Basalt fiber reinforced wood-plastic composite material and preparation method thereof

A wood-plastic composite material and basalt fiber technology, which is applied in the field of wood-plastic composite material and its preparation, can solve the problems of poor comprehensive mechanical properties and achieve the effects of improved mechanical properties, high cost performance, and excellent processing characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

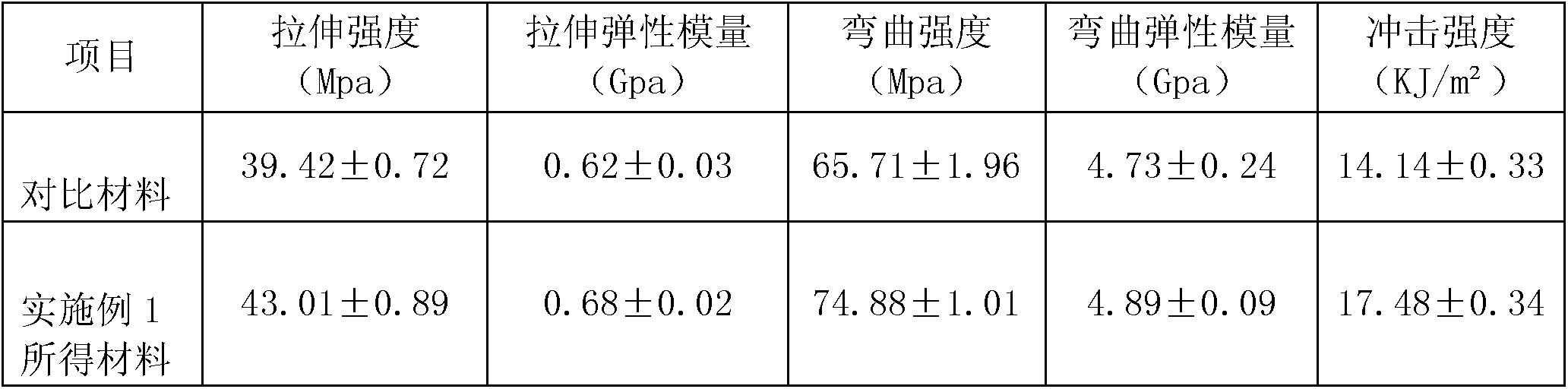

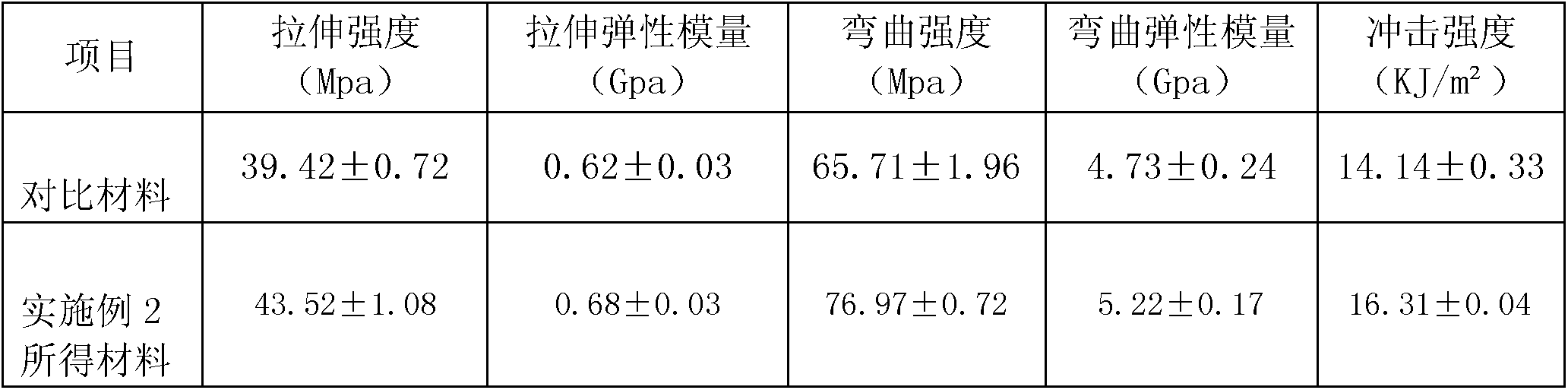

Examples

specific Embodiment approach 1

[0020] Specific Embodiment 1: The basalt fiber reinforced wood-plastic composite material in this embodiment consists of 95-105 parts by weight of thermoplastic, 50-300 parts of wood fiber material, 1-50 parts of modified basalt fiber, 5 ~20 parts of compatibilizer and 1~10 parts of lubricant; the thermoplastics are polystyrene, polyethylene, high-density polyethylene, low-density polyethylene, polyvinyl chloride, acrylonitrile-butadiene- One or more of styrene copolymers; lignocellulosic materials are any one or more of wood powder, bamboo powder, crop straw powder, and fruit shell powder; the compatibilizer is maleic anhydride grafted styrene-ethylene -Butadiene-styrene block copolymer, maleic anhydride grafted polypropylene, maleic anhydride grafted polyethylene, maleic anhydride grafted polystyrene, maleic anhydride-styrene block copolymer, titanic acid One or more of ester, isocyanate, hexamethyldisilazane, vinyltrimethoxysilane, aminopropyltriethoxysilane, methacryloxypr...

specific Embodiment approach 2

[0023] Embodiment 2: This embodiment differs from Embodiment 1 in that the basalt fiber reinforced wood-plastic composite material is composed of 100 parts of thermoplastic, 100 parts of wood fiber material, and 25 parts of modified basalt fiber according to the ratio of parts by weight. , 10 parts of compatibilizer, 5 parts of lubricant. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0024] Embodiment 3: This embodiment is different from Embodiment 1 or Embodiment 2 in that the lignocellulosic material is fine fibers of 20-100 mesh. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com