Two-stage foot braking master valve

A brake master valve and spot brake technology, applied in the field of automobile brake master cylinder, can solve the problems of affecting the suspension system, carbonization, affecting the braking effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

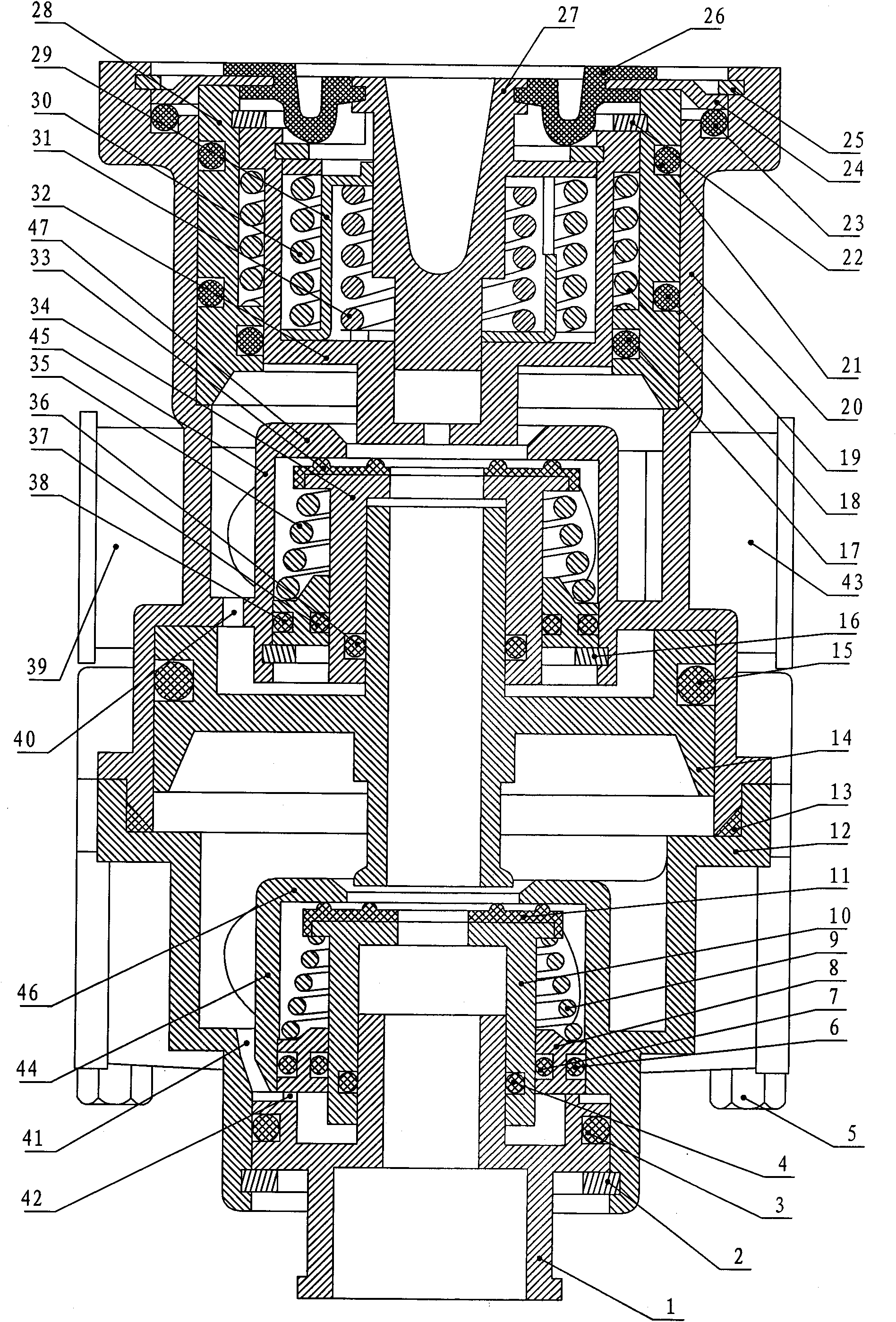

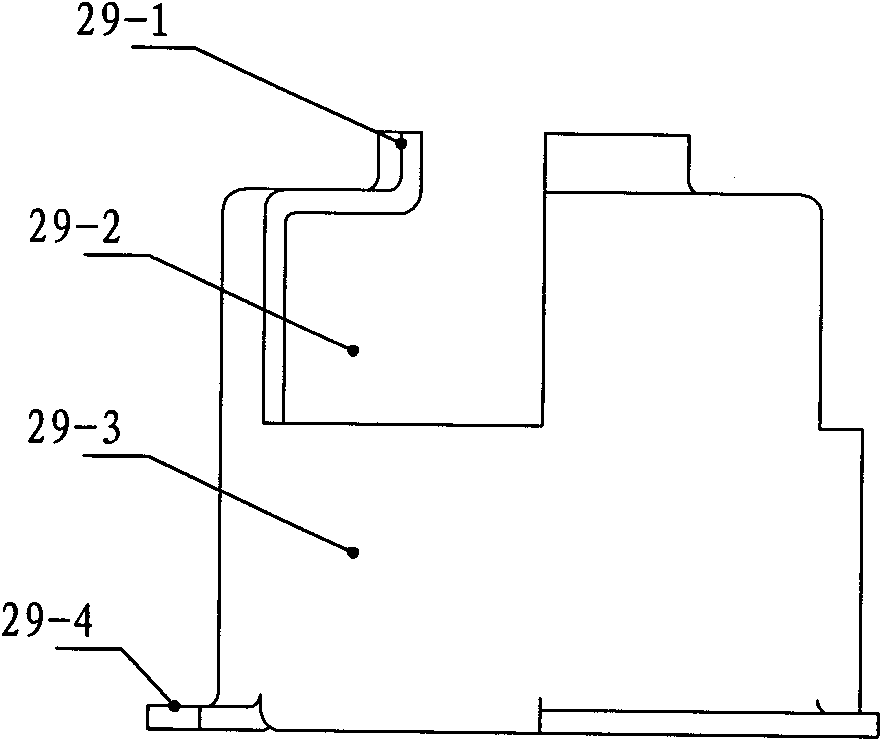

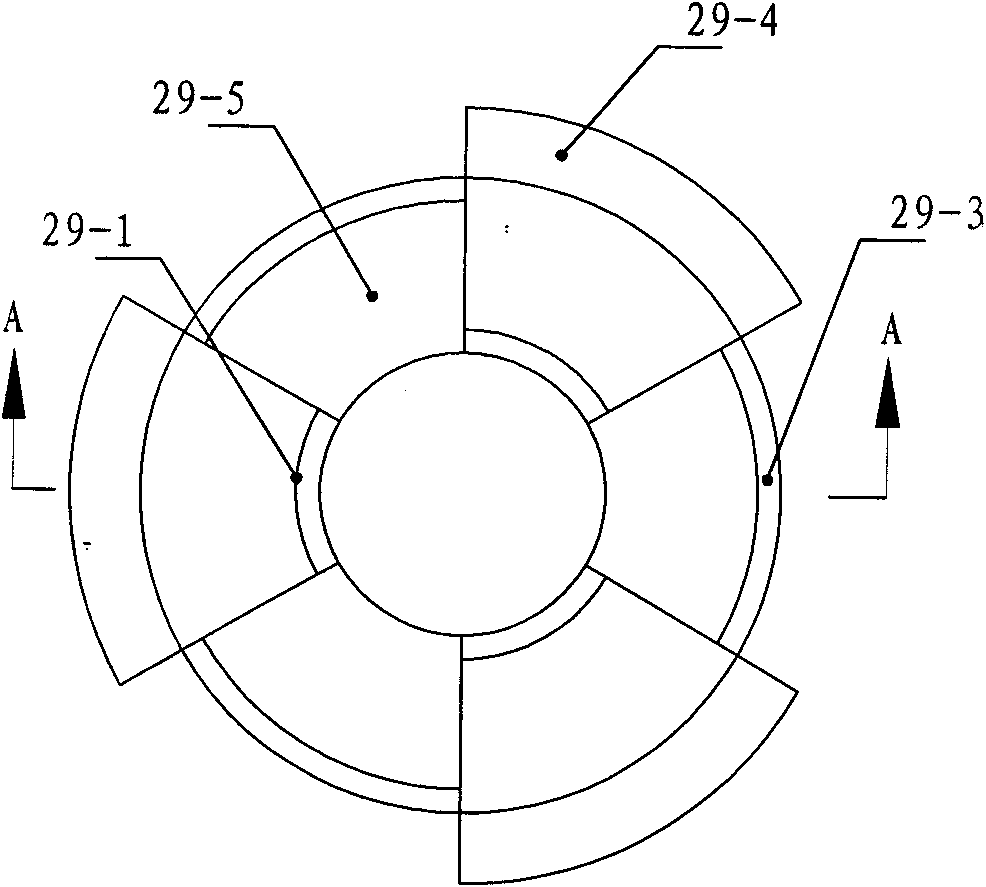

[0027]Embodiment: a kind of two-stage point braking master valve (type I), which contains an upper valve body and a lower valve body, and the upper valve body and the lower valve body are all provided with an air inlet hole and an air outlet hole, the described The lower edge of the upper valve body is inserted into the upper edge of the lower valve body, the upper piston assembly is installed in the upper part of the upper valve body, the upper valve assembly is installed in the middle of the upper valve body, and the lower valve assembly is installed in the lower valve body. The valve assembly, the upper and lower valve assemblies are driven by the lower piston installed in the lower part of the upper valve body. The spring and the clip pad are fixedly installed in the stepped hole on the upper part of the upper valve body. The upper piston is installed in the piston sleeve through the snap ring. The upper piston is a piston with a cavity inside. The outer surface of the uppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com