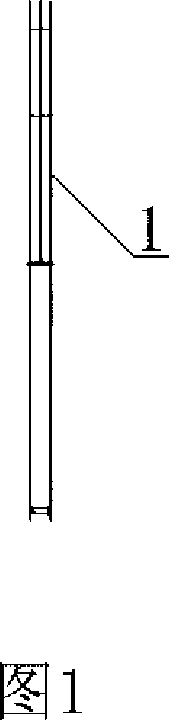

Post-grouting construction method for long helical bore grouting pile and its grouting device

A technology of long auger drilling and construction method, which is applied in the direction of sheet pile wall, foundation structure engineering, construction, etc., to achieve the effect of saving foundation engineering investment, expanding the scope of application, and reducing foundation settlement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

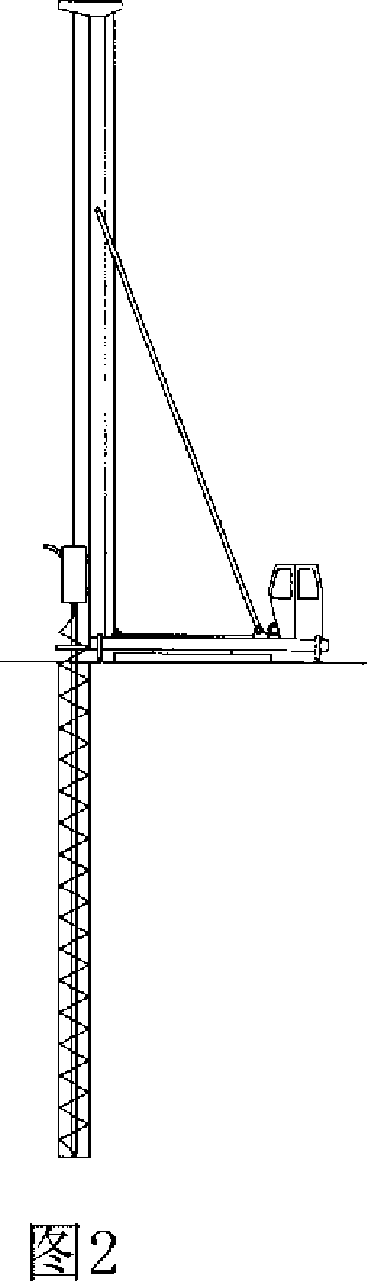

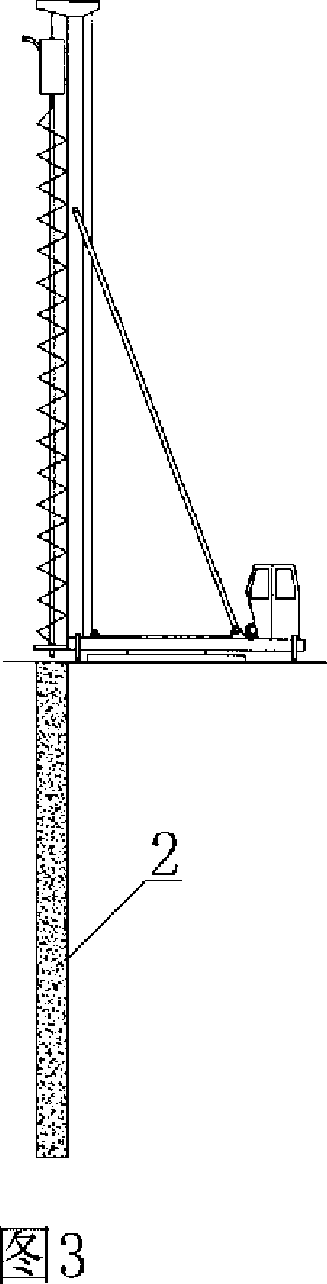

Embodiment 1

[0050]Referring to Figures 9 to 11, the first embodiment of the post-grouting device for long auger bored grouting piles of the present invention: the post-grouting device 1 includes at least two pile bottom grouting pipes 5 placed around the pile body , at least one pile side grouting pipe 6, the positioning reinforcement ring 9 fixedly connected with the pile bottom grouting pipe and the pile side grouting pipe, the pocket bottom steel bar 10 connected to the lower end of the rear grouting device, the vibrating hammer 3 and connected to Guide member 4 at the bottom of the vibratory hammer. The lower end of the pile bottom grouting pipe 5 is connected to the pile bottom grouting one-way valve 7 and extends to the bottom of the pile. The one-way valve 8 is arranged on the side of the pile, and the annular pile-side grouting check valve 8 communicates with the pile-side grouting pipe 6 through a tee. The distance between the above-mentioned positioning reinforcement ring 9 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com