Patents

Literature

8982results about "Fixed capacitor dielectric" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

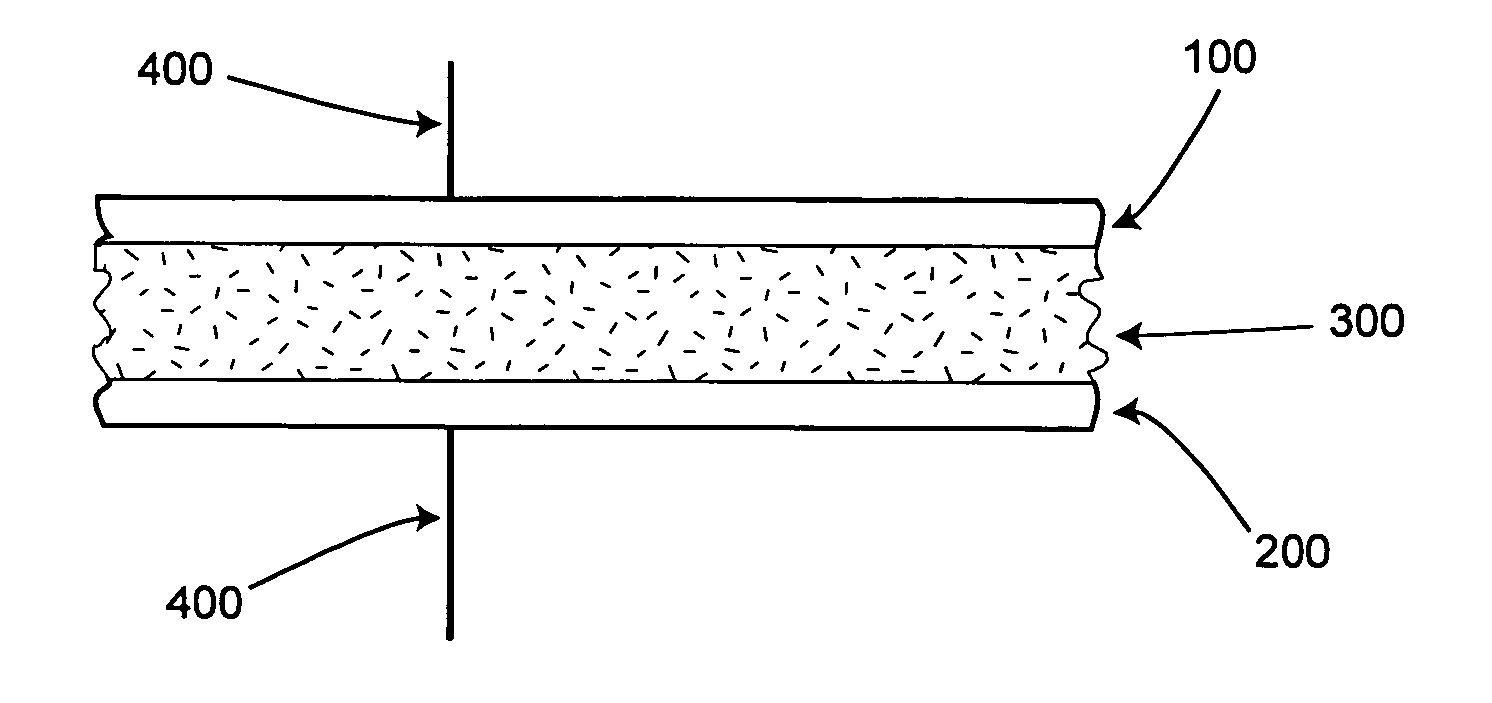

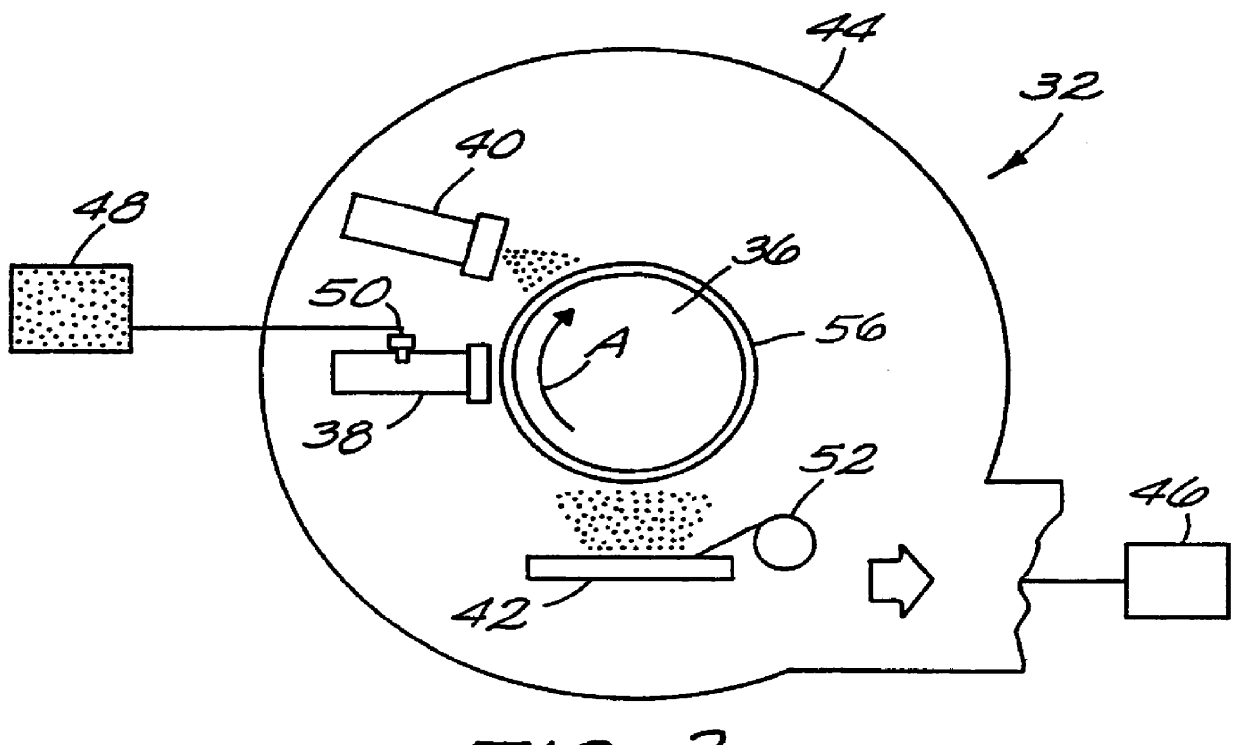

Method of forming a hybrid polymer film

InactiveUS6214422B1Fine surfaceLow costFixed capacitor dielectricSynthetic resin layered productsThermoplasticCross-link

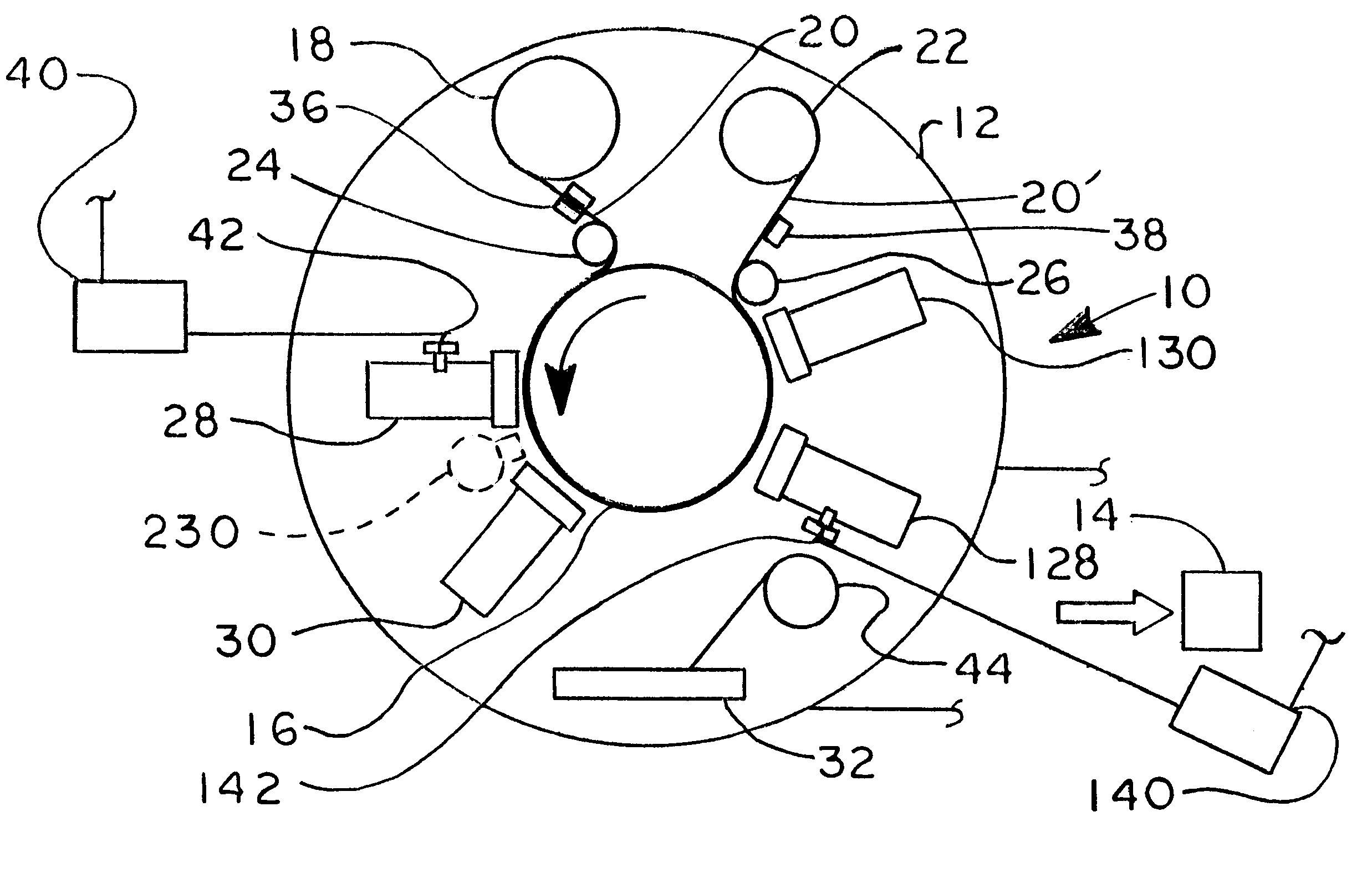

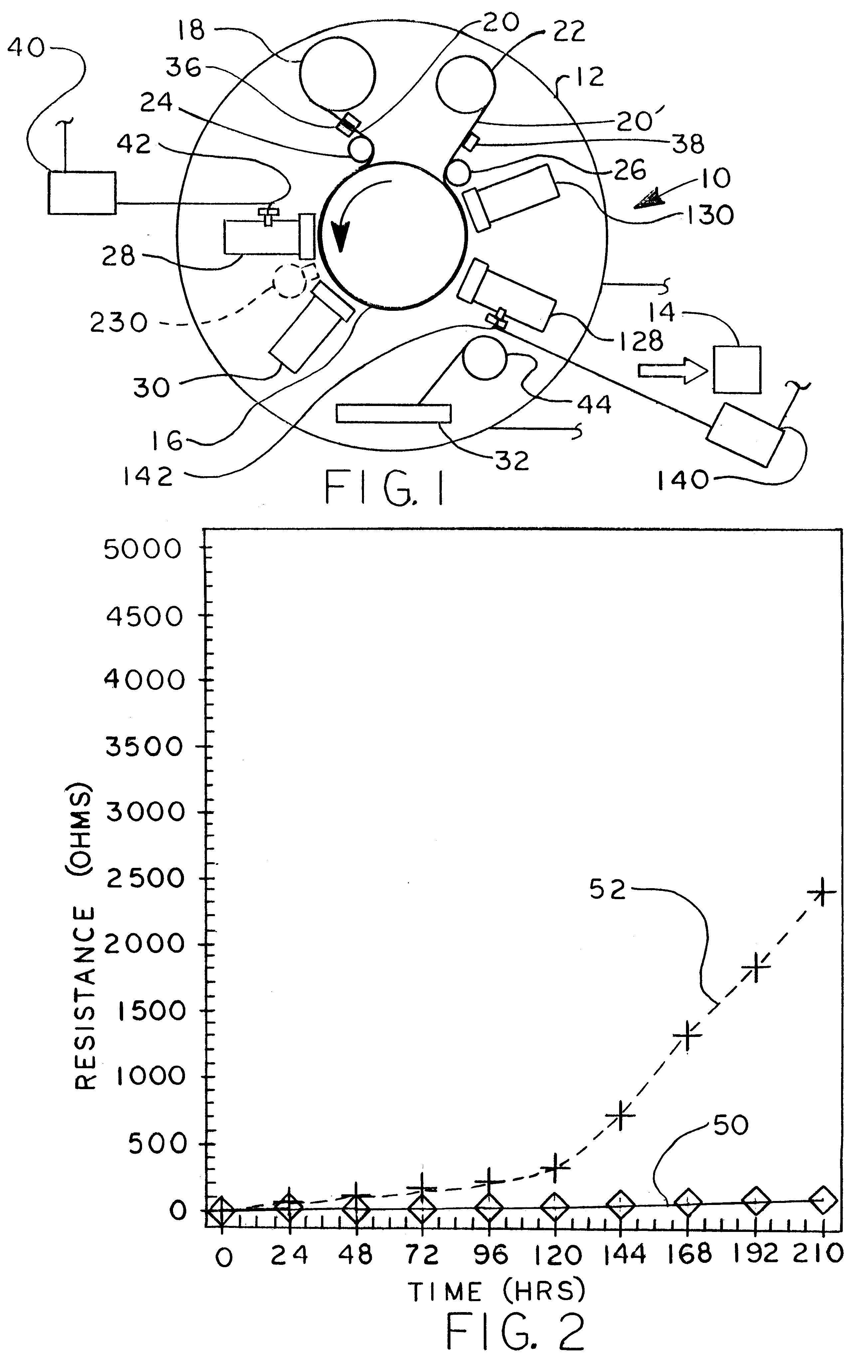

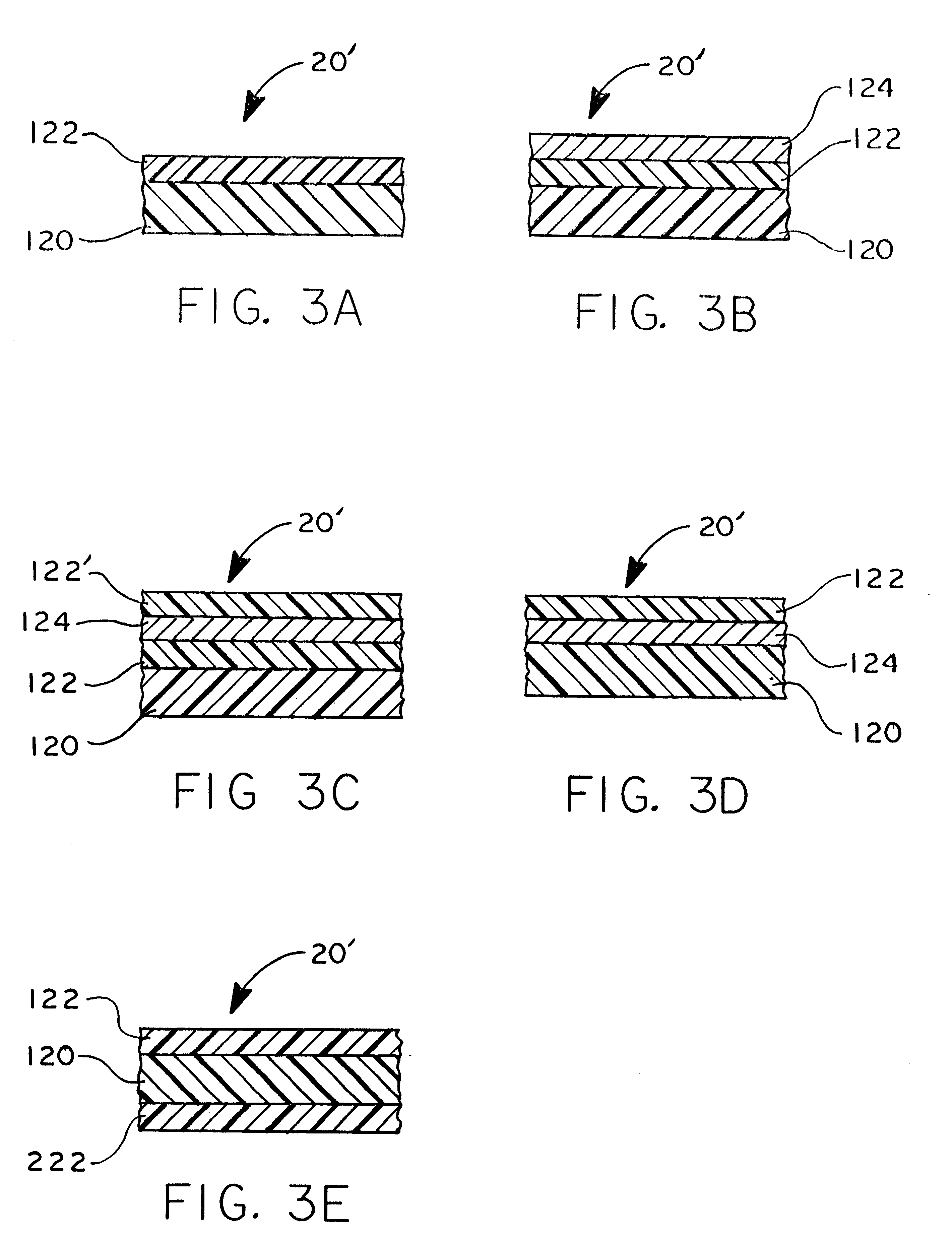

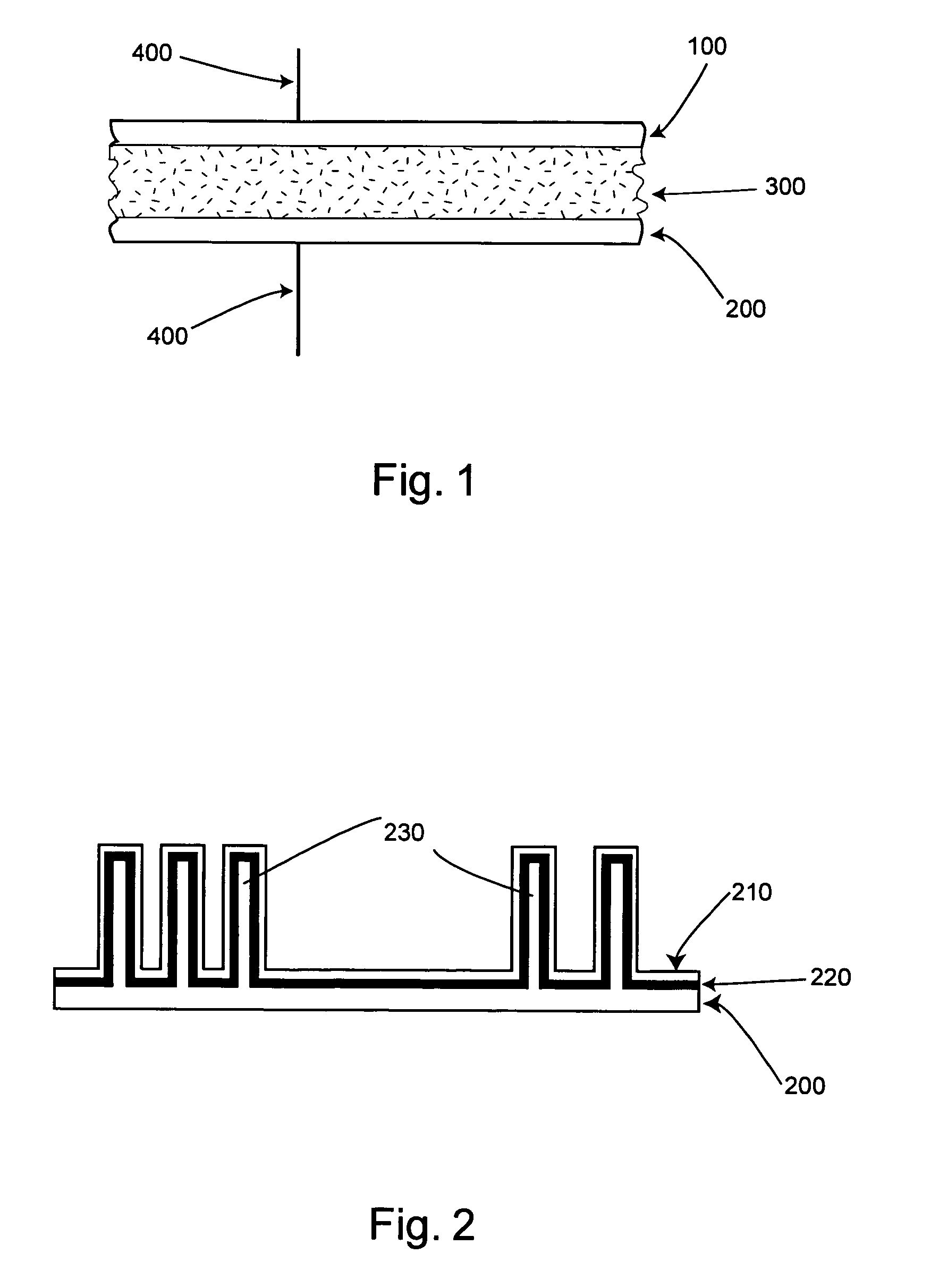

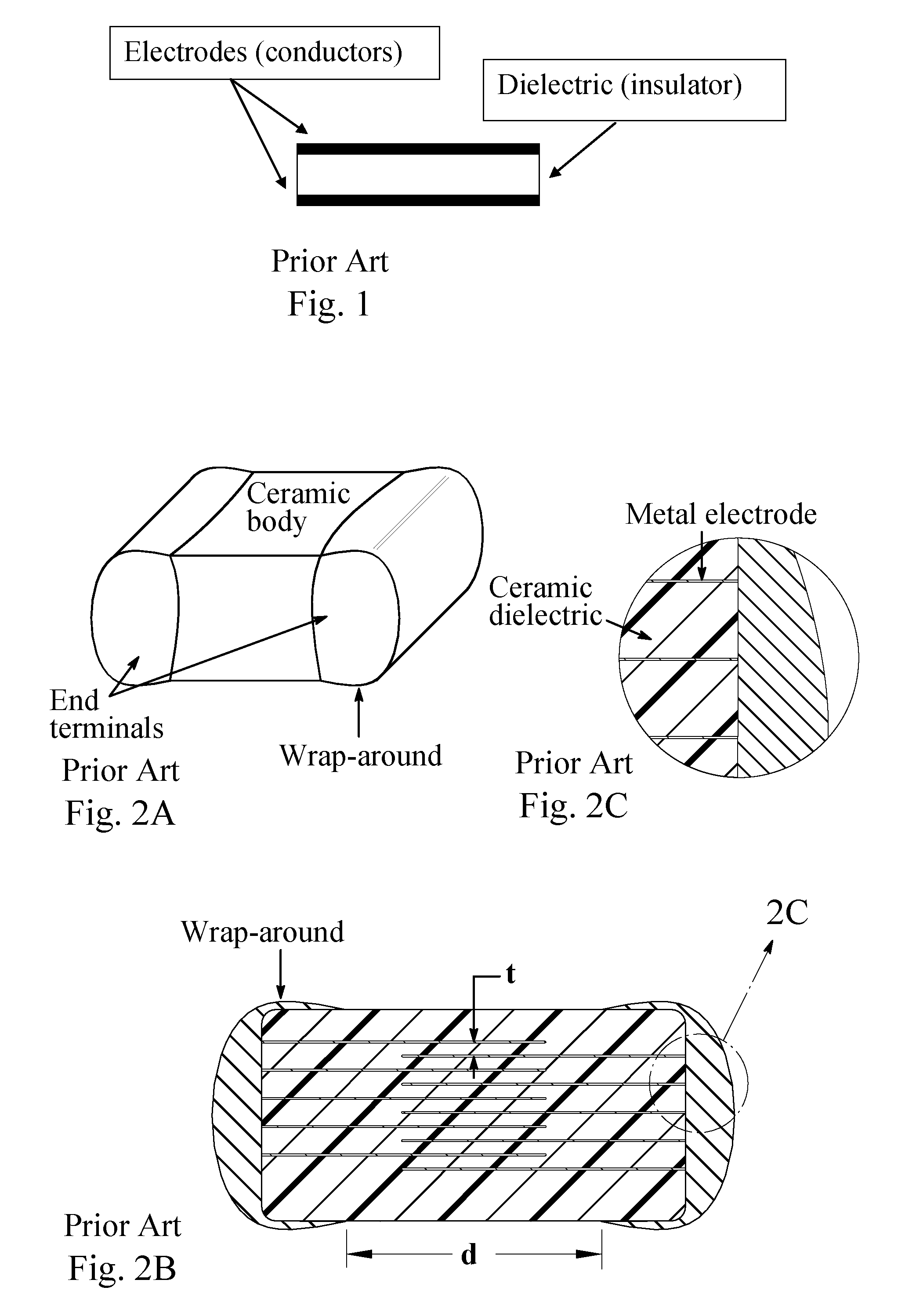

A hybrid film, comprising a first polymer film having a plasma-treated surface and a second polymer film having first and second surfaces, with the first surface of the second polymer film being disposed along the first plasma-treated surface of the first polymer film, has superior thermal and mechanical properties that improve performance in a number of applications, including food packaging, thin film metallized and foil capacitors, metal evaporated magnetic tapes, flexible electrical cables, and decorative and optically variable films. One or more metal layers may be deposited on either the plasma-treated surface of the substrate and / or the radiation-cured acrylate polymer A ceramic layer may be deposited on the radiation-cured acrylate polymer to provide an oxygen and moisture barrier film. The hybrid film is produced using a high speed, vacuum polymer deposition process that is capable of forming thin, uniform, high temperature, cross-liked acrylate polymers on specific thermoplastic or thermoset films. Radiation curing is employed to cross-link the acrylate monomer. The hybrid film can be produced in-line with the metallization or ceramic coating process, in the same vacuum chamber and with minimal additional cost.

Owner:SIGMA LAB OF ARIZONA

Graphitic nanofibers in electrochemical capacitors

Graphitic nanofibers, which include tubular fullerenes (commonly called "buckytubes"), nanotubes and fibrils, which are functionalized by chemical substitution, are used as electrodes in electrochemical capacitors. The graphitic nanofiber based electrode increases the performance of the electrochemical capacitors. Preferred nanofibers have a surface area greater than about 200 m2 / gm and are substantially free of micropores.

Owner:HYPERION CATALYSIS INT

Niobium suboxide powder

ActiveUS20050013765A1High currentReduce residual currentOxide/hydroxide preparationLiquid electrolytic capacitorsCapacitorTungsten

A niobium suboxide powder comprising 100 to 600 ppm of magnesium is described. The niobium suboxide powder may (alternatively or in addition to 100 to 600 ppm of magnesium) further include 50 to 400 ppm of molybdenum and / or tungsten. The niobium suboxide powder is suitable for the production of: capacitors having an insulator layer of niobium pentoxide; capacitor anodes produced from the niobium suboxide powder; and corresponding capacitors.

Owner:TANIOBIS GMBH

Method for manufacturing a polycrystalline dielectric layer

ActiveUS20120170170A1Format be limitIncrease ratingsThin/thick film capacitorFixed capacitor dielectricDielectric layerCapacitor

A method manufactures a capacitor having polycrystalline dielectric layer between two metallic electrodes. The dielectric layer is formed by a polycrystalline growth of a dielectric metallic oxide on one of the metallic electrodes. At least one polycrystalline growth condition of the dielectric oxide is modified during the formation of the polycrystalline dielectric layer, which results in a variation of the polycrystalline properties of the dielectric oxide within the thickness of said layer.

Owner:STMICROELECTRONICS (CROLLES 2) SAS

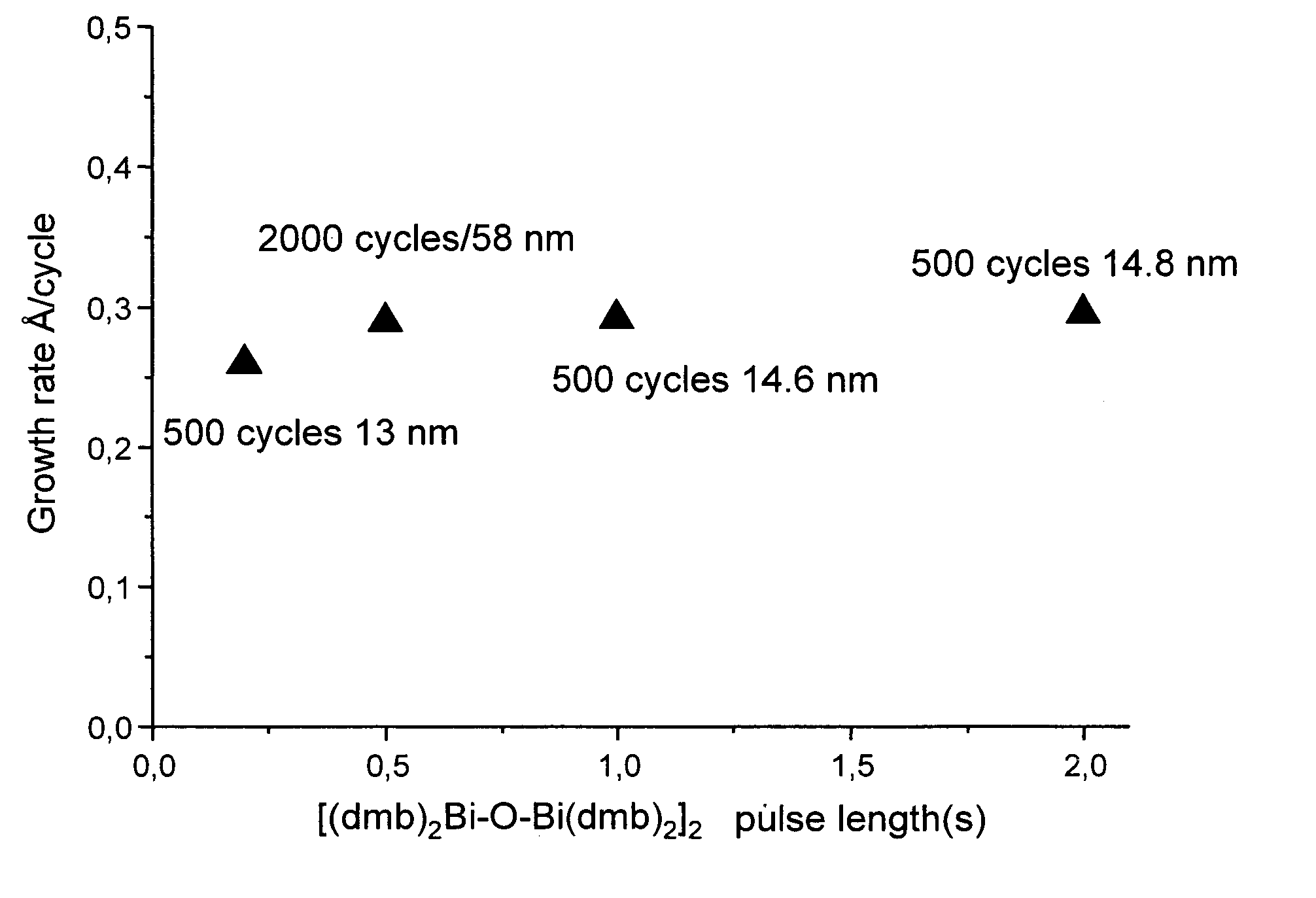

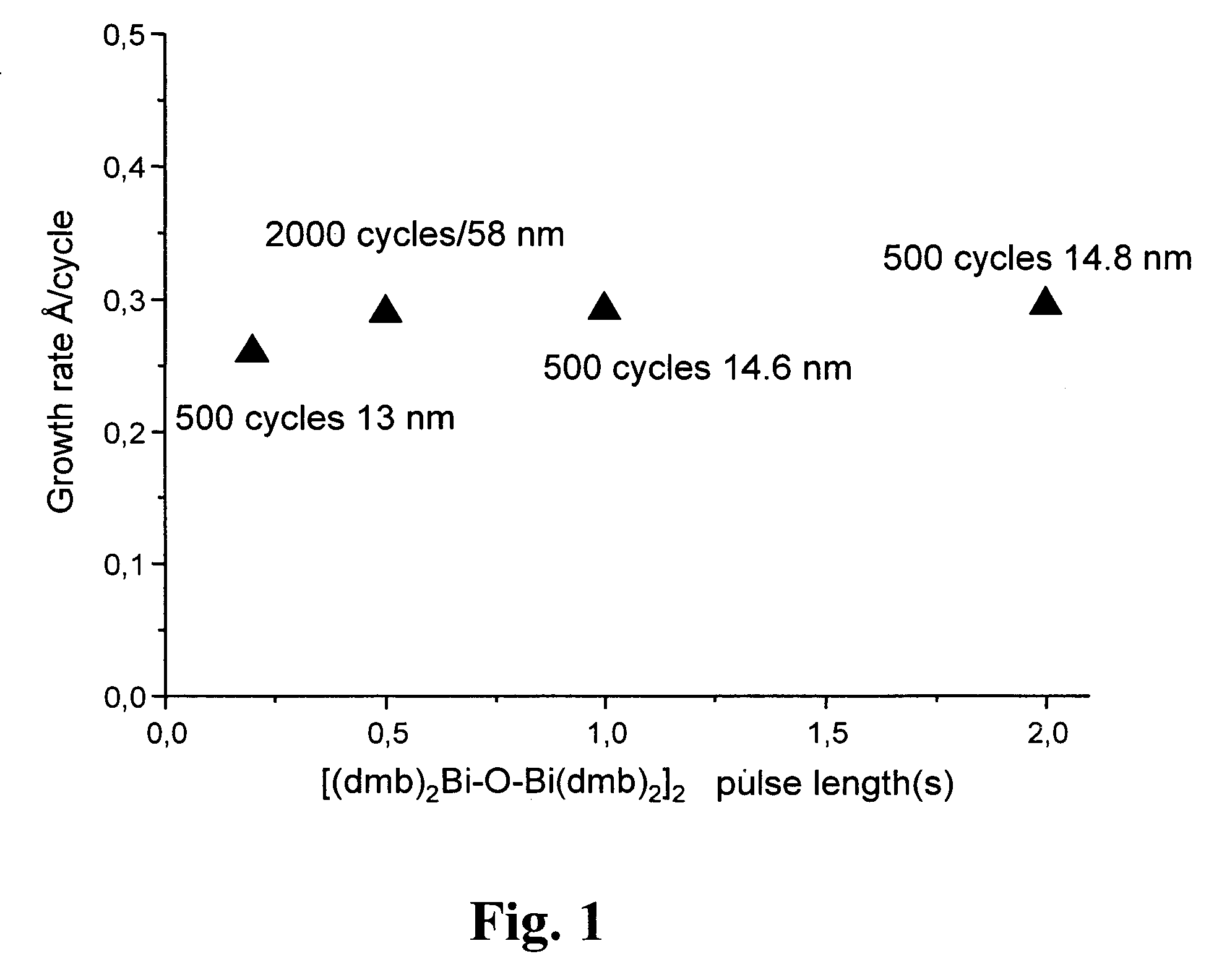

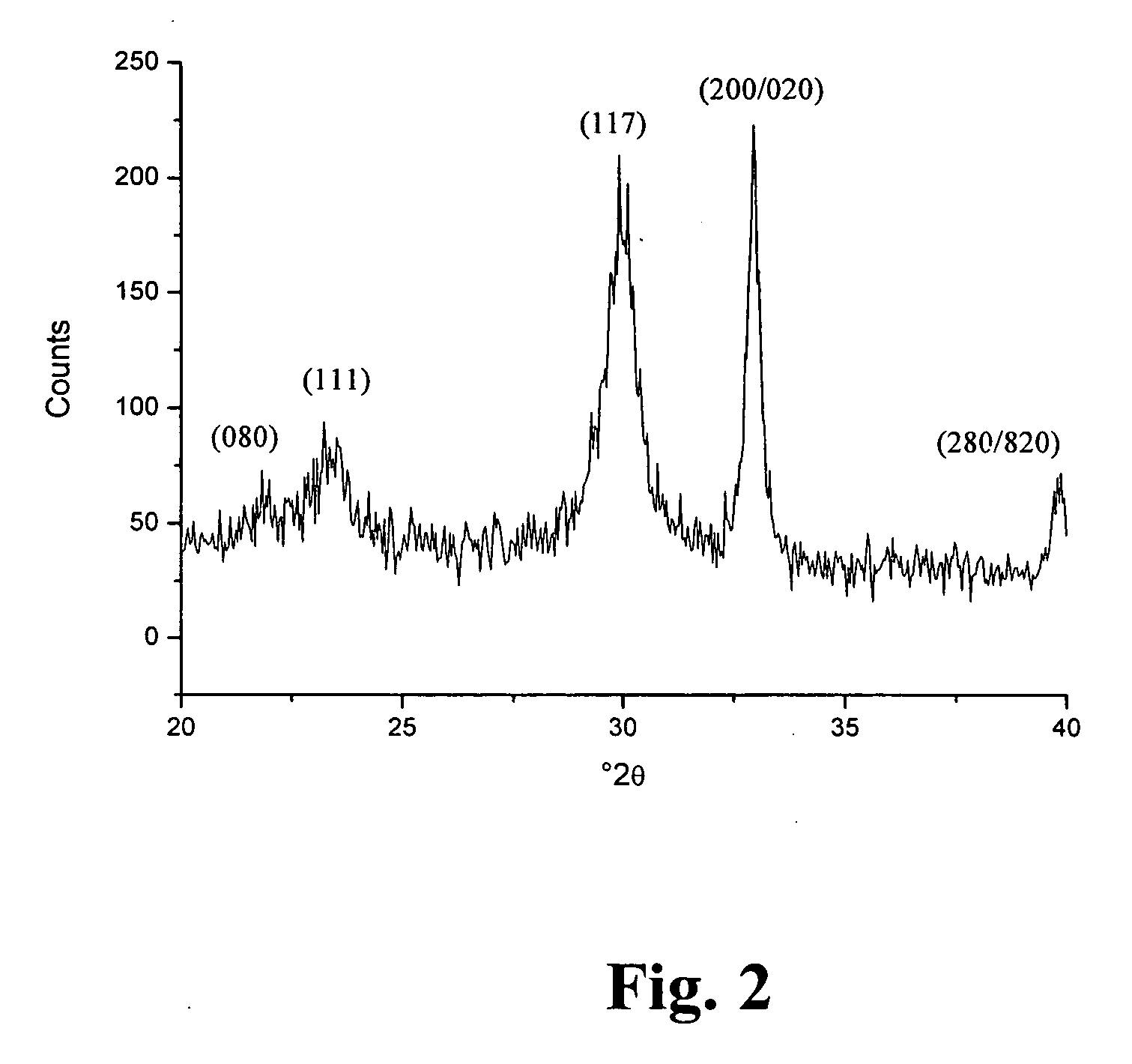

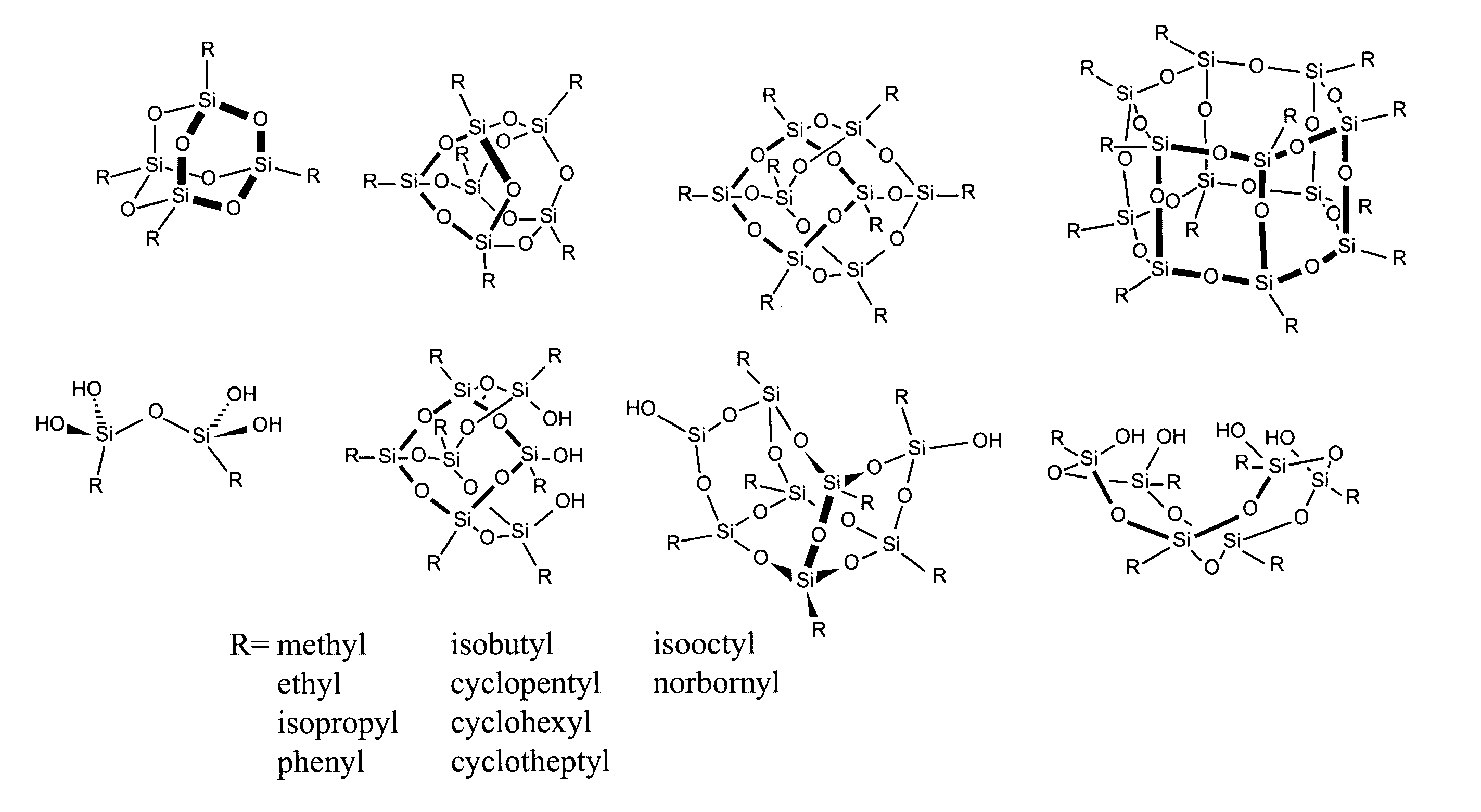

Process for producing oxide films

ActiveUS20070148347A1Group 5/15 element organic compoundsFixed capacitor dielectricSource materialBismuth compound

Processes are provided for producing bismuth-containing oxide thin films by atomic layer deposition. In preferred embodiments an organic bismuth compound having at least one monodentate alkoxide ligand is used as a bismuth source material. Bismuth-containing oxide thin films can be used, for example, as ferroelectric or dielectric materials in integrated circuits and as superconductor materials.

Owner:ASM INTERNATIONAL

Hybrid polymer film

InactiveUS6083628AFine surfaceLow costFixed capacitor dielectricSynthetic resin layered productsThermoplasticCross-link

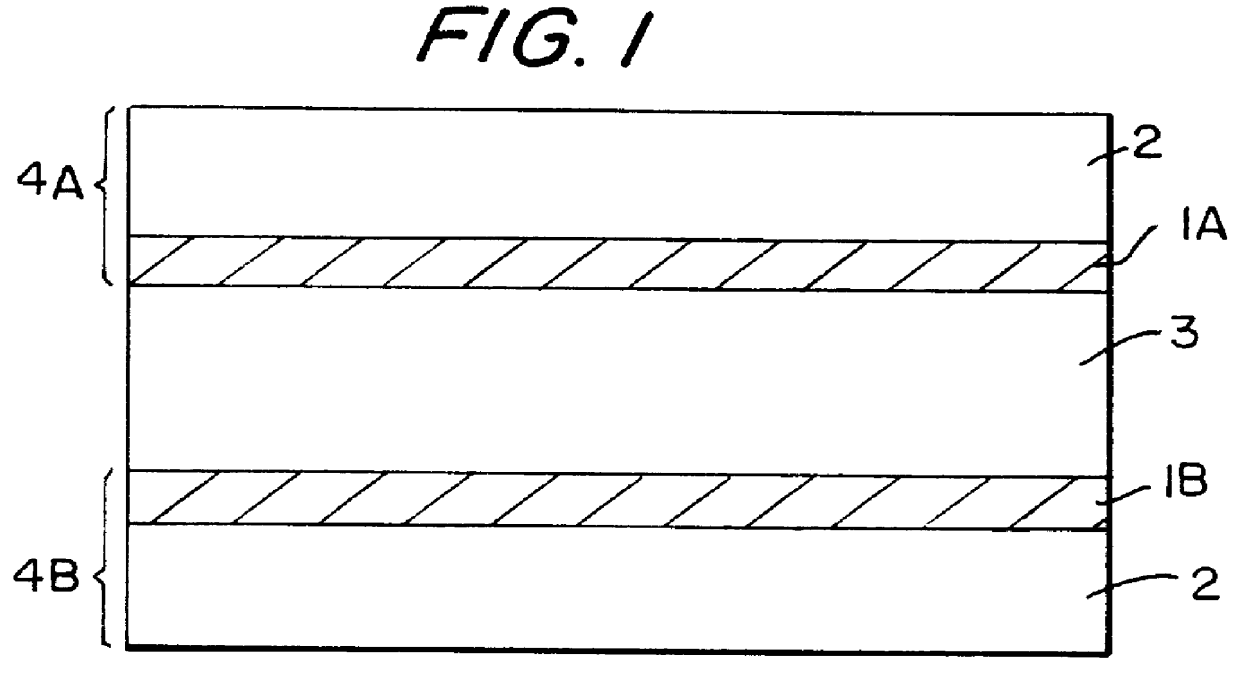

A hybrid film, comprising a first polymer film having a plasma-treated surface and a second polymer film having first and second surfaces, with the first surface of the second polymer film being disposed along the first plasma-treated surface of the first polymer film, has superior thermal and mechanical properties that improve performance in a number of applications, including food packaging, thin film metallized and foil capacitors, metal evaporated magnetic tapes, flexible electrical cables, and decorative and optically variable films. One or more metal layers may be deposited on either the plasma-treated surface of the substrate and / or the radiation-cured acrylate polymer. A ceramic layer may be deposited on the radiation-cured acrylate polymer to provide an oxygen and moisture barrier film. The hybrid film is produced using a high speed, vacuum polymer deposition process that is capable of forming thin, uniform, high temperature, cross-linked acrylate polymers on specific thermoplastic or thermoset films. Radiation curing is employed to cross-link the acrylate monomer. The hybrid film can be produced in-line with the metallization or ceramic coating process, in the same vacuum chamber and with minimal additional cost.

Owner:SIGMA LAB OF ARIZONA

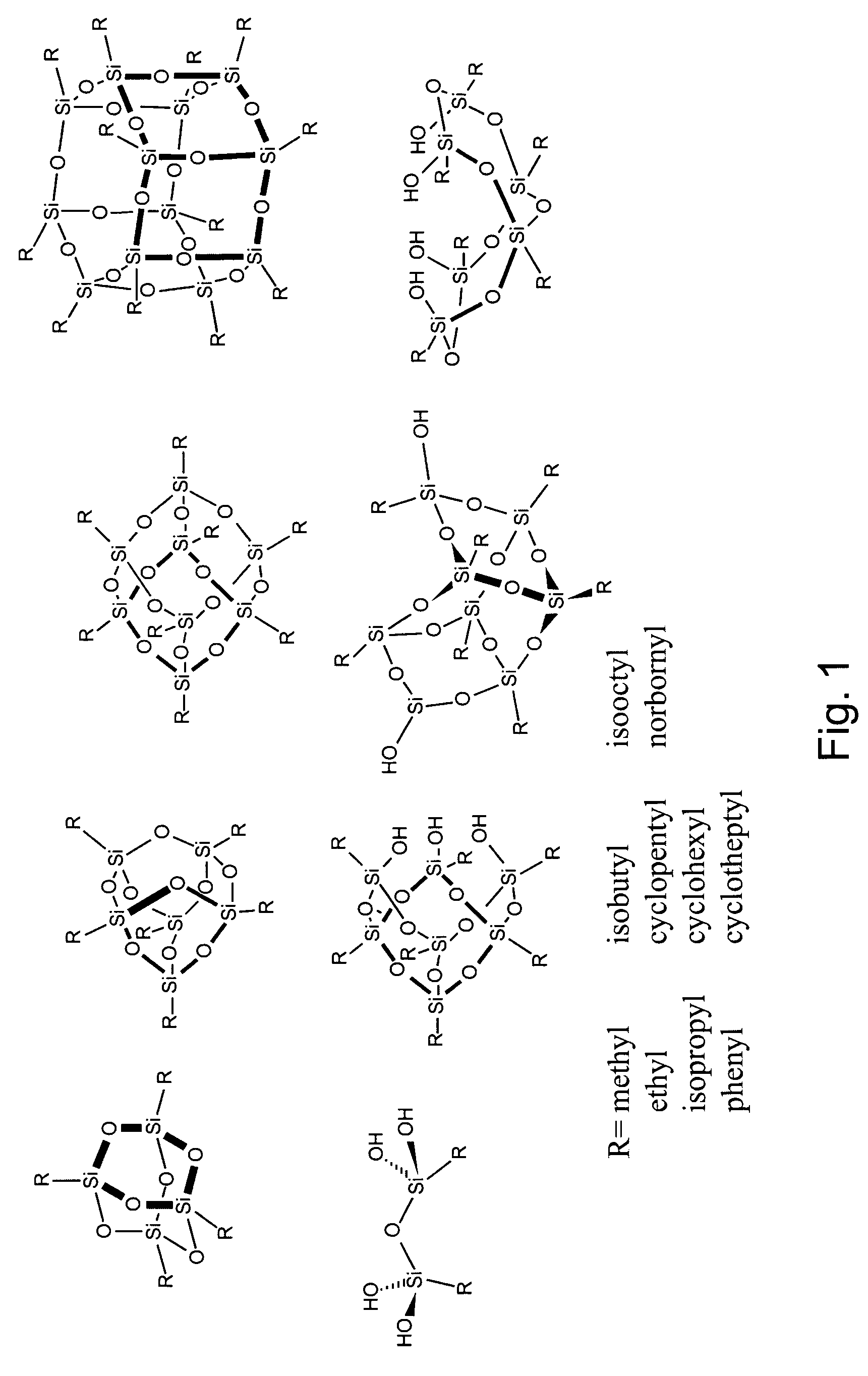

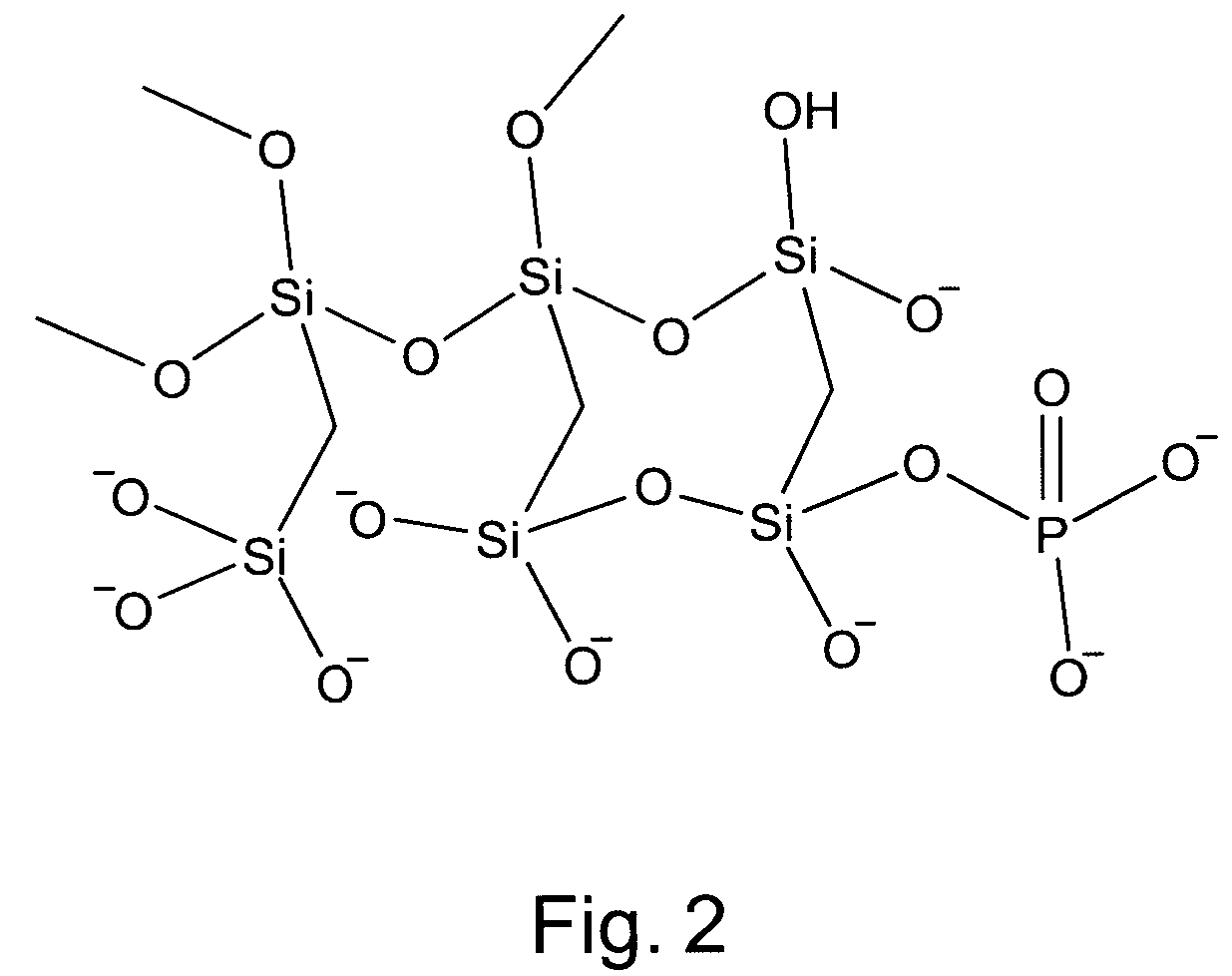

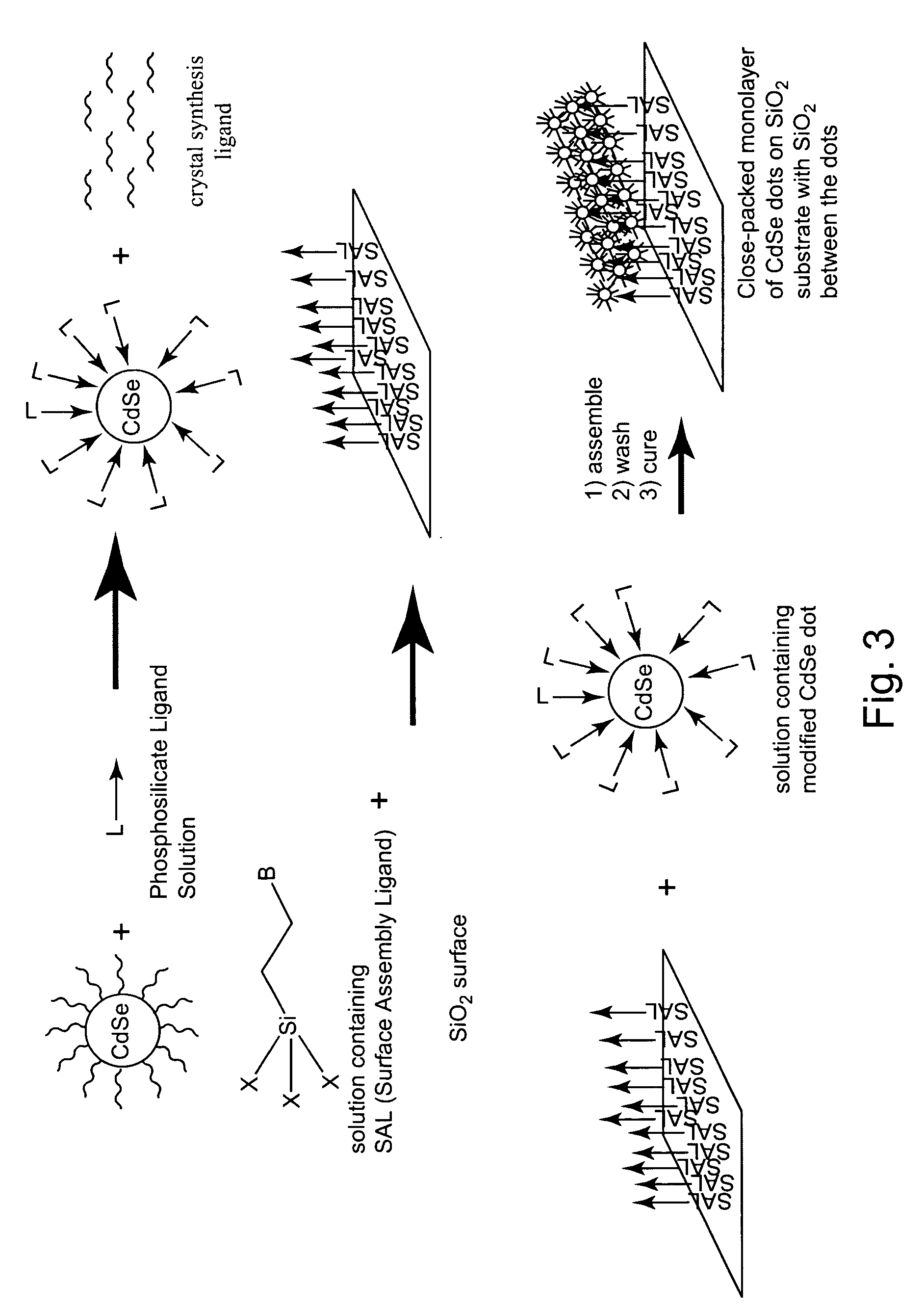

Post-deposition encapsulation of nanostructures: compositions, devices and systems incorporating same

ActiveUS20060040103A1Reduce and prevent other type of transmissionReduce probabilityMaterial nanotechnologyBoxes/cartons making machineryNanostructureNanometre

Ligand compositions for use in preparing discrete coated nanostructures are provided, as well as the coated nanostructures themselves and devices incorporating same. Methods for post-deposition shell formation on a nanostructure and for reversibly modifying nanostructures are also provided. The ligands and coated nanostructures of the present invention are particularly useful for close packed nanostructure compositions, which can have improved quantum confinement and / or reduced cross-talk between nanostructures.

Owner:WODEN TECH INC

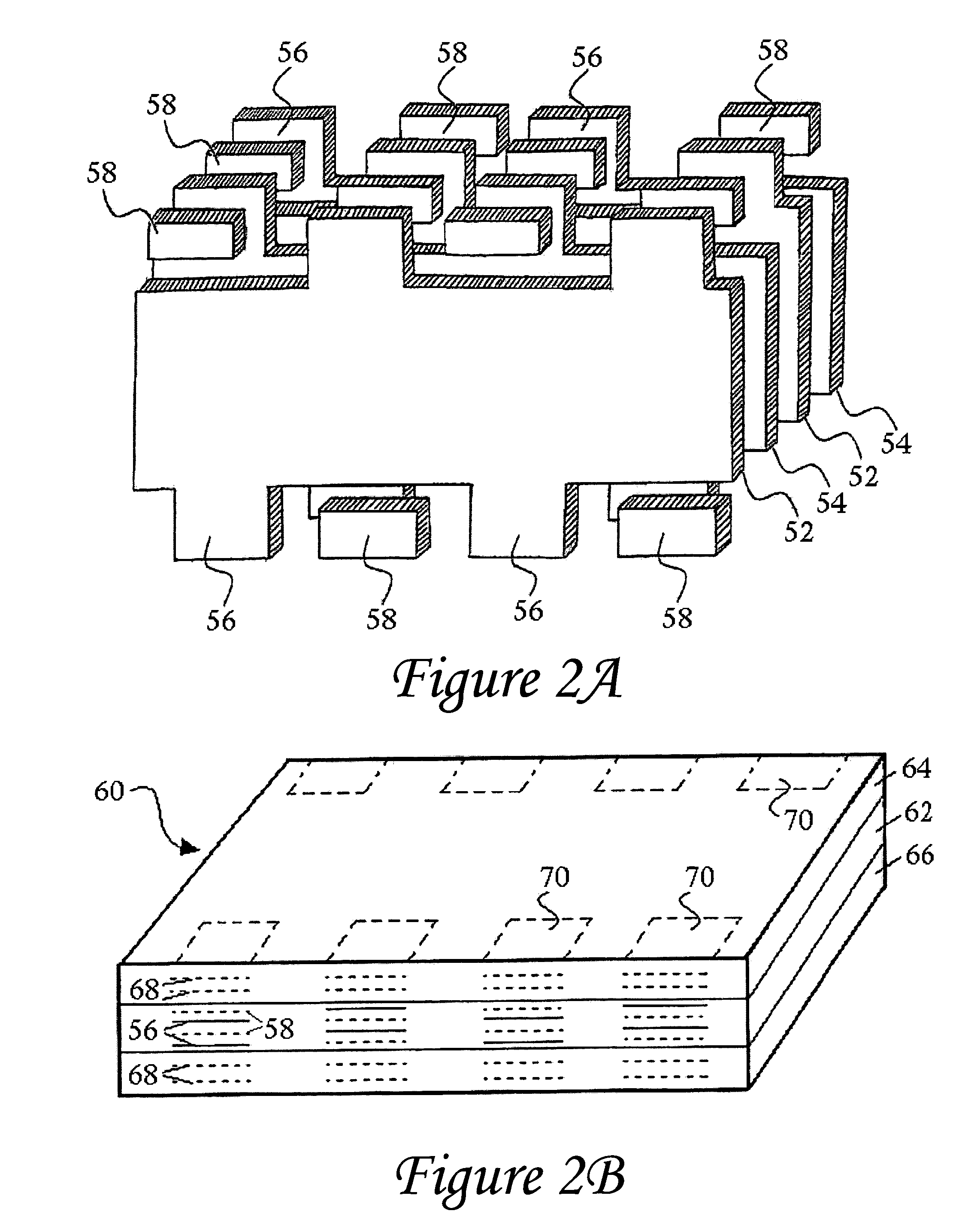

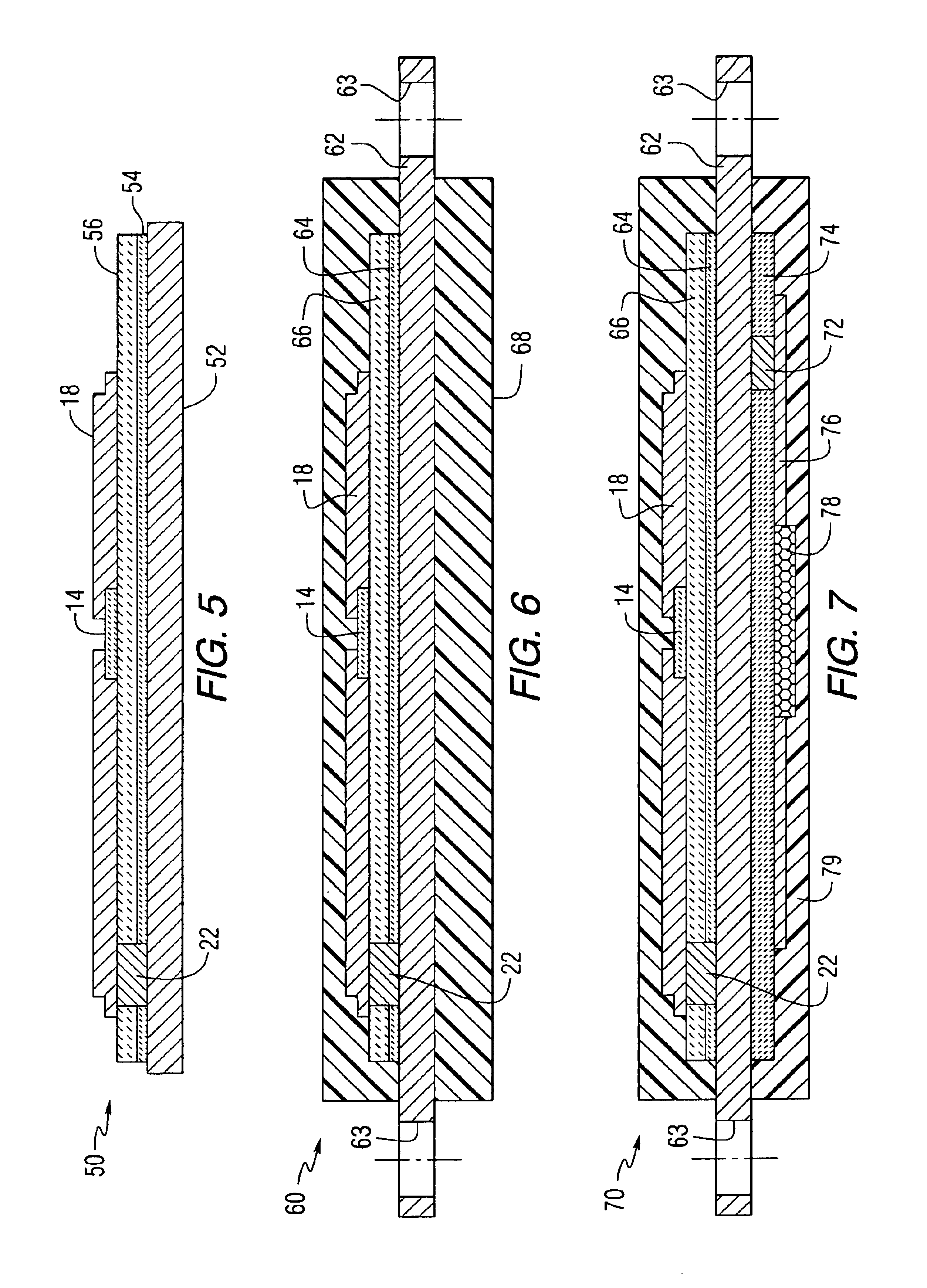

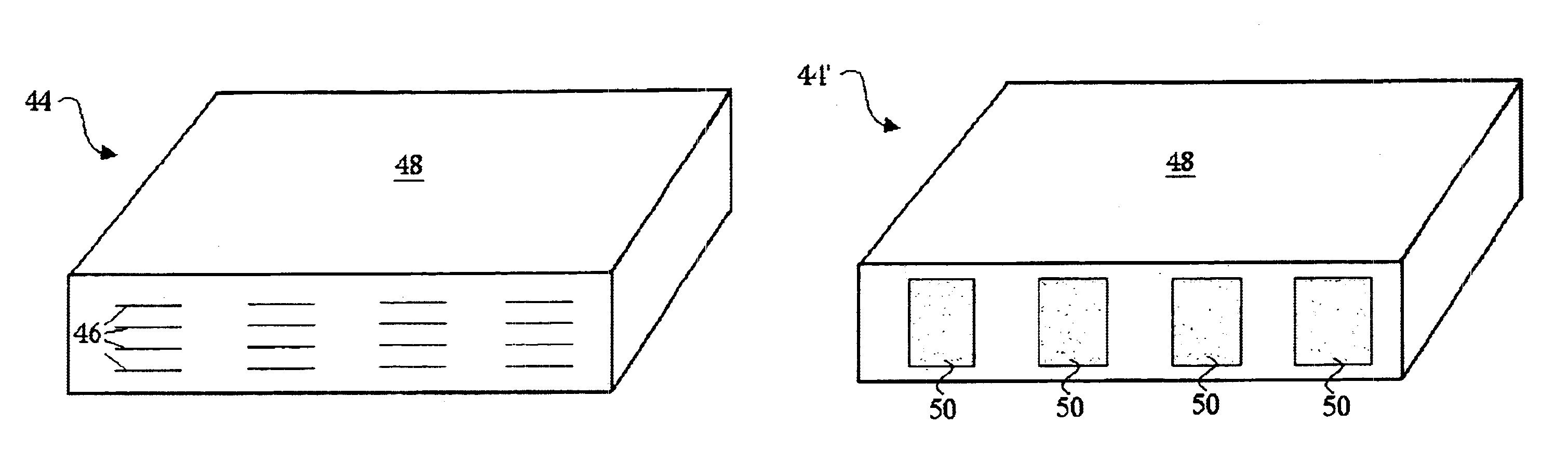

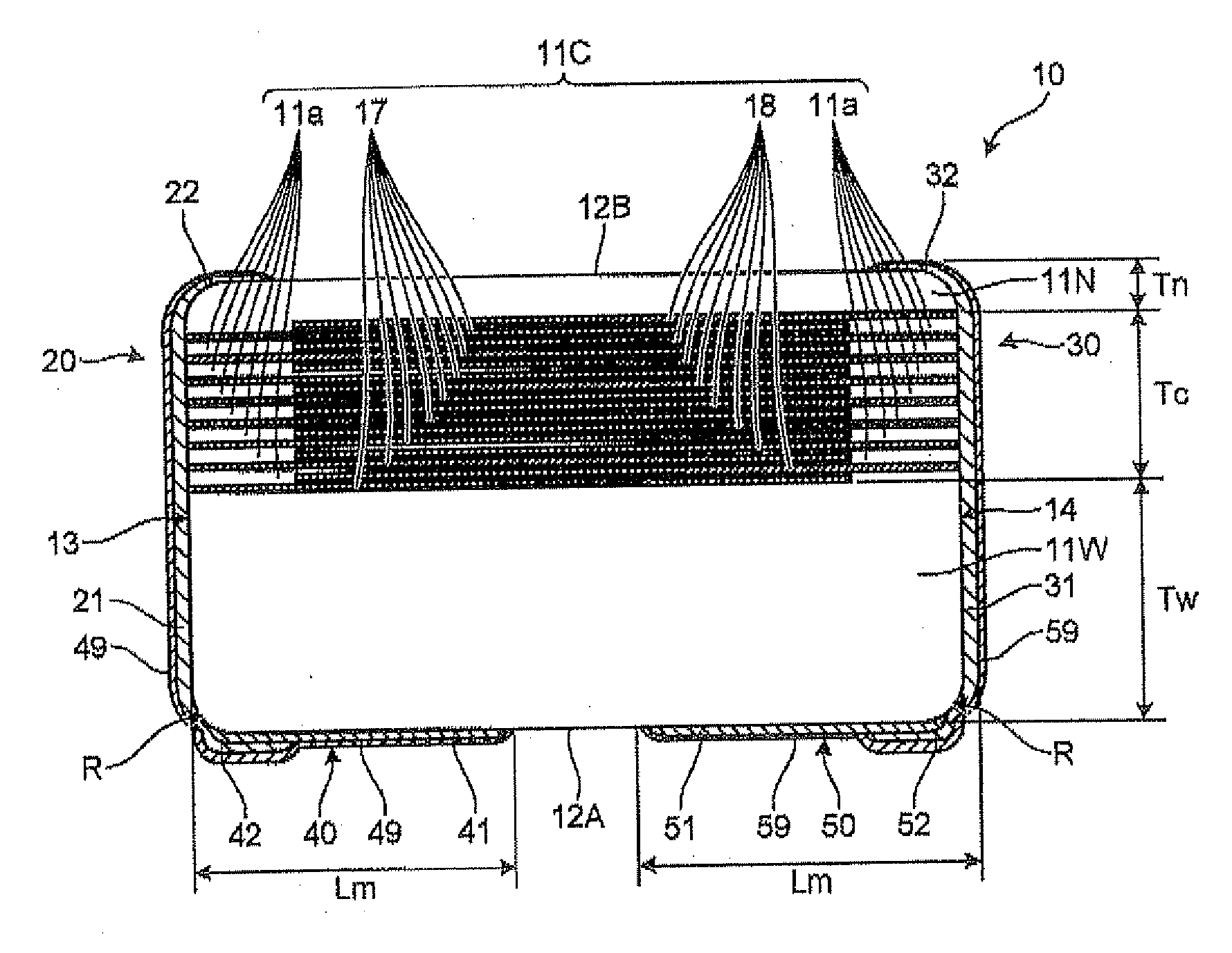

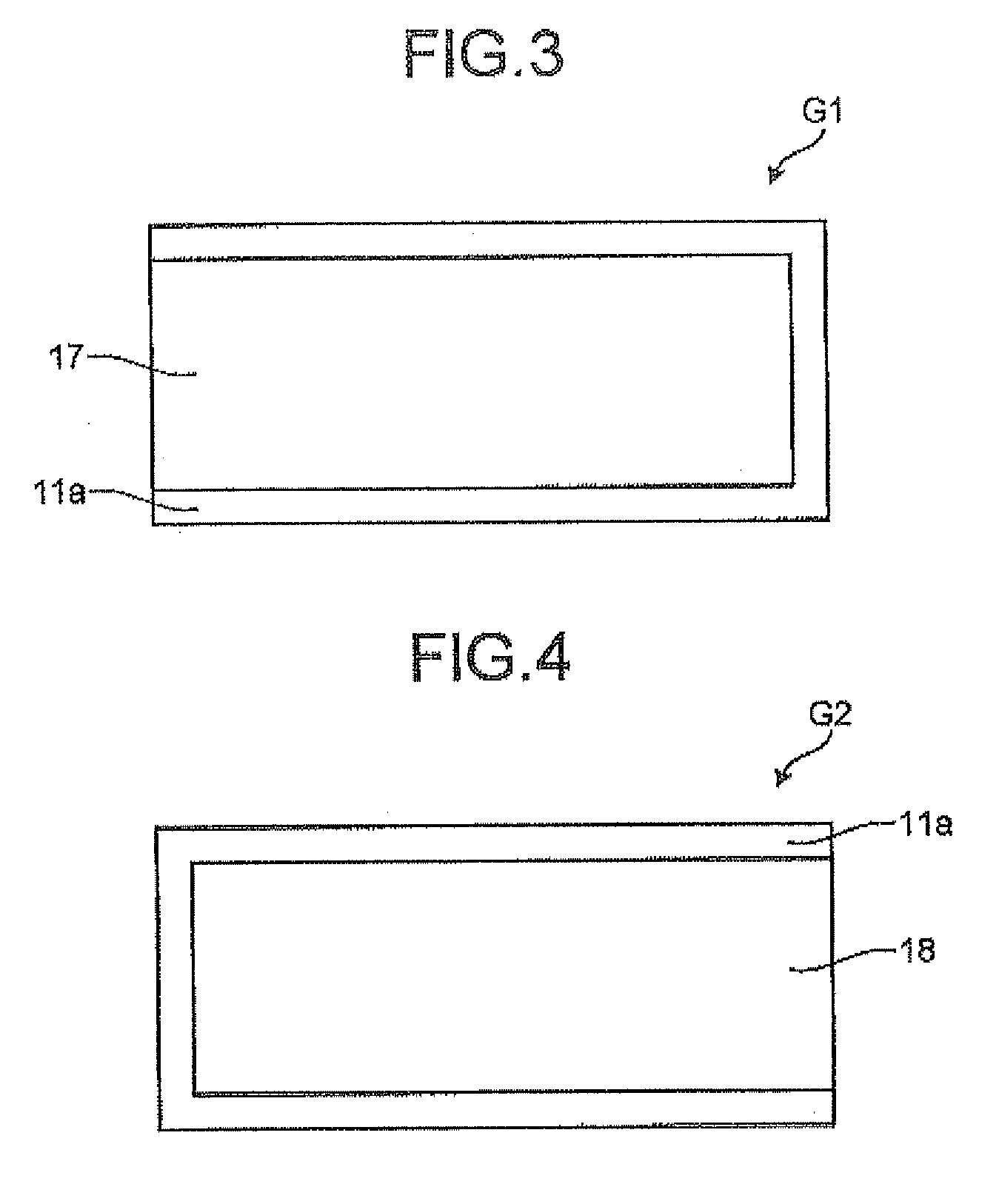

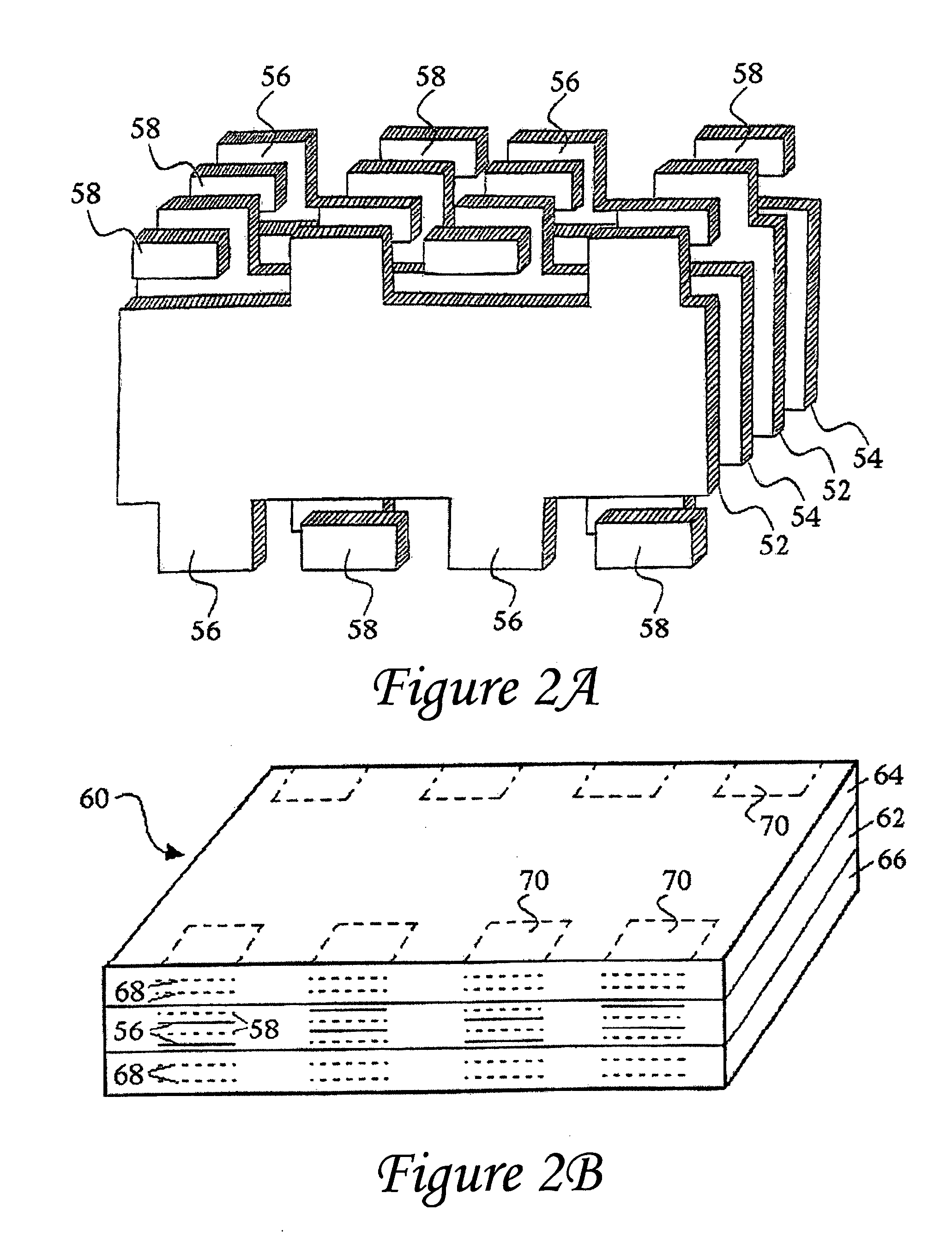

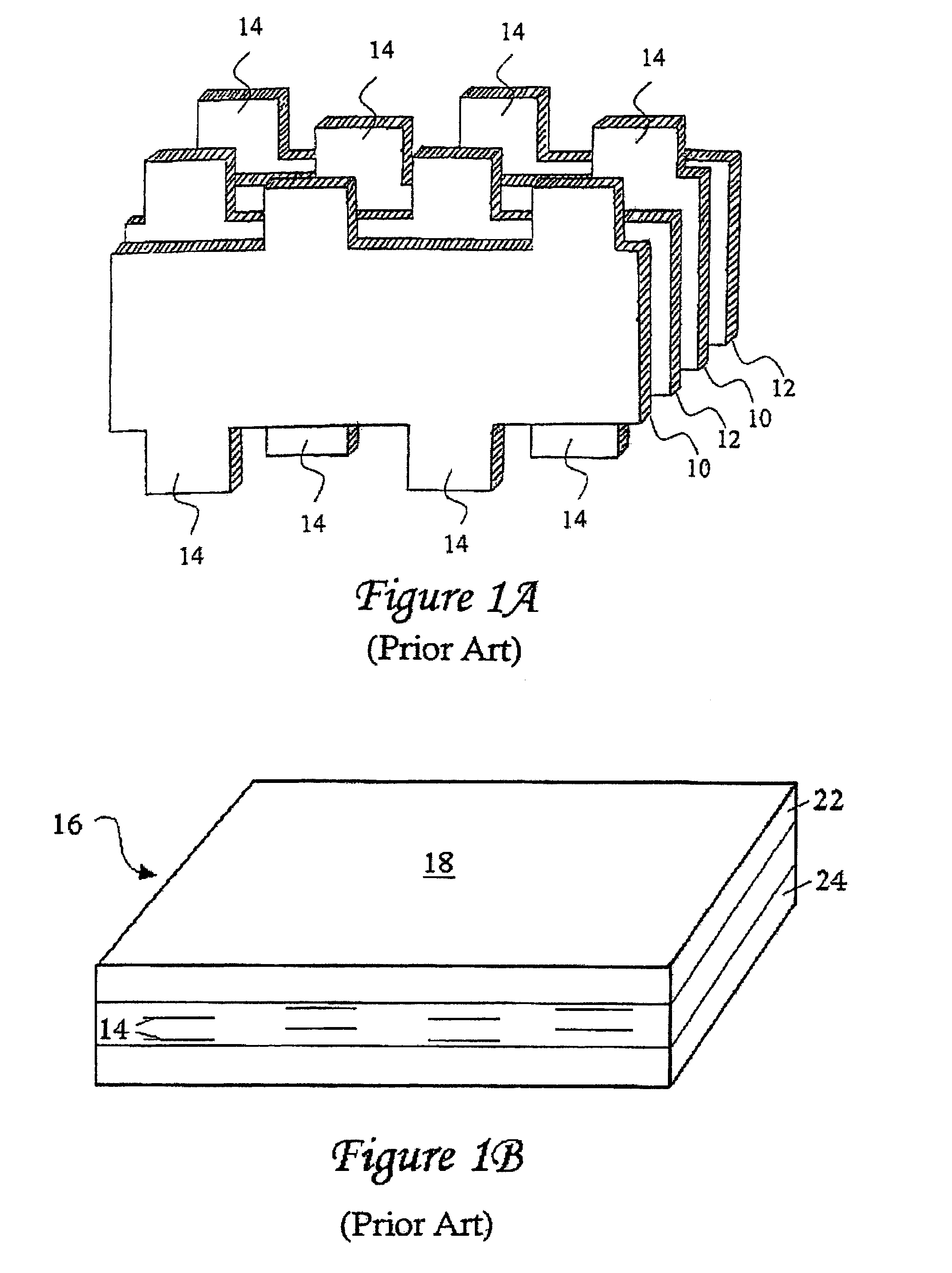

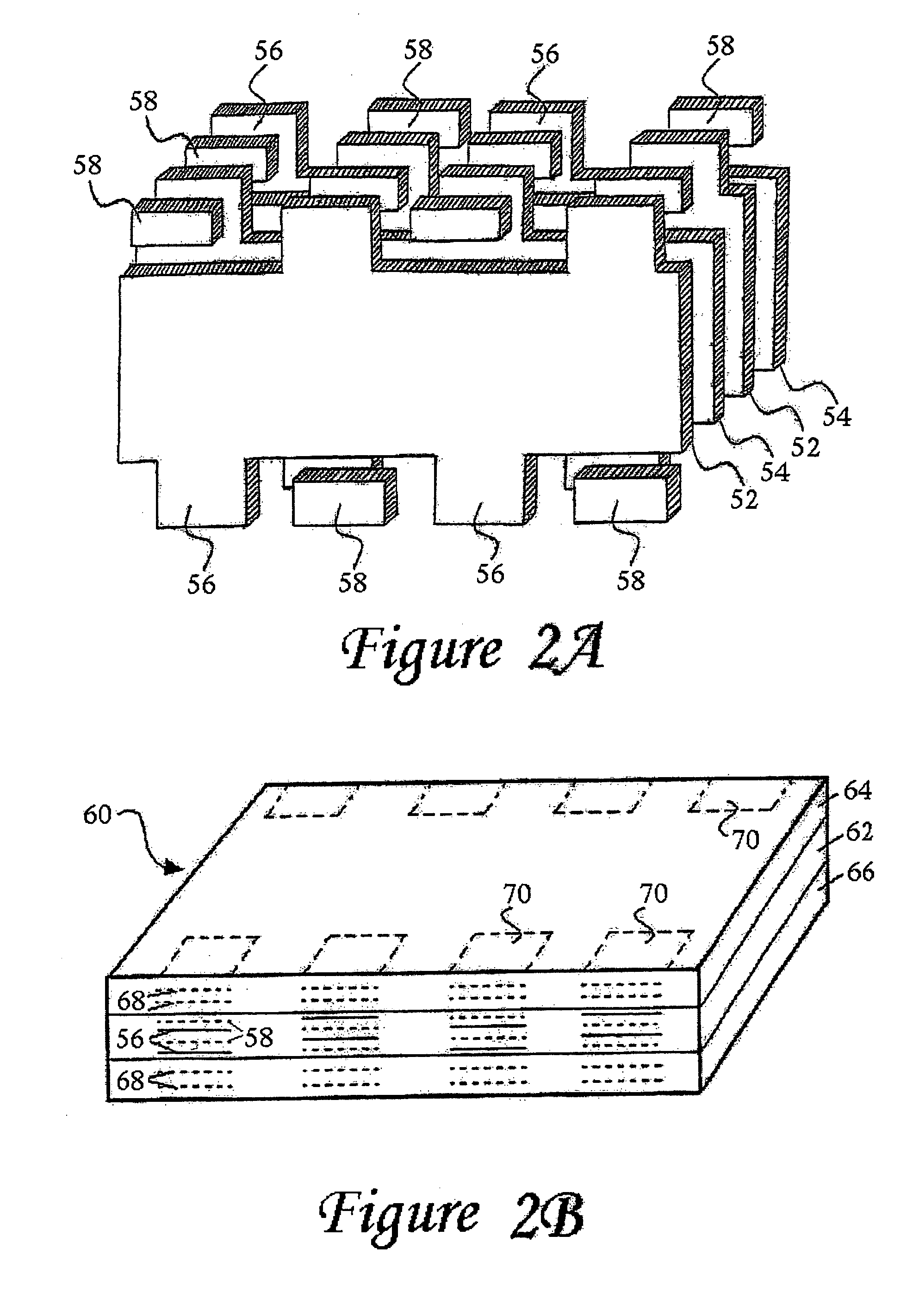

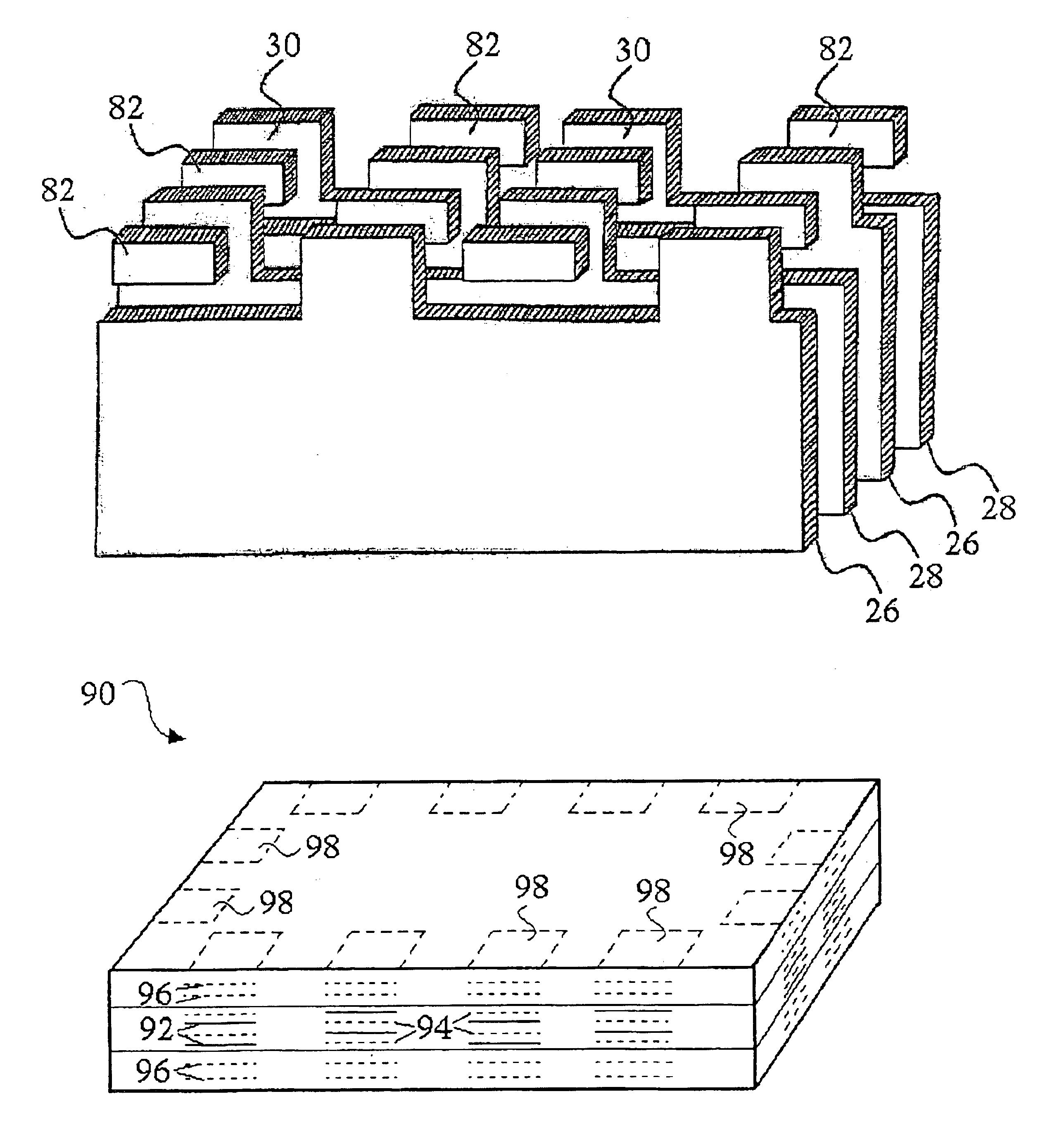

Plated terminations

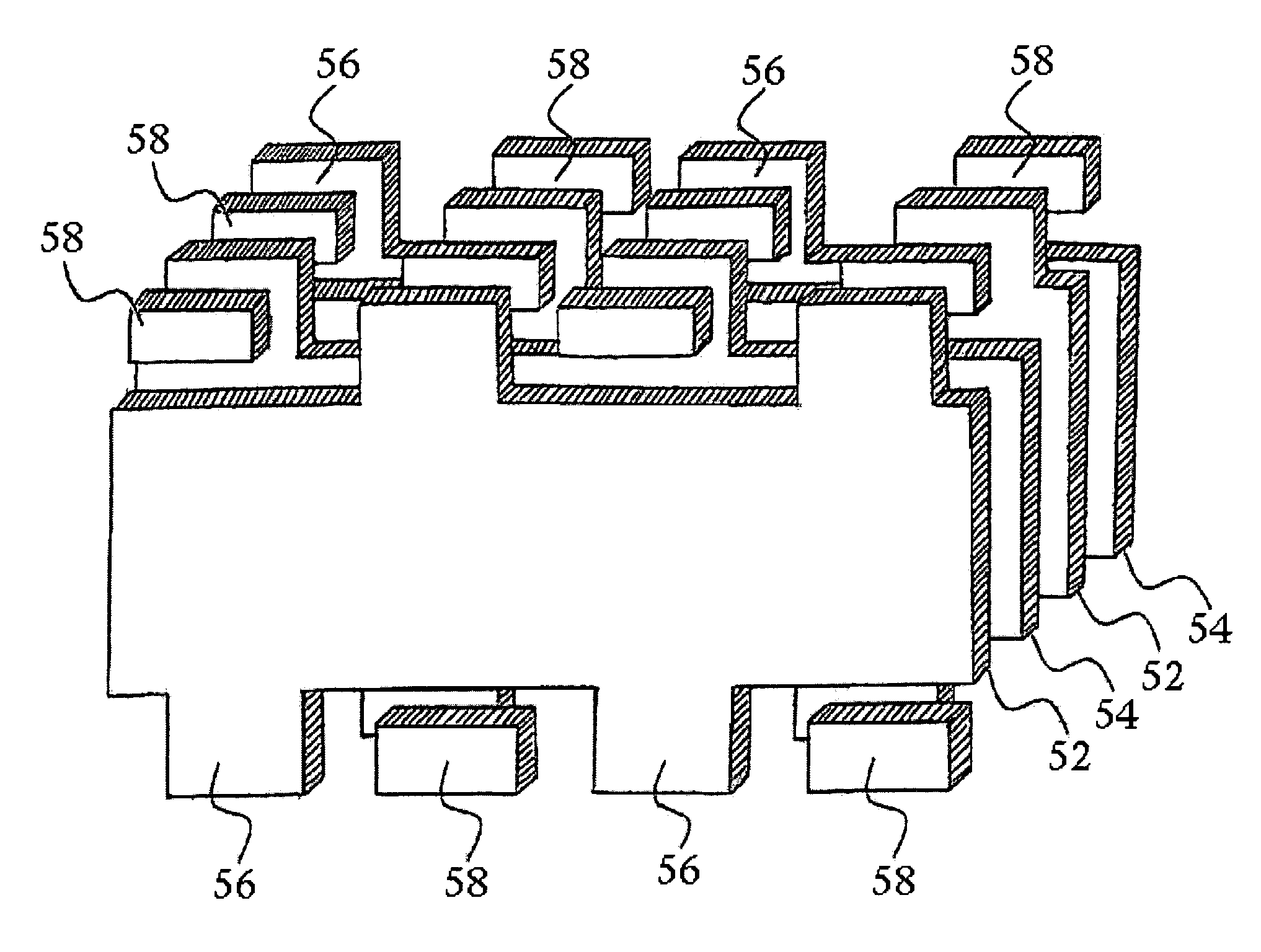

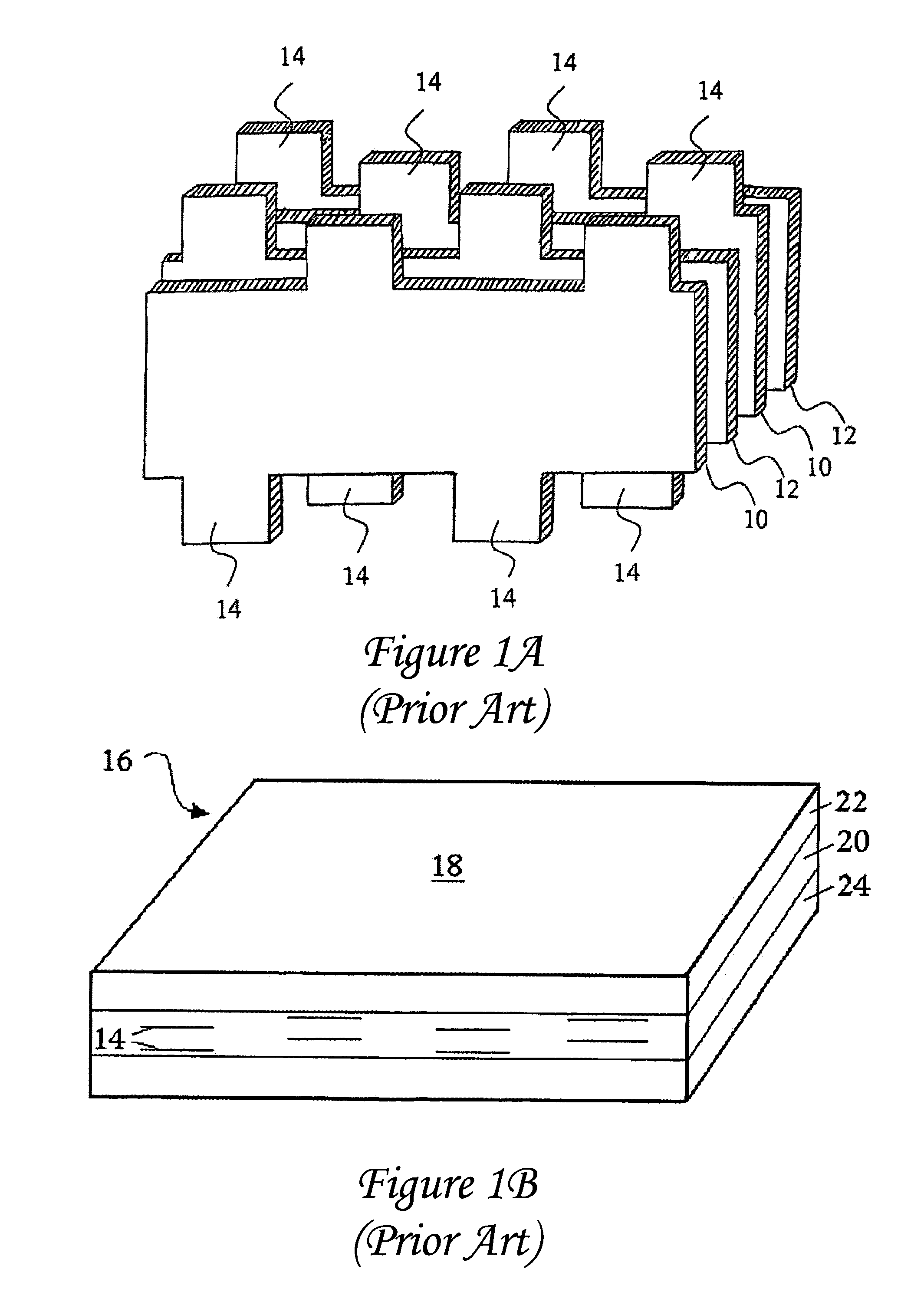

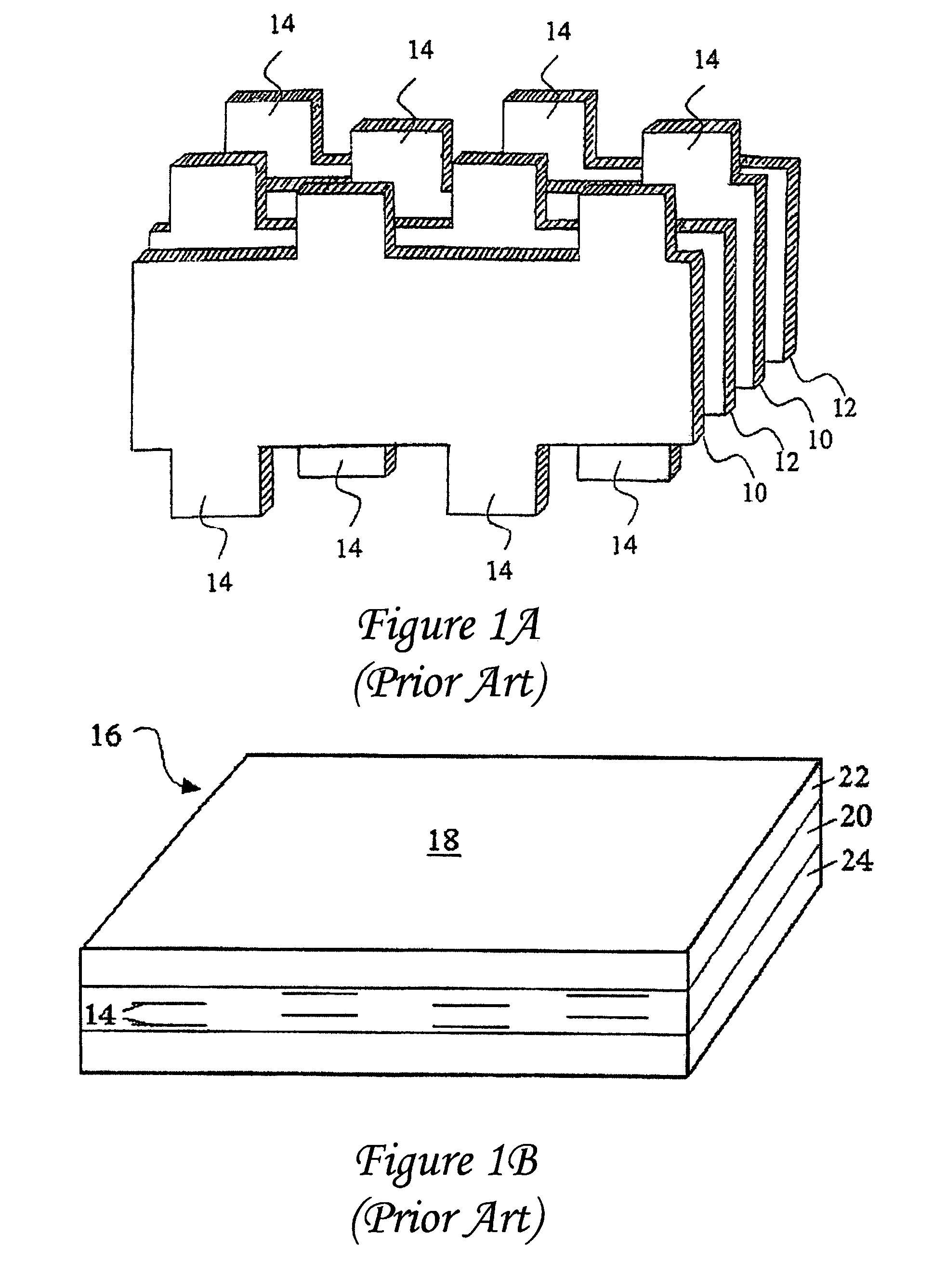

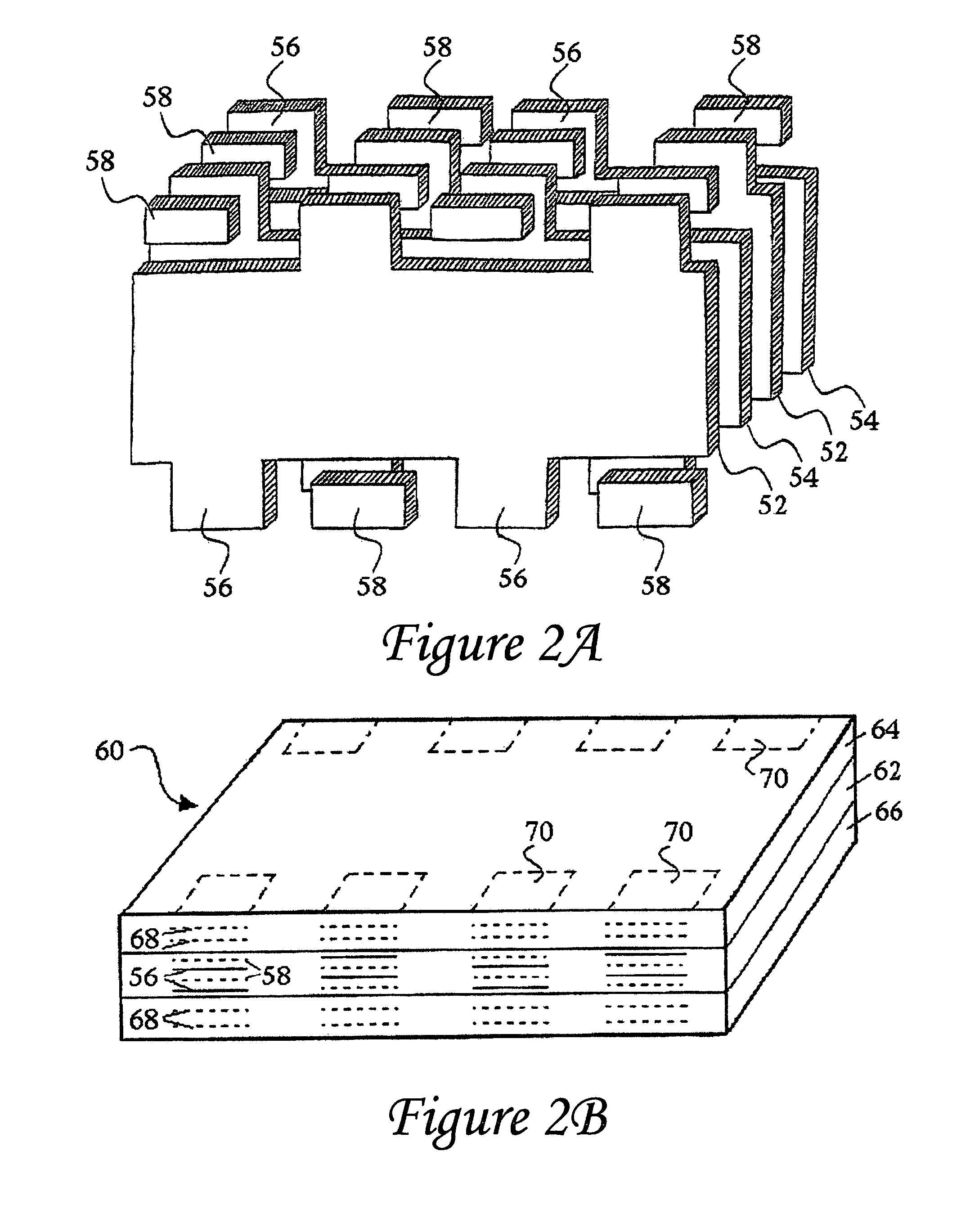

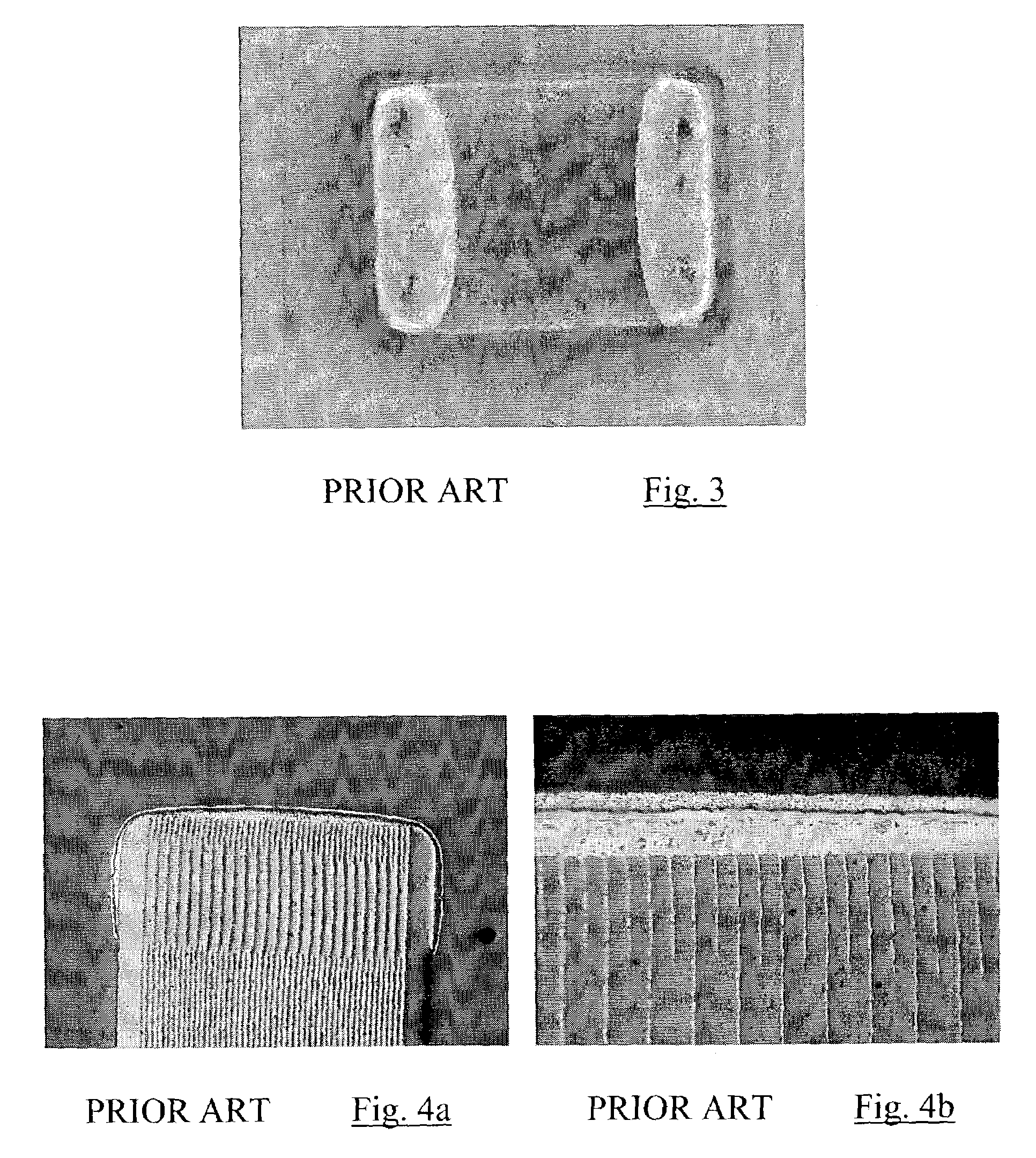

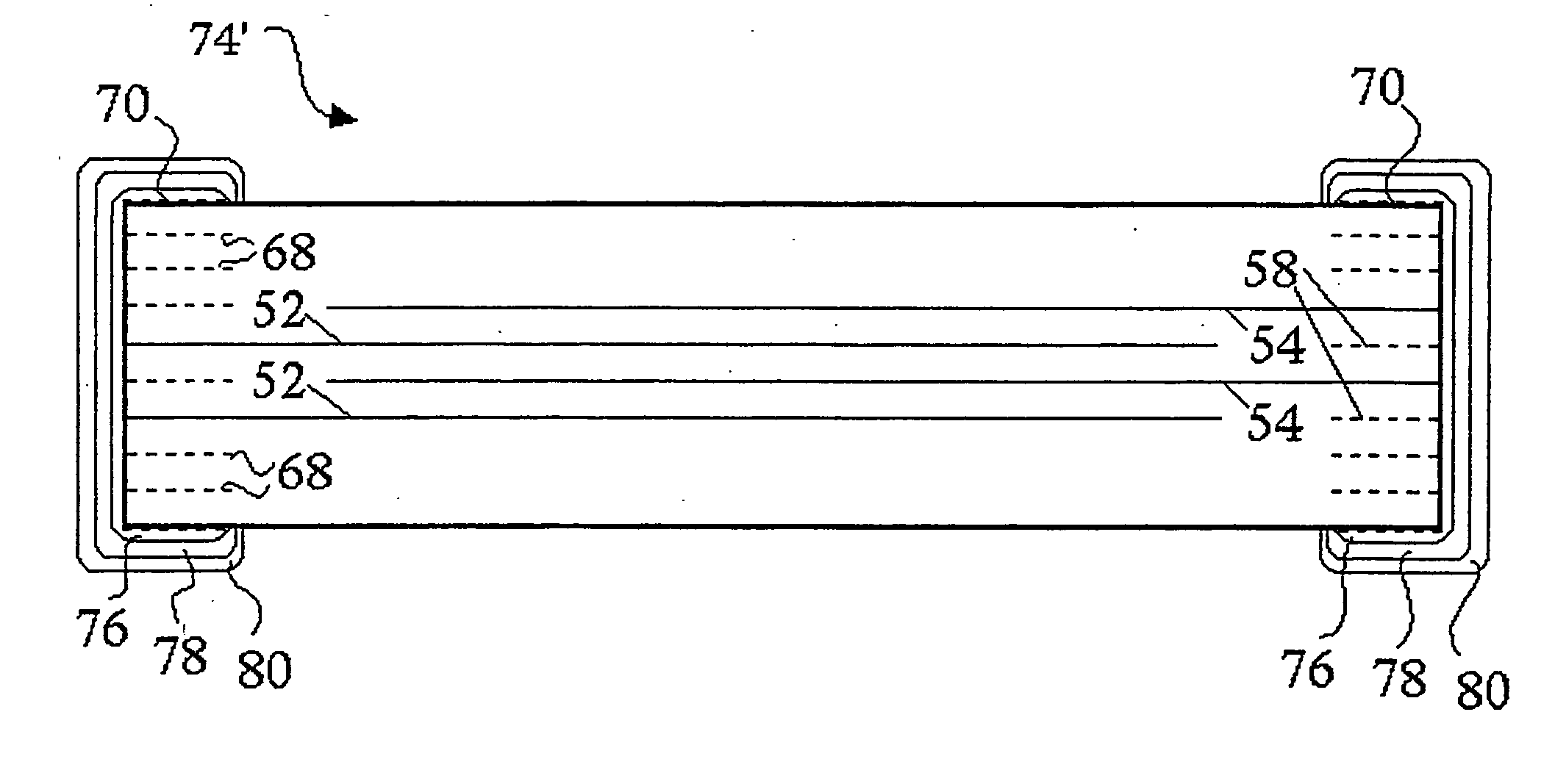

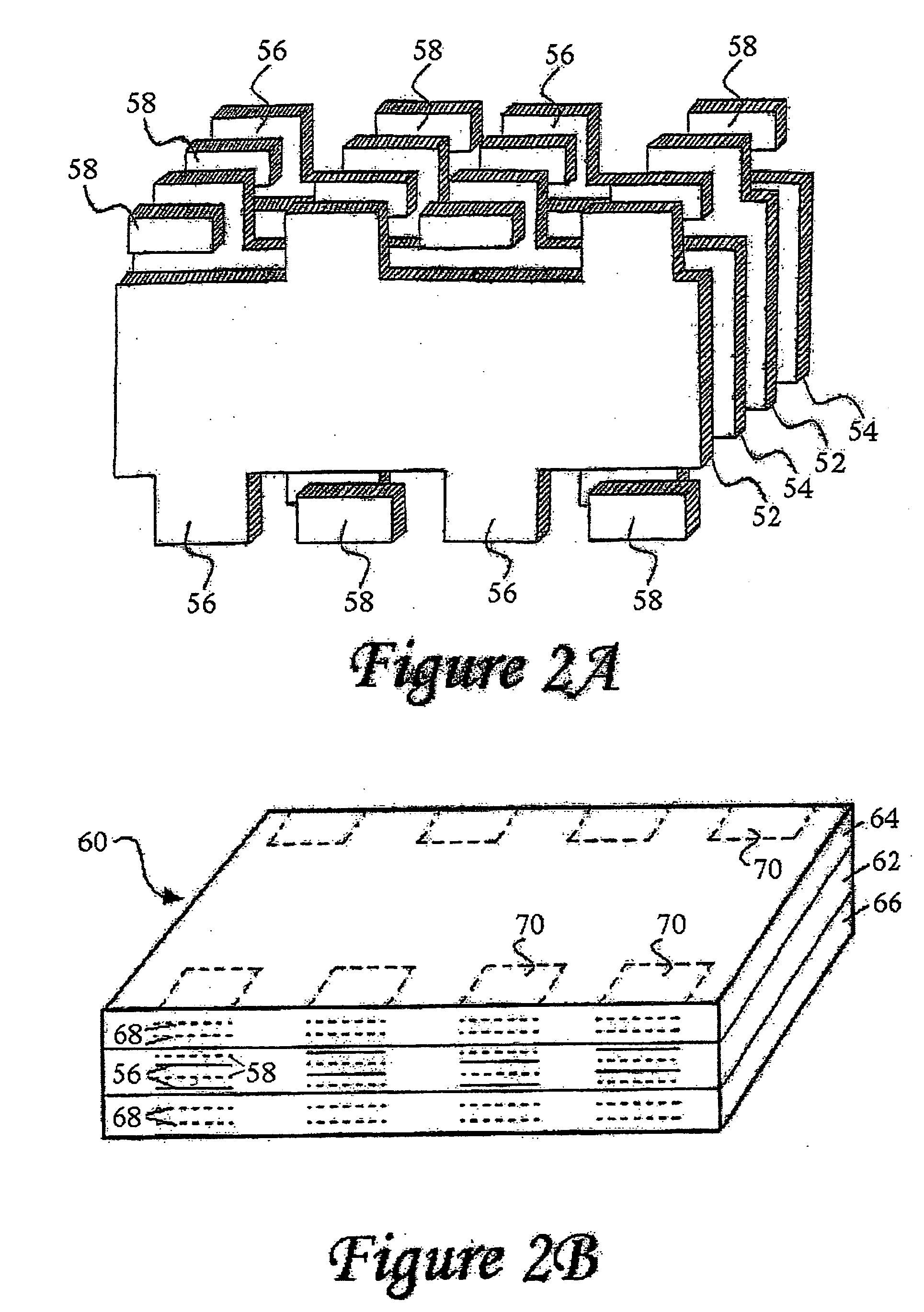

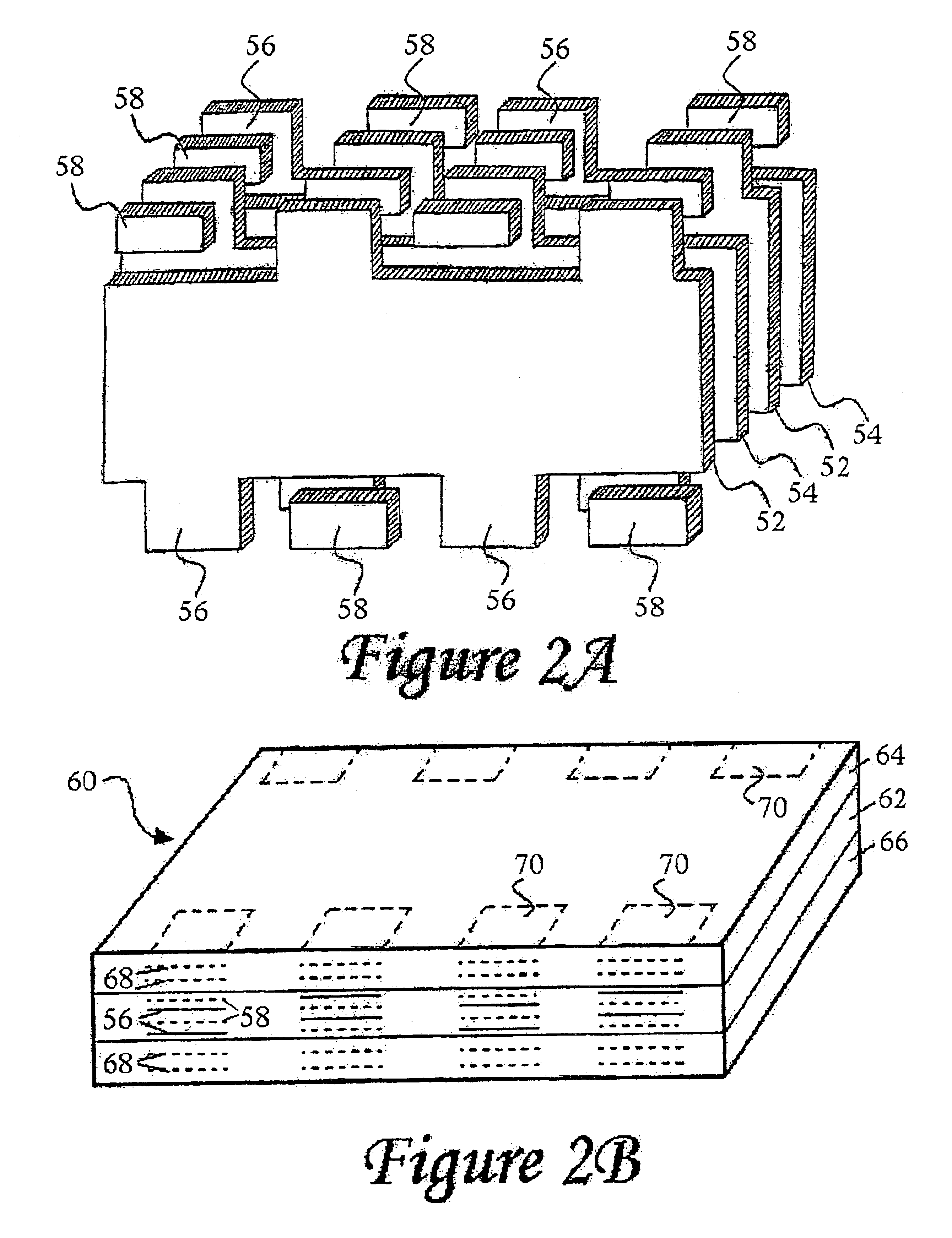

InactiveUS7177137B2Improved termination featureEliminate or greatly simplify thick-film stripesFixed capacitor electrodesFixed capacitor dielectricHigh densityEngineering

A multilayer electronic component includes a plurality of dielectric layers interleaved with a plurality of internal electrode elements and a plurality of internal anchor tabs. Portions of the internal electrode elements and anchor tabs are exposed along the periphery of the electronic component in one or more aligned columns. Each exposed portion is within a predetermined distance from other exposed portions in a given column such that bridged terminations may be formed by depositing one or more plated termination materials over selected of the respectively aligned columns. Internal anchor tabs may be provided and exposed in prearranged relationships with other exposed conductive portions to help nucleate metallized plating material along the periphery of a device. External anchor tabs or lands may be provided to form terminations that extend to top and / or bottom surfaces of the device. Selected of the conductive elements may be formed by a finite volume percentage of ceramic material for enhanced durability, and external lands may be thicker than internal conductive elements and / or may also be embedded in top and / or bottom component surfaces. A variety of potential internal electrode configurations are possible including ones configured for orientation-insensitive component mounting and for high density peripheral termination interdigitated capacitors.

Owner:KYOCERA AVX COMPONENTS CORP

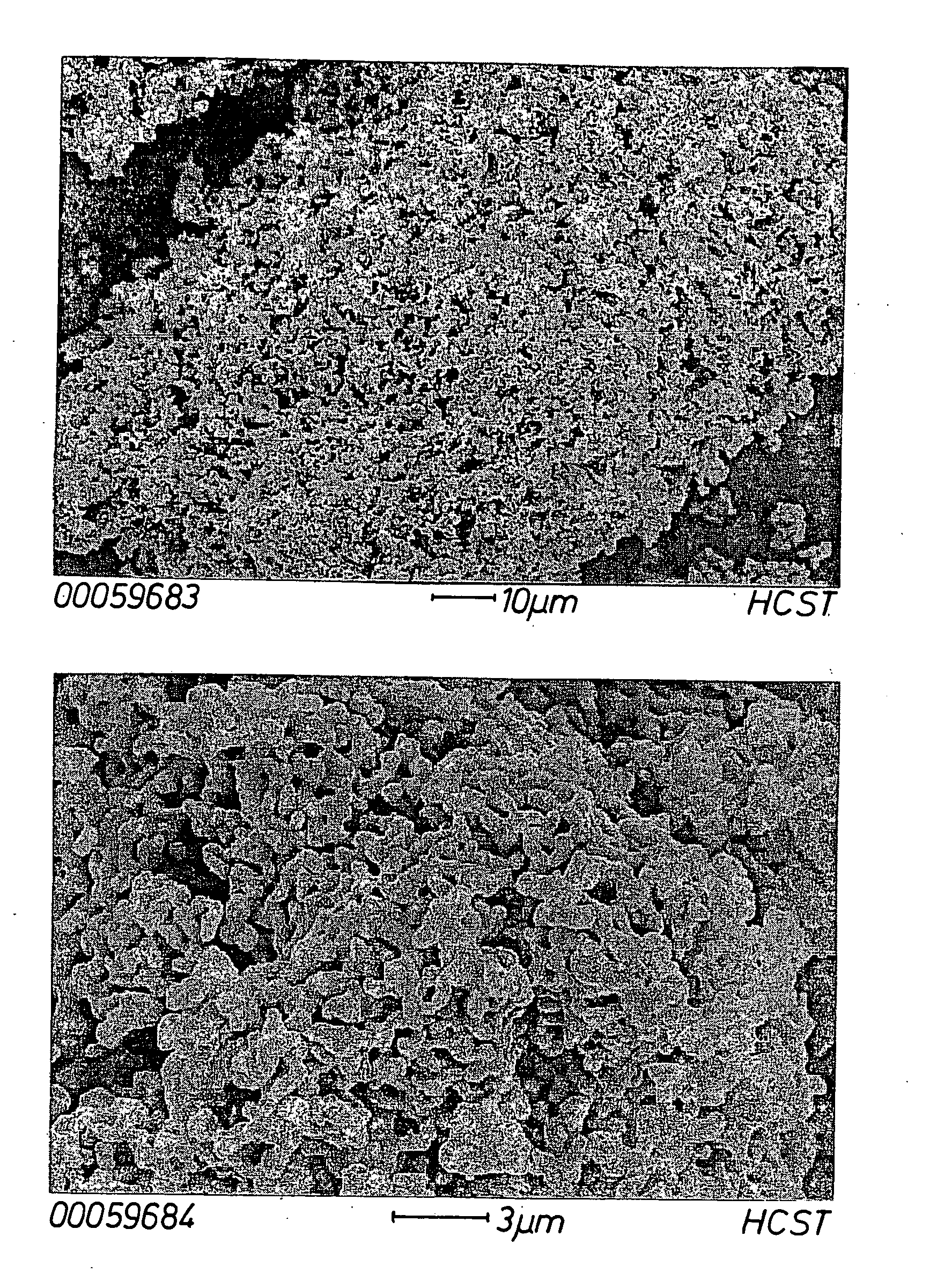

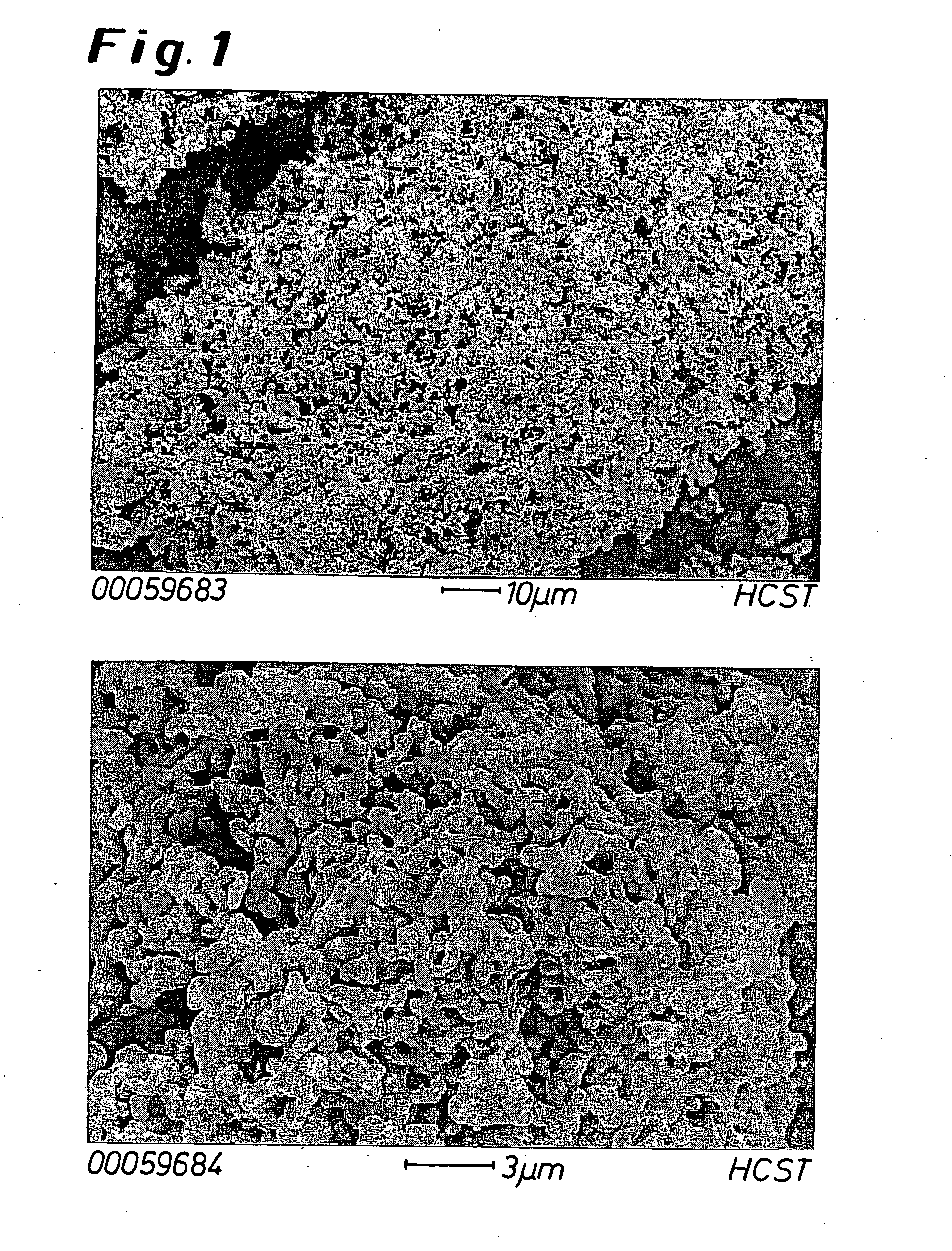

Tunable dielectric compositions including low loss glass

InactiveUS6905989B2Lower sintering temperatureIncrease varietyFixed capacitor dielectricCeramic layered productsBreakdown strengthStrontium titanate

Tunable dielectric materials including an electronically tunable dielectric ceramic and a low loss glass additive are disclosed. The tunable dielectric may comprise a ferroelectric perskovite material such as barium strontium titanate. The glass additive may comprise boron, barium, calcium, lithium, manganese, silicon, zinc and / or aluminum-containing glasses having dielectric losses of less than 0.003 at 2 GHz. The materials may further include other additives such as non-tunable metal oxides and silicates. The low loss glass additive enables the materials to be sintered at relatively low temperatures while providing improved properties such as low microwave losses and high breakdown strengths.

Owner:NXP USA INC

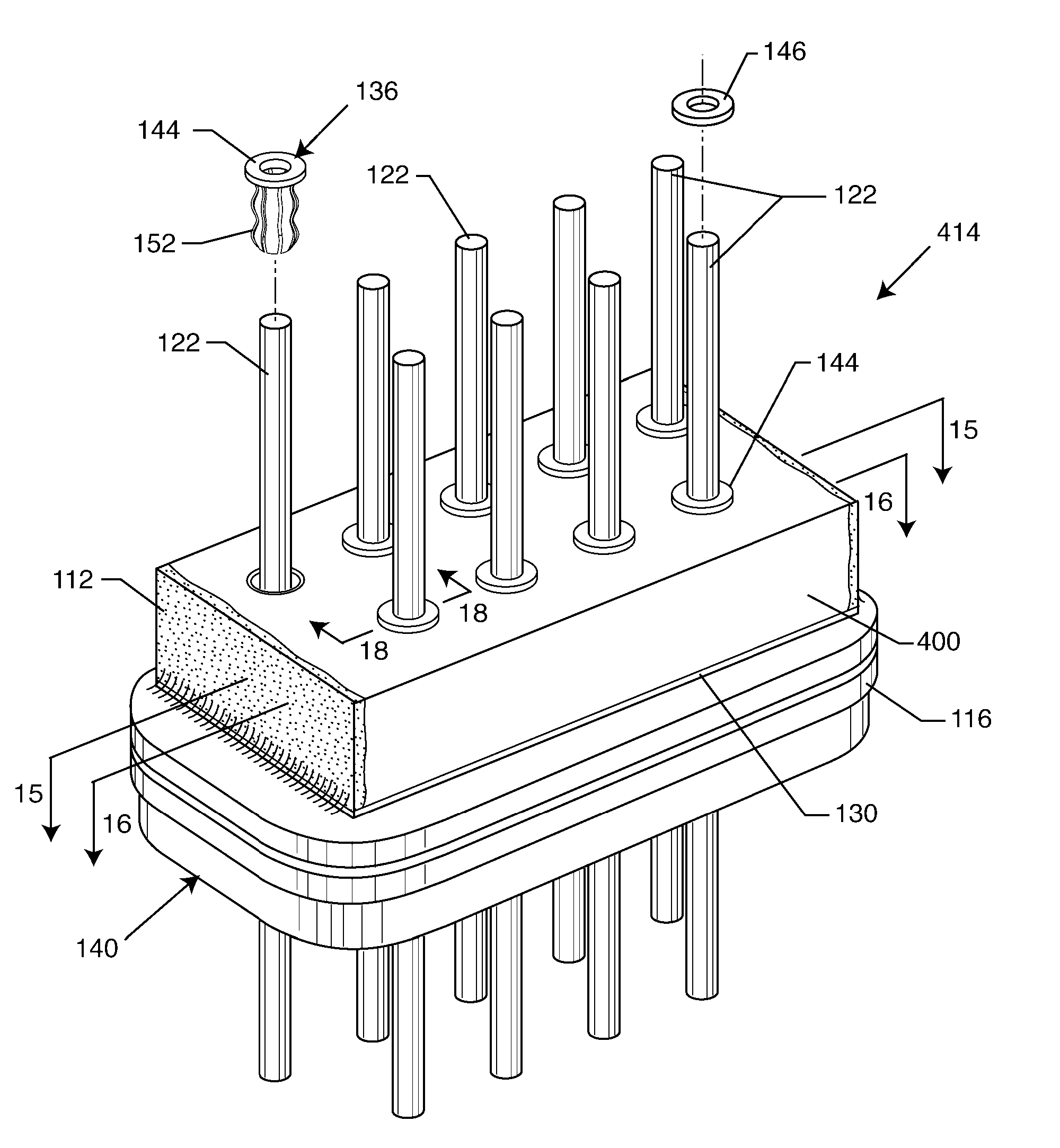

System and method of plating ball grid array and isolation features for electronic components

InactiveUS7463474B2Improved termination featureEliminate or greatly simplify thick-film stripesFixed capacitor dielectricStacked capacitorsEngineeringElectronic component

Owner:KYOCERA AVX COMPONENTS CORP

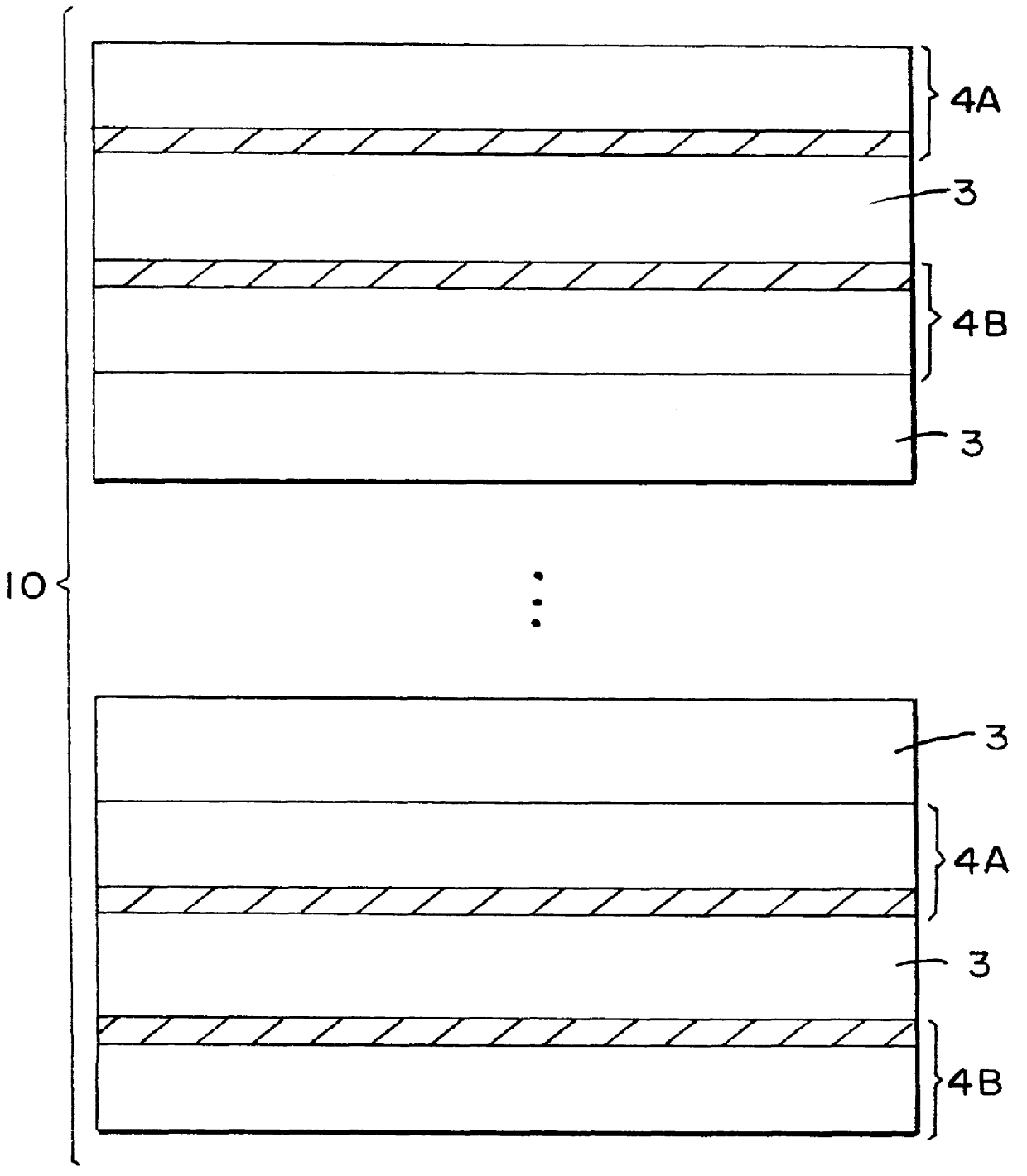

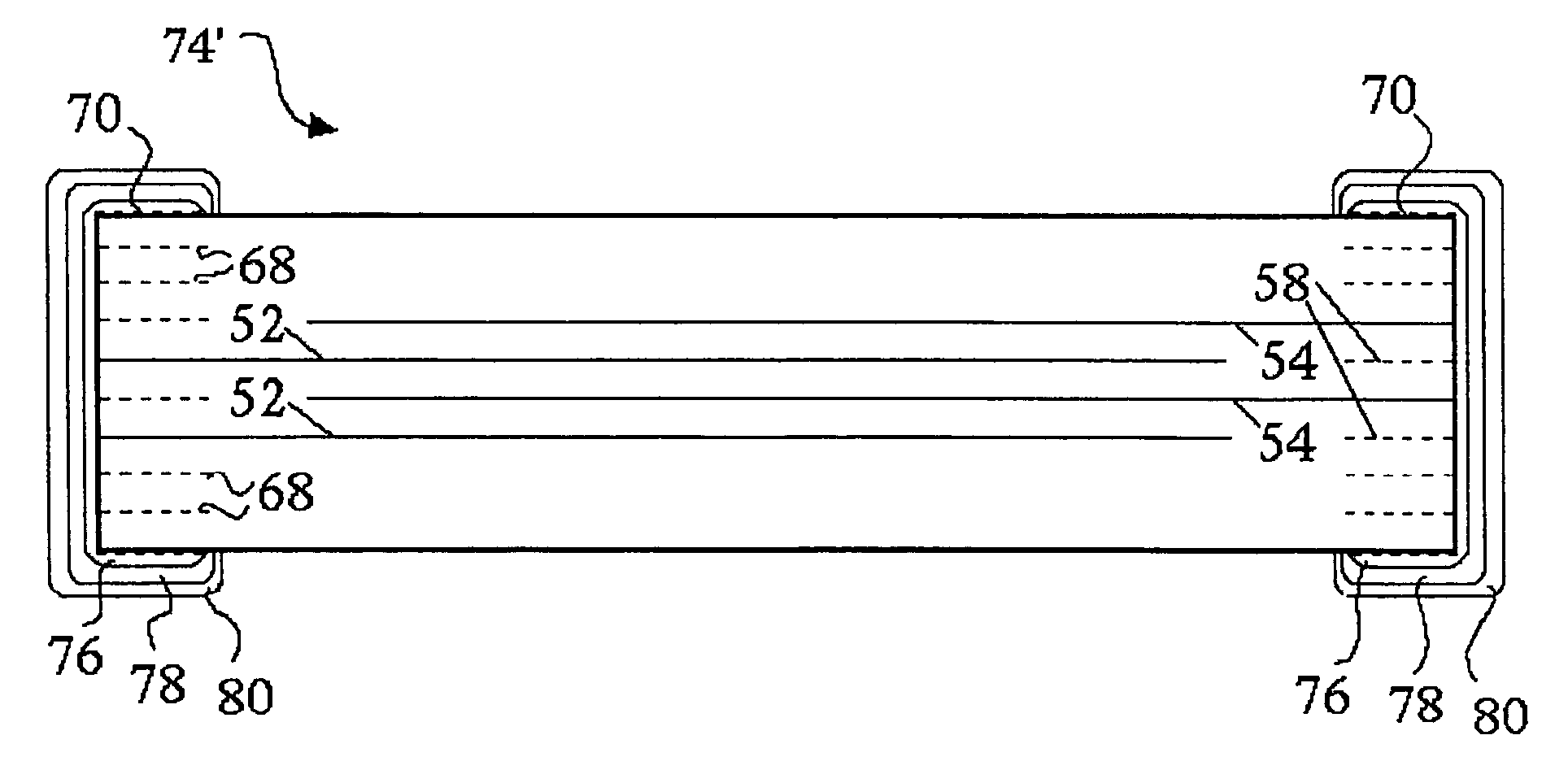

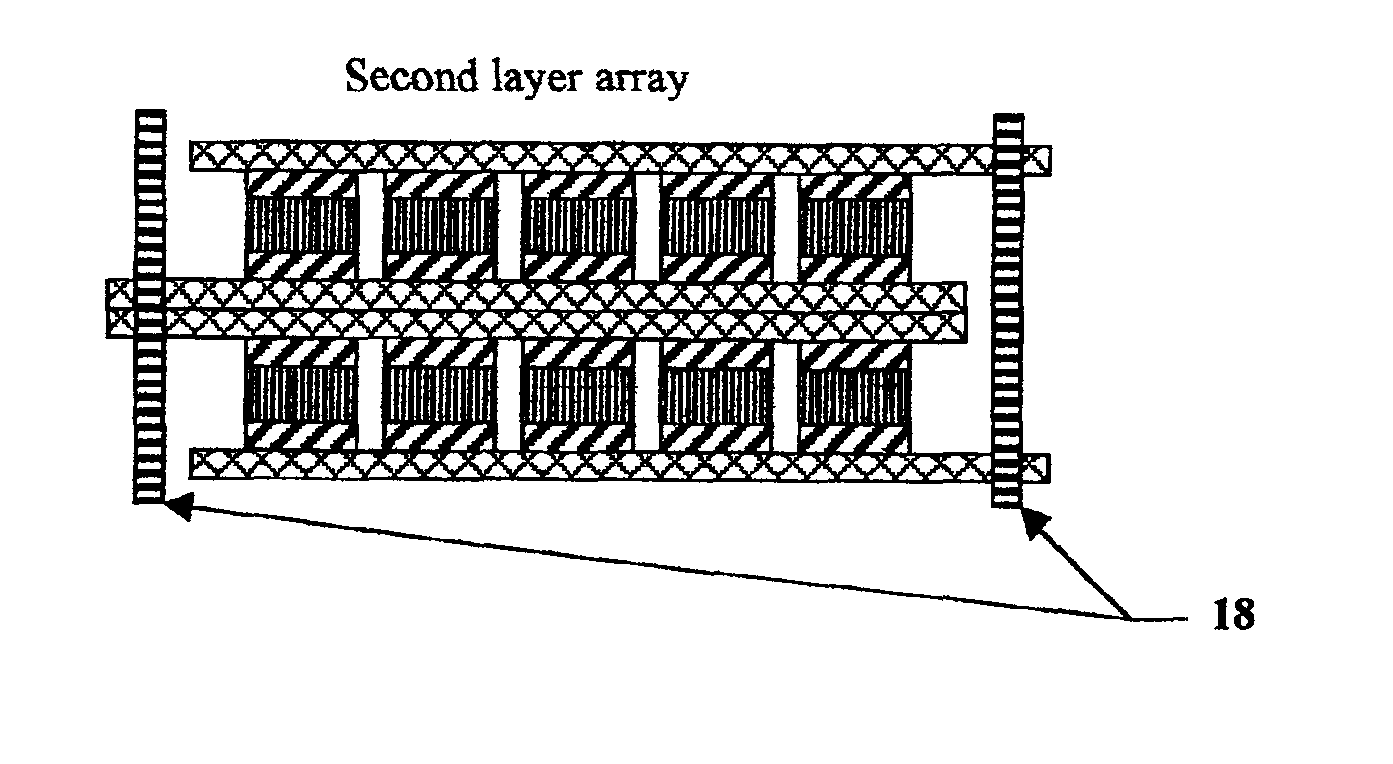

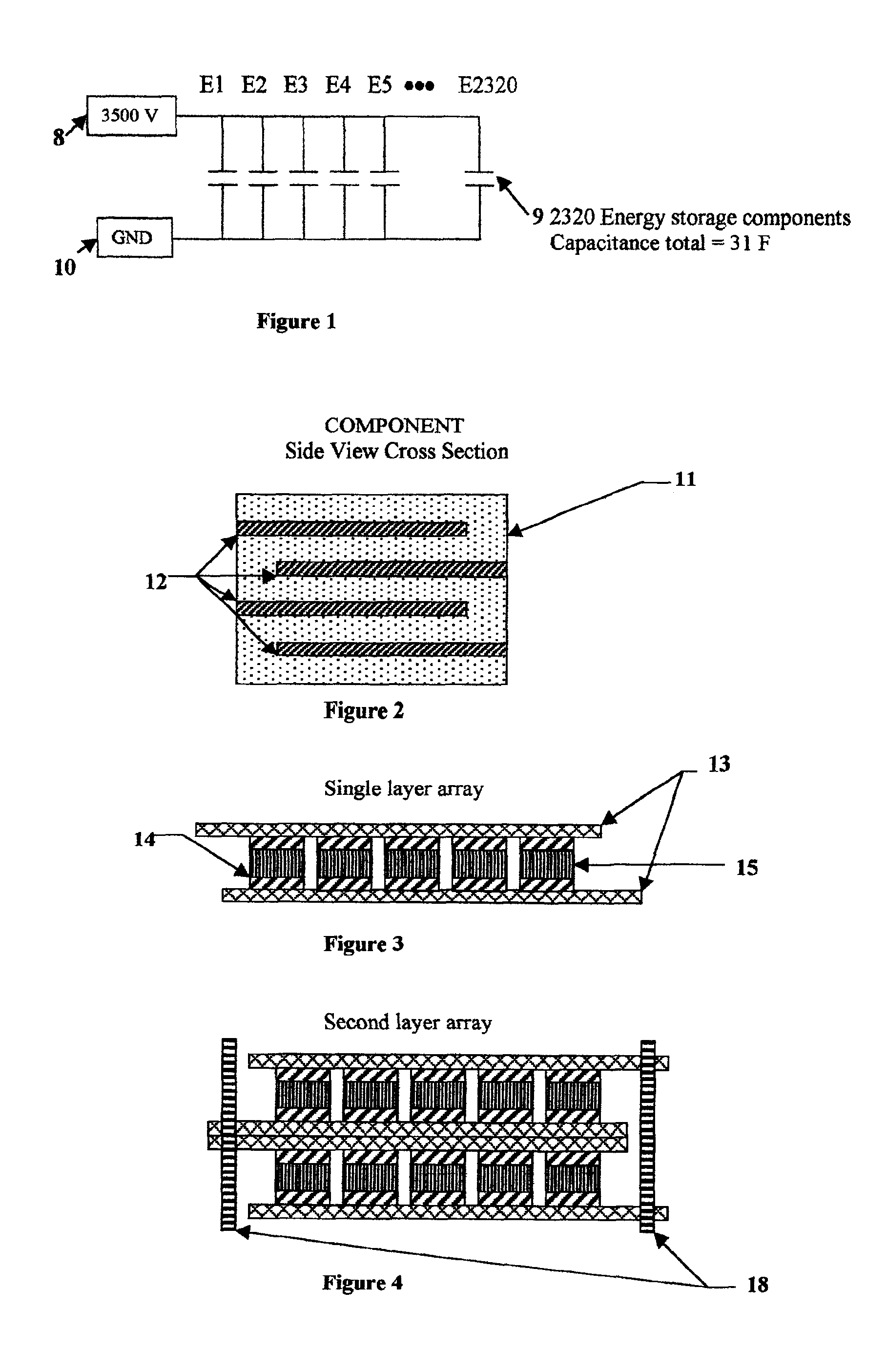

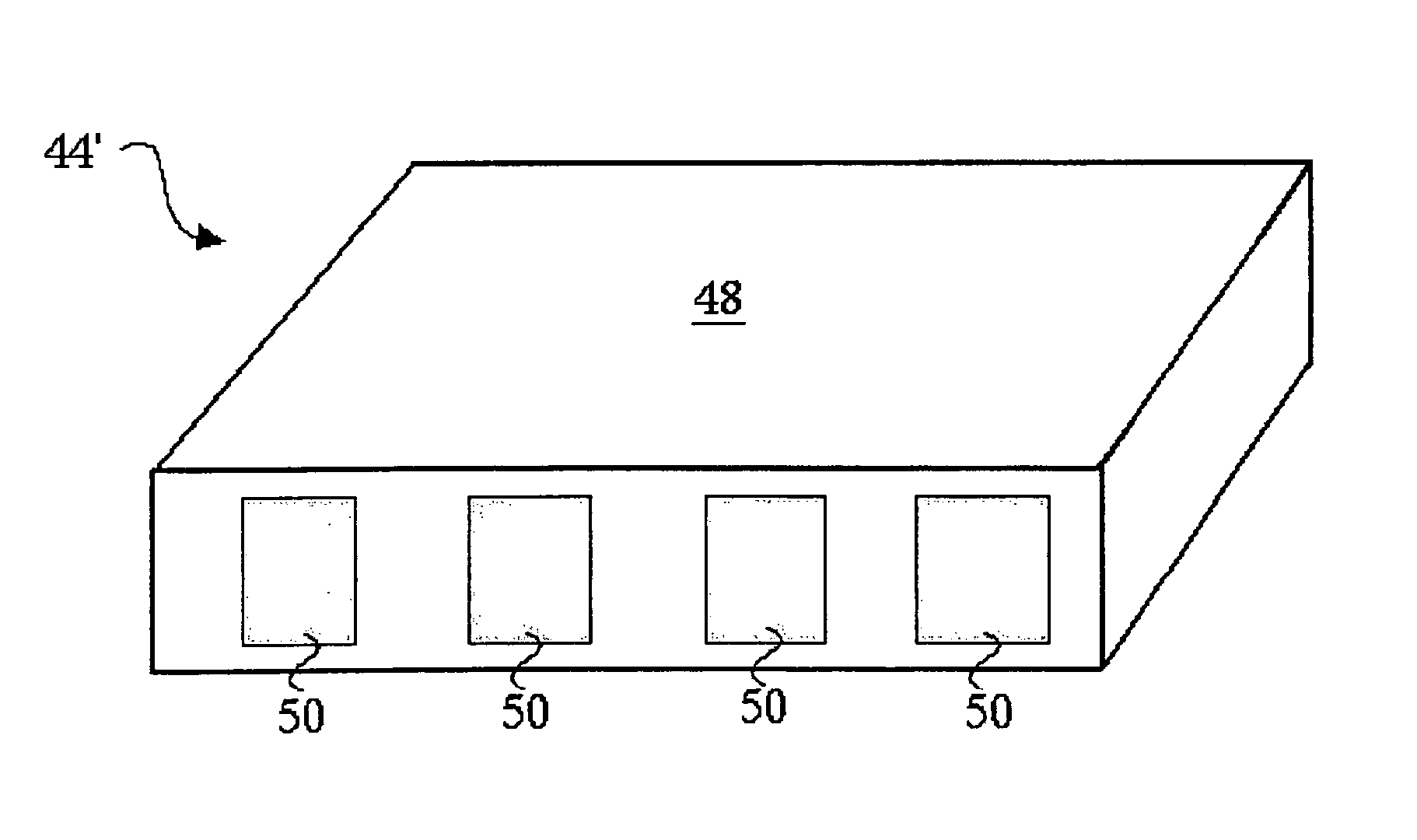

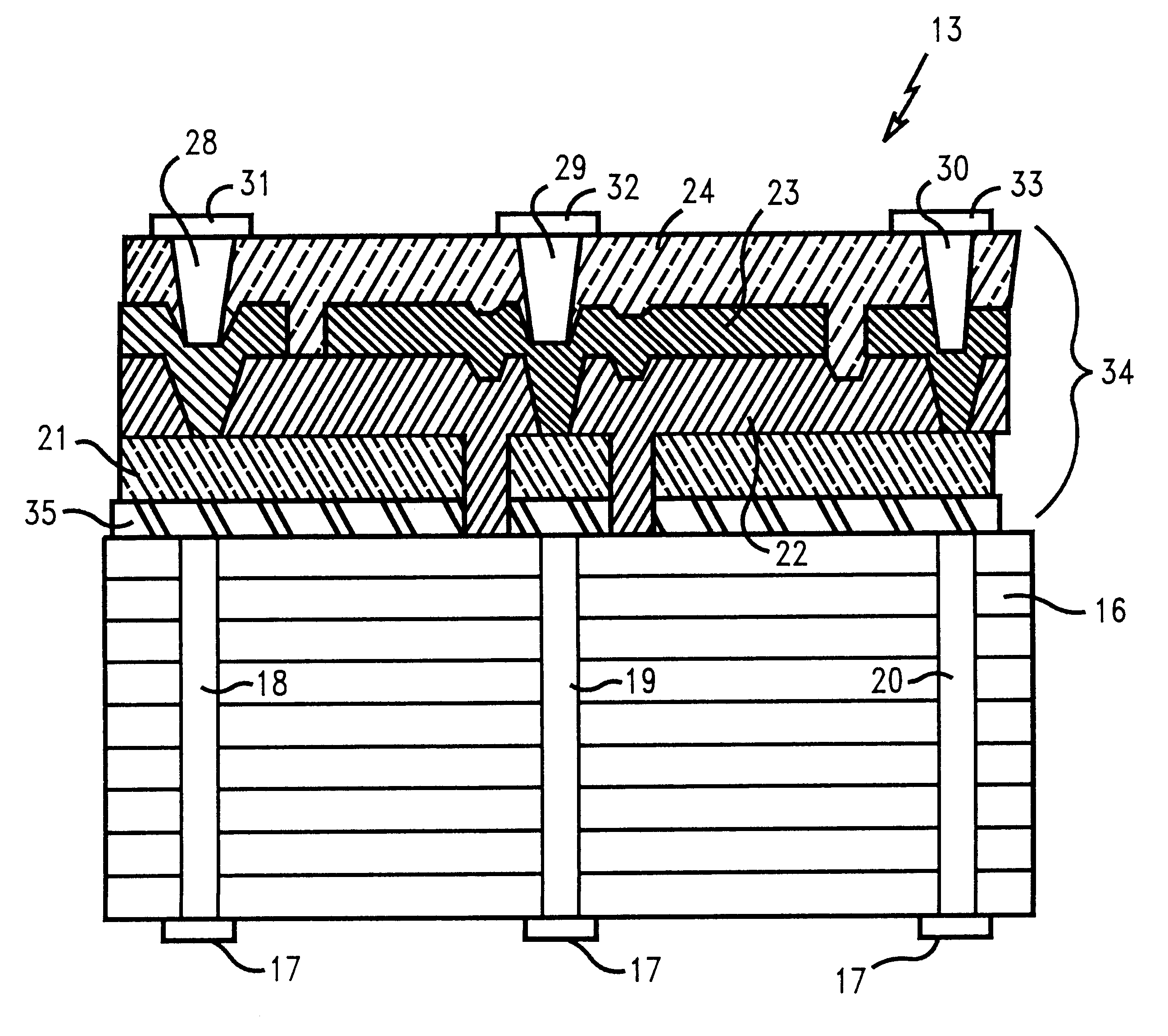

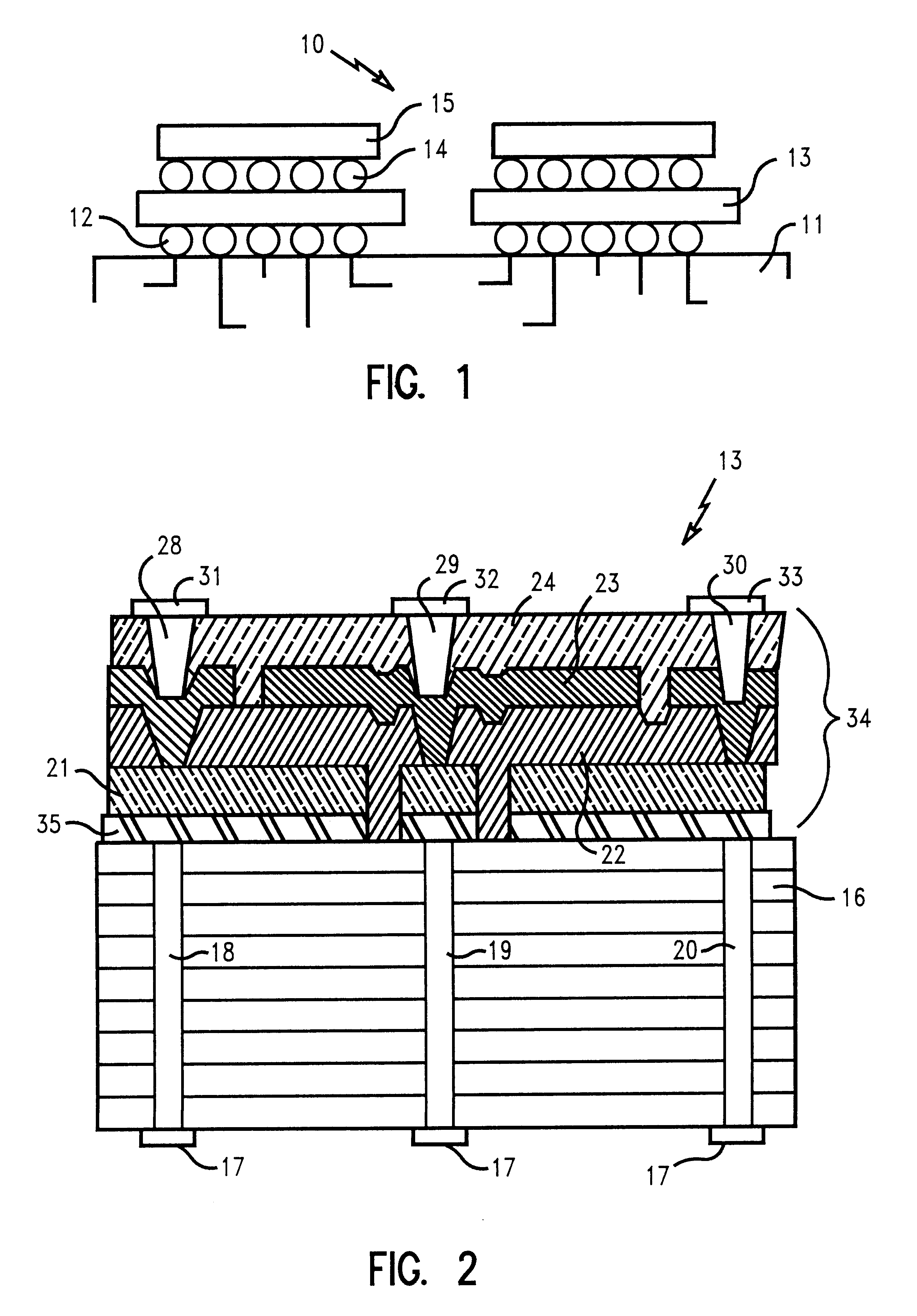

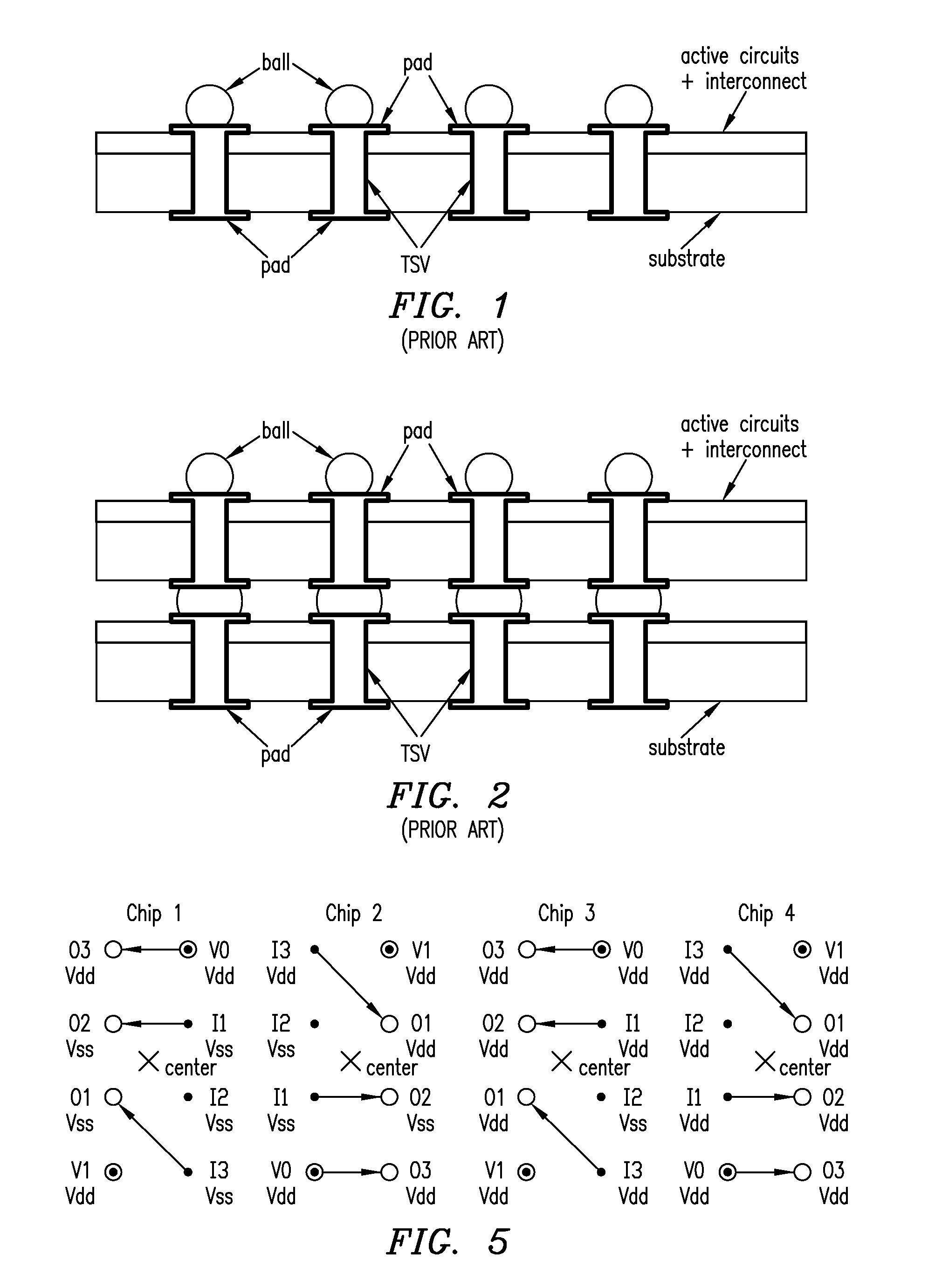

Electrical-energy-storage unit (EESU) utilizing ceramic and integrated-circuit technologies for replacement of electrochemical batteries

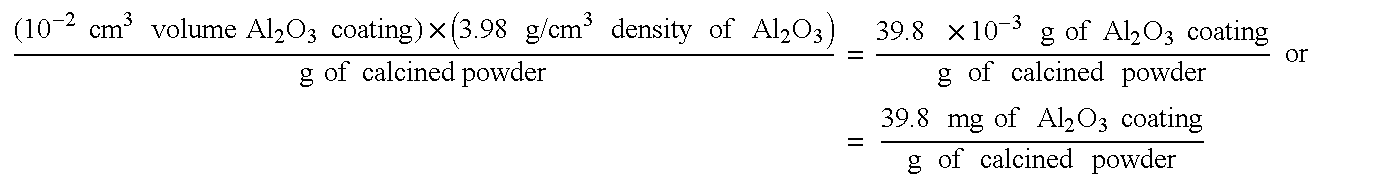

InactiveUS7033406B2Reduce sinteringLowering hot-isostatic-pressing temperatureElectrical storage systemFixed capacitor electrodesBarium titanatePermittivity

An electrical-energy-storage unit (EESU) has as a basis material a high-permittivity composition-modified barium titanate ceramic powder. This powder is double coated with the first coating being aluminum oxide and the second coating calcium magnesium aluminosilicate glass. The components of the EESU are manufactured with the use of classical ceramic fabrication techniques which include screen printing alternating multilayers of nickel electrodes and high-permittivitiy composition-modified barium titanate powder, sintering to a closed-pore porous body, followed by hot-isostatic pressing to a void-free body. The components are configured into a multilayer array with the use of a solder-bump technique as the enabling technology so as to provide a parallel configuration of components that has the capability to store electrical energy in the range of 52 kW·h. The total weight of an EESU with this range of electrical energy storage is about 336 pounds.

Owner:EESTOR

Post-deposition encapsulation of nanostructures: compositions, devices and systems incorporating same

ActiveUS7267875B2Reduce and prevent other type of transmissionReduce probabilityMaterial nanotechnologyBoxes/cartons making machineryNanostructureNanometre

Ligand compositions for use in preparing discrete coated nanostructures are provided, as well as the coated nanostructures themselves and devices incorporating same. Methods for post-deposition shell formation on a nanostructure and for reversibly modifying nanostructures are also provided. The ligands and coated nanostructures of the present invention are particularly useful for close packed nanostructure compositions, which can have improved quantum confinement and / or reduced cross-talk between nanostructures.

Owner:WODEN TECH INC

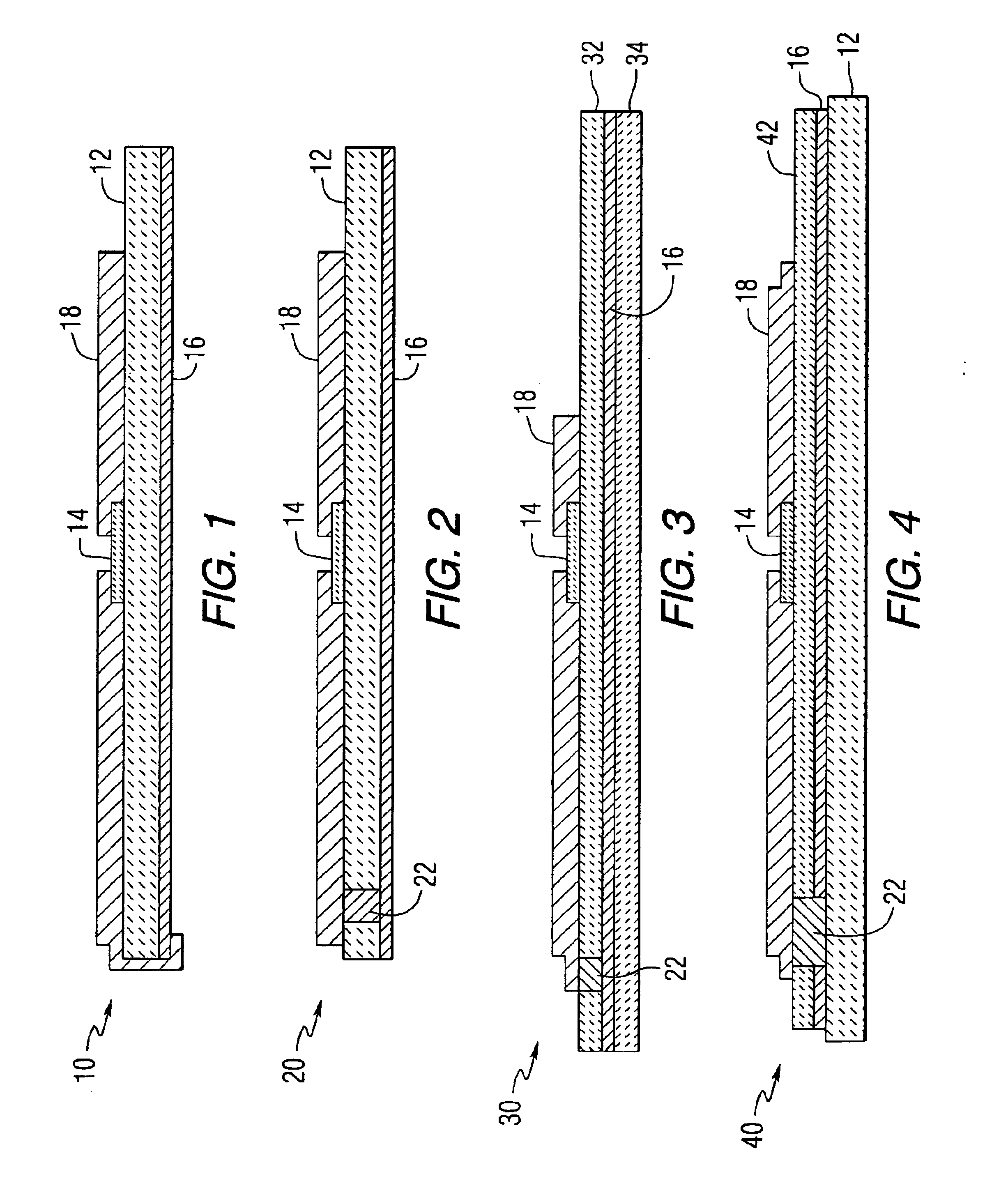

Plated terminations

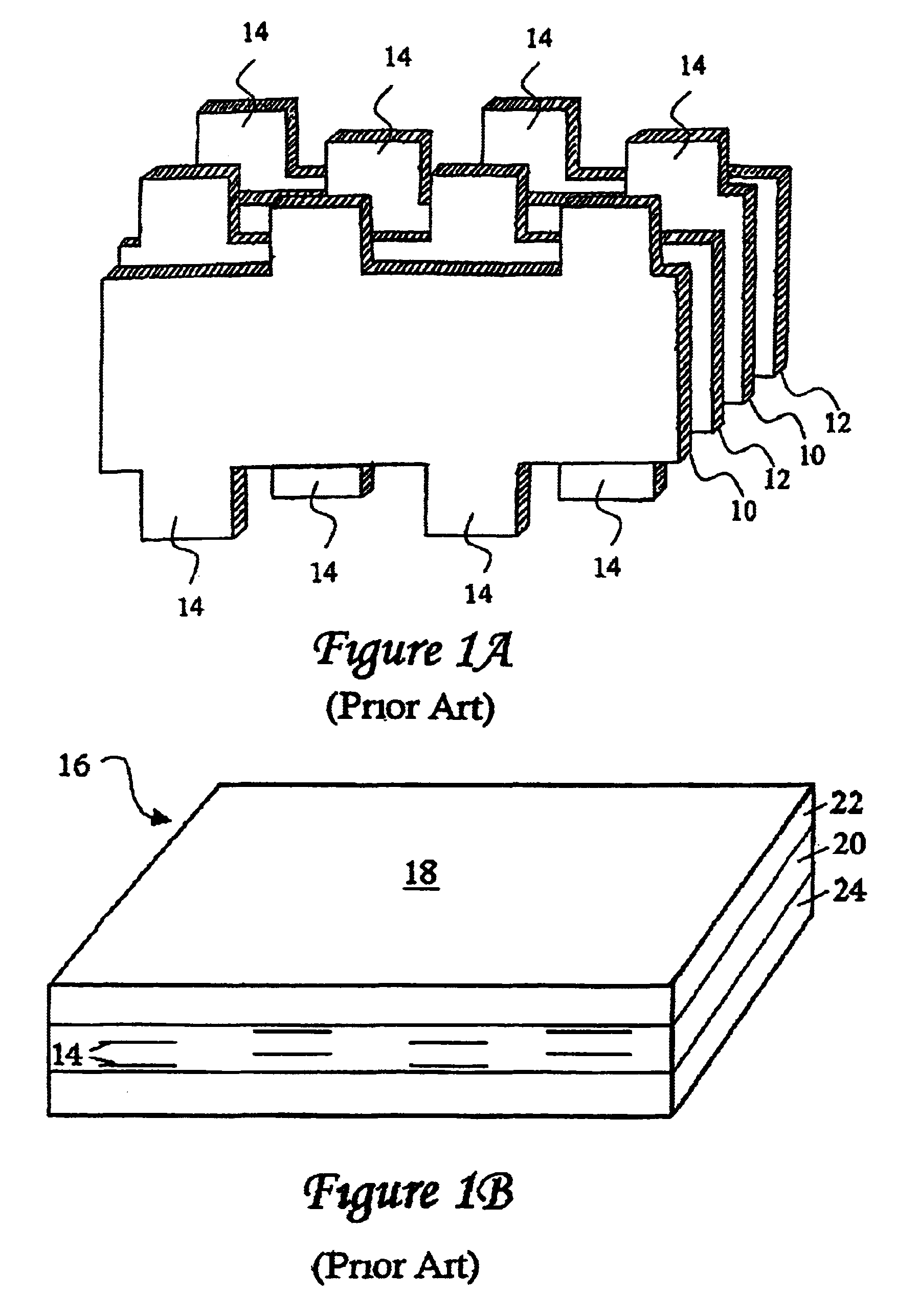

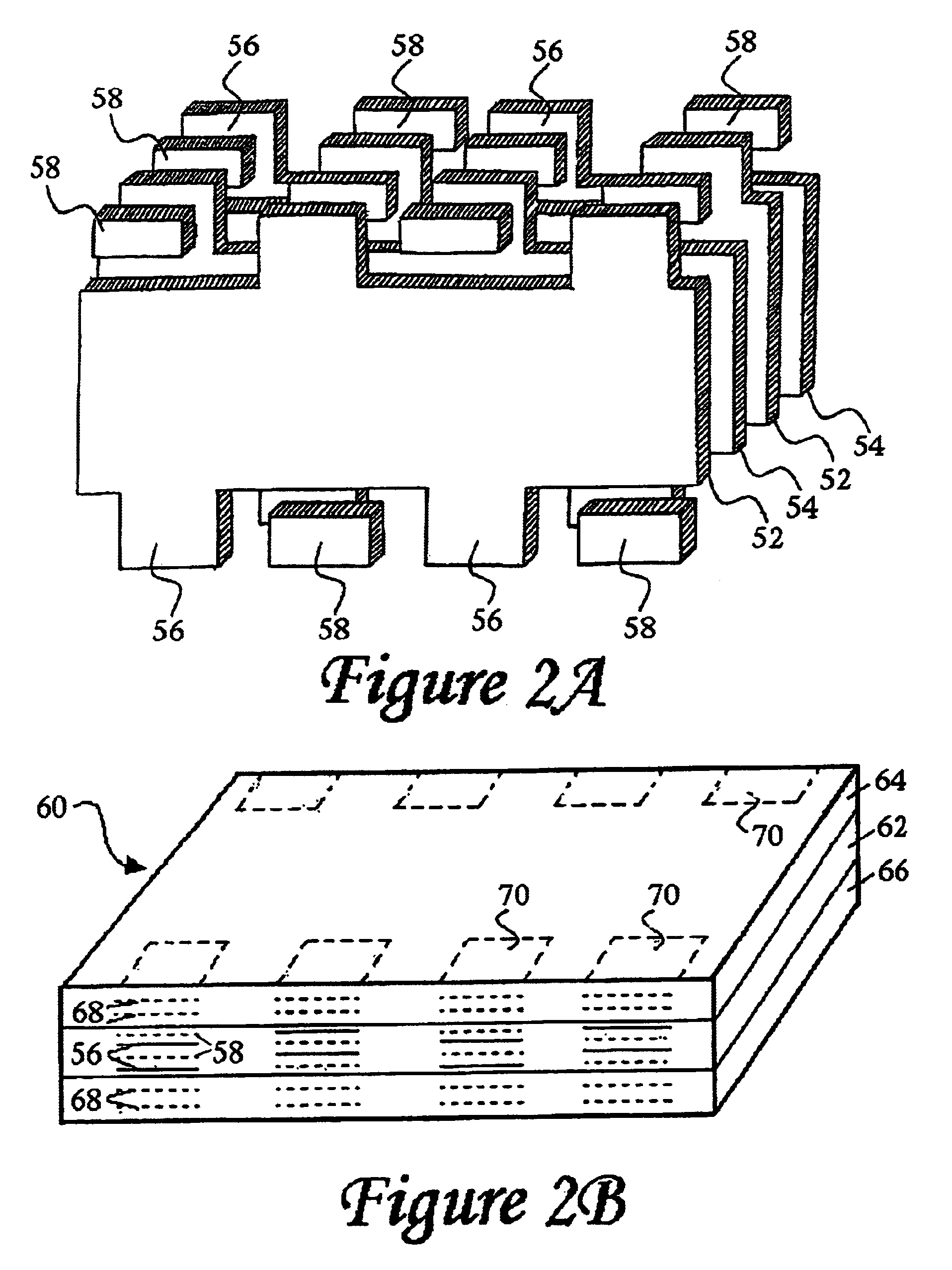

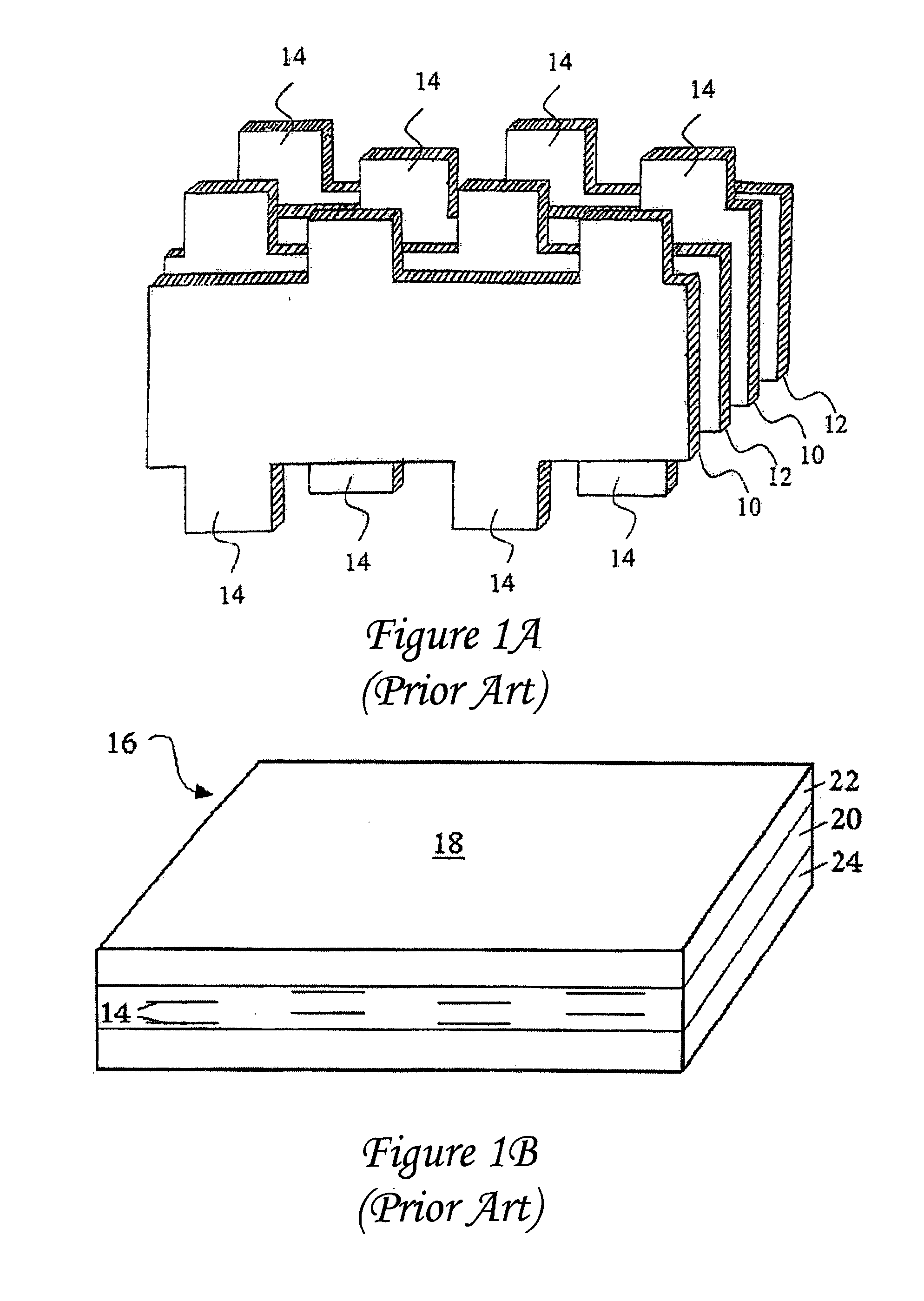

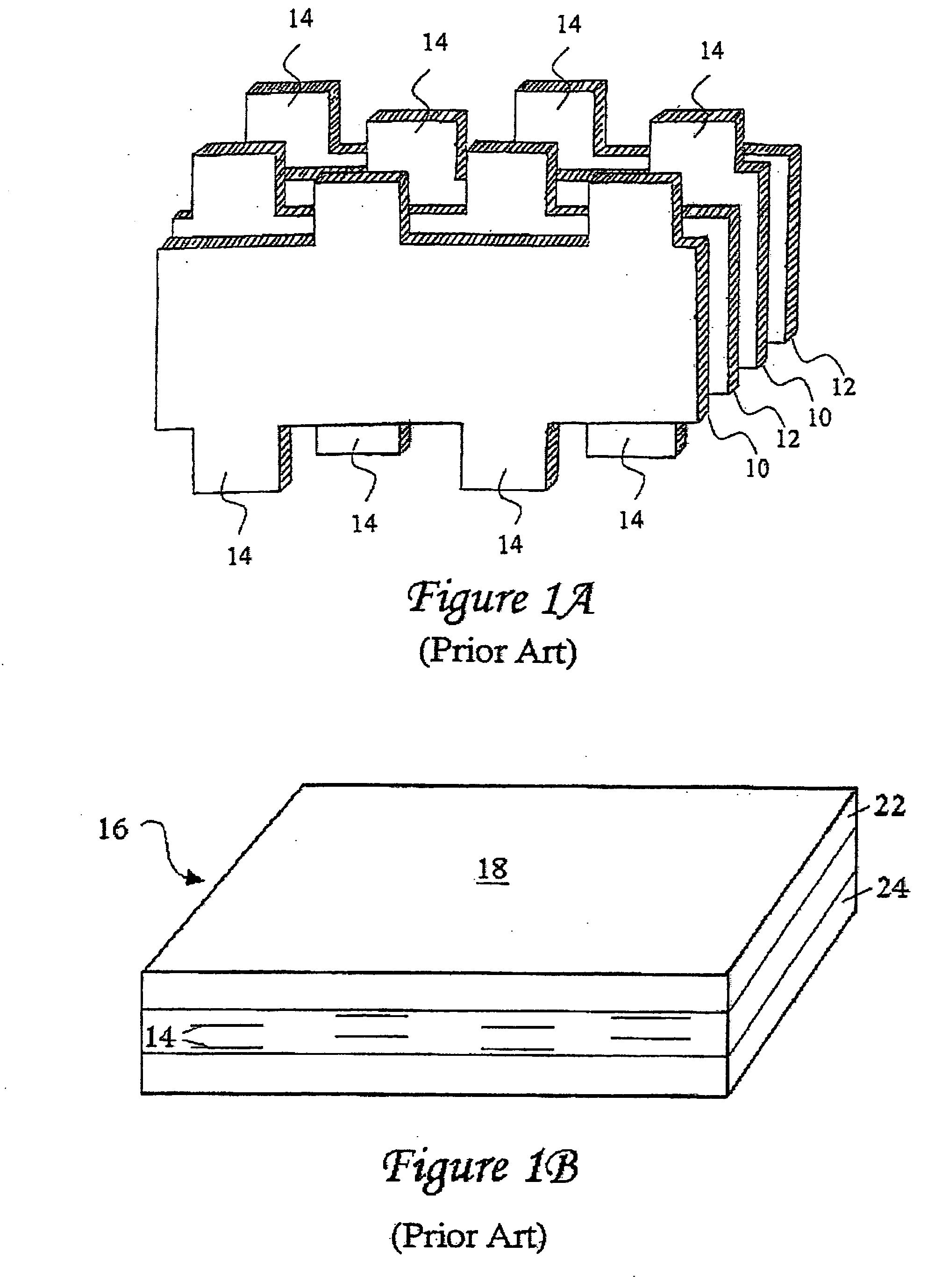

InactiveUS6960366B2Improved termination featureEliminate and greatly simplifyResistor terminals/electrodesFinal product manufactureTermination problemEngineering

Improved termination features for multilayer electronic components are disclosed. Monolithic components are provided with plated terminations whereby the need for typical thick-film termination stripes is eliminated or greatly simplified. Such termination technology eliminates many typical termination problems and enables a higher number of terminations with finer pitch, which may be especially beneficial on smaller electronic components. The subject plated terminations are guided and anchored by exposed internal electrode tabs and additional anchor tab portions which may optionally extend to the cover layers of a multilayer component. Such anchor tabs may be positioned internally or externally relative to a chip structure to nucleate additional metallized plating material. External anchor tabs positioned on one or both of top and bottom surfaces of a monolithic structure can facilitate the formation of selective wrap-around plated terminations. The disclosed technology may be utilized with a plurality of monolithic multilayer components, including interdigitated capacitors, multilayer capacitor arrays, and integrated passive components. A variety of different plating techniques and termination materials may be employed in the formation of the subject self-determining plated terminations.

Owner:KYOCERA AVX COMPONENTS CORP

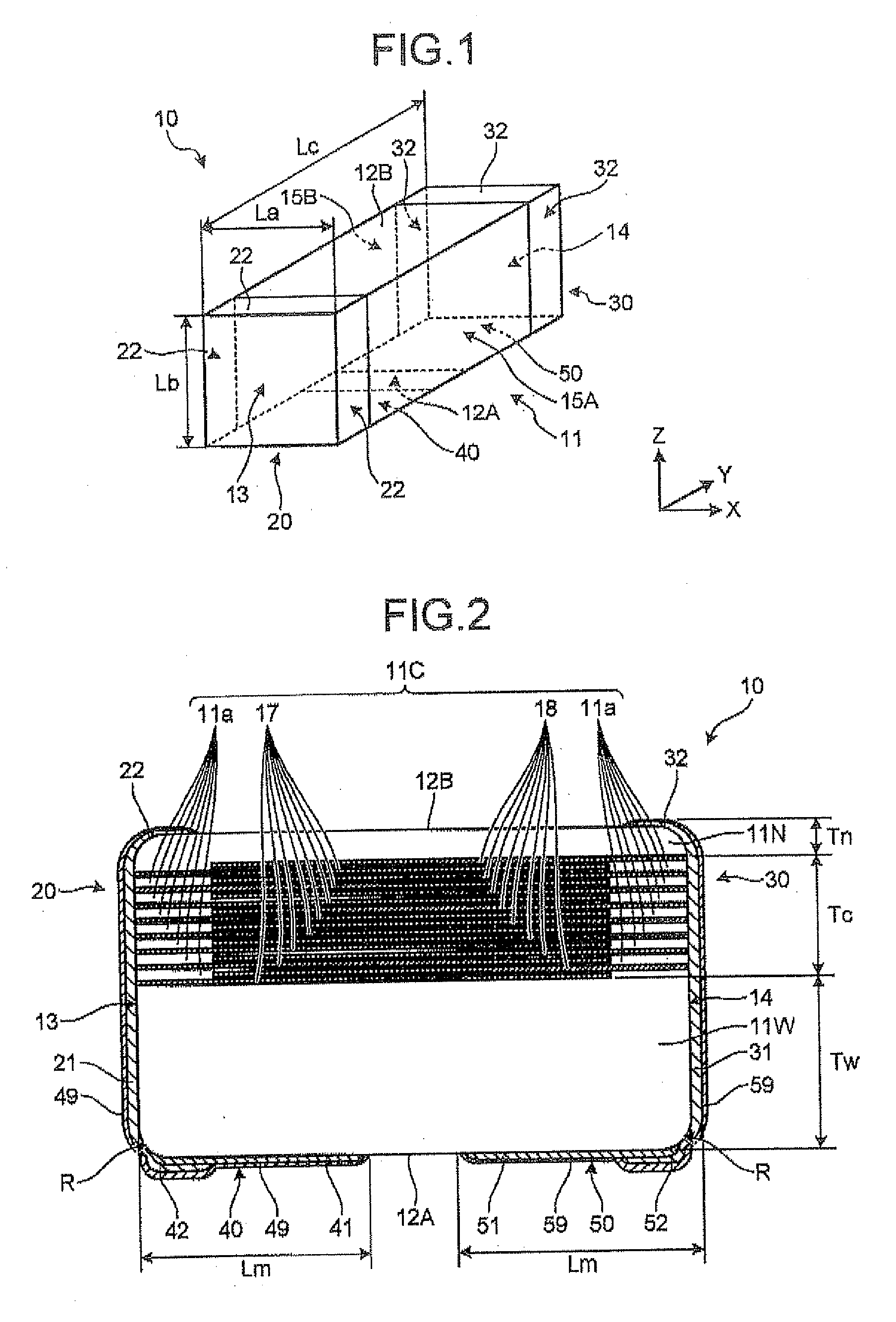

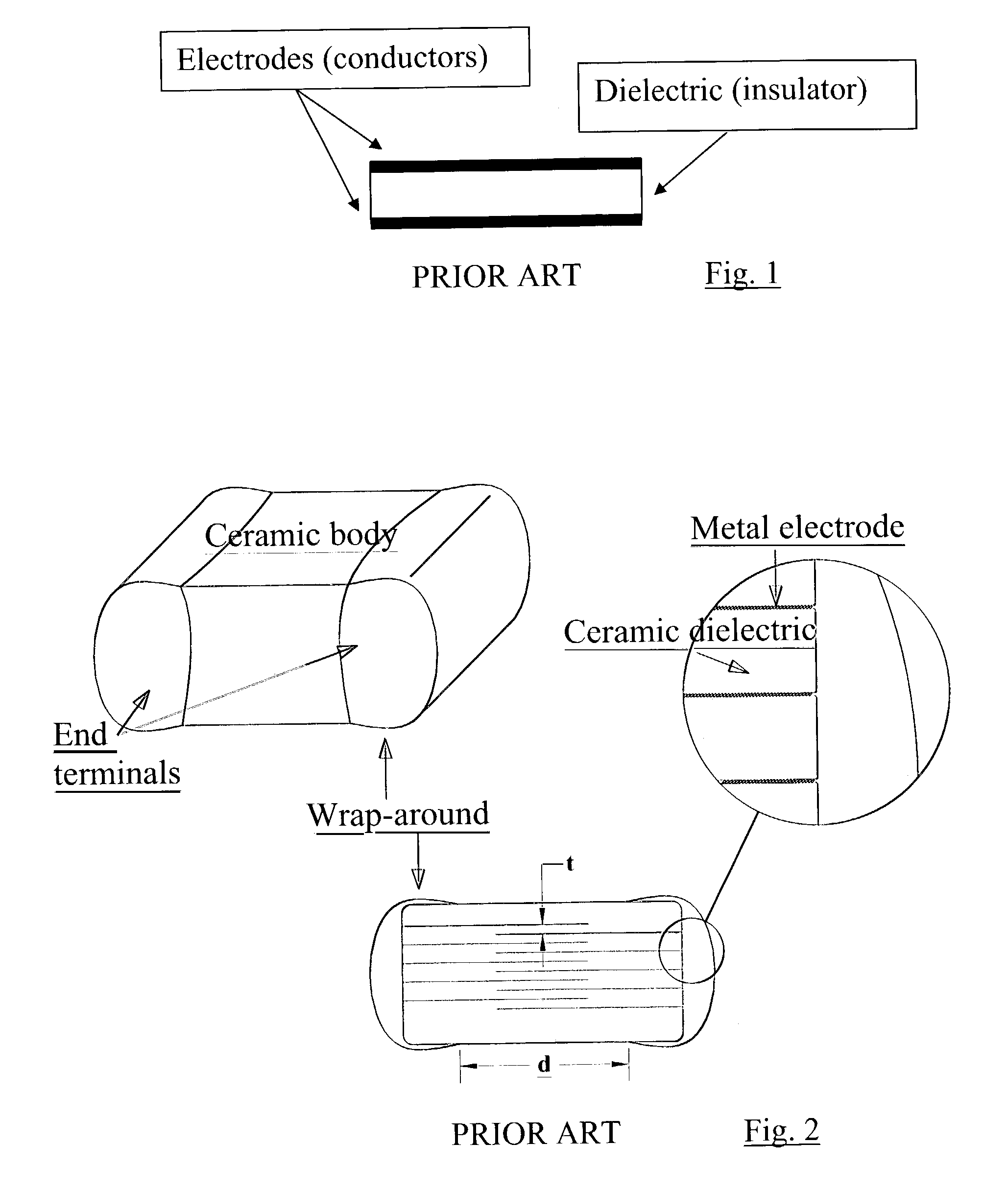

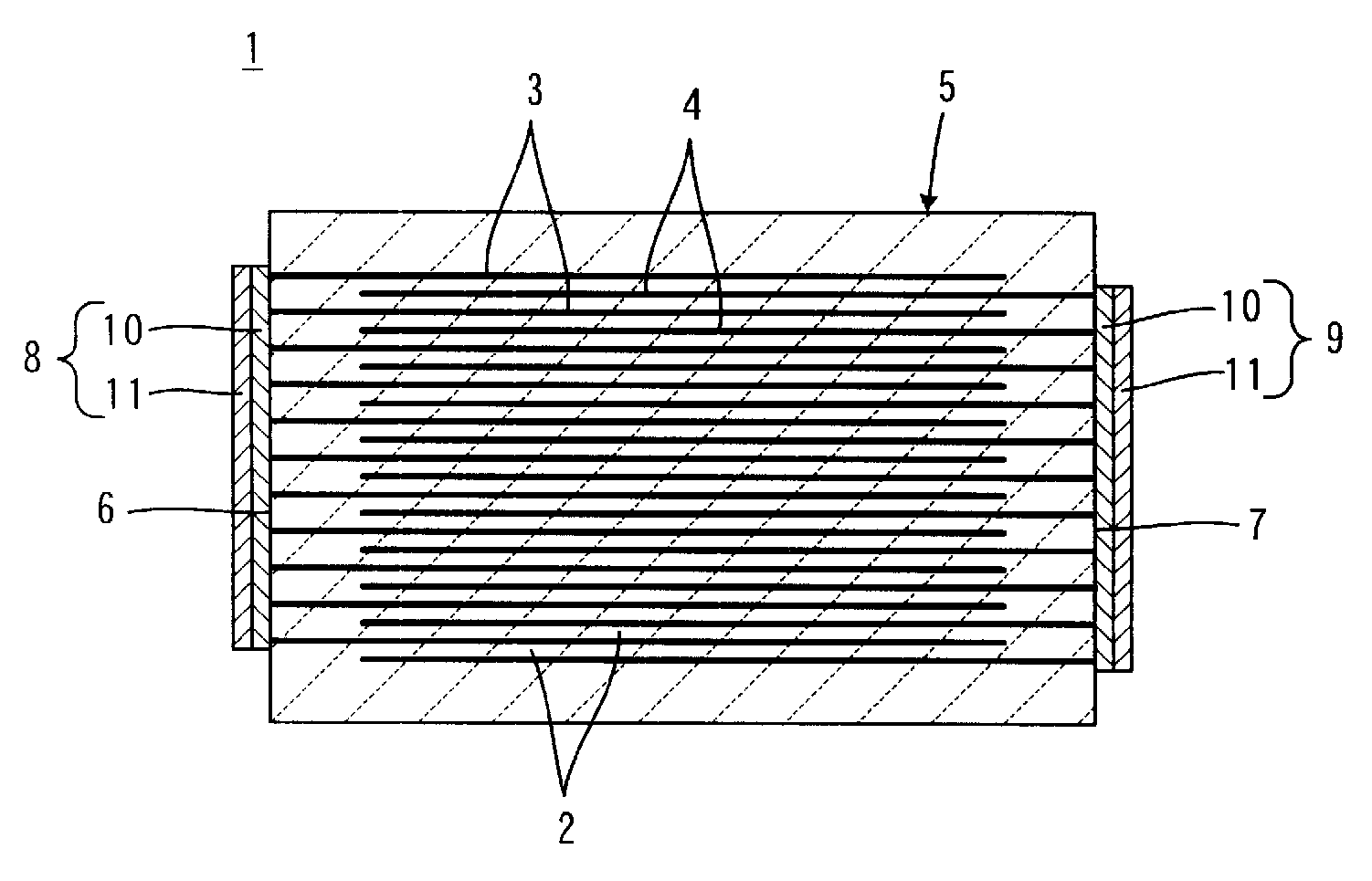

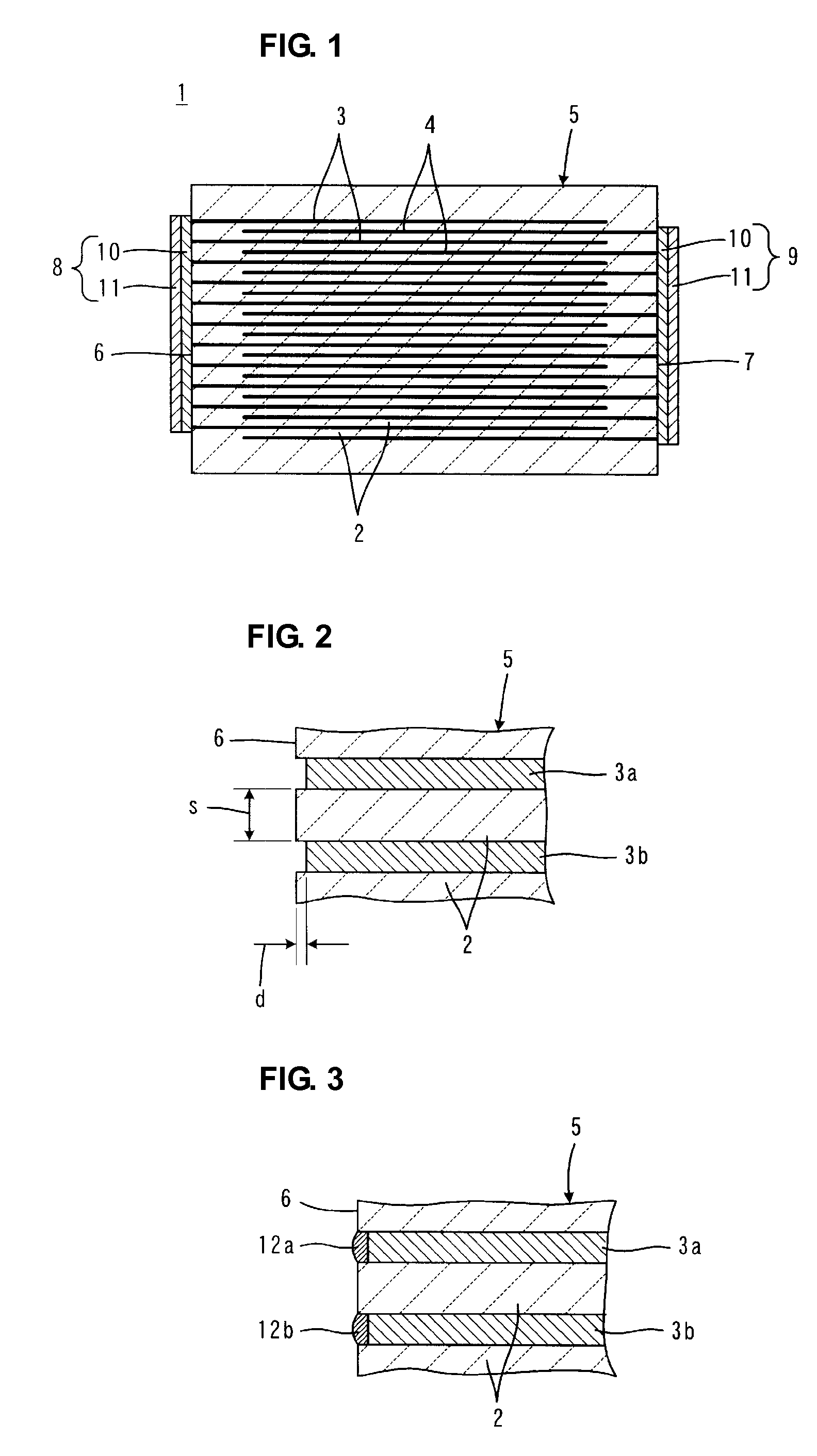

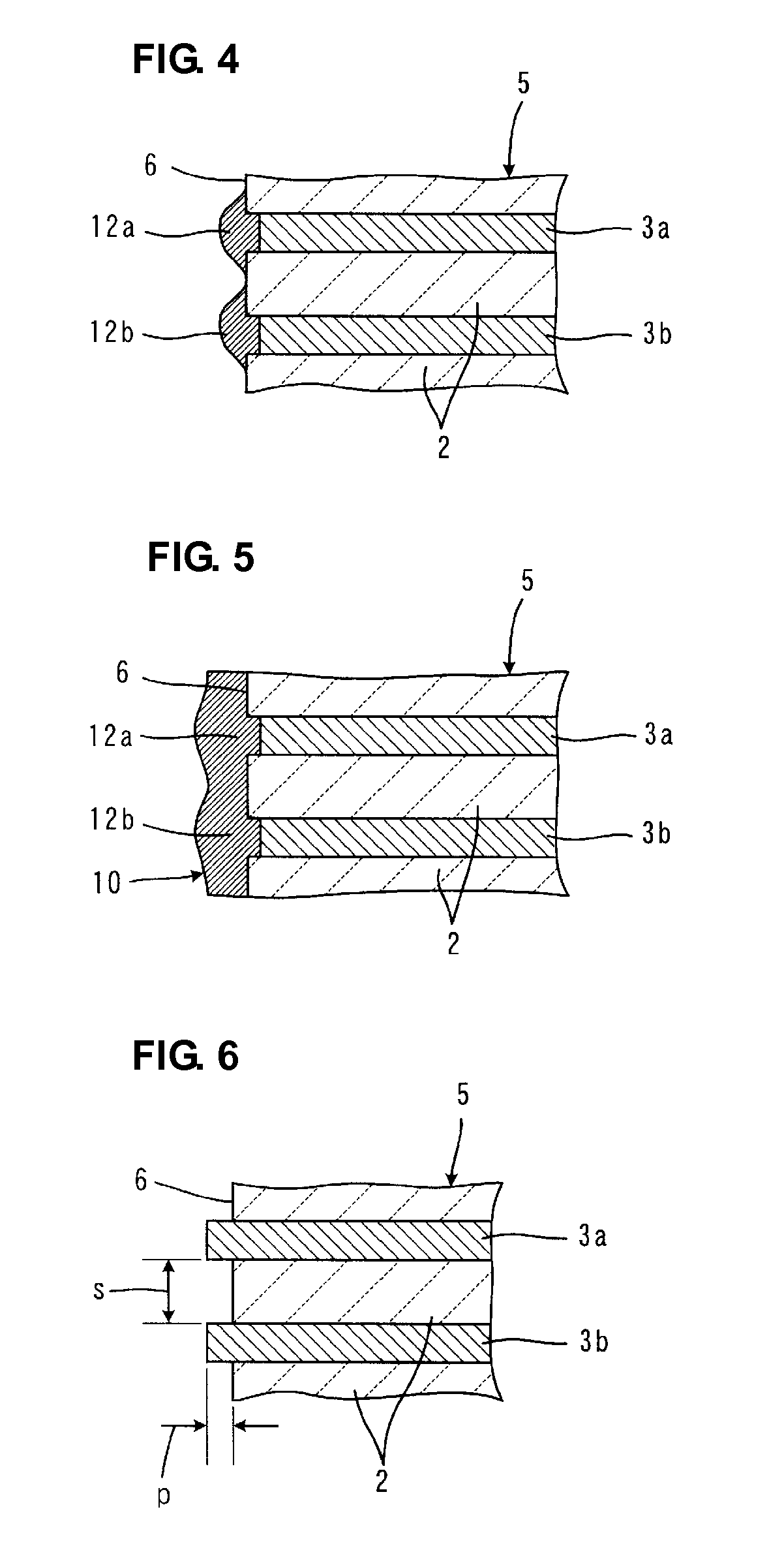

Multilayer capacitor and method for manufacturing the same

In a multilayer capacitor, a first dielectric layered product including a first body principal face is formed to be thicker than a second dielectric layered product including a second body principal face in a stacking direction thereof. A first external electrode and a second external electrode extend only to the first body principal face from a first body end face and a second body end face. Alternatively, the first external electrode and the second external electrode extend at least to the first body principal face from the first body end face and the second body end face and extend also to at least one of the second body principal face, a first body lateral face, and a second body lateral face.

Owner:TDK CORPARATION

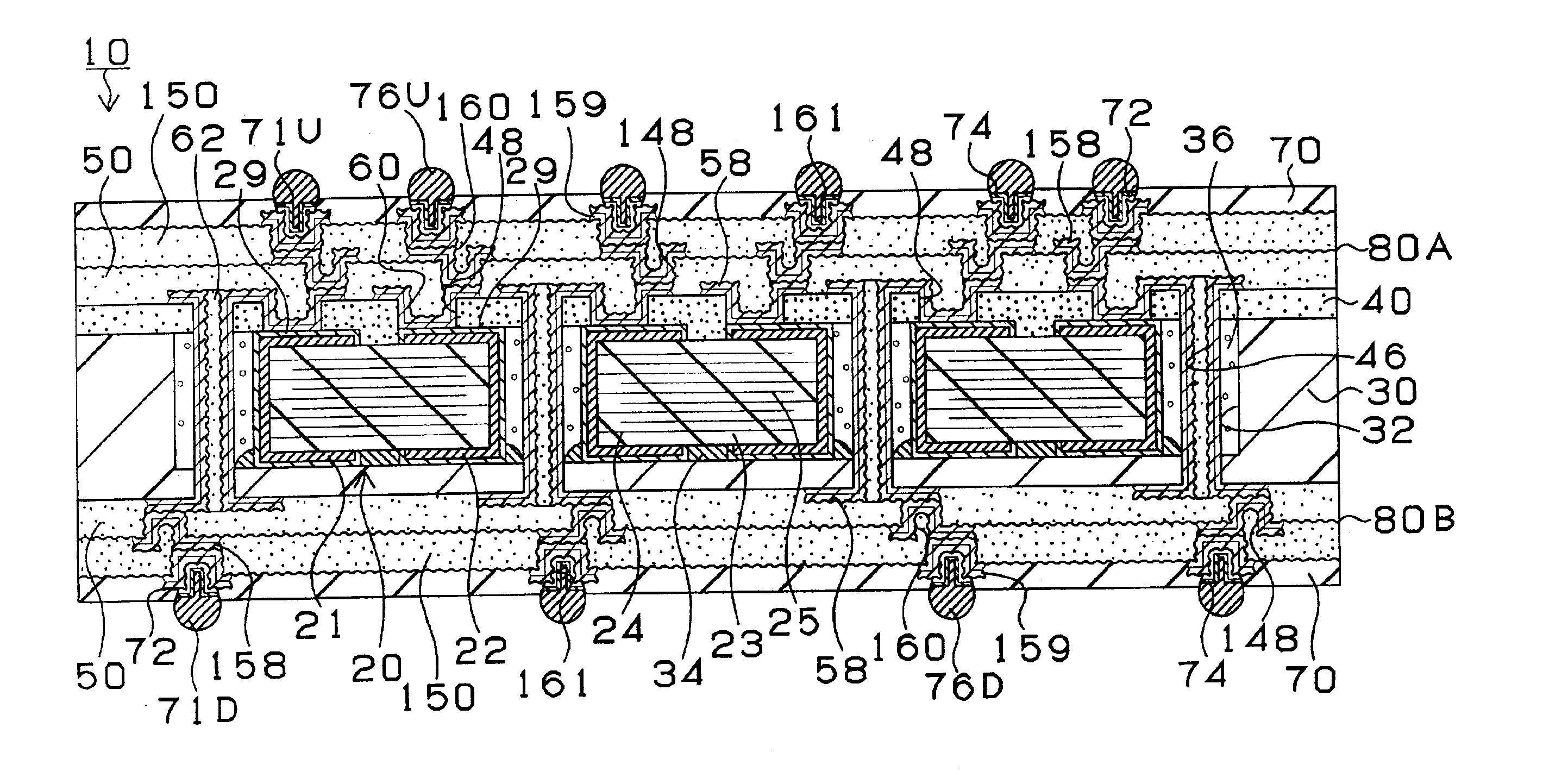

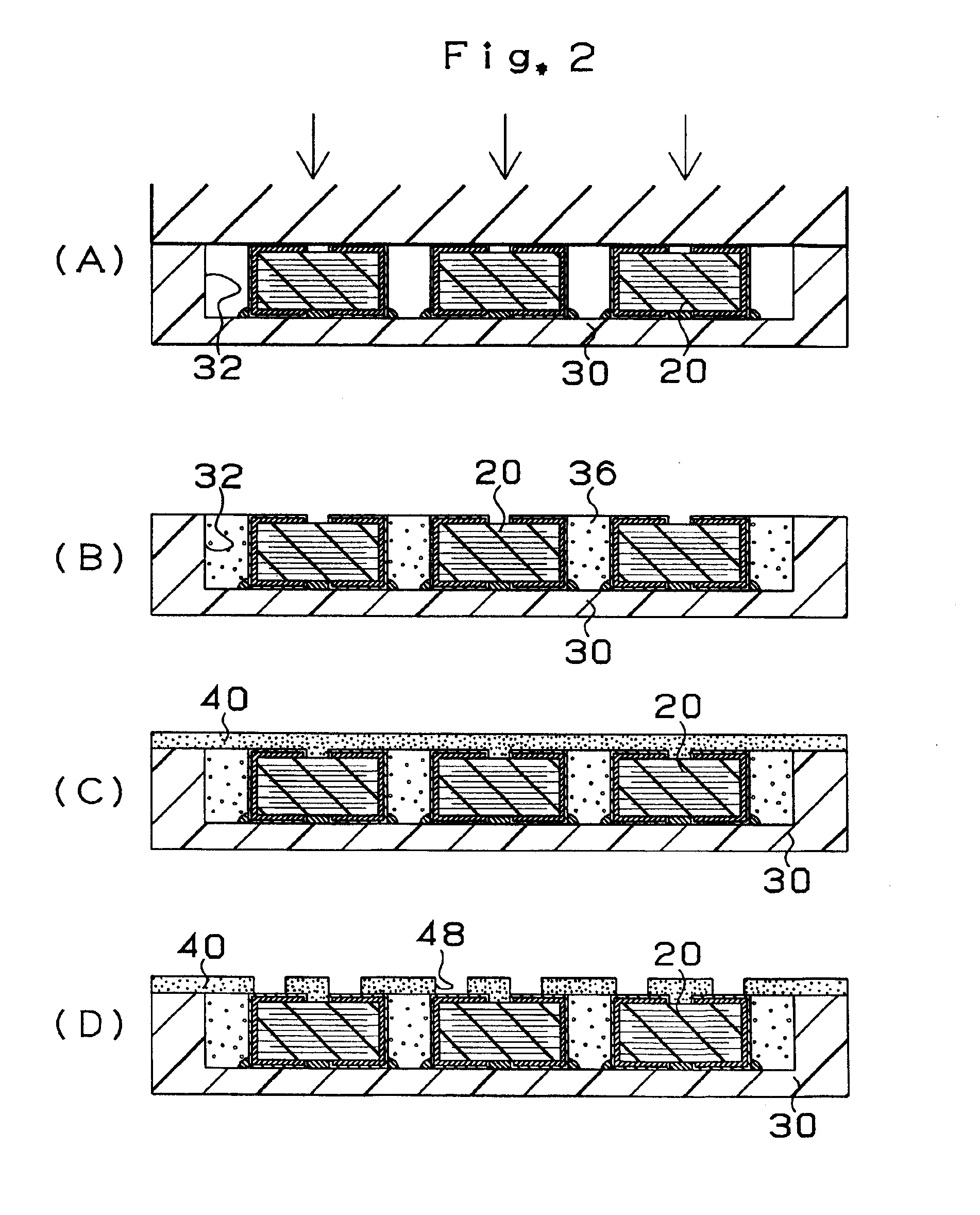

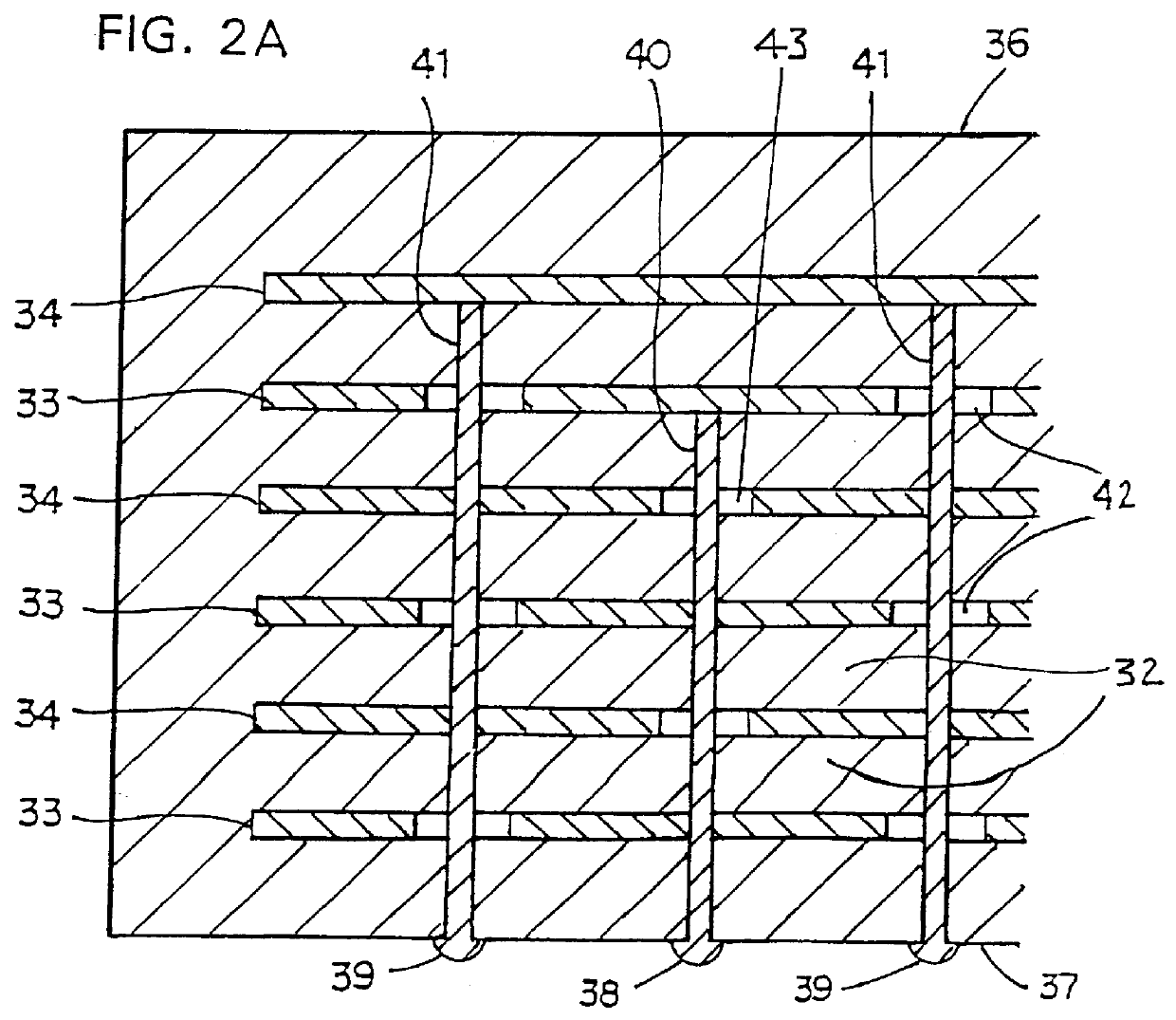

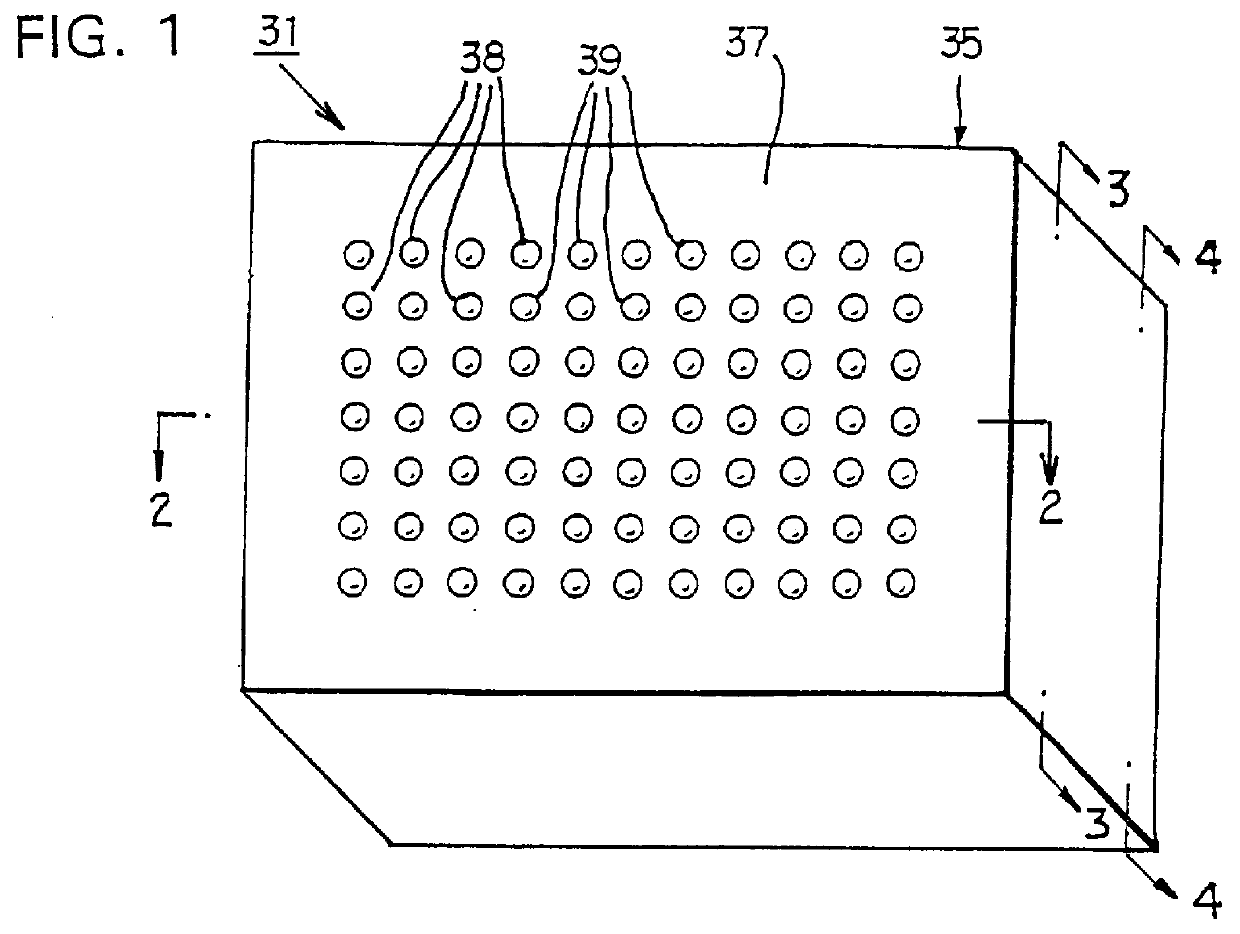

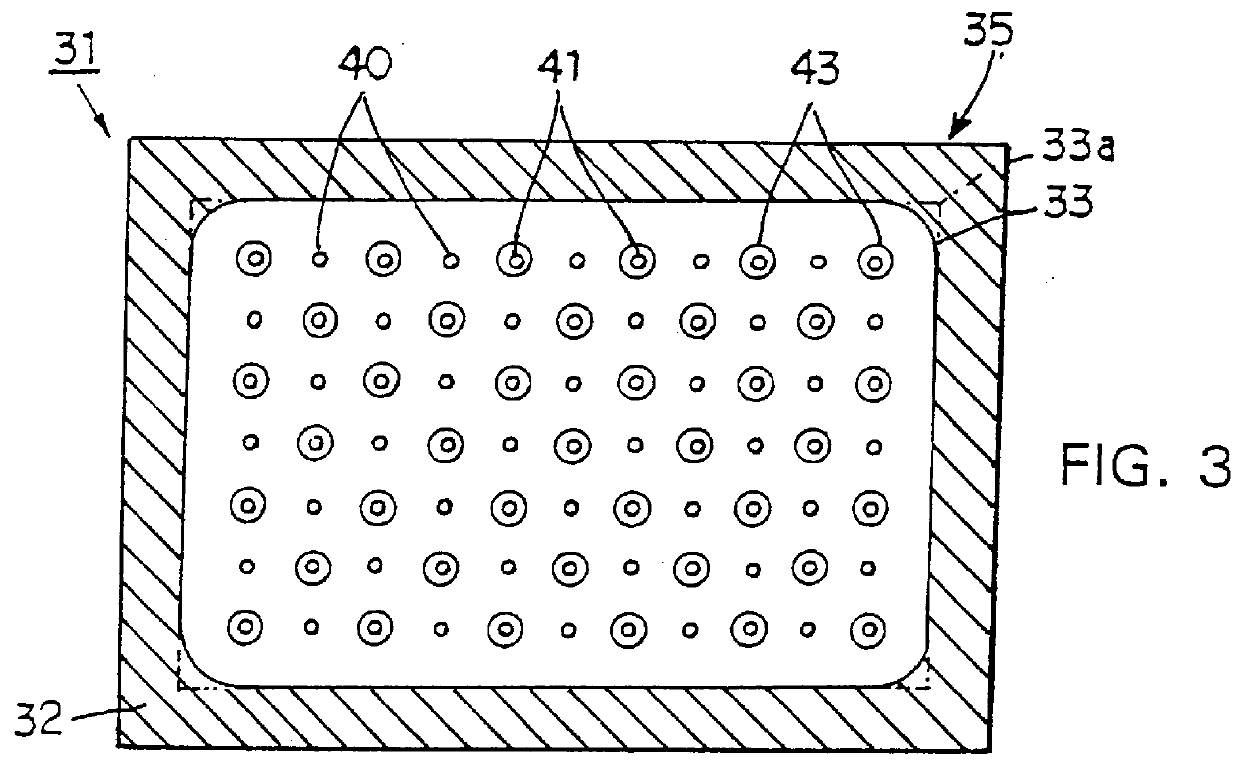

Printing wiring board and method of producing the same and capacitor to be contained in printed wiring board

InactiveUS6876554B1Improve reliabilityFlat surfaceFinal product manufactureSemiconductor/solid-state device detailsEngineeringPrinted circuit board

Chip capacitors 20 are provided in a printed circuit board 10. In this manner, the distance between an IC chip 90 and each chip capacitor 20 is shortened, and the loop inductance is reduced. In addition, the chip capacitors 20 are accommodated in a core substrate 30 having a large thickness. Therefore, the thickness of the printed circuit board does not become large.

Owner:IBIDEN CO LTD

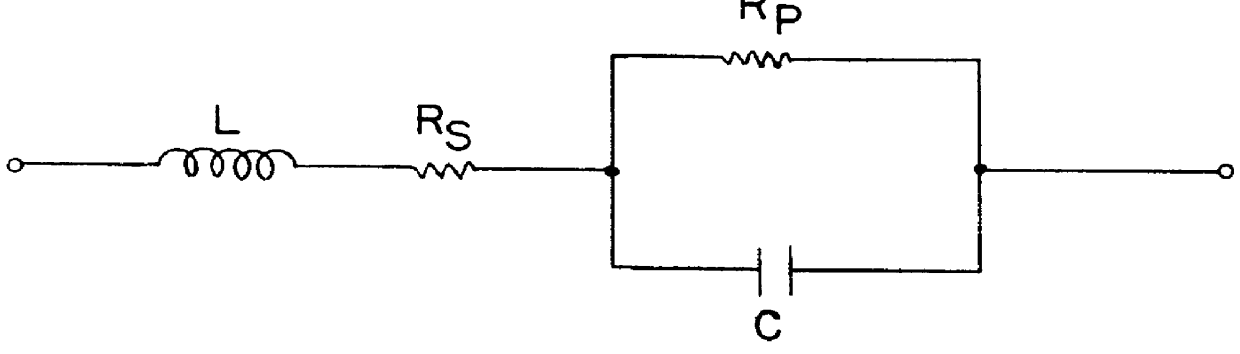

Multilayer capacitor

First and second external terminal electrodes are formed on the same principal surface of a capacitor main body. The connection between first internal electrodes in the capacitor main body, the first external terminal electrode and the mutual connection between the plurality of first internal electrodes is achieved by a first connection portion. The connection between second internal electrodes, the second external terminal electrode and the mutual connection between the plurality of second internal electrodes is achieved by a second connection portion. The first and second connection portions are arranged alternately. Currents flow through the connection portions in opposite directions with the result that components of magnetic flux generated by such currents are cancelled and the ESL is reduced.

Owner:MURATA MFG CO LTD

Plated terminations and method of forming using electrolytic plating

InactiveUS20070014075A1Improved termination featureEliminate and greatly simplifyElectrolytic capacitorsResistor terminals/electrodesCombined useEngineering

A multilayer electronic component includes a plurality of dielectric layers interleaved with a plurality of internal electrodes. Internal and / or external anchor tabs may also be selectively interleaved with the dielectric layers. Portions of the internal electrodes and anchor tabs are exposed along the periphery of the electronic component in respective groups. Each exposed portion is within a predetermined distance from other exposed portions in a given group such that termination structures may be formed by deposition and controlled bridging of a thin-film plated material among selected of the exposed internal conductive elements. Electrolytic plating may be employed in conjunction with optional cleaning and annealing steps to form directly plated portions of copper, nickel or other conductive material. Once an initial thin-film metal is directly plated to a component periphery, additional portions of different materials may be plated thereon.

Owner:KYOCERA AVX COMPONENTS CORP

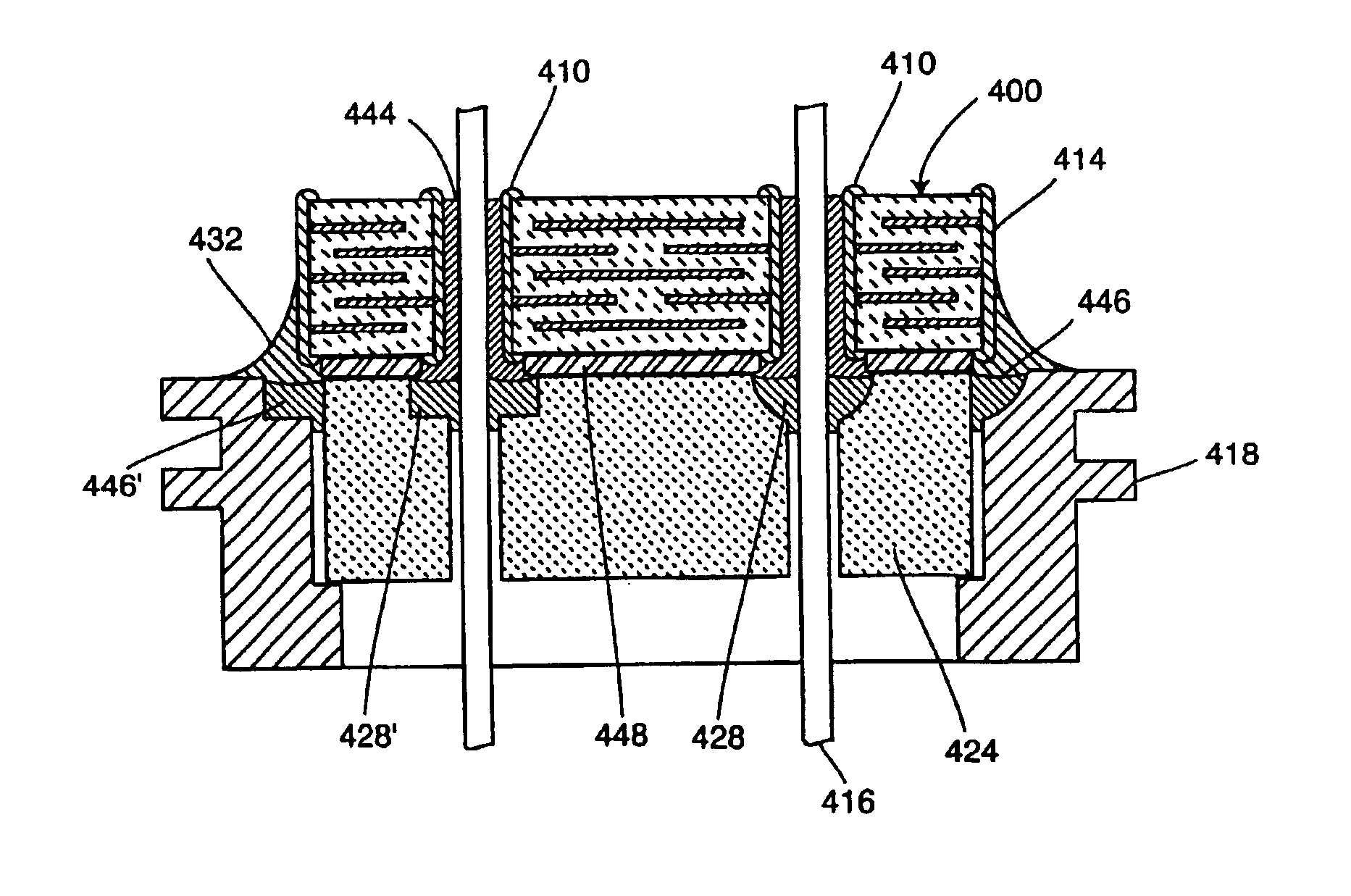

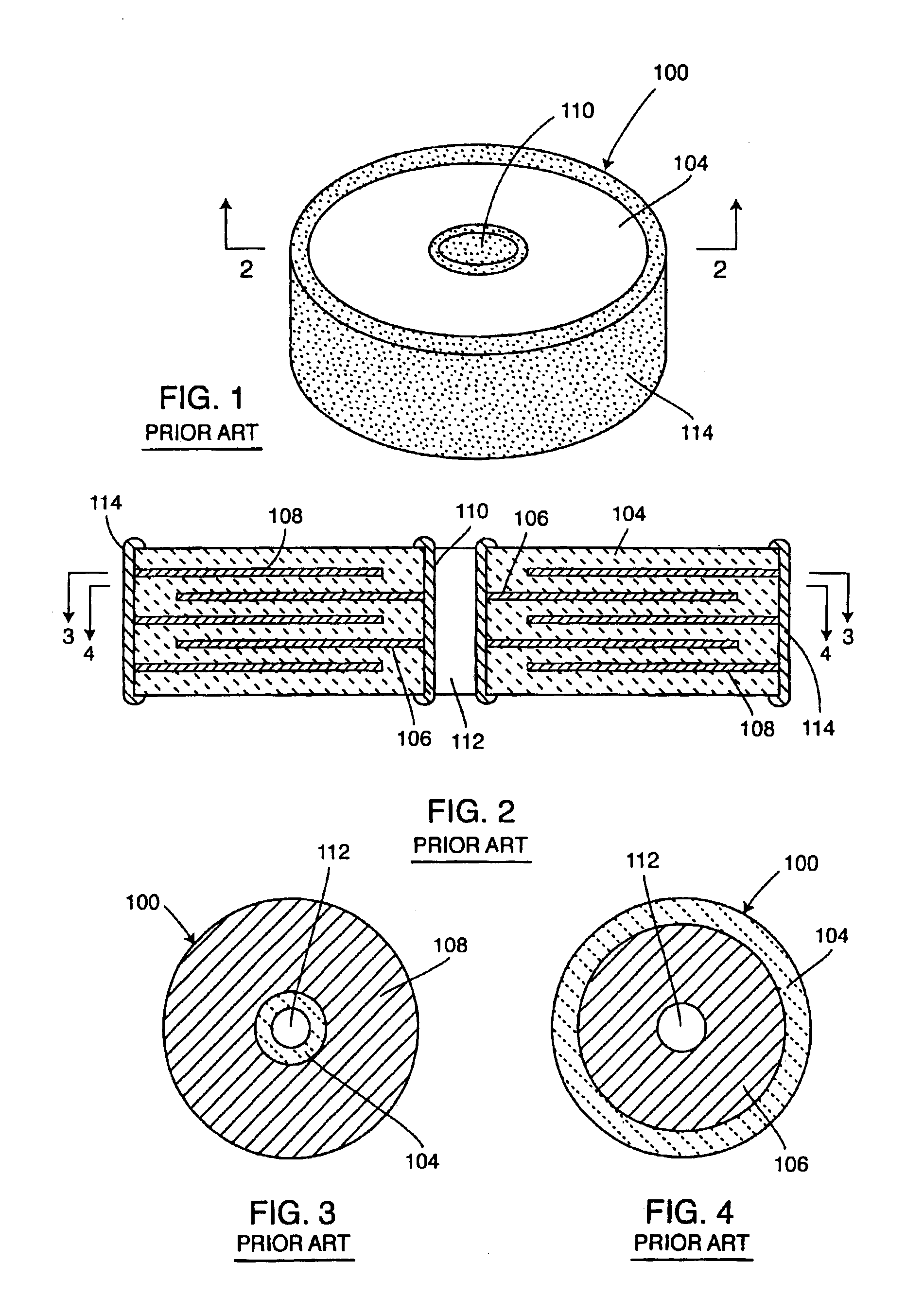

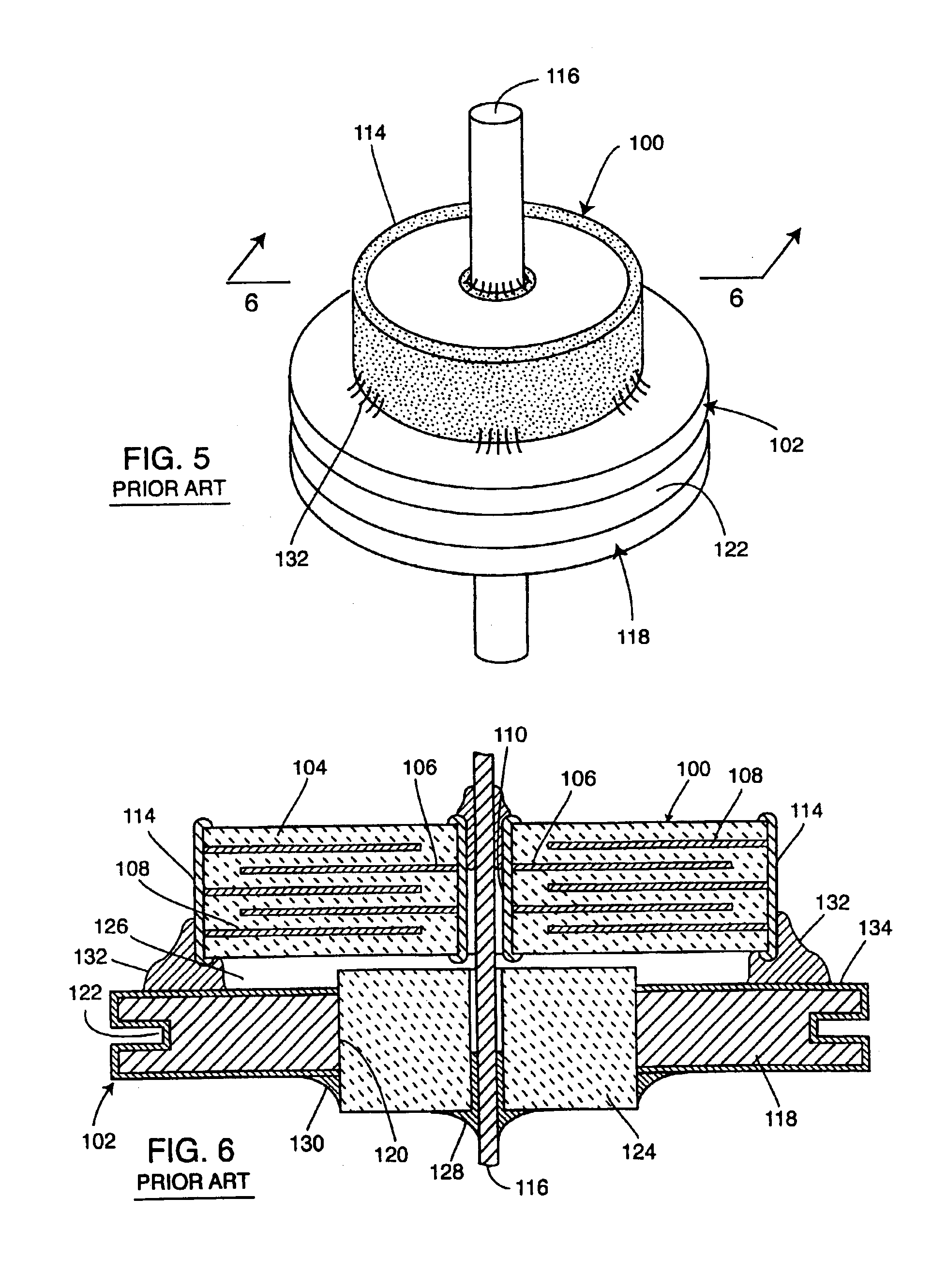

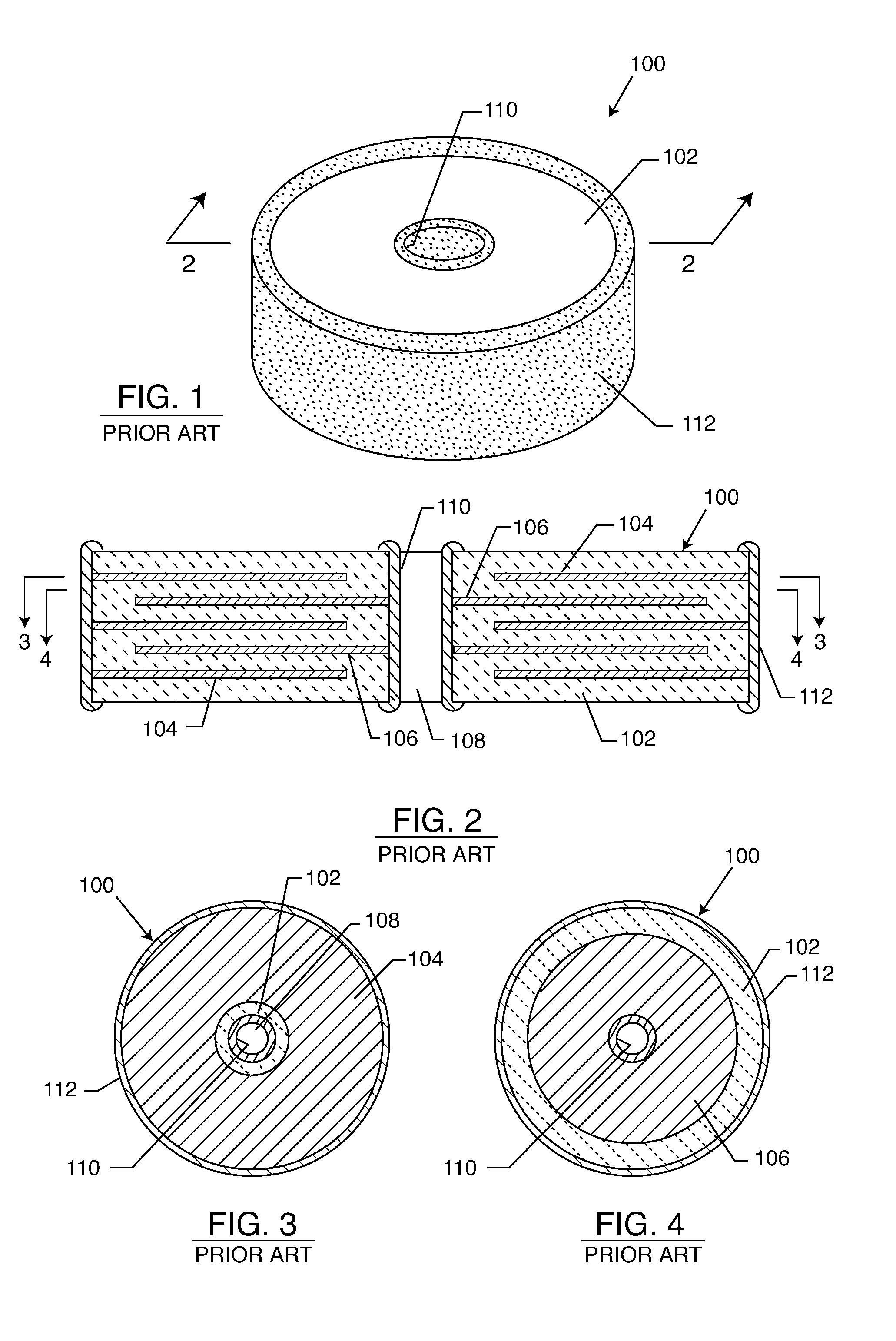

EMI feedthrough filter terminal assembly utilizing hermetic seal for electrical attachment between lead wires and capacitor

ActiveUS6888715B2Reliable electrical attachmentAnti-noise capacitorsElectrotherapyHermetic sealEngineering

EMI feedthrough filter terminal assembly includes a feedthrough filter capacitor having first and second sets of electrode plates, and a first passageway having a first termination surface conductively coupling the first set of electrode plates. At least one lead wire extends through the first passageway and is conductively attached to a first oxide resistant conductive pad. The first pad is conductively coupled to the first termination surface independently of the lead wire. The terminal assembly may also include a conductive ferrule through which the lead wire passes in non-conductive relation, and an insulator fixed to the ferrule for conductively isolating the lead wire from the ferrule. The ferrule and insulator form a pre-fabricated hermetic terminal pin sub-assembly. The capacitor may include a second passageway having a second termination surface conductively coupling the second set of electrode plates, and a conductive ground lead extending therethrough.

Owner:WILSON GREATBATCH LTD

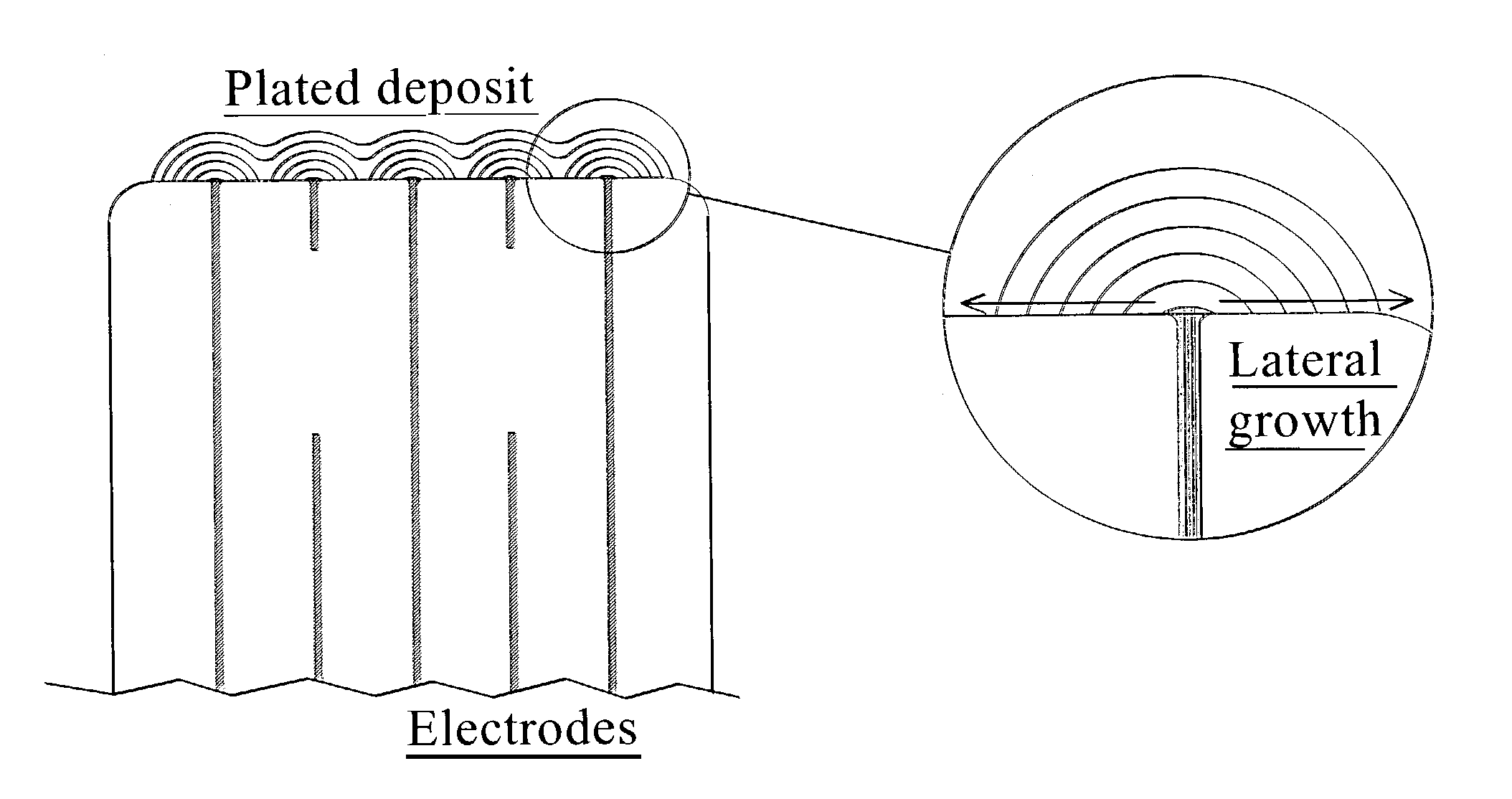

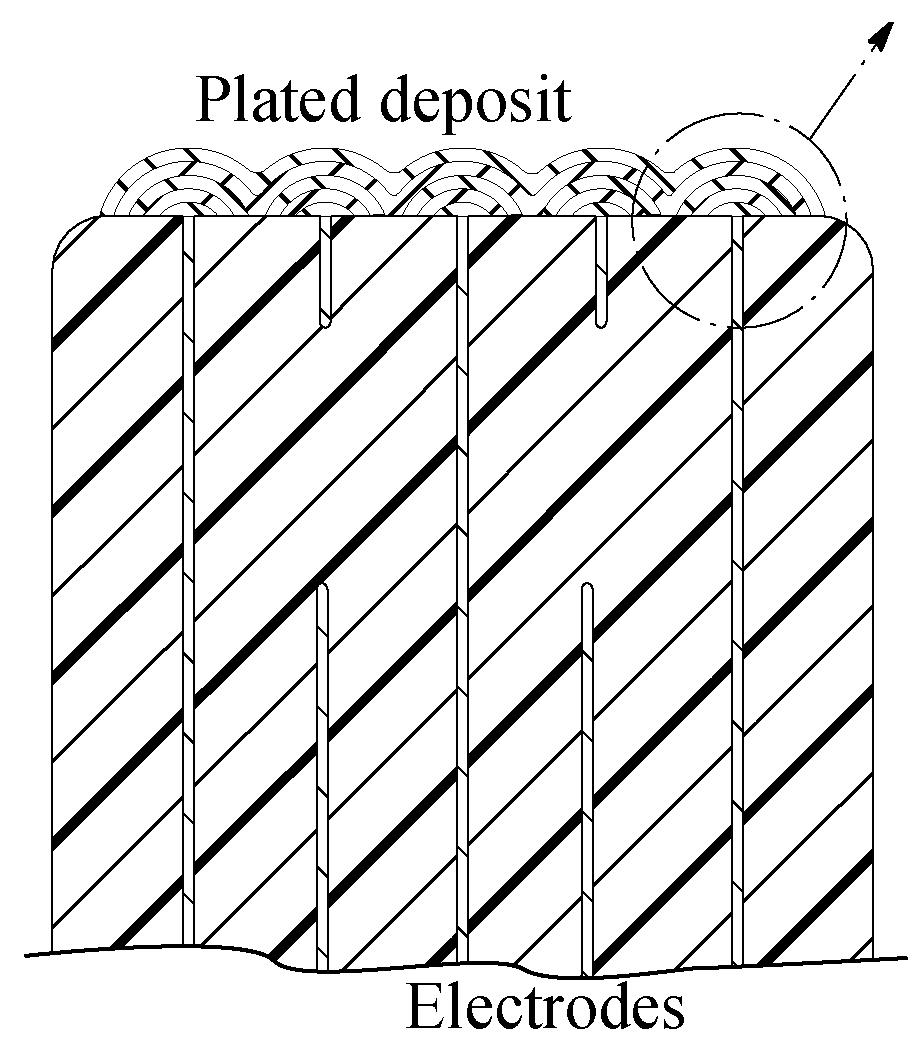

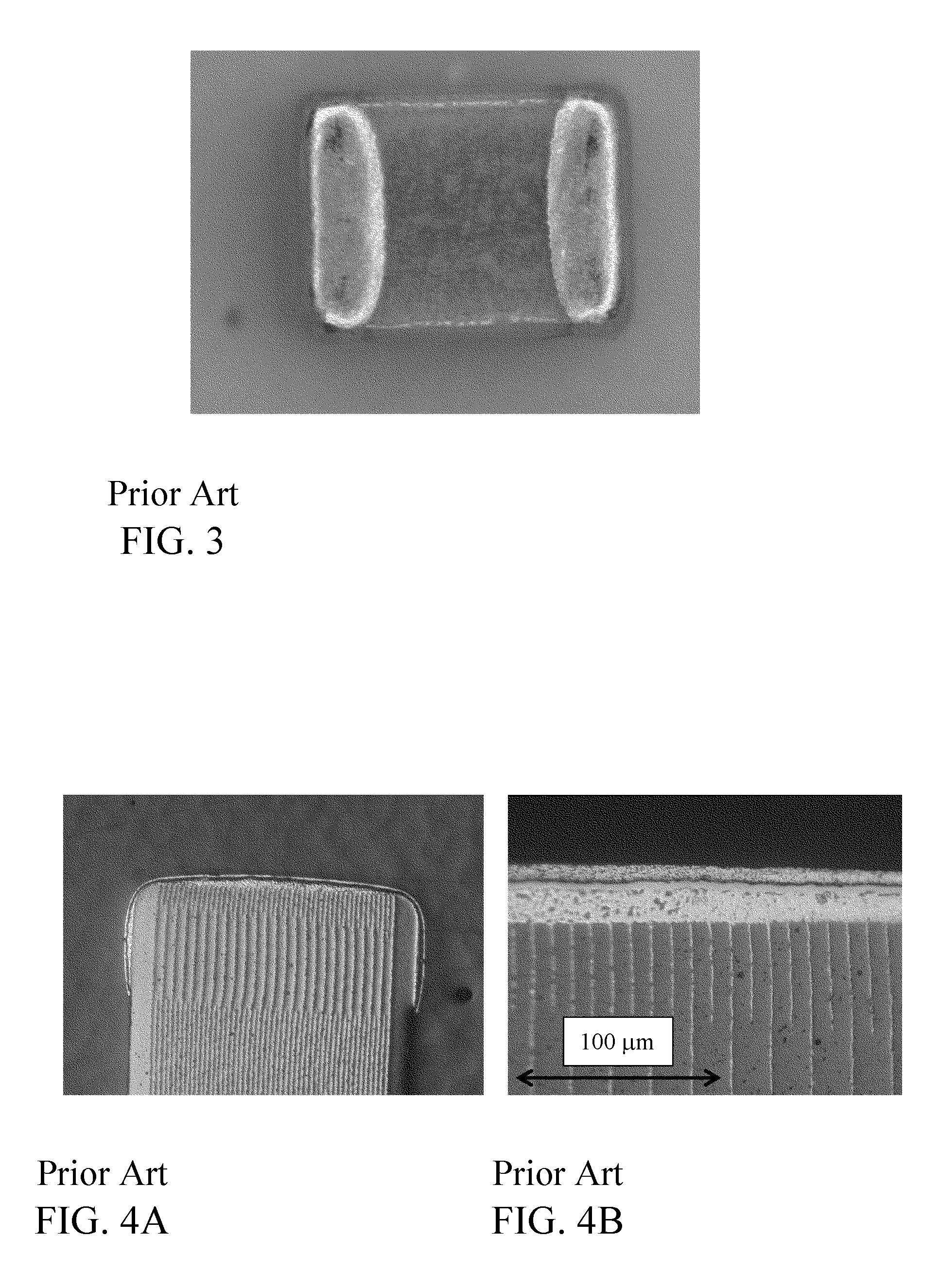

Multilayer ceramic capacitor with terminal formed by electroless plating

InactiveUS7345868B2High strengthFixed capacitor electrodesFixed capacitor dielectricElectrolysisCeramic capacitor

A terminal to, most commonly, a ceramic capacitor, most commonly a multilayer ceramic capacitor (MLCC), is formed by electroless plating, also known as electroless deposition or simply as electrodeposition. In the MLCC having a multiple parallel interior plates brought to, and exposed at, at least one, first, surface, an electrically-conductive first-metal layer, preferably Cu, is electrolessly deposited upon this first surface directly in contact with, mechanically connected to, and electrically connected to, the edges of these interior plates. Lateral growth of the electrolessly-deposited first-metal is sufficient to span from exposed plate to exposed plate, electrically connecting the plates. One or more top layers, preferably one of Ni and one of Sn and Pb, are deposited, preferably by plating and more preferably by electrolytic plating, on top of the electrolessly-deposited Cu.

Owner:PRESIDIO COMPONENTS

Plated terminations

InactiveUS20050046536A1Improved termination featureEliminate and greatly simplifyWave amplification devicesResistor terminals/electrodesTermination problemEngineering

Improved termination features for multilayer electronic components are disclosed. Monolithic components are provided with plated terminations whereby the need for typical thick-film termination stripes is eliminated or greatly simplified. Such termination technology eliminates many typical termination problems and enables a higher number of terminations with finer pitch, which may be especially beneficial on smaller electronic components. The subject plated terminations are guided and anchored by exposed internal electrode tabs and additional anchor tab portions which may optionally extend to the cover layers of a multilayer component. Such anchor tabs may be positioned internally or externally relative to a chip structure to nucleate additional metallized plating material. External anchor tabs positioned on top and bottom sides of a monolithic structure can facilitate the formation of wrap-around plated terminations. The disclosed technology may be utilized with a plurality of monolithic multilayer components, including interdigitated capacitors, multilayer capacitor arrays, and integrated passive components. A variety of different plating techniques and termination materials may be employed in the formation of the subject self-determining plated terminations.

Owner:KYOCERA AVX COMPONENTS CORP

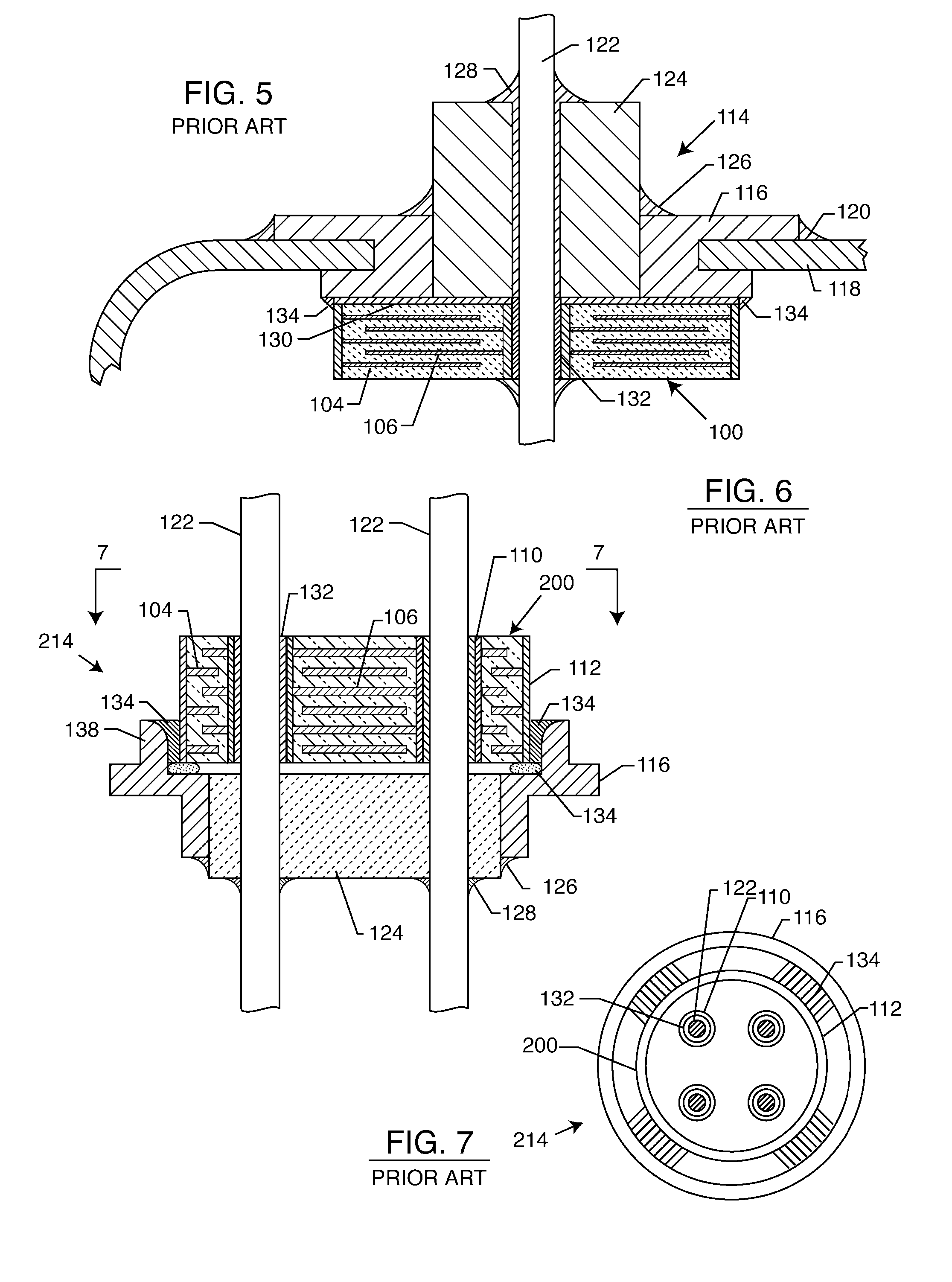

Hybrid spring contact system for EMI filtered hermetic seals for active implantable medical devices

InactiveUS7136273B2Prevent oxidation and corrosionEasy to assembleMultiple-port networksAnti-noise capacitorsHermetic sealElectrical connection

A feedthrough terminal assembly for an active implantable medical device utilizes an insert to establish a reliable electrical connection between capacitor electrode plates, via inner surface metallization of a capacitor aperture, and an associated terminal pin 10, which passes at least partially therethrough. The inserts are preferably resiliently flexible, such as a spring, to establish this connection. The insert also serves to establish a mechanical connection between the capacitor and the terminal pin.

Owner:WILSON GREATBATCH LTD

Plated terminations

InactiveUS7154374B2Improved termination featureEliminate or greatly simplify thick-film stripesResistor terminals/electrodesSemiconductor/solid-state device detailsTermination problemEngineering

Improved termination features for multilayer electronic components are disclosed. Monolithic components are provided with plated terminations whereby the need for typical thick-film termination stripes is eliminated or greatly simplified. Such termination technology eliminates many typical termination problems and enables a higher number of terminations with finer pitch, which may be especially beneficial on smaller electronic components. The subject plated terminations are guided and anchored by exposed internal electrode tabs and additional anchor tab portions which may optionally extend to the cover layers of a multilayer component. Such anchor tabs may be positioned internally or externally relative to a chip structure to nucleate additional metallized plating material. External anchor tabs positioned on top and bottom sides of a monolithic structure can facilitate the formation of wrap-around plated terminations. The disclosed technology may be utilized with a plurality of monolithic multilayer components, including interdigitated capacitors, multilayer capacitor arrays, and integrated passive components. A variety of different plating techniques and termination materials may be employed in the formation of the subject self-determining plated terminations.

Owner:KYOCERA AVX COMPONENTS CORP

Plated terminations

InactiveUS6972942B2Improved termination featureEliminate or greatly simplify thick-film stripesFixed capacitor dielectricSolid-state devicesTermination problemEngineering

Improved termination features for multilayer electronic components are disclosed. Monolithic components are provided with plated terminations whereby the need for typical thick-film termination stripes is eliminated or greatly simplified. Such termination technology eliminates many typical termination problems and enables a higher number of terminations with finer pitch, which may be especially beneficial on smaller electronic components. The subject plated terminations are guided and anchored by exposed internal electrode tabs and additional anchor tab portions which may optionally extend to the cover layers of a multilayer component. Such anchor tabs may be positioned internally or externally relative to a chip structure to nucleate additional metallized plating material. External anchor tabs positioned on one or both of top and bottom surfaces of a monolithic structure can facilitate the formation of selective wrap-around plated terminations. The disclosed technology may be utilized with a plurality of monolithic multilayer components, including interdigitated capacitors, multilayer capacitor arrays, and integrated passive components. A variety of different plating techniques and termination materials may be employed in the formation of the subject self-determining plated terminations.

Owner:KYOCERA AVX COMPONENTS CORP

High temperature, conductive thin film diffusion barrier for ceramic/metal systems

A multilayer ceramic substrate having a thin film structure containing capacitor connected thereto is provided as an interposer capacitor, the capacitor employing platinum as the bottom electrode of the capacitor. In a preferred capacitor, a dielectric material such as barium titanate is used as the dielectric material between the capacitor electrodes. The fabrication of the interposer capacitor requires an in-situ or post deposition high temperature anneal and the use of such dielectrics requires heating of the capacitor structure in a non-reducing atmosphere. A layer of a high temperature, thin film diffusion barrier such as TaSiN on the lower platinum electrode between the electrode and underlying multilayer ceramic substrate prevents or minimizes oxidization of the metallization of the multilayer ceramic substrate to which the thin film structure is connected during the fabrication process. A method is also provided for fabricating an interposer capacitor with a multilayer ceramic substrate base and a thin film multilayer structure having at least one capacitor comprising at least one bottom platinum electrode.

Owner:IBM CORP

Nanofiber surface based capacitors

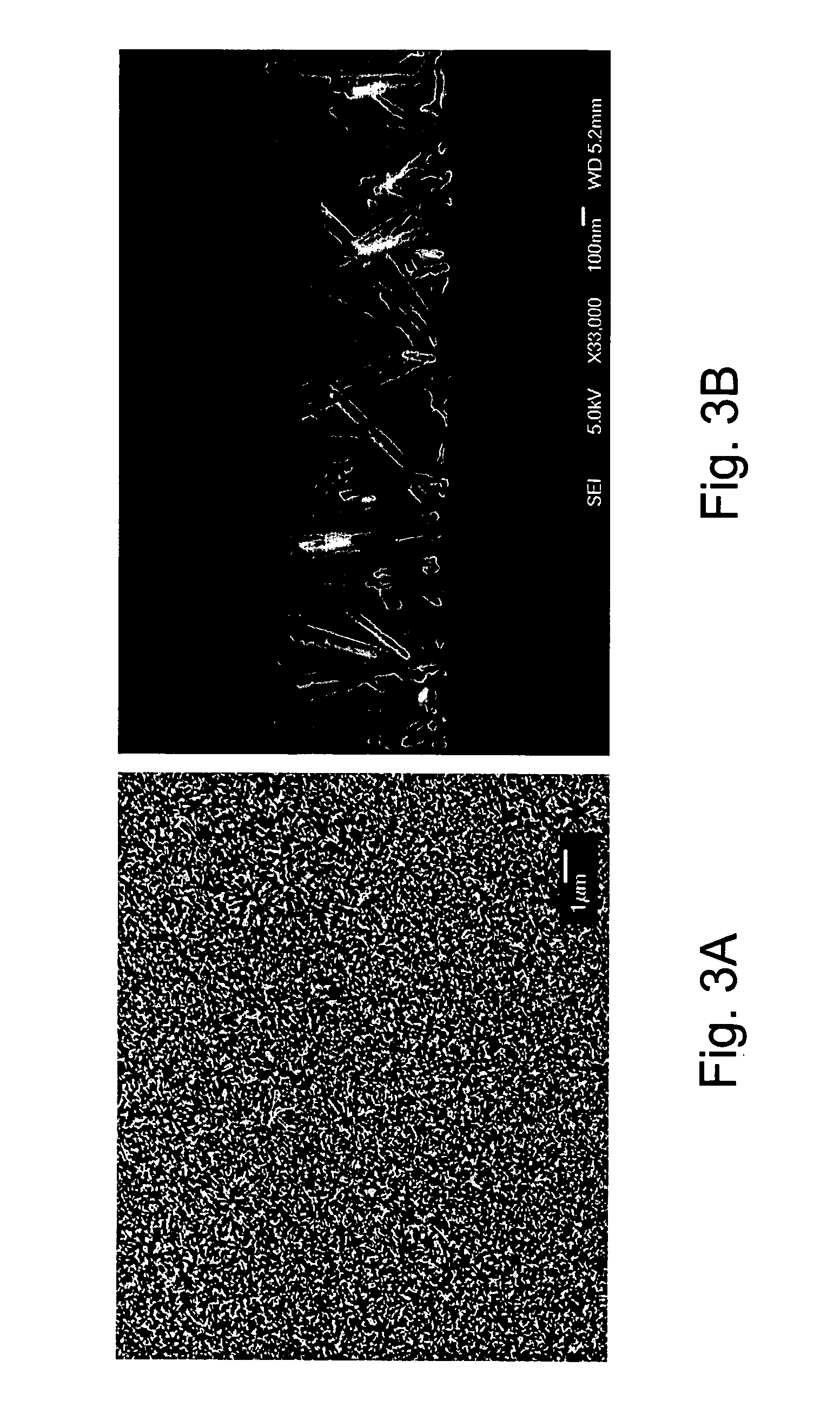

ActiveUS7057881B2Increase surface areaFixed capacitor electrodesThin/thick film capacitorNanofiberEngineering

This invention provides novel capacitors comprising nanofiber enhanced surface area substrates and structures comprising such capacitors, as well as methods and uses for such capacitors.

Owner:ONED MATERIAL INC

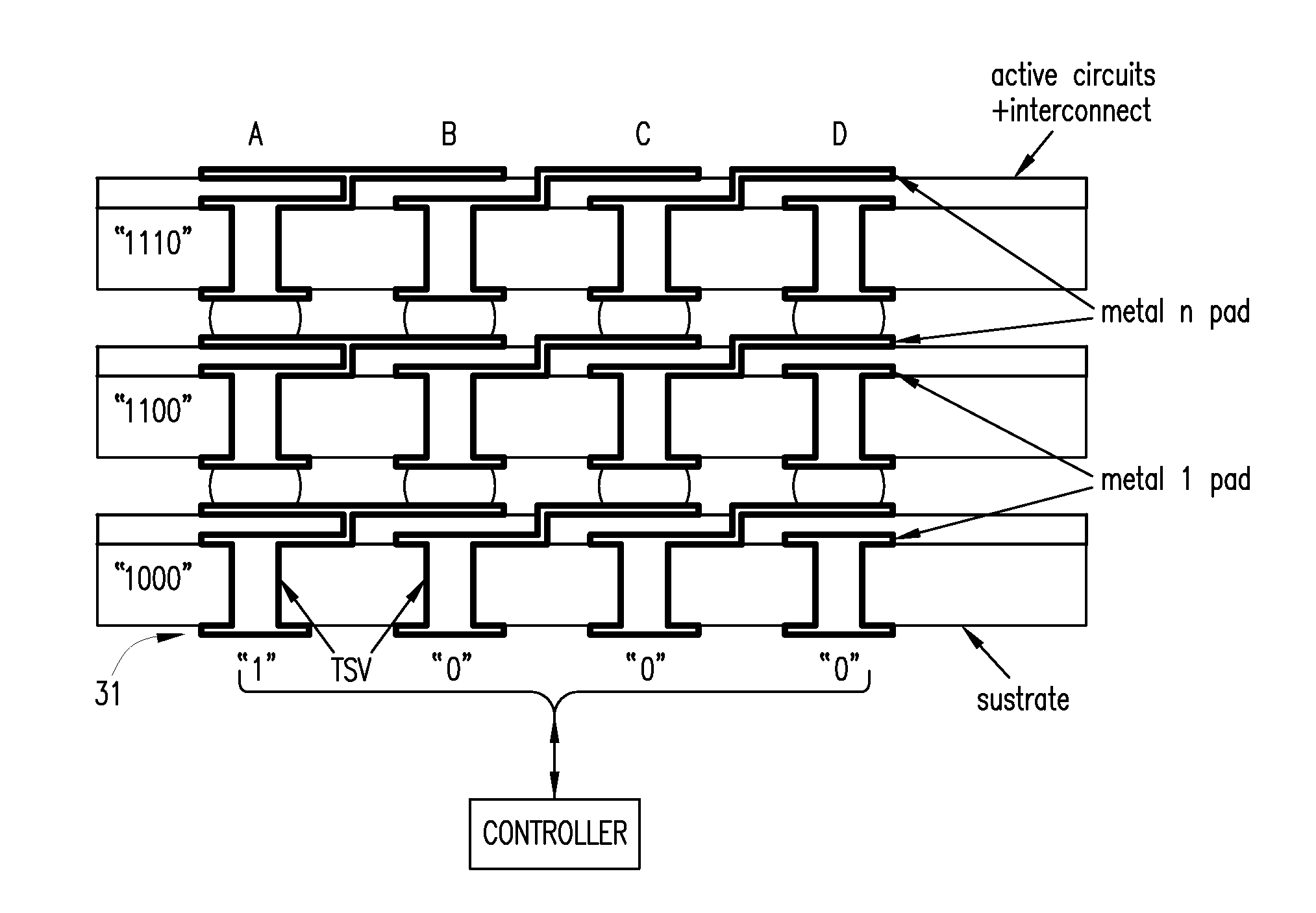

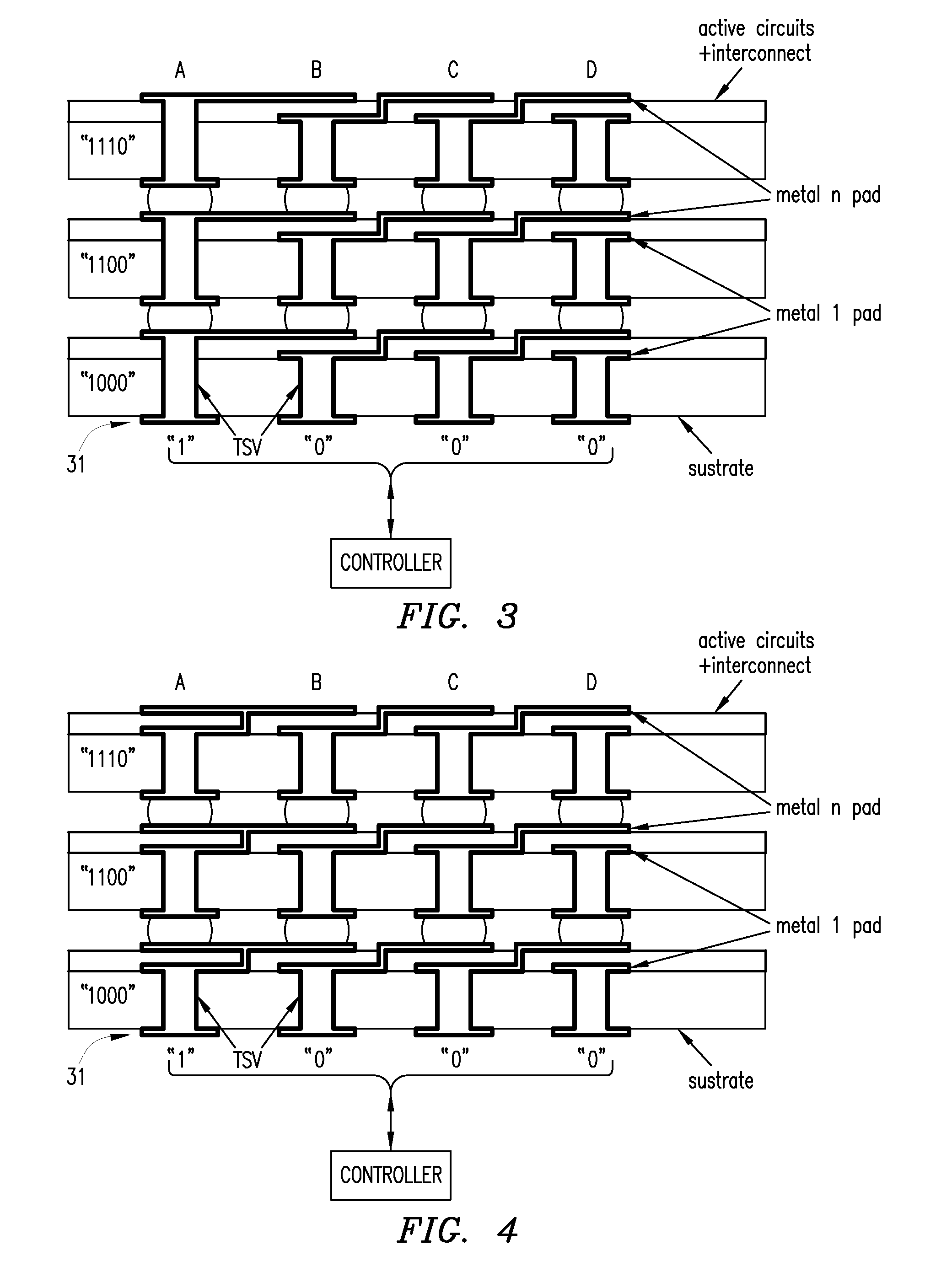

Using interrupted through-silicon-vias in integrated circuits adapted for stacking

In an integrated circuit (IC) adapted for use in a stack of interconnected ICs, interrupted through-silicon-vias (TSVs) are provided in addition to uninterrupted TSVs. The interrupted TSVs provide signal paths other than common parallel paths between the ICs of the stack. This permits IC identification schemes and other functionalities to be implemented using TSVs, without requiring angular rotation of alternate ICs of the stack.

Owner:MOSAID TECH

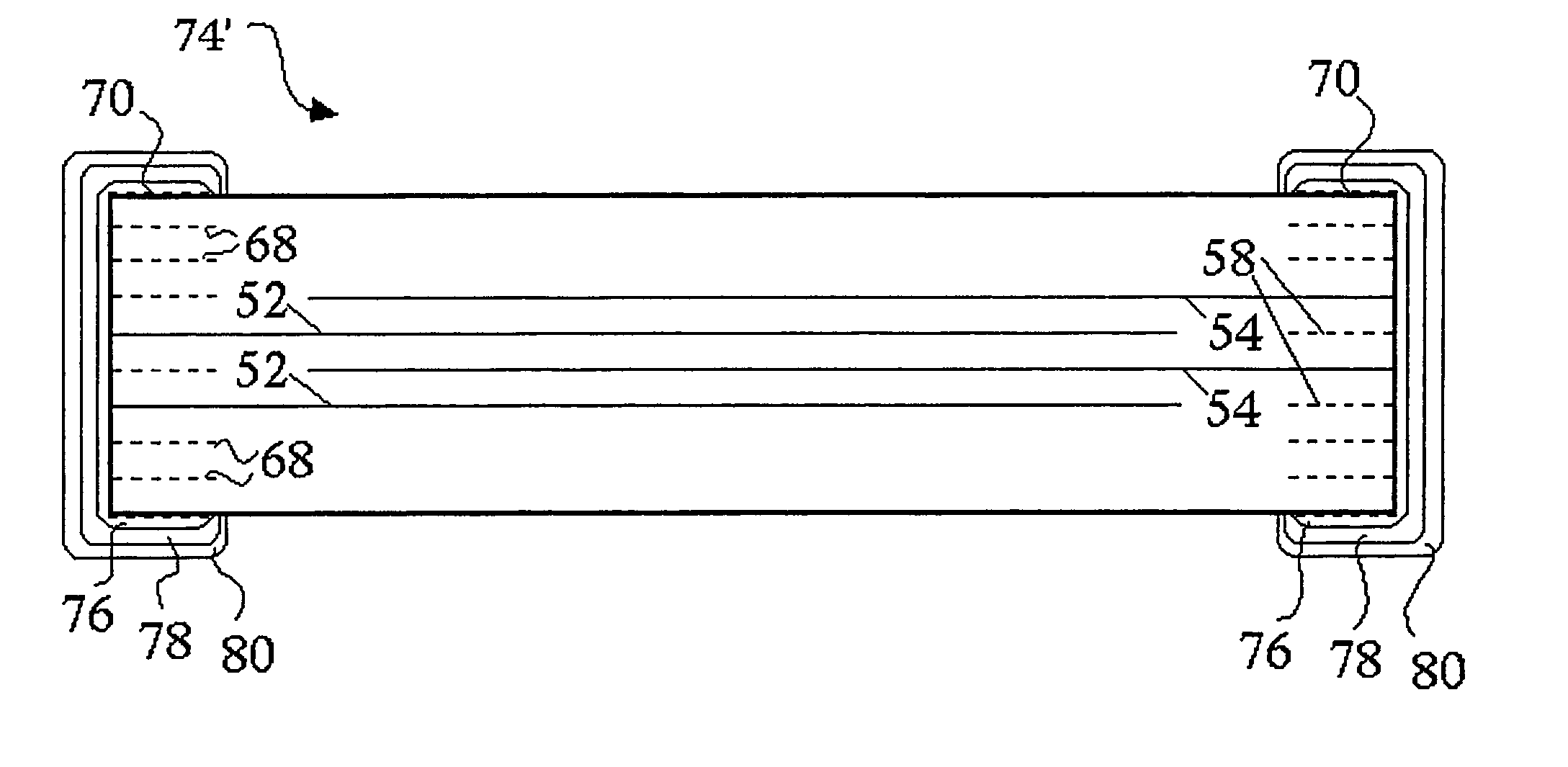

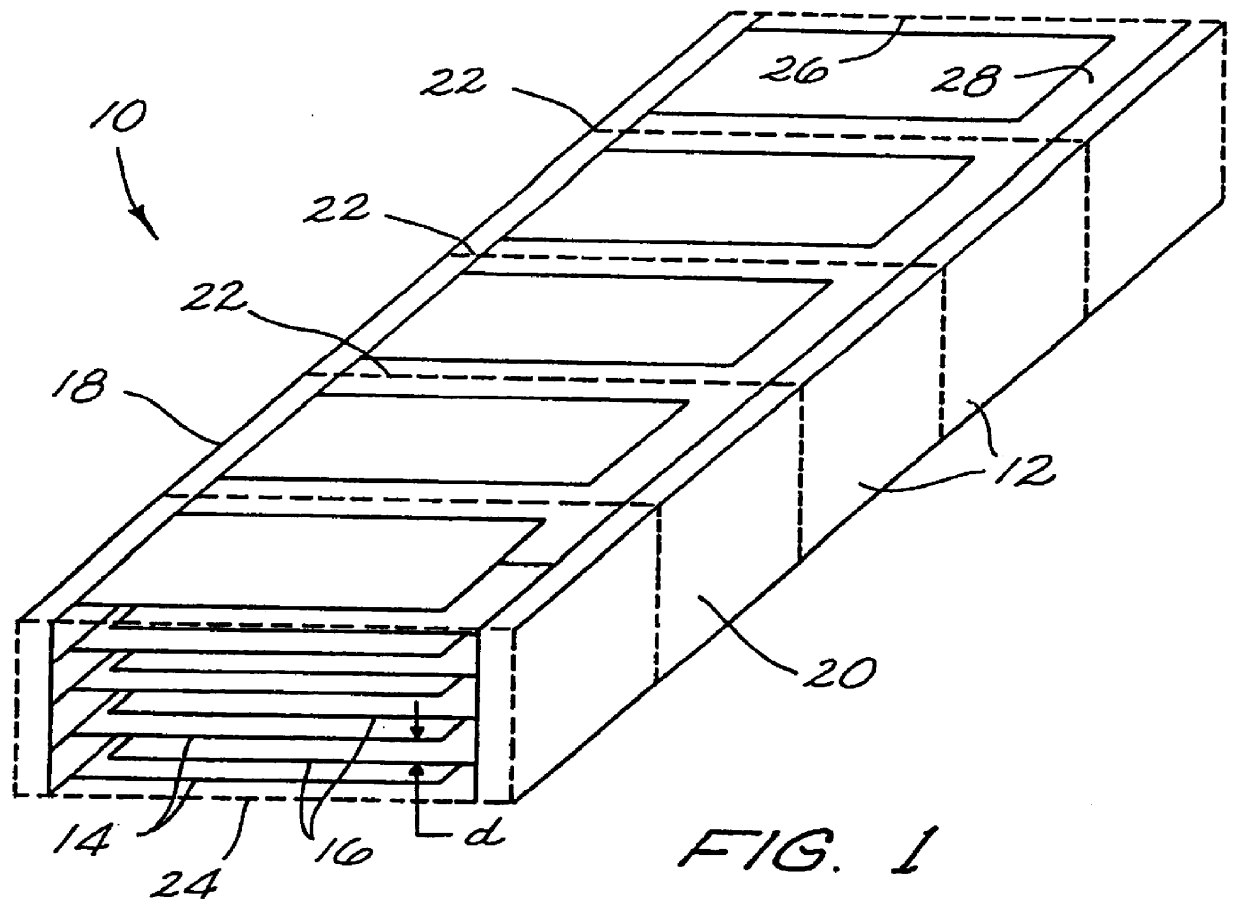

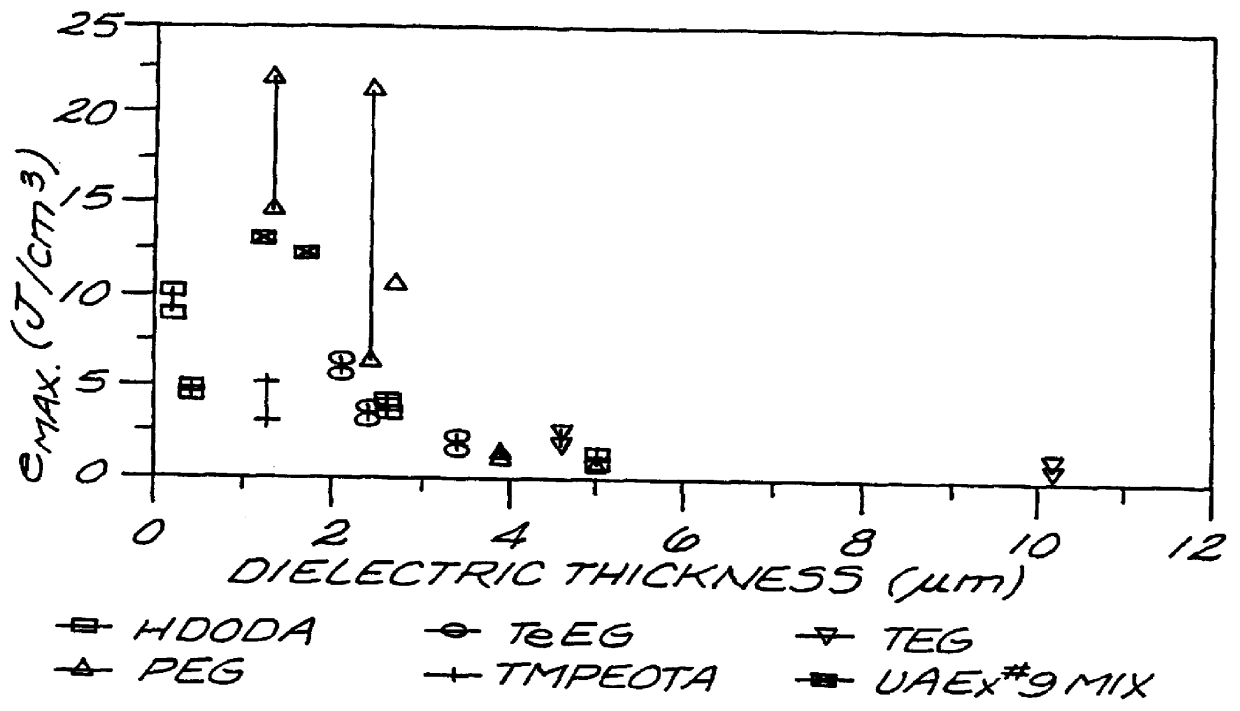

High energy density capacitor

A high energy density, high power density capacitor having an energy density of at least about 0.5 J / cm3 is provided. The capacitor comprises a plurality of interleaved metal electrode layers separated by a polymer layer. The interleaved metal electrode layers terminate at opposite ends in a solder termination strip. The high energy density aspect of the capacitors of the invention is achieved by at least one of the following features: (a) the dielectric thickness between the interleaved metal electrode layers is a maximum of about 5 mu m; (b) the polymer is designed with a high dielectric constant kappa of at least about 3.5; (c) the metal electrode layers within the polymer layer are recessed along edges orthogonal to the solder termination strips to prevent arcing between the metal electrode layers at the edges; and (d) the resistivity of the metal electrode layers is within the range of about 10 to 500 ohms per square, or a corresponding thickness of about 200 to 30 ANGSTROM .

Owner:SIGMA LAB OF ARIZONA

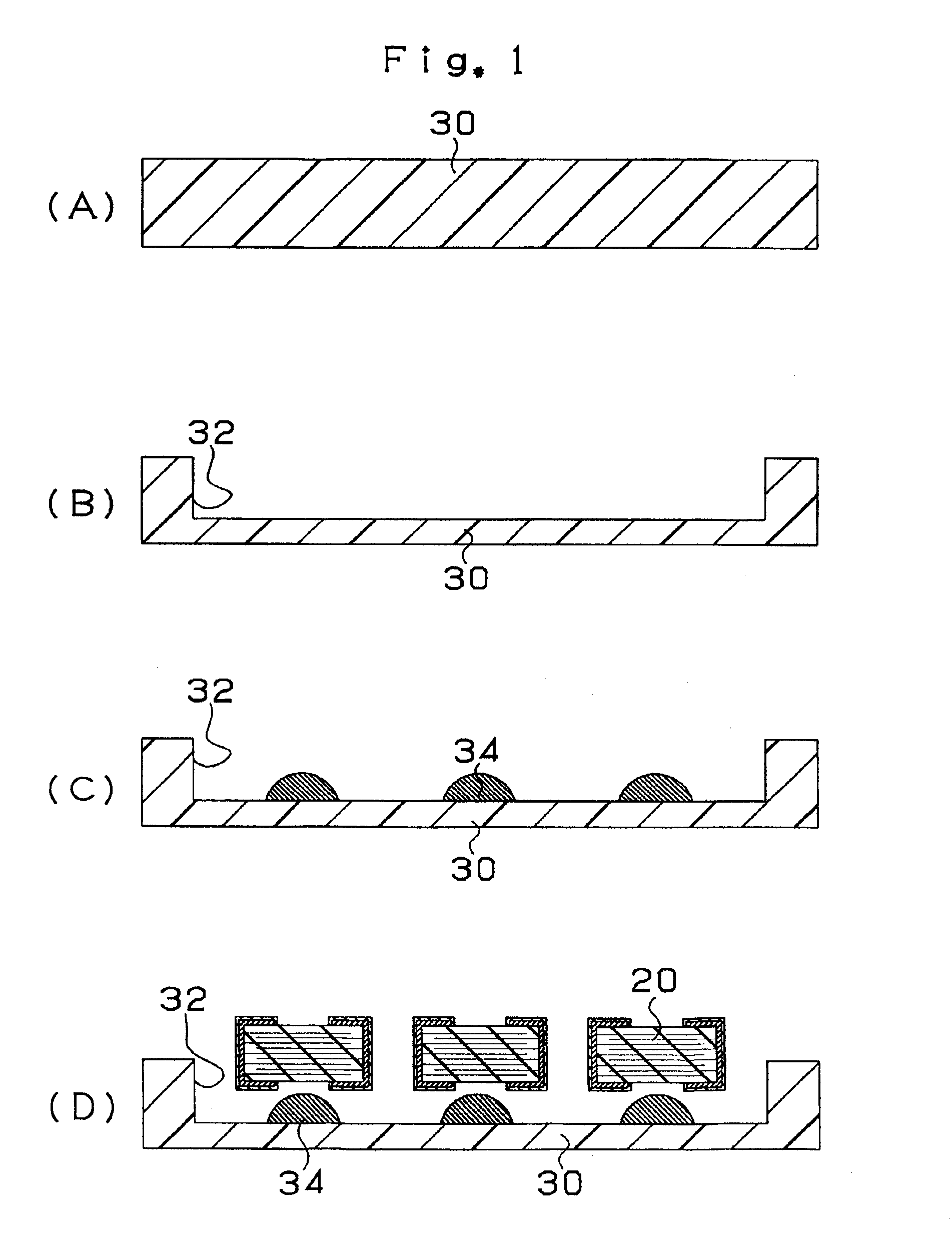

Laminated electronic component and method for manufacturing the same

ActiveUS20080123249A1Improve the effective volume ratioImprove reliabilityFixed capacitor dielectricStacked capacitorsElectronic componentElectron

A laminated body is prepared, in which at an end surface at which internal electrodes are exposed, the internal electrodes disposed adjacently are electrically isolated from each other, and a distance between the internal electrodes disposed adjacently is about 20 μm or less when measured along the thickness direction of an insulator layer, and a withdrawn-depth of the internal electrodes is about 1 μm or less when measured from the end surface. In a step of electroless plating, plating deposits formed at the end portions of the plurality of internal electrodes are increased in size so as to be connected to each other.

Owner:MURATA MFG CO LTD

Multilayer ceramic capacitor with terminal formed by electroless plating

InactiveUS20080158774A1High strengthFixed capacitor electrodesFixed capacitor dielectricCeramic capacitorElectroless deposition

A terminal to, most commonly, a ceramic capacitor, most commonly a multilayer ceramic capacitor (MLCC), is formed by electroless plating, also known as electroless deposition or simply as electrodeposition. In the MLCC having a multiple parallel interior plates brought to, and exposed at, at least one, first, surface, an electrically-conductive first-metal layer, preferably Cu, is electrolessly deposited upon this first surface directly in contact with, mechanically connected to, and electrically connected to, the edges of these interior plates. Lateral growth of the electrolessly-deposited first-metal is sufficient to span from exposed plate to exposed plate, electrically connecting the plates. One or more top layers, preferably one of Ni and one of Sn and Pb, are deposited, preferably by plating and more preferably by electrolytic plating, on top of the electrolessly-deposited Cu.

Owner:PRESIDIO COMPONENTS

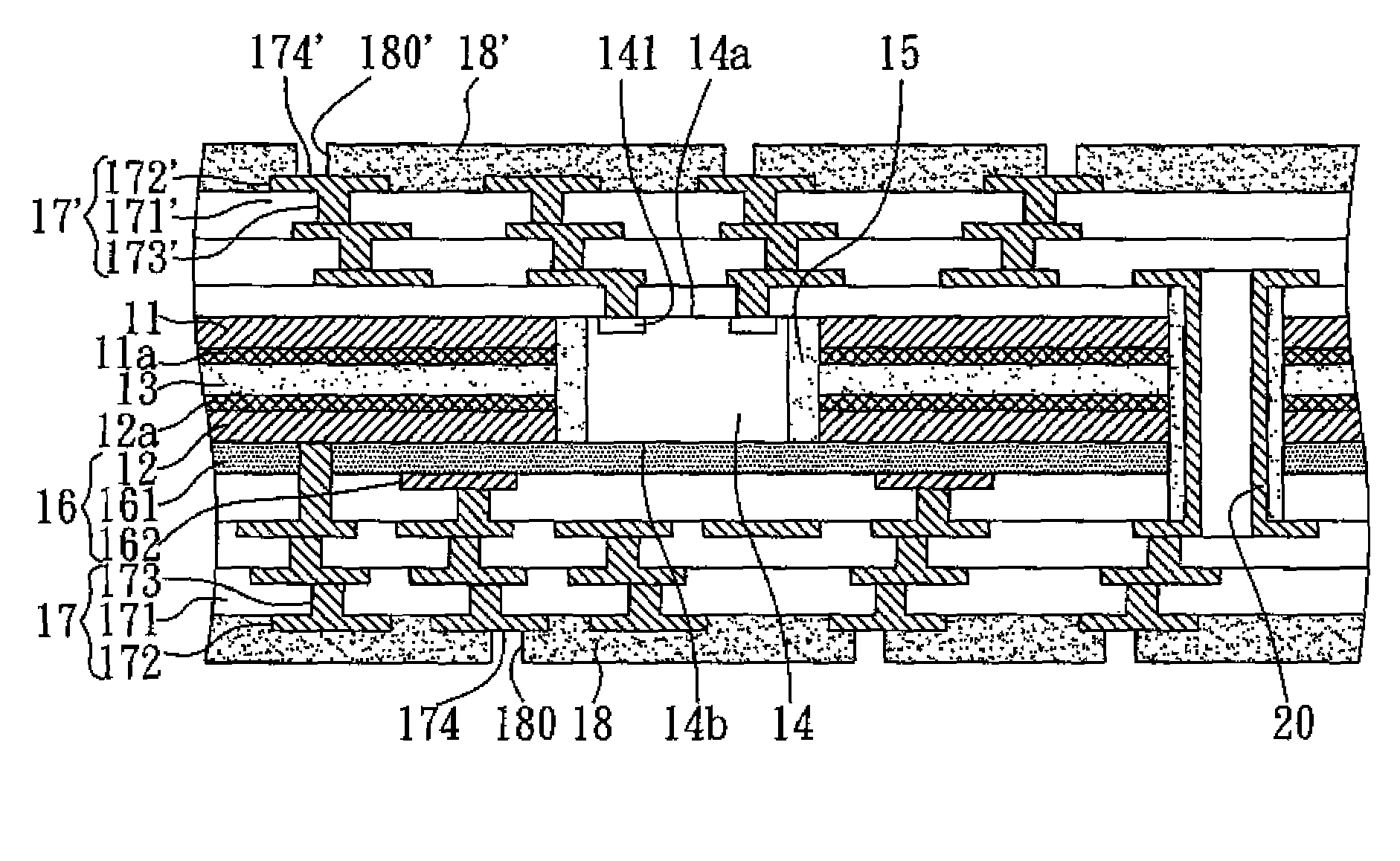

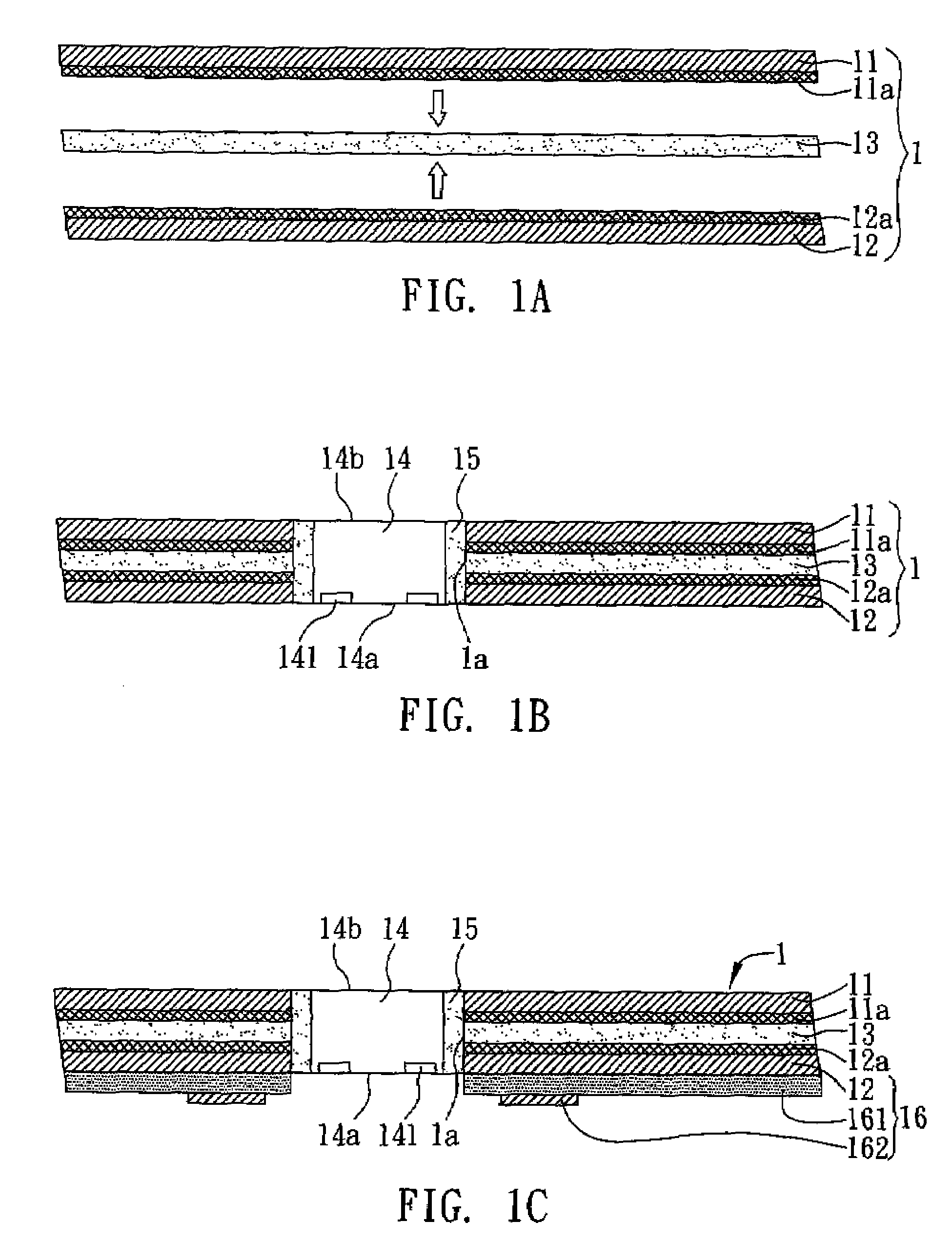

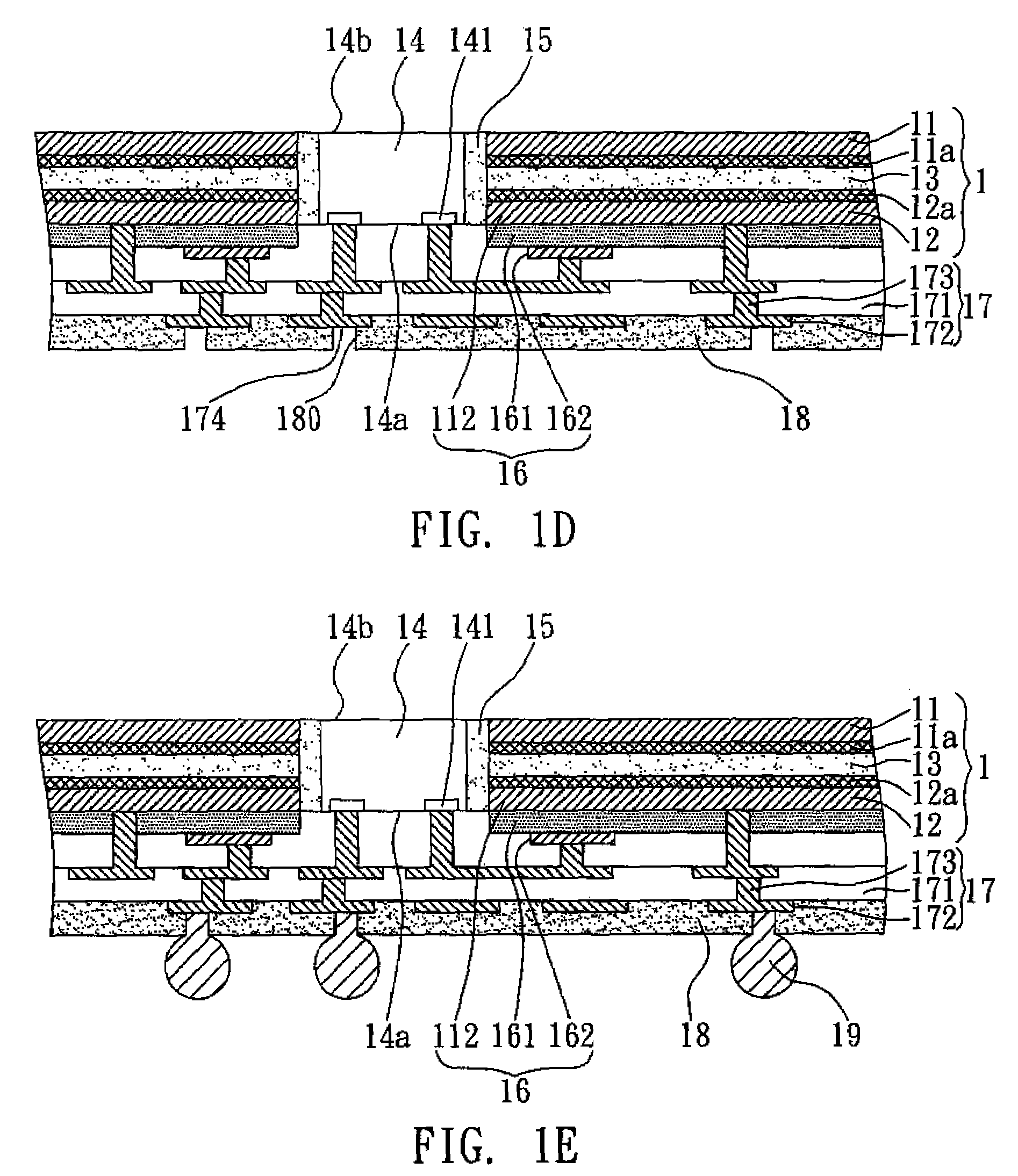

Circuit board structure with embedded electronic components

ActiveUS7639473B2Improve bending strengthSimple structureElectric spark ignitersFixed capacitor dielectricCapacitanceSemiconductor chip

A circuit board structure with embedded electronic components includes: a carrier board having an adhesive layer with two surfaces formed with first and second metal oxide layers covered by first and second metal layers and having at least one through hole; at least one semiconductor chip received in the through hole of the carrier board; an adhesive material filling a gap between the through hole and the semiconductor chip so as to secure the semiconductor chip in position to the through hole; a high dielectric material layer formed outwardly on the second metal layer; and at least one electrode board formed outwardly on the high dielectric material layer such that a capacitance component is formed with the second metal layer, high dielectric material layer, and electrode board. Accordingly, the capacitance component is integrated into the circuit board structure.

Owner:PHOENIX PRECISION TECH CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com