Patents

Literature

4445results about How to "Improve bending strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

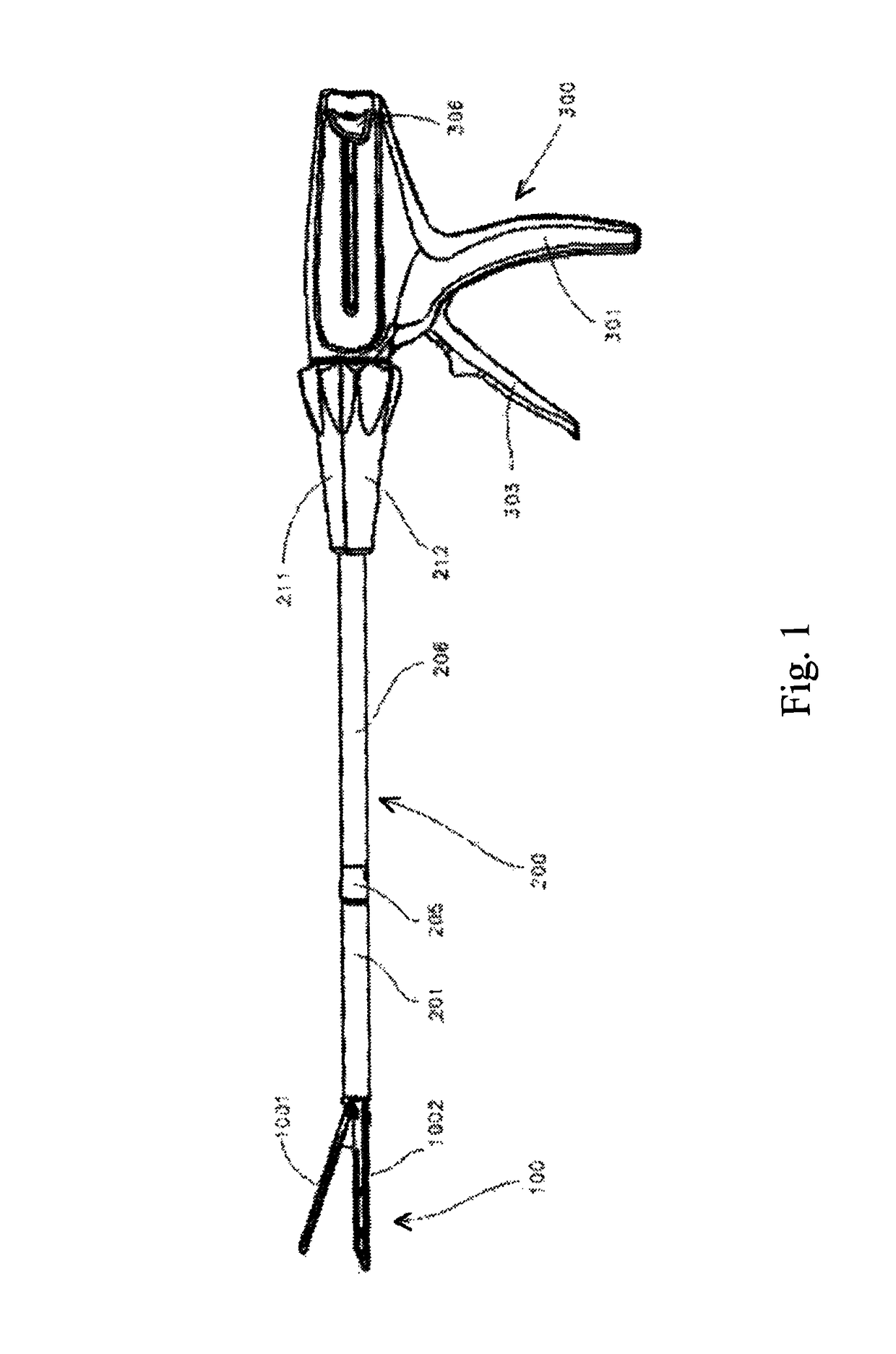

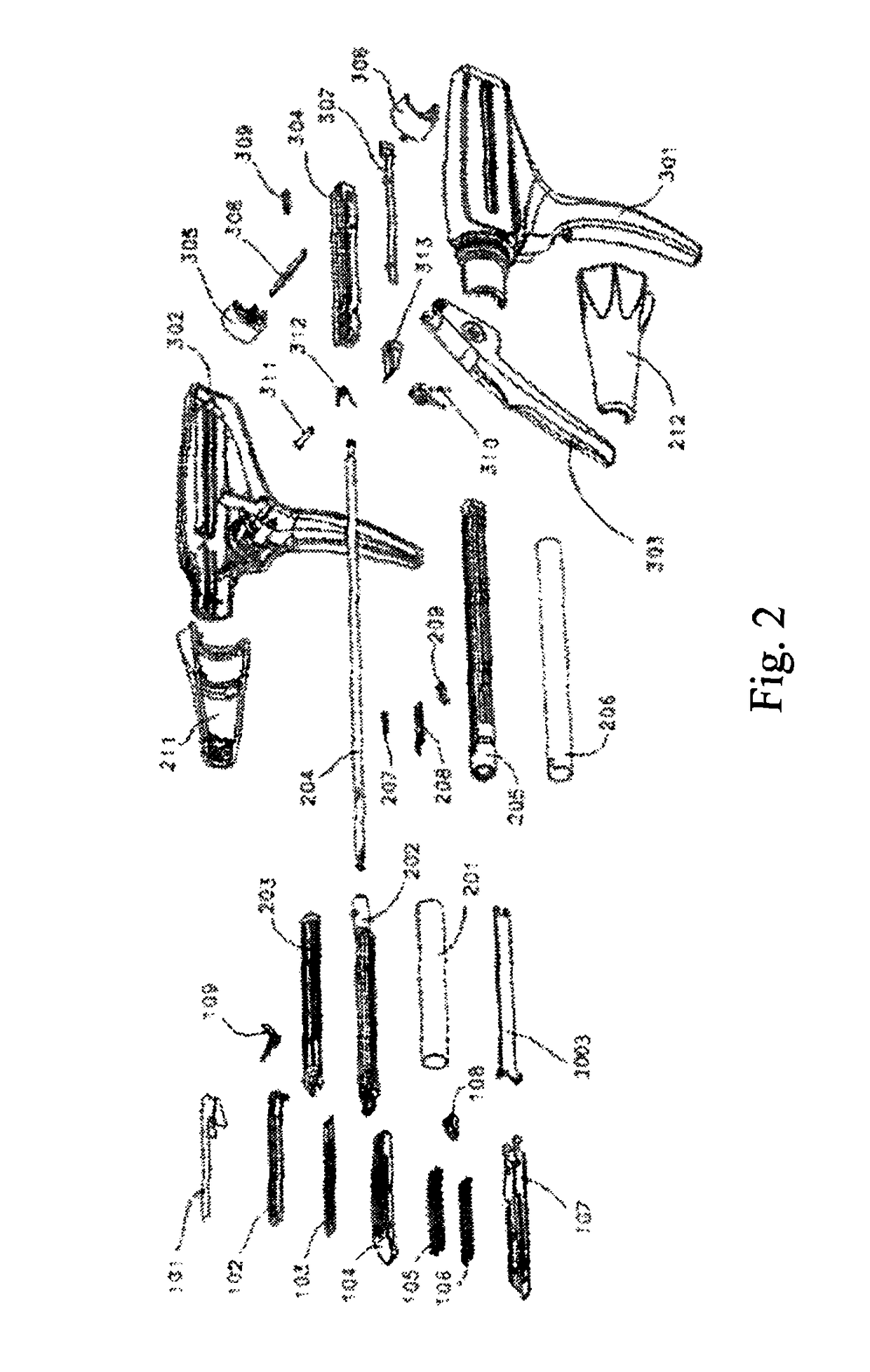

Surgical apparatus actuator

ActiveUS9924945B2Increase the difficultyImprove accuracySurgical staplesEngineeringMechanical engineering

Owner:EZISURG MEDICAL CO LTD

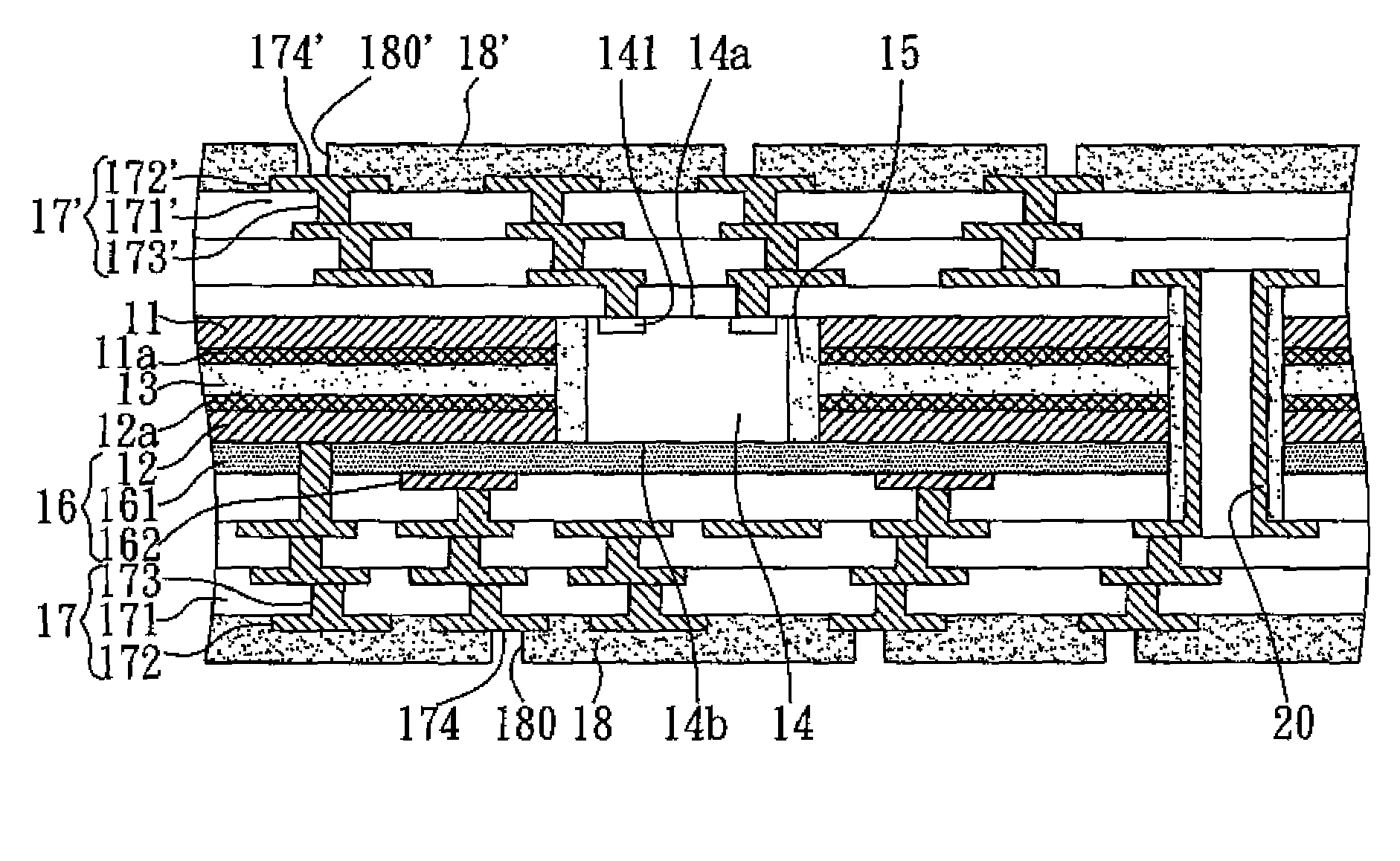

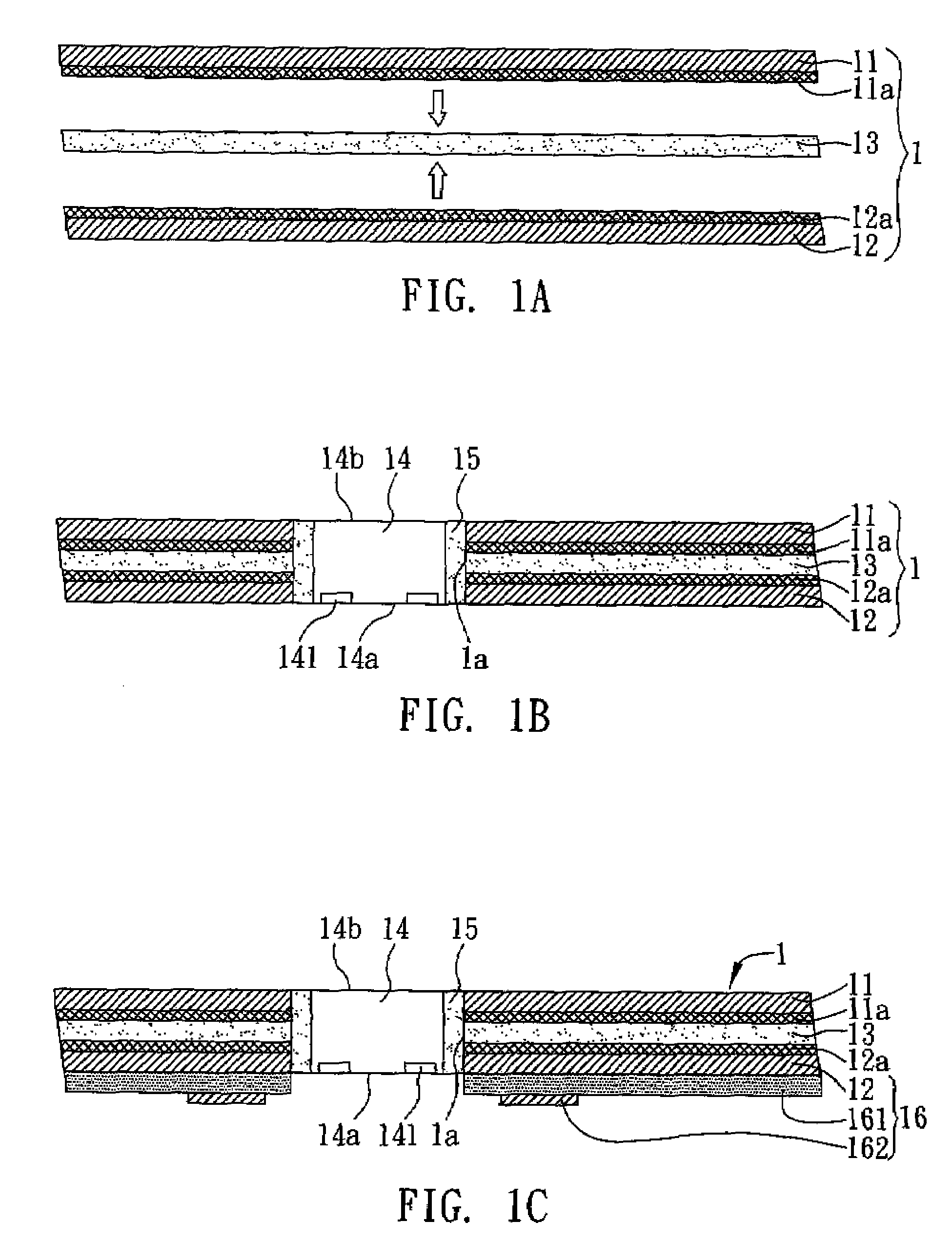

Circuit board structure with embedded electronic components

ActiveUS7639473B2Improve bending strengthSimple structureElectric spark ignitersFixed capacitor dielectricCapacitanceSemiconductor chip

A circuit board structure with embedded electronic components includes: a carrier board having an adhesive layer with two surfaces formed with first and second metal oxide layers covered by first and second metal layers and having at least one through hole; at least one semiconductor chip received in the through hole of the carrier board; an adhesive material filling a gap between the through hole and the semiconductor chip so as to secure the semiconductor chip in position to the through hole; a high dielectric material layer formed outwardly on the second metal layer; and at least one electrode board formed outwardly on the high dielectric material layer such that a capacitance component is formed with the second metal layer, high dielectric material layer, and electrode board. Accordingly, the capacitance component is integrated into the circuit board structure.

Owner:PHOENIX PRECISION TECH CORP

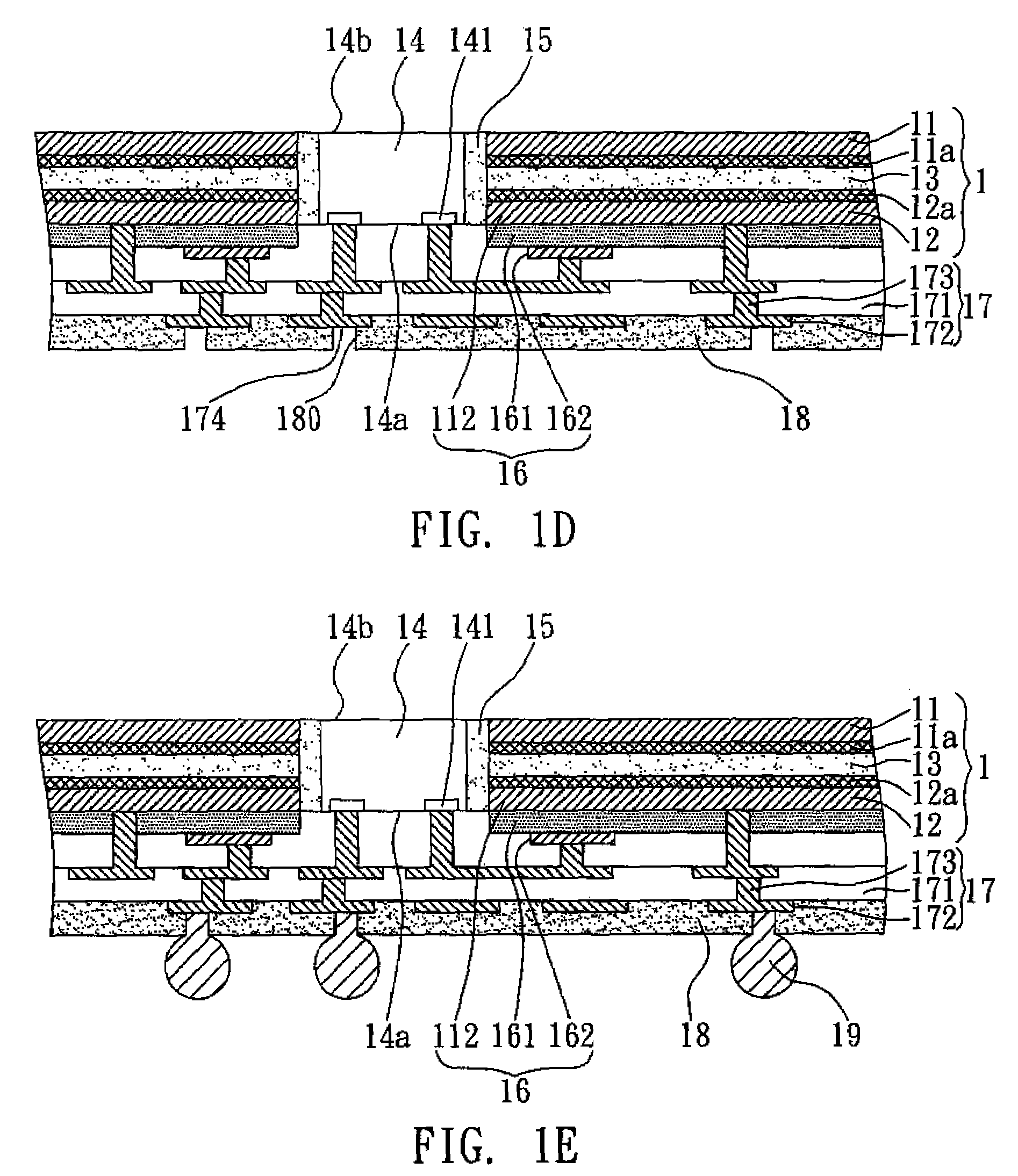

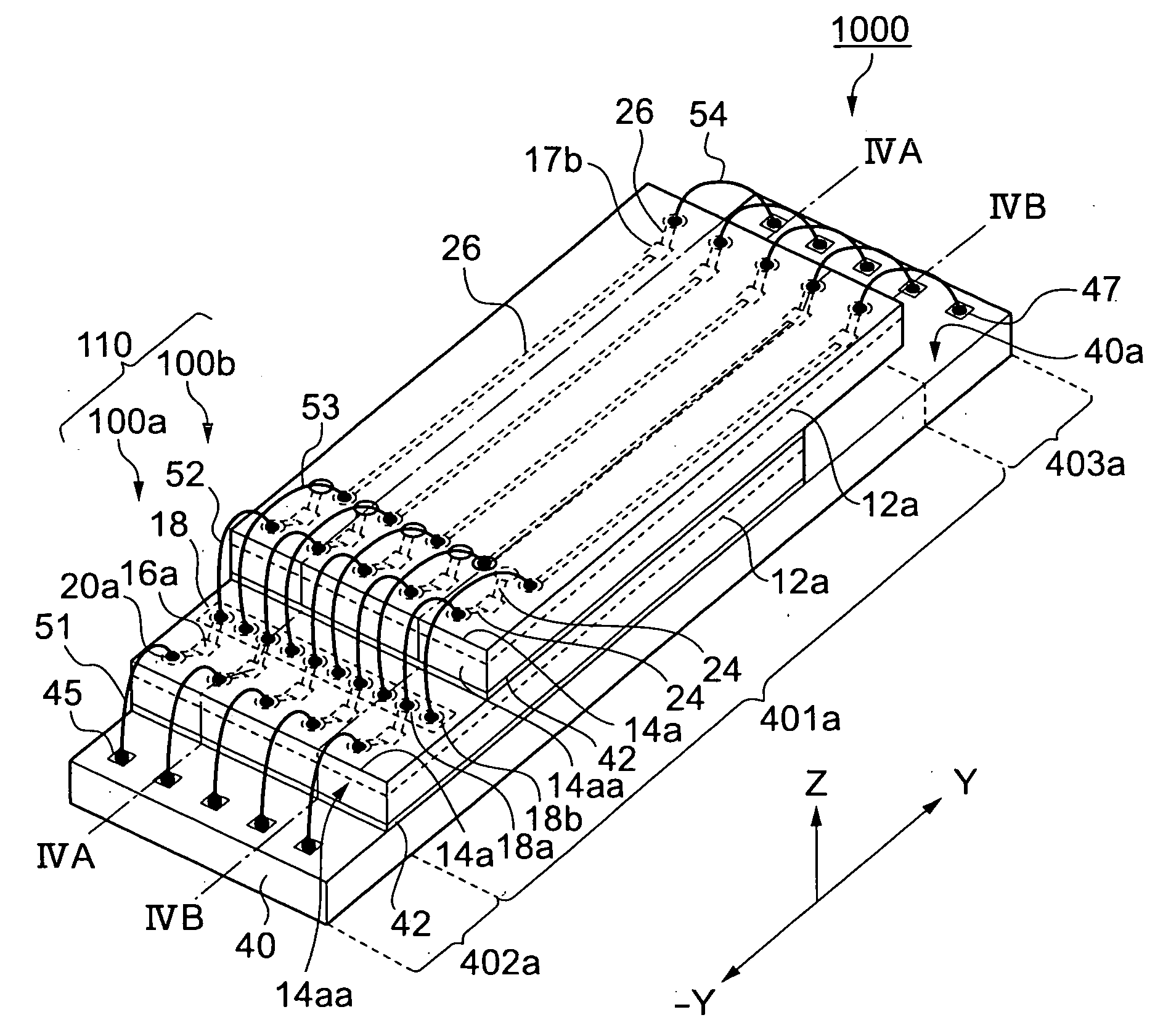

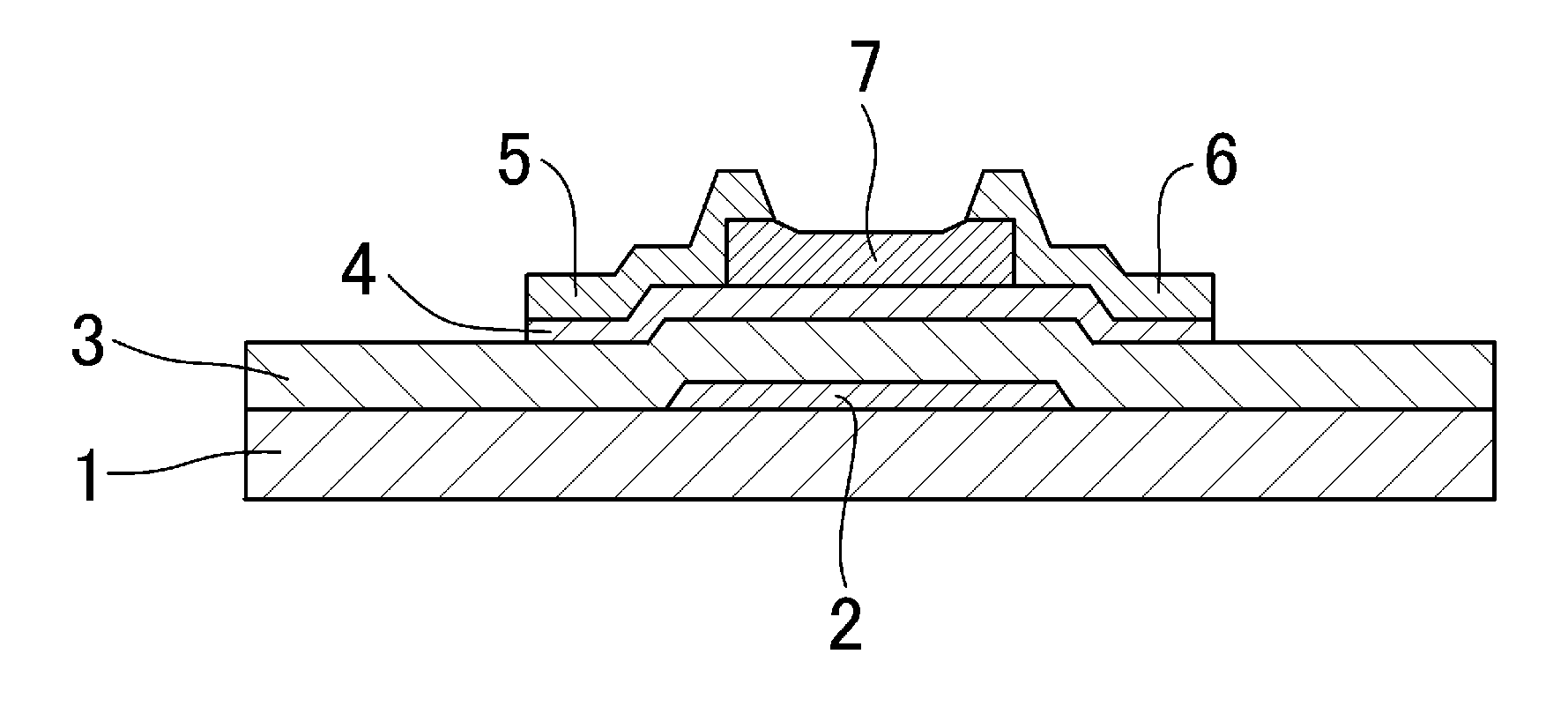

Semiconductor chip package and multichip package

ActiveUS20050139985A1Shorten the lengthReduce the overall heightSemiconductor/solid-state device detailsSolid-state devicesSemiconductor chipElectrode

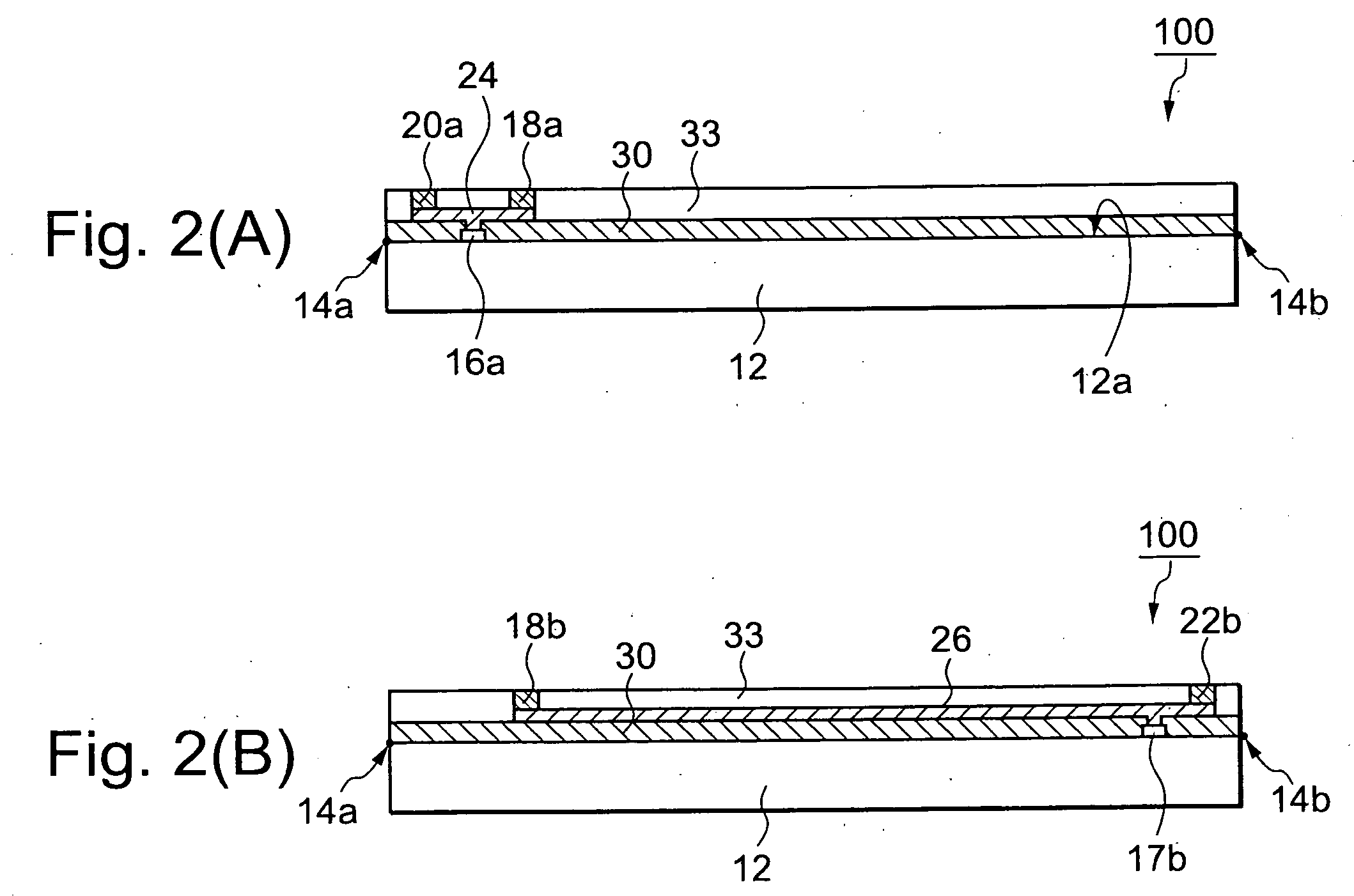

The present invention provides a multichip package wherein a plurality of semiconductor chip packages (100) in each of which first electrode pads (16a) provided in a main surface of a semiconductor chip, and first bonding pads (20a) and first central bonding pads (18a) formed in an upper area of the main surface are respectively electrically connected by first redistribution wiring layers (24) in a one-to-one correspondence relationship, and second electrode pads (17b), and second bonding pads (22b) and second central bonding pads (18b) formed in an upper area of the main surface are respectively electrically connected by second redistribution wiring layers (26) in a one-to-one correspondence relationship, are stacked on one another.

Owner:LAPIS SEMICON CO LTD

Continuous long fiber reinforced fire-retardant thermoplastic resin and its prepn

ActiveCN1810862ASimple recipeSimple process controlLong-fiber-reinforced thermoplasticPolymer chemistry

The present invention discloses one kind of continuous long fiber reinforced fire-retardant thermoplastic resin and its preparation process. It is prepared through mixing continuous long fiber reinforced thermoplastic resin agglomerate, which has reinforcing fiber content of 30-80 wt% and agglomerate length of 3-30 mm, and fire-retardant agglomerate, which has thermoplastic resin as carrier, fire retardant in 20-60 wt%, fire-retarding synergist 5-20 wt% and other additive 0-5 wt%. The continuous long fiber reinforced fire-retardant thermoplastic resin has continuous long fiber content of 5-60 wt%. The continuous long fiber reinforced fire-retardant thermoplastic resin has excellent mechanical performance, especially impact resistance, and excellent fire-retarding performance.

Owner:KINGFA SCI & TECH CO LTD +1

Composite natural polymer gel material

ActiveCN105837861ALarge specific surface areaImprove mechanical propertiesAerogel preparationColloidal chemistry detailsNon solventWater based

The invention discloses a composite natural polymer gel material with a cross-linking agent. The material comprises hydrogel, organogel, aerogel and bioplastics and mainly overcomes the problem of low mechanical strength of conventional natural polymer gel materials. According to the invention, a certain amount of the cross-linking agent is added into a natural polymer water-based solution or dispersion liquid, then stirring is carried out, the obtained mixture is placed in a non-solvent for physical cross-linking, and then washing is carried out so as to obtain composite natural polymer hydrogel; water in the composite natural polymer hydrogel is replaced with an organic solution so as to prepare composite natural polymer organogel; the composite natural polymer hydrogel or organogel is dried so as to prepare composite natural polymer aerogel; the composite natural polymer aerogel is subjected to hydrophobic treatment so as to obtain hydrophobic aerogel; the composite natural polymer aerogel is subjected to heat treatment so as to obtain carbon aerogel; and one or more selected from the above-mentioned gel materials are subjected to high-temperature pressing so as to prepare composite natural polymer bioplastics. The composite natural polymer gel material prepared in the invention has the advantages of excellent mechanical properties, a high specific surface area, high elongation at break, etc., and can be easily processed into molded products of a plurality of forms.

Owner:浙江绍兴万德福生物技术有限公司 +1

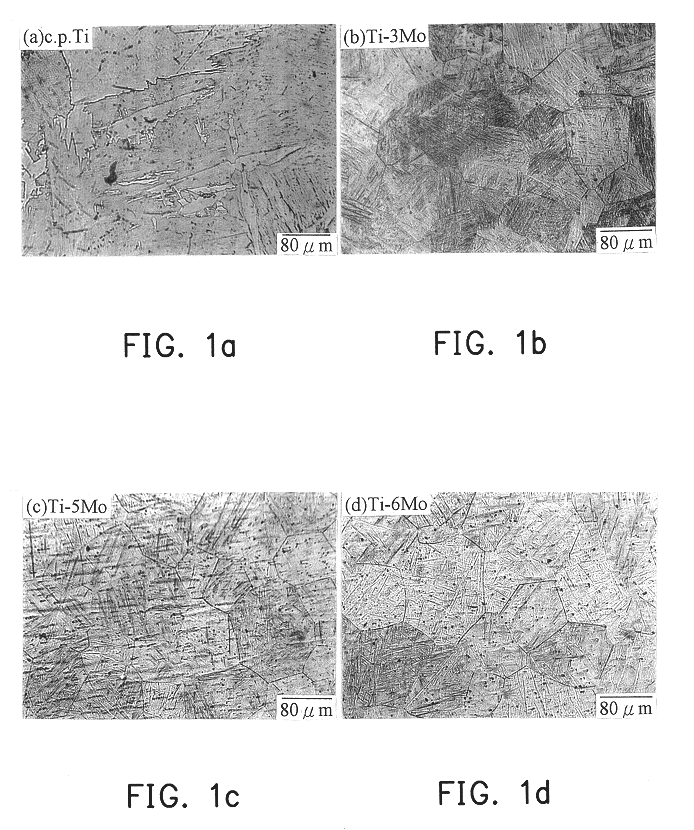

Biocompatible low modulus titanium alloy for medical implant

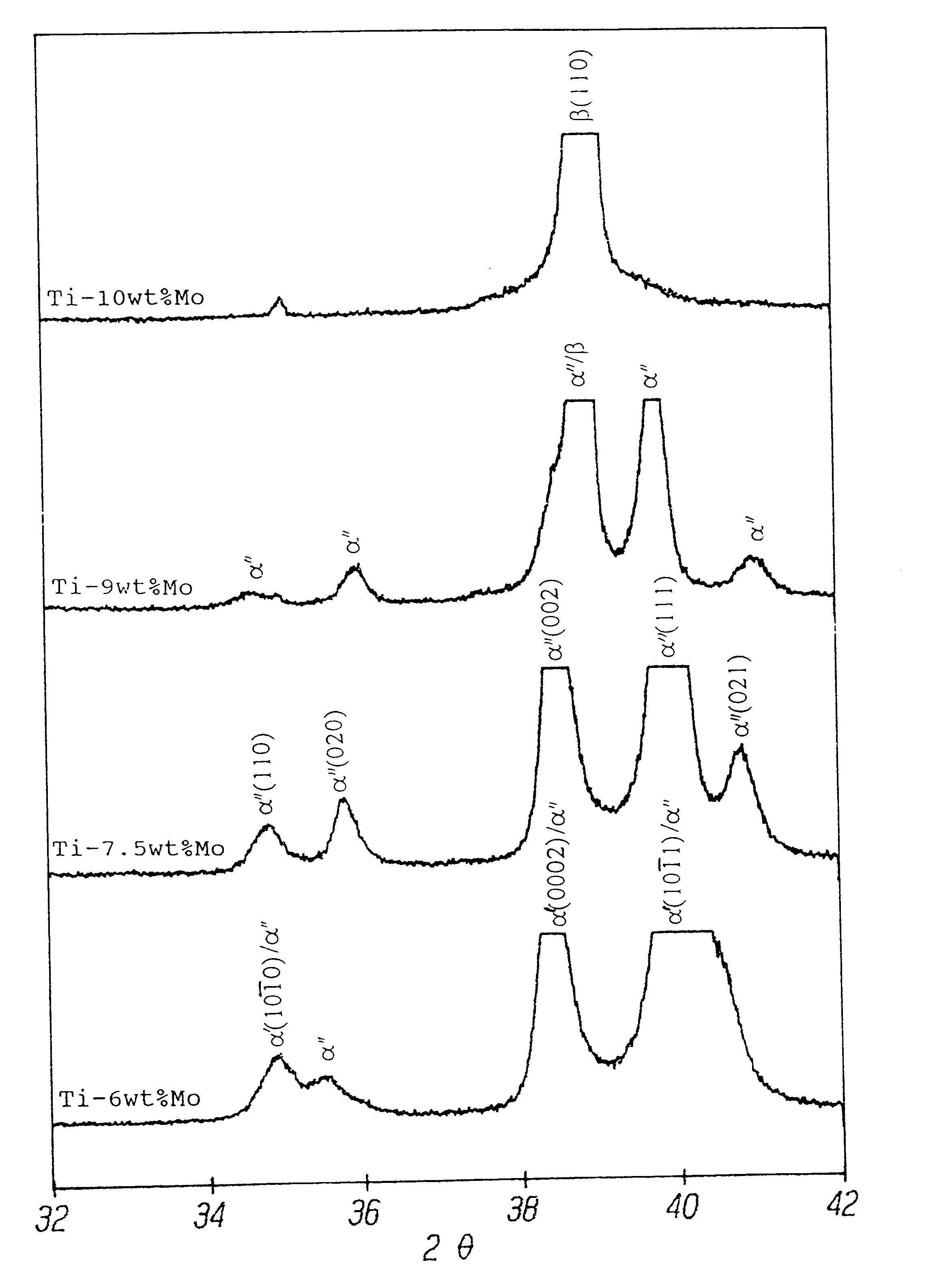

A biocompatible titanium alloy with low modulus comprising alpha'' phase as a major phase and containing from about 6 to about 9 wt % of molybdenum, from 0 to about 1 wt % of an alloying element and the balance titanium. The alloying element is niobium and / or zirconium. The biocompatible titanium alloy is suitable for use as a material for a medical prosthetic implant.

Owner:NAT CHENG KUNG UNIV +1

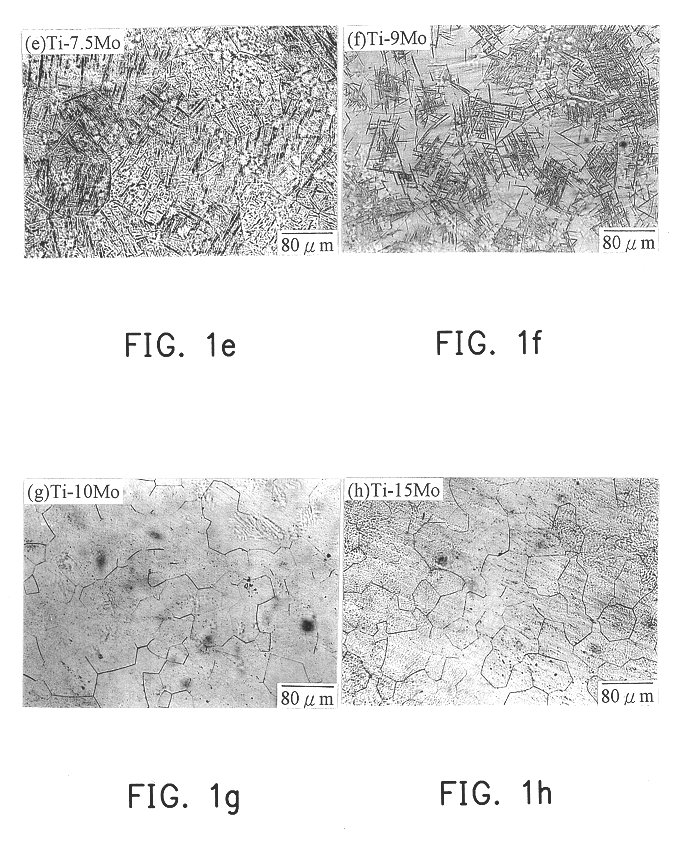

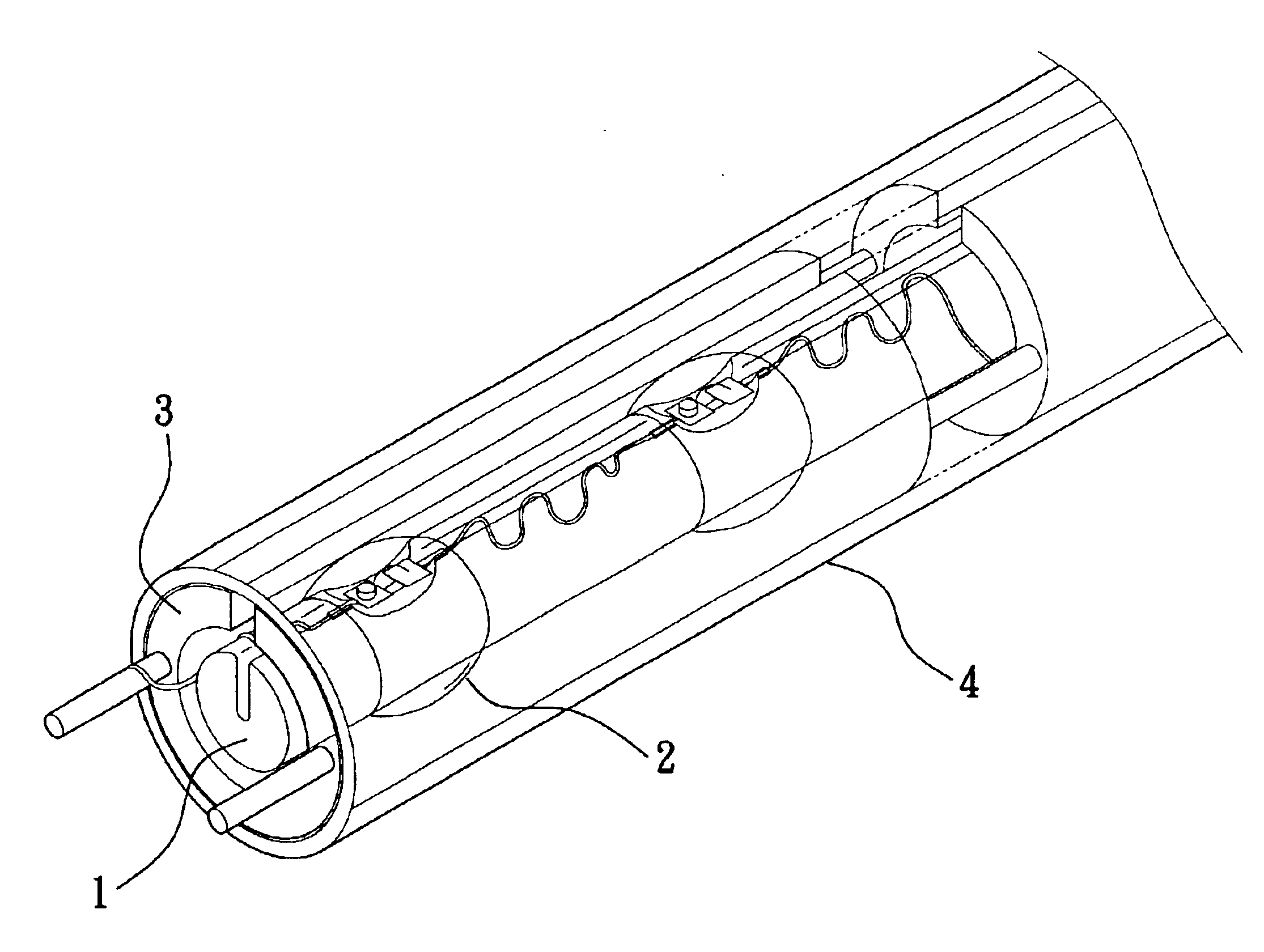

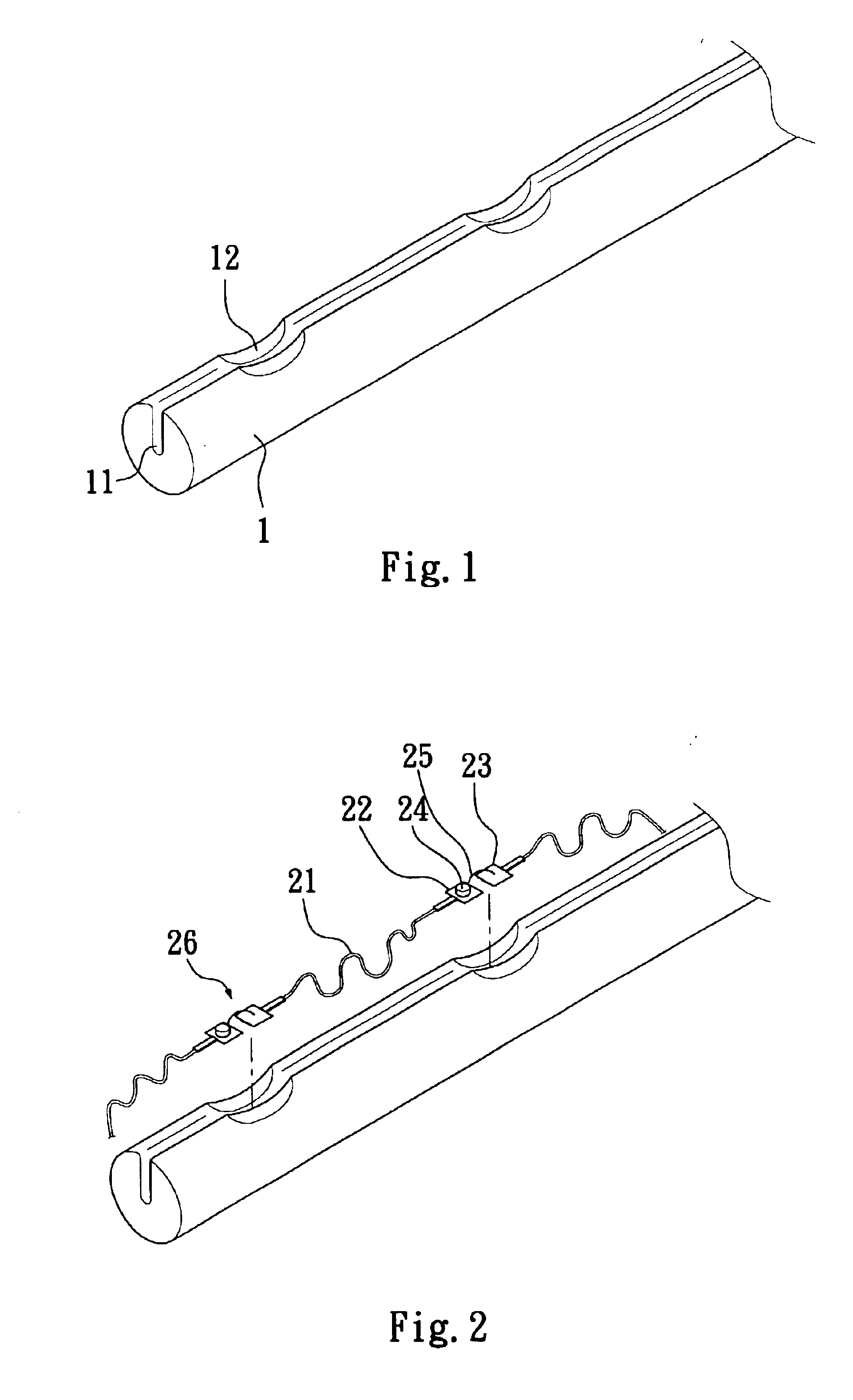

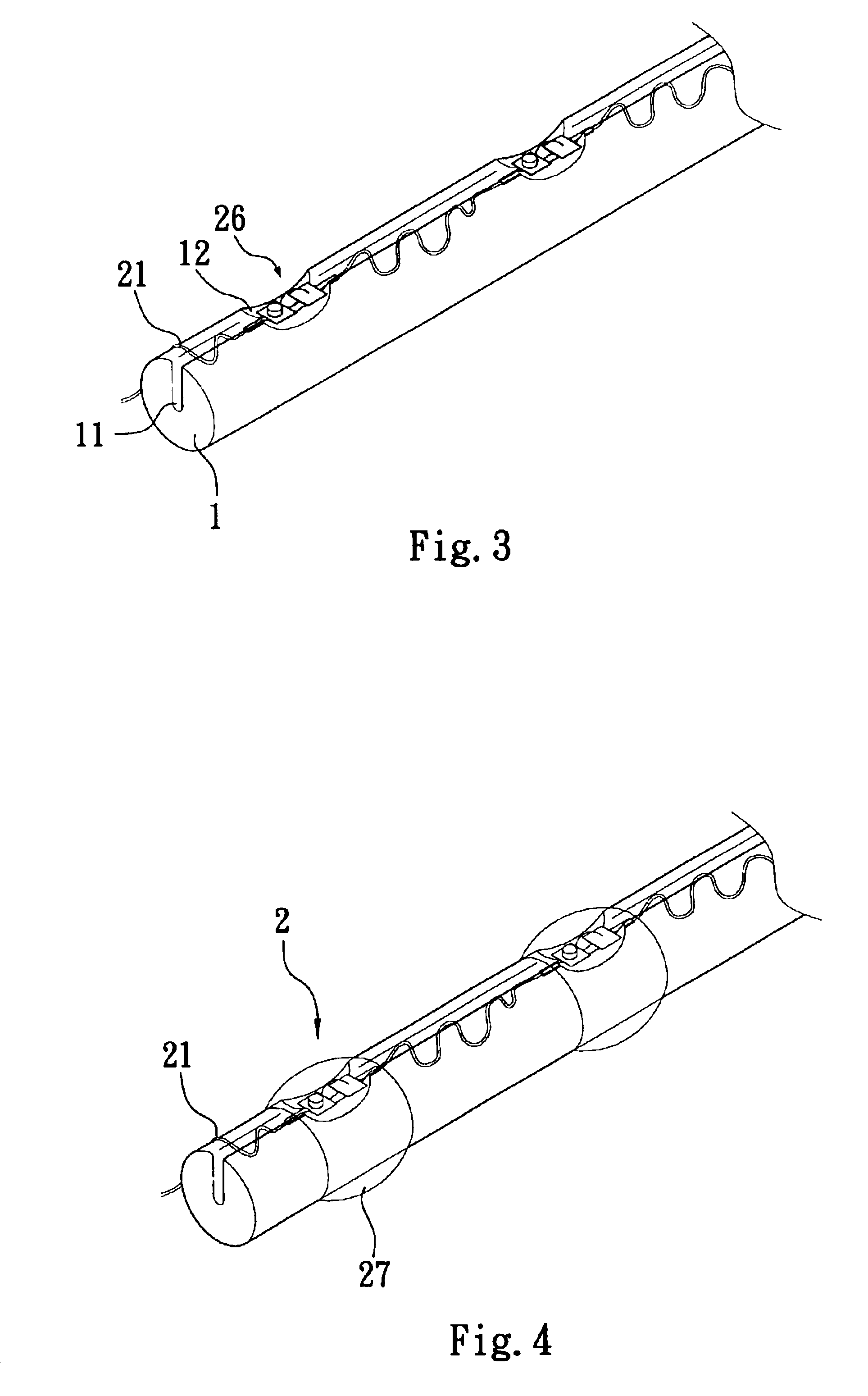

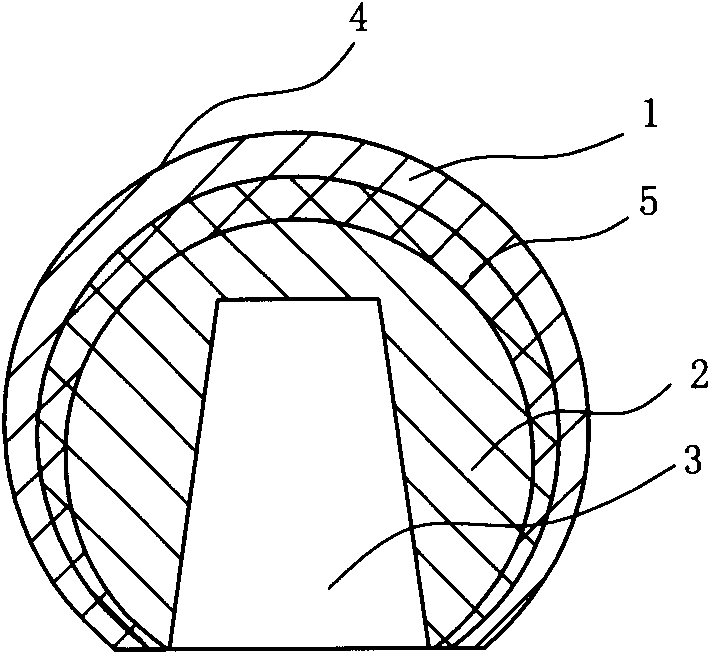

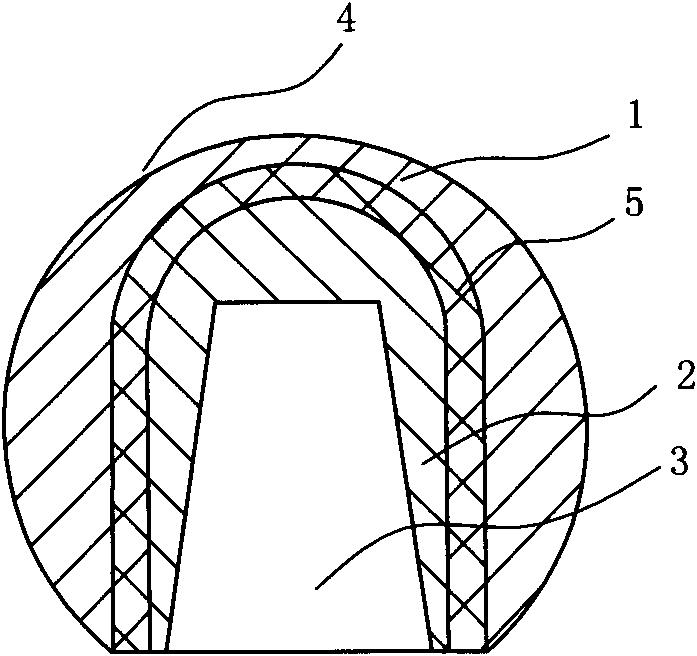

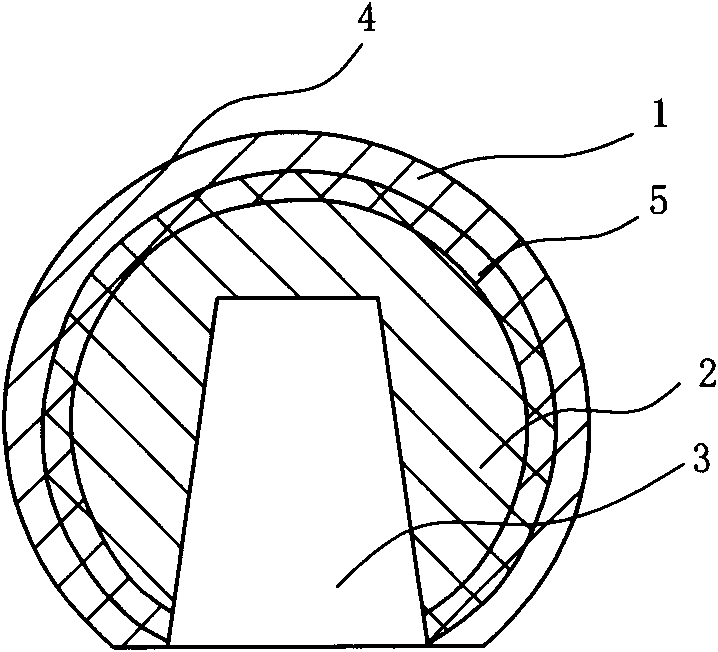

Method of producing an LED hose light

InactiveUS6857924B2Rapid positioningEasy to liftTube/lamp screens manufactureElectroluminescent light sourcesEngineeringLED lamp

A method of producing an LED hose light includes the steps of mounting a plurality of serially connected LED strings directly on a core tube, using an intermediate tube having embedded power cords for supplying power to the LED strings to enclose the core tube having the LED strings mounted thereon, so as to form an assembly of the core tube, the LED strings, and the intermediate tube, and extending the assembly of the core tube, the LED strings, and the intermediate tube through an outer tube. The LED hose light associating LED strings with the core tube is easily bendable and energy-saving and can be produced at largely reduced cost.

Owner:FU TA HAO +1

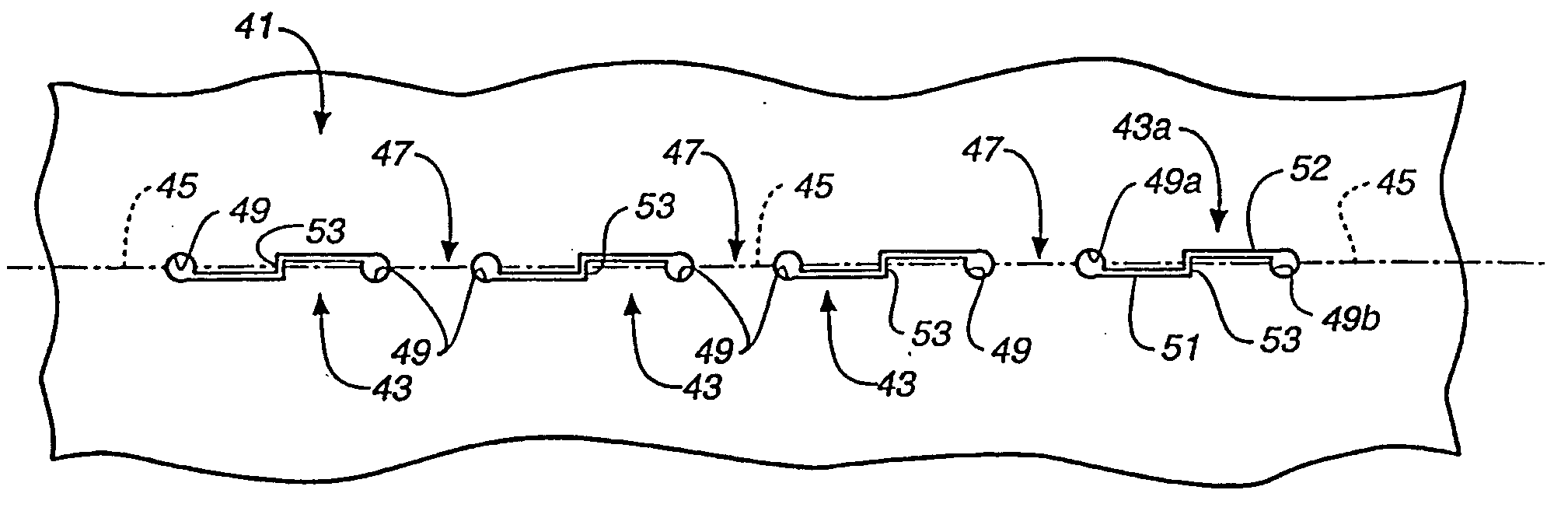

Techniques for designing and manufacturing precision-folded, high strength, fatigue-resistant structures and sheet therefor

InactiveUS20040134250A1High precisionImprove bending strengthAdditive manufacturing apparatusConstruction materialManufacturing technologyEngineering

A process for designing and manufacturing precision-folded, high strength, fatigue-resistant structures and a sheet therefore. The techniques include methods for precision bending of a sheet of material (41, 241, 341, 441, 541) along a bend line (45, 245, 345, 445,543) and a sheet of material formed with bending strap-defining structures, such as slits or grooves (43, 243, 343, 443, 542), are disclosed. Methods include steps of designing and then separately forming longitudinally extending slits or grooves (43, 243, 343, 443, 542) through the sheet of material in axially spaced relation to produce precise bending of the sheet (41, 241, 341, 441,541) when bent along the bend line (45, 245, 345, 445, 543). The bending straps have a configuration and orientation which increases their strength and fatigue resistance, and most preferably slits or arcs are used which causes edges (257, 457) to be engaged and supported on faces (255, 455) of the sheet material on opposite sides of the slits or arcs. The edge-to-face contact produces bending along a virtual fulcrum position in superimposed relation to the bend line (45, 245, 345, 445, 543). Several slit embodiments (43, 243, 343, 443, 542) suitable for producing edge-to-face engagement support and precise bending are disclosed, as is the use of the slit sheets to produce various three-dimensional structures and to enhance various design and fabrication techniques.

Owner:IND ORIGAMI INC CA US

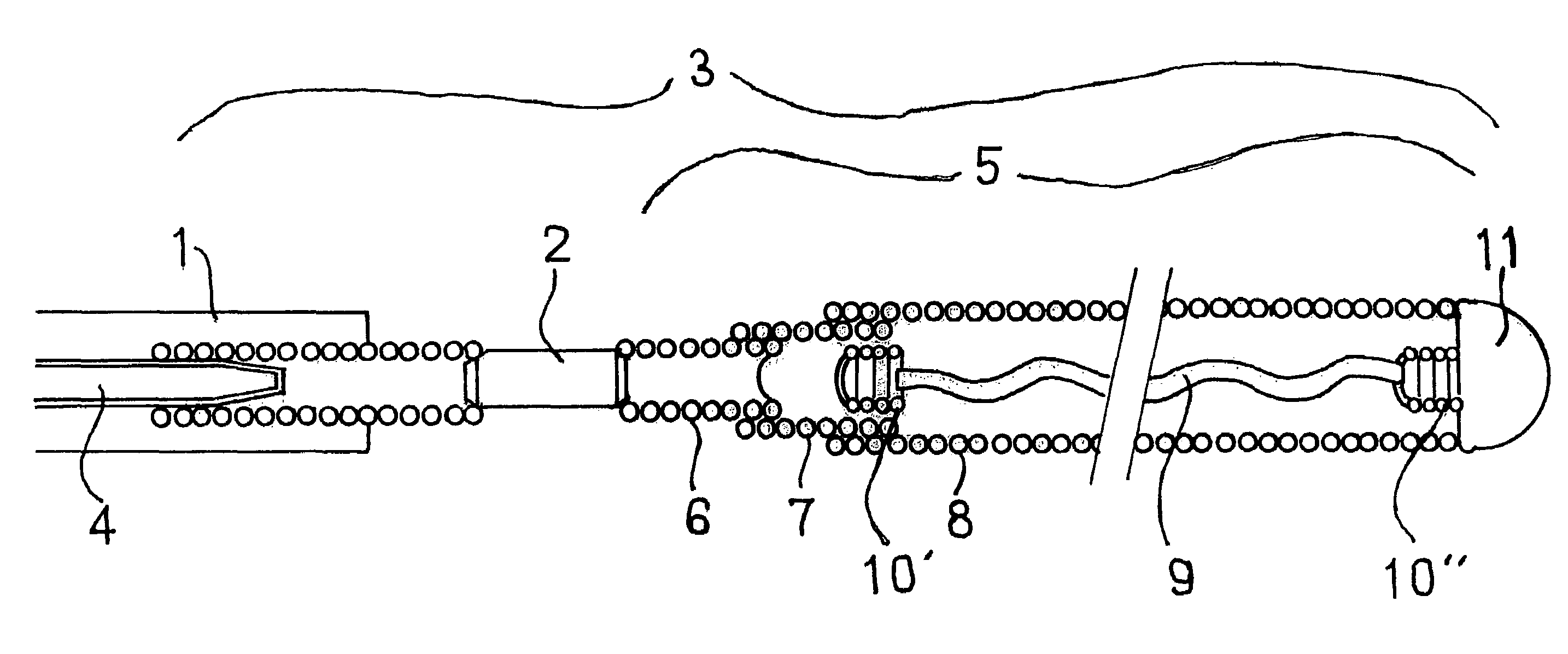

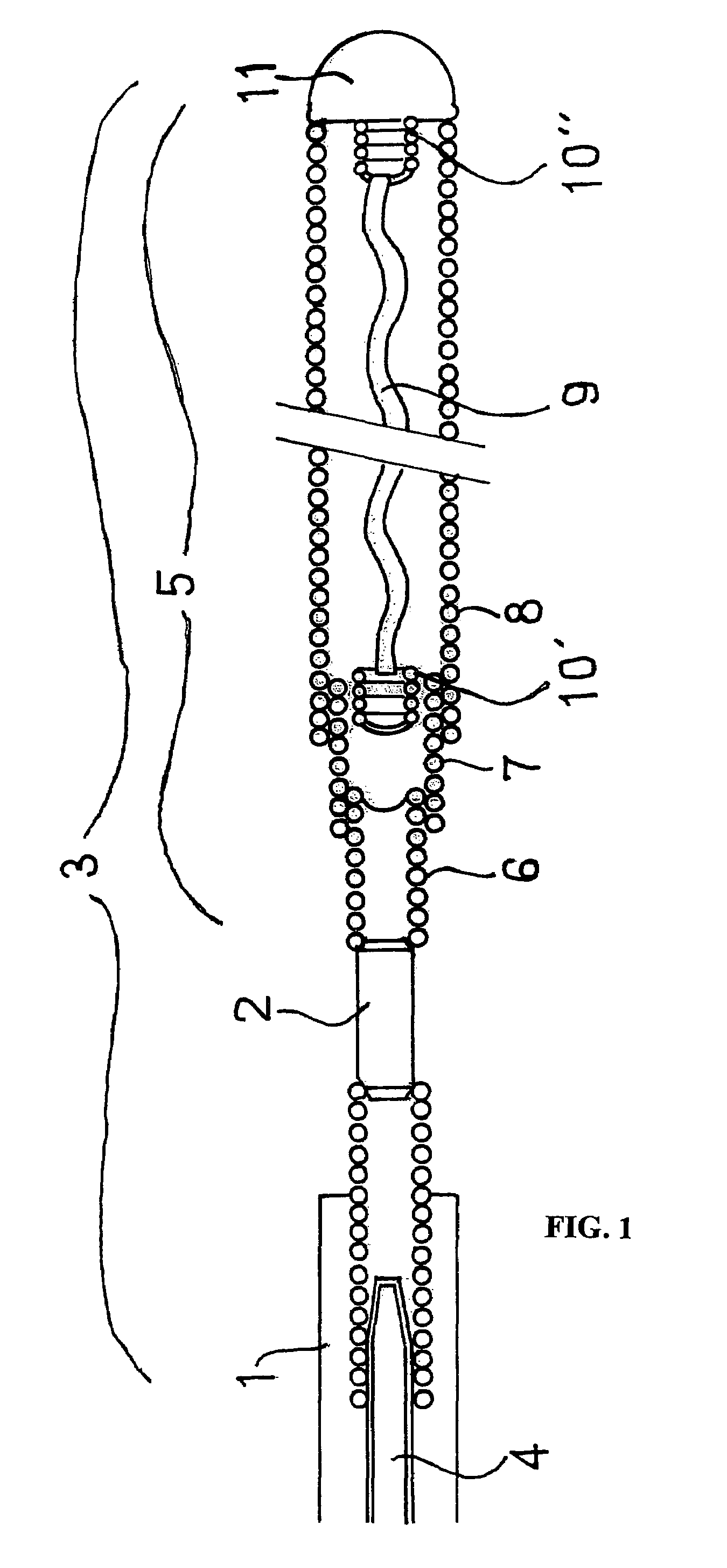

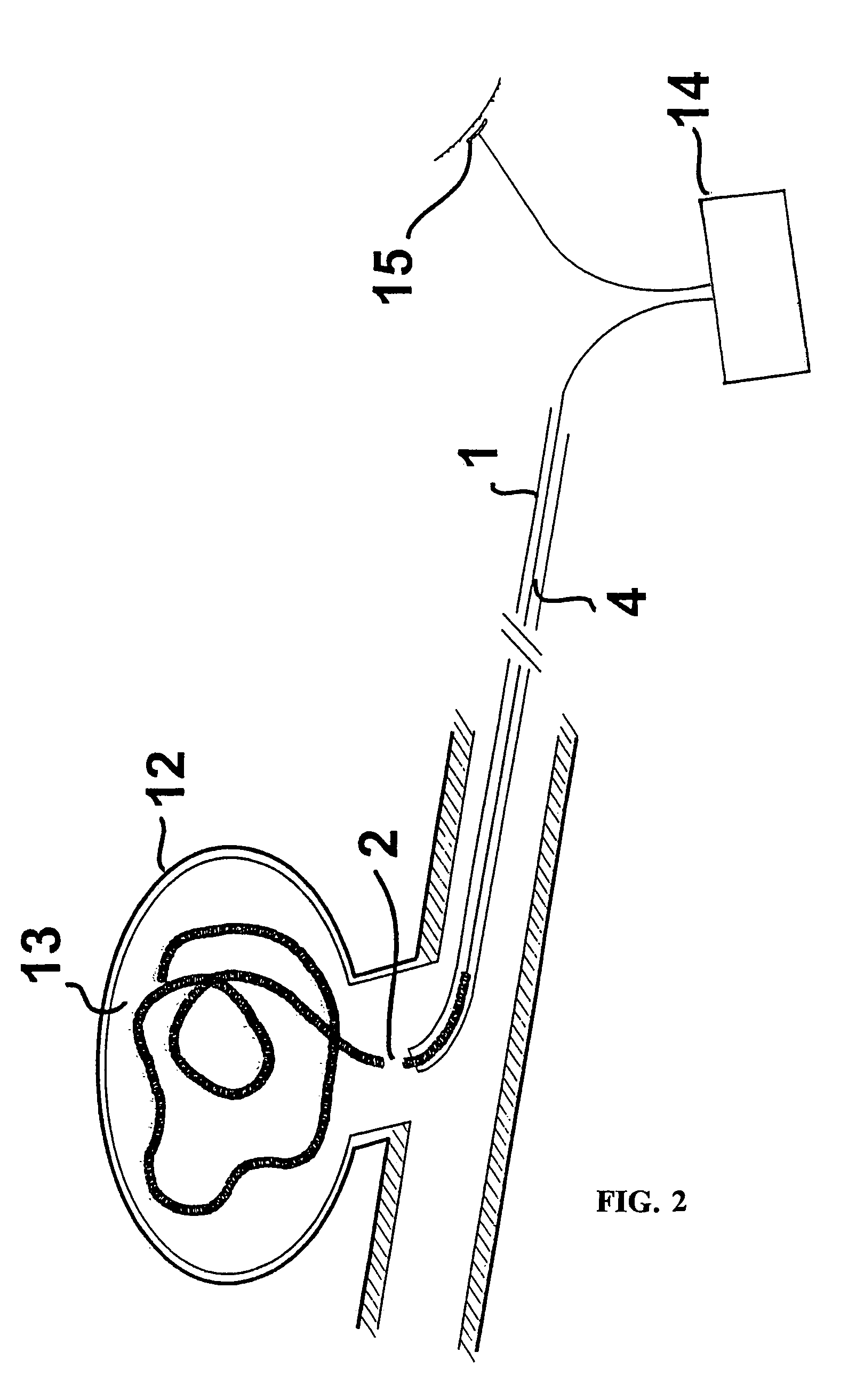

Device for implanting occlusion spirals

InactiveUS7238194B2Maximum degree of security against tearingImprove bending strengthEar treatmentDilatorsThree vesselsBody cavity

Device for implanting occlusion spirals in body cavities or blood vessels with a catheter, an occlusion spiral that can be moved within the catheter in the longitudinal direction, and at least one securing means attached in the occlusion spiral, structured as a flexible lengthwise element, which passes through the length of the occlusion spiral at least in a partial region, which is characterized in that the securing means contains a material with shape memory properties.

Owner:DENDRON

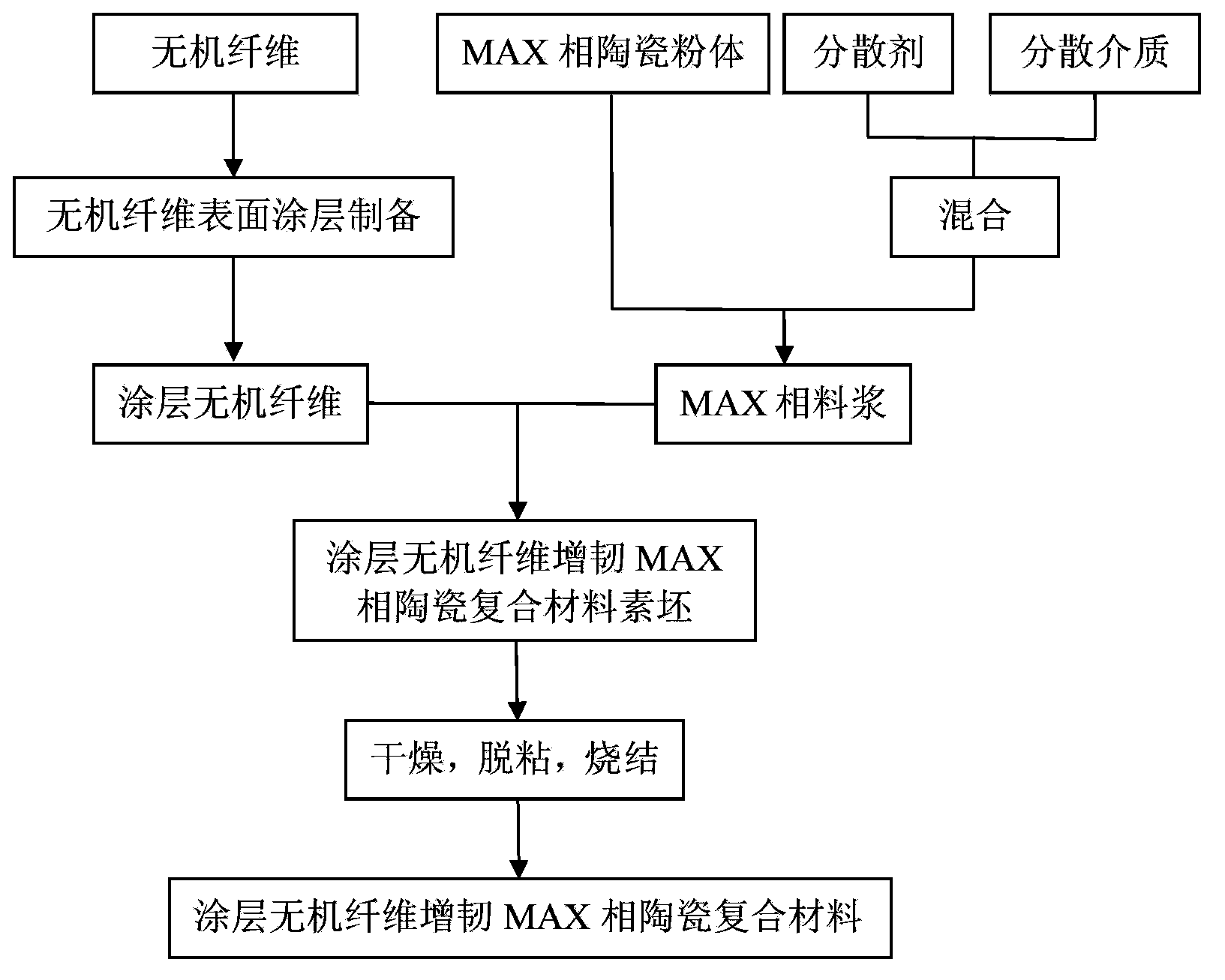

Coating inorganic fiber toughened MAX phase ceramic composite material, preparation method and uses thereof

ActiveCN103910532AAppropriate bonding interface strengthFree control of interface strengthNuclear energy generationContainmentAviationFiber

The present invention provides a coating inorganic fiber toughened MAX phase ceramic composite material and a preparation method thereof. The composite material adopts a MAX phase ceramic material as a matrix and adopts coating inorganic fibers as a toughening phase, wherein the coating inorganic fiber content is 0.5-90% (by volume), and the coating inorganic fibers are completely dispersed in the matrix and are inorganic fibers with the surface coated with the coating. Compared with the composite material in the prior art, the composite material of the present invention has the following characteristics that: the interface reaction between the inorganic fibers and the MAX phase ceramic can be effectively inhibited, the thermal expansion coefficient and elasticity modulus matching degree between the inorganic fibers and the MAX phase ceramic can be effective regulated, the effective improvement of the fracture toughness and the high temperature resistance of the MAX phase ceramic composite material can be achieved, the problems of high brittleness and insufficient use reliability of the MAX phase ceramic can be fundamentally solved, and the coating inorganic fiber toughened MAX phase ceramic composite material has potential application prospects in the high technology fields of civil use, aviation, aerospace, nuclear industry and the like, and is especially for the fission and fusion reactor nuclear power plant inner wall structure material.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Investment precision casting technology for producing automobile I-shaped front axle

InactiveCN101147954ALess investmentReduce manufacturing costFoundry mouldsFoundry coresSteelmakingWax

The present invention relates to a fusible pattern precision casting process for producing automobile H-shaped front axle. Said casting process includes the following steps; (1), preparing wax pattern; (2), applying coating material onto the wax pattern surface for several times, spreading sand and making the coating material hardened pattern shell be primarily formed, removing wax and forming pattern shell; (3), firing pattern shell; (4), pouring the molten steel into the pattern shell, before steel-smelting having to make analysis of charge mixture ratio, in the course of smelting steel having to make on-the-spot sample analysis and furnace rear analysis, adding required additive and deoxidant so as to make the molten steel be reached to the defined chemical components requirement; (5), removing pattern shell from obtained automobile H-shaped front axle casting, cleaning sand and cutting spure; (6), grinding, finishing and checking casting; (7), making quenching and tempering, heat treatment; (8), making correction and shot blasting treatment; and (9), making metalworking treatment.

Owner:NANPING AUTO FORGING & STAMPING FACTORY

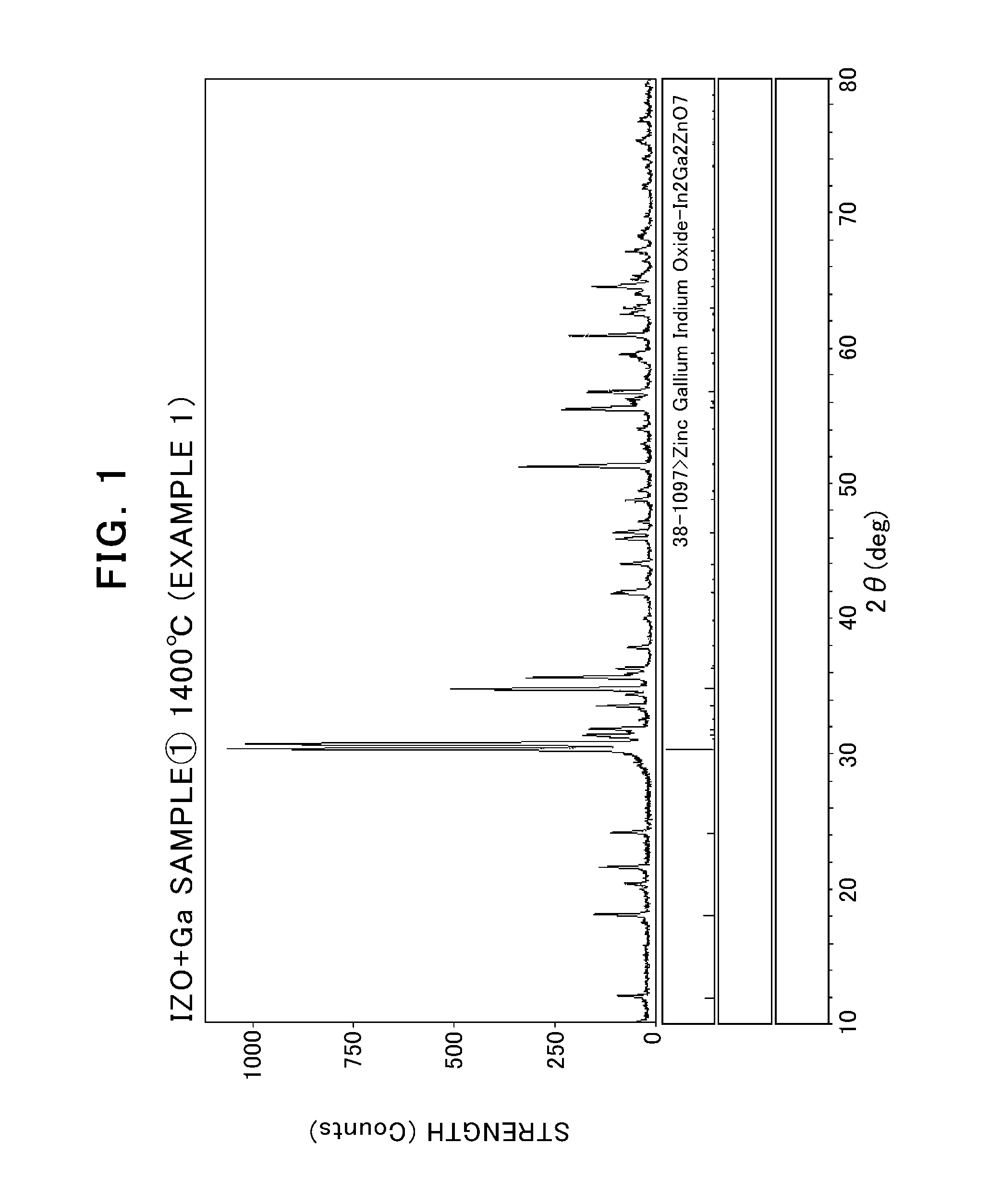

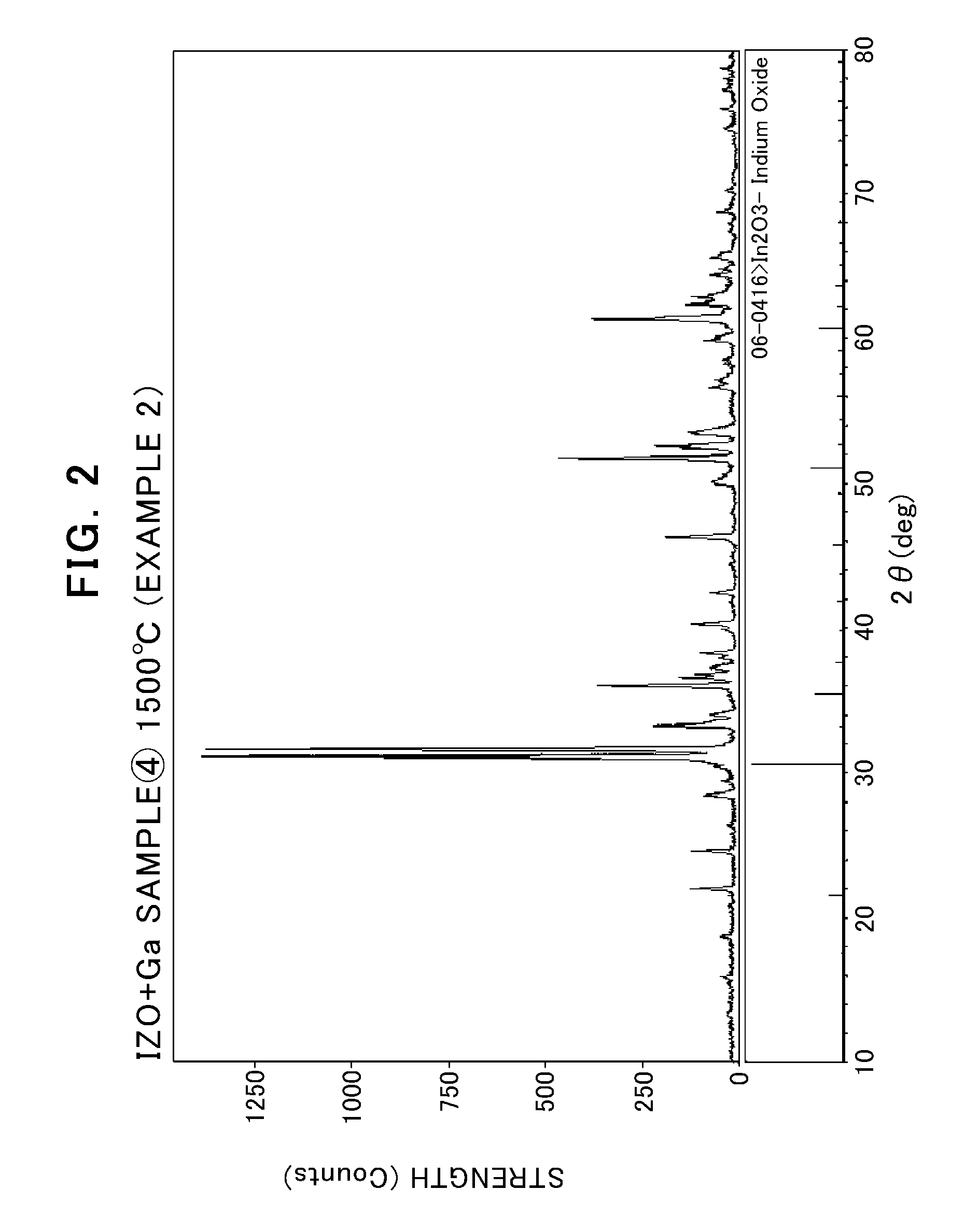

Sputtering target for oxide thin film and process for producing the sputtering target

ActiveUS20110168994A1Lower bulk resistanceHigh densityConductive materialVacuum evaporation coatingIndiumRare earth

Disclosed is a sputtering target that can suppress the occurrence of anomalous discharge in the formation of an oxide semiconductor film by sputtering method and can continuously and stably form a film. Also disclosed is an oxide for a sputtering target that has a rare earth oxide C-type crystal structure and has a surface free from white spots (a poor appearance such as concaves and convexes formed on the surface of the sputtering target). Further disclosed is an oxide sintered compact that has a bixbyite structure and contains indium oxide, gallium oxide, and zinc oxide. The composition amounts (atomic %) of indium (In), gallium (Ga), and zinc (Zn) fall within a composition range satisfying the following formula: In / (In+Ga+Zn)<0.75

Owner:IDEMITSU KOSAN CO LTD

Manufacturing method of multilayer shell-core composite structural part

ActiveCN102009175AShell surface hardness is highHigh surface finishJoint implantsCeramic layered productsComposite constructionHigh surface

The invention discloses a manufacturing method of a multilayer shell-core composite structural part, which comprises the following steps of: (1) respectively preparing feed for injection forming of a core layer, a transition layer and a shell layer, wherein powder in the feed of the core layer and the powder in the feed of the shell layer are selected from one or a mixture of some of metal powder, ceramic powder, or toughened ceramic powder and are different from each other, and the powder in the feed of the transition layer is gradient composite powder; (2) respectively manufacturing blanks of the multilayer shell-core composite structural part layer by layer with a powder injection forming method; (3) degreasing the blanks; and (4) sintering the blanks to obtain the multilayer shell-core composite structural part. The multilayer shell-core composite structural part is manufactured with the powder injection forming method, and has the advantages of high surface hardness, abrasion resistance, uniform thickness of the shell layer, stable and persistent performance, strong binding force between the shell layer and the core layer due to the transition layer, good integral bending strength and good impact toughness and is difficult to crack.

Owner:SUZHOU DINGAN ELECTRONICS TECH

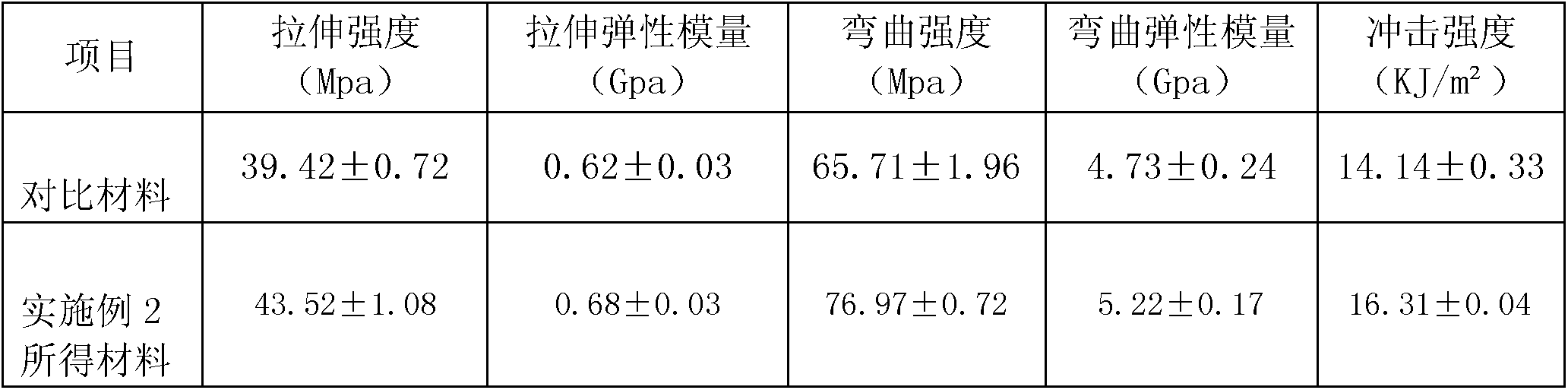

Inorganic nano particle modified high performance recovery plastic and its preparing process

InactiveCN1858101AHigh tensile strengthImprove bending strengthPlastic recyclingGlass fiberAlkali free

The inorganic nanometer particle modified high performance regenerated plastic consists of recovered plastic 5-98 wt%, new plastic in the same type 0-93 wt%, inorganic nanometer particle 1-30 wt%, flexibilizer and compatilizer 1-30 wt%, and alkali free glass fiber 0-45 wt%, and the surface of the alkali free glass fiber is treated with silane coupler in the amount of 0.2- 5% of the added alkali free glass fiber. The said components are mixed homogeneously through stirring, melted and extruded to form.

Owner:NANJING JULONG SCI&TECH CO LTD

Preparation method of tensile compressive high temperature resistant modified polypropylene power pipe

The invention discloses a preparation method of a tensile compressive high temperature resistant modified polypropylene power pipe. The pipe comprises 100 weight parts of modified polypropylene, 0.5-15 weight parts of tackifier, 0.1-15 weight parts of nano material, 0.1-15 weight parts of liquid crystal material, 0.5-15 weight parts of shock resistant modifier, 0.1-15 weight parts of nucleating agent, 0-30 weight parts of filling masterbatch, 0.1-5 weight parts of color masterbatch, 0.5-30 weight parts of engineering plastic, 0.5-15 weight parts of compatibilizer, 0.05-5 weight parts of antioxidant, and 0.05-5 weight parts of light stablilizer, and is prepared by carrying out mixing granulation on the raw materials and then conducting extrusion molding through a mold. According to the invention, compared with existing MPP pipe, the bending strength of the produced MPP pipe disclosed herein is raised by 30-50%, the bending elastic modulus is raised by 25-60%, the welding tensile strength reaches 26-33 MPa, 70 DEG C ring hot compression force is raised by 30-50%, the photooxidation aging resistant time is prolonged by 5-15 years, the vicat softening point is raised by 5-20 DEG C, the shock strength and corrosion resistance are good, thus the produced MPP pipe disclosed herein can meet the requirements for high standard quality electric power engineering, and the engineering cost is reduced.

Owner:HONGYUE PLASTIC GROUP

High wear-resistant wood-plastic composite and preparation method thereof

The invention provides a high wear-resistant wood-plastic composite and a preparation method thereof, and relates to a composite obtained by mixing modified plant fiber powder, modified nano ceramics particles and plastic powder. The high wear-resistant wood-plastic composite comprises the modified plant fiber powder, the modified nano ceramics particles, the recycled plastic powder and the like, wherein the modified nano ceramics particles comprises modified nano Al2O3, modified nano Si3N4, modified nano SiC or the mixture thereof, which can obviously improve the microhardness of the wood-plastic composite, reduce the wear rate and improve the mechanical property. The high wear-resistant wood-plastic composite is prepared from the components by the common melt-mixing method in the plastic processing. The surface hardness and the wearability of the wood-plastic composite are greatly increased, and the strength and the toughness are also greatly improved, so that the overall performance of the wood-plastic composite is greatly enhanced. The wood-plastic composite can be used in the fields of construction material, furniture, package and the like.

Owner:GUANGDONG XINXIU NEW MATERIAL CO LTD

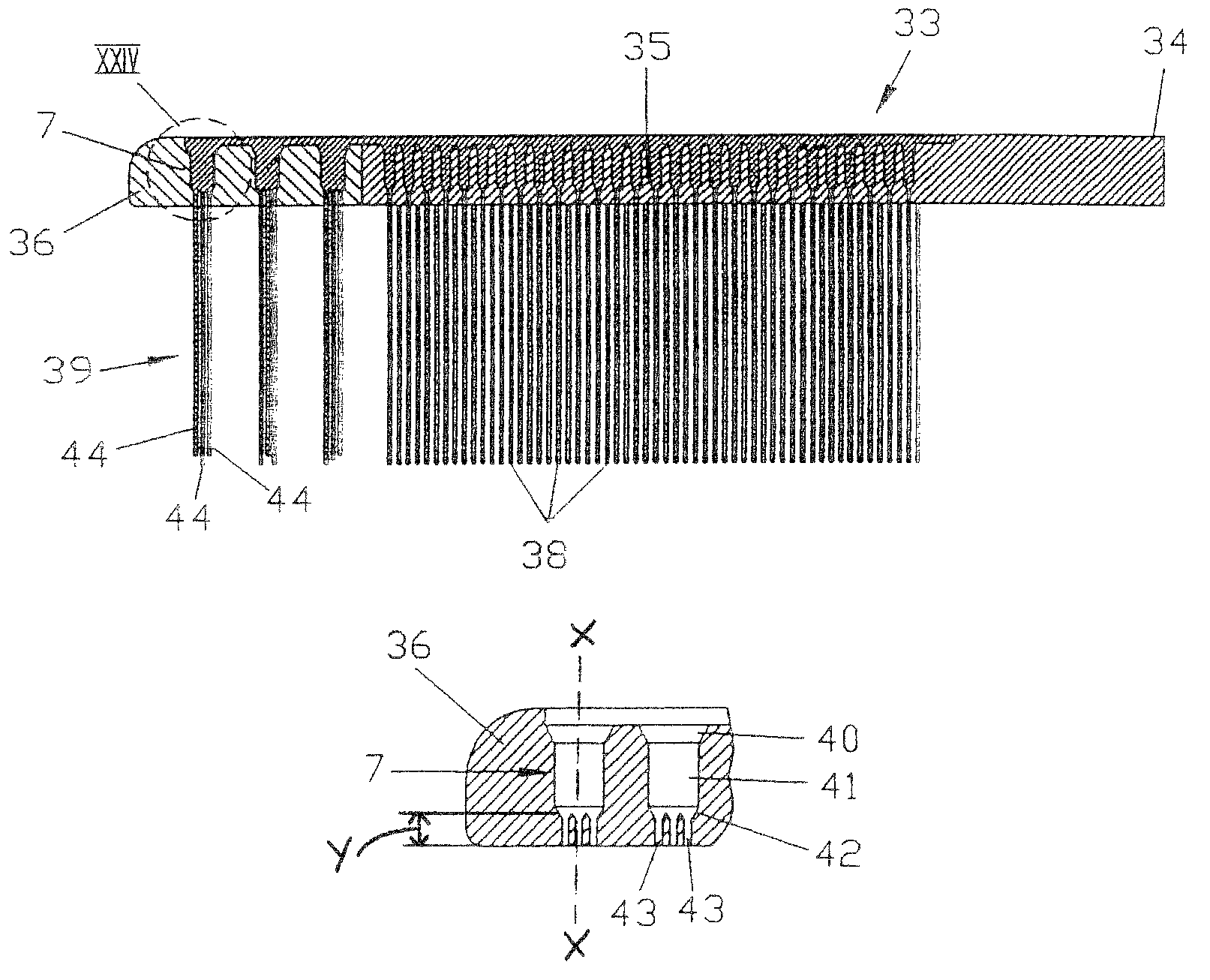

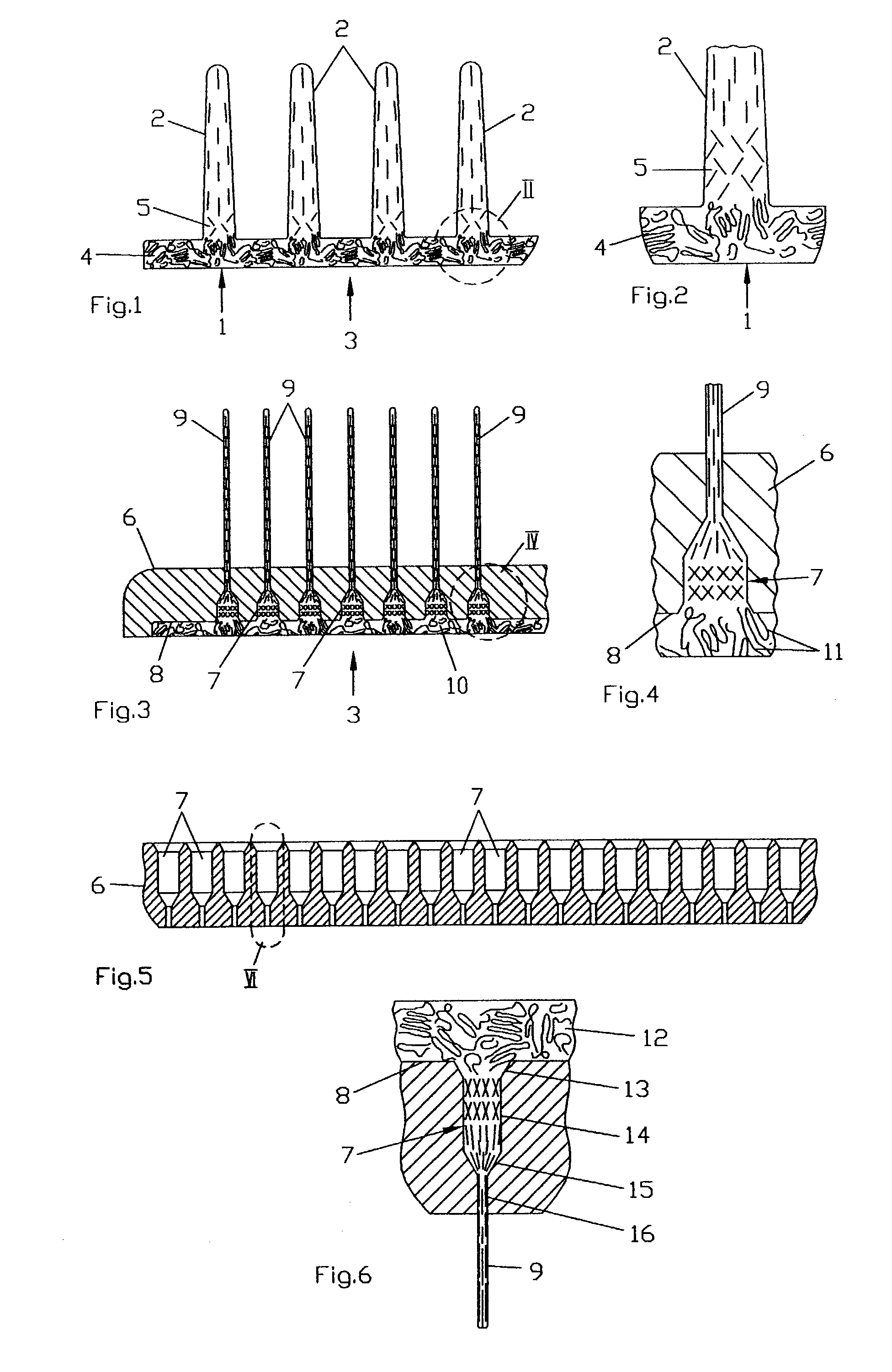

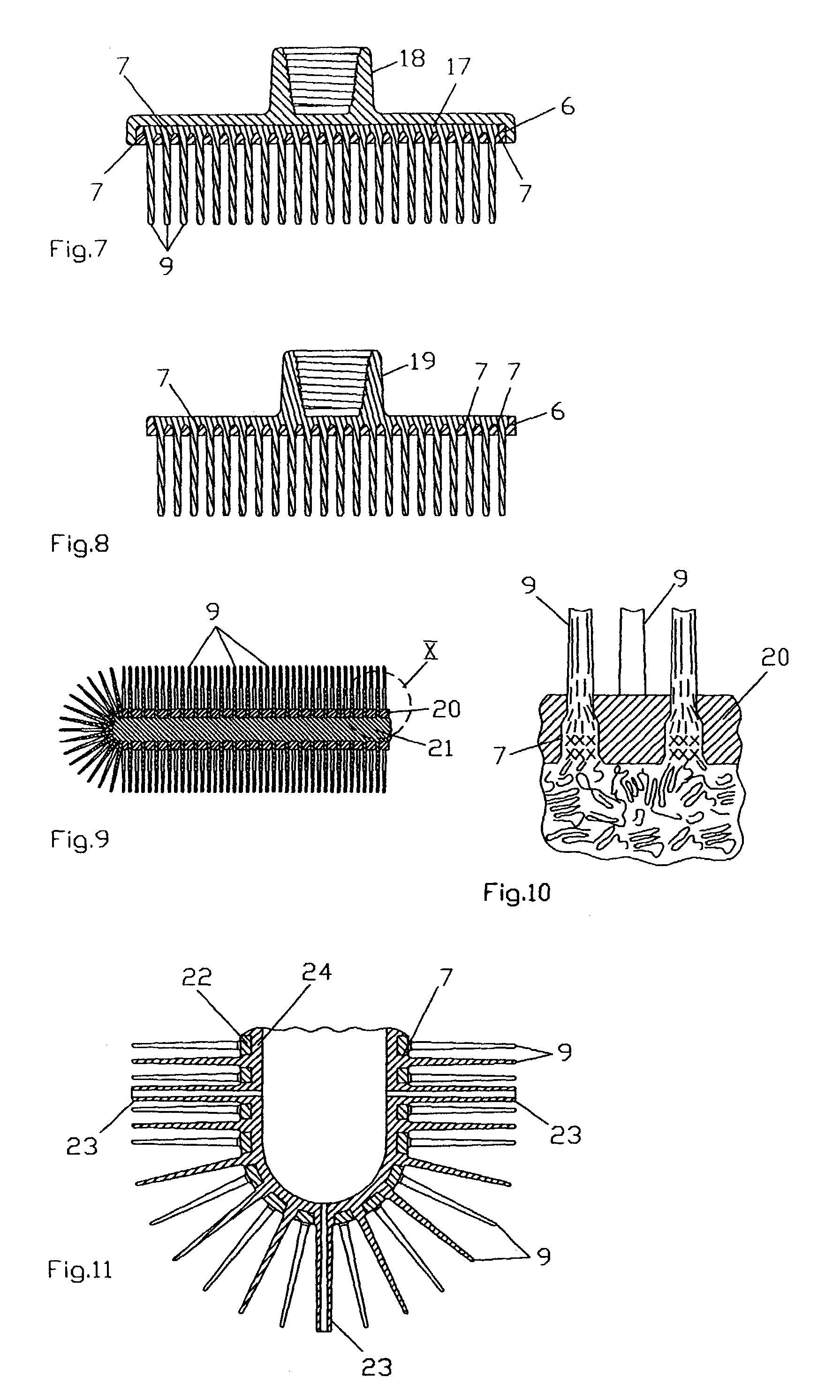

Method and device for producing bristle products and bristle products

InactiveUS7503093B2Improve abilitiesEasy to disassembleBrush bodiesBristle carriersBristlePlastic materials

Brush ware comprising at least one carrier and bristles made from a moldable plastic material disposed thereon, is produced by providing the carrier with through holes acting like spinning nozzles, to which bristle-shaped molding channels join and a plastic melt for the bristles is injected from at least one side of the carrier—the feed side of the melt—through the holes into the channels thereby forming the bristles, wherein the through holes have a minimal width along at least a portion of their length which is ≦3 mm and the ratio between this width and the flow path of the melt resulting from the depth of the through holes plus the length of the channels is ≦1:5. A device for carrying out the method and brush ware produced in accordance with the method is also described.

Owner:GEKA

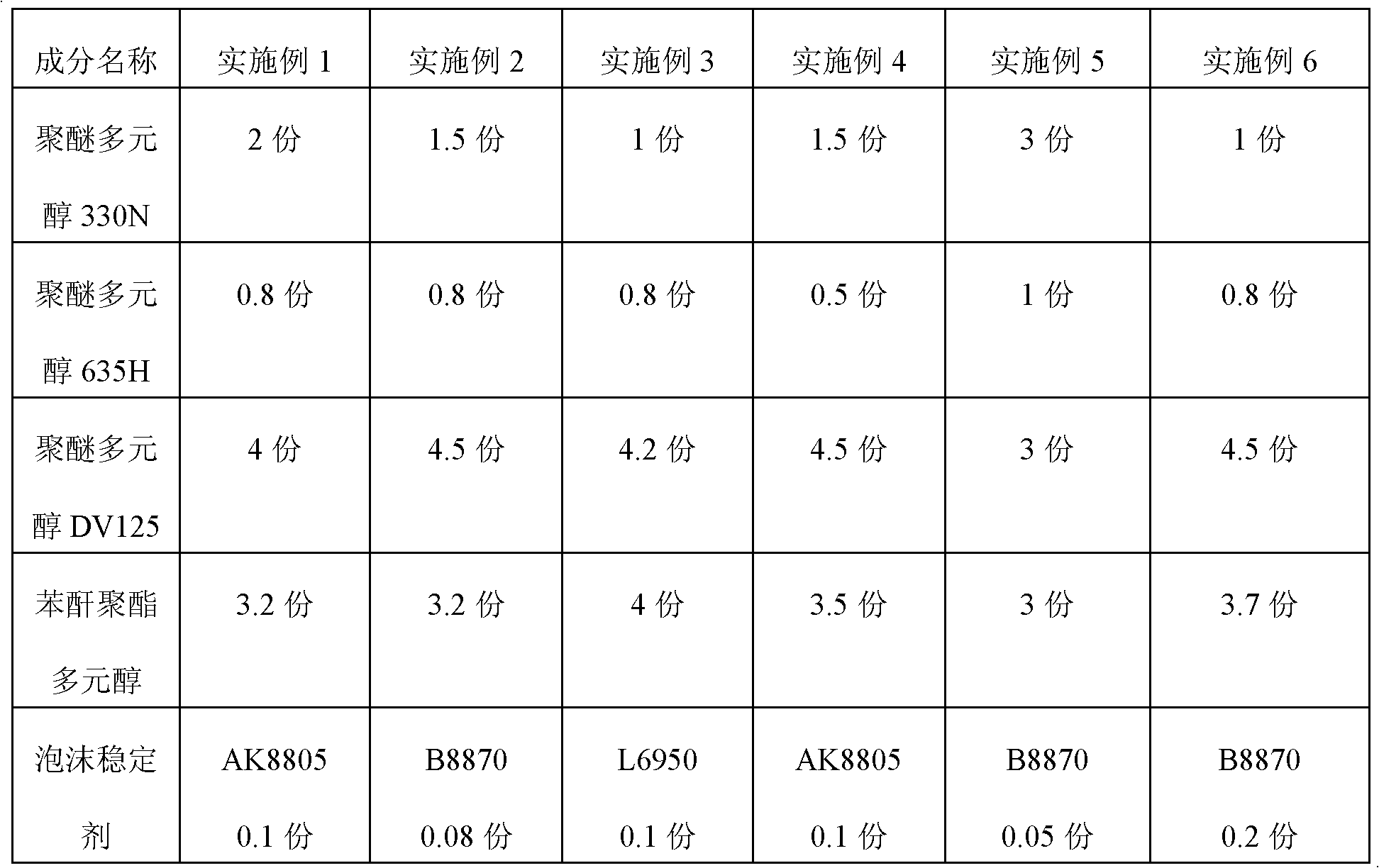

Composite polyether, polyurethane rigid foam as well as raw material composition and usage thereof

InactiveCN102093527AGood dimensional stabilityGood resistance to yellowingPolyesterBenzoic anhydride

The invention relates to a composite polyether which comprises 1-3 parts of polyether polyol 330N, 0.5-1 part of polyether polyol 635H, 3-5 parts of polyether polyol DV125, 3-4 parts of benzoic anhydride polyester polyol, 0.05-0.2 part of foam stabilizer, 0.05-0.2 part of cell opener, 0.02-0.1 part of polyurethane synthetic catalyst and 0.3-0.5 part of water. The invention also relates to polyurethane rigid foam as well as a raw material composition and usage thereof. The polyurethane rigid foam material can simultaneously have excellent cell opening property, size stability, bending strength and compression mildness, thus the polyurethane rigid foam material has the effects of light weight, heat isolation, sound absorption and the like and can well meet use requirements of car roof foam. Besides, the polyurethane rigid foam also has excellent yellowness resistance and prolonged service life.

Owner:SHANGHAI DONGDA POLYURETHANE

Target of intermetallic compound with B2-ordered lattice structure, production method thereof and magnetic recording medium having B2-structured underlayer

InactiveUS6159625AHigh bending strengthSmall grain sizeCellsBase layers for recording layersSputter depositionCrystallite

A target for sputter-depositing a B2-structured thin film for an underlayer of a magnetic recording medium. Since the target is made of a sintered body of an intermetallic compound being substantially a B2-ordered lattice structure, the target has a uniform small grain size and a high bending strength. The target produces a thin film with a small grain size and a minimized particle deposition.

Owner:HITACHI METALS LTD

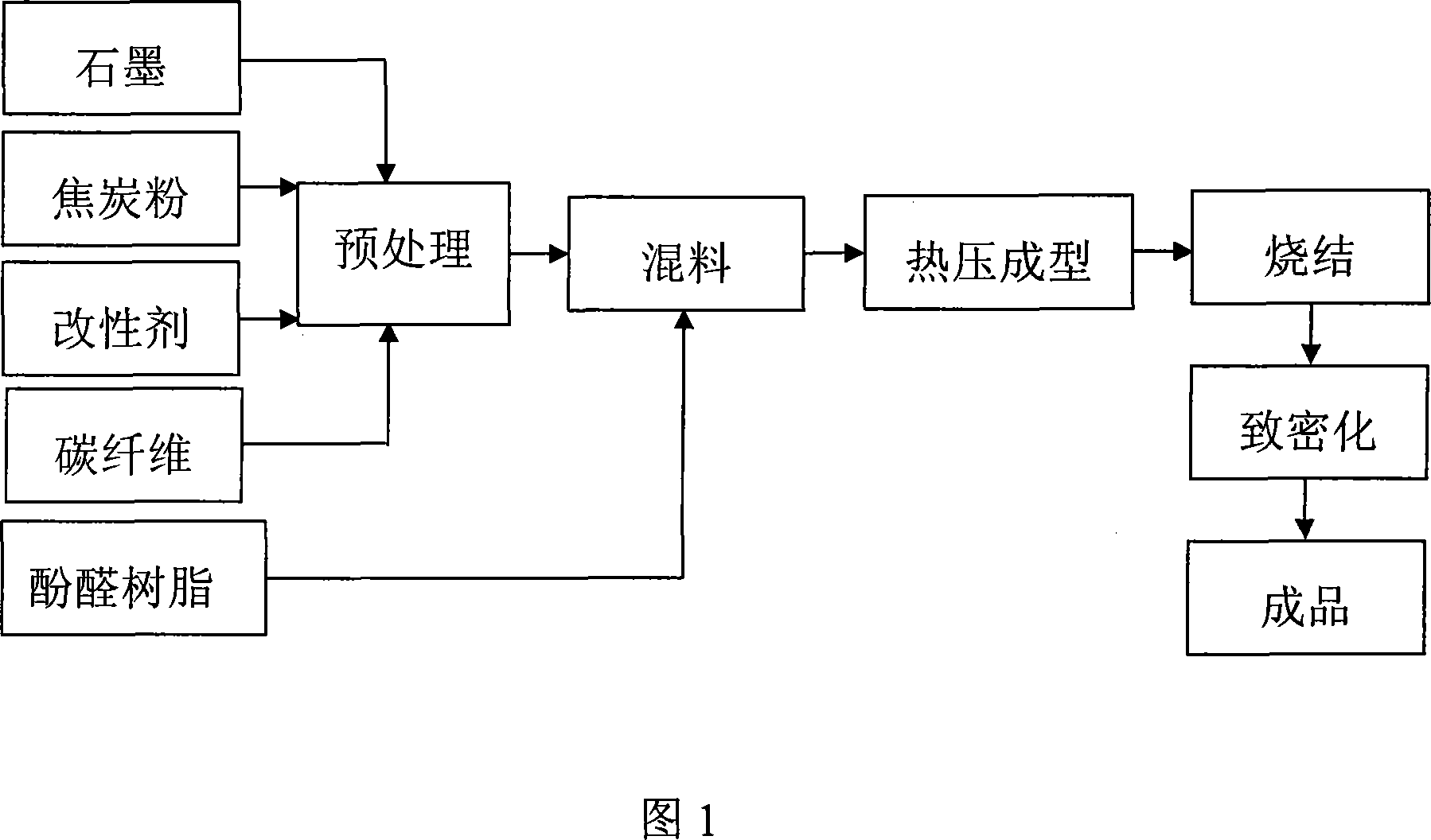

Preparation process of carbon base sliding block material for track vehicle

InactiveCN101165819AImprove conductivityImprove friction and wear propertiesNon-metal conductorsNon-conductive material with dispersed conductive materialFiberCarbon fibers

The preparation method comprises: 1) raw material processing: placing graphite, coke blacking, chopped carbon fiber and modifier at the drying cabinet to remove moisture from them; the drying temperature is 100 deg. C, and the drying time is 2-4 hours; 2) blending: evenly blending the graphite, coke blacking and chopped carbon fiber; adding the copper powder, copper fiber and modifier; in the last, adding phenolic resin to make mould material; 3) hot compacting and forming: placing the mould materials into die; heating and pressing it to make solidification forming; the press is 50-100MP, and the temperature is 160-170 deg. C; keeping 0.5-1 hours in room temperature; 4) sintering: making the sintering form the sample; the temperature is 800-900 deg. C, and the time length is 2-4 hours; 5) densification processing: after chemical vapor deposition or bituminizing, making the carbonizing treatment.

Owner:BEIHANG UNIV

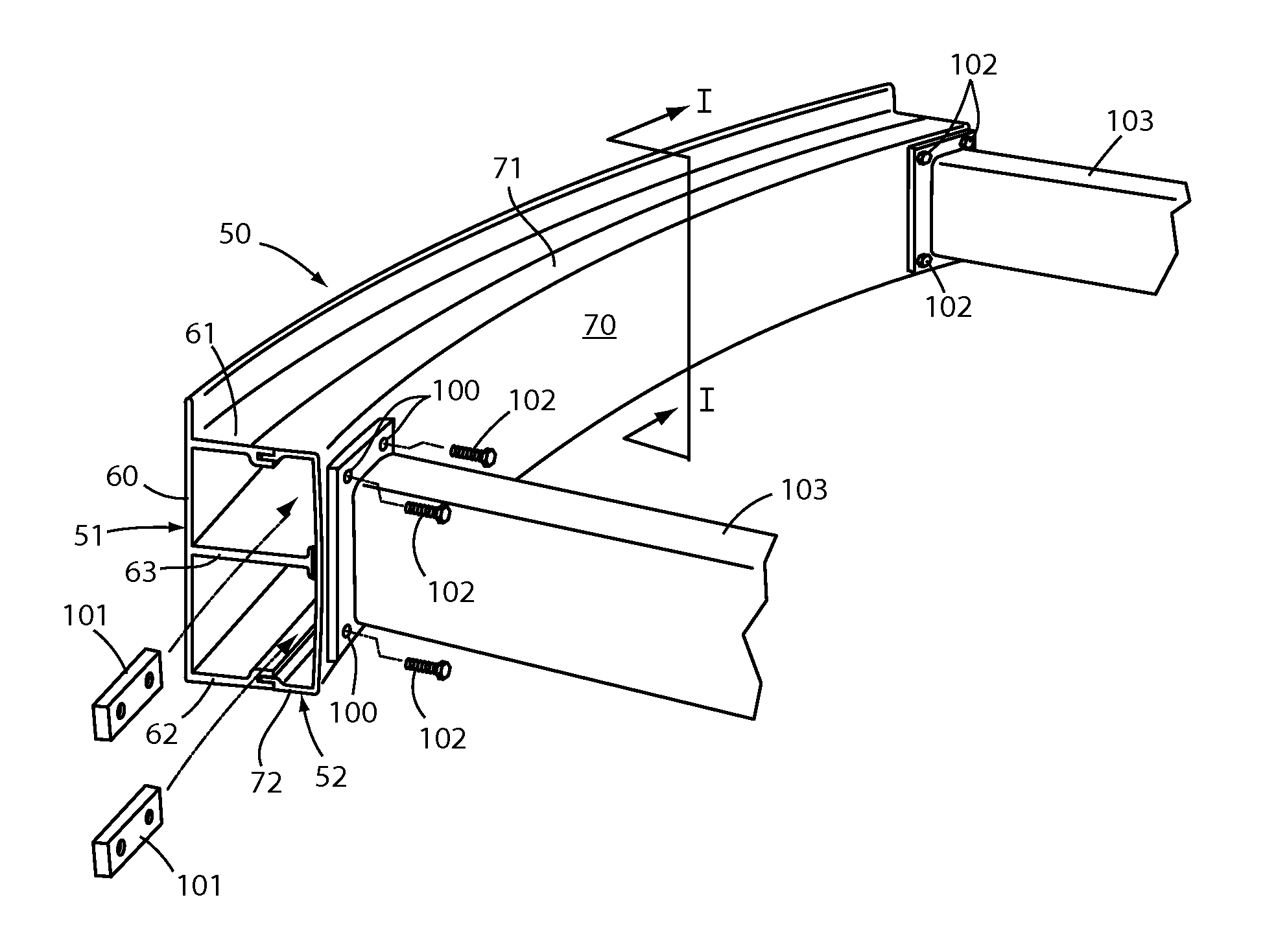

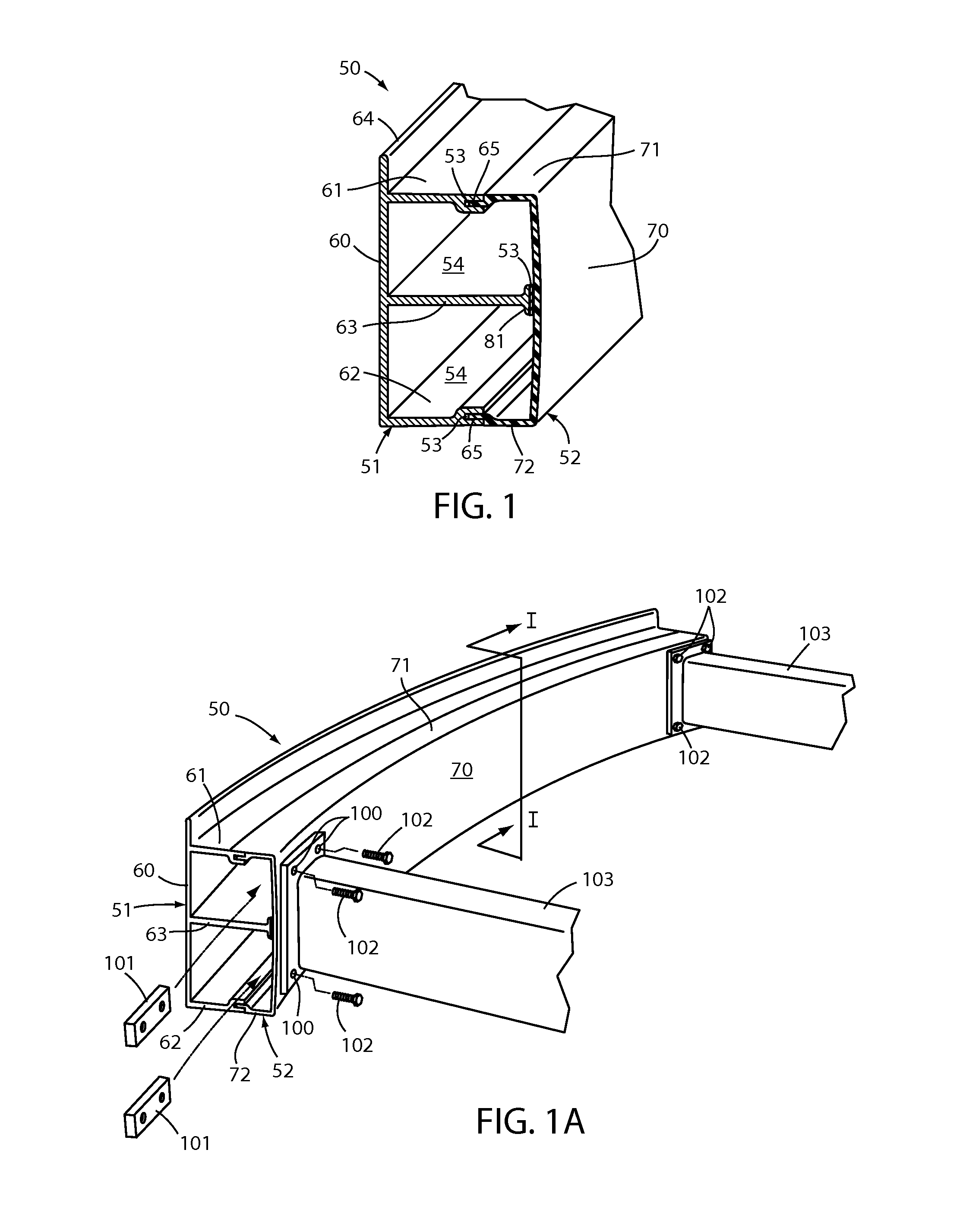

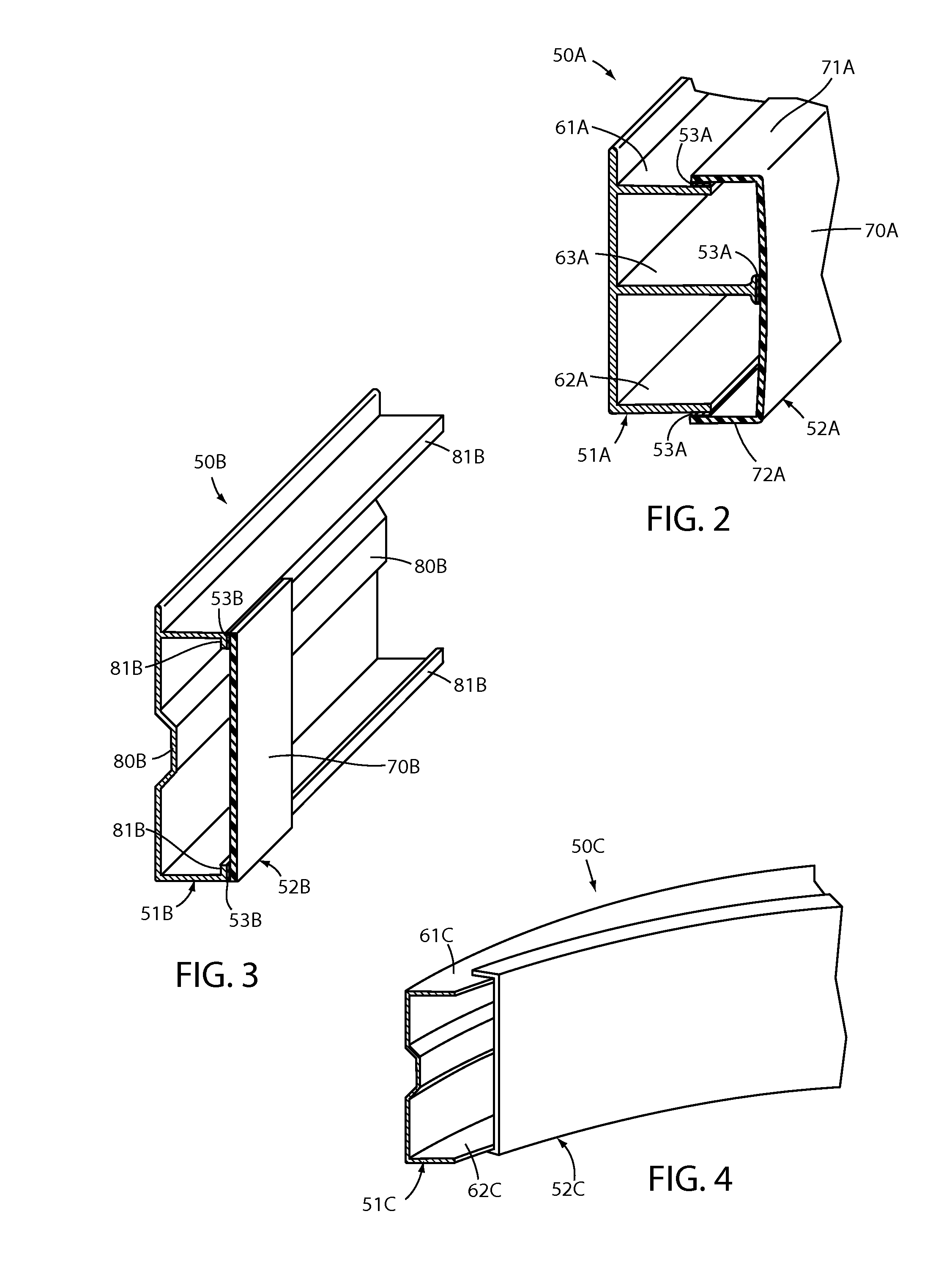

Beam incorporating aluminum extrusion and long-fiber reinforced plastic

InactiveUS20160159300A1Optimize locationReduce stressLaminationLamination apparatusCarbon fibersIn vehicle

A hybrid impact beam, suitable for use as a reinforced impact beam in vehicle bumpers, includes an extruded aluminum section, a fiber reinforced polymeric (FRP) section, and a structural adhesive bonding them together. The components are arranged so that during an impact, the aluminum section experiences compression and receives the direct impact, the FRP section experiences tension, and the adhesive experiences minimal stress by being on a neutral plane of the beam's bending moment. The extruded aluminum beam is preferably extruded as an open section, but becomes a closed section when the polymeric section is attached. The FRP section is preferably a continuous carbon fiber reinforced polymeric section, although different reinforcements can be used. A related method includes bonding an extruded aluminum and fiber-reinforced polymeric section together to form a closed bumper impact beam.

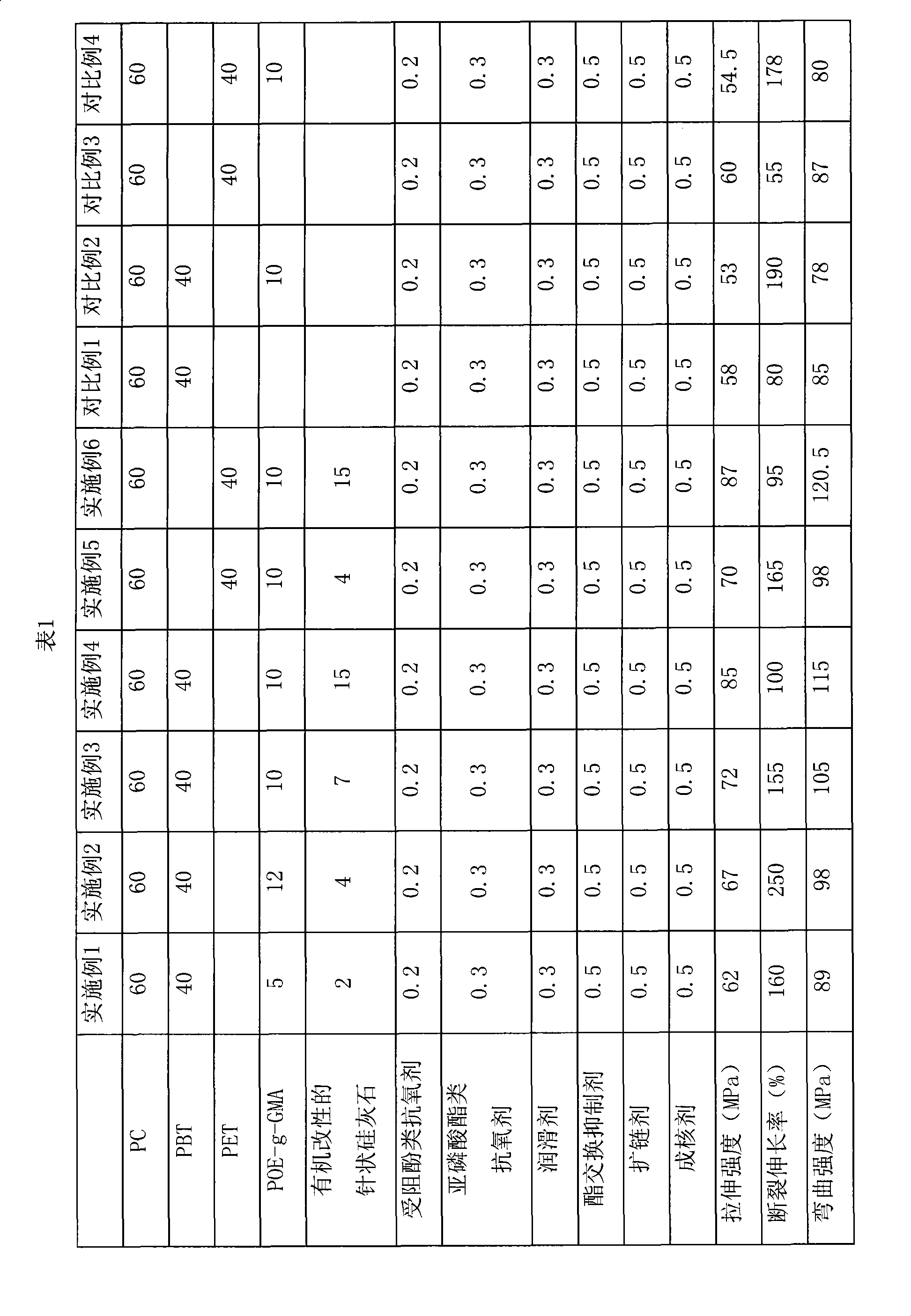

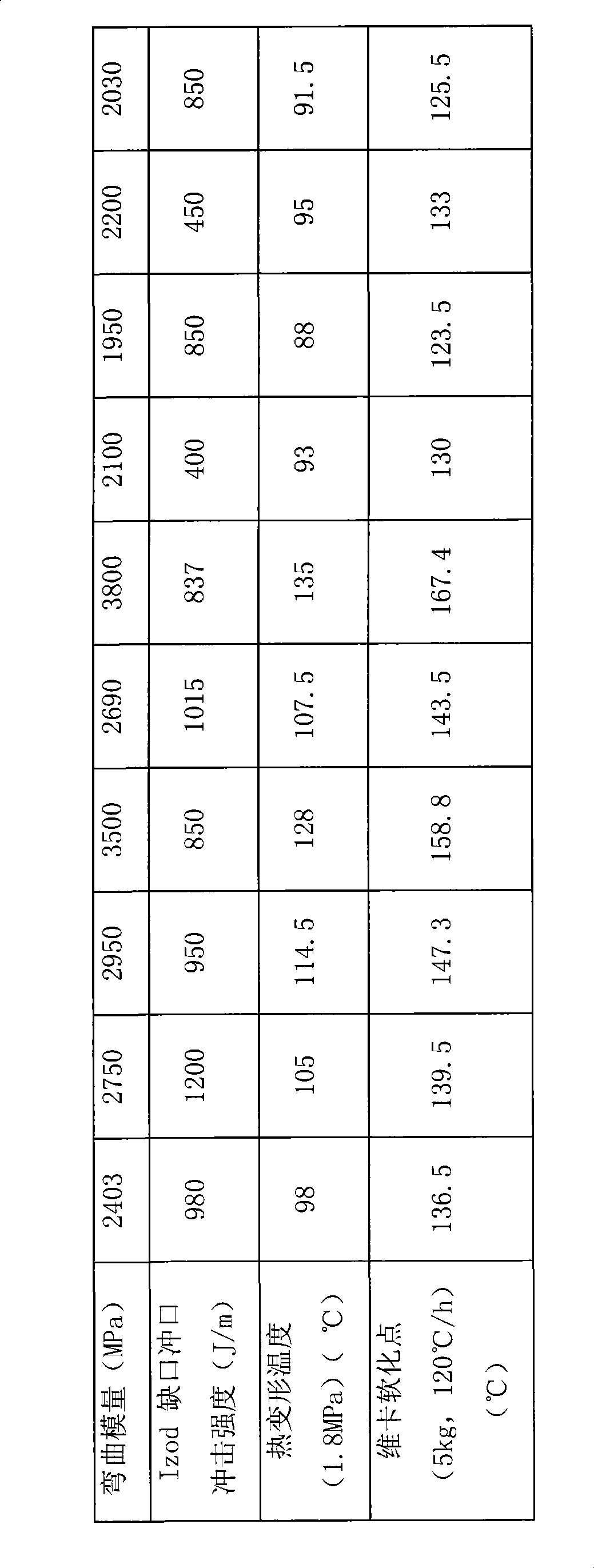

Method of manufacturing polycarbonate/polyester alloy

The invention discloses a preparation method of polycarbonate / polyester alloy. Glycidyl methacrylate grafted ethylene-octylene multipolymer / organic modified needle-shaped aedelforsite composite toughener, i.e. a technology of simultaneously using organic / inorganic rigid particle toughener is adopted; the glycidyl methacrylate grafted ethylene-octylene multipolymer, organic modified needle-shaped aedelforsite, polycarbonate and polyester are melted and mixed in a double-screw extruder, to obtain high-performance alloy material. The prepared polycarbonate / polyester alloy has excellent integrated mechanical properties and size stability, the notched impact strength reaches 1200J / m, the tensile strength reaches 67MPa, the elongation at break reaches 250 percent, the flexural strength is up to 98MPa, the flexural modulus reaches 2750MPa, and the thermal deformation temperature in high load (1.82MPa) is up to 105 DEG C. Therefore, the prepared polycarbonate / polyester alloy can be applied in cars, and to outer decorations, household electrical appliances, IT and the like industrial products.

Owner:SHANGHAI JIAO TONG UNIV +1

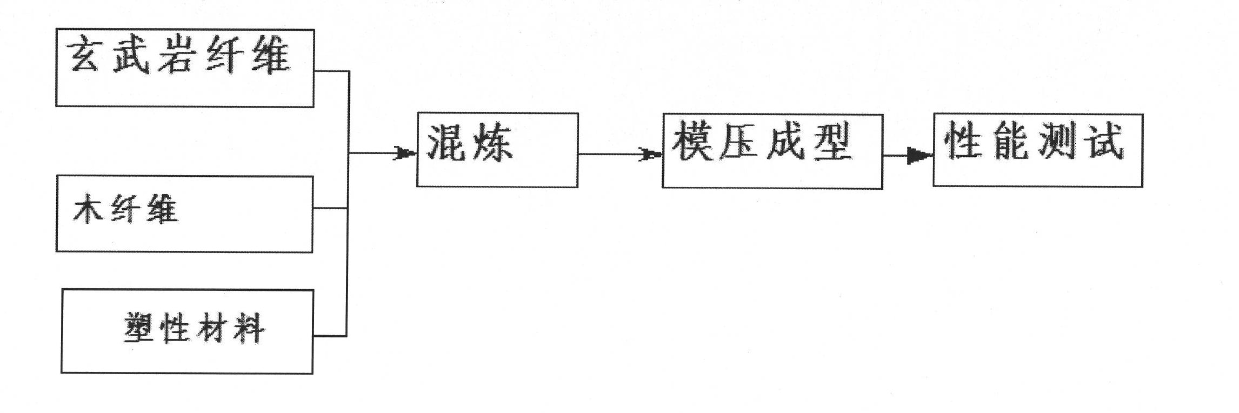

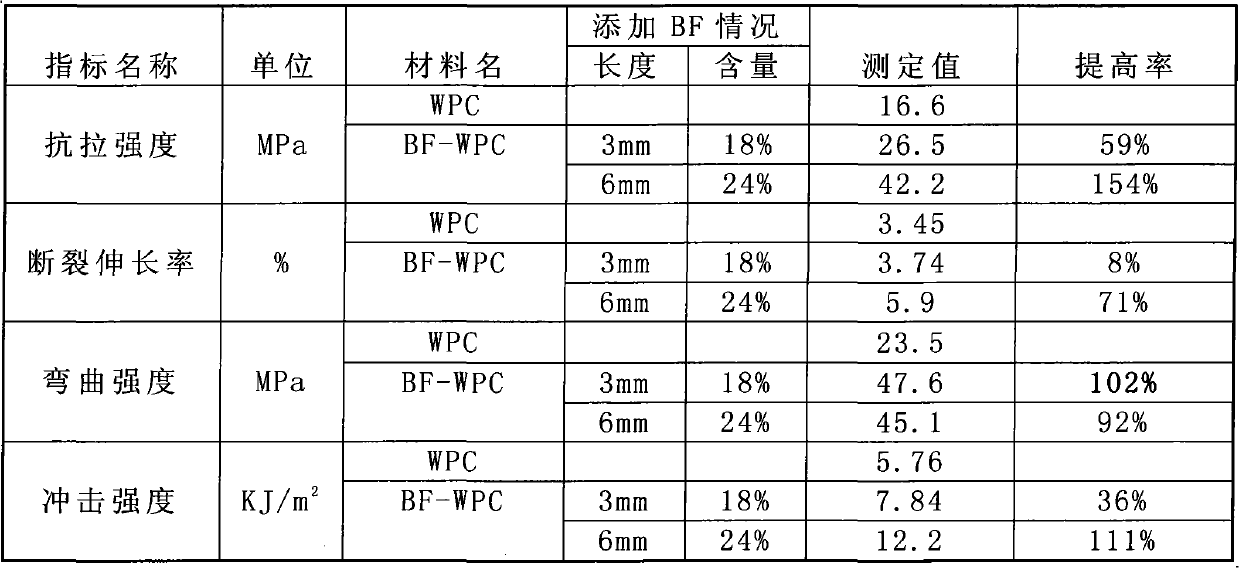

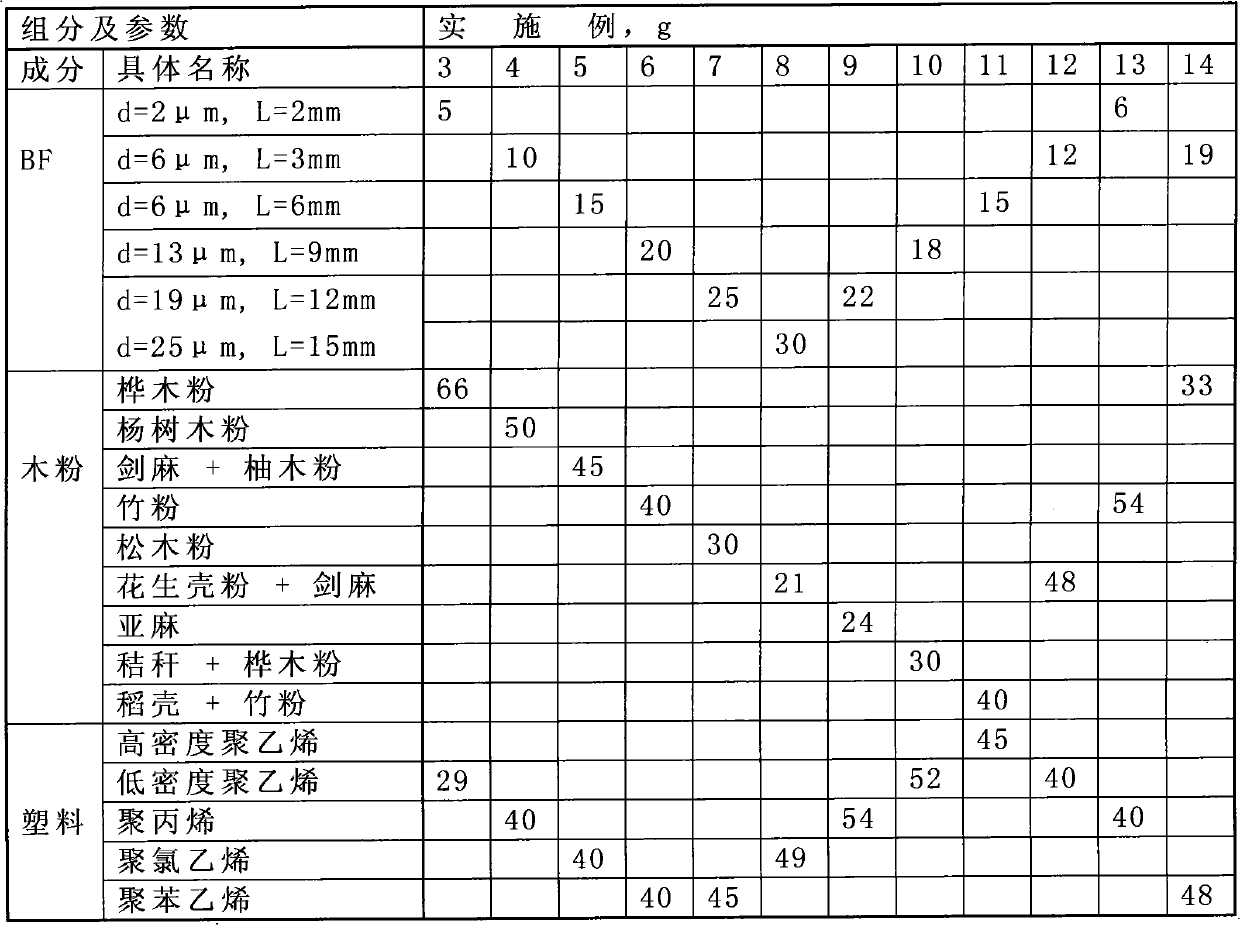

Basalt fiber reinforced wood-plastic composite material and preparation method thereof

The invention relates to a basalt fiber reinforced wood-plastic composite material. The composite material is characterized by comprising 5 to 30 parts of chopped basalt fiber with length of 2 to 15 millimeters and diameter of 2 to 25 microns, 21 to 66 parts of wood fiber and 21 to 66 parts of plastic material in part by weight. A preparation method comprises the following steps of: weighing each component according to a proportion, mechanically mixing the components and then feeding the mixture into a double-roll open mill to perform plasticizing and mixing, controlling the temperatures of front and rear rolls at 160 DEG C and 170 DEG C respectively, and mixing the components for 10 minutes till the system is mixed uniformly, namely no BF is observed from the surface; crushing the uniformly plasticized material by using a crusher till the diameters of the particles of the material are not more than 20 millimeters; and heating, mold-pressing and molding the crushed material by using a flat vulcanizing machine to obtain a plate sample. The tensile strength, bending strength and impact strength of the basalt fiber reinforced wood-plastic composite material obtained by the method are improved by over two times, and the composite material has good economic and social benefits.

Owner:SOUTHEAST UNIV

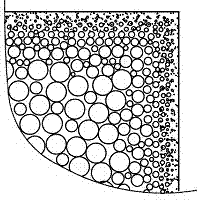

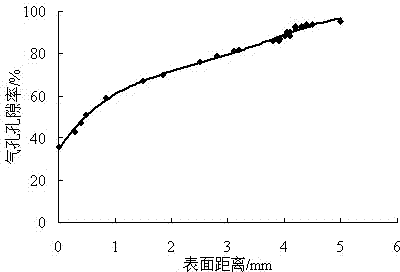

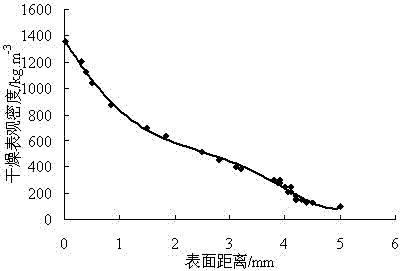

Functionally-graded cellular-concrete thermal-insulating material and preparation method thereof

ActiveCN102561532AOvercoming the Interface Breaking DilemmaImprove bending strengthHeat proofingCeramicwareFoam concreteThermal insulation

The invention relates to a functionally-graded cellular-concrete thermal-insulating material and a preparation method thereof. The functionally-graded cellular-concrete thermal-insulating material comprises a cellular-concrete thermal-insulating core, a plurality of air holes are uniformly distributed in the thermal-insulating material, and the surface of the cellular-concrete thermal-insulating core is wrapped with a functionally-graded layer; in the air holes of the functionally-graded cellular-concrete thermal-insulating material, the air hole in the cellular-concrete thermal-insulating core has a maximum diameter, then, the diameters and porosities of the air holes from the cellular-concrete thermal-insulating core to the outside are in a continuous graded change in a descending order, the thickness of the functionally-graded layer is 0.1-20 mm, the porosities of the air holes are in a continuous graded change in a range of 1- 95%, and the diameters of the air holes are in a continuous graded change in a range of 0.1-8 mm. According to the invention, the interior of the material is porous and thermal-insulating, and the surface of the material is high in density and strength, the mechanical strength of the material is gradually improved from the inside to the outside, and the thermal conductivity factor of the material is gradually reduced front the outside to the inside, thereby achieving an effect of integrating light weight, high strength, thermal insulation and fire prevention.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

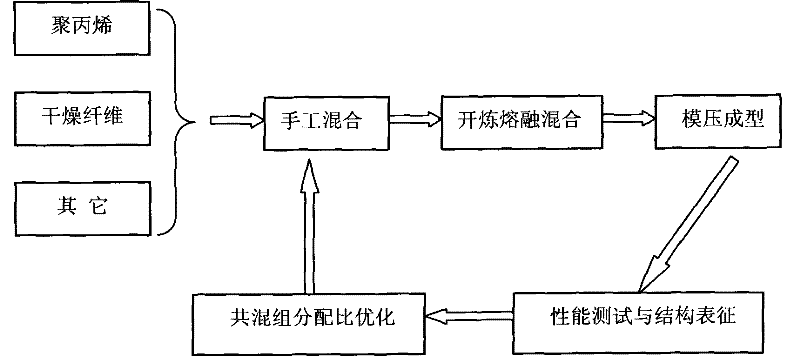

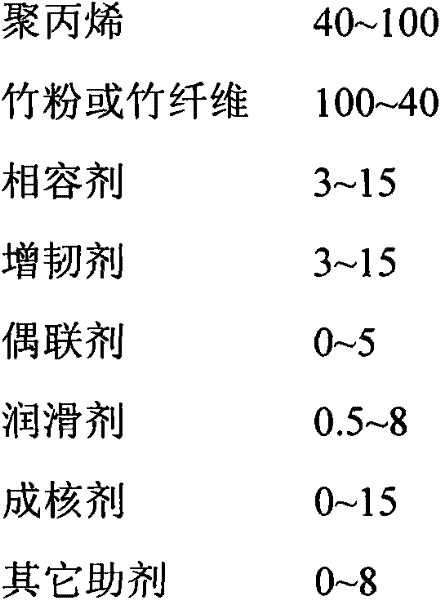

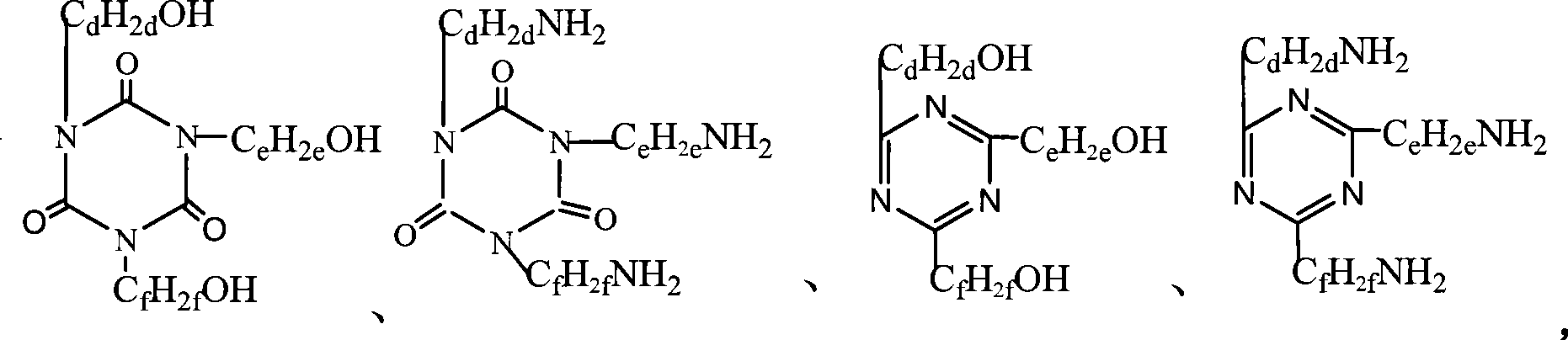

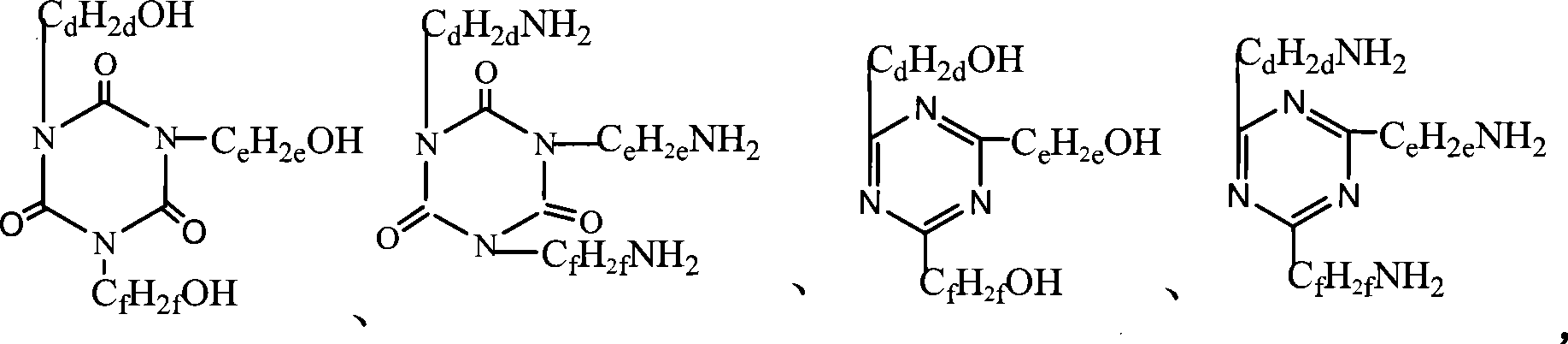

Novel bamboo-plastic composite material

The invention relates to a preparation method of a novel bamboo-plastic composite material, in particular to a bamboo-plastic composite material which has excellent mechanical property and is prepared by the step of adding reinforcing material bamboo powder (or bamboo fabric), a flexibilizer and other assistants to polypropylene used as a substrate resin, wherein the bamboo-plastic composite material comprises the following components in parts by mass: 40-100 parts of polypropylene, 40-100 parts of bamboo powder or bamboo fabric, 3-15 parts of compatilizer, 3-15 parts of flexibilizer, 0-5 parts of coupling agent, 0.5-8 parts of lubricant, 0-15 parts of nucleator and 0-8 parts of other assistants. According to the invention, by selecting proper types and proportions of flexibilizer, compatilizer and other assistants, the defect that the impact strength of the composite material is reduced greatly due to the addition of fiber is overcome.

Owner:EAST CHINA UNIV OF SCI & TECH

Chemically strengthened glass, substrate for information recording medium and information recording medium

InactiveUS20060216552A1High strengthImprove recording densityMagnetic materials for record carriersBase layers for recording layersFlexural strengthRecording layer

A glass for use in chemical reinforcement for use in a substrate of an information recording medium, having a composition comprising, denoted as mol %: SiO247 to 70% Al2O31 to 10%(where the total of SiO2 and Al2O3 is 57 to 80%)CaO2 to 25%BaO1 to 15%Na2O1 to 10%K2O0 to 15%(where the total of Na2O and K2O is 3 to 16%)ZrO21 to 12%MgO0 to 10%SrO0 to 15%(where the ratio of the content of CaO to the total of MgO, CaO,SrO, and BaO is greater than or equal to 0.5)ZnO0 to 10%(where the total of MgO, CaO, SrO, BaO, and ZnO is 3 to 30%)TiO20 to 10%and the total content of the above-stated components is greaterthan or equal to 95%.A glass for use in chemical reinforcement for use in the substrate of an information recording medium employed in a perpendicular magnetic recording system, in which the glass exhibits the glass transition temperature is greater than or equal to 600° C. A substrate for use in an information recording medium consisting of the above glass and being chemically reinforced. A substrate for an information recording medium consisting of a chemically reinforced glass having a glass transition temperature of greater than or equal to 600° C. and exhibiting a bending strength following heating for two hours at 570° C. of greater than or equal to 15 kgf / mm2. An information recording medium comprising an information recording layer on the above substrate for an information recording medium. The present invention provides glass having both high thermal resistance and high strength, a substrate for use in information recording media comprised of this glass, and an information recording medium employing such a substrate.

Owner:HOYA CORP

Preparation of hyperbranched polymer and hyperbranched epoxy resin

The invention relates to a preparation method for a hyperbranched epoxy resin. The preparation method comprises the following steps: (1) preparing a hyperbranched polymer with a functional end group; (2) carrying out the reaction of the hyperbranched polymer and chloroepoxy propane under the action of a ring opening catalyst to obtain an addition product; and (3) carrying out the ring closing reaction of the obtained addition product in an organic solvent and under the reaction of a basic catalyst to generate the hyperbranched epoxy resin, wherein the hyperbranched polymer is prepared under the action of the catalyst through the reaction of a first monomer and a second. Polybasic amine, polyol or the mixture thereof is taken as the first monomer; polyatomic acid, anhydride or the mixture thereof is taken as the second monomer; the dosage mol ratio of the first monomer to the second monomer is 1:0.3 to 2.5; and the first monomer at least comprises a heat resistant six-membered compound which is more than or equal to 1 percent of the total mol number of the first monomer. The prepared hyperbranched epoxy resin has low viscosity, high heat resistance, and the reinforcing and plasticizing functions for a common epoxy resin. The hyperbranched epoxy resin can be widely applied to the fields of electronic packaging, functional adhesives, and the like.

Owner:苏州海博特树脂科技有限公司

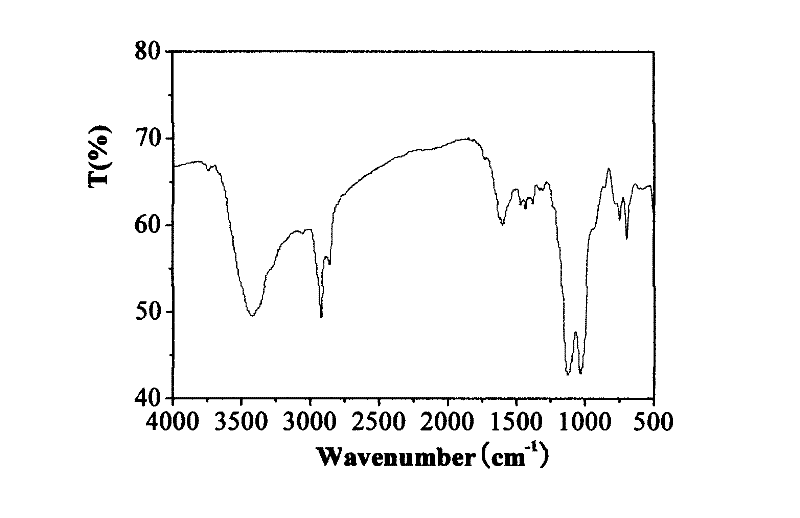

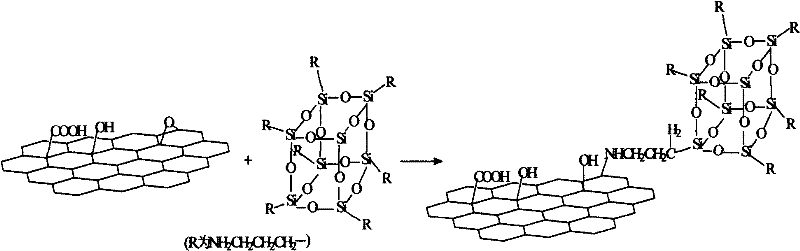

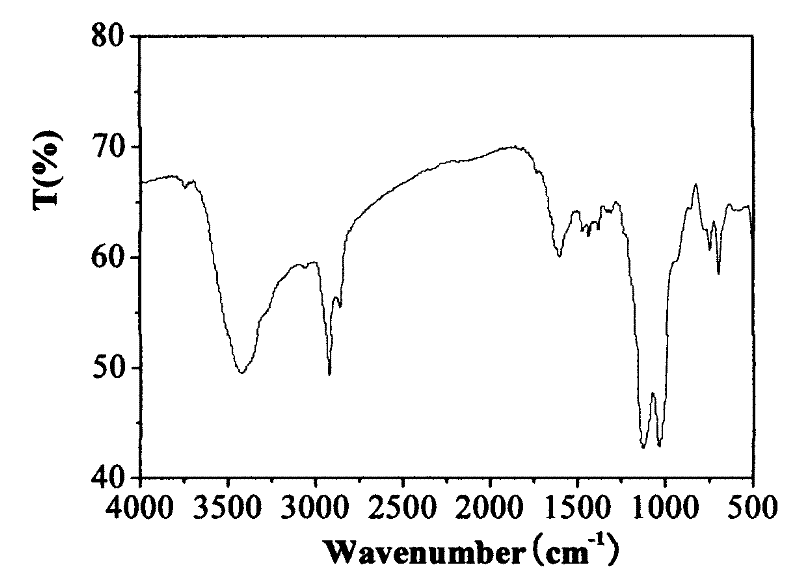

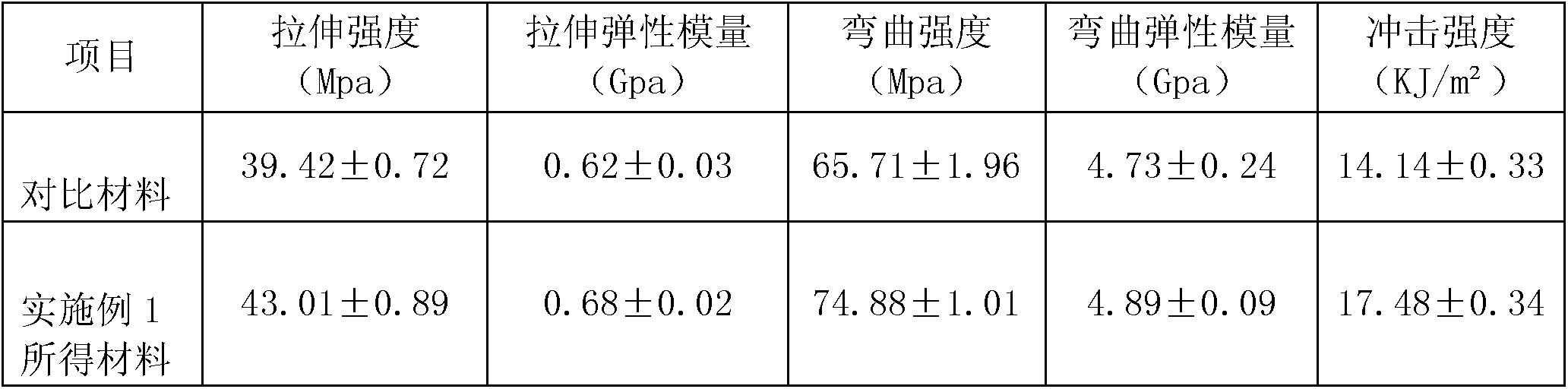

Preparation method of graphene oxide grafted POSS (polyhedral oligomeric silsesquioxane) modified epoxy resin

The invention discloses a preparation method of graphene oxide grafted POSS (polyhedral oligomeric silsesquioxane) modified epoxy resin. The preparation method comprises the following steps of: taking crystalline flake graphite as a raw material, preparing graphite oxide through adopting a Hummers oxidation method, further adding the graphite oxide into distilled water, forming a uniformly-dispersed graphene oxide mixed solution under an ultrasonic environment, further adding POSS and a strong catalyst, performing full reaction, then filtering, washing and drying to get black powder; and further uniformly dispersing graphene oxide / POSS in an epoxy resin matrix, cross-linking and bonding under the action of a curing agent to get a composite material, molding by casting, cooling and demolding. According to the preparation method disclosed by the invention, the POSS is successfully grafted on a graphene oxide sheet layer, and advantages of the graphene oxide structure and the POSS structure are complemented, so that the preparation method has the advantages of low cost and easy obtaining of the raw material, easy operation, simple process, good reproducibility and obvious toughening modification effect against the epoxy resin.

Owner:福州乐道知识产权运营有限公司

Basalt fiber reinforced wood-plastic composite material and preparation method thereof

The invention discloses a basalt fiber reinforced wood-plastic composite material and a preparation method thereof, and relates to a wood-plastic composite material and the preparation method thereof. The problem of bad comprehensive mechanical property of the current wood-plastic composite material is solved. The material is prepared from thermoplastic plastic, a wood fiber material, modified basalt fibers, a bulking agent and a lubricant. The preparation method comprises the following steps: 1. pre-treating the wood fiber material; 2. sequentially putting the raw materials in a high-speed mixer to be stirred, discharging the materials into a low-speed cold mixer to be stirred, and cooling the materials to obtain premix; and 3. carrying out extrusion forming on the premix. Beside keeping the advantages of good weather fastness, thermal insulation, water resistance, corrosion resistance, and the like, the basalt fiber reinforced wood-plastic composite material provided by the invention has the advantages that the mechanical property is greatly improved compared with common wood-plastic composite materials, and the problems of low mechanical strength and large brittleness of traditional wood-plastic composite material products are well solved. Leftover materials generated in the production process of the basalt fiber reinforced wood-plastic composite material provided by the invention can be entirely recycled, few additives are added, and the basalt fiber reinforced wood-plastic composite material is environment-friendly, thereby being a typical environment-friendly material.

Owner:JILIN HABOD NEW MATERIALS TECH

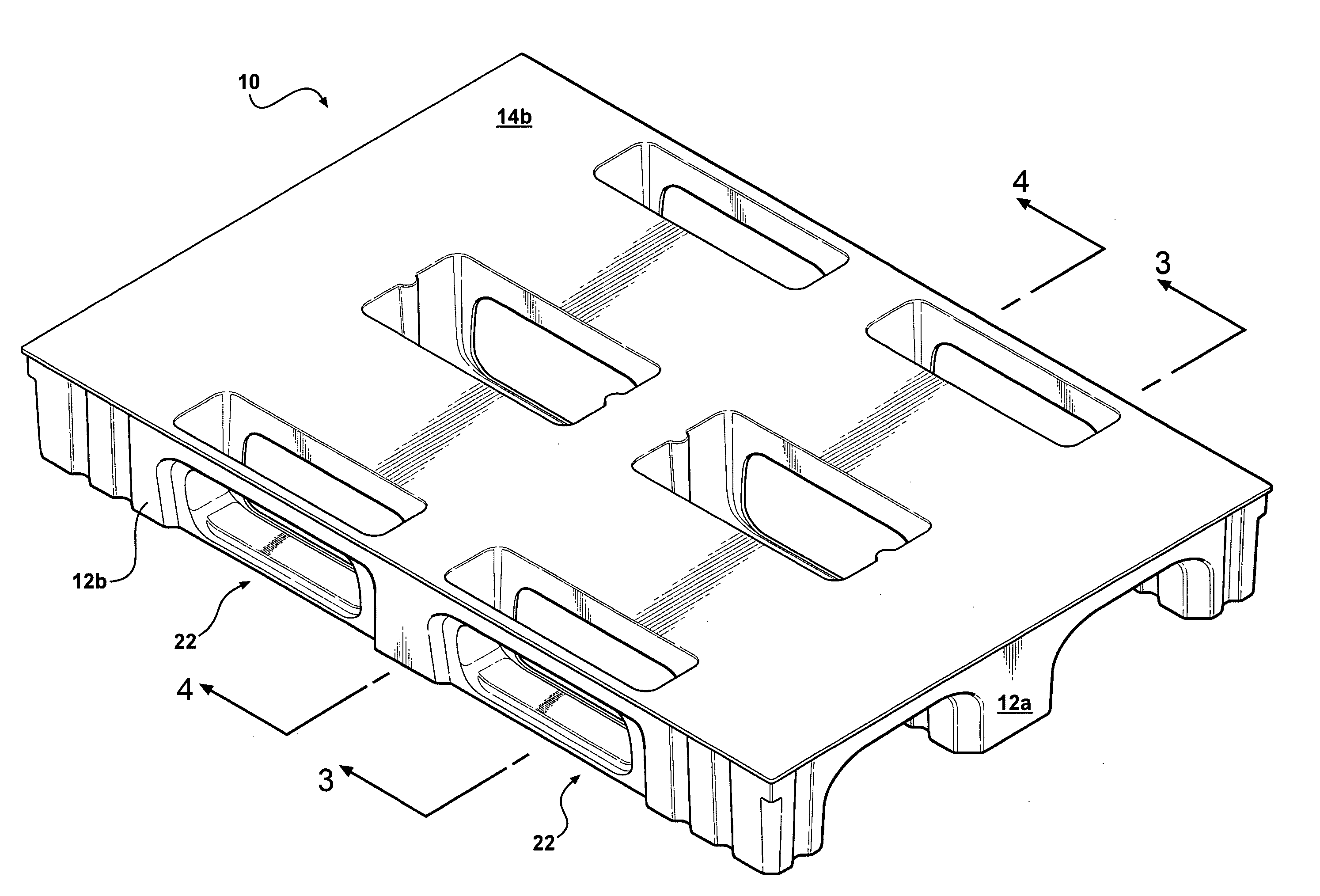

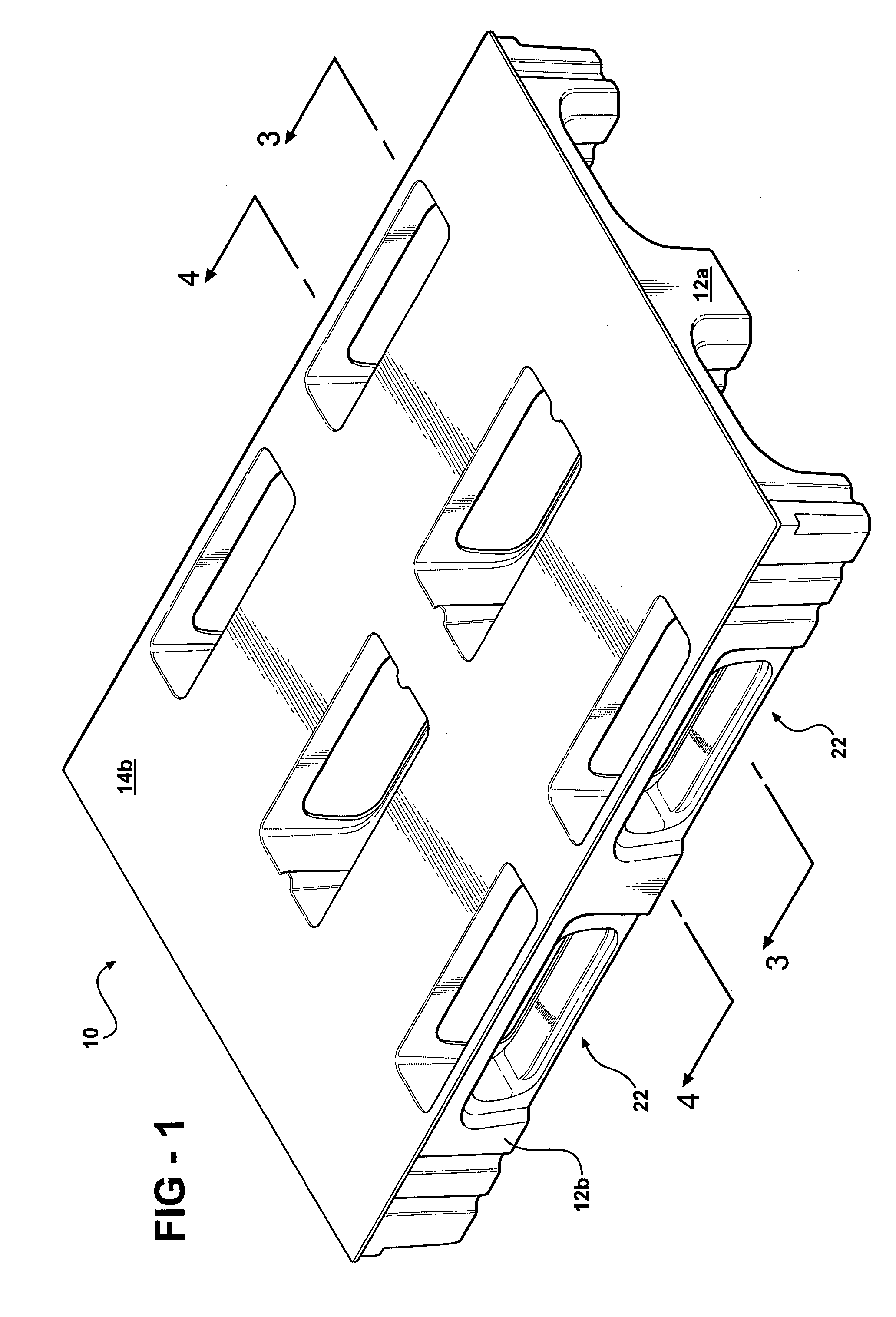

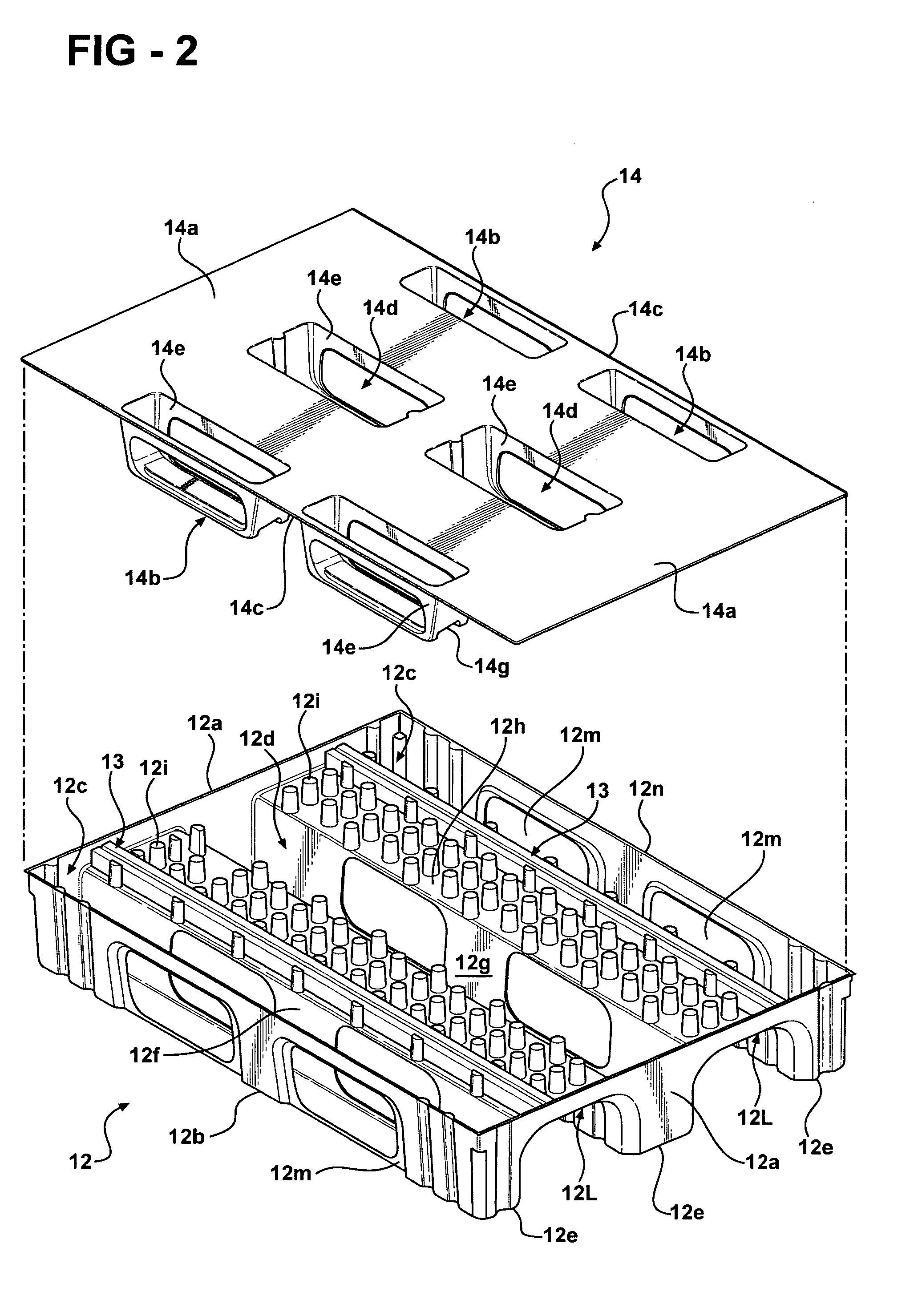

Twin sheet pallet

ActiveUS20060075939A1Prevent tippingFacilitates firm positive receiptRigid containersEngineeringPallet

A twin sheet plastic pallet comprising an upper plastic sheet and a lower plastic sheet selectively fused to the upper sheet. The lower sheet has a generally rectangular configuration, including sidewalls and end walls, and includes a plurality of separate parallel upwardly opening longitudinally extending U-shaped grooves extending from end to end of the sheet and a plurality of downwardly opening U-shaped grooves interspersed between the upwardly opening grooves and opening in the end walls of the sheet. The upper sheet defines a top wall, defining the platform surface of the pallet, and a plurality of upwardly opening U-shaped protrusions extending downwardly from the top wall and sized to nest within the upwardly opening grooves of the lower sheet, whereby with the upper sheet positioned over the lower sheet and the protrusions positioned in the upwardly opening grooves, the sheets may be fused together to form double thickness U-shaped wall structures at the interfaces of the protrusions and the upwardly opening grooves. The pallet further includes a pair of longitudinally extending metallic beams positioned between the upper and lower sheets, and laterally aligned slots are formed in the U-shaped wall structures to allow passage of the forks of a forklift truck.

Owner:SHUERT TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com