Patents

Literature

432results about How to "Avoid carbonization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

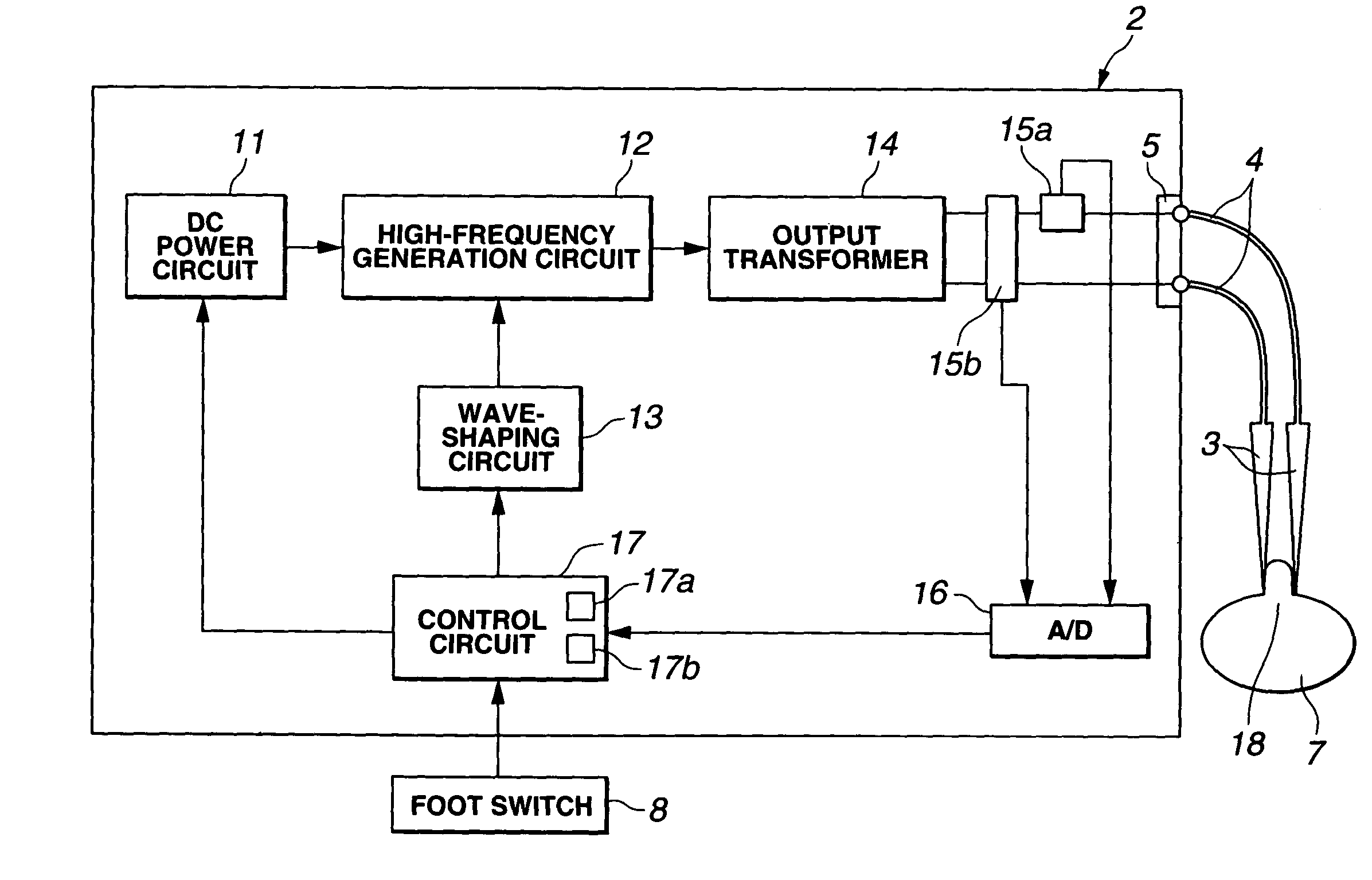

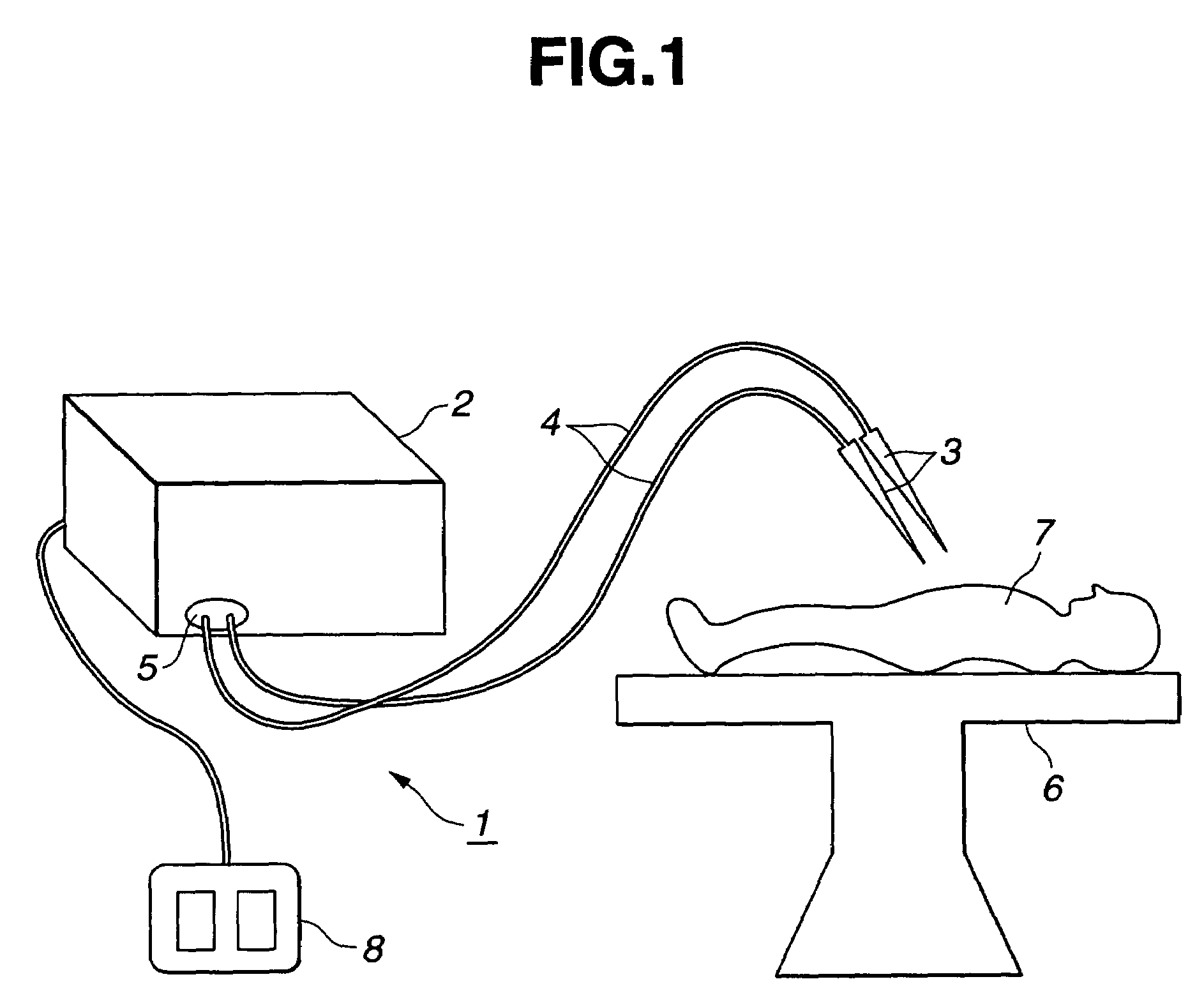

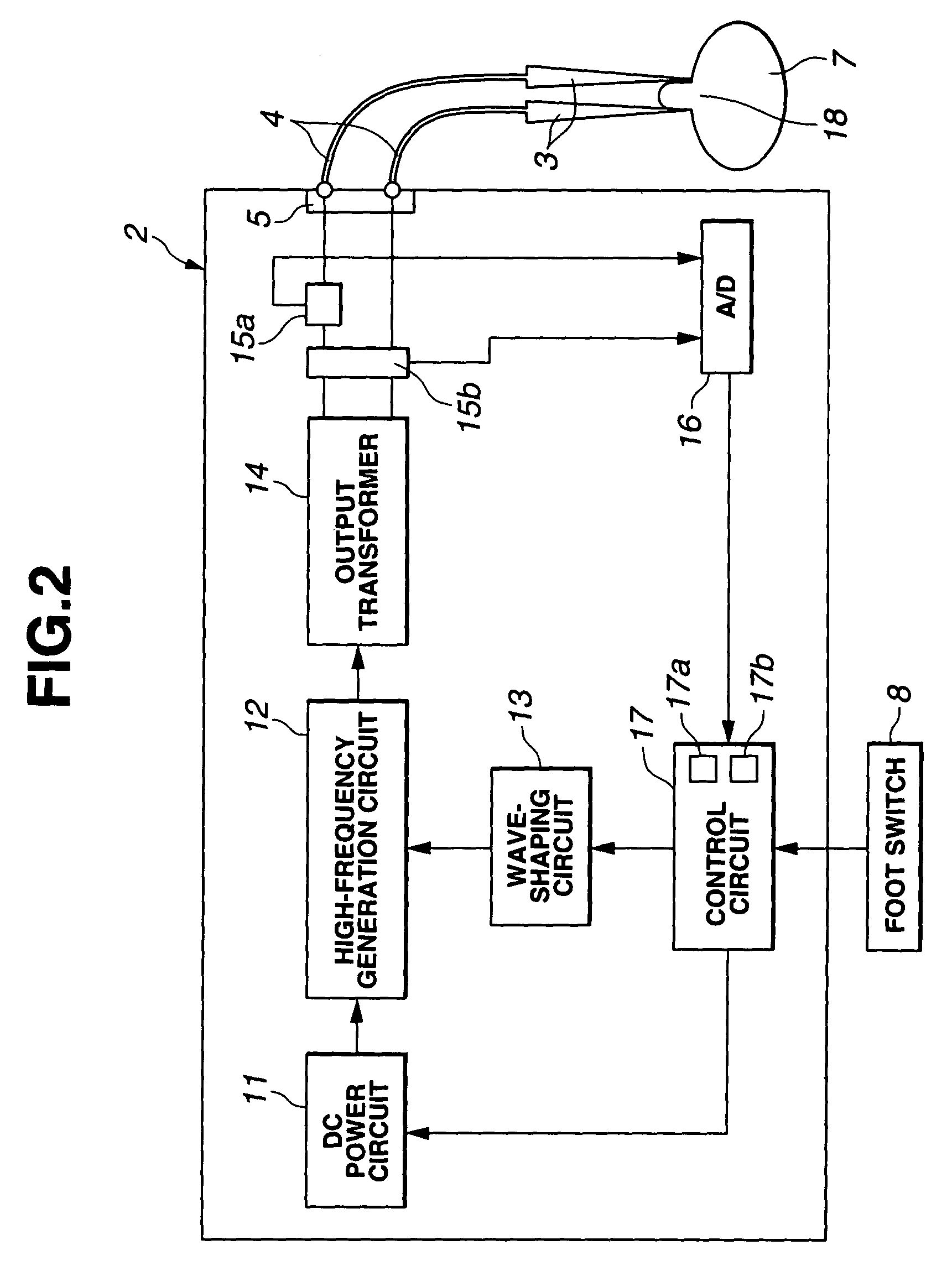

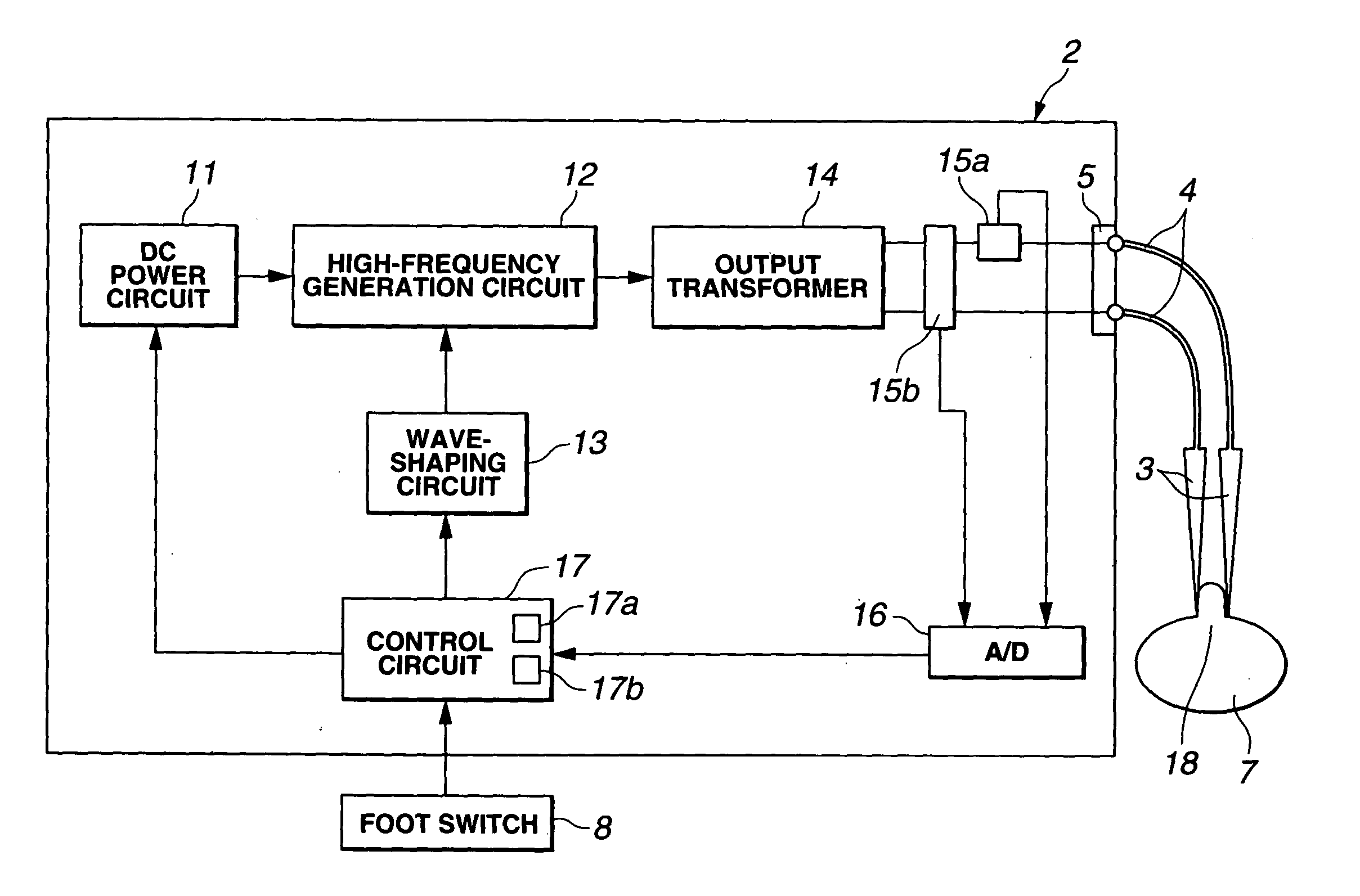

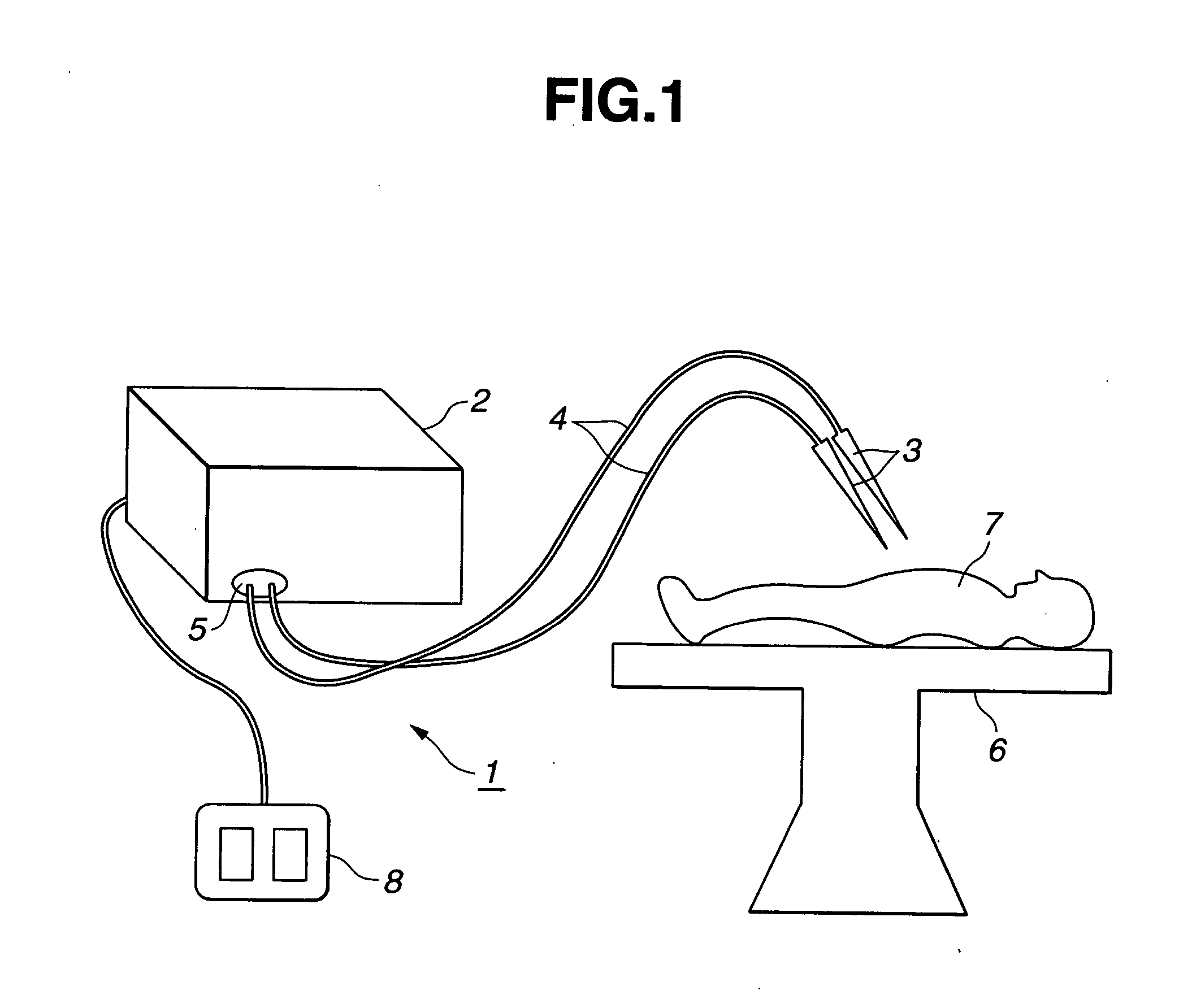

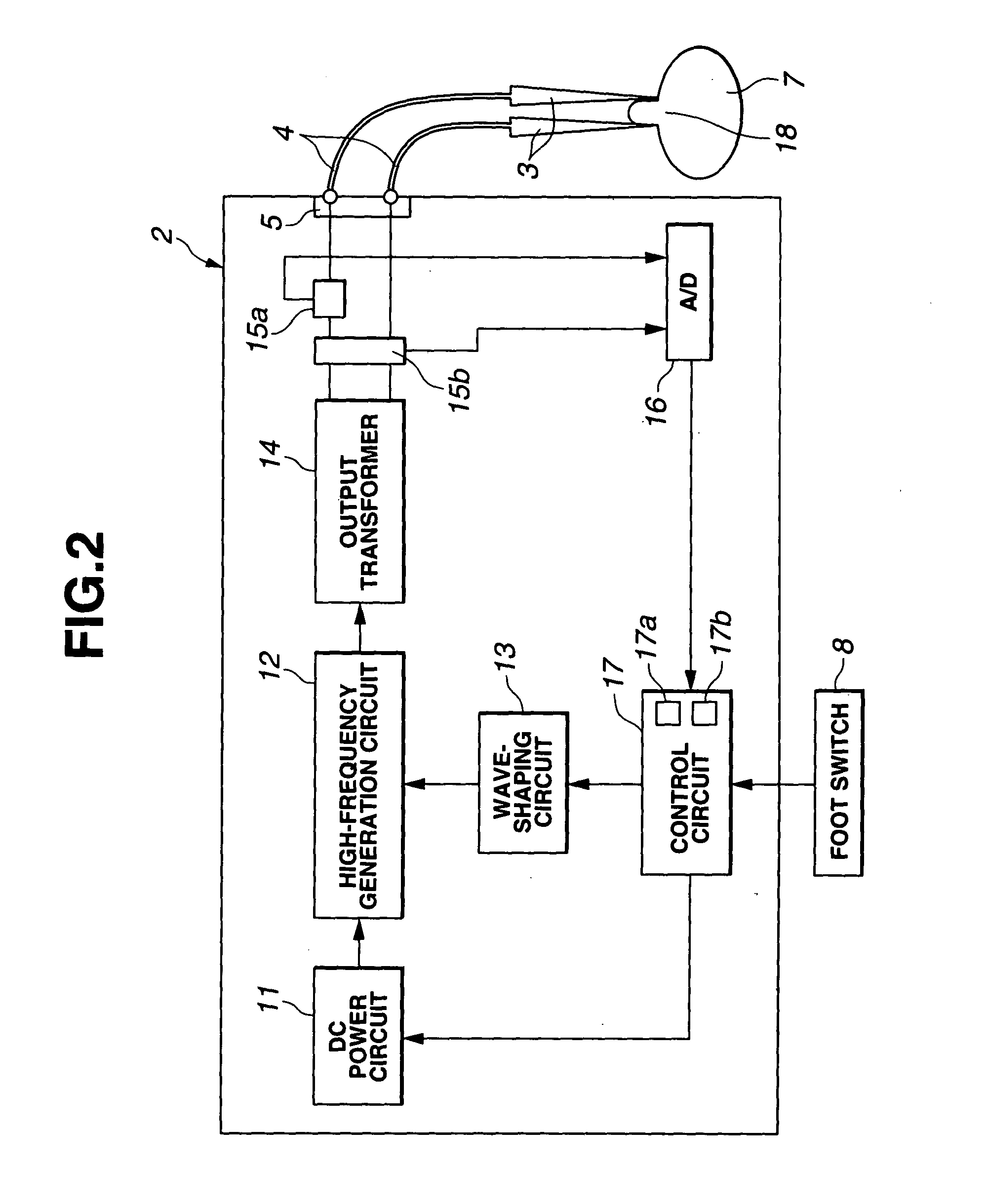

Electric operation apparatus

InactiveUS7172591B2Satisfactory coagulation abilityAvoid carbonizationControlling energy of instrumentSurgical instruments for heatingEngineeringControl circuit

When a user steps on a footswitch, high-frequency output power is delivered. A control circuit included in a diathermic power supply calculates the impedance ZSn that is offered by a living tissue immediately after delivery of high-frequency output power is started during the n-th delivery period. The control circuit also calculates the impedance ZEn that is offered thereby immediately before delivery of high-frequency output power is discontinued with elapse of predetermined time. The control circuit then discontinues delivery of high-frequency output power for the predetermined time, and calculates a difference ΔZn between the impedances. When the difference meets a predetermined condition that implies coagulation or when the number of times of delivery reaches a predetermined value, the control circuit discontinues delivery of high-frequency output power.

Owner:OLYMPUS CORP

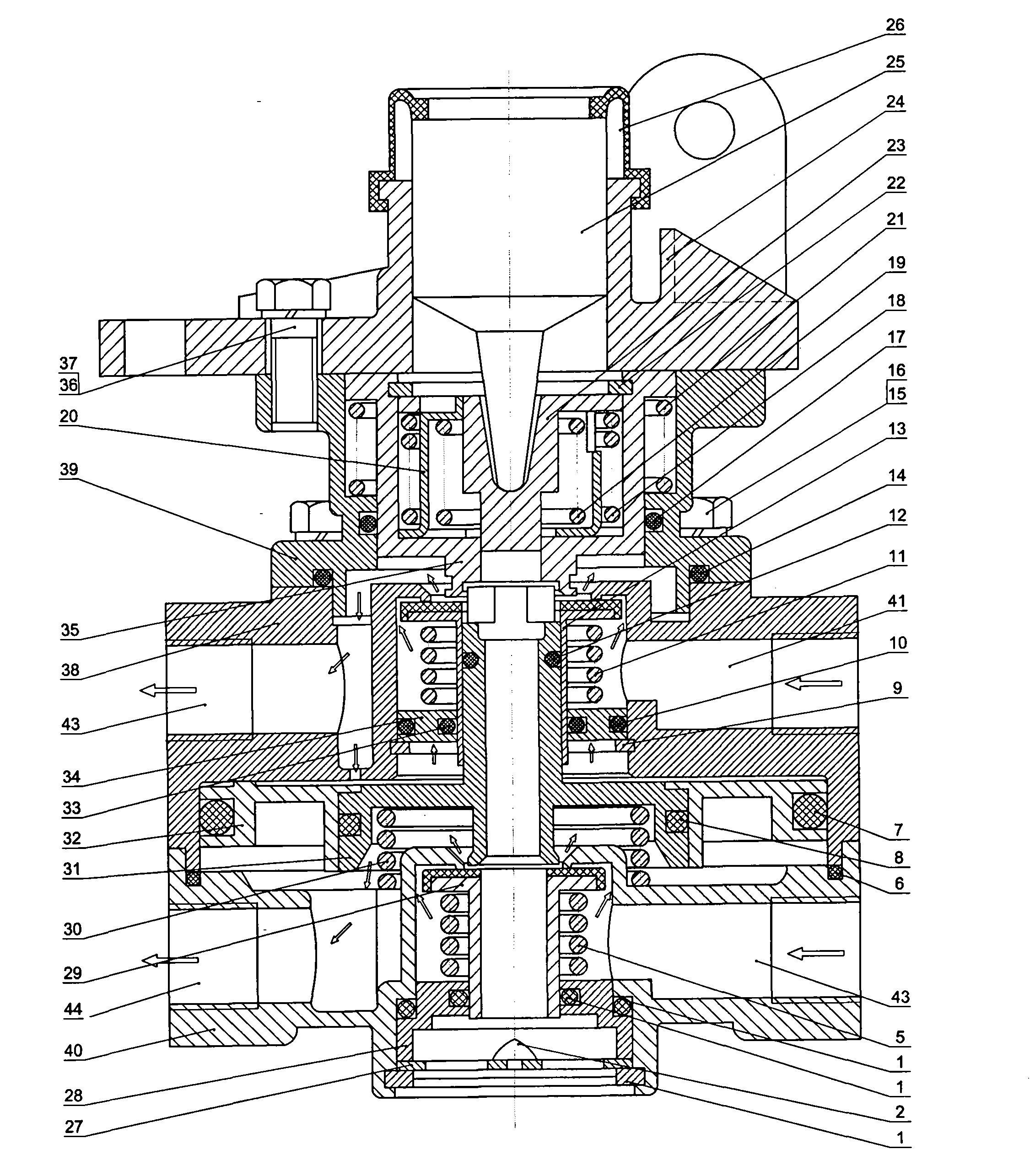

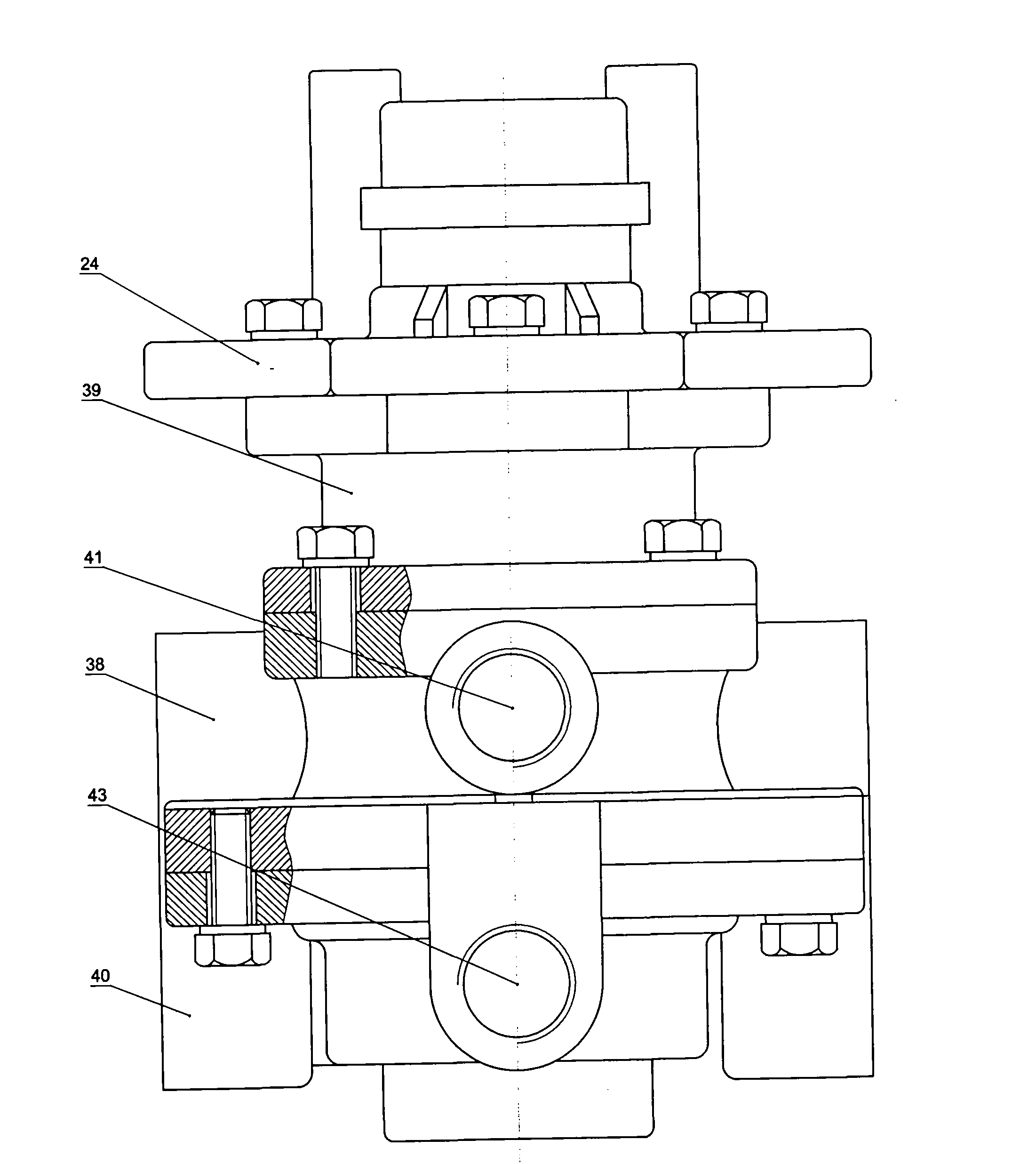

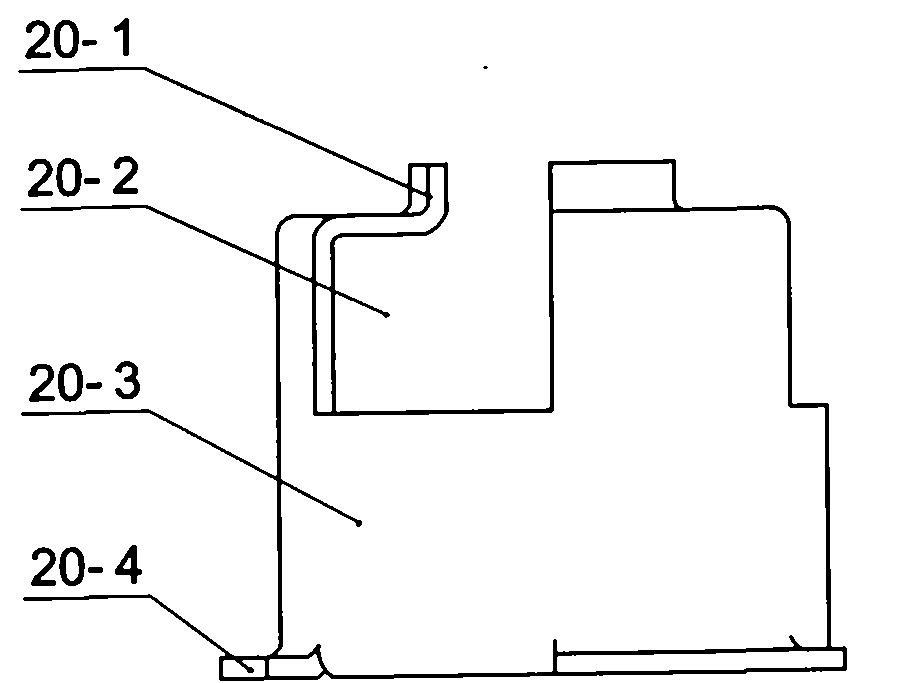

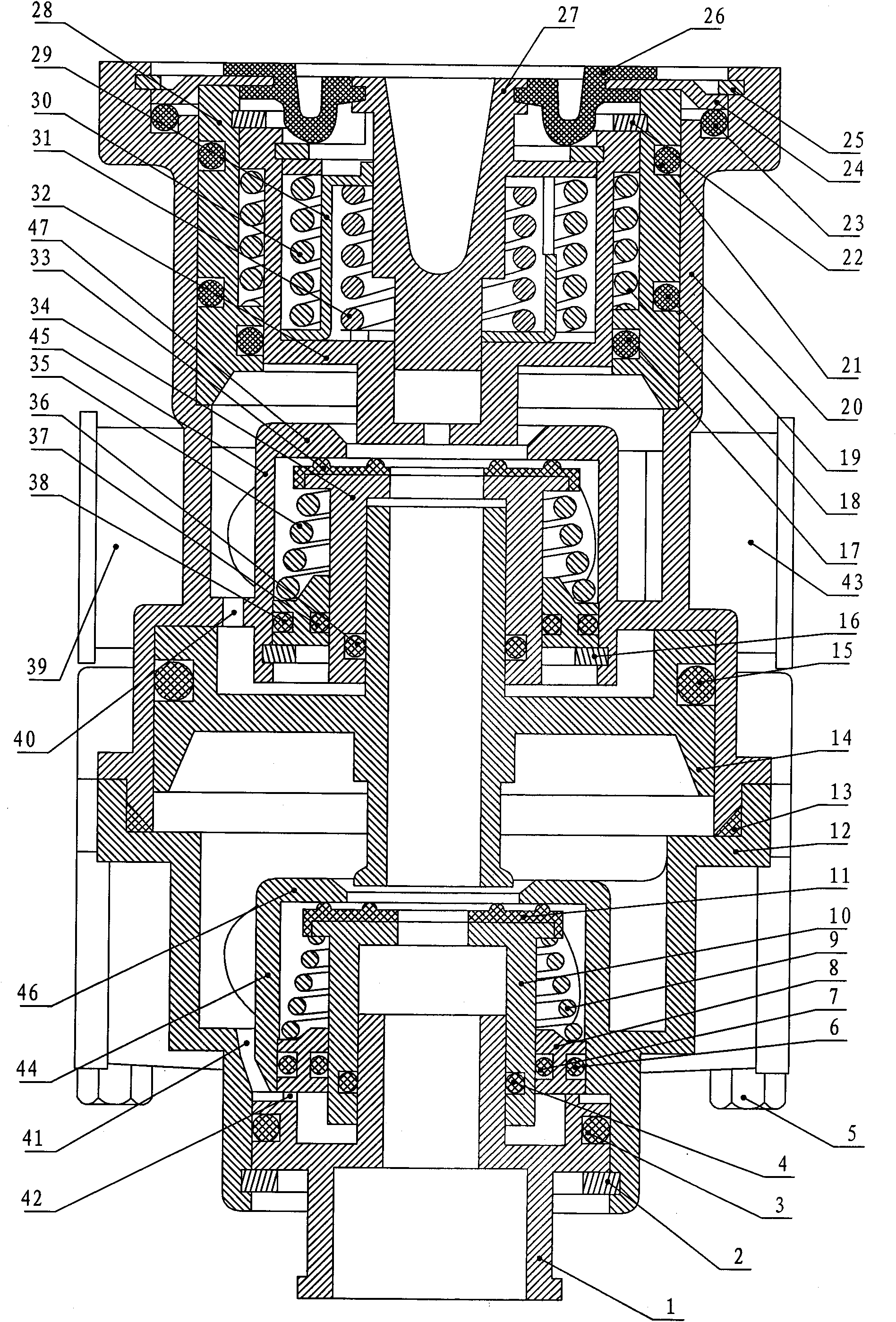

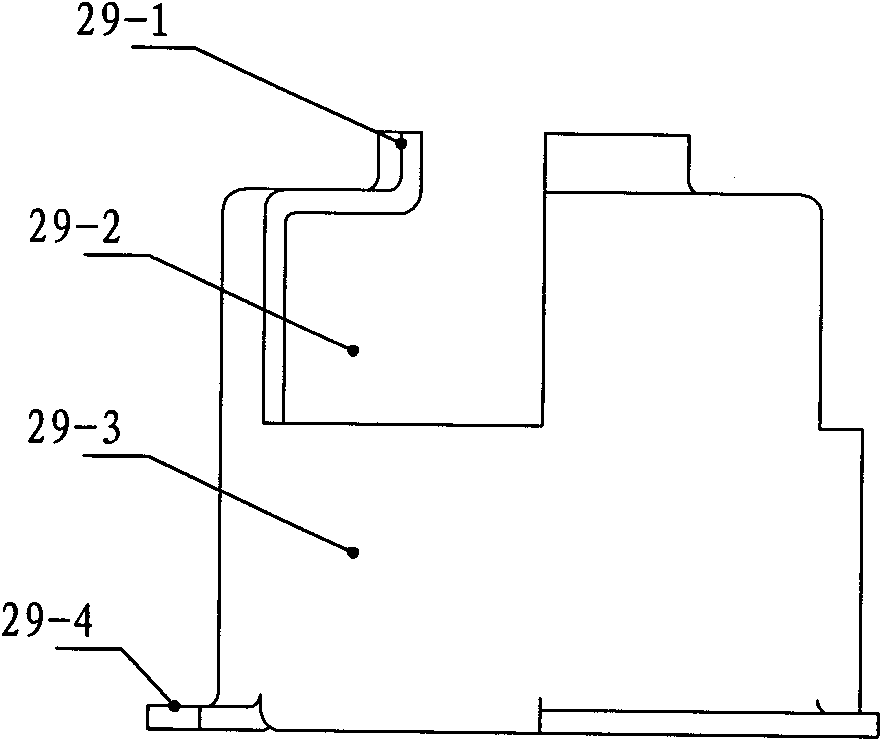

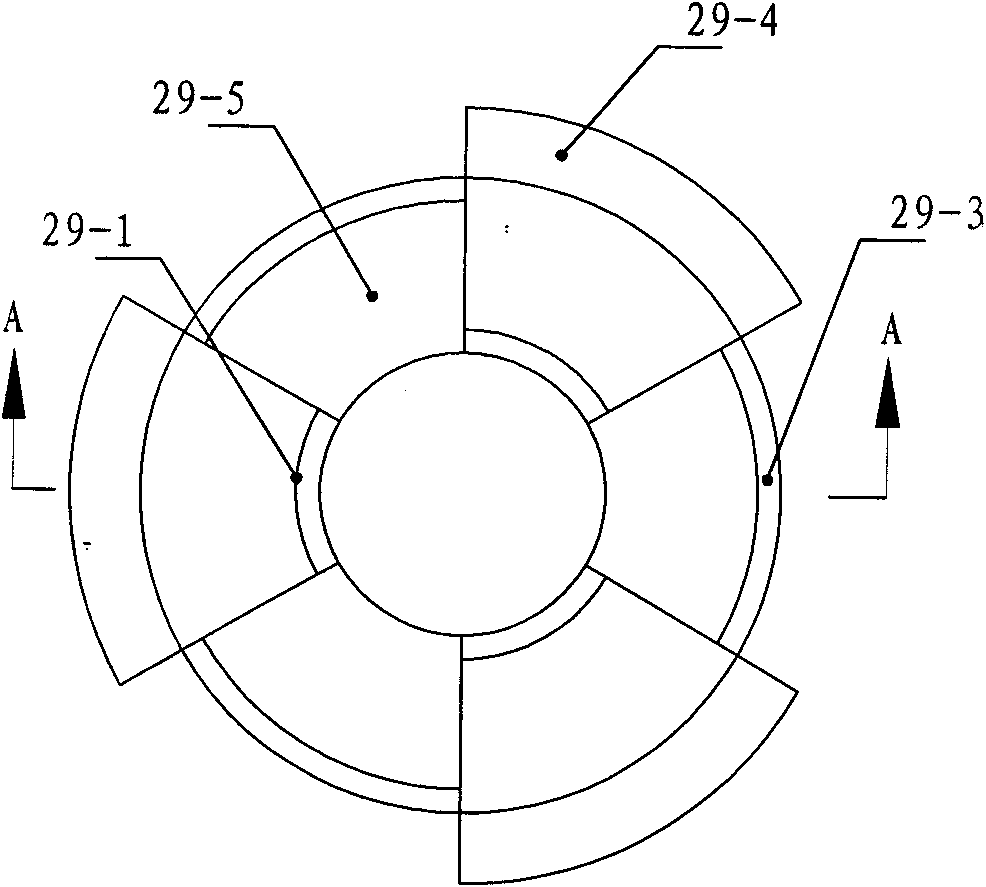

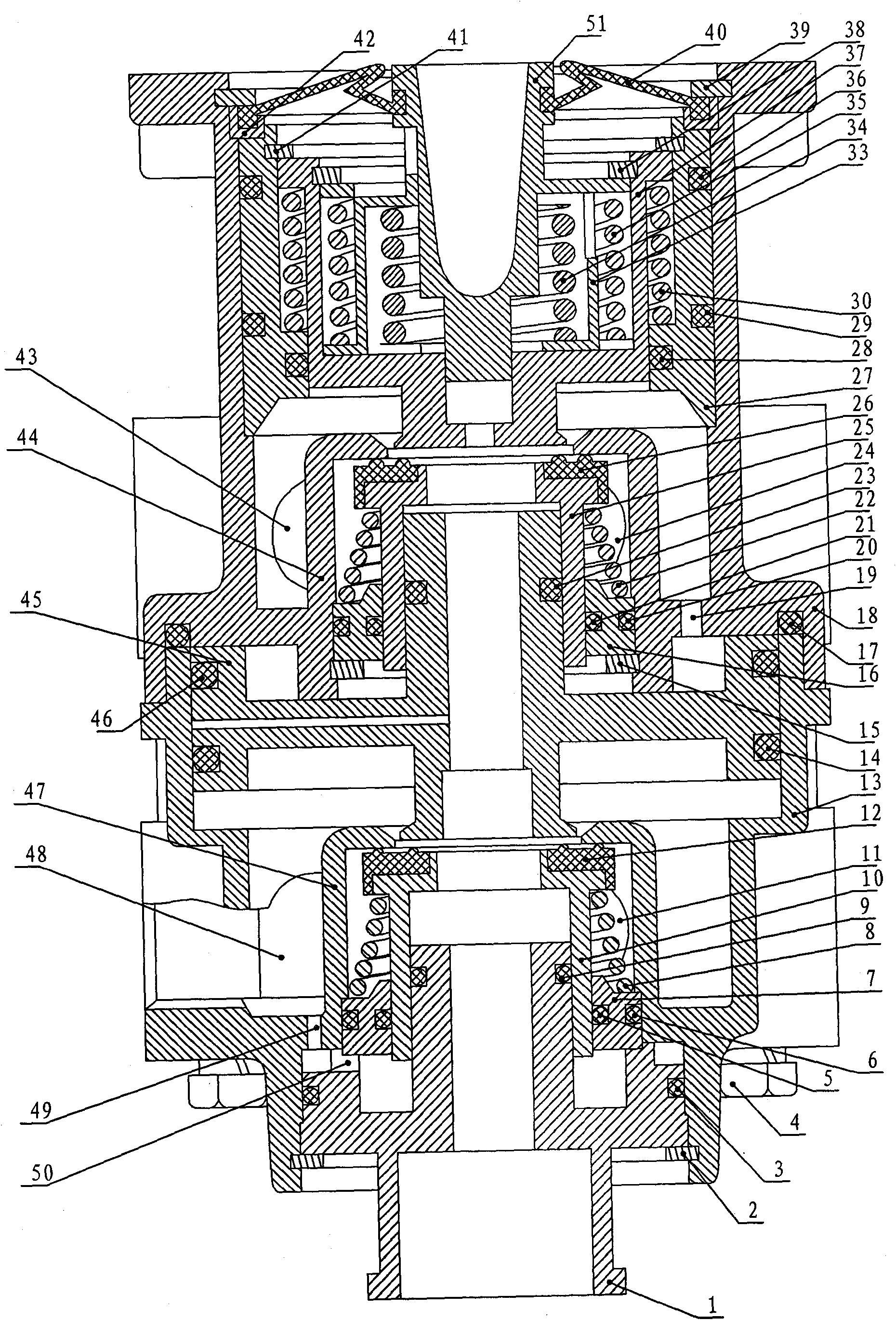

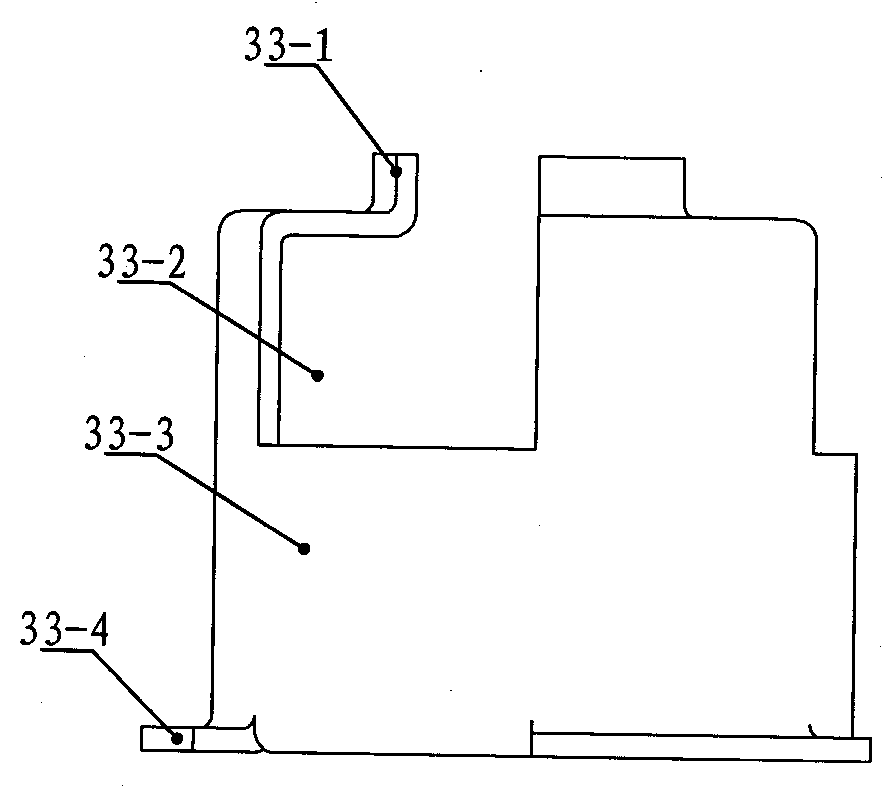

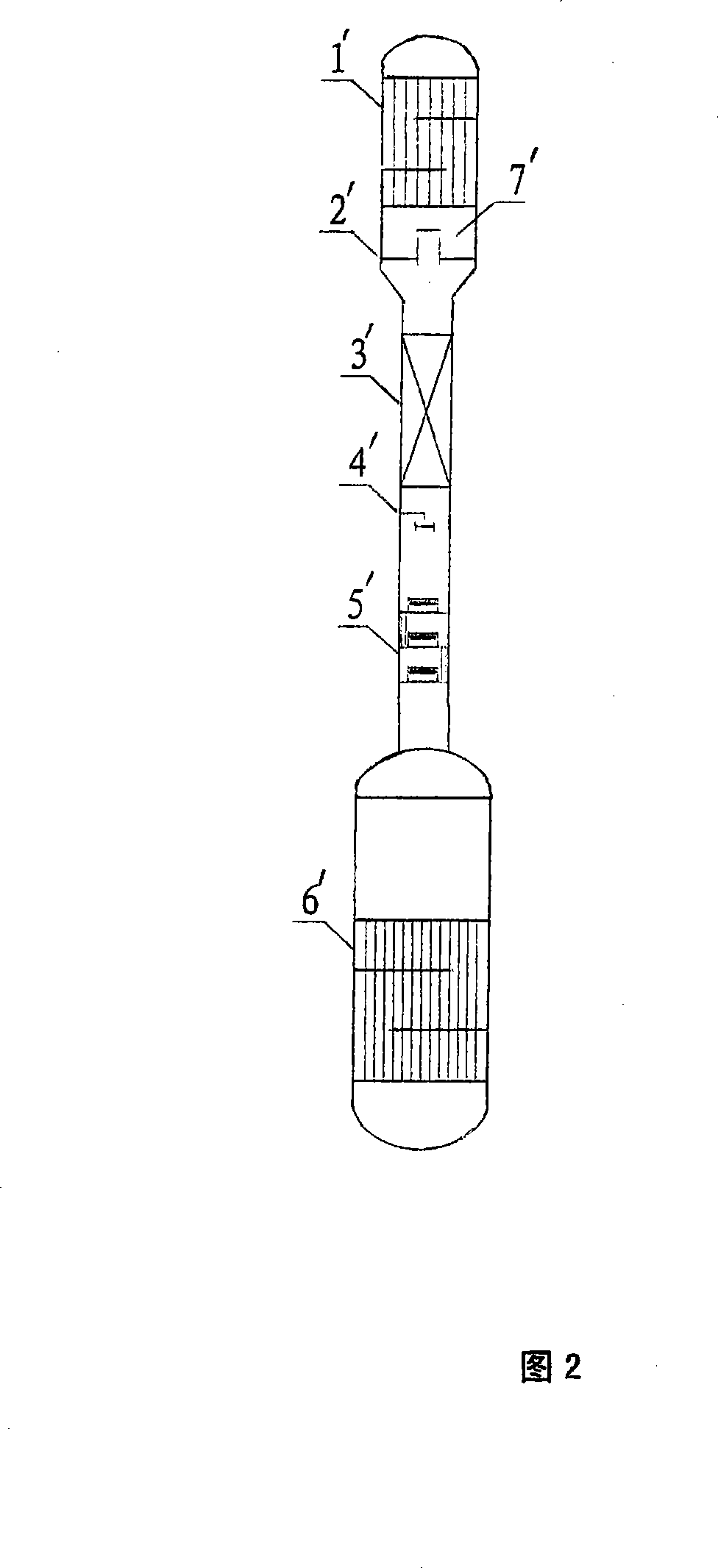

Two-stage cadence braking master valve (type V)

InactiveCN101837774AAvoid carbonizationFast and powerful combinationApplication and release valvesPiston cylinderCadence braking

The invention relates to a two-stage cadence braking master valve (type V), which comprises an upper valve body, a middle valve body and a lower valve body, wherein the upper valve body and the middle valve body are connected, sealed and fixed by a piston cylinder body; the upper edge of the lower valve body and the lower edge of the middle valve body are matched, nested, sealed and fixed; an upper piston assembly and a lower piston assembly are respectively arranged in the piston cylinder body and the middle valve body; an upper valve assembly and a lower valve assembly are respectively arranged in the middle valve body and the lower valve body; an inlet hole and an outlet hole are respectively arranged on the side surfaces of the middle valve body and the lower valve body; and the upperpiston assembly comprises an upper piston, a spring kit clamp and a mandril base. The braking master valve can generate sudden energy in the weak pressure phase at the beginning of braking, can promote rapid and powerful combination between a brake pad and a friction sheave to always maintain in a good combination condition and ensure a favorable braking effect. Meanwhile, the friction between the brake pad and the friction sheave can be reduced to the minimum extent, the brake pad is prevented from carbonizing and the service life of a braking system is prolonged.

Owner:CHANGTONG TECH

Resin bendable grinding wheel and preparation method and device

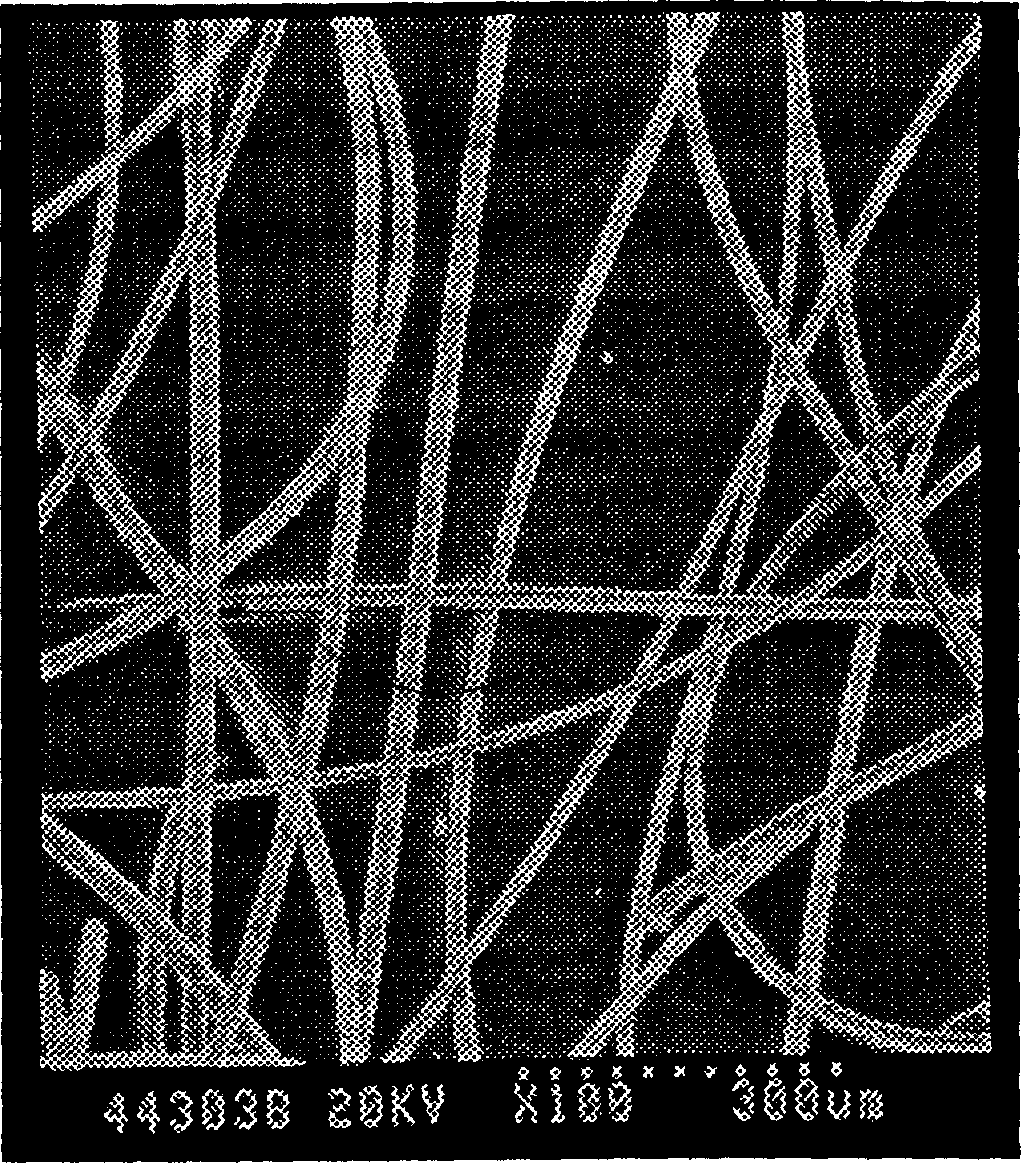

InactiveCN101804602AAvoid carbonizationIncrease contentFlexible-parts wheelsGrinding devicesFiberglass meshCarbide silicon

The invention discloses a resin bendable grinding wheel and a preparation method and a device thereof. The resin bendable grinding wheel consists of brown aluminium oxide, calcined alumina, white alundum, black silicon carbide, phenolic resin powder, phenolic resin liquid, cryolite, barium sulphate, pyretic, iron oxide red, Hunori gel, alkali-free high tensile glass fiber mesh and non-woven black cloth. Compared with the prior art, through the optimization configuration on the aspect of the material selection and working procedures, the strength, the flexibility and the aging resistance of the grinding wheel are greatly improved, and at the same time, the resource and the energy are saved; and the strength of the grinding wheel is more than 80m / s, the grinding ratio is more than or equal to 1:15, the maximum bendable angle can reach 40 degrees, the tensile strength is greatly improved, the service life is prolonged by two times, the energy consumption is reduced by 5 to 10 percent, and the yield of the finished product can reach more than 99 percent.

Owner:GUIZHOU FUSUN INDAL

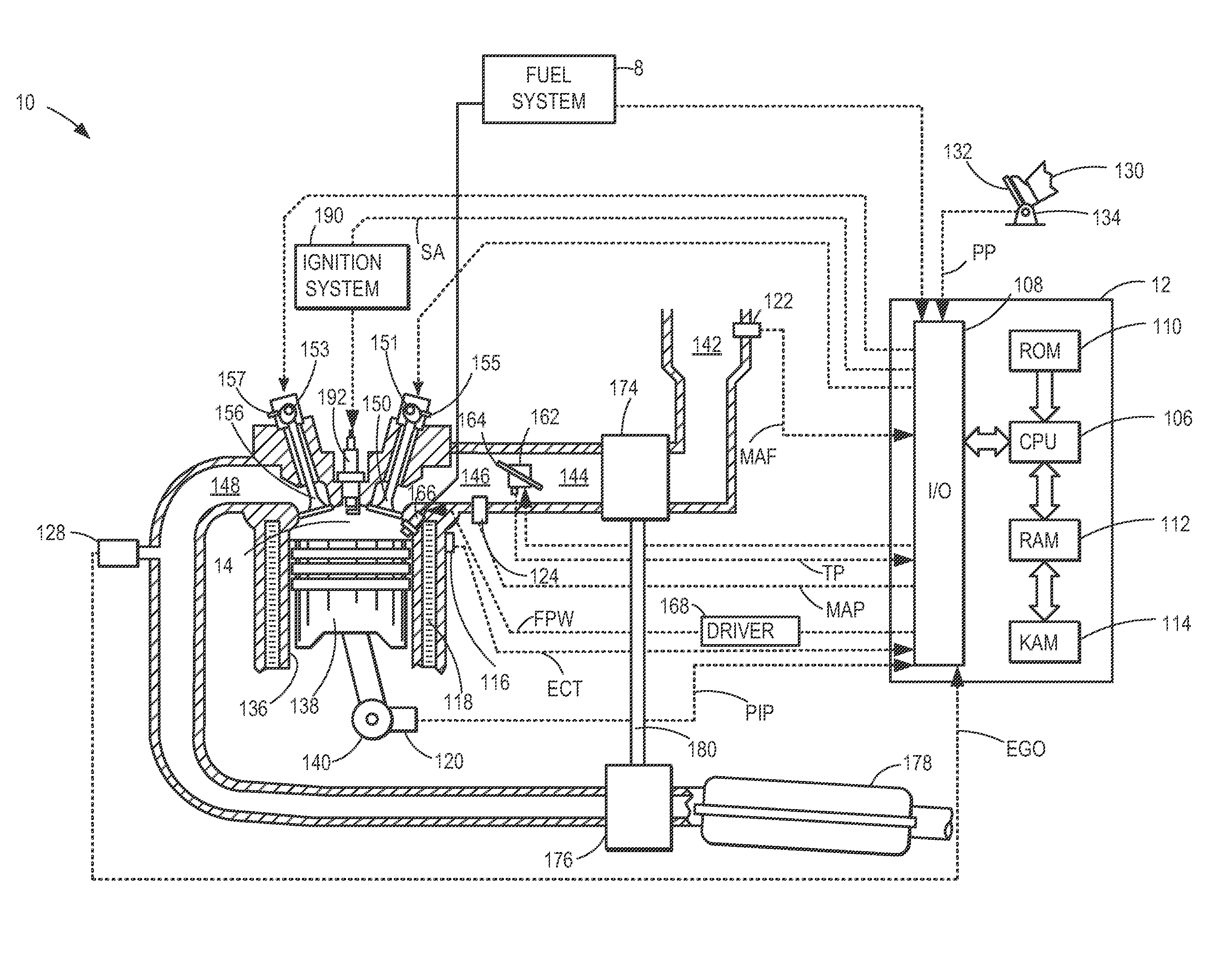

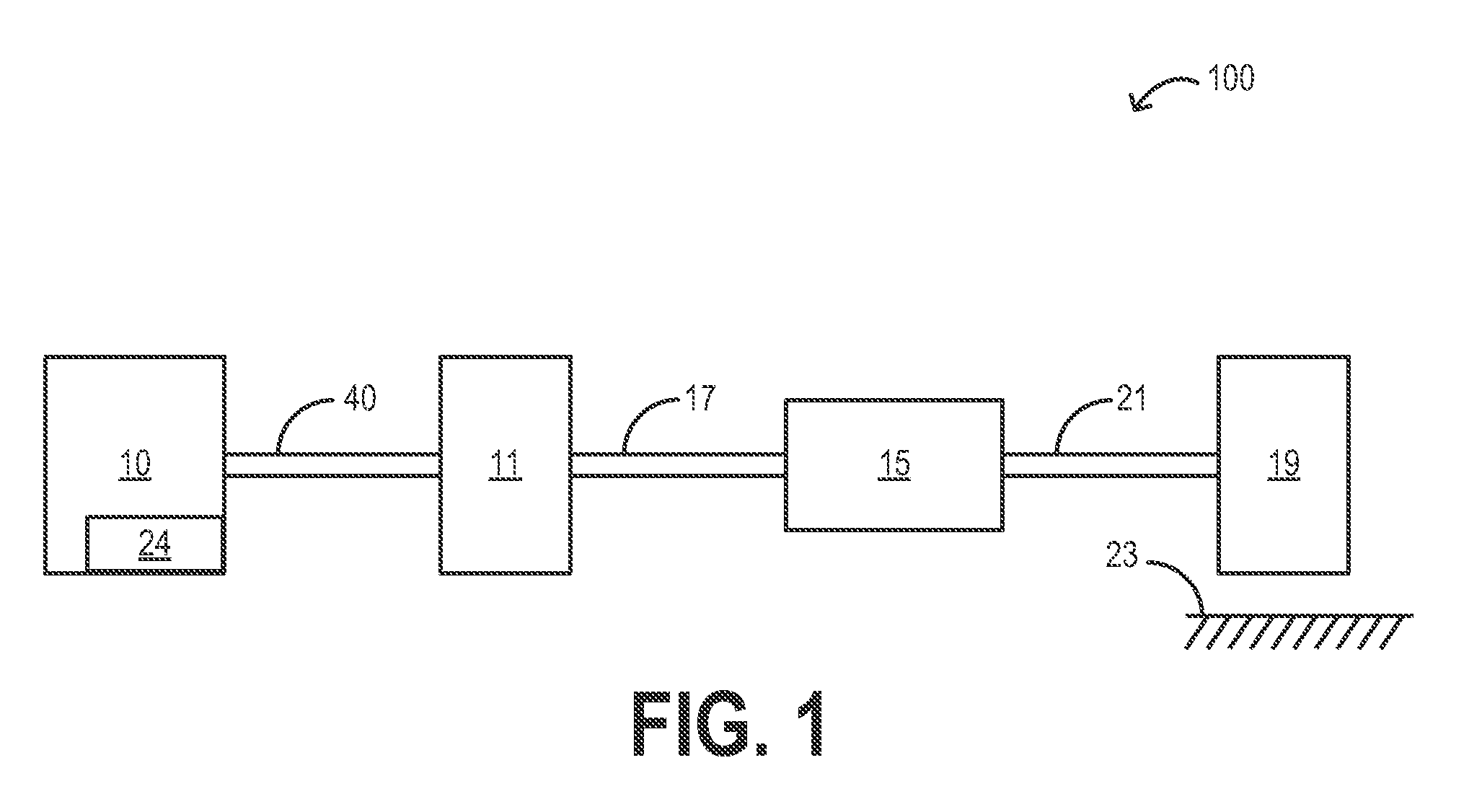

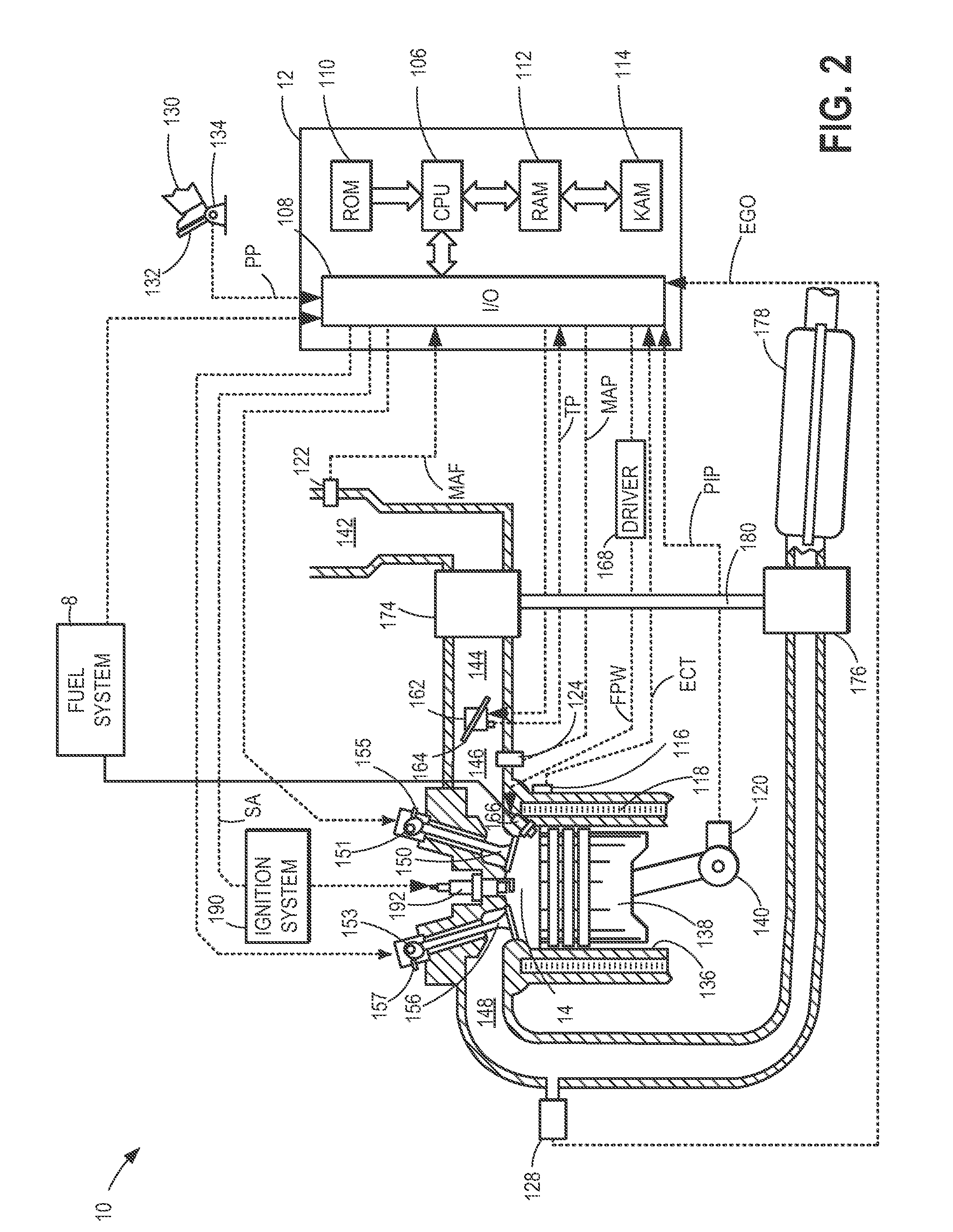

Method for avoiding turbocharger damage

ActiveUS20120123666A1Reduce fuel consumptionReduce exhaust gas emissionAnalogue computers for vehiclesElectrical controlMobile vehicleTurbocharger

A method for operating an engine of a motor vehicle is provided. The method comprises operating at least one turbocharger, operating a start / stop automatic system which automatically switches off the internal combustion engine when a stop condition is met, and automatically starts the internal combustion engine when a starting condition is met, and when the stop condition is met, delaying the automatic switching off of the internal combustion engine by a predefinable delay time (Δt). In one example, automatic shut off of the engine may be delayed in order ensure adequate cooling of the turbocharger.

Owner:FORD GLOBAL TECH LLC

Electric operation apparatus

InactiveUS20050101948A1Satisfactory coagulation abilityAvoid carbonizationControlling energy of instrumentSurgical instruments for heatingBiological bodyEngineering

When a user steps on a footswitch, high-frequency output power is delivered. A control circuit included in a diathermic power supply calculates the impedance ZSn that is offered by a living tissue immediately after delivery of high-frequency output power is started during the n-th delivery period. The control circuit also calculates the impedance ZEn that is offered thereby immediately before delivery of high-frequency output power is discontinued with elapse of predetermined time. The control circuit then discontinues delivery of high-frequency output power for the predetermined time, and calculates a difference ΔZn between the impedances. When the difference meets a predetermined condition that implies coagulation or when the number of times of delivery reaches a predetermined value, the control circuit discontinues delivery of high-frequency output power.

Owner:OLYMPUS CORP

Method for producing silicon dioxide silica aerogel by drying in atmosphere pressure with rice hull as raw material

The invention discloses a drying preparation method of silicon dioxide aerogel under atmospheric pressure, using rice husk as raw material, which comprises the following procedures: (1) preparation of rice husk sol; (2) aging of gel; (3) solvent exchange; (4) surface modification of gel; (5) drying under atmospheric pressure. Instead of expensive toxicant organ silicon source, agricultural trashes rice husk is used as raw material, thus greatly reduce the cost; instead of super-critical drying, drying under atmospheric pressure greatly reduces the requirements for the whole process on the equipment, greatly improves the safety performance on one hand, also greatly reduces the running cost on the other. The method in the invention has the advantages of simple technology, easy operation, which is suitable for scale production.

Owner:纳诺科技有限公司

Nano composite latex paint and preparing method thereof

The composition of the invented nano composite latex paint comprises (wt%) 0.3-1% of moistening dipersant, 2-70% of nano pulp, 1-4% of film-forming adjuvant, 0.5-2% of anti-sedimentation agent, 0.8-15% of antifreeze agent, 0.5-3% of defoaming agent, 5-30% of pigment, 0-30% of filling material, 10-45% of emulsion, 0.2-2% of thickening agent, 0.2-2% of leveling agent, 0-2% of pH regulating agent, 0-2% of microbiocide and 2-35% of water. Its preparation method includes two steps: firstly, preparing dispersion stable nano material pulp, then adding said nano material pulp into the latex component according to a certain process so as to obtain the invented high-performance product.

Owner:中科纳米涂料技术(苏州)有限公司

Two-stage foot braking master valve

InactiveCN101857018AExtended service lifeAvoid carbonizationApplication and release valvesMechanical engineeringPiston

The invention relates to a two-stage foot braking master valve (I type) which comprises an upper valve body and a lower valve body, wherein both the upper valve body and the lower valve body are provided with an air inlet hole and an air outlet hole, the lower edge of the upper valve body is inserted into the upper edge of the lower valve body, an upper piston assembly is installed at the upper part in the upper valve body, the upper piston assembly comprises a piston bush, an upper piston, a spring package clip and an ejector pin seat, the inside and the outside of the spring package clip are respectively provided with a pressure intensity spring and a steady pressure spring, a certain distance is reserved between the upper part of the pressure intensity spring and the lower surface of the wide disc of the ejector pin seat, and the distance enables the valve to produce a secondary pressure intensity to quickly and powerfully combine a brake block and a brake drum so as to maintain a favorable combination condition all the time and ensure a favorable brake effect all the time. Simultaneously, the friction between the brake block and the brake drum can be decreased to the greatest extent, and the brake block can be prevented from being carbonized so as to prolong the service life of the brake.

Owner:CHANGTONG TECH

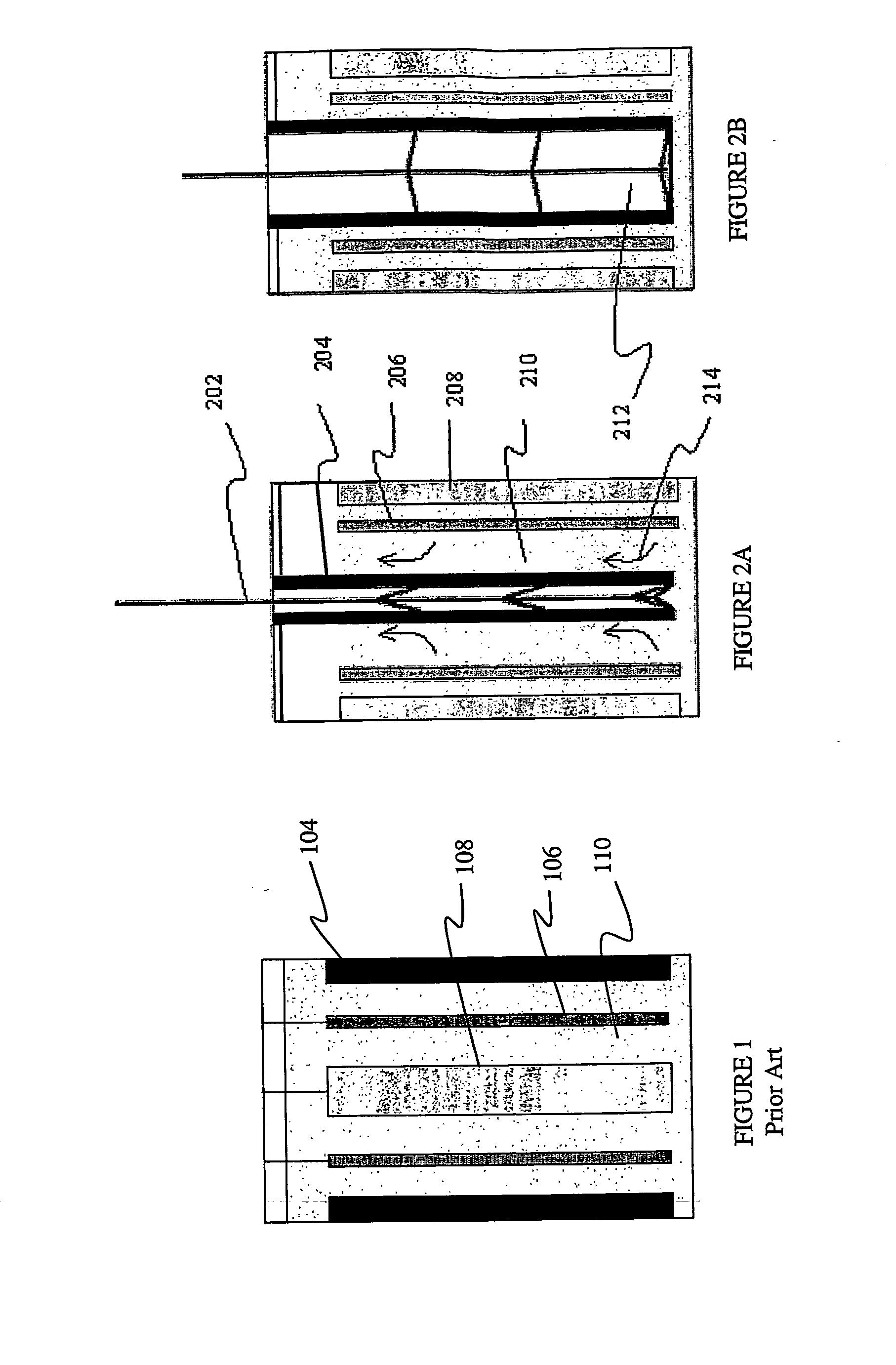

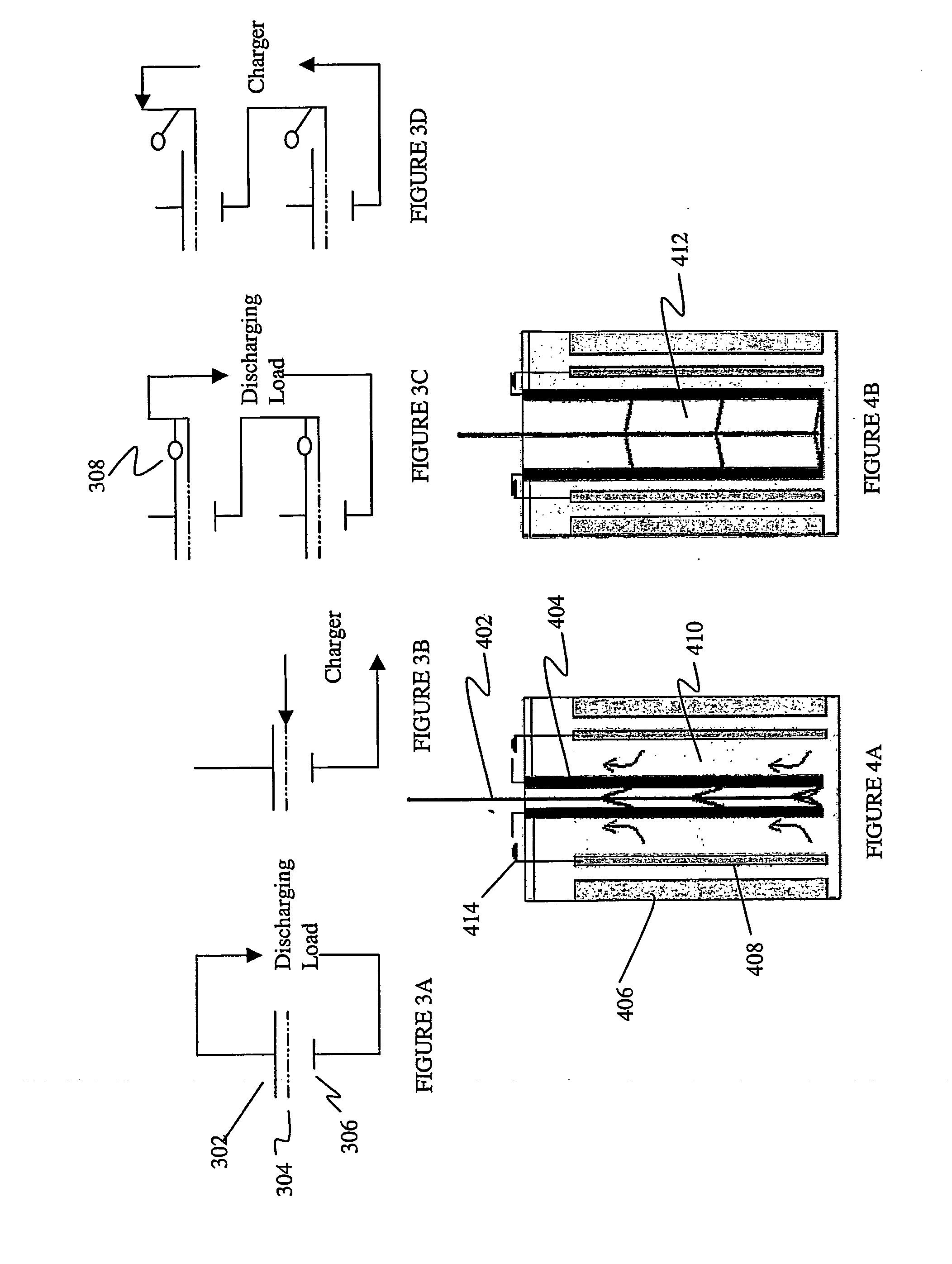

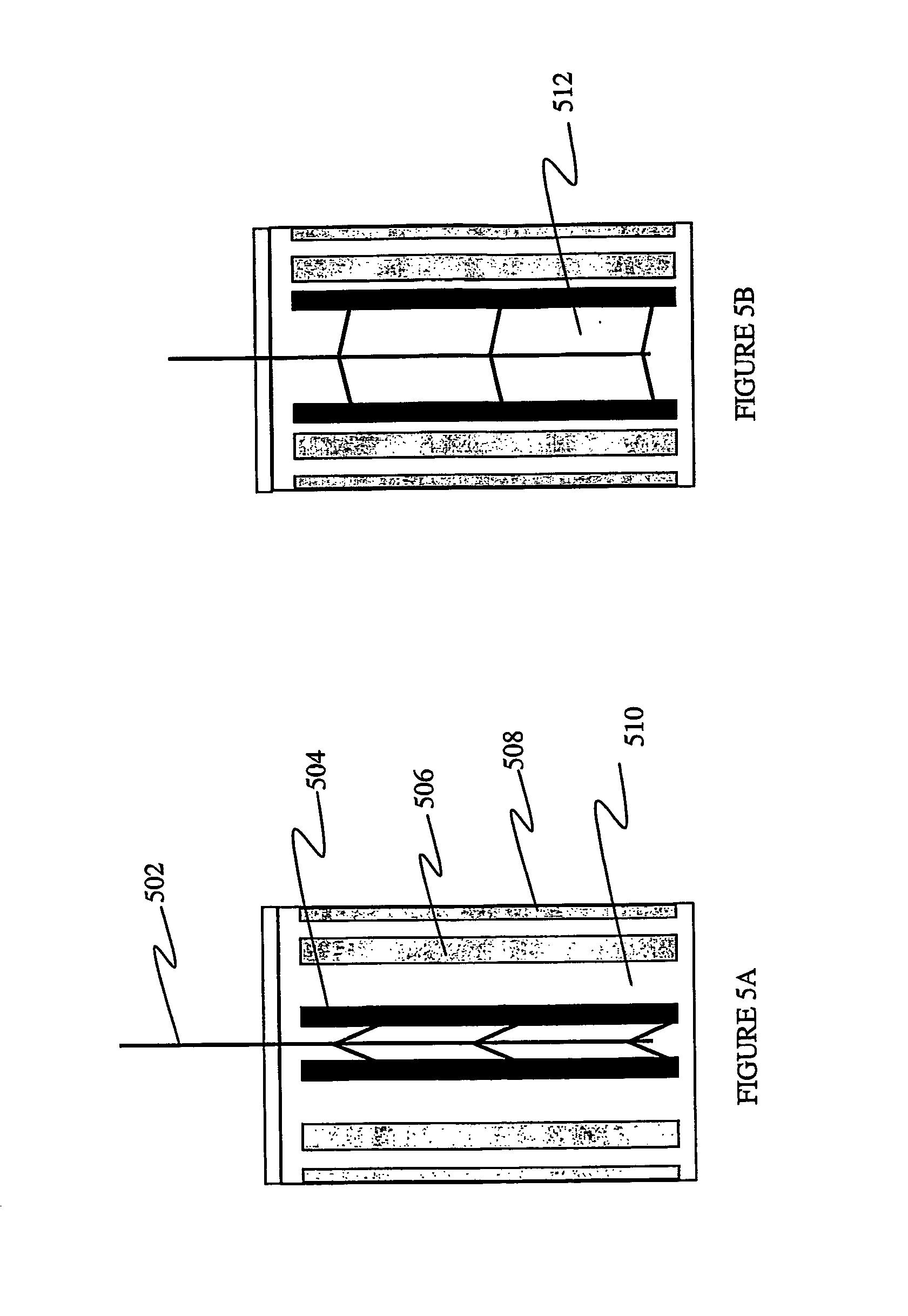

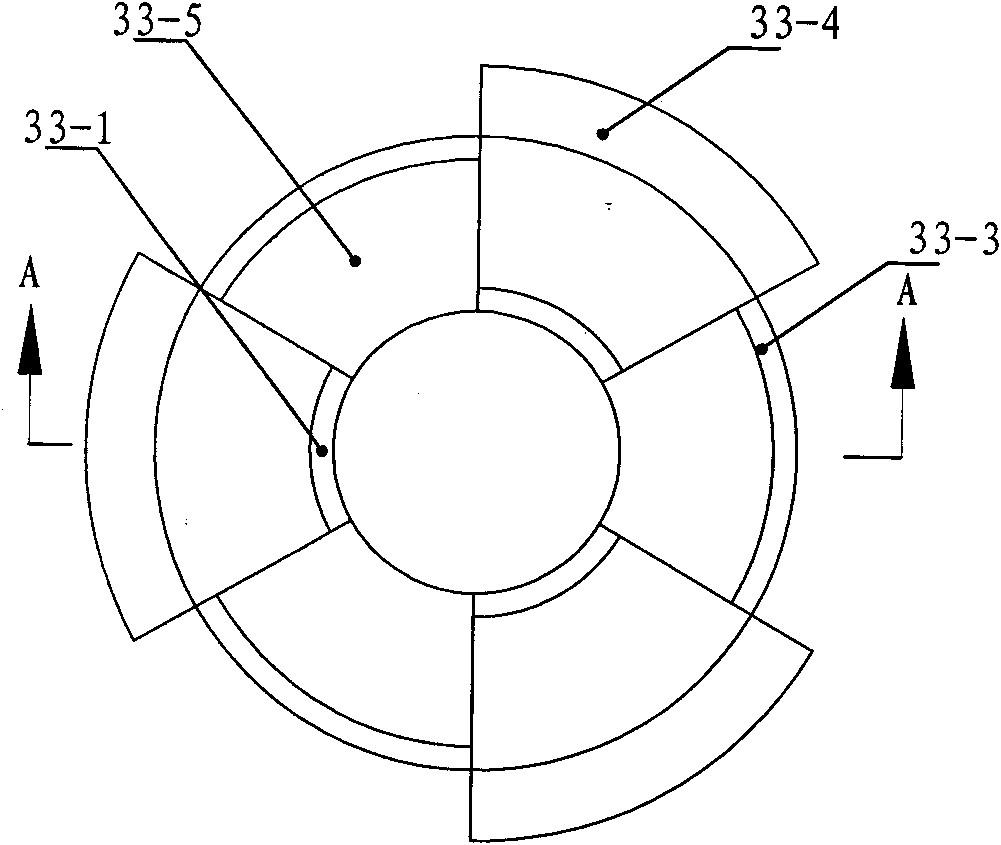

Rechargeable metal air electrochemical cell incorporating collapsible cathode assembly

InactiveUS20050019651A1Promotes Oxygen RemovalExtended service lifeFuel and primary cellsFuel and secondary cellsMetal–air electrochemical cellEngineering

The rechargeable metal air electrochemical cell generally includes a pair of air cathode portions centrally disposed and attached to each other with a collapsible mechanism. Anodes are disposed in ionic communication with each air cathode portions via a suitable electrolyte. For recharging, a pair of third charging electrodes is provided ionic communication with the anode portions.

Owner:EVIONYX INC

Self-cleaning nona composite environment-friendly type emulsion paint and preparation method thereof

The invention discloses a self-cleaning nanometer composite environmental protection latex paint and preparing method, which comprises the following parts: 0.5-5% wetting disperser, 0.5-50% nanometer concentrated slurry, 0.5-10% hydrophobic agent, 0.5-10% anion powder, 0.5-8% filming adjuvant, 0.1-2% anti-settling agent, 0.8-10% antifreeze agent, 0.1-3% defoamer, 4-30% dye, 0-30% filler, 15-45% emulsion, 0.1-4% thickener, 0.1-3% levelling agent, 0-3% pH adjuster, 0-4% microbe eliminating agent and 0.5-45% water. The preparing method comprises the following steps: 1) placing water in the container with high-speed disperser; adding microbe eliminating agent, nanometer condensing slurry, hydrophobic agent, anion powder; blending evenly; adding dye and filler; dispersing until finesse reaches 20-60um; 2) adding emulsion, pH value adjuster, thickener and leveling agent continuously.

Owner:中科纳米涂料技术(苏州)有限公司

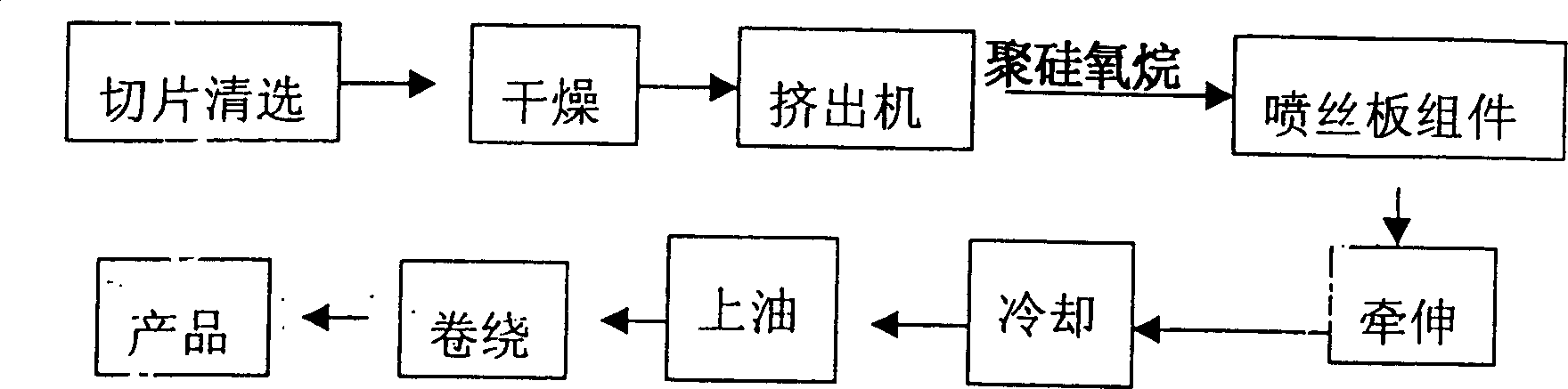

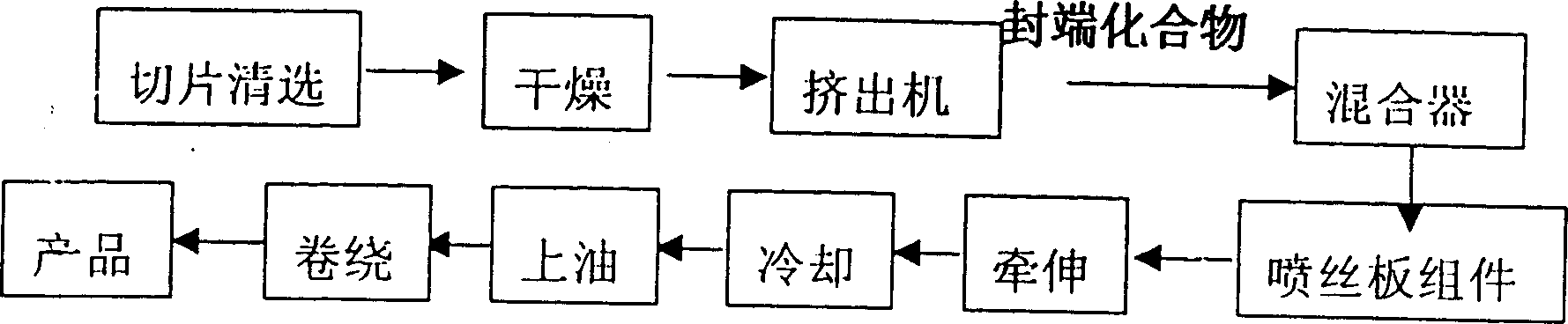

Preparation method of melt spinning polyurethane fiber thin denier filament

InactiveCN1410605ASolve the supporting use problemSolve the situation without crosslinkerMonocomponent polyurethanes artificial filamentSynthetic polymer filament chemical after-treatmentThermoplastic polyurethaneCarbonization

The method includes following steps. (1) With being added in the screw extruder, the thermoplastic polyurethane is melted and mixed. (2) The crosslinking agent is added in the metering section of theextruder or between the extruder and mixer. (3) The melted woven material through the nozzle plate is ejected, spun and wound. The invention solves the issue of the mating use between the thermoplastic polyurethane and the crosslinking agent and prevents the thermal degradationand the carbonization so as to obtain the product with excellent combination property.

Owner:江苏南黄海实业股份有限公司

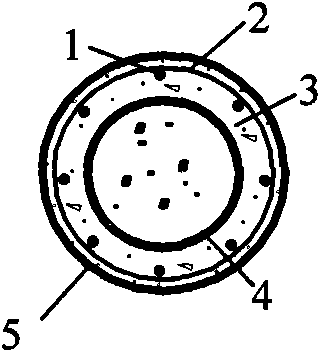

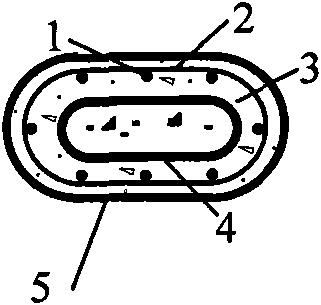

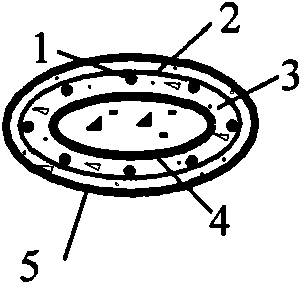

Plant functional polyester filament and preparation method thereof

InactiveCN110863252AHigh mechanical strengthImprove wear resistanceMonocomponent polyesters artificial filamentSynthetic polymer filament chemical after-treatmentPolyesterFiber

The invention discloses a plant functional polyester filament and a preparation method thereof. The plant functional polyester filament comprises 0.1-1.5% of plant extract. The preparation method includes a step of plant functional polyester master batch preparation, and the step of plant functional polyester master batch preparation includes: slicing PET, heating to melt, adding an antioxidant and a dispersing agent, and stirring; then, adding a protecting agent and the plant extract, and mixing at a high speed; finally, adding a modifying agent, well mixing to obtain a mixture, and extrudingfor granulation. The plant functional polyester filament integrates high mechanical strength of polyester fibers and the anti-mite and antibacterial performance of the plant extract and has advantages of antibacterial and deodorizing effects, high wear resistance, high elasticity, comfort in hand feeling and less proneness to pilling and fouling.

Owner:BESTEE MATERIAL (TSINGTAO) CO LTD

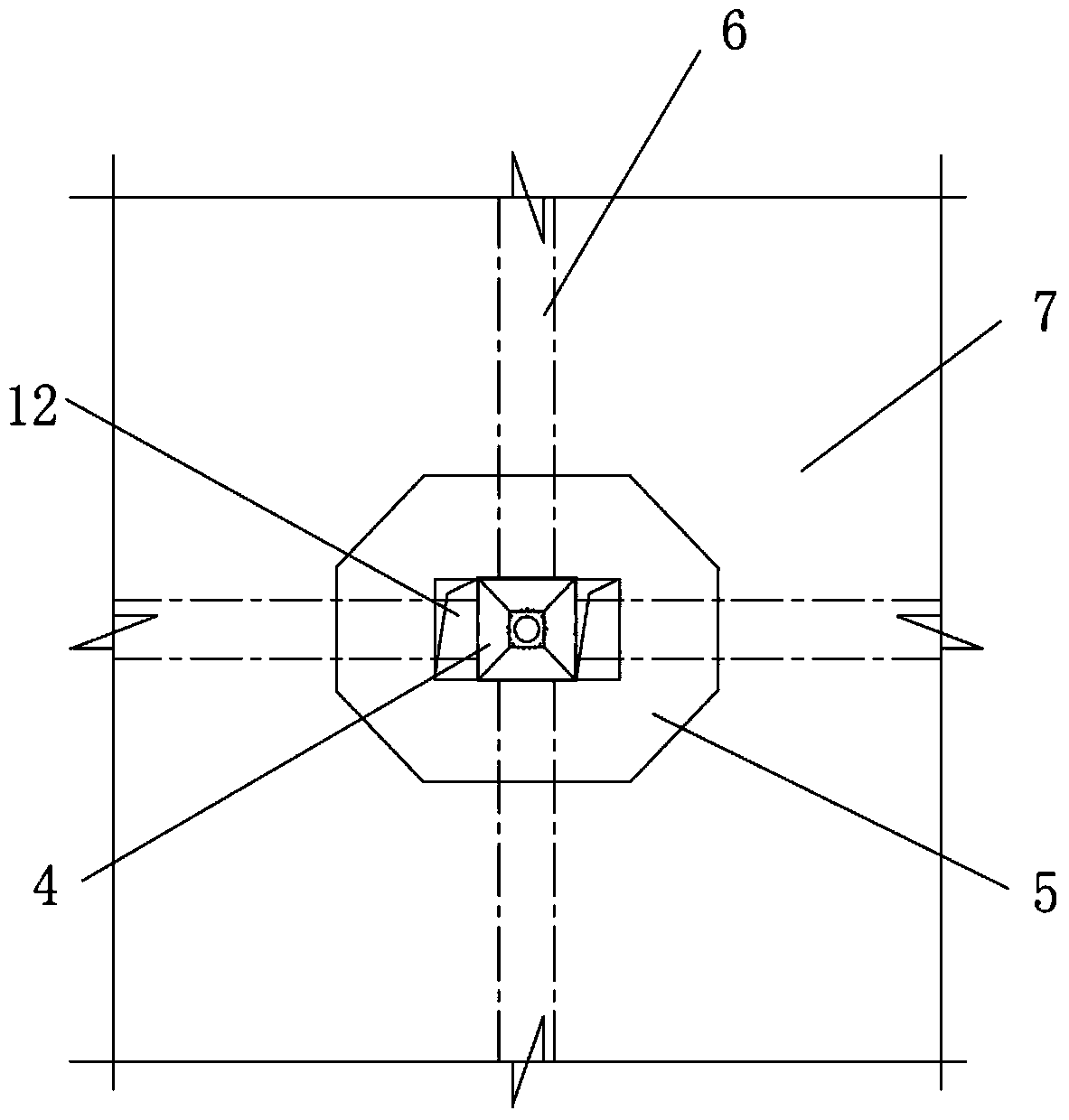

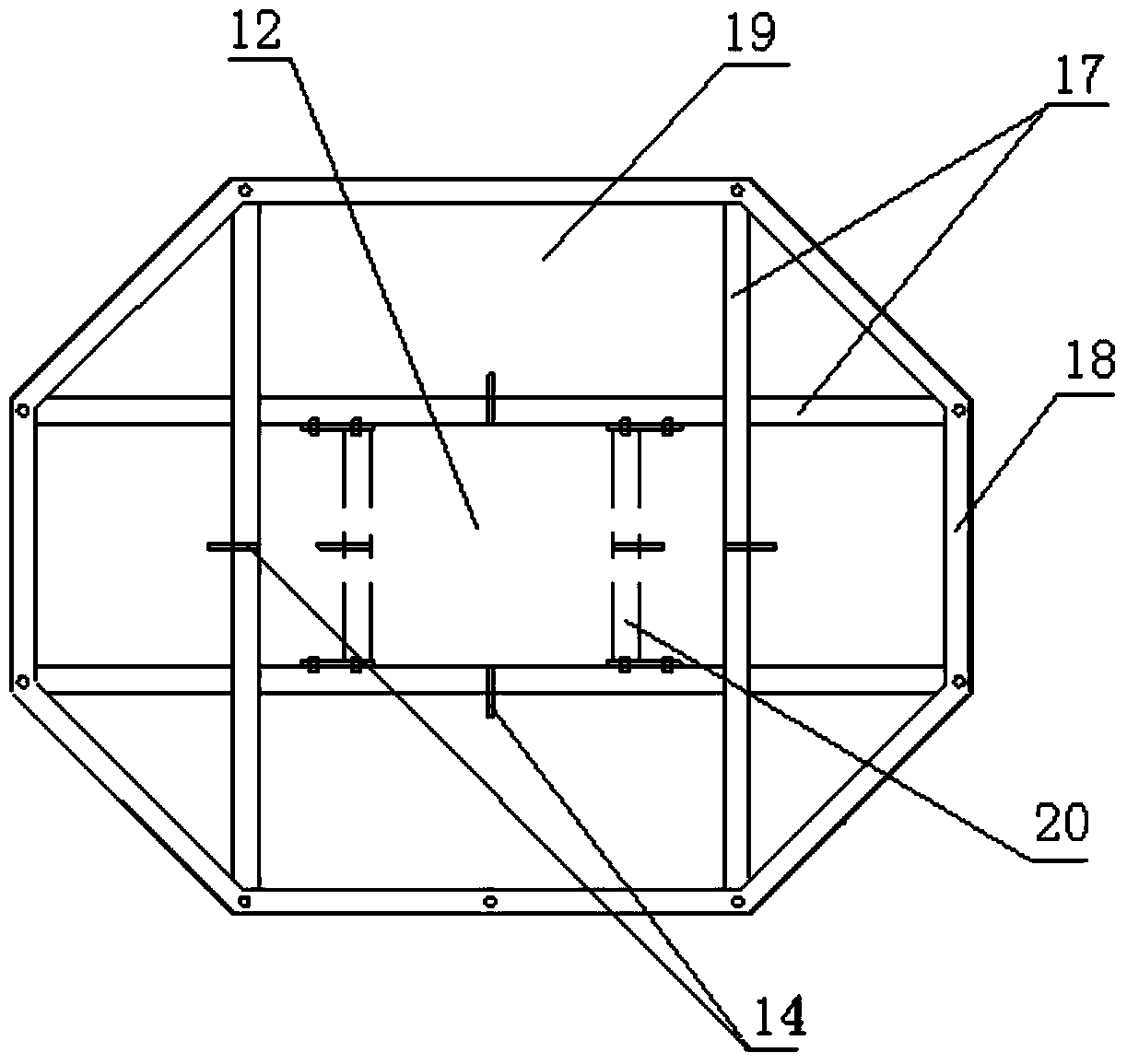

Polyvinyl chloride (PVC) pipe reinforced concrete and steel pipe concrete laminated member

InactiveCN101748861AEasy to operatePromote environmental protectionStrutsPillarsReinforced concreteOperating energy

The invention relates to a polyvinyl chloride (PVC) pipe reinforced concrete and steel pipe concrete laminated member which belongs to a civil engineering member. A PVC pipe is adopted in an outer layer of the member, a steel pipe is adopted in an inner layer, concrete is filled in the inner steel pipe, reinforced concrete is filled between the outer PVC pipe and the inner steel pipe, end faces of the outer PVC pipe reinforced concrete and the inner steel pipe concrete are level, and geometric centers of sections of the outer PVC pipe and the inner steel pipe are coincide. The outer PVC pipe and the inner steel pipe respectively adopt section forms of circle, square, rectangle, polygon, round end, ellipse and the like. The member has the advantages of common steel pipe concrete laminated members, can improve the bearing capacity and the corrosion resistance while increasing small dead weight, and can be applied to large-diameter pillars in bridge piers and buildings and other related towering structures or pillar members.

Owner:SHENYANG JIANZHU UNIVERSITY

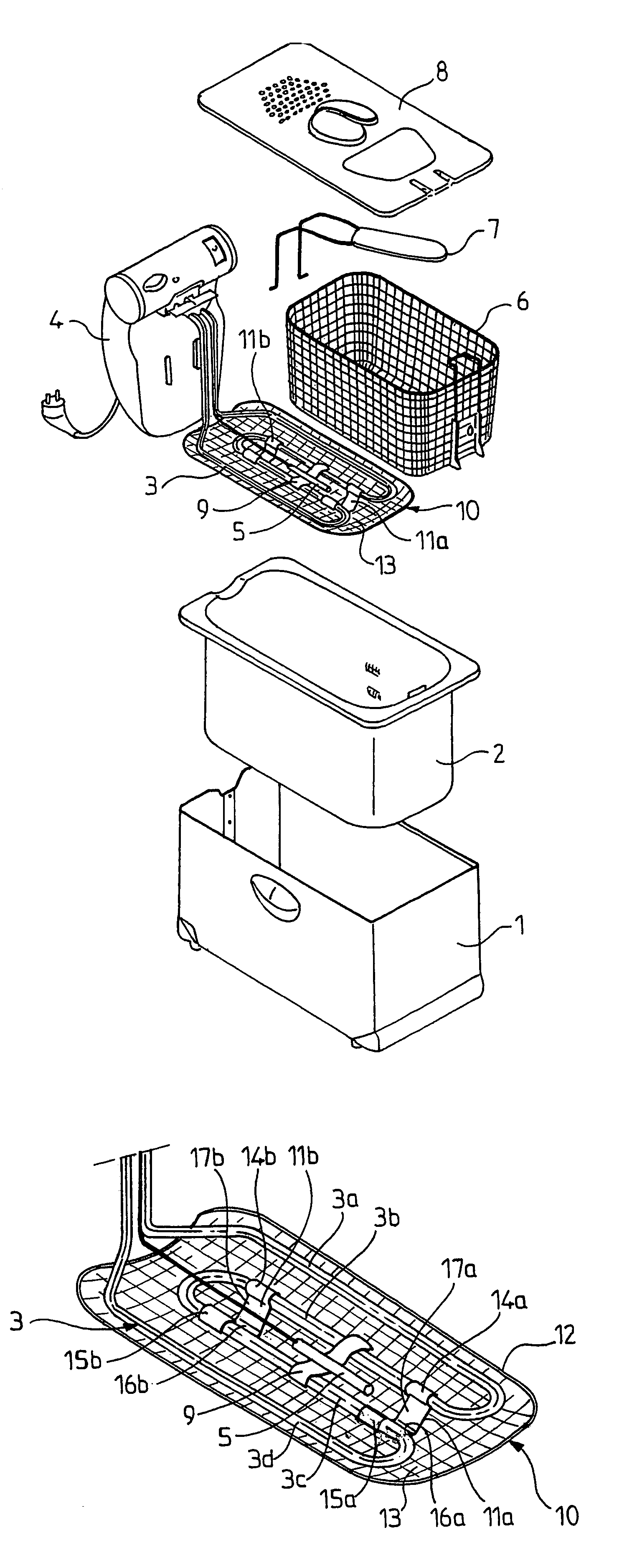

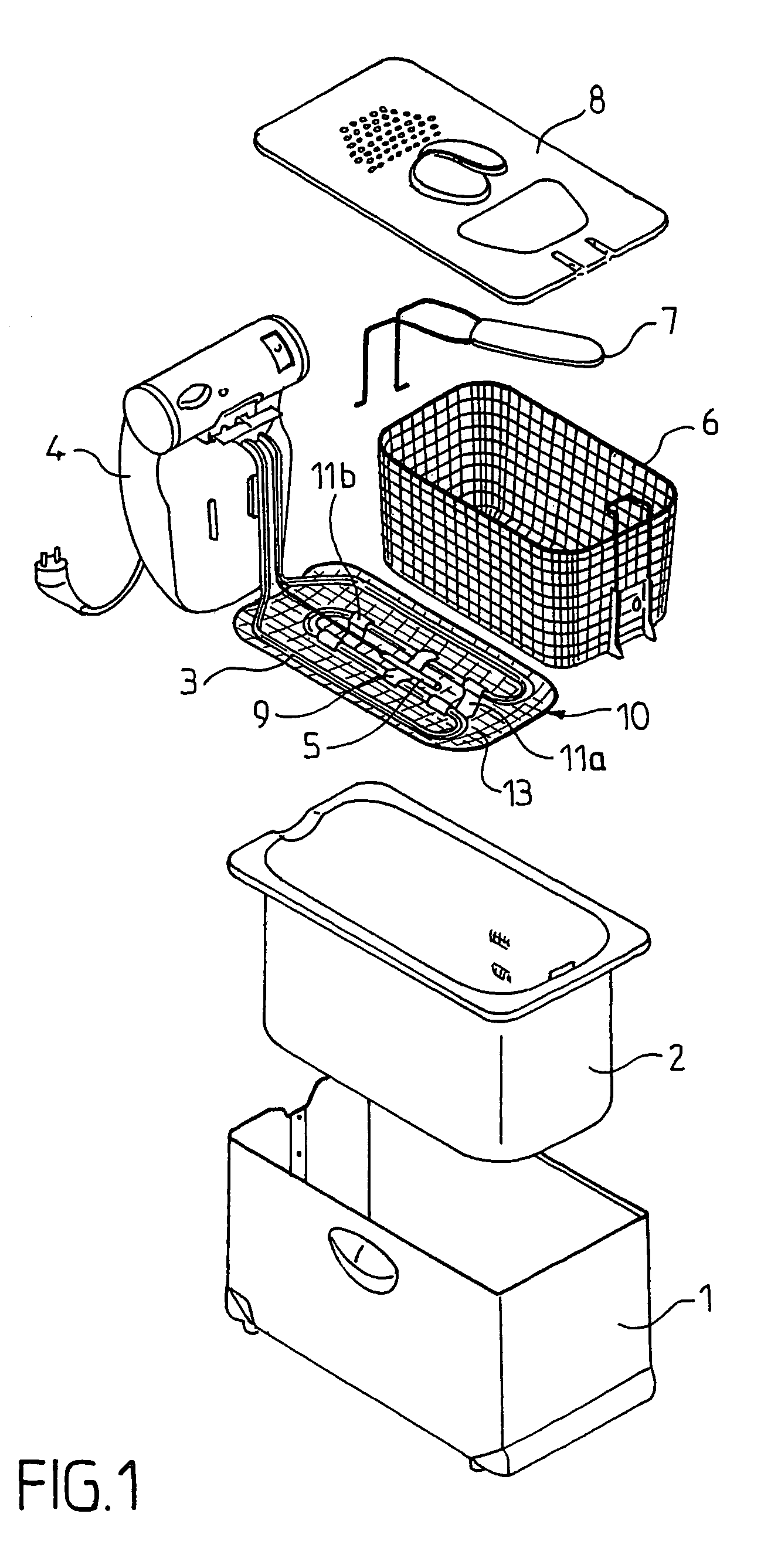

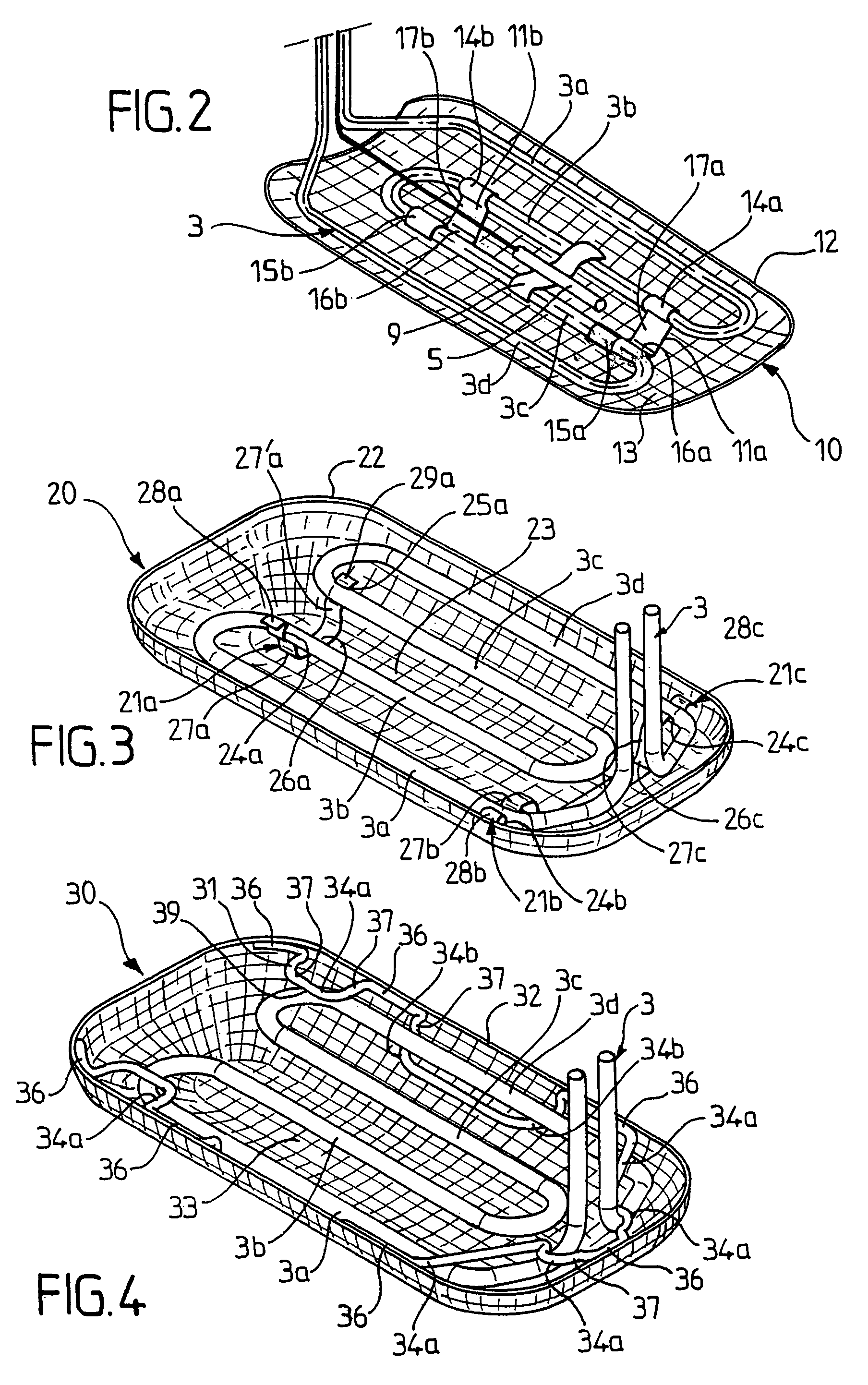

Device for filtration of the frying bath in an electric fryer having an immersed heating resistor

ActiveUS7098427B2Prevent degradationSimple wayElectric heating for furnacesDeep fat fryersFiltrationFuel tank

A device for filtering the frying bath of an electric fryer having a heating resistor that is immersed in a frying bath in a tank during frying, the device including: a filter screen adapted to extend beneath the immersed electric resistor; and at least one holding element for connecting said screen to the immersed electric resistor. An electric fryer composed of; a tank provided to receive a frying bath; an electric heating resistor provided to be immersed in the frying bath; and the device described above.

Owner:SEB SA

Supported composite photocatalytic coating and preparation method thereof

ActiveCN104830227AImprove photocatalytic efficiencyRealize building environmental protectionMolecular sieve catalystsUnspecified rubber coatingsHigh energyUltraviolet lights

The invention relates to a supported composite photocatalytic coating and a preparation method thereof. A supported photocatalytic coating and a waterproof adhesive layer are adhered to and combined with a substrate; a specially structured supporting material and a composite TiO2 / g-C3N4 photocatalyst are mixed in a high energy ball milling manner so as to effectively improve the supporting rate of the photocatalyst; and the response range can be widened to visible light from ultraviolet light through the composite photocatalyst, thus realizing effective photocatalysis efficiency. The supported composite photocatalytic coating and the preparation method thereof are simple in process, have relatively high economic and environment benefits and belong to high value-added resource utilization.

Owner:江苏倍立达新材料科技有限公司

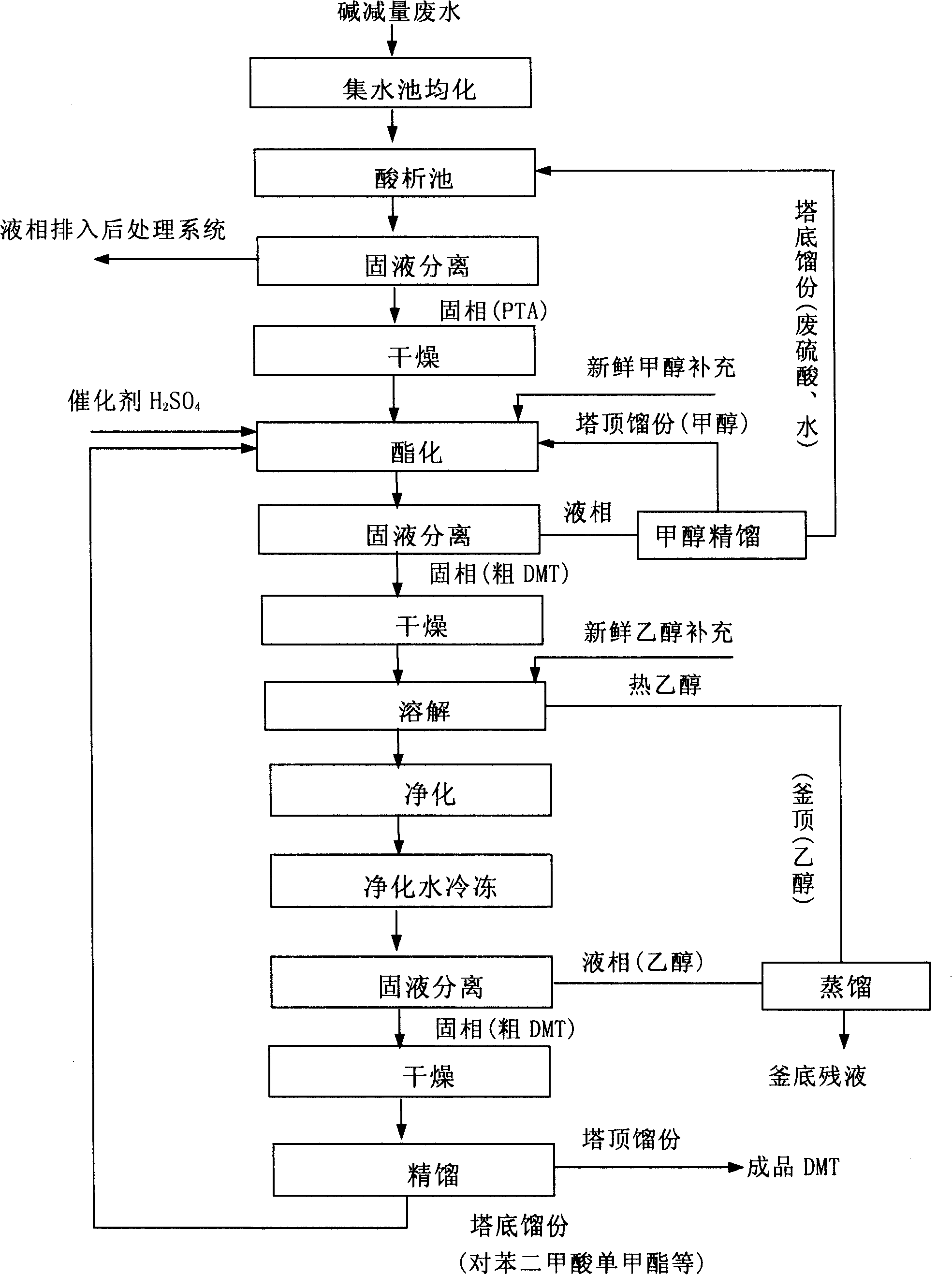

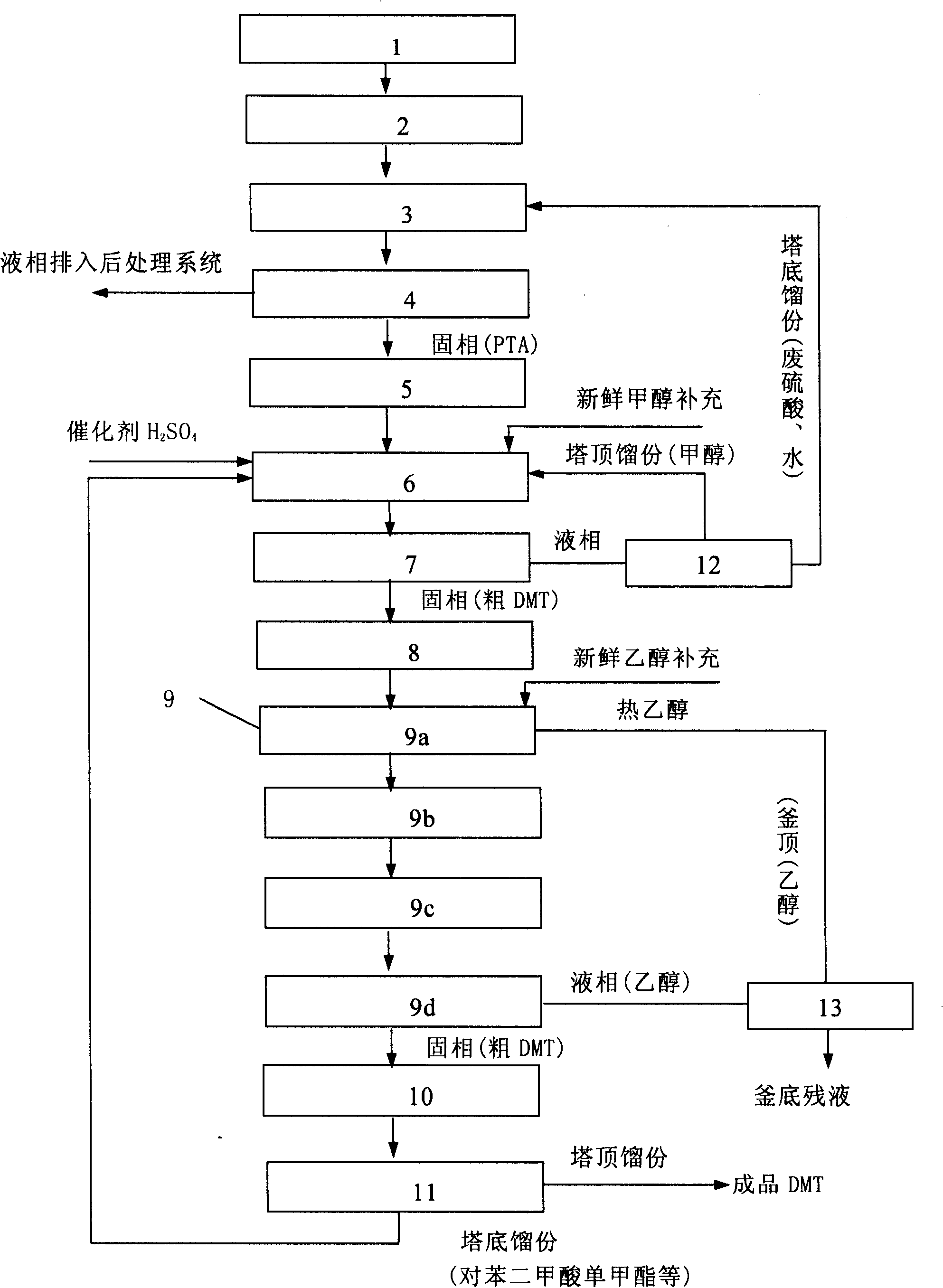

Alkali deweighting wastewater processing method and device

InactiveCN101244857AEliminate purification processEliminate polluting emissionsOrganic chemistryWater contaminantsDimethyl terephthalateIndustrial effluent

The invention provides a processing method for alkali-minimization wastewater, comprising a plurality of steps: (a) adjusting the PH value of alkali-minimization wastewater into 6.5 to 7, using the method of acid precipitation to obtain liquid phase and the solid phase with terephthalic acid; (b) carrying out esterification reaction for the solid phase from the procedure (a) in the presence of methanol to obtain a crude dimethyl terephthalate product. The method recovering terephthalic acid from alkali-minimization wastewater makes CODcr value of the wastewater removal of more than 75% and modifies the wastewater into Biodegradable industrial wastewater and at the same time changes the phthalic acid into dimethyl terephthalate.

Owner:SHAOXING COUNTY JINGSHENG RESIN TECH CO LTD

Prepn of photocatalytic titania fiber material

InactiveCN1772373AThe synthesis process is simpleMeet the requirements of "green chemistry"Physical/chemical process catalystsFiberSteam activation

The preparation process of photocatalytic titania fiber material includes the following steps: synthesizing polyacetyl ethyl acetate-titanium complex as the precursor; dissolving the synthesized polyacetyl ethyl acetate-titanium complex in tetrahydrofuran to compounding spinning liquid of viscosity 5-100 Pa.s, with the ratio between the synthesized polyacetyl ethyl acetate-titanium complex and tetrahydrofuran being 100 g to 400-800 ml; centrifugally spinning the spinning liquid of viscosity 5-100 Pa.s into short precursor fiber; dry spinning the spinning liquid of viscosity 50-100 Pa.s into continuous long precursor fiber; and final water steam activation of the precursor fiber and heat treatment and sintering. The preparation process has simple operation, easy control and low power consumption.

Owner:SHANDONG UNIV

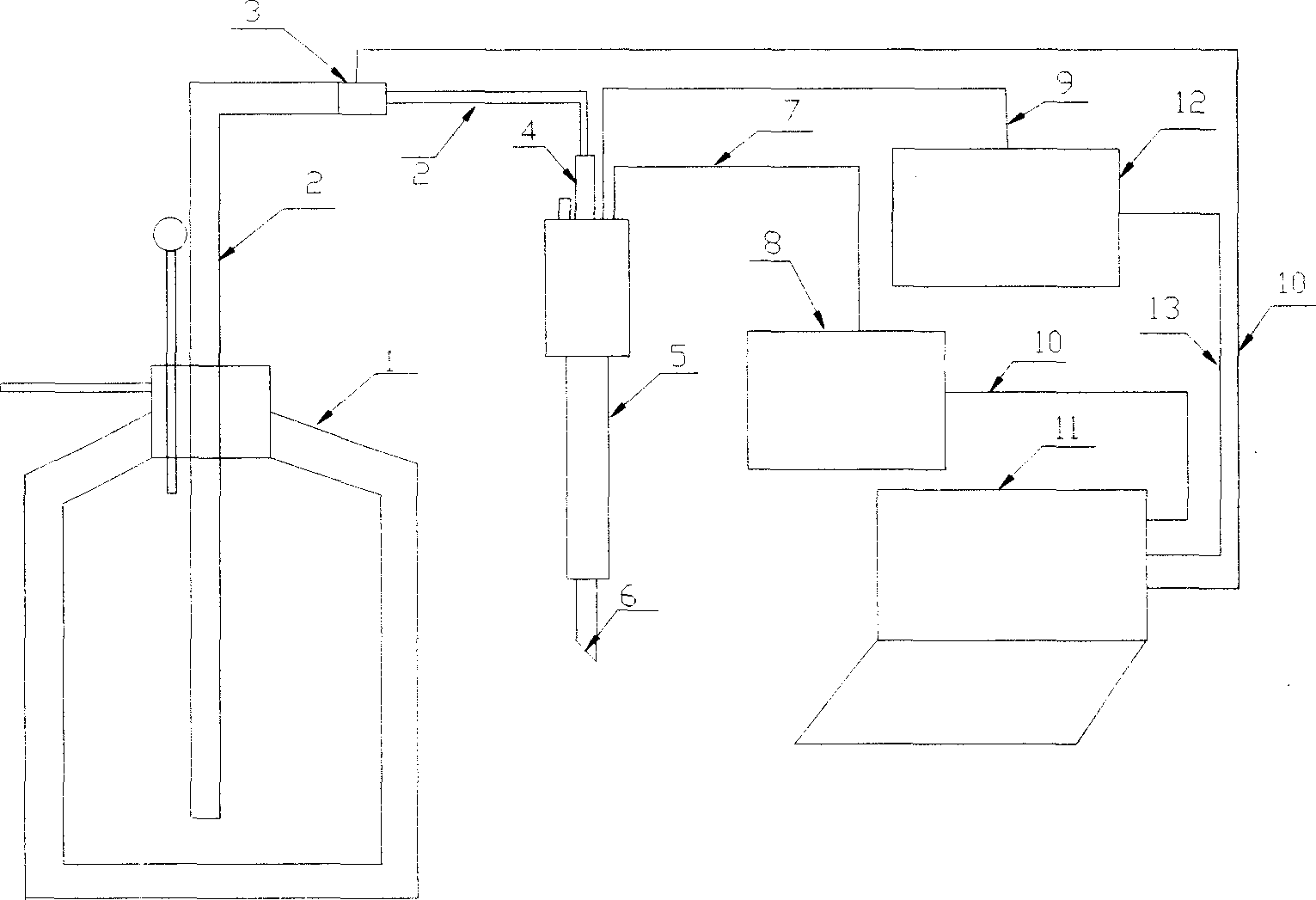

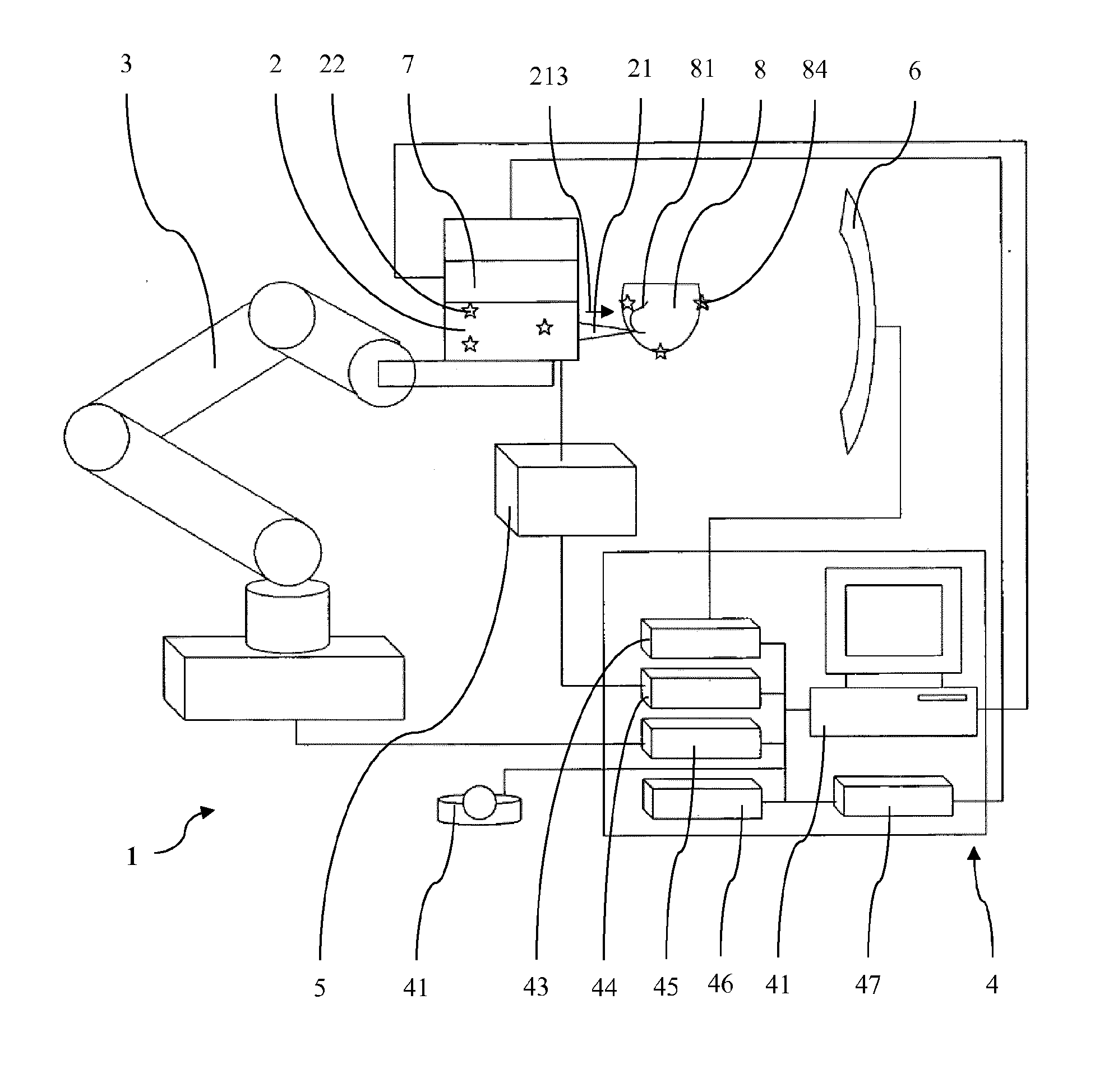

Temperature-rising-reducing rate controllable cold-hot alternating tumour therapeutical system

ActiveCN1709212AProtect health organizationOvercoming efficiency lossTherapeutic coolingTherapeutic heatingKilling rateRadio frequency

The present invention relates to a cold-heat alternative oncology therapy system whose temperature-rising and temperature-lowering rate can be controlled. Said system includes the following components: liquid nitrogen transferring pipe, high pressure liquid nitrogen Dewar's container, low-temperature electromagnetic valve, needle cold-heat alternative therapeutic head, gas-liquid separation device, radio frequency generation device, temperature collection device and control system. Said invention makes the low-temperature operating knife and radio frequency thermotherapy be combined together so as to raise killing rate of malignant tumor.

Owner:MAGI CO LTD

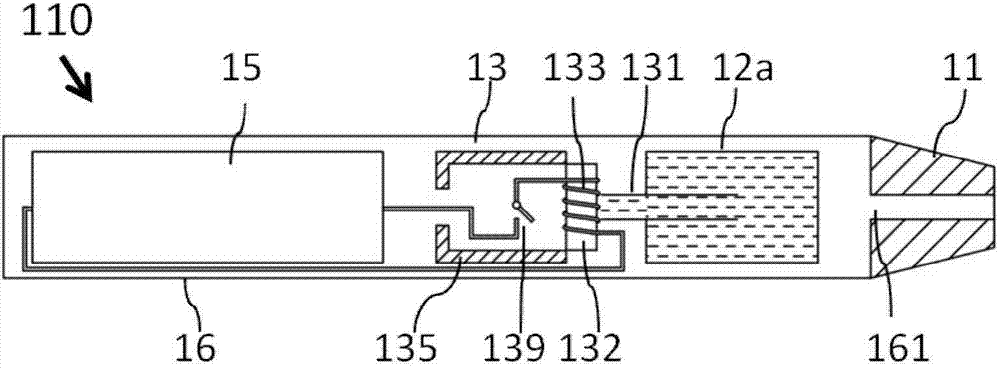

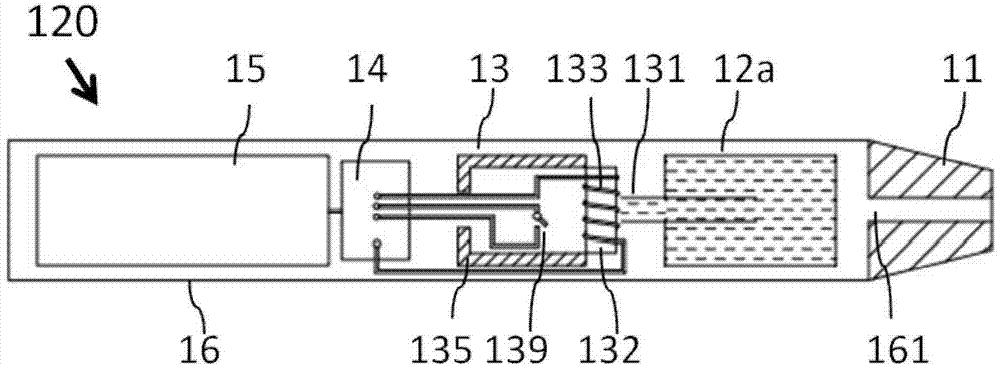

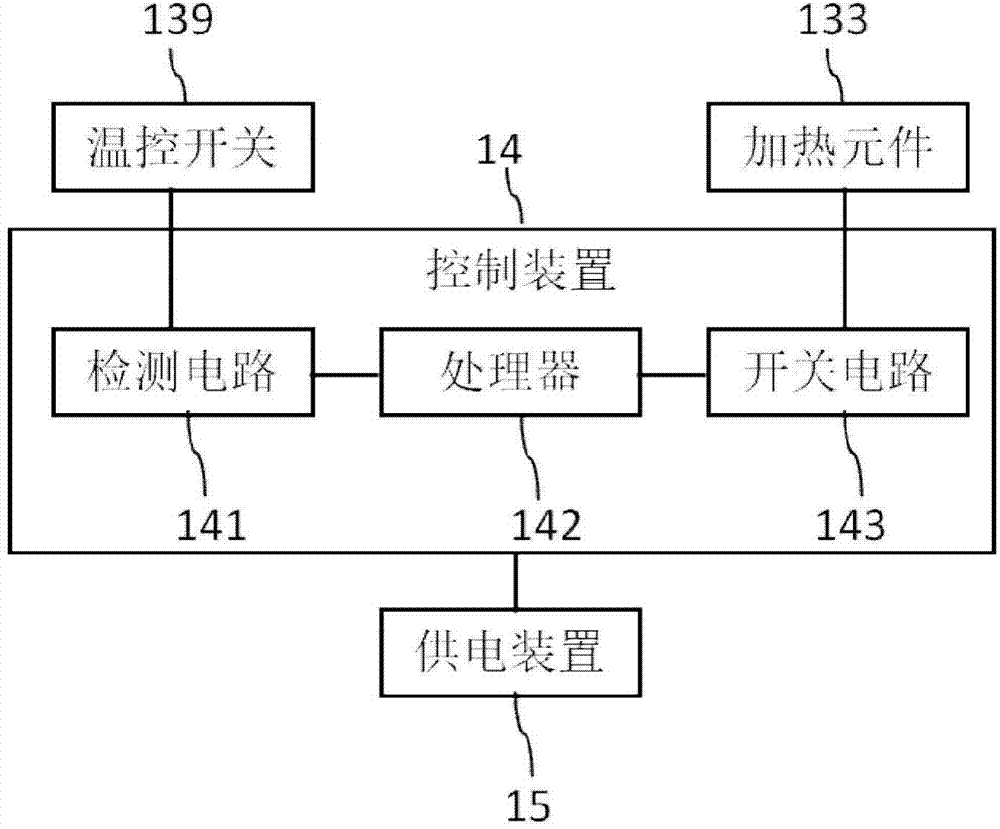

Atomization device and electronic cigarette with same

InactiveCN104720120AAvoid it happening againAvoid overall overheatingTobacco devicesTemperature controlElectrical connection

The invention discloses an atomization device which can induct the temperature variation of a heating component. The atomization device comprises the heating component and a temperature controlled switch; the temperature controlled switch is arranged near the heating component, or the heating component is arranged on the temperature controlled switch in a sleeving mode, and the heating component is connected with the temperature controlled switch in series. The invention further discloses an electronic cigarette with the atomization device, and a power supply device is arranged in the electronic cigarette. The power supply device is in electrical connection with the atomization device.

Owner:JOYETECH EURO HLDG

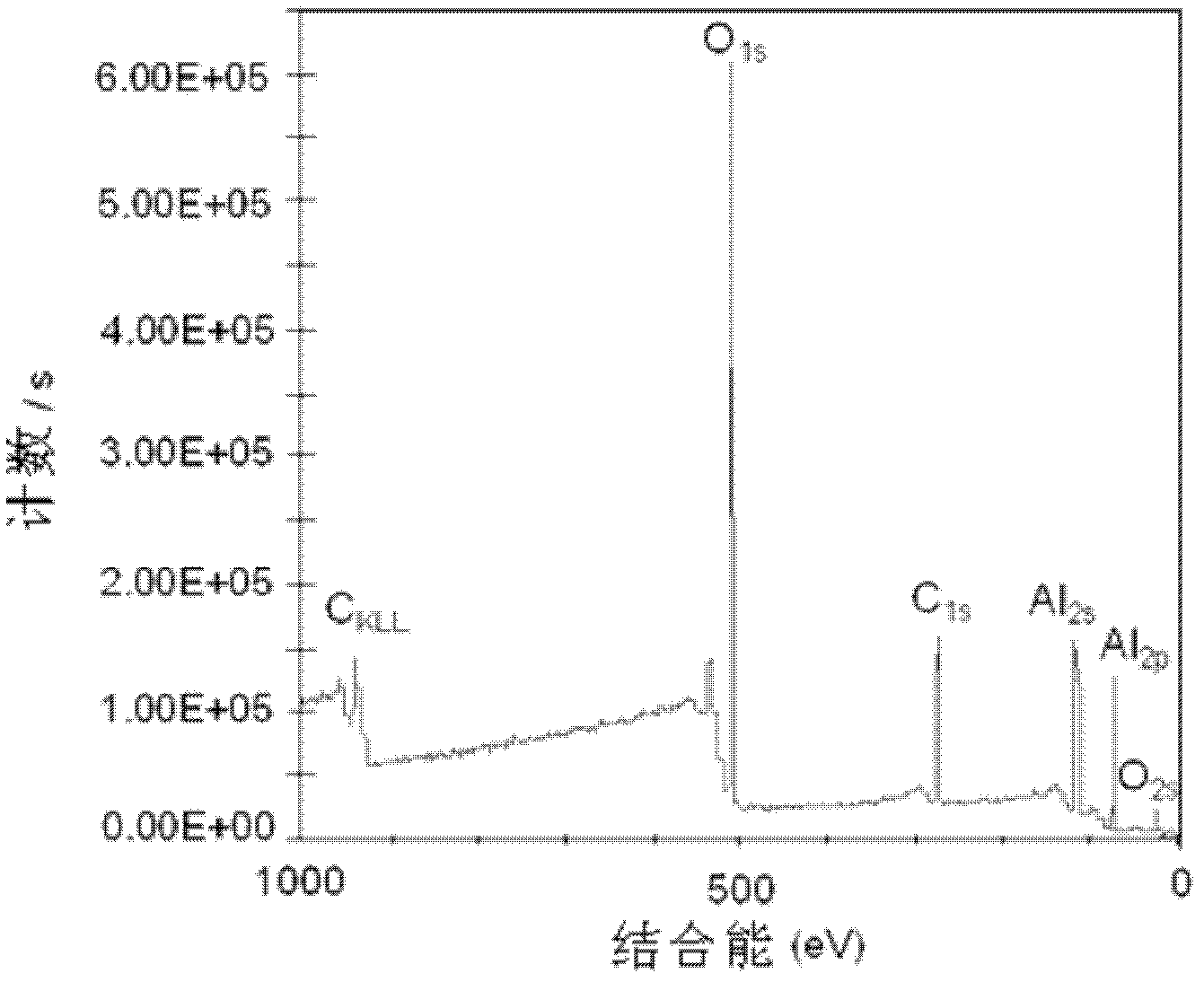

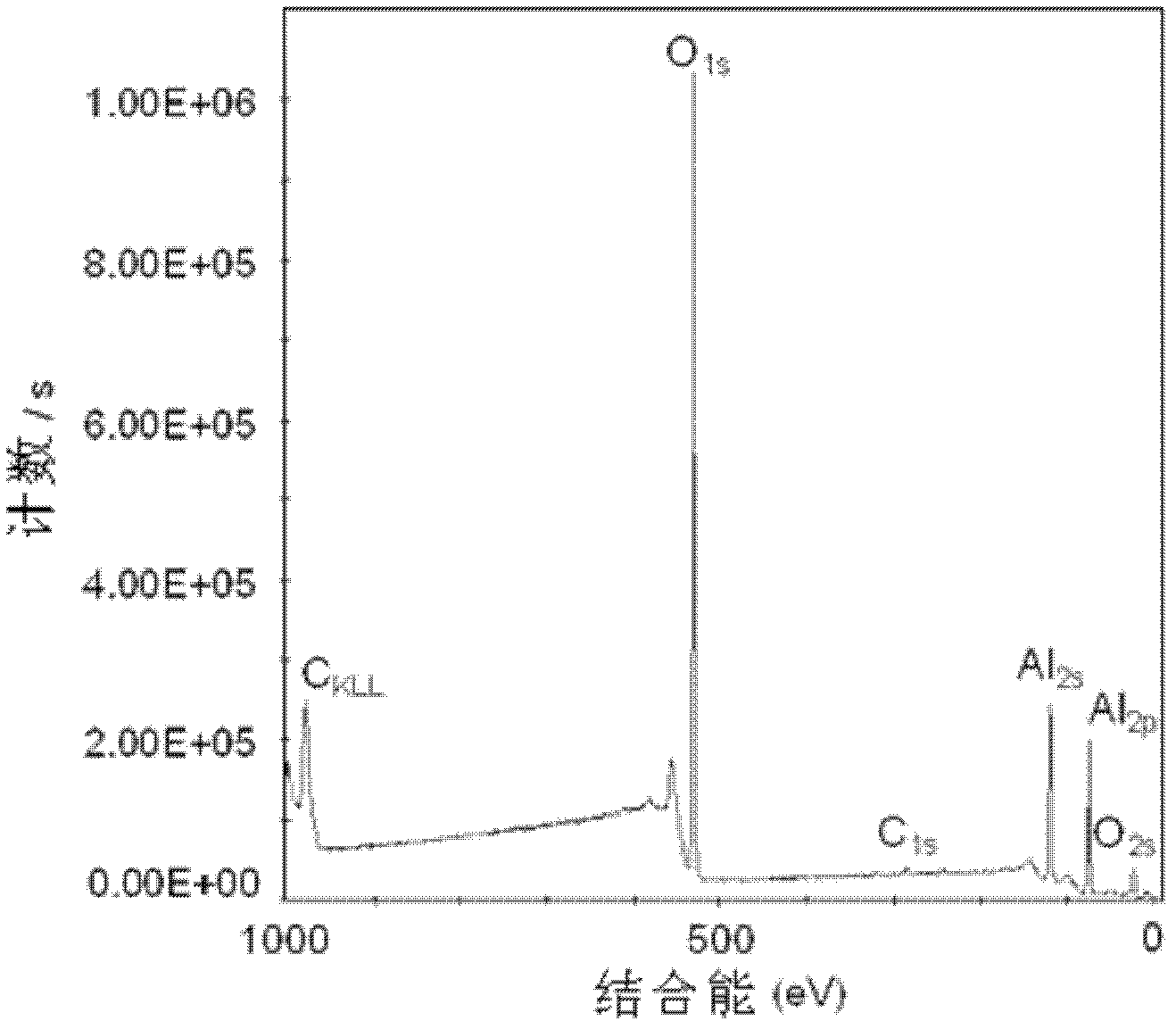

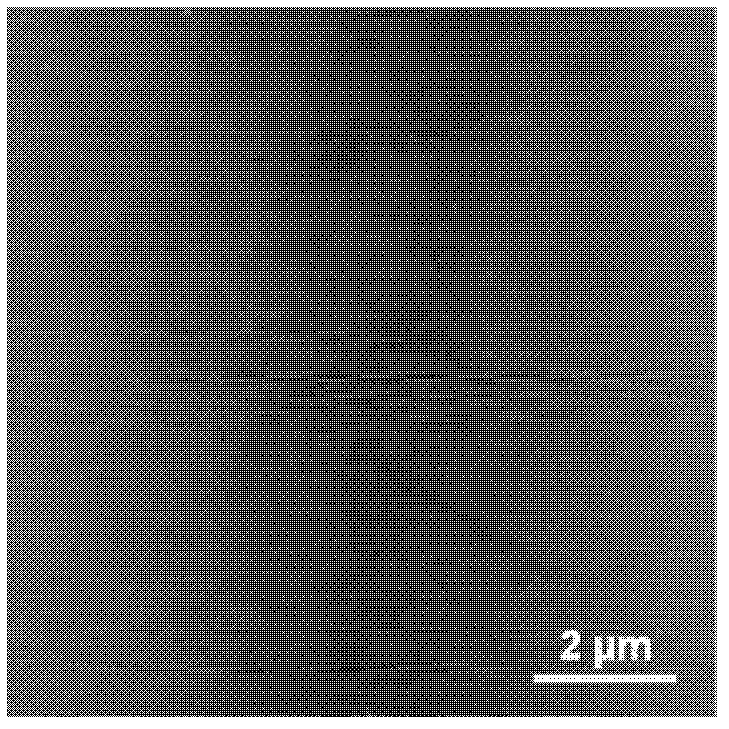

Method for cleaning alpha-Al2O3 monocrystal

ActiveCN102500573AImprove cleanlinessGood repeatabilityAfter-treatment detailsCleaning using liquidsSingle crystalPollution

The invention relates to a method for cleaning an alpha-Al2O3 monocrystal. According to the method, the problem that surface pollutants cannot be cleaned completely because the alpha-Al2O3 monocrystal has strong surface adsorbability and stable surface performance and is difficult to dissolve in the conventional method for cleaning the alpha-Al2O3 monocrystal is solved. The method for cleaning the alpha-Al2O3 monocrystal comprises the following steps of: soaking the alpha-Al2O3 monocrystal in ethanol and surfactant sequentially; and performing heat soaking treatment in a mixed solution of concentrated sulfuric acid and hydrogen peroxide, a mixed solution of ammonia water, hydrogen peroxide and water and a mixed solution of concentrated hydrochloric acid, hydrogen peroxide and water sequentially. The method for cleaning the alpha-Al2O3 monocrystal is a multi-step wet chemical cleaning method. By the method for cleaning the alpha-Al2O3 monocrystal, the pollutants on the surface of the alpha-Al2O3 monocrystal can be cleaned effectively and completely; the cleaned aluminum oxide monocrystal has high cleanliness; and the cleaning method is high in repeatability. Equipment for cleaning is simple, convenient to operate and easy to master; and the process is safe and pollution-free.

Owner:WUXI HAITE NEW MATERIAL RES INST

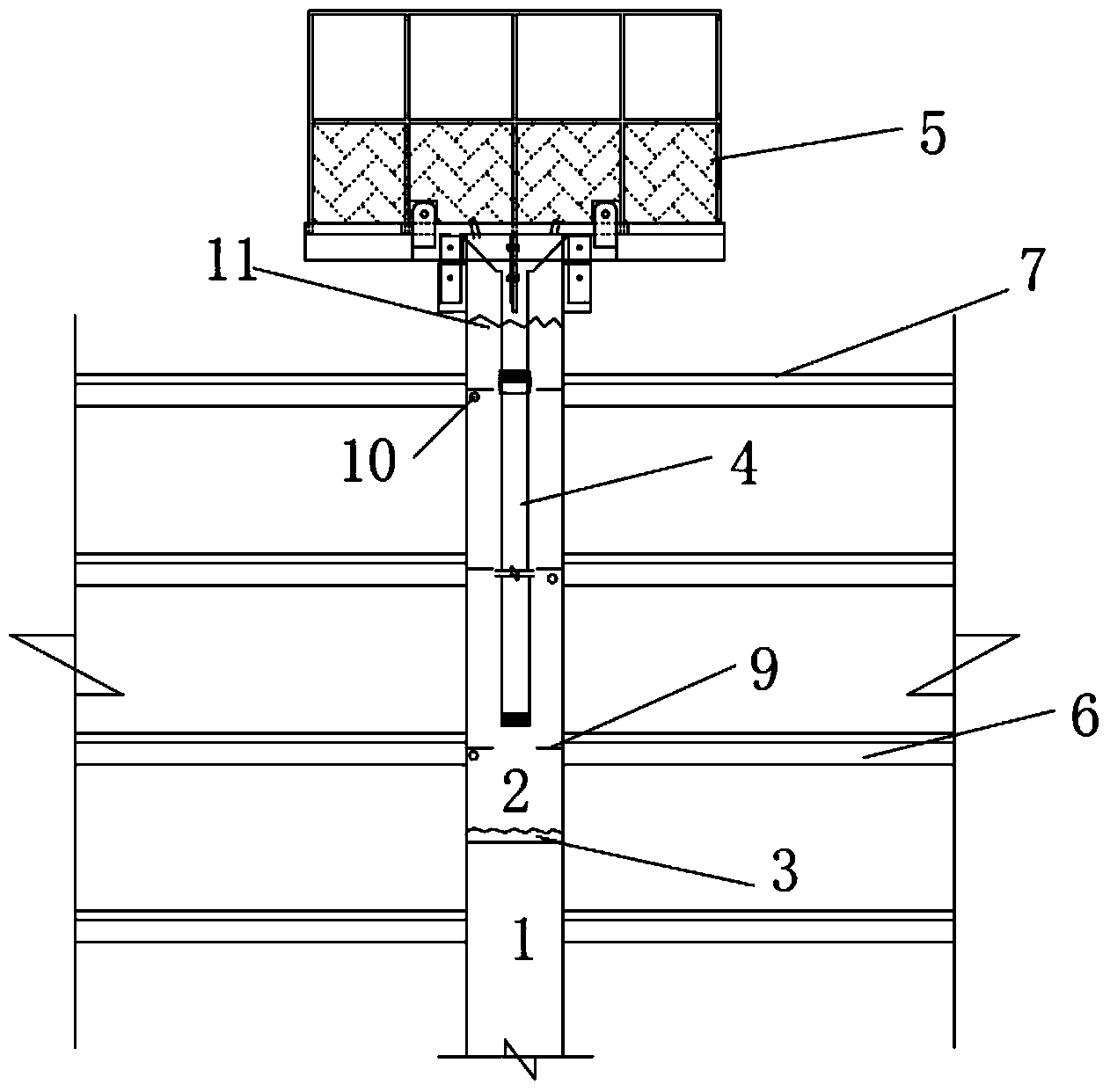

Super high-rise steel pipe column interior concrete pouring construction method

ActiveCN103526929ASimple and safe operationStrong construction applicabilityBuilding material handlingBuilding support scaffoldsSheet steelMaterial consumption

The invention discloses a super high-rise steel pipe column interior concrete pouring construction method. The method mainly comprises the steps of detaching a last section of steel pipe column top sealing hole thin steel plate; hoisting the present section of steel tube column; locating the present section of steel tube column after hoisting a first floor layer steel beam of the present section of steel tube column; arranging a detachable construction steel platform; enabling a sectional connectable serial barrel to extend into the steel pipe column through a locating hole of the construction steel platform; filling same-grade concrete protoplasmic into the steel pipe column; pouring concrete; when the concrete pouring height surpasses the single section serial barrel, detaching one section and continuing concrete pouring construction, and then conducting subsequent pouring; slowing down the speed of concrete discharging and the speed of pouring when a concrete puring face is close to a partition plate in the steel pipe column; pouring the concrete to a certain distance below the top of the steel pipe column and then stopping; adopting a thin steel plate to close the steel pipe column top pouring hole. By the adoption of the construction method, the concrete pouring construction is made to be more convenient, potential safety hazards are eliminated, the construction period is shortened, and manpower and turnover material consumption are reduced.

Owner:ZHEJIANG CONSTR ENG GRP CO LTD

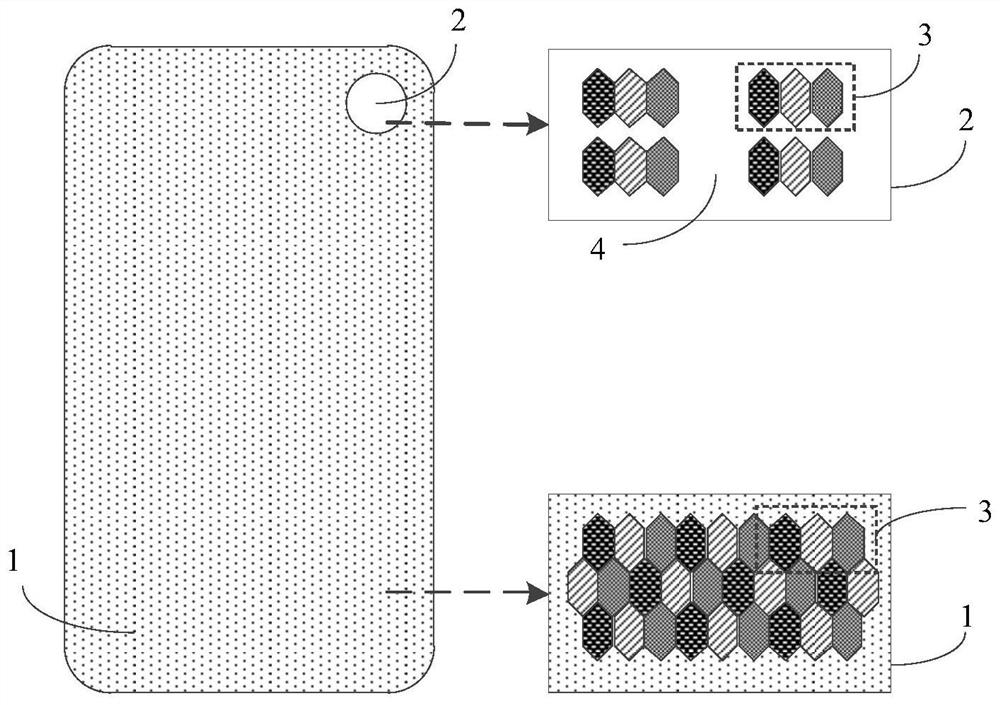

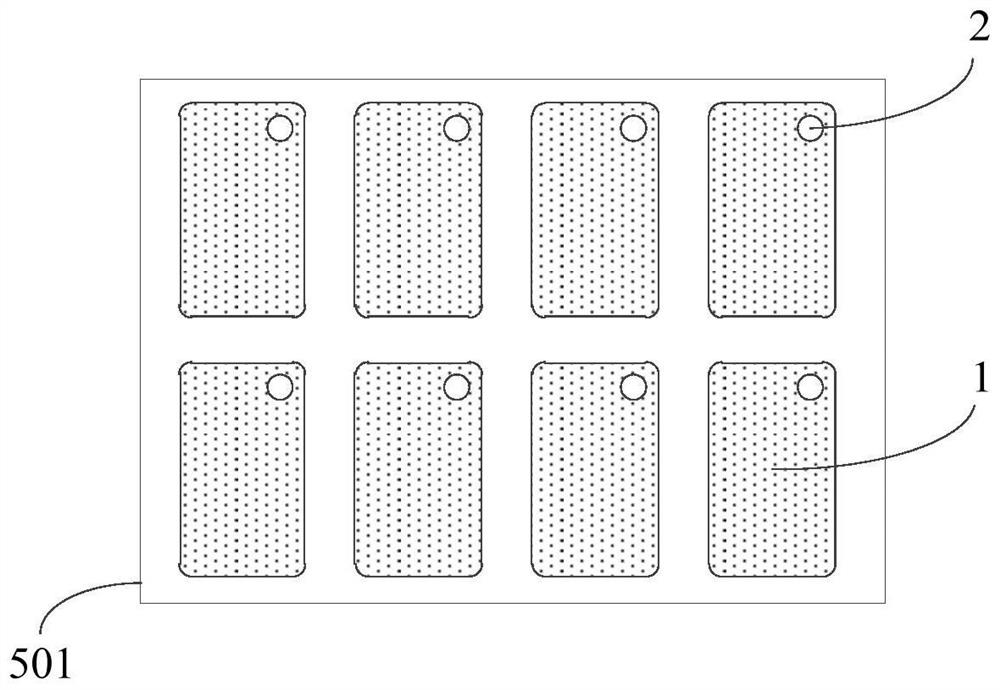

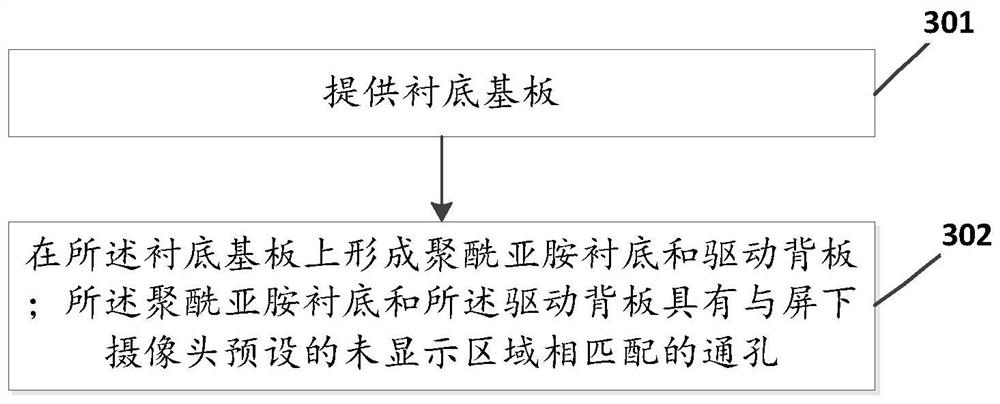

Display panel, preparation method and display device thereof

ActiveCN111799374AImprove transmittanceReduce laser energySolid-state devicesSemiconductor/solid-state device manufacturingPolyimide substrateHigh energy

The invention provides a display panel, a preparation method and a display device thereof. Specifically, the display panel comprises a polyimide substrate, and the polyimide substrate comprises polyimide and a polymer ultraviolet light absorber, the polyimide substrate comprises a through hole, and the through hole is matched with a preset non-display area of an under-screen camera. According to the technical scheme of the specification, the polymer ultraviolet light absorber is added into the polyimide substrate; the polyimide substrate can absorb part of ultraviolet light when a coating layer is removed through laser scanning, so that the laser energy actually absorbed by the polyimide is reduced, the polyimide is prevented from being carbonized under the action of high-energy laser, andthe technical effect of improving the transmittance of the display panel is achieved.

Owner:BOE TECH GRP CO LTD +1

Two-stage stab-braking brake master valve

InactiveCN101857020AExtended service lifeAvoid carbonizationApplication and release valvesEngineeringMechanical engineering

The invention relates to a two-stage stab-braking brake master valve (II type) which comprises an upper valve body and a lower valve body, wherein both the upper valve body and the lower valve body are provided with an air inlet hole and an air outlet hole, the upper edge of the lower valve body is inserted into the lower edge of the upper valve body, an upper piston assembly is installed at the upper part in the upper valve body, the upper piston assembly comprises a piston bush, an upper piston, a spring package clip and an ejector pin seat, the inside and the outside of the spring package clip are respectively provided with a pressure intensity spring and a steady pressure spring, a certain distance is reserved between the upper part of the pressure intensity spring and the lower surface of the wide disc of the ejector pin seat, and the distance enables the valve to produce a secondary pressure intensity to quickly and powerfully combine a brake block and a brake drum so as to maintain a favorable combination condition all the time and ensure a favorable brake effect all the time. Simultaneously, the friction between the brake block and the brake drum can be decreased to the greatest extent, and the brake block can be prevented from being carbonized so as to prolong the service life of the brake.

Owner:CHANGTONG TECH

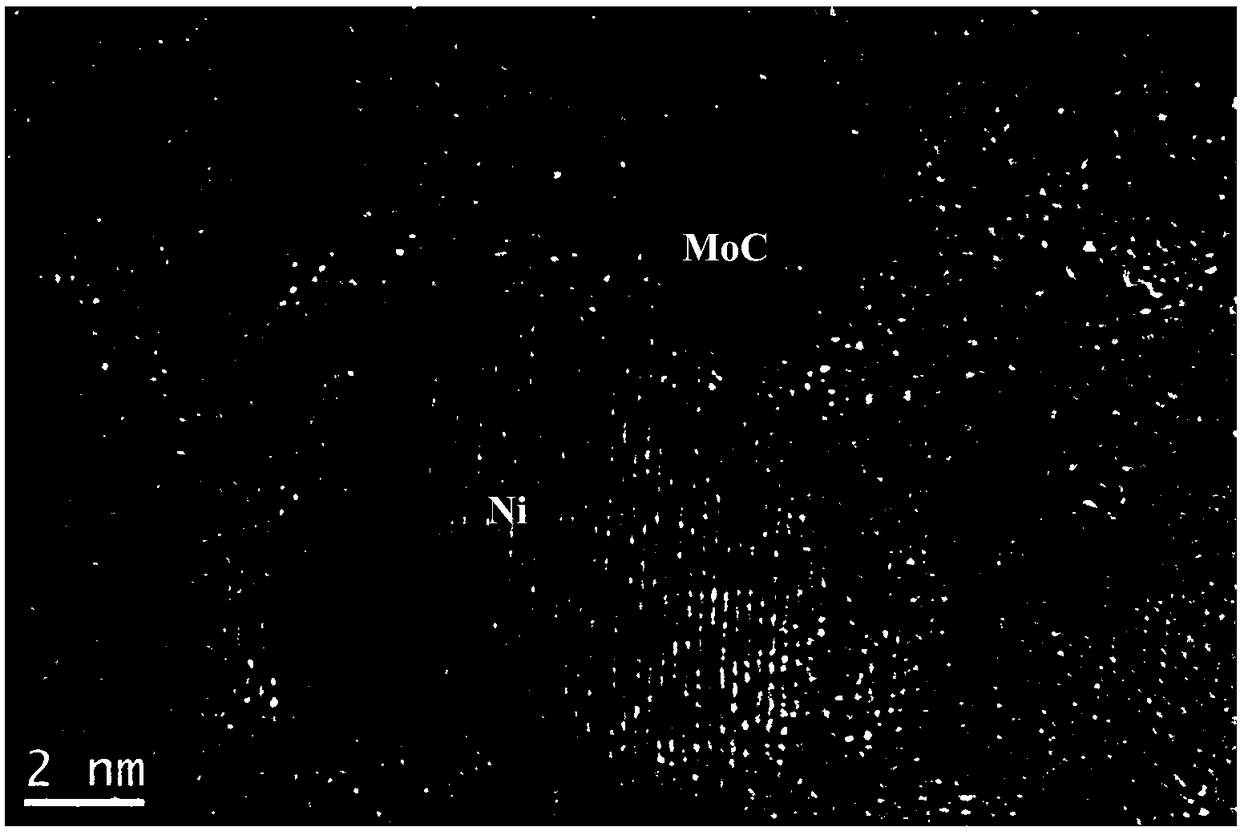

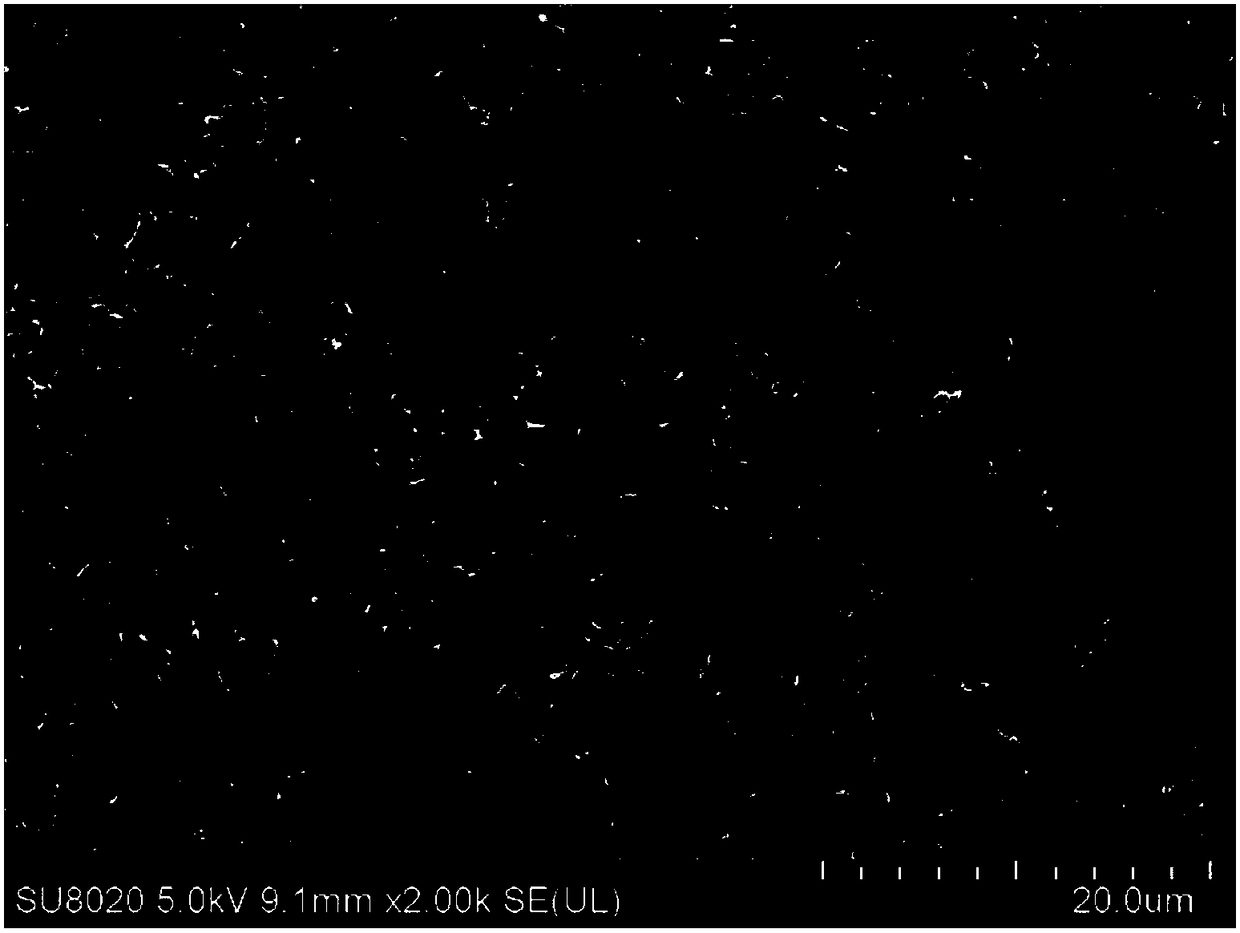

Supported molybdenum carbide/metal nanoparticle composite catalyst and its preparation method and application in catalytic degradation of heavy metal chromium

InactiveCN108311167AFacilitated DiffusionIncrease exposureWater contaminantsCatalyst activation/preparationN dimethylformamideMolybdenum carbide

The invention discloses a supported molybdenum carbide / metal nanoparticle composite catalyst and its preparation method and application in catalytic degradation of heavy metal chromium. The preparation method comprises synthesizing molybdenum carbide / metal nanoparticle homogeneous powder through a high-temperature pyrolysis one-step method, adding the powder, a dispersant and a carrier precursor into N, N-dimethylformamide, carrying out curing formation, and directly separating the supported molybdenum carbide / metal nanoparticle composite catalyst. The composite catalyst contains uniformly distributed active centers. The molybdenum carbide nanoparticles have no sintering or agglomeration phenomenon. The metal ion leaching degree is low. The supported catalyst has stable performances and excellent repeatability, can efficiently catalytically reduce the hexavalent chromium and can convert the hexavalent chromium into non-toxic trivalent chromium.

Owner:HEFEI UNIV OF TECH

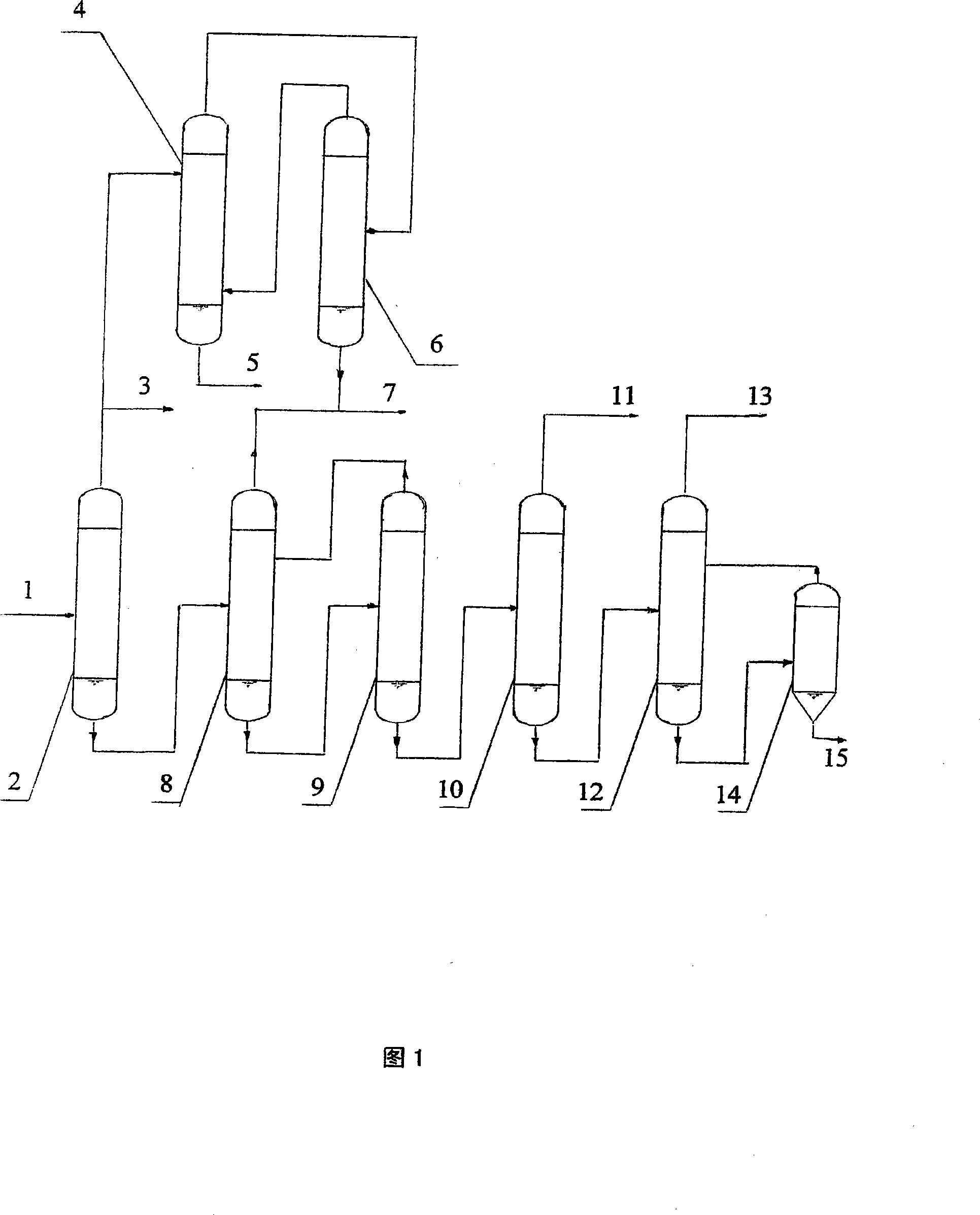

Novel process for extracting L-malic acid

ActiveCN103642853AAvoid carbonizationAvoid negative effectsMicroorganism based processesFermentationO-Phosphoric AcidUltrafiltration

The invention belongs to the technical field of production of amino acids, and relates to a process for extracting high-quality L-malic acid in biological fermentation liquor by acidolysis, neutralization, grading film filtration and ion exchange technologies. The process comprises the following steps: acidizing by using phosphoric acid, filtering with micro-filtration membranes and ultrafiltration membranes to remove bacterial protein, other macromolecule impurities, calcium phosphate and other solids; neutralizing fermentation liquor by using calcium hydroxide and calcium carbonate, acidizing by using phosphoric acid, filtering with micro-filtration membranes and ultrafiltration membranes to create a decisive condition for ion exchange and concentration crystallization of a cooling evaporator of the L-malic acid. According to the process, the purity of the L-malic acid extracted once is greater than 99%, the total yield is above 90%, the phosphoric acid is of moderate acidity, and membrane filtering equipment is high in automation degree, stable in operation and convenient for industrial popularization, so that the process has favorable economic benefit, environmental benefit and application prospect.

Owner:SHANDONG FUFENG FERMENTATION CO LTD

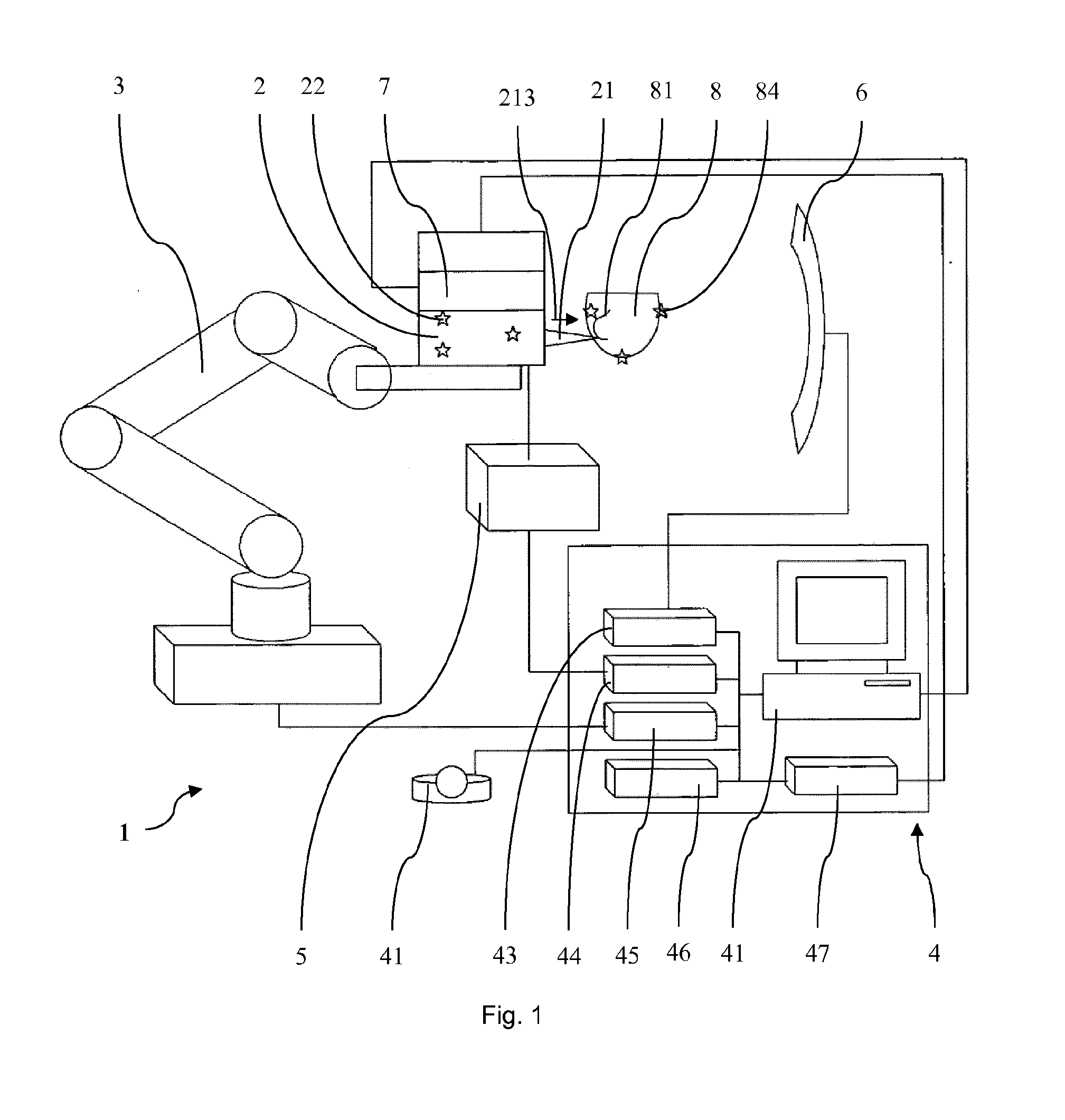

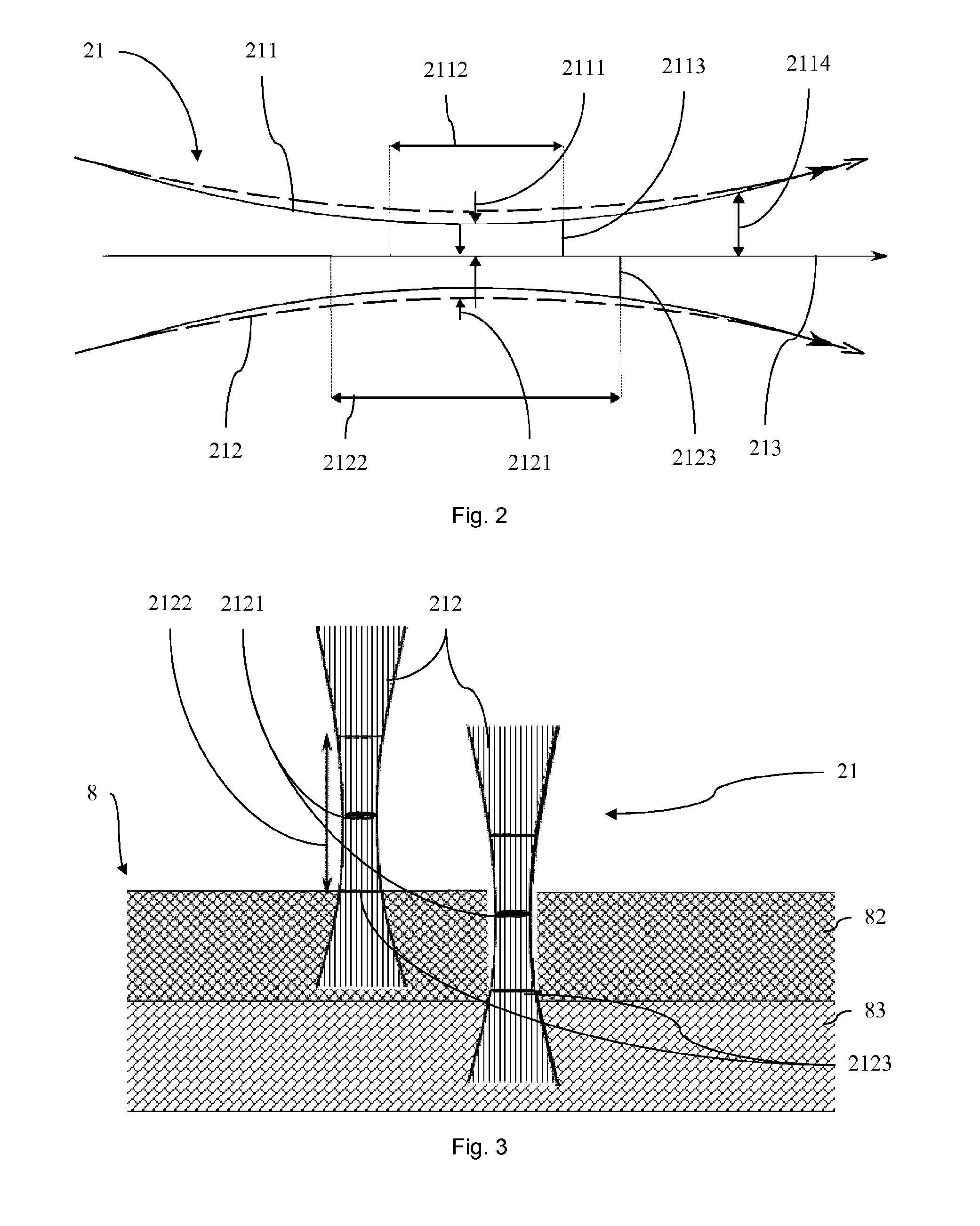

Depth controlled photoablation of human or animal tissue

ActiveUS20150327930A1Accurate detectionIncrease intensitySurgical instrument detailsDiagnostic recording/measuringPhysicsCarbonization

A photoablation device (1) for photoablation of human or animal tissue (8) comprises: a laser source (2) being arranged to propagate a focused laser beam (21) with a beam waist, wherein a radius of the laser beam (21) increases from the beam in waist into a direction of propagation (213) of the laser beam (21); an adjusting structure (41, 47) being arranged for adjusting an intensity of the laser beam (21); a position detector (6) for detecting a position of the laser source (2) in relation to the tissue (8); a positioning device (3) being arranged to move the laser source (2) in relation to the tissue (8); and a controller unit (4). The controller unit is arranged to define a photoablation zone of the laser beam (21), wherein the photoablation zone ends in a cutting face which is located at the beam waist or offset from the beam waist into the direction of propagation (213) of the laser beam (21), to adjust an intensity at the cutting face of the photoablation zone of the laser beam (21) by means of the adjusting structure (41, 47), and to move the laser beam (21) towards the tissue (8) by means of the positioning device (3), wherein the position of the laser source (2) detected by the position detector (6) is evaluated. The device according to the invention allows for conveniently controlling and determining the depth of the photoablation into the tissue by the movement of the laser beam towards the tissue. In particular, the depth can correspond to the movement of the laser beam towards the tissue. Furthermore, the photoablation energy or intensity can precisely be adjusted in accordance with the tissue. Like this, it is possible to take account of the individual properties of the tissue and to minimize heating of the tissue such that, e.g., carbonization of the tissue can be prevented.

Owner:ADVANCED OSTEOTOMY TOOLS - AOT

Method for separating catechol/hydroquinone from phenol hydroxylation reaction solution

ActiveCN101225025AImprove liquidityAvoid carbonizationOrganic chemistryOrganic compound preparationReboilerHydroquinone products

The invention discloses a method of separating catechol / hydroquinone in phenol hydroxylation reaction solution, which is characterized in that: phenol and hydrogen peroxide are reacted under catalyst action to produce reaction solution comprising water, phenol, catechol, hydroquinone and tar; vacuum rectification dehydration, de-phenol, catechol separating, hydroquinone separating and tar removing are made upon the reaction solution to prepare the catechol and the hydroquinone product; thermal medium oil independent circulation stepwise condensation / heat mode is adopted for the distillation system separating the catechol and the hydroquinone; vertical sieve plate is adopted for stripping section of the distillation tower; high-efficiency structured packing is adopted for the distillation section; embedded type structure in the tower is adopted for the condenser and the reboiler of the distillation tower. The method of separating catechol / hydroquinone in phenol hydroxylation reaction solution has the advantages of solving the problems of difficultly liquefying the catechol and the hydroquinone for the condenser at the top part of the distillation tower and easily causing material condensing or gasifying due to small difference value between the boiling point and the freezing point during vacuum rectifying for the catechol and the hydroquinone, prolonging production period, lowering unit consumption of product and reaching more than 99% for product purity of the catechol and the hydroquinone.

Owner:SHANGHAI HUAYI NEW MATERIAL

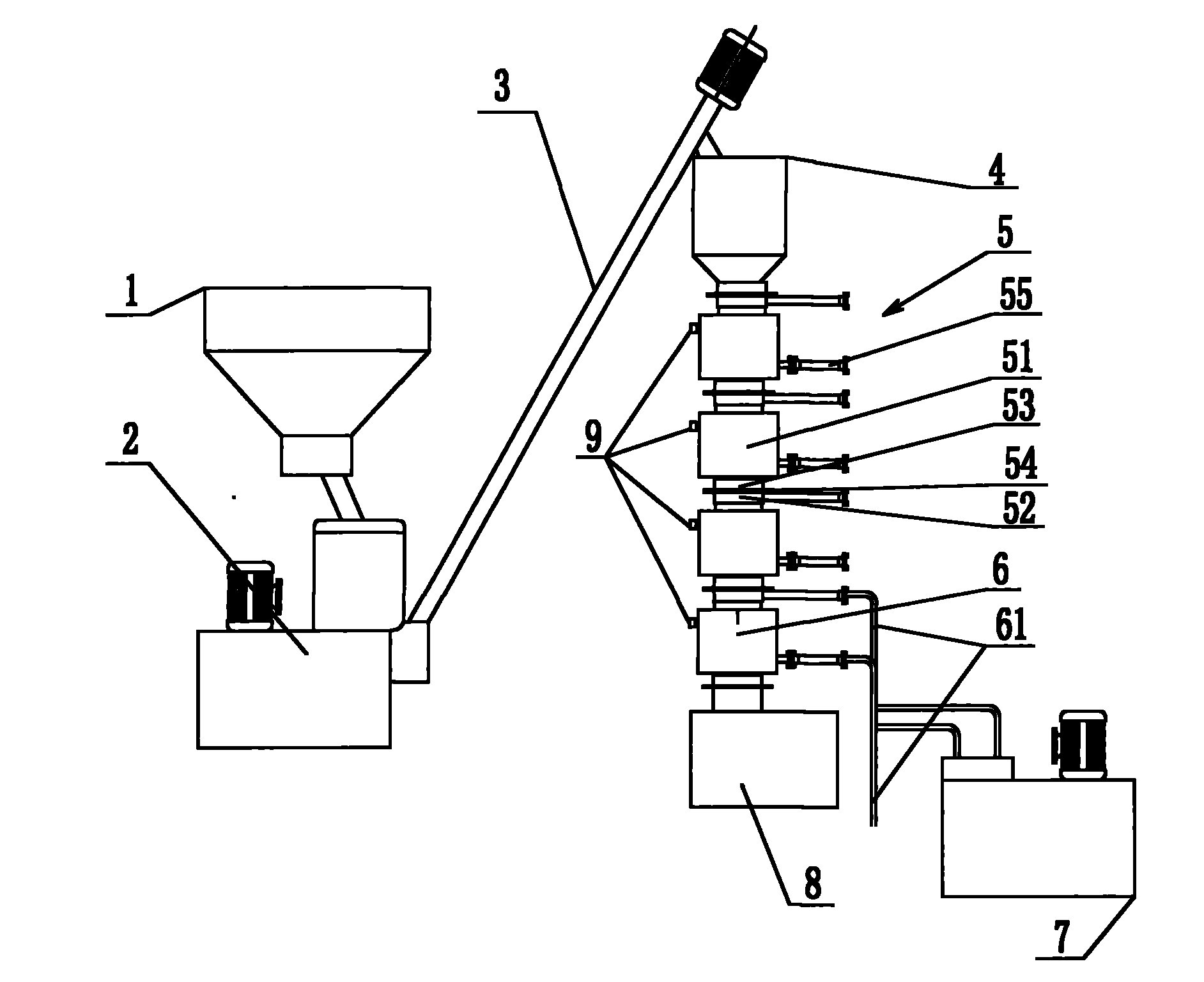

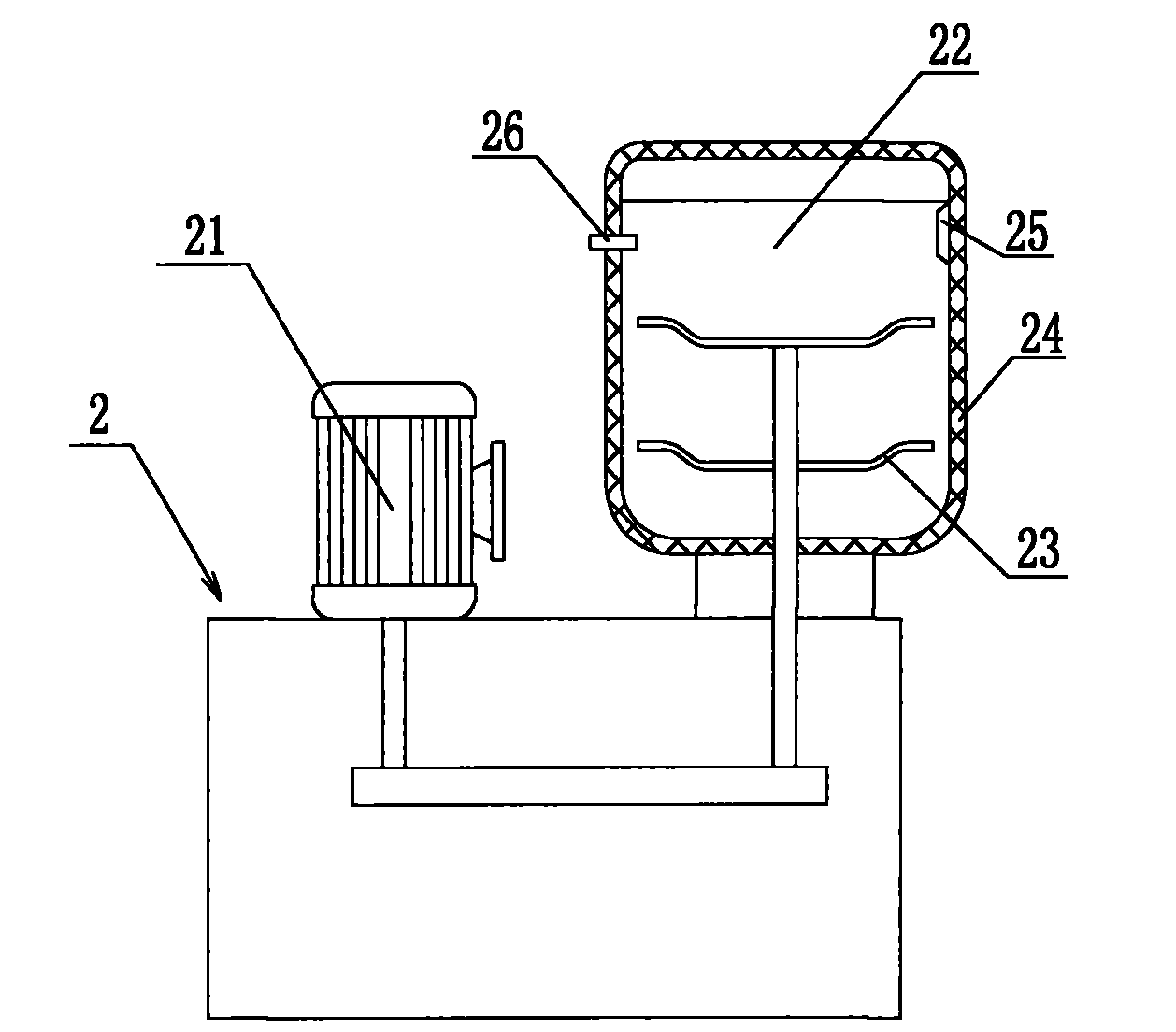

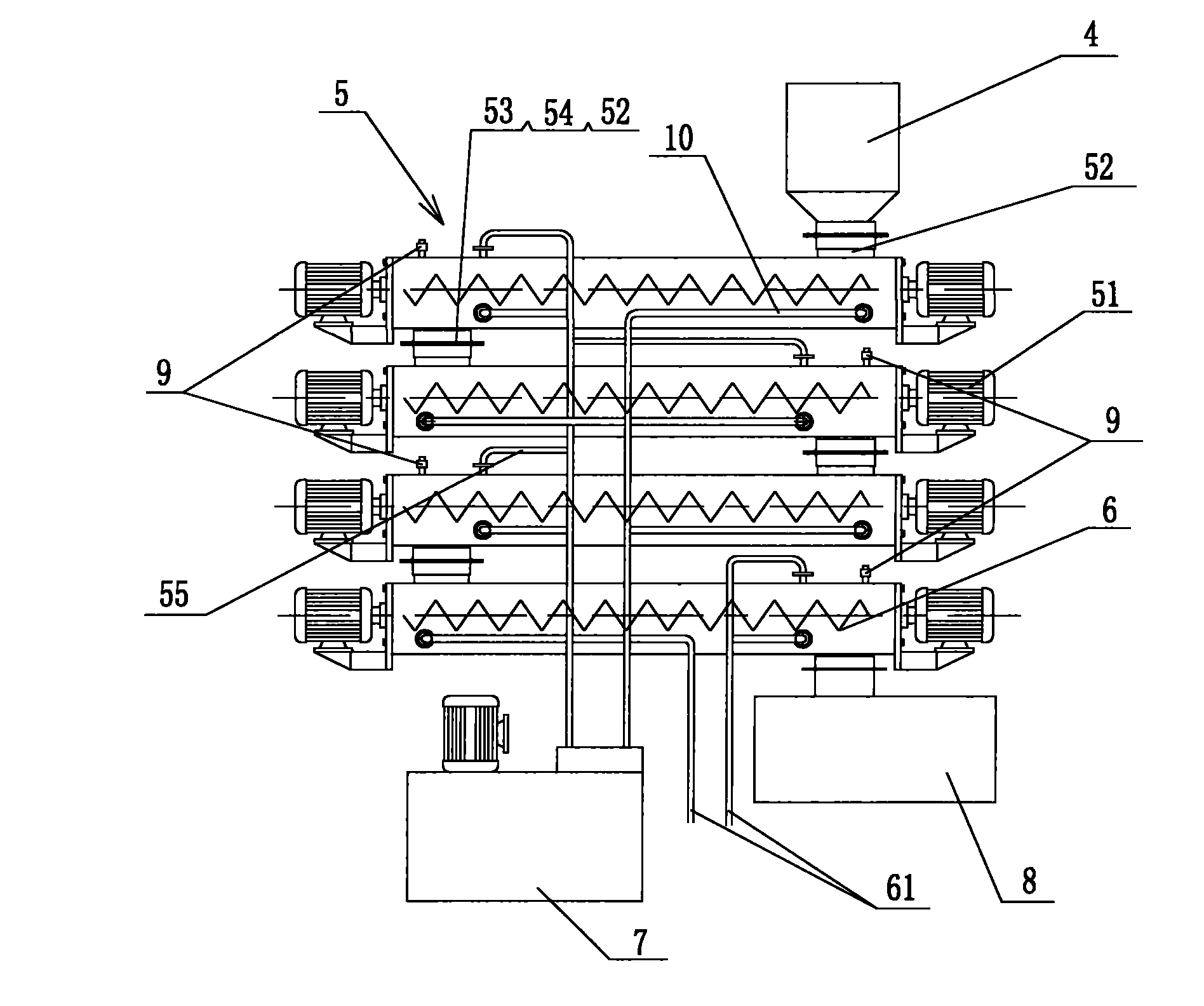

Automatic devulcanizing and plasticizing device and method for waste rubber powder

The invention provides automatic devulcanizing and plasticizing device and method for waste rubber powder. In the automatic devulcanizing and plasticizing device, a plastic highly stirring machine is applied to the automatic devulcanizing and plasticizing device for the waste rubber powder, which can realize high-speed stirring, enable ingredients to be mixed sufficiently and uniformly and realize the bulking, the immersing and the swelling of raw materials; a thermal reaction device comprises single or a plurality of plasticizing units; each screw material rod of a double-screw conveying device inside the thermal reaction device feeds by adopting differential motion; and if the thermal reaction device comprises a plurality of plasticizing units, the plasticizing units are arranged in a vertical spacing way, and each plasticizing unit is provided with an independent heating device which has short heating time and ensures the reaction to be sufficient. Because each screw material rod feeds by adopting the differential motion, the screw material rods are enabled to have self-cleaning function; meanwhile, the plasticizing units adopt a modular design, which enables the plasticizing units to be freely collated according to the different requirements of users on devulcanizing depth, thereby fully reducing equipment manufacturing cost and product production cost; and because of the adoption of a vertical spacing distribution structure, the equipment can be both expanded and conveniently maintained and overhauled.

Owner:袁红利

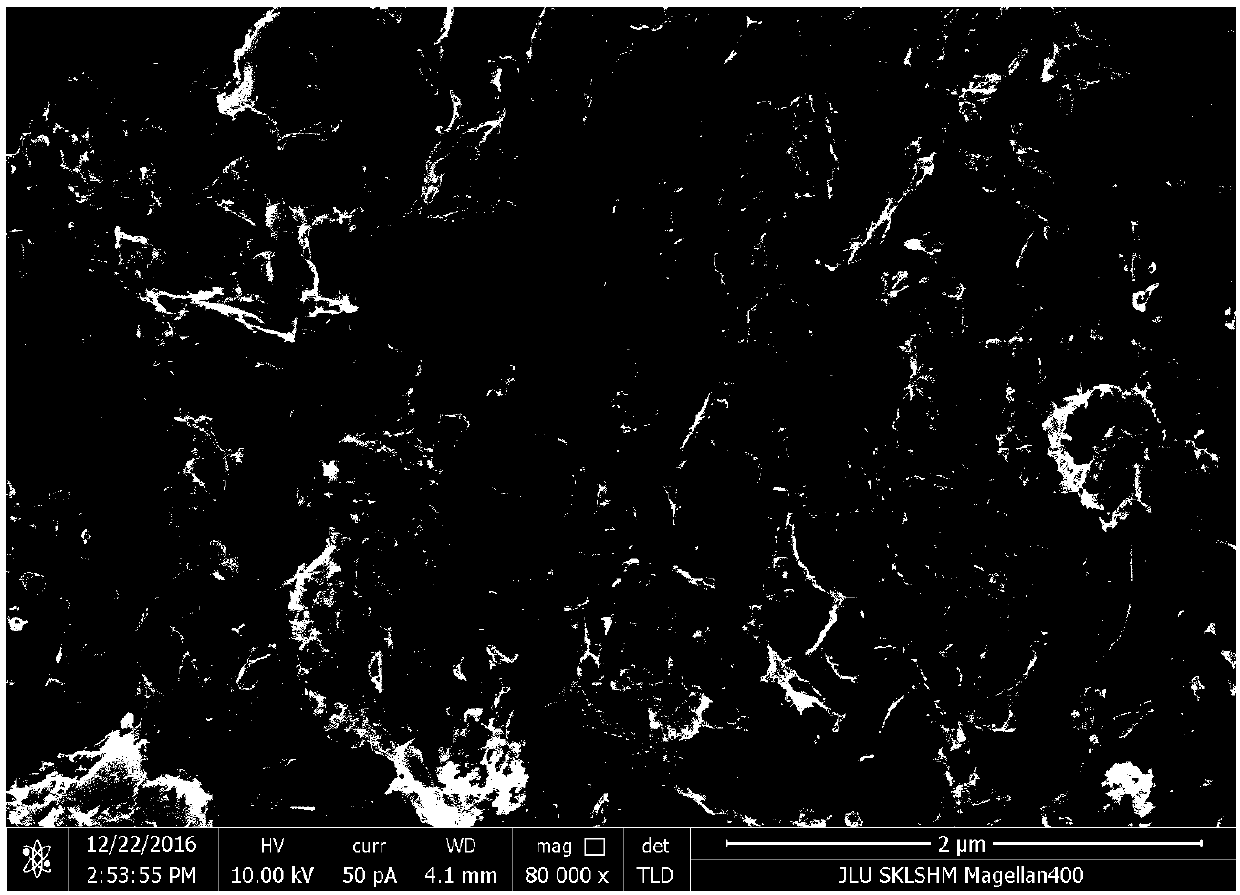

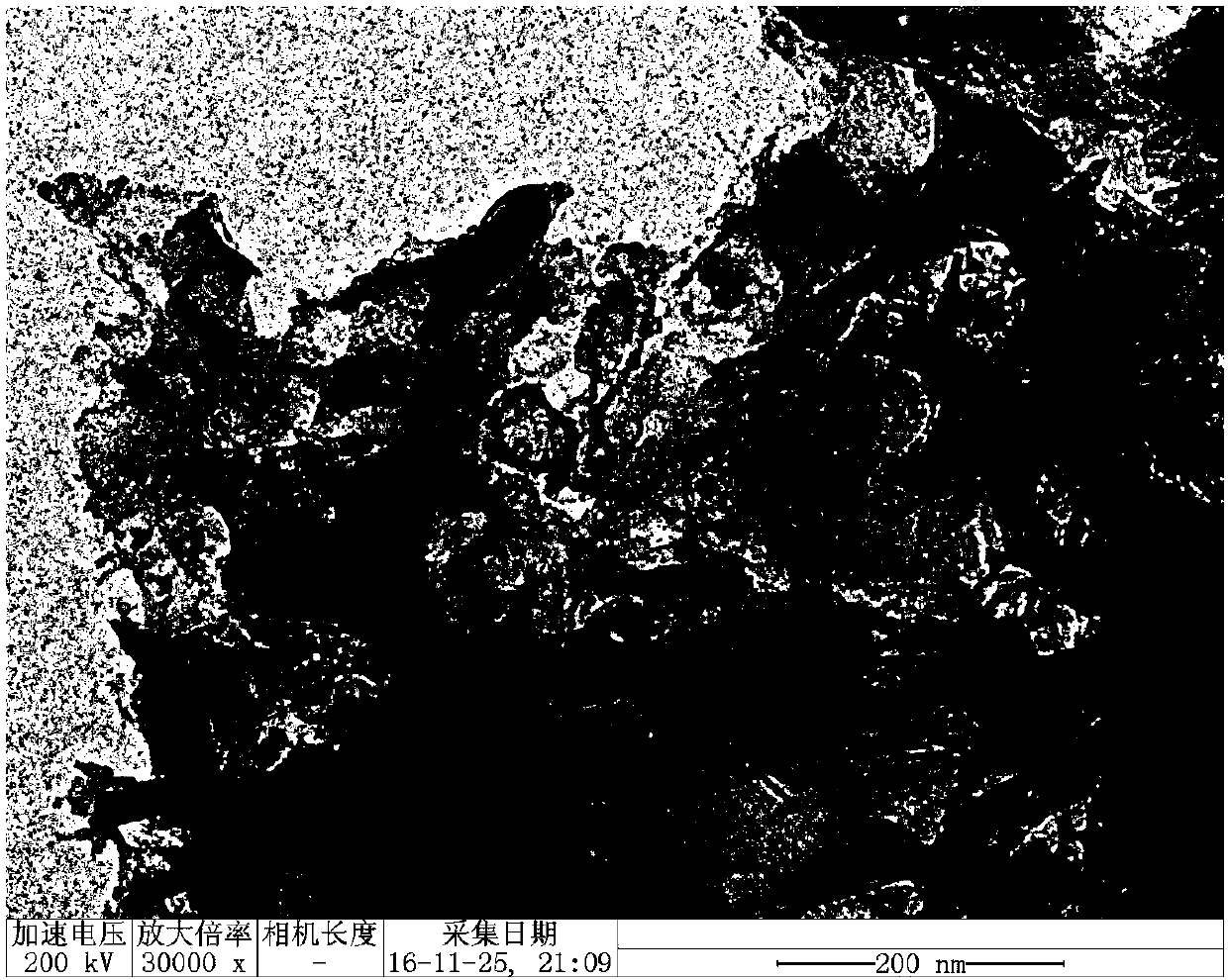

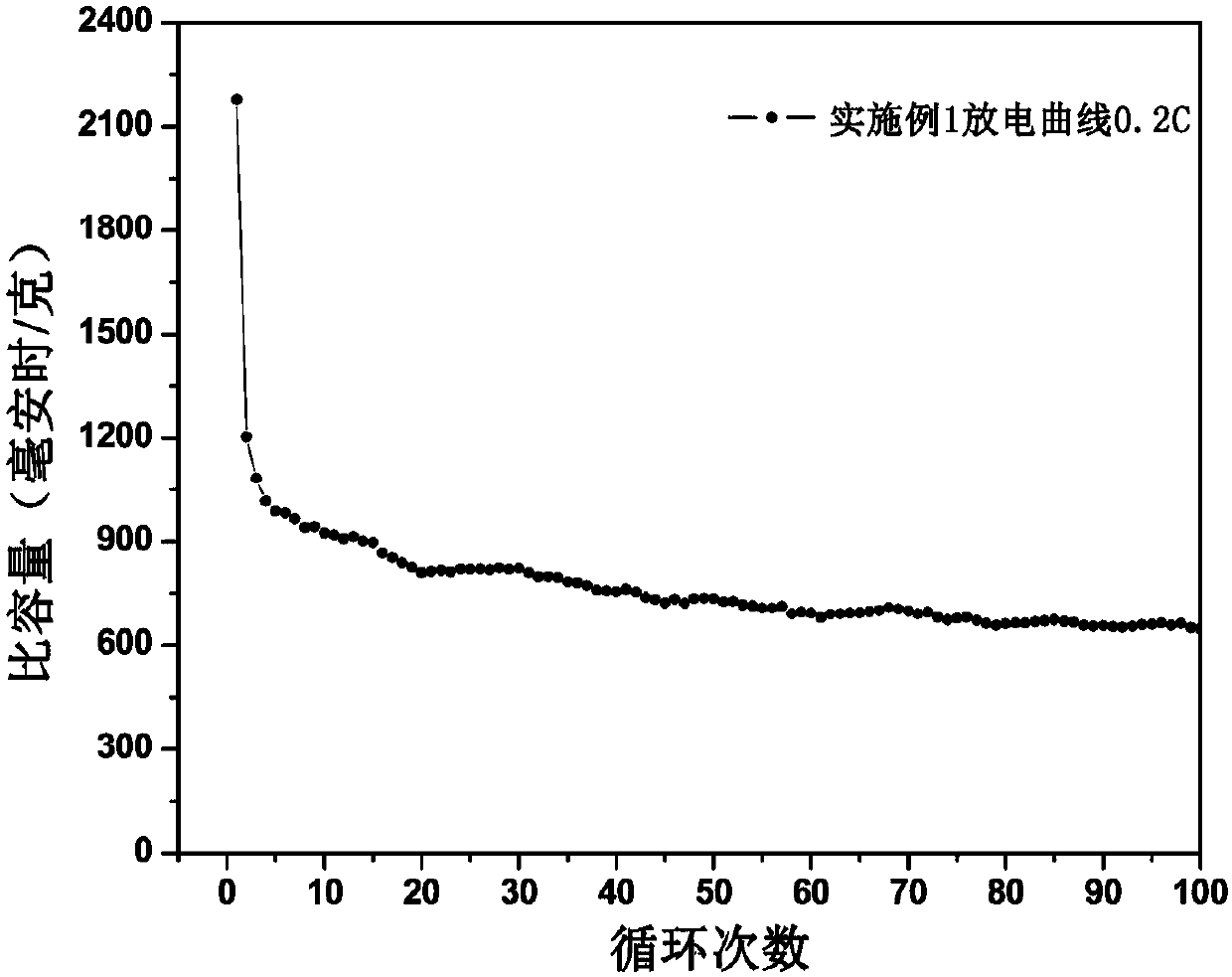

Preparation method of porous biomass carbon, porous biomass carbon and application

ActiveCN108033447AReduce pollutionLow priceCarbon compoundsCell electrodesBiomass carbonCarbonization

The invention relates to a preparation method of porous biomass carbon, porous biomass carbon and application. The preparation method of the porous biomass carbon comprises the following steps: mixingstraw with a calcium chloride solution, and leaving to stand for 12-24 hours so as to obtain a mixture, wherein the mass ratio of the straw to calcium chloride in the calcium chloride solution is (1:1.5)-(1:3); drying the mixture, and performing low-temperature carbonization for 2-3 hours at 300-350 DEG C so as to obtain a low-temperature carbide; heating the low-temperature carbide to 500-700 DEG C, and performing high-temperature activation treatment for 1-3 hours so as to obtain a pre-product; soaking the pre-product into an inorganic strong acid for 12-24 hours, and further washing with water of 70-80 DEG C till being neutral, thereby obtaining the porous biomass carbon. By adopting the porous biomass carbon prepared by using the preparation method of the porous biomass carbon, the charge / discharge specific capacity of a lithium ion battery is increased, and the circulation stability of the lithium ion battery is improved.

Owner:JILIN UNIV +1

Continuous casting crystallizer casting powder for ultra-low-carbon steel

ActiveCN103817301ADoes not affect the melting rateAvoid the phenomenon of carbonizationActivated carbonMetallurgy

The invention discloses a continuous casting crystallizer casting powder for ultra-low-carbon steel. Active carbon is added in the casting powder, so that air can be made to pass through a casting powder layer to enable the carbon to be oxidized rapidly to generate carbon dioxide gas to be discharged; the active carbon itself has a powerful adsorption function and a part of air is stored, so that the oxidation rate is improved, it is guaranteed that the carbon is removed rapidly after the casting powder is melted rapidly and the casting powder does not contain the carbon, and therefore the recarburization phenomenon of the ultra-low-carbon steel is prevented from occurring from the source. After the active carbon is oxidized rapidly, gaps disappear due to consumption of the active carbon, and the casting powder enables steel billet to be sealed and isolated from the air rapidly so as to prevent the steel billet from being oxidized again. The continuous casting crystallizer casting powder for the ultra-low-carbon steel is low in cost, practical, good in effect and worthy of popularization and application.

Owner:XIXIA LONGCHENG METALLURGICAL MATERIALS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com