Patents

Literature

2780 results about "Molybdate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In chemistry a molybdate is a compound containing an oxoanion with molybdenum in its highest oxidation state of 6. Molybdenum can form a very large range of such oxoanions which can be discrete structures or polymeric extended structures, although the latter are only found in the solid state.The larger oxoanions are members of group of compounds termed polyoxometalates, and because they contain only one type of metal atom are often called isopolymetalates. The discrete molybdenum oxoanions range in size from the simplest MoO²⁻₄, found in potassium molybdate up to extremely large structures found in isopoly-molybdenum blues that contain for example 154 Mo atoms. The behaviour of molybdenum is different from the other elements in group 6. Chromium only forms the chromates, CrO²⁻₄, Cr₂O²⁻₇, Cr₃O²⁻₁₀ and Cr₄O²⁻₁₃ ions which are all based on tetrahedral chromium. Tungsten is similar to molybdenum and forms many tungstates containing 6 coordinate tungsten.

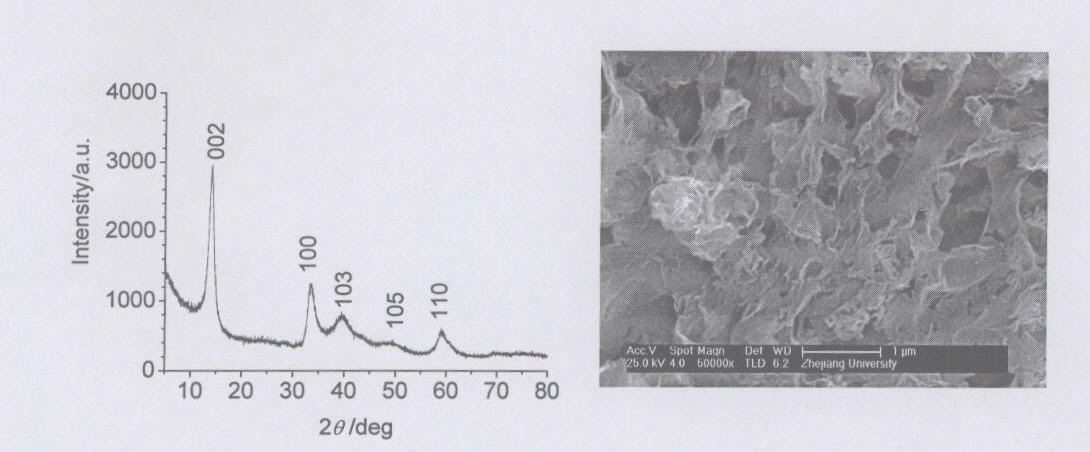

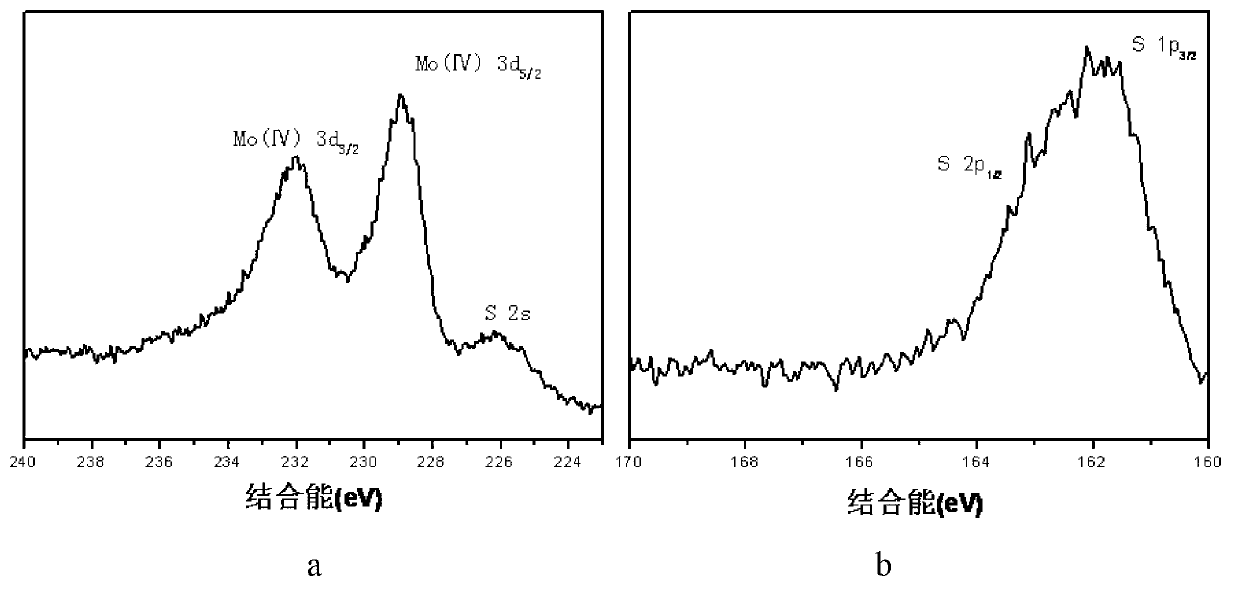

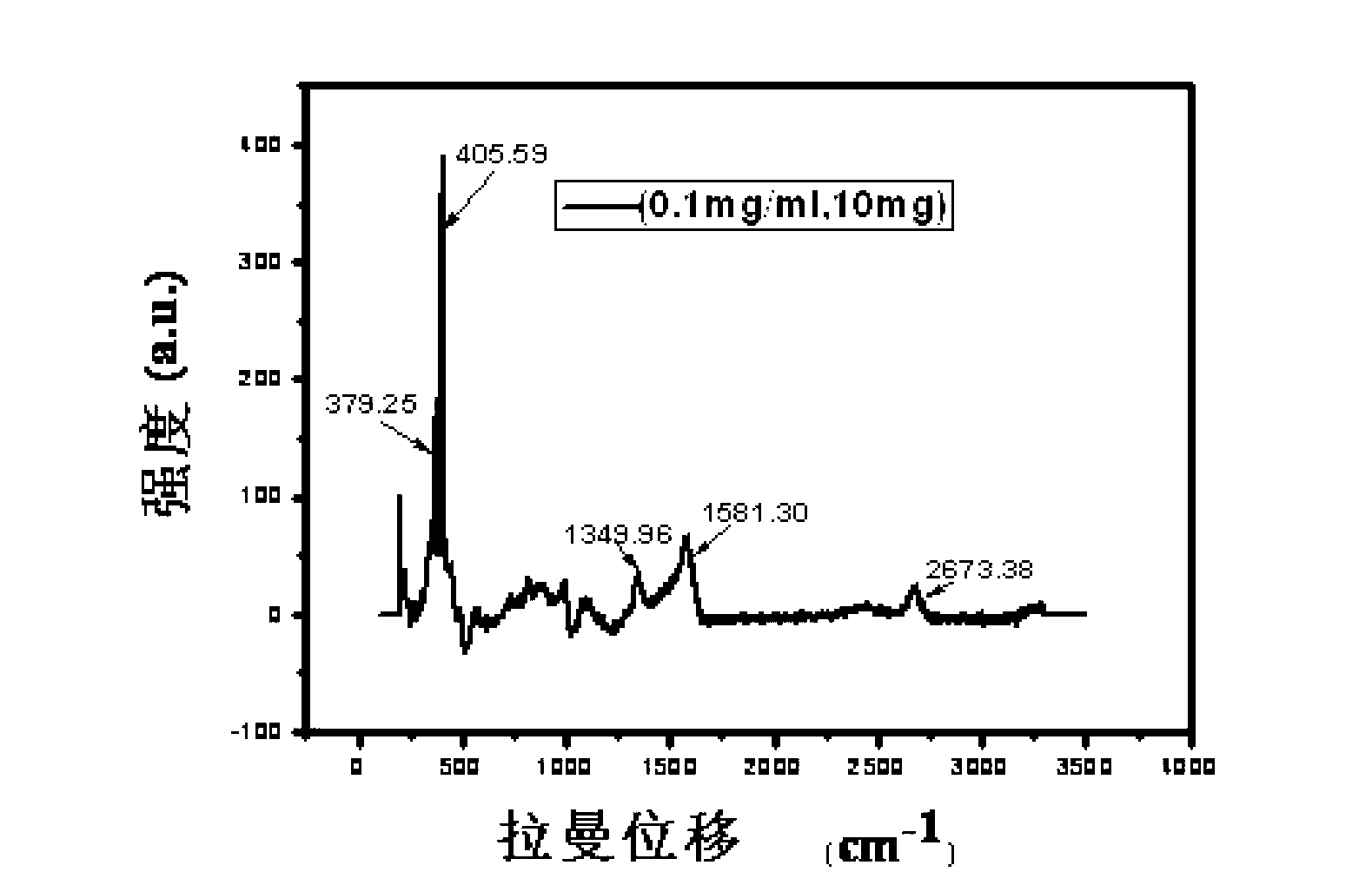

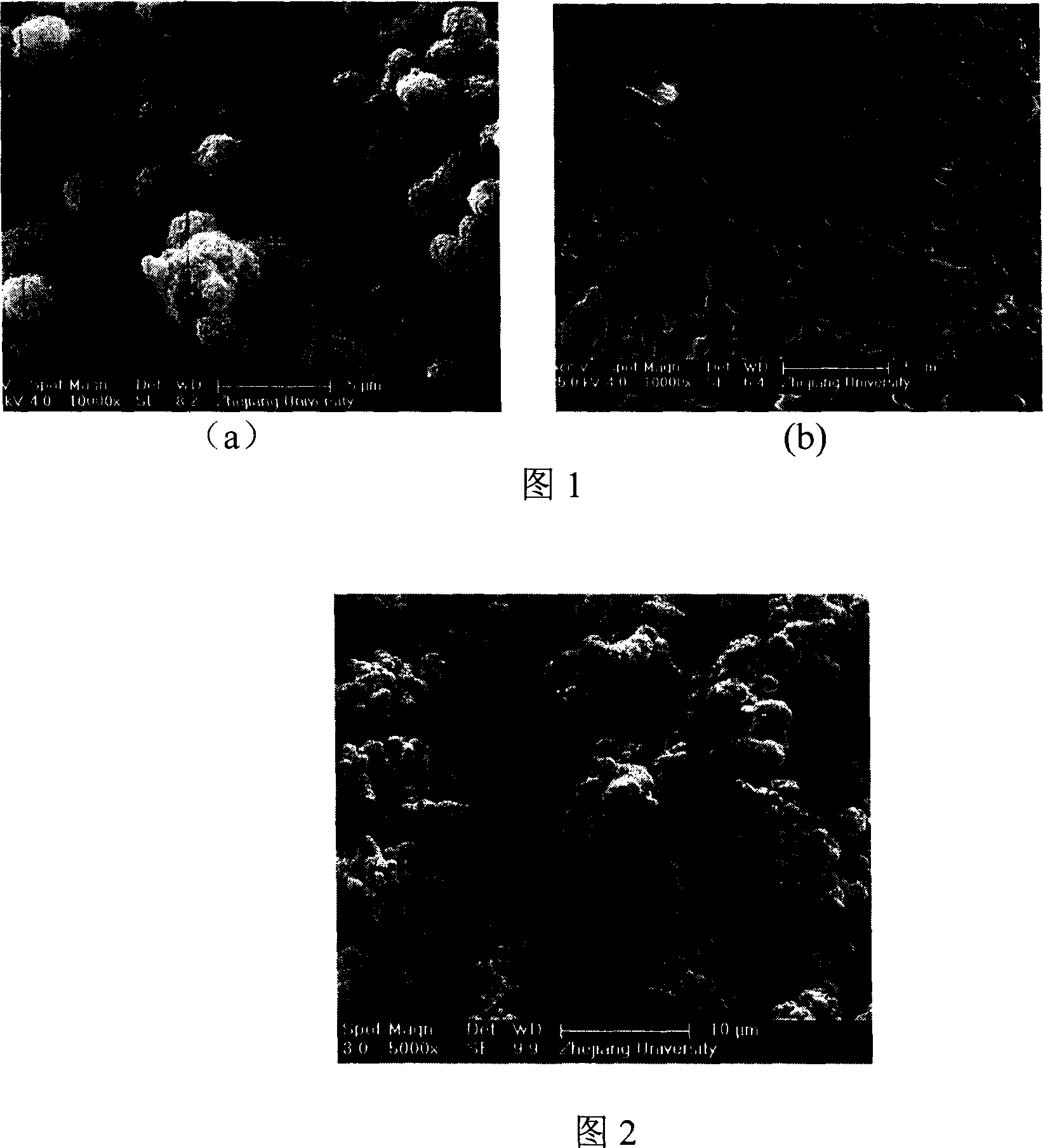

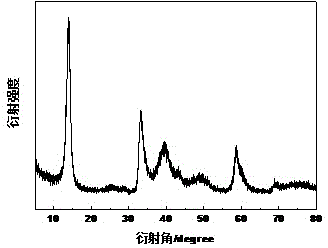

Graphene nano sheet/MoS2 composite nano material and synthesis method thereof

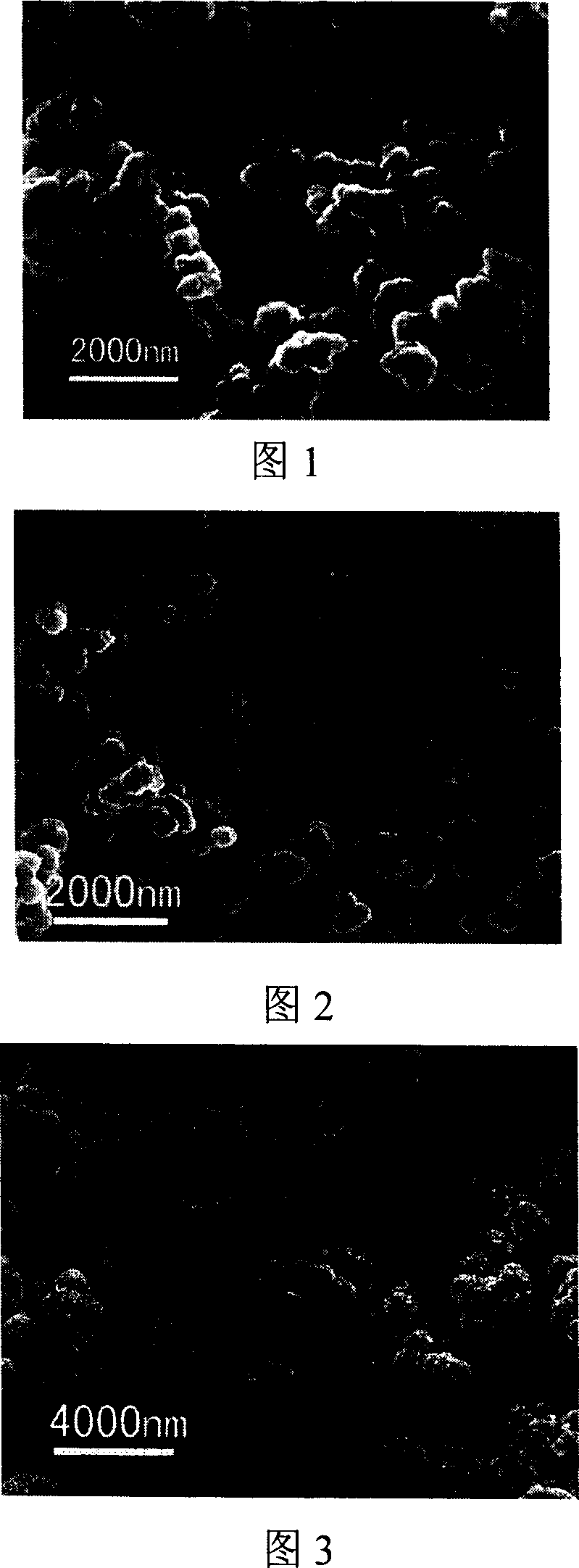

InactiveCN102142551AMild reaction conditionsSimple processMaterial nanotechnologyCell electrodesSynthesis methodsThiourea

The invention discloses a graphene nano sheet / MoS2 composite nano material and a synthesis method thereof. The method comprises the following steps of: preparing a graphite oxide nano sheet from graphite by using a chemical oxidation method, then dissolving molybdate into deionized water to form a solution of 0.02 to 0.07M, and adding thioacetamide or thiourea serving as a sulfur source and a reducer, wherein the mass ratio of the thioacetamide or the thiourea to the molybdate is 5:1-12:1; and adding the graphite oxide nano sheet into the solution, performing ultrasonic treatment for 1 to 2 hours so that the graphite oxide nano sheet is fully dispersed in a hydrothermal reaction solution, transferring the mixture into a hydrothermal reaction kettle, sealing, reacting for 20 to 36 hours at the temperature of between 220 and 260 DEG C, and obtaining the graphene nano sheet / molybdenum disulfide composite nano material by one-step hydrothermal synthesis, wherein the mass ratio of the graphene nano sheet to the molybdenum disulfide in the composite material is 1:2-4:1. The method has the characteristics of mild reaction condition and simple process. The synthesized graphene nano sheet / molybdenum disulfide composite nano material serving as an electrochemical lithium storage and electrochemical magnesium storage electrode material has wide application.

Owner:ZHEJIANG UNIV

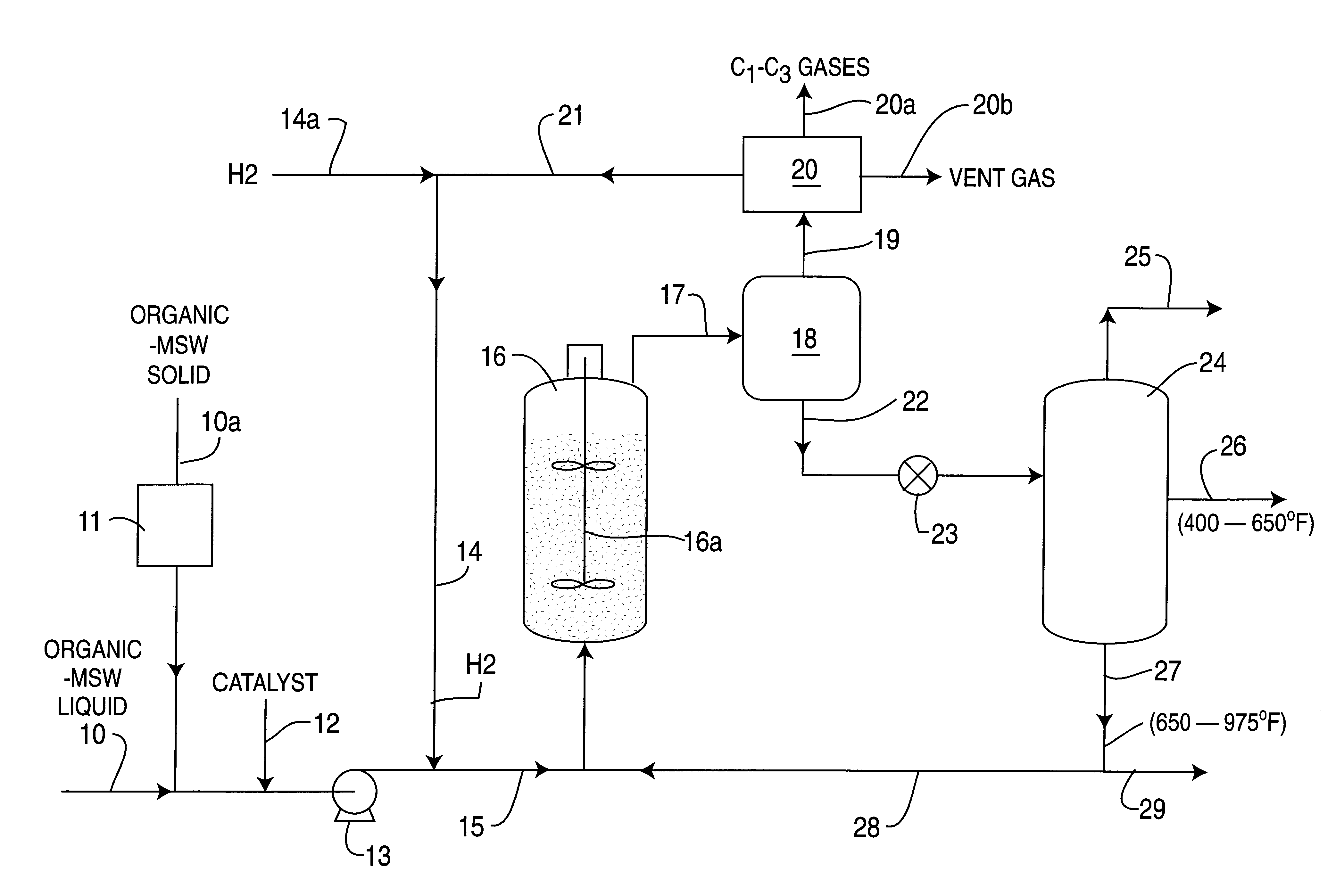

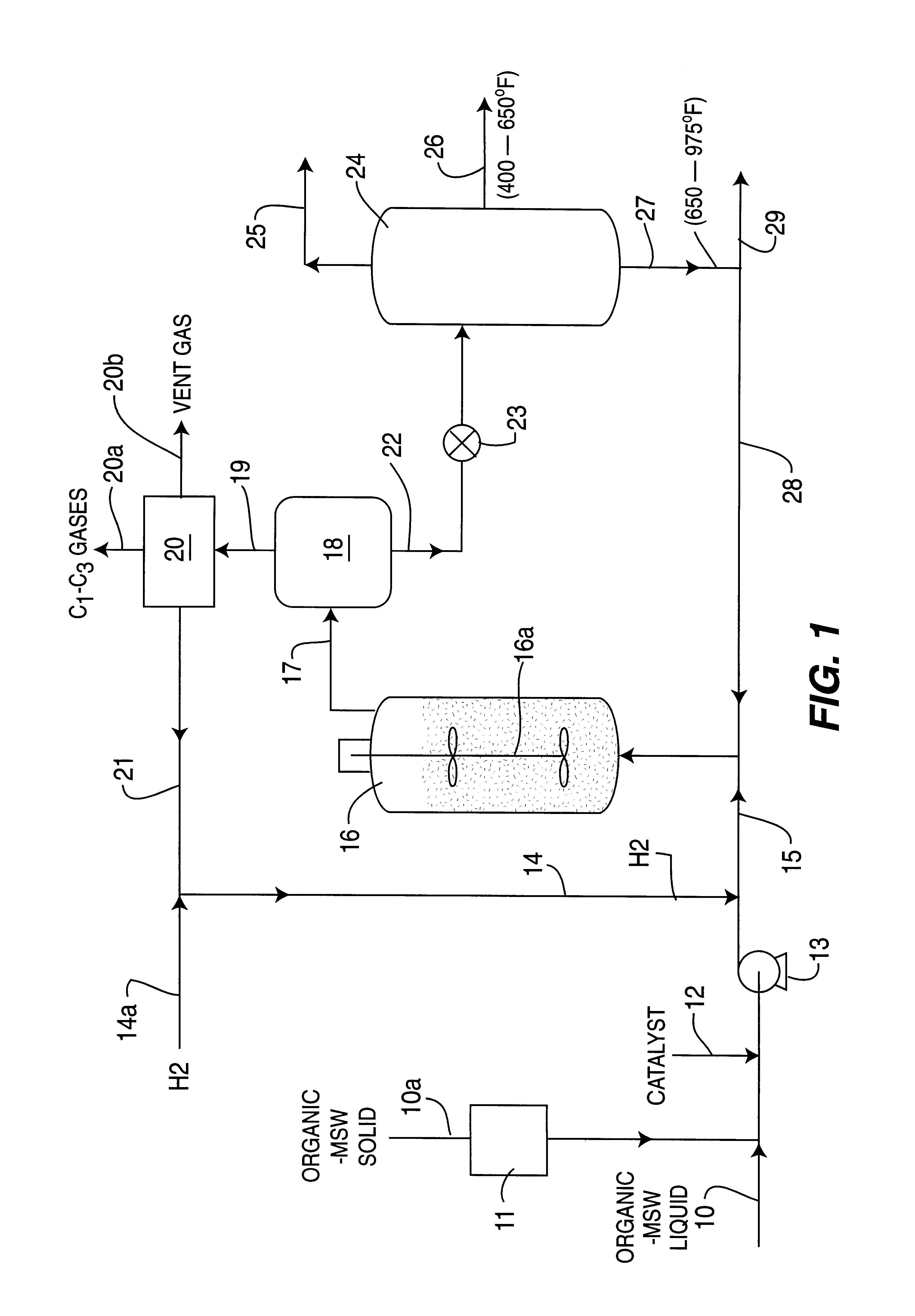

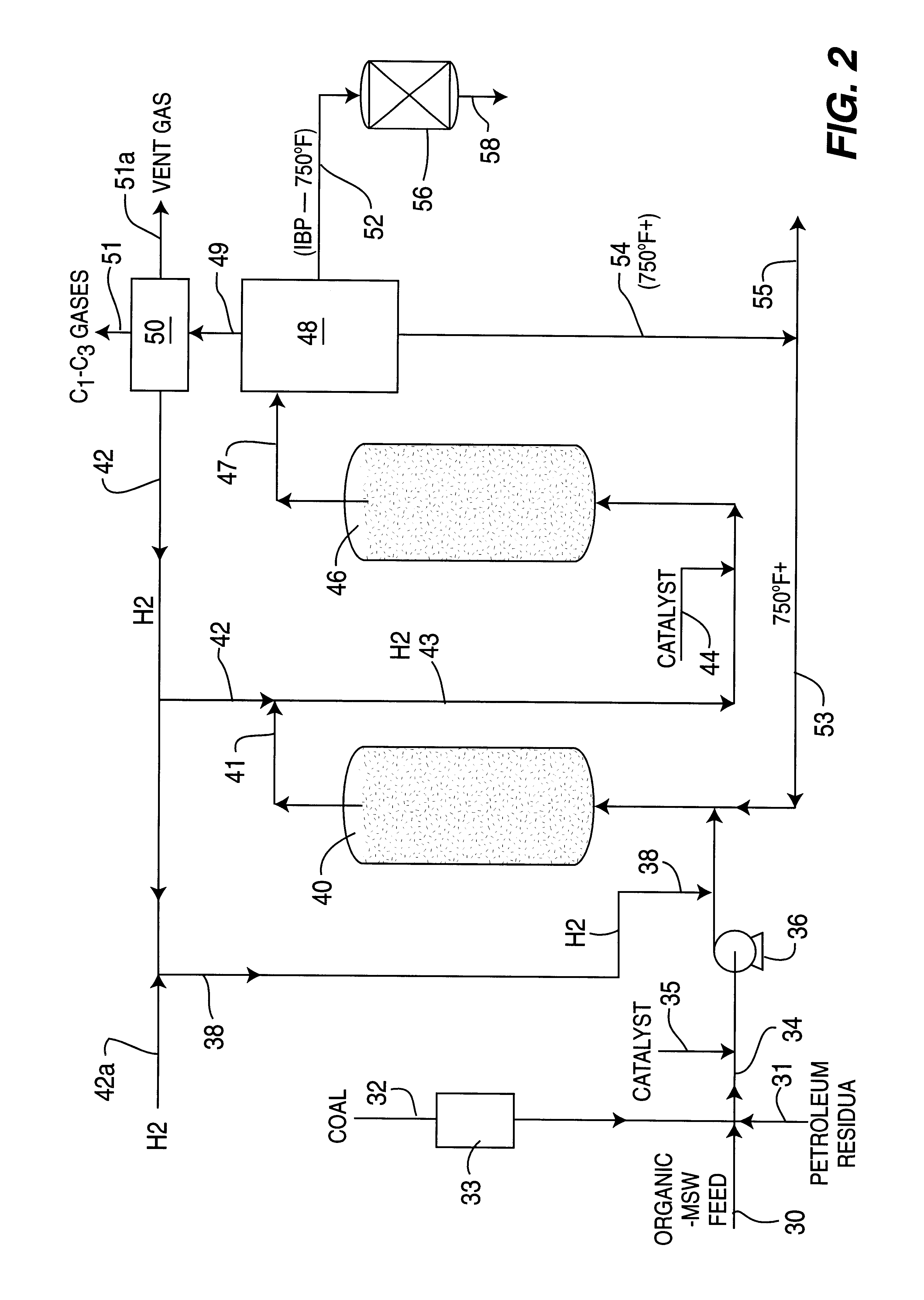

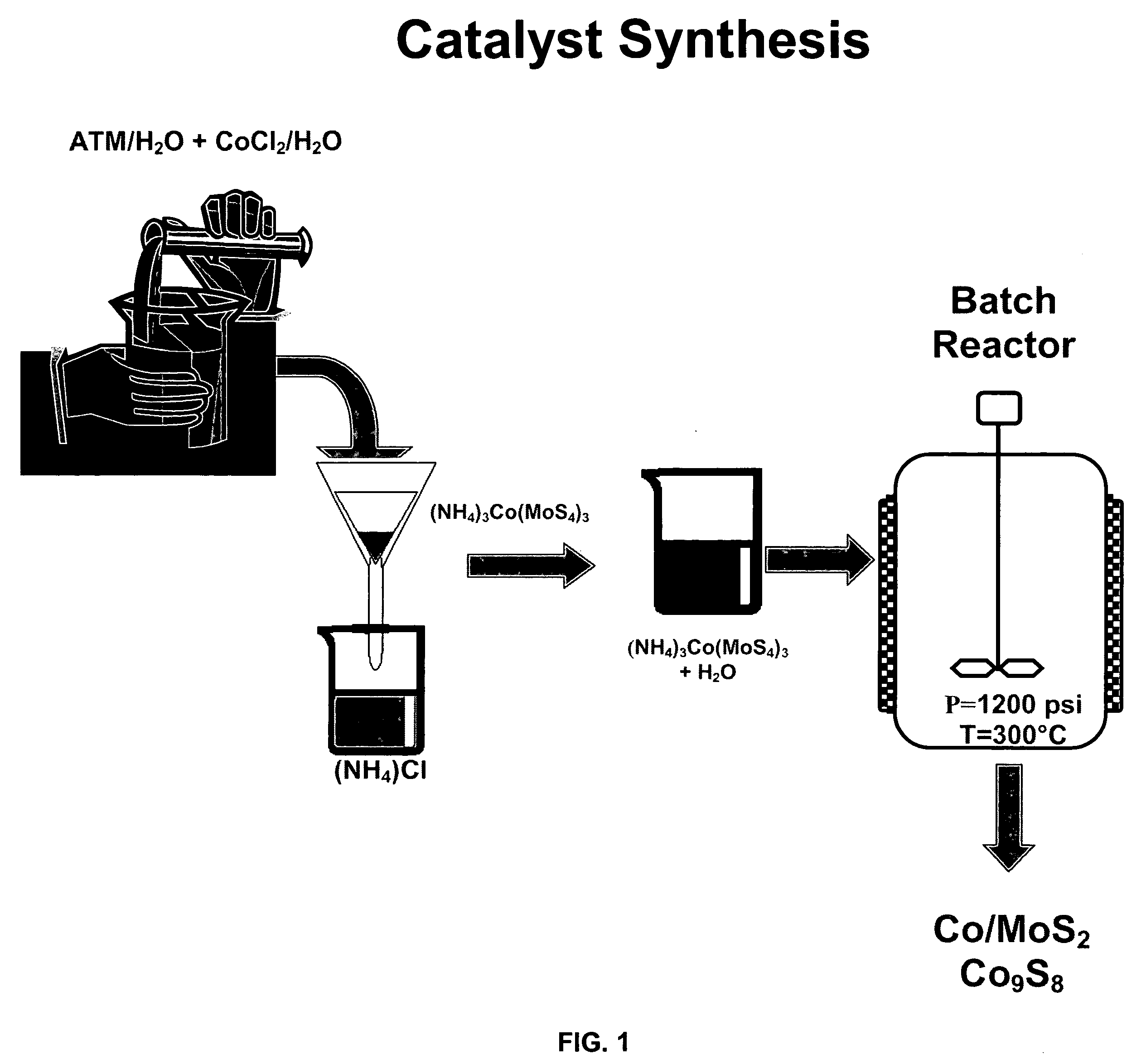

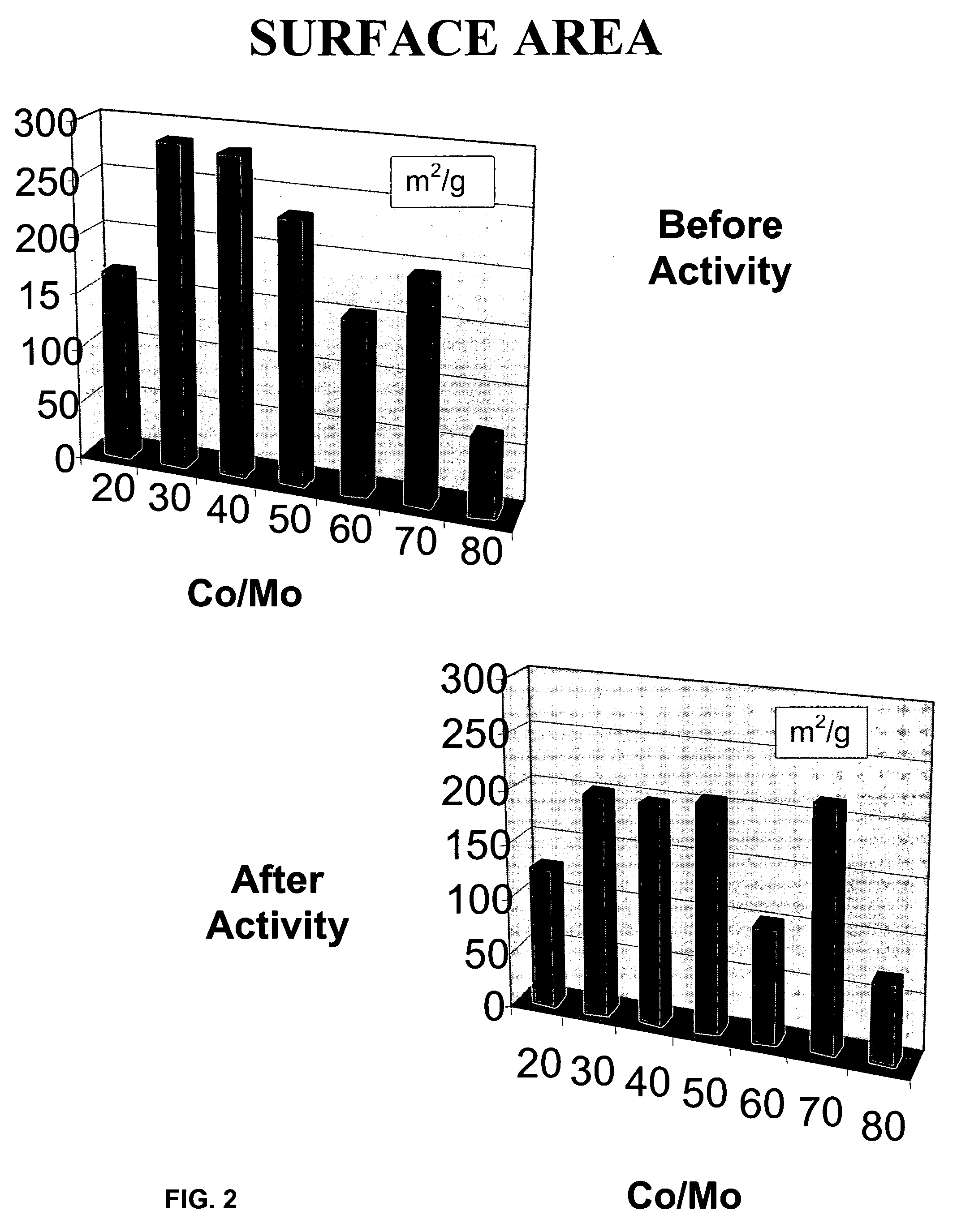

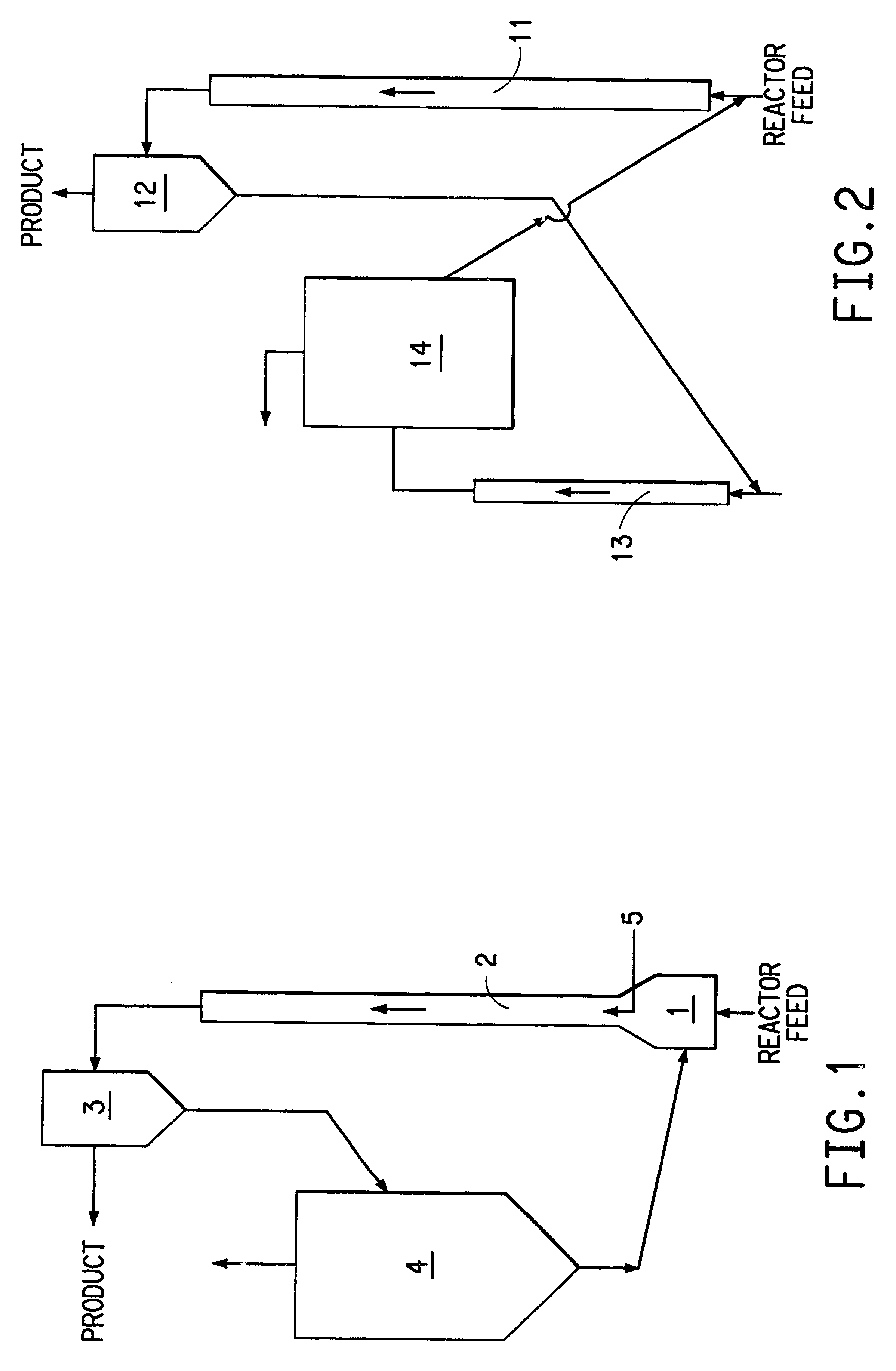

Catalytic hydroconversion of chemically digested organic municipal solid waste materials

InactiveUS6270655B1Increase surface areaReduce total nitrogenLiquid hydrocarbon mixture productionHydrocarbon oil crackingParticulatesLiquid product

A hydrocarbon liquid feedstock containing at least 50 wt. % chemically digested organic-MSW material is catalytically hydroconverted utilizing either a single stage or two-stage catalytic reaction process to produce desirable lower-boiling hydrocarbon liquid products. The catalyst can be either a particulate supported type catalyst such as containing cobalt and / or molybdenum and / or nickel on alumina support, or a dispersed slurry type catalyst containing mainly iron oxide with anions of molybdate, phosphate, sulfate or tungstate, and combinations thereof. Broad useful reaction conditions are 600-860° F. (315-460° C.) temperature, 1000-3000 psi hydrogen partial pressure, and fresh feed rate of 20-60 pounds / hr / ft3 reactor volume. Effluent material from the final stage catalytic reactor is phase separated and the resulting liquid portion is fractionated to produce the desired low-boiling hydrocarbon liquid products particularly useful as transportation fuels. If desired, the chemically digested organic-MSW feedstock can be blended with petroleum residua and / or particulate coal and / or mixed waste plastics and the blended feed material processed in catalytic two-stage reactors to produce similar desirable low-boiling hydrocarbon liquid products.

Owner:HYDROCARBON TECH

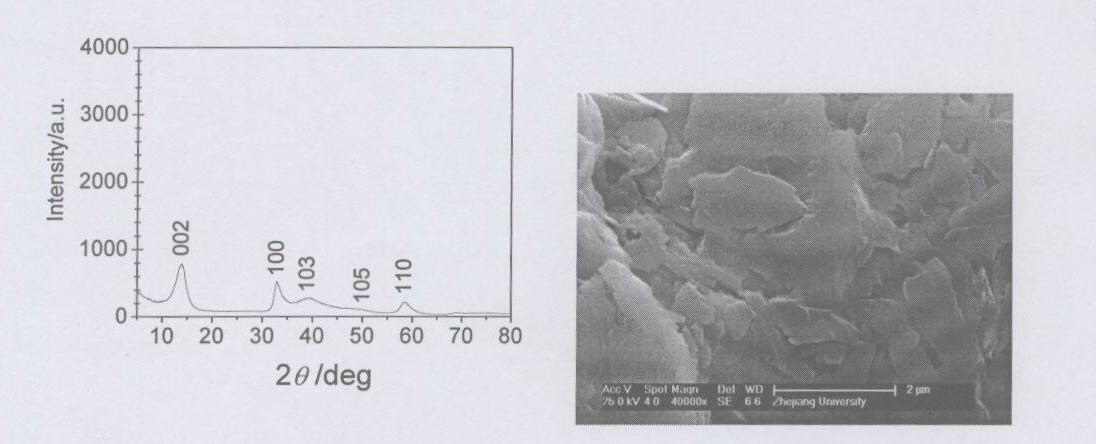

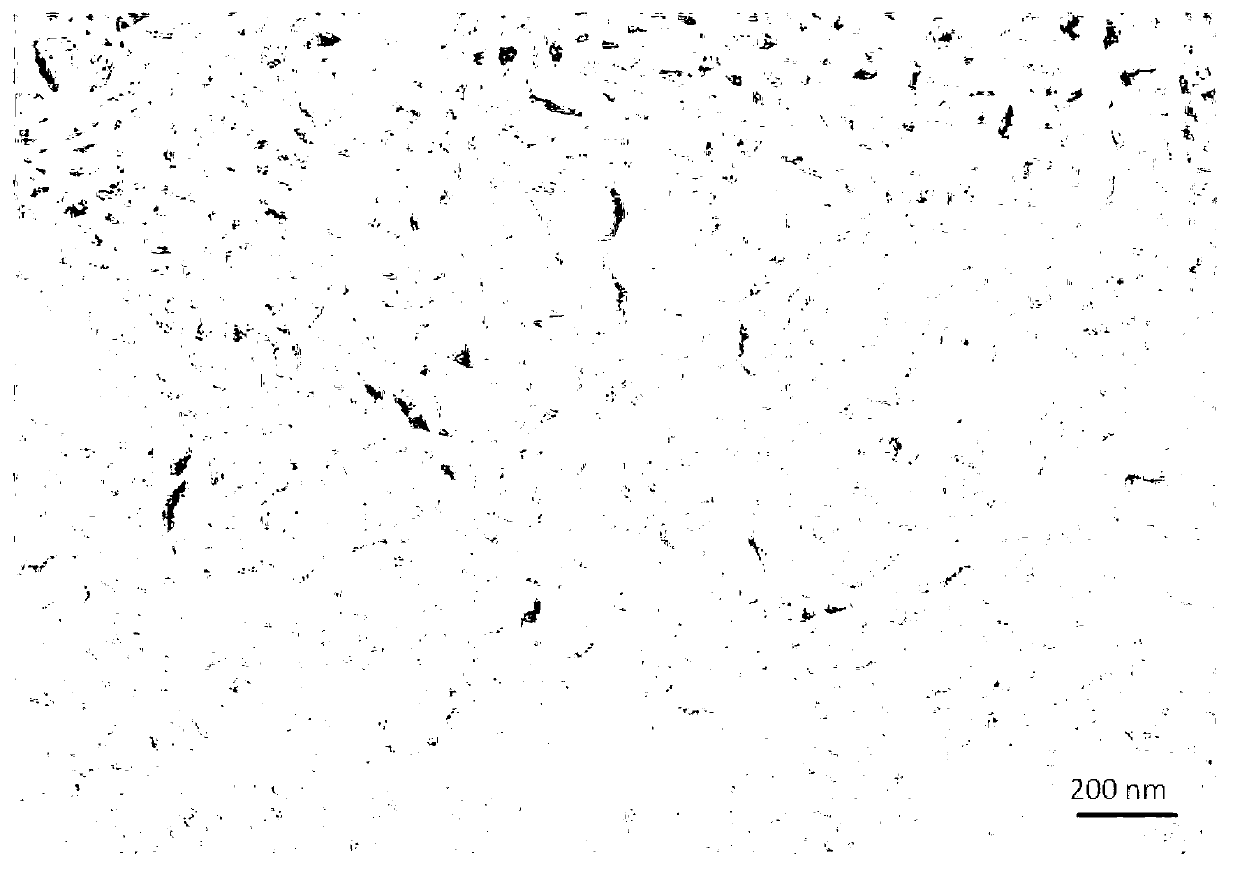

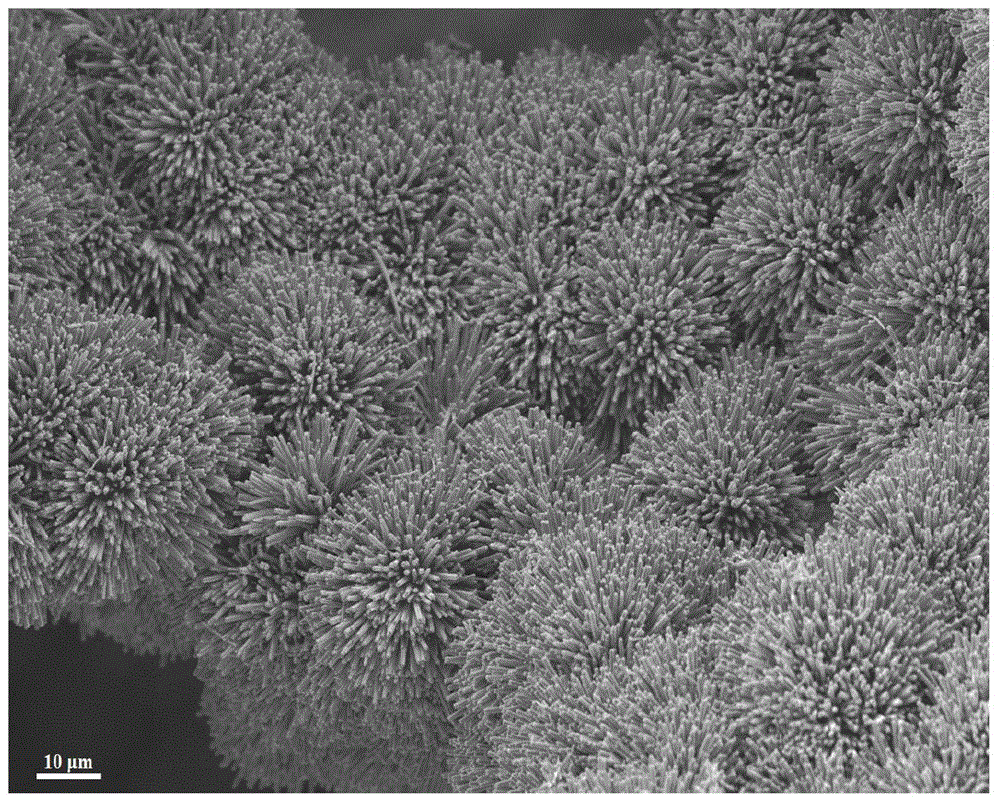

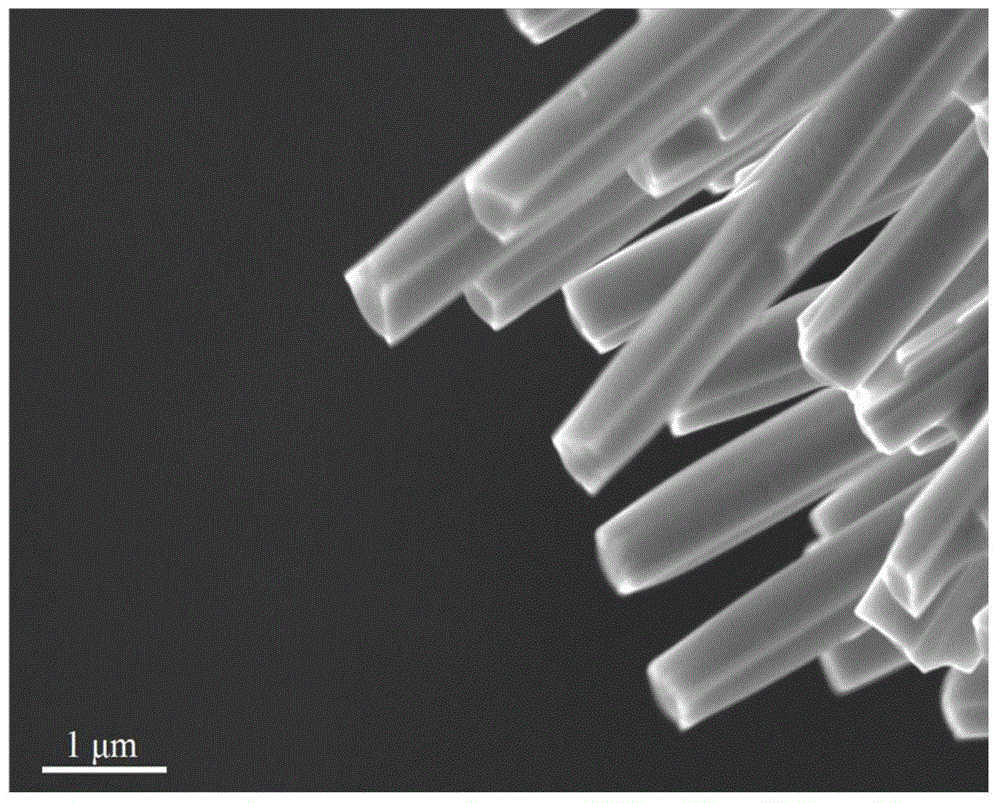

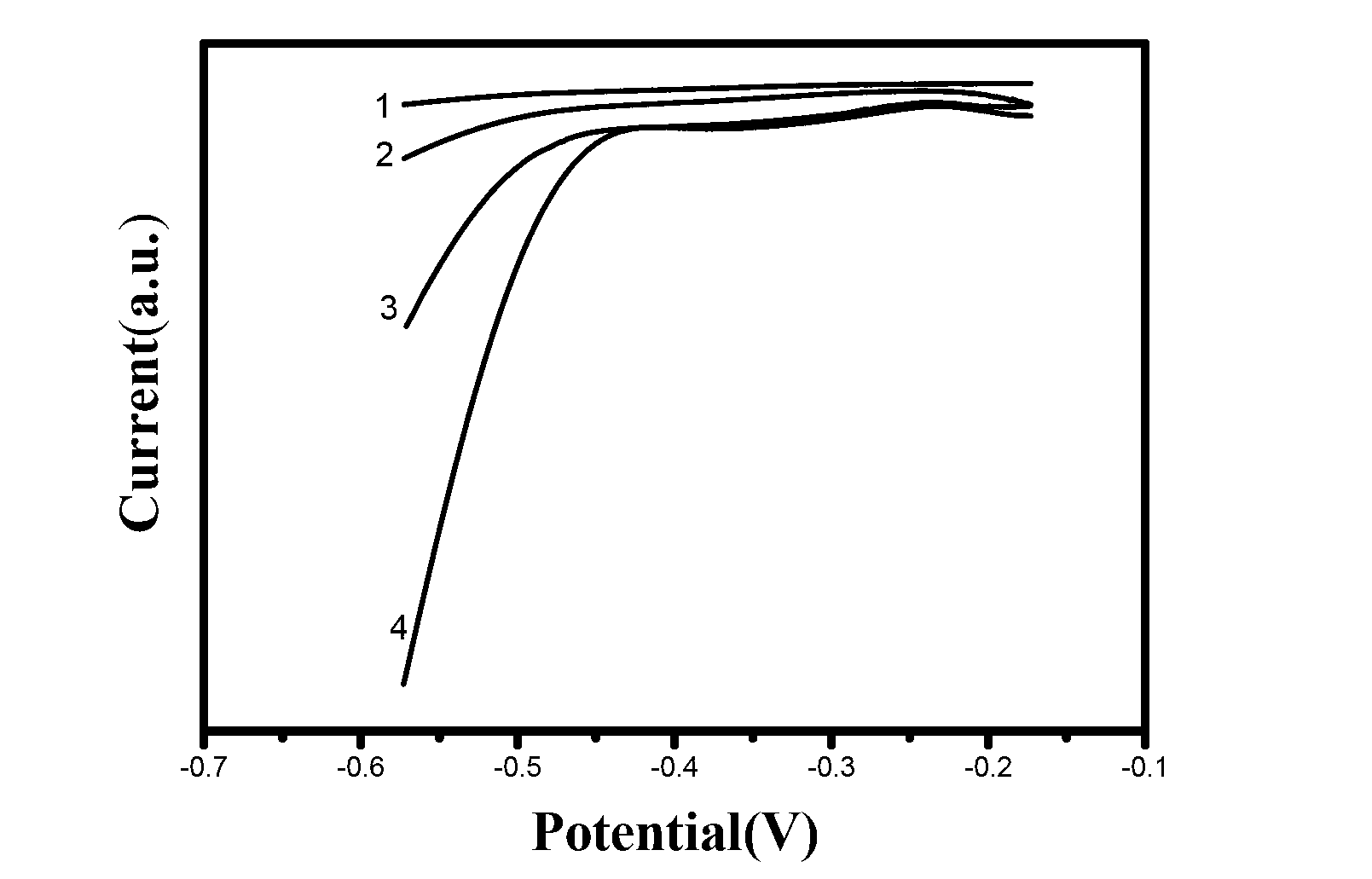

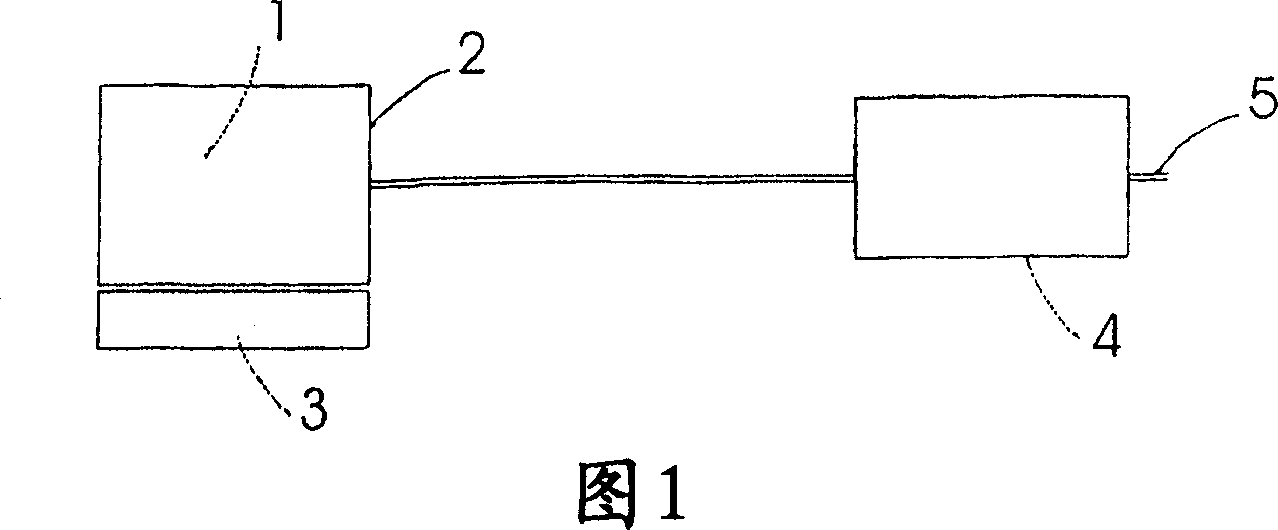

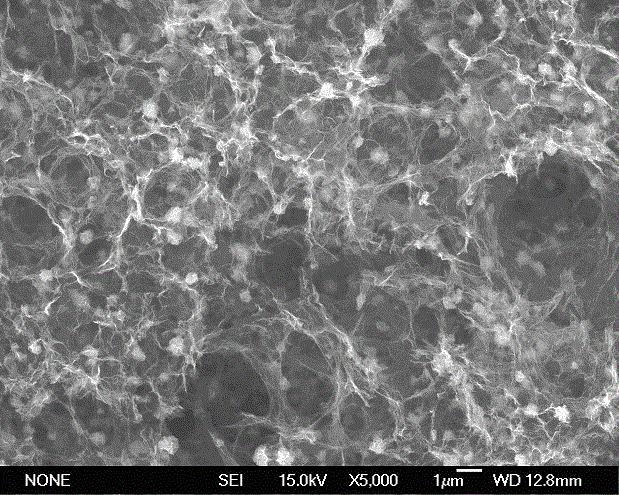

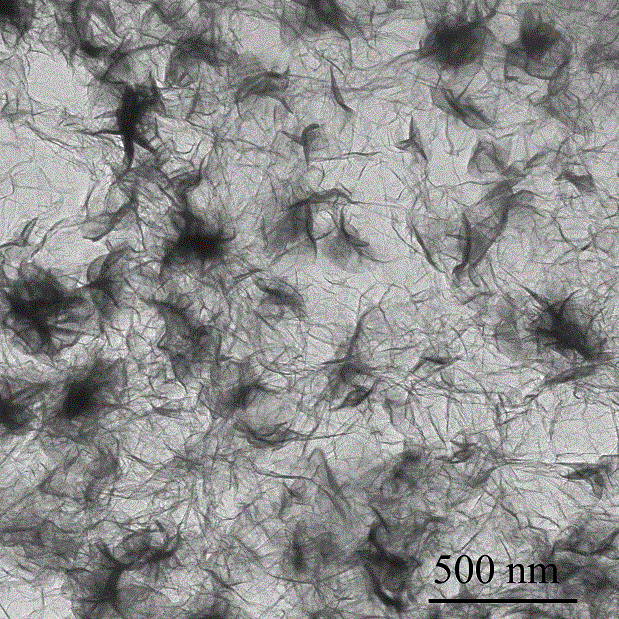

Molybdenum disulfide nano-sheet film material and its preparation methods

ActiveCN102849798AImprove hydrogen evolution performanceShape is easy to controlMaterial nanotechnologyCable/conductor manufactureThioureaFilm material

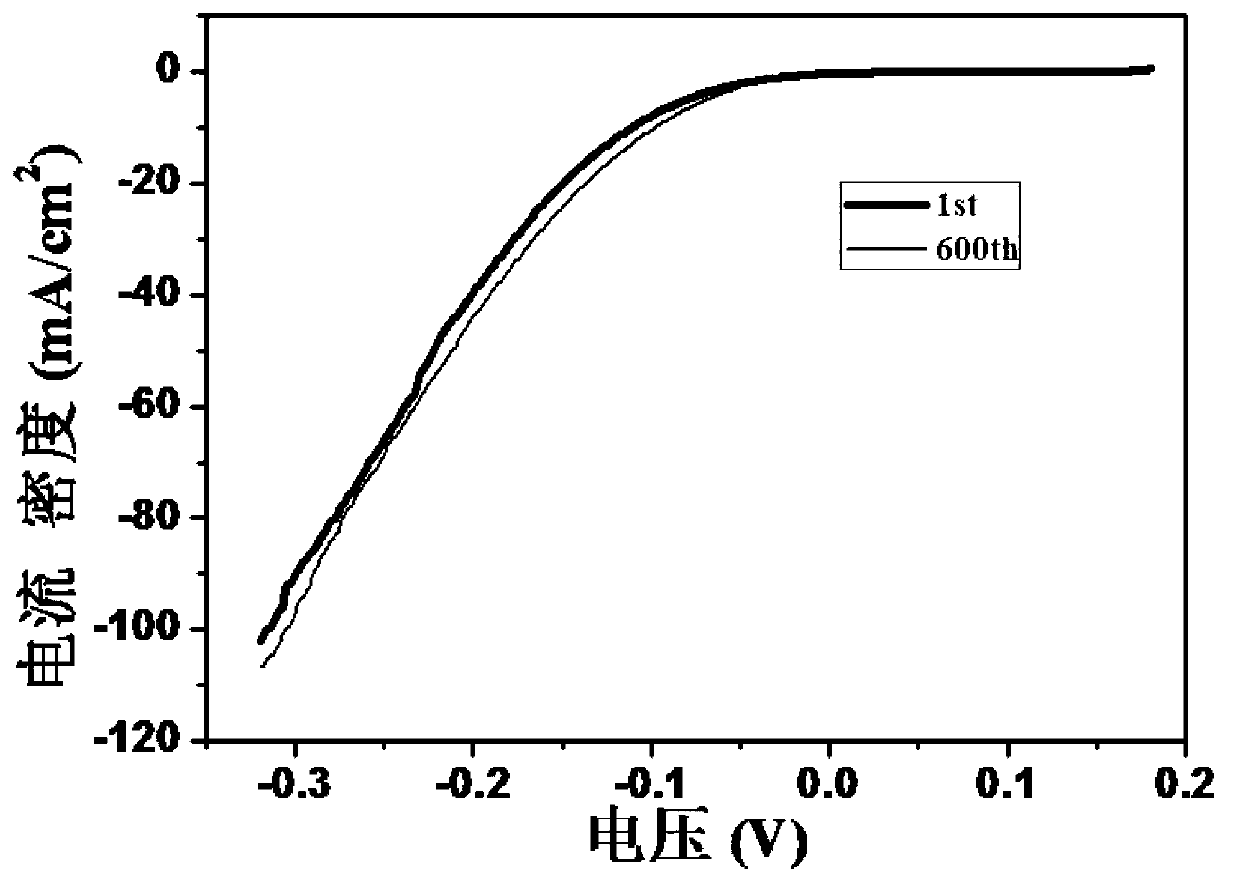

The invention discloses a molybdenum disulfide (MoS2) nano-sheet film material and its preparation methods. The film material is characterized in that MoS2 nano-sheets vertically and sequentially grow on a conductive substrate, and the diameters and the thicknesses of the MoS2 nano-sheets are 0.05-2mum and 2-30nm respectively. There are two preparation methods of the film material. One preparation method comprises the following steps: a substrate which can be a copper sheet, a silver sheet, a titanium sheet, a tungsten sheet, a molybdenum sheet or carbon is placed in a solution comprising a molybdate and sulfur-containing compounds (comprising thiourea, thioacetamide and L-cysteine); and the sulfur-containing compounds undergo a hydrothermal reaction to grow the compactly-grown and uniformly-sequential MoS2 nano-sheet films on the substrate. Another method comprises the following steps: the molybdenum sheet is directly placed in a solution of the sulfur-containing compounds (comprising thiourea, thioacetamide and L-cysteine); and the sulfur-containing compounds undergo a sulfuration reaction under a hydrothermal condition to form the compact and uniform MoS2 nano-sheet ordered films. The film has a low hydrogen evolution overpotential (-30mv), a small Tafel slope (52mV / dec) and a high electrochemical stability, and is a hydrogen evolution electrode material extremely having an application prospect.

Owner:深圳海氢科技有限公司

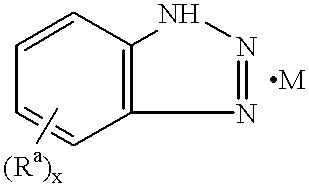

Coating composition and article coated therewith

InactiveUS20050215670A1Improve corrosion resistancePlastic/resin/waxes insulatorsAnti-corrosive paintsEpoxyTriazole antifungals

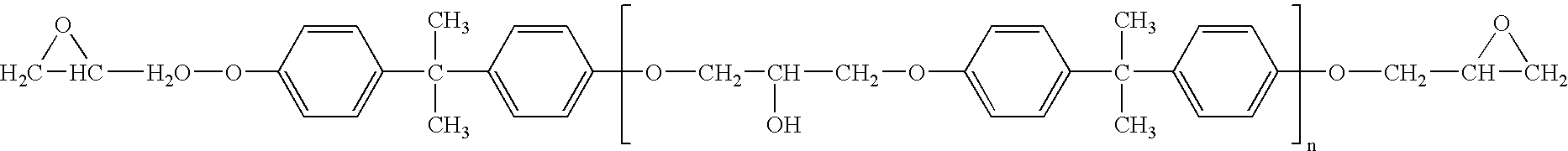

A coating composition used for coating of a steel material and / or aluminum material comprises a corrosion inhibitor, a base resin and a curing agent. The corrosion inhibitor may be selected from cerium compounds, lanthanum compounds, molybdate salt compounds, gluconic acid derivative salts, porous base materials, triazole compounds, thiazole compounds, tetracyclines, and metal phosphate salt compounds of ascorbic acid. The base resin may include a xylene-formaldehyde-resin-modified amino-containing epoxy resins obtained by reacting an epoxy resin having an epoxy equivalent of from 180 to 2500 with a xylene formaldehyde resin and an amino-containing compound. The curing agent may be a blocked polyisocyanate compound obtained by blocking an isocyanate group of a polyisocyanate compound with a blocking agent.

Owner:KANSAI PAINT CO LTD

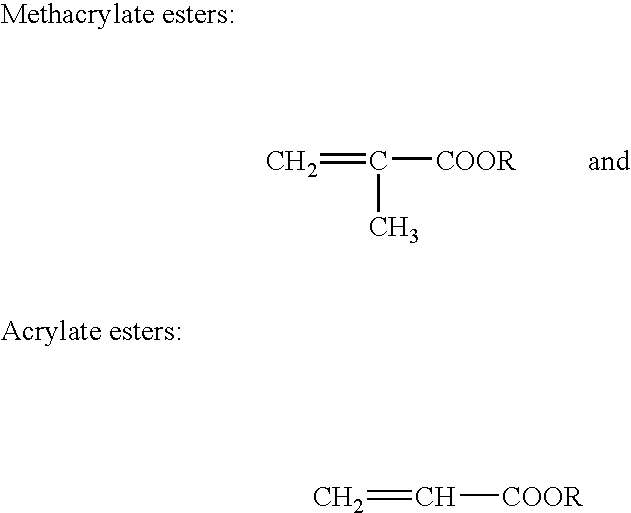

Two-part structural adhesive systems and laminates incorporating the same

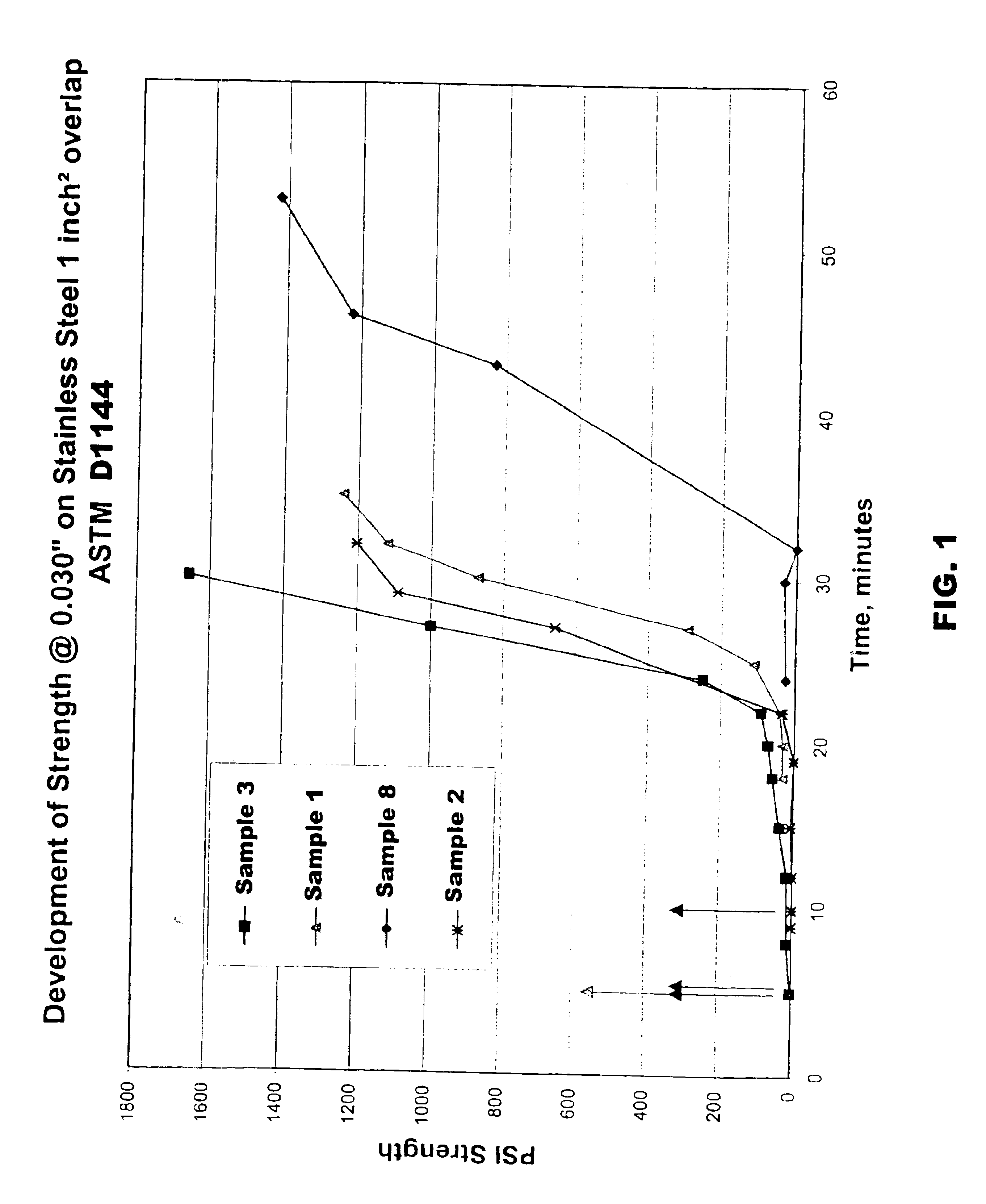

InactiveUS6869497B2Improve handlingExtended opening timeSynthetic resin layered productsEster polymer adhesivesMolybdateAdhesive

A two-part adhesive systems exhibiting improved fixture and open times are disclosed. In one embodiment, the system includes (a) an adhesive part being a mixture formed from (I) an ethylenically unsaturated monomer, (II) a metal molybdate, (III) a metal salt of an ethylenically unsaturated carboxylic acid in an amount less than 3 weight percent, and (IV) an ethylenically unsaturated carboxylic acid, and (b) an activator part which includes a free radical generator. In another embodiment, the system includes the above-described adhesive part substantially free of a metal salt of an ethylenically unsaturated carboxylic acid. Curable adhesives and laminates prepared with the two-part system are also disclosed.

Owner:ILLINOIS TOOL WORKS INC

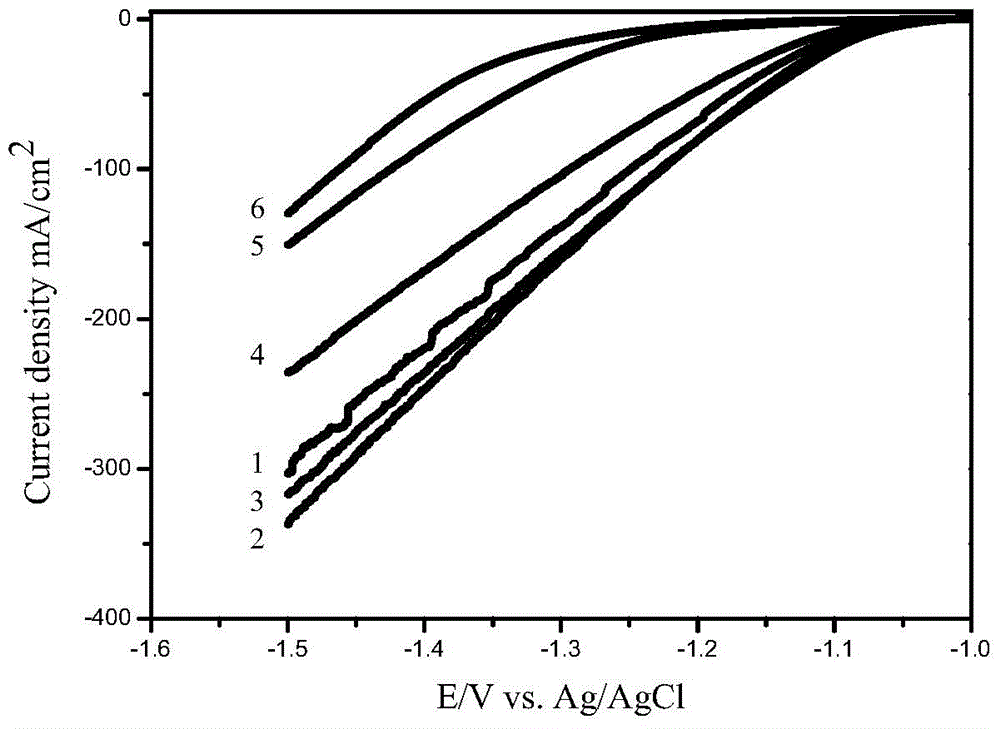

Method for preparing high-performance molybdenum-based hydrogen evolution electrode by phosphatizing molybdate precursor

The invention provides a method for preparing a high-performance molybdenum-based hydrogen evolution electrode by phosphatizing a molybdate precursor and belongs to the fields of water electrolysis and electric catalytic hydrogen evolution in the chlor-alkali industry. The method comprises the steps of pre-processing foamed nickel, growing the molybdate precursor in situ on the surface of a pre-processed foamed nickel base with the hydrothermal synthesis method, and finally placing the prepared precursor and a phosphorus source into a rube furnace together for phosphating of the molybdate precursor so that the high-performance molybdenum-based hydrogen evolution electrode can be prepared. The method is novel, the technology adopted is simple, production cost is low, the requirement for equipment is low, and the method is suitable for industrial production. Furthermore, the electrode is large in specific area, can be combined with the base firmly, has excellent hydrogen evolution activity and stability, and can be widely applied to the fields of water electrolysis and hydrogen evolution in the chlor-alkali industry.

Owner:CHONGQING UNIV

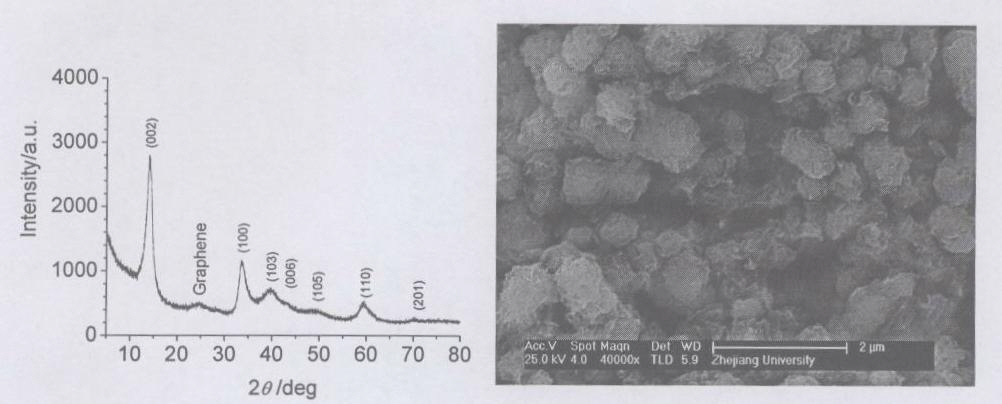

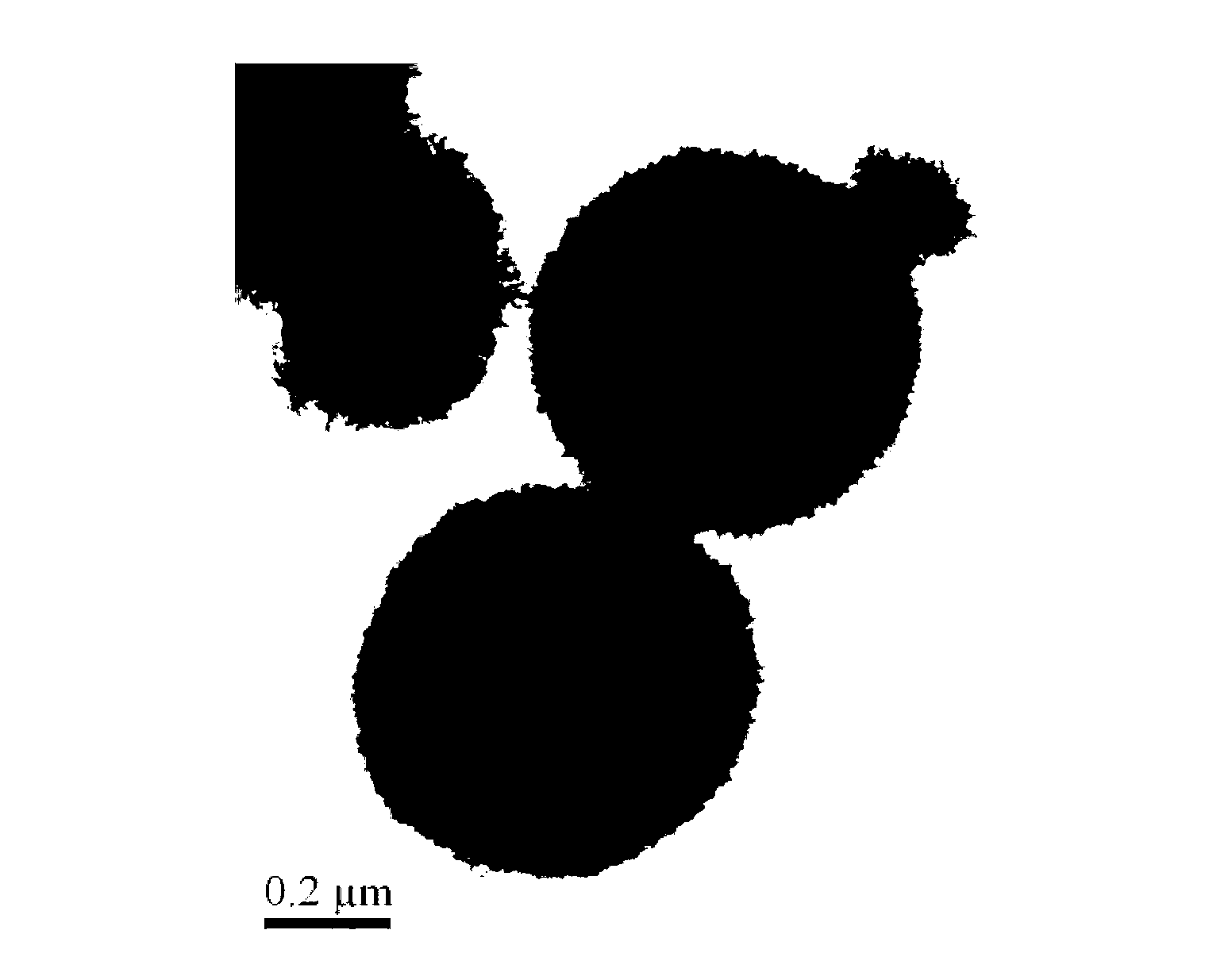

Preparation method of one-step hydrothermal synthesis of carbon/molybdenum disulfide composite microsphere

InactiveCN1994896AUniform particle sizeSimple methodVanadium oxidesMolybdenum sulfidesSucroseMicrosphere

The invention discloses a making method of carbon / molybdenum disulfide composite microball through water heat method, which comprises the following steps: dissolving molybdate in the deionized water to form 0.02-0.1m solution; adding thioacetamide or sulfourea as sulfur source with molar rate of thioacetamide or sulfourea and molybdate at 31-51; stirring evenly; adding glucose or sucrose as carbon source with the molar rate of glucose or sucrose and molybdate at 51-251; stirring completely; transmitting solution into water heat reacting autoclave to react under 200-240 deg. c for 20-24h; cooling naturally; separating; washing; drying to obtain the product.

Owner:ZHEJIANG UNIV

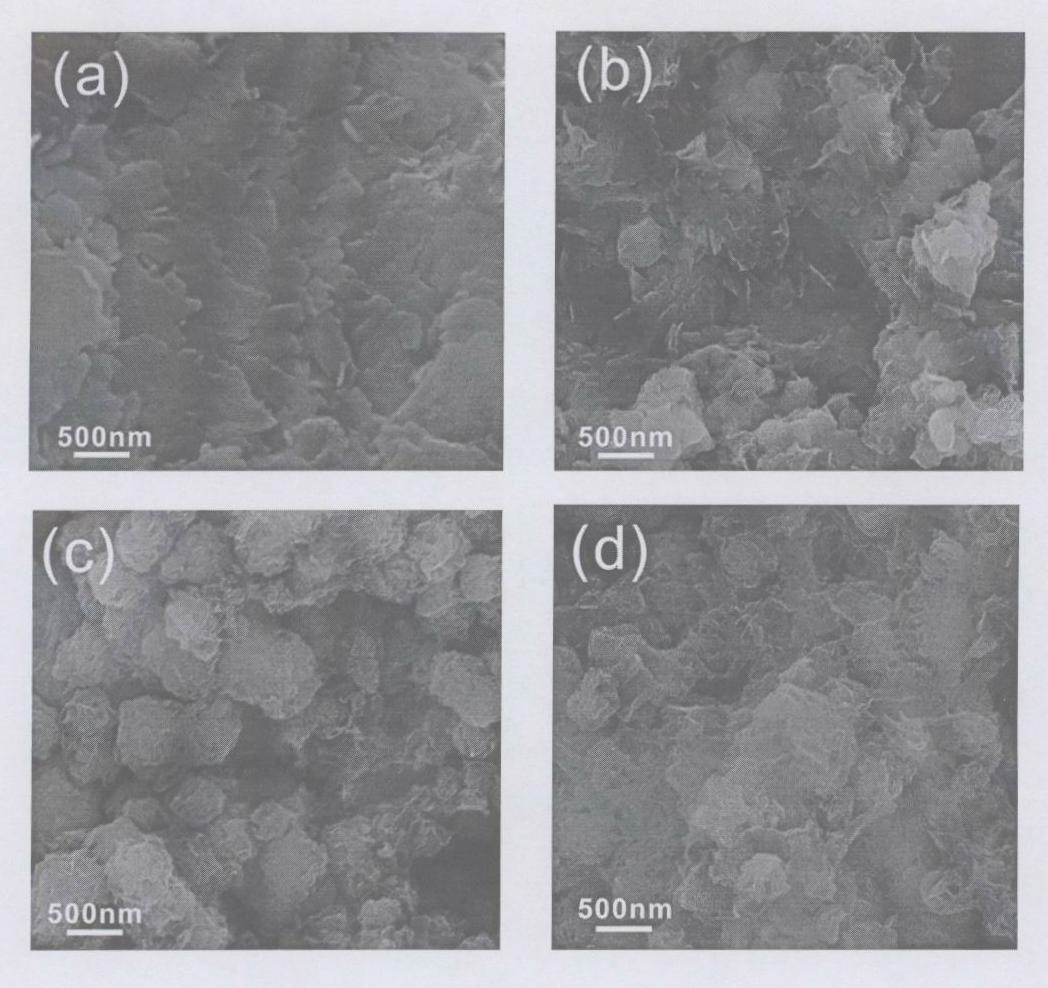

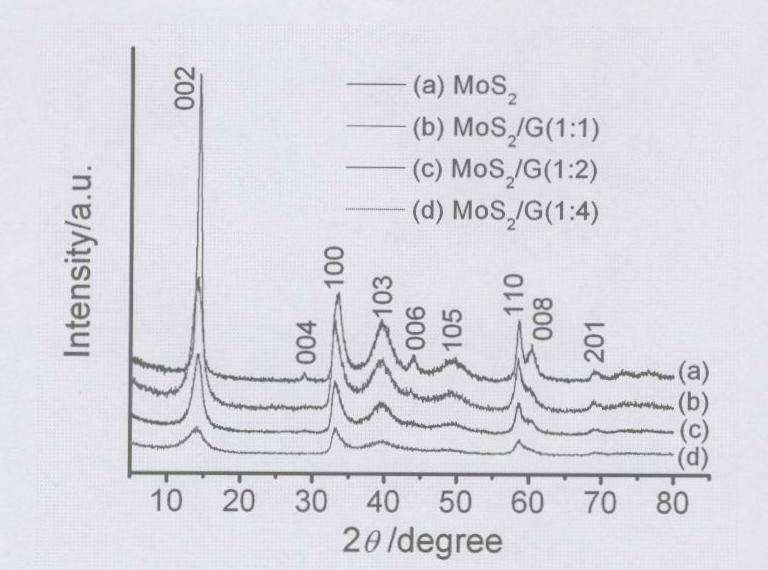

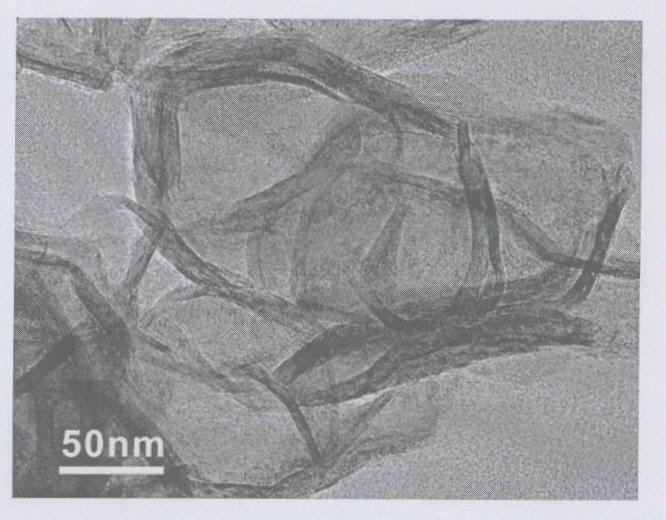

Compound nano material of graphene and MoS2 and preparation method thereof

InactiveCN102142548AMild reaction conditionsSimple preparation processMaterial nanotechnologyCell electrodesCysteine thiolateNew energy

The invention discloses a compound nano material of graphene and molybdenum disulfide (MoS2) and a preparation method thereof. The compound material is formed by mixing graphene and a MoS2 nano material in a mass ratio of (1 to 1)-(4 to 1). The preparation method comprises the following steps of: preparing an oxidized graphite nano slice from graphite by a chemical oxidization method; then dissolving molybdate into deionized water so as to form 0.02 to 0.07M of solution; adding L-cysteine serving as a sulfur source and a reduction agent, wherein the mass ratio of the L-cysteine to the molybdate is (5 to 1)-(12 to 1); adding the oxidized graphite nano slice into the solution, and ultrasonically treating so that the oxidized graphite nano slice can be fully dispersed in the hydrothermal reaction solution; transferring the mixture into a hydrothermal reaction kettle and sealing; and synthesizing by a one-step hydrothermal method to obtain the compound nano material of graphene and MoS2, wherein the mass ratio of the graphene nano slice to the MoS2 is (1 to 1)-(4 to 1). The method has the characteristics of mild reaction condition and simple process. The compound nano material of graphene and MoS2 synthesized by the method can be widely used as electrode materials of new energy batteries, high-performance national lubricants, catalyst carriers and the like.

Owner:ZHEJIANG UNIV

Graphene/molybdenum disulfide composite electrode material and preparation method thereof

The invention relates to the fields of a novel chemical electric power source and a new energy material, and particularly discloses a graphene / molybdenum disulfide composite electrode material and a preparation method of the composite electrode material. The preparation method comprises the steps of: (1) preparing graphite oxide from graphite as a raw material by an oxidation and intercalation method; (2) dissolving prepared graphite oxide with deionized water, carrying out ultrasonic stripping to obtain a graphene oxide solution, then adding DMF (dimethyl formamide) and molybdate, finally adding a reducing agent, and dispersing uniformly to obtain a mixed solution; and (3) transferring the mixed solution to a reaction kettle, keeping the temperature in the temperature condition of greater than or equal to 180 DEG C for 5-10h, centrifuging and washing the product to remove DMF, and drying to obtain the graphene / molybdenum disulfide composite electrode material product. The preparation method of the graphene / molybdenum disulfide composite electrode material is simple, uniform in reaction system and low in production cost, and is particularly suitable for requirements of industrial large scale production; and the prepared product graphene / molybdenum disulfide composite electrode material has better electrochemical performances.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

Preparation of hydrogenation catalyst

ActiveCN101439289AOrganic reductionMetal/metal-oxides/metal-hydroxide catalystsMolybdateActive component

The invention discloses a preparation method for a hydrogenation catalyst. The metal components of the catalyst comprise one or two metals from Co and Ni as well as one or two metals from Mo and W; carbamide or ammonia is used as a reaction addition agent; a method of reaction in-situ in the hole of a carrier is adopted to lead the metal active components to generate nickel molybdate (cobalt) or nickel tungstate (cobalt) compounds, thereby being capable of avoiding the reaction between the metals and the carrier, simultaneously leading the metal active components to be easier to be sulfurized and being capable of improving the activity of the hydrogenation catalyst.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

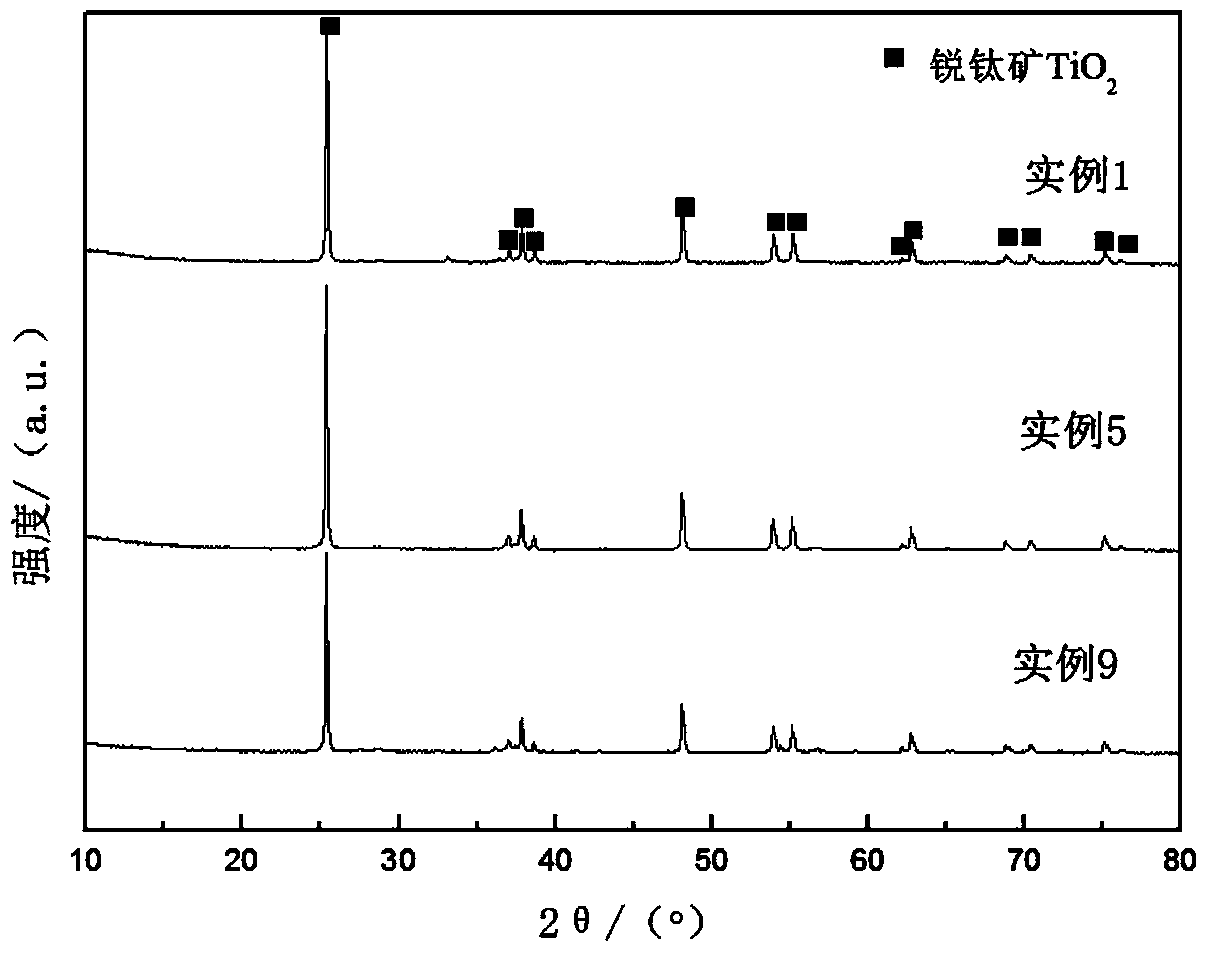

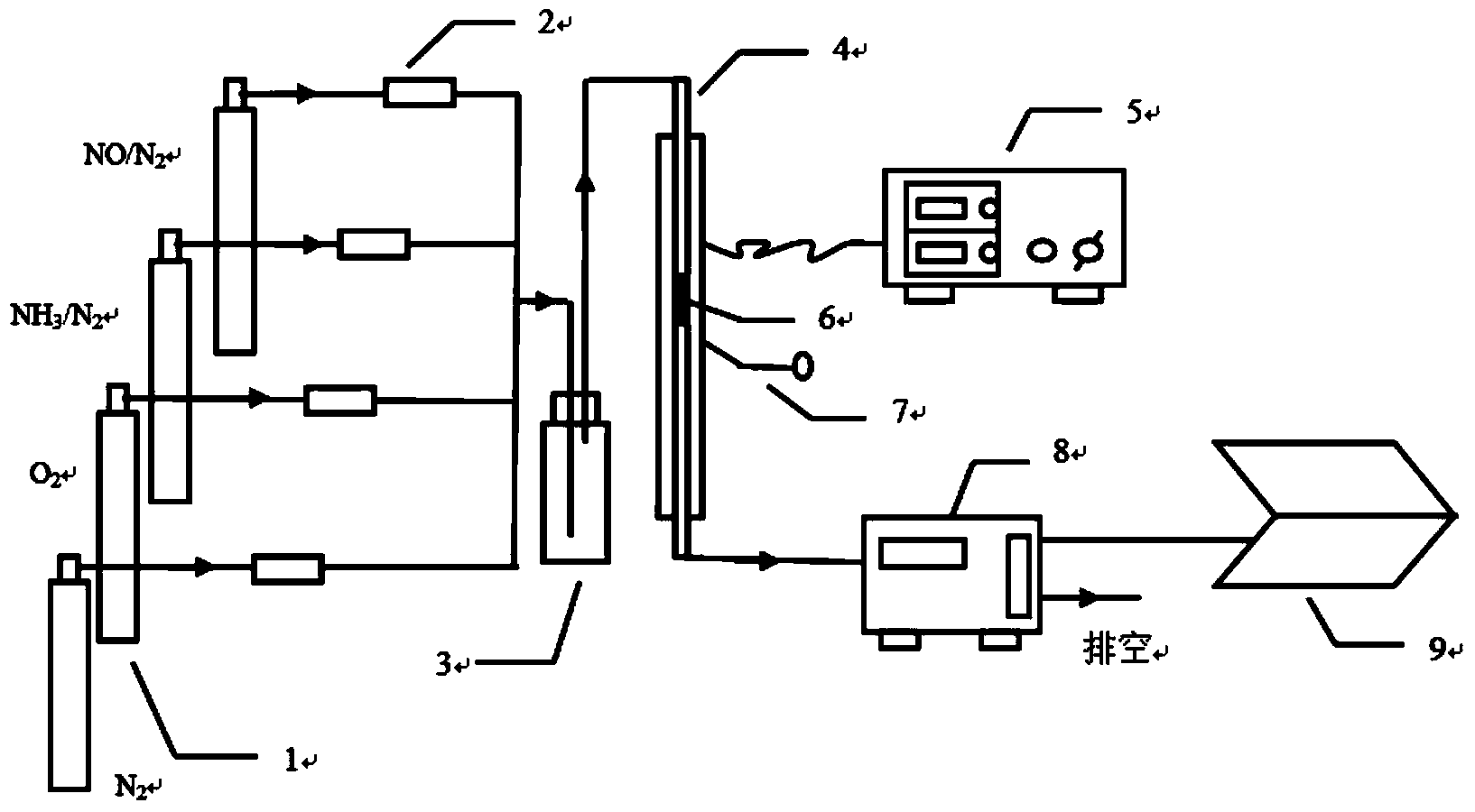

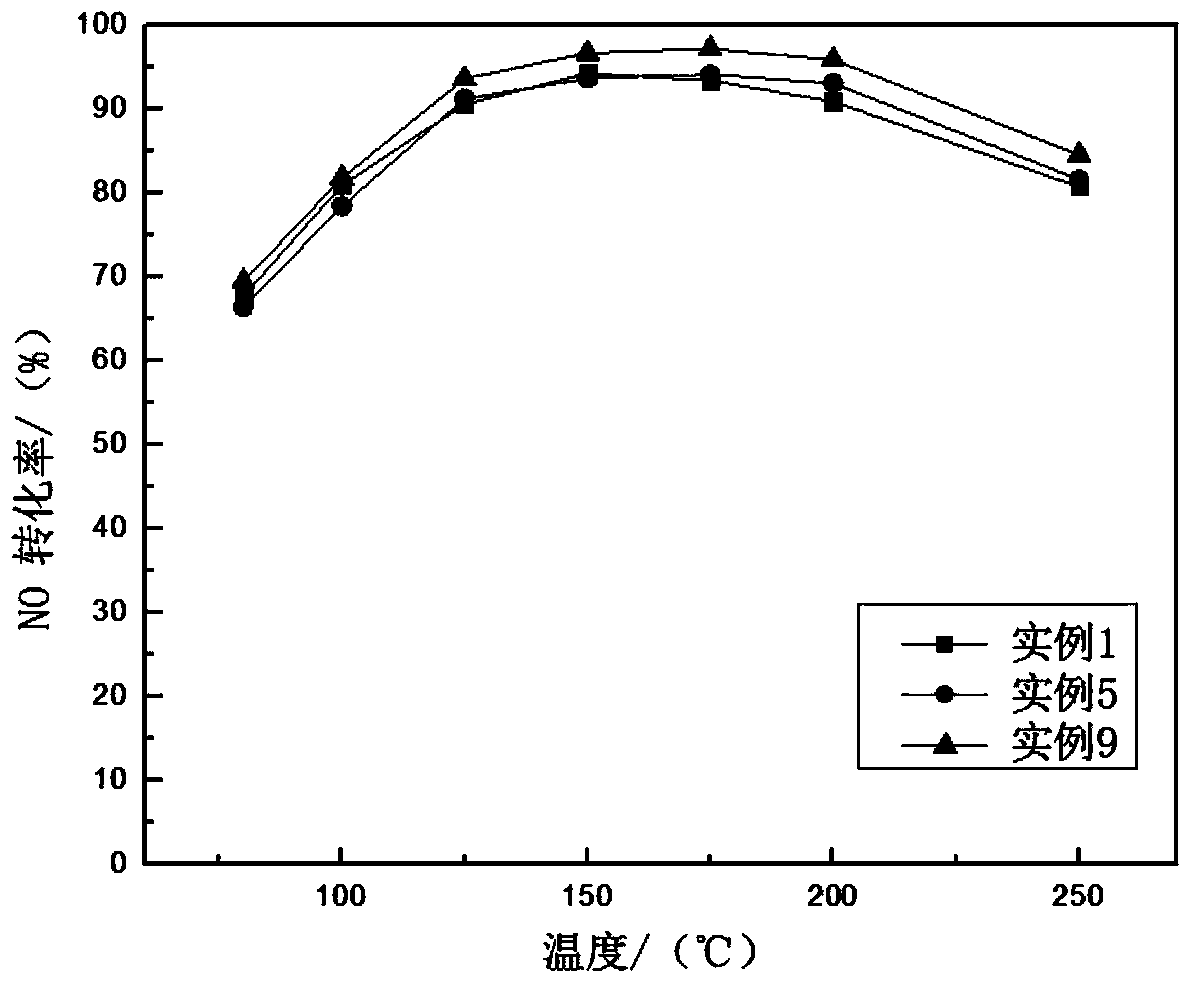

SCR (selective catalytic reduction) catalyst for denitrating low-temperature smoke of cement kiln and preparation method thereof

ActiveCN103638942AHigh low temperature activityImprove anti-poisoning performanceDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsNiobiumManganese

The invention provides an SCR (selective catalytic reduction) catalyst for denitrating low-temperature smoke of a cement kiln and a preparation method thereof. The SCR catalyst is characterized in that by adjusting the technological conditions such as proportions of active components, mass ratio of carriers and active components, calcining temperature and the like, a composite metal oxide which is formed by one or more metal elements out of manganese (Mn), ferrum (Fe), copper (Cu), cerium (Ce), lanthanum (La), bismuth (Bi), niobium (Nb), tantalum (Ta) and the like is loaded on a carrier by adopting an impregnation method, and tungsten and molybdate are used as active assistants. The active components in the SCR catalyst are uniformly distributed on the surface of the carrier in an unformed shape, the low-temperature activity of the catalyst is improved by utilizing the synergistic effect of multiple metals, the SCR catalyst is particularly suitable for the denitration of the smoke which is discharged from a dust collector on the tail of the cement kiln, the denitration rate can reach higher than 70 percent at the temperature of 80 DEG C, the denitration rate is higher than 90 percent in the temperature range of 125 DEG C to 200 DEG C, and the toxicity resistance is strong.

Owner:CHINA BUILDING MATERIALS ACAD

Environment-friendly type composite corrosion and scale inhibitor

InactiveCN1919752ACreate pollutionStrong scale resistanceScale removal and water softeningMolybdateSuccinic acid

The invention discloses an environmental-protective composite inhibiting antisludging agent, which comprises the following parts: inhibiting component, antisludging component and deionized water, wherein the inhibiting component is composed of one or more materials in the molybdate, tungstate, borate, organic substituted carboxylic acid or organic heterocyclic compound; the inhibiting component contains one or more materials in the natural macromolecular compound, epoxy succinic acid or acroleic acid ternary copolymer.

Owner:BEIJING HANBOYING ELECTRIC POWER TECH

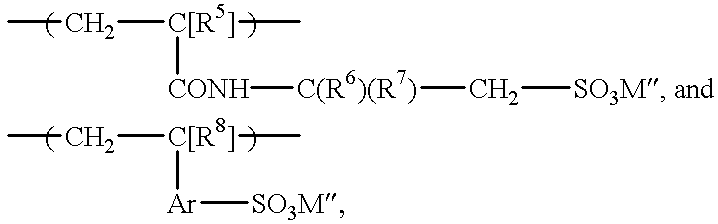

Method for treating water circulating systems

Water-circulating systems are treated with an aqueous, alkaline composition comprisingI) an organo-phosphorus chelating agent,II) an acrylate homopolymer,III) a salt of an acrylic copolymer, a portion of the repeating units of which contain sulfonate groups,IV) a molybdate salt, andV) a salt of a fused-ring aromatic triazole.This composition (which is formulated in accordance with a specific order of addition of the ingredients) is effective against white rust (corrosion of galvanized metal parts). When the water-circulating system is also fouled with a biofilm, it is preferred to introduce a biofilm remover having biocidal, surfactant, and chelating properties into the system, but the biofilm remover is introduced separately from the above-described composition. The preferred biofilm removers are compounds of the formula R-S-A-NR1R2whereR is an aliphatic group having at least 8 carbon atoms,A is an alkylene group having 1 to 6 carbon atoms,R1 and R2 are the same or different and are hydrogen or an aliphatic group, or R1 and R2, together with the nitrogen of formula I, form a heterocyclic aliphatic group.

Owner:FONTANA MICHAEL W

Molybdenum sulfide/carbide catalysts

InactiveUS7223713B2High activityImprove stabilityCell electrodesCatalyst activation/preparationMolybdateNitrogen

The present invention provides methods of synthesizing molybdenum disulfide (MoS2) and carbon-containing molybdenum disulfide (MoS2-xCx) catalysts that exhibit improved catalytic activity for hydrotreating reactions involving hydrodesulfurization, hydrodenitrogenation, and hydrogenation. The present invention also concerns the resulting catalysts. Furthermore, the invention concerns the promotion of these catalysts with Co, Ni, Fe, and / or Ru sulfides to create catalysts with greater activity, for hydrotreating reactions, than conventional catalysts such as cobalt molybdate on alumina support.

Owner:GABRIEL ALONSO +2

Non-Phosphorus composite anti incrustation eorrosion snhibiter and its application in water treatment

ActiveCN1785853AImprove performanceExcellent resistance to CaCO

<sub>3</sub>

Dirt performanceScale removal and water softeningMolybdatePolyaspartic acid

The present invention relates to a phosphorus-free composite antiincrustation corrosion inhibitor. It includes polyaspartic acid and / or polyepoxysuccinic acid and at least one kind of scale inhibition and dispersion agent, in which the scale inbibition and dispersion agent is polymer containing carboxylic acid group, or it includes polyaspartic acid and / or polyepoxysuccinic acid, zinc salt, molybdate or tungstate and polymer containing carboxylic acid group. Said invention is applicable to treatment of circulating cooling water.

Owner:BEIJING YANHUA PETRO CHEM

Composition used in scale-inhibition corrosion inhibitor, scale-inhibition corrosion inhibitor, and application thereof

ActiveCN103253777AHigh calcium and alkali toleranceGood scale and corrosion inhibitionScale removal and water softeningHigh concentrationTungstate

The invention discloses a composition used in a scale-inhibition corrosion inhibitor, a scale-inhibition corrosion inhibitor, and an application thereof. The composition used in the scale-inhibition corrosion inhibitor comprises cyclodextrin and / or a cyclodextrin derivative, a carboxylic-acid-group-containing homopolymer, a sulfonic-acid-group-containing copolymer, and selectively hydroxycarboxylic acid with a weight ratio of 1:0.2-20:0.04-15:0.2-30:0-20. The scale-inhibition corrosion inhibitor provided by the invention is environment-friendly. According to the invention, the application of phosphorus-containing compound or non-renewable molybdate or tungstate is prevented, such that the scale-inhibition corrosion inhibitor is phosphorus-free and nitrogen-free. The scale-inhibition corrosion inhibitor has high tolerance to calcium and alkali, resistance to corrosion of high-concentration chloride ion and sulfate ion, and wide applicability to water quality. Therefore, technical condition is provided for operation of circulation water under high concentration multiple and for reducing sewage discharge. The scale-inhibition corrosion inhibitor provided by the invention has excellent scale inhibition and corrosion inhibition performances in circulation water system application. With the scale-inhibition corrosion inhibitor, a dose is low, scale-inhibition treatment process is simple and substantial effect is provided. The scale-inhibition corrosion inhibitor is suitable for popularization.

Owner:CHINA PETROLEUM & CHEM CORP +1

Vapor phase oxidation of propylene to acrolein

InactiveUS6437193B1Organic compound preparationCarbonyl compound preparation by oxidationChemistryOxygent

An improved method for the selective vapor phase oxidation of propylene to acrolein in a recirculating solids reactor system using a bismuth molybdate multimetal oxide involving specific reactant concentrations (preferably 5 mol % to 30 mol % propylene, 0 to 20 mol % oxygen, and the remainder inert gas), particle size (1 to 300 micrometers), temperature (250 to 450.degree. C.) and gas (1 to 15 seconds) and solids (2 to 60 seconds) residence times. Such a process leads to improved selectivity and propylene conversion.

Owner:EI DU PONT DE NEMOURS & CO +1

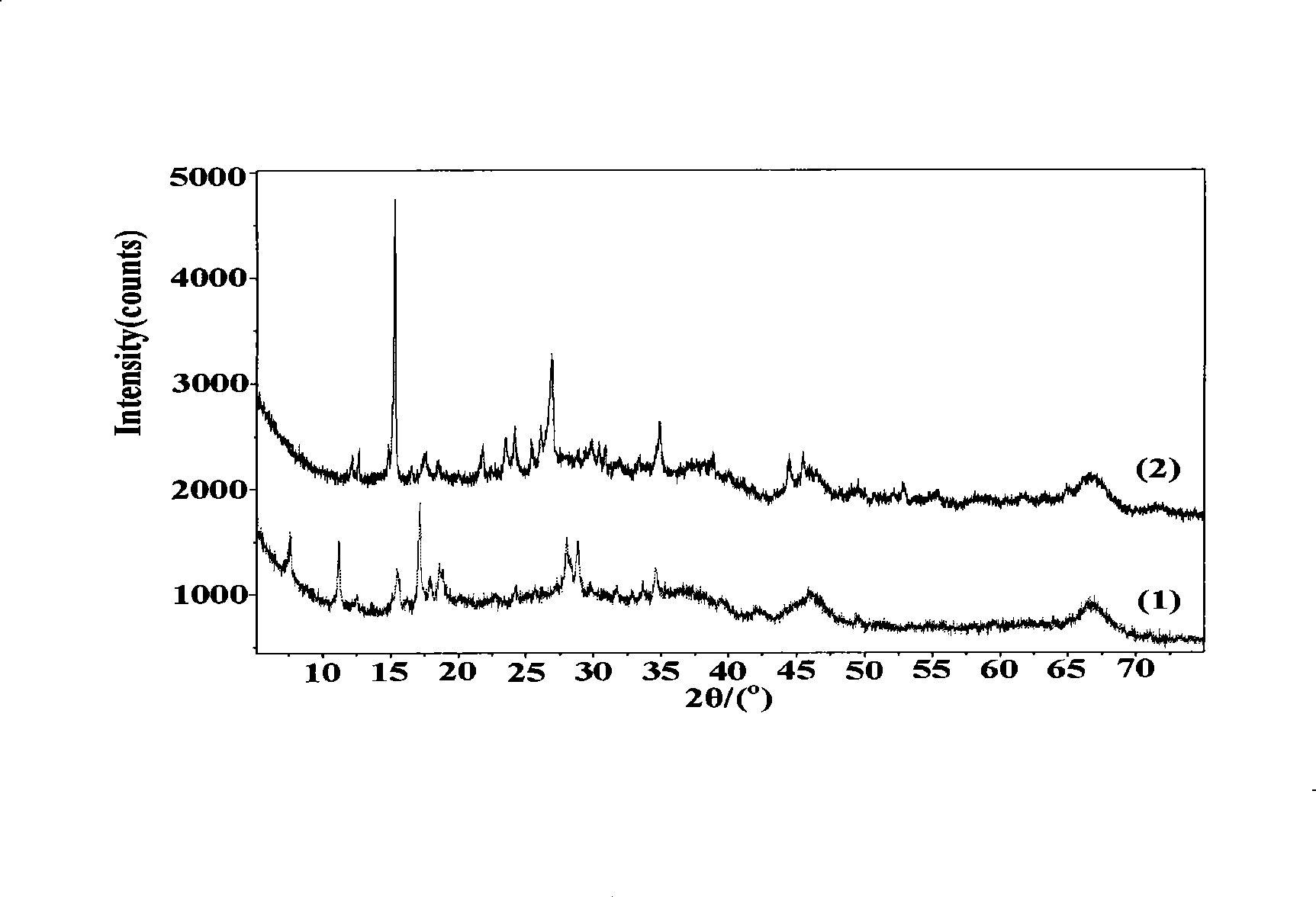

Synthetic method of visible light catalyst Bi2MoO6

InactiveCN101254463AEvenly dispersedSmall particle sizeMetal/metal-oxides/metal-hydroxide catalystsMolybdateSynthesis methods

A synthetic method of a novel visible light photocatalyst Bi2MoO6 (bismuth molybdate) is provided. The method includes the following steps: weighing Bi(NO3)3*5H2O and (NH4)6Mo7O24*4H2O solids at the theoretical ratio by mass of 14:1, dispersing the weighed solids into an appropriate amount of deionized water, stirring to obtain white curdy precipitates, placing the precipitates in a magnetic stirrer and stirring at normal temperature for 30 minutes, subjecting to ultrasonic treatment with a ultrasonic generator for 30 minutes to allow intensively mixing, allowing reactions of the treated white precipitates at 150-200 DEG C under sealed conditions, filtering the reaction product to collect flavescent precipitates, washing, drying, and grinding to obtain Bi2MoO6 (bismuth molybdate) photocatalyst. The photocatalyst has good photodegradation effect on target pollutants; and when the temperature of hydrothermal synthesis is 160 DEG C, the removal rate of target pollutant 4BS after photodegradation for 90 minutes reaches 99.5%. The inventive synthetic method has the advantages of simple process and low requirement for equipment, and is suitable for the synthesis of highly-active visible light photocatalyst Bi2MoO6 (bismuth molybdate).

Owner:NANJING UNIV

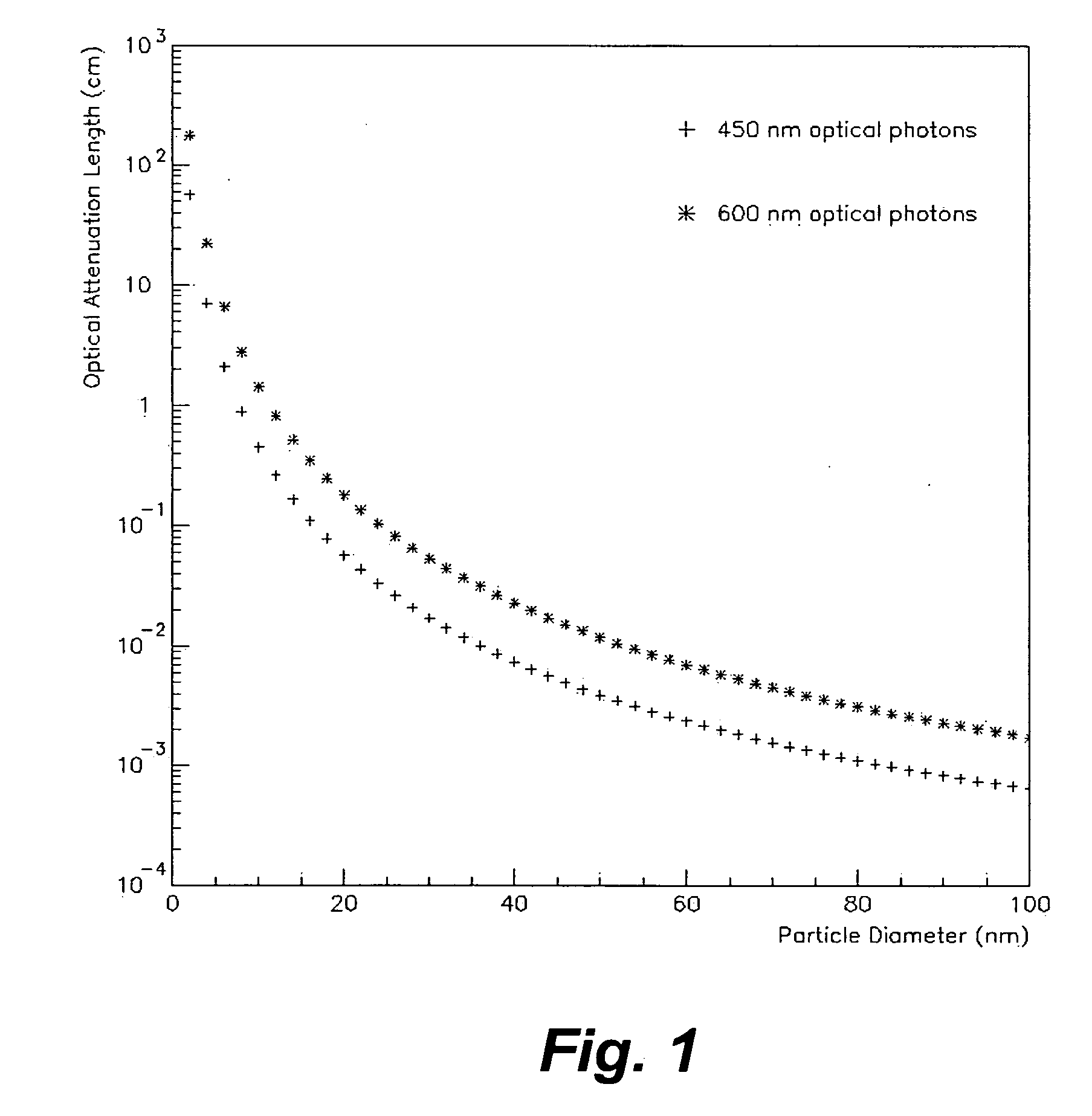

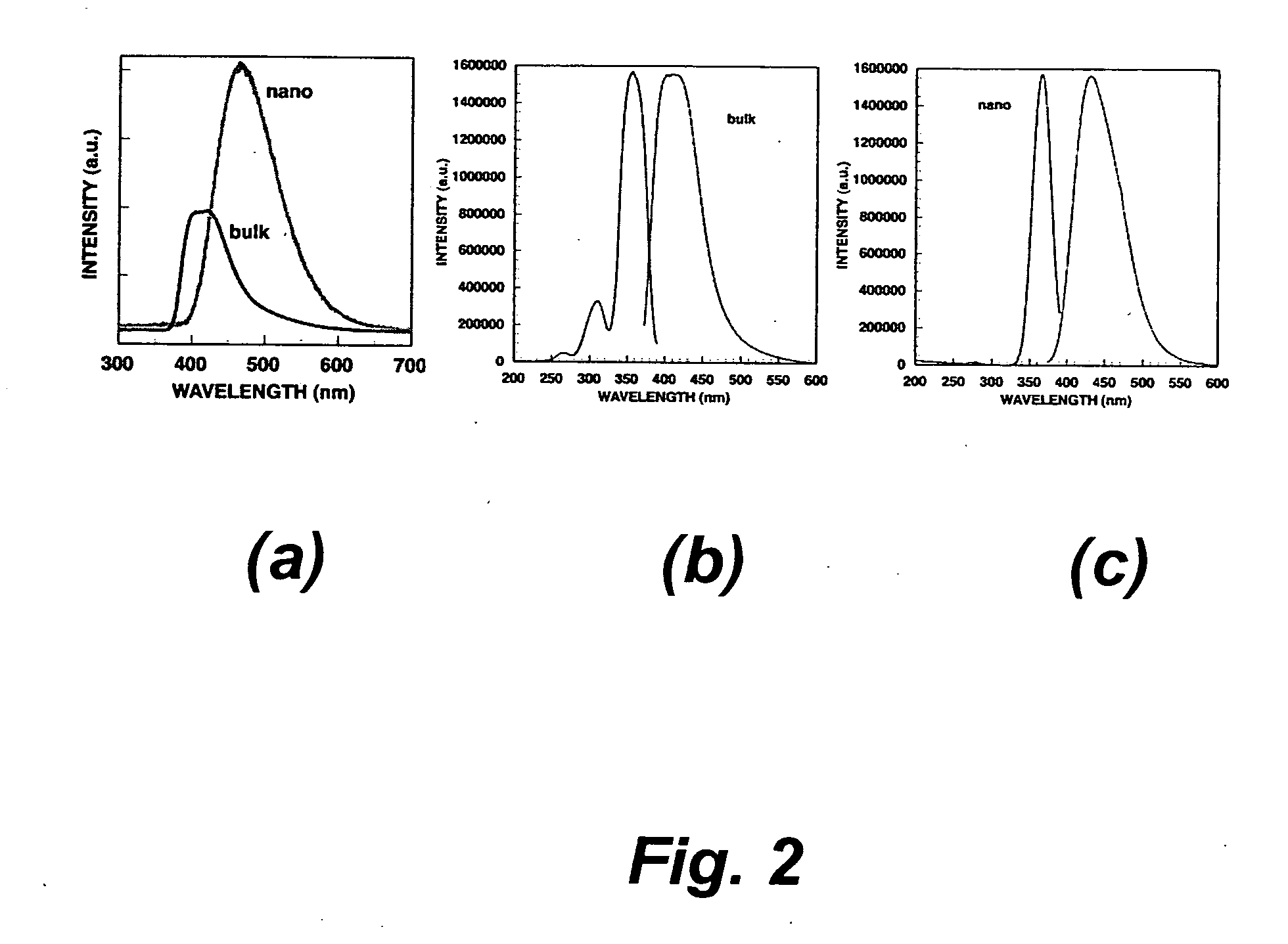

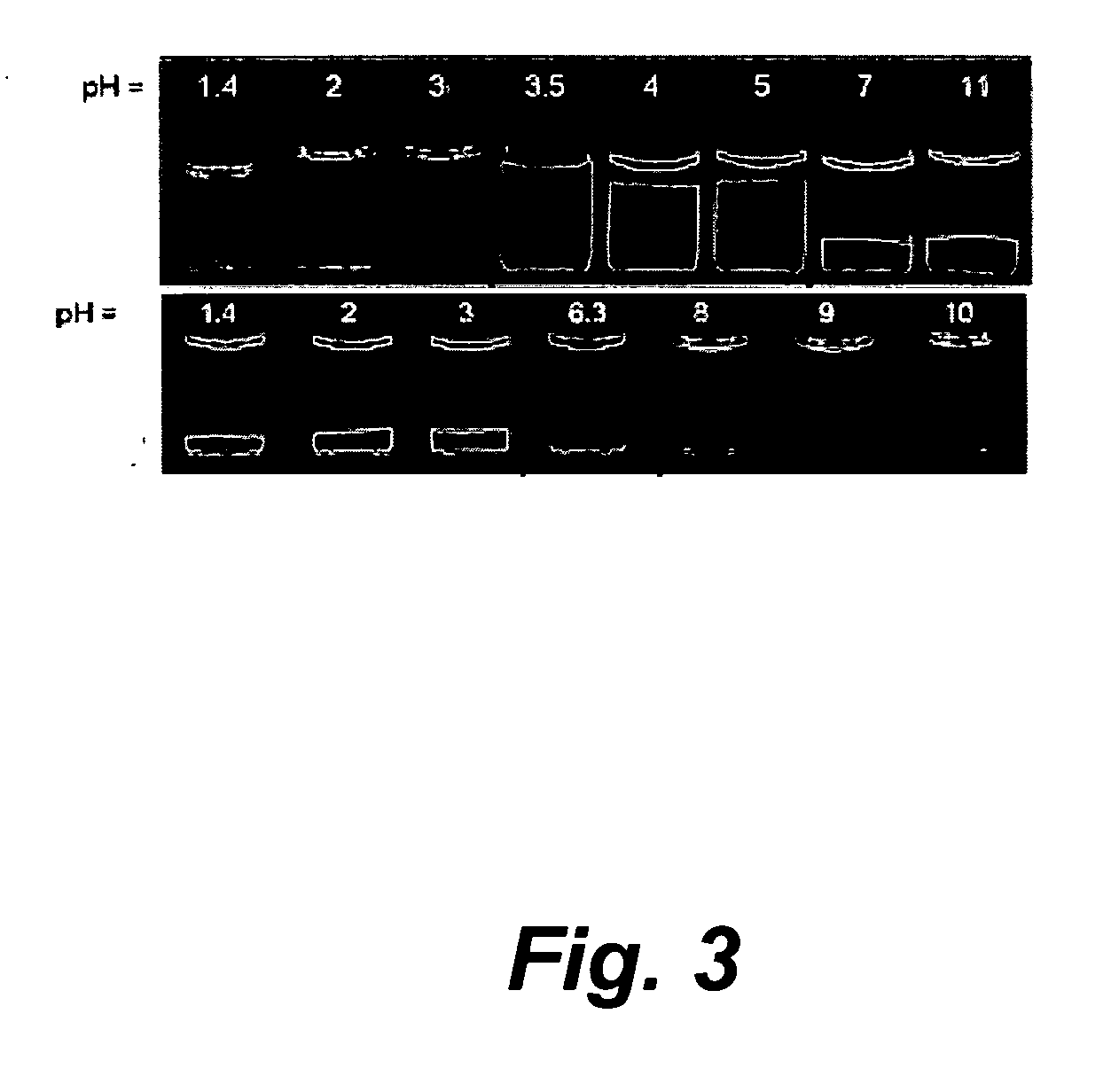

Nanocomposite scintillator, detector, and method

InactiveUS20080093557A1Material analysis by optical meansLuminescent compositionsSodium iodideTungstate

A compact includes a mixture of a solid binder and at least one nanopowder phosphor chosen from yttrium oxide, yttrium tantalate, barium fluoride, cesium fluoride, bismuth germanate, zinc gallate, calcium magnesium pyrosilicate, calcium molybdate, calcium chlorovanadate, barium titanium pyrophosphate, a metal tungstate, a cerium doped nanophosphor, a bismuth doped nanophosphor, a lead doped nanophosphor, a thallium doped sodium iodide, a doped cesium iodide, a rare earth doped pyrosilicate, or a lanthanide halide. The compact can be used in a radiation detector for detecting ionizing radiation.

Owner:RGT UNIV OF CALIFORNIA

Method of electroplating zinc, nickel, molybdenum and their alloys by using ionic liquid

The invention discloses a novel cleaning plating technology by using an ionic liquid which is a non-aqueous media as an electroplate liquid. Through using the technology, problems of bad environment and unstable qualities of electroplates existing in the condition of electroplating zinc, nickel, molybdenum and their alloys in an aqueous system can be solved. Qualities of coatings generated by using the technology are better than the qualities of coatings generated in the traditional system. The technology comprises the following steps: dissolving zinc salts, nickel salts and molybdate salt into the ionic liquid which is regarded as an electrolyte to prepare the electroplate liquid; electroplating at a current density of 1-30mA / cm2, wherein metallic zinc, nickel, molybdenum and their alloys are taken as soluble anode or graphite, complex carbon, glassy carbon, metal tungsten and titanium base plating platinum are taken as insoluble anode, and components which are needed to be electroplated are taken as cathode. Needed depth of coating can be obtained through controlling the current density and electroplating time.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

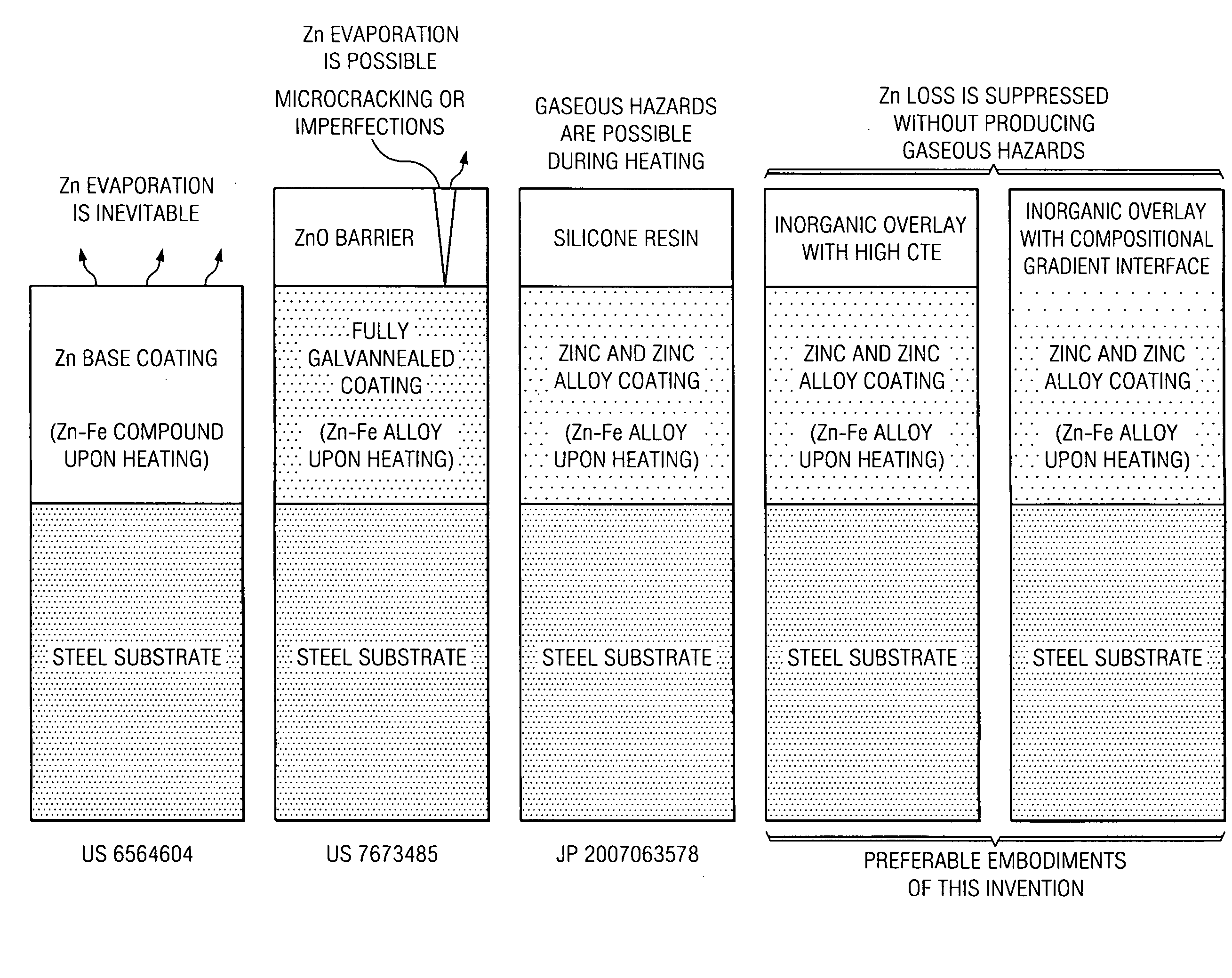

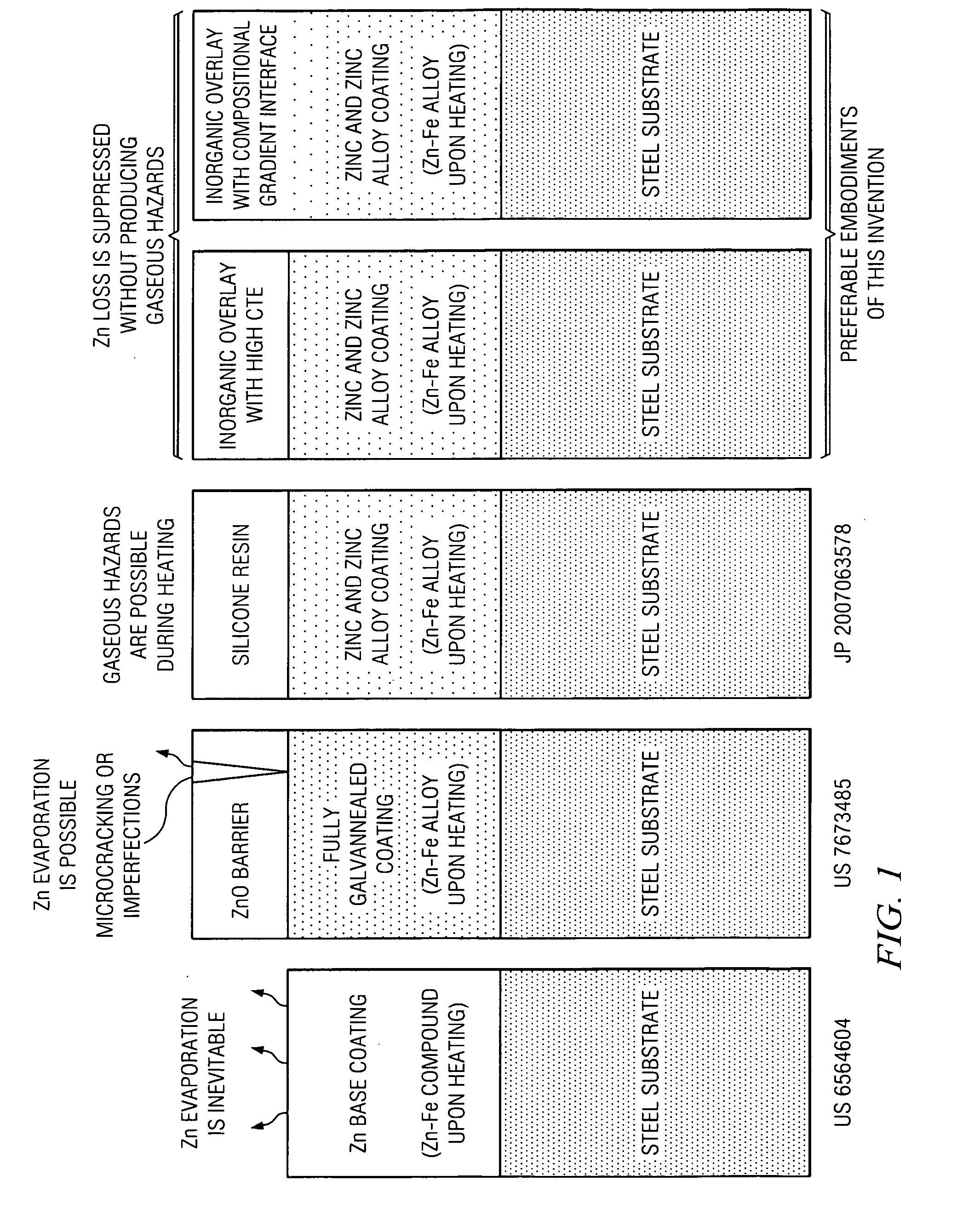

Zinc coated steel with inorganic overlay for hot forming

InactiveUS20120118437A1Retard and restrict lossReduce hardnessHot-dipping/immersion processesPretreated surfacesTungstatePhosphate

The present invention is of zinc or zinc alloy coated steel for hot forming having an inorganic overlay covering the zinc or zinc alloy coating to prevent loss of zinc during heating and hot forming. In one embodiment, the inorganic overlay has a coefficient of thermal expansion greater than the coefficient of thermal expansion of zinc oxide. In another embodiment, the inorganic overlay has a compositional gradient interface with the zinc or zinc alloy coating. Preferably the inorganic overlay may be comprised of material selected from phosphates, oxides, nitrates, carbonates, silicate, chromate, molybdate, tungstate, vanadate, titanate, borate, fluoride and mixtures thereof. A method of preparing the steel for hot forming and a method for hot forming the steel are provided.

Owner:WANG JIAN +1

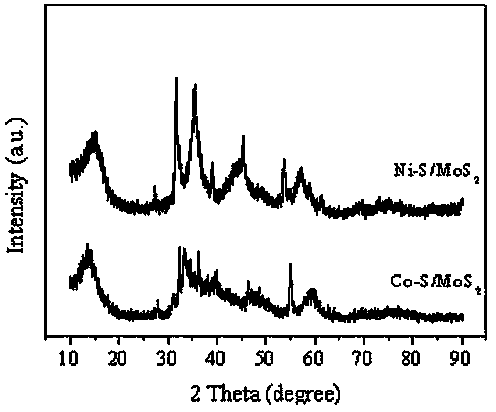

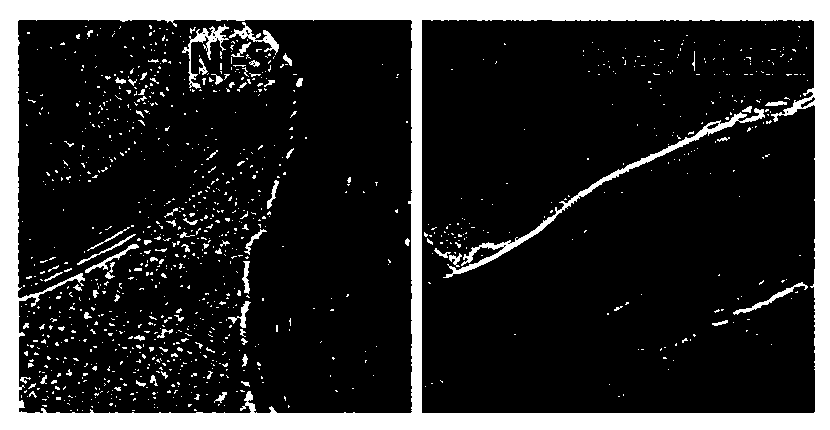

Double-metal-sulfide catalyst with high hydrodeoxygenation activity and preparation method thereof

InactiveCN103920506ALarge specific surface areaHigh catalytic activityPhysical/chemical process catalystsRefining to eliminate hetero atomsNickel saltVulcanization

The invention relates to a preparation method for a double-metal-sulfide catalyst. Soluble molybdate and nickel salt or cobalt salt serves as a raw material, thiourea or thioacetamide serves as a sulfur source, and a Ni(Co)-S / MoS2 catalyst is prepared through a two-step hydrothermal method. The method particularly comprises the following steps: MoS2 is prepared in a high pressure reactor through the hydrothermal method first, then the nickel salt or cobalt salt and the sulfur source are added into the reactor of the obtained MoS2 to be evenly mixed, the reactor is sealed and heated, a reaction is conducted for a certain period of time, and Ni-S or Co-S is deposited on the MoS2, so that the Ni(Co)-S / MoS2 catalyst is prepared. The preparation method is characterized in that the specific area of the Ni(Co)-S / MoS2 catalyst prepared through the two-step hydrothermal method is large, high temperature vulcanization is not required in the preparation process, the preparation condition is mild, the catalyst is used for hydrodeoxygenation, a target product has high yield and good repeatability, and hydrodeoxygenation activity of the catalyst is high.

Owner:XIANGTAN UNIV

Preparation method for ion liquid assisted hydrothermal synthesis of MoS2 microsphere

InactiveCN1994895AImprove performanceMild reaction conditionsMolybdenum sulfidesTetrafluoroborateMolybdate

The invention discloses a making method of MoS2 microball synthesized by ionic liquid auxiliary water, which comprises the following steps: dissolving molybdate in the deionized water to form 0.05-0.1m solution; adding thioacetamide or sulfourea as sulfur source with molar rate of thioacetamide or sulfourea and molybdate at 31-51; stirring evenly; adding 1-butyl-3-methyl imidazole tetrafluoride borate as ionic liquid with the bulk rate of ionic liquid and synthetic solution at 1300-1 50; stirring completely; transmitting solution into water heat reacting autoclave to react under 200-240 deg. c for 20-24h; cooling naturally; separating; washing; drying to obtain the product.

Owner:ZHEJIANG UNIV

Boiler coal combustion-improving desulfurizing and denitrifying agent composition and preparation method thereof

The invention provides a boiler coal combustion-improving desulfurizing and denitrifying agent composition. The composition comprises the following raw materials in parts by weight: 2-7 parts of sodium carbonate, 1-3 parts of alumina, 2-8 parts of aluminium hydroxide, 2-5 parts of ferric trichloride, 2-6 parts of ferric oxide, 3-10 parts of potassium permanganate, 3-10 parts of potassium chlorate, 10-35 parts of activated attapulgite clay, 15-30 parts of urea, 2-4 parts of ammonium formate, 2-4 parts of ammonium chloride, 6-23 parts of ammonium acetate, 3-9 parts of manganese oxide, 9-12 parts of copper chloride, 1-3 parts of copper oxide, 2-4 parts of zinc sulfate, 1-3 parts of zinc nitrate, 7-18 parts of potassium dichromate, 1.0-1.5 parts of titanium dioxide, 0.5-1.0 part of barium molybdate, 0.5-1.5 parts of cobalt sulfate, 0.5-1.5 parts of vanadium pentoxide, 0.3-0.7 part of cerium oxide, 0.1-0.2 part of sodium dodecyl benzene sulfonate and 0.1-0.2 part of alkyl glyceryl ether. The composition is convenient to use, has stable properties, plays roles of combustion improving, desulfurization and denitrification, has coal saving rate of 8-25% and can remove fixed sulfur by 50-70%.

Owner:兰州熙瑞化工科技有限公司

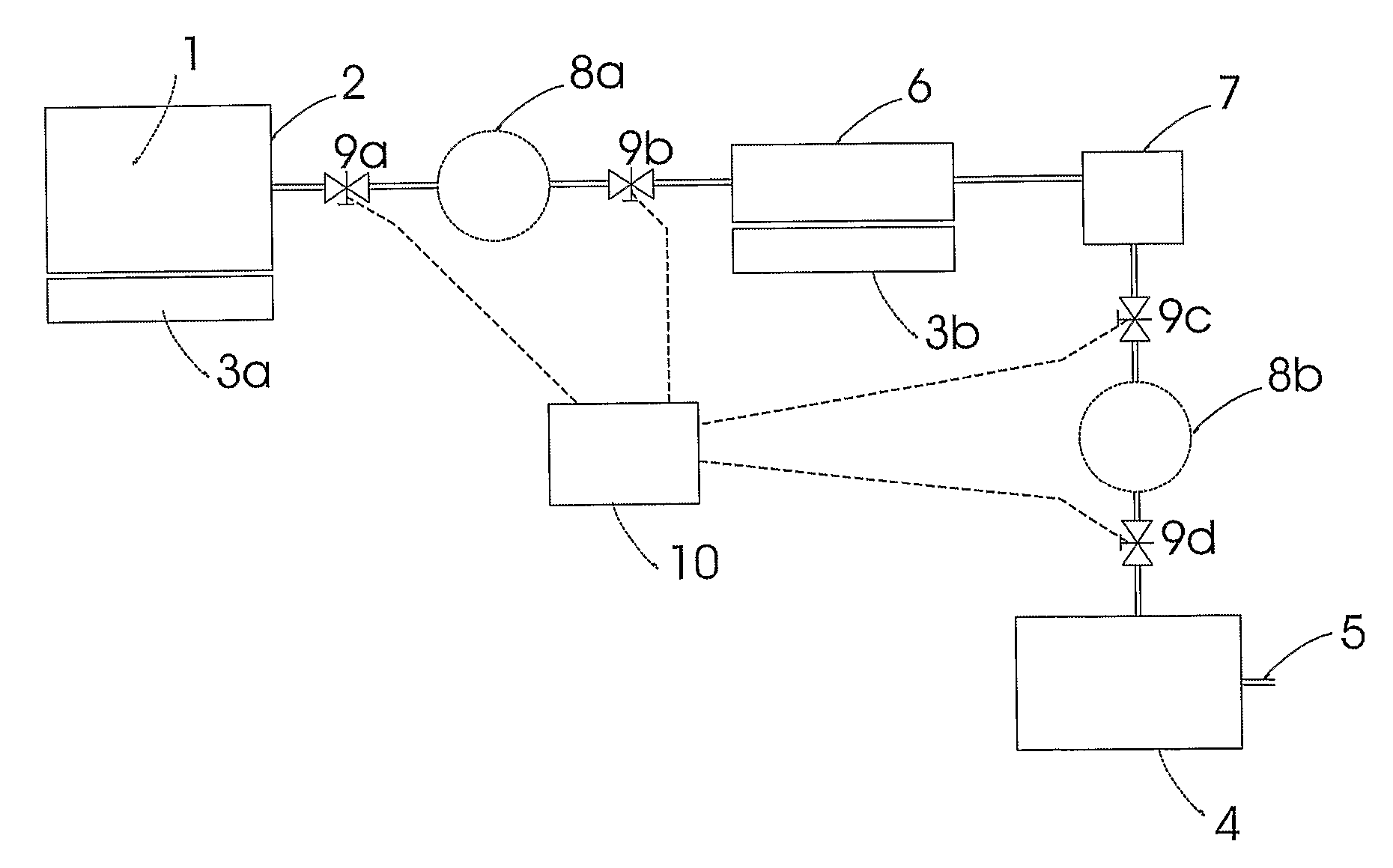

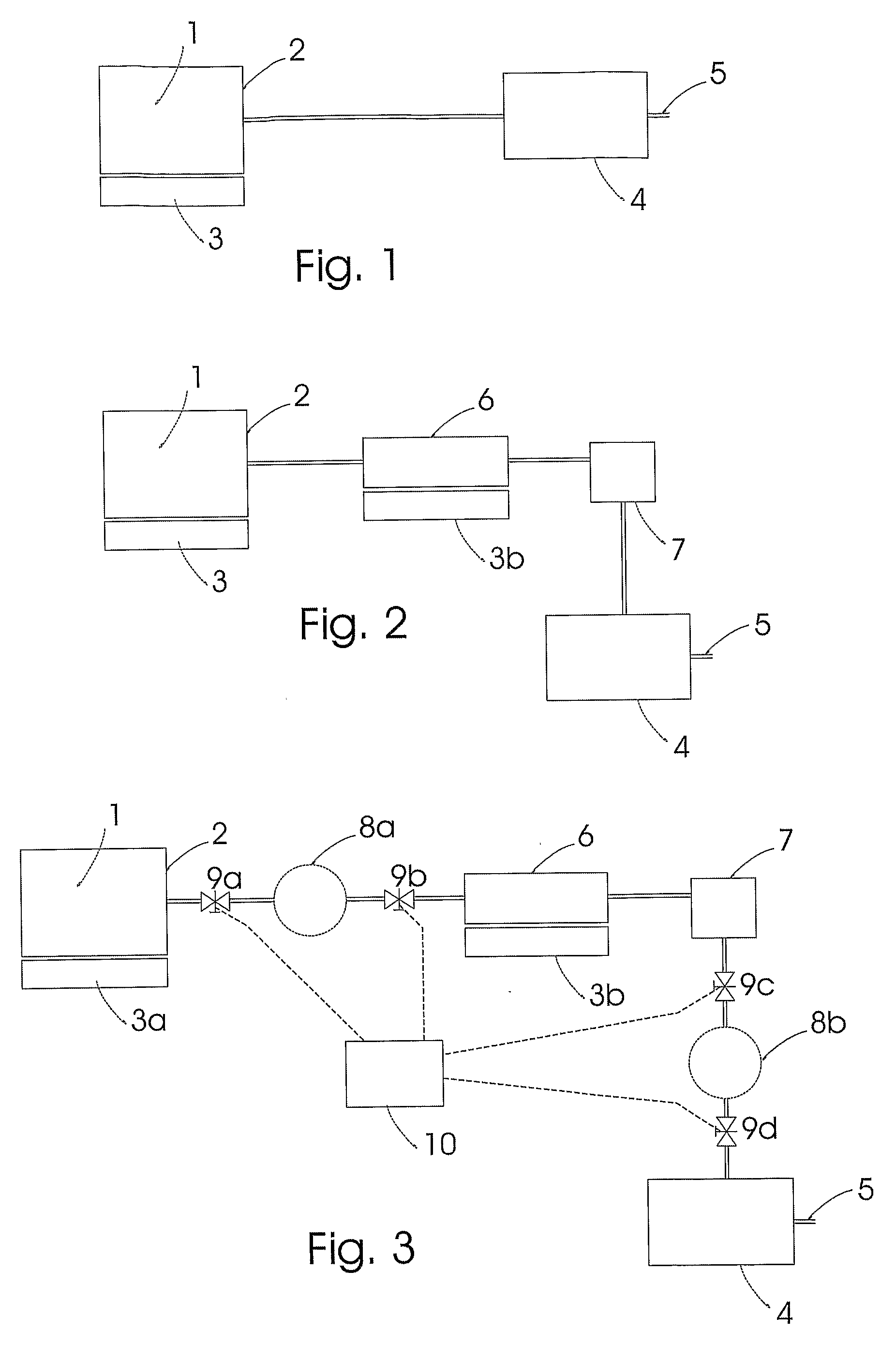

Use of an ammonia storage device in production of energy

An electric power generating unit comprising (i) an ammonia storage device in the form of a container comprising an ammonia absorbing and releasing salt of the general formula: Ma(NH3)nXz, wherein M is one or more cations selected from alkali metals, alkaline earth metals, and transition metals such as Li, K, Mg, Ca, V, Cr, Mn, Fe, Co, Ni, Cu or Zn, X is one or more anions selected from fluoride, chloride, bromide, iodide, nitrate, thiocyanate, sulphate, molybdate, phosphate, and chlorate ions, a is the number of cations per salt molecule, Z is the number of anions per salt molecule, and n is the coordination number of 2 to 12. (ii) means for heating said container and ammonia absorbing and releasing salt for releasing ammonia gas and (iiia) a fuel cell for converting ammonia directly into electric power; or (iiib1) a reactor for dissociating ammonia into hydrogen and nitrogen and (iiib2) a fuel cell for converting hydrogen into electric power.

Owner:AMMINEX

Method for separating and extracting tungsten-molybdenum from mixed solution of tungstate-molybdate

InactiveCN101880780AEfficient separationRealize recyclingProcess efficiency improvementMagnesium saltDecomposition

Owner:CENT SOUTH UNIV

Use Of An Ammonia Storage Device In Production Of Energy

InactiveUS20070207351A1Reactant parameters controlMagnesium halidesAlkaline earth metalAmmonia storage

An electric power generating unit comprising (i) an ammonia storage device in the form of a container comprising an ammonia absorbing and releasing salt of the general formula: Ma(NH3)nXz, wherein M is one or more cations selected from alkali metals, alkaline earth metals, and transition metals such as Li, K, Mg, Ca, V, Cr, Mn, Fe, Co, Ni, Cu or Zn, X is one or more anions selected from fluoride, chloride, bromide, iodide, nitrate, thiocyanate, sulphate, molybdate, phosphate, and chlorate ions, a is the number of cations per salt molecule, Z is the number of anions per salt molecule, and n is the coordination number of 2 to 12. (ii) means for heating said container and ammonia absorbing and releasing salt for releasing ammonia gas and (iiia) a fuel cell for converting ammonia directly into electric power; or (iiib1) a reactor for dissociating ammonia into hydrogen and nitrogen and (iiib2) a fuel cell for converting hydrogen into electric power is useful for large stationary energy producing facilities, but also for use for is useful for large stationary energy producing facilities, but also for use for small rechargeable and / or replaceable power supply units for micro-fabricated or miniaturized ammonia decomposition reactors for use in mobile units and portable devices may be used for large energy producing facilities, and by use of small rechargeable and / or replaceable ammonia storage decomposition reactors, it is also possible to provide energy for mobile units and portable devices.

Owner:AMMINEX

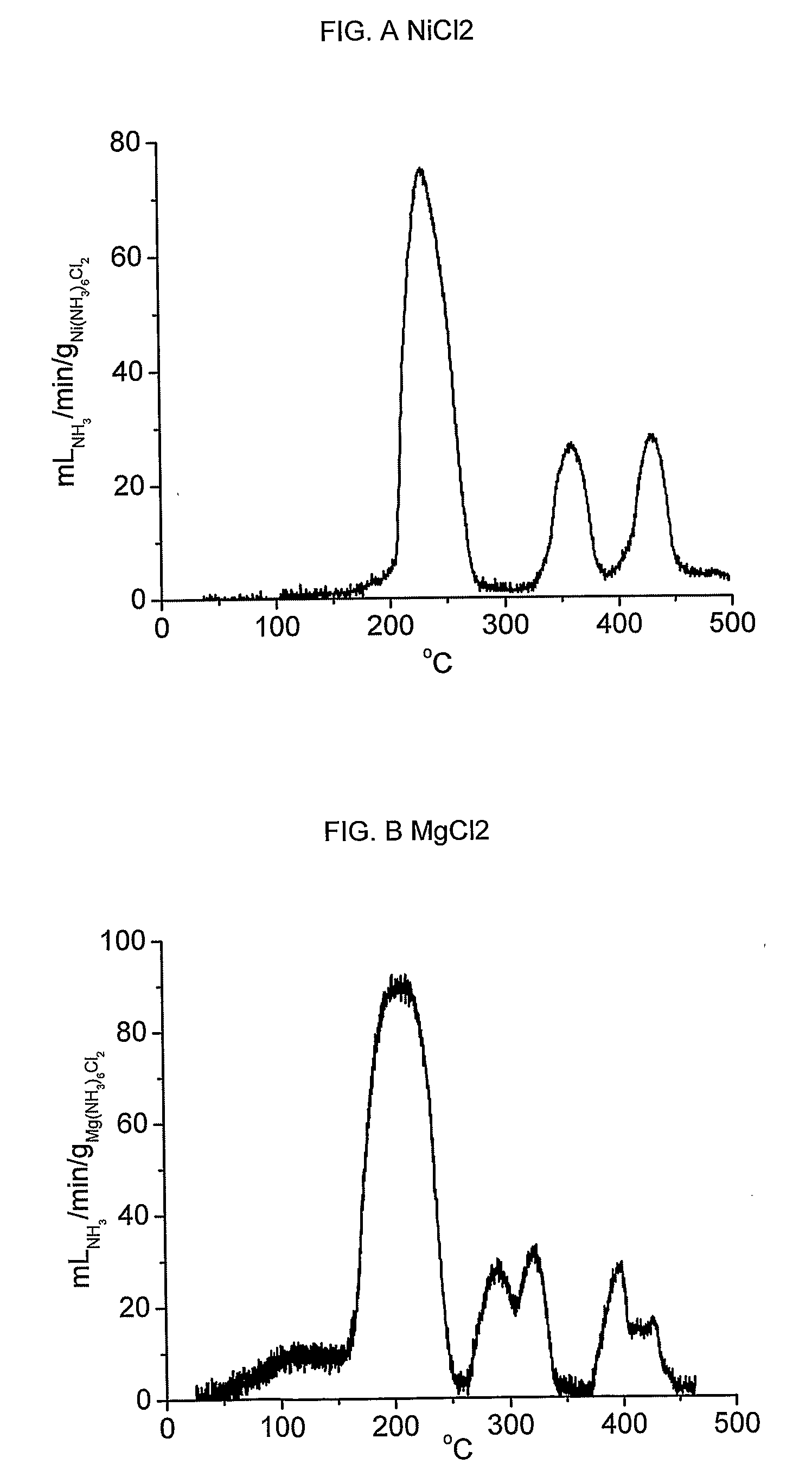

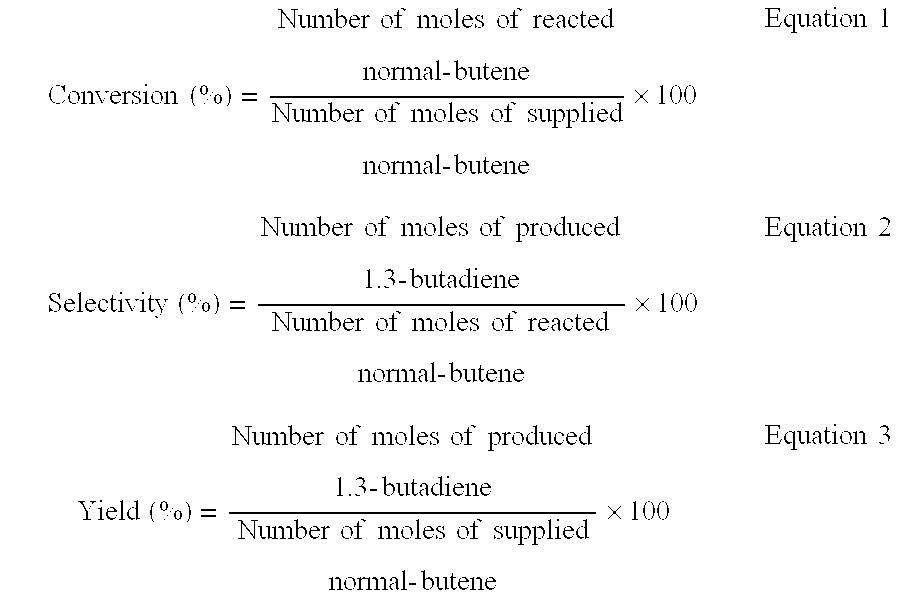

Method for preparing 1,3-butadiene as high yield

ActiveUS20130281748A1Excellent catalytic performanceHigh dehydrogenation activityDistillation purification/separationCatalystsButenePolymer science

Disclosed is a method for producing 1,3-butadiene through oxidative dehydrogenation of normal-butene using a parallel reactor in which catalysts are charged into fixed bed reactors and are not physically mixed. More specifically, disclosed is a method for efficiently producing 1,3-butadiene through oxidative dehydrogenation of normal-butene using the parallel reactor containing multi-component bismuth molybdate-based catalysts exhibiting different activities to oxidative dehydrogenation for normal-butene isomers (1-butene, trans-2-butene and cis-2-butene), and butene separated from a C4 mixture containing normal-butene and normal-butane, as a reactant.

Owner:LG CHEM LTD

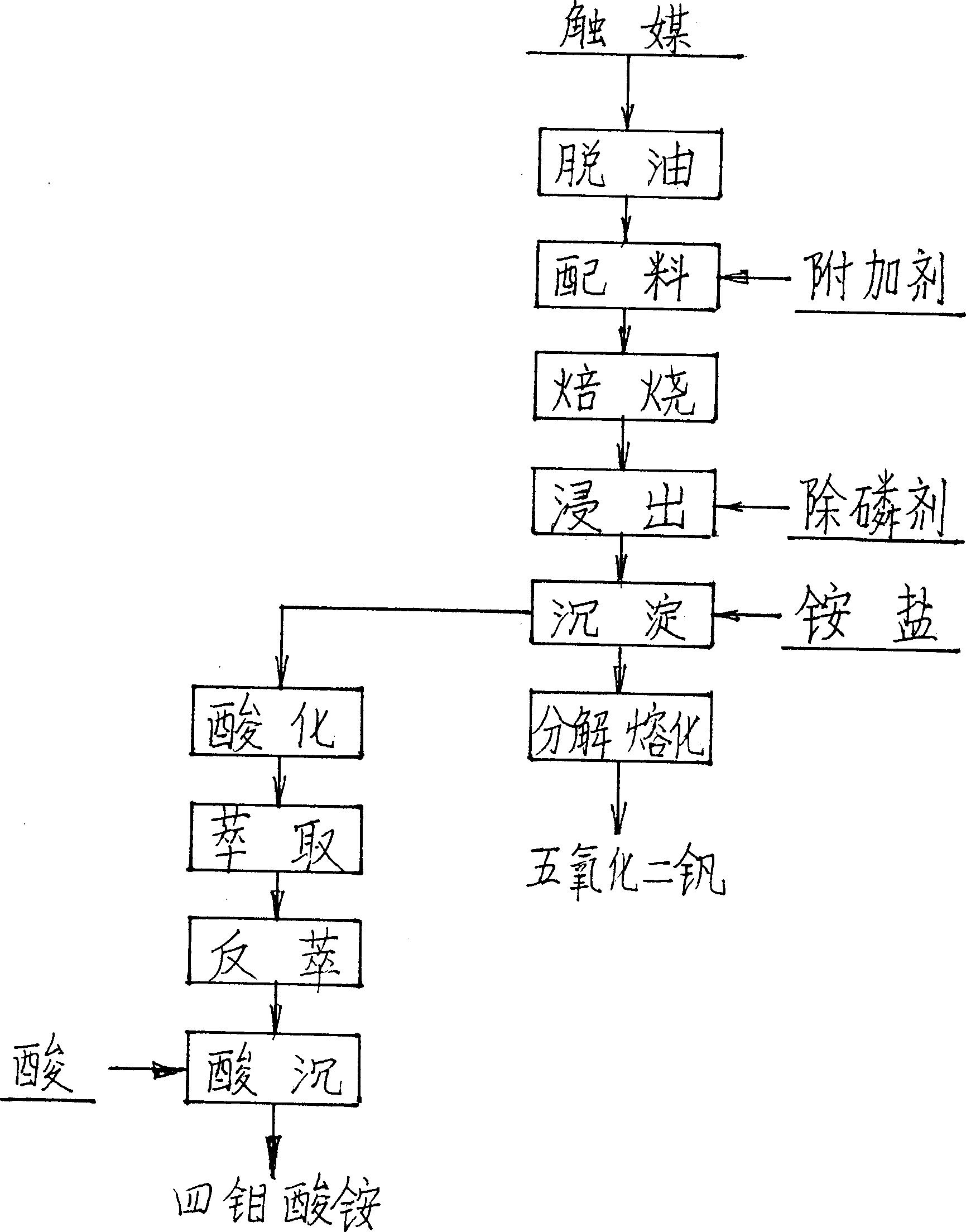

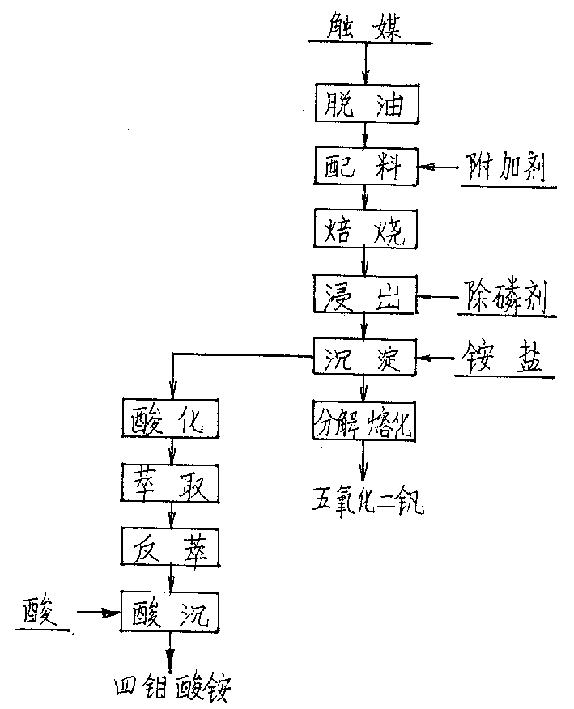

Wet process of extracting vanadium and/or molybdenum from waste catalyst

InactiveCN1453379ALess investmentReduce consumptionProcess efficiency improvementMagnesium saltAmmonium metavanadate

The present invention is wet process of extracting vanadium and / or molybdenum form waste petrochemical catalyst alumina carrier containing V, Mo and other elements. The wet process includes high-temperature deoiling the catalyst in natural granularity, mixing with sodium carbonate, high-temperature oxidation and roasting in a kiln or furnace to obtain water soluble sodium vanadate and sodium molybdate; countercurrent water soaking of the chamotte to obtain solution containing V and Mo in certain concentration, adding calcium salt and magnesium salt to eliminate P and other impurities, addingammonium salt solution into the clear solution to obtain ammonium metavanadate, decomposing and melting ammonium metavanadate to obtain V2O5 product; adding acid to the supernatant and organic phase extraction of Mo, ammonia water reverse extraction to obtain ammonium molybdate, and adding acid to precipitate ammonium tetramolybdate or molybdate product.

Owner:CITIC JINZHOU METAL

Flake MoS2/graphene composite aerogel and preparation method thereof

InactiveCN104600315AHigh electrical conductivityDeformation stableCell electrodesThioureaFreeze-drying

The invention relates to a flake MoS2 / graphene composite aerogel and a preparation method thereof and belongs to the technical field of anode materials of lithium ion batteries. The preparation method comprises the following steps: ultrasonically dispersing a certain quantity of graphene oxide solution into deionized water, adding a certain quantity of water-soluble molybdate and thiourea, then adding 0.1-3mL organic amine solution, taking out a cylindrical product after hydrothermal reaction at the temperature of 160-240 DEG C, freeze-drying, and then carrying out thermal treatment for 2h in the mixed atmosphere of argon and hydrogen at the temperature of 800 DEG C to obtain the flake MoS2 / graphene composite aerogel. According to the flake MoS2 / graphene composite aerogel and the preparation method thereof disclosed by the invention, thin layers of graphene are connected with one another in a staggering mode to form a three-dimensional ordered conductive network and form micron pore canals, MoS2 is uniformly dispersed on the ultra-large superficial area, and thus, the problems of volume expansion and crushing materials are effectively solved; meanwhile, the structure stability and the cycle performance of the flake MoS2 / graphene composite aerogel, serving as the anode material, are improved.

Owner:SHANGHAI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com