Patents

Literature

2786results about How to "Uniform temperature distribution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

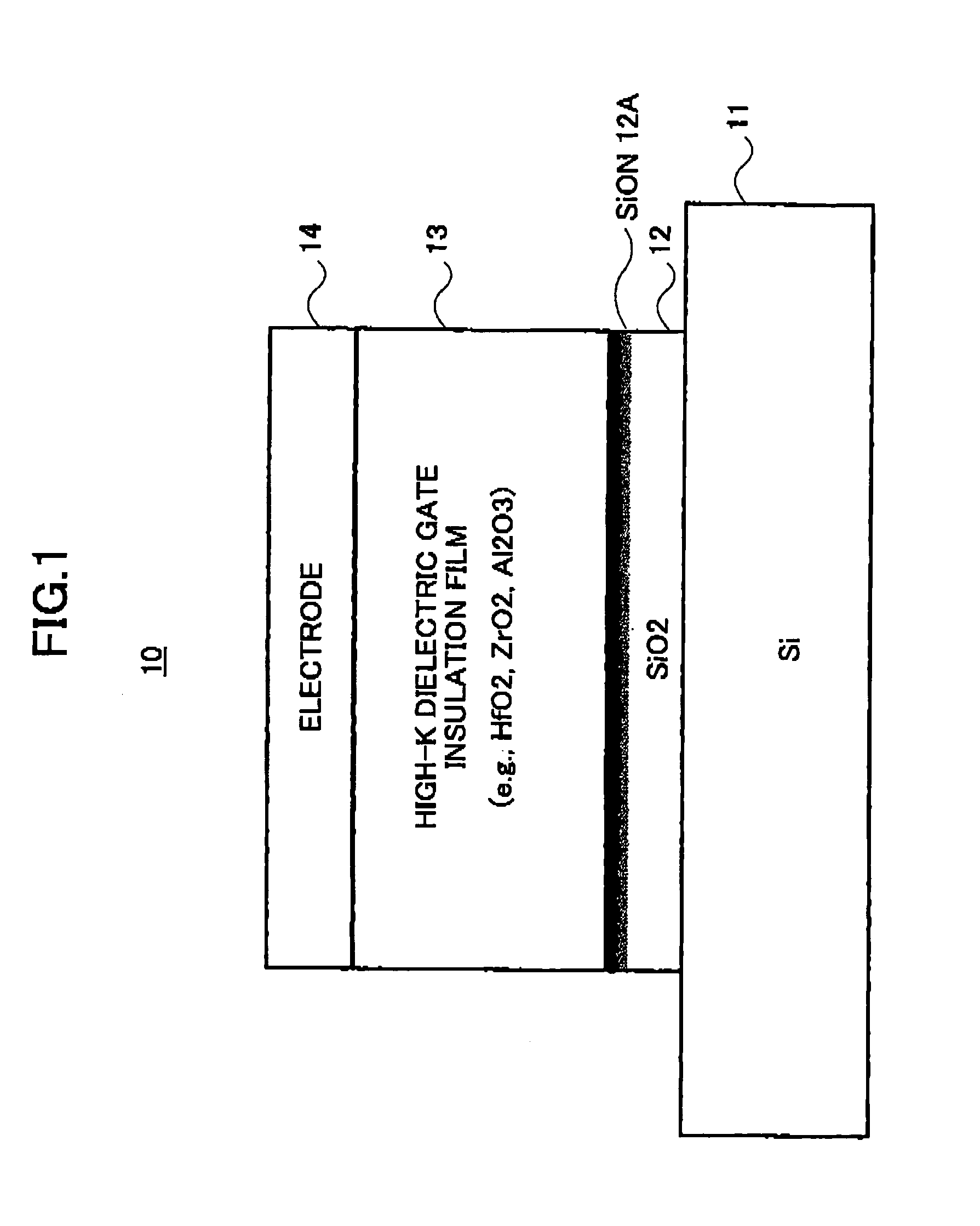

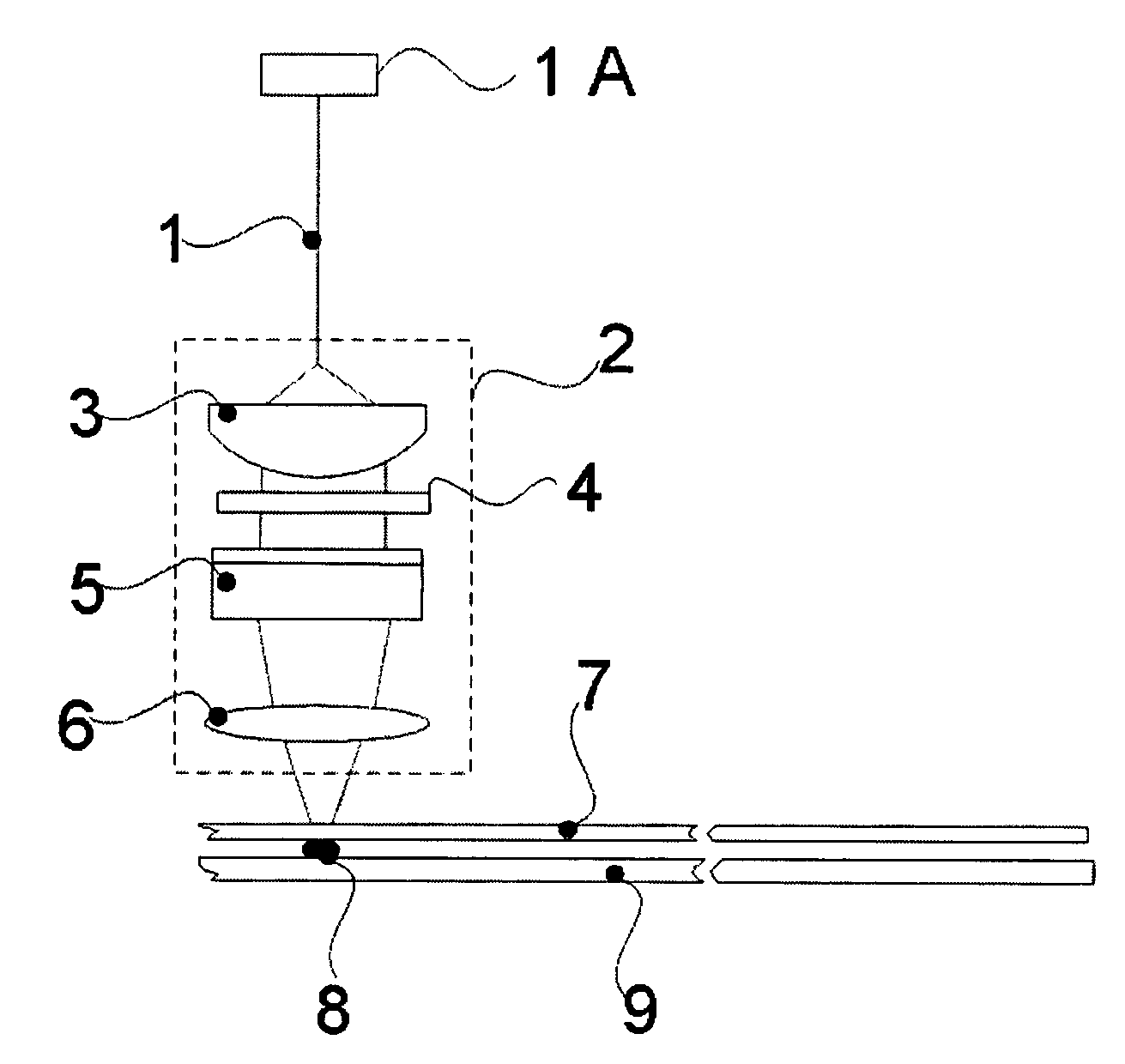

Heating apparatus, heat treatment apparatus, computer program and storage medium

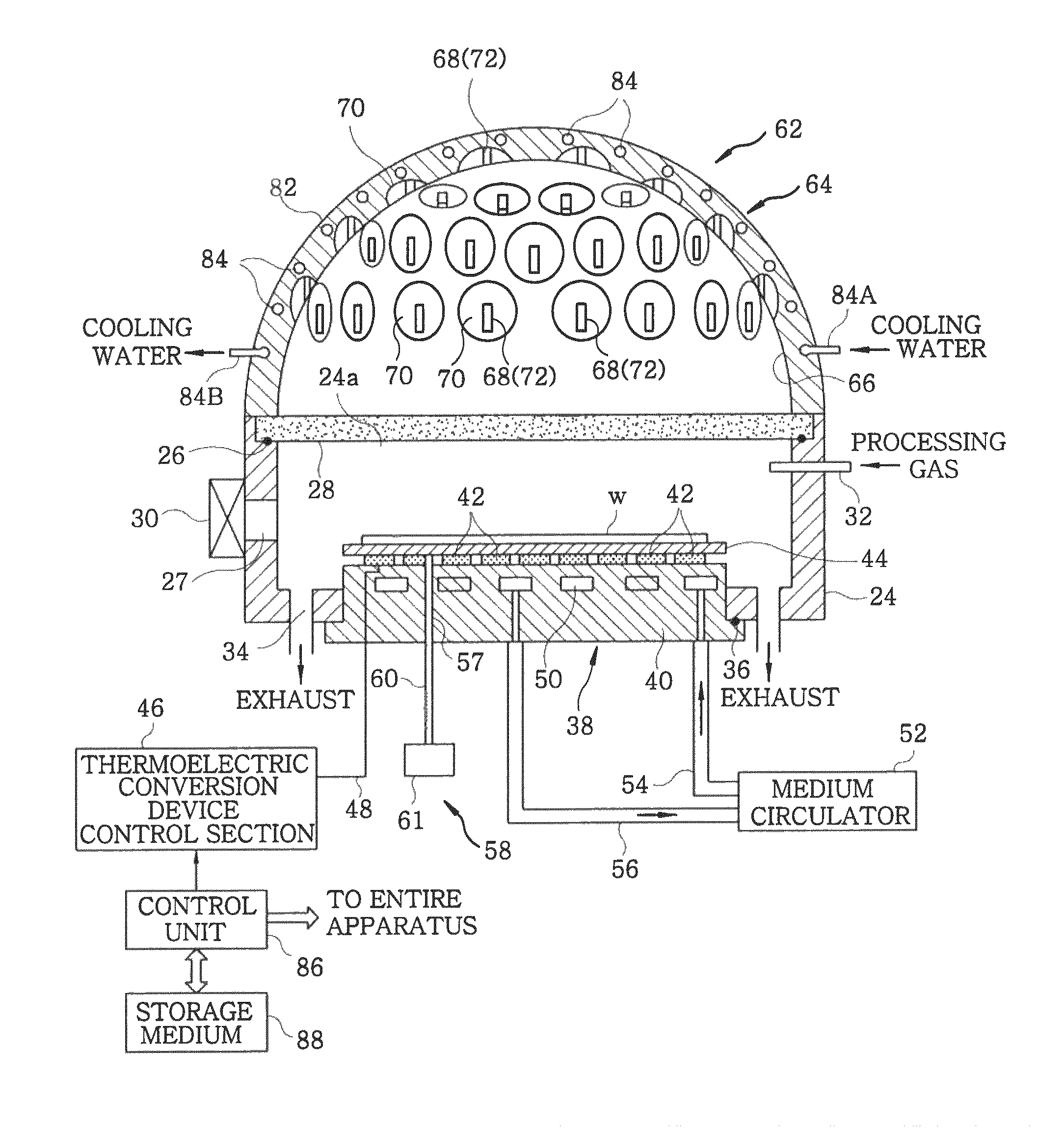

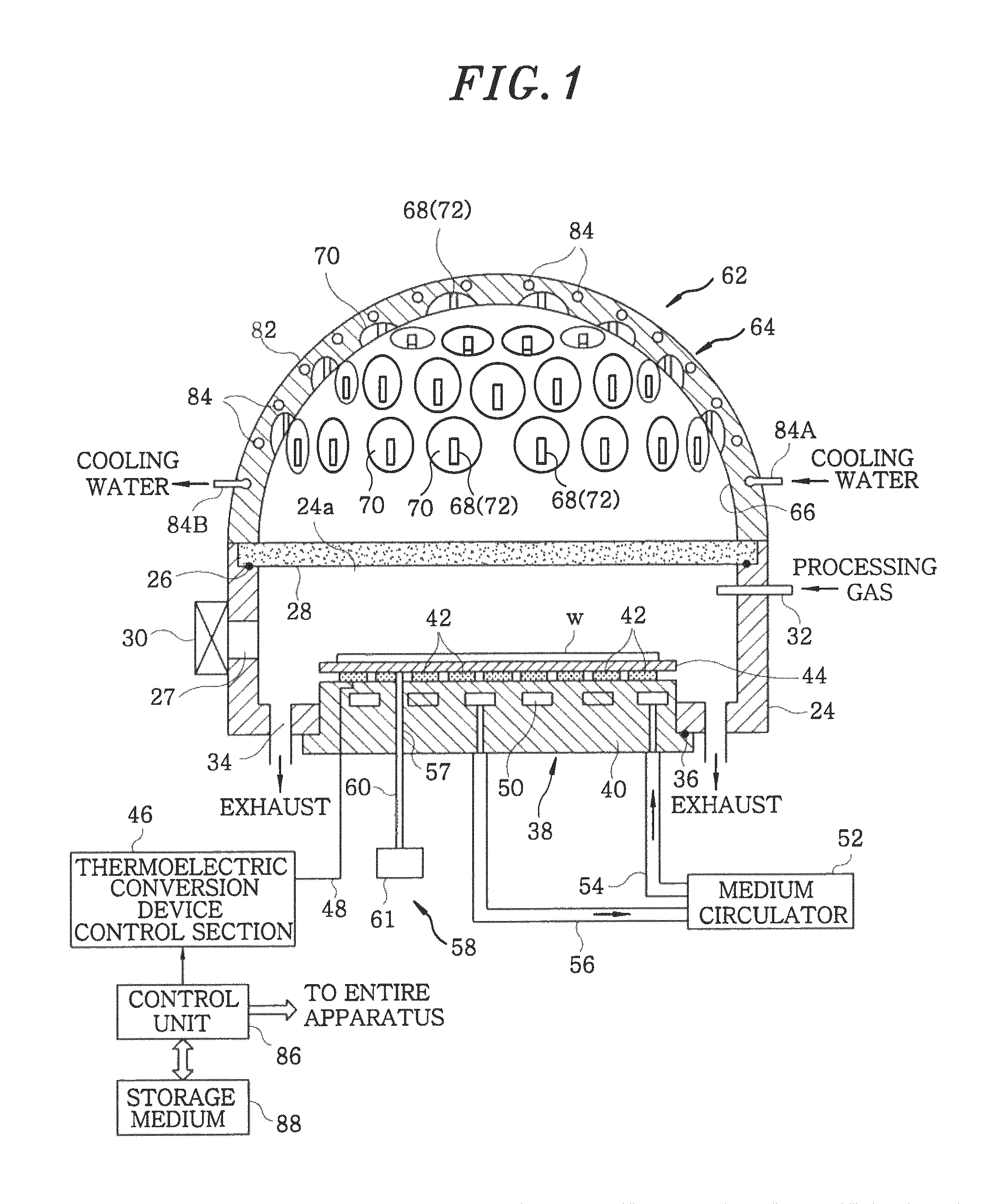

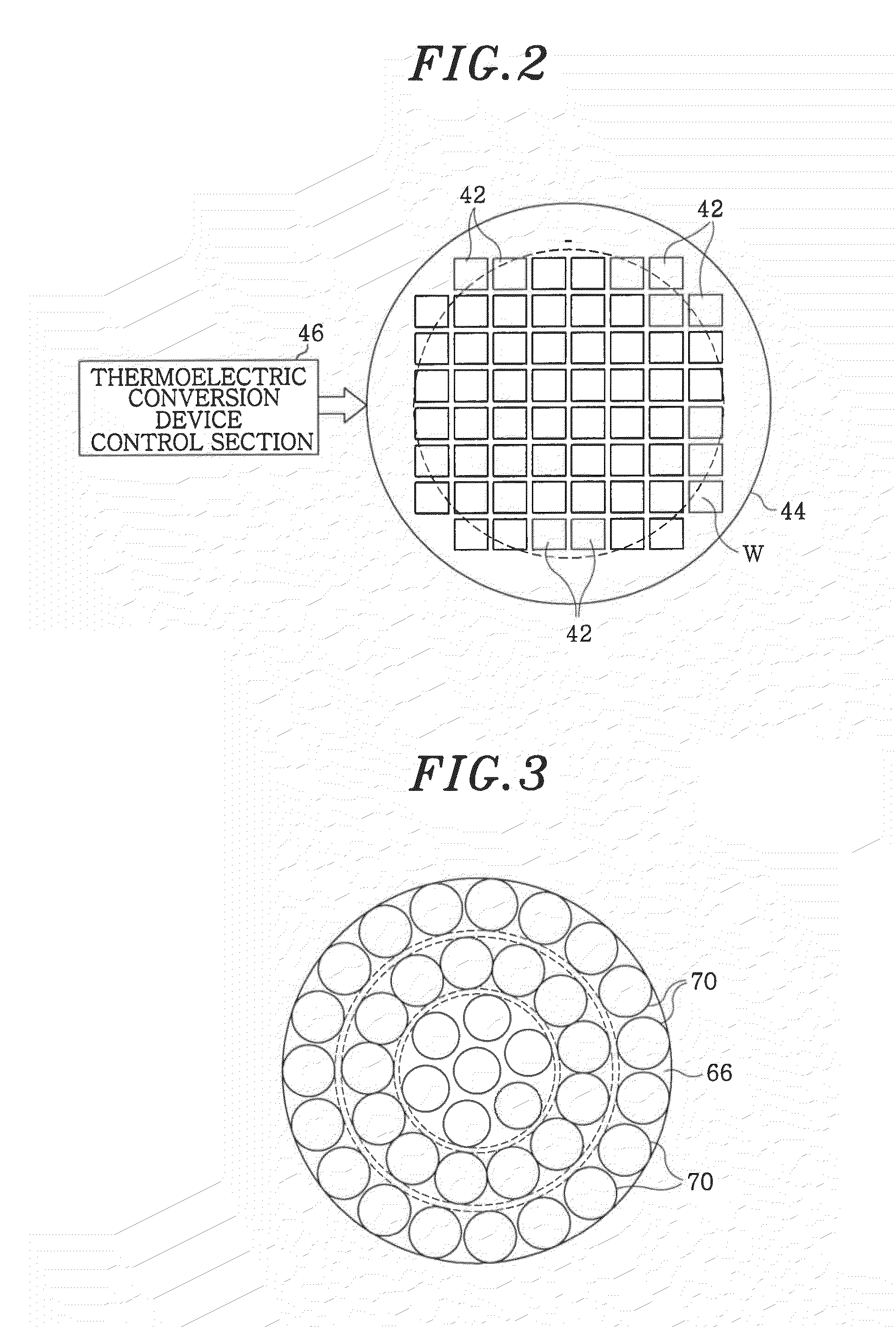

ActiveUS8041197B2Efficient solutionRapidly heating up and coolingDomestic stoves or rangesDrying solid materials with heatLength waveSemiconductor

A heating apparatus for heating a target object W is provided with a plurality of heating light sources, including LED elements for applying heating light having a wavelength within a range from 360 to 520 nm to the object. Thus, a temperature of only the shallow surface of the object, such as a semiconductor wafer, is increased / reduced at a high speed in uniform temperature distribution, irrespective of the film type.

Owner:TOKYO ELECTRON LTD

Unit for varying a temperature of a test piece and testing instrument incorporating same

ActiveUS7115838B2Easy to control temperatureUniform temperature distributionDrying solid materials with heatDomestic cooling apparatusInstrumentationCoolant

Owner:ESPEC CORP

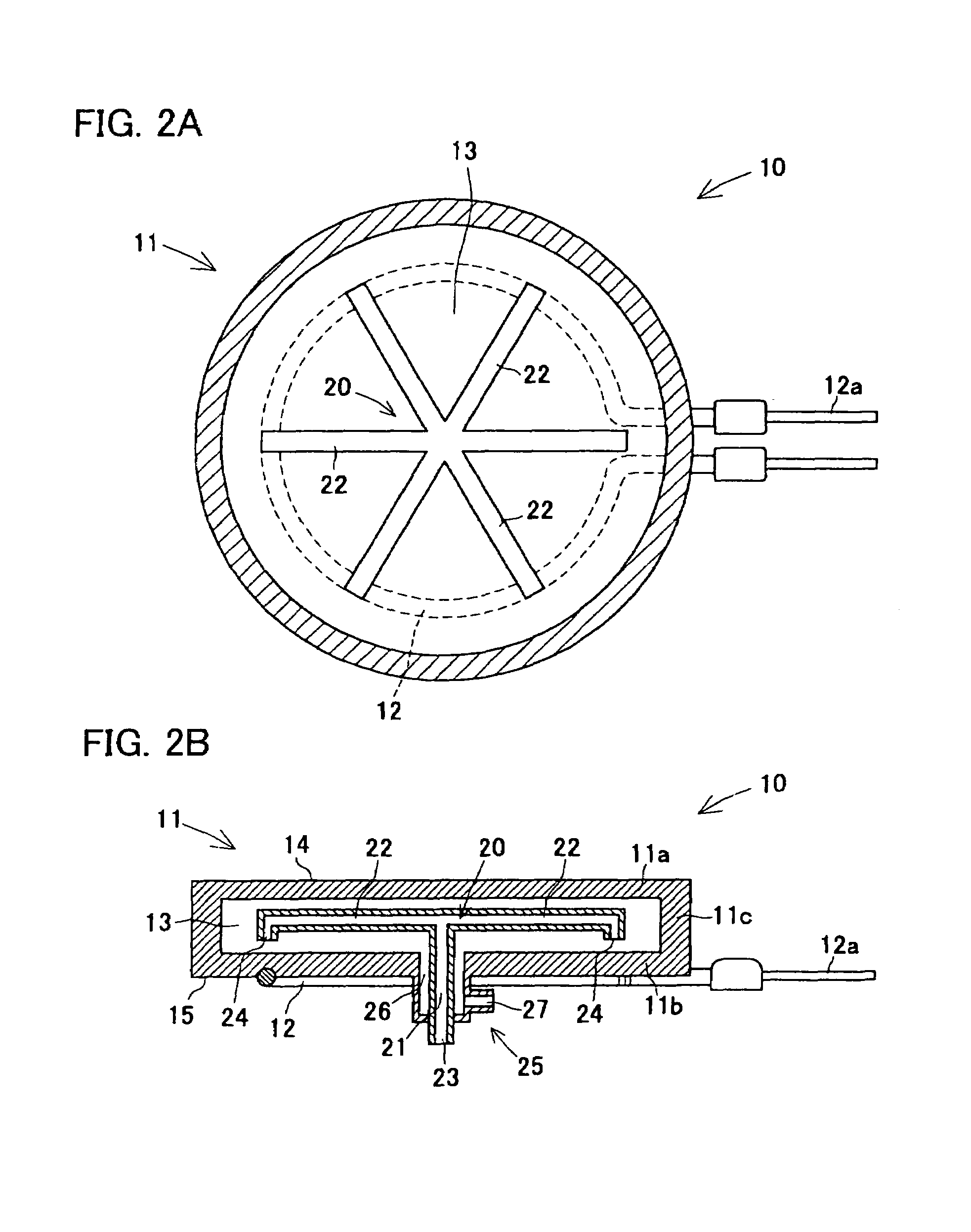

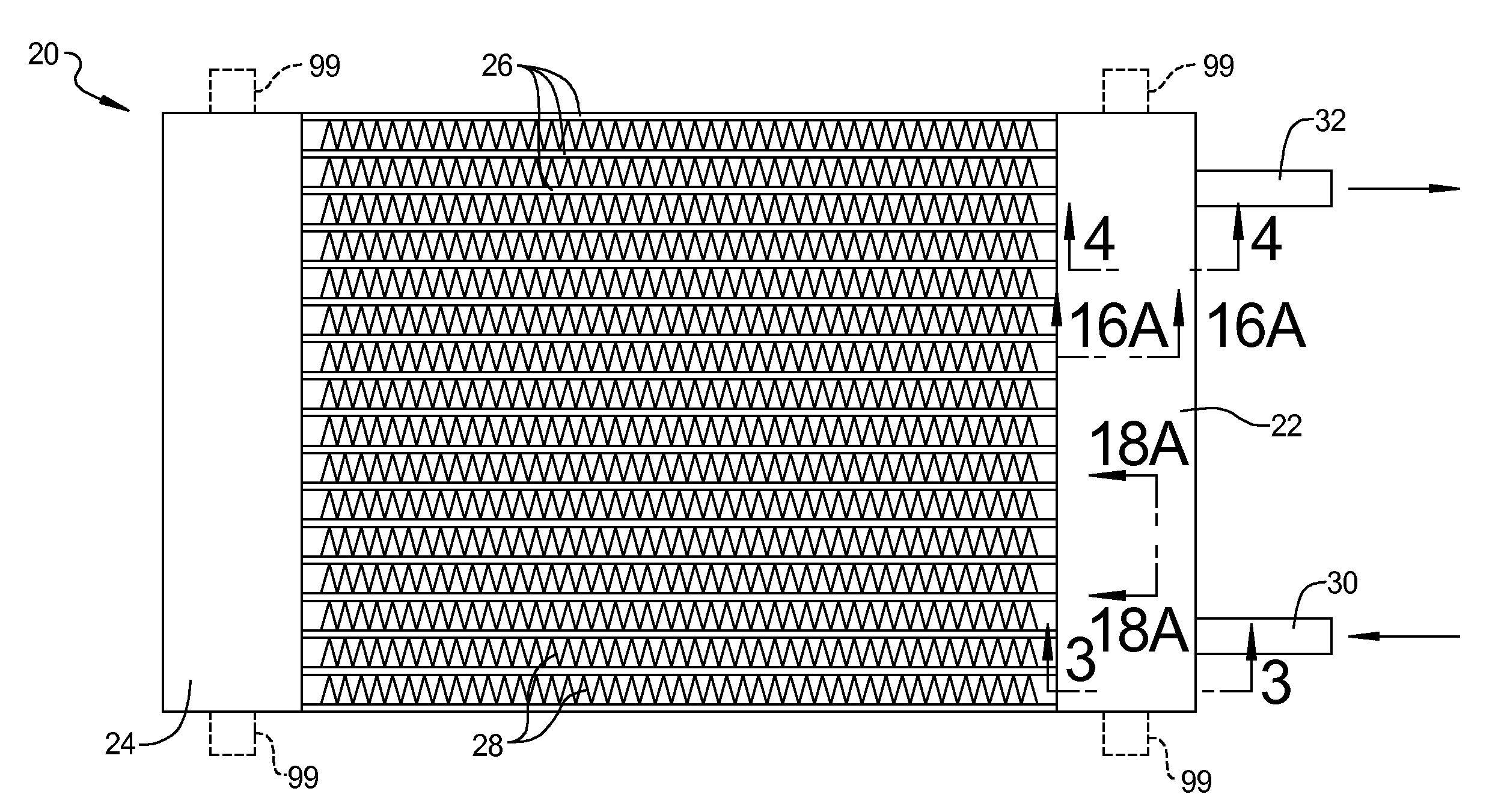

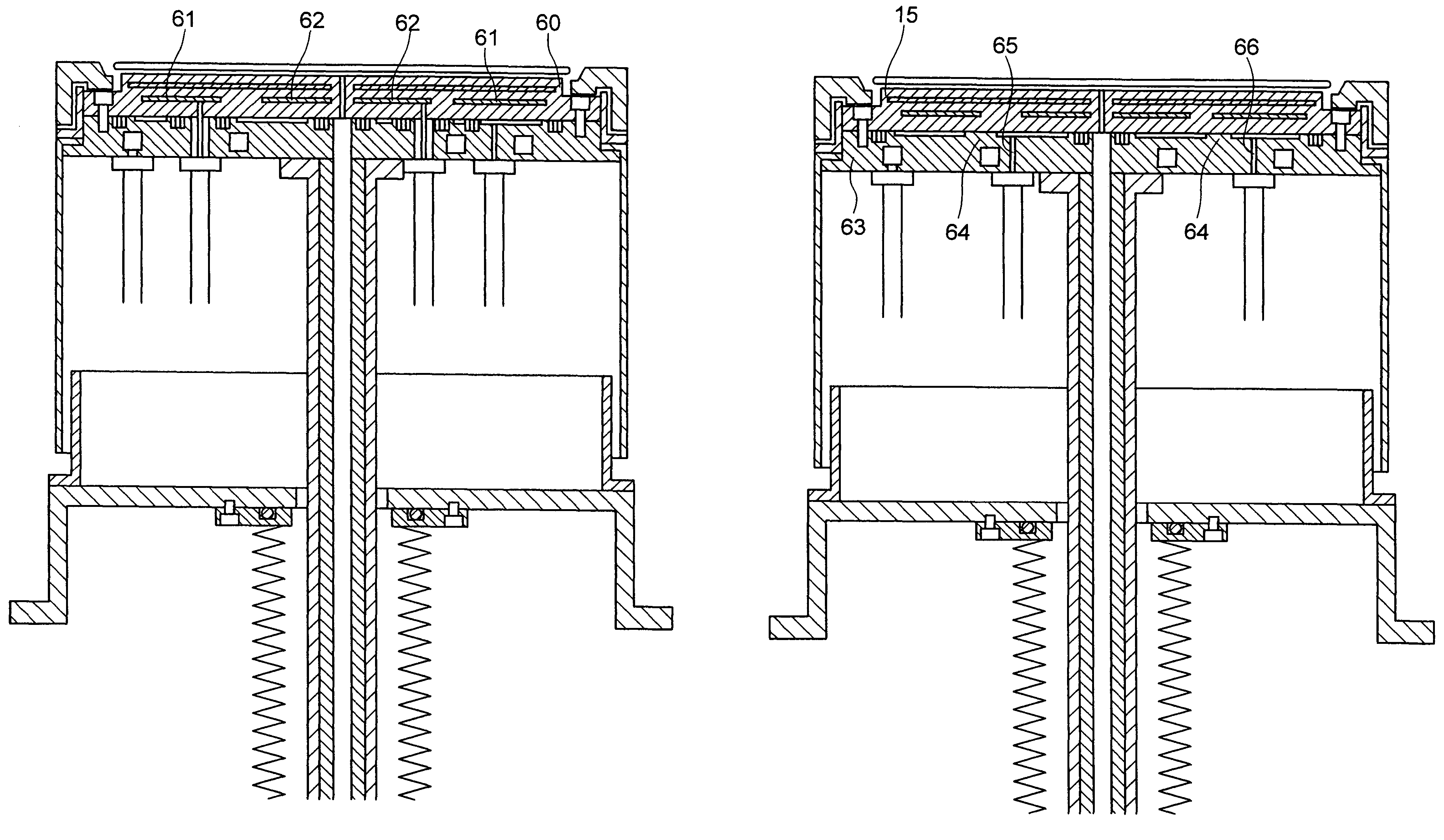

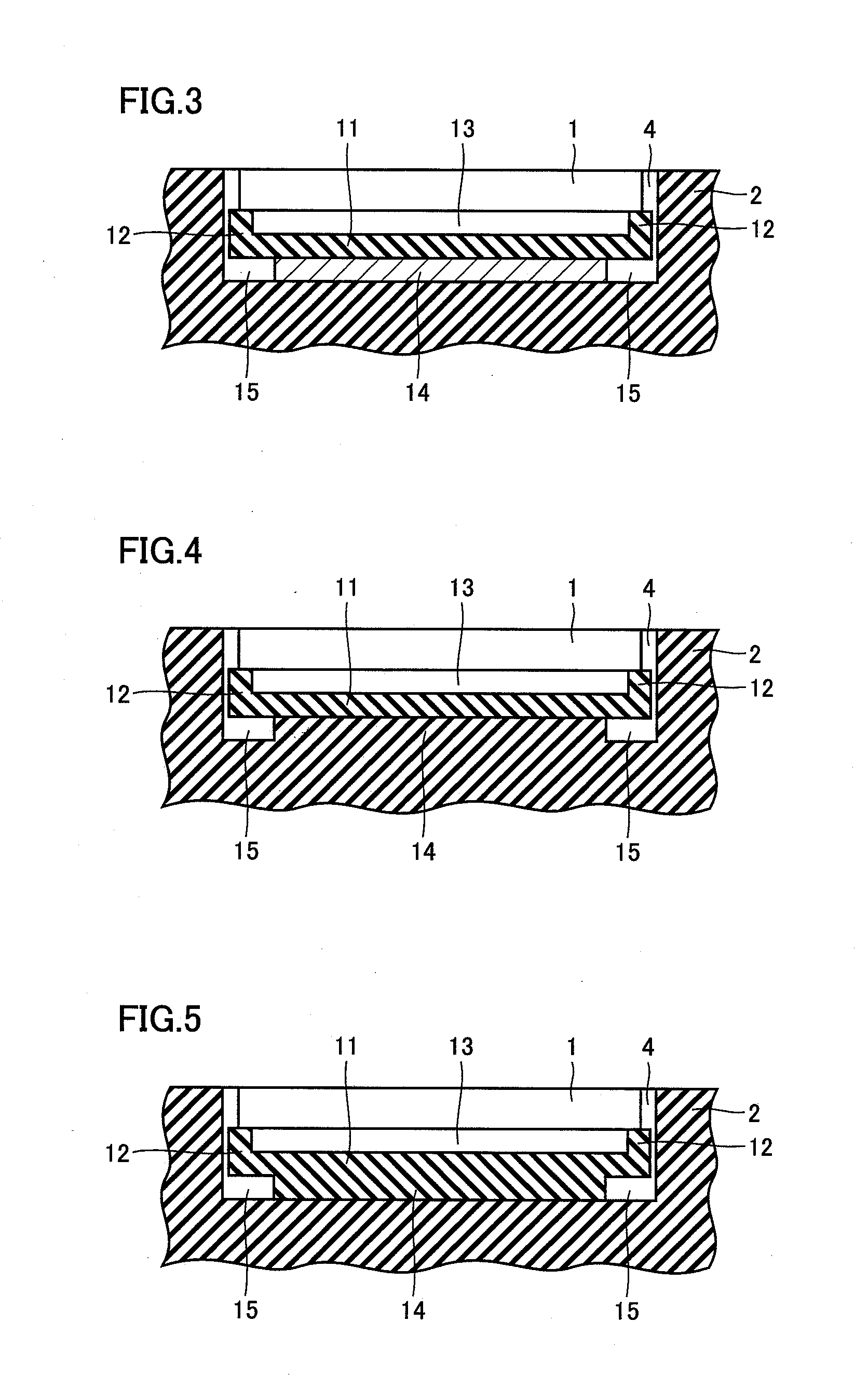

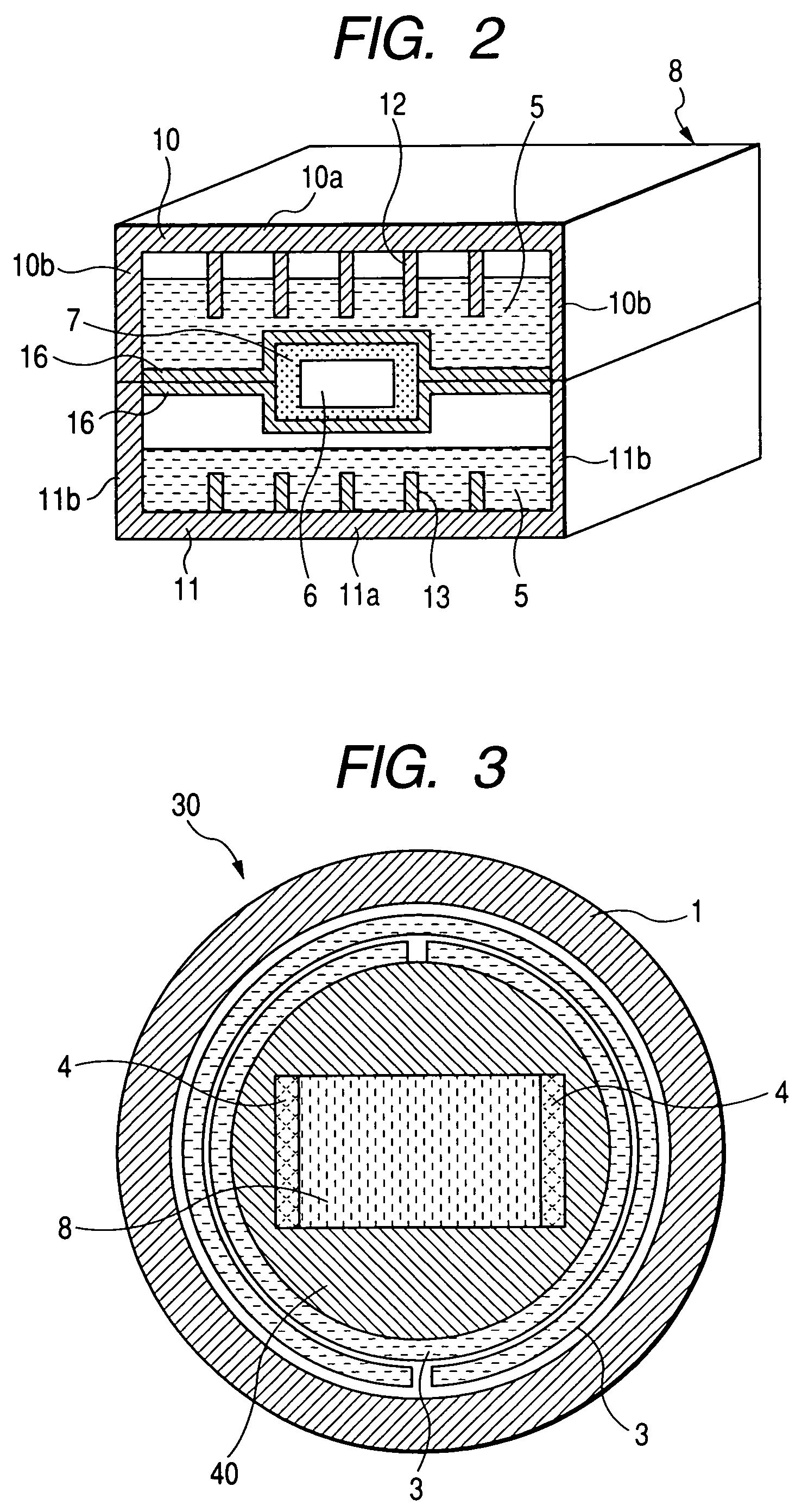

Shower head and plasma processing apparatus having same

InactiveUS20100230051A1Improve uniformityUniform temperature distributionElectric discharge tubesSemiconductor/solid-state device manufacturingEngineeringCopper

A shower head is provided, in a processing chamber in which a substrate is processed, to face a mounting table for mounting the substrate thereon. The shower head includes: a facing surface that faces the mounting table to supply a gas to the substrate in a form of shower through a plurality of gas injection holes formed on the facing surface; an opposing surface provided opposite to the facing surface; and a plurality of bar-shaped heat transfer columns standing on the opposing surface. Here, the heat transfer columns have varying lengths and / or thicknesses to adjust heat capacities thereof. The heat transfer columns are made of one of aluminum, stainless steel, and copper.

Owner:TOKYO ELECTRON LTD

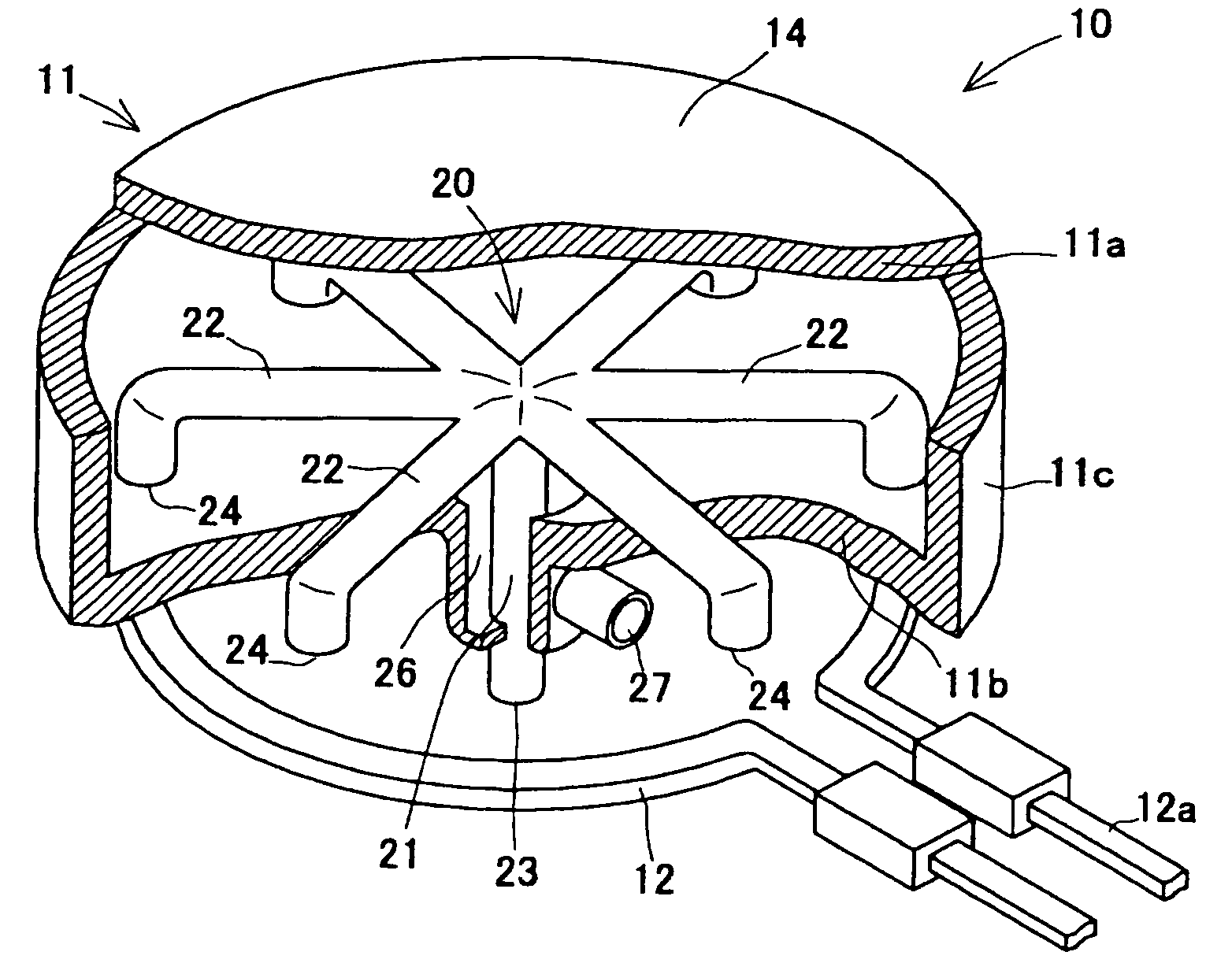

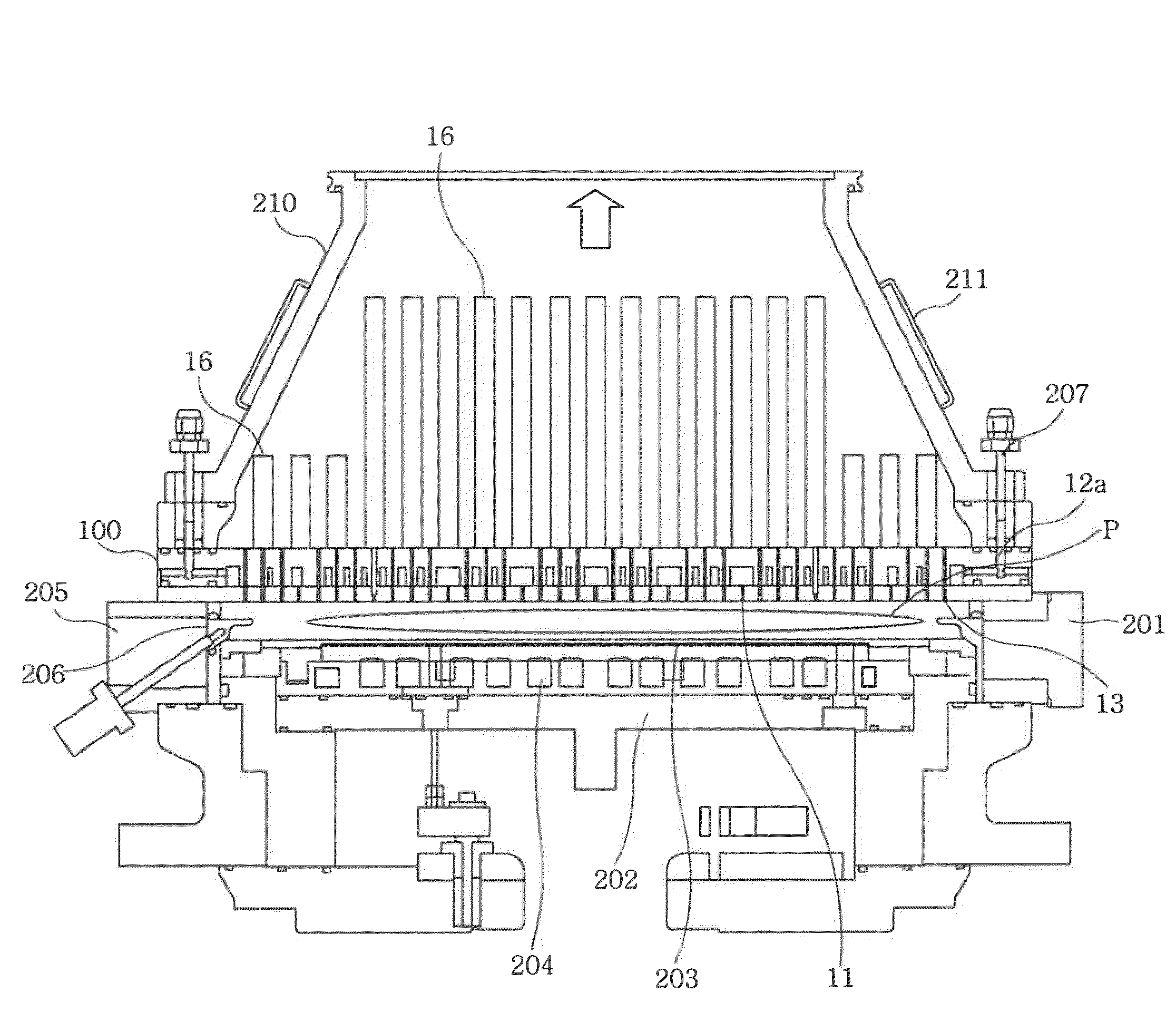

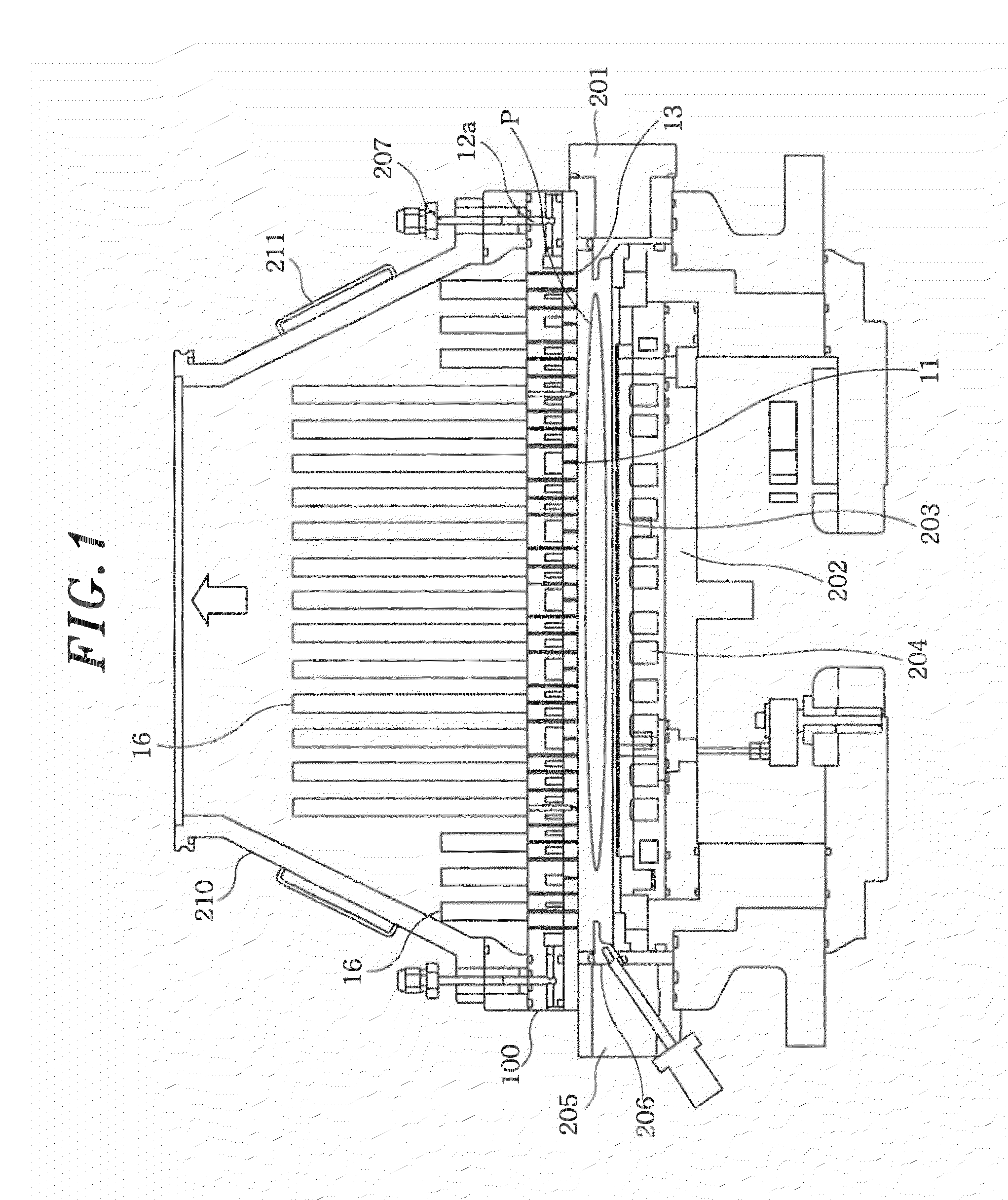

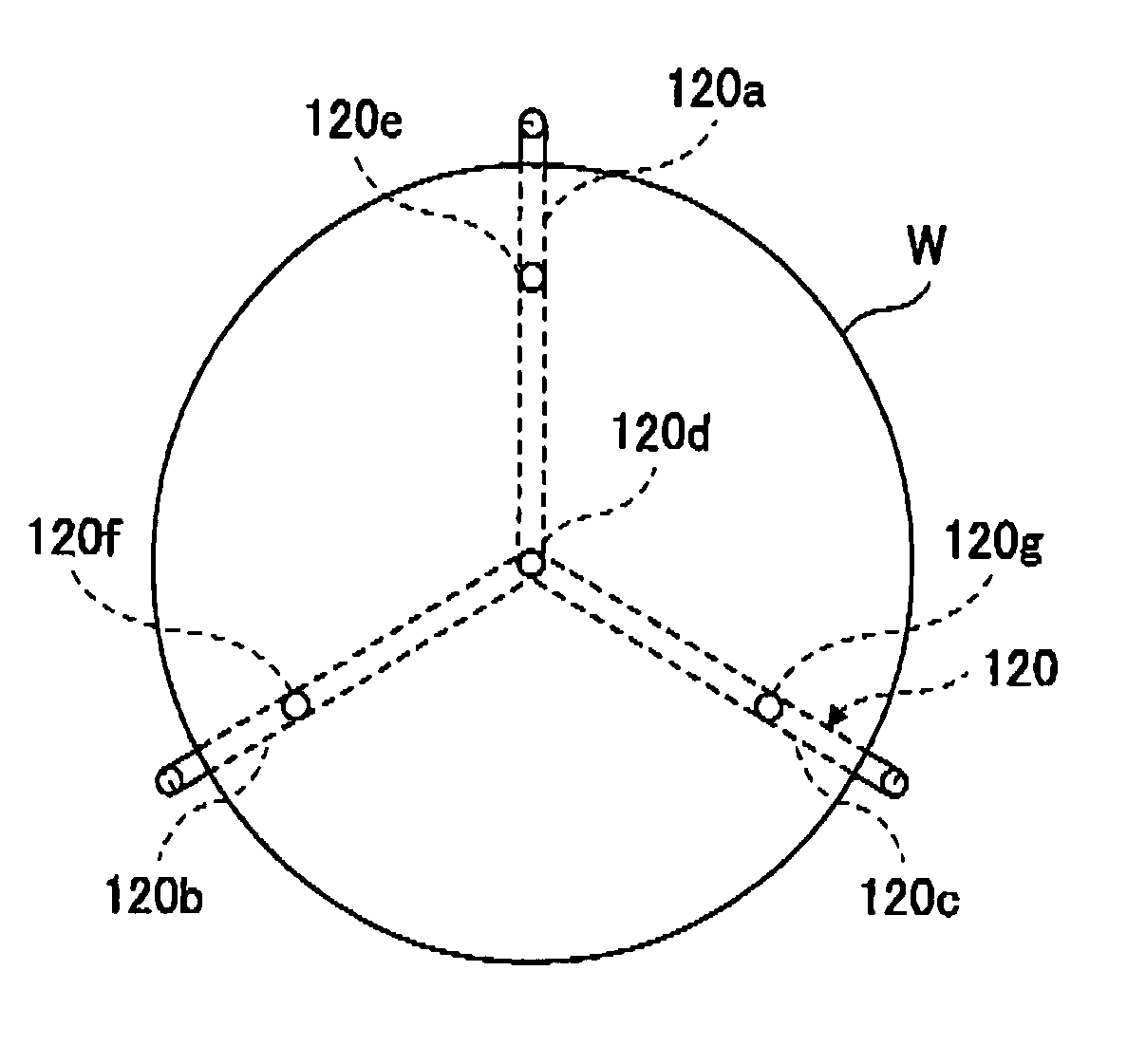

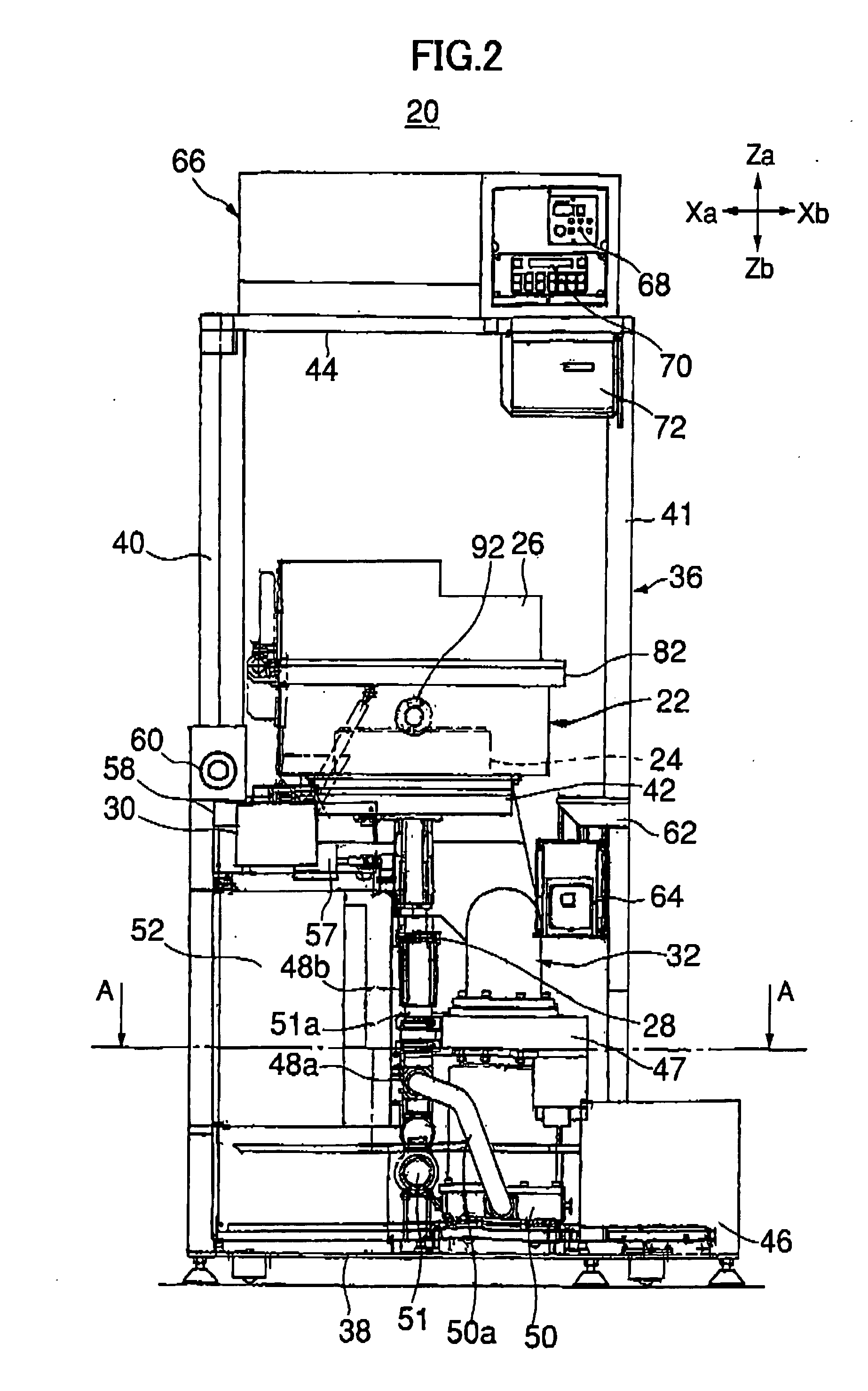

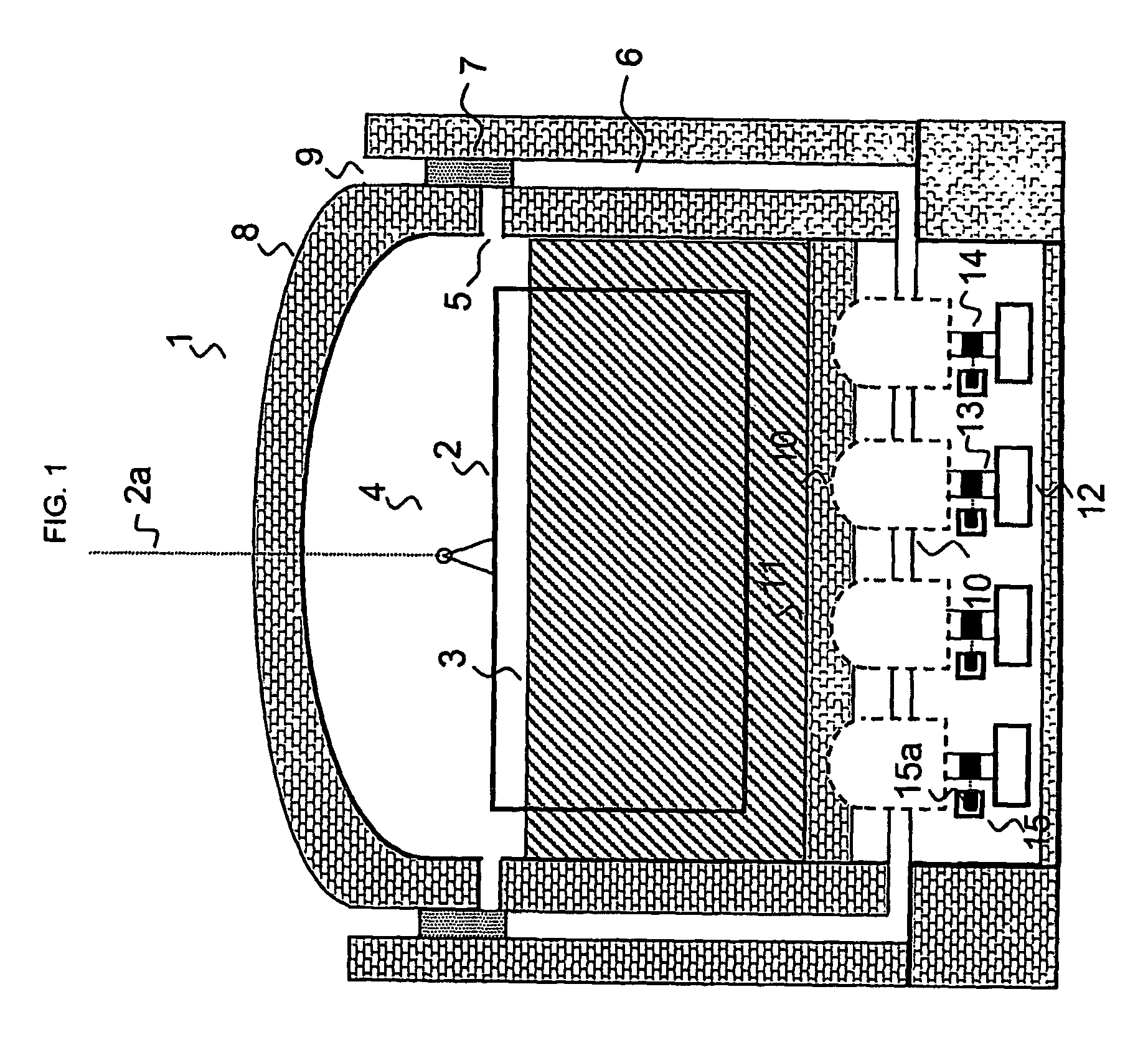

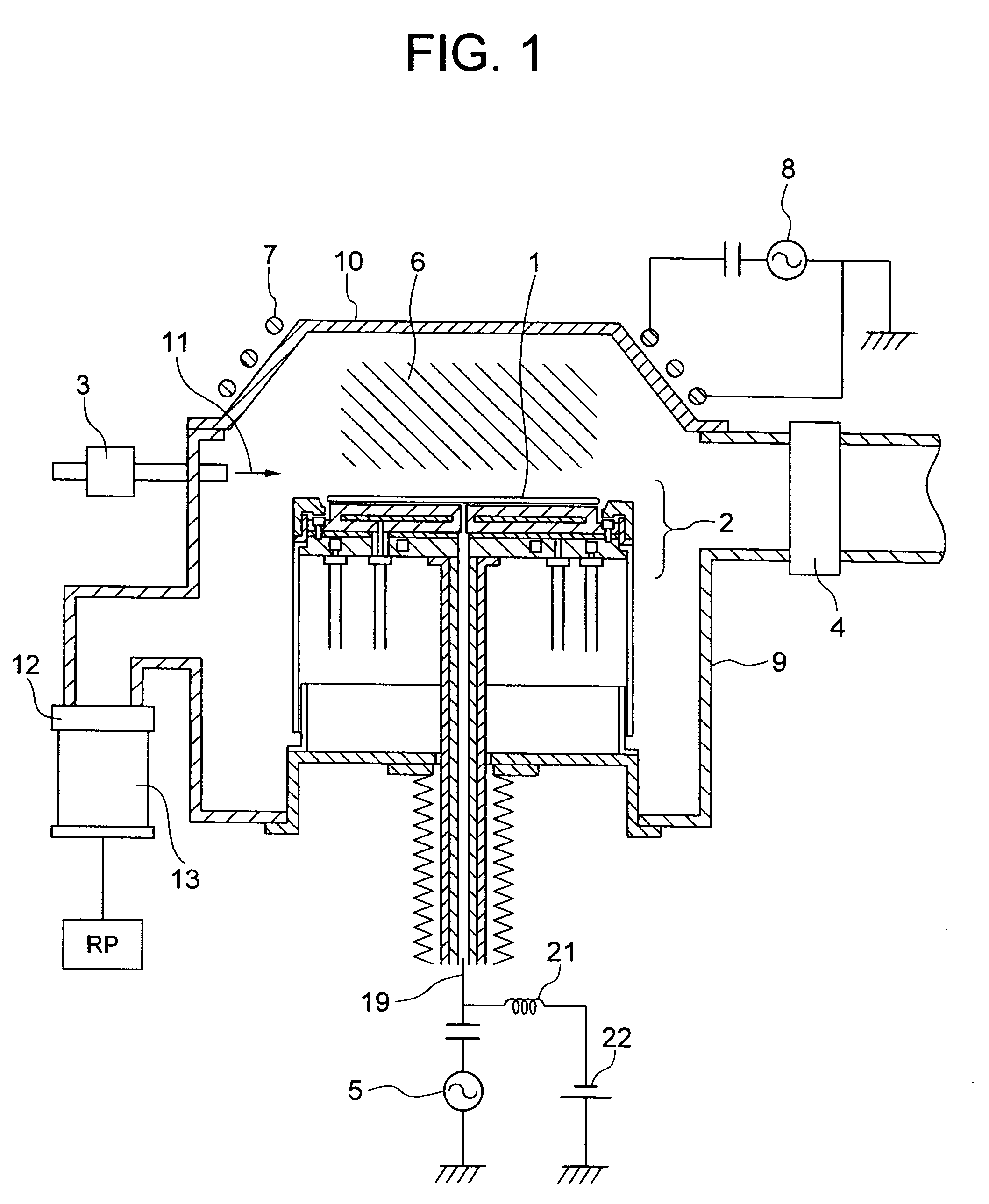

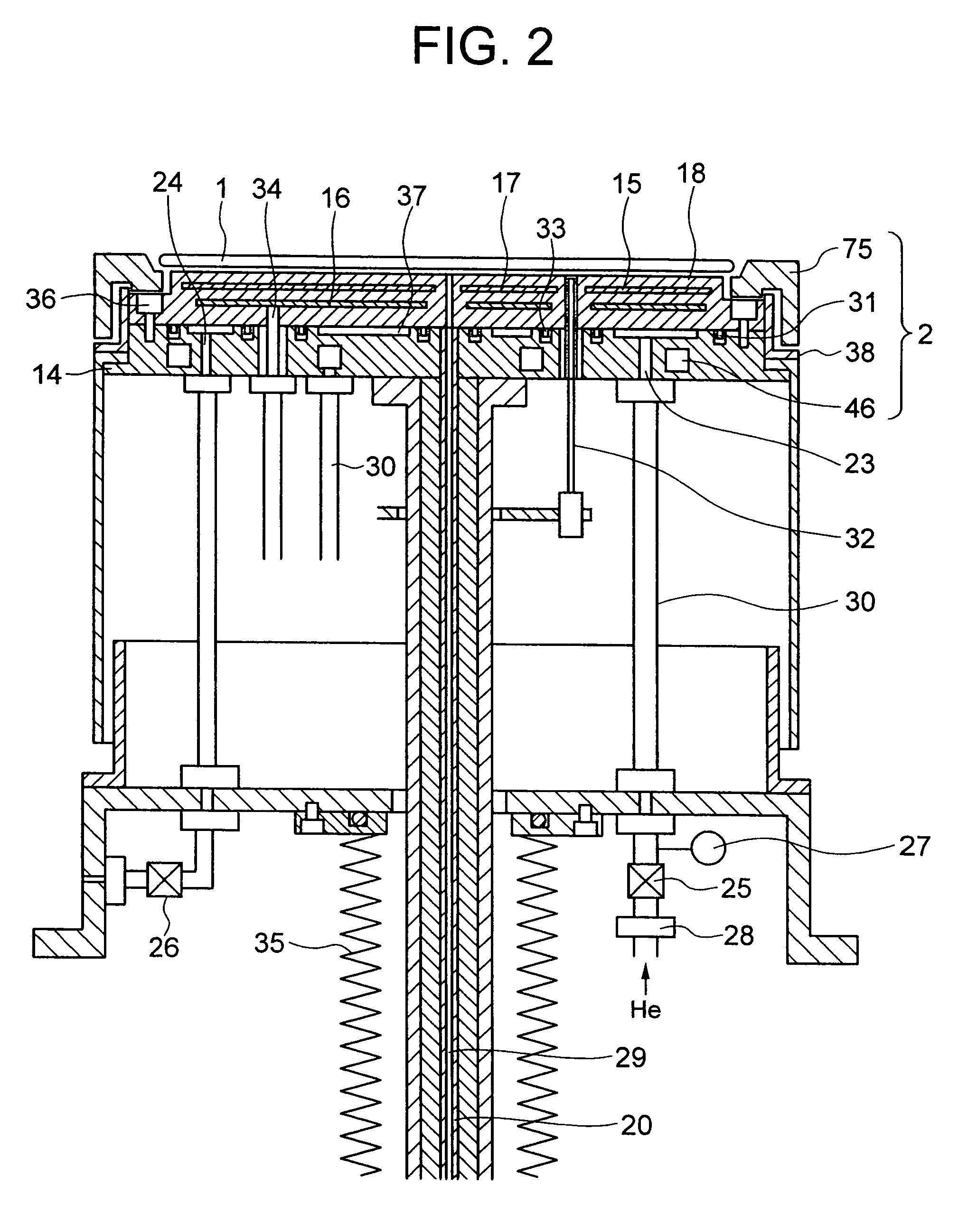

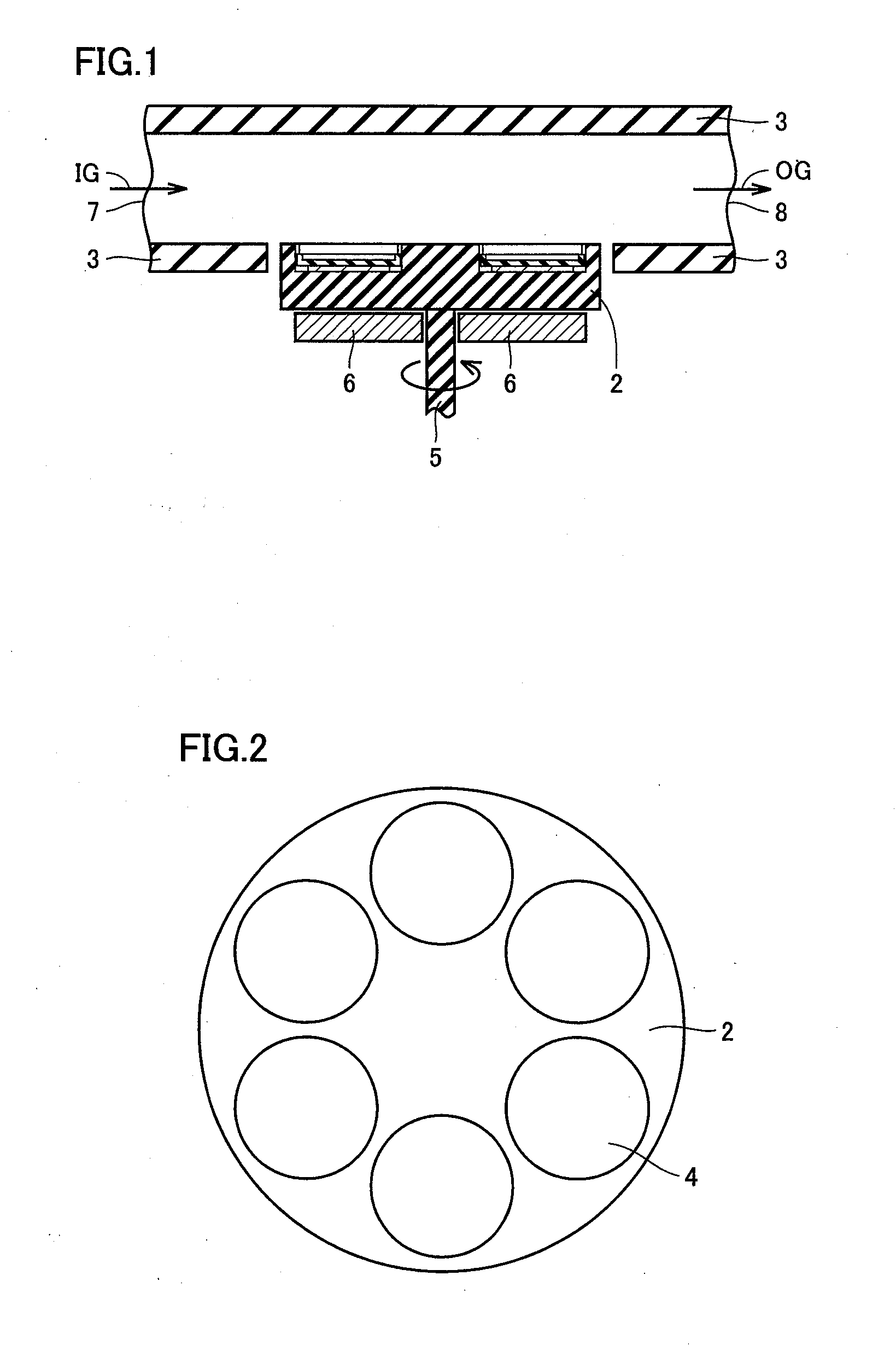

Substrate processing apparatus

InactiveUS20060057799A1Reliable formingAvoid pollutionSemiconductor/solid-state device manufacturingChemical vapor deposition coatingUltraviolet lightsEngineering

A substrate processing apparatus stably and efficiently conducts a film forming process on a substrate to be processed. In the substrate processing apparatus, the substrate to be processed is supported at a position facing a heater portion, and a holding member for holding the substrate is rotated, whereby the temperature distribution of the substrate is kept uniform and a warp of the substrate is suppressed. The inner wall of the processing vessel is covered with a quartz liner which is made of opaque quartz, and thus protected from ultraviolet rays emitted from an ultraviolet light source. The temperature rise of the inner wall caused by heat from the heater portion is suppressed due to the heat insulating effect of the quartz liner. Consequently, the life cycle of the processing vessel can be prolonged.

Owner:TOKYO ELECTRON LTD

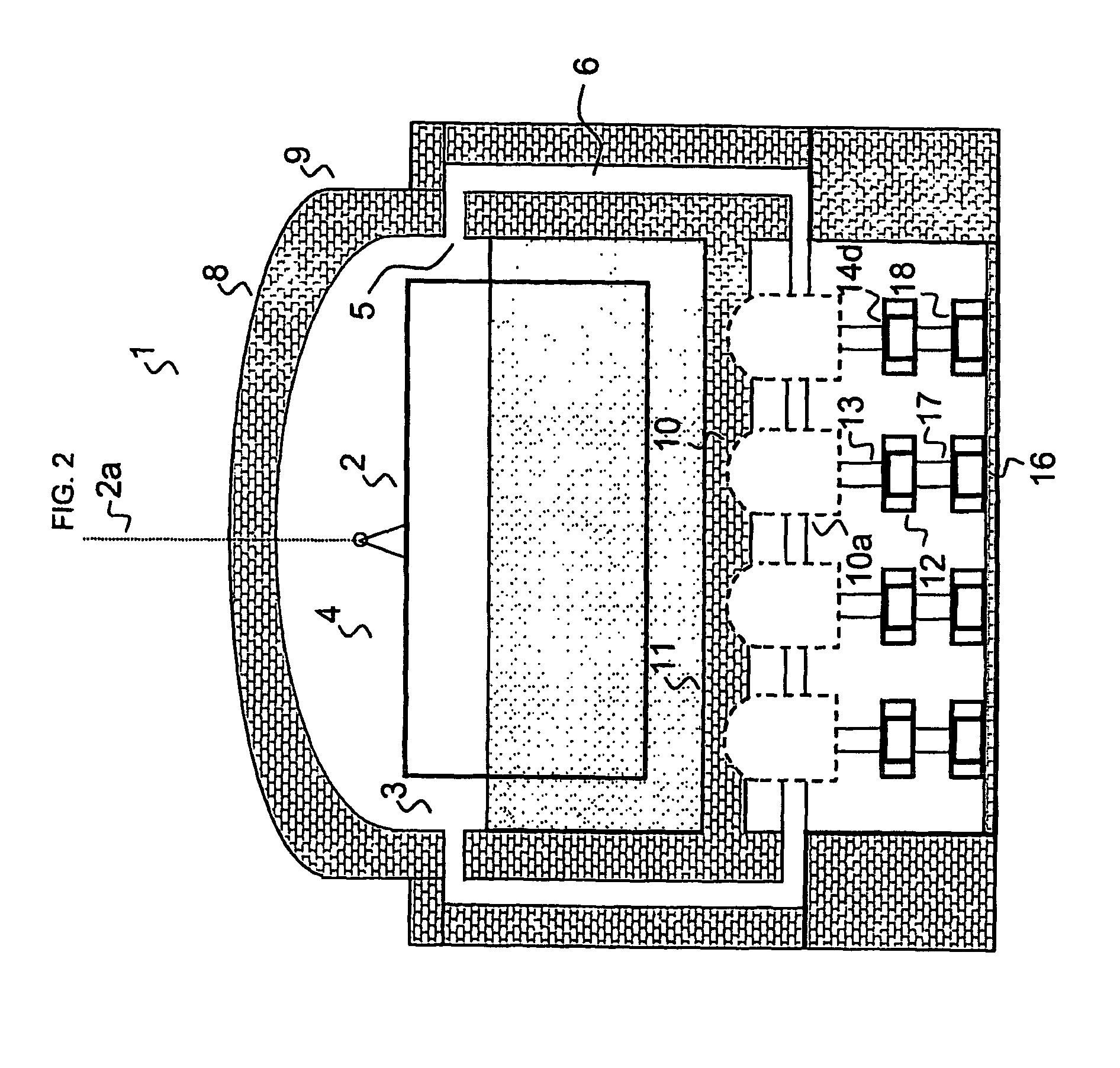

Substrate processing apparatus

ActiveUS20060048710A1Avoid pollutionUniform temperature distributionSemiconductor/solid-state device manufacturingChemical vapor deposition coatingEngineeringDeposition process

The substrate processing apparatus according to the present invention is aimed to stably and efficiently perform a deposition process on a substrate W. The substrate processing apparatus supports the substrate W in a position facing a heater portion and thus rotates a holding member holding the substrate W. Furthermore, the heating portion houses a SiC heater and a heat reflecting member in an internal portion of a quartz bell jar made of transparent quartz, and depressurizes an internal space of a processing vessel and an internal space of the quartz bell jar at the same time; thereby allowing the thickness of the quartz bell jar to be thinner, and thus improving thermal conductivity of heat from the SiC heater and preventing contamination by the SiC heater.

Owner:TOKYO ELECTRON LTD

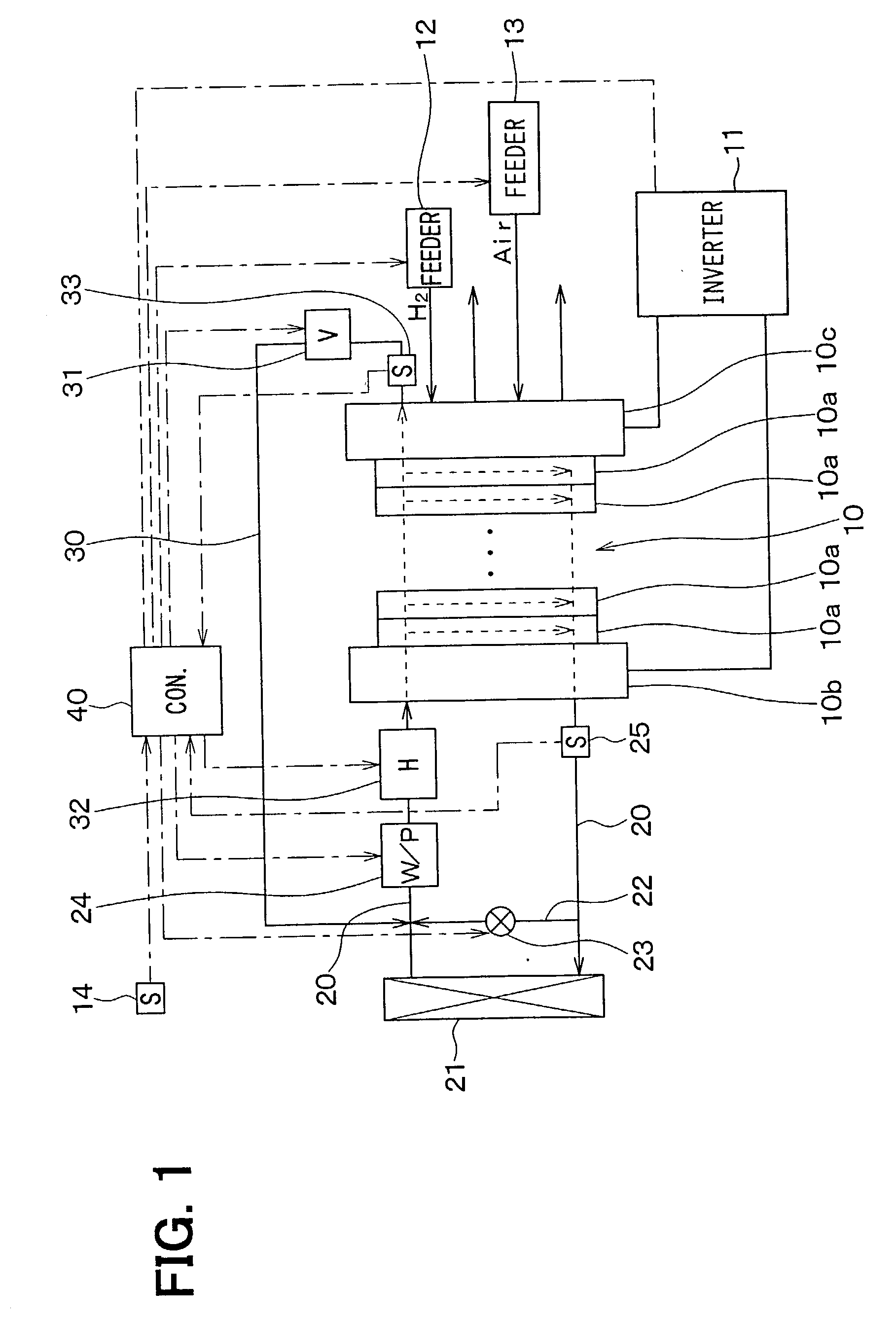

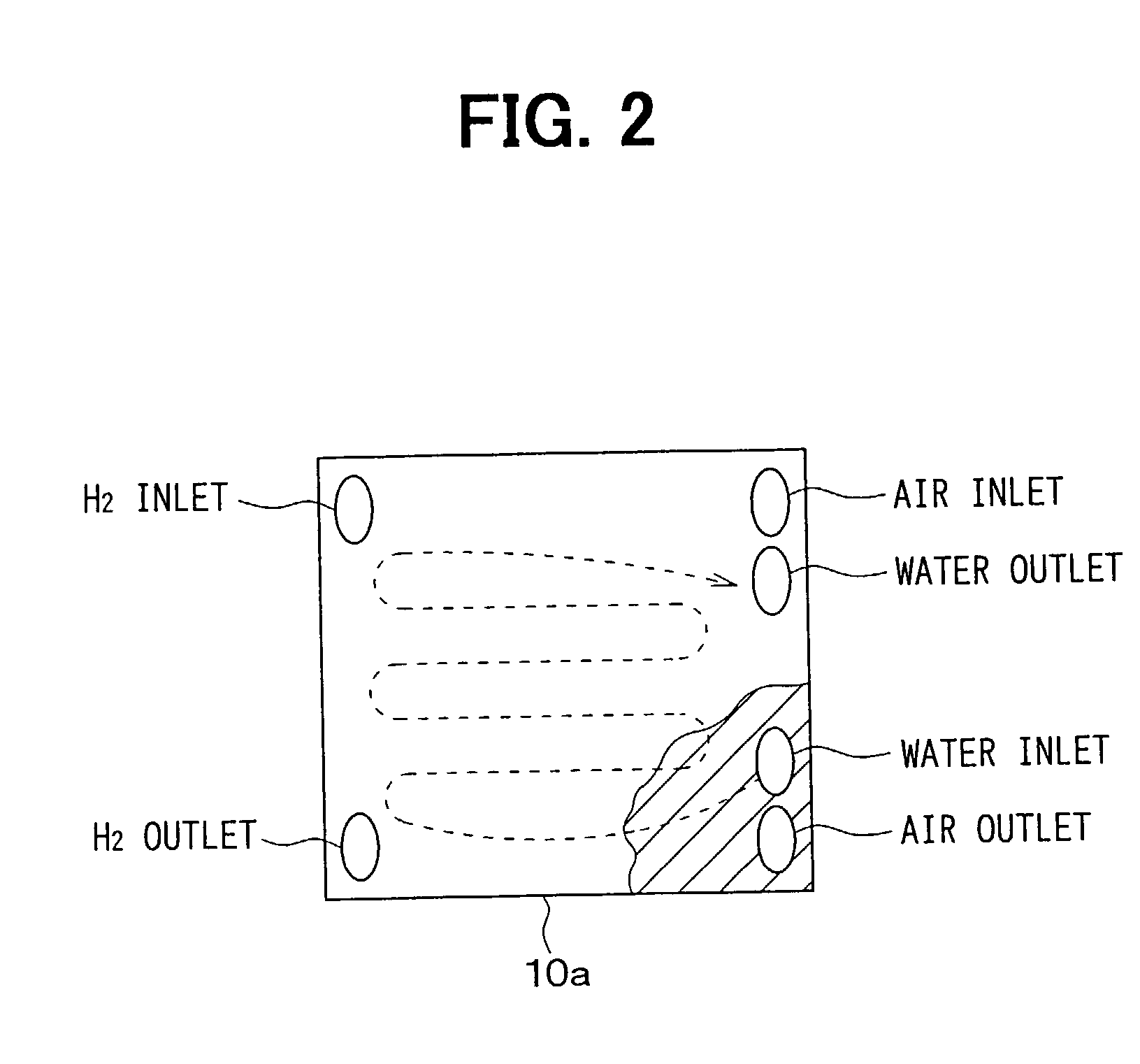

Fuel cell system

InactiveUS20030031905A1Small sizeHeating up fastFuel cell heat exchangeFuel cells groupingFuel cellsEngineering

A fuel cell system includes a fuel cell constructed by plural stacked cells, a circulation path through which a thermal medium is circulated into each cell, a heater for heating the thermal medium, a bypass path through which the thermal medium is circulated into a part of each cell while bypassing the other part thereof, and a flow control valve for controlling a flow amount of the thermal medium circulated in the bypass path. The thermal medium can be circulated into only the part of each cell in a warm-up operation, so that the part of each cell is collectively heated. An amount of the thermal medium circulated into the other part of each cell is controlled, so that all of each cell is finally warmed up in the warm-up operation.

Owner:DENSO CORP

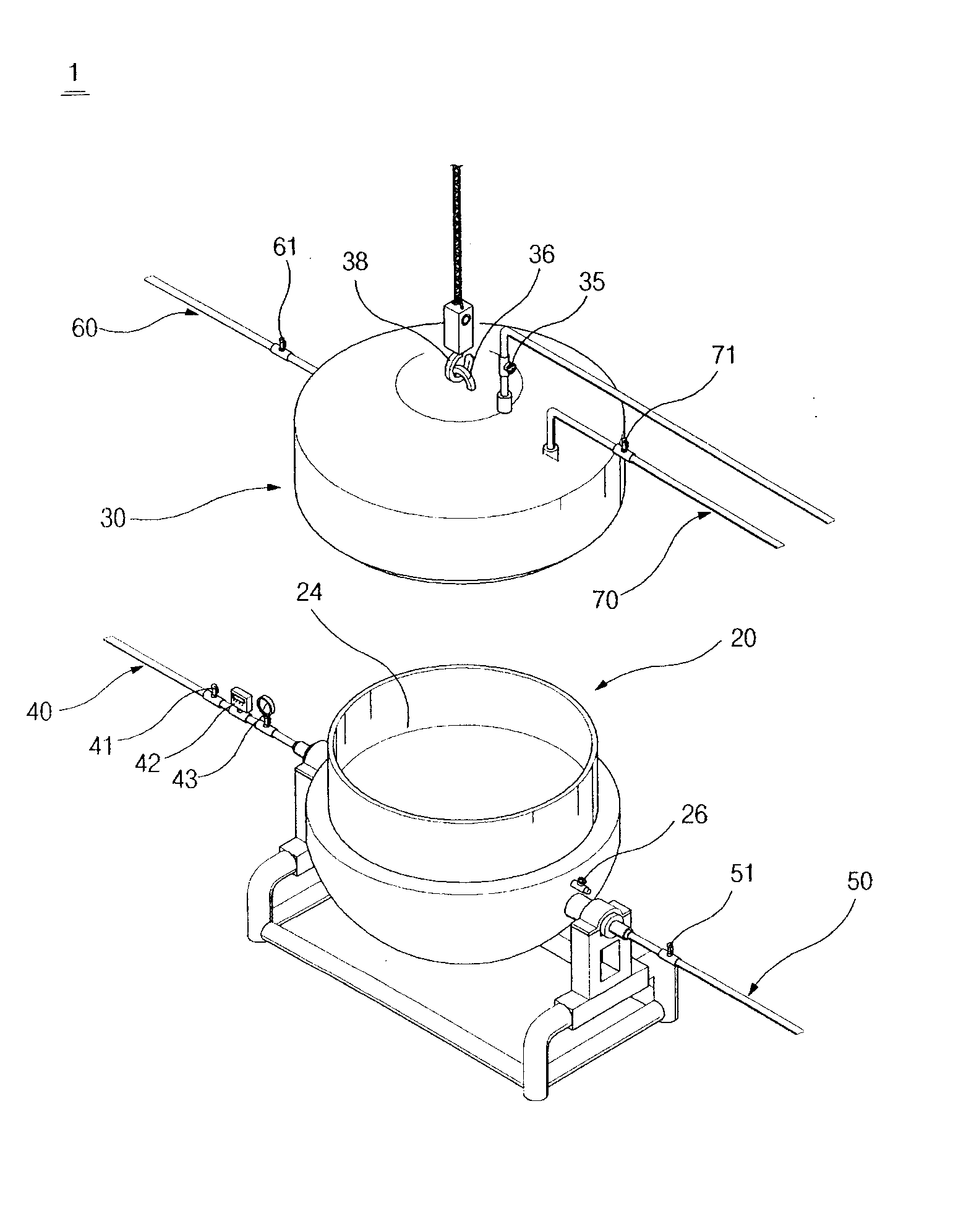

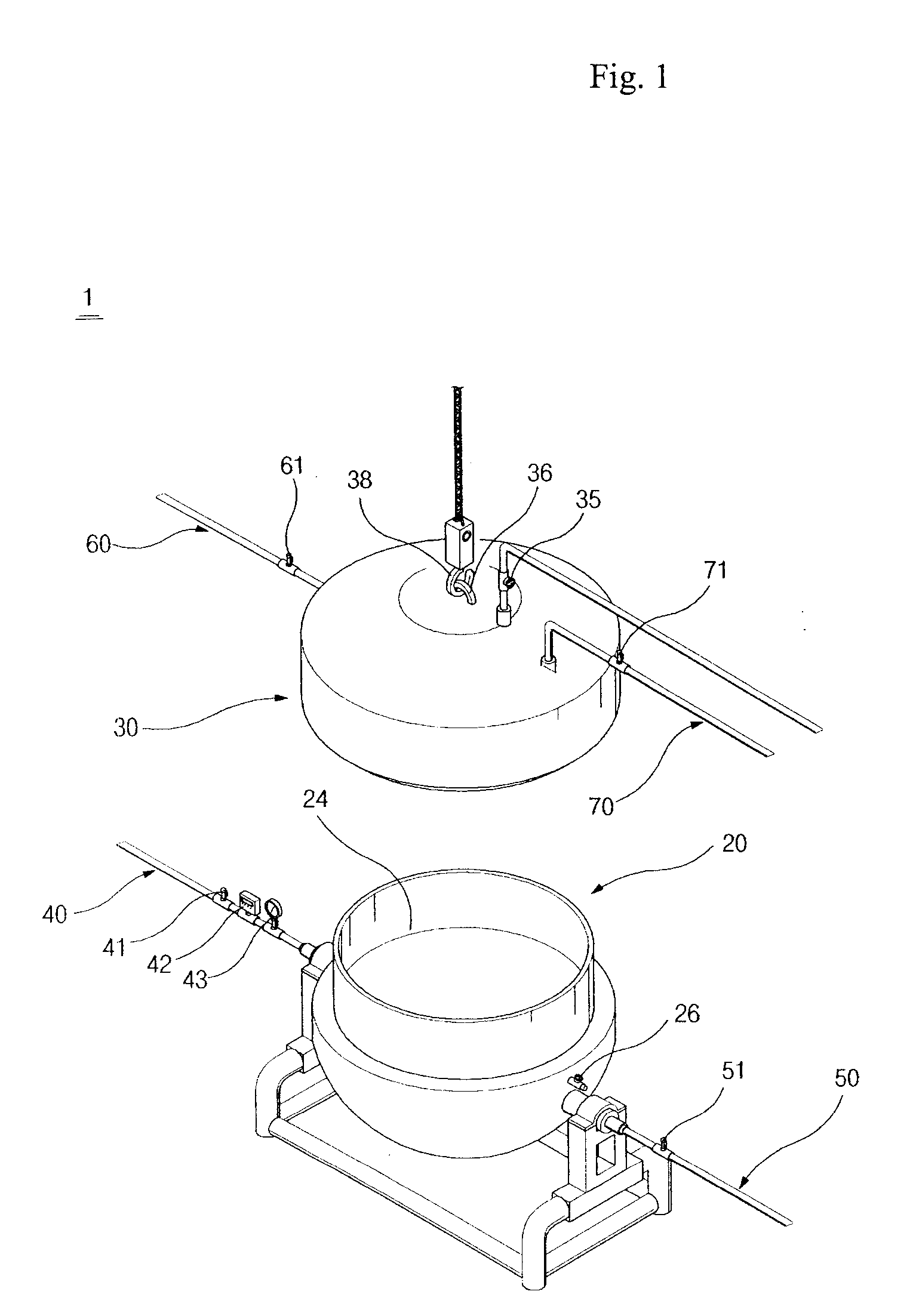

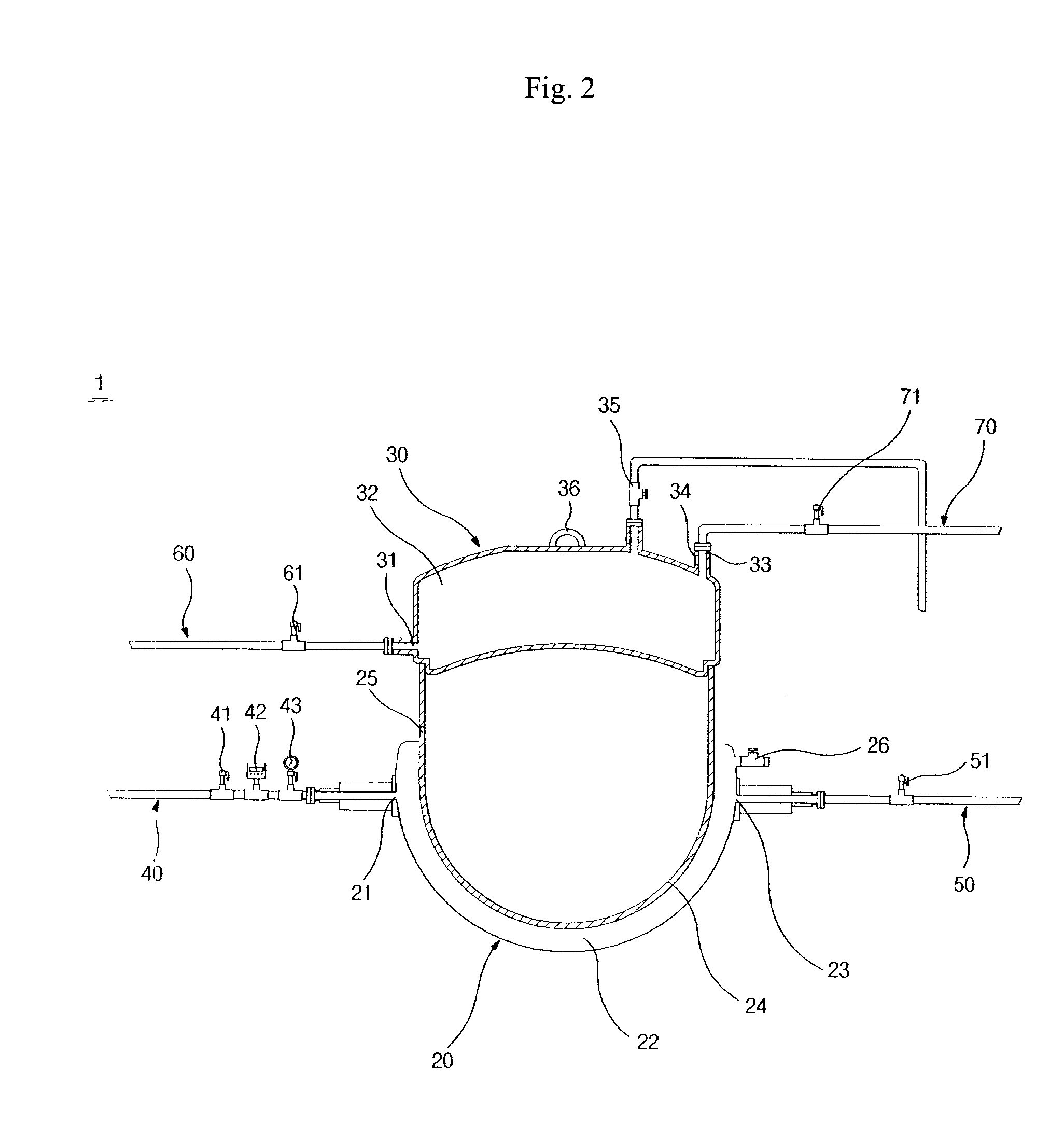

Vapor Heating Type Cooking Apparatus

InactiveUS20070209656A1Avoid stickingImprove the inconvenienceLighting and heating apparatusCooking-vessel lids/coversInterior spaceWater discharge

The present invention relates to a vapor heating type cooking apparatus cooking food materials using high pressure vapor as a heat source. A vapor heating type cooking apparatus includes: a vapor supply section generating the high pressure vapor; a vapor supply pipe and a vapor discharge pipe for introducing and discharging the high pressure vapor; a body section including a vapor introduction opening connected to the vapor supply pipe, an interior space having a dual structure so as to circulate the high pressure vapor in the caldron in which food materials are accommodated, a vapor discharge opening provided between the interior space and the vapor discharge pipe; a cooling water supply pipe and a hot water discharge pipe; a lid section including a cooling water introduction opening connected to the cooling water supply pipe, a storage space having a dual structure, in which the cooling water is temporarily stored, and a hot water discharge opening provided between the storage space and the hot water discharge pipe; and a control section for controlling introduction and discharge of the high pressure vapor, the cooling water, and the hot water.

Owner:LEE WON KI

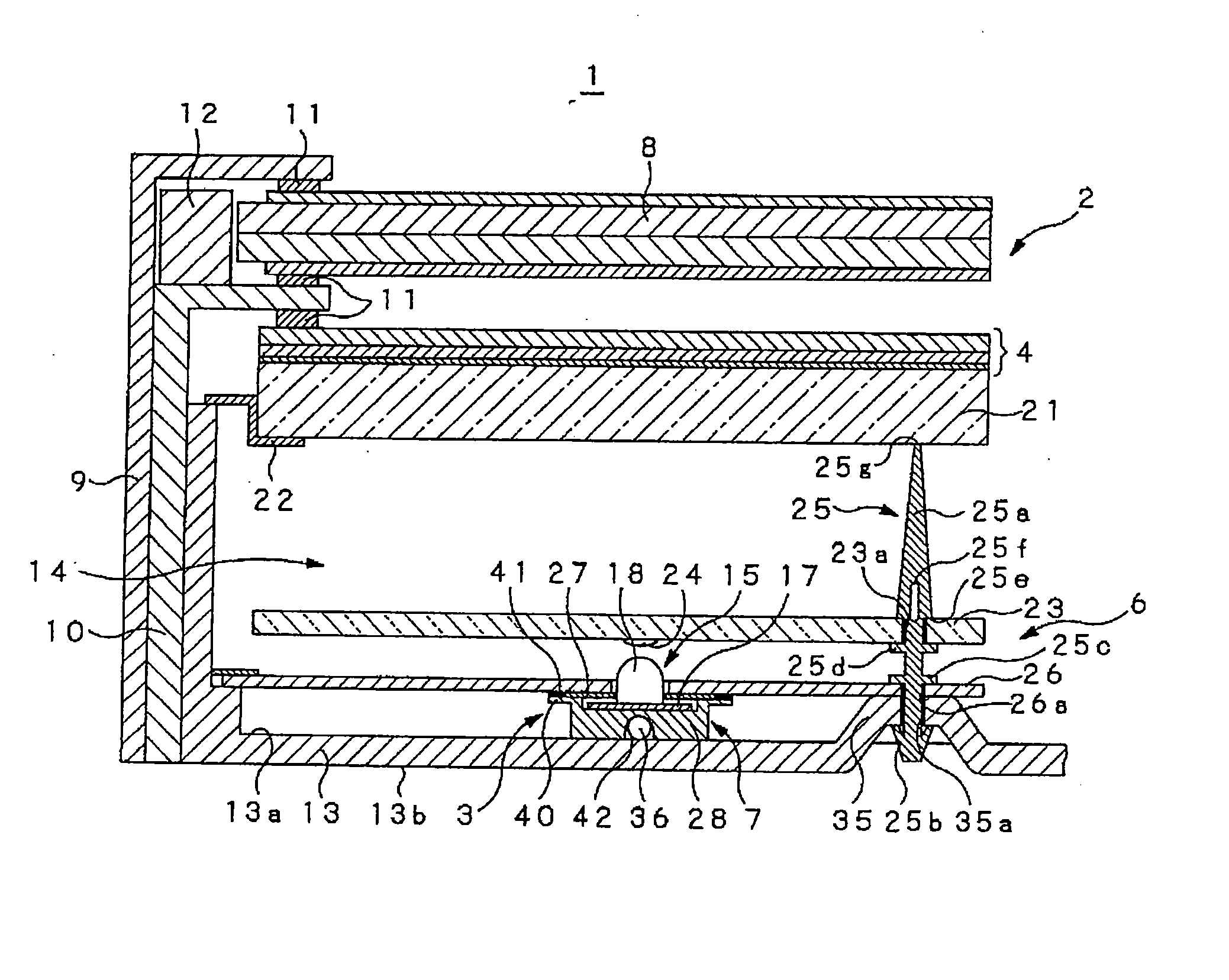

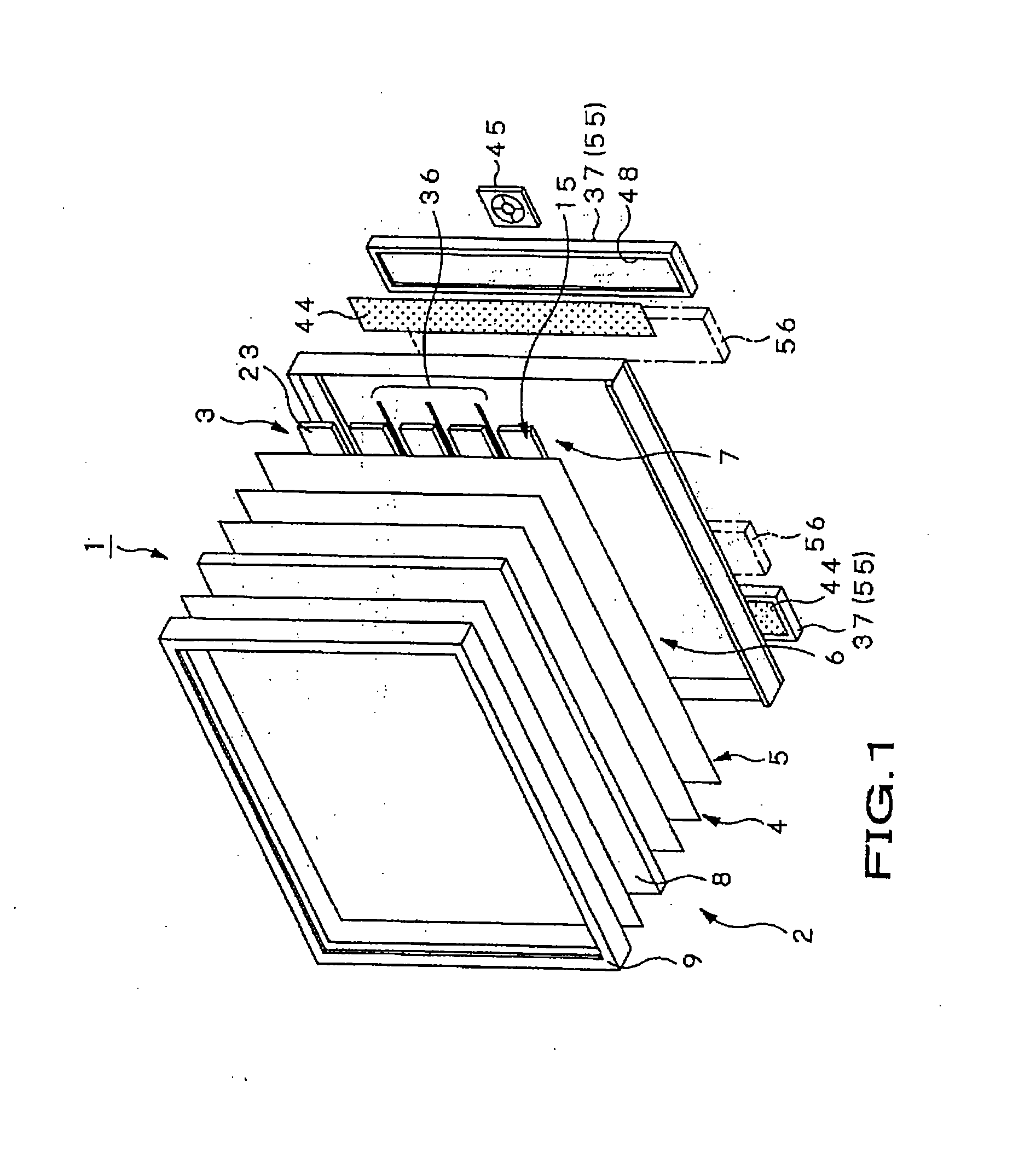

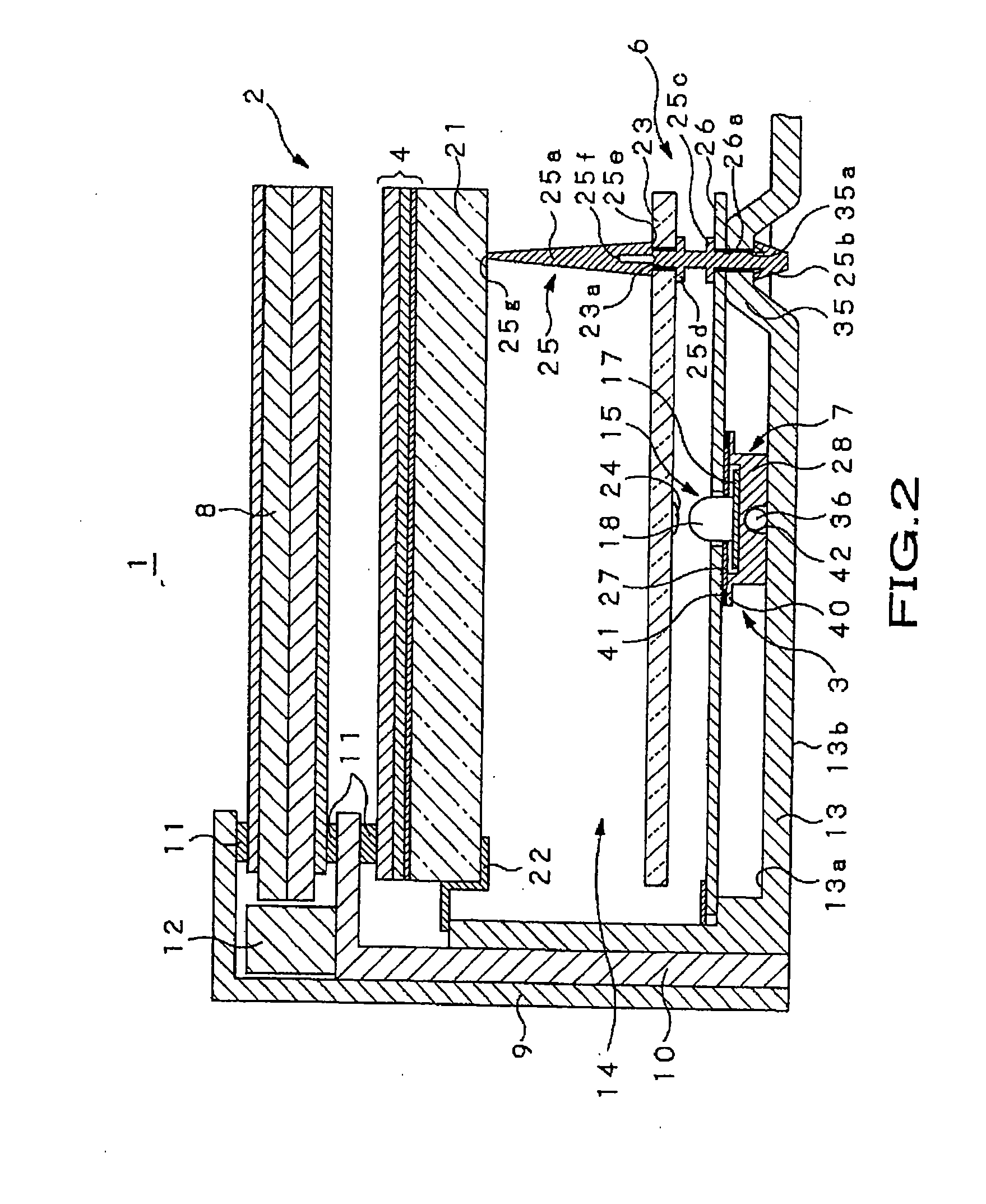

Heat radiator and display unit

InactiveUS20070211205A1Improve thermal conductivityAvoid it happening againPoint-like light sourceLighting heating/cooling arrangementsDisplay deviceEngineering

Disclosed is a heat radiator which is provided in a transmissive display unit in which a plurality of rows of light emitting arrays constituted by arranging a plurality of light emitting units including a plurality of LEDs mounted on a wiring substrate are arranged on the back surface side of a transmissive display panel, and illuminating light emitted from the LEDs is irradiated onto the display panel. In the heat radiator, a radiation plate (28) supporting LEDs (18) and a heat sink (37) constitute an overlap area (57) with a back panel (13) interposed therebetween and are integrated with each other through the back panel by a fixing member in the overlap area. The back panel, radiation plate, and heat sink are firmly mounted to each other, achieving effective heat radiation.

Owner:SONY CORP

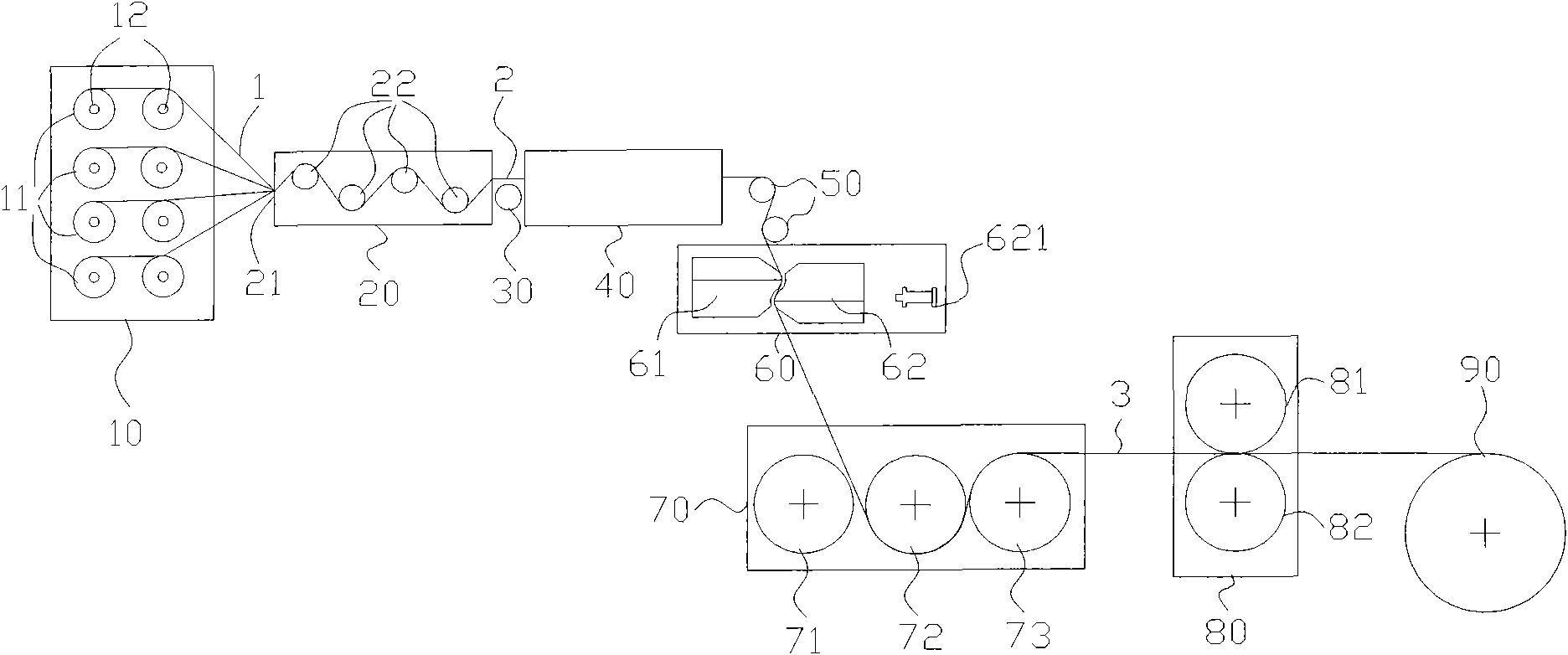

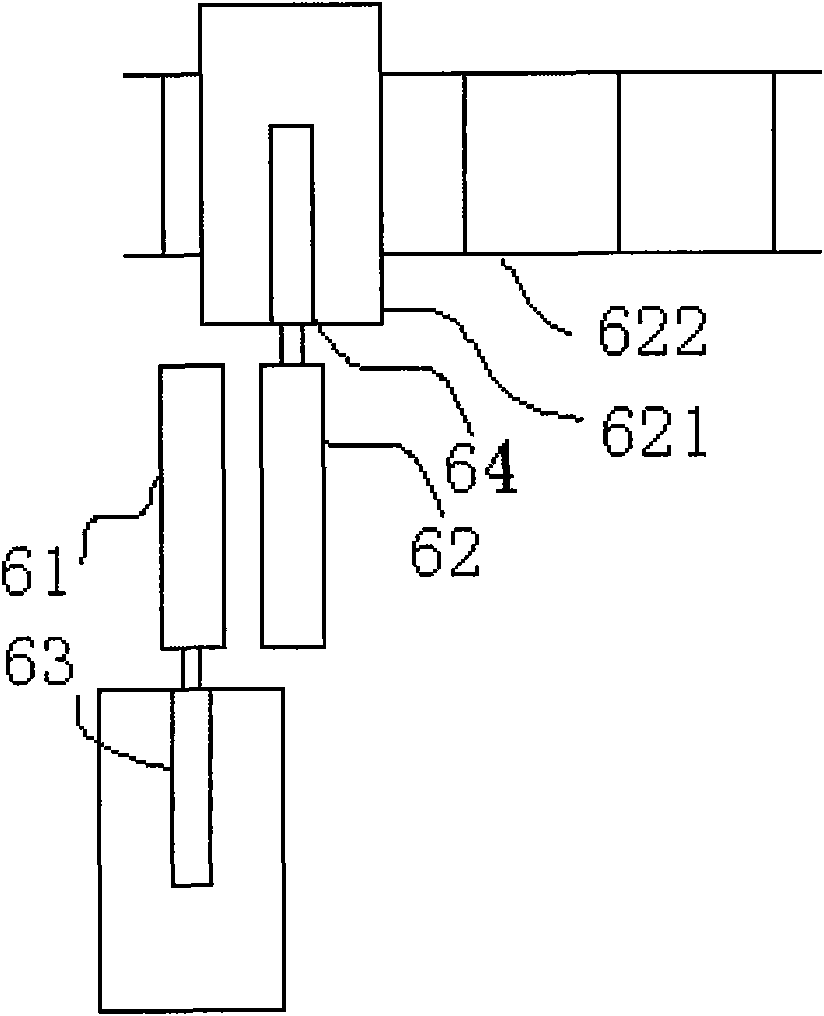

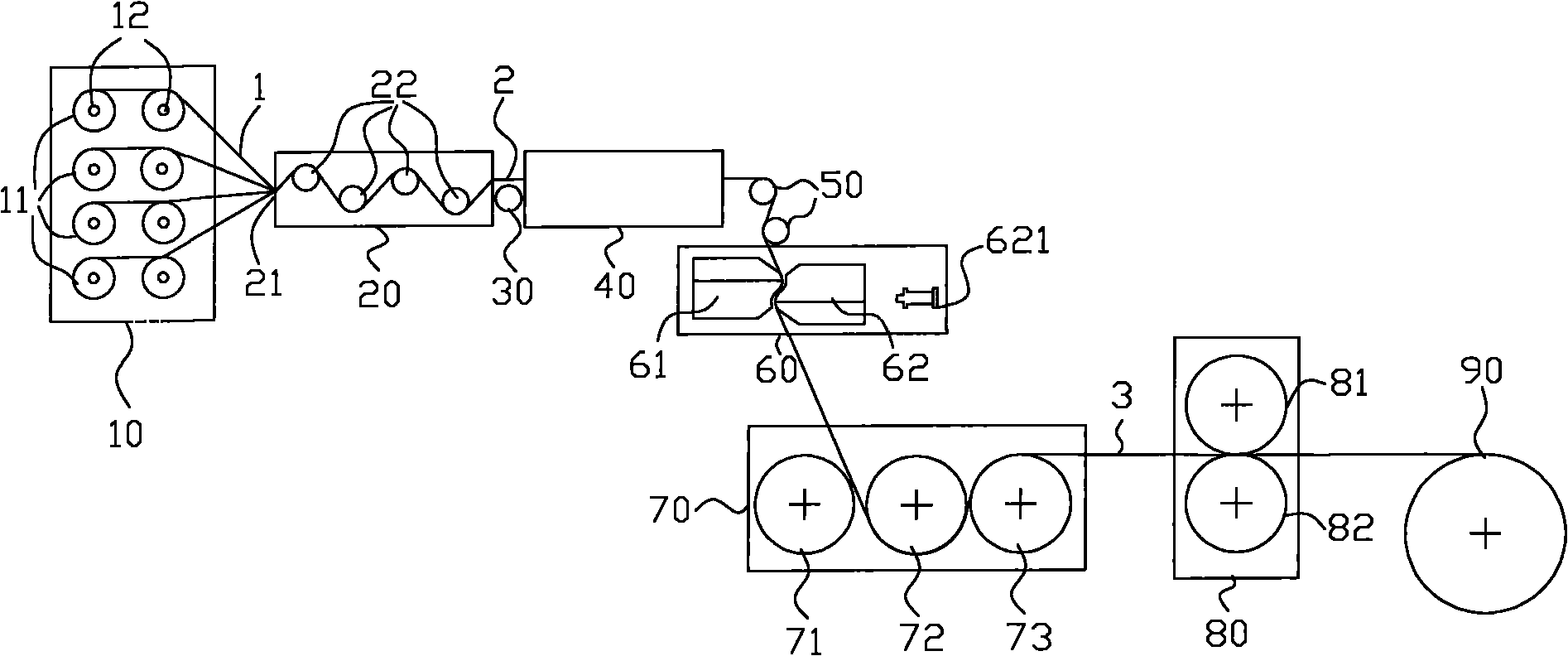

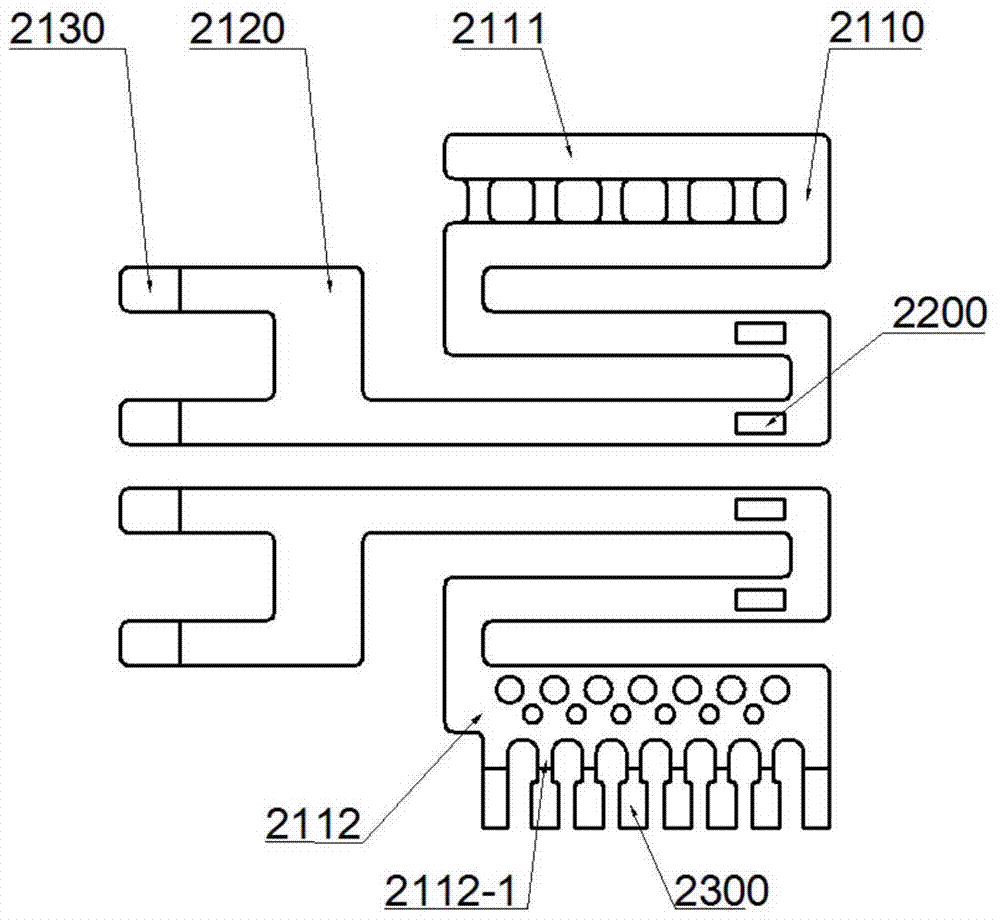

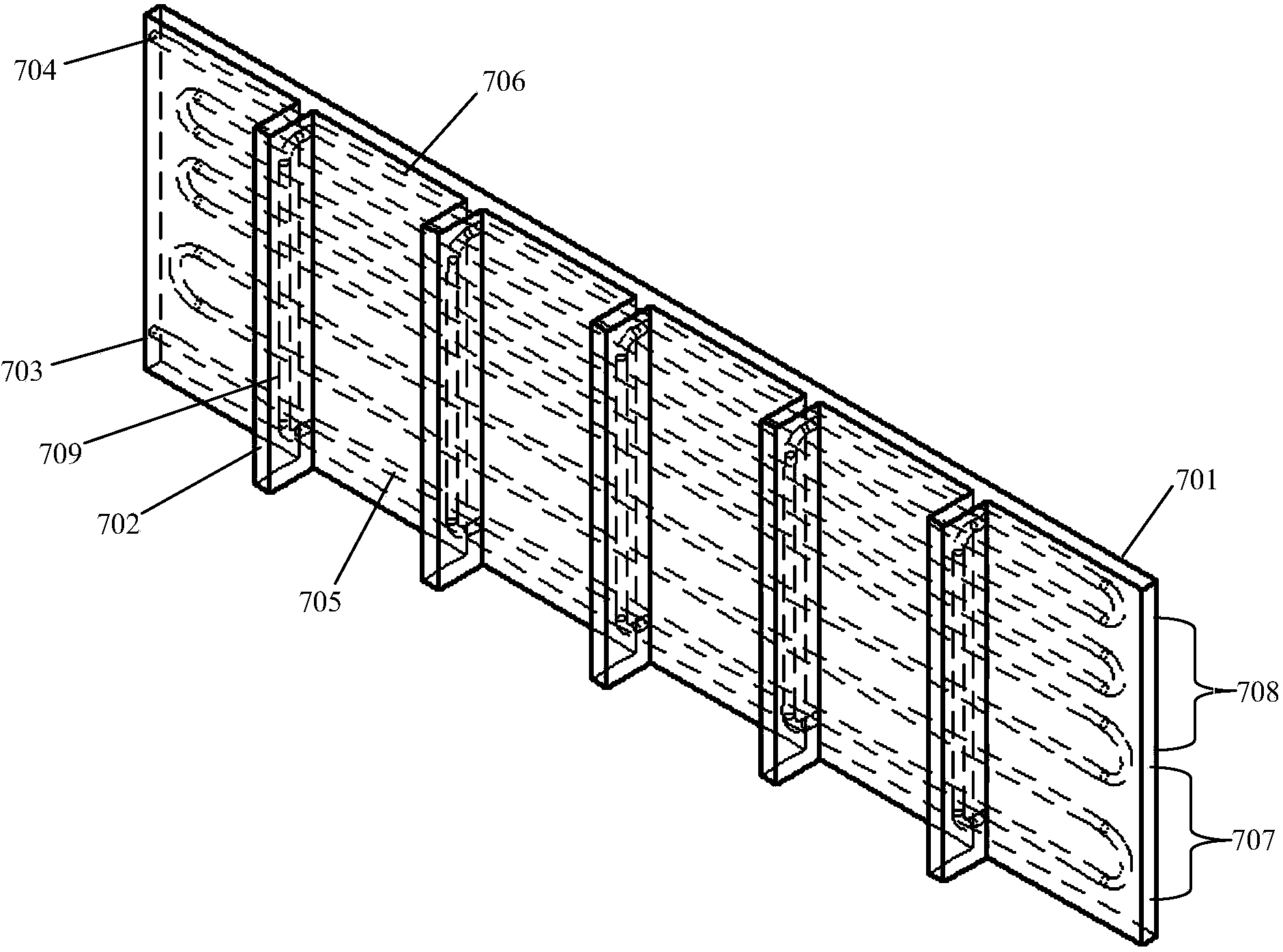

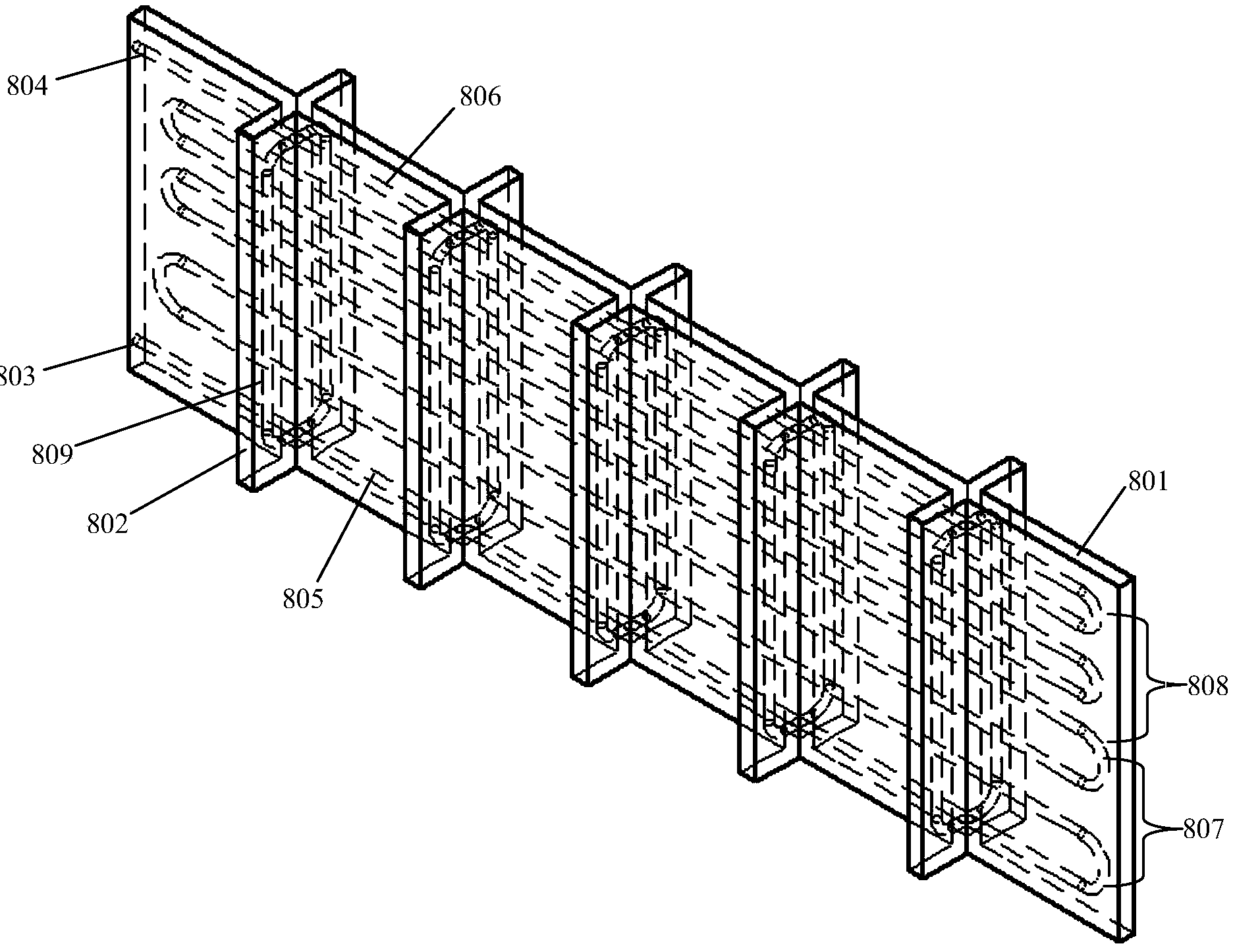

Preparation method of continuous fiber reinforced thermoplastic composite material prepreg and equipment thereof

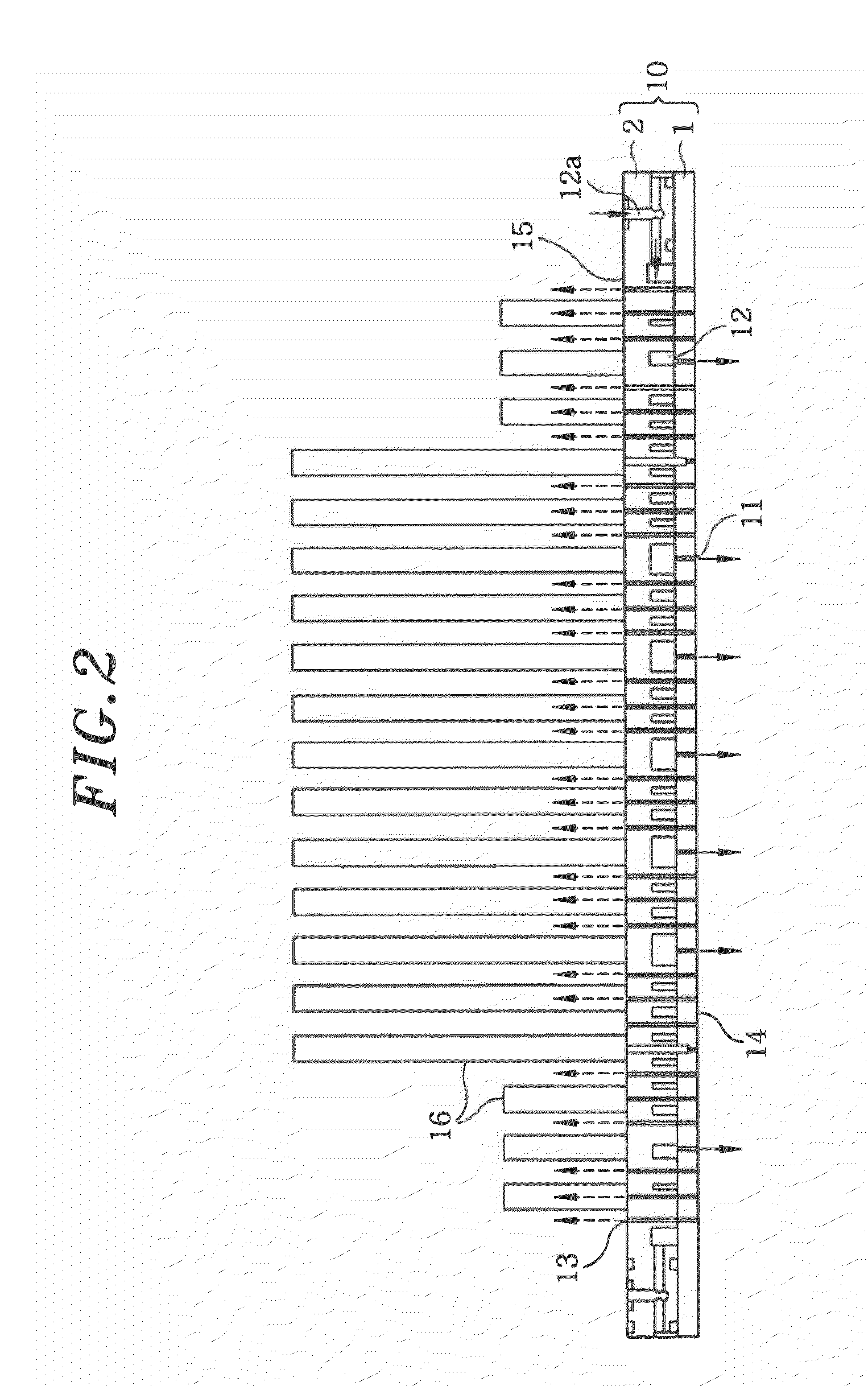

The invention relates to a preparation method of a continuous fiber reinforced thermoplastic composite material prepreg and equipment thereof. The method comprises the following steps: (a) leading out and unfolding continuous fiber from a creel (10) to pass a tension adjusting device (20) and a static elimination device (30) in sequence, sending the fiber to a preheating oven (40) to preheat, and then passing a tension adjusting device (50); (b) leading a preheated continuous fiber band into a dual-extrusion die head set which can be opened and closed in a staggered manner to presoak; and (c) leading the presoaked continuous fiber band into a soaked rolling roll set (70) to soak, then cooling by a cooling roll-in device (80), and finally leading into a traction rolling device (90) for shaping by winding to obtain the product. Compared with the prior art, the invention significantly improve the dispersion, infiltrating property and operability of the fiber, and obtains the continuous fiber reinforced thermoplastic composite material prepreg which has uniformly dispersed and completely soaked fiber.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

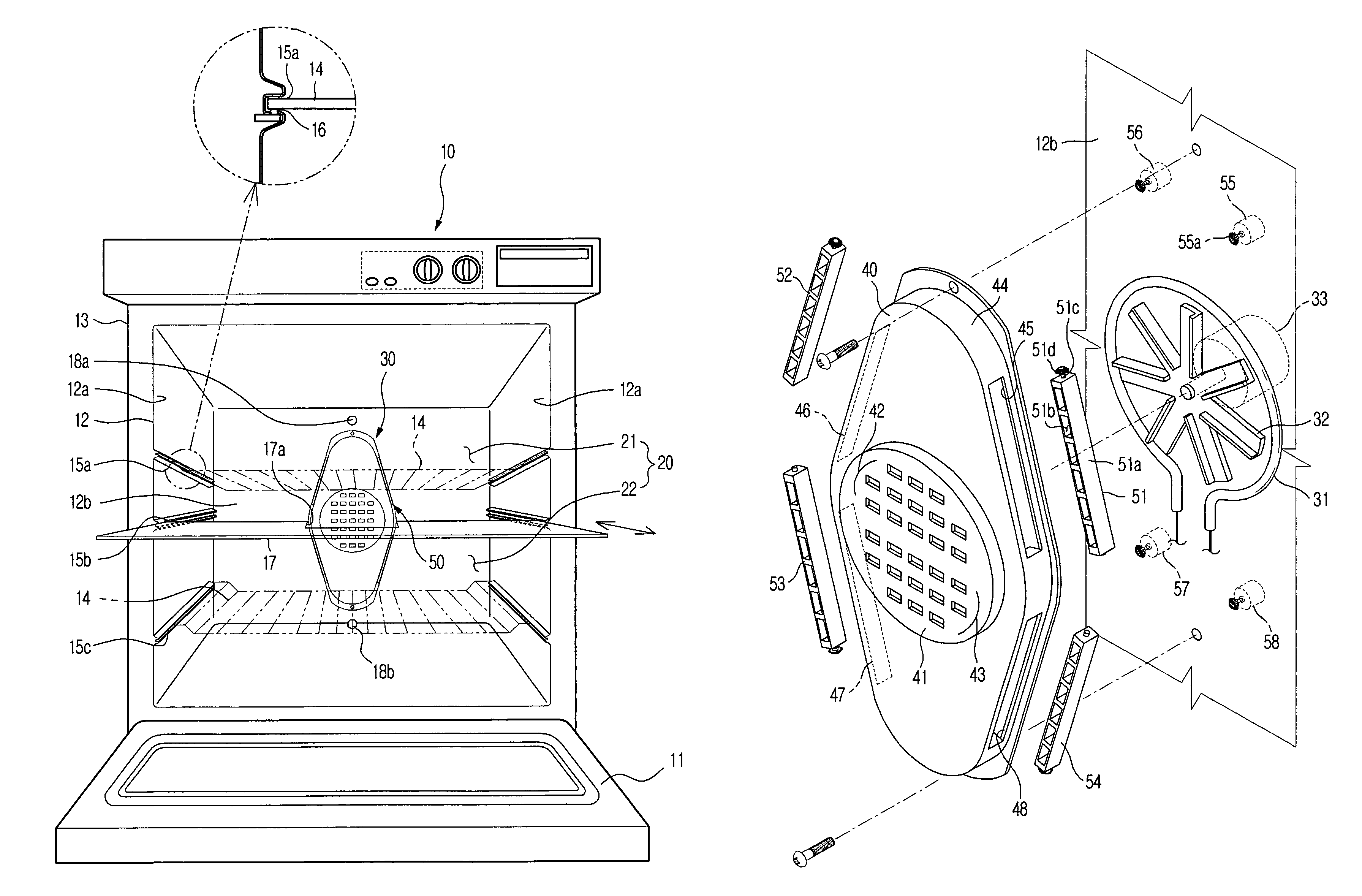

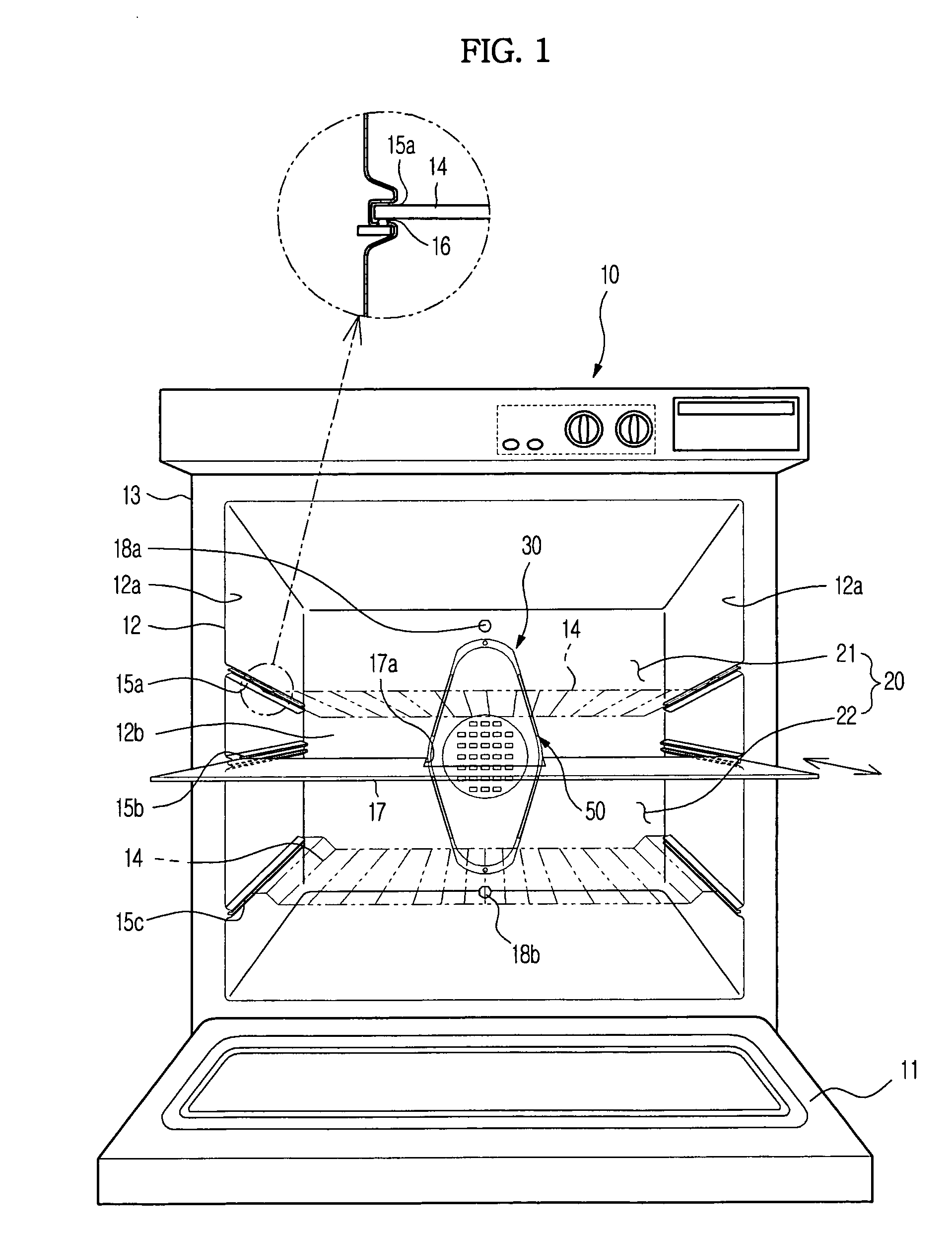

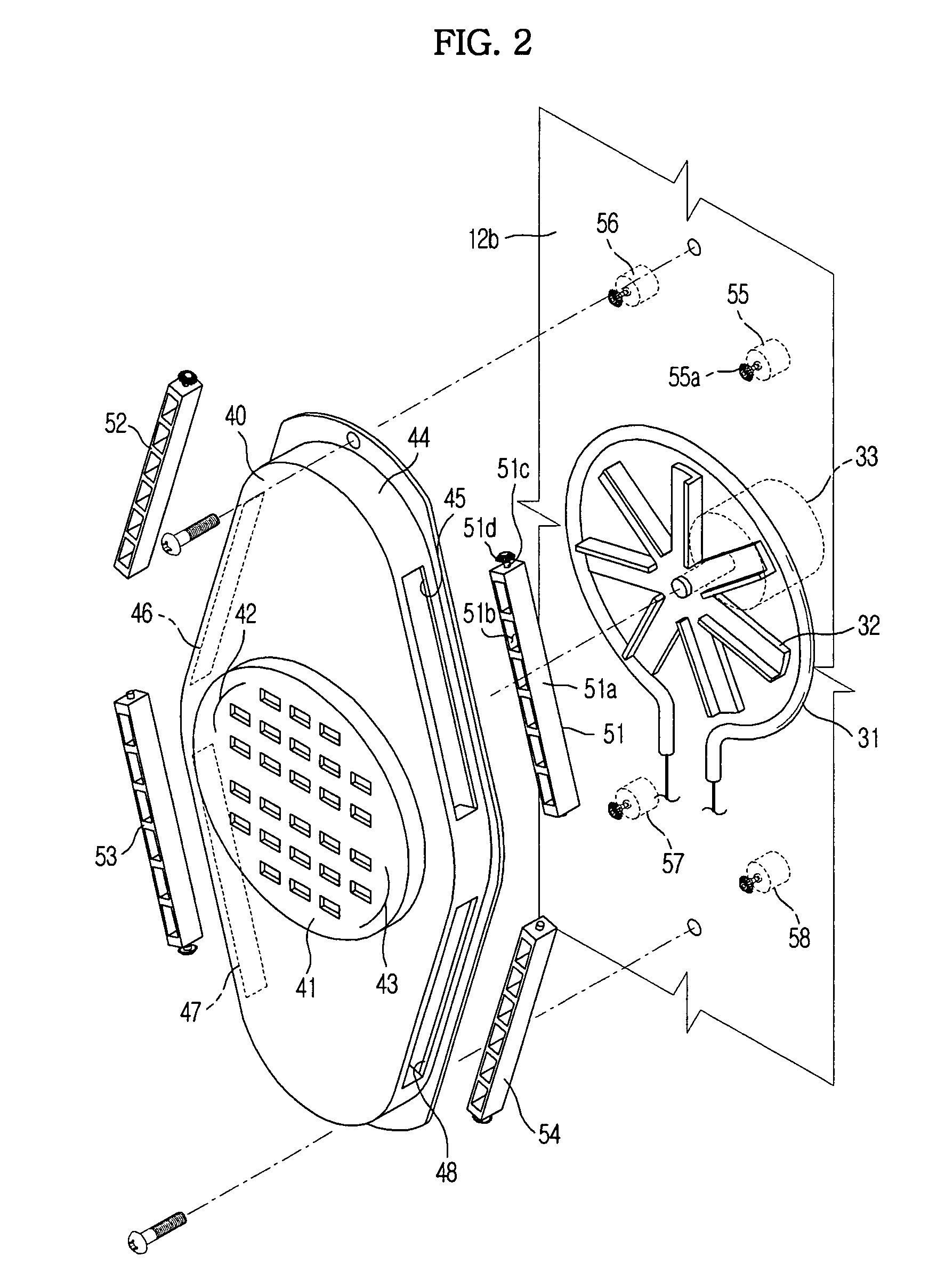

Cooking apparatus and method for controlling the same

InactiveUS7766003B2Uniform temperature distributionAvoid dischargeSelf-cleaning stoves/rangesElectrical heating fuelProcess engineering

A cooking apparatus to change the direction of hot air to be fed into a cooking chamber. The cooking apparatus includes a cooking chamber, a hot-air feeder to feed hot air into the cooking chamber, and an air-direction regulator to change a direction of the hot air fed from the hot-air feeder.

Owner:SAMSUNG ELECTRONICS CO LTD

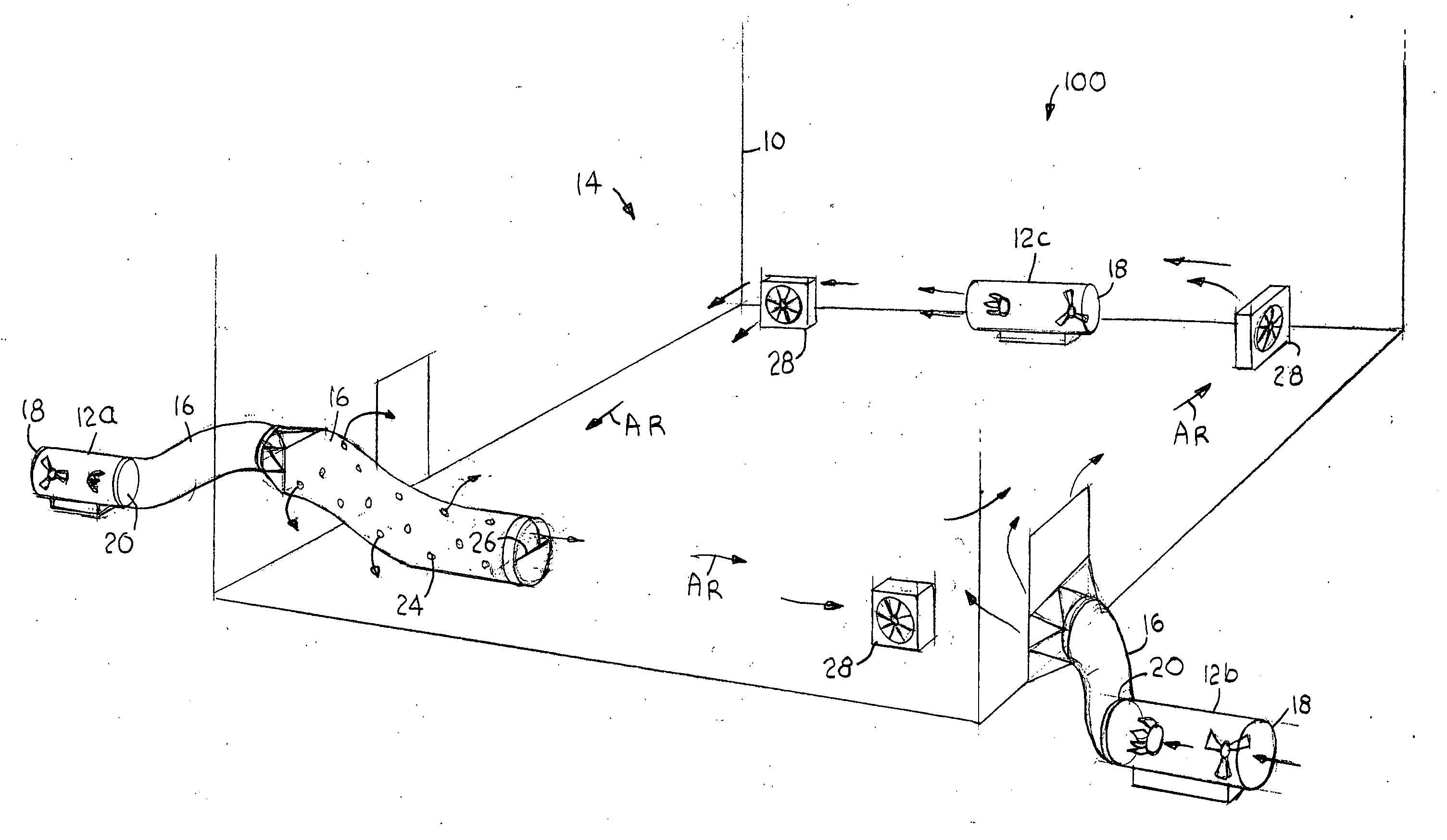

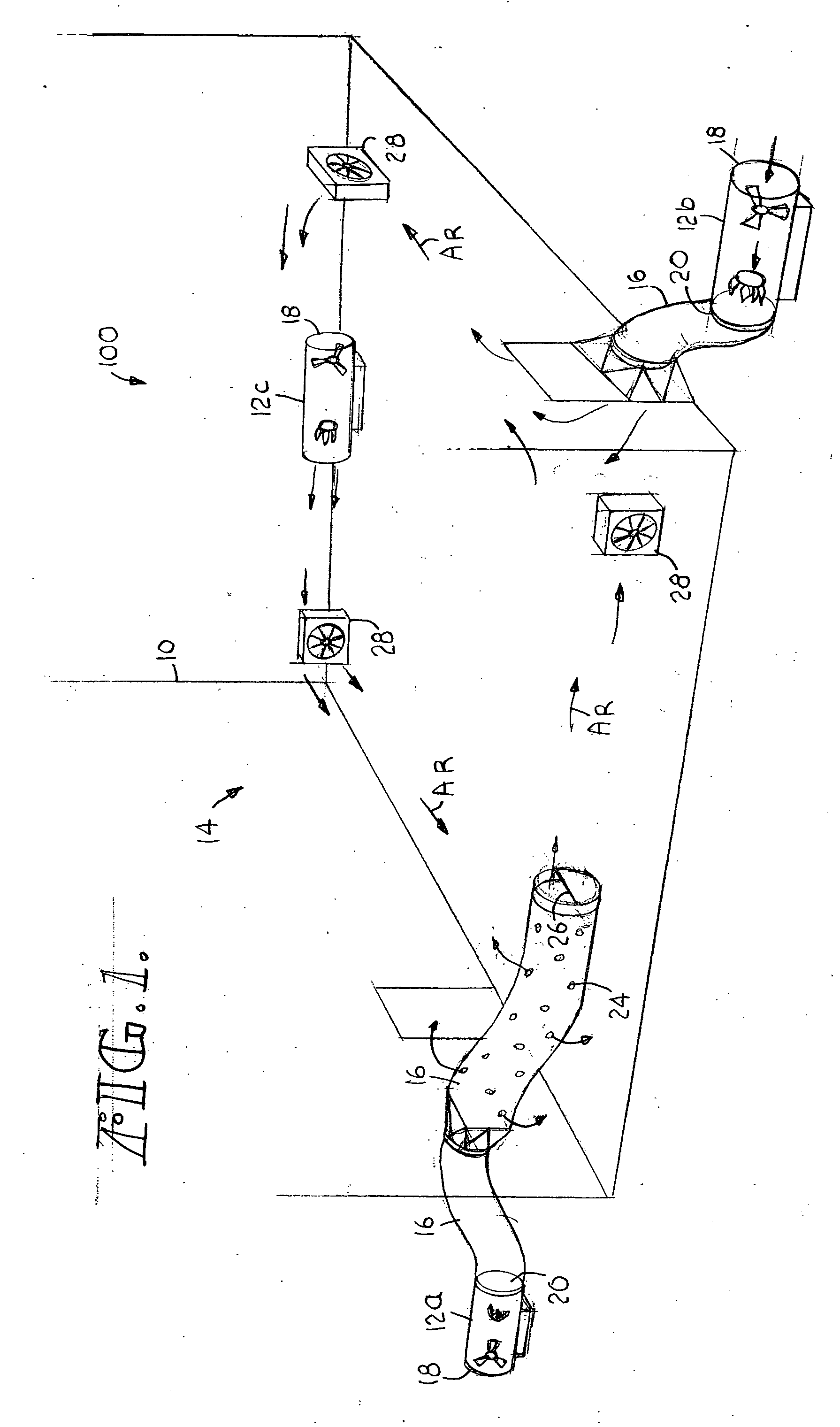

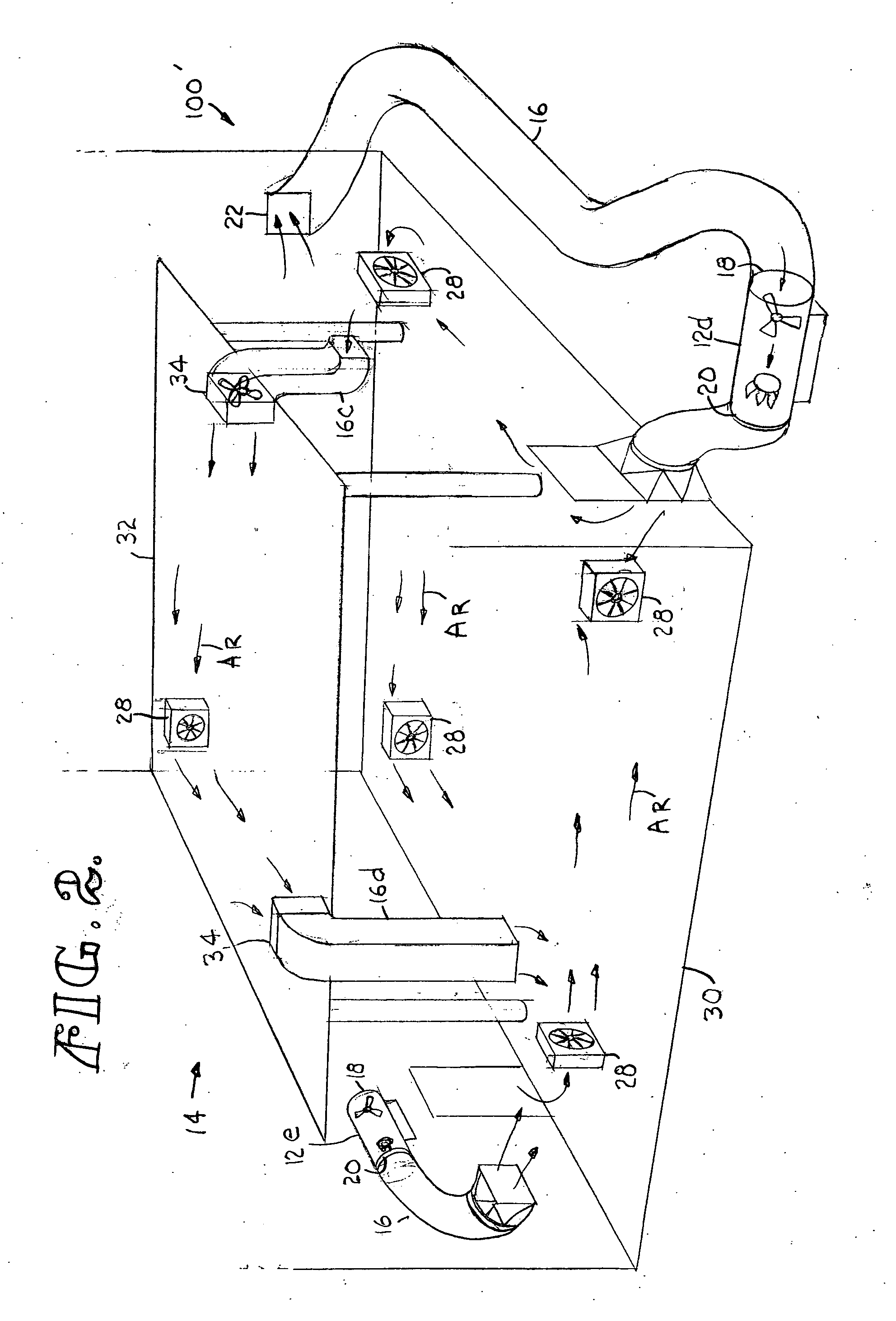

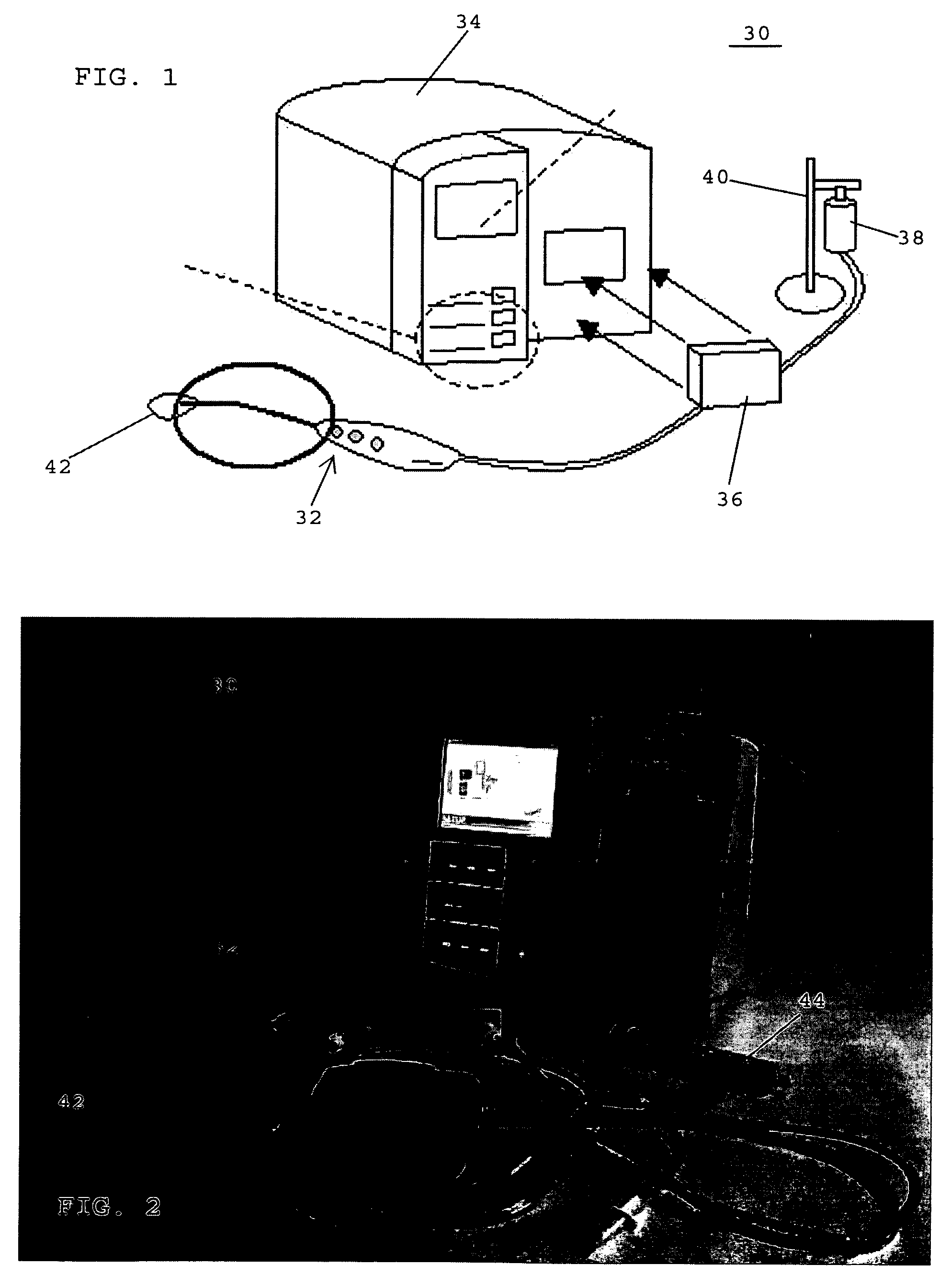

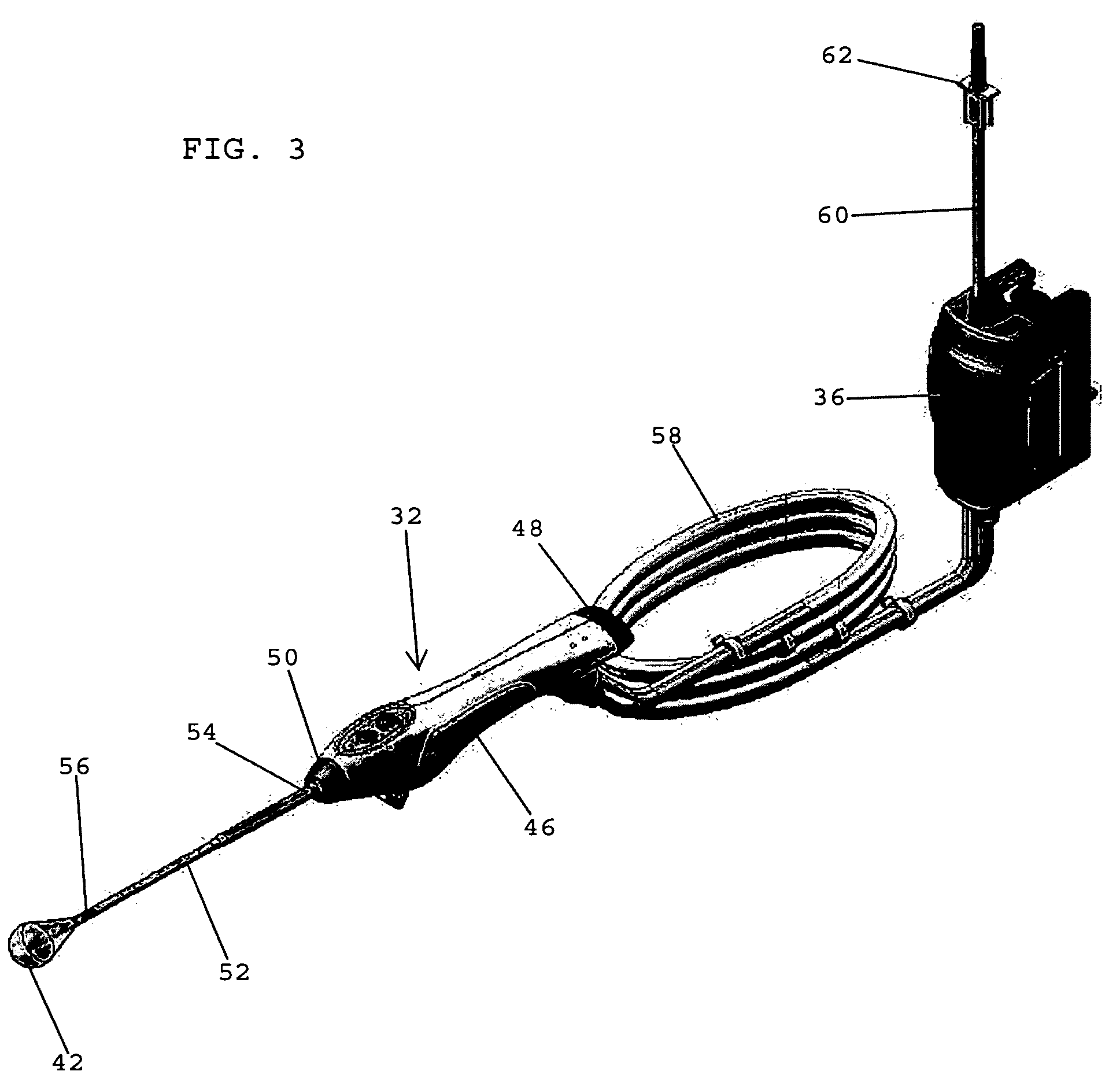

Method of extermination utilizing heated air

InactiveUS20050246942A1Conducive to pest controlUniform temperature distributionHot-air central heatingOther heat production devicesTemperature stratificationEngineering

A method of exterminating organisms is provided utilizing heated circulating air. First, a determination is made as to which enclosed areas of the building or other structure are to undergo extermination. This step defines an application zone. Next, a desired elevated temperature limit is established for heated air that is to be circulated through the application zone. Heaters are provided in airflow communication with the application zone, and circulation fans are positioned throughout the application zone to move the heated air for proper heat distribution. The heaters utilize an amount of recirculated air already present in the application zone to cut down on the amount of energy needed to raise the air temperature within the application zone towards the desired elevated temperature limit, and to eliminate the need for high CFM airflow heaters to achieve air temperature elevation. The temperature at various nodes within the application zone may be monitored to allow personnel to redirect circulating airflow within the application zone to balance out areas of higher air temperature with areas of lower air temperature. The method takes advantage of convection heat transfer to raise the temperature evenly within an application zone, minimizing temperature stratification which could result in ineffective pest extermination and / or damage to equipment and facilities.

Owner:IND FUMIGANT

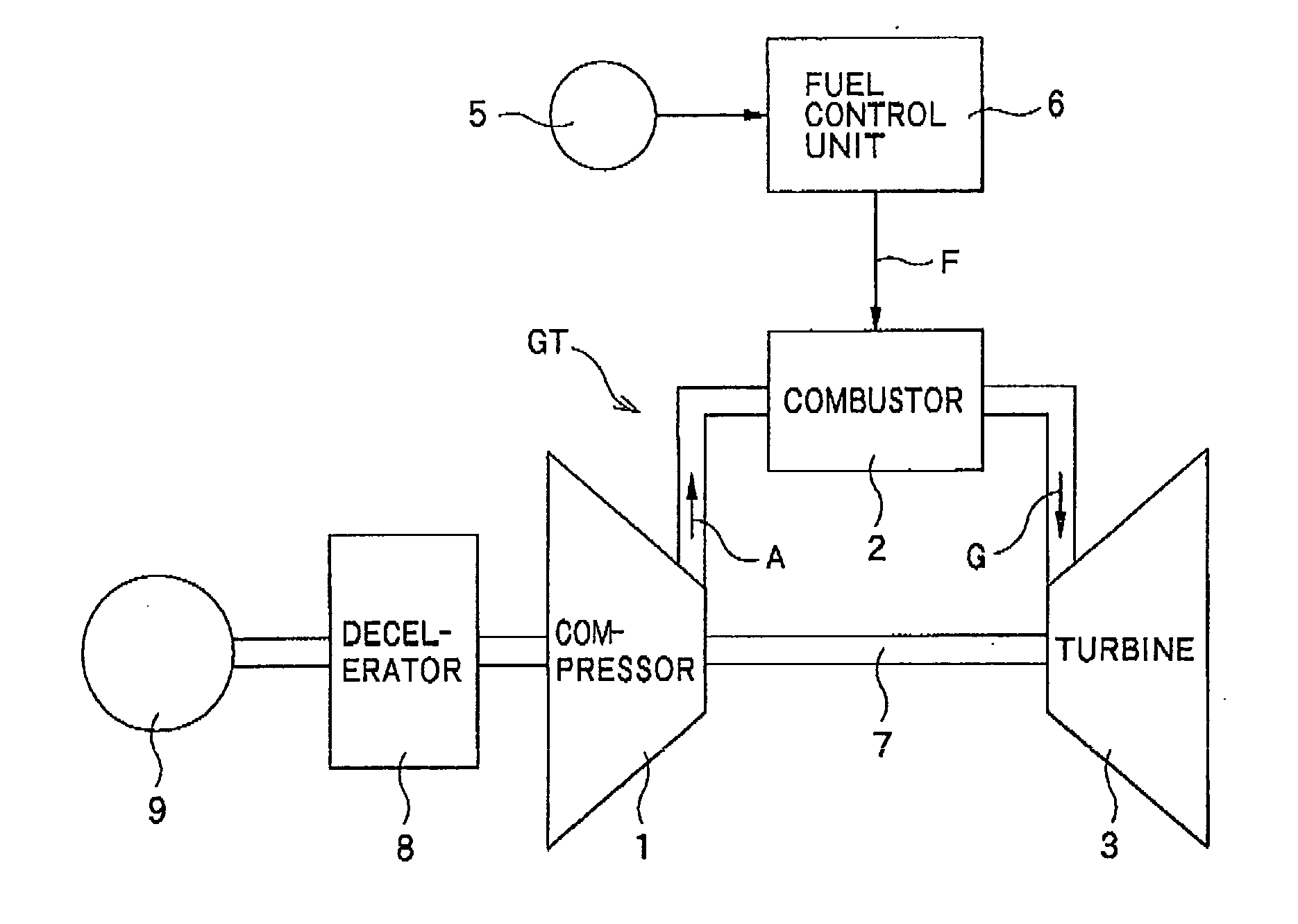

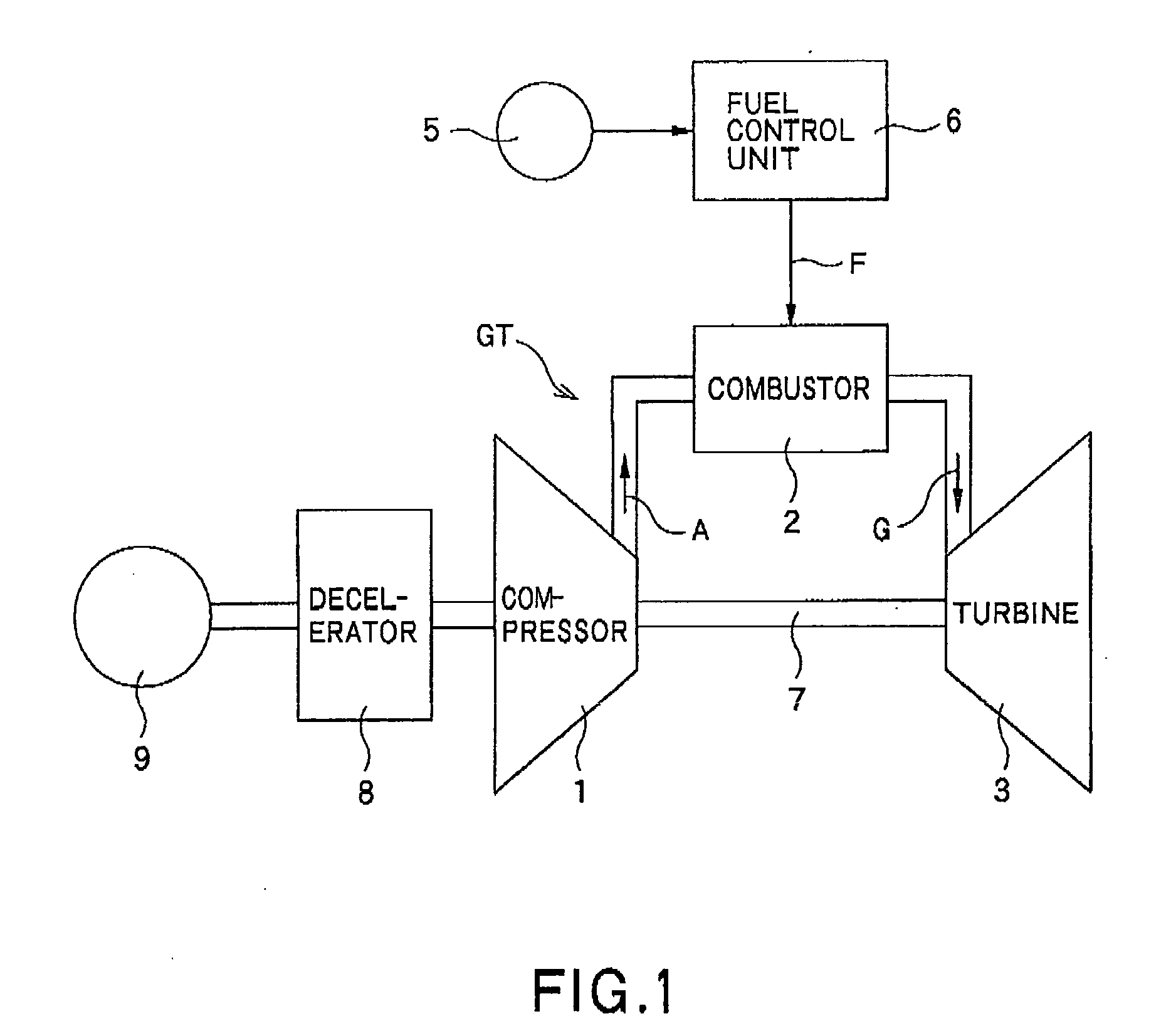

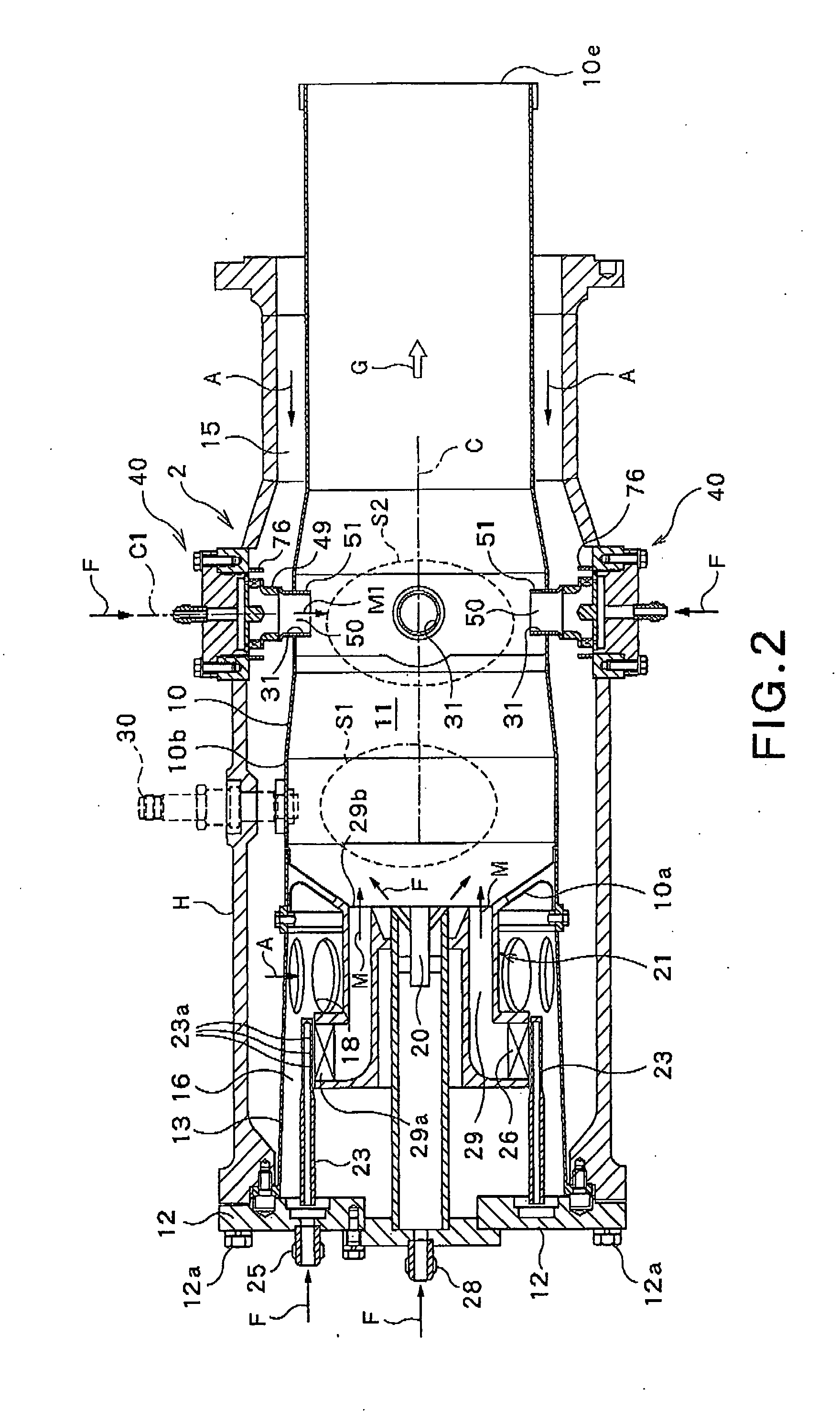

Gas turbine combustor

ActiveUS20100229557A1Reduce unevennessMixing effectContinuous combustion chamberTurbine/propulsion fuel supply systemsCombustorCombustion chamber

This invention provides a gas turbine combustor including: a main burner at a head portion of a combustor cylinder; and a pre-mixing type supplemental burner at a downstream portion of the combustor cylinder and extending through a circumferential wall thereof. The supplemental burner includes: an introducing passage configured to deflect a part of the compressed air radially inward, the compressed air flowing from an air passage between the circumferential wall of the combustor cylinder and a housing surrounding the circumferential wall toward the head portion of the combustor cylinder, and introduce the compressed air into the combustor cylinder; and a fuel nozzle configured to supply the fuel from fuel injection holes to the compressed air introduced into the introducing passage to produce a pre-mixed gas in the introducing passage.

Owner:KAWASAKI HEAVY IND LTD

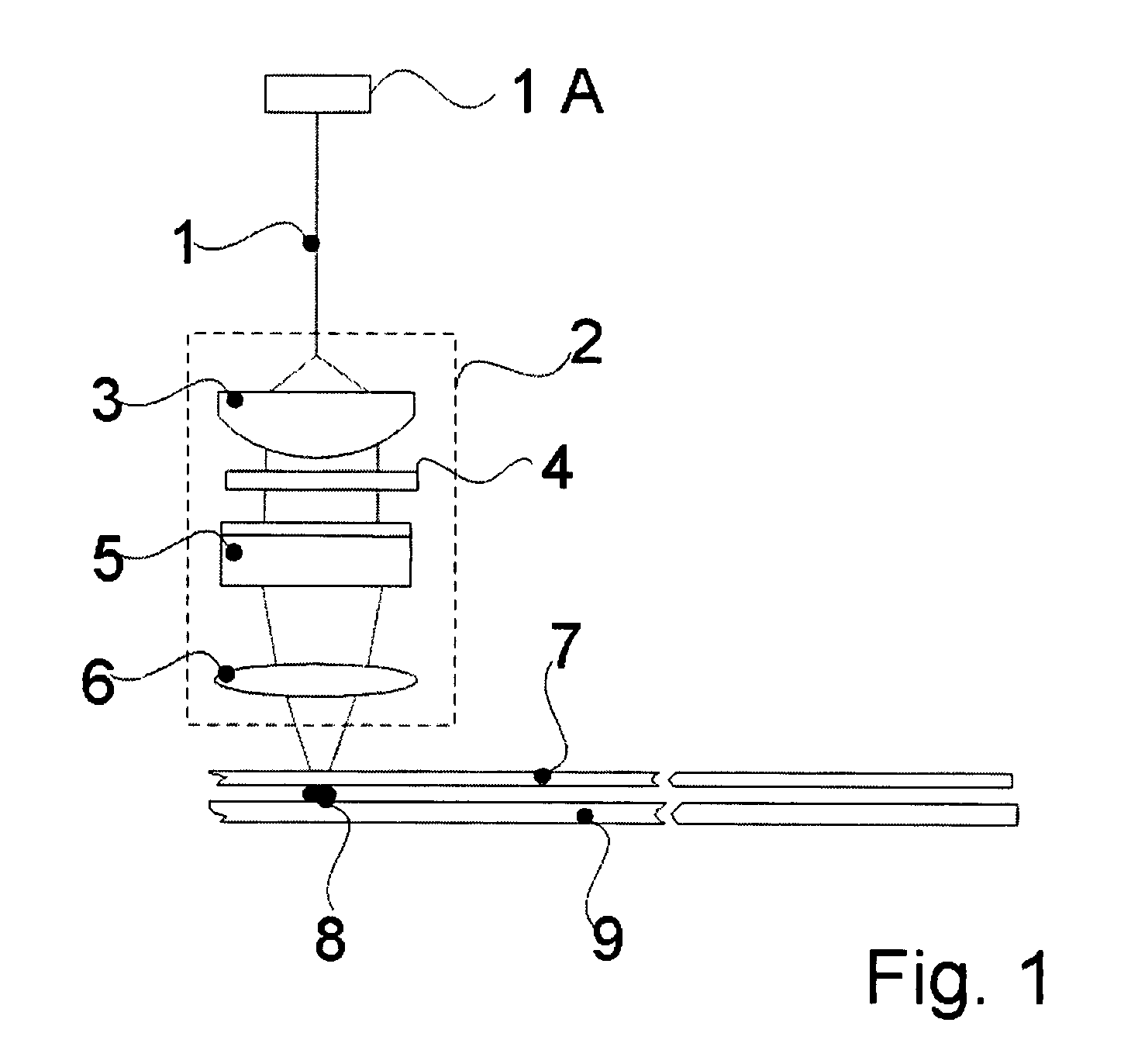

Method and apparatus for frit sealing with a variable laser beam

InactiveUS20090086325A1Uniform temperature distributionImprove overall utilizationDiffusing elementsElectroluminescent light sourcesFritLight beam

A beam shaper is implemented to seal an OLED. The beam shaper comprises a first and second lens and a beam shaper. Changing the relative position of the first, second lens and beam shaper relative to each other enables the beam shaper to generate laser beams with different shapes and intensity profiles.

Owner:CORNING INC

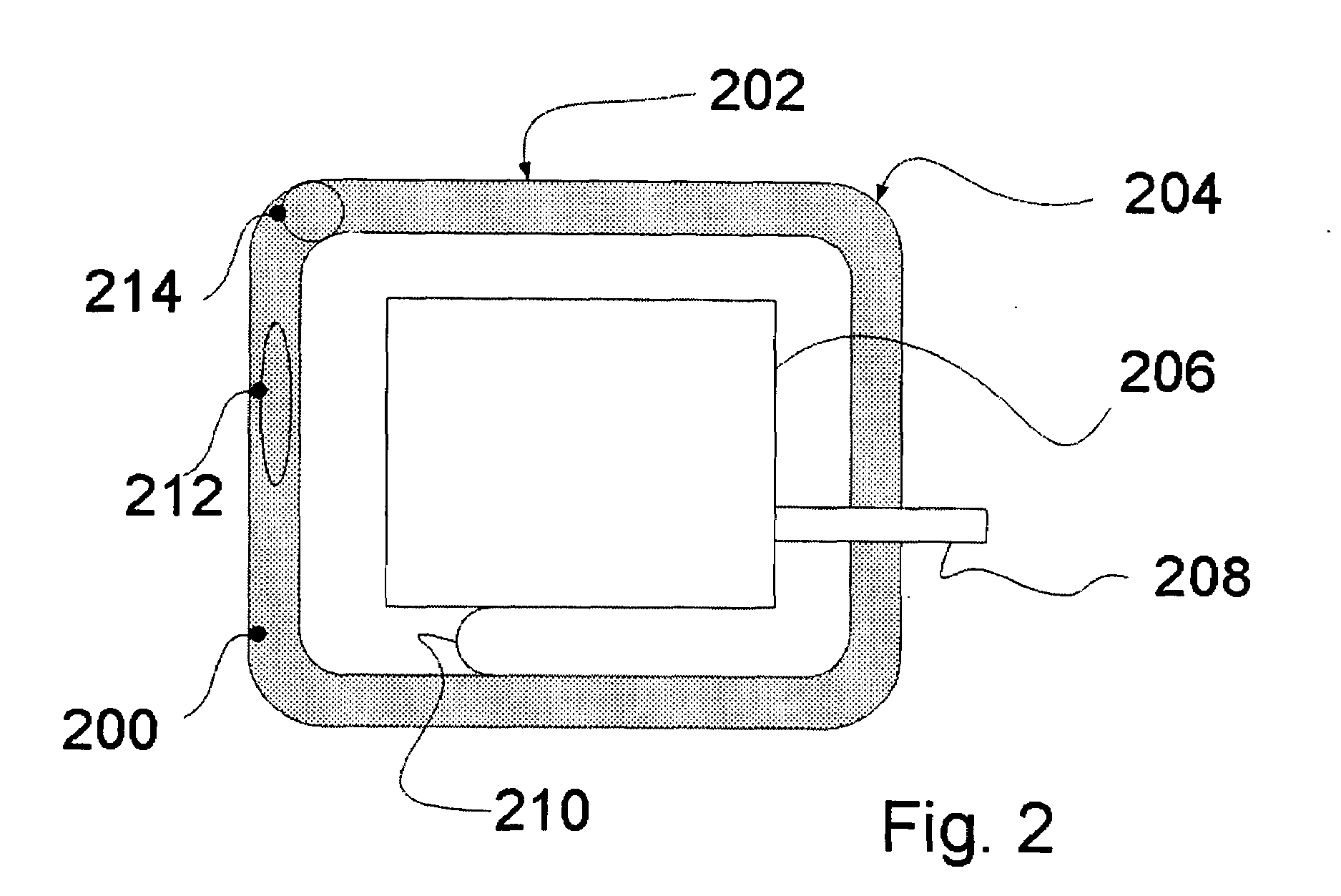

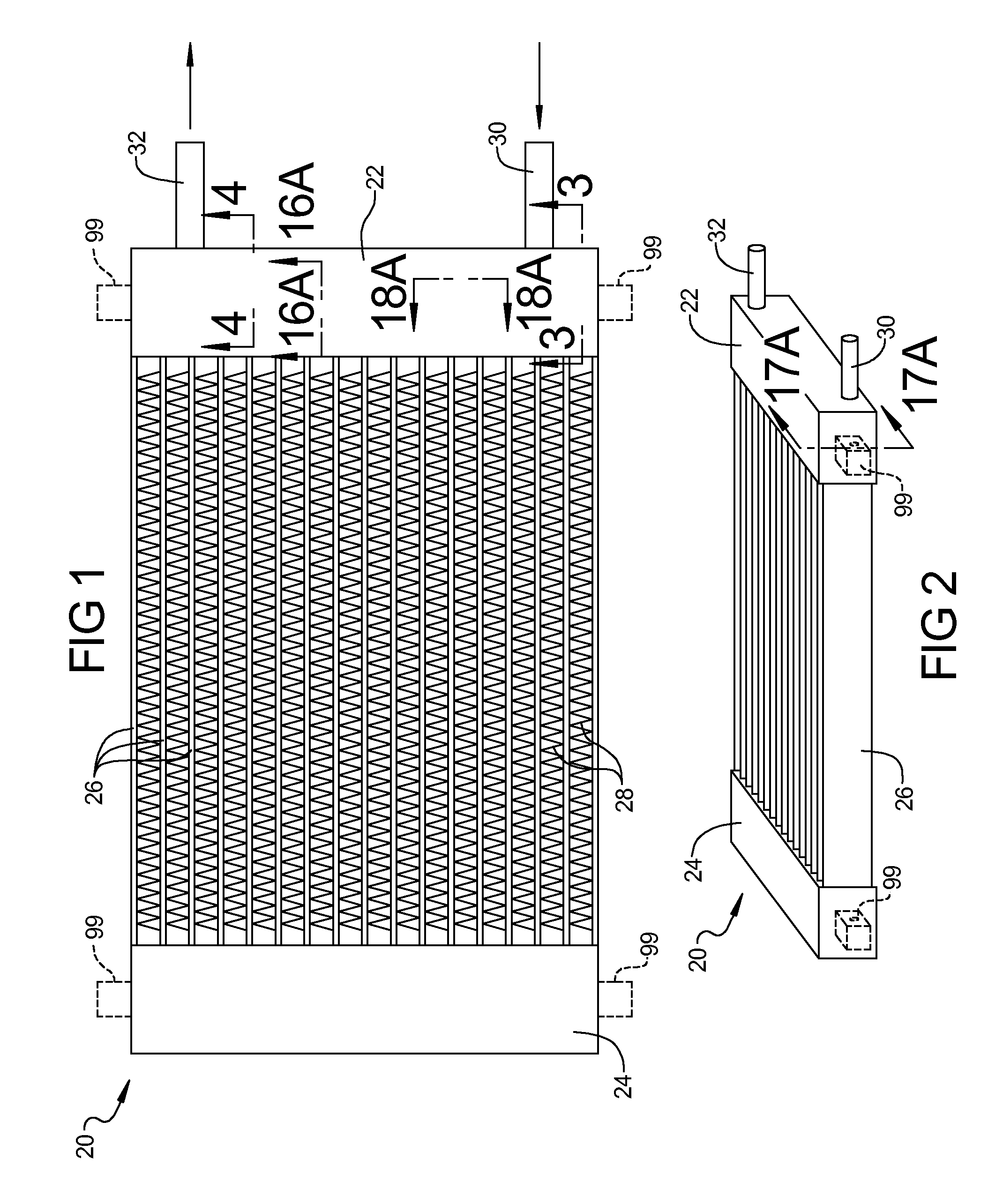

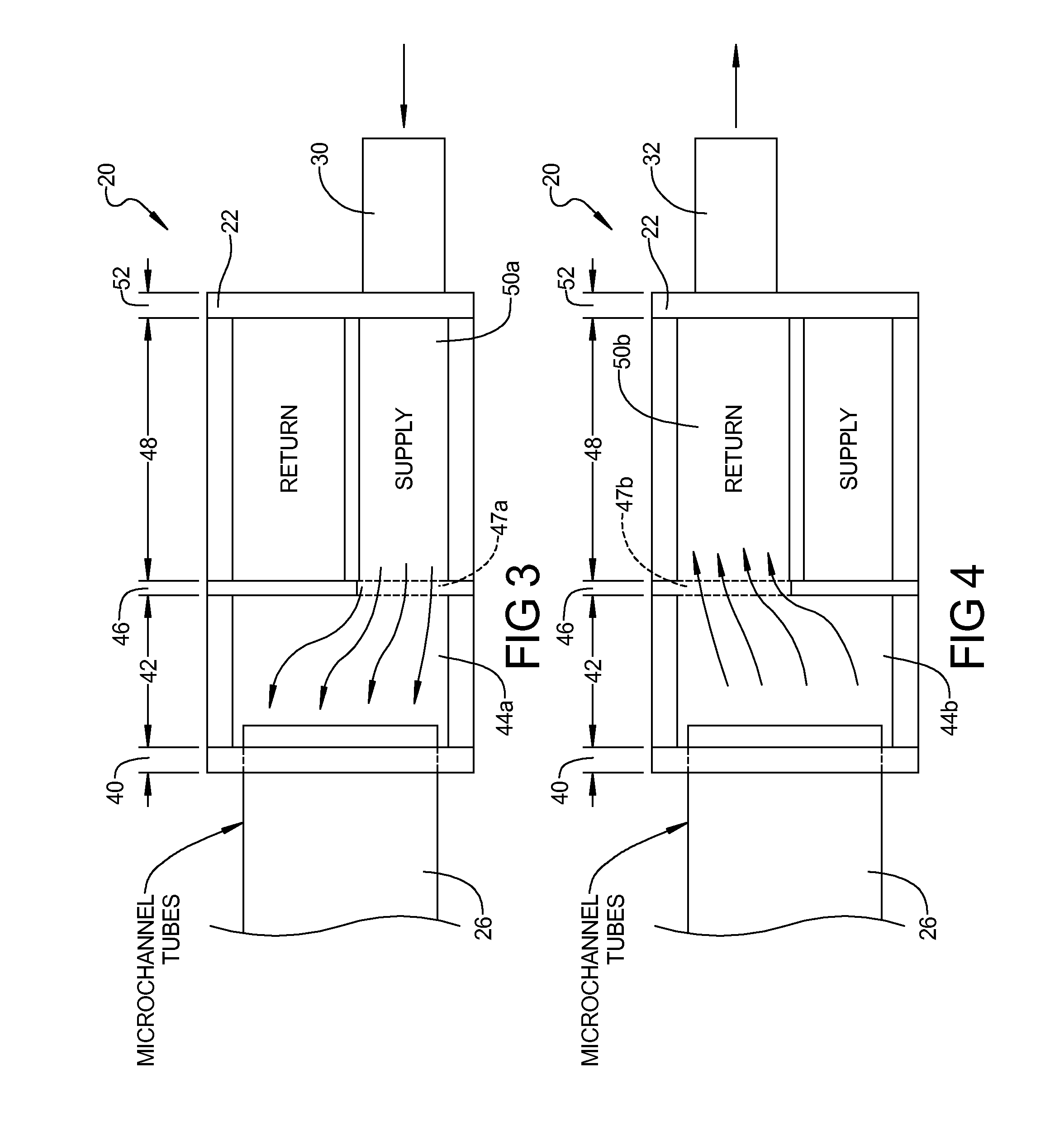

Laminated sheet manifold for microchannel heat exchanger

ActiveUS20090211743A1Easy to useLimited space availableStationary conduit assembliesHeat exchanger casingsPlate heat exchangerCoolant flow

A heat exchanger can have a manifold which includes a plurality of laminated sheets that allow a customization of the heat exchanger. The design can allow for a more optimal flow of coolant to areas of high load, thereby making the temperature distribution across the heat exchanger more uniform, or intentionally non-uniform. Furthermore, the laminated sheets can allow multiple circuits to be employed in the heat exchanger such that different coolants can be utilized therein and maintained separate from one another. The tubes can be microchannel tubes. A single set of manifolds can be used with multiple heat exchanger cores to provide a more compact heat exchanger. Mounting features can be integral with a group of the sheets.

Owner:VERTIV CORP

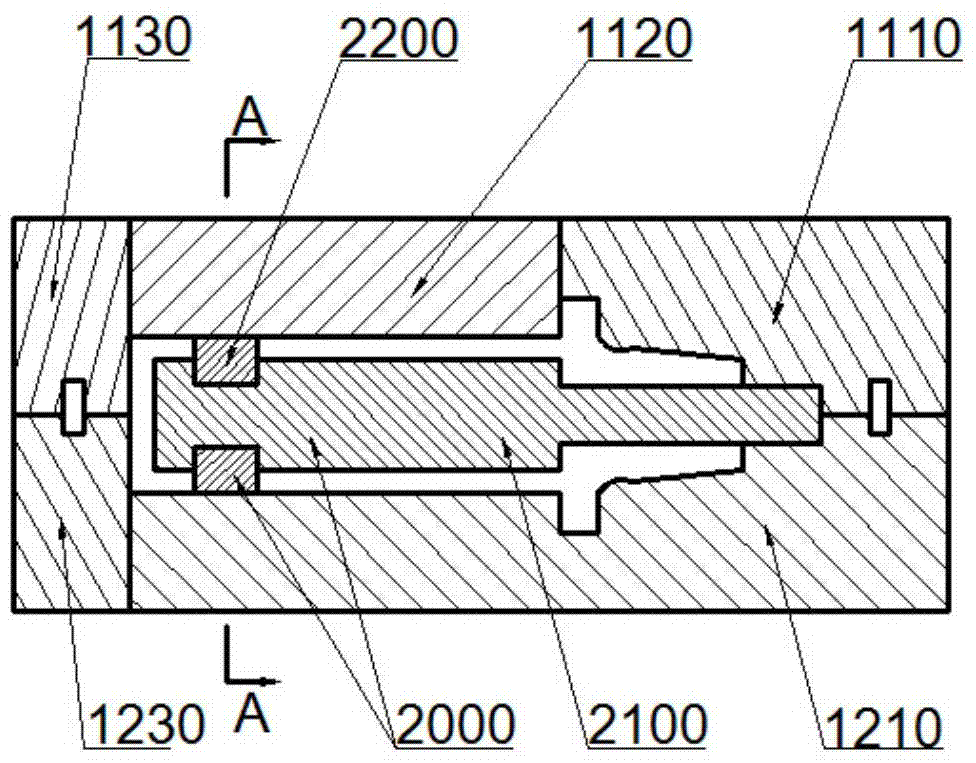

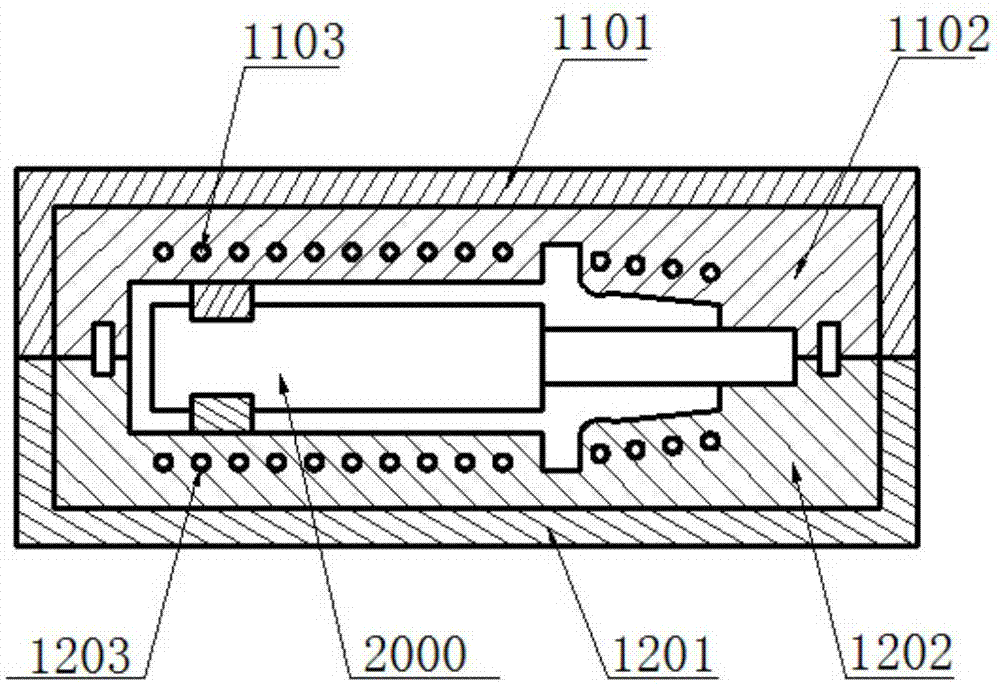

Wax injection mold for investment casting of hollow turbine blades and method for rapidly manufacturing wax injection mold

The invention discloses a wax injection mold for investment casting of hollow turbine blades and a method for rapidly and accurately manufacturing the wax injection mold. The mold consists of a cavity mold, a mold core and an accessory structure, wherein the cavity mold comprises an upper mold and a lower mold of a combined structure; each mold block forming the cavity mold consists of an external aluminum mold frame, an internal cast zinc alloy inlay and a conformal cooling copper pipe embedded into the inlay; a mold core positioning piece which can be decomposed at a high temperature is arranged on a longitudinal rib of the mold core; and water-soluble core blocks used for forming exhaust openings in the rear edges of the turbine blades are arranged on rear edge ribs of the mold core. The matching precision of the mold core positioning piece and the cavity mold is guaranteed by adopting a cavity mold interior running-in method, and the matching precision of the water-soluble core blocks and the cavity mold is guaranteed by adopting a cavity mold interior adhesion method. The wax injection mold disclosed by the invention is low in manufacturing cost and short in period, and the high wax pattern precision and core positioning precision can be obtained.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Heater and heating device with heaters

InactiveUS20060197454A1Uniform lossReduce device sizeLamp incadescent bodiesSemiconductor/solid-state device manufacturingElectrical and Electronics engineering

A heating device in which uniform heating of an article to be processed is possible even in the case a temperature change which leads to a loss of the uniformity of the temperature distribution in a narrowly delineated area, and in which a reduction in the size of the device is possible. The heating device has a plurality of heaters, each heater having a single bulb of transparent material in which there is a filament that is divided in the axial direction into several filament parts and the respective filament parts are supplied with power independently of each other.

Owner:USHIO DENKI KK

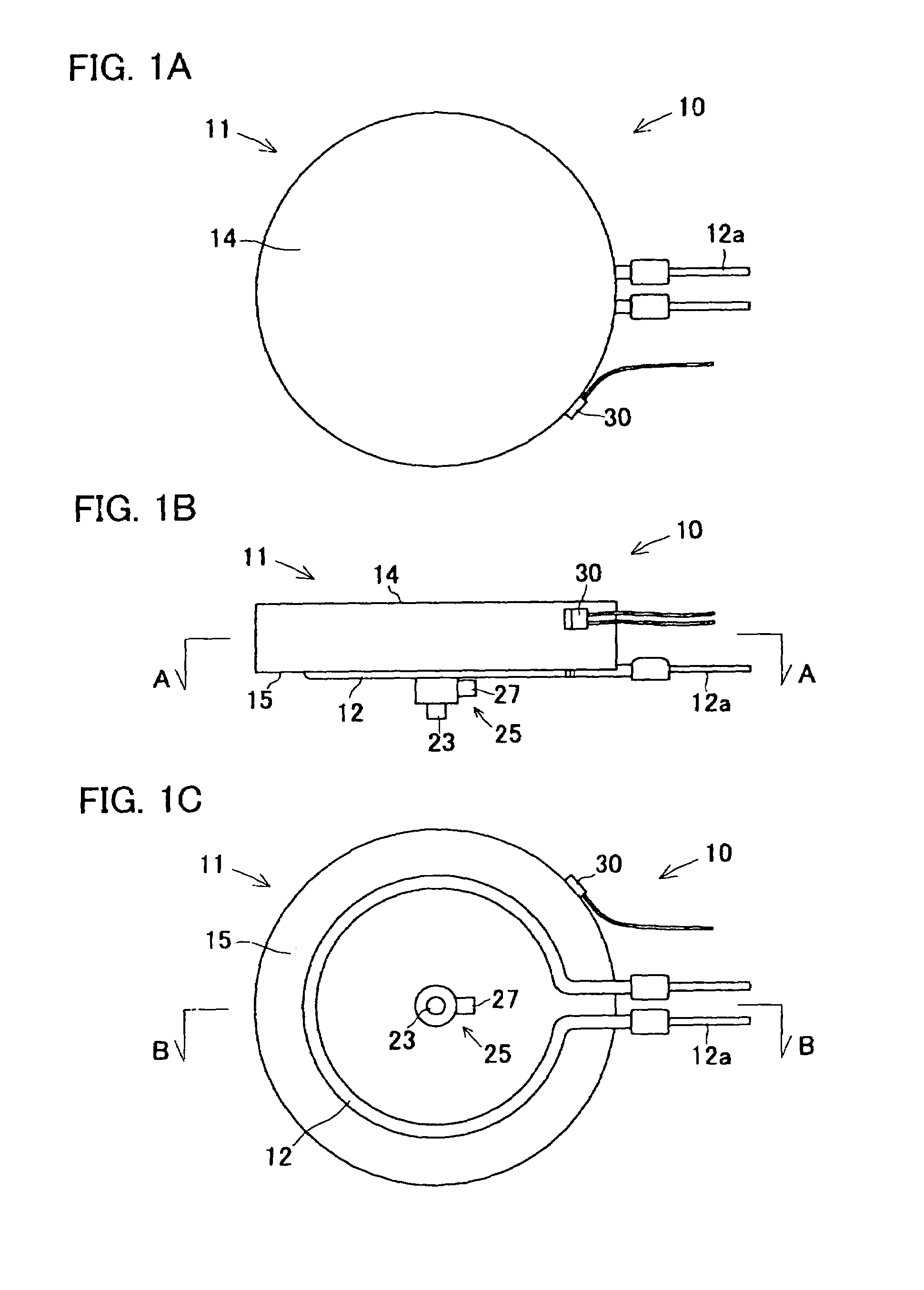

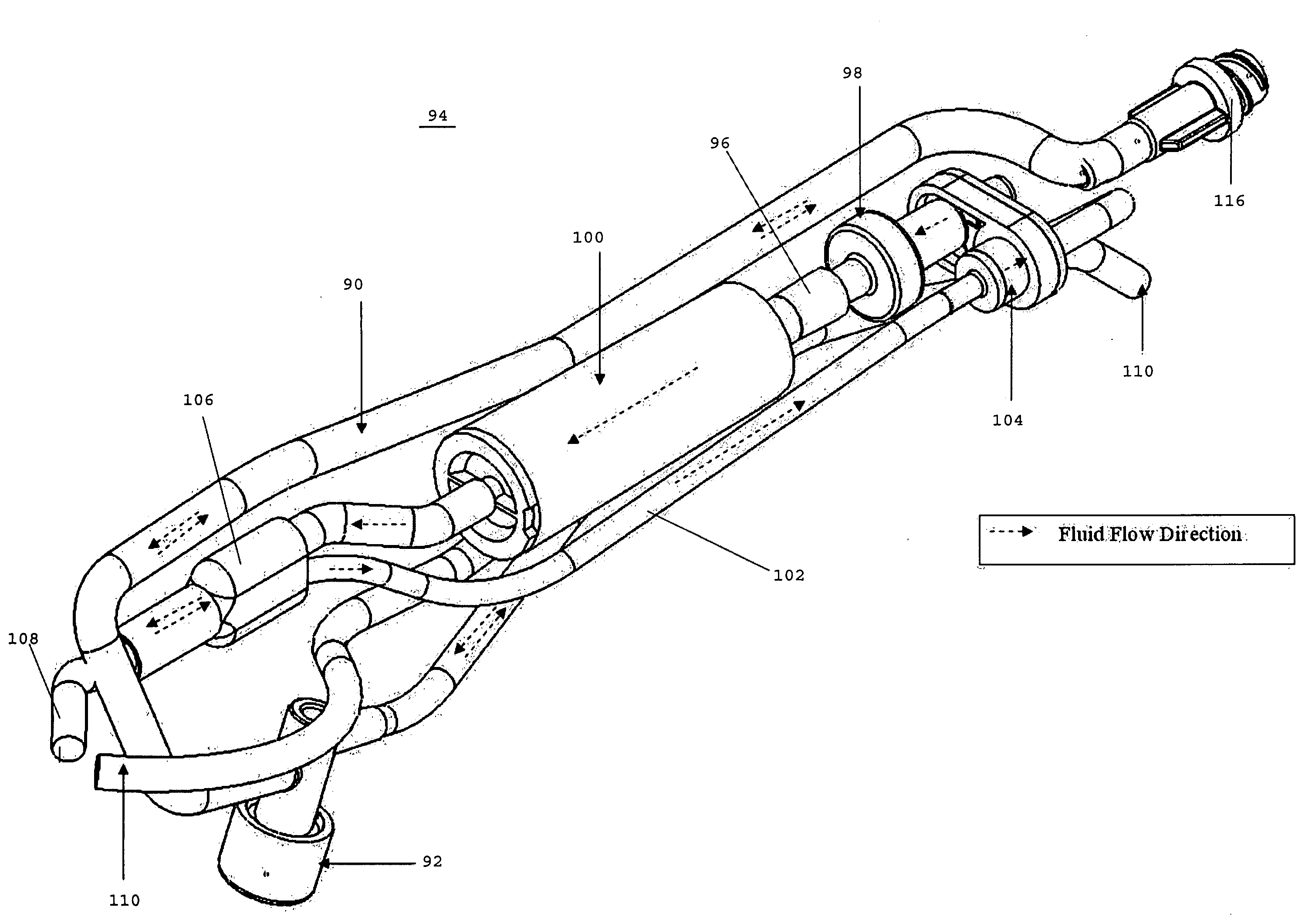

Balloon catheter systems for treating uterine disorders having fluid line de-gassing assemblies and methods therefor

InactiveUS20100004595A1Effective heat absorptionEfficient heatingStentsBalloon catheterUterine DisorderDisease

A system for treating uterine disorders includes a catheter with a cannula having a proximal end and a distal end, and a degassing system in communication with the distal end of the cannula. The degassing system has a fluid insertion path having a first check valve and a gas filter, and a fluid extraction path that is separate from the fluid insertion path and includes a second check valve. The catheter may include an inflatable balloon secured to the distal end of the cannula with the degassing system in communication with the inflatable balloon. In one embodiment, a heating assembly is disposed inside the inflatable balloon for heating the fluid introduced into the balloon.

Owner:ETHICON INC

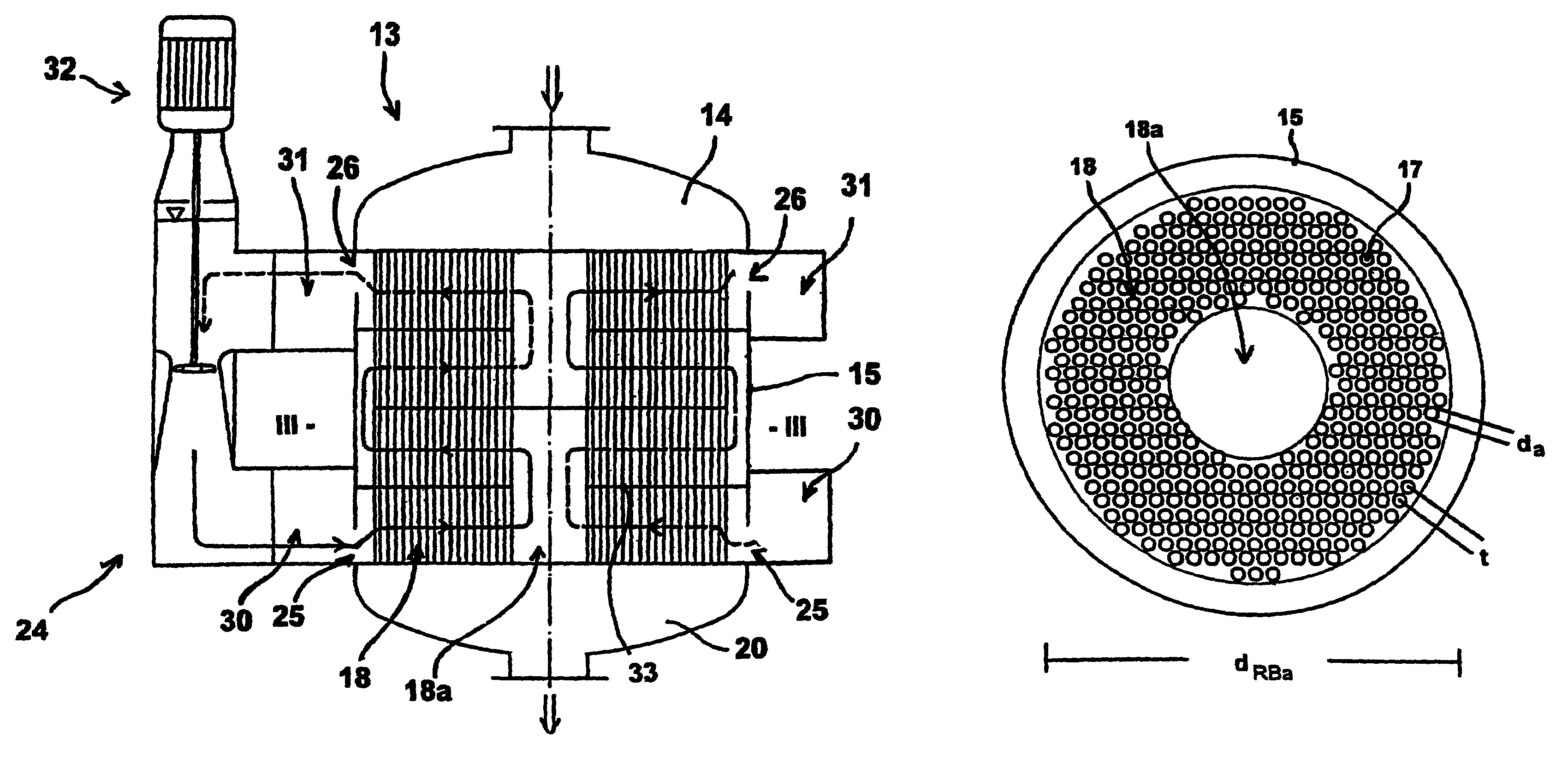

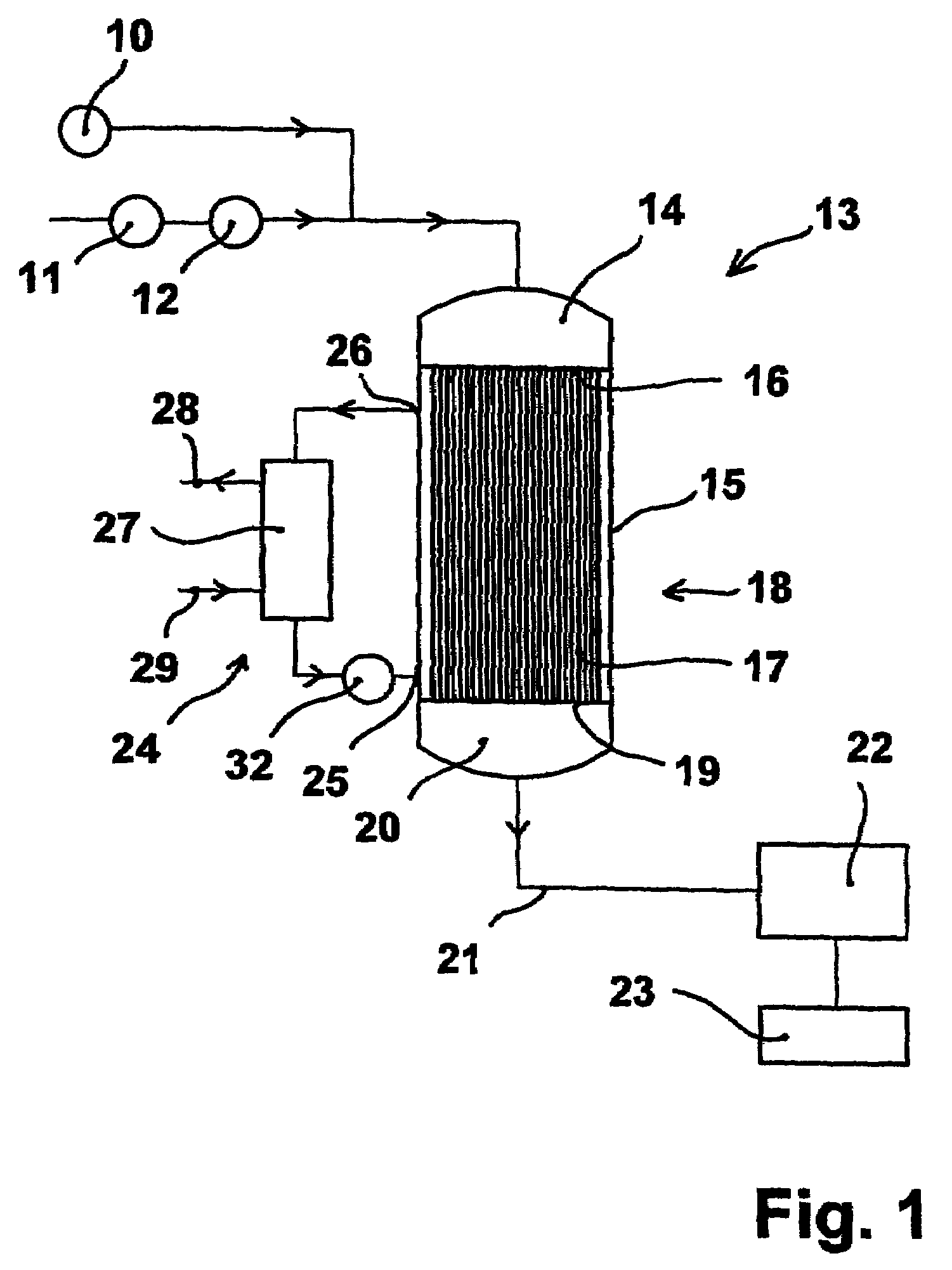

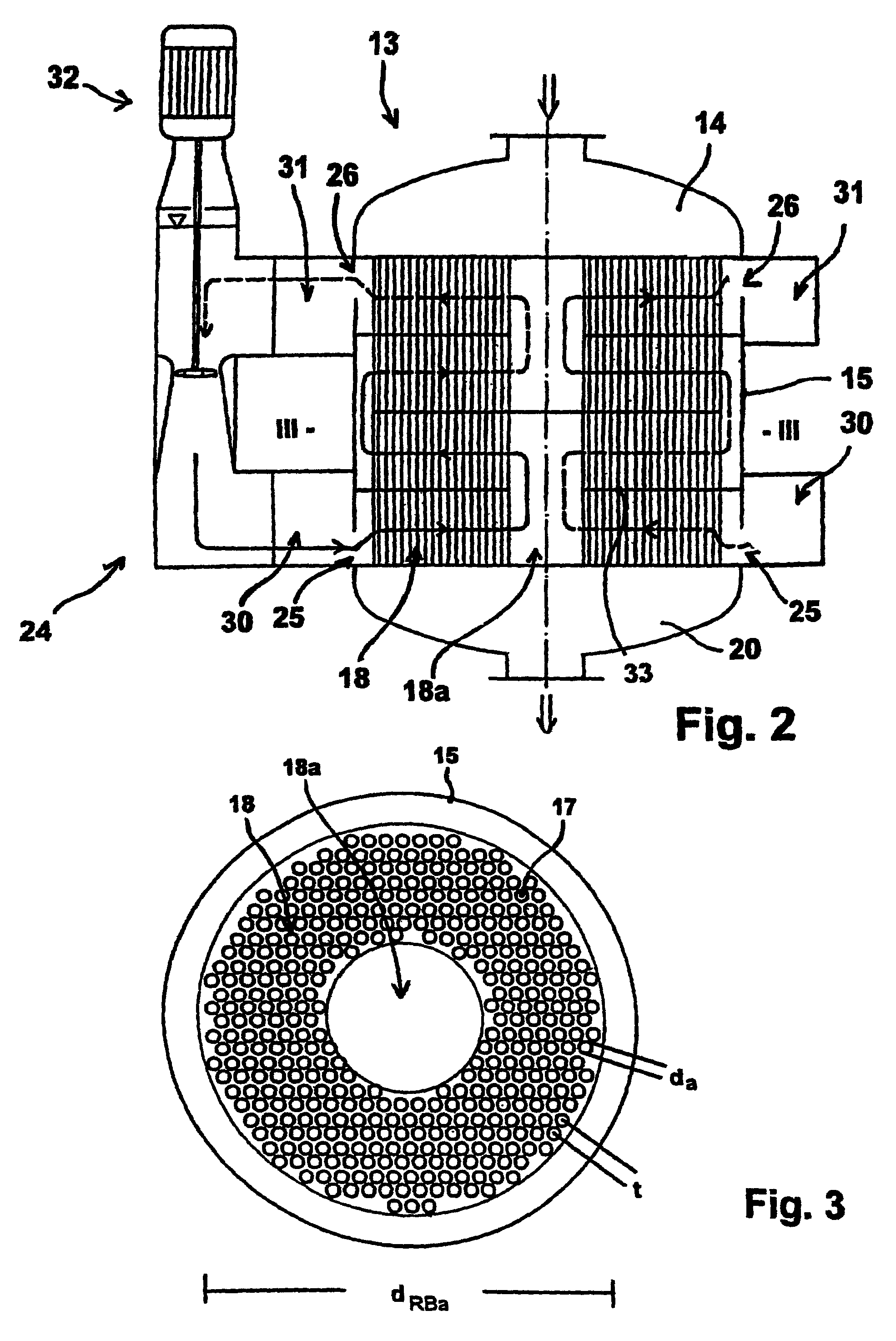

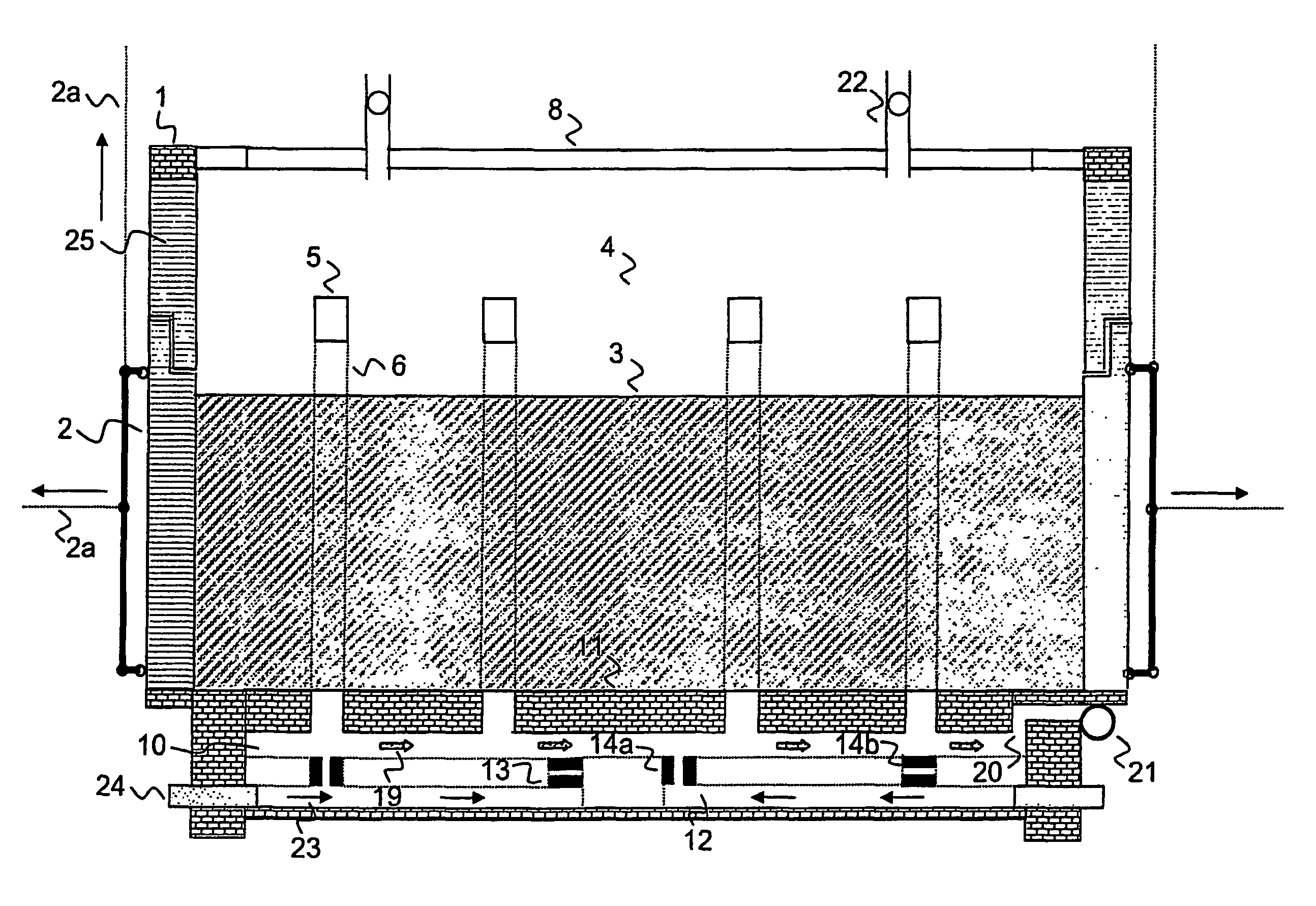

Multi-tube fixed-bed reactor, especially for catalytic gas phase reactions

InactiveUS7226567B1Uniform distribution of temperatureReduce heat transferOrganic compound preparationChemical/physical/physico-chemical stationary reactorsMaleic anhydrideAcrolein

A multitube fixed bed reactor and the use of such a reactor for carrying out catalytic gas-phase reactions, in particular for carrying out exothermic and endothermic catalytic gas-phase reactions such as the preparation of phthalic anhydride (PA), acrylic acid, methacrylic acid (MAA), acrolein, maleic anhydride (MA), glyoxal, phosgene, hydrocyanic acid or vinyl formamide (VFA). In a relatively large multitube reactor in which a large amount of heat of reaction is generated owing to the numerous catalyst tubes (17) and has to be removed, it is proposed that the ratio of tube spacing t to external tube diameter da be made dependent on the reactor diameter or on the external tube bundle diameter dRBa. At an external diameter of the catalyst tube bundle (18) of more than 4 meters, a ratio of tube spacing d to external tube diameter da of at least 1.3 is preferred.

Owner:BASF SE

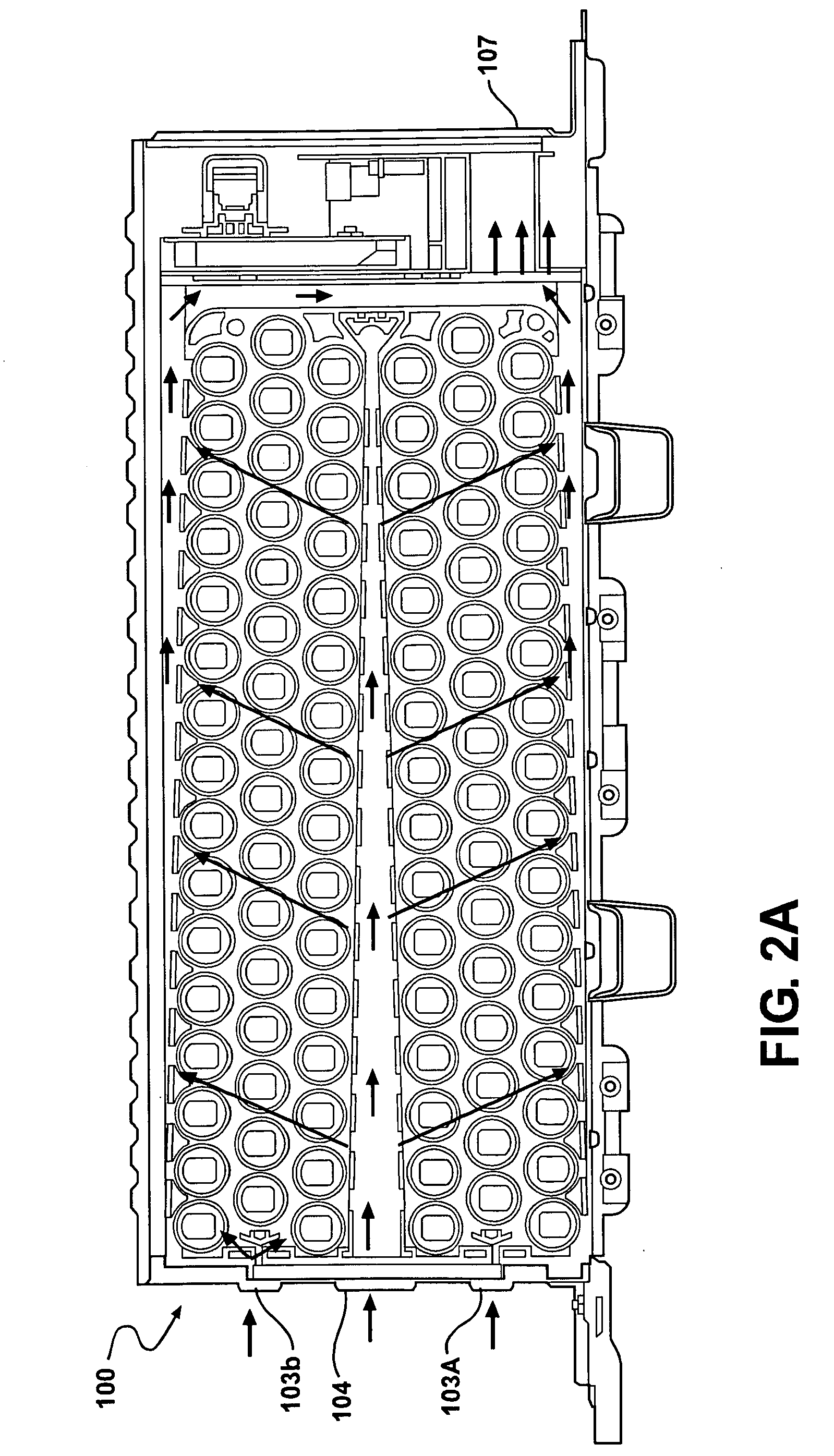

Battery pack

ActiveUS20090191452A1Efficient thermal managementImprove performanceCell temperature controlSecondary cells manufactureEngineeringElectrochemical cell

Disclosed herein is a multi-cell battery pack having optimal temperature distribution throughout the battery pack and optimal air flow through the battery pack. Disclosed herein is a battery pack which provides optimal temperature distribution throughout the battery pack, wherein maximum cell temperature (Tmax) and temperature differential amongst all cells in the battery pack (ΔTcell) are optimized for efficient thermal management providing safety, improved performance and extended life of the battery pack and electrochemical cells. Also disclosed herein is a battery pack which provides optimal flow through the battery pack and minimal pressure drop (ΔP) throughout the battery pack.

Owner:COBASYS LLC

Controllable air ducts for feeding of additional combustion air into the area of flue gas channels of coke oven chambers

ActiveUS9039869B2Reduce carbonizationGood heat distributionCombustible gas coke oven heatingCoke oven safety devicesBrickCombustion

A device for feeding and controlling secondary air from secondary air ducts into flue gas channels of horizontal coke oven chambers is shown. The flue gas channels are located underneath the coke oven chamber floor on which coal carbonization is realized. The flue gas channels serve for combustion of partly burnt coking gases from the coke oven chamber. The partly burnt gases are burnt with secondary air, thus heating the coke cake also from below to ensure even coal carbonization. Secondary air comes from the secondary air ducts connected to atmospheric air and to the flue gas channels. Controlling elements are mounted in the connecting channels between the flue gas channels and secondary air ducts which can precisely control the air flow into the flue gas channels. Thereby, it is possible to achieve a much more regular heating and heat distribution in coke oven chambers. The actual controlling devices in the connecting channels can be formed by turnable pipe sections, wall bricks, or metal flaps. It is particularly advantageous to utilize a hump-like facility (tabouret) which sits in the secondary air ducts and which is comprised of a tabouret plate with a central opening that is slid under the corresponding embranchment to regulate the gas stream. The controlling mechanism can be actuated manually, electrically, or pneumatically. Thereby, the controlling device can also be automated.

Owner:UHDE GMBH

Method of sheet billet continuously casting and rolling to produce thin strip steel coil

ActiveCN101108394AShort production processSave construction investmentMetal rolling arrangementsProduction lineStrip mill

A method of using thin plate adobe continuous casting and rolling to producing thin band steel coil is provided, which belongs to rolling metal at once after continuous casting, in particular relating to thin standard band steel production method. The invention is characterized in that: a conticaster, a swing shear, a roller-hearth type heating furnace, a scale breaker, a vertical miller, 7 mill groups, laminar flow cooling device and reeling machine are connected to a CSP produce line, the produce line adopts reasonable temperature system, rolling equipment, rolling way and combining with cooling after rolling, the molten steel after continuous casting is a casting adobe of 50 to 70mm thick and 900 to 1300 wide, after cutting, heating, scale breaking, proceed continuous rolling to form a thin band of 1.2 to 1.5mm thick and 900 to 1300 wide, then after cooling to reel steel coil. The production flow is short, the equipment is few, the investment is less and the running expense is low; The technics and equipment is reasonable and high efficient, double locomotive and double flow casting, heating by two furnaces, seven rolling machines roll continuously, the production is smooth and saves energy with high production efficiency; the product performance is even and stable, the board shape is regular with high accuracy and good surface quality.

Owner:MAANSHAN IRON & STEEL CO LTD

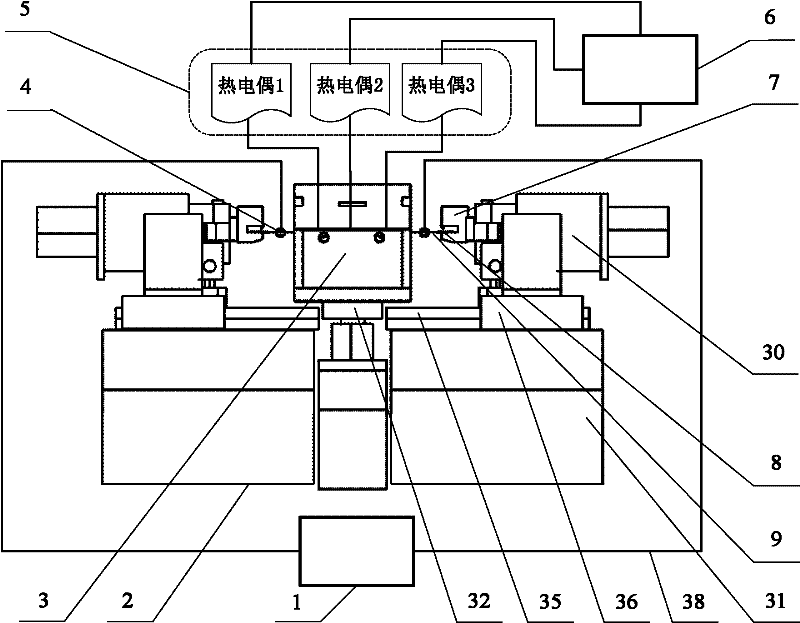

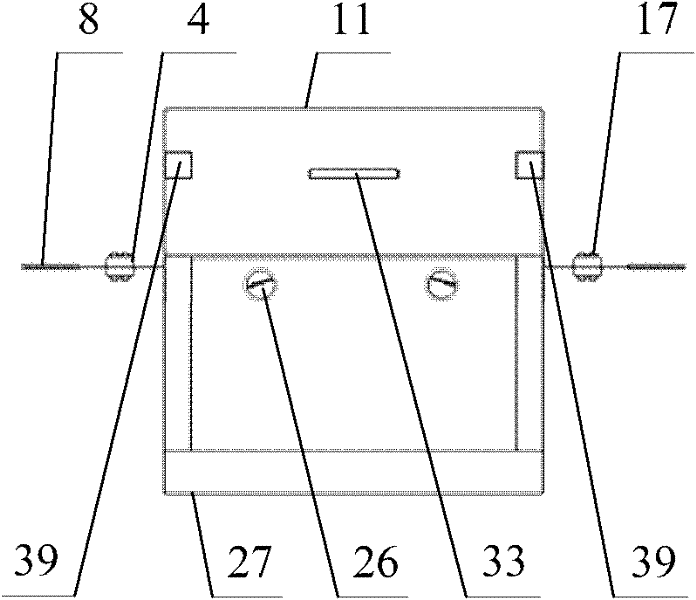

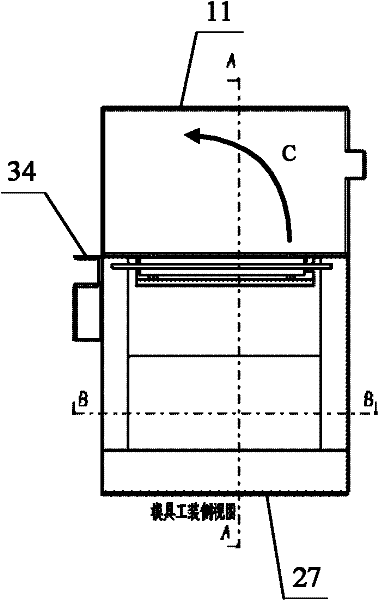

Hot forming tool of titanium alloy thin-wall part and machining method of hot forming tool

ActiveCN102500675AViscoplastic deformation facilitatesAvoid lostShaping toolsTemperature controlProcess integration

The invention provides a hot forming tool of a titanium alloy thin-wall part, comprising five parts, namely stretching equipment, a mould device, a blank, a power supply system and a temperature control system, wherein the mould device is arranged on a central worktable of the stretching equipment; the blank passes through a side wall crack of the mould device; an insulating and heat-insulation cushion layer is used for insulating the blank, a clamp of the stretching equipment, the surface of a mould and a tool of the mould; the power supply system is switched on to electrify an electrode clamping plate and generate a current in the blank; the blank is heated and the temperature of the blank is measured and controlled by the temperature control system; and after the temperature of the blank reaches a target temperature, the part is formed on the surface on the mould by the blank in an adhered manner through carrying out hot forming processes successively including stretching, covering, stretching, heat preservation and creep deformation and the like on the stretching equipment. A machining method of the hot forming tool of the titanium alloy thin-wall part comprises eight steps. According to the invention, the heating efficiency, the process integration, the material formation and the formation precision of the titanium alloy thin-wall part in manufacture are greatly improved, so that the hot forming tool of the titanium alloy thin-wall part and the machining method of the hot forming tool have a practical value and a popularization value.

Owner:BEIHANG UNIV

Pure electric vehicle power battery cooling and heating device with liquid cooling plate

InactiveCN103943913ASave powerQuick changeSecondary cellsCell component detailsPower batteryWhole body

The invention discloses a pure electric vehicle power battery cooling and heating device with a liquid cooling plate. The cooling and heating device comprises a plurality of battery modules which are connected in series and parallel to form a power supply, the cooling plate, a radiator, an electronic fan, a water pump and a cooling pipeline. When a pure electric vehicle works under a relatively sever hot environment, the whole body of each battery module can be effectively cooled by the device; when the pure electric vehicle works under a low-temperature environment, the battery modules can be effectively heated by the device. Besides, the temperatures of all the batteries are distributed evenly, so that the optimum running condition of the vehicle is achieved. The large-scaled production of the radiator and the electronic fan is achieved already, so that the cost of the device is low. In addition, due to the use of the cooling plate, a liquid can be prevented from being directly in contact with the batteries and consequently potential safety hazards are avoided; if one single battery discharges unsuccessfully, the battery can be very conveniently replaced.

Owner:SOUTH CHINA UNIV OF TECH

Wafer processing method

InactiveUS7138606B2Improve temperature distributionUniform temperatureDrying solid materials with heatMuffle furnacesEngineeringLiquid circulation

A wafer processing method for use with a wafer processing apparatus having a liquid cooling jacket with a built-in coolant liquid circulation path and a ceramic plate as attached onto the liquid cooling jacket and having therein a heater and an electrode for an electrostatic chuck. The method enables performance of wafer processing while letting a wafer be mounted on the ceramic plate by a wafer transport. The method includes causing the wafer transport to transport the wafer onto the ceramic plate, pre-heating the wafer while the wafer is held on the ceramic plate for a predetermined length of time, and mounting the preheated wafer on the ceramic plate.

Owner:HITACHI HIGH-TECH CORP

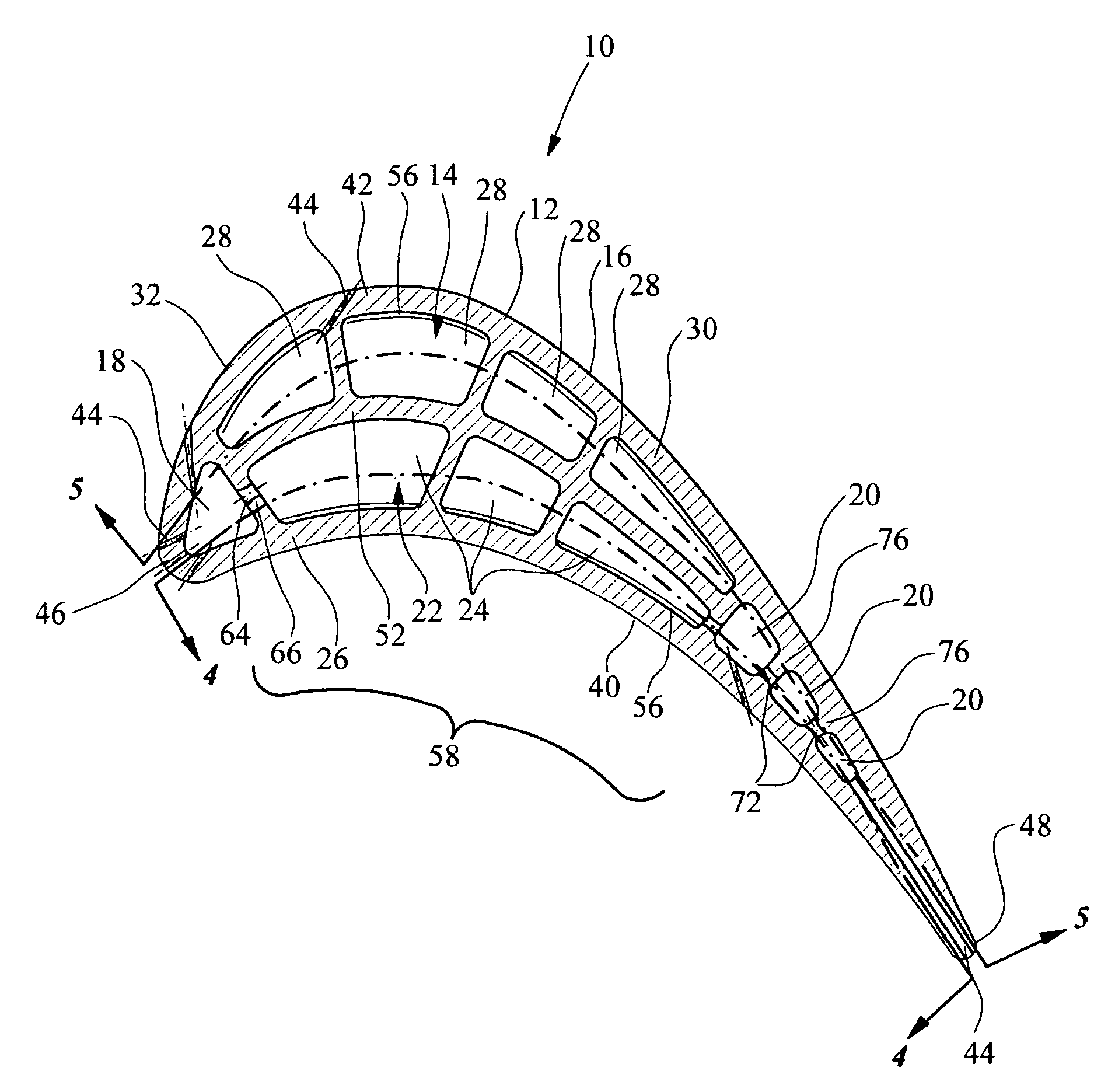

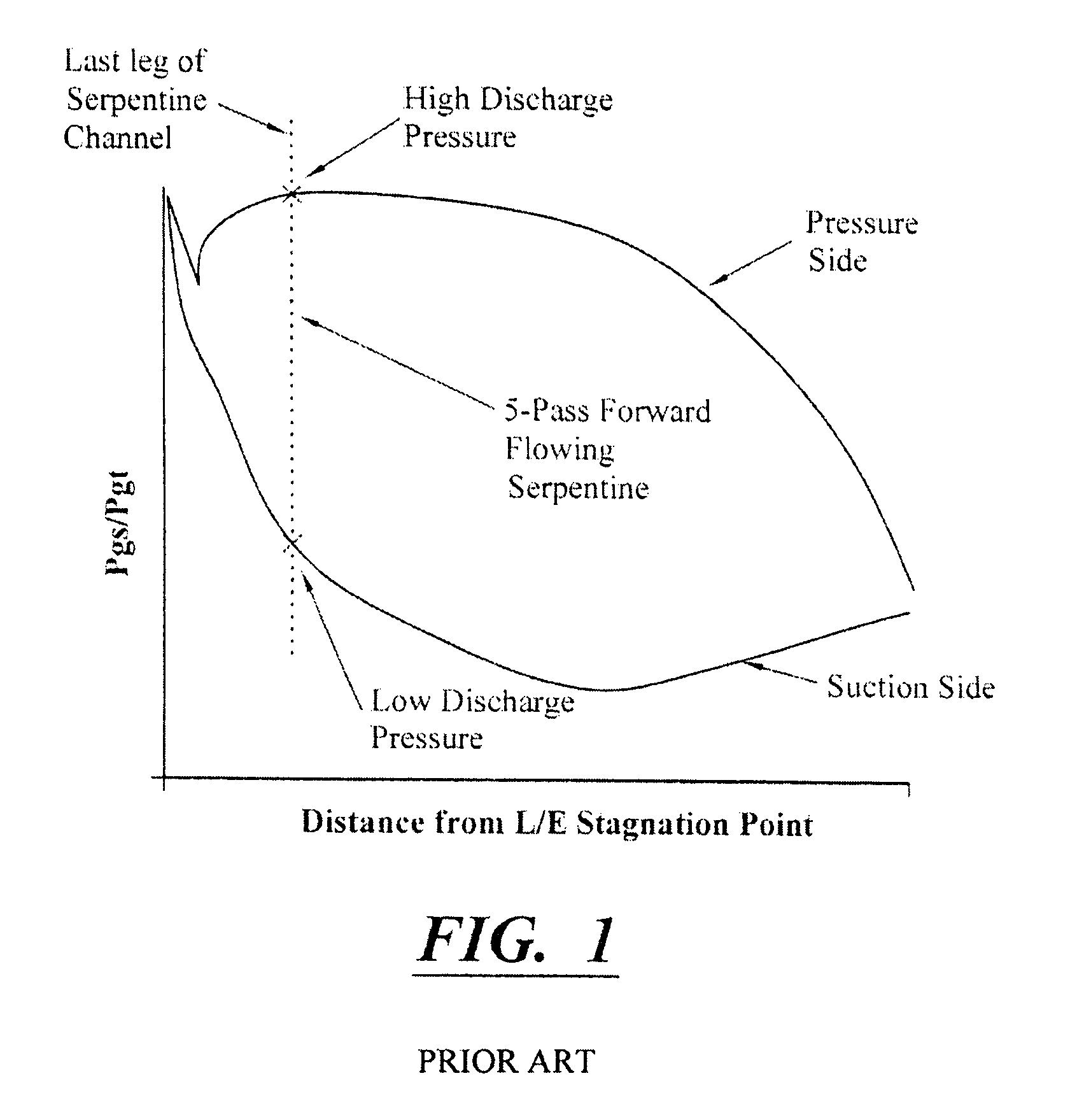

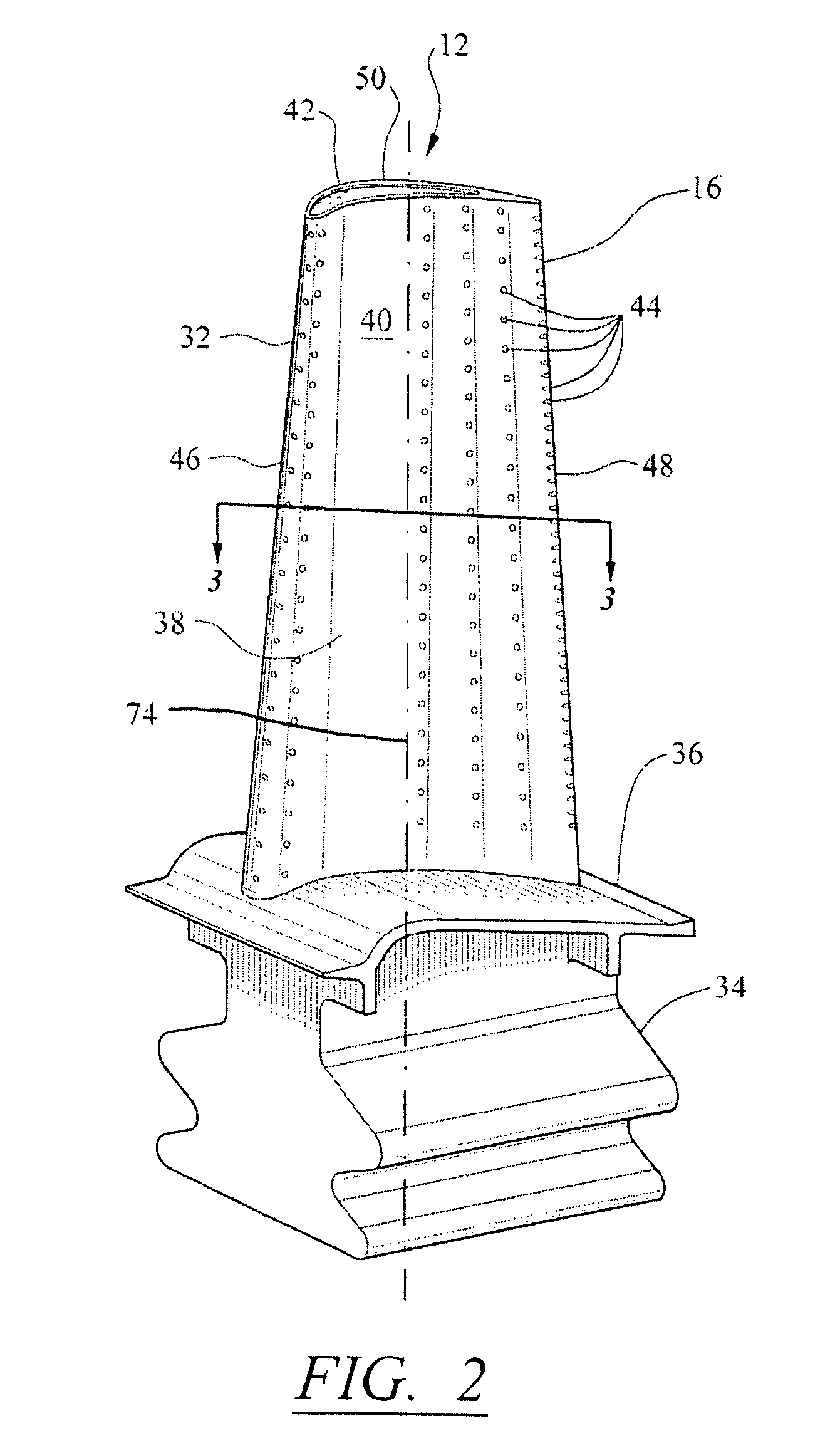

Turbine blade cooling system with bifurcated mid-chord cooling chamber

InactiveUS7413407B2Uniform temperature distributionImprove efficiencyEngine manufactureEngine fuctionsSuction stressTurbine blade

A cooling system for a turbine blade of a turbine engine having a bifurcated mid-chord cooling chamber for reducing the temperature of the blade. The bifurcated mid-chord cooling chamber may be formed from a pressure side serpentine cooling channel and a suction side serpentine cooling channel. The pressure side and suction side serpentine cooling channels may flow counter to each other, thereby yielding a more uniform temperature distribution than conventional serpentine cooling channels.

Owner:SIEMENS ENERGY INC

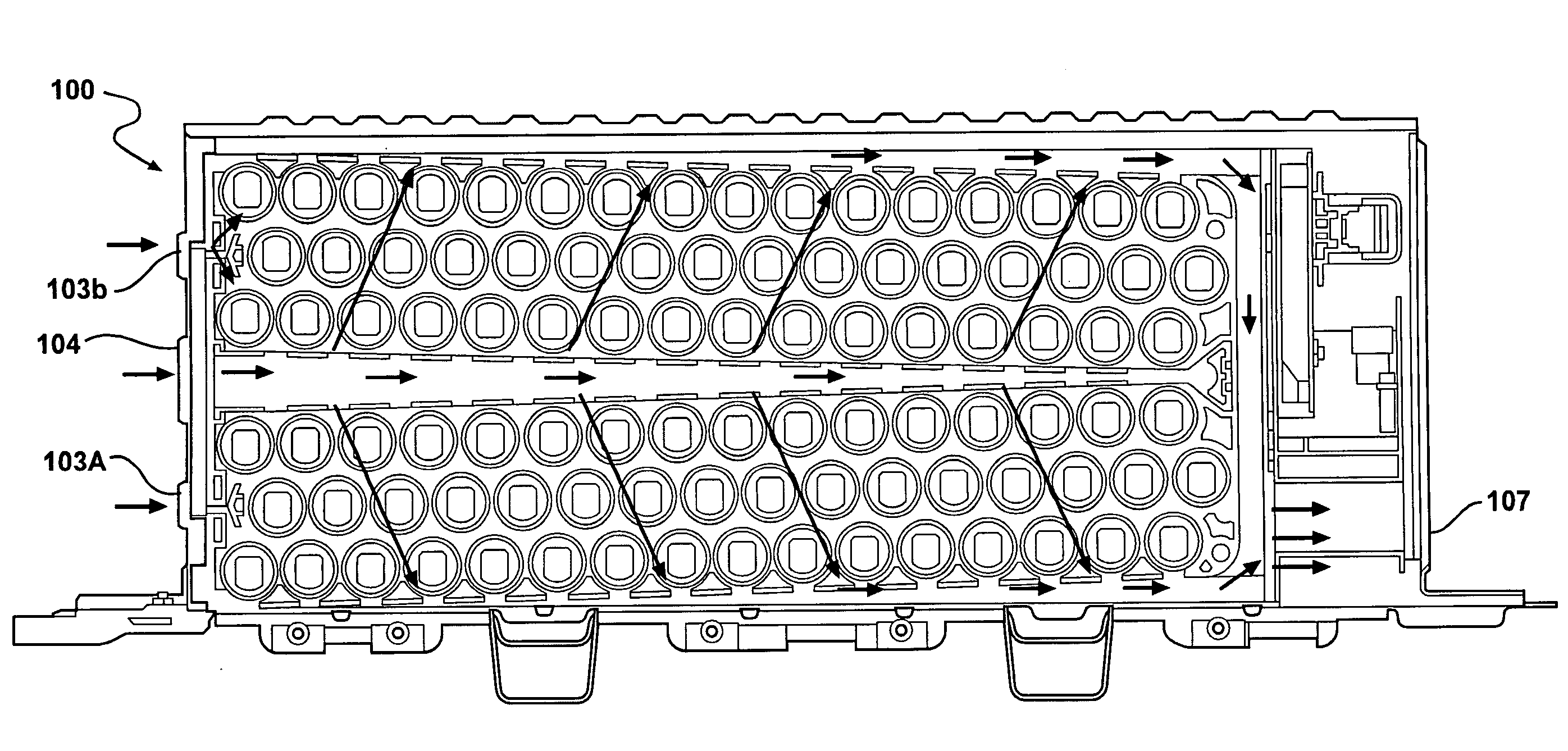

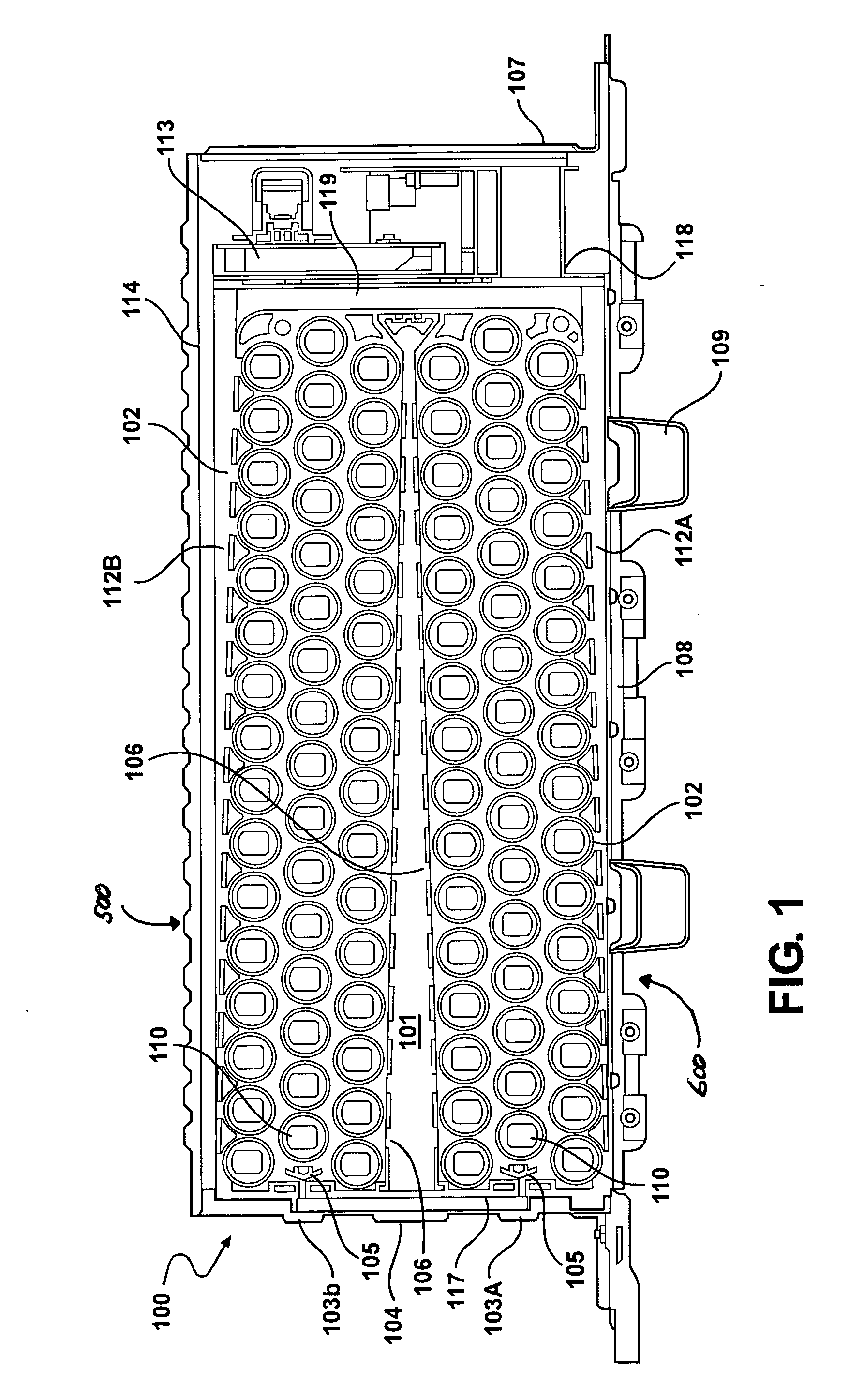

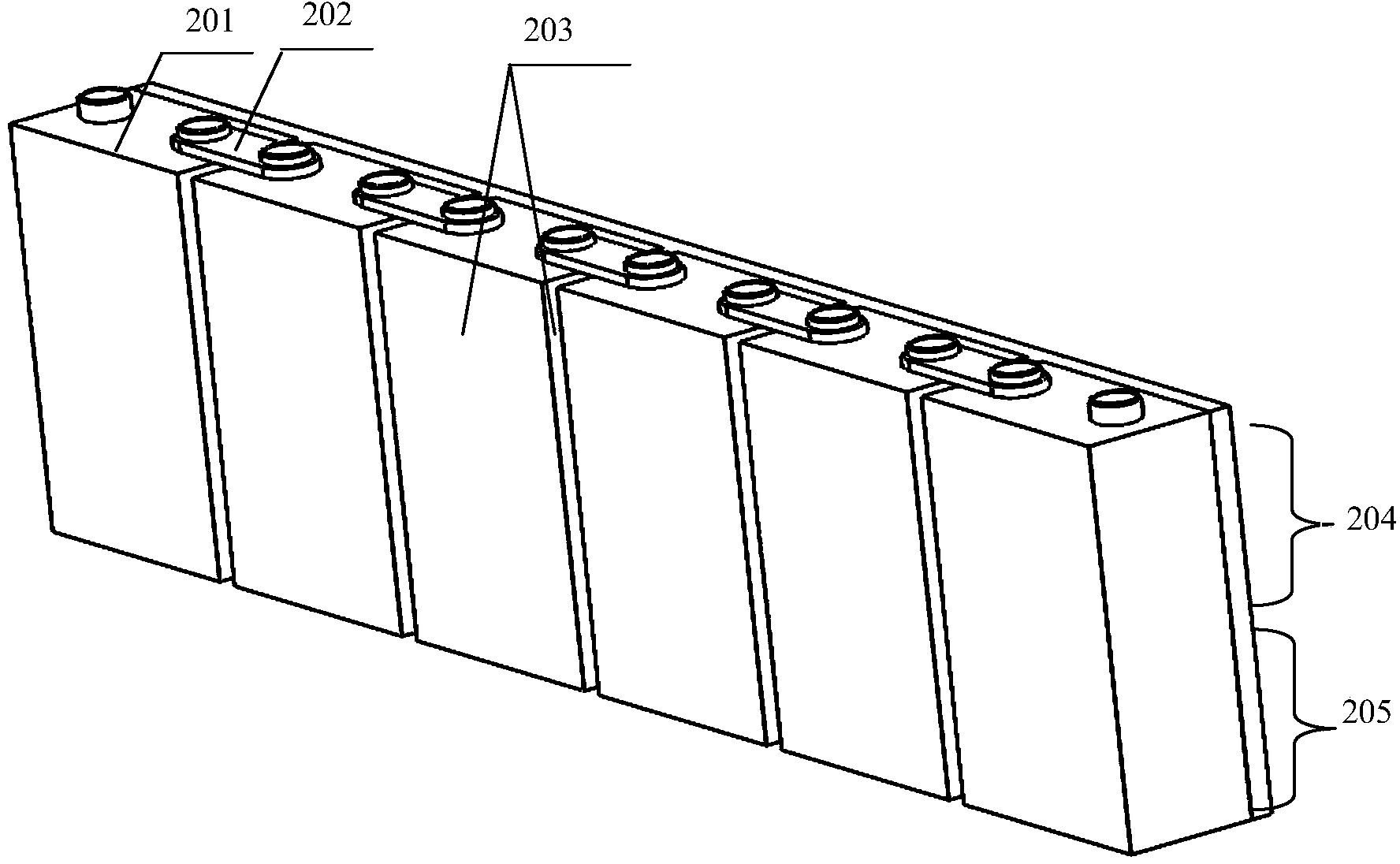

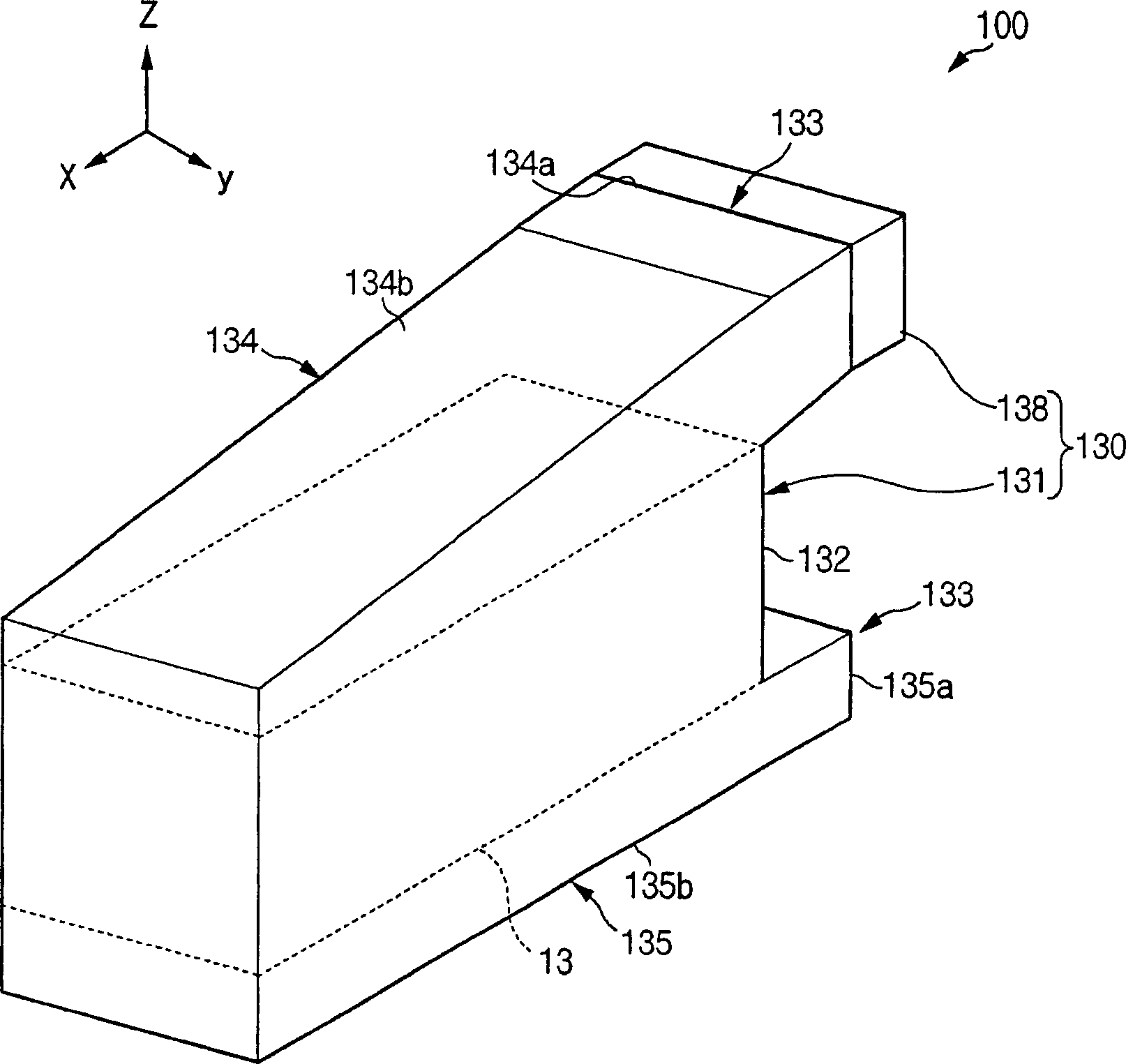

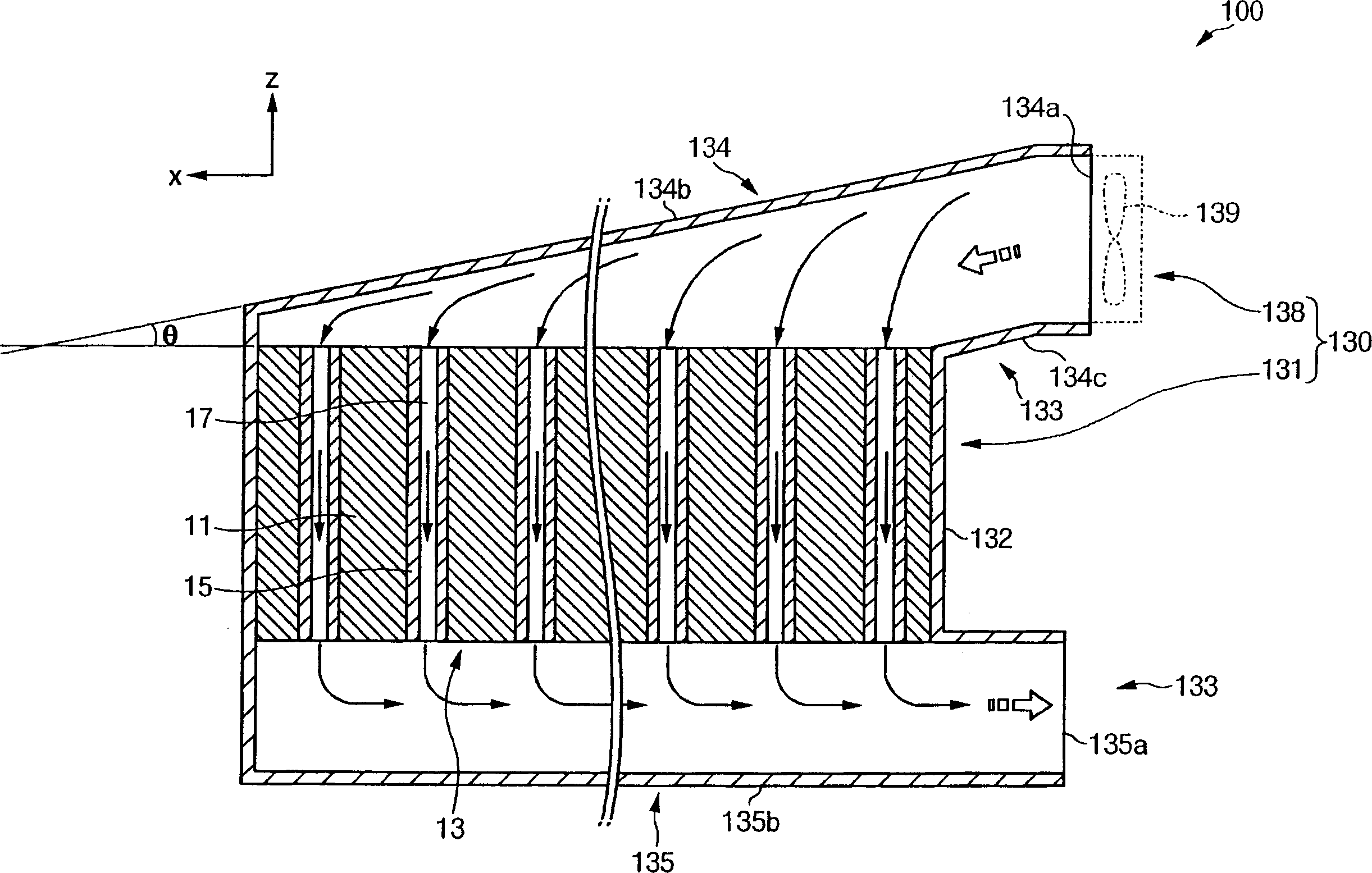

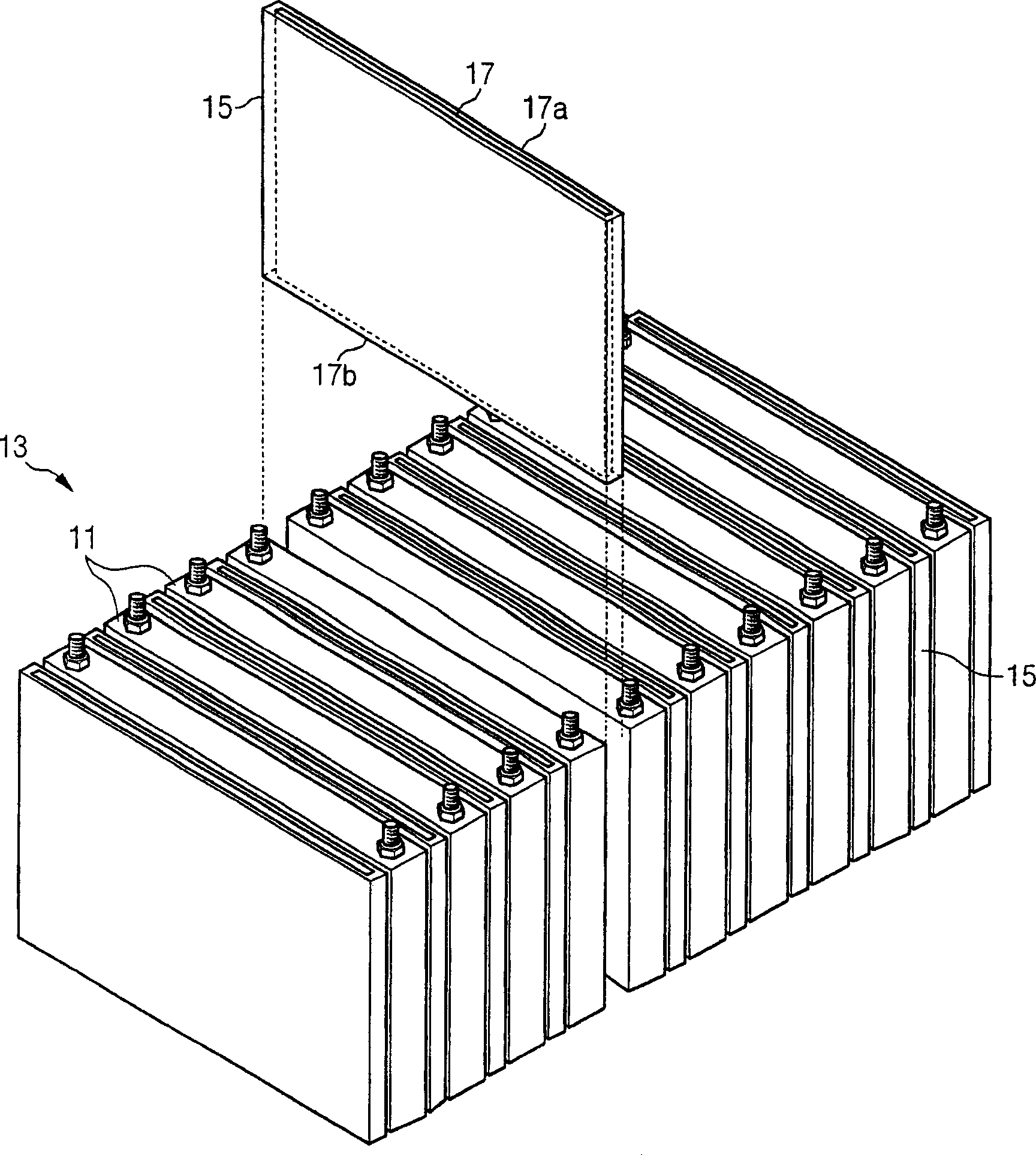

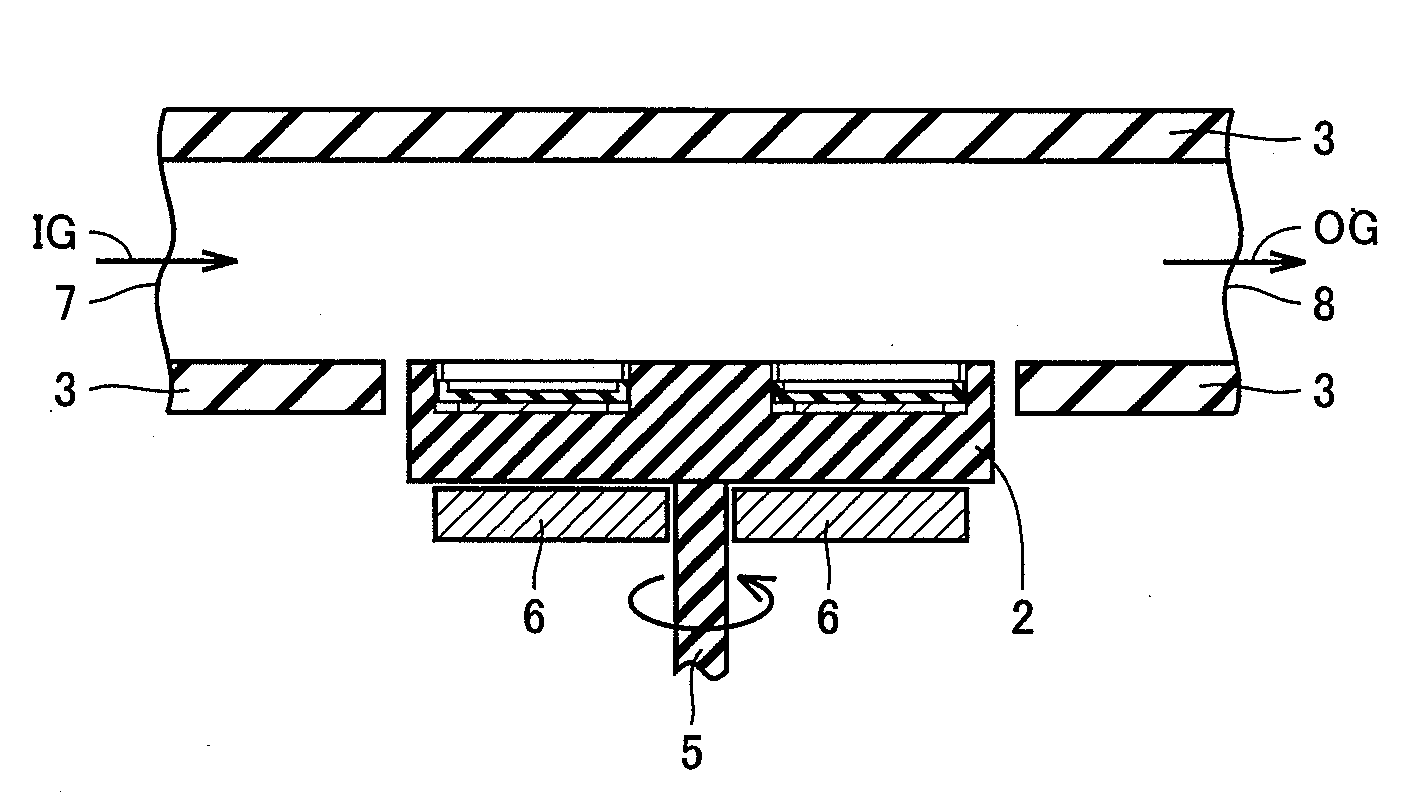

Battery module and cooling device for battery module

InactiveCN1812182AImproved air ventilation structureUniform temperature distributionFinal product manufactureSecondary cells manufactureDischarge efficiencyTemperature control

The invention discloses a battery module with a cooling system which enables the capacity of air which flows through each unit battery to be same. The battery module comprises a plurality of battery units which are separated mutually and a shell which is used to contain the battery units inside. The shell is provided with inclined inflow guiding sides which are vertical to the surfaces of a plurality of unit batteries, air inlets which are used to induce temperature control air and air outlets which are used to discharge the air which flows through the unit battery. Since the battery module of the invention is provided with an improved shell air ventilation structure, the capacity of air which is prearranged can be flowed through an air ventilation channel which is arranged between neighboring unit batteries, thereby the temperature on the whole region of unit battery components is distributed evenly, the cooling efficiency of the unit battery components can be optimum, and the charging and discharging efficiency of the battery module can be further increased.

Owner:SAMSUNG SDI CO LTD

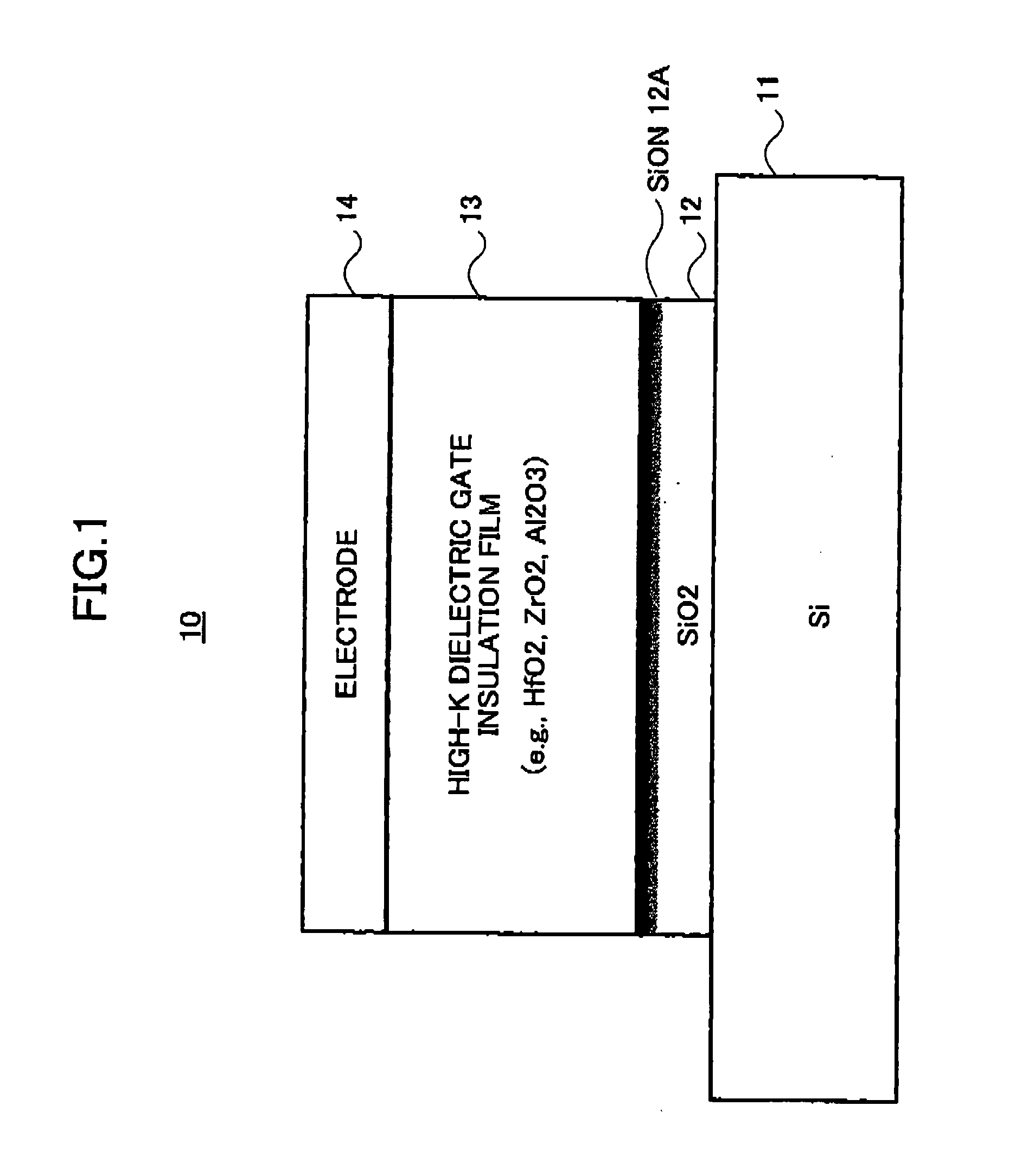

Fabrication apparatus and fabrication method of semiconductor device produced by heating substrate

InactiveUS20090075409A1Uniform temperature distributionReduce heat transferLiquid surface applicatorsSemiconductor/solid-state device manufacturingSusceptorEngineering

A fabrication apparatus and fabrication method of a semiconductor device are provided, allowing the temperature distribution of a substrate to be rendered uniform. The fabrication apparatus for a semiconductor device includes a susceptor holding the substrate, a heater arranged at a back side of the susceptor, a support member located between the substrate and susceptor, including a support portion, and a spacer located between the susceptor and support member. The spacer has an opening formed corresponding to the site where said support portion is located, at an opposite face side of the support member.

Owner:SUMITOMO ELECTRIC IND LTD

Isothermal transportation container

InactiveUS7412846B2Simple structureUniform temperature distributionLighting and heating apparatusLarge containersEngineeringElectrical and Electronics engineering

Owner:HITACHI LTD

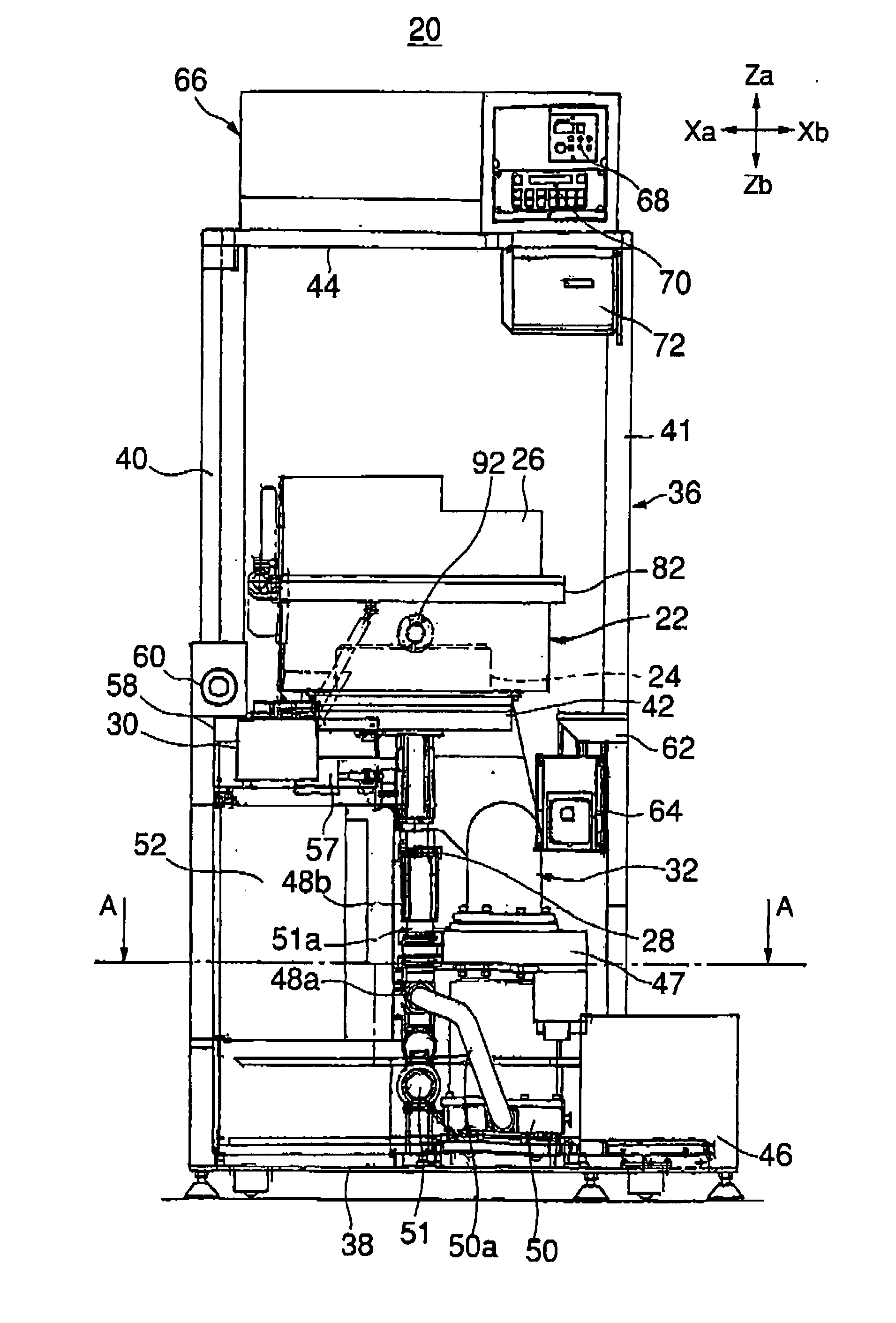

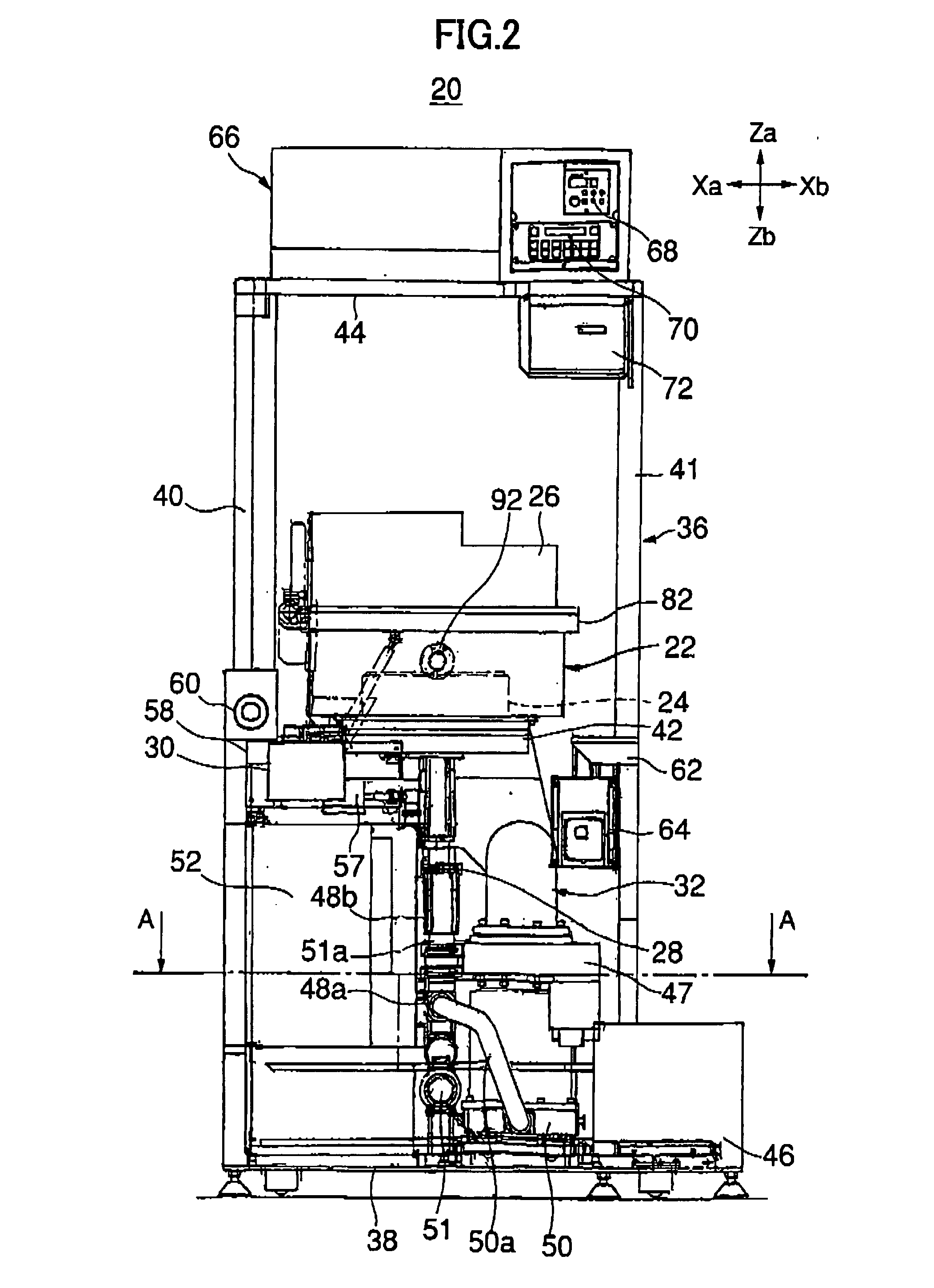

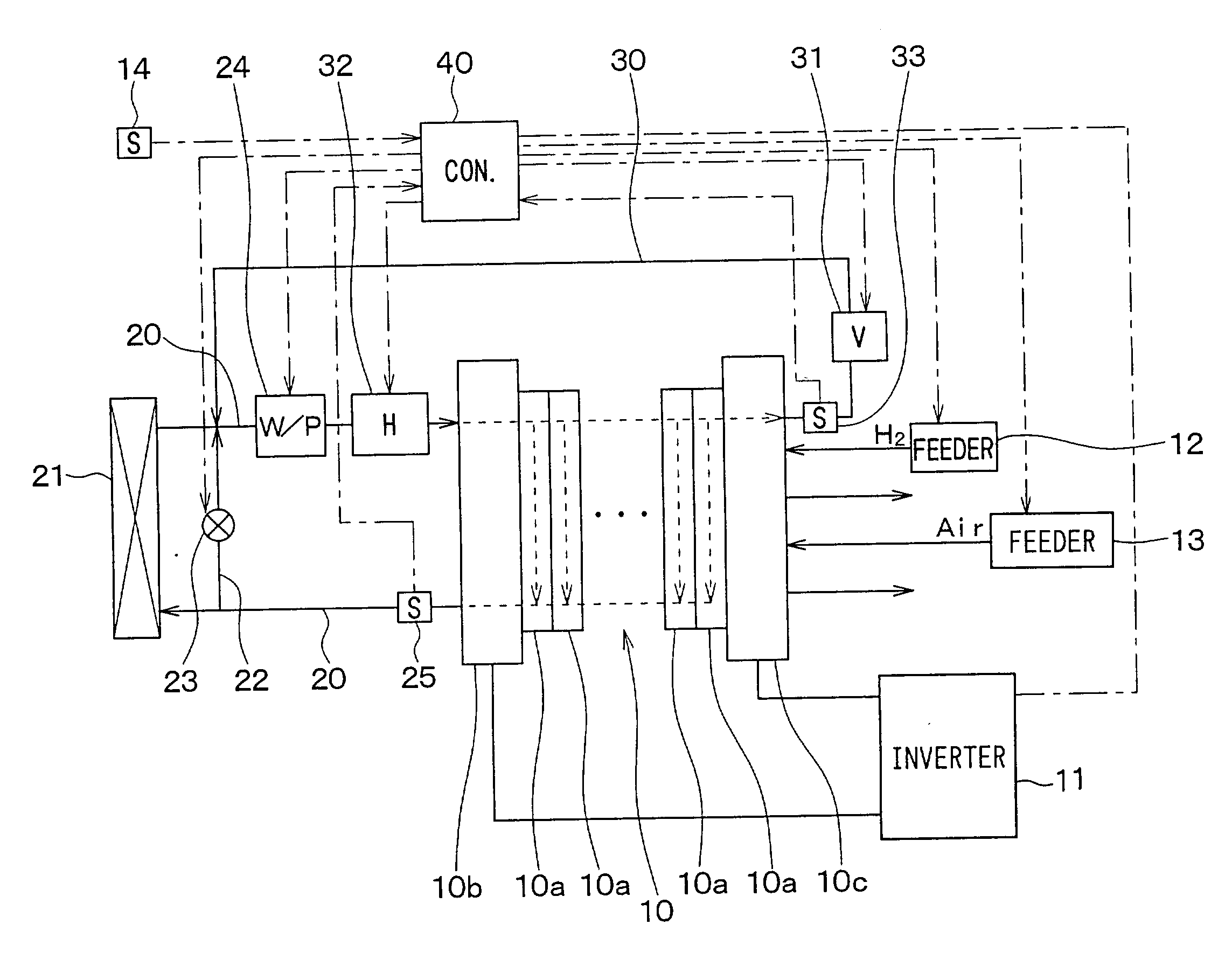

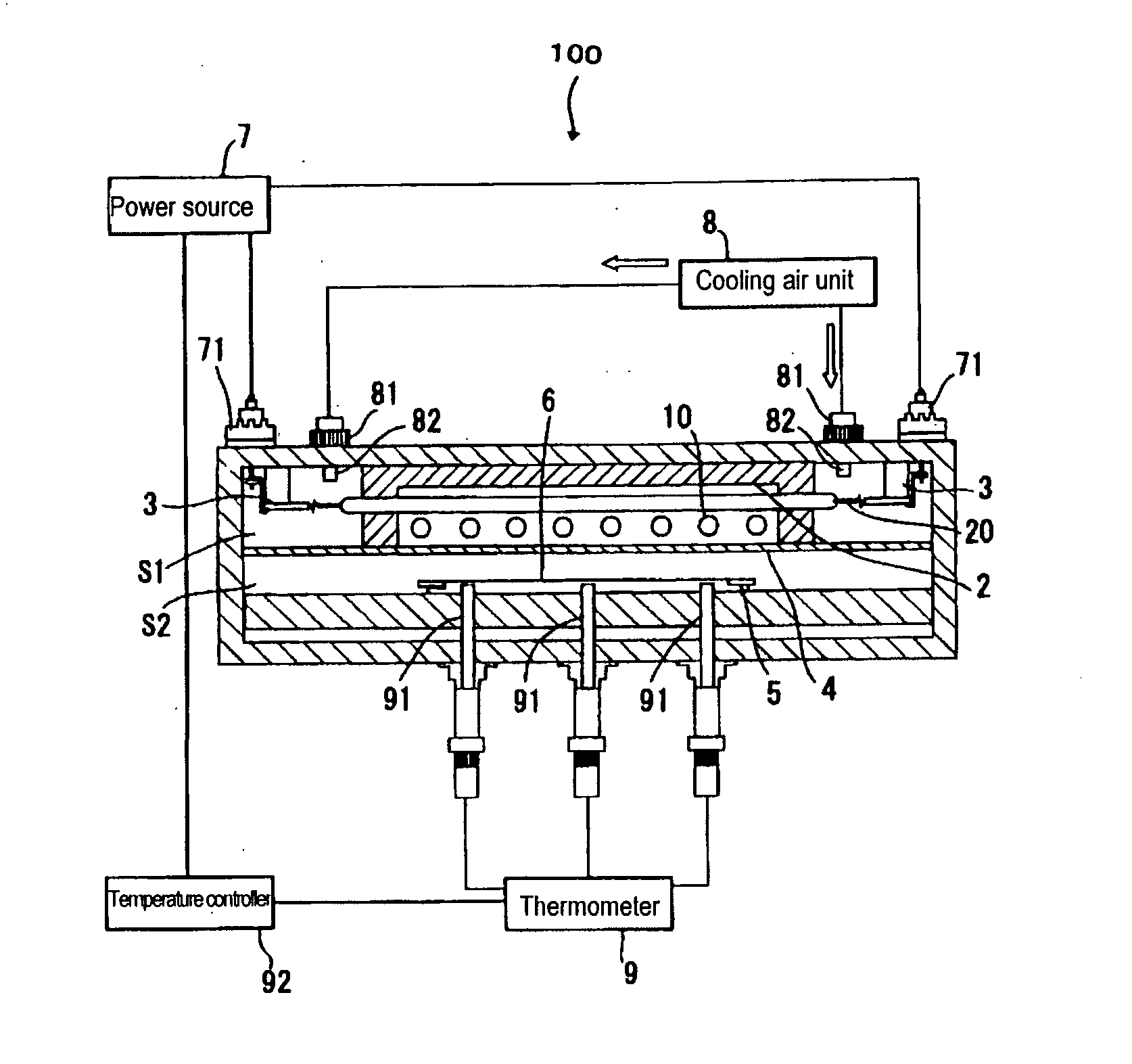

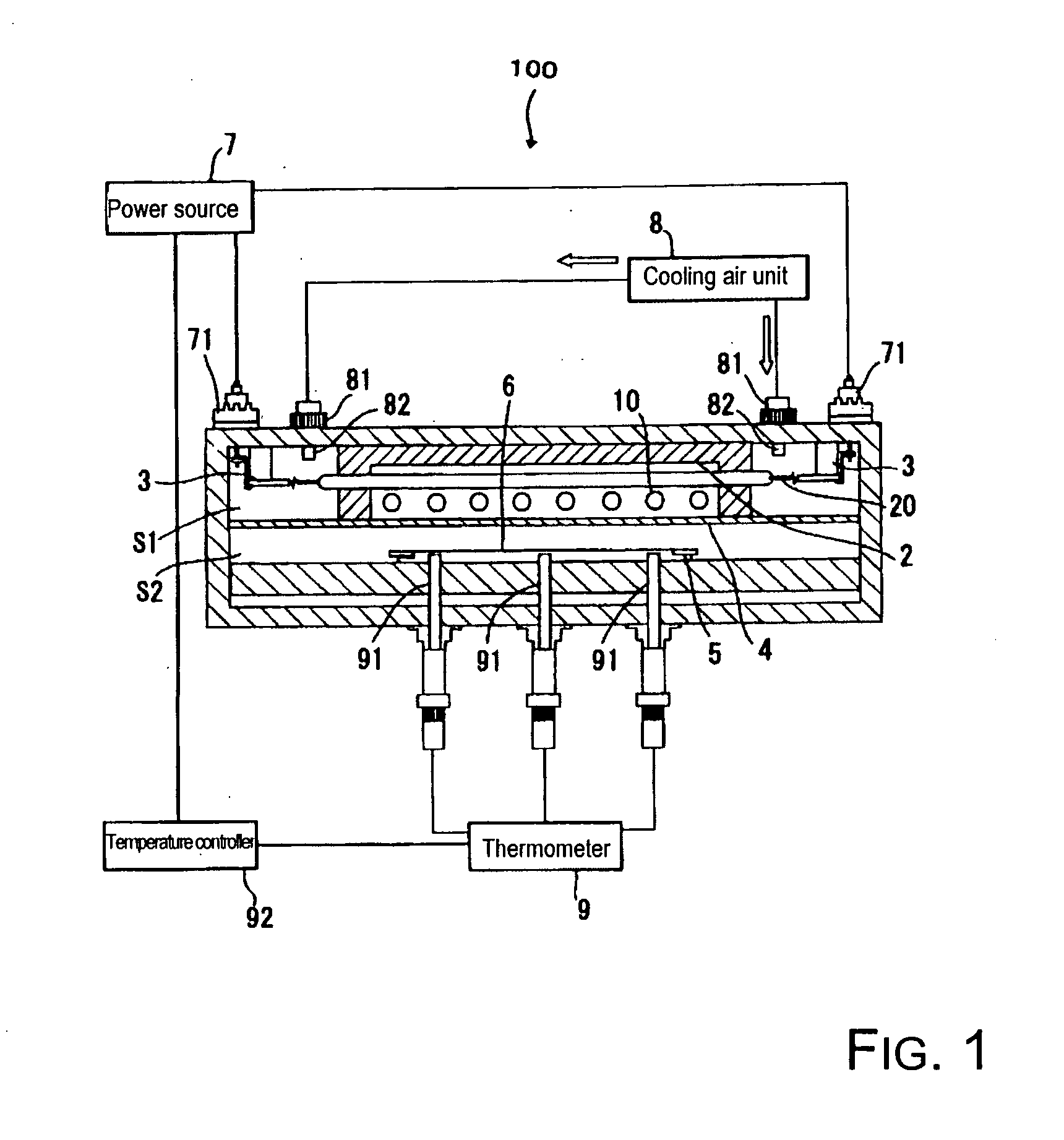

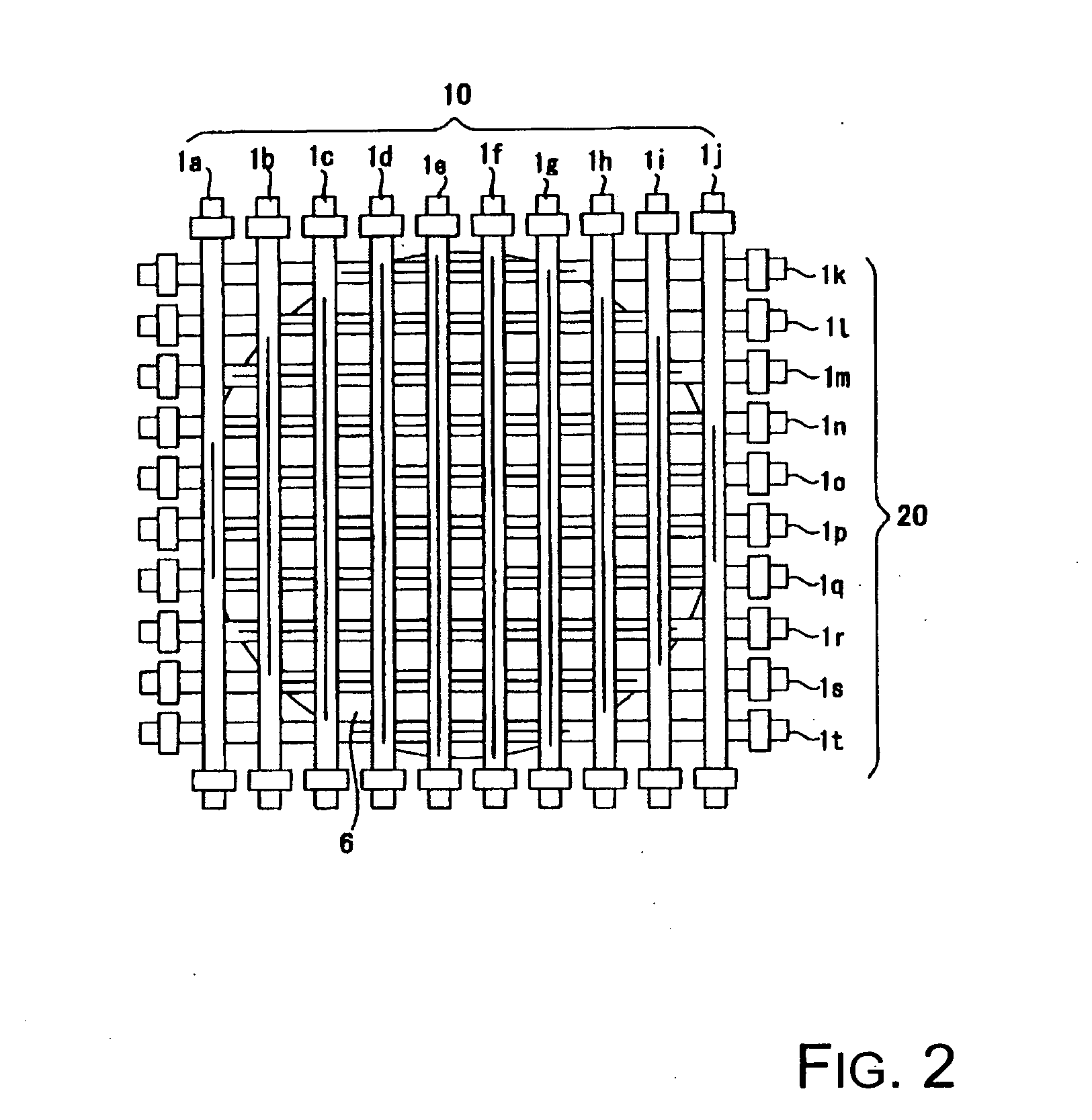

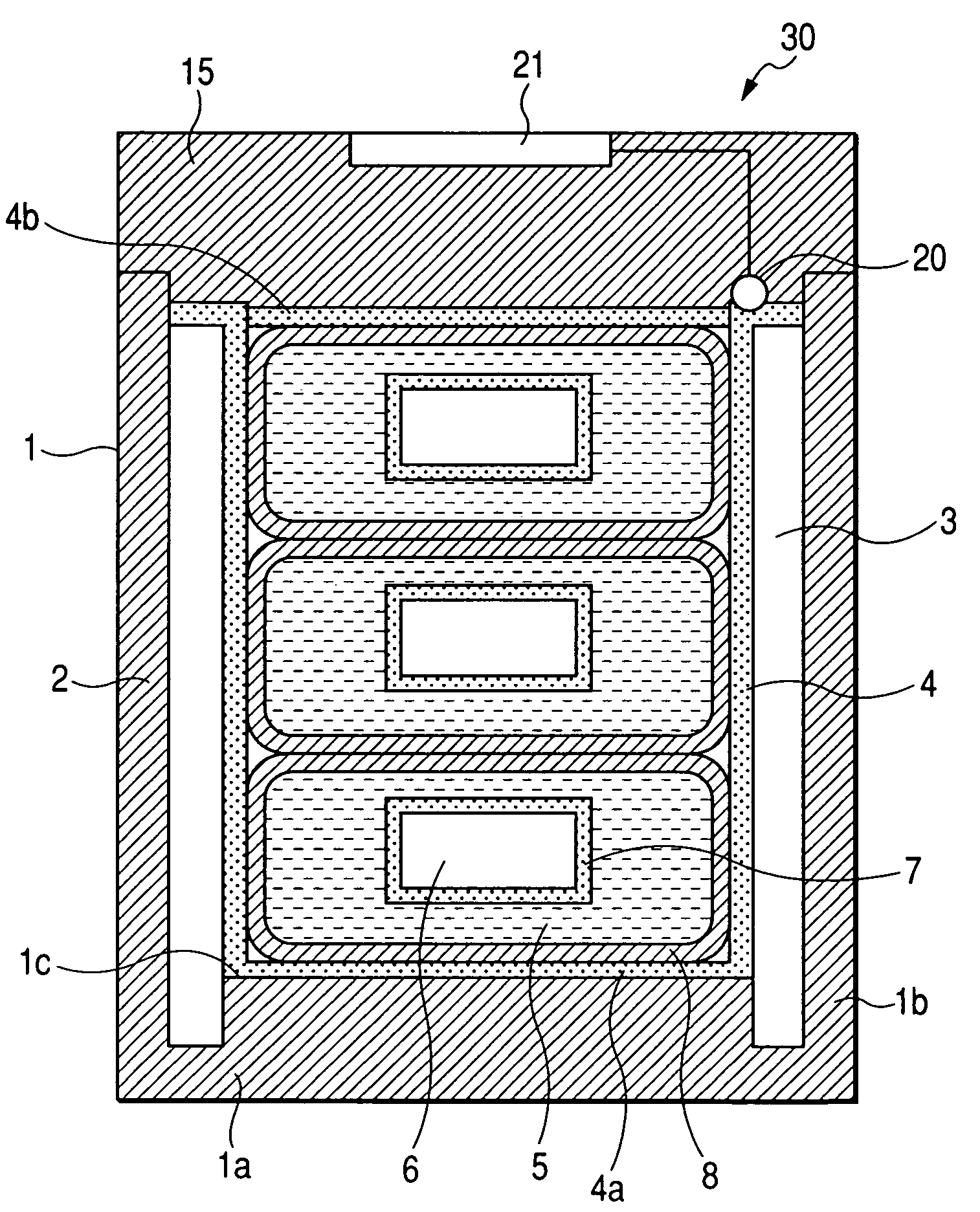

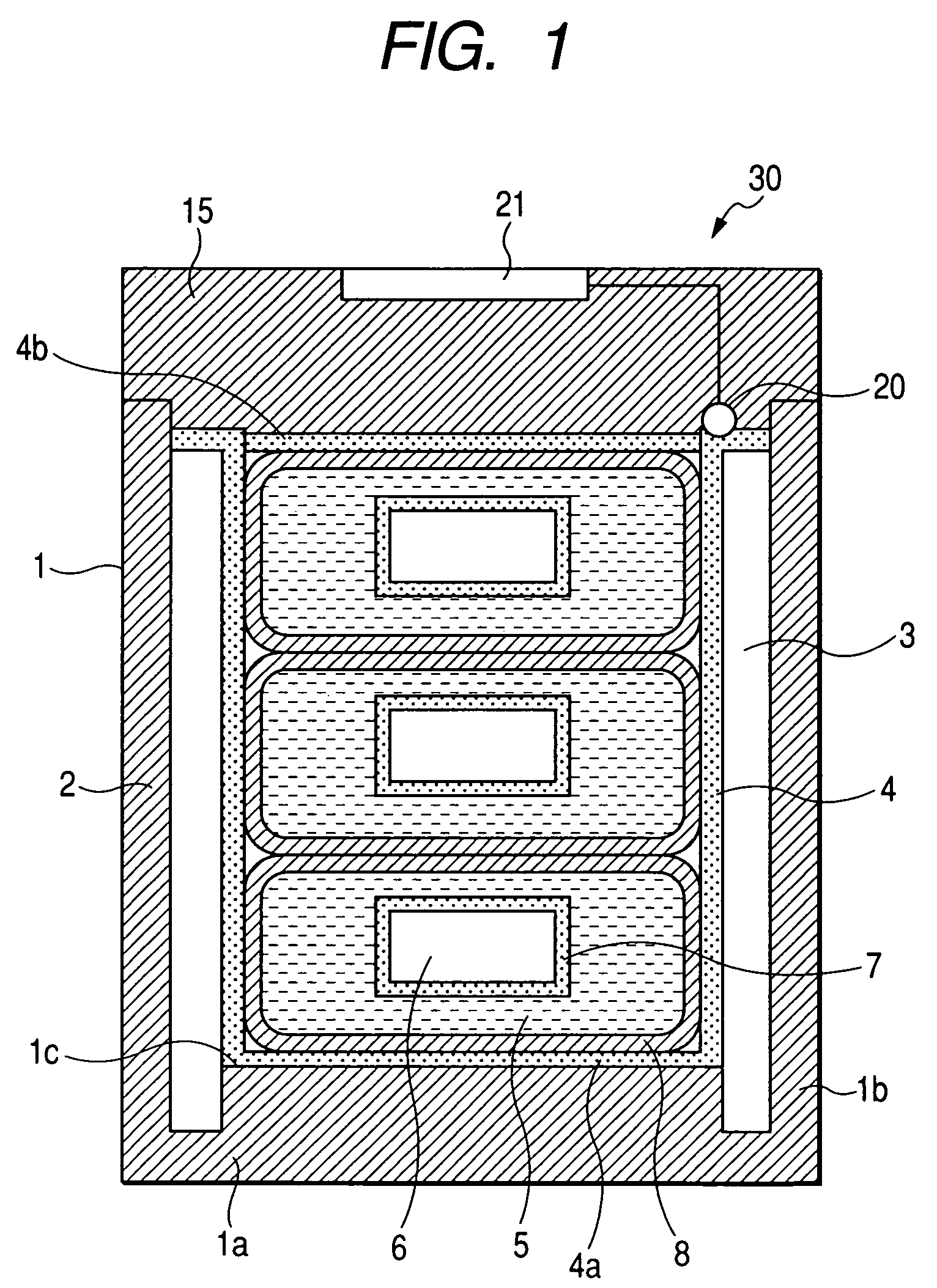

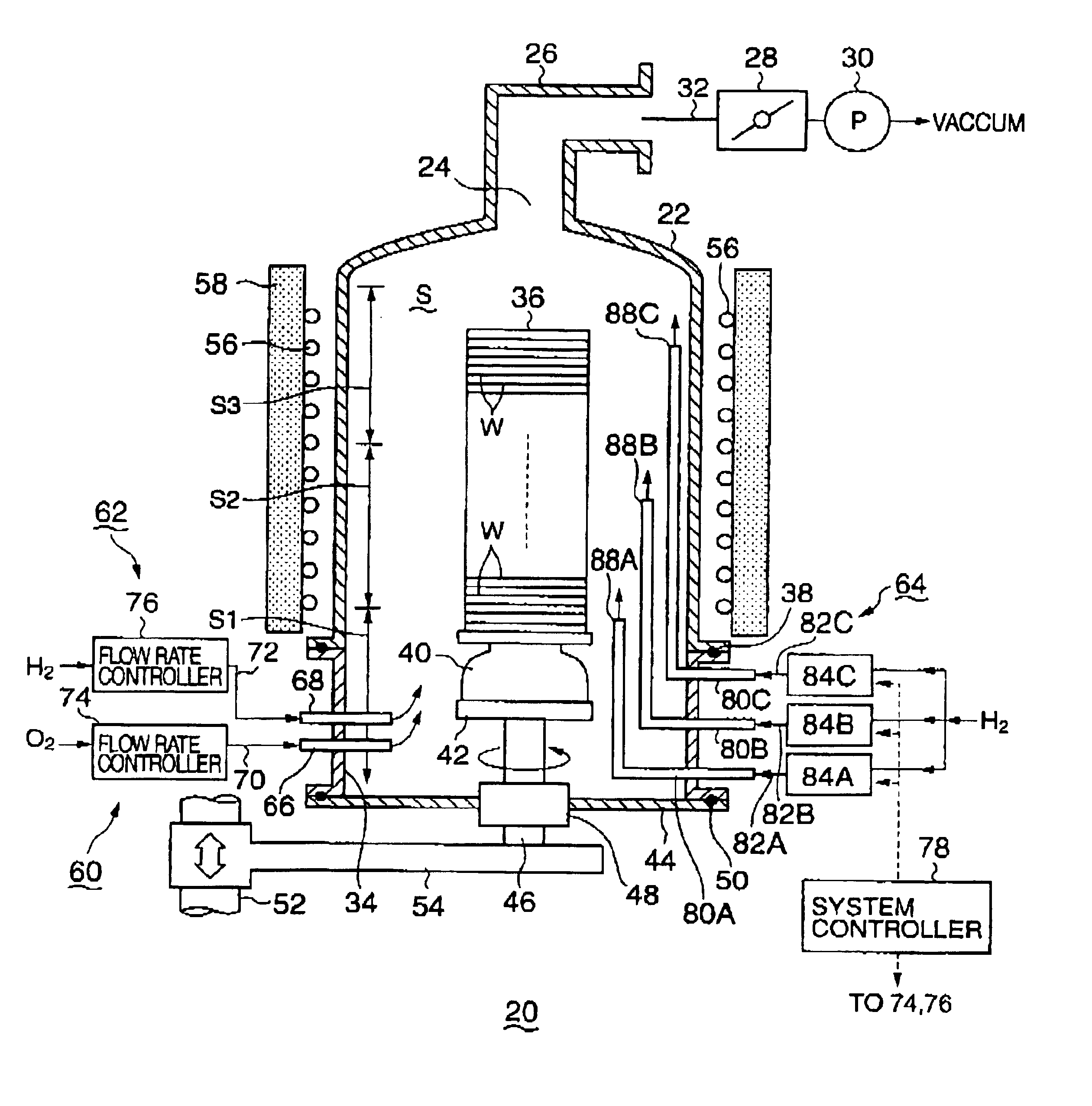

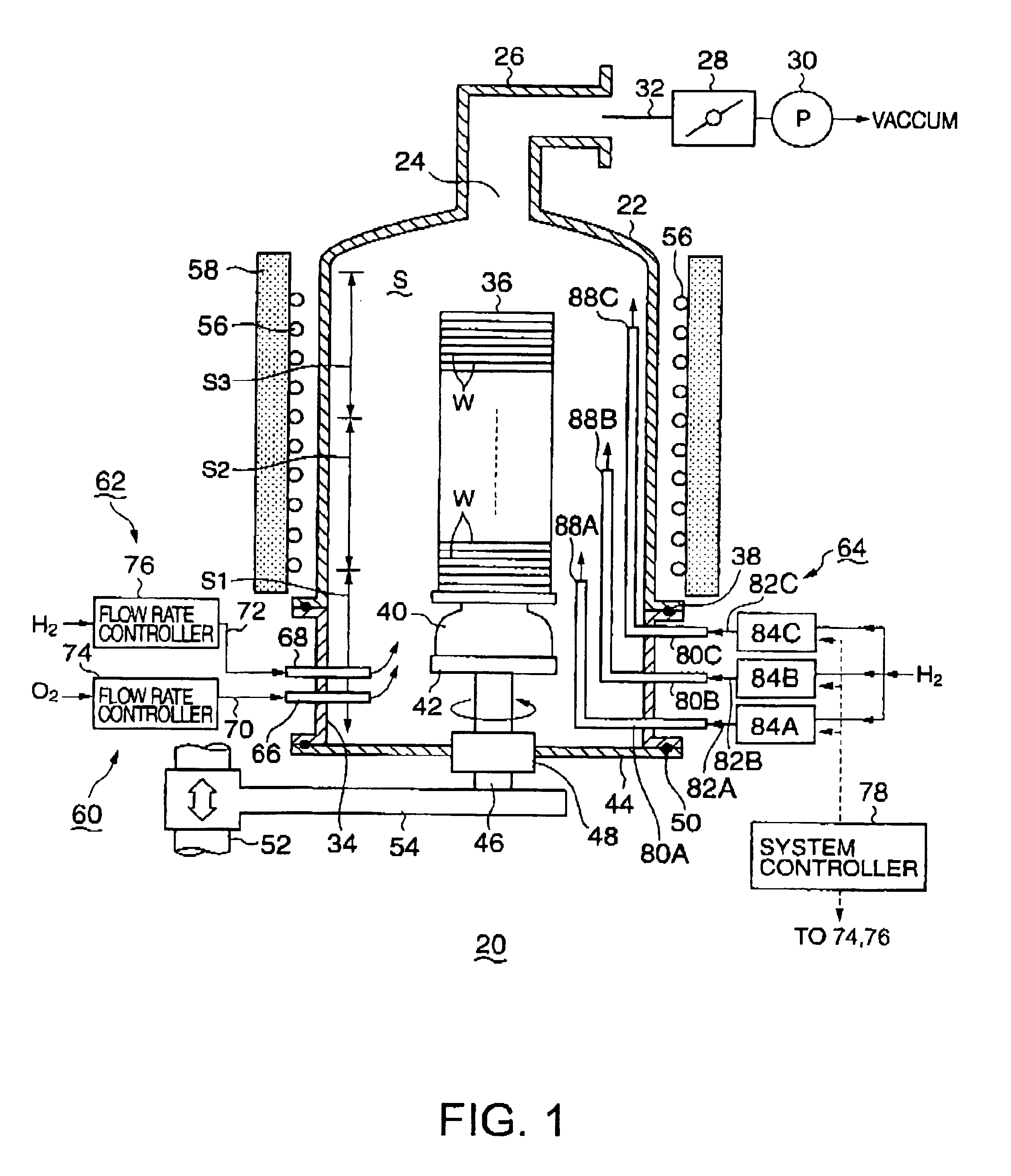

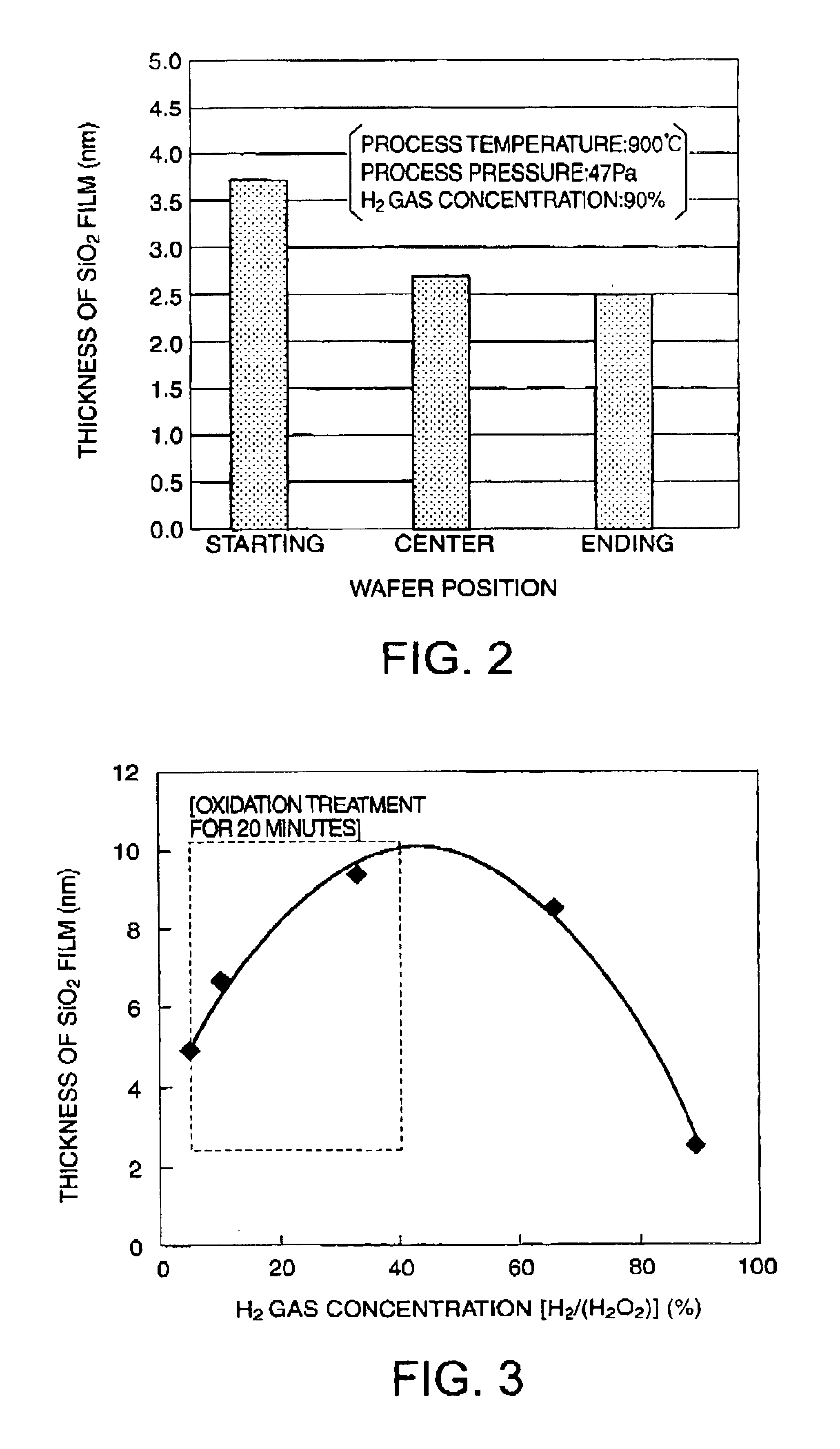

Method of oxidizing work pieces and oxidation system

ActiveUS6869892B1Good effectHigh interfilm thickness uniformitySemiconductor/solid-state device manufacturingSolid state diffusion coatingAtmospheric airProduct gas

A method of oxidizing work pieces according to the present invention comprises the steps of: containing a plurality of work pieces W in a processing vessel 22 which has a predetermined length and is capable forming a vacuum therein, oxidizing surfaces of the work pieces in an atmosphere including active oxygen species and active hydroxyl species which are generated by supplying an oxidative gas and a reductive gas into the processing vessel to interact the gases. The oxidative gas and the reductive gas are respectively supplied into the processing vessel in the longitudinal direction. Parts of the reductive gas are additionally supplied from at least two or more independently controlled gas nozzles located at separate locations in the longitudinal direction of the processing vessel. The gas flow rate through each nozzle is set depending on any combination of the work pieces composed of product wafers, dummy wafers, and monitor wafers in the processing vessel.

Owner:TOKYO ELECTRON LTD +1

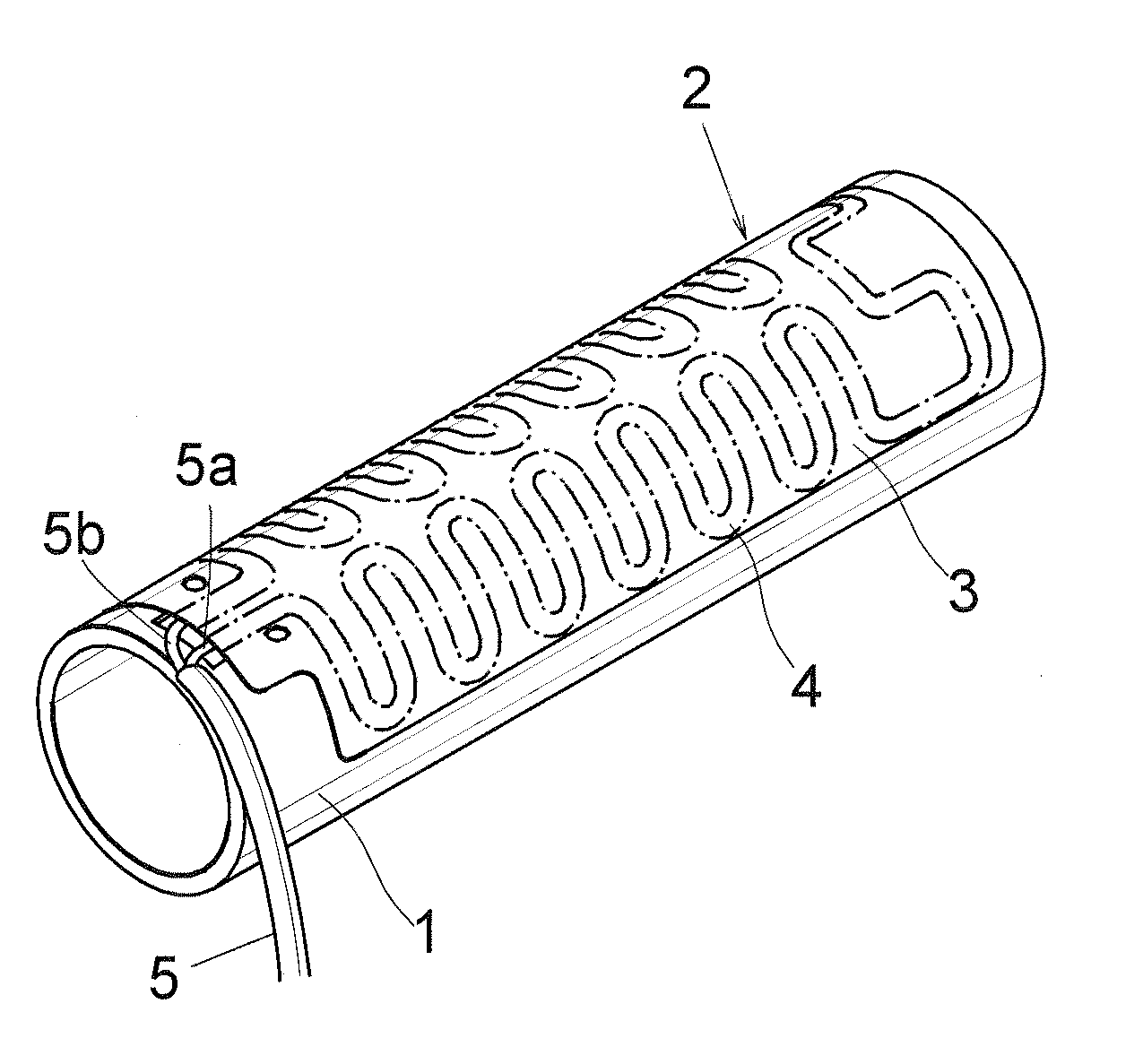

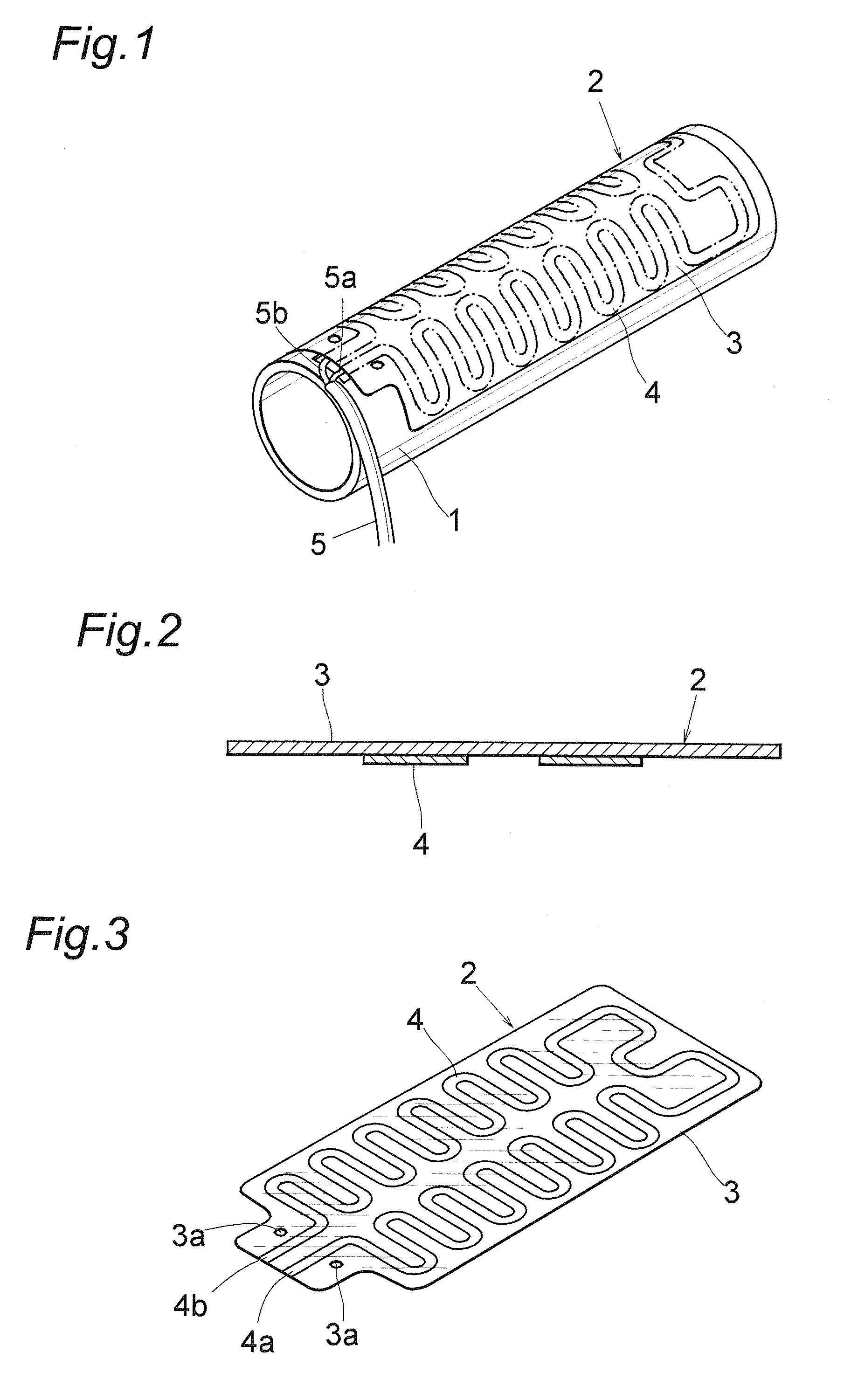

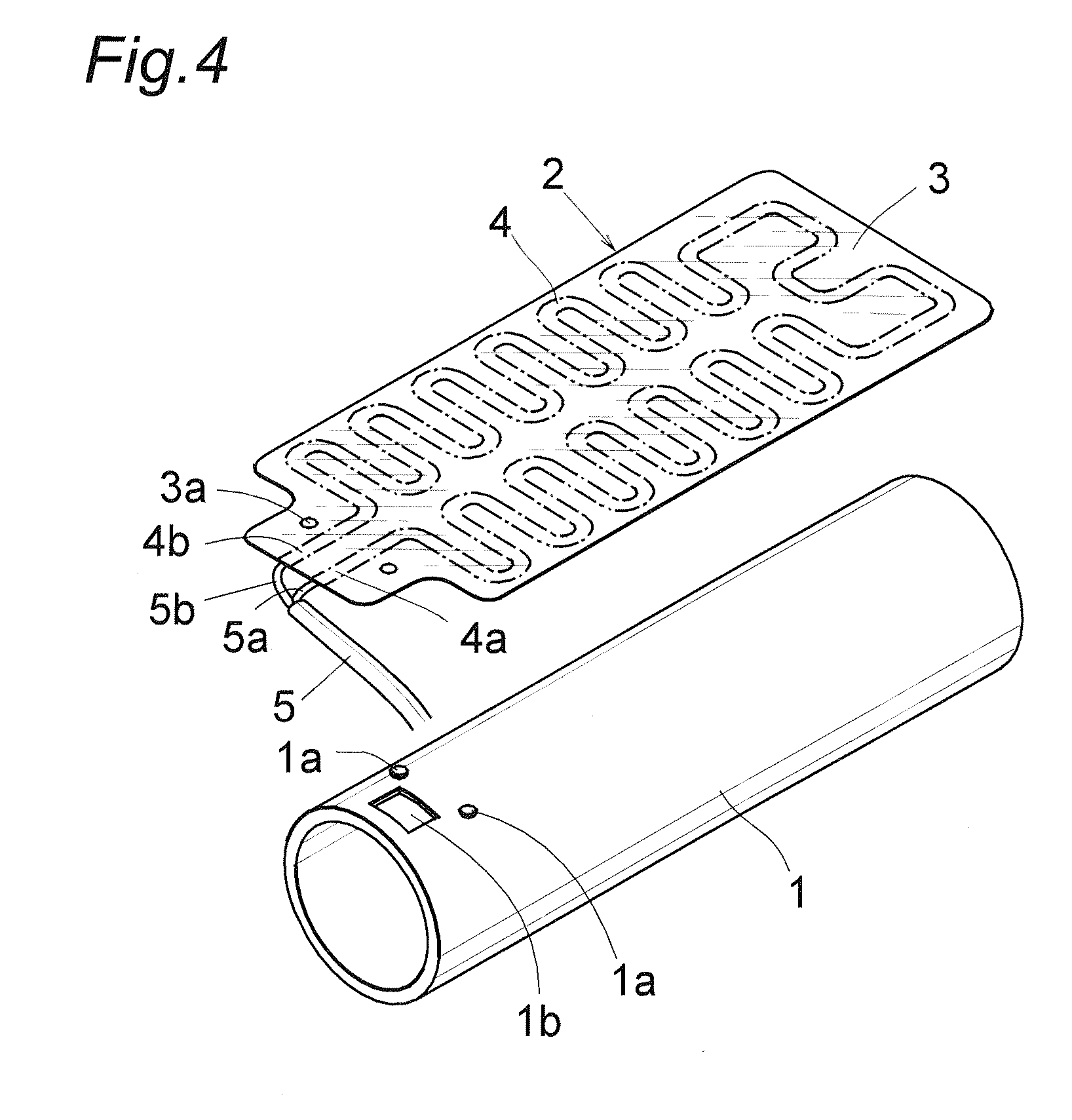

Handle grip with heater

InactiveUS20070007266A1Uniform temperature distributionSmall amount of materialSteering deviceHeating element shapesElectrical resistance and conductanceEngineering

Onto a surface of a cylindrical core body 1 made of synthetic resin, is adhered a heater unit 2 which is formed by adhering, with an adhesive agent, an electric resistance member 4 made of a SUS foil on an inner surface of a flexible electrically insulating plate 3 made of synthetic resin. The electric resistance member 4 is formed by half-punching the SUS foil uniformly applied on the electrically insulating plate into a given configuration and removing an unnecessary portion. The electric resistance member 4 has a small width, a large length and a zigzag shape to increase electric resistance. Both ends of the electric resistance member constitute connecting portions for an electric power supply wire 5 and are arranged side by side at one end of the electrically insulating plate.

Owner:HONDA ACCESS CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com