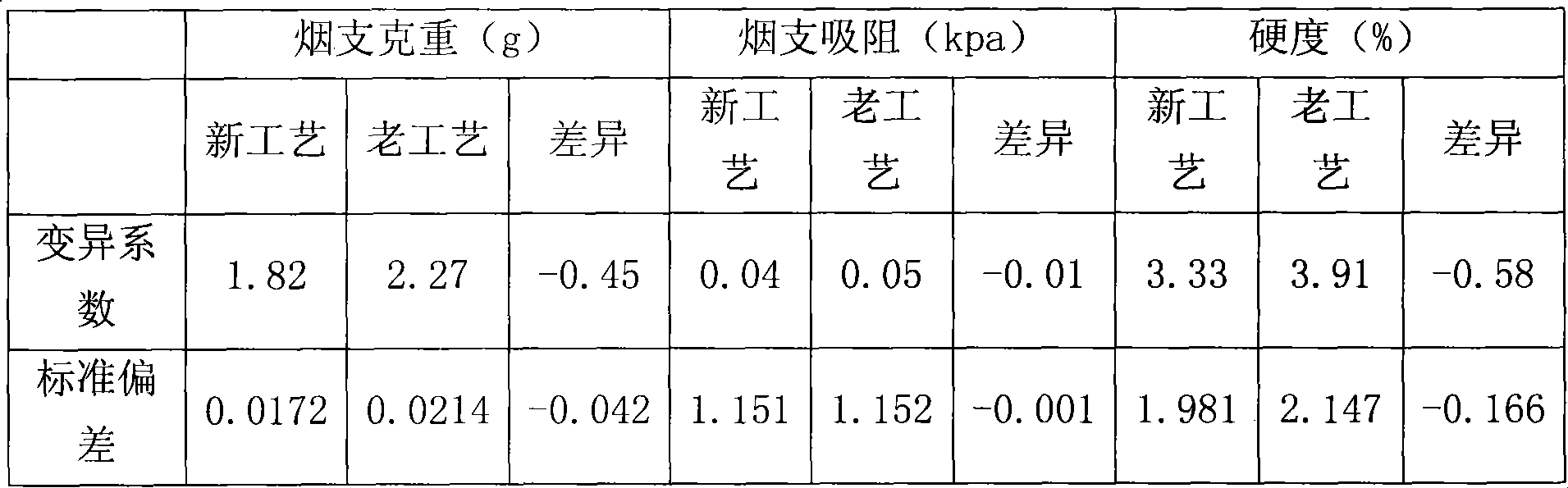

A cut rolled stem processing procedure

ActiveCN101444328ASmall mass volatilityImprove quality stabilityTobacco preparationTobacco treatmentEngineeringIncrease temperature

The invention discloses a cut rolled stem processing procedure, comprising the following processes: increasing temperature and humidity of stem, cutting the stem; increasing temperature of the cut rolled stem; expanding the cut rolled stem; cutting the cut rolled stem; storing. Increasing temperature and humidity of stem employs an apparatus for increasing temperature and humidity of stem, to rise the temperature of the stem from normal temperature to 60 DEG C, and to rise water ratio of the stem from 33% to 34-40%. Cutting the stem employs a stem cutter to cut the stem into pieces having thickness of 0.12 to 0.3mm. Increasing temperature of the cut rolled stem employs an apparatus for increasing temperature of the cut rolled stem, to rise the temperature of the cut pieces to 70 to 90 DEG C. Expanding the cut rolled stem is to rapidly dehydrate the pieces and enlarge volume at high temperature from 150 to 170 DEG C. Cutting the cut rolled stem is to cut the expanded pieces into the cut rolled stem having thickness of 0.8 to 1.2 mm. The cut rolled stem produced according to the invention has small fluctuation of quality and prominent improved quality stability. On the basis of maintaining steady aesthetic quality, the cut rolled stem is changed from piece shape into filament shape, which enhances useful value of the cut rolled stem, lessens formulation cost of product and offers efficient means for coking reduction of the product.

Owner:SHANGHAI TOBACCO GRP CO LTD

Method for fabrication of aligned nanowire structures in semiconductor materials for electronic, optoelectronic, photonic and plasmonic devices

InactiveUS20100147674A1High beam qualityImprove brightness qualityMaterial nanotechnologySemiconductor/solid-state device detailsInterstitial defectSemiconductor materials

The present invention describes a method of fabrication of nanocomposite semiconductor materials comprising aligned arrays of metal or semiconductor nanowires incorporated into semiconductor material for application in various electronic, optoelectronic, photonic and plasmonic devices employing self-assembling of the nanowires under light illumination from charged interstitial defect atoms, which are either inherently present in the semiconductor material or artificially introduced in the matrix semiconductor material.

Owner:ANTEOS INC & ALTAIR CENT

Non-quenching high-toughness cold-working die steel and production process

InactiveCN101713052AReasonable ratioImprove compactnessMetal-working apparatusManufacturing technologyIntermediate frequency

The invention relates to a non-quenching high-toughness cold-working die steel belonging to the technical field of metallurgical manufacture. The novel cold-working die steel is developed by optimizing and creating a product component formula, adding alloy elements, rolled and cold thinned texture and adopting the processes of remelting and fining electroslag in an electric furnace, forging many times in a great forging proportion and special heat treatment. The manufacture process comprises the following flows: selecting a chemical component range; drawing an ingredient scheme according to the chemical component range; melting at an intermediate frequency; remelting (refining) the electroslag; annealing; discharging; extending hydrogen; forging; normalizing; tempering; mechanically processing; and detecting. The important manufacture process comprises the steps: (1) refining; (2) forging; (3) extending hydrogen; and (4) normalizing; and tempering so as to obtain non-quenching high-toughness cold-working die steel. The invention has reasonable chemical component proportion, low manufacture cost, good alloying effect, great forging transformer ratio, favorable density of metal structure and high toughness performance index. Various performance indexes of the product reach or exceed the levels of similar international and national products.

Owner:SHANDONG YUANDA MATERIAL TECH CO LTD

Long glass fibre reinforced polypropylene material and preparation method thereof

The invention belongs to field of a polymer material and shaping thereof, in particular to a long glass fiber reinforced polypropylene material and a preparation method thereof. The long glass fiber reinforced polypropylene material is prepared from the following components: 35-68wt% of polypropylene, 30-60wt% of long glass fiber, 1-5wt% of compatilizer and 0.3-1.0wt% of antioxidant, wherein the polypropylene is polypropylene with a melt index as high as 50-500g / 10min. The preparation method comprises the following steps: mixing the polypropylene, the compatilizer and the antioxidant; feeding the mixture in a double-screw extruder; enabling the long glass fiber to be fully soaked by melts through a soaking die; and cooling, drawing and pelletizing the fully soaked long glass fiber to obtain the long glass fiber reinforced polypropylene material. By the invention, the soaking effect of the glass fiber in polypropylene melts can be reinforced, substances harmful to human bodies can be eliminated or reduced, the odor is lightened, and the soaking effect and mechanical property of the material can be effectively improved.

Owner:NANJING JULONG SCI&TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com