Vapor Heating Type Cooking Apparatus

a technology of heating type and cooking apparatus, which is applied in the direction of heating types, instruments, heat measurement, etc., can solve the problems of high energy waste, easy sticking of food materials or coagulated soup to the cooking vessel or being burned, and wasting energy, so as to prevent sticking, improve the inconvenience of stirring food with a scoop, and improve the heat distribution rate of the caldron

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Hereinafter, the structure, the operation, and the effects of a vapor heating type cooking apparatus according to the present invention will be described in detail through a preferred embodiment of the present invention.

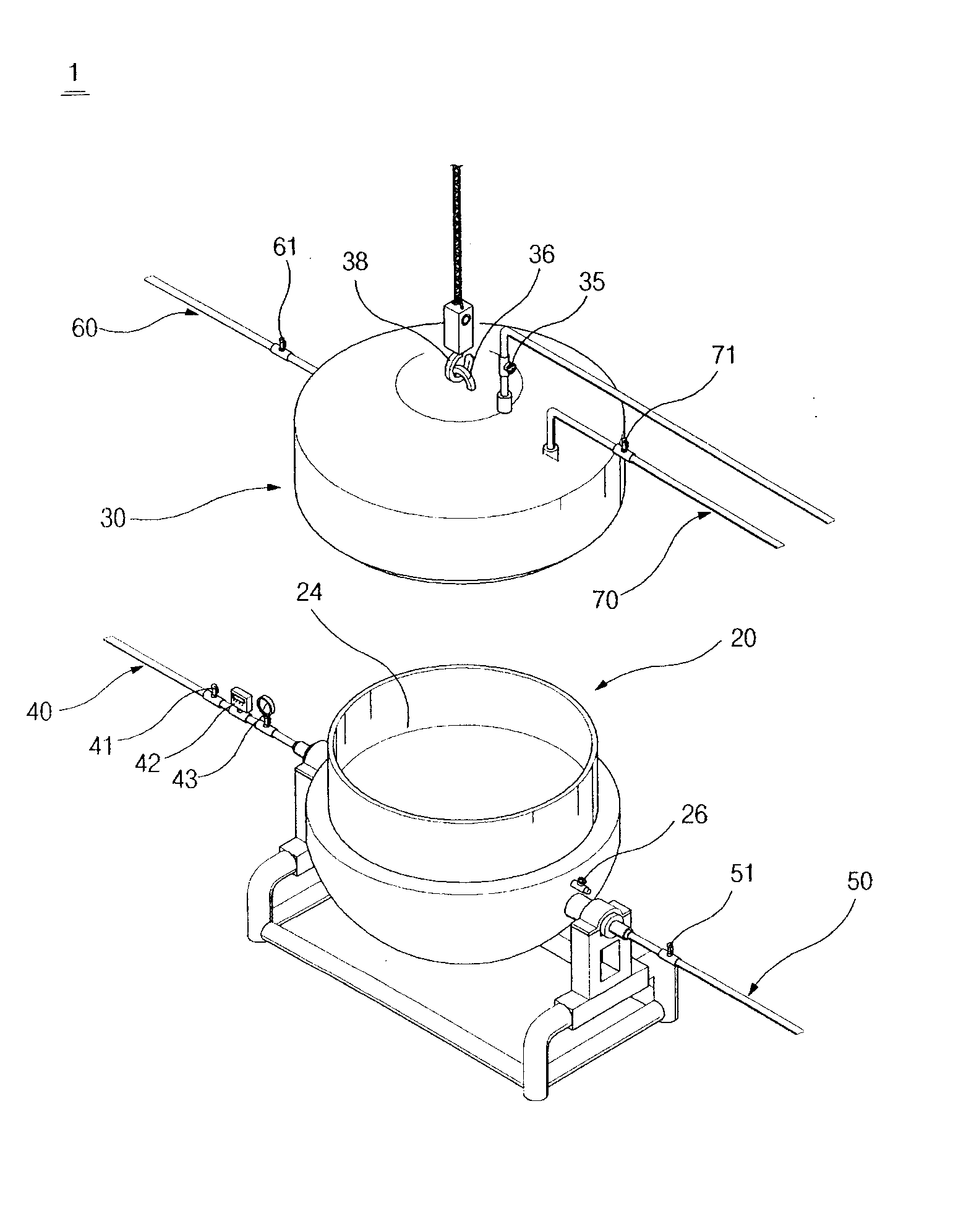

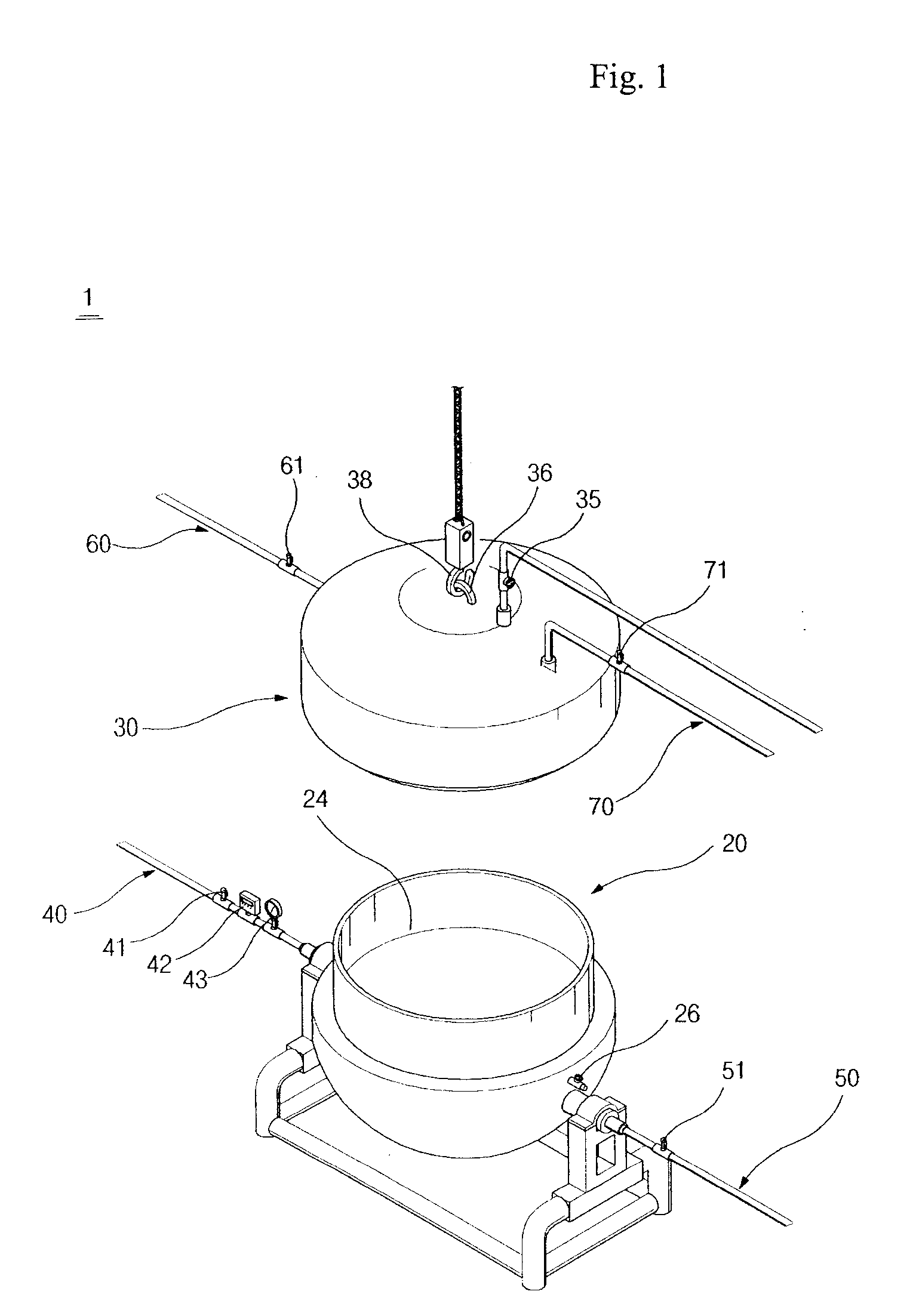

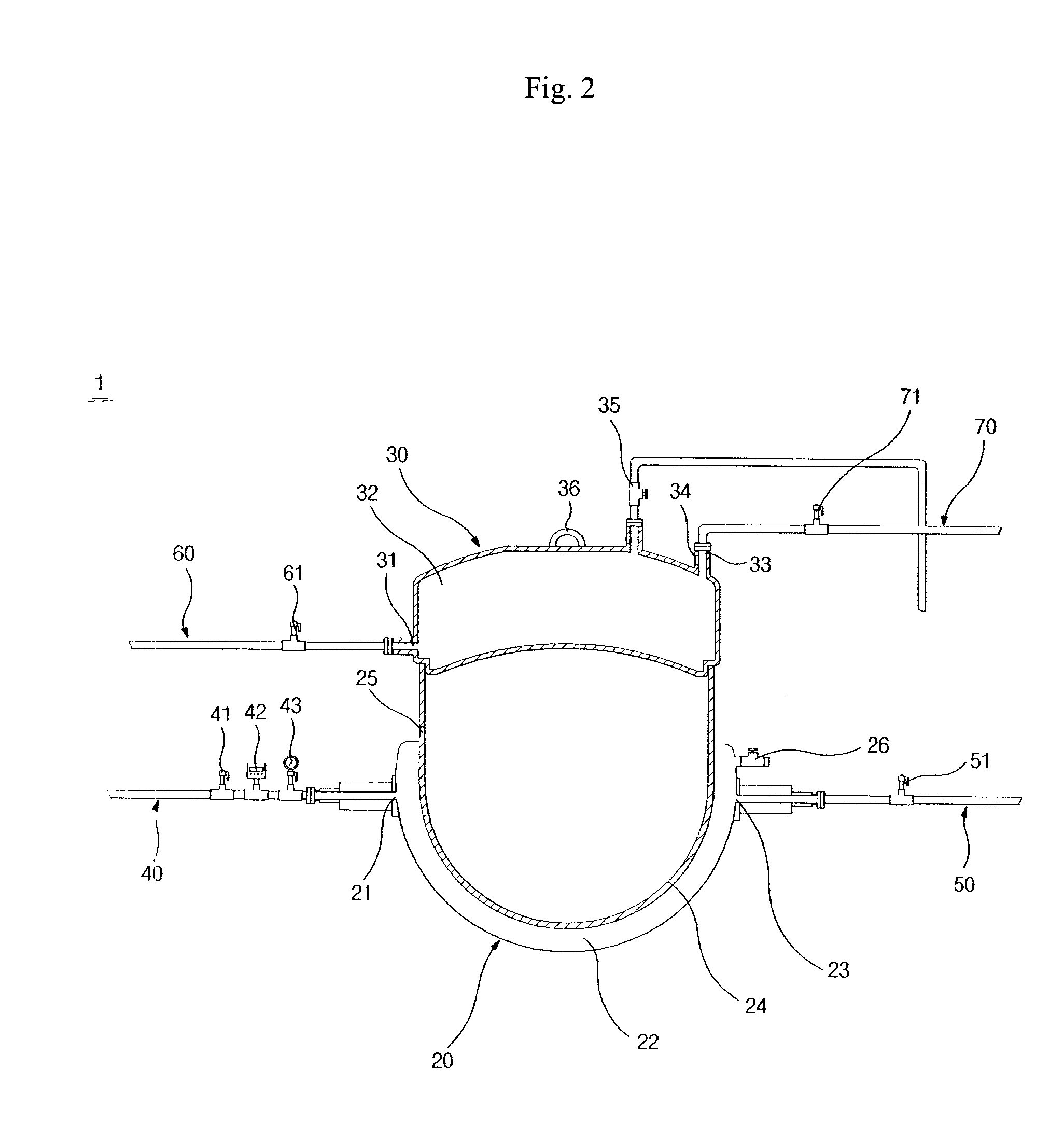

[0024]FIG. 1 is a schematic perspective view showing a vapor heating type cooking apparatus according to the present invention. FIG. 2 is a cross-sectional view showing the vapor heating type cooking apparatus according to the present invention. FIG. 3 is a view for explaining the operation of the vapor heating type cooking apparatus according to the present invention. FIG. 4 is a view showing the used state of the vapor heating type cooking apparatus according to the present invention.

[0025] Referring to FIGS. 1 and 2, the vapor heating type cooking apparatus 1 according to the present invention receives heat from high pressure vapor of a predetermined temperature to cook food materials accommodated in a body section 20.

[0026] The vapor heating type cookin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com