Supported molybdenum carbide/metal nanoparticle composite catalyst and its preparation method and application in catalytic degradation of heavy metal chromium

A technology of metal nanoparticles and composite catalysts, which is applied in the direction of catalyst activation/preparation, physical/chemical process catalysts, chemical instruments and methods, etc., and can solve problems such as poor stability, easy sintering and agglomeration of molybdenum carbide, and secondary pollution , to achieve the effect of increasing surface catalytic active sites, improving overall performance, and accelerating proton transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The preparation method of supported molybdenum carbide / metal nanoparticle composite catalyst in the present embodiment is as follows:

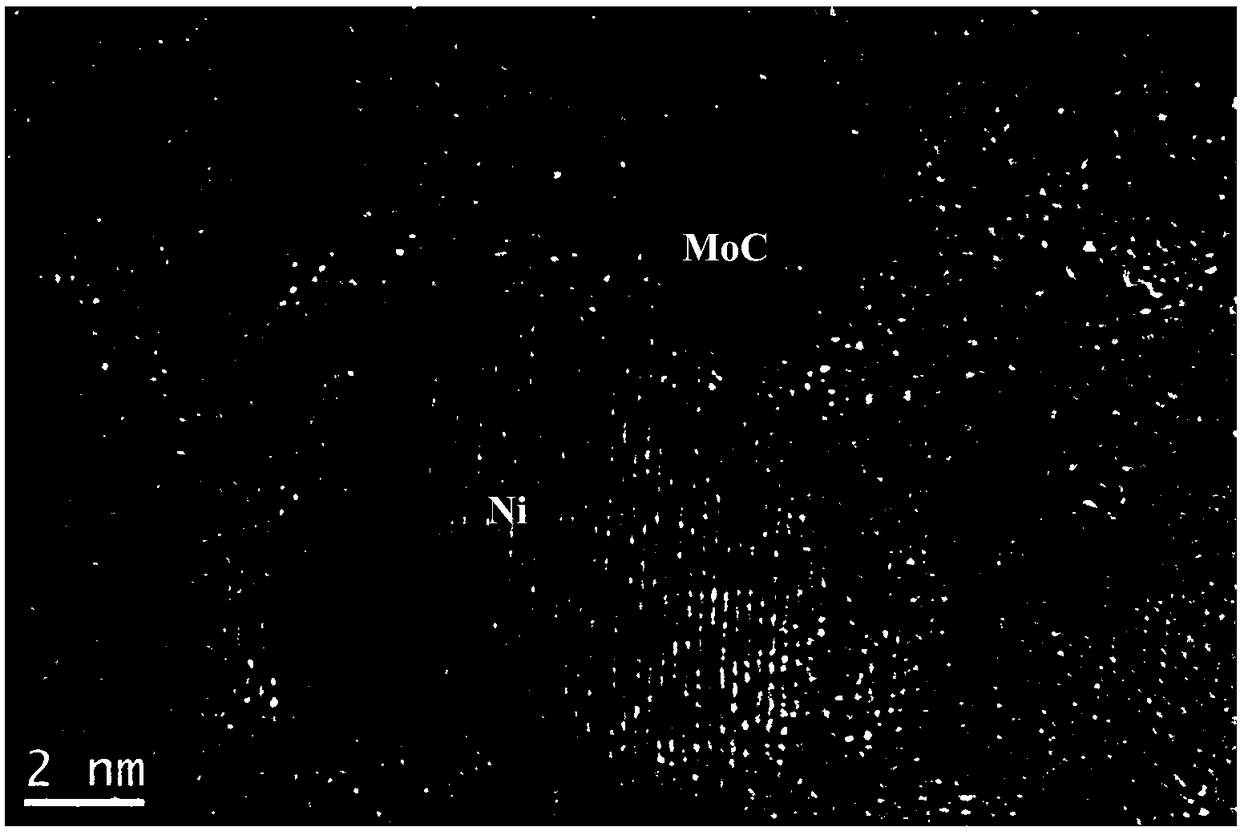

[0036] 1. Preparation of molybdenum carbide / metal nanoparticle homogeneous powder

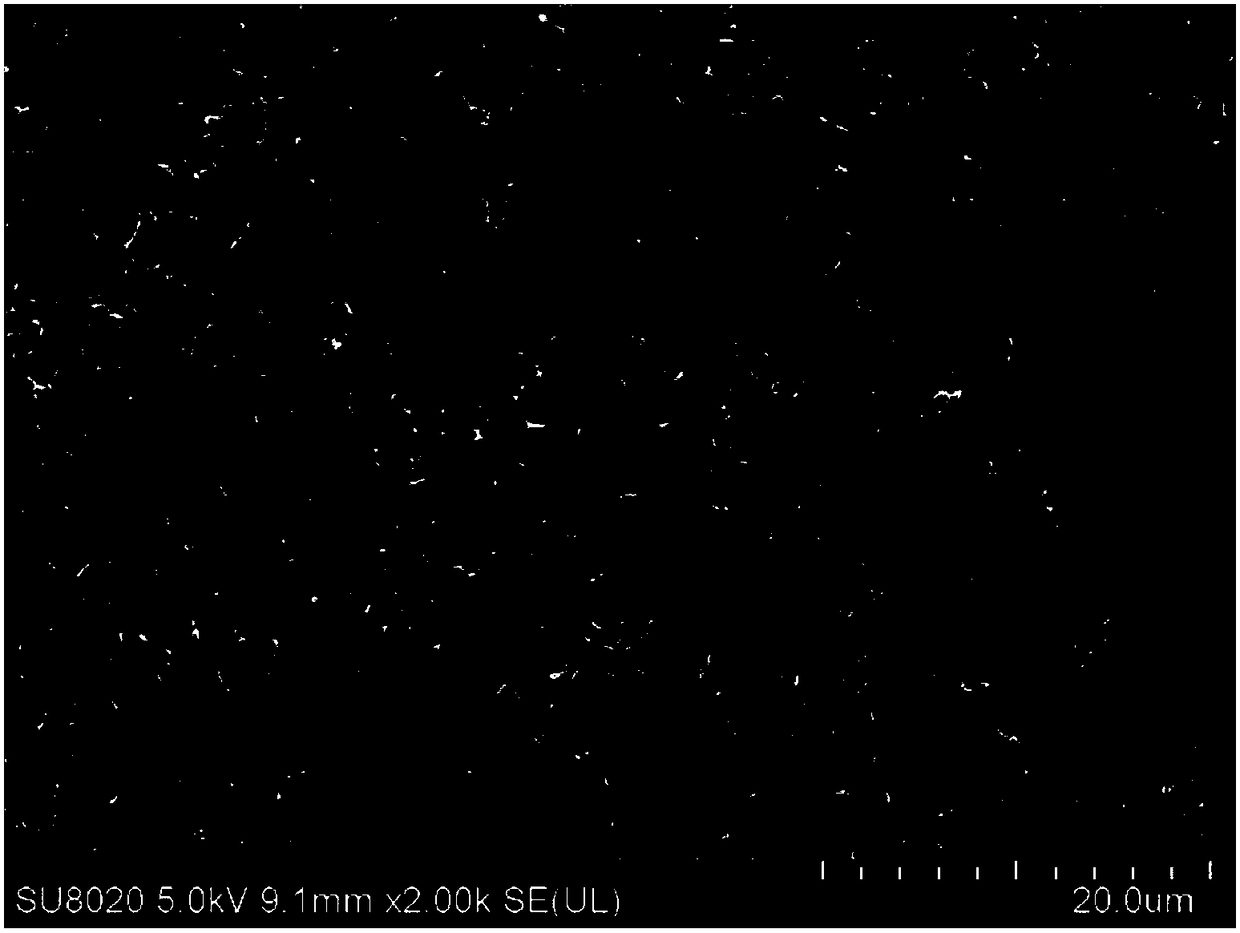

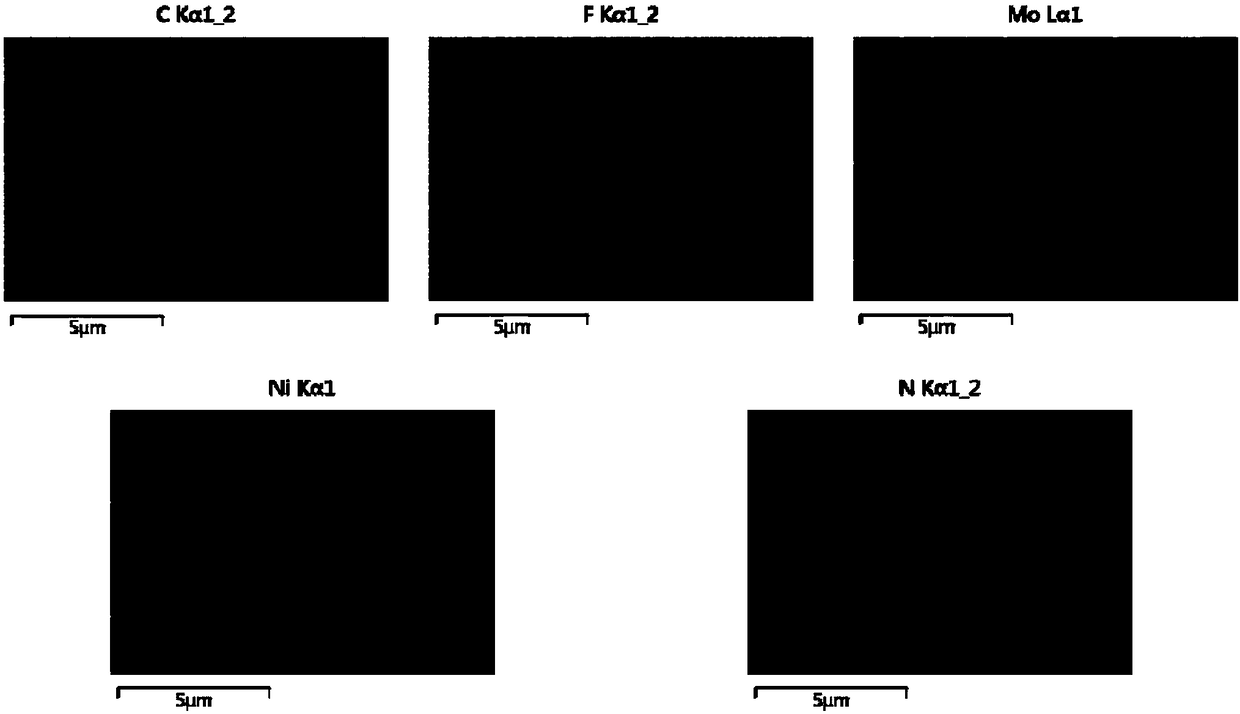

[0037] Add 1.26g (10mmol) melamine to an aqueous solution containing 2.52g (20mmol) oxalic acid dihydrate and 0.2g (0.22mmol) ammonium molybdate tetrahydrate, and continue stirring at 70°C for 6 hours to obtain a homogeneous solution; Add 10mL of an aqueous solution containing 0.4g (1.68mmol) of nickel chloride hexahydrate, continue stirring at 25°C for 12 hours, then evaporate, dry, and grind to obtain a homogeneous powder; place the obtained homogeneous powder in a constant temperature tube-type resistance furnace In the zone, the temperature was raised to 900°C at a rate of 10°C / min and kept at a temperature of 2 hours. After the reaction was completed, it was cooled to room temperature to obtain a pyrolysis product of nitrogen-doped carbon-coated molyb...

Embodiment 2

[0046] The preparation process of the composite catalyst in this example is the same as that in Example 1, the only difference being that 0.4g (1.68mmol) of nickel chloride hexahydrate is replaced by 0.33g (1.68mmol) of ferrous chloride tetrahydrate.

[0047] This example adopts the same method as Example 1 to catalytically reduce hexavalent chromium, the only difference is that the composite catalyst prepared in this example is used to replace the PVDF-supported nitrogen-doped carbon-coated molybdenum carbide / nickel in Example 1 Nano particle composite catalyst, the final degradation rate of hexavalent chromium is 98%.

Embodiment 3

[0049] The preparation process of the composite catalyst in this example is the same as in Example 1, the only difference being that 0.4g (1.68mmol) of nickel chloride hexahydrate is replaced by 0.4g (1.68mmol) of cobalt chloride hexahydrate.

[0050] This example adopts the same method as Example 1 to catalytically reduce hexavalent chromium, the only difference is that the composite catalyst prepared in this example is used to replace the PVDF-supported nitrogen-doped carbon-coated molybdenum carbide / nickel in Example 1 Nano particle composite catalyst, the final degradation rate of hexavalent chromium is 96%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com