Patents

Literature

1260 results about "High stiffness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

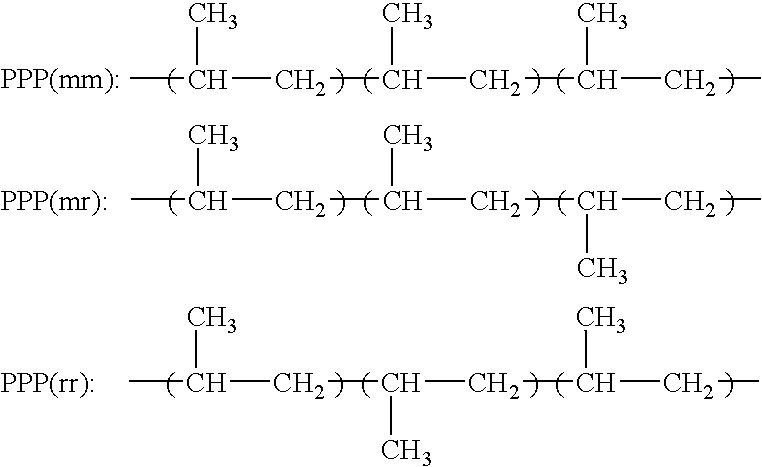

Plasticized hetero-phase polyolefin blends

InactiveUS20080045638A1Increase stiffnessImprove impact toughnessPigment pastesPolyolefinHigh stiffness

This invention relates to hetero-phase polyolefin compositions comprising: a) 30 to 99.7 wt % of a polypropylene-based TPO comprising at least 50 wt % propylene and at least 10 wt % ethylene, and b) 0.1 to 20 wt % of one or more non-functionalized plasticizer, and c) 0.2 to 50 wt % of one or more filler; based upon the weight of the composition, and having: i) an MFR of 5 dg / min or more, and ii) a flexural modulus of 500 MPa or more, and iii) a notched Charpy impact strength at −30° C. of 1 kJ / m2 or more or a notched Izod impact strength at −18° C. of 50 J / m or more.These compositions are especially useful in applications such as automotive parts that demand both high stiffness and high impact toughness, as well as good processibility during fabrication.

Owner:EXXONMOBIL CHEM PAT INC

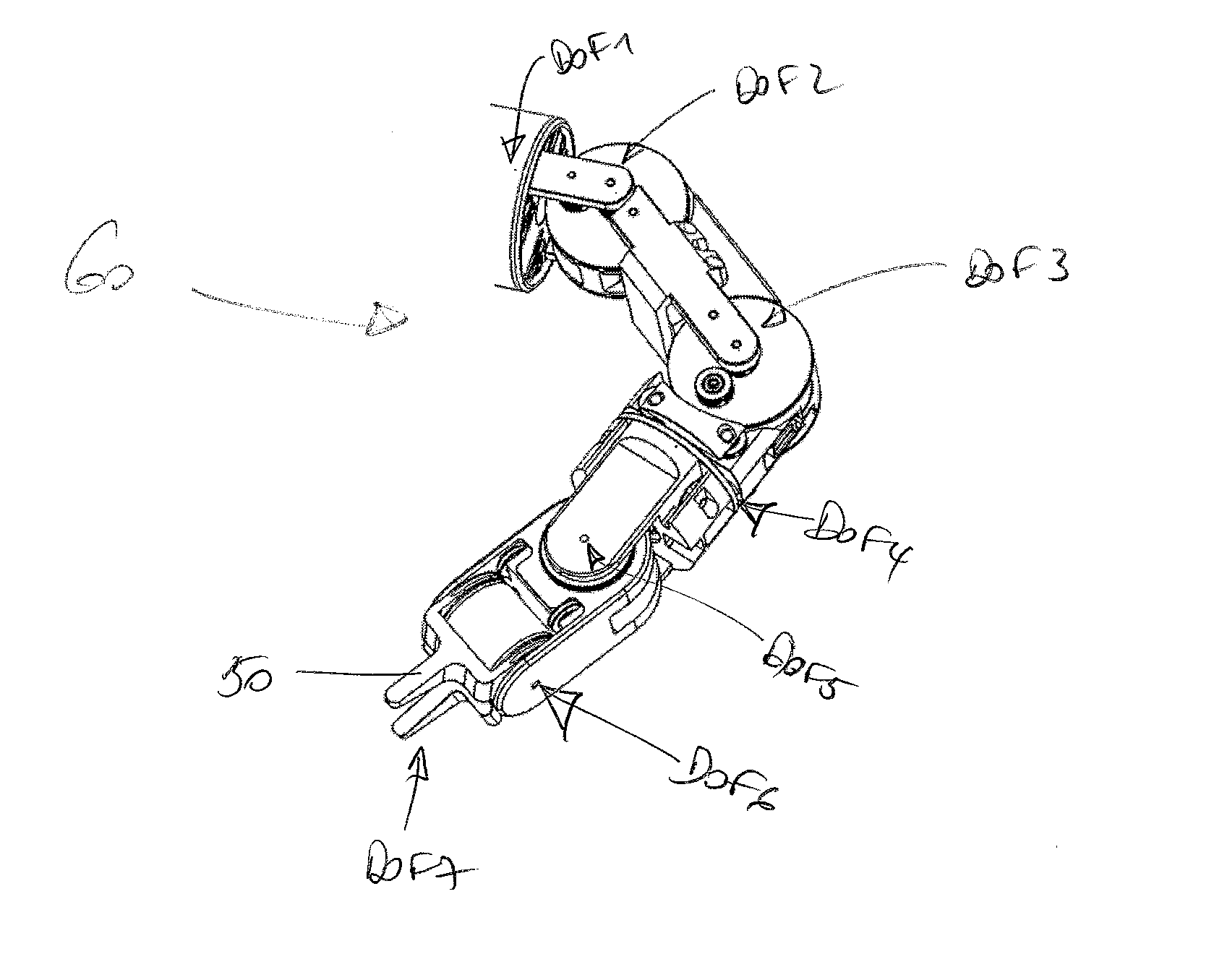

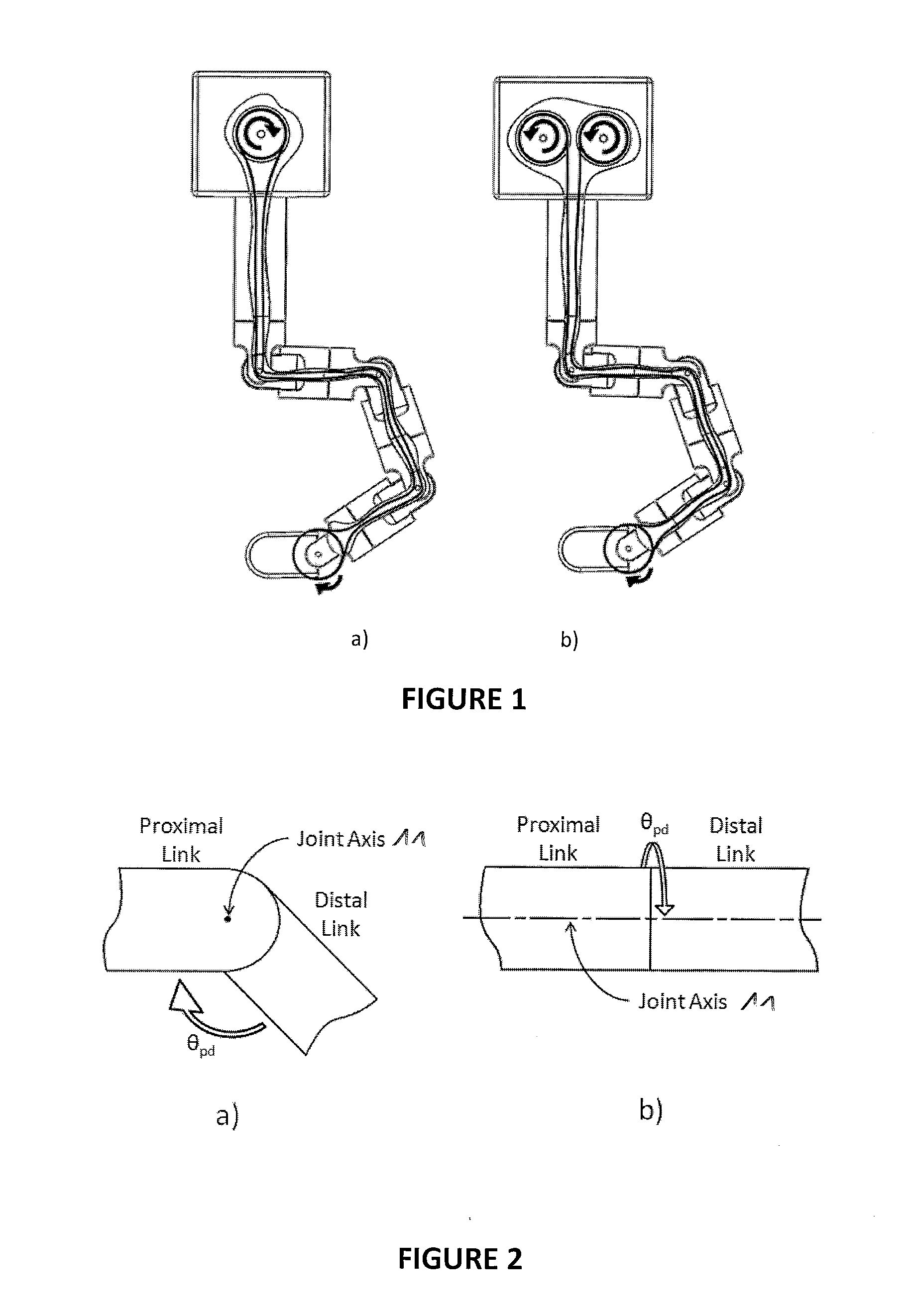

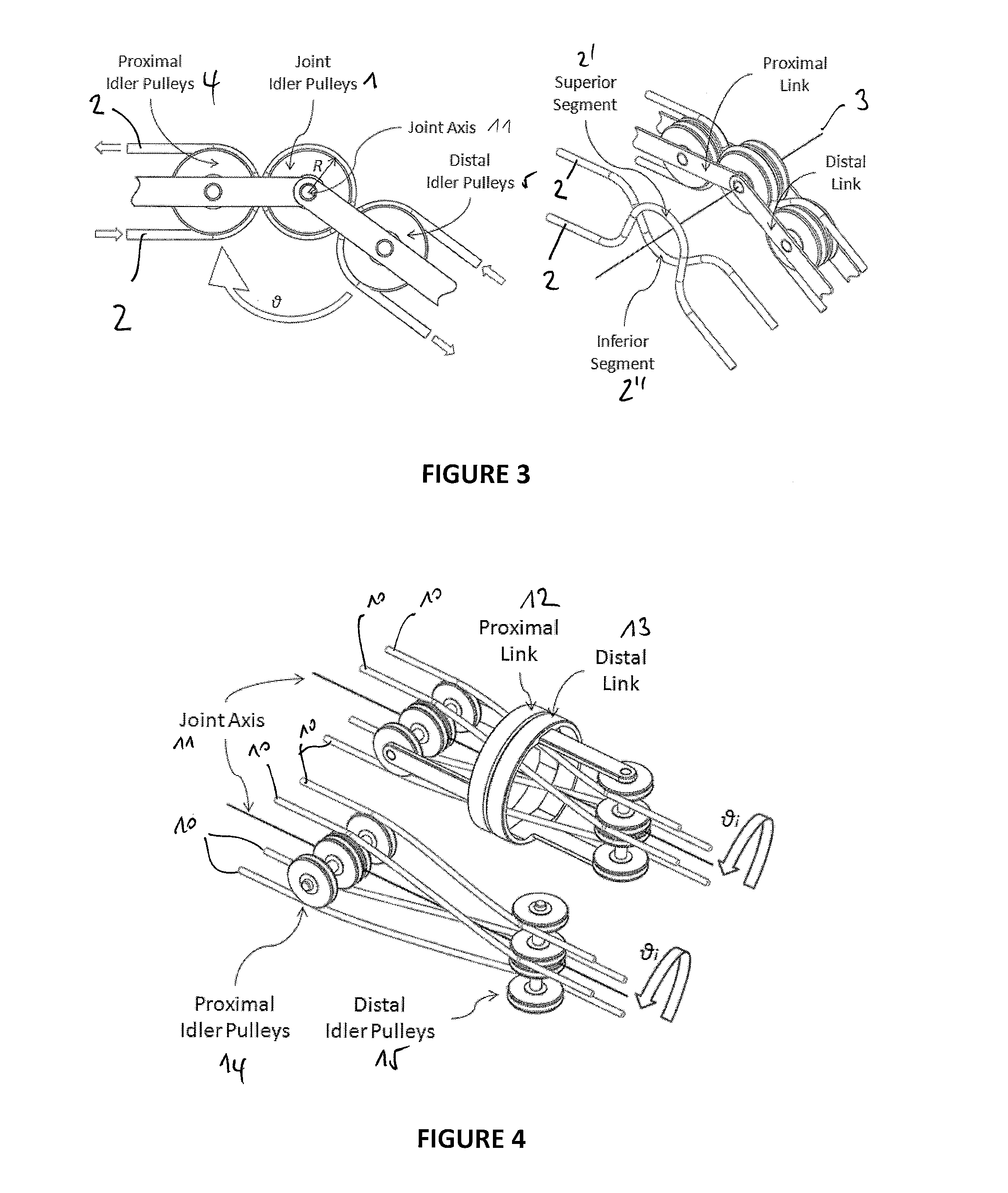

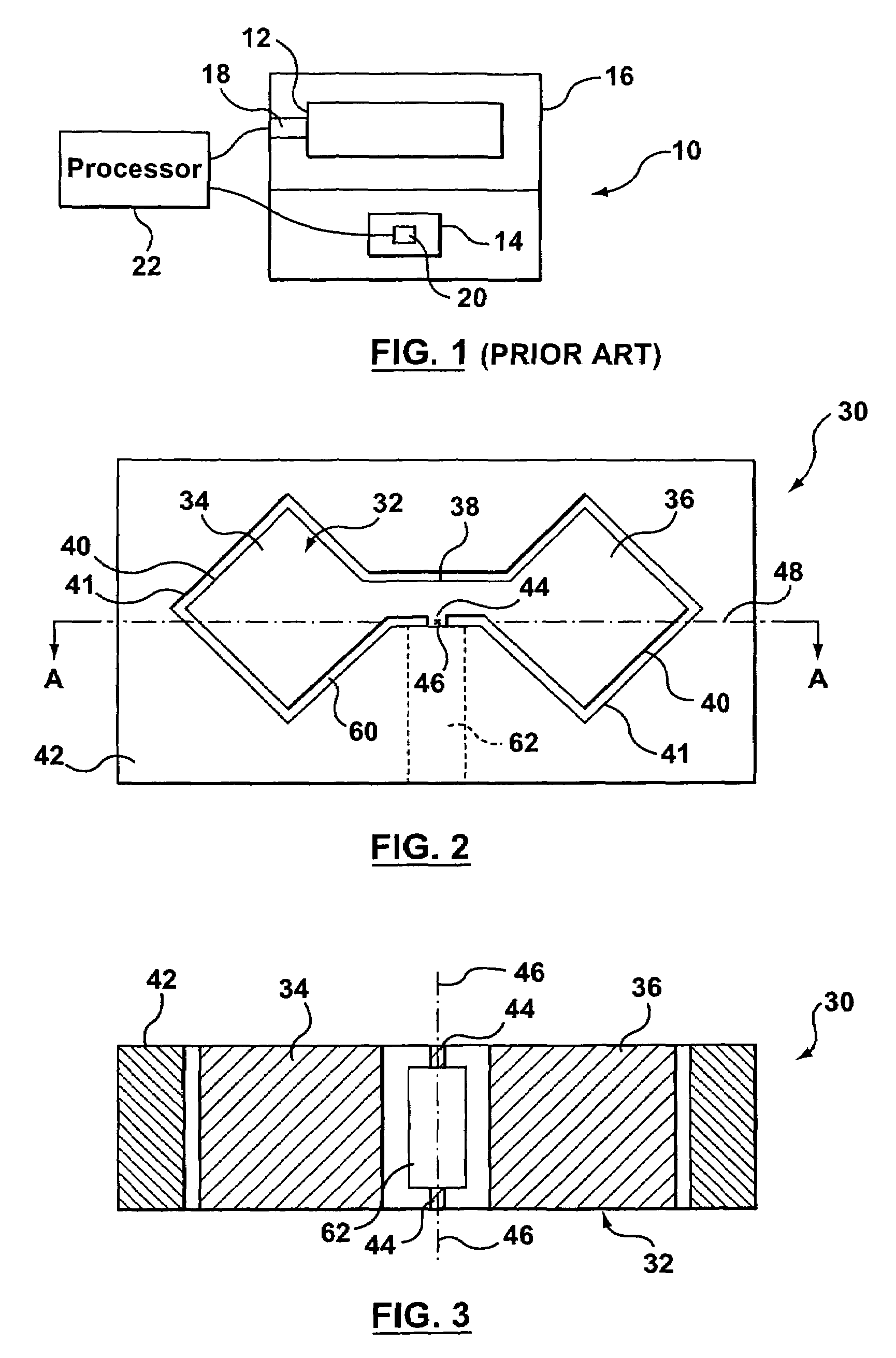

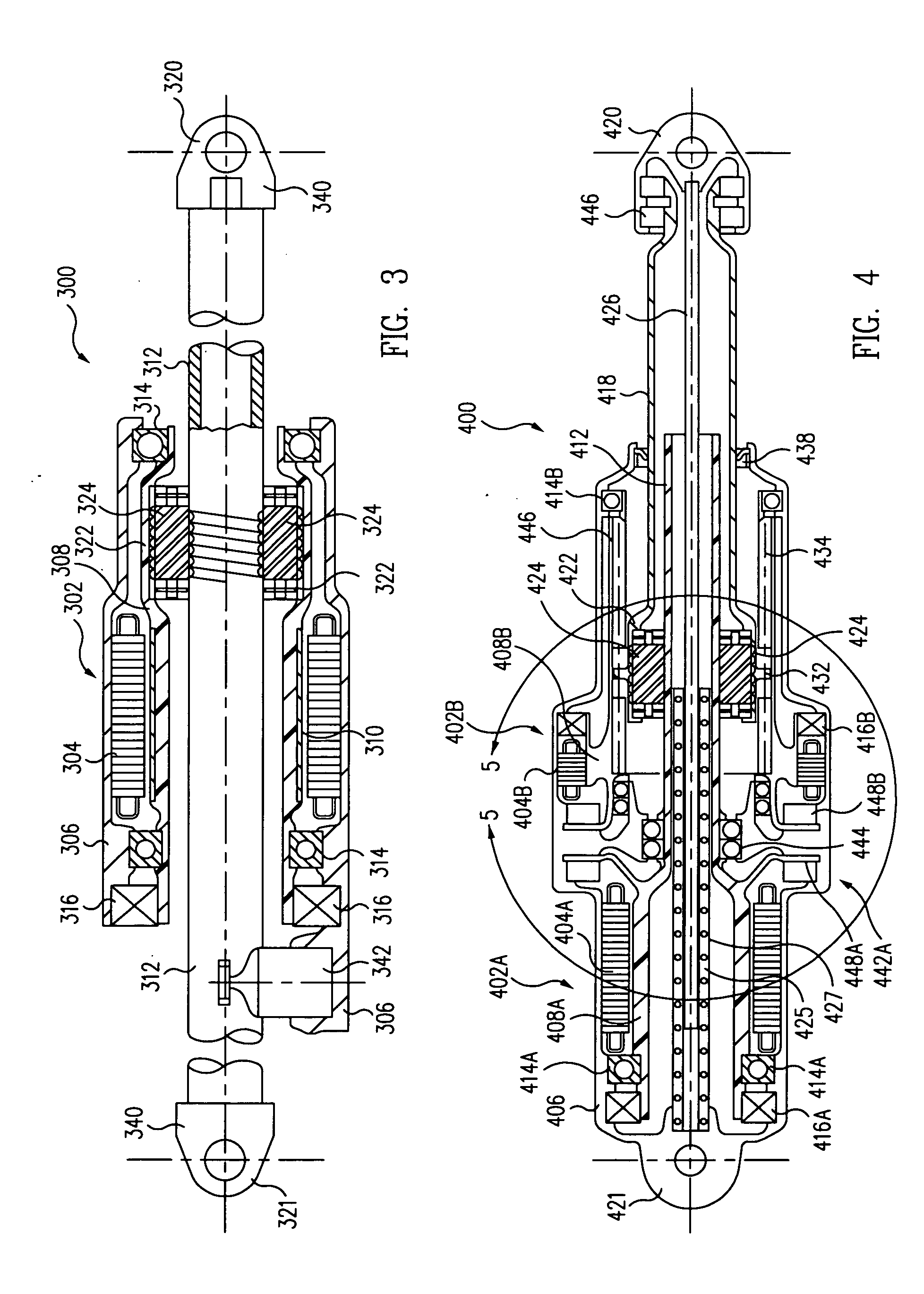

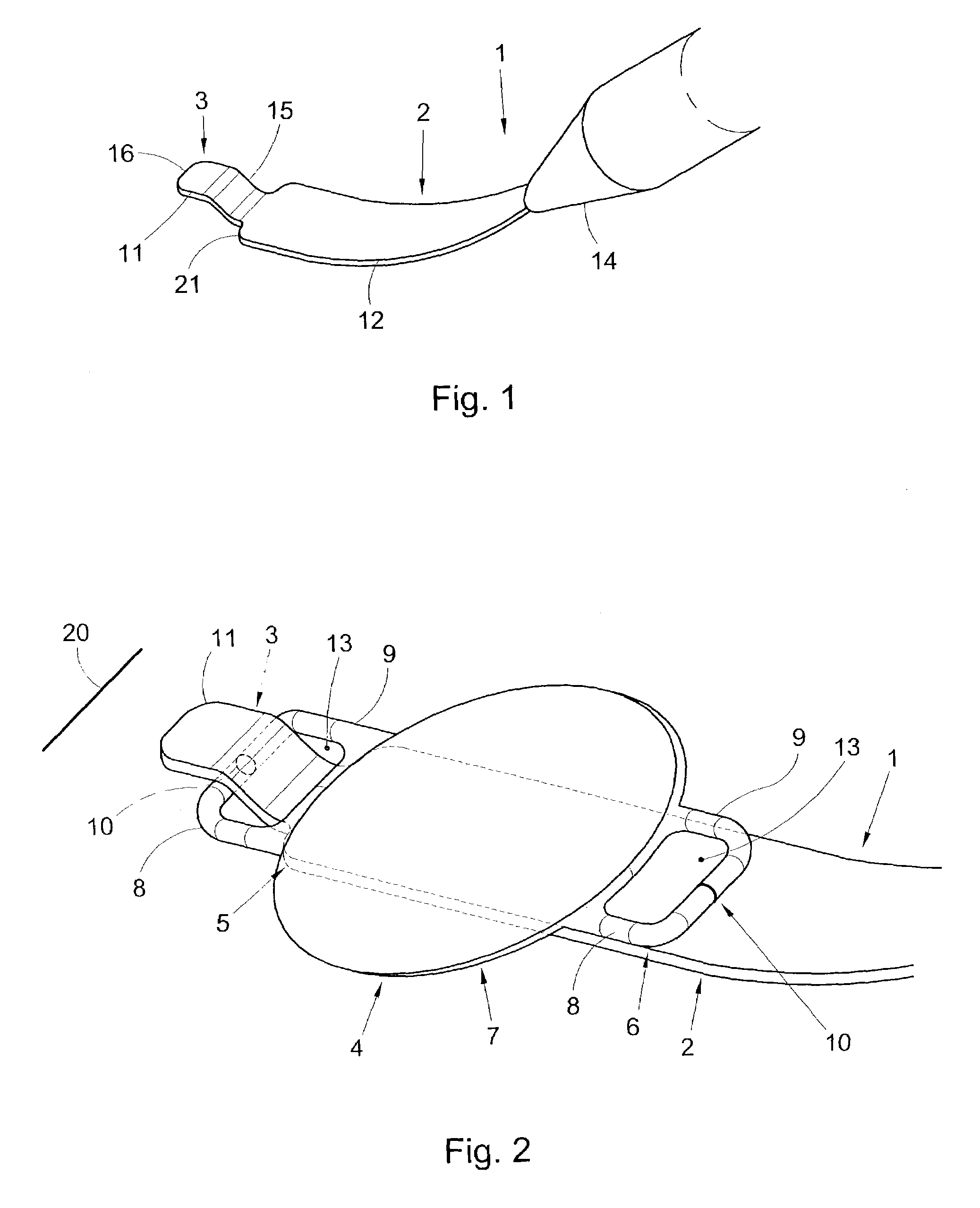

Mechanical manipulator for surgical instruments

ActiveUS20130304084A1Solve the lack of stiffnessSolve the lack of precisionDiagnosticsSurgical manipulatorsConventional laparoscopyEngineering

A novel mechanical system, based on a new cable driven mechanical transmission, able to provide sufficient dexterity, stiffness, speed, precision and payload capacity to actuate multi-DOF micro-manipulators. Besides the possibility of being used in several articulated surgical instruments and robotic systems for surgery or other applications involving remote manipulation, it enables the design of a novel fully mechanical surgical instrument, which offer the advantages of conventional laparoscopy (low cost, tactile feedback, high payload capacity) combined with the advantages of single port surgery (single incision, scarless surgery, navigation through several quadrants of the abdominal cavity) and robotic surgery (greater degrees of freedom, short learning curve, high stiffness, high precision, increased intuition). The unique design of the proposed system provides an intuitive user interface to achieve such enhanced manoeuvrability, allowing each joint of a teleoperated slave system to be driven by controlling the position of a mechanically connected master unit.

Owner:ECOLE POLYTECHNIQUE FEDERALE DE LAUSANNE (EPFL)

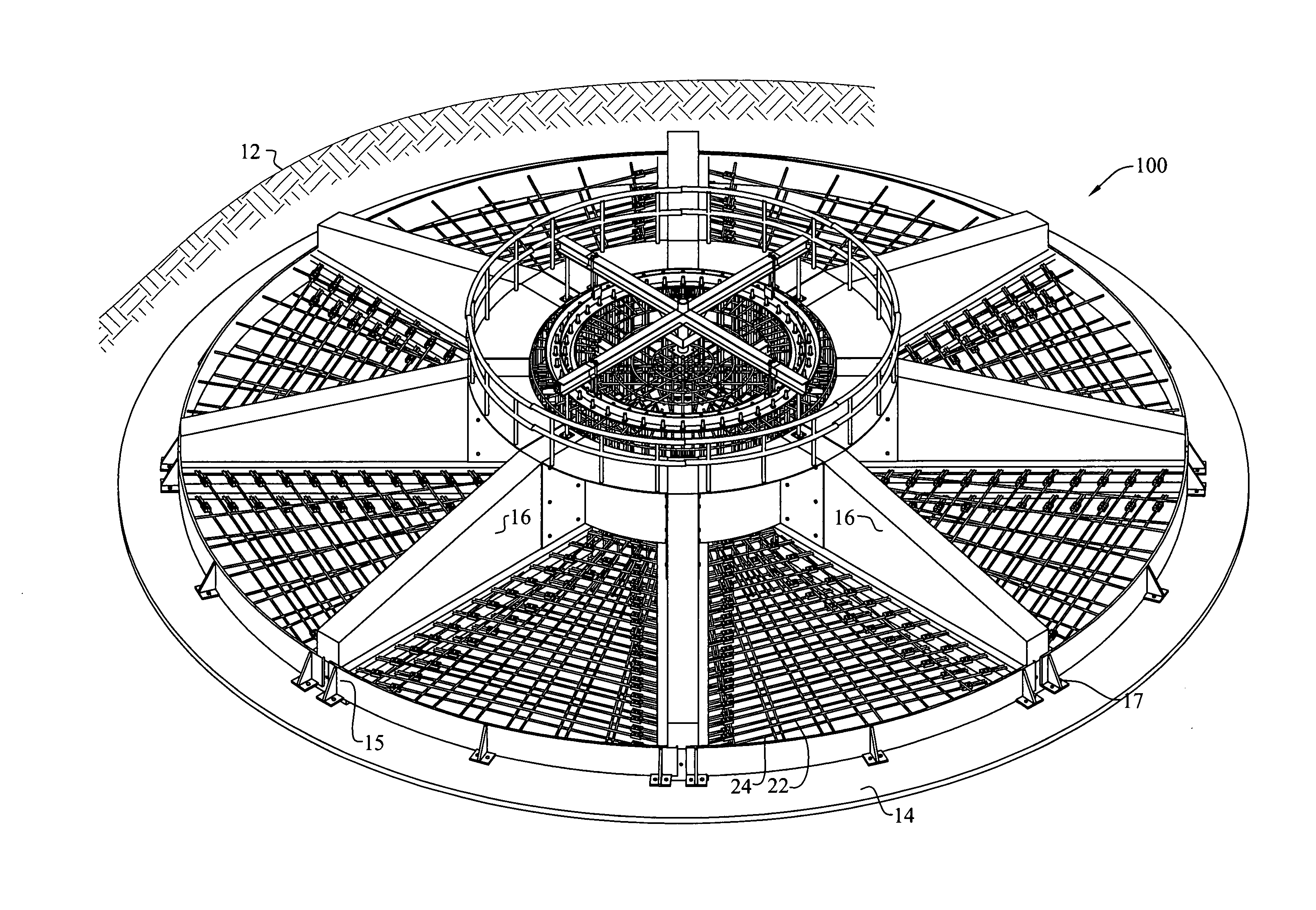

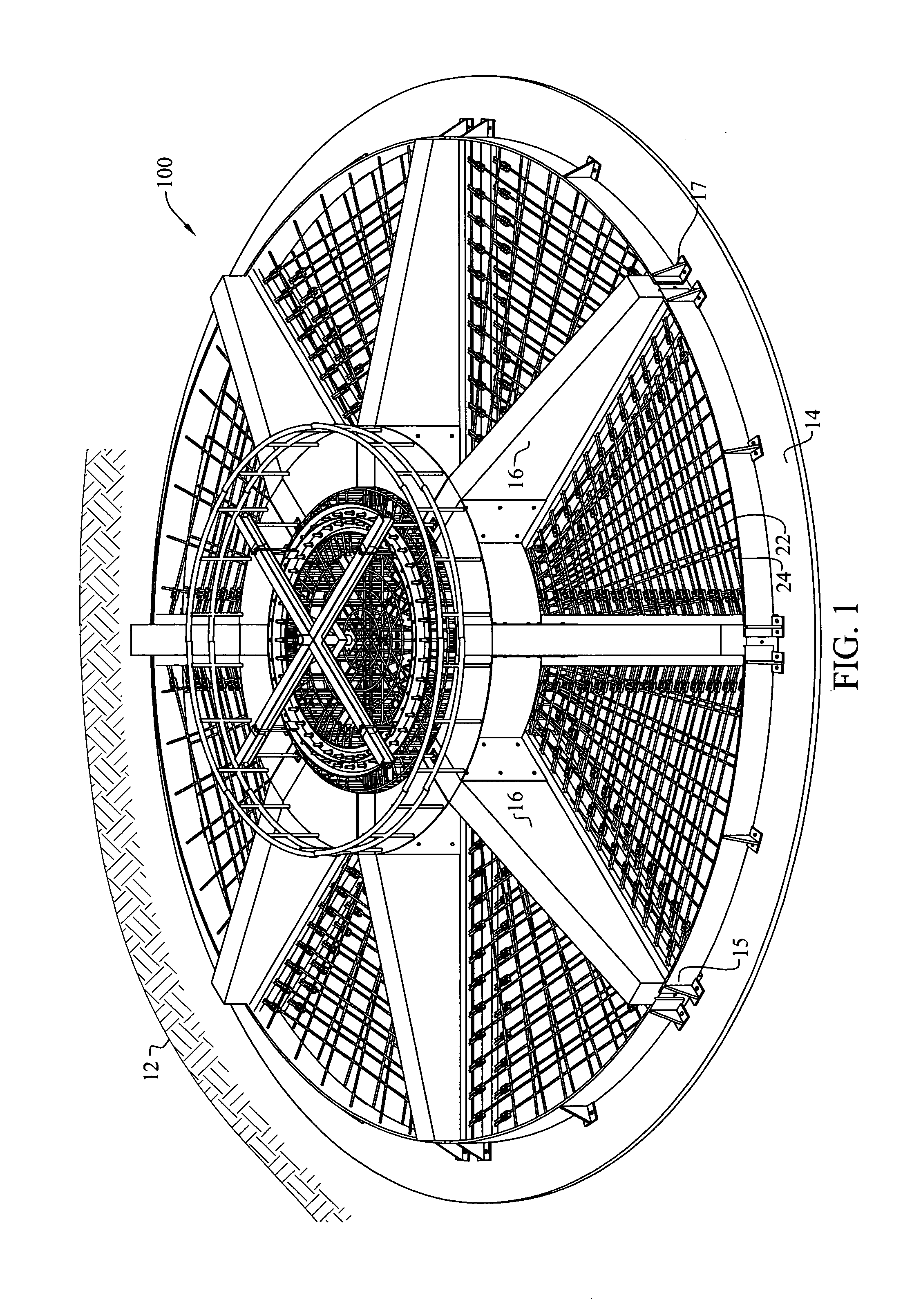

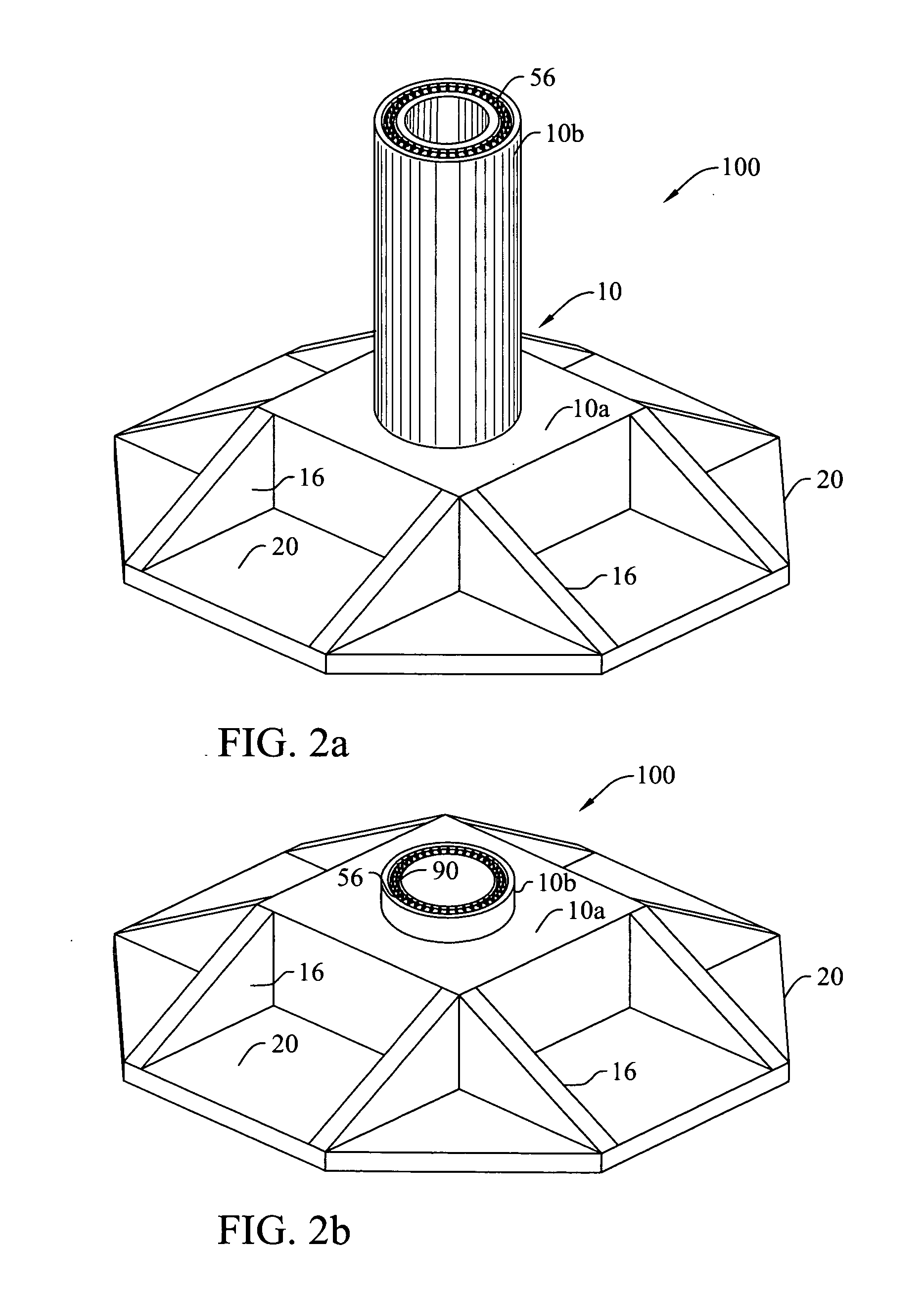

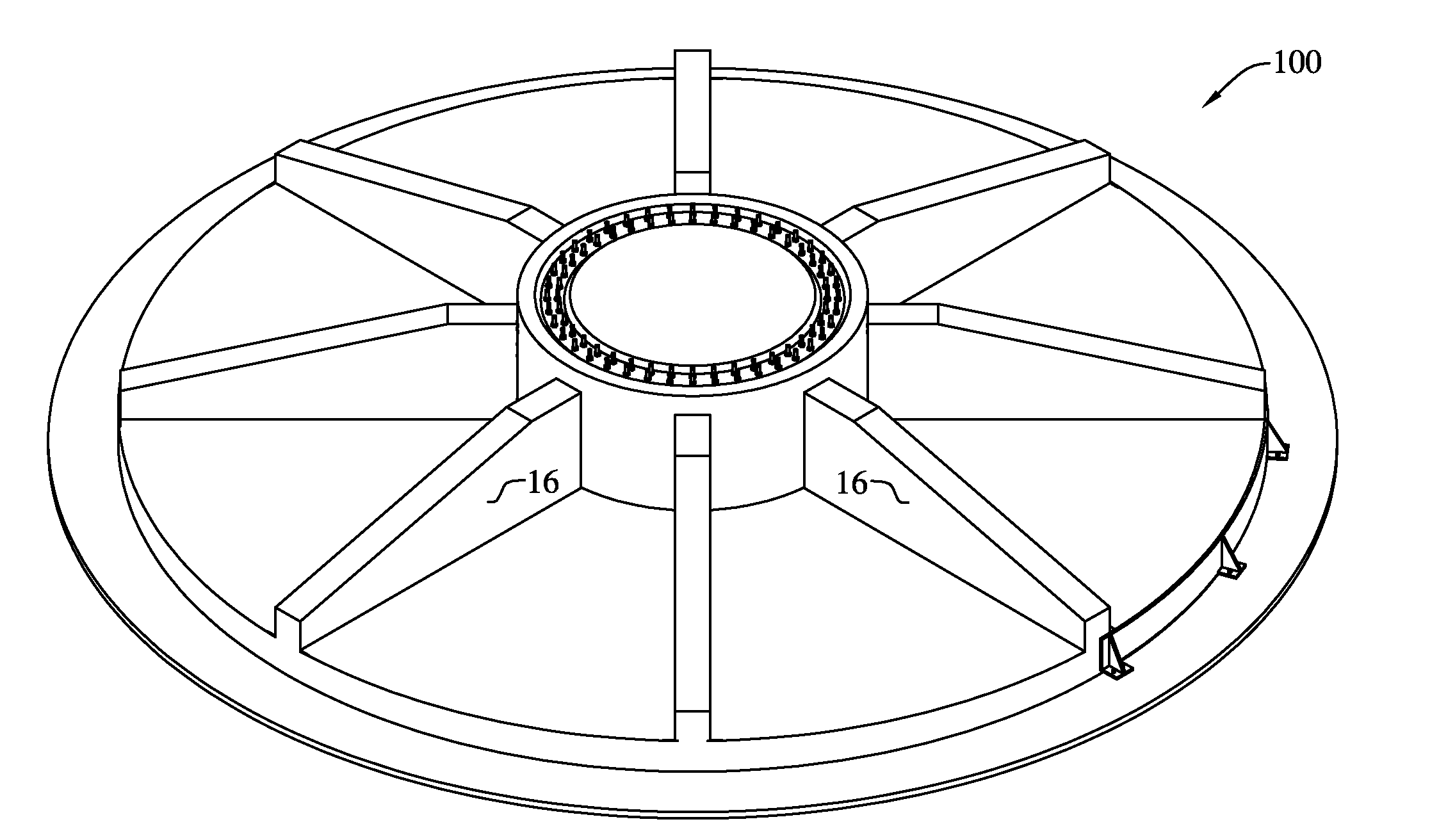

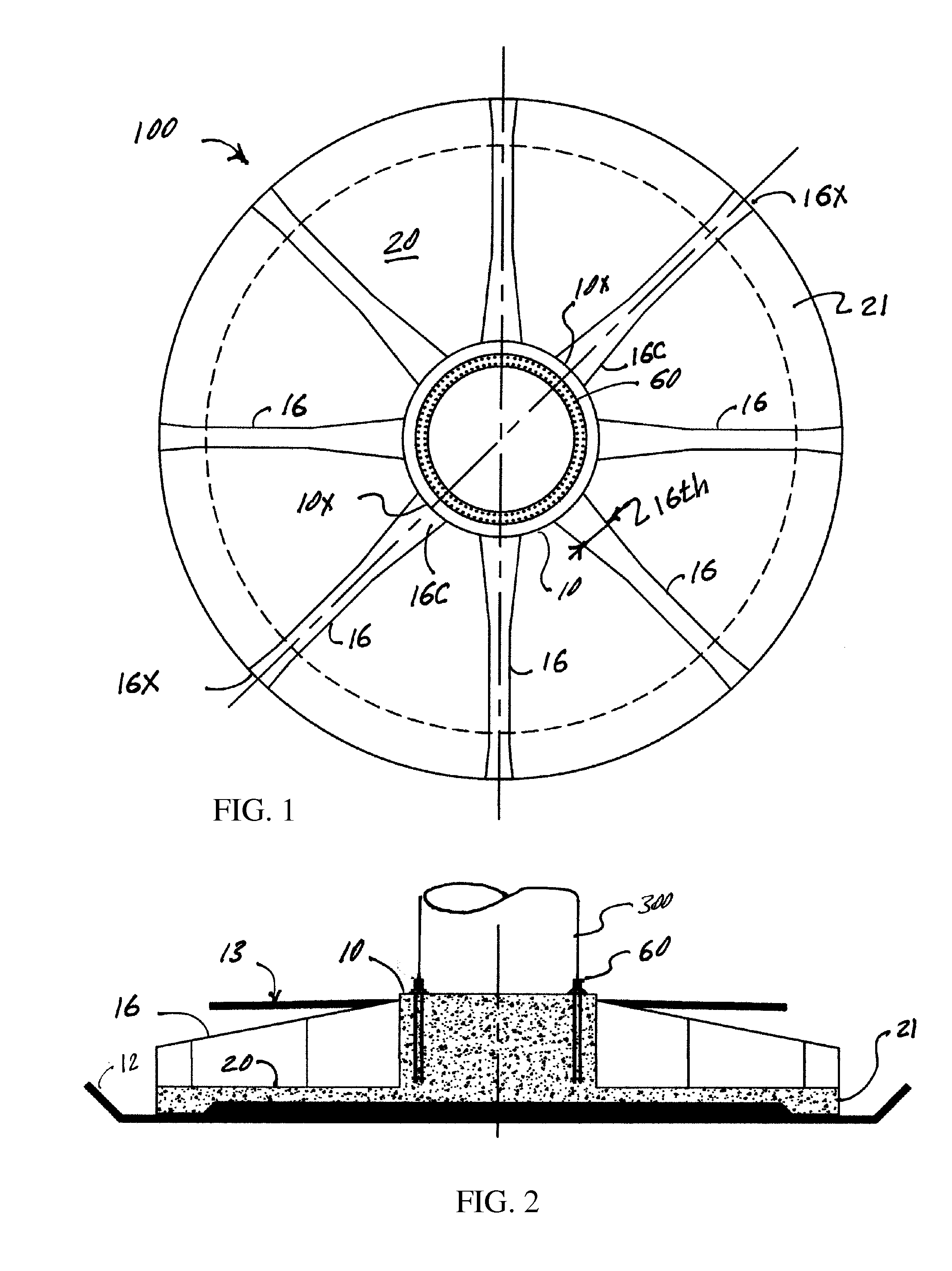

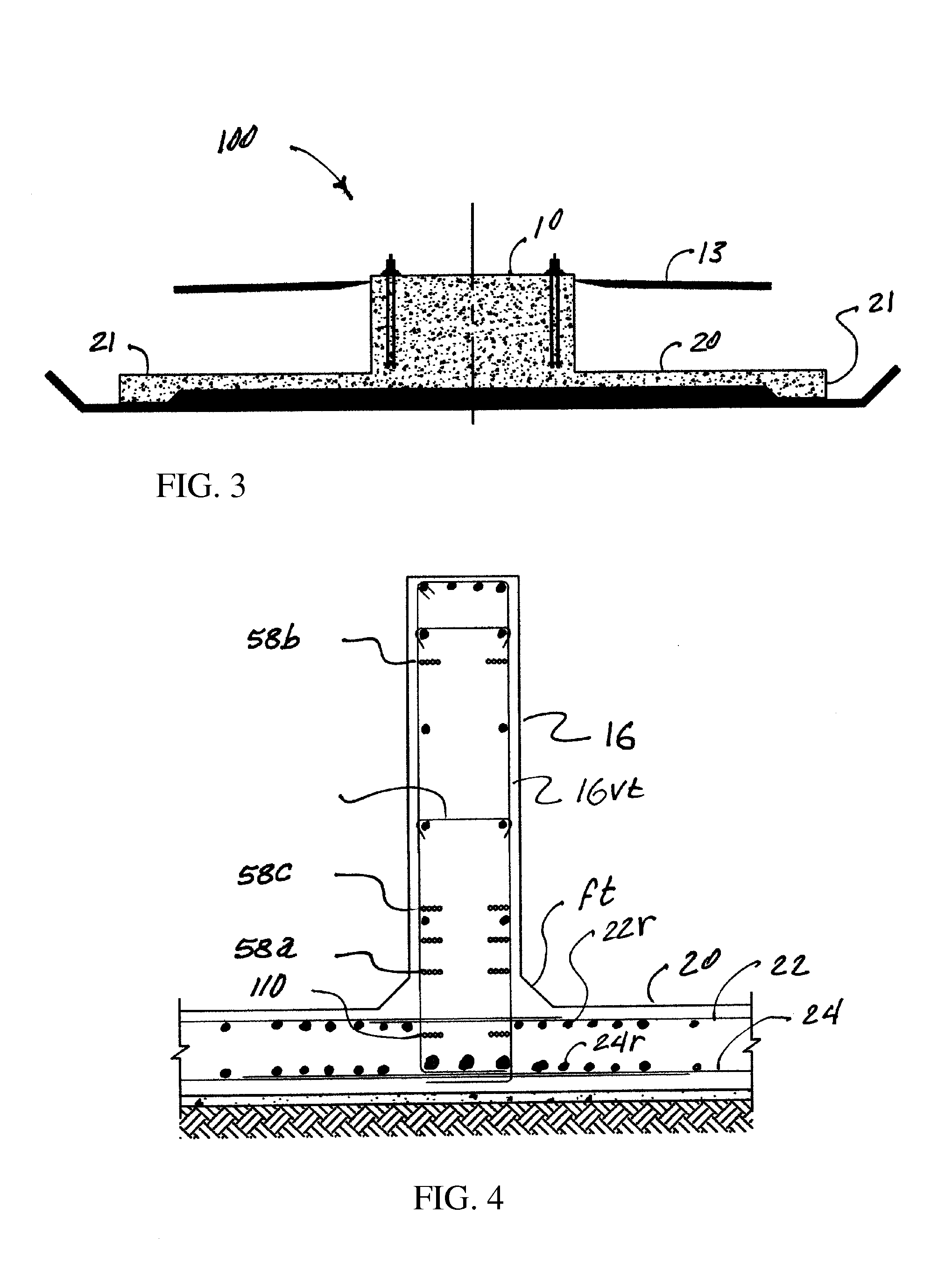

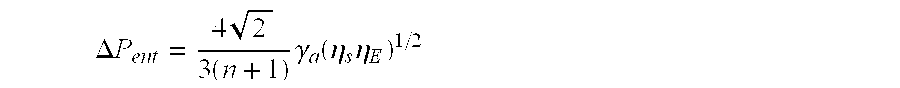

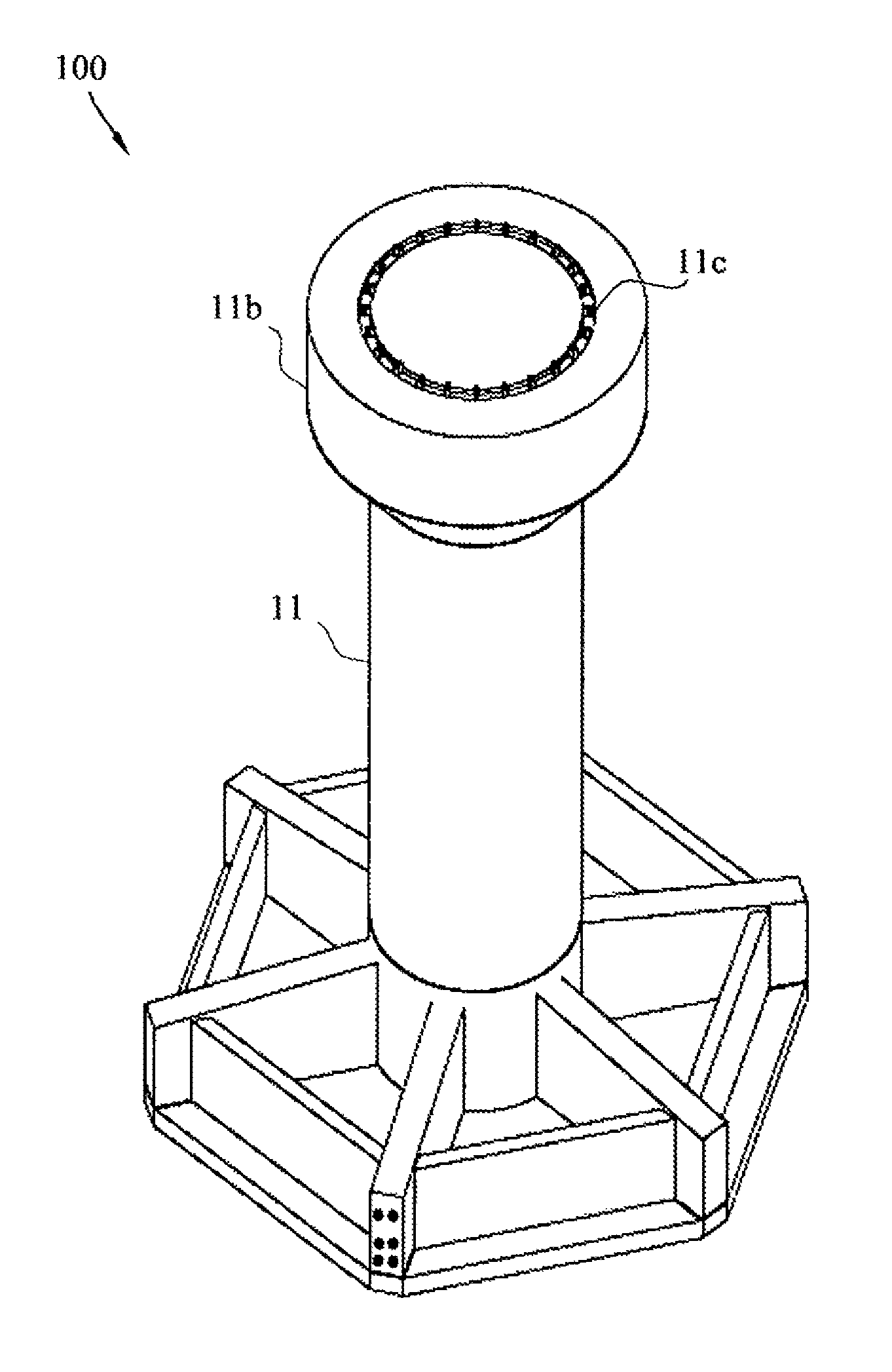

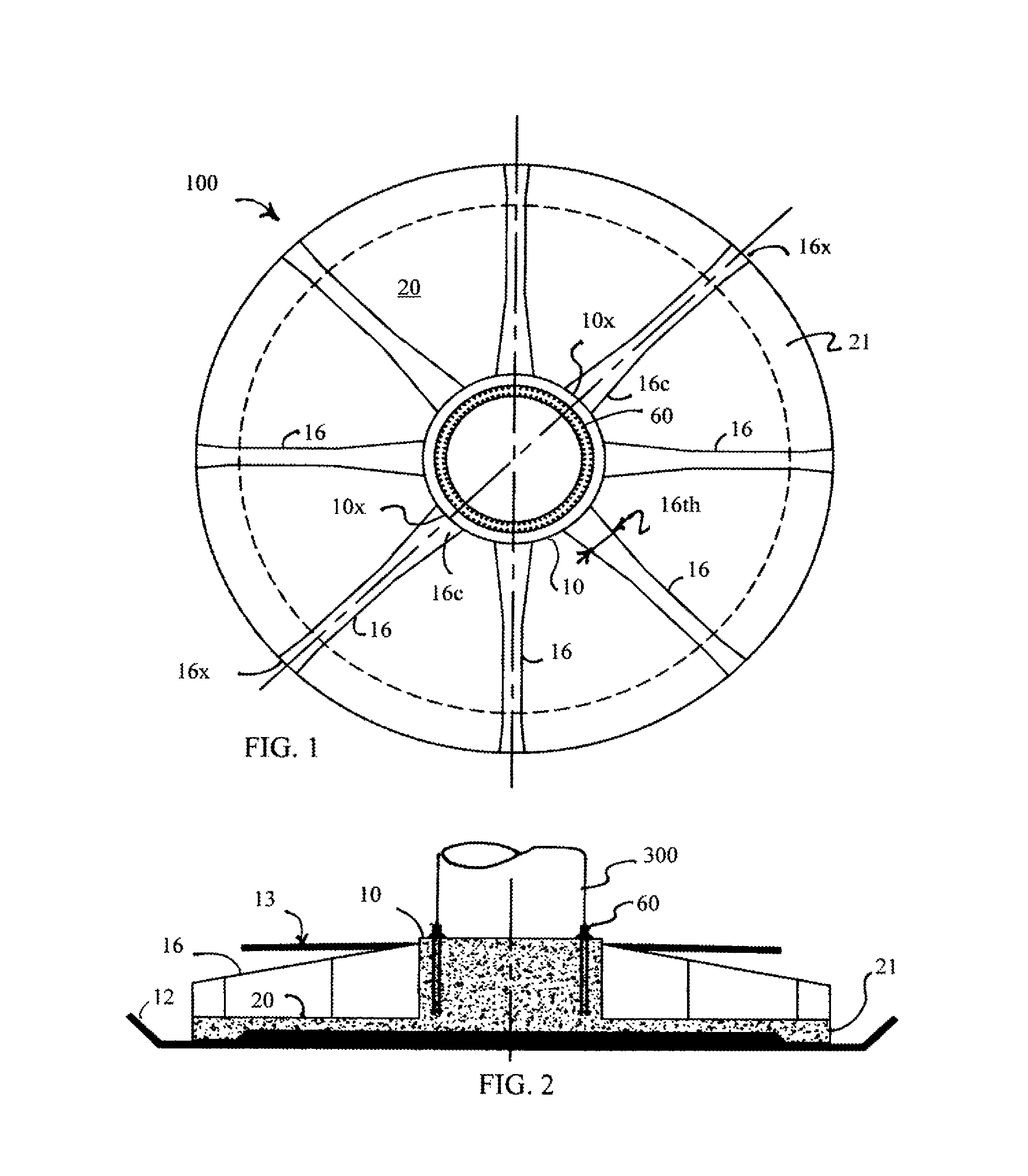

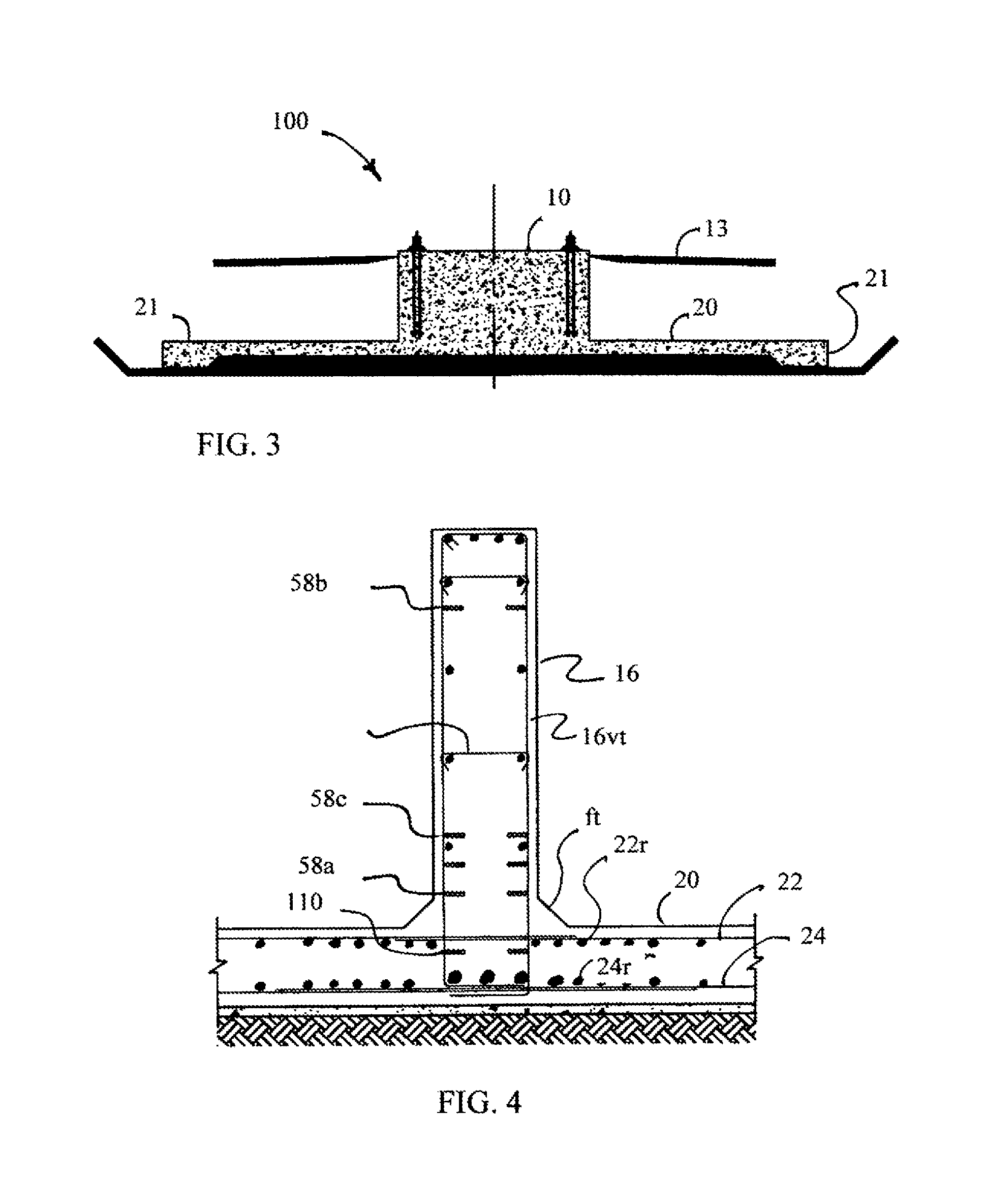

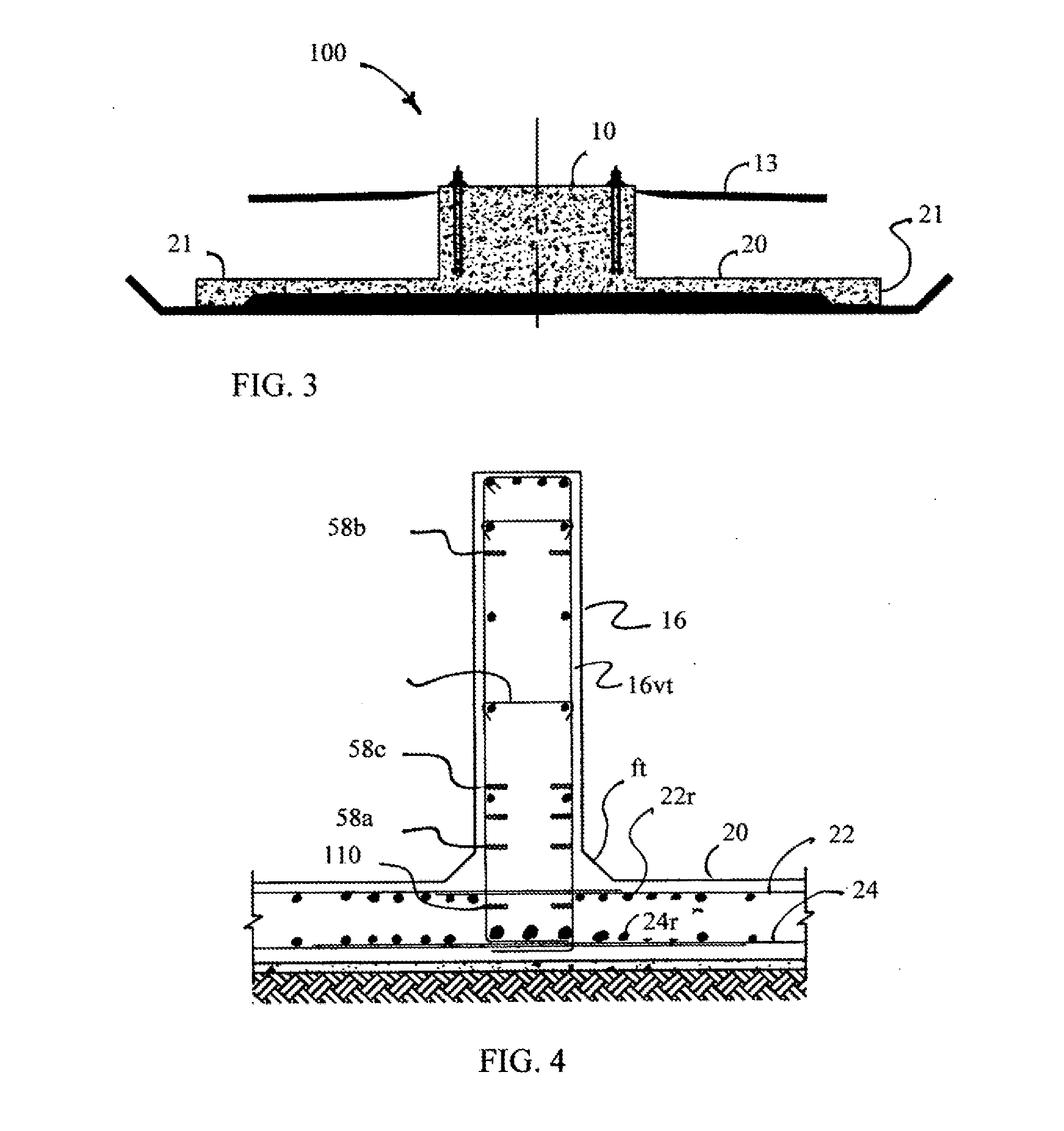

Fatigue reistant foundation system

InactiveUS20110061321A1Reduce construction material and laborCost-effectiveArtificial islandsEngine manufactureHigh stiffnessTower

A fatigue resistant gravity based spread footing under heavy multi-axial cyclical loading of a wind tower having a central vertical pedestal, a substantially horizontal continuous bottom support slab with a stiffened perimeter, a plurality of radial reinforcing ribs extending radially outwardly from the pedestal and a three-dimensional network 500 of post-tensioning elements that keep the structural elements under heavy multi-axial post compression with a specific eccentricity that is intended to reduces stress amplitudes and deflections and allows the foundation to have a desirable combination of high stiffness and superior fatigue resistance. The foundation design reduces the weight and volume of materials used, reduces cost, and improves heat dissipation conditions during construction by having a small ratio of concrete mass to surface area thus eliminating the risk of thermal cracking due to heat of hydration.

Owner:PHULY AHMED

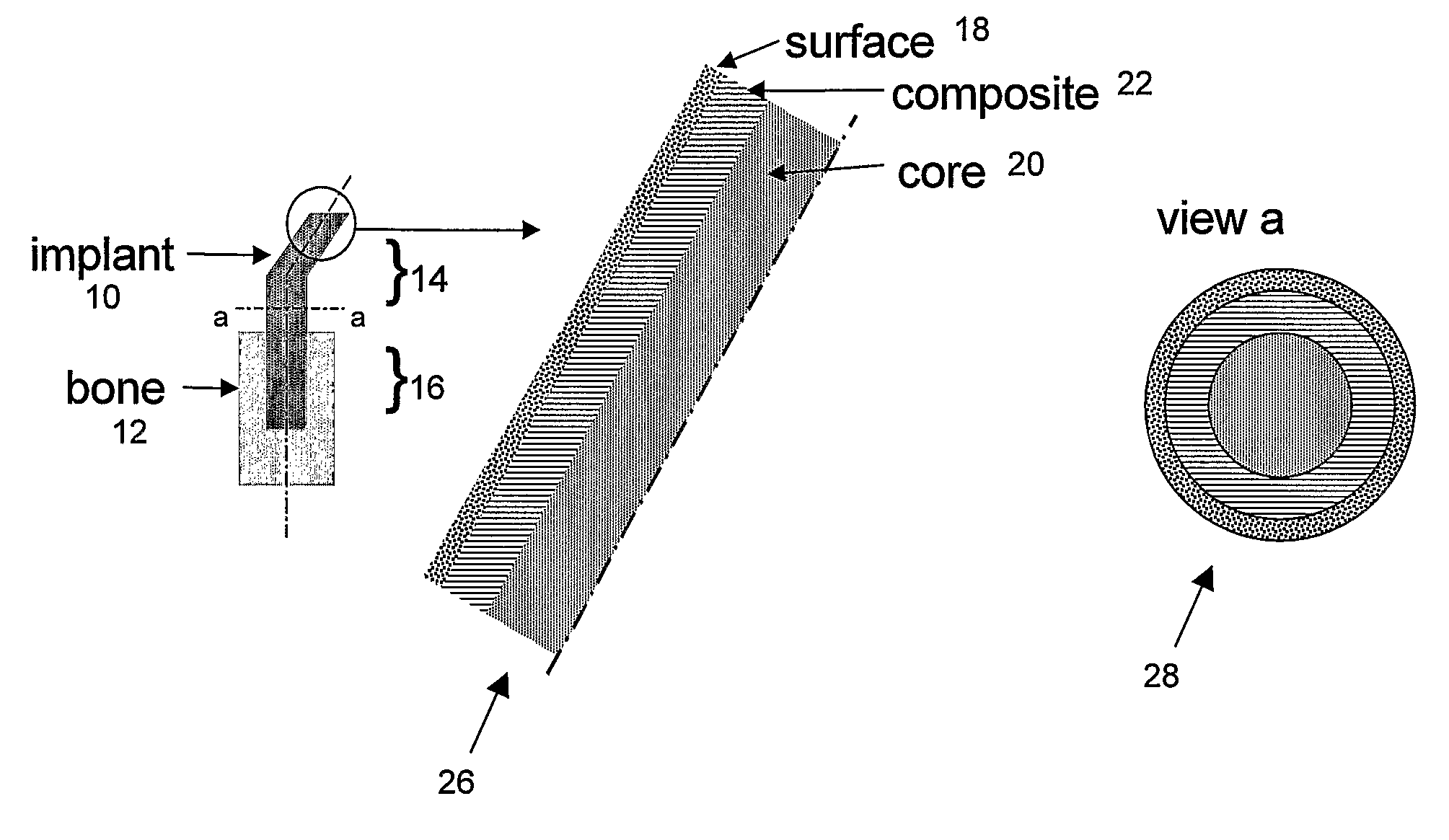

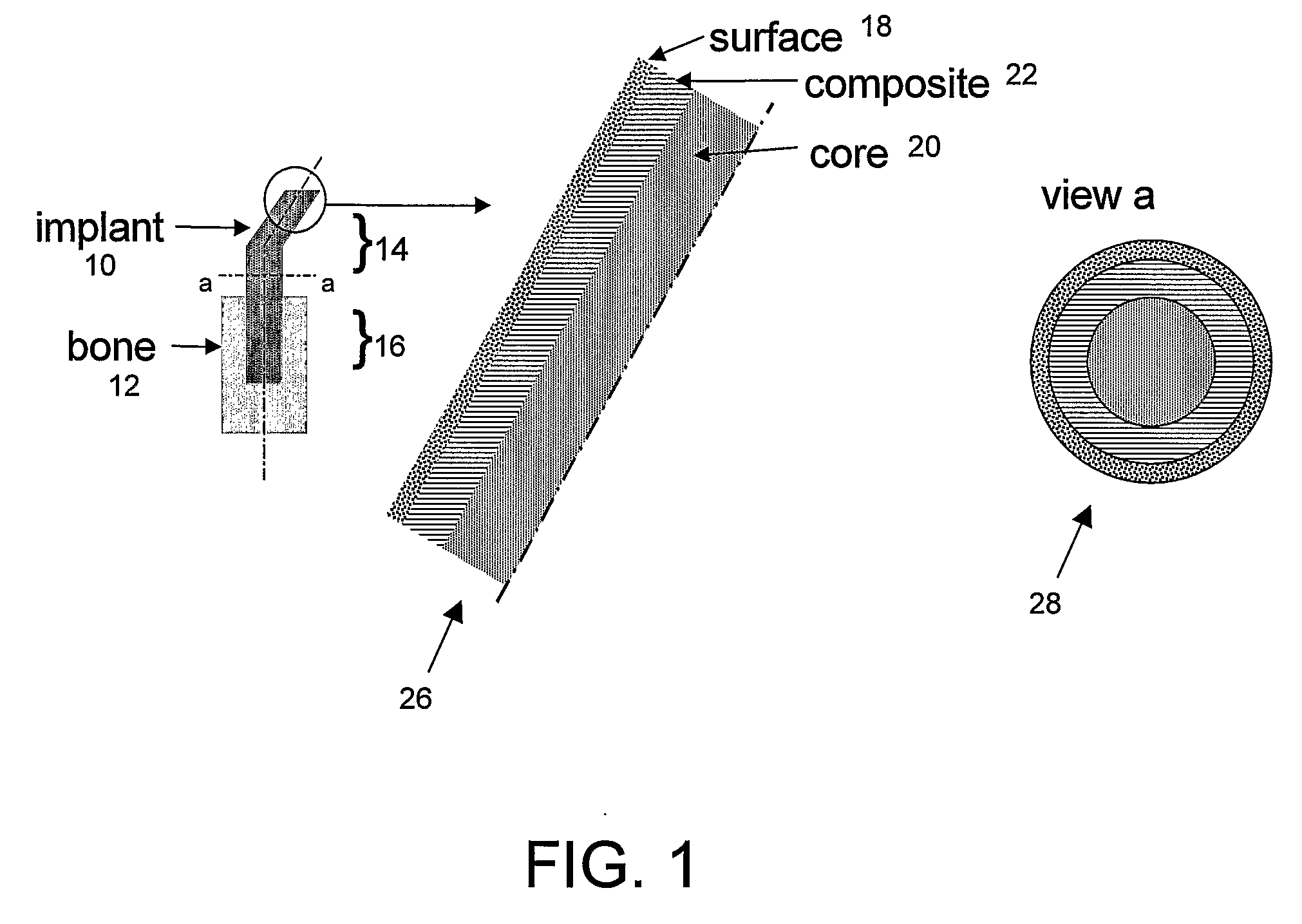

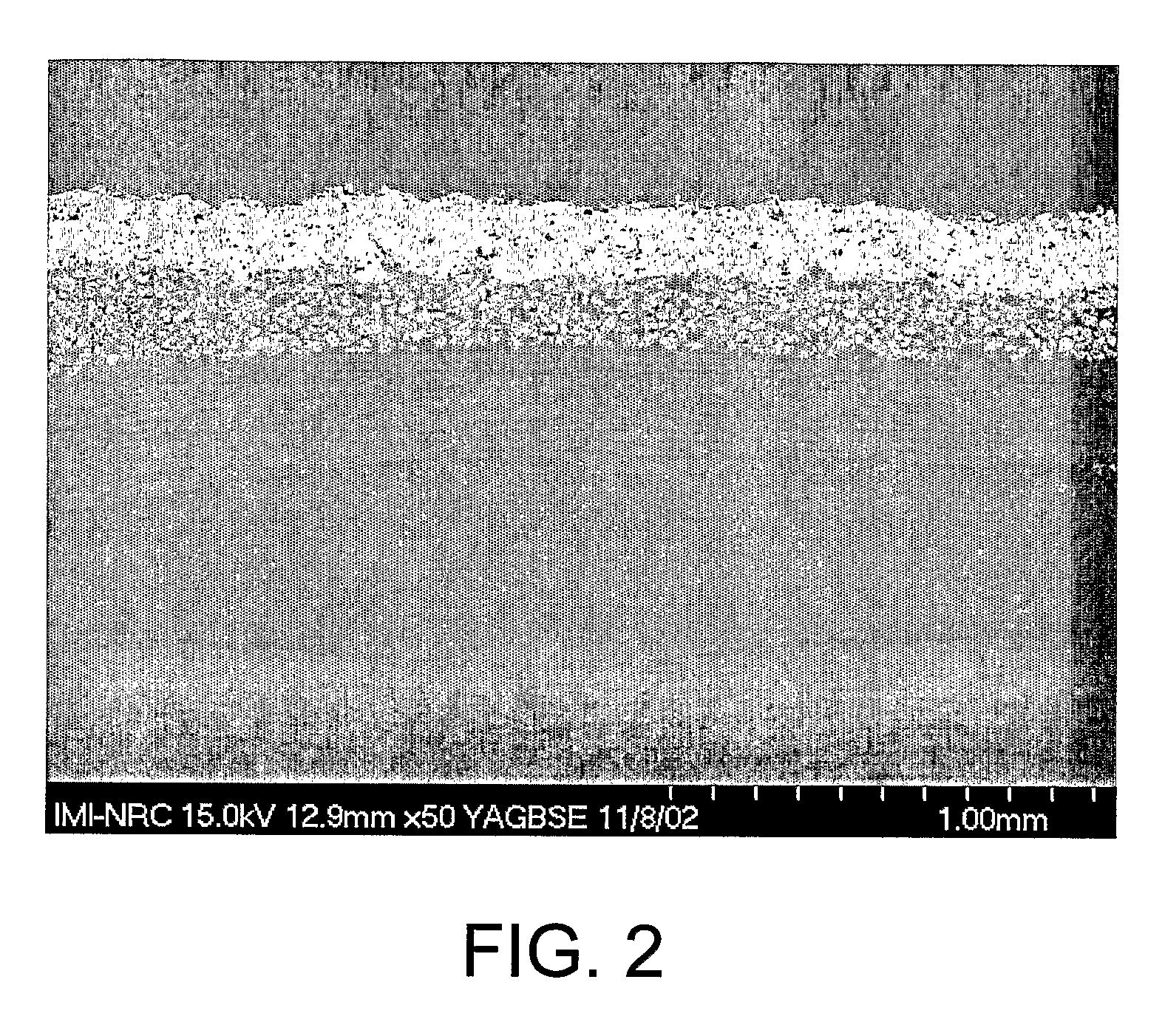

Implantable biomimetic prosthetic bone

InactiveUS20090177282A1Reduce riskMolten spray coatingLamination ancillary operationsNormal boneFiber-reinforced composite

Bone tissue at the interface of a bone implant is shielded from stresses found in normal bone because of the higher stiffness or rigidity in the implant versus in bone. The resulting “stress shielding” of the bone by the implant eventually results in resorption of bone at the bone-implant interface and ultimately necessitates replacement of the bone implant. To overcome these problems, an implantable biomimetic prosthetic bone having a porous surface, a fiber-reinforced composite structure, and a polymer-based core is disclosed. The prosthetic bone is a good match for structure, stiffness, viscoelastic properties, specific weight and overall structure as real bone or host tissues adjacent to the prosthetic bone. The prosthetic bone may be formed as a total hip prosthesis.

Owner:NAT RES COUNCIL OF CANADA

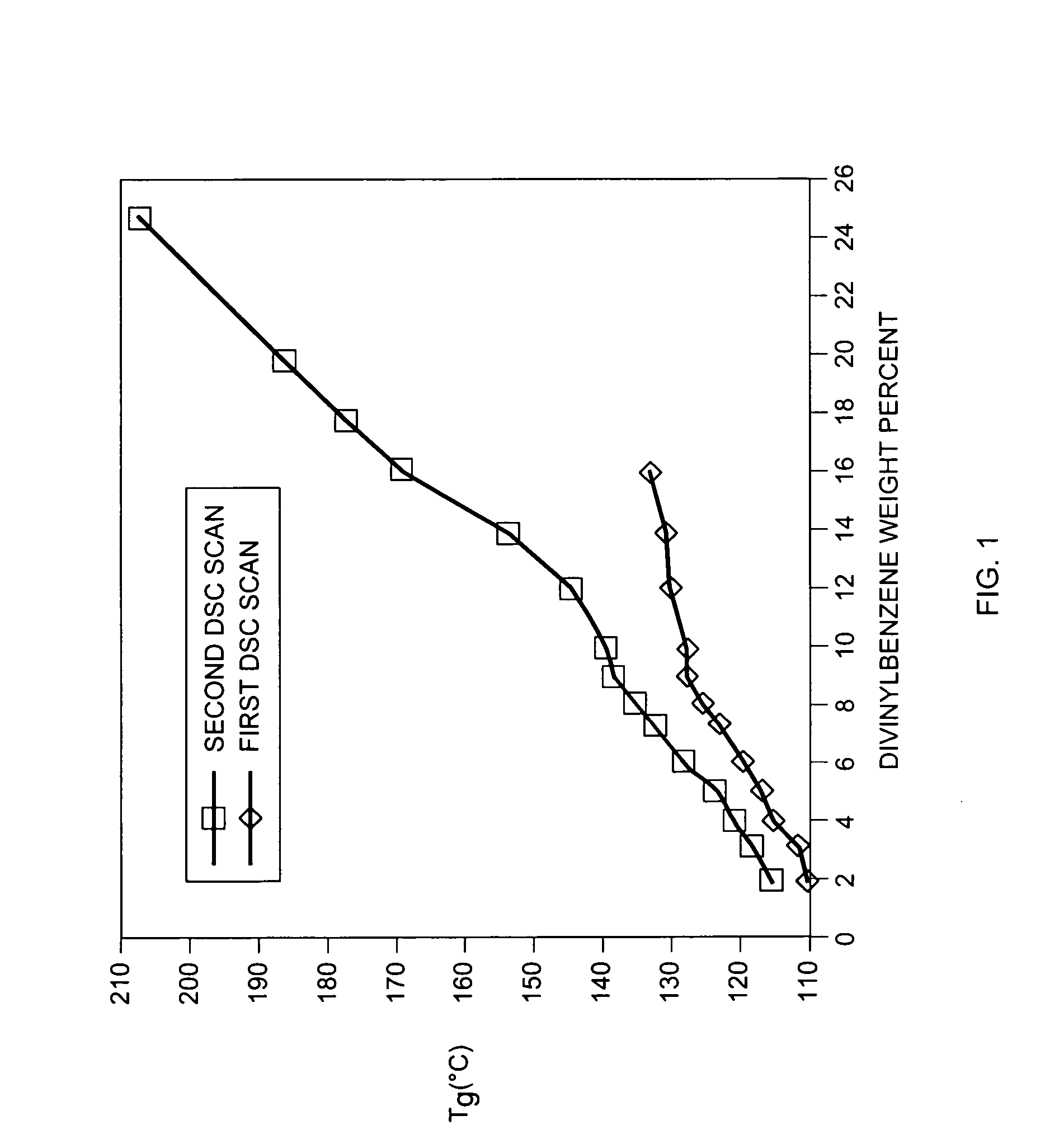

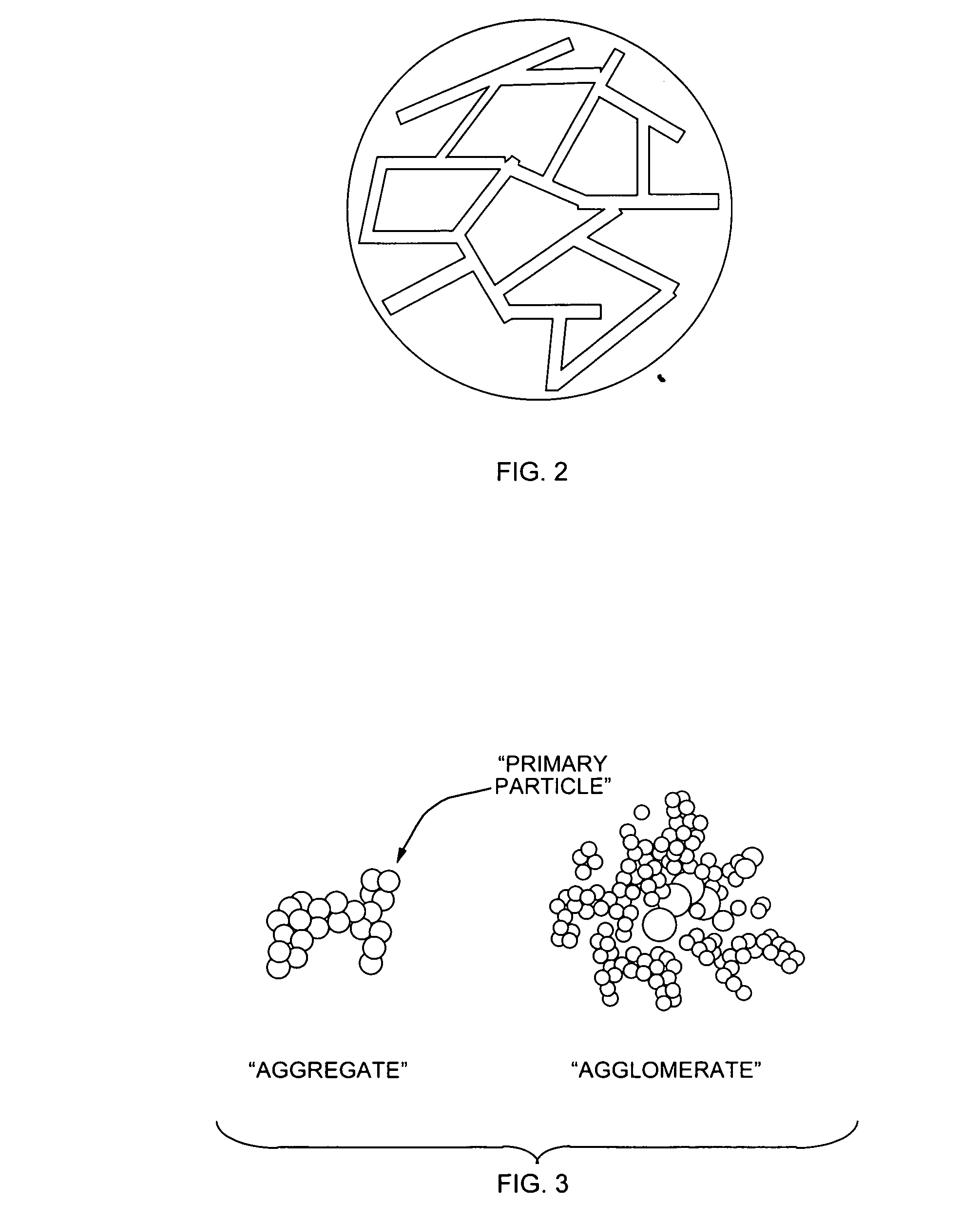

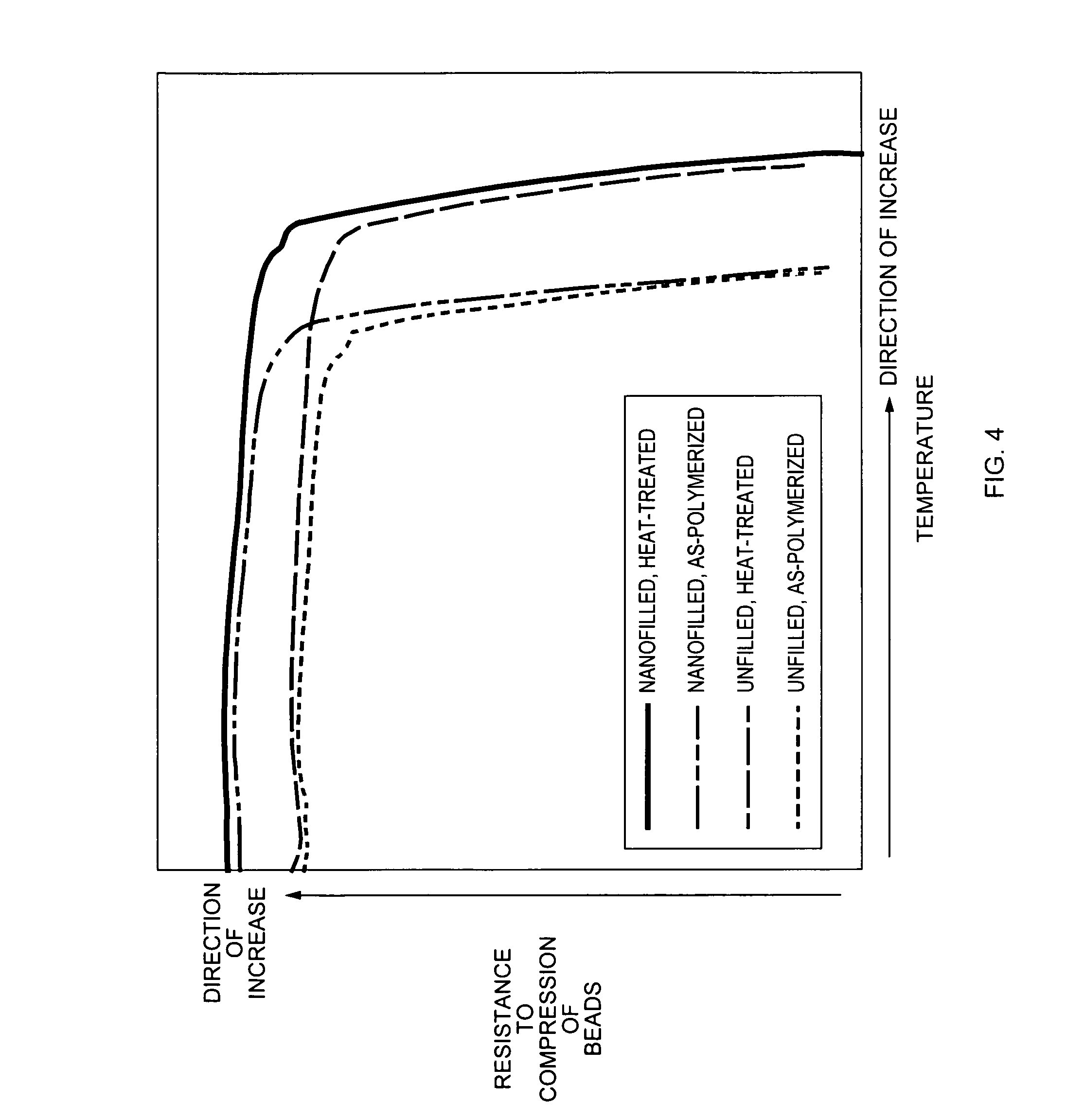

Thermoset nanocomposite particles, processing for their production, and their use in oil and natural gas drilling applications

ActiveUS20070066491A1Improve curingImprove heat transfer performanceMaterial nanotechnologySynthetic resin layered productsEnvironmental resistanceBall bearing

Thermoset polymer particles are used in many applications requiring lightweight particles possessing high stiffness, strength, temperature resistance, and / or resistance to aggressive environments. The present invention relates to the use of two different methods, either each by itself or in combination, to enhance the stiffness, strength, maximum possible use temperature, and environmental resistance of such particles. One method is the application of post-polymerization process steps (and especially heat treatment) to advance the curing reaction and to thus obtain a more densely crosslinked polymer network. In general, its main benefits are the enhancement of the maximum possible use temperature and the environmental resistance. The other method is the incorporation of nanofillers, resulting in a heterogeneous “nanocomposite” morphology. In general, its main benefits are increased stiffness and strength. Nanofiller incorporation and post-polymerization heat treatment can also be combined to obtain the benefits of both methods simultaneously. The present invention relates to the development of thermoset nanocomposite particles. It also relates to the optional further improvement of the heat resistance and environmental resistance of said particles via post-polymerization heat treatment. Furthermore, it also relates to processes for the manufacture of said particles. Finally, it also relates to the use of said particles in the construction, drilling, completion and / or fracture stimulation of oil and natural gas wells; for example, as a proppant partial monolayer, a proppant pack, an integral component of a gravel pack completion, a ball bearing, a solid lubricant, a drilling mud constituent, and / or a cement additive.

Owner:SUN DRILLING PRODS

Article comprising a fine-grained metallic material and a polymeric material

InactiveUS20060135282A1Strength-to-weight ratio can be improvedGood damping propertiesWalking sticksMaterial nanotechnologyPolymer scienceHigh stiffness

Lightweight articles comprising a polymeric material at least partially coated with a fine-grained metallic material are disclosed. The fine-grained metallic material has an average grain size of 2 nm to 5,000 nm, a thickness between 25 micron and 5 cm, and a hardness between 200 VHN and 3,000 VHN. The lightweight articles are strong and ductile and exhibit high coefficients of restitution and a high stiffness and are particularly suitable for a variety of applications including aerospace and automotive parts, sporting goods, and the like.

Owner:INTEGRAN TECH

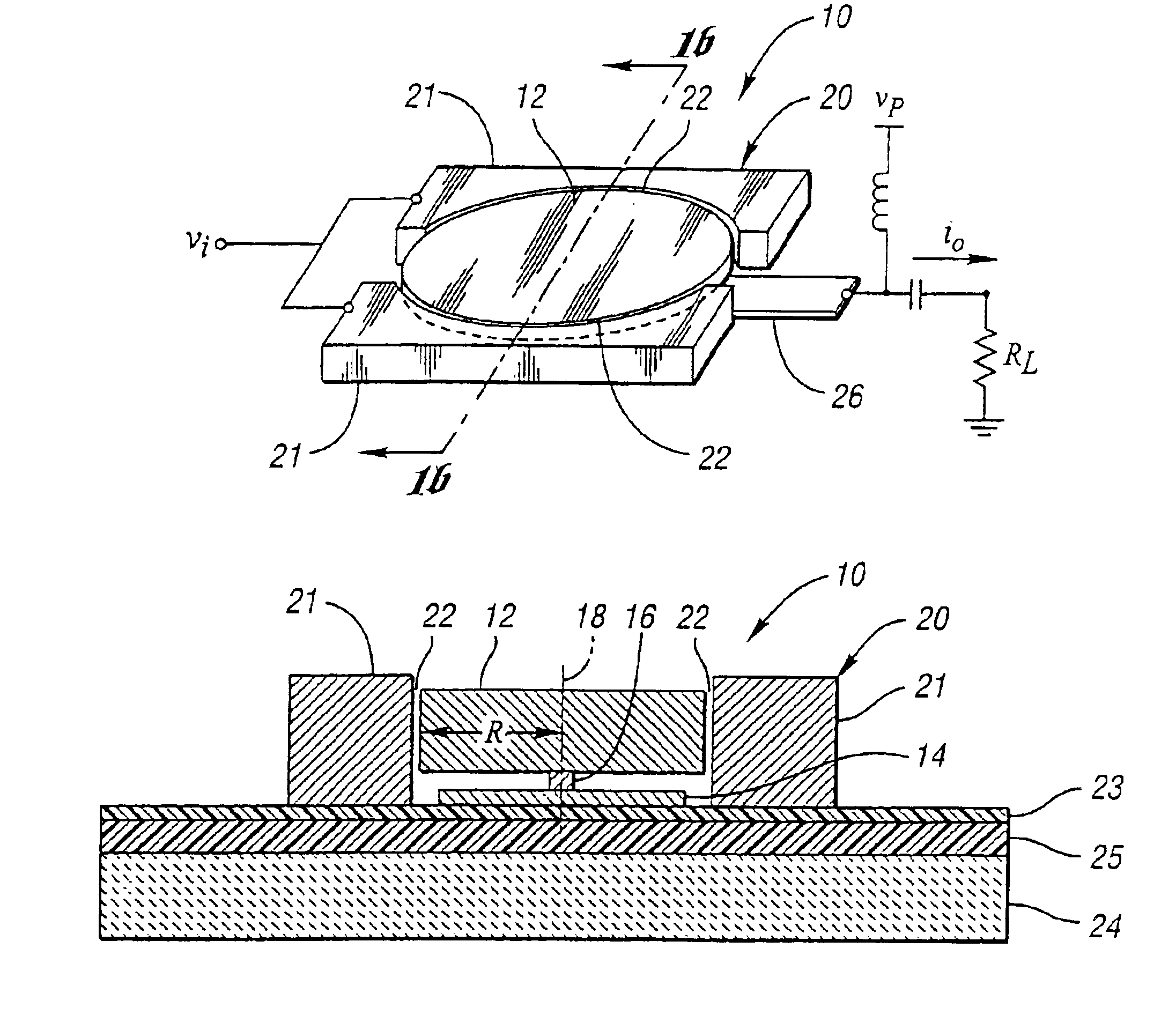

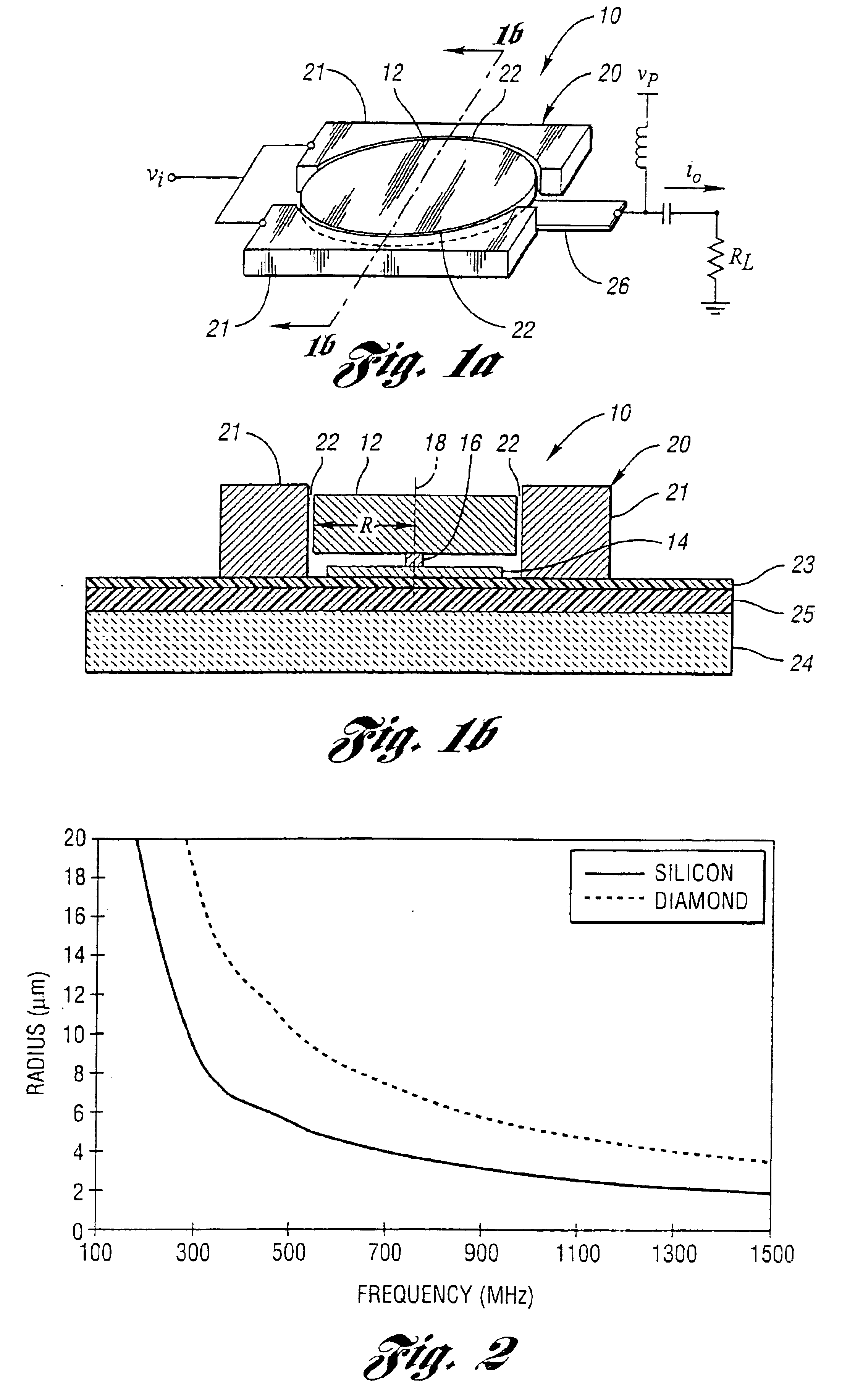

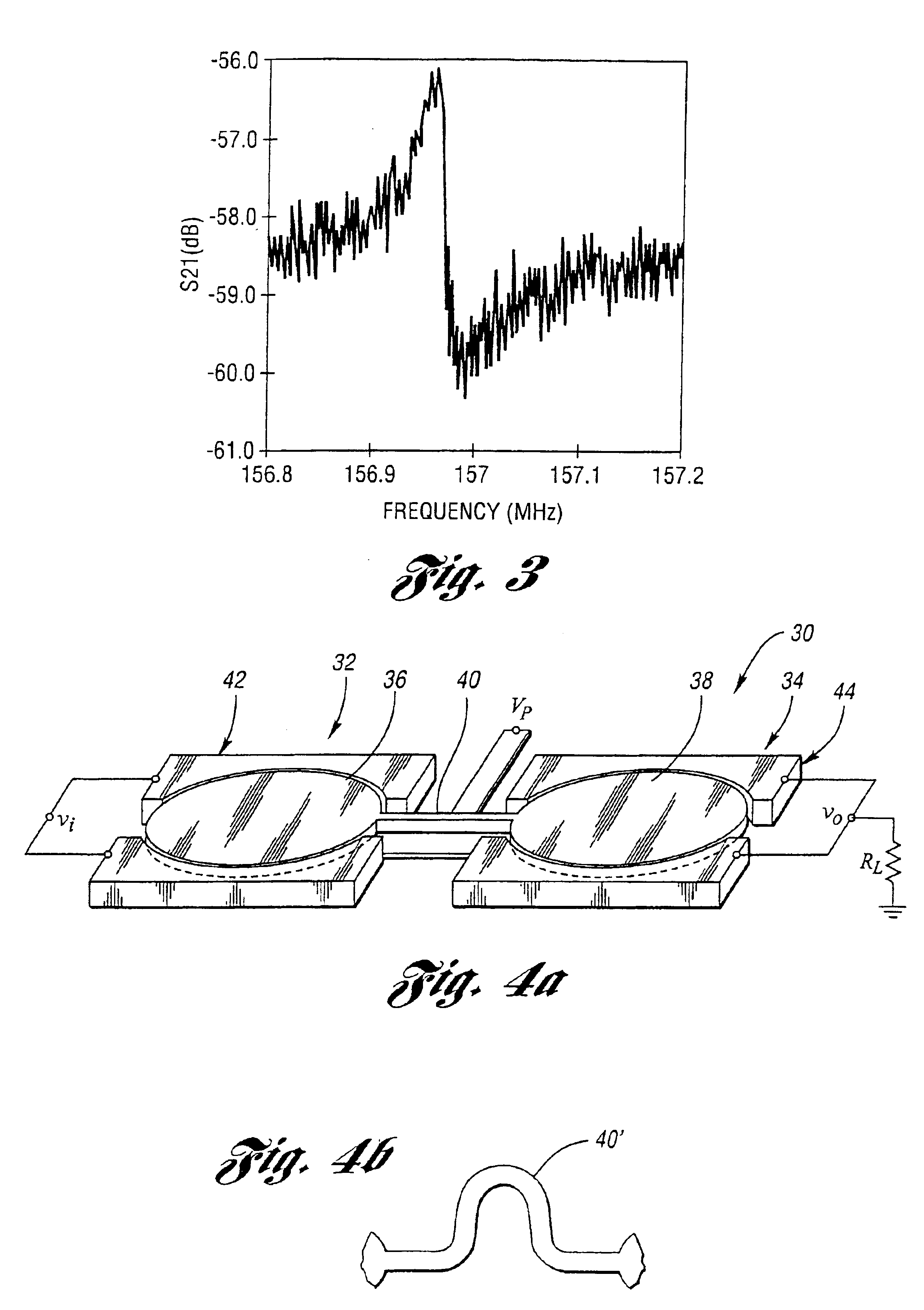

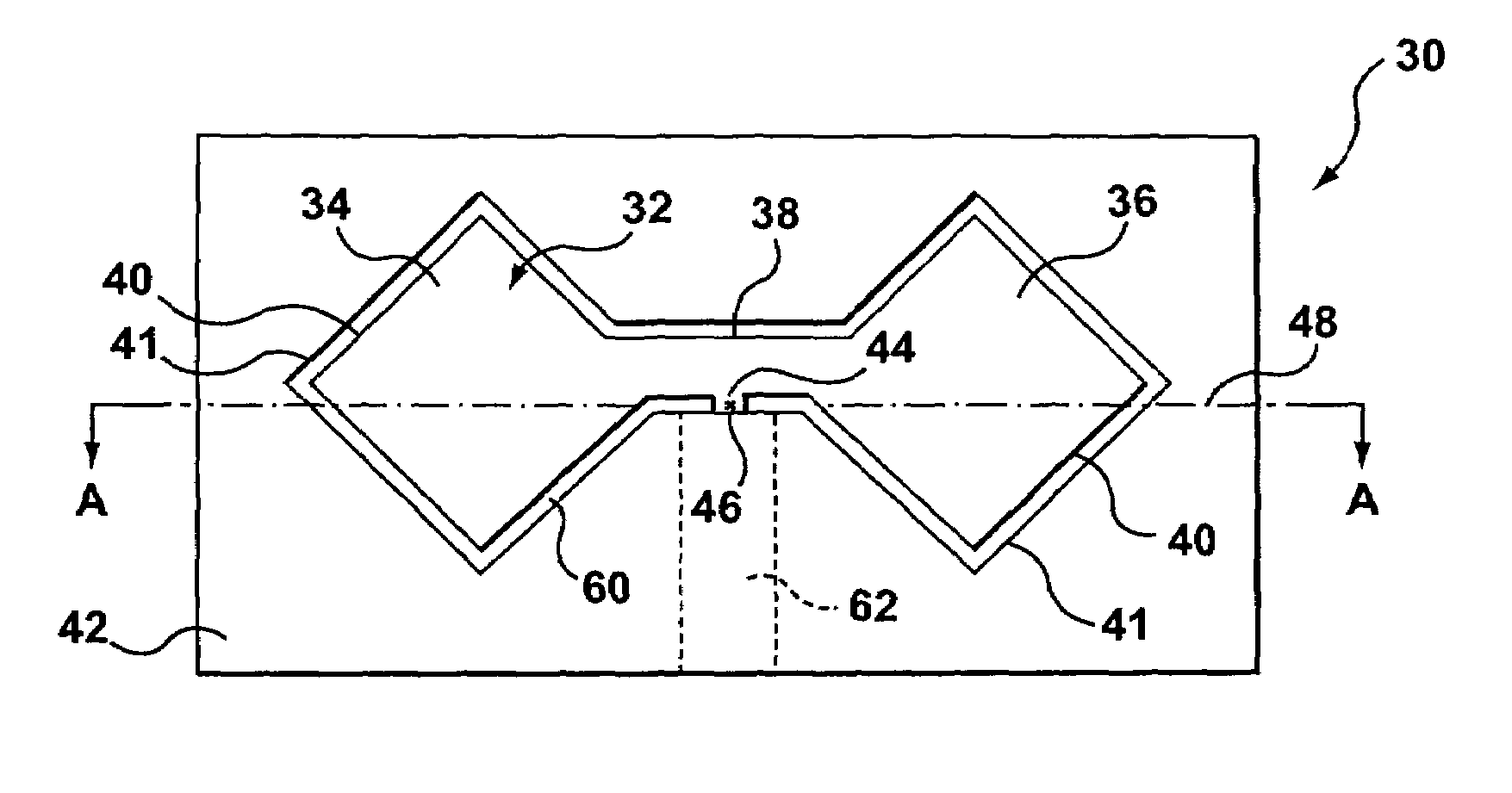

Micromechanical resonator device and micromechanical device utilizing same

InactiveUS6856217B1Improving QHigh Power Handling CapabilityPiezoelectric/electrostriction/magnetostriction machinesImpedence networksWireless transceiverTransceiver

A micromechanical resonator device and a micromechanical device utilizing same are disclosed based upon a radially or laterally vibrating disk structure and capable of vibrating at frequencies well past the GHz range. The center of the disk is a nodal point, so when the disk resonator is supported at its center, anchor dissipation to the substrate is minimized, allowing this design to retain high-Q at high frequency. In addition, this design retains high stiffness at high frequencies and so maximizes dynamic range. Furthermore, the sidewall surface area of this disk resonator is often larger than that attainable in previous flexural-mode resonator designs, allowing this disk design to achieve a smaller series motional resistance than its counterparts when using capacitive (or electrostatic) transduction at a given frequency. Capacitive detection is not required in this design, and piezoelectric, magnetostrictive, etc. detection are also possible. The frequency and dynamic range attainable by this resonator makes it applicable to high-Q RF filtering and oscillator applications in a wide variety of communication systems. Its size also makes it particularly suited for portable, wireless applications, where, if used in large numbers, such a resonator can greatly lower the power consumption, increase robustness, and extend the range of application of high performance wireless transceivers.

Owner:RGT UNIV OF MICHIGAN

Gravity gradiometer

ActiveUS7360419B2Improve featuresStatic/dynamic balance measurementGravitational wave measurementHigh stiffnessRoom temperature

A gravity gradiometer having quadrupole responders in which a mass quadrupole is supported by a torsional spring forming a flexure allowing rotation of the mass quadrupole about its center of mass. The flexure can be a pair of spaced apart posts. The flexure can be made from glassy metal having at room temperature a high elastic limit, high stiffness, high strength and low internal damping. The flexure can alternatively be a web made of glassy metal.

Owner:GEDEX

Polypropylene resin composition and use thereof

A polypropylene resin composition exibiting a high melt tension and superior moldability, which can be molded efficiently by a high-speed molding into scarcely deformable larger molded articles of better appearance with high stiffness and which comprises polypropylene as a main component and has the following characteristic features 1) to 4), namely,1) that a melt flow rate (MFR, determined at 230° C. under a load of 2.16 kg) is in the range of 0.01 to 5 g / 10 min.,2) that a content of a high molecular weight polypropylene exhibiting an intrinsic viscosity [eta], determined at 135° C. in decalin, of 8-13 dl / g is in the range of 15 to 50% by weight,3) that a gel areal density in number is 3,000 / 450 cm2 or less and4) that a molecular weight distribution determined by gel permeation chromatography (GPC) is 6-20, as expressed by Mw / Mn, and is 3.5 or higher, as expressed by Mz / Mw.

Owner:PRIME POLYMER CO LTD

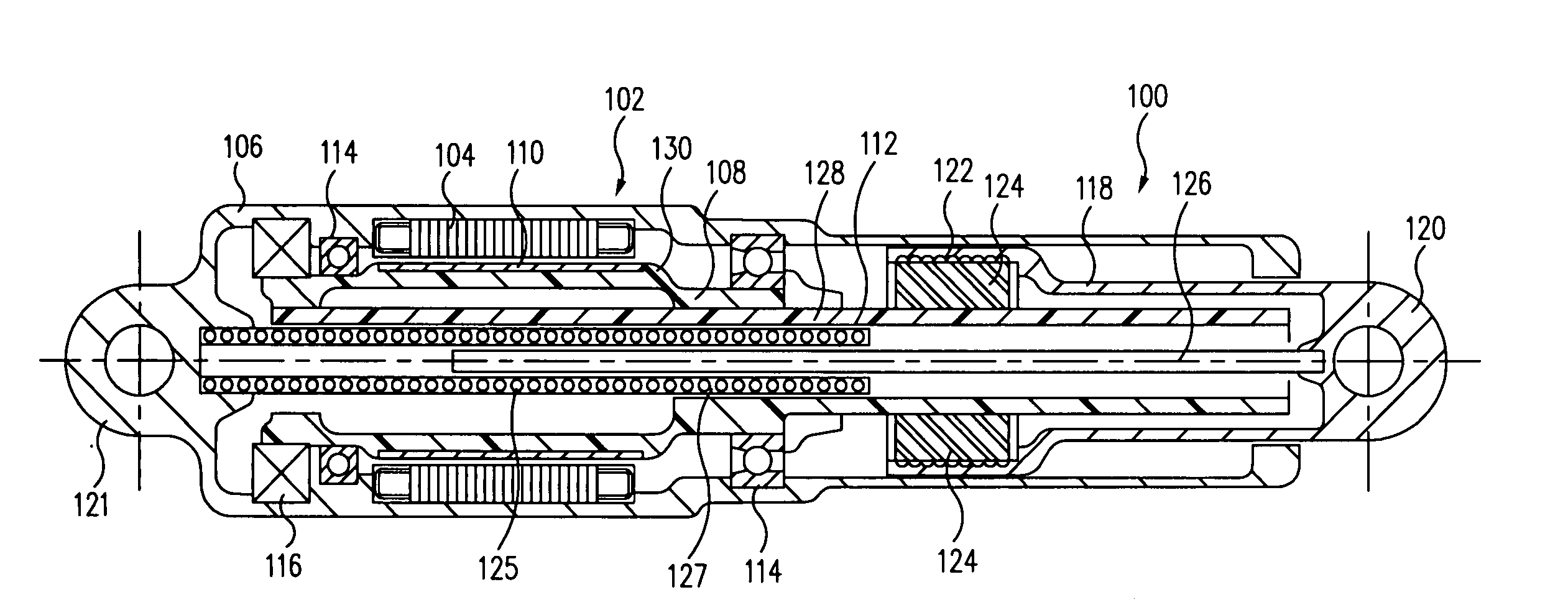

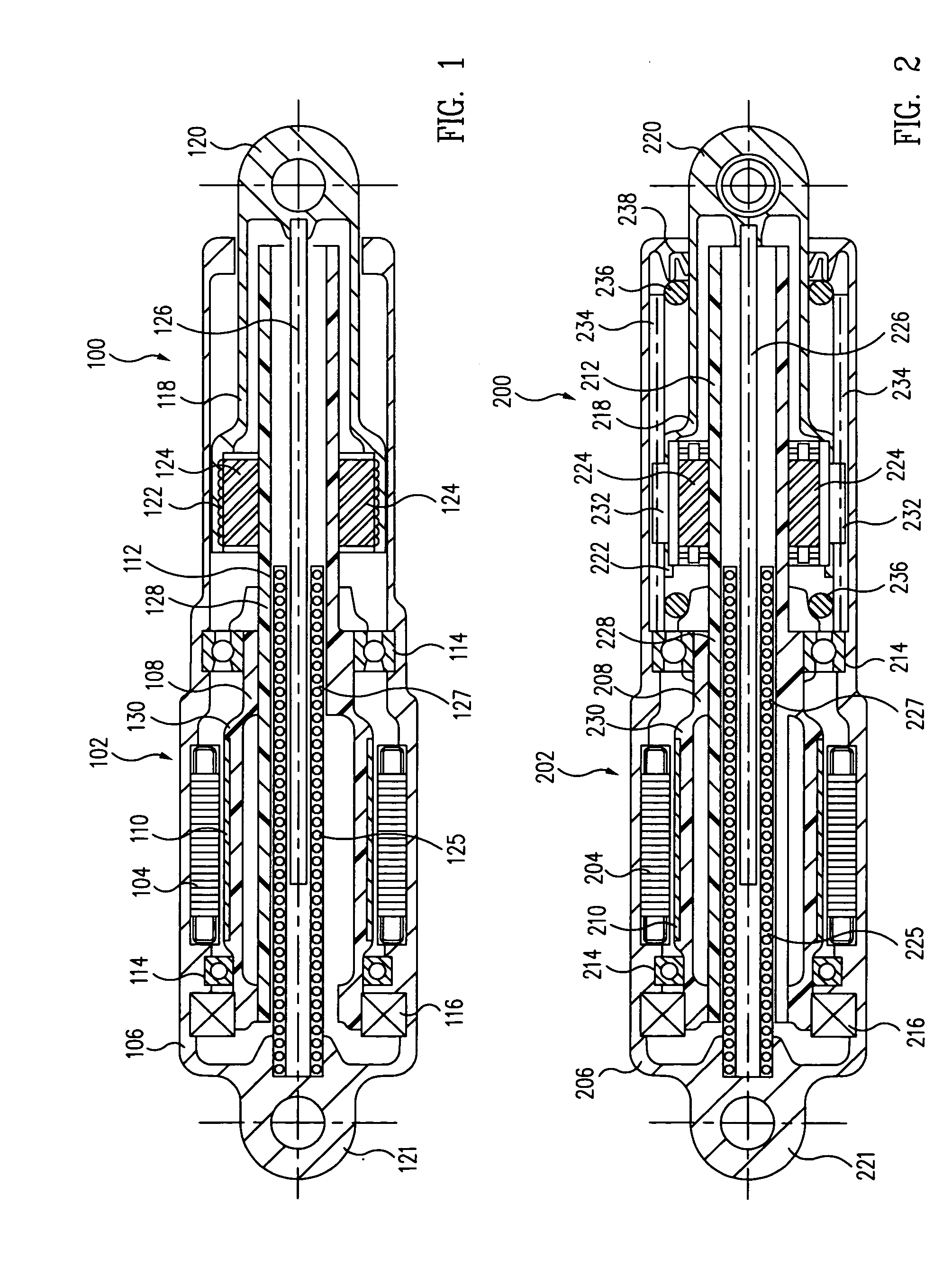

Direct drive electromechanical linear actuators

Direct drive electromechanical rotary-to-linear actuators include one or more electric motors mounted in a housing. Each motor includes a stator and a rotor. The motor drives a planetary drive mechanism that includes an elongated central shaft having one or more helical threads on an external surface coupled to the rotor for conjoint rotation. A planetary nut having helical threads on an internal surface is disposed concentric to the shaft, and a plurality of planetary rollers are disposed concentrically between the shaft and the planetary nut. Each of the rollers has a helical thread on an external surface that is complementary to and in engagement with a thread of the shaft and a thread of the nut. Rotation of the rotor is converted with mechanical advantage into linear movement of the planetary nut. The actuators provide backlash-free operation, higher stiffnesses, slew rates and frequency responses, and better overall efficiency.

Owner:THE BOEING CO

Methods and apparatus for a rugged mobile device housing

InactiveUS20070138920A1Minimization requirementsLarge deflectionFurniture partsCabinetsGlass fiberThermoplastic

A rugged mobile device housing is provided for protecting a component (e.g., a liquid crystal display, a keyboard, a printed circuit board, or the like) and includes one or more first structures comprising a first material provided in a region of the housing capable of withstanding deflection, wherein the first material is an elastomer, and one or more second structures bonded to the first structure, wherein the second structure is a high-stiffness plastic. In one embodiment, the first material is a high-stiffness elastomer and the second material is a long glass fiber filled thermoplastic (“LGF” plastic). In one embodiment, the first structure is located at a corner of the housing and the second structure is located in the middle of the housing. In another embodiment, the first structure is located in the center of the housing and the second structures are located at the ends. In yet another embodiment, a projecting handle and hinge are provided, where the first structure is located at the handle and the second structure is located at the hinge.

Owner:SYMBOL TECH INC

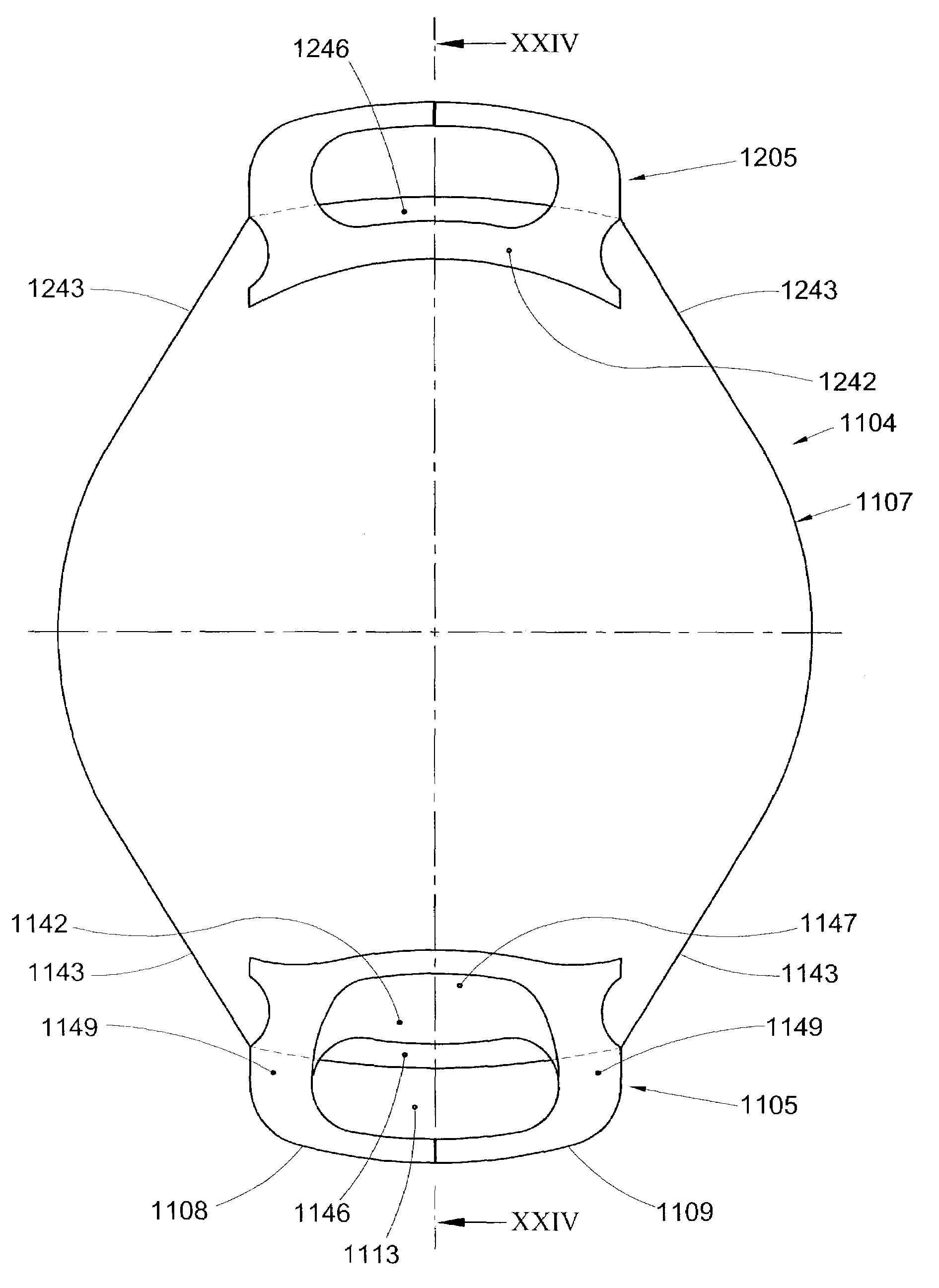

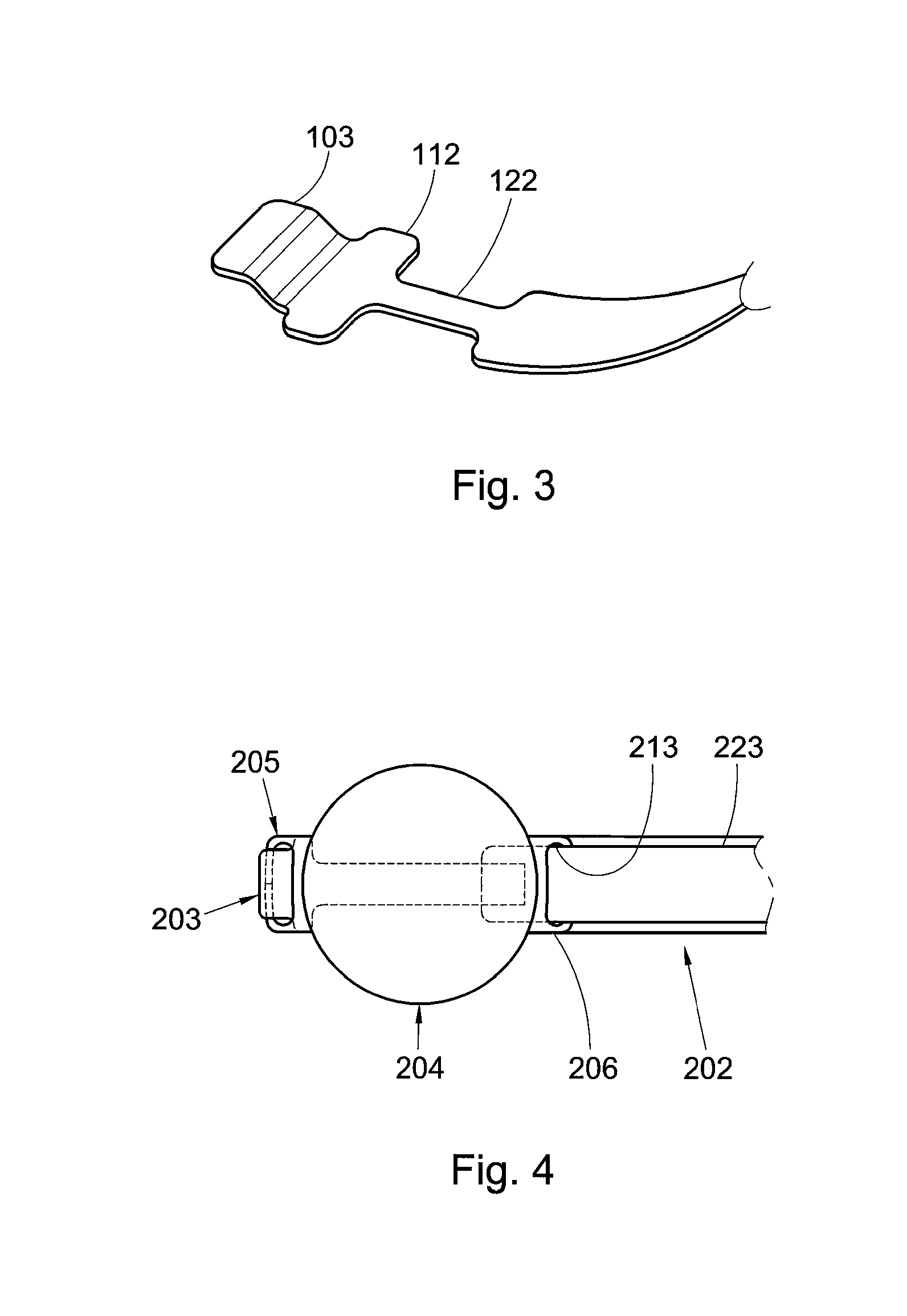

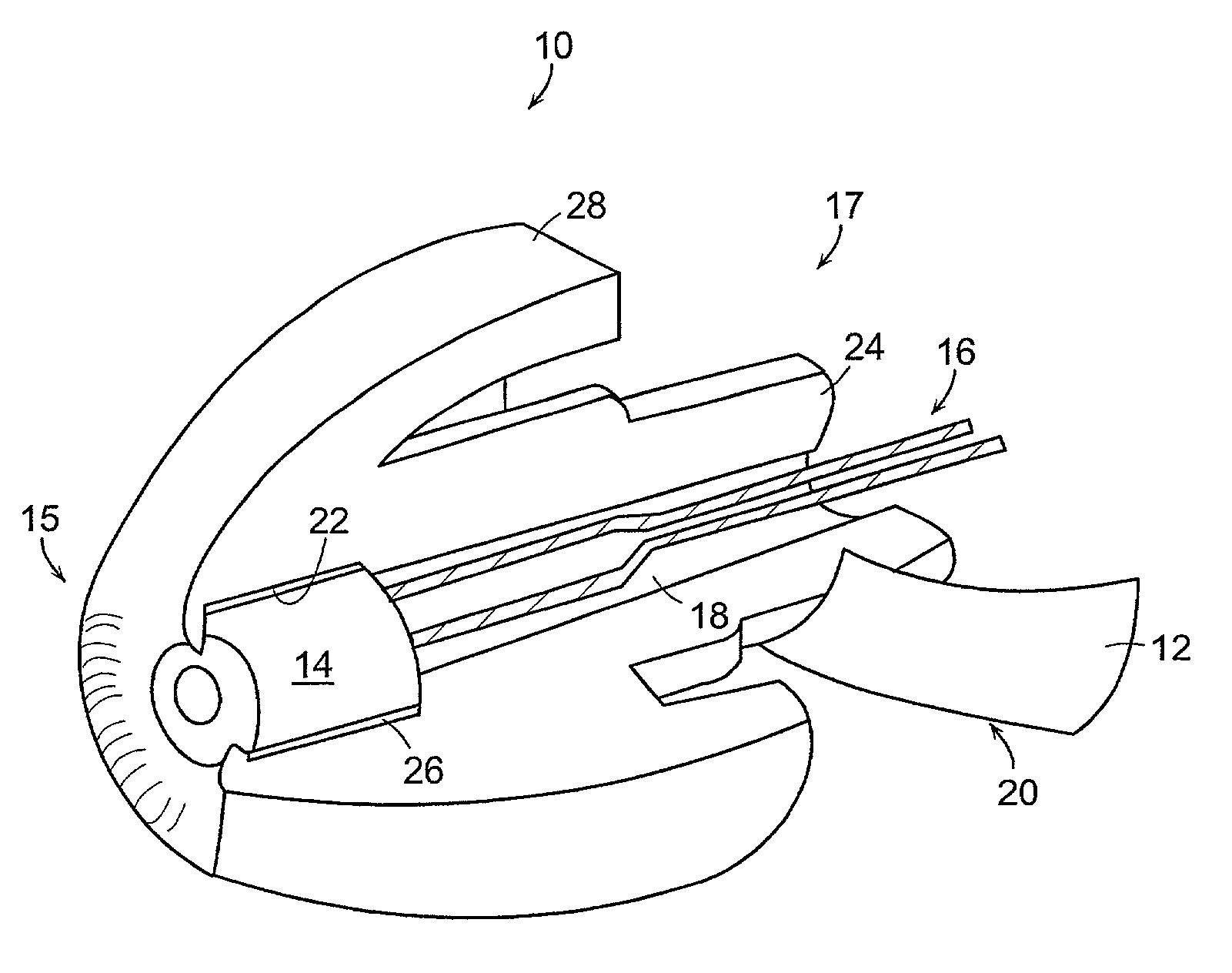

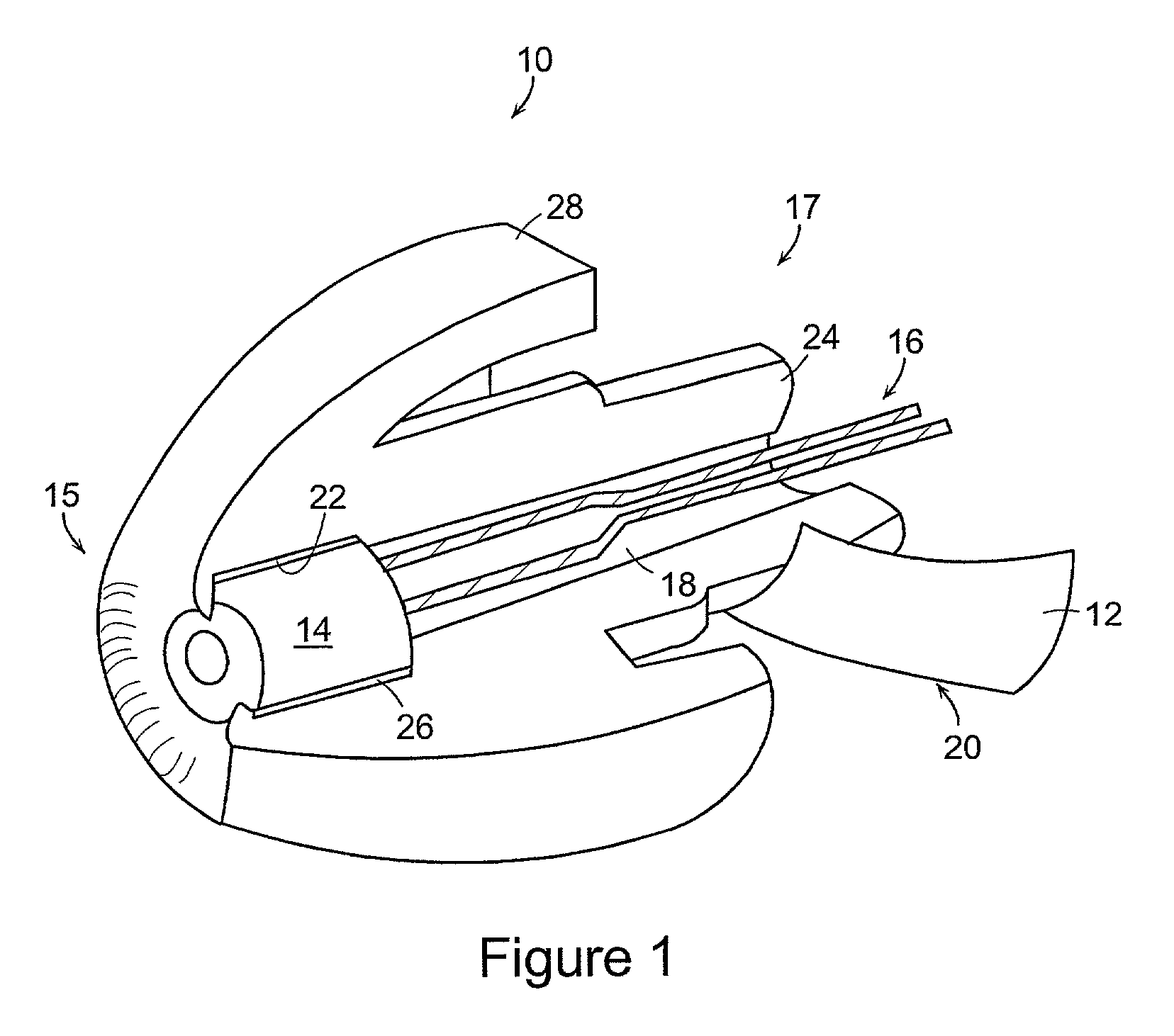

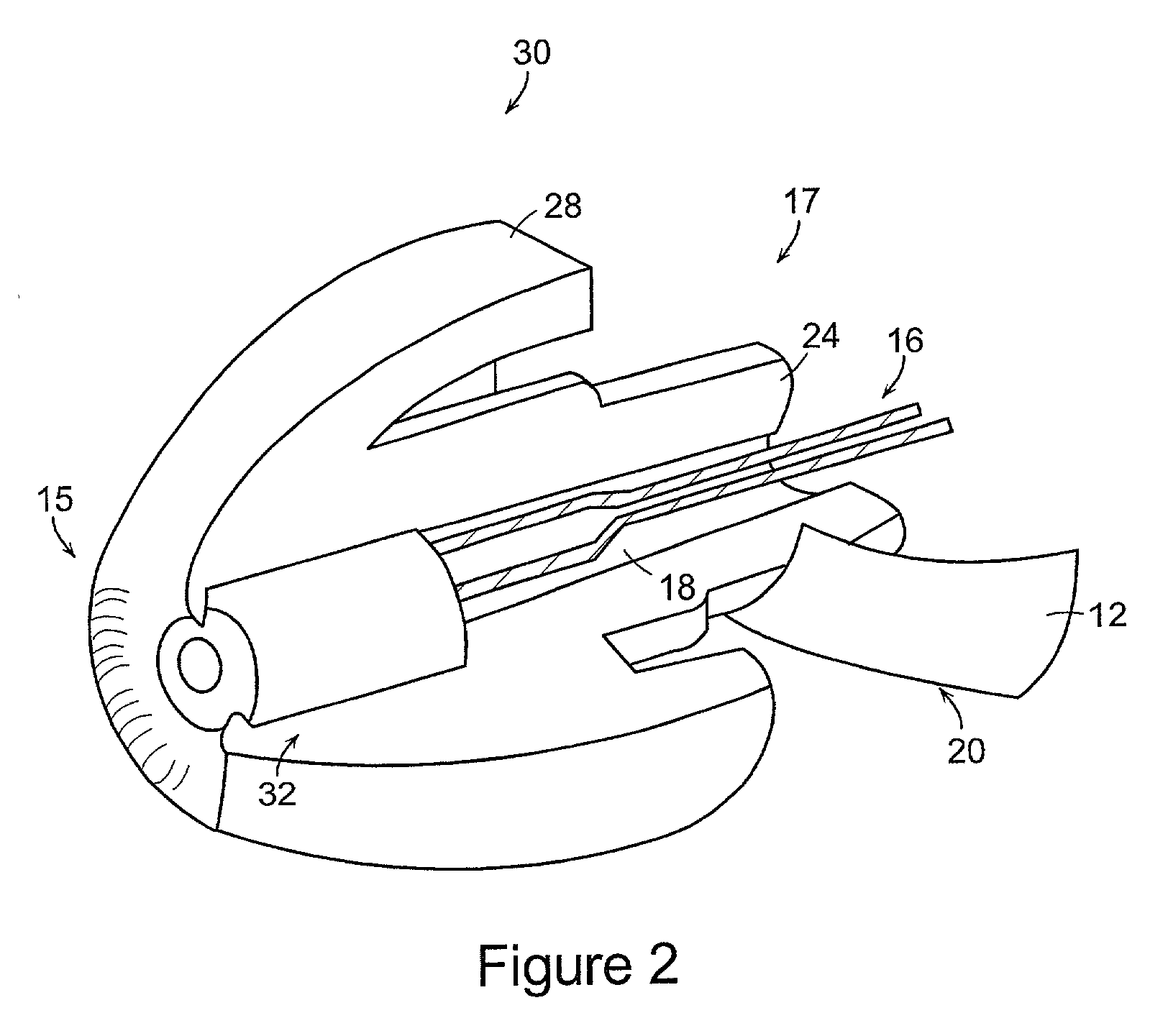

Intraocular lens for implantation in an eye and instrument and methods for insertion of such a lens

InactiveUS7179292B2Easy to controlReduce riskEye treatmentIntraocular lensIntraocular lensHigh stiffness

An intraocular lens includes an optical portion (7; 607; 907; 1107) of a transparent, deformable material, at least one haptic (5, 6; 205, 206; 405, 406, 706; 806; 905; 1005; 1105; 1205) radially projecting from the optical portion for supporting the optical portion in a position parallel to and against an anterior iris surface plane (936; 1136), and at least one aperture (13; 213; 713; 913; 1013; 1113) bounded by the haptic. At least a stiff portion of the haptic has a higher stiffness against bending about an axis in the radial direction than the optical portion. Furthermore, the stiff portion has a width (a) measured parallel to the plane and perpendicular to the radial direction, which is smaller than the size (b) of the optical portion in the direction of the width. An instrument and methods for preparing and carrying out insertion of such a lens are also described.

Owner:OPHTEC

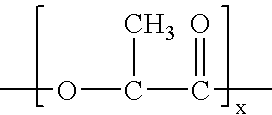

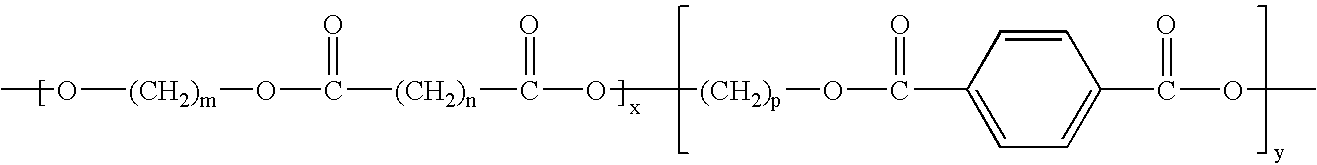

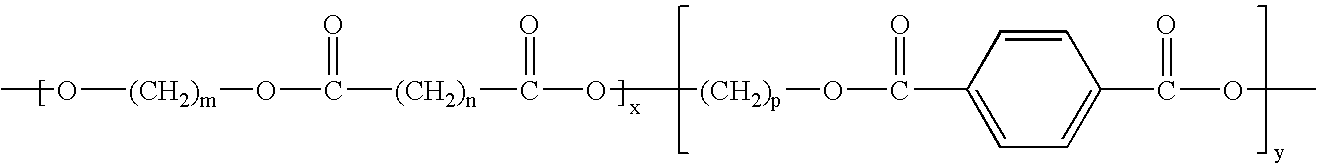

Biodegradable Packaging Film

InactiveUS20090324917A1Conductive materialSynthetic resin layered productsWater vaporMechanical property

A biodegradable packaging film is provided. The film is formed from a blend that contains a thermoplastic starch and polylactic acid. Starch is a relatively inexpensive natural polymer that is also renewable and biodegradable. Polylactic acid is likewise an inexpensive synthetic polymer that is biodegradable and renewable, yet also capable of providing increased tensile strength to the film. Although providing a good combination of biodegradability / renewability and increased tensile strength, the polylactic acid is also relatively rigid and can result in films having a relatively high stiffness (e.g., high modulus of elasticity) and low ductility. While more ductile than polylactic acid, the thermoplastic starch is often difficult to melt process in film forming processes and very sensitive to moisture and water vapor, reducing its ability to be used as a stand alone packaging film. In an effort to counteract the effect of such polymers, an aliphatic-aromatic copolyester is also employed in the blend of the present invention. While such copolyesters are biodegradable, they also possess the melt properties and ductility that lend them well to the formation of films. Although the combination of these polymers may achieve a good balance between biodegradability / renewability, high tensile strength, and good ductility (e.g., high peak elongation), it is still often difficult to achieve a precise set of mechanical properties as desired for packaging films. In this regard, the blend also contains a filler. Due to its rigid nature, the amount of the filler may be readily adjusted to fine tune the blend to the desired degree of ductility (e.g., peak elongation) and stiffness (e.g., modulus of elasticity).

Owner:KIMBERLY-CLARK WORLDWIDE INC

Boron carbide composite bodies, and methods for making same

InactiveUS6862970B2Less expensivelyLow production costDoor/window protective devicesLayered productsReaction bonded silicon carbideHigh stiffness

A composite body produced by a reactive infiltration process that possesses high mechanical strength, high hardness and high stiffness has applications in such diverse industries as precision equipment and ballistic armor. Specifically, the composite material features a boron carbide filler or reinforcement phase, and a silicon carbide matrix produced by the reactive infiltration of an infiltrant having a silicon component with a porous mass having a carbonaceous component. Potential deleterious reaction of the boron carbide with silicon during infiltration is suppressed by alloying or dissolving boron into the silicon prior to contact of the silicon infiltrant with the boron carbide. In a preferred embodiment of the invention related specifically to armor, good ballistic performance can be advanced by loading the porous mass or preform to be infiltrated to a high degree with one or more hard fillers such as boron carbide, and by limiting the size of the largest particles making up the mass. The instant reaction-bonded silicon carbide (RBSC) composite bodies surpass previous RBSC's as armor materials, and in this capacity approach the ballistic performance of current carbide armor ceramics but with potentially lower cost manufacturing methods, e.g., infiltration techniques.

Owner:II VI DELAWARE INC +1

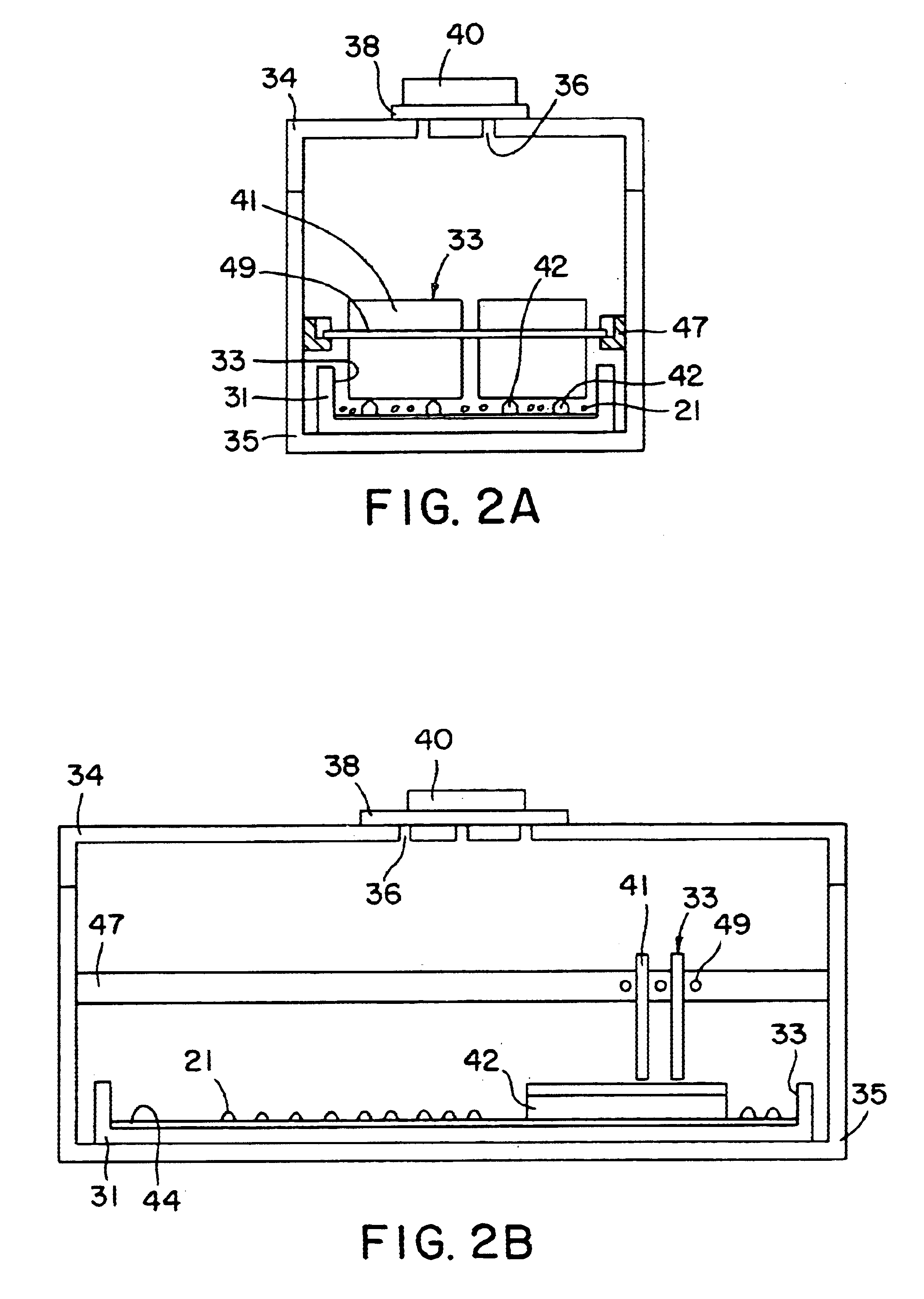

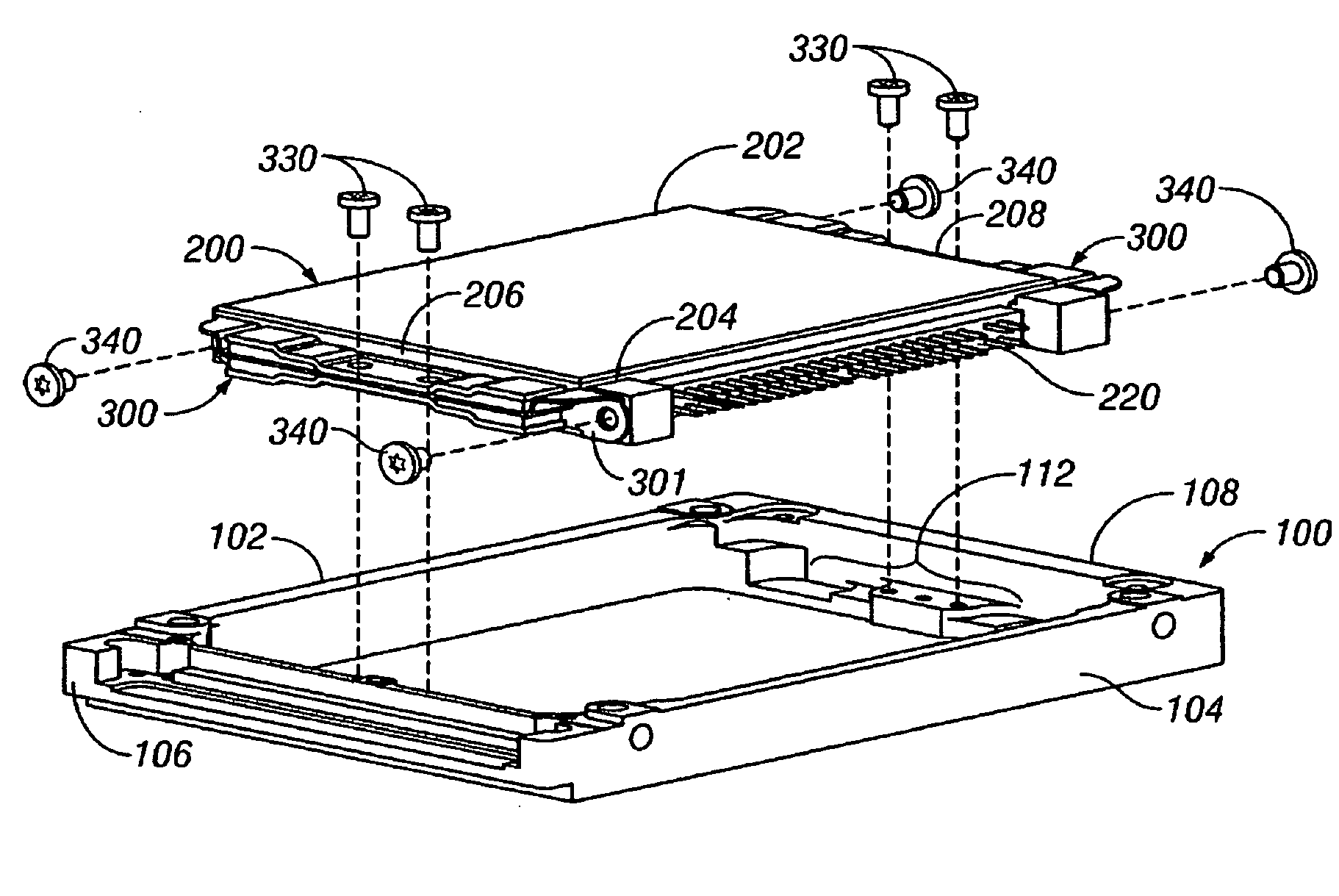

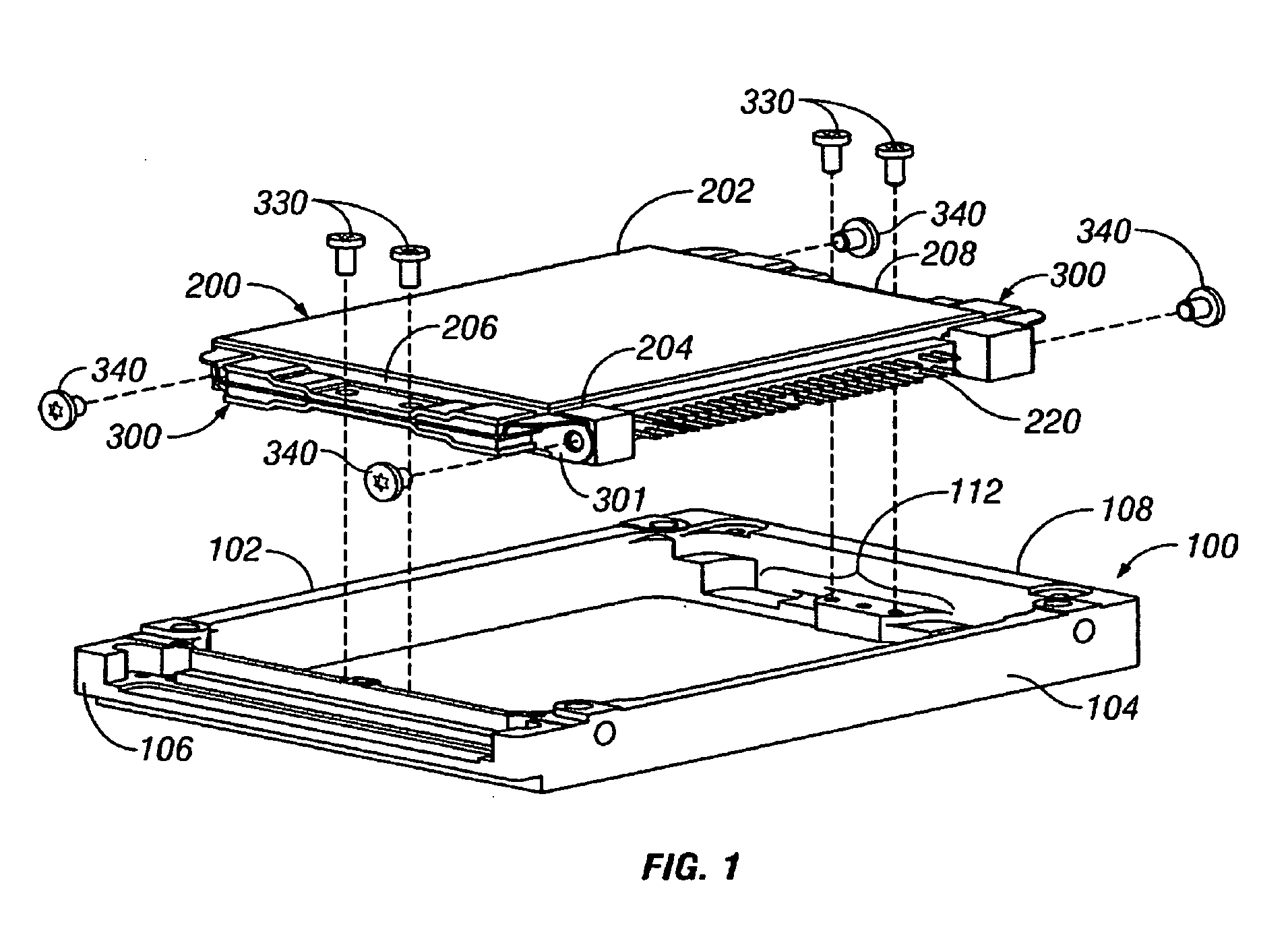

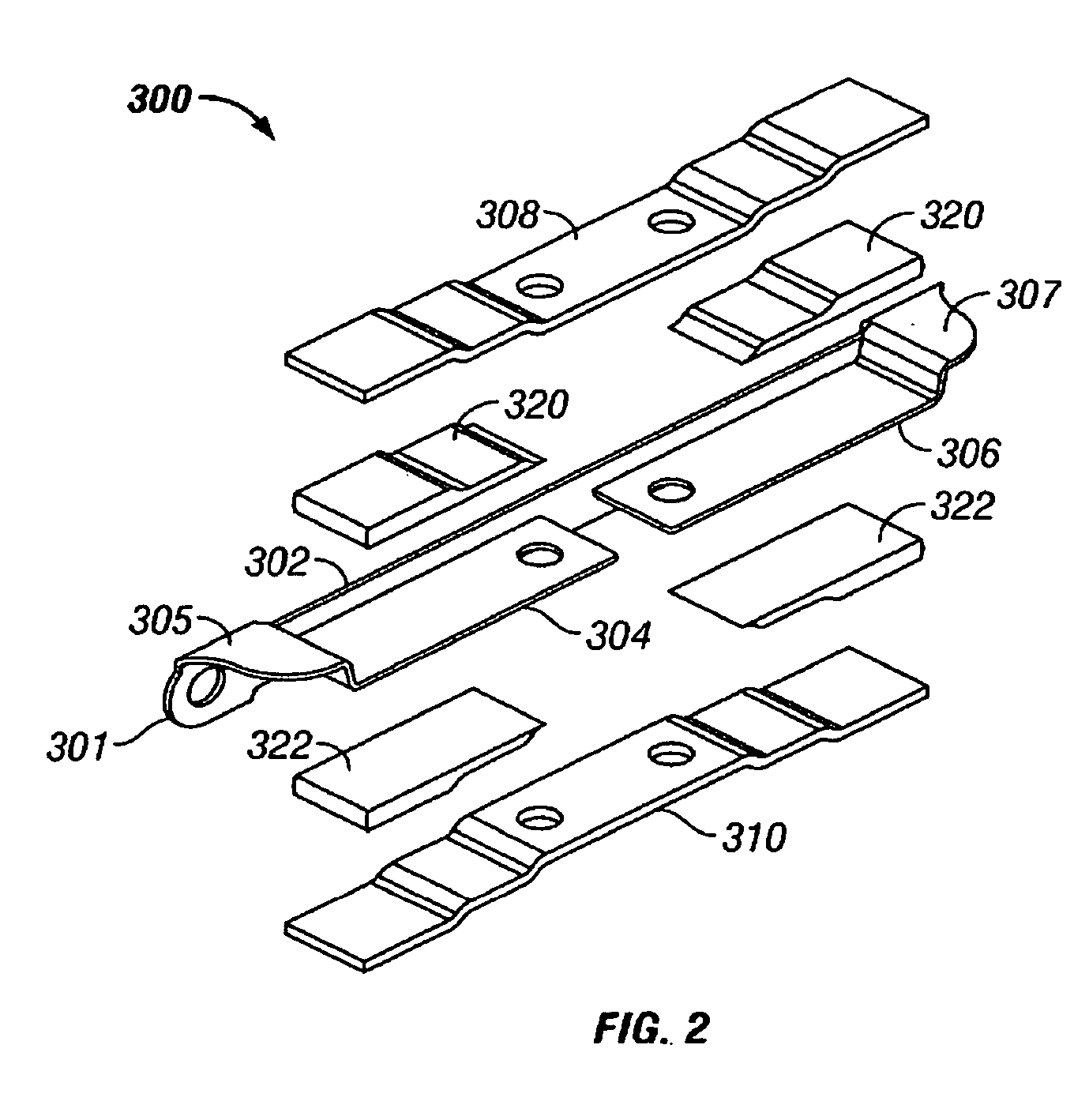

Shock mount assembly for attachment of an electronic device to a support structure

ActiveUS7106582B2Increase stiffnessGood shockproofDigital data processing detailsNon-rotating vibration suppressionCantilevered beamHigh stiffness

A mechanical-shock-mount assembly enables attachment of a mechanical-shock-sensitive electronic device to a support structure. Two identical shock-mount structures are attached and located on opposite sides of an electronic device. Each shock-mount structure has a pair of generally planar spring-like cantilever beams that have their free ends for attachment to the support structure. Damping material is located on the surfaces of the cantilever beams between the beams and clamping surfaces. At least one clamping surface is a plate that compresses the damping material between itself and the beam and / or compresses the damping material between the beam and a surface of the support structure when it is attached to the support structure. This shock-mount structure acts as a highly-damped nonlinear spring system that provides mechanical-shock resistance for the device in a direction perpendicular to the cantilevered beams and high stiffness in a direction in the plane of the beams. If desired, the shock-mounts can be first assembled to the support structure before attaching the device. The support structure can optionally have additional features for attaching other components of the device host.

Owner:WESTERN DIGITAL TECH INC

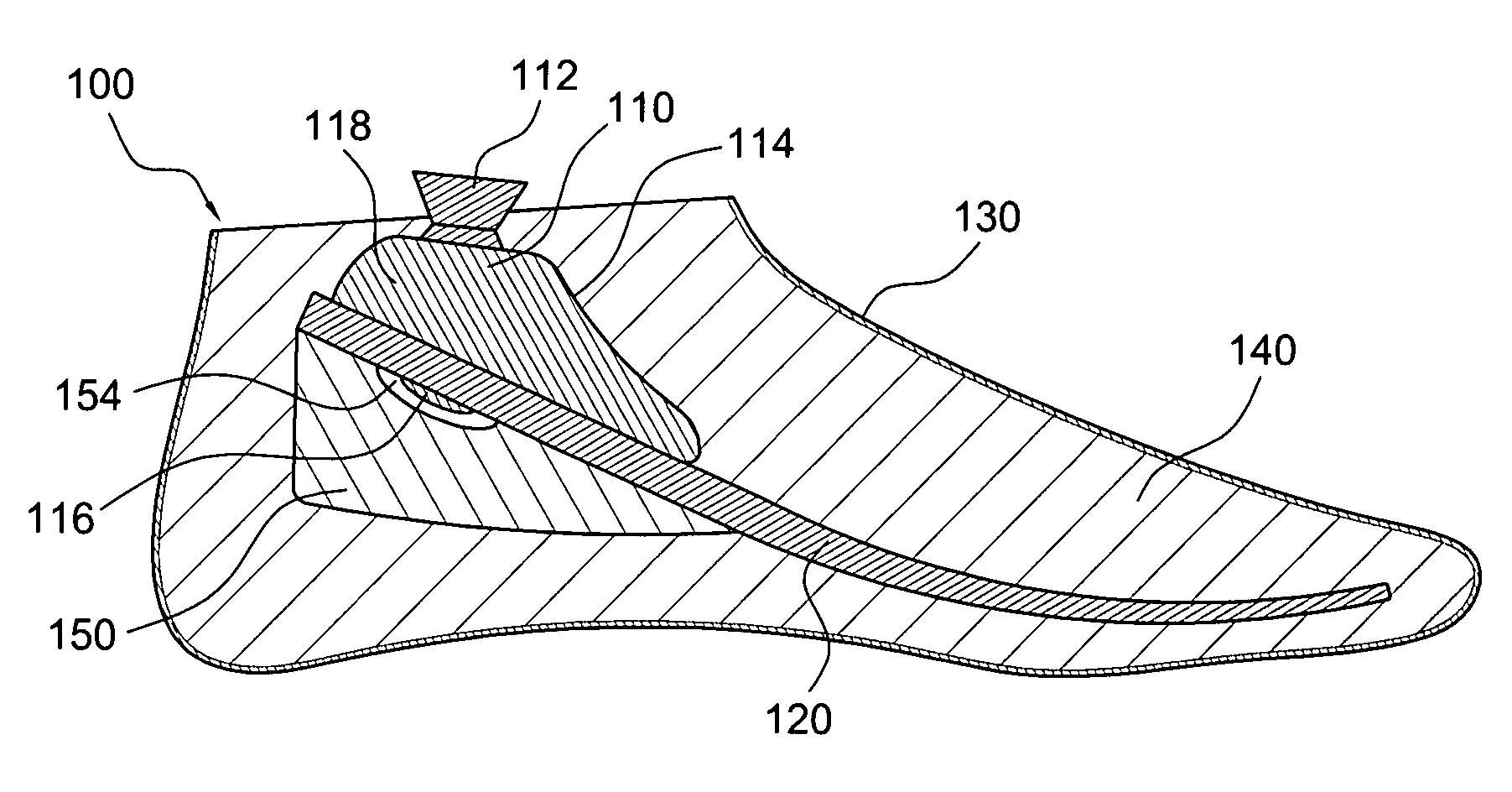

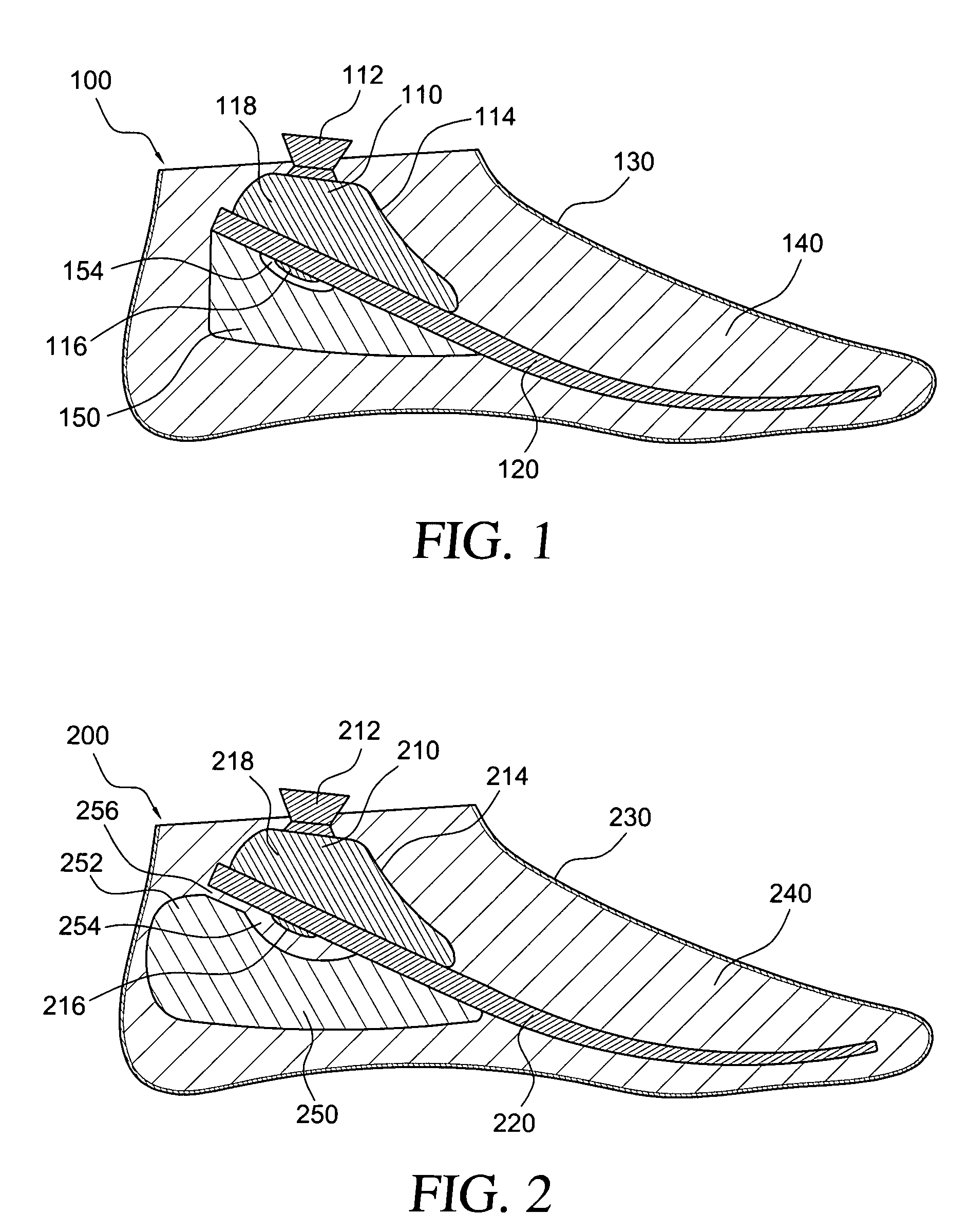

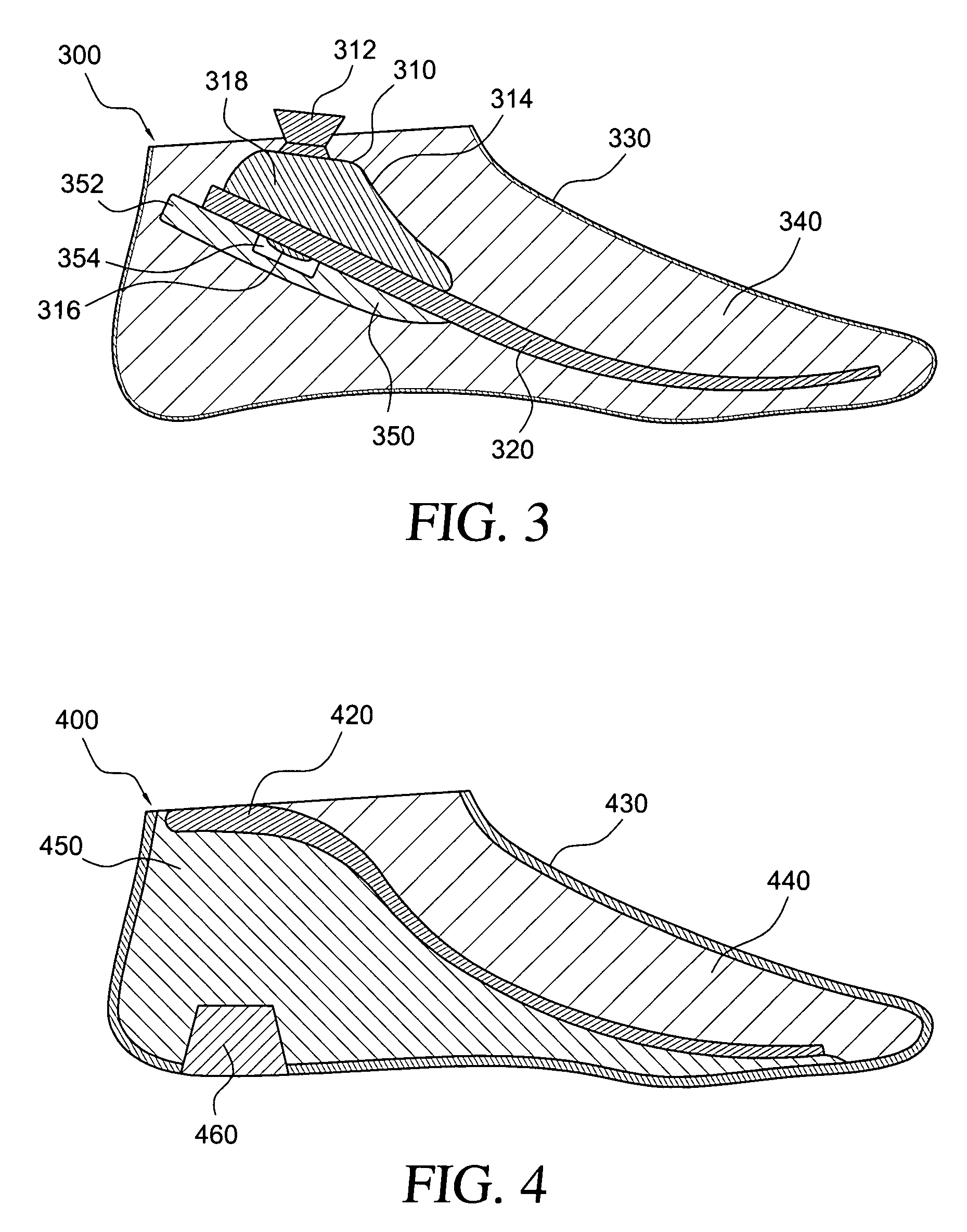

Prosthetic foot

ActiveUS7503937B2Low costImproved prosthetic feetArtificial legsHigh stiffnessBiomedical engineering

Embodiments of low cost prosthetic feet include a footplate with a connection mechanism embedded within a first foam element having a first stiffness. A second foam element is bonded to the footplate and has a recess in a proximal surface and a stiffness greater than the first foam element. The second foam element may have a portion extending past the terminal end of the footplate. A cosmesis encloses the components of the prosthetic foot. A third foam element that extends through the cosmesis into the second foam element may be provided. The third foam element may have a higher stiffness than the first and second foam elements.

Owner:KAUPTHING BANK

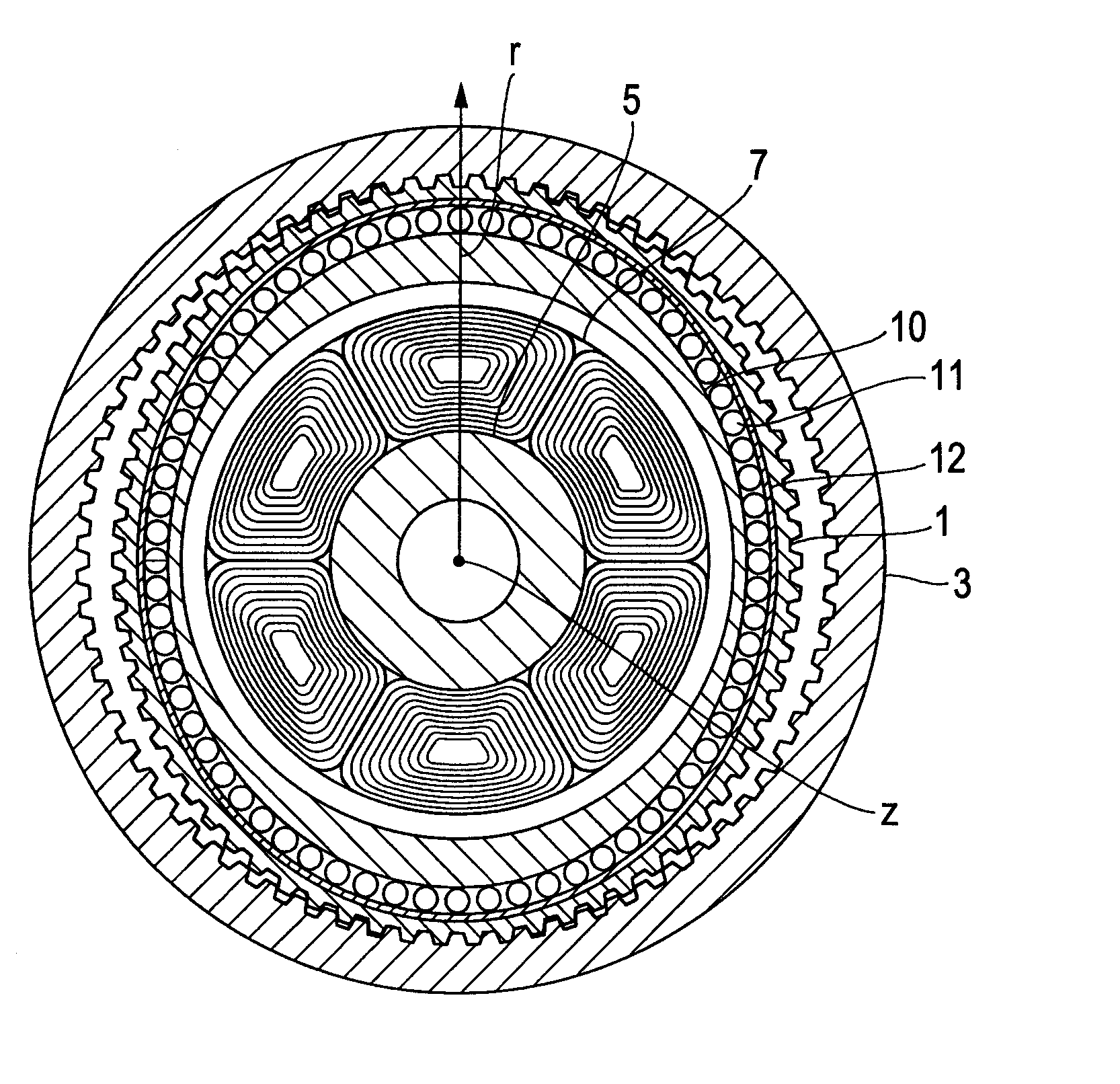

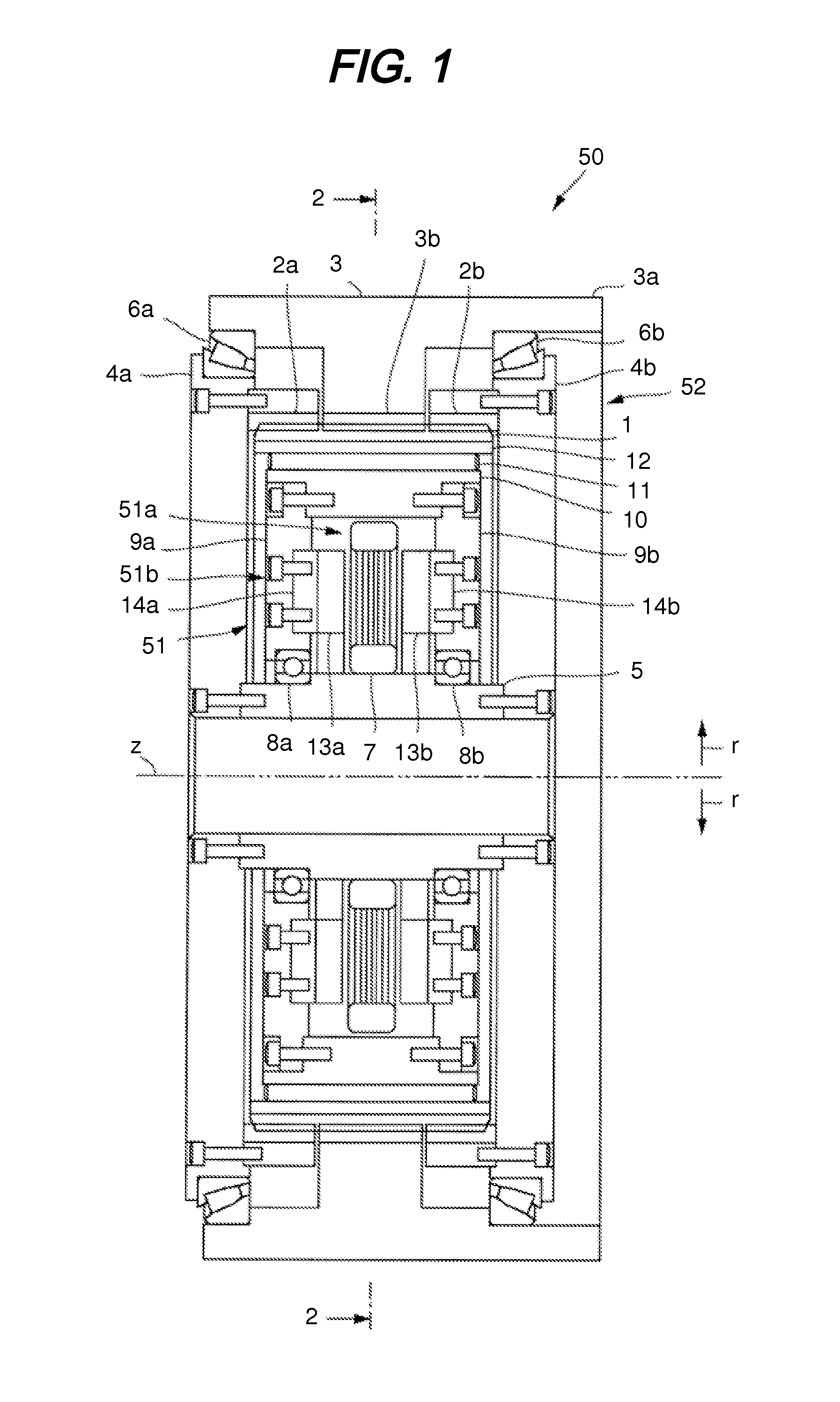

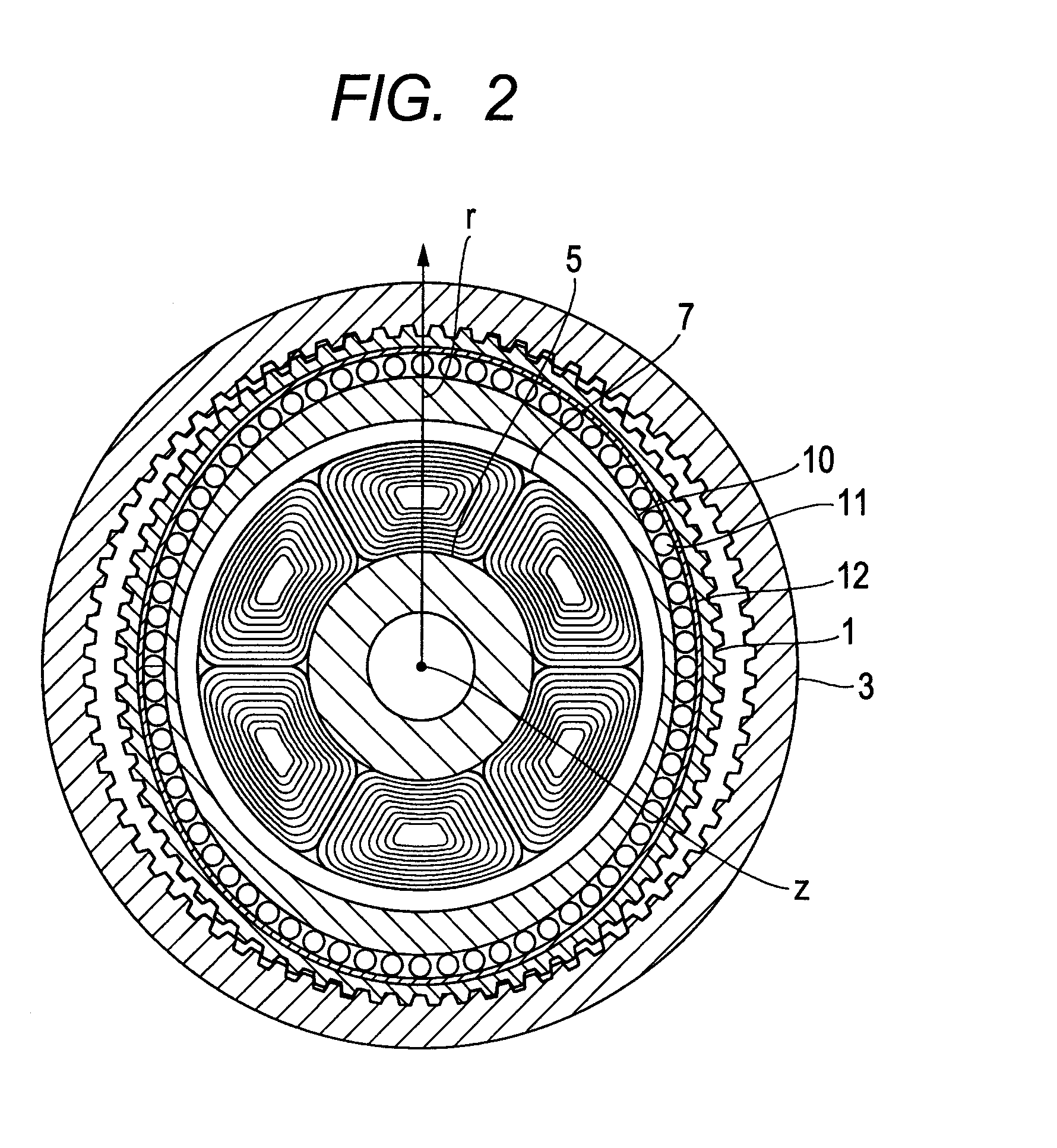

Strain wave gearing and robotic arm

InactiveUS20110245006A1Increase stiffnessProgramme-controlled manipulatorToothed gearingsHigh stiffnessGear wheel

Provided is a strain wave gearing having a high stiffness and no limitation imposed on rotation, and a robotic arm including the strain wave gearing. A strain wave gearing includes an electric motor and a strain wave gearing reducer. The strain wave gearing reducer includes: an outer ring member including a first internal gear; a pair of second internal gears each having internal teeth formed along an inner periphery thereof, and the pair of second internal gears differing from the first internal gear in number of teeth; a flexible gear; and a cam member, which distorts the flexible gear in a radial direction to cause the flexible gear to engage with the first internal gear and the pair of second internal gears. The pair of second internal gears is fixed to a pair of fixing plates coupled to each other by a shaft penetrating the cam member.

Owner:CANON KK

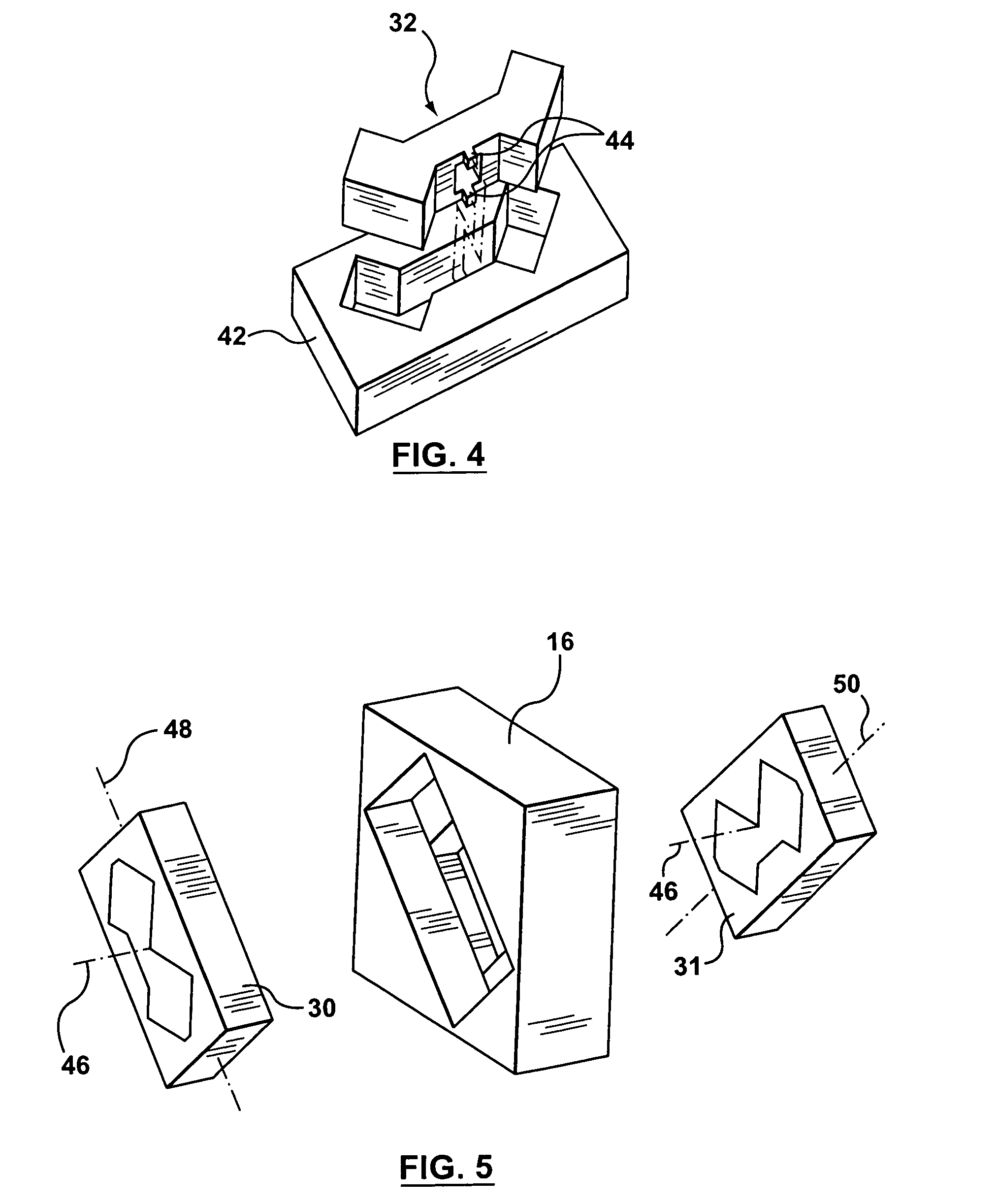

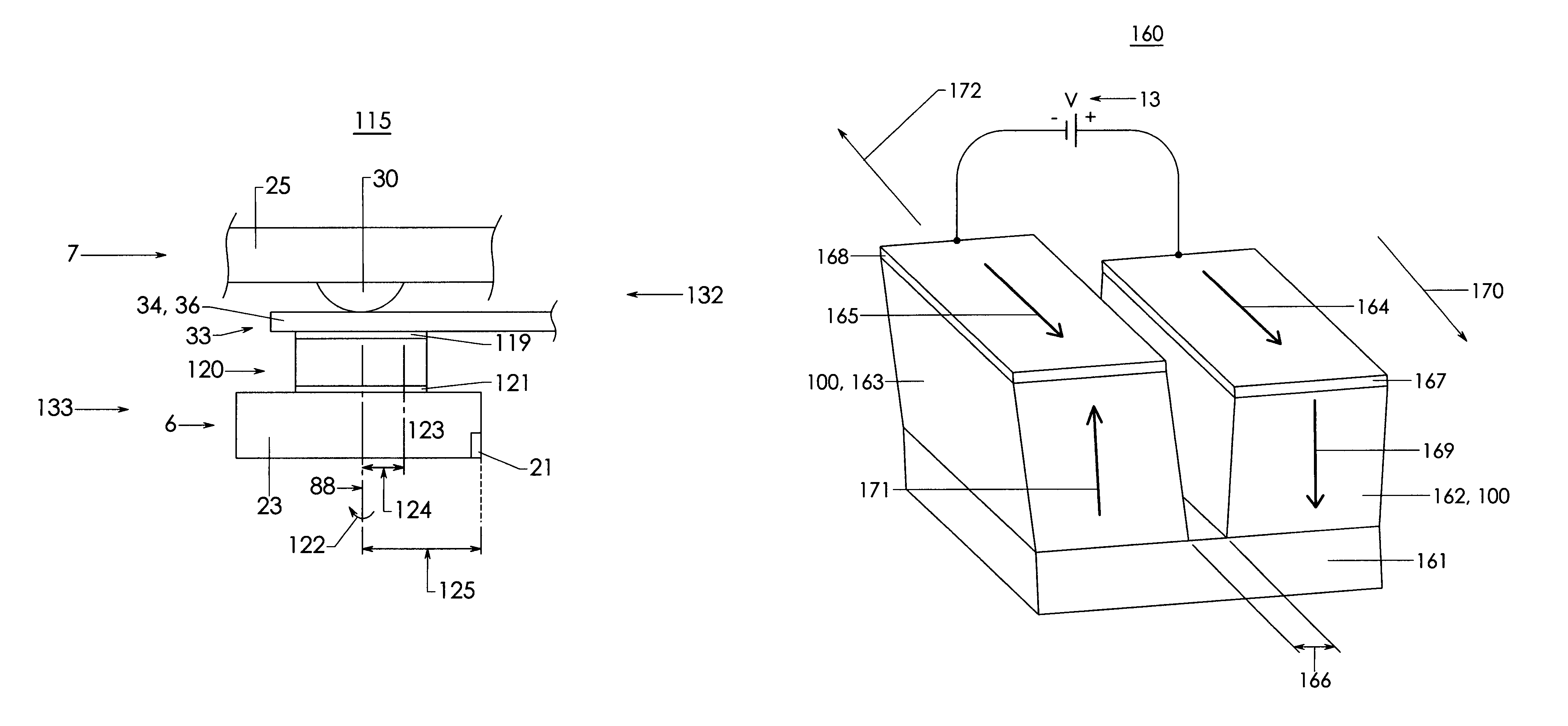

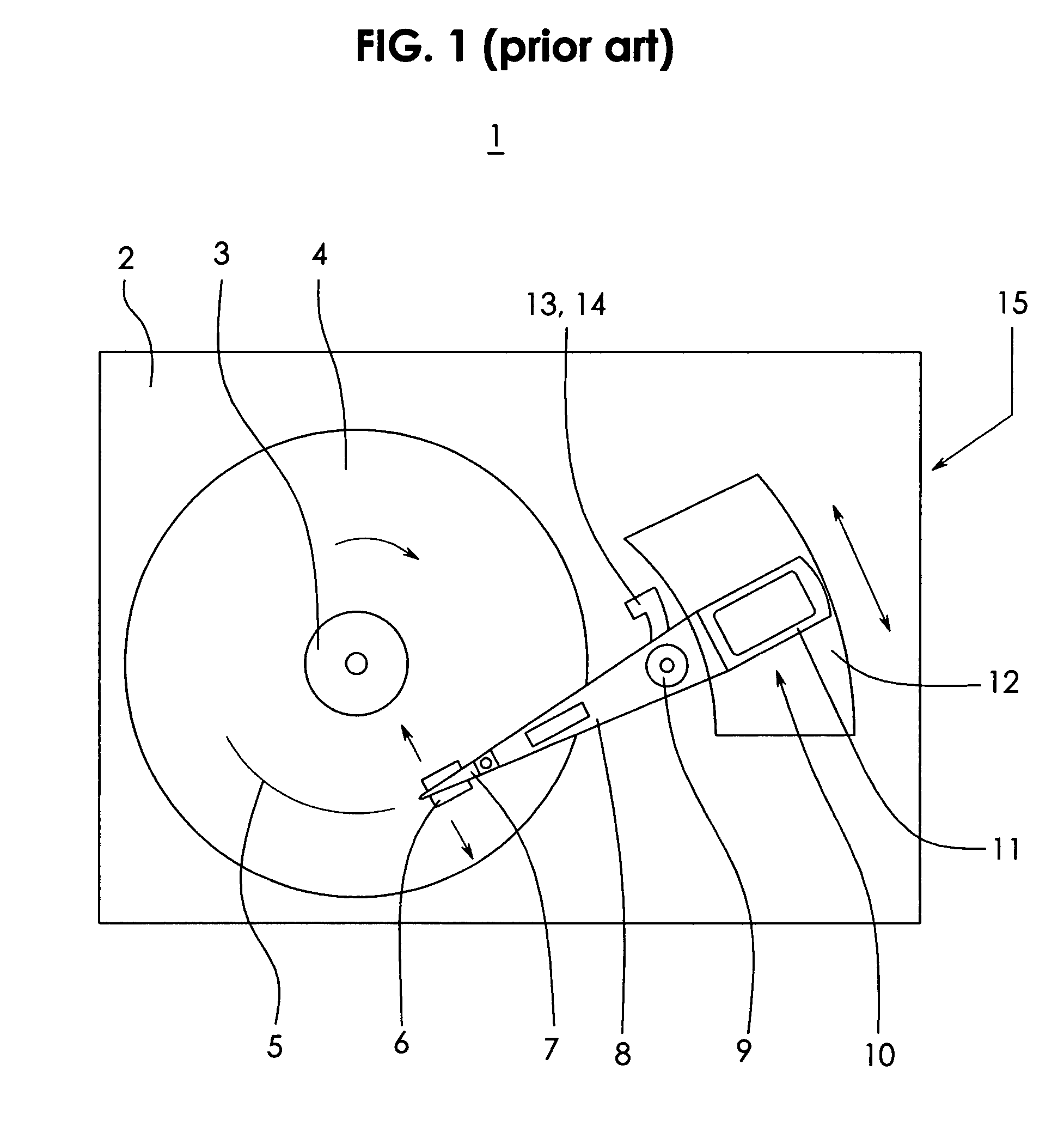

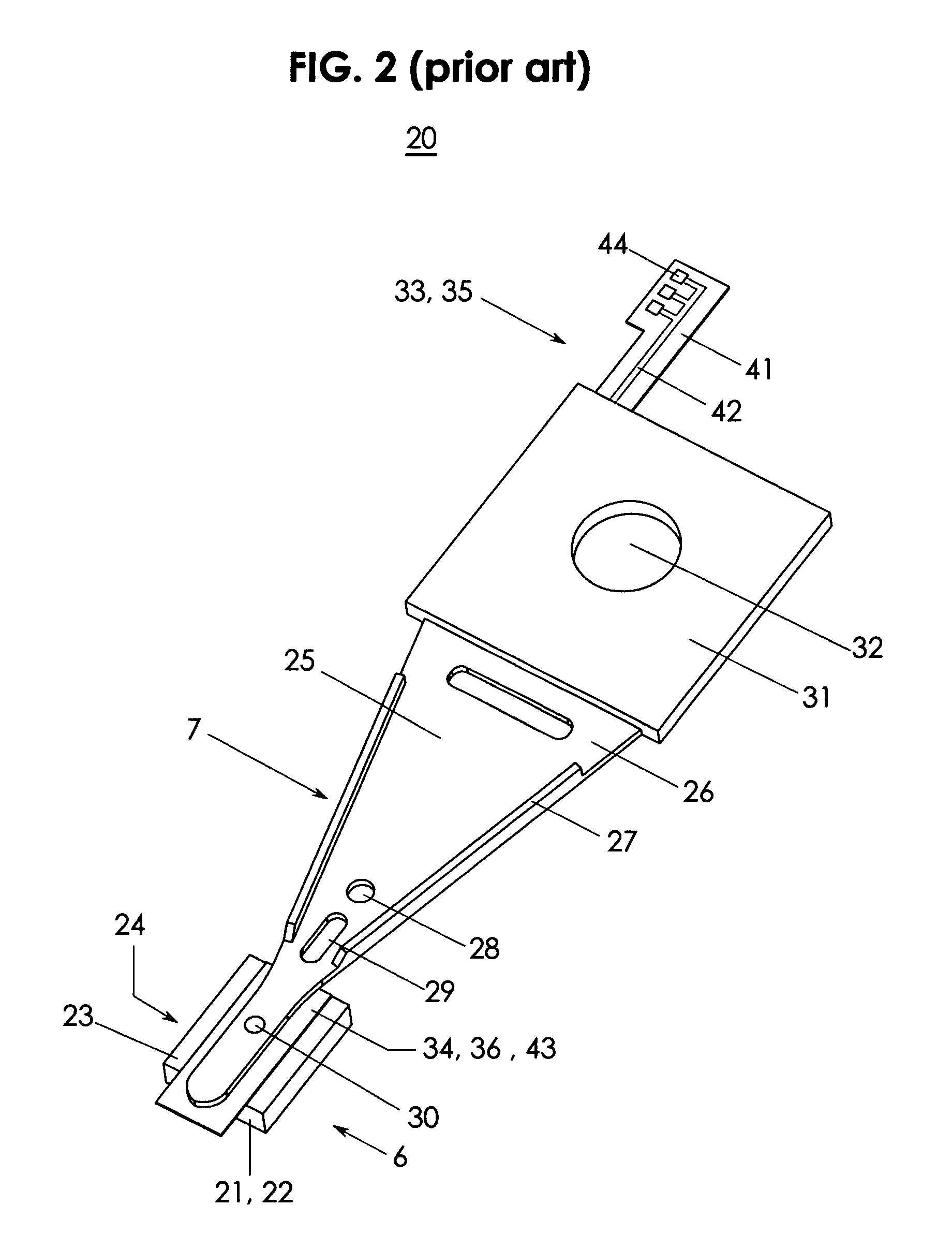

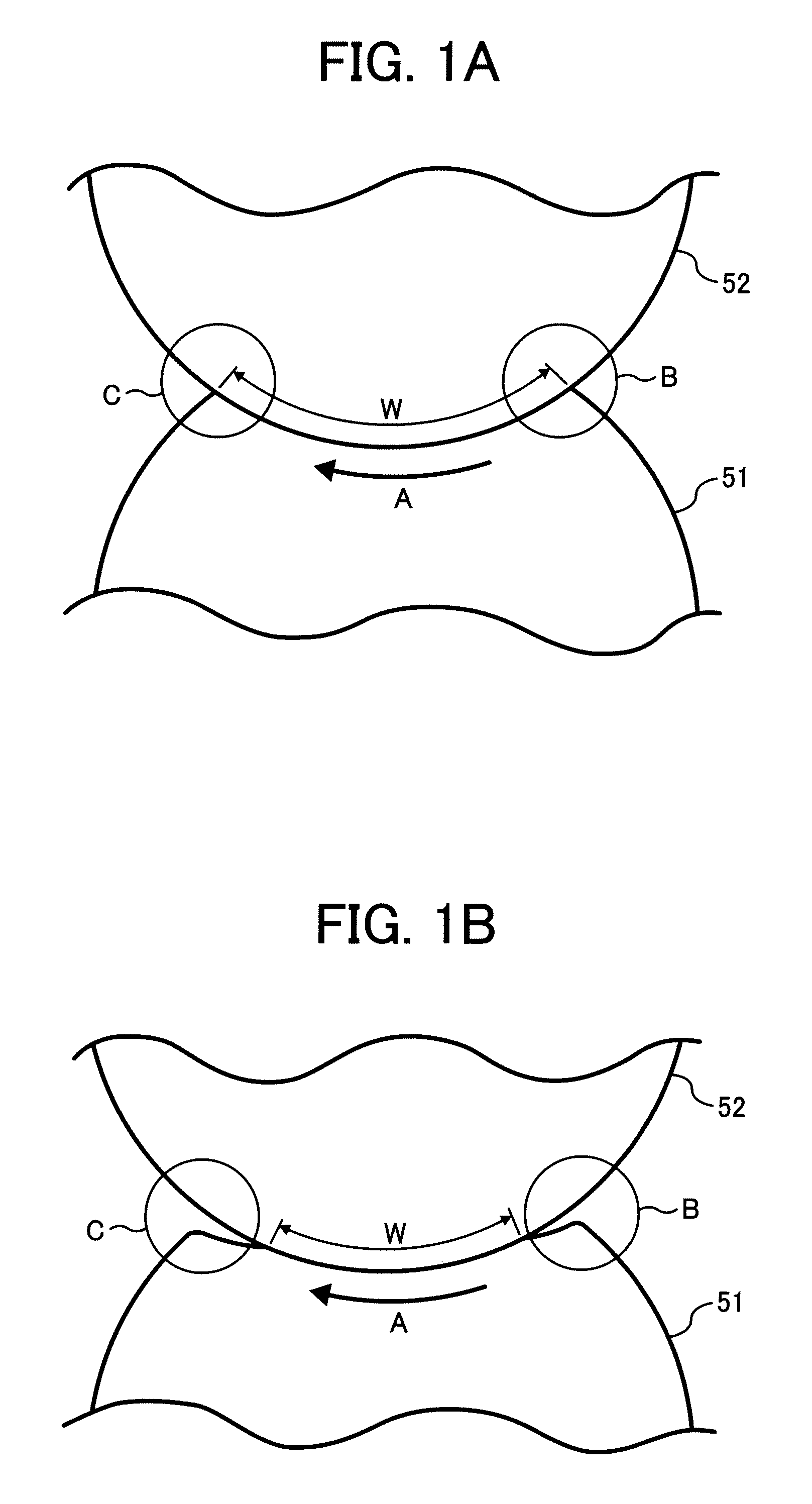

Rotational, shear mode, piezoelectric motor integrated into a collocated, rotational, shear mode, piezoelectric micro-actuated suspension, head or head/gimbal assembly for improved tracking in disk drives and disk drive equipment

ActiveUS8125741B2High track densityImprove data storage capacityDriving/moving recording headsArm with actuatorsShock resistanceControl theory

A rotational, shear mode, piezoelectric motor is integrated with a suspension, head or head gimbal assembly (HGA) into a collocated, rotational, shear mode, piezoelectric micro-actuated suspension, head or head gimbal assembly (HGA) for use in disk drives and disk drive manufacturing equipment. When excited by a control voltage, the collocated, shear mode, piezoelectric micro-actuated HGA rotates the head enabling high frequency, high resolution track positioning of the read / write element. The motor is integrated with the head and flexure (collocation). The head rotates about a rotation axis that is ideally located at the center of mass of the head. A shear mode piezoelectric motor rotates the head. A collocated, rotational, shear mode, piezoelectric micro-actuated HGA has high stiffness, high frequency response, high positioning resolution, low mass and low internal vibration for improved tracking, increased track density and greater disk drive storage capacity. Furthermore, its solid integration improves shock resistance and reduces micro-contamination.

Owner:MAGNECOMP +1

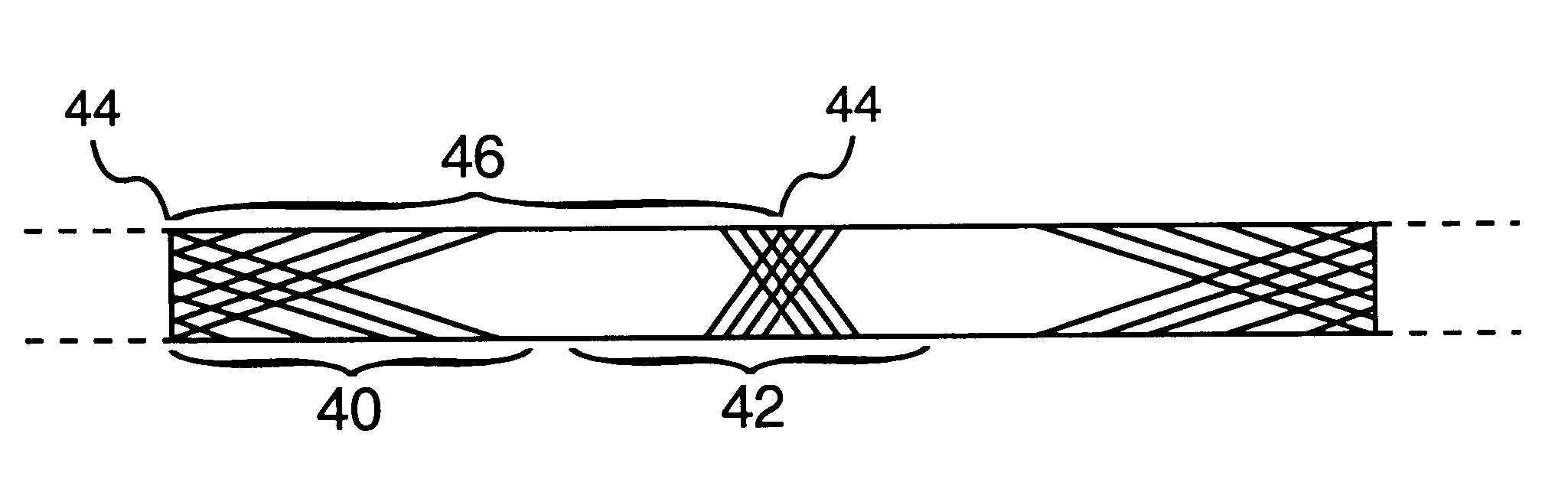

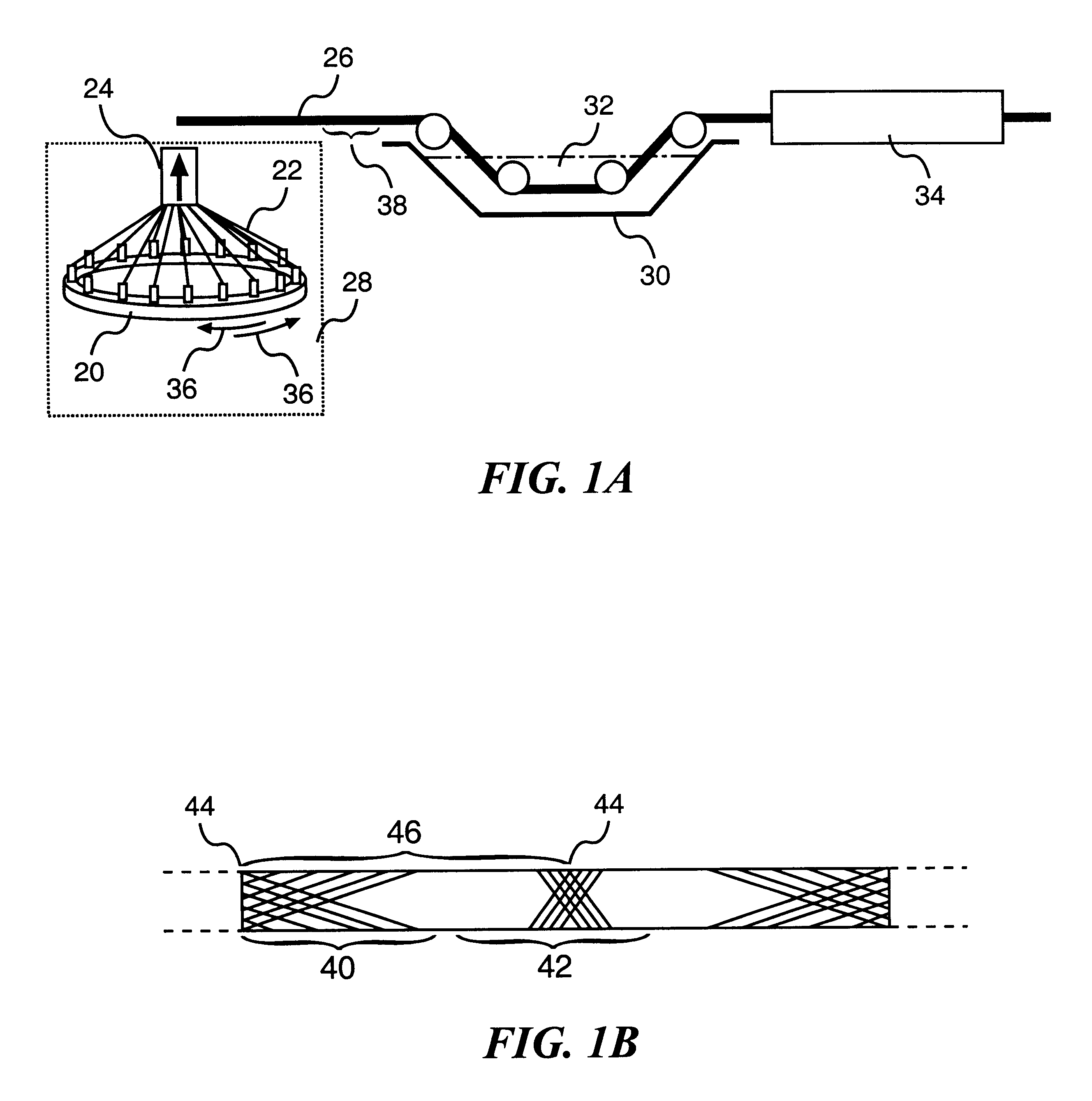

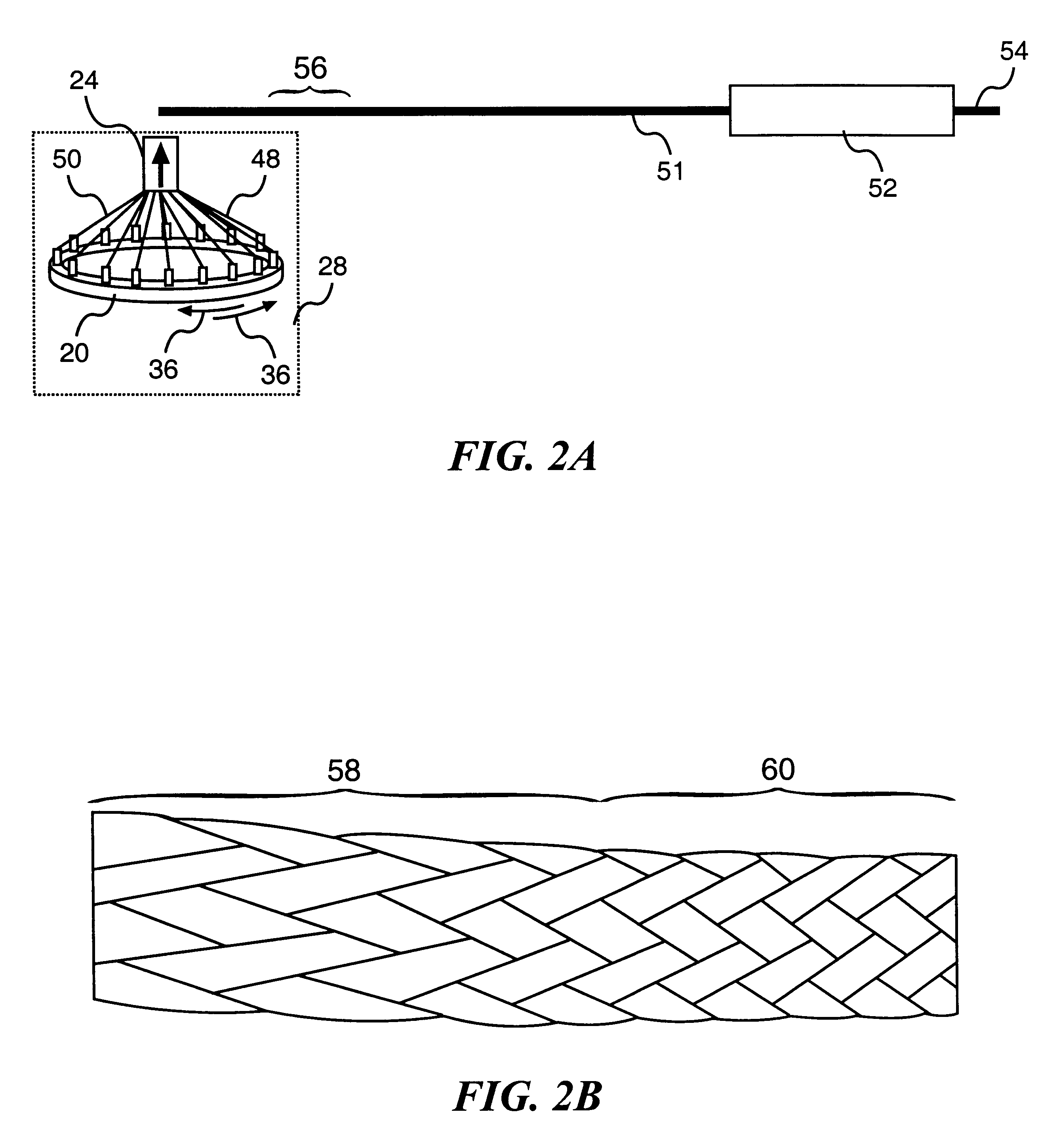

Fiber-reinforced composite product with graded stiffness

A fiber-reinforced composite material with graded stiffness, and method of making the same. The degree of stiffness variation may be controlled via modifications to the fabrication processes. Products with varying stiffness along their lengths are described. In one example, a dental post is fabricated from material according to the present invention which has one end with low stiffness adapted for insertion into the root of the tooth, and a high stiffness end suitable to support the restoration.

Owner:AGENCY FOR SCI TECH & RES

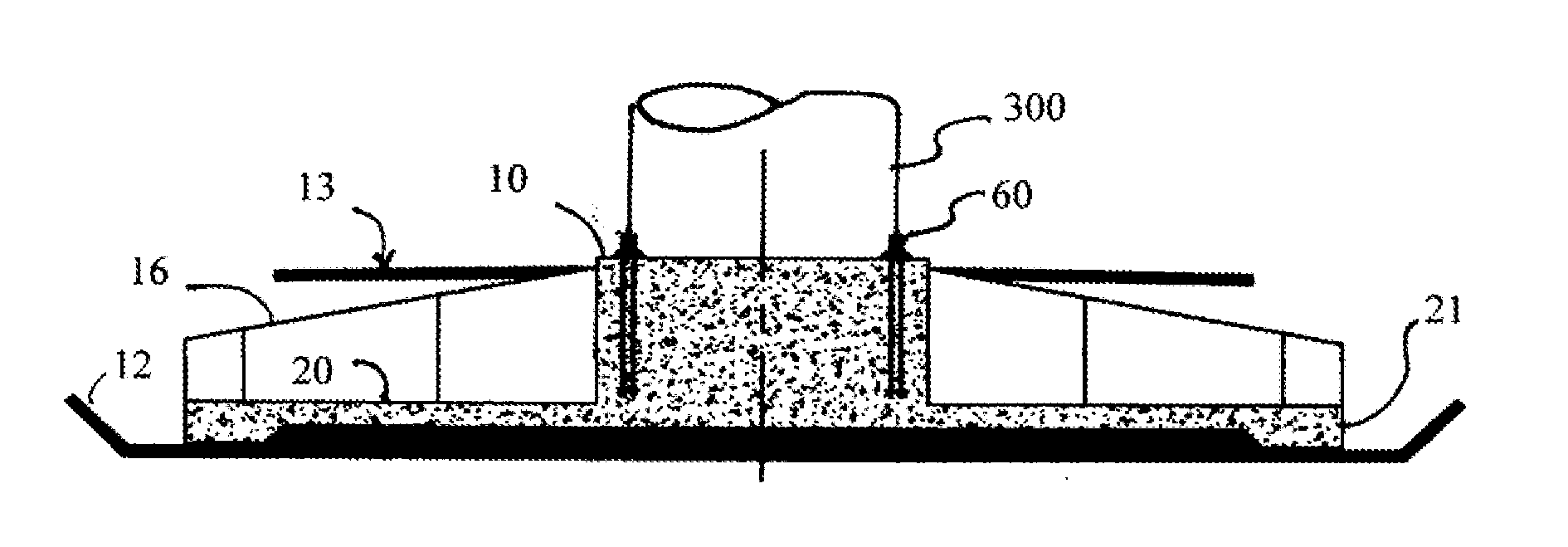

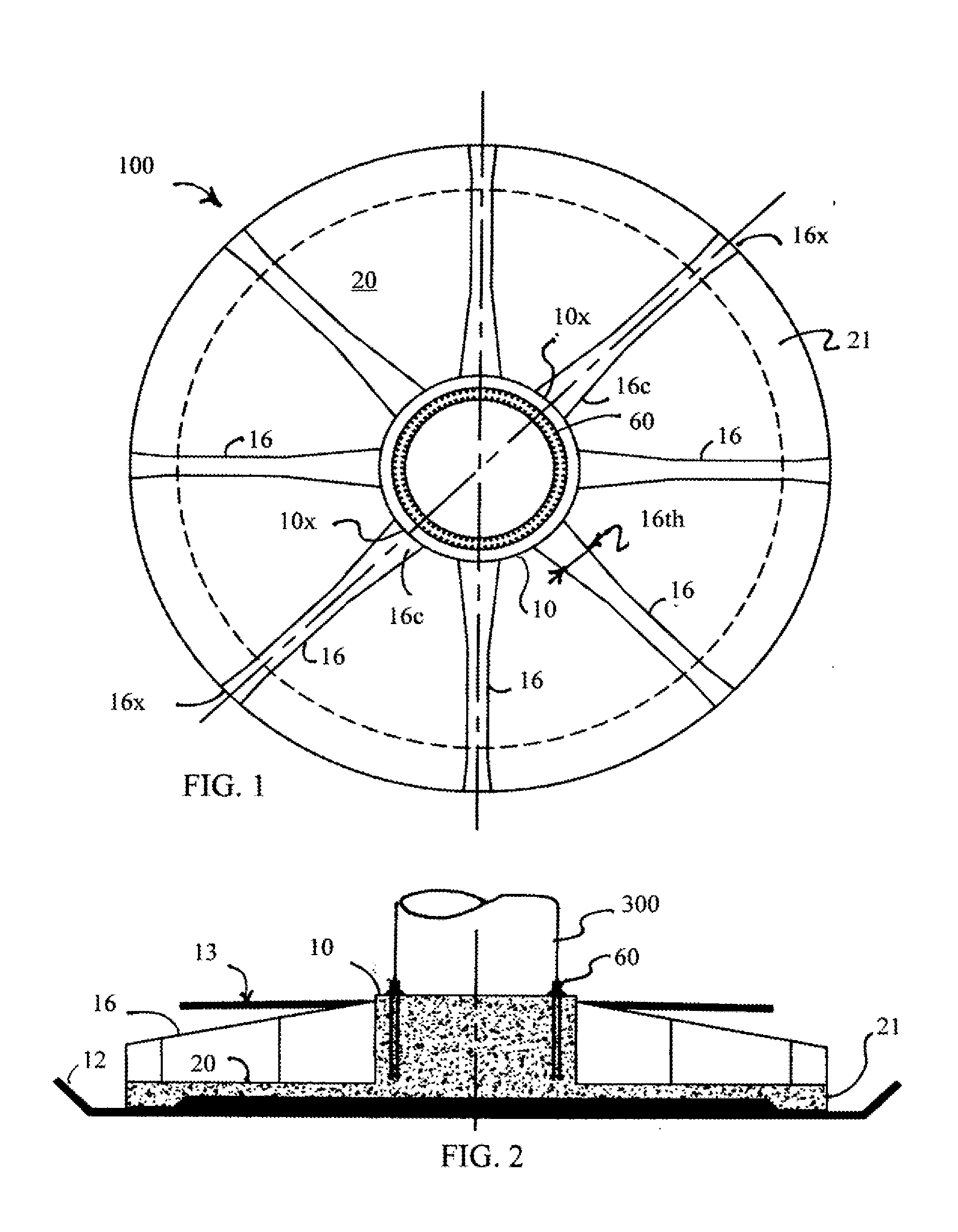

Fatigue resistant foundation

ActiveUS20120047830A1Reduce the amount requiredCost-effectiveArtificial islandsWind motor supports/mountsHigh stiffnessTower

A fatigue resistant gravity based spread footing under heavy multi-axial cyclical loading of a wind tower. The foundation having a central vertical pedestal, a substantially horizontal continuous bottom support slab with a stiffened perimeter, a plurality of radial reinforcing ribs extending radially outward from the pedestal. The pedestal, ribs and slab forming a continuous monolithic structure. The foundation having a three-dimensional network of post-tensioning elements that keep the structural elements under heavy multi-axial post compression with a specific eccentricity intended to reduce stress amplitudes and deflections and allows the foundation to have a desirable combination of high stiffness and superior fatigue resistance. The foundation design reduces the weight and volume of materials used, reduces cost, and improves heat dissipation conditions during construction by having a small ratio of concrete mass to surface area thus eliminating the risk of thermal cracking due to heat of hydration.

Owner:PHULY AHMED

Biaxially oriented polypropylene film

InactiveUS20040053064A1Low heat shrinkageGood dimensional stabilityFixed capacitor dielectricSynthetic resin layered productsFiberHigh stiffness

A biaxially stretched polypropylene film of the present invention has high stiffness in the film longitudinal direction and can be manufactured by a conventional longitudinal-transverse sequential biaxial stretching method, since the biaxially stretched polypropylene film comprises a polypropylene which comprises a polypropylene having controlled specific values of a melt strength (MS) and a melt flow rate (MFR) at 230° C. or consists of a polypropylene having controlled specific values of a melt strength (MS) and a melt flow rate (MFR) at 230° C. and / or a Trouton ratio of the polypropylene is controlled at a specific value, moreover, the biaxially stretched polypropylene film contains regulated longitudinal fibrils.

Owner:TORAY IND INC

Foundation with slab, pedestal and ribs for columns and towers

ActiveUS9096985B1Reduce the amount requiredCost-effectiveArtificial islandsEngine manufactureHigh stiffnessTower

A fatigue resistant gravity based spread footing under heavy multi-axial cyclical loading of a wind tower. The foundation having a central vertical pedestal, a substantially horizontal continuous bottom support slab with a stiffened perimeter, a plurality of radial reinforcing ribs extending radially outward from the pedestal. The pedestal, ribs and slab forming a continuous monolithic structure. The foundation having a three-dimensional network of post-tensioning elements that keep the structural elements under heavy multi-axial post compression with a specific eccentricity intended to reduce stress amplitudes and deflections and allows the foundation to have a desirable combination of high stiffness and superior fatigue resistance. The foundation design reduces the weight and volume of materials used, reduces cost, and improves heat dissipation conditions during construction by having a small ratio of concrete mass to surface area thus eliminating the risk of thermal cracking due to heat of hydration.

Owner:PHULY AHMED

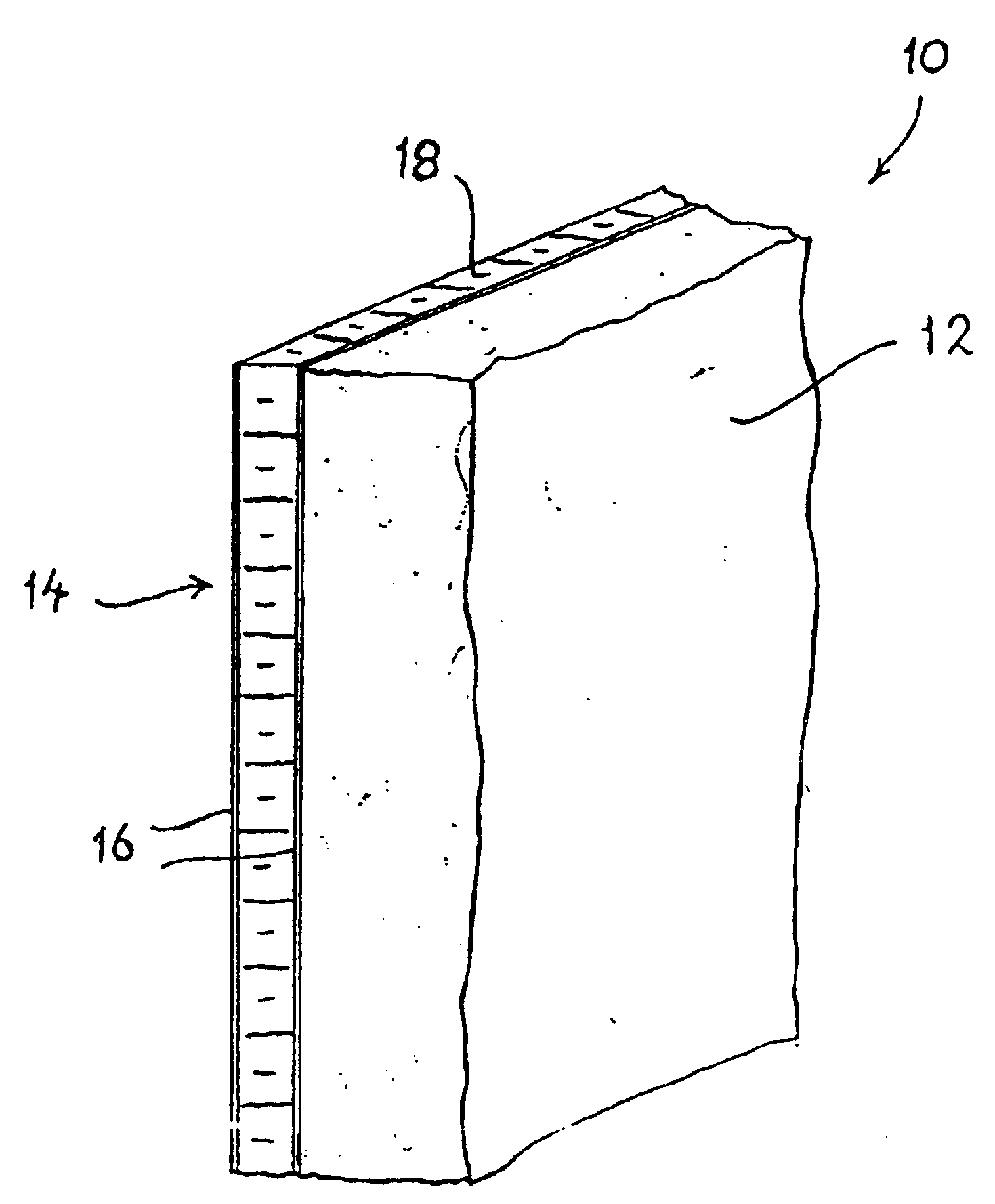

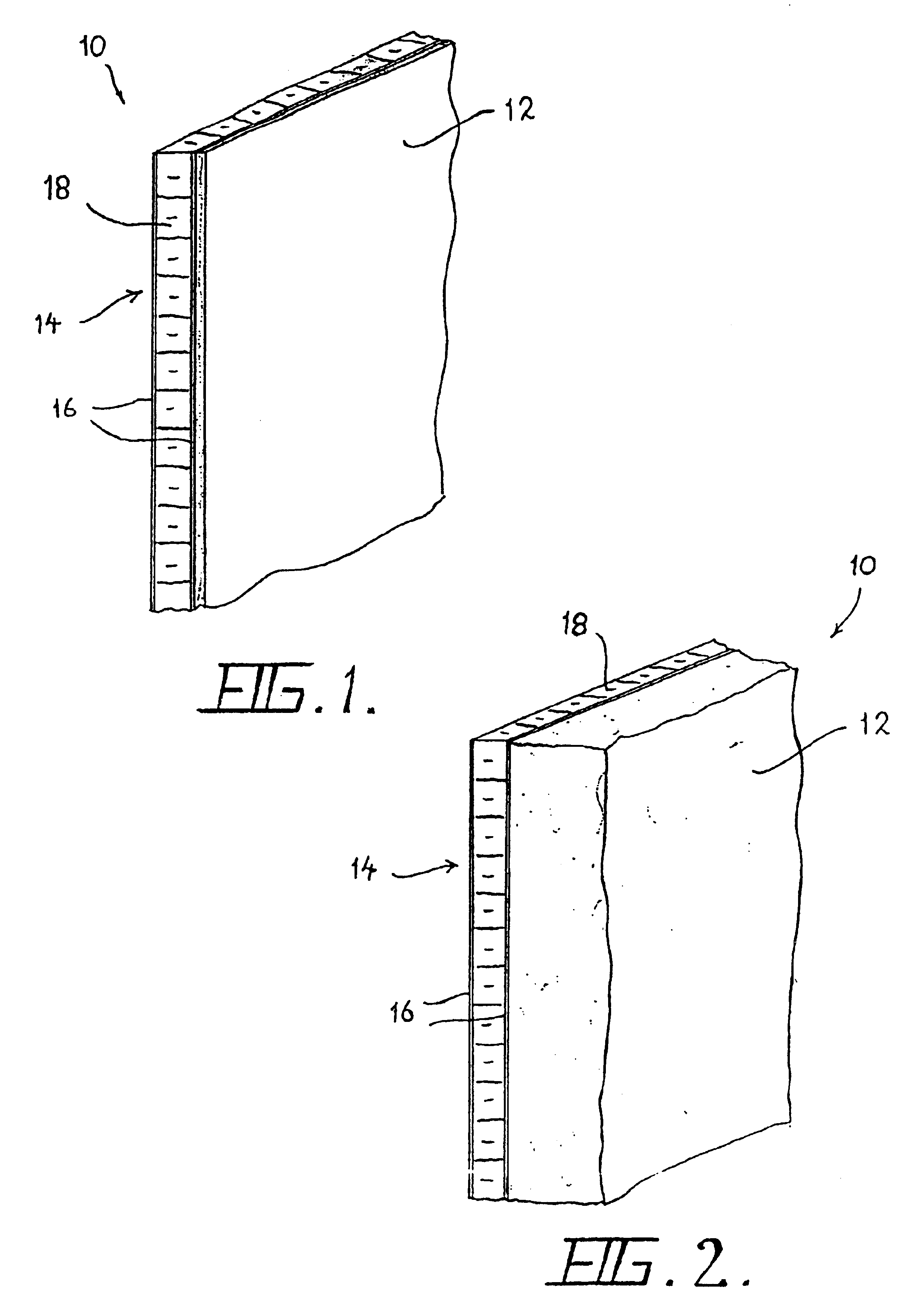

Fire barrier panel

A fire barrier panel of the kind suitable for lining car decks and engine rooms of high speed aluminum ferries is described. The panel (10) includes a relatively thin layer of inorganic insulating material (12) adhered to a lightweight support structure (14). The layer of inorganic insulating material may be an intumescent material made from mineral fibers. The decribed lightweight support structure (14) is a honeycomb panel having a honeycomb core (18) of non-combustible aluminum foil provided with two face skins made of glass reinforced plastics resin material (16). This construction of the honeycomb panel (14) is lightweight and has high stiffness and rigidity suitable for stiffening and supporting the insulating material into a rigid panel. The layer of intumescent material (12) supported on the panel expands when exposed to high temperatures to form a thick fire insulating barrier panel. Because the panels are self-supporting, and therefore support structures, installation costs are much lower than for prior art fire insulation systems.

Owner:ASHMERE HLDG

Fatigue Resistant Foundation

ActiveUS20150376859A1Reduce the amount requiredCost-effectiveWind motor supports/mountsCeramic shaping apparatusHigh stiffnessTower

A fatigue resistant gravity based spread footing under heavy multi-axial cyclical loading of a wind tower. The foundation having a central vertical pedestal, a substantially horizontal continuous bottom support slab, a plurality of radial reinforcing ribs extending radially outward from the pedestal. The pedestal, ribs and slab forming a continuous monolithic structure. The foundation having a three-dimensional network of post-tensioning elements that keep the structural elements under heavy multi-axial post compression with a specific eccentricity intended to reduce stress amplitudes and deflections and allows the foundation to have a desirable combination of high stiffness and superior fatigue resistance. The foundation design reduces the weight and volume of materials used, reduces cost, and improves heat dissipation conditions during construction by having a small ratio of concrete mass to surface area thus eliminating the risk of thermal cracking due to heat of hydration.

Owner:PHULY AHMED

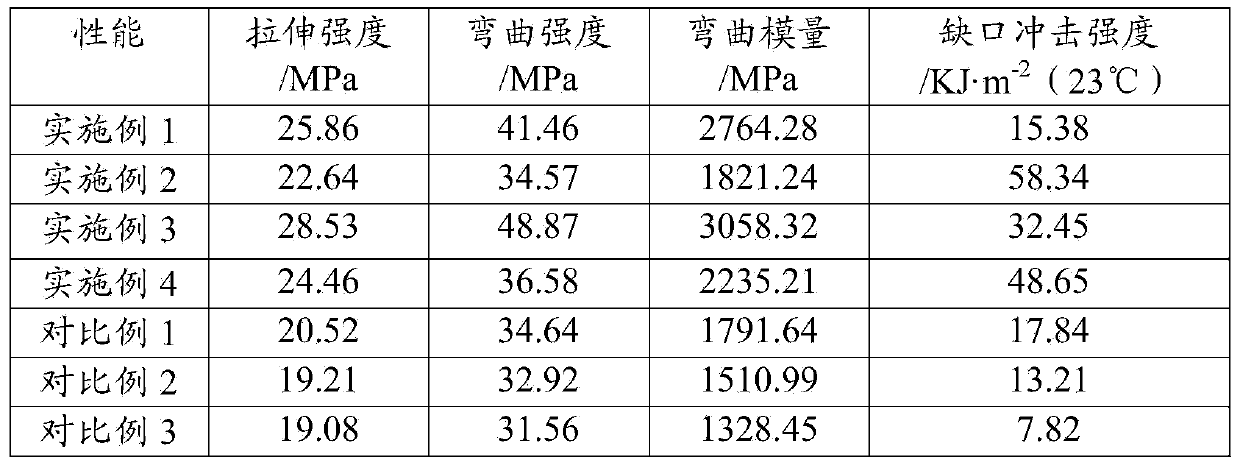

Polypropylene composition and preparation method thereof

The invention provides a polypropylene composition. The polypropylene composition consists of the following components in parts by mass: 10-90 parts of first polypropylene, 3-20 parts of a flexibilizer and 10-80 parts of nano filler master batch, so that the nano-scale polypropylene composition with excellent dispersion and high stiffness-toughness balance is obtained. The invention further provides a preparation method for the polypropylene composition. According to the preparation method provided by the embodiment of the invention, the nano filler is treated by virtue of a modifier, so that the surface polarity of the nano filler is changed into lipophilicity from hydrophily, the compatibility between the nano filler and polypropylene is improved, excellent dispersion of a nano material in polypropylene is realized by virtue of a phase interface transfer process, and thus, the comprehensive performances of the nano polypropylene composition are improved.

Owner:惠州市沃特新材料有限公司

Flame resistant semicaromatic polyamide resin composition and articles therefrom

Polyamide compositions containing semi-crystalline polyamide, amorphous polyamide, non-halogenated flame retardant, zinc borate and fillers that have a high stiffness and hardness, a low warpage, and external appearance, such as gloss and reduced corrosion effects on melt processing equipment.

Owner:EI DU PONT DE NEMOURS & CO

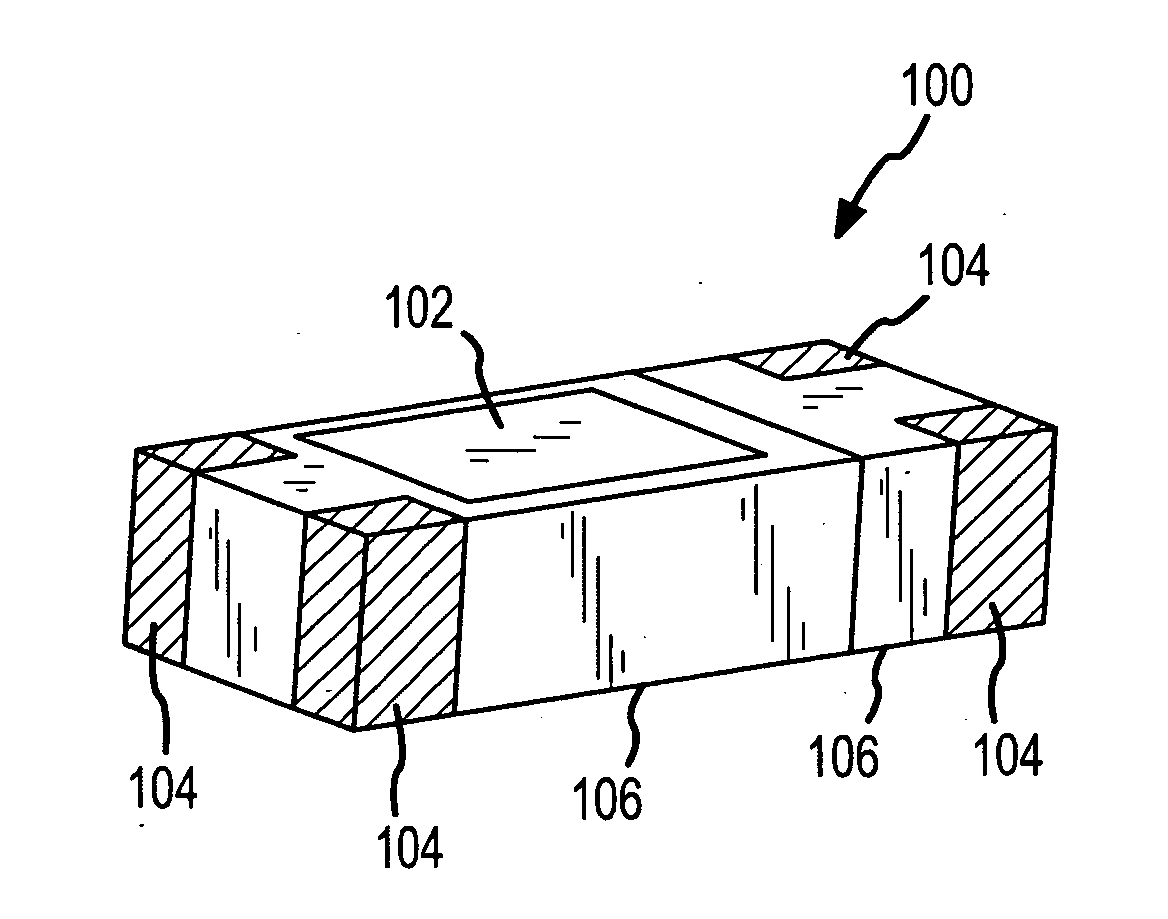

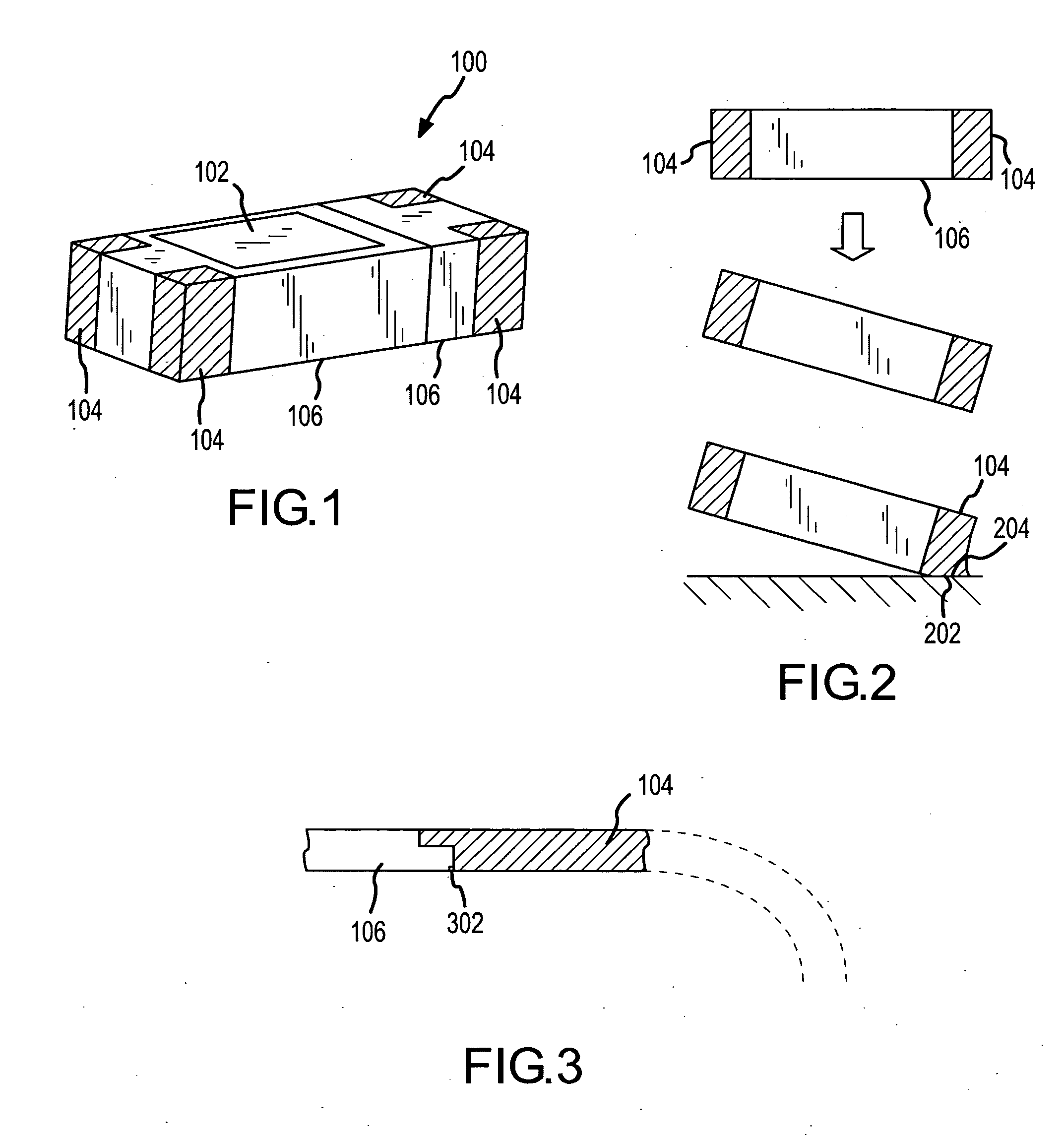

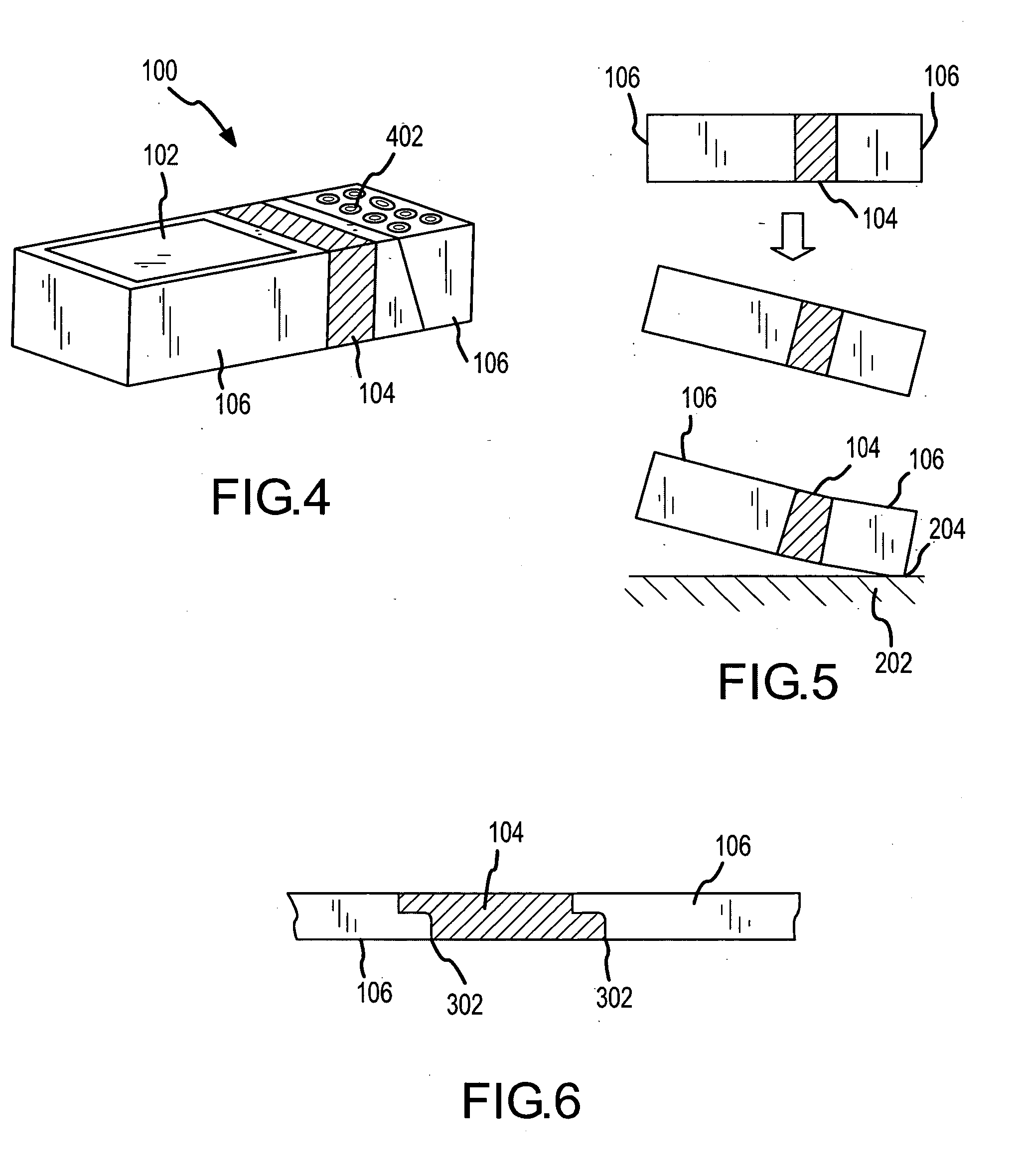

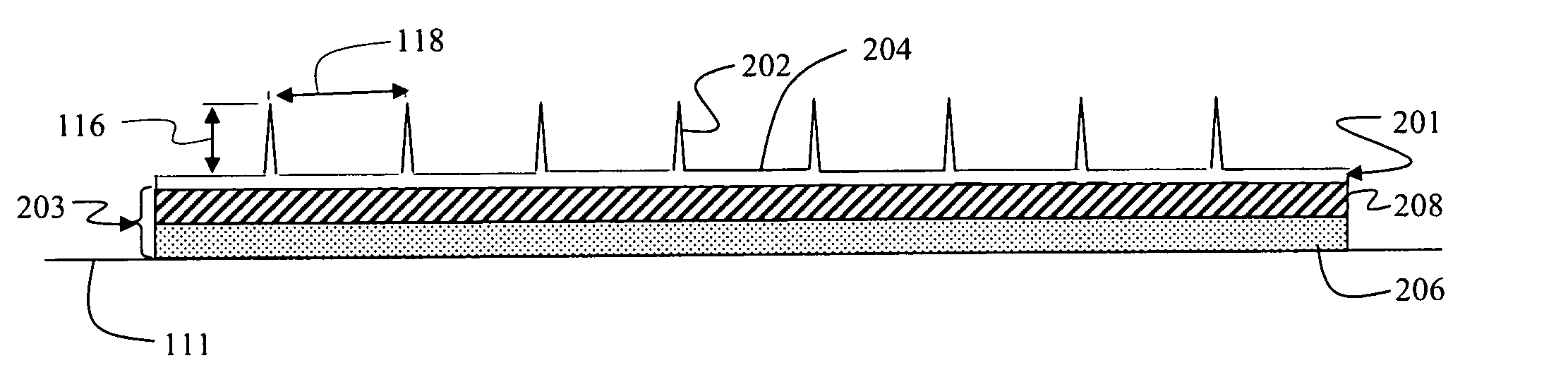

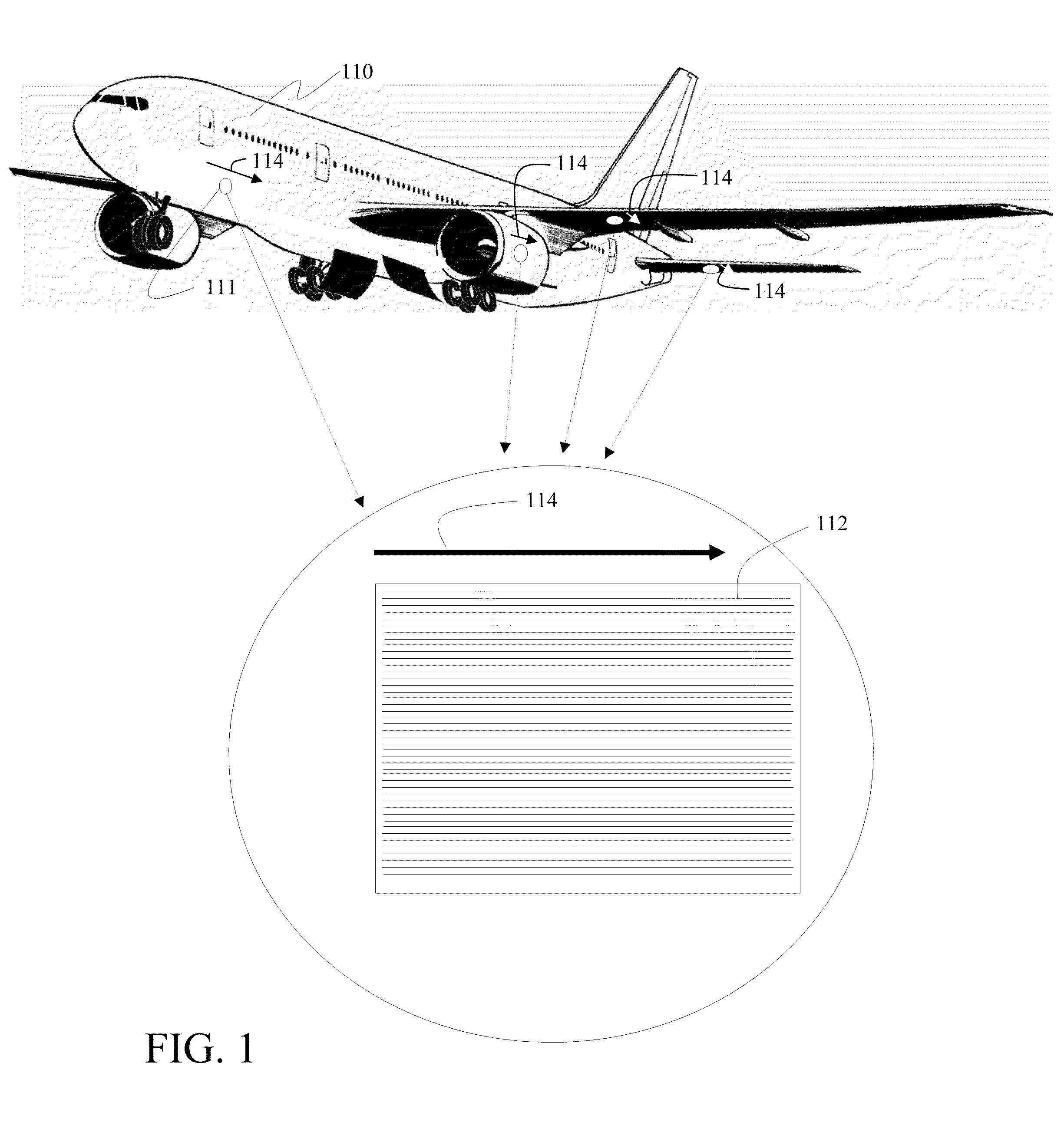

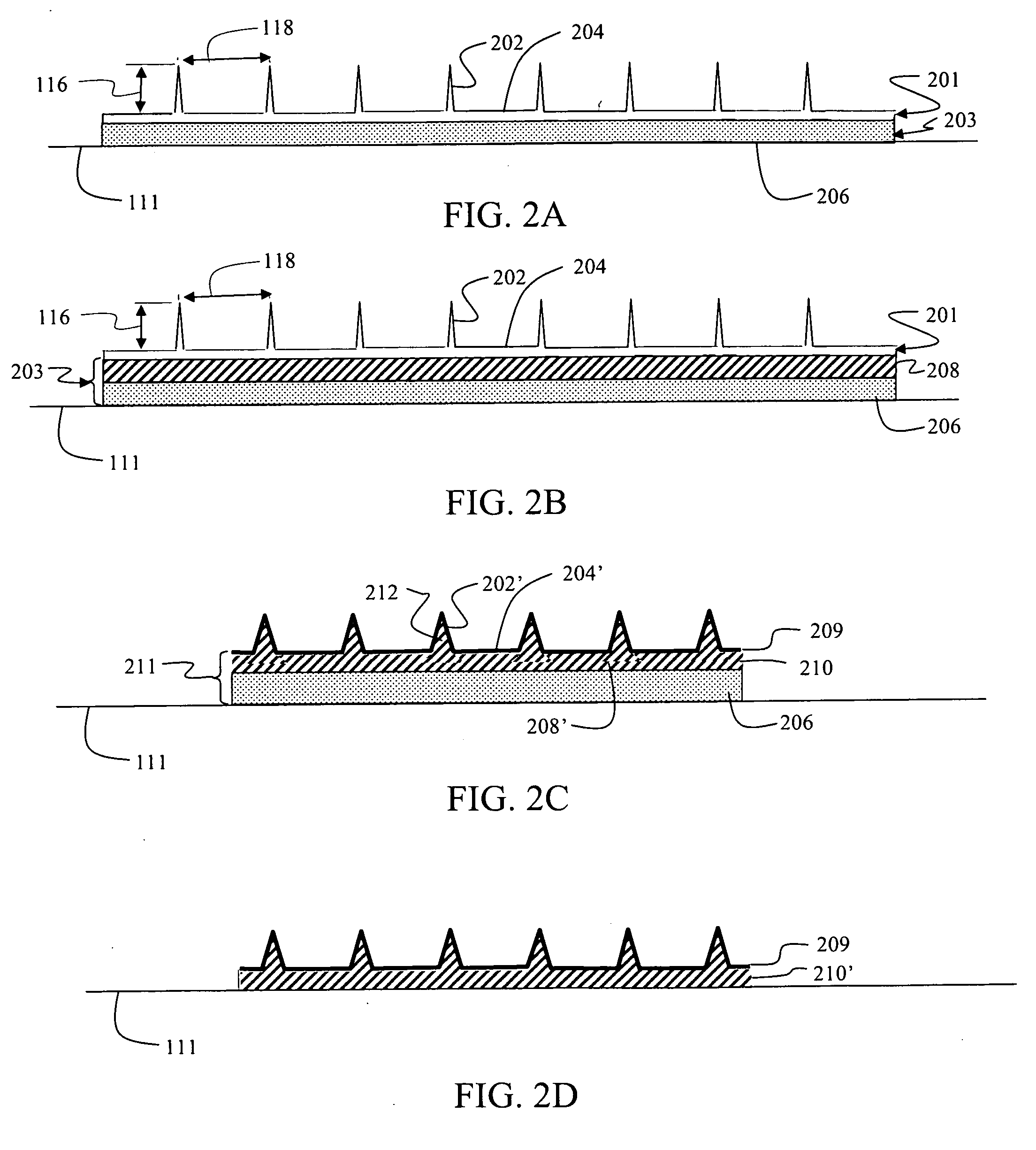

Amorphous metal riblets

ActiveUS20100187361A1Increase stiffnessLong-term durabilityFluid dynamicsRecord information storageHigh stiffnessMechanical engineering

An array of aerodynamic riblets is created by a plurality of high stiffness tips with a layer supporting the tips in predetermined spaced relation and adhering the tips to a vehicle surface.

Owner:THE BOEING CO

Flexible hearing aid tip with an integral receiver

InactiveUS7082206B2Small sizeReduce the amount of powerHearing aids mounting/interconnectionTransverse axisHigh stiffness

A flexible tip for a hearing aid includes a mushroom shaped tip, an inner portion having a bore and a receiver mounted within the bore. The receiver can be housing and sealed within a receiver housing. The receiver housing can include a spring having a high compliance along a longitudinal axis and transverse axis, to provide flexibility in the flexible tip. The spring can also having a high stiffness along a radial direction about the circumference of the spring to provide support of the flexible tip from radially directed loads.

Owner:HIMPP

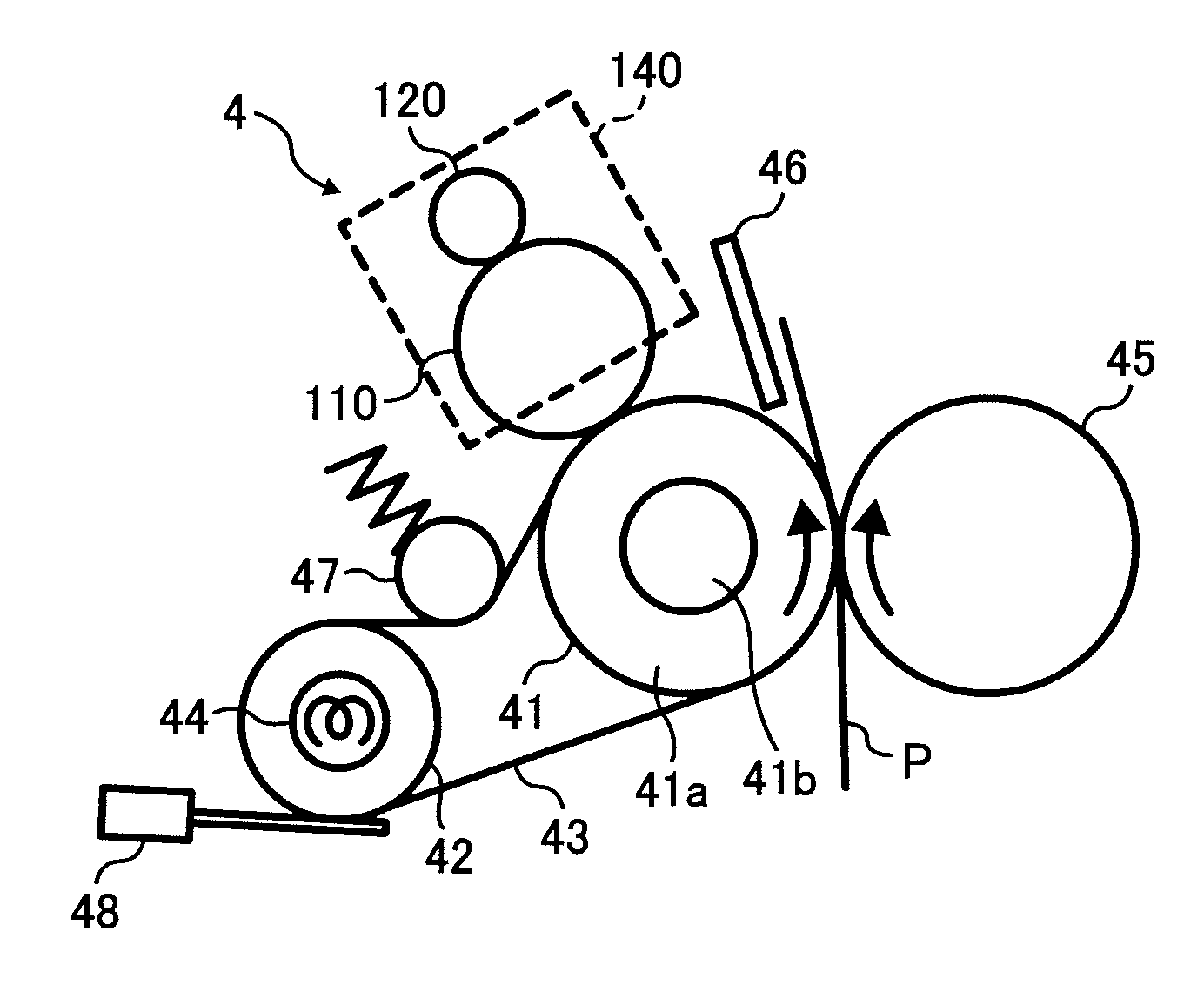

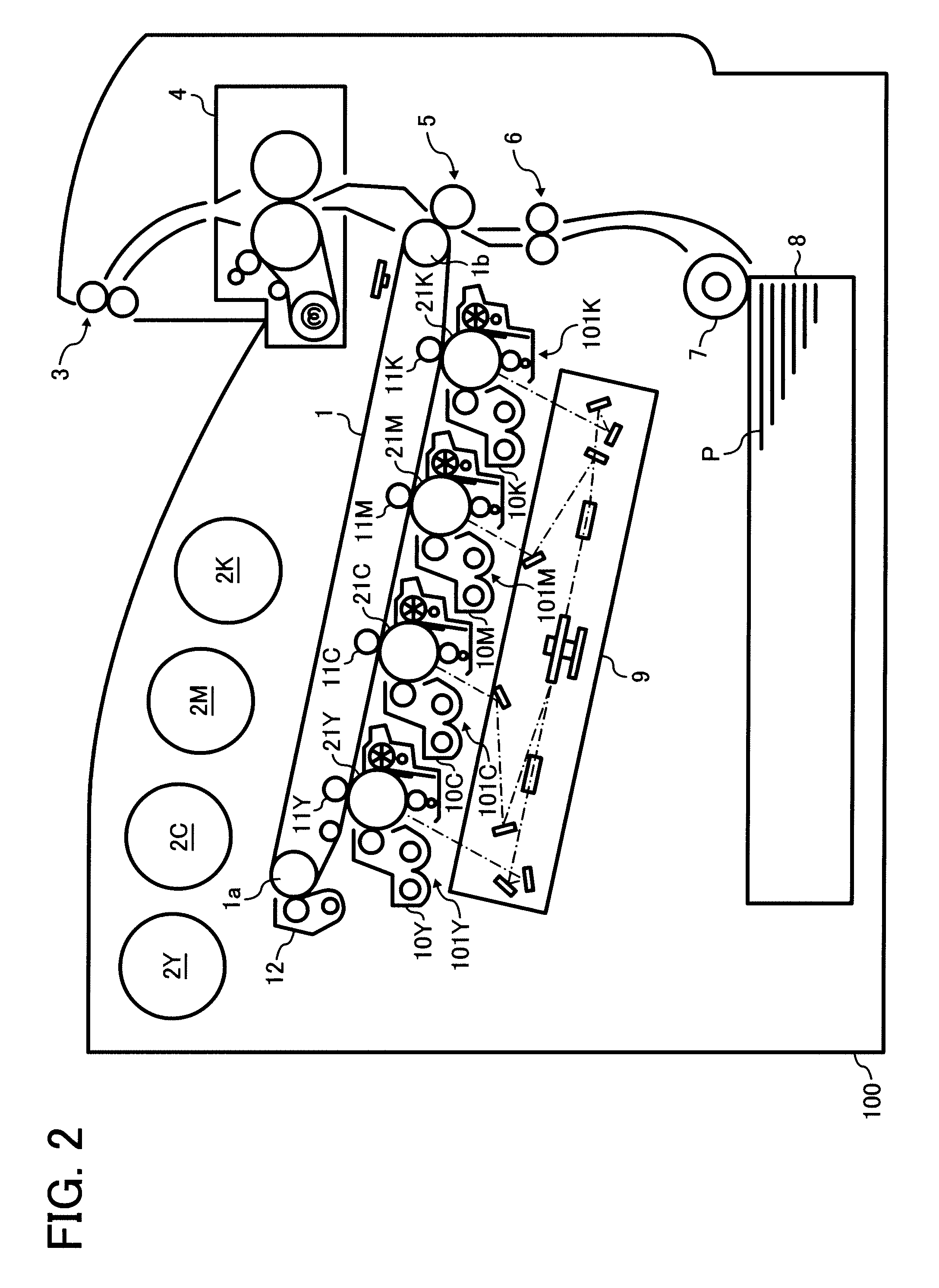

Image forming apparatus including a fixing apparatus capable of effectively maintaining fixability for an extended period of use

InactiveUS20070166085A1Reduce widthOhmic-resistance heatingElectrographic process apparatusHigh stiffnessImage formation

An image forming apparatus includes a toner image forming mechanism that forms a toner image on a recording medium and a fixing mechanism that fixes the toner image on the recording medium. The fixing mechanism includes a fixing apparatus. The fixing apparatus includes: an elastic roller having a stiffness greater than or equal to 28 Hs and less than or equal to 34 Hs on an Asker C scale and including a sponge-like elastic layer having a density greater than or equal to 0.38 g / cm3; a high-stiffness roller having a stiffness greater than the stiffness of the elastic roller and forms a fixing nip between the elastic roller and the high-stiffness roller; and a heating mechanism that heats the fixing nip.

Owner:RICOH KK

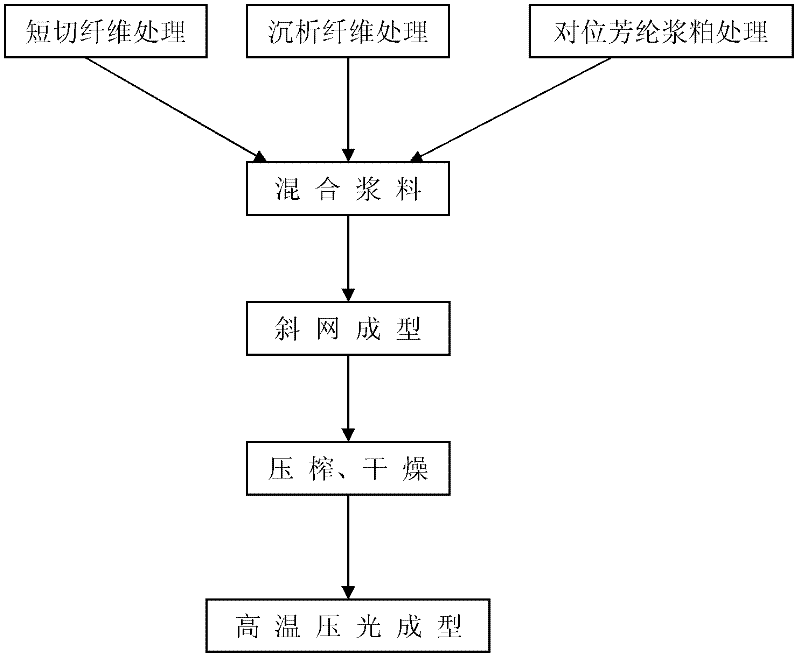

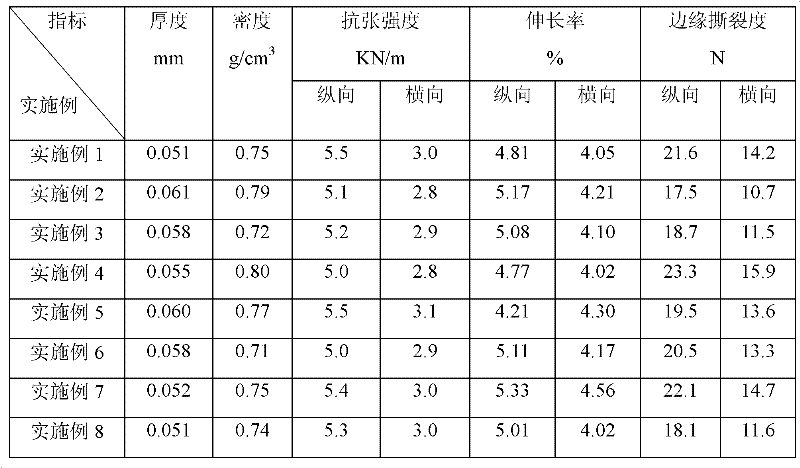

Preparation method of pure p-aramid paper

InactiveCN102517976AImprove interface affinityHigh tensile strengthSynthetic cellulose/non-cellulose material pulp/paperHigh stiffnessHigh density

The invention relates to a preparation method of pure p-aramid paper. The preparation method of the pure p-aramid paper comprises the following steps of 1, respectively preparing p-aramid chopped fiber pulp, p-aramid fibrid pulp and p-aramid pulp, and mixing the p-aramid chopped fiber pulp, the p-aramid fibrid pulp and the p-aramid pulp, 2, approaching flows of the mixed pulp onto a net for molding, 3, carrying out squeezing and drying, and 4, carrying out high-temperature press-polish molding. The preparation method of the pure p-aramid paper has the advantages that p-aramid fibrids are utilized as bonding materials of the pure p-aramid paper so that interface affinity of fibers is improved and fiber paper mechanical properties of tensile strength, tearing strength and wear resistance are improved; p-aramid pulp has a high specific surface area so that a hydrogen bond binding capacity of fibers is improved and the pure p-aramid paper having high density, high stiffness and high strength is obtained; and in a preparation process, concentrated sulfuric acid is not needed so that the problems of equipment corrosion and dilute sulphuric acid recovery complexity are solved.

Owner:YANTAI METASTAR SPECIAL PAPER +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com